Patents

Literature

11802results about How to "Avoid errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

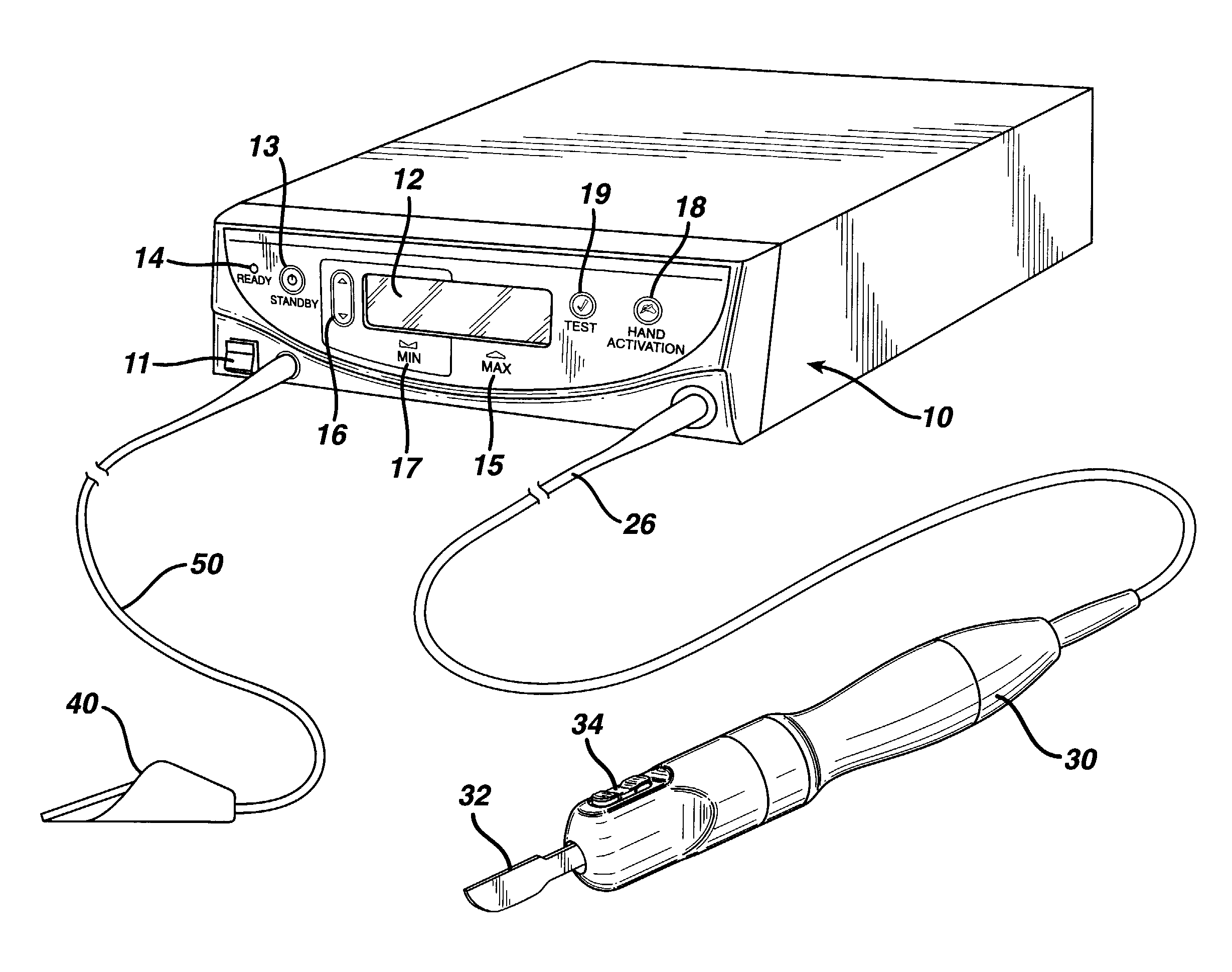

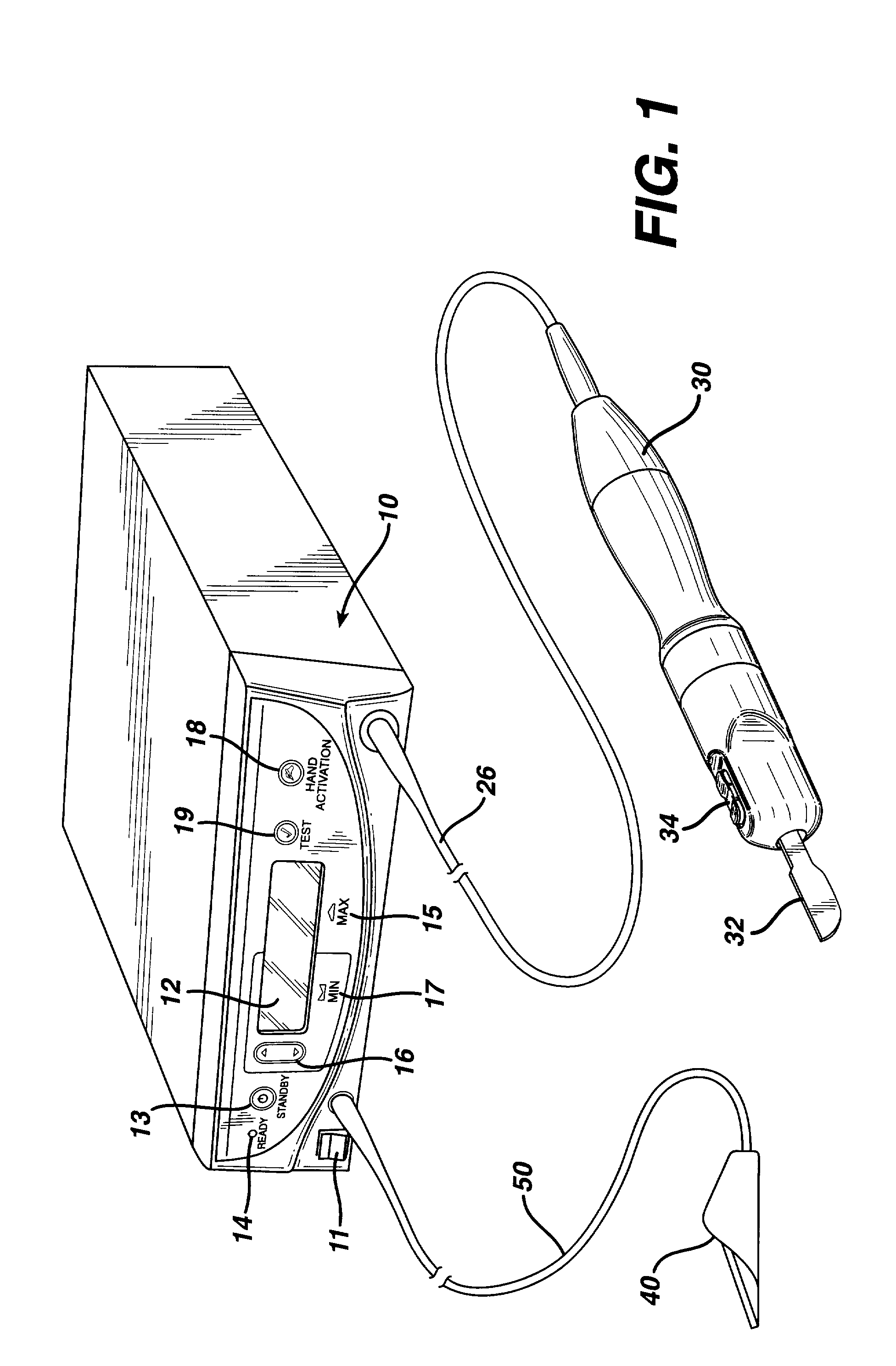

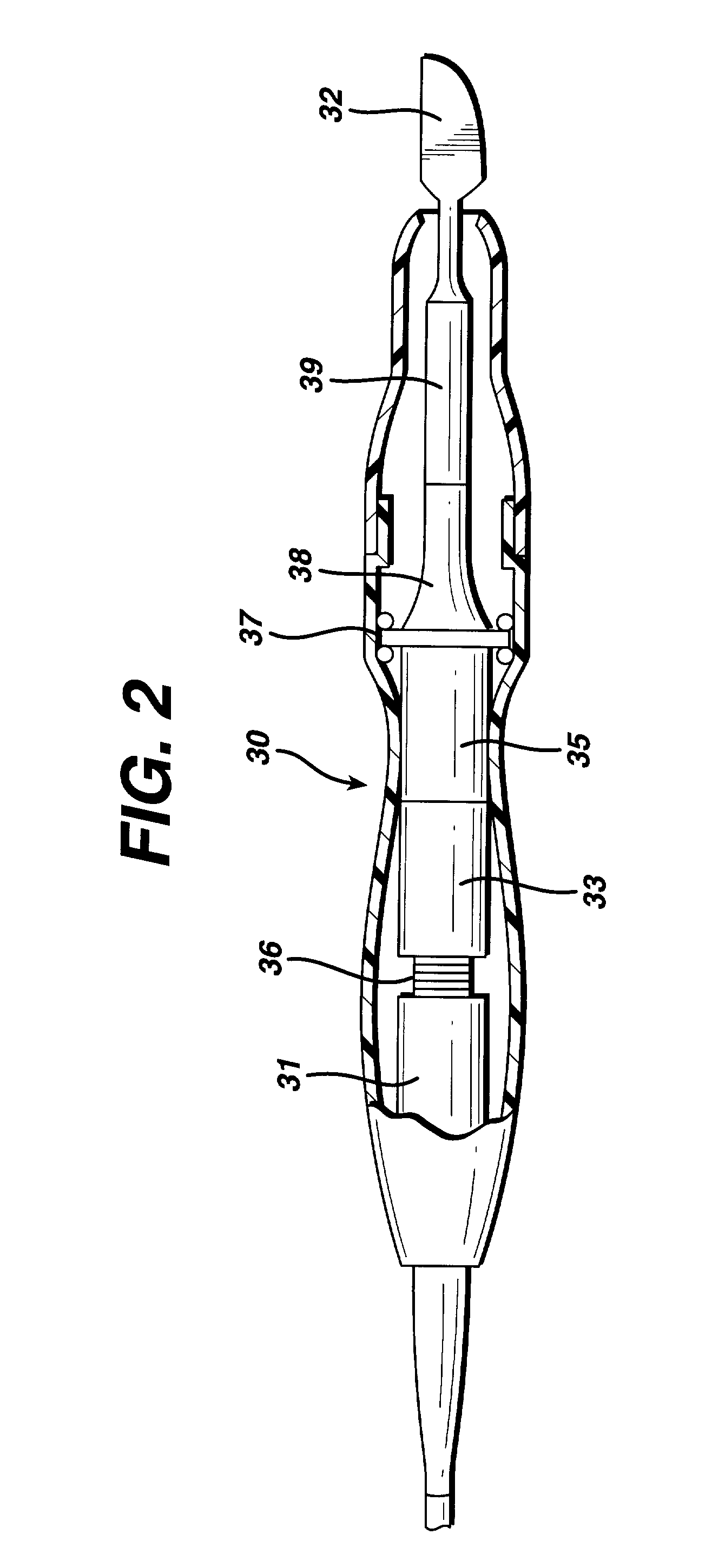

Apparatus and method for alerting generator functions in an ultrasonic surgical system

InactiveUS7273483B2Avoid errorsNew system functionalityIncision instrumentsSurgical instrument detailsElectric generatorPower flow

The present invention provides a system for surgery which includes an ultrasonic hand piece having a end-effector, a console having a digital signal processor (DSP) for controlling the hand piece, and a memory disposed in the end-effector. The generator console sends a drive current to drive the hand piece which imparts ultrasonic longitudinal movement to the blade. As the generator console reads the memory, the hand piece is authenticated for use with the generator console if a copyrighted data string is present in the memory. In a particular embodiment, the data string is an encrypted code, where the hand piece is authenticated for use with the console by decoding a corresponding encryption algorithm resident in the generator console and providing a responding data pattern.

Owner:ETHICON ENDO SURGERY INC

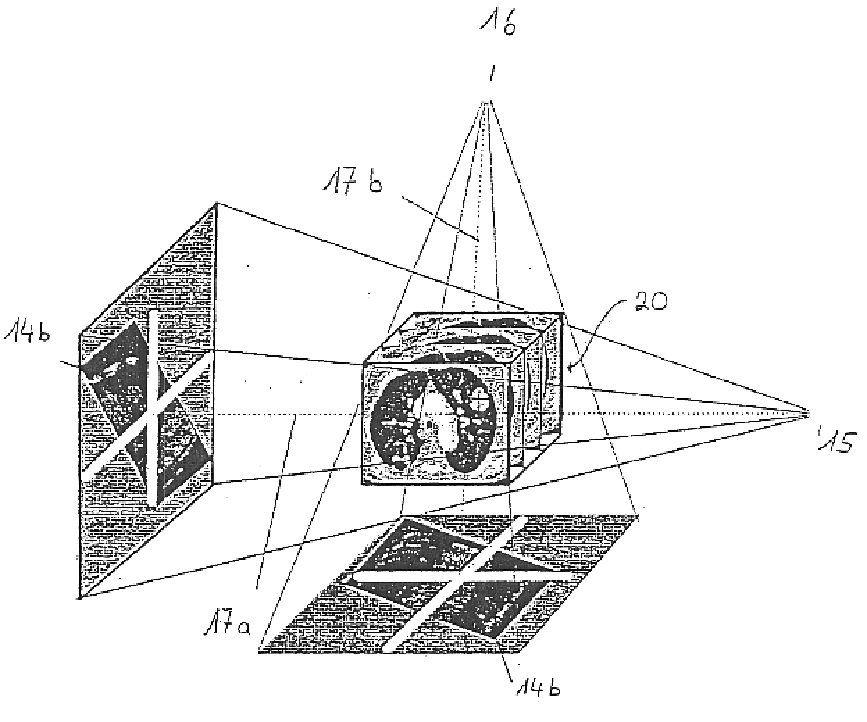

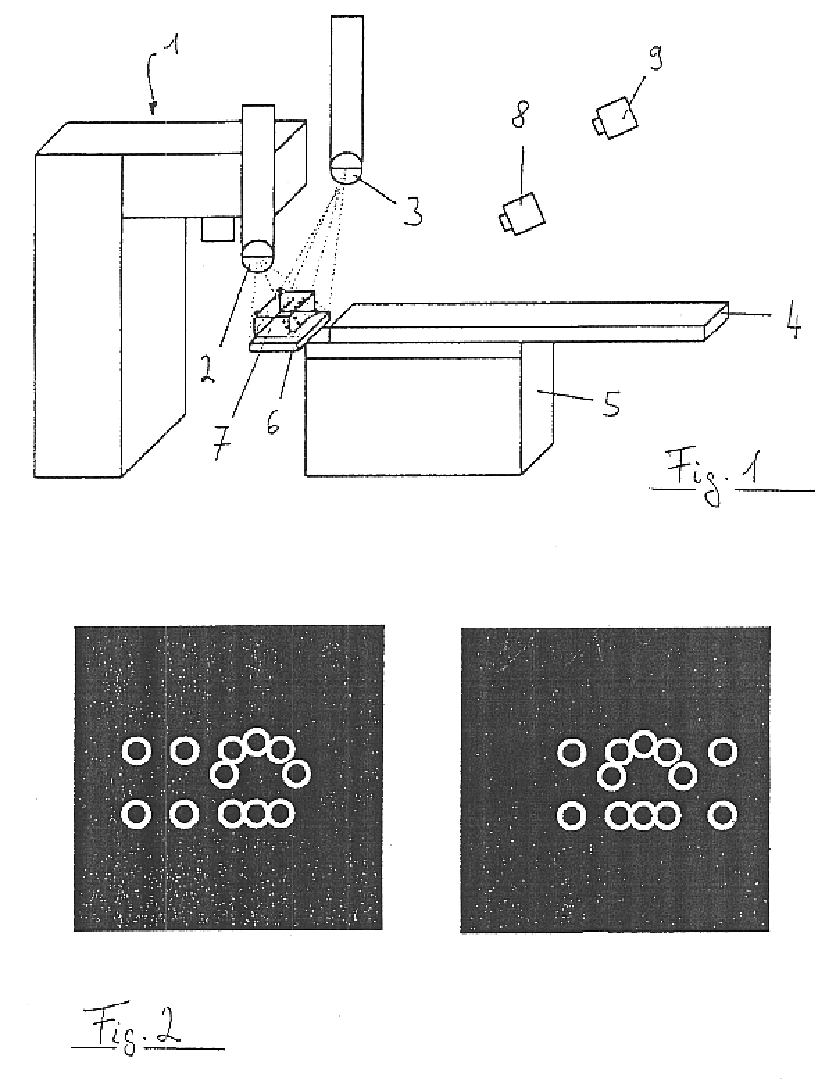

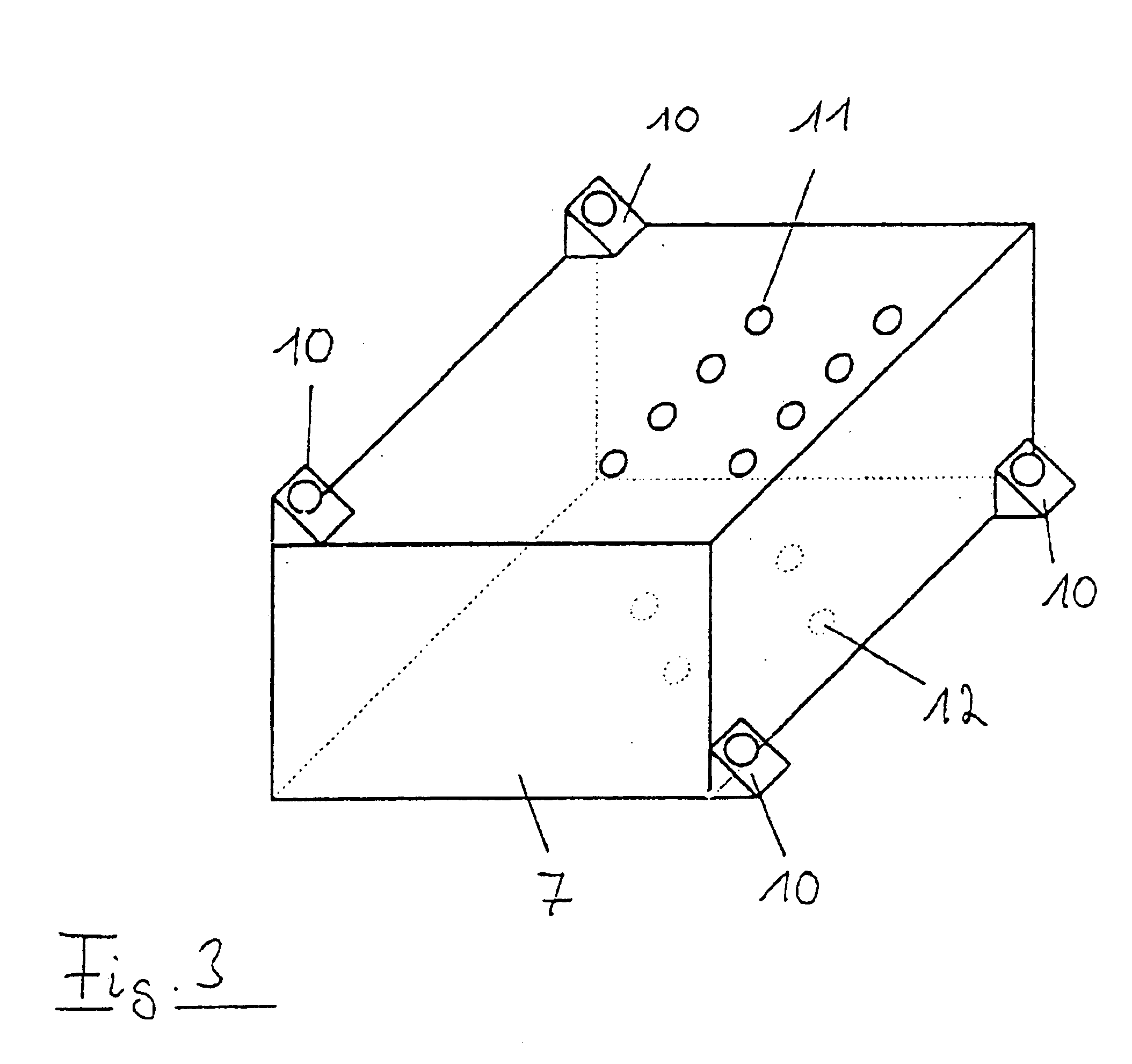

Method and device for accurately positioning a patient in radiotherapy and/or radiosurgery

InactiveUS6865253B2Precise positioningGood flexibilityForeign body detectionRadiation beam directing meansX ray imageSoft x ray

A method for accurately positioning a patient for radiotherapy and / or radiosurgery, comprising the following steps: the patient is pre-positioned as accurately as possible with respect to a linear accelerator; at least two x-ray images of the patient and / or one of the parts of his body in the vicinity of the radiation target point are produced from different respective recording angles on a single image recorder; the x-ray image is spatially localized; at least one reconstructed image, corresponding to each x-ray image and deriving from a three-dimensional patient scan data set, is produced, the reconstructed images containing the desired image contents of the x-ray images when the patient is correctly positioned; and the real x-ray images are superimposed, and the positioning error is determined electronically and / or with computer guidance by way of particular landmarks and / or the intensity gradient or the contours in the two images; and the position of the patient is corrected by way of the determined positioning error.

Owner:BRAINLAB

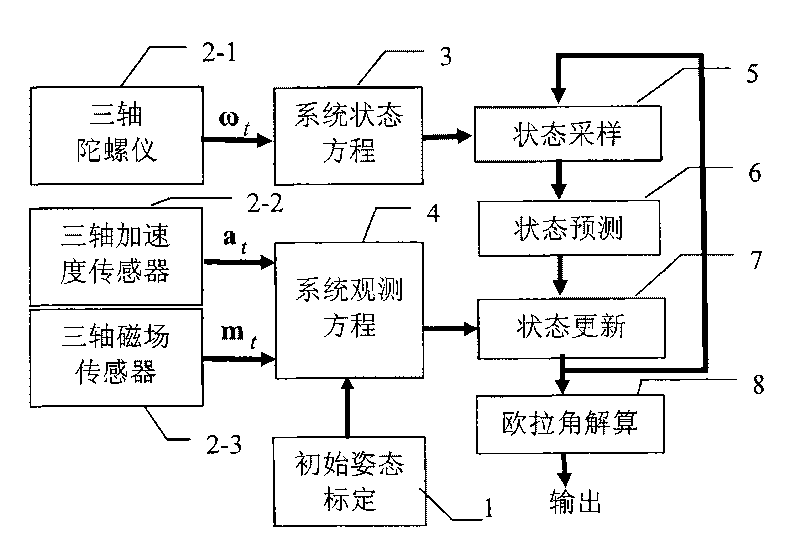

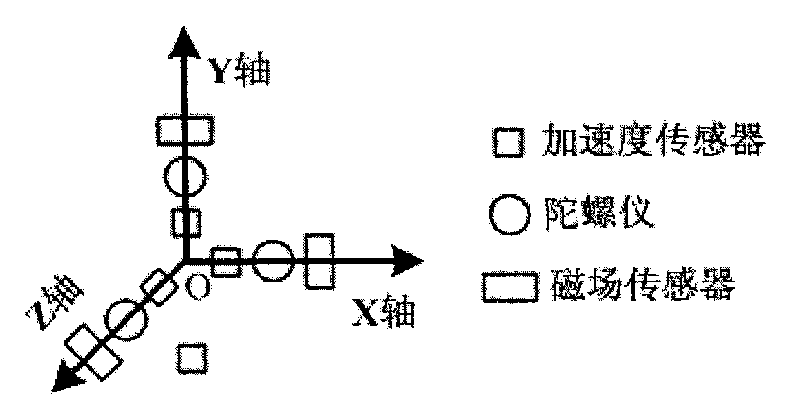

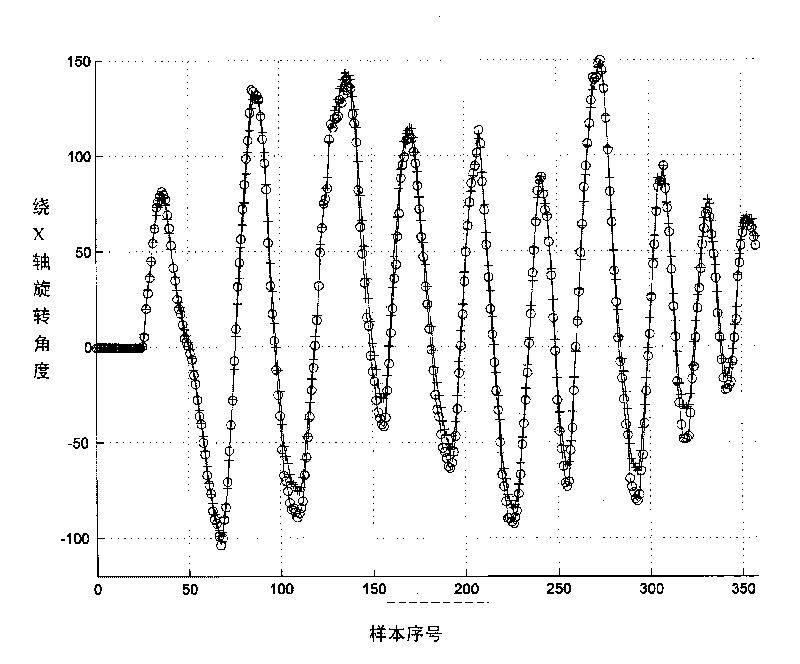

Unscented Kalman filter-based method for tracking inertial pose according to acceleration compensation

InactiveCN101726295AAvoid errorsThe estimate is accurateNavigation by speed/acceleration measurementsAccelerometerGyroscope

The invention provides an unscented Kalman filter-based method for tracking an inertial pose according to acceleration compensation, which is used for an inertial measurement unit integrating a three-axis micro-gyroscope, a three-axis micro-accelerometer and a three-axis magnetoresistive sensor, and realizes pose tracking estimation on a device carrier by using rotary angular velocity vectors, acceleration vectors and magnetic field sensor vectors which are detected by the device by means of filter technology. The method comprises the following steps: 1) treating the acceleration vectors as combination of the acceleration vectors and gravity acceleration vectors of the device carrier self, and constructing observation equations respectively for amplitude and normalized direction vectors of the acceleration vectors and the gravity acceleration vectors; 2) describing quaternion, accumulated error vectors of the gyroscope and the acceleration vectors of the device carrier self by using the pose to construct a system state vector; and 3) realizing a filter estimating process of the system by using the unscented Kalman filter technology because of nonlinearity of the observation equations. Compared with the conventional method ignoring the acceleration of the carrier self, the method not only can provide a more accurate estimation result, but also widens the application range of the system.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

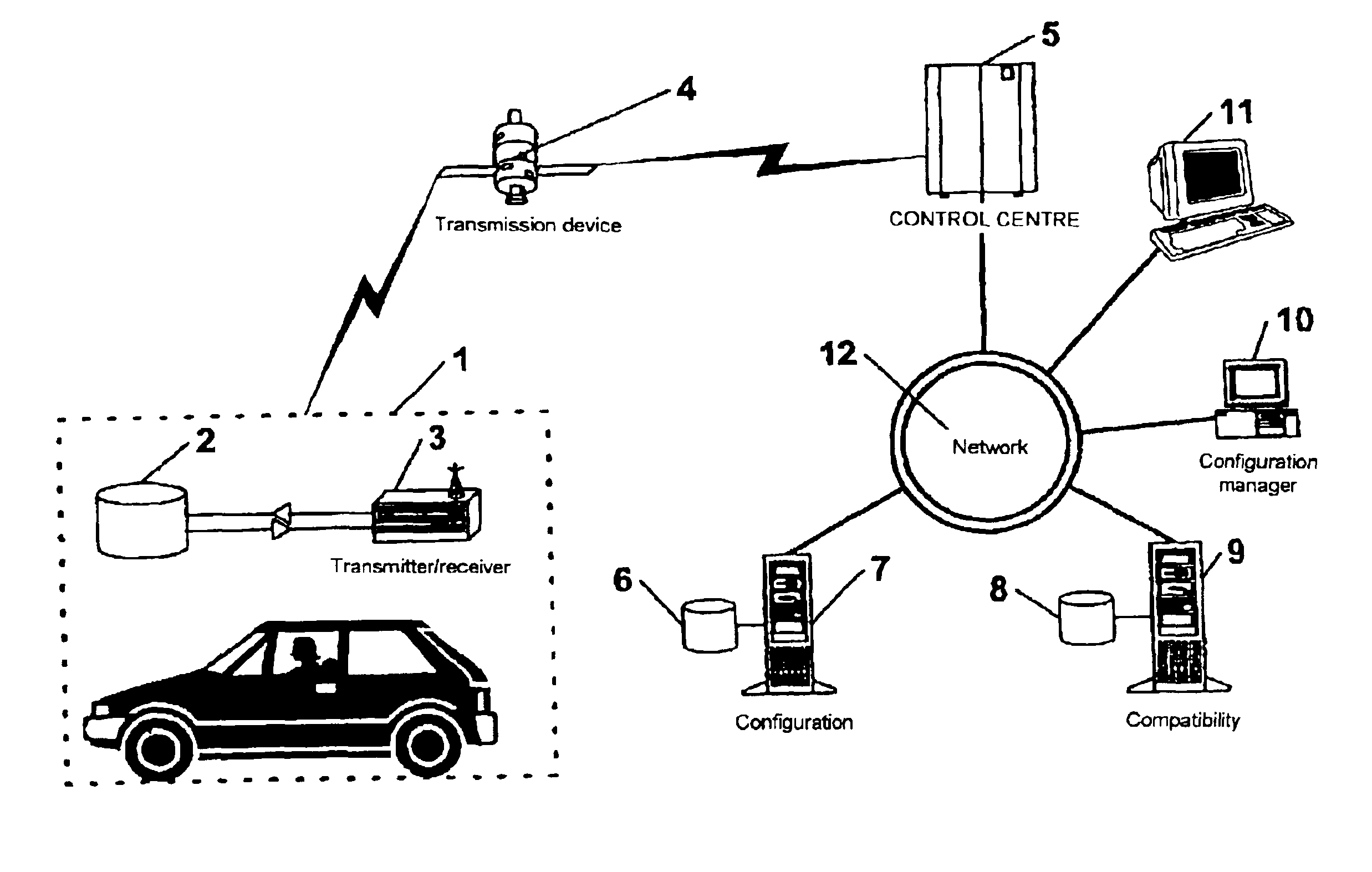

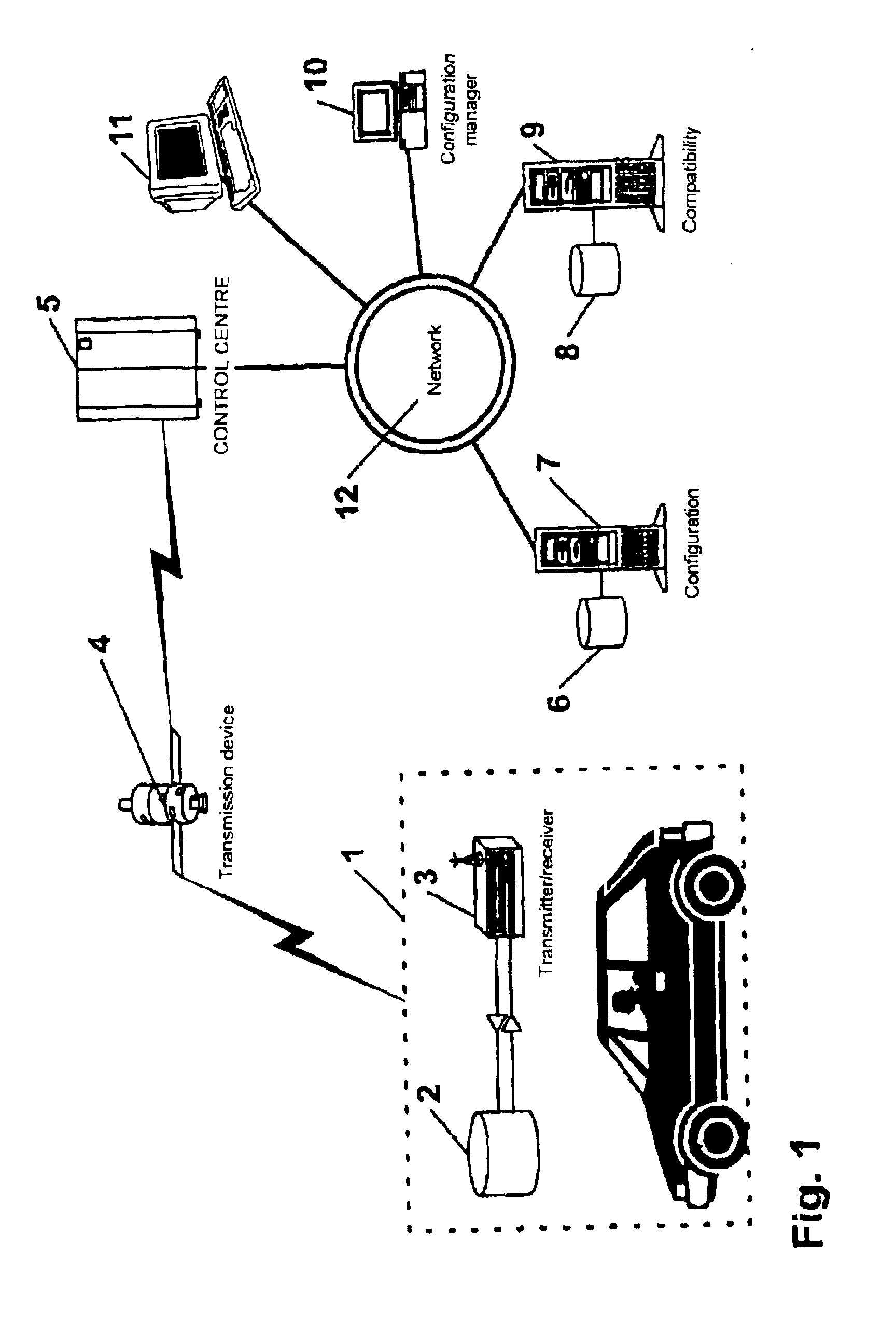

Method for documentation of data for a vehicle

InactiveUS6842762B2Fast updateAvoid errorsVehicle testingData processing applicationsEmbedded systemDocumentation procedure

A method for documentation of data for a vehicle, with the data being stored in a data memory (2) in the vehicle (1), the data in the data memory (2) being updated in the event of changes, and this data being transmitted via a wireless data transmission device (4) to a control center (5) outside the vehicle (1), in which case the control center (5), triggered by an initiation signal, passes on the data to a configuration documentation server (7), the data is stored in a database (6), in particular in a chronological sequence and broken down into products, in order to record the configuration standard outside the vehicle (1) for replacement of products on the vehicle (1).

