Patents

Literature

129results about How to "Low strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimicrobial radiation curable coating

InactiveUS7098256B2The environment is moreOptimal for incorporationBiocideAntifouling/underwater paintsCross-linkCarbamate

Owner:MICROBAN PROD CO INC

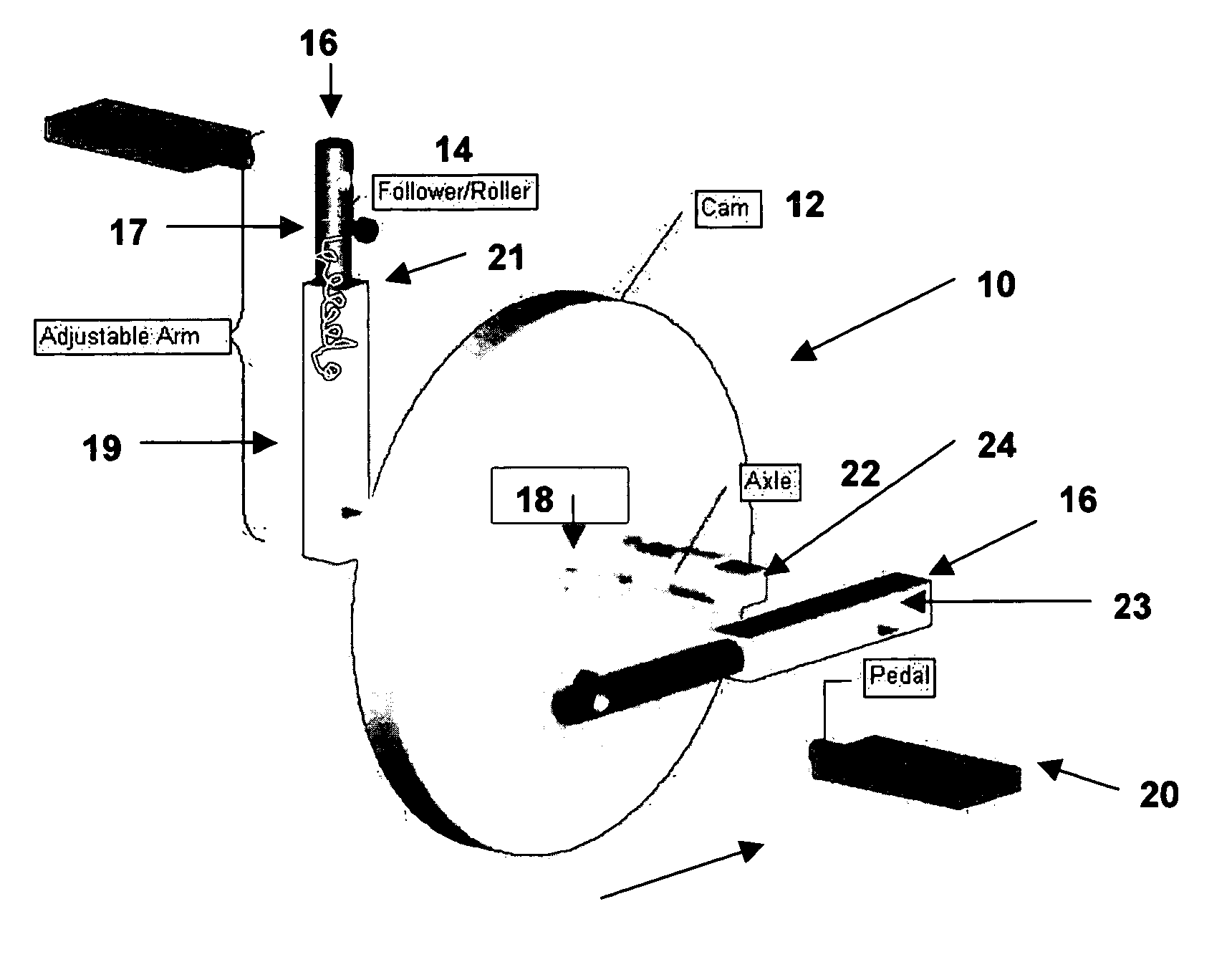

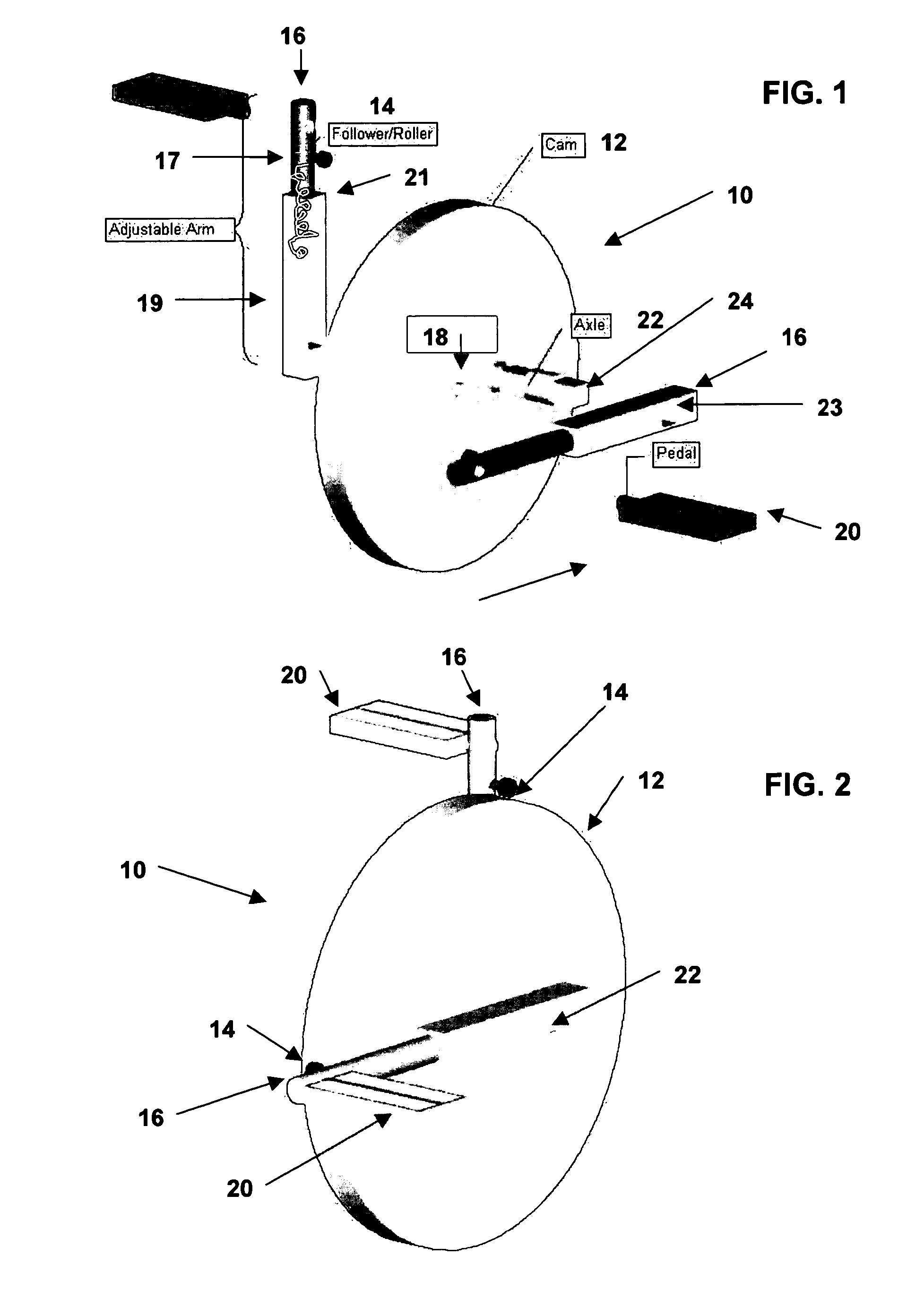

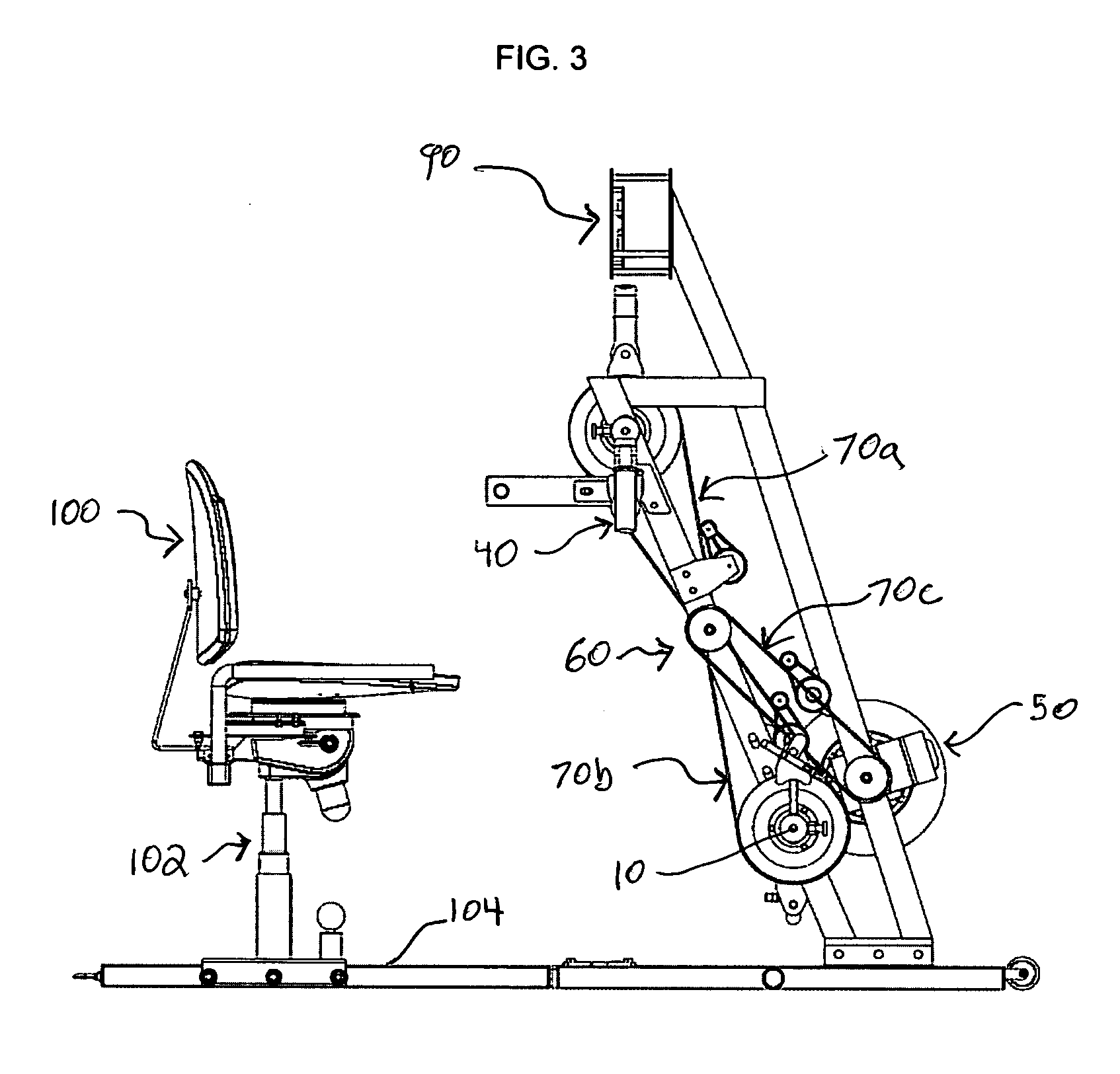

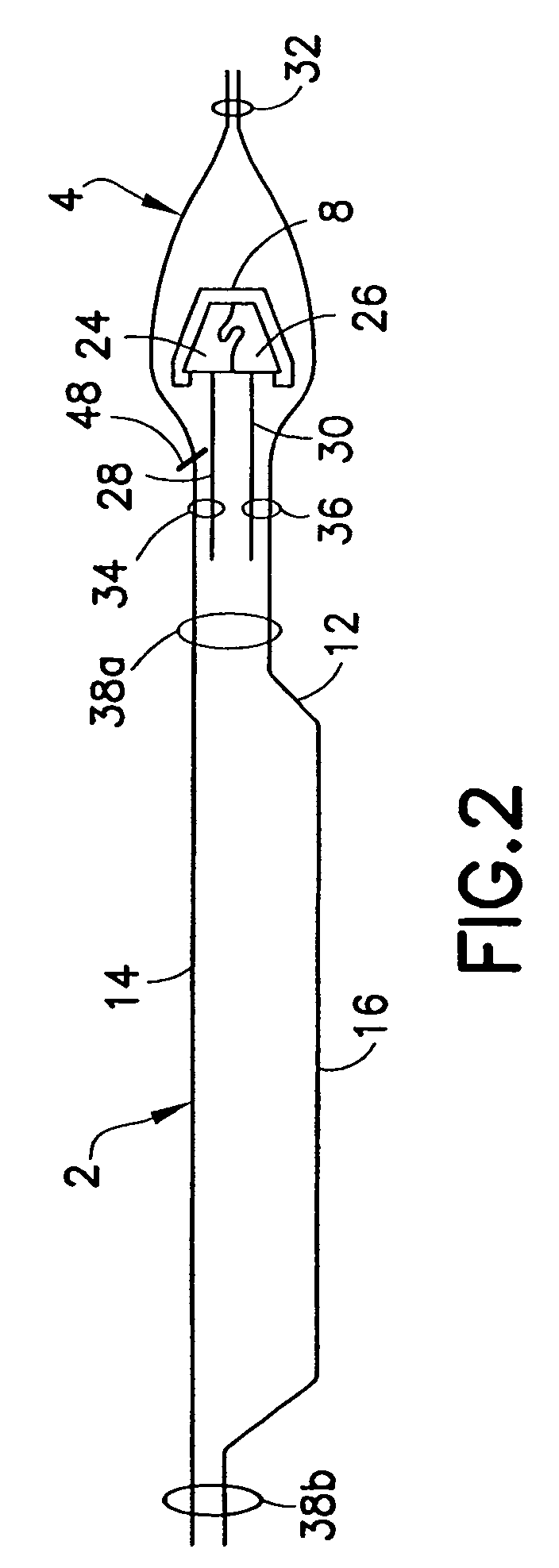

Independent and separately actuated combination fitness machine

InactiveUS20060003871A1Reduce manufacturing costMeet needsMuscle exercising devicesMovement coordination devicesClutchEngineering

An exercise apparatus combining a stationary bike and upper body extremity hand cycle, includes an upper hand crank assembly rotatable under a resistance load for upper body conditioning and a lower foot crank assembly rotatable under a resistance load for lower body conditioning. The upper hand crank assembly and lower foot crank assembly are independently connected to the resistance load through respective upper and lower driving belts. Either an upper clutch or lower clutch, communicating with the upper or lower crank assemblies respectively, selectively engages the driving belts to drive the resistance load. The upper and lower crank assemblies are independent of each other, and each is operable to separately engage the resistance load to transfer the resistance load to the respective upper hand crank assembly or lower foot crank assembly.

Owner:DISABILITY INCLUSION SOLUTIONS

Semi-aromatic polyamide resin

InactiveUS20090098325A1Good adhesive propertyHigh residence stability and hot water resistanceSynthetic resin layered productsFlexible pipesDiamineCarboxylic group

A semi-aromatic polyamide resin is provided which has a high level of residence stability, hot-water resistance and chemical resistance and is also excellent in adhesive properties and compatibility with other resins and the like.The semi-aromatic polyamide resin comprises: dicarboxylic acid units in which 50 to 100 mol % of the dicarboxylic acid units are aromatic dicarboxylic acid units; and diamine units in which 60 to 100 mol % of the diamine units are aliphatic diamine units having 9 to 13 carbon atoms. Furthermore, at least 10% of terminal groups of molecular chains of the polyamide resin are blocked with a terminal-blocking agent, and the amount of terminal amino groups of the molecular chains is 60 μeq / g or more and 120 μeq / g or less. In addition, [NH2] / [COOH]≧6 is satisfied, where [NH2] (μeq / g) represents the amount of the terminal amino groups and [COOH] (μeq / g) represents the amount of terminal carboxyl groups.

