Patents

Literature

1646 results about "Face shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

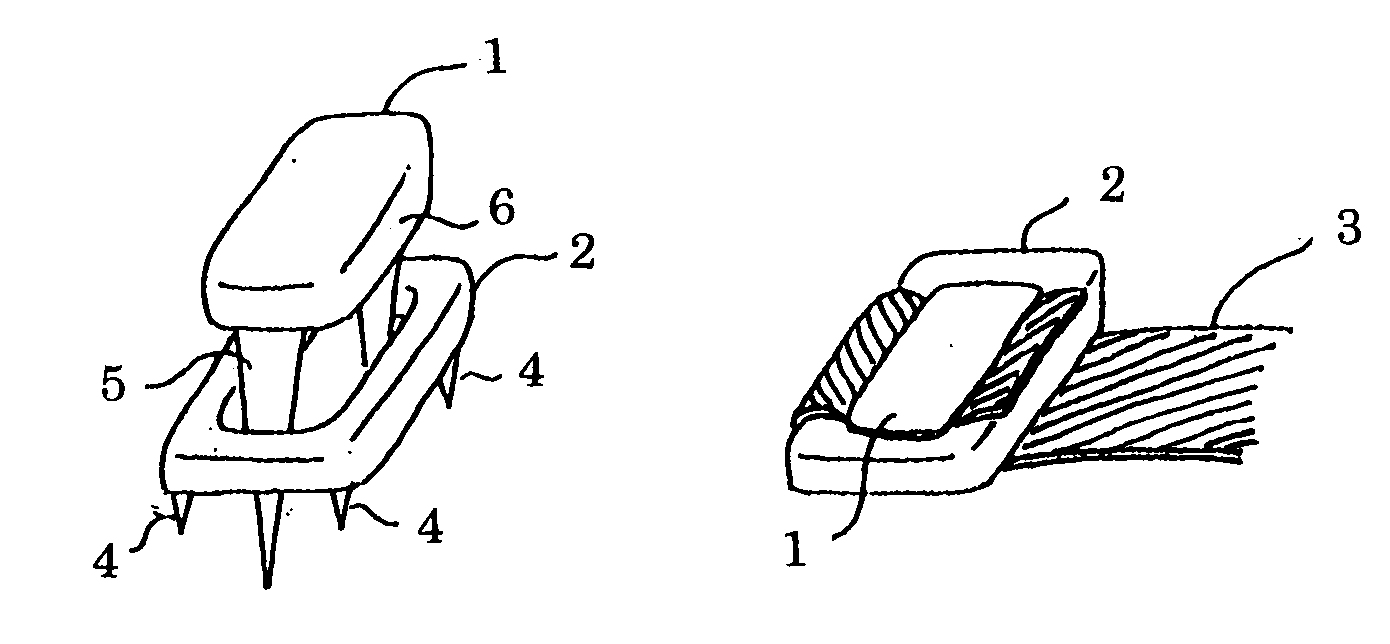

Ligament fixing system

An inexpensive ligament fixing system capable of providing an efficient fixing force and accurately driving a staple with less invasion, comprising a flat-shaped plate having a plurality of drilled holes and curved bottom and upper surfaces and formed by casting and a cross bar used to allow a parallelism, to be checked, wherein the plate is fixed to a ligament and the folded-up ligament is further fixed with the staple, the tips of the leg parts of the staple are moved from the centerline to the inside, a cut-in is provided on the insides of the leg parts, the cross sections of the leg parts are formed in a polyhedron, the plate is pressed and driven by a driving device having a driving structure by a thrust bar is used.

Owner:KOSEKI TOMOAKI

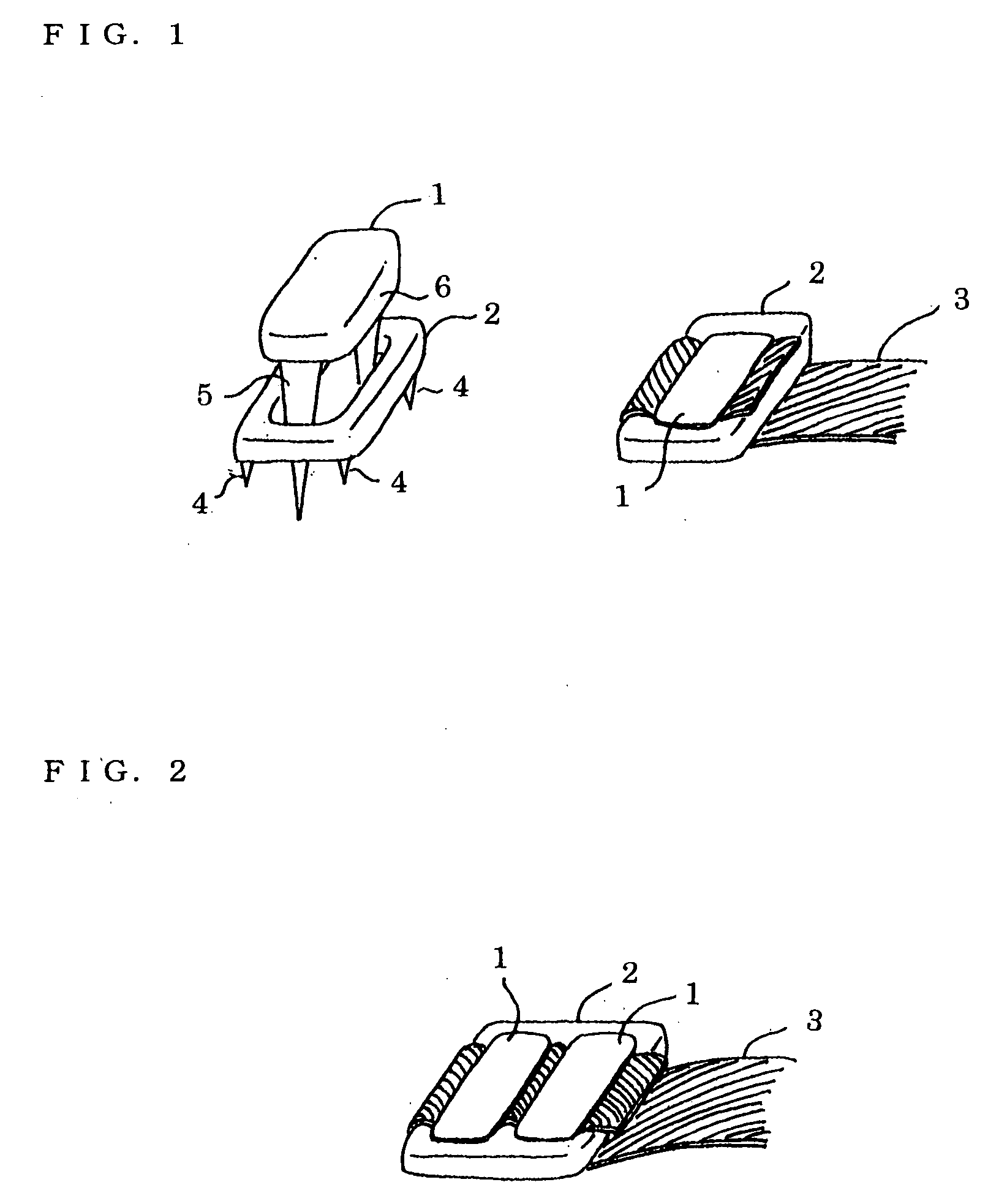

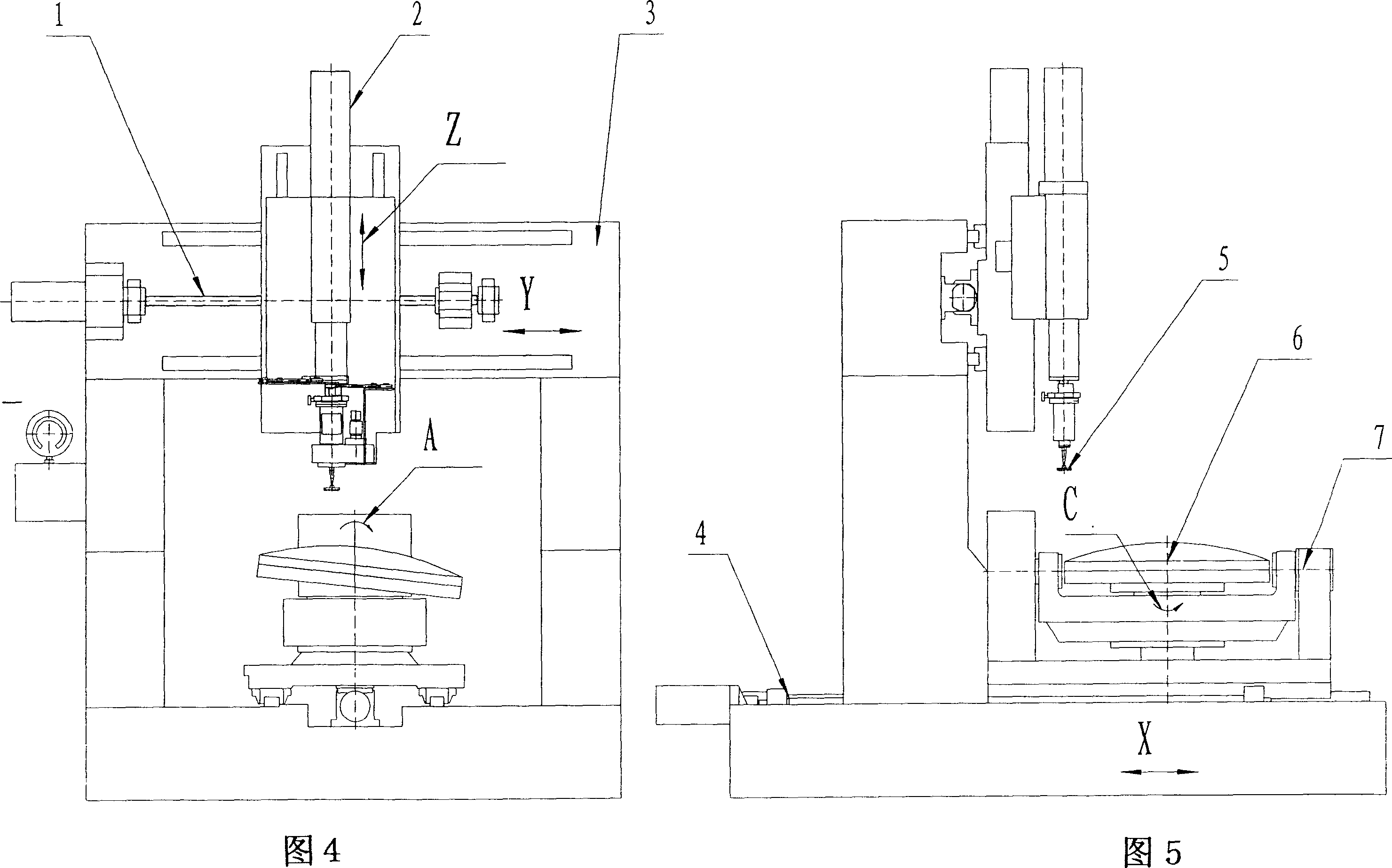

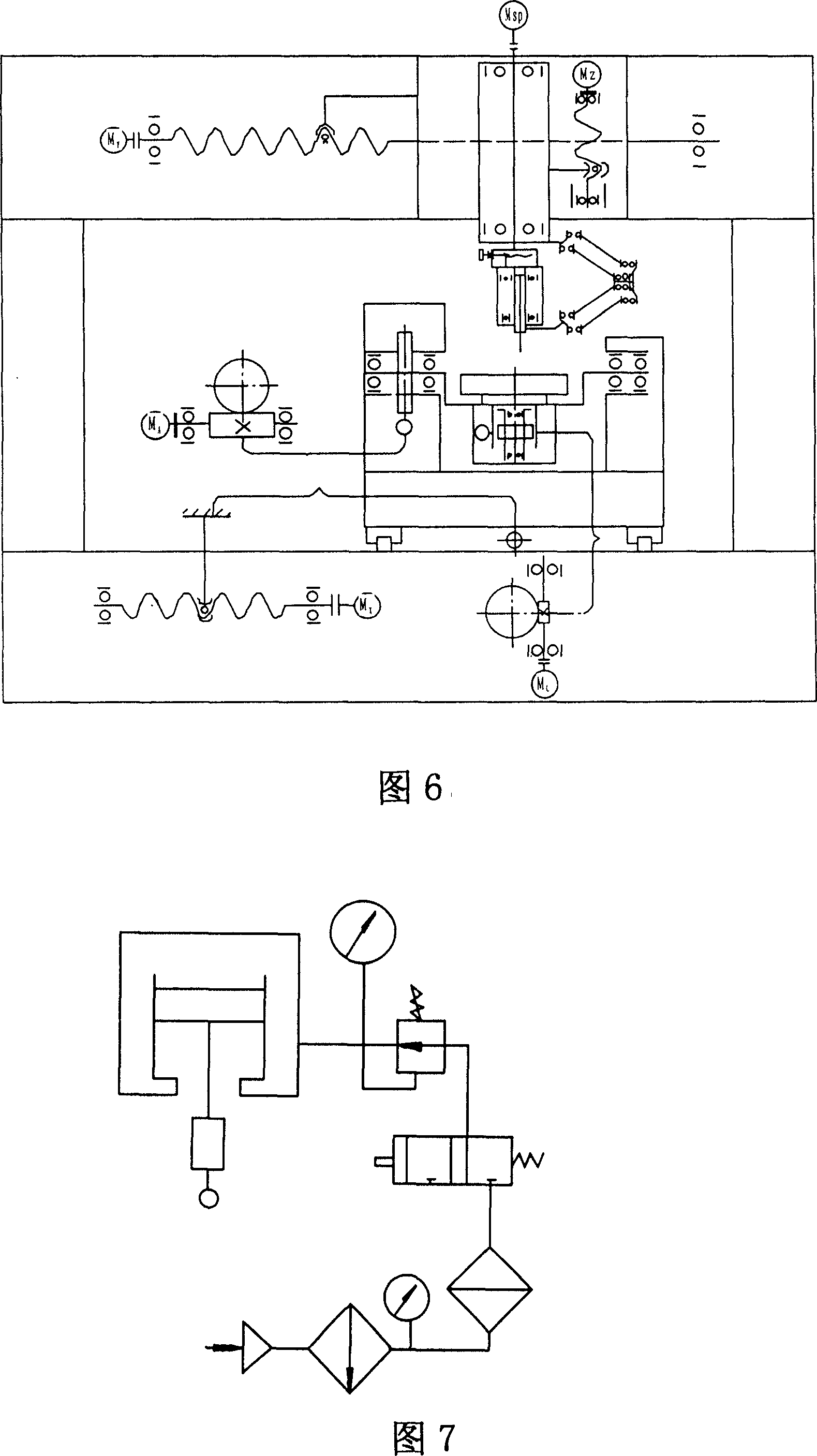

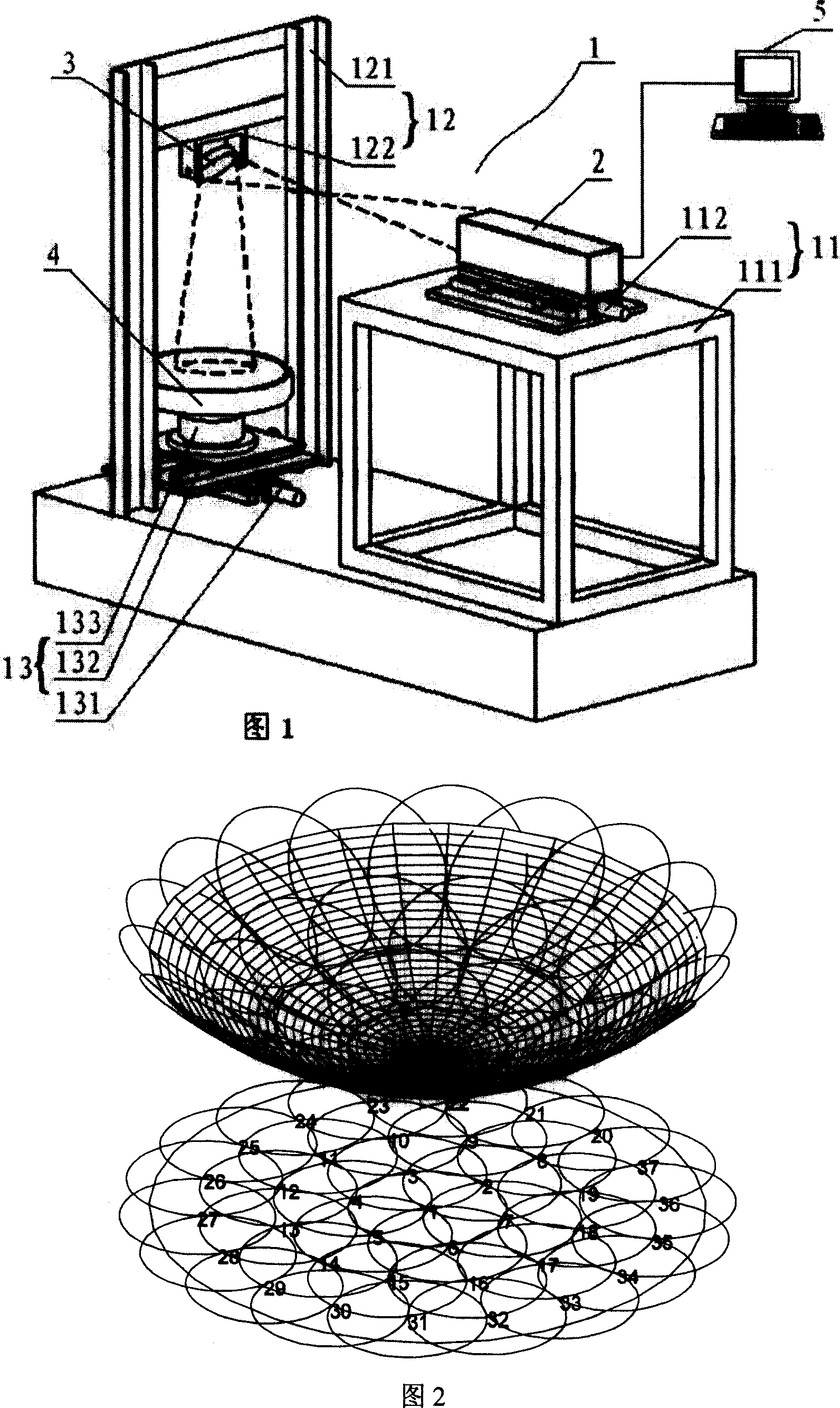

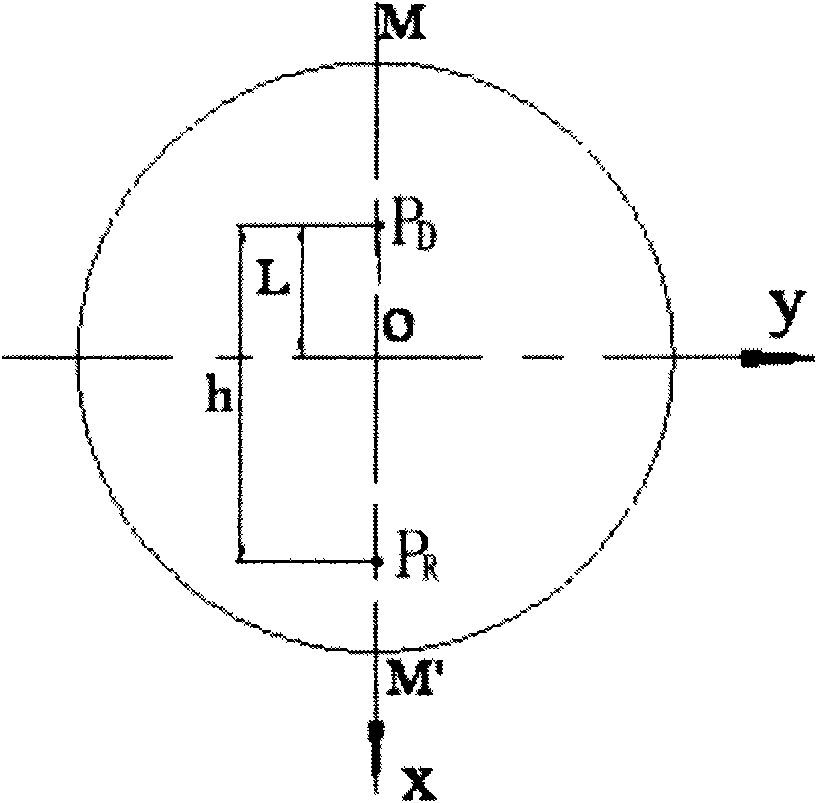

Efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements

InactiveCN101088705AReduce dependenceImprove efficiencyOptical surface grinding machinesOptical surfaceMachining process

The efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements belongs to the field of precise optical machine technology. The polishing process includes: constituting polishing process model based on the profile data obtained through measurement with interferometer or other instrument, determining the machining path, speed, pressure and other parameters of the element under the control of computer to perform simulating machining, verifying the technological parameters based on the simulating machining results and determining the ultimate technological parameters, creating NC program and machining. The present invention has high machining efficiency and high machining precision.

Owner:CHANGCHUN EQUIP TECH RES INST

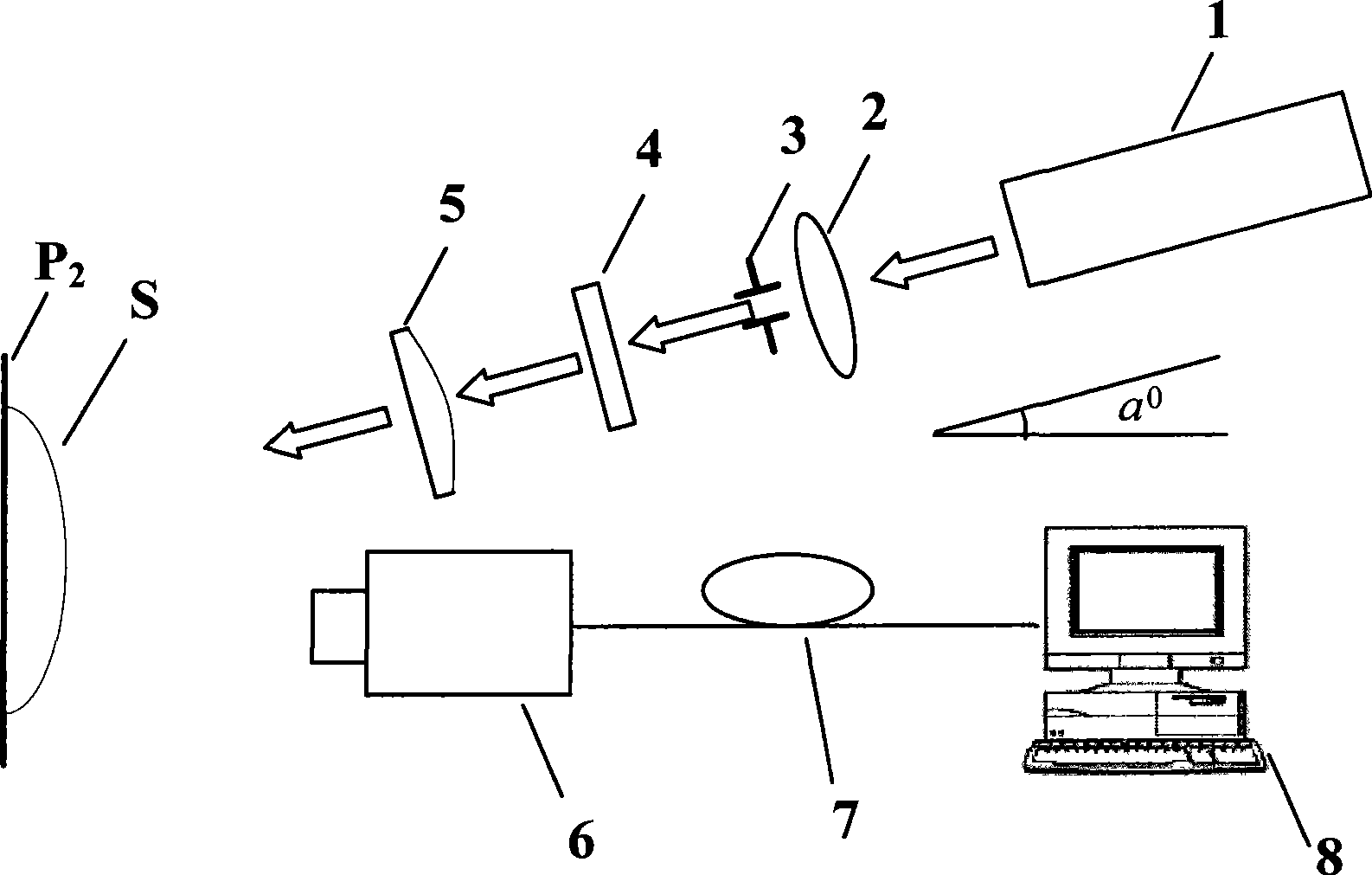

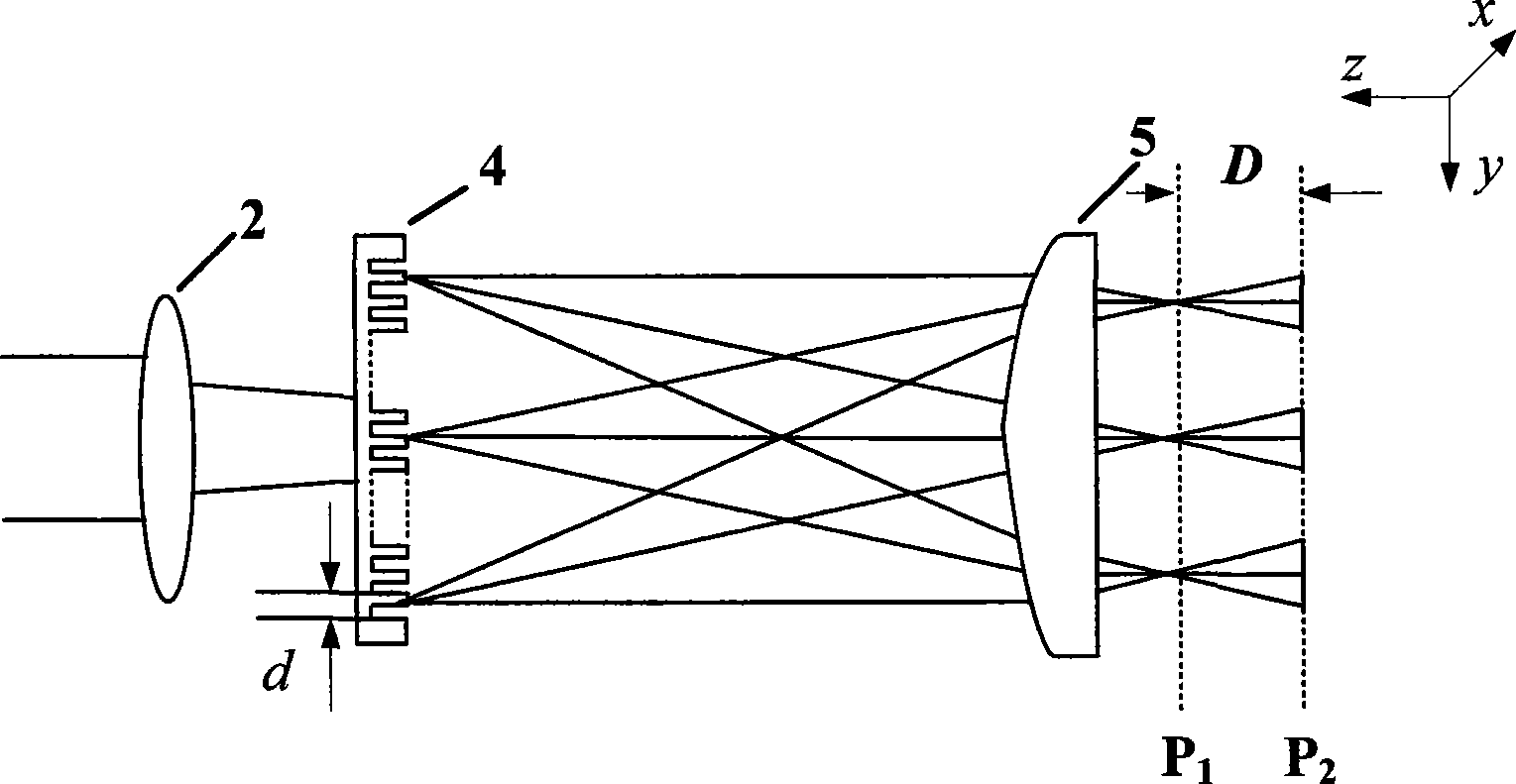

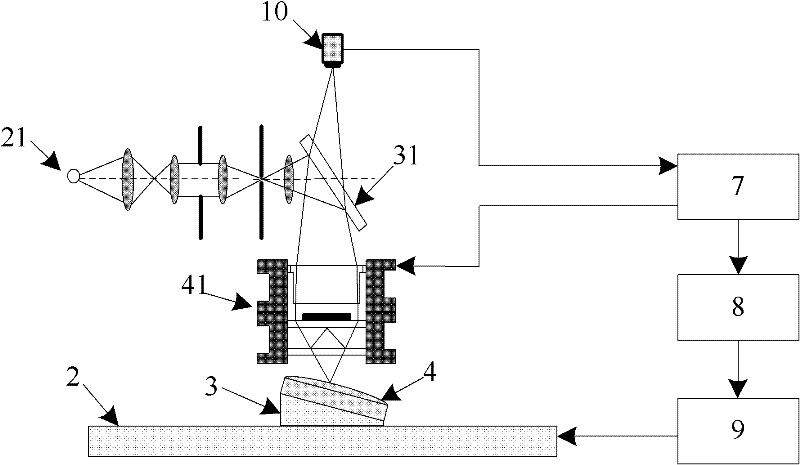

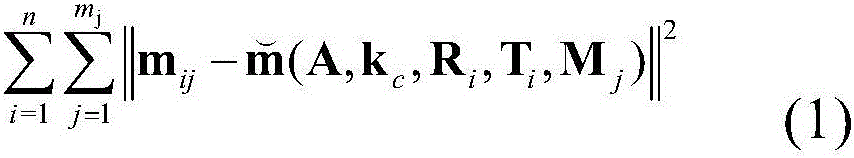

Object three-dimensional contour outline measuring set and measuring method

ActiveCN101451826AUniform light intensity at the spectral pointImprove energy utilizationUsing optical meansInformation processingMeasurement device

