Patents

Literature

202results about How to "Increase the support surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

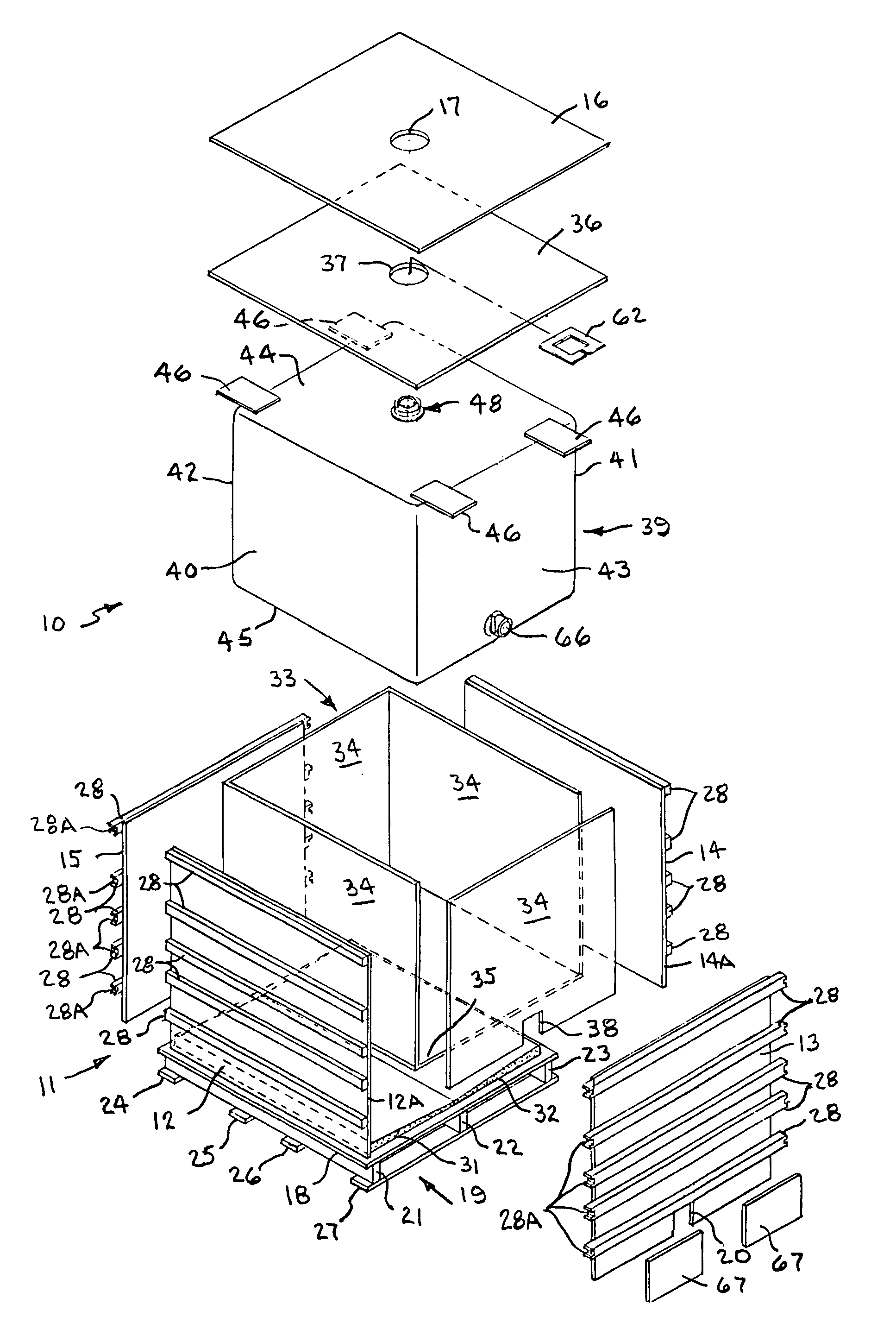

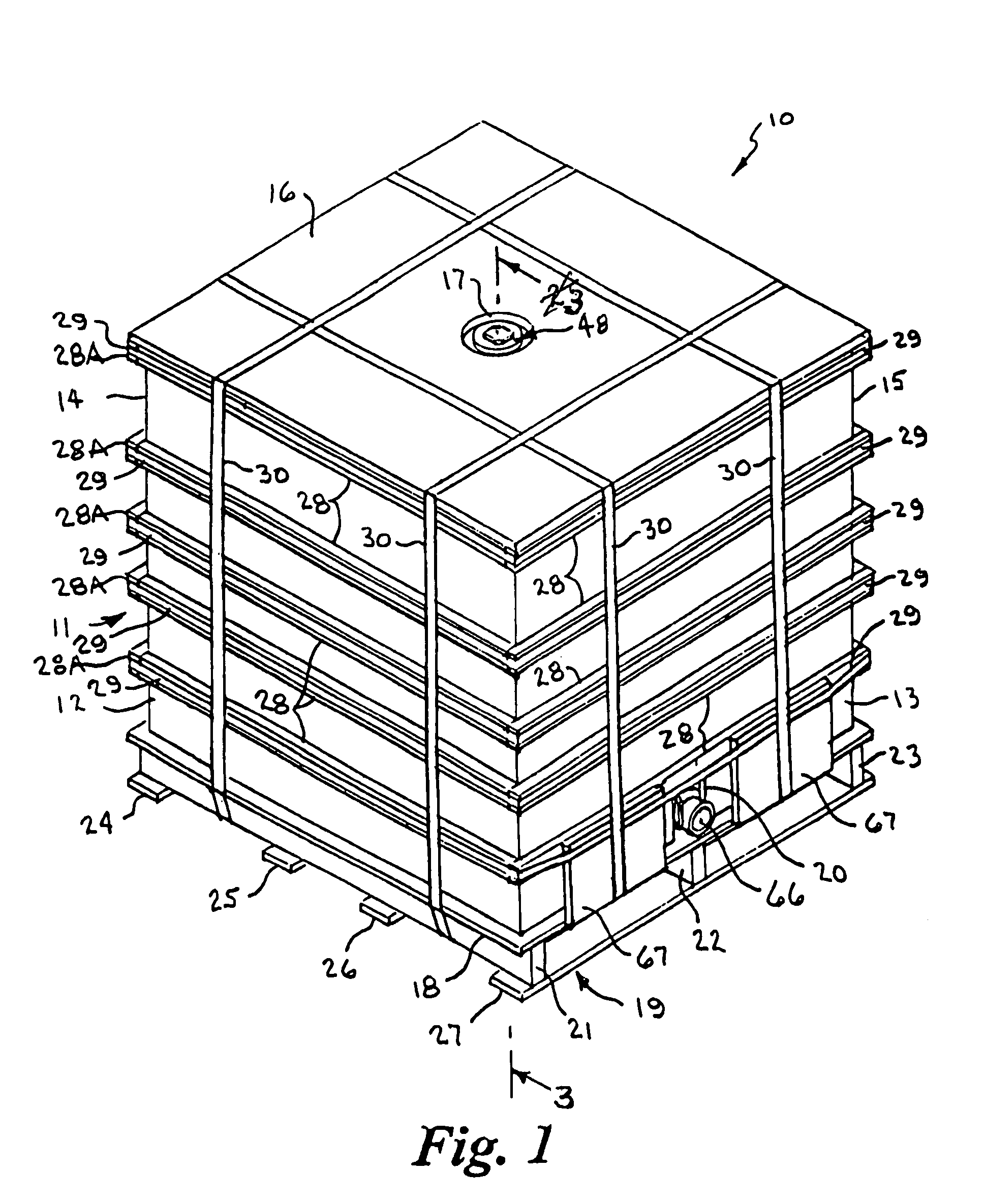

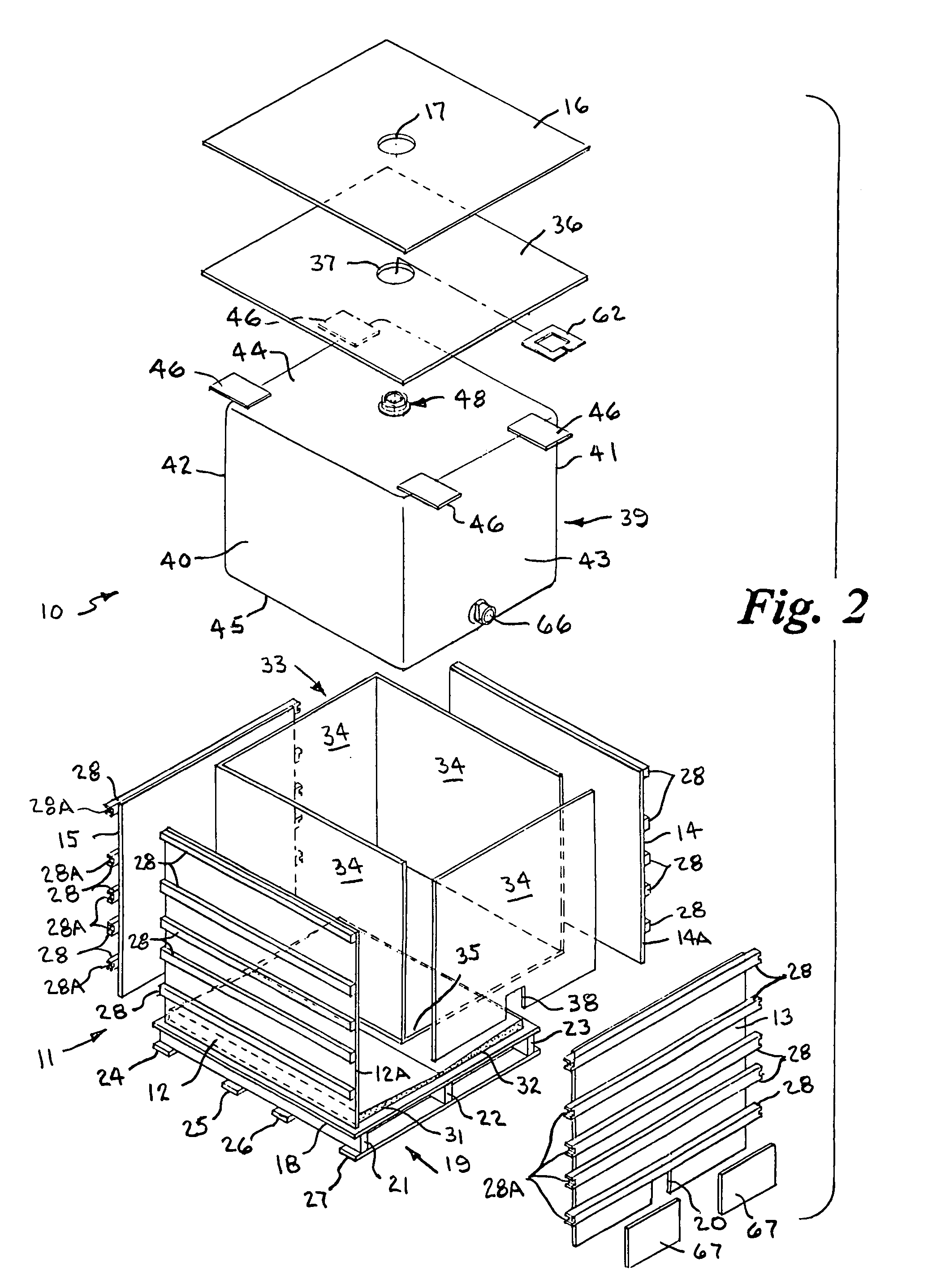

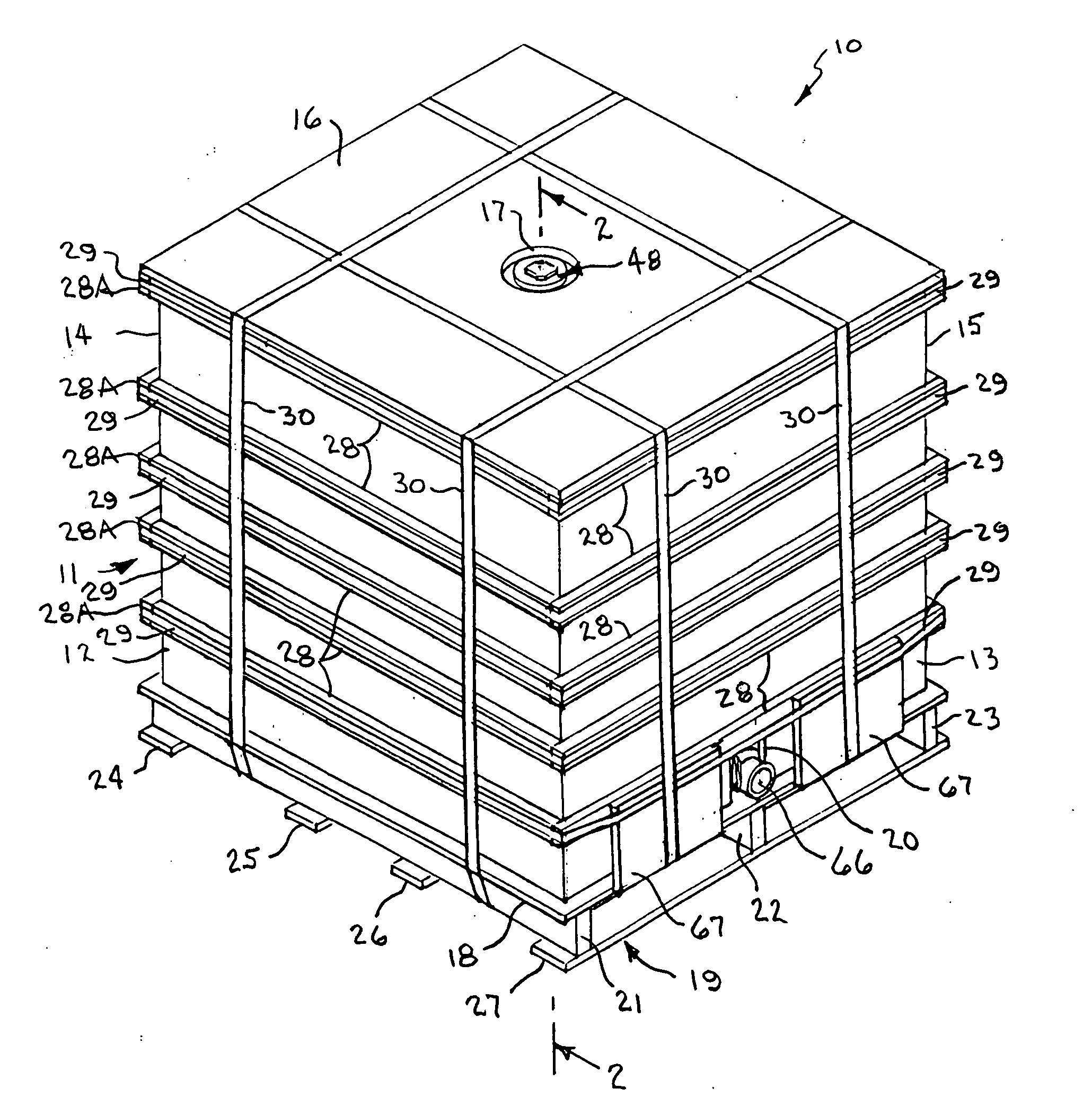

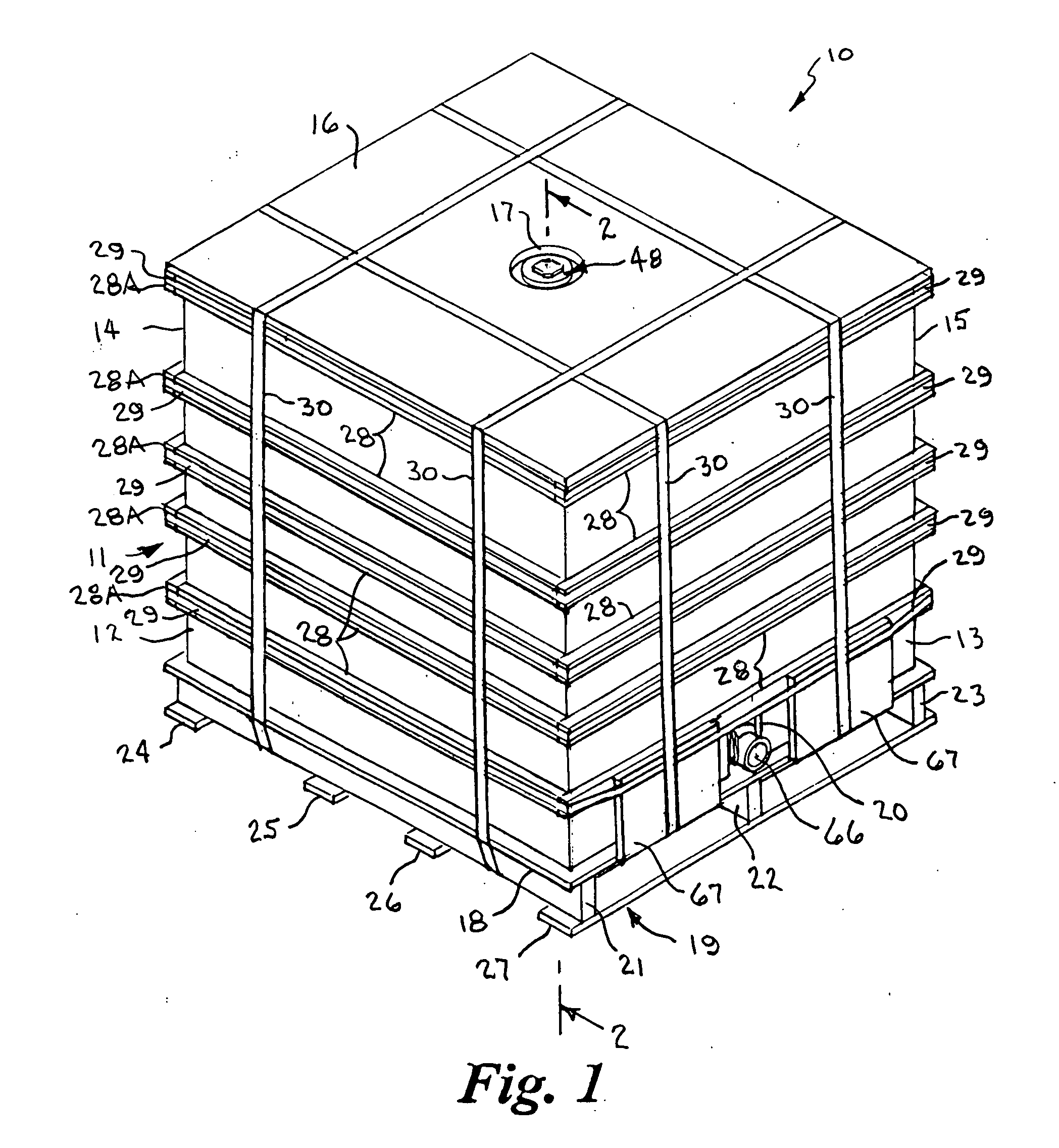

Container for bulk handling of fluids

InactiveUS7337908B2Prevent the top of the bag from saggingReduce the amount requiredLarge containersOther accessoriesCushioningEngineering

Owner:MILLAN BOX

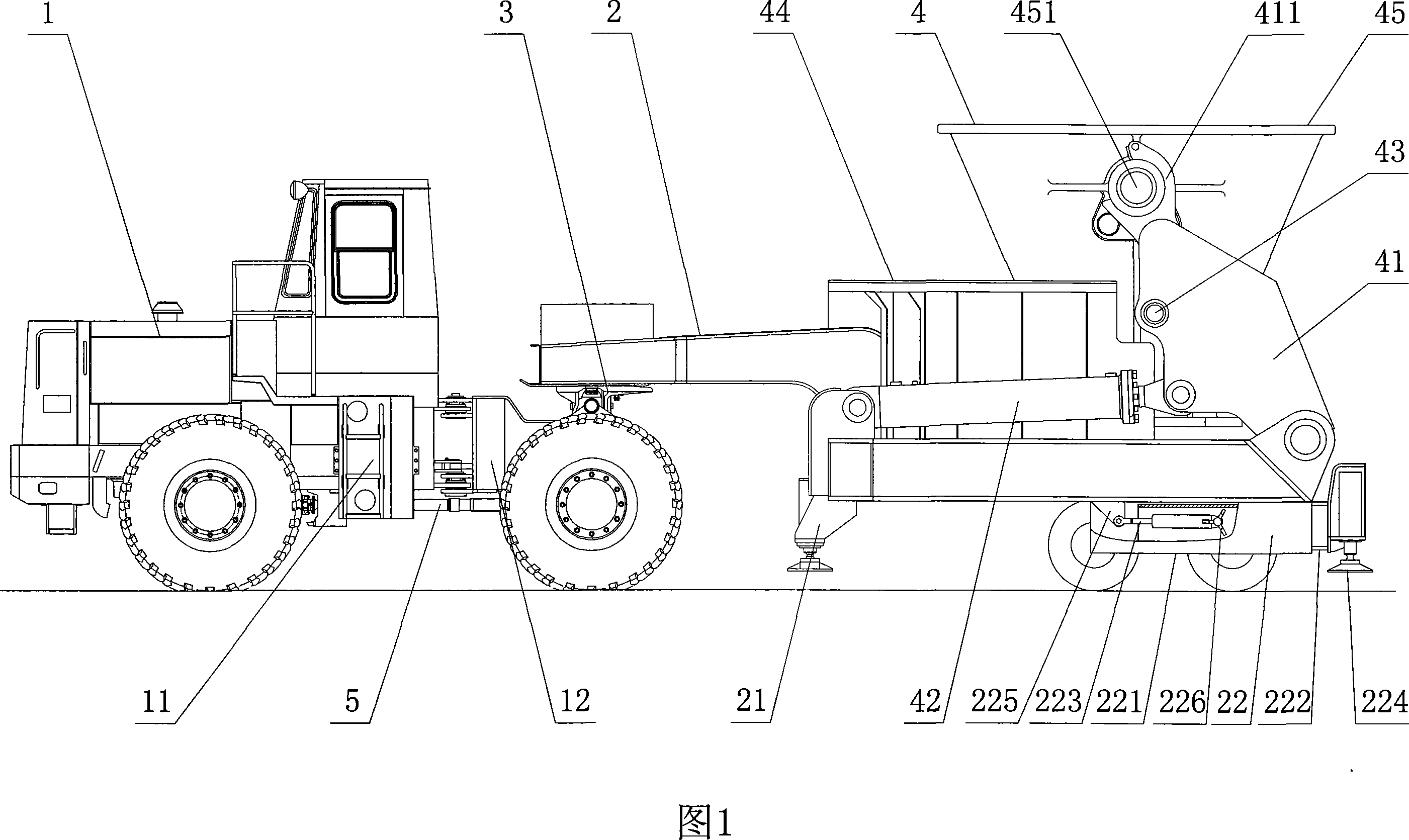

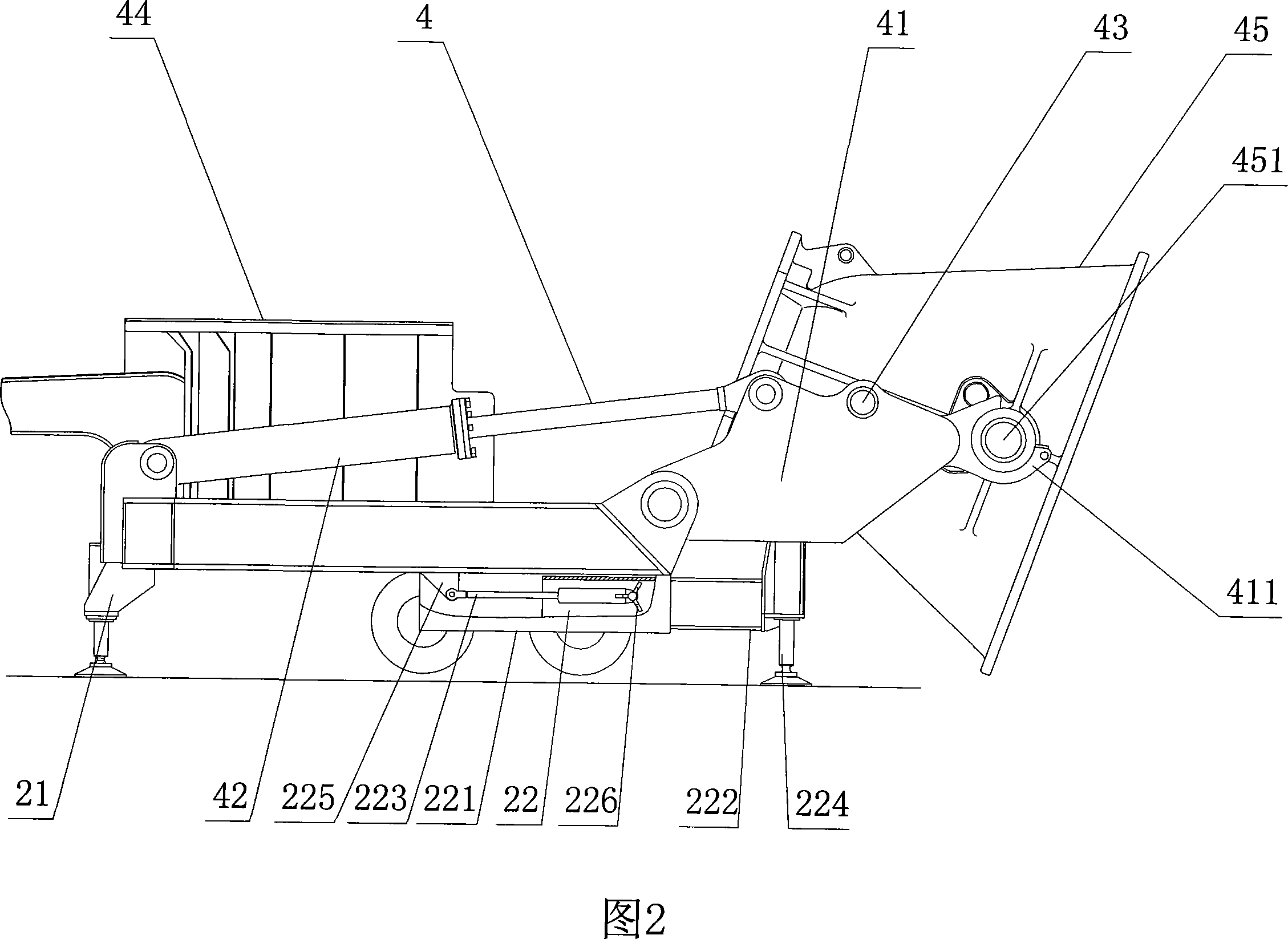

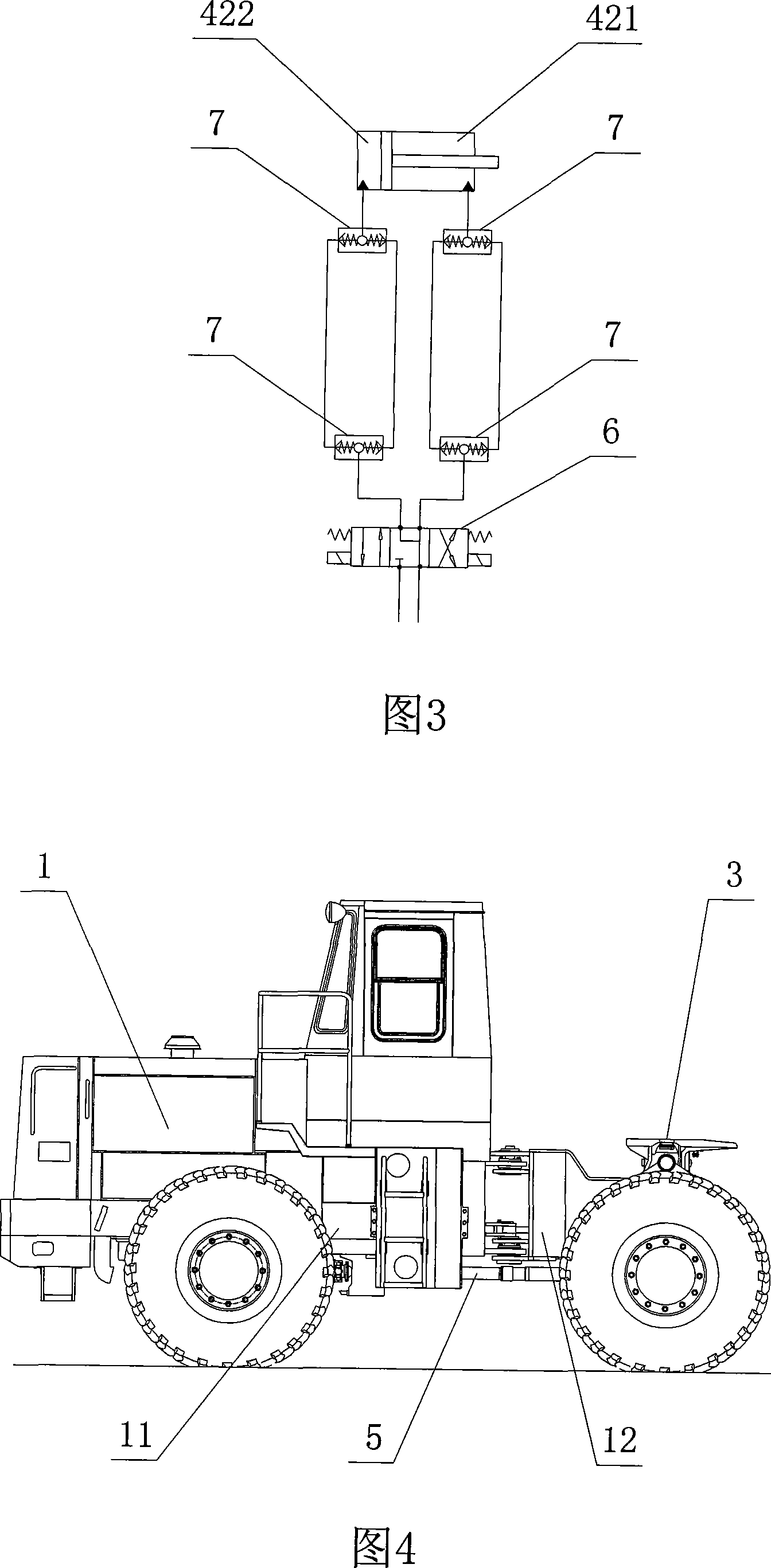

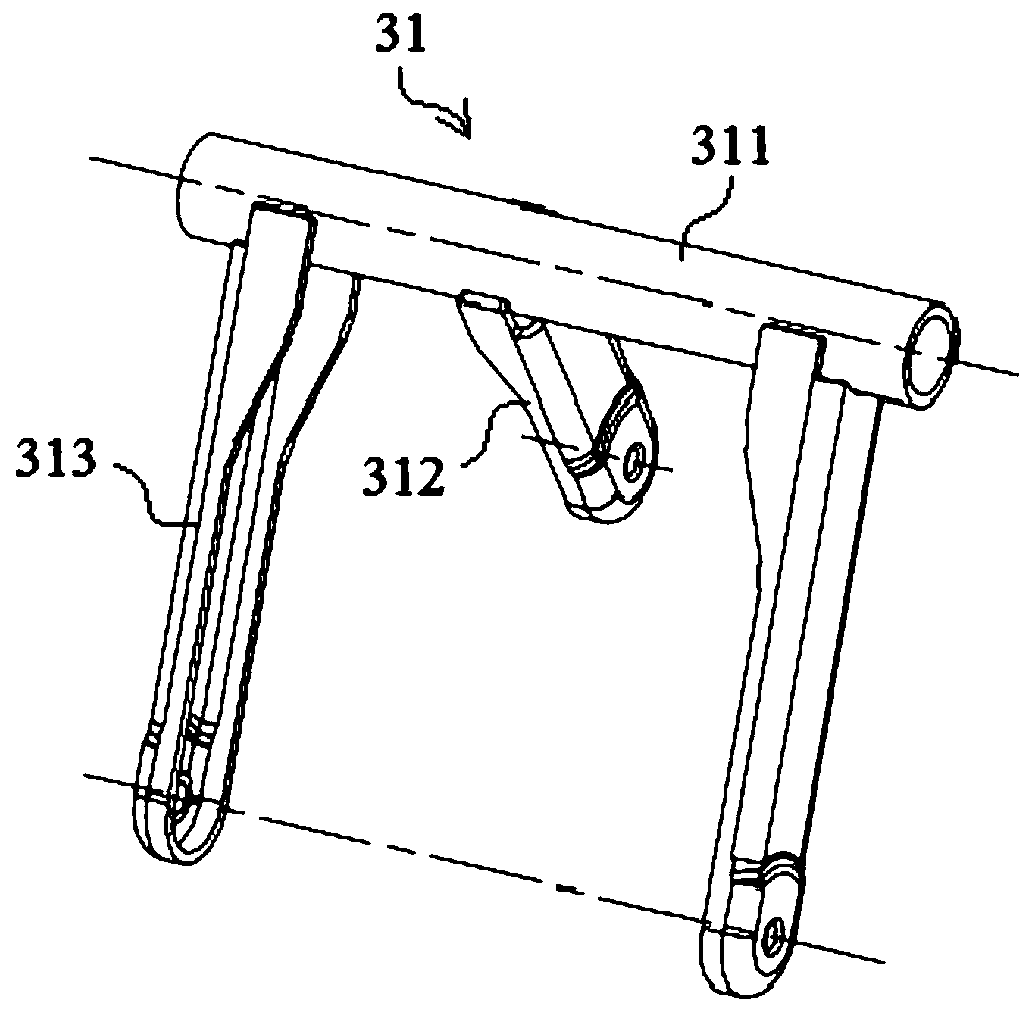

Hinged tailing type cylinder tailer with telescopic legs

ActiveCN101070064AShorten the lengthIncrease job securityMelt-holding vesselsVehicle fittings for liftingEngineeringStructural engineering

The invention discloses an articulated tractor-trailer tank car with scalable outrigger which can be used in steel mill. Its back outrigger is adjustable on level, hydraulic system has high safety and it has flexible turning. It contains tractor, semi-trailer, saddle and tank structure. The semi-trailer links the back of the tractor by the saddle. The tank structure locates on the semi-trailer. The semi-trailer has front and back outriggers on both sides of its front and levelly scalable back ends separately. The back outrigger contains edge beam, box beam, level cylinder and outrigger. The edge beam fixes on both sides of the back of the semi-trailer. One end of the box beam covers in the edge beam and its other end links the outrigger. Two ends of cylinder link box beam and edge beam separately.