Owner:KURARAY CO LTD

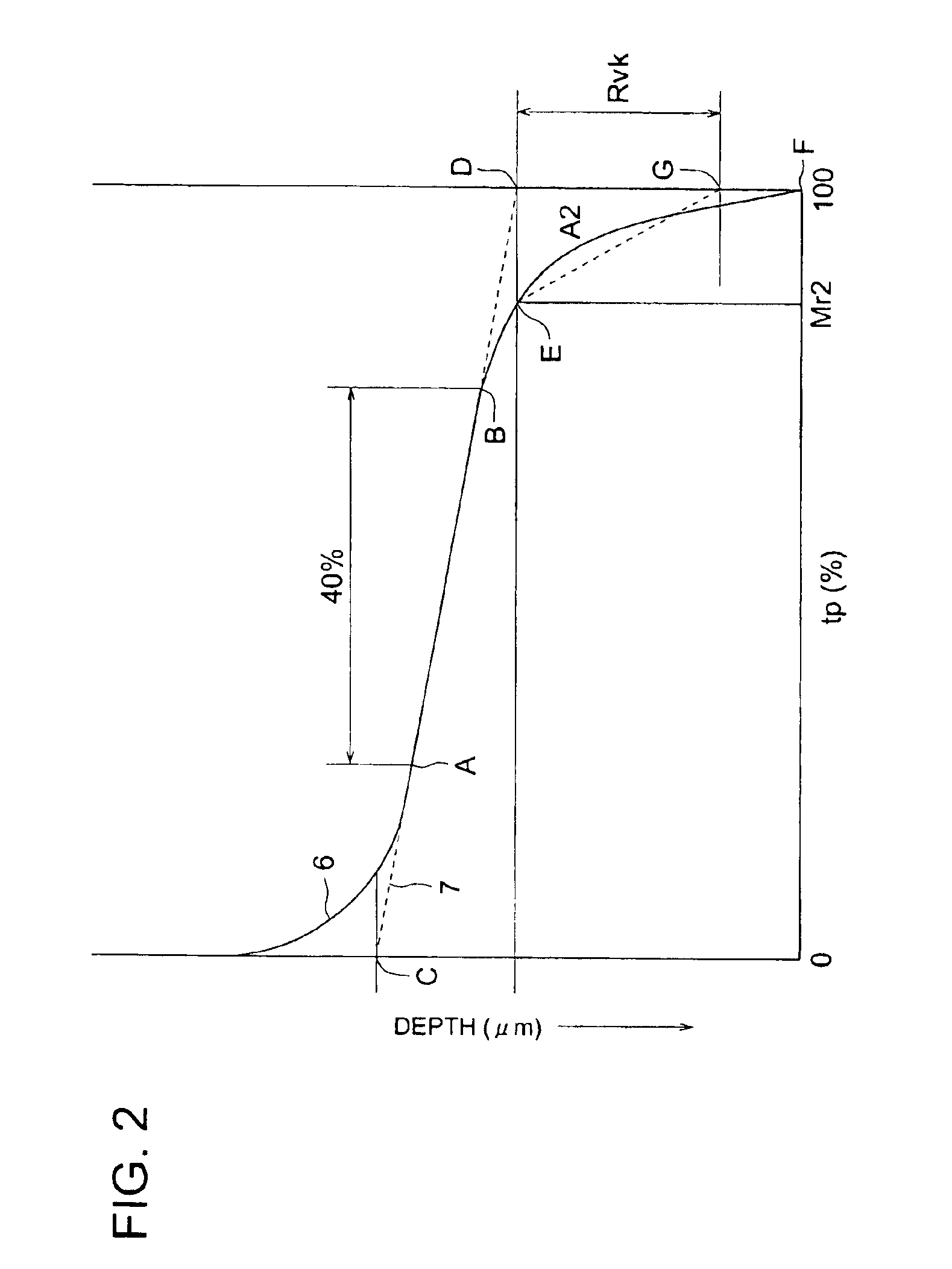

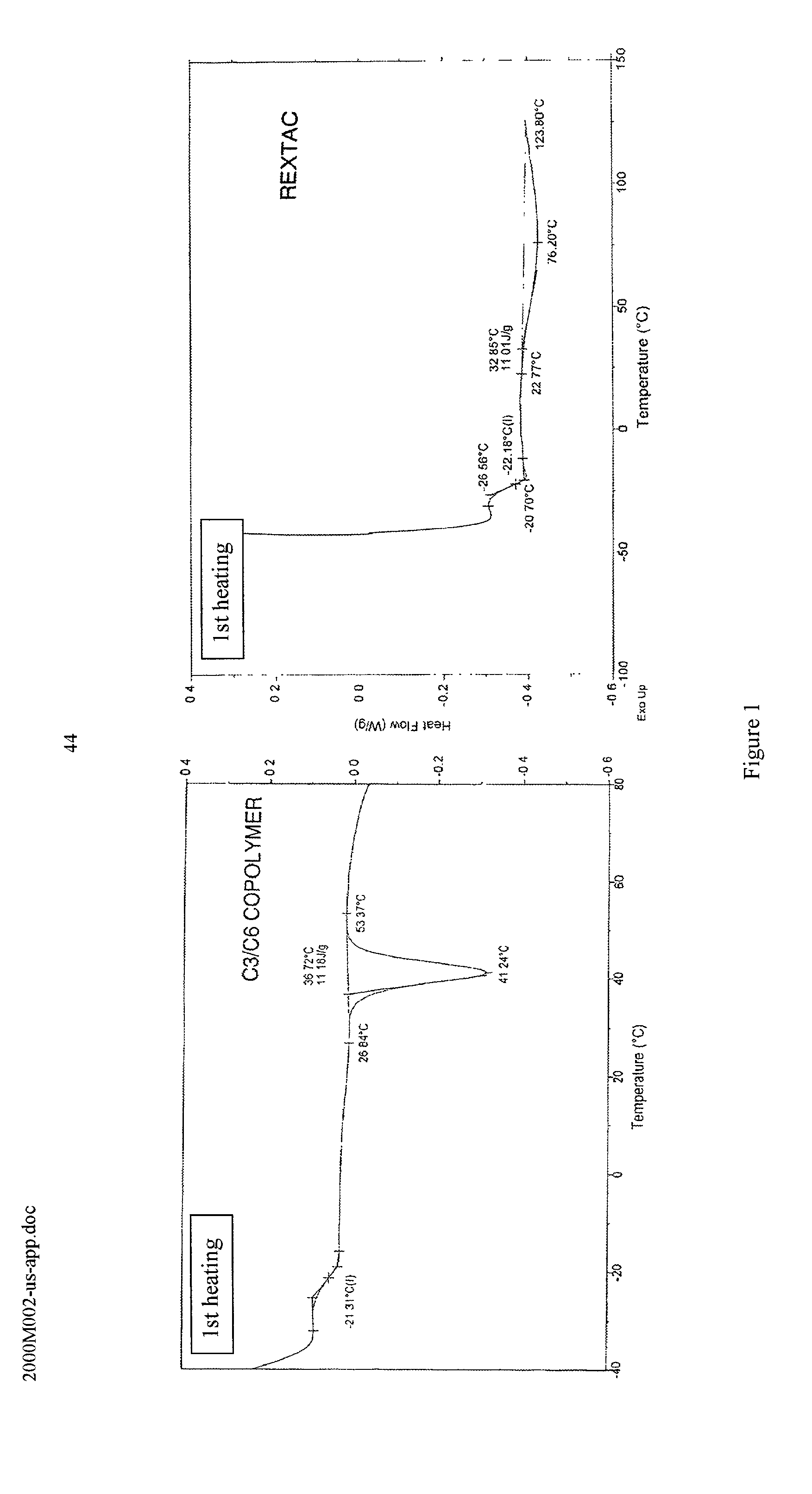

Adhesive alpha-olefin inter-polymers

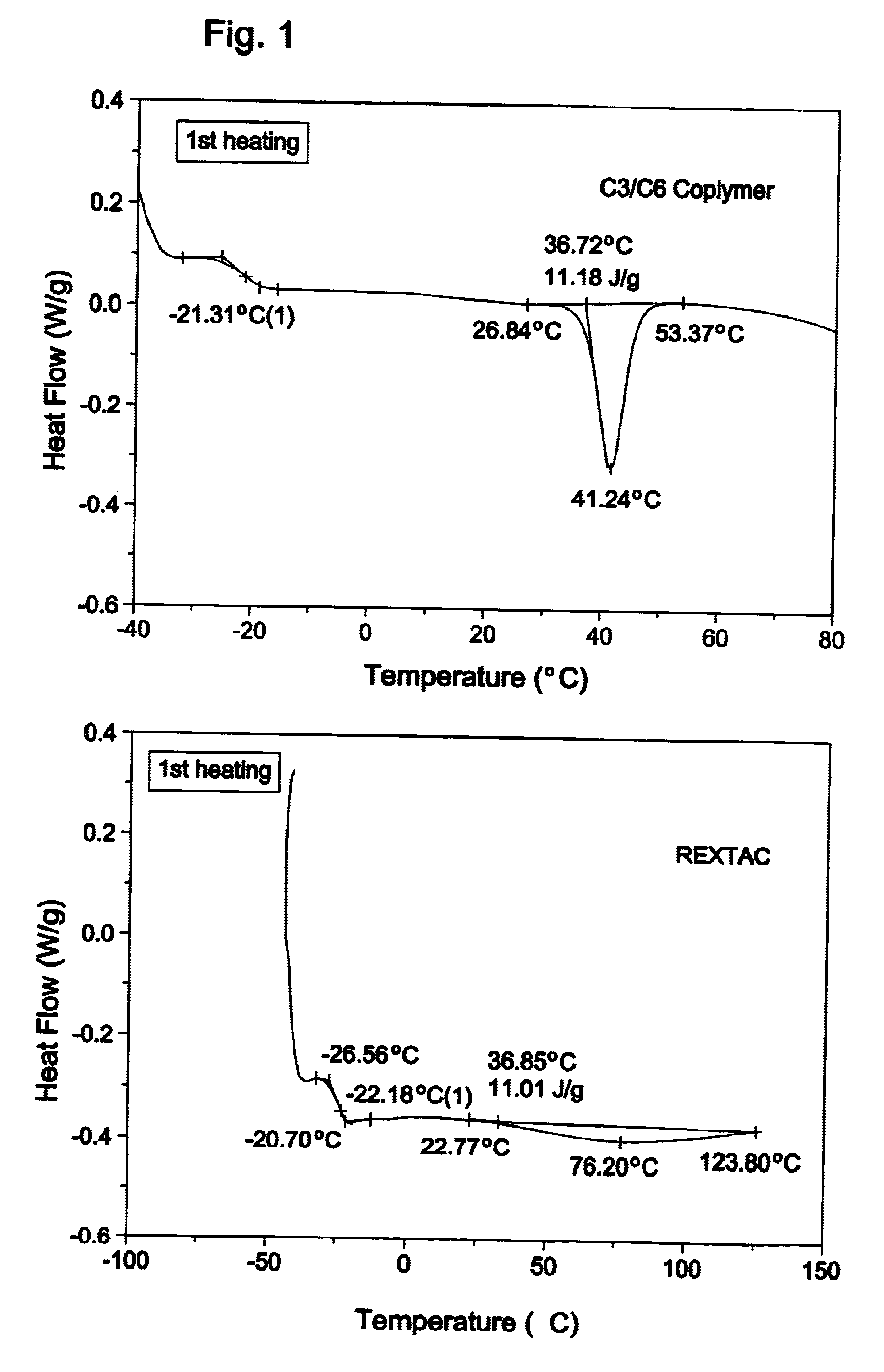

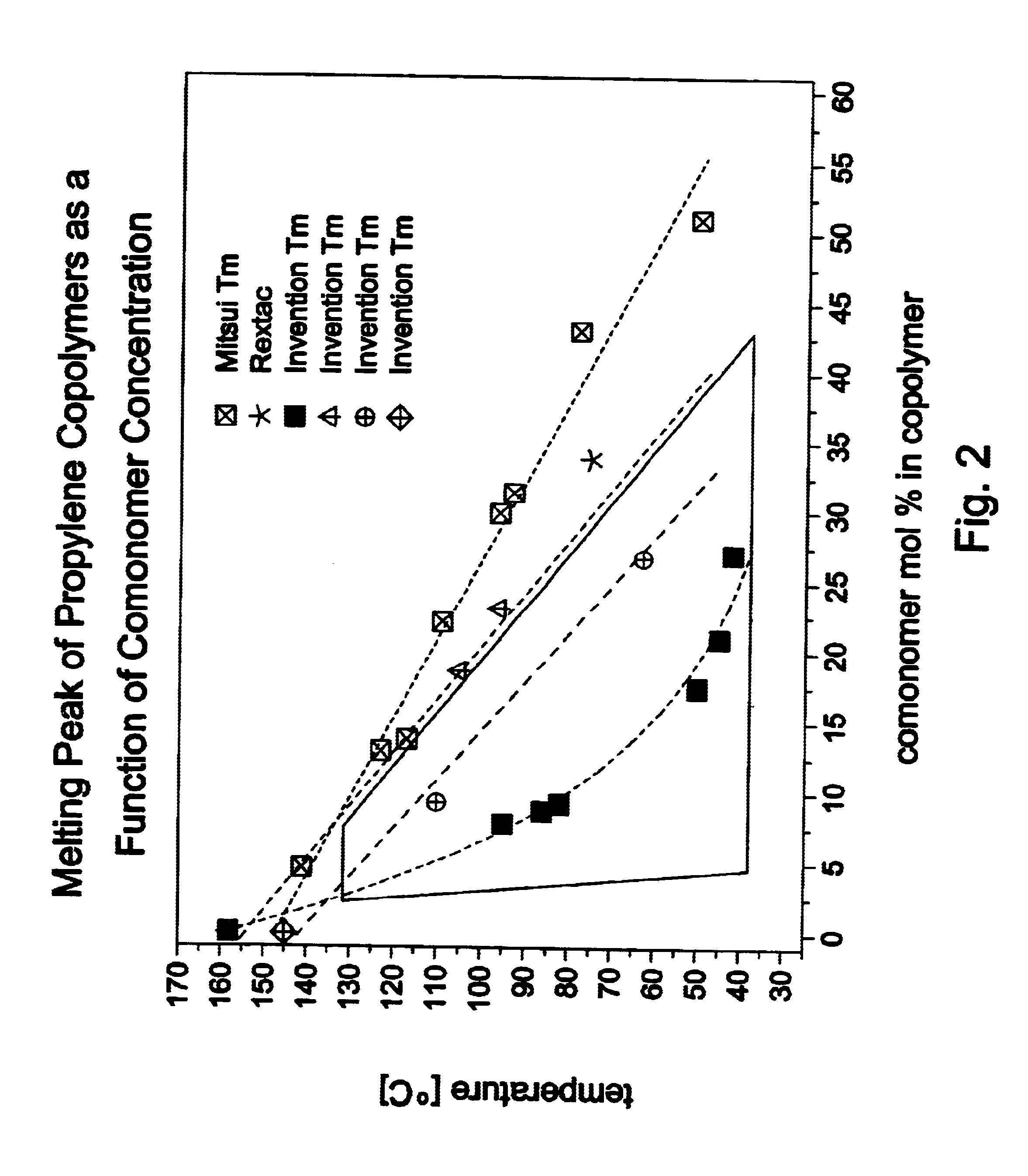

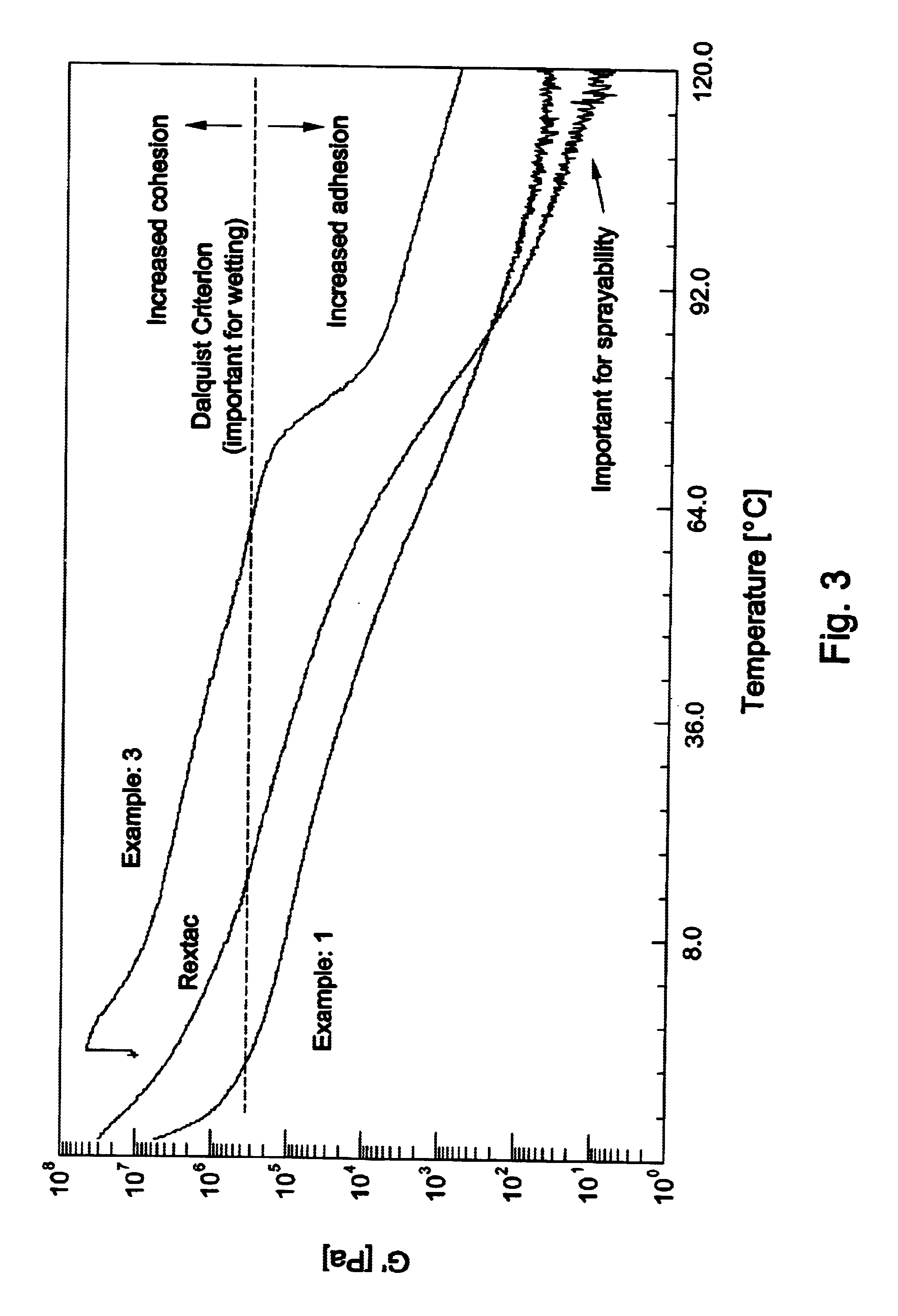

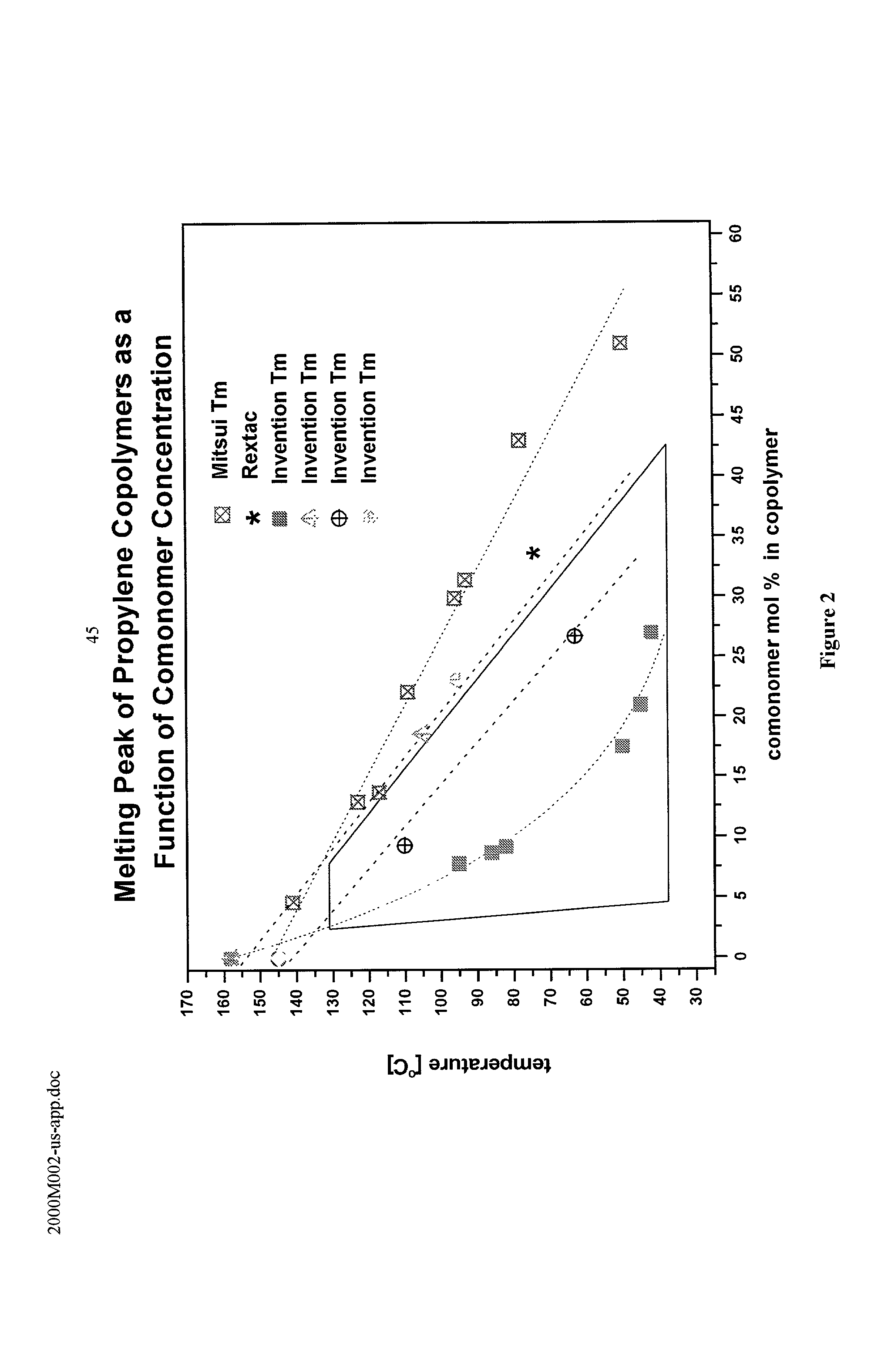

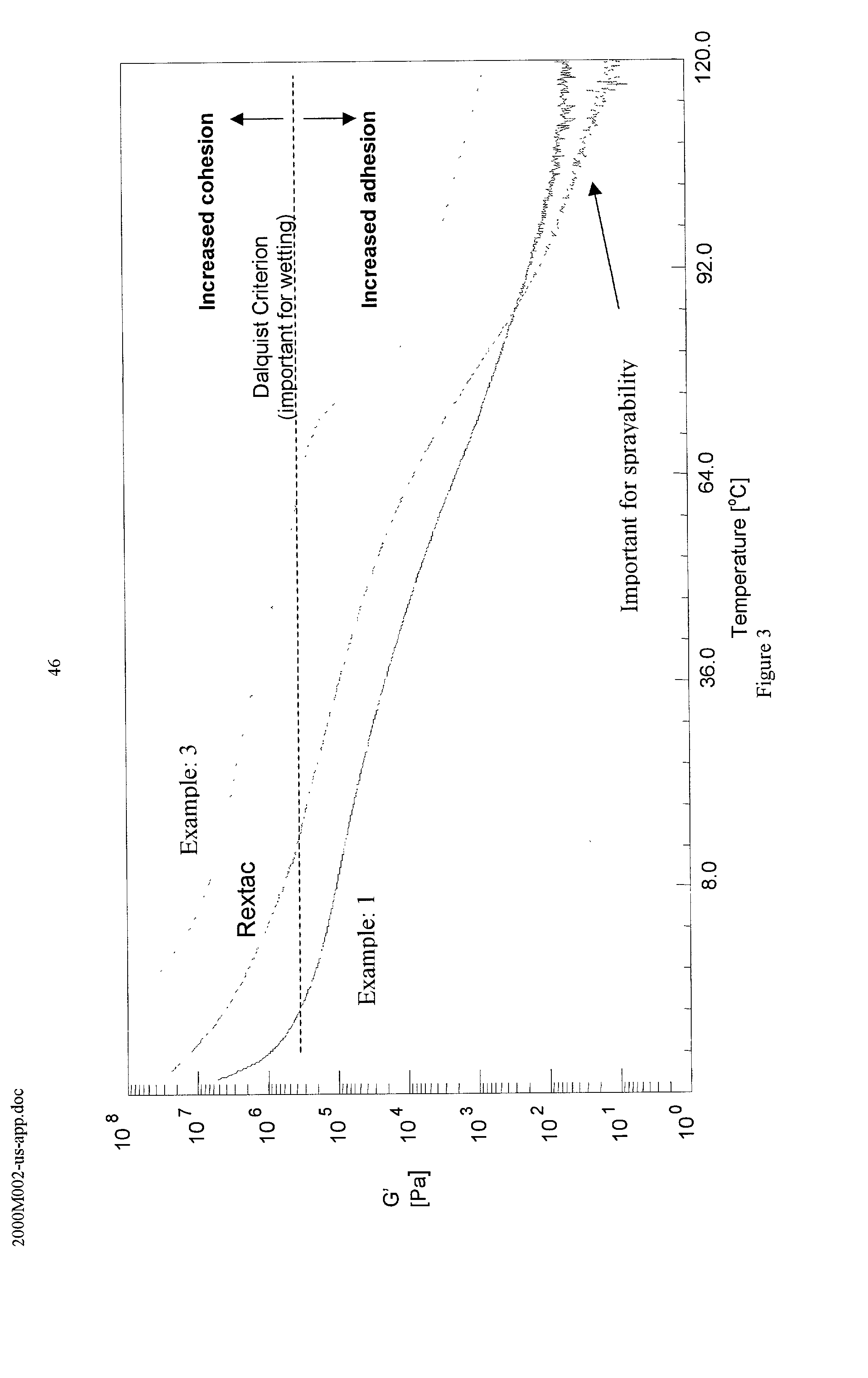

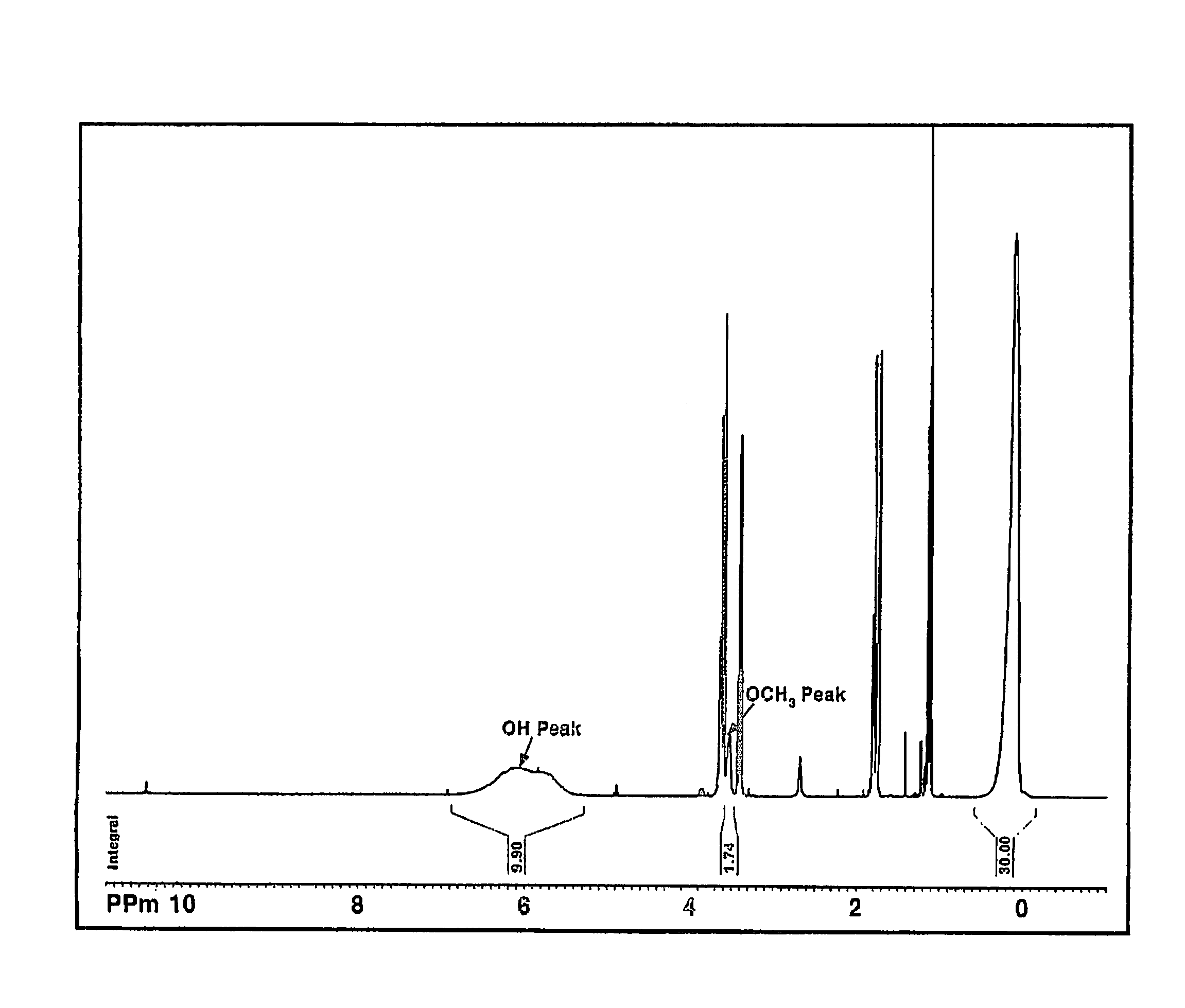

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a rheological behavior that makes them suitable for adhesive use, both without and with minimized amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 mol % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by <13>C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.10<5 >Pa at a temperature of less than 85° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

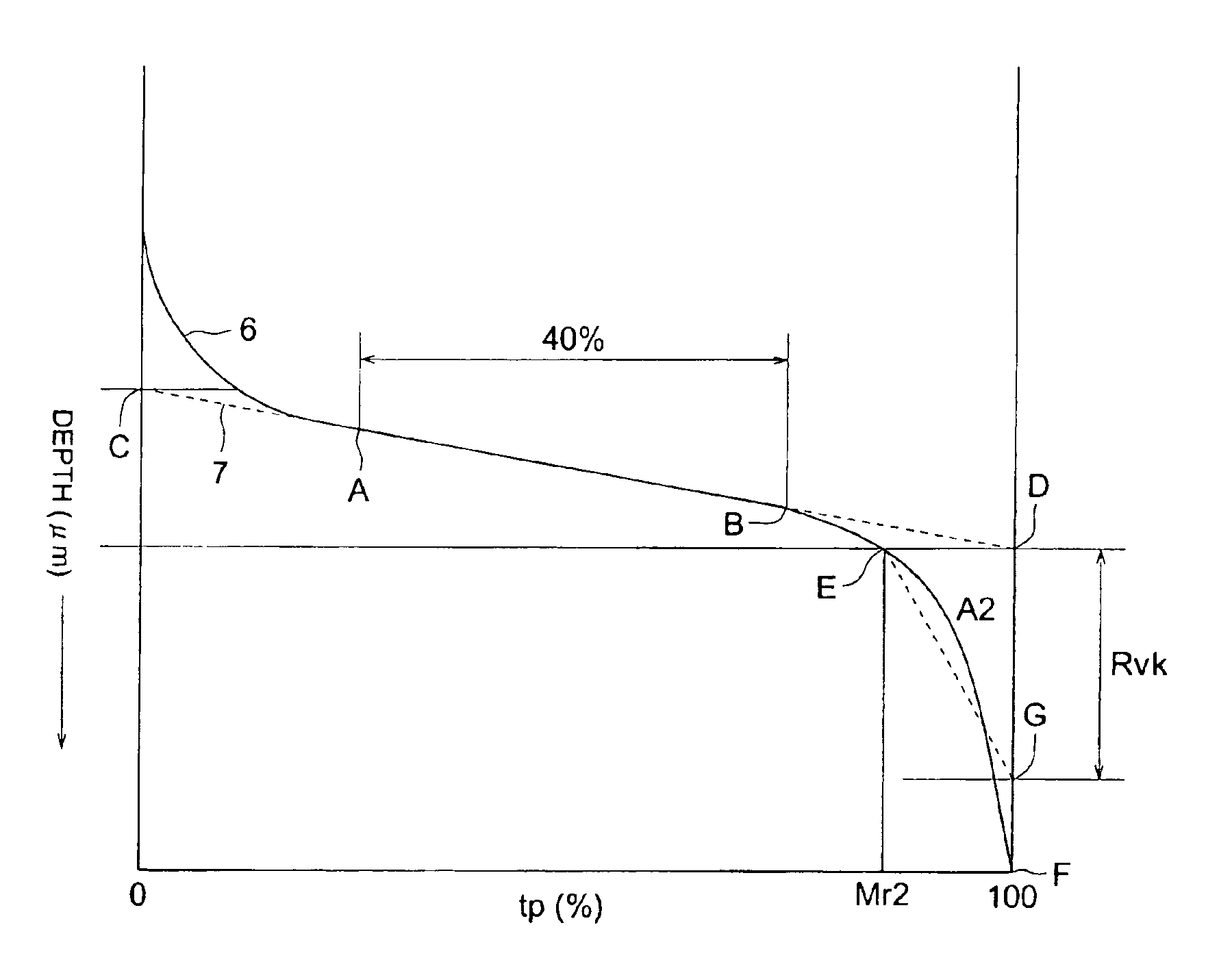

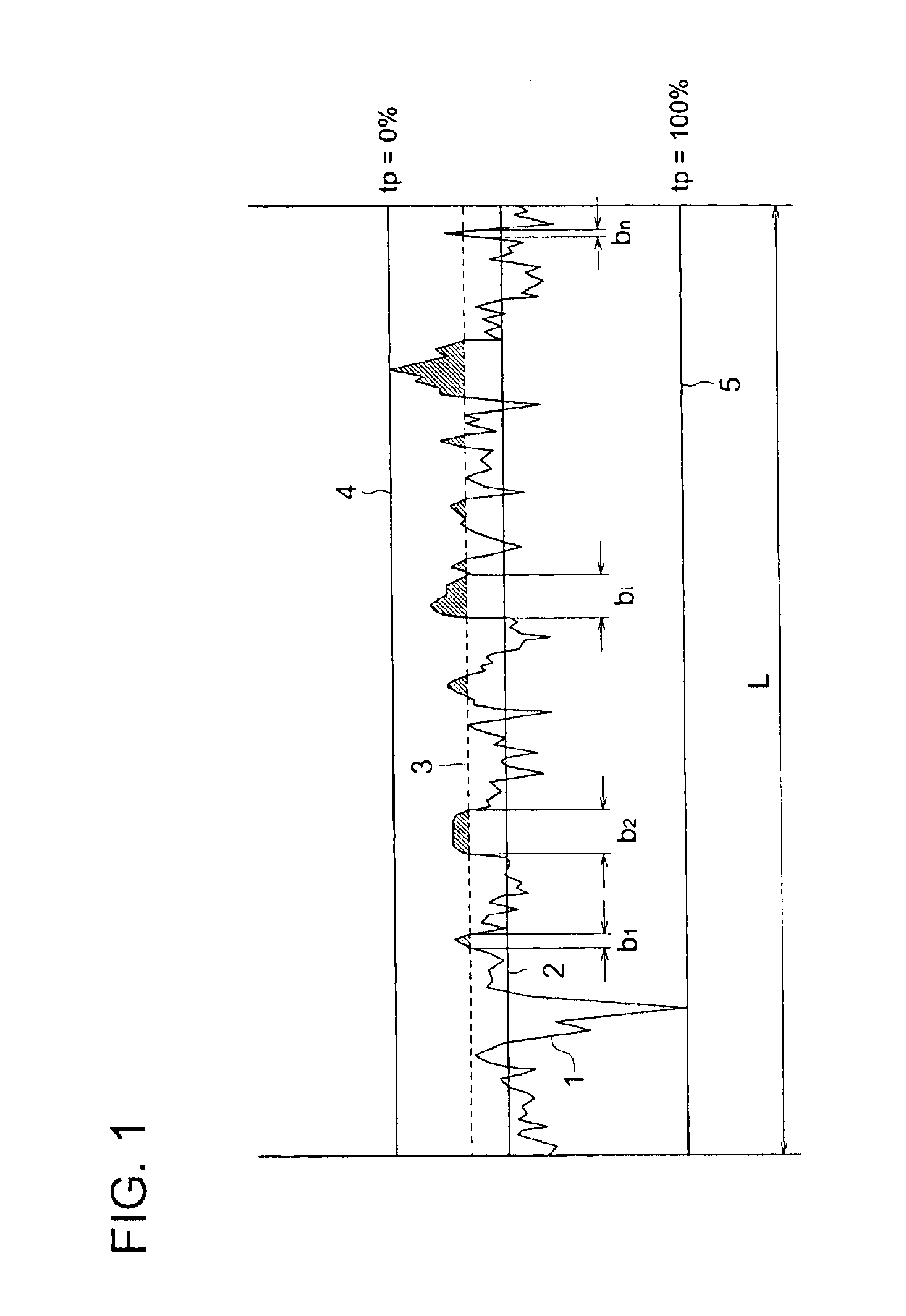

Printing plate material

ActiveUS6912956B2Low strengthHigh strengthSemiconductor/solid-state device manufacturingPlate printingMaterials scienceOil retention

