Patents

Literature

301results about How to "Improve quality performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

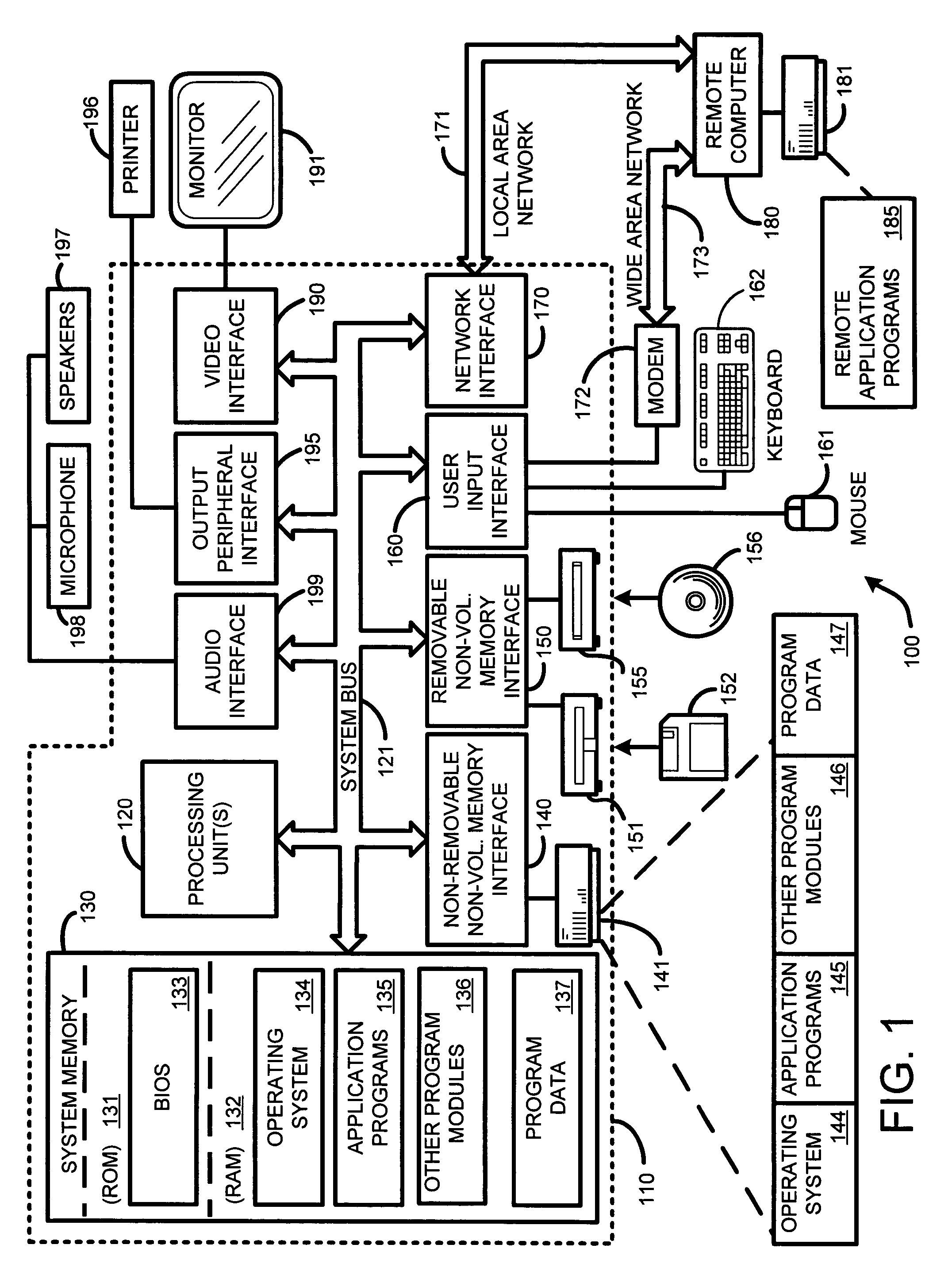

Content delivery network by-pass system

InactiveUS20030174648A1Increase capacityIncrease in sizeError preventionTransmission systemsWeb sitePeering

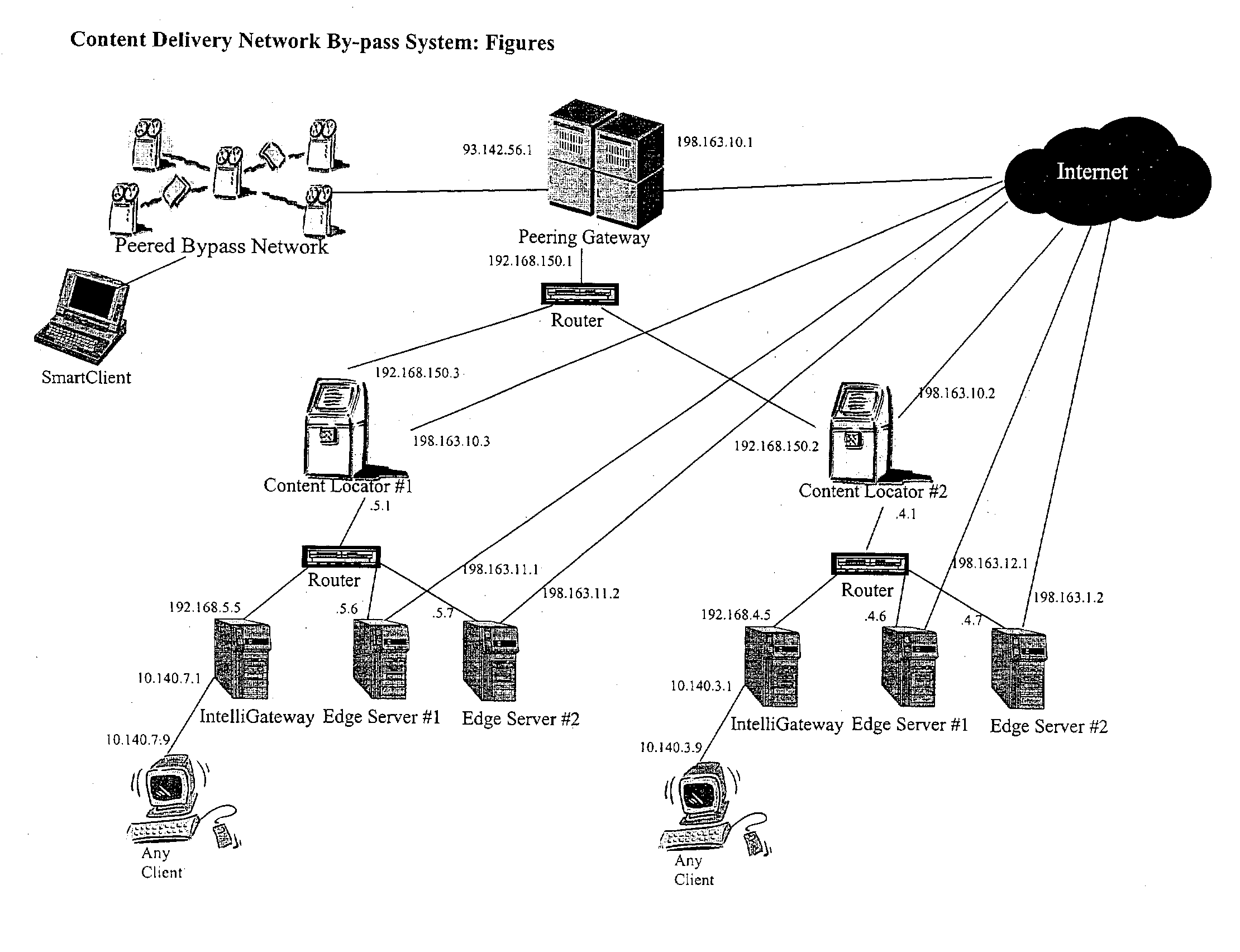

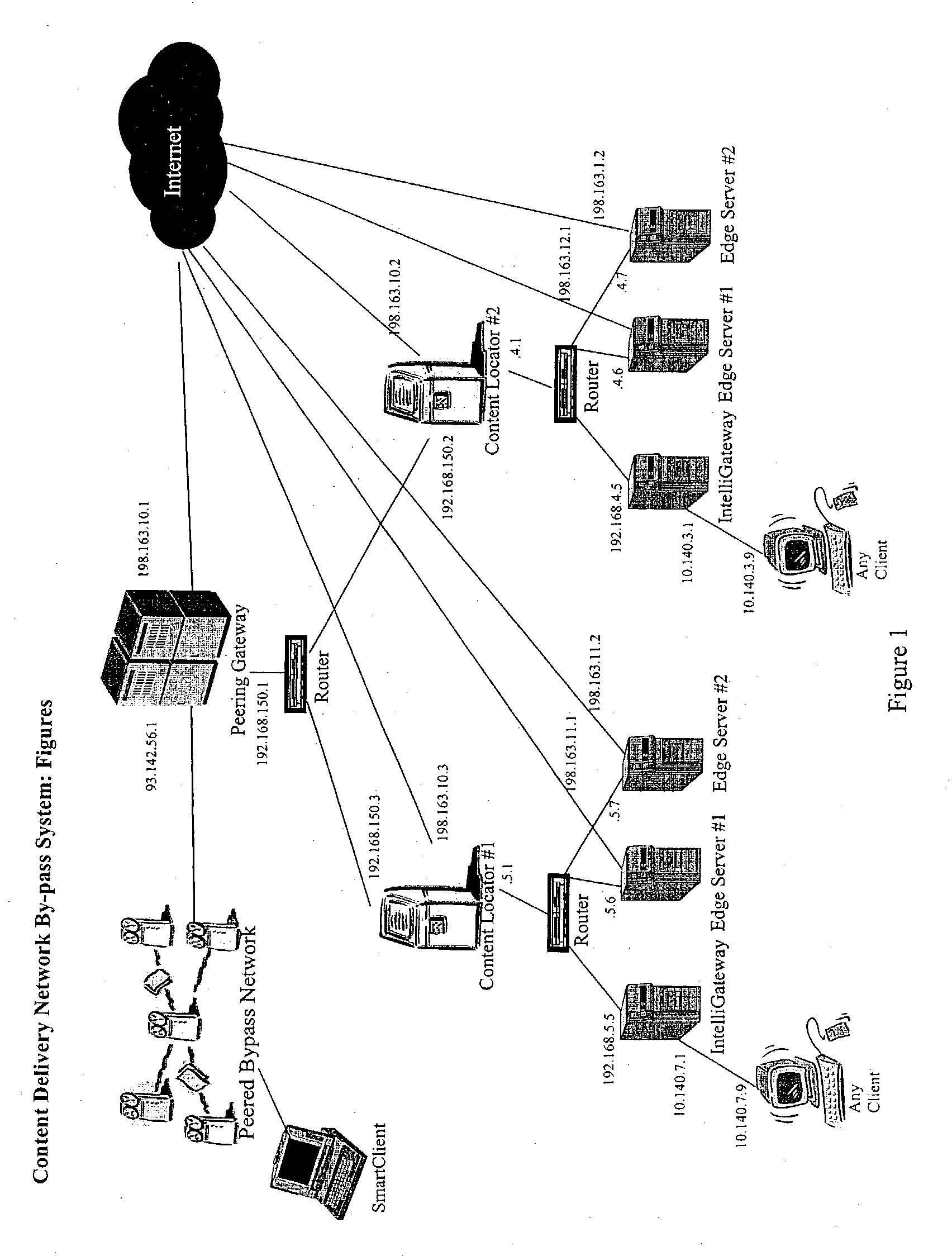

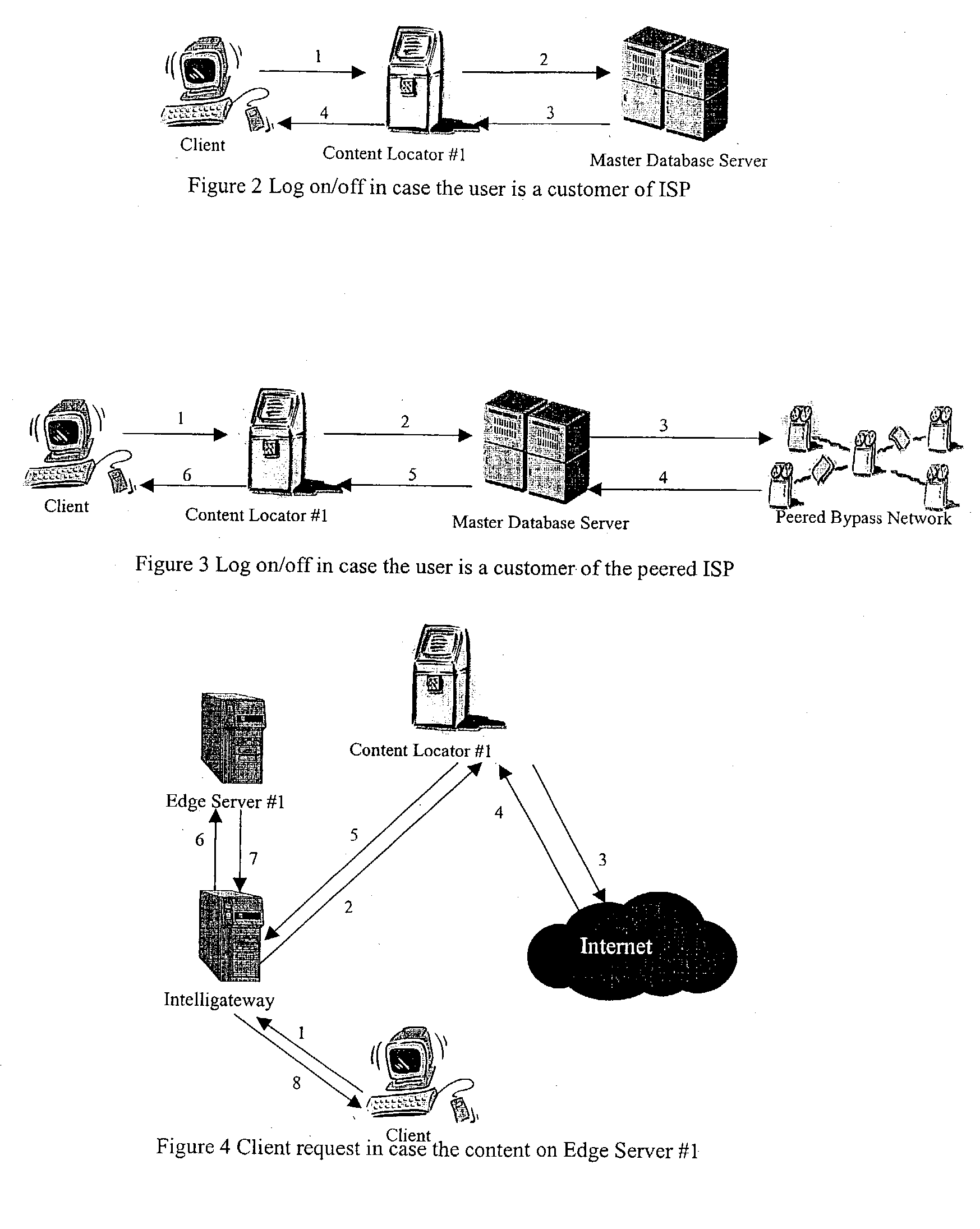

The bypass network is designed to provide fast access and high quality streaming media services anywhere anytime. There are five major components including Peering Gateway, Content Locator, Edge Server, Gateway and Client. The whole bypass network is divided into number of self-managed sub-networks, which are referred as local networks in this document. Each local network contains Edge Servers, gateways, and a Content Locator. The Edge Servers serve as cache storage and streaming servers for the local network. The gateways provide a connection point for the client computers. Each local network is managed by a Content Locator. The Content Locator handles all client requests by communicating with the Peering Gateway and actual web sites, and makes the content available on local Edge Servers. The Content Locator also balances the load on each Edge Server by monitoring the workload on them. One embodiment is designed for home users whose home machine does not move around frequently. A second embodiment is designed for business users who travel around very often where the laptops would self-configure as a client of the network.

Owner:TELECOMM RES LAB

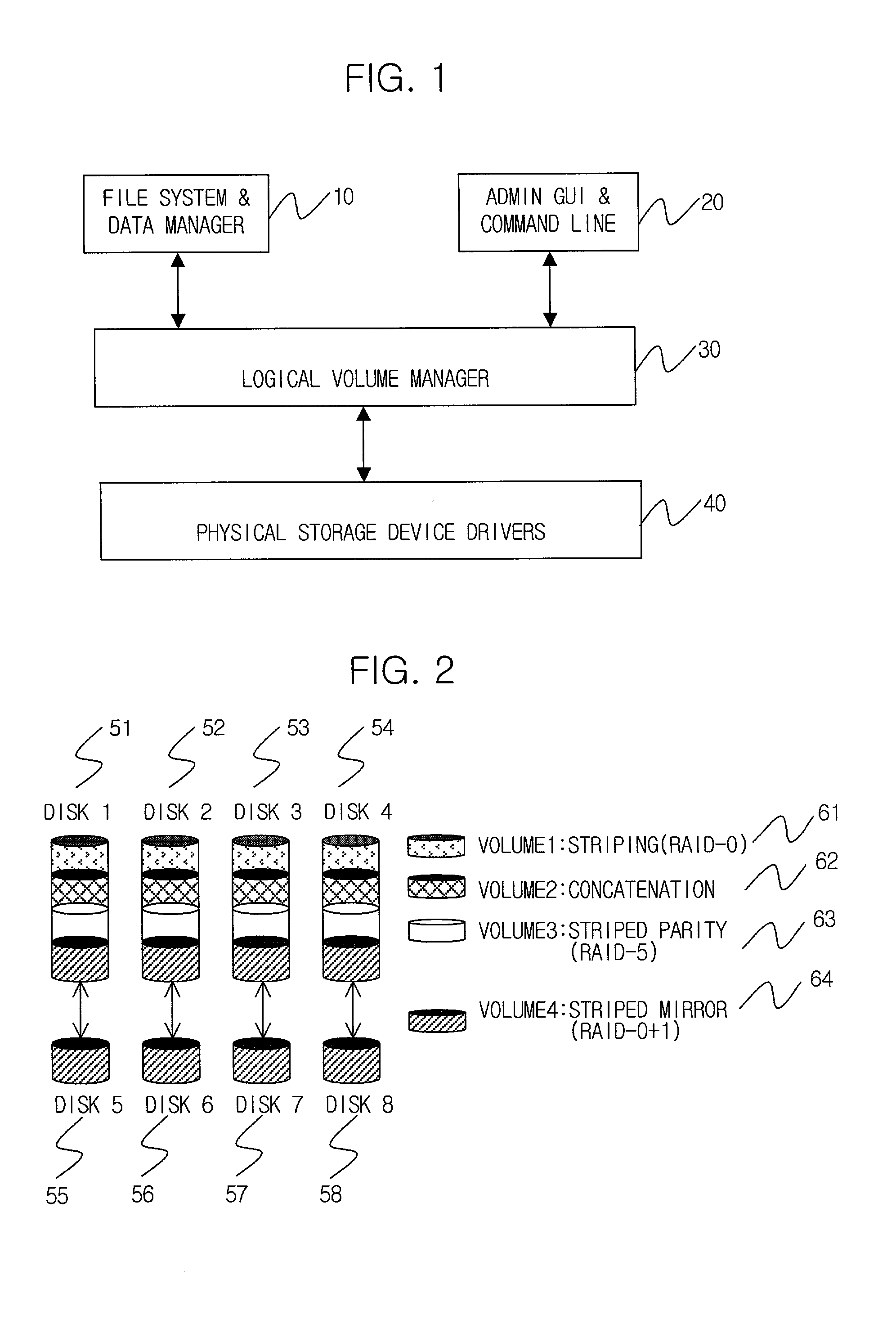

Method for managing logical volume in order to support dynamic online resizing and software raid

InactiveUS20030023811A1Increase volume sizeIncrease spaceInput/output to record carriersMemory adressing/allocation/relocationRAIDDatabase

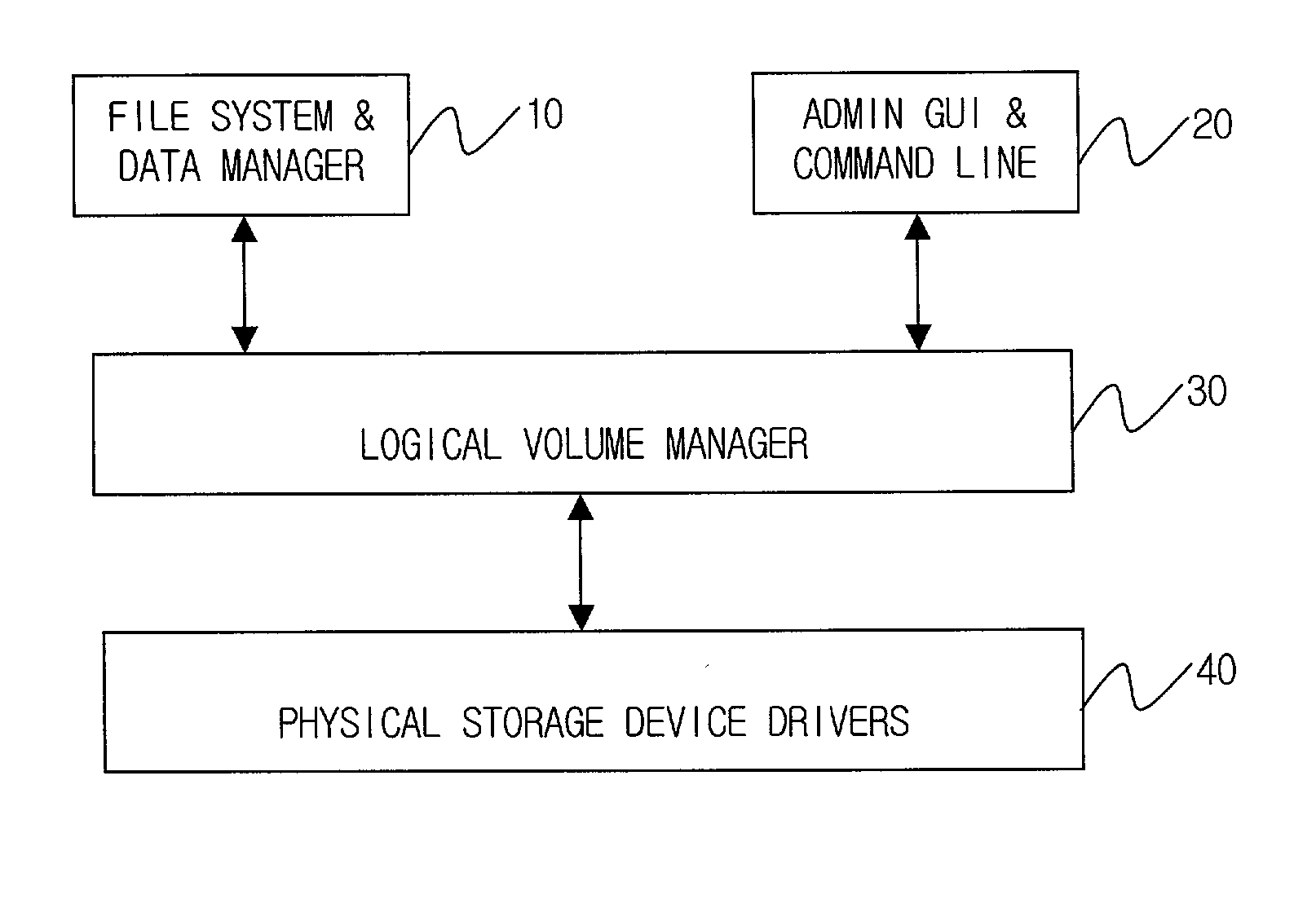

A method for managing a logical volume for minimizing a size of metadata and supporting dynamic online resizing, computer-readable recoding medium storing a program or data structure for embodying the method are disclosed. The method for managing a logical volume in order to support dynamic online resizing and minimizing a size of metadata, said method comprising steps of: a) creating a logical volume by rounding up disk partitions in response to a request of constructing the logical volume on a physical storage space; b) generating metadata including information of the logical volume and the disk partitions participating to the logical volume and storing it to the disk partitions participating to the logical volume; c) dynamically resizing the logical volume in response to a request of resizing, and modifying the metadata on the disk partitions participating to the logical volume; and d) calculating and returning a physical address corresponding to a logical address of the logical volume by using mapping information of the metadata containing information of the physical address corresponding to the logical address.

