Patents

Literature

13341results about How to "Large capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

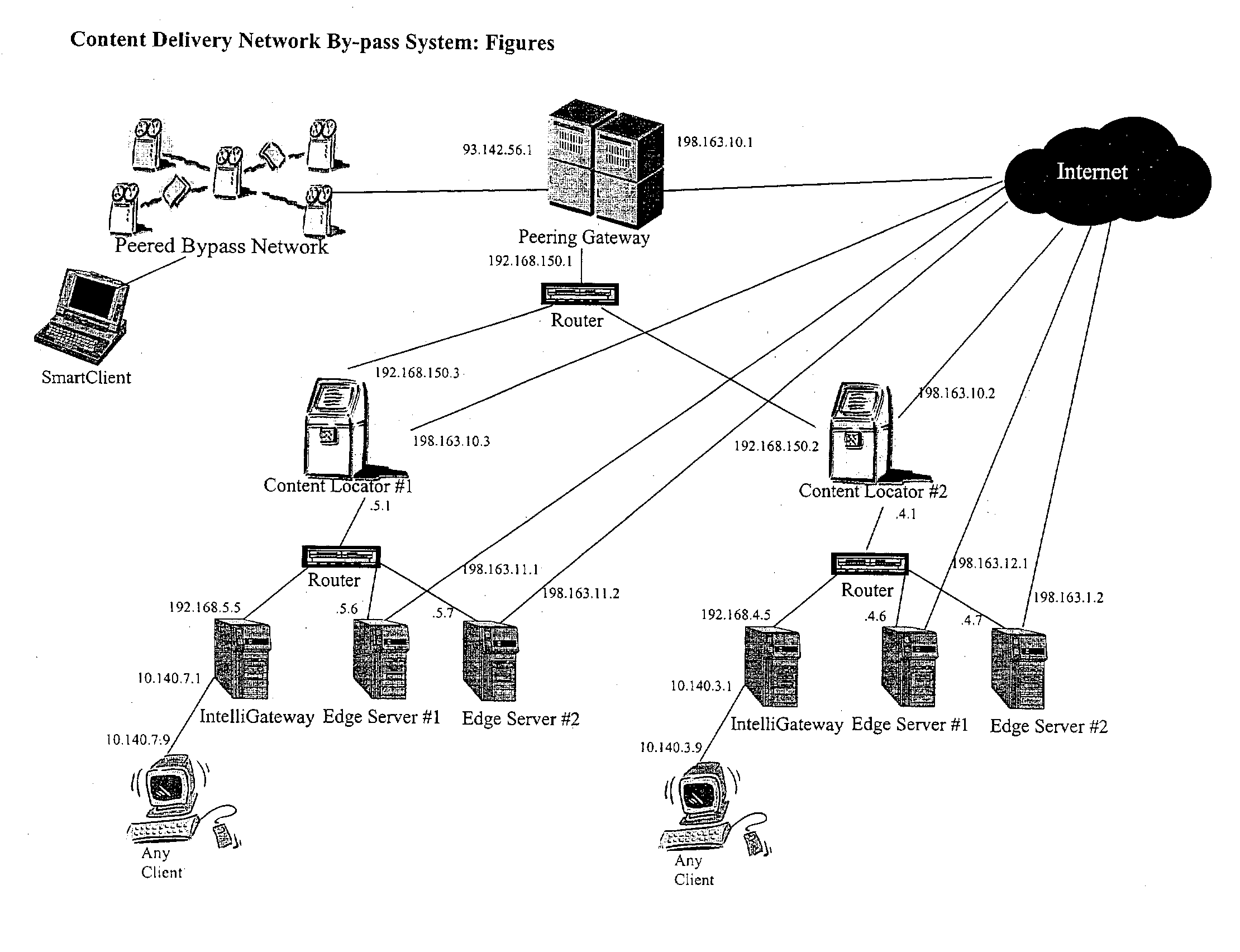

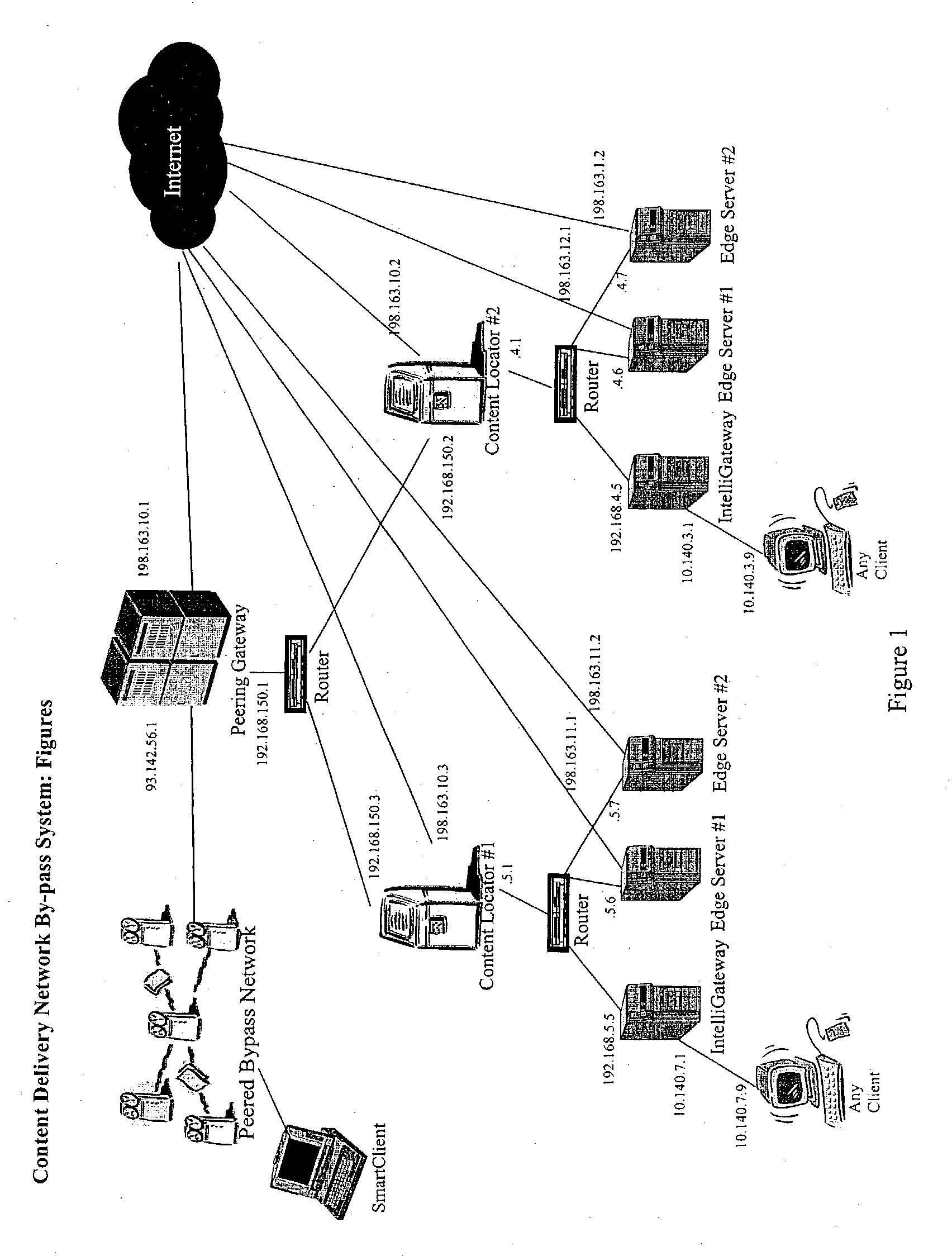

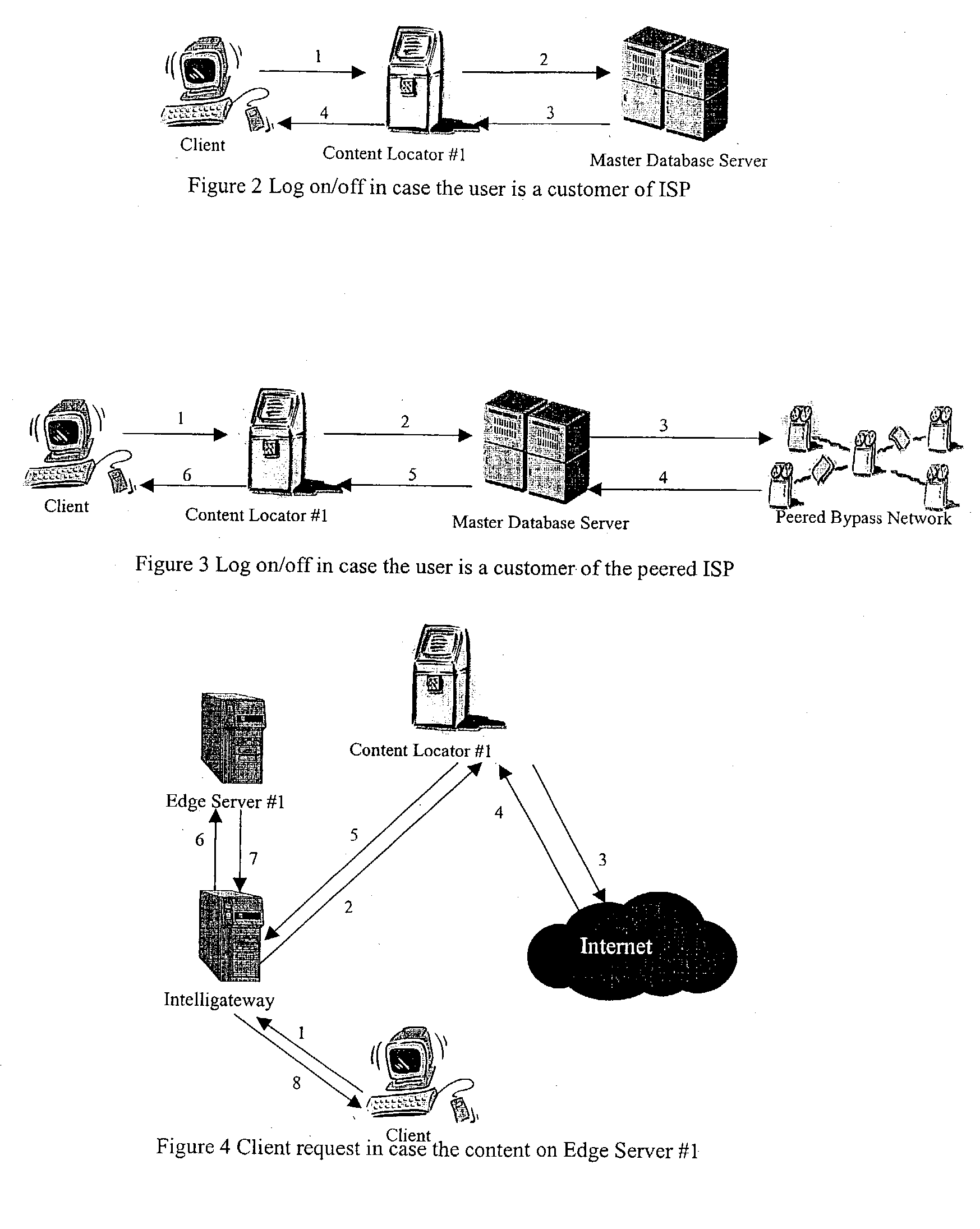

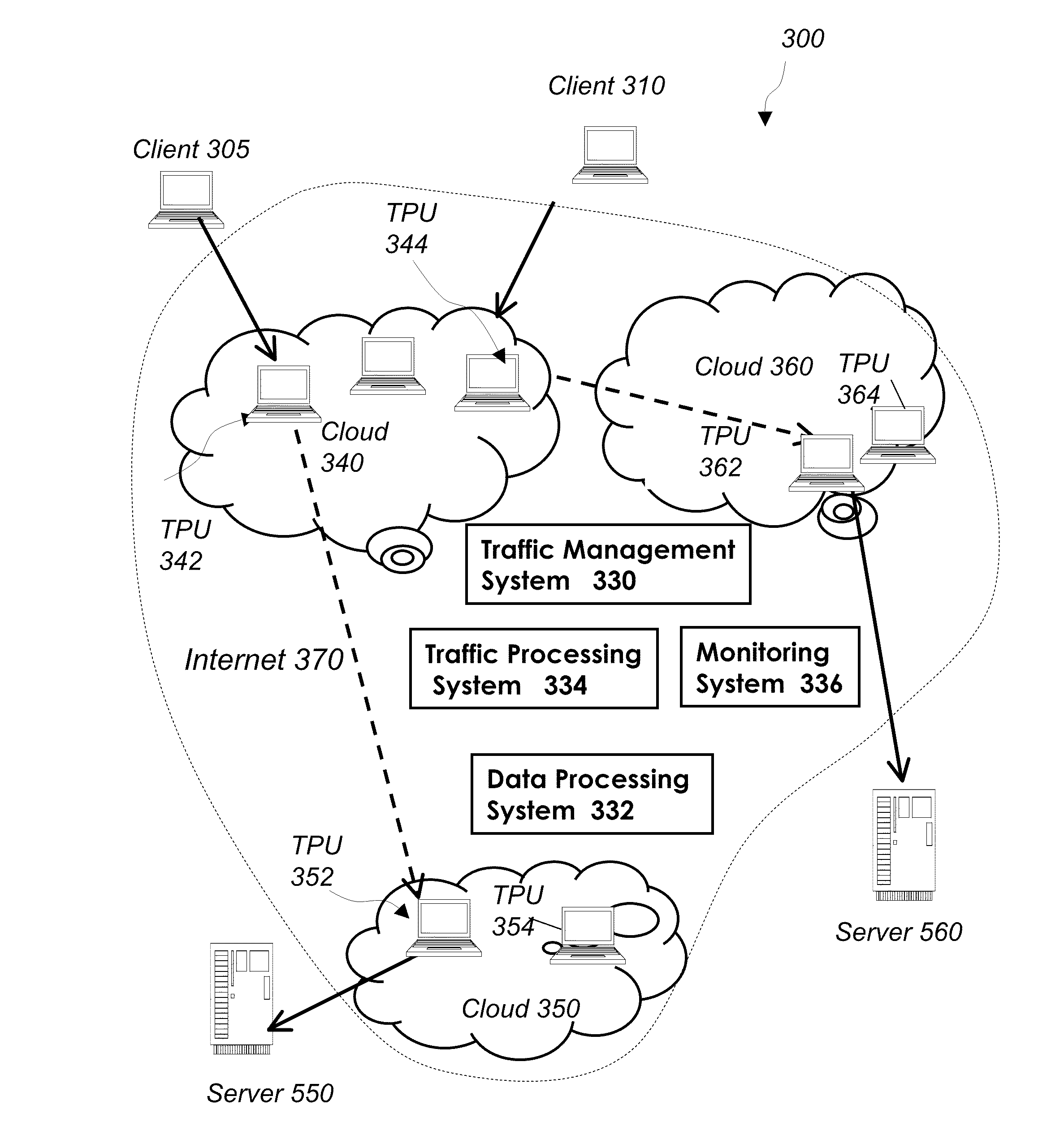

Content delivery network by-pass system

InactiveUS20030174648A1Increase capacityIncrease in sizeError preventionTransmission systemsWeb sitePeering

The bypass network is designed to provide fast access and high quality streaming media services anywhere anytime. There are five major components including Peering Gateway, Content Locator, Edge Server, Gateway and Client. The whole bypass network is divided into number of self-managed sub-networks, which are referred as local networks in this document. Each local network contains Edge Servers, gateways, and a Content Locator. The Edge Servers serve as cache storage and streaming servers for the local network. The gateways provide a connection point for the client computers. Each local network is managed by a Content Locator. The Content Locator handles all client requests by communicating with the Peering Gateway and actual web sites, and makes the content available on local Edge Servers. The Content Locator also balances the load on each Edge Server by monitoring the workload on them. One embodiment is designed for home users whose home machine does not move around frequently. A second embodiment is designed for business users who travel around very often where the laptops would self-configure as a client of the network.

Owner:TELECOMM RES LAB

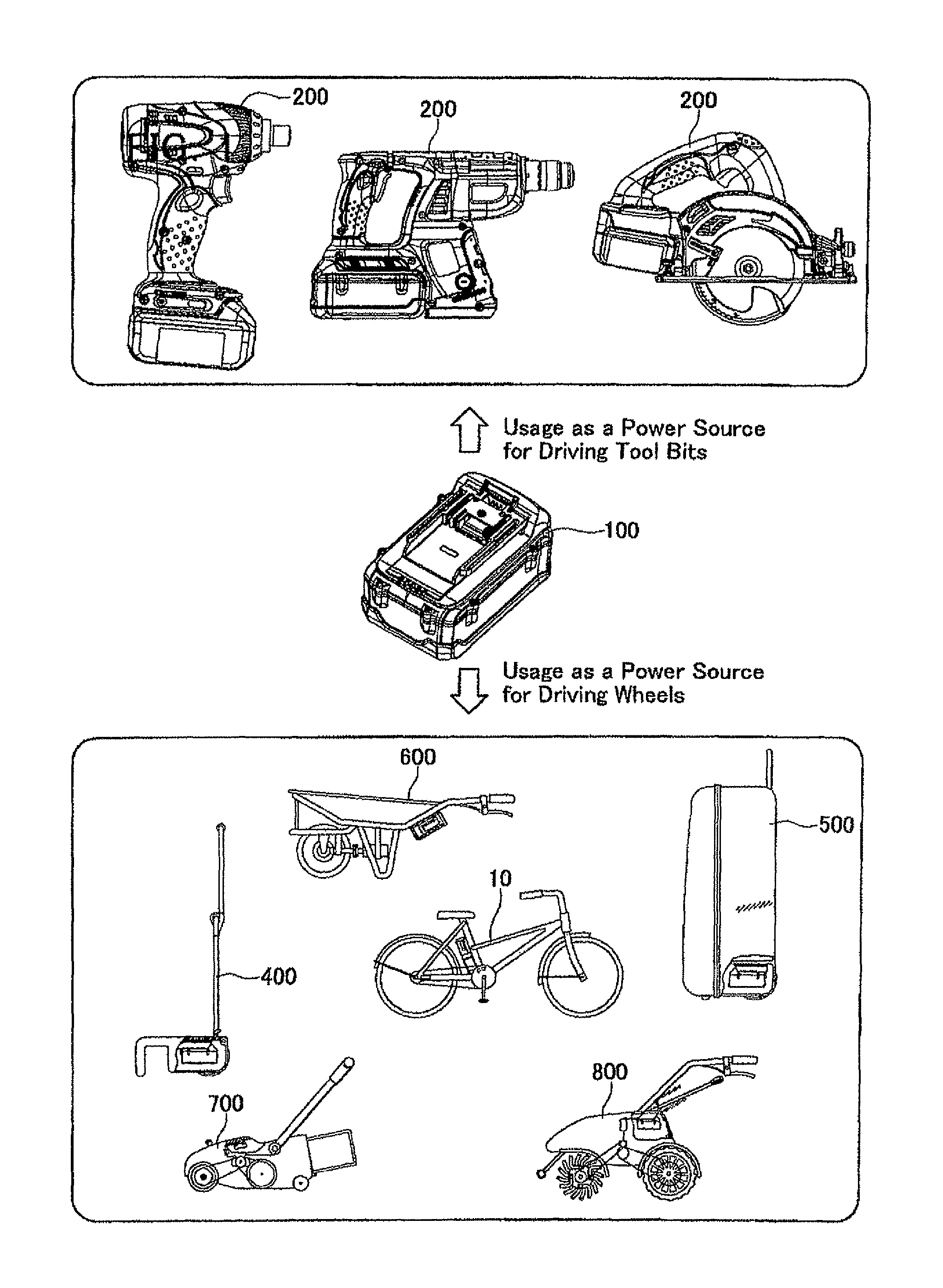

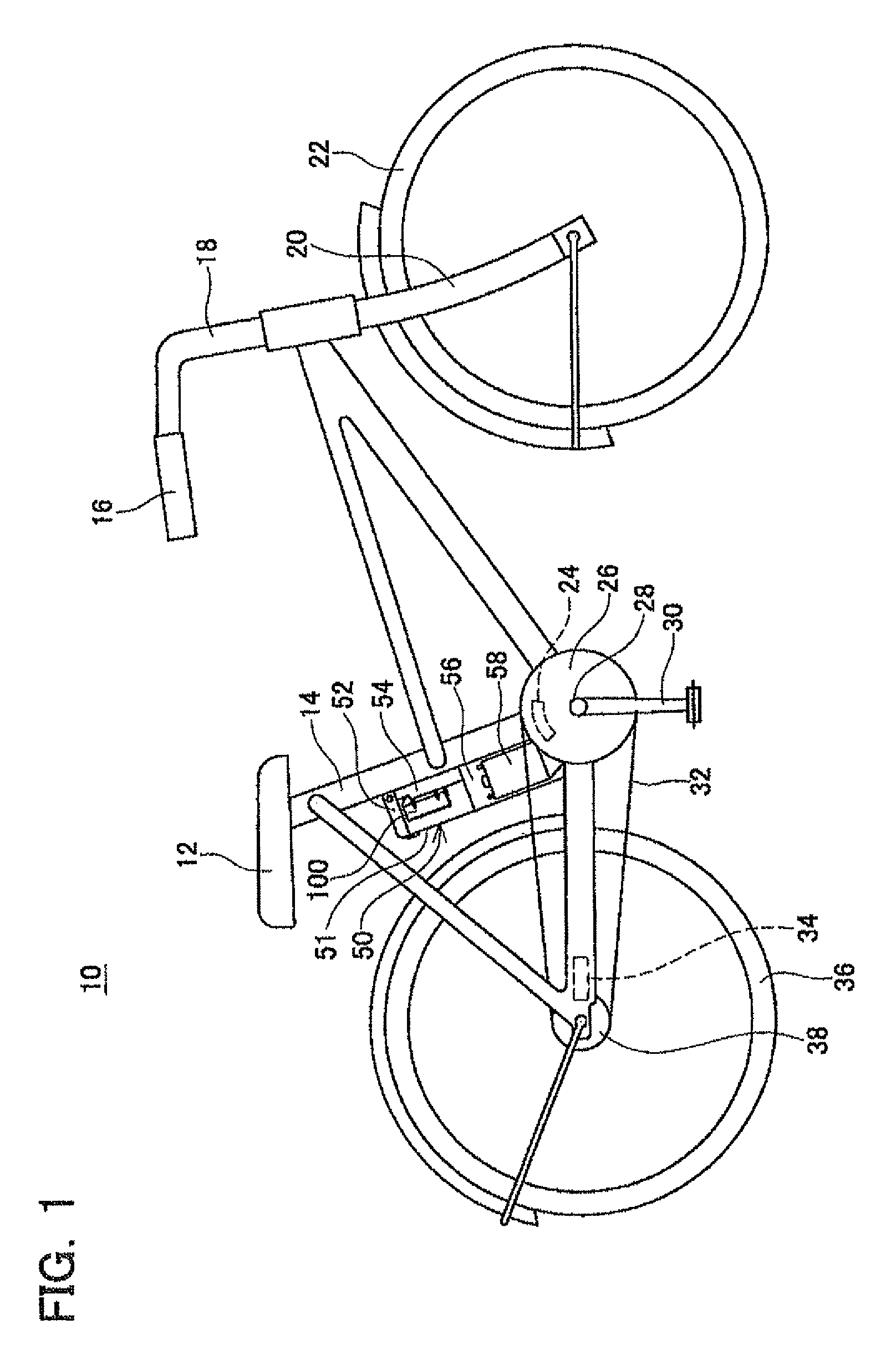

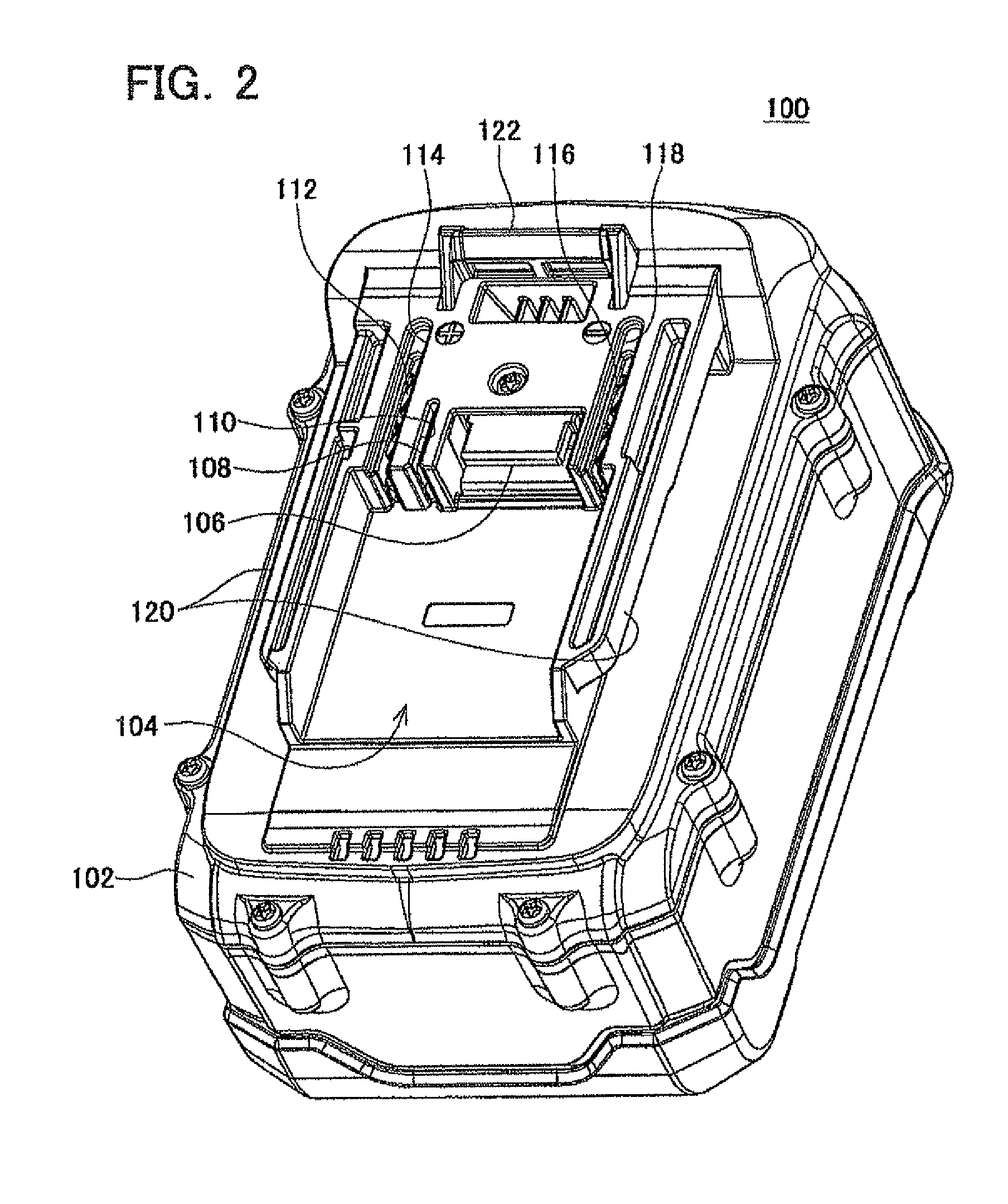

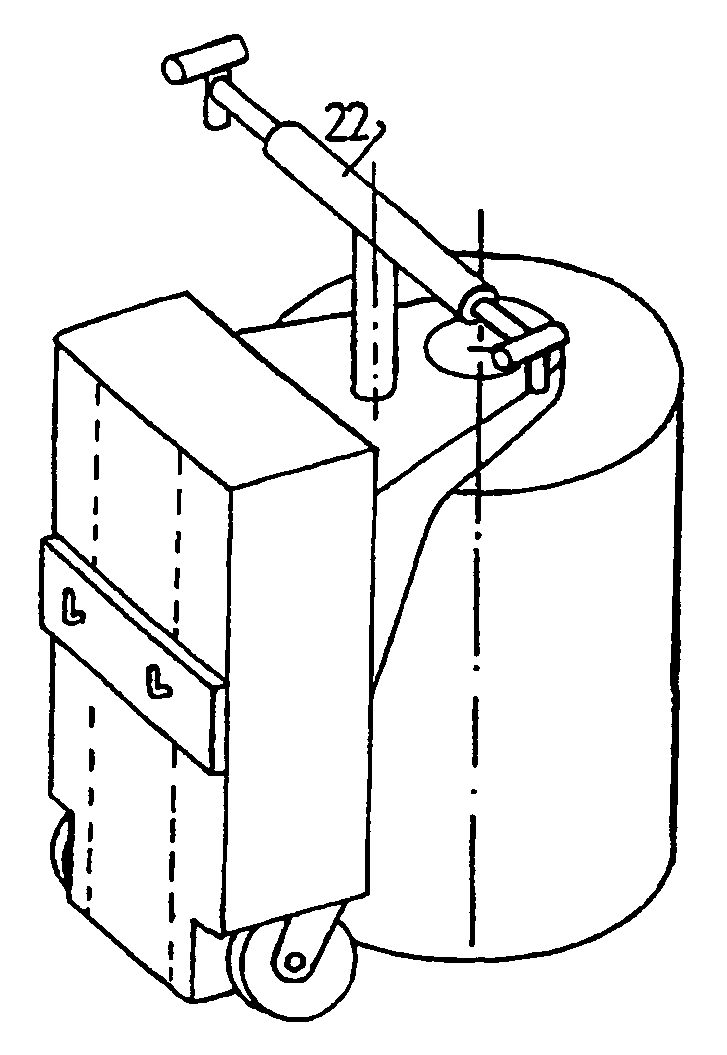

Electric wheeled apparatus

ActiveUS8851215B2Increase the output voltageLarge capacityMowersTilling equipmentsElectricityElectric power system

Owner:MAKITA CORP

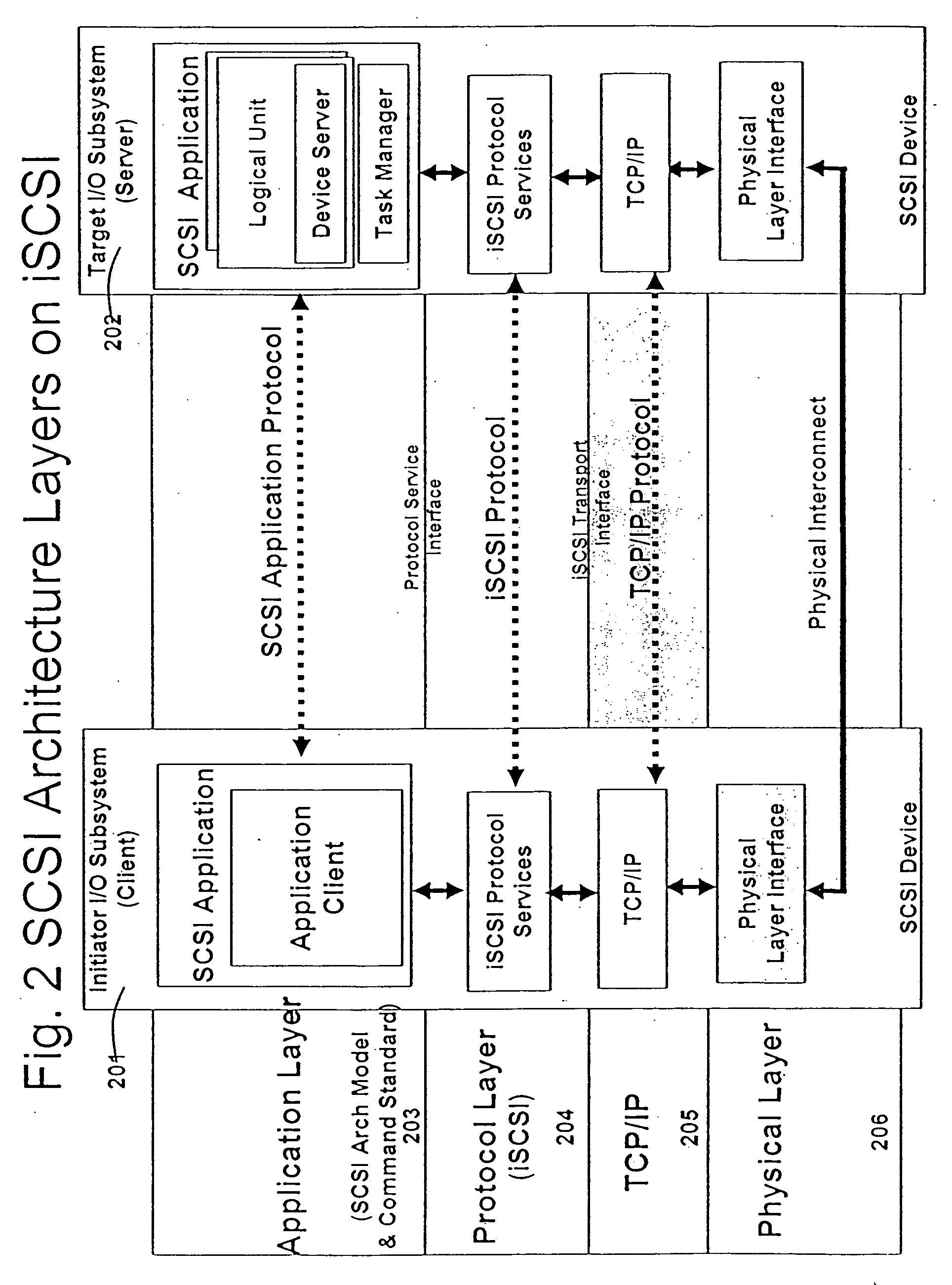

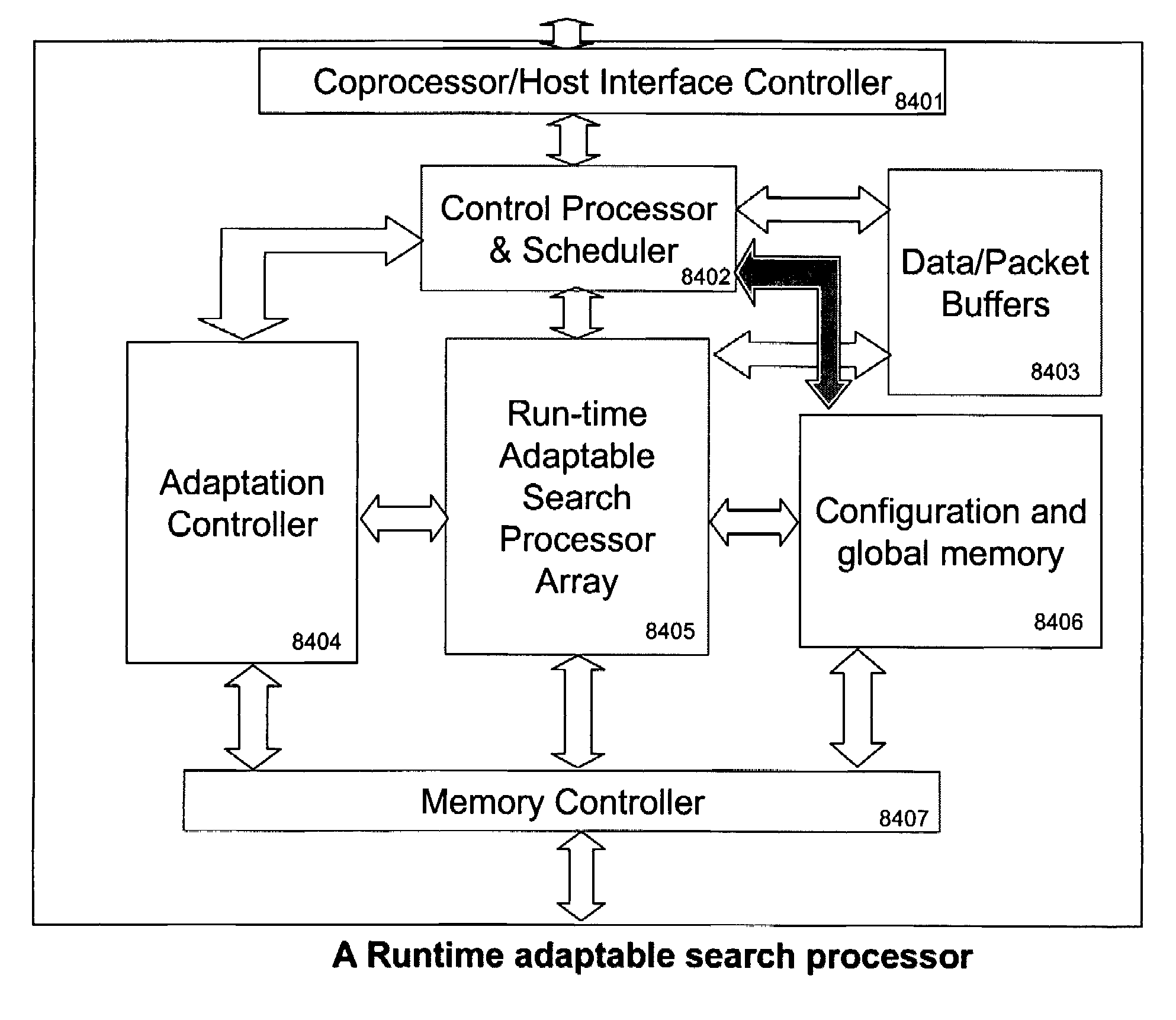

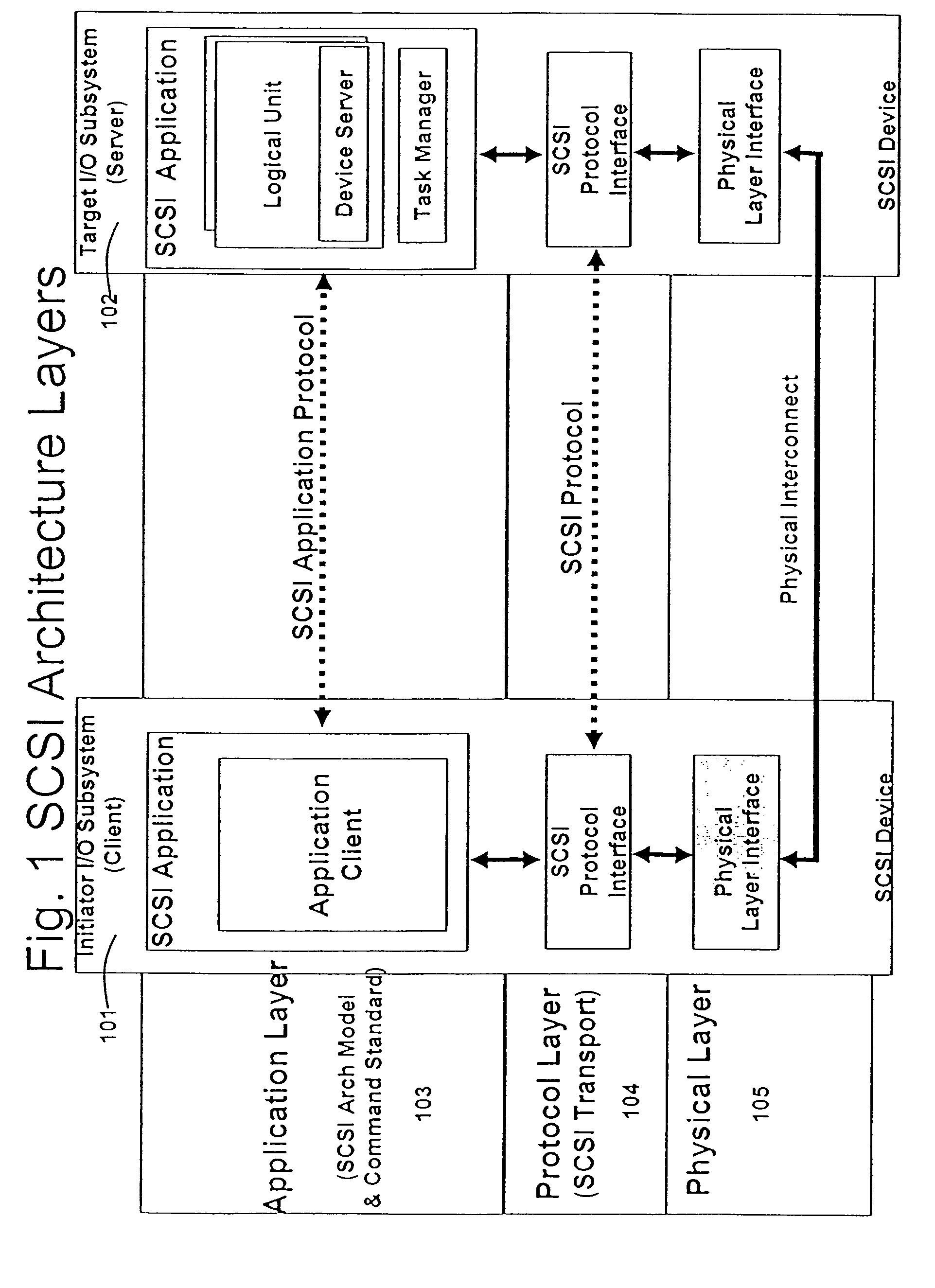

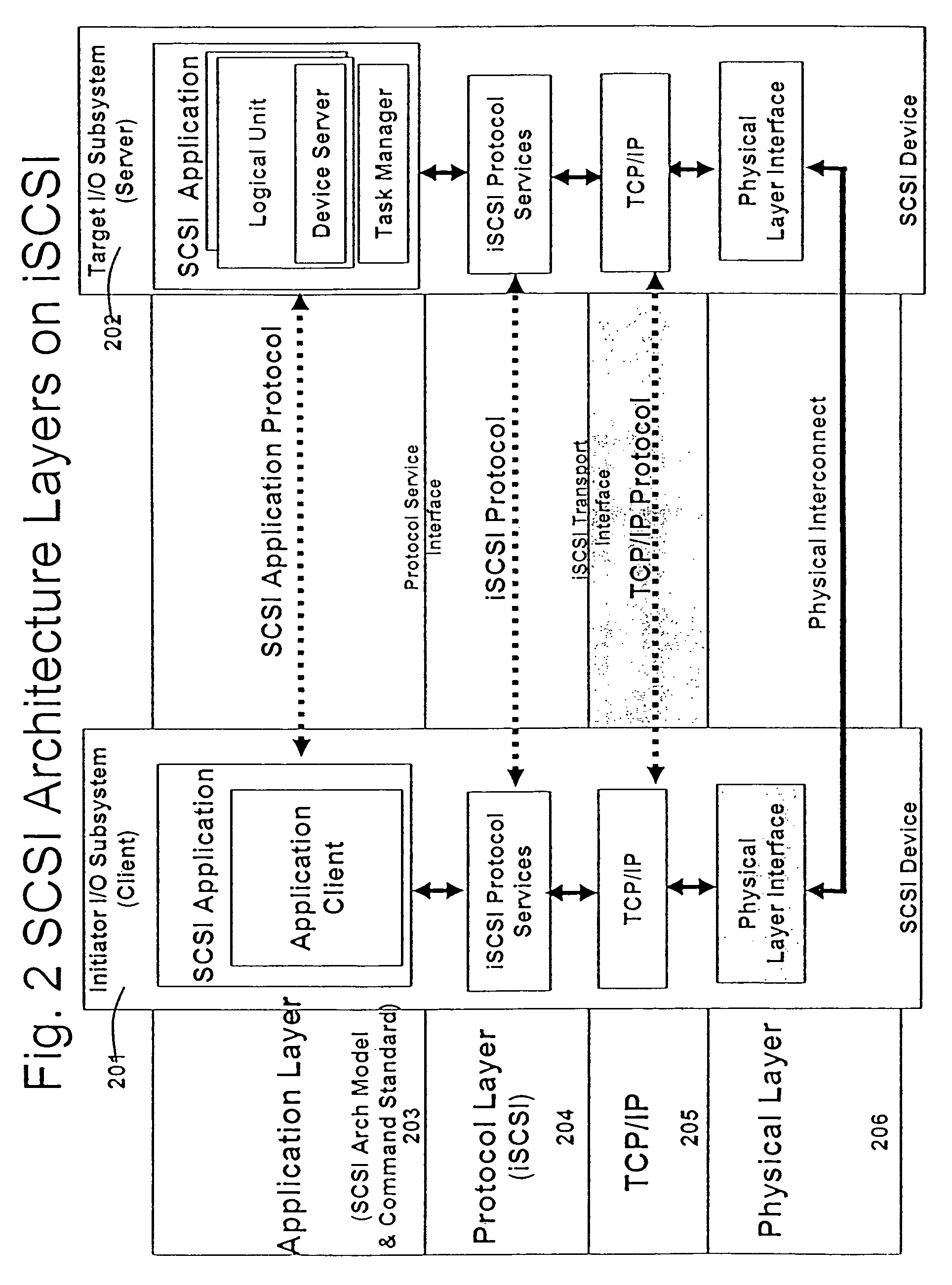

Runtime adaptable search processor

ActiveUS20060136570A1Reduce stacking processImproving host CPU performanceWeb data indexingMultiple digital computer combinationsData packInternal memory

