Light conducting plate carved by laser impulse and method for producing the same

A technology of laser pulse and light guide plate, applied in light guide, engraving, light guide of lighting system, etc., can solve the problems of large chemical ink, low brightness, poor light refraction effect, etc., and achieve exquisite technical specifications, high light conversion rate, and luminescence high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is specifically described below in conjunction with accompanying drawing

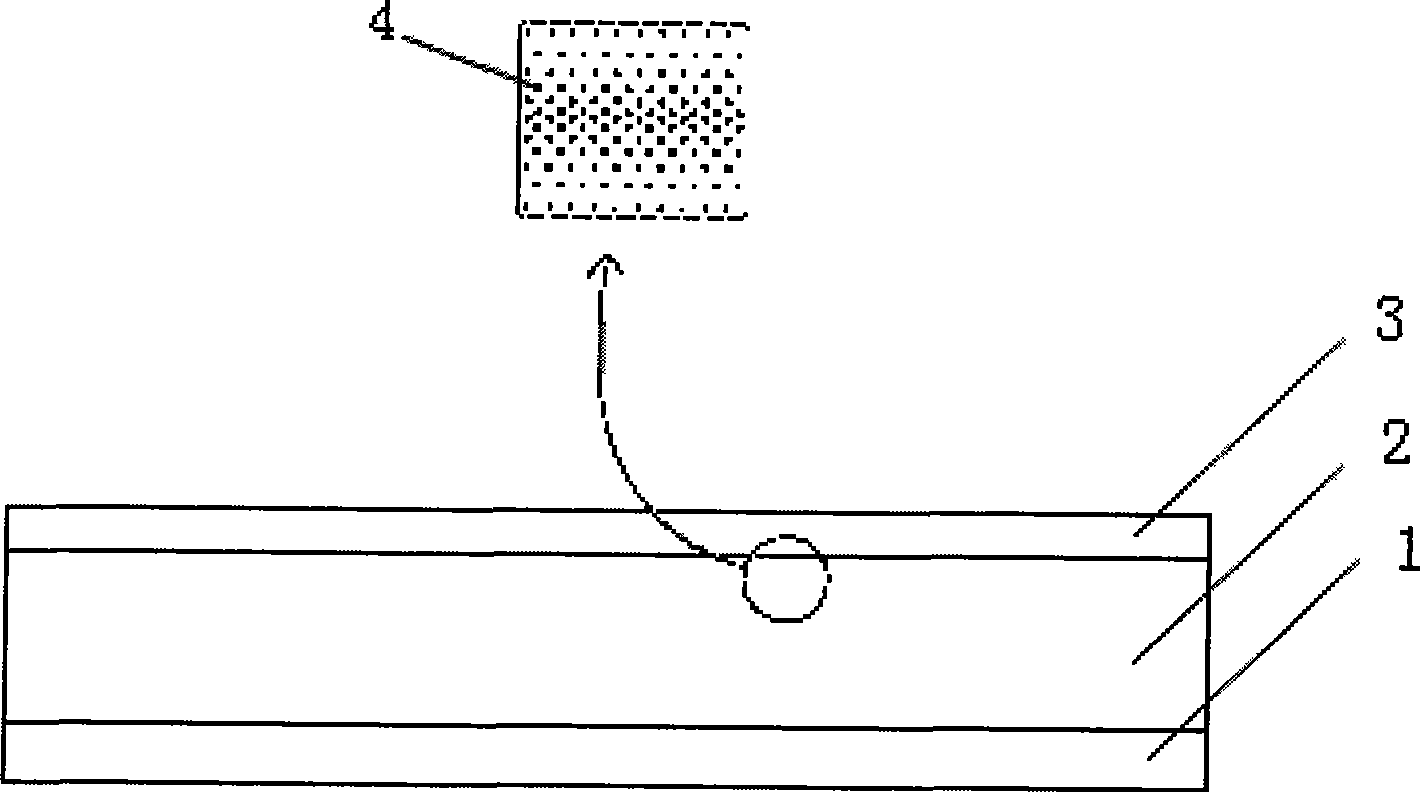

[0036] see figure 1 , a kind of light guide plate utilizing laser pulse engraving according to the present invention, the light guide plate made of acrylic flat plate includes a reflective layer 1 made of a high reflectivity material, a high light transmittance material The light guide layer 2 made and the diffusion layer 3 made of homogeneous material are composed; it is characterized in that the light guide layer 2 of the light guide plate is distributed with reflective diffusion points or diffusion grooves 4 engraved with laser pulses; the diffusion The distance between the dots or diffusion grooves is less than or equal to 5mm, the depth is 0.001-1mm controlled by laser energy, and the diameter of the diffusion dots is 0.005-2mm.

[0037] In addition, the reflective layer of the light guide plate is a layer of PET (polyethylene terephthalate) material with high light re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com