Printed circuit board apparatus

A printed circuit board and printed circuit technology, applied in the direction of electrical components, support structure installation, electrical equipment construction parts, etc., can solve the problems of small anti-vibration ability and insufficient mechanical strength of printed circuit board devices, and achieve anti-vibration performance The effect of improving, strength and mechanical stability is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

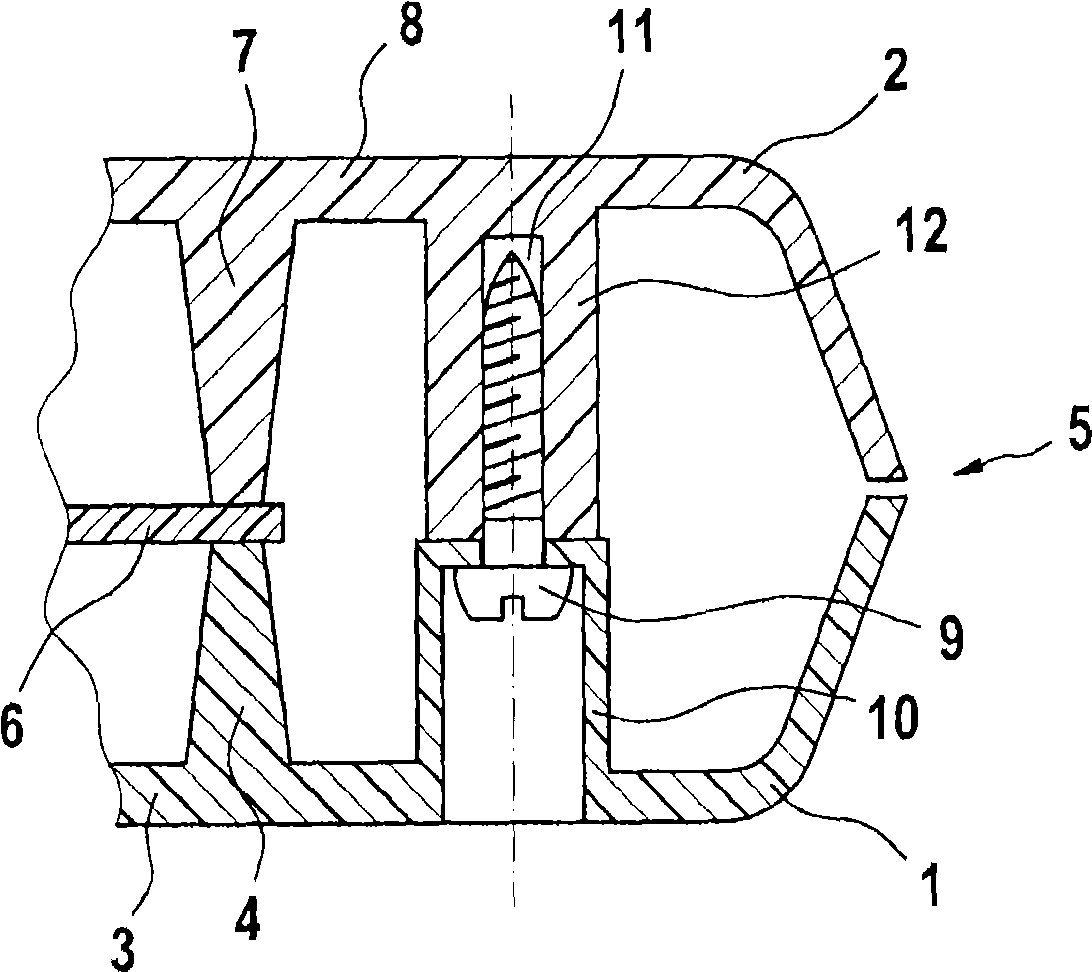

[0019] In the figures, identical components and components having the same function are designated with the same reference numerals.