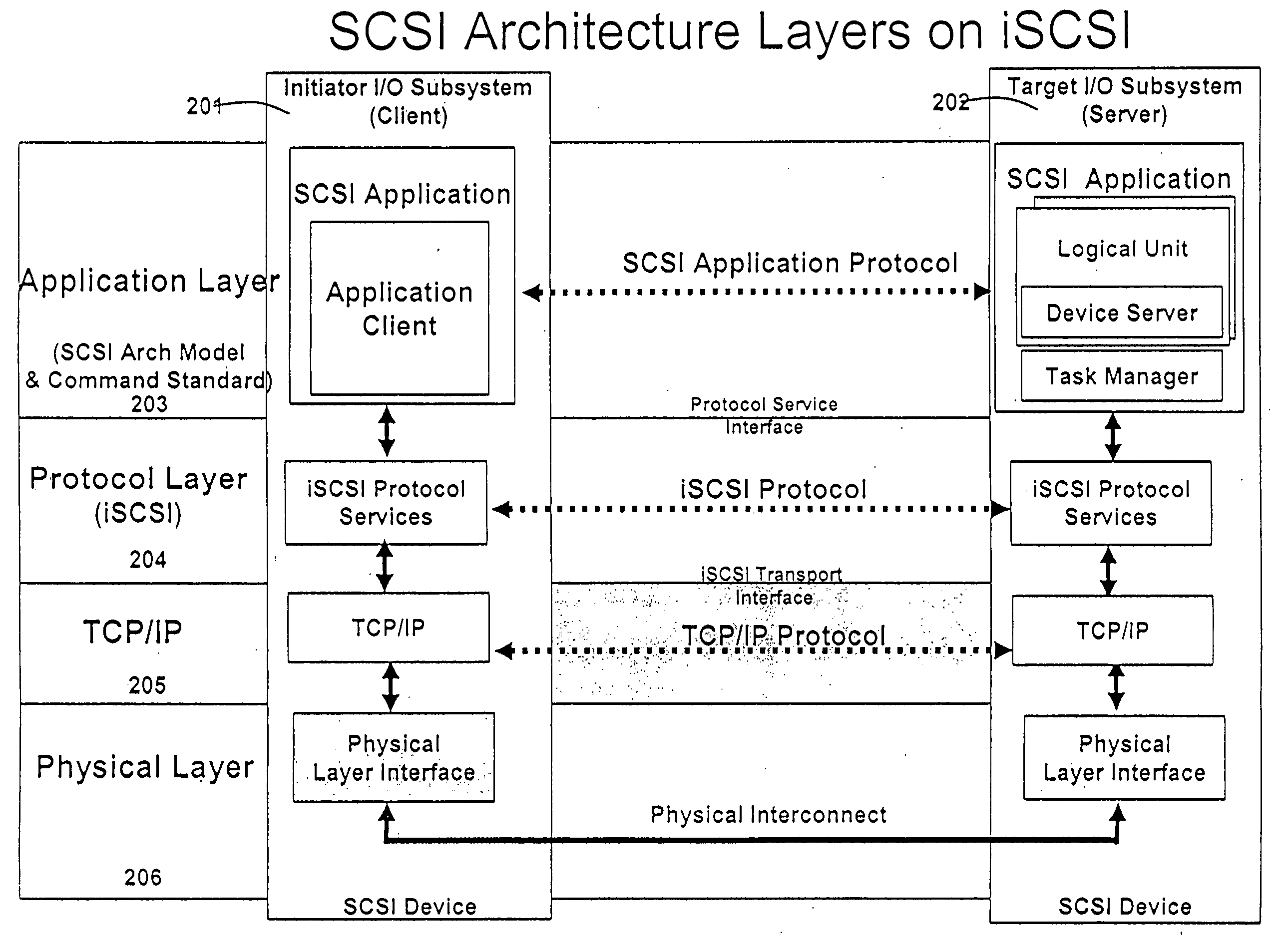

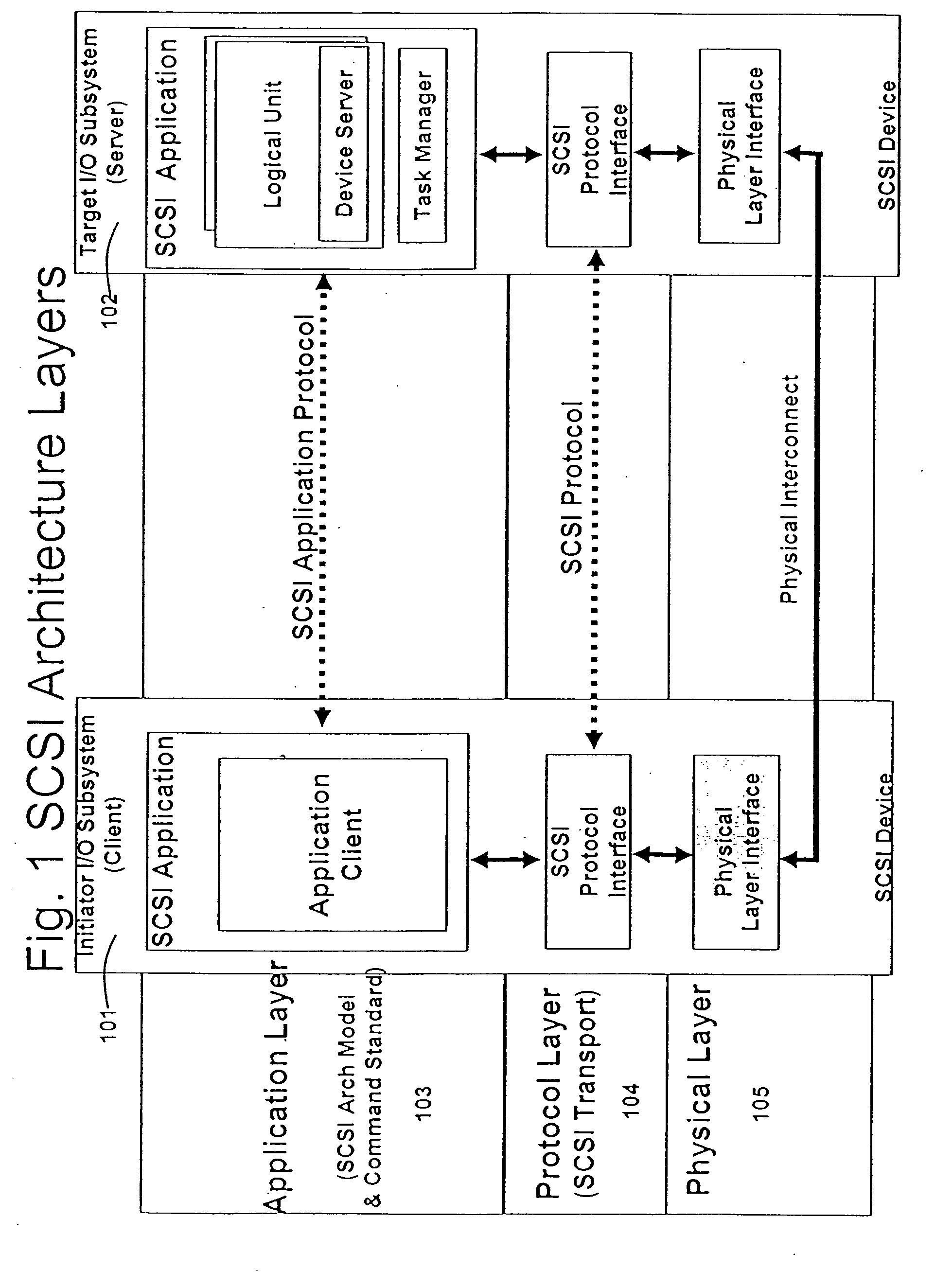

A runtime adaptable search processor is disclosed. The search processor provides high speed content search capability to meet the performance need of network line rates growing to 1 Gbps, 10 Gbps and higher. he search processor provides a unique combination of NFA and DFA based search engines that can process incoming data in parallel to perform the search against the specific rules programmed in the search engines. The processor architecture also provides capabilities to transport and process Internet Protocol (IP) packets from Layer 2 through transport protocol layer and may also provide packet inspection through Layer 7. Further, a runtime adaptable processor is coupled to the protocol processing hardware and may be dynamically adapted to perform hardware tasks as per the needs of the network traffic being sent or received and / or the policies programmed or services or applications being supported. A set of engines may perform pass-through packet classification, policy processing and / or security processing enabling packet streaming through the architecture at nearly the full line rate. A high performance content search and rules processing security processor is disclosed which may be used for application layer and network layer security. scheduler schedules packets to packet processors for processing. An internal memory or local session database cache stores a session information database for a certain number of active sessions. The session information that is not in the internal memory is stored and retrieved to / from an additional memory. An application running on an initiator or target can in certain instantiations register a region of memory, which is made available to its peer(s) for access directly without substantial host intervention through RDMA data transfer. A security system is also disclosed that enables a new way of implementing security capabilities inside enterprise networks in a distributed manner using a protocol processing hardware with appropriate security features.

Owner:MEMORY ACCESS TECH LLC

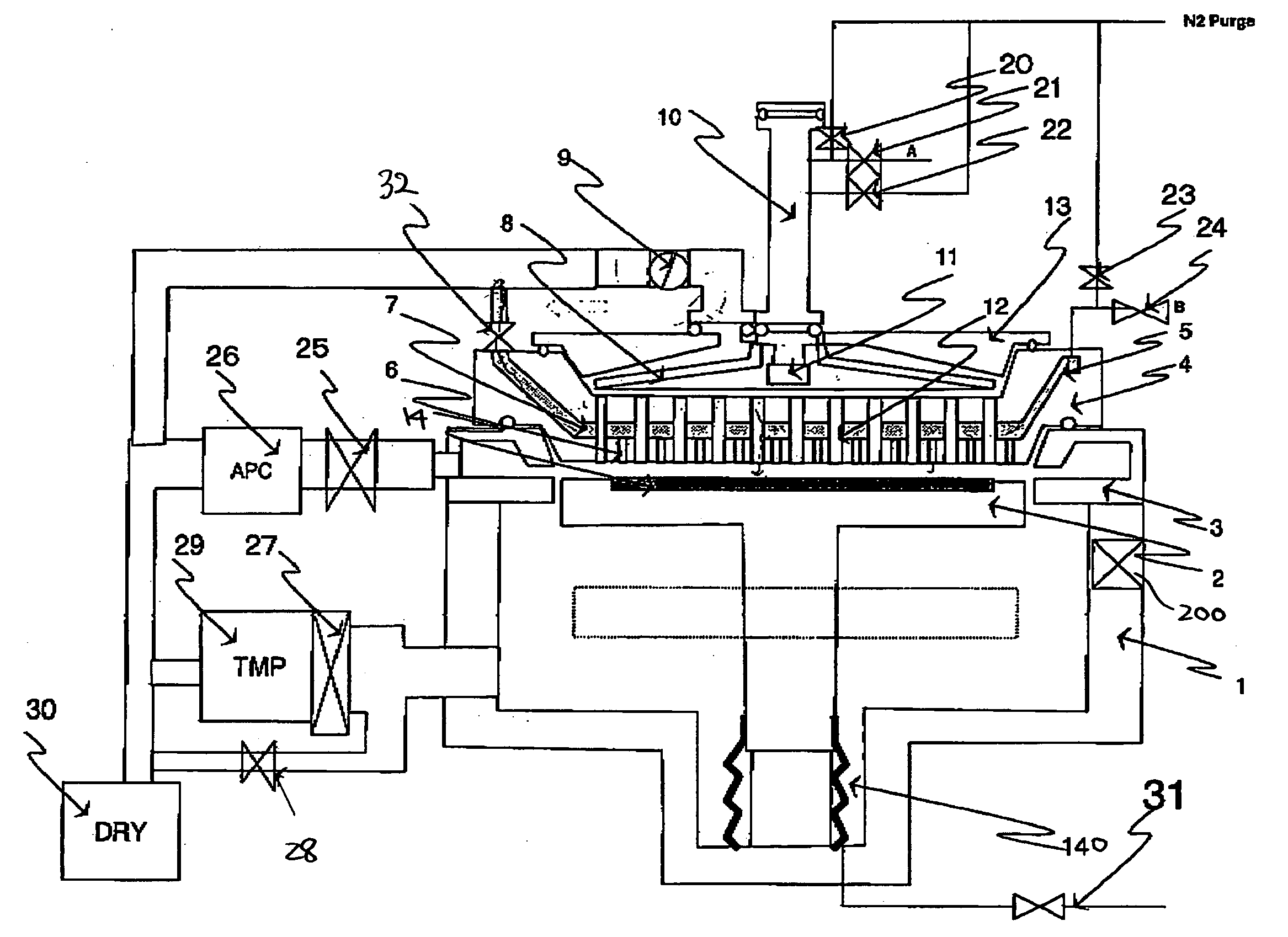

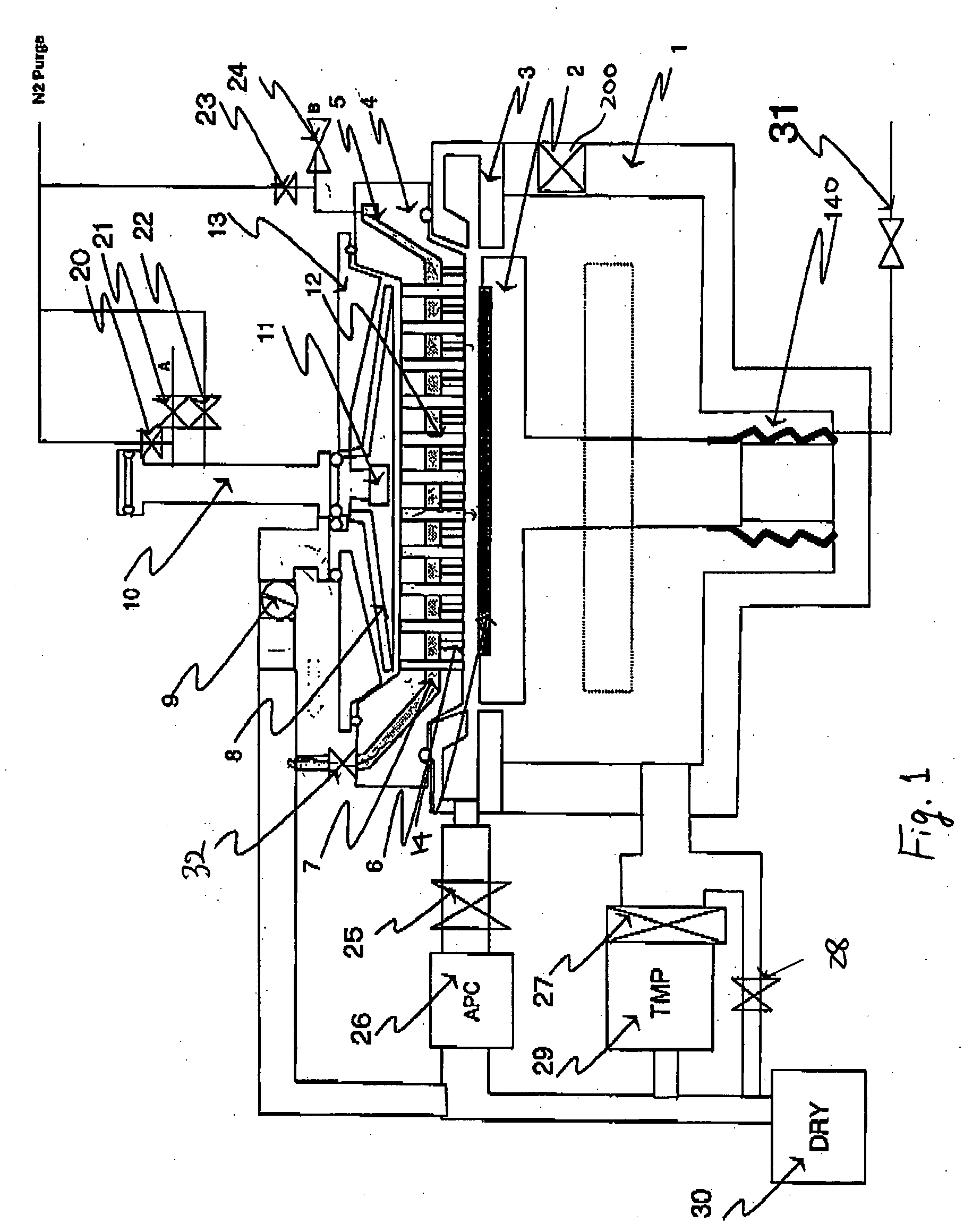

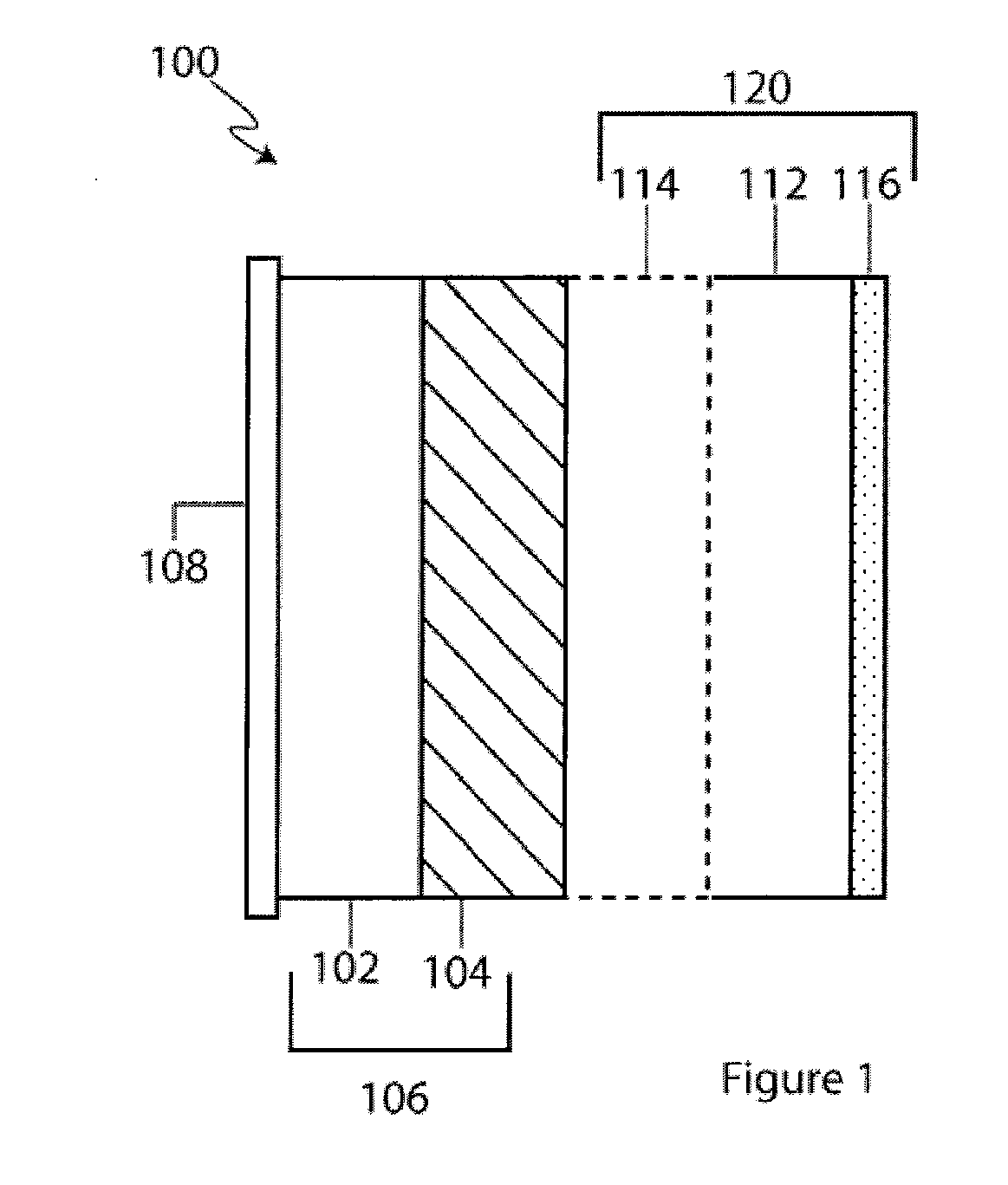

Thin-film deposition apparatus

ActiveUS20050229848A1Hinder reactionAvoid reactionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

A gas-feeding apparatus configured to be connected to an evacuatable reaction chamber includes a gas-distribution head for introducing gases into the chamber through a head surface. The gas-feeding head includes a first section for discharging a gas through the head surface toward a susceptor and a second section for discharging a gas through the head surface toward the susceptor. The first and the second sections are isolated from each other in the gas-distribution head, at least one of which section is coupled to an exhaust system for purging therefrom a gas present in the corresponding section without passing through the head surface.