Owner:长沙凯瑞重工机械有限公司

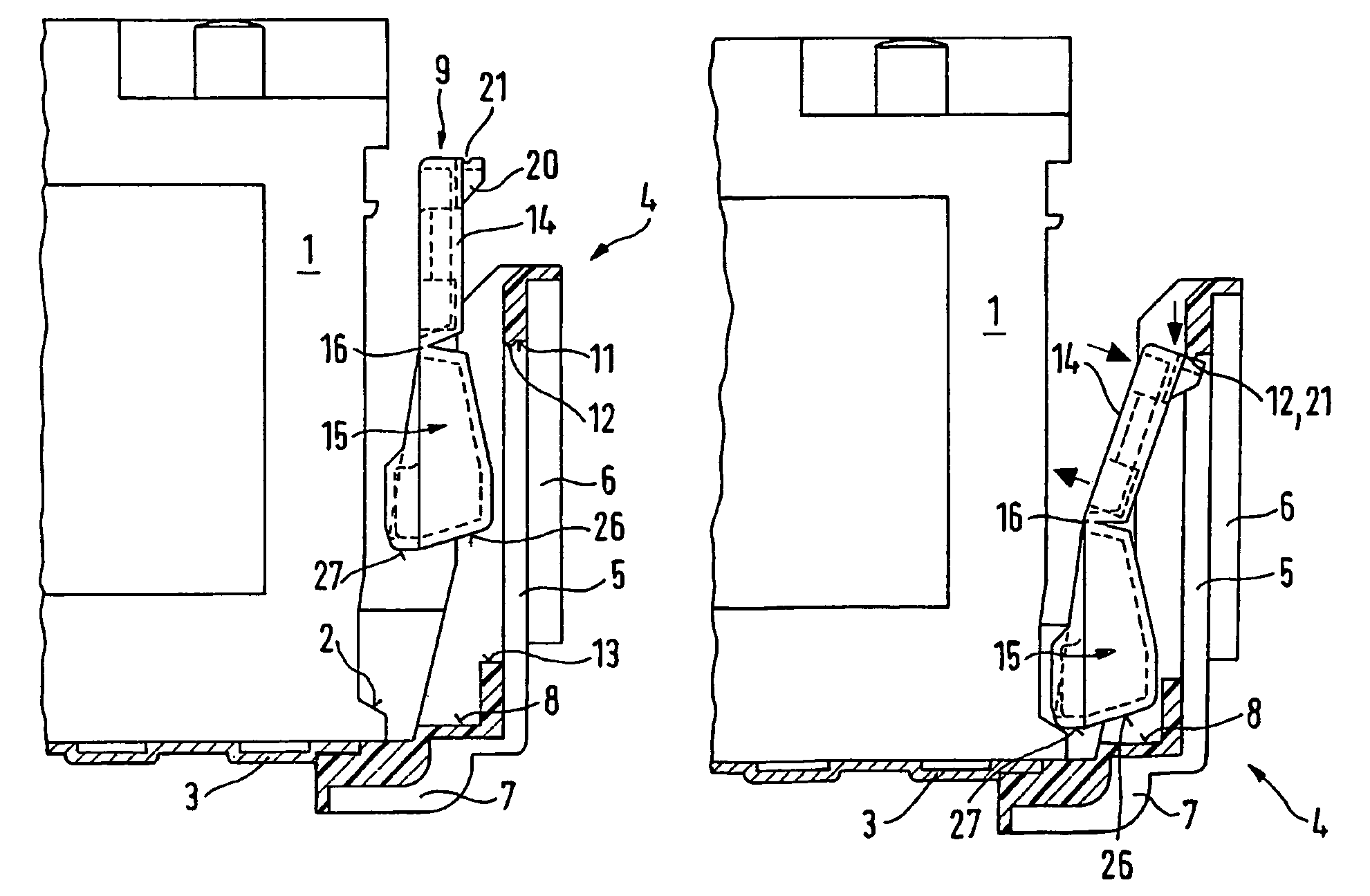

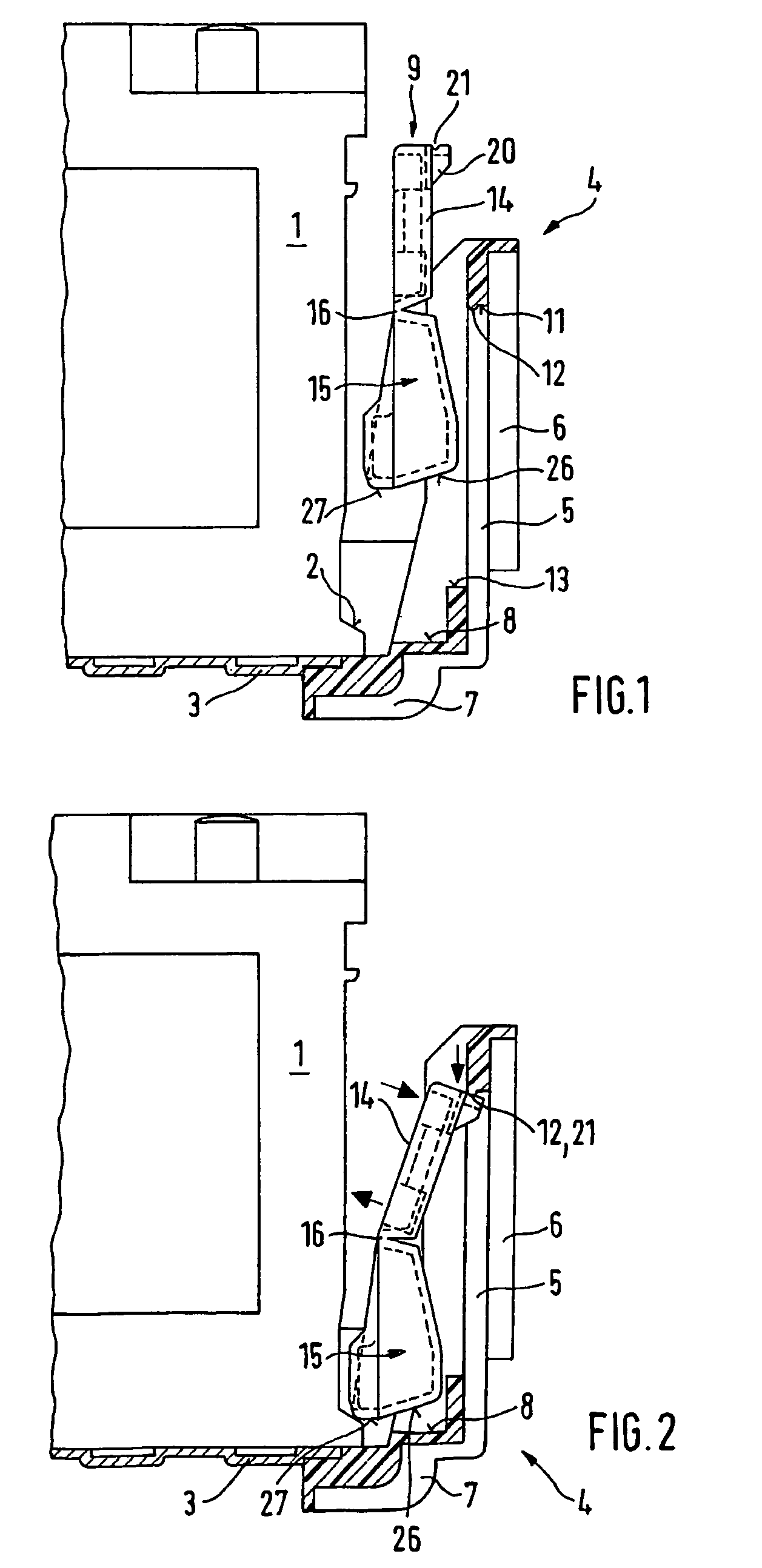

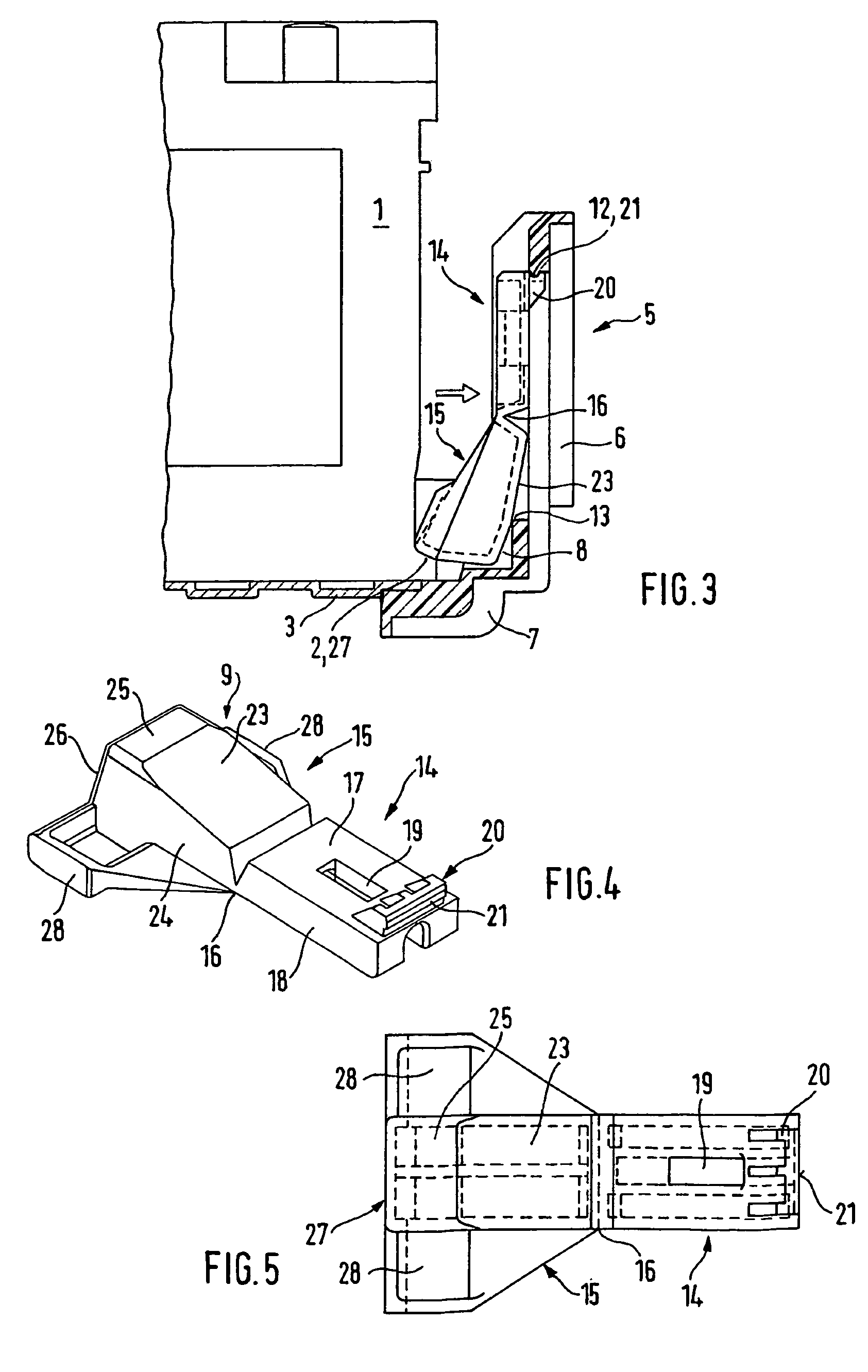

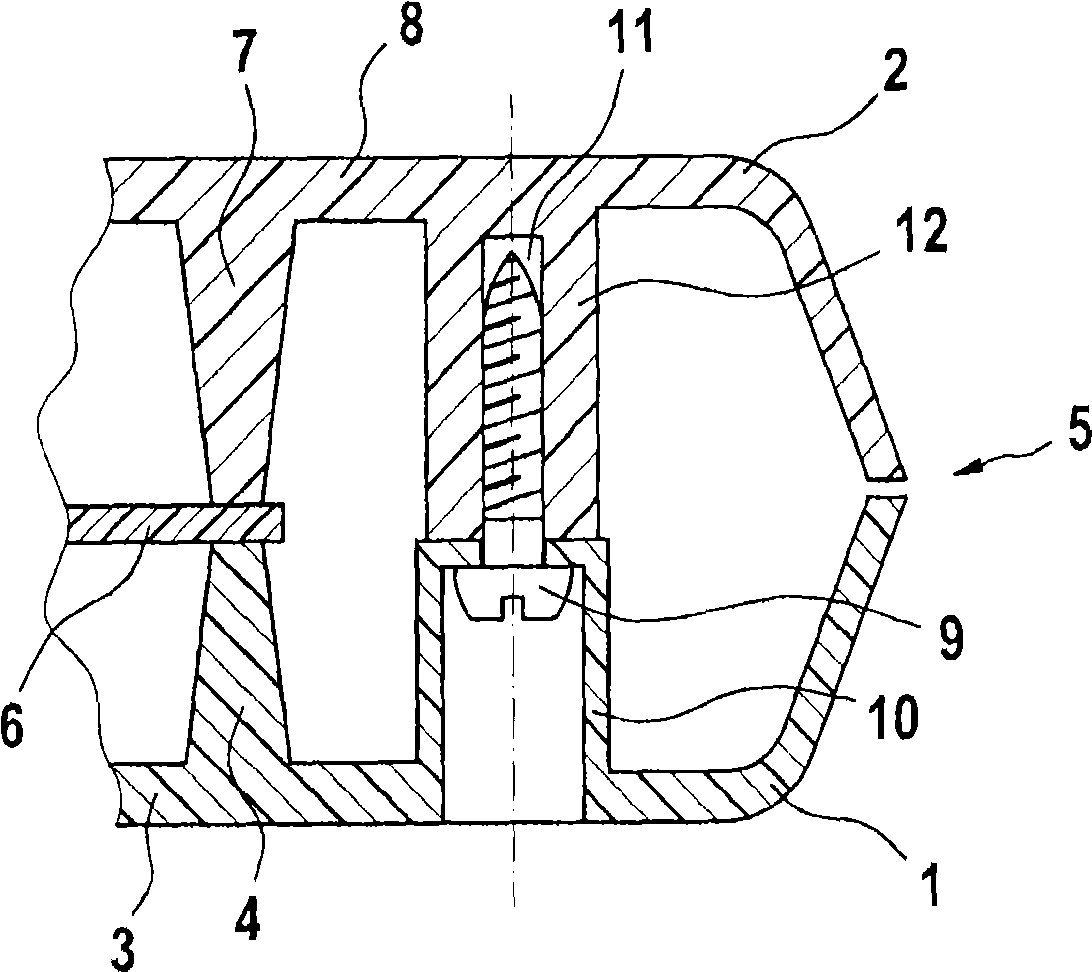

Device for fixing a housing, especially a housing pertaining to a motor vehicle battery, to a carrier plate

InactiveUS7389841B2Relax quicklyMinimum expenditure of forceCell component detailsElectric/fluid circuitMobile vehicleEngineering

A device for fixing a housing (1), especially a housing pertaining to a motor vehicle battery, to a carrier plate (3). The device consists of a fixing bracket (4) and a separate fixing element (9). The fixing bracket (4) is fixed or moulded onto a edge of the carrier plate (3) projecting past the housing (1), and comprises a vertical limb (5) which extends at a distance from the housing wall, parallel to the same. The separate fixing element (9) is inserted into the intermediate region between the housing wall and the vertical limb (5) of the fixing bracket (4), and is wedged fast therein. According to the invention, the housing (1) can be fixed to the carrier plate (3) with few, simple movements and without using a tool. All parts of the fixing device can be reused if the housing (1) needs to be replaced. No scrap or other waste elements are accumulated, thus also solving the recycling problem.

Owner:A RAYMOND & CO

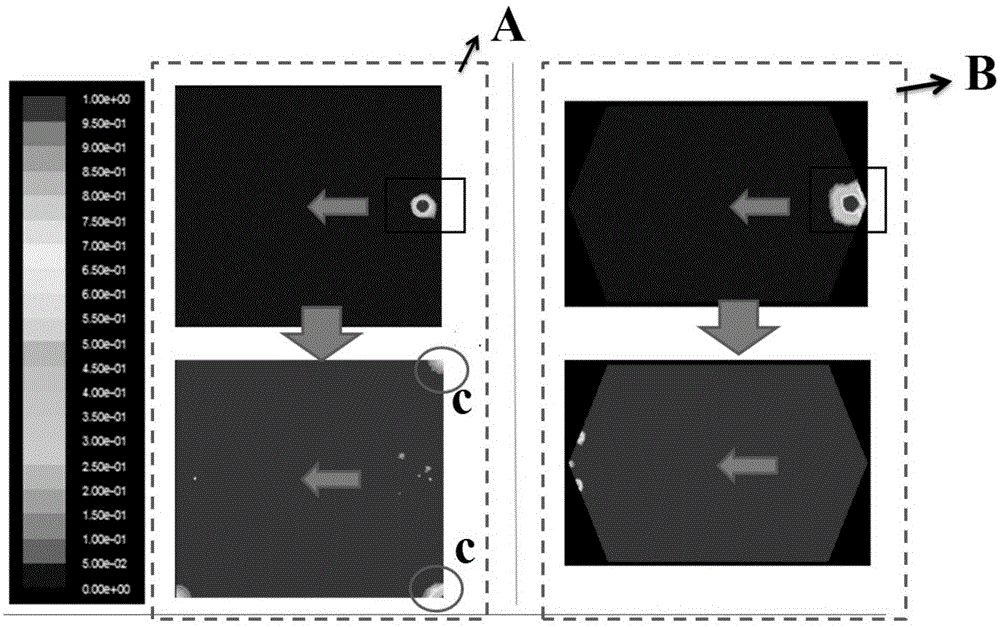

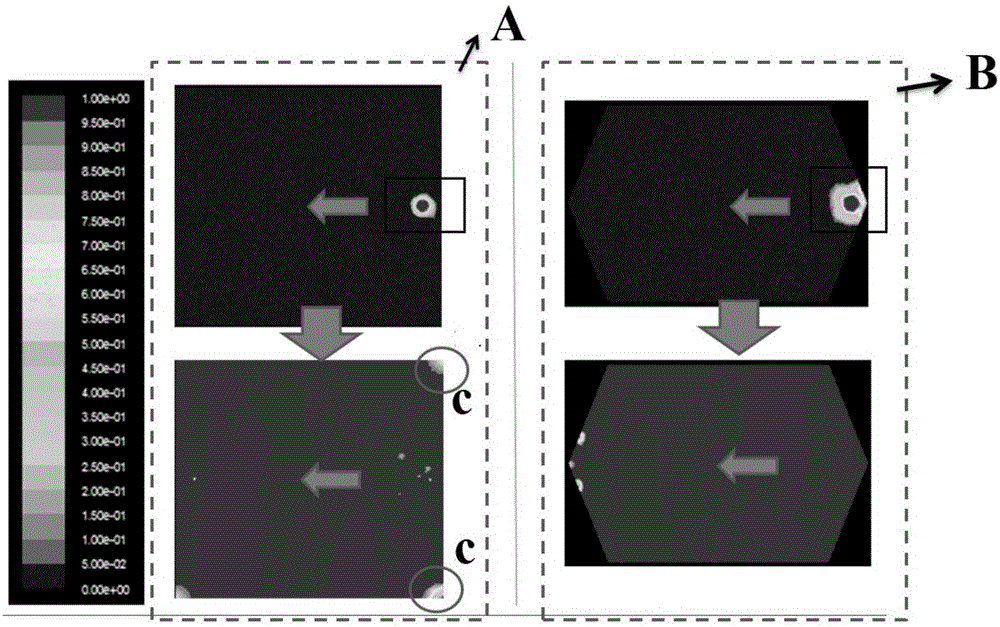

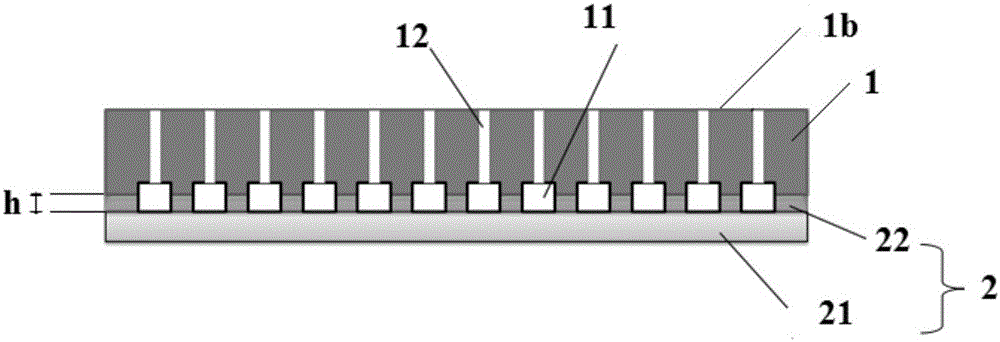

Manufacturing method of unimolecular sequencing chip

ActiveCN105112290AImprove flow field distributionIncrease the support pointBioreactor/fermenter combinationsBiological substance pretreatmentsOxygen plasmaEngineering

The invention provides a manufacturing method of a unimolecular sequencing chip. The manufacturing method includes the following steps: (1), taking a baseplate, and adopting a photoetching method to make an anodic film of a reaction tank array on the surface of the baseplate; (2), using model glue to pour the anodic film, curing for 1-3h at 90-100 DEG C after vacuum degassing, uncovering the anodic film to obtain a groove with multiple runners, punching a hole in each of two ends of each runner to form fluid input and output holes, and obtaining a substrate; (3), taking a transparent base, and preparing a polymethylglutarimide (PMGI) layer on the surface of the transparent base to obtain a transparent base with the surface modified; (4), subjecting the substrate and the transparent base to oxygen plasma cleaning and press-fitting, and injecting a reagent into each runner to clean the corresponding PMGI layer contacting with each runner to obtain the unimolecular sequencing chip. The manufacturing method is simple in process and low in manufacturing cost.

Owner:GENEMIND BIOSCIENCES CO LTD

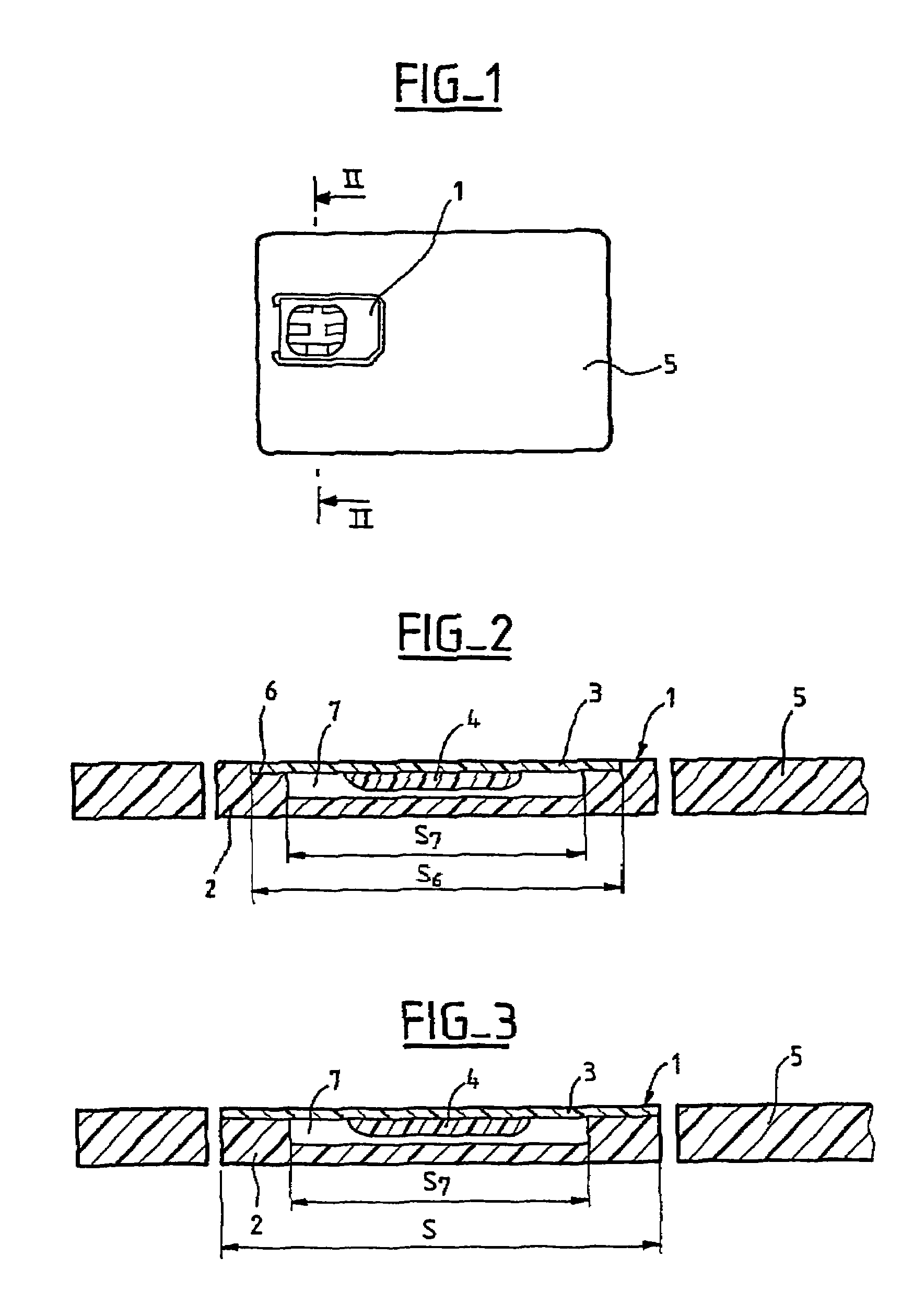

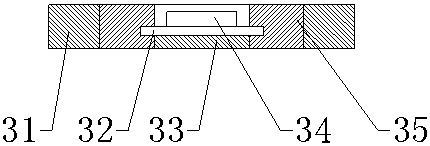

Smart card with extended surface module

InactiveUS7686228B2Fine surfaceImprove reliabilityOther printing matterSolid-state devicesComputer moduleEngineering

A smart card includes a card bearing a module that is made up of a support supporting at least an electronic chip. The support is fixed on one surface of the card. This surface extends up to at least one of the edges of the card.

Owner:GEMPLU

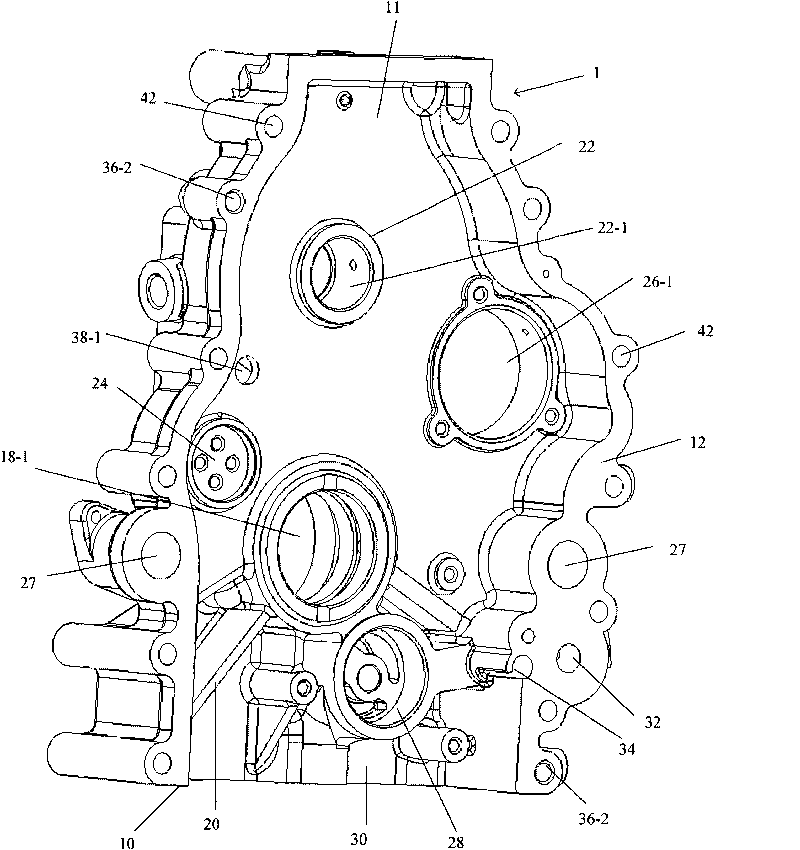

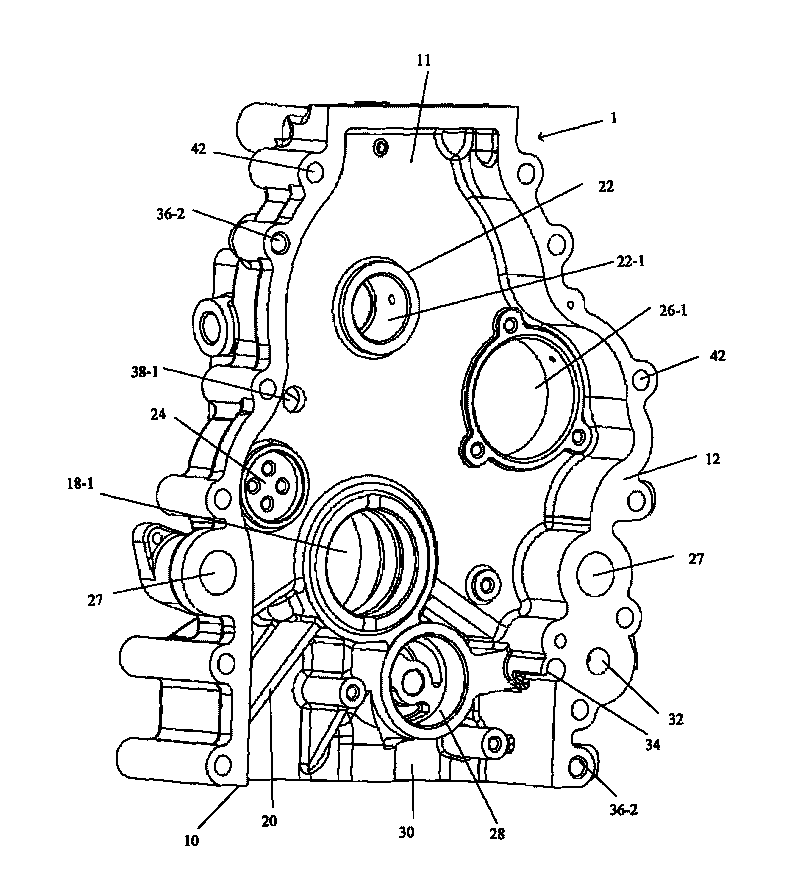

Gear chamber cover of crank round sliding block internal-combustion engine, engine block assembly and internal-combustion engine thereof

ActiveCN101761417AIncrease the support surfaceStrongCasingsMachines/enginesEngineeringInternal combustion engine

The invention discloses a gear chamber cover of a crank round sliding block internal-combustion engine, which is used for sealing a gear chamber by matching with an engine block and an oil bottom shell of the crank round sliding block internal-combustion engine. The gear chamber cover comprises a crankshaft bearing seat which is arranged thereon and is used for supporting a crankshaft of the internal-combustion engine; a through hole arranged on the bearing seat with a cylindrical structure is used for containing a crankshaft bearing and is called a crankshaft bearing containing hole; when the gear chamber cover is fixedly assembled on the engine block of the internal-combustion engine due to the position of the crankshaft bearing seat on the gear chamber cover, central axes of the crankshaft bearing containing hole of the crankshaft bearing seat on the gear chamber cover and that on the engine block of the internal-combustion engine are located on the same line. The invention can meet the requirement of the gear chamber cover assembled on the engine block of the crank round sliding block internal-combustion engine. In addition, the invention further provides an engine block assembly and an internal-combustion engine of the crank round sliding block internal-combustion engine.

