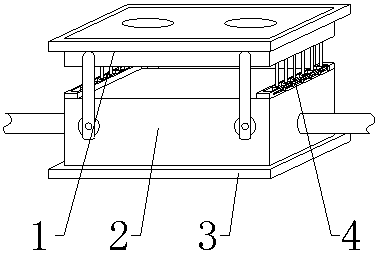

Protection structure of LED driving power supply

A technology of LED drive and protective structure, applied in cooling/ventilation/heating transformation, chassis/cabinet/drawer parts, etc. The effect of supporting effect, improving service life and improving protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

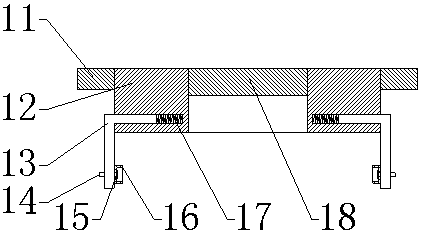

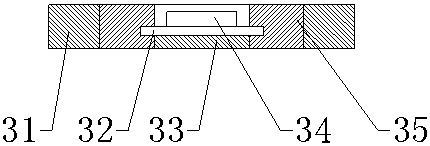

specific Embodiment approach

[0027]Specific implementation method: when in use, the user holds the clamping rod 13 and moves outward, the outward movement of the clamping rod 13 drives the suction cup 16 to move outward, and at the same time the outward movement of the clamping rod 13 drives the tension spring 17 to stretch deformation, and then the user places the suction cup 16 on the front and rear sides of the power supply body 2, and then the user releases the clamping rod 13, and then drives the suction cup 16 to move inward under the action of the tension spring 17 recovering the deformation, and the suction cup 16 Moving inward can achieve adsorption with the power supply body 2, and then the user starts the cooling fan 18, and the cooling fan 18 works to generate air flow, and then realizes blowing the power supply main body 2, thereby realizing heat dissipation. When it needs to be disassembled, the user holds the Hold the push rod 14 and move inward, and the inward movement of the push rod 14 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com