Owner:ASM JAPAN

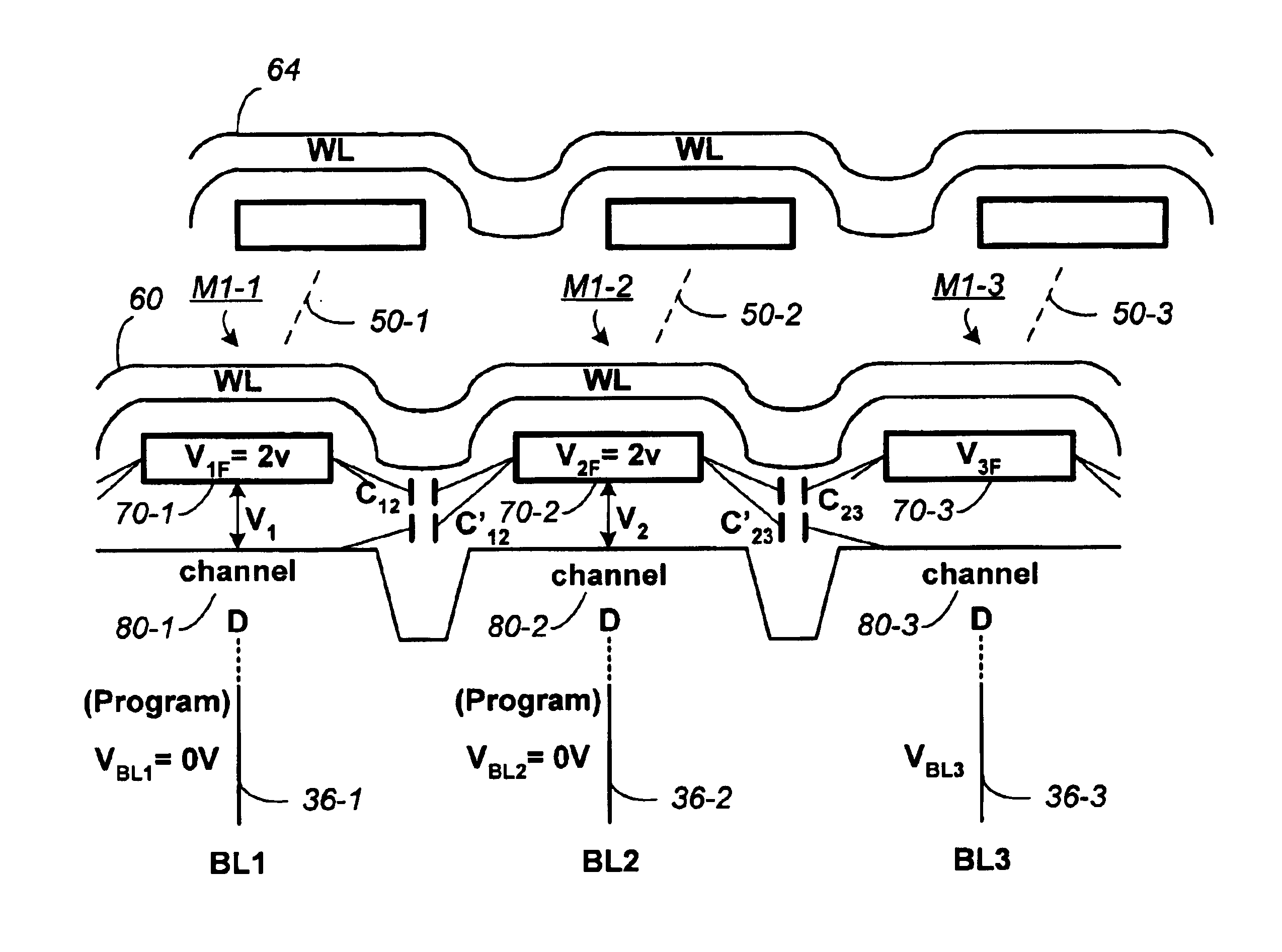

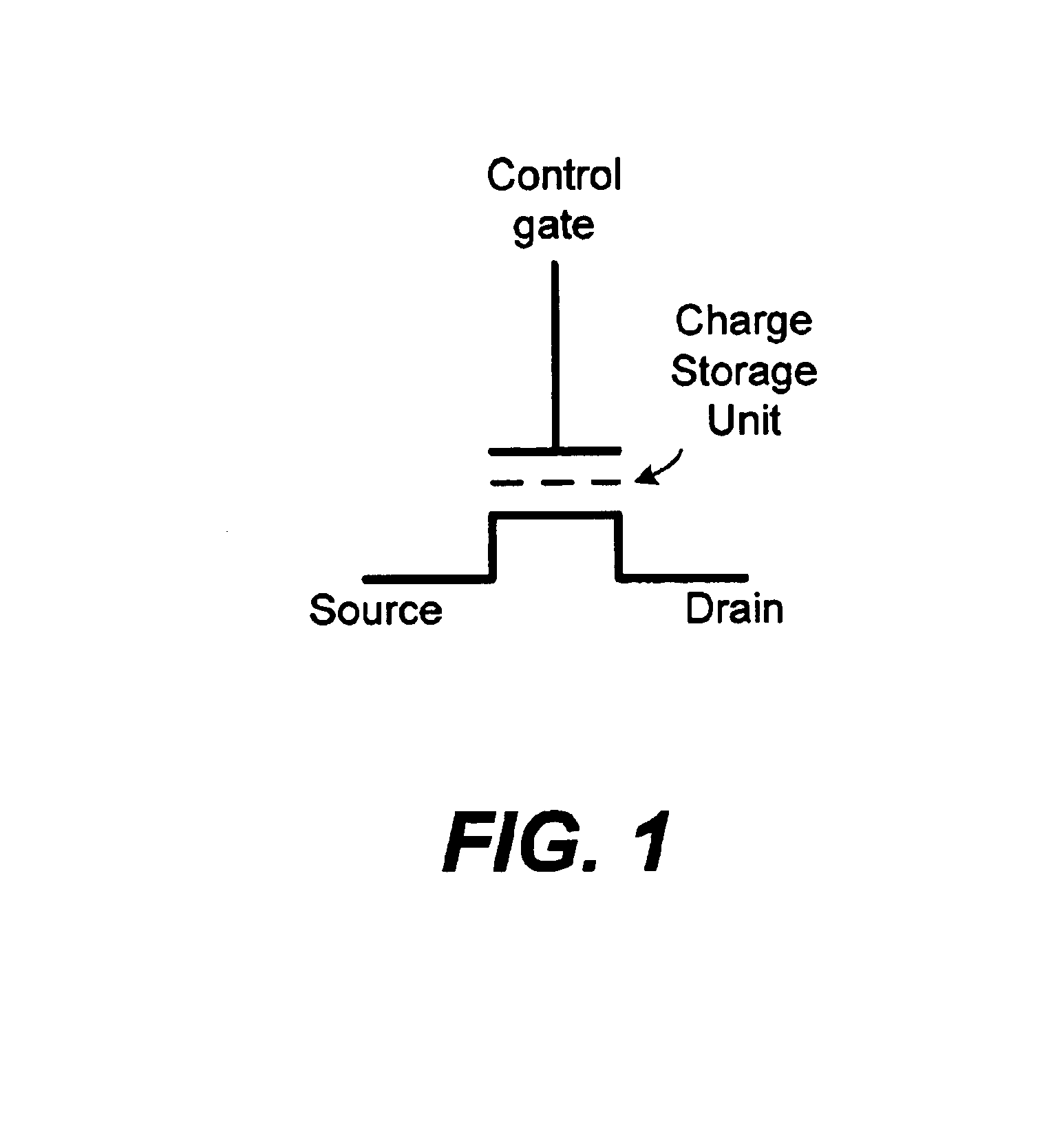

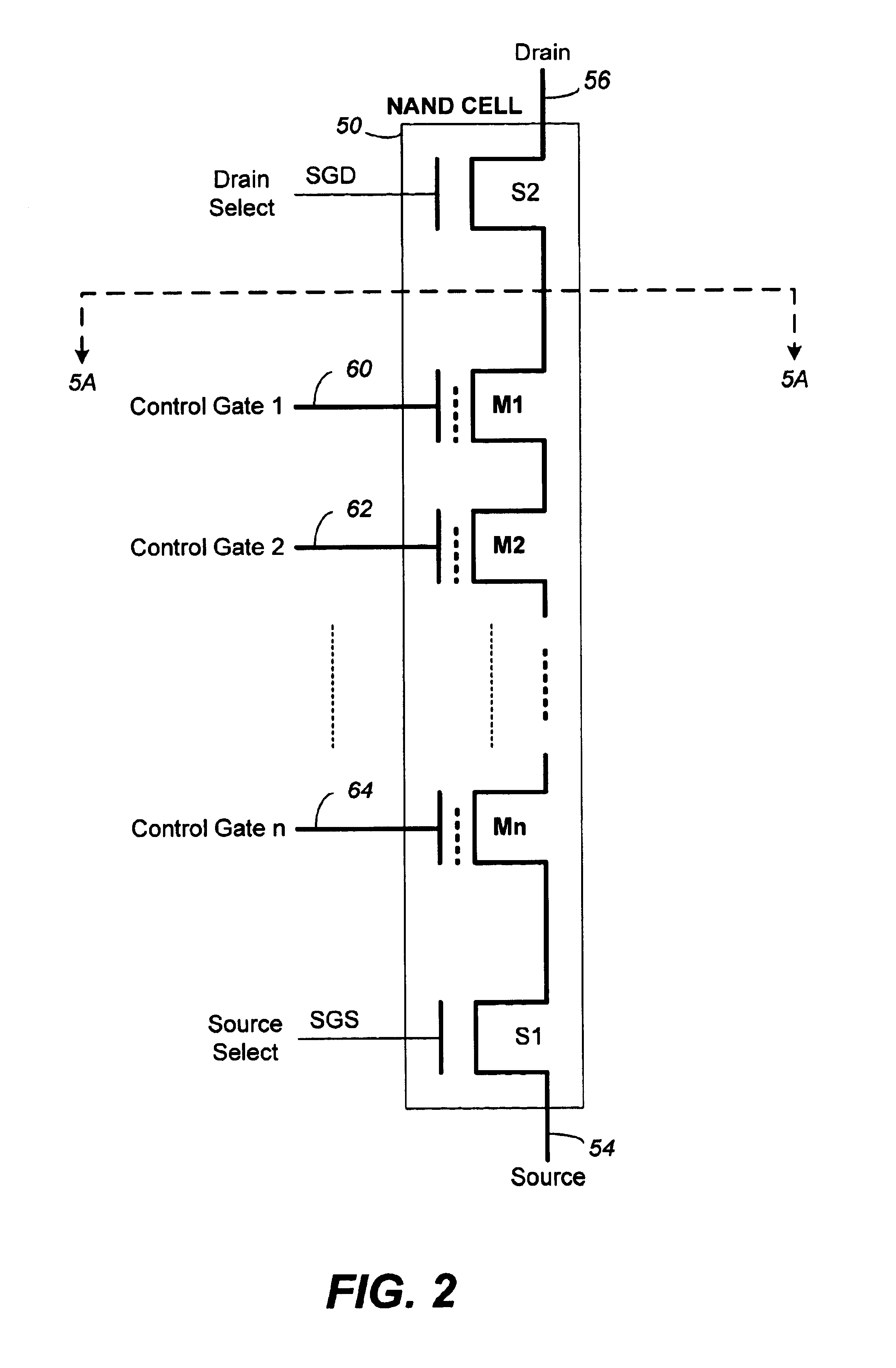

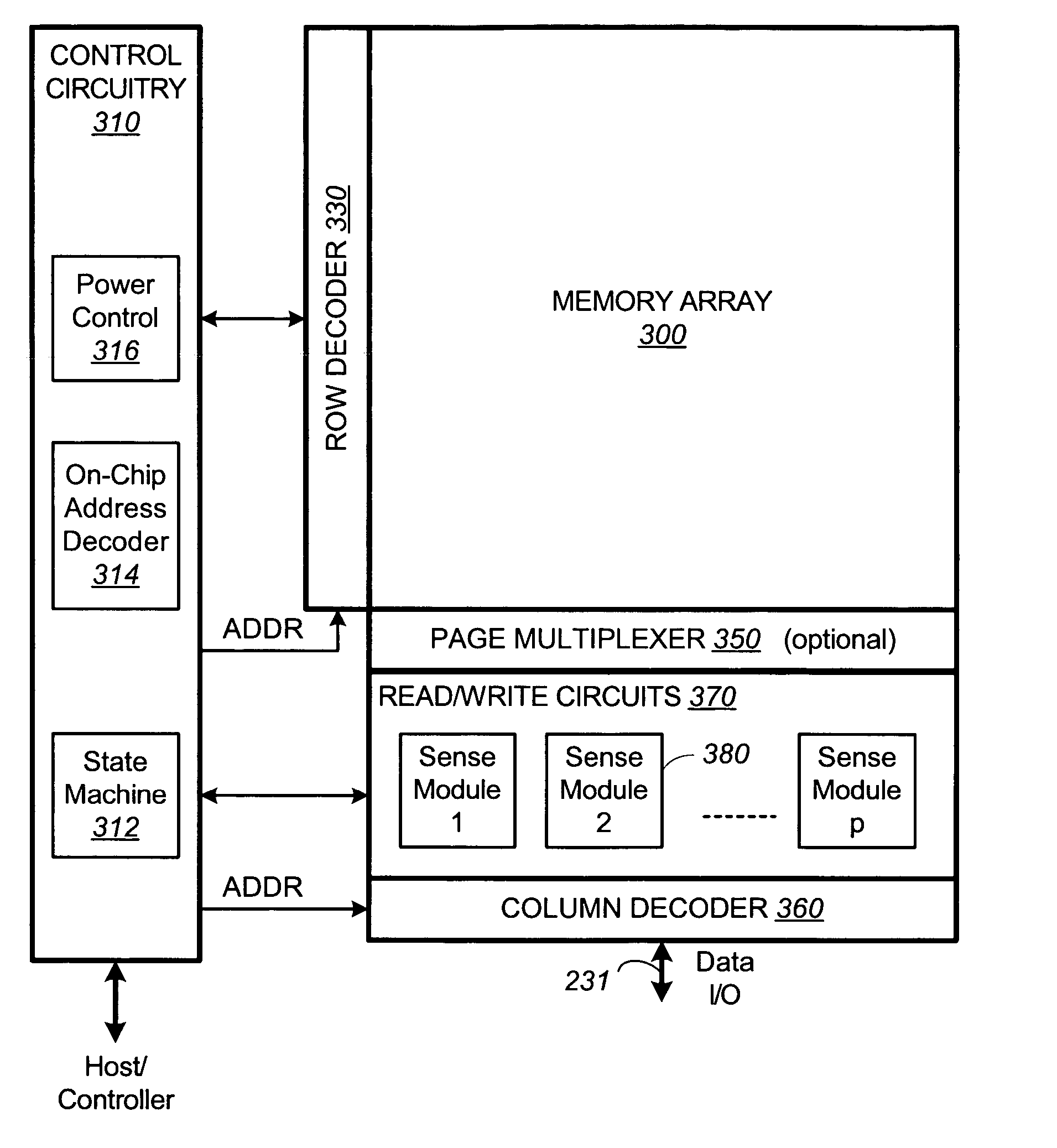

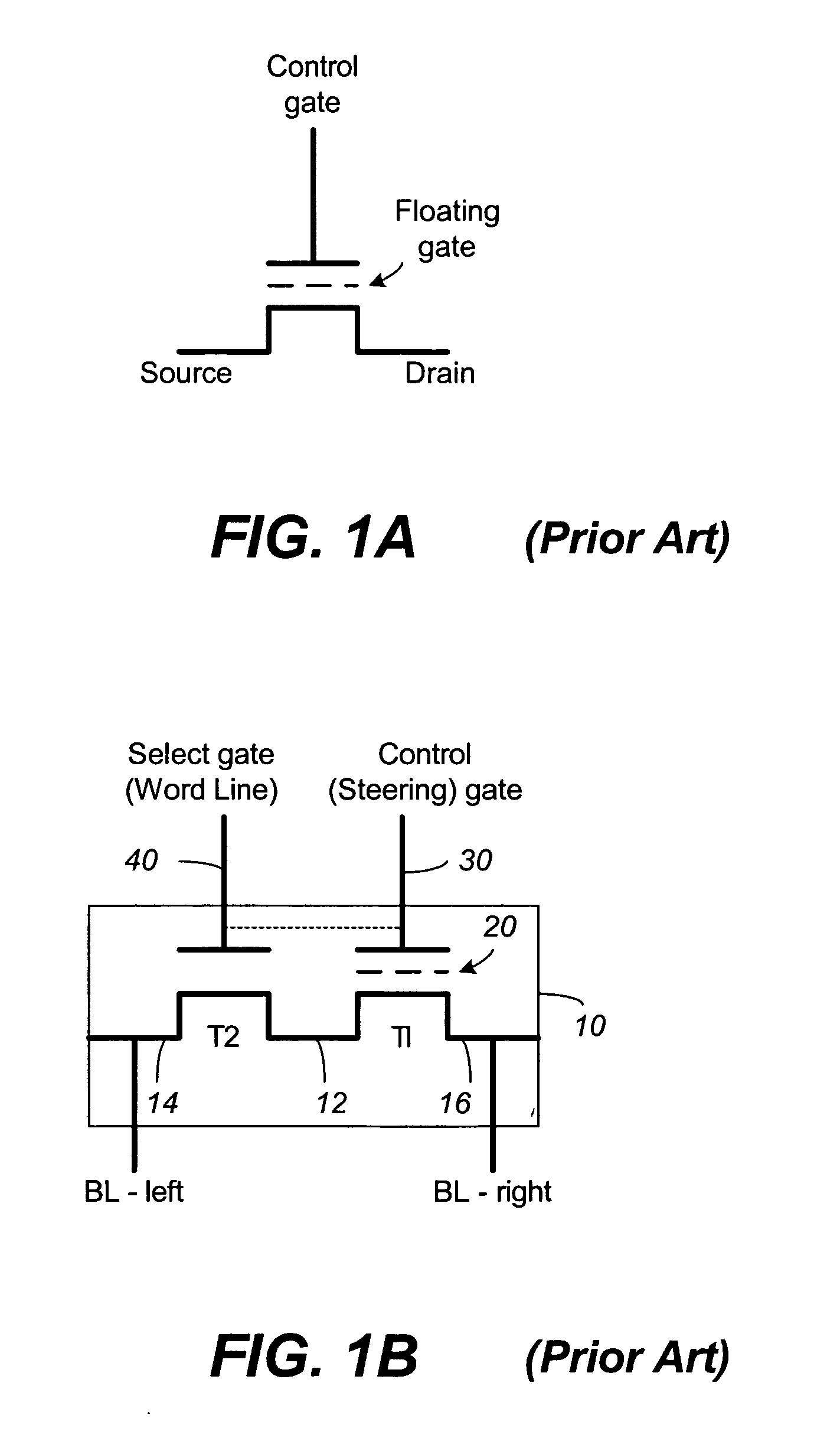

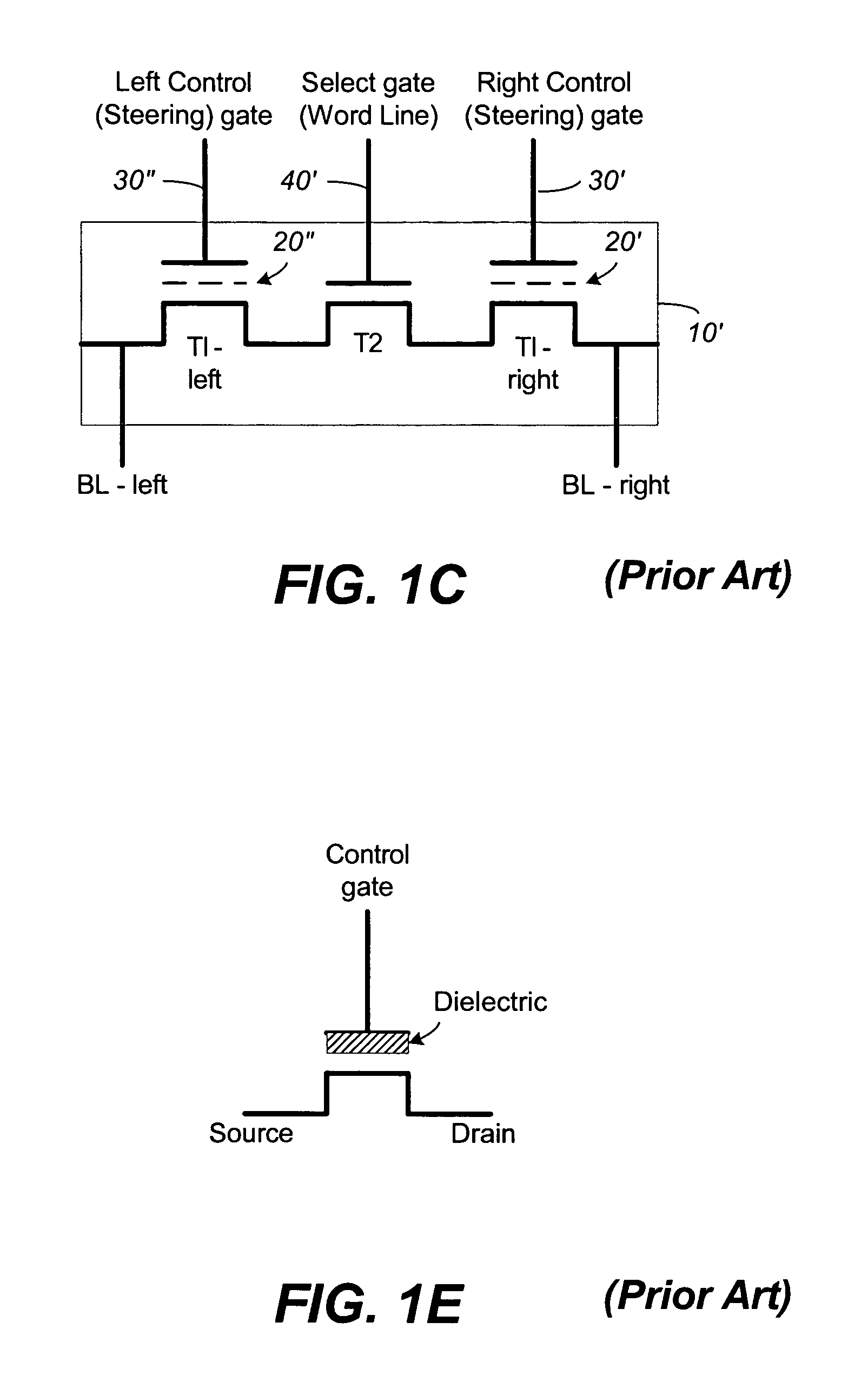

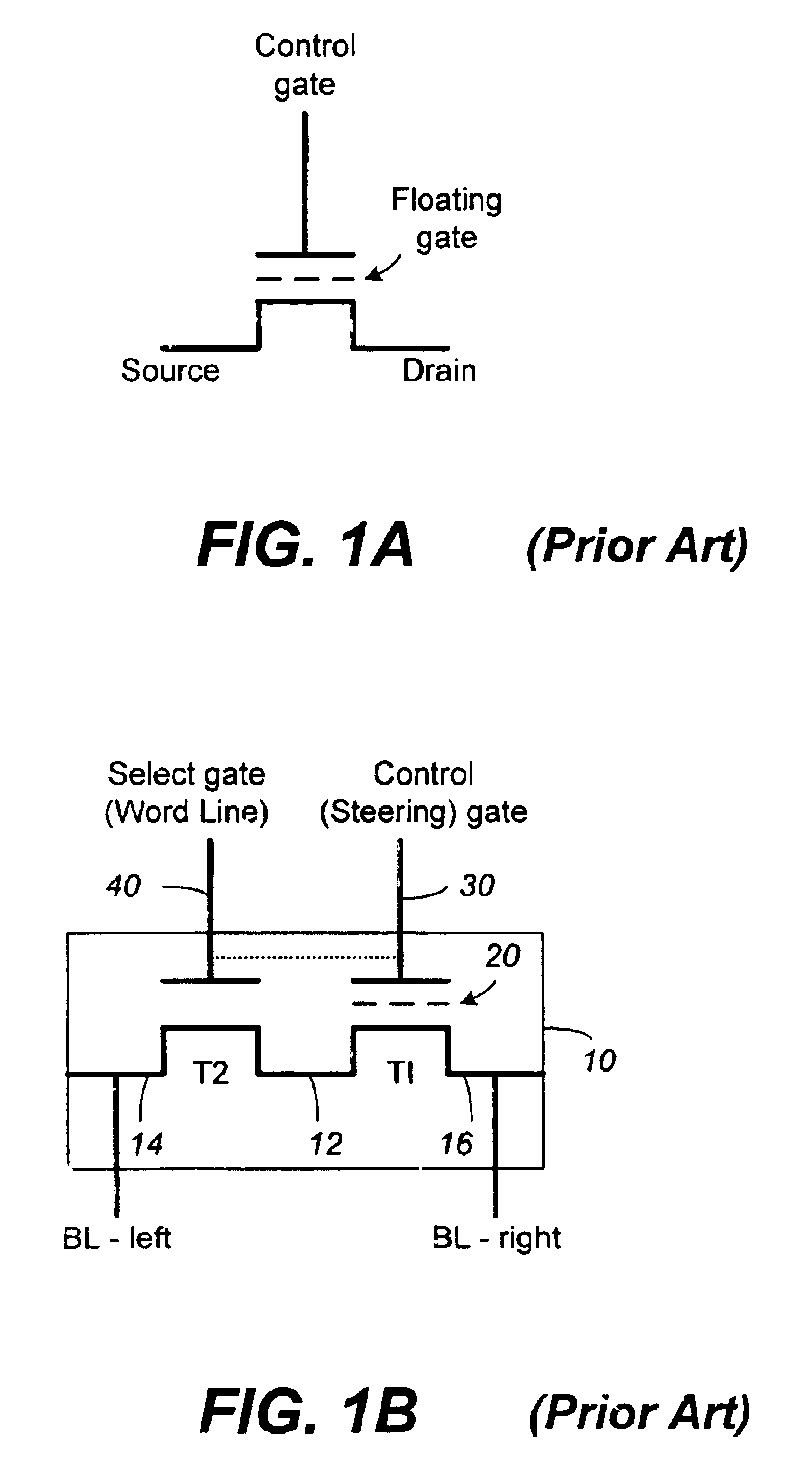

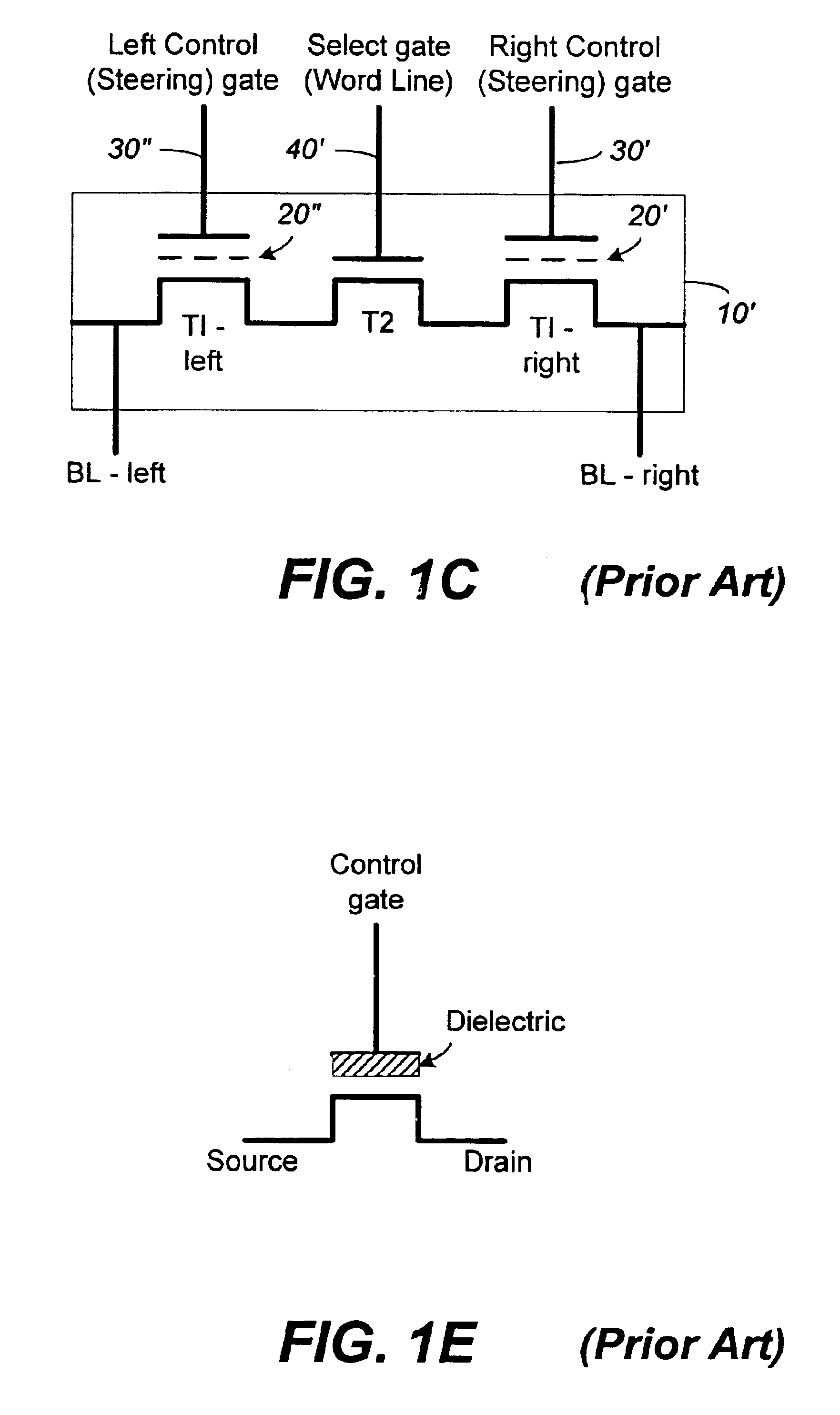

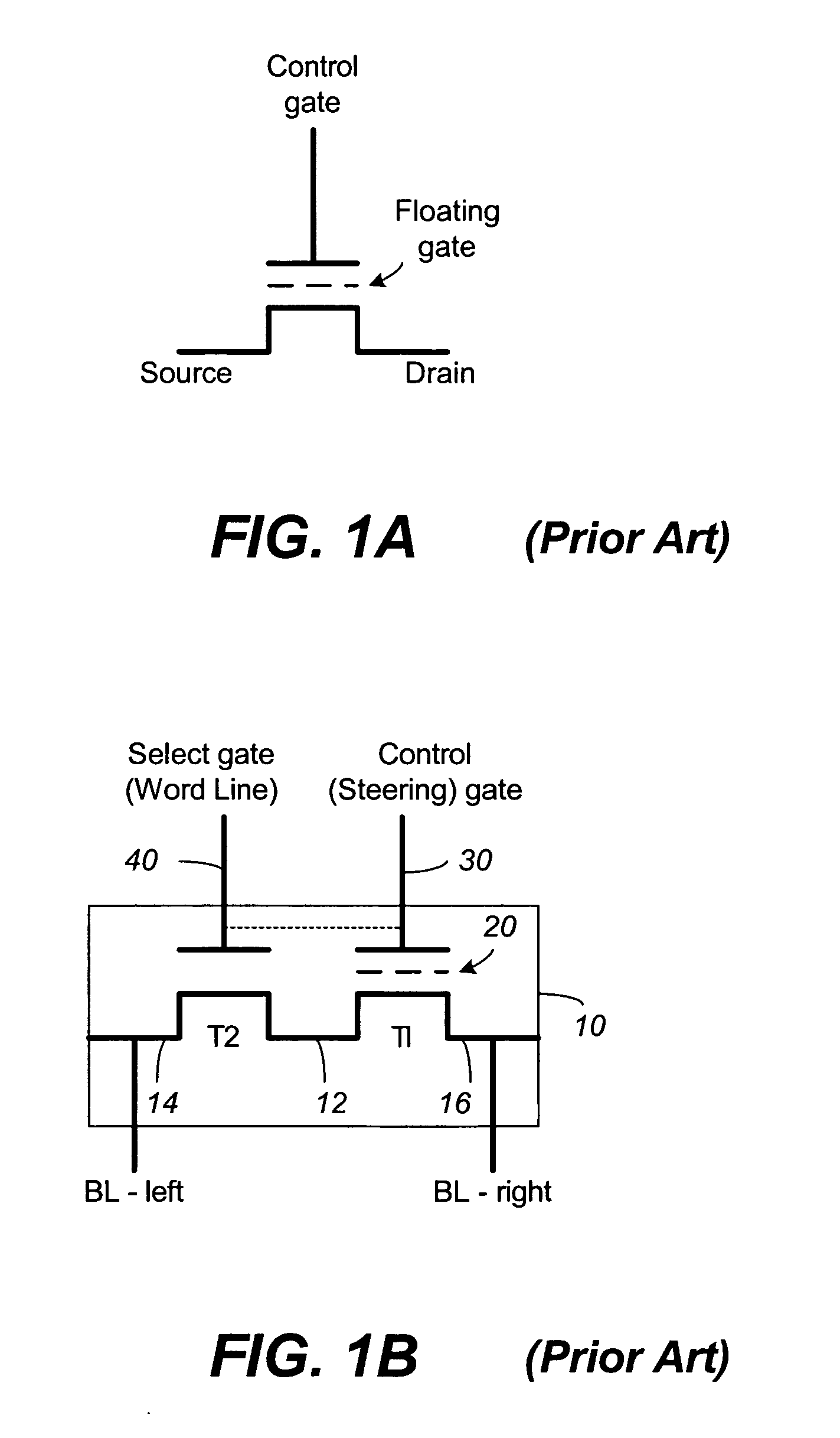

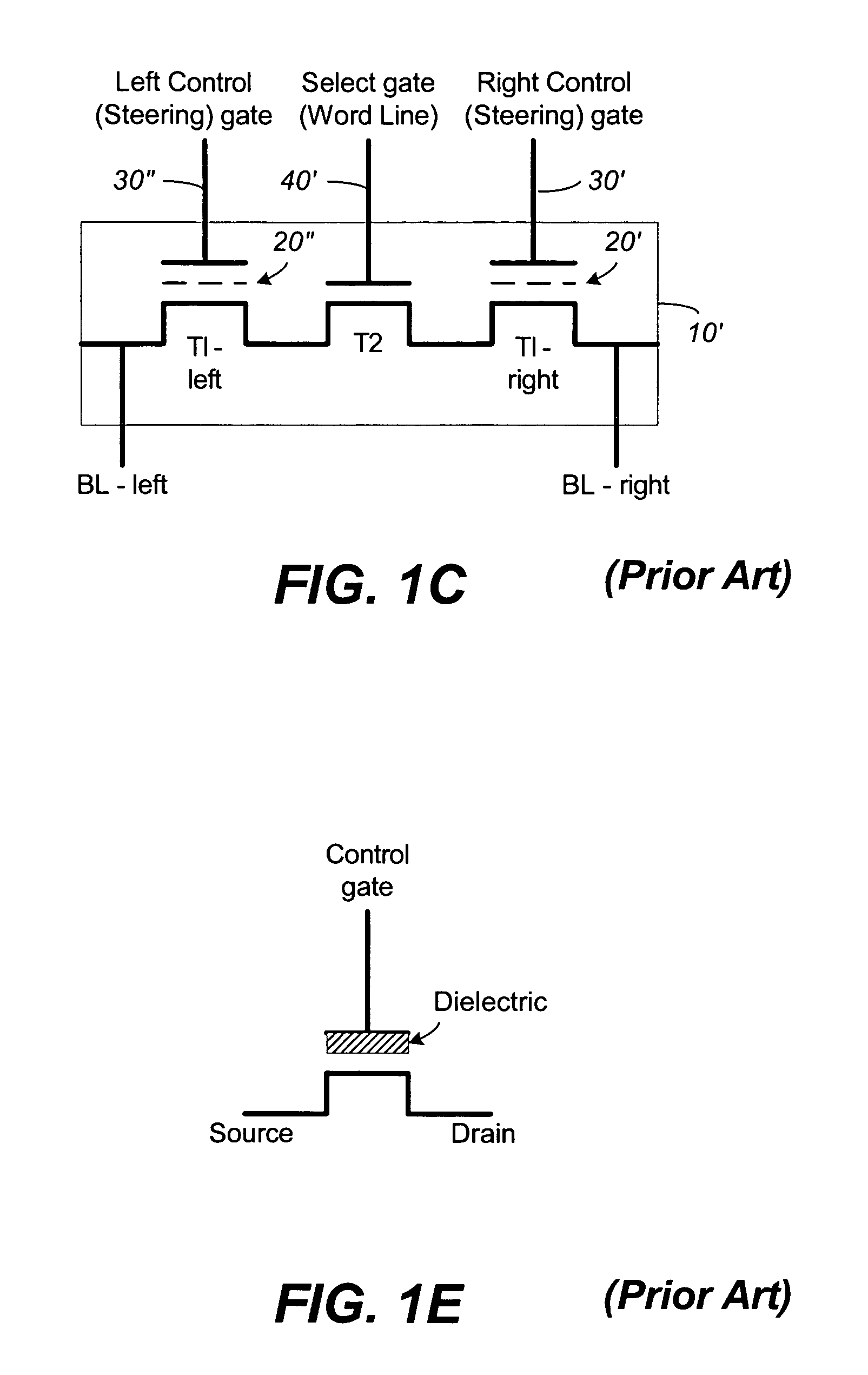

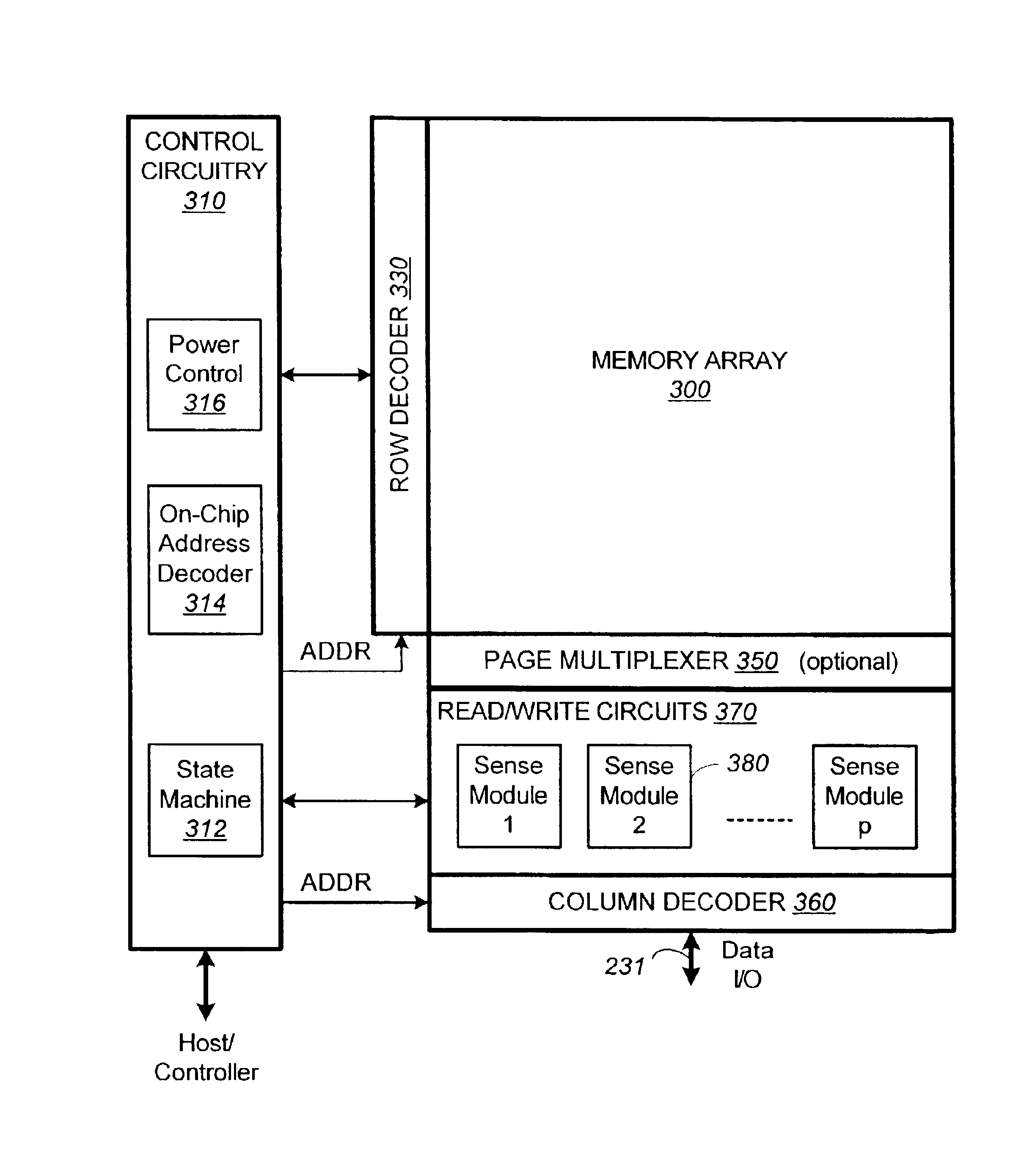

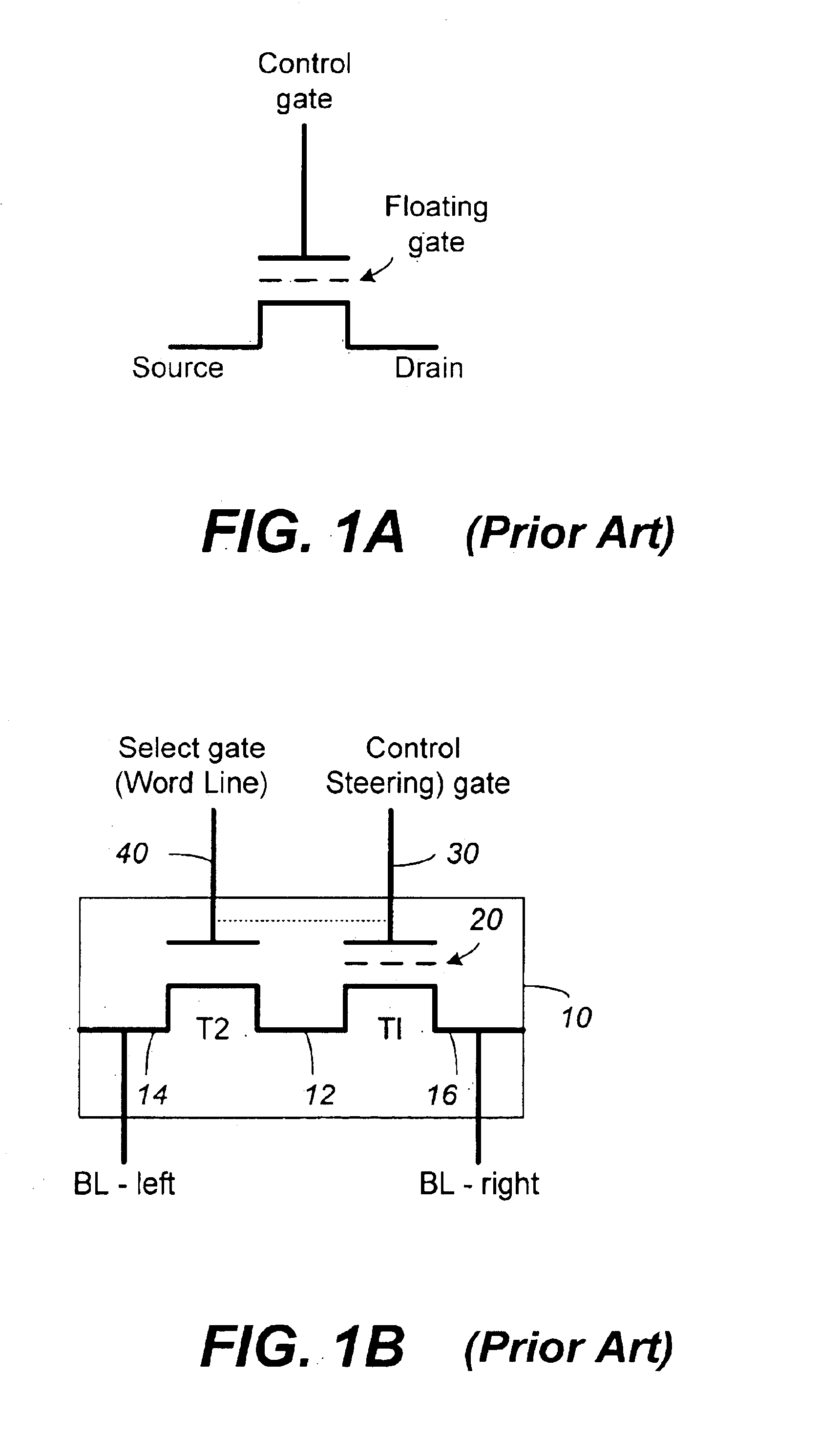

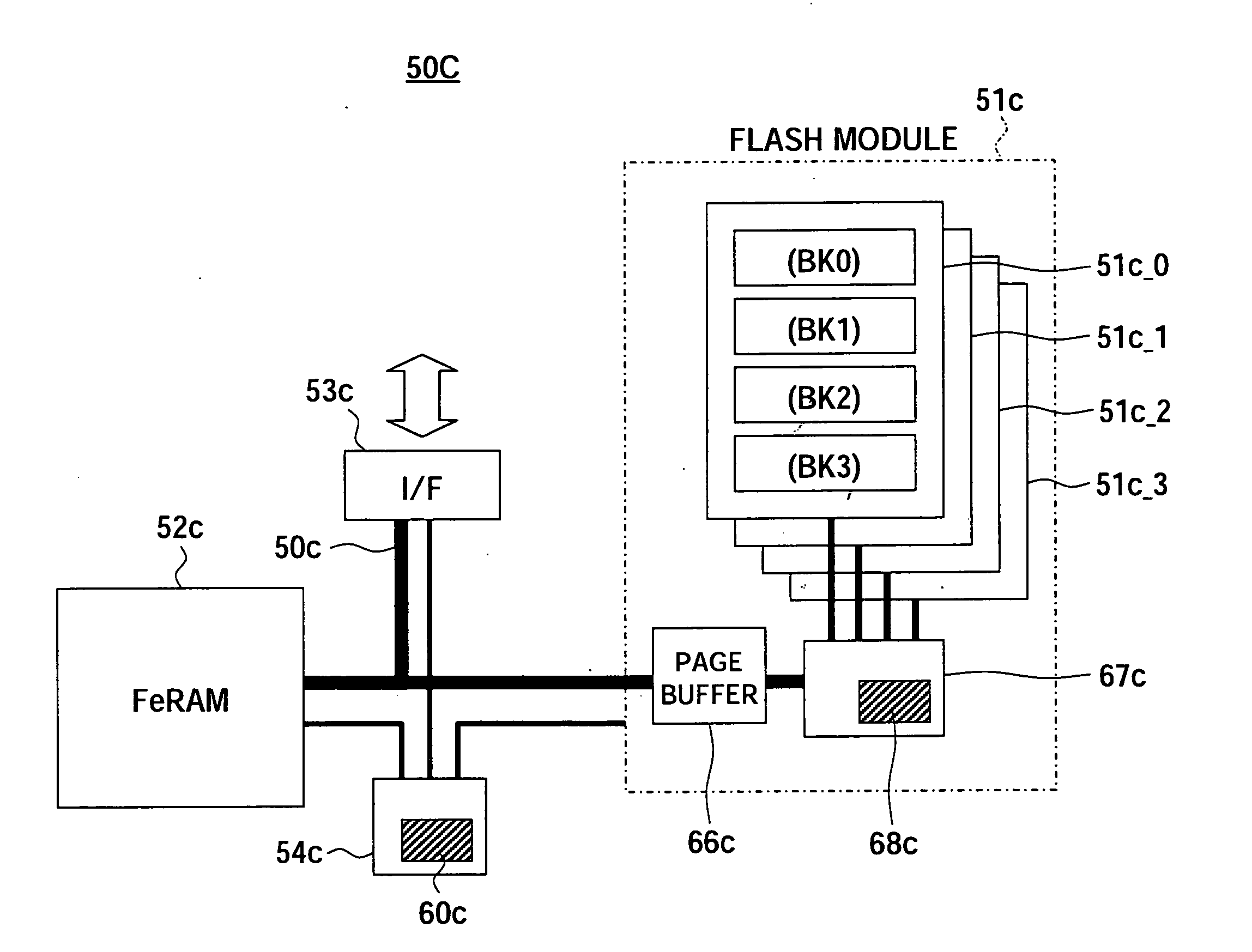

Non-volatile memory and method with bit line compensation dependent on neighboring operating modes

ActiveUS6956770B2Large capacityImprove performanceRead-only memoriesDigital storageBit lineHigh density

When programming a contiguous page of memory storage units, every time a memory storage unit has reached its targeted state and is program-inhibited or locked out from further programming, it creates a perturbation on an adjacent memory storage unit still under programming. The present invention provides as part of a programming circuit and method in which an offset to the perturbation is added to the adjacent memory storage unit still under programming. The offset is added as voltage offset to a bit line of a storage unit under programming. The voltage offset is a predetermined function of whether none or one or both of its neighbors are in a mode that creates perturbation, such as in a program inhibit mode. In this way, an error inherent in programming in parallel high-density memory storage units is eliminated or minimized.

