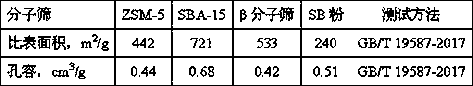

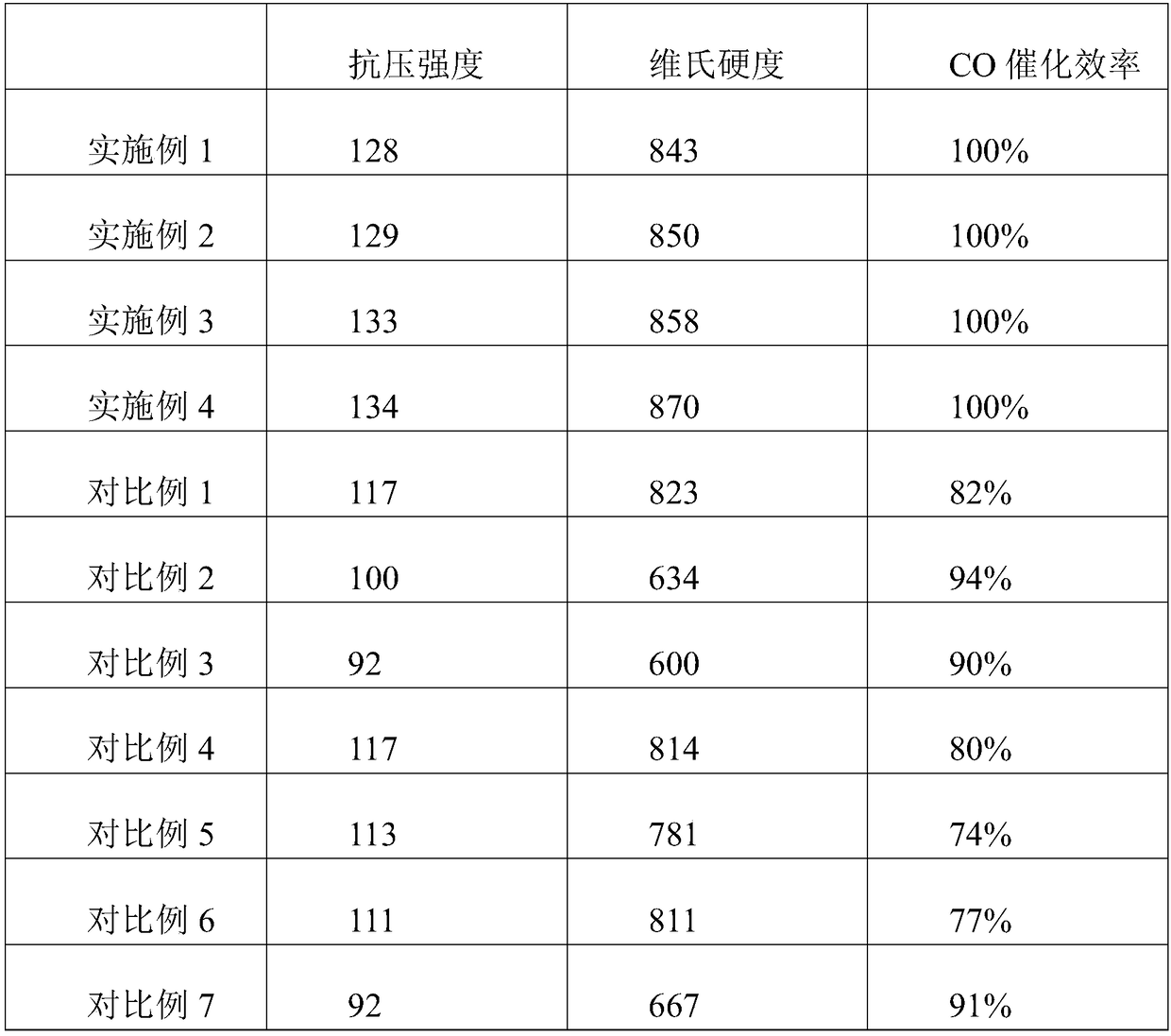

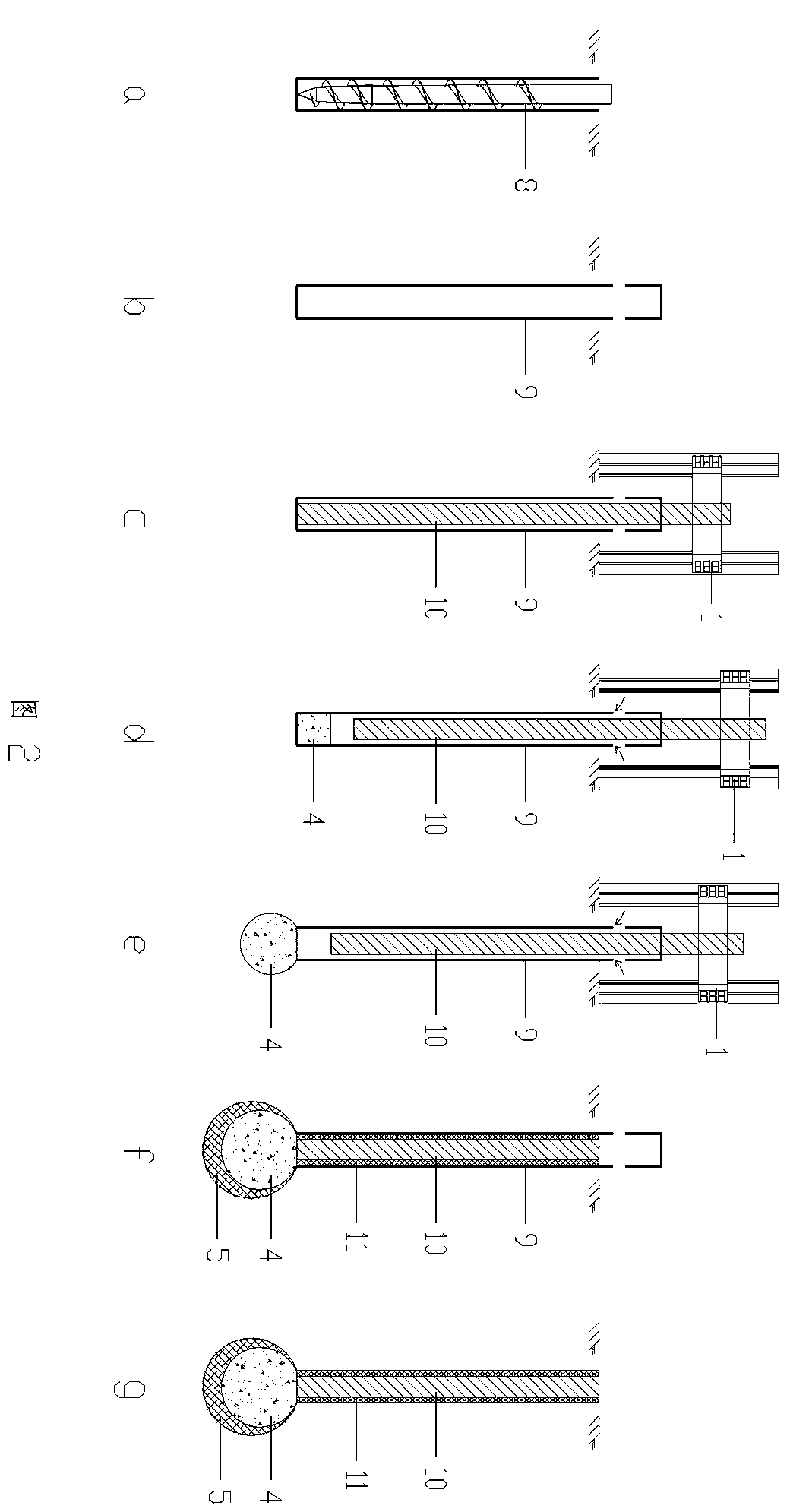

Patents

Literature

30results about How to "Improve carrier strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

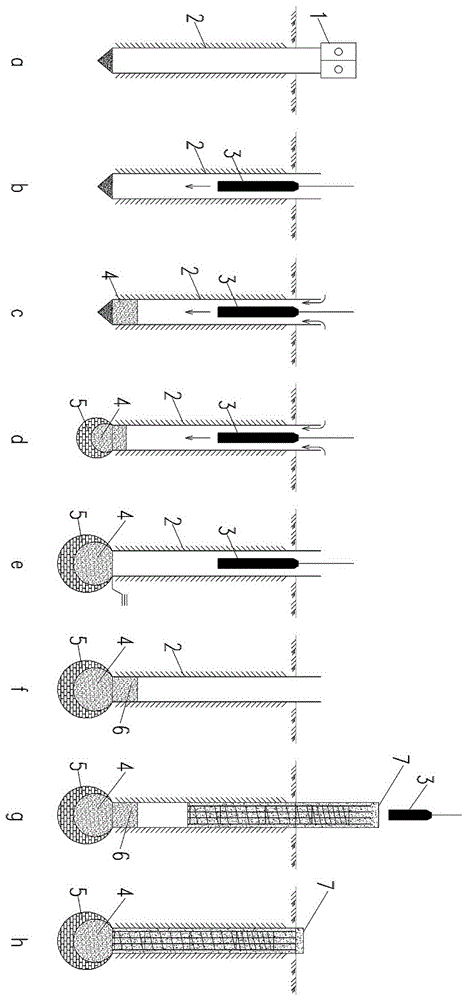

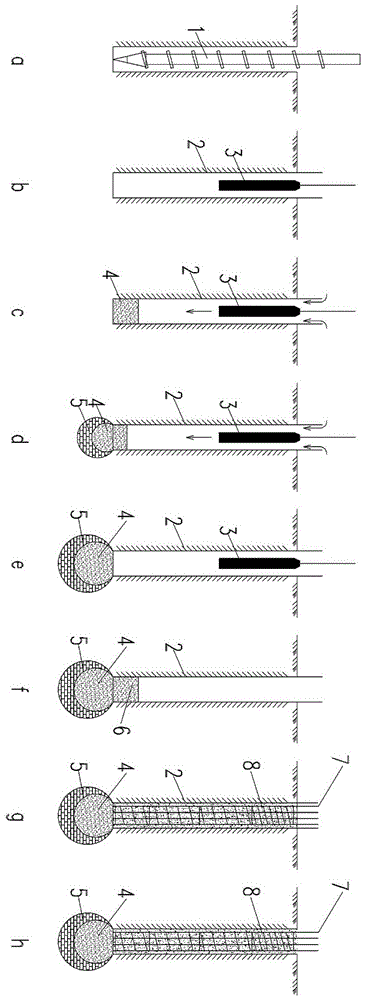

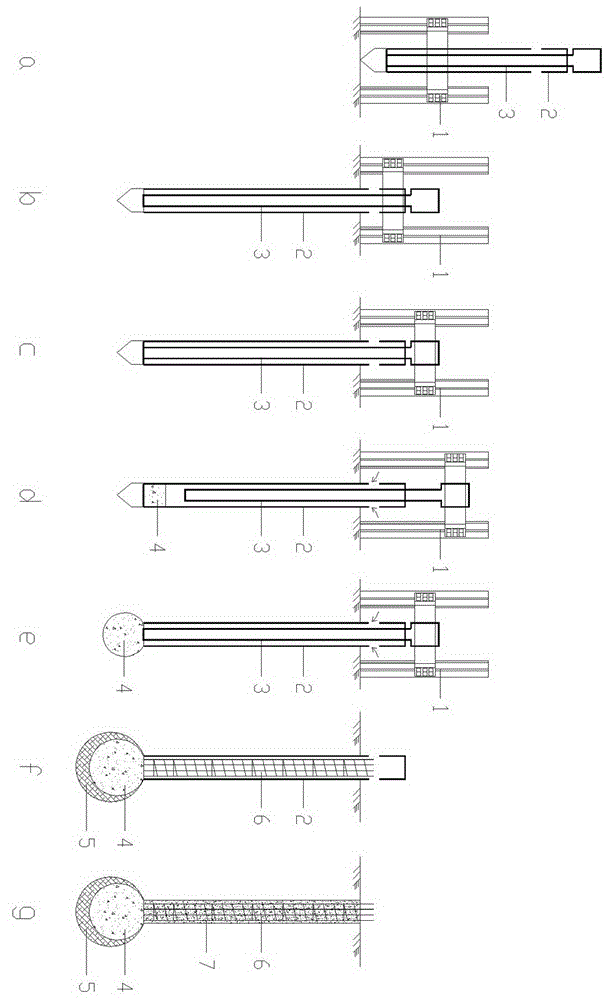

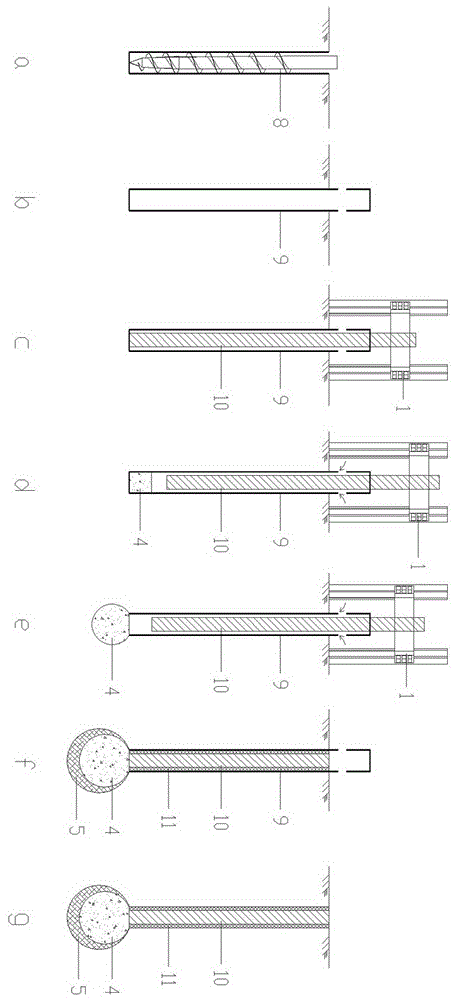

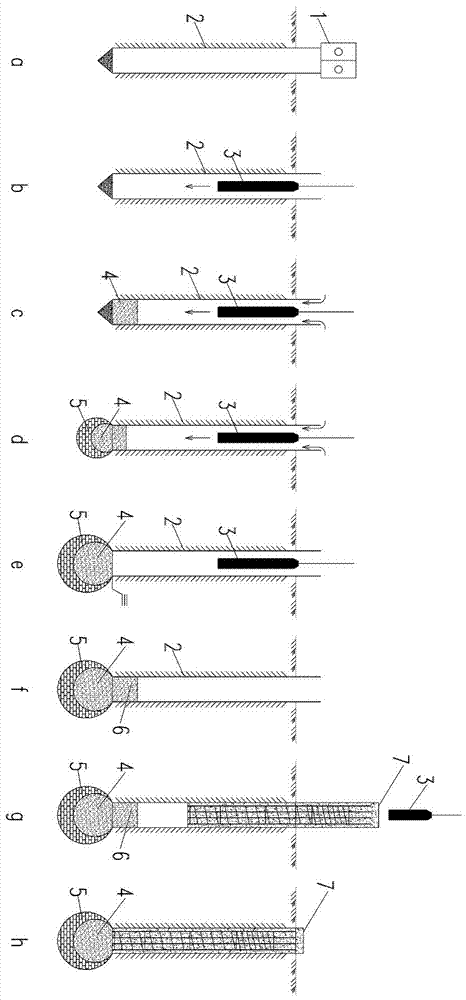

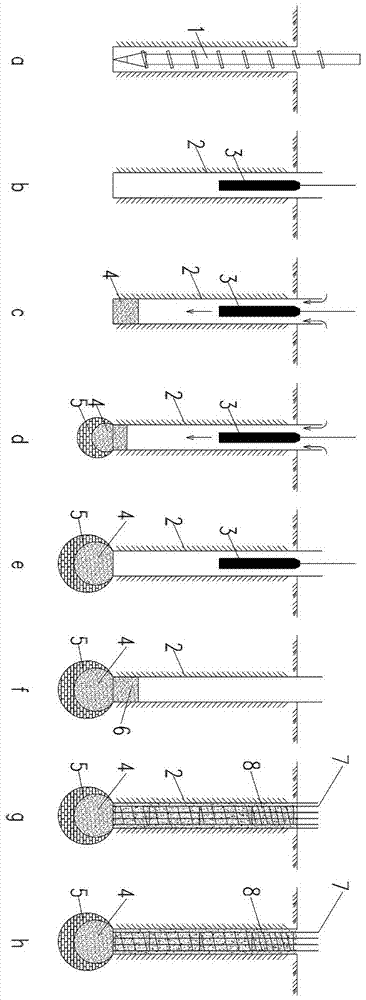

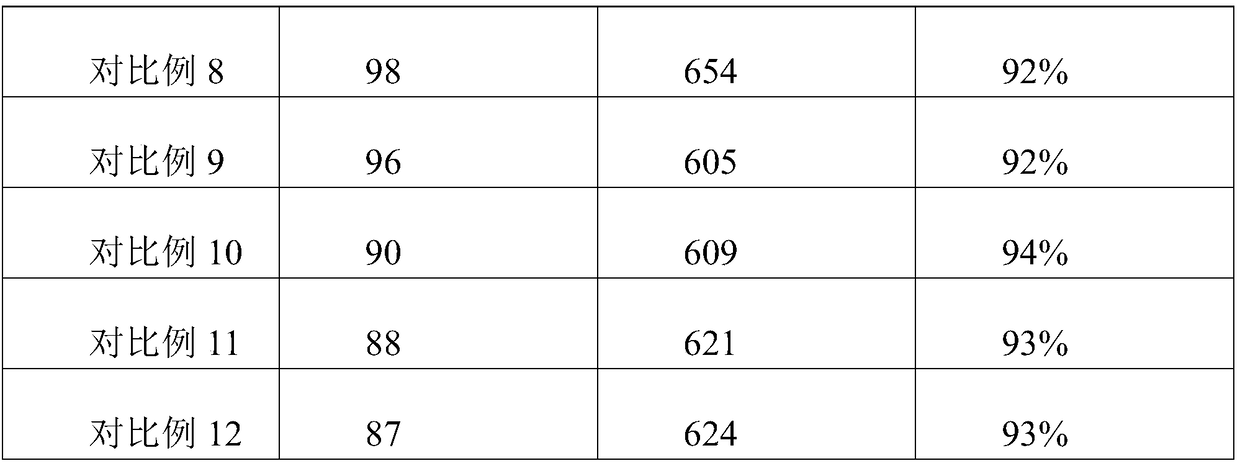

Construction method for carrier pile

ActiveCN105821836ALow dropLow drop distance for low tamping energyBulkheads/pilesEngineeringCement paste

