Patents

Literature

636 results about "Wear particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

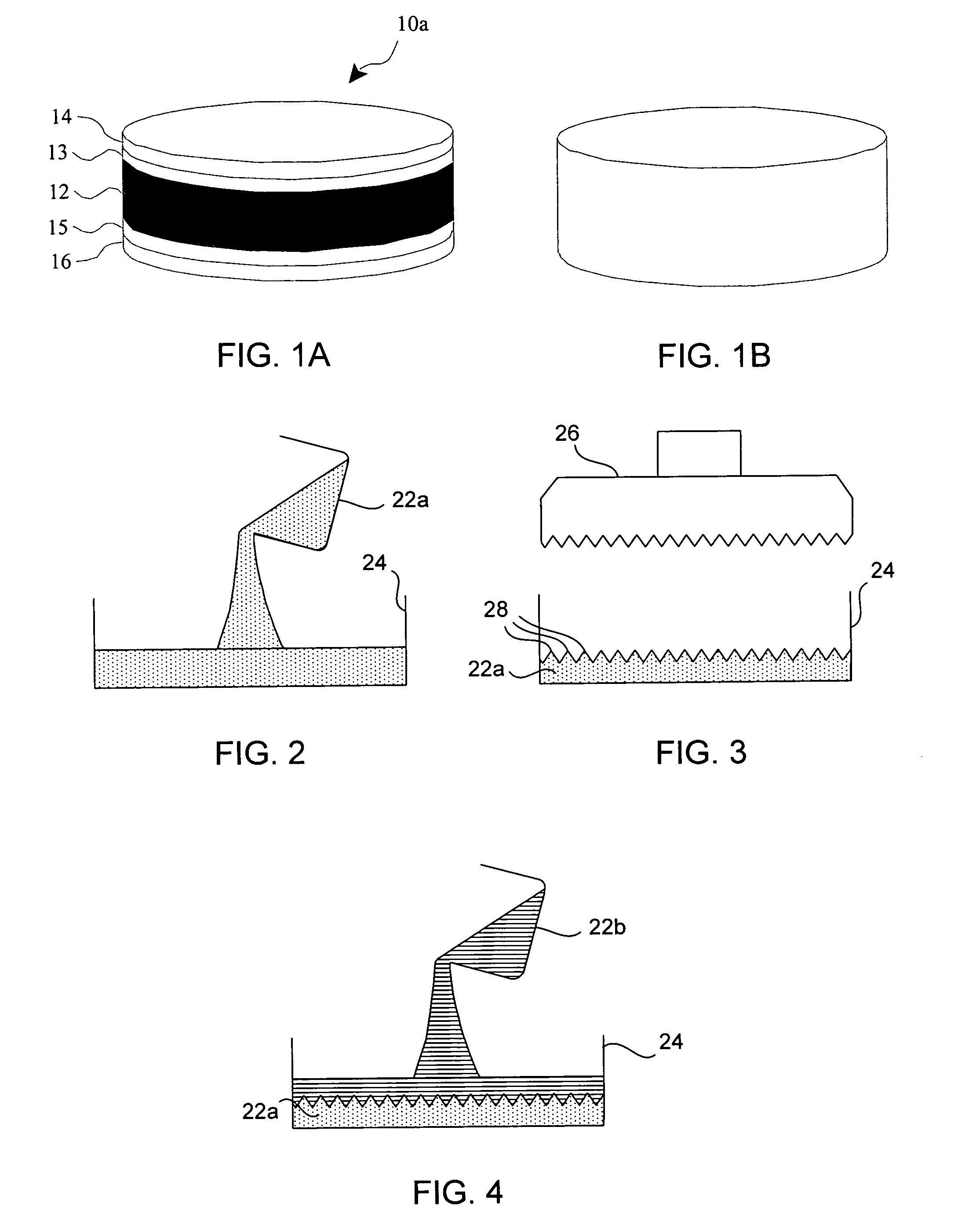

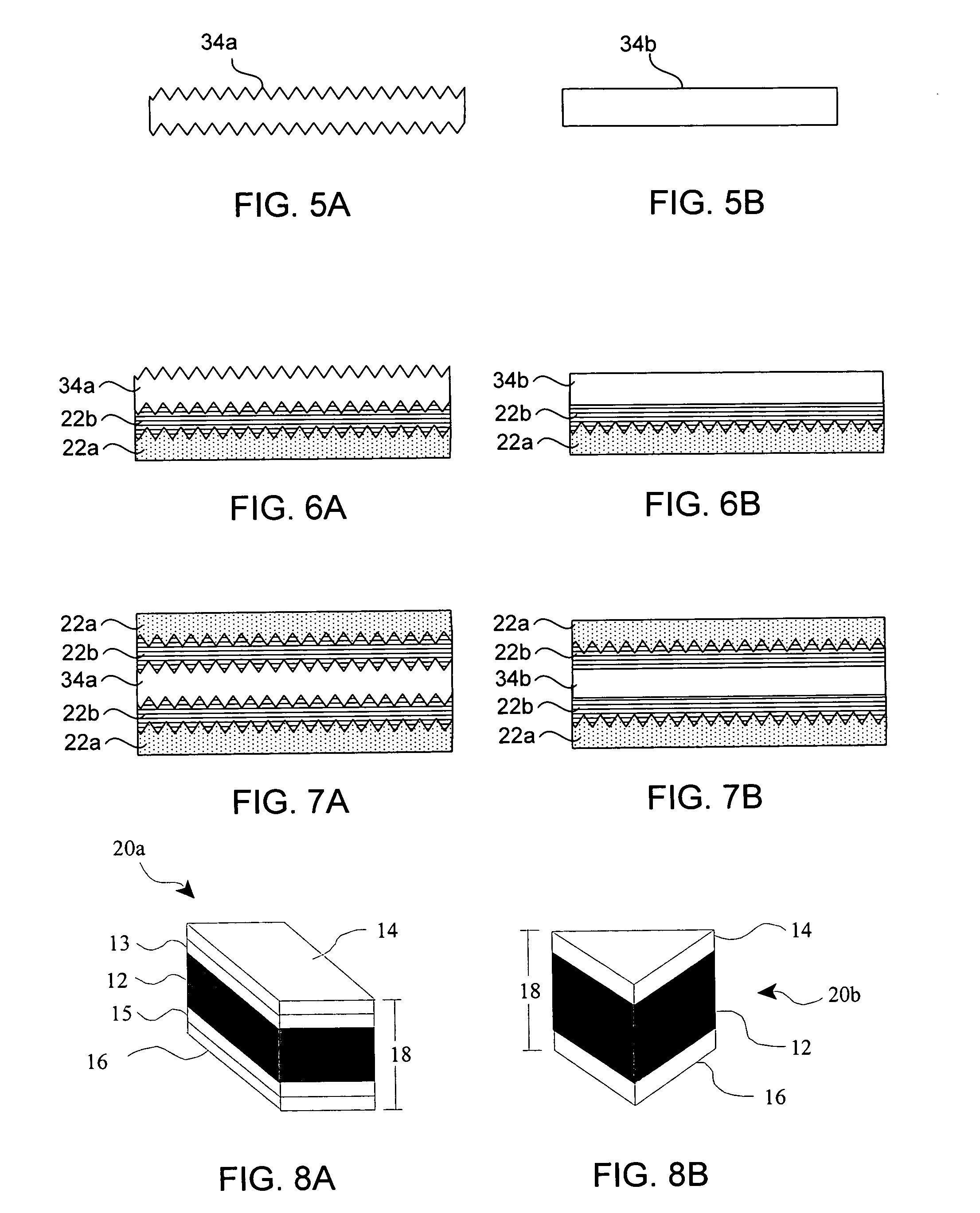

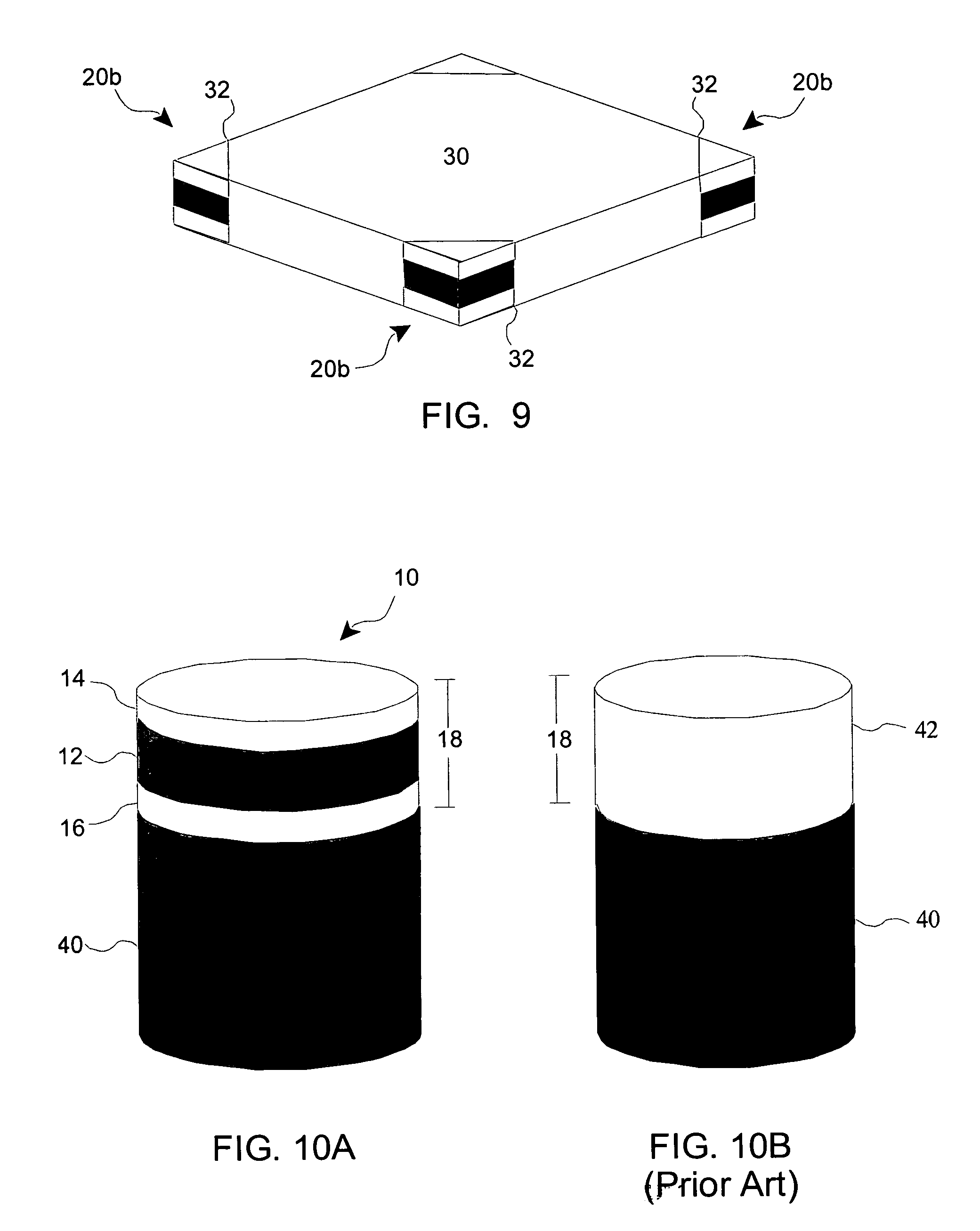

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

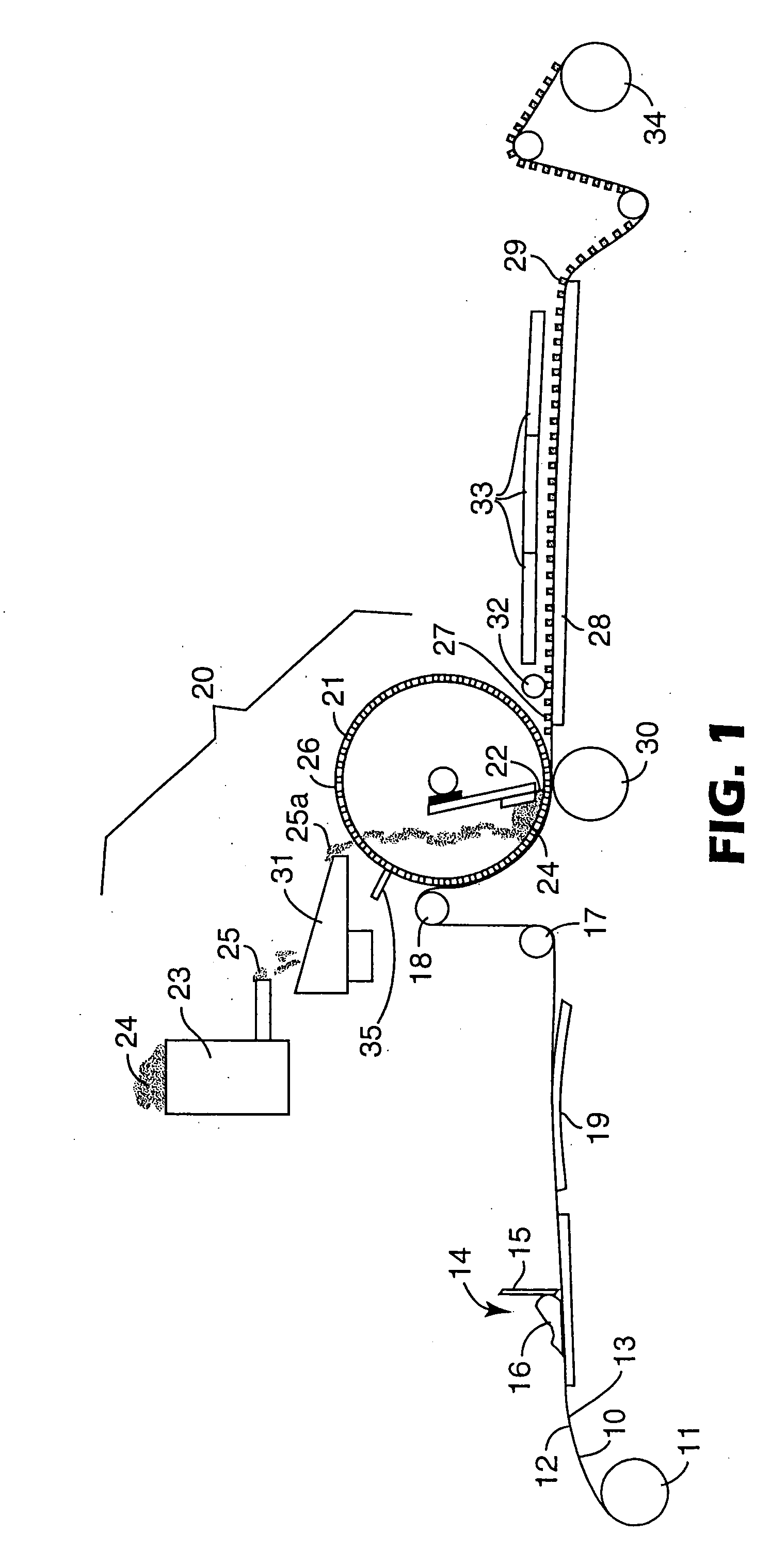

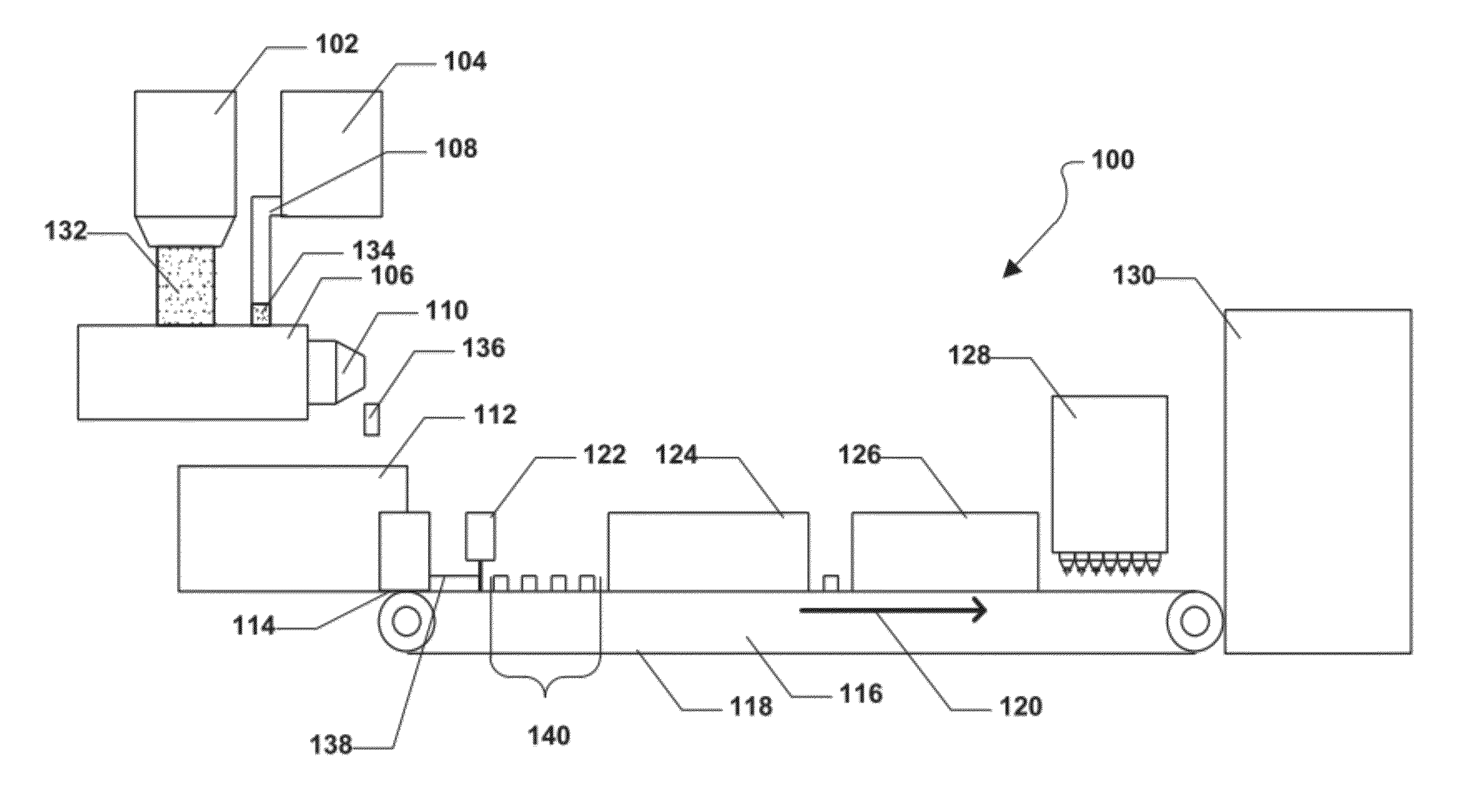

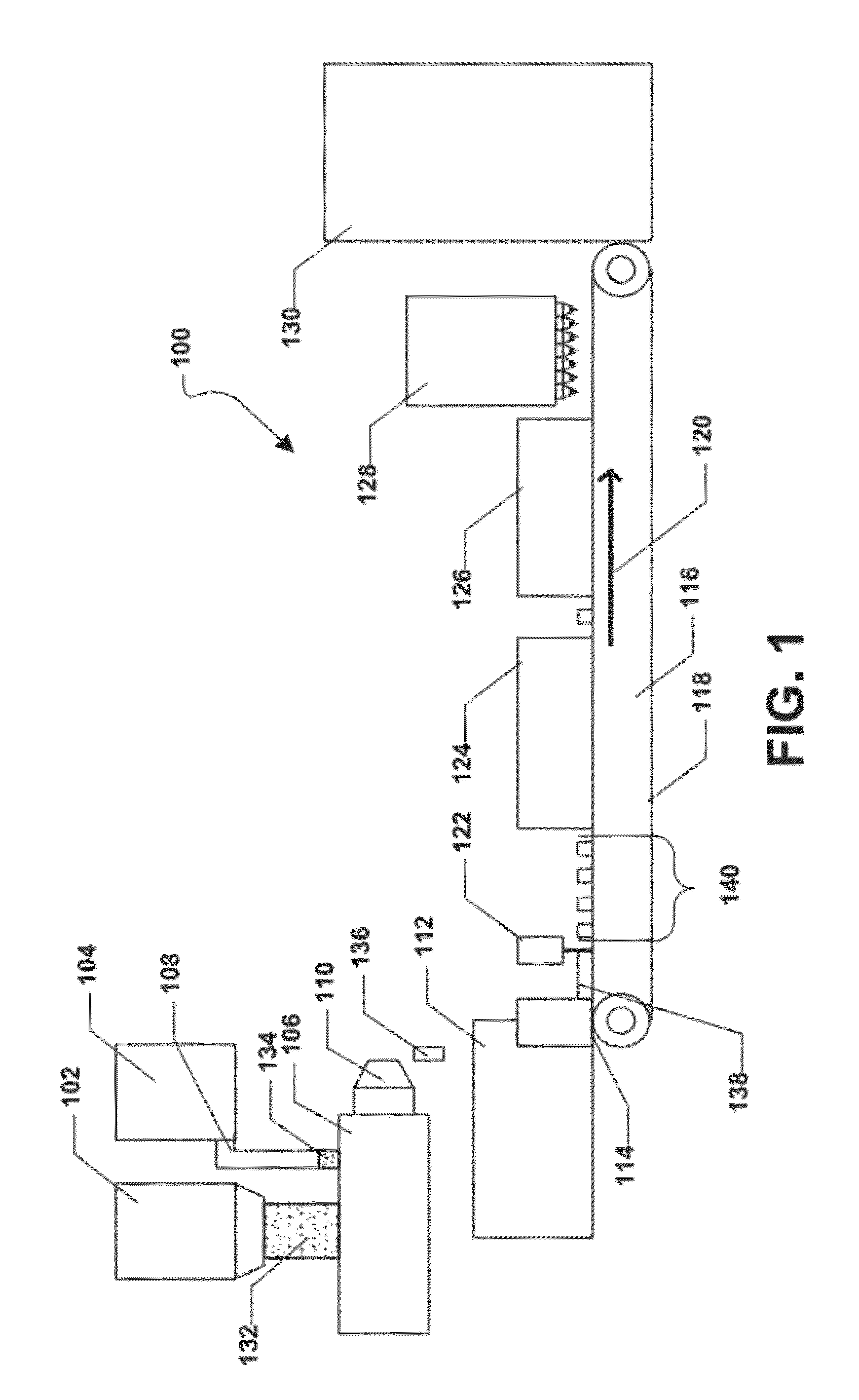

Abrasive product, method of making and using the same, and apparatus for making the same

The invention provides a method and apparatus for making an abrasive product comprising providing a substantially horizontally deployed flexible backing having a first surface bearing an at least partially cured primer coating and an opposite second surface; providing a dry flowable particle mixture comprising abrasive particles and particulate curable binder material; depositing a plurality of temporary shaped structures comprised of said particle mixture on the at least partially cured primer coating of the first surface of the backing; softening said particulate curable binder material to provide adhesion between adjacent abrasive particles; and curing the softened particulate curable binder material to convert said temporary shaped structures into permanent shaped structures and cure the at least partially cured primer coating on the first surface of the backing. The invention also provides an abrasive product made by the method.

Owner:3M INNOVATIVE PROPERTIES CO

Method of forming a shaped abrasive particle

A method for making abrasive grains, the method comprising mixing one or more solids with one or more liquids in a twin screw extruder to form a mixture, transferring the mixture to a high pressure piston extruder; and extruding the mixture from the high pressure piston extruder through a die to form an extrude. The method further includes segmenting the extrudate to form extruded shaped abrasive particles.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

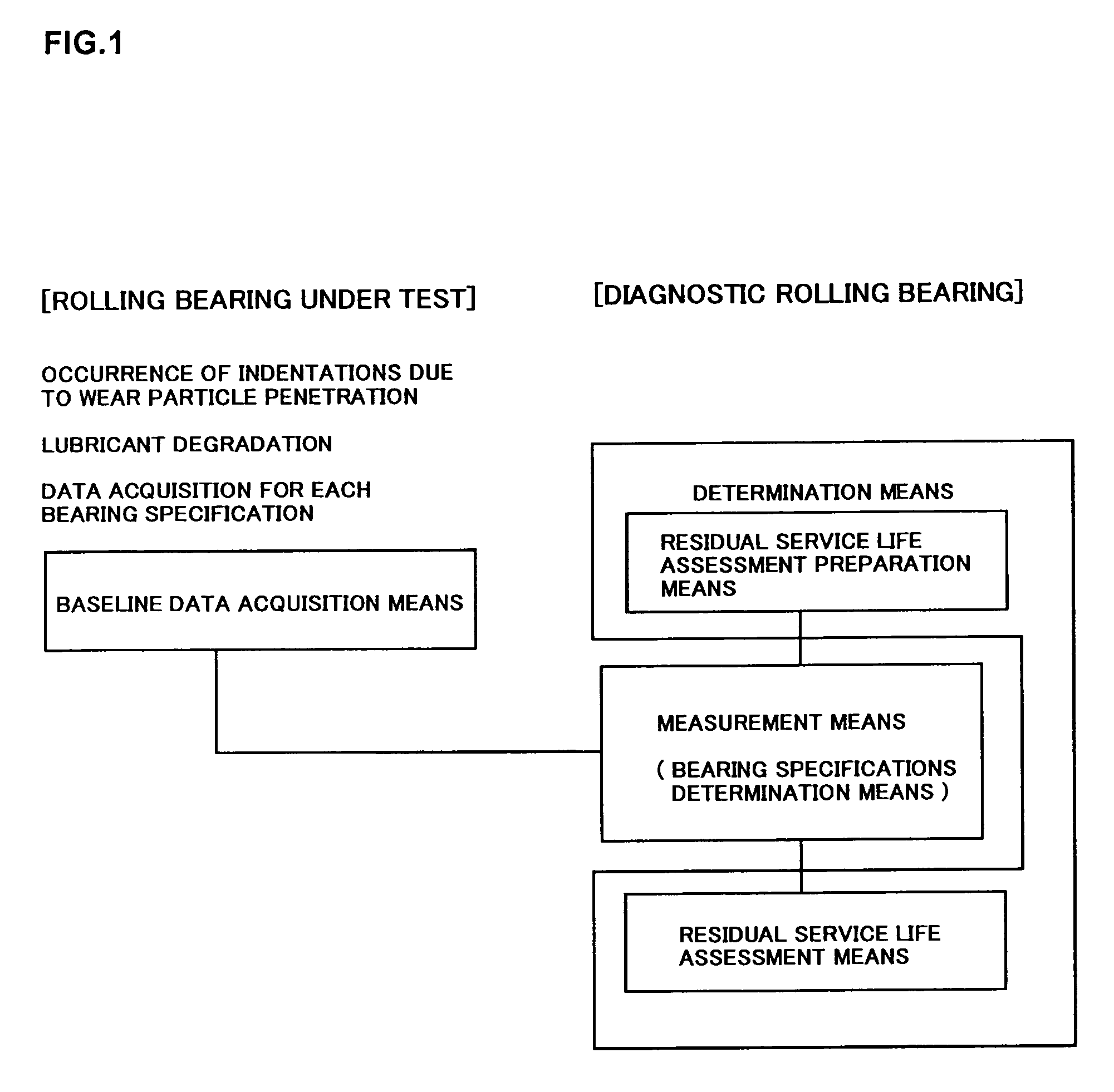

Method And Device For Assessing Residual Service Life Of Rolling Bearing

InactiveUS20070277613A1Improve accuracyVibration measurement in solidsMachine part testingBaseline dataAccelerometer

Degradation of the lubricant due to contamination of the lubricant with wear particles or moisture, which greatly affects the service life of rolling bearings, can be detected in a cost-effective manner through the use of a resonance frequency band signal or high-frequency signal of an accelerometer, and the service life of a rolling bearing can be estimated with high precision at an early stage on the basis of the detected state of the wear particles and lubricant. Provided is a method comprising baseline data acquisition means for obtaining vibration signals by using an accelerometer 4 and using a testing device to acquire resonance frequency band signals detectable at the highest sensitivity, for each specification such as model number, manufacturer name, and other specifications for a rolling bearing 3 as pertains to the relationship between the state of wear particle penetration in a rolling bearing 3 and the vibration / bearing service life, and to lubricant degradation and vibration / bearing service life; measurement means whereby an accelerometer 4 is used to obtain vibration signals for the rolling bearing 3 whose remaining service life is being assessed and which resides on a fan, a pump, or another rotating device 1, 2, for the purpose of measuring resonance frequency band signals detectable at the highest sensitivity; and determination means for estimating the state of wear particle penetration and the state of lubricant degradation of the diagnostic rolling bearing 3, and computing the remaining service life of the diagnostic rolling bearing 3 by using measurement values obtained by the measurement means, determination results of the bearing specification determination means, and data obtained by the baseline data acquisition means.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

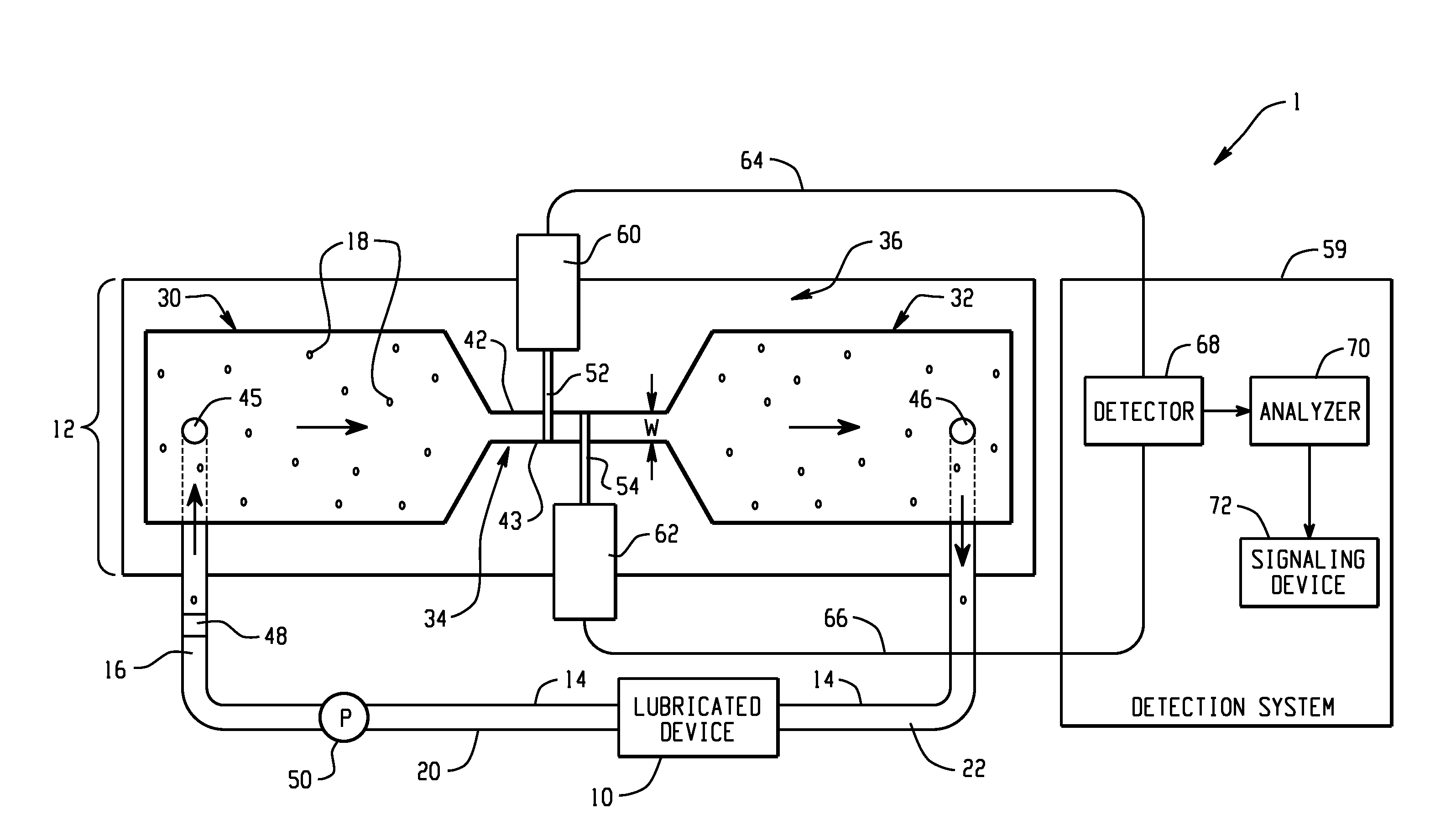

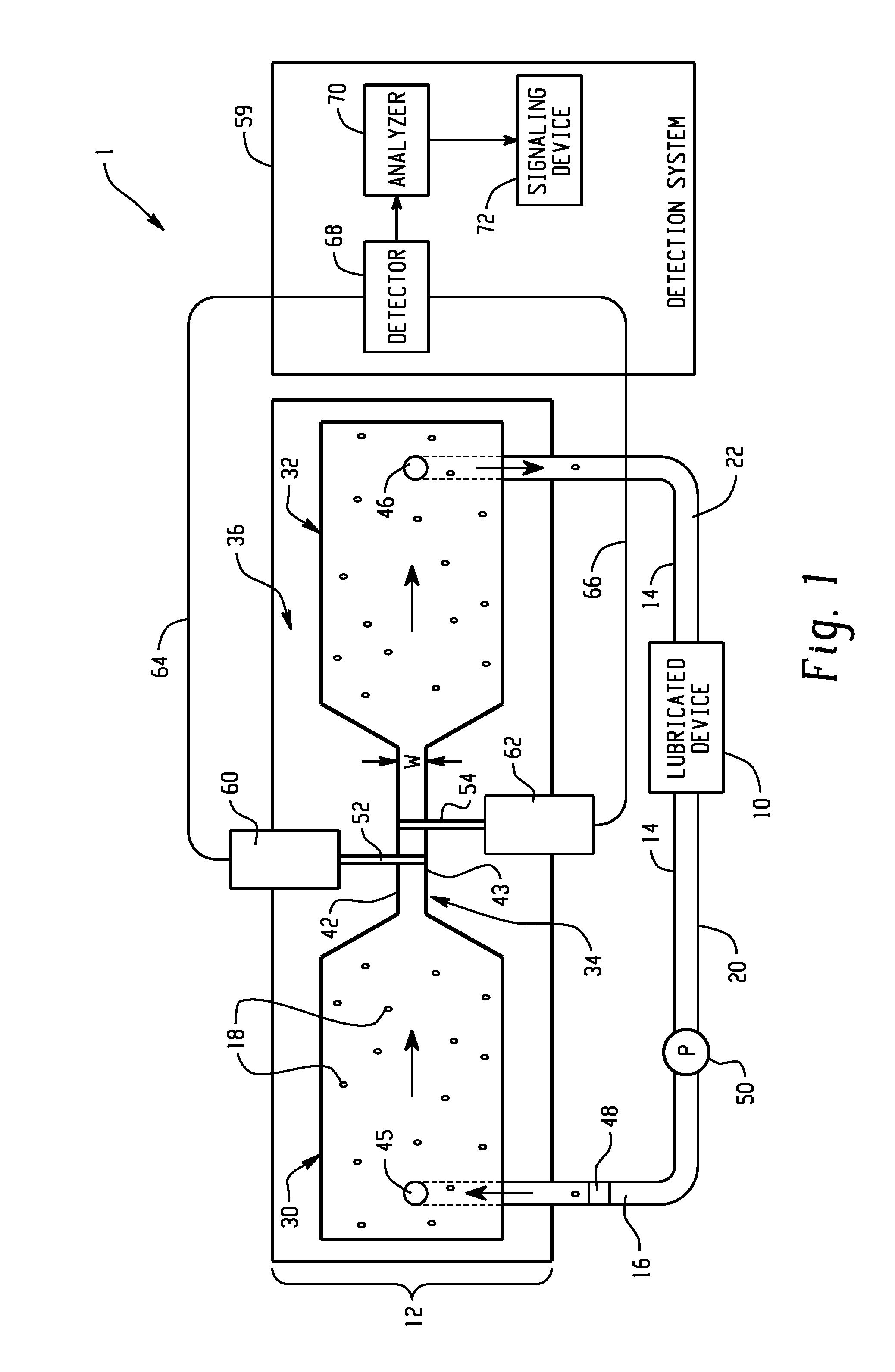

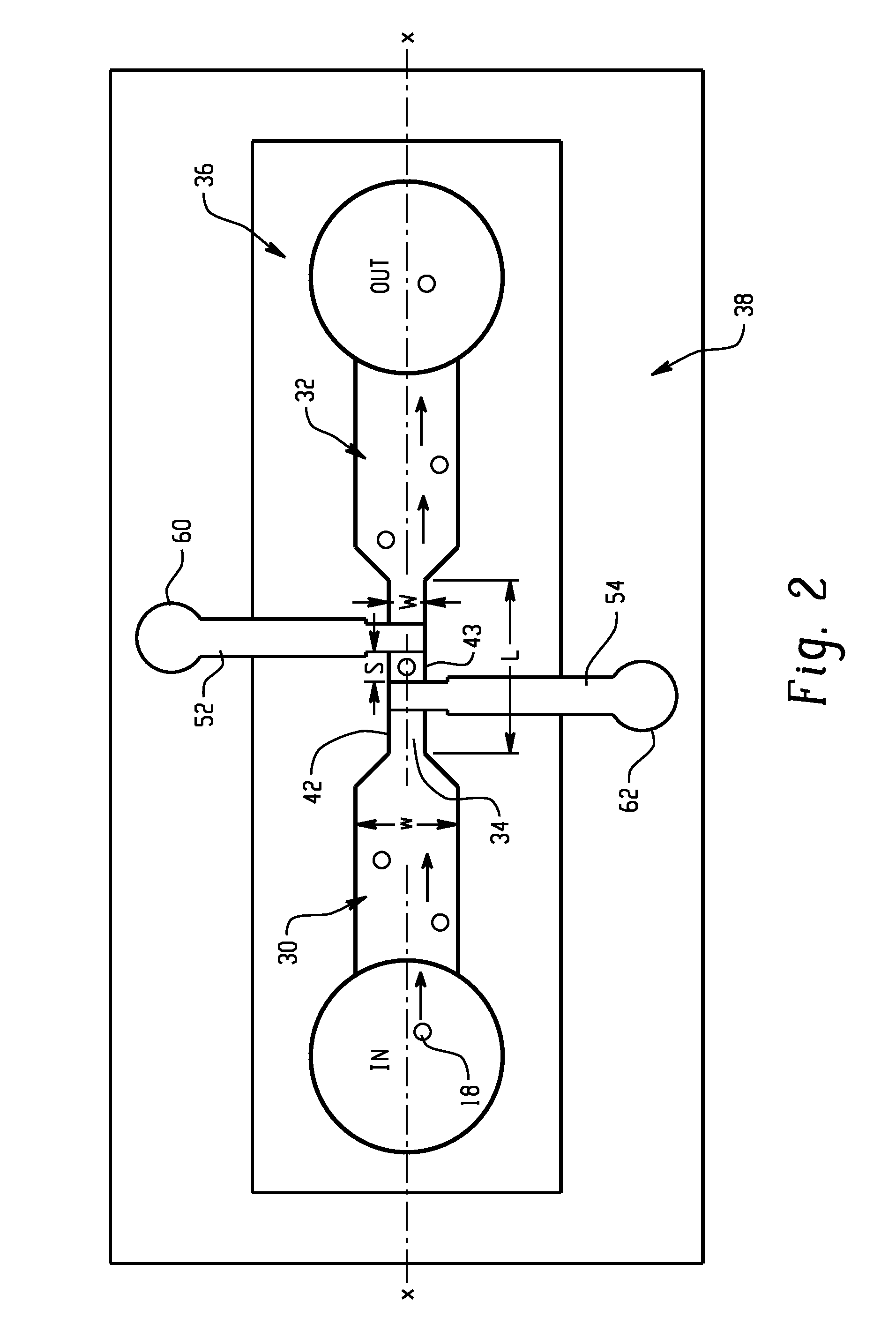

Metal wear detection apparatus and method employing microfluidic electronic device