Owner:ELECTRONICS & TELECOMM RES INST

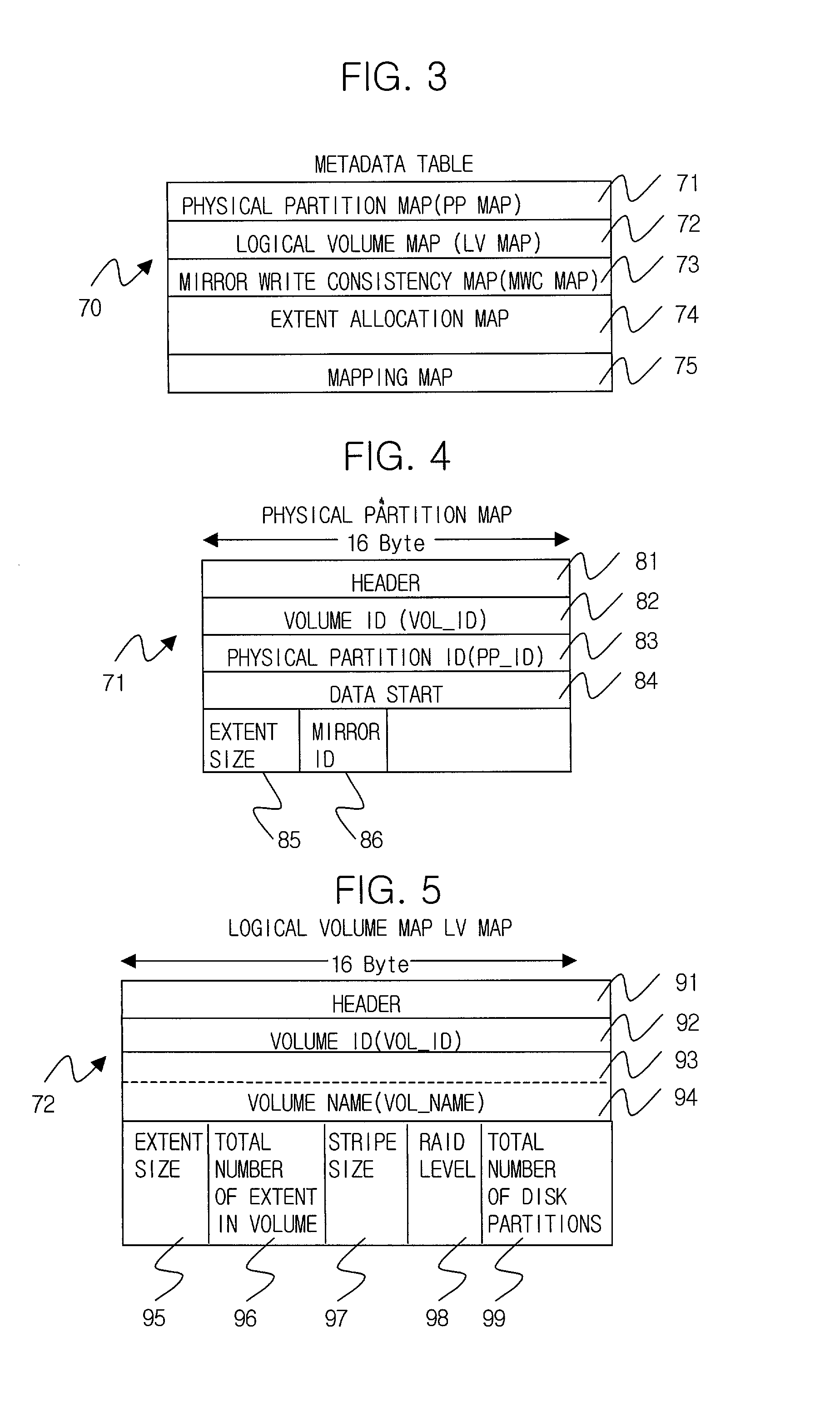

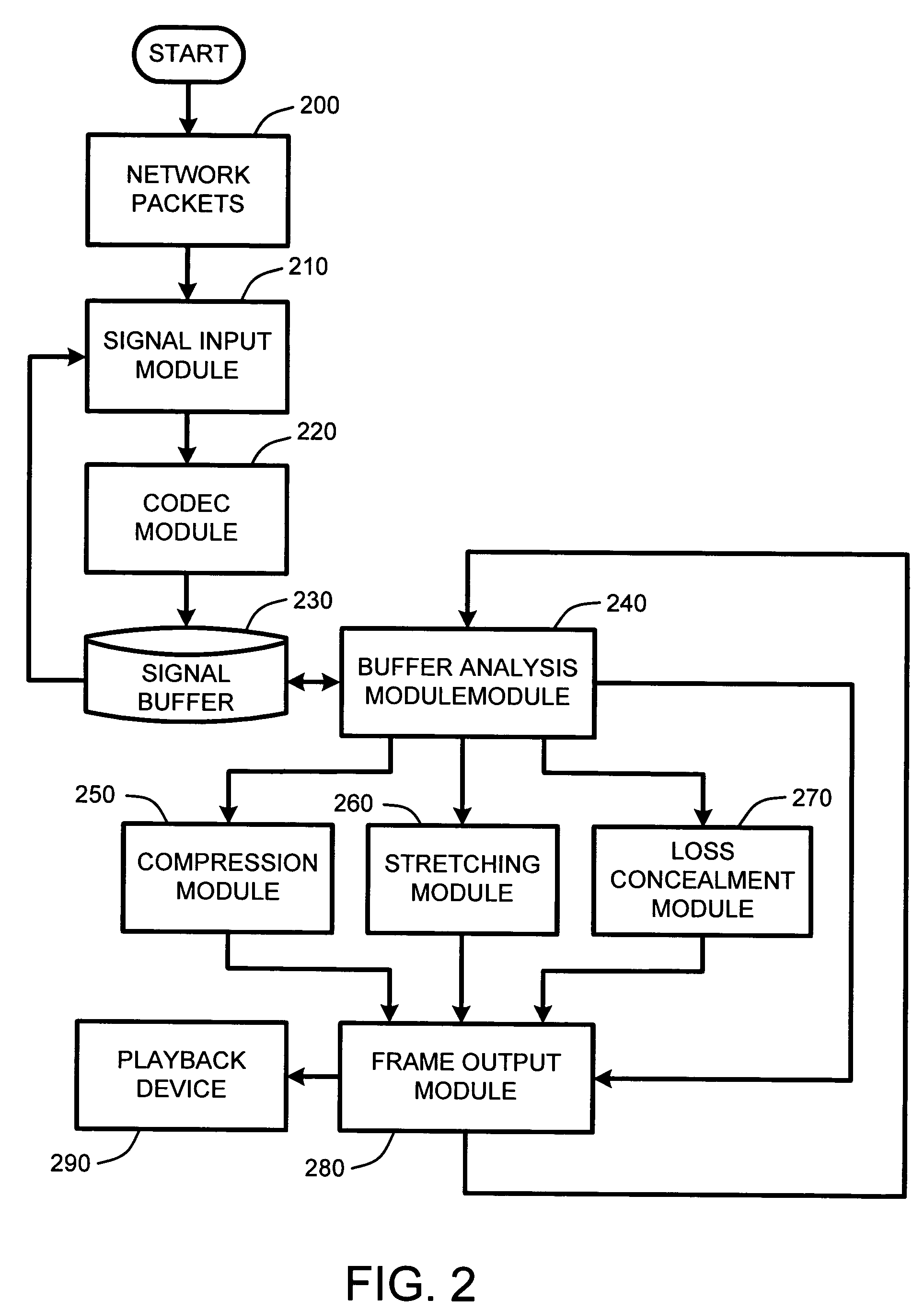

System and method for real-time jitter control and packet-loss concealment in an audio signal

InactiveUS20050058145A1Improve signal qualityImprove quality performanceSpeech analysisTime-division multiplexSelf adaptiveEngineering

An “adaptive audio playback controller” operates by decoding and reading received packets of an audio signal into a signal buffer. Samples of the decoded audio signal are then played out of the signal buffer according to the needs of a player device. Jitter control and packet loss concealment are accomplished by continuously analyzing buffer content in real-time, and determining whether to provide unmodified playback from the buffer contents, whether to compress buffer content, stretch buffer content, or whether to provide for packet loss concealment for overly delayed or lost packets as a function of buffer content. Further, the adaptive audio playback controller also determines where to stretch or compress particular frames or signal segments in the signal buffer, and how much to stretch or compress such segments in order to optimize perceived playback quality.

Owner:MICROSOFT TECH LICENSING LLC

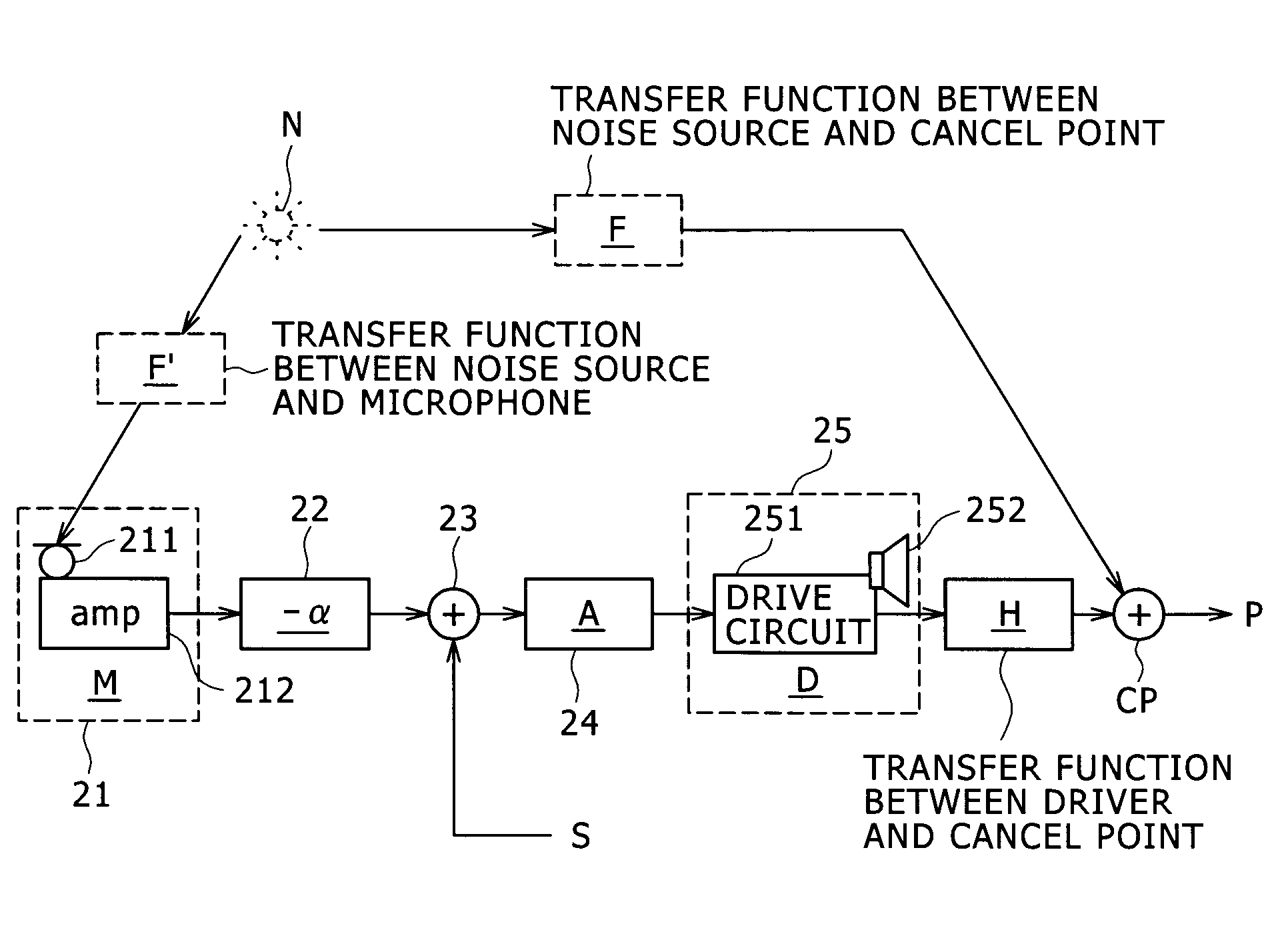

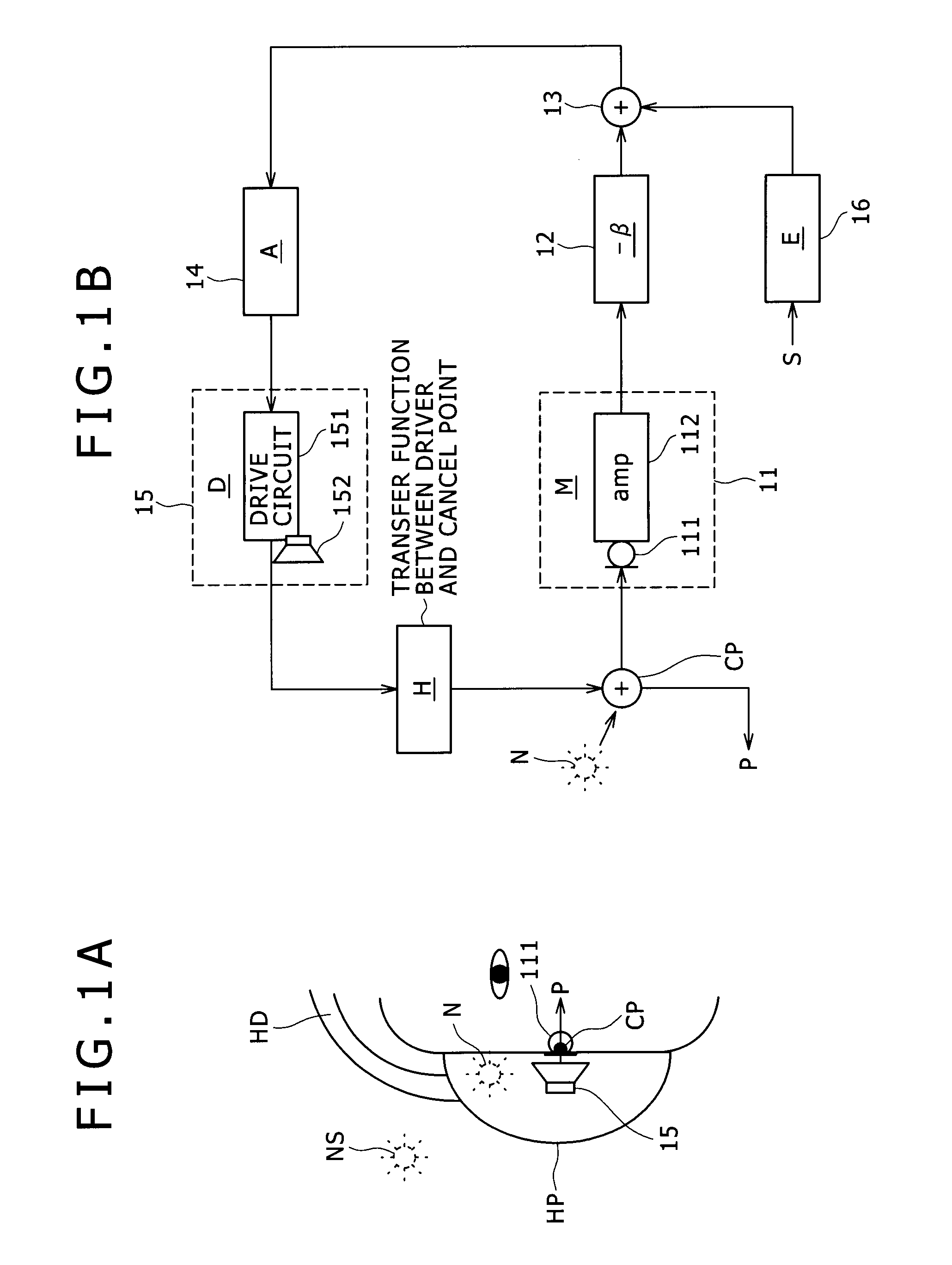

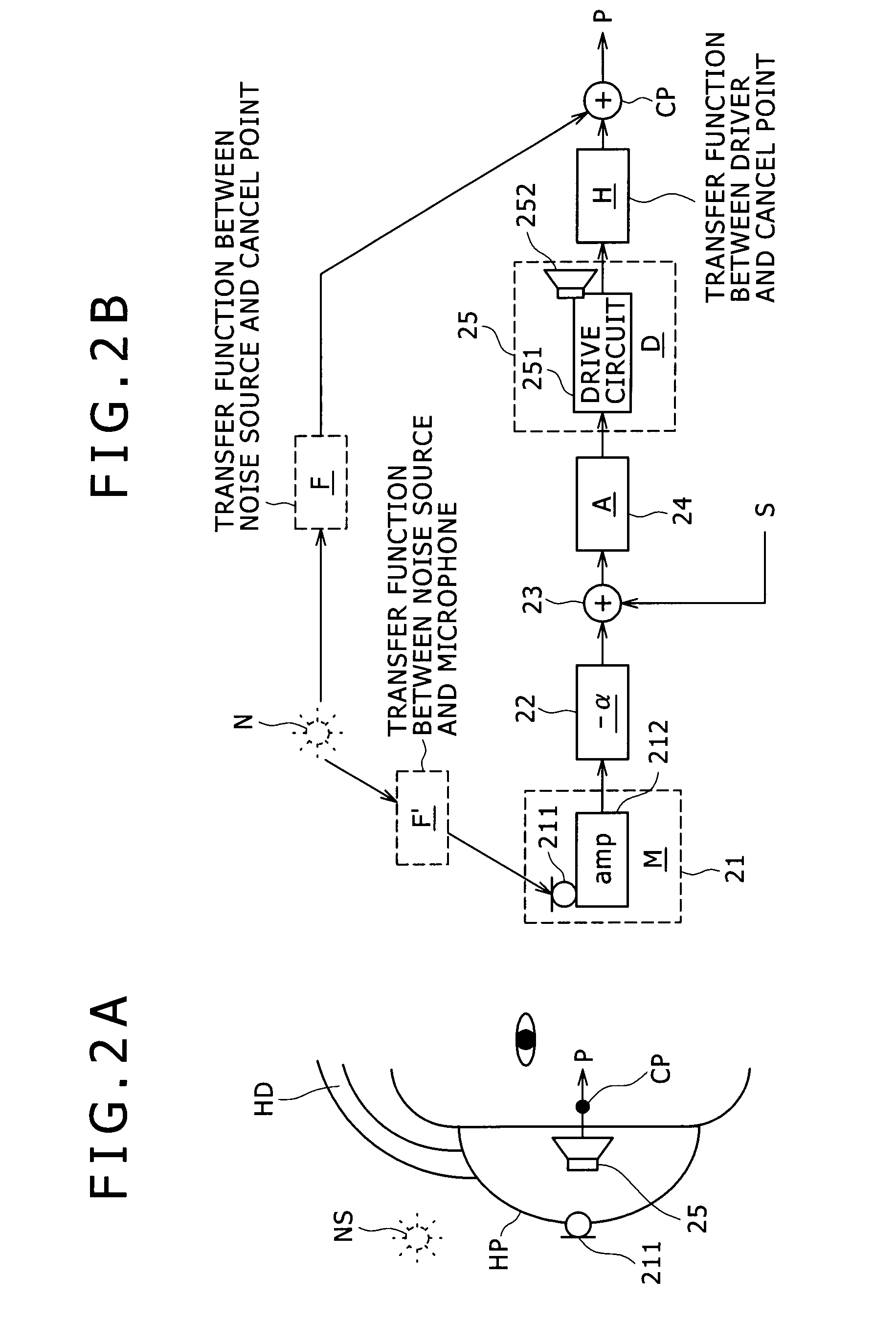

Filter circuit for noise cancellation, noise reduction signal production method and noise canceling system

There is provided a filter circuit for producing a noise reduction signal for reducing a noise signal collected by a microphone, including: a digital section including an analog / digital conversion section configured to convert the noise signal into a digital noise signal, a digital filter section configured to produce a digital noise reduction signal based on the digital noise signal, and a digital / analog conversion section configured to convert the digital noise reduction signal into an analog noise reduction signal; an analog path connected in parallel to said digital section and configured to output the noise signal as it is or after processed by an analog filter; and a synthesis section configured to synthesize the analog noise reduction signal outputted from said digital / analog conversion section of said digital section and the analog signal outputted from said analog path to produce a noise reduction signal to be used for noise reduction.

Owner:SONY CORP

Total-biodegradation plastic film and preparation method thereof

InactiveCN101240086AQuality improvementImprove performanceFlat articlesPlastic filmMechanical property

A full-biodegradable plastic membrane, which uses thermoplastic starch with diameter of 1-9 mu m, biodegradable polymer and auxiliary component as raw material, processed by screw extruding apparatus and membrane producing apparatus. The raw material comprises 30-70 parts by weight of thermoplastic starch with diameter of 1-9 mu m, 10-40 parts by weight of biodegradable polymer, 5-10 parts by weight of compatible modified component, 3-5 parts by weight of complex plasticized component, 10-30 parts by weight of lubricant. These materials are mixed and processed by screw extruding apparatus and membrane producing apparatus, wherein the lubricant is at least adding into other materials for mixture before process by screw extruding apparatus and during melt blending, and the adding amount of lubricant before process by screw extruding apparatus is not more than 1 / 3 of the total amount thereof. By highly increasing dosage of lubricant and changing mixing way, thermoplastic degree of starch is increased, rheological property of the system and processing quality of product are dramatically improved, mechanical property of the product is enhanced.

Owner:上海悦仕生物材料有限公司 +1

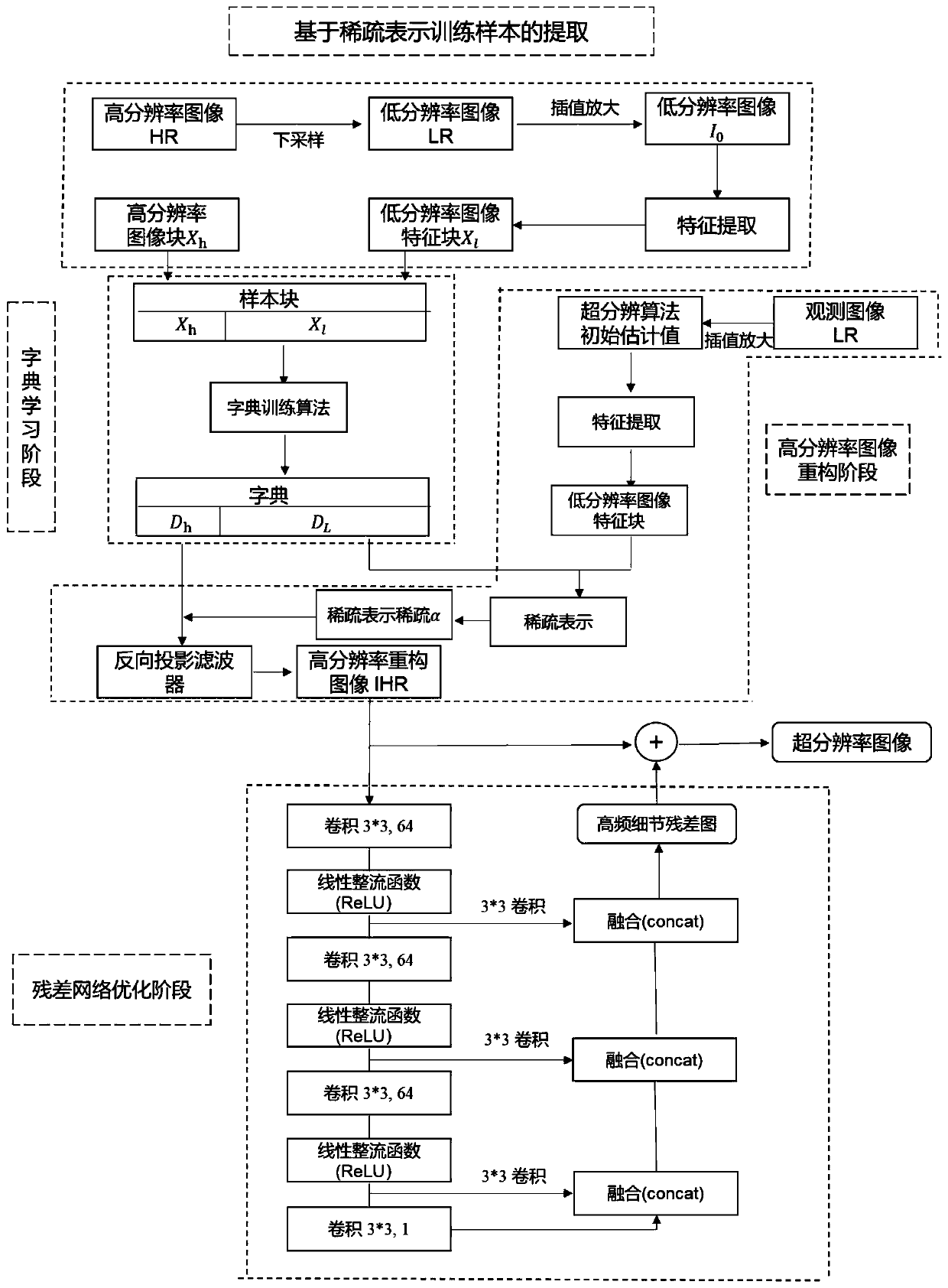

An image super-resolution reconstruction method based on sparse representation and deep learning

ActiveCN109741256AReduce mistakesRich high-frequency detail informationImage enhancementGeometric image transformationComputation complexityReconstruction method

The invention discloses an image super-resolution reconstruction method based on sparse representation and deep learning, and solves the problems that the image super-resolution process is complex incalculation and the quality of a reconstructed image is poor. The method comprises the following implementation steps: collecting and extracting training data blocks and a chromaticity and brightnessdictionary for combined optimization training; independently reconstructing a high-resolution image block; Carrying out high-resolution image reconstruction of sparse representation; Training a residual error network based on deep learning to optimize high-frequency details; Image super-resolution reconstruction. In order to prevent an edge effect and a fuzzy effect, chroma and brightness data aredistinguished and independently reconstructed; in order to optimize high-frequency detail information of a sparse representation output high-resolution image, the high-resolution image based on sparse representation reconstruction is input into a residual network, and a high-frequency residual image is output through four times of convolution feature extraction and feature fusion and input bitwise addition to reconstruct a super-resolution image. The method is low in calculation complexity, high in image reconstruction quality and widely applied to the fields of remote sensing monitoring, criminal investigation, traffic management and the like.

