CCOS shear thickening polishing method

A polishing liquid and thickening agent technology, applied in grinding/polishing equipment, polishing compositions containing abrasives, optical surface grinders, etc., can solve the limitation of mass production of workpieces and the convergence of surface quality, surface shape and roughness The speed is slow, the surface of the workpiece is prone to scratches, etc., to achieve the effect of good shear thickening effect, strong particle aggregation effect, and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

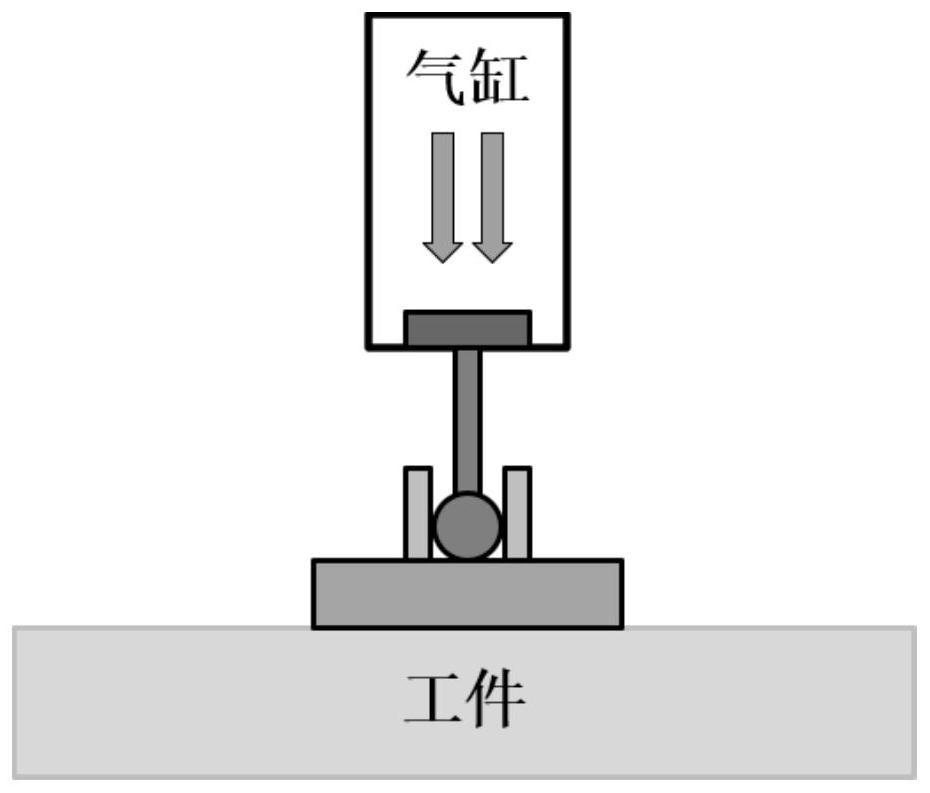

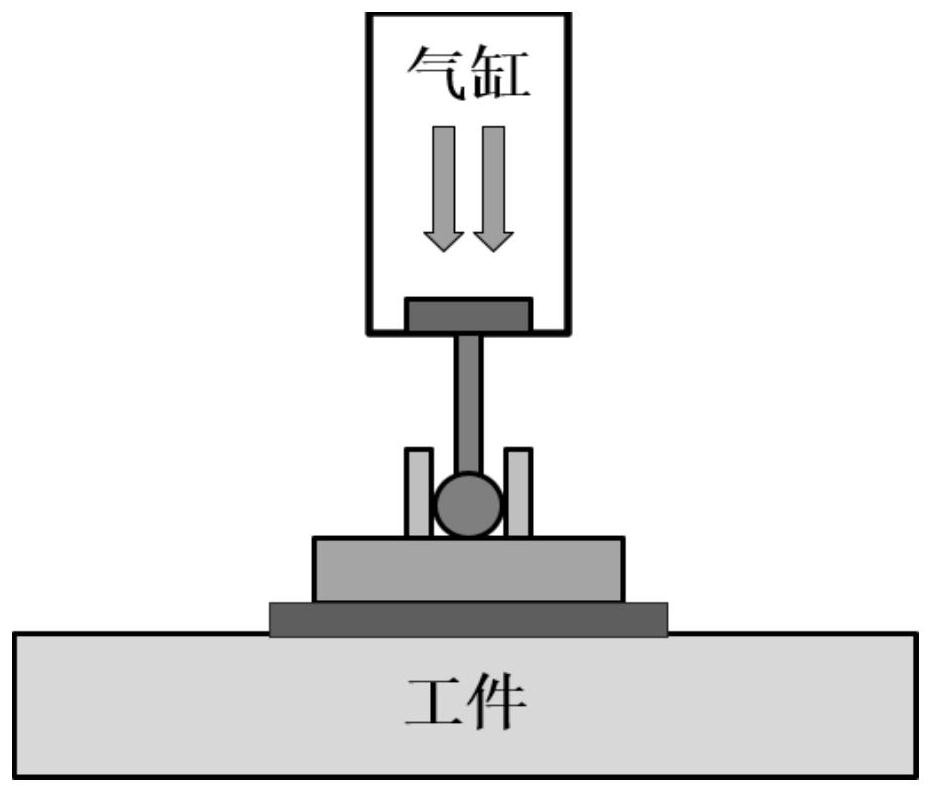

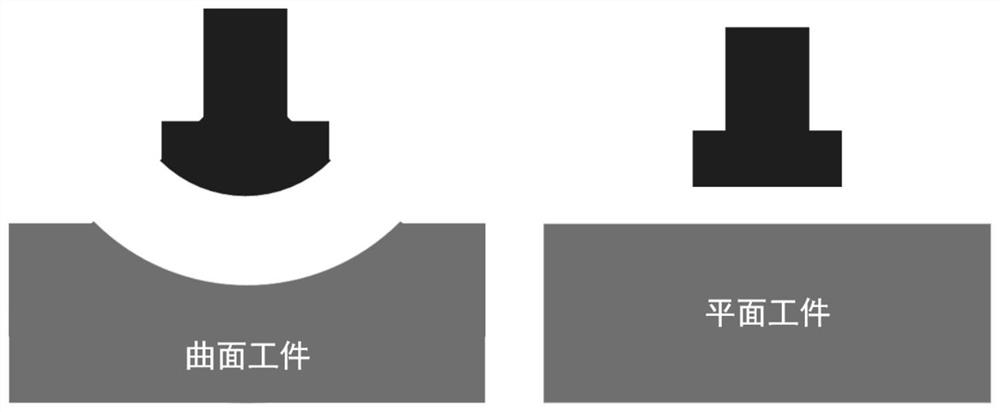

[0068] In this example, the polishing method of CCOS shear thickening applies the thickening and lubricating properties of shear thickeners uniformly to CCOS processing.

[0069] The mathematical model of the deterministic removal of the modification device based on shear thickening polishing in this embodiment is the Preston equation, namely:

[0070] R(x,y)=kP(x,y,t)V(x,y,t)

[0071] In the above formula, (x, y) is the coordinate of a certain point on the workpiece, R(x, y) represents the removal efficiency, k represents the coefficient related to the processed material, process parameters, etc., P(x, y, t) Indicates the pressure exerted by the polishing disc on a certain point on the workpiece surface at time t, that is, the pressure distribution function on the workpiece surface, and V(x, y, t) indicates the relative movement speed between the point and the polishing disc at time t.

[0072] Specific steps are as follows:

[0073] 1. Prepare a suitable shear thickener to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com