Owner:BAYERISCHE MOTOREN WERKE AG

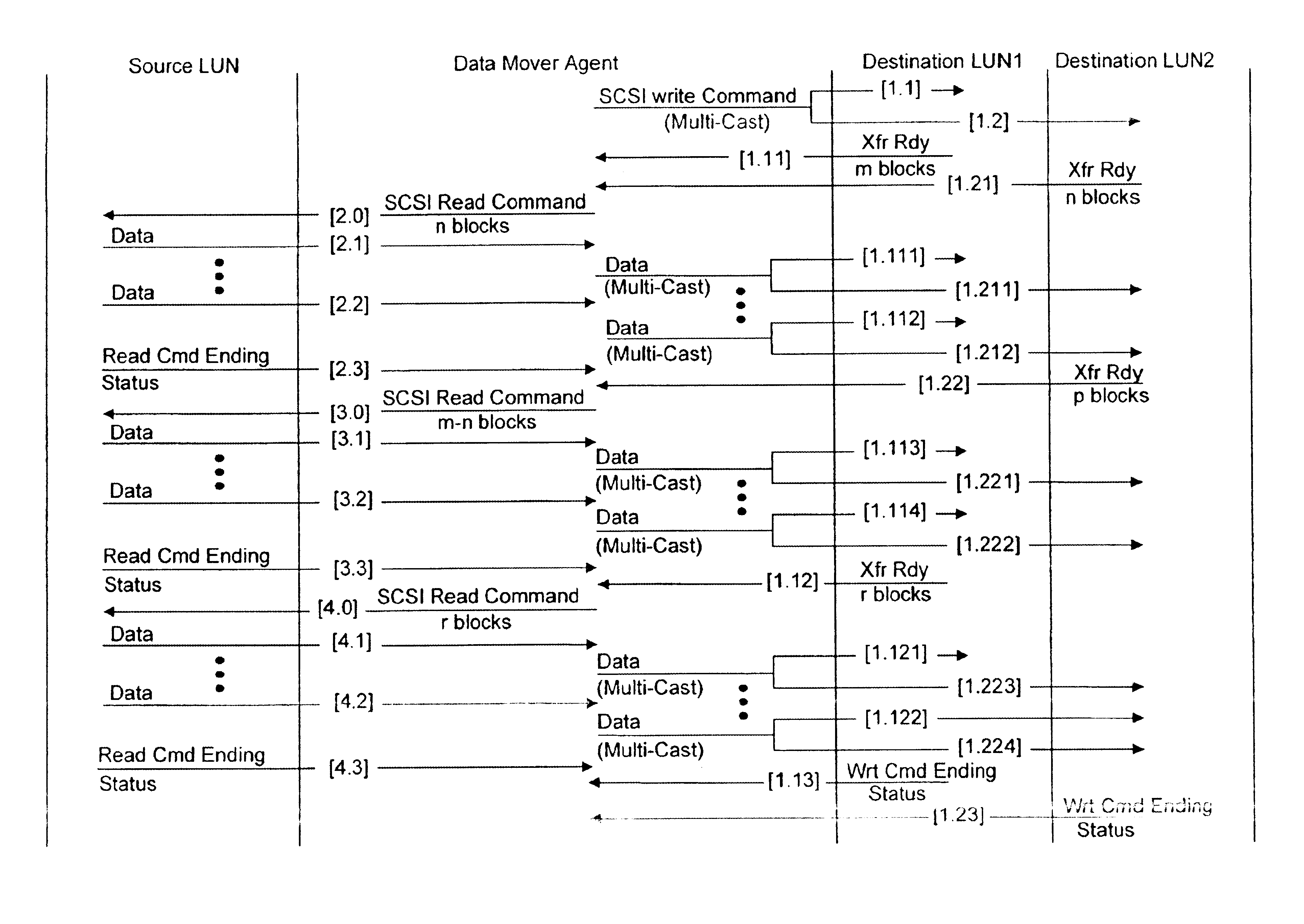

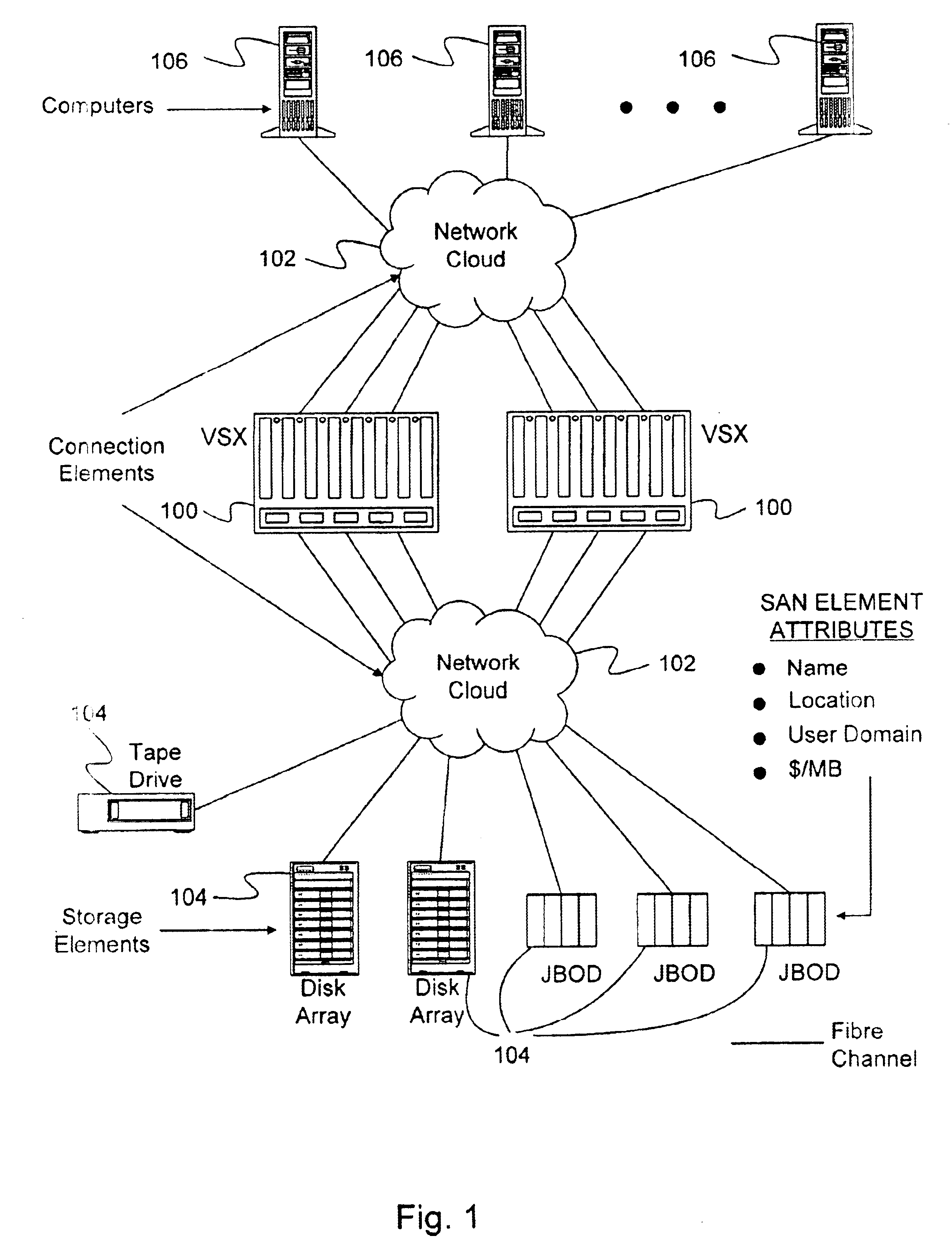

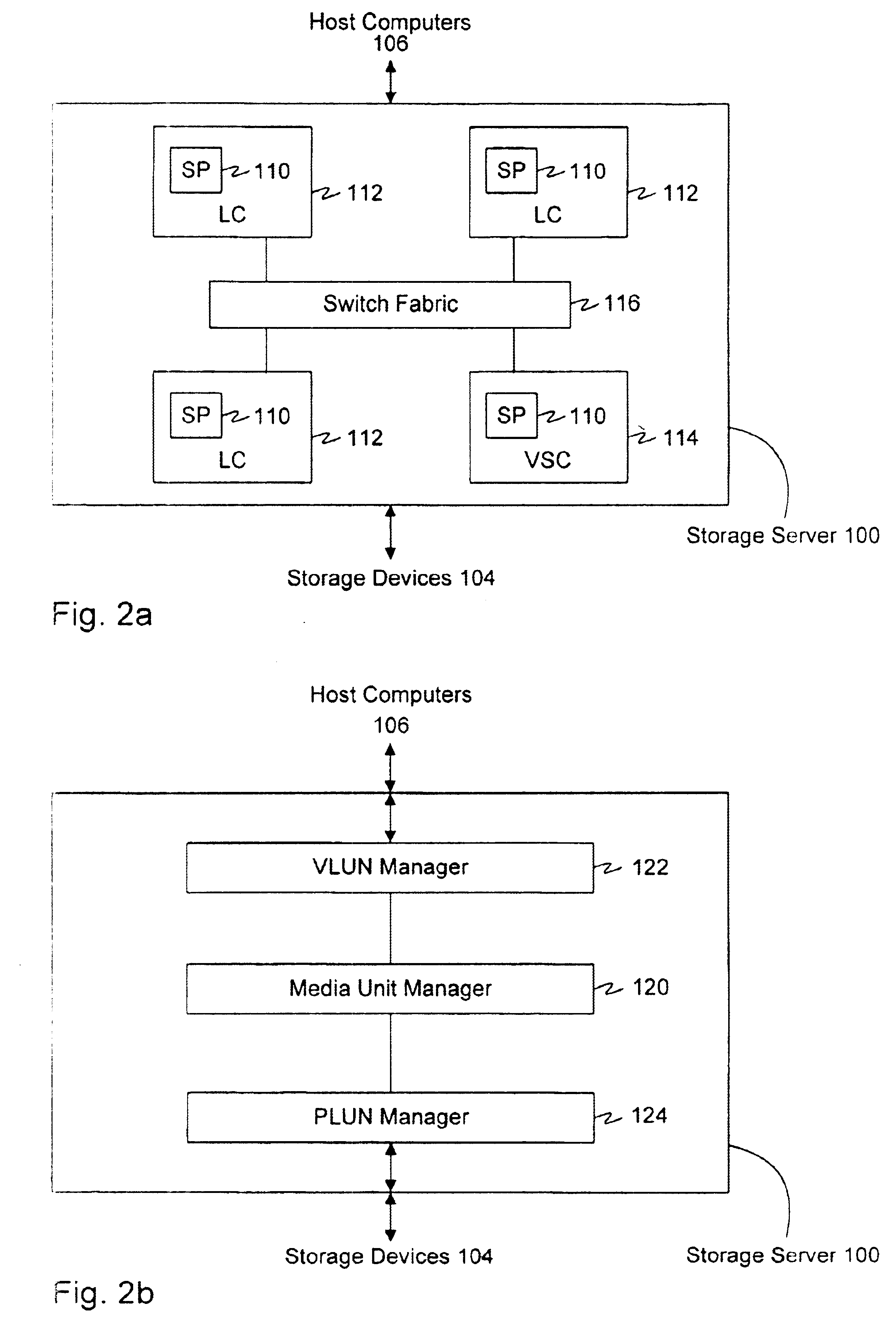

Data mover mechanism to achieve SAN RAID at wire speed

InactiveUS6880062B1Avoid dataAvoid errorsMultiple digital computer combinationsTransmissionRAIDWire speed

A Virtual Storage Server is provided for transferring data between a source storage device and one or more destination storage devices. A write command is issued to the one or more destinations for an amount of data. In response, one or more Transfer Ready Responses are returned indicating the amount of data the destinations are prepared to receive. The Virtual Storage Server then sends a read command to the source for an amount of data based on the amounts of data in the Transfer Ready Responses. The data is then transferred from the source storage device through the Virtual Storage Server to the one or more destination storage devices. Because data is transferred only in amounts that the destination is ready to receive, the Virtual Storage Server does not need a large buffer, and can basically send data received at wire speed. This process continues until the amount of data in the write command is transferred to the one or more destination storage devices.

Owner:NETWORK APPLIANCE INC

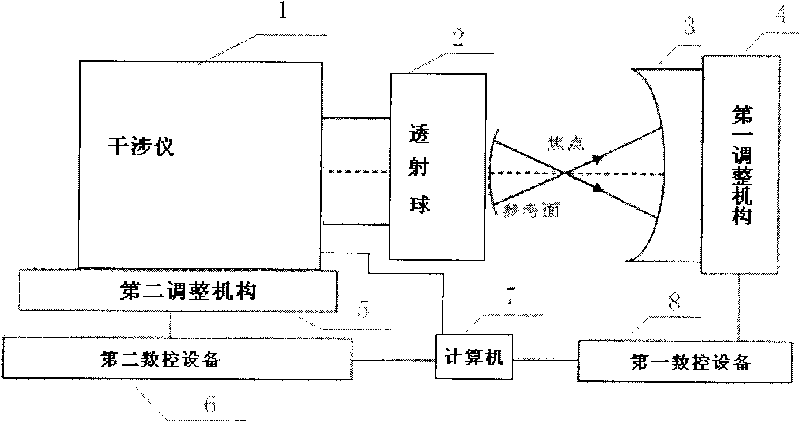

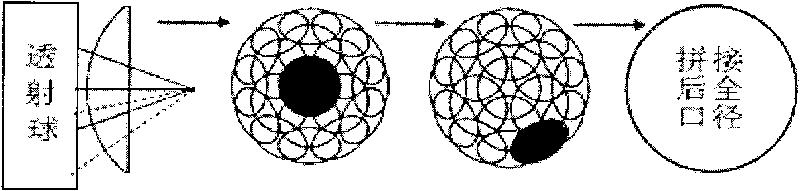

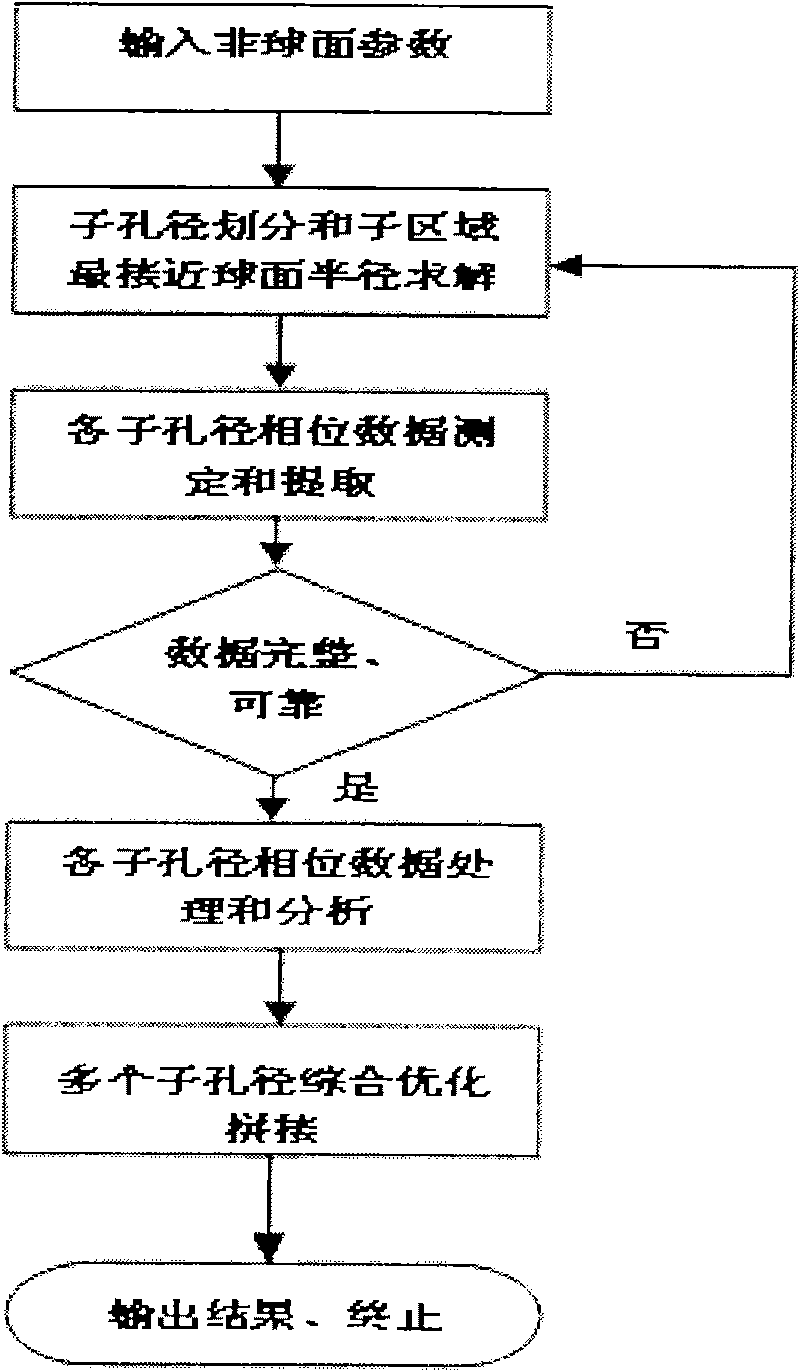

Device for detecting surface shape of optical aspheric surface by sub-aperture stitching interferometer

InactiveCN101709955AWiden horizontallyExpand the scope ofUsing optical meansNumerical controlFace shape

The invention relates to a device for detecting a surface shape of an optical aspheric surface by a sub-aperture stitching interferometer, which comprises an interferometer, a transmission sphere, an adjusting mechanism, a numerical control device and a computer, wherein parallel light emitted by the interferometer is changed into a standard spherical wave through the transmission sphere; the computer controls the action of the adjusting mechanism by the numerical control device to adjust the relative position of the interferometer and an aspheric surface to be detected so that the standard spherical wave is incided to each sub-aperture of the detected optical aspheric surface sequentially and returns to the interferometer; and the computer extracts phase distribution data of each sub-aperture measured by the interferometer for analysis and processing, and the error distribution of the surface shape of a full aperture of the detected optical aspheric surface is obtained by a stitching algorithm. The device broadens horizontal and vertical dynamic range tested by the interferometer, can detect surface shapes of large-aperture concave and convex aspheric surfaces and an off-axis aspheric surface in high resolution and high precision without other auxiliary optical elements, and has low testing cost and short construction period.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

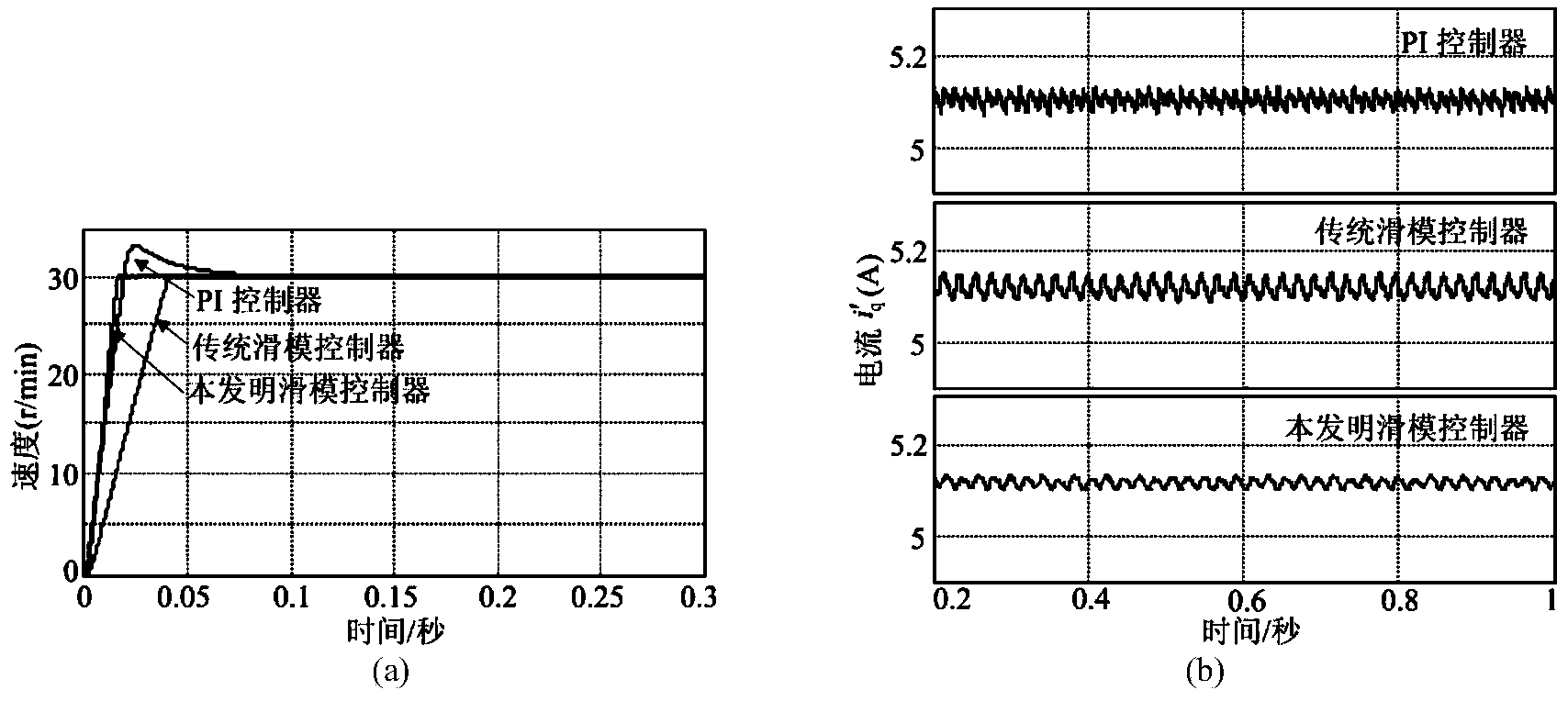

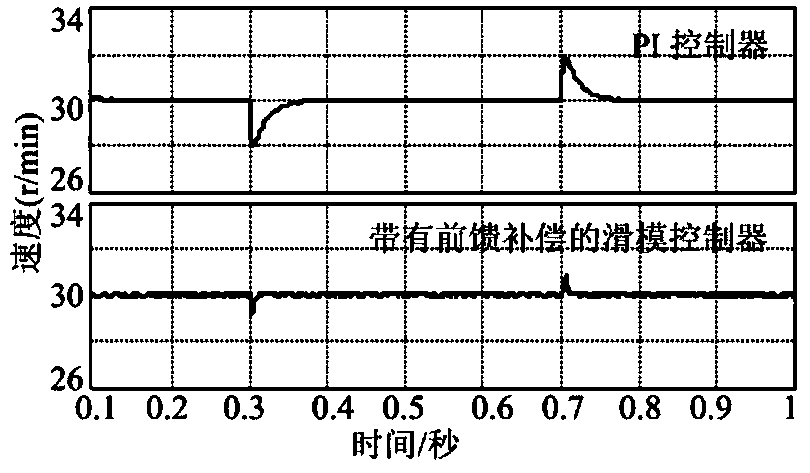

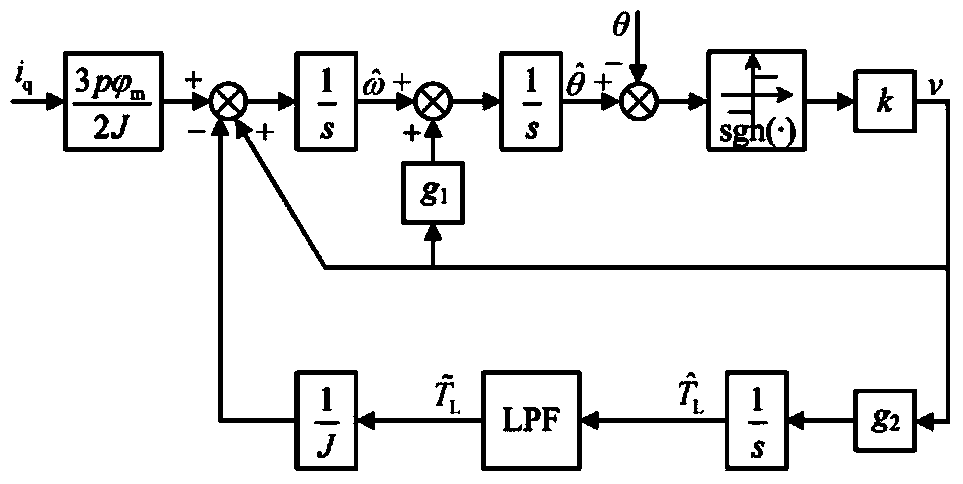

Permanent magnet motor sliding mode control strategy

ActiveCN103647490AReduce the valueSolve chattering problemsElectronic commutation motor controlVector control systemsControl vectorLoop control

The invention pertains to the technical field permanent magnet motors, and relates to a permanent magnet motor sliding mode control strategy. The permanent magnet motor is controlled by adopting double-closed speed current. The permanent magnet motor sliding mode control strategy is characterized in that a sliding mode speed controller and an extended sliding mode observer are adopted in the control strategy, the sliding mode speed controller adopts an exponential approach law containing the speed error and the sliding mode surface information, the deviation between a given rotating speed and a feedback rotating speed is taken as the input quantity, and a q-axis current given value is outputted through the sliding mode control quantity; the extended sliding mode observer is used to estimate the rotor position, the rotating speed and the load torque on a real-time basis, the rotating speed and the rotor position are used to provide the information of speed closed-loop control and coordinate transformation, and the load torque is compensated to the sliding mode speed controller, so that the high-accuracy vector control of the permanent magnet motor can be realized. The control strategy of the invention can be used to make the system fast track a given speed in the dynamic state, reduce the speed overshoot and the current fluctuation, and improve the disturbance resistance performance of the system.

Owner:TIANJIN UNIV

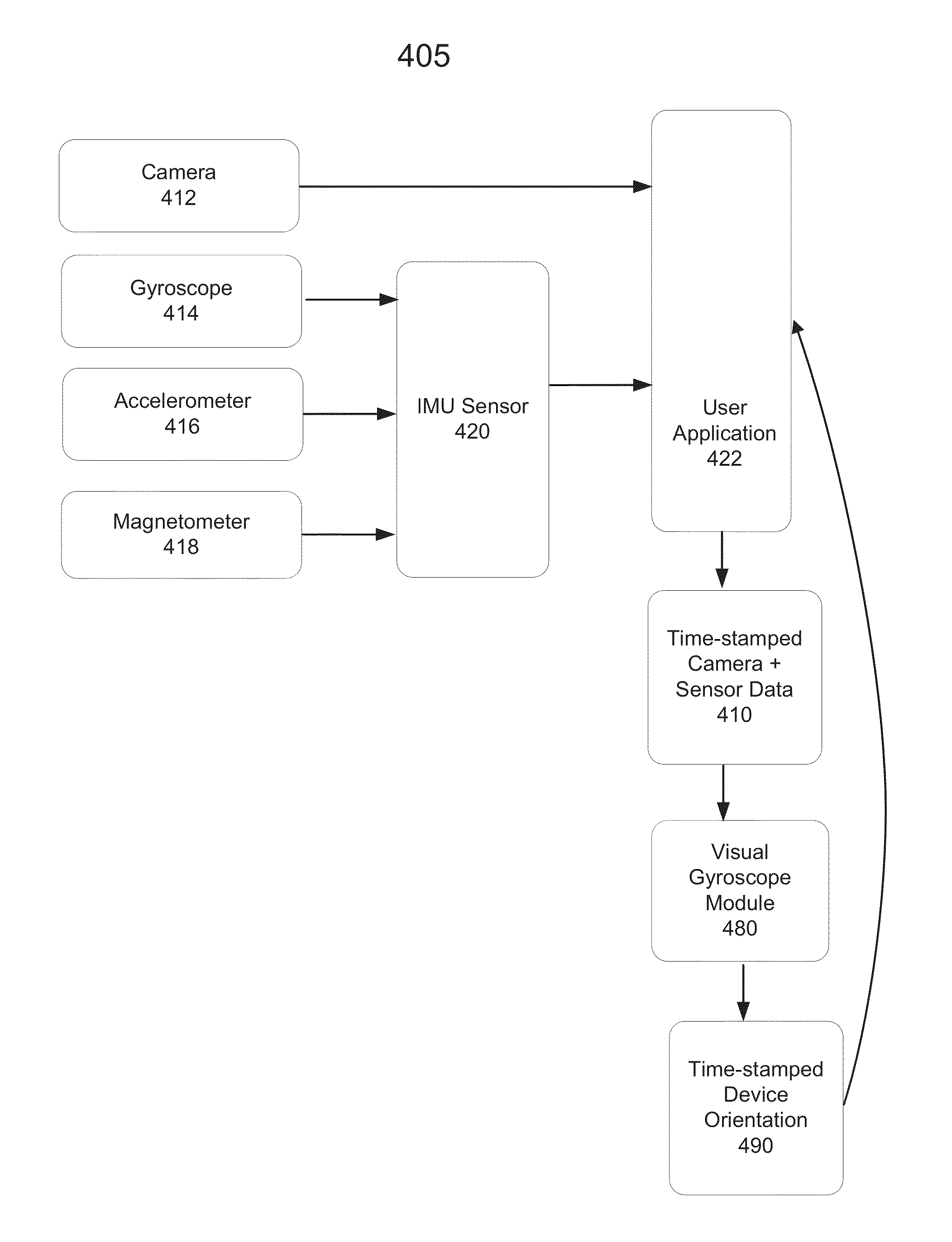

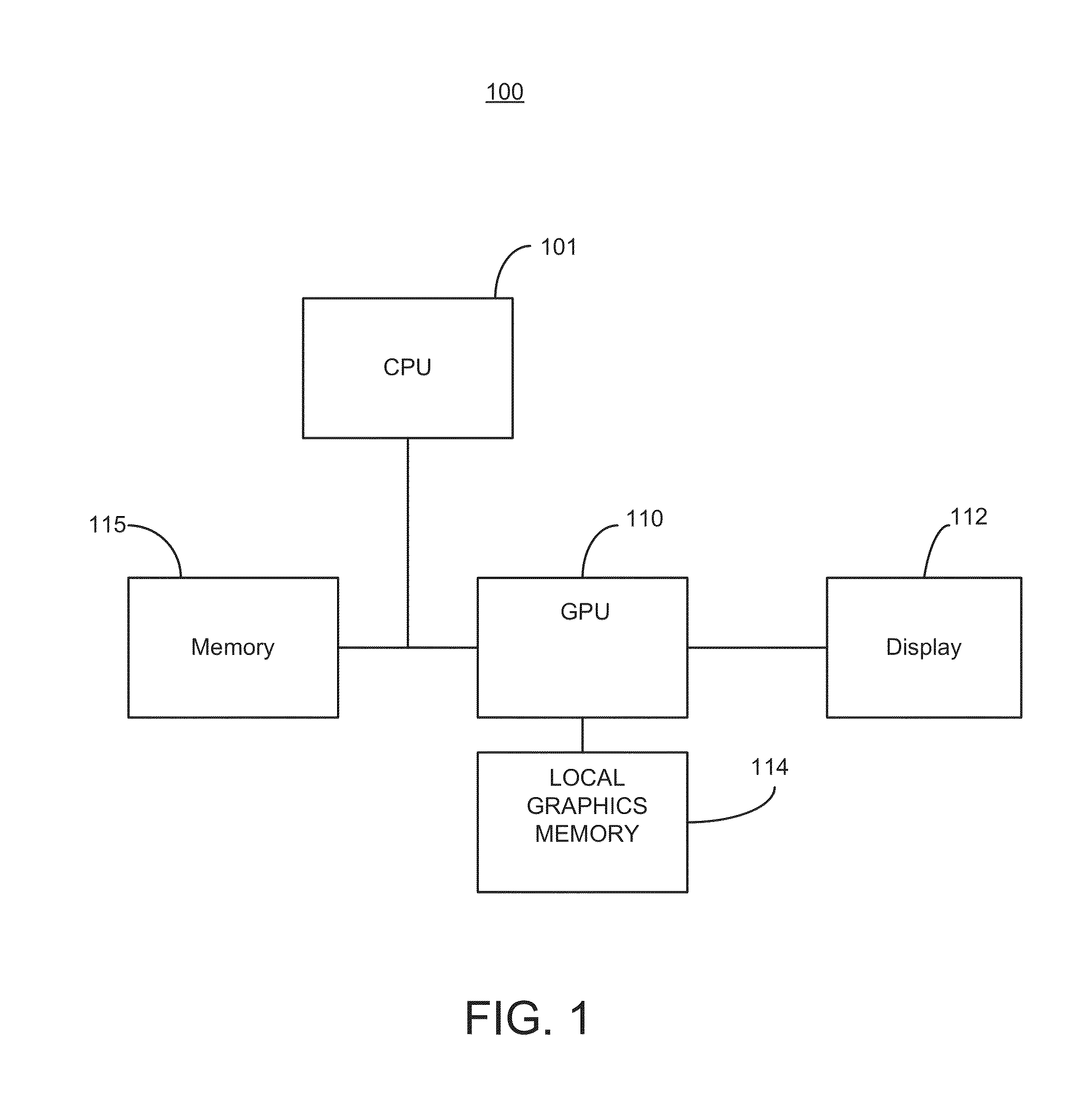

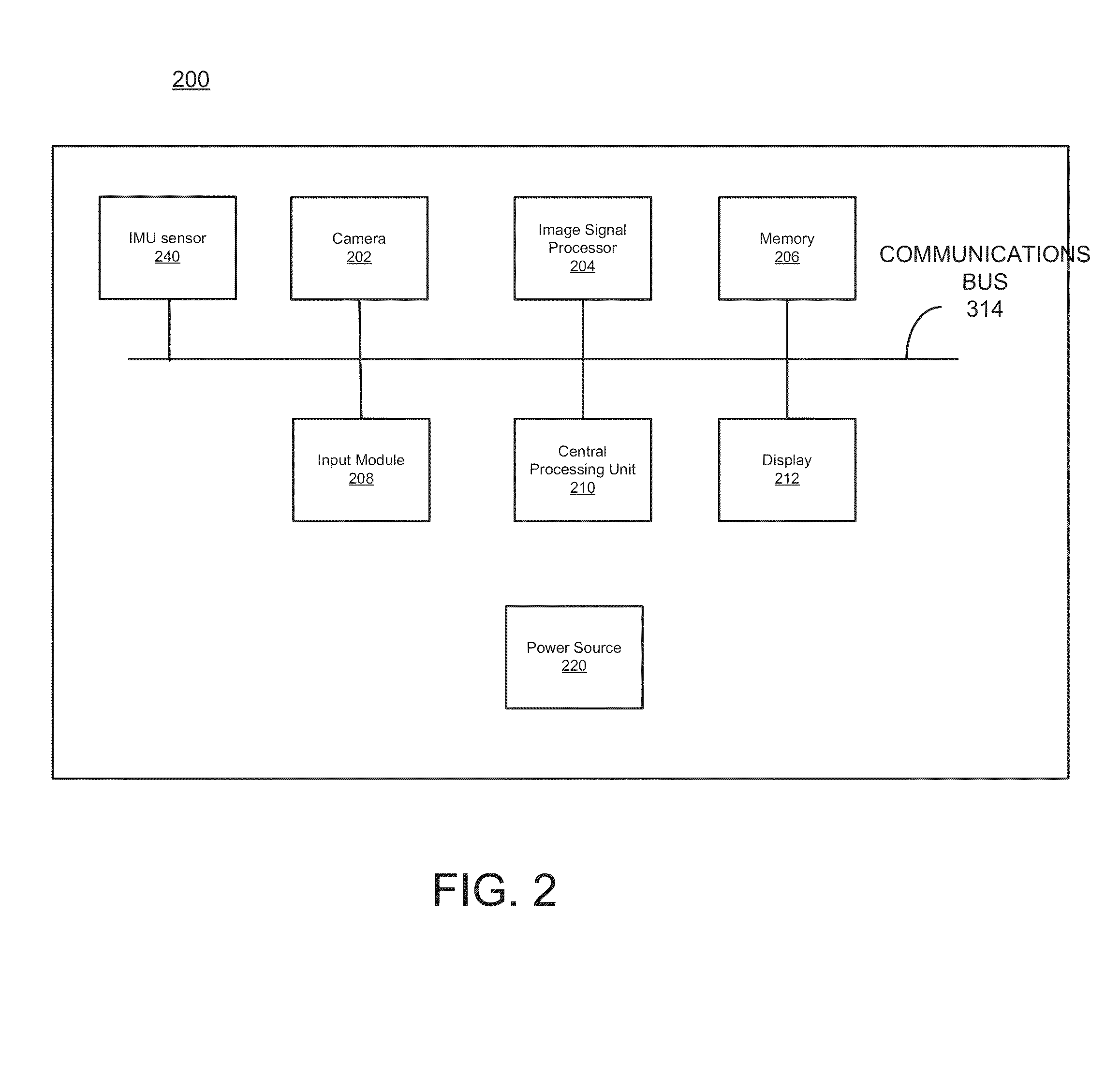

Method and apparatus for device orientation tracking using a visual gyroscope

InactiveUS20150103183A1Small computational footprintEasy to trackImage enhancementTelevision system detailsGyroscopeKey frame

A method for tracking device orientation on a portable device is disclosed. The method comprises initializing a device orientation to a sensor orientation, wherein the sensor orientation is based on information from an inertial measurement unit (IMU) sensor. It also comprises initiating visual tracking using a camera on the portable device and capturing a frame. Next, it comprises determining a plurality of visual features in the frame and matching the frame to a keyframe, wherein capture of the keyframe precedes capture of the frame. Subsequently, it comprises computing a rotation amount between the frame and the keyframe. Responsive to a determination that a rotational distance between the frame and the keyframe exceeds a predetermined threshold, promoting the frame to a keyframe status and adding it to a first orientation map and adjusting the frame with all prior captured keyframes.