Owner:SANDISK TECH LLC

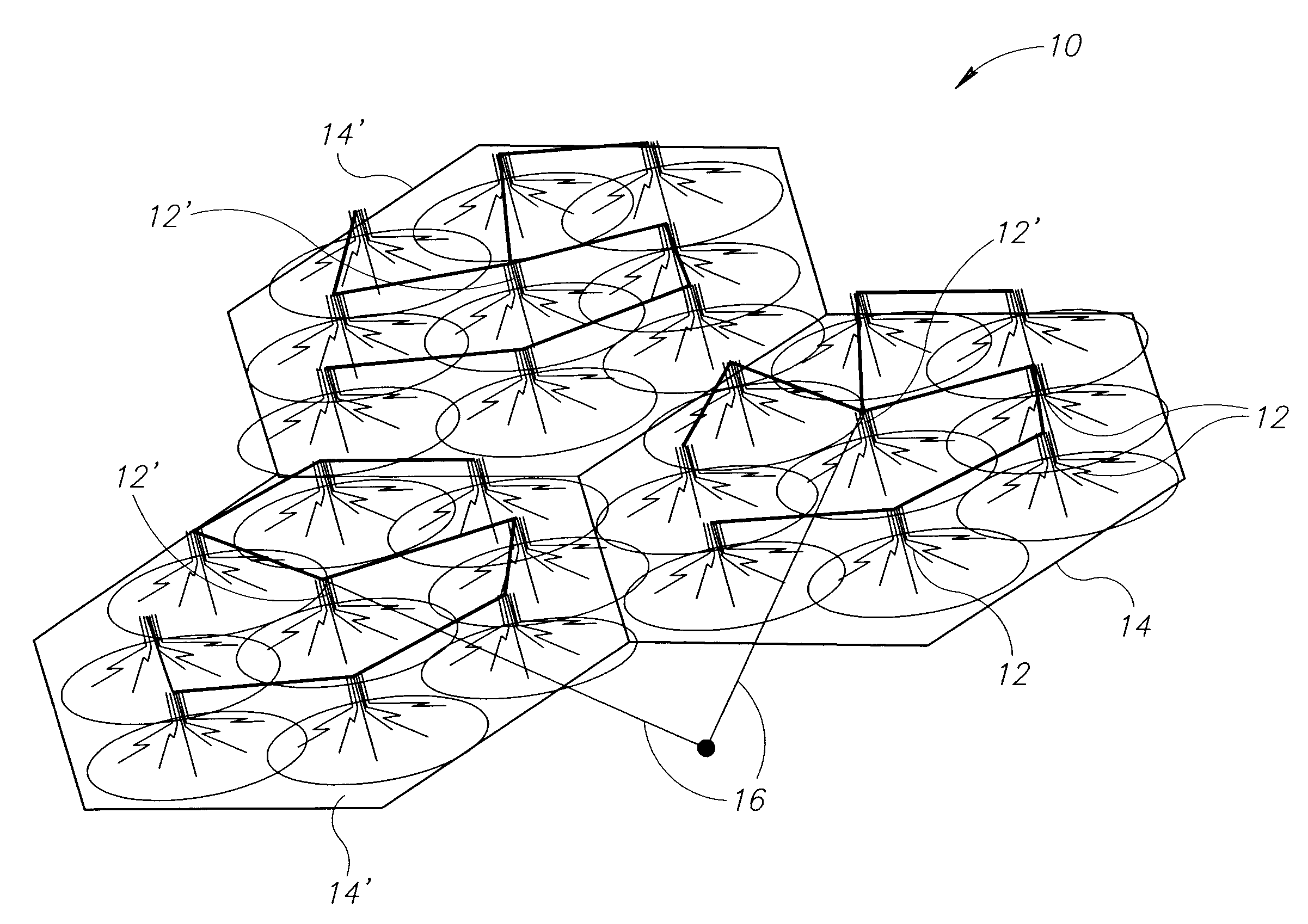

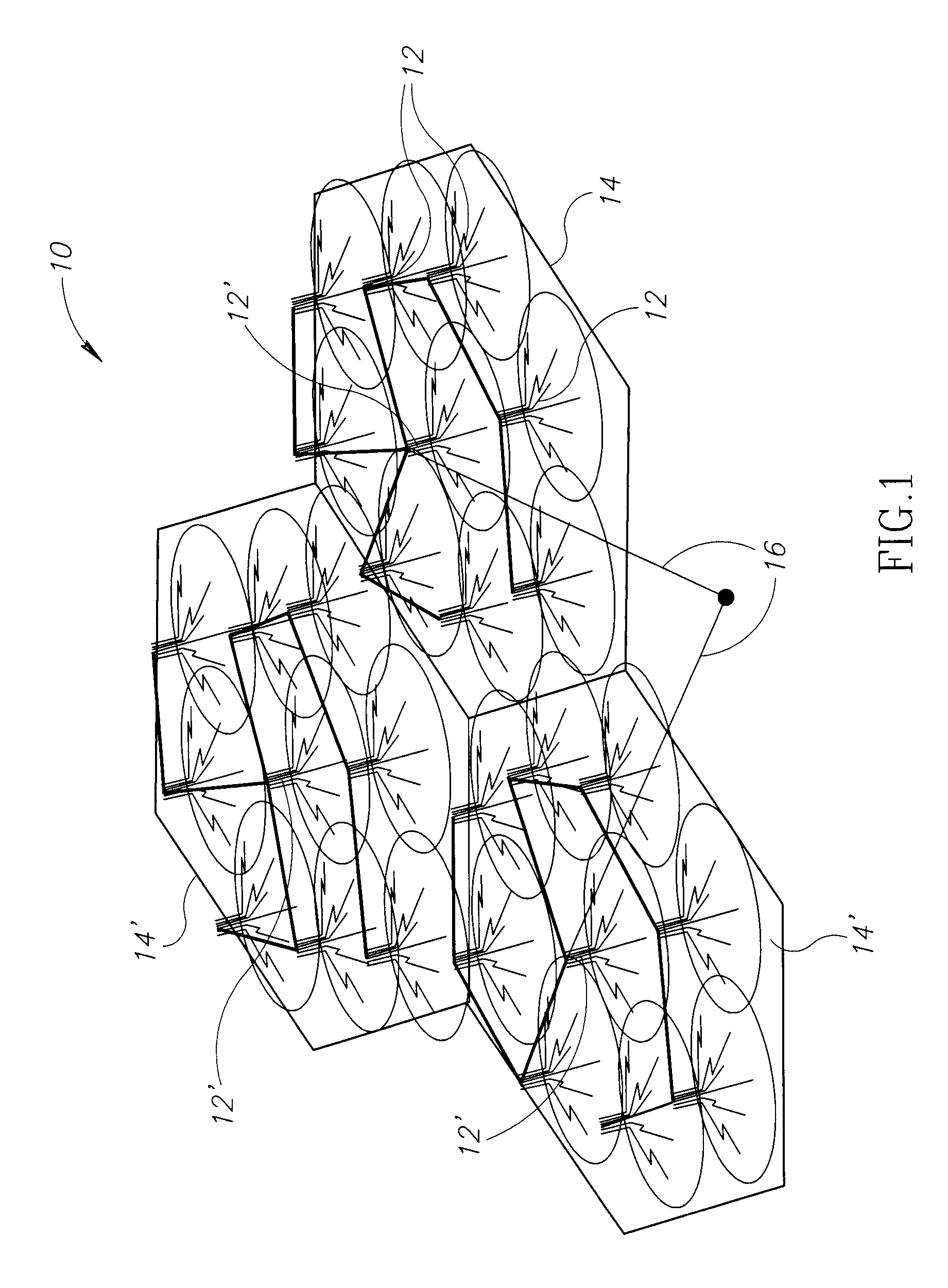

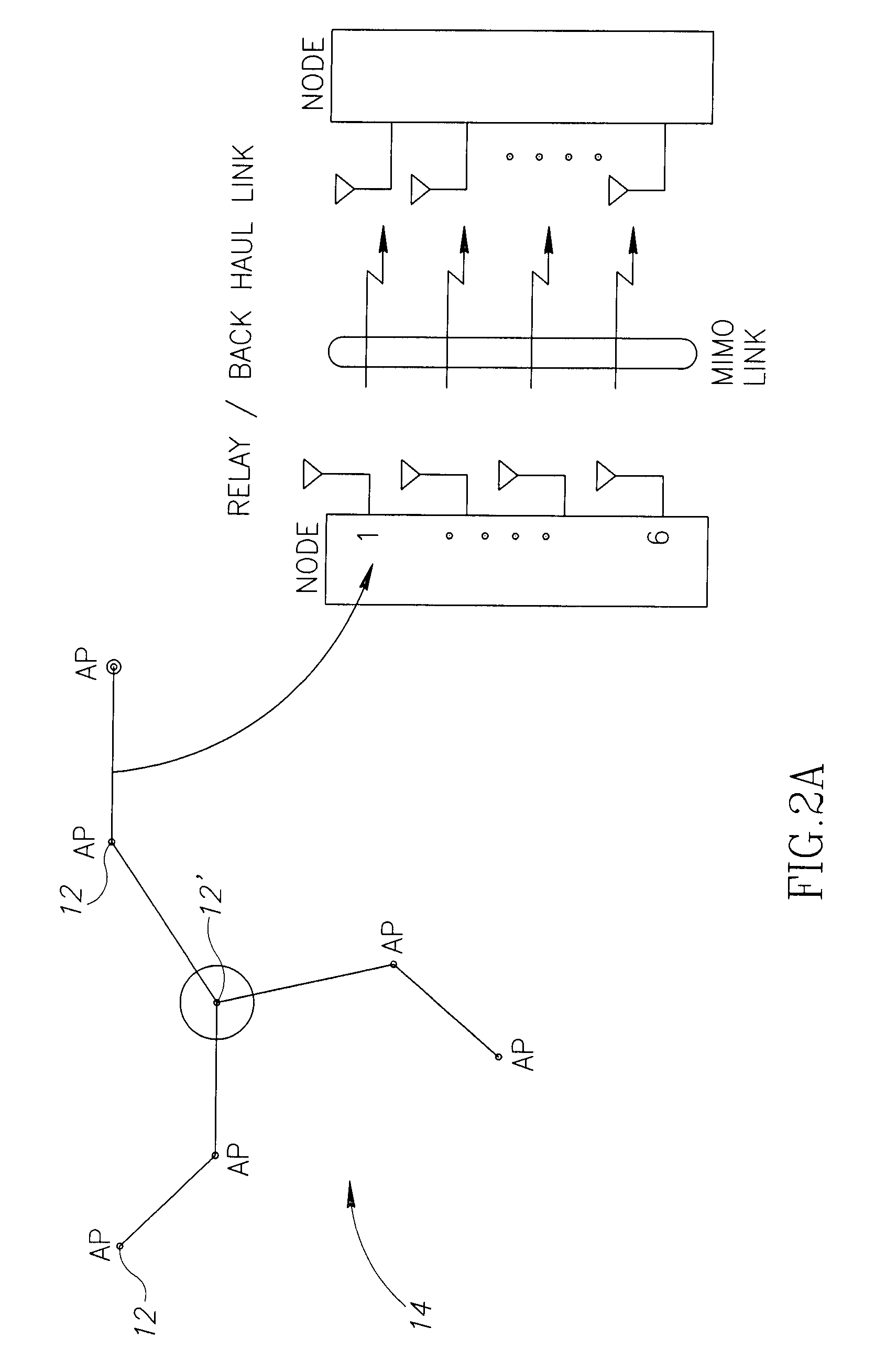

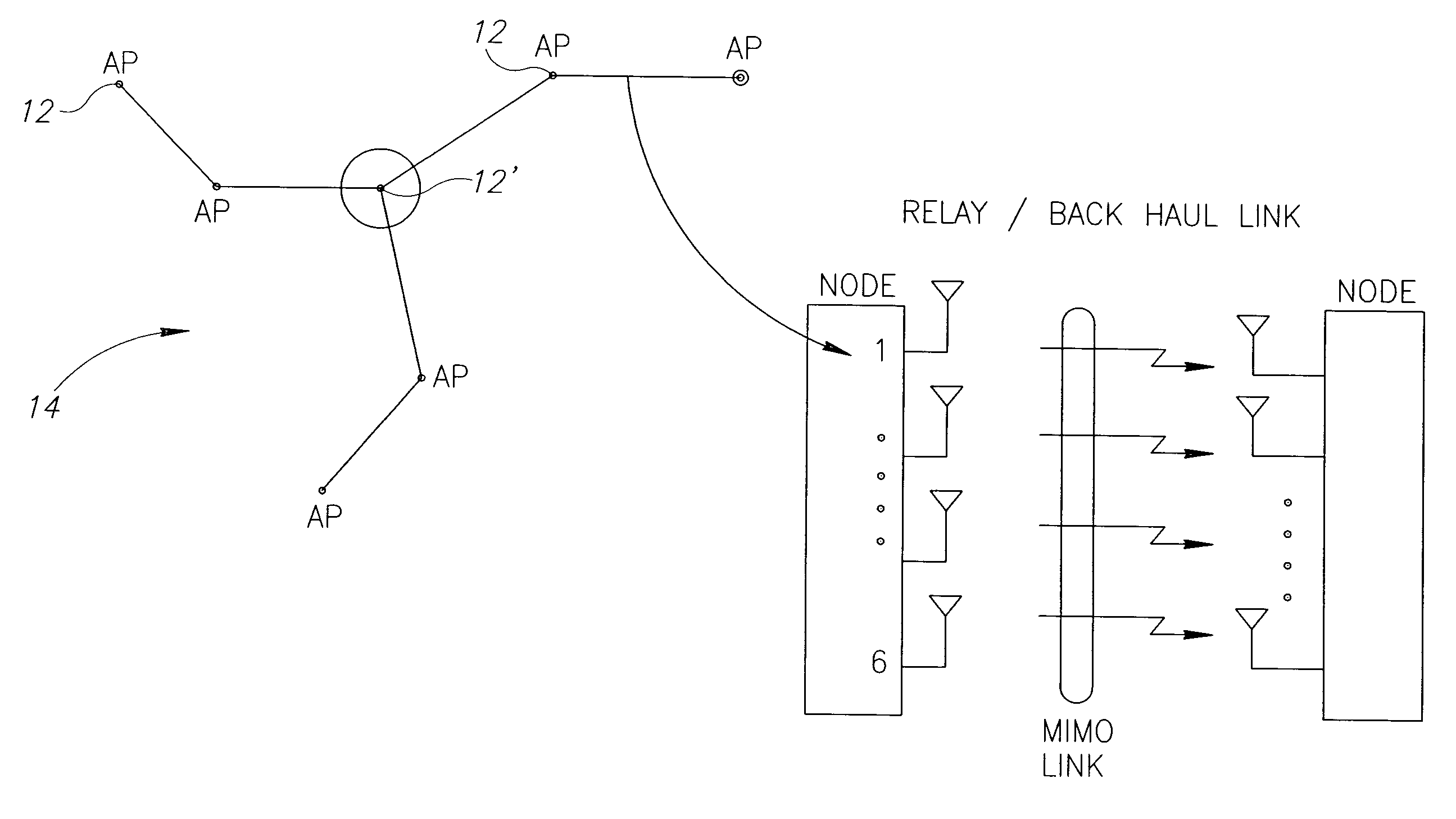

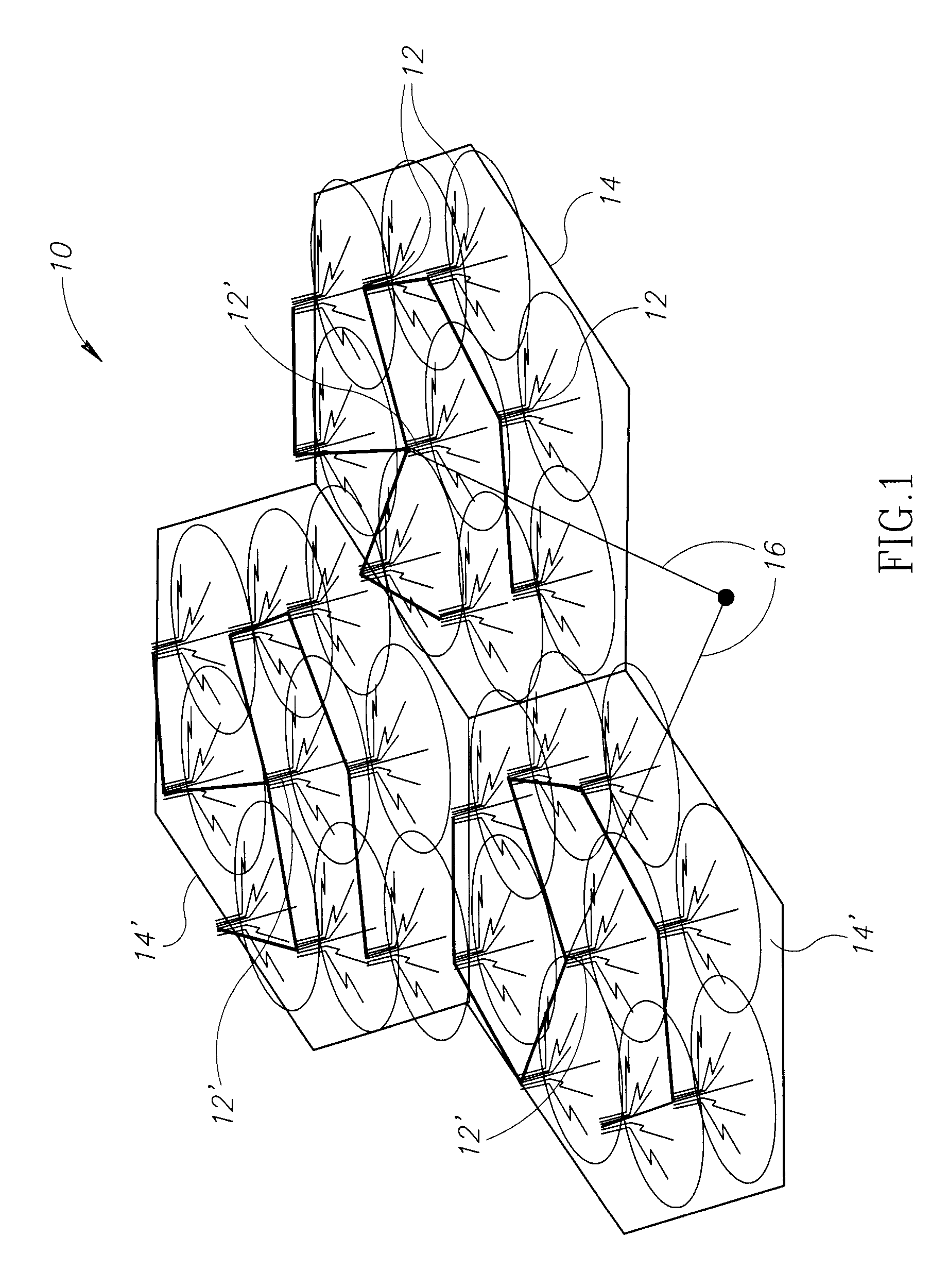

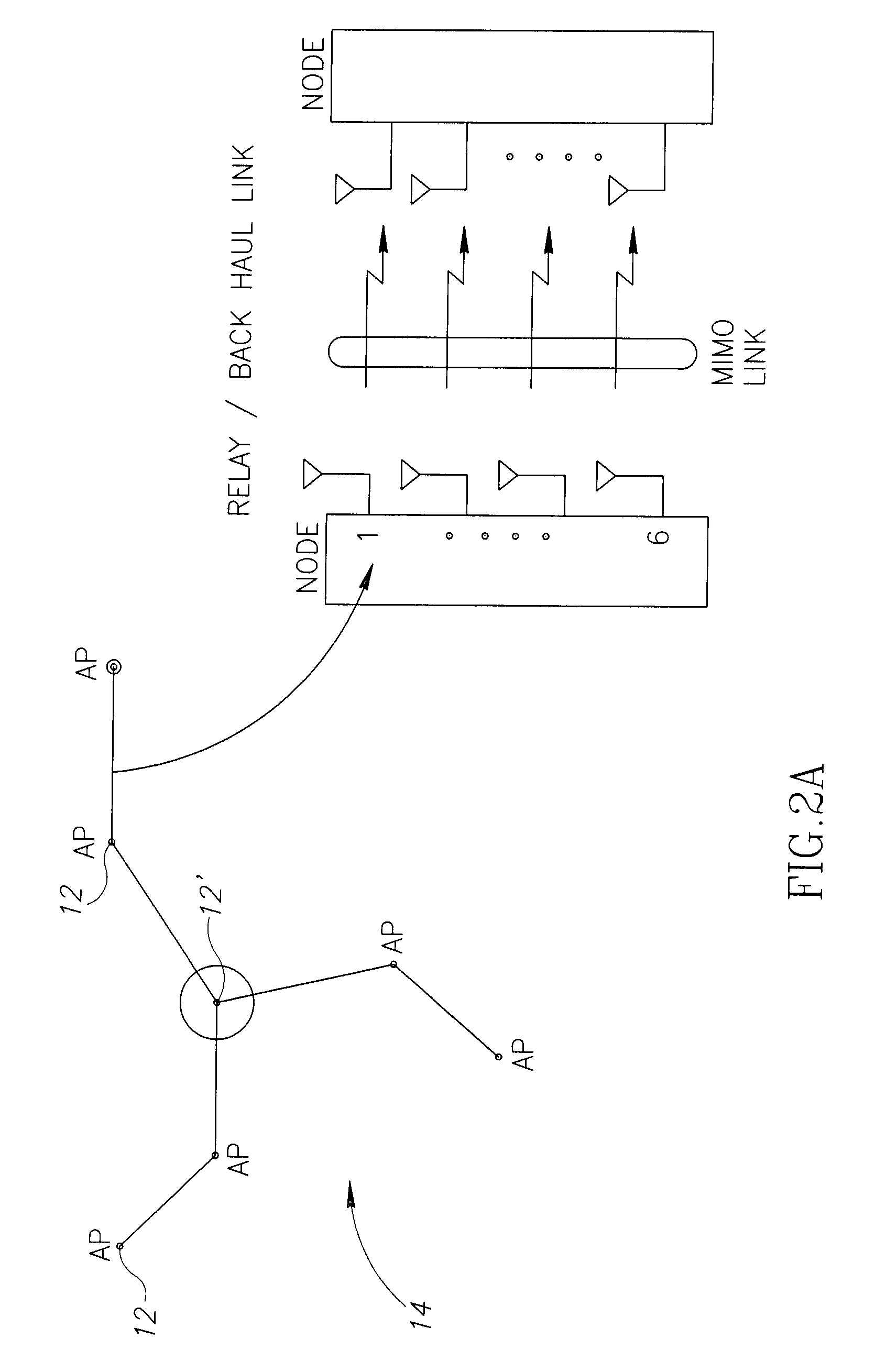

WiMAX ACCESS POINT NETWORK WITH BACKHAUL TECHNOLOGY

ActiveUS20080090575A1Low costLarge capacityPower managementNetwork traffic/resource managementTransceiverModem device

A WiMAX network and communication method, the network including a plurality of WiMAX nodes deployed in micro or pico cells for providing access service to a plurality of mobile subscribers, a plurality of these nodes being arranged in a cluster, one of the nodes in each cluster being a feeder node coupled to a core network, the modes in each cluster being couple for multi-hop transmission to the feeder node. According to a preferred embodiment, each node includes a transceiver with associated modem, an antenna arrangement coupled to the modem and arranged for multiple concurrent transmissions, and a MAC controller for controlling the transceiver, modem and antenna arrangement for providing both access and backhaul communication.

Owner:QUALCOMM INC

Runtime adaptable search processor

ActiveUS7685254B2Improve application performanceLarge capacityWeb data indexingMemory adressing/allocation/relocationPacket schedulingSchema for Object-Oriented XML

A runtime adaptable search processor is disclosed. The search processor provides high speed content search capability to meet the performance need of network line rates growing to 1 Gbps, 10 Gbps and higher. The search processor provides a unique combination of NFA and DFA based search engines that can process incoming data in parallel to perform the search against the specific rules programmed in the search engines. The processor architecture also provides capabilities to transport and process Internet Protocol (IP) packets from Layer 2 through transport protocol layer and may also provide packet inspection through Layer 7. Further, a runtime adaptable processor is coupled to the protocol processing hardware and may be dynamically adapted to perform hardware tasks as per the needs of the network traffic being sent or received and / or the policies programmed or services or applications being supported. A set of engines may perform pass-through packet classification, policy processing and / or security processing enabling packet streaming through the architecture at nearly the full line rate. A high performance content search and rules processing security processor is disclosed which may be used for application layer and network layer security. Scheduler schedules packets to packet processors for processing. An internal memory or local session database cache stores a session information database for a certain number of active sessions. The session information that is not in the internal memory is stored and retrieved to / from an additional memory. An application running on an initiator or target can in certain instantiations register a region of memory, which is made available to its peer(s) for access directly without substantial host intervention through RDMA data transfer. A security system is also disclosed that enables a new way of implementing security capabilities inside enterprise networks in a distributed manner using a protocol processing hardware with appropriate security features.

Owner:MEMORY ACCESS TECH LLC

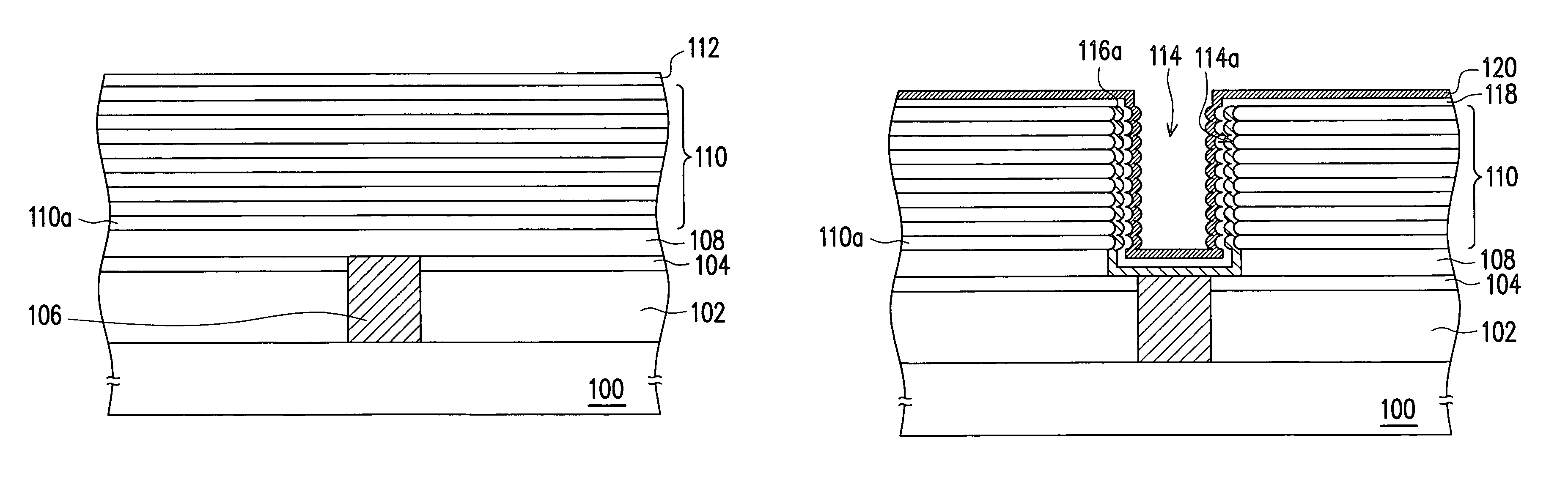

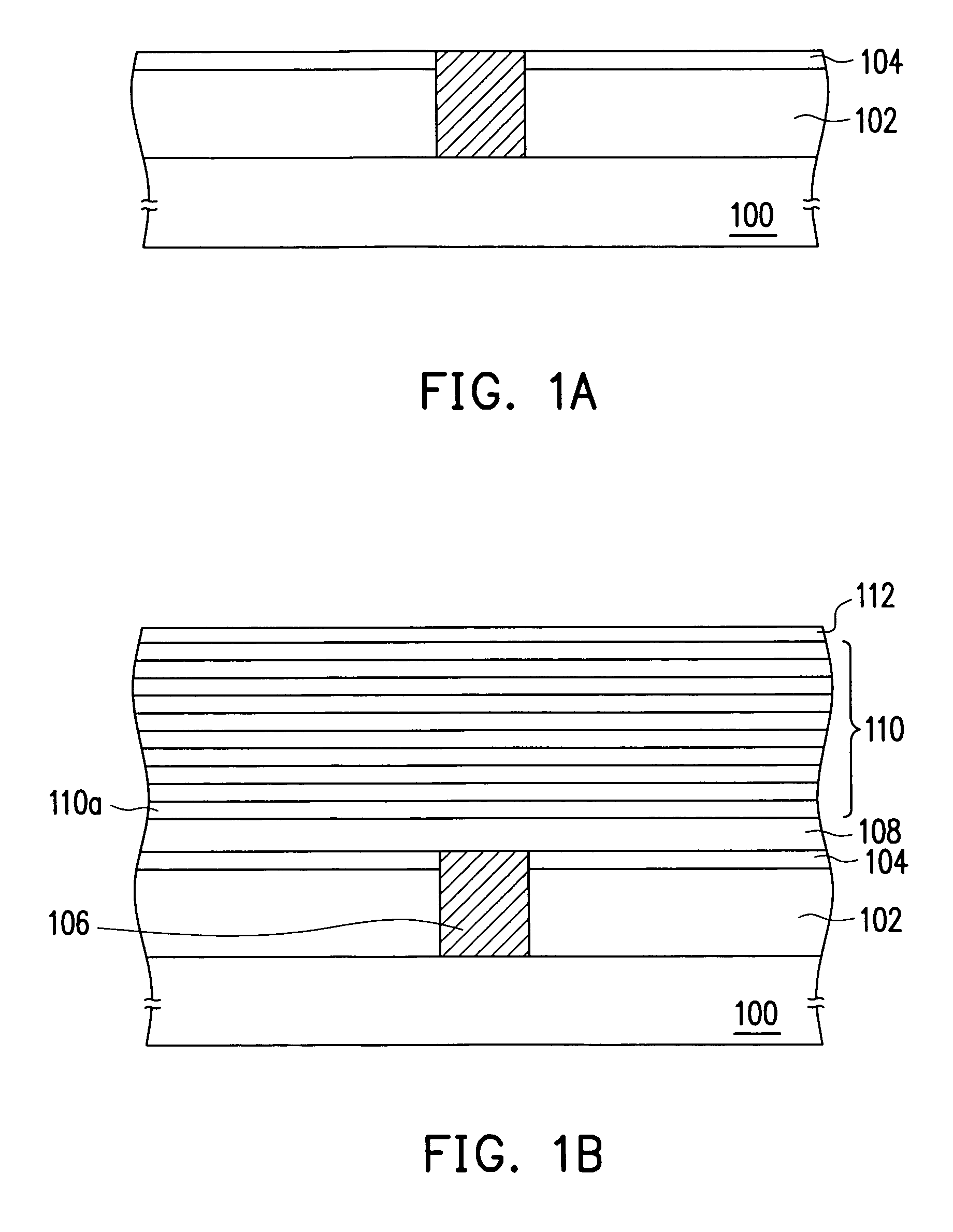

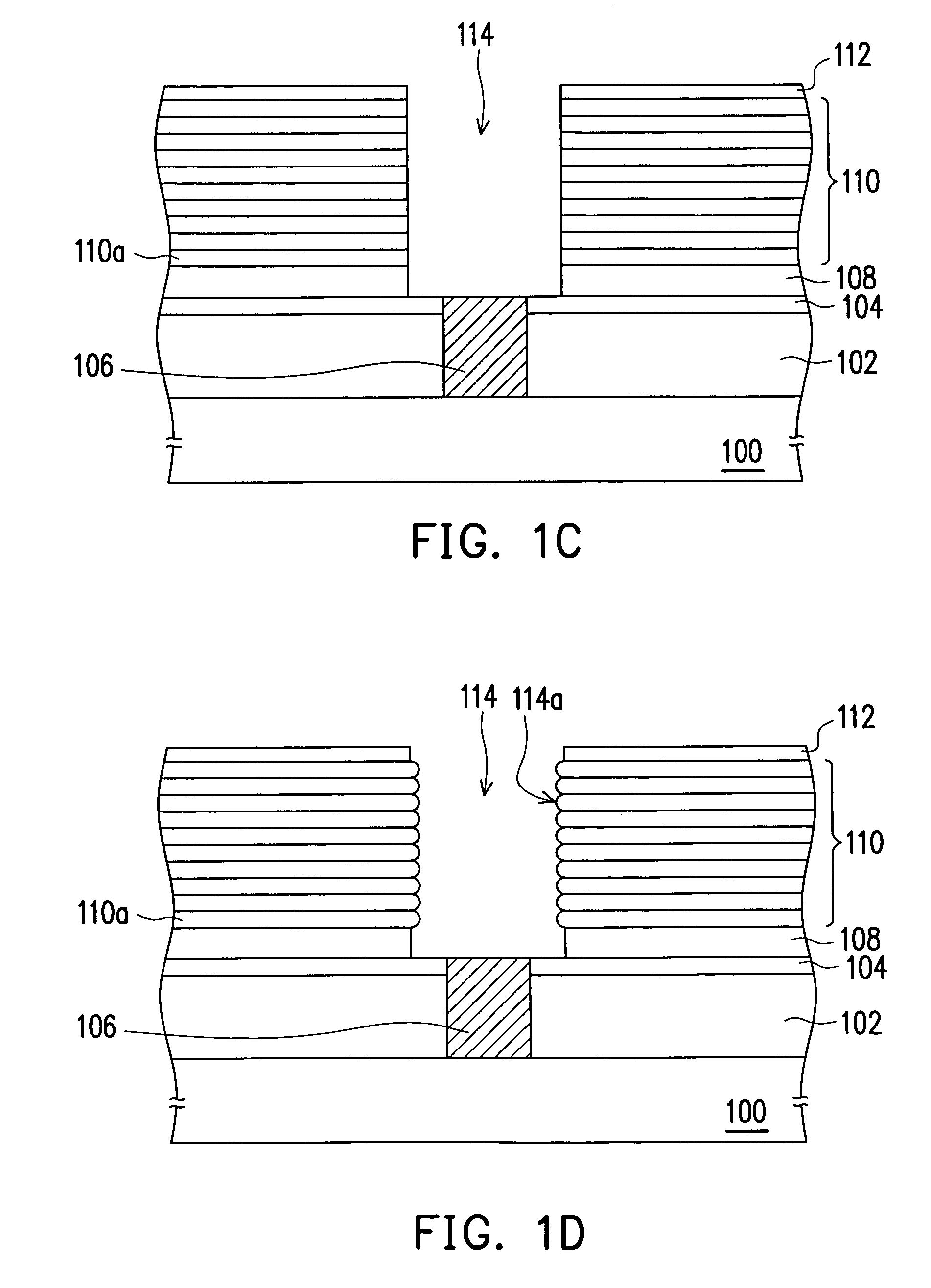

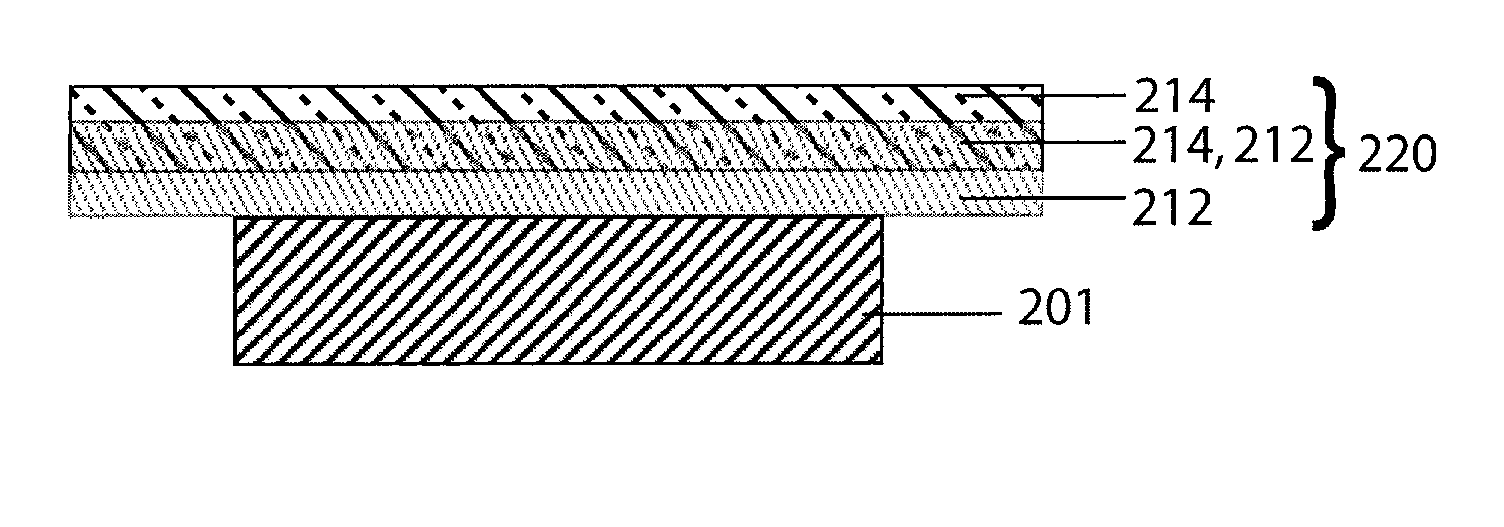

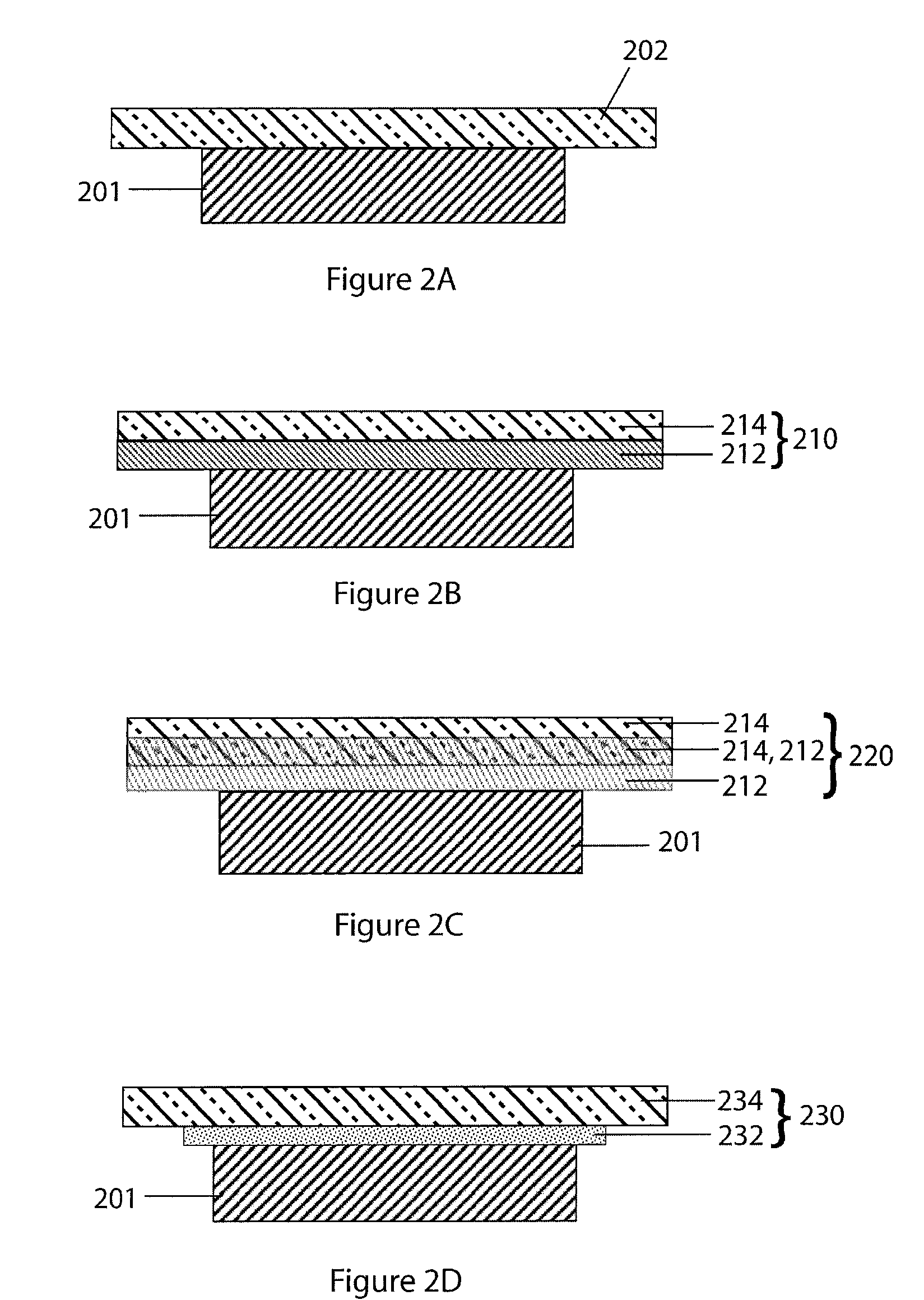

Method of manufacturing charge storage device

InactiveUS7405166B2Increase electrode areaEasy to produceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceHydrogen fluoride

Owner:IND TECH RES INST

Mobile broadband wireless access point network with wireless backhaul

ActiveUS7620370B2Low costLarge capacityPower managementNetwork traffic/resource managementTransceiverModem device

A WiMAX network and communication method, the network including a plurality of WiMAX nodes deployed in micro or pico cells for providing access service to a plurality of mobile subscribers, a plurality of these nodes being arranged in a cluster, one of the nodes in each cluster being a feeder node coupled to a core network, the nodes in each cluster being coupled for multi-hop transmission to the feeder node. According to a preferred embodiment, each node includes a transceiver with associated modem, an antenna arrangement coupled to the modem and arranged for multiple concurrent transmissions, and a MAC controller for controlling the transceiver, modem and antenna arrangement for providing both access and backhaul communication.