The invention provides a construction method for a carrier pile. The construction method comprises the steps that 1, a pile casing is sunk into the set depth; 2, a heavy hammer is sunk into the pile casing, the clearance between the heavy hammer and the pile casing can form an airflow channel, and a cement mixture can smoothly pass the airflow channel; 3, material filling and heavy hammer tamping operation are simultaneously conducted, when the heavy hammer is upwards lifted, the bottom end of the heavy hammer does not leave an upper opening of the pile casing, and when the heavy hammer falls to conduct tamping, the bottom end of the heavy hammer is not knocked out of the pile casing so that low-falling-distance small-energy tamping can be ensured; 4, the step 3 is repeated to enable a pile end soil body to be reinforced and compacted; 5, the compactness is controlled through the three-strike penetration or the filler quantity standard, and a pile end carrier is formed; 6, cement paste or cement mortar is poured; and 7, cast-in-place constructing or prefabricating of a concrete pile body is conducted. The construction method for the carrier pile has the technical characteristics and advantages that 1, the tamping mode of the heavy hammer is changed; 2, material filling and heavy hammer tamping are simultaneously conducted by redesigning filler, the heavy hammer and the pile casing; 3, the component of the filler is changed, and the strength of the carrier is improved; and 4, the processes of material filling, tamping and compactness controlling are continuously completed.