Owner:BEIJING SINOCEP ENGINE TECH

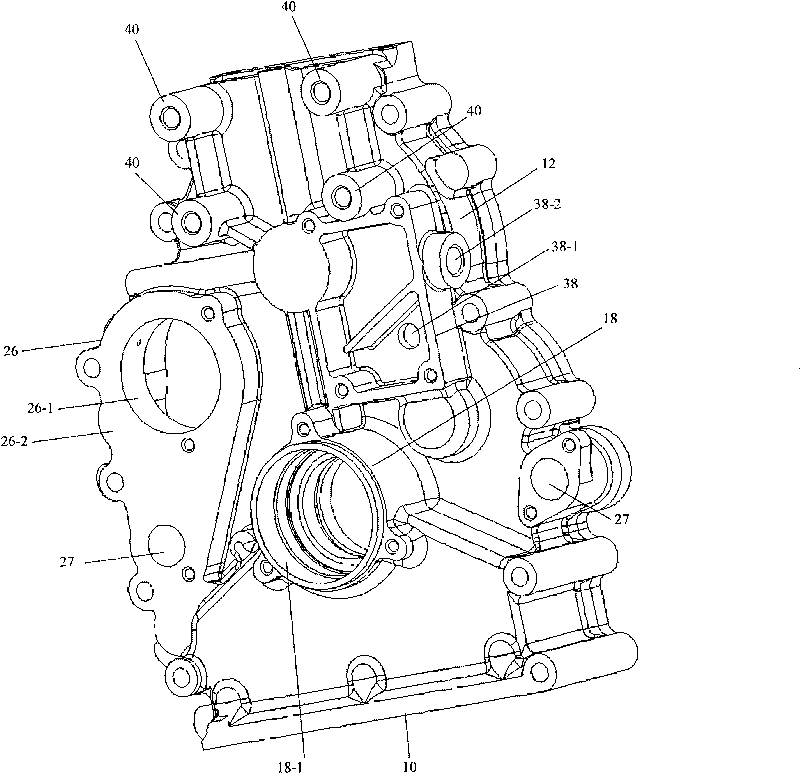

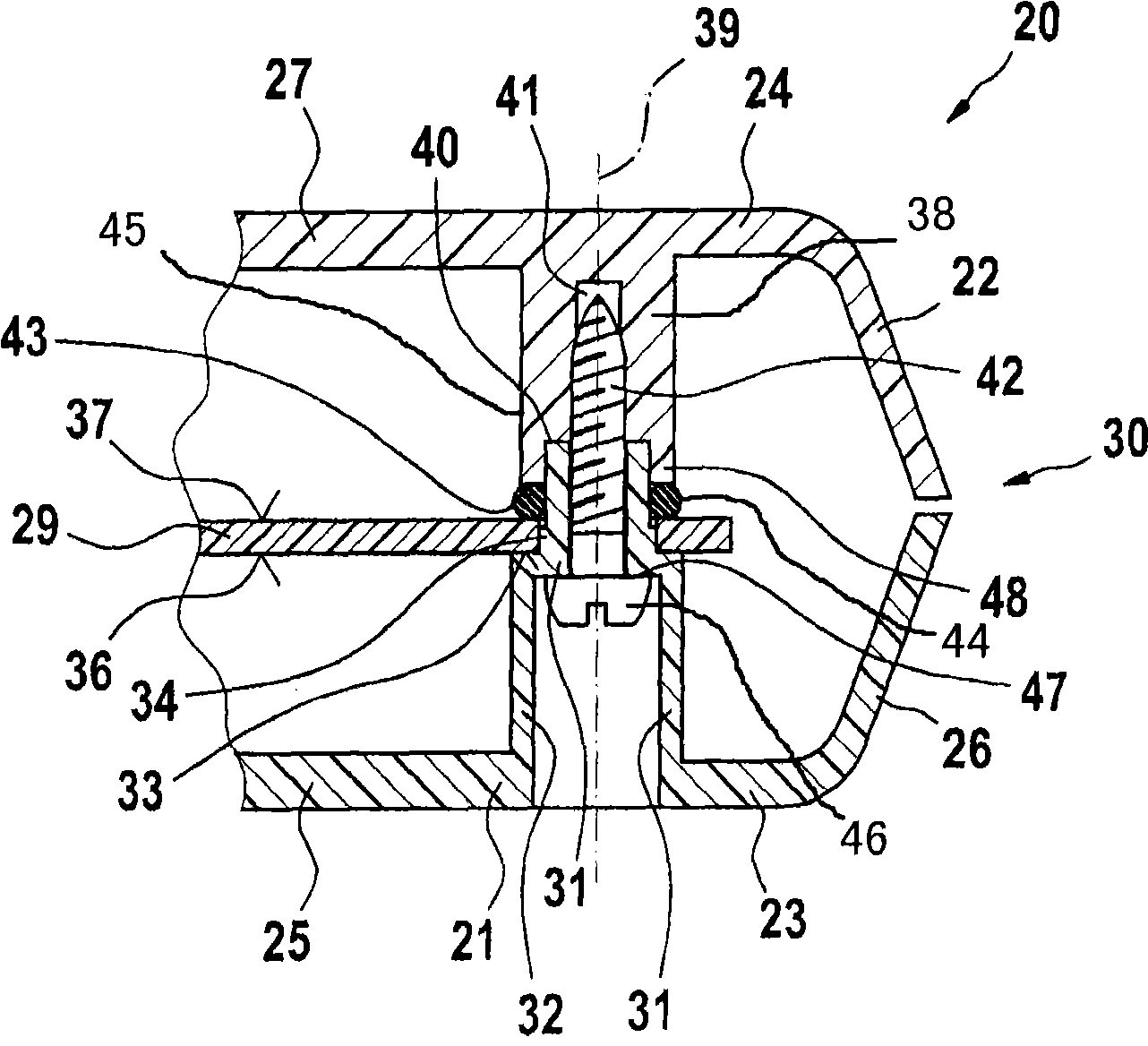

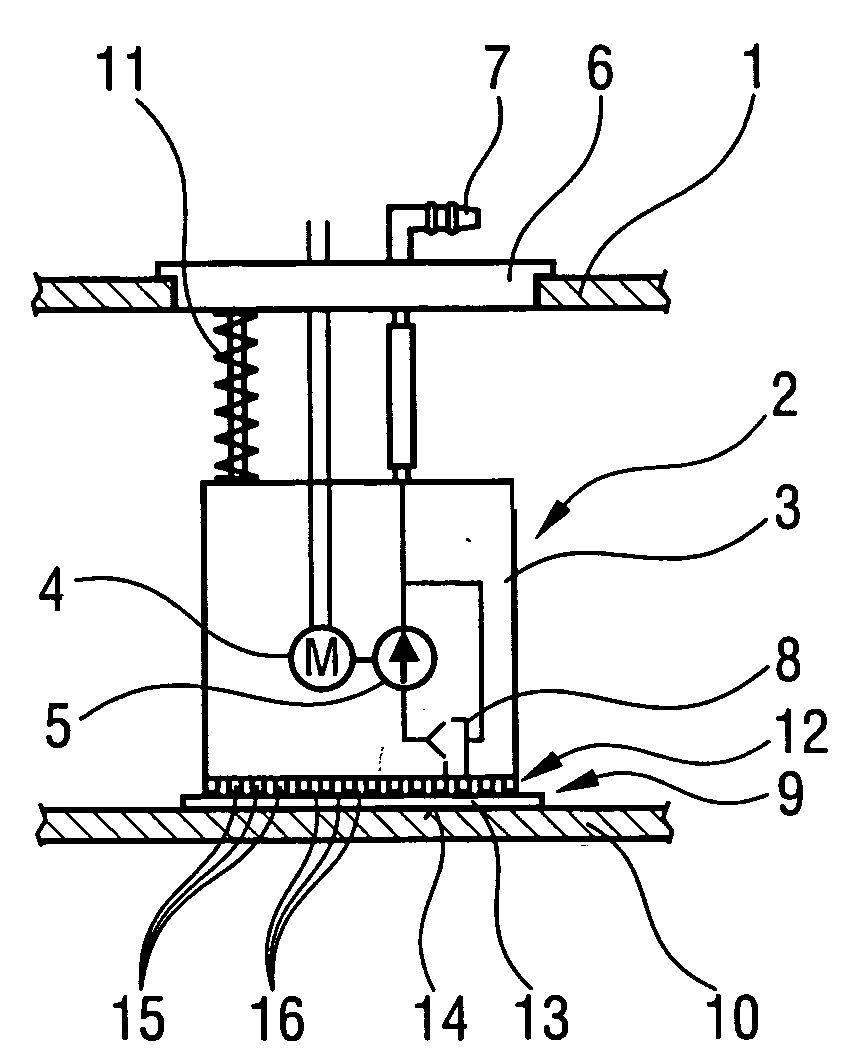

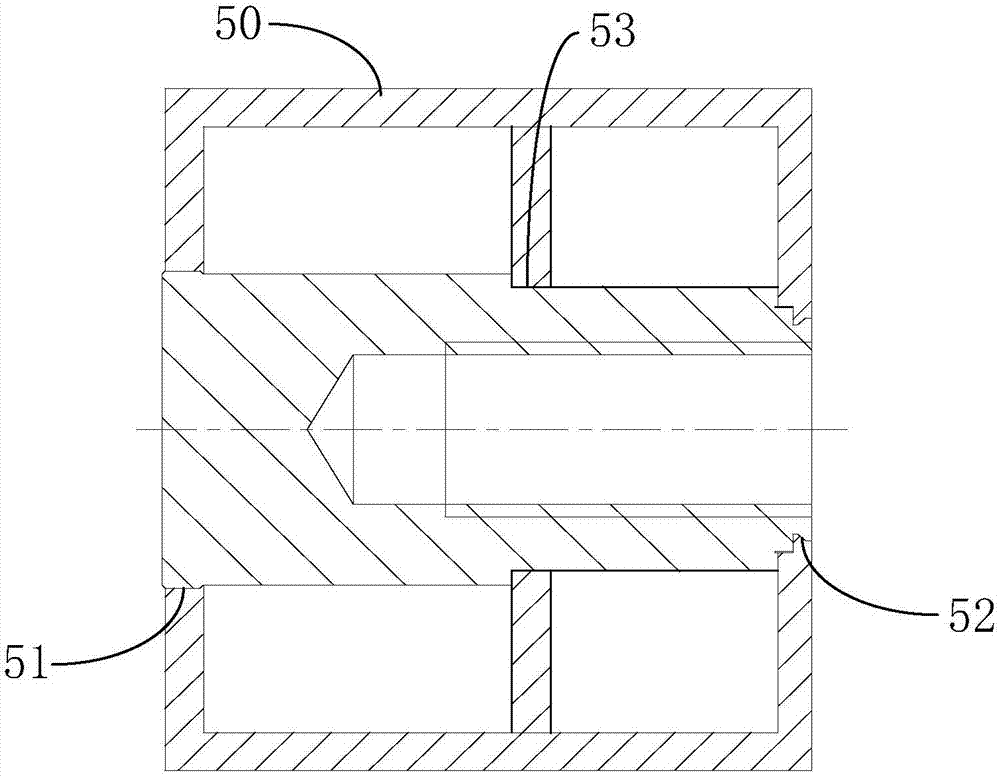

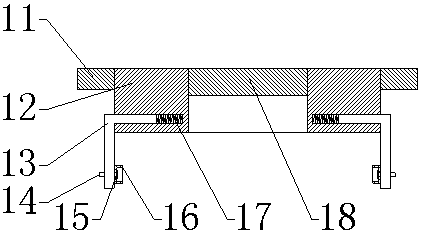

Printed circuit board apparatus

InactiveCN101522009AReduce intensityReduced mechanical stabilitySupport structure mountingClosed casingsEngineeringPrinted circuit board

The invention relates to a printed circuit board apparatus(20), comprising a housing(30) which includes a first housing part(21) and at least a second housing part(22); the second housing part is fixed on the first housing part(21) by at least a fixing component(42); wherein a printed circuit board(29) is axially clamped between a first support section(31) of the first housing part(21) and a second support section(38) of the second housing part(22). According to the invention, the fixing component(42) is arranged to act on the two support section(31,38).