Owner:QUALCOMM INC

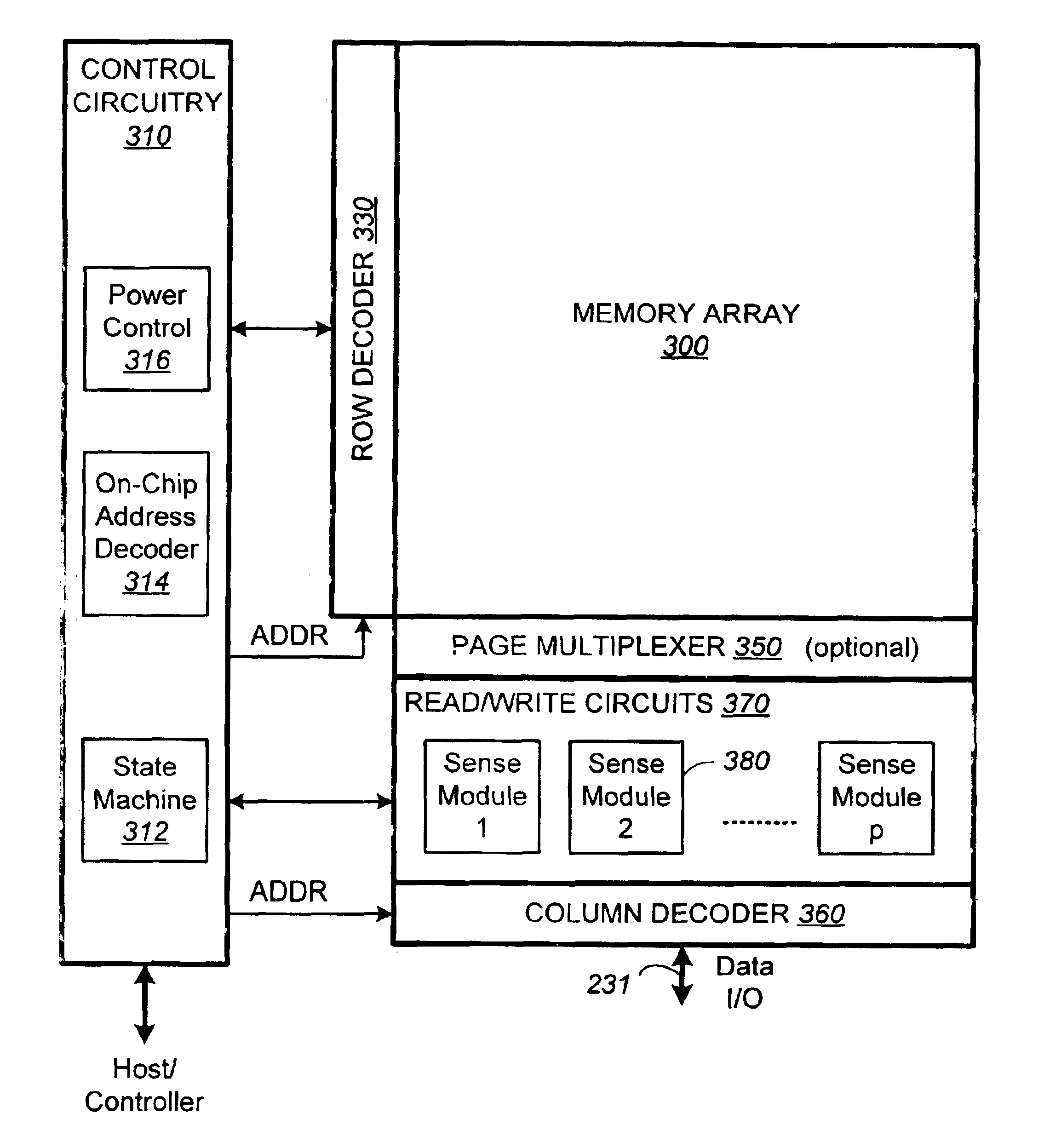

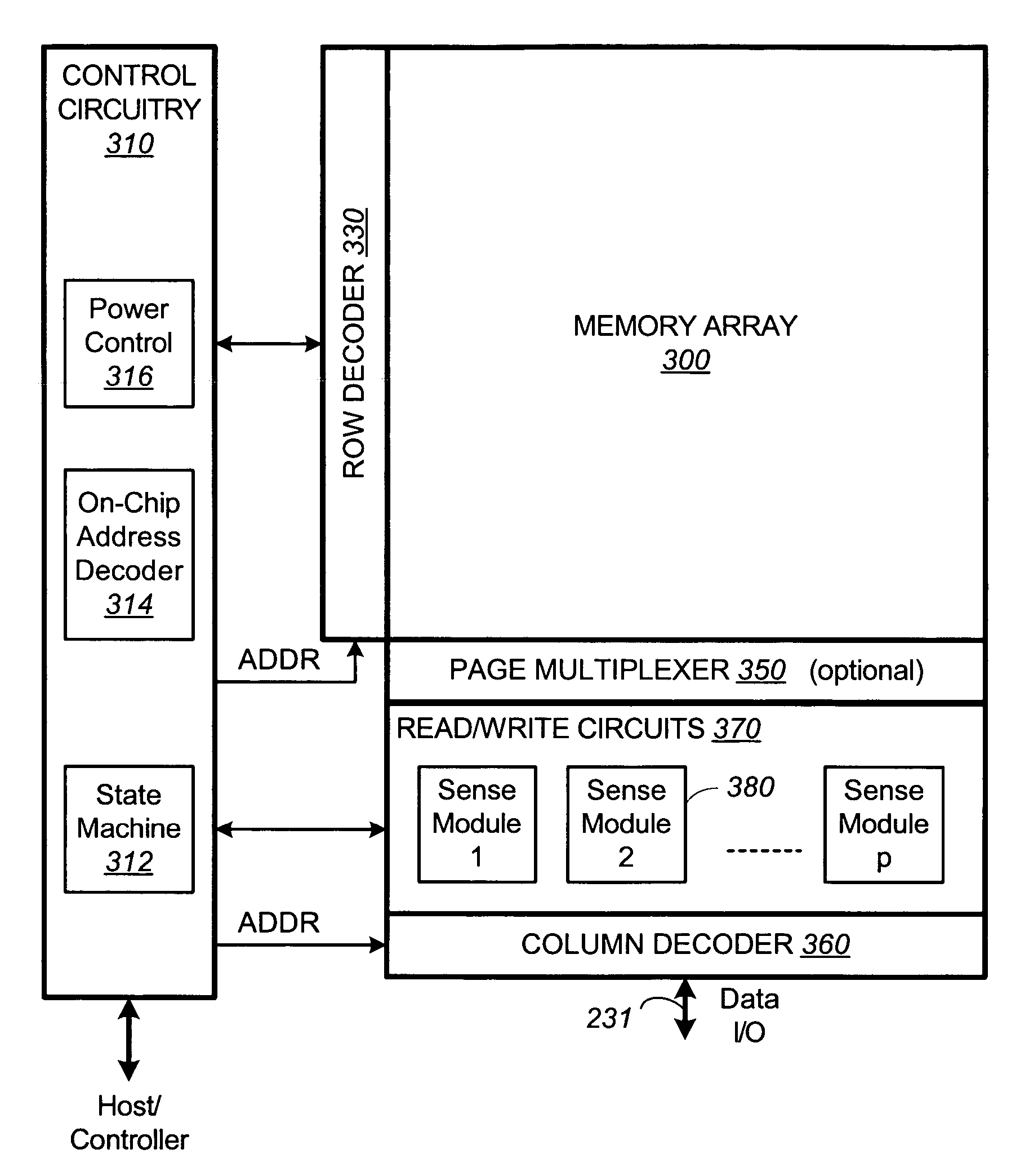

Memory sensing circuit and method for low voltage operation

InactiveUS20050169082A1Large capacityImprove performanceRead-only memoriesDigital storageConduction currentConstant voltage

A sensing module operates with a sense amplifier sensing a conduction current of a memory cell via a coupled bit line under constant voltage condition in order to minimize bit-line to bit-line coupling. The rate of discharge of a dedicated capacitor as measured by a change in the voltage drop there across in a predetermined period is used to indicate the magnitude of the conduction current. The voltage cannot drop below a minimum level imposed by a circuit for maintaining the constant voltage condition on the bit line. A voltage shifter is used to boost the voltage during the discharge and to unboost the voltage after the discharge, so that the change in voltage drop properly reflects the rate of discharge without running into the minimum level.

Owner:SANDISK TECH LLC

Non-volatile memory and method with improved sensing

InactiveUS7023736B2Large capacityImprove performanceRead-only memoriesDigital storageAudio power amplifierMultiple pass

A method for reducing source line bias is accomplished by read / write circuits with features and techniques for multi-pass sensing. When a page of memory cells are being sensed in parallel, each pass helps to identify and shut down the memory cells with conduction current higher than a given demarcation current value. In particular, the identified memory cells are shut down after all sensing in the current pass have been completed. In this way the shutting down operation does not disturb the sensing operation. Sensing in subsequent passes will be less affected by source line bias since the total amount of current flow is significantly reduced by eliminating contributions from the higher current cells. In another aspect of sensing improvement, a reference sense amplifier is employed to control multiple sense amplifiers to reduce their dependence on power supply and environmental variations.

Owner:SANDISK TECH LLC

Memory sensing circuit and method for low voltage operation

InactiveUS7046568B2Large capacityImprove performanceRead-only memoriesDigital storageBit lineAudio power amplifier

A sensing module operates with a sense amplifier sensing a conduction current of a memory cell via a coupled bit line under constant voltage condition in order to minimize bit-line to bit-line coupling. The rate of discharge of a dedicated capacitor as measured by a change in the voltage drop there across in a predetermined period is used to indicate the magnitude of the conduction current. The voltage cannot drop below a minimum level imposed by a circuit for maintaining the constant voltage condition on the bit line. A voltage shifter is used to boost the voltage during the discharge and to unboost the voltage after the discharge, so that the change in voltage drop properly reflects the rate of discharge without running into the minimum level.

Owner:SANDISK TECH LLC

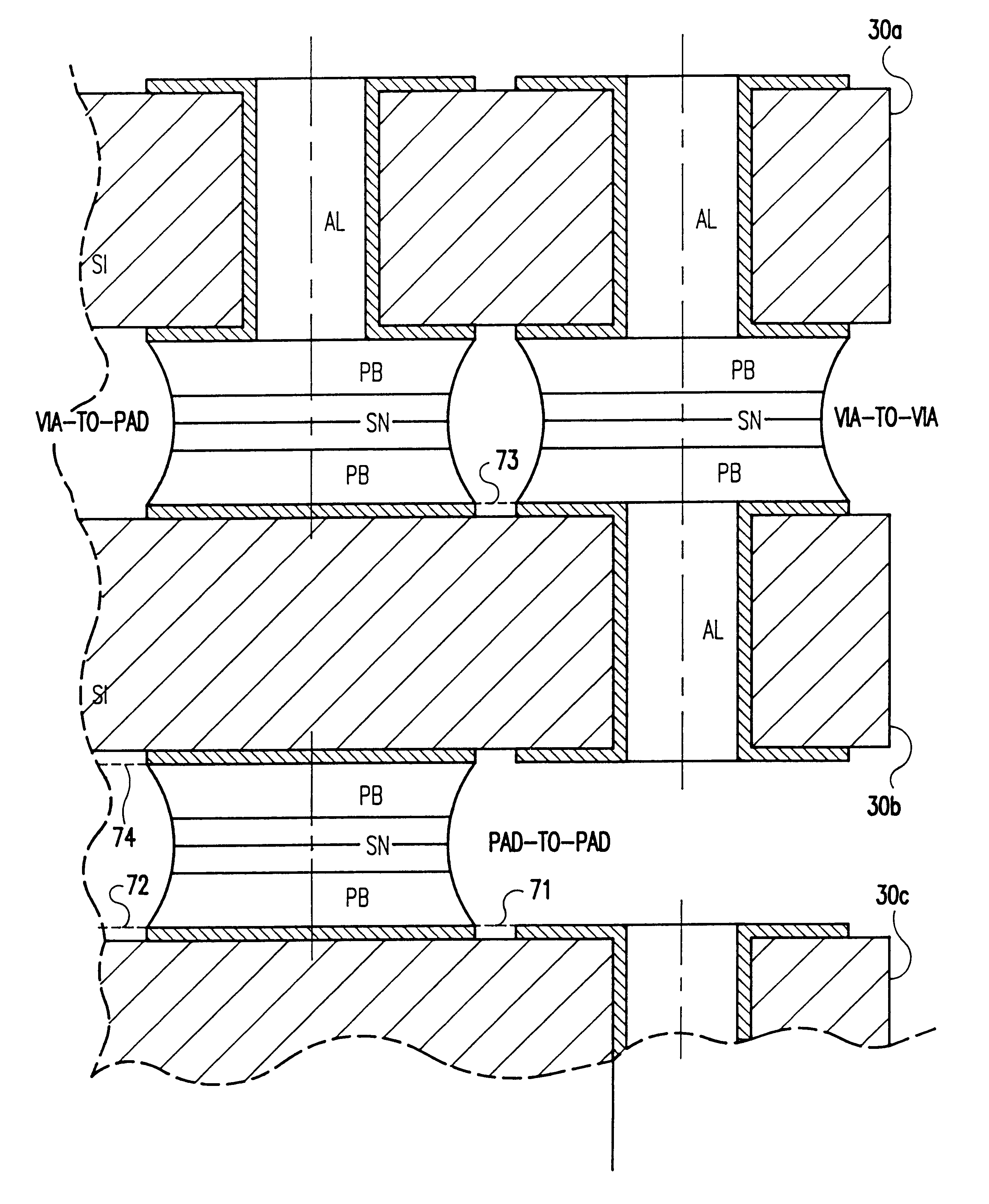

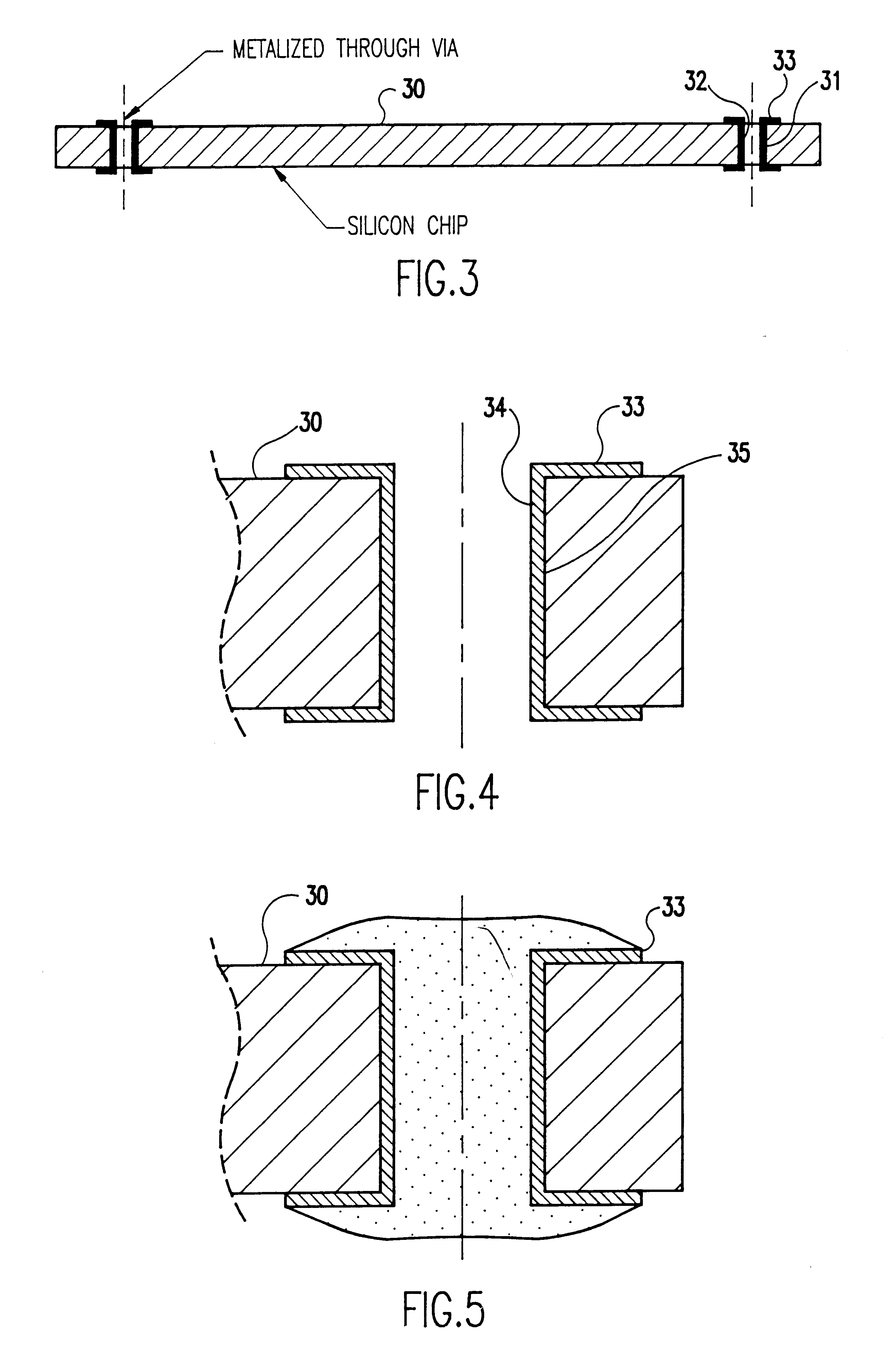

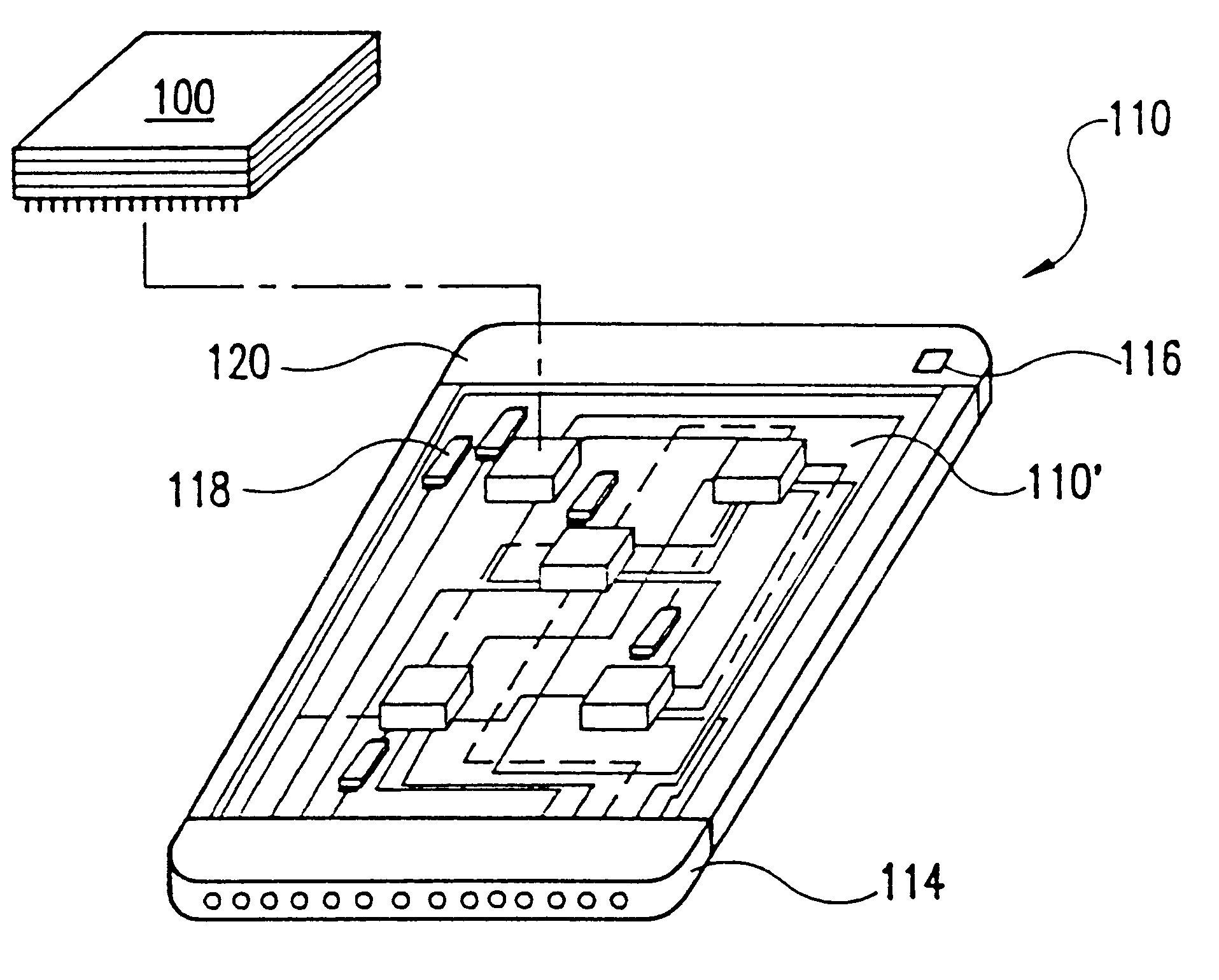

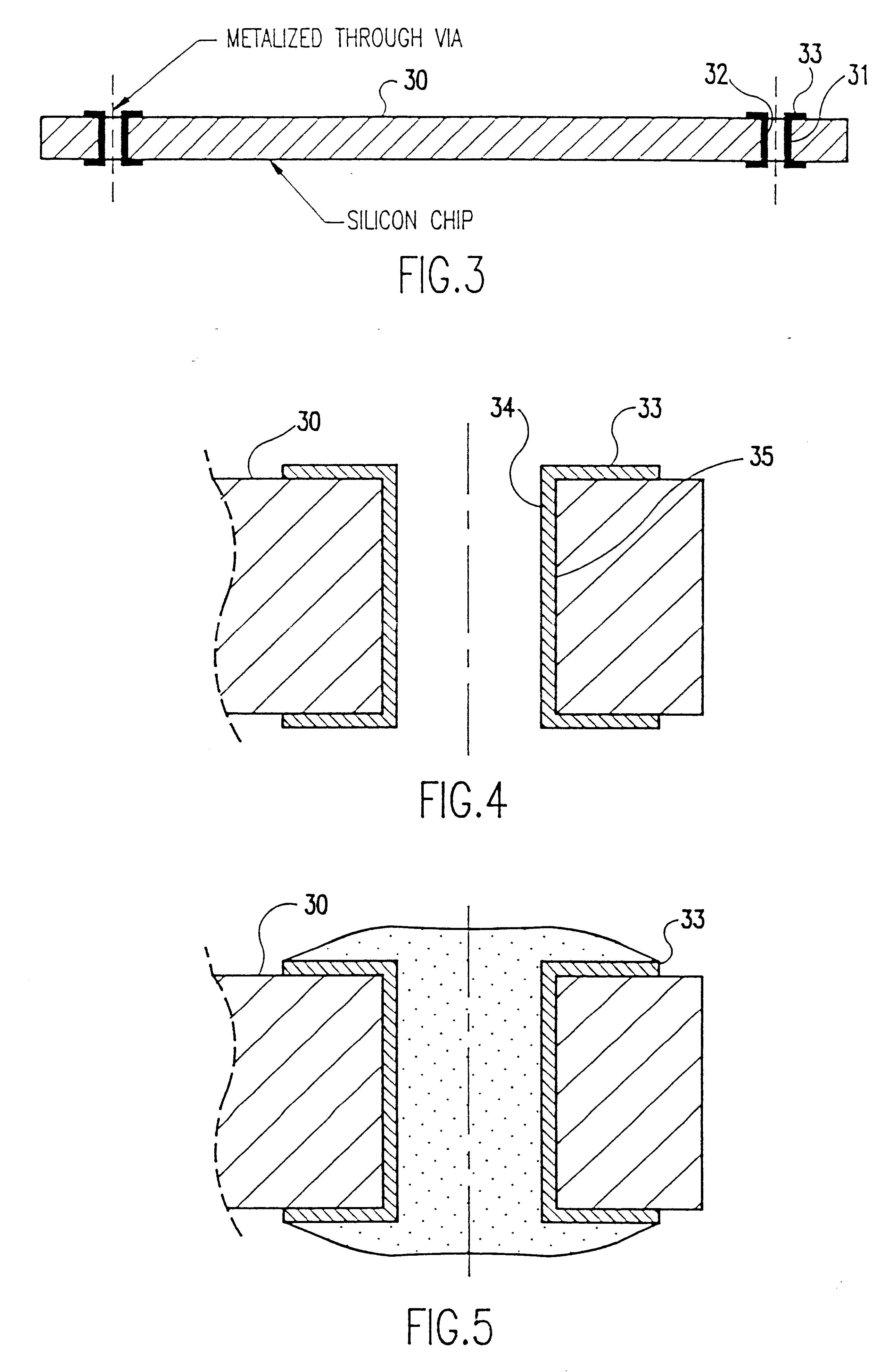

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

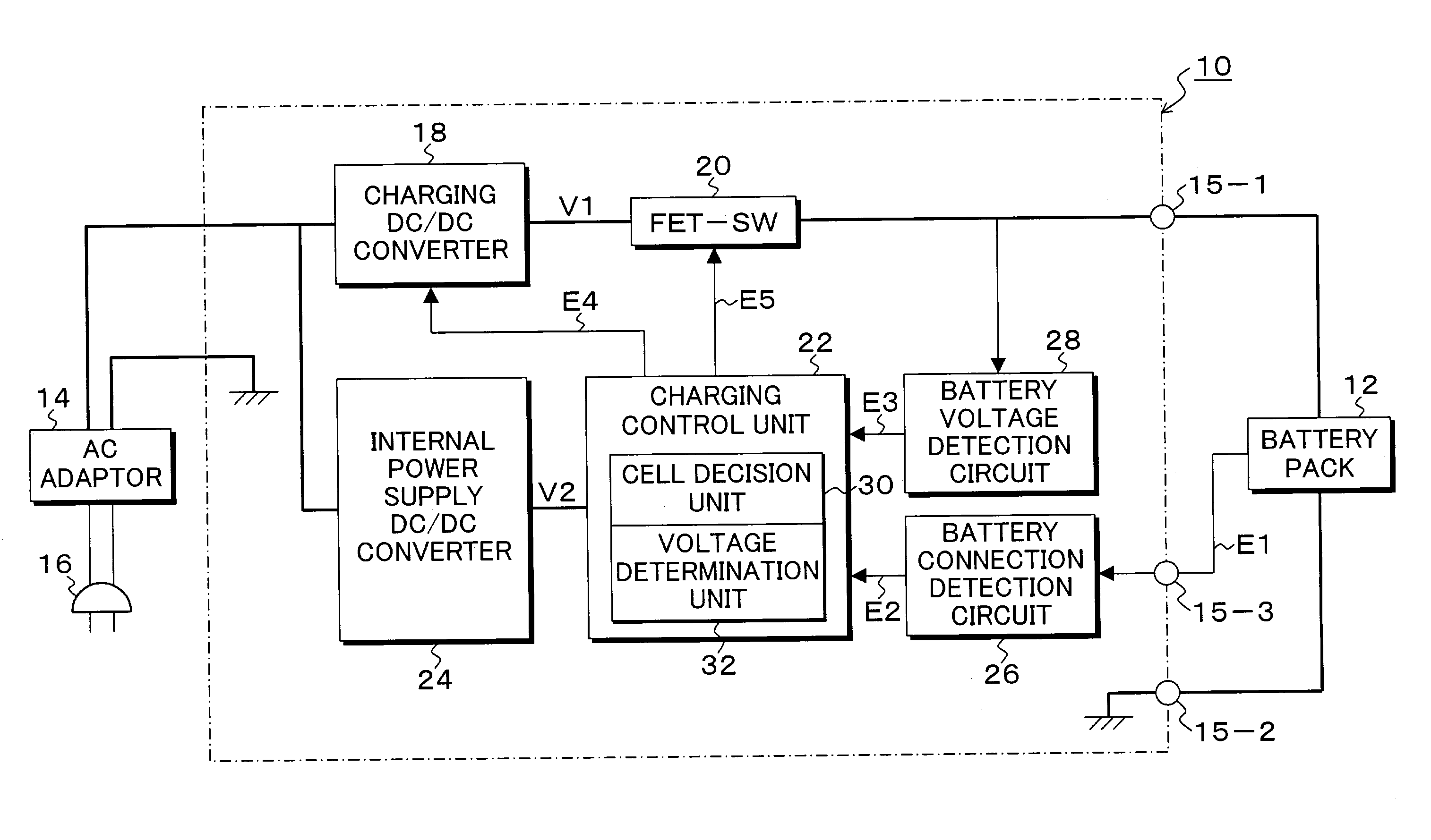

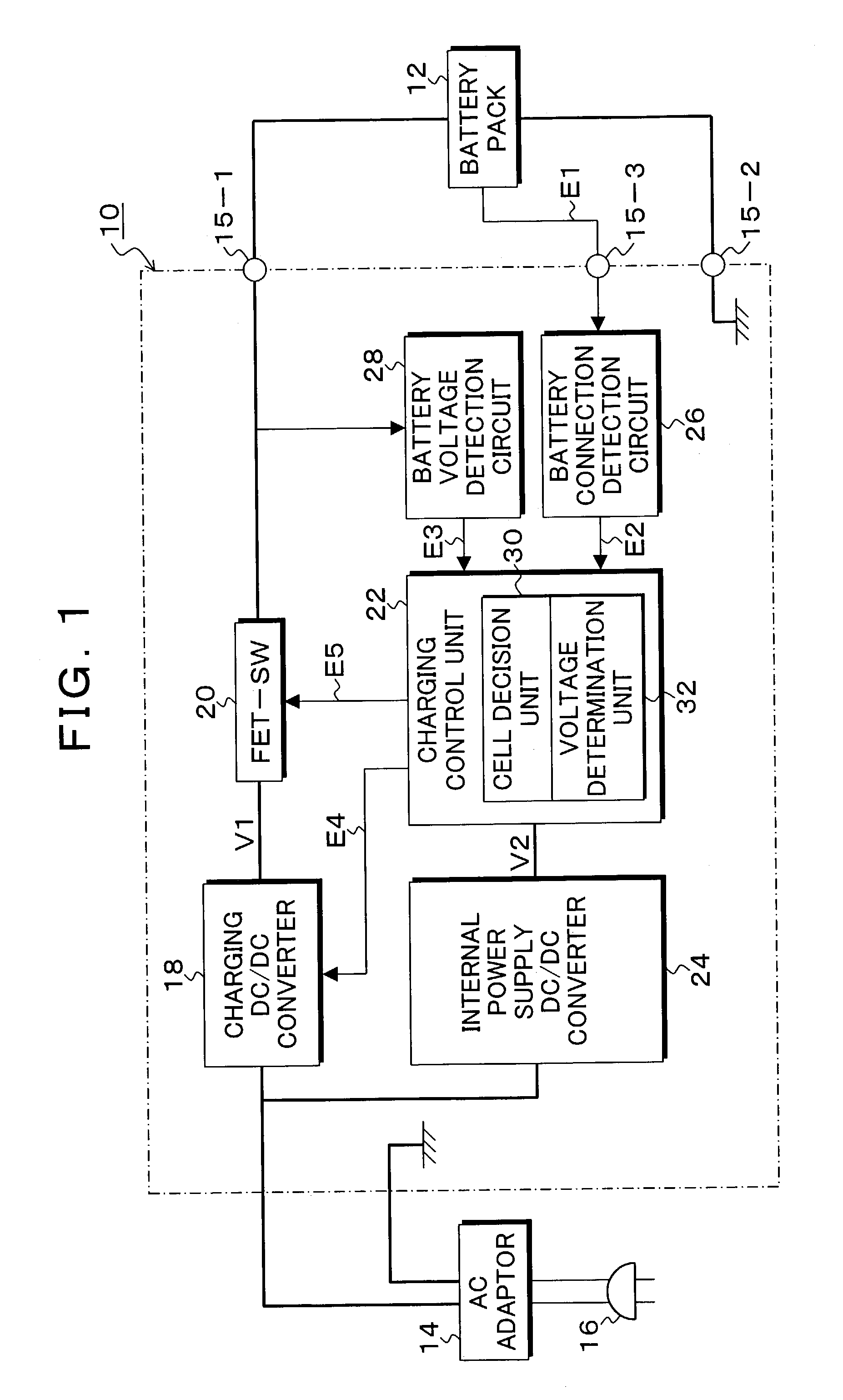

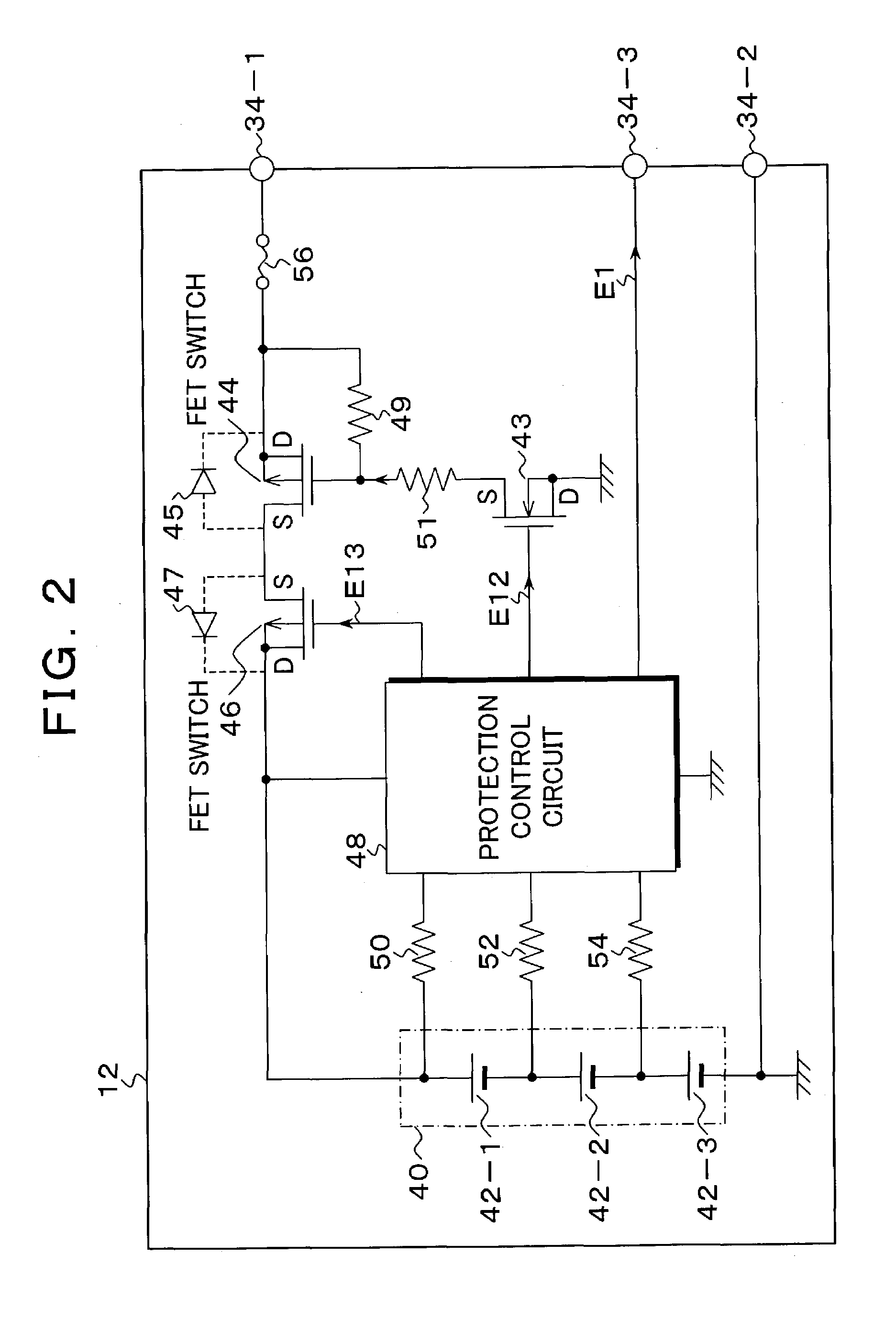

Electric charger and power supply device for portable terminal

InactiveUS7183748B1Prevents wasteful power consumptionCancel a battery cutoff operationElectric powerArrangements for several simultaneous batteriesCharge controlBattery cell

A charging control unit decides the number of battery cells on the basis of an output voltage of a battery pack, and an output voltage of a charging circuit is determined in accordance with the decided number of battery cells. Even though supply of an external power supply is detected, when a battery connection is not detected, the power supply circuit of the charging control unit is set in a stop state. In addition, when disconnection of the battery is detected, a canceling voltage for canceling a cutoff state caused by overdischarging of the battery is output. In a power supply device for a portable terminal, a capacitor electrically charged by an output voltage of main DC / DC converter is connected as an auxiliary power supply of a backup DC / DC converter to make exchange of the auxiliary battery unnecessary.

Owner:FUJITSU FRONTECH LTD

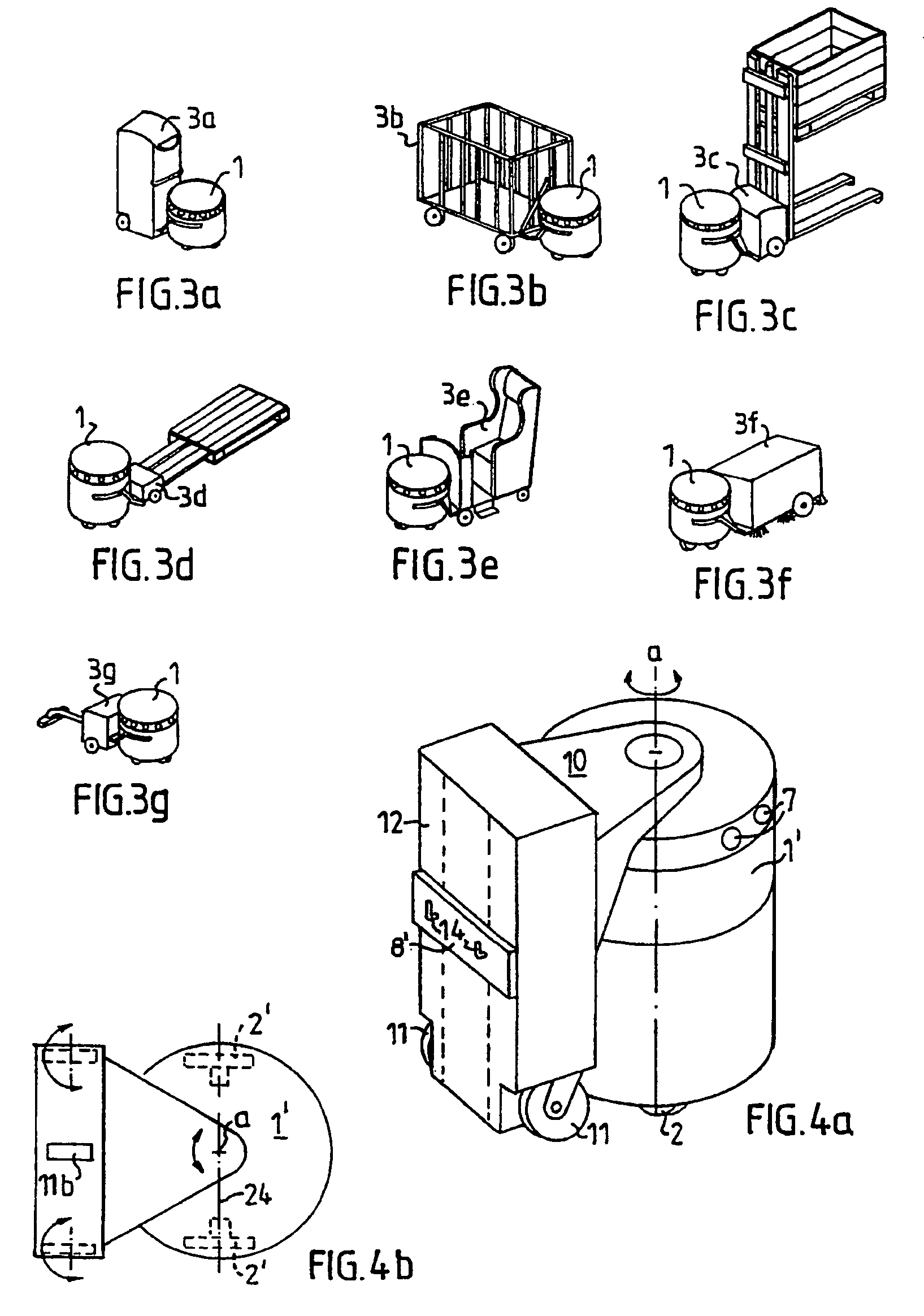

Robot system

InactiveUS7066291B2Good flexibilityEasy to operateProgramme-controlled manipulatorElectric devicesRobotic systemsCommunications system

A mobile robot system for performing a plurality of separate operations, and including at least one autonomous wheeled mobile robot having at least one wheel-driving motor, an on-board computer, a system for navigation, orientation, and maneuvering in an environment with moving obstacles, a sensor system, a wireless communication system operative to receive and send signals, and a plurality of dockable operation modules and operative to be selectively coupled to the autonomous mobile robot to form an operation unit, wherein the autonomous wheeled mobile robot autonomously docks to the dockable operation modules.