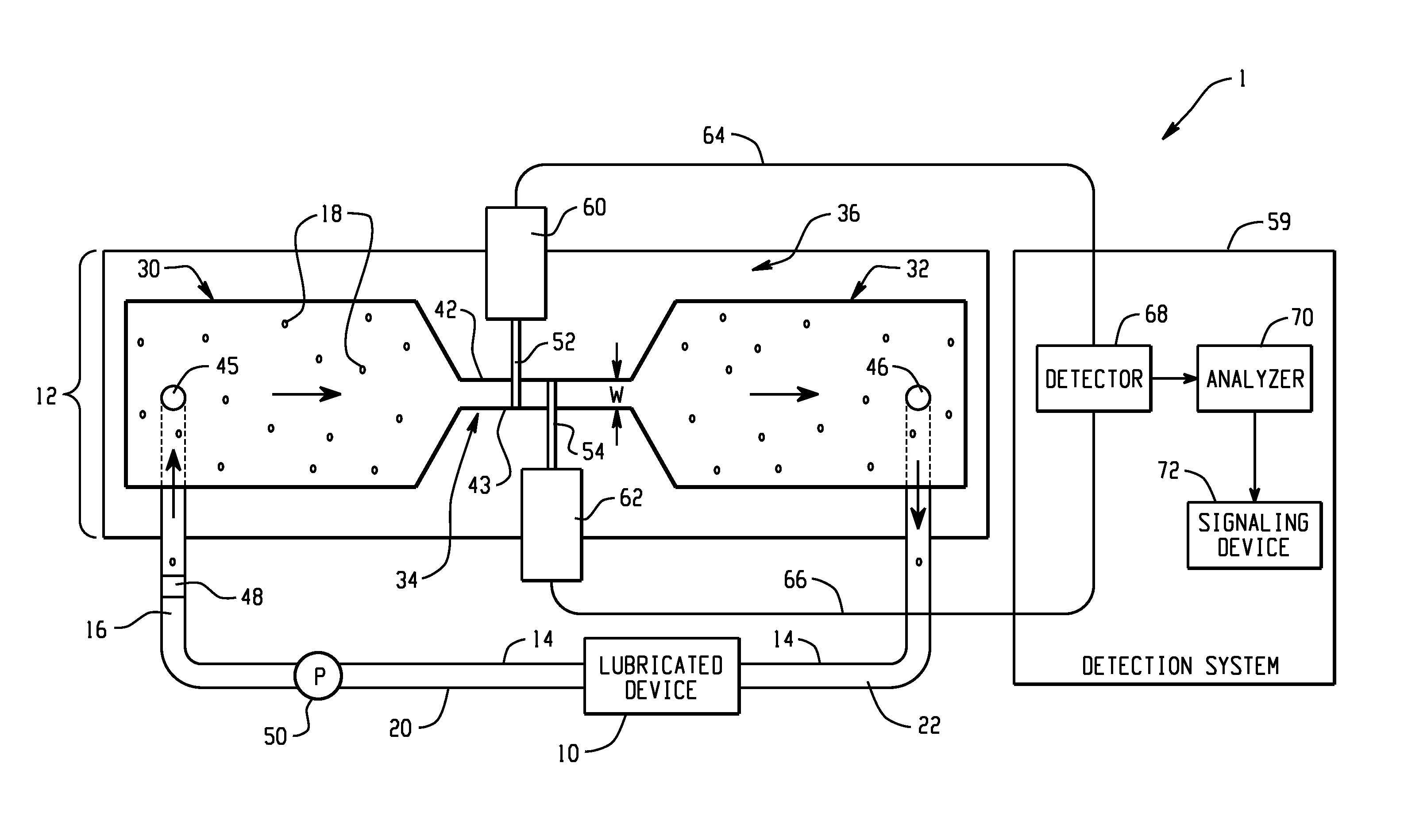

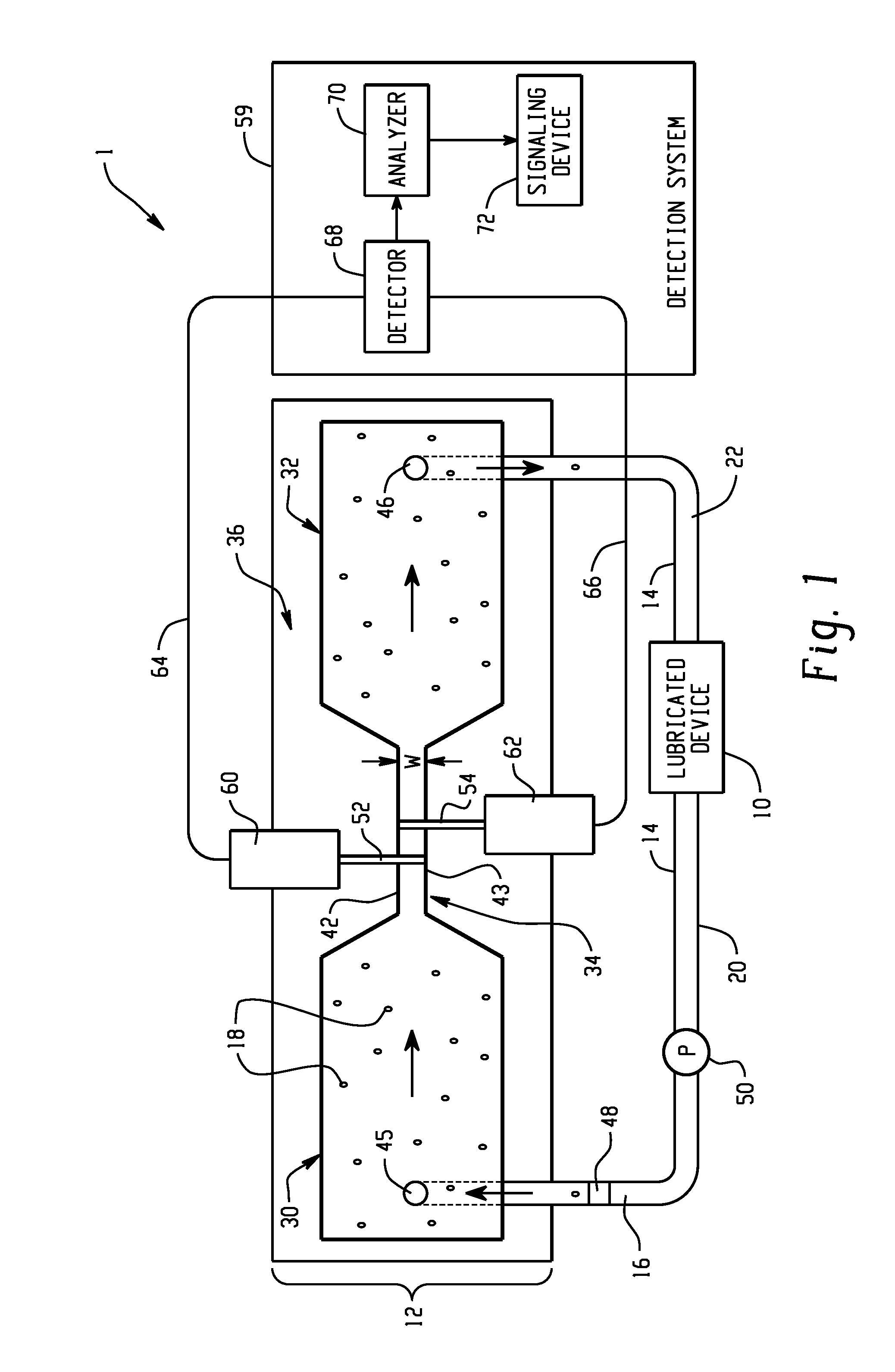

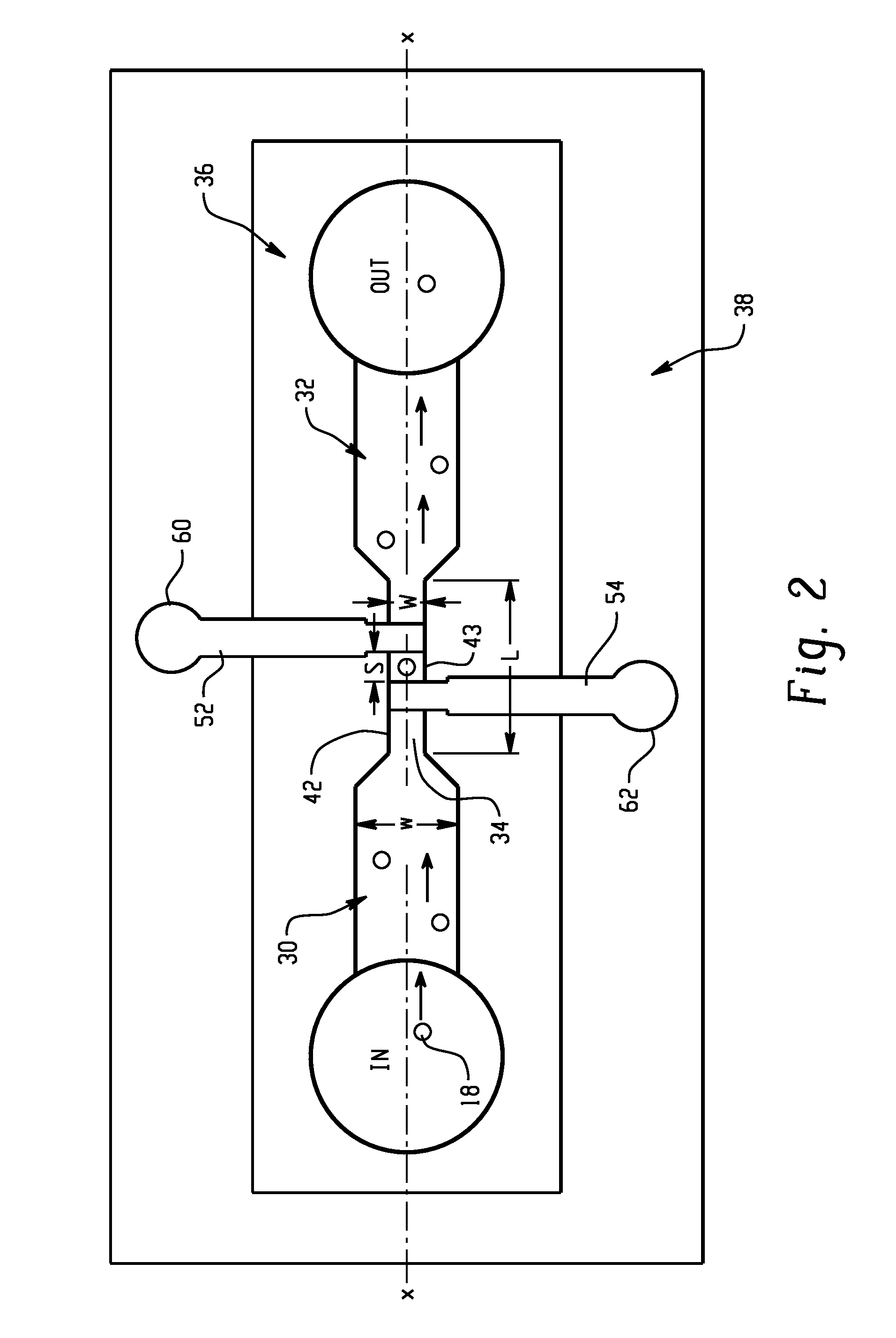

ActiveUS20100109686A1Rapid responseMachine gearing/transmission testingResistance/reactance/impedenceCapacitanceWear particle

An apparatus and a method for detection of wear particles in a lubricant are disclosed. The apparatus includes a microfluidic device including a microchannel sized for a lubricant containing wear particles to pass therethrough and first and second electrodes extending into the microchannel. A detection system is coupled with the electrodes for detection of wear particles passing through the microchannel, based on a change in capacitance of the electrodes.

Owner:THE UNIVERSITY OF AKRON

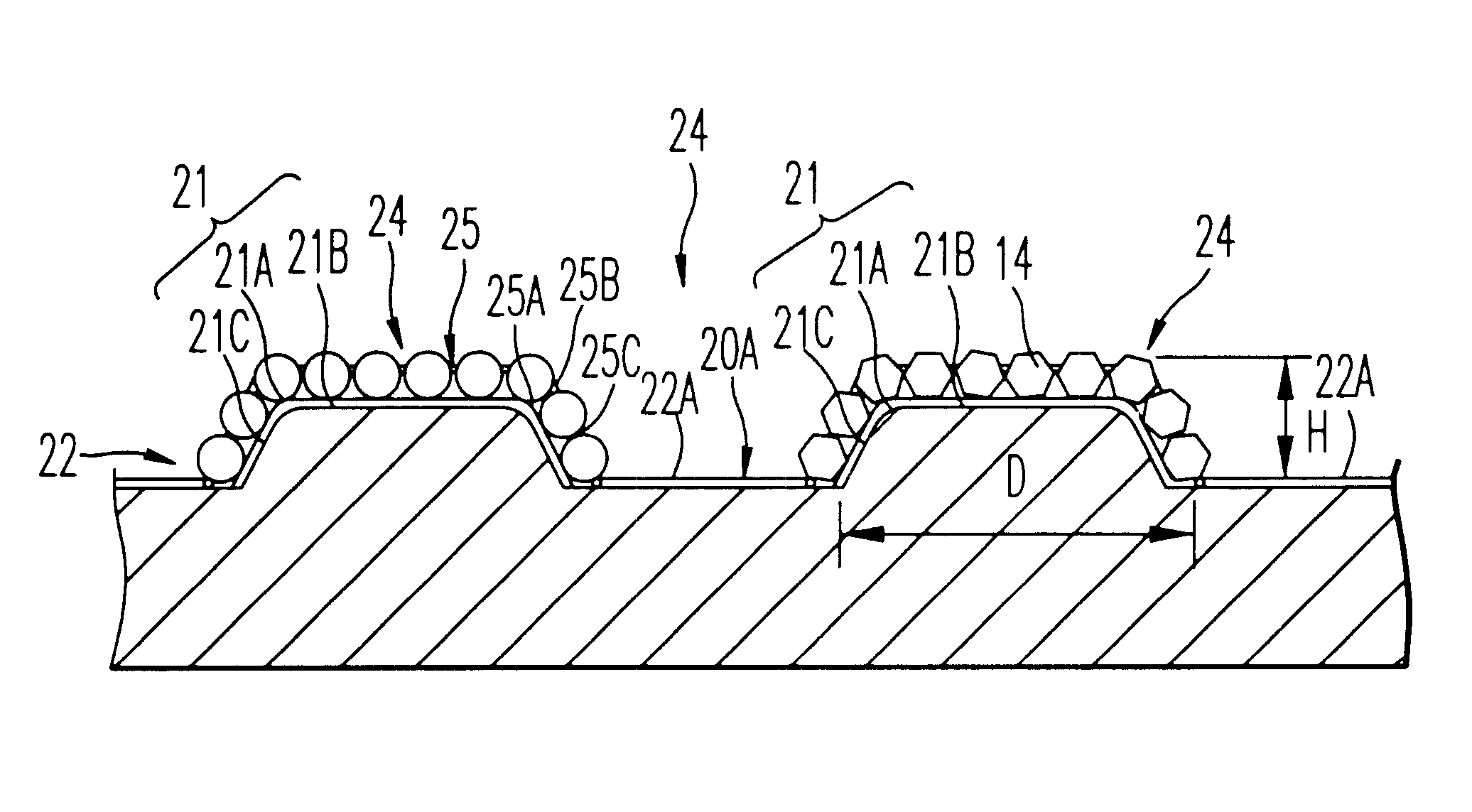

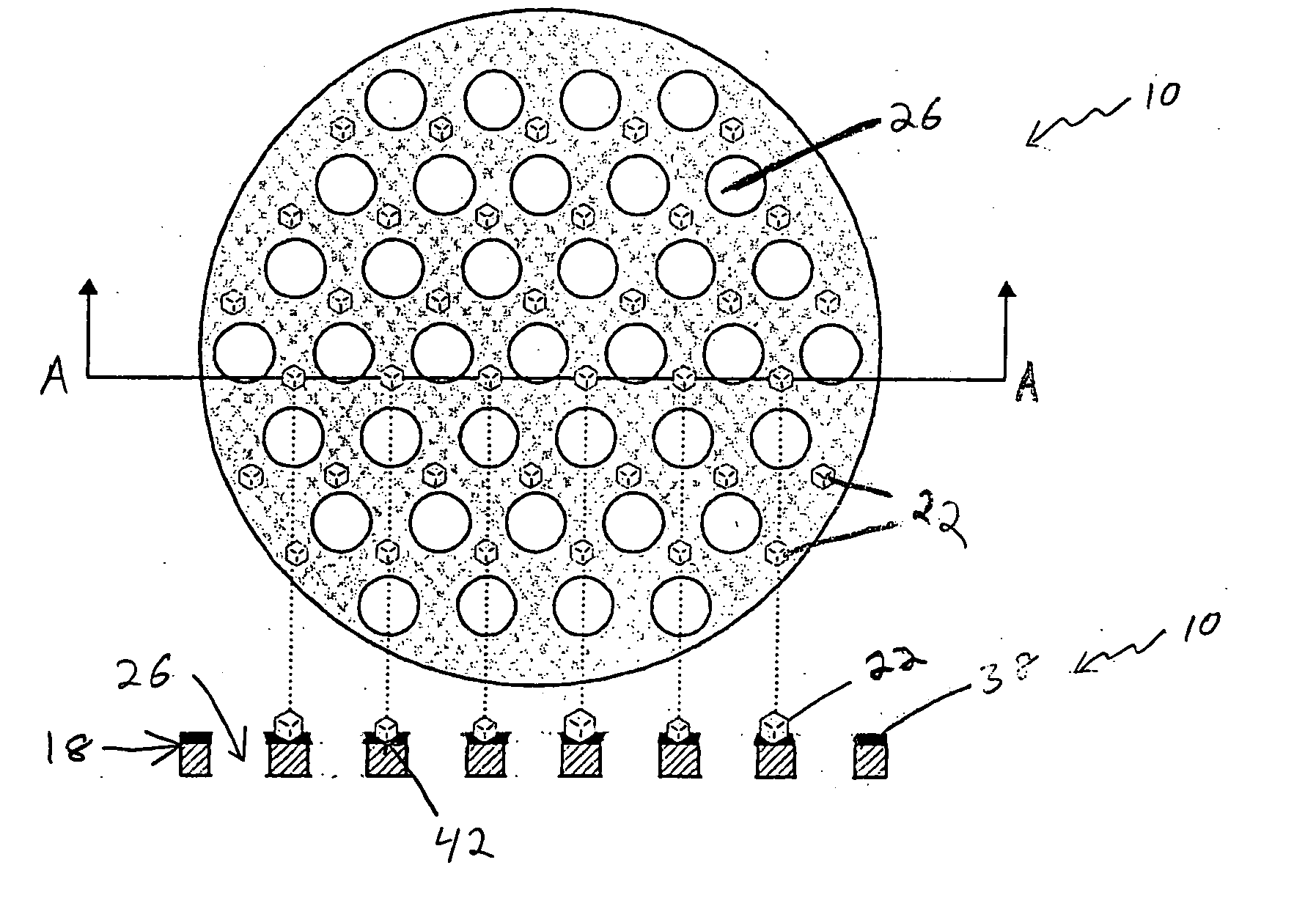

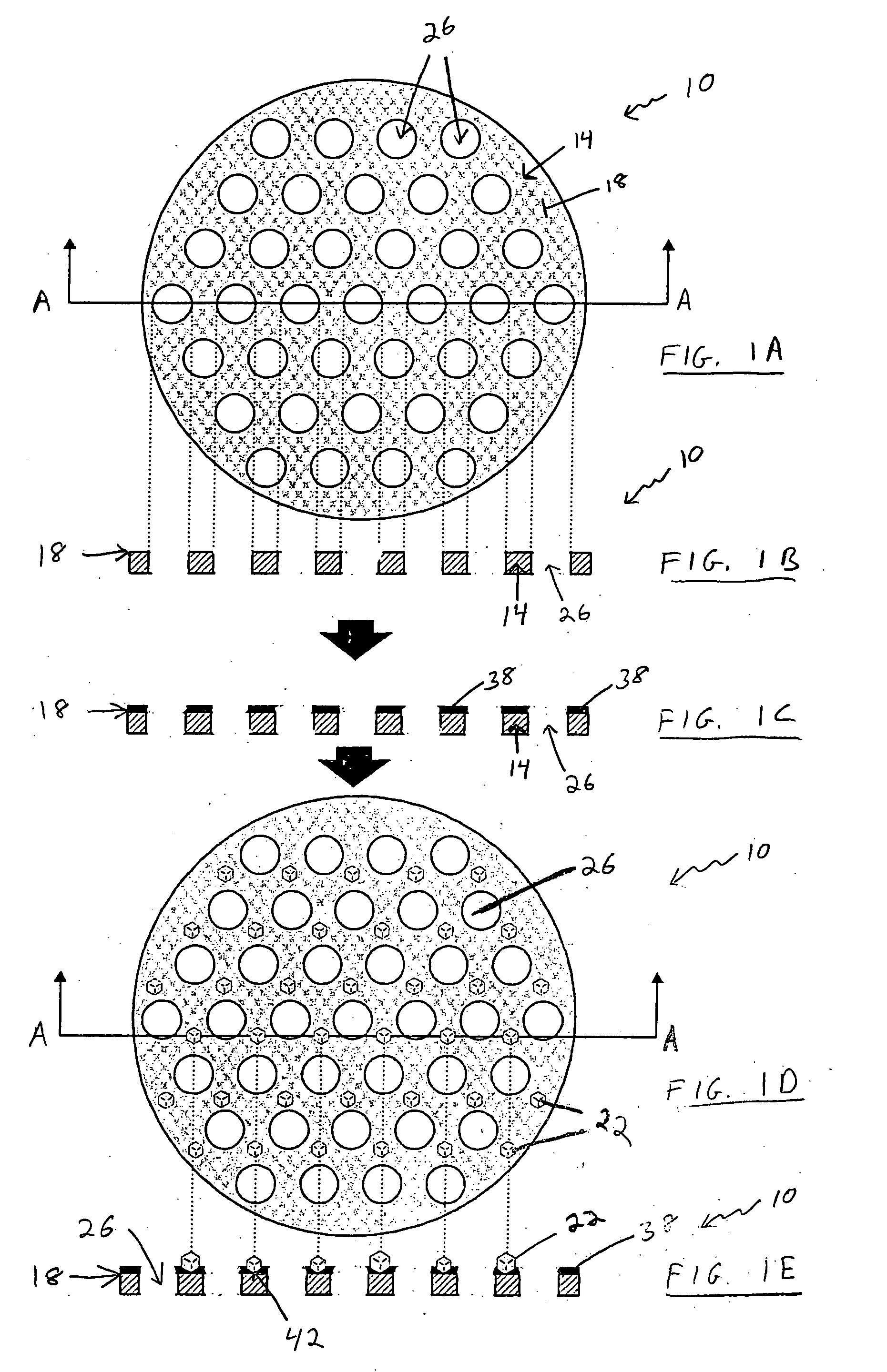

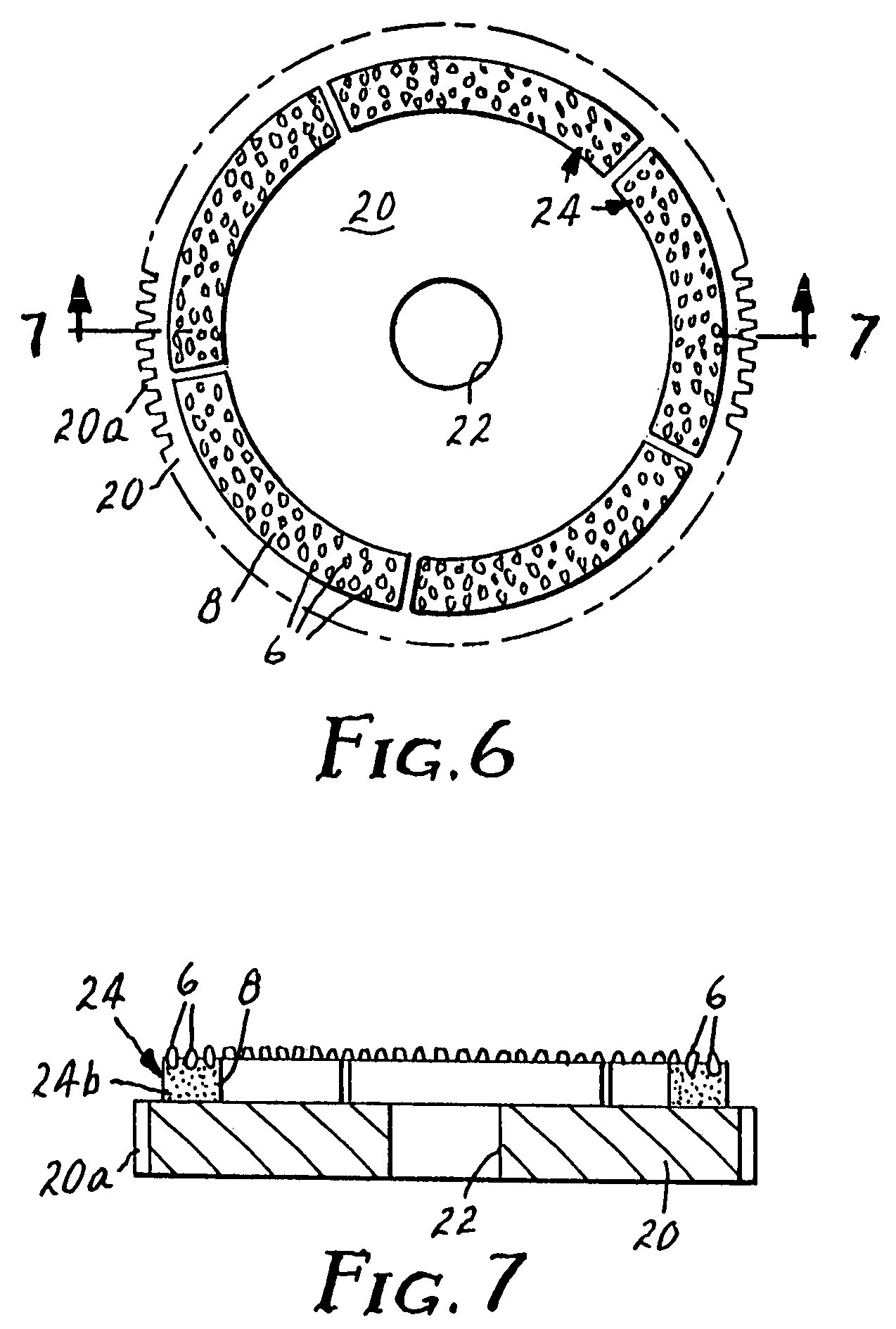

Abrasive tool with metal binder phase

InactiveUS6419574B1Sufficient sharpnessImprove discharge performanceRevolution surface grinding machinesGrinding drivesWear particleMetal

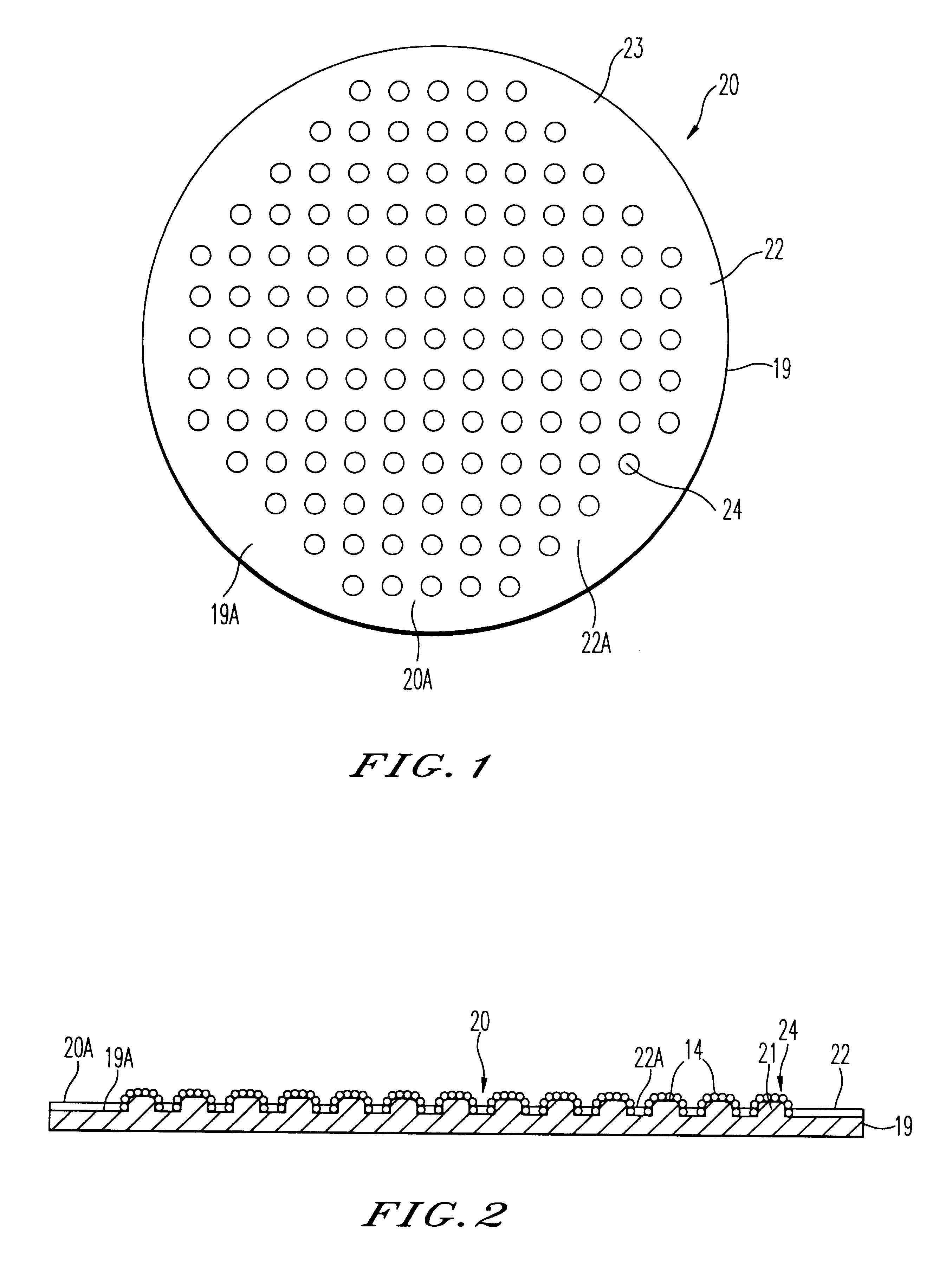

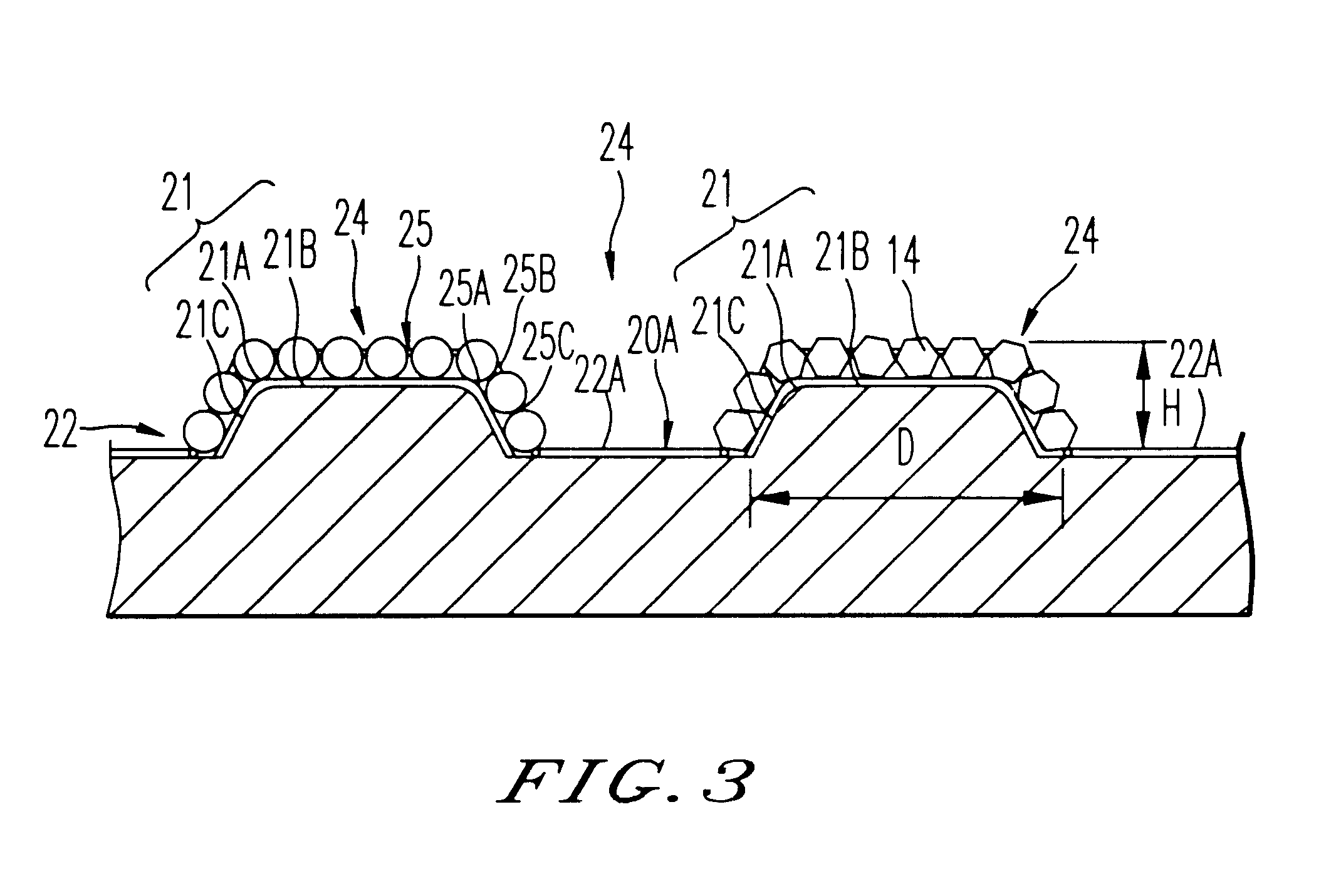

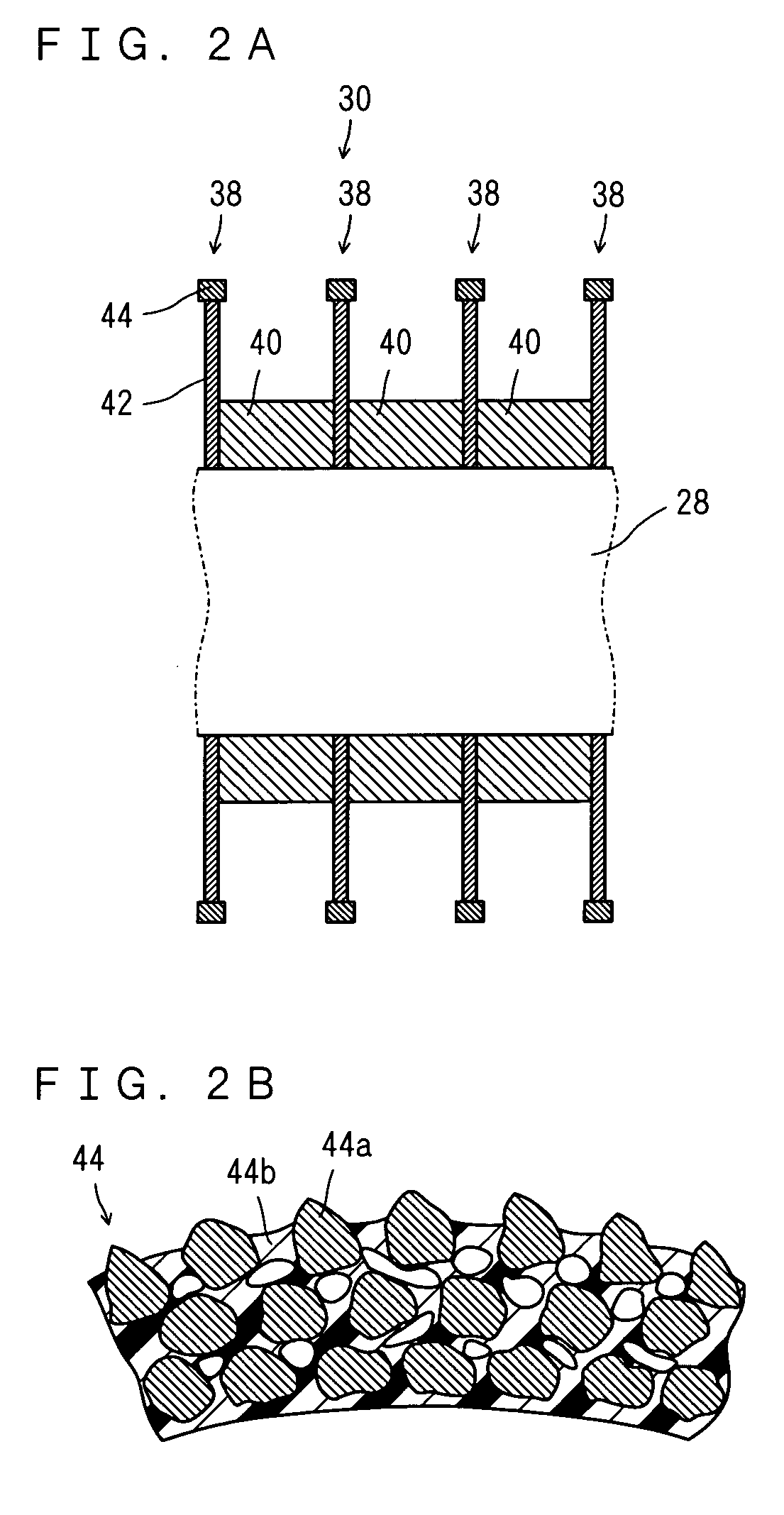

In the electrodeposited abrasive wheel 20 of the abrasive tool according to the present invention, plural mound parts 21, which are upheaved at the central domain of base metal 19 in almost columnar shape, are arranged mostly in the shape of lattice. An abrasive grain layer 22 is formed on a base metal 19, and plural ultra abrasive grains 14 are adhered only to each mound parts 21 by electrodeposited metal phase 25, and referred as the small abrasive-grain-layer parts 24, respectively. Ultra abrasive grains are laid out at corner R part 21a and top 21b of the mound parts 21 at the small abrasive-grain-layer parts 24. Ultra abrasive grains at each small abrasive-grain-layer parts are set as 11-500 pieces, and the rate which ultra abrasive grains occupy to the whole area of abrasive grain layer accounted by plane projection is set as 20%-80% of the range. At the time of grinding, only ultra abrasive grains contact to grinding work piece, then high abutment pressure is maintained, and sharpness and the discharge performance of ground wastes are good.

Owner:MITSUBISHI MATERIALS CORP

Abrasive article and method for making the same

InactiveUS20150290771A1Reduce the amount requiredMaximize efficiencyPigmenting treatmentOther chemical processesChemical LinkageWear particle

An abrasive article comprising a plurality of abrasive grains that are precisely arranged in accordance with a predetermined pattern and are chemically bonded with a matrix material, and a method for the making thereof are disclosed. A coating layer on each of the abrasive grains functions as a bridge to form chemical bonding between the abrasive grains and the matrix material. In addition to a plated material, the matrix material can include a braze, a solder, a sintered material, an infiltrant, an organic material, and a vitrified material. The method for making the abrasive article comprises the steps of: coating abrasive grains with a coating layer that chemically bonds to each of the abrasive grains; arranging the coated abrasive grains in accordance with a predetermined pattern; and chemically bonding the coated abrasive grains with a matrix material.