Owner:XIDIAN UNIV

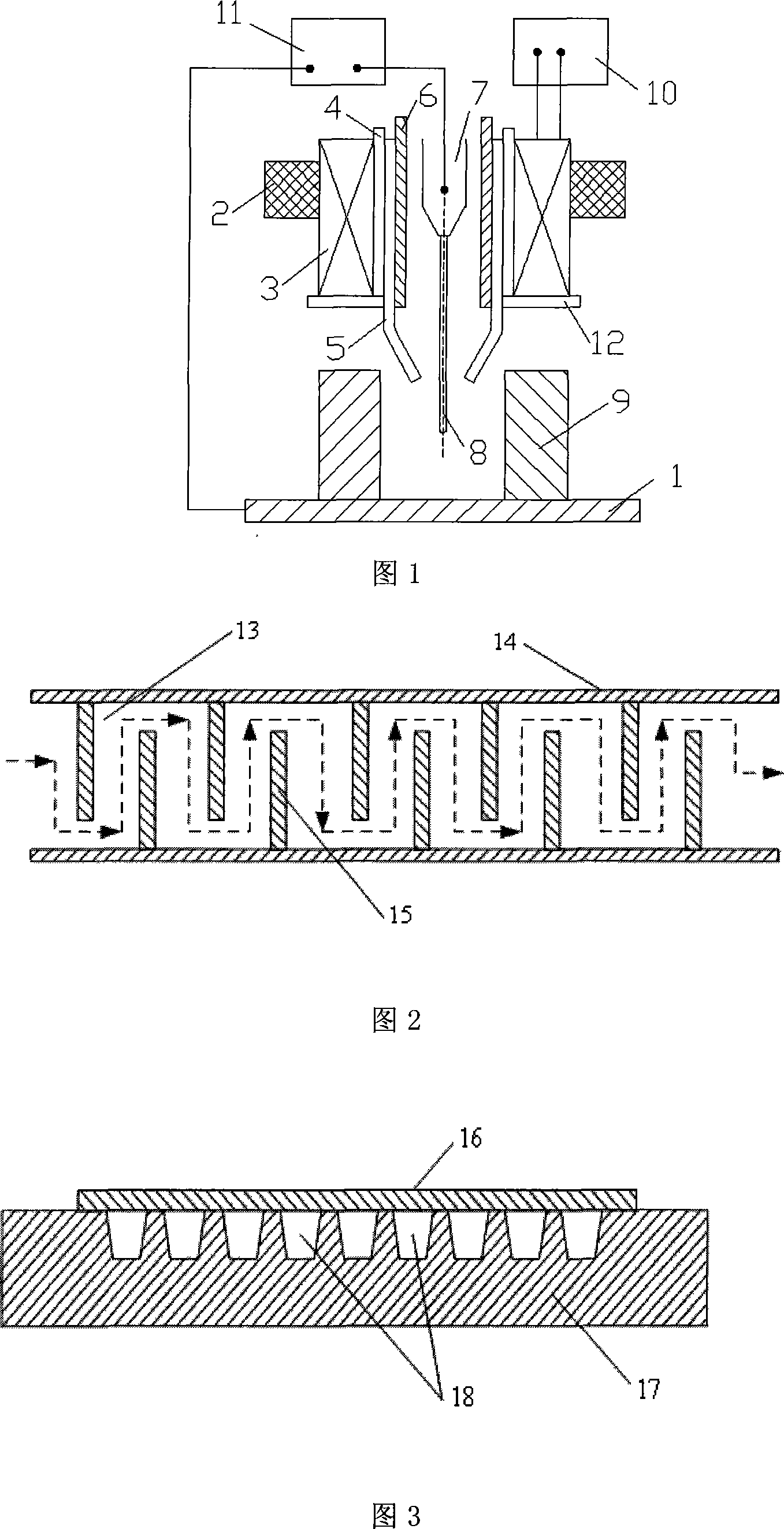

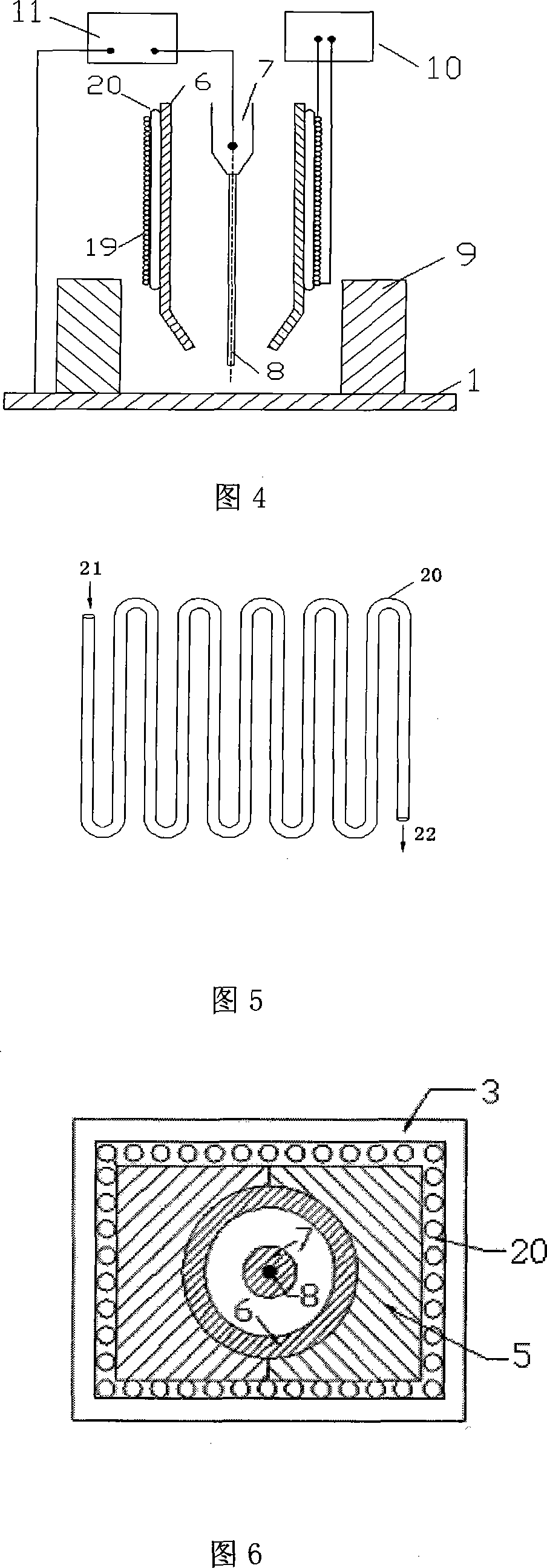

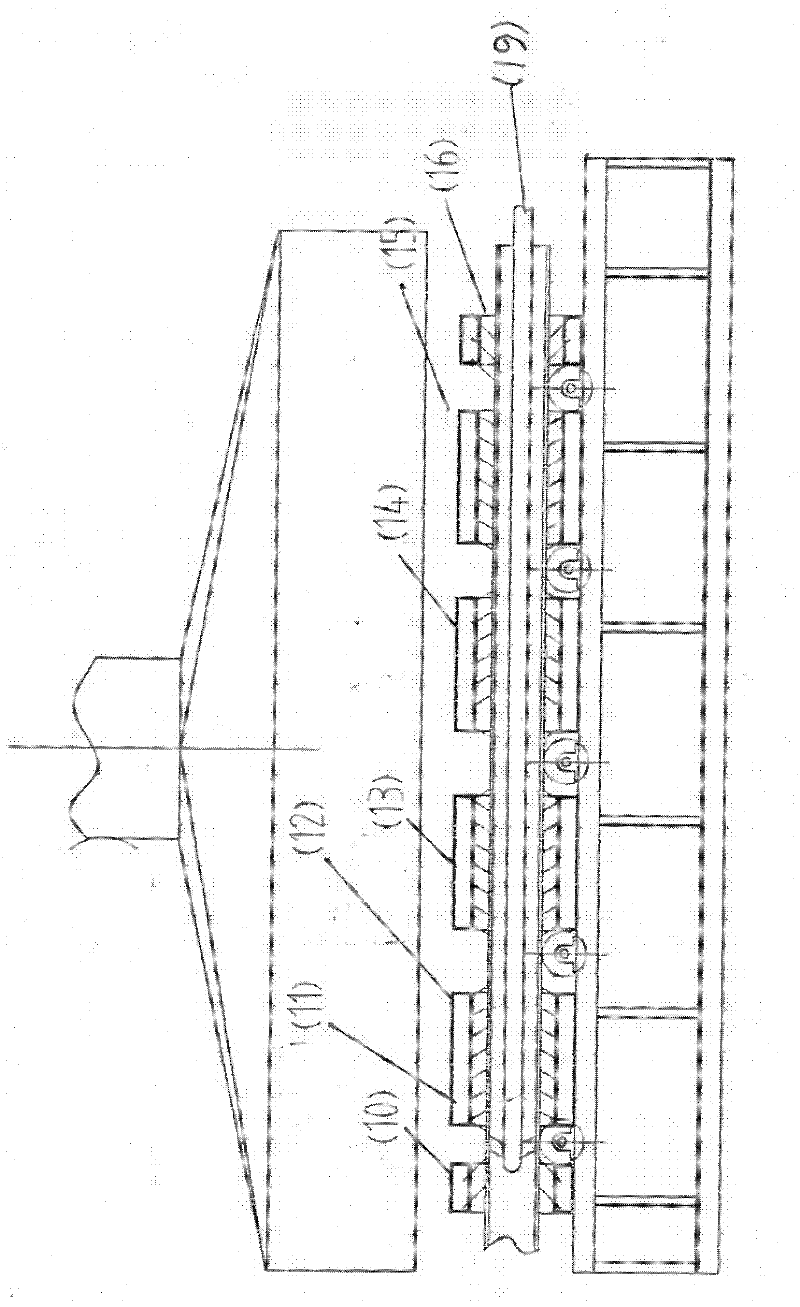

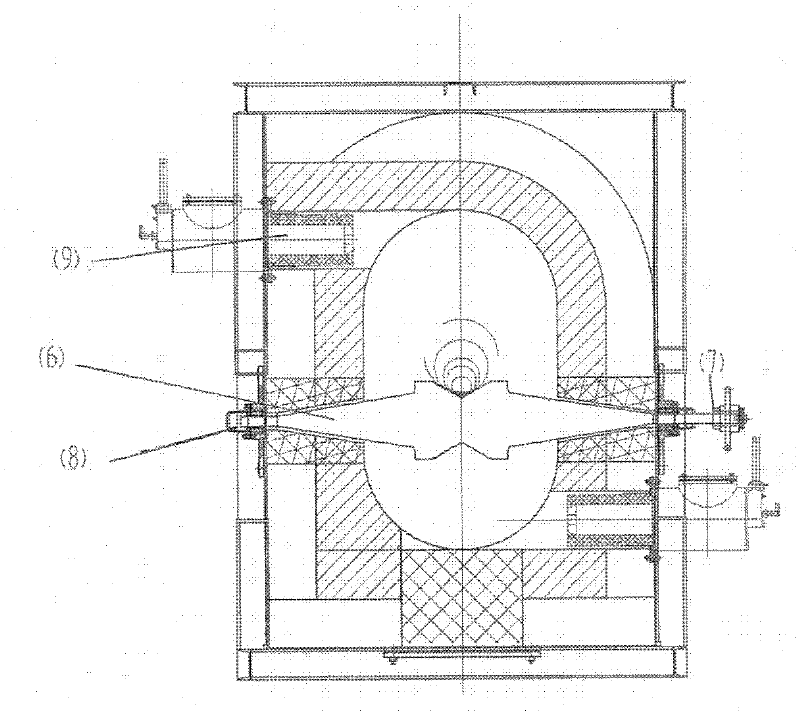

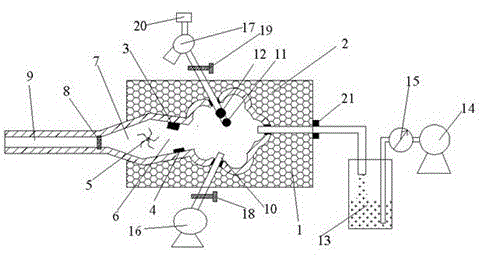

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

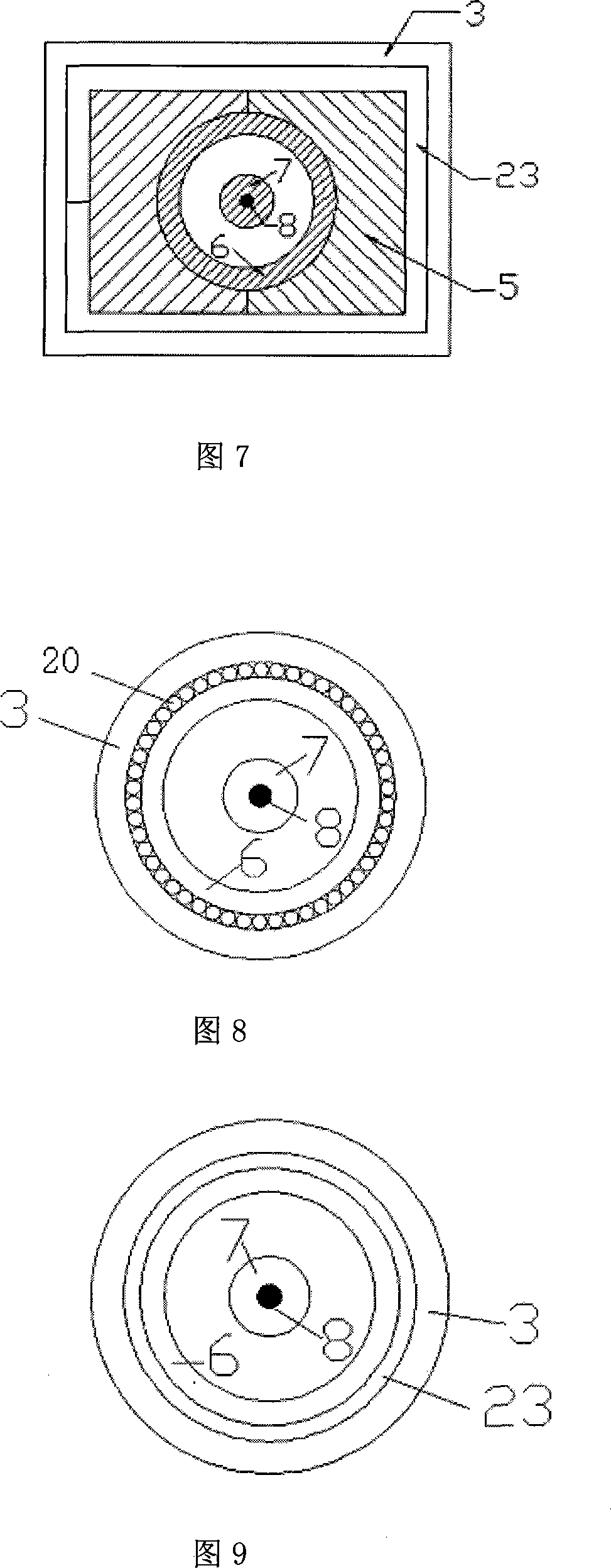

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

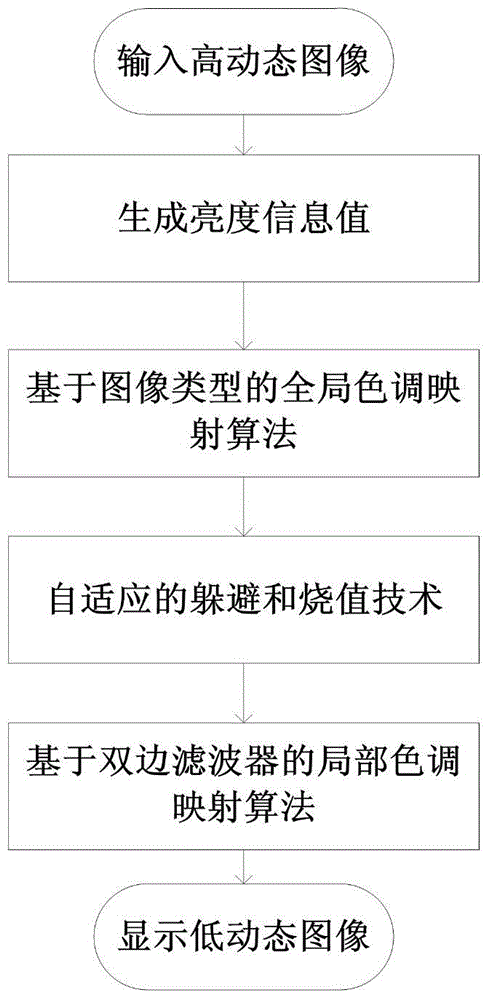

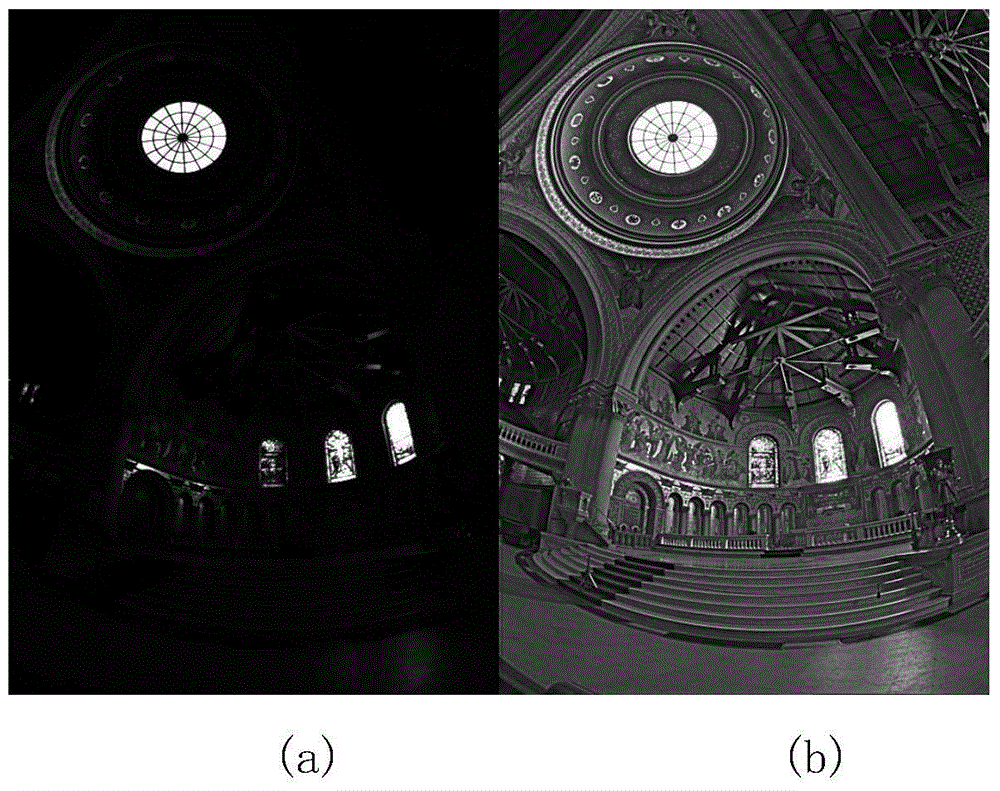

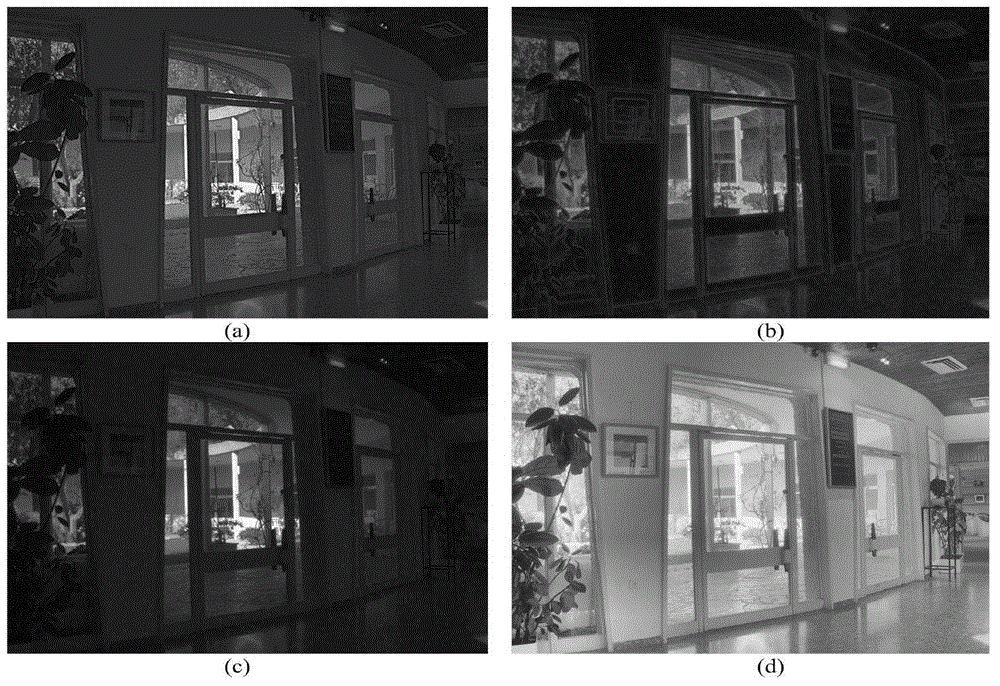

High dynamic range image compression method based on mixed tone mapping algorithm

InactiveCN104408752AGuaranteed quality effectImprove quality performanceImage enhancementImage codingVisibilityTone mapping

The invention belongs to the technical field of image and video processing, and particularly discloses a high dynamic range image compression method based on a mixed tone mapping algorithm. According to the high dynamic range image compression method, the problem about image distorsion when a high dynamic image displays on general display equipment is mainly solved. The high dynamic range image compression method comprises the following steps: firstly, using global linear compression based on image types to save the integral effect of the image; secondly, further enhancing the naturalness of the image by using an adaptive avoiding and value burning technology; finally, improving the visibility of image detailed information by using a local tone mapping algorithm based on a dual-side filter. According to the high dynamic range image compression method disclosed by the invention, a natural distinct low dynamic image result can be obtained; the high dynamic range image compression method can be widely applied to relevant fields of image and video processing.

Owner:XIDIAN UNIV

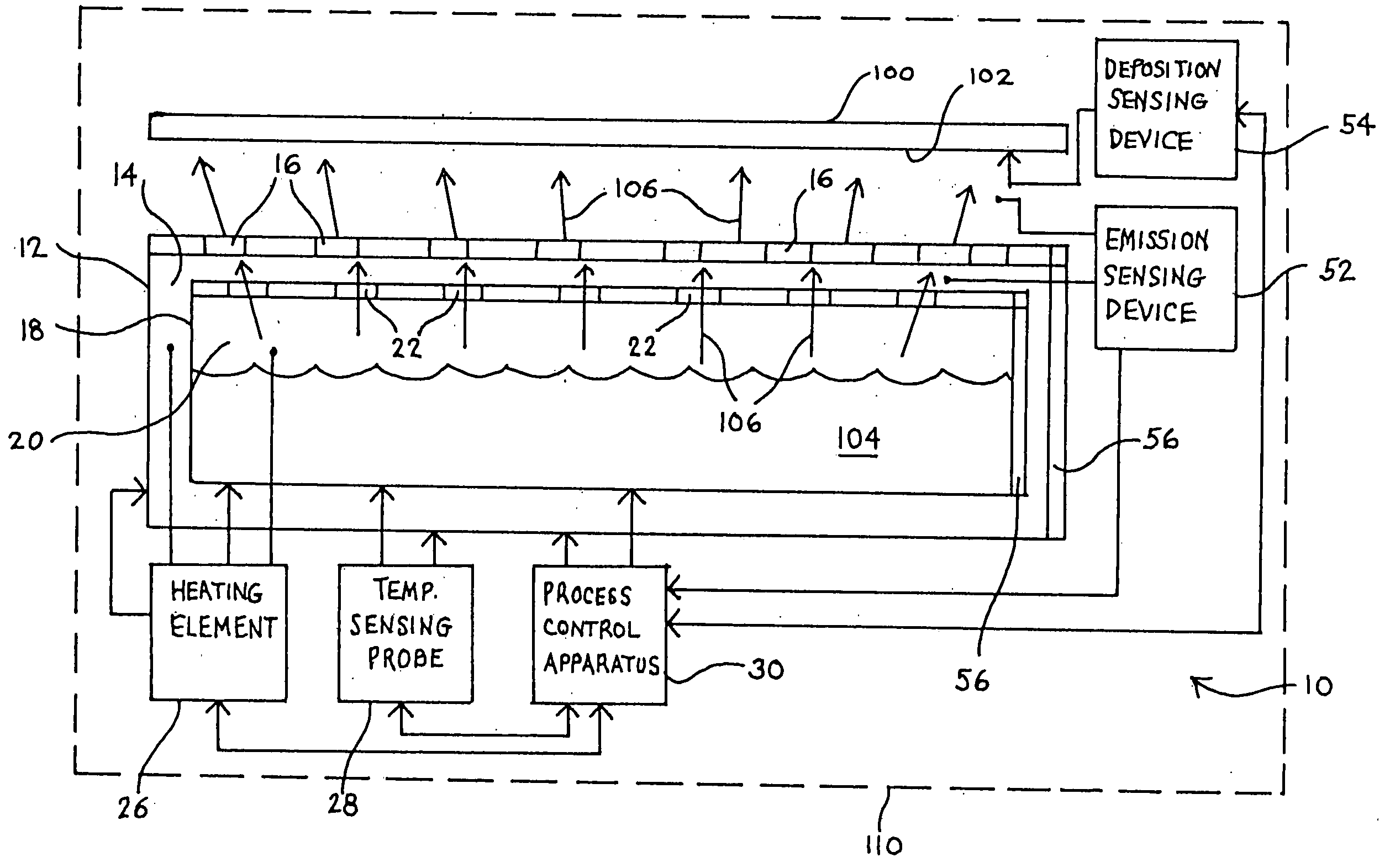

Material deposition system and a method for coating a substrate or thermally processing a material in a vacuum

InactiveUS20050147753A1Shorten the separation distanceImprove device performanceVacuum evaporation coatingSputtering coatingEngineeringBiomedical engineering

Disclosed is a material deposition system for depositing material onto a surface of a substrate. The system includes a first body element with an interior cavity and an exit aperture extending through the first body element, and a second body element having an interior cavity and an exit aperture extending through the second body element. The interior cavity of the second body element contains the material, and the exit aperture of the second body element is spacially separated from and in fluid communication with the exit aperture of the first body element. The first body element and the second body element are rotatable, such that the exit apertures of the first body element and the second body element can be aligned and misaligned. A material deposition system with novel aperture spacing and separation and methods of coating a substrate and thermally processing a deposition material are also disclosed.