An object three-dimensional outline measurement device and a measurement method are disclosed, the device is composed of a laser diode, a lens, an aperture diaphragm, a two-dimensional Dammam grating, a cylindrical mirror and an area array CCD camera, a transmission line and a computer, the connection relationship therebetween is as below: a beam emitted by the laser diode passes through the lens, the aperture diaphragm, the two-dimensional Dammam grating, and the cylindrical mirror sequentially to form one-dimensional projection array stripes, which illuminates the surface of an objective to be measured, the area array CCD camera collects the grating projection strips modulated by three-dimensional digital shape on the surface of the measured objective and outputs the strips to the computer via the transmission line, the computer includes an image collecting interface, image collecting software and three-dimensional measurement information reconstruction algorithm software. The invention has, by utilizing the Fourier transform three-dimensional outline measurement structure, the advantages of high energy utilization rate, simple measurement structure, high measurement precision, convenient computer reconstruction information processing and great easiness for operation.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

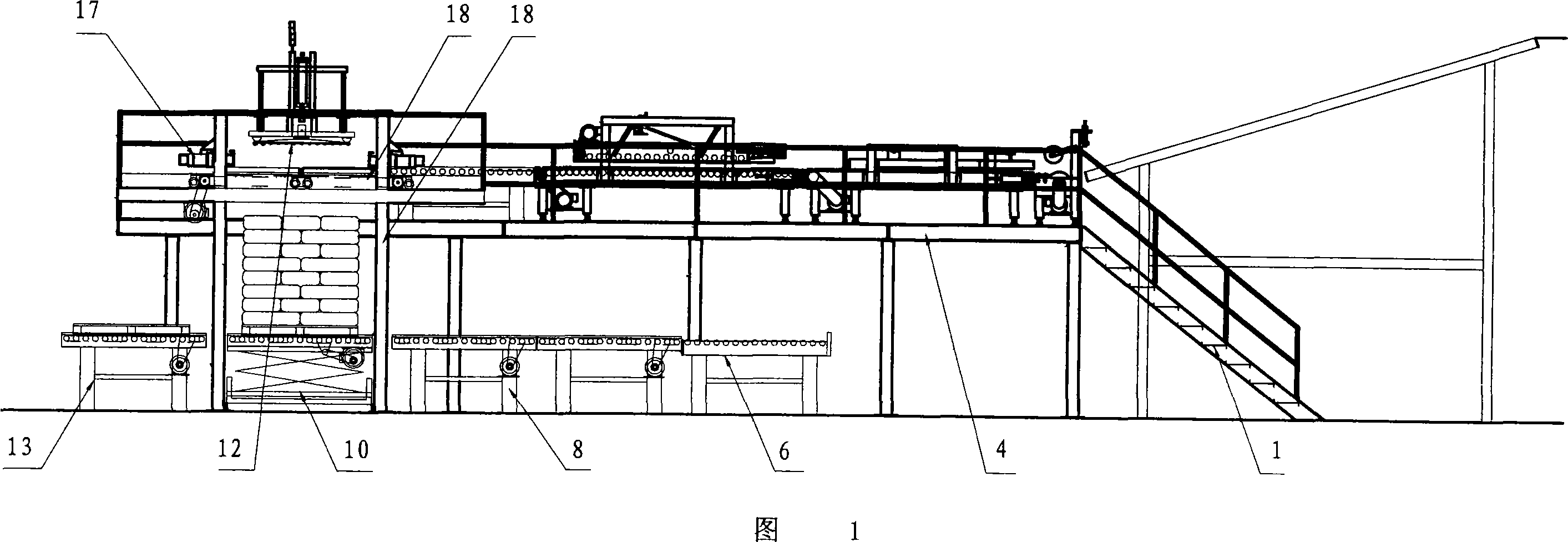

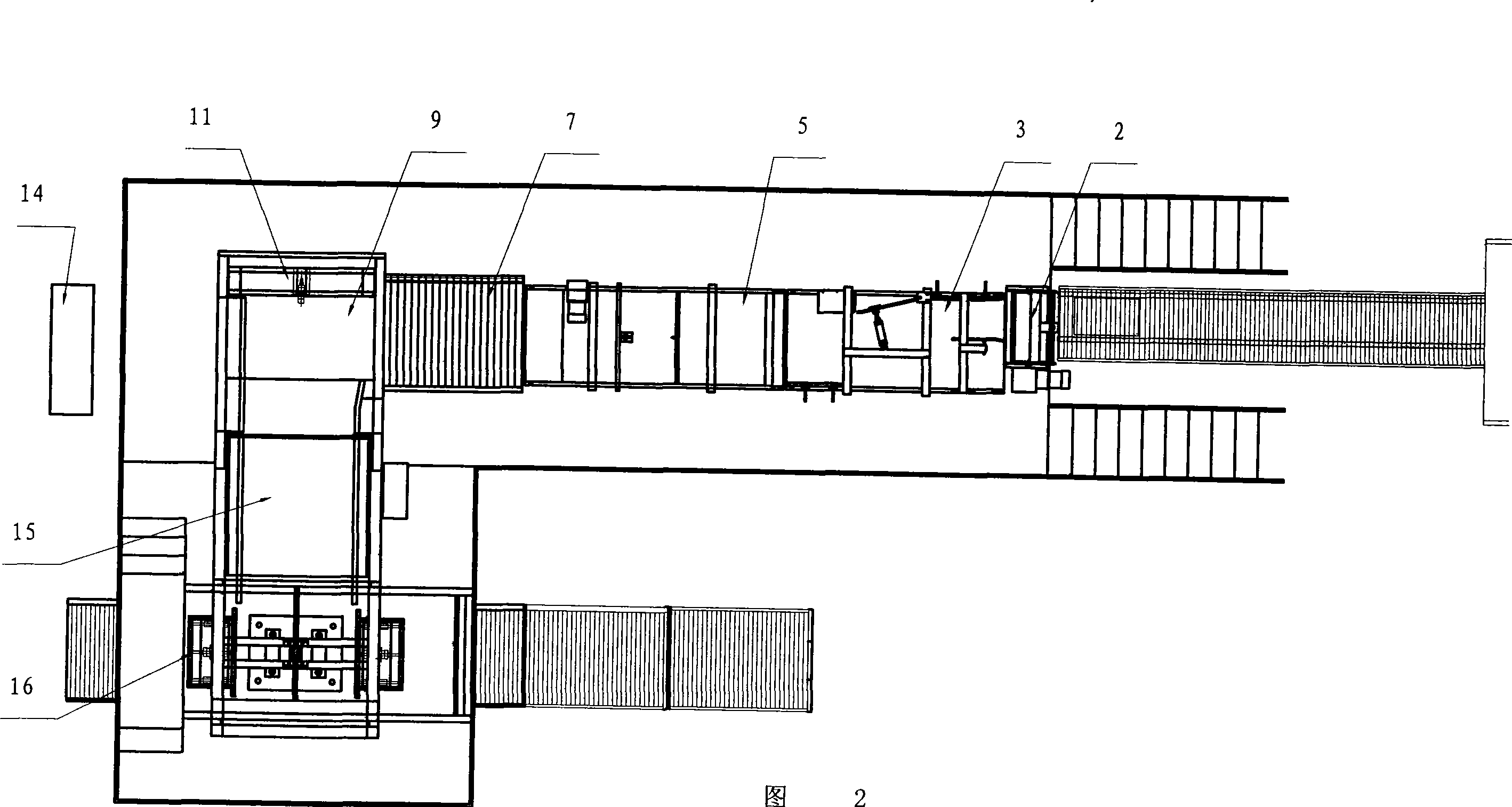

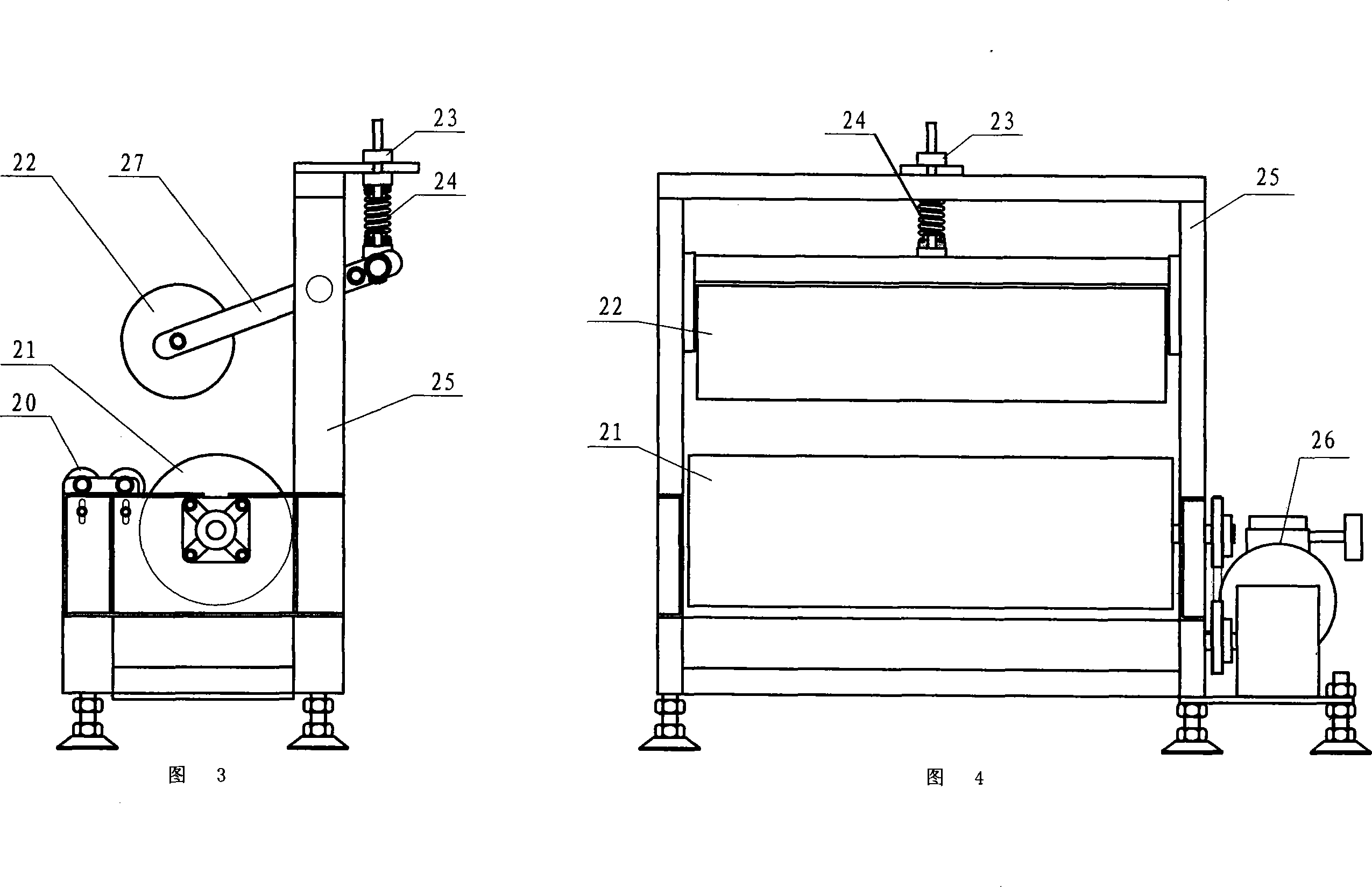

Piling machine

ActiveCN101168415AReasonable structural designLow costStacking articlesConveyor partsOutput deviceElectric control

The invention relates to a pallet machine which can automatically pallet bagged materials as bulked cement, chemical materials, rice or the like. The invention comprises a feeder, a bag rotation transmitter, a compression transmitter, a buffer transmitter, a grouped transmitter, a grouped bag pusher, a layering machine, a side face shape corrector, a vibration shape corrector, a lifter, a disc feeder, a pallet bearing outputting device, an output transmitter, a pallet disc storage transmitter, an electric control cabinet, a walk bench, and an arm rest lift. The invention has reasonable structure, low cost, and high speed, which combines a plurality of single machines, with clear and reasonable structure and simple maintenance.

Owner:HEBEI HANGUANG HEAVY IND

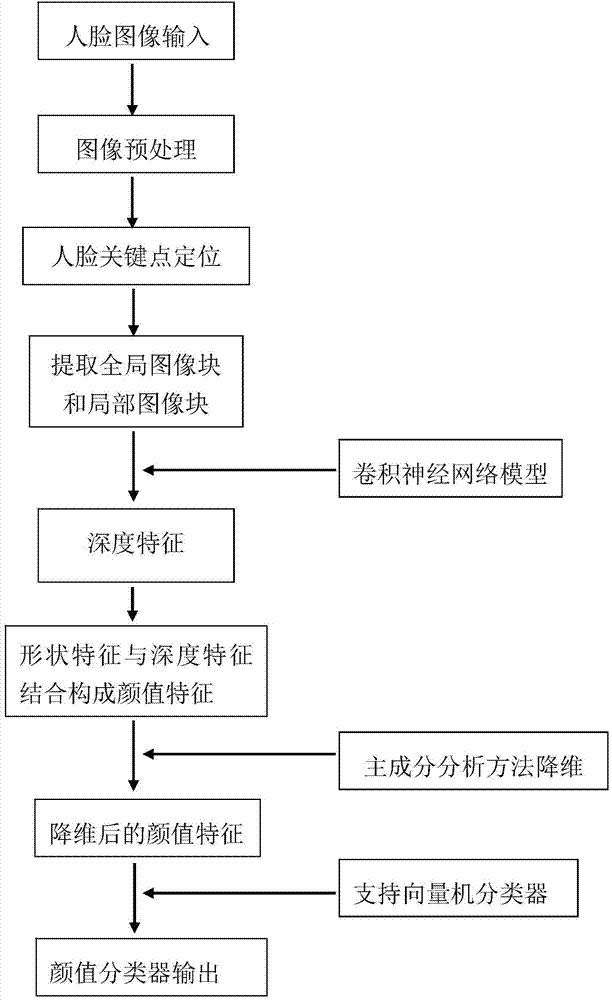

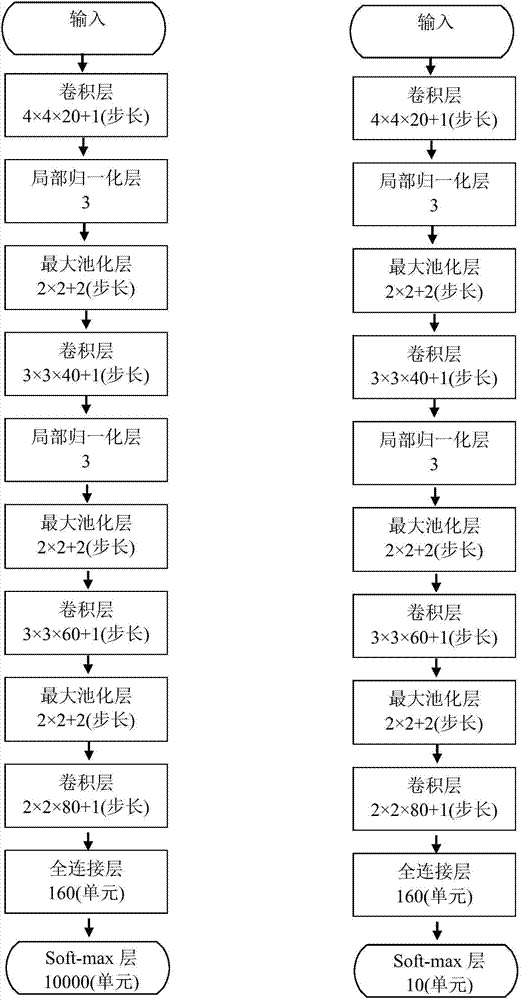

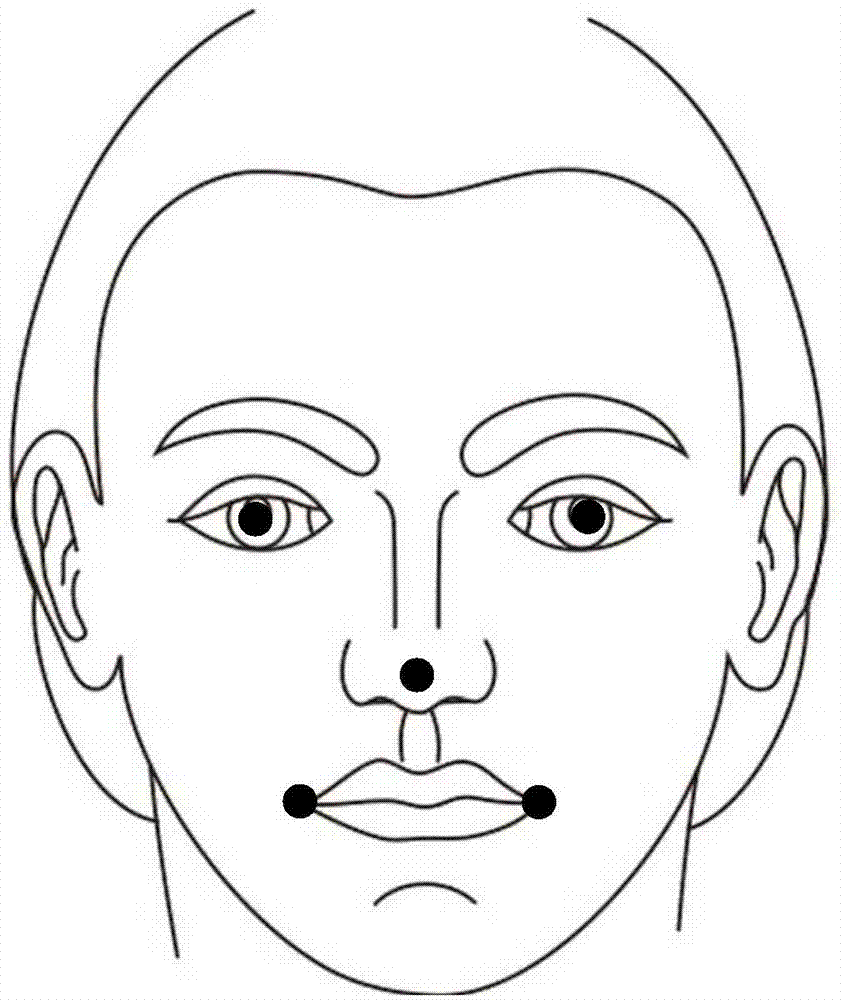

Facial image face score calculating method based on convolutional neural network

ActiveCN104850825AHigh class discriminativeImprove robustnessCharacter and pattern recognitionCrucial pointFace shape

The present invention discloses a facial image face score calculating method based on convolutional neural networks. The method comprises acquiring facial images with and without face score labels; performing earlier-stage pretreatment to acquire key points of a face and extract overall and partial face image blocks; pre-training and then tuning the convolutional neural networks, and extracting and combining depth characters and shape features of the face to serve as face score features; inputting the face score features into a classifier to train to obtain a face score classifier; and performing the above steps on the facial images to be detected in turn to obtain respectively face score features, and calculating the face score features of the facial images by the face score classifier to obtain respective face scores. According to the calculating method provided by the present invention, the convolutional neural networks are adopted to extract depth characters of the overall and partial facial images, and through combination with the face shape features, face score calculating uncertainty under complex situations is overcome, the robustness is high, and excellent effects in engineering application are achieved.

Owner:CHINA JILIANG UNIV

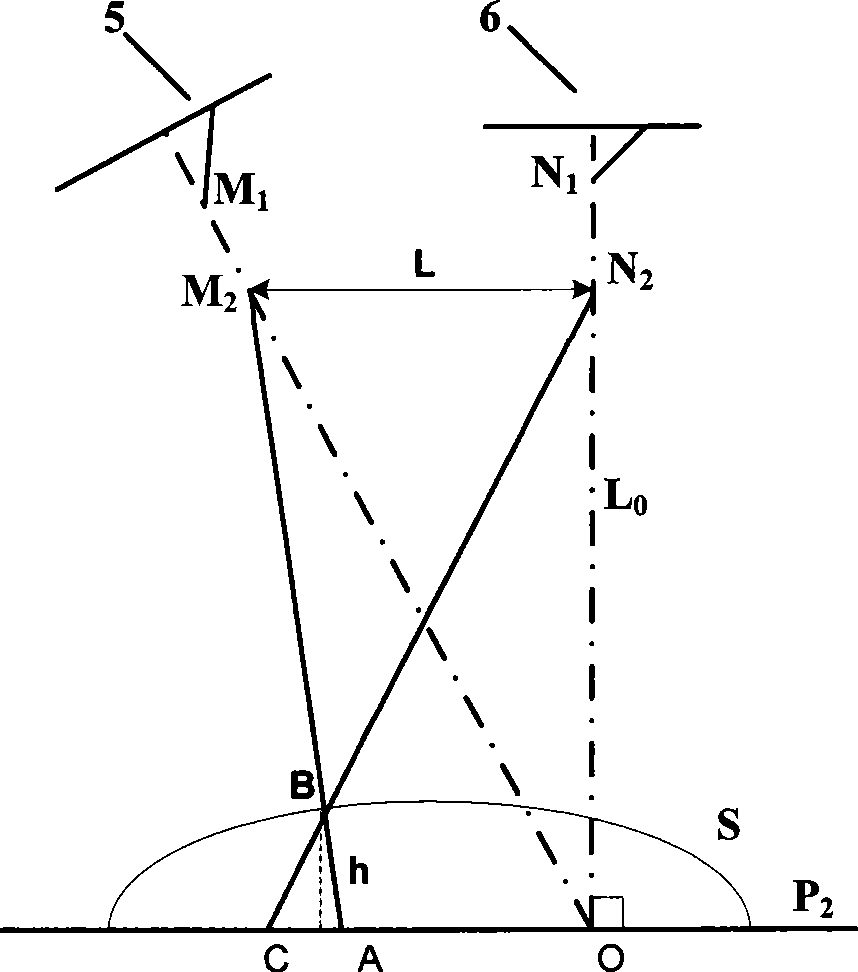

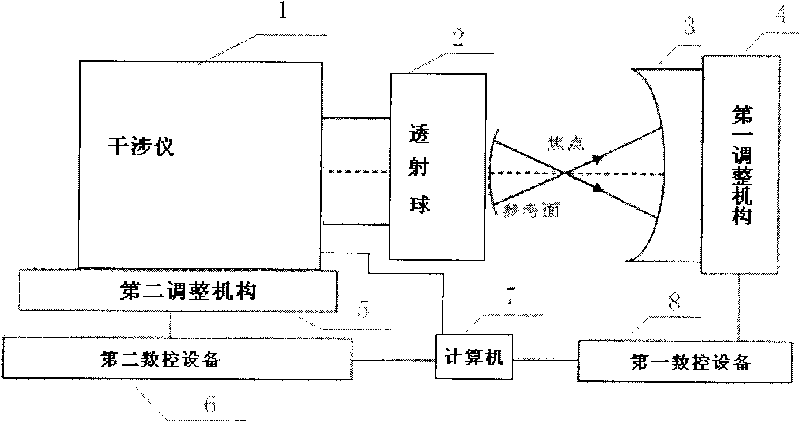

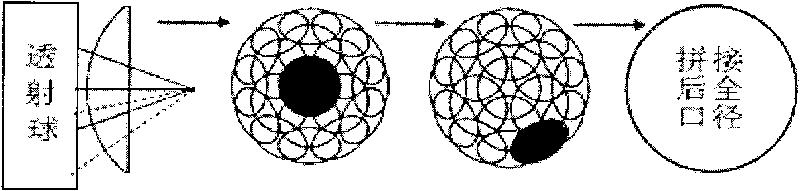

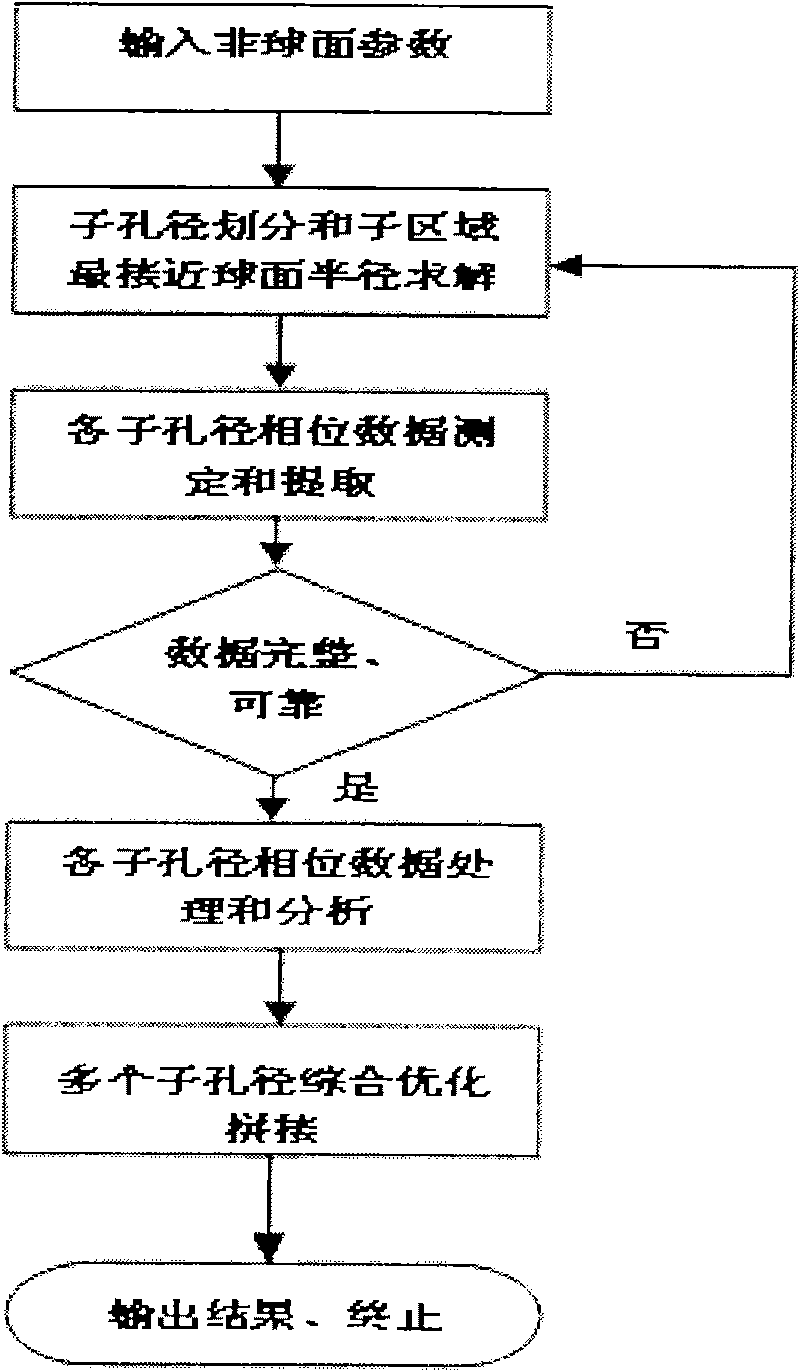

Device for detecting surface shape of optical aspheric surface by sub-aperture stitching interferometer

InactiveCN101709955AWiden horizontallyExpand the scope ofUsing optical meansNumerical controlFace shape

The invention relates to a device for detecting a surface shape of an optical aspheric surface by a sub-aperture stitching interferometer, which comprises an interferometer, a transmission sphere, an adjusting mechanism, a numerical control device and a computer, wherein parallel light emitted by the interferometer is changed into a standard spherical wave through the transmission sphere; the computer controls the action of the adjusting mechanism by the numerical control device to adjust the relative position of the interferometer and an aspheric surface to be detected so that the standard spherical wave is incided to each sub-aperture of the detected optical aspheric surface sequentially and returns to the interferometer; and the computer extracts phase distribution data of each sub-aperture measured by the interferometer for analysis and processing, and the error distribution of the surface shape of a full aperture of the detected optical aspheric surface is obtained by a stitching algorithm. The device broadens horizontal and vertical dynamic range tested by the interferometer, can detect surface shapes of large-aperture concave and convex aspheric surfaces and an off-axis aspheric surface in high resolution and high precision without other auxiliary optical elements, and has low testing cost and short construction period.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