Owner:LI YUNDONG

Diesel engine water pump with improved water seal

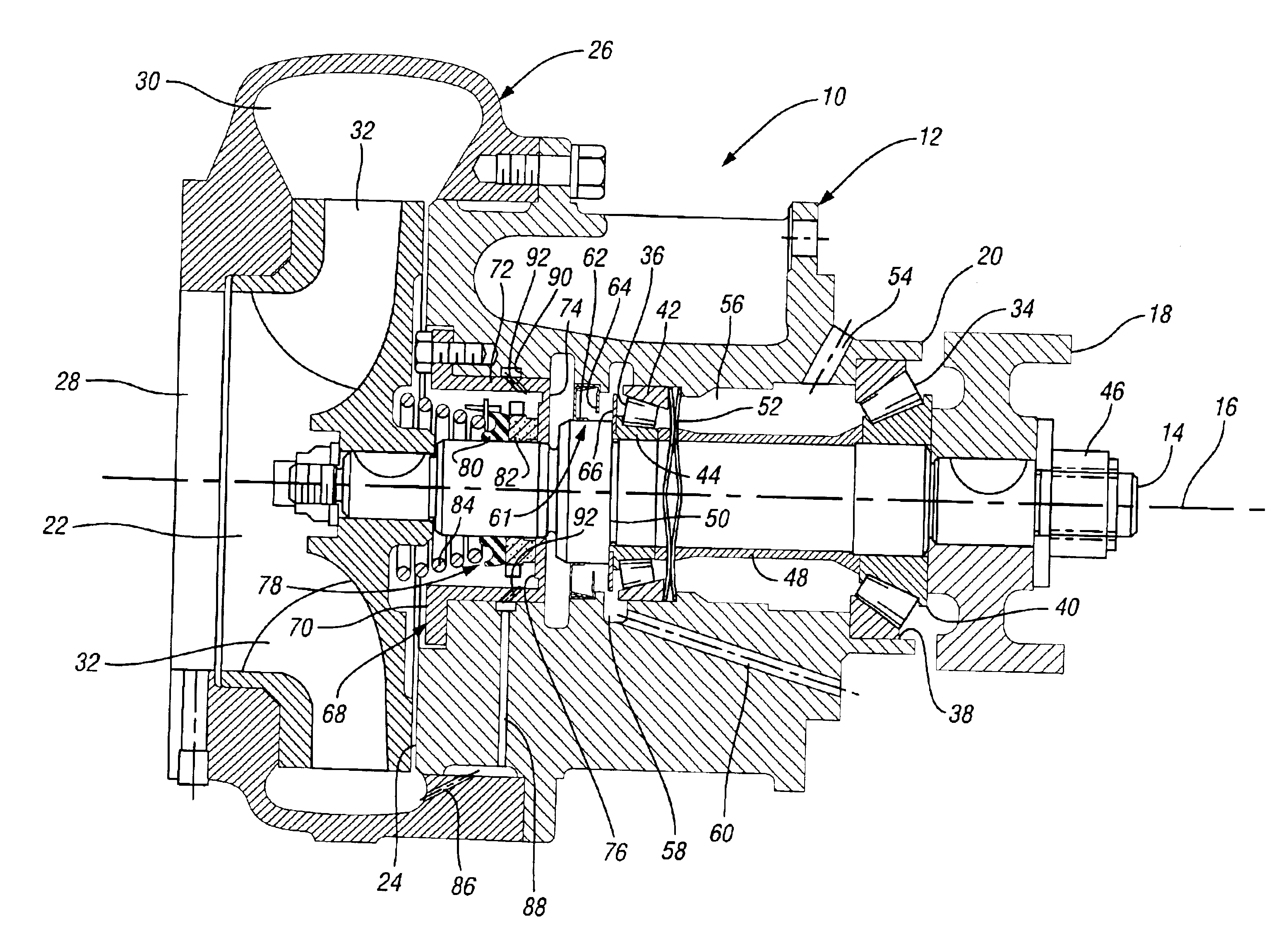

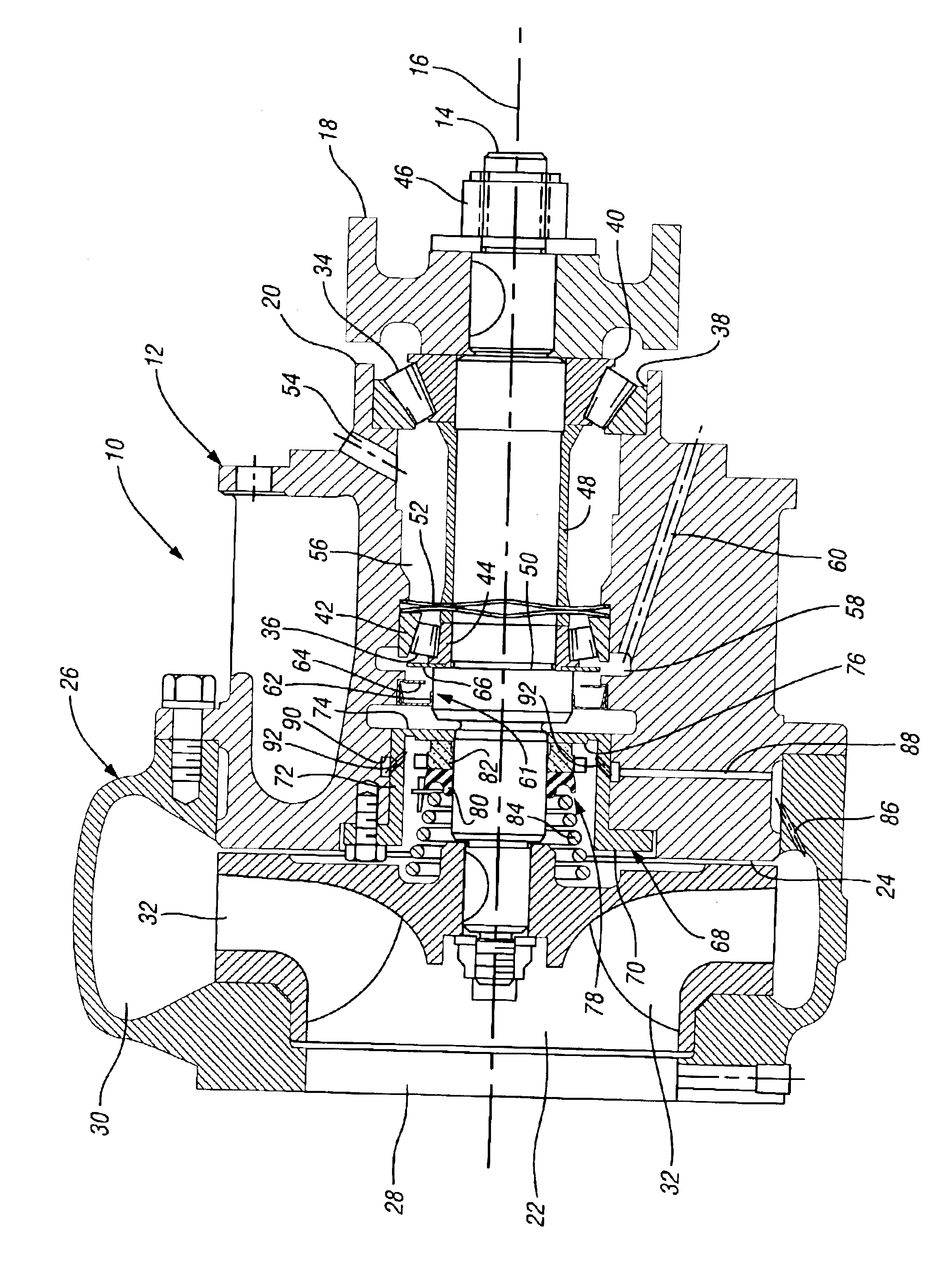

ActiveUS6884022B2Extended service lifeEasy constructionRotary bearingsEngine sealsImpellerWear particle

An improved diesel engine water pump includes three main features that aid in extending the maintenance-free life of the pump. The impeller shaft is carried by tapered roller shaft support bearings of which the impeller bearing has a floating outer race that is urged axially by a preload spring to provide a prescribed axial preload that maintains concentricity of the shaft with the axis and prolongs bearing life. An improved oil seal combines an oil slinger, a stationary deflector and a lip oil seal with a return passage to the engine to more effectively limit oil leakage from the pump. An improved water seal includes pressurized water jets fed from the pump volute that flush wear particles from the water seal surface and increase water seal life. Further details of these features are also disclosed.

Owner:ELECTRO-MOTIVE DIESEL

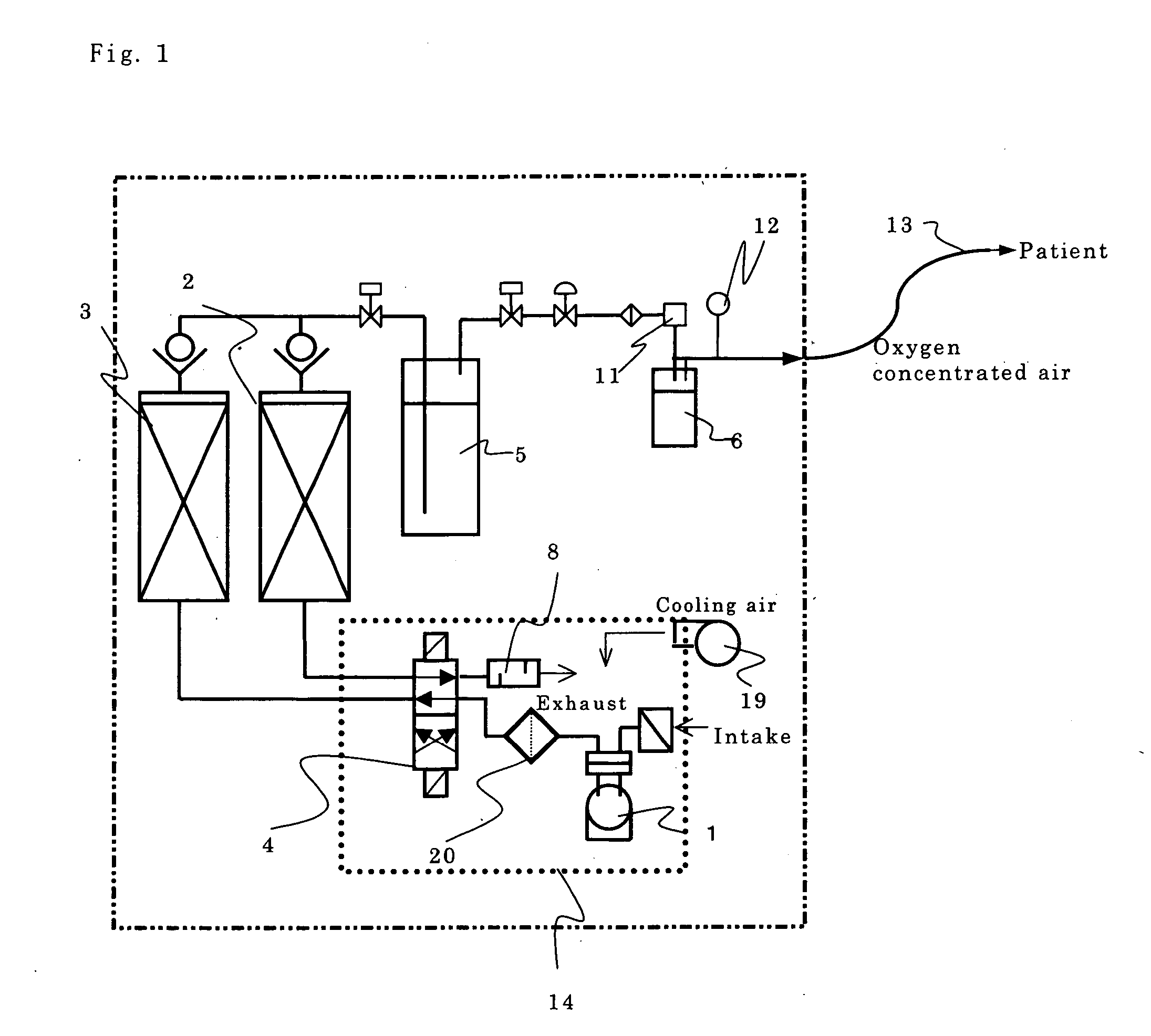

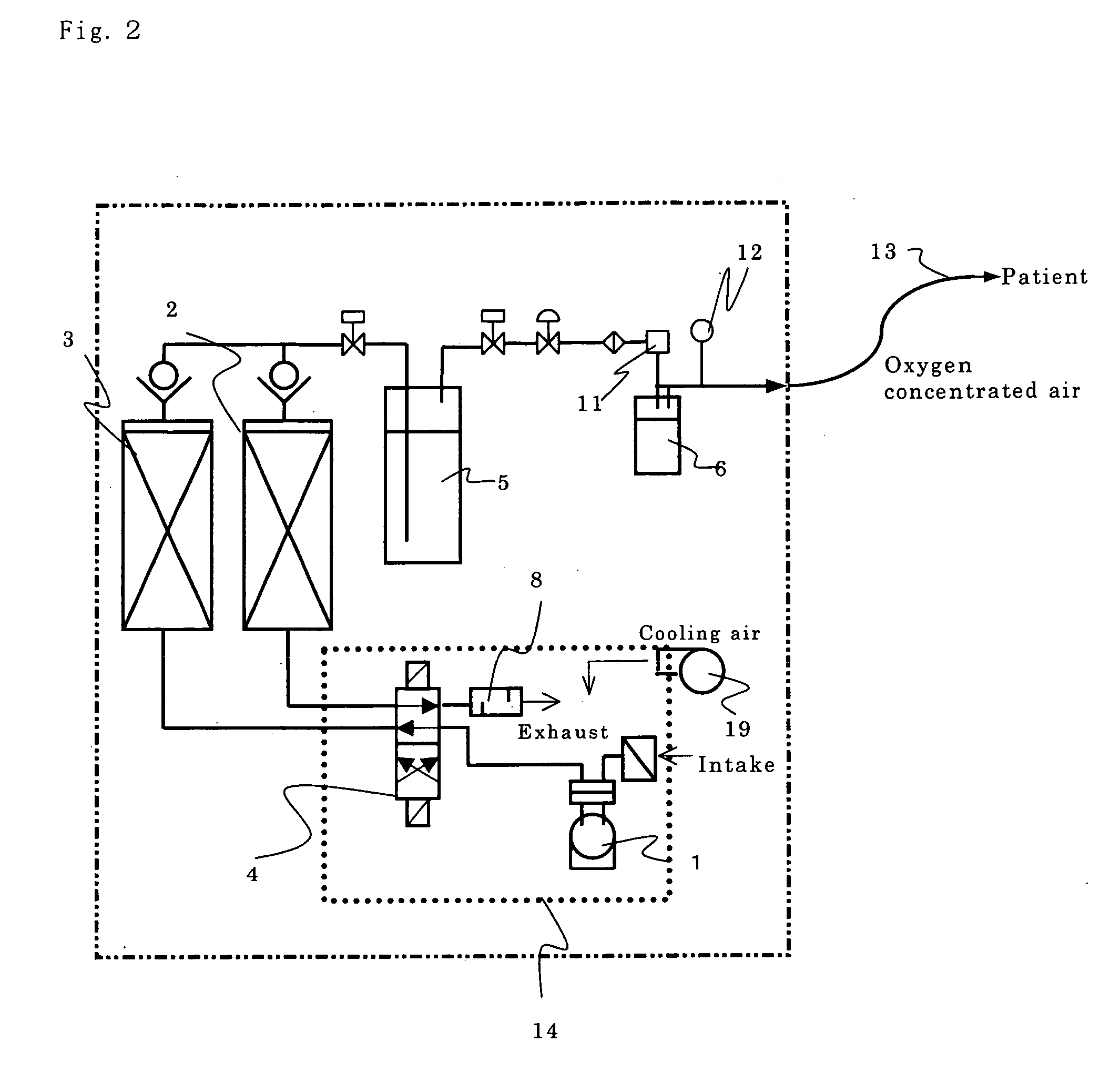

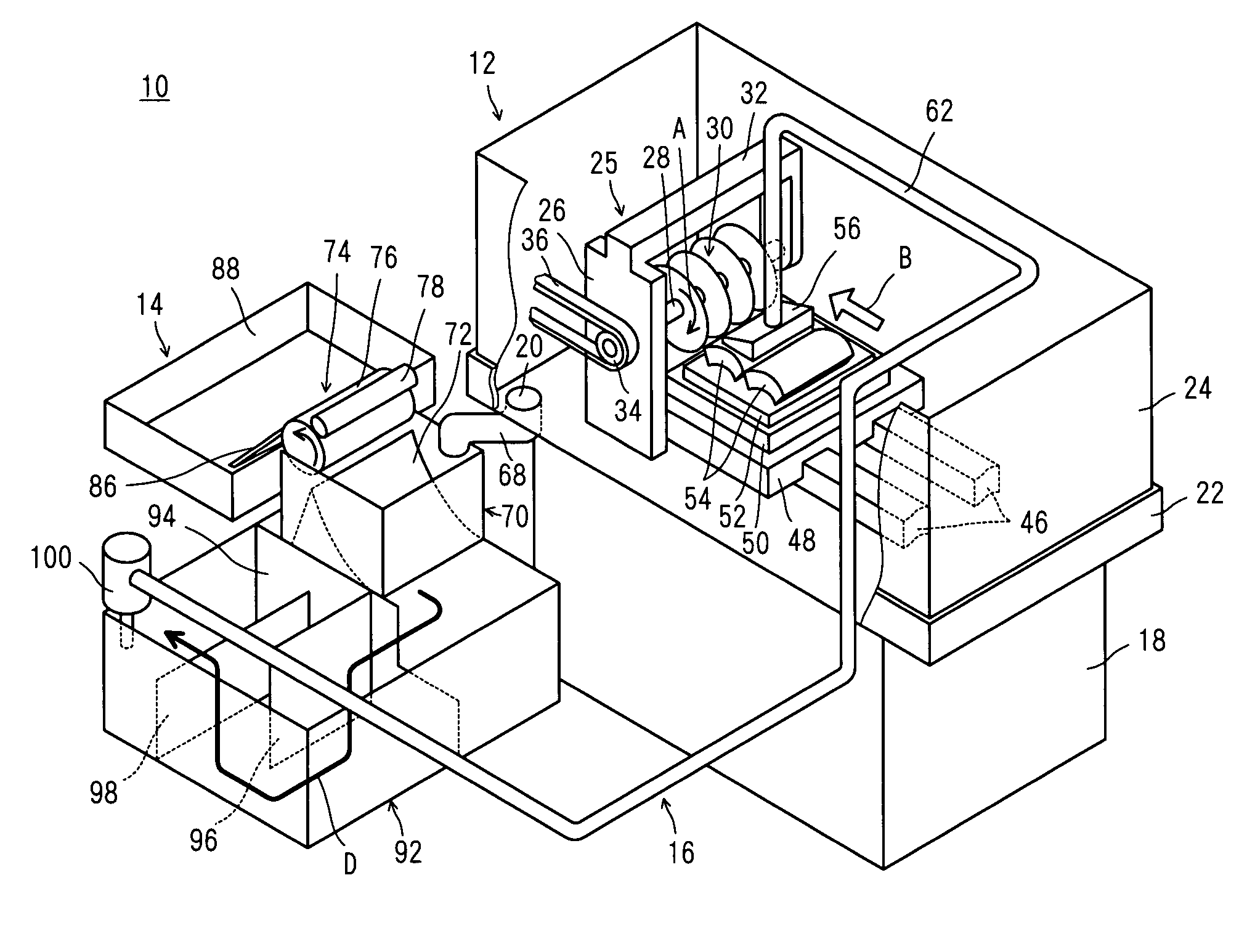

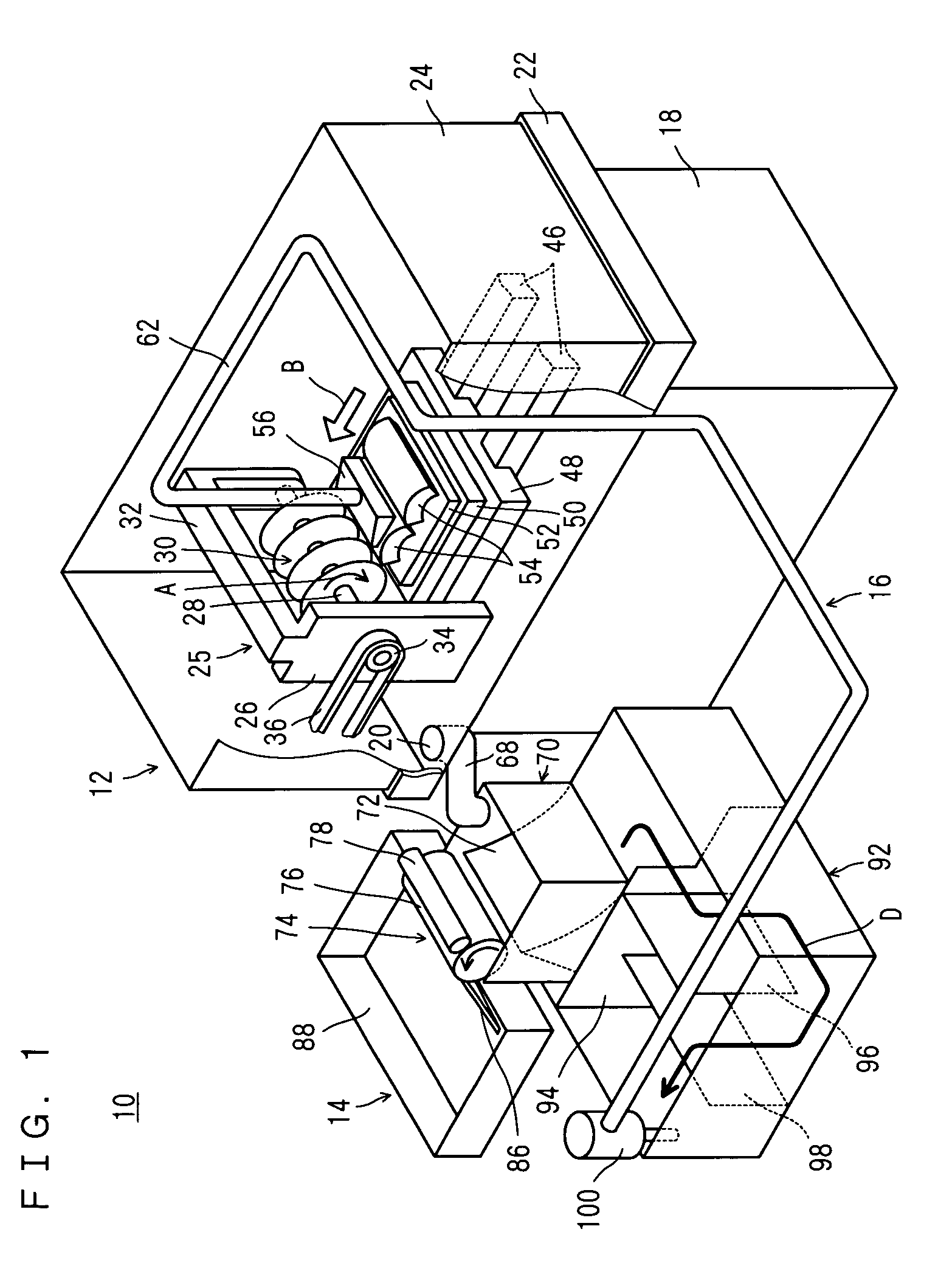

Oxygen concentrator for medical treatment

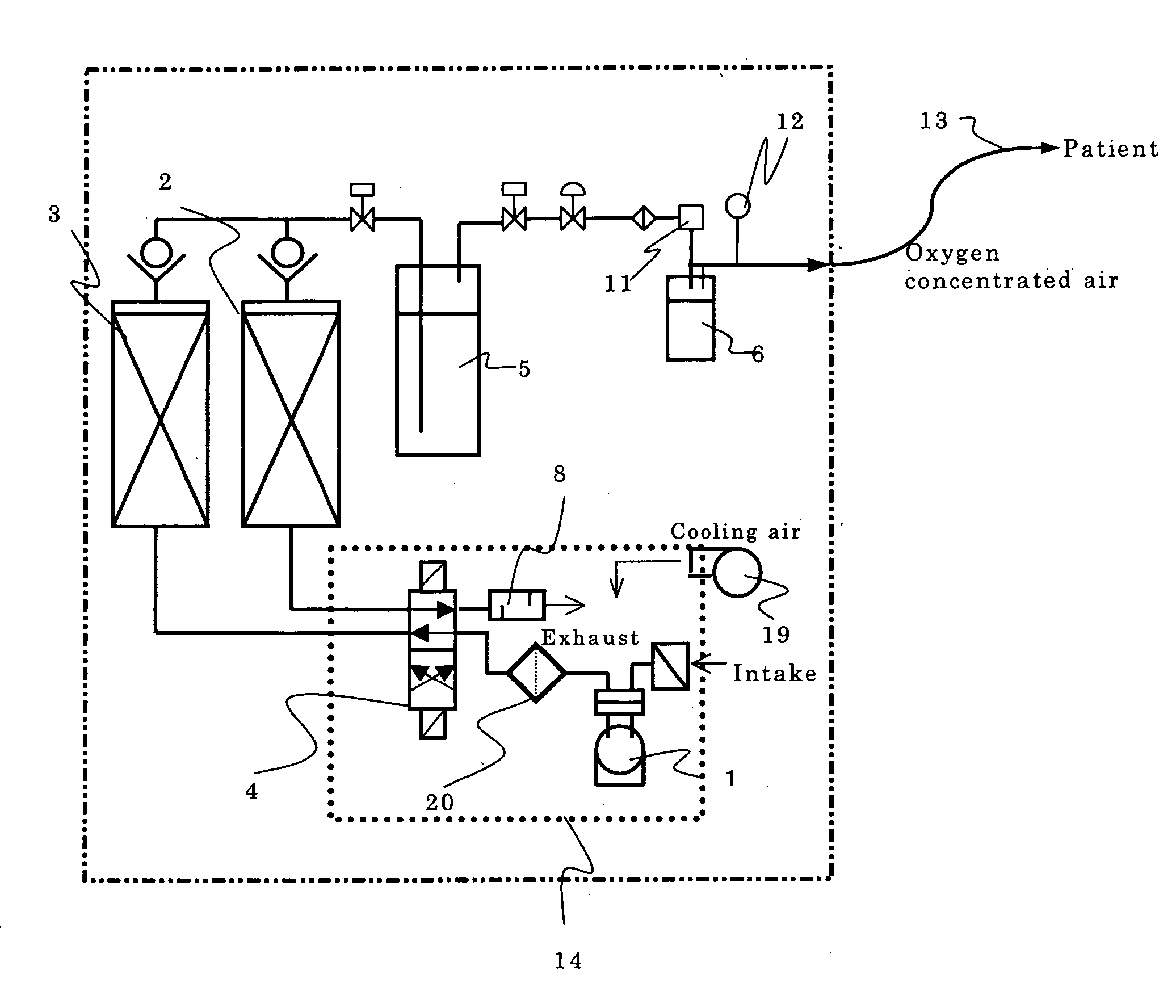

InactiveUS20060137522A1Avoid vibrationLow rate of occurrenceRespiratorsGas treatmentWear particleNitrogen

The present invention provides, as a pressure swing adsorption type oxygen concentrator aiming to be used for the home oxygen therapy, and having the device reliability ensuring a low failure occurrence rate, and the adsorption performance stability, ensuring the stable oxygen concentration performance even over a long period, a pressure swing type oxygen concentrator having at least one adsorption column charged with an adsorbent capable of preferentially adsorbing nitrogen rather than oxygen, and an air compressor for pressure supplying and / or vacuum exhausting air to and / or from the adsorption column, characterized by including a nonwoven fabric filter for collecting sealing material wear particles in an air channel between the adsorption column and the air compressor.