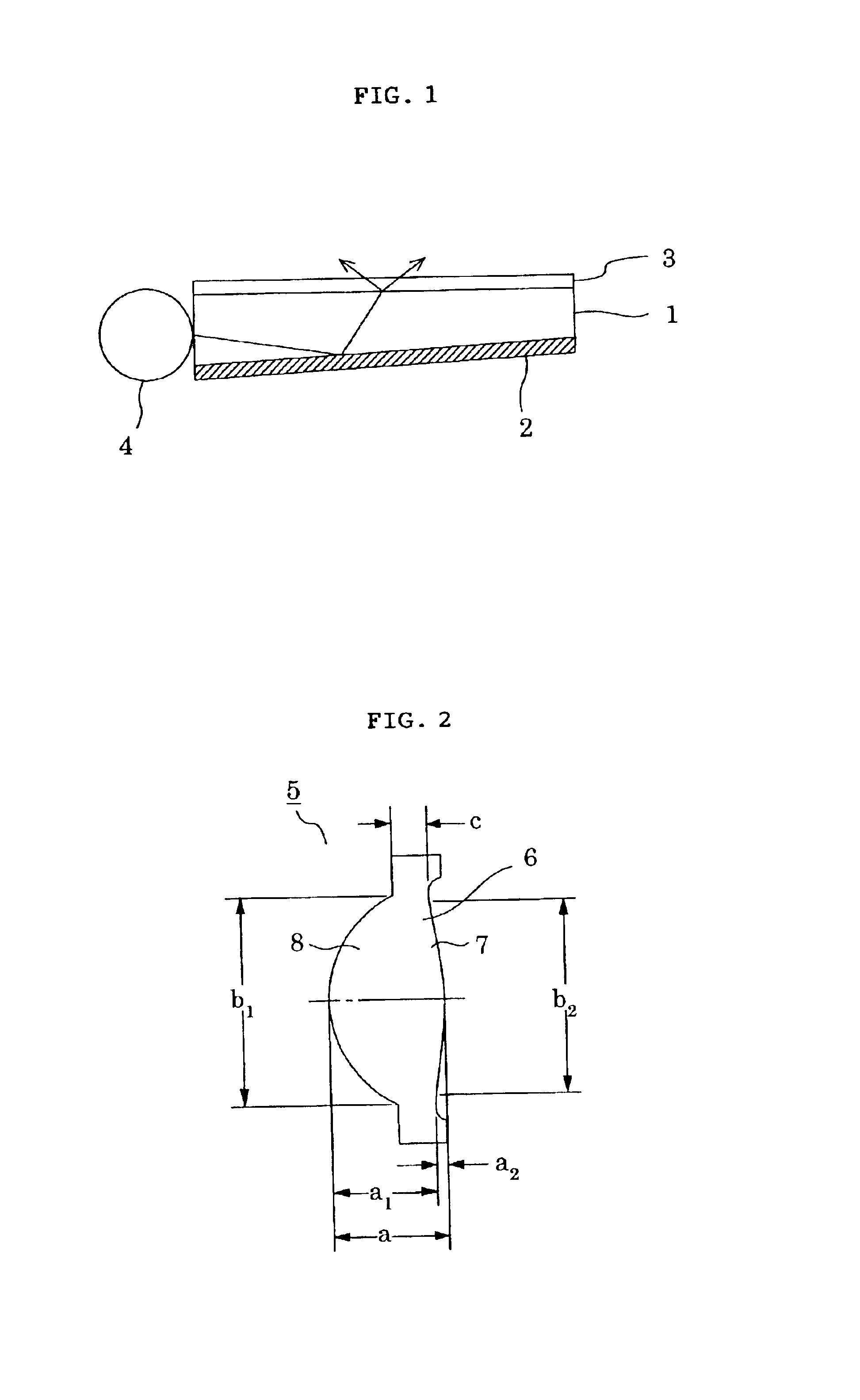

Disclosed is a printing plate material comprising a substrate and a component layer provided thereon, the substrate having a center line average surface roughness Ra of from 0.2 to 1.0 μm, and an oil-retention volume A2 of from 1 to 10, wherein the center line average surface roughness Ra is obtained from three dimension surface roughness measurement according to JIS-B-0601, and wherein an image is capable of being recorded on the component layer by imagewise exposure of infrared laser.

Owner:KONICA MINOLTA INC

Antimicrobial radiation curable coating

InactiveUS20050080158A1Activity depletedInferior antimicrobial efficacyBiocideAntifouling/underwater paintsCross-linkOligomer

The invention is a radiation curable coating containing an antimicrobial agent, where upon irradiation with UV light, the radiation curable coating rapidly cures to a polymeric coating. The polymeric coating has durable antimicrobial properties, being especially effective at preventing the growth of Staphylococcus aureaus and Kleibsella pneunoniae on wood flooring and furniture. The major components in the radiation curable coating are a urethane acrylic oligomer, a radiation cure package, an antimicrobial agent, a cross-linking agent, and optionally, an additive package. The radiation curable urethane oligomer is a relatively short chain backbone urethane polymer that is end capped with a radiation curable moiety, where the moiety is an acrylic. The cross-linking agent is one or more monomers used to lower the viscosity and promote cross-linking, and include acrylate esters of mono-, di-, tri-, or tetrafunctional alcohols. The radiation cure package contains at least one photoinitiator.

Owner:MICROBAN PROD CO INC

Adhesive alpha-olefin inter-polymers

InactiveUS20020007033A1Minimize adverse interactionHigh activityWax adhesivesPolymer scienceUnsaturated hydrocarbon

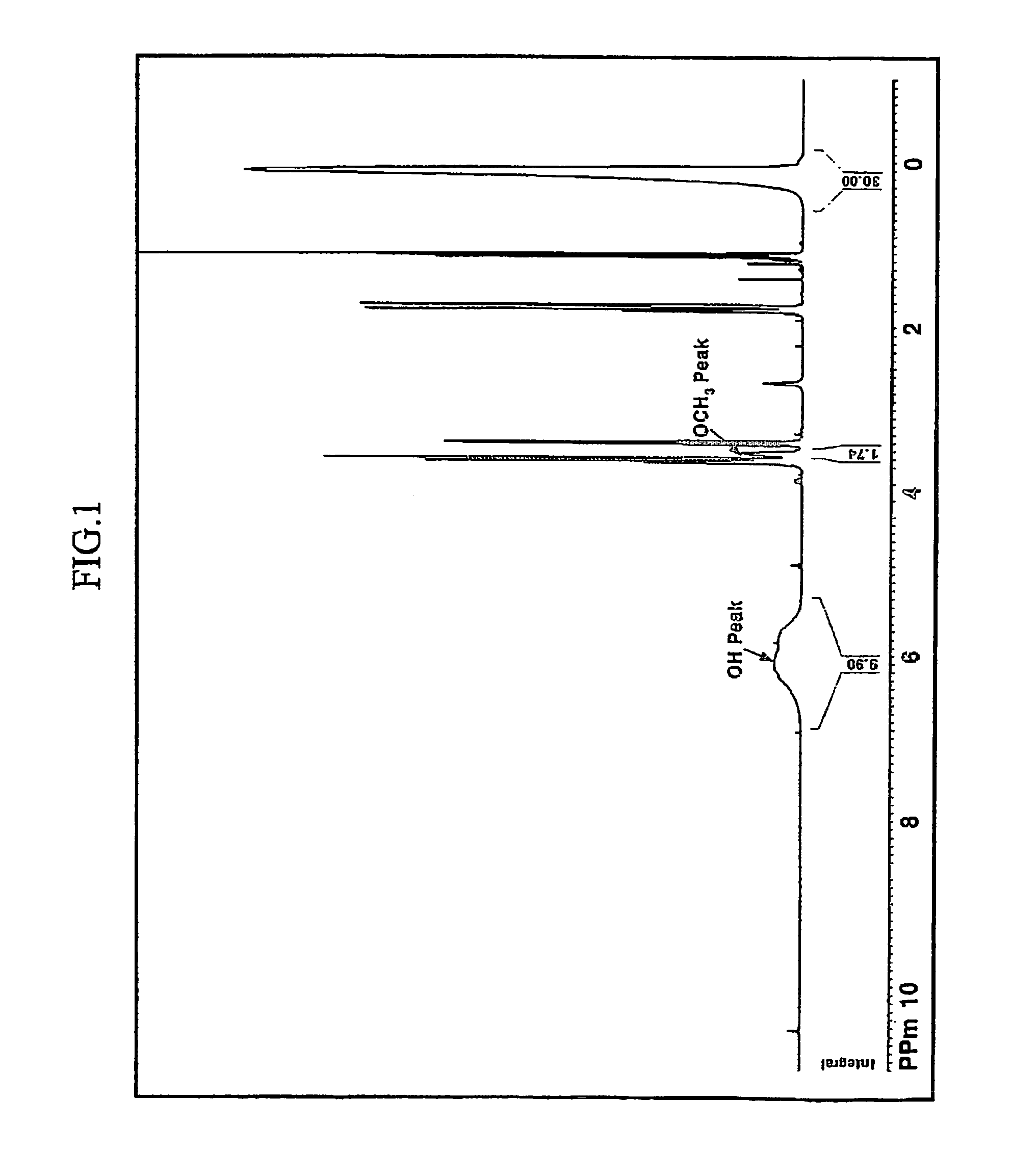

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a Theological behavior that makes them suitable for adhesive use, both without and with minimzed amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by 13C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.105 Pa at a temperature of less than 85 ° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

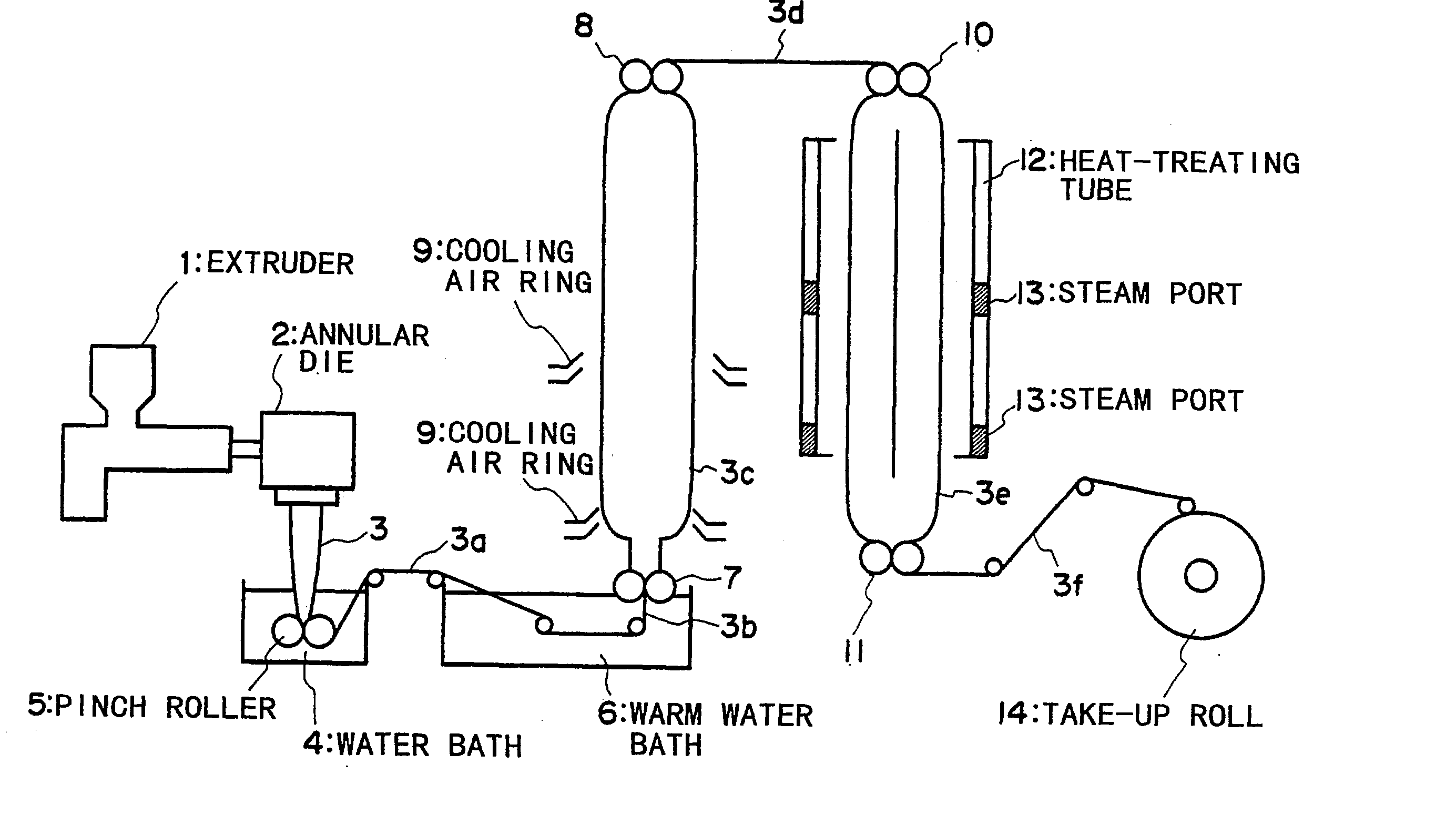

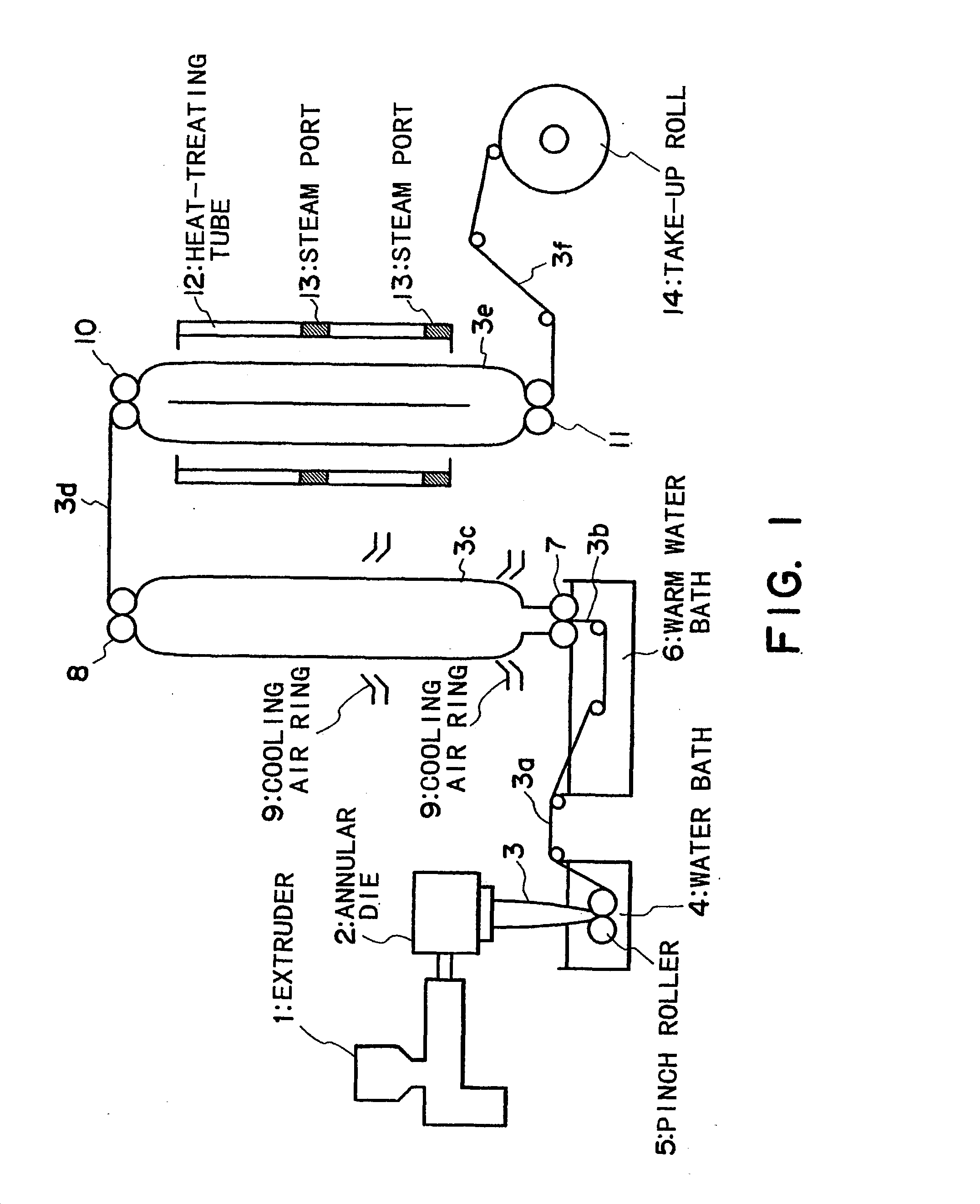

Low-temperature impact-resistant polyamide-based stretch-oriented mutilayer film

InactiveUS20030157350A1High low temperature impact resistanceIncrease elasticityFlexible coversWrappersSurface layerPolyamide

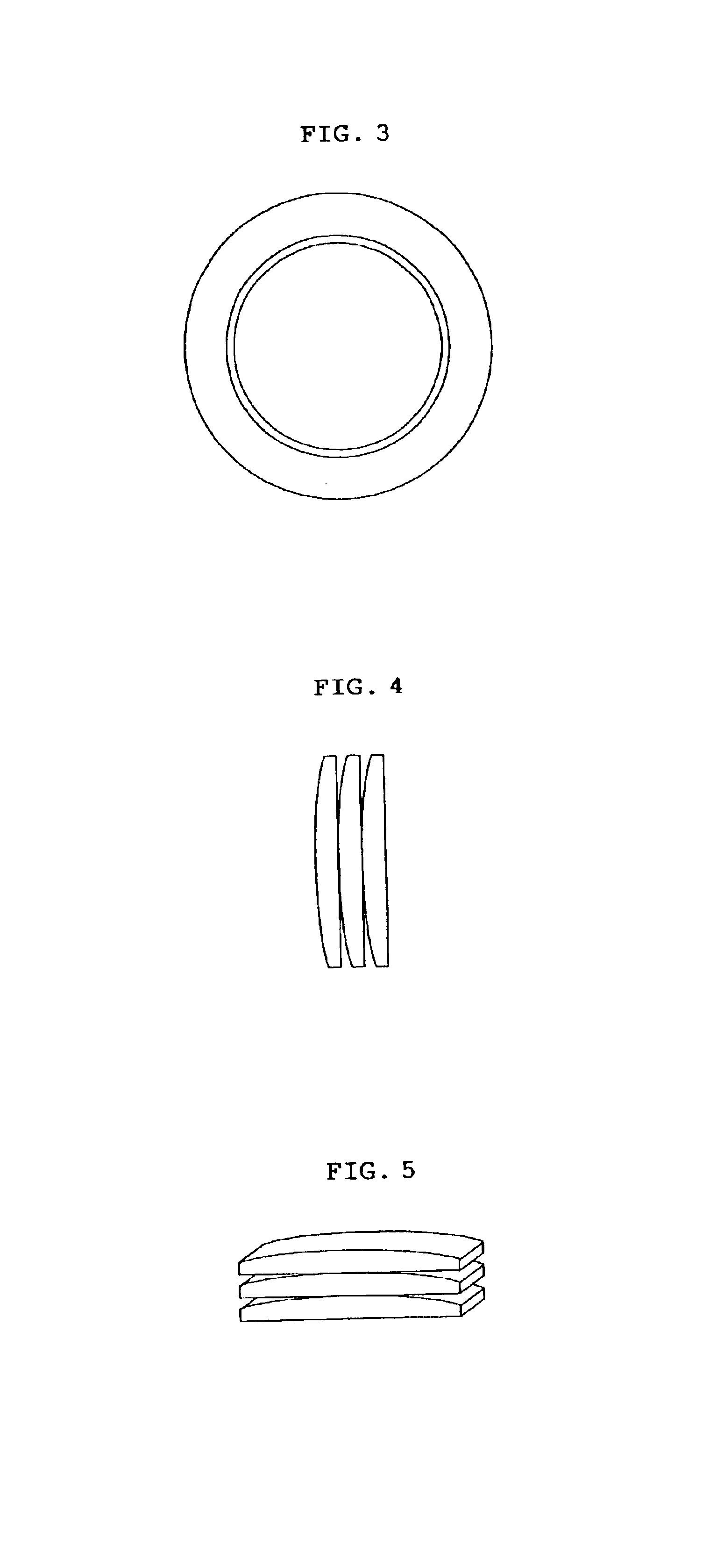

A stretch-oriented multilayer film suited for use as a freeze packaging material, a deep drawing packaging material, a vertical pillow packaging material, etc., is provided as a stretch-oriented multilayer film, comprising at least three layers including a surface layer (a) comprising a thermoplastic resin, an intermediate layer (b) comprising a polyamide resin and a surface layer (c) comprising a sealable resin, said multilayer film exhibiting an impact energy of at least 1.5 Joule at a conversion thickness of 50 mum at -10° C. The multilayer film is produced through an inflation process using water having a large capacity as a cooling and a heating medium and including a combination of a high degree of stretching and a high degree of relaxation heat treatment not exercised heretofore.

Owner:KUREHA KAGAKU KOGYO KK

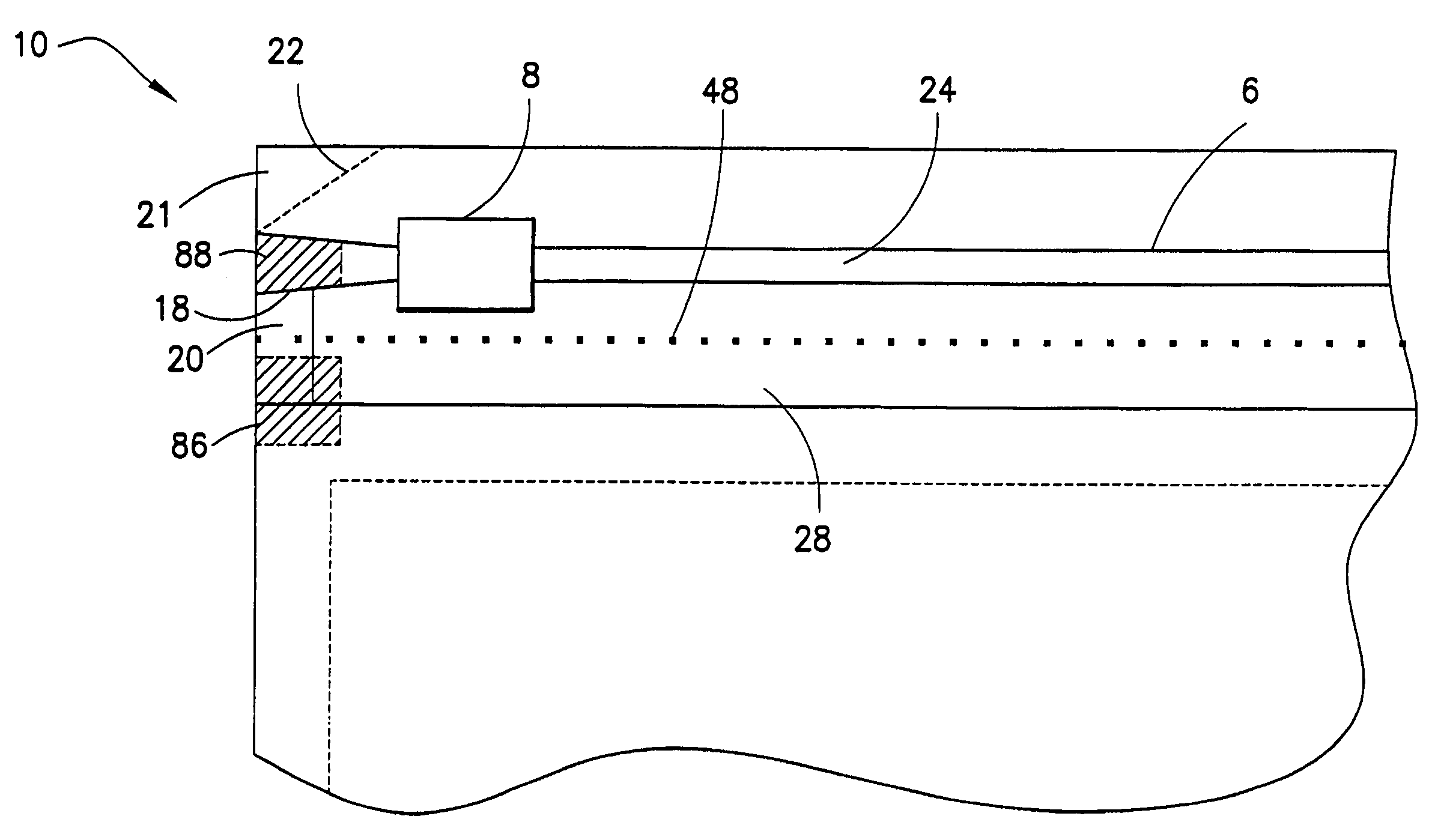

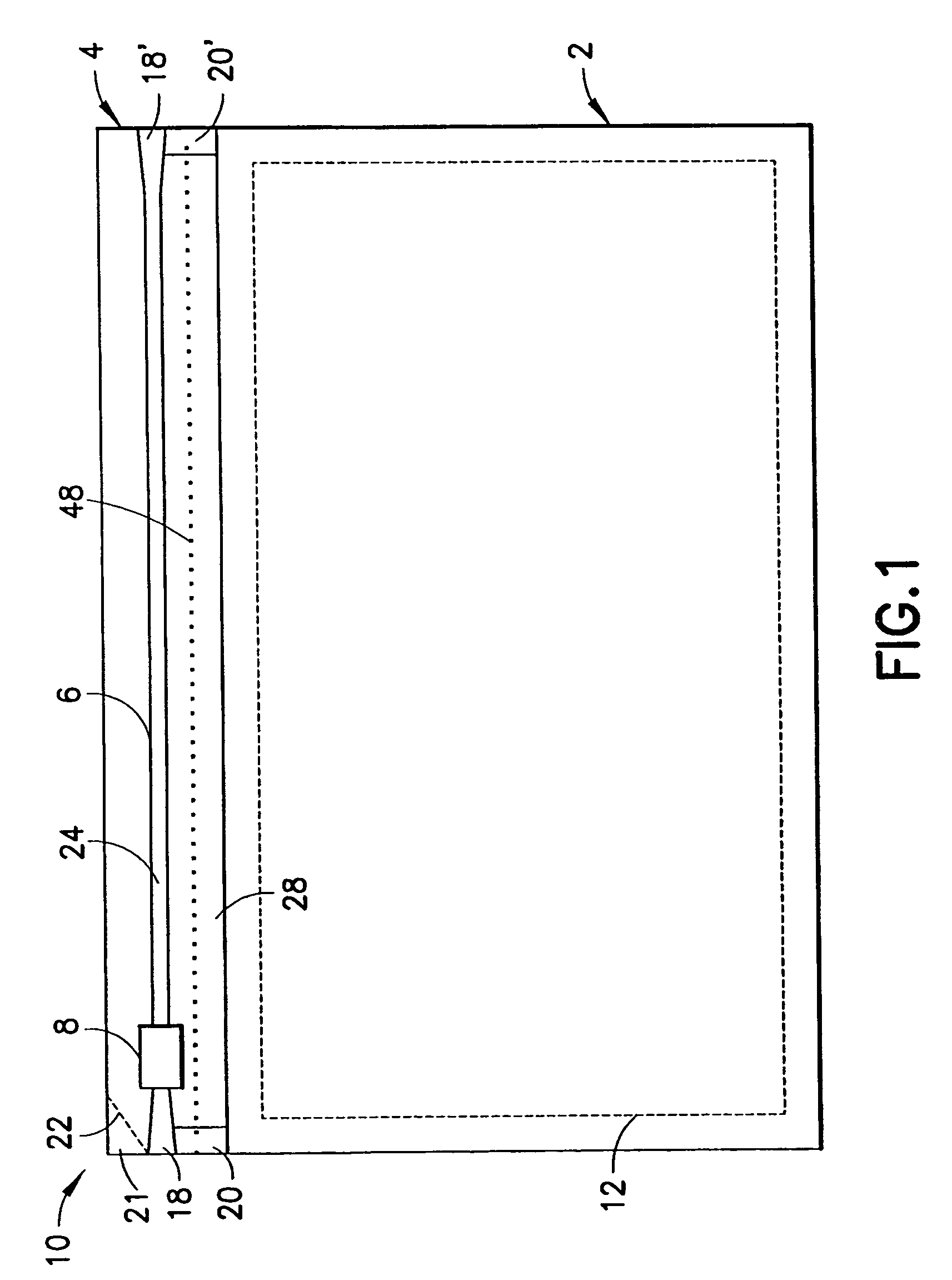

Point-to-Point Fiber Insertion

ActiveUS20150230008A1Low costLow efficiencyMultiplex system selection arrangementsWaterborne vesselsFiberCommunications system