Owner:NVIDIA CORP

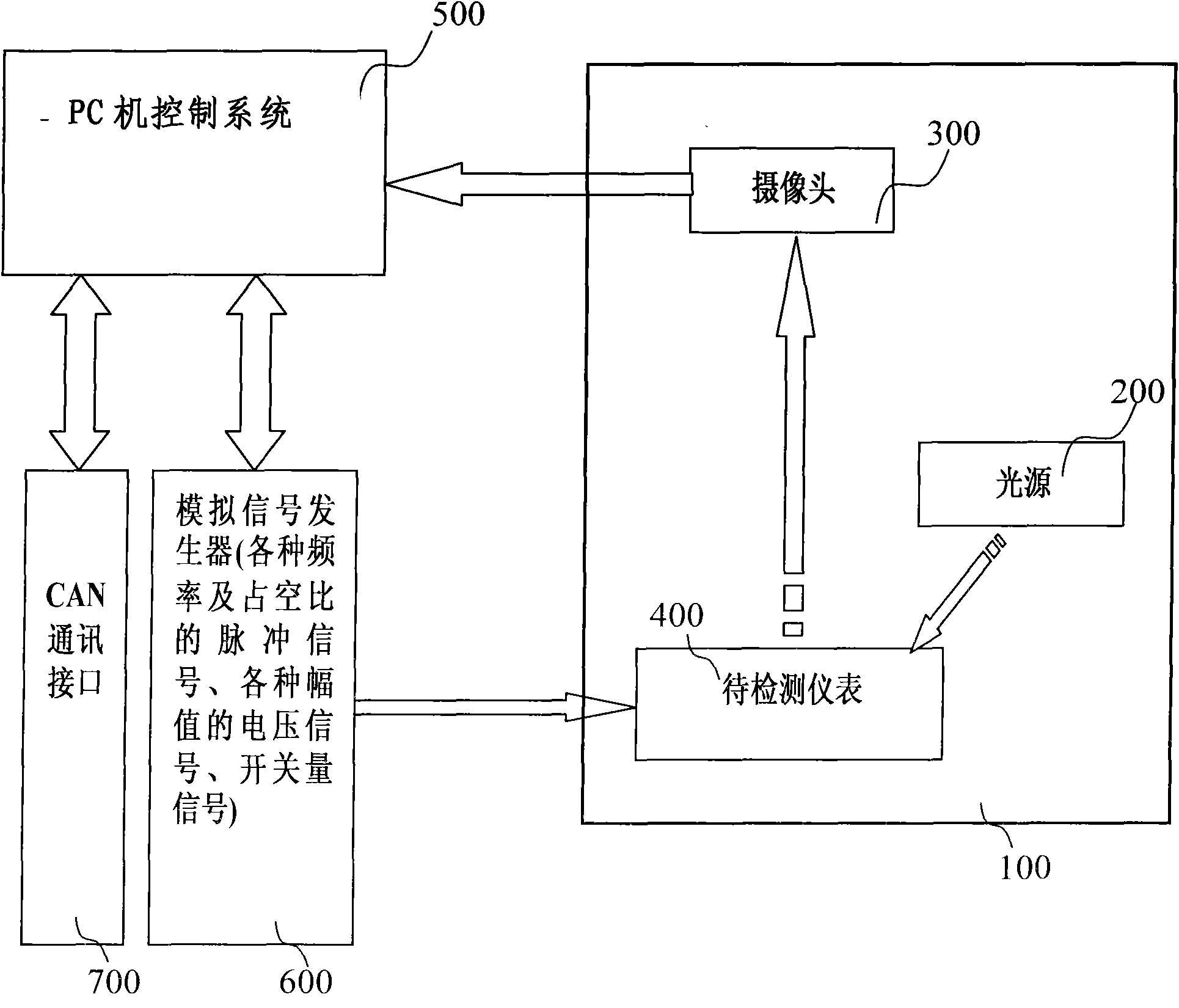

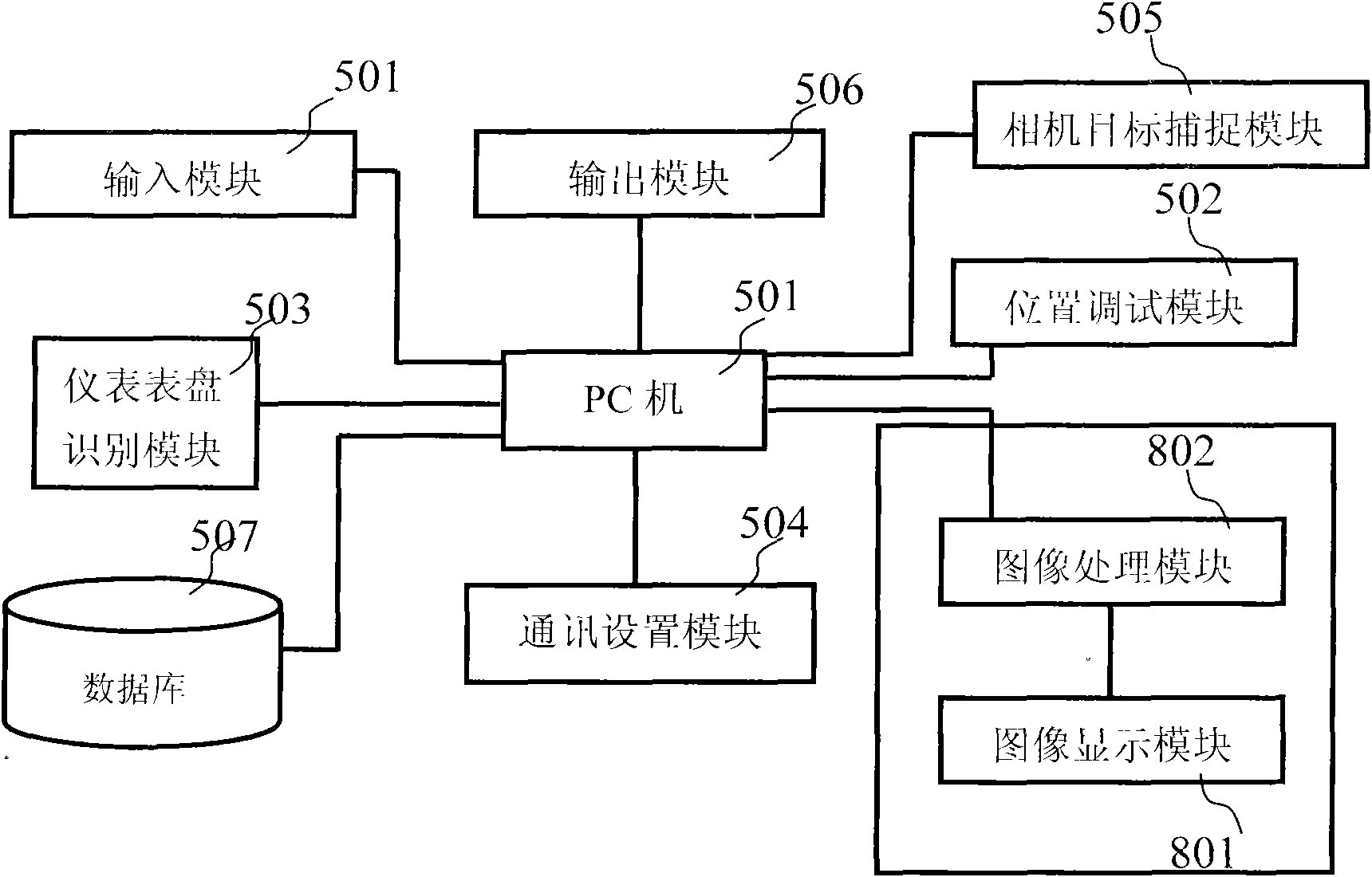

Auto meter visual detecting system based on computer and detecting method thereof

ActiveCN101672663AAvoid errorsImprove reliabilityPhotogrammetry/videogrammetryTesting/calibration of speed/acceleration/shock measurement devicesImaging processingTarget capture

The invention discloses an auto meter visual detecting system based on a computer, comprising a light source, a detecting box body, a camera connected with a PC control system, and an analog signal generator connected with the PC control system, wherein the analog signal generator comprises a frequency circuit and a resistance circuit and is used for receiving commands sent by the PC control system so as to generate frequency and a resistance signal needed by meter detection; the PC control system comprises an input module, a position adjusting module, a meter dial plate identification module,a communication setting module, a camera target capturing module and an output module which are respectively connected with a PC. The position adjusting module promotes two stepping motors in a camera position adjusting mechanism to run by sending serial port commands; and the communication setting module is used for realizing Ethernet communication setting and serial port communication setting.The camera comprises an image displaying module and an image processing module. The invention also discloses a detecting method of the detecting system.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

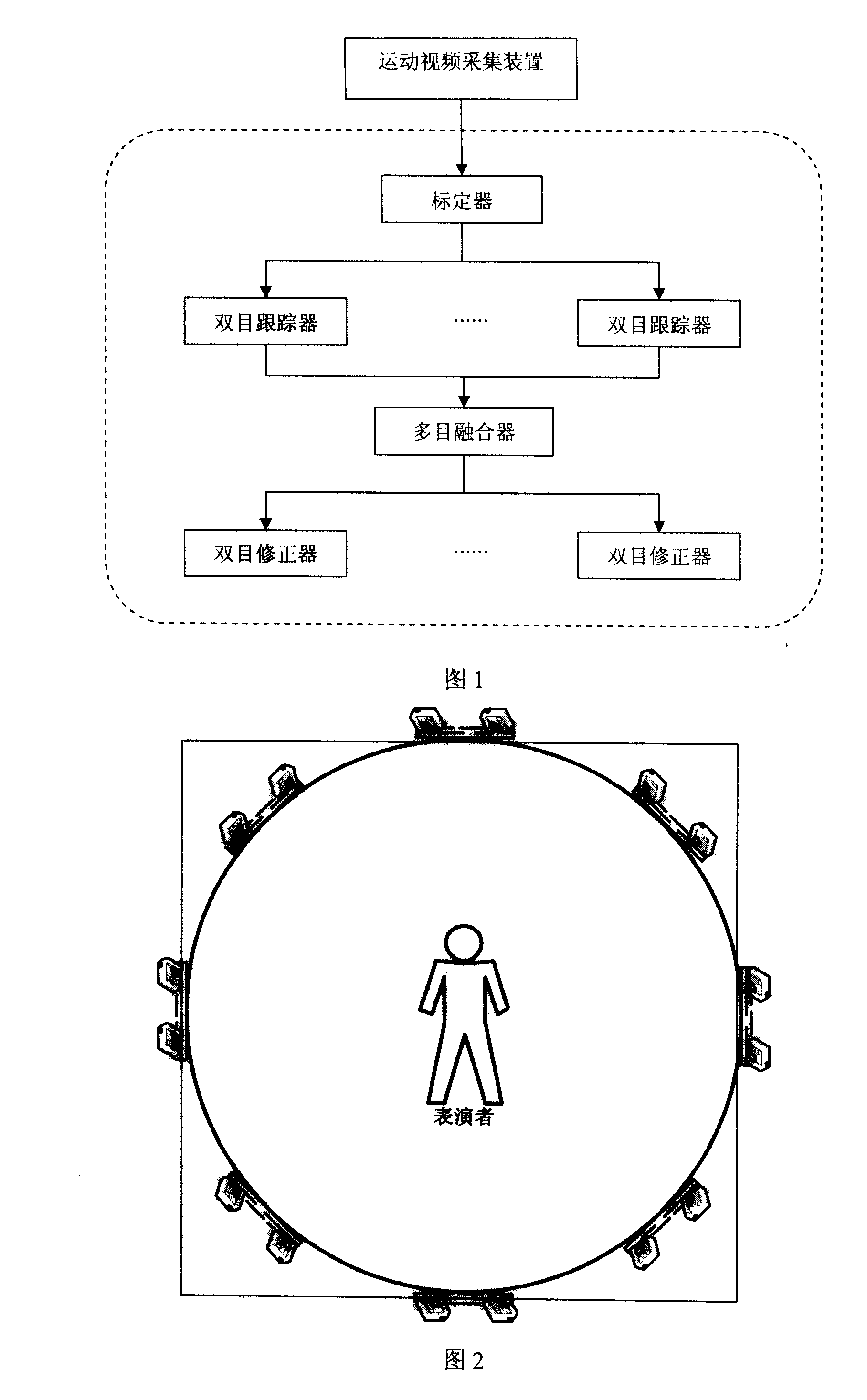

Method for capturing movement based on multiple binocular stereovision

The invention discloses a movement capturing method based on multiple binocular stereo vision. A movement video collecting device is constructed, and human movement video sequences from different orientations are collected by the movement video collecting device. Multiocular movement video sequences shot by a plurality of cameras are calibrated. Marked points matching and tracking of each binocular tracker is finished. Data fusion of three-dimensional tracking result of multiple binocular trackers is completed. The three-dimensional movement information of the marked points acquired by a multiocular fusion device is fed back to the binocular tracker to consummate binocular tracking. On the basis of binocular three-dimensional tracking realized by binocular vision, the invention fuses multiple groups of binocular three-dimensional movement data, resolves parameter acquiring problem of three-dimensional position, tracking, track fusion and the like for a plurality of marked points, increases number of traceable market points and enables the tracking effect to be comparable with three-dimensional movement acquiring device employing multi-infrared cameras for collecting.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

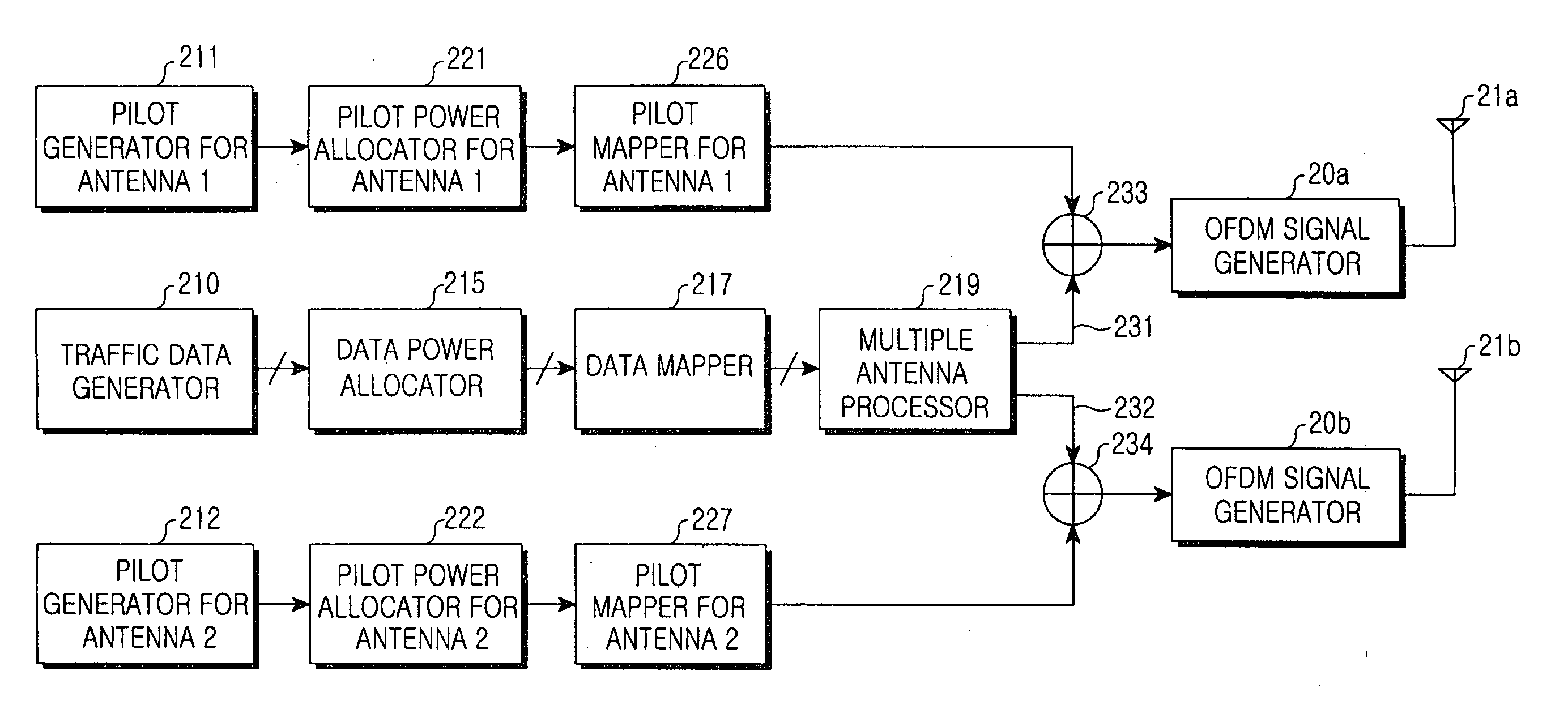

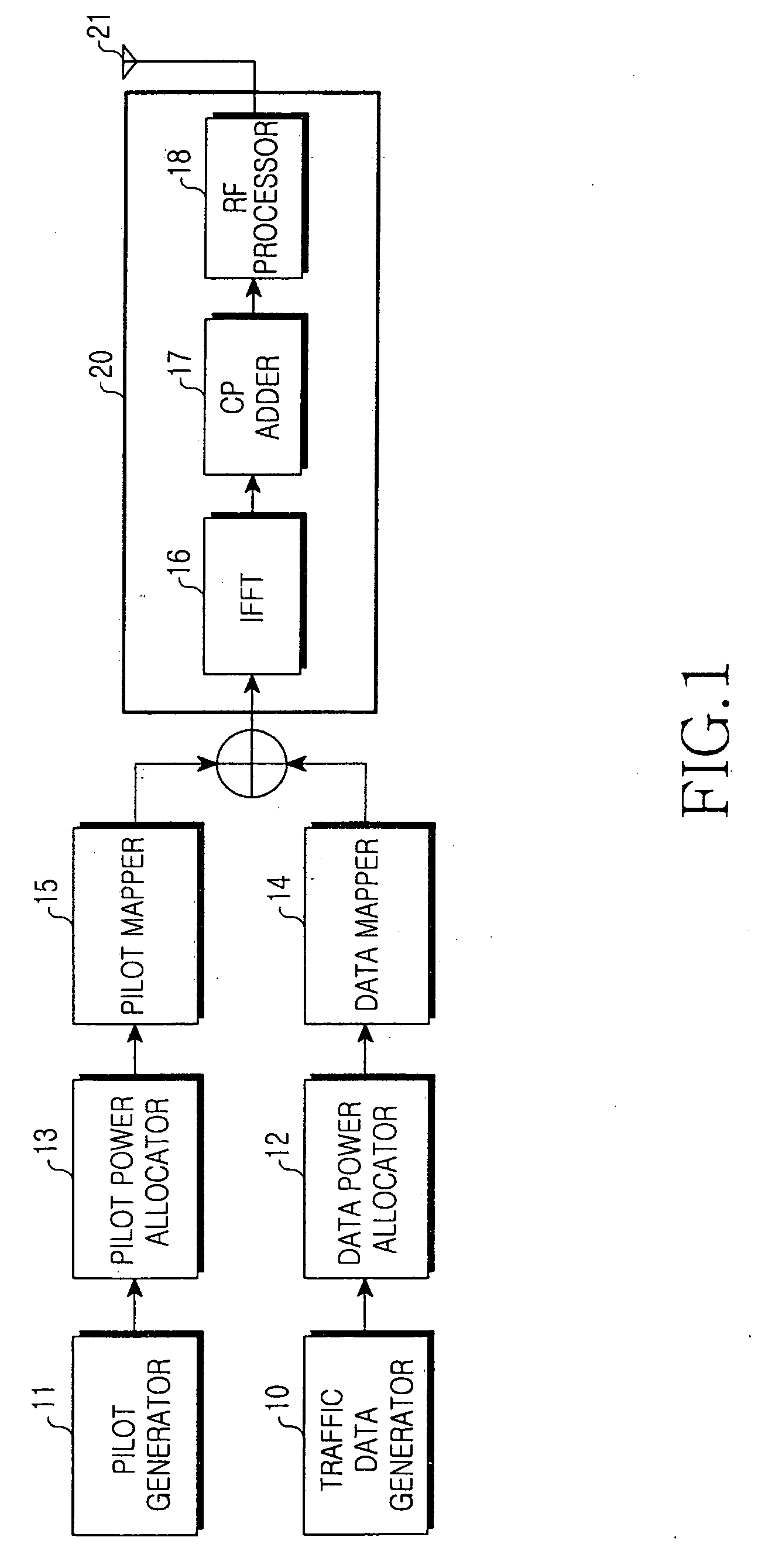

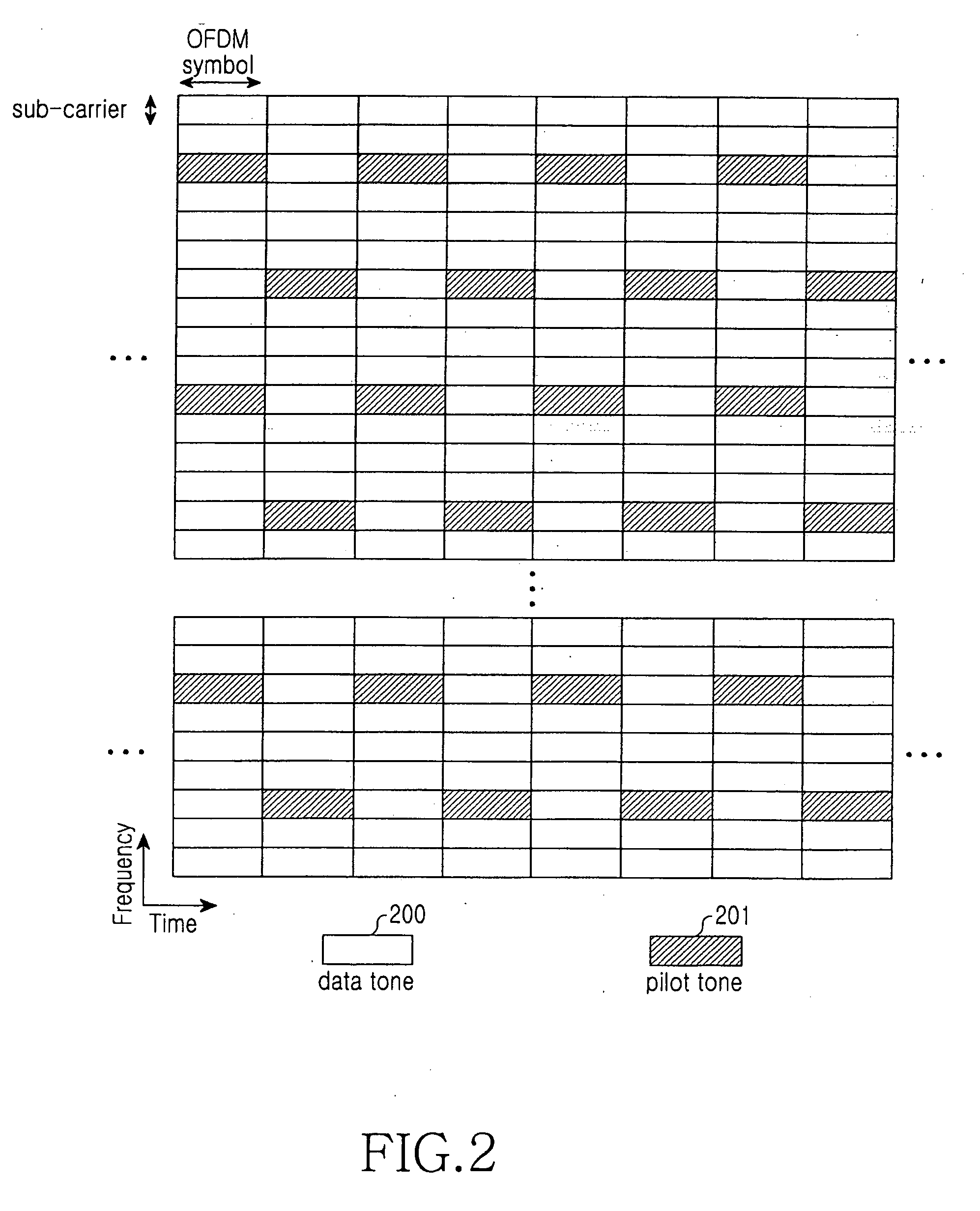

Apparatus and method for transmitting and receiving pilot signal using multiple antennas in a mobile communication system

InactiveUS20060285479A1Avoid mistakesAccurate estimateRadio transmissionMultiplex code allocationCarrier signalMobile communication systems

An apparatus and method are provided for transmitting and receiving a pilot signal using multiple antennas in an OFDM mobile communication system. In the pilot transmitting apparatus, at least one Walsh coverer Walsh-covers a pilot signal to be sent through each of transmit antennas. At least one transmitter allocates the Walsh-covered pilot signals to a predetermined subcarrier in every OFDM symbol and transmits the allocated pilot signals through the transmit antennas.

Owner:SAMSUNG ELECTRONICS CO LTD

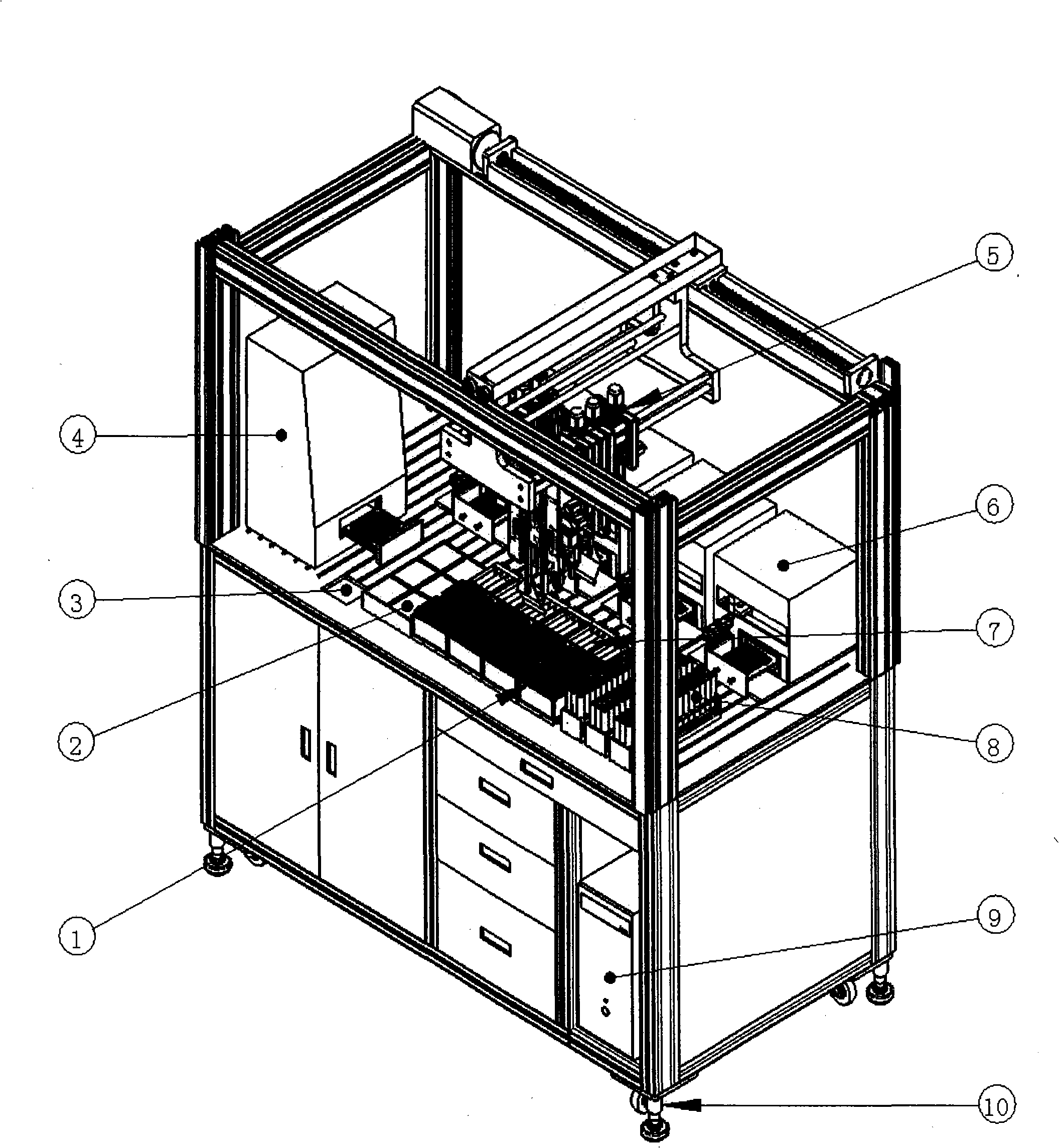

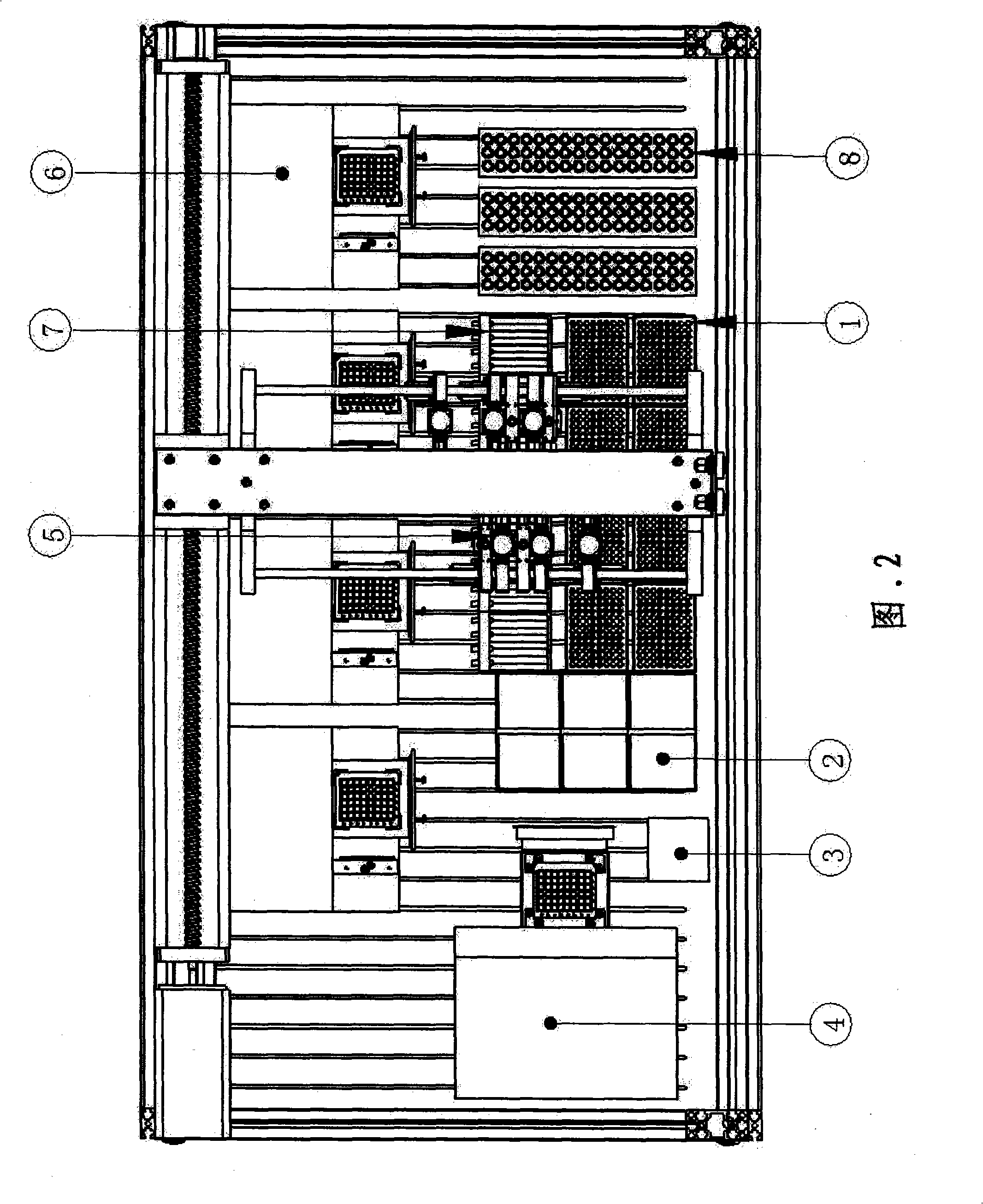

Full-automatic biological chips detection system

ActiveCN101334402AImprove stabilityImprove reliabilityMicrobiological testing/measurementBiological testingComputer moduleEngineering

The invention discloses a full automatic biochip detection system belonging to the clinical detection field of multi-marker biochips. The system adopts modular structure and comprises an automatic sample processing module, a reaction washing module, a detection module, a Tip head storage module, a reagent storage module, a biochip storage module, a sample storage module, a system base, an electric control box and a computer, the electric control box and all the modules are operated under the control of software, so as to realize the automatic sampling, the sample adding, the reaction, the washing, the detection and other processes. All the modules can work independently and can also be combined together and matched for work. The full automatic biochip detection system can overcome the shortcomings of the existing biochip detector and reduce the errors caused by human operation, and has stable and reliable detection result and good flexibility, so that the full automatic biochip detection system can not only greatly improve the detection efficiency, but also can be conductive to the accuracy of the detection result; the system has simple operation, therefore, the system is not only applicable to the scientific research and the applications of laboratories and hospitals, but also can be used for large-scale sample screening of large-scale hospitals and blood stations.