Owner:TEIJIN PHARMA CO LTD

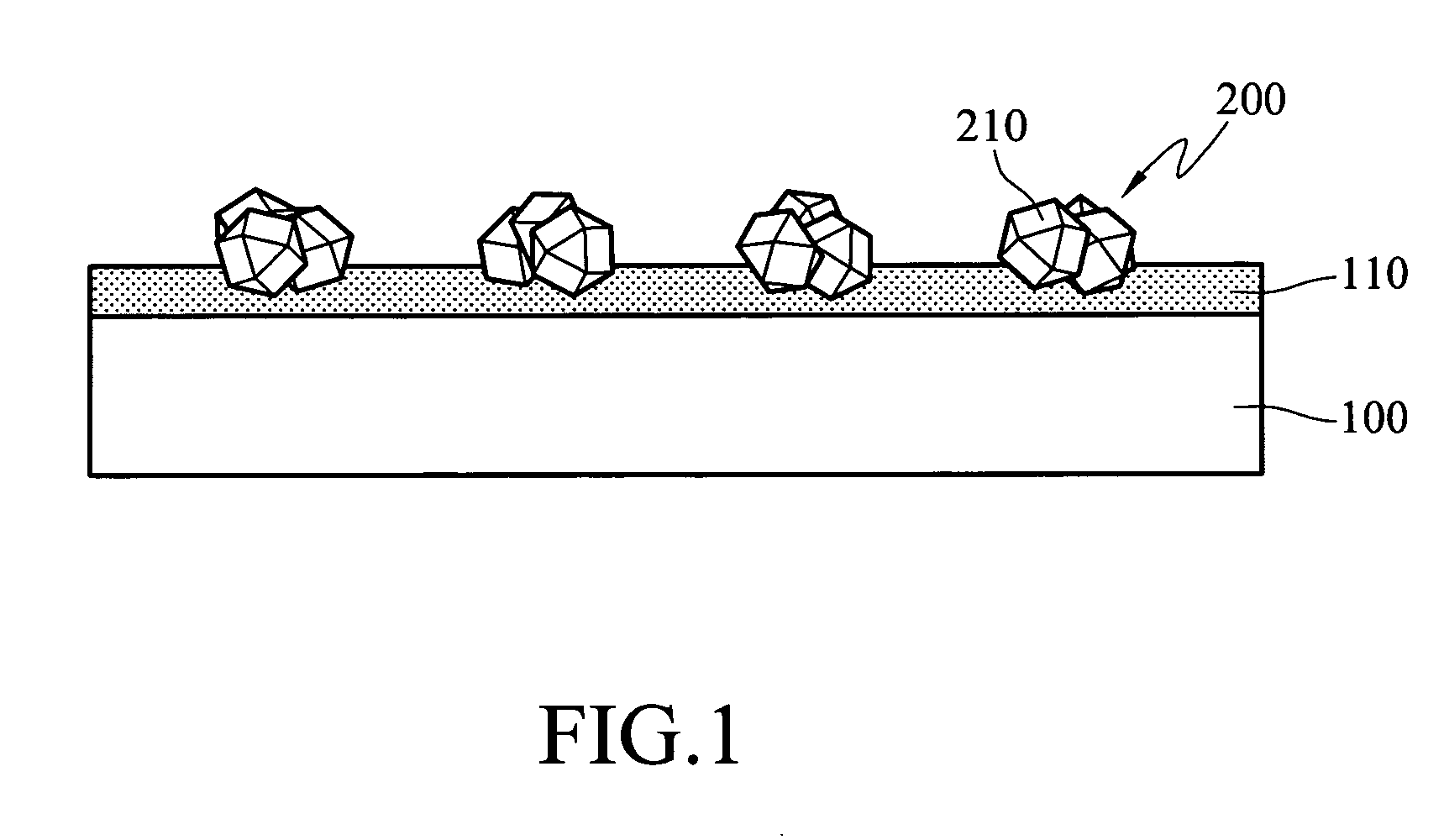

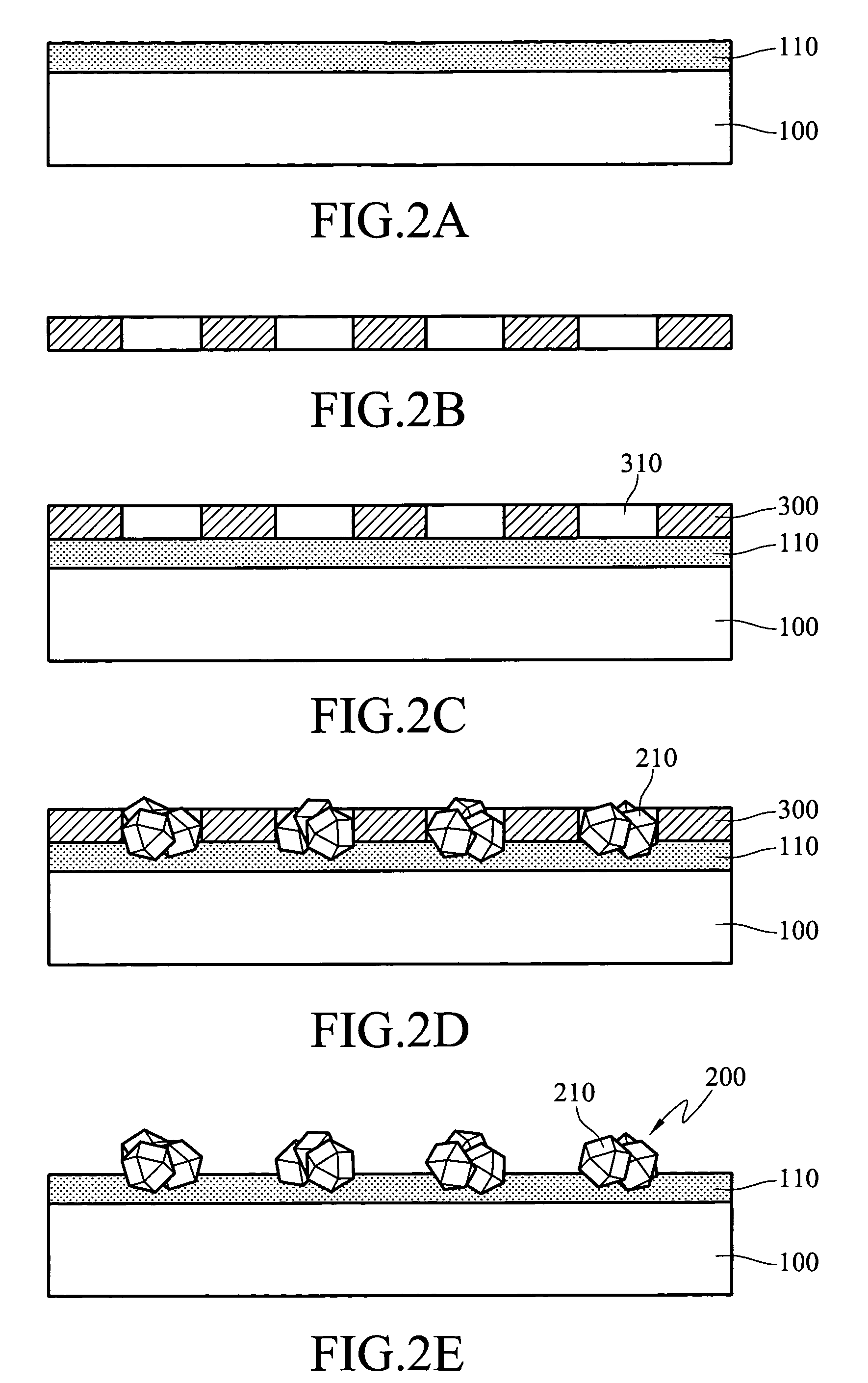

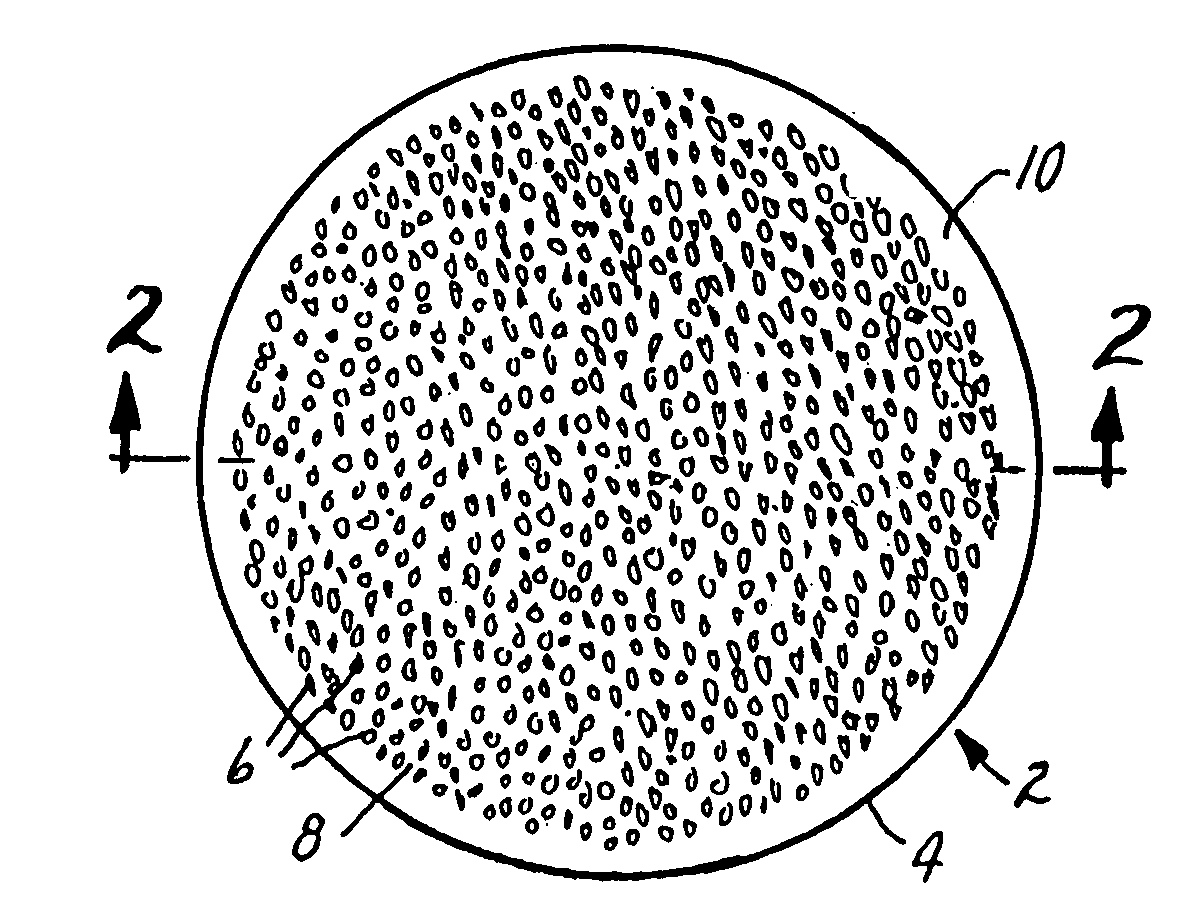

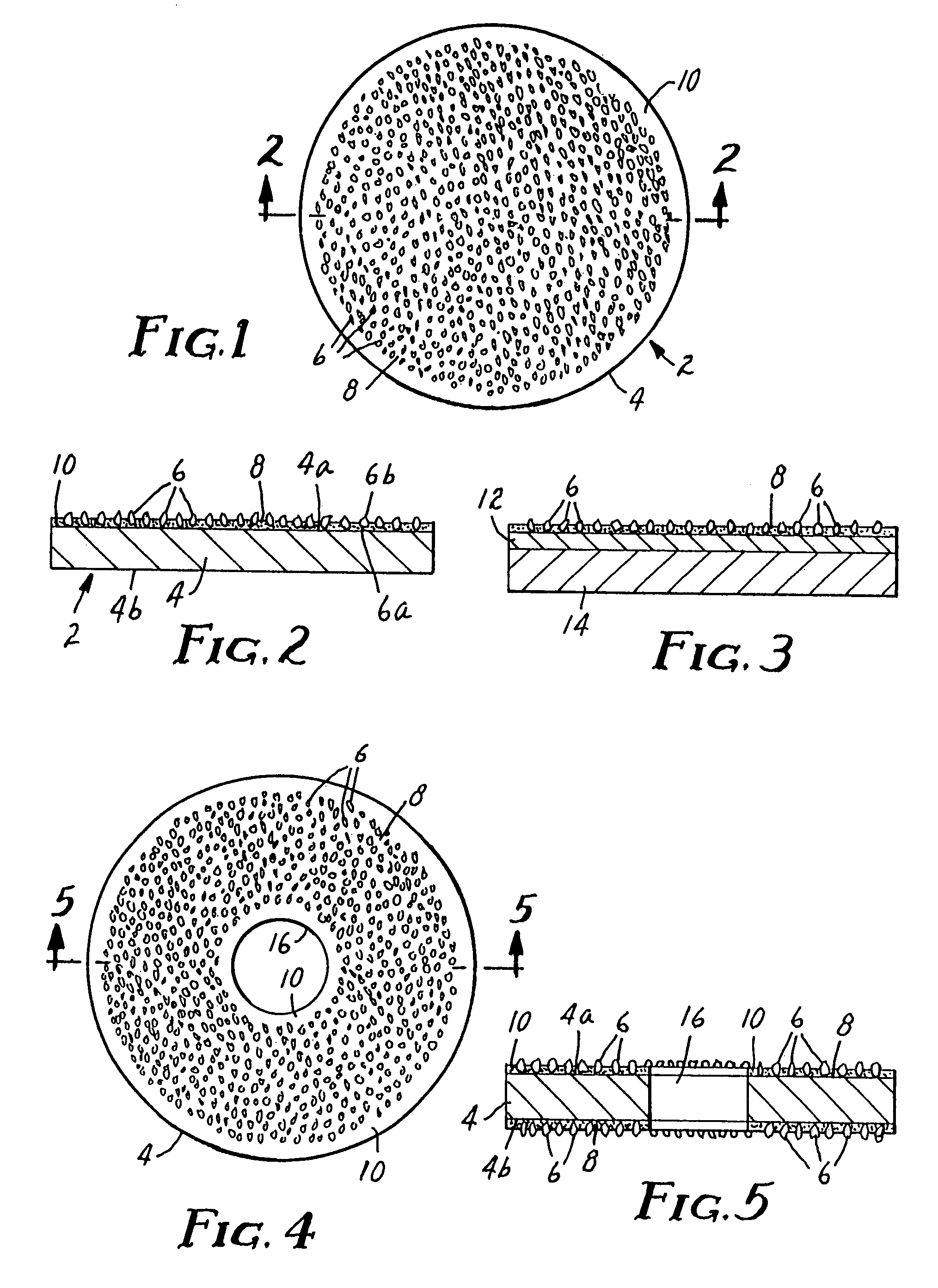

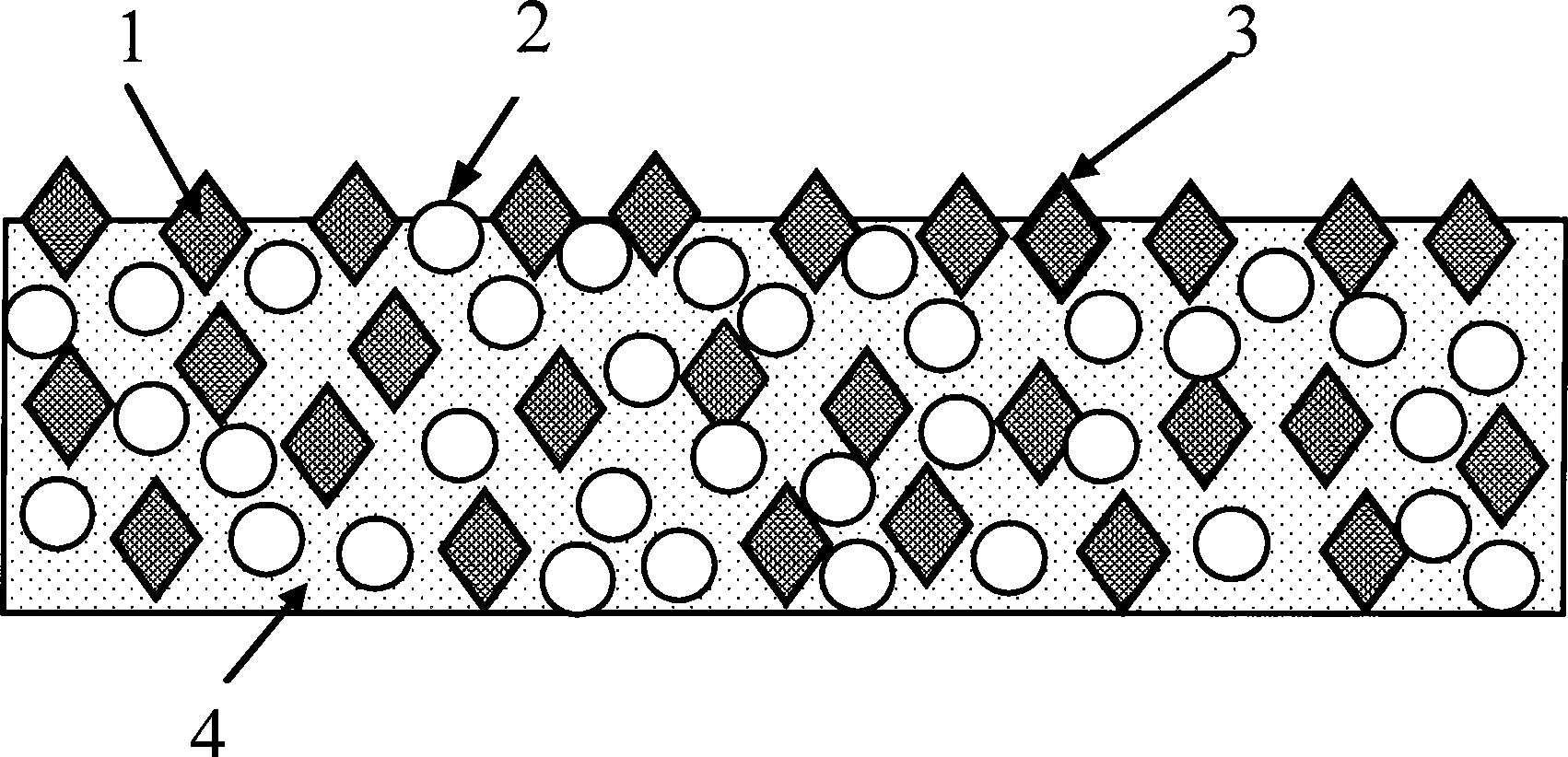

Abrasive tool and method of making the same

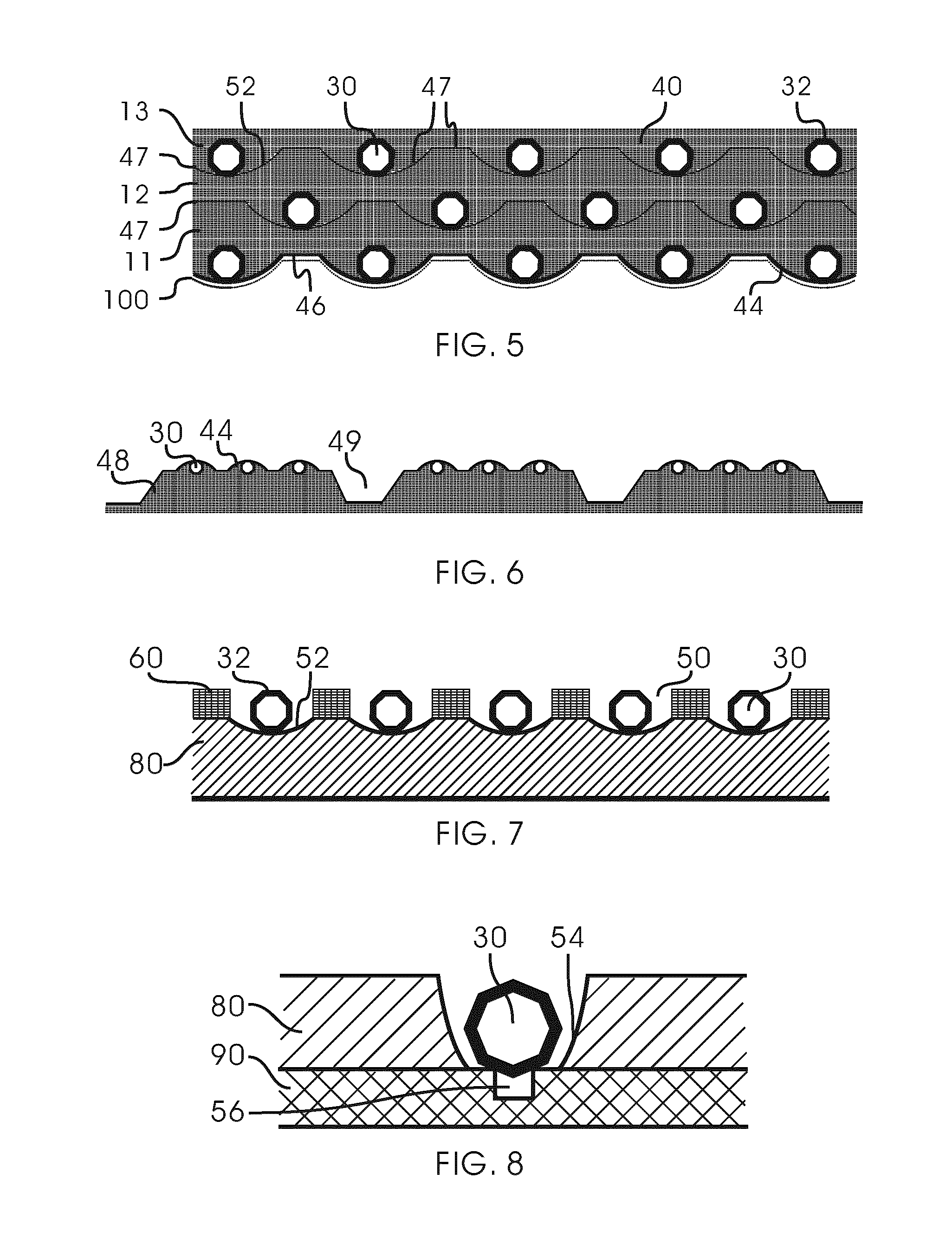

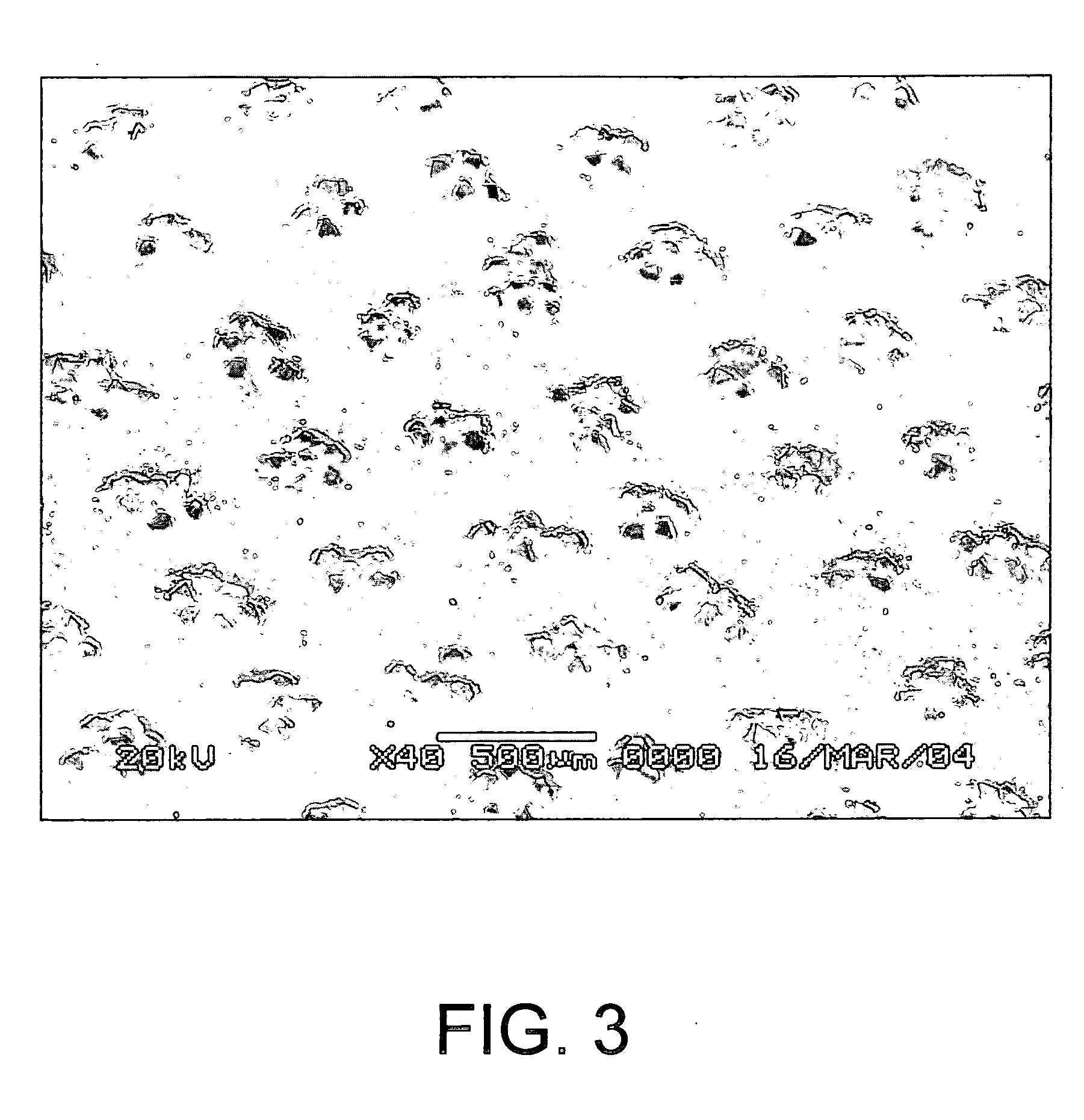

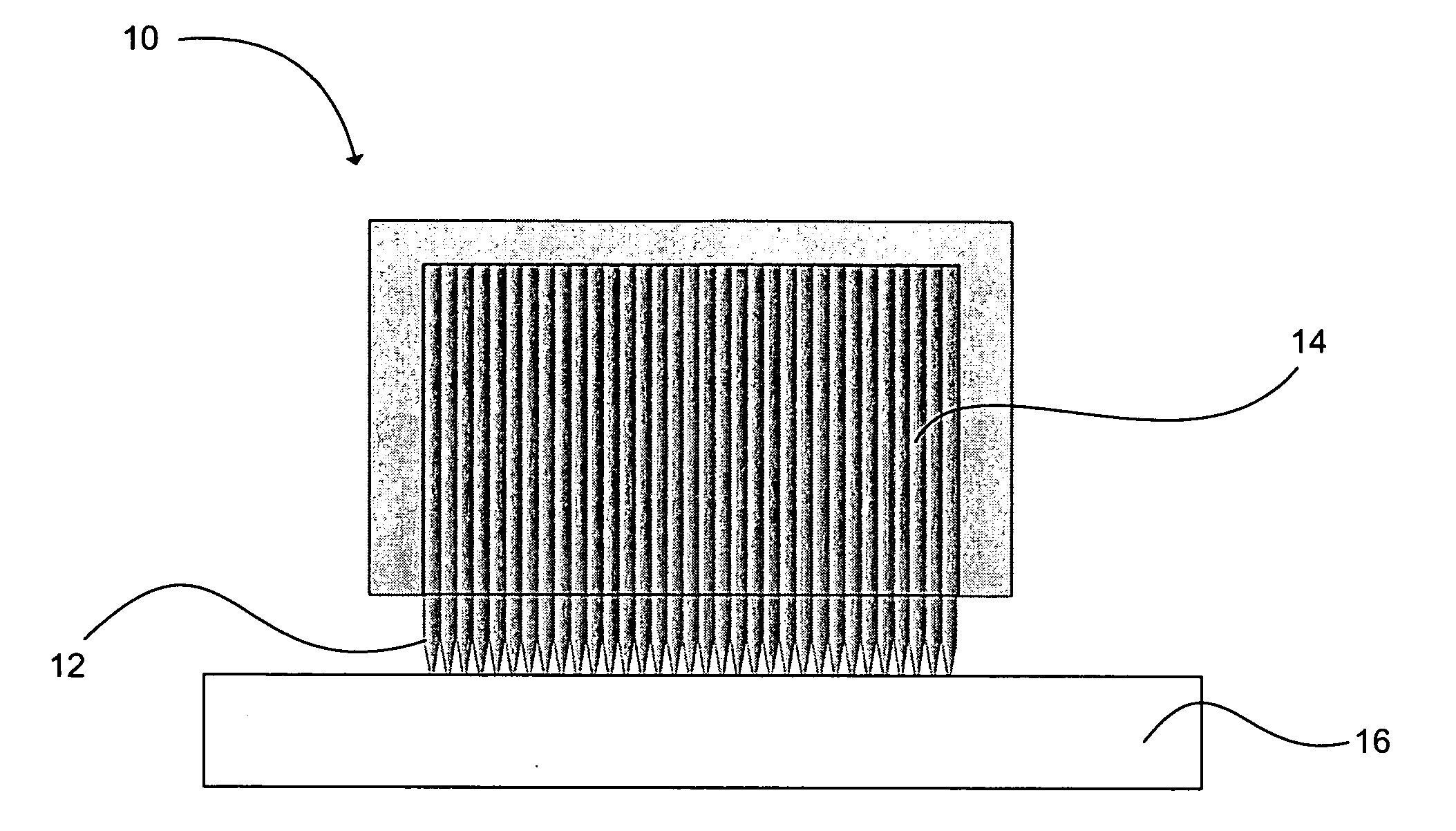

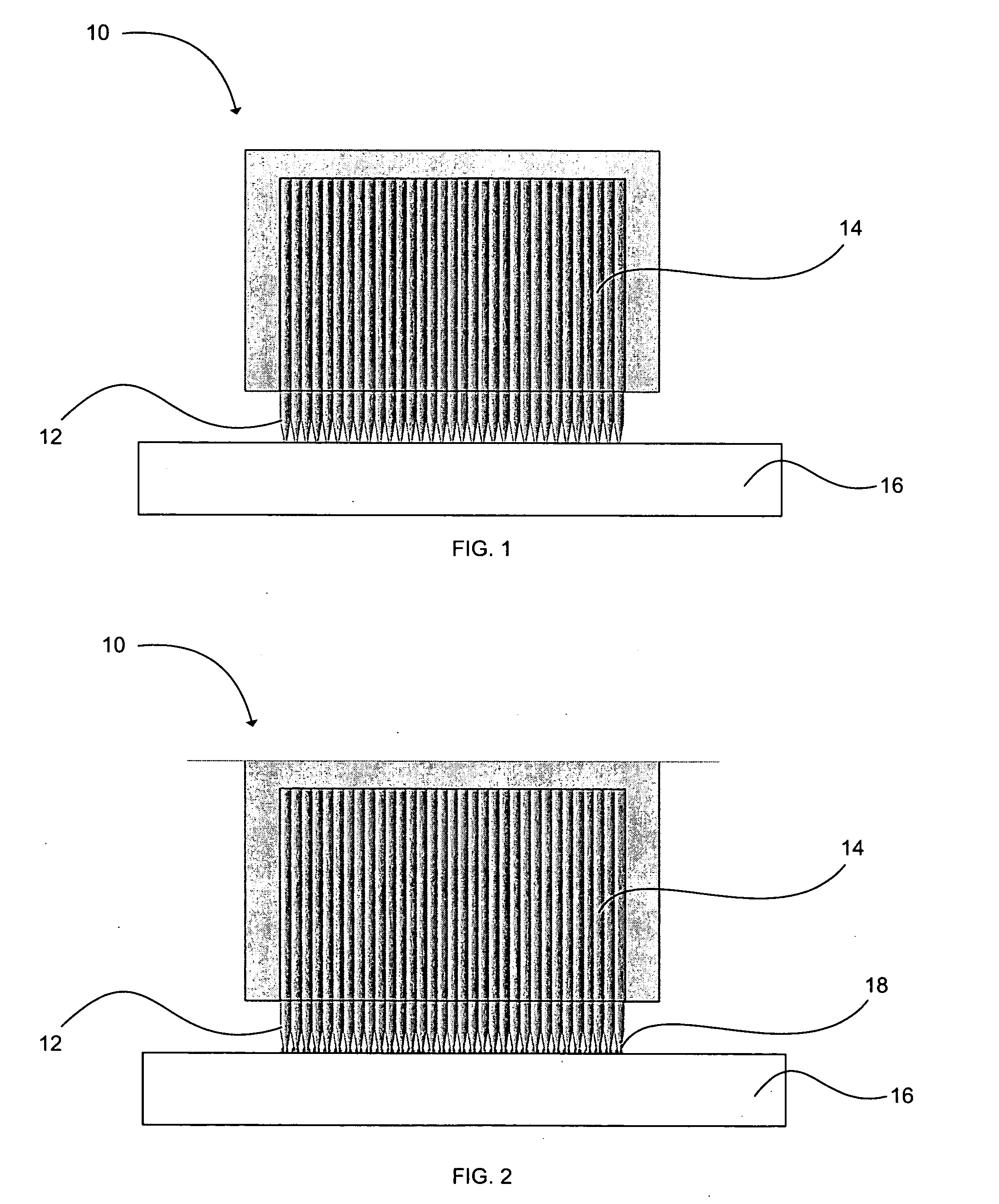

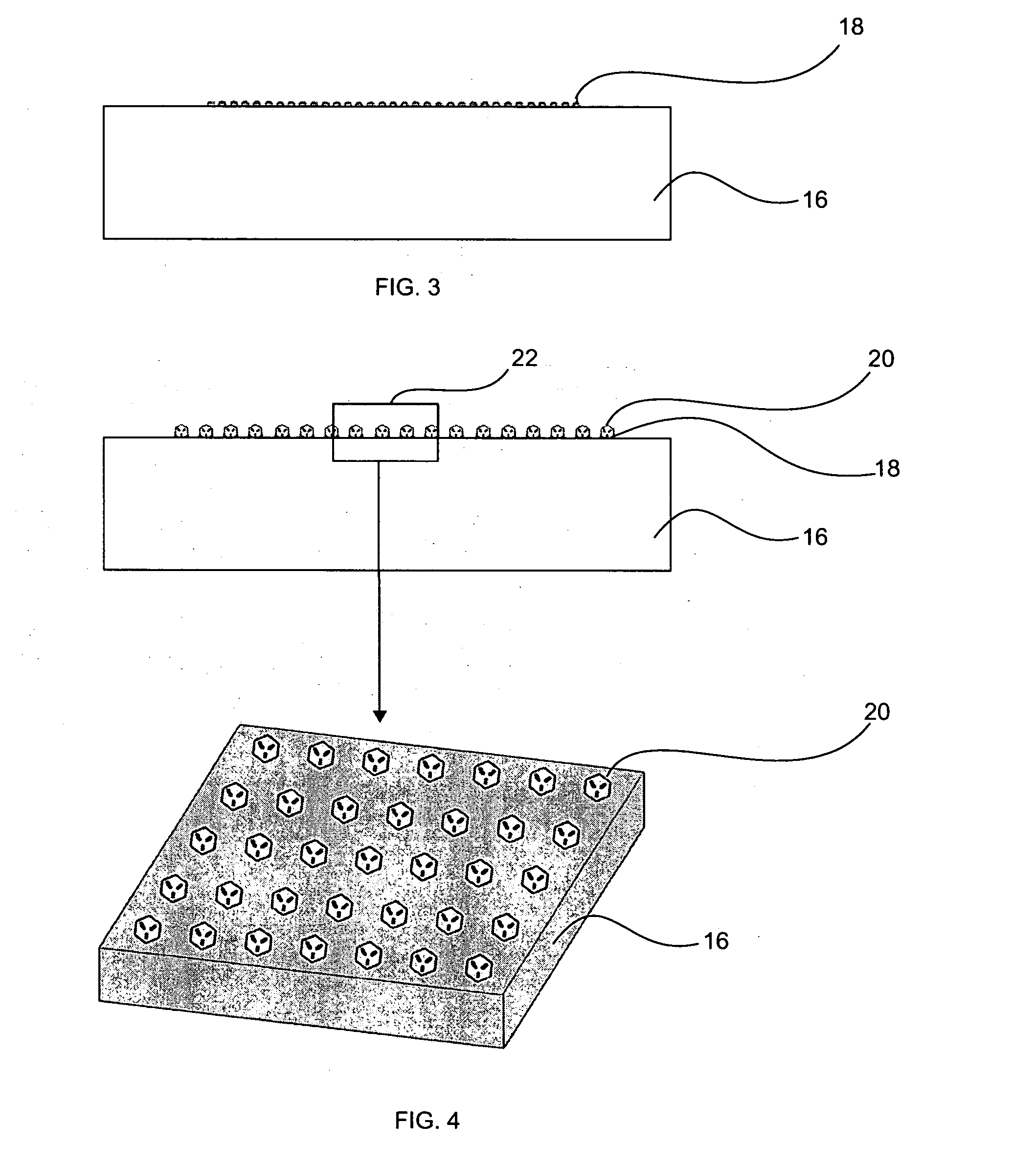

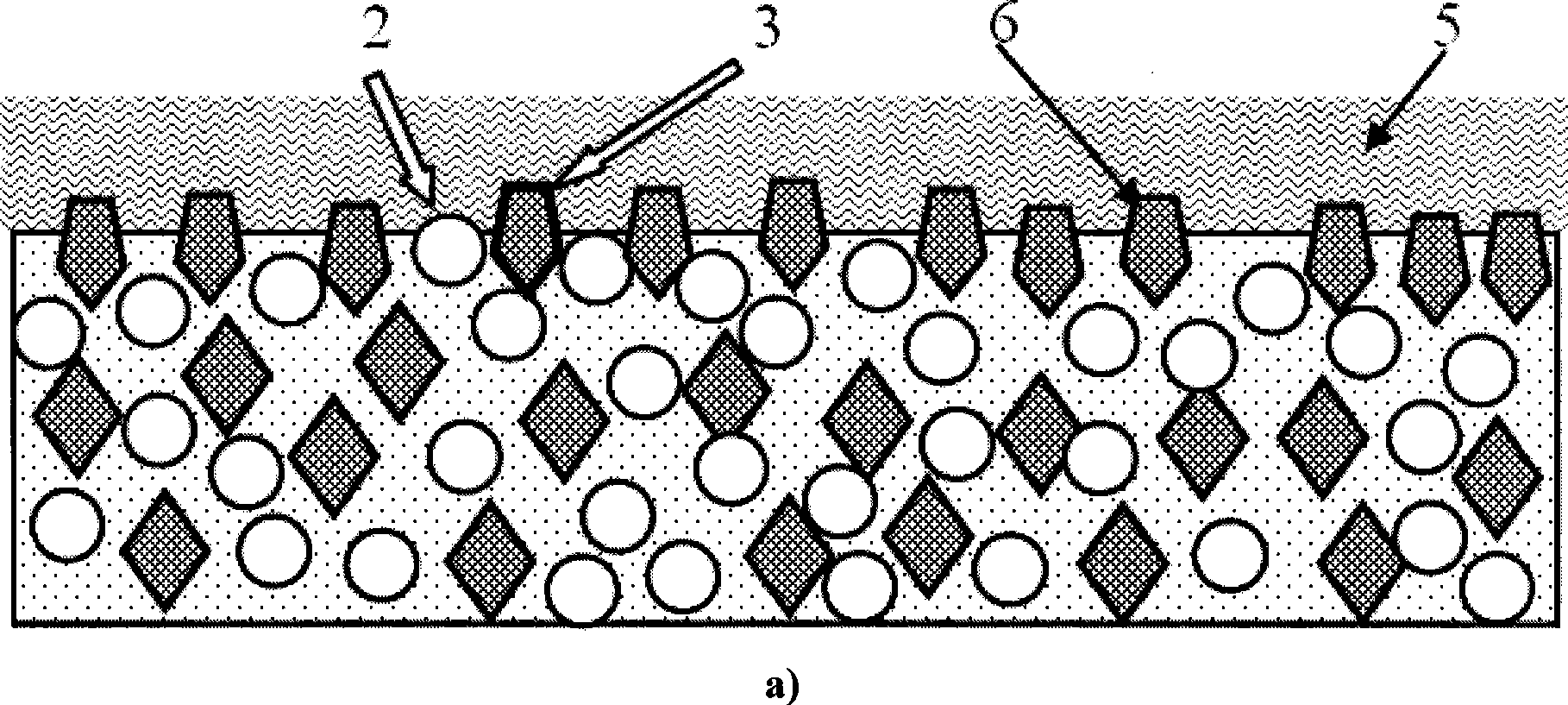

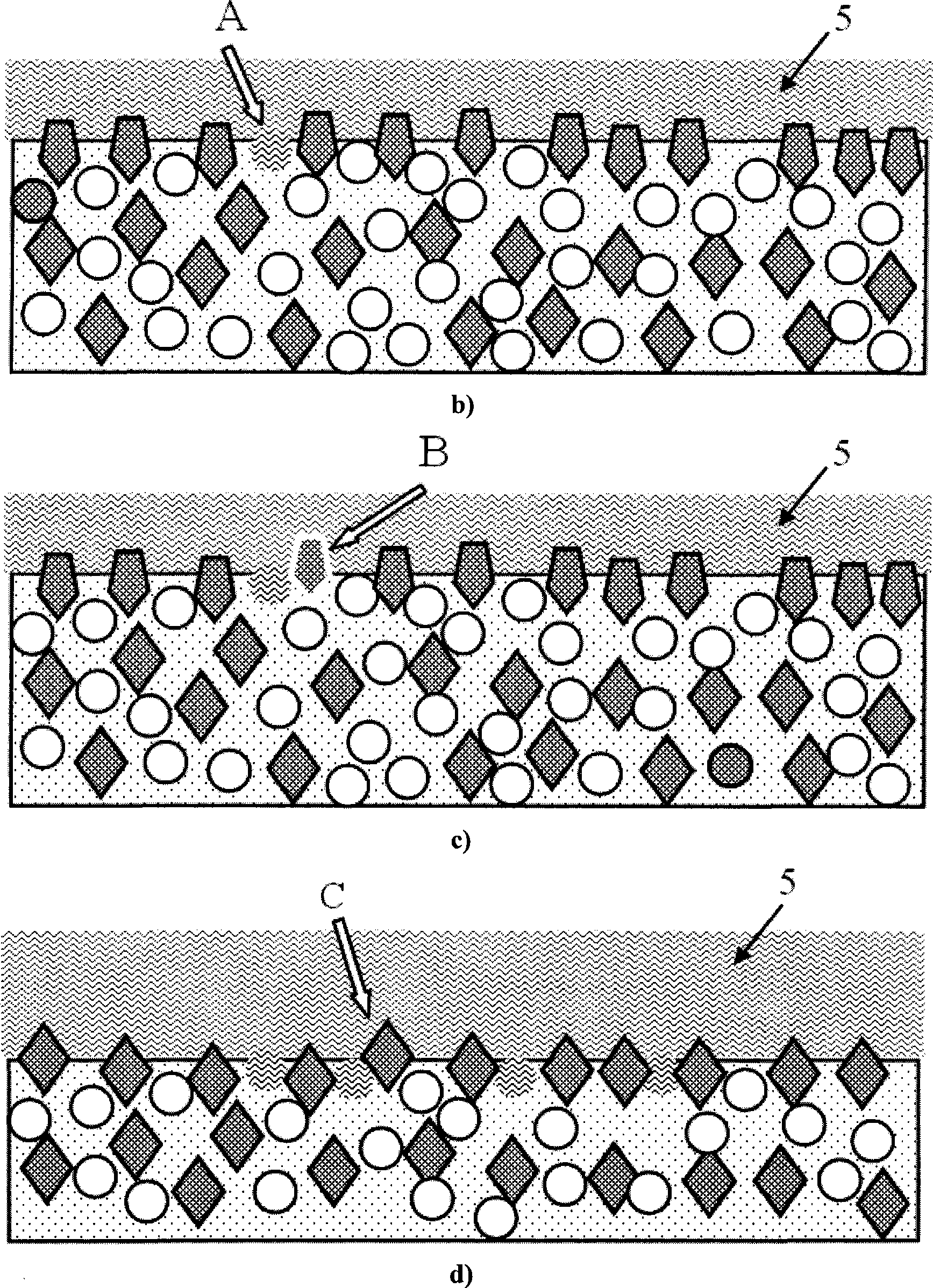

InactiveUS20060254154A1Small sizeKeep the pressure evenPigmenting treatmentOther chemical processesRegular patternWear particle

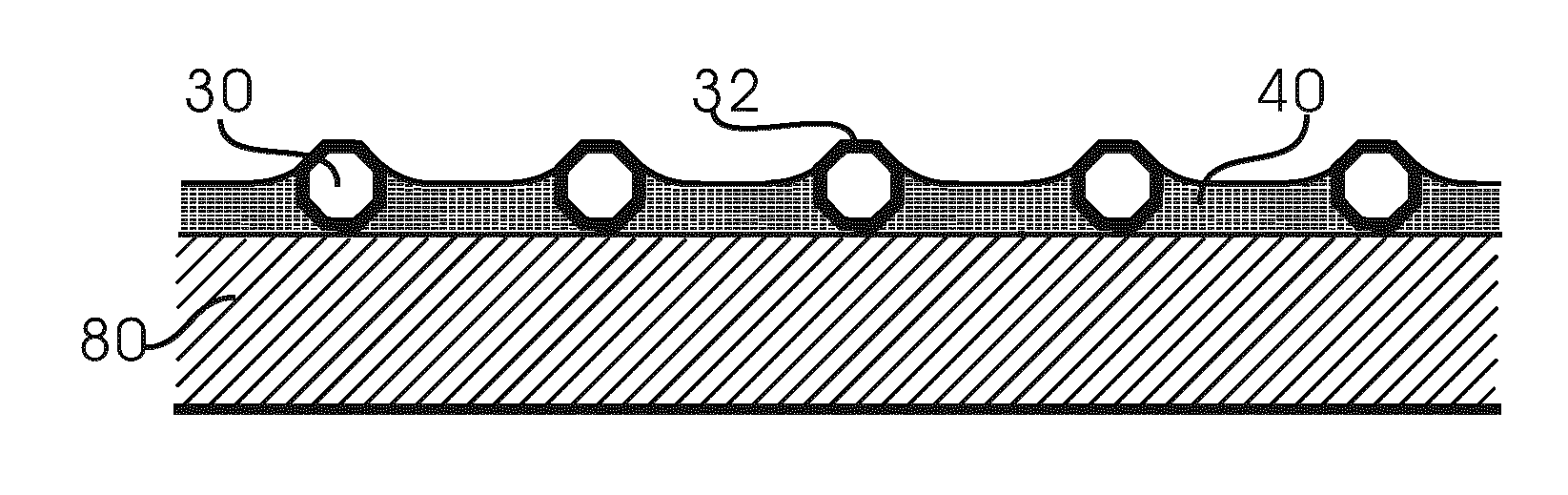

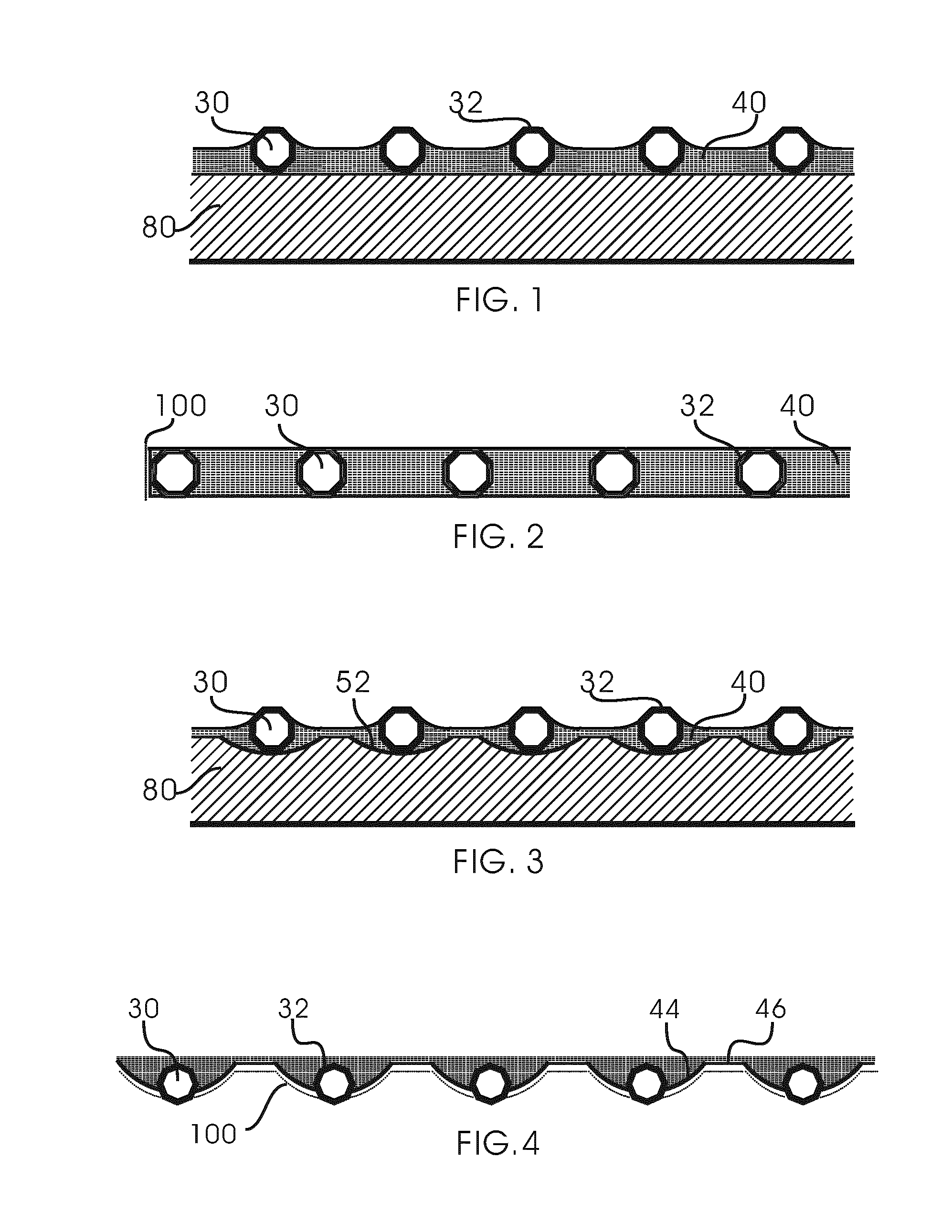

An abrasive tool includes a substrate, a plurality of abrasive particle groups, and a bonding layer. The abrasive particle group consists of a plurality of abrasive particles grouped together. The abrasive particle groups are disposed in a regular pattern on the surface of the substrate and fixed on the surface by the bonding layer. To control the disposition of the abrasive particle groups, an abrasive particle template is used to form the required pattern. The size of the abrasive particle positioning holes on the template is used to adjust the number of particles in an abrasive particle group.