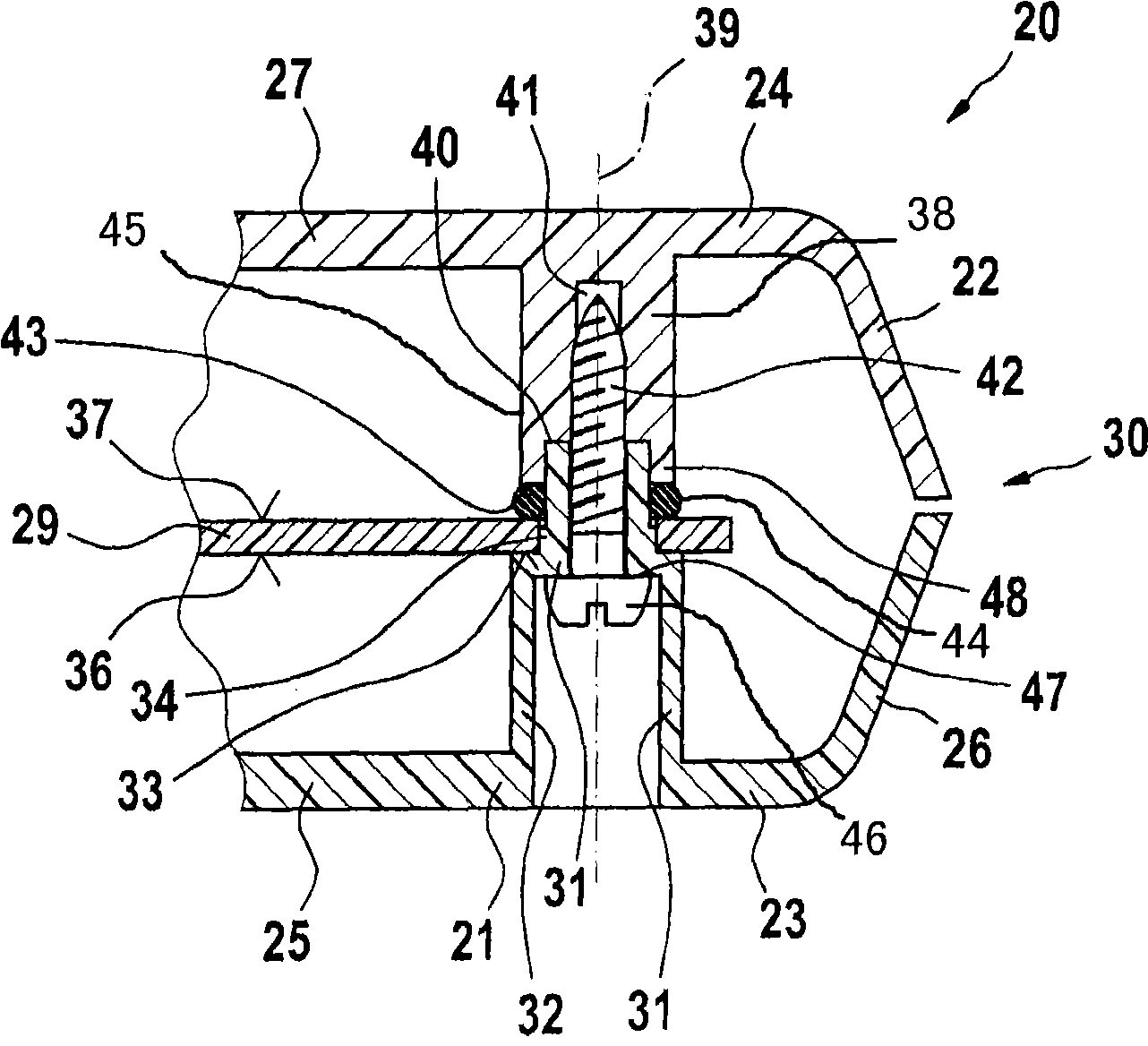

[0020] exist figure 1 A printed circuit board assembly 20 (printed circuit board holding device) is shown in . It comprises two housing parts constructed as plastic injection-molded parts, namely a first housing part 21 located below in the drawing and an opposite second housing part 22 arranged above in the drawing. The two housing parts 21 , 22 are designed as housing shells and comprise a first outer wall 23 and a second outer wall 24 . The first outer wall 23 is formed by a flat bottom wall section 25 and a peripheral first side wall section 26 adjoining it on the edge side, which extends at an angle to the first bottom wall section 25 . Similarly, the second outer wall 24 is formed by a second base wall section 27 and a second side wall section 28 extending at an angle thereto in the direction of the first side wall section 26 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com