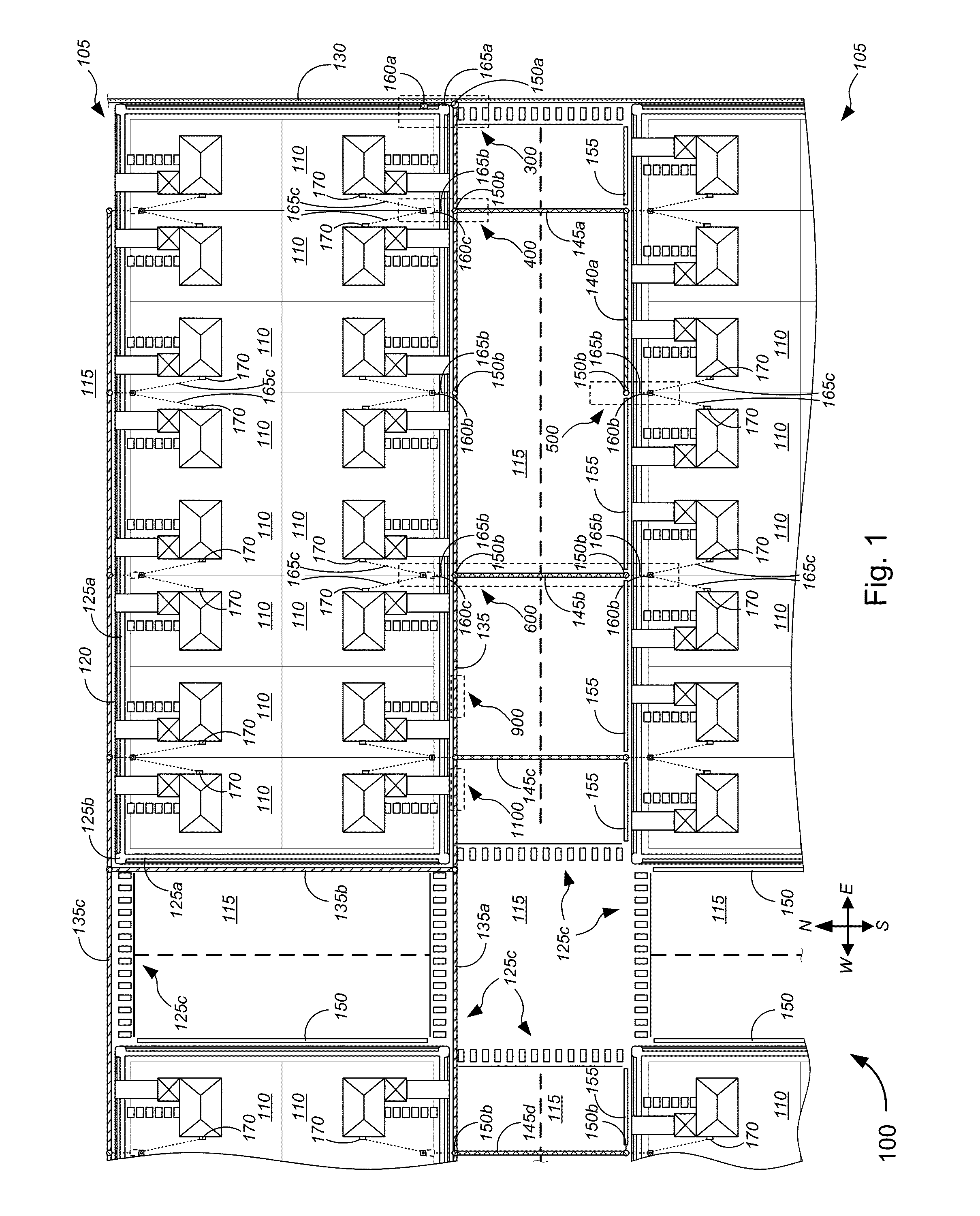

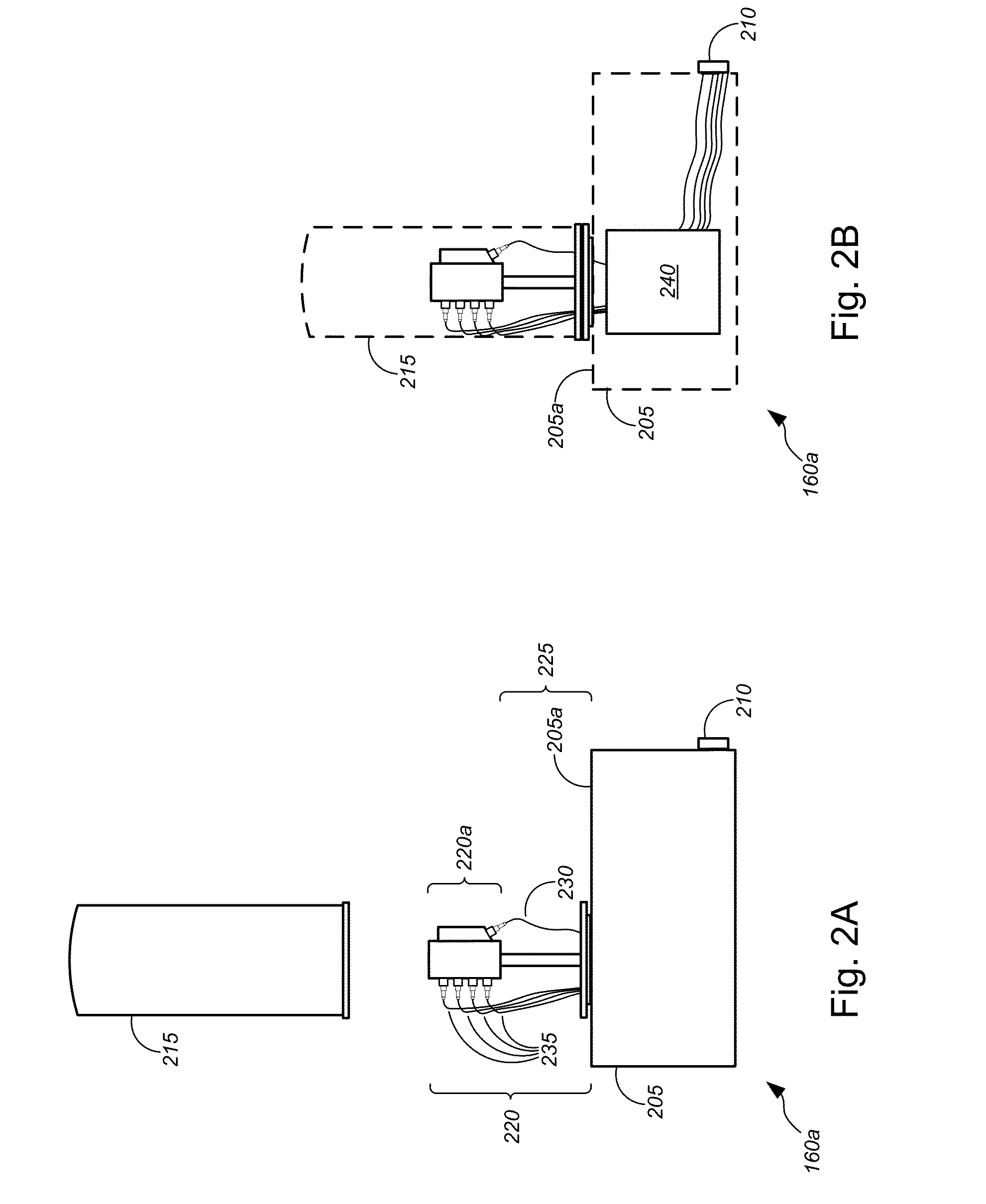

Novel tools and techniques are provided for implementing point-to-point fiber insertion within a passive optical network (“PON”) communications system. The PON communications system, associated with a first service provider or a first service, might include an F1 line(s) routed from a central office or DSLAM to a fiber distribution hub (“FDH”) located within a block or neighborhood of customer premises, via at least an apical conduit source slot, an F2 line(s) routed via various apical conduit components to a network access point (“NAP”) servicing customer premises, and an F3 line(s) distributed, at the NAP and from the F2 line(s), to a network interface device or optical network terminal at each customer premises via various apical conduit components (e.g., in roadway surfaces). Point-to-point fiber insertion of another F1 line(s), associated with a second service provider or a second service, at either the NAP or the FDH (or outside these devices).

Owner:CENTURYLINK INTPROP

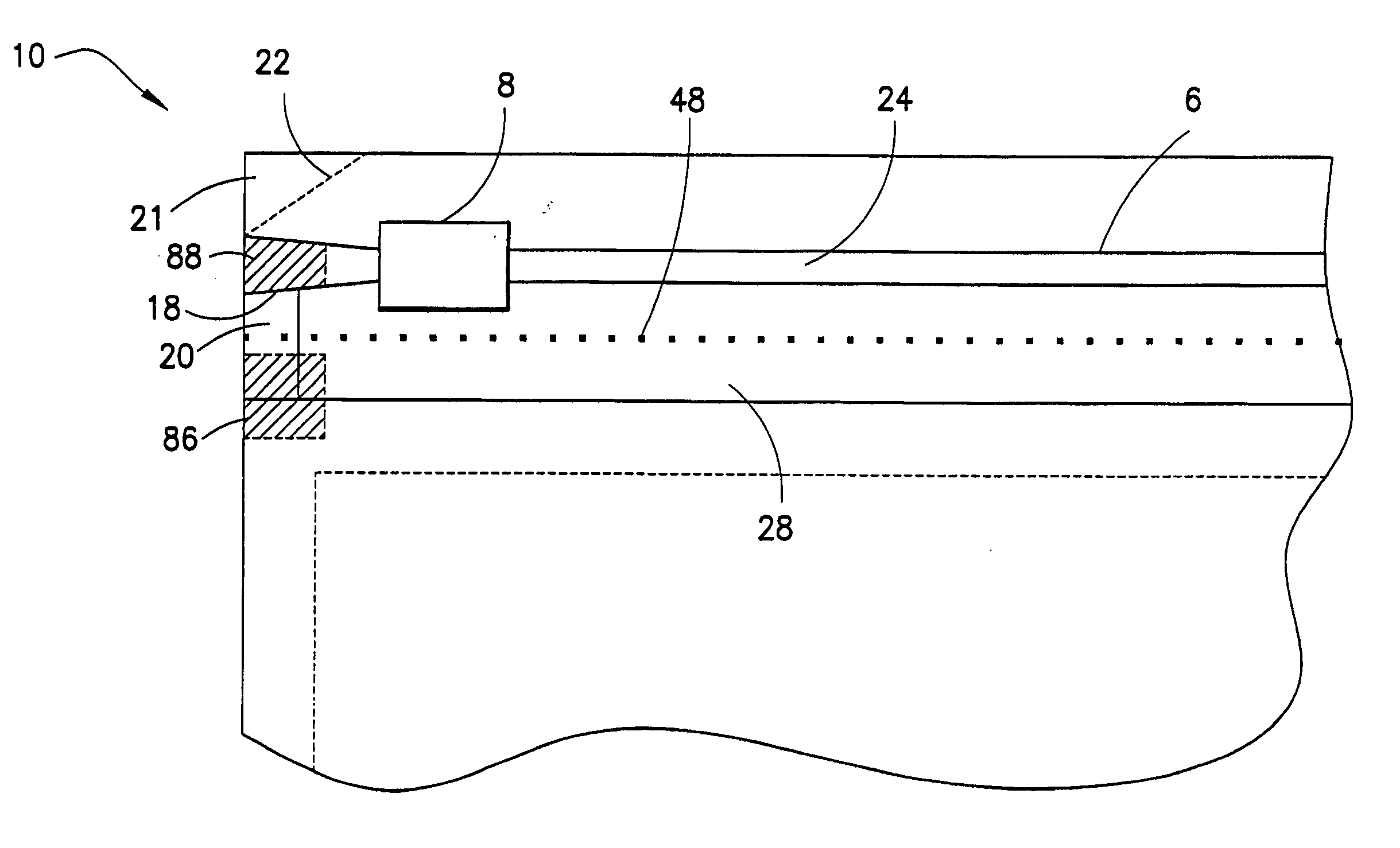

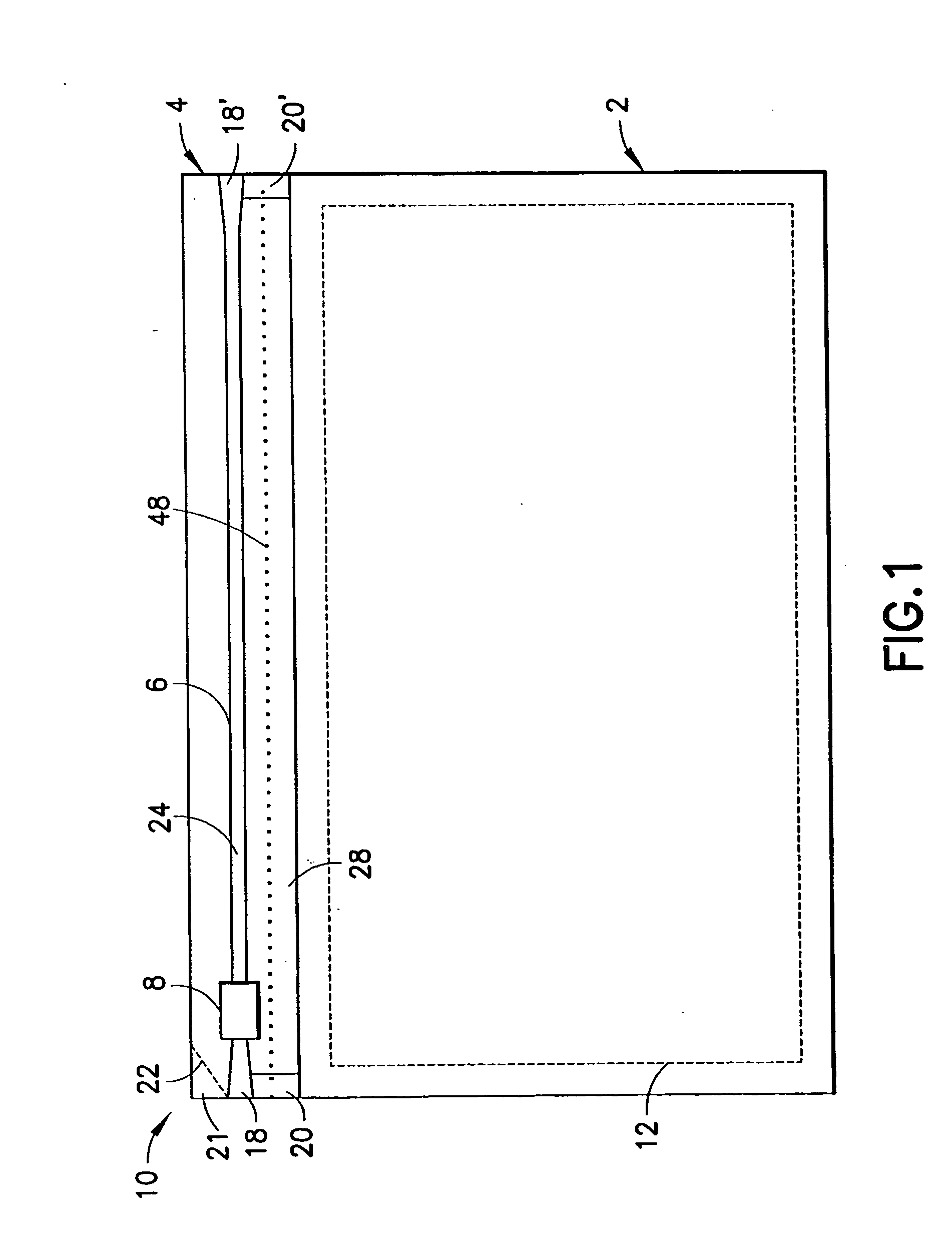

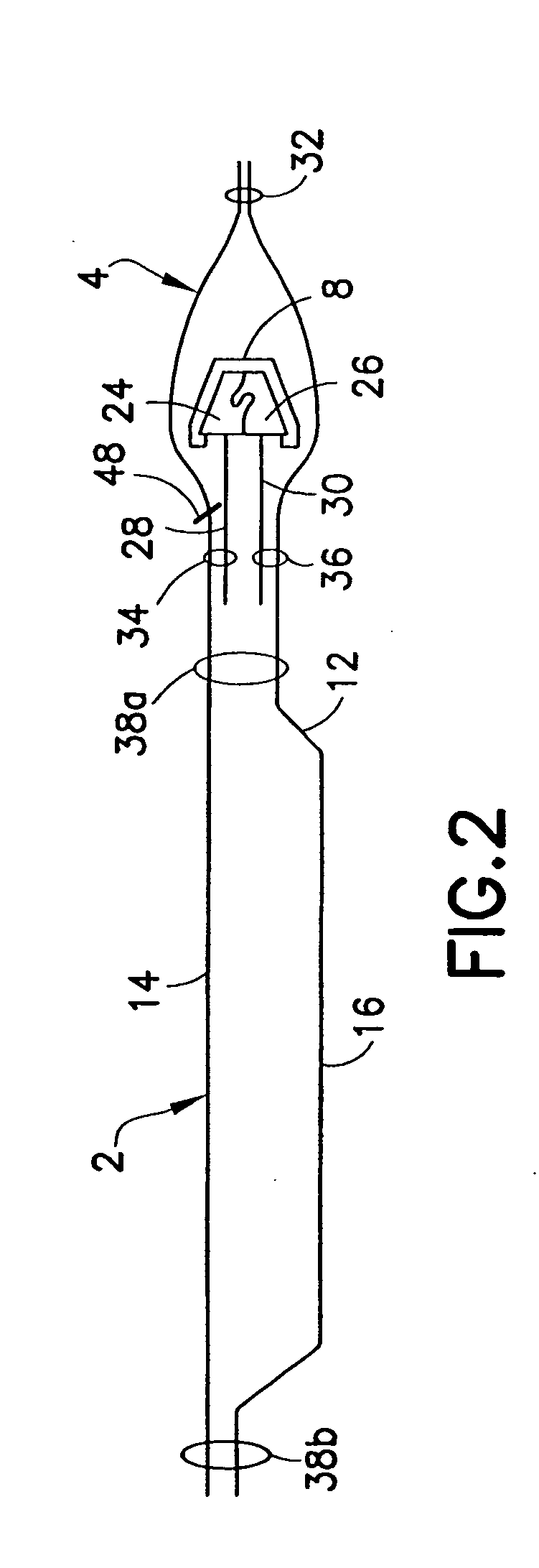

Fiber-to-the-Premises (FTTP) Methods and Systems

ActiveUS20150110453A1Low costLow efficiencyOptical fibre/cable installationFibre mechanical structuresFiberNetwork interface device

Novel tools and techniques are provided for implementing FTTx, which might include Fiber-to-the-Home (“FTTH”), Fiber-to-the-Building (“FTTB”), Fiber-to-the-Premises (“FTTP”), and / or the like. In some embodiments, a method might include routing an F1 line(s) from a central office or DSLAM to a fiber distribution hub (“FDH”) located within a block or neighborhood of customer premises, via at least an apical conduit source slot. From the FDH, an F2 line(s) might be routed, via any combination of apical conduit main slot(s), cross slot(s), far-side slot(s), missile bore(s), bore hole(s), and / or conduit(s) (collectively, “Apical Conduit Components”), to a network access point (“NAP”) servicing one or more customer premises. An F3 line(s) might be distributed, at the NAP and from the F2 line(s), to a network interface device (“NID”) or optical network terminal (“ONT”) at each customer premises, via any combination of the Apical Conduit Components, which include channels in at least portions of roadways.