Owner:KURT J LESKER

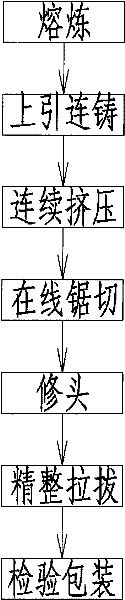

Large-section oxygen-free copper busbar and preparation method thereof

InactiveCN102262924AHigh purityImprove conductivitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsBusbarOxygen content

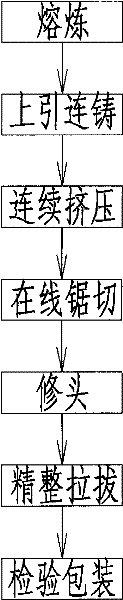

The invention relates to an oxygen-free copper busbar and a preparation method thereof, in particular to a large-section oxygen-free copper busbar and a preparation method thereof, belonging to the technical field of nonferrous metal processing. The technological process of the present invention is: smelting→upward continuous casting→continuous extrusion→online sawing→head trimming→drawing→inspection and packaging. The invention solves the shortcomings of the traditional process of large-section copper bus bars, provides a production technology with short process flow, high degree of automation, low oxygen content, excellent product quality, environmental protection and pollution-free, and effectively improves the quality and performance of products , has the advantages of high purity, low oxygen content, high electrical conductivity, and excellent surface quality.

Owner:SHANDONG ZHONGJIA NEW MATERIALS

Light conducting plate carved by laser impulse and method for producing the same

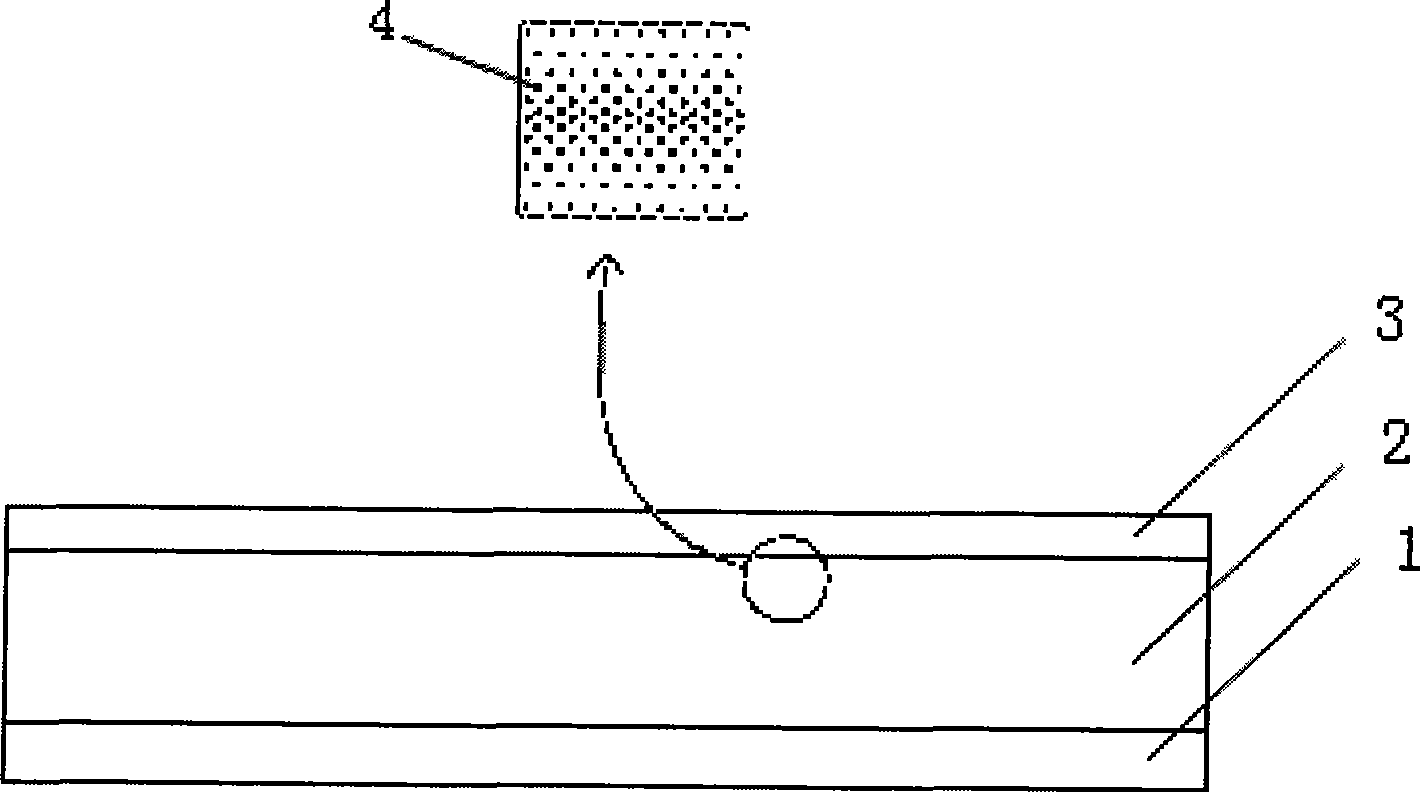

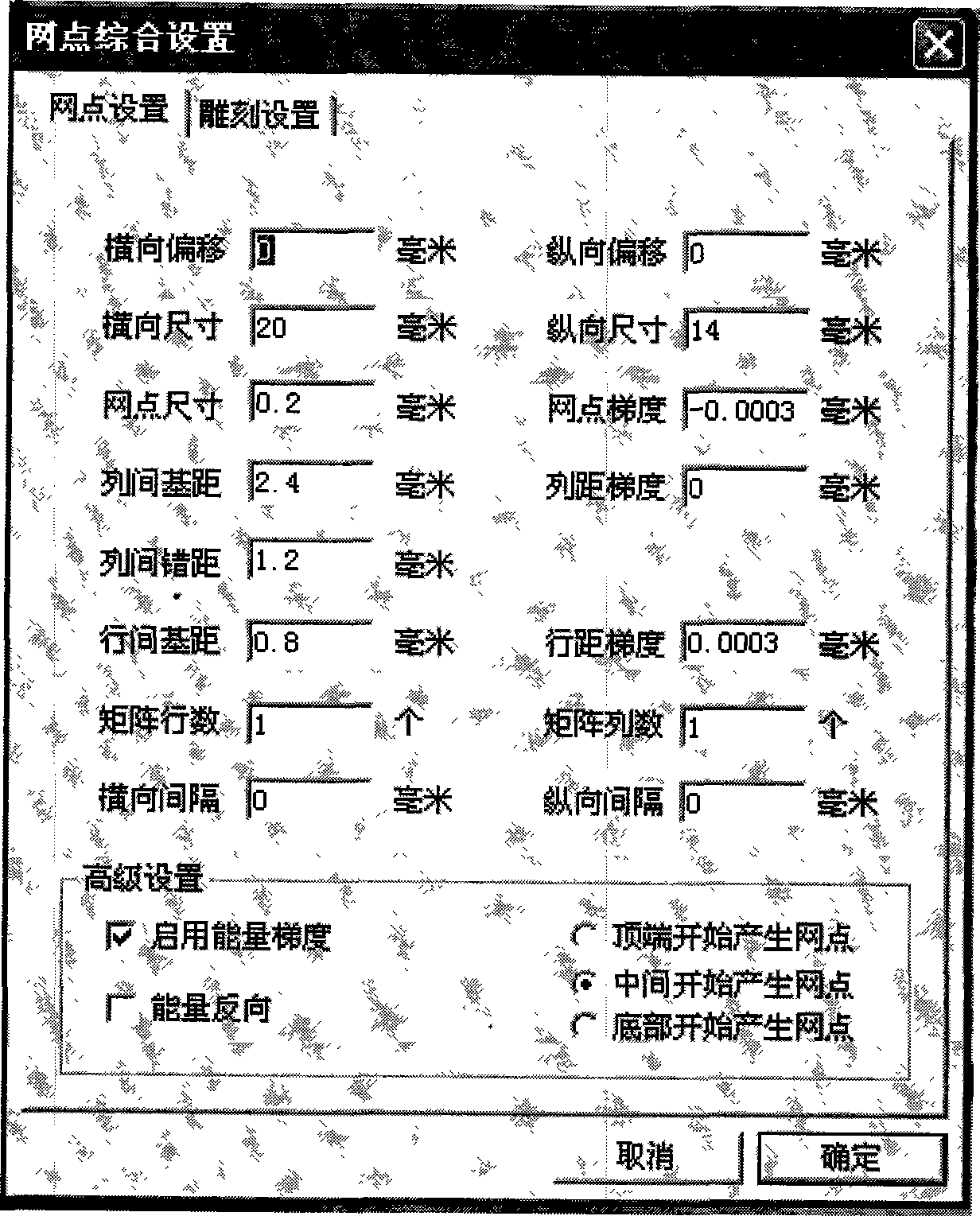

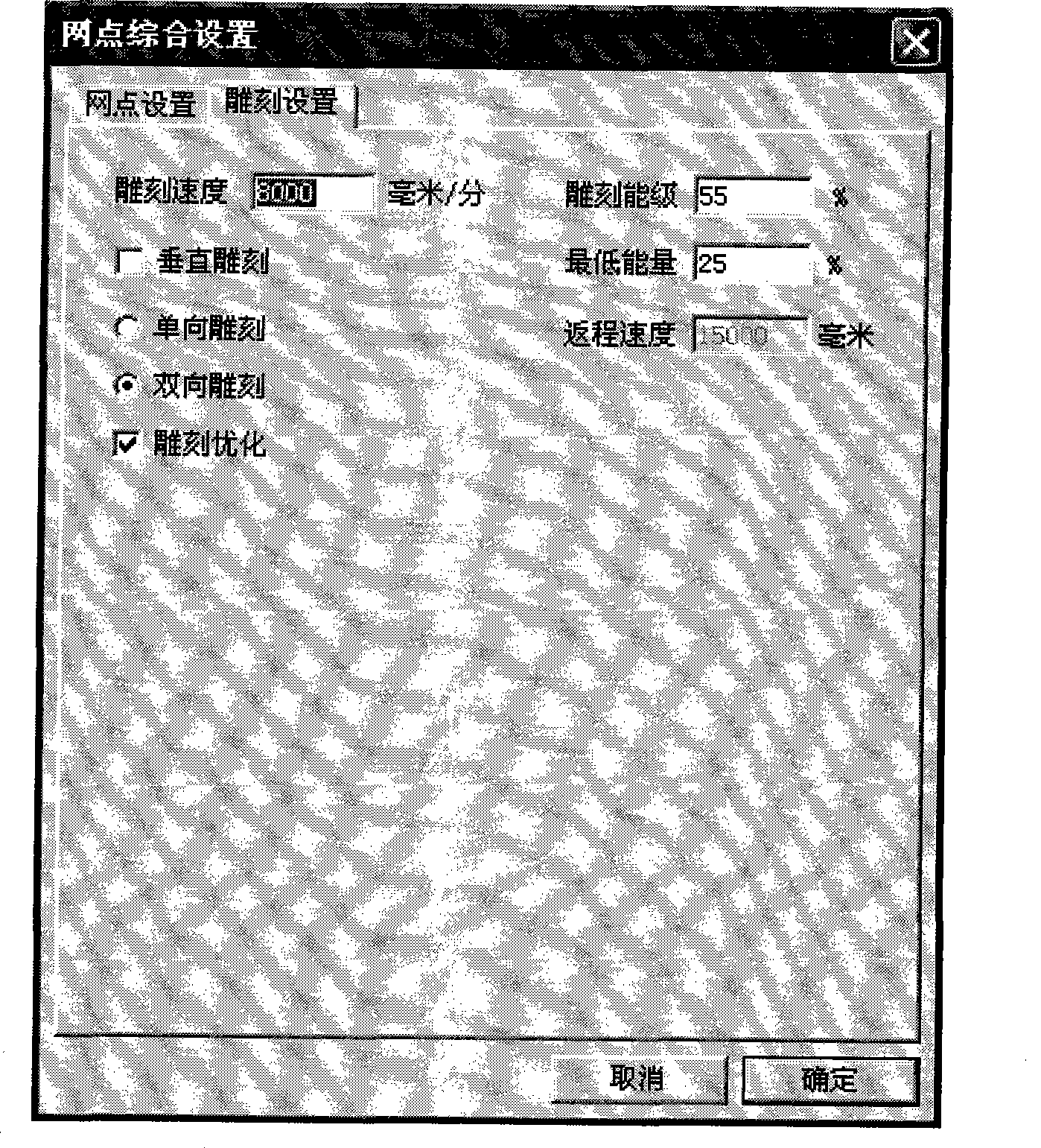

InactiveCN101470230AImprove quality performanceRefined technical specificationsMechanical apparatusLight guides for lighting systemsDiffusionLight guide

The invention discloses a light guide plate engraved by laser pulse, which comprises a reflective layer made of high reflective non-light-absorptive materials, a light guide layer made of high light transmittance materials and a diffusion layer made of light uniform scattering materials. The light guide plate is characterized in that reflecting diffusion sites or diffusion grooves engraved by laser pulse are distributed on the light guide layer of the light guide plate, spacing among the reflecting diffusion sites or diffusion grooves is smaller than or equal to 5mm, the depth of the reflecting diffusion sites or diffusion grooves under control of laser energy ranges from 0.001mm to 1mm, and the diameter of the diffusion sites ranges from 0.005mm to 2mm. In addition, the invention further discloses a method for preparing the light guide plate. The light guide plate manufactured by the method has the advantages of ultra-thinness, super-brightness, uniform light scattering, saving energy, environmental protection, durability, etiolation resistance, fast and simple installation and maintenance and the like without dark spaces.

Owner:SHANGHAI EDGE LIGHT IND

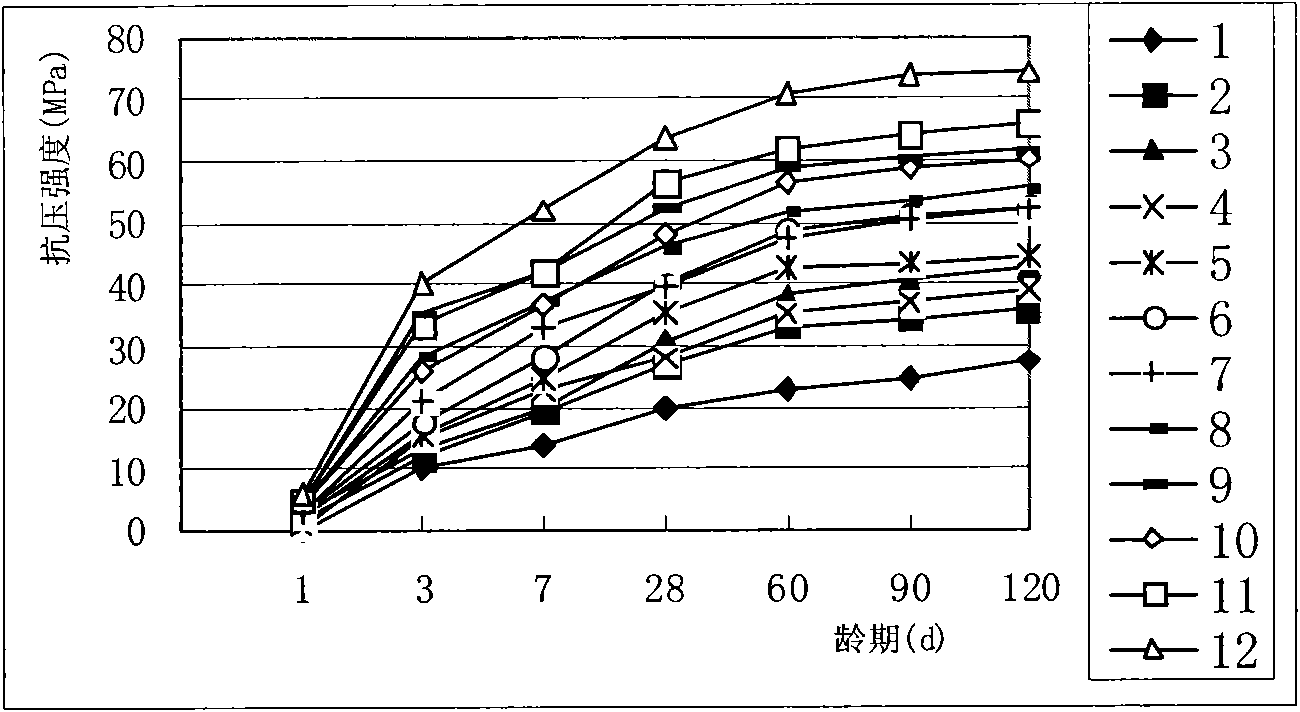

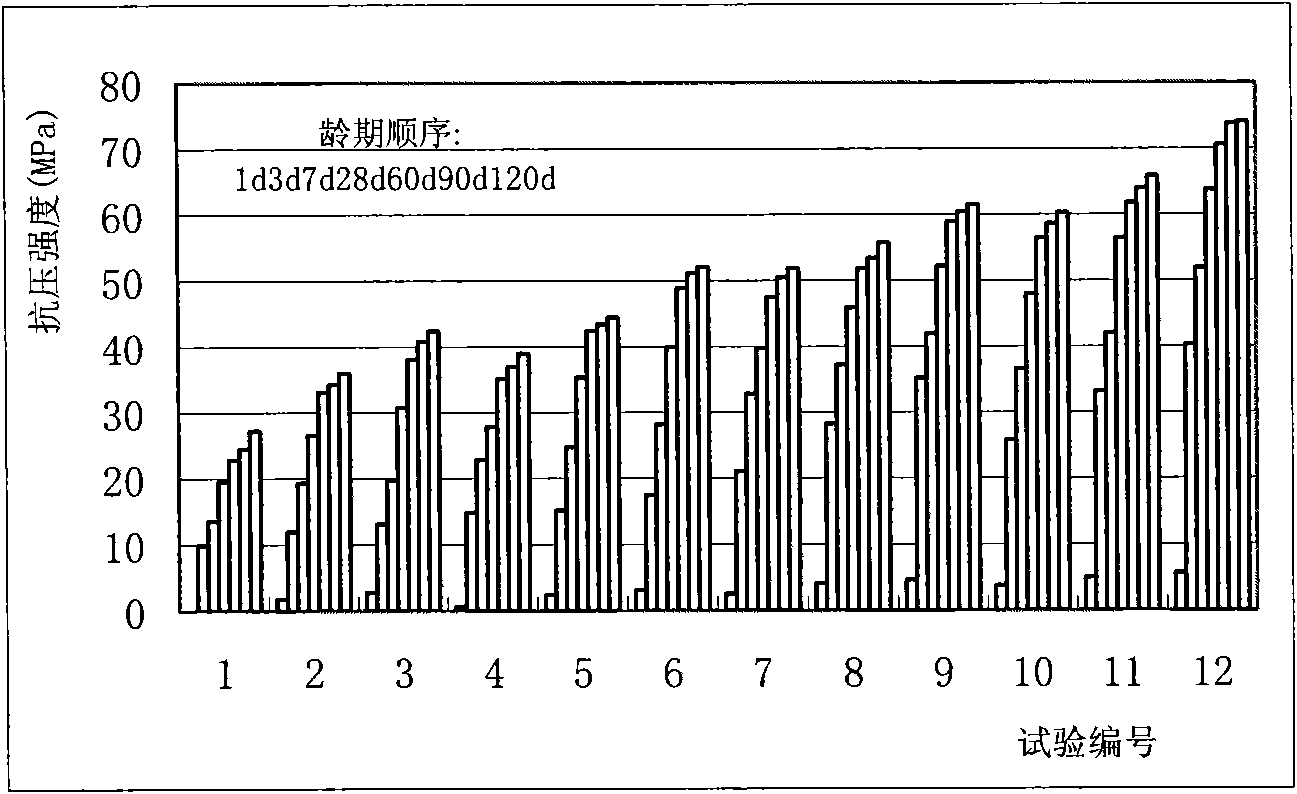

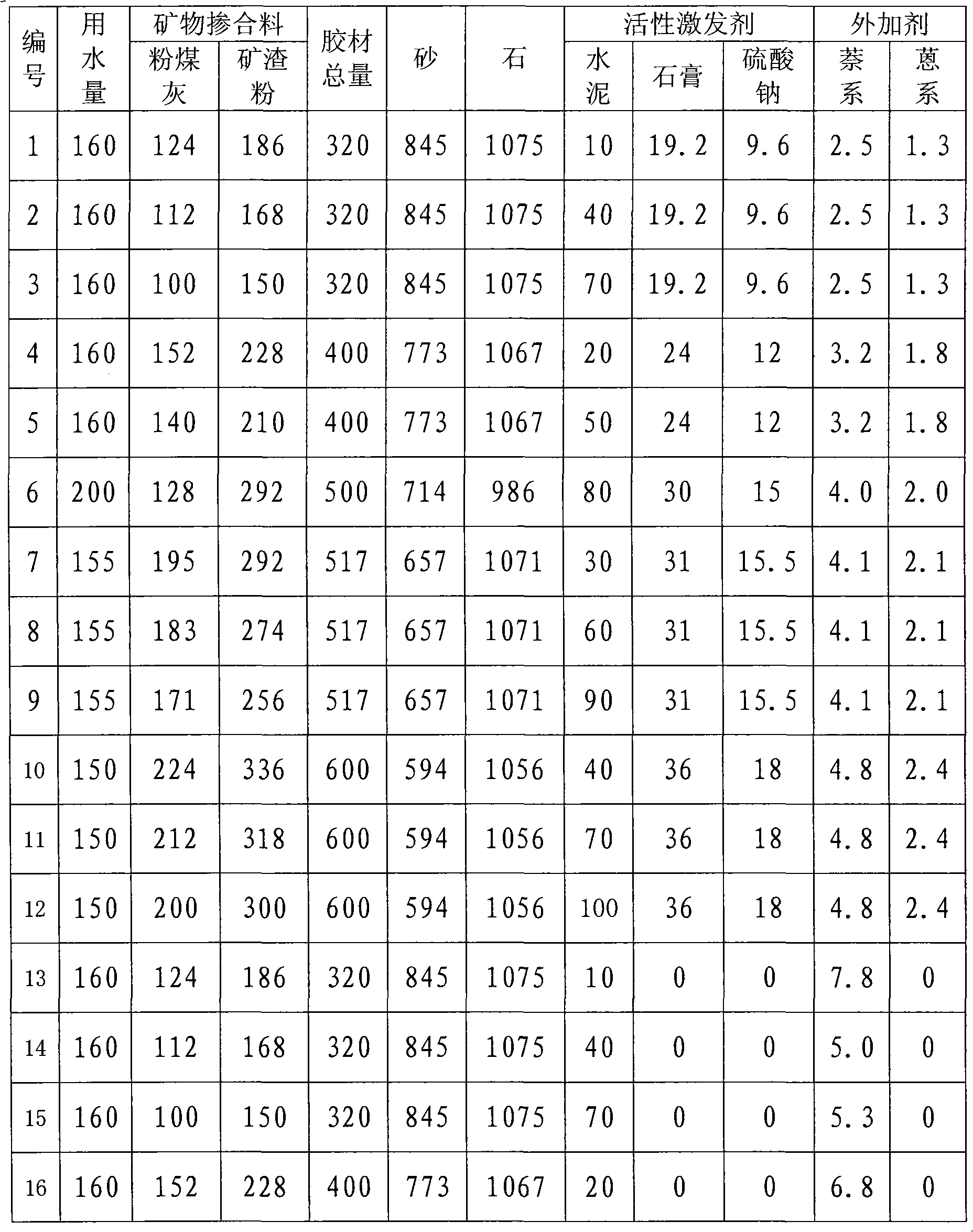

Mineral admixture concrete

The invention relates to a mineral admixture concrete. Mineral admixtures are used as concrete cementitous materials, common concrete and a complex of gypsum and sodium sulfate are added and used as activity excitants so as to coordinate the combined action of naphthalenesulfonate formaldehyde condensate and a crude anthracene sulfonate superplasticizer, and the high-efficiency concrete is prepared. Compared with the prior art, the excitants in the invention has the advantages that early excitation effect is good, mixing amount is less, the early or later strength and durance of the concrete can be greatly improved, the concrete dosage is reduced by 5-20% under the condition of maintaining the strength and workability of the concrete not to be changed, and the gypsum and sodium sylfate are both industrial byproducts with low costs. In the invention, concrete plaster is mixed in advance by using a secondary feeding method, residual materials are added in the mixed concrete plaster, and the strength of the concrete is improved while reducing the abrasion of coarse aggregates on equipment. The concrete has the advantages of good workability and less bleeding, is convenient for construction, and can be applied to large-volume concrete engineering, underground engineering, seaport engineering and the like.