Owner:上海裕隆生物科技有限公司

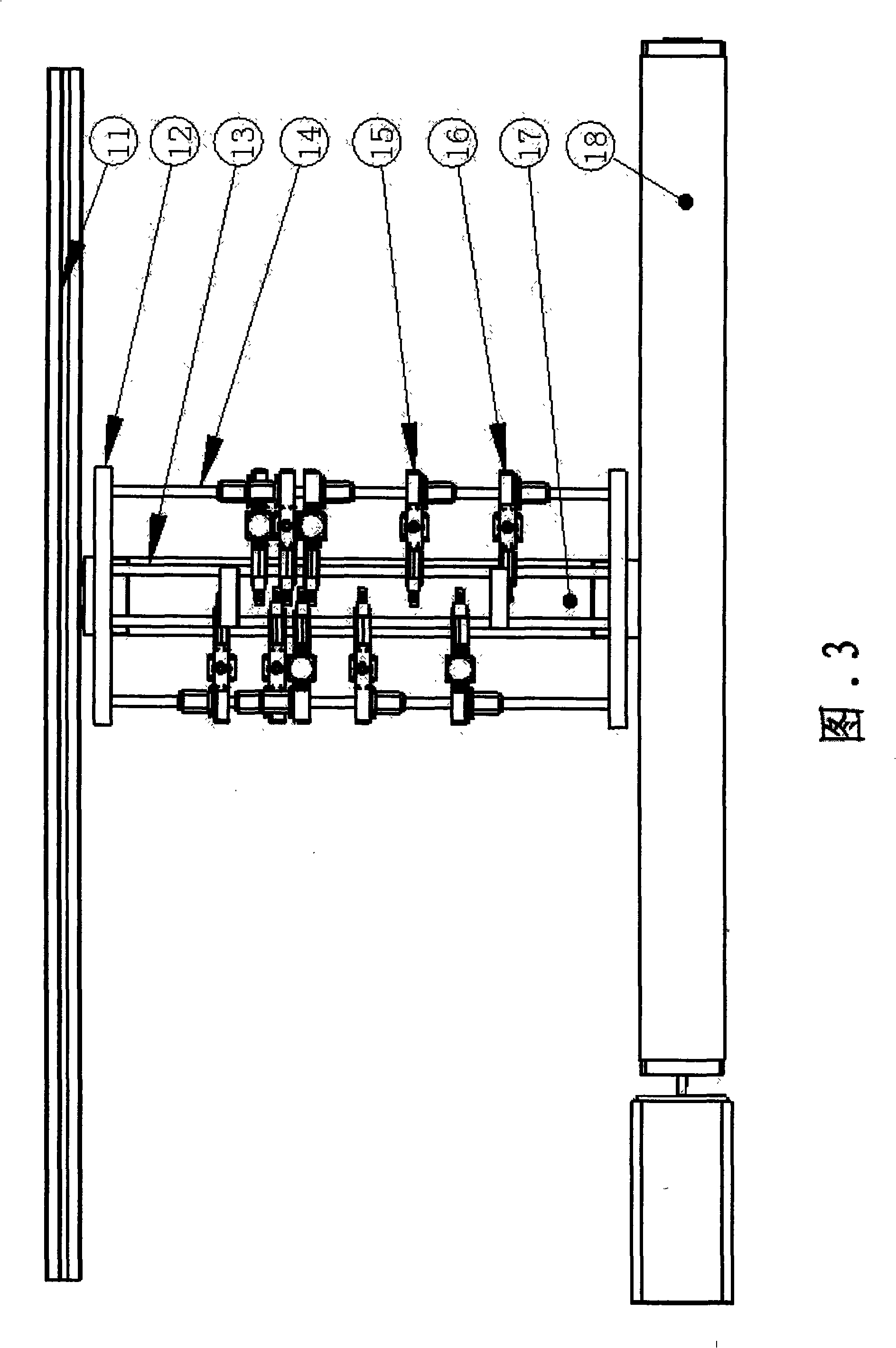

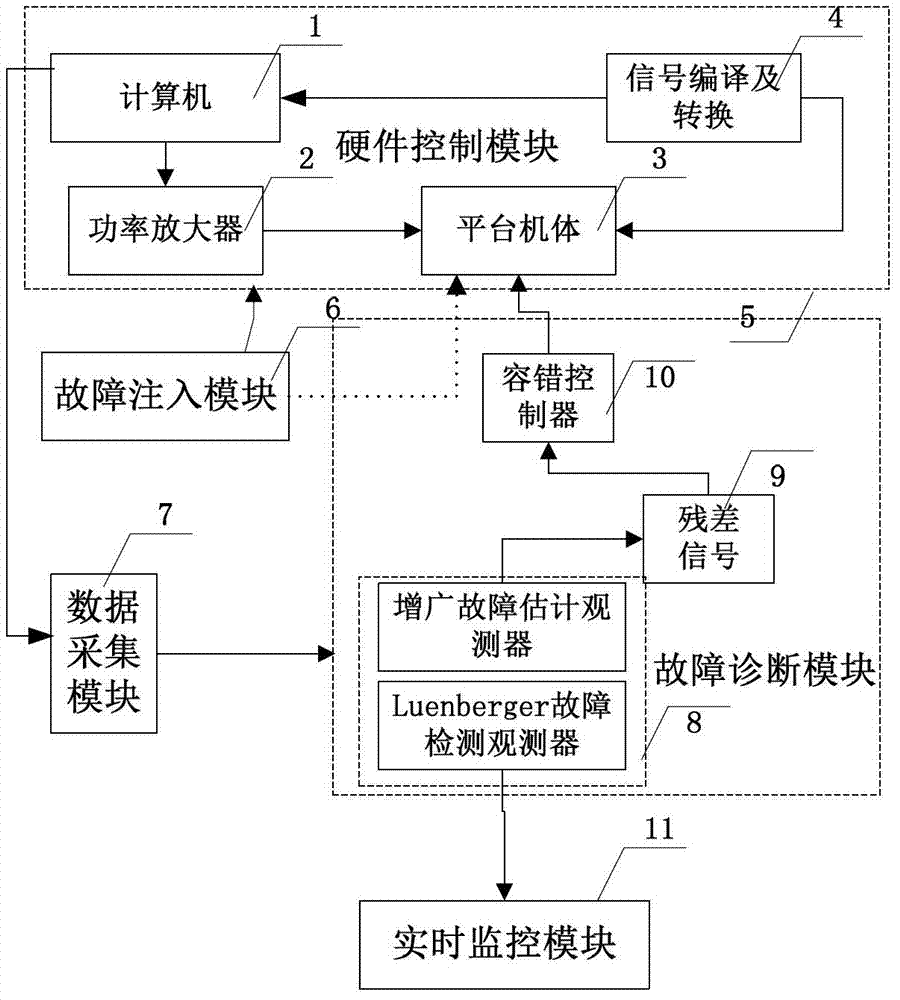

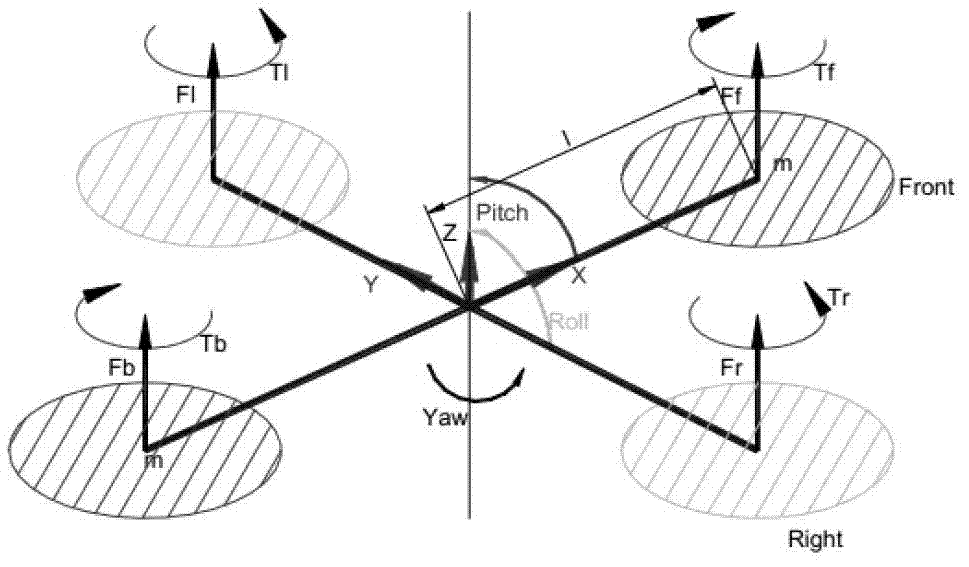

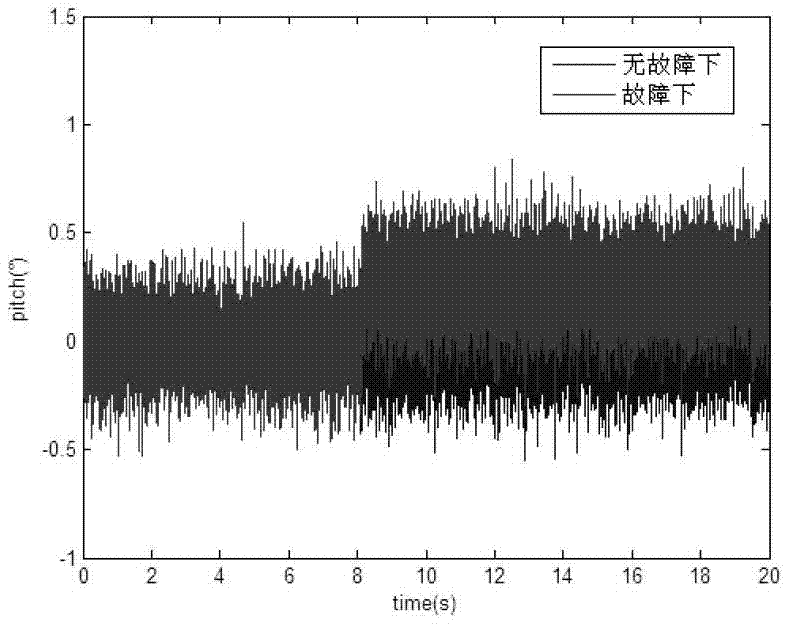

A plurality of united observer based fault diagnosis and fault-tolerant control device and method

ActiveCN102854874AAvoid serious coupling problemsAvoid errorsElectric testing/monitoringAviationDiagnosis methods

The invention discloses a plurality of united observer based fault diagnosis and fault-tolerant control device and a method and belongs to the field of aerospace. The plurality of united observer based fault diagnosis and fault-tolerant control device comprises following modules of a fault injection module, a fault diagnosis module, a real time monitoring module and a hardware control module. According to the method, the problem that traditional observer based fault diagnosis methods are limited by conditions is mainly solved, the operation is simple, the implementability is high, and the method can be used for diagnosing faults of actuating mechanisms of a four rotor wing helicopter and verifying feasibility of state monitoring.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

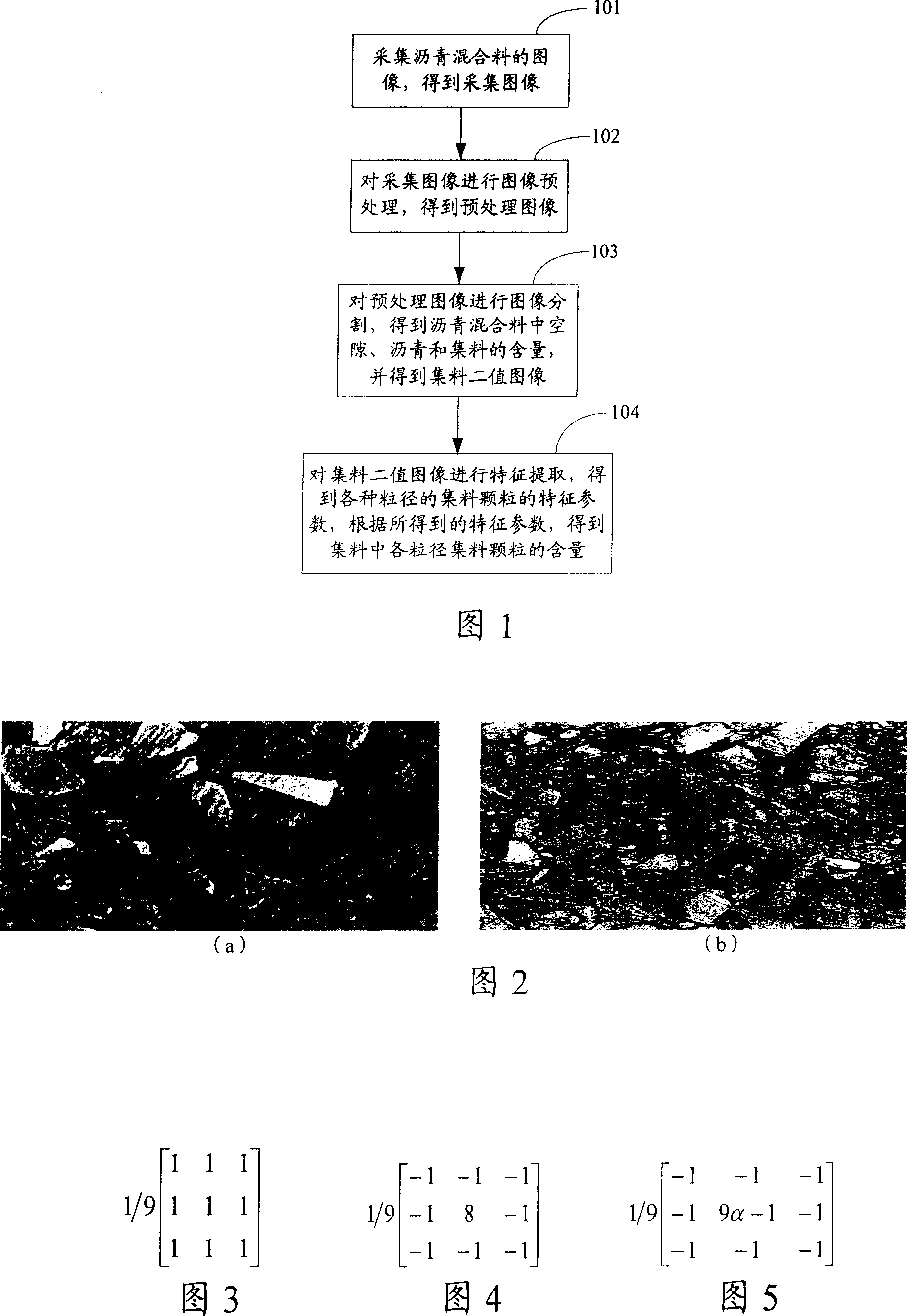

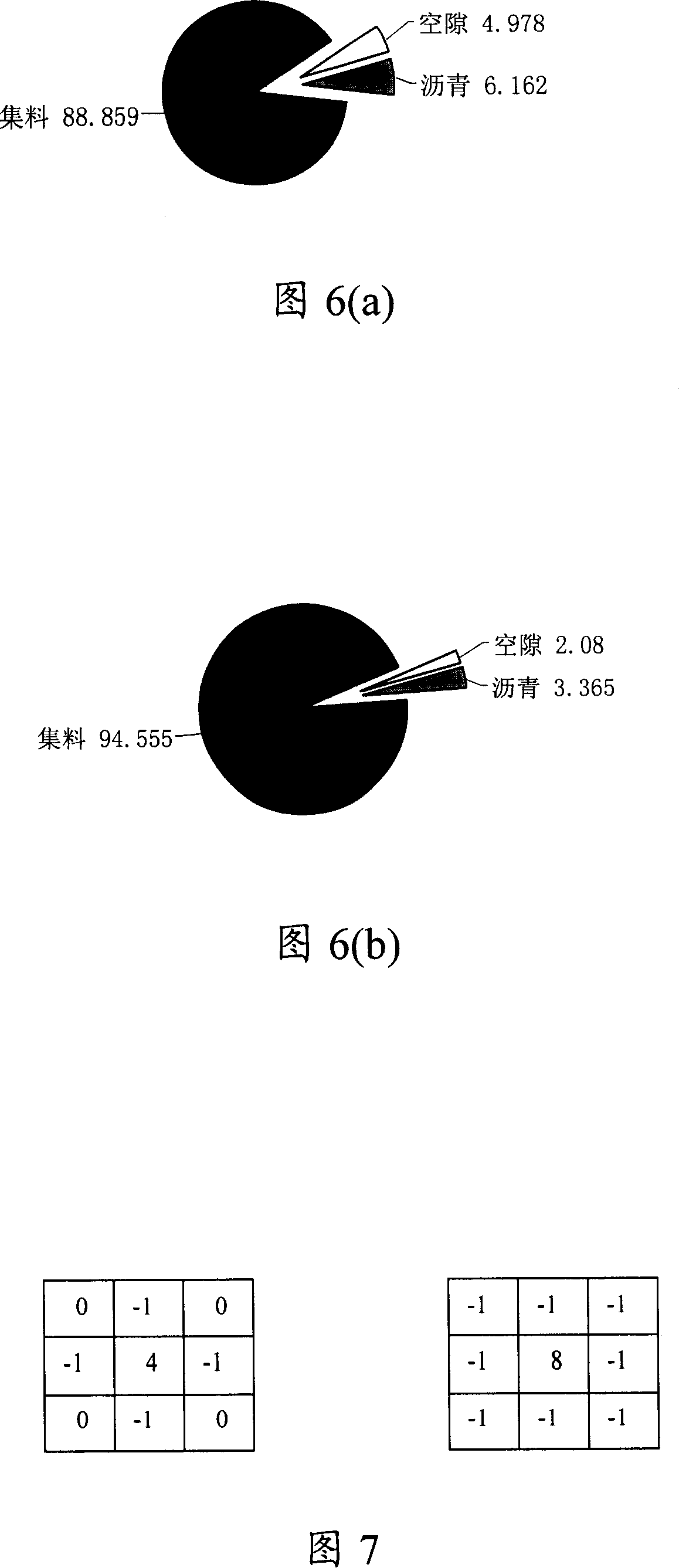

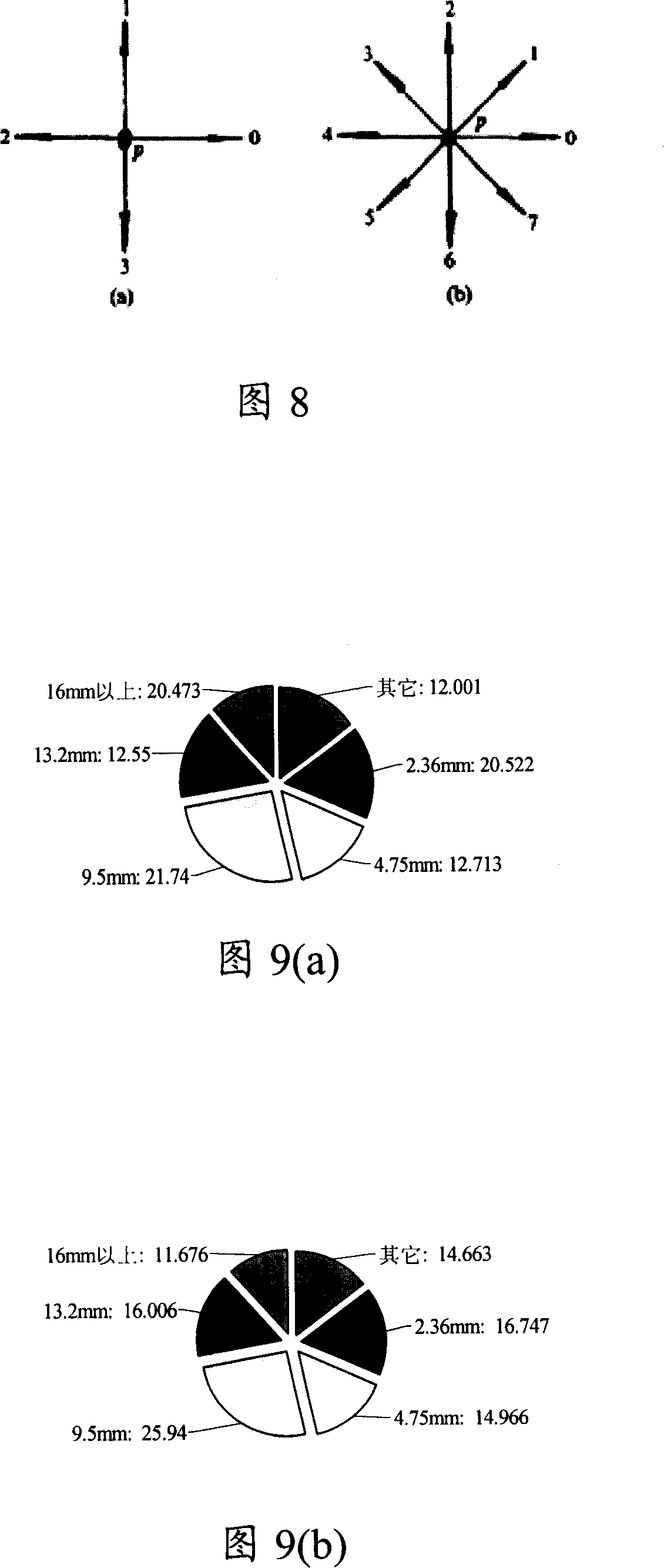

Method and system for detecting asphalt mixture

InactiveCN101153850AEfficient automatic detectionLow costImage enhancementMaterial analysis by optical meansImaging processingPavement engineering

The invention discloses a detection method of bituminous mixture, including the following steps: digital image collection of bituminous mixture is completed; image processing of the acquired digital image is completed to obtain the content of compositions of the bituminous mixture. Moreover, the invention also discloses a detection system for the bituminous mixture. Both the method and the system can complete effective separation and extraction of bitumen, airgap, aggregate and aggregate particle of different particle diameter and realize direct determination and calculation of volumetric composition characteristic parameter of the bituminous mixture through converting the obtained characteristic parameter into volume ratio; moreover, the invention improves the mechanical property of the bituminous mixture and provides reliable basis for the scientificity in bituminous pavement engineering research.

Owner:CHANGAN UNIV

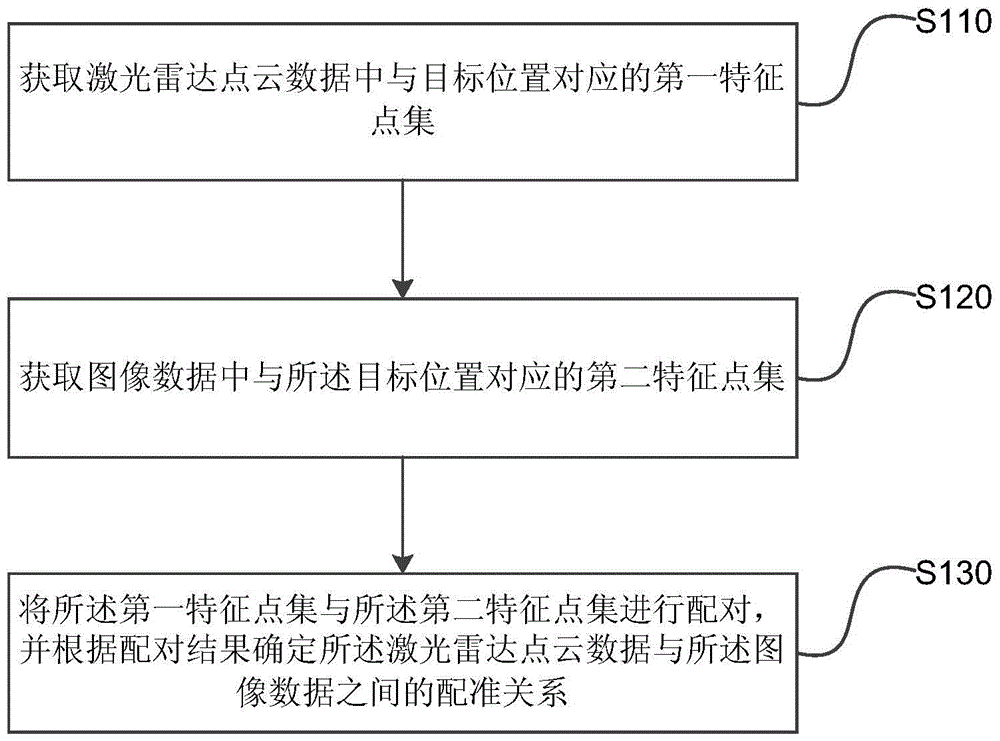

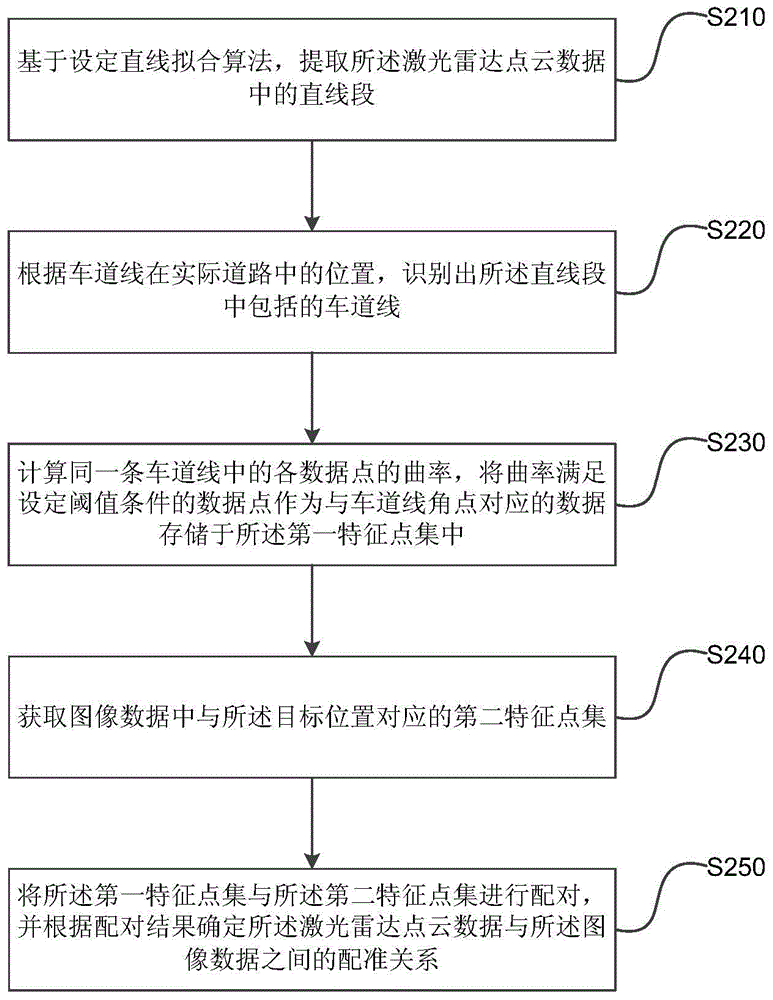

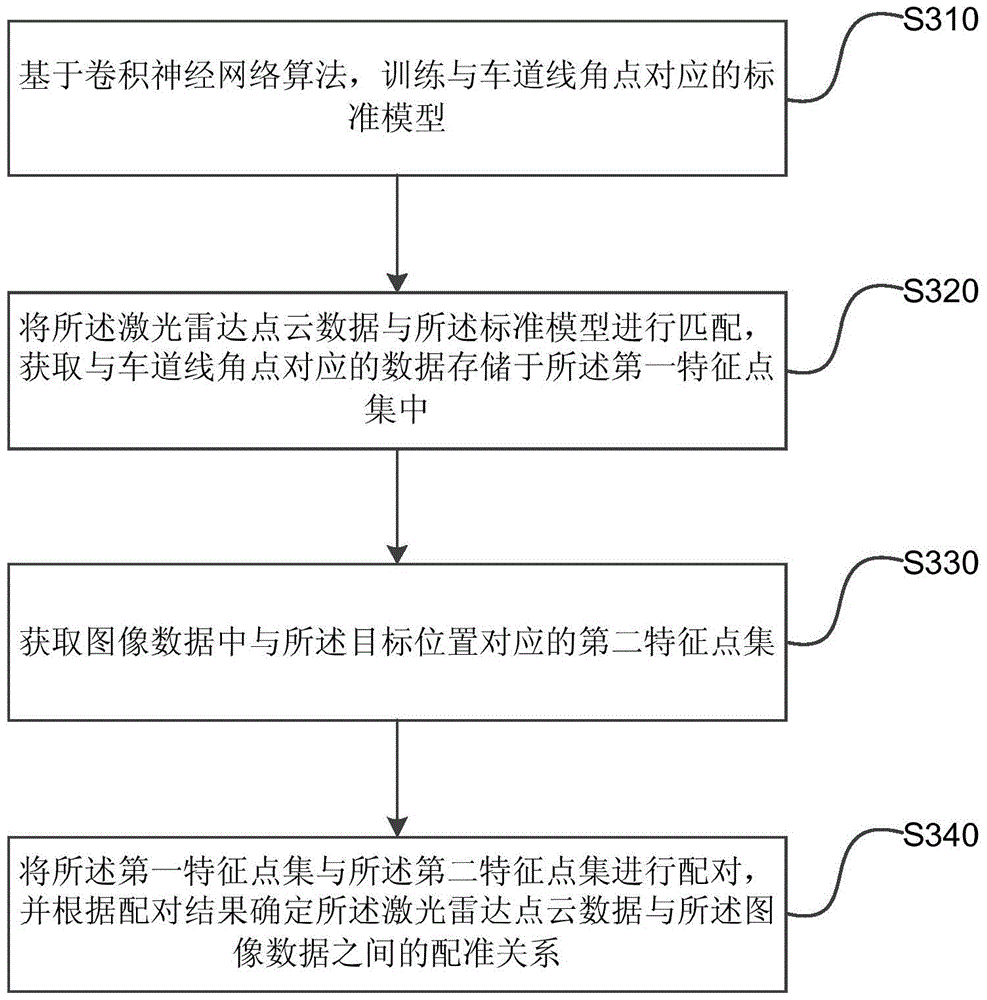

High-precision map data registration relationship determination method and device

The embodiment of the present invention discloses a high-precision map data registration relationship determination method and device. The method comprises the steps of obtaining a first characteristic point set corresponding to a target position in the laser radar point cloud data; obtaining a second characteristic point set corresponding to the target position in the image data; pairing the first characteristic point set and the second characteristic point set, and determining a registration relationship between the laser radar point cloud data and the image data according to a pairing result. According to the embodiment of the present invention, and by adopting the above technical scheme, the registration relationship between the laser radar point cloud data and the image data can be determined without needing to set a special calibration field and measure the position of a target spot artificially, the workload needed at the registration of the laser radar point cloud data and the image data can be reduced, also the registration precision of the laser radar point cloud data and the image data can be improved effectively, and the user experience is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