Owner:UNIBAP AB

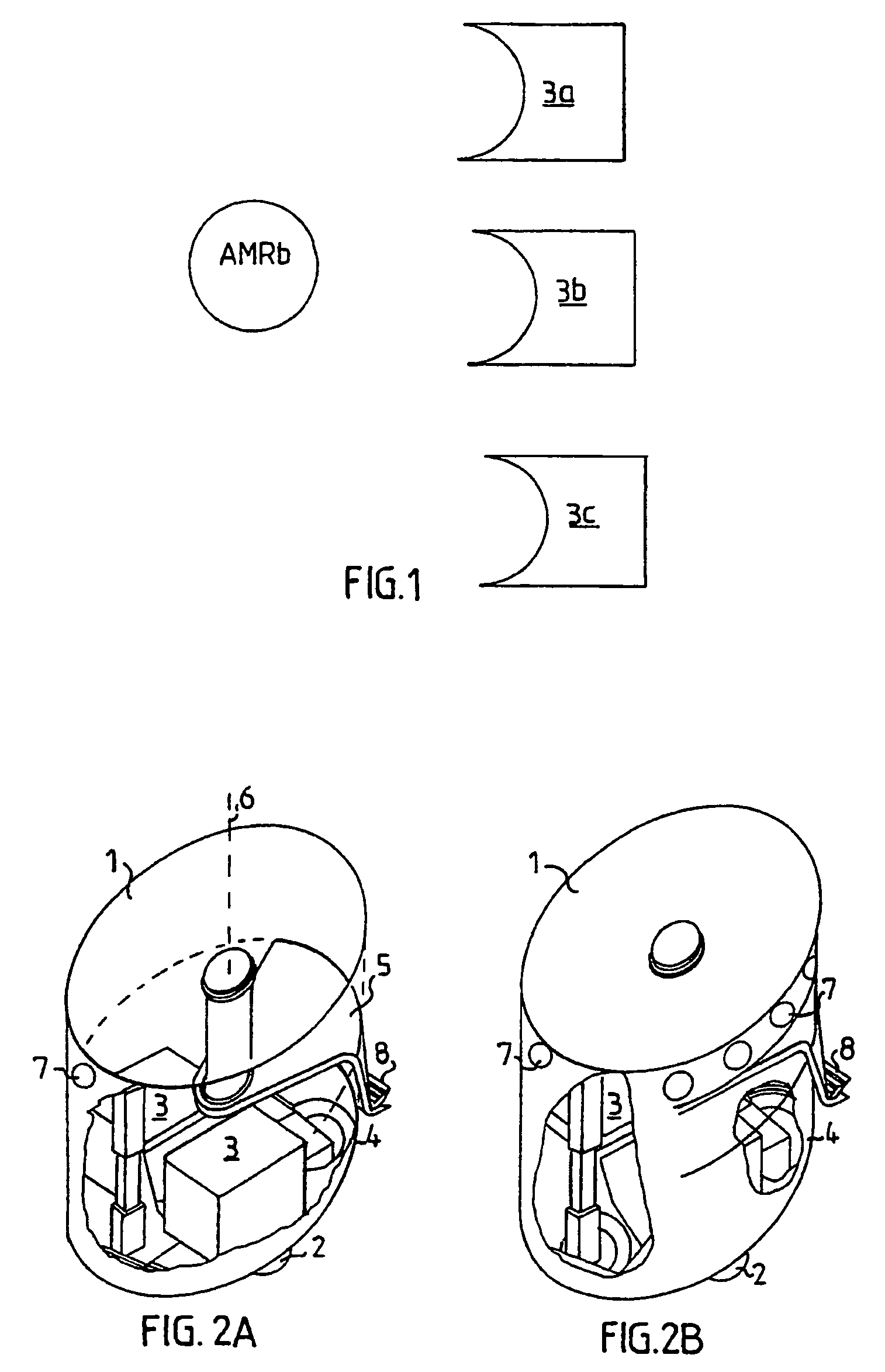

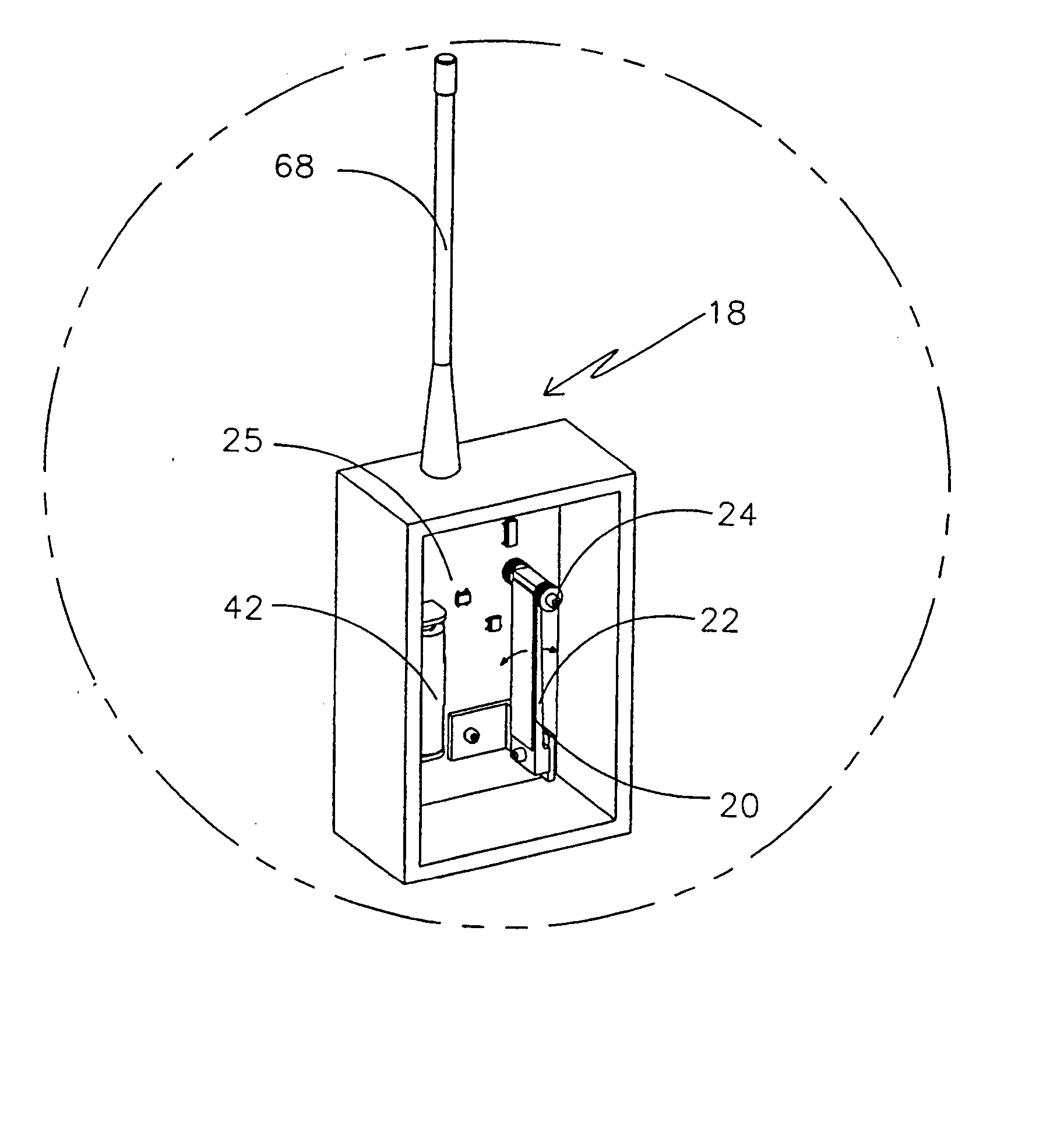

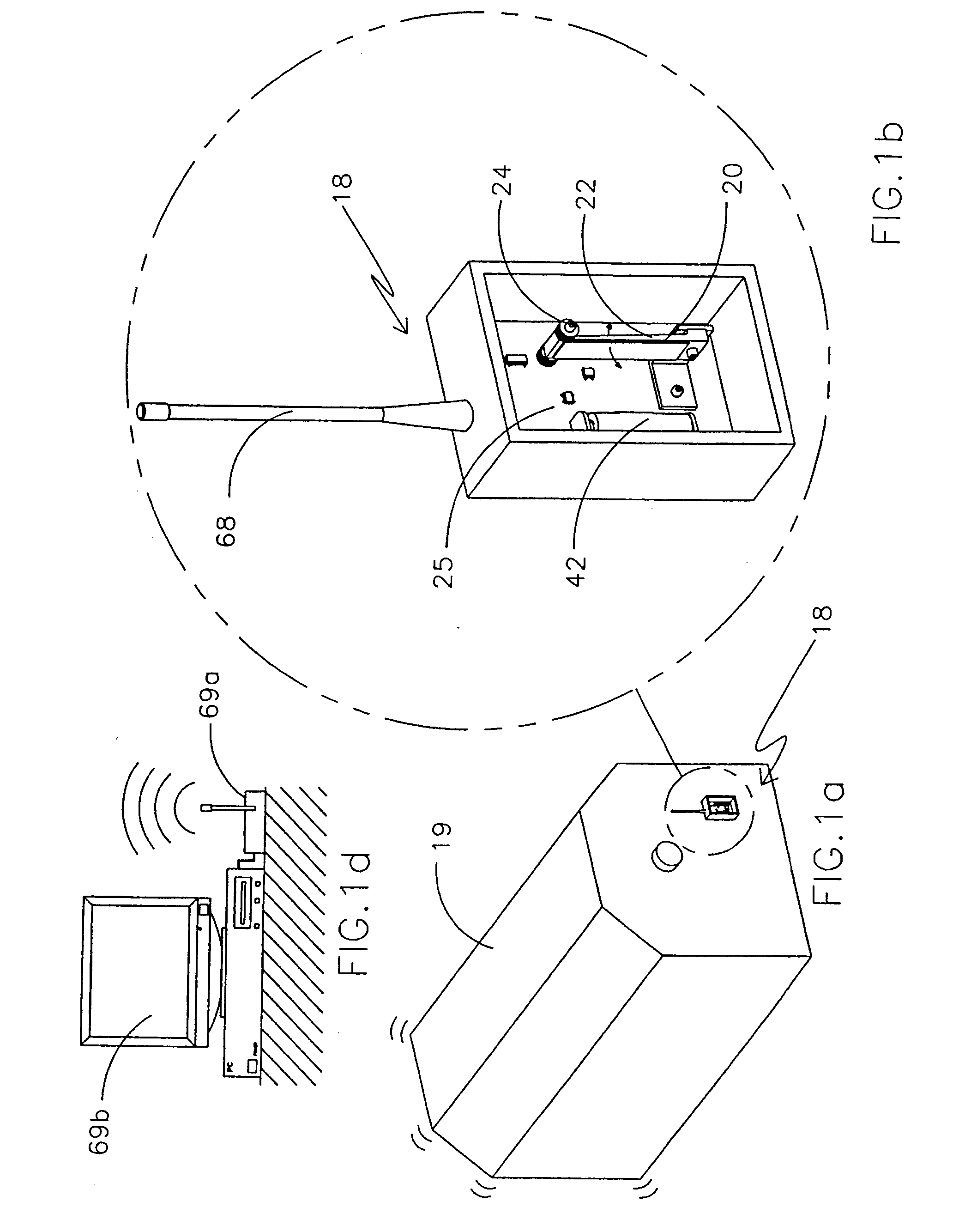

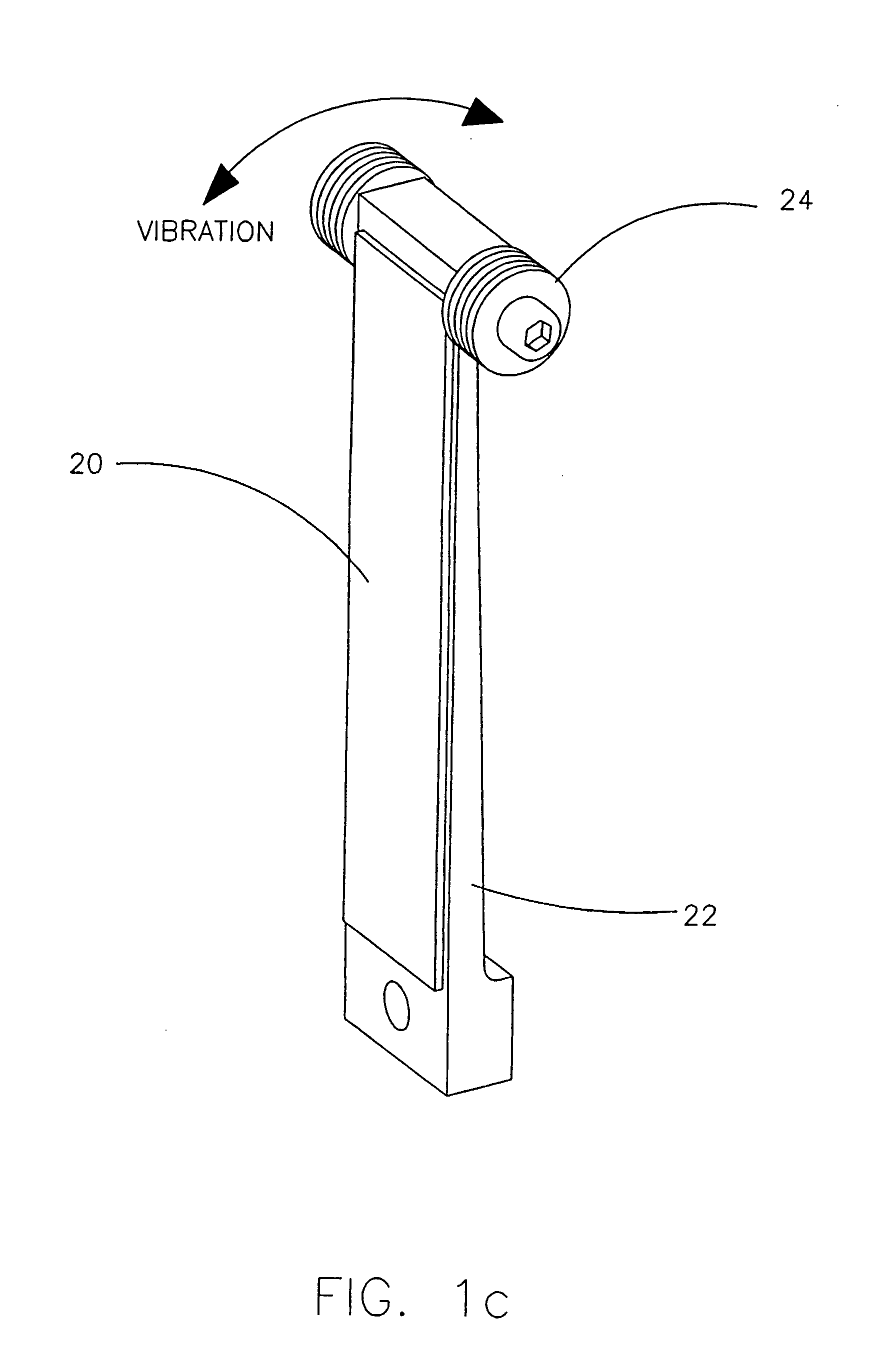

Shaft mounted energy harvesting for wireless sensor operation and data transmission

InactiveUS20050017602A1Provide informationEfficiently transferring energyBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesLine sensorRotational axis

A device for monitoring a rotating shaft is provided. The device measures strain in the shaft and provides angular velocity and torque in the shaft. The device includes a sensor, sensor conditioning circuitry, a microprocessor, and a transmitter, all located on a rotating shaft. The device obtains power by harvesting mechanical energy of the rotating shaft itself. Coils are provided rotating with the shaft and permanent magnets are mounted adjacent the rotating shaft so electrical energy is induced in the coils as they rotate through the magnetic field of the permanent magnets. A battery or capacitor is connected to the coils for storing energy. A microprocessor is connected to the sensors, the storage device, and the transmitter for managing power consumption and for monitoring the amount of electrical energy stored in the storage device and for switchably connecting the storage device to the transmitter when the stored energy exceeds a threshold.

Owner:LORD CORP

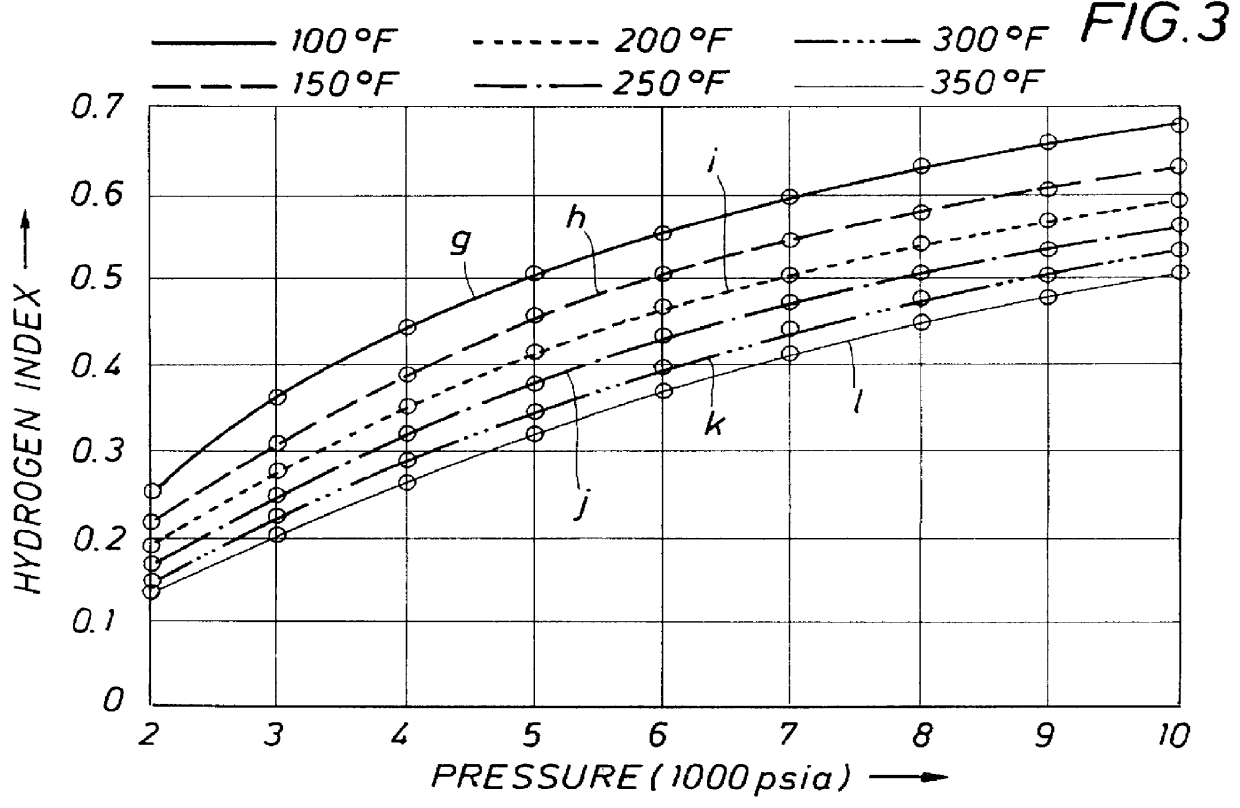

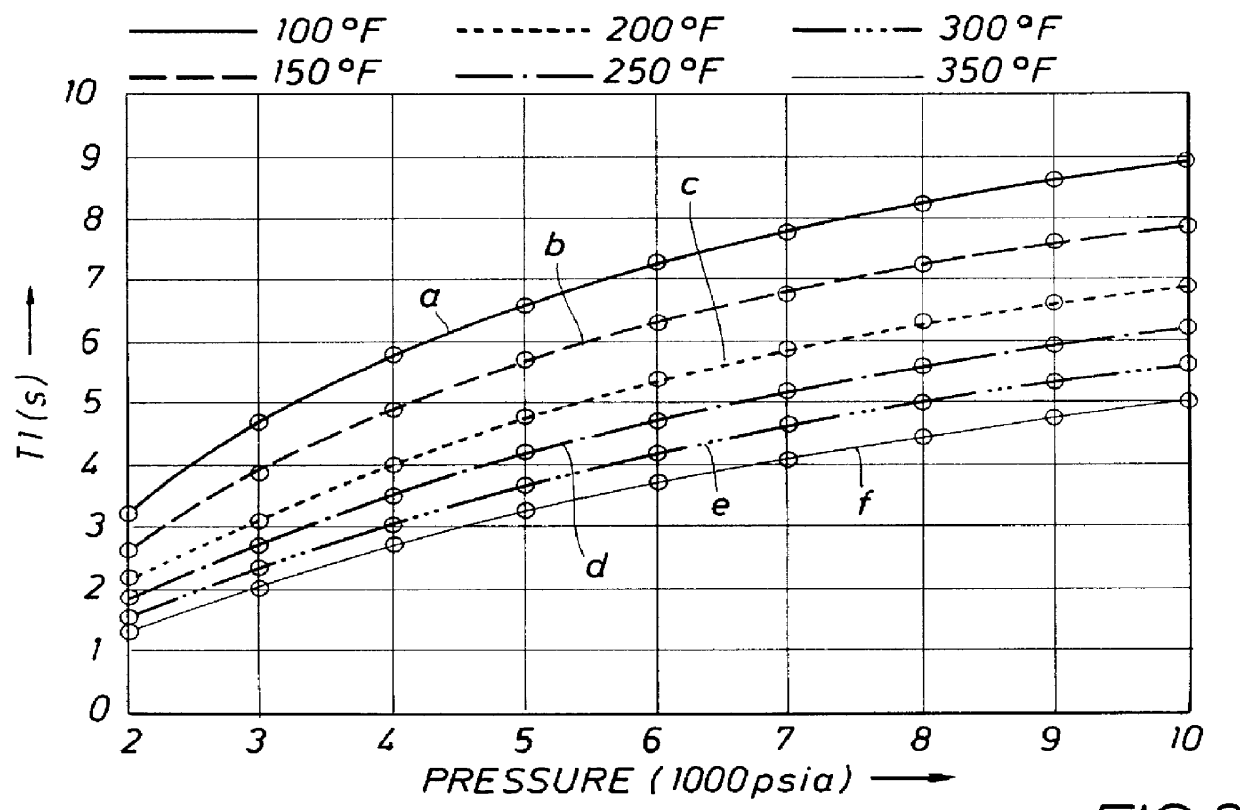

NMR logging of natural gas reservoirs

InactiveUS6094048ALarge capacityElectric/magnetic detection for well-loggingMaterial analysis by using resonanceRadio frequencyNuclear magnetic resonance logging

A method is provided to estimate the pore volume of a formation occupied by hydrocarbon phase or phases, the method comprising the steps of: obtaining a first pulsed NMR log of the formation, the pulse sequence of the first NMR log comprising an initial 90 DEG radio frequency pulse, followed by a series of 180 DEG radio frequency pulses starting at a time period tcp1 after the initial 90 DEG pulse, and the series of pulses comprising magnetic pulses each separated by a time period 2tcp1; obtaining a second pulsed NMR log of the formation, the pulse sequence of the second NMR log comprising an initial 90 DEG radio frequency pulse, followed by a series of 180 DEG pulses starting at a time period tcp2 after the initial 90 DEG pulse, and the series of 180 DEG pulses comprising radio frequency pulses each separated by a time period 2tcp2 wherein the time tcp2 is a time that is different from tcp1 by an amount of time sufficient to separate resultant peaks of transverse relaxation times attributable to the hydrocarbon phase or phases within the formation; and determining, from the first and the second NMR logs, the pore volume of a formation occupied by hydrocarbon phase or phases within the formation. In a preferred embodiment, pore volume occupied by hydrocarbon gas is determined, and tcp2 is a time that is greater than that which results in the measured transverse relaxation time of the hydrocarbon gas being less than about 2x10-3 seconds and tcp1 is a time that is less than that which results in the measured transverse relaxation time of the hydrocarbon gas being greater than about 4x10-3 seconds.

Owner:SHELL OIL CO

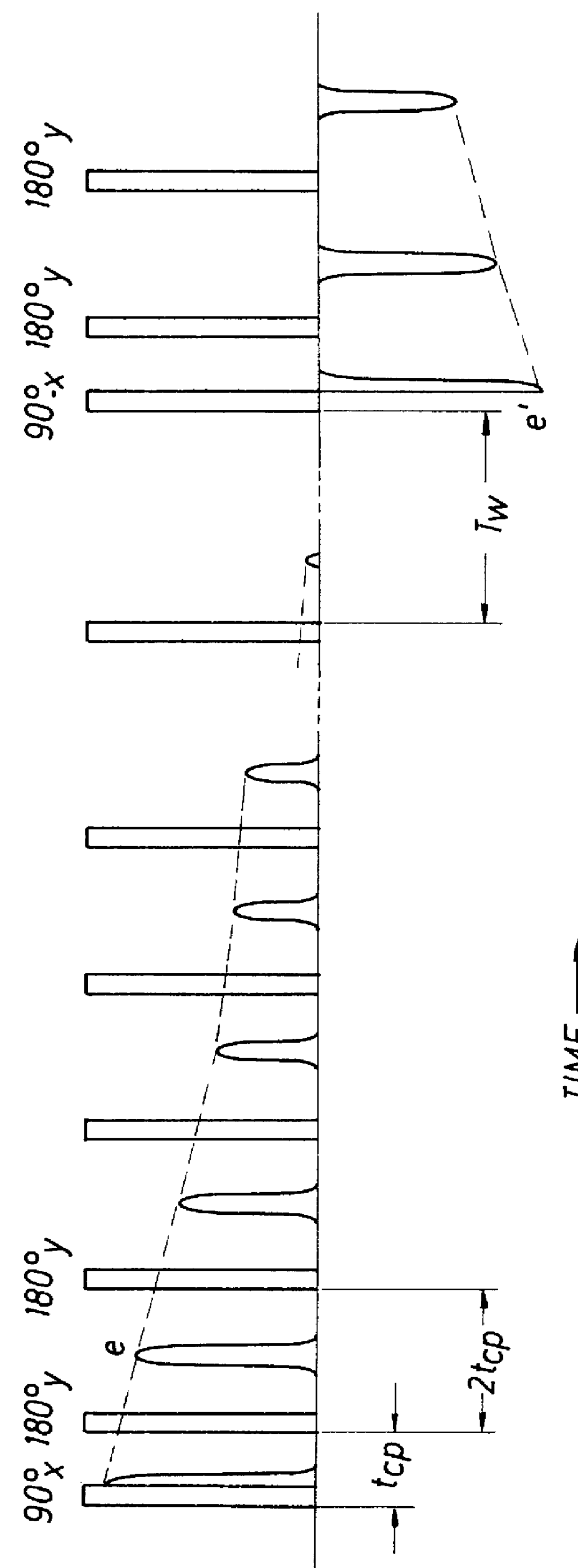

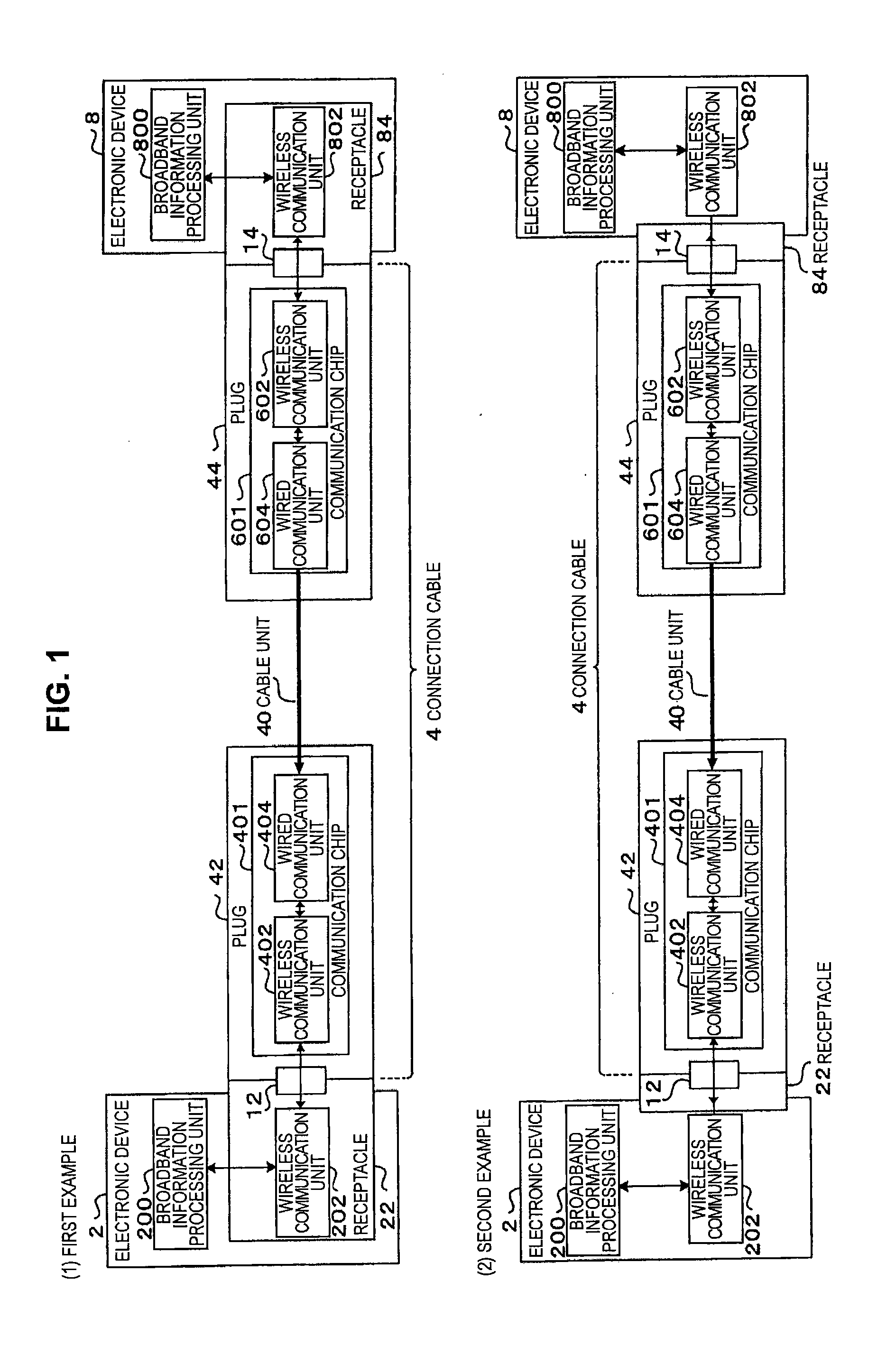

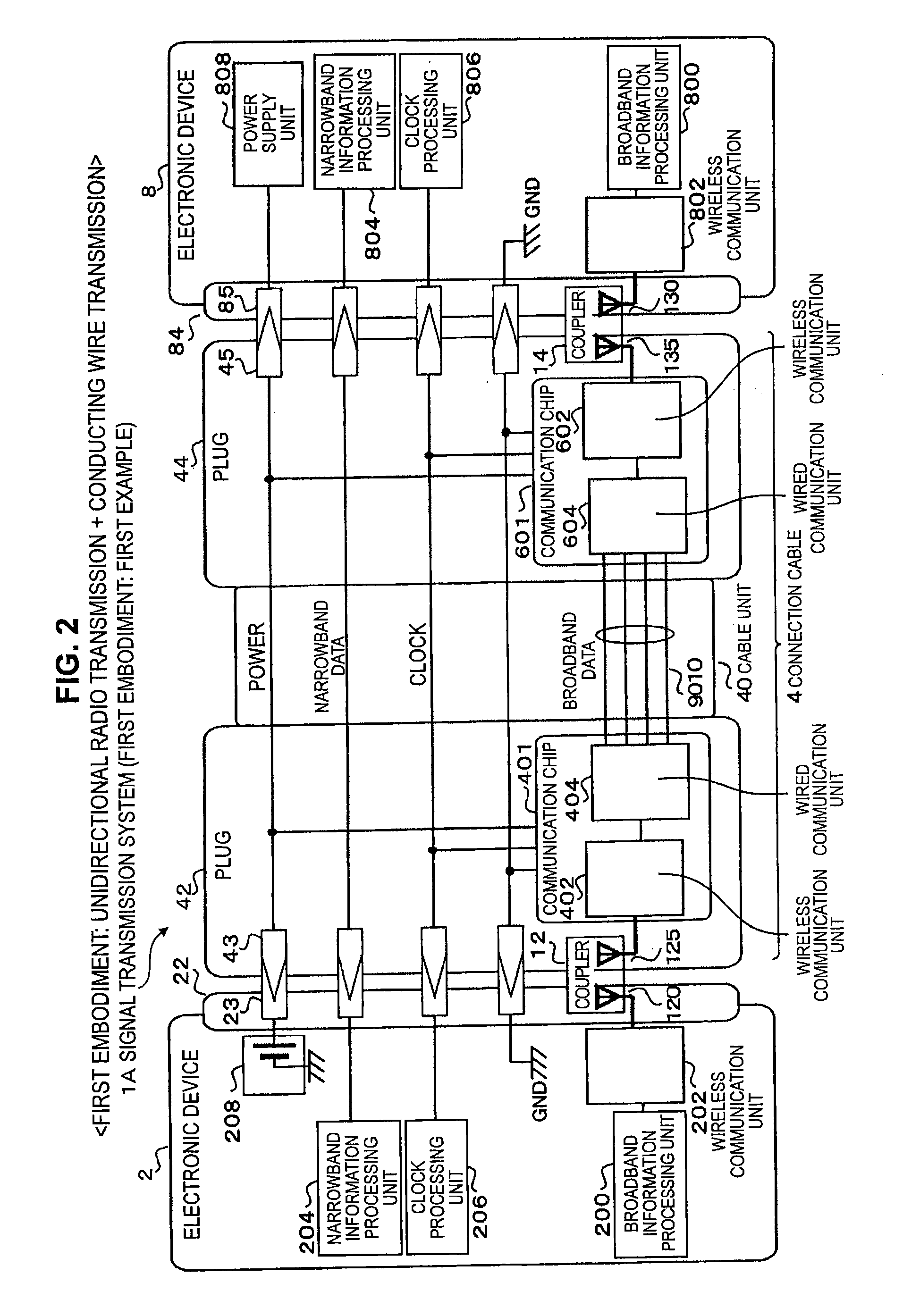

Signal transmission system, connector apparatus, electronic device, and signal transmission method

ActiveUS20130109317A1Increase speedLarge capacityTwo pole connectionsPower distribution line transmissionElectromagnetic field couplingRadio signal

A signal transmission system including: a first connector apparatus, and a second connector apparatus that is coupled with the first connector apparatus. The first connector apparatus and the second connector apparatus are coupled together to form an electromagnetic field coupling unit, and a transmission object signal is converted into a radio signal, which is then transmitted through the electromagnetic field coupling unit, between the first connector apparatus and the second connector apparatus.

Owner:SONY SEMICON SOLUTIONS CORP

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6187678B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionPrism

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:IBM CORP

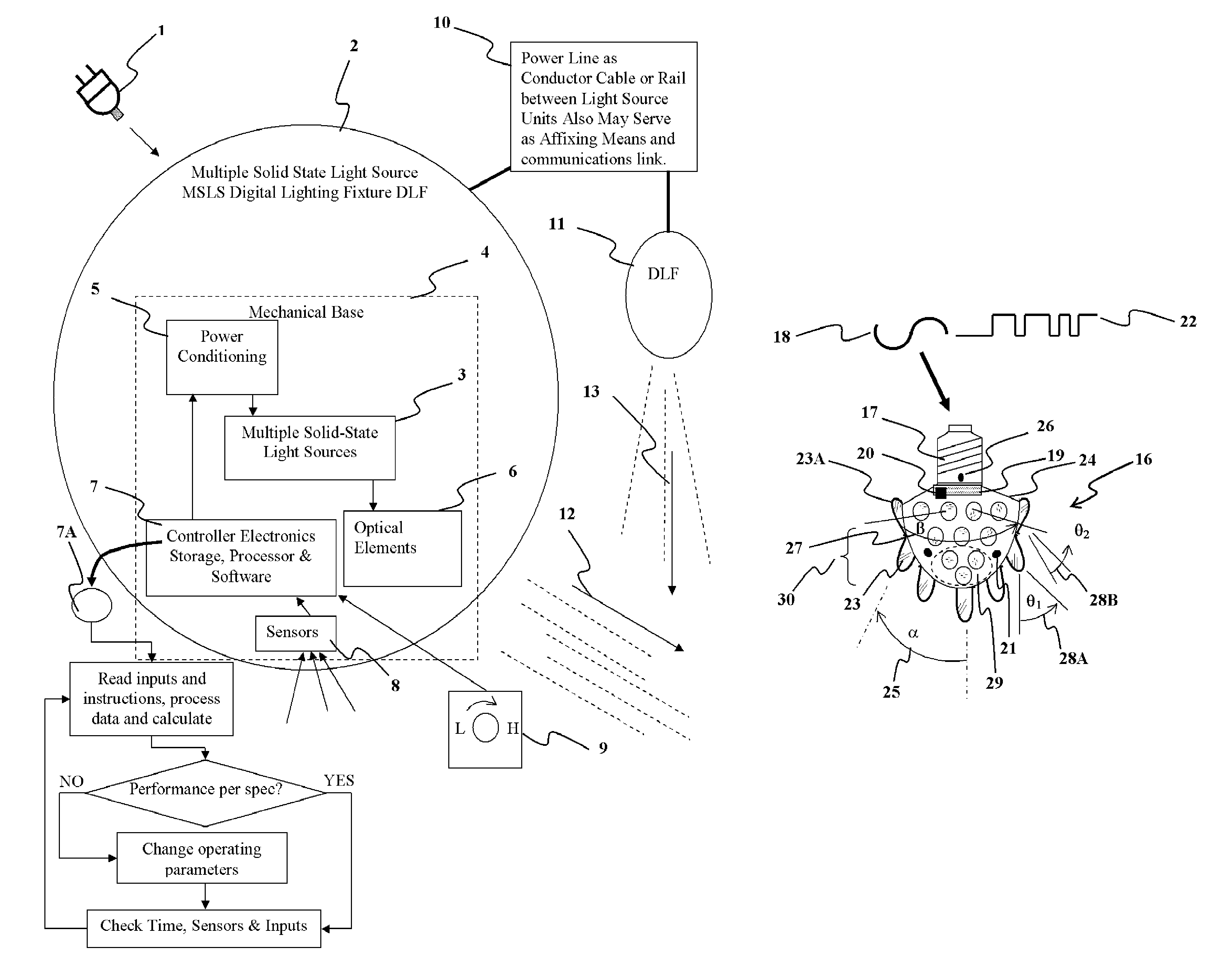

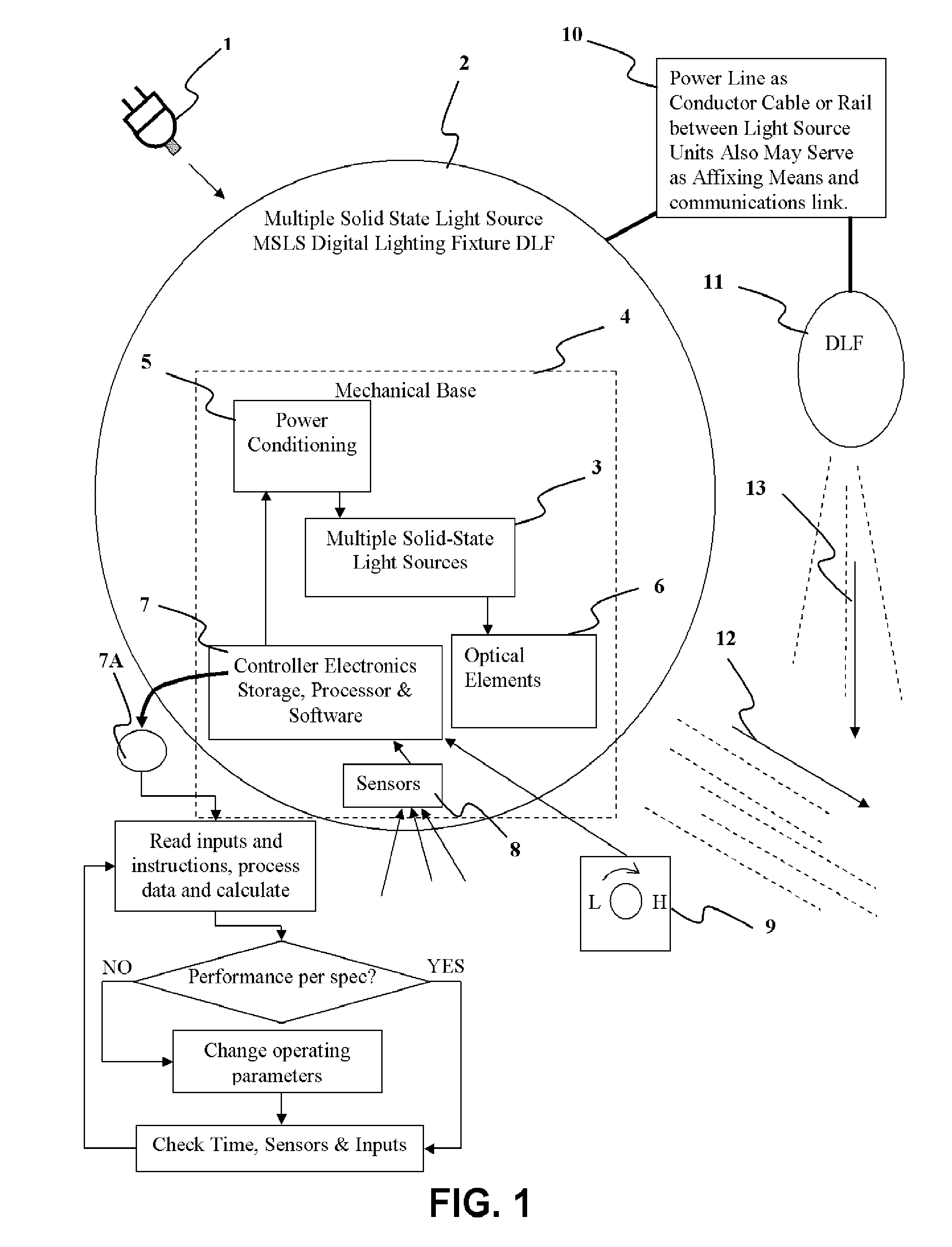

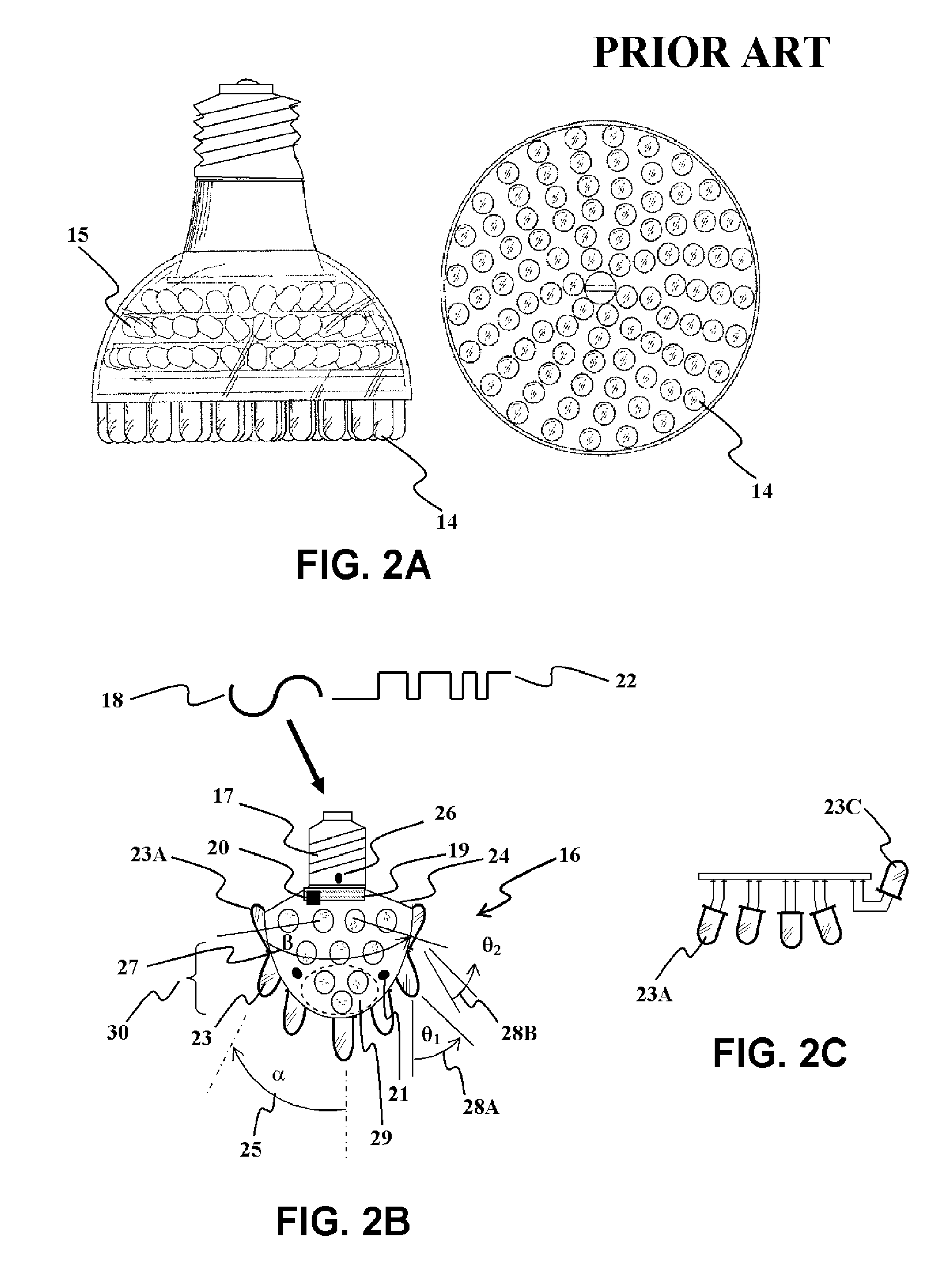

Multiple light-source illuminating system

InactiveUS8100552B2OptimizationAvoid narrow scopeMechanical apparatusLight source combinationsUser needsEngineering

A method and apparatus is provided for a multiple light-source illuminating device, the design and construction of which is derived from the lighting requirements of a specific lighting application. The resulting illuminating device (16) provides illumination according to the principles of lighting practice for the optimal performance of visual tasks. Coupling with sensors (21) and logical control (20) allows illumination intensity and spectrum to be varied according to changing user needs. The illuminating device includes multiple discrete light emitting components of different spatial intensity distribution and color spectrum mounted in specific orientations such that the application oriented combined lighting effect is created. The control is provided via a differentiated power supply (19) capable of affecting the current, voltage and duty cycle determining the relative contribution of each light source effecting a different spatial intensity distribution and color spectrum.