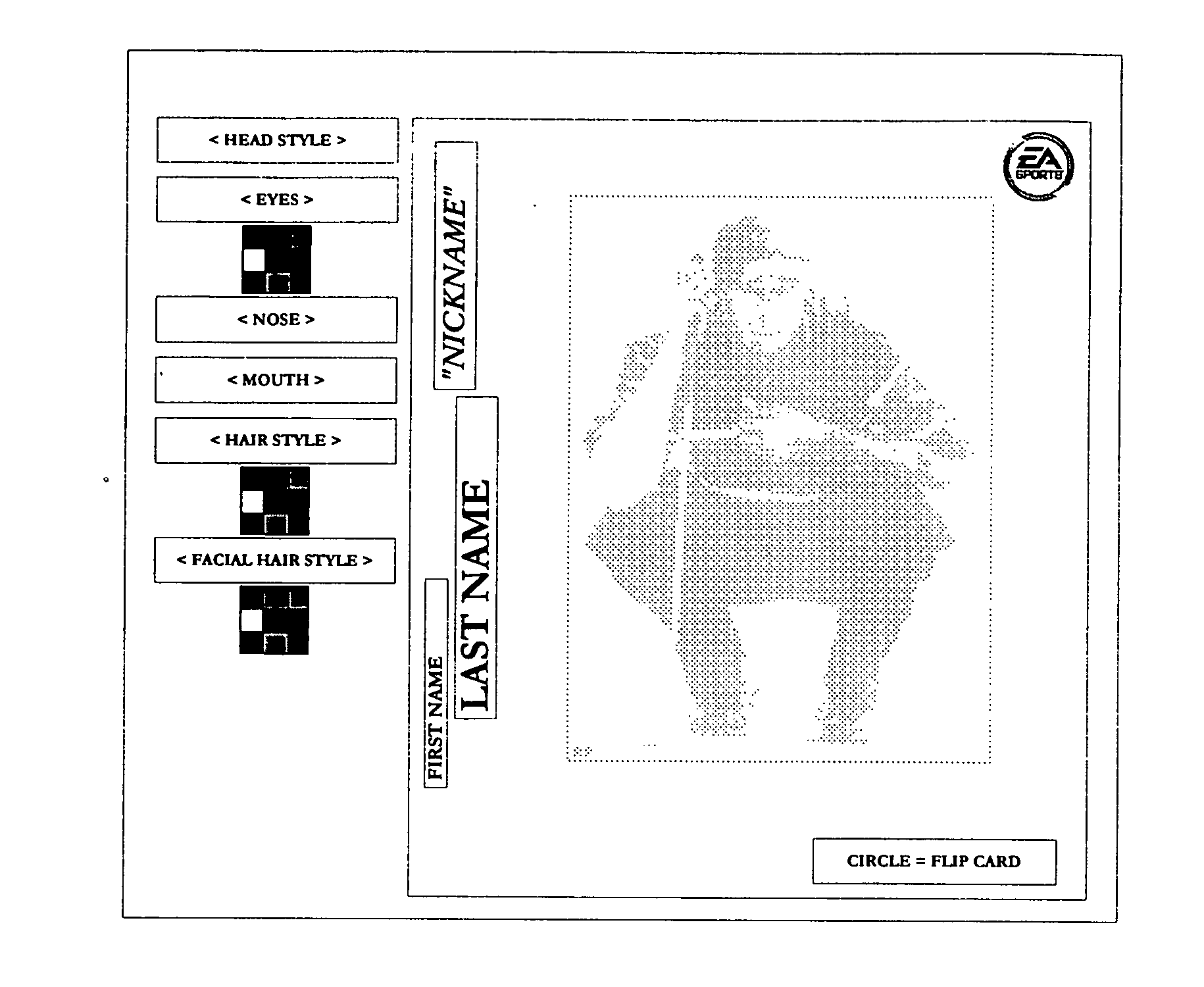

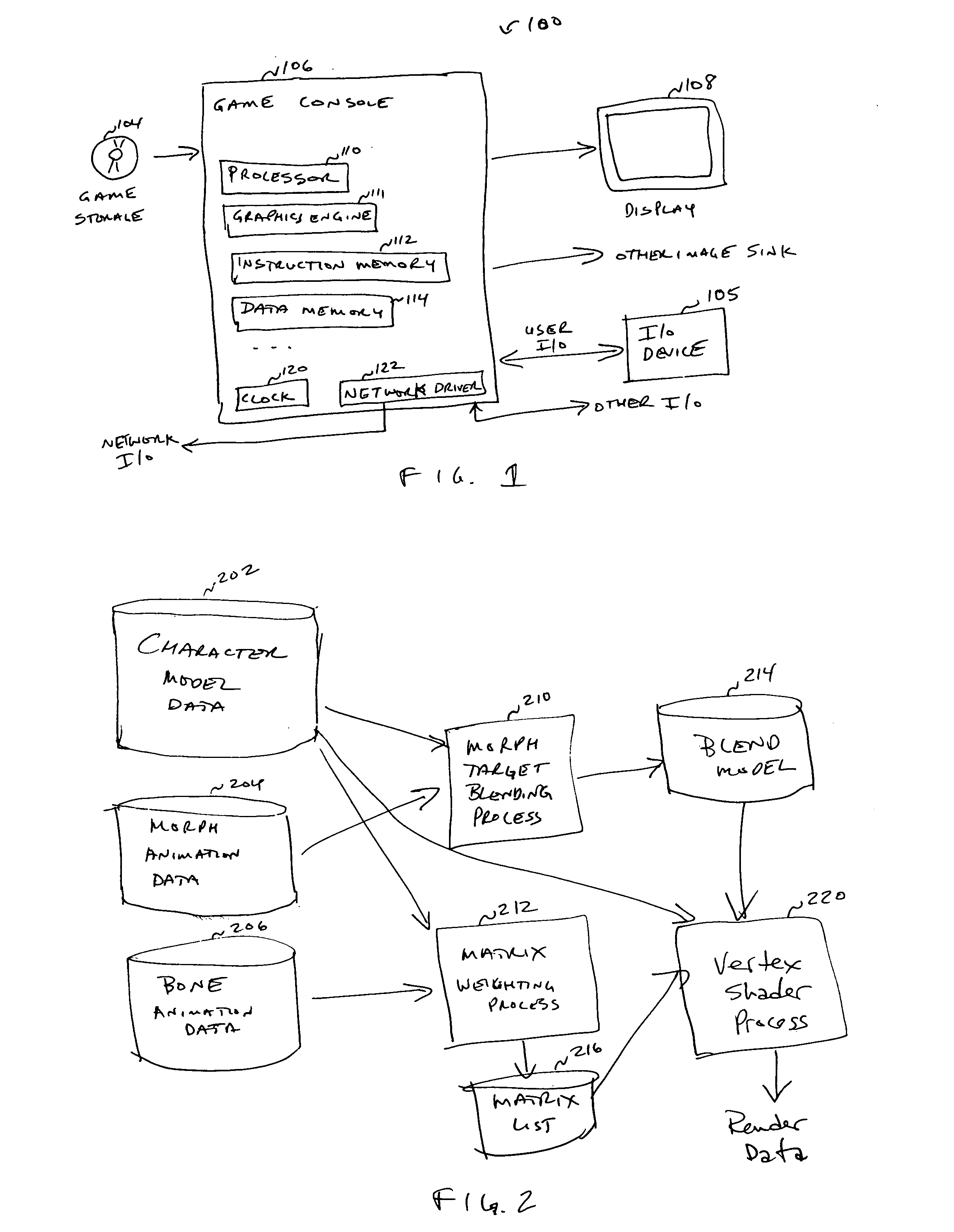

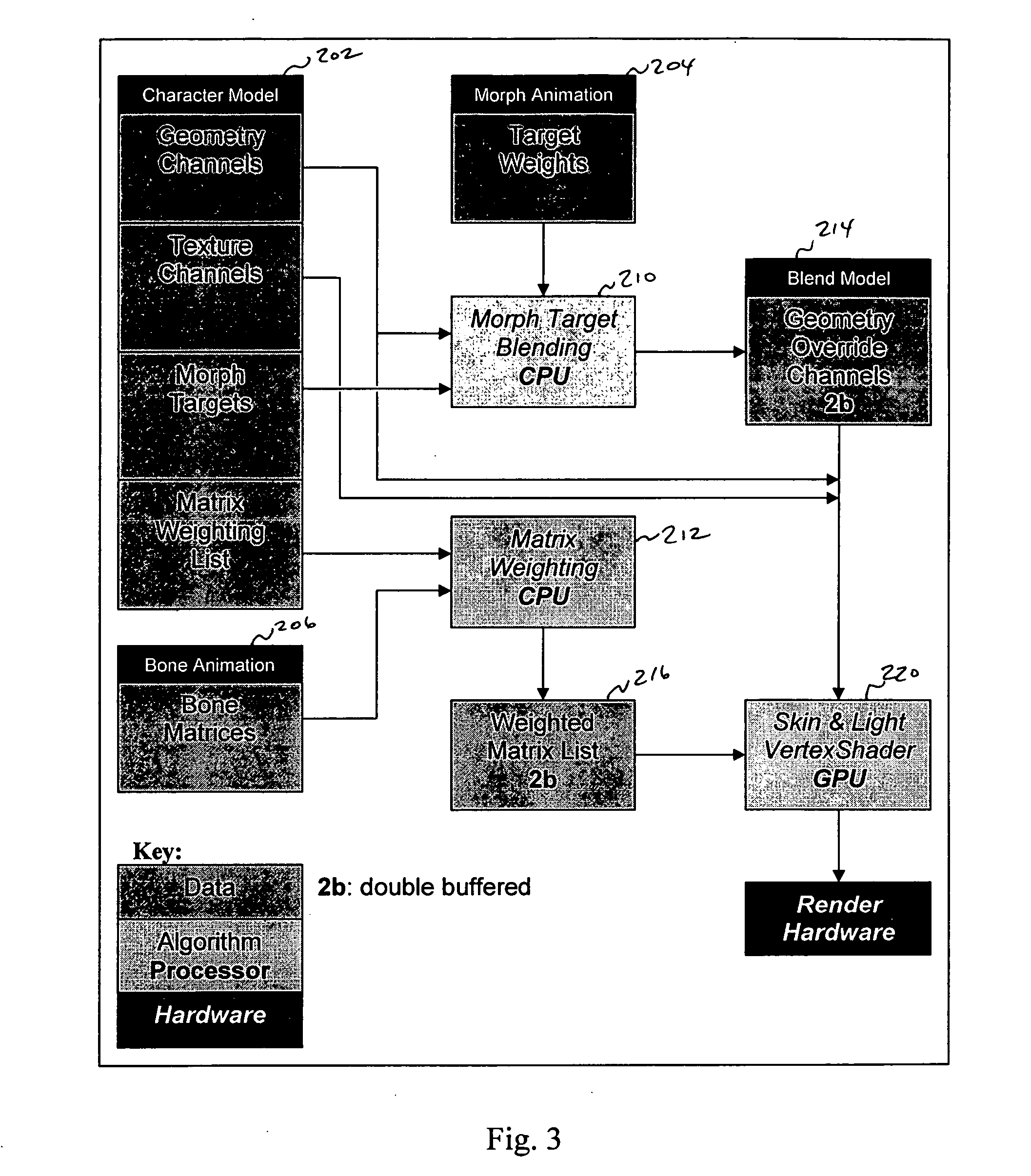

Customizing players in a video game using morphing from morph targets and other elements

In a video game, a player is allowed to create a character in the video game by selecting feature variables that define a character feature according to two or more target features and a feature variable. The target features can be are morph targets and the feature variable might represent relative distance of the player's desired feature relative to the morph targets. In a specific example, the player might be presented with two face shapes as morph targets and an input slider for a corresponding feature variable where the resulting face feature of the character matches one of the morph targets when the input slider is at one extreme, matches the other morph target when the input slider is at the other extreme and is a combination of the morph targets when the input slider is between the extremes. The character features might include face shape, height, weight, skin color, skin texture, body build, particular sports figures' faces, clothing, hair, eyes, nose, mouth, lips, hands, feet, etc. The player can also purchase items from a shop according to restrictions on cost, sponsorship, availability, time of day, date and / or day of year.

Owner:ELECTRONICS ARTS INC

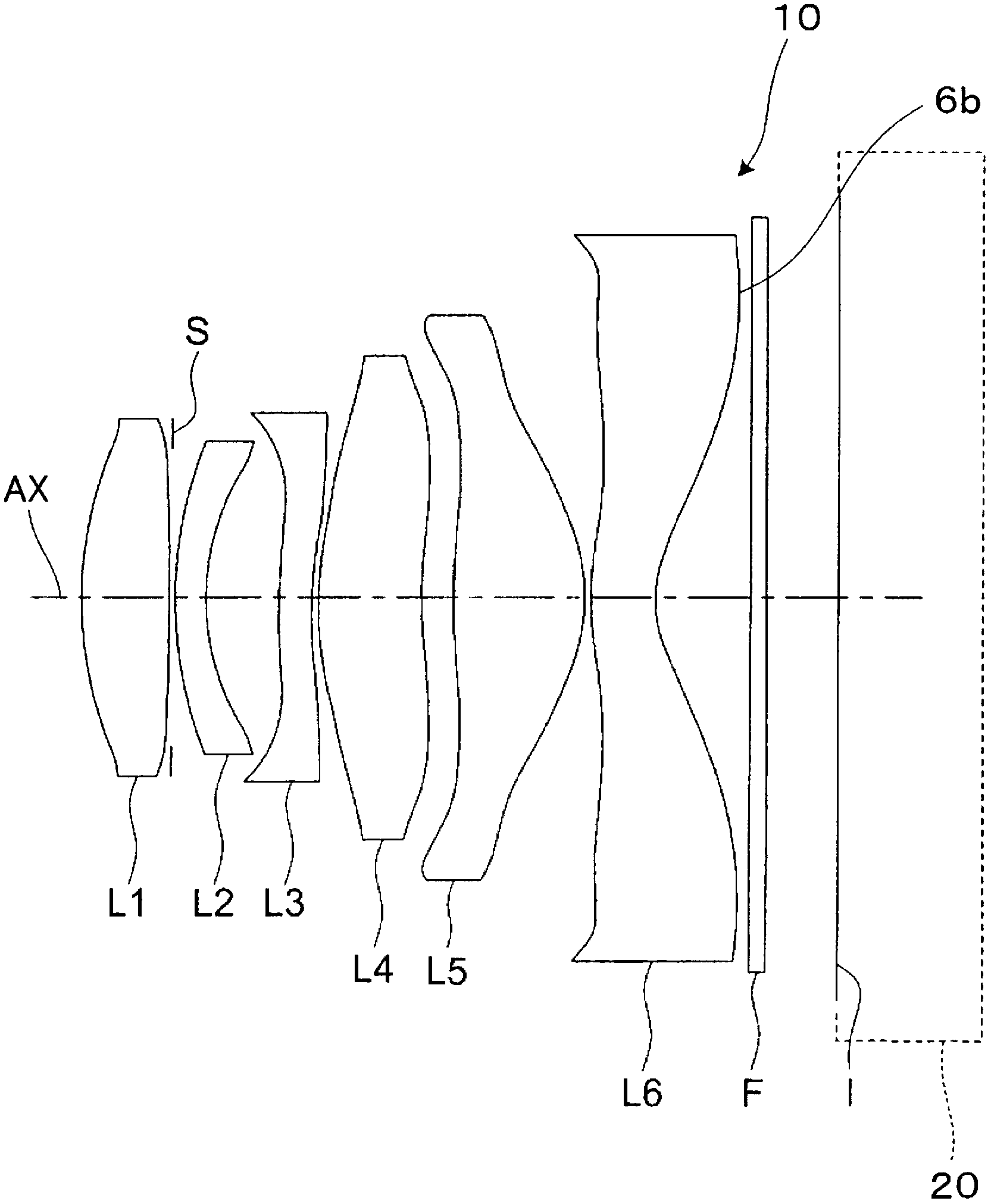

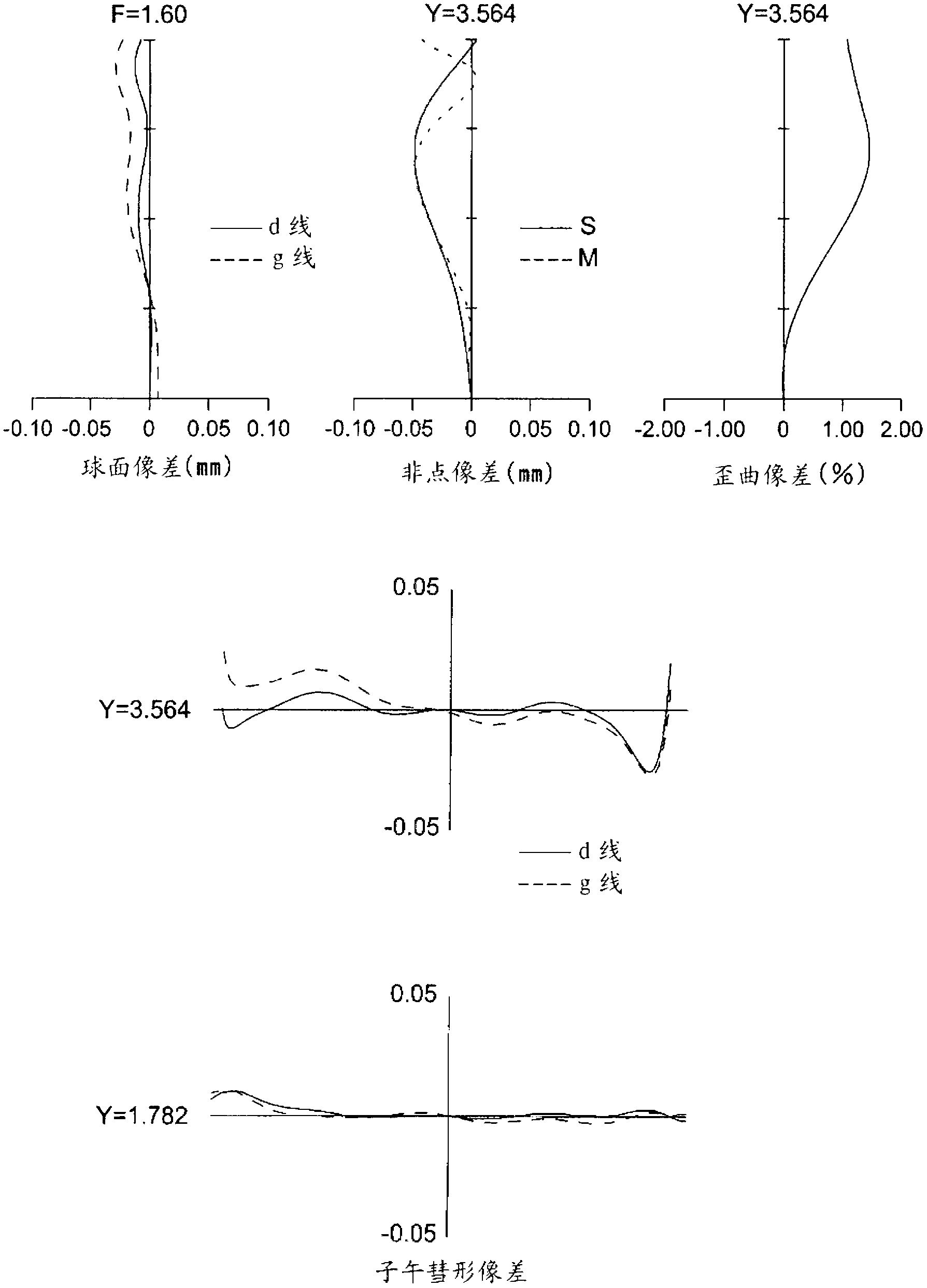

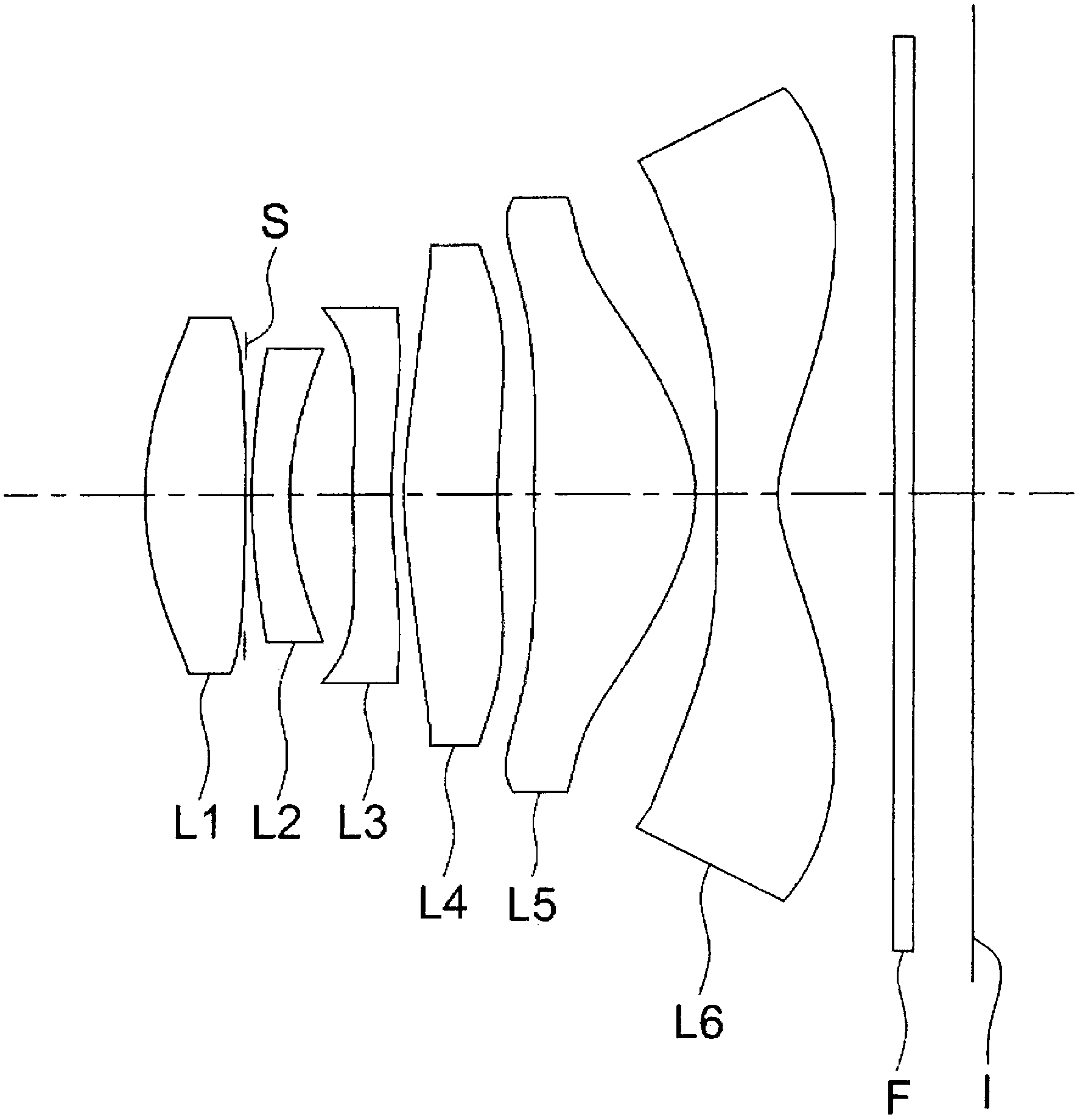

Image capture lens

ActiveCN102985865ASmall outer diameterInhibition lossTelevision system detailsLensNegative refractionCamera lens

Provided is a six-layer configuration image capture lens that is compact and has adequate light at F2 or less, and wherein all aberrations are effectually corrected. In order from the object side, the image capture lens is configured of a first lens having a positive refraction and with a convex face oriented toward the object side; a second lens having a negative refraction and with a concave face oriented toward the imaging side; a third lens having either a positive or a negative refraction; a fourth lens having a positive refraction; a fifth lens having a positive refraction and with a convex face oriented toward the imaging side; and a sixth lens having a negative refraction and with a concave face oriented toward the imaging side. The imaging side face of the sixth lens further comprises an aspherical face shape, has an inflection point in a location other than a point of intersection with the optical axis, and satisfies the following formulae: ? d1 > 50, and ? d2 = 30, wherein ? d1 is the Abbe's number of the first lens, and ? d2 is the Abbe's number of the second lens.

Owner:KONICA MINOLTA INC

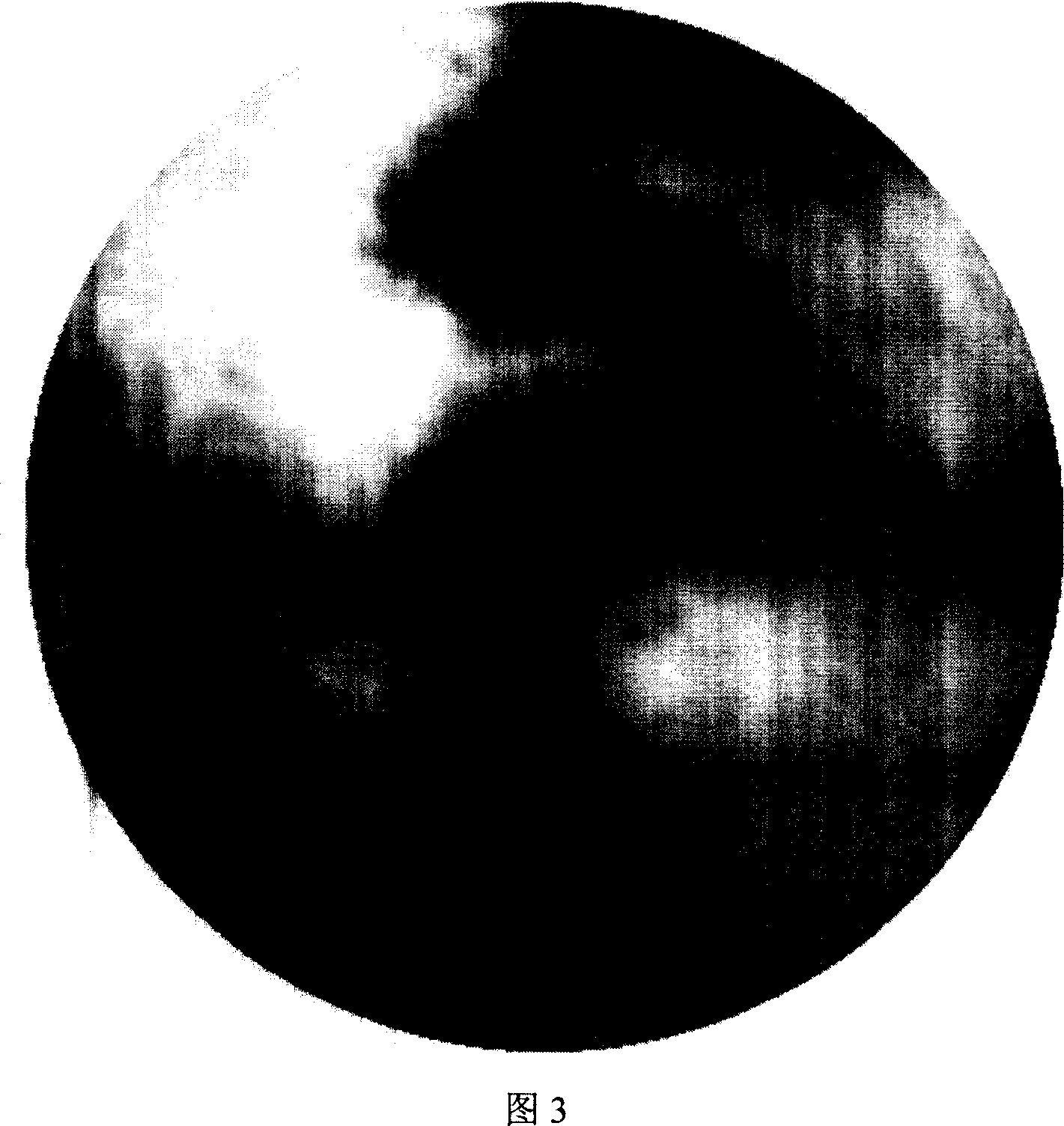

High-frequency error detecting apparatus and method for heavy caliber heavy relative aperture aspherical mirror

InactiveCN101013027AIncrease horizontal resolutionIncrease the vertical measurement rangeUsing optical meansTesting optical propertiesMultiple pointError surface

The invention discloses a high-frequency error detection device and method in the large caliber large relative aperture non-spherical mirror, the device including the five-axis movement adjustment platform with the interferometer focusing platform, the side swing reflecting mirror side swing platform located in front of the interferometer focusing platform, and the measured non-spherical mirror 3D movement adjustment platform located below the side swing reflection mirror side swing platform, and the multiple points supporting machine with the laser wave surface interferometer, the side swing reflection mirrors, and the measured non-spherical mirror installed on the corresponding platforms, and the main control computer with built-in detection data-processing algorithm program connecting with the laser wave surface interferometer. The device uses the main control computer to process the detection data-processing algorithm, which can combine the detected multiple part regions error surface maps into error surface map with medium or high frequency in full caliber, including the initial pose determining method, the overlapping regional data extraction algorithm and the regional data stitching algorithm. The invention is a high-frequency error detection device and method with low-cost, high-precision, high-efficiency in the large caliber large relative aperture non-spherical mirror.