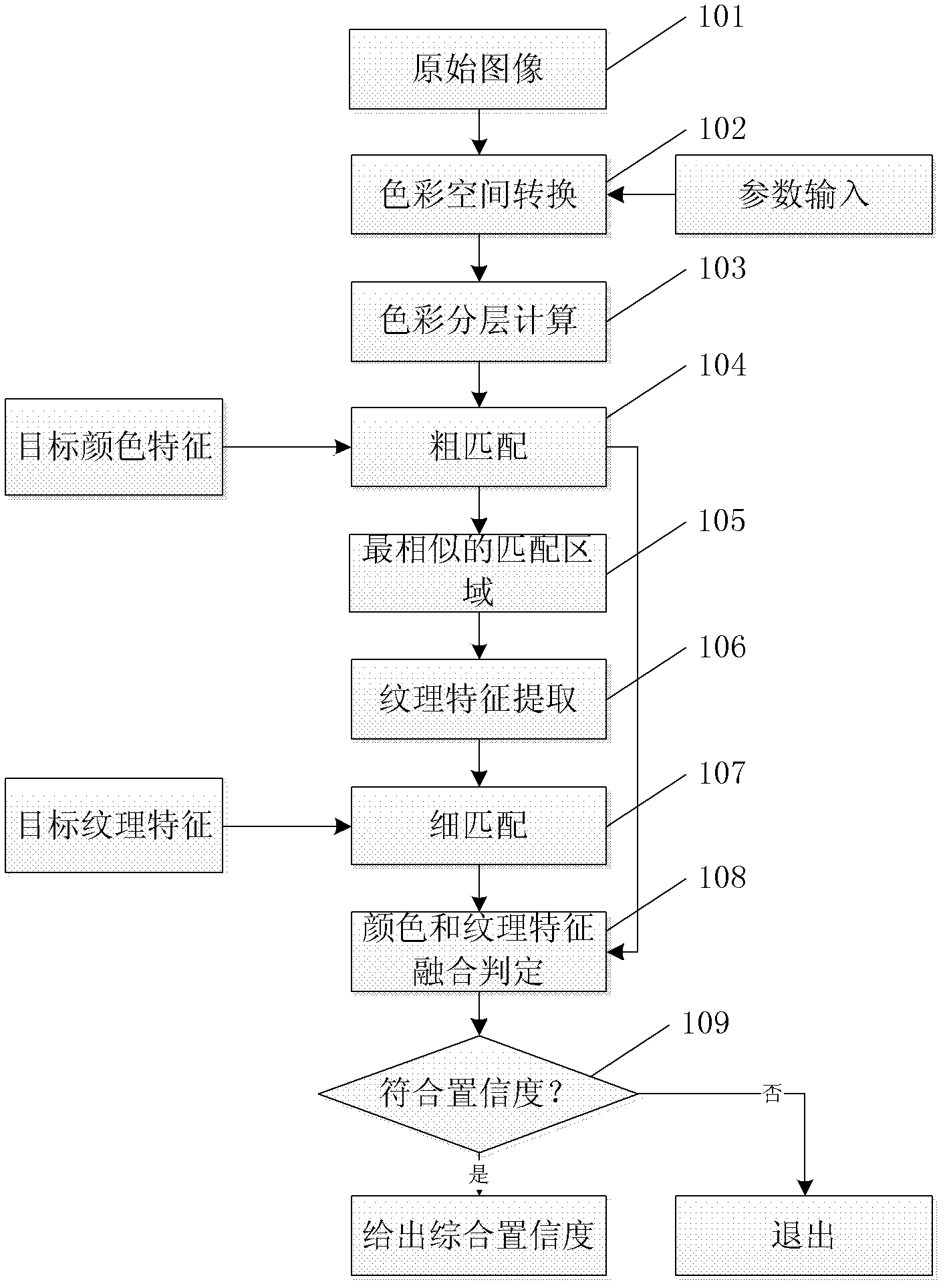

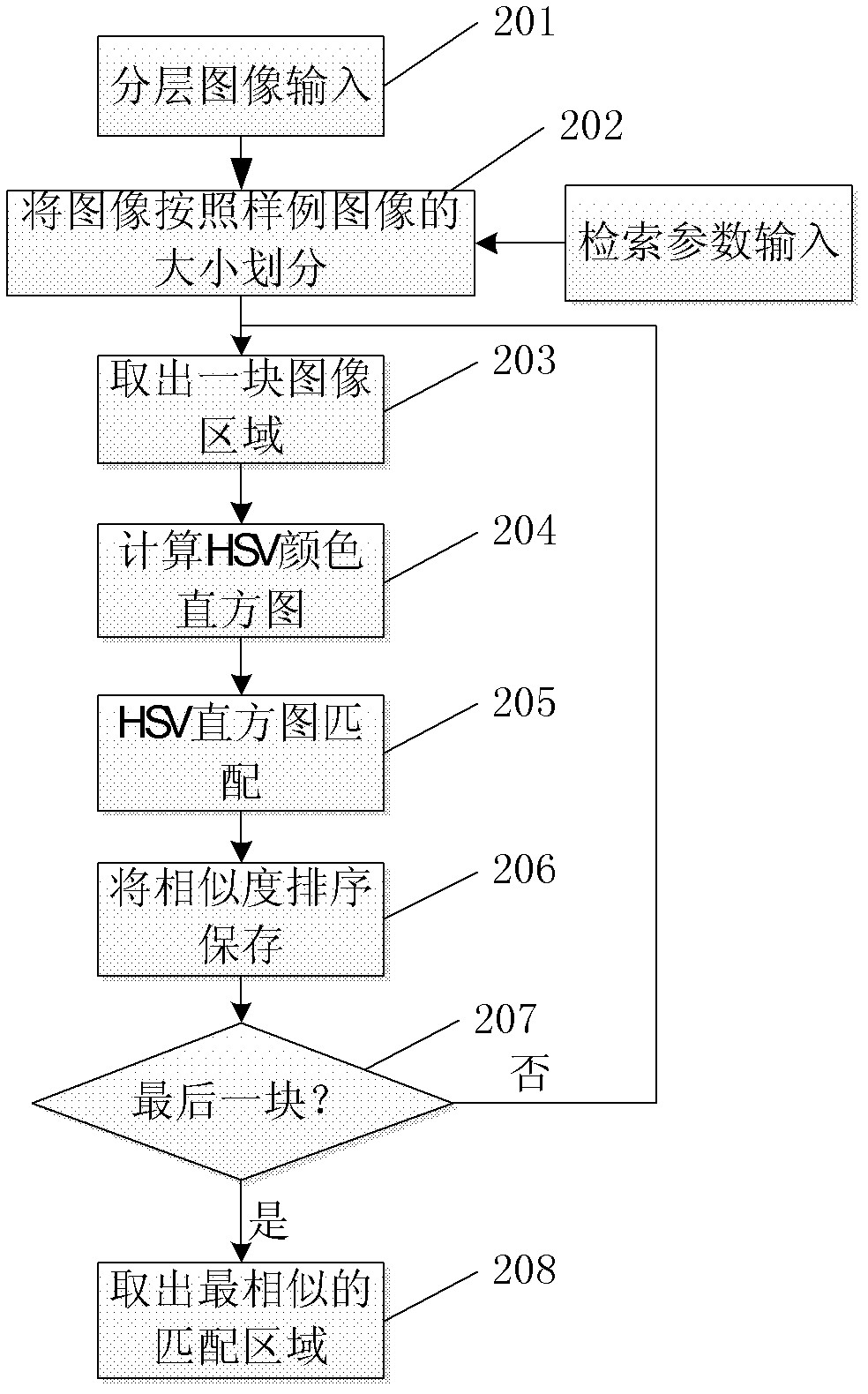

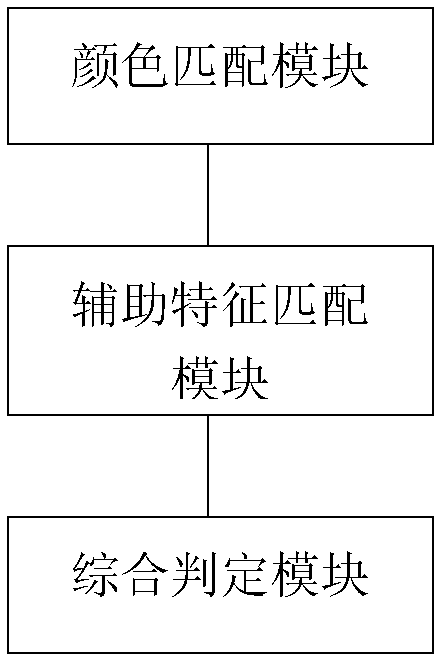

Image multifeature extraction and fusion method and system

ActiveCN102663391AMatching is fast and efficient and accurateSave manpower and material resourcesImage analysisCharacter and pattern recognitionPattern recognitionColor matching

The invention provides an image multifeature extraction and fusion method and the system, comprising the following steps of, extracting color features from an image to be matched, matching color with the target image, making sure the color similarity degree, if the color similarity degree exceeds the given color similarity degree threshold, entering the next step; extracting additional feature from the image to be matched, matching the auxiliary features with the target image, determining the auxiliary feature similarity degree, the auxiliary features comprise at least one of texture feature and shape feature; on the base of color similarity degree and auxiliary features similarity degree, making synthesis judgment and acquiring the synthesis similarity degree between the image to be matched and the target image, or matching the target image with the auxiliary features extracted from the matching zone of the image to be matched. The method and the system of the invention apply a cascade connected way to match from roughness to exactness, and can determine exactly the similarity zone of the target image and the image to be matched. The method and the system of the invention achieve a rapid and highly effective matching effect and save manpower and resources.

Owner:中安科股份有限公司

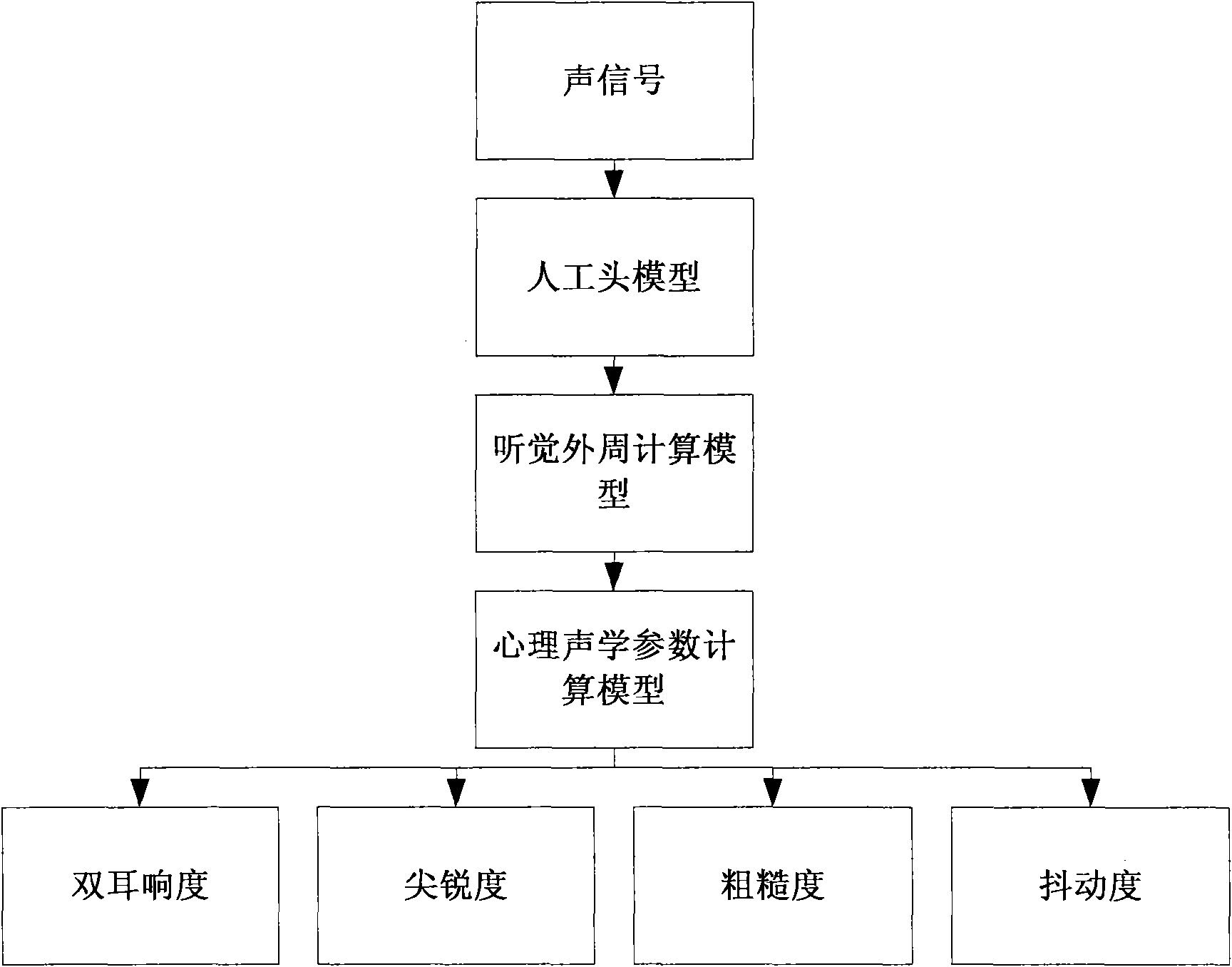

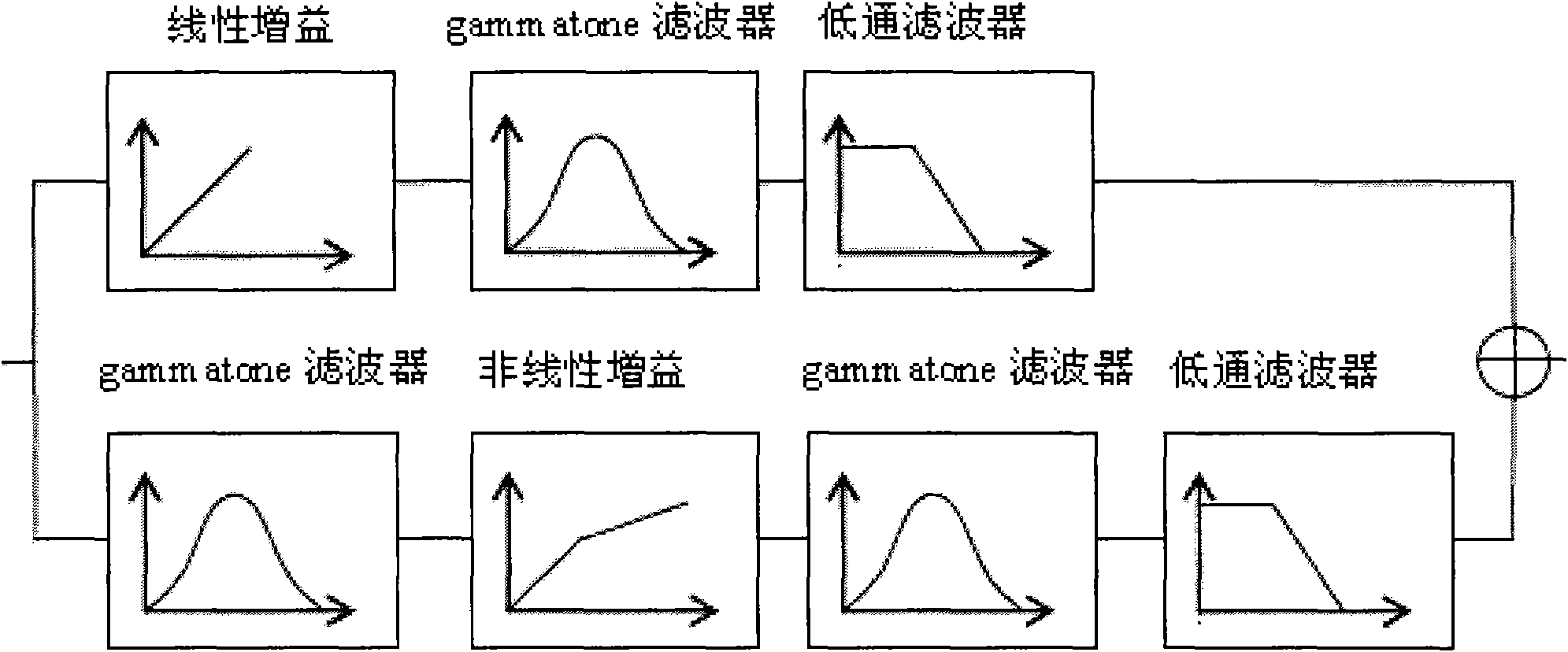

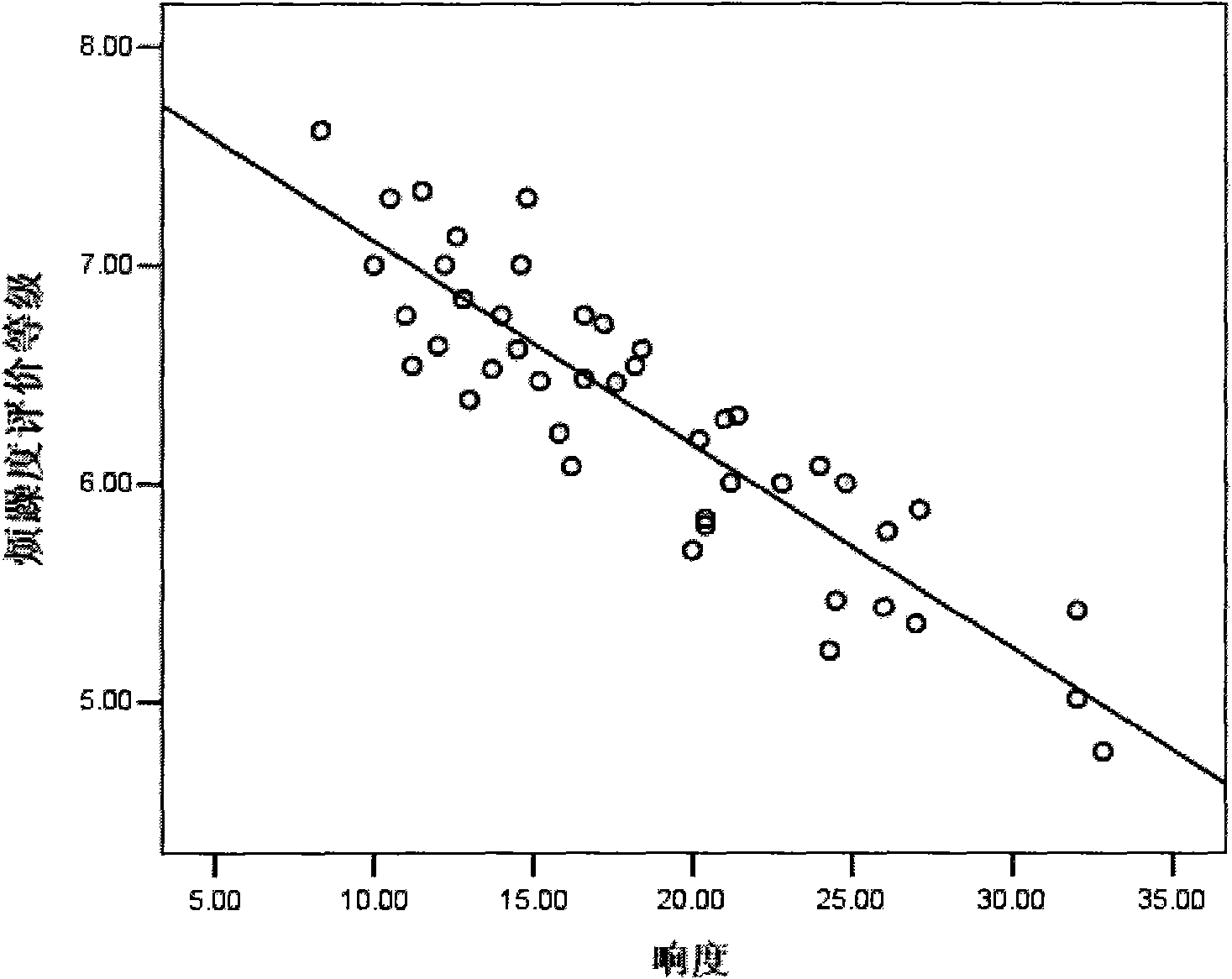

Method for objectively and quantifiably evaluating noise fret degree in vehicle based on auditory model

InactiveCN101672690AImprove performanceOvercoming complexityVibration measurement in fluidPsychotechnic devicesHuman bodyProcess mechanism

The invention relates to a method for objectively and quantifiably evaluating noise fret degree in a vehicle based on an auditory model, in particular to an evaluation method of psychoacoustics and vehicle sound quality. The method comprises the following steps: designing a dummy head model; imitating a processing mechanism of the middle ear and the inner ear of a human body to the sound by usingan auditory peripheral calculation model; collecting vehicle noise signals under the working conditions of uniform, accelerated and idle speed; pre-treating the noise sample and processing the loudness in specification; obtaining a psychoacoustics parameter by using a sound quality calculation model; obtaining subjective evaluation result test data by using a grouped and paired comparison method;calculating and painting a correlated scatter plot chart between each parameter and the ranking value of the subjective evaluation result; and analyzing and calculating to obtain the objectively quantifiable model of the subjective fret degree under each working condition. The invention can realize the psychoacoustic parameter calculation of objectively evaluating the sound quality with differentvehicle types, gears and speeds, wherein the calculated value has good pertinence and consistency with the evaluated result of the subjective evaluation method. The invention has stable evaluated result and high reliability, and can improve the sound quality and competitiveness of vehicles combined with the design of new CAE cars.

Owner:JILIN UNIV

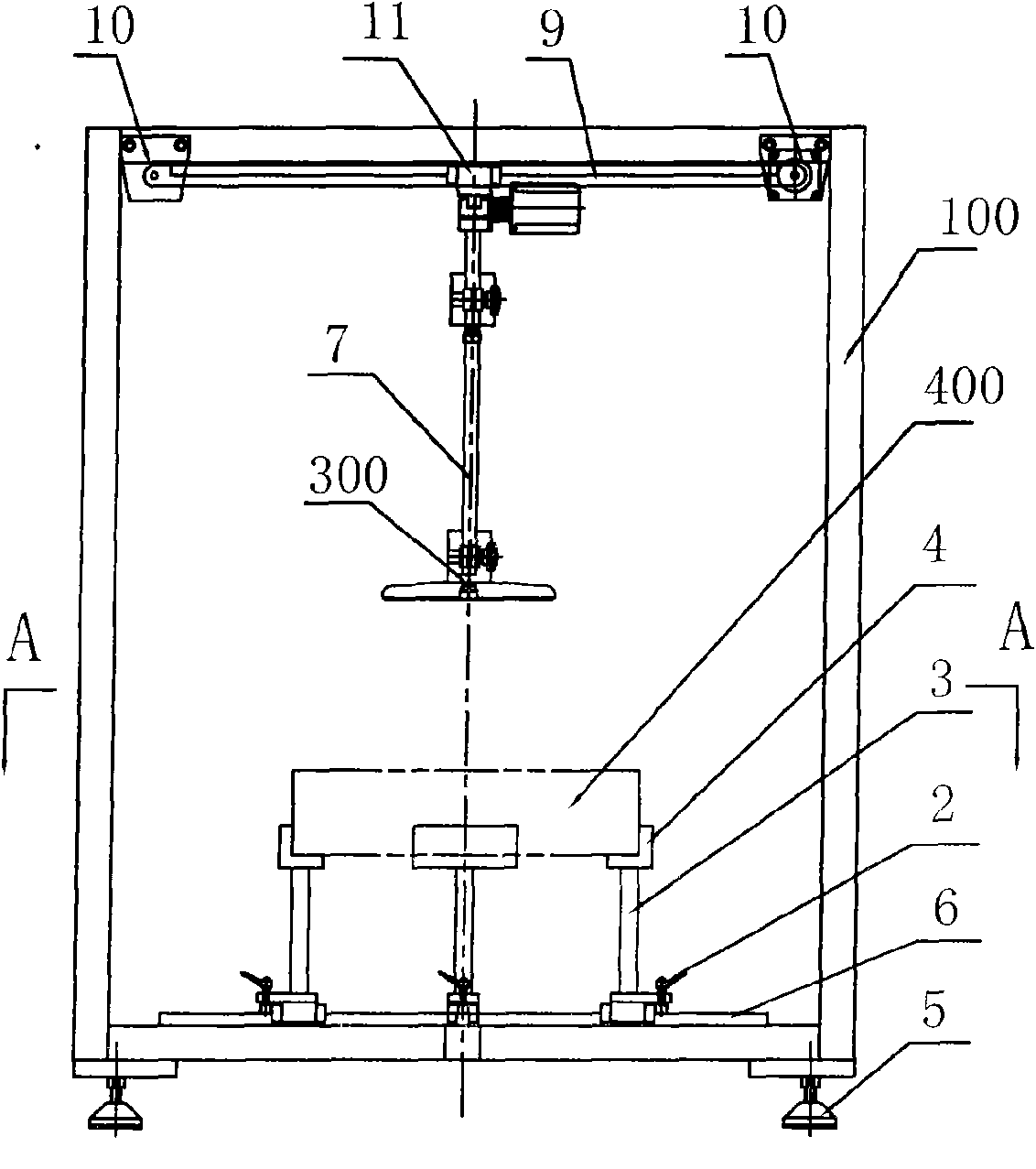

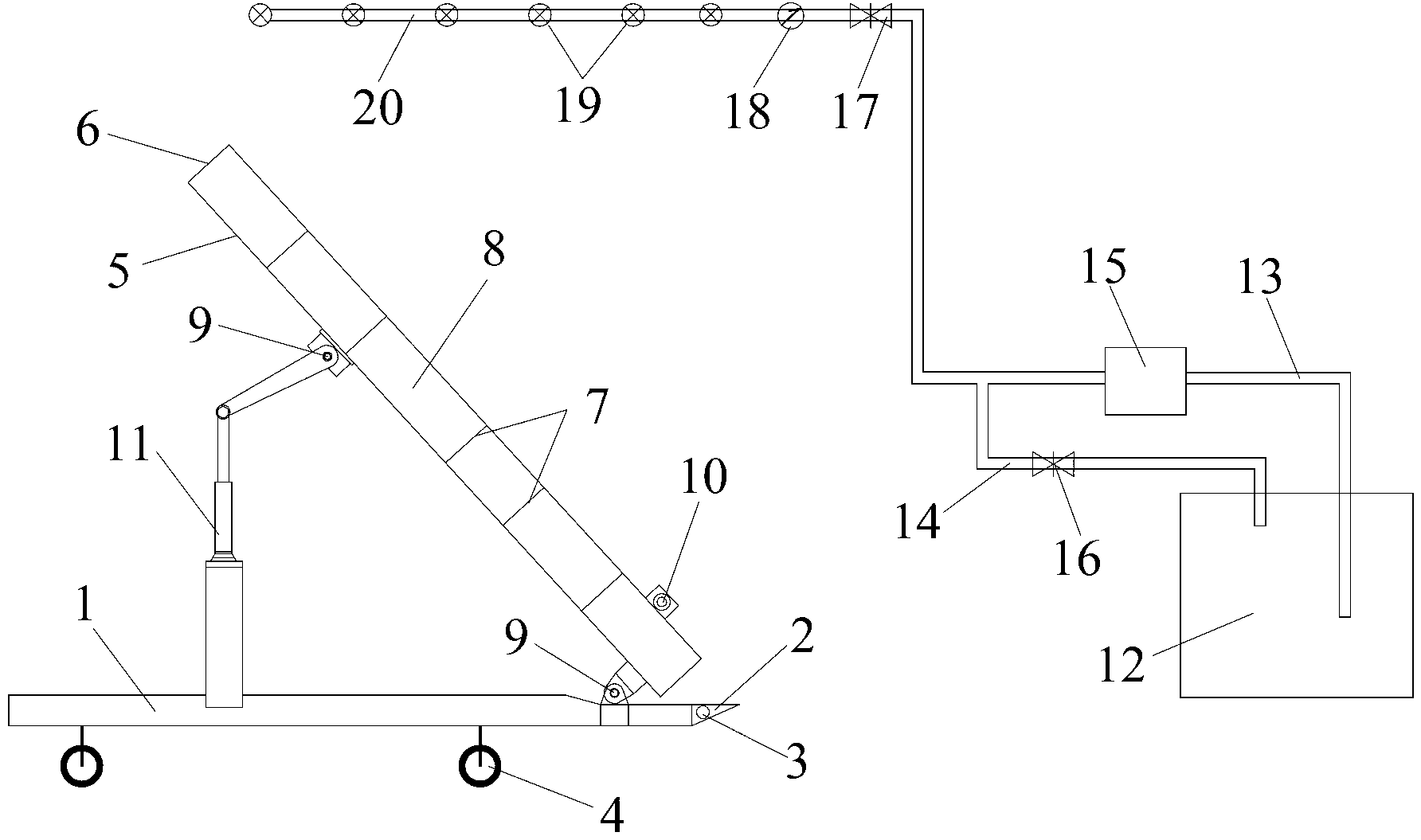

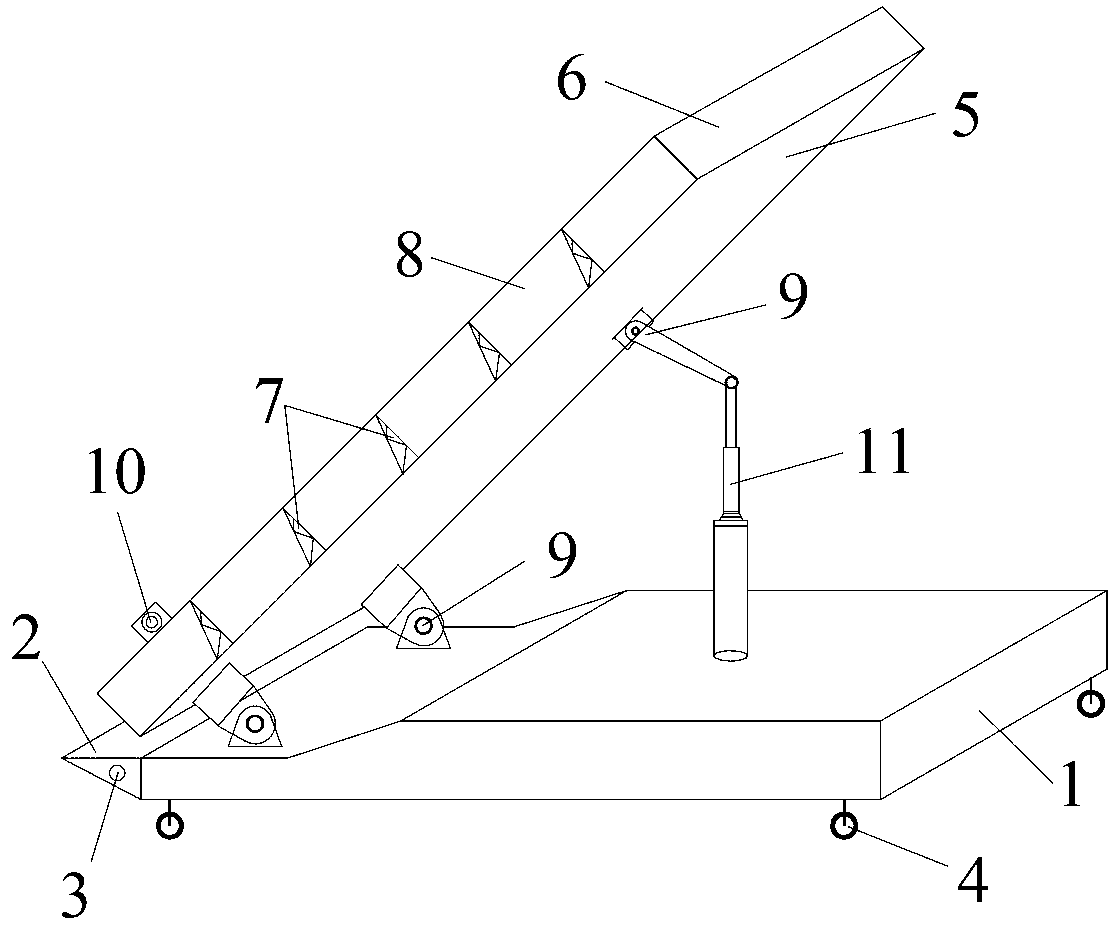

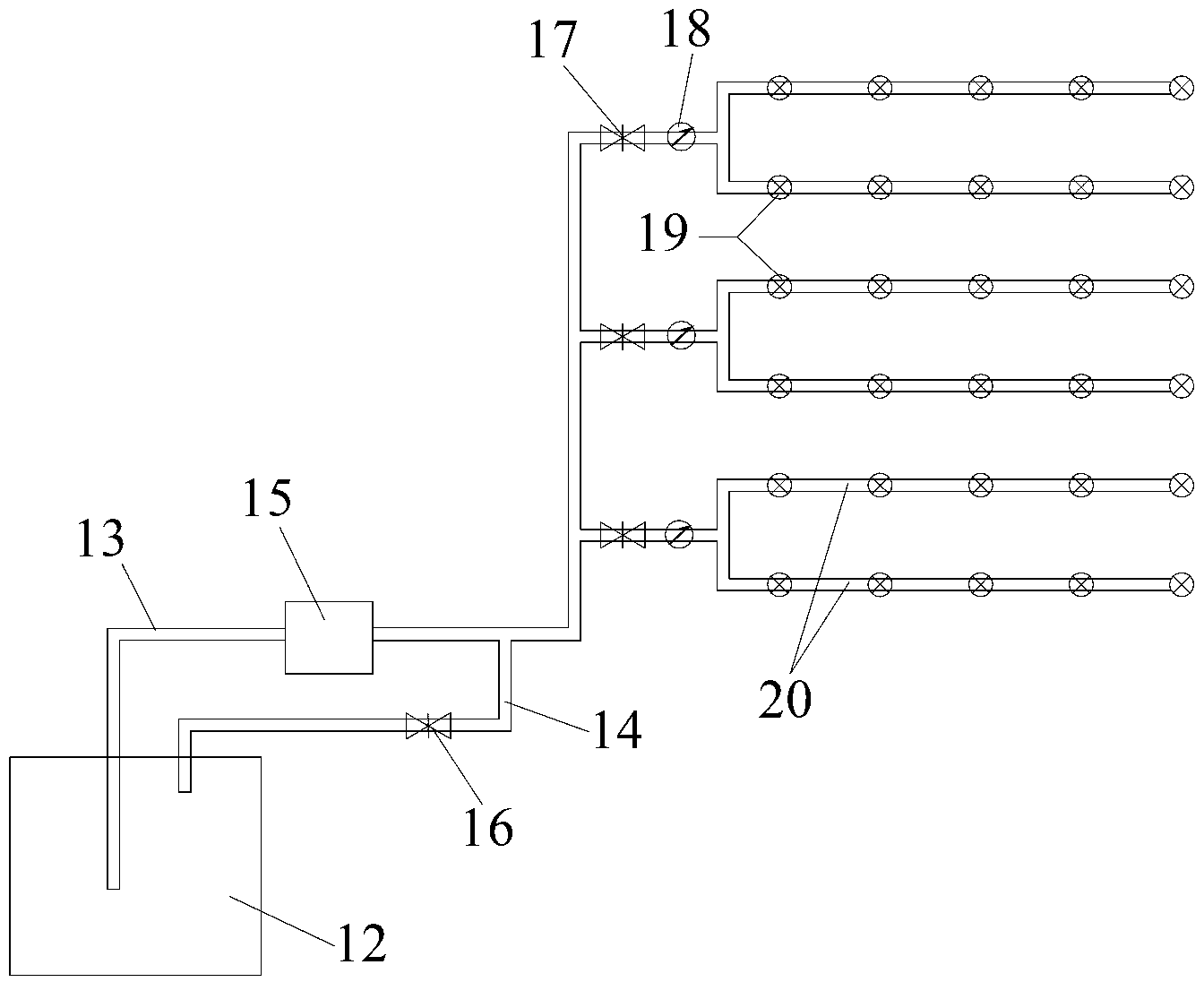

Indoor analog experiment device for roadbed slope erosion

InactiveCN103245772AAdequate test basisSimple structureEarth material testingPropellerAgricultural engineering

The invention discloses an indoor analog experiment device for roadbed slope erosion. The indoor analog experiment device comprises a movable liftable slope analog device and an artificial rainfall analog device, wherein the movable liftable slope analog device comprises a base device, a panel groove device and a slope gradient adjusting device, the base device and the panel groove device are connected together through a movable hinge, and the panel groove device can rotate freely around the hinge; the artificial rainfall analog device comprises a water supply device, a support device and a spraying device, the water supply device comprises a water supply pool, a water pipe, a water pump, an adjusting valve, a branch valve and a hydrometric propeller, the support device comprises movable wheels, an expansion bracket, a transverse support rod and a longitudinal support rod, and the spraying device comprises a water guide pipe and a prayer head. According to the indoor analog experiment device, a large amount of roadbed slope erosion data is obtained under different working conditions and different rainfall conditions within a short period of time. The indoor analog experiment device is simple in structure, convenient to operate, safe and reliable, low in cost and high in efficiency, and is convenient to popularize and apply.