Owner:ROBERT BOSCH GMBH

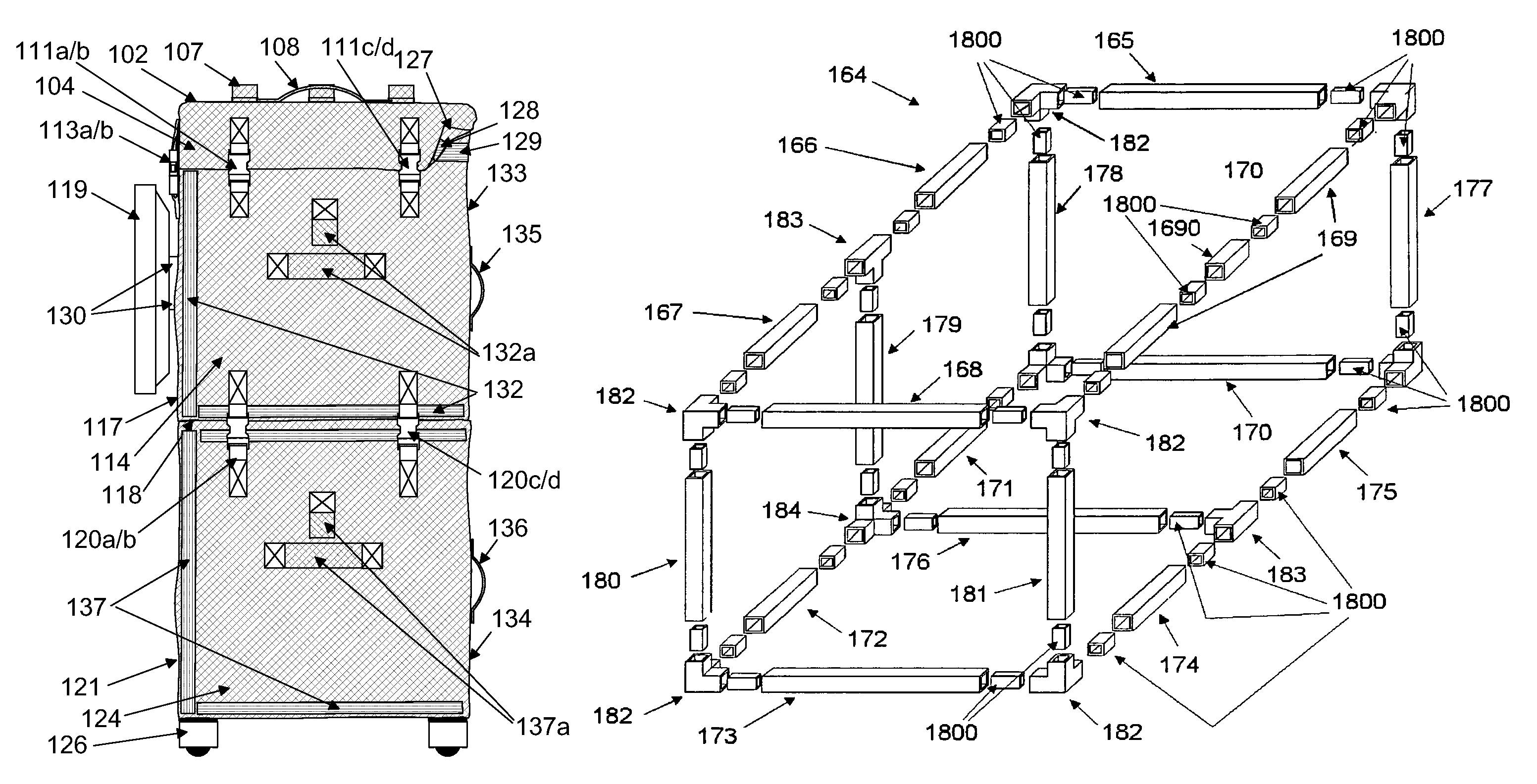

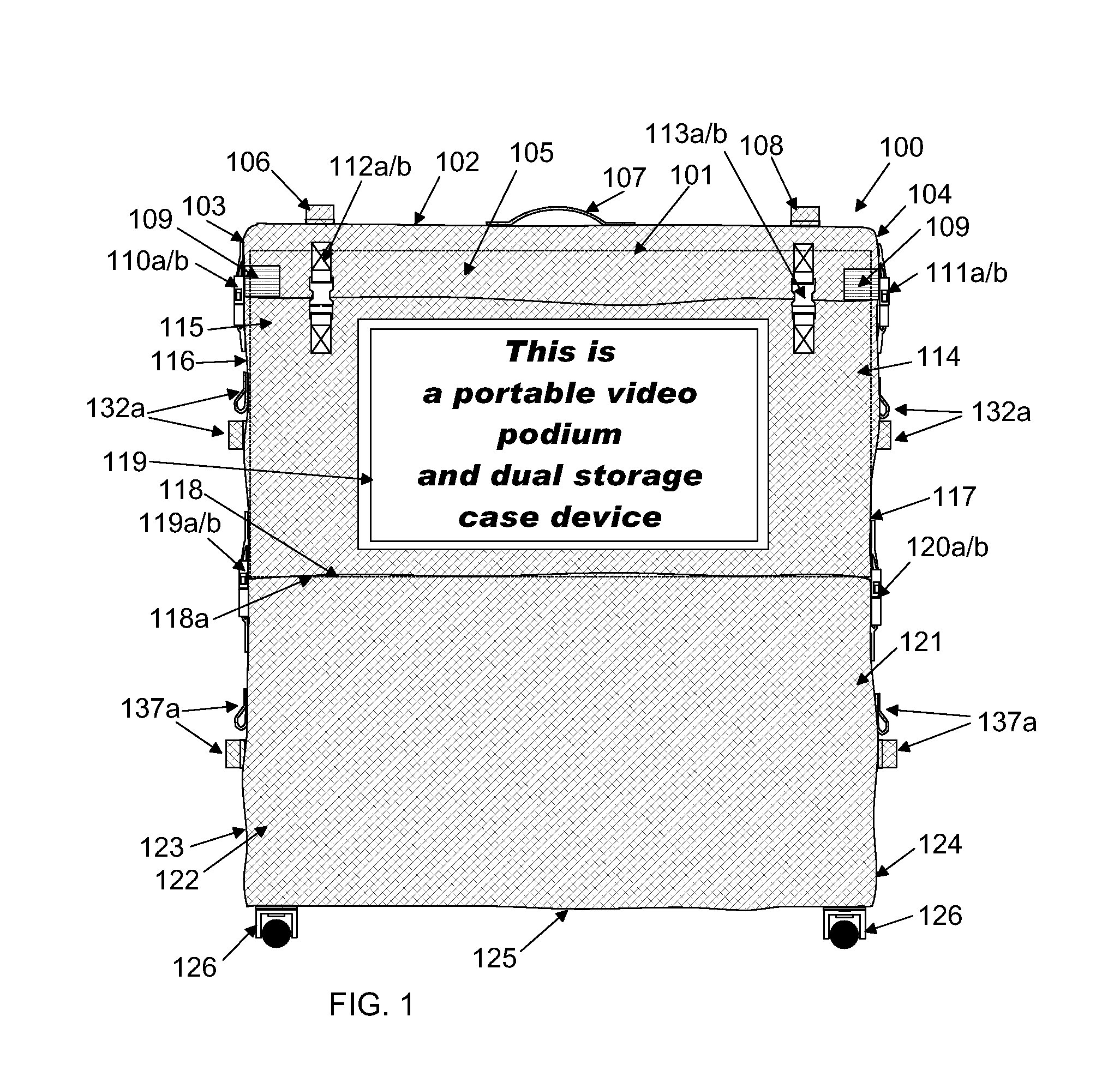

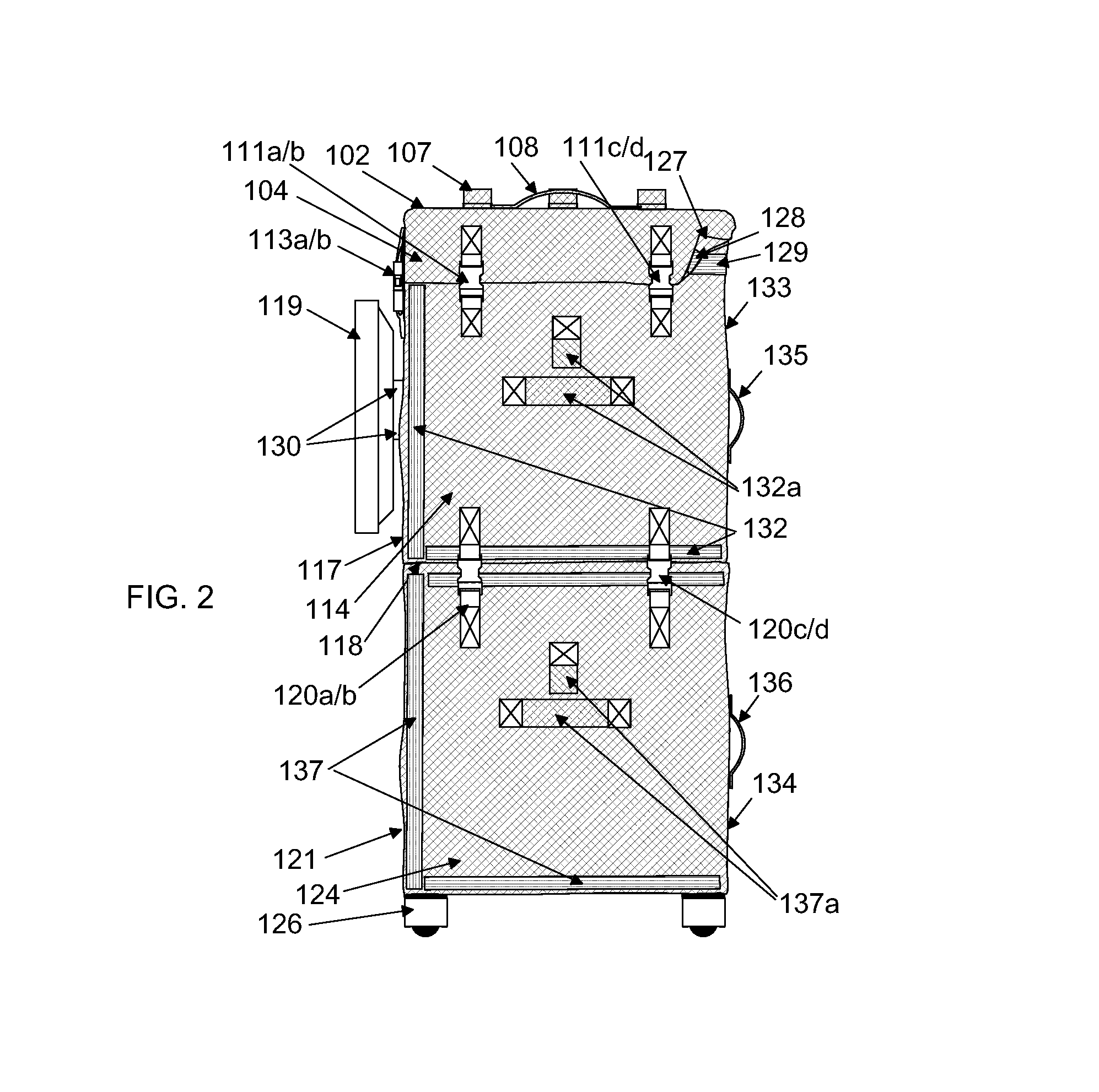

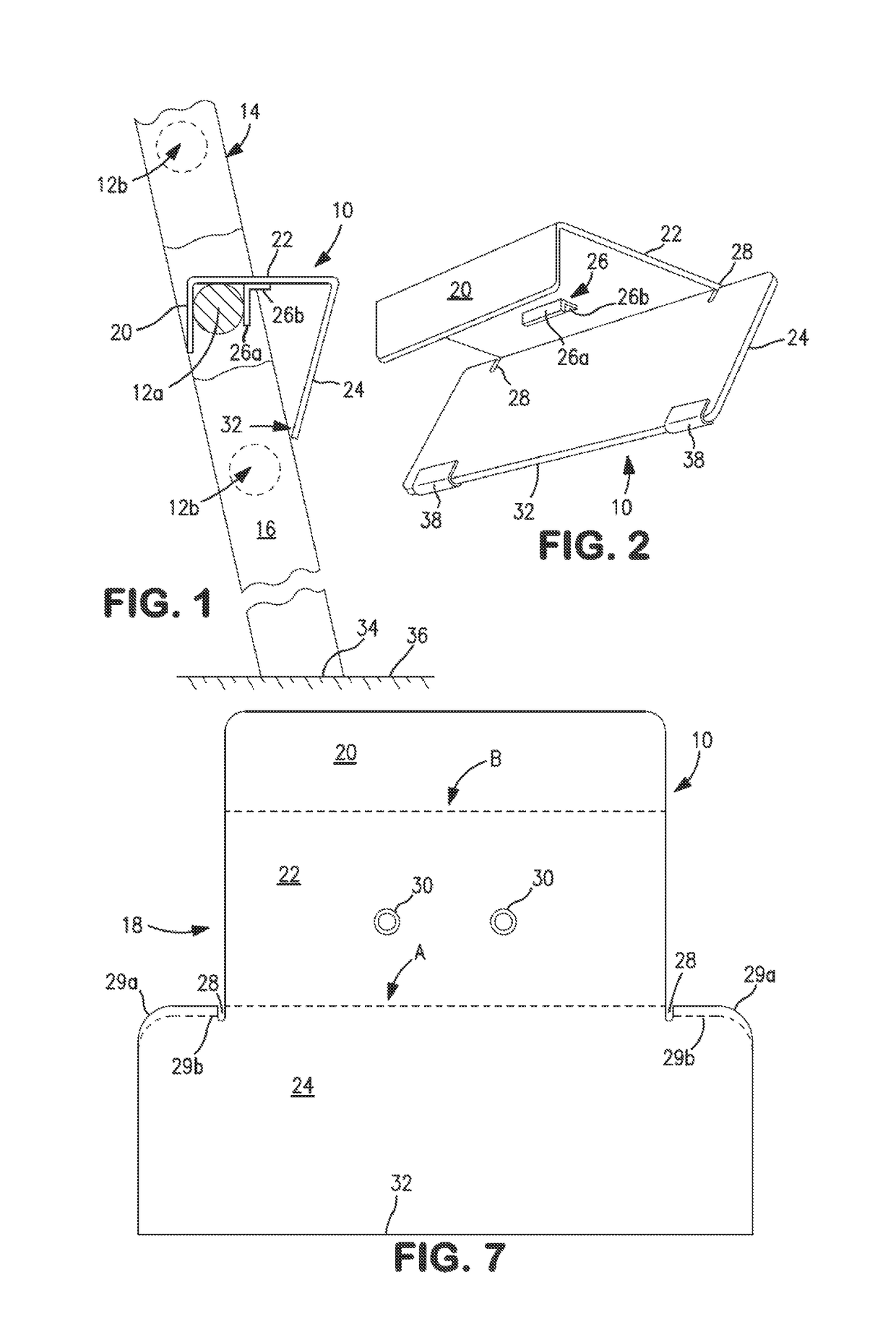

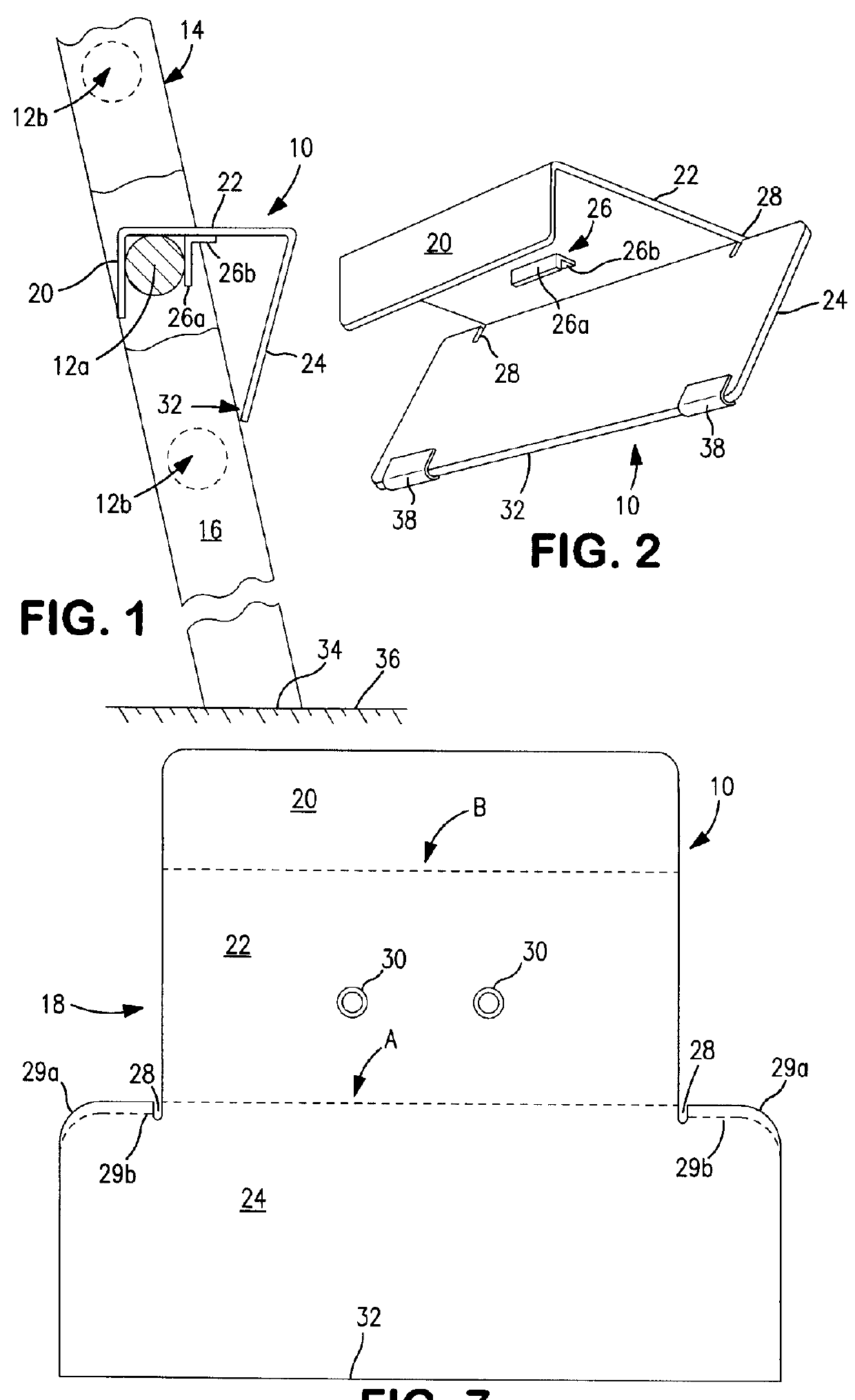

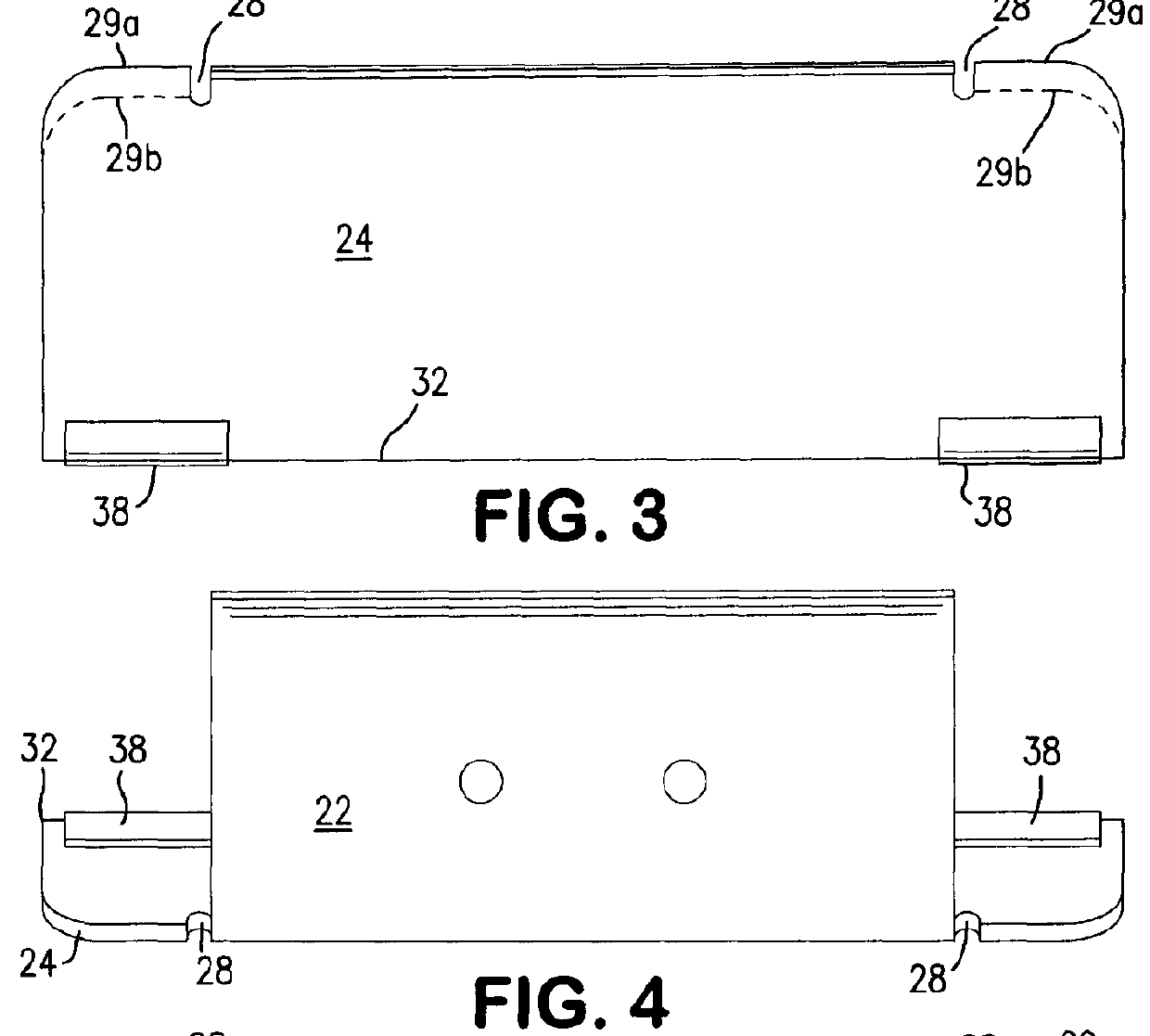

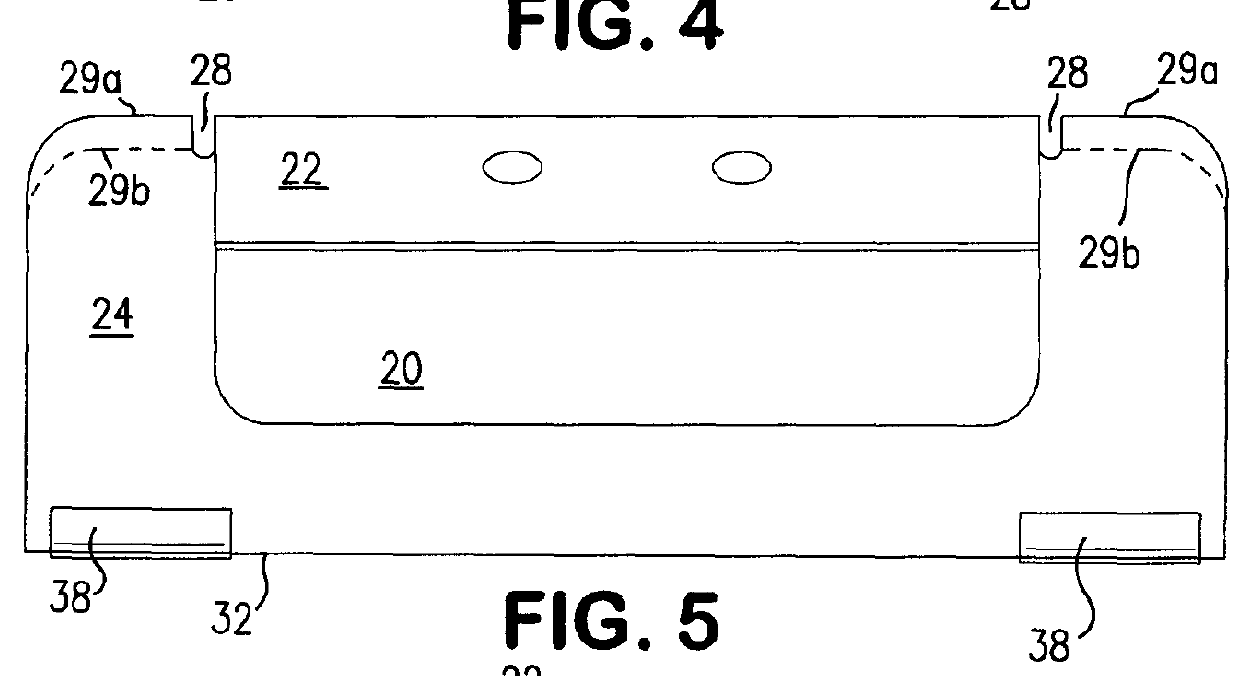

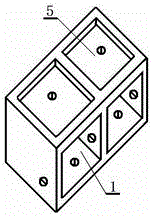

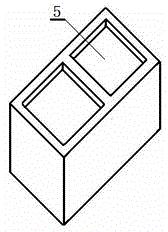

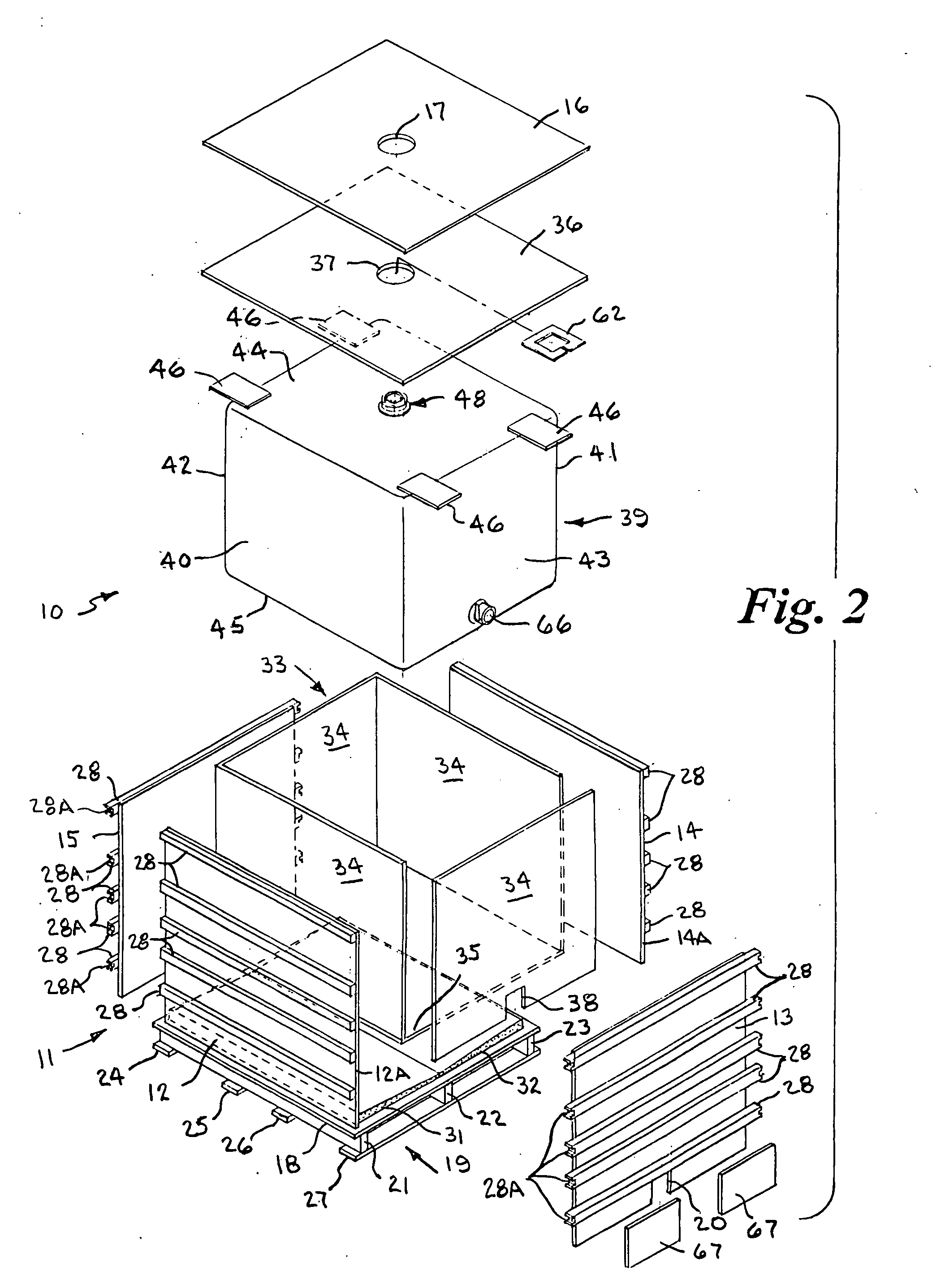

Portable video podium, presentation case, and dual storage boxes

ActiveUS8231185B1Easy to disassembleIncrease the support surfaceSpecial buildingFurniture partsMultimedia

A multi-purpose assembly capable of being used for many activities. In a first embodiment, a portable podium is formed from two lightweight frame boxes which quickly disconnect and disassemble completely. The first embodiment secures a flat screen video display unit to a front side of the podium to allow a presenter to present a video and audio presentation while standing behind the podium. In a second embodiment, a presentation is provided when the podium device is viewed from a back side and doors on that side are opened and secured to vertical right and left side walls. Multiple, removable support containers are arranged on the exposed interior of the presentation case and upon the exposed inside surfaces of the doors. Lights and sound can accompany presentation of goods or entertainment acts.

Owner:TRUSTY JON

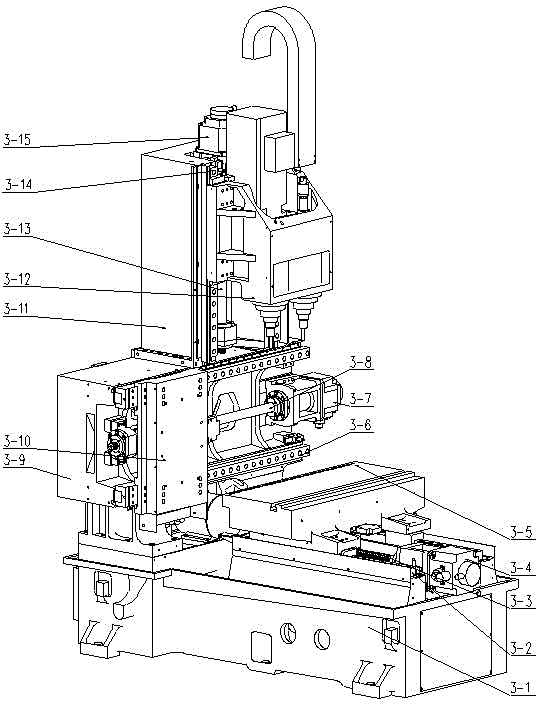

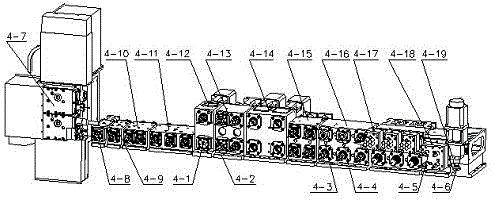

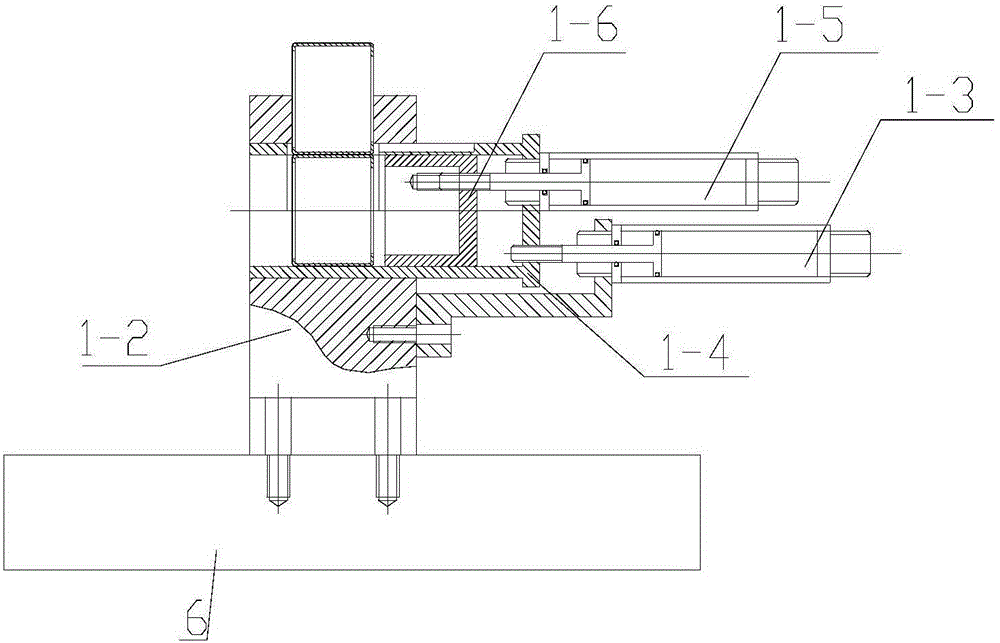

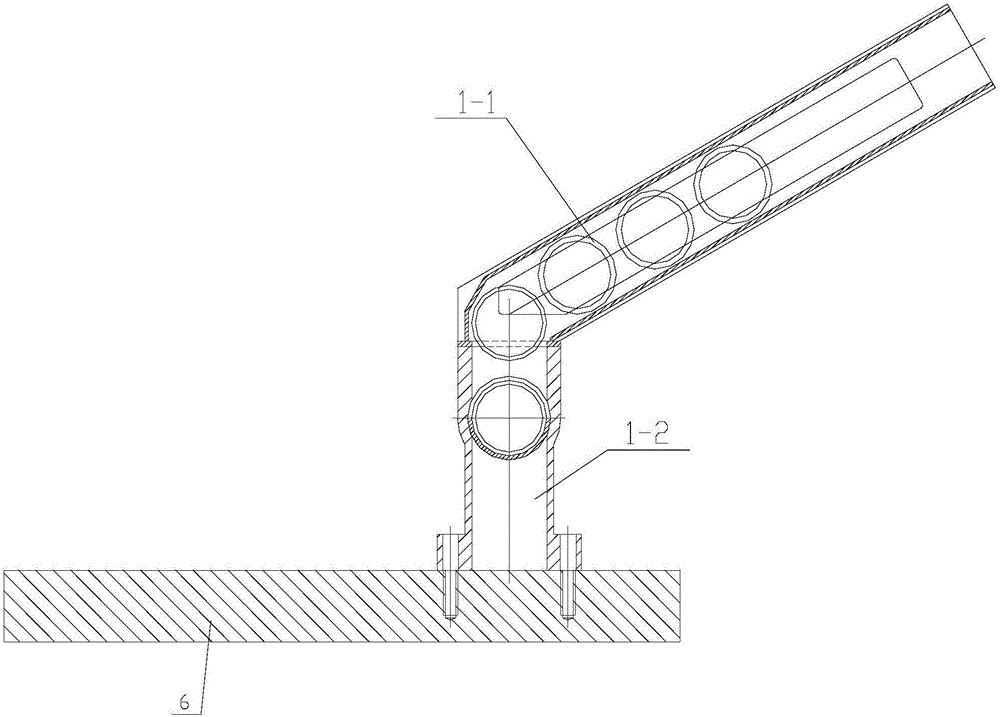

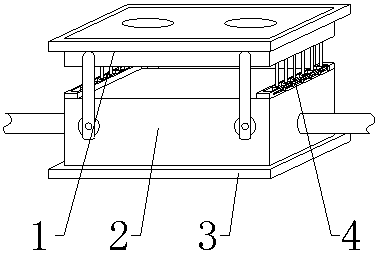

Drilling, tapping, milling and boring combined numerical control machine tool with multi-workpiece processing function

InactiveCN103143989ALarge spanLarge span, large supportFeeding apparatusLarge fixed membersNumerical controlBall screw

The invention relates to a drilling, tapping, milling and boring combined numerical control machine tool with a multi-workpiece processing function. The numerical control machine tool comprises an electric control system; an X-axis saddle is vertically mounted at one end of a machine tool base; a Z-axis working table is mounted on the machine tool base through a Z-axis roller linear track, and a Z-axis ball screw is matched with the Z-axis working table and is driven by a Z-axis servomotor to drive the Z-axis working table to perform a Z-axis stroke action along the Z-axis roller linear track; X-axis roller linear tracks are mounted on the inner side surface of the X-axis saddle, an X-axis working table is located on the X-axis roller linear tracks, and an X-axis servomotor is mounted on the X-axis saddle between the X-axis roller linear tracks and drives the X-axis working table to traverse along the X-axis roller linear tracks through an X-axis ball screw; and a Y-axis saddle is mounted on an upper end surface of the X-axis saddle, a Y-axis roller linear track is vertically mounted on the inner side surface of the Y-axis saddle, and a Y-axis spindle seat is located on the Y-axis roller linear track and matched with a Y-axis ball screw on the back surface of the Y-axis spindle seat.

Owner:HANGZHOU BAKER MASCH CO LTD

Component subpackaging fixer

Owner:LANZHOU GEELY AUTOMOBILE IND +1

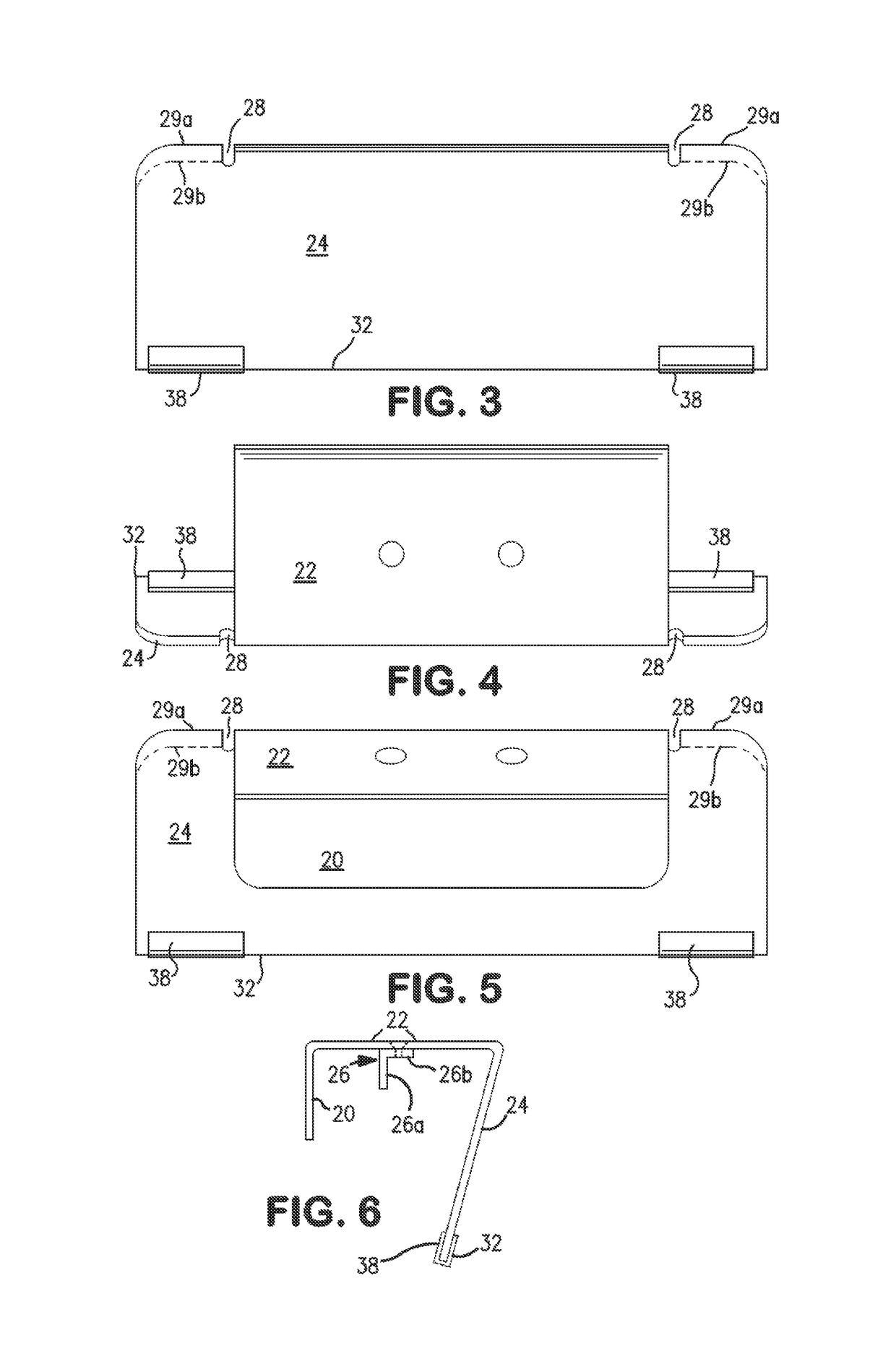

Step adapter for rung ladders

Step adapters for a rung ladder to provide an increased support surface or area is described. In one embodiment, the step adapter includes a brace, a platform, a lock and a safety bar. The lock, safety bar and platform are provided to structurally engage or embrace a rung of a ladder, and the brace supports the adapter against the rails of a ladder so that in total the step adapter provides an extended step structure to ease standing on the ladder, especially for an extended period of time. In another embodiment, the step adapter includes brace, platform and lock sections, where the platform section side edges are configured to lock the step adapter in place on a rung of a ladder. A tray overlay is also described which when used in combination with the step adapter (which serves as a support) provides a service area for holding work-related items.

Owner:WILLOW STEP INC

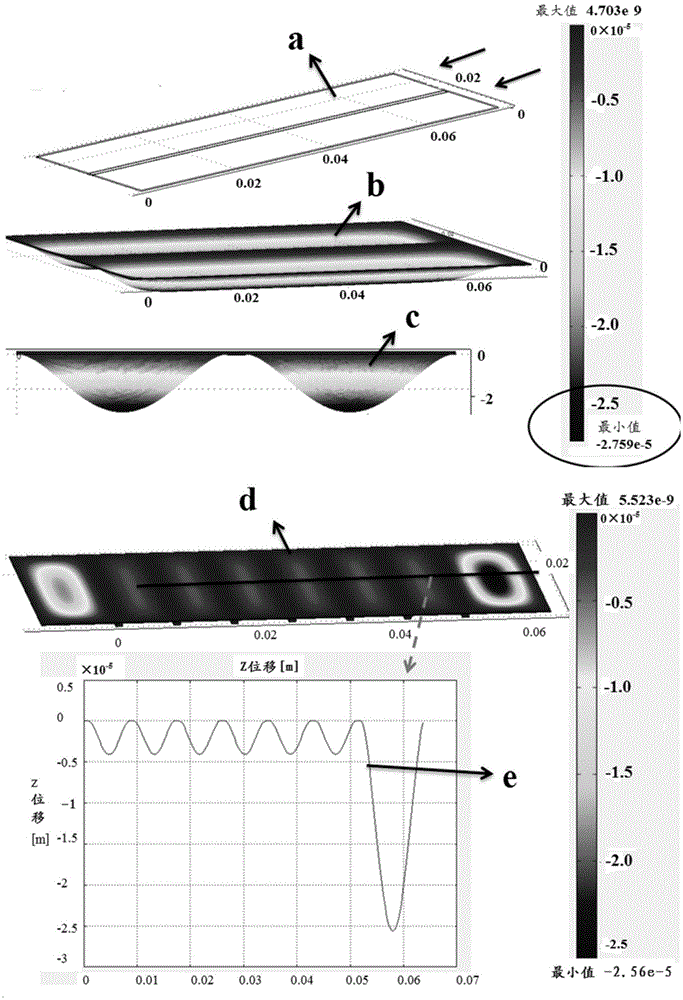

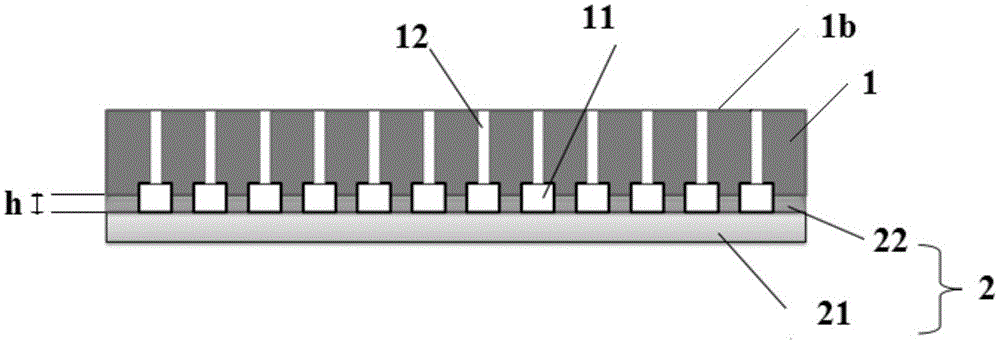

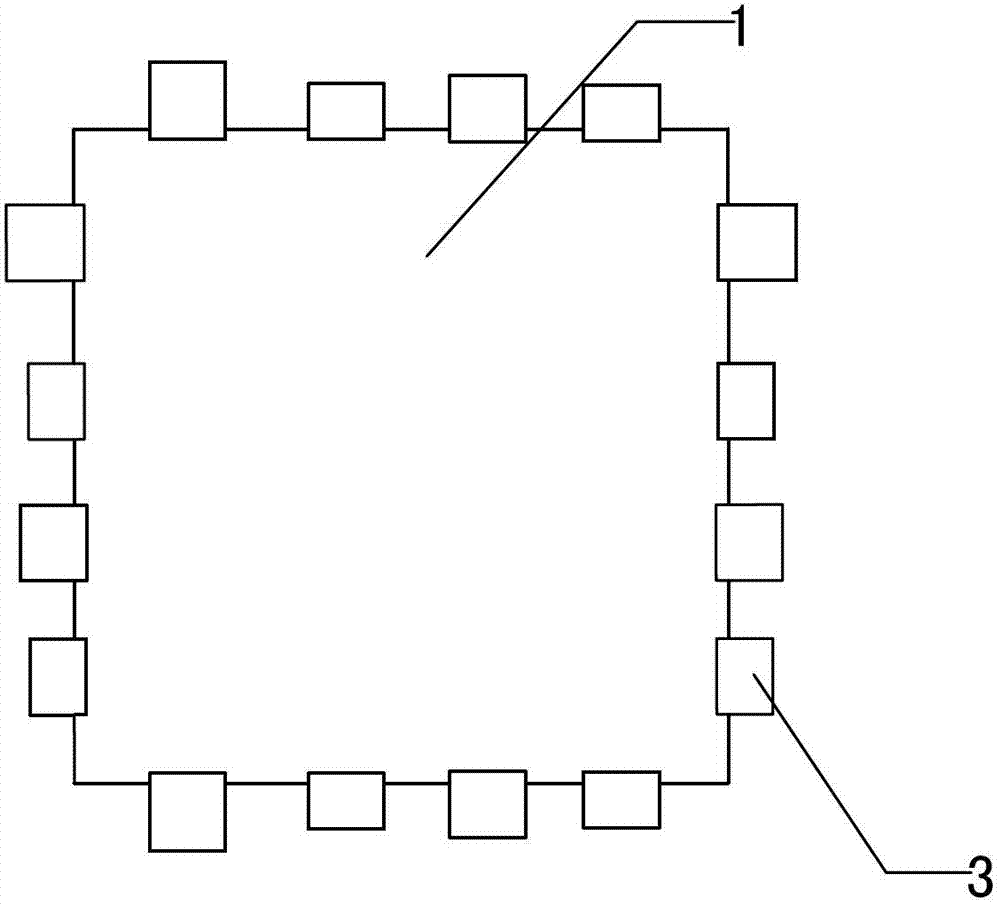

Single-molecule sequencing chip

ActiveCN105154323AImprove flow field distributionIncrease the support pointBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFluid input

The invention provides a single-molecule sequencing chip, which comprises a substrate and a base layer which is arranged in a mode of being laminated with the substrate, wherein the substrate comprises a first surface and a second surface which are oppositely arranged; a reaction tank array which is formed by a plurality of runners is arranged on the first surface of the substrate in a spacing mode; two opposite sidewalls of each runner extend in the length direction of the runner and are intersected at two ends of the runner to form two conical tail ends having included angles; fluid input holes and fluid output holes which are communicated with the second surface of the substrate are respectively formed in the surfaces of the two conical tail ends; the base layer comprises a transparent base and a spacing layer which is arranged on the surface of the transparent base; and the spacing layer is contacted with the first surface of the substrate and the spacing layer, corresponding to the locations of the runners, is formed with corrosion grooves. The chip is good in flow field distribution, the base in the chip is low in deformation rate and fluid in the chip is thorough in flushing switching.

Owner:GENEMIND BIOSCIENCES CO LTD

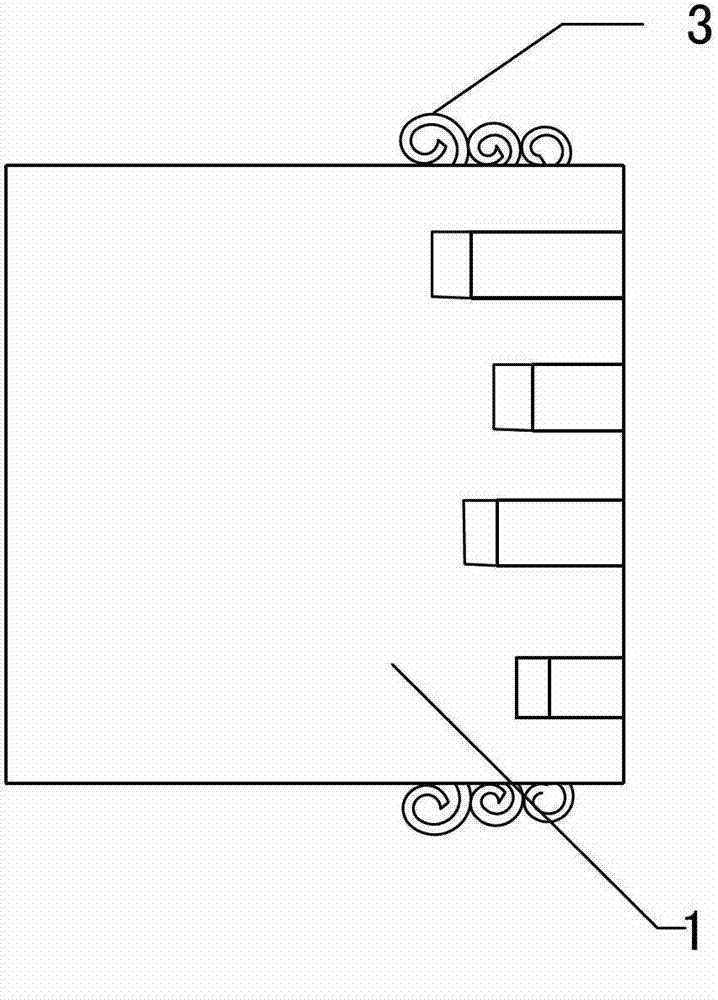

Air cushion bed capable of monitoring temperature and pressure

InactiveCN107019373AIncrease the support surfaceRelieve pressureFluid mattressesActive monitoringEngineering

The invention discloses an air cushion bed capable of monitoring temperature and pressure, which is composed of a control system, an air cushion bed, leather tubes I and leather tubes II, one end of several leather tubes I is connected to the control system, and the other end of the leather tube I is connected to the On the air-cushion bed, at least two leather tubes II are installed inside the air-cushion bed, and the leather tube II and the leather tube I are adhered together; Composed of mother and child stick II, the air cushion bed is composed of several long air cushions, and the air cushion is composed of a cushion body layer and an air bag; an active pressure regulator and temperature and humidity monitoring and adjustment functions are added to monitor each air (water) of the air cushion bed in real time According to the pressure of the chamber and the temperature of the internal medium, active pressure reduction and medium temperature adjustment are implemented for the part with long-term high pressure, so as to change the pressure part, reduce the local temperature, promote blood circulation, and reduce the formation of pressure sores.