Owner:NAT UNIV OF DEFENSE TECH

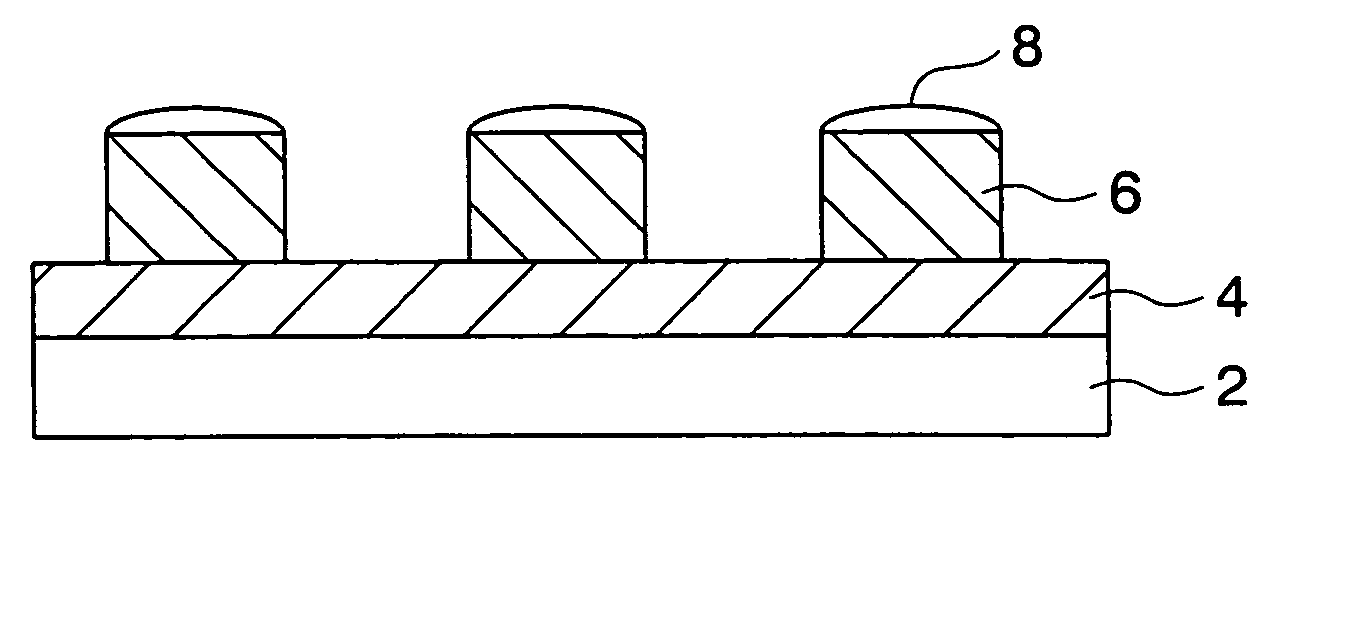

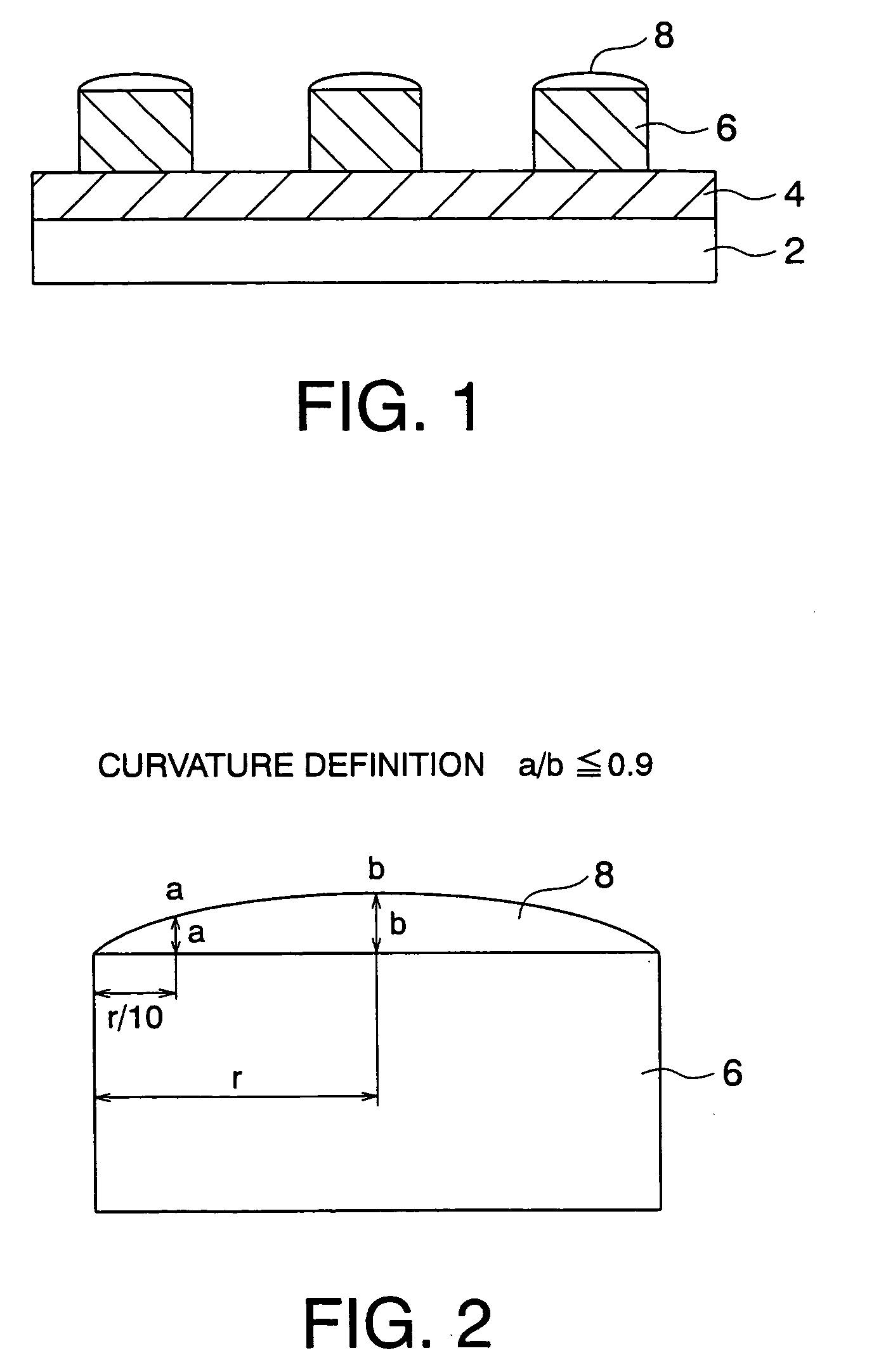

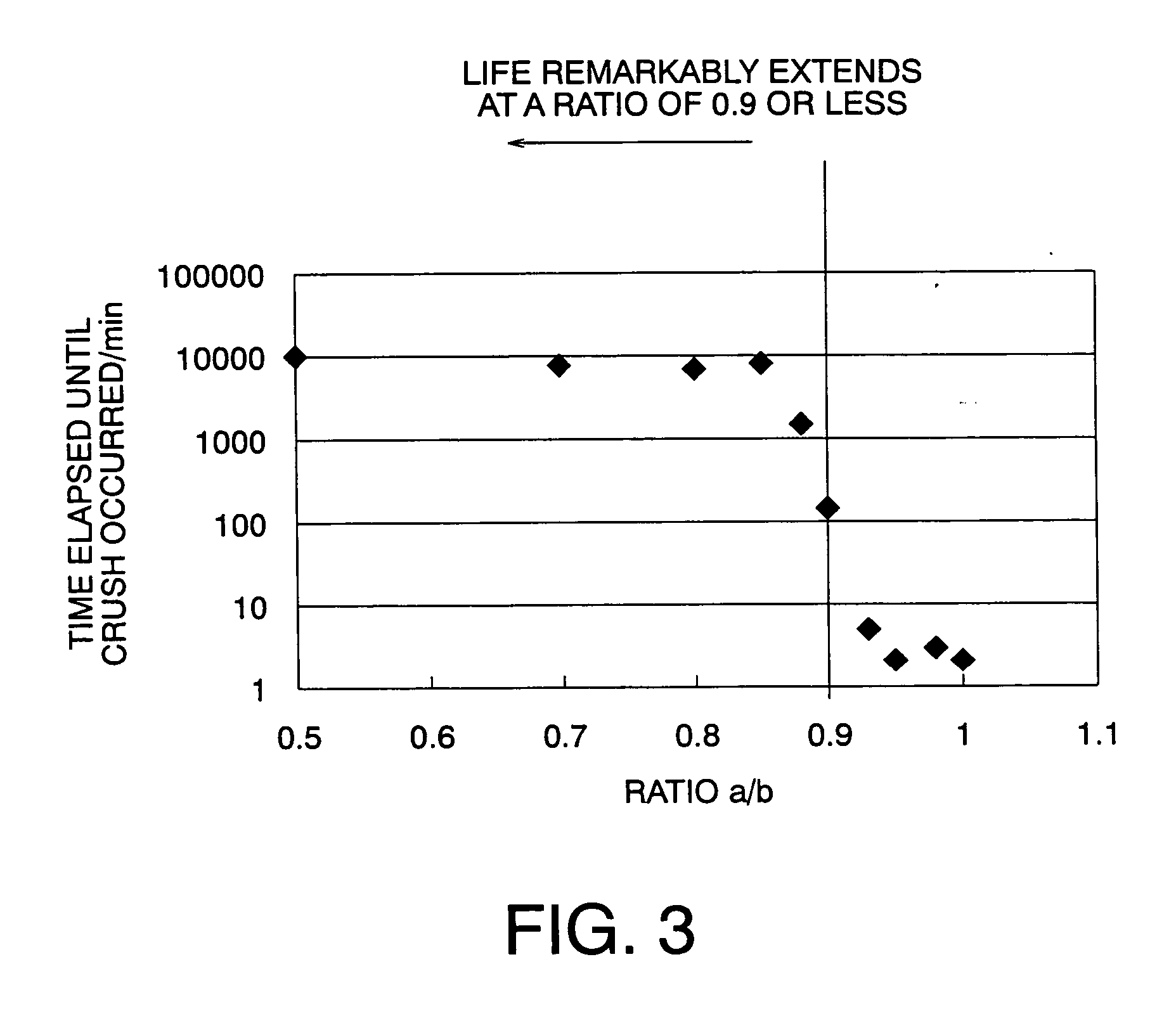

Magnetic recording medium and method for manufacturing the same

ActiveUS20050069732A1High-density recordingIncreased durabilityProtective coatings for layersLayered productsCarbon filmHigh density

A magnetic recording medium which allows high density recording and has excellent durability can be obtained. A magnetic recording medium includes: a plurality of ferromagnetic material dots arranged on a soft magnetic layer formed on a non-magnetic substrate so as to be separated from one another; and carbon films which are formed on the respective ferromagnetic material dots, each carbon film having a smooth film face shape in a section passing through the center of each ferromagnetic material dot and a film thickness gradually decreasing from the center of the ferromagnetic material dot toward an outer edge thereof.

Owner:KK TOSHIBA

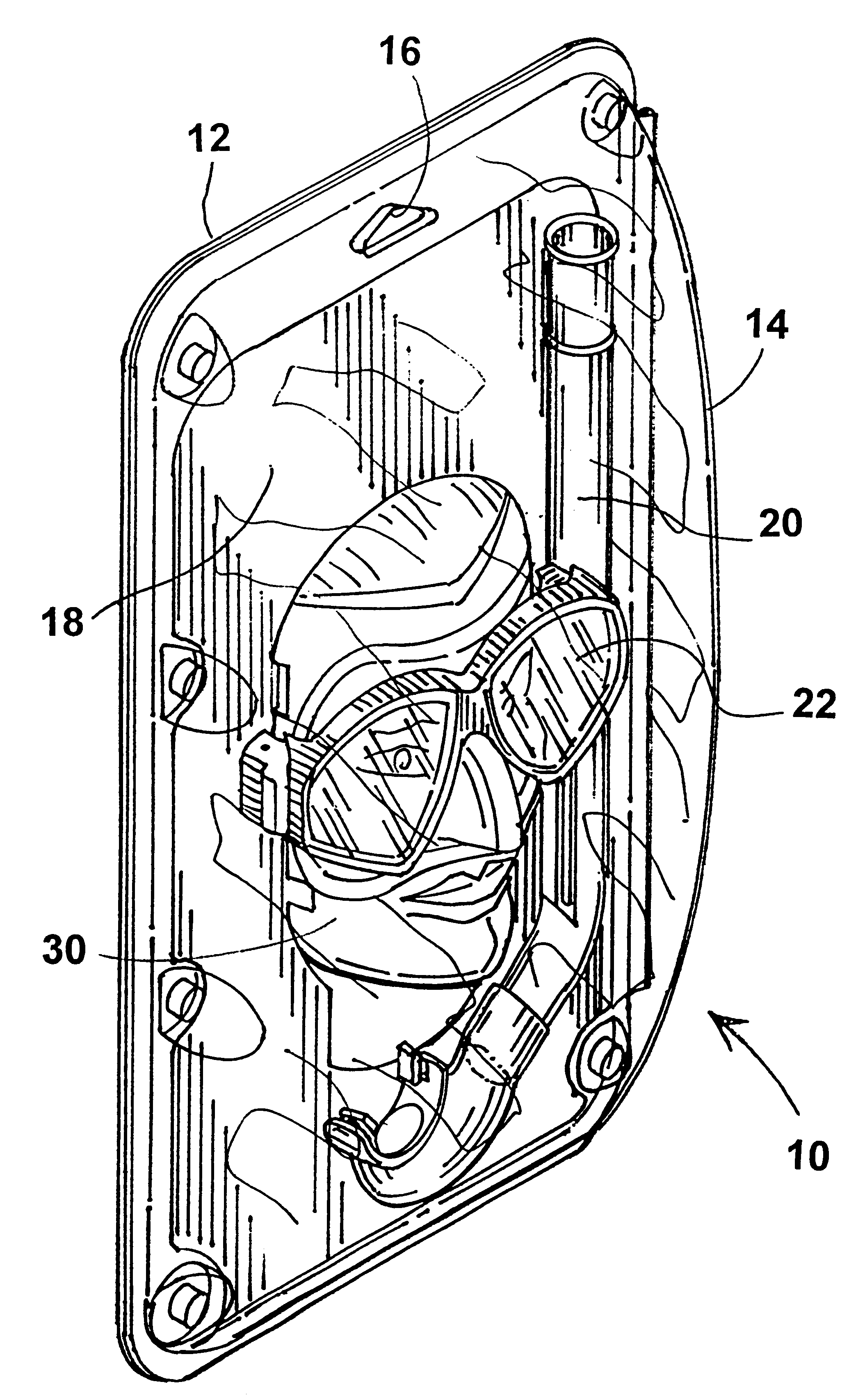

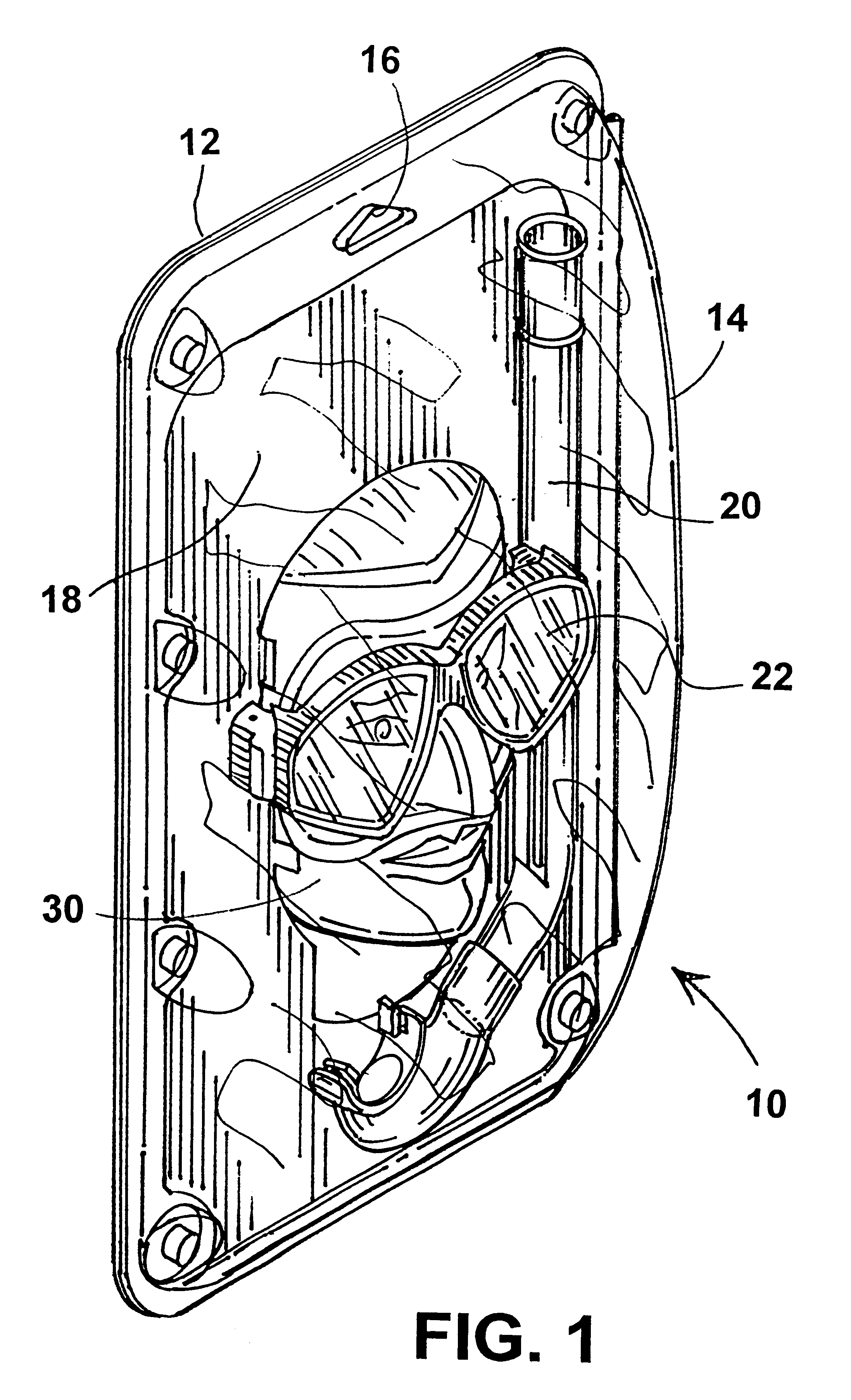

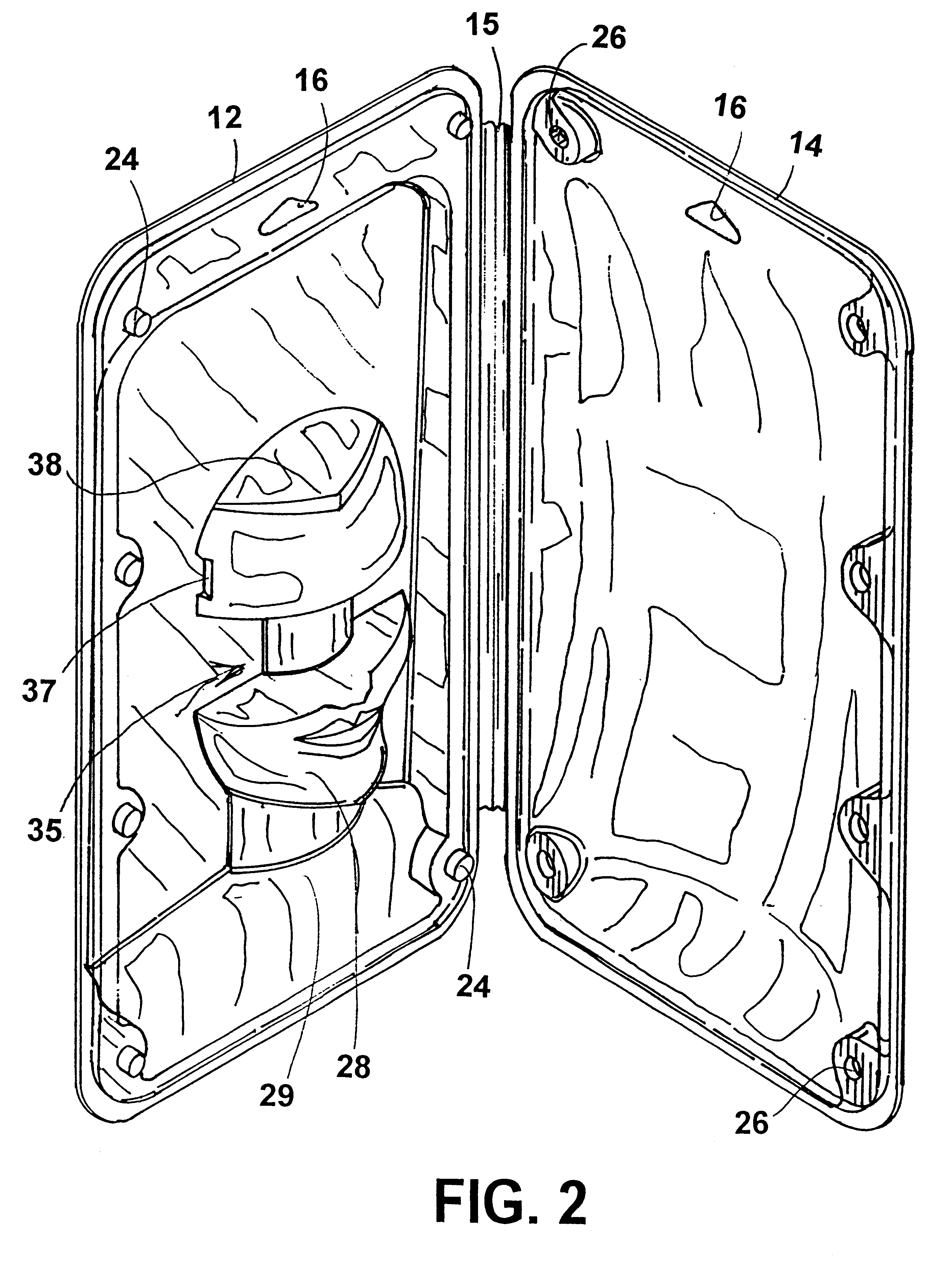

Combined clamshell and mannequin form packaging assembly

A retail display packaging assembly which combines a transparent plastic clamshell and a mannequin face (or other mannequin body parts) to provide an advantageous display for selected products. In a preferred embodiment disclosed herein, the product comprises a snorkeling set having a snorkel tube and a swimmer's mask. The mannequin face is positioned within the clamshell for retaining the swimmer's mask over the eyes and nose of the mannequin in much the same manner as an actual swimmer would wear the mask. In addition, the snorkel tube is positioned relative to the mannequin face in much the same manner as it would be positioned adjacent a swimmer's face. The clamshell is vacuum formed from a clear sheet of PVC plastic and the bottom portion of the clamshell is configured to provide upper and lower parts that are congruent to the mannequin face and have a gap for receiving the strap of the swimmer's mask. The mannequin face is secured to the congruent parts by respective tabs and recesses and thus secures the mask which encircles the mannequin face. The mannequin face is preferably vacuum formed from an opaque PVC plastic and thus provides a highly visible face-shaped structure "wearing" the mask and snorkel within a transparent packaging container.

Owner:CHAPMAN MICHAEL

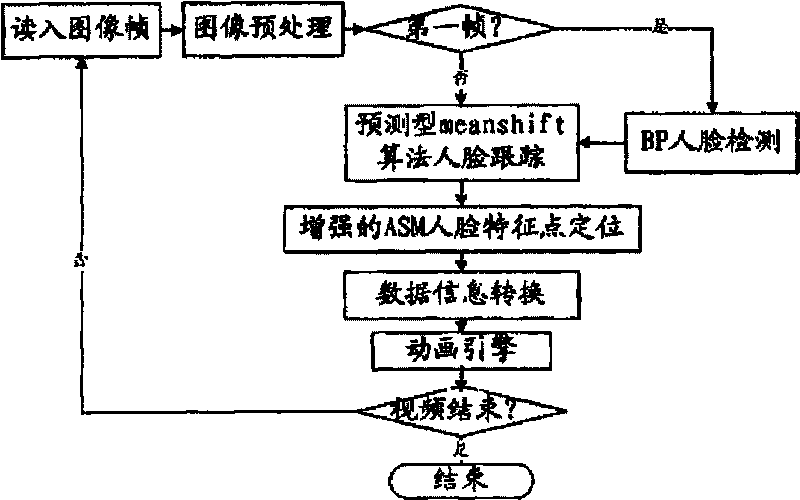

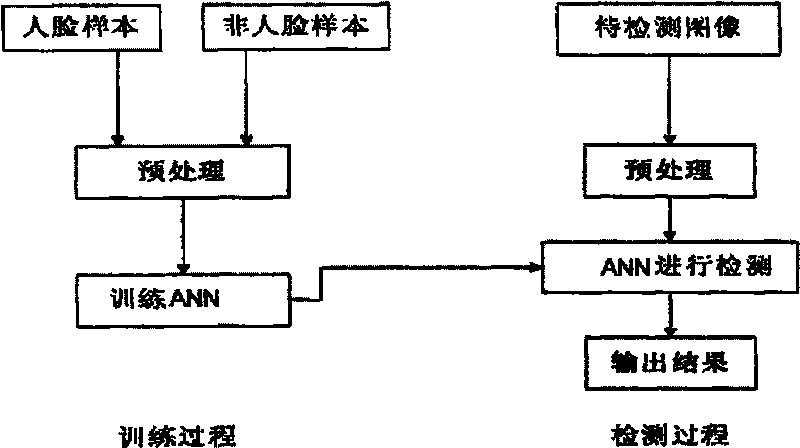

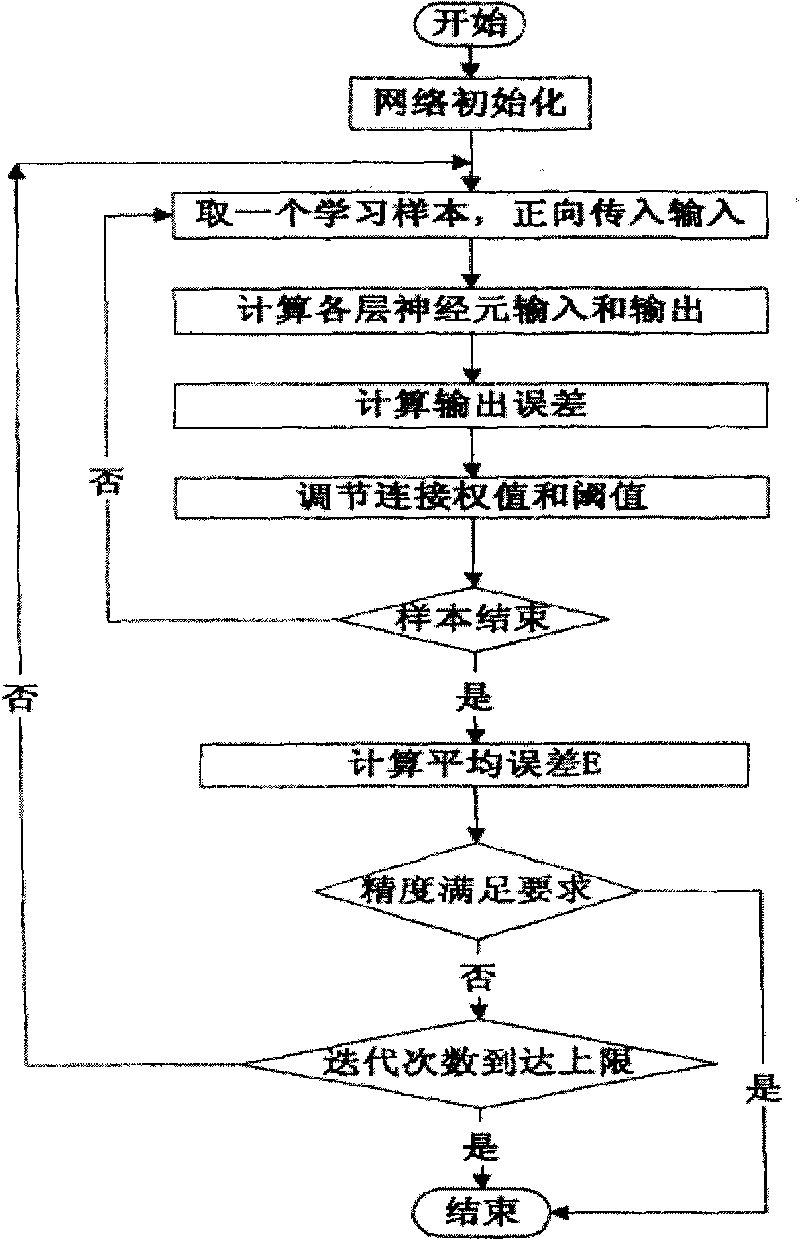

Video-based 3D human face expression cartoon driving method

InactiveCN101739712ASufficient prior knowledgeGood tracking resultCharacter and pattern recognition3D-image renderingFace detectionPattern recognition

The invention discloses a video-based 3D human face expression cartoon driving method, which comprises the following steps: (1) image preprocessing, namely improving the image quality through light compensation, Gaussian smoothing and morphology operation of a gray level image; (2) BP human face detection, namely detecting a human face in a video through a BP neural network algorithm, and returning the size of the position of the human face for providing a smaller search range for human face characteristic point positioning of the next step to ensure instantaneity; (3) ASM human face characteristic point positioning and tracking, namely precisely extracting characteristic point information of human face shape, eyes, eyebrows, mouth and nose through an enhanced active shape model algorithm and a predicted meanshift algorithm, and returning the definite position; and (4) data information conversion, namely converting the data information acquired in the human face characteristic point positioning and tracking step to acquire the motion information of the human face. The method can overcome the defects in the prior art, and can achieve live human face cartoon driving effect.

Owner:SICHUAN UNIV

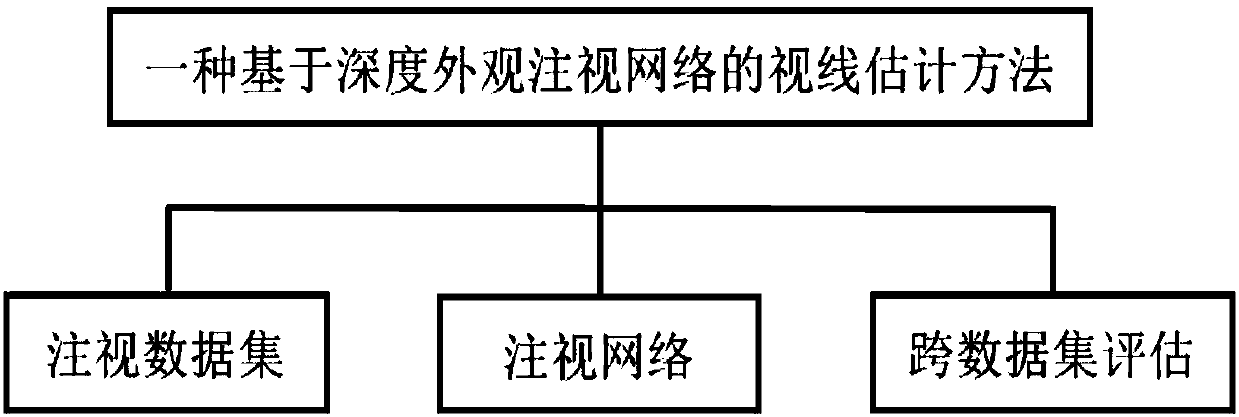

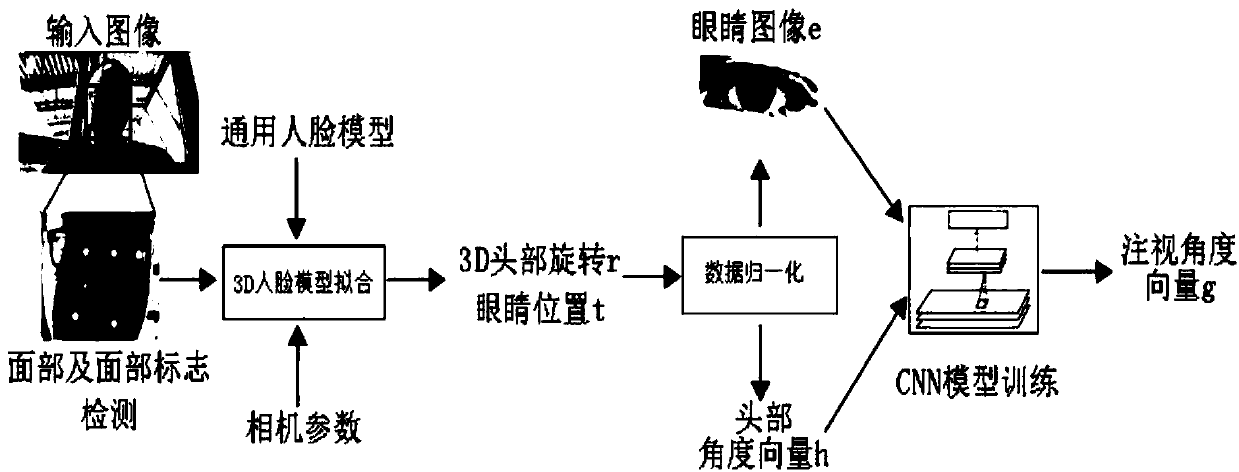

Line-of-sight estimation method based on depth appearance gaze network

The invention provides a line-of-sight estimation method based on a depth appearance gaze network. Main content of the method includes a gaze data set, a gaze network, and cross-data set evaluation. The method comprise the following steps: a large number of images from different participants are collected as a gaze data set, face marks are manually annotated on subsets of the data set, face calibration is performed on input images obtained via a monocular RGB camera, a face detection method and a face mark detection method are adopted to position the marks, a general three-dimensional face shape model is fitted to estimate a detected three-dimensional face posture, a spatial normalization technique is applied, the head posture and eye images are distorted to a normalized training space, and a convolutional neural network is used to learn mapping of the head posture and the eye images to three-dimensional gaze in a camera coordinate system. According to the method, a continuous conditional neural network model is employed to detect the face marks and average face shapes for performing three-dimensional posture estimation, the method is suitable for line-of-sight estimation in different environments, and accuracy of estimation results is improved.