Owner:北京波森特岩土工程有限公司

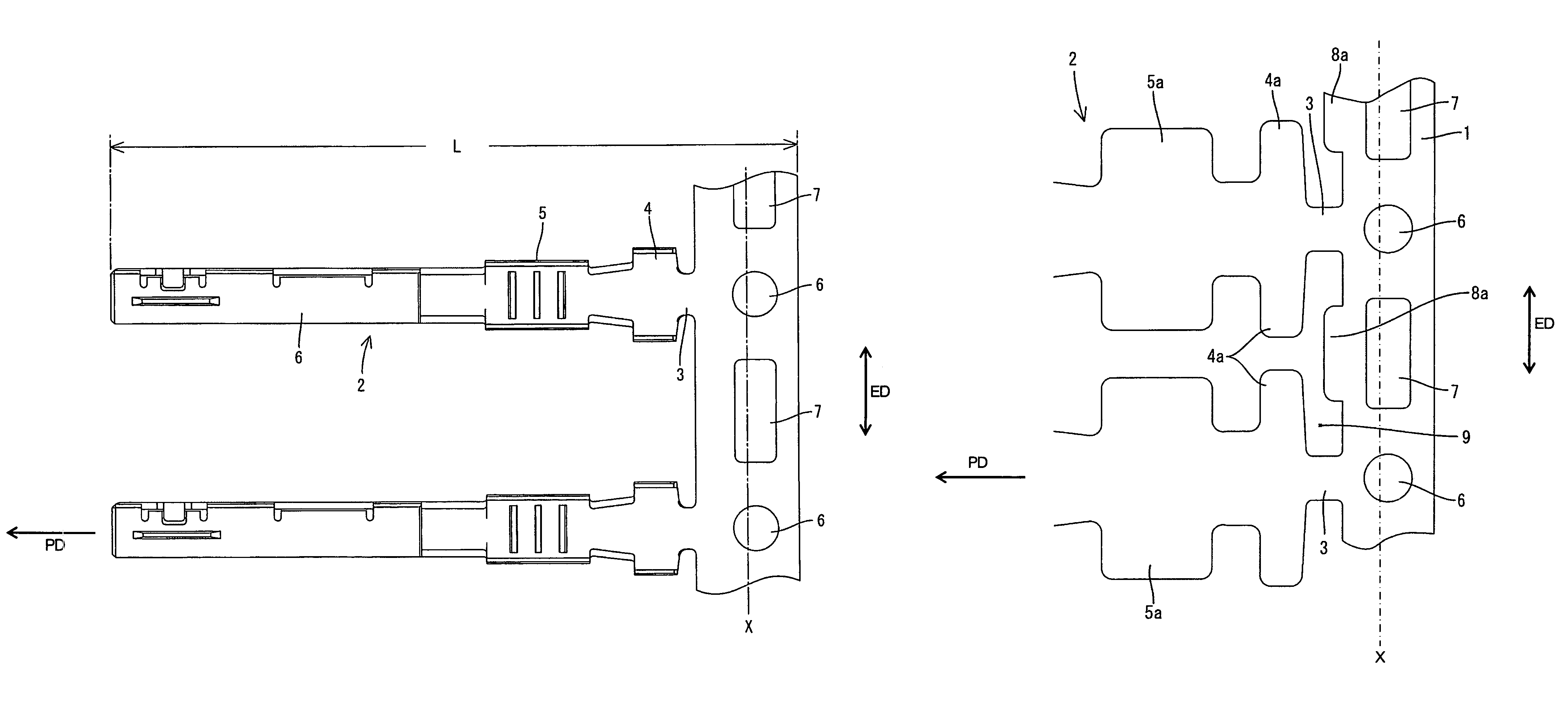

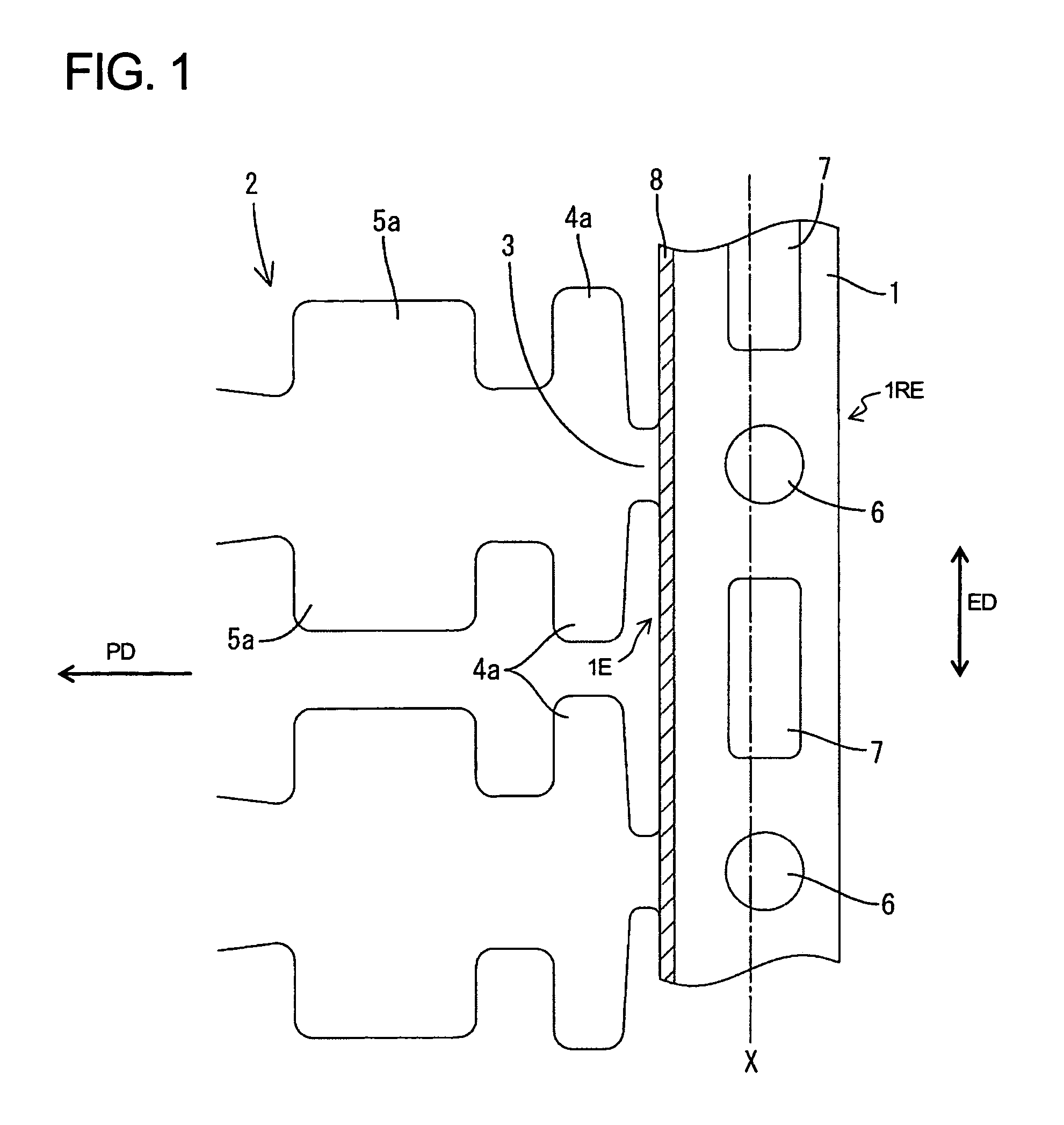

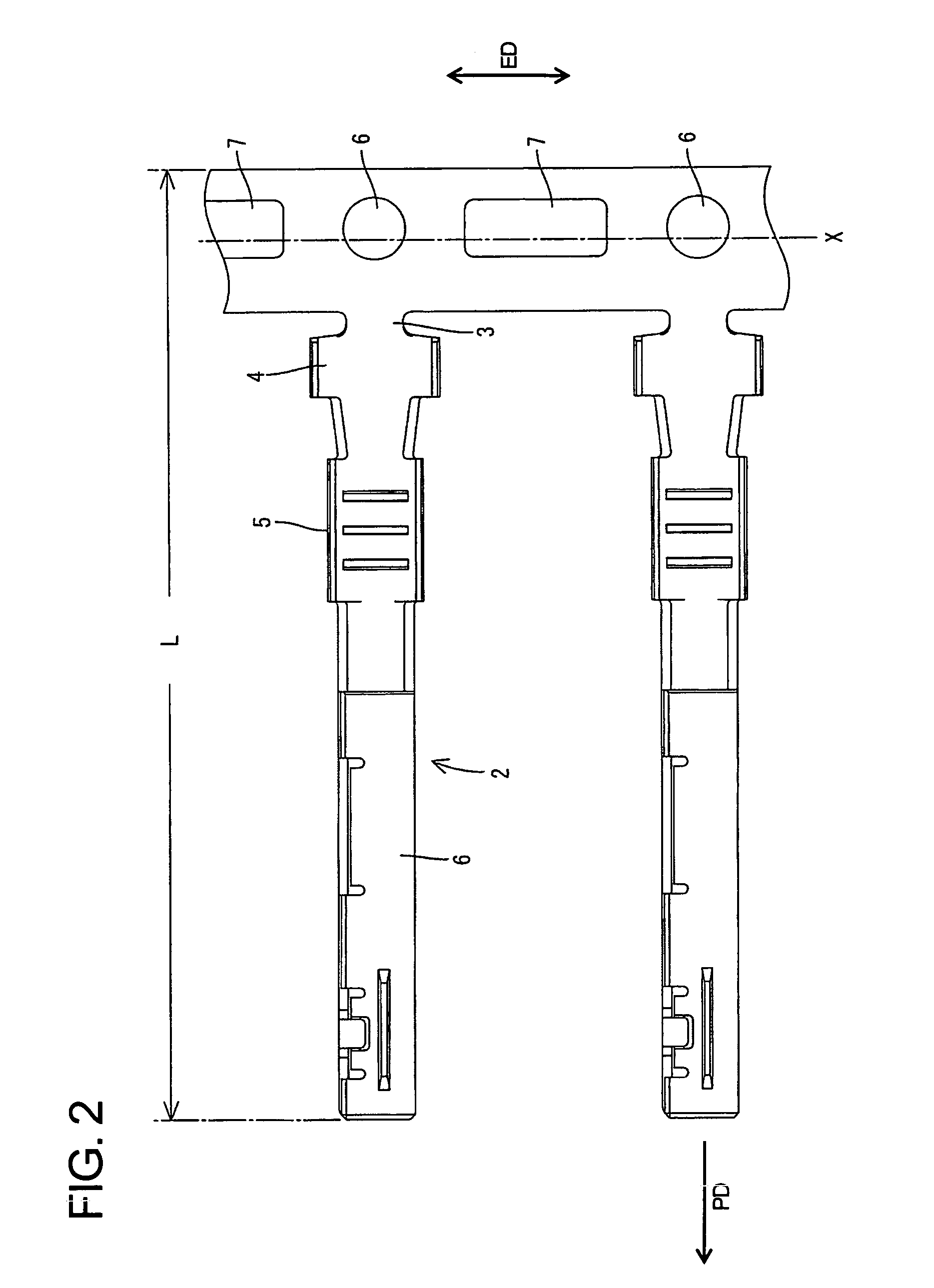

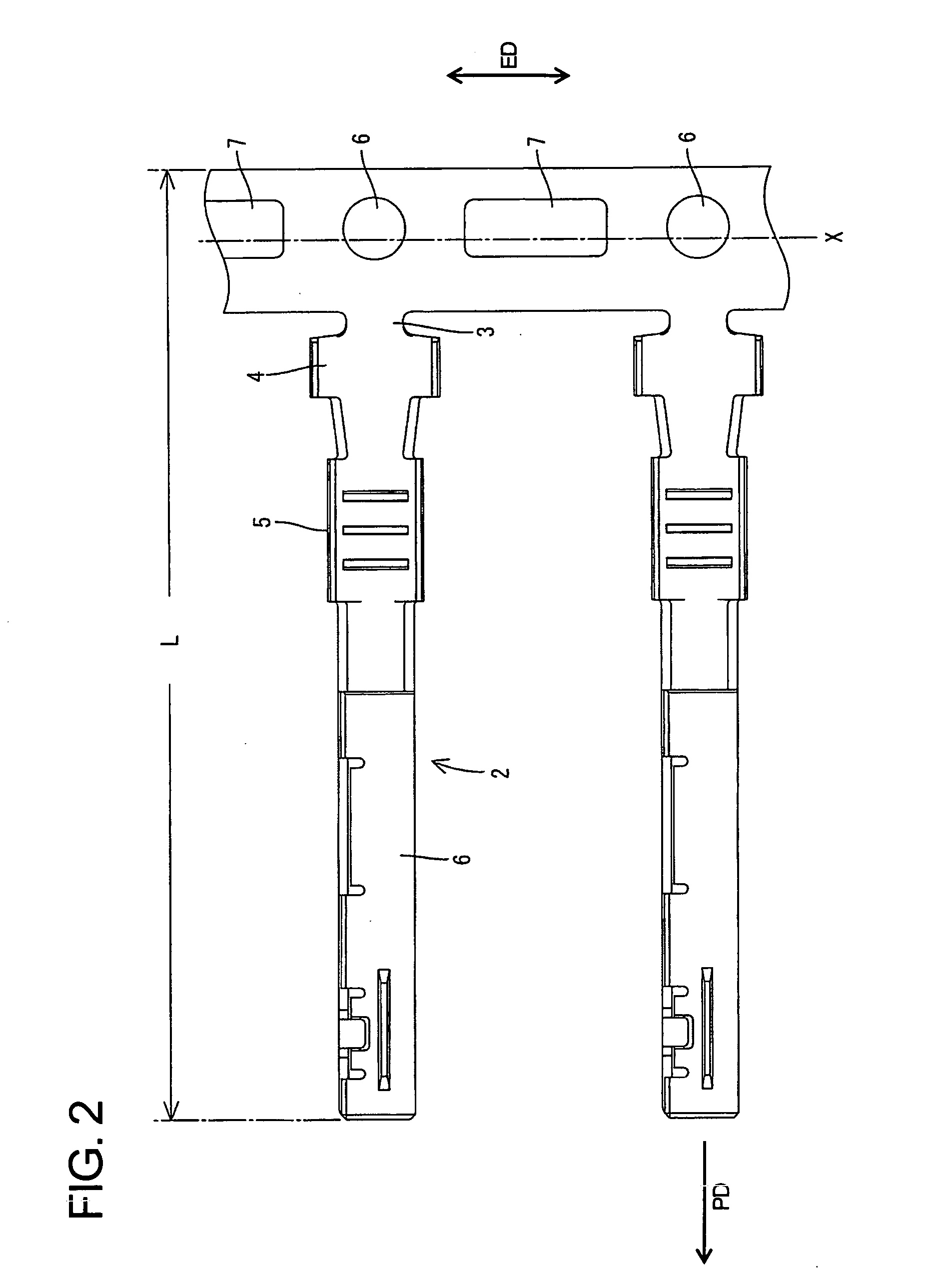

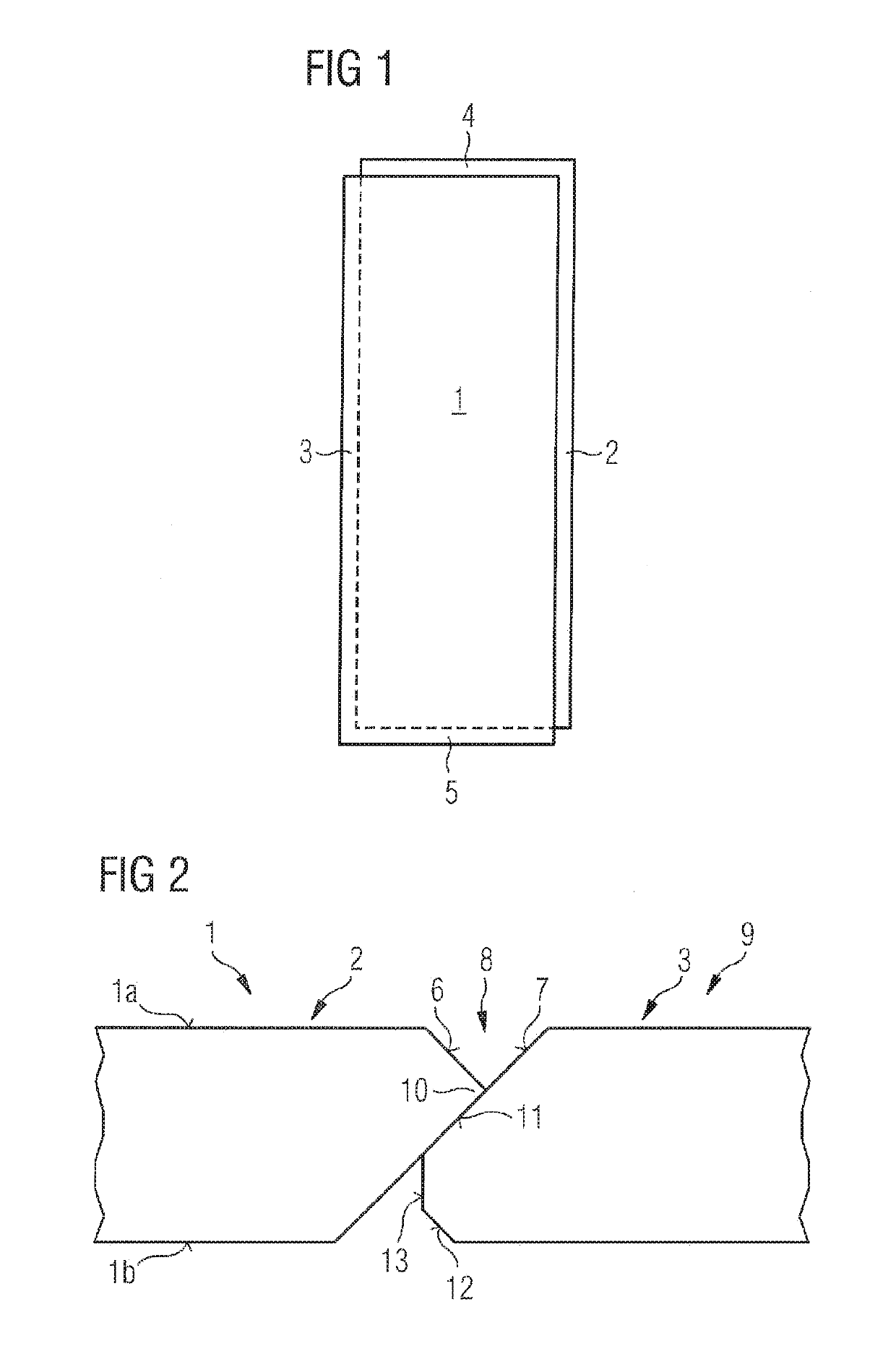

Chained terminals and method of forming chained terminals

InactiveUS7226323B2Improve carrier strengthIncrease widthContact member manufacturingElectrically conductive connectionsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

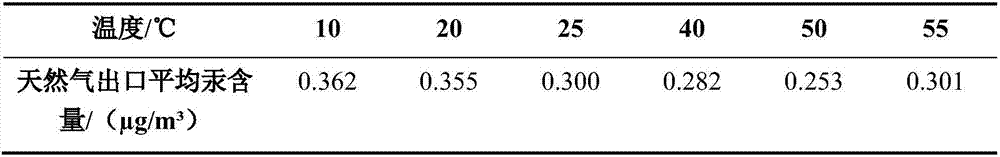

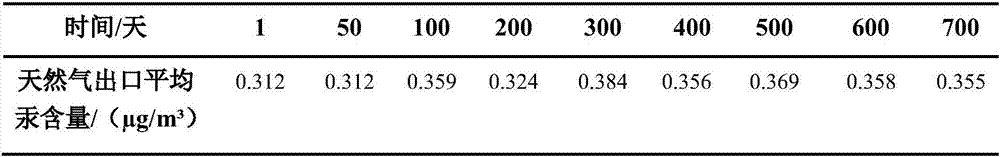

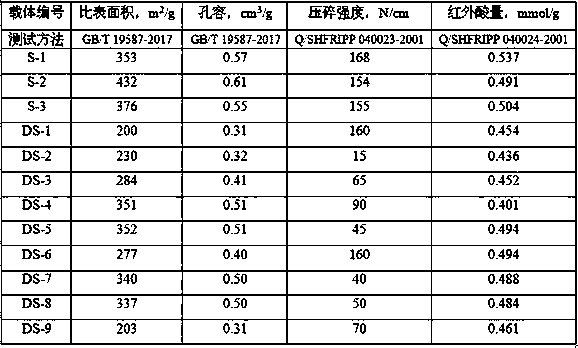

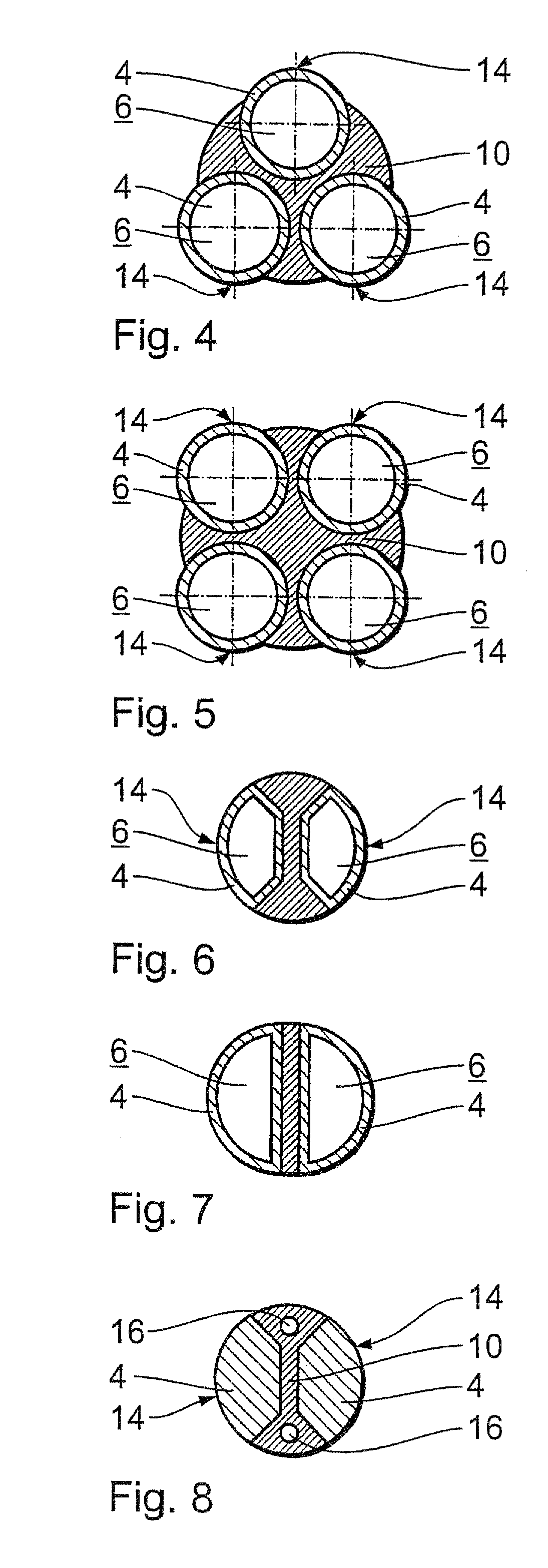

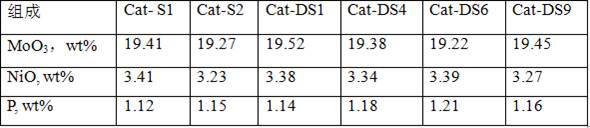

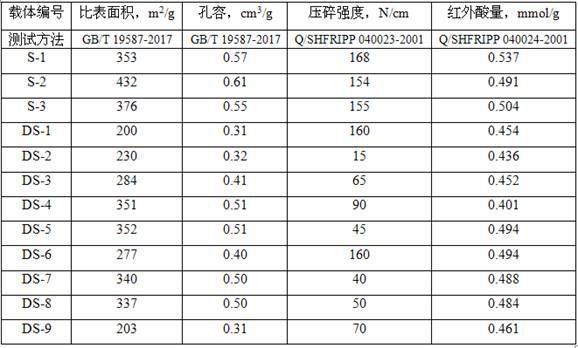

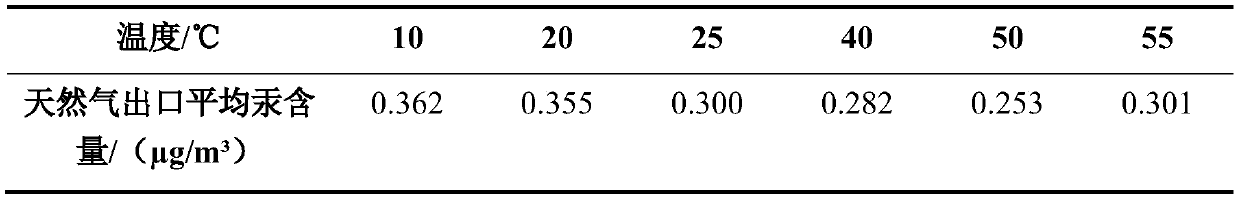

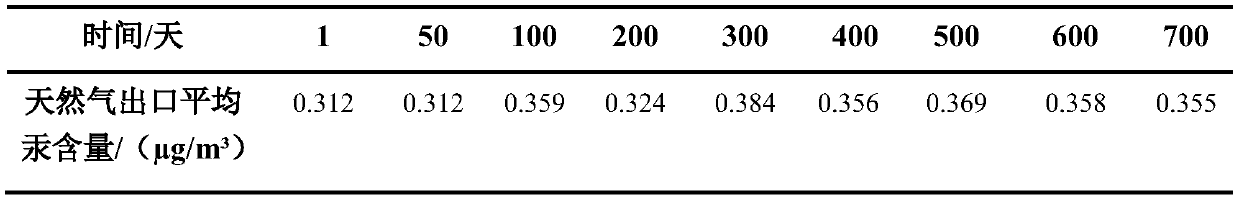

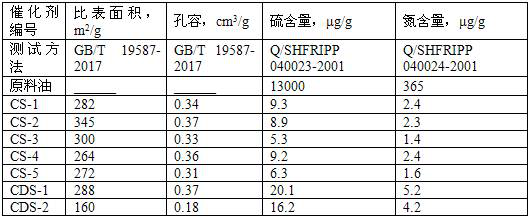

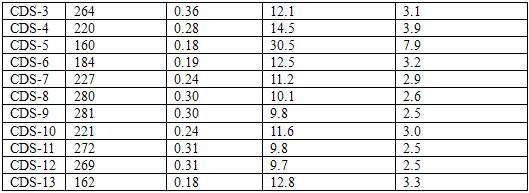

Natural gas demercuration adsorbent and preparation method

ActiveCN107486133AImprove carrier strengthFast mercury removalOther chemical processesGaseous fuelsVulcanizationSorbent

The invention discloses a natural gas demercuration adsorbent and a preparation method. The natural gas demercuration adsorbent comprises the following components in parts by mass: 82-95% of Al2O3, 4-12% of sulfur and 1-6% of copper sulfide. The preparation method comprises the following steps: (1) dipping Al2O3 in a sulfur solution; (2) soaking the product of the step (1) with a dissoluble copper solution; (3) exposing the product of the step (2) in a vulcanization environment for vulcanization; (4) washing with deionized water; (5) drying, thereby obtaining the natural gas demercuration adsorbent. The natural gas demercuration adsorbent prepared according to the preparation method disclosed by the invention is high in carrier strength, stable in specific surface, pore volume and pore size, high in demercuration speed, large in mercury capacity and small in use amount.

Owner:CHANGZHOU UNIV

Waste gas treatment compound adsorption material preparation method

InactiveCN105561926AImprove adsorption capacityBoth adsorption andOther chemical processesDispersed particle separationMaterials preparationPhysical chemistry

The present invention discloses a waste gas treatment compound adsorption material preparation method, a waste gas treatment compound adsorption material comprises a carrier, a functional component and a catalysis component, components of the carrier are mixed and ball-ground into a corresponding particle diameter, and then mixed, components of the functional component are mixed for preparing a solution, components of the catalysis component are prepared into a suspension, slurry can be obtained by mixing, diluting and stirring, the slurry is dried and crushed, and the waste gas treatment compound adsorption material has the advantages of good adsorption effect, low cost and simple preparation.