Owner:HUNAN UNIV

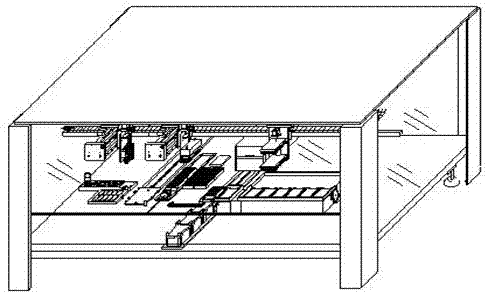

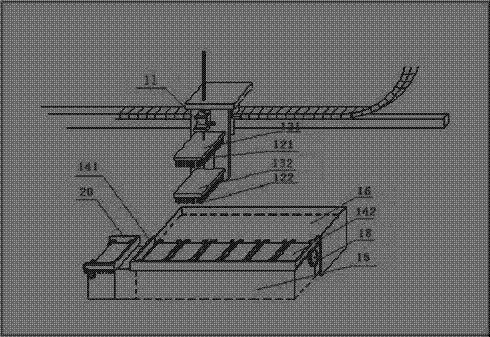

Automated instrument for nucleic acid extraction and mass spectrum sample application

ActiveCN102492603AAccurate extractionReduce infectionBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadMass analyzer

The invention discloses an automated instrument applied to nucleic acid extraction and continuous operation process of a mass spectrum sample application chip in biomass spectrometry analysis of a nucleic acid sample. The automated instrument comprises three main devices, namely, a nucleic acid extraction and purification device, a nucleic acid liquor relief distributing device and a mass spectrum chip sample application device, wherein nucleic acid in body fluid is extracted by using a magnetic bead method, a mechanical arm is utilized to complete a nucleic acid extraction action, the extracted nucleic acid is dispensed onto a sample board through a dispenser, a pipettor is used for transferring the sample board onto a chip sample application instrument, and the mass spectrum and relatedinformation of the nucleic acid are obtained through laser sampling of a mass spectrometer, so that the nucleic acid is analyzed rapidly, directly and continuously. The automated instrument is high-precision in controlling the volume of dispensed liquor, high-cleanliness in controlling the quality of the dispensed liquor and high-efficiency in meeting sample application requirements of large-batch samples; meanwhile, the samples are uniformly distributed under the control of a computer program, volume errors and possible foreign pollution caused by manual operation are avoided, and the speed and efficiency in sample application are increased at the same time.

Owner:BIOYONG TECH

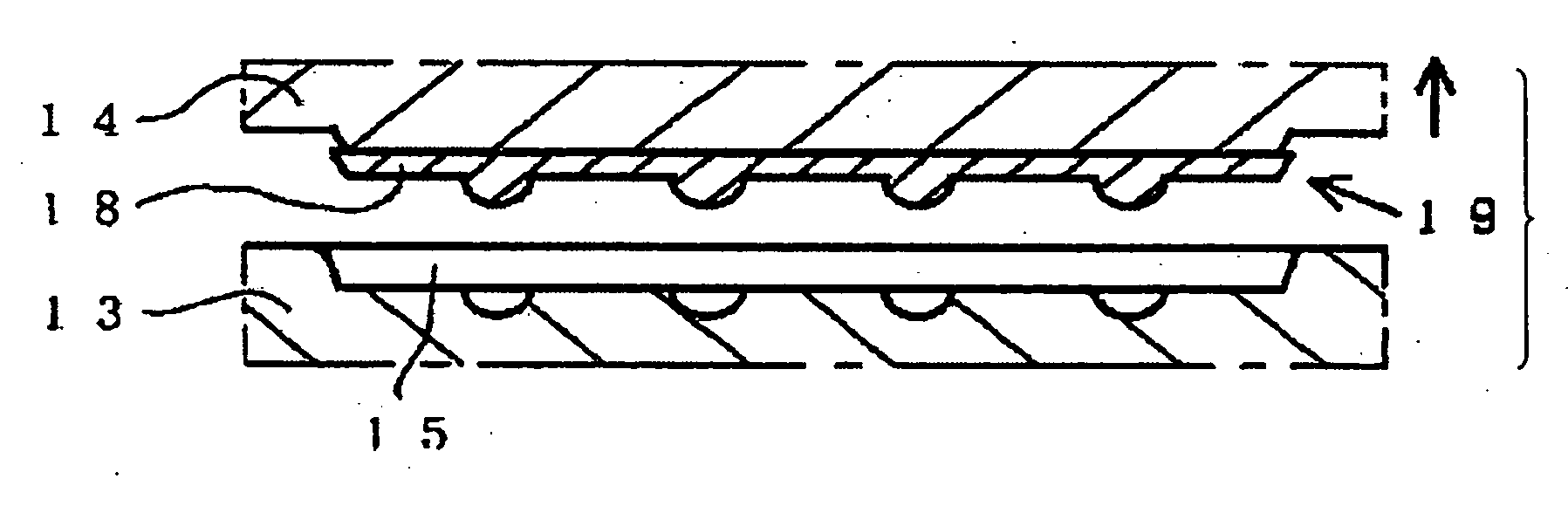

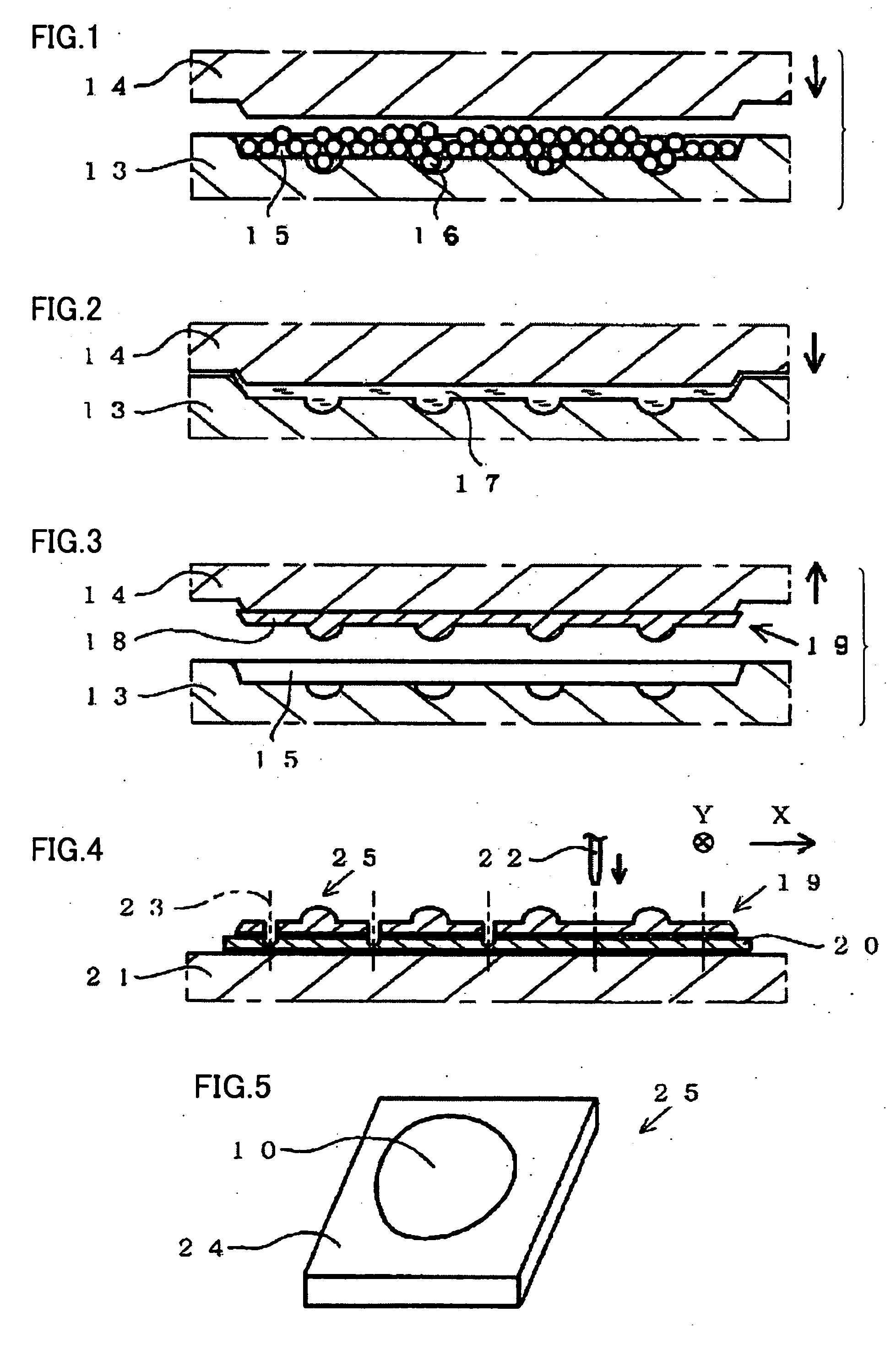

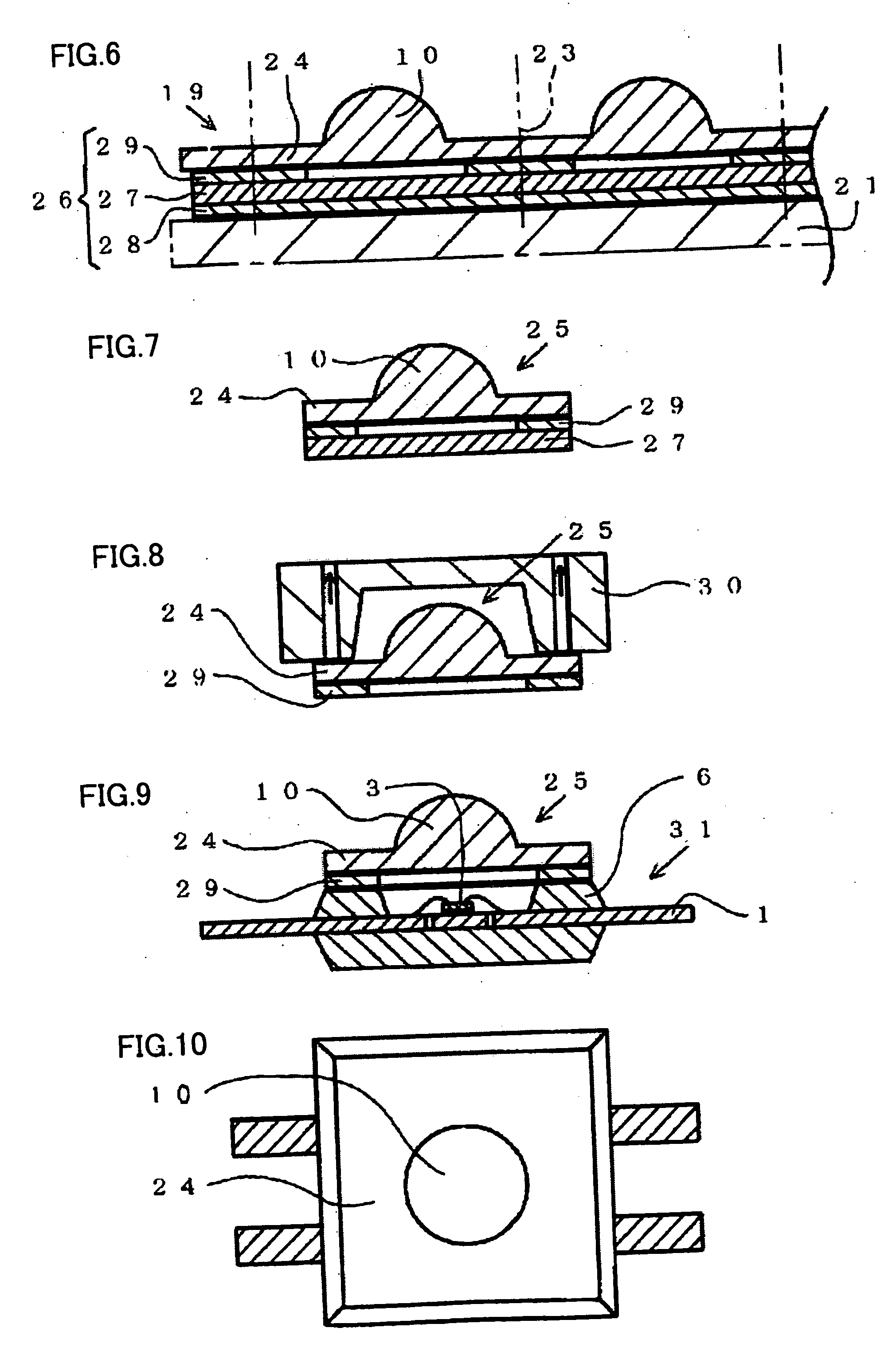

Transparent member, optical device using transparent member and method of manufacturing optical device

InactiveUS20060252169A1Improve efficiencyQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingEngineering

In a method of manufacturing an optical device, a whole substrate is first prepared which has a plurality of regions corresponding to substrates constituting a plurality of optical devices, respectively. A plurality of chips are then mounted to the plurality of regions, respectively. A whole sealing member having a plurality of sealing members is integrally attached to the whole substrate to form an intermediate body. The intermediate body is divided into the above-described regions. Thus, the optical device having a substrate, a chip as an optical element mounted to the substrate and a sealing member with transparency provided at the substrate for the purpose of sealing the chip is manufactured. This manufacturing method improves the efficiency of manufacturing an optical device.

Owner:TOWA

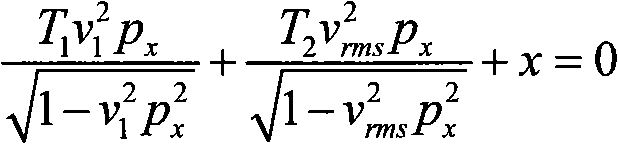

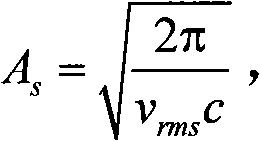

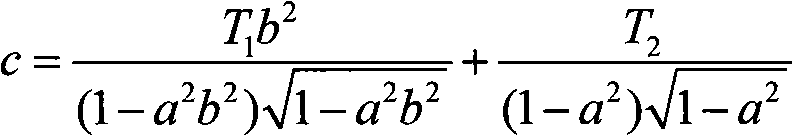

Heaved earth surface collected seismic data direct prestack time migration method

InactiveCN101285894AReduce processing linksAvoid errorsSeismic signal processingMineral SourcesEarth surface

The invention relates to a direct prestack time migration method for the seismic data acquired under the undulant ground surface. The method is applied to reflection seismic data processing during earthquake exploration and is a prestack migration imaging method aiming at the seismic data acquired under the undulant ground surface. The method can be directly applied to the seismic data which is acquired under the undulant ground surface and is acquired at shot points and demodulation points of different heights. Accordingly, the method can avoid errors caused by field static correction processing as well as correct the speed of a speed reducing belt in a migration process. The method can self-adaptively determine time-varying migration aperture and can correctly compensate geometric spreading effect of seismic waves during an imaging process so as to obtain an amplitude-preserved common reflection point gather. The core of the method is to use a one-way wave theory and a stable phase point principle to analyze so that the travel time and the amplitude of the seismic waves, which depend on the speed and thickness of the speed reducing belt, the heights of the shot points and the demodulation points, and stacking speed based on a floating datum plane, are obtained. The method has important application value for the explorations of oil, gas and mineral resources in areas with complex ground surfaces.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

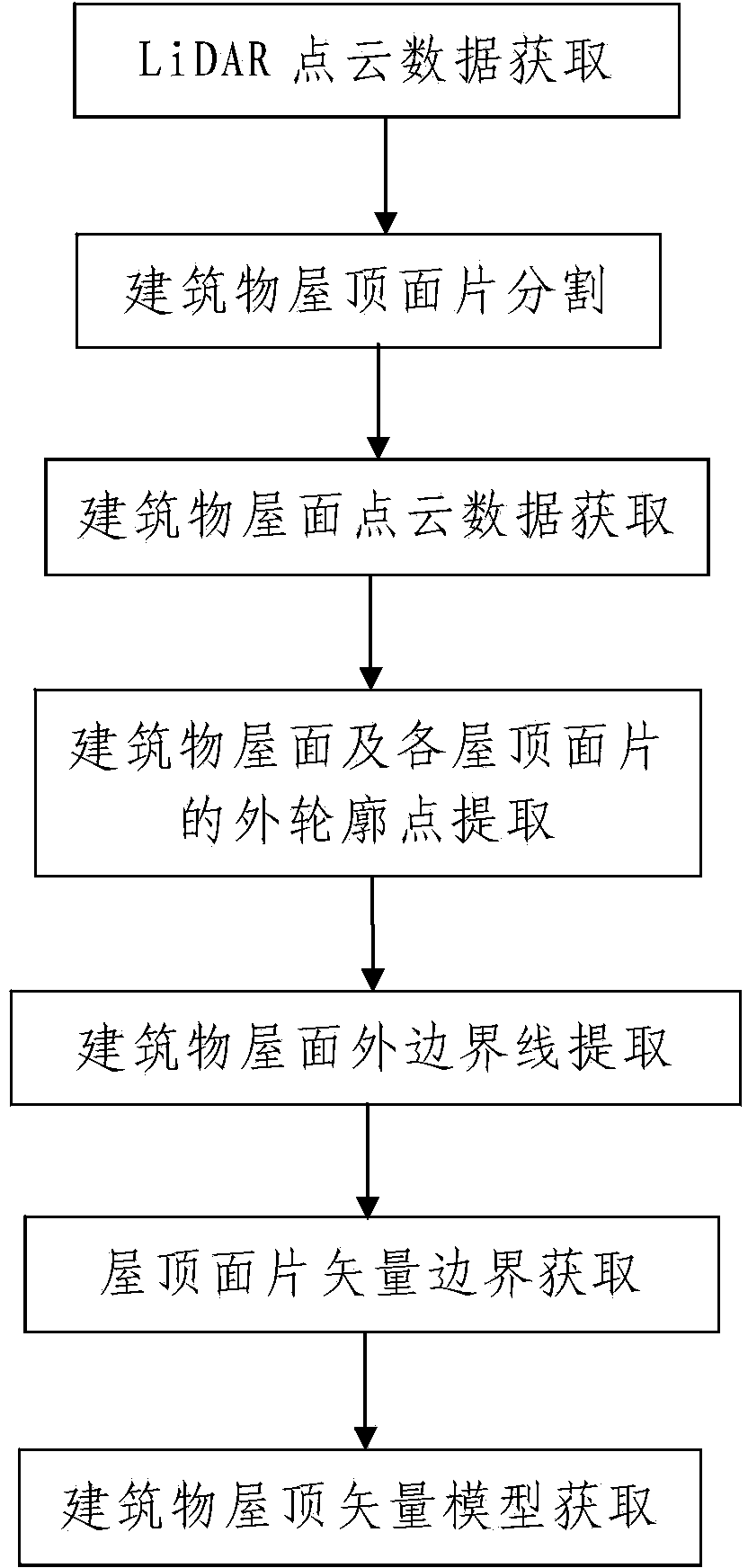

Building roof reconstruction method based on airborne LiDAR data

ActiveCN104036544AThe method steps are simpleReasonable design3D modellingPoint cloudNeighborhood search

Owner:AERIAL PHOTOGRAMMETRY & REMOTE SENSING CO LTD

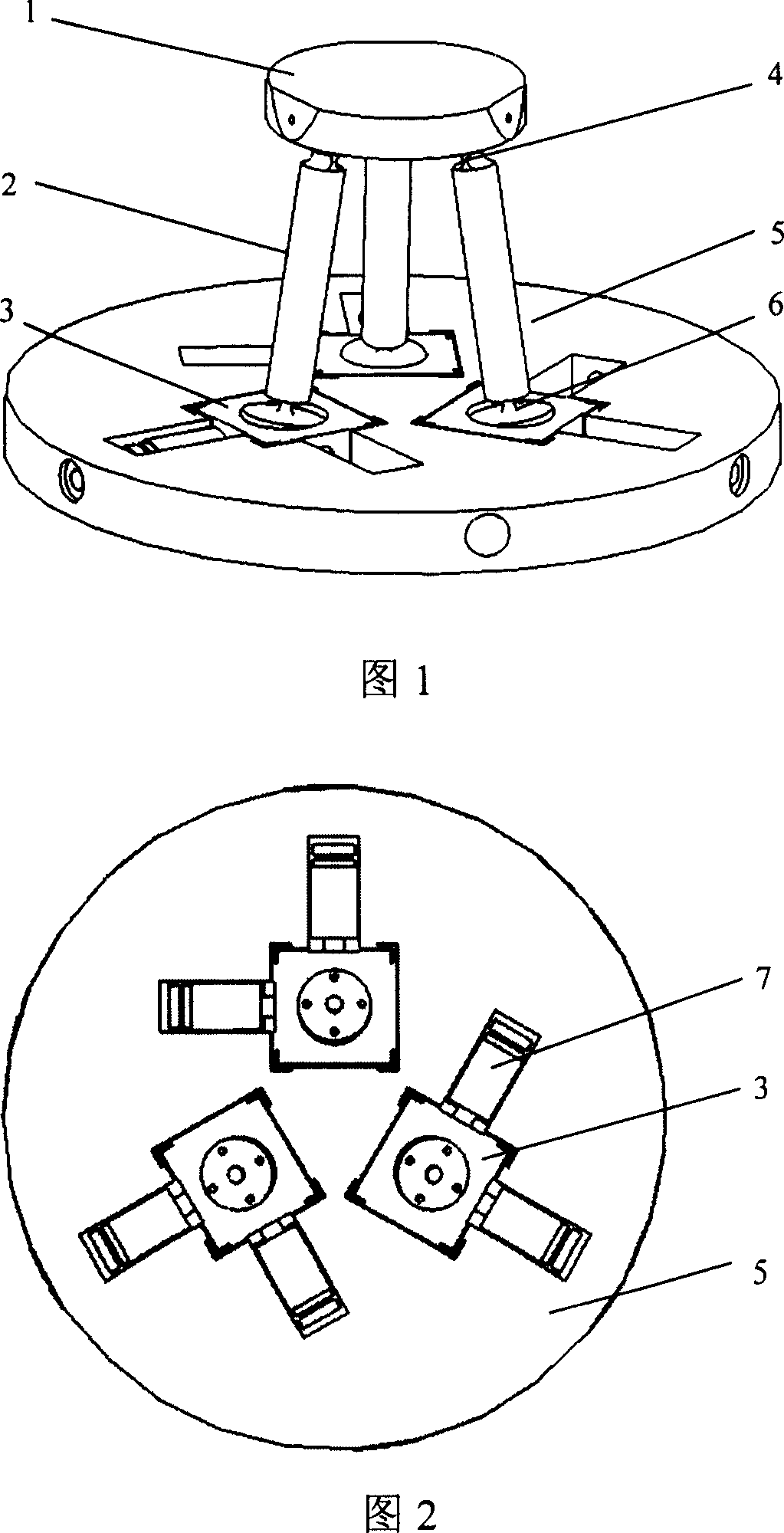

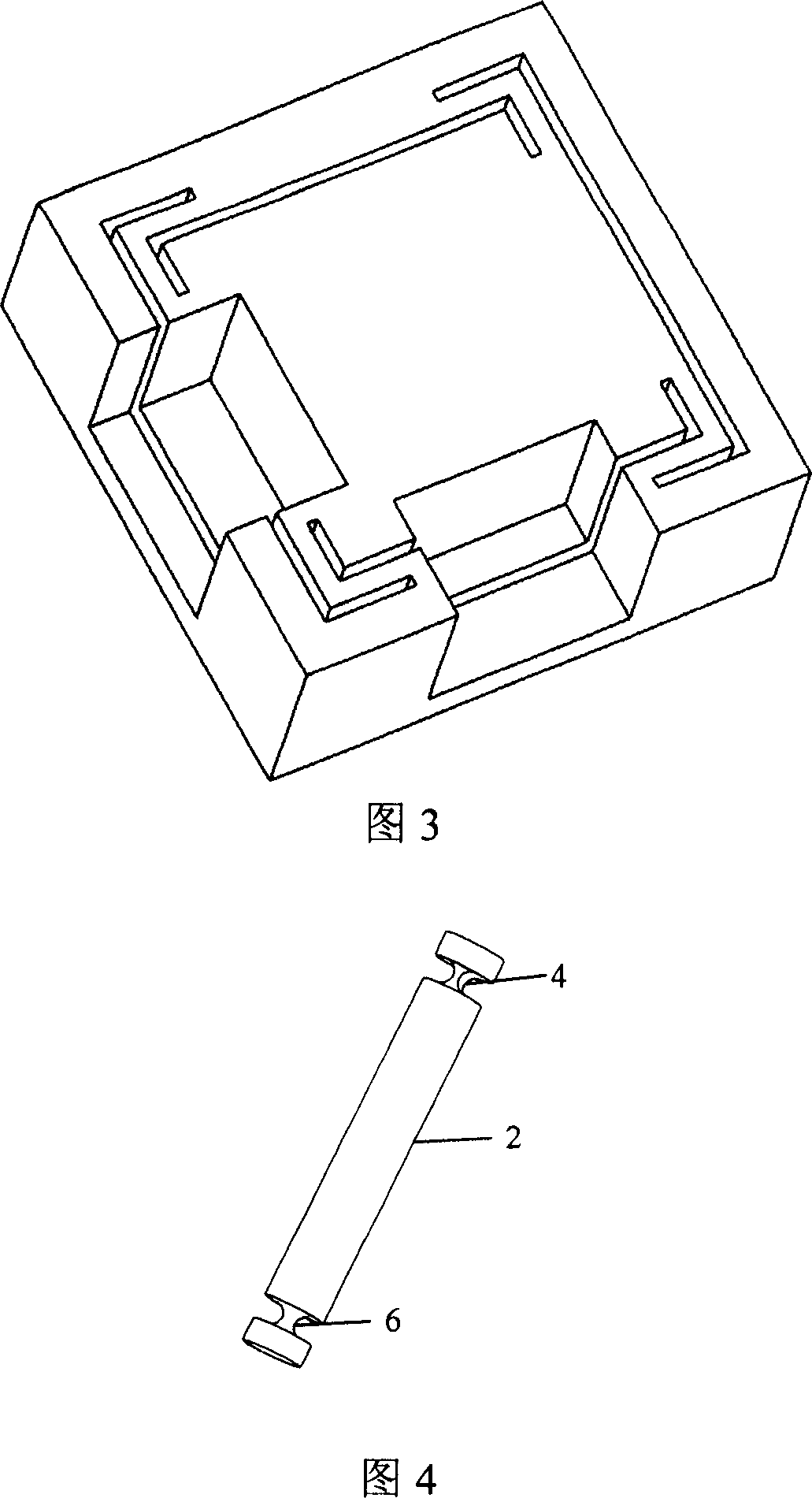

Three-branch chain six-freedom degree parallel flexible hinge micromotion mechanism

InactiveCN1962209AAvoid errorsCompact structureProgramme-controlled manipulatorElectricityEngineering

The invention relates to a three-chain six-freedom parallel flexible hinge micro motion device, wherein it comprises base platform, movable platform, driver on the base platform, and three support rods via flexible joints connected to the driver and movable platform. Said driver comprises three flexible plates on the base platform and piezoelectric ceramic driver connected to the flexible plates; three flexible plates are integrated processed, while each plate is connected to two piezoelectric ceramic drivers in right angle. The invention has compact structure and low installment error.