Owner:KINIK

Methods for securing individual abrasive particles to a substrate in a predetermined pattern

InactiveUS20080098659A1Pigmenting treatmentPolycrystalline material growthEngineeringParticle growth

A method for temporarily securing superabrasive particles to a substrate such as a tool substrate or a growth precursor and articles formed therefrom are provided. The method can include applying an array of adhesive droplets onto at least a portion of a substrate in accordance with a predetermined pattern. The pattern may be uniform grid equally spacing each adhesive droplet. The adhesive droplets can be suitable to each secure only a single superabrasive particle. The method may further include adhering a single superabrasive particle to each adhesive droplet. As a result of the method can yield a tool substrate and grow precursor having enhance particle growth and wear properties.

Owner:SUNG CHIEN MIN

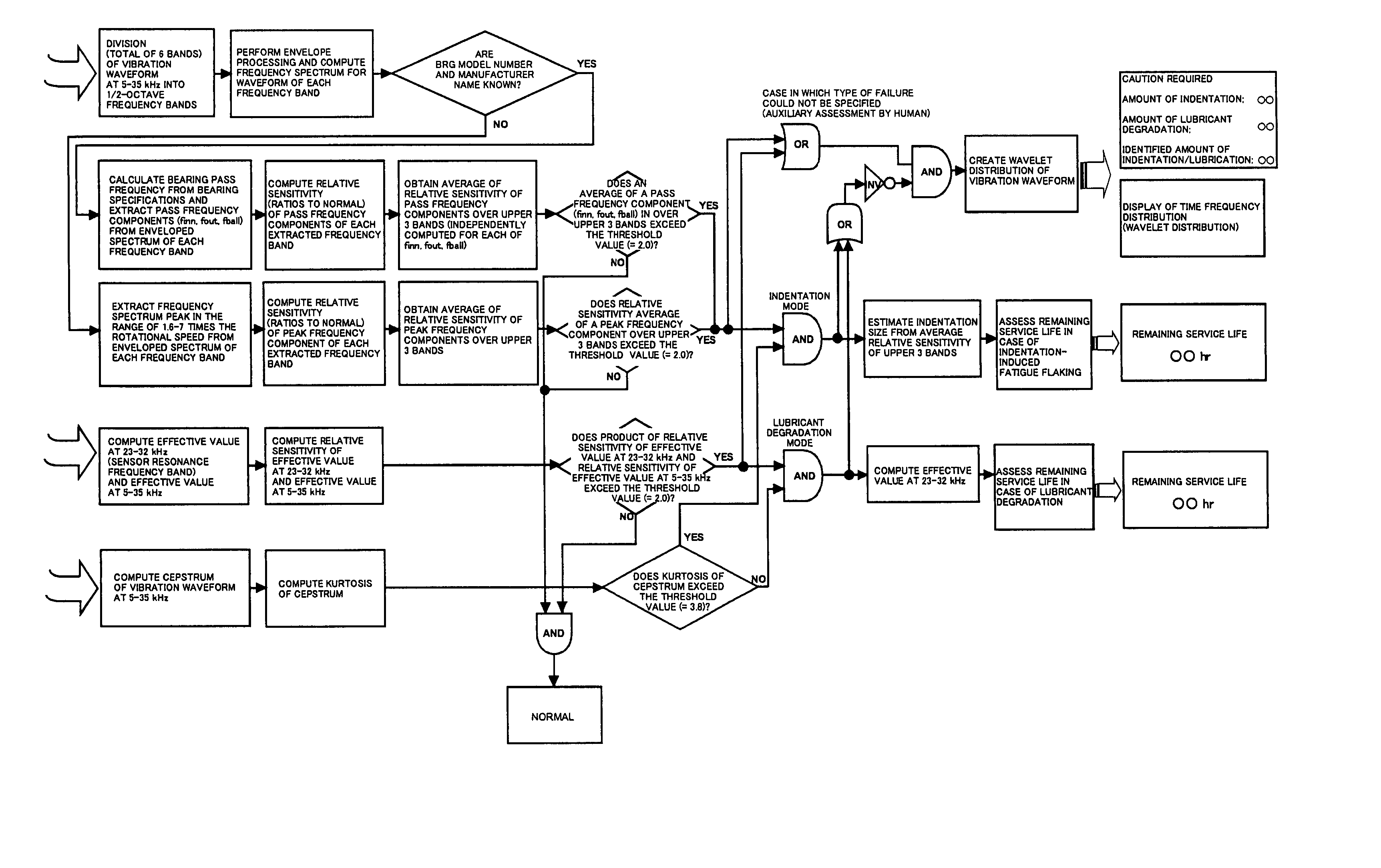

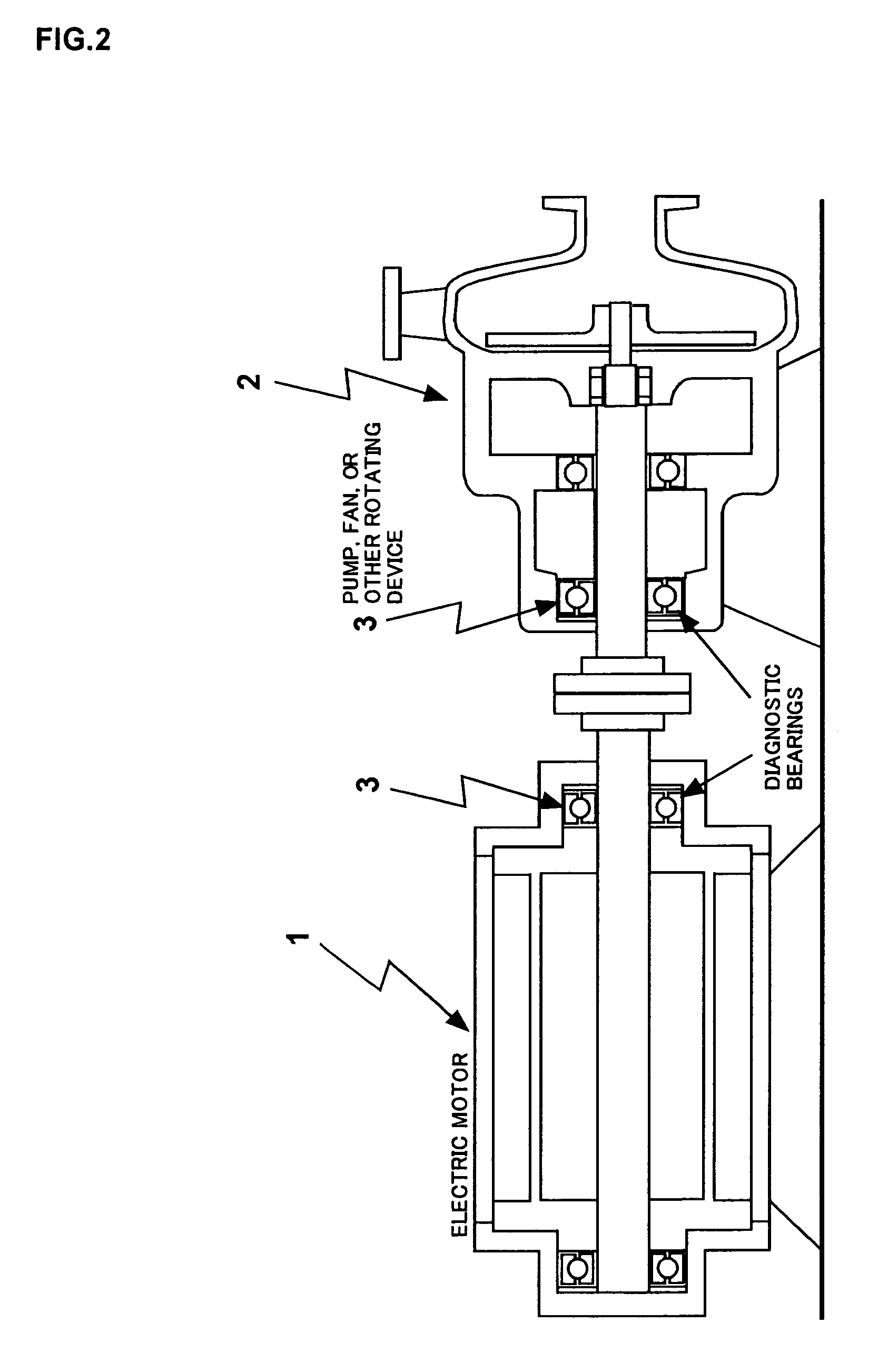

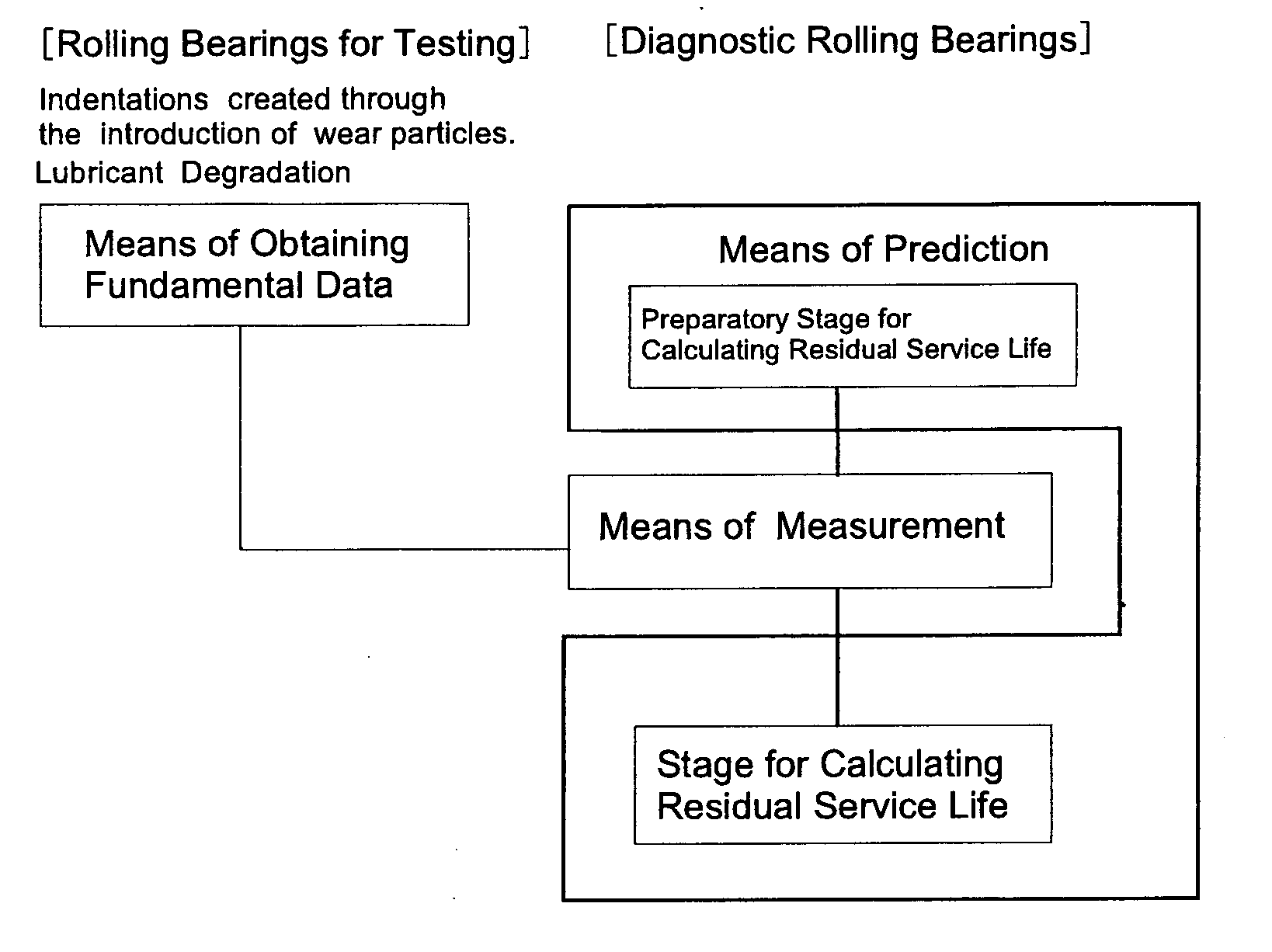

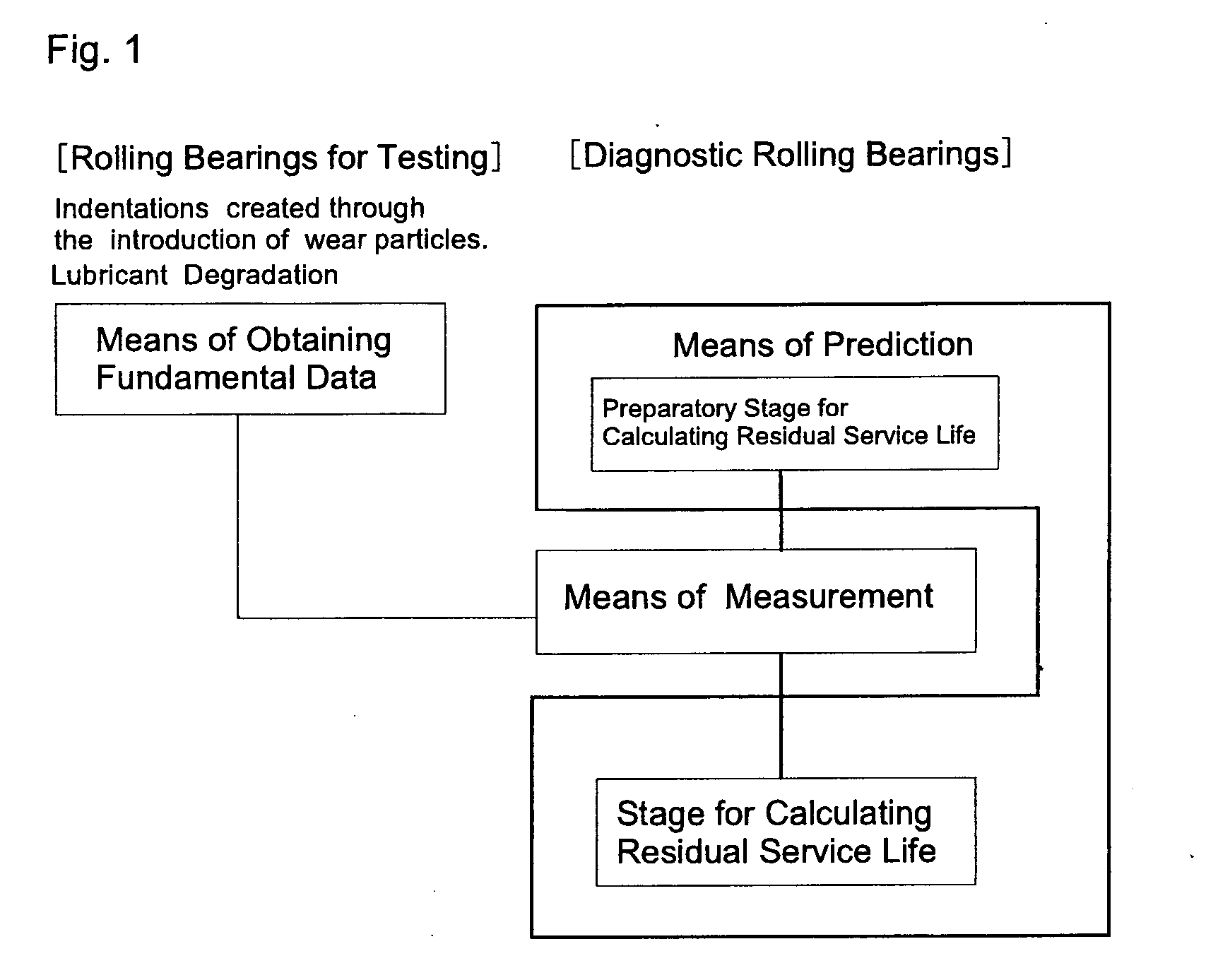

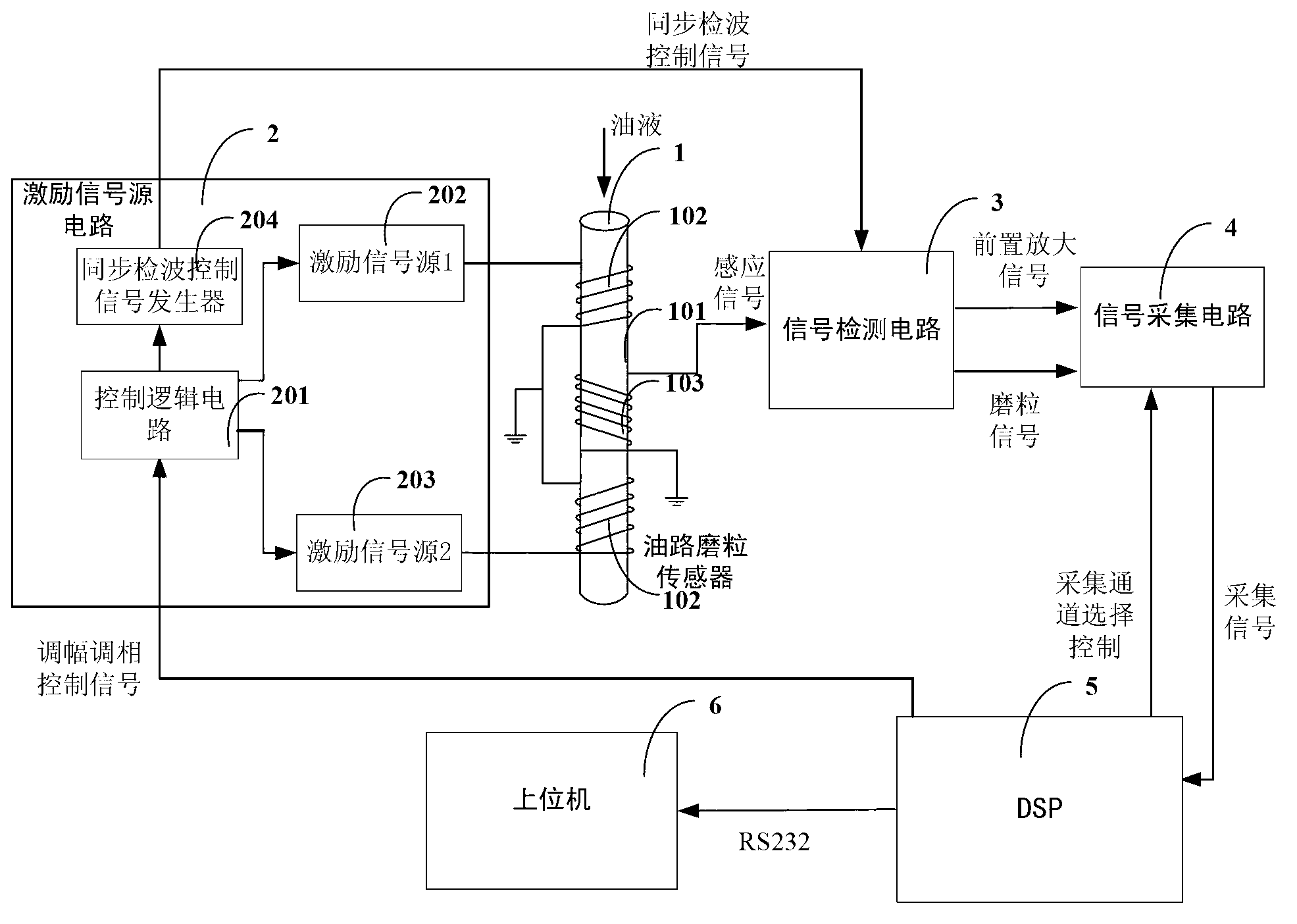

Method and apparatus for diagnosing residual life of rolling element bearing

InactiveUS20050246150A1Effective maintenanceEasy to implementVibration measurement in solidsPump componentsAccelerometerPredictive methods

An invention that utilizes signals from an accelerometer in resonant frequency bands or high frequency bands to, in a cost-effective manner, measure wear particle penetration of lubricant and lubricant degradation, both of which greatly affect prediction of residual service life; and, using as a basis these measurements of wear particle penetration and lubricant degradation, enables accurate estimation of residual service life for rolling bearings in the early stages. The invention is comprised of a means of obtaining fundamental data that uses a testing device to obtain data regarding the relationship, for rolling bearings (3), of wear particle penetration levels to vibration levels and service life, or to obtain data regarding the relationship, for rolling bearings (3), of lubricant degradation levels to vibration levels and service life; a means of measurement, where an accelerometer (4) is used to obtain vibration signals of diagnostic rolling bearings (3) residing on mechanical rotating devices (1, 2) for the purpose of measuring signals in resonant frequency bands only detectable at extremely high levels of sensitivity or signals in high frequency bands; and a means of prediction that uses readings obtained via said means of measurement and data obtained via said means of obtaining fundamental data to predict, for diagnostic rolling bearings (3), wear particle penetration levels and lubricant degradation levels, and to calculate residual service life for diagnostic rolling bearings (3).

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

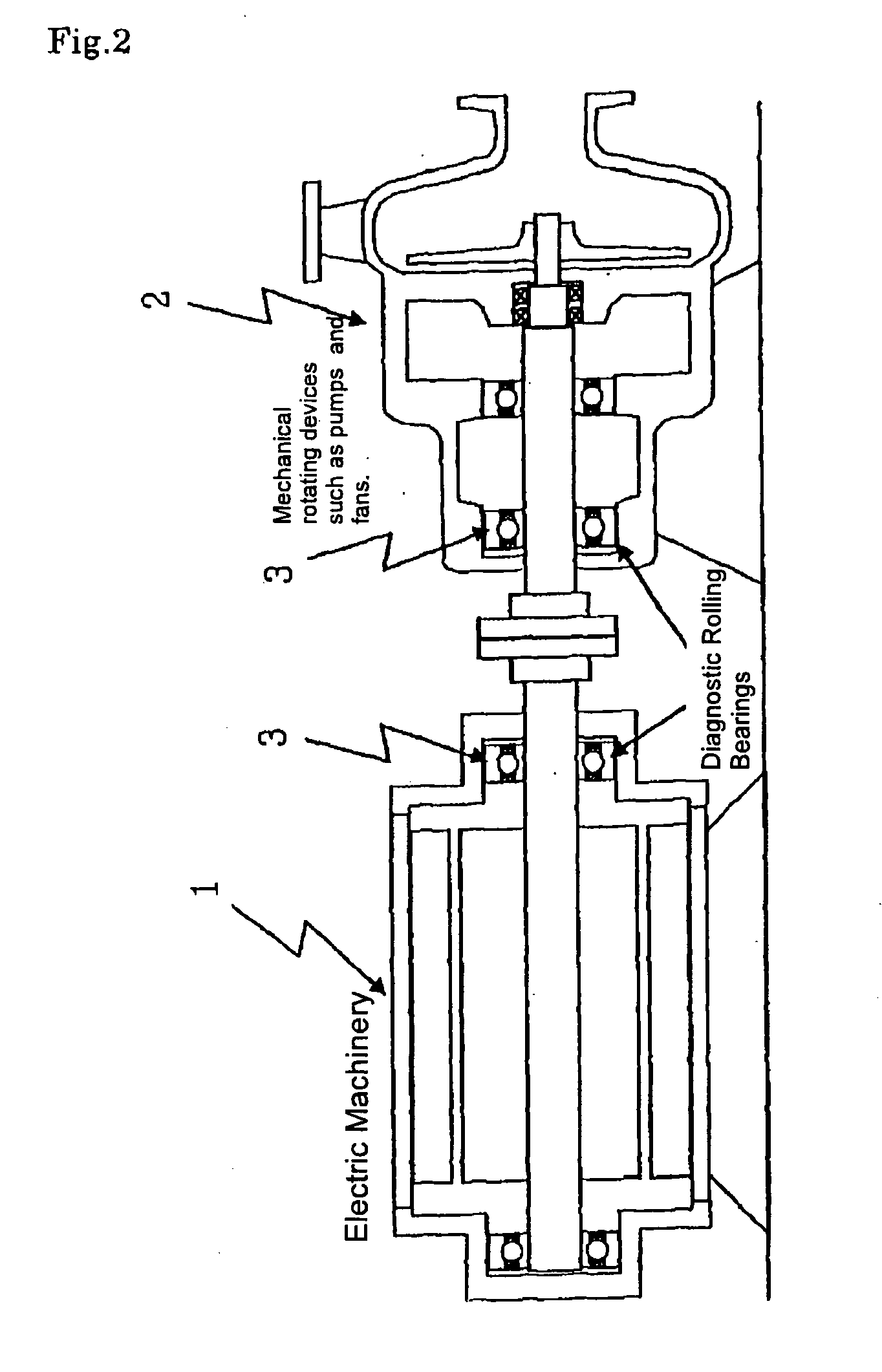

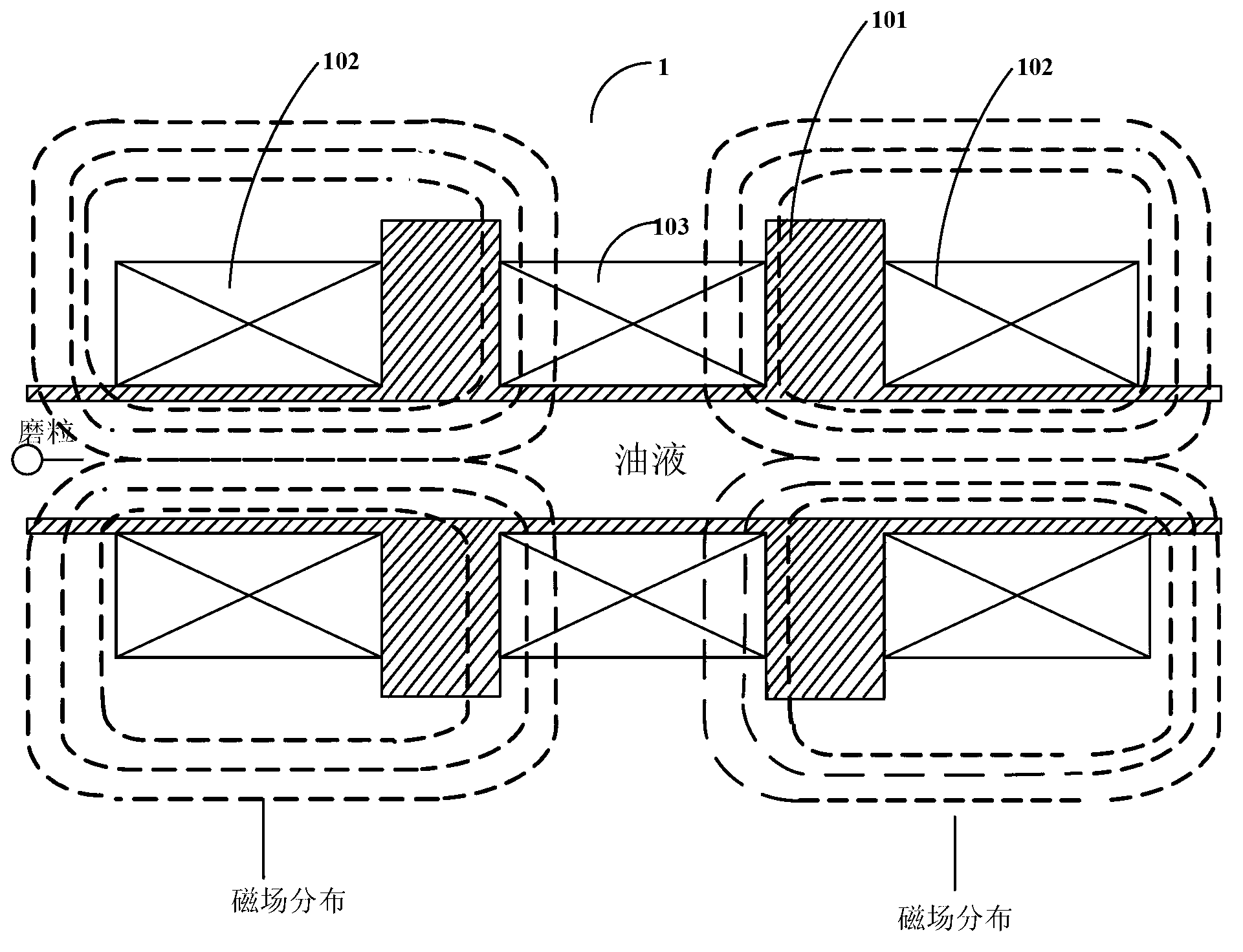

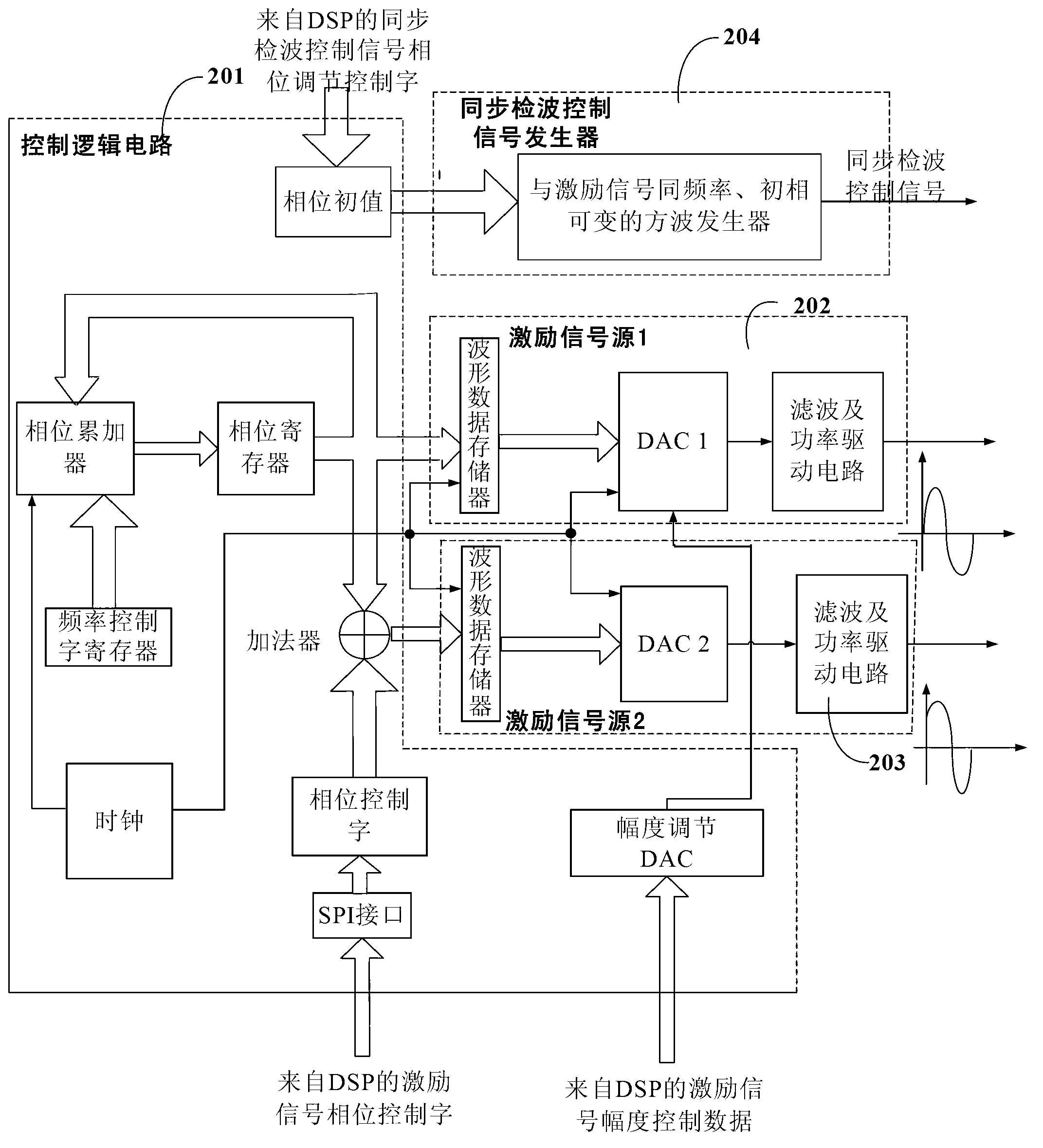

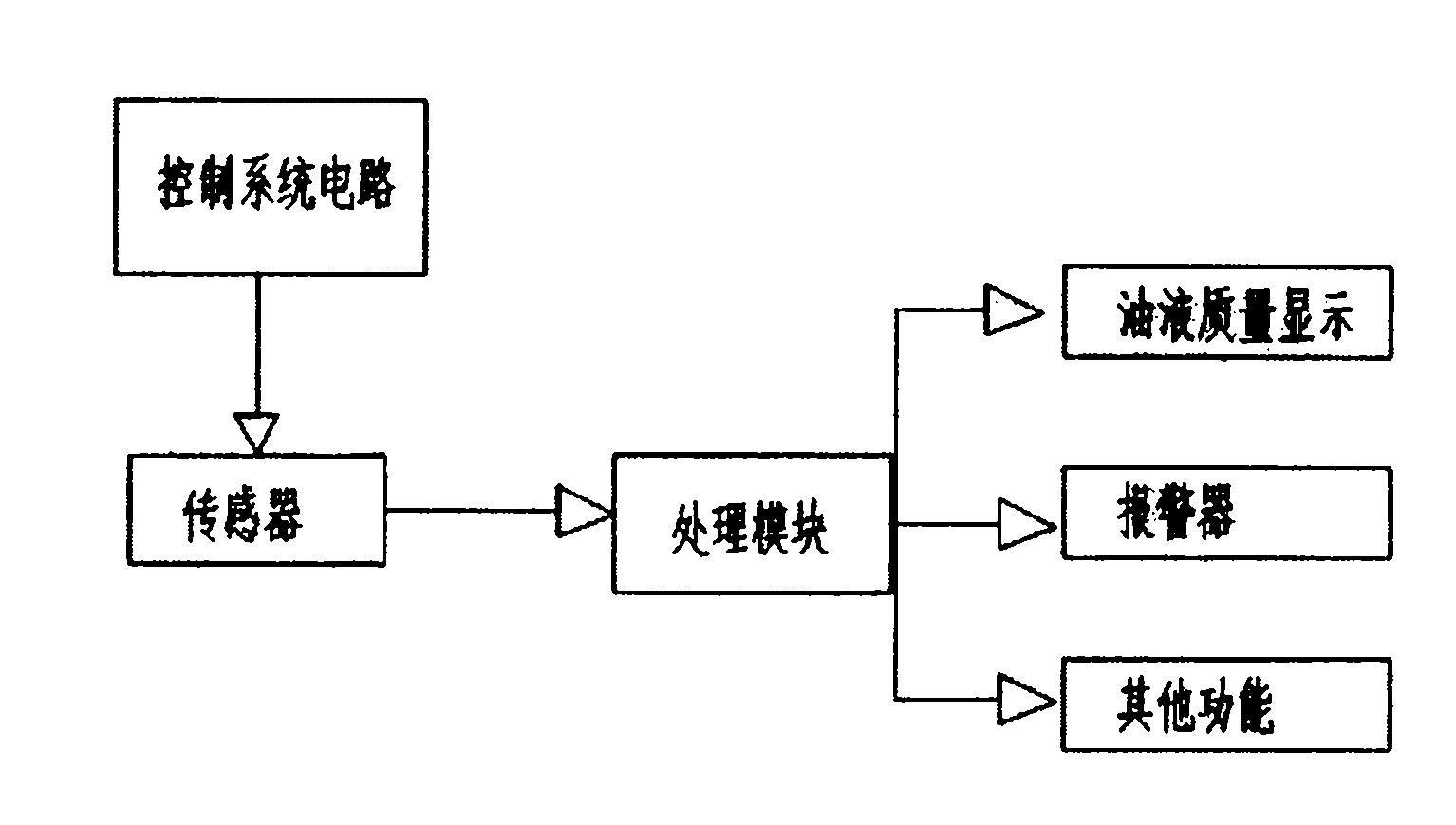

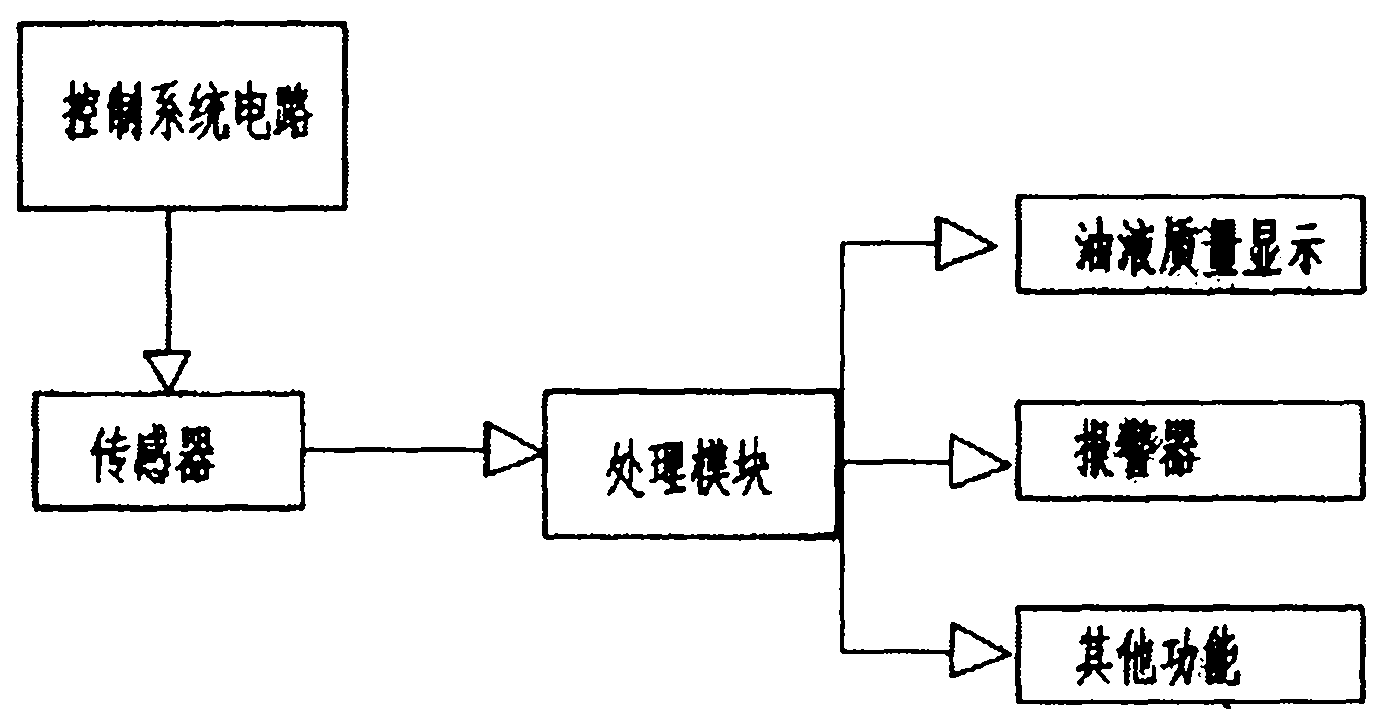

Online oil way abrasive particle monitoring device

InactiveCN103217365ARealize monitoringGet health status in real timeMaterial analysisElectricityPhase difference

The invention discloses an online oil way abrasive particle monitoring device. An amplitude difference and a phase difference of excitation signals on two groups of excitation coils of an oil way abrasive particle sensor are adjusted during initially electrifying, so that the polarities of magnetic fields generated by the two excitation coils of the oil way abrasive particle sensor are reversed and neutralized in a middle detection coil. Consequently, when oil liquid without abrasive particles passes through the oil way abrasive particle sensor under ordinary circumstance, only a small carrier signal is output from the detection coil; when oil liquid with abrasive particles passes through the sensor, generated abrasive particle signals are modulated on the carrier signal and subsequently transmitted into a signal detecting circuit to amplify and demodulate, so that effective abrasive particle signals can be acquired; the abrasive particle signals are transmitted to a DSP (Digital Signal Processor) to process so as to acquire parameters, such as the size, the number and the material, of the abrasive particles; and due to the parameters, the abrasion condition of a monitored mechanical device is reflected, so that the health condition of the monitored device is acquired in real time and the online monitoring on the oil way abrasive particles is realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