Owner:CENTURYLINK INTPROP

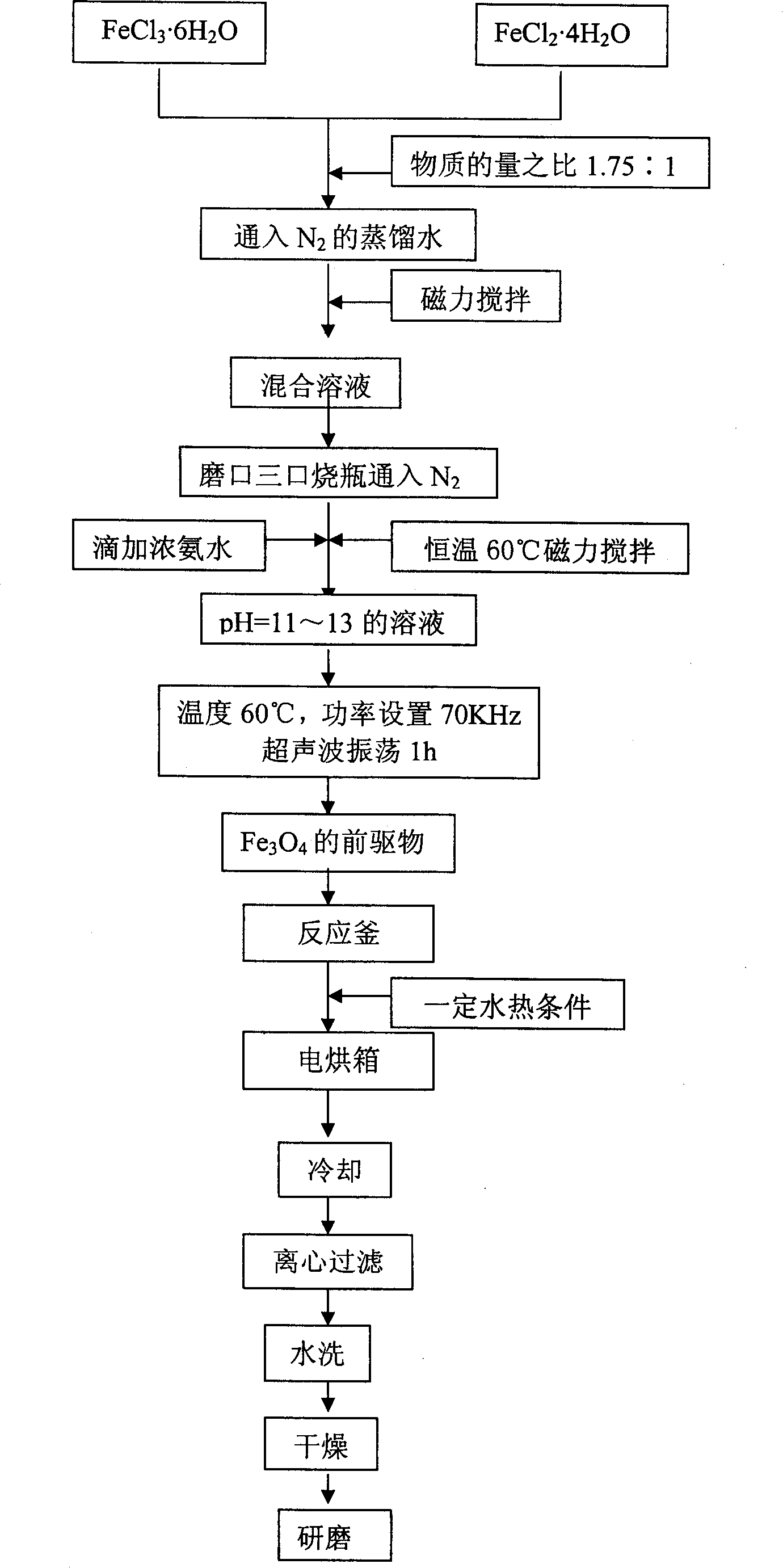

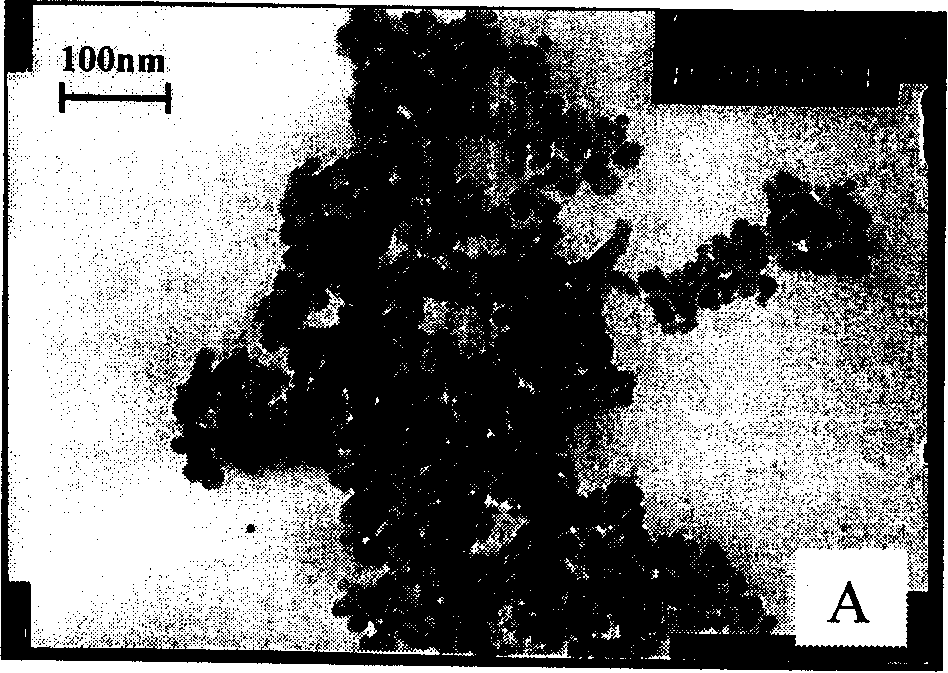

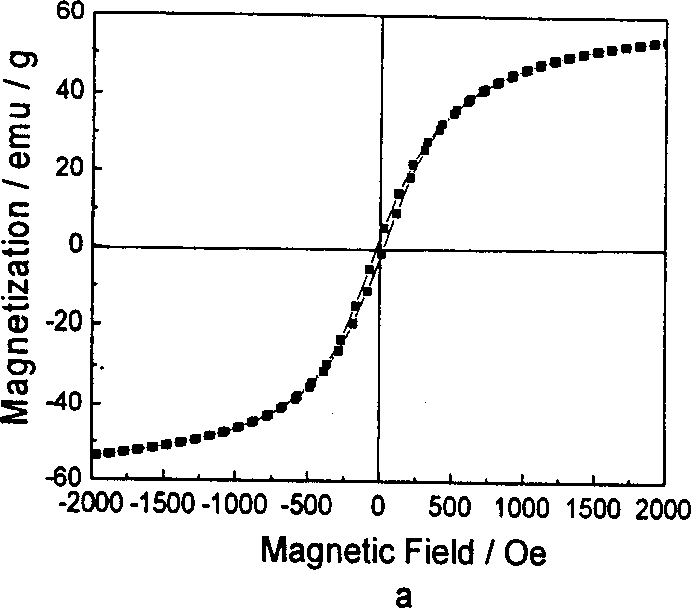

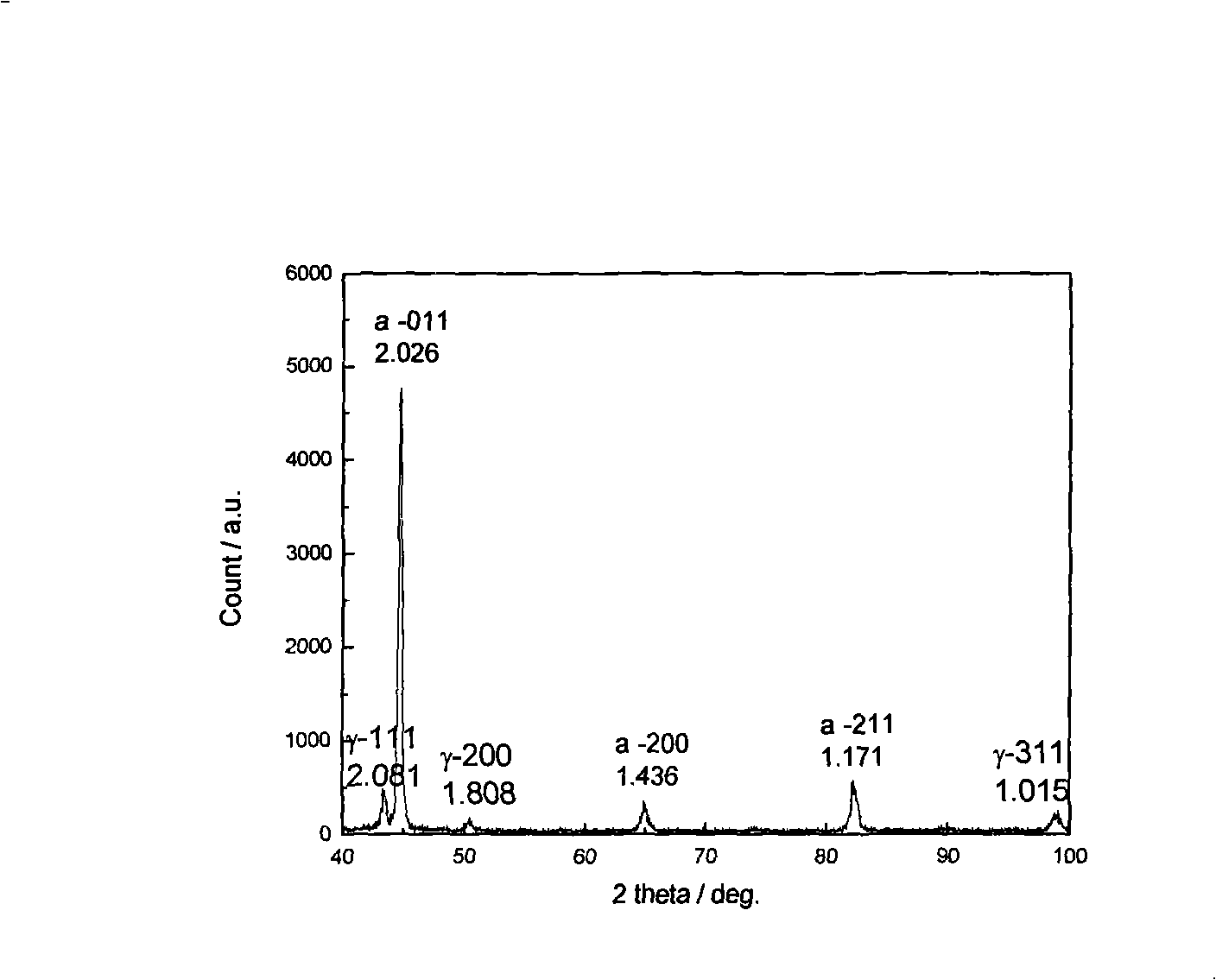

Ultrasound wave auxiliary hydrothermal synthesis technique for magnetic magnetic iron oxide nano ultra-tiny grain

The invention discloses an ultrasonic assistant hydro-thermal synthesis process for magnetic Fe3O4 nanometer super fine grain. The invention solves the problems of impure products and large grain diameter. The invention has the technical proposal that the form of Fe3O4 crystal nucleus is promoted in the cavitation effect of ultrasonic; cavitation gas bubble is produced in mediums; the pH value of strong ammonia is adjusted to 11 to 13; and the nanometer grain diameter size and the magnetic characteristics are controlled by controlling the hydro-thermal synthesis temperature within range from 140 DEG C to 160 DEG C and within time of 3 to 5 hours, and by changing the micro environment of the air bubble chamber, so as to obtain the dry product which is black magnetic Fe3O4 nanometer powder after being milled. The invention comprises no organic solvent, belonging to full green environmental protection which is a break in the field, and the invention is also the first to use the ultrasonic technology for assistant hydro-thermal synthesis. The invention has the advantages of simple technology, low cost, small powder granularity and even grain diameter. The powder not only can be used as duplicate ink powder, but also can be board used in aspects such as medical, biological technology, magnetic immunocyte separation, DNA separation, nucleic acid hybridization, and preparation for magnetic butt directional medicine carrying micron ball.

Owner:CIVIL AVIATION UNIV OF CHINA

Heat-conduction and electric-conduction hot melt glue and preparation method thereof

InactiveCN103540280AGood compatibilityReduce the amount addedNon-macromolecular adhesive additivesElectrically-conducting adhesivesThermoplasticPolymer science

The invention relates to a heat-conduction and electric-conduction hot melt glue and a preparation method thereof. The hot melt glue is high in heat-conduction and electric-conduction properties under a precondition that the elasticity and bonding strength of the original hot melt glue; the heat conduction coefficient reaches more than 2.0w / m.k. According to the hot melt glue, base materials comprise styrene thermoplastic elastomers (SEBS) and styrene-butadiene-styrene thermoplastic elastomers (ESBS) modified by epoxidation; a thickening agent comprises two of hydrogenated rosin, terpene resin and C9 petroleum resin; a filler is graphene solid powder with heat-conduction and electric-conduction functions; the addition amount of the base materials accounts for 30-40%; the addition amount of thickening resin accounts for 30-50%; the addition amount of the solid graphene powder accounts for 1.5-3.5%; the addition amount of the other accessory ingredient naphthenic oil accounts for 15-18%; the addition amount of an antioxidant accounts for 1-2%; the heat-conduction and electric-conduction hot melt glue is prepared from the components of the hot melt glue through a melt blending method.

Owner:SHENYANG JIANZHU UNIVERSITY

Header end tack seal for reclosable package

InactiveUS20050281490A1Maintain cleanlinessMaintain aestheticsFlexible coversWrappersEngineeringUltimate tensile strength

A tamper-evident reclosable package having a header that is tack sealed to the zipper. A light tack, in the form of a light weld, is made at the end of the package header. The header is the top portion of the package and is designed to shroud the zipper. The header serves as a tamper-evident feature, and also serves to maintain cleanliness and aesthetics of the package. The header must be tom before a person can gain access to the contents of the package. Typically, means for preferential tearing are provided for easy removal of the header. The tack seal contributes to the maintenance of the cleanliness and aesthetics of the package, while still allowing easy removal of the header. The tack is light (i.e., low bond strength or pull-off force) in order to not make it significantly more difficult to open the package.

Owner:ILLINOIS TOOL WORKS INC

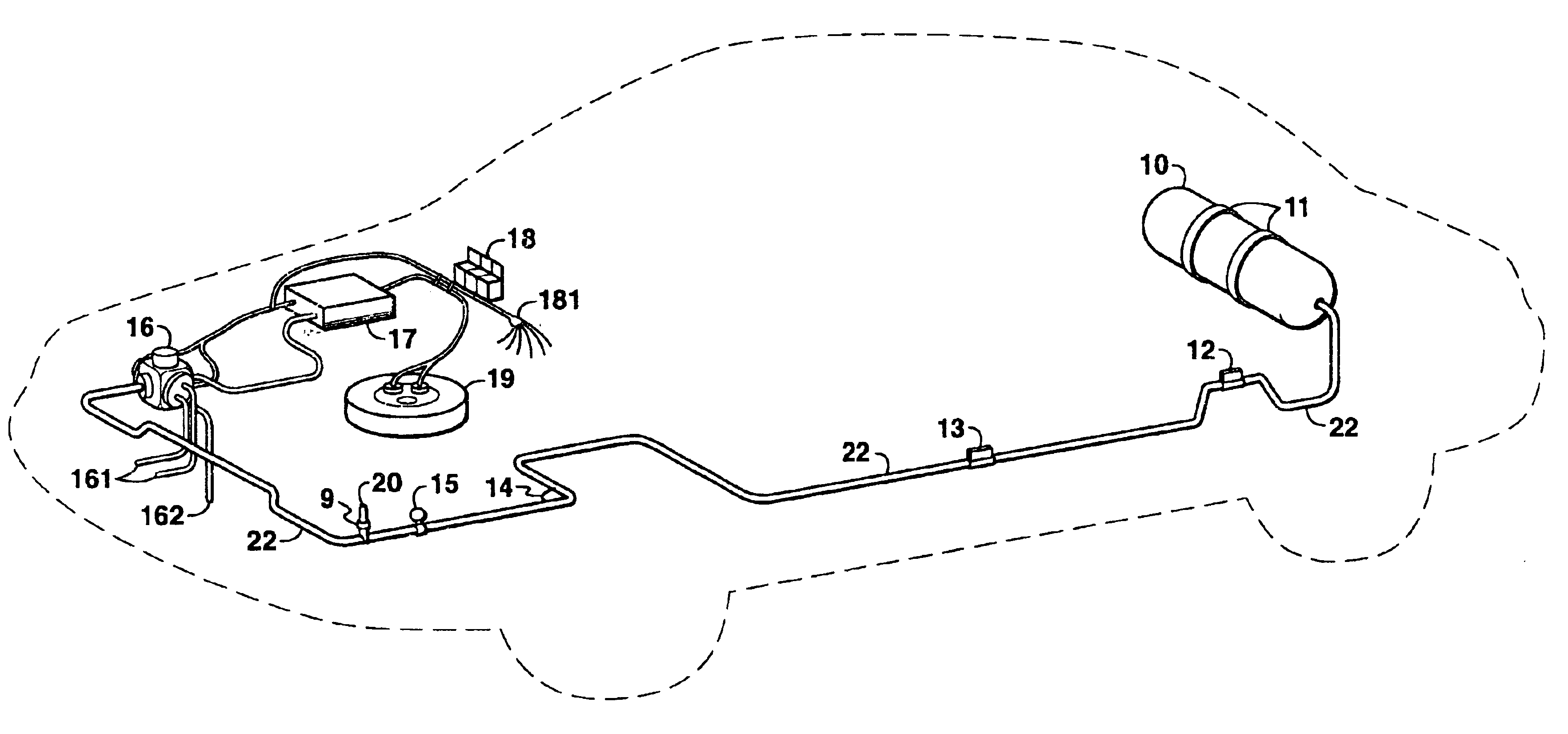

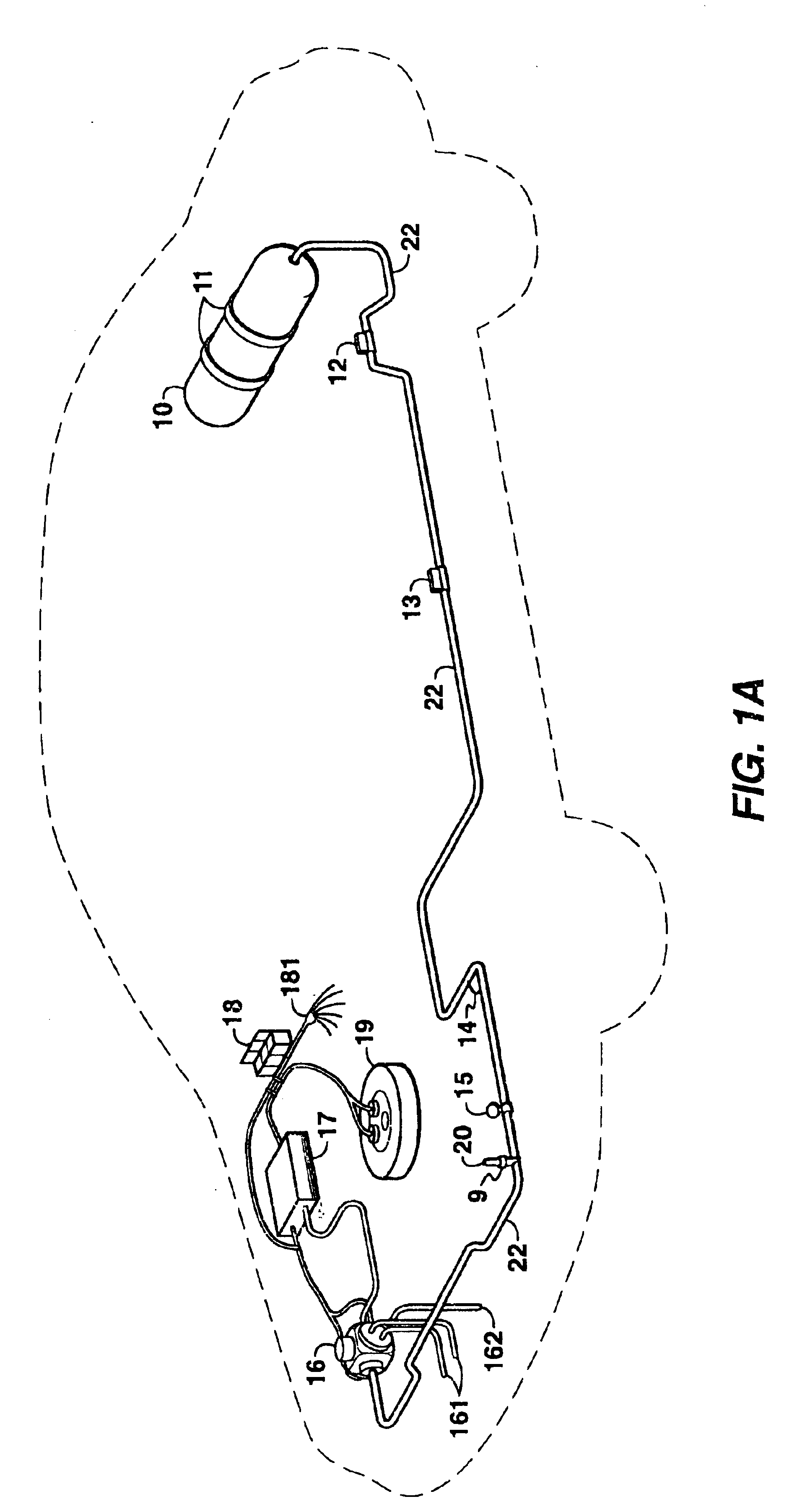

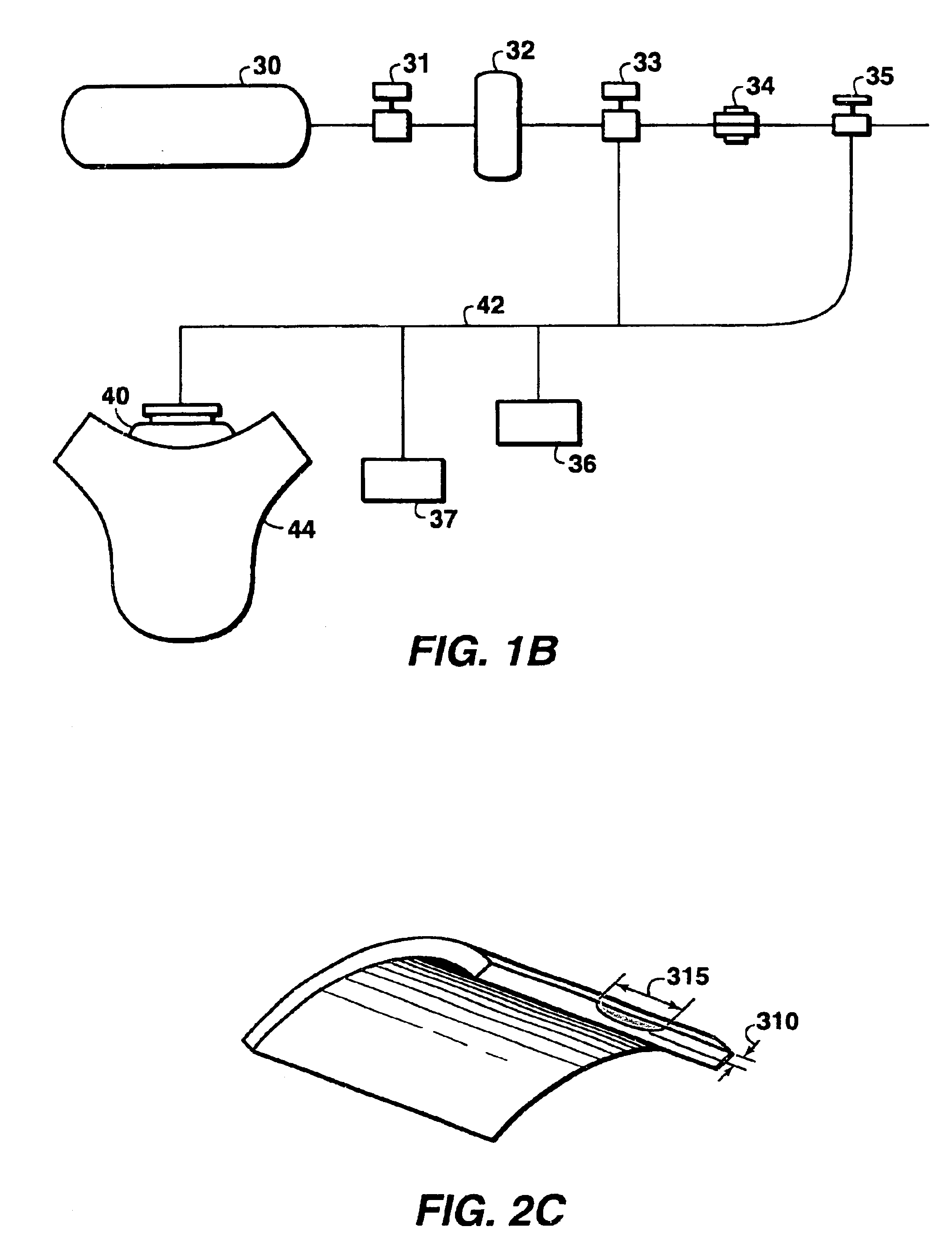

CNG fuel storage and delivery systems for natural gas powered vehicles

InactiveUS6843237B2Low strengthUltra-high strengthInternal combustion piston enginesVessel geometry/arrangement/sizeDriving rangeLoad carrying

Fuel storage and delivery systems for compressed natural gas are provided that are constructed from ultra-high strength, low alloy steels containing less than 2.5 wt % nickel and having a tensile strength greater than 900 MPa (130 ksi). A primary benefit is that systems of this invention have substantially lower weight than that of currently available steel-based systems. Consequently, the fuel efficiency of a CNG vehicle can be improved due to the lower weight of the system of this invention, or the driving range of the CNG vehicle can be improved by increased fuel storage for the same volume at an elevated pressure, or the load-carrying capacity of the CNG vehicle can be improved. Another primary benefit is that systems of this invention have a cost per unit strength substantially lower than that of currently available systems.

Owner:EXXONMOBIL UPSTREAM RES CO

Lignocellulosic composites

InactiveUS7163974B2Reduce environmental problemsEasy to handleBiocideAnimal repellantsCelluloseCalcium borate

Lignocellulosic-based woodfiber-plastic composite products containing a pesticidal amount of calcium borate is resistant to attack by wood destroying fungi and insects. The preferred calcium borates are the calcium polytriborates having a CaO:B2O3 molar ratio of about 2:3 and calcium hexaborates, having a CaO:B2O3 ratio of 1:3. Composites can be produced by combining the calcium borate with particles of the lignocellulosic material and the thermoplastic resin binder, and heating and extruding the resultant mixture through a die to form the composite product.

Owner:U S BORAX INC

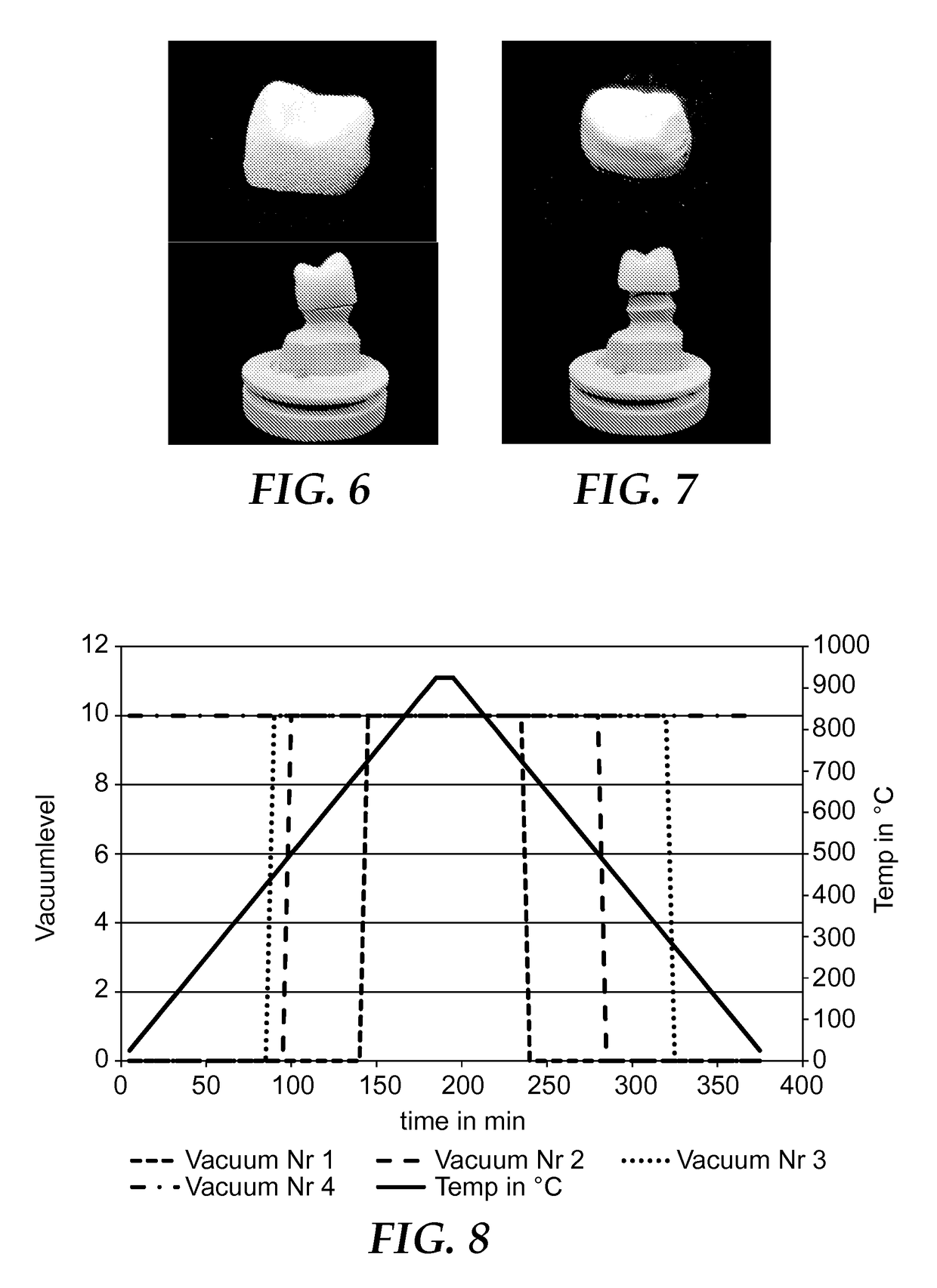

Process for producing a sintered lithium disilicate glass ceramic dental restoration and kit of parts

InactiveUS20170128174A1Easily be individualizedLow strengthAdditive manufacturing apparatusImpression capsMetallurgyAtmospheric pressure

The present invention is directed to a process for producing a sintered lithium disilicate glass ceramic dental restoration out of a porous 3-dim article, the process comprising the step of sintering the porous 3-dim article having the shape of a dental restoration with an outer and inner surface to obtain a sintered lithium disilicate ceramic dental restoration, the sintered lithium disilicate glass ceramic dental restoration comprising—Si oxide calculated as SiO2 from 55 to 80 wt.-%, —Li oxide calculated as Li2O from 7 to 16 wt.-%, —Al oxide calculated as Al2O3 from 1 to 5 wt.-%, and—P oxide calculated as P2O5 from 1 to 5 wt.-%, wt.-% with respect to the weight of the dental restoration, the sintering being done under reduced atmospheric pressure conditions, the reduced atmospheric pressure conditions being applied at a temperature above 600° C. The present invention is also directed to a kit of parts comprising a porous 3-dim article having the shape of a dental milling block and a respective instruction of use.

Owner:3M INNOVATIVE PROPERTIES CO

Composition used for high strength and impermeable concrete

ActiveUS20130104777A1High strengthImprove impermeabilitySolid waste managementShell moldingHigh intensity

A composition used for high-strength impermeable concrete. The composition contains sand, stone, cement, water reducer, water and reinforced impermeable sand. The reinforced impermeable sand includes aeolian sand and binder covering the surface of the aeolian sand. The reinforced impermeable sand can fill the gap between the sand and the stone, and well combine various components in the composition, and suppress the seepage phenomenon of the molded concrete, thereby greatly improving the strength and impermeability of the concrete.