Owner:山东永辰环境科技有限公司

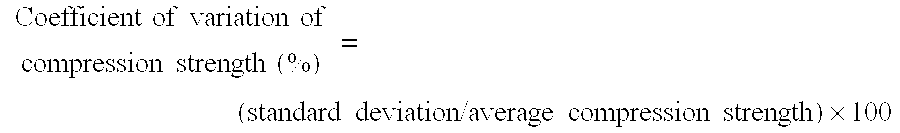

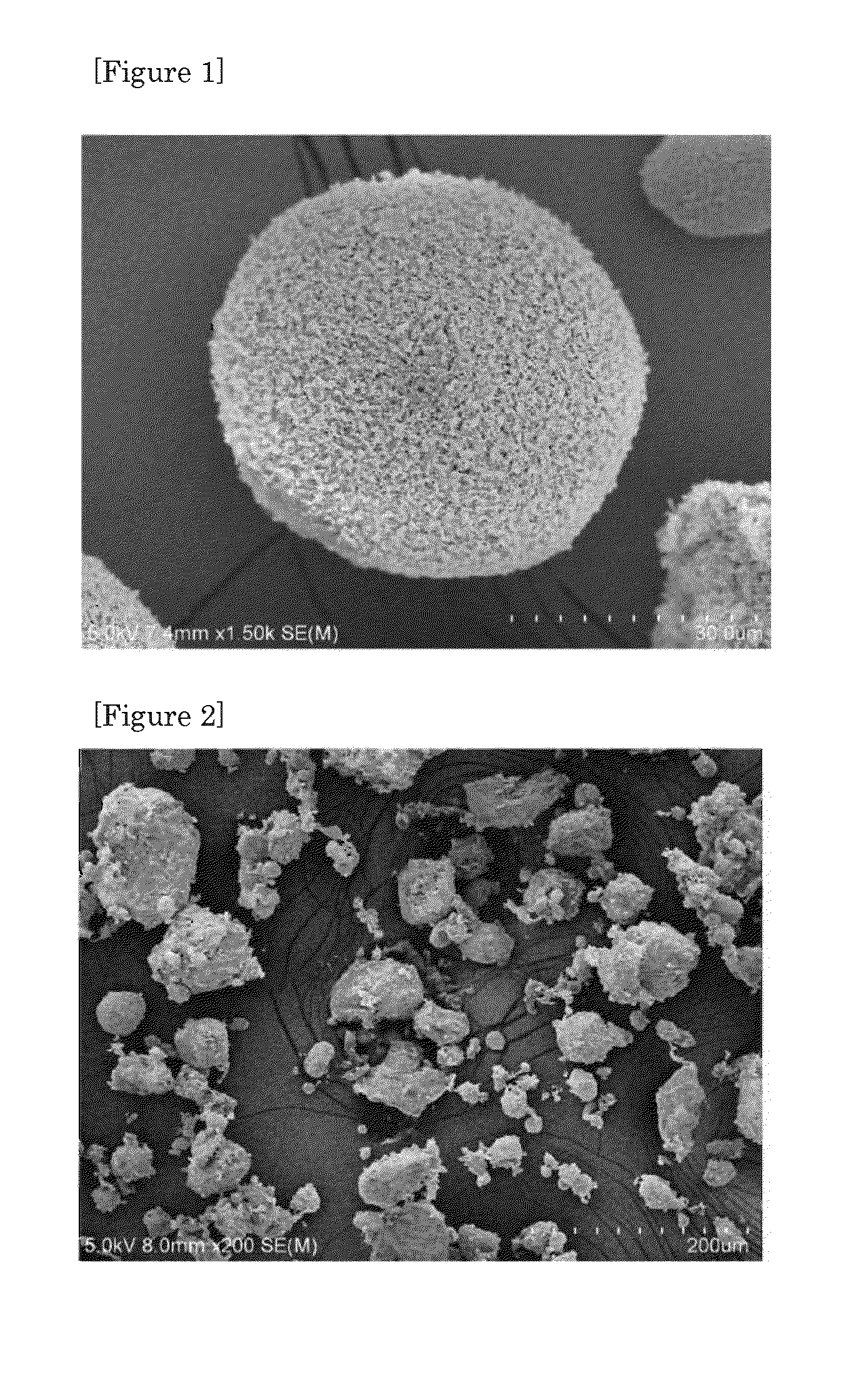

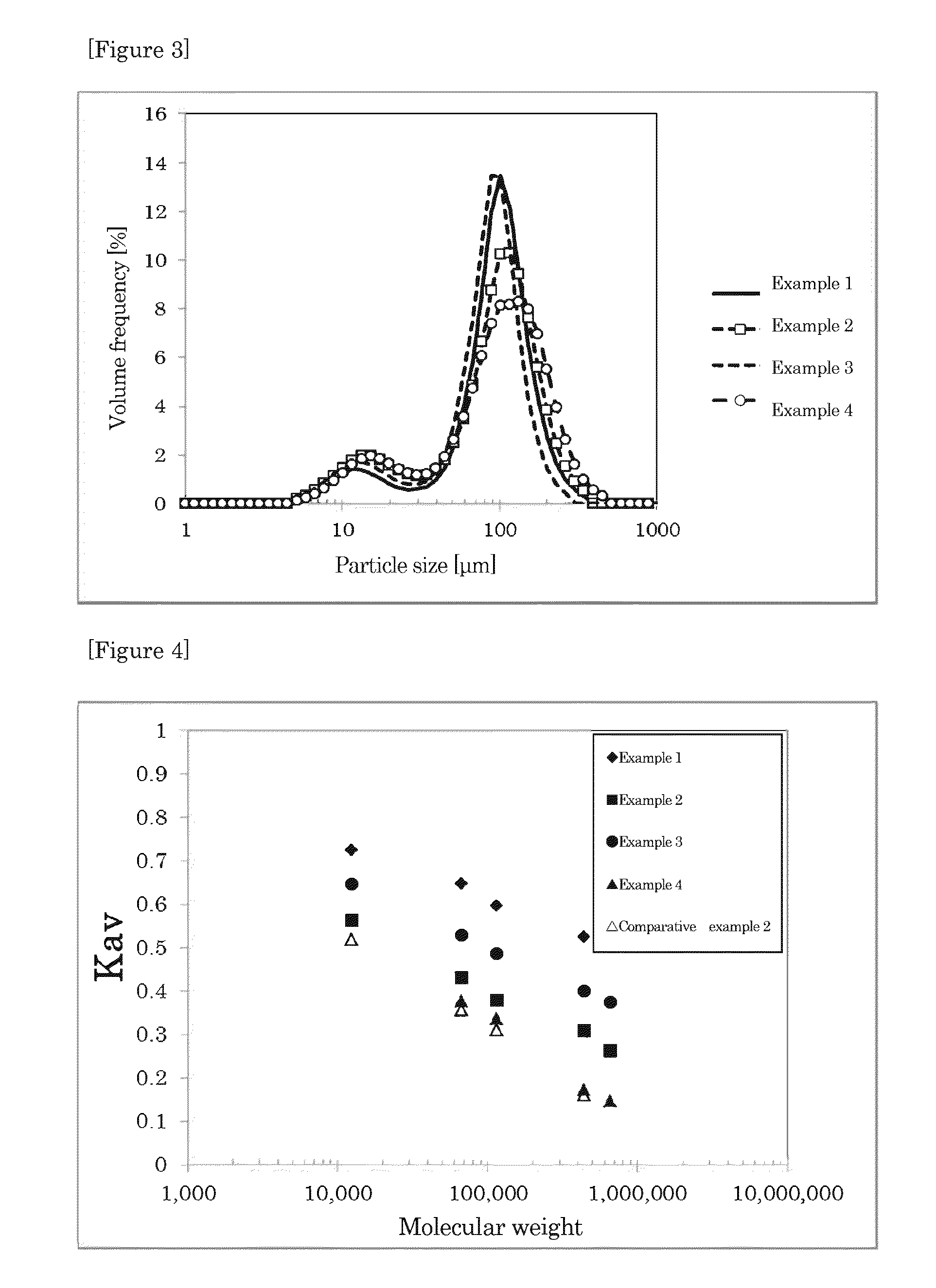

Core material for resin-filled ferrite carrier and ferrite carrier for electrophotographic developer, and electrophotographic developer using the ferrite carrier

Disclosed are a resin-filled ferrite carrier core material for an electrophotographic developer, including a porous ferrite particle having an average compression strength of 100 mN or more and a coefficient of variation of the compression strength of 50% or less, a ferrite carrier obtained by filling a resin in the voids of the ferrite carrier core material, and an electrophotographic developer using the ferrite carrier.

Owner:POWDERTECH

Application of volcanic used as titanium dioxide loaded photocatalyst

ActiveCN104549355AImprove carrier strengthGood for recyclingMetal/metal-oxides/metal-hydroxide catalystsUreaChemistry

The invention relates to application of a volcanic used as a titanium dioxide loaded photocatalyst. The application comprises the following steps: (1) removing impurities on the surface of the volcanic to prepare a volcanic carrier; (2) dissolving Ti(SO4)2 and urea into water according to proportions to prepare load solutions; (3) soaking the volcanic carrier into the load solutions for reacting, adding urea solutions or ammonia water in a reaction process; aging, filtering, drying and baking to prepare the volcanic loaded titanium dioxide photocatalyst. The volcanic is used as a carrier of the titanium dioxide photocatalyst, so that the intensity of the carrier is high, and the performance of the loaded photocatalyst can be improved to a certain extent; in addition, the carrier has a rich honeycomb porous structure, and is high in specific surface area and high in adsorption performance; because of the carrier of the photocatalyst, the load firmness and the photocatalytic performance of the loaded catalyst can be improved.

Owner:山东默锐环境产业股份有限公司

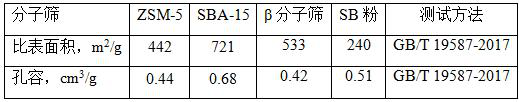

Preparation method of hydrogenation catalyst

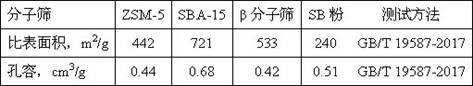

ActiveCN111068757AAvoid reunionEffective control formationMolecular sieve catalystsCatalyst activation/preparationPolycyclic aromatic hydrocarbonMolecular sieve

The invention discloses a preparation method of a hydrogenation catalyst. The preparation method of the hydrogenation catalyst comprises the following steps: (1) impregnating a molecular sieve with animpregnation solution I containing a VIII group metal compound, drying, and roasting to obtain a modified molecular sieve; (2) uniformly mixing the modified molecular sieve, pseudo-boehmite precursorslurry and organic alcohol to obtain a slurry A; (3) adding a silane coupling agent into the slurry A, uniformly mixing, and then adjusting the pH value of the slurry to 7.5-11 to obtain a slurry B;(4) aging the slurry B obtained in the step (3), filtering to remove water from the material after aging is finished, adding organic amine and a silane coupling agent, kneading into a plastic body, molding, drying, and roasting to obtain a composite carrier; and (5) loading a VIII group metal and a VIB group metal onto the composite carrier to prepare the hydrogenation catalyst. The catalyst has high hydrogenation performance, and is easy for post-hydrogenation desulfurization of sulfides which are difficult to directly remove and hydrogenation saturation of polycyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

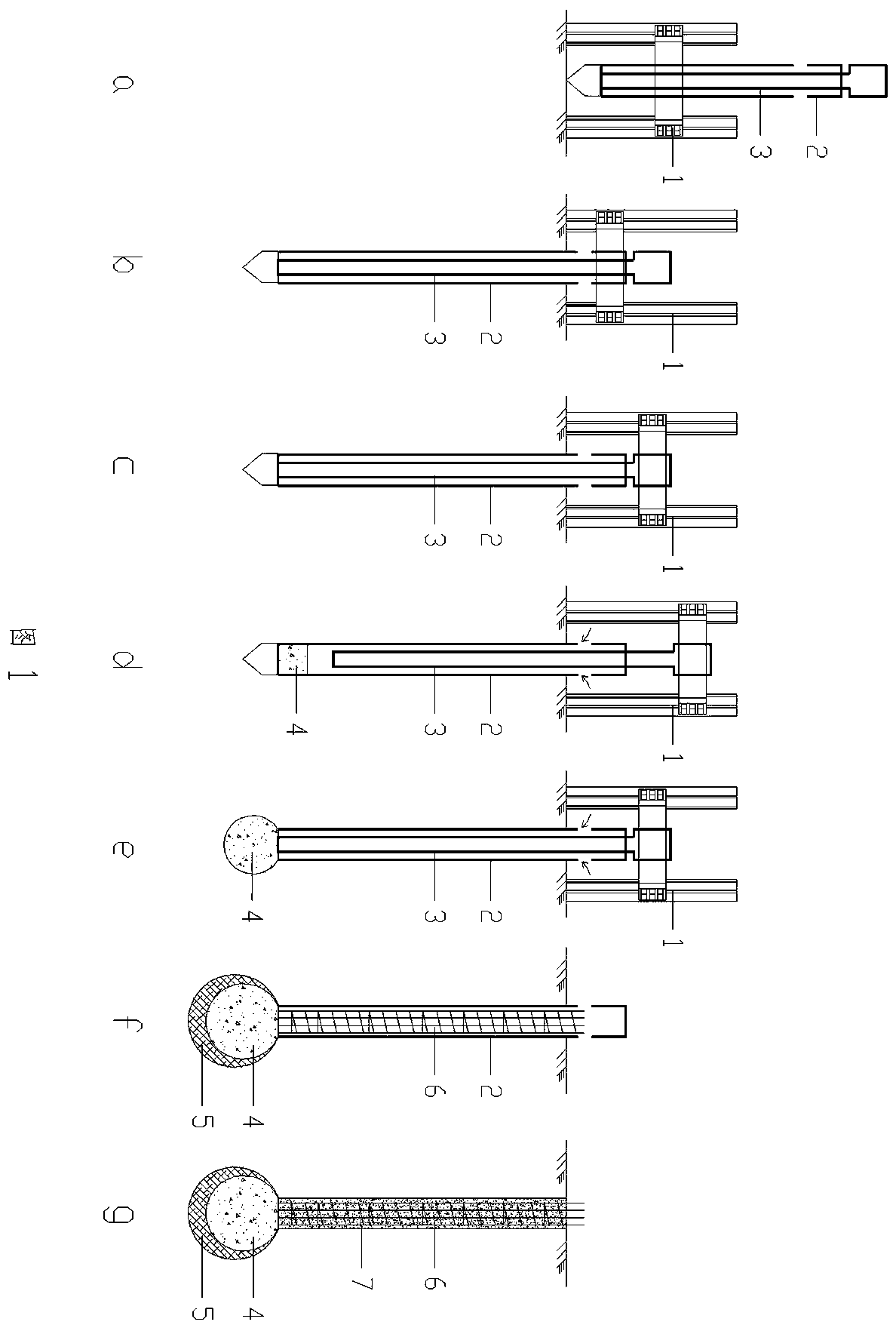

Construction method for static pressure carrier pile

ActiveCN105926621AAvoid destructionSmall particle sizeBulkheads/pilesParticle packingStructural engineering

The invention provides a construction method for a static pressure carrier pile. The construction method for the static pressure carrier pile includes the steps that firstly, an outer pipe is clasped by a clamping system of a static pile driver, and an inner pipe is sleeved with the outer pipe in an overlapped manner; secondly, the outer pipe is pressed by the designed depth in a static pressing manner; thirdly, the inner pipe is clasped by the clamping system; fourthly, the inner pipe is lifted up, a gap between the inner pipe and the outer pipe is filled with a fine particle packing material, the inner pipe is clasped, and the packing material is pressed downwards; fifthly, downward-pressing operation of the packing material is repeated till a carrier is formed at the bottom end of the pile, and the tip resistance pressure numerical value is observed; and sixthly, a cast-in-situ or embedded concrete pile body is manufactured. The other construction method for the static pressure carrier pipe includes the steps that firstly, sinking of a pile casing is conducted; secondly, a prefabricated pile body is clasped by the clamping system of the static pile driver and is sunk into the pile casing; thirdly, the prefabricated pile body is lifted up, a gap between the pile casing and the prefabricated pile body is filled with the fine particle packing material, the prefabricated pile body is clasped, and the packing material is pressed downwards; fourthly, downward-pressing operation of the packing material is repeated till the carrier is formed at the bottom end of the pile, and the tip resistance pressure numerical value is observed; and fifthly, the gap between the pile casing and the prefabricated pile body is filled with cement mortar, the pile casing is lifted out, and the pile is formed.