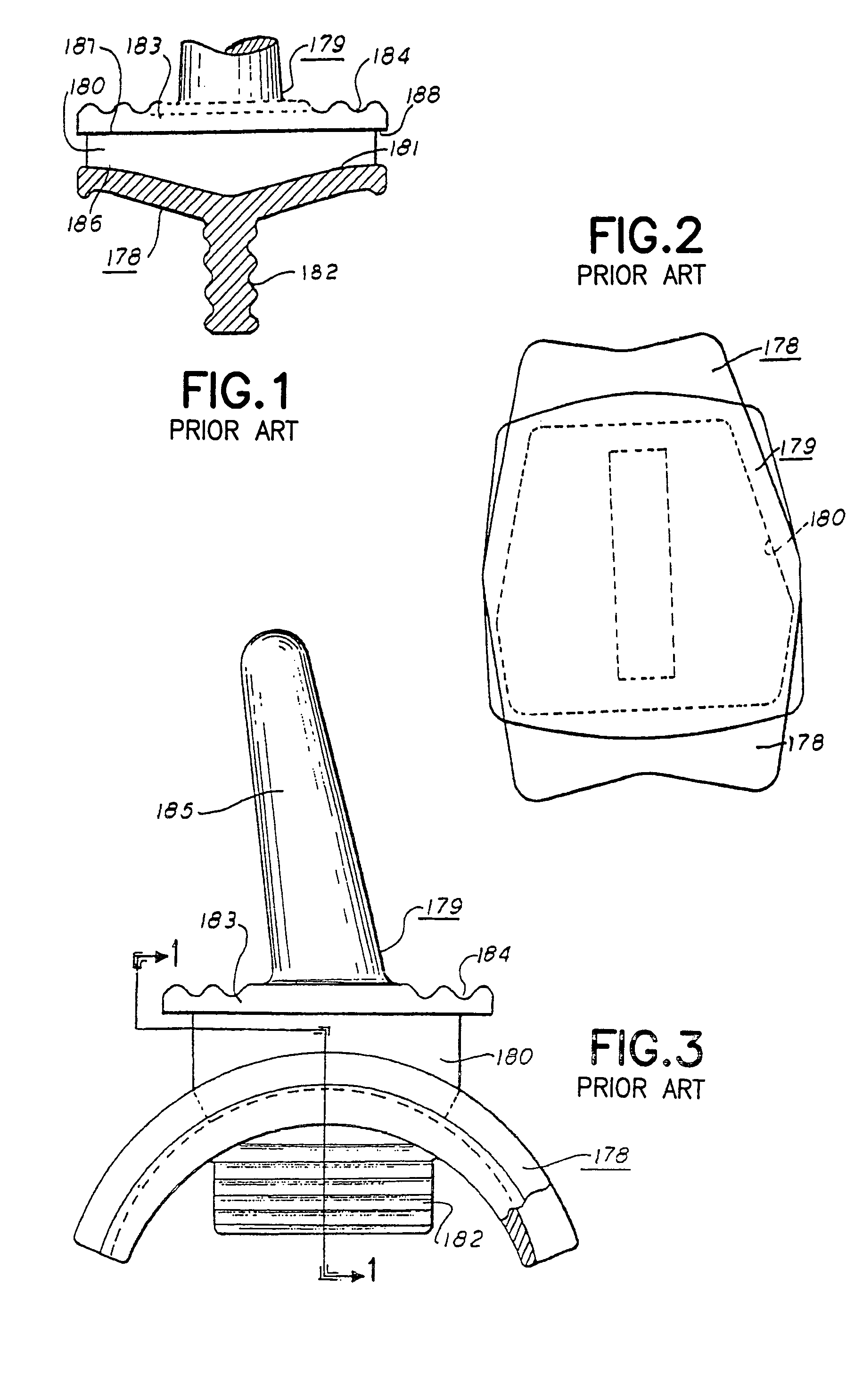

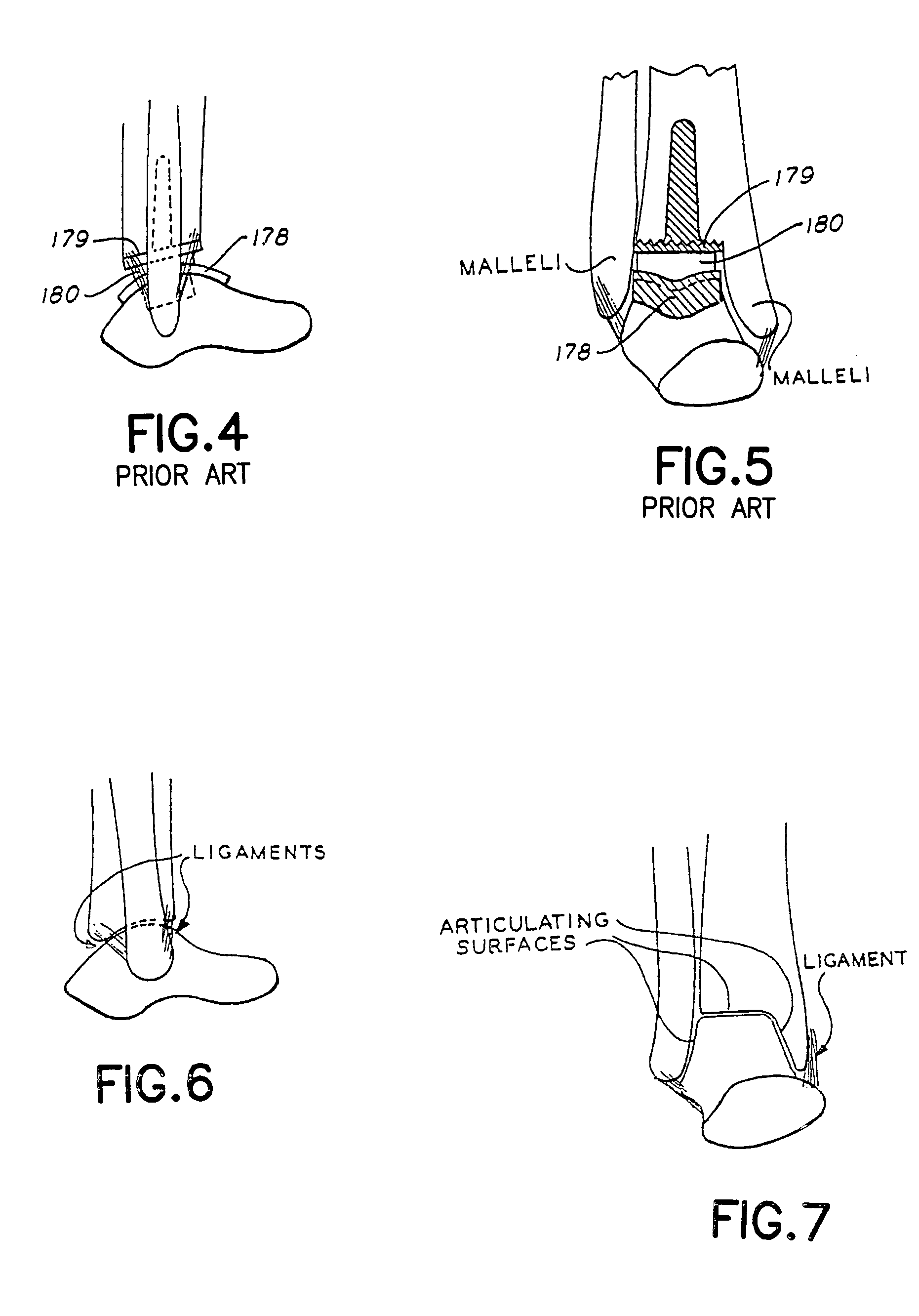

Ankle prosthesis including tibial component having peripheral wall for preventing the formation of bone cysts

InactiveUS7485147B2Reduce possible abrasionEffectively shielding the bearingAnkle jointsJoint implantsTibiaWear particle

The tibial component of a prosthetic ankle joint including a tibial component, a talar component, and an intermediate sliding plastic bearing, with the tibial component including a depending peripheral wall that surrounds and is spaced from the plastic bearing and is intended to reduce rubbing of the plastic bearing against tissue which would produce wear particles that lead to the formation of bone cysts. The depending peripheral wall of the tibial component is intended to reduce such possible abrasions by at least partially shielding the plastic bearing from the surrounding tissue.

Owner:BUECHEL PAPPAS TRUST

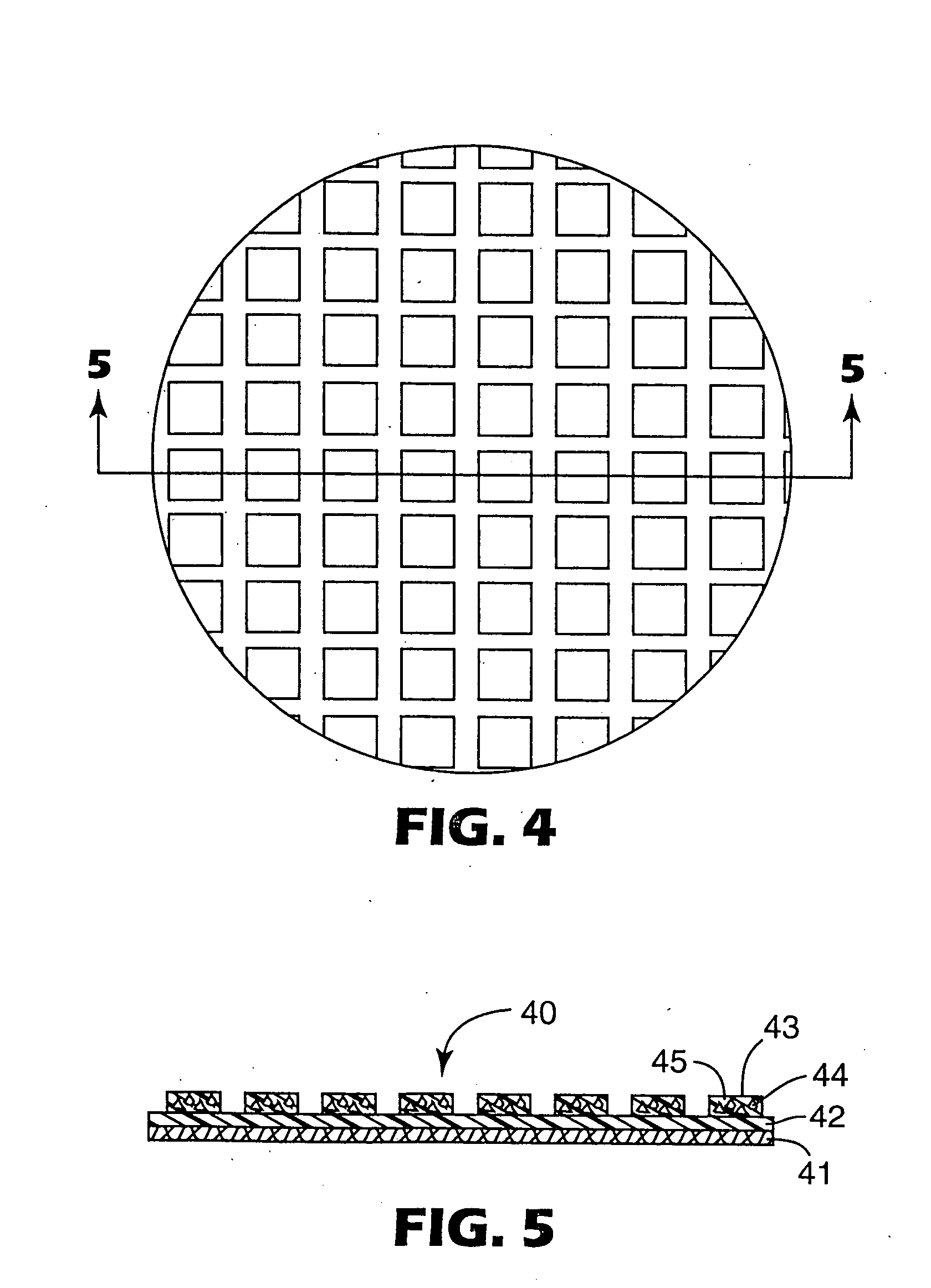

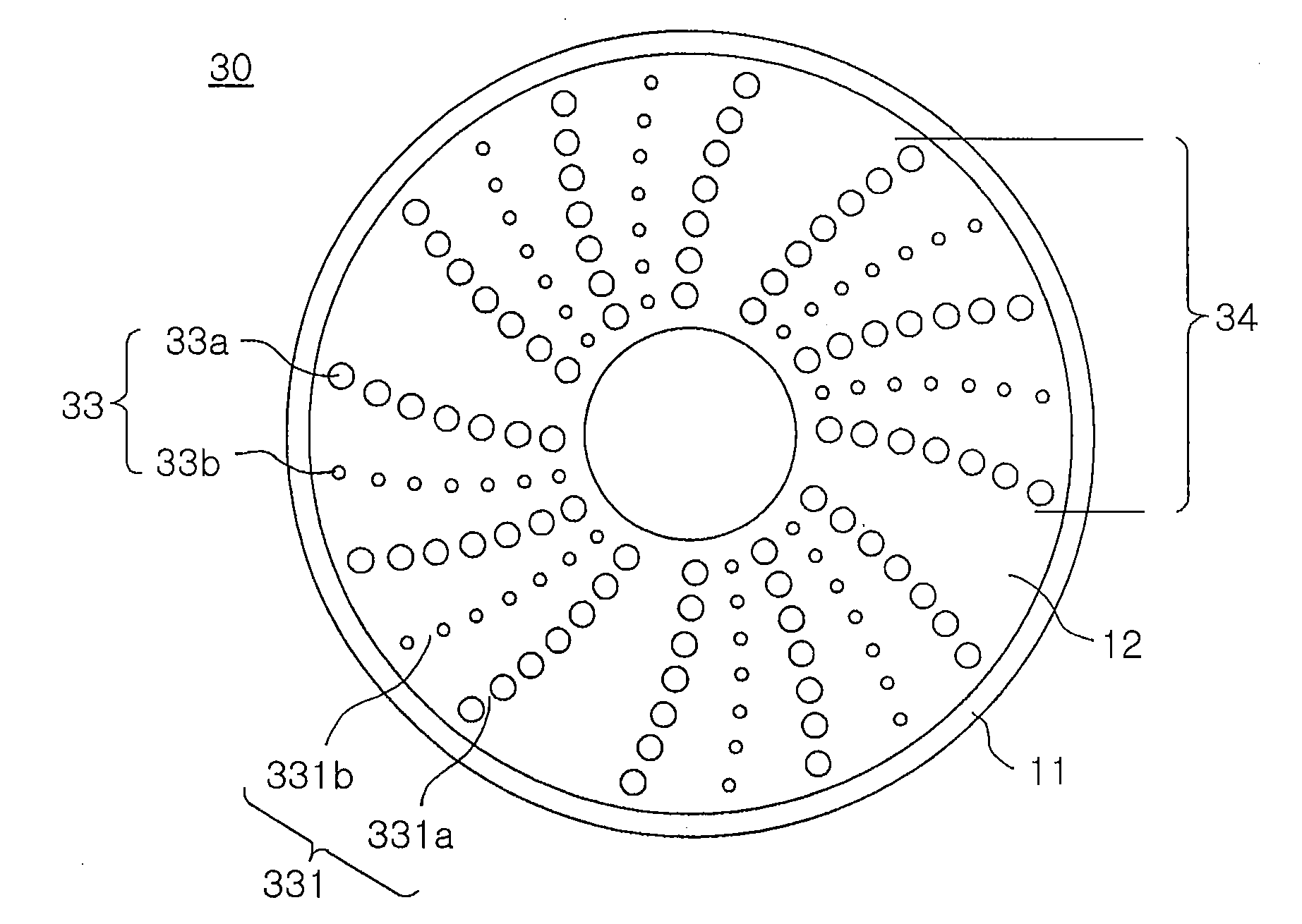

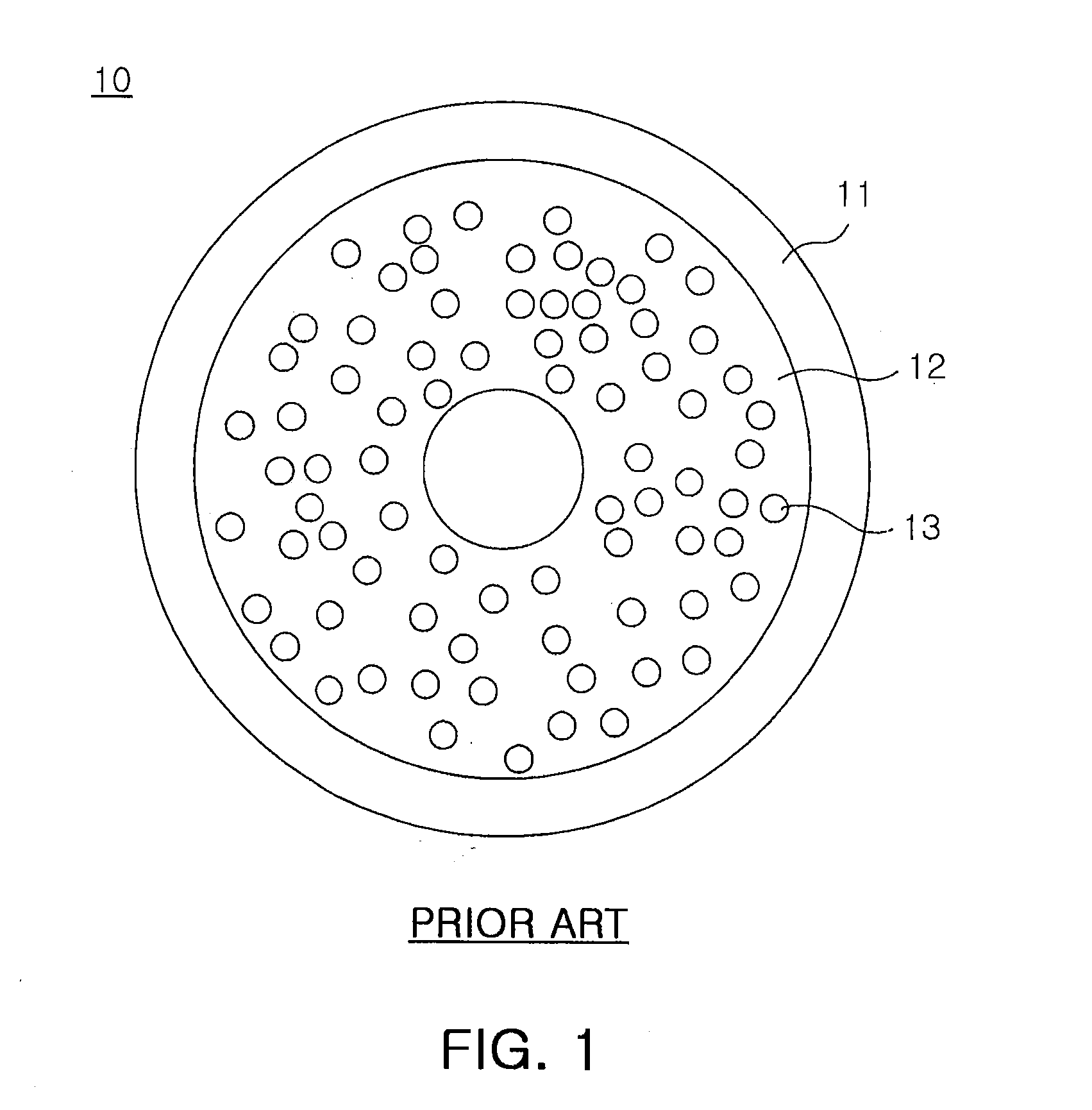

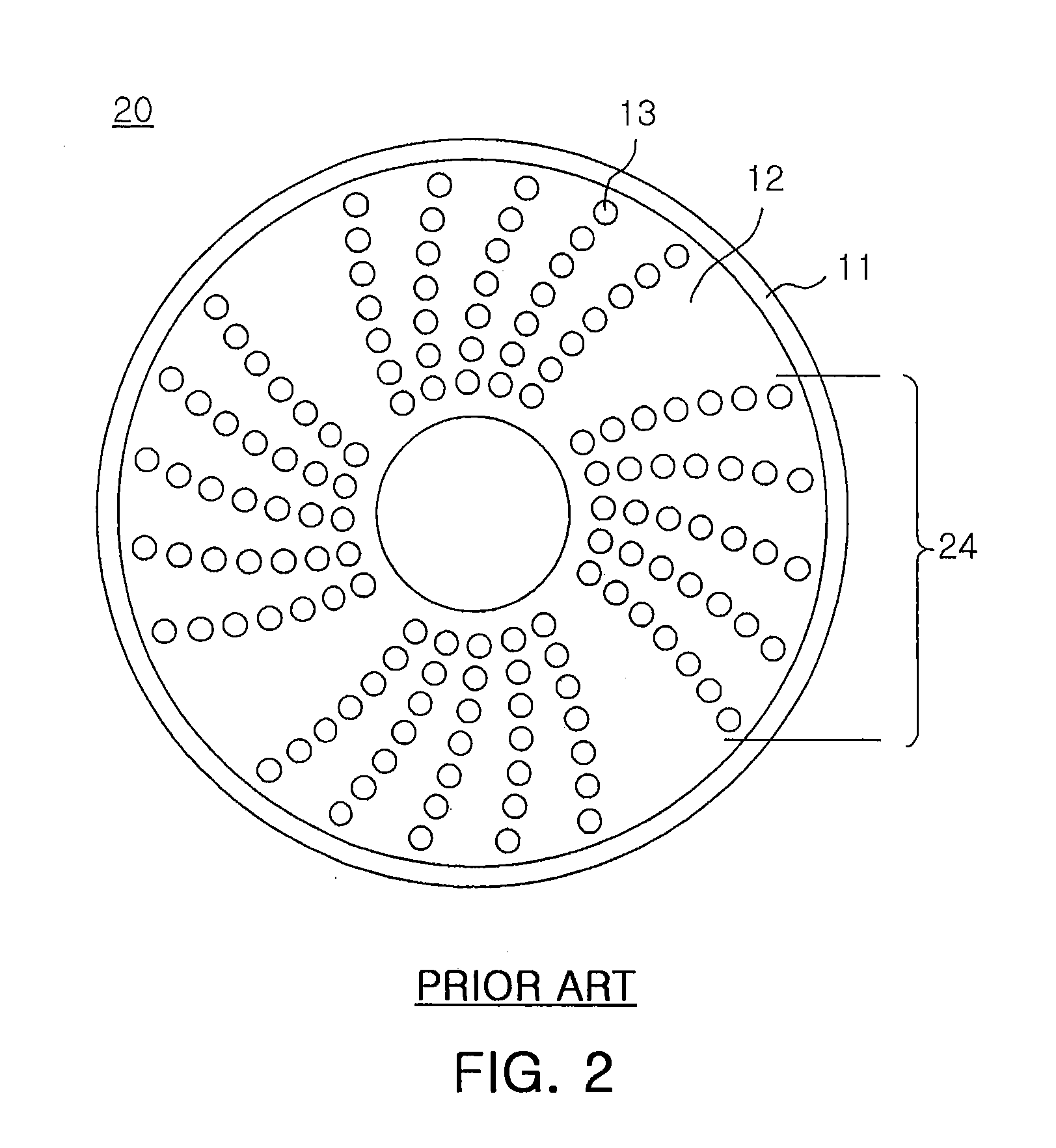

Conditioner for Chemical Mechanical Planarization Pad

InactiveUS20100015898A1Uniform dressingImprove efficiencyGrinding drivesBelt grinding machinesWear particleChemical-mechanical planarization

The present invention provides a conditioner for CMP pad required for global planarization of wafer to achieve high integration of a semiconductor element. The conditioner for CMP pad includes a metal substrate having abrasive particles fixed thereto, a plurality of abrasive particles fixed to the metal substrate, and a layer of metal binder fixing the abrasive particles to the metal substrate. The abrasive particles include at least one pattern. The pattern includes at least one row of abrasive particles and the abrasive particles include bigger abrasive particles and smaller abrasive particles. In addition, a diameter difference between smaller and bigger abrasive particles is 10 to 40%. The present invention ensures uniform dressing of conditioner, superior dressing efficiency and superior performance reproducibility.

Owner:AN JUNG SOO +2

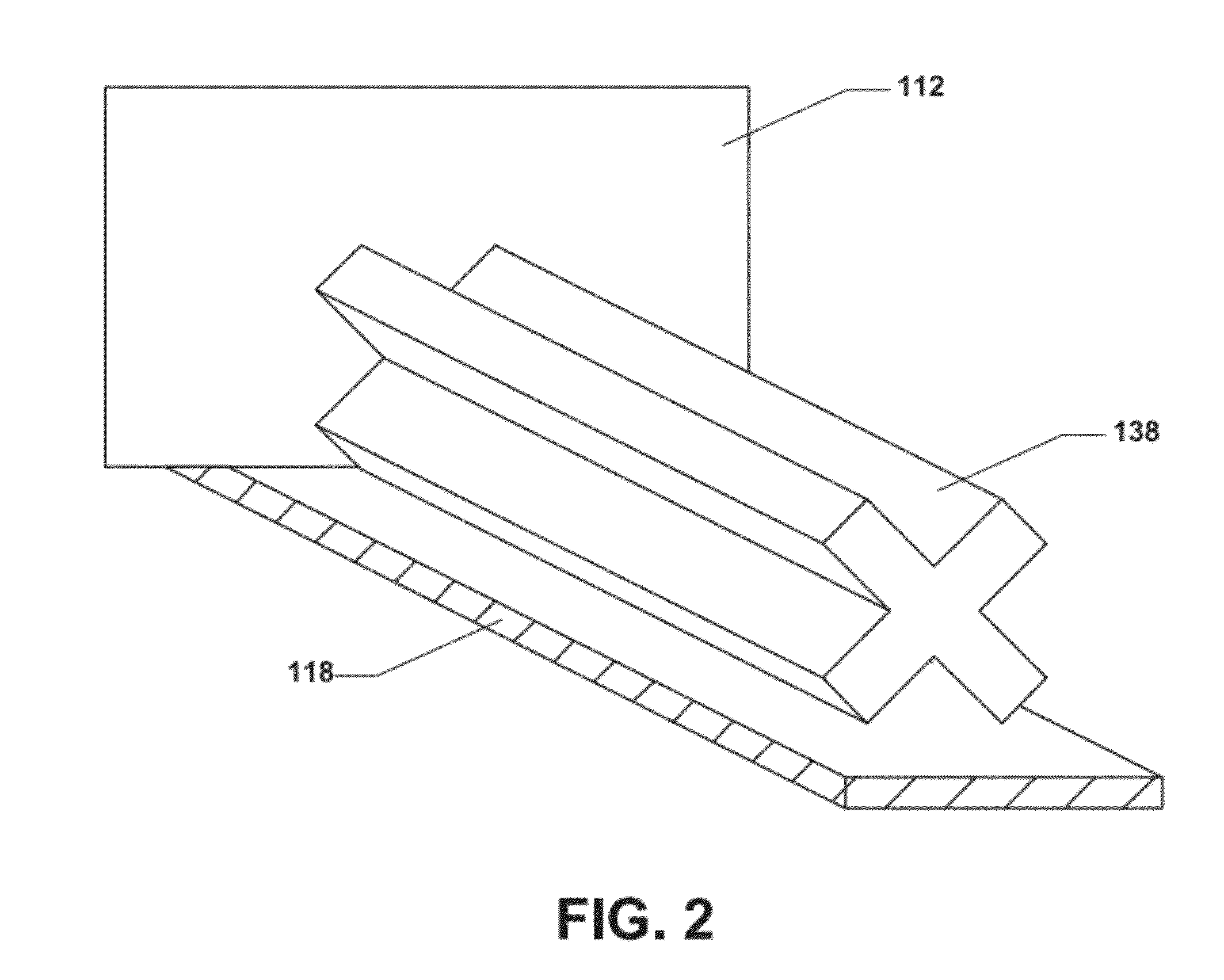

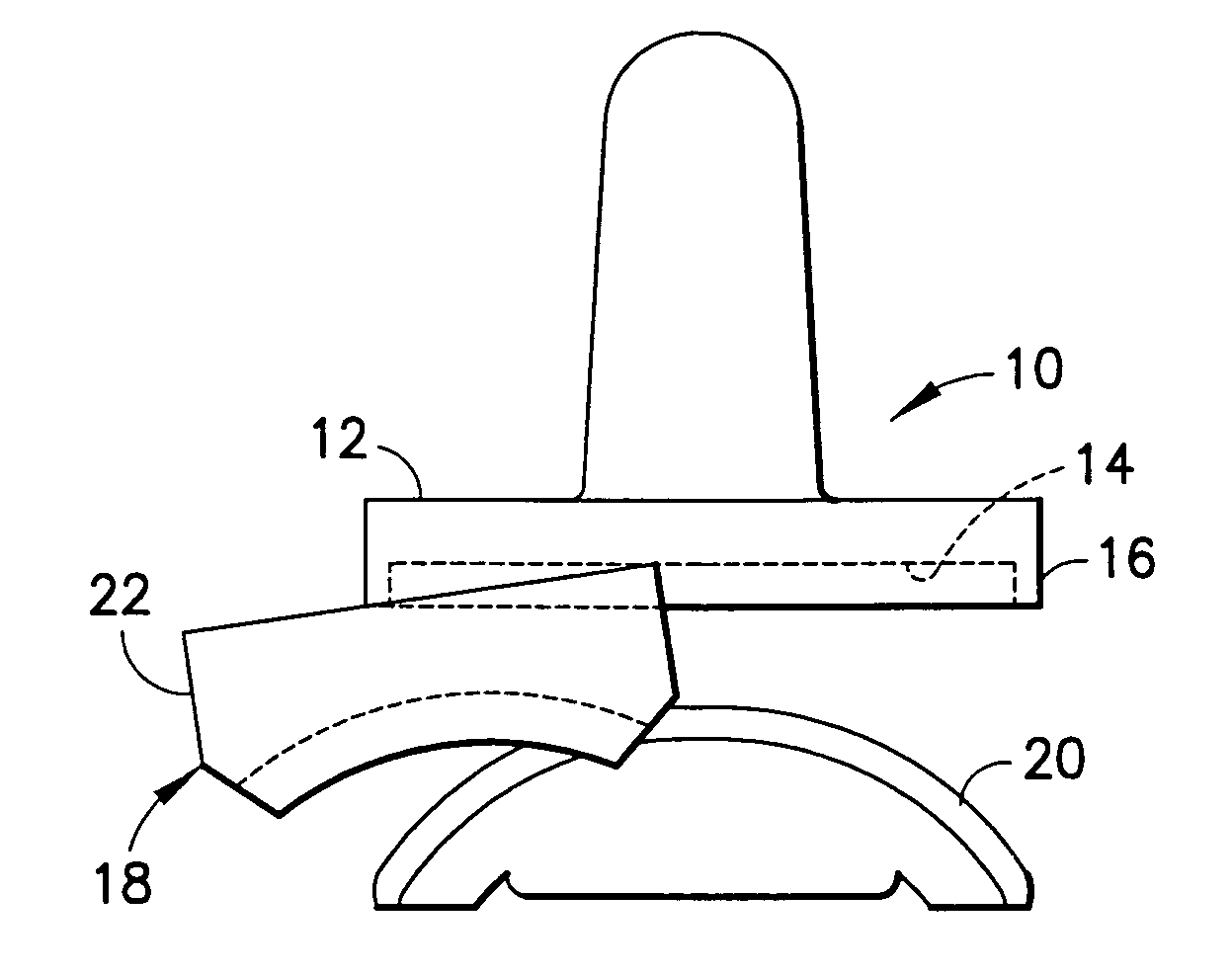

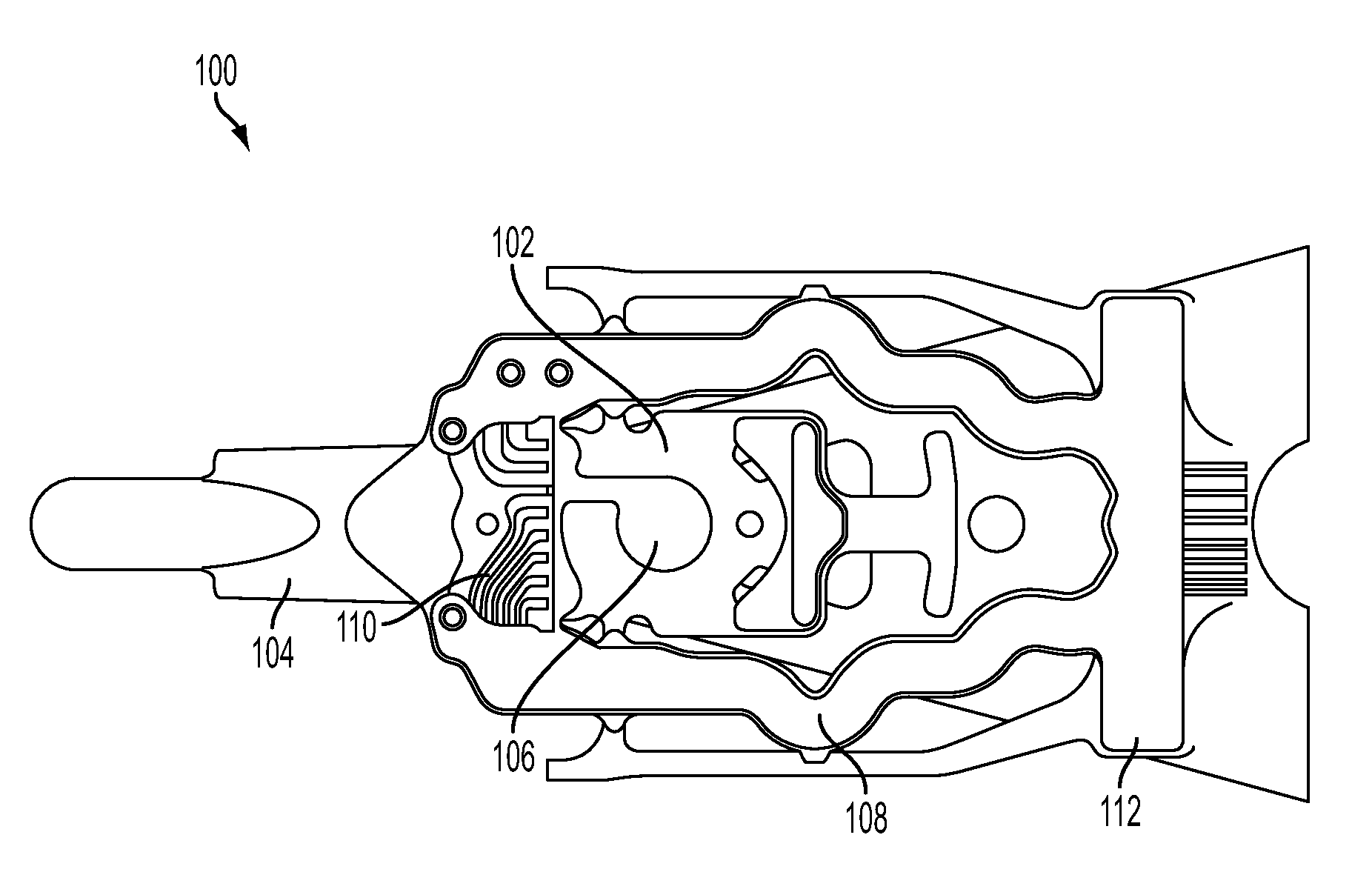

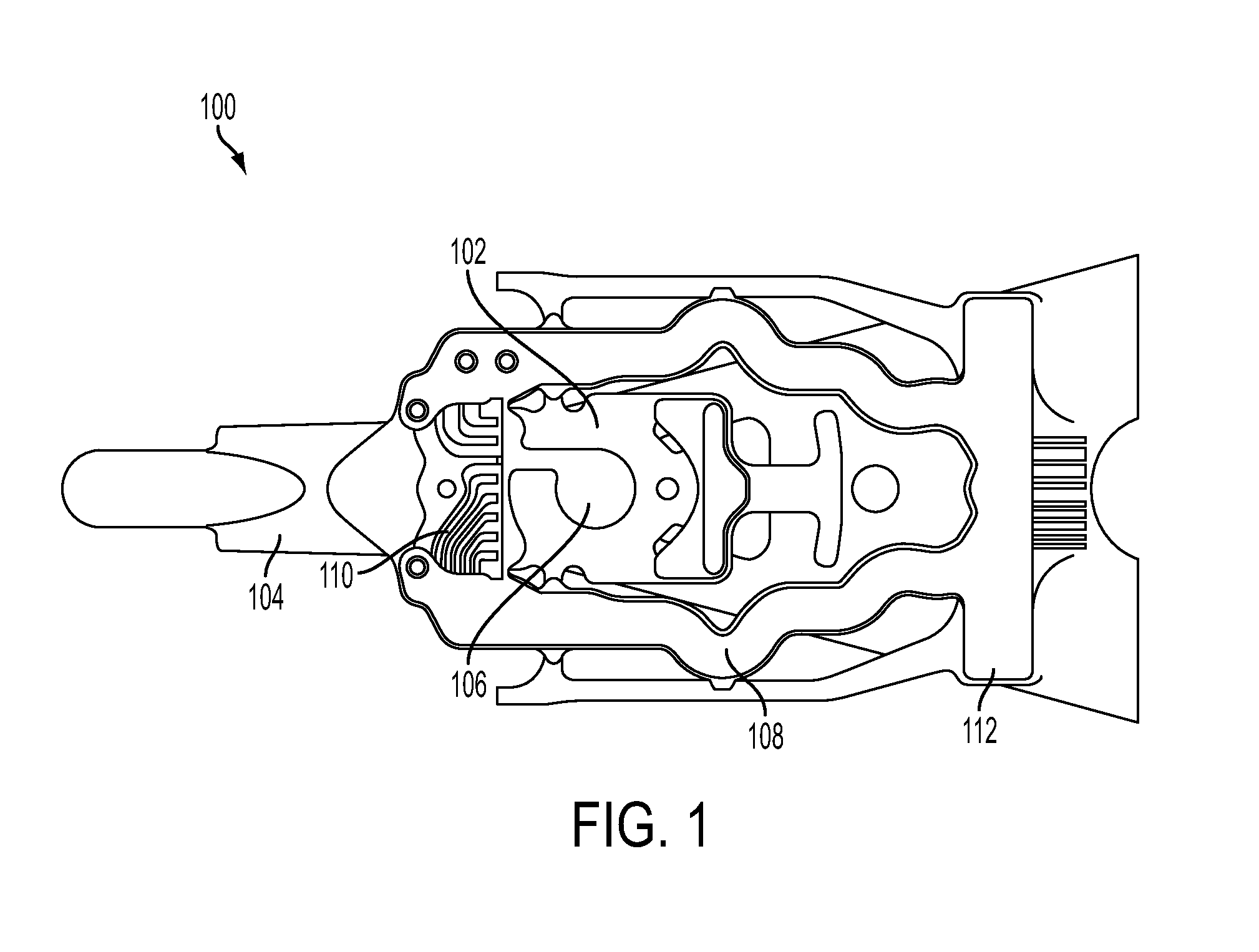

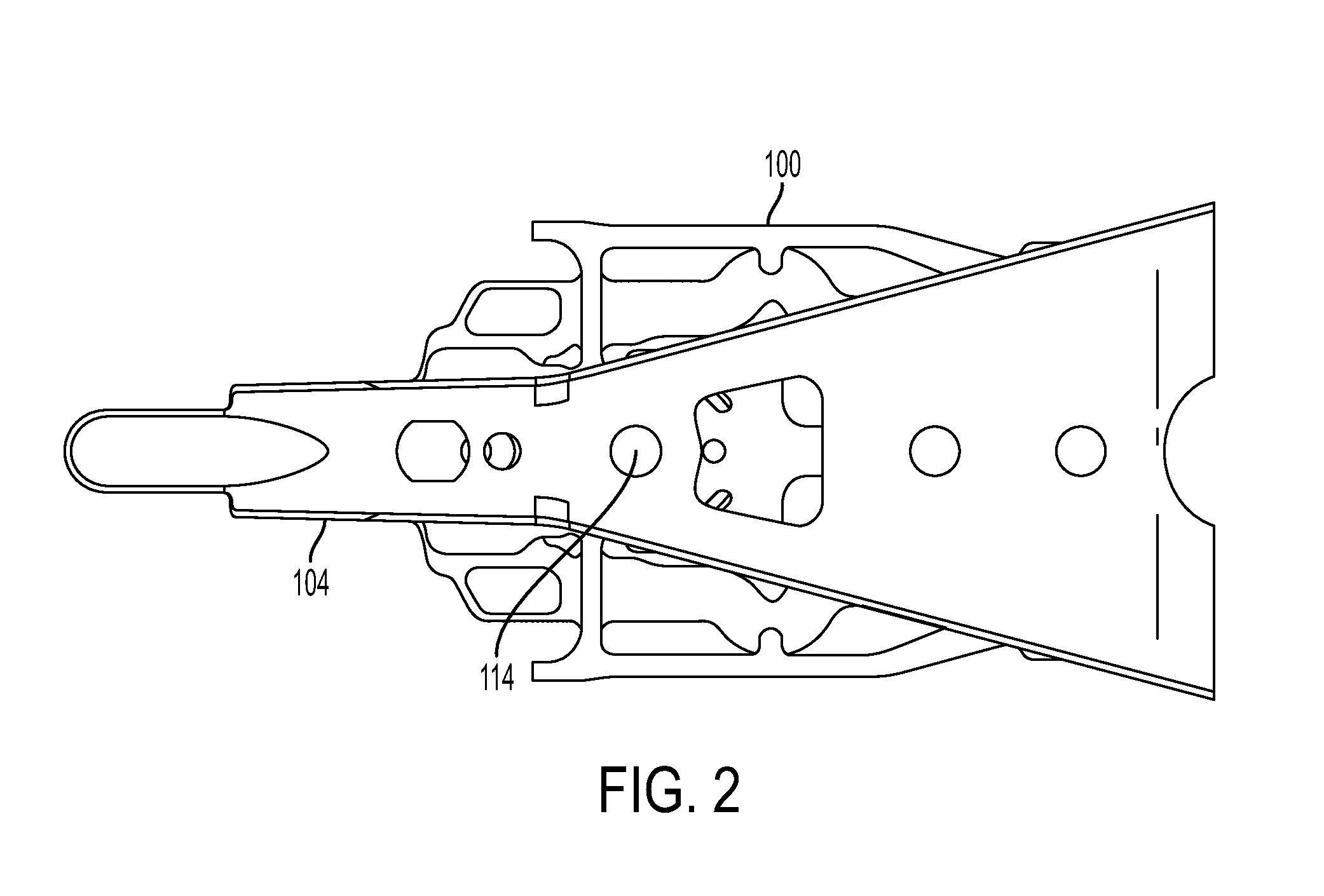

Gimbal assembly with a gold tongue/dimple interface and methods of making the same

ActiveUS20130265674A1Electrical connection between head and armRecord information storageDual stageWear particle

A gimbal assembly of a single or dual stage actuator is provided with gold at a tongue / dimple interface where a dimple of a supporting loadbeam contacts a tongue on the gimbal assembly. Using gold at the tongue / dimple interface greatly reduces the amount of wear particles formed during assembly and operation of the microactuator. The tongue may include a gold coating on the tongue at the tongue / dimple interface, or the tongue may have a hole etched in a stainless steel layer at the tongue / dimple interface to expose a gold layer disposed below the stainless steel layer. The tongue portion of the tongue / dimple interface may also be formed from a gold-coated copper pad with a polymer coating over the gold.