Owner:SPERO YECHEZKAL EVAN

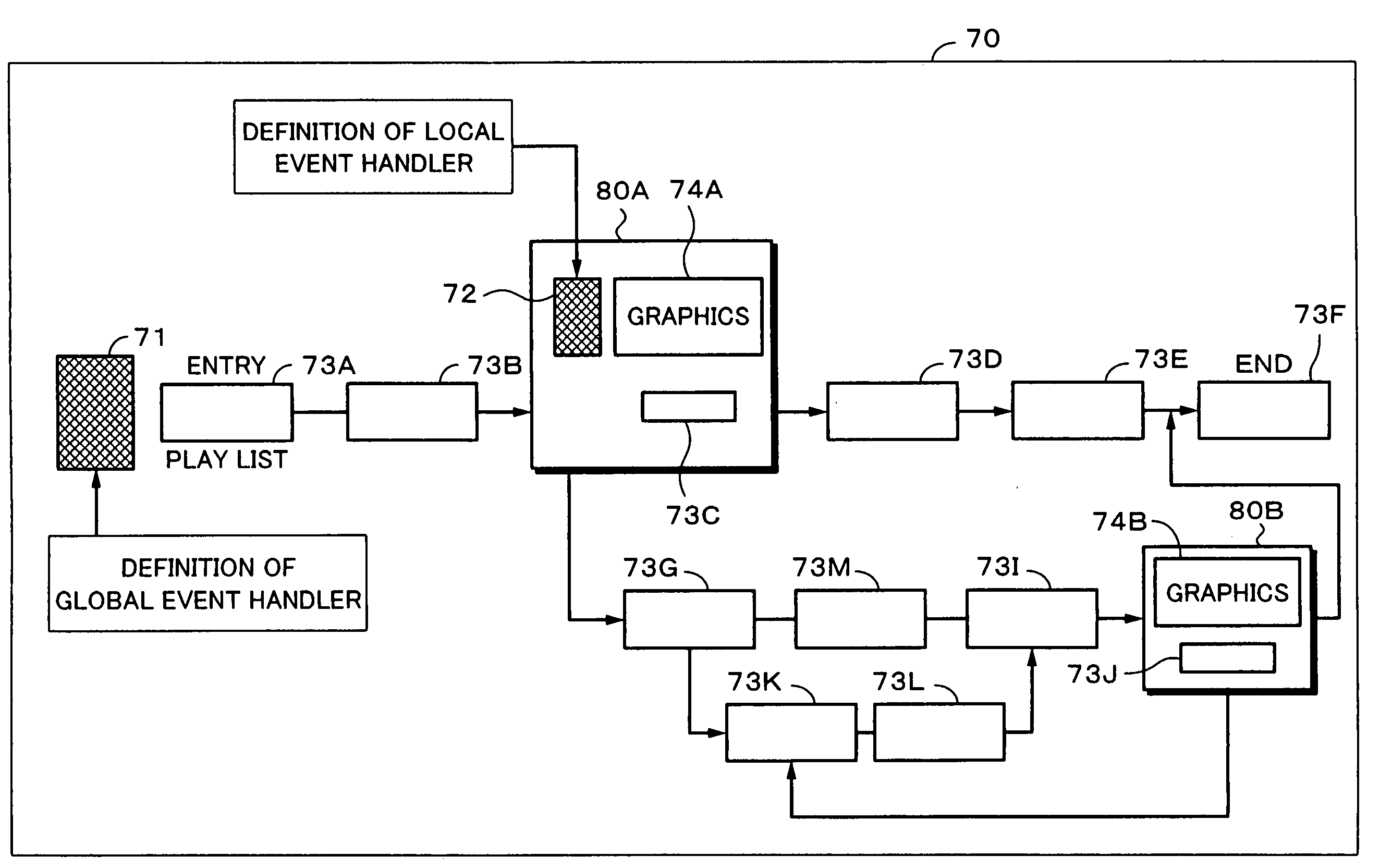

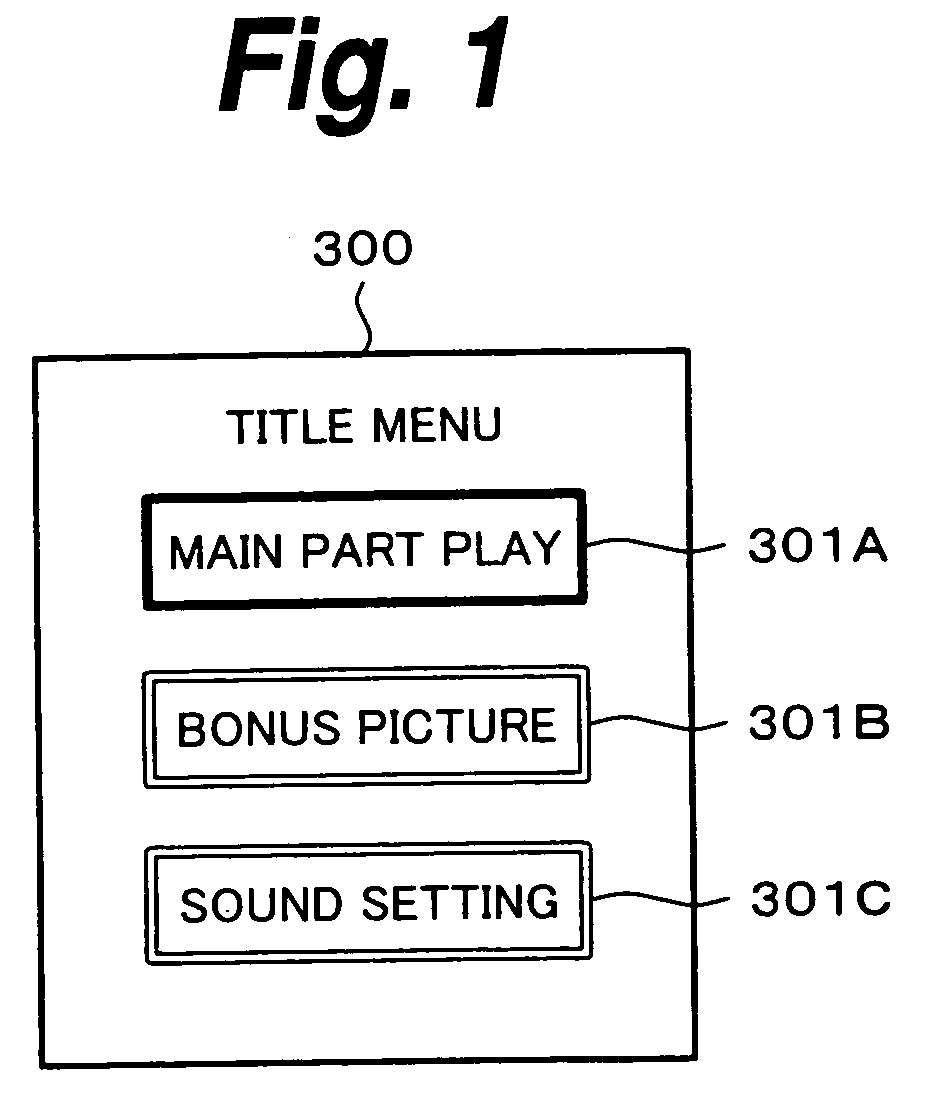

Reproducing device, reproduction method, reproduction program, and recording medium

ActiveUS20050105888A1Easy to displayIncrease flexibilityTelevision system detailsPicture reproducers using cathode ray tubesComputer hardwareGraphics

For a content-prerecorded large capacity disc-shaped recording medium, a user interface having high flexibility is accomplished. Button image data, corresponding sound data as an effect sound, and control commands for the sound data and image data are multiplexed with a stream and recorded on the disc. A scenario reproduced from the disc is stored in a buffer 104. The image data and sound data are stored in a buffer 105. Image data is read from the buffer 105 in accordance with a scenario and expanded to a graphics plane 133. In addition, corresponding sound data is read from the buffer 105 and reproduced by a sound player 106D. When a button image is varied in accordance with a state change of the button, an effect sound is reproduced. As a result, a more effective user interface is accomplished.

Owner:SONY CORP

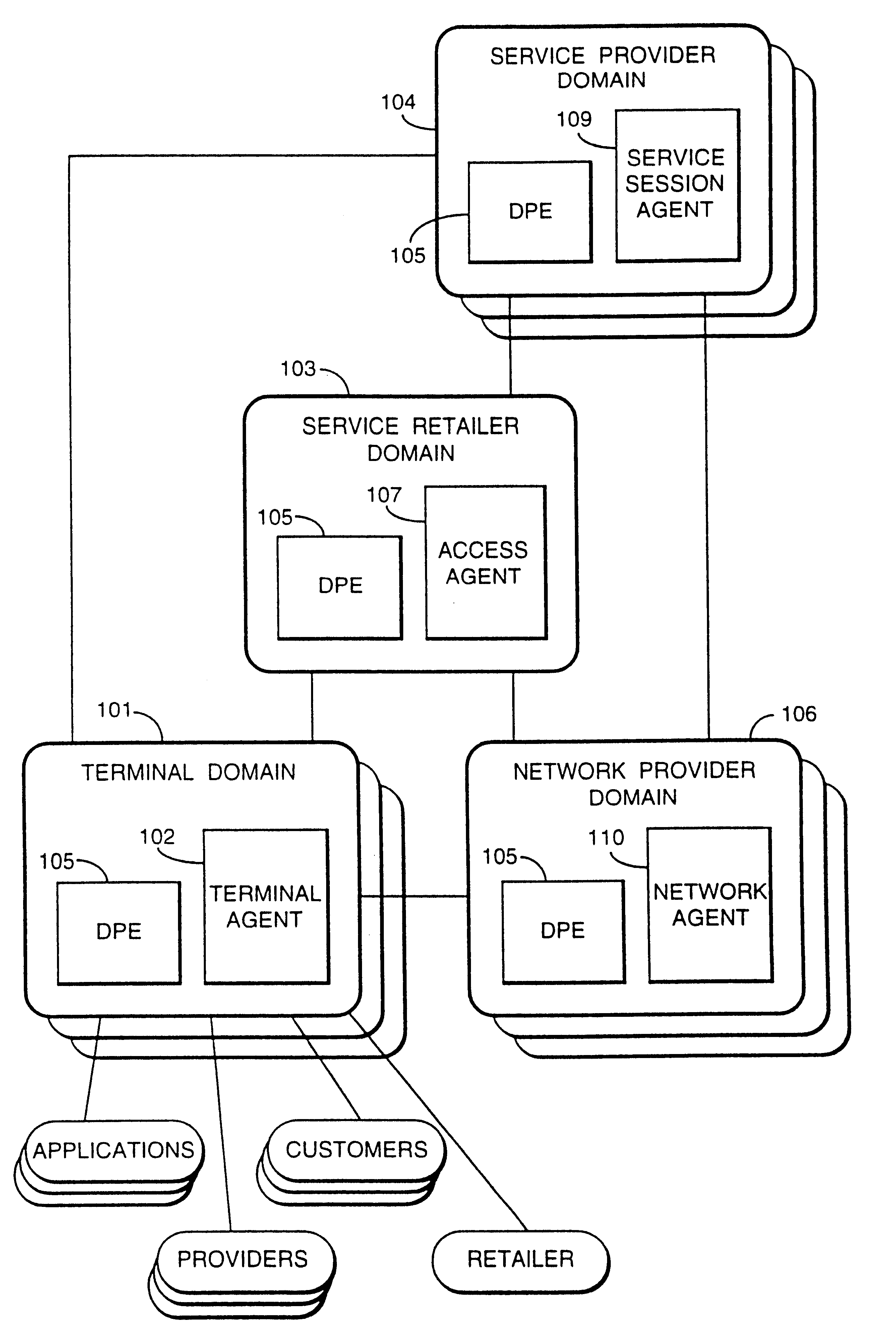

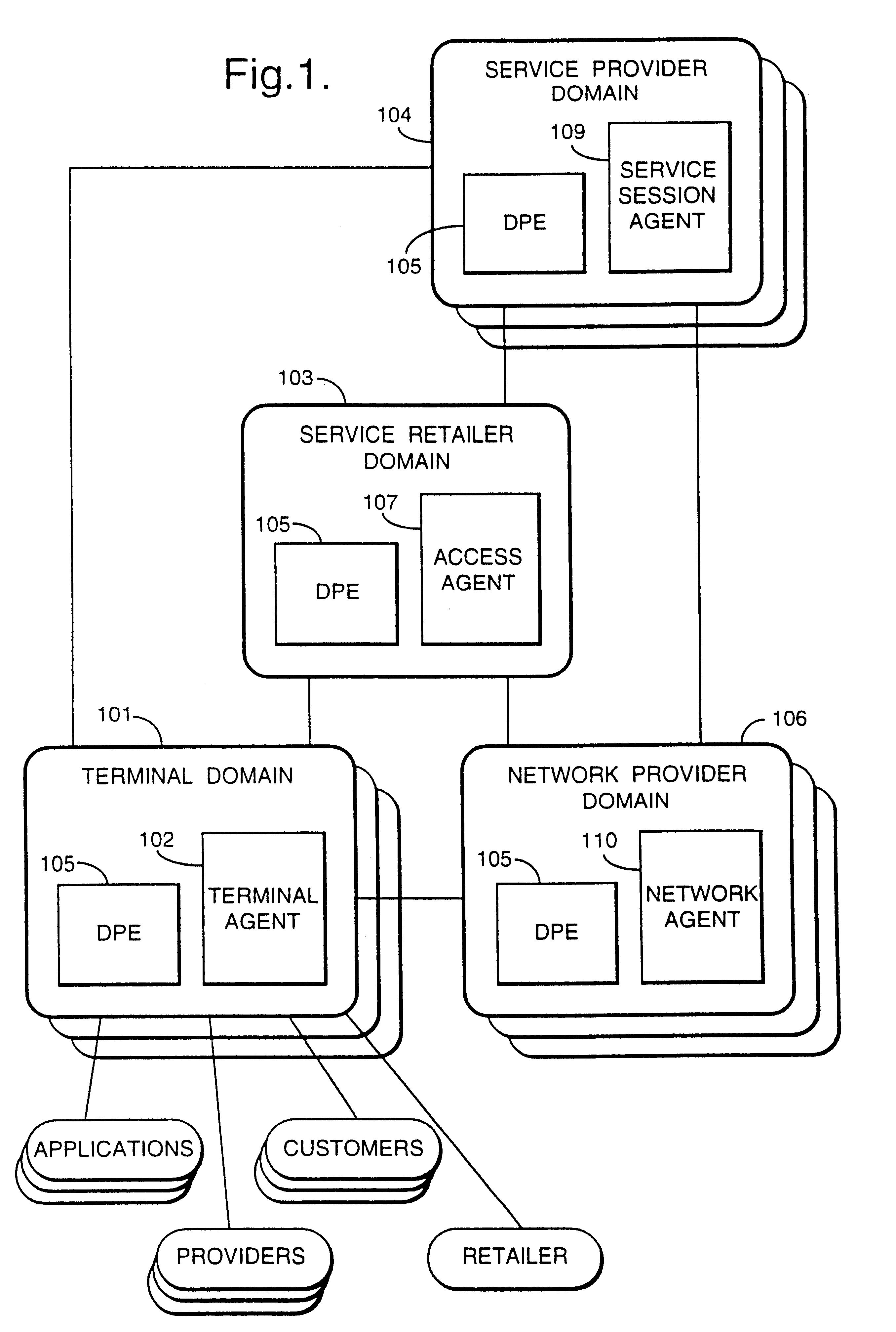

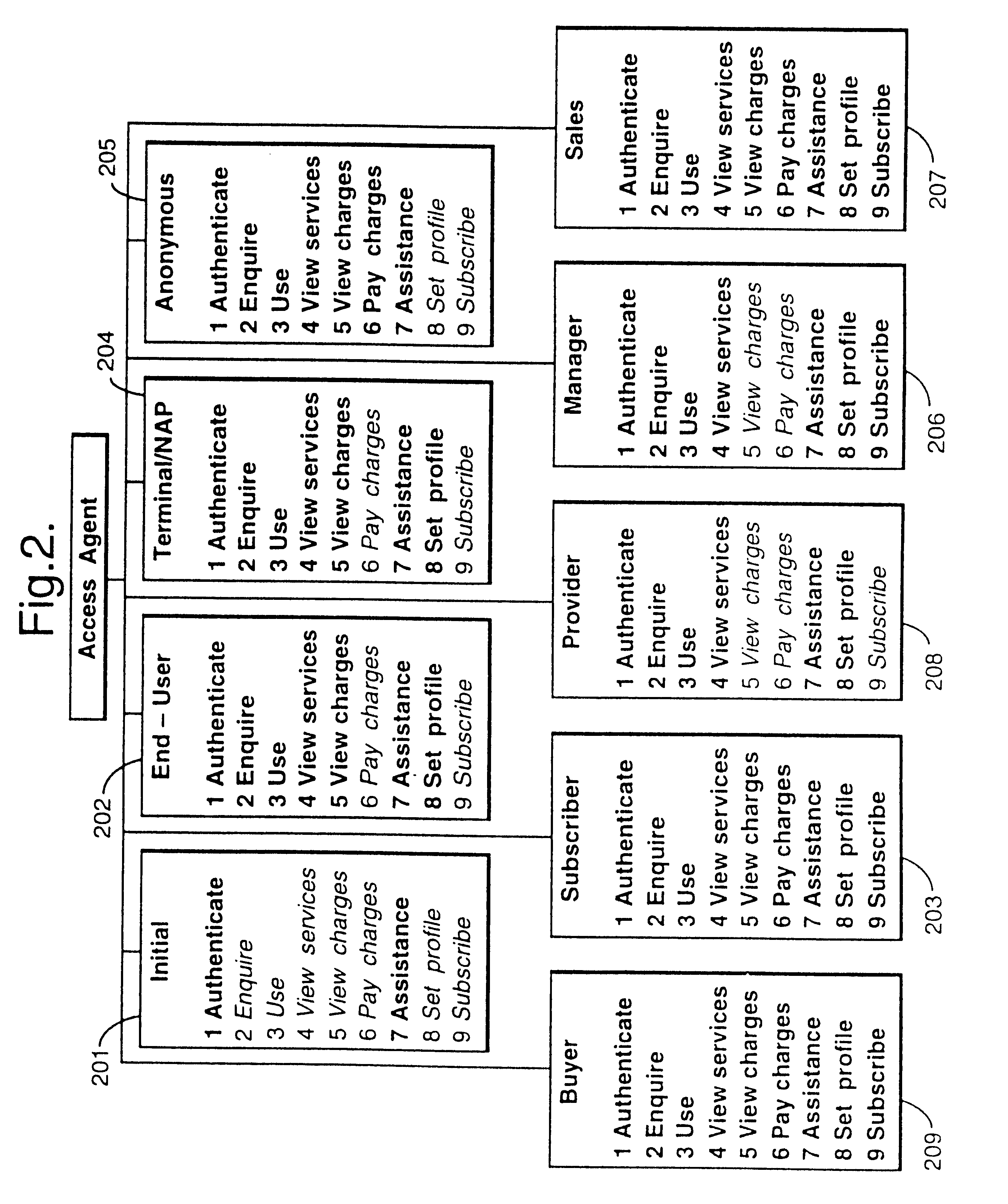

Reconfigurable service provision via a communication network

InactiveUS6330586B1Customer base for information services is particularly wideLarge capacityMultiplex system selection arrangementsData processing applicationsReconfigurabilityReusable software

A services provision system provides information services over one or more communications networks and has a software infrastructure divided into domains. Each domain has an intelligent software agent and this community of agents sits in a computing environment represented in each domain by a DPE kernel. The community of agents co-operates to provide service and service management functionality to a user. At least one of the agents is reconfigurable to change the functionality the system makes available. Reconfigurability is based on the use of a plurality of reusable software modules, the agent reconfiguring by selecting a new combination of modules. The software modules themselves incorporate rules, or policies, which determine process steps offered by the modules at run-time. These policies are external to the modules and may be loaded at run-time, allowing dynamic modification to functionality of the system. The system as a whole offers functionality associated with using services, providing them and managing them and the reconfigurability allows it to offer the different types of functionality in an efficient way. It also allows access control to functionality at different levels with particularly good security against fraudulent use.

Owner:BRITISH TELECOMM PLC

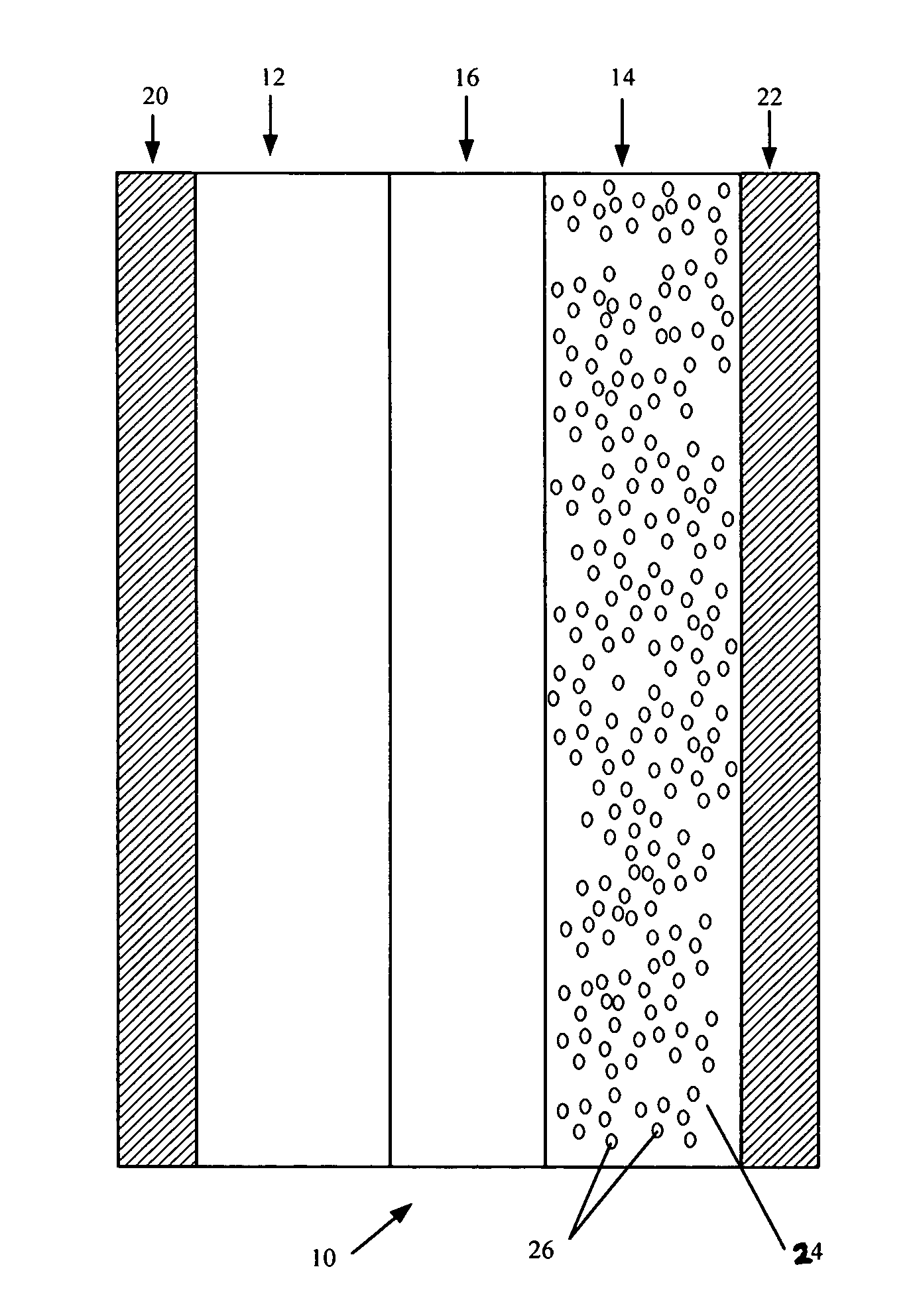

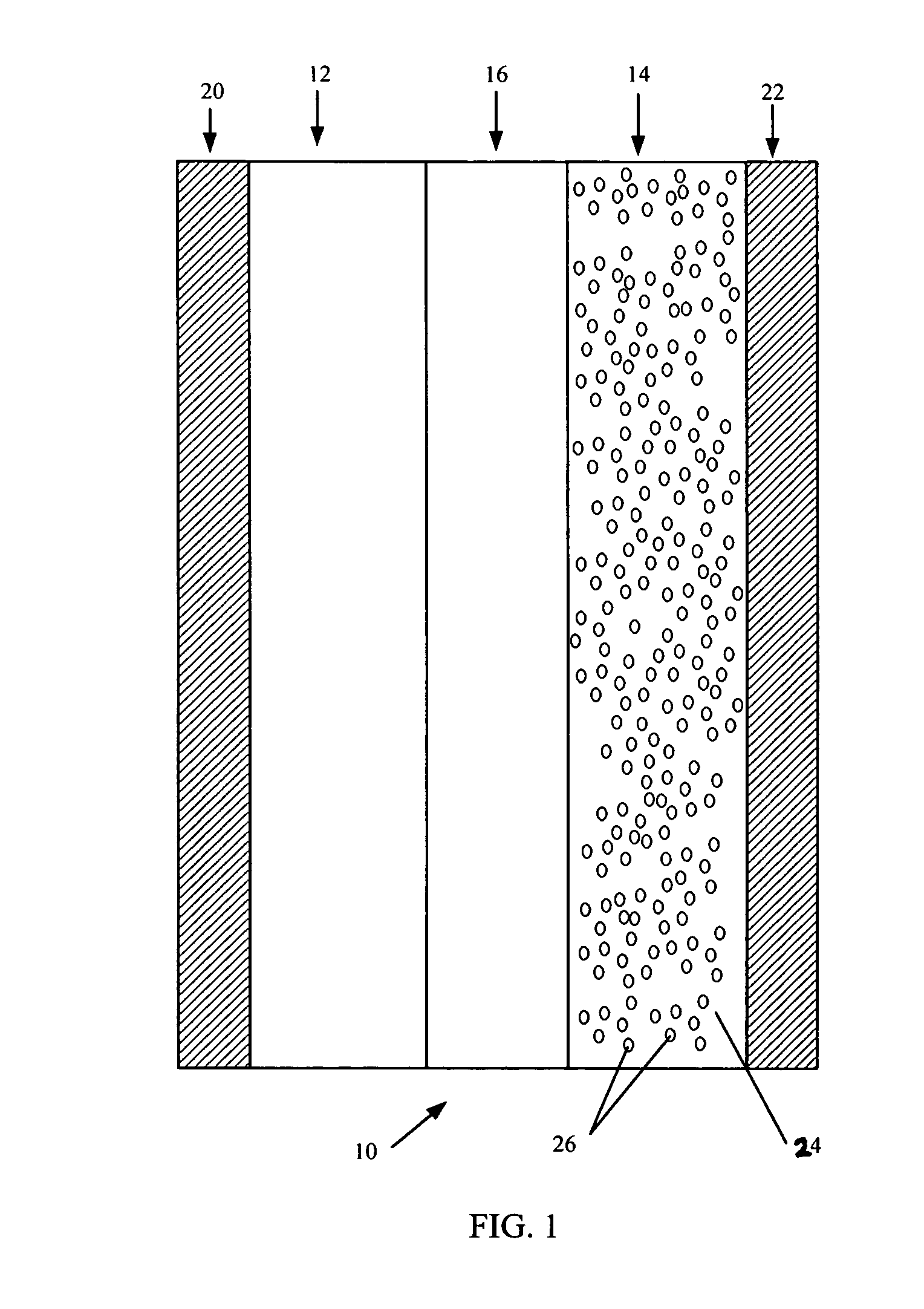

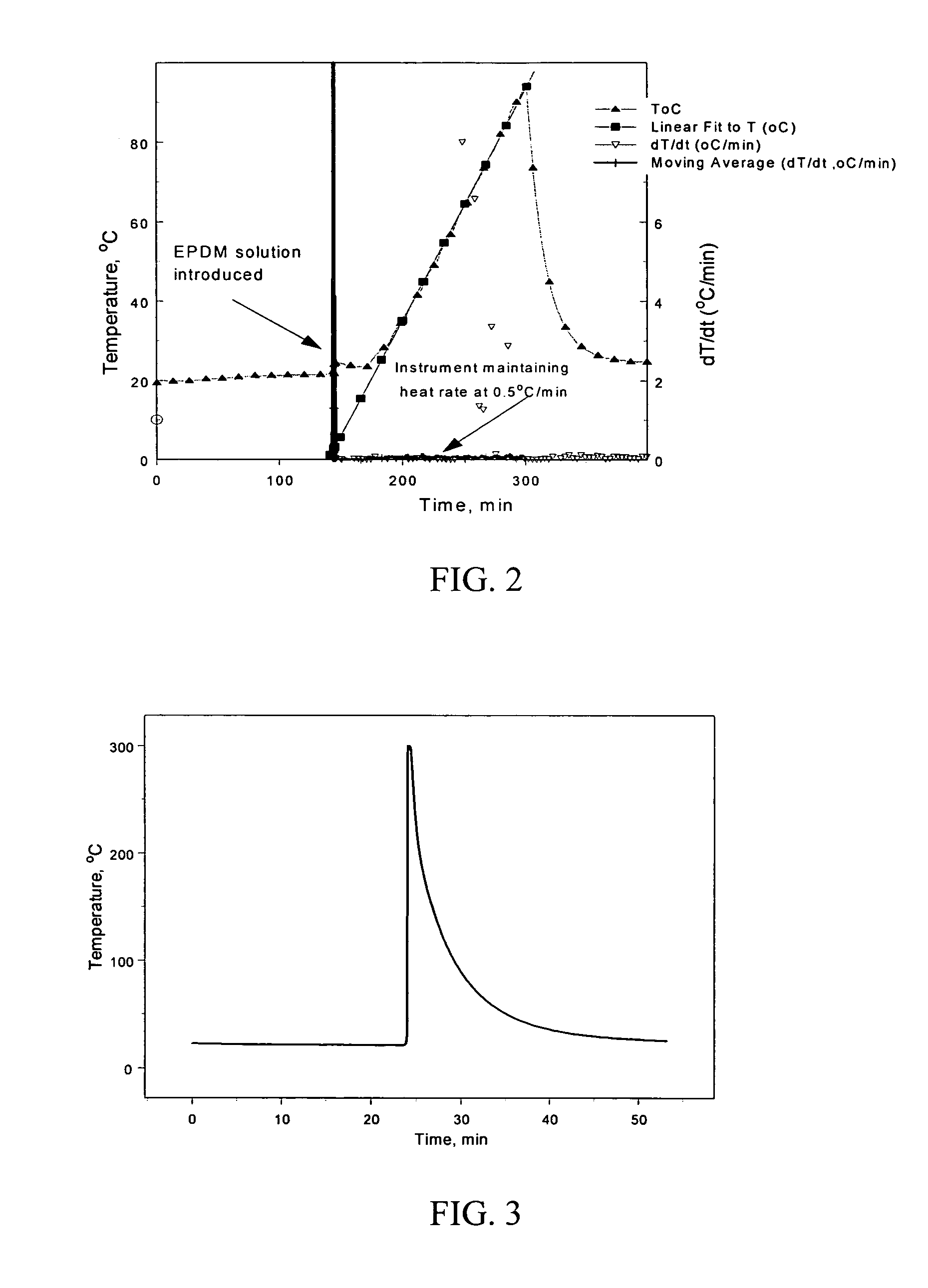

Li/air non-aqueous batteries

ActiveUS20070117007A1Improve battery performanceLarge capacityFuel and primary cellsFuel and secondary cellsLithiumOxygen

Non-aqueous alkali metal (e.g., Li) / oxygen battery cells constructed with a protected anode that minimizes anode degradation and maximizes cathode performance by enabling the use of cathode performance enhancing solvents in the catholyte have negligible self-discharge and high deliverable capacity. In particular, protected lithium-oxygen batteries with non-aqueous catholytes have this improved performance.