Owner:HARBIN INST OF TECH

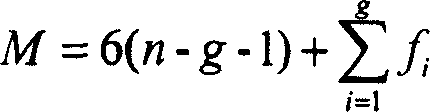

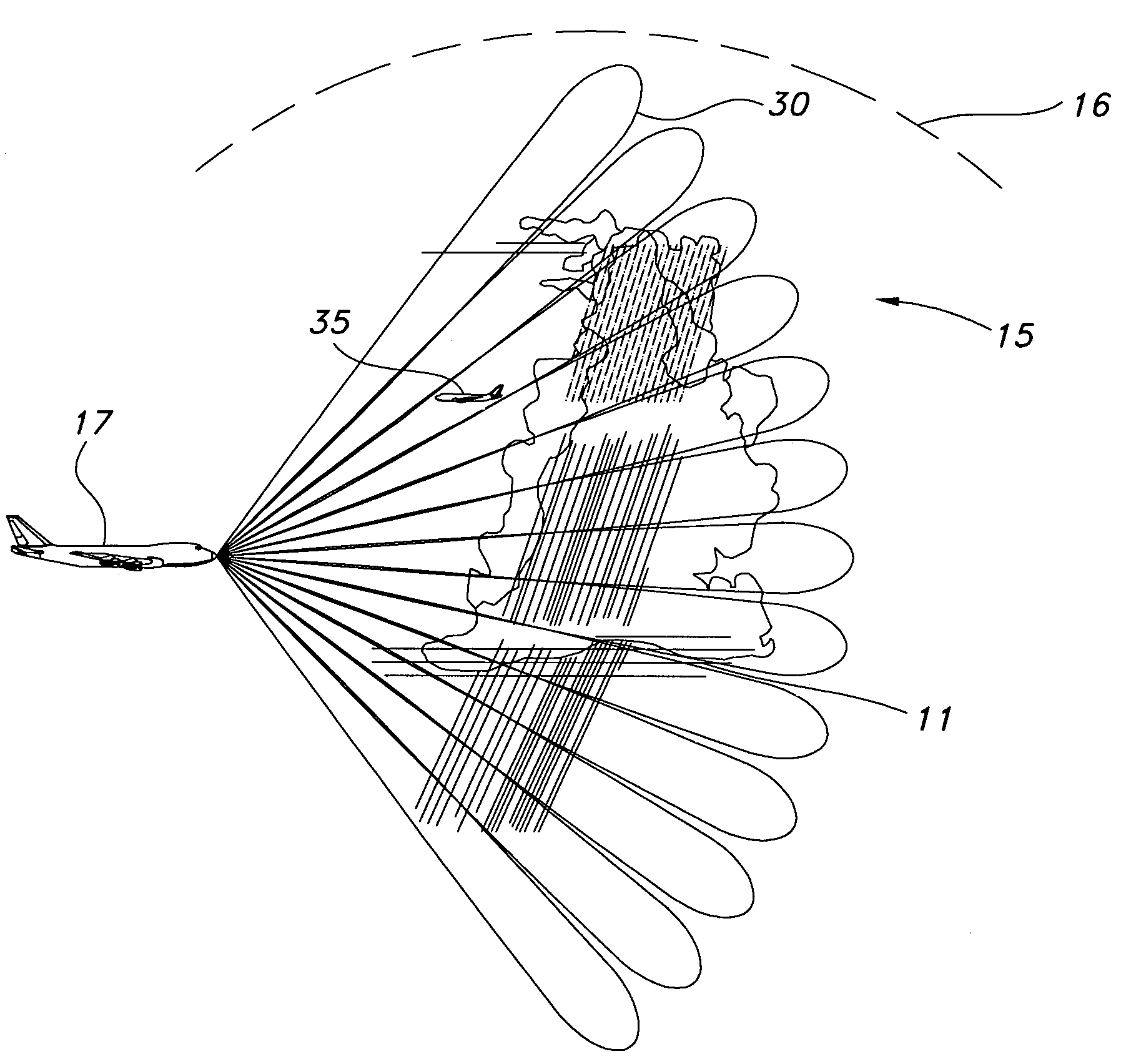

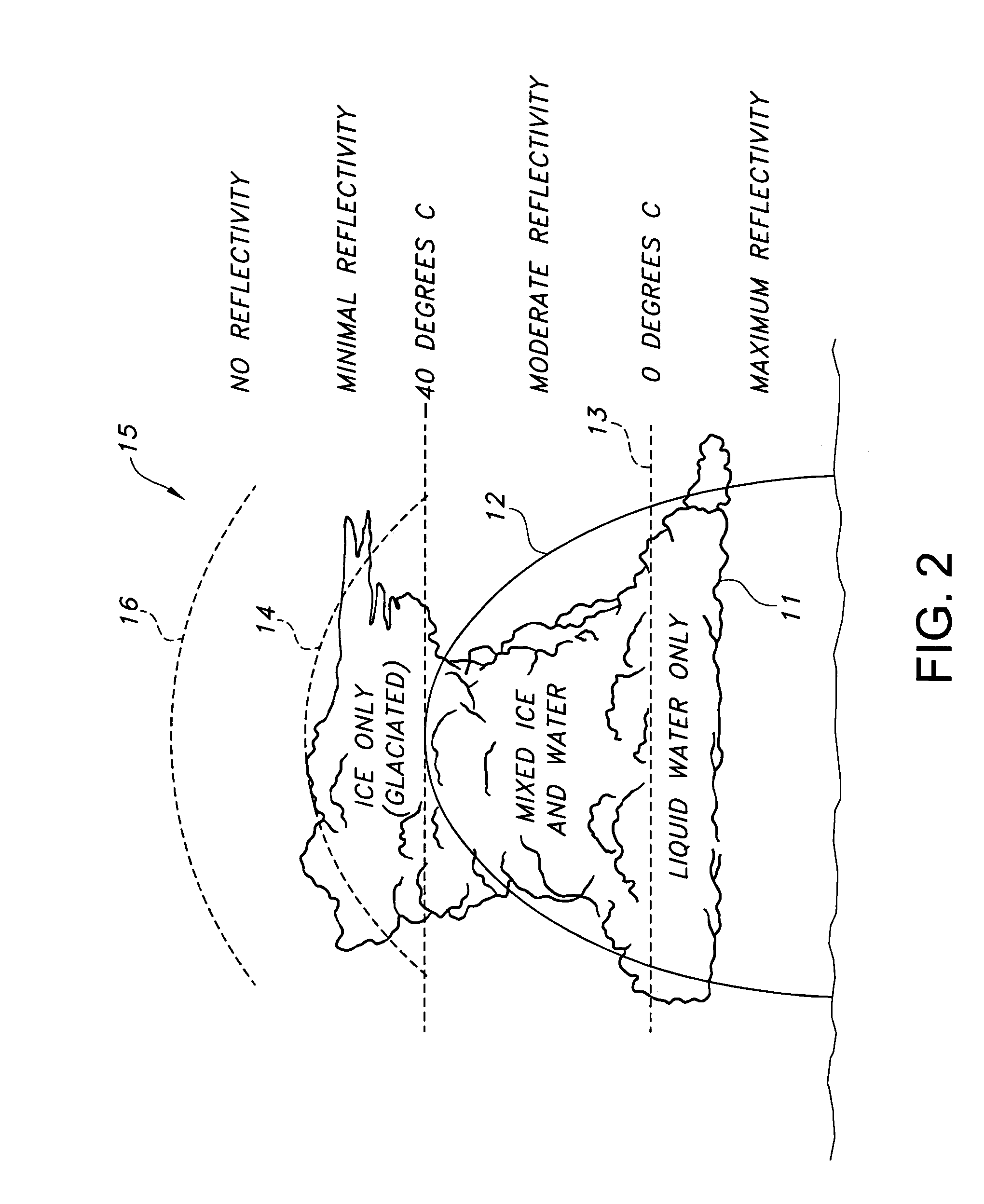

Removal of spurious aircraft detections on weather radar

ActiveUS7417578B1Improve performanceAvoid confusionRadio wave reradiation/reflectionICT adaptationDoppler velocitySpectral width

A weather radar detects and removes spurious aircraft from a weather radar display by using one of the methods of differentiating radar return length, estimating a vertical gradient of reflectivity, tracking radar returns into regions that are eliminated from the weather display to provide differentiation, tracking areas of radar returns that allow detection and removal of the spurious aircraft in relative geometries, differentiating Doppler velocity, and differentiating spectral width. The methods may be used individually or in combination to improve performance.

Owner:ROCKWELL COLLINS INC

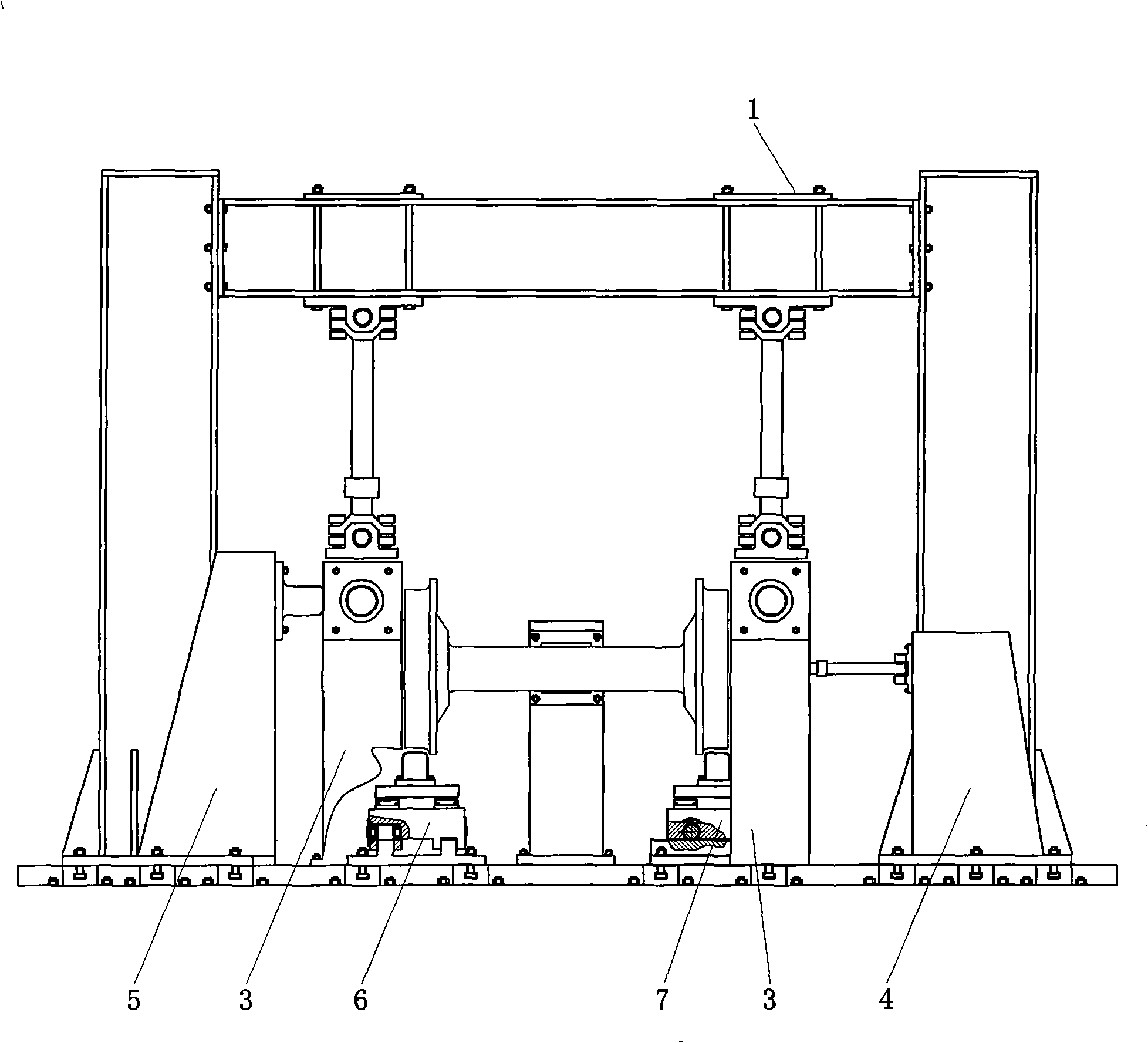

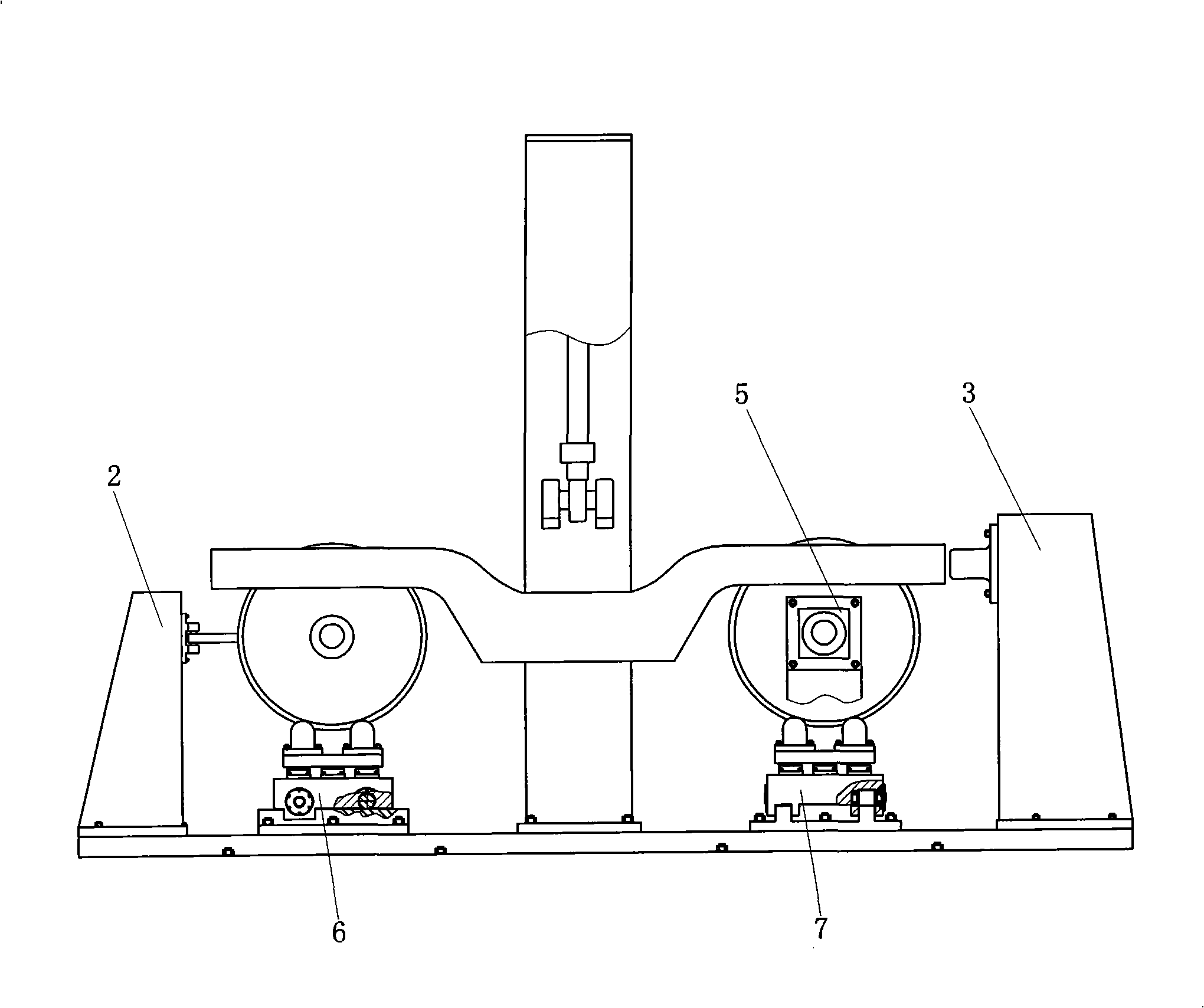

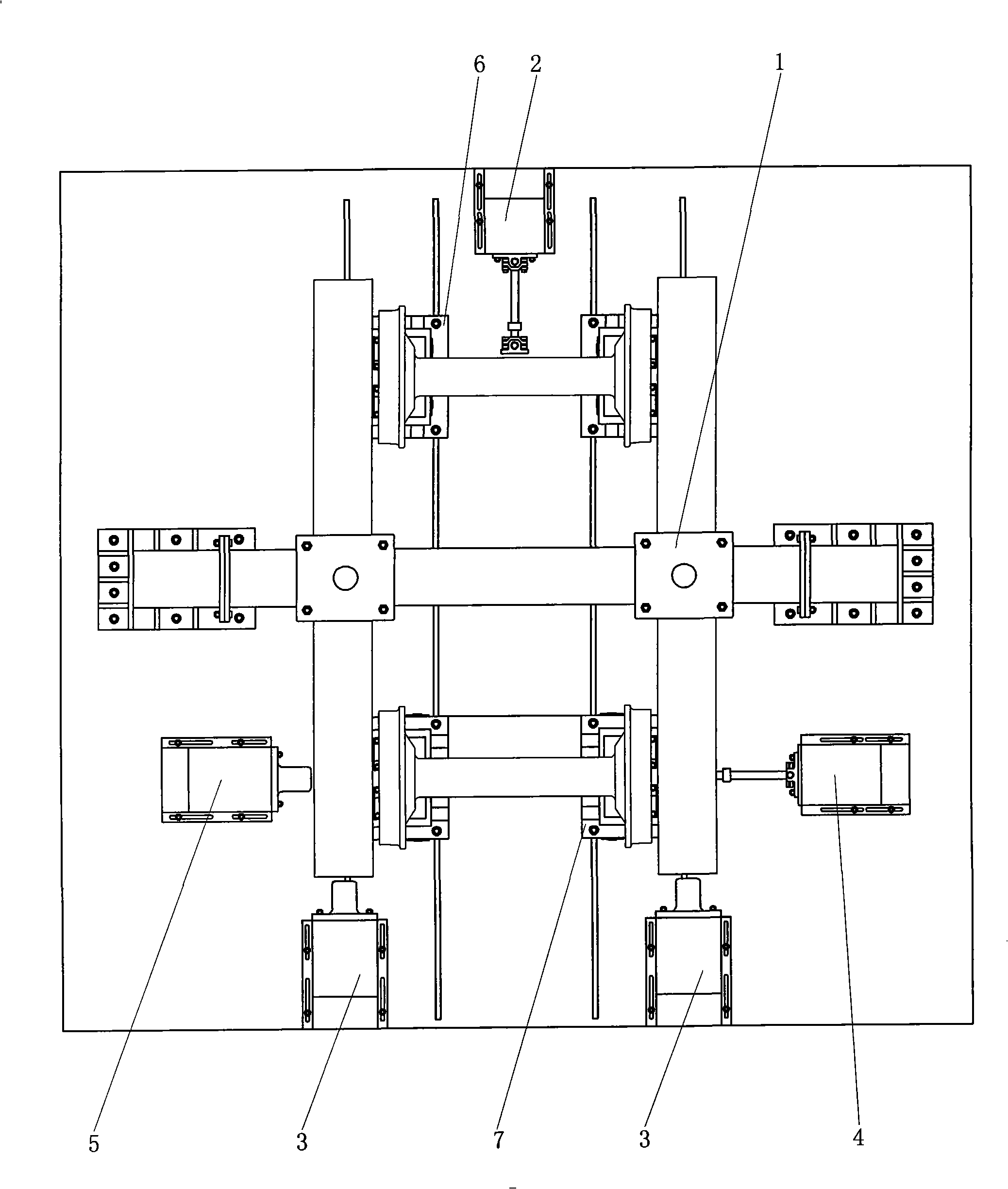

Test stand capable of simultaneously measuring railway stock bogie three-way rigidity

The invention discloses a measurement testing bench which can measure three-direction rigidity of bogies of railway vehicles at the same time. A longitudinal or transverse rail wheel supporting base has the structure that an upper supporting plate is connected with a lower longitudinal or transverse movable platform by a load sensor; the longitudinal or transverse movable platform is internally provided with a cylinder roller which can be longitudinally rolled or transversely rolled by a bearing; two cylinder rollers are respectively arranged on a longitudinal or transverse convex beam of the base. During the testing, the rolling movement of the base and the movable platform is realized by the rolling of the cylinder rollers, with small friction force and smart movement. Parameters of vertical rigidity, longitudinal rigidity, transverse rigidity and geometrical structure of the bogies of the railway vehicles can be tested on the measurement testing bench which has the advantages of exact measurement value, high precision, simple structure, convenient operation and easy maintenance.

Owner:SOUTHWEST JIAOTONG UNIV

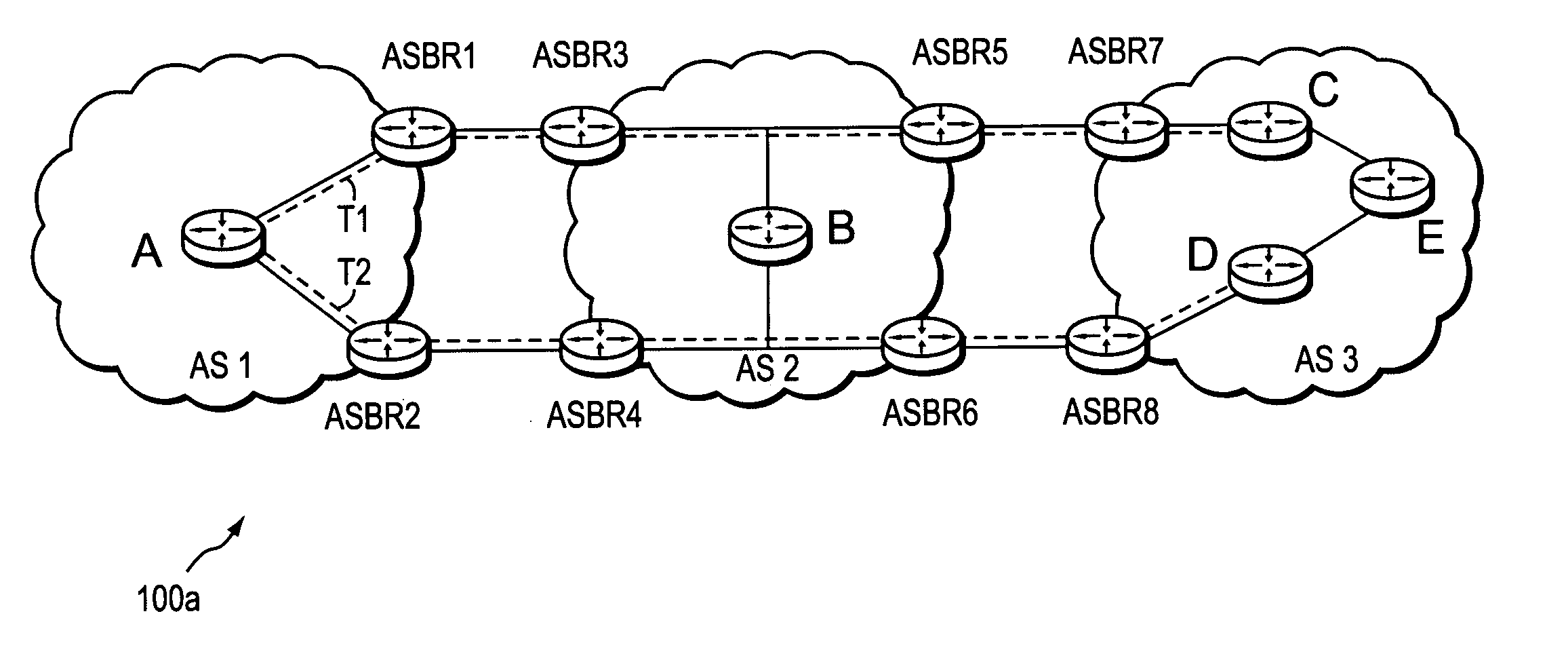

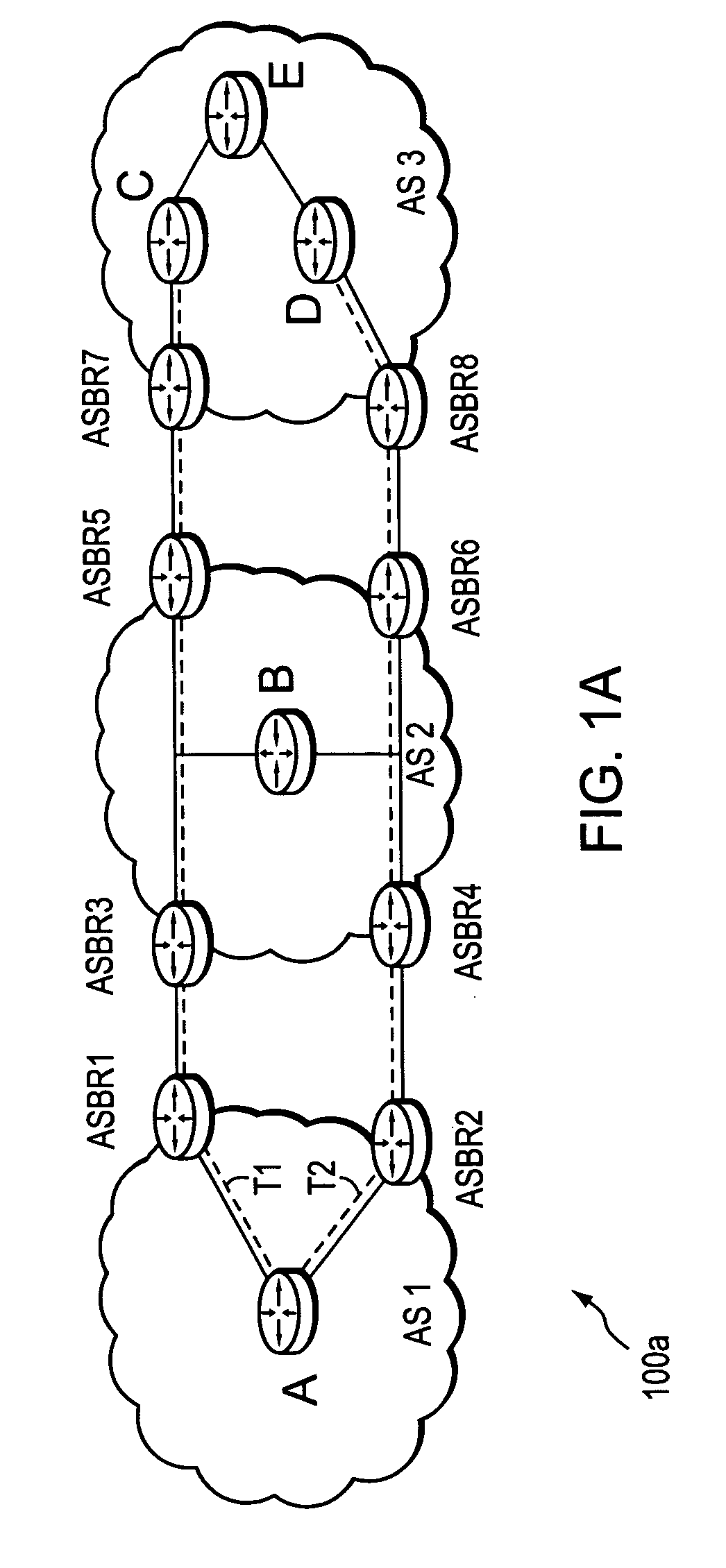

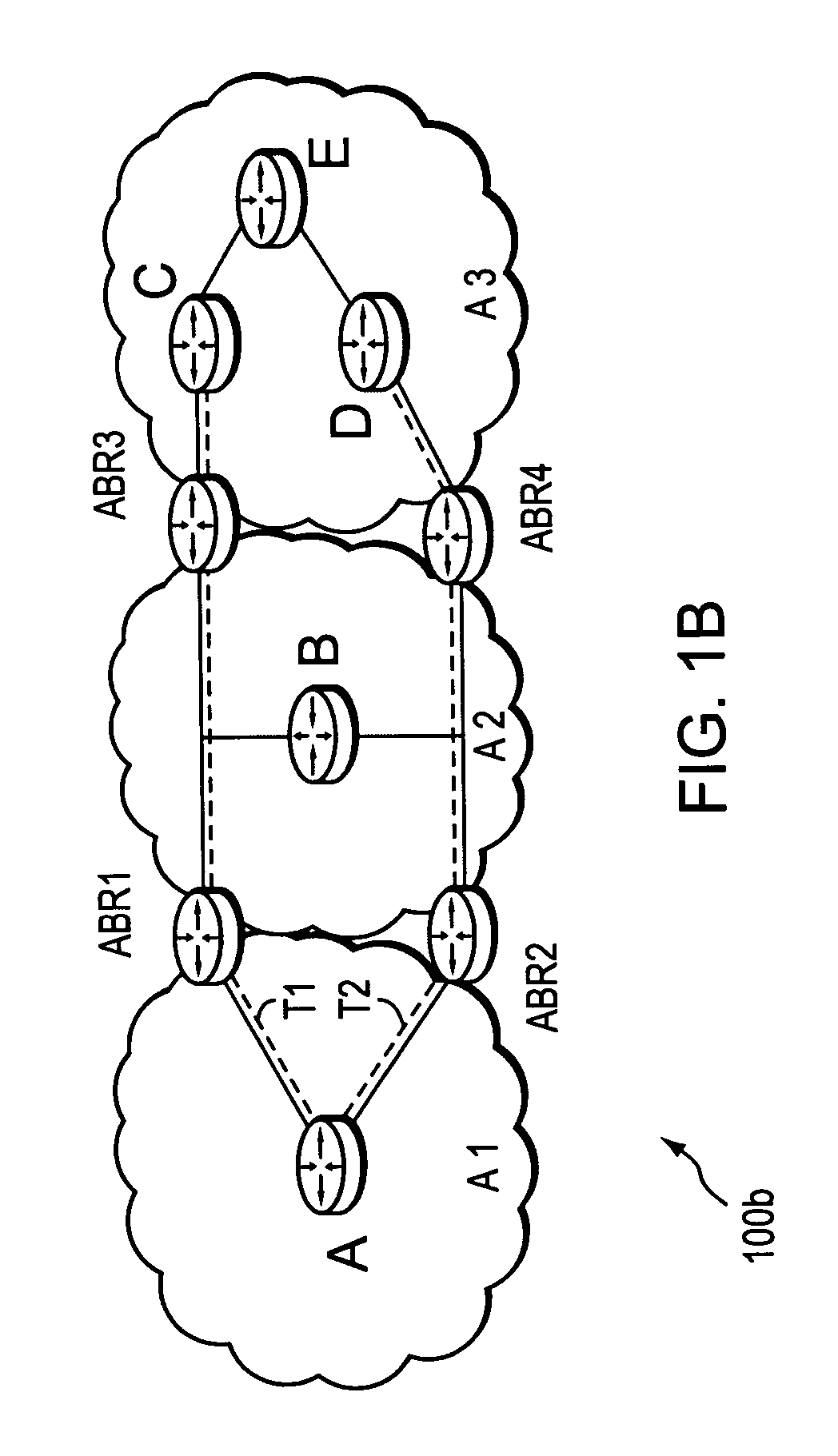

Inter-domain TE-LSP selection

InactiveUS20060120288A1Avoid errorsReduce riskError preventionFrequency-division multiplex detailsTraffic capacityReachability

A technique selects a traffic engineering (TE) label switched path (LSP) from among a plurality of TE-LSPs, each of which spans multiple domains of a computer network from a head-end node of a local domain to a tail-end node of a remote domain, in order to reach one or more address prefixes within the remote domain. The inter-domain TE-LSP selection technique comprises a selection algorithm executed by the head-end node and based on predetermined TE-LSP attributes (e.g., bandwidth, cost, etc.) and / or address prefix reachability attributes (e.g., cost from a tail-end node to the prefix) to select an appropriate inter-domain TE-LSP for the reachable address prefix. The selection algorithm is embodied in one of two modes: (i) a hierarchical selection mode, or (ii) a weighted selection mode. In addition, the technique comprises a load balancing aspect that cooperates with the selection algorithm to enable the head-end node to balance traffic loads among the multiple TE-LSPs based on the results of the selection algorithm.

Owner:CISCO TECH INC

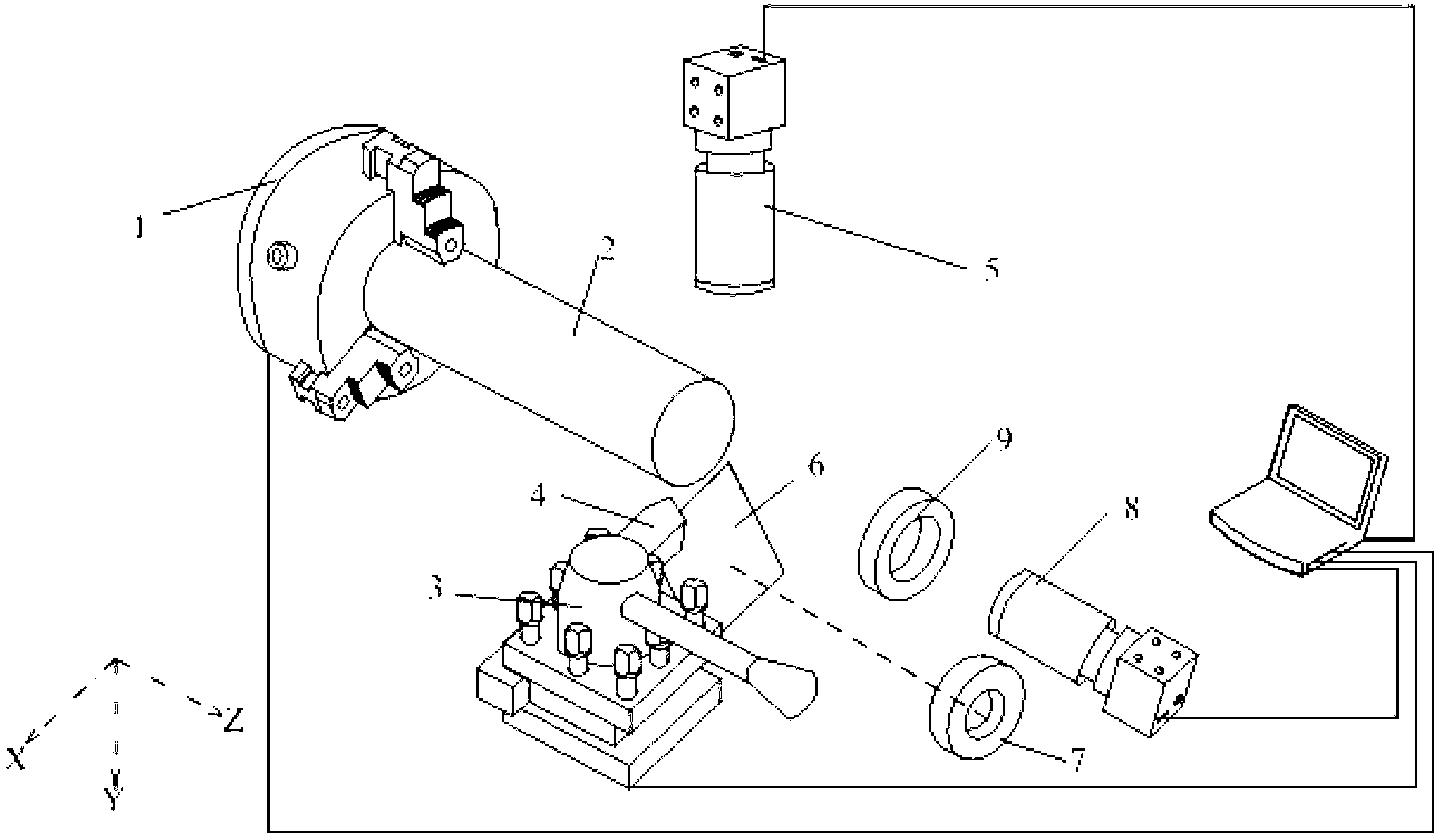

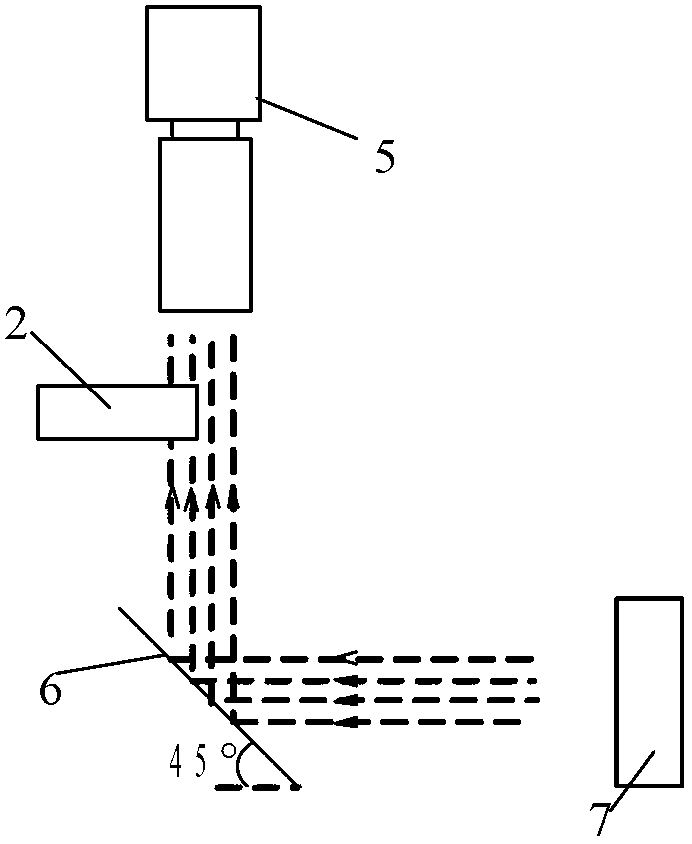

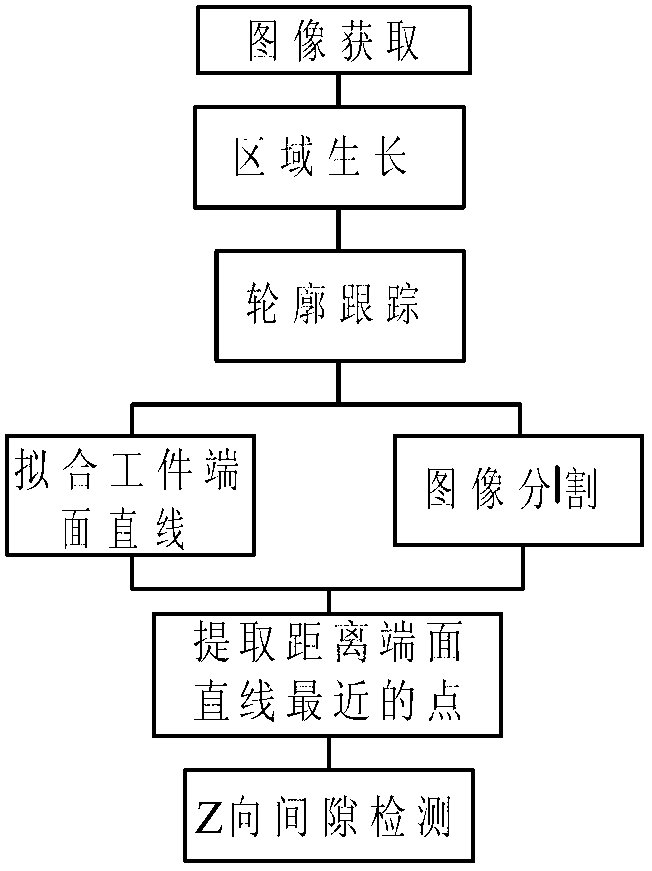

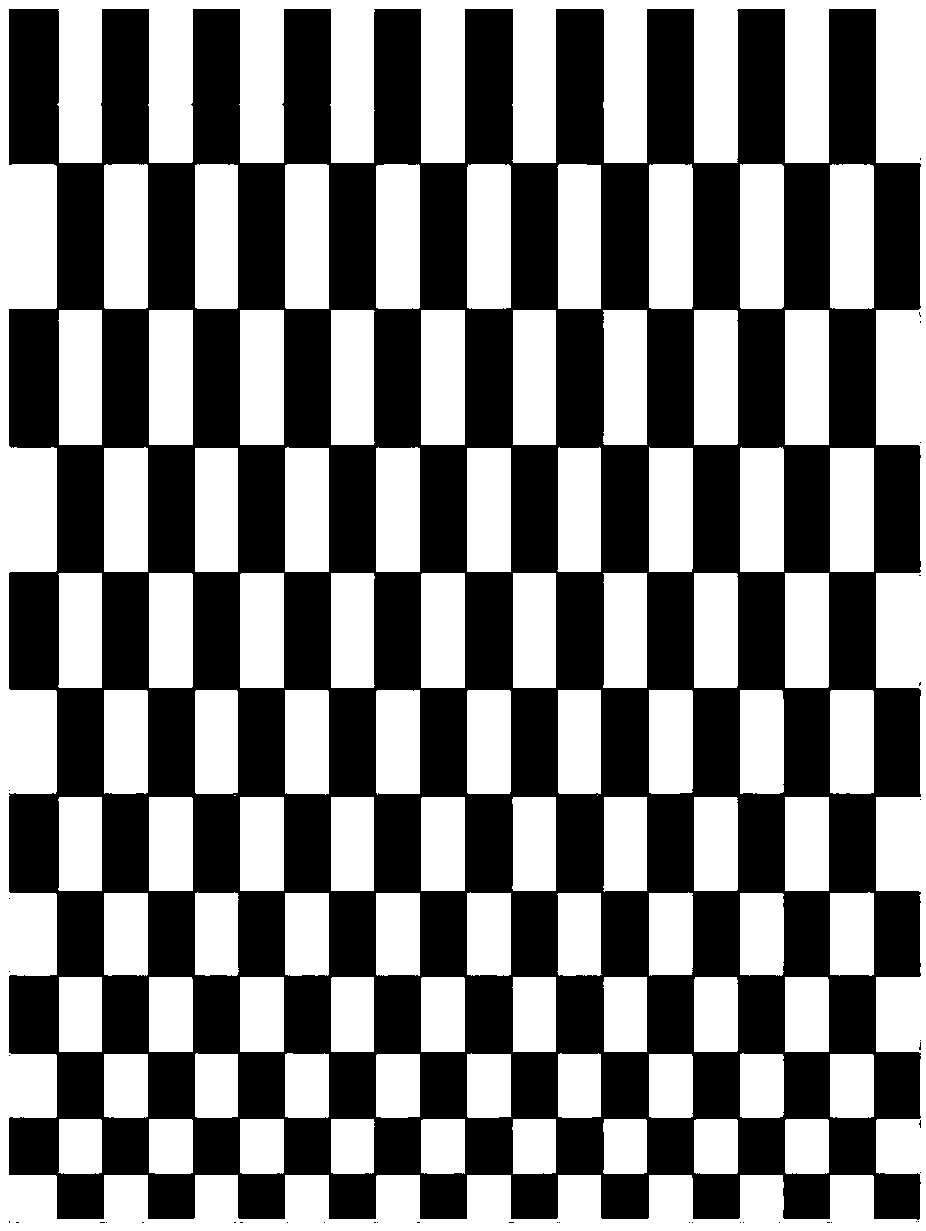

Tool setting device and method for micro lathe

ActiveCN102699359AReal-time measurementImprove stabilityAuxillary equipmentCcd cameraMachining process

