Abrasive flow micropore polishing device and polishing process thereof

A polishing device and abrasive flow technology, applied in abrasive feeding device, used abrasive processing device, abrasive and other directions, can solve the problems of unsafe equipment, difficulty, hydraulic components and pipeline requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below.

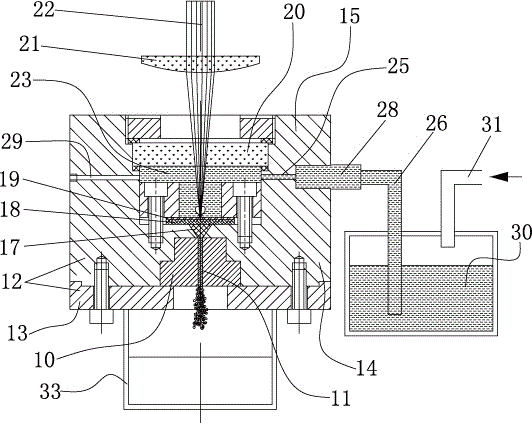

[0024] Such as figure 1 As shown, an abrasive particle flow microhole polishing device of the present invention includes a fixture 12 for clamping a workpiece 10 and positioning the microhole 11 to be polished in the workpiece 10, a base plate 15 installed on the fixture 12, The cavity provided on the inner side of the base plate 15 and the clamp 12 and correspondingly communicated with the microhole 11 of the workpiece 10 is arranged in the cavity to divide the cavity into a cavitation cavity 23 for containing deionized water and a cavity for containing viscose. The spacer of the liquid storage chamber 17 of the elastic abrasive fluid, the laser high-transparency protective mirror 20 covering the side of the cavitation chamber 23 opposite to the workpiece 10, the laser that can generate the laser beam 22 towards the cavitation chamber 23, A focusing lens 21 located between the laser and the laser hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com