Owner:POLYPLUS BATTERY CO INC

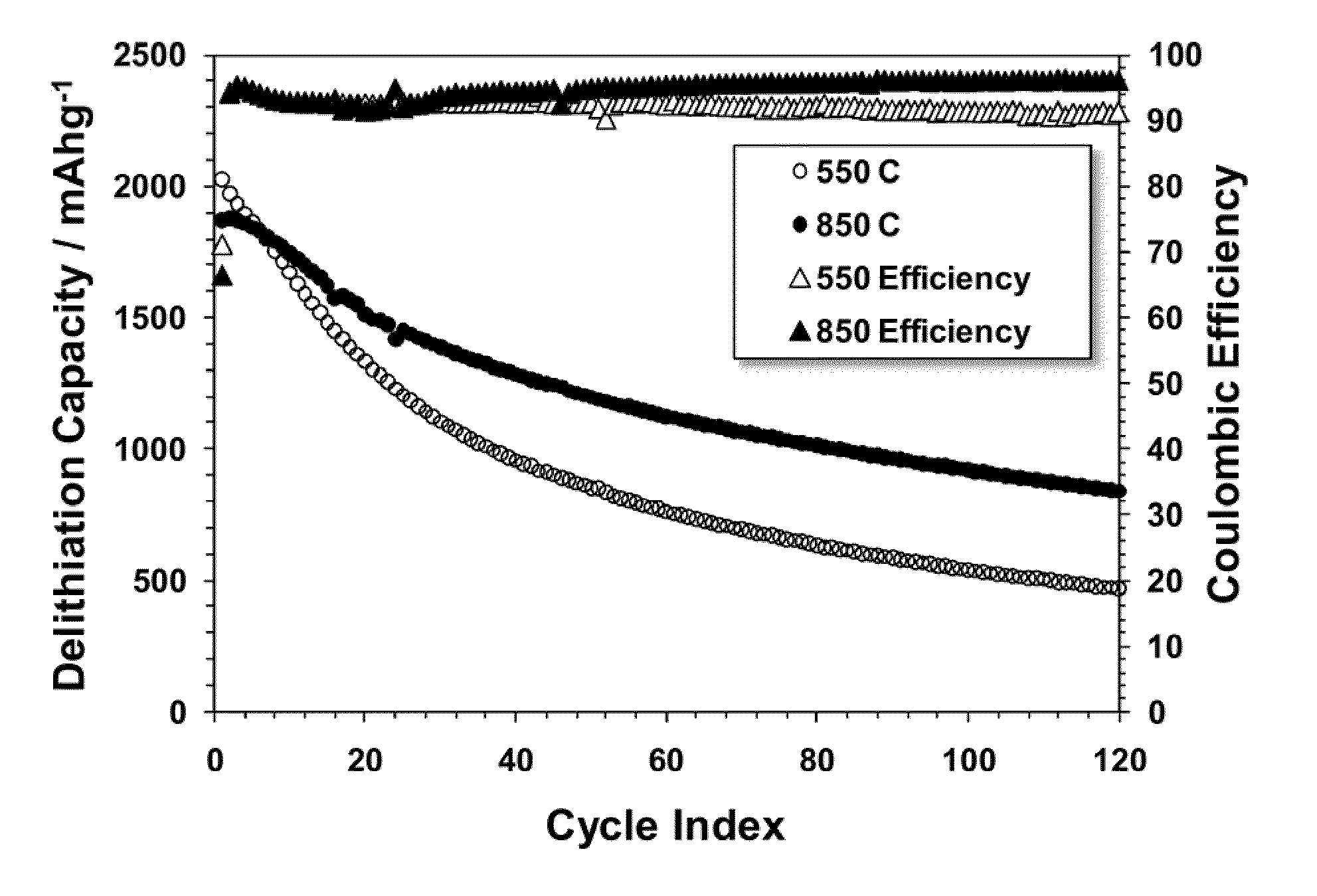

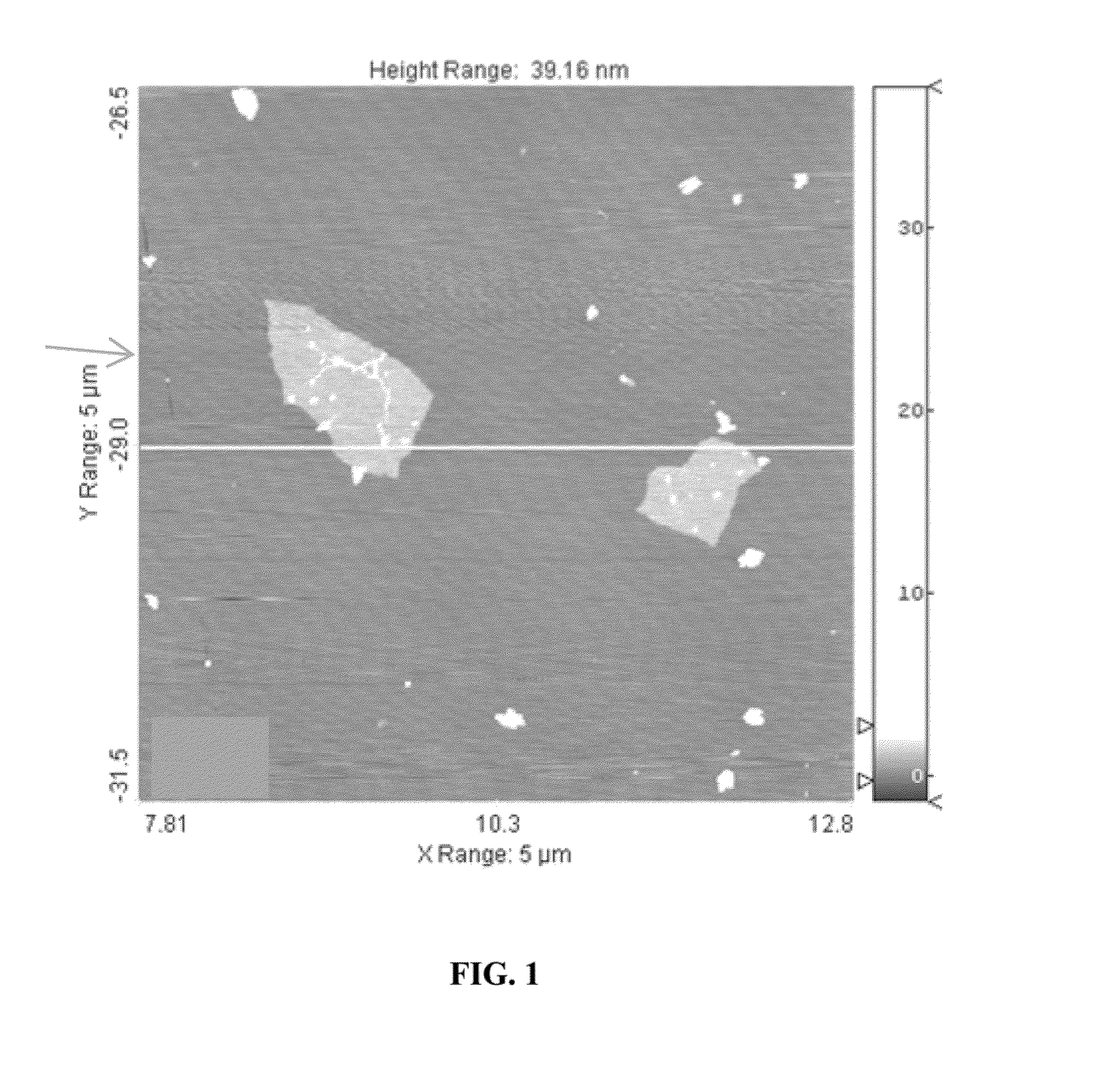

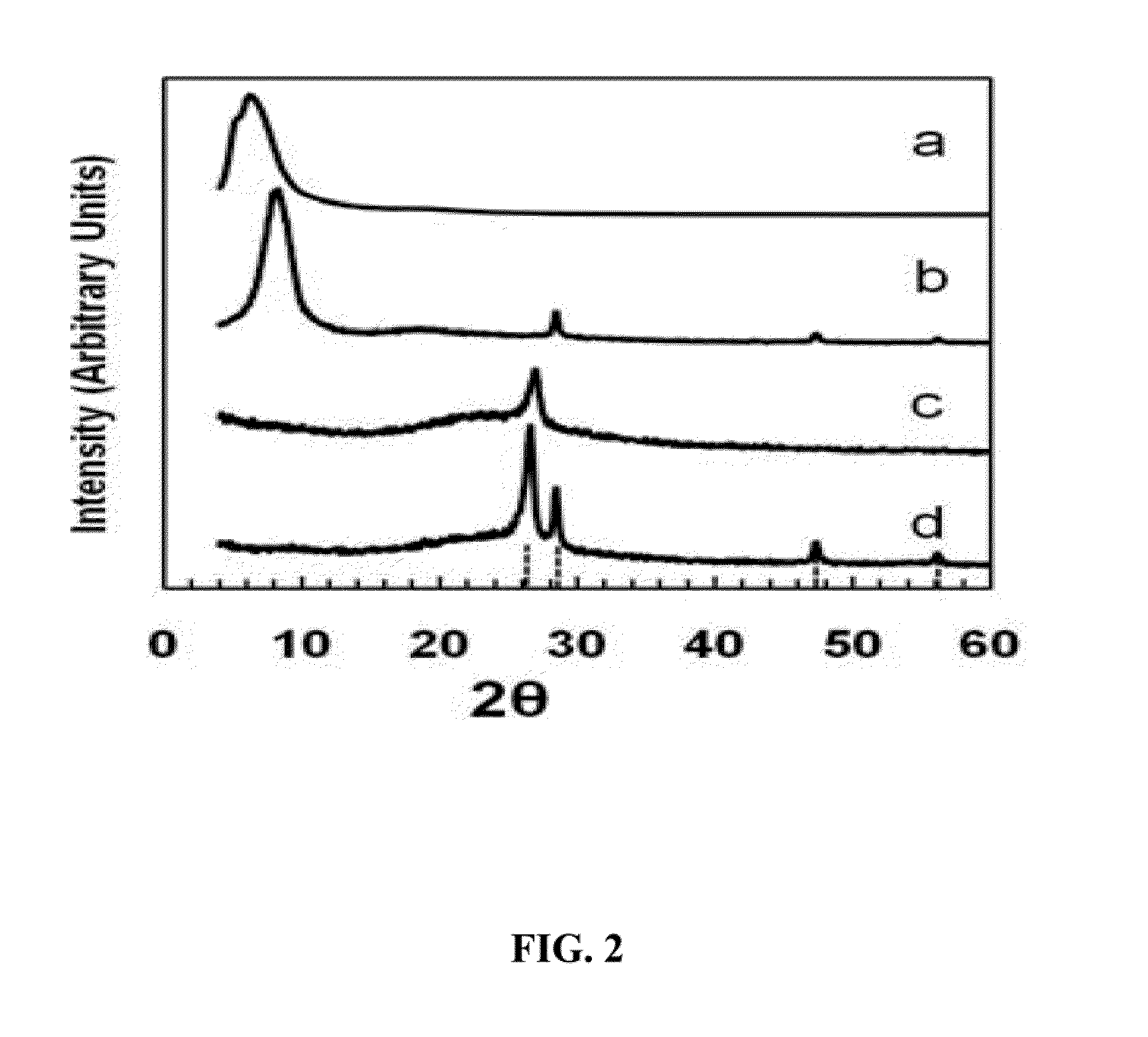

Electrode material comprising graphene composite materials in a graphite network formed from reconstituted graphene sheets

ActiveUS20110111303A1Weight increaseIncrease storage capacityConductive materialNon-conductive material with dispersed conductive materialGraphiteCvd graphene

A durable electrode material suitable for use in Li ion batteries is provided. The material is comprised of a continuous network of graphite regions integrated with, and in good electrical contact with a composite comprising graphene sheets and an electrically active material, such as silicon, wherein the electrically active material is dispersed between, and supported by, the graphene sheets.

Owner:NORTHWESTERN UNIV

Non-volatile memory and method with reduced source line bias errors

ActiveUS7196931B2Large capacityImprove performanceRead-only memoriesDigital storageVoltage dropEngineering

Source line bias is an error introduced by a non-zero resistance in the ground loop of the read / write circuits. During sensing the control gate voltage of a memory cell is erroneously biased by a voltage drop across the resistance. This error is minimized when the current flowing though the ground loop is reduced. A method for reducing source line bias is accomplished by read / write circuits with features and techniques for multi-pass sensing. When a page of memory cells are being sensed in parallel, each pass helps to identify and shut down the memory cells with conduction current higher than a given demarcation current value. In this way, sensing in subsequent passes will be less affected by source line bias since the total amount of current flow is significantly reduced by eliminating contributions from the higher current cells.

Owner:SANDISK TECH LLC

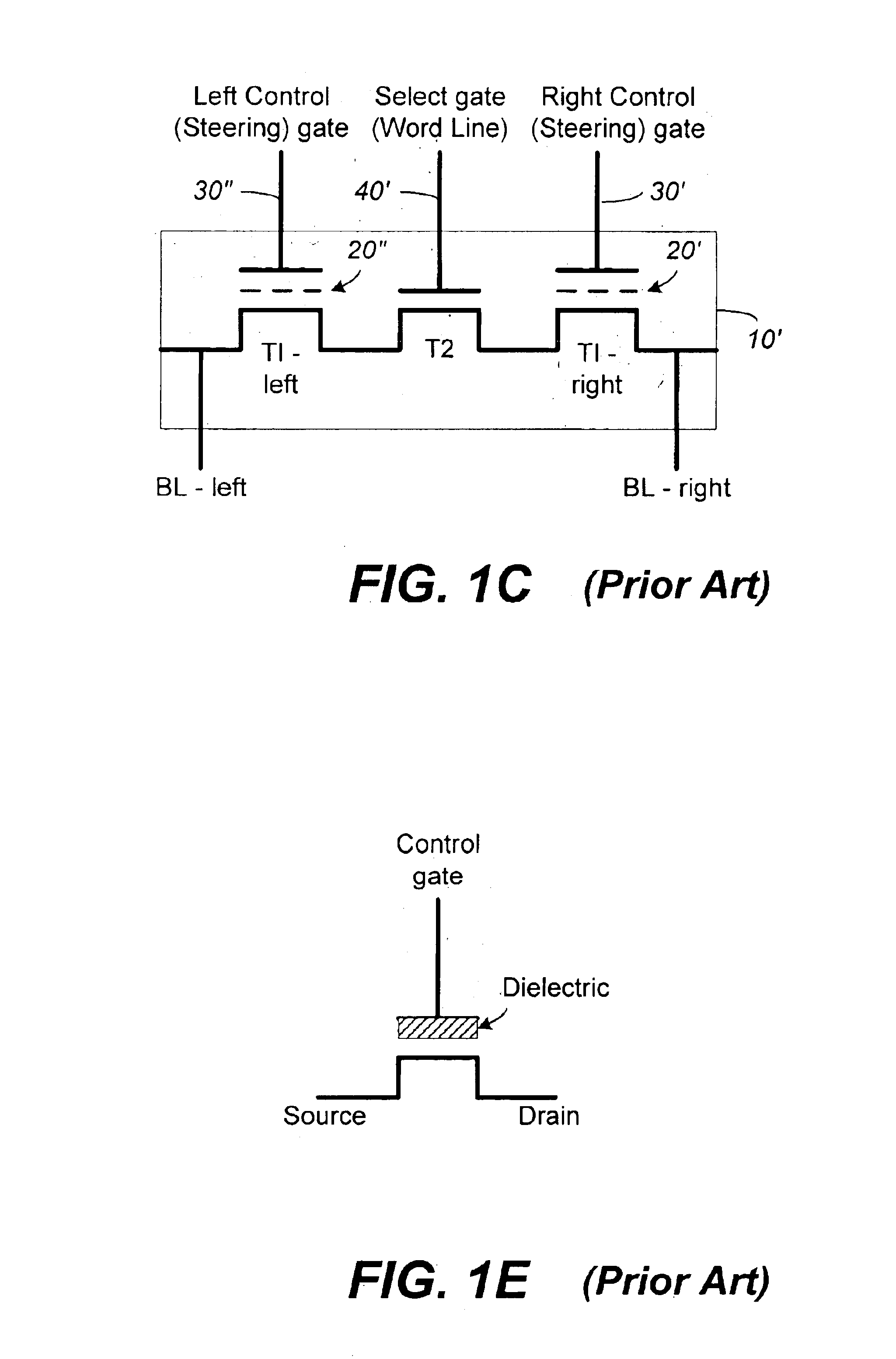

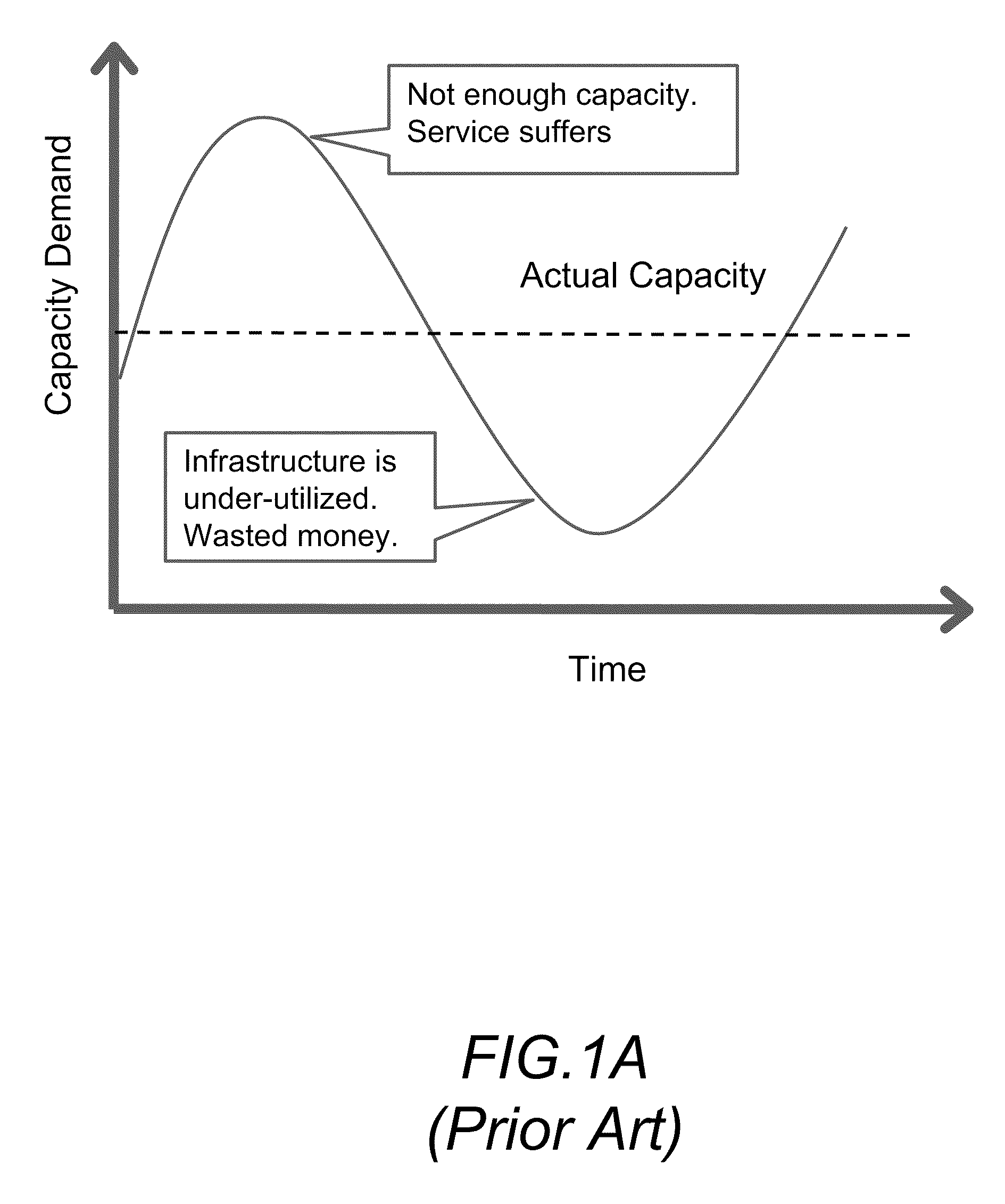

Adaptive network with automatic scaling

InactiveUS20100220622A1Quality improvementIncrease capacityError preventionTransmission systemsNetwork linkProcessing element

A method for automatic scaling the processing capacity and bandwidth capacity of a network includes providing a network comprising a plurality of traffic processing units and a plurality of network links. Next, providing monitoring means for monitoring processing capacity demand and bandwidth capacity demand of the network. Next, providing managing means for adding traffic processing units to the network, removing traffic processing units from the network, connecting links to the network and disconnecting links from the network. Next, monitoring processing capacity demand and bandwidth capacity demand of the network via the monitoring means and then dynamically adjusting processing capacity of the network by selectively adding or removing traffic processing units in the network via the managing means upon observation of processing capacity demand increase or processing capacity demand decrease, respectively. The method also includes dynamically adjusting bandwidth capacity of the network by selectively connecting or disconnecting links in the network via the managing means upon observation of bandwidth capacity demand increase or bandwidth capacity decrease, respectively.

Owner:YOTTAA

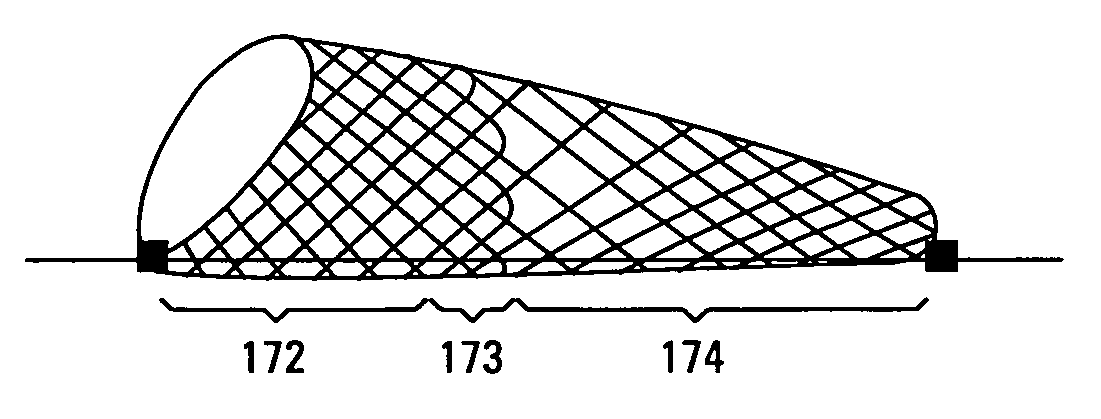

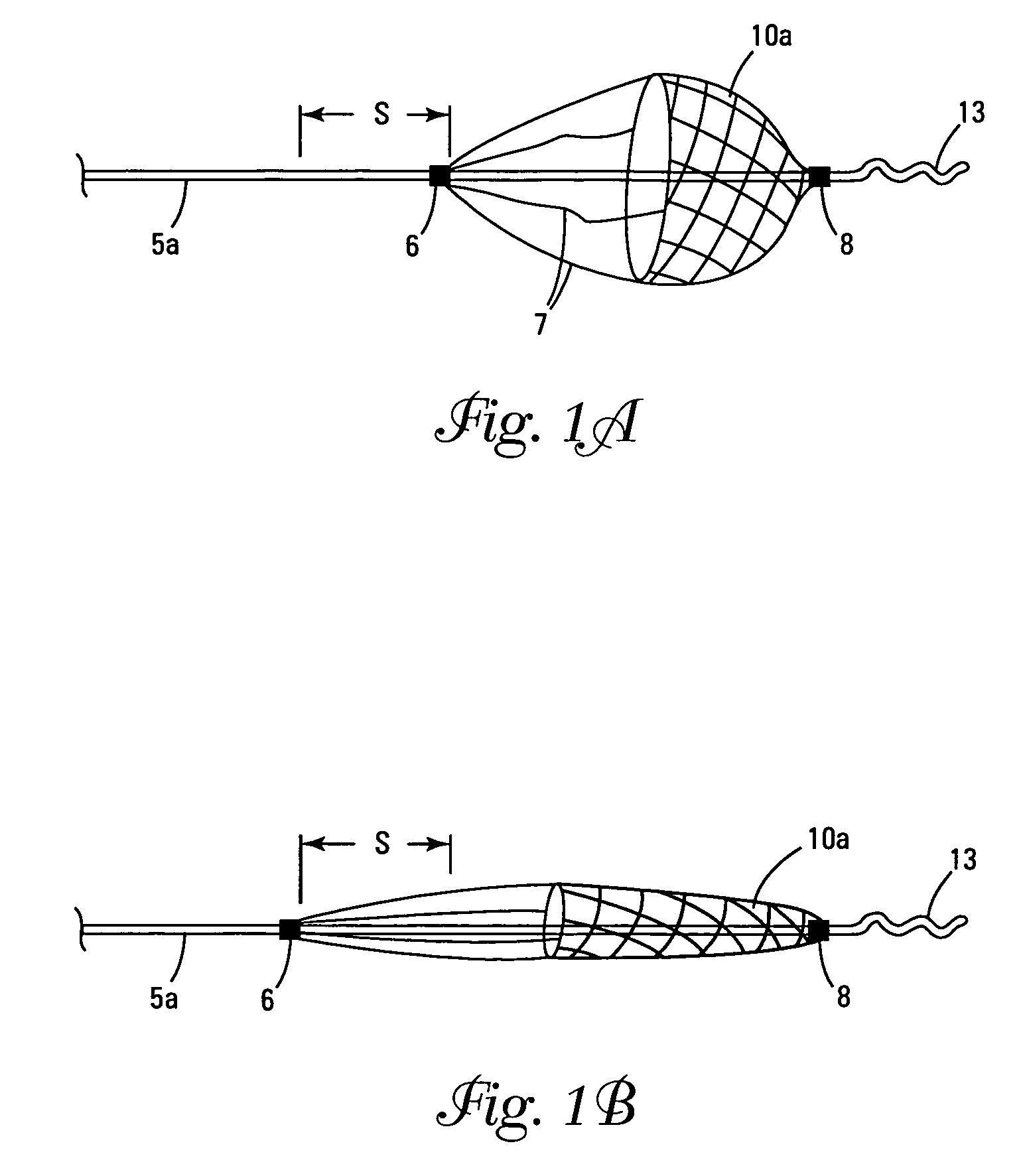

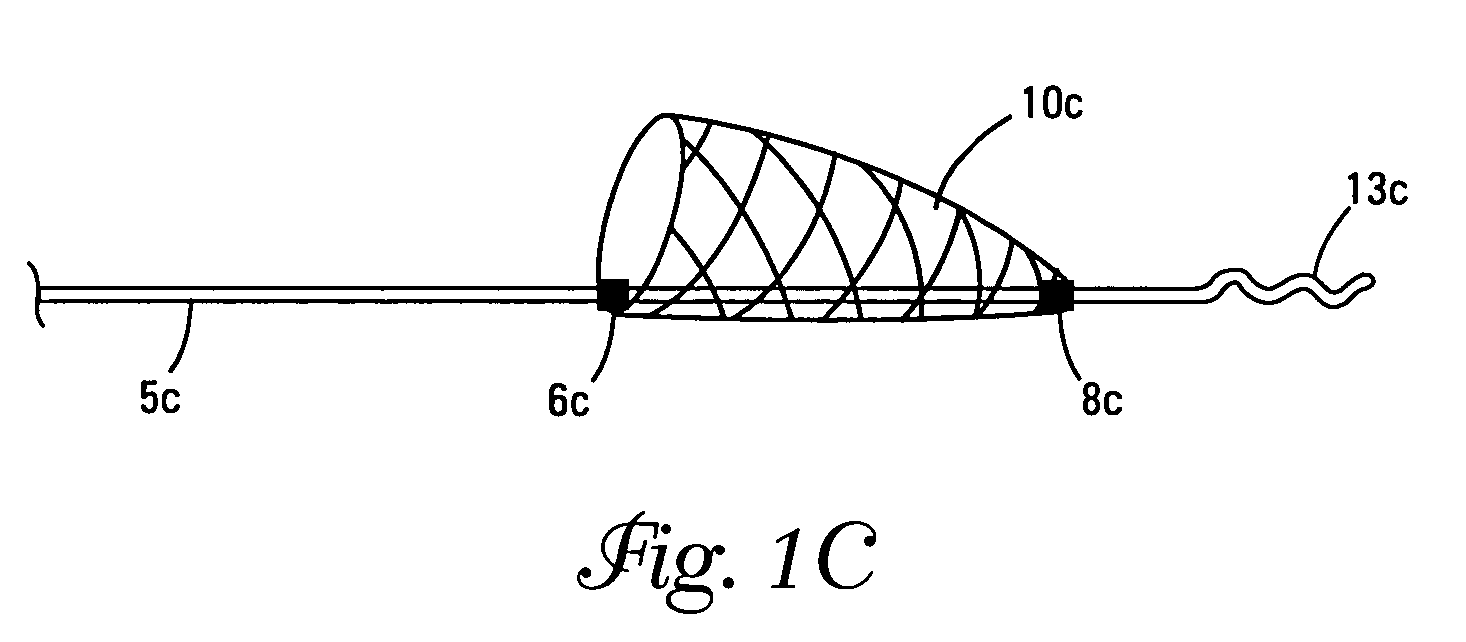

Embolic filters with controlled pore size

The invention provides a device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body comprising a filter element. The filter is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained, and the filter element comprises a self-expanding material having pores. When the filter element is in the expanded configuration, the average pore size is from 30 to 300 microns and the standard deviation of the pore size is less than 20 percent of the average pore size.

Owner:COVIDIEN LP

Lithium metal dispersion in electrodes

InactiveUS20050130043A1High specific capacityPromote circulationElectrode rolling/calenderingElectrode thermal treatmentLithium metalHost material

Electrodes, such as anodes and cathodes, can include a host material that is prelithiated or undergoes lithiation upon electrolyte introduction into a battery. Lithiation of the host material can occur by the agitation of lithium metal and a host material, the agitation of a lithium metal powder and a host material at a temperature greater than room temperature, the application of pressure to a lithium metal and host material mixture, contact of the host material with molten lithium metal, the lamination of lithium foil or lithium mesh onto an electrode containing the host material, or by lamination of lithium metal or mesh onto an electrode at elevated temperatures.

Owner:AEA TECH BATTERY SYST +1

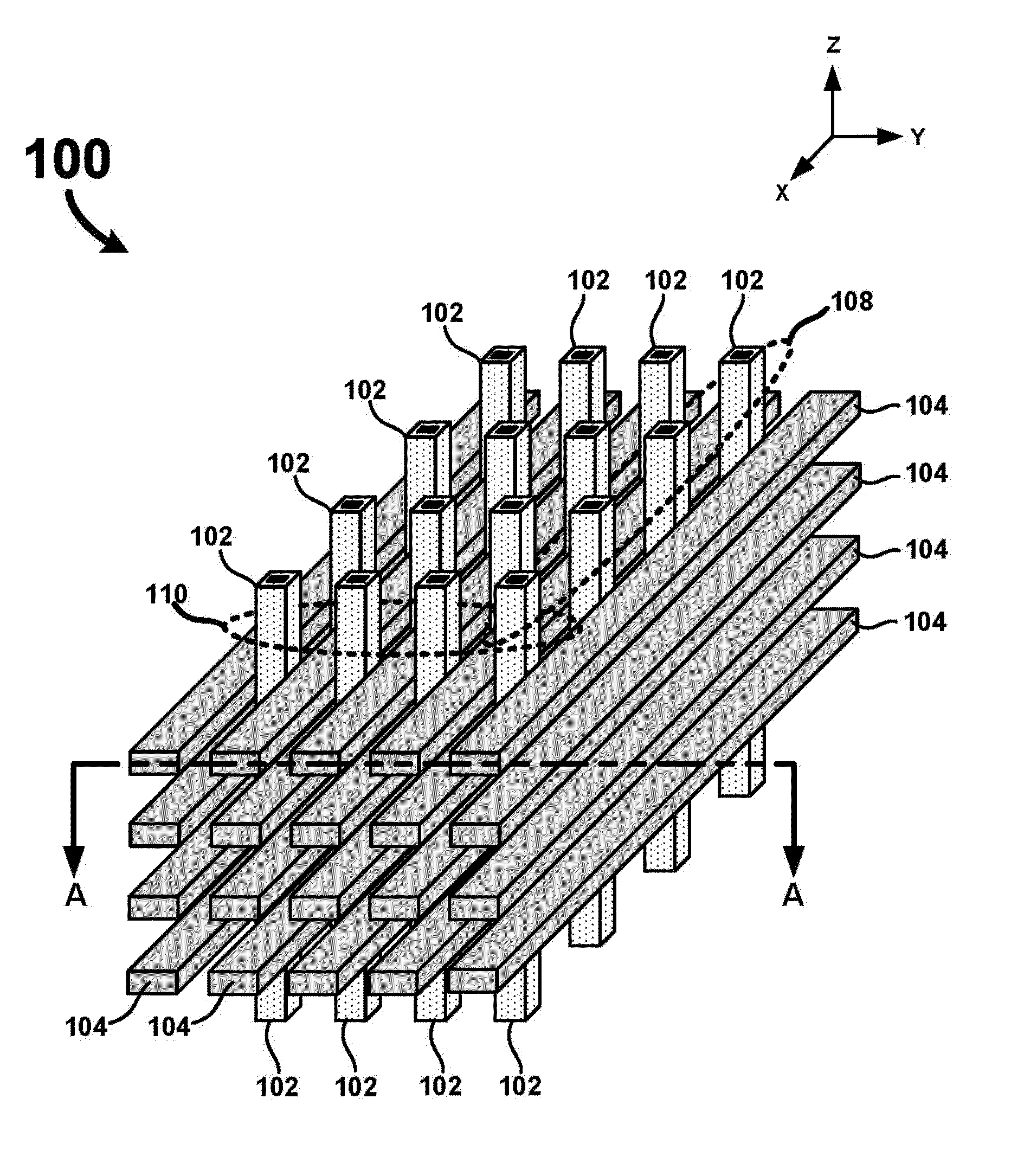

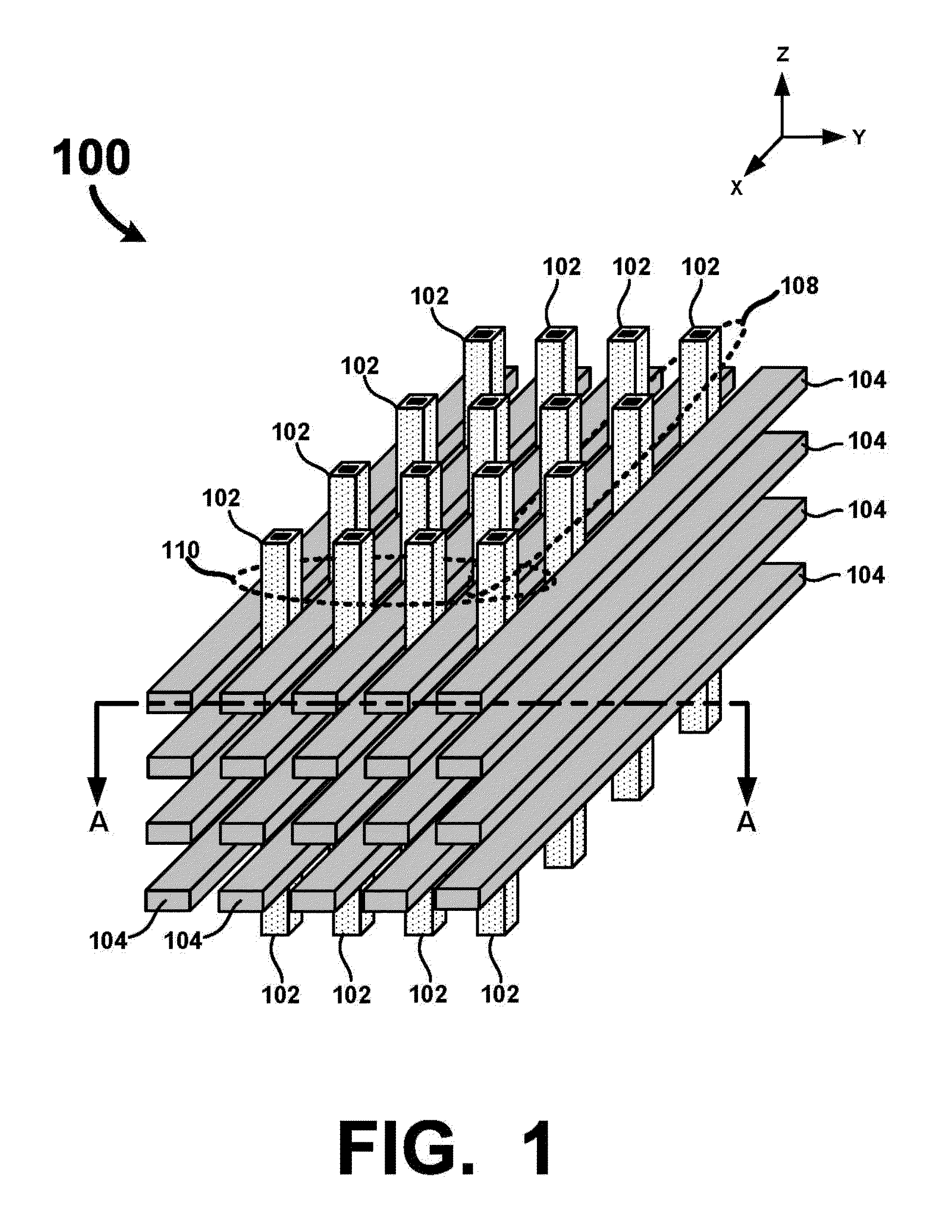

Vertical Cross Point Arrays For Ultra High Density Memory Applications

An ultra-high-density vertical cross-point array comprises a plurality of horizontal line layers having horizontal lines interleaved with a plurality of vertical lines arranged in rows and columns. The vertical lines are interleaved with the horizontal lines such that a row of vertical lines is positioned between each consecutive pair of horizontal lines in each horizontal line layer. Each vertical line comprises a center conductor surrounded by a single or multi-layered memory film. Accordingly, when interleaved with the horizontal lines, two-terminal memory cells are integrally formed between the center conductor of each vertical line and each crossing horizontal line. By configuring the vertical and horizontal lines so that a row of vertical lines is positioned between each consecutive pair of horizontal lines, a unit memory cell footprint of just 2F2 may be realized.

Owner:UNITY SEMICON

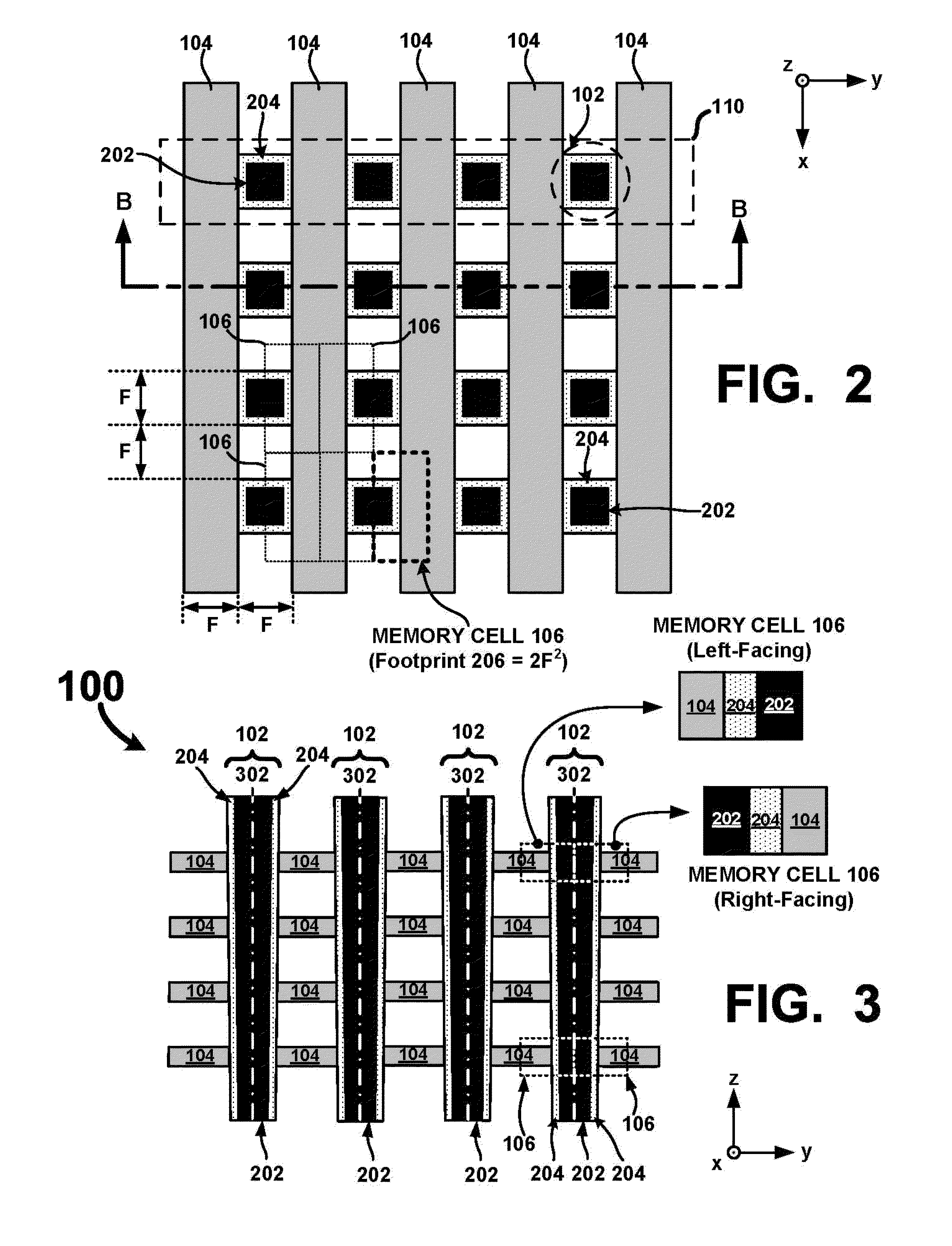

Storage device and information processing system

ActiveUS20060087893A1Significant overheadSolve the real problemMemory architecture accessing/allocationEnergy efficient ICTInformation handling systemControl circuit

A storage device able to make a redundant write operation of unselected data unnecessary and able to optimize an arrangement of pages to a state having a high efficiency for rewriting, wherein the storage device has a first memory unit, a second memory unit having a different access speed from the first memory, and a control circuit, wherein the control circuit has a function of timely moving the stored data in two ways between the first memory unit and the second memory unit having different access speeds in reading or rewriting.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com