Owner:王继忠

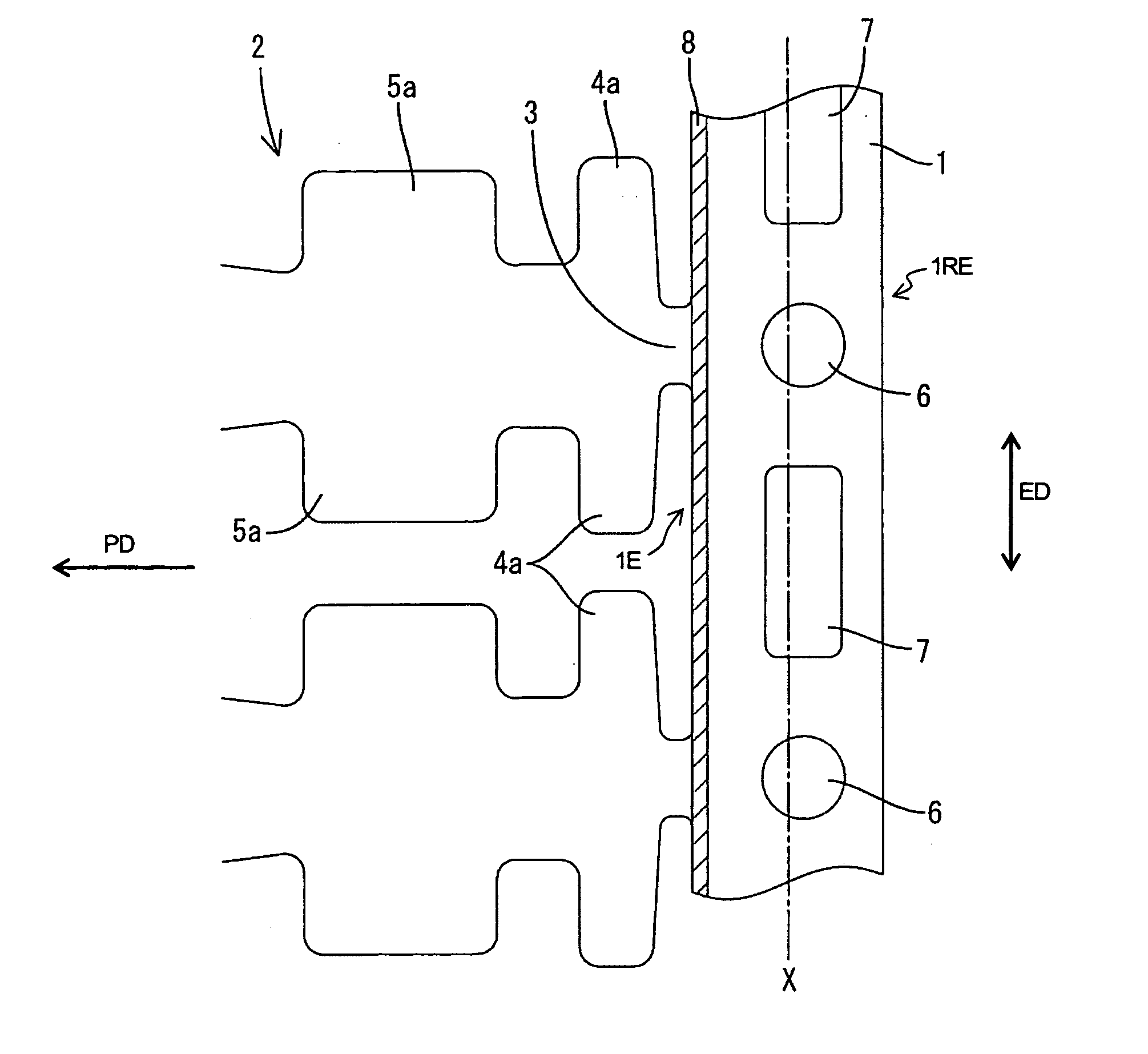

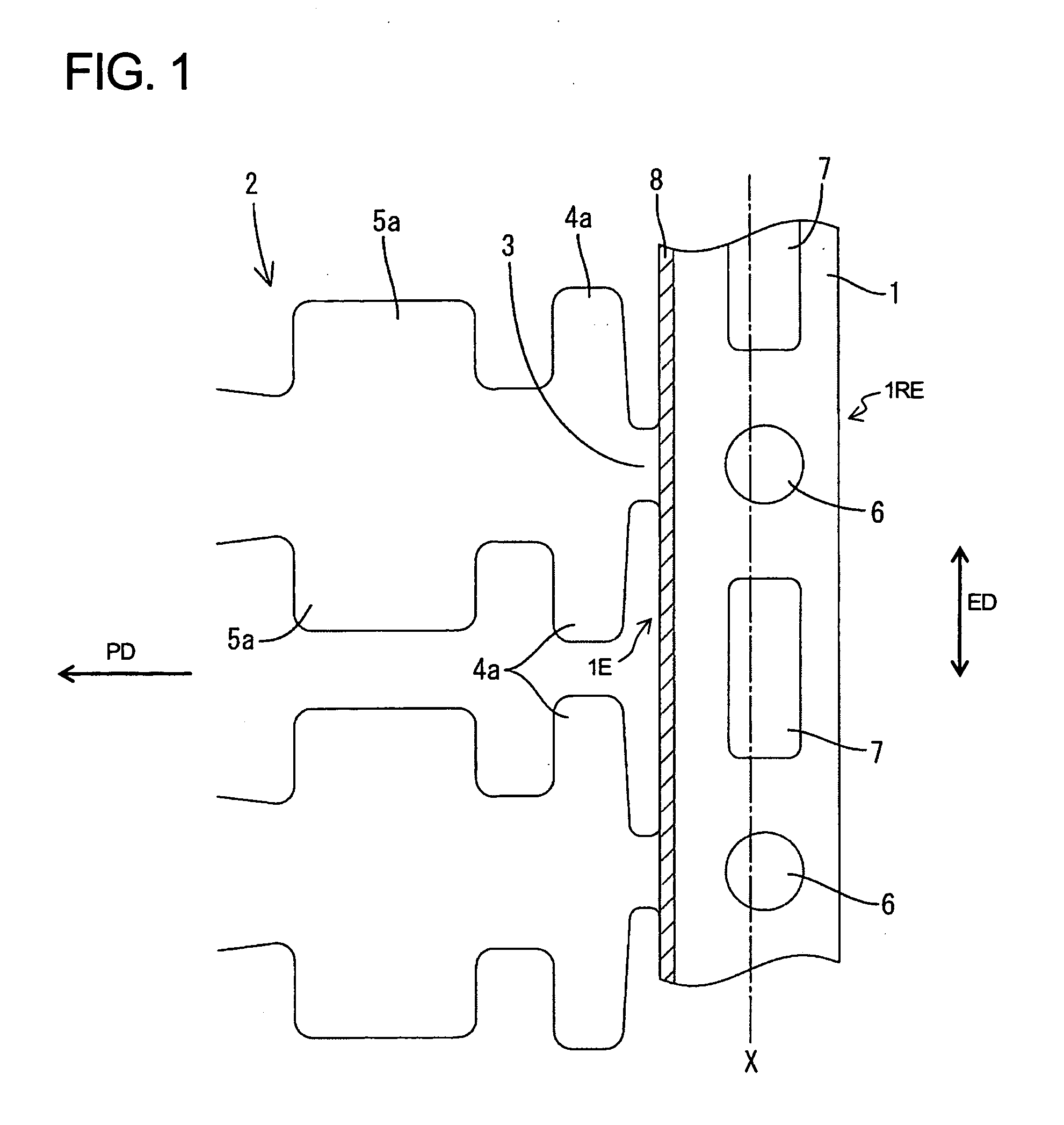

Process for producing porous cellulose beads using alkali aqueous solution, carrier for ligand immobilization, and adsorbent

ActiveUS20160244483A1High compressive strengthReduced strengthOther chemical processesSolid sorbent liquid separationCelluloseSorbent

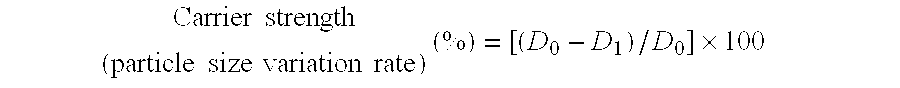

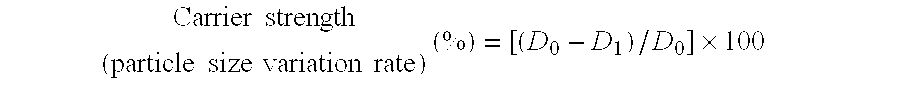

A process for producing porous cellulose beads of the present invention is characterized by comprising the steps ofa) mixing an alkali aqueous solution and cellulose to prepare cellulose micro dispersion at low temperature,b) adding water to the cellulose micro dispersion to prepare cellulose slurry, andd) bringing the cellulose slurry into contact with coagulation solvent.A carrier for ligand immobilization of the present invention is characterized by being by shrinking polysaccharide porous beads not less than 10% by a shrinkage rate defined by the following formula, and crosslinking the polysaccharide porous beads:Shrinkage rate (%)=(1−V2 / V1)×100(wherein, V1 indicates the gel volume of polysaccharide porous beads before shrinkage, and V2 indicates the gel volume of polysaccharide porous beads after shrinkage).

Owner:KANEKA CORP

Chained terminals and method of forming chained terminals

InactiveUS20060211312A1Low strengthImprove overall strengthContact member manufacturingElectrically conductive connectionsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

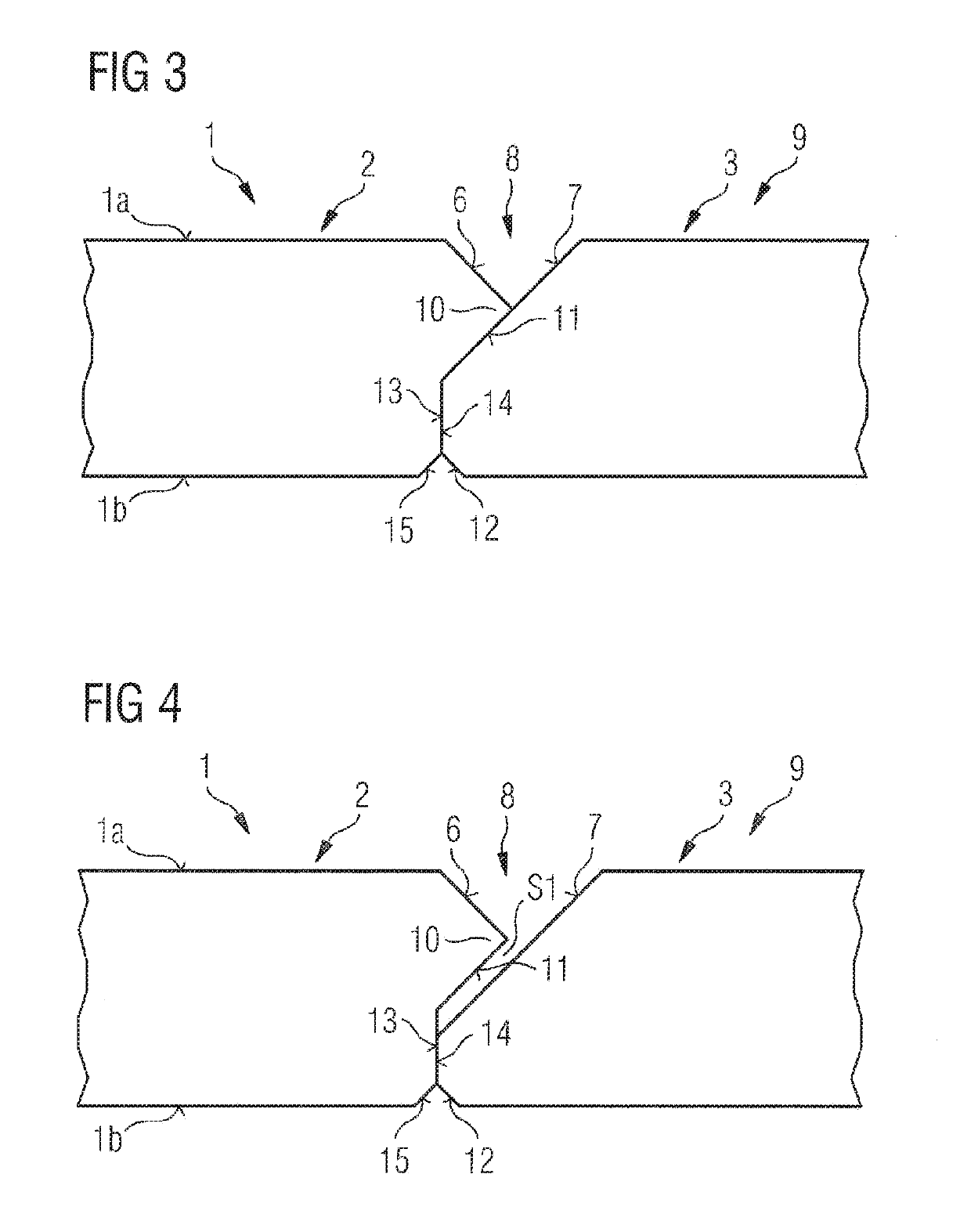

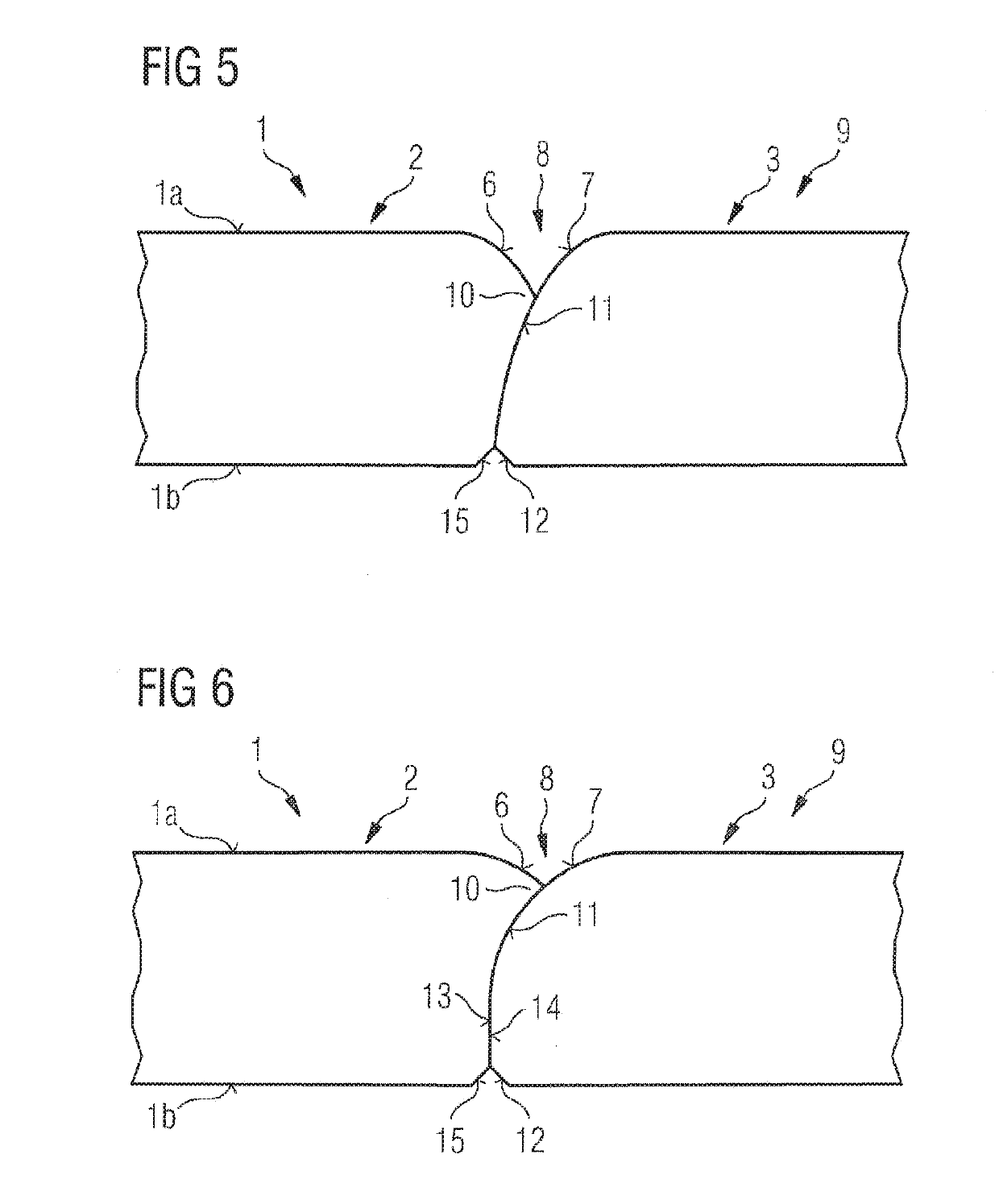

Panel

ActiveUS10458124B2Effective manufacturing processAdvantageous elasticity and water compatibilityCovering/liningsWallsAerospace engineeringSurface plate