Owner:北京元泰达环保科技有限公司

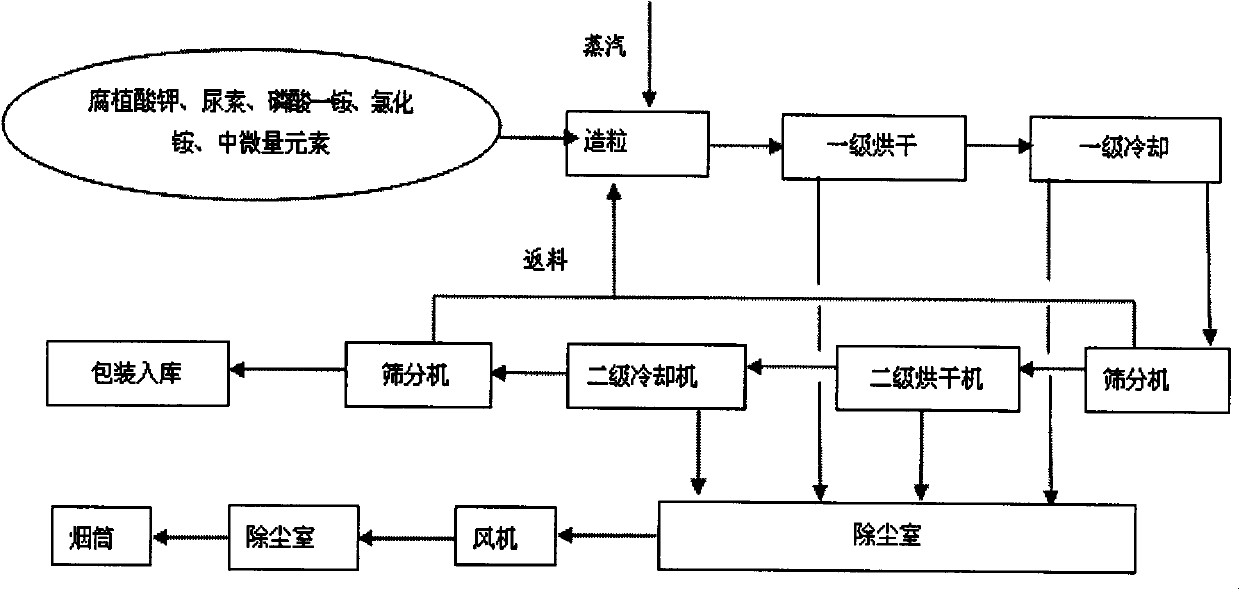

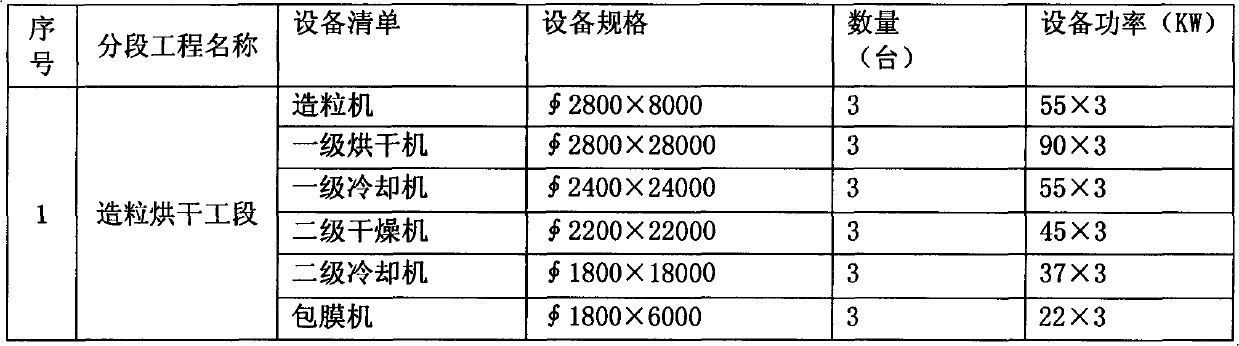

Potassium humate compound fertilizer and preparation method thereof

InactiveCN102001898AImprove aggregate structureSimple structureFertilizer mixturesSodium BentonitePhosphate

The invention belongs to the field of a fertilizer, in particular to a potassium humate compound fertilizer and a preparation method thereof. The potassium humate compound fertilizer is prepared by mixing urea, potassium humate, monoammonium phosphate, ammonium chloride, calcium powder and bentonite with magnesium sulfate, zinc sulfate and medium / trace elements. The potassium humate compound fertilizer granulated by using a steam drum physical agglomeration method and the preparation method of the compound fertilizer have the advantages that the prepared potassium humate compound fertilizer has large particle size and high strength and does not agglomerate; the capabilities of water and fertility retention, heat preservation and ventilation of the soil are enhanced; the soil structure is improved; the soil fertility is increased; the problems of reduced soil fertility, environmental pollution, soil hardening, nutrition unbalance and stress resistance of crops are solved; the utilization rate of the fertilizer is improved; the defects of low fertilizer efficiency, insufficient nutrition utilization, overproof pesticide residue, severe nitrate accumulation and heavy metal pollution are overcome; the sustained-release effect against pesticide is realized; the agroecological environment is protected; and the efficiency, yield and crop quality are improved.

Owner:李林

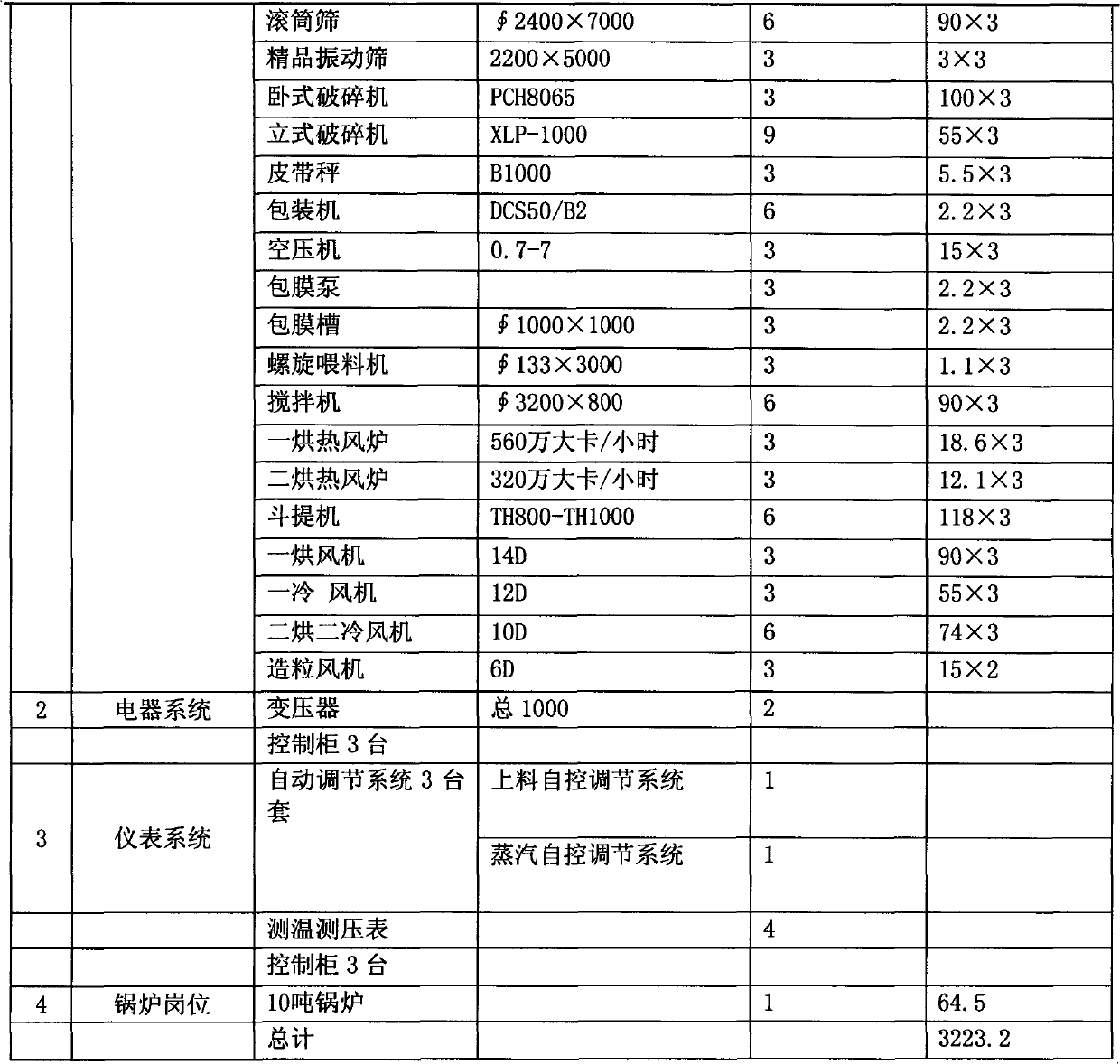

Video processing system and method

ActiveCN104581199AImprove quality performanceFulfil requirementsSelective content distributionVideo storageVideo processing

The invention provides a video processing system and method. The video processing system comprises a video saving module, a scene pre-distinguishing module, a video feature analyzing module, an intelligent matching module and a function module, wherein the video saving module is used for saving a video to be processed or an already-processed video; the scene pre-distinguishing module acquires the video to be processed from the video saving module, and distinguishes a scene according to front and back correlation in the video to be processed; the video feature analyzing module generates feature parameter information of each video segment according to scene information; the intelligent matching module matches the feature parameter information of each video segment with a preset processing mode; the function module invokes relevant functions and processes each video segment according to a matching result of the intelligent matching module. The video processing system and method have the advantages that the requirements that a processing standard is unified, the quality effect of an image is improved and the effect satisfies audiences are met, the processing efficiency is improved, and the labor cost is reduced.

Owner:百视通网络电视技术发展有限责任公司

Preparation method of special organic fertilizer for flue-cured tobacco with wormcast as substrate

InactiveCN107082726ASave raw materialsImprove disease resistanceBio-organic fraction processingExcrement fertilisersPotassium sulfateSoil fertility

The invention relates to a preparation method of special organic fertilizer for flue-cured tobacco with wormcast as a substrate. The preparation method comprises the following steps: (1) preparing a mixed base material; (2) fermenting the mixed base material; (3) adding EM bacteria; (4), laying a earthworm material bed; (5), preparing mixed raw materials; (6), mixing and producing the fertilizer: pelletizing the mixed raw materials, then adding a diluted EM bacteria solution, stirring evenly to get a granular base material, finally according to weight percentage, mixing 60% of the granular base material, 10% urea, 18% of ammonium dihydrogen phosphate, and 12% of potassium sulfate evenly, packaging, and obtaining the special organic fertilizer for the flue-cured tobacco. The organic fertilizer prepared by the invention not only improves the microbial living environment in soil, enhances the soil fertility and the air permeability, but also improves the utilization rate of inorganic fertilizer so as to achieve the goal of improving the yield and quality of tobacco leaves.

Owner:河南龙之锦农业发展有限公司

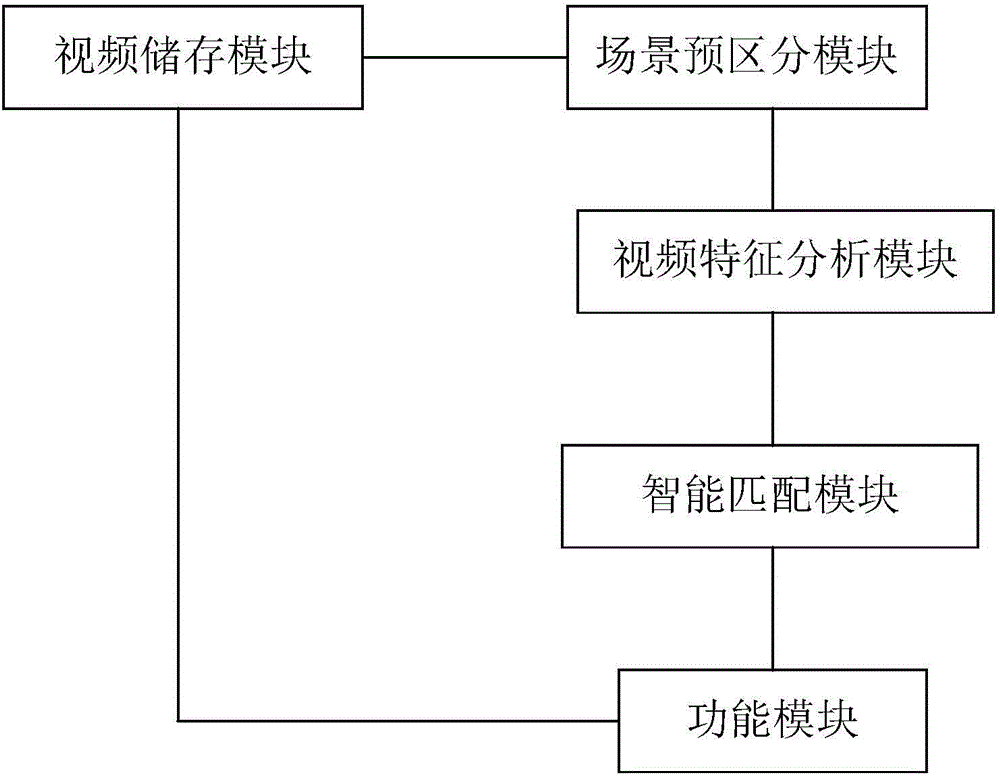

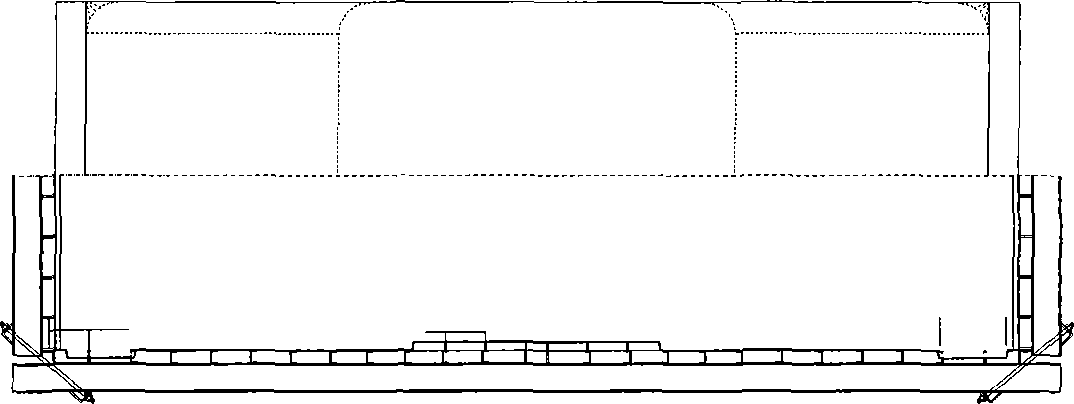

Continuous Quenching Line for Large Diameter Tube and Bar

ActiveCN102268523ALow costImprove product quality performanceFurnace typesHeat treatment furnacesAutomatic controlAutomated control system

A continuous quenching line for large-diameter tube and bar materials is provided. Along the moving direction of tube and bar materials, a V-shaped inclined roll transmission continuous heating furnace is connected to an end of an automatic material charging machine; a multifunctional quenching machine is connected to an end of the V-shaped inclined roll transmission continuous heating furnace; the multifunctional quenching machine is connected to an automatic material discharging machine; a water collecting pool is disposed at the lower part of the multifunctional quenching machine; an automatic control system controls the devices from the automatic material charging machine to the automatic material discharging machine; continuous horizontal heat processing of alloy steel, stainless steel, light alloy bar and tube materials with a diameter of 100-800 mm and a length of above 2000 mm (a wall thickness of below 100 mm) can be performed. During the heating and quenching processes, the material both moves forward and performs self-rotation, does not bend or deform, is heated and quenched uniformly, and has a deep quenched layer, and the invention has the functions of performing quenching, solid solution treatment, normalization processing, annealing processing and the like of alloy tool steel tube and bar materials, alloy structure steel tube and bar materials, heat resistant steel tube and bar materials, various stainless steel tube and bar materials, aluminium alloy tube and bar materials, and the like.

Owner:ARES IND FURNACE TIANJIN

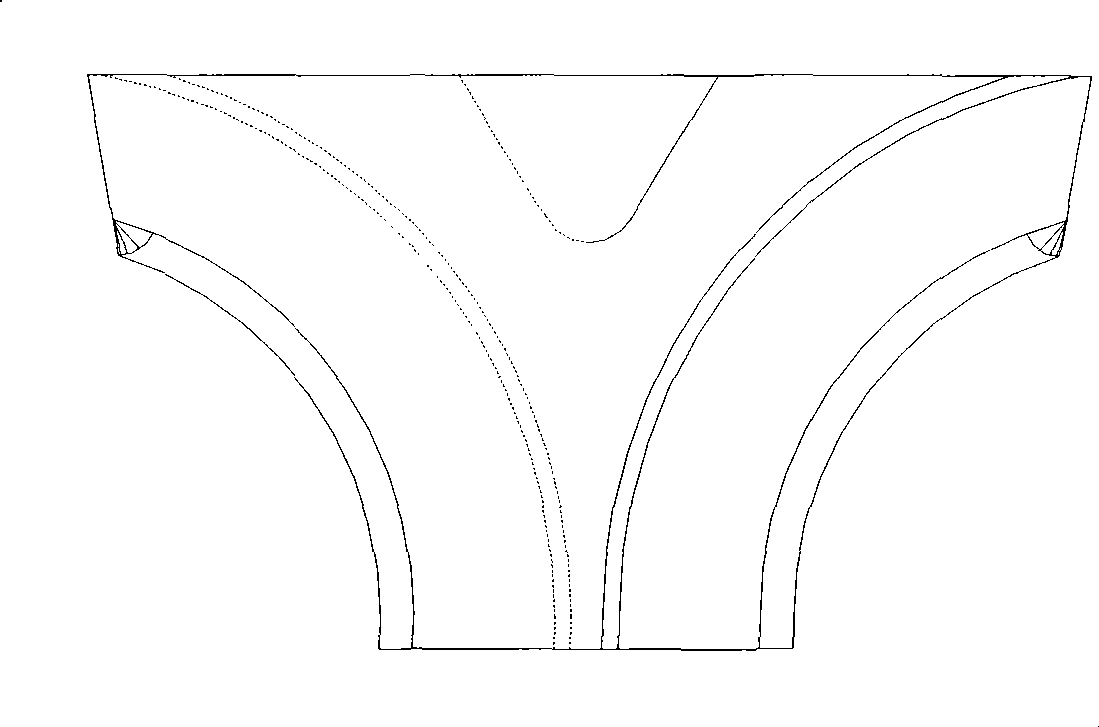

Reinforced concrete pier stud with capping beam or irregular Y-shaped reinforced concrete pier stud once-forming construction method

InactiveCN101446073AImprove quality performanceLabor savingBridge erection/assemblyFalseworkReinforced concrete

The invention relates to a construction technology of a viaduct reinforced concrete pier stud with a capping beam or irregular Y-shaped reinforced concrete pier stud. A reinforced concrete pier stud with a capping beam or irregular Y-shaped reinforced concrete pier stud once-forming construction method provided by the invention comprises the steps of designing a template, setting up scaffolds, binding a capping beam and reinforcing steel bars, installing the template and casting concrete, wherein, the step of designing the template is that a lower straight pier stud steel mould and an upper capping beam steel mould are designed as being capable of being assembled at a time; when the template is installed, a linear portion and the capping beam template are all installed piece by piece; the linear portion is installed in right angle; two lengthways lateral moulds of the capping beam template are installed, and then two transverse lateral circular arc bottom moulds and head end templates are installed. The method adopts the once-forming of a pier stud and a capping beam, thereby ensuring that the appearance quality effect of a product is improved greatly, the pier stud and the capping beam are integrated as a whole; and the method takes certain effect on beautifying the environment. The method can save labor and materials for repairing joints during the constructing process and changes the common fault of color difference caused by twice casting.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

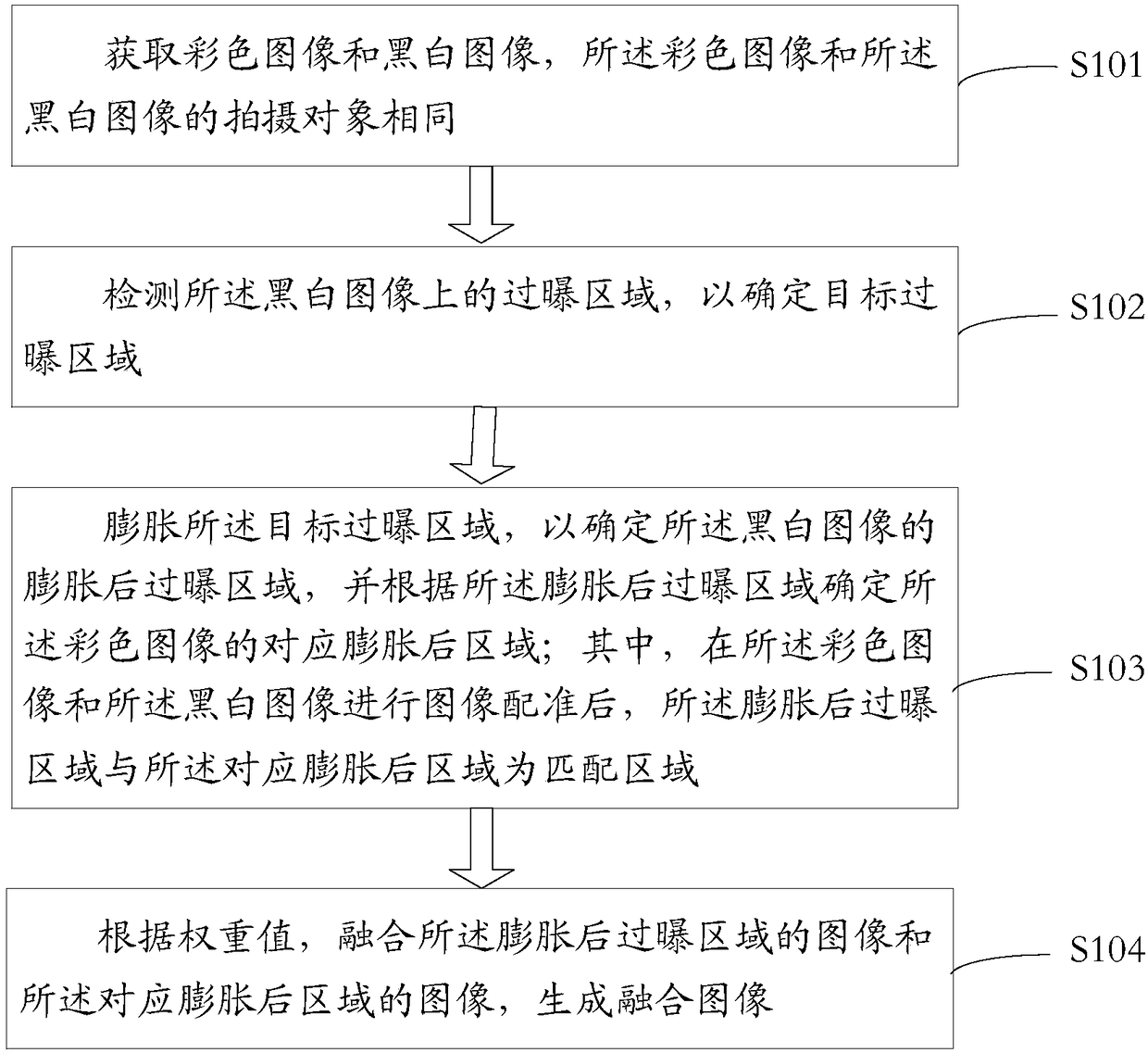

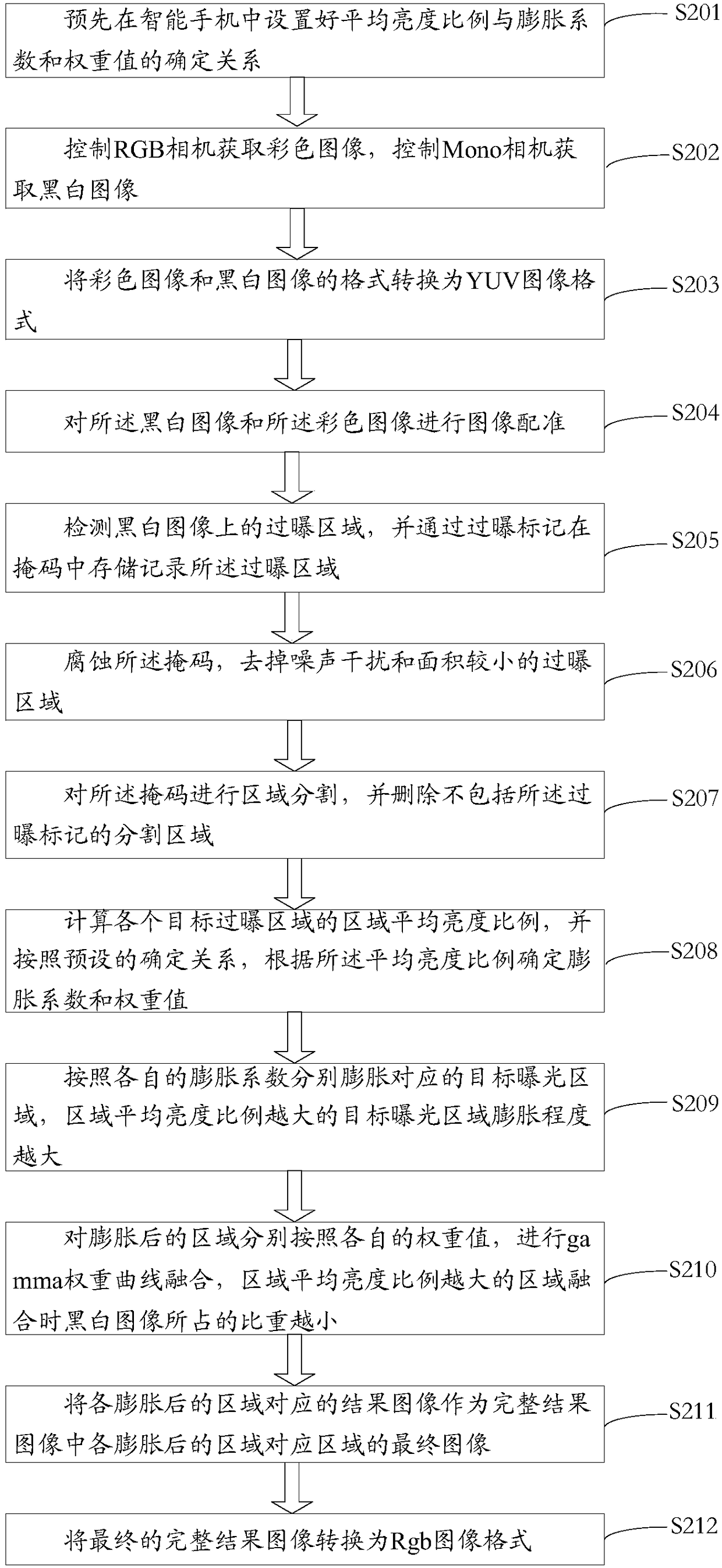

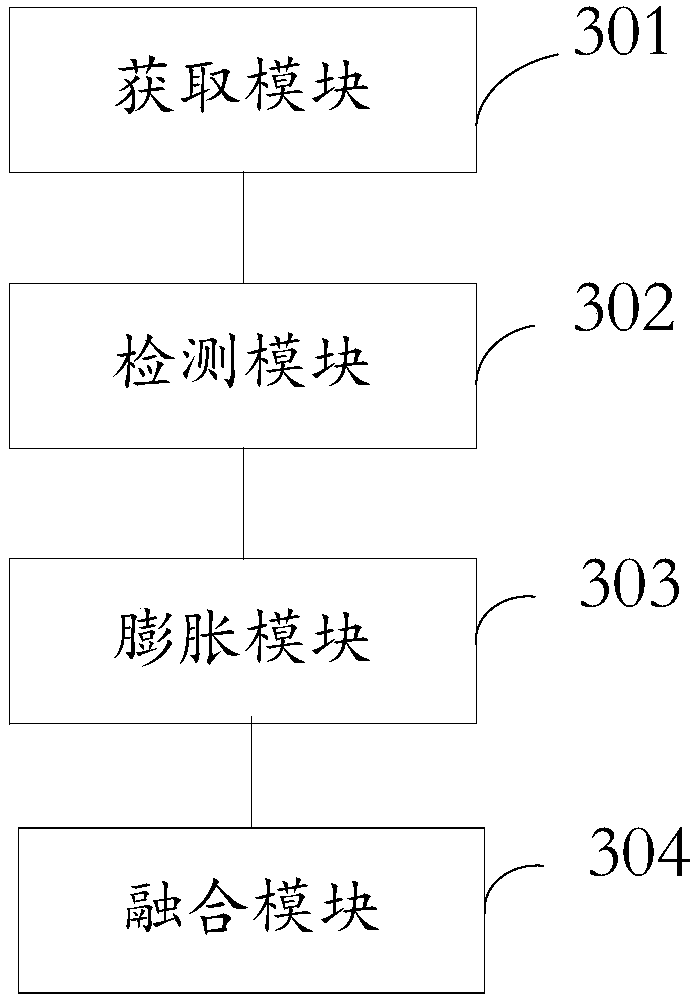

Image fusion method and device, electronic device and medium

ActiveCN108364275AIncrease fusion rangeReduce loss of detailImage enhancementColor imagePoor Quality Image

The present invention discloses an image fusion method and device, an electronic device and a medium. The method comprises the steps of: obtaining a color image and a black-and-white image, wherein the shooting objects of the two images are the same; detecting an overexposure area on the black-and-white image to determine a target overexposure area; expanding the target overexposure area to determine an overexposure area of the black-and-white image after expanding, and determining an area after expanding corresponding to the color image according to the overexposure area after expanding, wherein after the color image and the black-and-white image are subjected to image registration, the overexposure area after expanding and the corresponding area after expanding are matching areas; and according to a weight value, fusing an image of the overexposure area after expanding and an image of the corresponding area after expanding to generate a fusion image. The image fusion method and device, an electronic device and a medium solve the problem that the overexposure area edge is excessively unnatural to cause poor image quality and achieve the technical effect of improving the image quality.