Owner:徐州市第一人民医院

Step adapter for rung ladders

ActiveUS10006248B2Relieve pressureIncrease the support surfaceLaddersSoftware engineeringSupport surface

Owner:WILLOW STEP INC

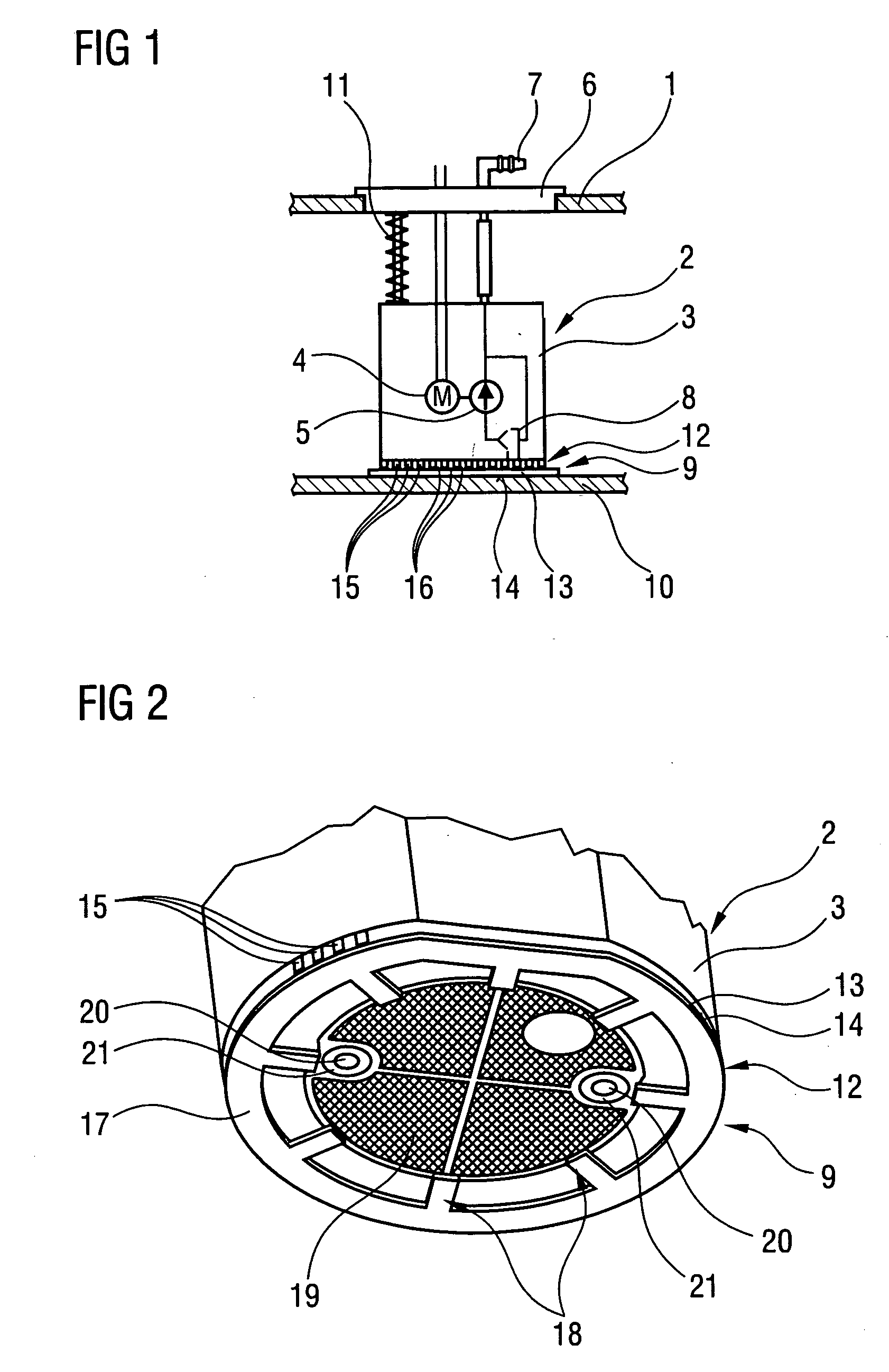

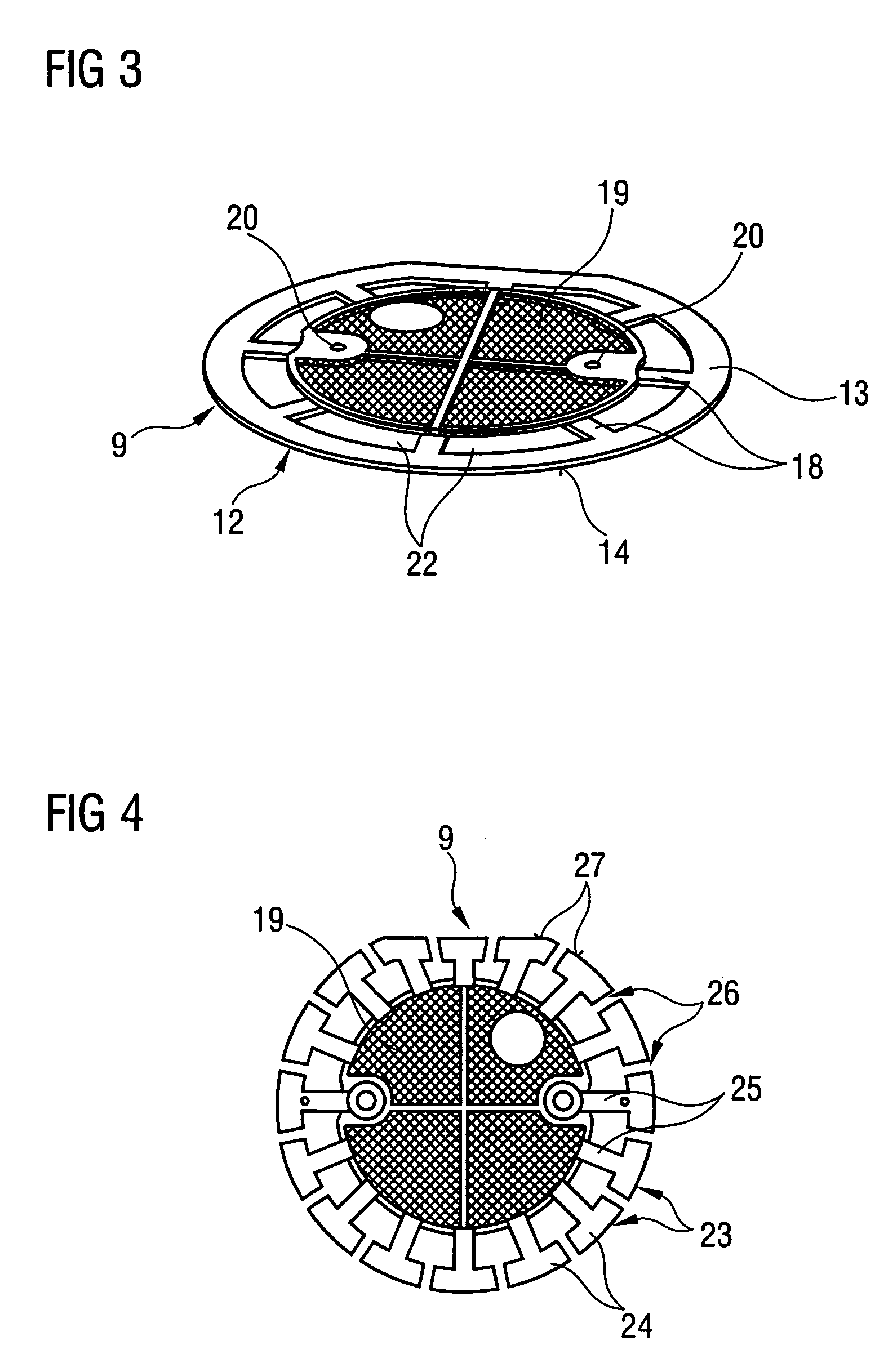

Supporting element having a supporting surface for supporting a fuel feed unit, and fuel feed unit

ActiveUS20060011172A1Cost-effective manufacturingImprove stabilityUsing liquid separation agentLarge containersFuel tankEngineering

A supporting element (9) for supporting a fuel feed unit (2) on the bottom of a fuel tank has a curved element (13) having a supporting surface (17). The curved element (13) is fastened to the lower side of the fuel feed unit (2) and is manufactured as a single piece with a coarse filter (19). Fuel sucked up through the coarse filter (19) is guided over the curved element (13), so that dirt particles are retained at a tangential edge (14) of the supporting element (9).

Owner:VITESCO TECH GERMANY GMBH

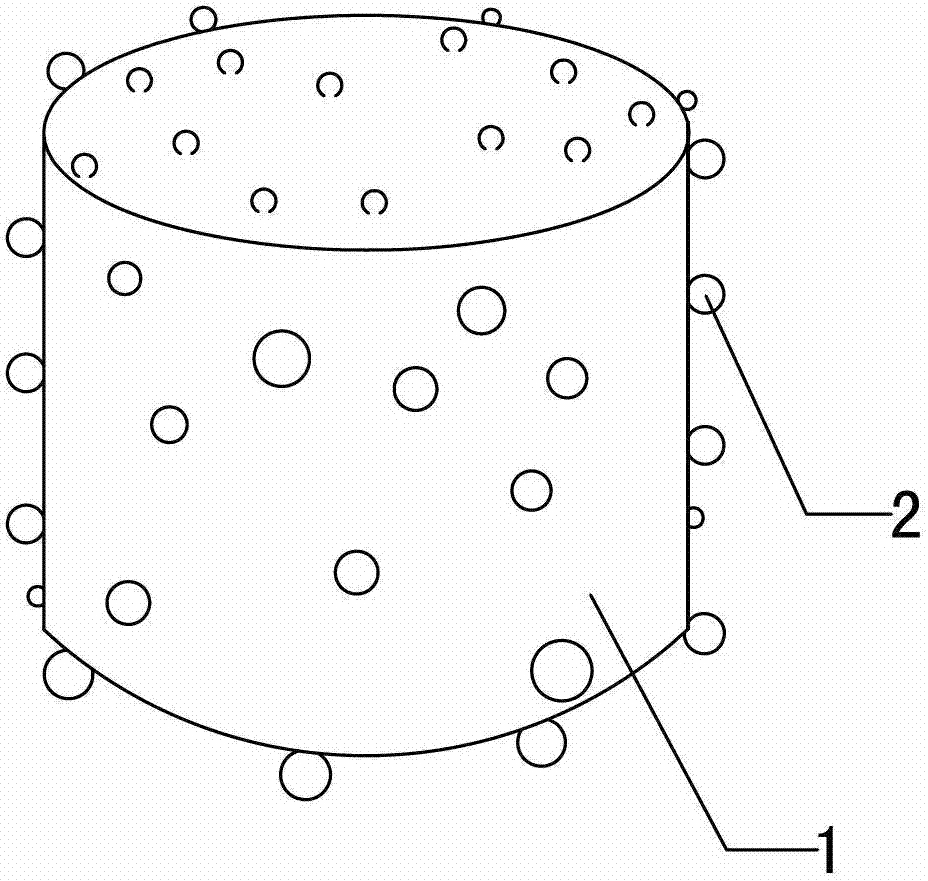

Novel plant wall

InactiveCN104912254AIncrease green areaIncrease soil capacityWallsReceptacle cultivationGrowth plantMortise and tenon

The present invention discloses a novel plant wall, which comprises bricks and is characterized in that the brick adopts an inorganic building material or plastic and is a hollow brick made through a mold and provided with at least a hole or at least a concave groove, the hollow bricks with the approximately-same sizes are adhered and connected through cement or are subjected to mortise and tenon connection overlaying building to form the hollow wall with planting holes, the upper layer hollow bricks and the lower layer hollow bricks in the hollow wall with the planting holes are dislocated, soft body pockets or soft body bags filled / wrapped with planting mediums and planted plants are placed in the planting holes, and are provided with plant growth openings at the planted plant positions, and the opening is small and the internal is large or the pockets or bags are inclined outward.

Owner:孙希贤

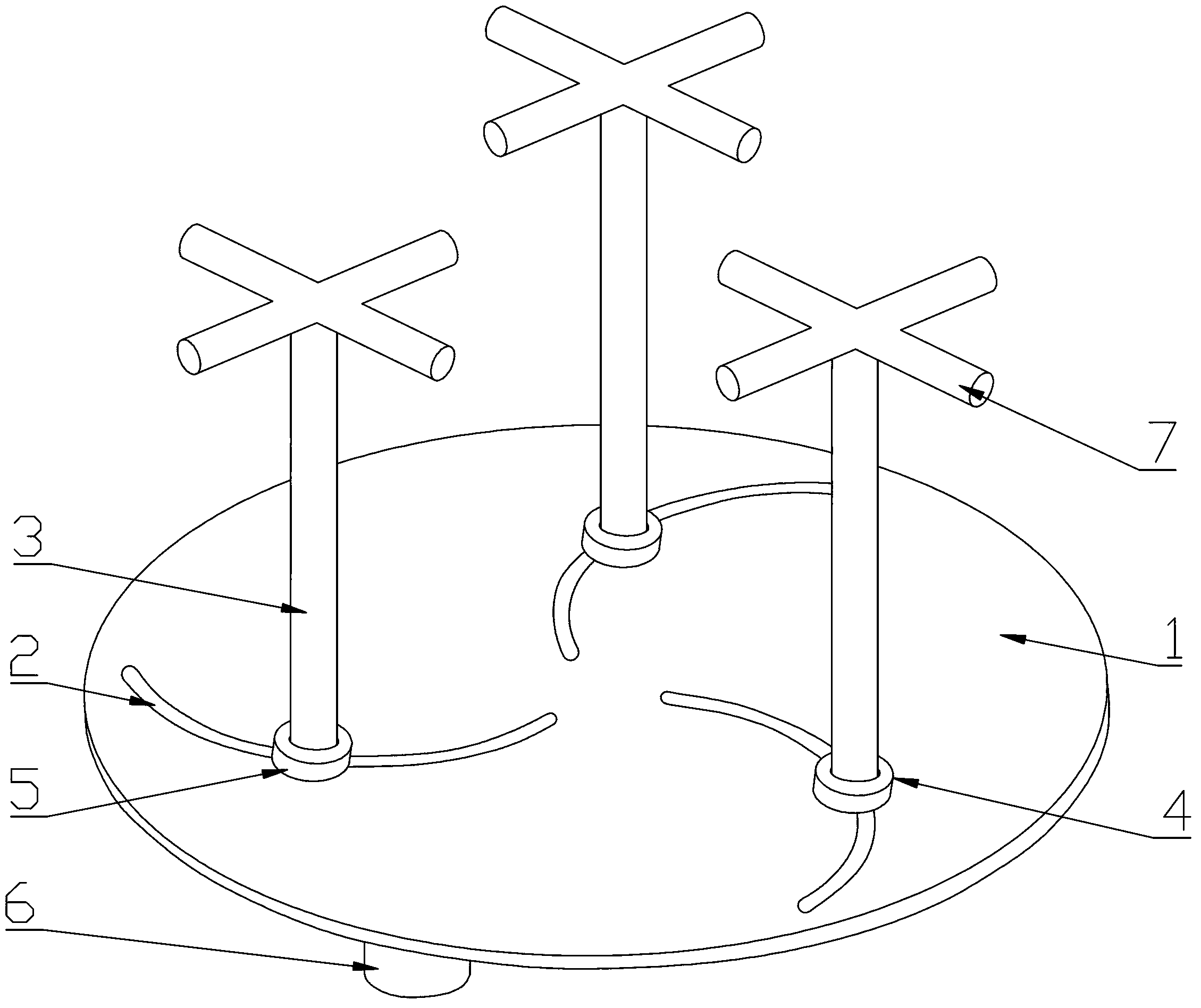

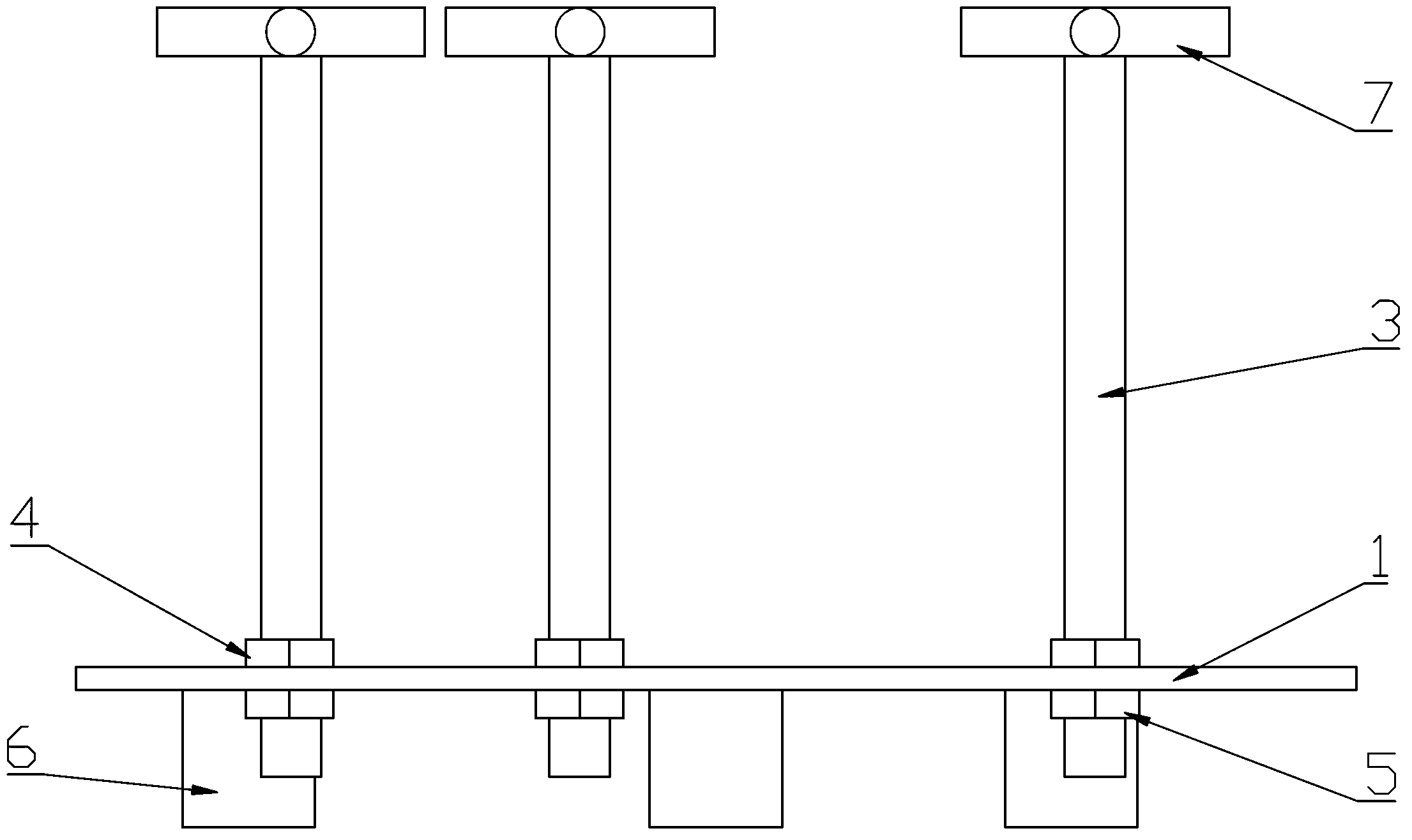

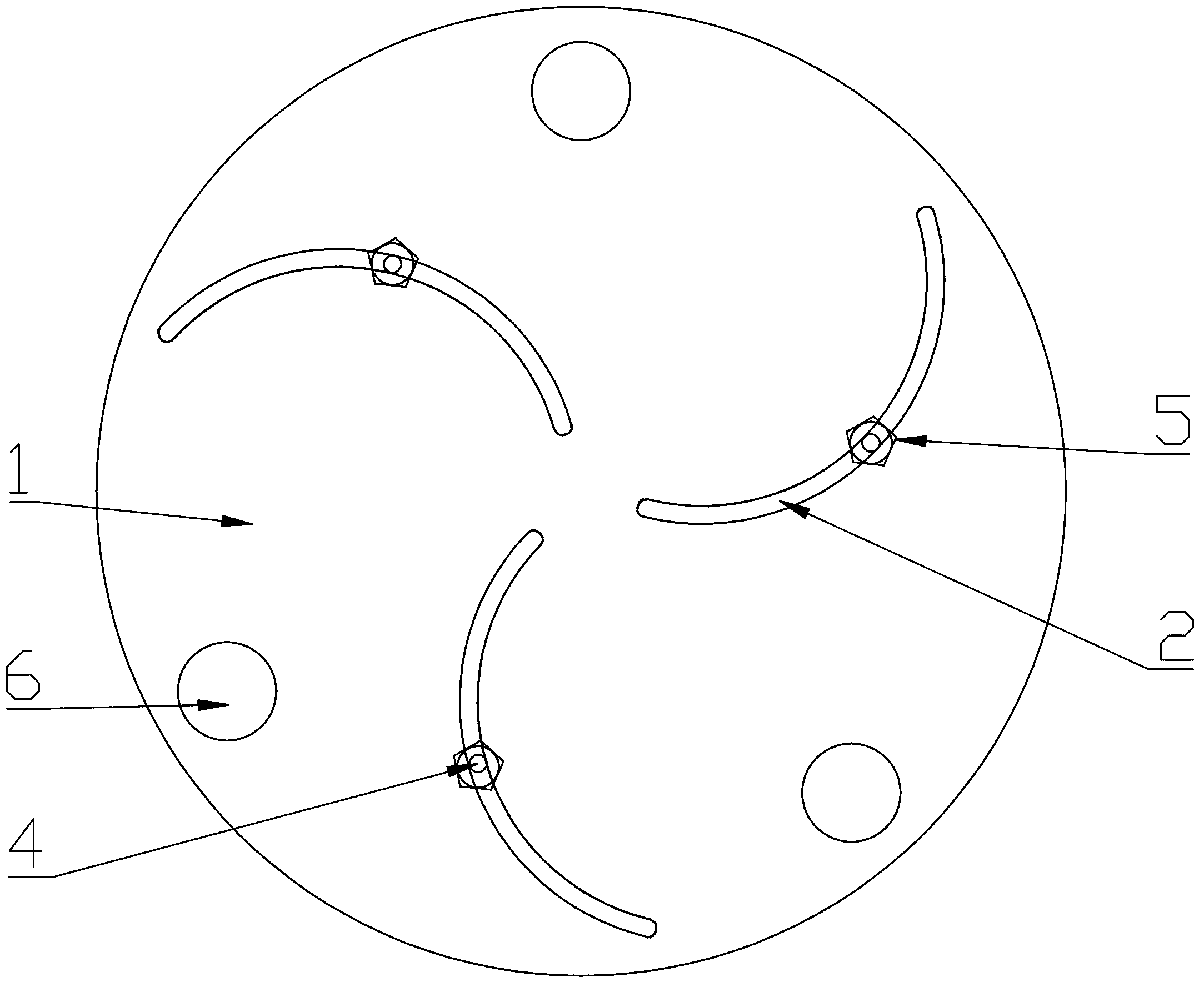

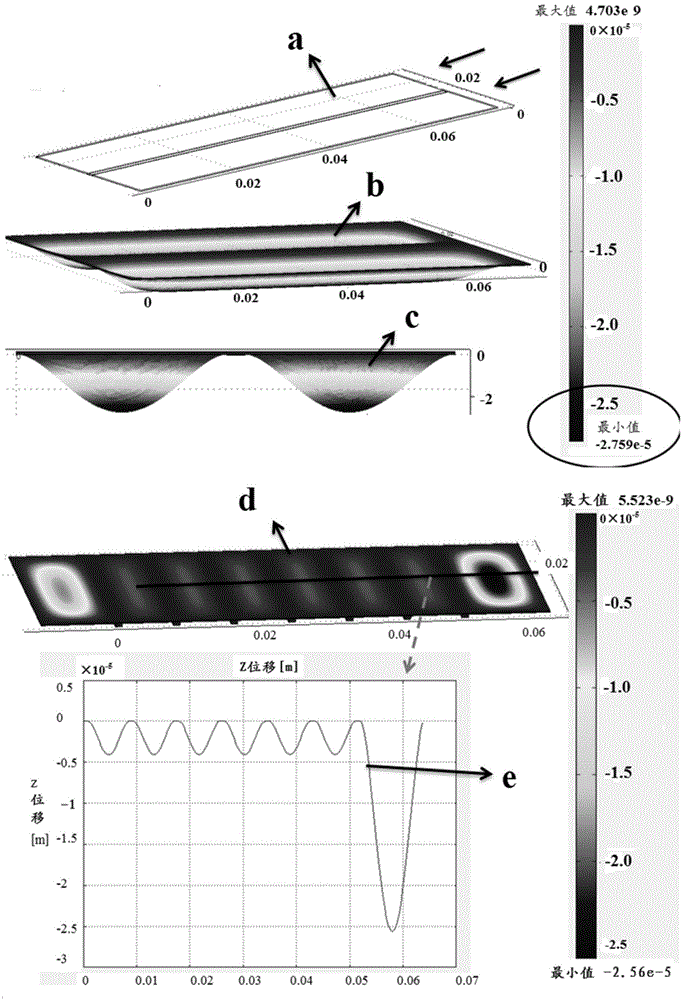

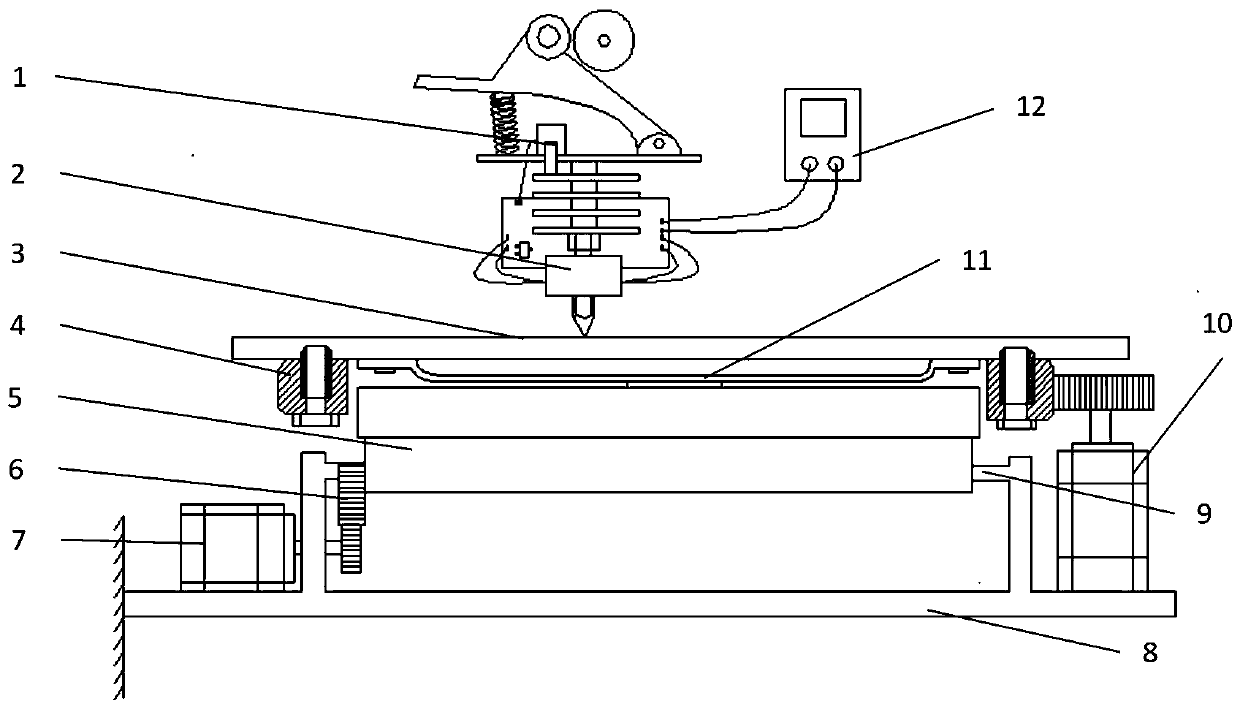

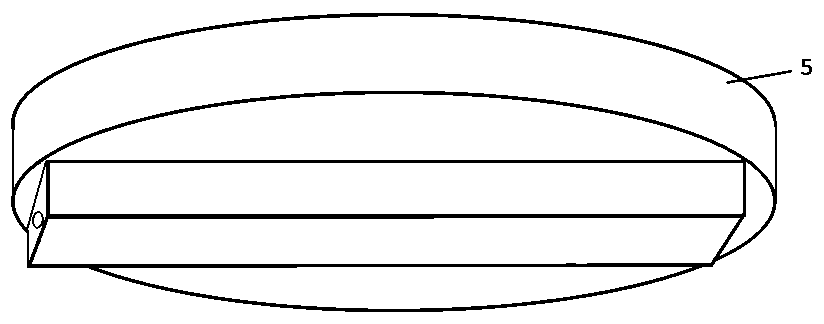

Automatic leveling method and leveling device for hot bed of 3D printer

InactiveCN107672172AAvoid scratchesHorizontal state real-time monitoringManufacturing heating elementsAngular degreesHeight difference

The invention discloses an automatic leveling method and leveling device for a hot bed of a 3D printer. Spatial coordinates of arbitrary three points which are not located on the same straight line onthe hot bed are measured; spatial coordinates N(x,y,z) of all points on a spatial circle determined by the three points are calculated through the algorithm of determining a circle by threepoints; the highest point M and the lowest point m on the spatial circle are determined according to the z value, and a vector Mm connecting M and m and passing through the center of the spatial circle is obtained; the included angle lambda of the vector Mm and the X axis and the half height difference H of the vector Mm in the Z axis direction are calculated; the hot bed is driven to rotate bythe angle lambda along a vertical rotating shaft perpendicular to the XOY plane, and a horizontal rotating shaft is driven to drive the hot bed to swing by the height H; and the steps are repeated till measured H meet the precision requirement. According to the leveling method and the leveling device, automatic detection and leveling of the hot bed of the 3D printer can be achieved, and the quality of a 3D printed product is improved.