Owner:SHENZHEN WEITESHI TECH

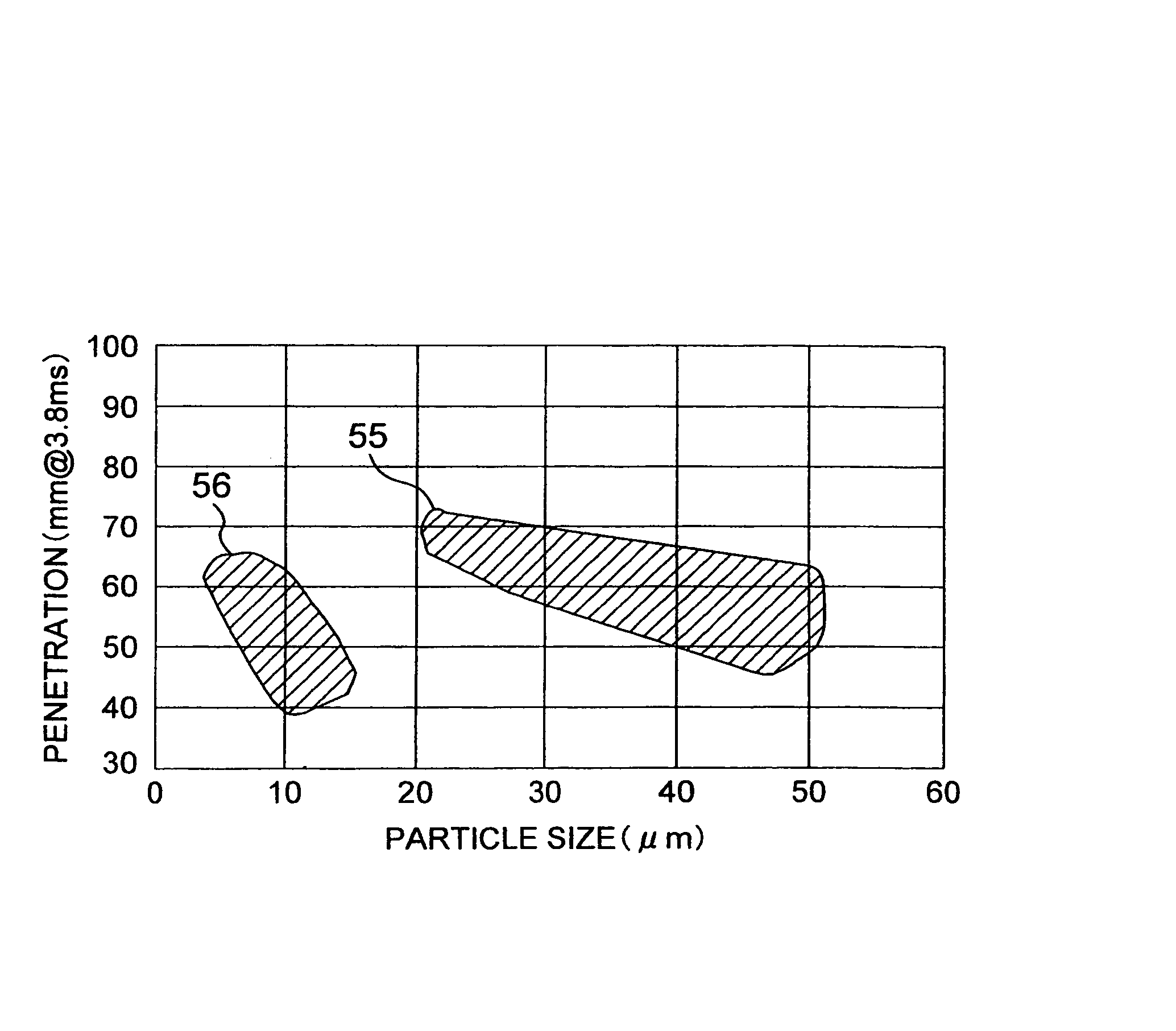

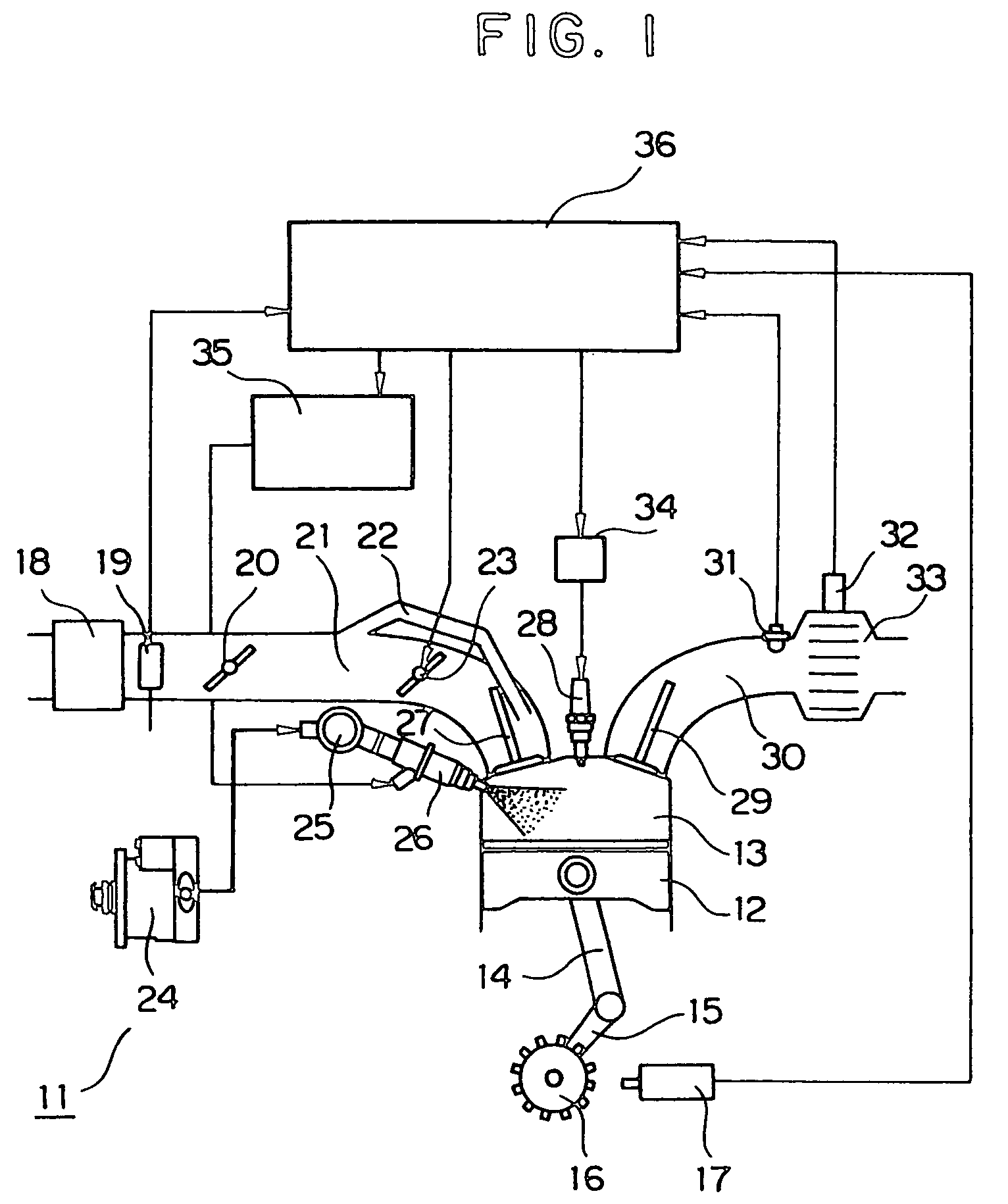

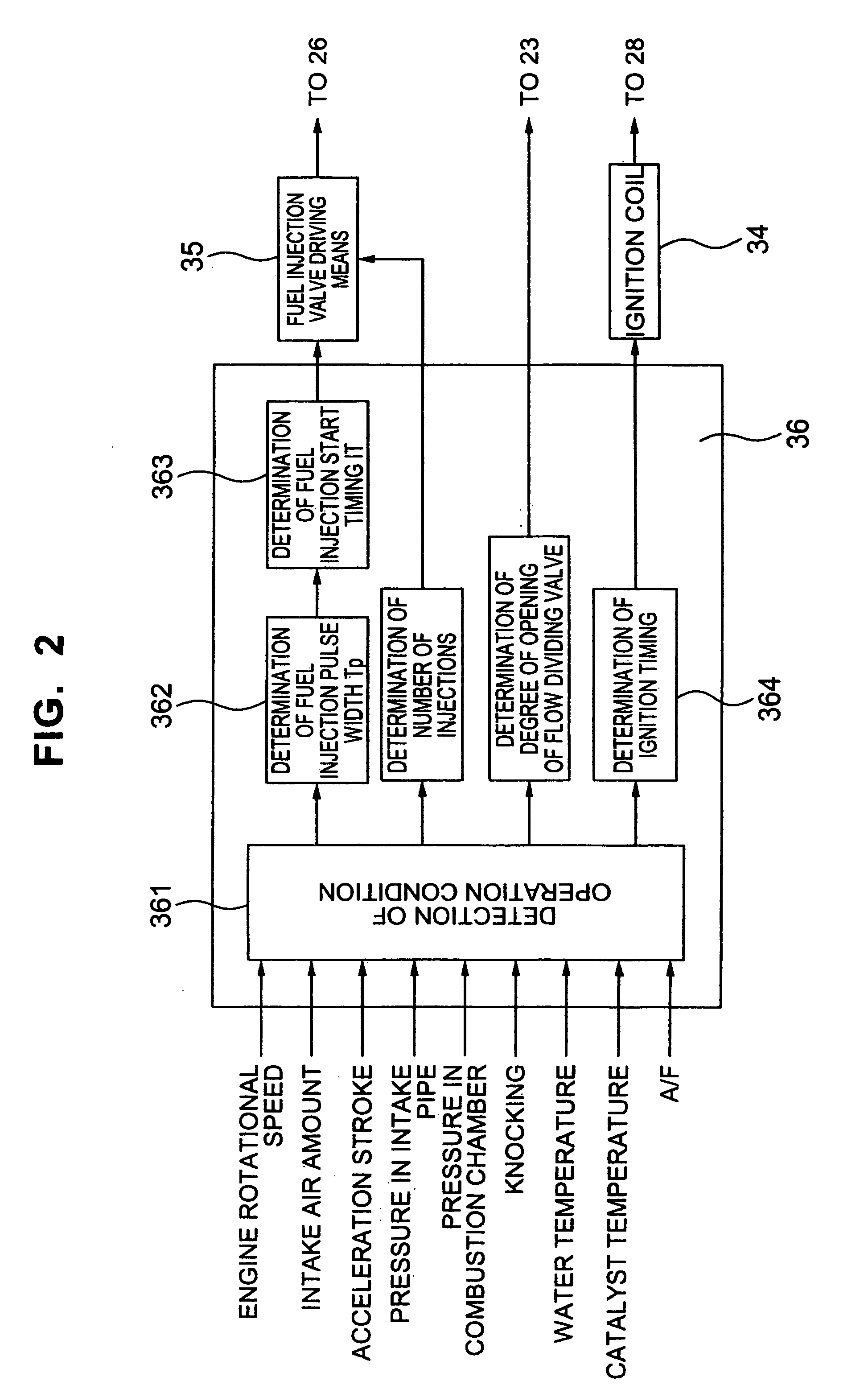

Cylinder injection type internal combustion engine, control method for internal combustion engine, and fuel injection valve

InactiveUS7013863B2Electrical controlInternal combustion piston enginesExternal combustion engineFuel efficiency

There is provided a cylinder injection type internal combustion engine capable of performing stratified charge operation at the time of a vehicle speed of 120 km / h and / or an engine rotational speed of 3200 rpm to enhance the fuel efficiency and / or to observe the emission regulations. In the internal combustion engine, a stratum of air and / or air flow is formed between a fuel spray injected from an injection valve and the top face of a piston and / or the wall surface of a combustion chamber, and a face shape contrived to guide the air flow is formed on the top face of the piston.Also, the stratified charge operation can be performed even at the time of cold start or cranking.

Owner:HITACHI LTD

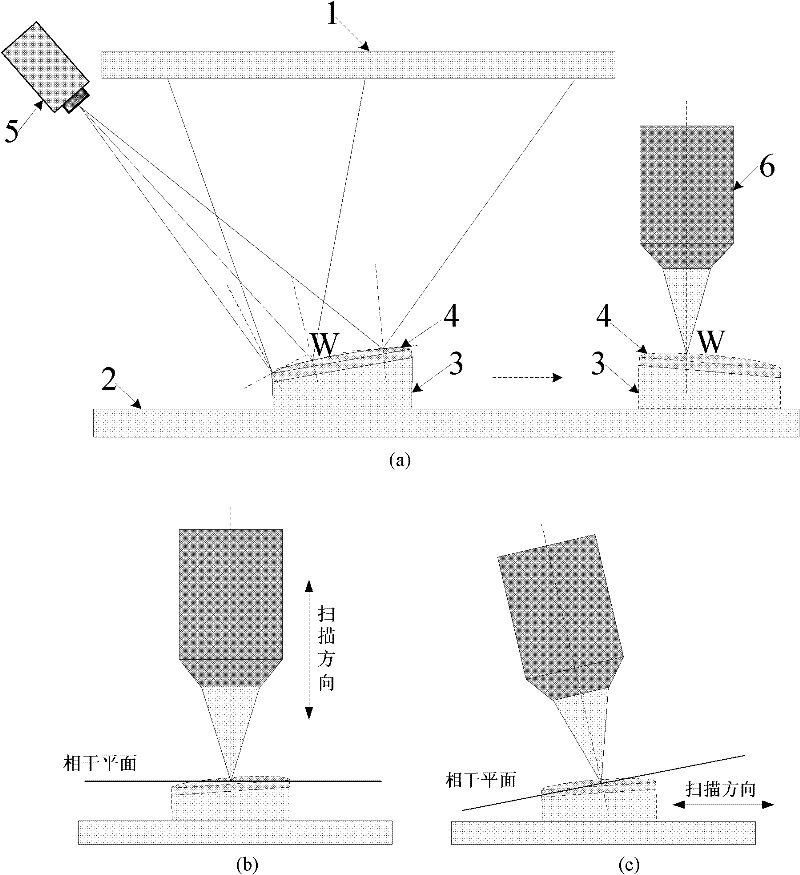

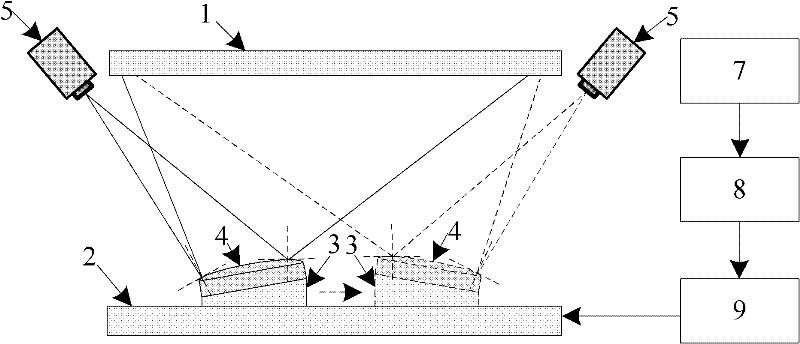

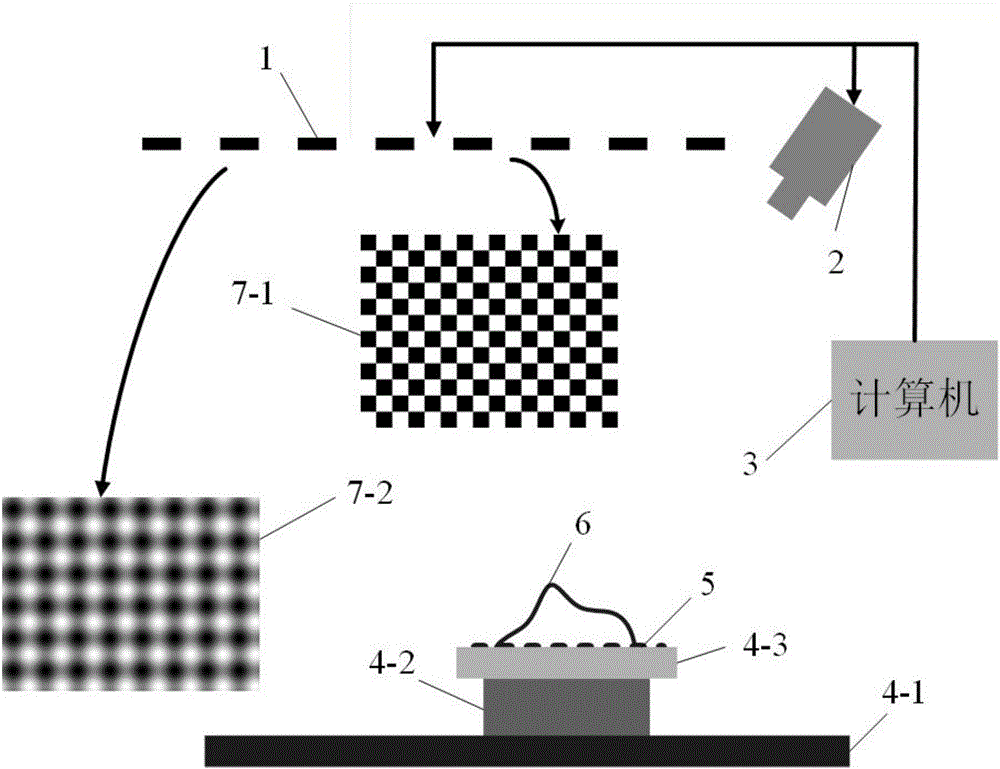

High-precision non-contact measurement method and device for three-dimensional profile of optical freeform curved surface

InactiveCN102305601AImprove detection accuracyImprove resolutionUsing optical meansGratingError separation

The invention relates to high-precision in-situ detection for complicated curved-surface parts with high-curvature surface form. In order to provide non-contact for the parts and detection for the surfaces of the parts, the invention provides the following technical scheme, namely a high-precision non-contact measurement method and a high-precision non-contact measurement device for a three-dimensional profile of an optical freeform curved surface. A grating projection device is used for projecting a sine grating stripe onto the surface of a measured object; an image acquisition device acquires a deformed stripe pattern modulated by the surface of the measured object and sends the deformed stripe pattern into a computer to recover the three-dimensional profile of the surface of the measured object; a white light scanning interference measuring head is used for scanning and measuring local characteristics of the measured object in nano-scale precision; a white light scanning image acquisition device acquires an interfered stripe pattern and sends the interfered stripe pattern into the computer to acquire data of the three-dimensional profile of a measurement region; and a result can be obtained according to data obtained by measurement of a grating projection vision detection unit and a white light scanning interference measurement unit through a multi-sensor massive data combination algorithm and corresponding error separation and compensation measures. The invention is mainly applied to the high-precision in-situ detection of the parts.

Owner:TIANJIN UNIV

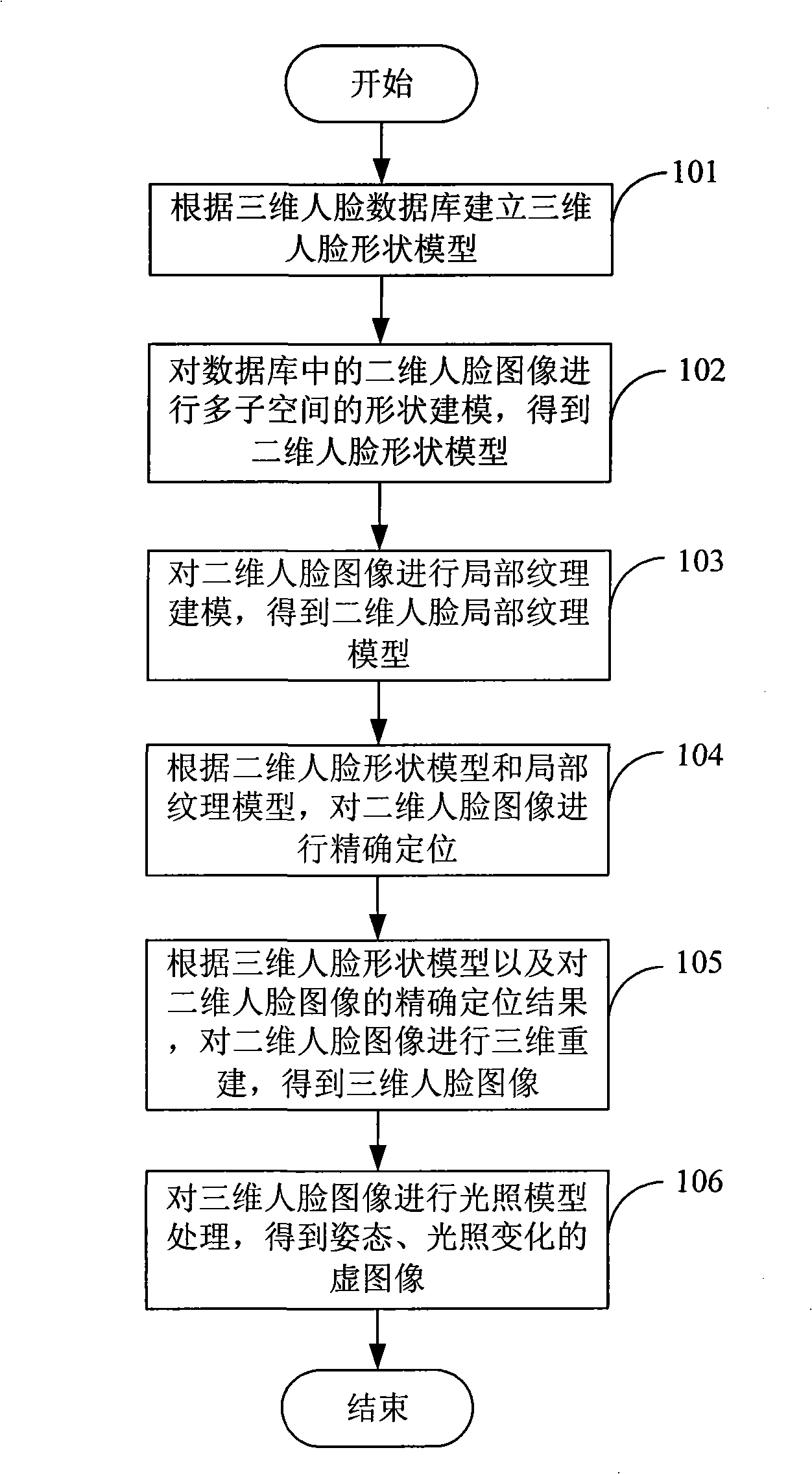

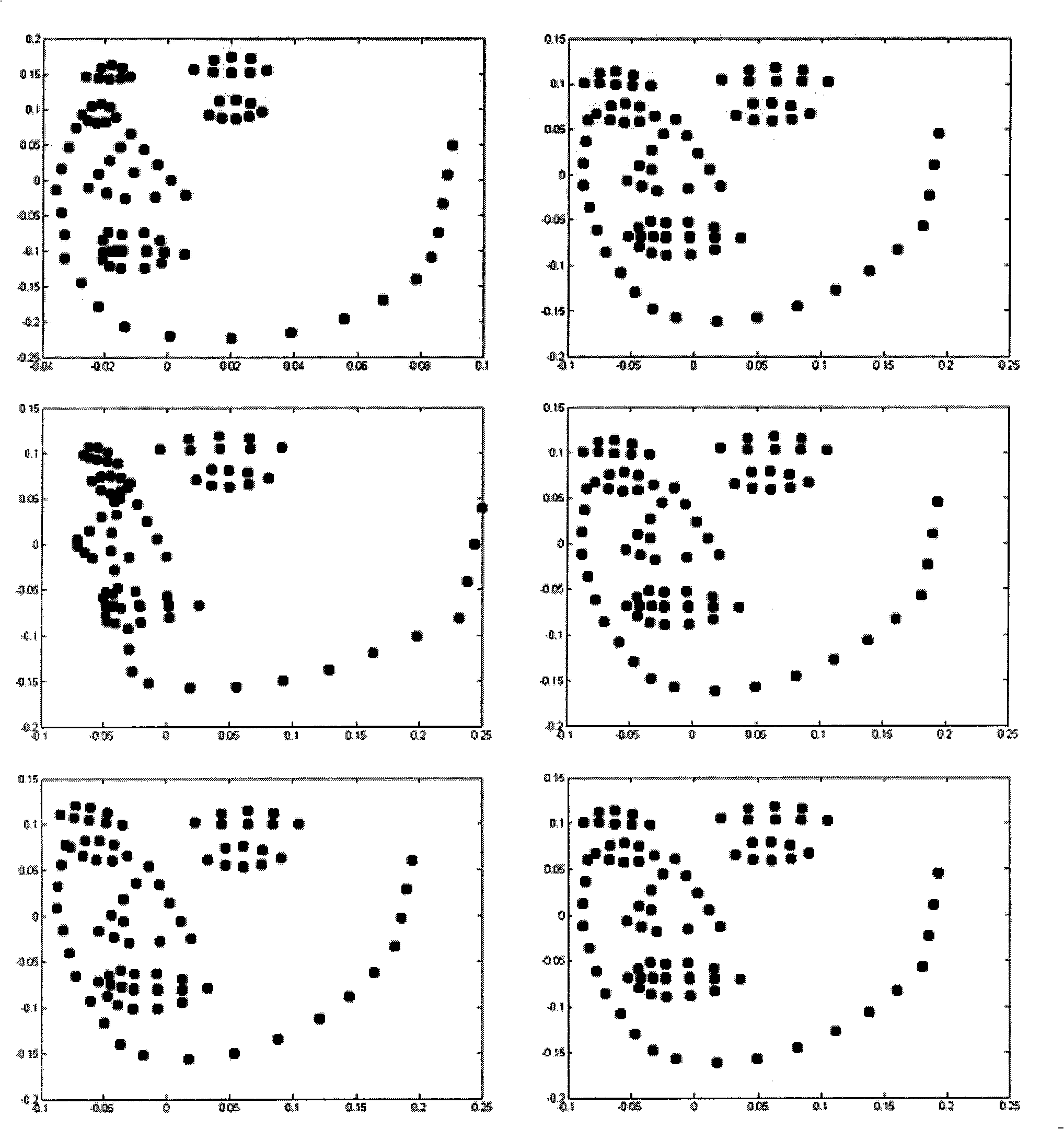

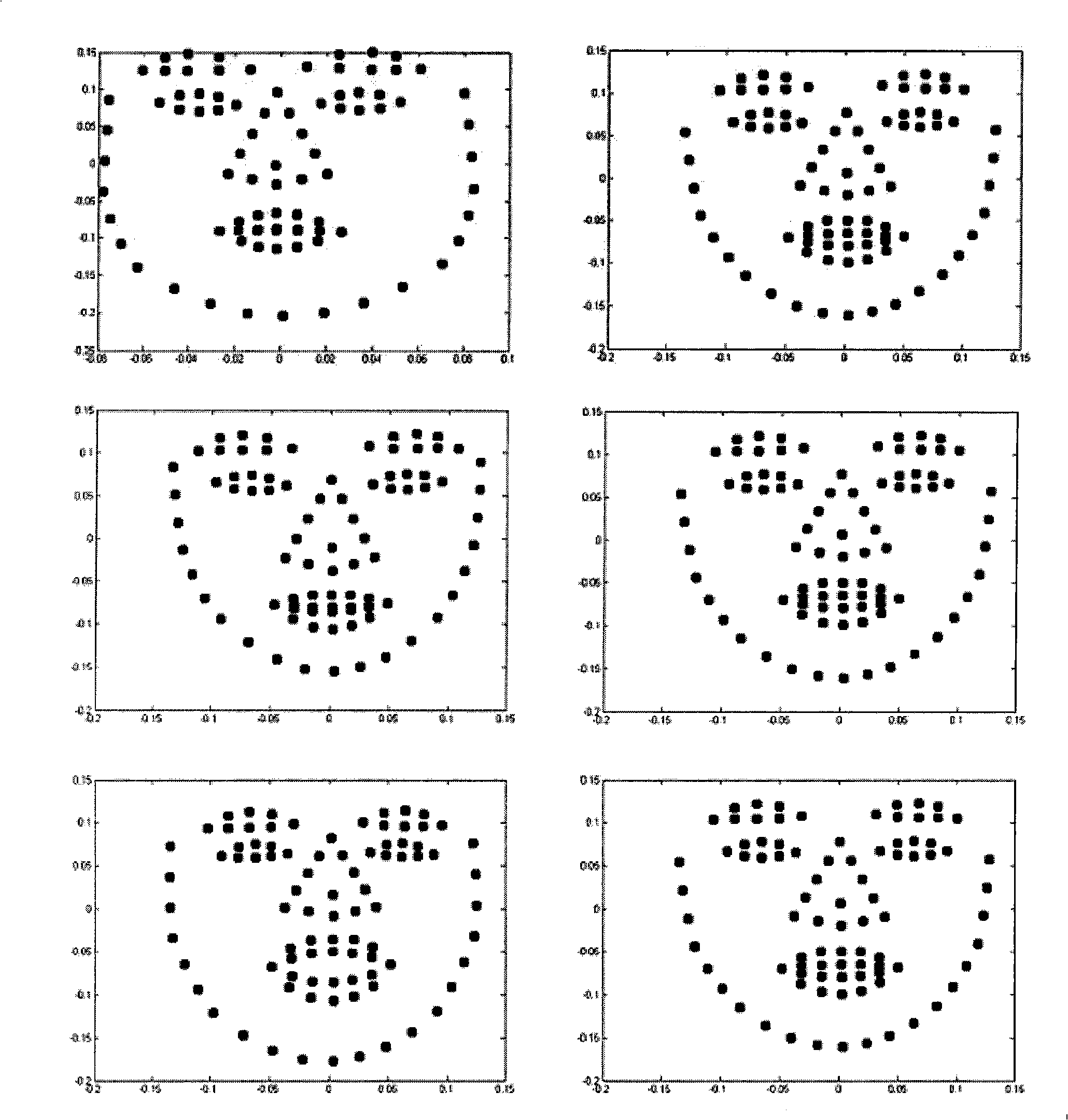

Three-dimensional human face recognition method based on human face full-automatic positioning

ActiveCN101320484AImprove efficiencyEasy to identify2D-image generationCharacter and pattern recognitionVeinFace shape

The present invention discloses a three-dimensional human face identifying method based on human face full-automatic positioning and belongs to the computer vision and mode identifying field. A human face virtual image generating method comprises the steps as follows: a two-dimensional human face shape model and a partial veins model are established; a two-dimensional human face image is positioned exactly; the two-dimensional human face image is processed for three-dimensional reconstruction according to the positioning result to obtain a three-dimensional human face image; the three-dimensional human face image is processed for illumination model treatment to obtain a virtual image with changeable gestures and illumination. The method comprises the steps as follows: characteristics are picked up from the human face image to be identified and compressed; the human face is identified according to the compressed and processed characteristics. The present invention embodiment generates the virtual image by the three-dimension reconstructing of the two-dimensional human face image and by processing the illumination model, thereby increasing the sample space of the gesture and the illumination change of the image; at the same time, the three-dimension reconstructing speed is improved greatly, thereby ensuring that human face image identification has higher efficiency and recognition rate.