Owner:AKZENTA PANEELE PROFILE GMBH

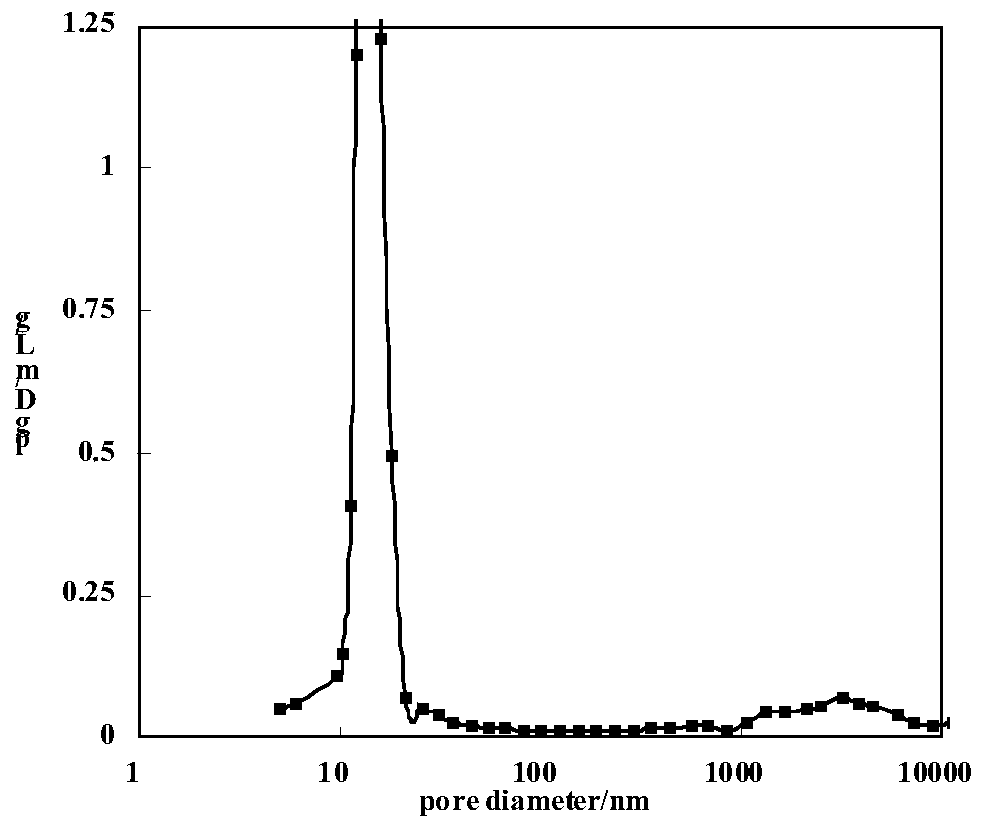

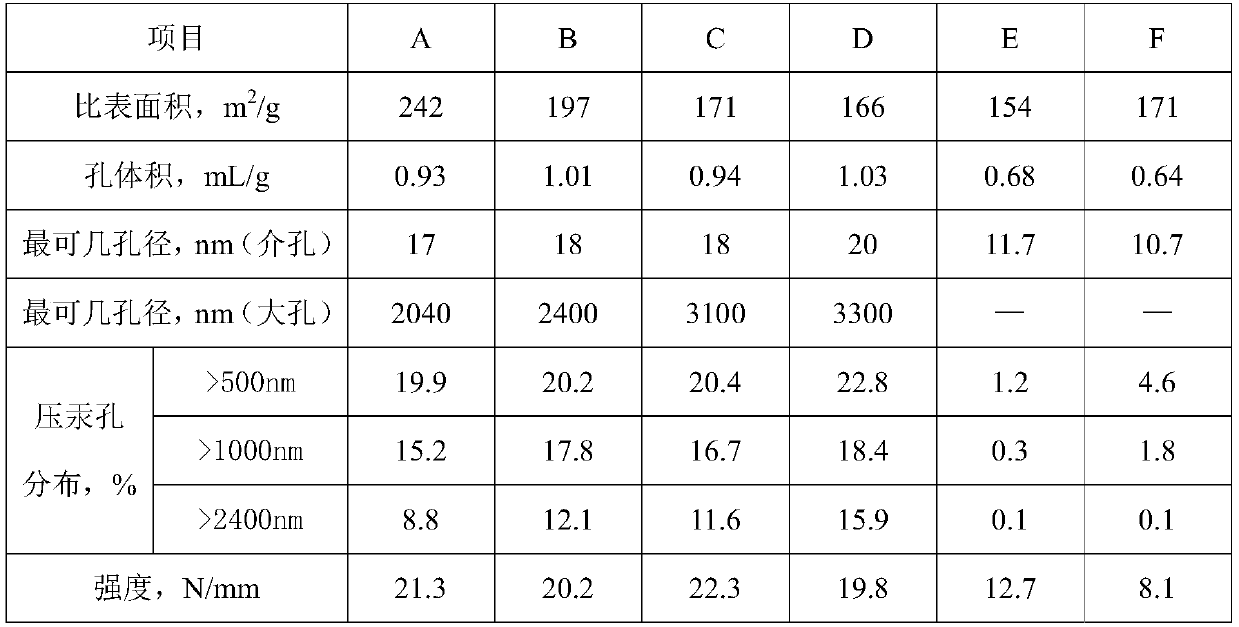

Alumina carrier with bimodal pore structure and preparation method thereof

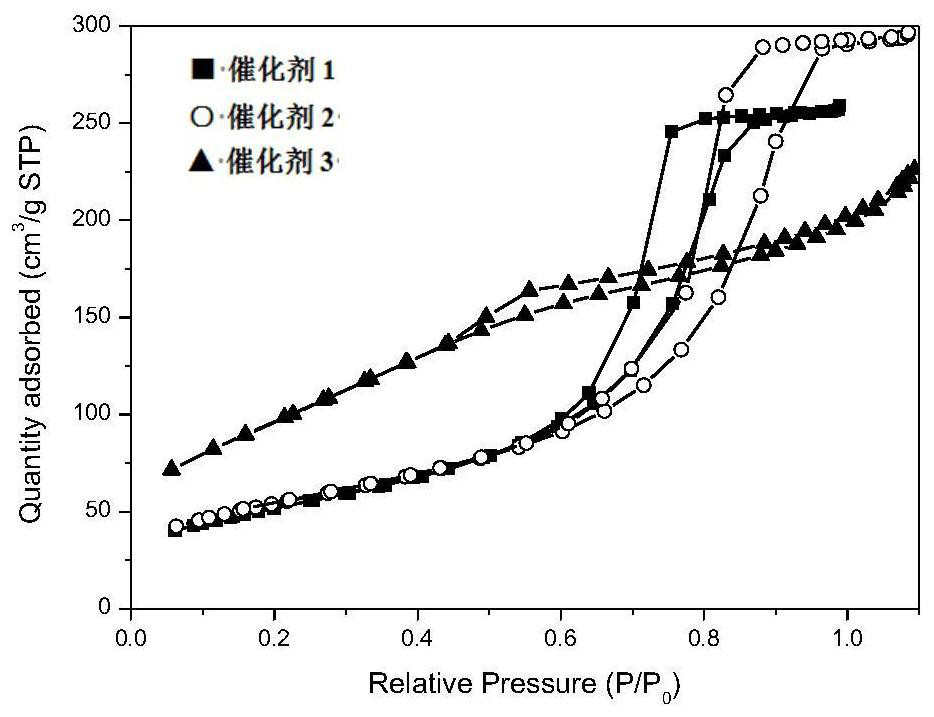

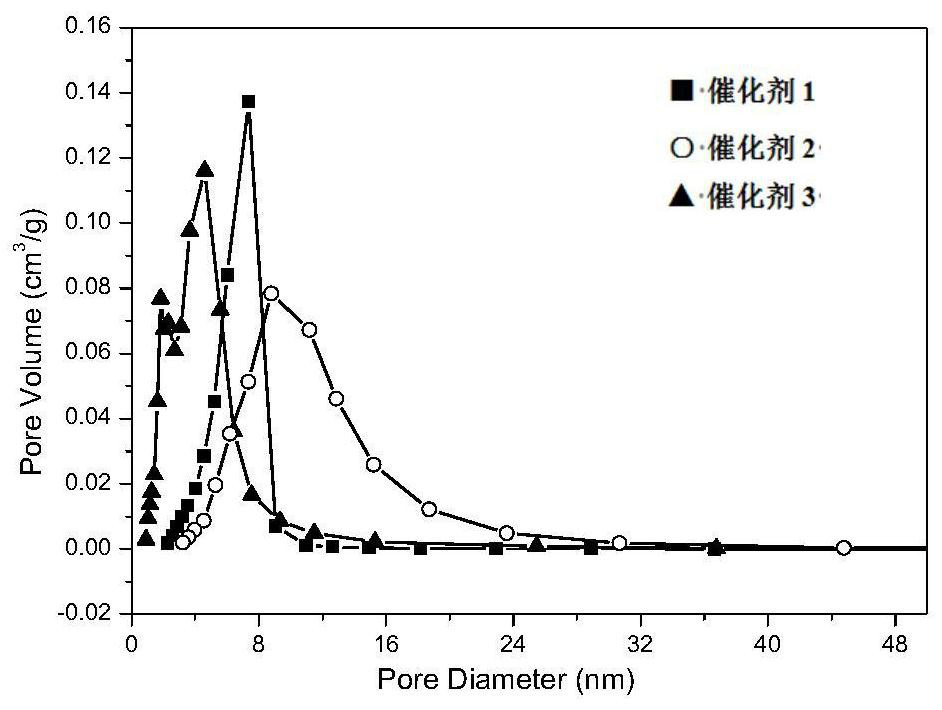

ActiveCN111420710ADiffusion pore size is largeIncrease contentCatalyst carriersCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses an alumina carrier with a bimodal pore structure of a heavy oil hydrogenation catalyst and a preparation method of the alumina carrier. The pore volume of the alumina carrier is 0.8-1.5 mL / g, the specific surface area is 120-350m<2> / g, the most probable pore diameter of mesopores is 15-30nm, the most probable pore diameter of macropores is 2000-4000nm, and the pore volume of macropores of 2400 nm or above accounts for 5-25% of the total pore volume. The alumina carrier provided by the invention has the advantages of large pore volume, large pore diameter and excellent diffusivity, and is suitable for being used as a hydrogenation catalyst alumina carrier for treating colloid and heavy oil with high asphaltene content.

Owner:CCTEG CHINA COAL RES INST

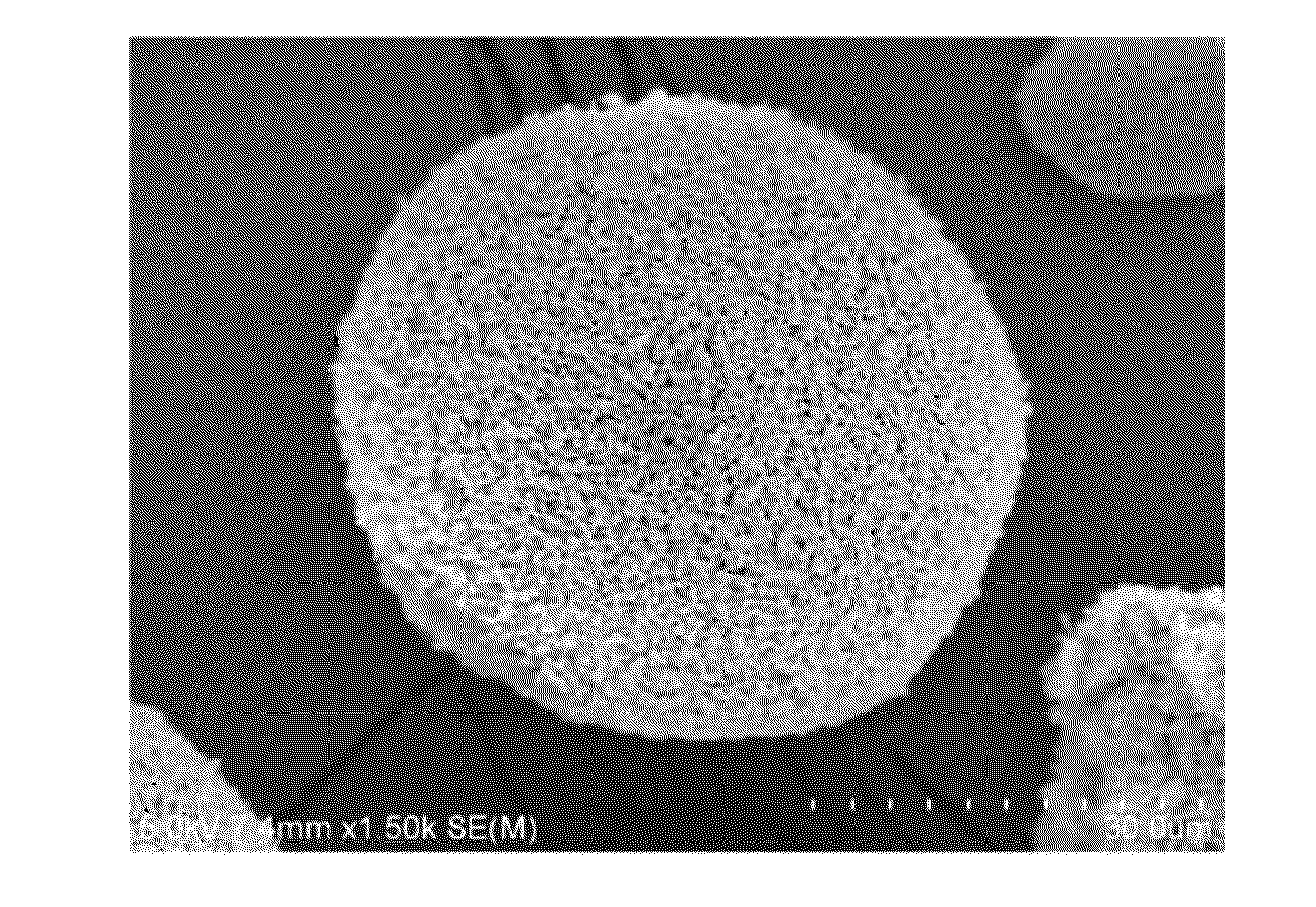

Preparation method of composite carrier

ActiveCN111068751AUniform and strong bondingUniform carrier propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveAlcohol

The invention discloses a preparation method of a composite carrier. The preparation method of the composite carrier comprises the following steps: (1) uniformly mixing pseudo-boehmite precursor slurry, a molecular sieve and organic alcohol to obtain a slurry A; (2) adding a silane coupling agent into the slurry A obtained in the step (1), uniformly mixing, and then adjusting the pH value of the slurry to 7.5-11 to obtain a slurry B; and (3) aging the slurry B obtained in the step (2) under a certain pressure, filtering to remove a certain amount of water from the material after aging is finished, adding organic amine and a silane coupling agent, kneading to form a plastic body, molding, drying, and roasting to obtain the composite carrier. According to the method, a molecular sieve is introduced in the growth process of an aluminum oxide crystal nucleus, a silane coupling agent is added, and the aluminum oxide crystals and the molecular sieve are orderly combined through hydrolysis ofthe silane coupling agent, so that the agglomeration of the aluminum oxide and the molecular sieve is avoided, and the formation of the pore channels and the surface acid of the carrier is effectively controlled.

Owner:CHINA PETROLEUM & CHEM CORP +1

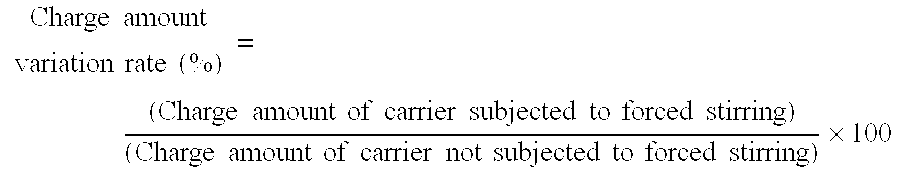

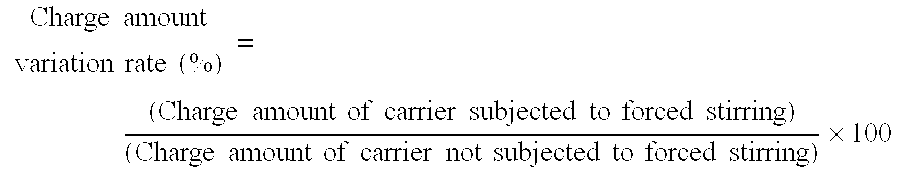

Resin-coated carrier for electrophotographic developer and electrophotographic developer using the resin-coated carrier

ActiveUS9557682B2Reduce weightHigh particle strengthDevelopersElectrographic process apparatusEngineeringUltimate tensile strength

Object of the present invention is to provide a resin-coated carrier for an electrophotographic developer with reduced carrier weight, carrier beads carry over is prevented, and further, excellent in carrier strength and stable charging property in endurance printing. To achieve the object, the carrier having a coated resin layer on the surface of a porous ferrite core material and the pore volume and the peak pore size of the porous ferrite core material are 55 to 160 mm3 / g and 0.2 to 0.7 μm, respectively, and an electrophotographic developer using the resin-coated carrier is adopted.