Owner:BEIJING RECHSAND SCI & TECH GRP

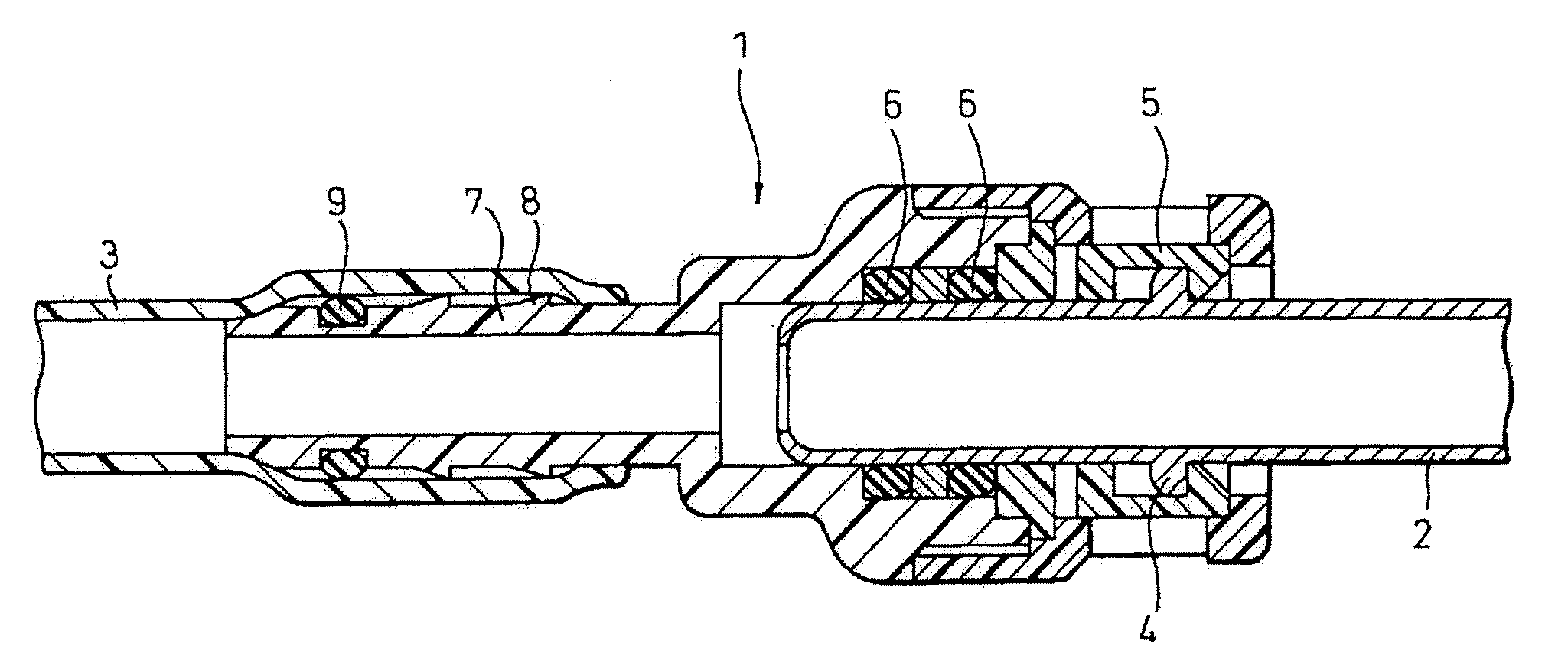

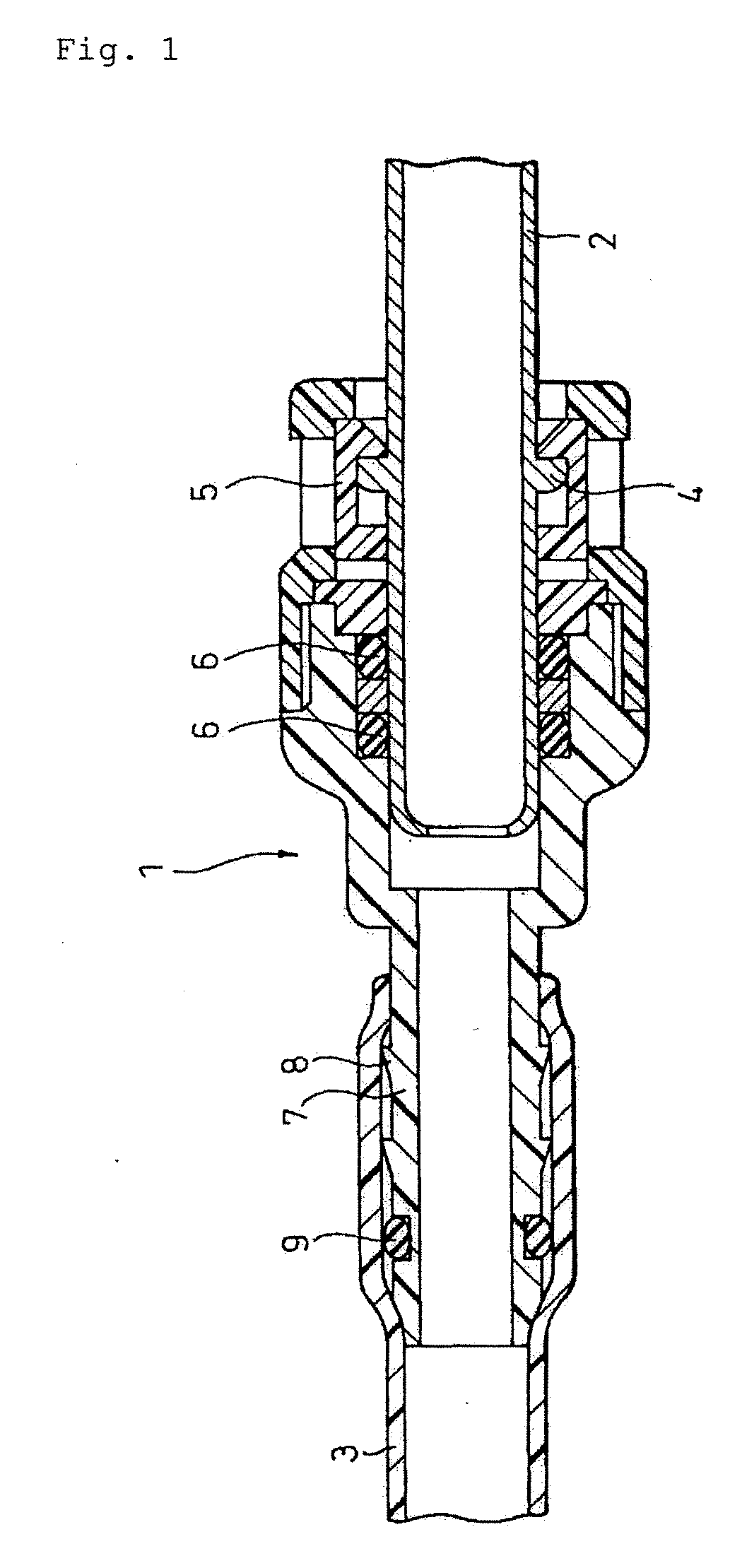

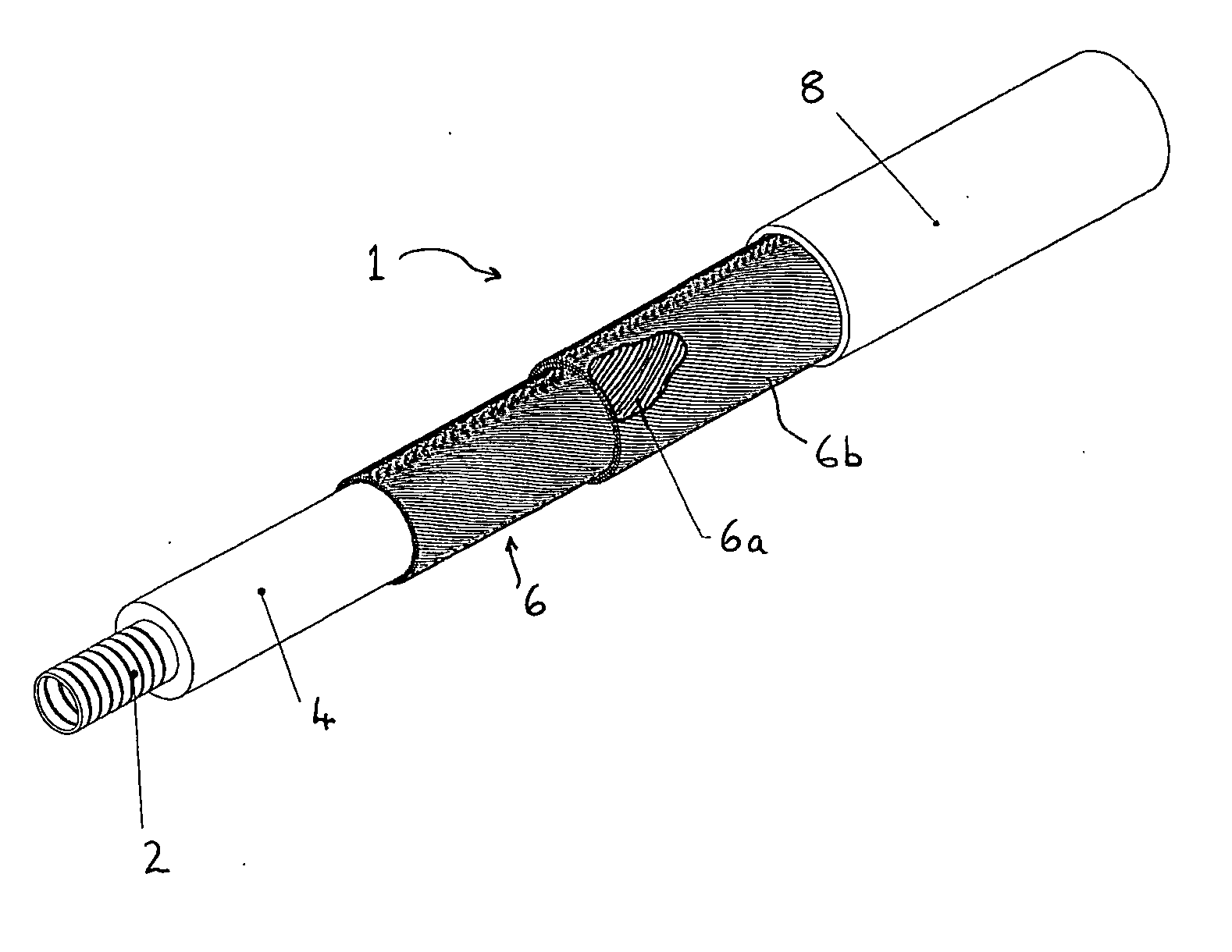

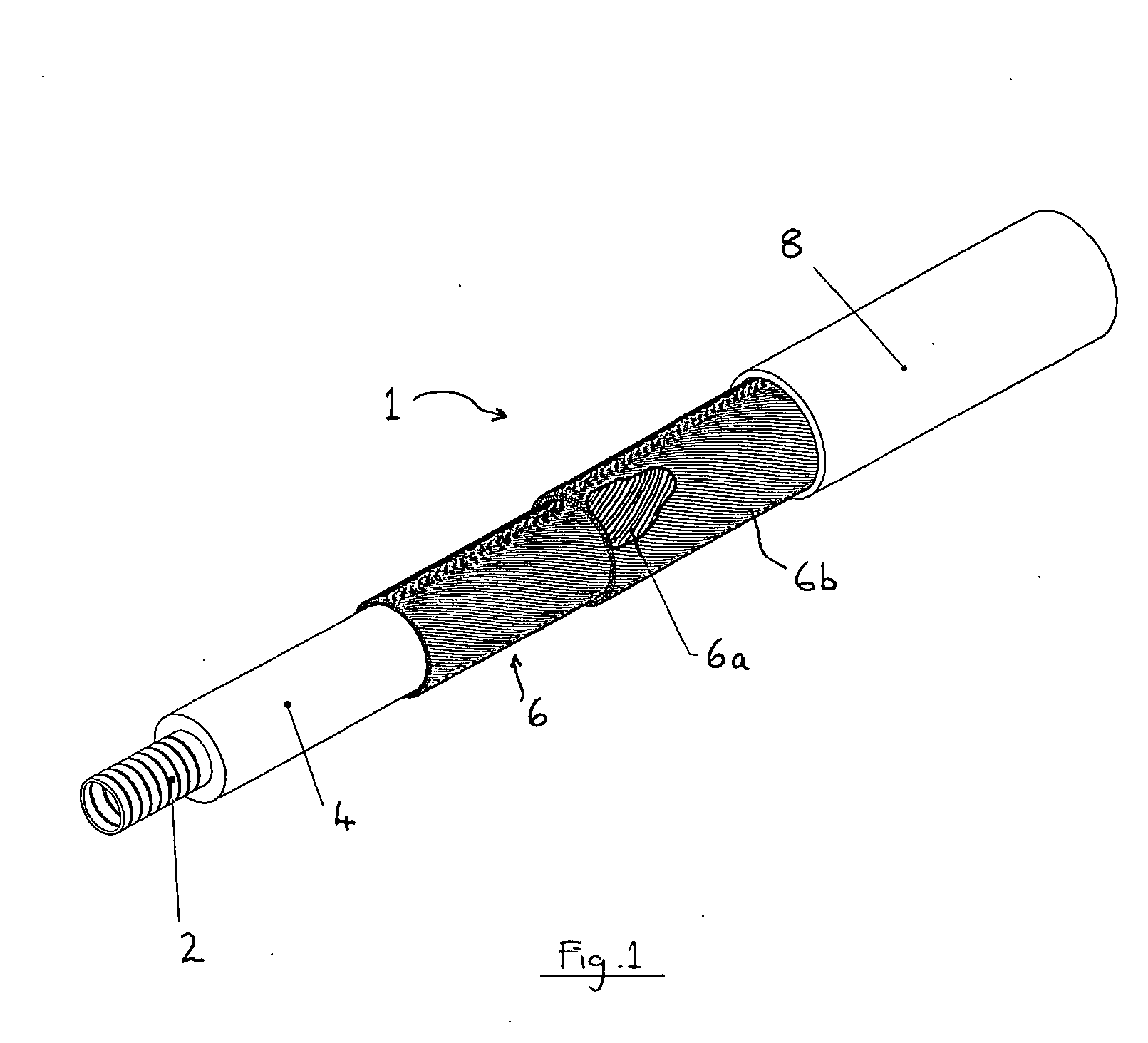

Fluid conduit

The present invention relates to fluid conduit (1) suitable for use in the transportation of working fluids to a wellhead or the like from a topside location or the like. The fluid conduit (1) is suitable for use in a multi-conduit umbilical. The conduit comprises an inner flexible collapse resistant hose (2) surrounded by a hose liner (4), and at least one pair of helically contra-wound high tensile wires (6a, 6b). Each turn of each wire (6a, 6b) is in substantially close contact with adjacent turns thereof. A multi-conduit umbilical comprising a plurality of the fluid conduits bundled together and provided with an outer sheath is also described.

Owner:OCEANEERING INT SERVICES

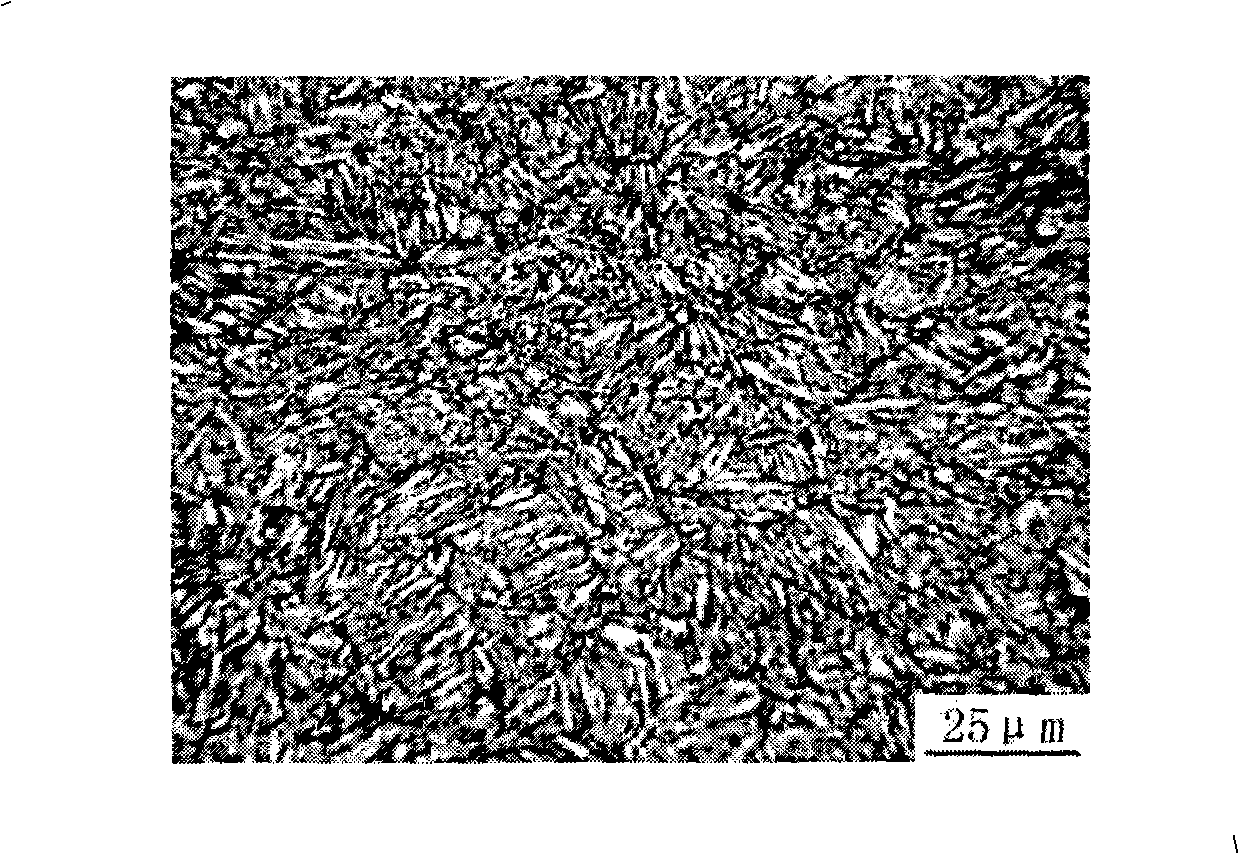

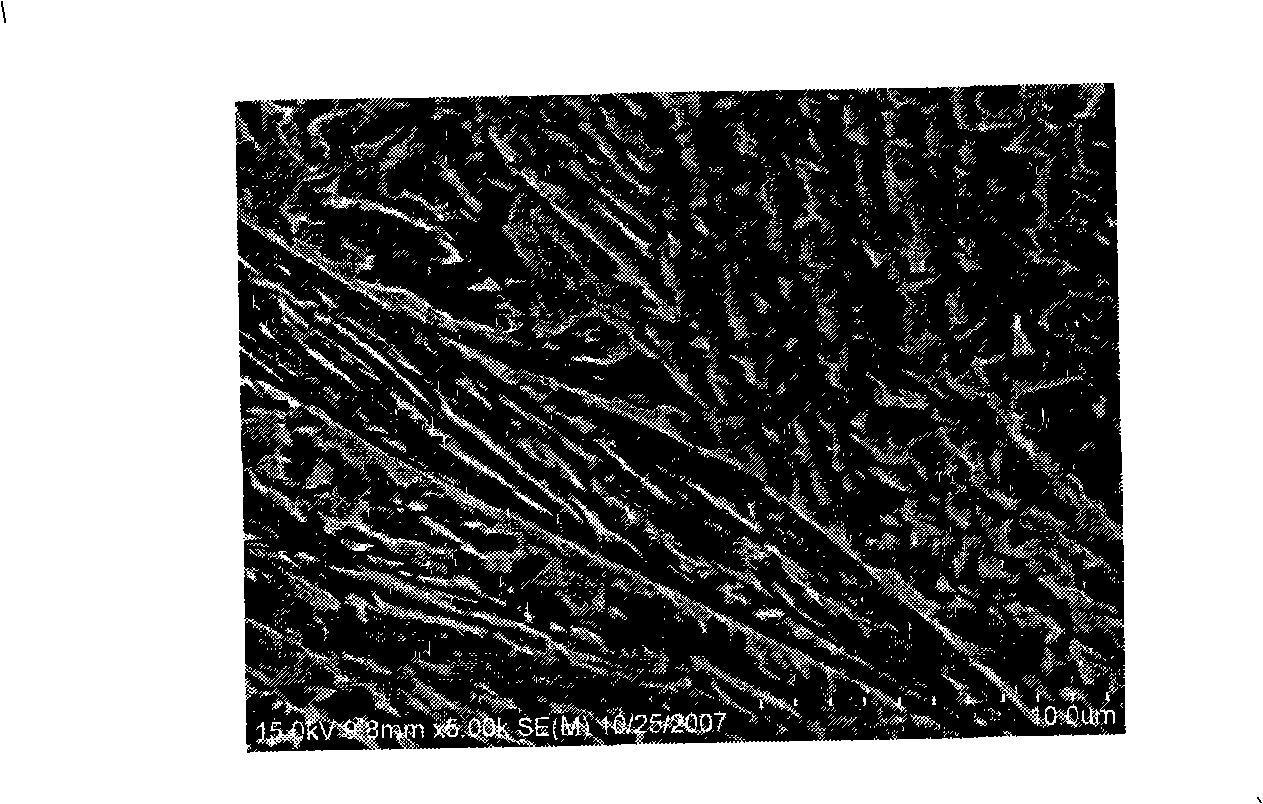

Carbides-free bainite wear resistant steel plate and production process thereof

ActiveCN101338399AImprove hardenabilityHigh strengthTemperature control deviceProduction lineWear resistant

The invention relates to a steel and a production technique thereof, in particular to a non-carbide bainite wear-resistant steel plate and a production technique thereof; the component weight percentages are: 0.15 to 0.25 percent of C, 1.50 to 2.00 percent of Mn, 0 to 0.015 percent of P, 0 to 0.006 percent of S, 1.30 to 2.00 percent of Si, 0.20 to 0.60 percent of Al, 0.60 to 1.00 percent of Cr, 0.25 to 0.50 percent of Mo, 0.010 to 0.035 percent of Nb and the rest is Fe. The production technique is carried out according to the following working procedures: (1) feeding a continuous casting plate to a heating furnace for heating; (2) feeding the continuous casting plate after being heated into a hot rolling production line to carry out the rolling of controlled rolling and controlled cooling; (3) carrying out middle-low temperature drawing temper on a rolling steel plate after the rolling is finished. The non-carbide bainite wear-resistant steel plate can be produced by the working procedures without carrying out online or offline hardening and tempering thermal processing which not only can simplify the working procedures of production, but also can improve the performance and the quality of a product as well as obtain the bainite wear-resistant steel with high intensity and high toughness.