The invention discloses a tool setting device and a tool setting method for a micro lathe and belongs the technical field of mechanical automation. The device comprises a machine tool clamp plate, a tool rest, a tool, a guide rail, a first charge coupled device (CCD), a reflector, a first light source, a second CCD, a second light source and an outer computer. The method comprises the following steps of: calibrating pixels in the horizontal direction and pixels in the vertical direction respectively, and transmitting images containing actual distance information to the outer computer; monitoring and adjusting the tool to ensure that the tool approaches an end surface of a workpiece; displaying the distance between a tool nose and the rotary center of the end surface of the workpiece by a technology and software; manually adjusting the distance between the workpiece and the tool according to the obtained distances in the three directions, or controlling the relative motion of the tool and the workpiece by outputting corresponding signals through the computer so as to realize high-precision tool setting of the micro lathe. According to the device and the method, an image measurement technology is adopted, so that tool setting gaps can be automatically detected and can be measured in real time; and therefore, the tool setting difficulty is reduced, and the machining process can be well monitored.

Owner:CHANGCHUN UNIV OF SCI & TECH

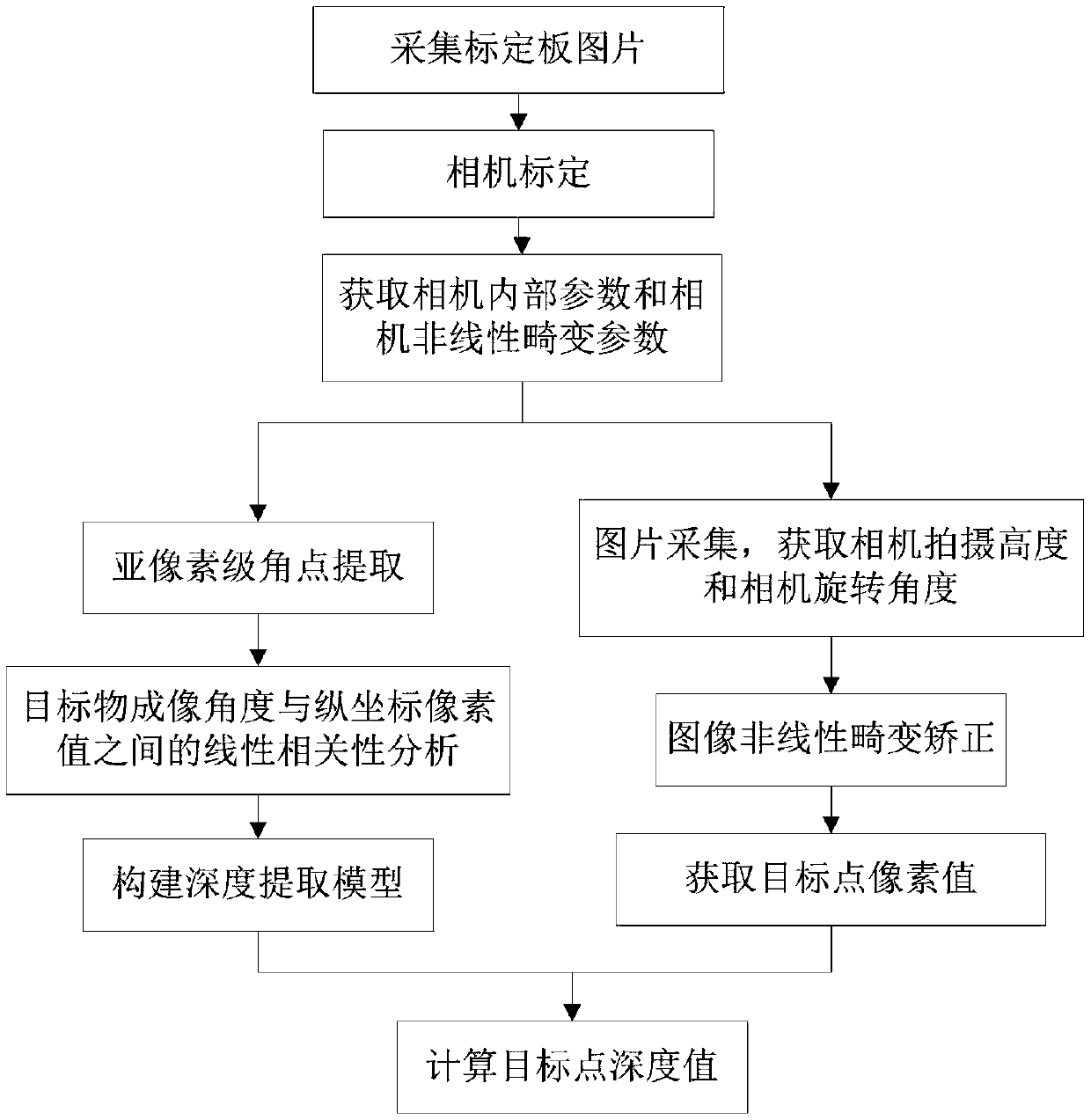

Depth extraction method based on monocular vision

The invention discloses a depth extraction method based on monocular vision. The method comprises: 1, demarcating the camera of a phone to obtain the inner parameters and image resolution of the camera; 2, establishing a depth extraction model described in the descripton; 3, acquiring the pixel value u, v of the target point through image acquisition of the target to be measured; 4, calculating the depth value of the object to be measured on the image by using the camera internal parameter and the pixel value of the object point obtained in the step 1 and combining with the camera depth extraction model. The depth extraction method based on monocular vision of the invention can be applied to cameras with different parameters such as field angle, focal length, image resolution, etc. to improve ranging accuracy and provide support for object measurement in machine vision and three-dimensional reconstruction of real scene.

Owner:ZHEJIANG FORESTRY UNIVERSITY

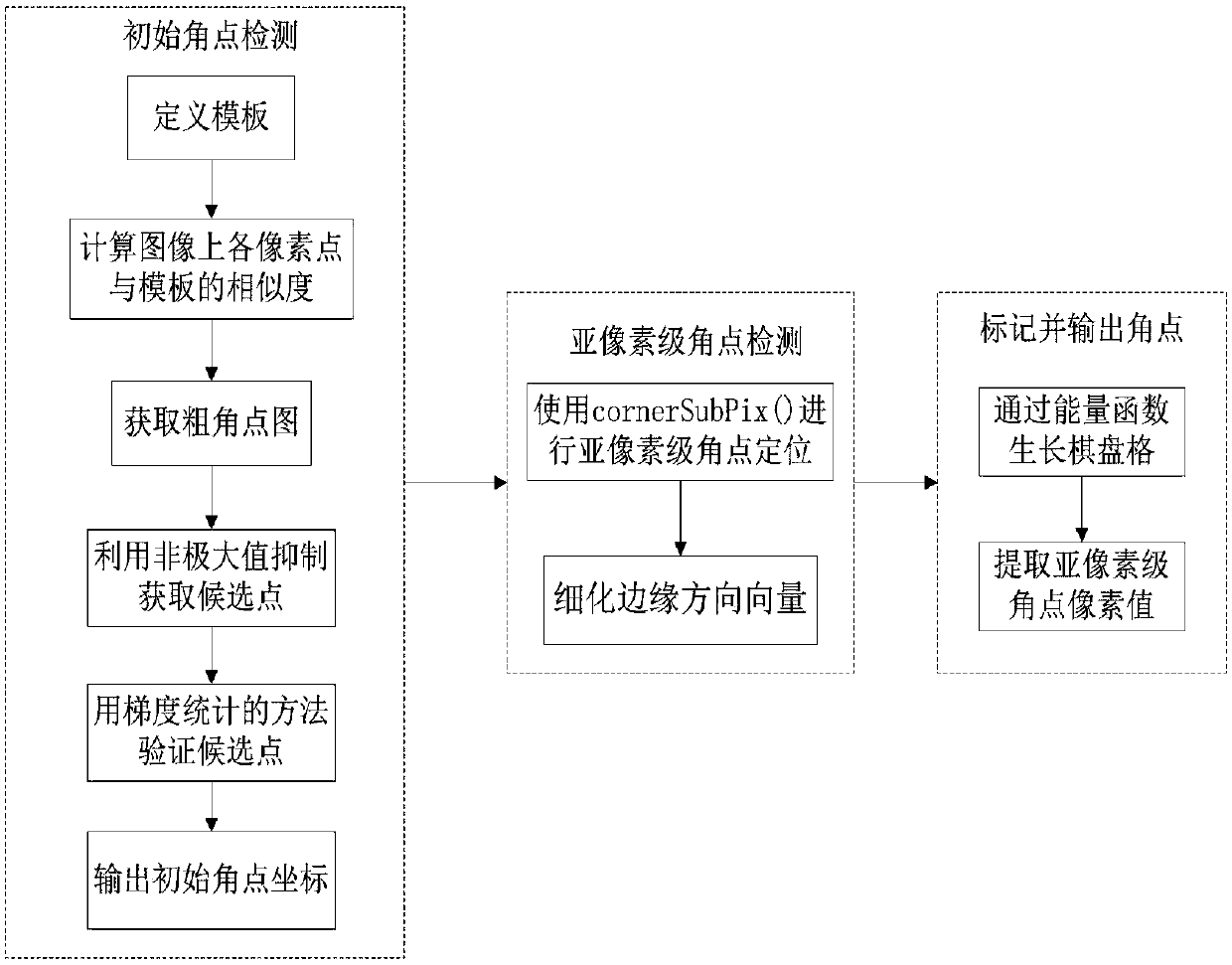

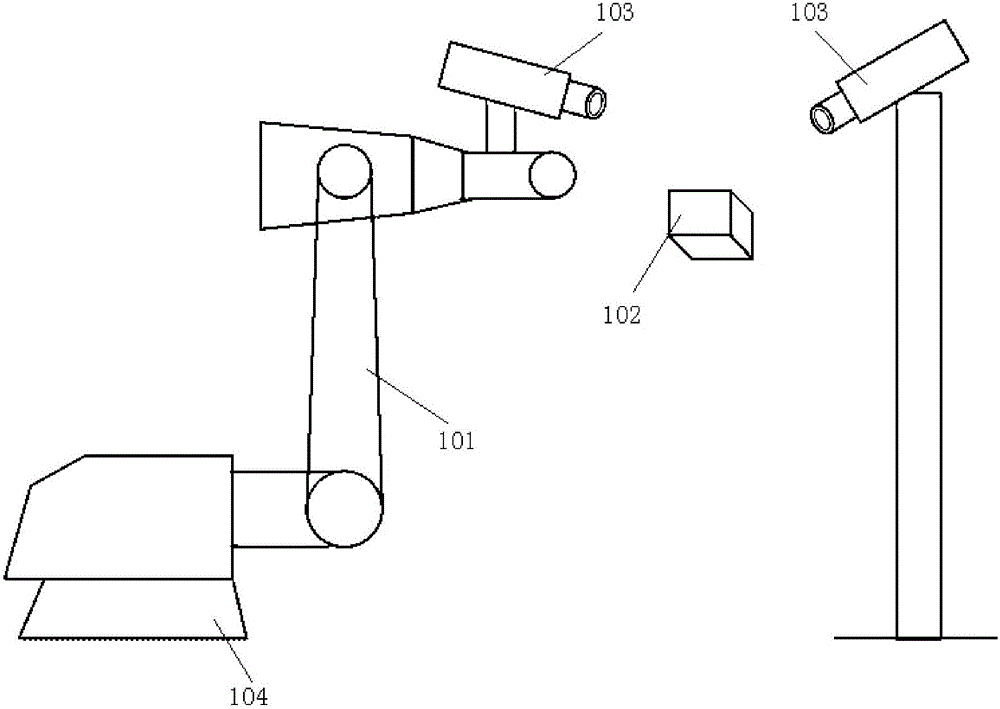

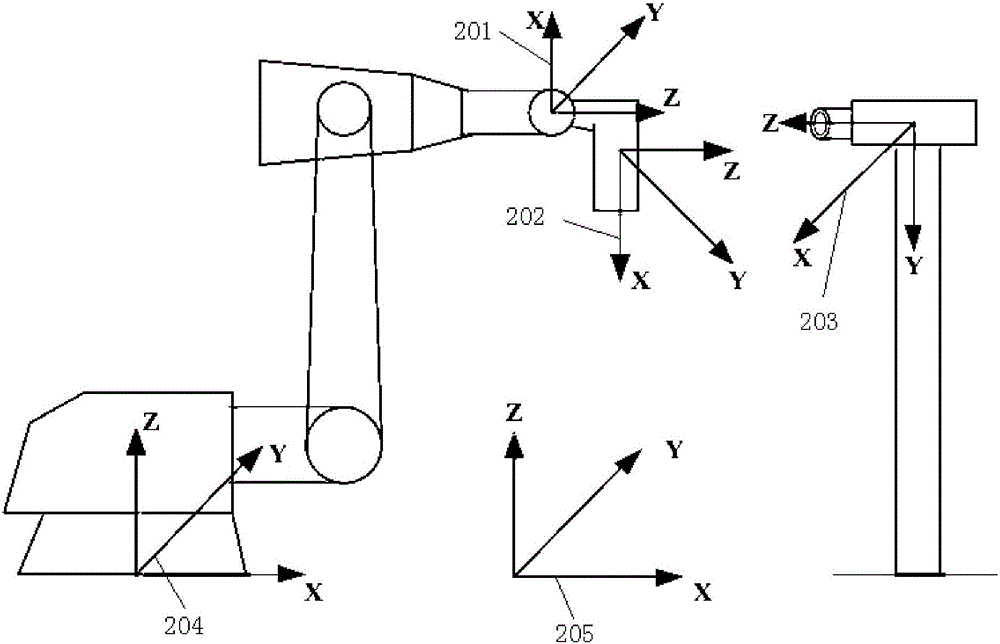

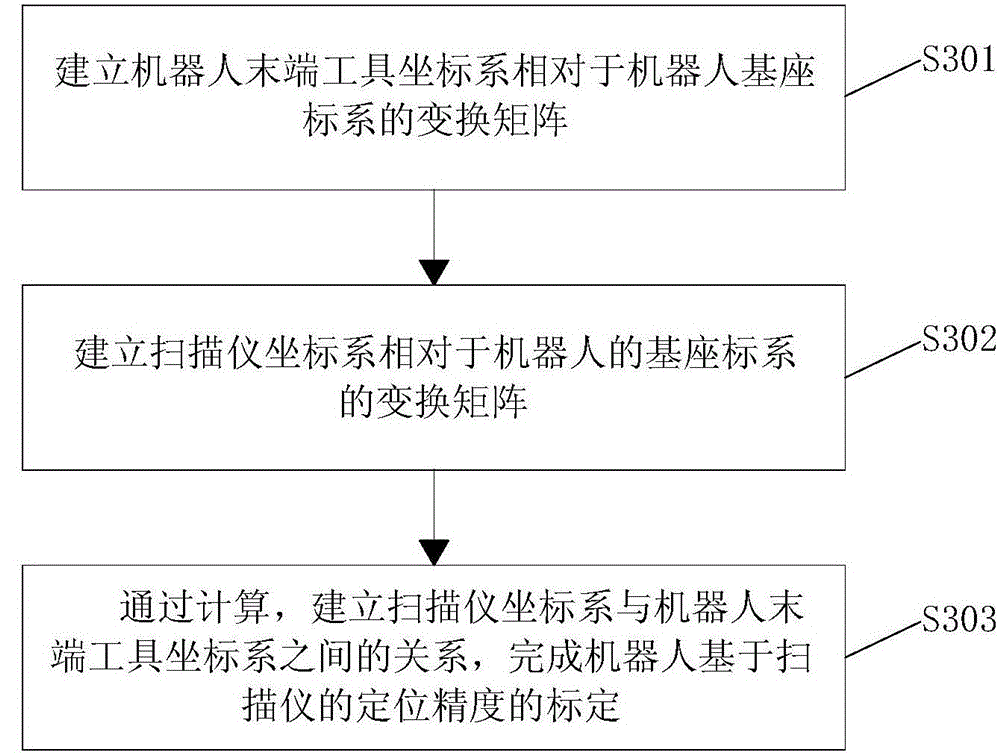

Robot hand and eye calibrating method based on scanner

The invention discloses a robot hand and eye calibrating method based on a scanner. The robot hand and eye calibrating method comprises the steps that a transformation matrix of an end tool coordinate system of a robot relative to a base coordinate system of the robot is established; a transformation matrix of a coordinate system of the scanner relative to the base coordinate system of the robot is established; and calibration of the positioning precision of the robot based on the scanner is completed by calculating the relation between the coordinate system of the scanner and the end tool coordinate system of the robot. By means of the robot hand and eye calibrating method based on the scanner, the calibration of the positioning precision of the robot based on the scanner is completed to calculate the fixed position relation of the scanner relative to the robot so that the scanner can then be used for scanning an end clamping tool of the robot to obtain the actual position of the end tool of the robot relative to the end coordinate system of the robot; errors generated due to inaccuracy of technical operation such as installation are eliminated so that the calibrated robot can precisely scan workpieces on different occasions, and the machining precision is improved.

Owner:无锡中车时代智能装备研究院有限公司

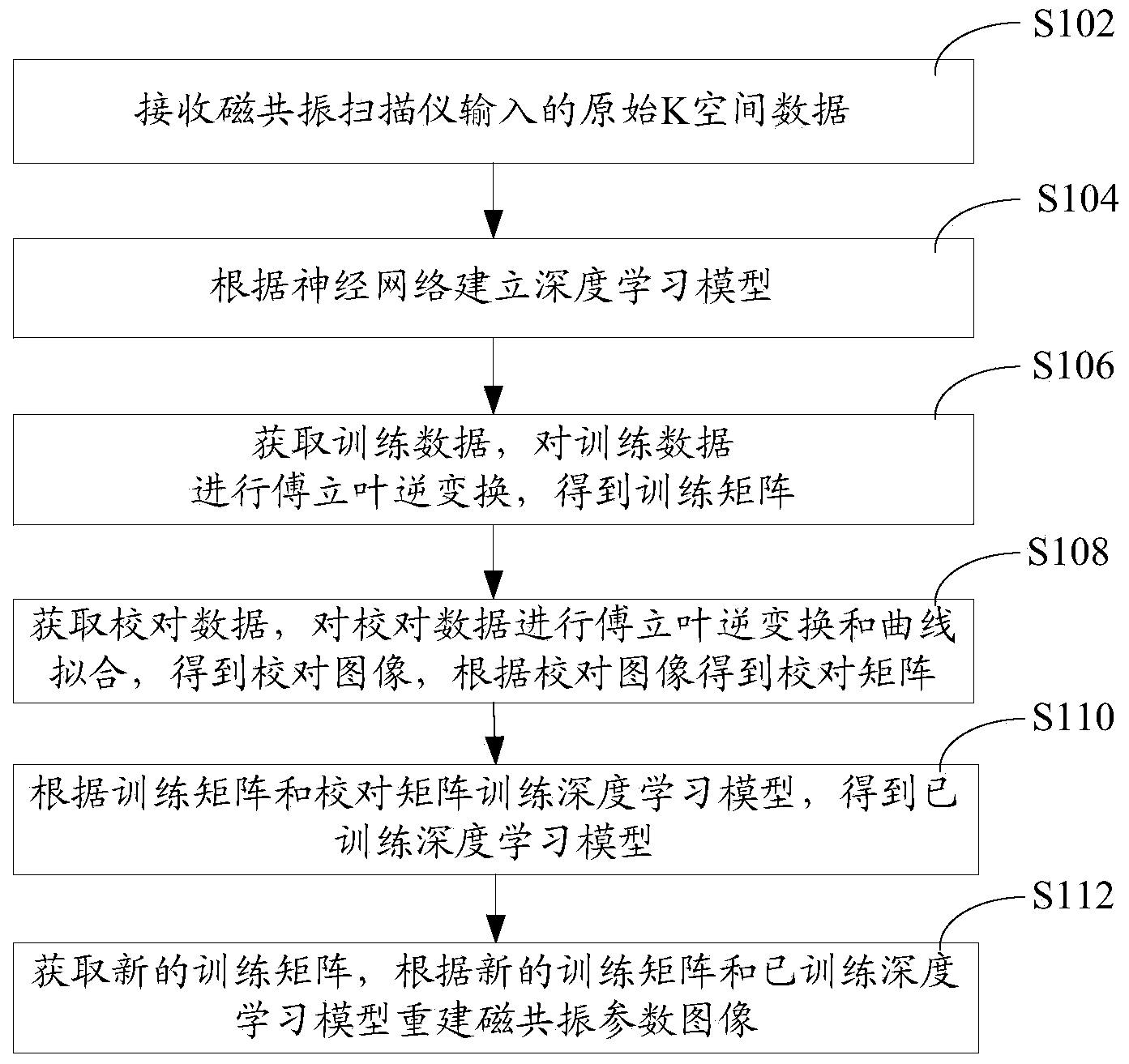

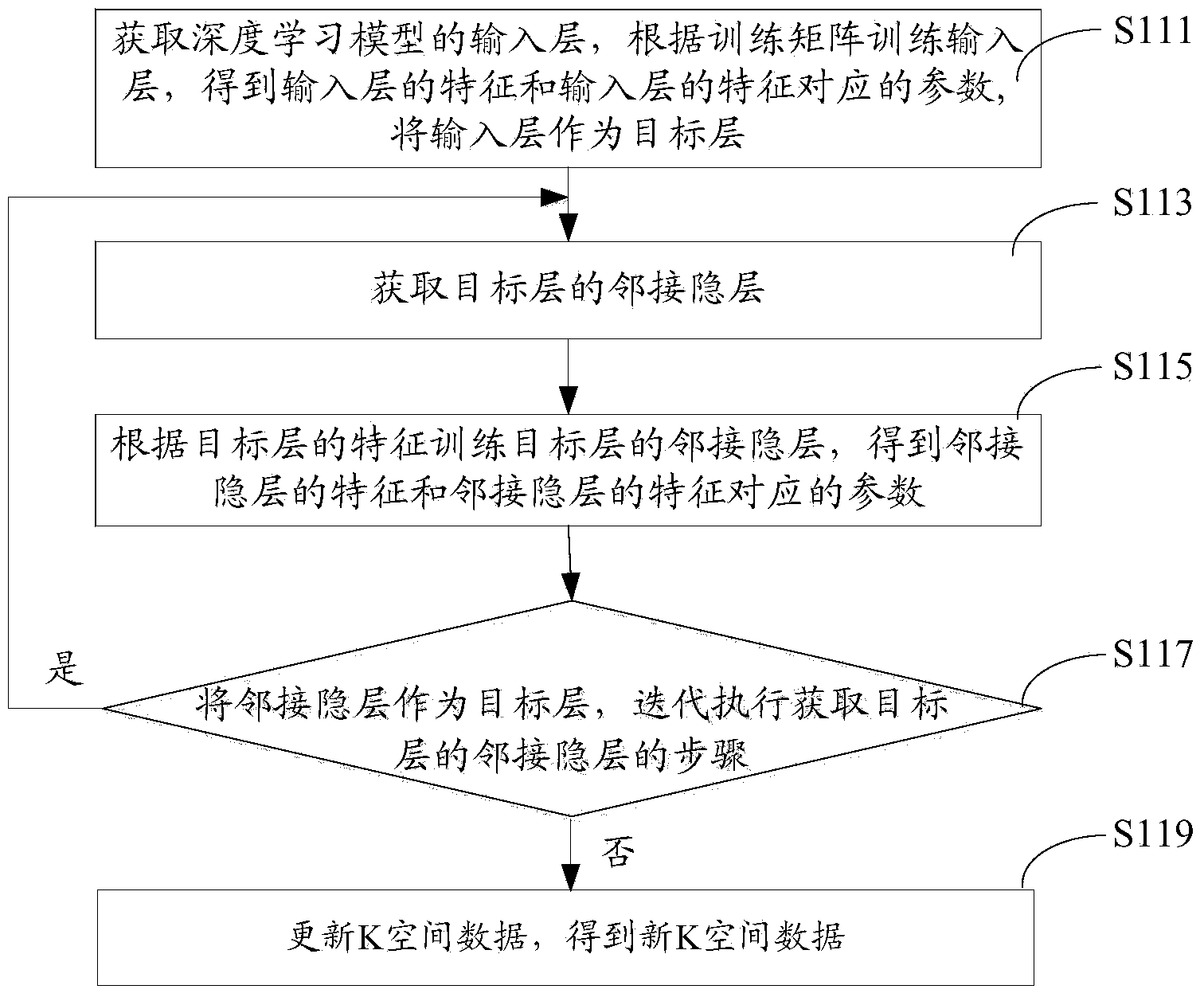

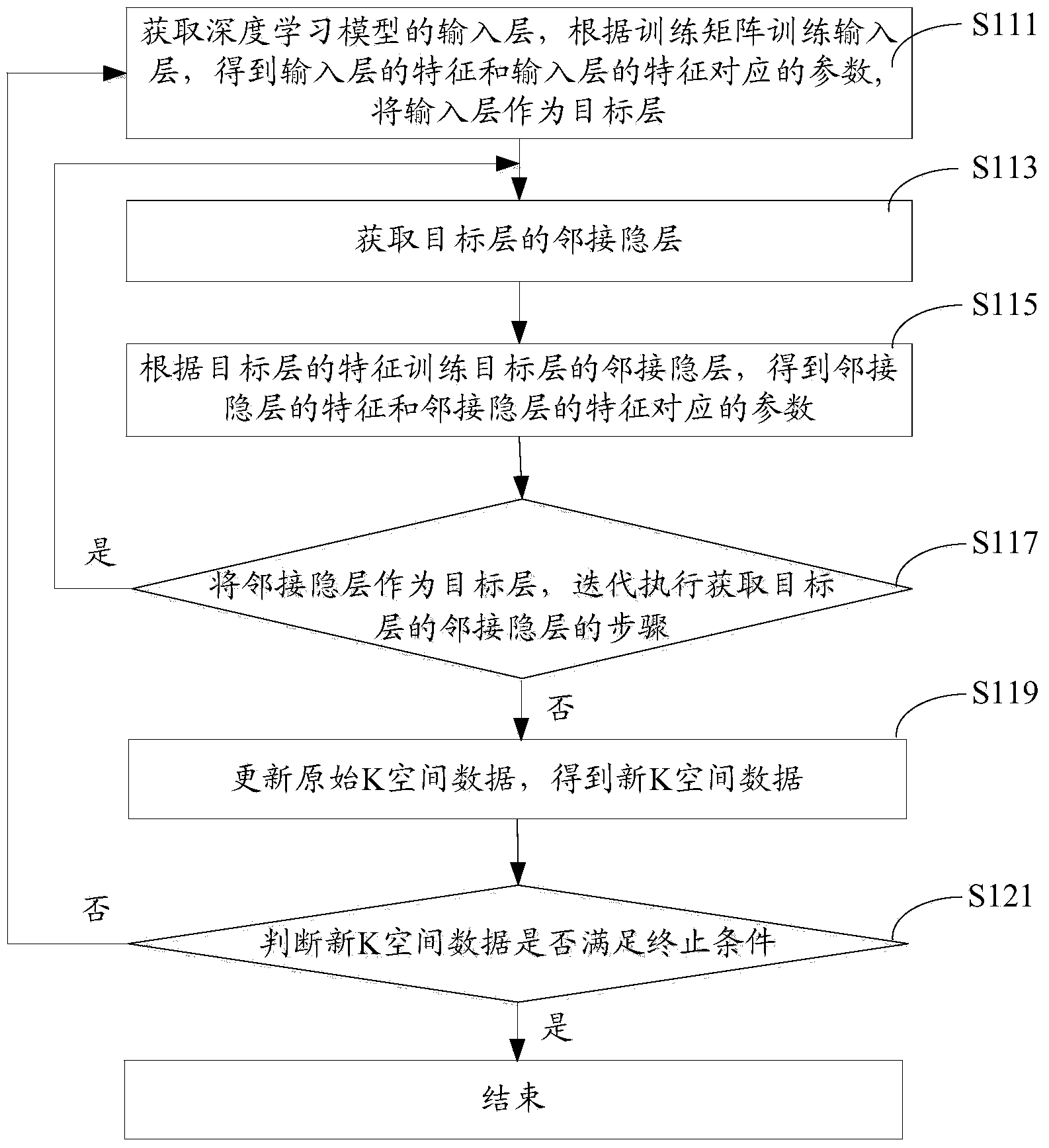

Magnetic resonance rapid parameter imaging method and system

ActiveCN103646410AAvoid errorsQuality improvementImage analysis2D-image generationPattern recognitionNerve network

The invention provides a magnetic resonance rapid parameter imaging method comprising the following steps: original K-space data inputted by a magnetic resonance scanner are received; a deep learning model is established according to a nerve network; training data are acquired, and Fourier inverse transformation is performed on the training data so that a training matrix is obtained; proofreading data are acquired, and Fourier inverse transformation and curve fitting are performed on the proofreading data so that a proofreading image is obtained, and a proofreading matrix is obtained according to the proofreading image; the deep learning model is trained according to the training matrix and the proofreading matrix so that the trained deep learning model is obtained; and a new training matrix is acquired, and a magnetic resonance parameter image is reconstructed according to the new training matrix and the trained deep learning model. Quality of the reconstructed image can be effectively enhanced by using the method. Besides, the invention also provides a magnetic resonance rapid parameter imaging system.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com