Owner:ZHONGBEI UNIV

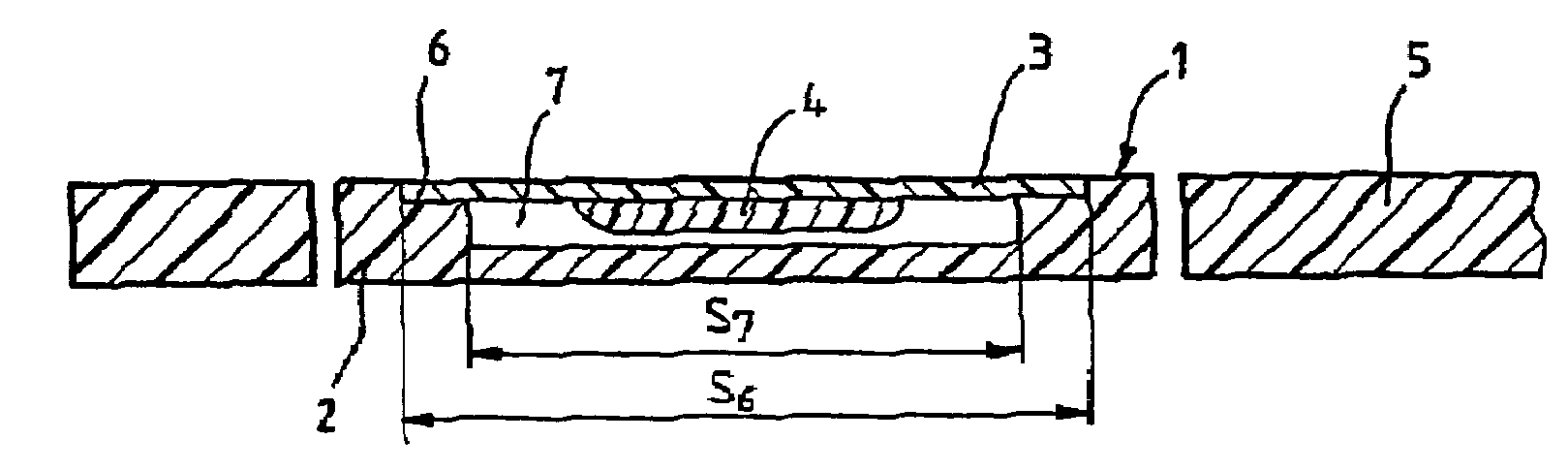

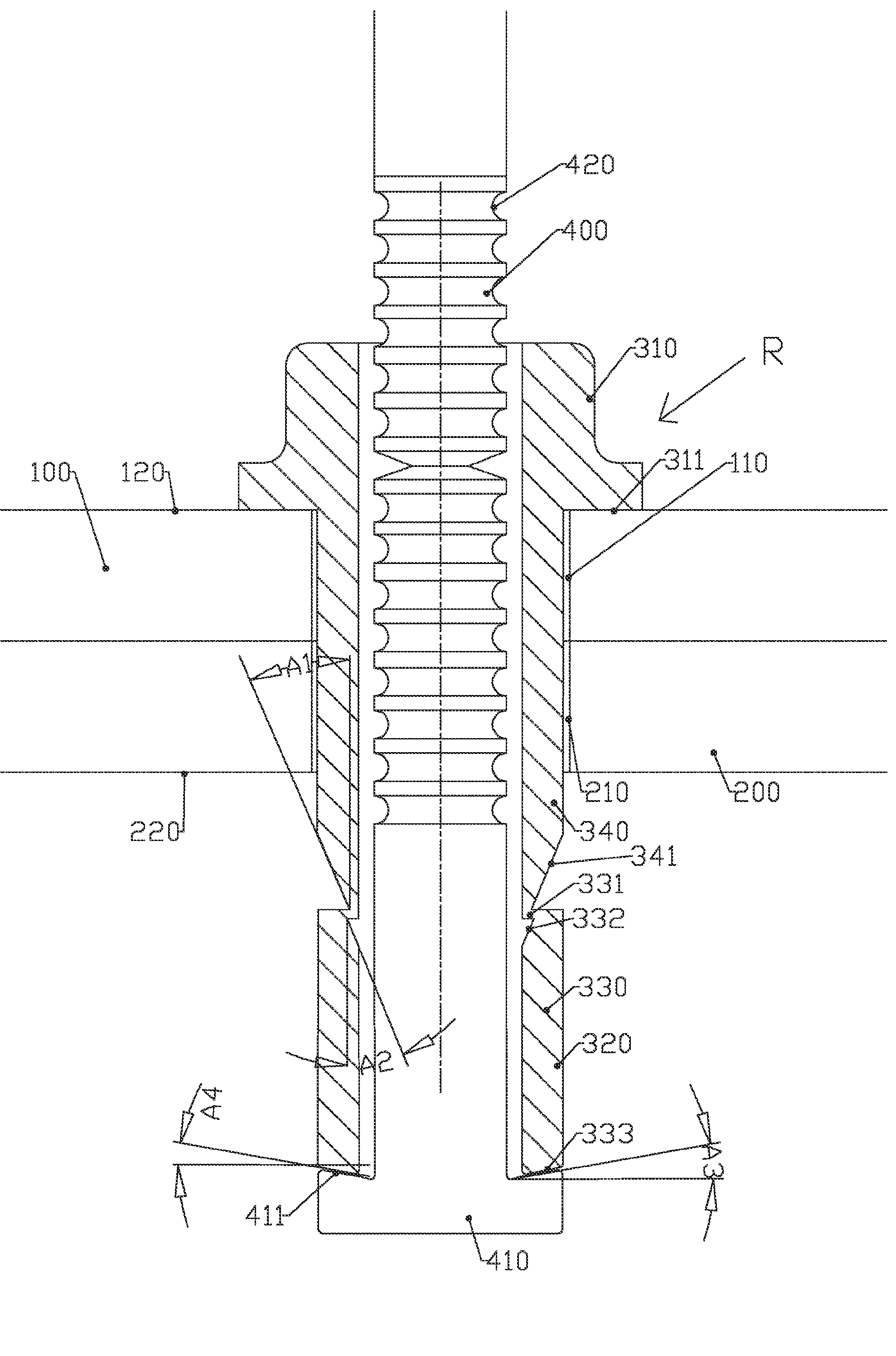

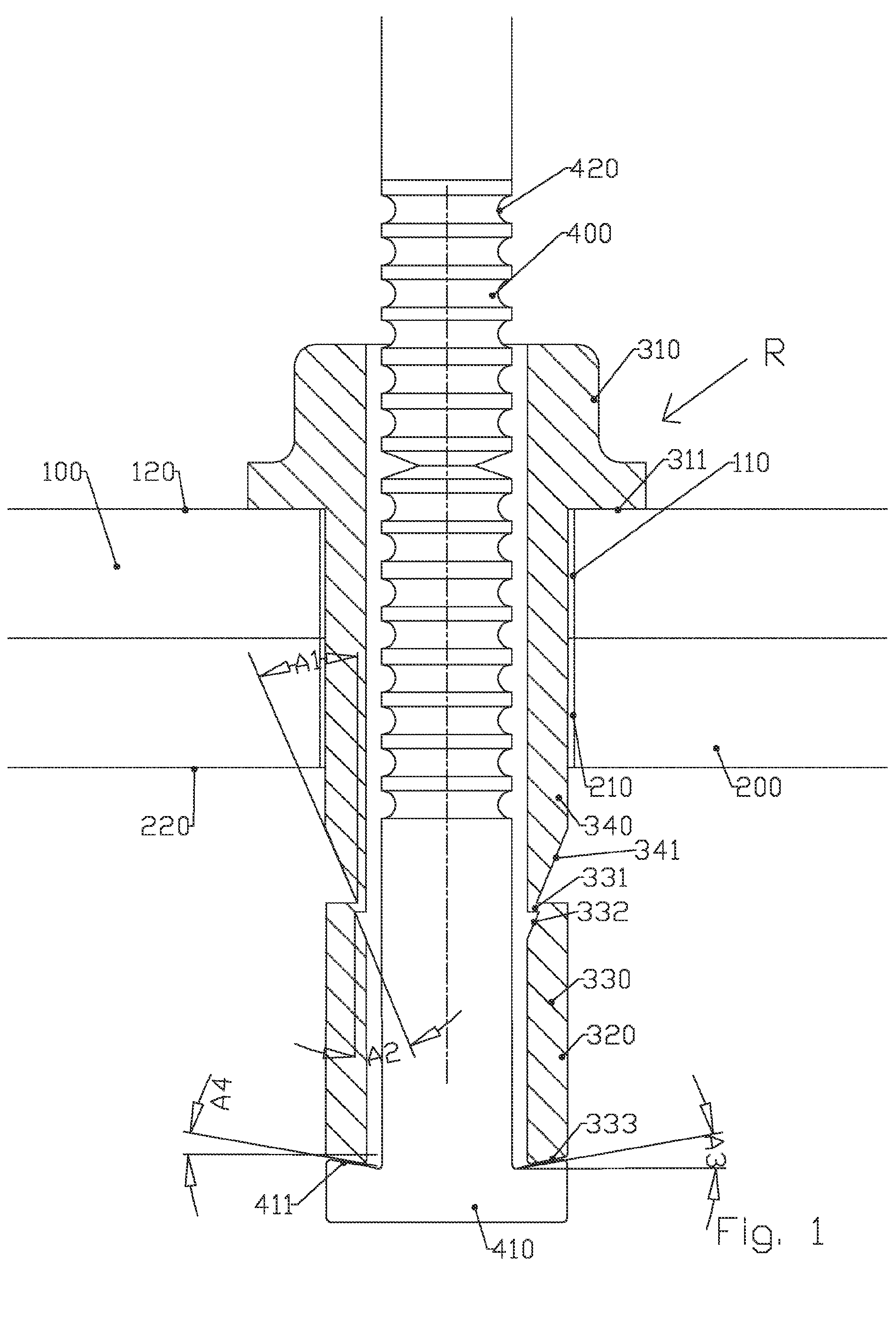

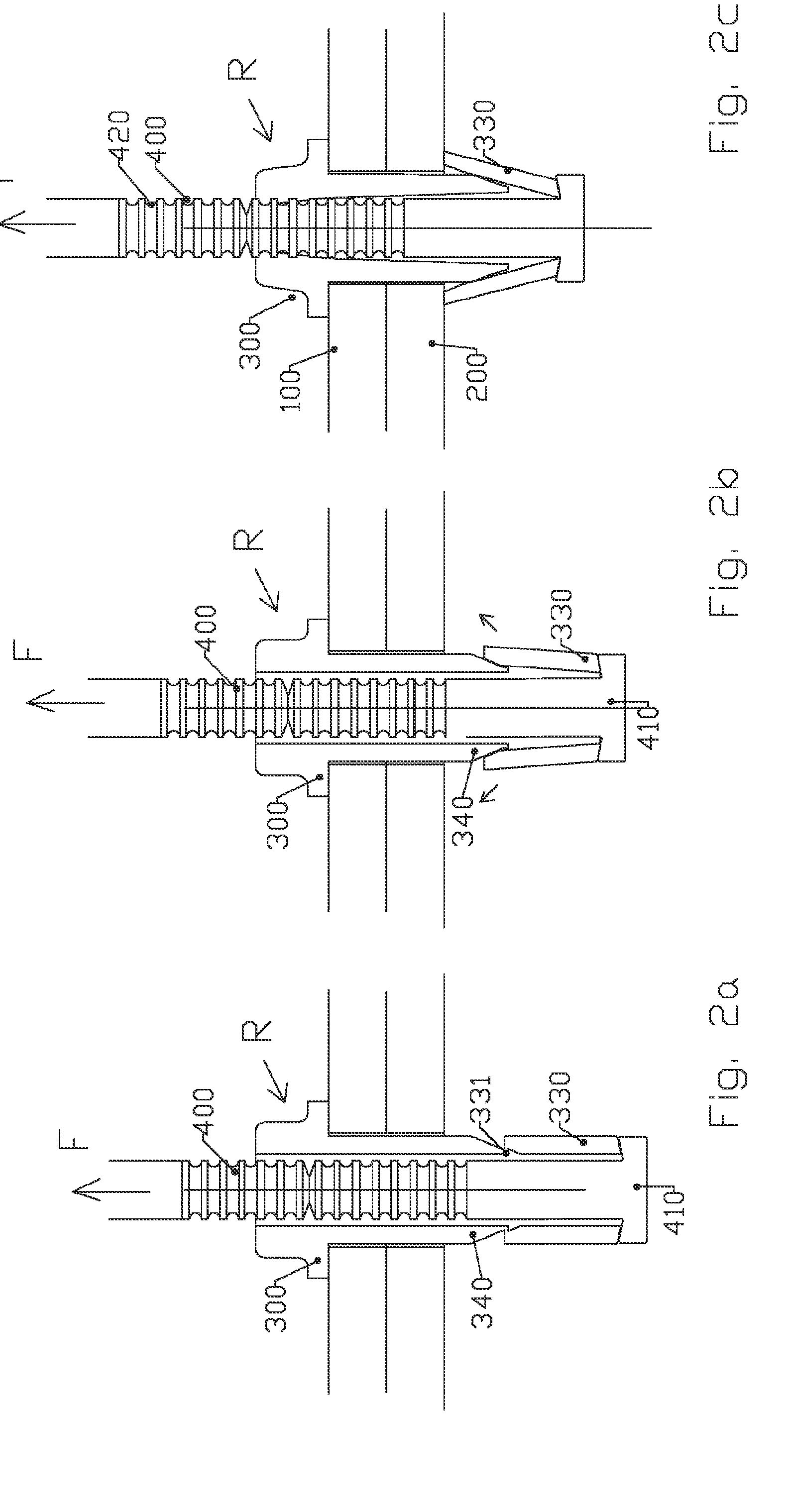

Blind rivet in particular for fixing a structure and method for inserting same

The invention concerns a blind rivet (R) of the type consisting of a deformable bushing (300) and a cleavable mandrel (400), the thus formed assembly being urged to be positioned and pass through the orifices (110 and 120) made substantially coaxial and provided in at least two elements (100 and 200) to be assembled. Said rivet is characterized in that the bushing (300) consists of one single piece but preformed to have a second end (320) in two parts (330 and 340) which, under the action of an axial load (arrow F), are cleaved apart so that one part of the bushing (330) moved by the tensile load of the mandrel (400) is urged to be opened around the fixed part of the bushing (340), the expansion of the mobile part (330) called sleeve being produced without folding. The invention also concerns a method for inserting such a rivet. The invention is applicable to rivet fixing.

Owner:ATELIERS DE LA HAUTE GARONNE ETS AURIOL & CIE +2

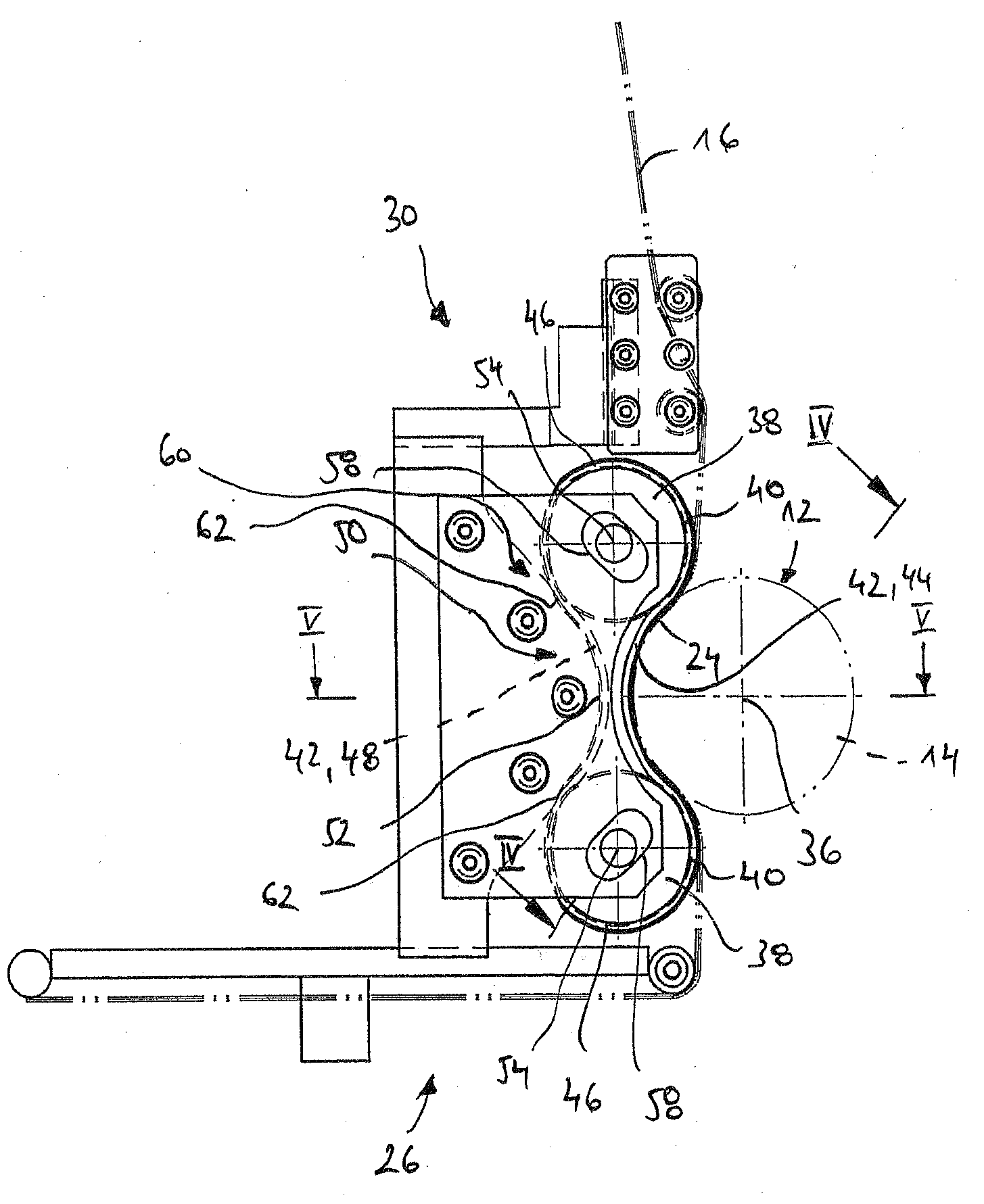

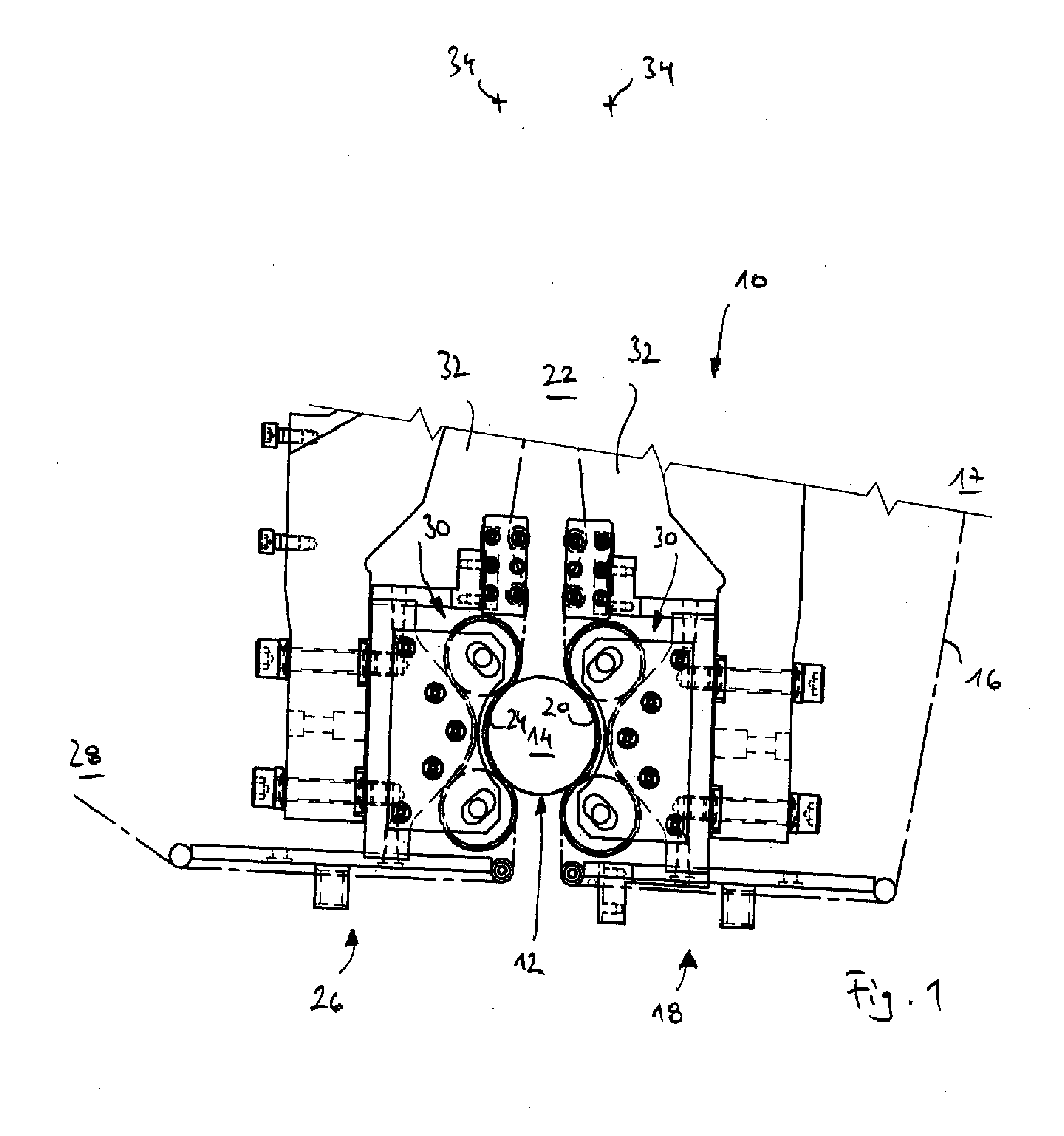

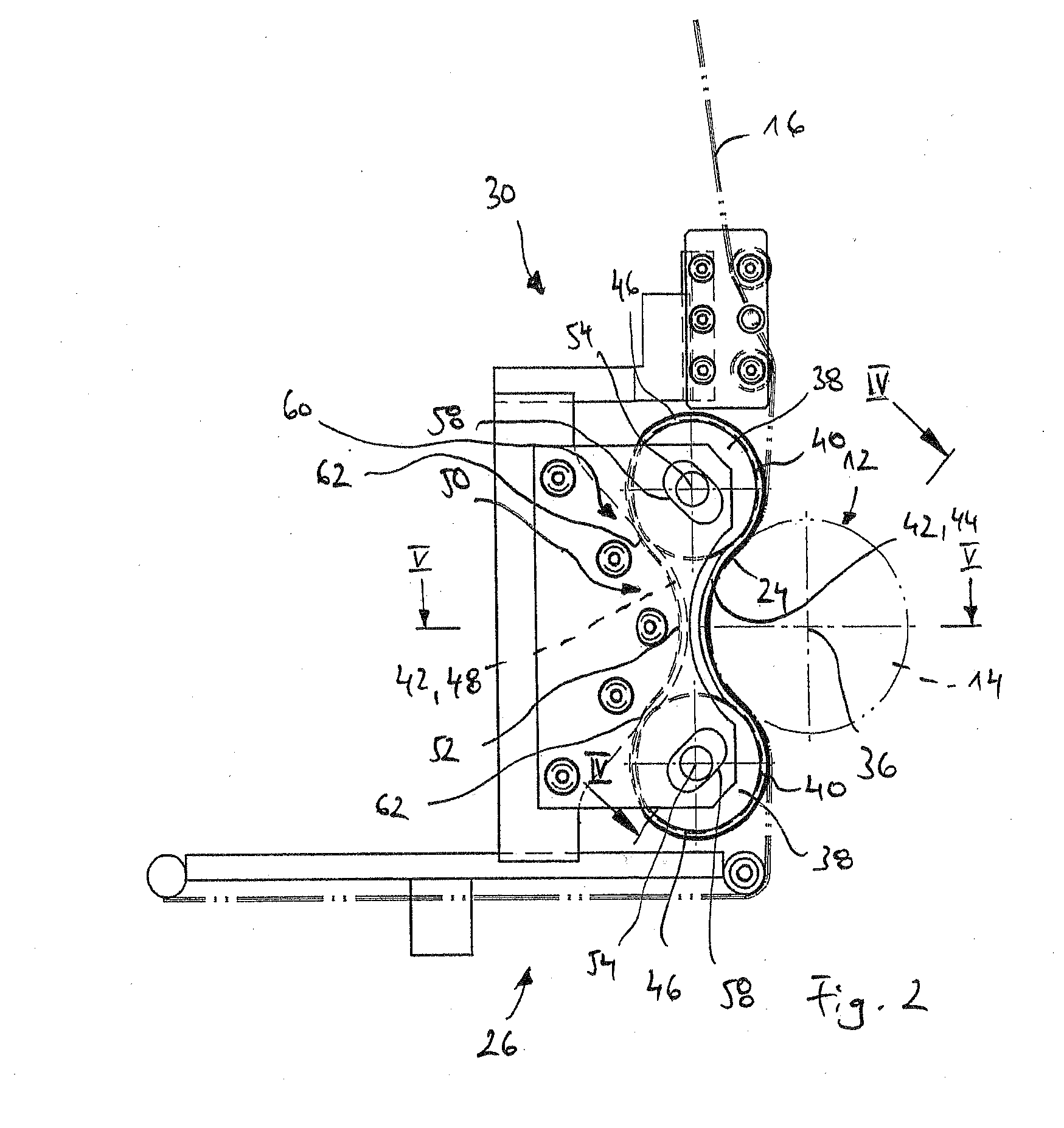

Belt finishing device, belt finishing system and method for producing a belt finishing device

ActiveUS20140094099A1Easy to controlRelieve pressureBelt grinding machinesSuperfinishing machinesEngineeringBearing surface

A belt finishing device includes a finishing belt, two bearing surfaces that are spaced-apart in a running direction of the finishing belt, and a pressing device for pressing the finishing belt against a workpiece surface. The pressing device has a pressure belt that is supported on the two spaced-apart bearing surfaces. At least one of a bearing surface and the pressure belt have a profile that deviates in a width direction of the finishing belt from a straight course.

Owner:SUPFINA GRIESHABER GMBH & CO KG

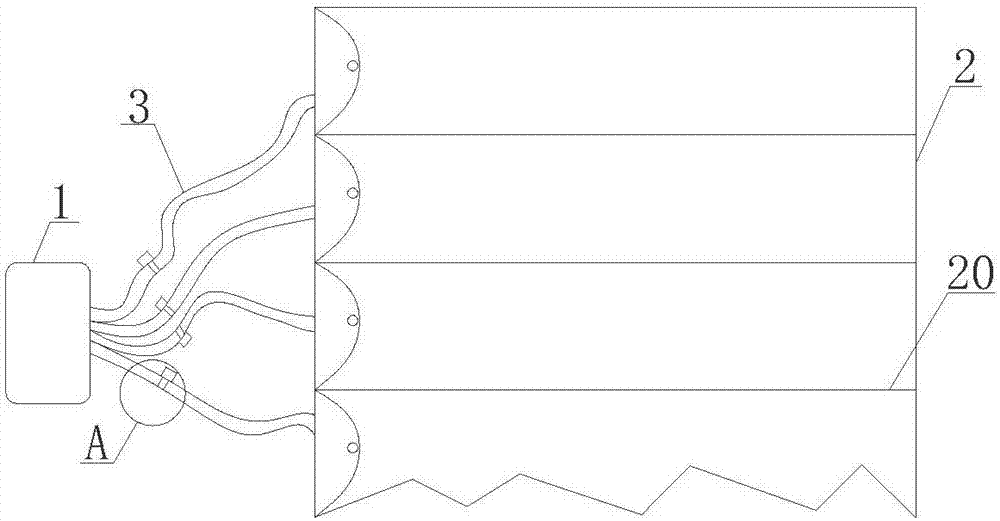

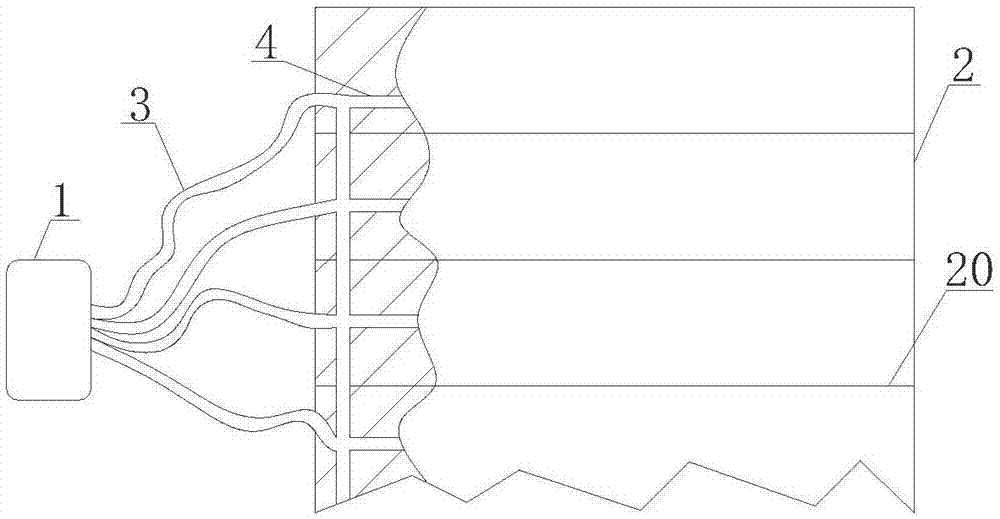

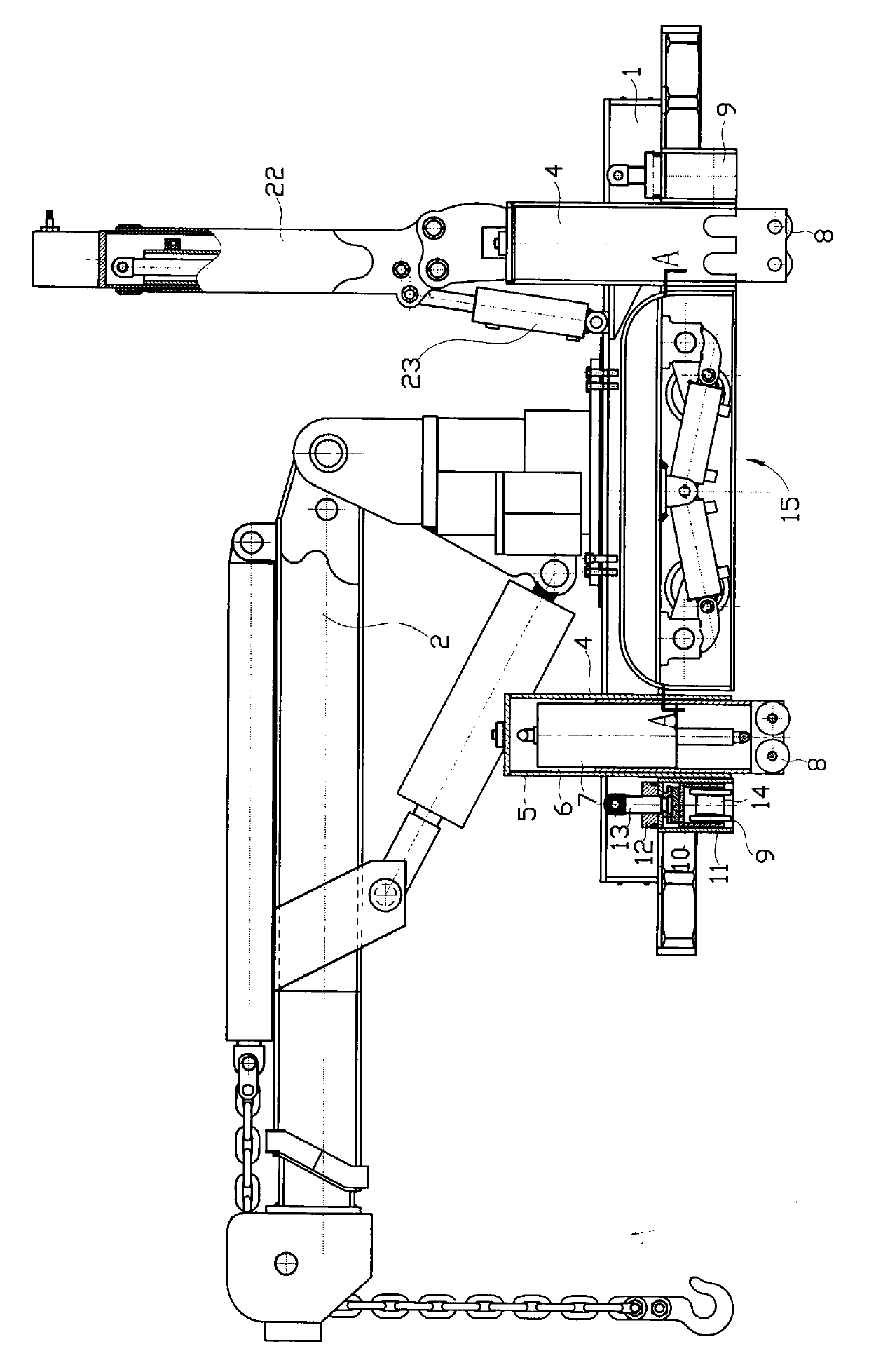

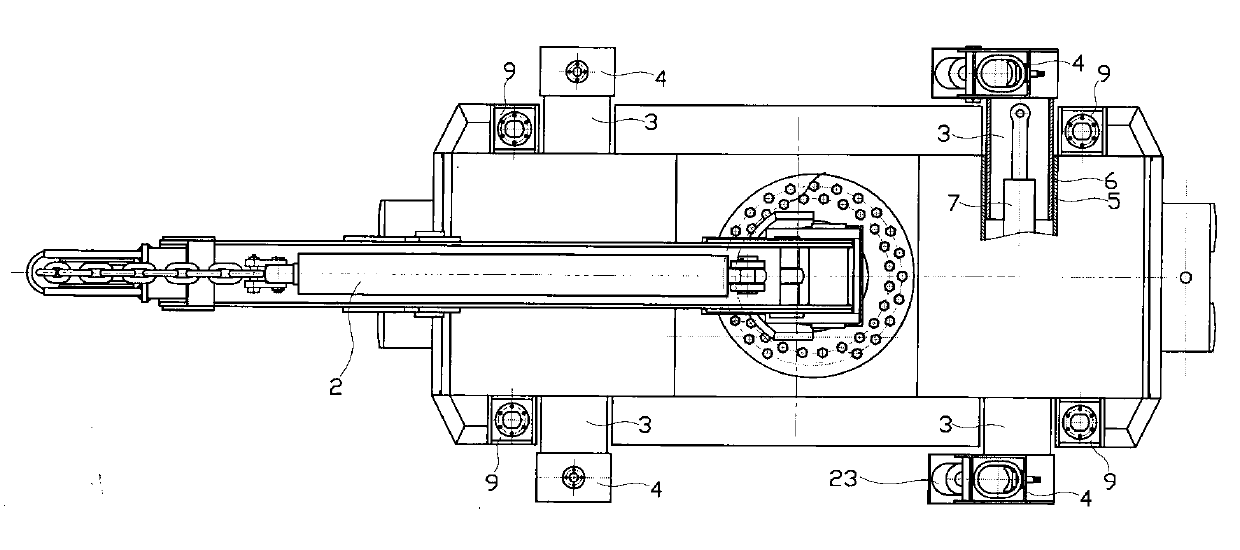

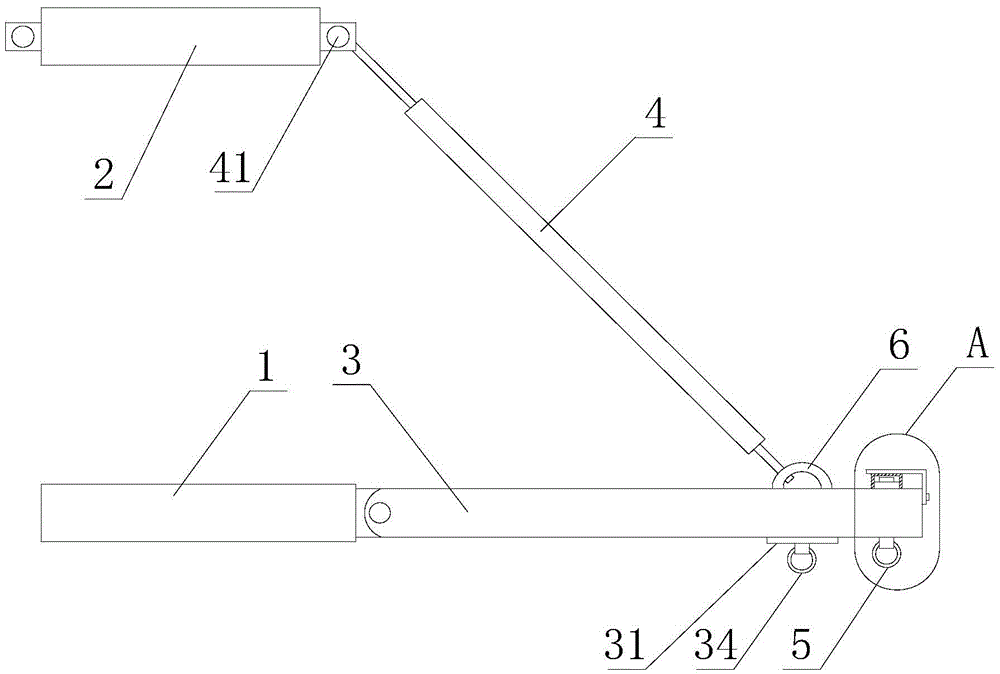

Hydraulic crane of underground transfer rail

InactiveCN103101845AExpand the scope of workIncrease the support surfaceCranesHydraulic cylinderVehicle frame

The invention discloses a hydraulic crane of an underground transfer rail. A hydraulic lifting rack is arranged in the middle of a plate frame; lateral hydraulic telescopic booms are respectively connected with the front part and the rear part of the left side and the right side of the frame; downward hydraulic telescopic booms are arranged at the outer ends of the lateral hydraulic telescopic booms; longitudinal operation wheels are connected to the lower ends; downward screw driving telescopic booms are arranged at four corners of the frame; the lower ends of the frame are connected with transverse operation wheels; longitudinal moving wheels driven by a hydraulic lever lifting mechanism are arranged below the frame; the upper ends of the downward hydraulic telescopic booms at the left and right rear parts are connected with supporting hydraulic cylinders; and the supporting hydraulic cylinders are connected with a swing hydraulic cylinder. The hydraulic crane of the underground transfer rail comprises operation wheels in the length direction and the operation wheels in the width direction, is large in operation range and high in stability of lifting operation, also comprises moving wheels, and can move on a flat car track for rail transferring without a flat car in a coal mine roadway; the swing hydraulic cylinder can enable the supporting hydraulic cylinder to be parallel to the plate frame; the hydraulic crane of the underground transfer rail is small in size and convenient to move in a narrow roadway.