Owner:CHENGDU CK TECH

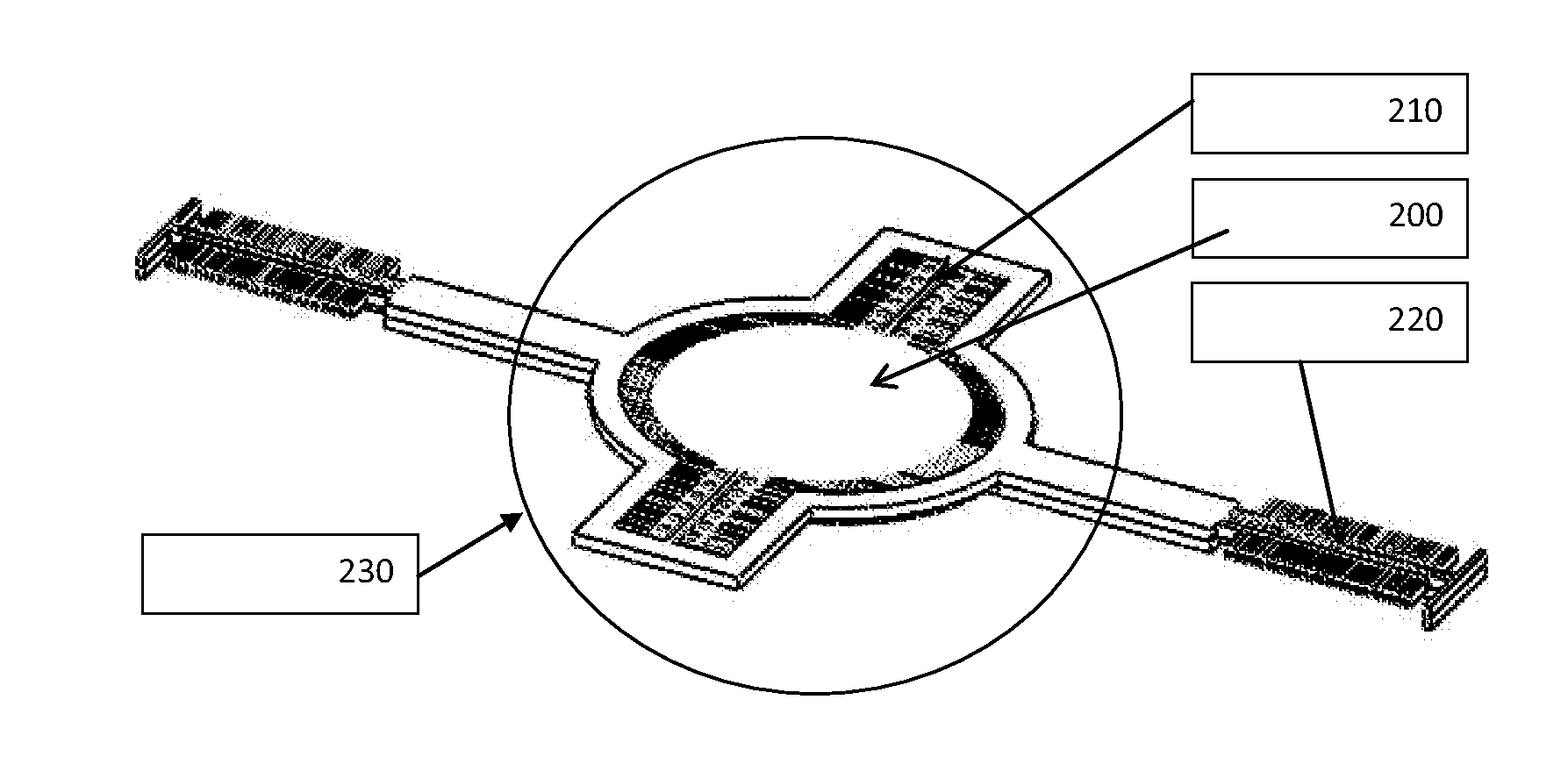

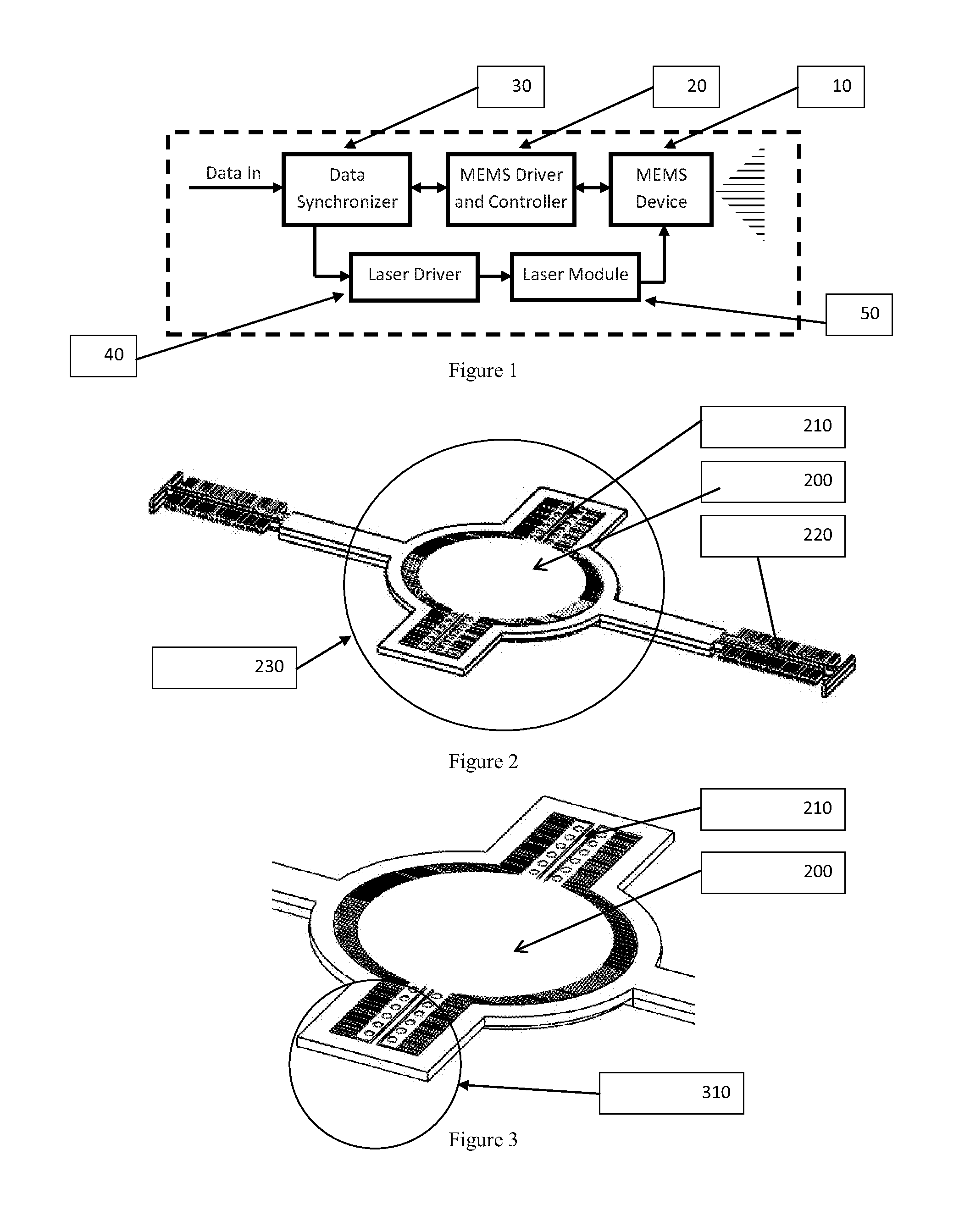

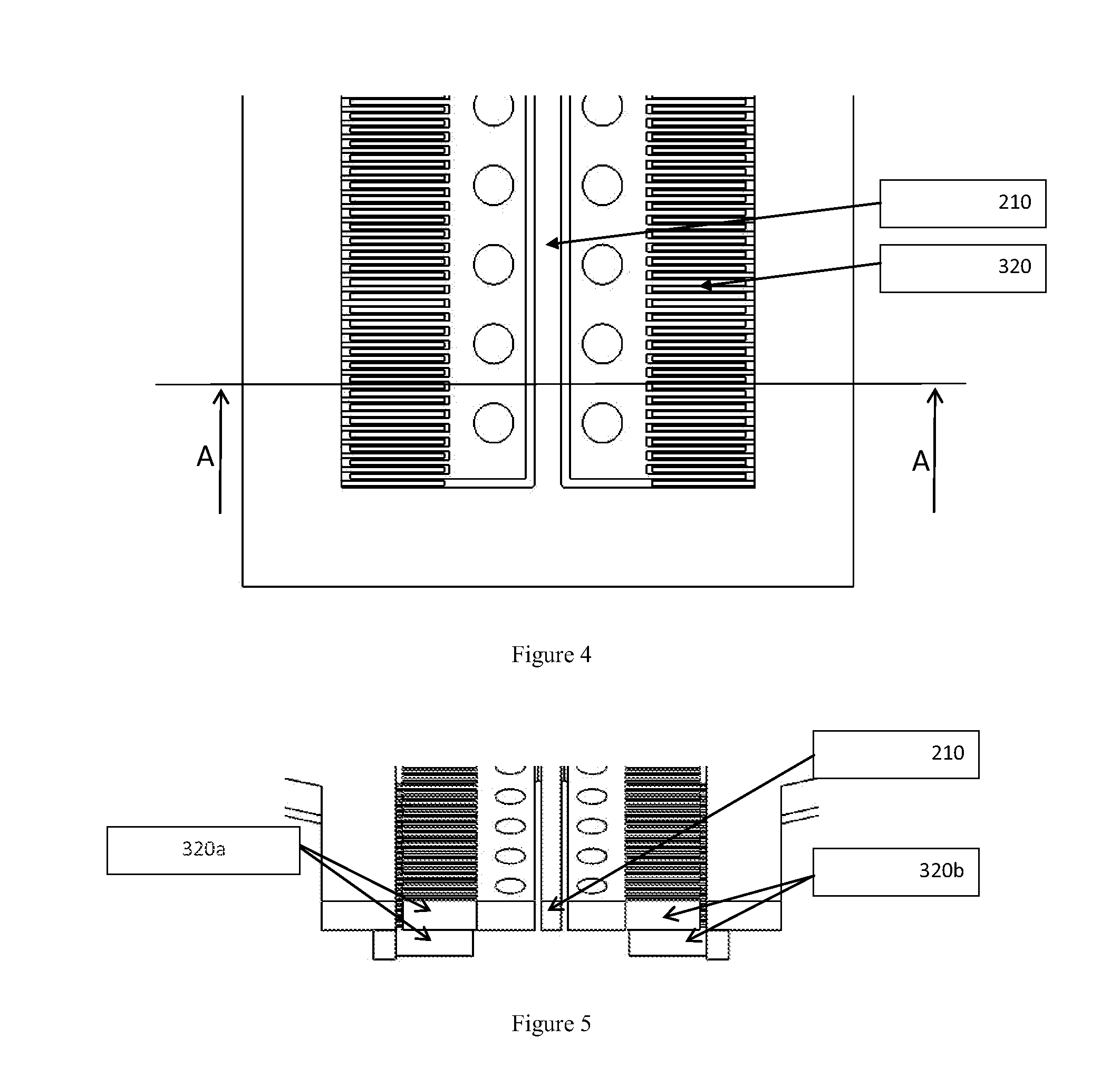

Apparatus and methods for locking resonating frequency of a miniature system

ActiveUS20140218700A1Improve performanceReduces dimensionStatic indicating devicesProjectorsResonanceSoftware engineering

A resonance locking system for a pico-projector, the system comprising a resonance frequency sensor operative for sensing change in resonance frequency of a miniature mechanical device (10) including a moving mirror assembly having a driving frequency, by comparing a current resonance frequency to a reference; and a feedback loop changing at least one aspect of use of the miniature moving mirror assembly responsive to a current value of the resonance frequency measured by the sensor.

Owner:MARADIN

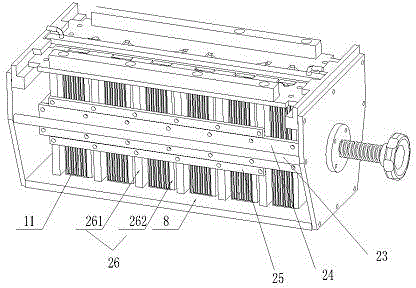

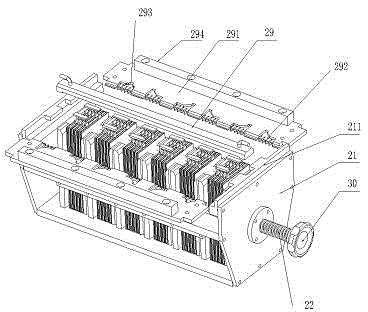

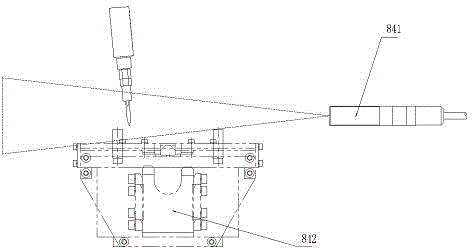

Novel lead storage battery automatic flame welding machine

InactiveCN103846526AWeld firmlyReliable weldingWelding/cutting auxillary devicesAuxillary welding devicesPressure systemReducer

The invention discloses a novel lead storage battery automatic flame welding machine, which comprises a work table, a driving chain wheel, a driven chain wheel, a chain and a speed reducer, wherein the driving chain wheel and the driven chain wheel are respectively arranged at two ends of the work table, the chain is engaged with the driving chain wheel and the driven chain wheel, a rotating shaft of the speed reducer is fixedly connected with the driving chain wheel, the speed reducer drives the driving chain wheel to rotate, a plurality of welding clamps are fixedly arranged on the chain, a sealing cover is arranged on the work table, at least one X-axis single-arm mechanical hand is arranged in the sealing cover, a corresponding Z-axis air cylinder and a welding assembly are arranged on the corresponding X-axis single-arm mechanical hand, a welding gun of the welding assembly is vertically positioned above a corresponding clamp clamping device, and an automatic ignition device and an automatic detecting device are arranged on the welding gun. The novel lead storage battery automatic flame welding machine has the advantages that the welding is carried out in a sealed work space, harmful gas generated in the welding process is pumped out by a factory negative pressure system and is purified by dust removal equipment to be exhausted, and in addition, the welding of the automatic flame welding machine is firm and stable.

Owner:JIANGSU RONGWEI ENVIRONMENTAL PROTECTION TECH

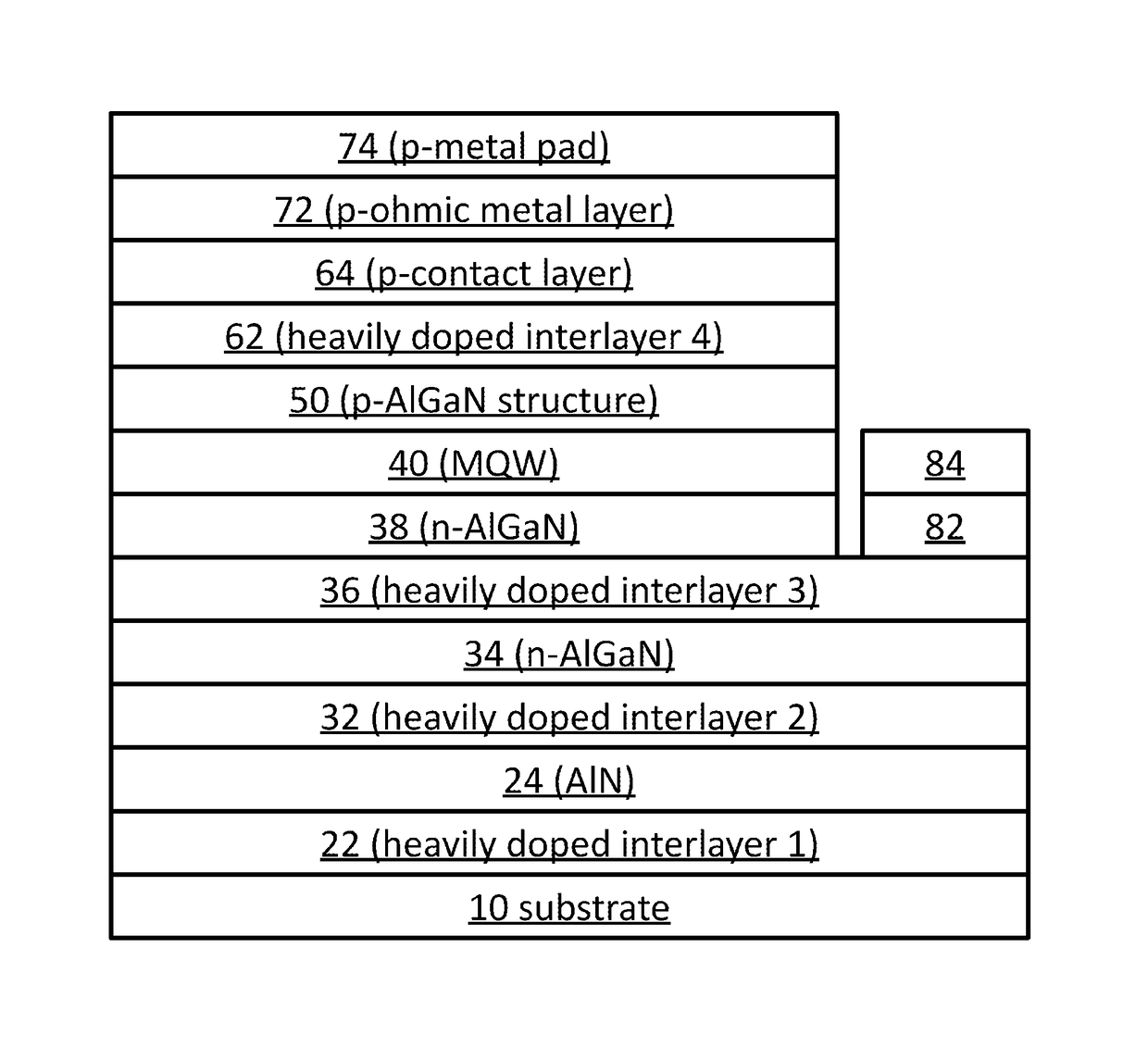

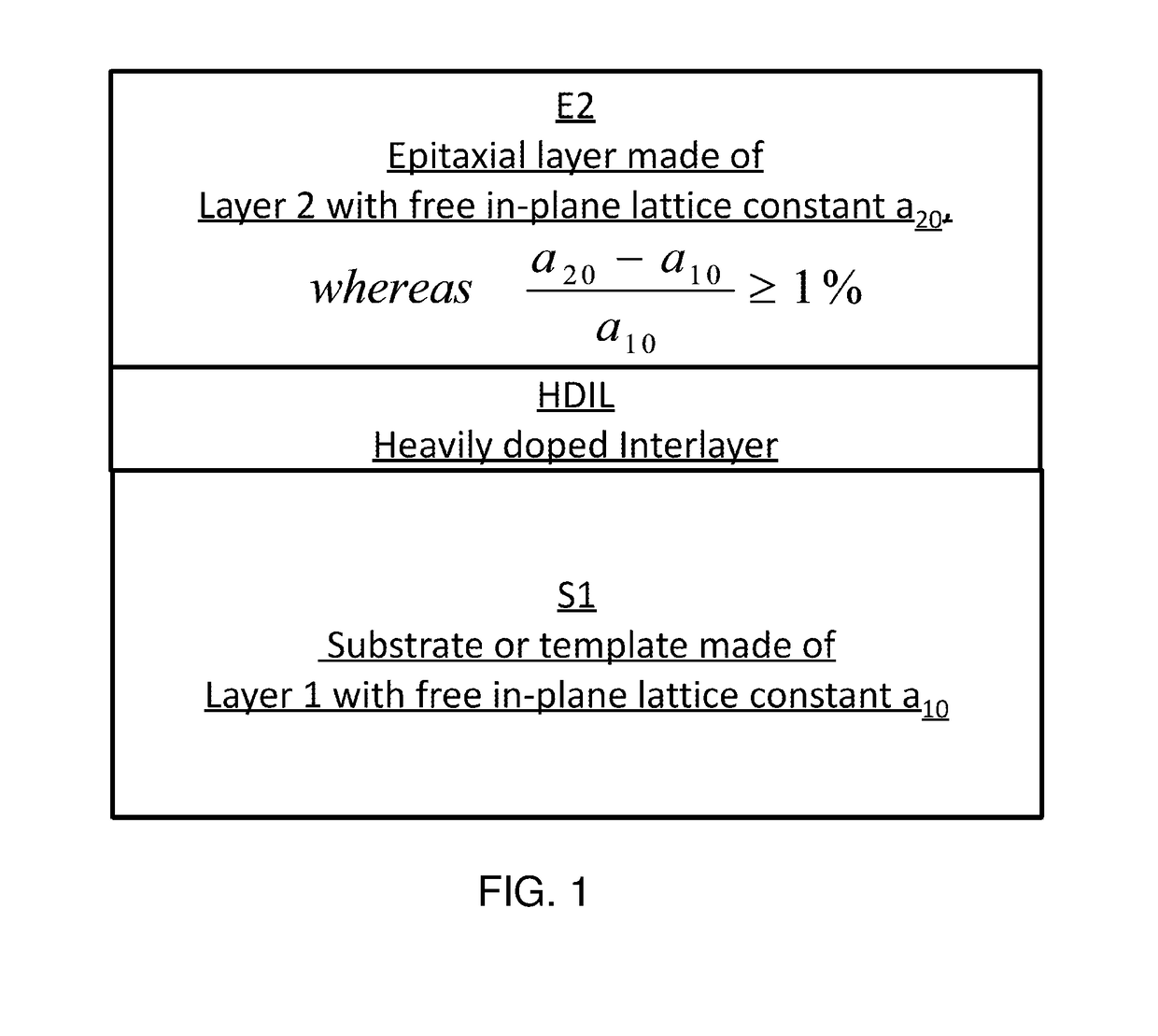

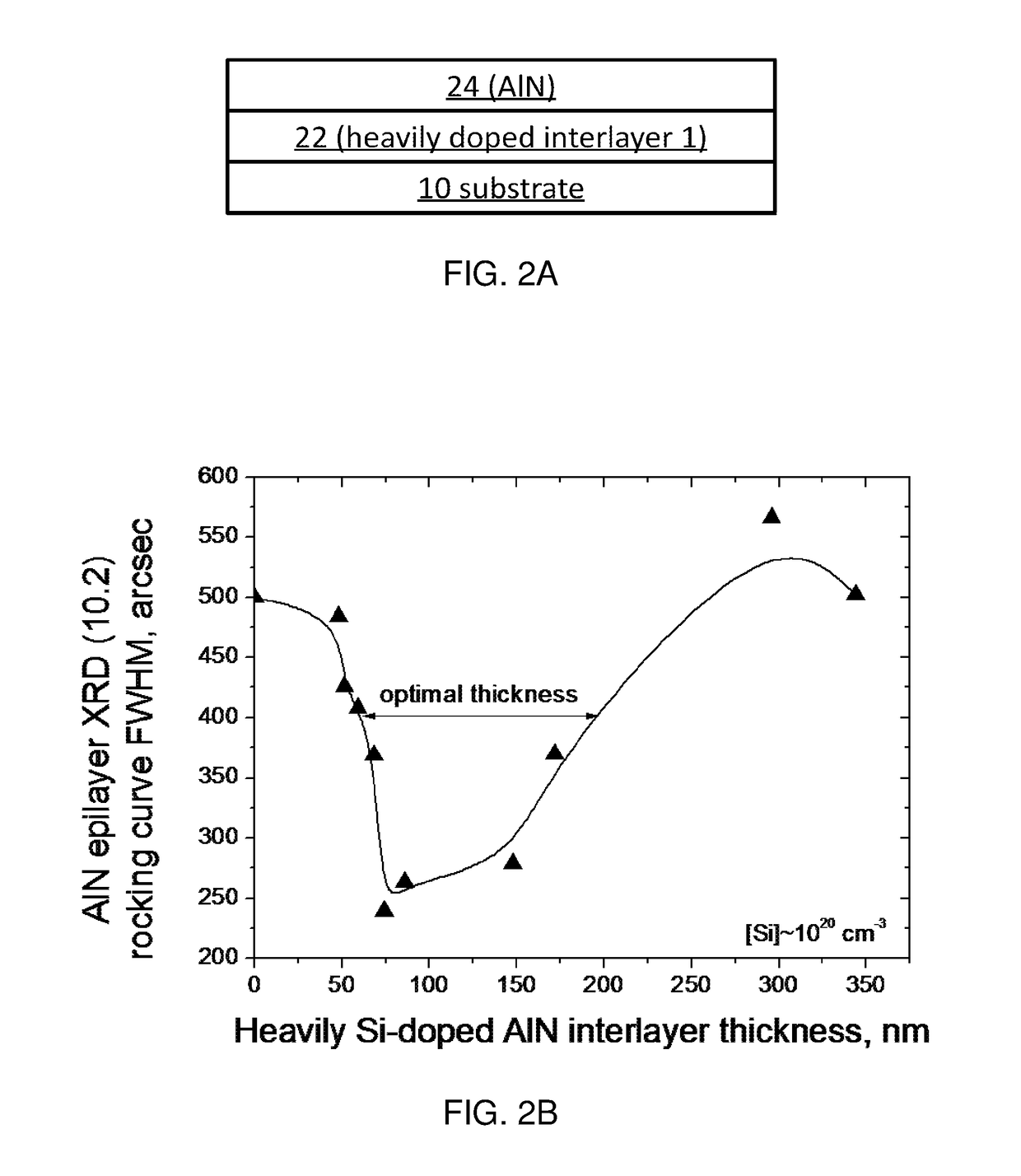

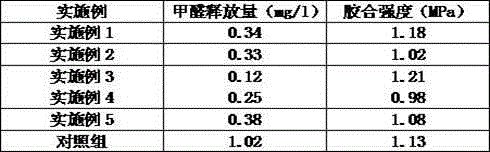

Ultraviolet light-emitting device with a heavily doped strain-management interlayer

ActiveUS9680056B1Efficient and cost-effective approachImprove device performanceSemiconductor devicesIn planeUltraviolet lights

A heteroepitaxy strain-management structure for a light emitting device includes: a substrate or template; an epitaxial layer to be epitaxially formed over the substrate or template, wherein a calculated in-plane compressive strain to be exerted by the substrate or template to the epitaxial layer is equal to or larger than 1%; and a heavily doped interlayer inserted in-between the epitaxial layer and the substrate or template; wherein the heavily doped interlayer is of substantially the same material composition as that of the epitaxial layer, with a thickness of 40-400 nm, and doped at a doping level in the range of 5×1019 to 5×1020 cm−3. Also provided is an ultraviolet light emitting device having a heteroepitaxy strain-management structure.