Owner:TSINGHUA UNIV

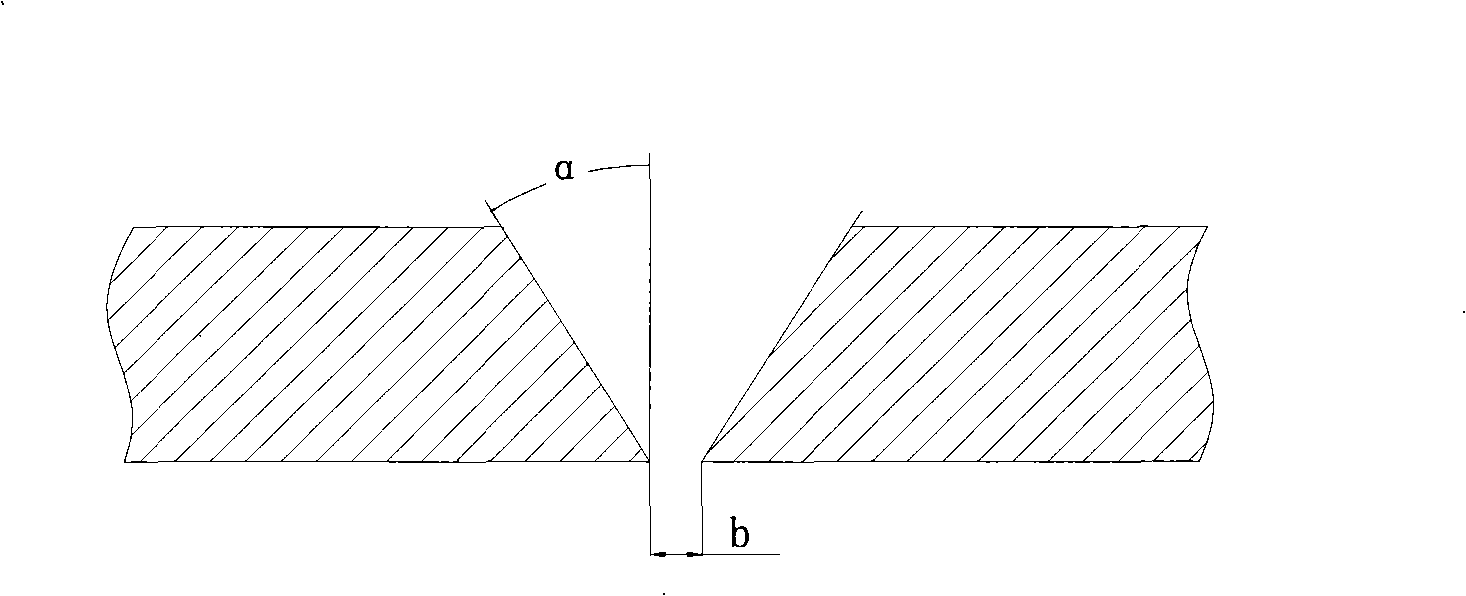

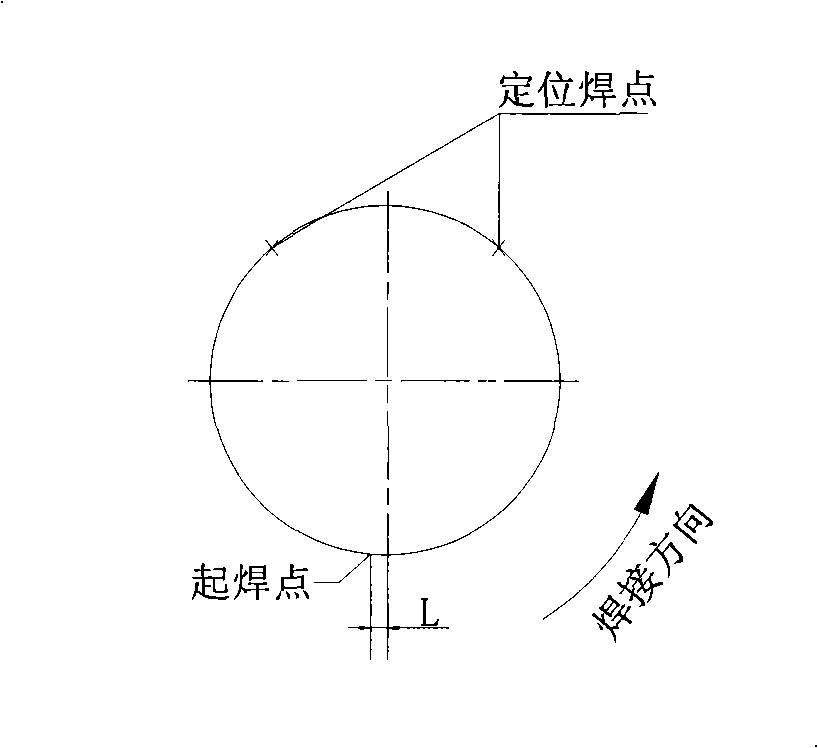

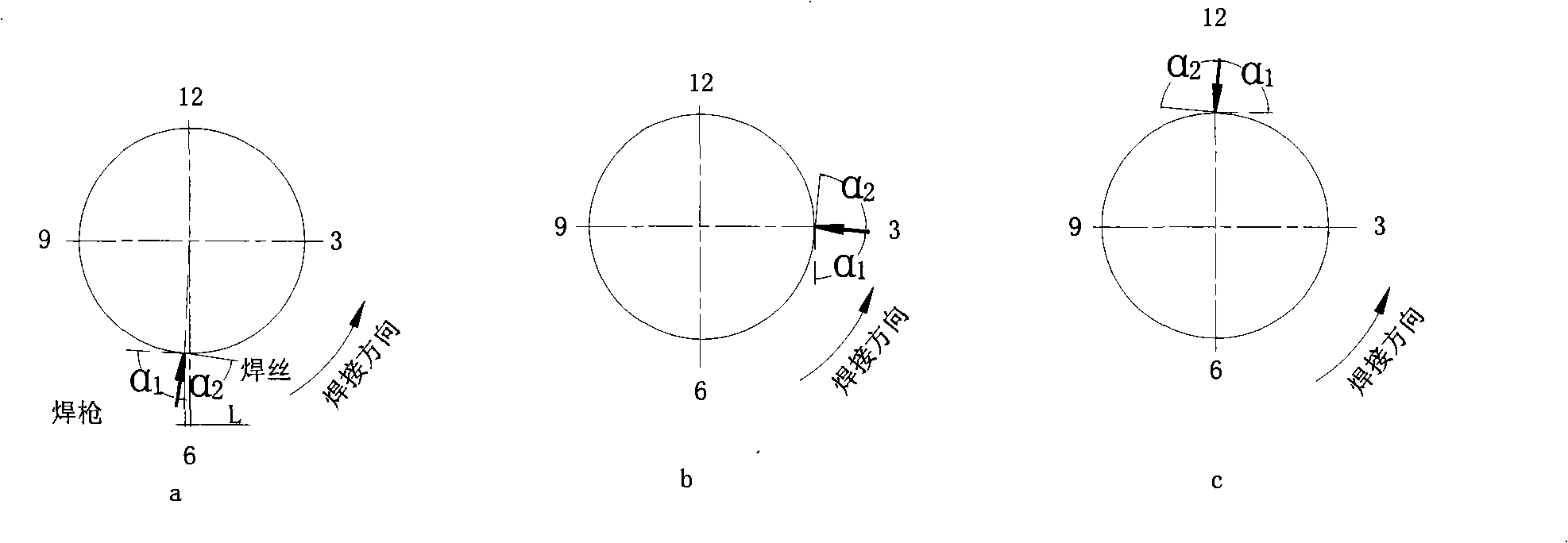

Large caliber aluminium alloy pipeline non-pad tungsten electrode argon arc single face welding and double face shaping method

InactiveCN101301699ABeautiful weldWell formed inside and outArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

The invention discloses a method for large-calibre aluminium-alloy pipeline no-liner tungsten electrode argon arc one-side welding both-side formation, comprising the following steps of: assembling of groove angle and clearance, grinding of tungsten electrode, cleaning before welding, adjusting welding process parameters, tack welding, and welding of a bottom coating, a filling layer and a covering layer. The pipe is horizontally fixed and the position is marked by hour; the welding sequence is left half-ring and right half-ring; each half-ring comprises overhead welding, vertical position welding and downhand welding; the welding is started at a position where L is equal to 5-10mm close to six of the overhead welding; the vertical position welding is then carried out; finally, the front half-ring is ended at 12 of the downhand welding; before the rear half-ring starts welding, the connection is grinded as a slope; the welding seam formed by the connection and the front half-ring welding position is overlapped by 3-5mm; the welding of the rear half-ring is started from 6 of the overhead welding and ended at 12 of the downhand welding through the vertical position welding; the welding is carried out by a continuous feeding method. The surface of the welding seam of the method has no pores or cracks, is completely welded and beautiful, and has good internal and external forming; by the non-destructive testing, the first-time qualification rate achieves 100%, the welding seam achieves the class-1 quality, the construction procedures are reduced, and the construction cost is reduced.

Owner:ANGANG CONSTR CONSORTIUM

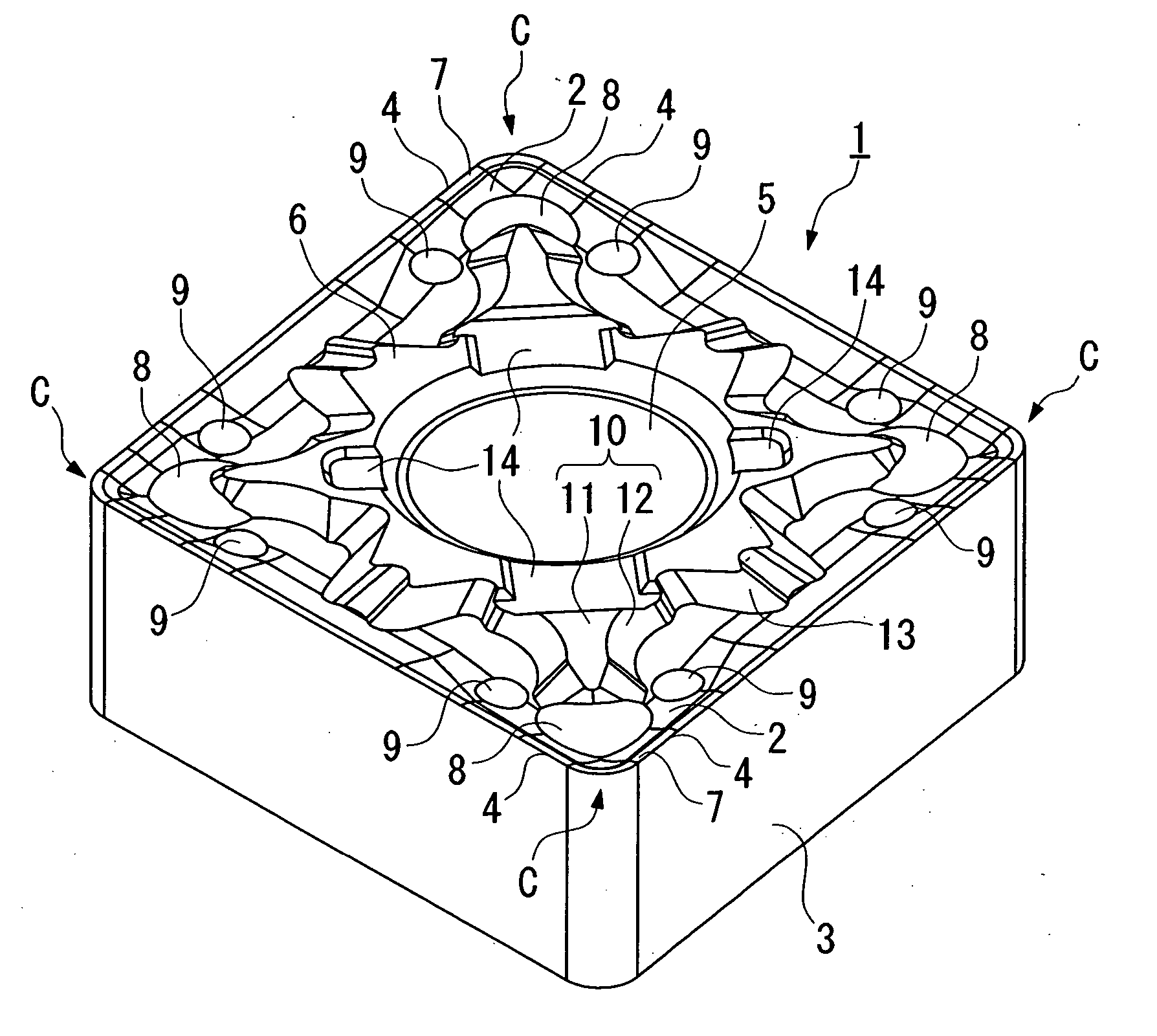

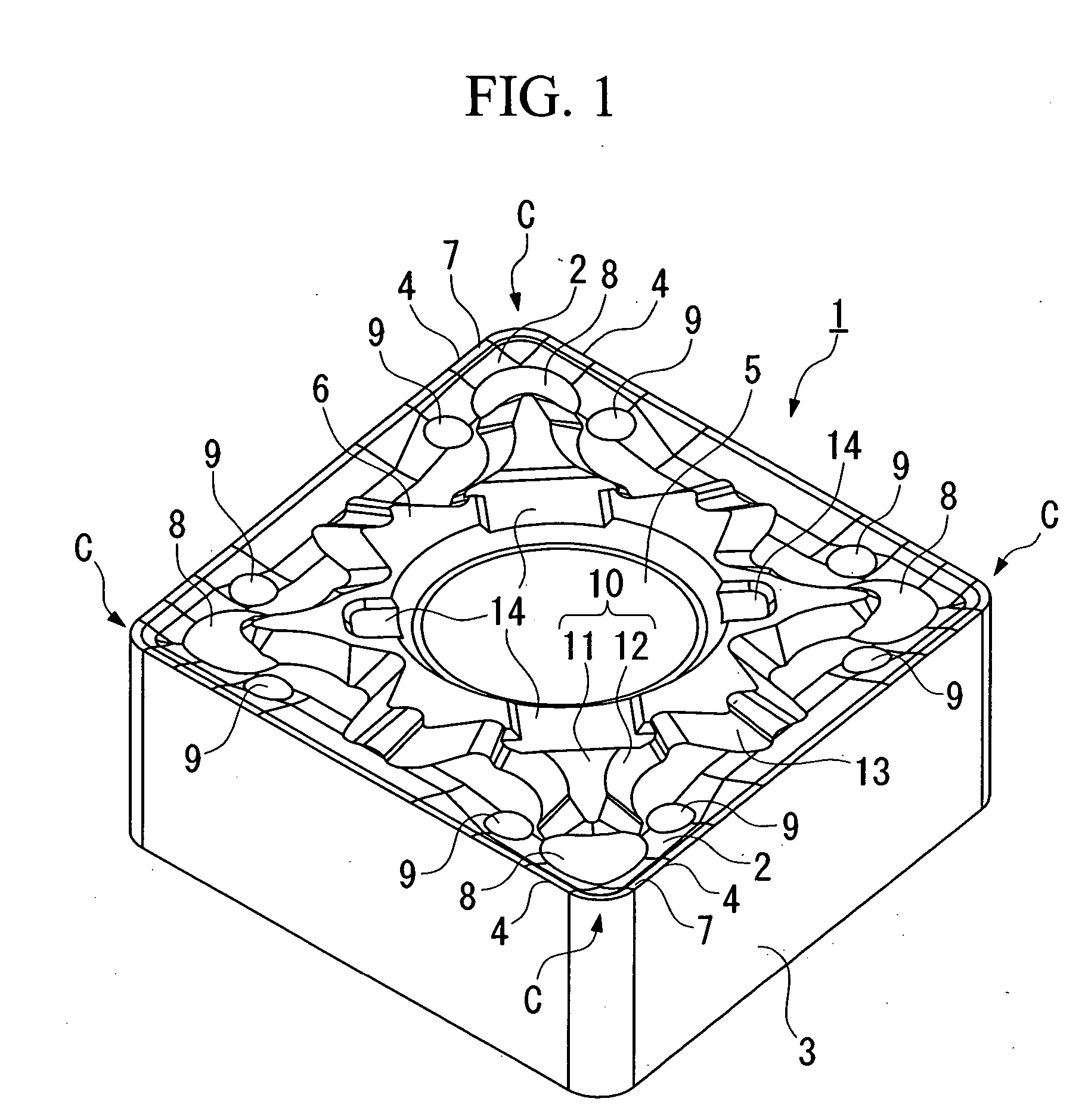

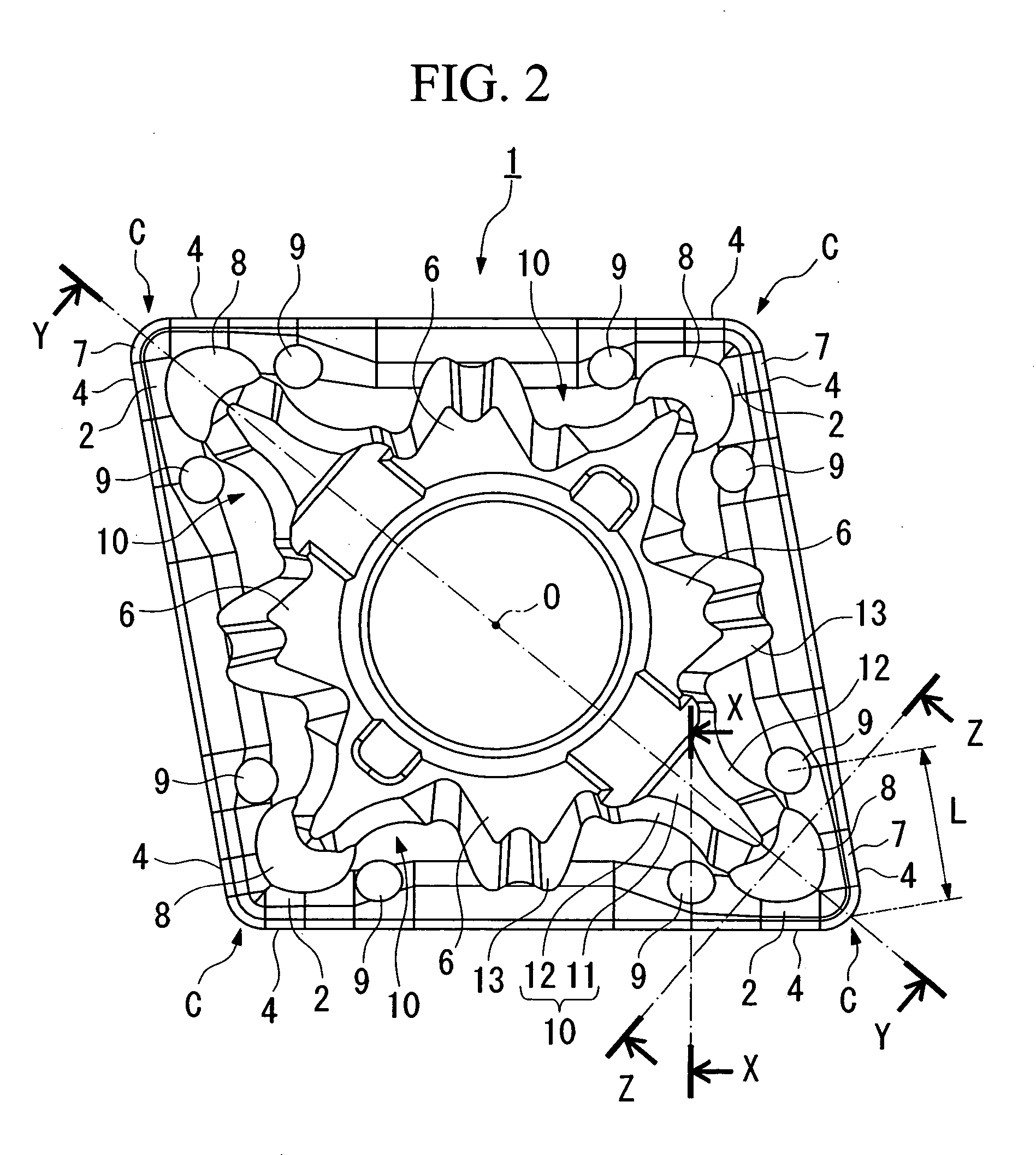

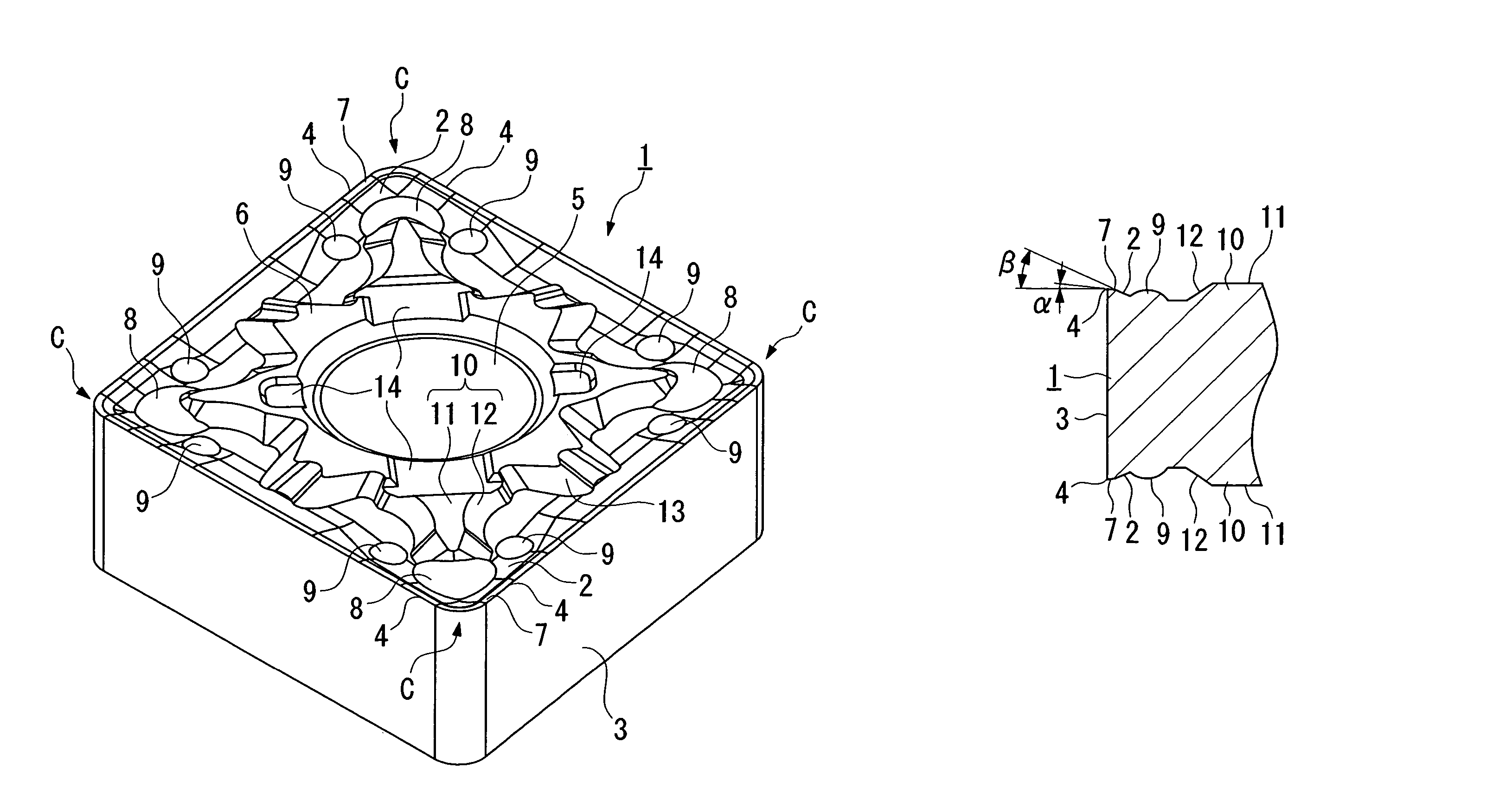

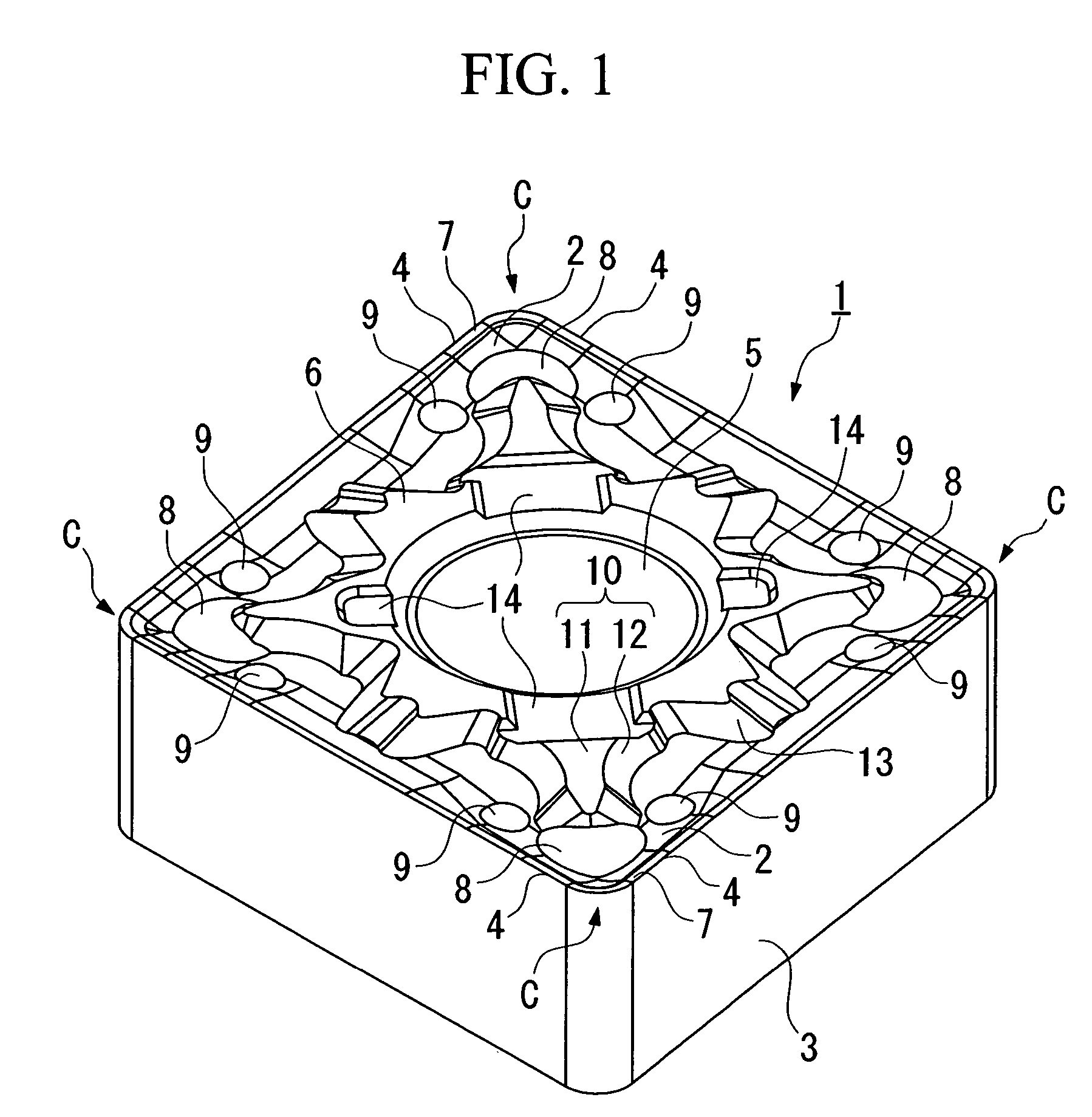

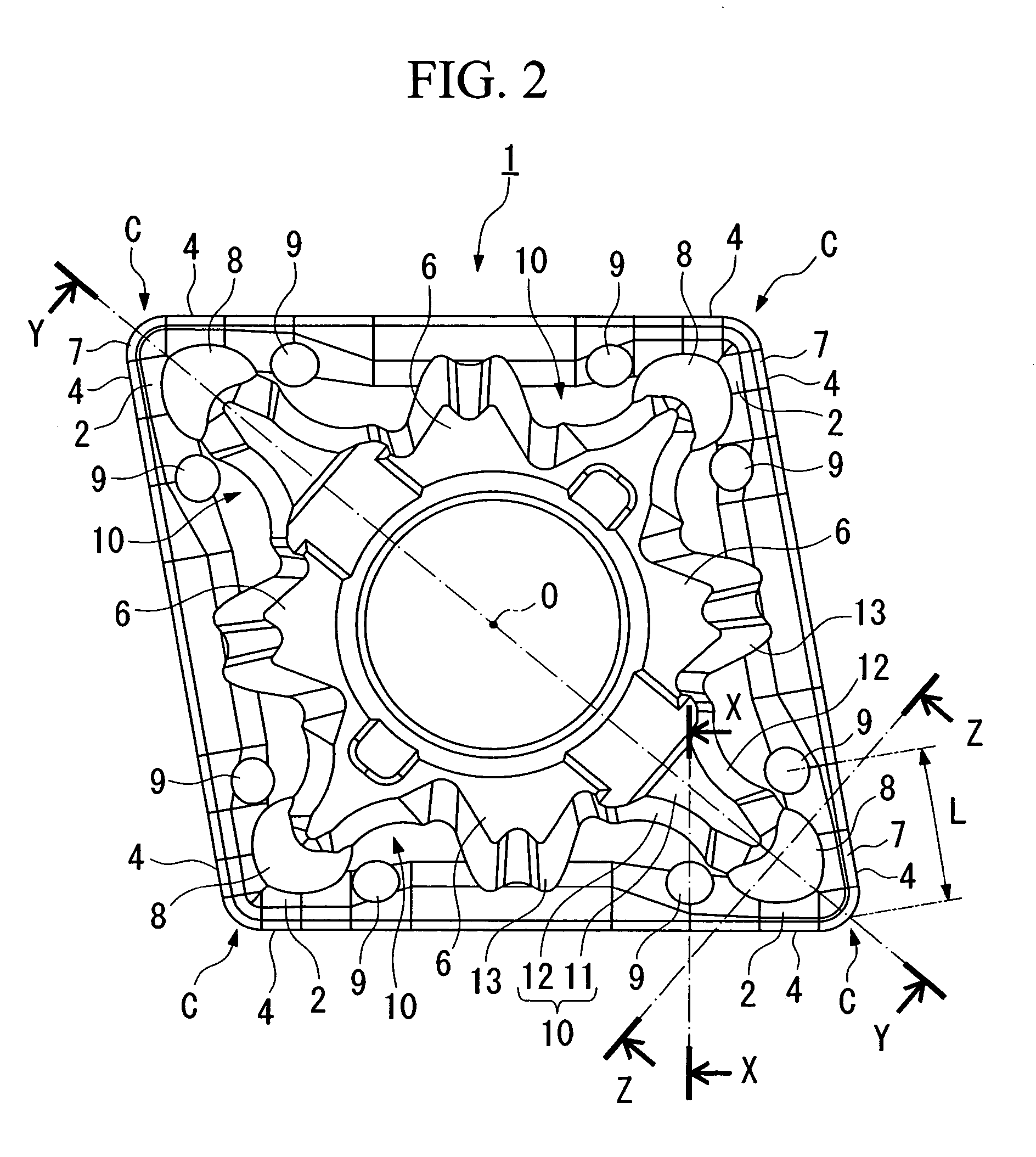

Throwaway tip

InactiveUS20050019111A1Reliable processing can be inhibitedSolve the broken effect is not goodCutting insertsTurning toolsConvex sideEngineering