Owner:NANJING IRON & STEEL CO LTD

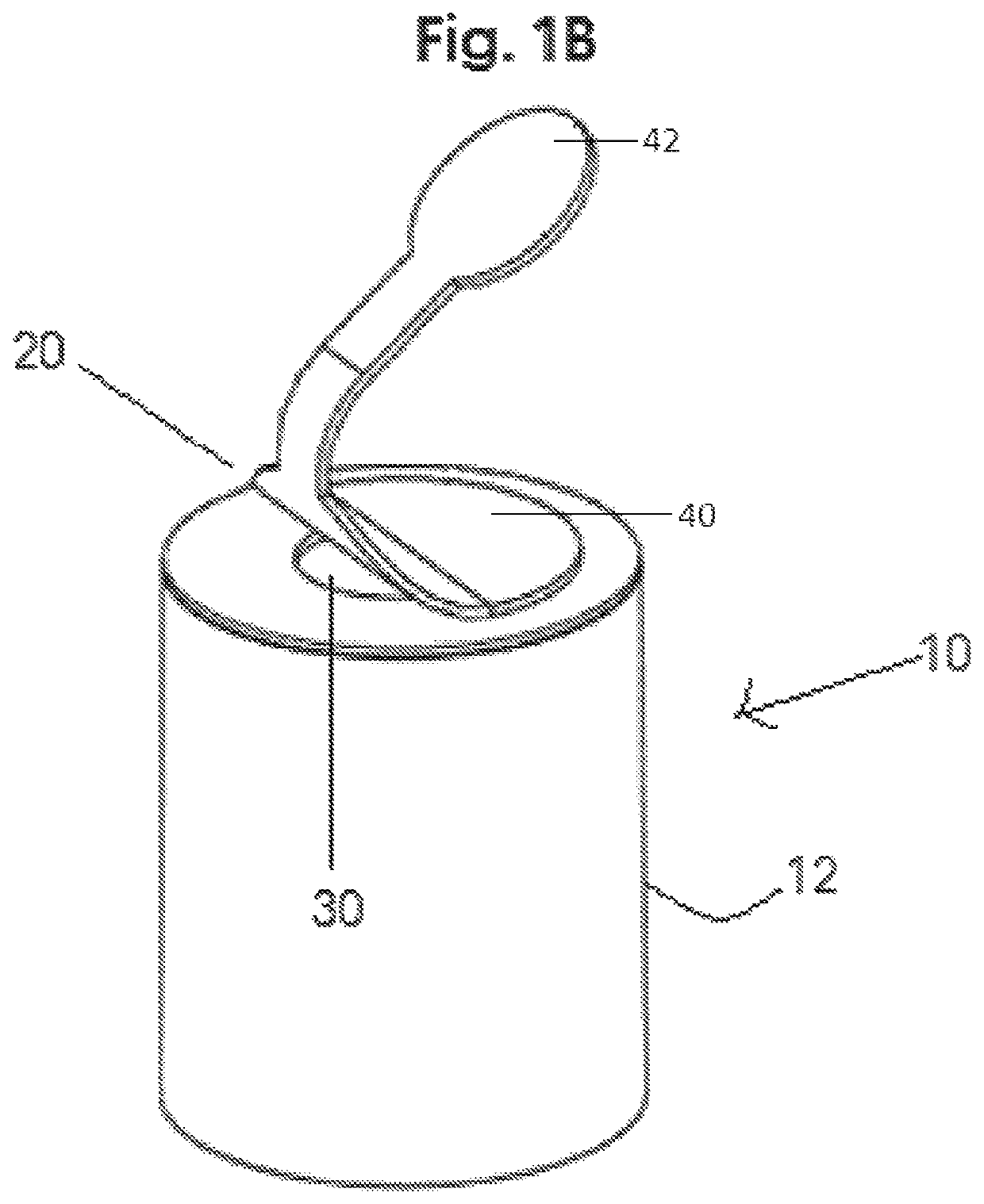

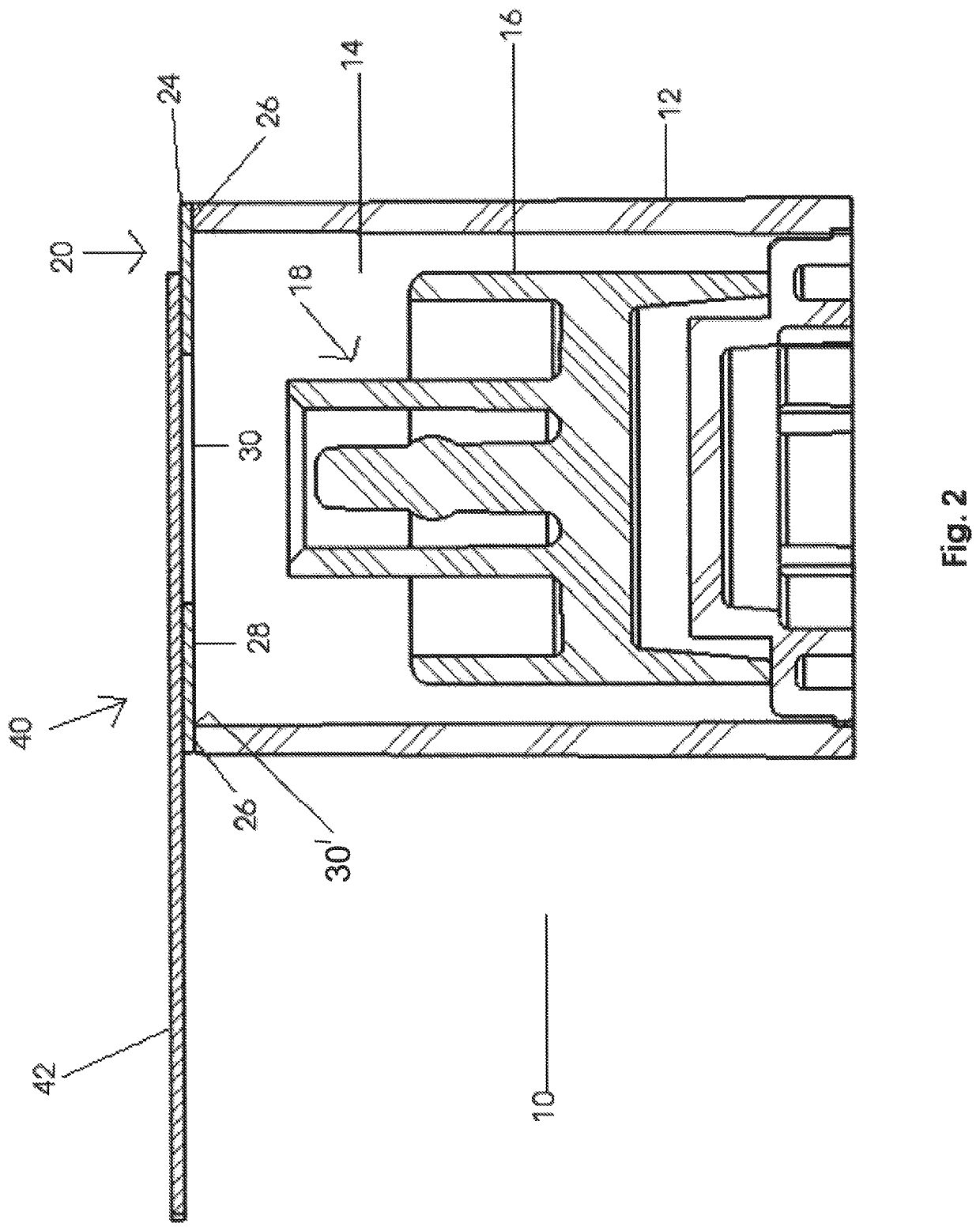

Indicator member of low strength resistance for a tamper evident closure

ActiveUS10933202B1Easy to peelFacilitate establishmentInfusion syringesPharmaceutical containersStructural engineeringMedical device

A tamper evident closure, intended primarily for a luer-slip or like frictional connection between one or more components associated with the closure and a syringe or other medical device, includes a housing having an open end and a tip cap disposed within the housing. An indicator member is connected to the housing in at least partially covering relation to the open end and includes an access opening disposed in accessible relation with the tip cap. A cover is removably disposed in overlying engagement with at least a portion of said indicator member in covering relation to the access opening. The indicator member has an inner segment disposed in contiguous surrounding relation to the access opening and has a reduced breakaway resistance, capable of being easily ruptured, ripped or torn during passage of said tip cap through the access opening, concurrent to the tip cap being connected to the medical device.

Owner:INT MEDICAL INDS

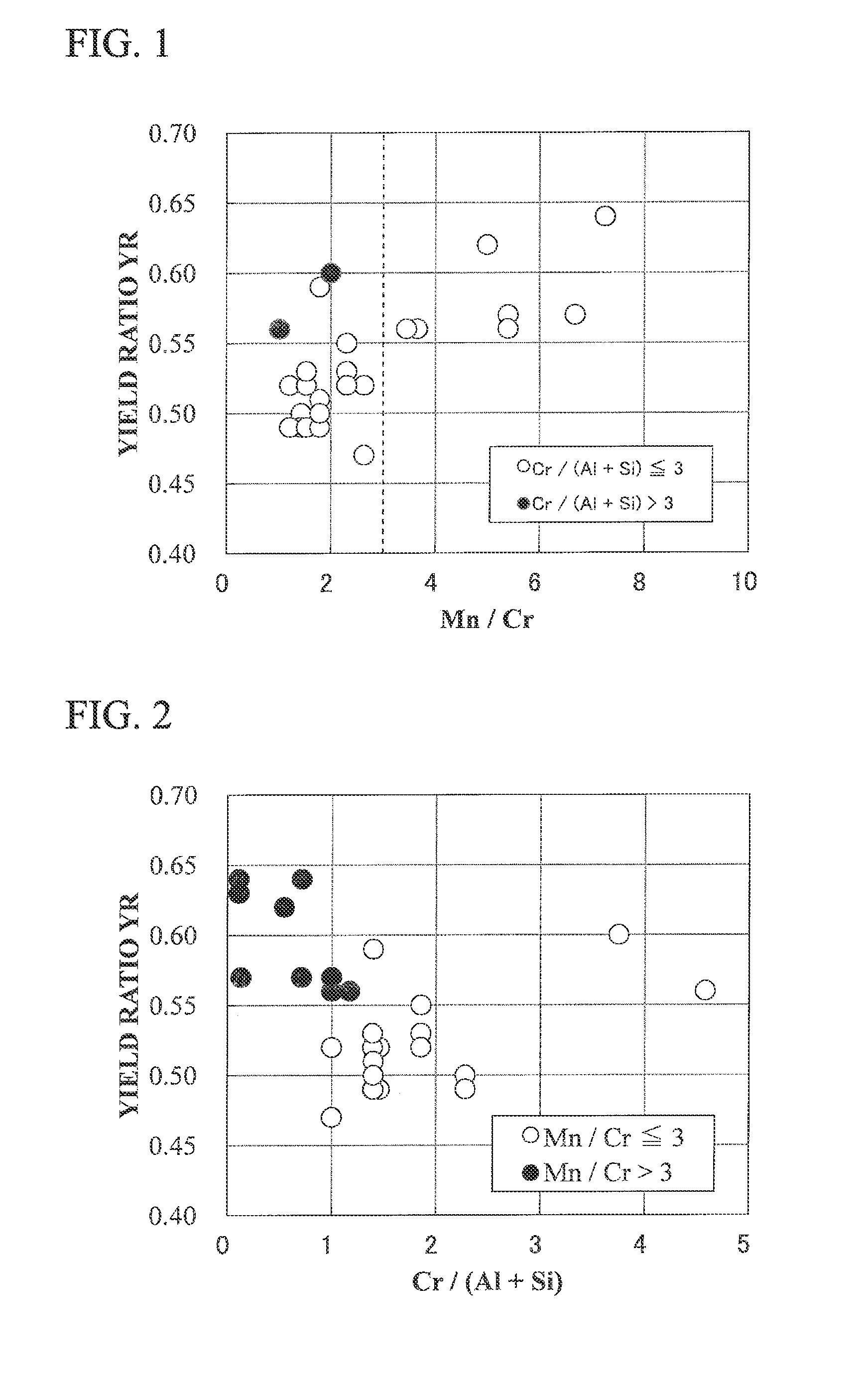

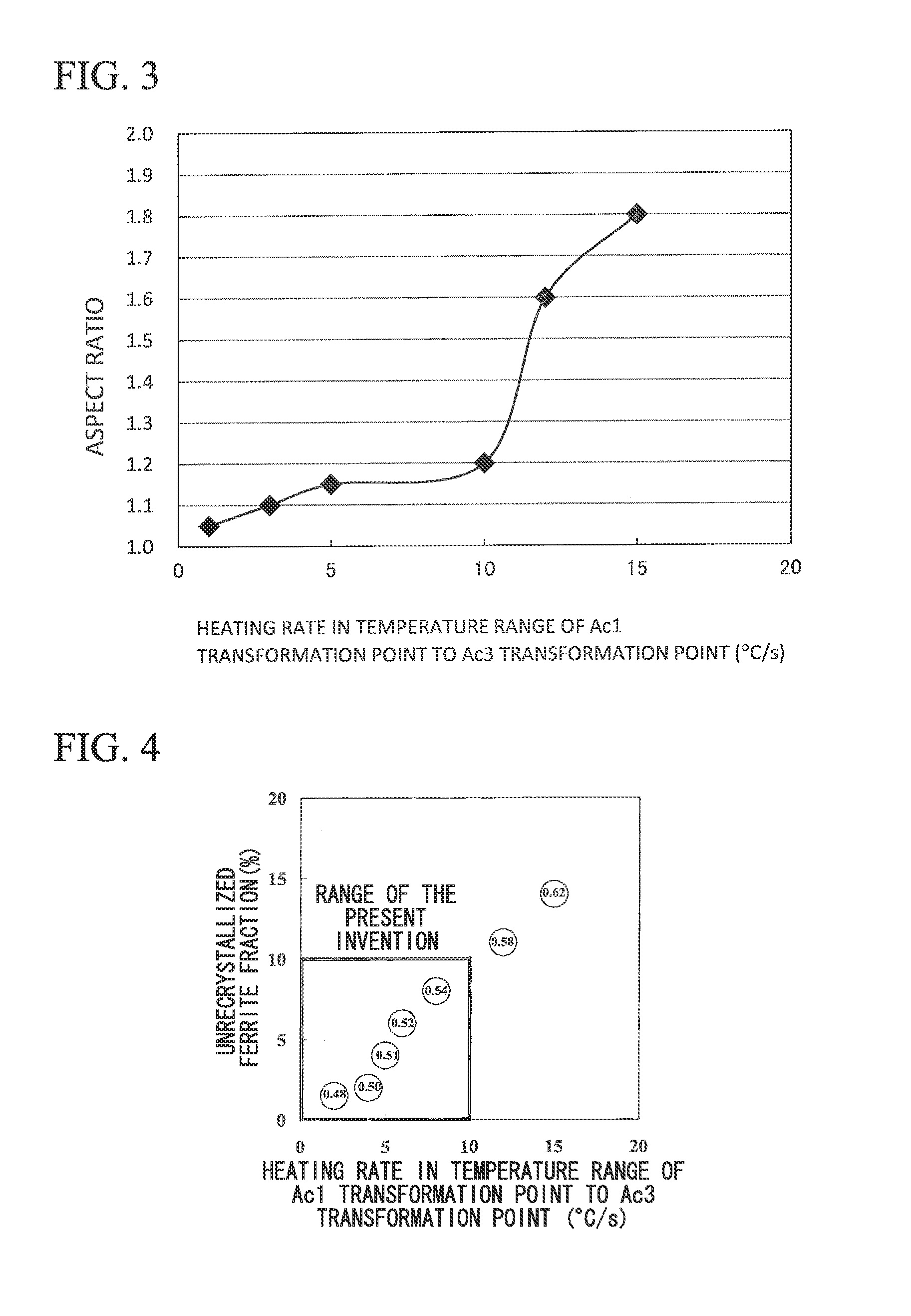

High-strength steel sheet having excellent processability and paint bake hardenability, and method for producing of high-strength steel sheet

InactiveUS20120282487A1Lower ratioLow strengthHot-dipping/immersion processesFurnace typesManganeseMaterials science

The high-strength steel sheet includes, by mass %: C: 0.01% to 0.10%; Si: 0.15% or less; Mn: 0.80% to 1.80%; P: 0.10% or less; S: 0.015% or less; Al: 0.10% to 0.80%; Cr: 0.01% to 1.50%; N: 0.0100% or less; and a balance consisting of iron and inevitable impurities, in which a metallic structure is composed of ferrite and a hard second phase, the area fraction of the ferrite is 80% or more, the area fraction of the hard second phase is 1% to 20%, the fraction of unrecrystallized ferrite in the ferrite is less than 10%, the ferrite grain sizes are 5 μm to 20 μm, and the fraction of the ferrite crystal grains having an aspect ratio of 1.2 or less in the entire ferrite crystal grains is 60% or more.

Owner:NIPPON STEEL CORP

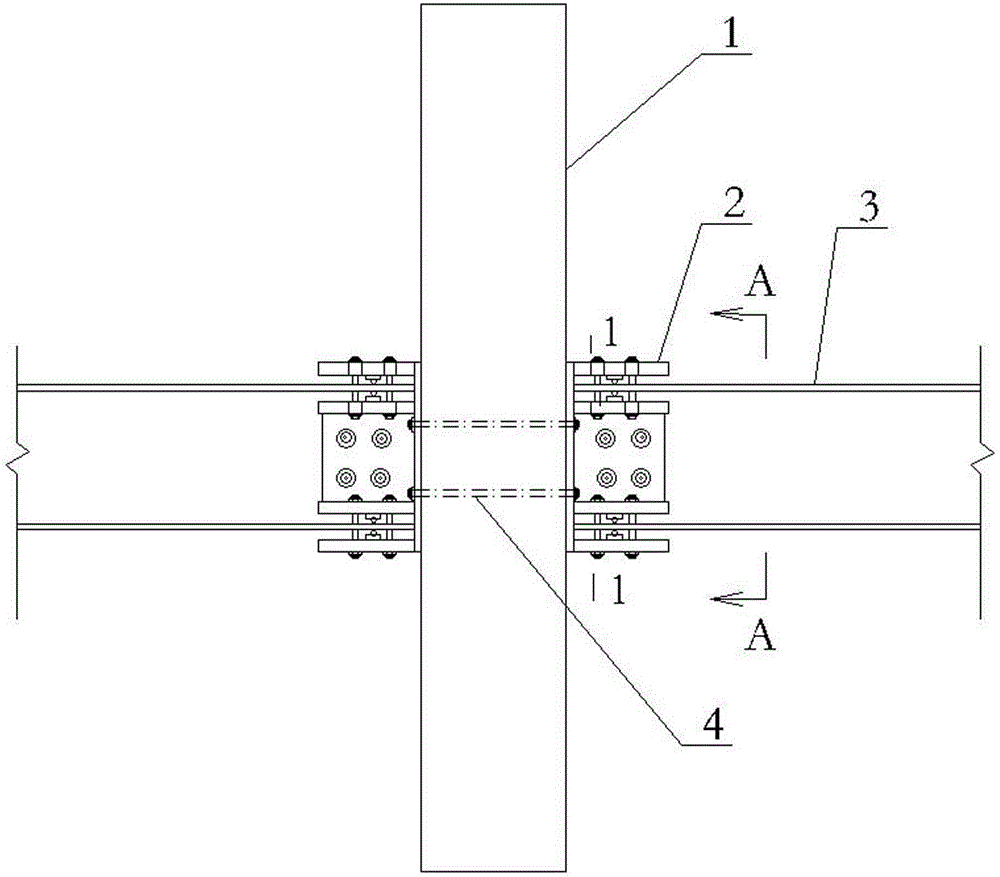

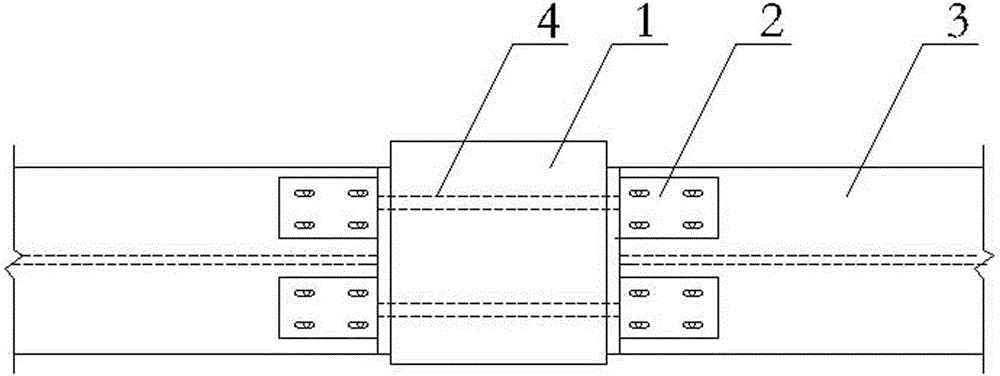

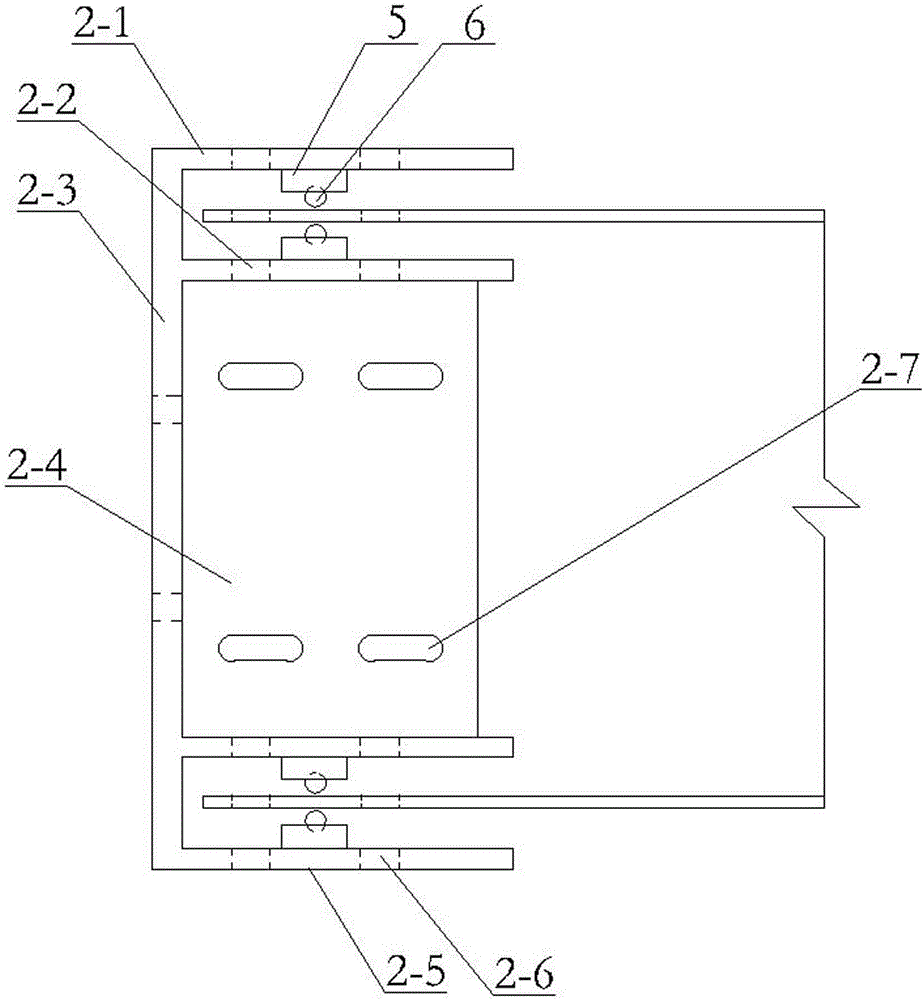

Assembly type beam column joint and construction method thereof

InactiveCN105155685AImprove energy consumptionLow strengthBuilding material handlingShock proofingUltrasound attenuationResidual deformation

The invention discloses an assembly type beam column joint and a construction method thereof. An upper flange of a connecting pair is connected with an upper flange of an H-shaped steel beam through bolts; a lower flange of the connecting pair is connected with a lower flange of the H-shaped steel beam through bolts; holes, which are connected with the bolts, of the upper flange and the lower flange of the connecting pair are slot holes of which the length directions are positioned in the length direction of the H-shaped steel beam; and an end plate of the connecting pair is attached to a concrete column. The construction method comprises the following steps of (1) manufacturing the concrete column; (2) manufacturing the H-shaped steel beam and the connecting pair; (3) mounting a particle damping energy-consuming device; (4) connecting the H-shaped steel beam and the connecting pair; and (5) connecting the column and the beam. When an earthquake comes, the bolts can slide in the slot holes, and earthquake energy can be consumed. Even if the joint deforms greatly, attenuation of strength and rigidity and participation deformation are small, residual deformation of the joint can be reduced after the earthquake, and the assembly type beam column joint has good deformation recovery capability and structure function recoverability.

Owner:SHANDONG JIANZHU UNIV

Header end tack seal for reclosable package

InactiveUS7364362B2Maintain cleanliness and aestheticMaintenance of cleanliness and aestheticFlexible coversWrappersEngineeringUltimate tensile strength

A tamper-evident reclosable package having a header that is tack sealed to the zipper. A light tack, in the form of a light weld, is made at the end of the package header. The header is the top portion of the package and is designed to shroud the zipper. The header serves as a tamper-evident feature, and also serves to maintain cleanliness and aesthetics of the package. The header must be tom before a person can gain access to the contents of the package. Typically, means for preferential tearing are provided for easy removal of the header. The tack seal contributes to the maintenance of the cleanliness and aesthetics of the package, while still allowing easy removal of the header. The tack is light (i.e., low bond strength or pull-off force) in order to not make it significantly more difficult to open the package.

Owner:ILLINOIS TOOL WORKS INC

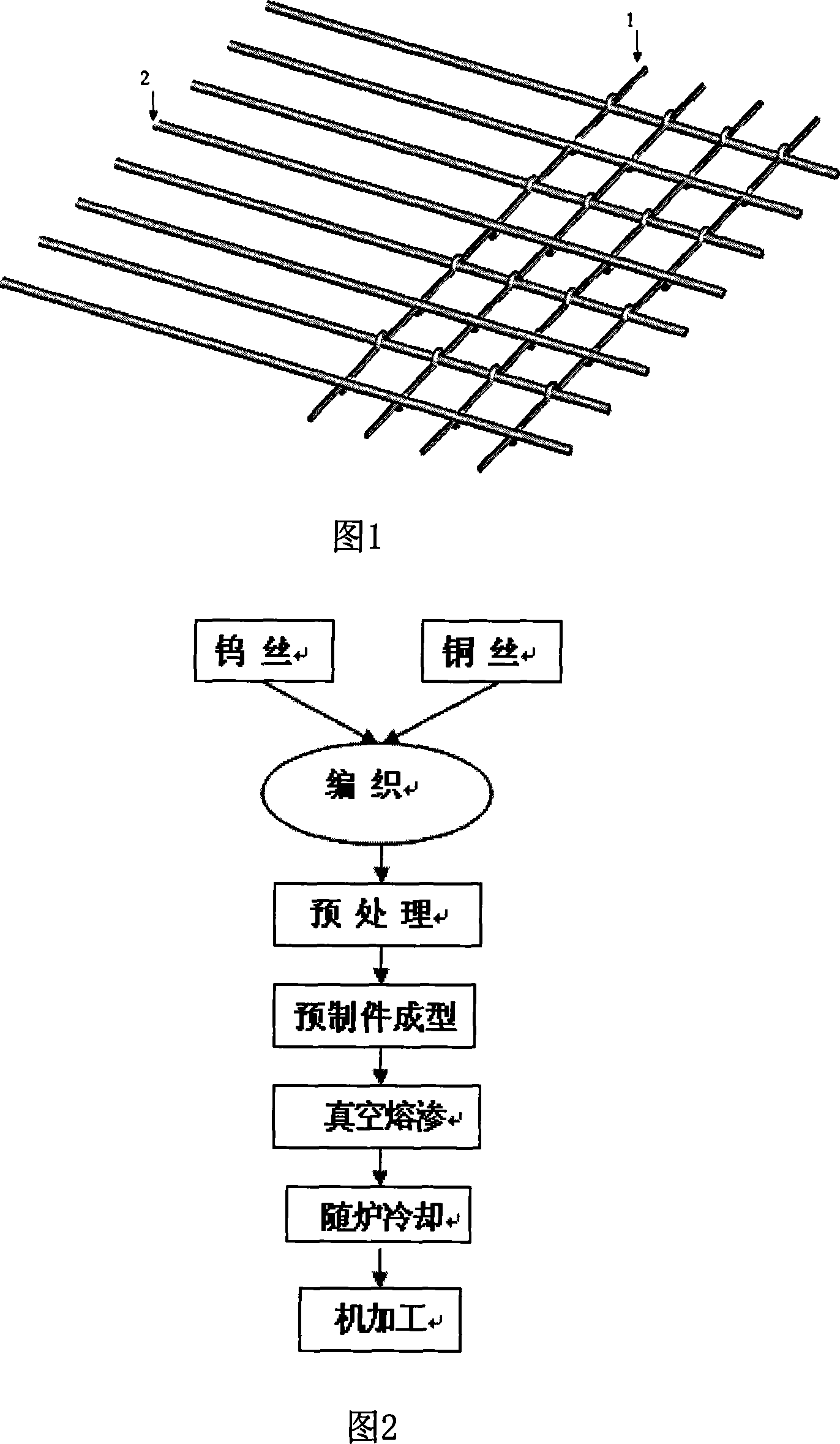

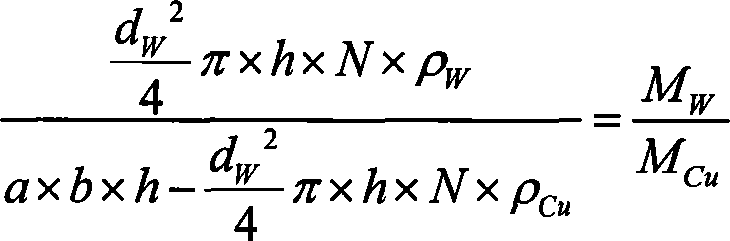

Method for preparing wolfram steel or composite material of tungsten and silver

InactiveCN101092669AImprove conductivityThe probability of arcing is smallCable/conductor manufactureComposite cathodeNitrogen

This invention discloses a process for preparing W-Cu or W-Ag composite material. The method comprises: (1) selecting W wires, washing with acid, and cleaning; (2) using Cu wires or Ag wires as the weft threads and W wires as the warp threads, and performing two-dimensional weaving to obtain a net; (3) tailoring the net into sheets according to the requirement, laminating and packing; (4) placing Cu ingot or Ag ingot above the packed sheets, and infiltrating in a vacuum sintering furnace; (5) cooling to room temperature, and taking out to obtain W-Cu or W-Ag composite cathode bar; (6) performing mechanical processing to obtain W-Cu or W-Ag composite material. The W-Cu or W-Ag composite material has such advantages as low oxygen, nitrogen and inclusion contents, and high compactness.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Rubber composition for inner liner and tire having inner liner including thereof

InactiveUS20100331473A1Improve air permeation resistanceImprove the immunitySpecial tyresMicaMicaCarbon black

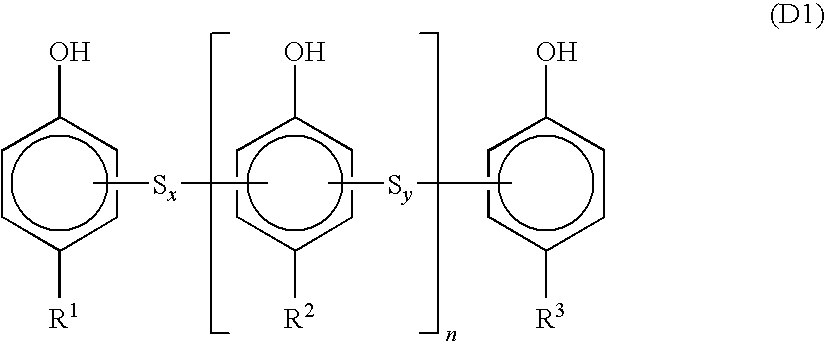

It is the purpose of the present invention to improve air permeation resistance, low heat build-up property and strength at break. The present invention provides a rubber composition for an inner liner including (B) specific mica, (C) carbon black and / or silica and (D) an alkylphenol-sulfur chloride condensate indicated by the formula (D1):(Wherein R1 to R3 are an alkyl group having 5 to 12 carbons; x and y are an integer of 2 to 4; and n is an integer of 0 to 10), based on (A) specific rubber component.