Owner:BOLB

Dual composite lithium-based lubricating grease and preparation method thereof

The invention discloses dual composite lithium-based lubricating grease and a preparation method thereof. According to the technical scheme, the dual composite lithium-based lubricating grease is prepared from the following raw materials in parts by weight: 24-36 parts of base oil, 5-7 parts of 12-hydroxystearic acid, 3-5 parts of stearic acid, 2-3 parts of lithium hydroxide, 0.2-0.4 part of calcium hydroxide, 0.4-0.6 part of boric acid, 0.5-1.5 parts of azelaic acid, 0.5-1.5 parts of phosphodiester, 1-1.4 parts of polybutylene terephthalate and 1.9-2 parts of additive. Functional groups in lithium-based lubricating grease molecules are sufficiently utilized, and a composite structure is added in each molecule when a composite structure is preserved, so that the quality of the composite lithium-based lubricating grease is improved, meanwhile, the soap component of the lithium-based lubricating grease is reduced, and the production cost is reduced.

Owner:XINXIANG HENGXING TECH CO LTD

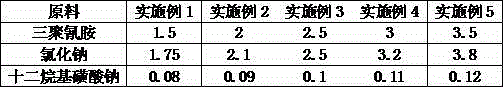

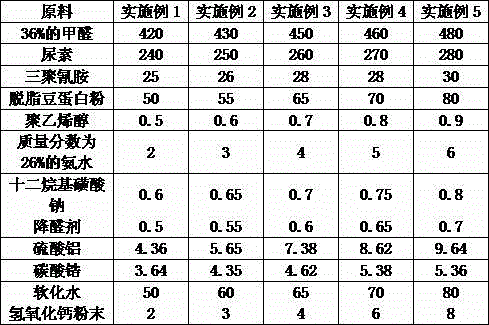

Urea-formaldehyde adhesive and preparation method thereof

InactiveCN104592920AImprove quality performanceLow costNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCalcium hydroxidePolymer science

The invention relates to the technical field of urea-formaldehyde adhesives, and particularly relates to a urea-formaldehyde adhesive additive for artificial boards and a preparation method thereof. The urea-formaldehyde adhesive is composed of the following components in parts by mass: 420-480 parts of 36% formaldehyde, 240-280 parts of urea, 25-30 parts of melamine, 50-80 parts of degreased bean albumen powder, 0.5-0.9 part of polyvinyl alcohol, 2-6 parts of 26 wt% ammonia water, 0.6-0.8 part of sodium dodecylsulfate, 0.5-0.7 part of aldehyde reducing agent, 8-15 parts of complexing agent, 50-80 parts of softened water and 2-8 parts of calcium hydroxide powder. The urea-formaldehyde adhesive additive lowers the amount of free formaldehyde in the urea-formaldehyde glue adhesive, enhances the quality performance of the urea-formaldehyde adhesive, increases the viscosity to some extent, and greatly improves the stability and water resistance. The urea-formaldehyde adhesive has the advantages of low cost and simple preparation process, and is convenient for popularization and use.

Owner:金思思

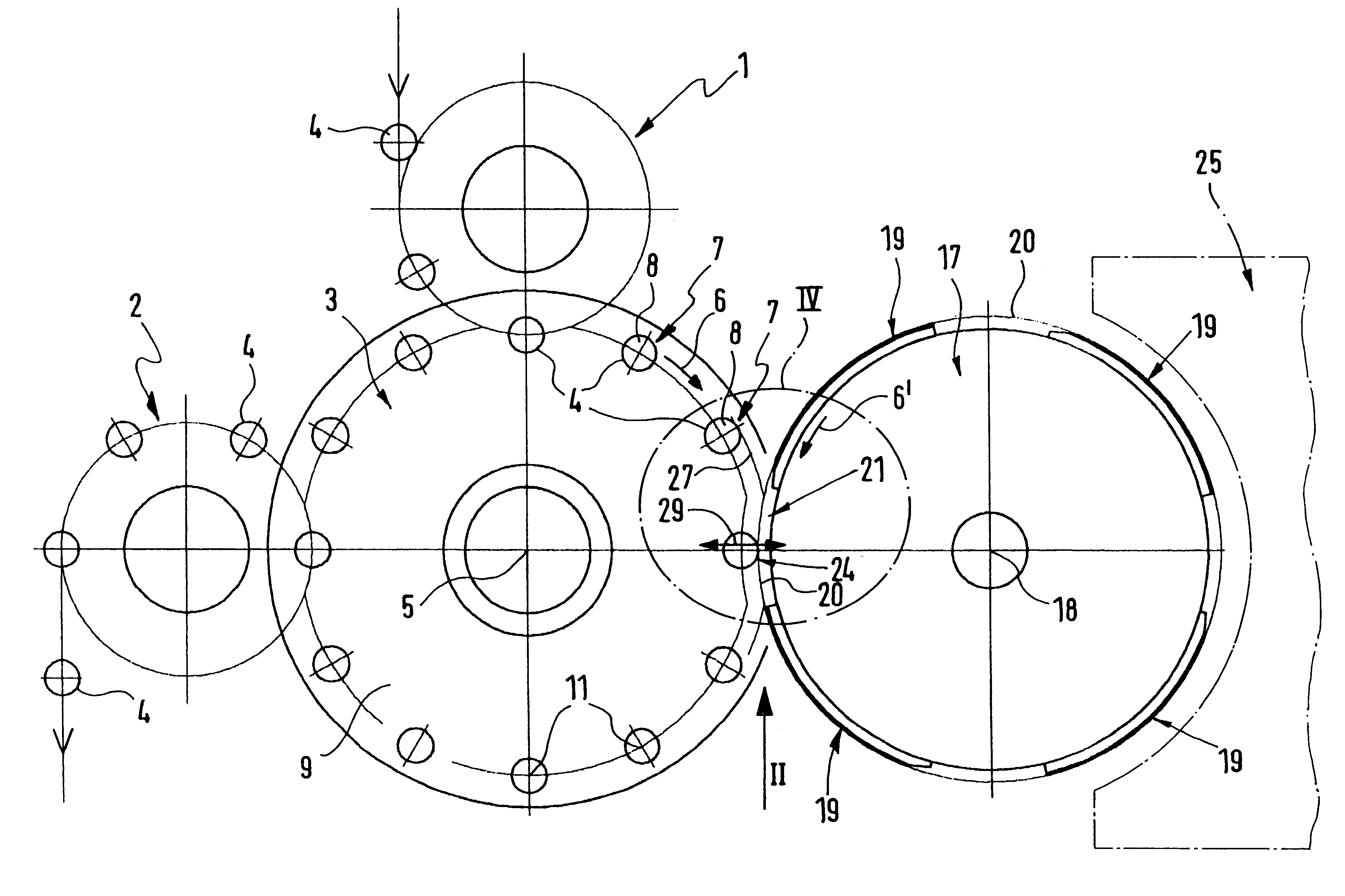

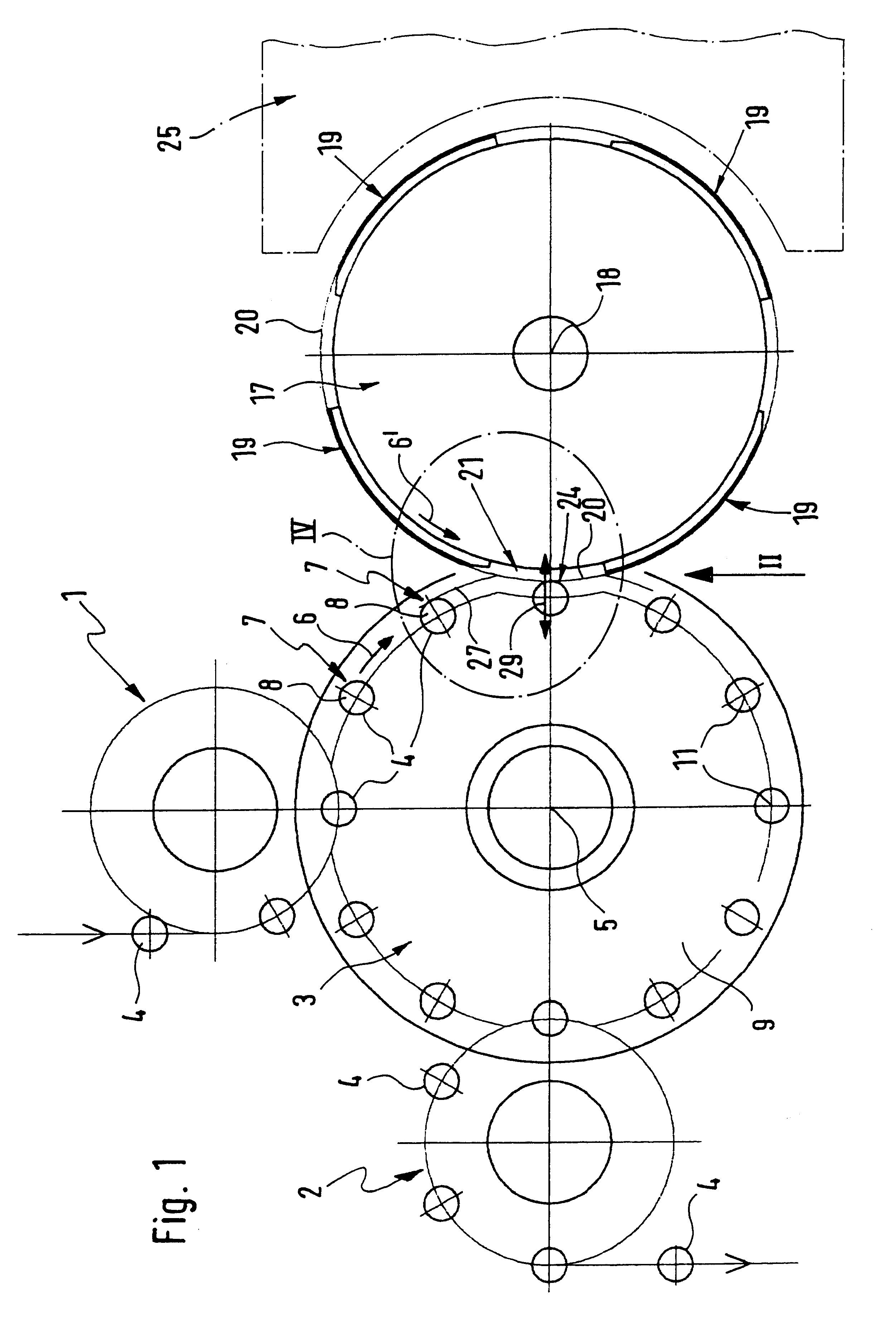

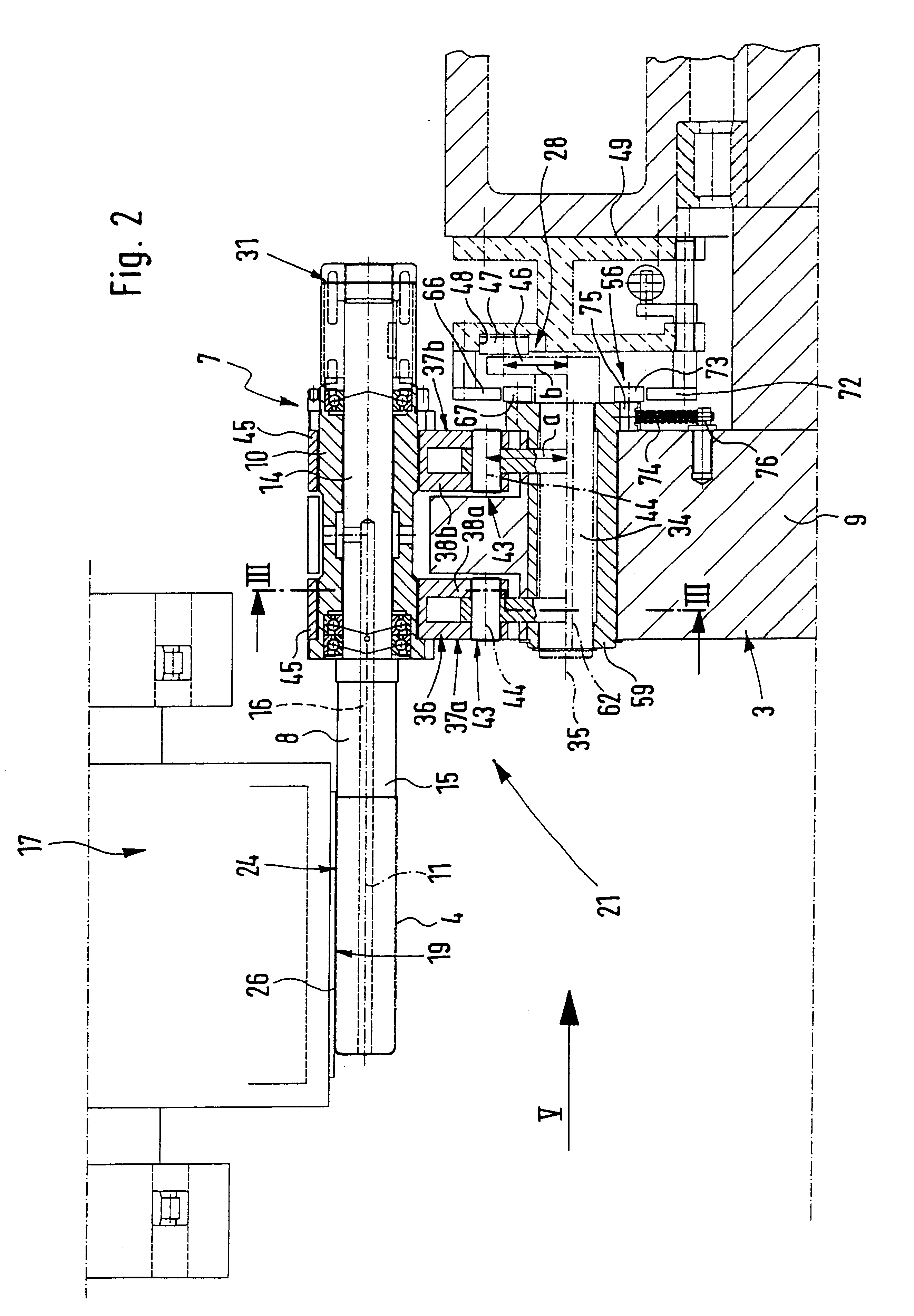

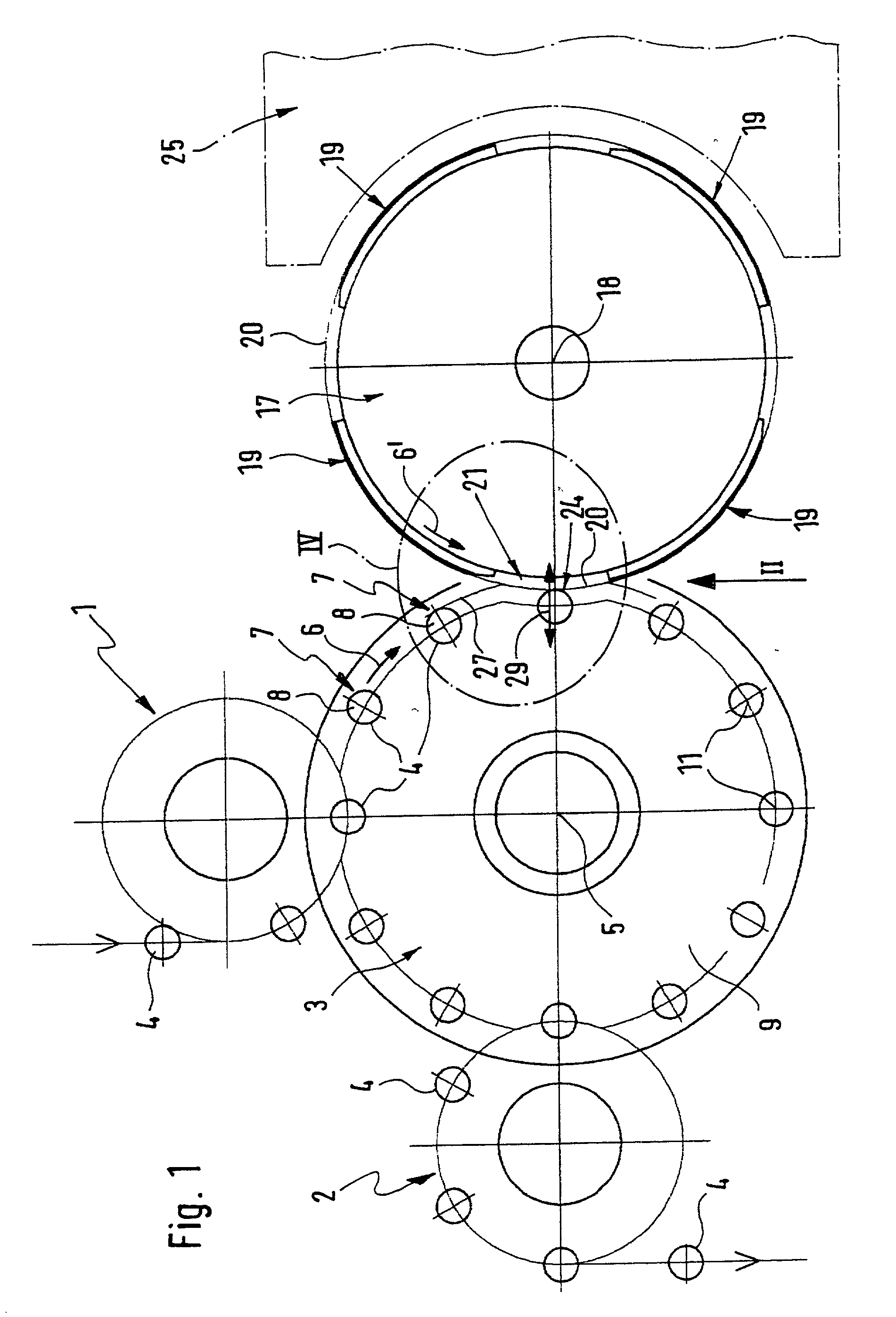

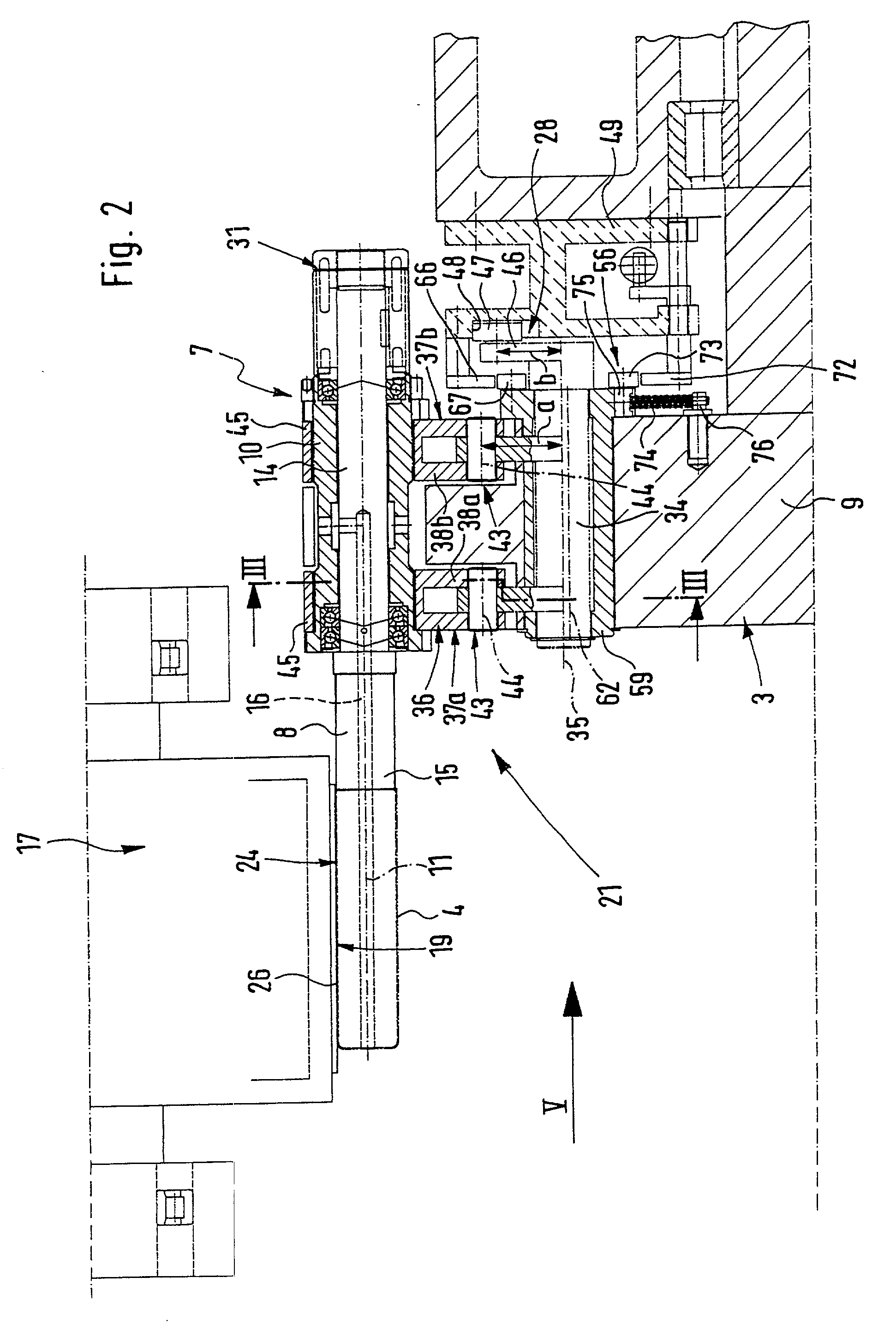

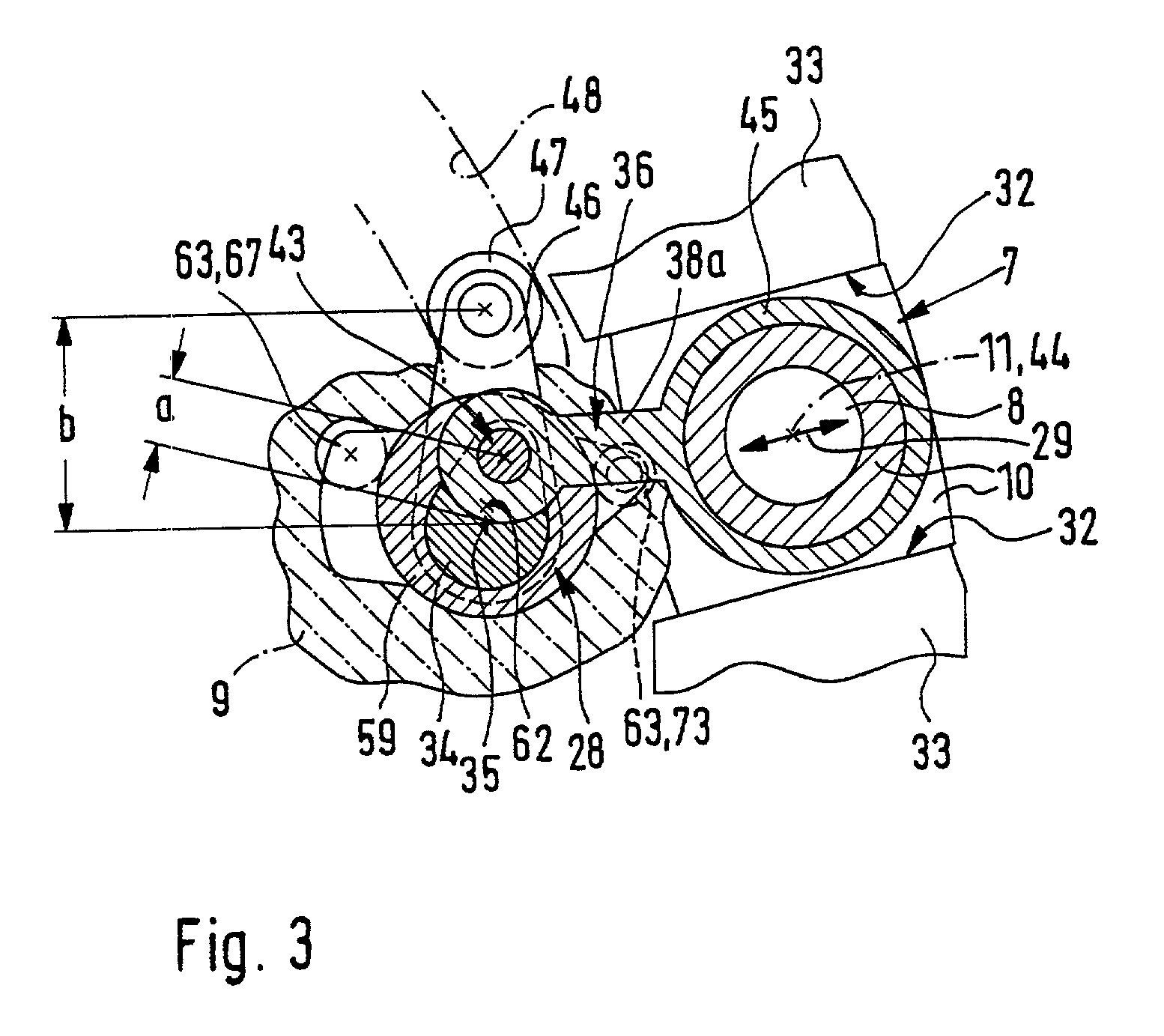

Machine for printing or otherwise decorating hollow bodies

InactiveUS6490969B2Not easy to wearImprove accuracyTransportation and packagingMixingEngineeringOrbit

A machine for printing on or otherwise decorating hollow bodies. It comprises a rotationally driven decoration application drum, which peripherally is provided with decoration faces, which are able to be moved along a first orbit. On an adjacent capstan plate receiving capstans are arranged for capstan units for carrying hollow bodies. On rotation of the capstan plate the radially inwardly facing sections of the hollow bodies proceed along a second orbit. Pitman units serve to so correct the second orbit on passage through a decoration zone that it coincides with the first orbit.