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

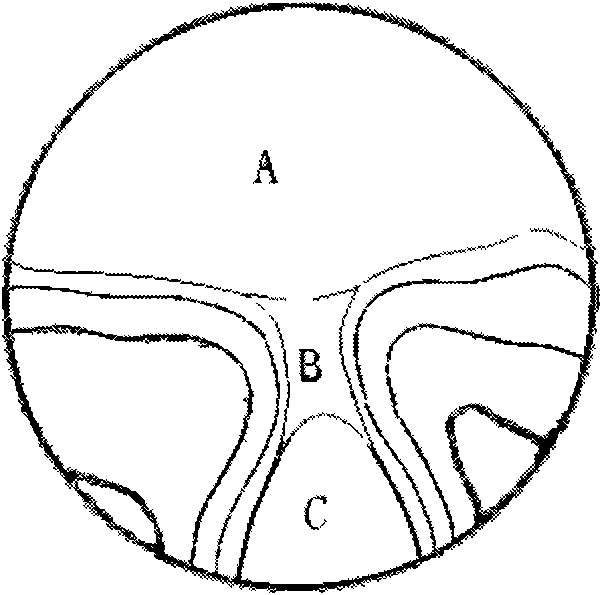

Indexable insert

InactiveUS7182555B2Easily brokenReadily broken and processedCutting insertsTurning toolsEngineeringKnife blades

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

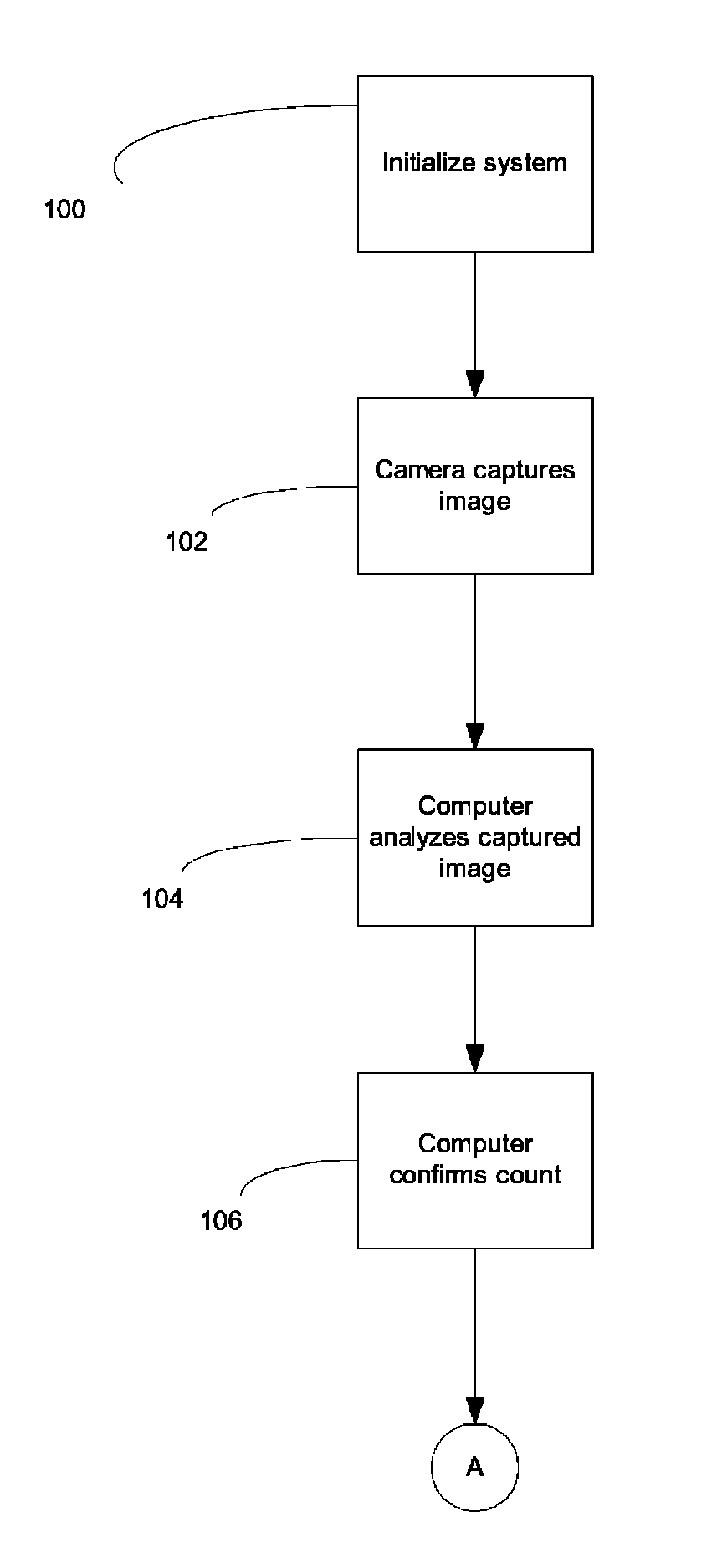

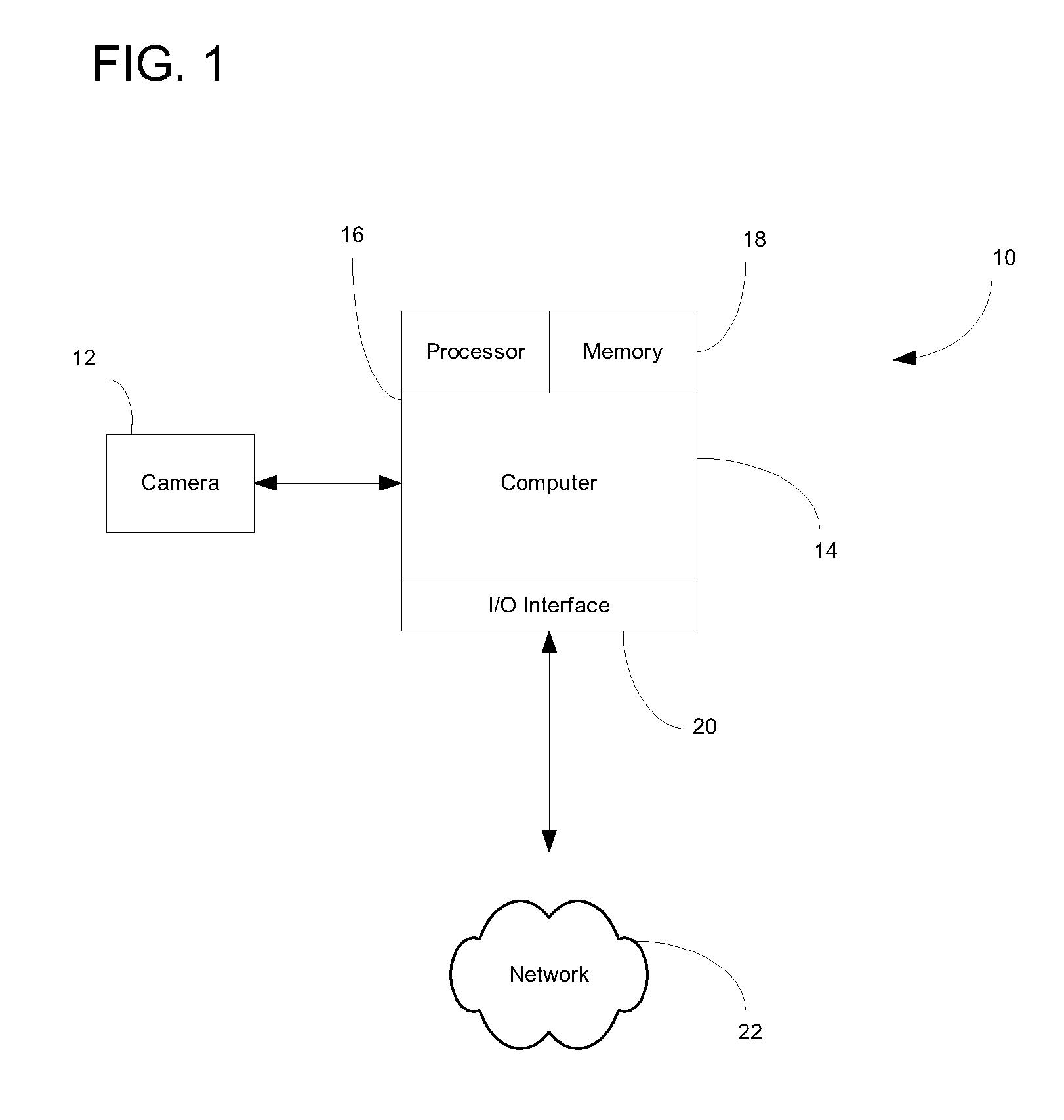

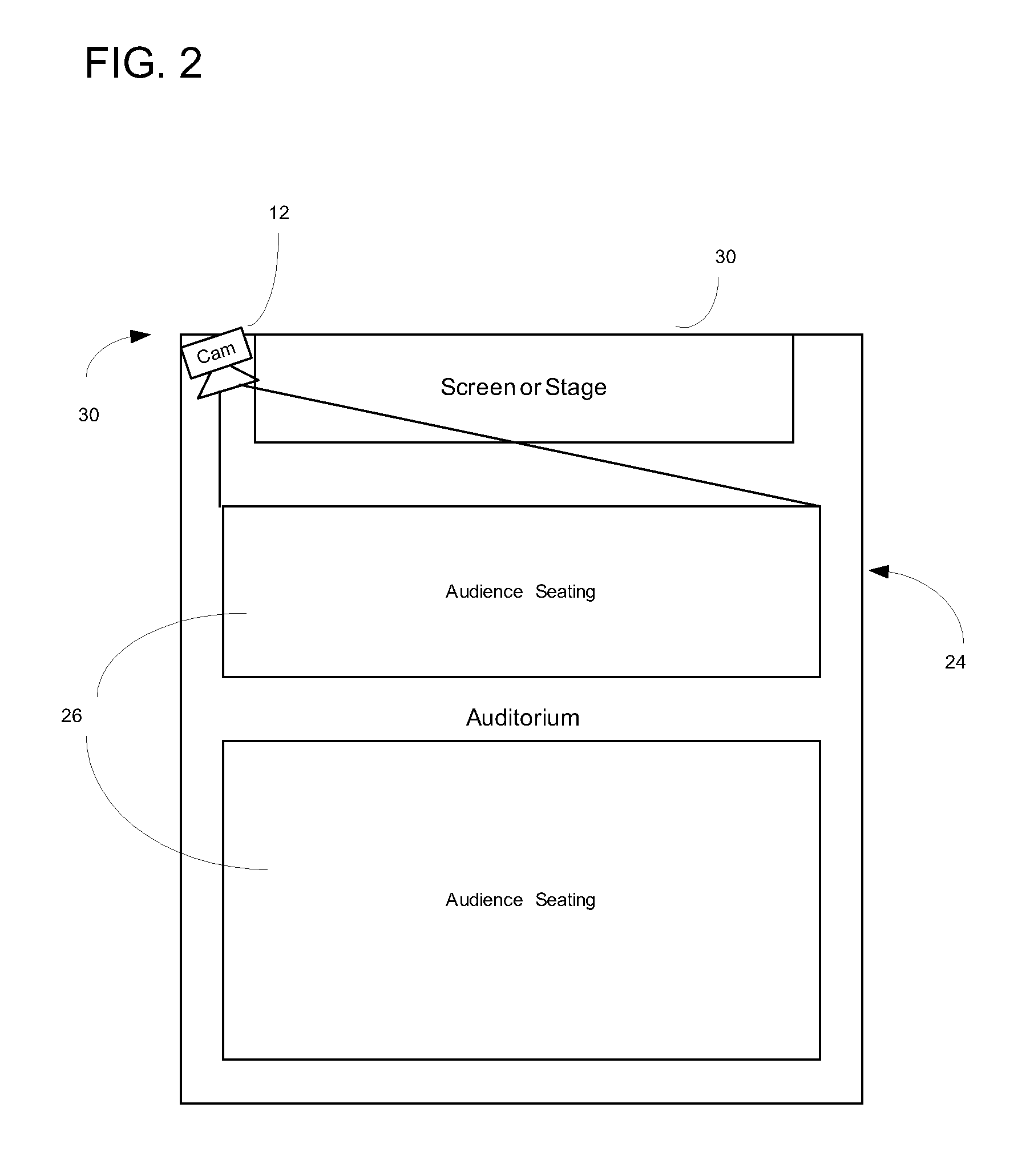

System and method for counting people

InactiveUS8228382B2Television system detailsCharacter and pattern recognitionVideo recordingFace shape

A system for counting people in a specified area. The system includes a camera for capturing an image of the specified area and a computer for receiving the captured image. The computer analyzes the image to detect people by detecting head or face shapes in the image. The computer counts the detected head or face shapes to determine a number of people within the specified area. The computer may confirm that the head or face shapes are human by determining if the shapes have the approximate coloration of a human. The system may detect stationary or moving persons. In addition, the system may detect the presence of video recording devices in a room. The system may also detect if a seat is occupied by determining that a pattern in the seat is blocked or the outline of the seat is blocked.

Owner:PH TECHN LABS

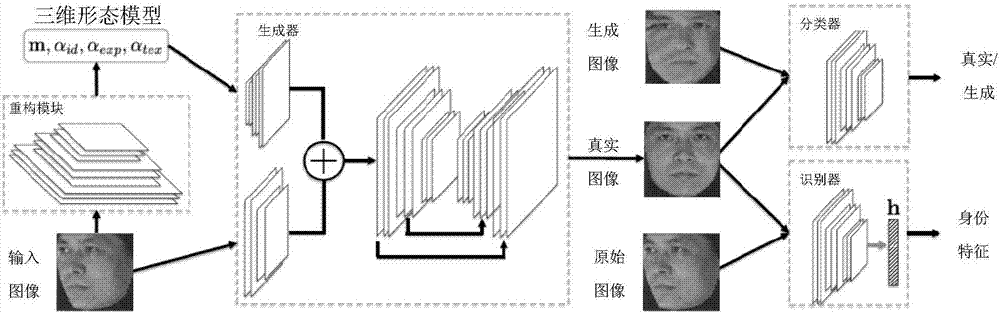

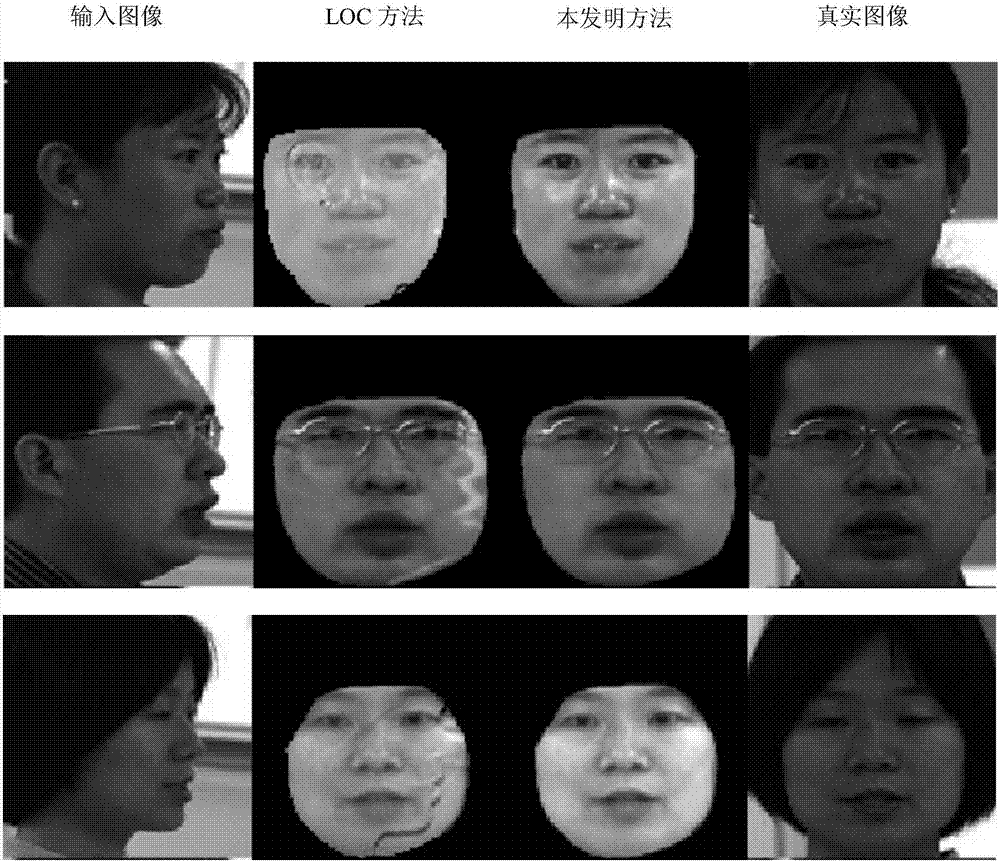

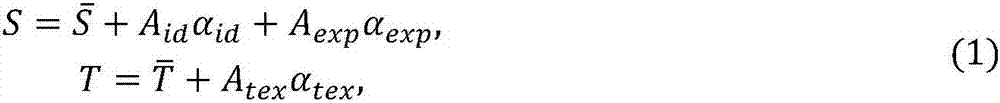

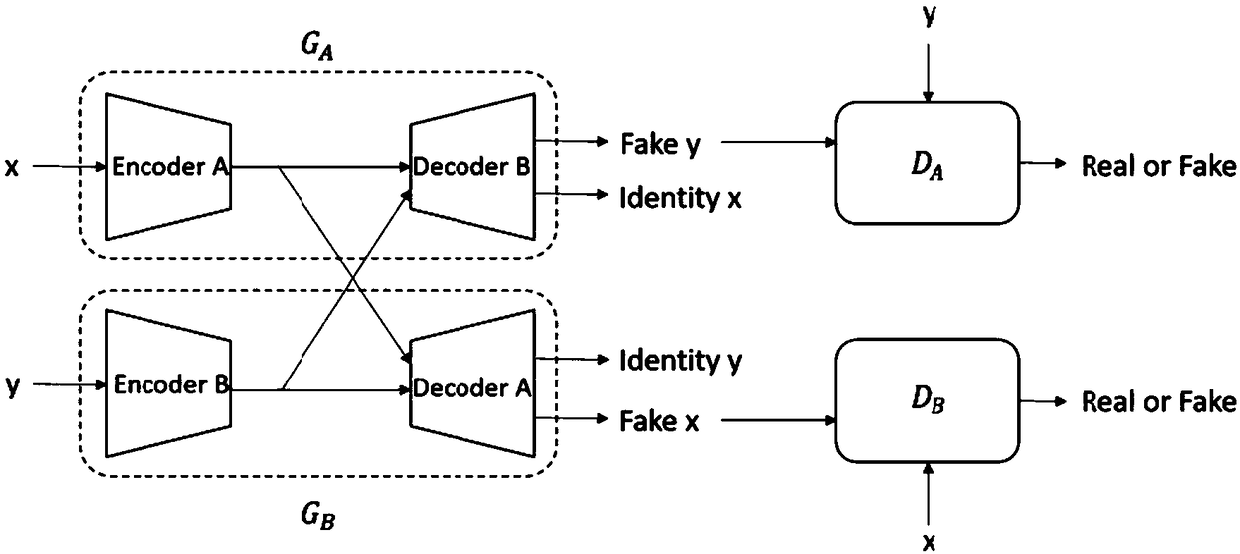

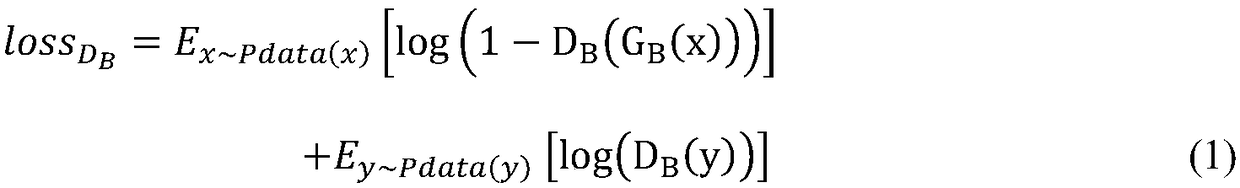

Large-amplitude face straightening method by means of adversarial network and three-dimensional morphological model

The invention provides a large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model. The main content of the large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model includes a reconstruction module, a generation network and classification module, and an identification module. The large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model includes the steps: a generator generates a forward front face image by taking a non-forward front face image as input, and at the same time a classifier tries to determine whether the image is a real image and utilizes the fed back information to promote the image generated from the generator to be more close to the real image, and at the same time an identification engine is used to maintain the original identity characteristics in the input image. The large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model can process the non forward face, especially a large-amplitude deflected face image, can provide a generation network and a morphological model to straighten the face, and can greatly improve the effect of face identification and straightening at the same time.

Owner:SHENZHEN WEITESHI TECH

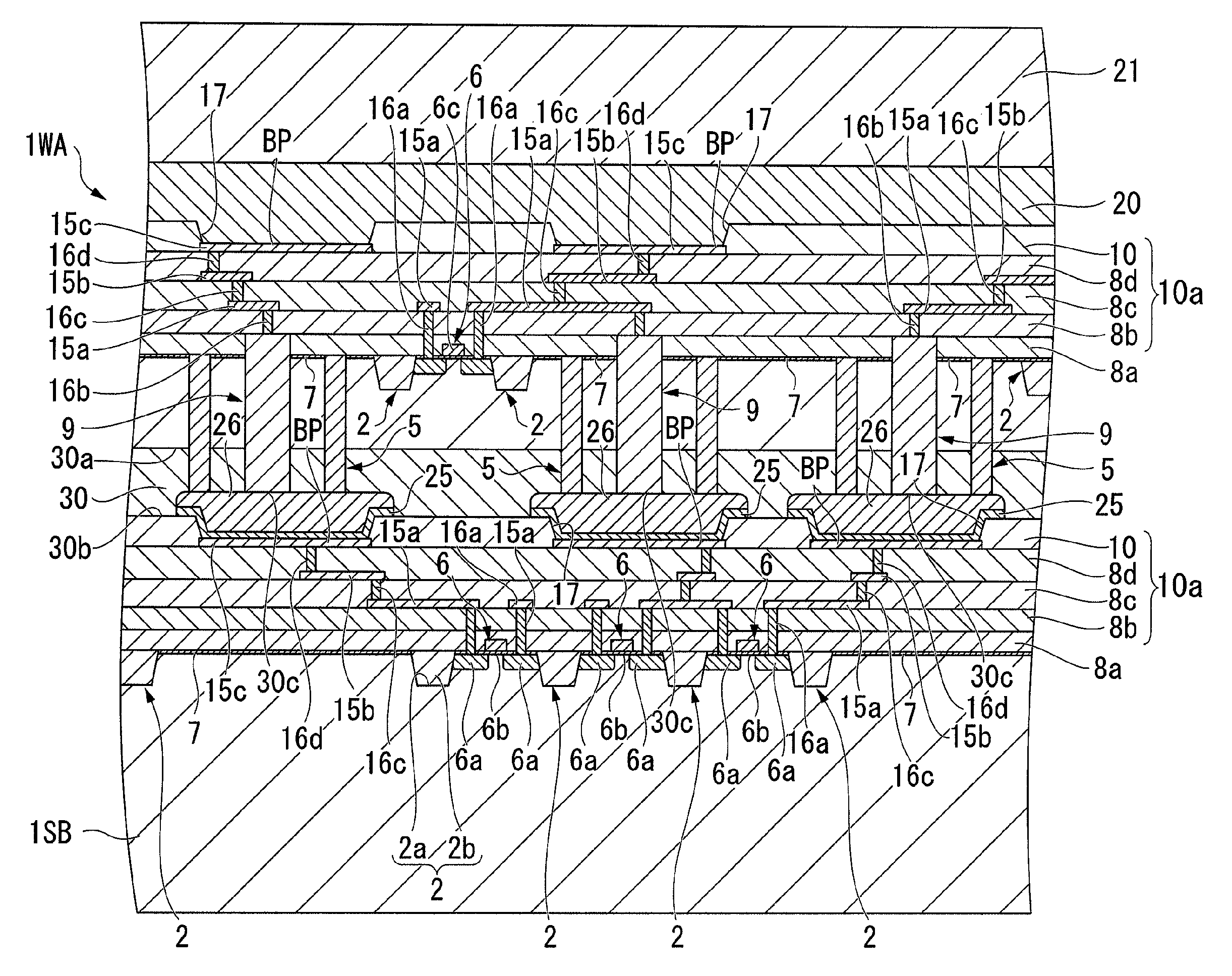

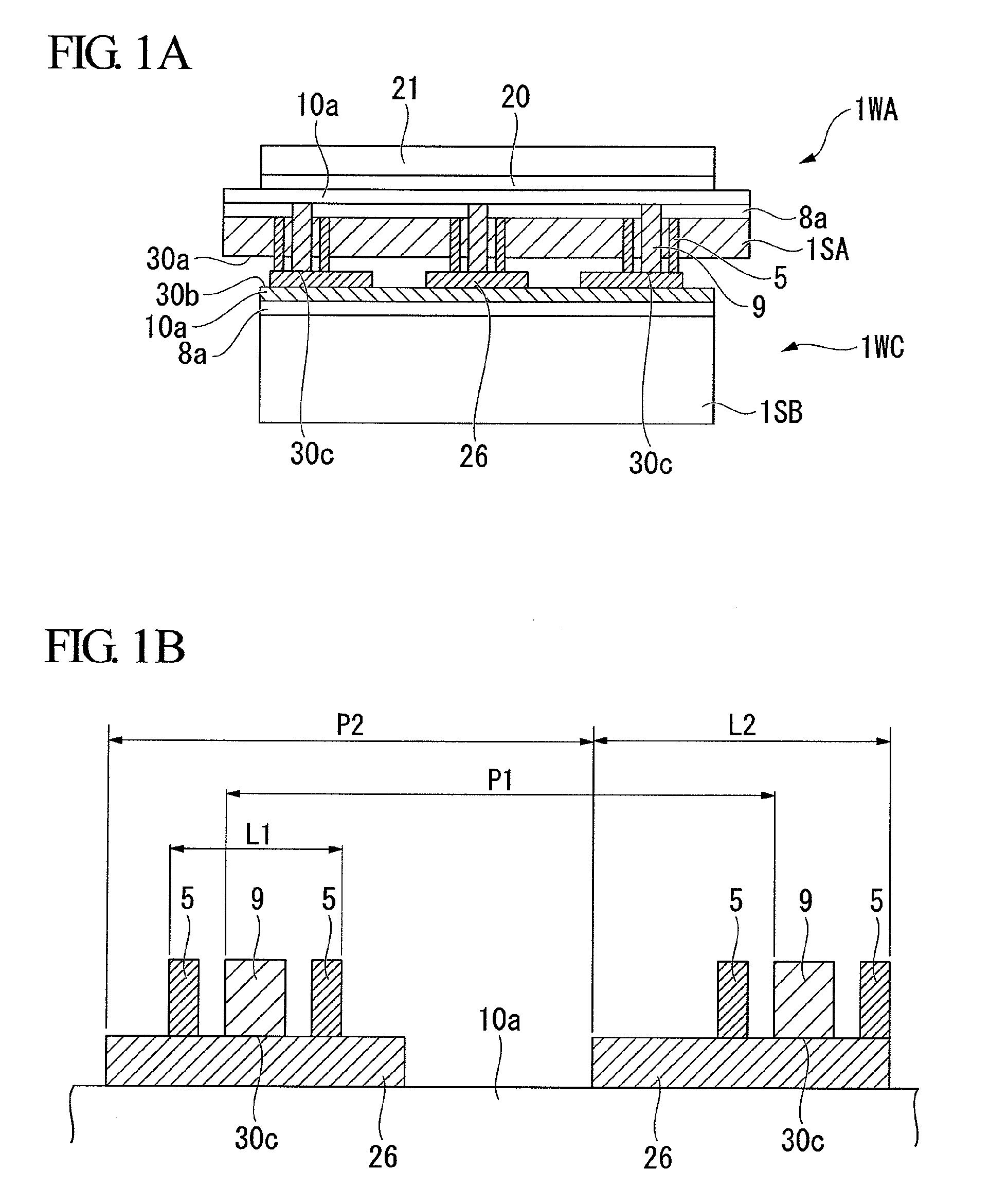

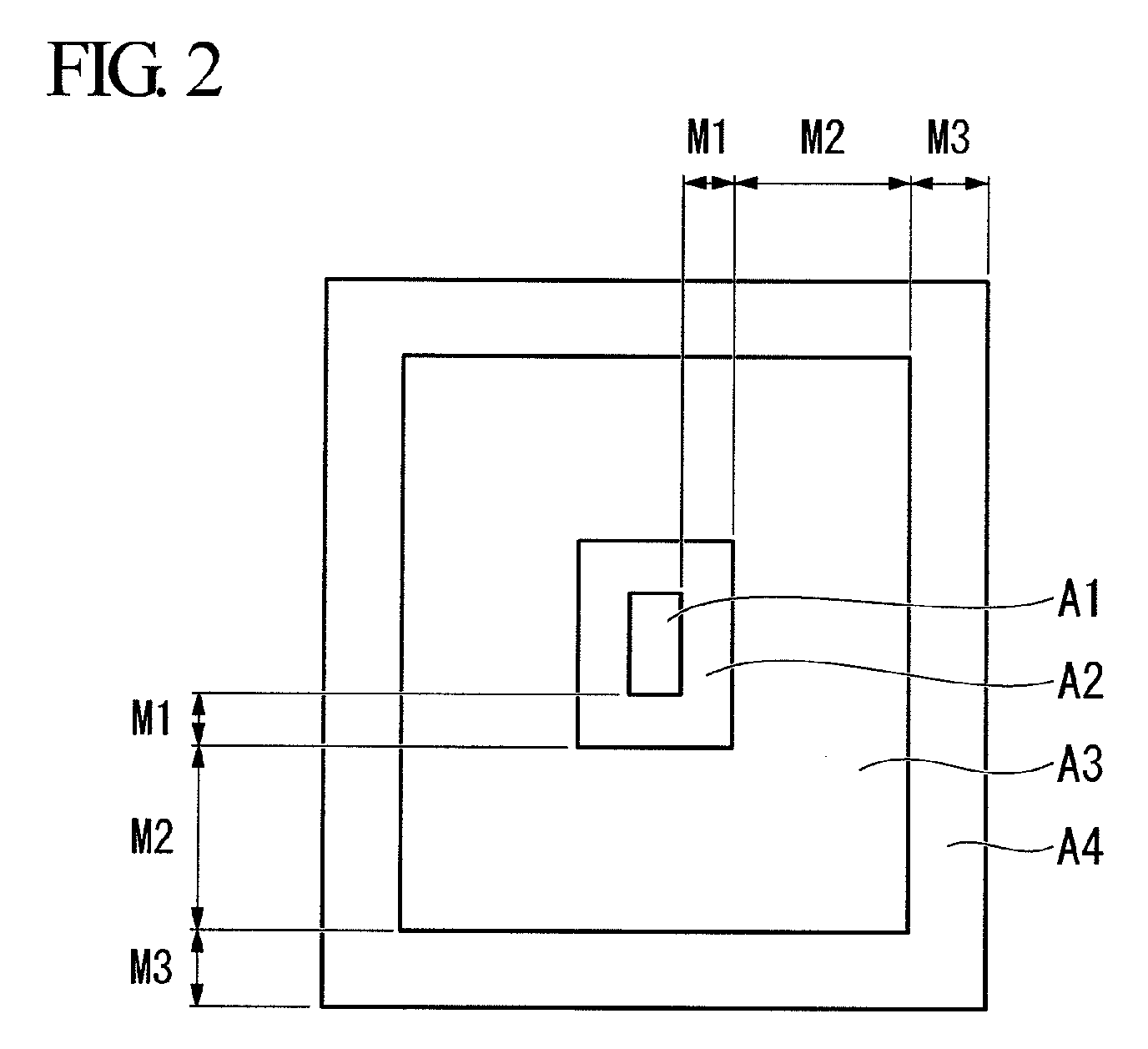

Semiconductor device

InactiveUS20090057890A1High reliability in electrical connectionIncrease the areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringFace shape

In this semiconductor device, connection parts between wafers are electrically insulated from each other, and a junction face shape of second electrical signal connection parts is larger than the shape of a positioning margin face that is formed by an outer shape when the periphery of a minimum junction face, which has half the area of a junction area of the first electrical signal connection part, is enclosed by a same width dimension as a positioning margin dimension between the first wafer and the second wafer.