Owner:LIAONING XINFENG MINE IND GRP CO LTD

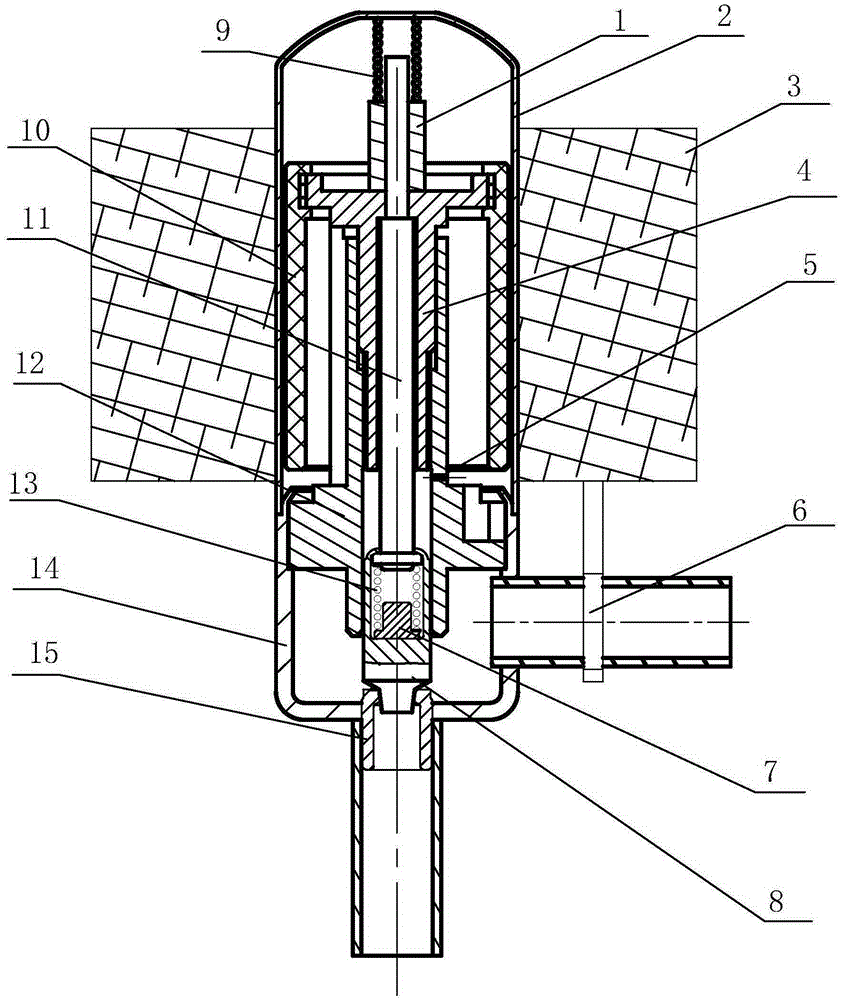

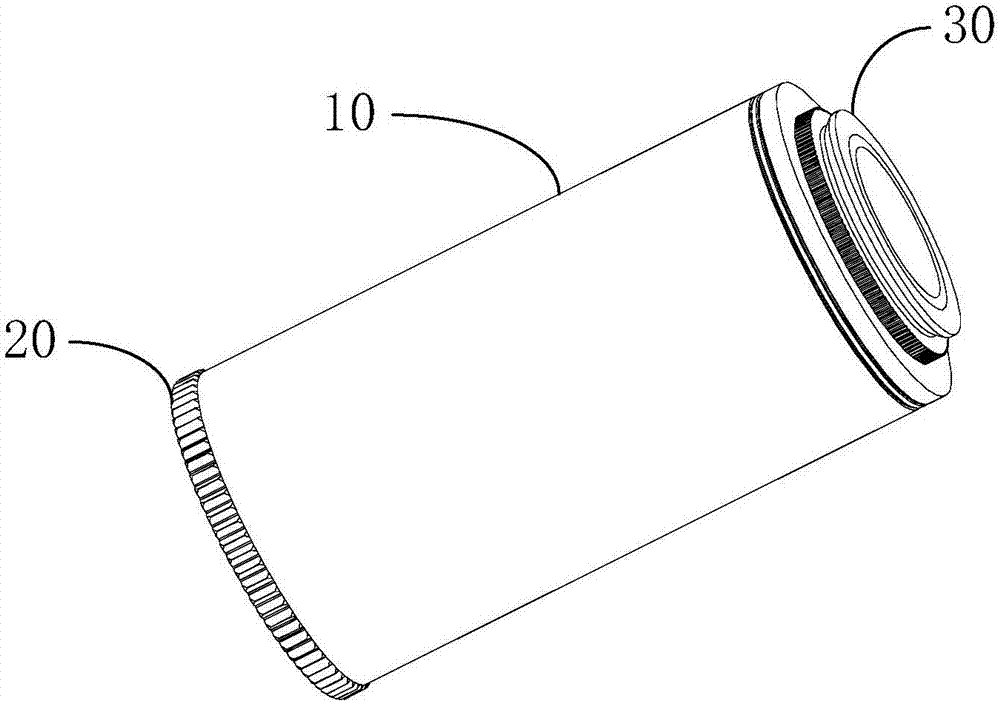

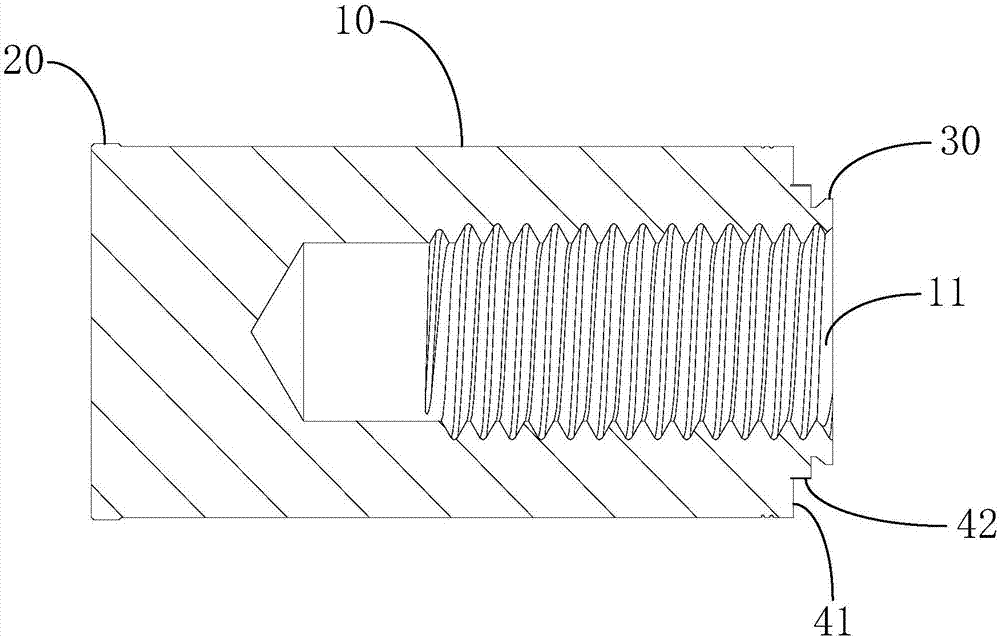

Thread transmission type electronic expansion valve

InactiveCN106766418AIncrease the support surfaceImprove installation firmnessOperating means/releasing devices for valvesEfficient regulation technologiesCavity wallButt joint

The invention relates to a thread transmission type electronic expansion valve, and belongs to valves. An existing electronic expansion valve is large in running noise, and abrasion or clamping of a magnetic steel sleeve is prone to occurrence; the thread transmission type electronic expansion valve is characterized in that a backward step end face leaning shoulder is arranged on the outer circle face of a front base sleeve, the opening end of a back base sleeve is in butt joint with the step end face leaning shoulder in a fixedly welding manner to form a straight-cylinder-shaped shell with two ends closed, a front section of a nut sleeve is inserted into an inner cavity wall of the front base sleeve, and an end face leaning shoulder on the inner cavity wall and an inward turning edge of the opening end of the front base sleeve are used for limiting and fixing; a valve is installed in a hollow inner cavity of a valve rod sleeve fixed to the magnetic steel sleeve in a penetrating manner, the back end of the valve extends out of the back end of the magnetic steel sleeve, and a spacer bush and a spring arranged outside the valve rod in a sleeving manner are used for back stroke limiting; and the valve rod sleeve is matched with inner threads in an axial through hole of the nut sleeve through outer threads to drive the valve rod to move, a buffer connecting piece connected with the front end of the valve rod is arranged on the front section of the axial through hole of the nut sleeve to conduct guide supporting on the valve rod, circumferential limiting protrusions and limiting leaning shoulders which are matched with each other are arranged for front stroke limiting, and the collision noise and friction are reduced.

Owner:新昌县儒岙镇锦云机械厂

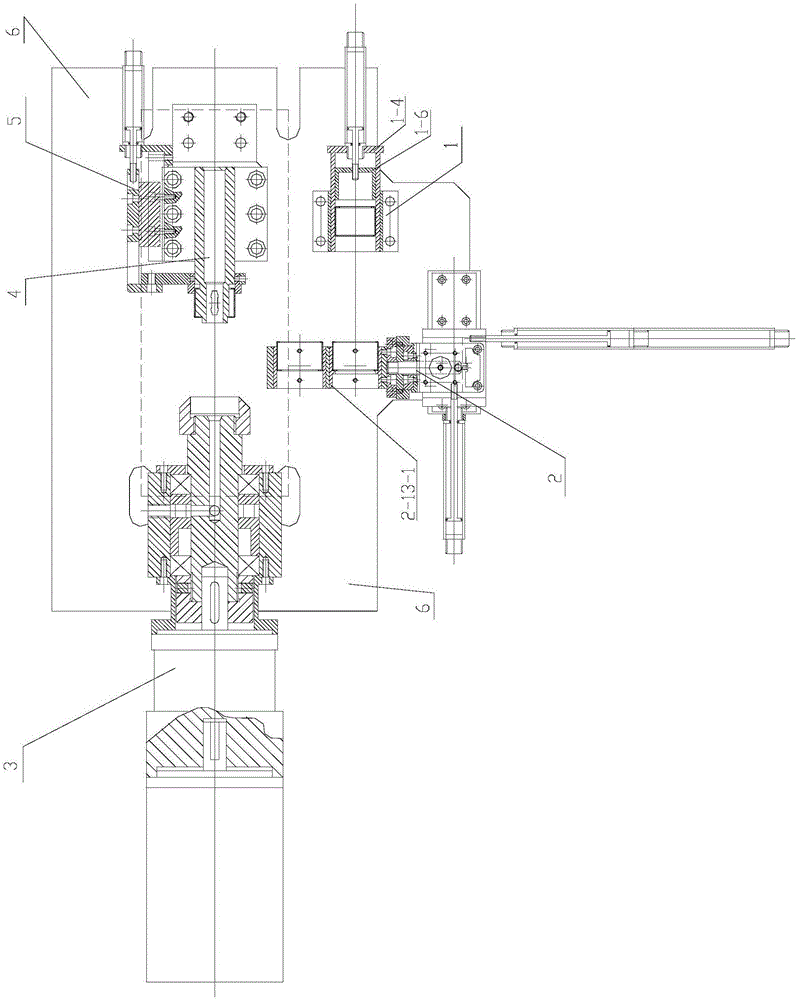

Full automatic window punching device for radial bearing cage

ActiveCN105149476AIncrease productivityReduce manufacturing costMetal-working feeding devicesBearing componentsPunchingReducer

The invention relates to a full automatic window punching device for a radial bearing cage. The window punching device comprises a feeding component, a conveying component and a punching die fixation component which are arranged on a frame, and also comprises an apex equal-division driving component and a window punching positioning component, wherein the window punching positioning component comprises a positioning cylinder, a processing positioning sleeve, a positioning slide rail and a positioning slide block, the processing positioning sleeve is connected with the positioning slide block by a positioning connection block and sleeved on a punching die, so as to greatly increase the production efficiency, reduce the production cost and fully automatically accomplish conveying, window punching and blanking steps. The apex equal-division driving component comprises an apex cylinder, an apex tie rod, an apex slide rail, a servo motor, a speed reducer, a bearing seat, an apex axle and an apex, wherein the servo motor is in transmission link with the apex by the speed reducer and the apex axle, the apex is driven to rotate, the workpiece is driven to perform the equal-division rotation; during the workpiece window punching process, the uniform equal-division is ensured, the angle is adjustable, the division is conveniently used, and the quality of the cage window punching is greatly improved.

Owner:CHANGZHOU DONGFENG BEARING

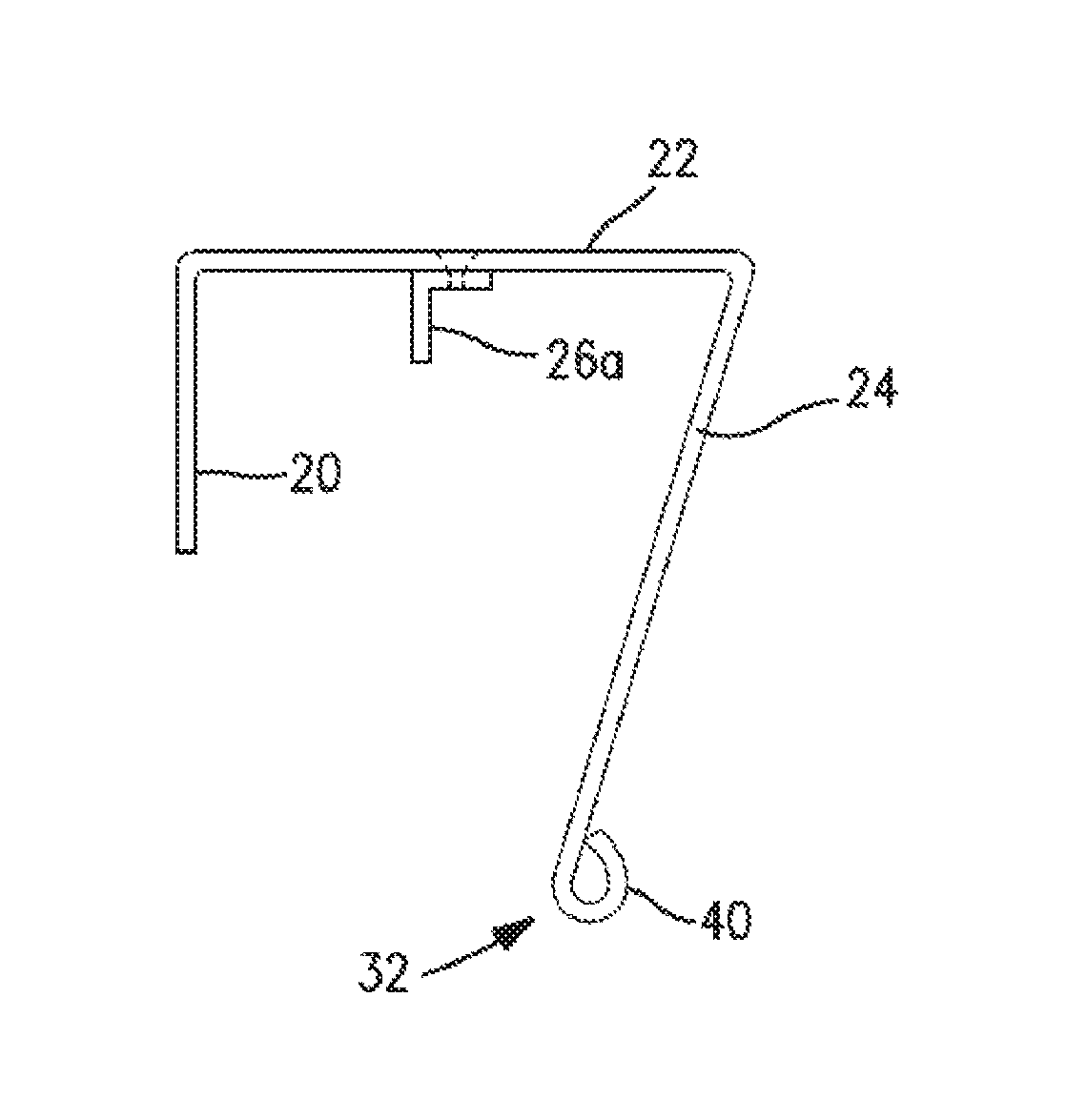

Container for bulk handling of fluids

InactiveUS20070102314A1Minimizing shockVibration minimizationOther accessoriesContainer/bottle contructionCushioningEngineering

A palletized shipping container for bulk handling of fluid materials has a rigid box-like outer shell within which is positioned a flexible bag and an intermediate corrugated liner sandwiched between the walls of the bag and shell. The bag has flap-like extensions at an upper end attached to the walls of the shell to maintain the bag in an erect uncollapsed configuration, a non-removable bung at its top end, and a non-removable discharge valve adjacent its bottom end. The bung is releasably retained at the top of the liner to maintain the bung in a proper position and prevent sagging of the bag. An inwardly and downwardly angled cushioned surface at the bottom of the shell supports the liner and bag, provides additional cushioning, facilitates emptying of the bag, and reduction of residual material. The pallet allows 4-sided entry of fork lift forks.

Owner:MILLAN BOX

Profile material reinforcement connecting structure part

ActiveCN106907567AFirmly connectedEasy to installElongated constructional elementsShrinkage connectionsInterference fitEngineering

The invention relates to a profile material reinforcement connecting structure part used for fastening connection of profile materials with at least two parallel vertical surfaces. The profile material reinforcement connecting structure part comprises a barrel. First teeth arranged in the peripheral direction of the outer surface of the barrel are arranged at one end of the barrel. Interlocking keys arranged in the peripheral direction are arranged at the other end of the barrel. The first teeth and the interlocking keys are fixedly connected with the two parallel vertical surfaces of the profile materials correspondingly. At least one of the two ends of the barrel is fixedly connected with a matched fitting through a connector. According to the profile material reinforcement connecting structure part, the first teeth are in interference fit connection with one vertical surface of the profile materials, the interlocking keys achieve self-fastening with the other vertical surface of the profile materials through flowing of materials, fastening connection of the profile materials is realized through the structure part, and no special requirements exist for the wall thickness, width and tolerance of the profile materials. Installation is convenient, welding and re-tapping are not needed, and the cost and energy consumption are lowered. The two vertical surfaces of the profile materials are connected at the same time, the connecting reliability is increased, the barrel can serve as a reinforcement bar, and therefore the rigidity of the profile materials is increased.

Owner:PEM CHINA

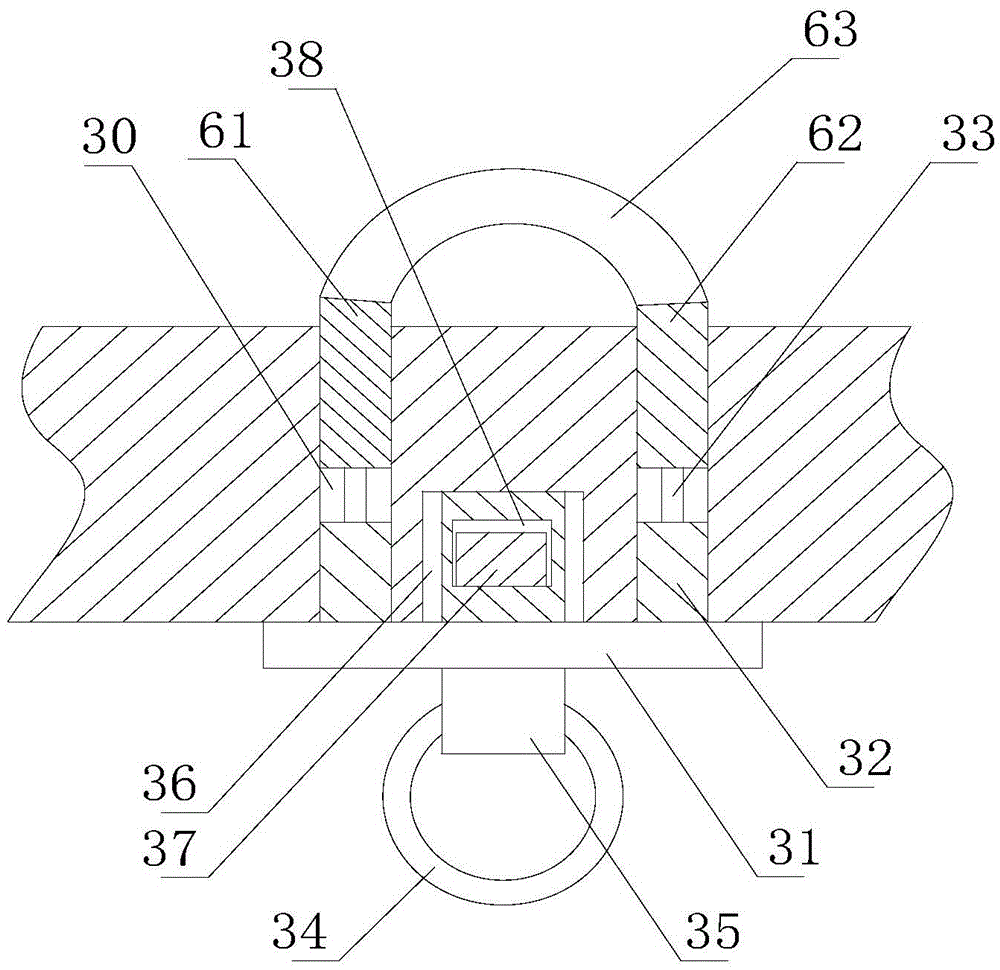

Portable distribution transformer lifting frame

ActiveCN105552757AShorten the timeReduce weightSwitchgearDistribution transformerIndustrial engineering

The invention relates to a portable distribution transformer lifting frame, comprising a loose-leaf hold hoop, a fixed hold hoop and a supporting rod; one end of the supporting rod is rotationally connected on the loose-leaf hold hoop; a length adjustable adjusting assembly is arranged on the fixed hold hoop; the adjusting assembly is connected to the other end of the supporting rod; a connecting element is arranged on the supporting rod. The lifting frame of the invention is advantaged by that the supporting rod is fixedly connected to an electric pole through the loose-leaf hold hoop and the fixed hold hoop; the connecting element is connected with power distribution equipment; the supporting rod is lifted through adjusting the length of the adjusting assembly; compared with the lifting of the existing forklift and crane, the existing lifting time is greatly reduced; the tool is light in weight; the installation workload is low; the security performance is high; the installation cost is low; the fixing effect is improved by matching the loose-leaf hold hoop, the fixed hold hoop and the electric pole; close adhesion with the electric pole is ensured; the supporting area is large; the security performance is high; the position of the supporting rod on the loose-leaf hold hoop can be adjusted through adjusting the length of the adjusting assembly; and the installation flexibility is improved.

Owner:ZHEJIANG TAILUN POWER GRP CO LTD

Method for preparing high-density concrete with uniform aggregate and aggregate thereof

ActiveCN102733607AThe construction process parameters are clearImprove efficiencyBuilding material handlingHigh densitySlurry

The invention discloses a method for preparing high-density concrete with a uniform aggregate and an aggregate thereof, and particularly relates to a method for preparing high-density concrete, belonging to the technical field of concrete preparation. The method is characterized in that the disturbance area of a slurry caused by subsidence trend of an iron aggregate or a lead aggregate is larger than or equal to the equivalent area of the aggregate; a mixture hand sample is produced on an experiment table according to the calculated mix proportion before the mixture is tried; the subsidence condition of the iron aggregate or the lead aggregate is detected, and the detection data is recorded; and the concrete is poured in a split level when being poured in a layered mode. By adopting the method and the aggregate, the uniform distribution rate of the aggregates is improved, and the ray-preventing capability of projects is more uniform.