Owner:NHK SPRING CO LTD

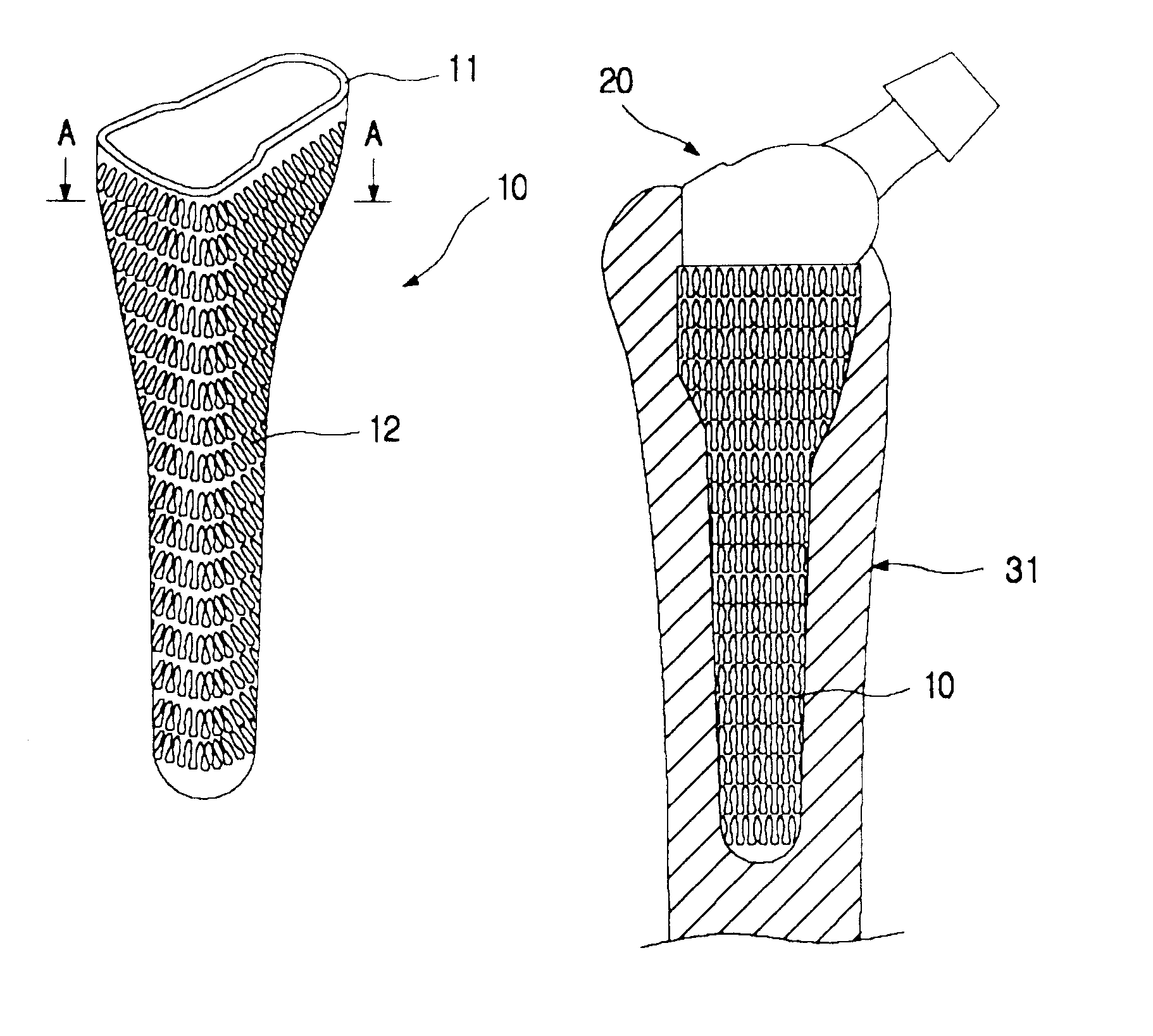

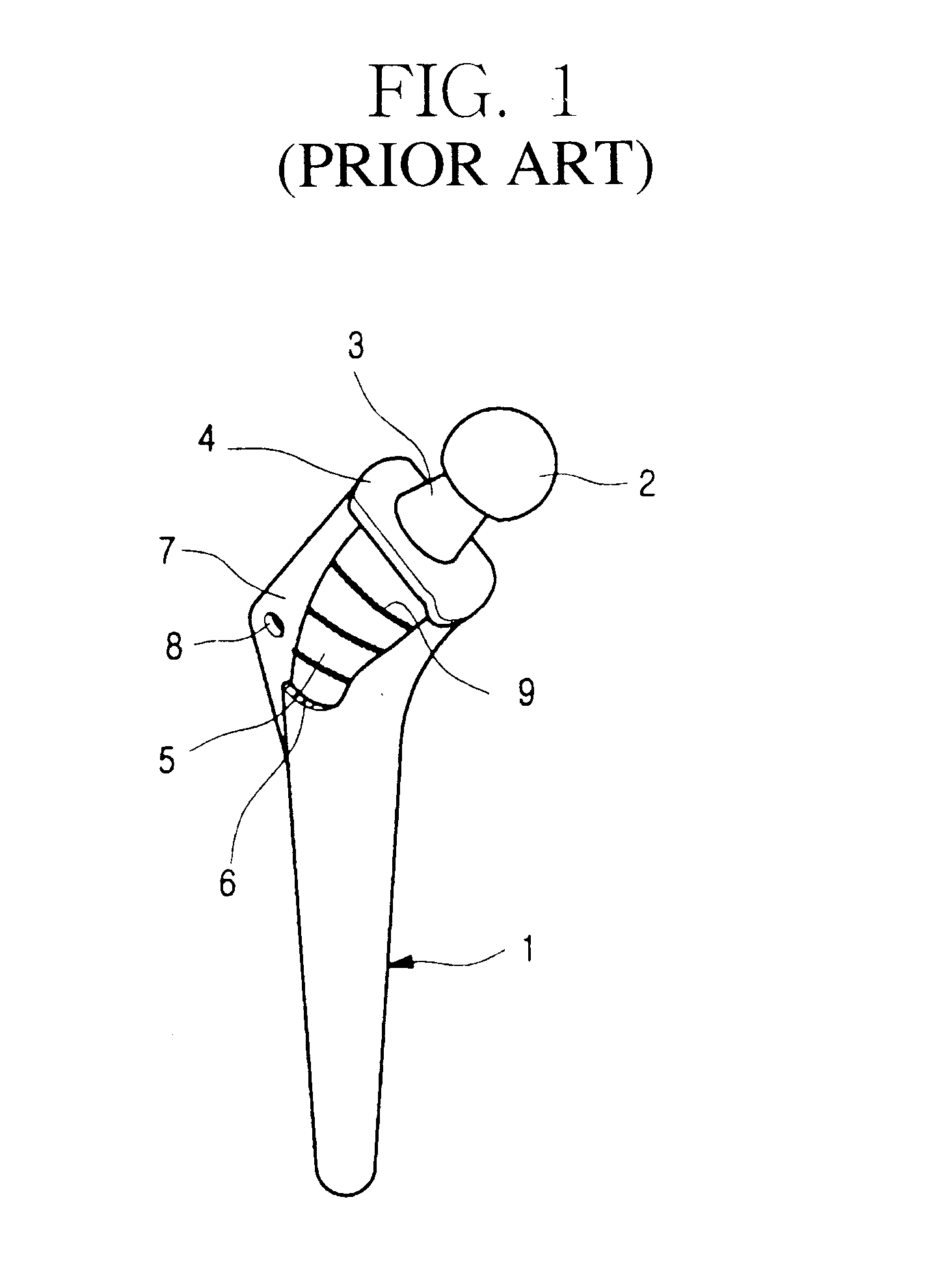

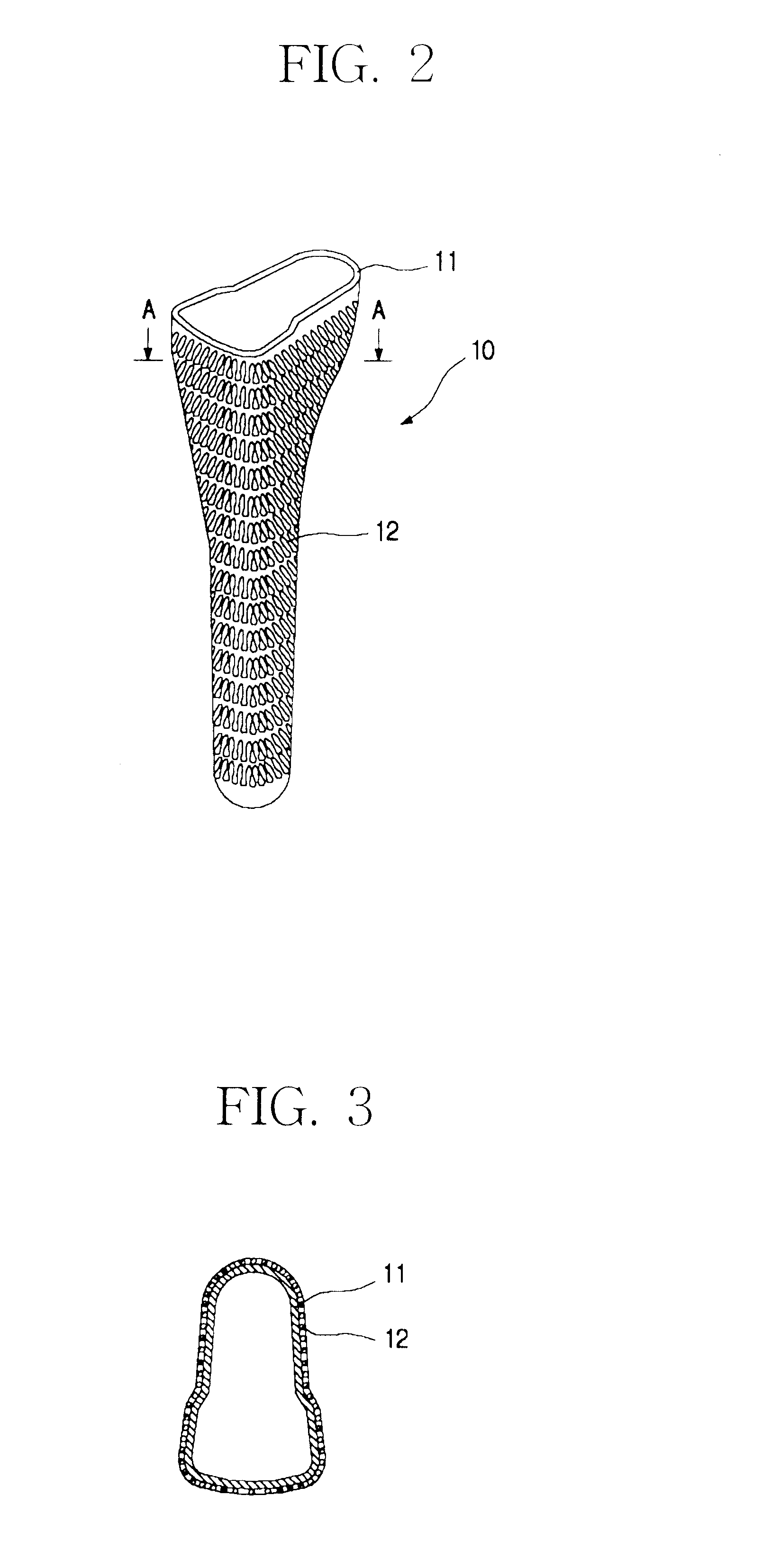

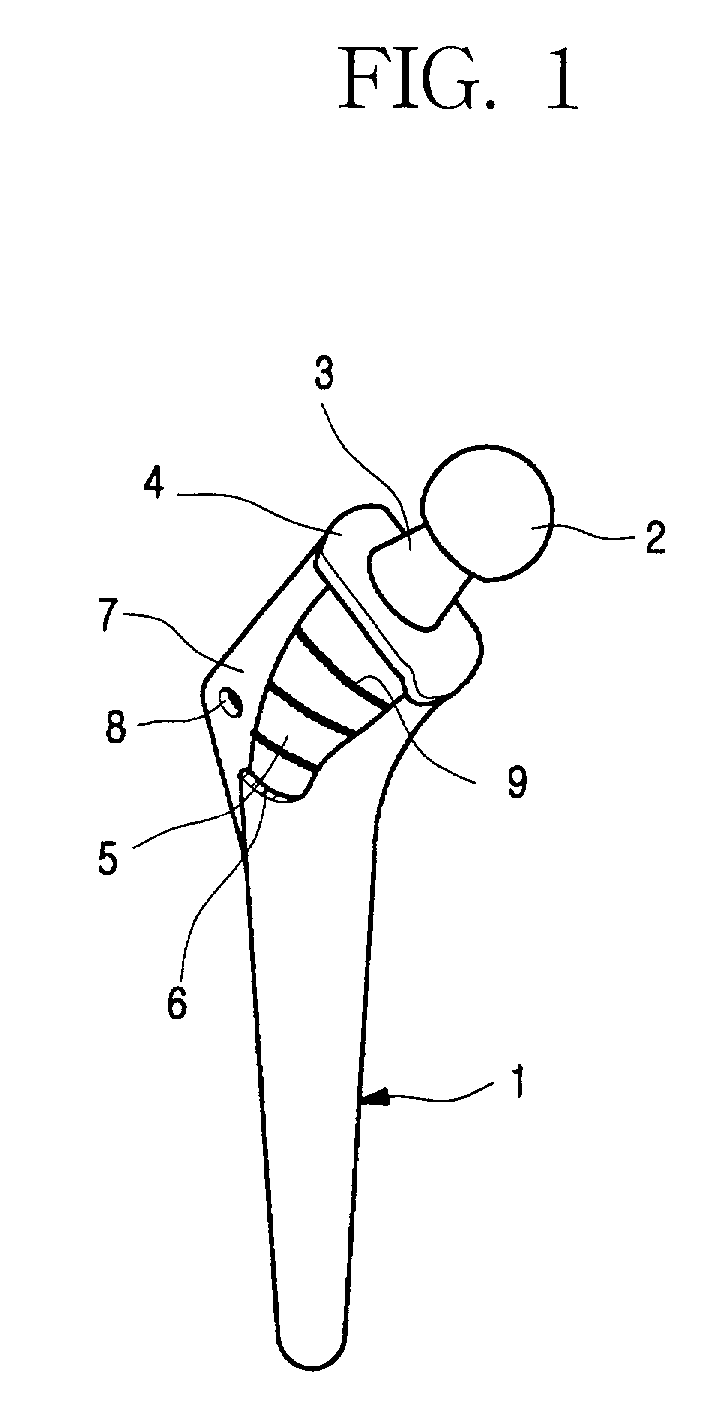

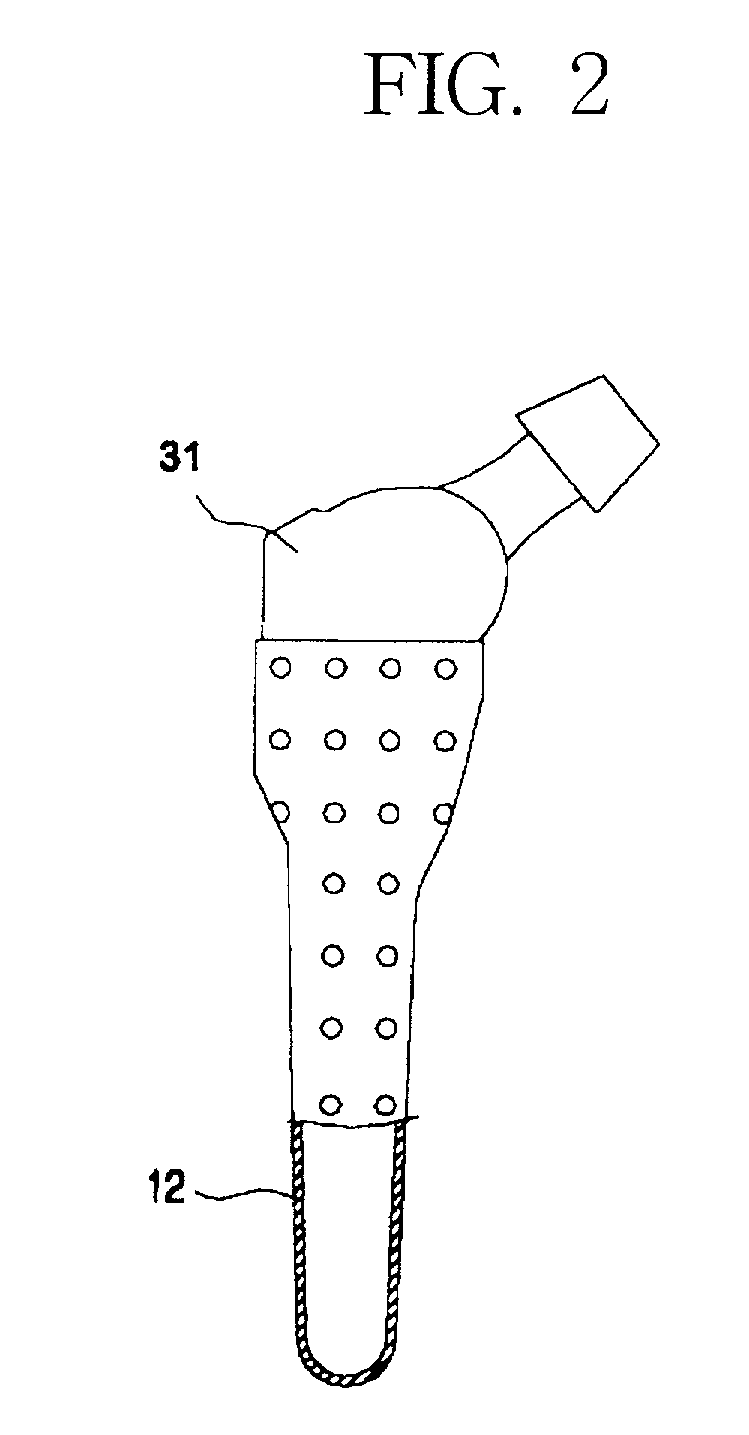

Metal jacket for a cementless artificial joint stem and artificial joint having the jacket

InactiveUS6497728B2Suppress formationMinimize osteolysisBone implantJoint implantsHuman bodyArtificial joints

The present invention is intended to provide a metal jacket for a cementless artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced and stress shielding phenomena can also be markedly relieved, due to the construction of the metal jacket which can be fixed to the bone and can enclose the surface of the stem so as to allow for the stem of artificial joint to slide vertically relative to the bone, and wherein osteolysis of a bone due to the infiltration of wear particles can be minimized by curbing the gap formation between the bone and the stem.To that end, there is provided according to the invention, a metal jacket for a cementless artificial joint stem, which jacket is so formed as to enclose at least a part of the cementless artificial joint stem 21, said stem with jacket being inserted longitudinally in the opening formed in the bone canal of a human body, and on the surface of which jacket surface-processed metal layer or metal wires 12 is formed so that the bone can make interlocking with the metal jacket as the bone gets on-growth onto the metal jacket.

Owner:KOREA ADVANCED INST OF SCI & TECH

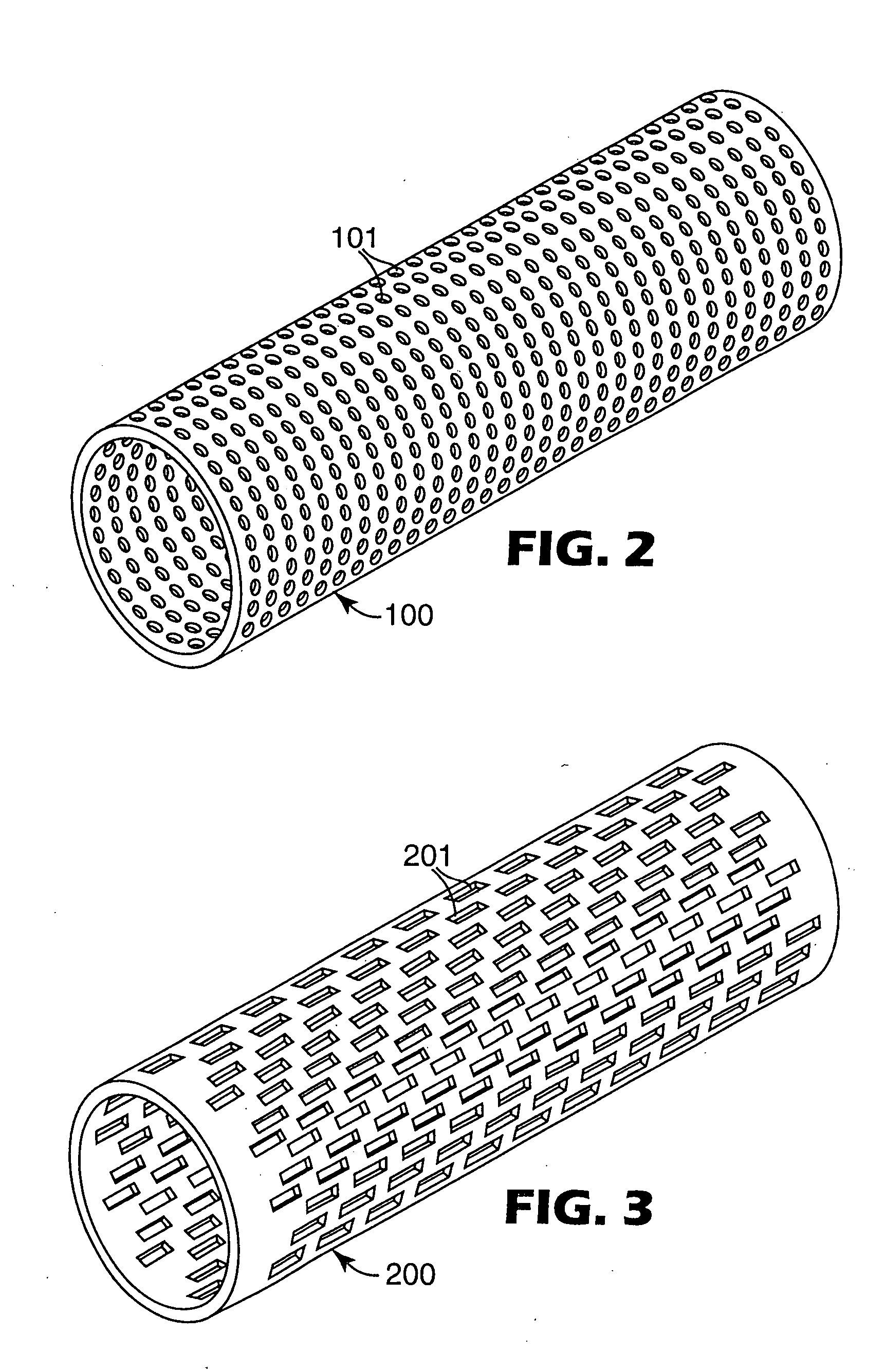

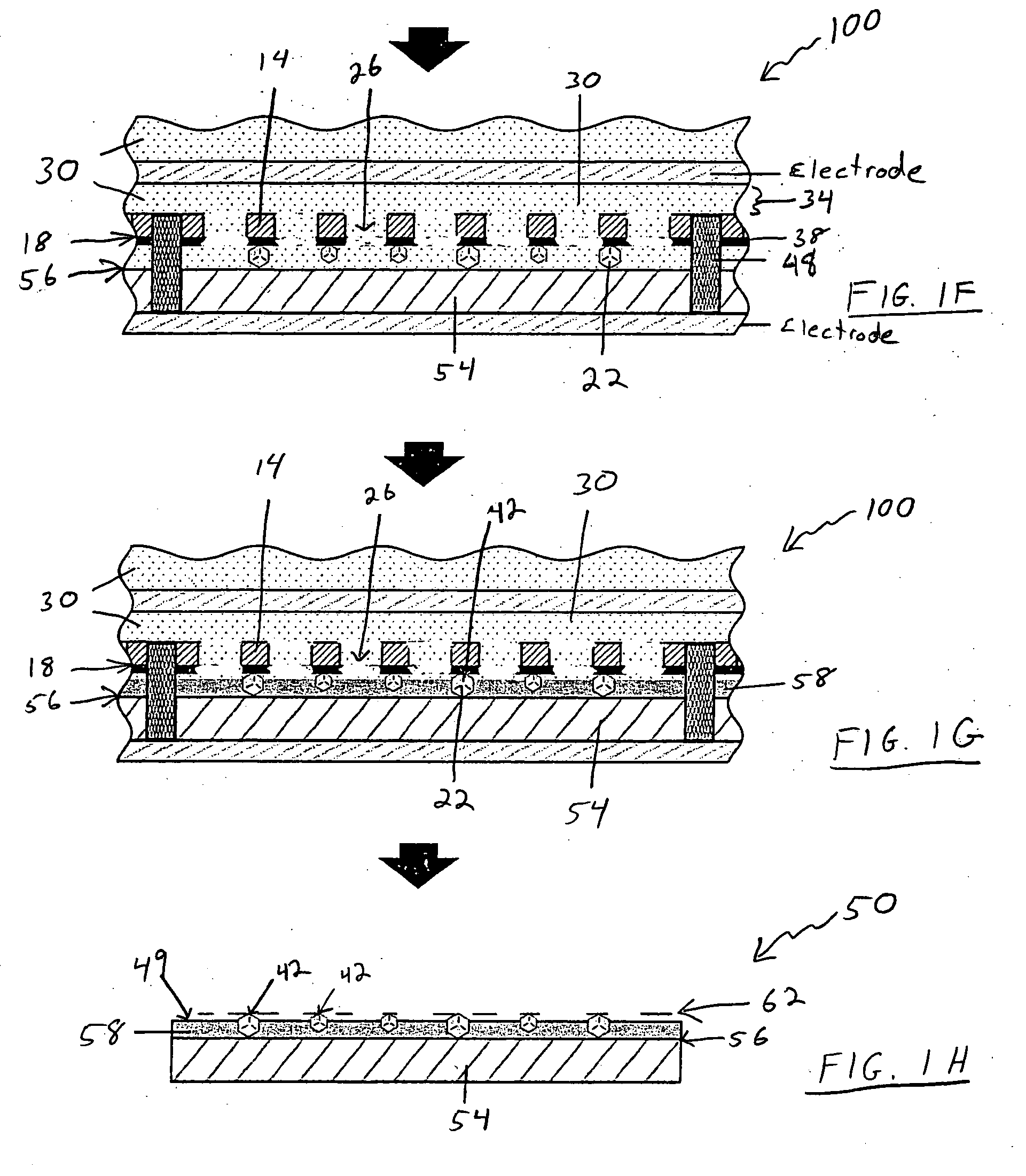

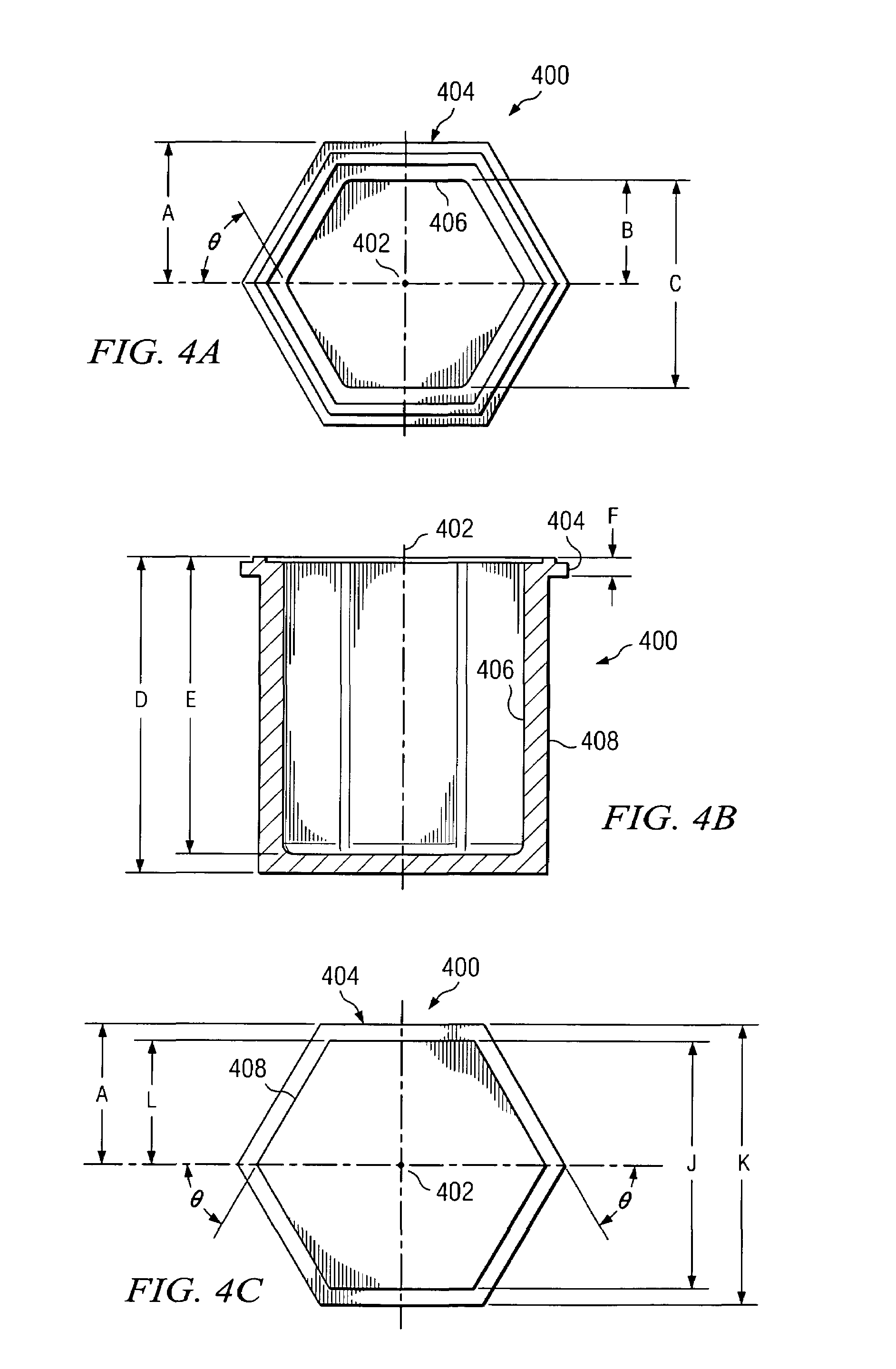

Electroplated abrasive tools, methods, and molds

InactiveUS20070128994A1Revolution surface grinding machinesGrinding devicesWear particleElectroplating

The present invention provides for a mold that can position and hold abrasive particles, which are to be electrolytically attached to an electrically conductive substrate during an electrolytic process. The mold can include an insulating material with a molding surface suitable for holding the abrasive particles in place during this process. Additionally, a method for making an abrasive tool using such a mold is provided, as well as abrasive tools made thereby. In one aspect of this invention, abrasive tools can have abrasive particle tips that are arranged in accordance with a predetermined vertical pattern and / or a predetermined horizontal pattern in a manner that requires little or no post electrodeposition processing.

Owner:SUNG CHIEN MIN

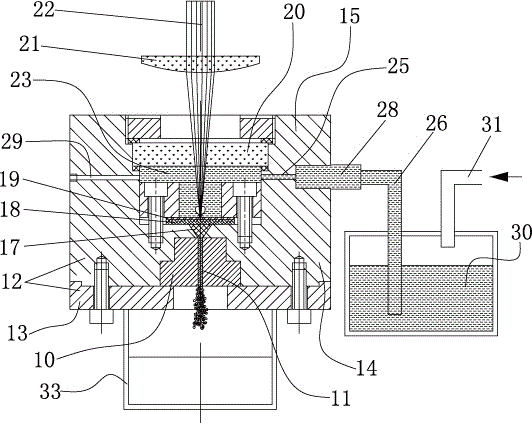

Abrasive flow micropore polishing device and polishing process thereof

InactiveCN104440584AAchieve polishReduce roughnessAbrasive feedersAbrasive machine appurtenancesCavitationWear particle

The invention discloses an abrasive flow micropore polishing device, comprising a clamping tool, a base plate, a cavity, a separation device, a laser high-transparency protective lens, a laser, a focusing lens, a flow guiding passage and a one-way valve, wherein the clamping tool is used for clamping a workpiece and locating micropores of the workpiece; the base plate is arranged on the clamping tool; the cavity is arranged in the base plate and the clamping tool and correspondingly communicate with the micropores; the separation device is arranged in the cavity and divides the cavity into a cavitation cavity and a liquid storage cavity; the laser high-transparent protective lens covers the cavitation cavity; the laser can generate laser beams facing to the cavitation cavity; the focusing lens is arranged between the laser and the laser high-transparent protective lens and is used for focusing laser beams in the cavitation cavity; the flow guiding passage can guide deionized water into the caviation cavity; the one-way valve is arranged in the flow guiding passage. According to the abrasive flow micropore polishing device, lasers are focused to cavitate the deionized water to form a large local pressure and impact the separation device, and the abrasive fluid flows and is pushed into the micropores at high speed and rubs the pore walls of the micropores to reduce the roughness of the inner surface of the micropores, so as to achieve the polishing on the micropores. The invention further discloses an abrasive flow micropore polishing process for highly effectively and ultra-precisely polishing the micropores.