Owner:SUMITOMO RUBBER IND LTD

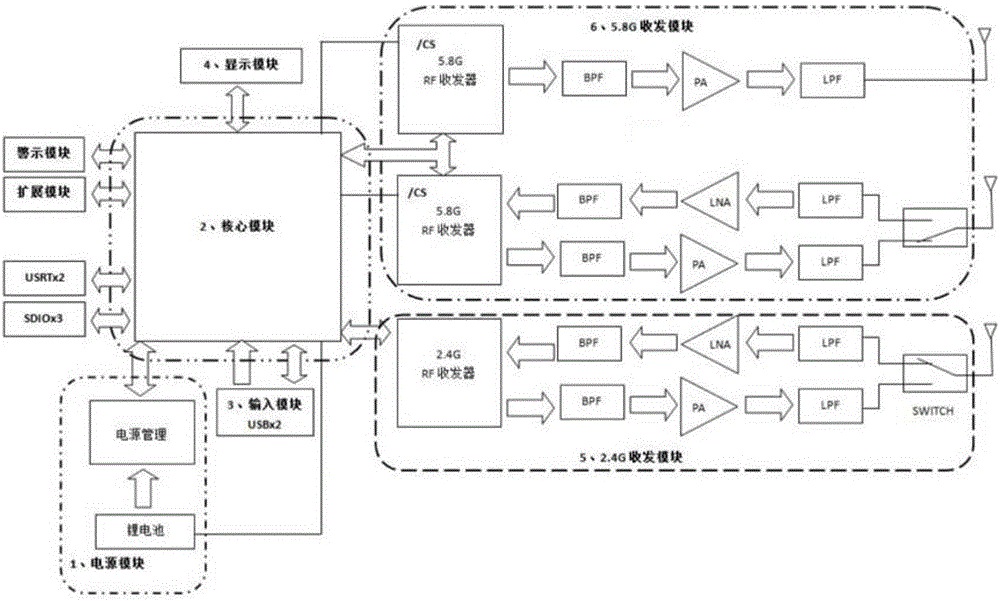

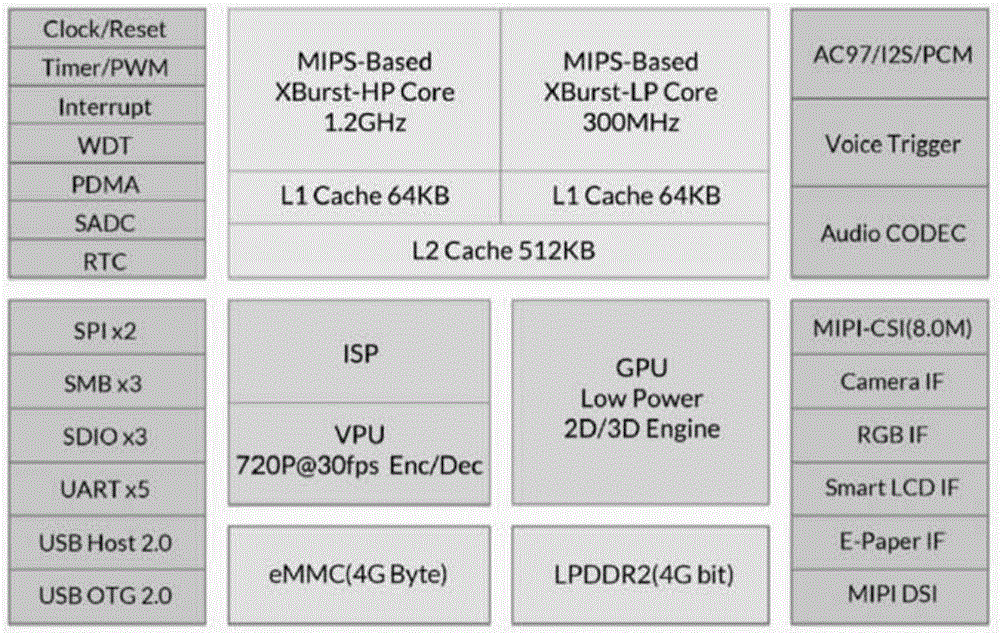

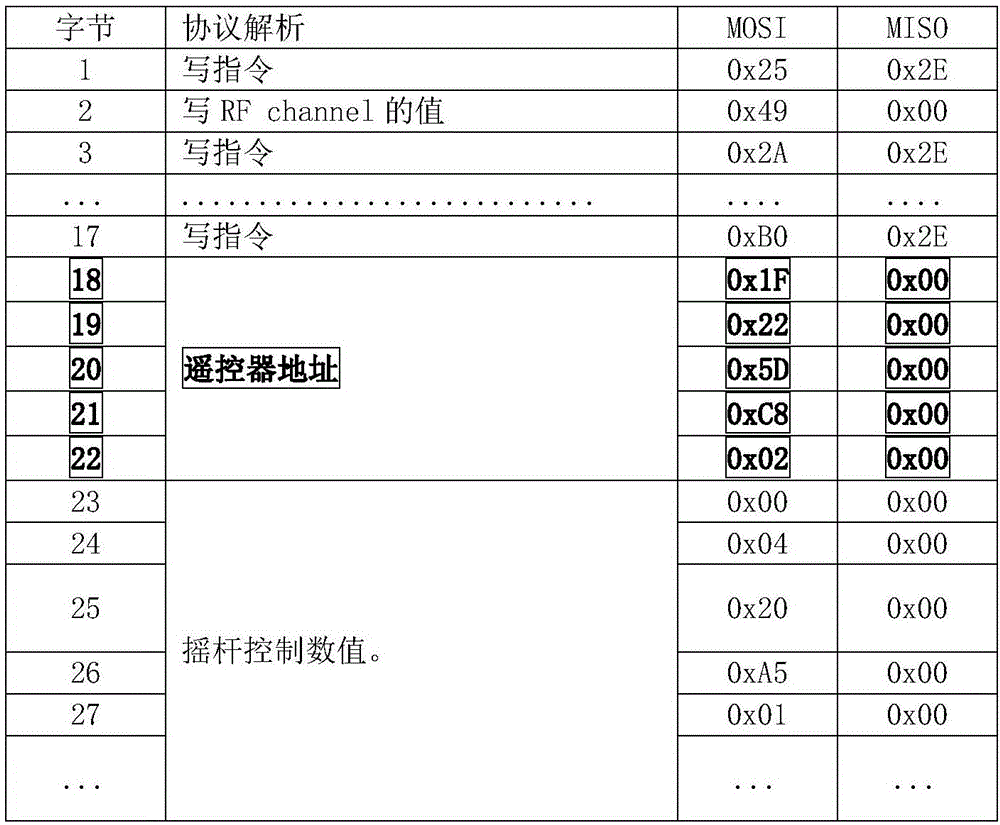

Unmanned plane interference method and system

InactiveCN106683378AReduce transmit powerReduce volumeTransmission systemsCommunication jammingControl signalElectromagnetic interference

The invention provides an unmanned plane interference method and system. The system comprises a radio-frequency transceiving module, a core module, a power supply module and the like, wherein the core module comprises a main control unit; the main control unit is respectively connected with the radio-frequency transceiving module and the power supply module; the radio-frequency transceiving module is used for receiving an unmanned plane control signal and transmitting the unmanned plane control signal to the main control unit; the main control unit is used for analyzing the unmanned plane control signal to acquire unmanned plane remote controller address and generate an interference signal; and the main control unit is used for transmitting the interference signal through the radio-frequency transceiving module to interfere with the flight of the unmanned plane. The system has the advantages of high interference accuracy, low interference signal intensity, small electromagnetic interference range, long accurate interference distance, low transmission power, small size, light weight, favorable portability and low hardware cost, and can inhibit the unmanned planes in the blacklist from takeoff.

Owner:XIAMEN ANSCEN NETWORK TECH CO LTD

Coating composition for insulating film production, preparation method of insulation film by using the same, insulation film for semi-conductor device prepared therefrom, and semi-conductor device comprising the same

ActiveUS7345351B2High mechanical strengthLow dielectric constantTransistorLiquid surface applicatorsPolymer chemistrySemiconductor

Owner:LG CHEM LTD

Block copolymer, process for producing the same, and molded object

InactiveUS6965003B2Low birefringenceLow light transmittanceFilm/foil adhesivesPolymer scienceWaveguide

A block copolymer comprising a polymer block [A] and a polymer block [B]. The polymer block [A] contains mainly a repeating unit having an alicyclic structure, and the polymer block [B] contains the repeating unit having an alicyclic structure and a repeating unit derived from a diene based monomer and / or a vinyl based monomer. In any block, the carbon-carbon unsaturated bonds are hydrogenated. The block copolymer is molded into optical disks, optical waveguides, films, sheets, containers, and optical lenses.

Owner:ZEON CORP

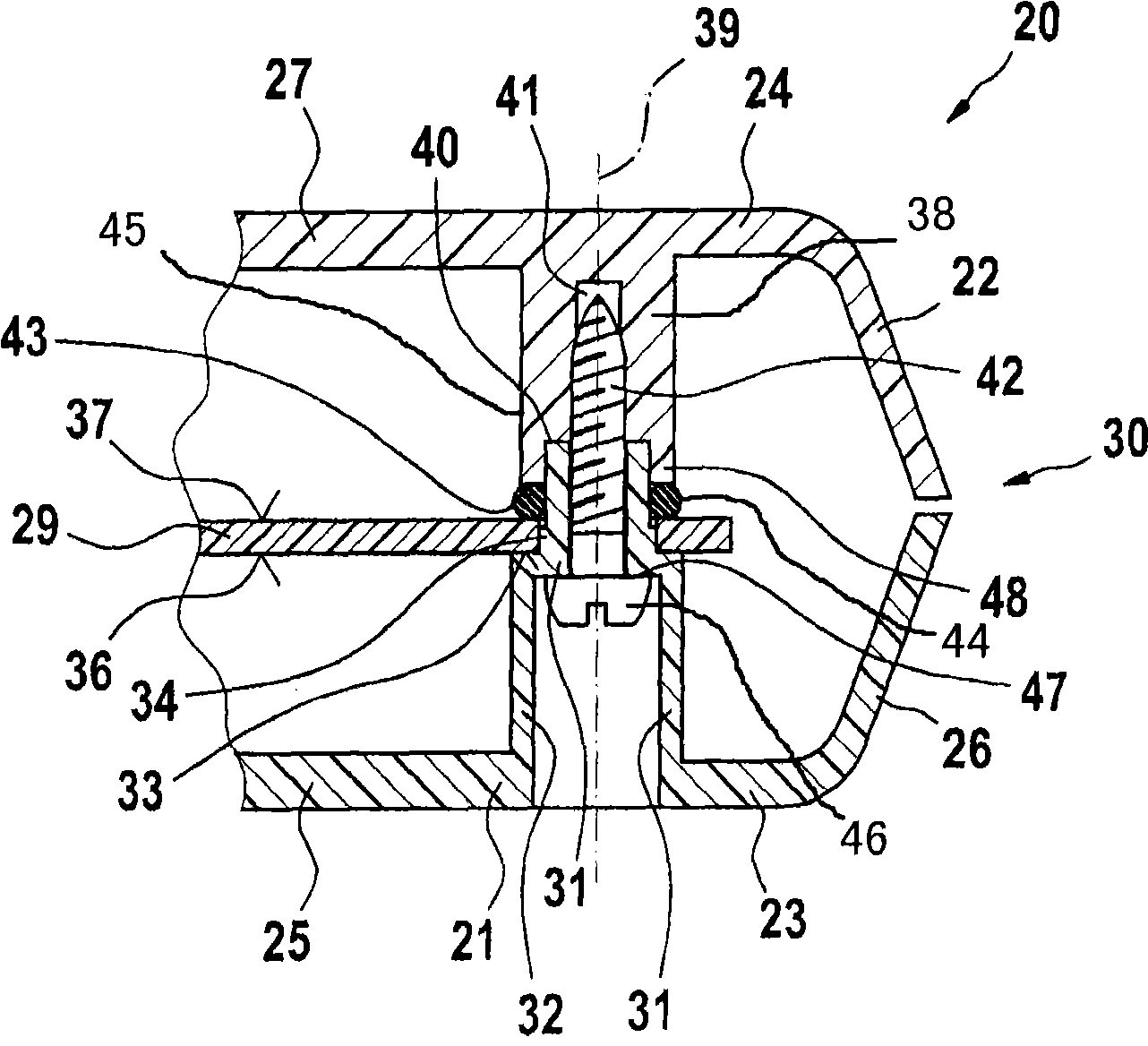

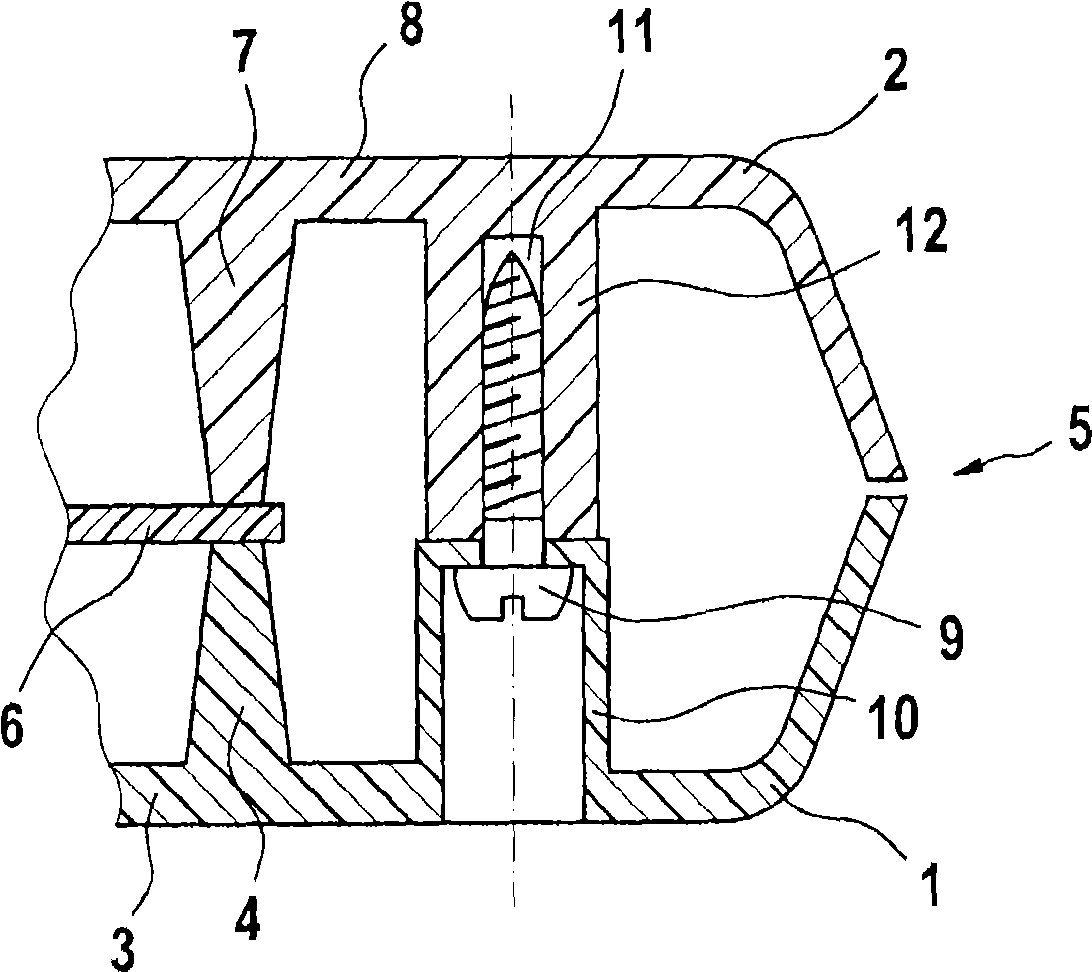

Printed circuit board apparatus

InactiveCN101522009AReduce intensityReduced mechanical stabilitySupport structure mountingClosed casingsEngineeringPrinted circuit board

The invention relates to a printed circuit board apparatus(20), comprising a housing(30) which includes a first housing part(21) and at least a second housing part(22); the second housing part is fixed on the first housing part(21) by at least a fixing component(42); wherein a printed circuit board(29) is axially clamped between a first support section(31) of the first housing part(21) and a second support section(38) of the second housing part(22). According to the invention, the fixing component(42) is arranged to act on the two support section(31,38).

Owner:ROBERT BOSCH GMBH

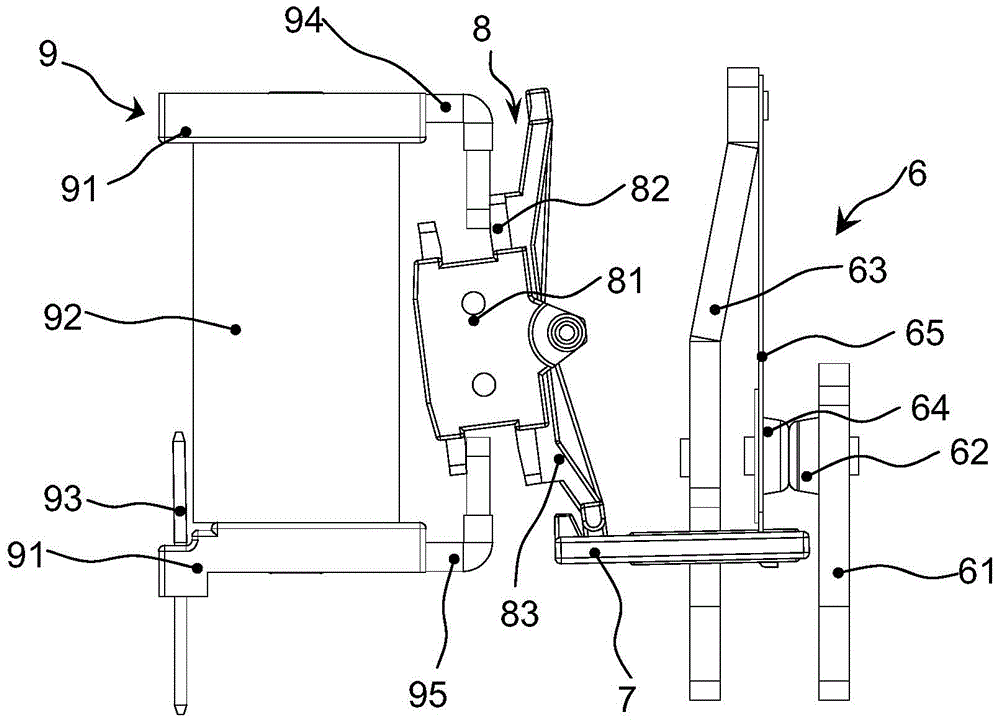

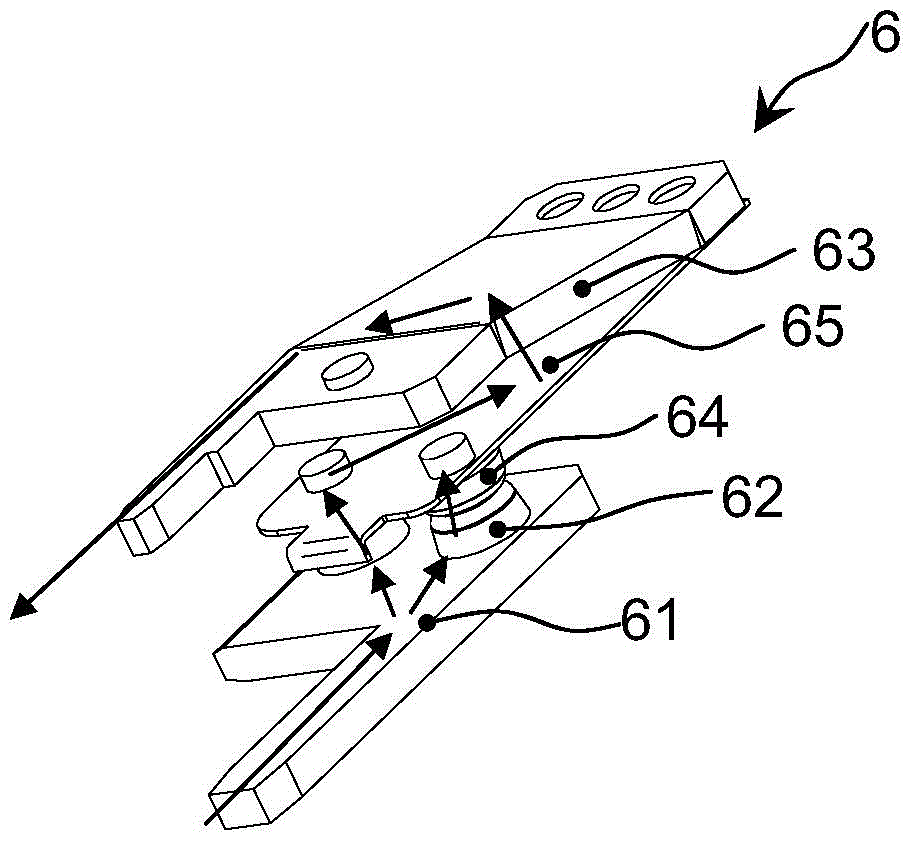

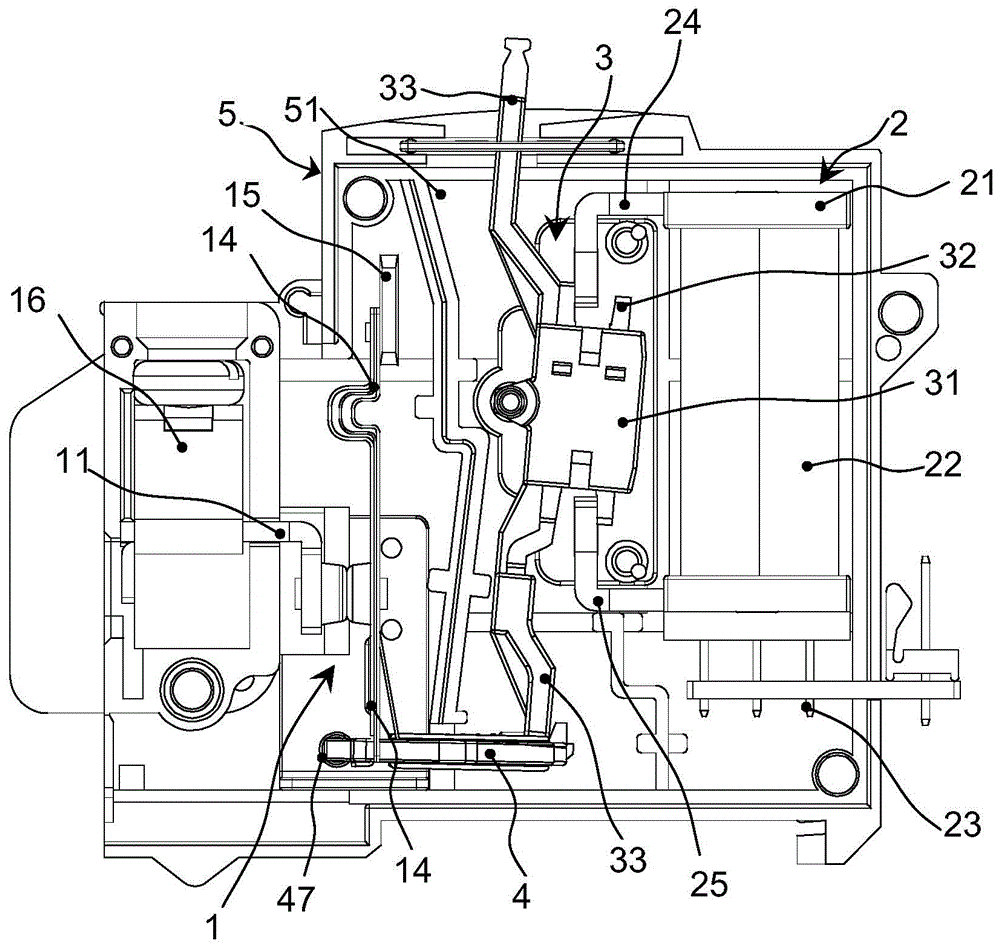

Large-current magnetic latching relay, movable contact spring of large-current magnetic latching relay, and contact assembly of large-current magnetic latching relay

ActiveCN104091725AImprove pressure resistanceExtend your lifeElectromagnetic relay detailsNon-polarised relaysEngineeringConductive materials

The invention provides a large-current magnetic latching relay, a movable contact spring of the large-current magnetic latching relay, and a contact assembly of the large-current magnetic latching relay. The large-current magnetic latching relay comprises the contact assembly, an electromagnetic assembly, an armature assembly and a pushing clamp, and under the magnetic attraction action of permanent magnet steel inside the armature assembly, the contact assembly keeps in the normally open state or in the normally closed state; the contact assembly is triggered by pulse electric signals to be switched between the normally open state and the normally closed state, so that the electromagnetic assembly drives the armature assembly to drive the pushing clamp to shift, and the contact assembly is switched between the normally open state and the normally closed state through shifting of the pushing clamp. The movable contact spring of the large-current magnetic latching relay is made of elastic conductive materials and is fixedly provided with at least two movable contacts, the movable contact spring is provided with a fixed first end portion and a second end portion capable of elastically swinging, the movable contacts are fixed to the second end portion and are electrically connected through the movable contact spring, and the second end portion of the movable contact spring is driven by the pushing clamp to swing.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com