Owner:山东起凤建工股份有限公司 +1

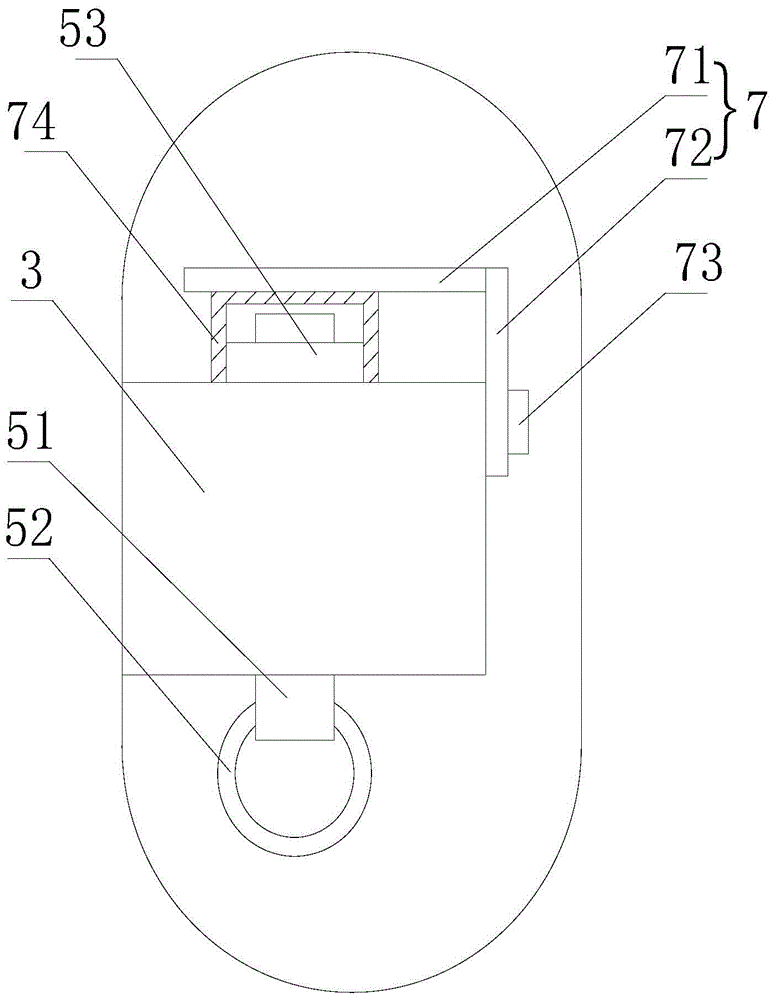

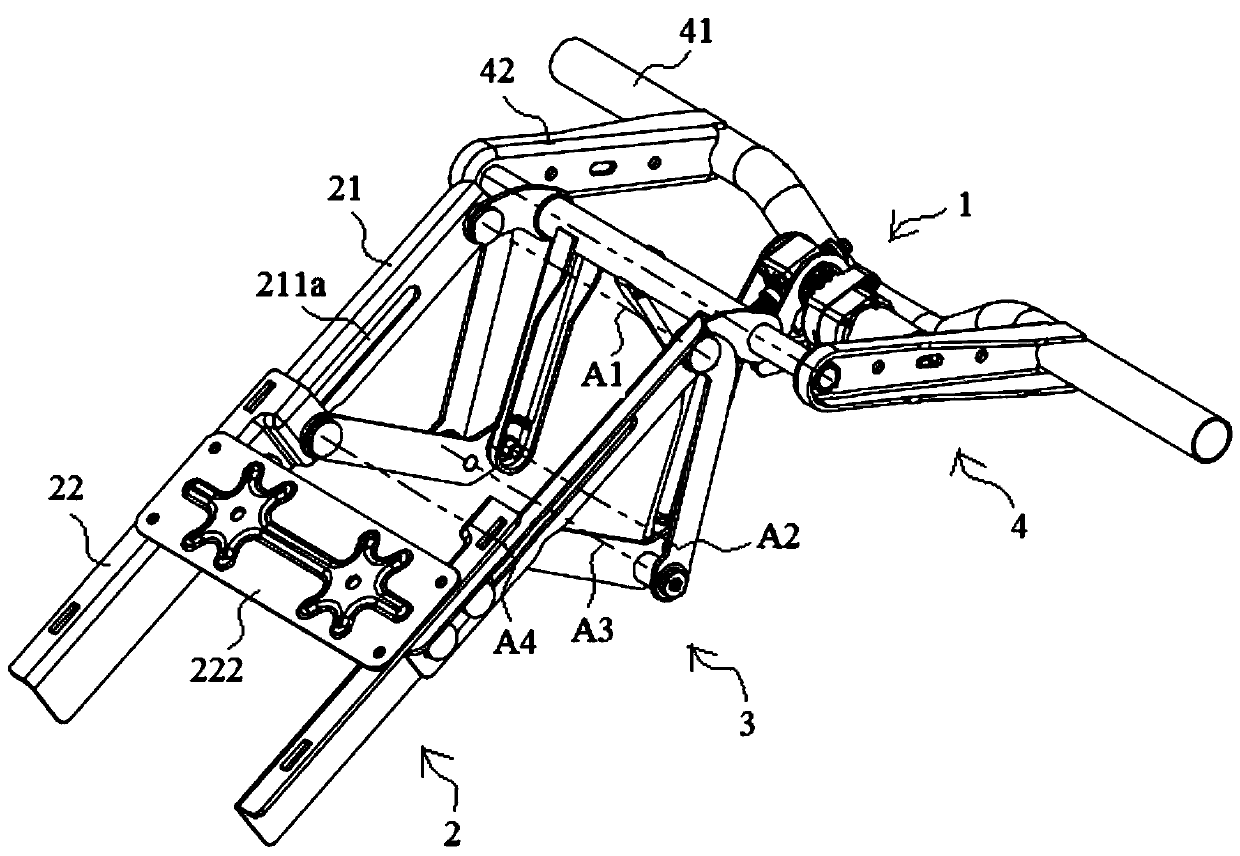

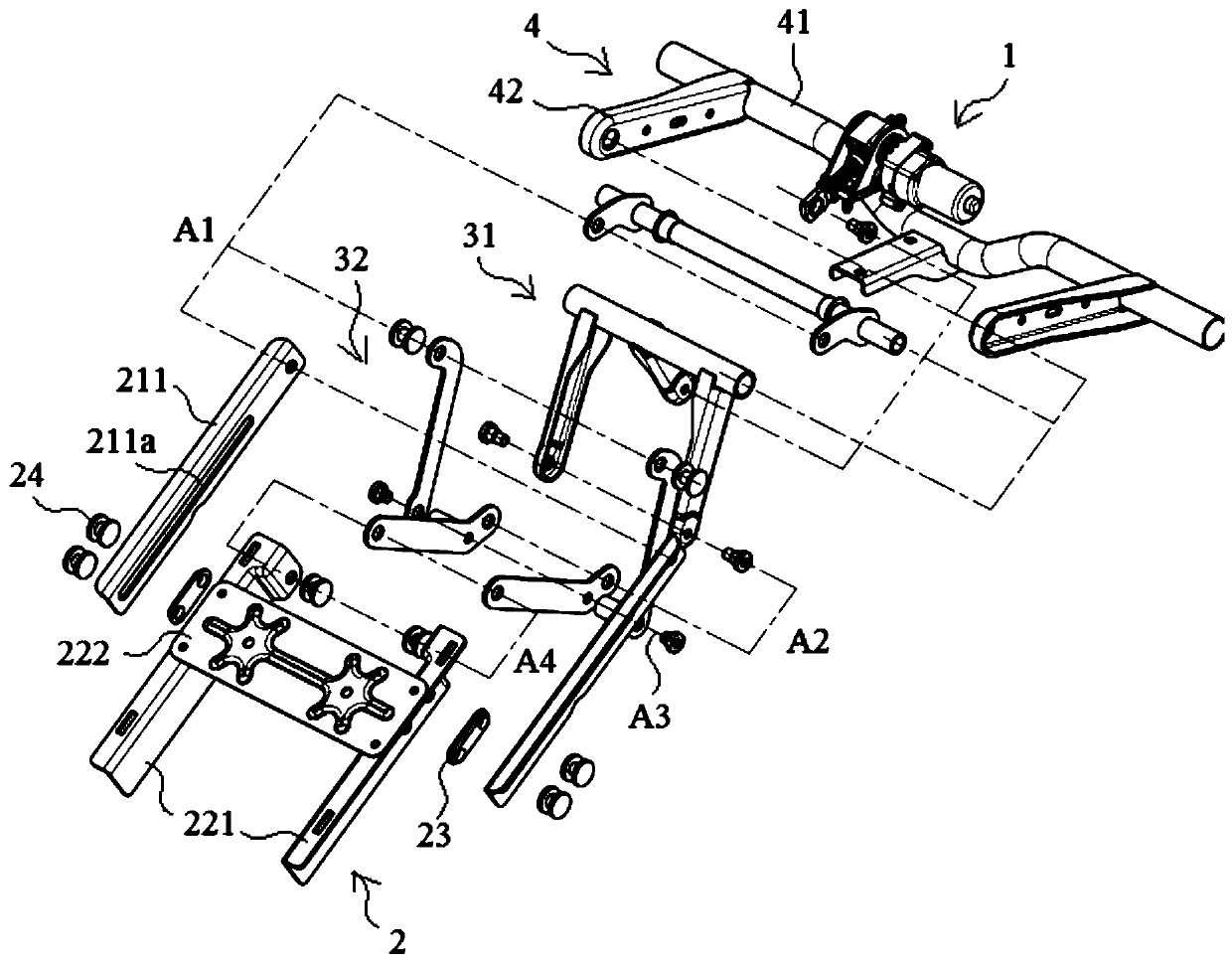

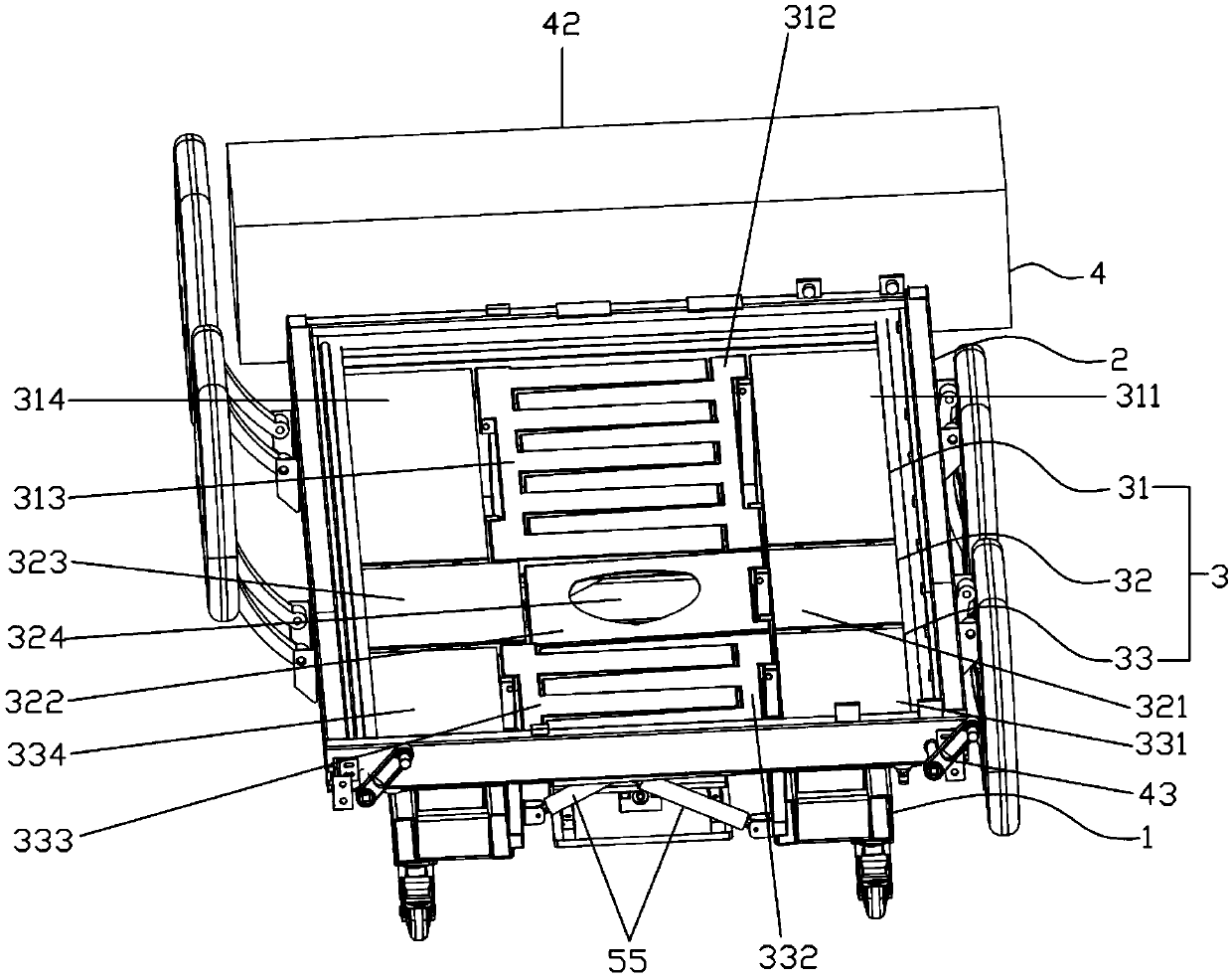

Seat and leg support mechanism

The invention discloses a seat and a leg support mechanism. The leg support mechanism comprises a drive assembly, a leg support assembly and a connecting beam assembly. The drive assembly is mounted on a fixed support. The leg support assembly comprises a first leg support component and a second leg support component. The first leg support component is provided with a hole type or groove type sliding fit portion, the second leg support component is in sliding connection with the first leg support component in the extending direction of the sliding fit portion, and a first hinged point is formed at the upper end of the first leg support component. The connecting beam assembly comprises a power input portion and a power output portion, the power input portion is connected with a drive portion of the drive assembly, and the power output portion is connected with the second leg support component. When the drive assembly is started, the power output portion can drive the first leg support component to rotate relative to the first hinged point, so that the leg support assembly is switched between a folded state and a stretching-out state. In the stretching-out state, the second leg support component stretches out relative to the first leg support component; and in the folded state, the second leg support component retracts relative to the first leg support component.

Owner:HUBEI HAPM MAGNA SEATING SYST CO LTD

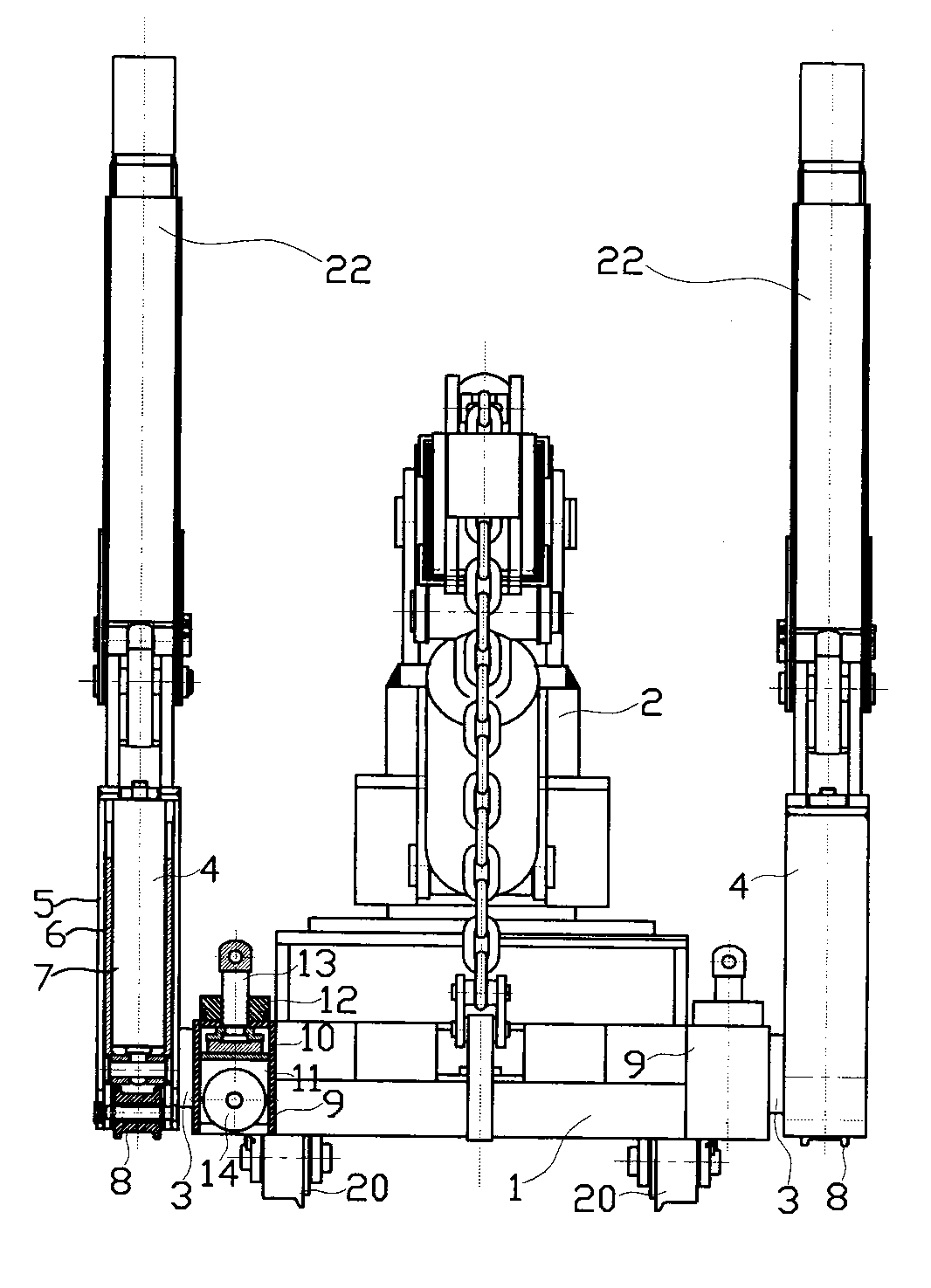

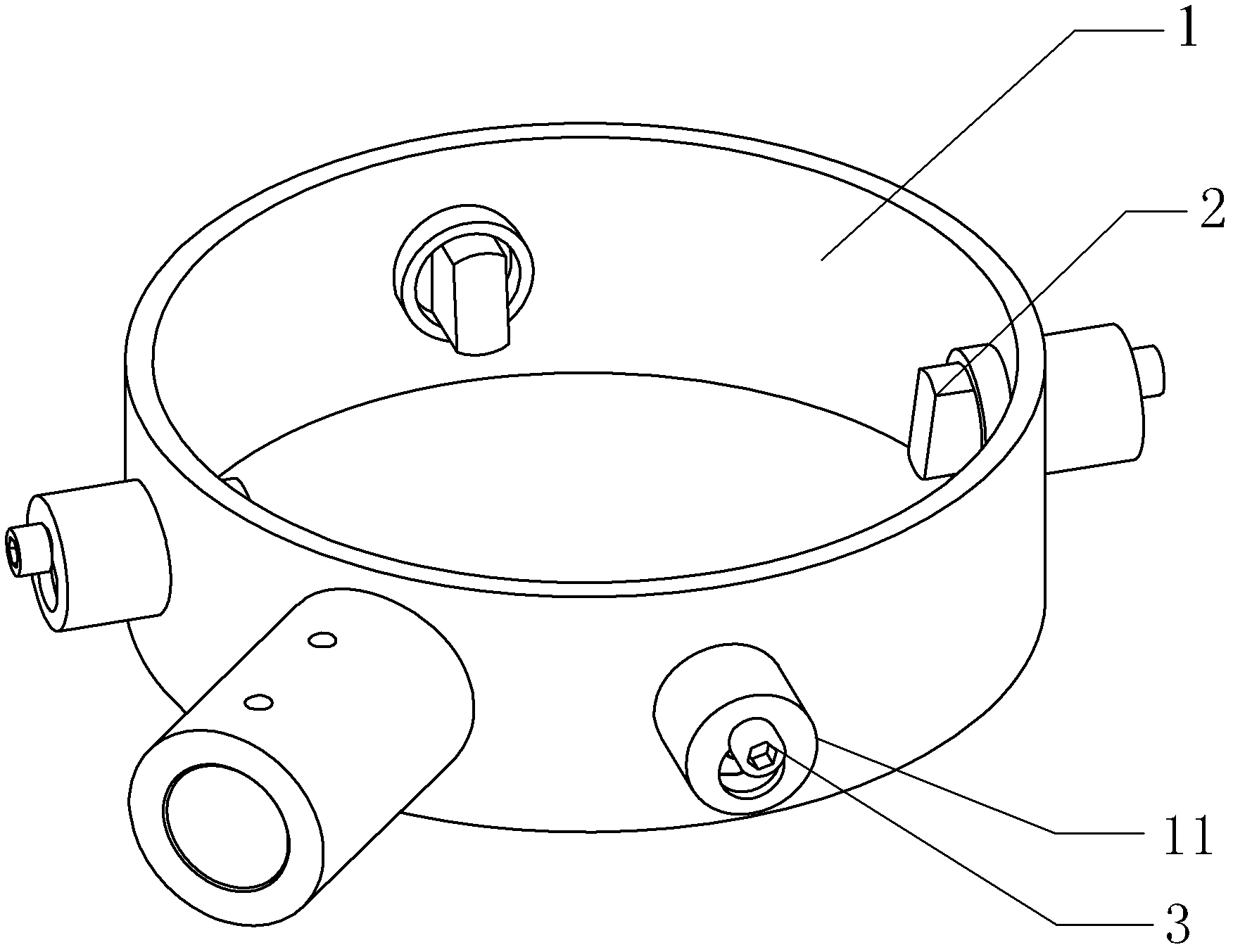

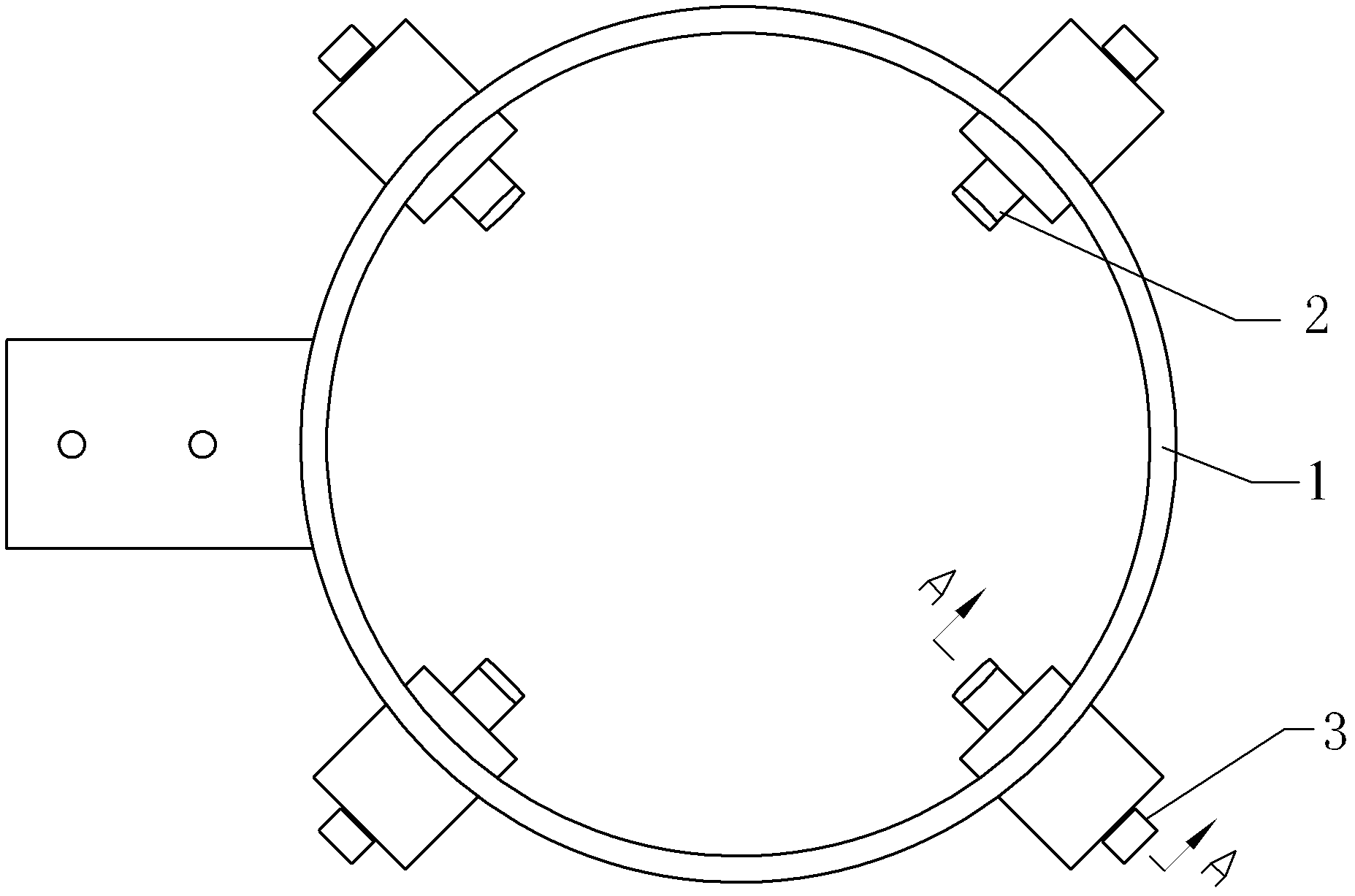

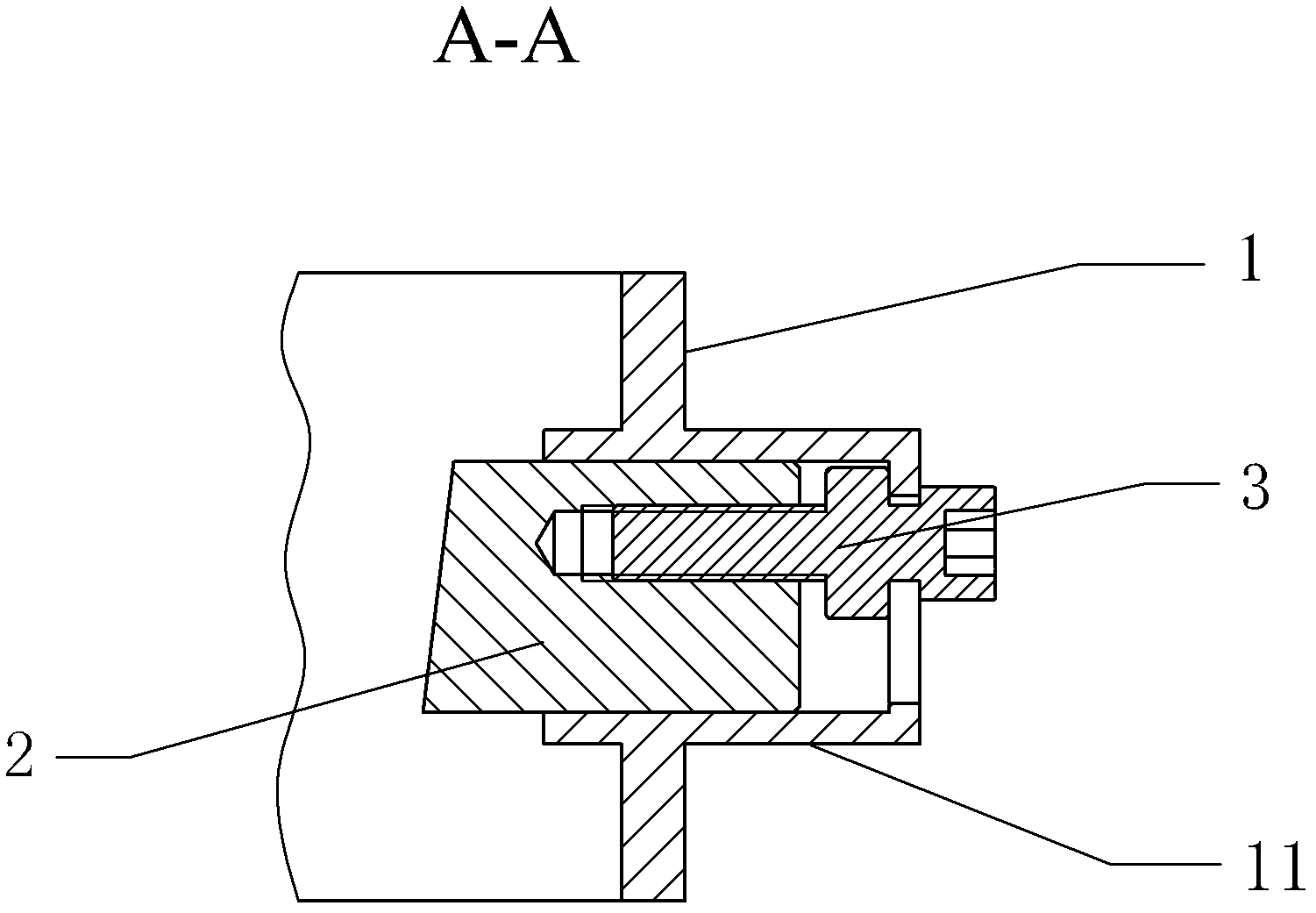

Adjustable ladle fixing device

InactiveCN102615275AEasy to adjustIncrease the support surfaceMelt-holding vesselsFixed frameBarrel Shaped

The invention discloses an adjustable ladle fixing device, which comprises a fixed frame, a support bar and an adjustable screw. The adjustable ladle fixing device is characterized in that a holding end and at least two groups of installation holes are arranged on the fixed frame, each installation hole comprises a barrel-shaped outer wall fixed on the fixed frame and a limiting wall provided with a through hole and fixed at the outer end of the barrel-shaped outer wall, a long hole for the adjustable screw to penetrate is further arranged on the limiting wall with the through hole, and a thread hole matched with the adjustable screw is arranged on the support bar which is fixed in the installation holes of the fixed frame through the adjustable screw. The adjustable ladle fixing device adopts the screw to control support ends to radially move along a ladle frame, can rapidly change support diameter, can adapt to ladles in different standards, and enlarges operation scope.

Owner:DALIAN MARITIME UNIVERSITY

Protection structure of LED driving power supply

InactiveCN107613695AEasy to disassembleImprove the protective effectCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringComputer fan

Owner:惠勇

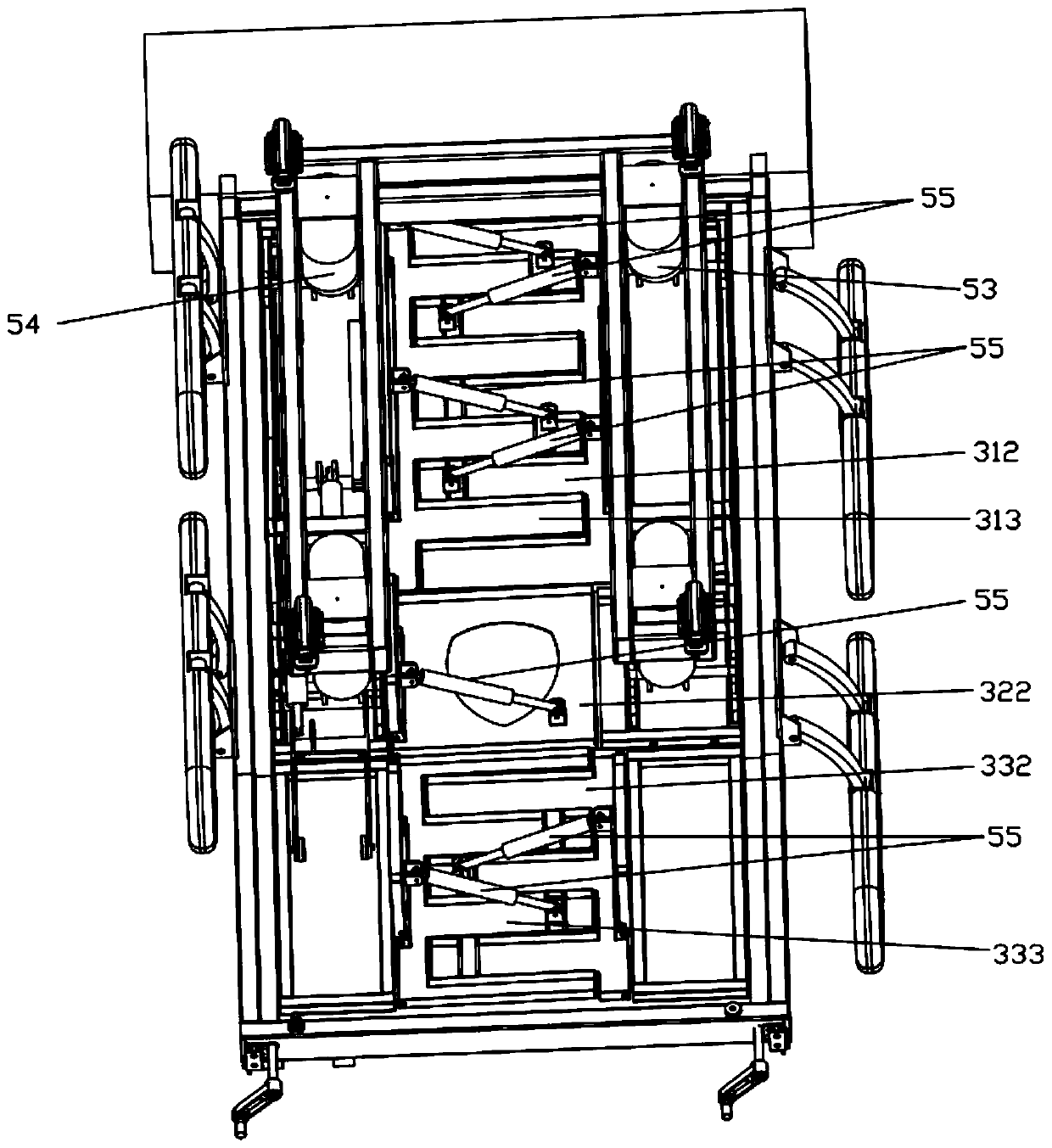

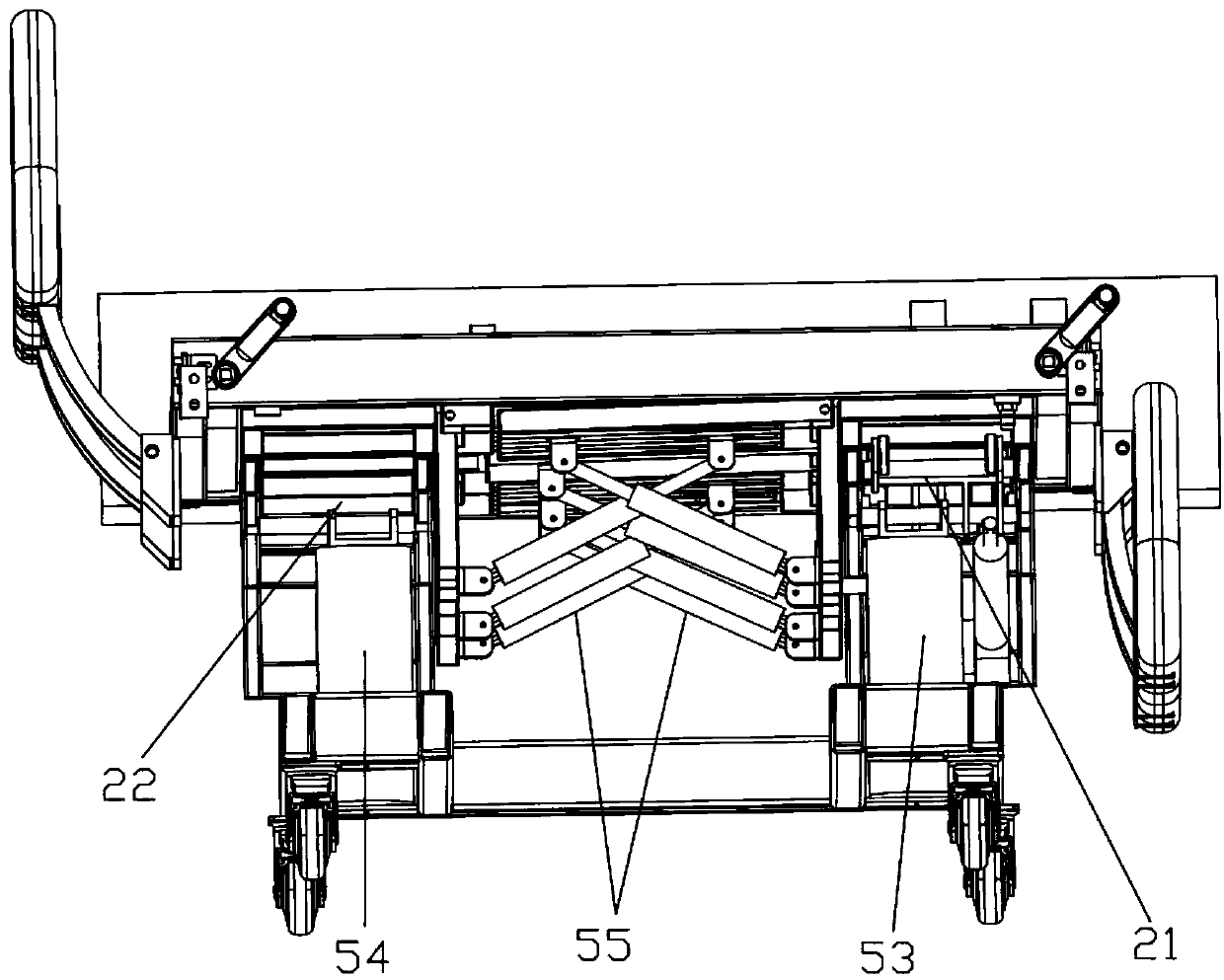

Comb tooth type nursing bed with bathing function

The invention discloses a comb tooth type nursing bed with a bathing function, which comprises a bed body support, a bed board frame arranged on the bed body support, a combined bed board arranged onthe bed board frame, a bathing mechanism and a driving device for driving the combined bed board to move; the combined bed plate comprises a back plate, a hip plate and a leg plate which are sequentially arranged in the length direction. According to the invention, a comb tooth type bed surface structure is adopted, so that a user does not feel uncomfortable in a lying and resting process; according to the invention, the comb tooth type bed surfaces on the left side and right side are matched with an isolation plate, so that the separation of people from the bed surfaces is achieved, the actions of moving, lifting, holding and the like in prior bathing process are omitted, the labor intensity of a nursing worker is greatly reduced, and the risk in the nursing process is also reduced; according to the invention, turning over is finished by utilizing the height difference of the fixed boards at the two sides through the comb tooth type bed surface; in the turning over mode, the supporting surface of the back is relatively large; the safety feeling and the comfort feeling of a user are better; and the distance between the comb teeth can well release back pressure, so that bedsore is prevented.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com