Owner:GUANGDONG UNIV OF TECH

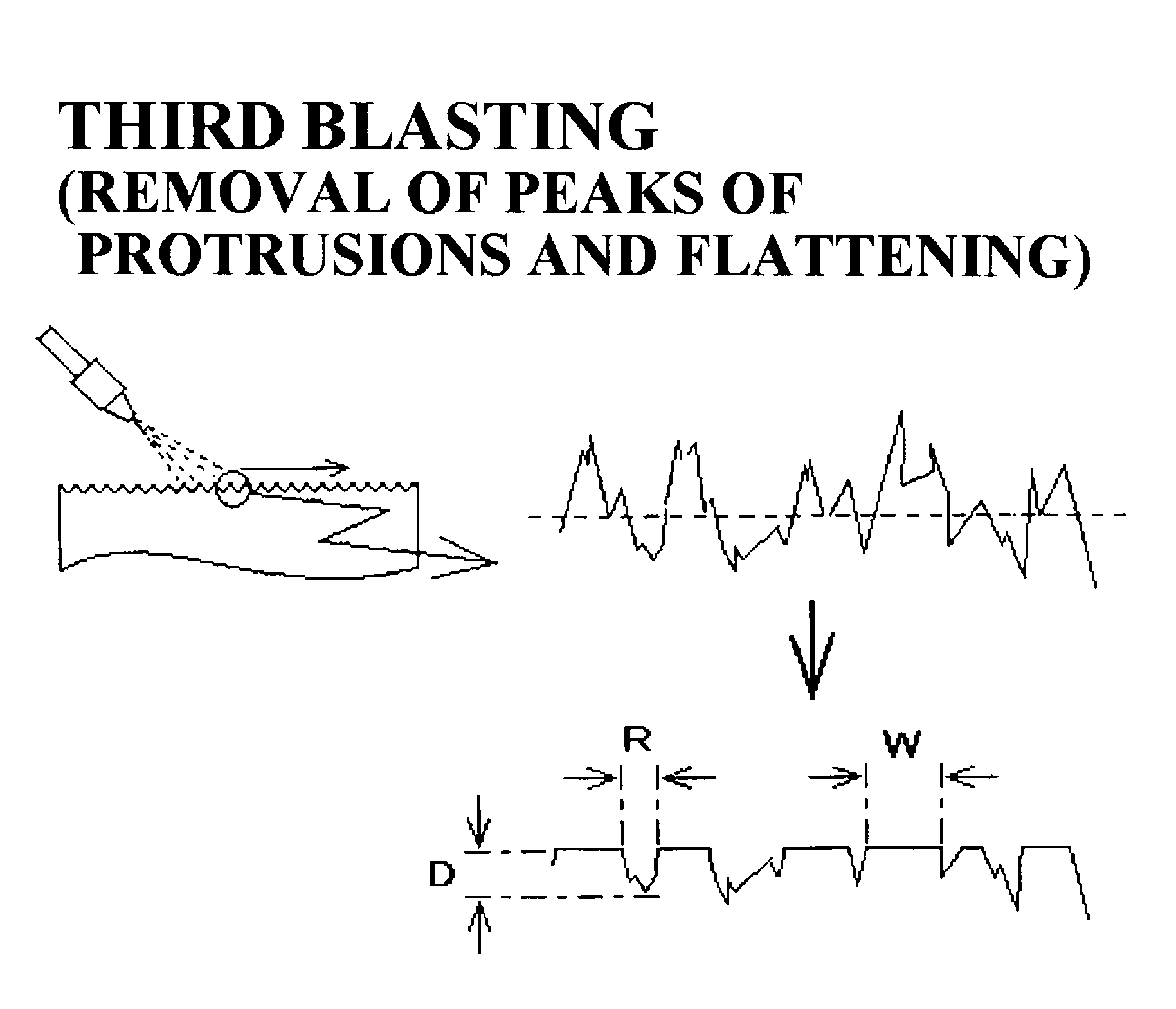

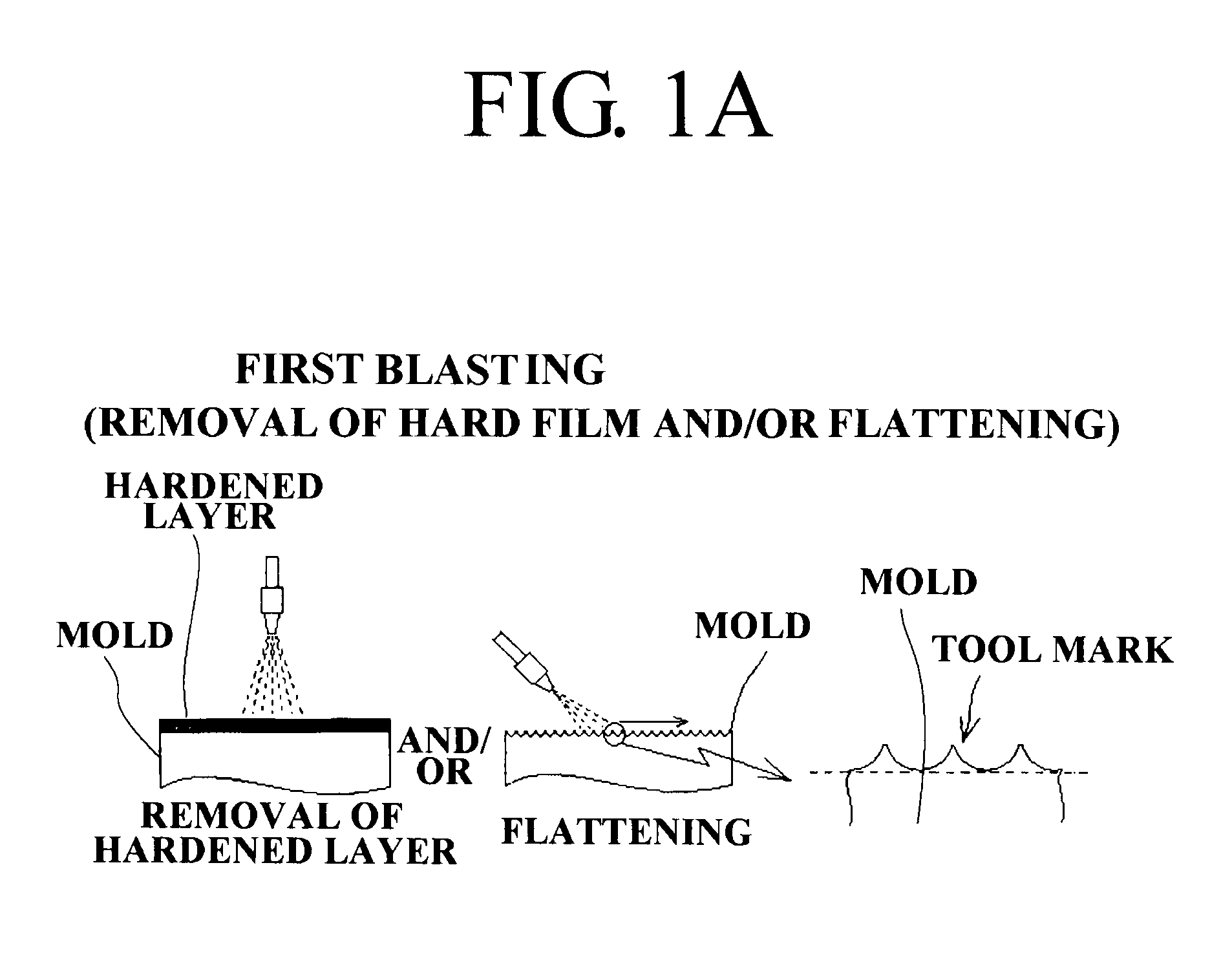

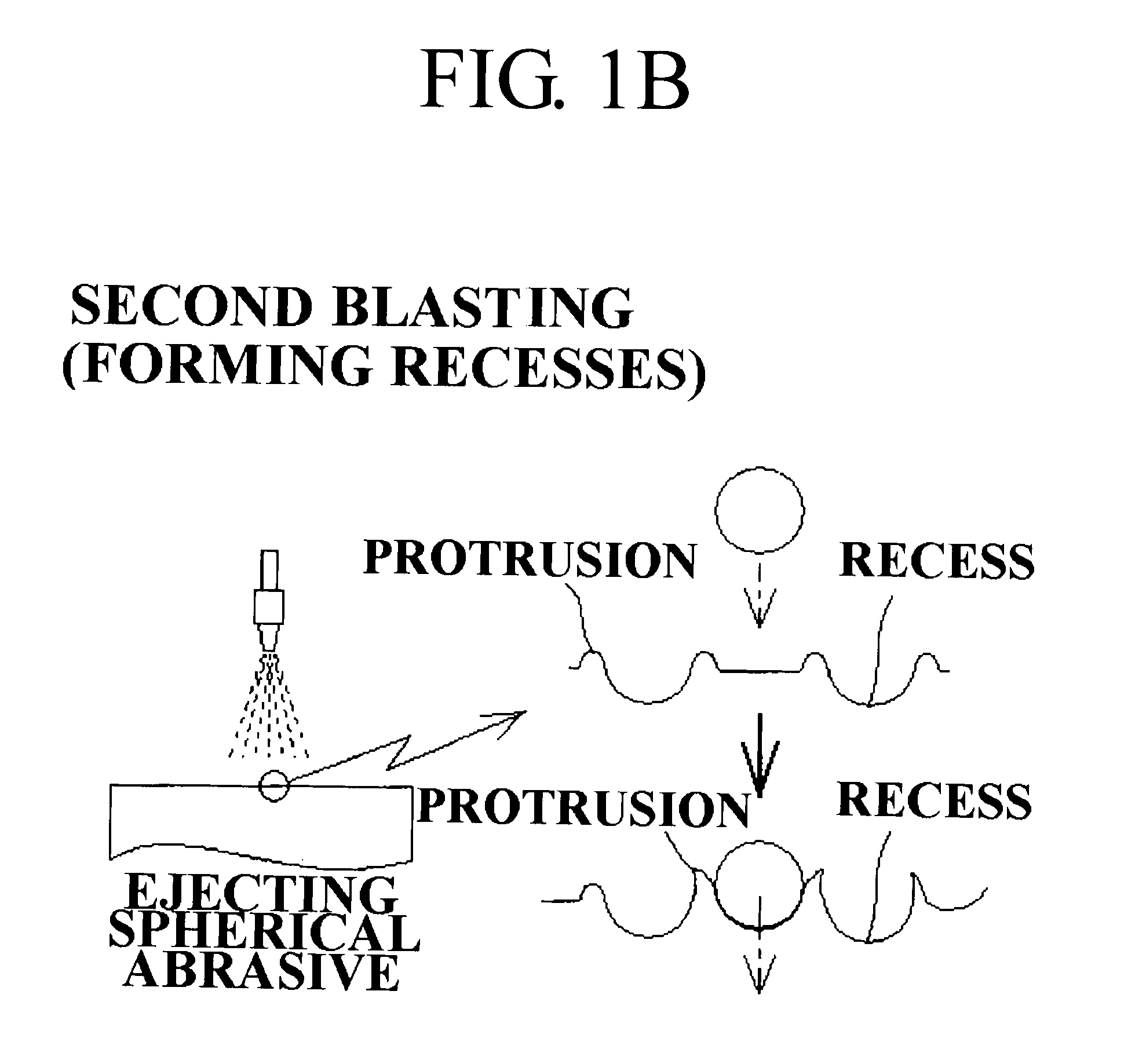

Method of treating surface of mold and mold having surface treated by said method

ActiveUS20120043044A1Good release effectEasy procedureFoundry mouldsFoundry coresElastomerAbrasive blasting

Provided is a method of treating a surface of a mold to achieve good demoldability and capable of preventing wearing of the mold by avoiding load concentration on one part of the surface of the mold. After a first blasting is performed on the surface of the mold to remove a hardened layer produced on the surface and / or to adjust the surface roughness, a second blasting is performed to create fine irregularities on the surface. Then, an elastic abrasive in which abrasive grains are carried on an elastic body, or a plate-like abrasive having a planar shape with a maximum length that is 1.5 to 100 times the thickness thereof, is ejected onto the surface of the mold at an inclined ejection angle such that the abrasive is caused to slide along the mold surface to flatten peaks of the irregularities created on the mold surface.

Owner:FUJI MFG CO LTD

Conditioning disk

InactiveUS7641538B2Low costImprove adhesionGrinding drivesBelt grinding machinesWear particleCorrosion resistant

An abrasive article includes a plurality of abrasive particles securely affixed to a substrate with a corrosion resistant matrix material. The matrix material includes a sintered corrosion resistant powder and a brazing alloy. The brazing alloy includes an element which reacts with and forms a chemical bond with the abrasive particles, thereby securely holding the abrasive particles in place. A method of forming the abrasive article includes arranging the abrasive particles in the matrix material, and applying sufficient heat and pressure to the mixture of abrasive particles and matrix material to cause the corrosion resistant powder to sinter, the brazing alloy to flow around, react with, and form chemical bonds with the abrasive particles, and allow the brazing alloy to flow through the interstices of the sintered corrosion resistant powder and form an inter-metallic compound therewith.

Owner:3M INNOVATIVE PROPERTIES CO

Lubricating oil oil quality online detector

InactiveCN102279144AReduce blindnessSystem installation is simpleFlow propertiesMaterial testing goodsData acquisitionOil quality

An on-line detector for lubricating oil quality, relating to the field of mechanical lubrication, including a system control circuit, a sensor and a processing module, characterized in that: the system control circuit controls the sensor, and the sensor and the processing module perform information transmission, and the described The processing module includes system data processing software, which is set with oil quality standard value, can store data, and is also equipped with a display terminal and alarm equipment. The sensor adopts a fluid characteristic sensor, which can simultaneously monitor the viscosity of the oil, the concentration of wear particles and the transparency, and can also be connected with the secondary instrument or controller in the control room to detect ferrite particles larger than 1 μm in the lubricating oil. Real-time dynamic online monitoring of the amount of wear particles. The beneficial effects of the present invention are: due to the use of an intelligent data acquisition and analysis system and a high-sensitivity fluid characteristic sensor, online real-time monitoring can be performed to reduce the blindness of oil maintenance. Targeted maintenance and repair, simple system installation, can be applied to friction failure monitoring and early warning of various large-scale mechanical lubrication systems.

Owner:沈怡茹

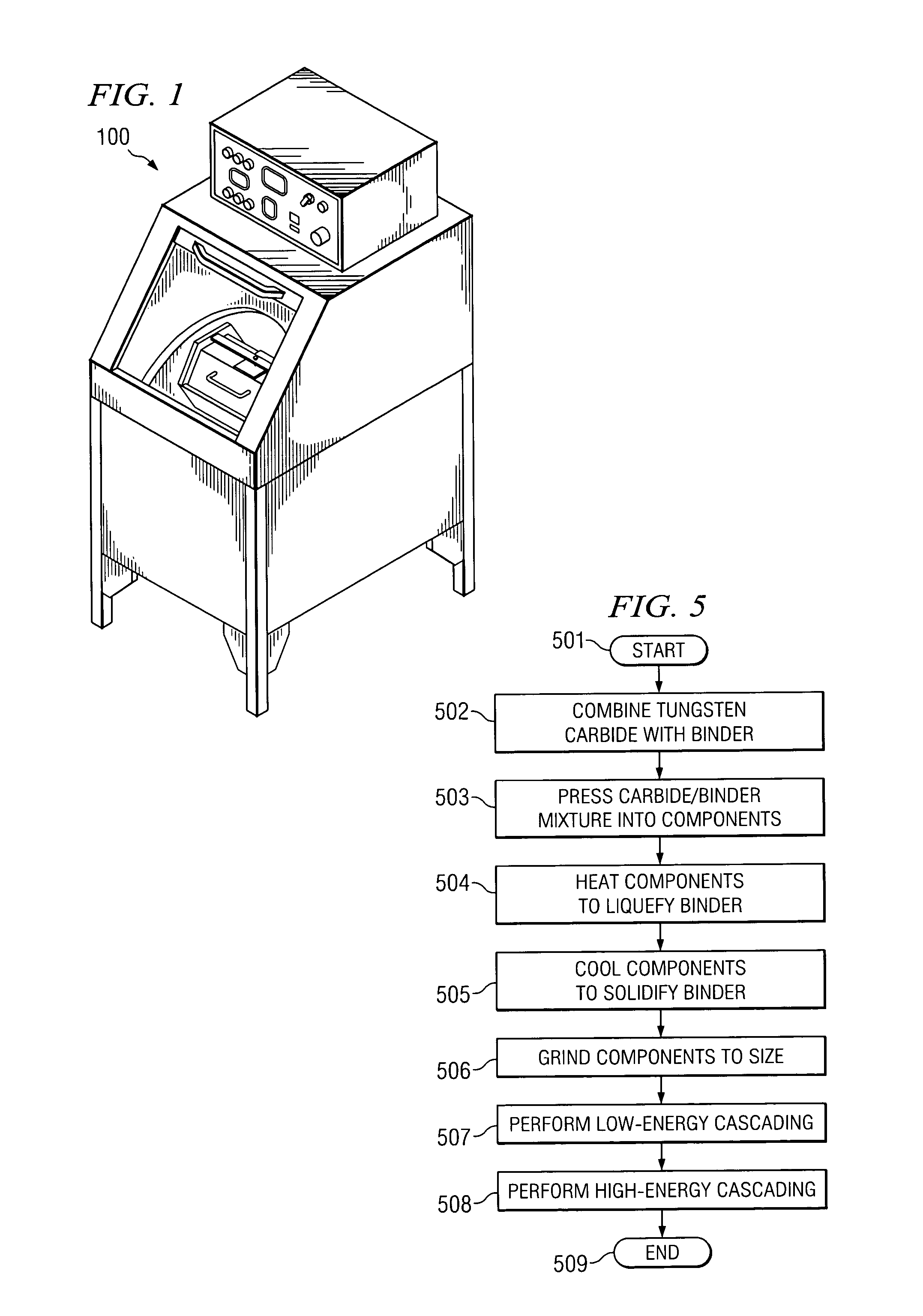

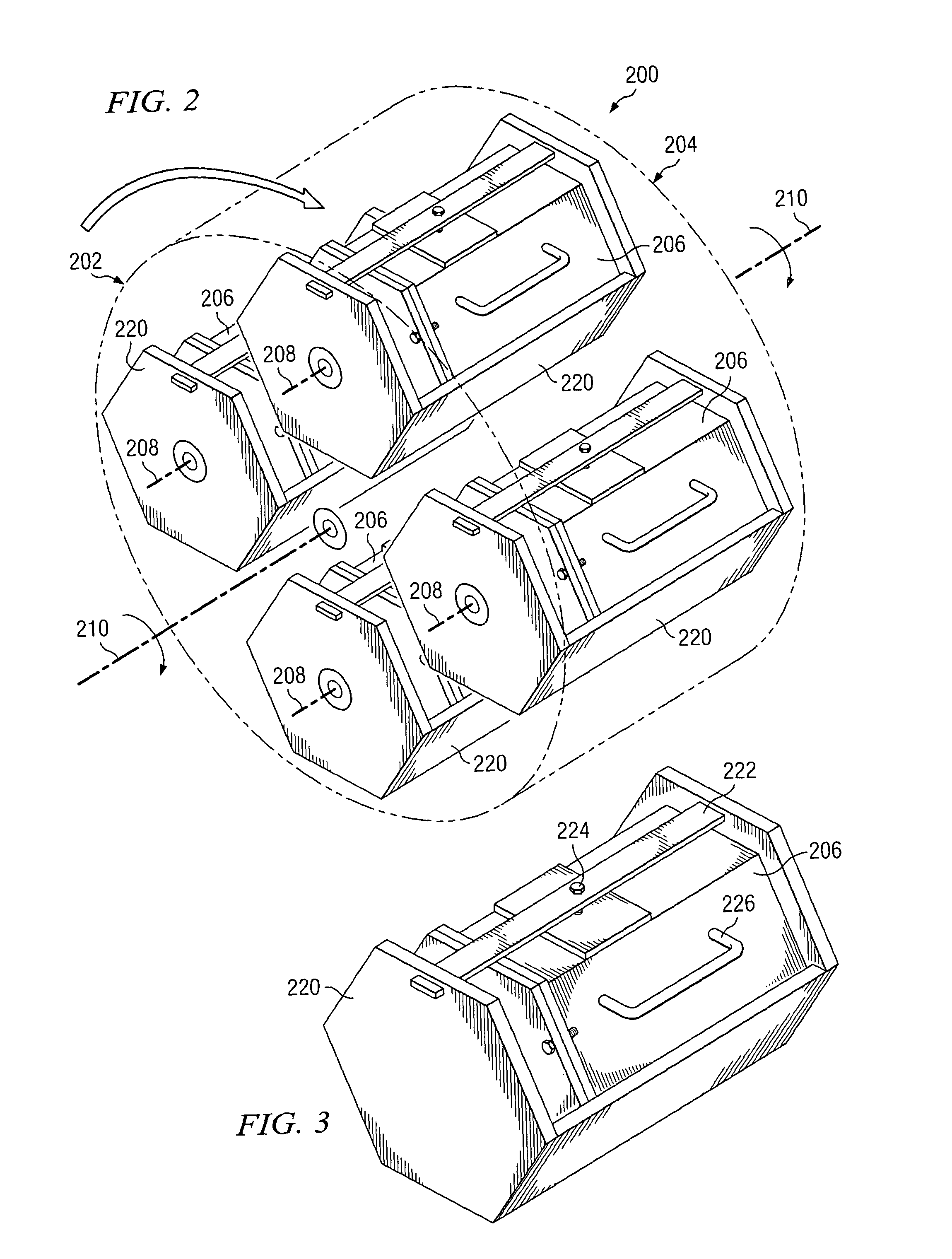

High-energy cascading of abrasive wear components

ActiveUS7258833B2Increases near surface hardness and toughnessPrevents and reduces chipping and cracking and fractureEdge grinding machinesPolishing machinesHigh energyTungsten carbide

In accordance with the present invention, a method for manufacturing tungsten carbide components is provided. The method includes forming a composite material out of tungsten carbide powder and binder powder, pressing the composite material into a plurality of components, heating the plurality of components, optionally under pressure, to liquefy the binder, cooling the plurality of components until the binder solidifies, optionally grinding each of the plurality of components to a desired size, and cascading the plurality of components in a cascading machine under high energy conditions.

Owner:CREDIT SUISSE AG CAYMAN ISLANDS BRANCH

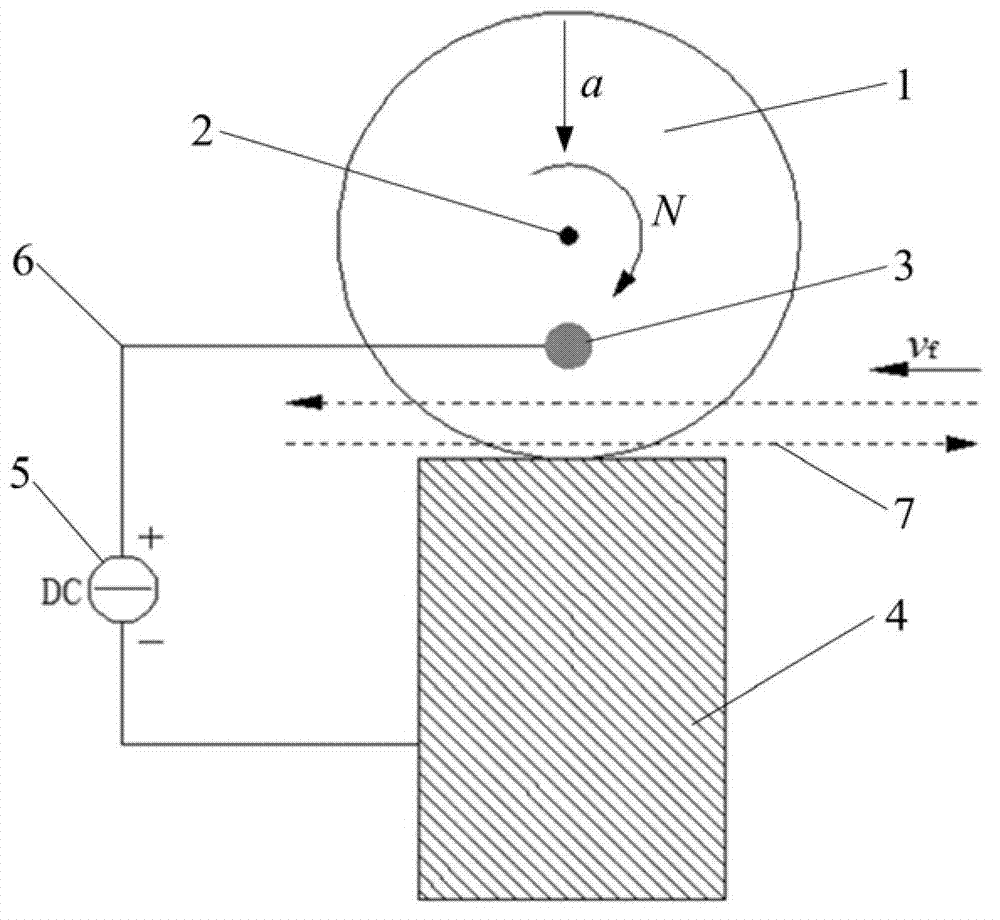

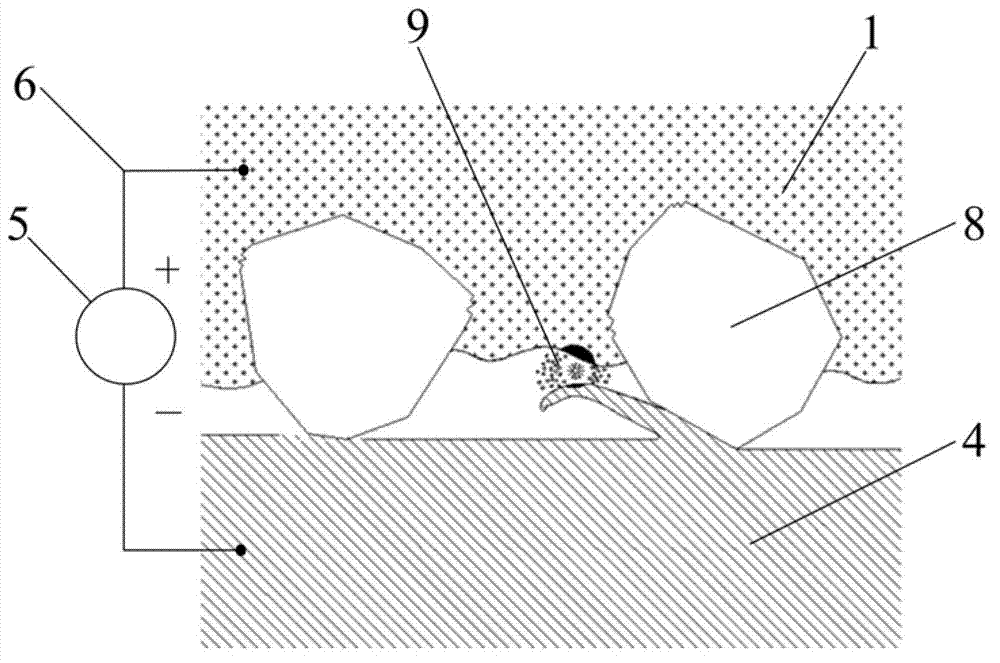

In-gas discharge dressing and truing method for large-particle diamond grinding wheel

ActiveCN103395002AWon't burnAvoid arcingAbrasive surface conditioning devicesWear particleCopper electrode

The invention discloses an in-gas discharge dressing and truing method for a large-particle diamond grinding wheel. The method includes: fixing the diamond grinding wheel on a grinding wheel shaft, and fixing a conducting electrode on the horizontal plane; connecting the diamond grinding wheel, the electrode, a graphite brush, a power source and a wire to form a discharge circuit; connecting a positive pole of the power source to the grinding wheel, and connecting a negative pole of the power source to the electrode. When rotating, the diamond grinding wheel linearly reciprocates on the surface of the electrode; metal bond is removed by pulse sparks generated between the electrode and the metal bond of the grinding wheel, so that diamond abrasive particles are edged from the surface of the grinding wheel; spark discharge occurs between the metal bond and whirling conducting chips generated when the edged diamond abrasive particles cut the copper electrode, generated instant high temperature is transmitted to cutting edges of the diamond abrasive particles in contact cutting through the chips, the tips of the cutting edges are pneumatically dressed, and accordingly micro edging, dressing and truing of the grinding wheel are achieved, more effective abrasive particles are generated and efficient grinding of smooth mirrors is achieved.

Owner:SOUTH CHINA UNIV OF TECH

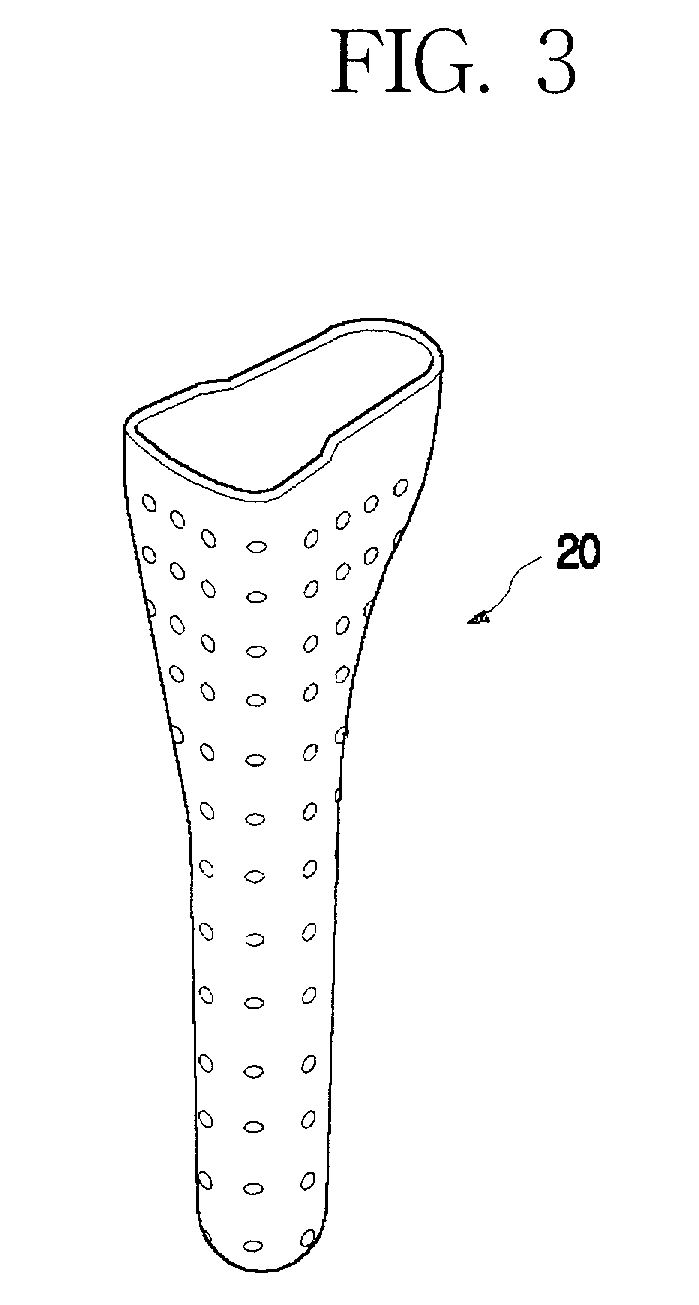

Plastic jacket for a cementless artificial joint stem and artificial joint having the jacket

The present invention is intended to provide a plastic jacket for a cementless artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced and stress shielding phenomena can also be markedly relieved, due to the construction of the plastic jacket which can be fixed to the bone canal and can enclose the surface of the stem so as to allow for the stem of artificial joint to slide vertically relative to the bone, and wherein osteolysis of a bone due to the infiltration of wear particles can be minimized by curbing the gap formation between the bone and the stem. To that end, there is provided according to the invention, a plastic jacket 20 for a cementless artificial joint stem 31, which is made of plastics and is so formed as to enclose at least a part of the stem 31 of a cementless artificial joint 30, said stem with jacket being inserted longitudinally in the opening formed in the bone canal of a human body, and which has a porous or roughened surface so that a femur can make interlocking with the plastic jacket as the bone gets in-growth onto the porous plastic jacket surface.

Owner:KOREA ADVANCED INST OF SCI & TECH

Method and apparatus for grinding magnetic member and method and apparatus for treating waste fluid

InactiveUS7040969B1Easy to separateCompact and effective in separationInductances/transformers/magnets manufactureGrinding machinesSludgeWear particle

An apparatus for grinding a magnetic member comprises a cutting blade having a cutting edge including heat resistant resin and abrasive grain. A magnetic member including a rare-earth alloy is ground by the cutting blade while grinding fluid primarily made of water is supplied to a grinding region. A magnet separator having a surface magnetic flux density not smaller than 0.25 T magnetically separates sludge from used grinding fluid. Further, the grinding fluid is introduced into a tank, where the sludge contained in the grinding fluid is allowed to coagulate and sediment. The grinding fluid separated from the sludge is used in circulation. The same separation process can be used for separation of sludge containing a rare-earth alloy from waste fluid.

Owner:HITACHI METALS LTD

Metal wear detection apparatus and method employing microfluidic electronic device

ActiveUS8522604B2Machine gearing/transmission testingMagnetic property measurementsCapacitanceWear particle

Owner:THE UNIVERSITY OF AKRON

Chemical mechanical abrasive slurry and method of using the same

InactiveUS20050112892A1Other chemical processesSemiconductor/solid-state device manufacturingWear particleCompound (substance)

The invention provides a chemical mechanical abrasive slurry for use in semiconductor processing. The slurry comprises composite abrasive particles consisting of substrate particles coated with alumina. The invention further relates to a chemical mechanical polishing method of using said slurry in polishing the surfaces of semiconductor wafers.

Owner:ETERNAL MATERIALS CO LTD

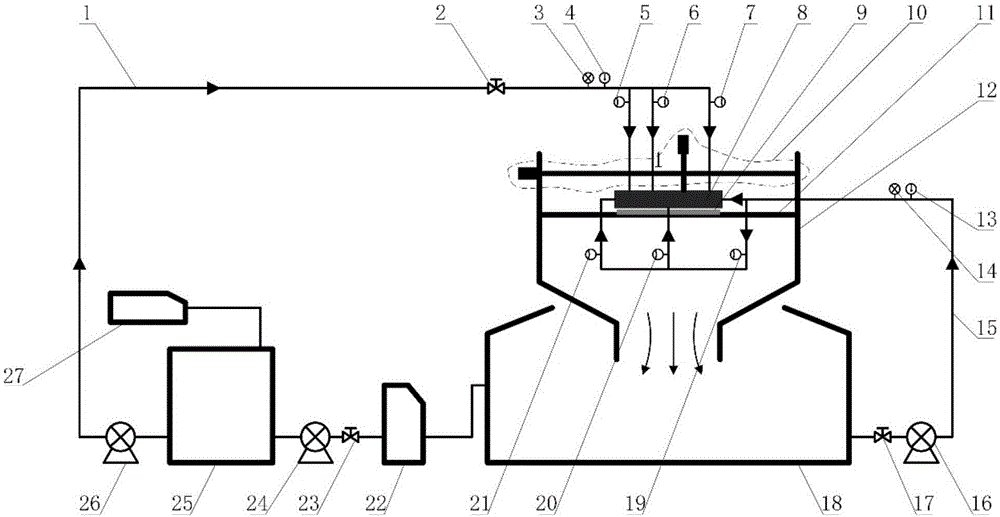

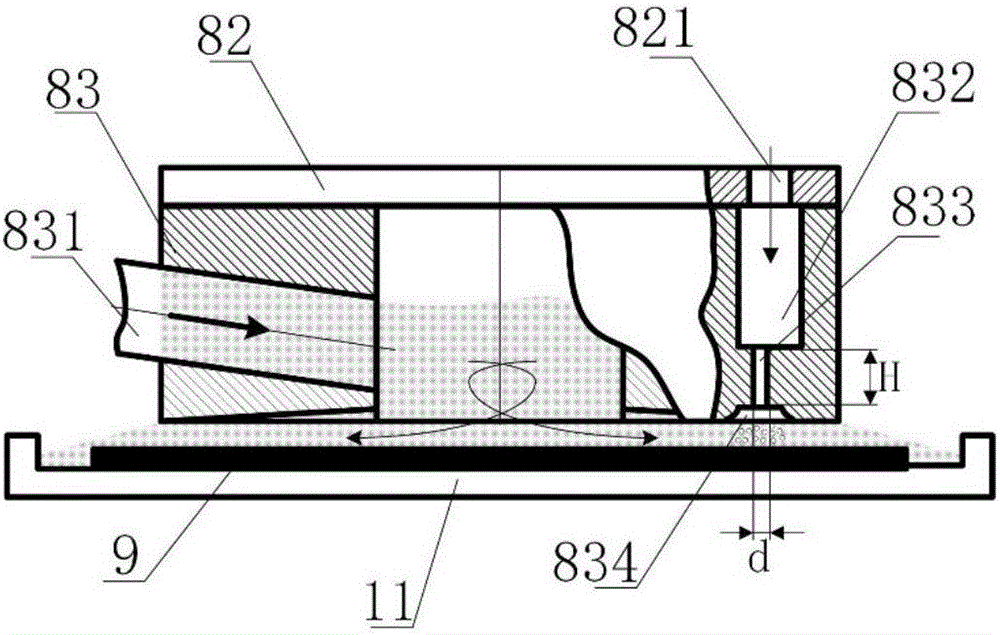

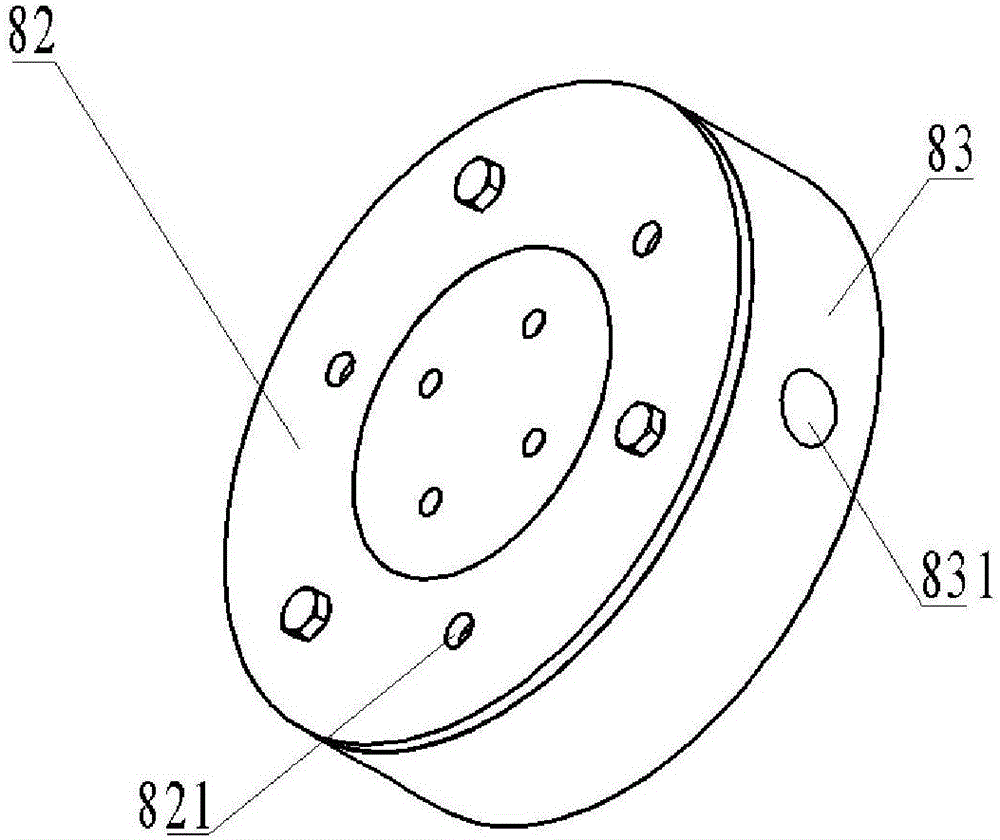

Efficient fluid finishing method and device based on structure cavitation effect

ActiveCN106392863ACollapse drive effect is obviousSimple structureEdge grinding machinesPolishing machinesBubble cavitationWear particle

The invention discloses an efficient fluid finishing method based on the structure cavitation effect. According to the efficient fluid finishing method, the Venturi tube cavitation effect is introduced to fluid finishing, strong bubble cavitation action is formed in the effective polishing area formed between a processing tool and a workpiece to be processed by arranging a Venturi tube structure on the processing tool, and the bubble cavitation action is utilized to drive a liquid-solid abrasive flow in the formed effective polishing area to move in a high-speed turbulent vortex mode to achieve processing on the surface of the workpiece to be processed through abrasive particles. According to the efficient fluid finishing method based on the structure cavitation effect, the Venturi tube structure is utilized to achieve growth and collapse of bubbles in the microspur gap between the processing tool and the workpiece to be processed so as to achieve unordered and high-speed turbulent flow of the abrasive particles; compared with processing equipment adopting ultrasonic waves, the structure is simpler and the cost is lower; and compared with normal bubble-free-collapse processing equipment, the controllability is better, and the bubble collapse driving effect is more obvious.

Owner:ZHEJIANG UNIV OF TECH

Pore self-generation superhard abrasives grinding tool and shaving method thereof

The invention discloses an automatic pore generation ultrahard abrasive grinding tool and a method for dressing the same. The grinding tool at least consists of abrasive grains, a bonding agent and a 'soluble' filling agent. The 'soluble' agent soluble in a certain solvent is added into the bonding agent of the automatic pore generation ultrahard abrasive grinding tool, and a layer of the 'soluble' filling agent can be coated on the ultrahard abrasive grain surface layer according to requirement. The 'soluble' filling agent and the bonding agent act together to hold the abrasive grains and ensure excellent strength of the grinding tool. In a grinding process of the grinding tool, when the abrasive grains on the surface of the grinding tool are passivated and the grinding tool needs to be dressed, the method can deliver the certain solvent to the surface of the grinding tool to dissolve the 'soluble' filling agent on the surface layer of the grinding tool and generate pores in the bonding agent to reduce the structural strength of the bonding agent and holding force of the bonding agent to the sounding abrasive grains and make the abrasive grains on the surface layer of the grinding tool easy to fall off, thereby automatically dressing the grinding tool and revealing new abrasive grains.

Owner:吴寿麟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com