Owner:POWDERTECH

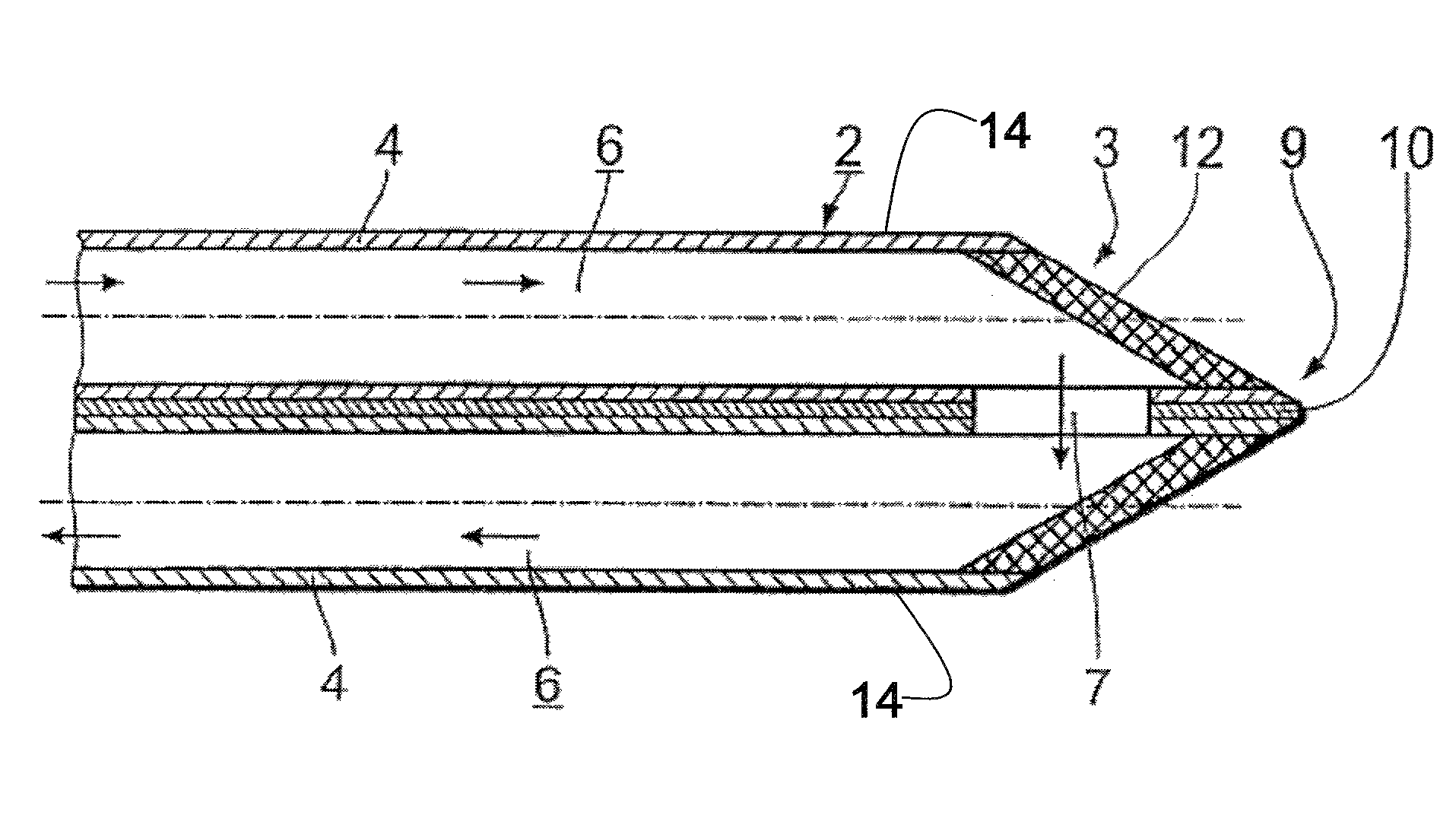

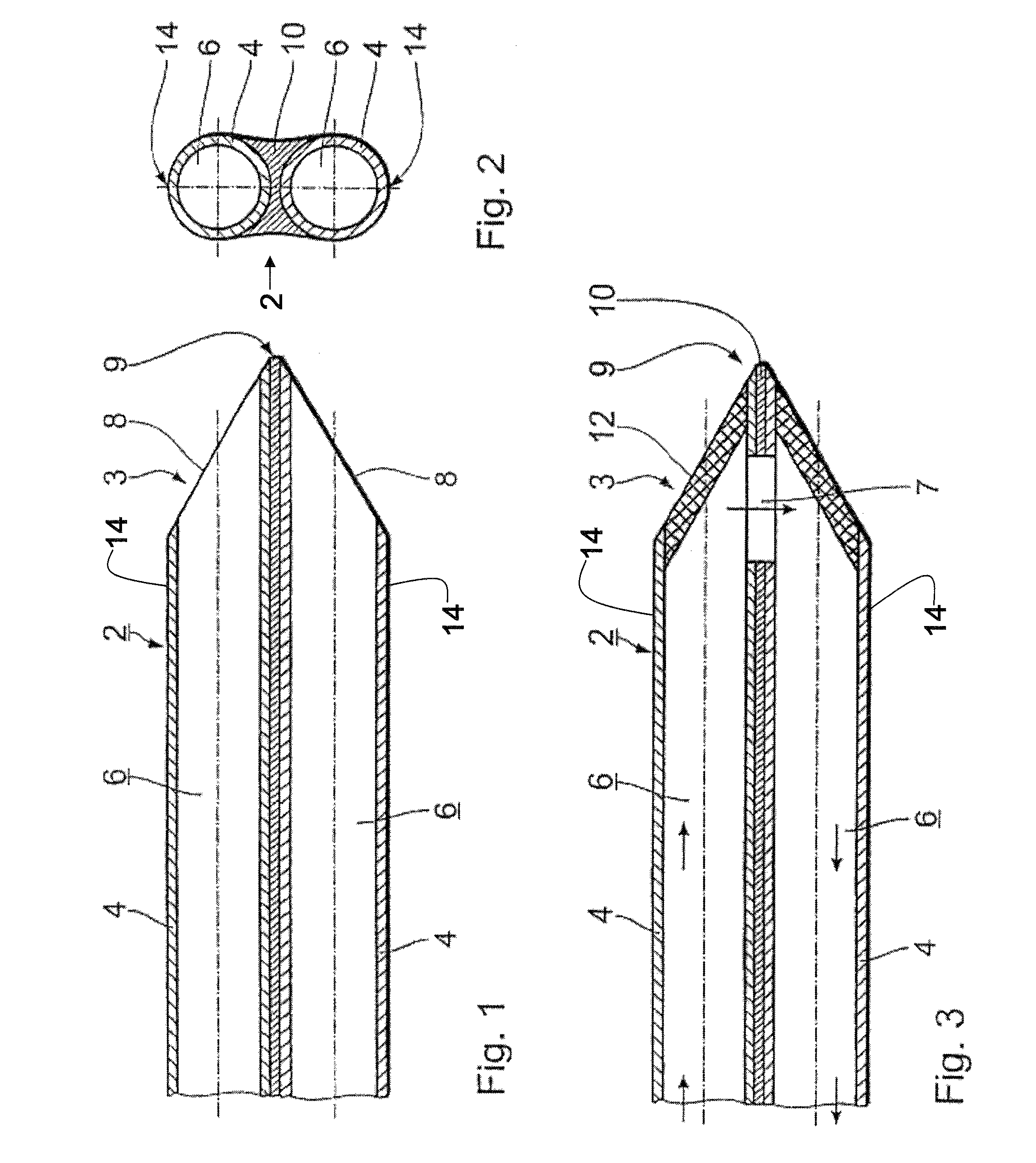

Electrode arrangement for surgical instrument

InactiveUS7666183B2Simple to produceEasy accessDiagnosticsSurgical instruments for heatingSurgical instrumentElectric heating

The invention concerns an electrode arrangement for a surgical instrument for the electrothermal coagulation of human or animal tissue, comprising an elongate carrier, at least two electrodes which extend in the longitudinal direction of the carrier and which are connectable to an external ac voltage, and a plurality of self-supporting metal bar profile members which extend in the longitudinal direction of the carrier and which are connected together by means of one or more insulating spacer elements and form the electrodes. It is achieved in that at least one bar profile member is in the form of a hollow profile member or a solid profile member.

Owner:CELON MEDICAL INSTR

Construction method of a carrier pile

ActiveCN105821836BLow dropLow drop distance for low tamping energyBulkheads/pilesCement pasteRe engineering

The invention provides a construction method for a carrier pile. The construction method comprises the steps that 1, a pile casing is sunk into the set depth; 2, a heavy hammer is sunk into the pile casing, the clearance between the heavy hammer and the pile casing can form an airflow channel, and a cement mixture can smoothly pass the airflow channel; 3, material filling and heavy hammer tamping operation are simultaneously conducted, when the heavy hammer is upwards lifted, the bottom end of the heavy hammer does not leave an upper opening of the pile casing, and when the heavy hammer falls to conduct tamping, the bottom end of the heavy hammer is not knocked out of the pile casing so that low-falling-distance small-energy tamping can be ensured; 4, the step 3 is repeated to enable a pile end soil body to be reinforced and compacted; 5, the compactness is controlled through the three-strike penetration or the filler quantity standard, and a pile end carrier is formed; 6, cement paste or cement mortar is poured; and 7, cast-in-place constructing or prefabricating of a concrete pile body is conducted. The construction method for the carrier pile has the technical characteristics and advantages that 1, the tamping mode of the heavy hammer is changed; 2, material filling and heavy hammer tamping are simultaneously conducted by redesigning filler, the heavy hammer and the pile casing; 3, the component of the filler is changed, and the strength of the carrier is improved; and 4, the processes of material filling, tamping and compactness controlling are continuously completed.

Owner:北京波森特岩土工程有限公司

Preparation method of degradable cellulose base filler used for water treatment

ActiveCN102603081BLow costMild dissolution conditionsBiological water/sewage treatmentCelluloseFiber

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

A kind of industrial wastewater treatment method

InactiveCN105541042BAvoid releachingAvoid harmTreatment involving filtrationMultistage water/sewage treatmentTreatment pondSludge

Owner:SHANDONG UNIV OF TECH

A kind of preparation method of hydrogenation catalyst

ActiveCN111068757BUniform and strong bondingUniform carrier propertiesMolecular sieve catalystsCatalyst activation/preparationPolycyclic aromatic hydrocarbonMolecular sieve

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of composite carrier

ActiveCN111068751BUniform and strong bondingUniform carrier propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveAlcohol

The invention discloses a preparation method of a composite carrier. The preparation method of the composite carrier of the present invention includes the following contents: (1) uniformly mixing pseudo-boehmite precursor slurry, molecular sieve and organic alcohol to obtain slurry A; (2) adding silane coupling agent to step (1 ) mixed evenly in the obtained slurry A, and then adjusted the pH value of the slurry to 7.5~11 to obtain the slurry B; (3) The slurry B obtained in step (2) was aged under a certain pressure, and after the aging was completed, the material was removed by filtration After a certain amount of water is added, organic amine and silane coupling agent are added to knead to form a plastic body, and after molding, drying and roasting, a composite carrier is obtained. In this method, molecular sieves are introduced during the growth process of alumina crystal nuclei, and a silane coupling agent is added. Through the hydrolysis of the silane coupling agent, the combination of alumina crystals and molecular sieves occurs in an orderly manner, avoiding the agglomeration of alumina and molecular sieves, and effectively controlling the carrier. pores and surface acid formation.

Owner:CHINA PETROLEUM & CHEM CORP +1

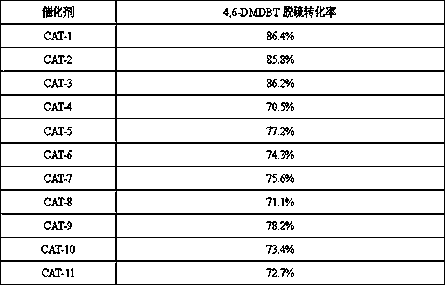

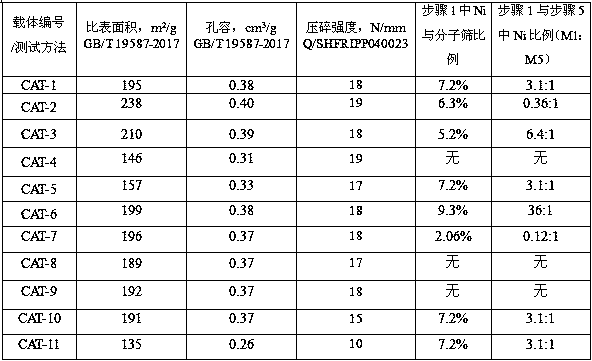

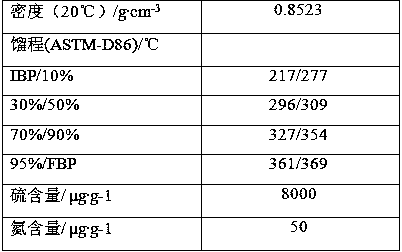

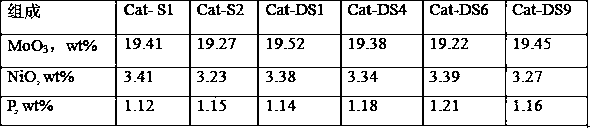

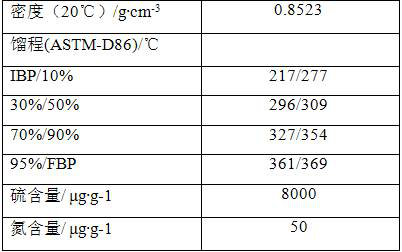

Preparation method of hydrodesulfurization and dearomatization catalyst

ActiveCN113522352AAvoid reunionEffective control formationMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrodesulfurization and dearomatization catalyst, which comprises the following steps: (1) loading group VIII metal onto a molecular sieve to obtain a material A; (2) uniformly mixing the material A, pseudo-boehmite precursor slurry and organic alcohol, then adding a silane coupling agent I, uniformly mixing the components, and adjusting the pH value to be alkaline to obtain slurry; (3) aging the slurry obtained in the step (2), after the aging is finished, filtering the material to remove certain moisture, adding organic amine and a silane coupling agent II, kneading into a plastic body, forming, drying and roasting the plastic body, and reducing group VIII metal in a hydrogen atmosphere to obtain a composite carrier; (4) loading group VIII metal and group VIB metal onto the composite carrier to prepare the catalyst. The catalyst prepared by the method gives full play to the acidity and hydrogen overflow effect of the molecular sieve, has very high hydrogenation performance, and is easy to desulfurize after hydrogenation of which sulfides are difficult to directly remove and carry out hydrogenation saturation of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of adsorbent for removing mercury from natural gas and its preparation method

ActiveCN107486133BImprove carrier strengthFast mercury removalOther chemical processesGaseous fuelsVulcanizationSorbent

The invention discloses a natural gas demercuration adsorbent and a preparation method. The natural gas demercuration adsorbent comprises the following components in parts by mass: 82-95% of Al2O3, 4-12% of sulfur and 1-6% of copper sulfide. The preparation method comprises the following steps: (1) dipping Al2O3 in a sulfur solution; (2) soaking the product of the step (1) with a dissoluble copper solution; (3) exposing the product of the step (2) in a vulcanization environment for vulcanization; (4) washing with deionized water; (5) drying, thereby obtaining the natural gas demercuration adsorbent. The natural gas demercuration adsorbent prepared according to the preparation method disclosed by the invention is high in carrier strength, stable in specific surface, pore volume and pore size, high in demercuration speed, large in mercury capacity and small in use amount.

Owner:CHANGZHOU UNIV

A modified alumina carrier and its preparation method and hydrorefining catalyst

ActiveCN111068750BImprove adsorption capacityHigh reactivityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a modified alumina carrier, its preparation method and a hydrofining catalyst. Based on the weight of the modified alumina carrier, it includes molecular sieve, graphene and alumina, and has a specific surface area of 300-400m 2 / g, the pore volume is 0.5‑0.8cm 3 / g, the average pore size is 7‑9nm. The preparation method of the carrier is as follows: (1) Mix pseudo-boehmite precursor slurry, mesoporous molecular sieve, graphene and organic alcohol to obtain slurry A; (2) Add silane coupling agent to slurry A and mix evenly, Then adjust the pH value to obtain the slurry B; (3) Aging the slurry B. After the aging is over, the material is filtered to remove a certain amount of water, and then an organic amine and a silane coupling agent are added to knead into a plastic body. After molding, drying and roasting , to obtain a modified alumina carrier. The modified alumina carrier of the present invention has better adsorption capacity of hydrogen molecules and hydrogen overflow properties, and the hydrogenation refining catalyst prepared by the carrier is suitable for a liquid phase circulation hydrogenation process and has good hydrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

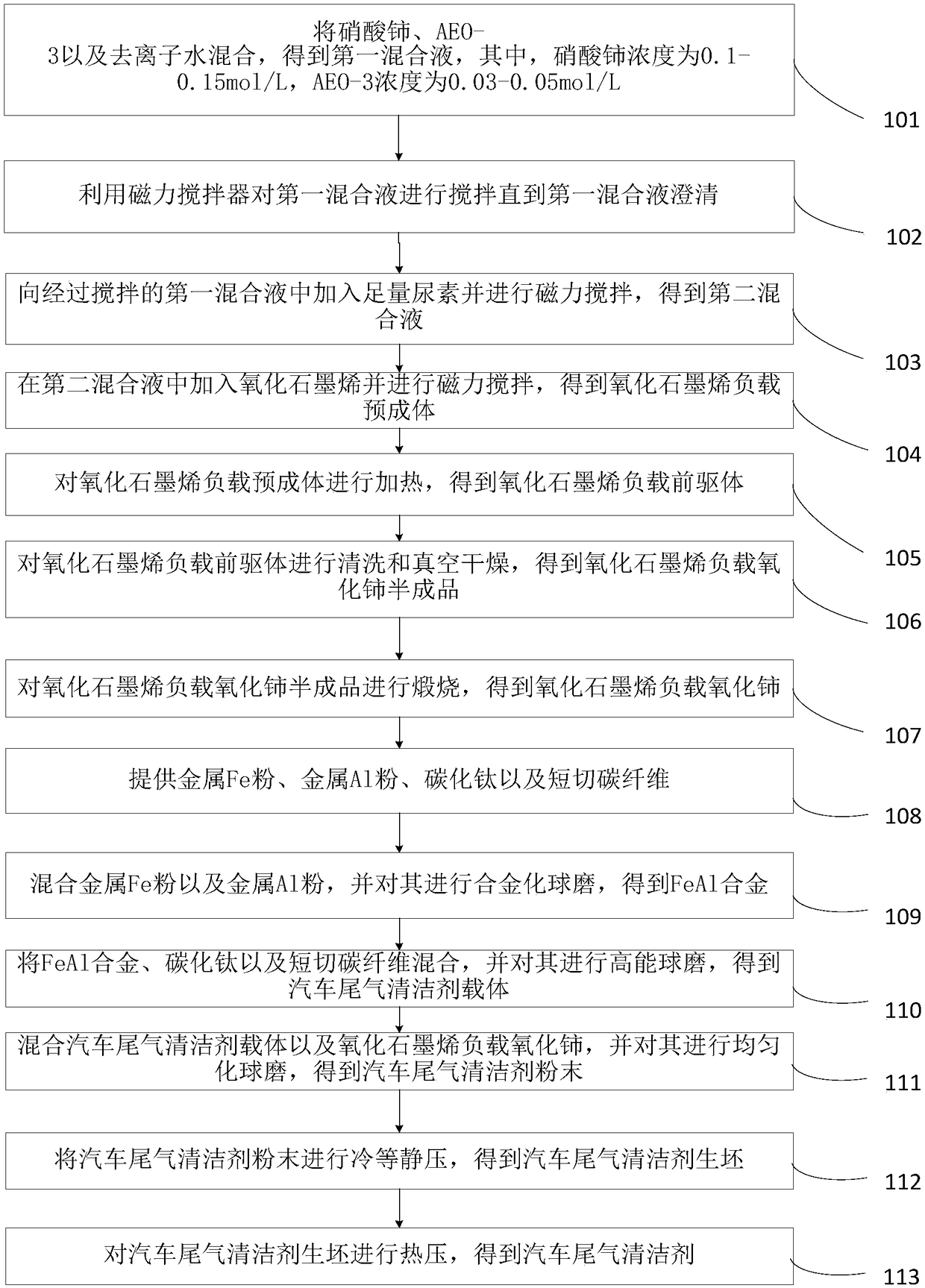

Green and environment-friendly automobile tail gas cleaning agent and preparation method thereof