Owner:HINTERKOPF

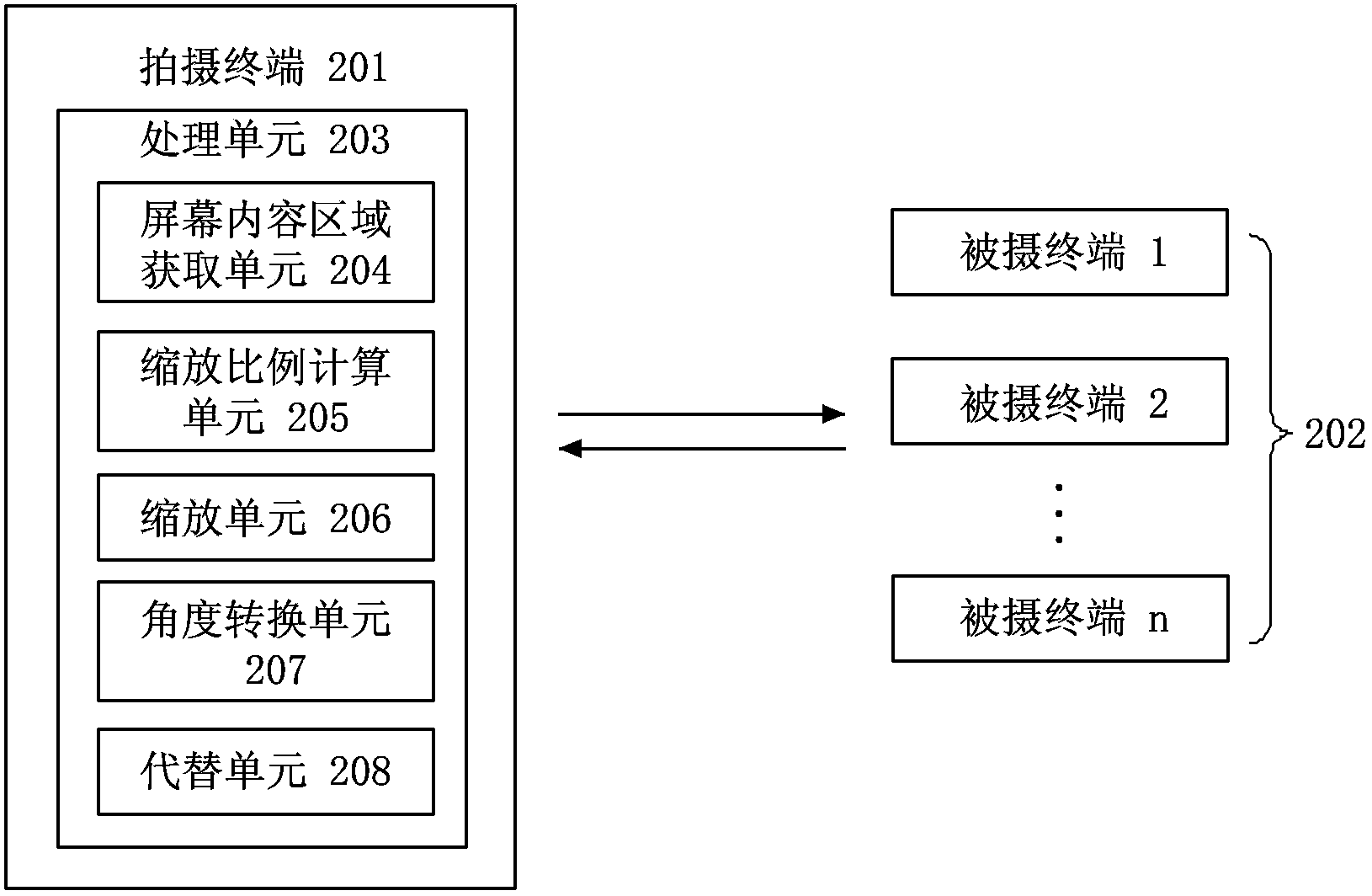

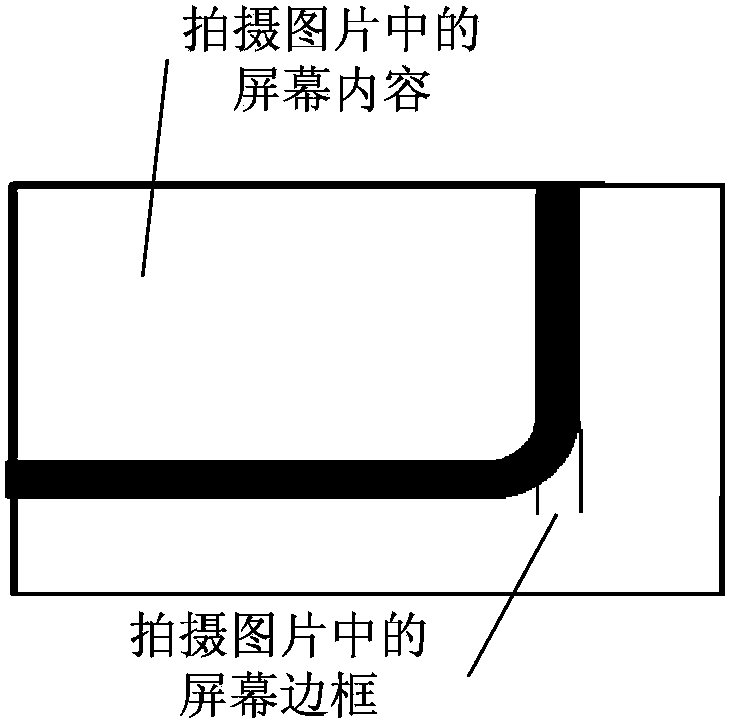

Method and system for replacing shooting content by using screenshot content

ActiveCN104102421AImprove quality performanceImprove experienceGeometric image transformationInput/output processes for data processingComputer graphics (images)Computer terminal

The invention provides a method and a system for replacing shooting content by using screenshot content. The method comprises the steps of sending a request for obtaining an image from a shooting terminal to a shot terminal, shooting a display screen of the shot terminal, and obtaining a shooting image; carrying out screenshot by the shot terminal in response to the request, and sending a screenshot image and a display screen parameter of the shot terminal to the shooting terminal; processing the screenshot image and the shooting image based on at least one of the display screen parameters of the shot terminal and a shooting parameter of the shooting terminal, and replacing screen content in the shooting image by using content corresponding to the screen content in the shooting image and the screenshot image. According to the method and the system for replacing the shooting content by using the screenshot content, provided by the invention, a water ripple phenomenon generated when an electronic screen is shot by using the shooting terminal in practice is solved, thus the quality effect of the shooting image is increased, and better user experience is brought.

Owner:SAMSUNG ELECTRONICS CHINA R&D CENT +1

Signboard manufacturing technology

InactiveCN106782055AImprove quality performanceImprove claritySignsScreen printingManufacturing technology

The invention discloses a signboard manufacturing technology. The technology is characterized in that a signboard is manufactured through the procedures of signboard body surface treatment, etching, anti-corrosion treatment, primer spraying, polishing, finish spraying, paint drying, printing, drying, varnish spraying, inspection, packaging and the like. A signboard body is subjected to anti-corrosion treatment so that the corrosion speed of the signboard body can be reduced, the quality property of the signboard body is improved, and the service life of the signboard is prolonged; the signboard body is coated with primer and finish, and then silk-screen printing is conducted after finish spraying is completed so that the definition of an identification message on the signboard body can be improved, the identification message can be prevented from falling off from the signboard body, and the quality property of the signboard is further improved; the identification message is coated with varnish, so the stability of the identification message on the signboard is improved, the quality property of the signboard is enhanced and the service life of the signboard is prolonged; meanwhile, the manufacturing technology also has the advantages of being convenient to use during manufacturing, high in manufacturing efficiency and the like.

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

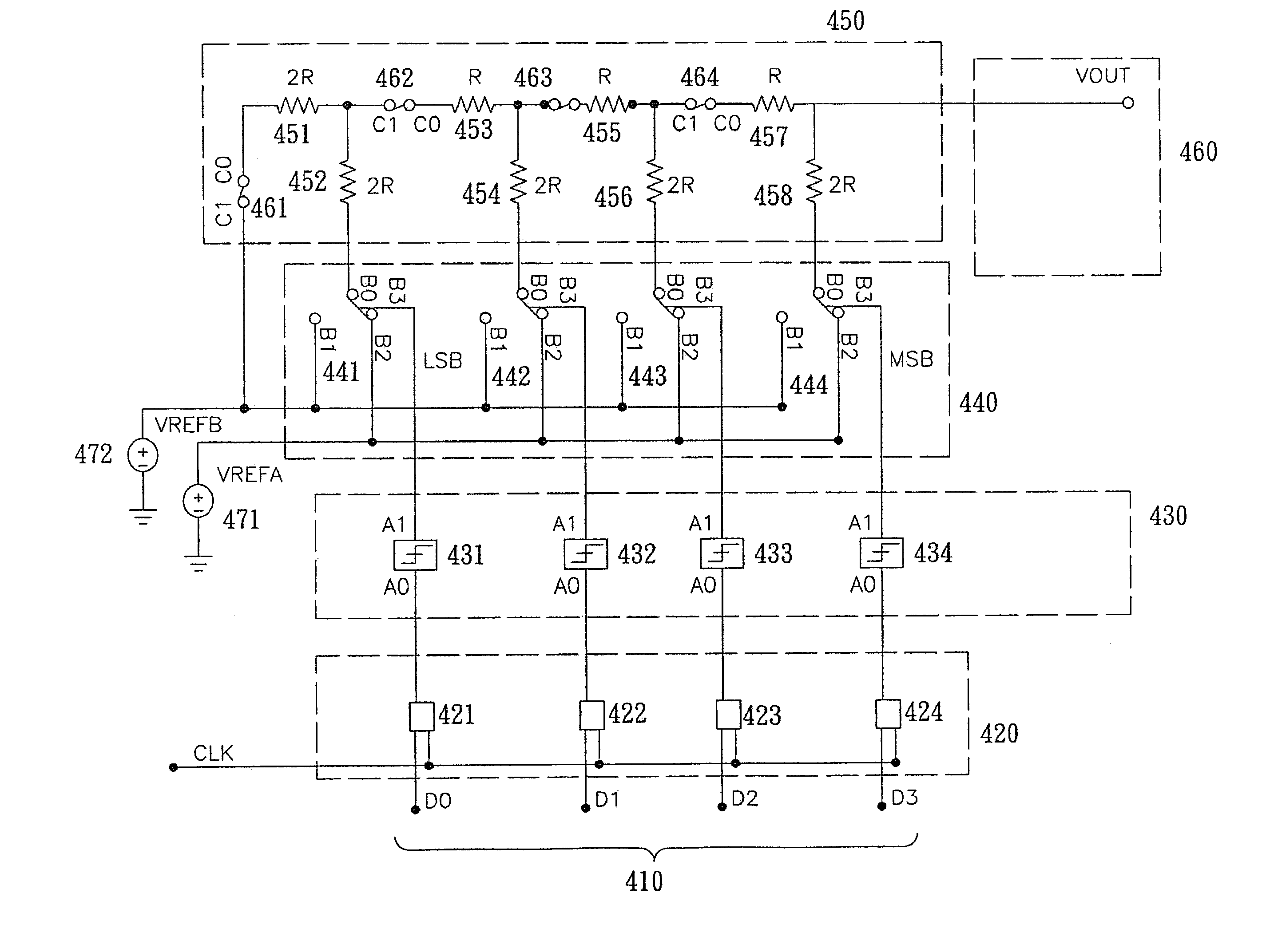

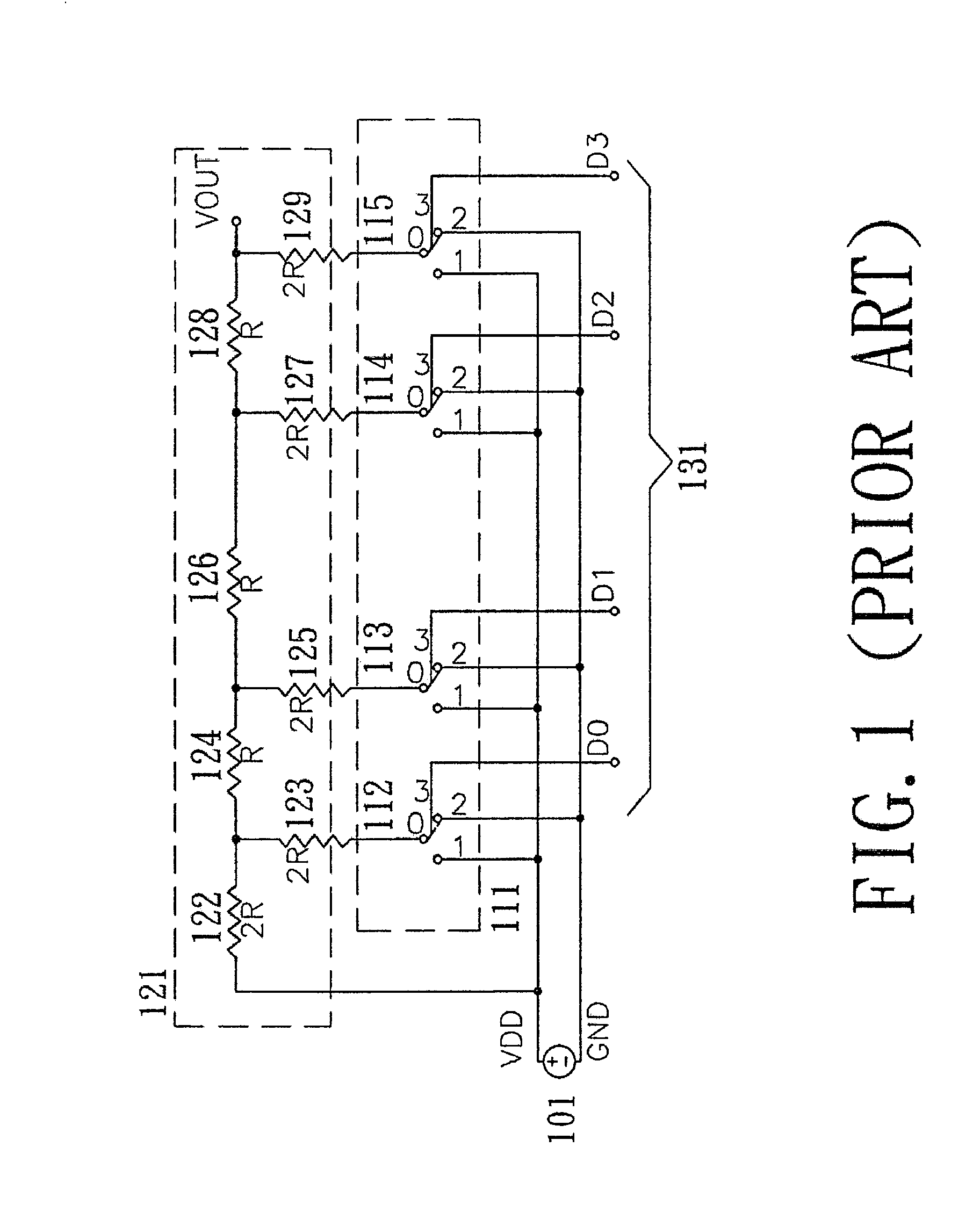

Digital to analog converter

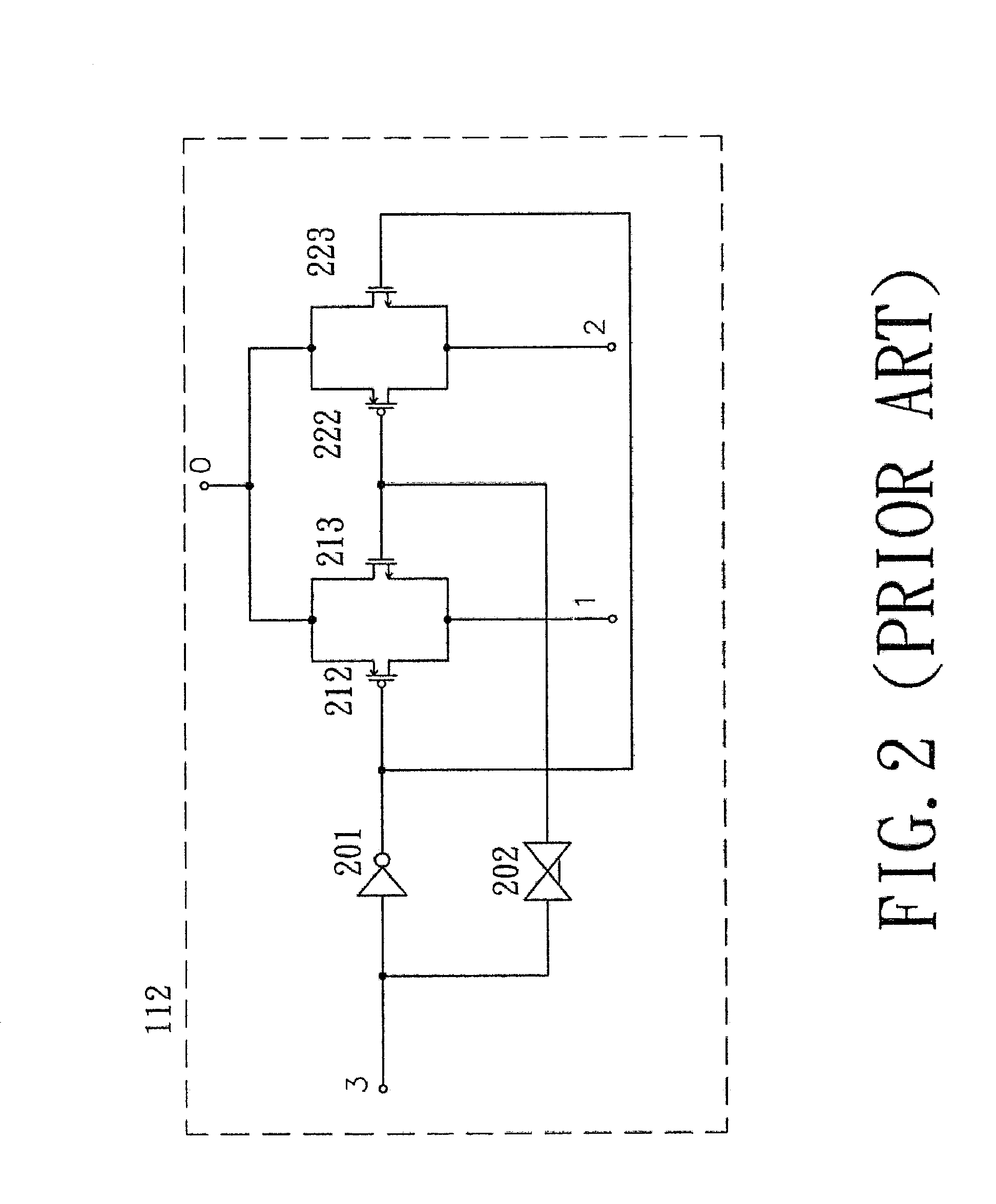

InactiveUS7129878B1Improve quality performanceEasy to convertElectric signal transmission systemsDigital-analogue convertorsDigital analog converterLiquid-crystal display

A digital to analog converter for an analog Liquid Crystal Display (LCD) includes a digital inlet, a latching circuitry, a voltage level shifter circuitry, a switching circuitry, and a resistance network with a resistance compensatory circuitry. The resistance network with the resistance compensatory circuitry is electrically connecting with the switching circuitry and adapted to regulate a pattern of the analog output signal so as to optimize the analog output signal. Specifically, the resistance network with a resistance compensatory circuitry is to produce the best linear conversion from the digital signal to the analog signal for use by the LCD.

Owner:BEYOND INNOVATION TECH

Machine for printing or otherwise decorating hollow bodies

InactiveUS20010025573A1Not easy to wearImprove accuracyTransportation and packagingMixingEngineeringOrbit

A machine for printing on or otherwise decorating hollow bodies. It comprises a rotationally driven decoration application drum, which peripherally is provided with decoration faces, which are able to be moved along a first orbit. On an adjacent capstan plate receiving capstans are arranged for capstan units for carrying hollow bodies. On rotation of the capstan plate the radially inwardly facing sections of the hollow bodies proceed along a second orbit. Pitman units serve to so correct the second orbit on passage through a decoration zone that it coincides with the first orbit.

Owner:HINTERKOPF

Calming herbal tea and preparation method thereof

InactiveCN104623423AKeep aliveKeep healthyDigestive systemBird material medical ingredientsChild healthAdditive ingredient

The invention discloses calming herbal tea. The calming herbal tea comprises a major ingredient, wherein the major ingredient is prepared from the following components in parts by weight (metered by mass of the major ingredient in a raw material state): 40-80 parts of coix seeds, 10-50 parts of hawthorns, 30-70 parts of lophatherum gracile, 5-15 parts of liquorice, 40-80 parts of red beans, 40-80 parts of malt and 10-30 parts of endothelium corneum gigeriae galli. The calming herbal tea disclosed by the invention is prepared form natural raw materials, is gentle in taste, has good effects of clearing away heat and toxic materials, calming and soothing the nerves and improving sleeping; meanwhile, the calming herbal tea disclosed by the invention can be used for effectively improving infant digestive function, eliminating fervor of milk powder and treating disturbed sleep at night and susceptibility to oral ulcers, is low in doping amount of auxiliary materials and can avoid influence on child health due to excessive intake.

Owner:NINGBO LIWAH PHARM CO LTD

Gas-liquid-solid abrasive flow feeding device

ActiveCN105033870AWell mixedImprove liquidityAbrasive feedersAbrasive machine appurtenancesWear particleThree-phase

The invention provides a gas-liquid-solid abrasive flow feeding device which comprises a three-phase mixing mold, a heat preservation protective layer, a temperature sensor, a heater, a stirrer, a first abrasive flow mixing section, a second abrasive flow mixing section, a filtering film, an abrasive flow feeding outlet and a controller. According to the gas-liquid-solid abrasive flow feeding device, a cavity in the three-phase mixing mold is set to be a quincunx shape, the characteristic that the inner surface of the quincunx is large is utilized, and the cavity is matched with a rotary nozzle arranged on a solution medium jet orifice, so that three-phase abrasive flows are mixed more evenly, and the mixing flow and polishing properties of the abrasive flows are improved. An abrasive particle feeding device is set to be suspended, the property of feeding abrasive flows can be further improved, flow rate control valves are arranged for all media, the controller can be adjusted according to actual ratio needs, and proportioning of abrasive flow mixed liquid of various ratios is achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com