InactiveCN109364714AExtended service lifeSimple processGas treatmentDispersed particle separationAl powderFiber

The invention provides a green and environment-friendly automobile tail gas cleaning agent. A preparation method of the cleaning agent includes the steps: mixing cerium nitrate, AEO-3 and deionized water to obtain first mixed solution; stirring the first mixed solution until the first mixed solution is clarified, adding sufficient urea into the first mixed solution to magnetically stir mixture toobtain second fixed liquid; adding graphene oxide into the second fixed liquid to magnetically stir mixture, heating the mixture, performing cleaning and vacuum drying to obtain a graphene oxide loaded cerium oxide semi-finished product; calcining the graphene oxide loaded cerium oxide semi-finished product to obtain graphene oxide loaded the cerium oxide; providing metal Fe powder, metal Al powder, titanium carbide and short carbon fibers; repeatedly ball-milling the metal Fe powder, the metal Al powder, the titanium carbide, the short carbon fibers and the graphene oxide loaded the cerium oxide to obtain automobile tail gas cleaning agent powder; performing isostatic cool pressing and hot pressing on the automobile tail gas cleaning agent powder to obtain the automobile tail gas cleaningagent. The method is high in production efficiency, and the automobile tail gas cleaning agent is high in treatment efficiency.

Owner:方雪美

Construction method of a static pressure carrier pile

ActiveCN105926621BAvoid destructionSmall particle sizeBulkheads/pilesStructural engineeringEngineering

The invention provides a construction method for a static pressure carrier pile. The construction method for the static pressure carrier pile includes the steps that firstly, an outer pipe is clasped by a clamping system of a static pile driver, and an inner pipe is sleeved with the outer pipe in an overlapped manner; secondly, the outer pipe is pressed by the designed depth in a static pressing manner; thirdly, the inner pipe is clasped by the clamping system; fourthly, the inner pipe is lifted up, a gap between the inner pipe and the outer pipe is filled with a fine particle packing material, the inner pipe is clasped, and the packing material is pressed downwards; fifthly, downward-pressing operation of the packing material is repeated till a carrier is formed at the bottom end of the pile, and the tip resistance pressure numerical value is observed; and sixthly, a cast-in-situ or embedded concrete pile body is manufactured. The other construction method for the static pressure carrier pipe includes the steps that firstly, sinking of a pile casing is conducted; secondly, a prefabricated pile body is clasped by the clamping system of the static pile driver and is sunk into the pile casing; thirdly, the prefabricated pile body is lifted up, a gap between the pile casing and the prefabricated pile body is filled with the fine particle packing material, the prefabricated pile body is clasped, and the packing material is pressed downwards; fourthly, downward-pressing operation of the packing material is repeated till the carrier is formed at the bottom end of the pile, and the tip resistance pressure numerical value is observed; and fifthly, the gap between the pile casing and the prefabricated pile body is filled with cement mortar, the pile casing is lifted out, and the pile is formed.

Owner:王继忠

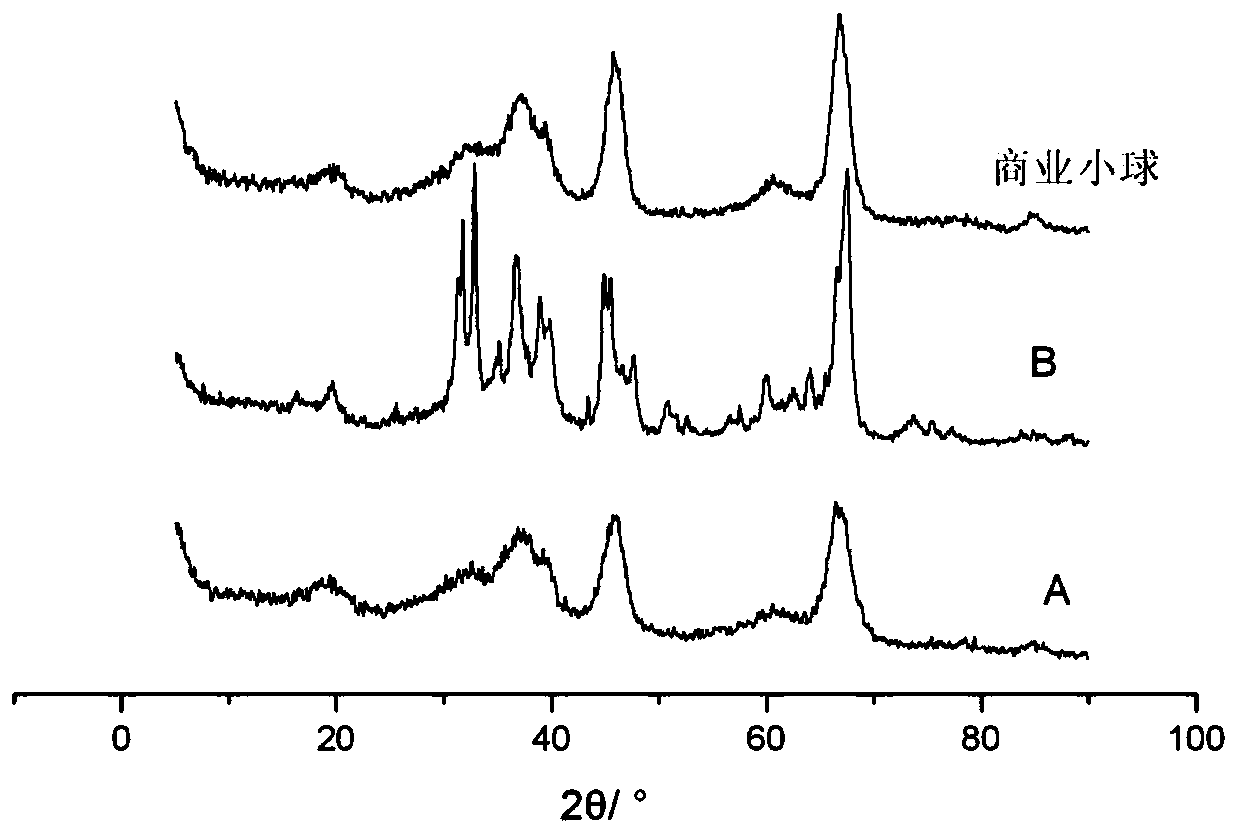

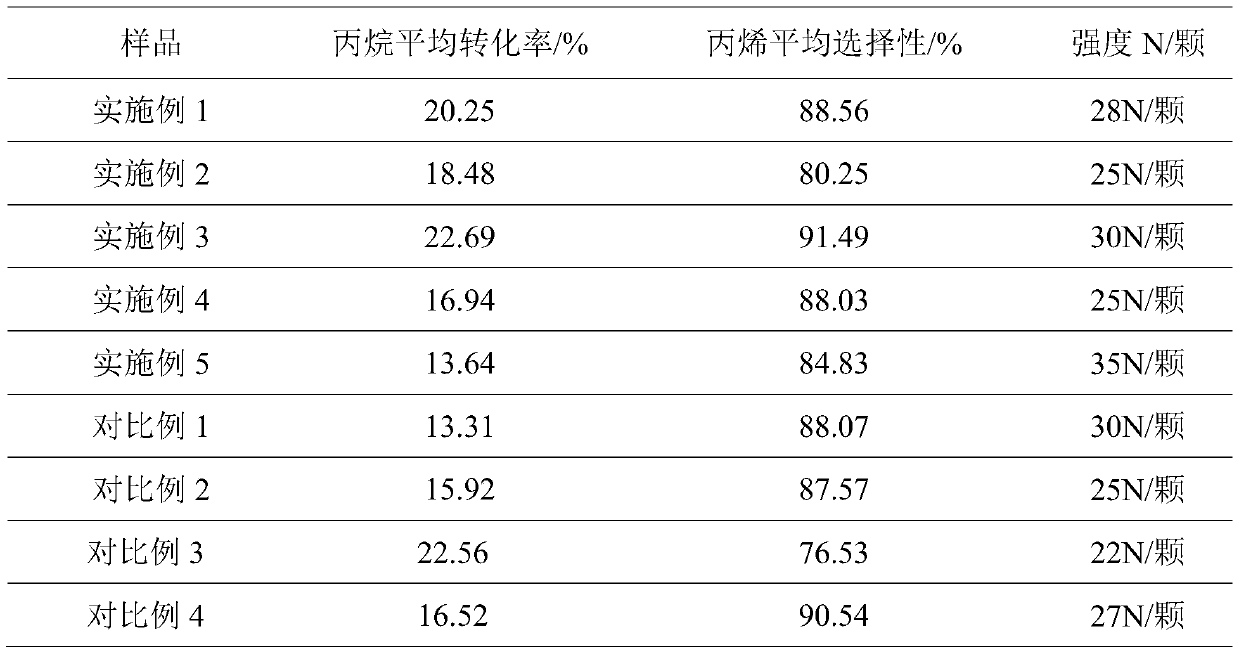

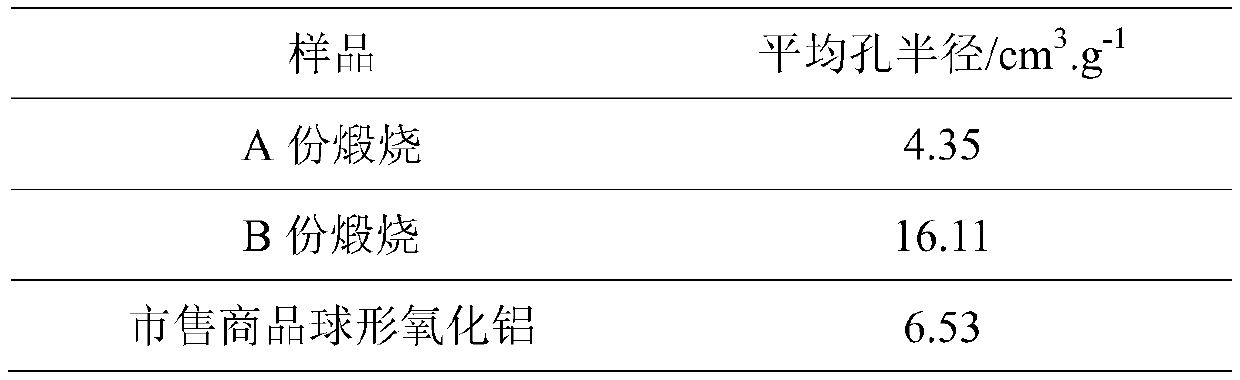

A kind of propane dehydrogenation propylene composite alumina support catalyst and preparation method thereof

ActiveCN107899619BMeet the requirements of hydroconversionImprove conversion rateCatalyst carriersCatalyst activation/preparationPseudoboehmiteActive component

The invention provides a composite alumina carrier catalyst for propane dehydrogenation for producing propylene, and belongs to the technical field of dehydrogenation catalysts. The catalyst comprises0.1-0.4% of a precious metal Pt, 0.5-4.0% of a modifier, and the balance of a composite alumina carrier, and the composite alumina carrier is a gamma-alumina and theta-alumina mixture, and the mass fraction of the gamma-alumina in the carrier is 30-80%. The invention also provides a preparation method of the catalyst. The preparation method comprises the following steps: dividing pseudoboehmite into a part A and a part B, calcining the part A and the part b in different modes to respectively obtain the gamma-alumina and theta-alumina, mixing the gamma-alumina with the theta-alumina, adding modification elements, and carrying out impregnation to load an active component. The gamma-alumina and theta-alumina are used as a composite alumina carrier, the pores of the catalyst carrier are adjusted, and the carrier is modified with multiple component elements, so the catalyst has the advantages of excellent propane dehydrogenation activity and stability, simple forming technology, high strength, high applicability and excellent industrial application prospect.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Core material for resin-filled ferrite carrier and ferrite carrier for electrophotographic developer, and electrophotographic developer using the ferrite carrier

ActiveUS9201328B2Increased durabilityImprove carrier strengthDevelopersUltimate tensile strengthCoefficient of variation

Disclosed are a resin-filled ferrite carrier core material for an electrophotographic developer, including a porous ferrite particle having an average compression strength of 100 mN or more and a coefficient of variation of the compression strength of 50% or less, a ferrite carrier obtained by filling a resin in the voids of the ferrite carrier core material, and an electrophotographic developer using the ferrite carrier.

Owner:POWDERTECH

A kind of preparation method of p-fluoronitrobenzene

ActiveCN108586257BReasonably adjust the dosage ratioImprove carrier strengthOrganic chemistryOrganic compound preparationPtru catalystOrganic synthesis

The invention discloses a novel preparation method of p-fluoronitrobenzene, and relates to the field of organic synthesis. The method concretely comprises the following steps of firstly crushing durian shells; adding ethanol; performing ball milling to prepare durian shell powder; then, mixing the durian shell powder with urea; performing sintering treatment at a certain temperature to obtain mixed powder; adding the mixed powder into a tetrabutylammonium chloride solution for stirring and still standing treatment; then, performing drying to obtain a catalyst; adding reaction raw materials ofpara-nitrochloro-benzene, potassium fluoride and the catalyst into a reaction kettle; performing sealing; performing reaction at a certain temperature; after the reaction is completed, performing water washing and layering treatment; performing organic layer rectification to obtain a target product. The method disclosed by the invention has the advantages that the operation is simple; a solvent isnot used in the reaction process; the cost is effectively reduced; the product yield is high.

Owner:SHANGYU XIES CHEM IND

Catalyst for producing isobutene by dehydrogenating isobutane

InactiveCN112717919ALow selectivityHigh selectivityCatalyst carriersHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention relates to a catalyst for producing isobutene by dehydrogenating isobutane, which takes VIB group elements in a periodic table of elements as main active components, at least one element in IIA group of the periodic table of elements as an alkaline assistant, at least one element in IVB group and VB group of the periodic table of elements as other assistants, and silicon-aluminum oxide as a carrier; wherein the carrier is treated by a hot solution containing group IIA elements in the periodic table of elements, and then is loaded with other components to obtain the dehydrogenation catalyst with the specific surface area of 100-300 m2 / g and the average pore size of 2-20 nm. The catalyst obtained by the method can improve the activity and selectivity of the isobutane dehydrogenation catalyst prepared by the prior art, and can be used for industrial application of isobutane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for alumina carrier

ActiveCN102309997BNo pollution in the processImprove carrier strengthCatalyst carriersMicron scalePtru catalyst

The invention discloses a preparation method for an alumina carrier. Two kinds of different pseudo-boehmite dry colloid powder are adopted in the method, wherein the first pseudo-boehmite has relatively low crystallization degree and large pore volume and can provide pores with diameter of 30 to 100 nanometers; and the second pseudo-boehmite has relatively high crystallization degree and can provide pores of micron scale, the second pseudo-boehmite represents extremely hard blocks after drying due to high acidic index, and the crushed second pseudo-boehmite can completely pass through a 50-mesh sieve, so that the number of micro-scale pores can be increased, and the strength of the catalyst carrier can be improved. By adjusting the mixing proportion of the two kinds of pseudo-boehmite, the alumina carrier with high strength, high stacking density, large pore volume and low abrasion rate can be prepared. The alumina carrier is particularly suitable to be used as a carrier of heavy oil or residuum hydro-treating protecting agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com