Owner:HONDA MOTOR CO LTD

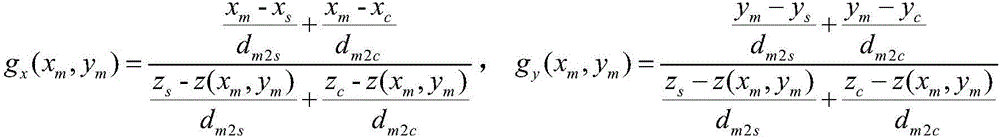

Device and method of measuring surface topographies of mirror and mirror-like objects

InactiveCN105783775AIncreased complexityGuarantee authenticityUsing optical meansMeasurement deviceLiquid-crystal display

The invention discloses a method and a device for measuring surface topographies of mirror and mirror-like objects. Phase measurement deflectometry is adopted to measure mirror and mirror-like surface shapes, a combination between a liquid crystal display and a planar mirror serves as a calibration plate, the liquid crystal display is fixed and can not move, the planar mirror moves freely for four times, an image reflected by the planar mirror is photographed by a CCD detector, linear solution and beam method adjustment are then used for completing calibration on inner parameters of the camera, global pose estimation is used for completing calibration on the relative relation between the liquid crystal display and the camera, and finally, a three-dimensional topography of a to-be-detected mirror surface is calculated and obtained through a gradient integral of the phase measurement deflectometry. According to the device and the method of the invention, defects that the calibration plate is needed and a precise positioning control point is attached to the planer mirror during the calibration process in the traditional method are overcome, the measurement cost is low, and he measurement speed is quick; and constraint conditions such as rotation matrix orthogonality during a perspective imaging process and a fourier transform method are introduced for corresponding point matching, and influences by high noise and multiframe processing on three-dimensional topography recovery can be overcome.

Owner:TSINGHUA UNIV

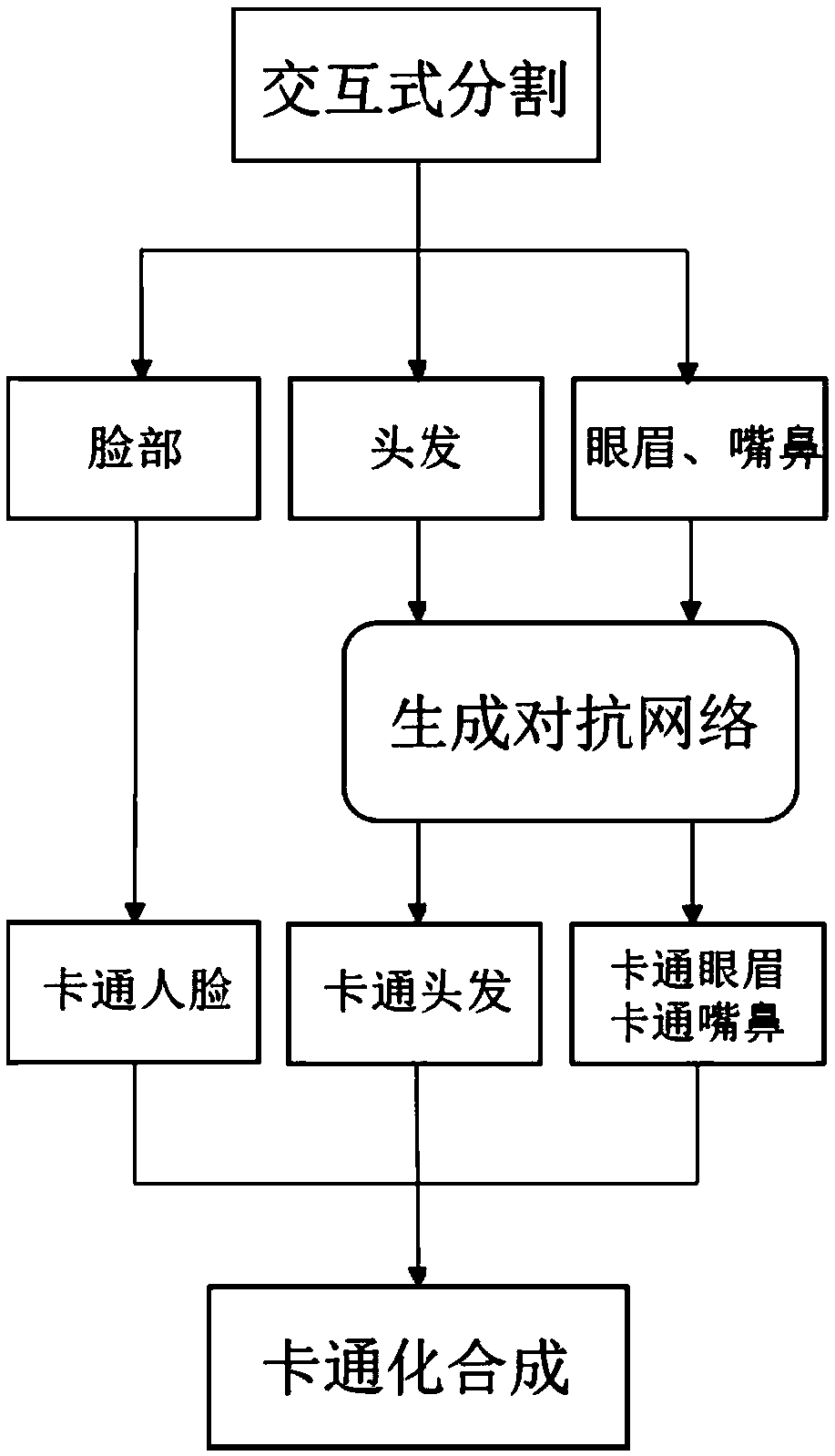

An interactive face cartoon method based on generative adversarial networks

ActiveCN109376582AEliminate differencesCharacter and pattern recognitionNeural architecturesPattern recognitionNose

The invention discloses an interactive face cartoon method based on generative adversarial networks. The image to be processed is firstly subjected to interactive segmentation processing to obtain eyebrow-eye, mouth-nose, hair and face images, and then eyebrow-eye, mouth-nose and hair images are respectively input into three trained eye, mouth-nose and hair generation models to output corresponding cartoon five-feature images. Based on the cartoon processing of face image, the cartoon face can be obtained directly. Then the facial features are synthesized on the cartoon face and superimposed on the hair effect to get the final cartoon image. The invention utilizes the advantages of interactive and generating antagonistic network, obtains the five features of human hair, face shape and facethrough interactive segmentation, eliminates the difference between training samples due to different backgrounds, converts the style of each part through generating antagonistic network, and retainsas much information of eye corner, mouth corner and other detail parts as possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

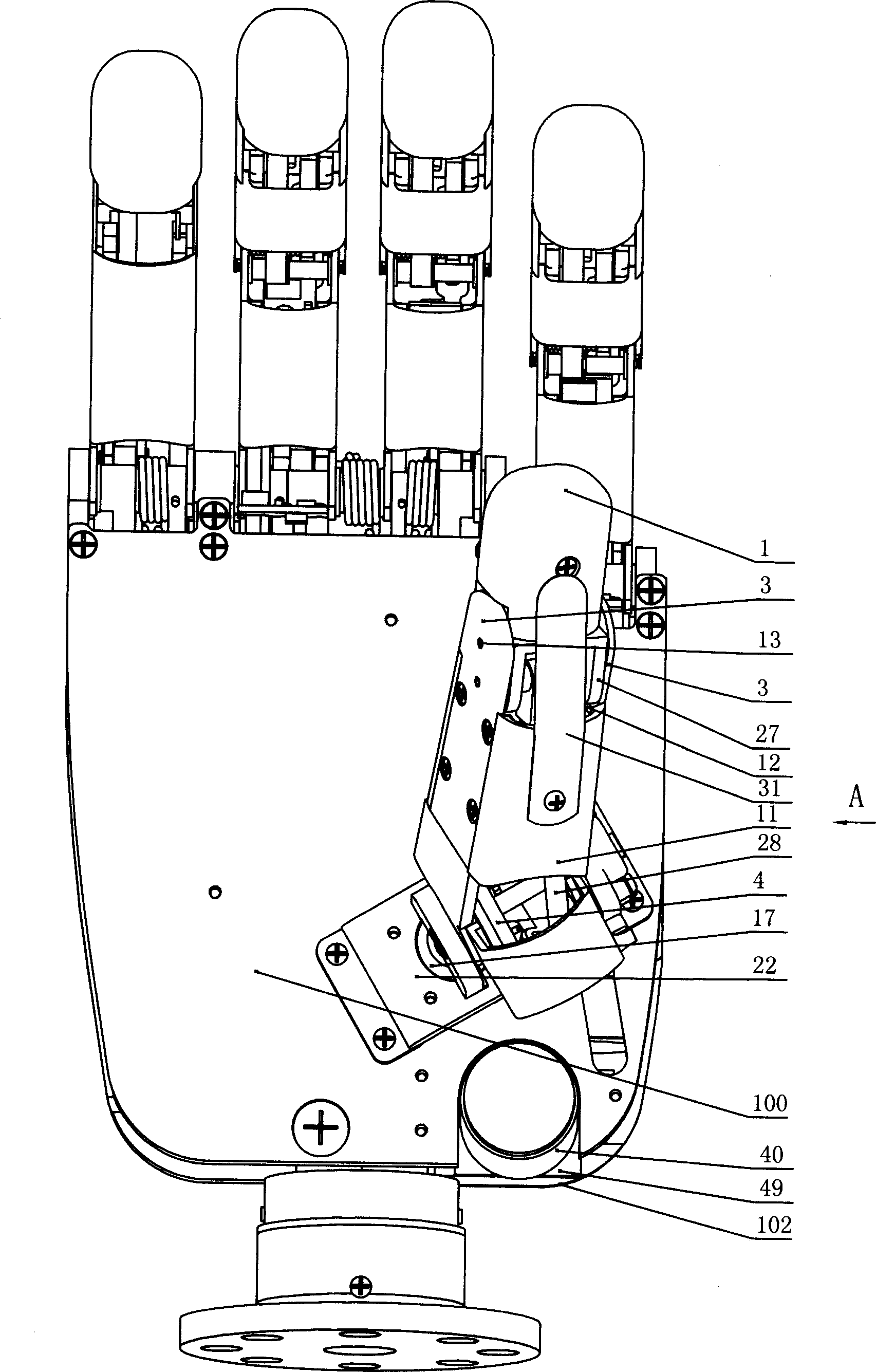

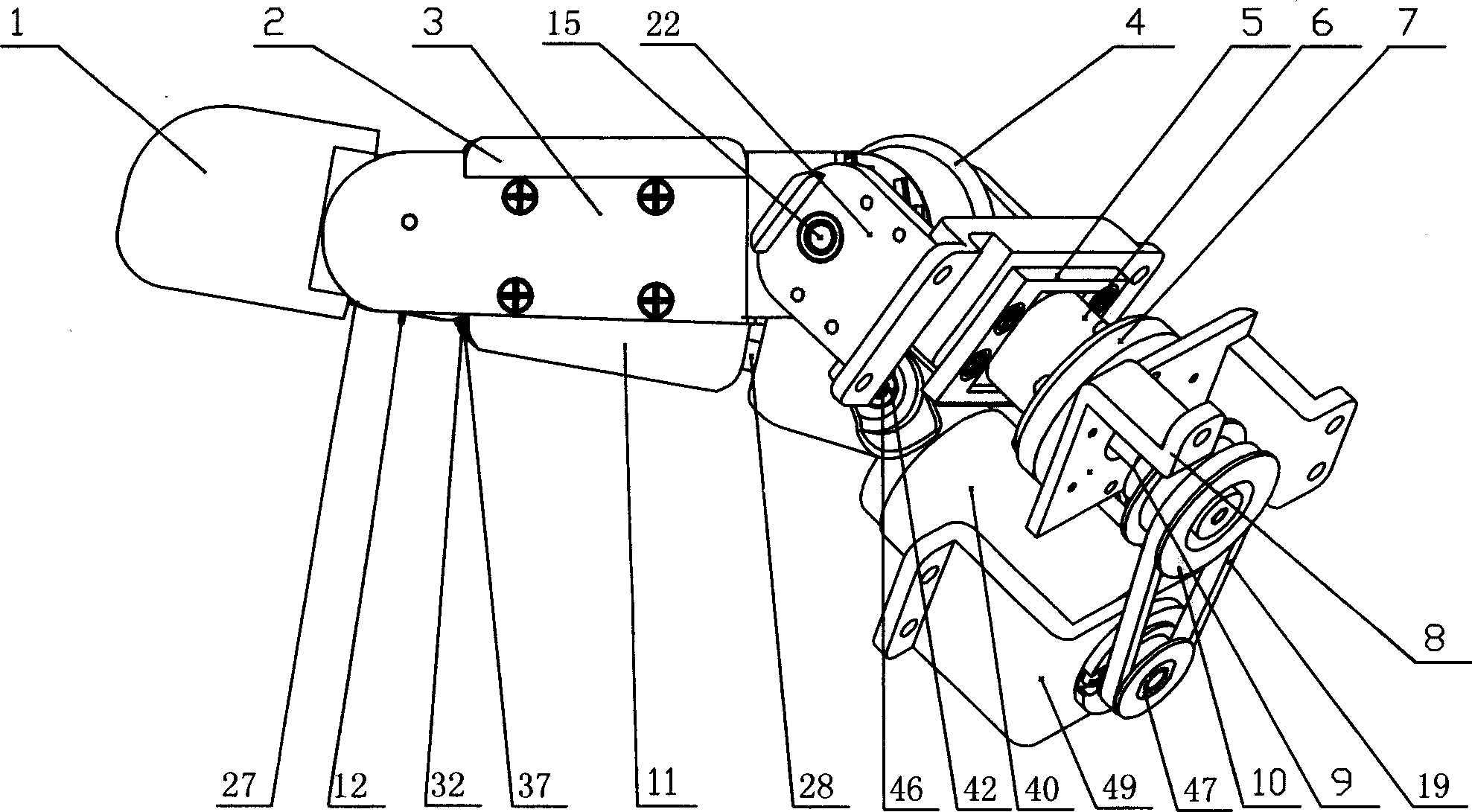

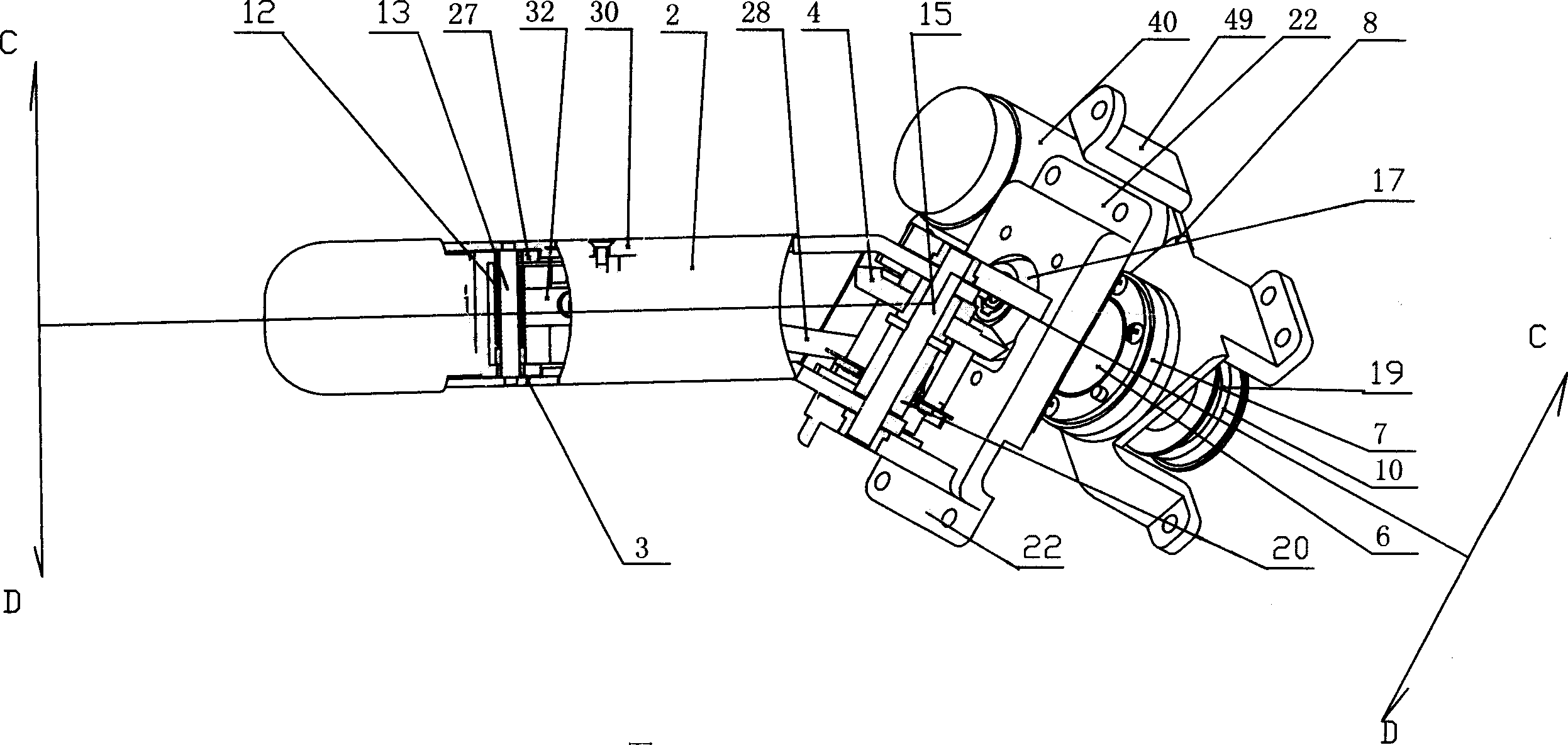

Thumb mechanism of underactuated self-adaptive hand prosthesis

The invention discloses a thumb device of little-driving self-adaptive artificial hand, which is characterized by the following: connecting one end of thumb finger-tip pin case (32) with the thumb finger-tip connecting rod pin shaft (37); fixing the thumb wheeled bearing (55) on the wave generator axle (54) under the thumb decelerator wheel (10); connecting the thumb decelerator wheel (10) with the wheeled pad (9) through the wheeled fixation pin (57); fixing the wave generator (52) of harmonic gear decelerator on the other end of the wave generator axle (54) of wheeled pad (9). The invention can display a 130 deg conical moving space in the moving course to realize the finger-pin little-driving movement, which is adaptive for the object shape to reach full-covering the object and stable grasping.

Owner:HARBIN INST OF TECH

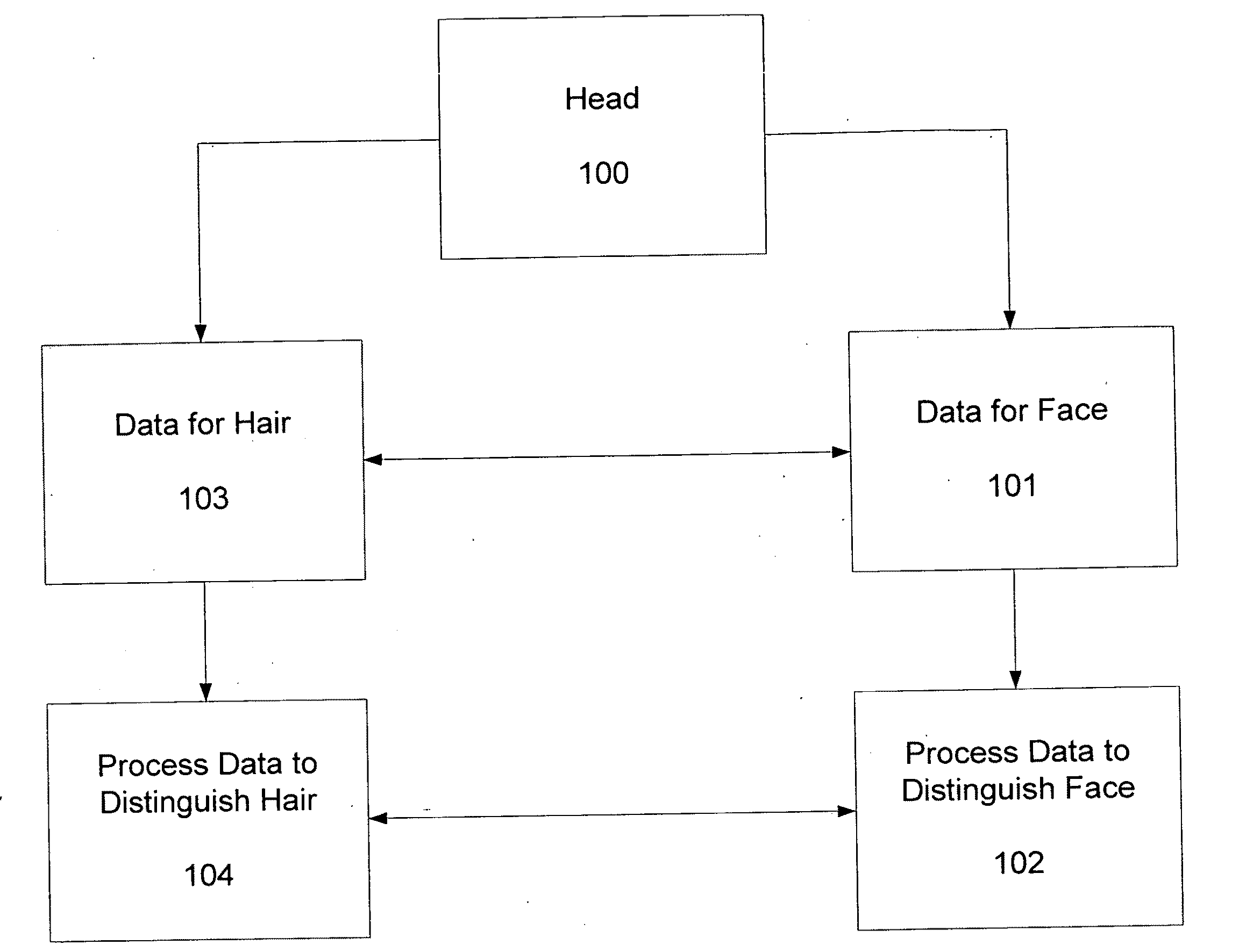

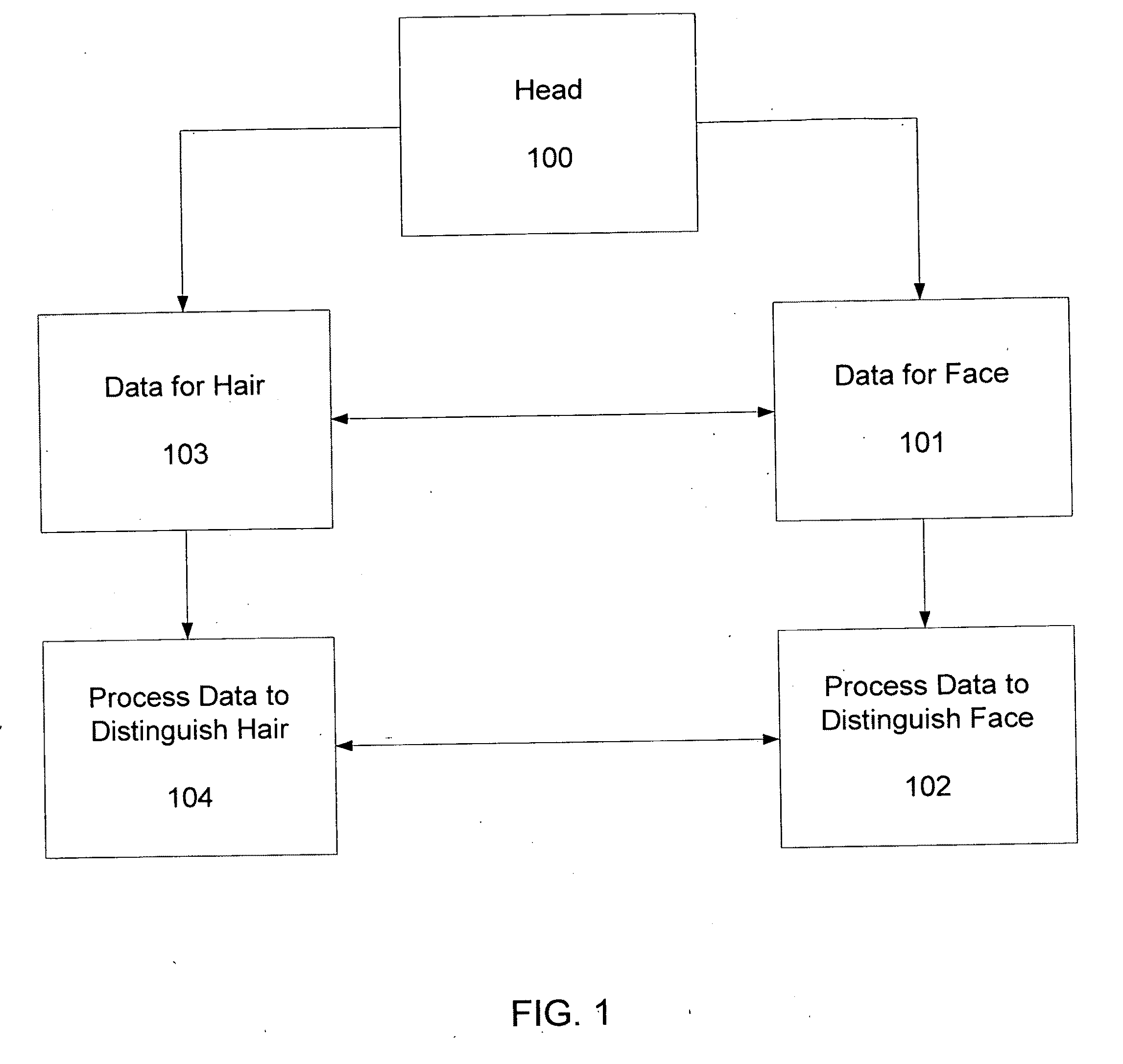

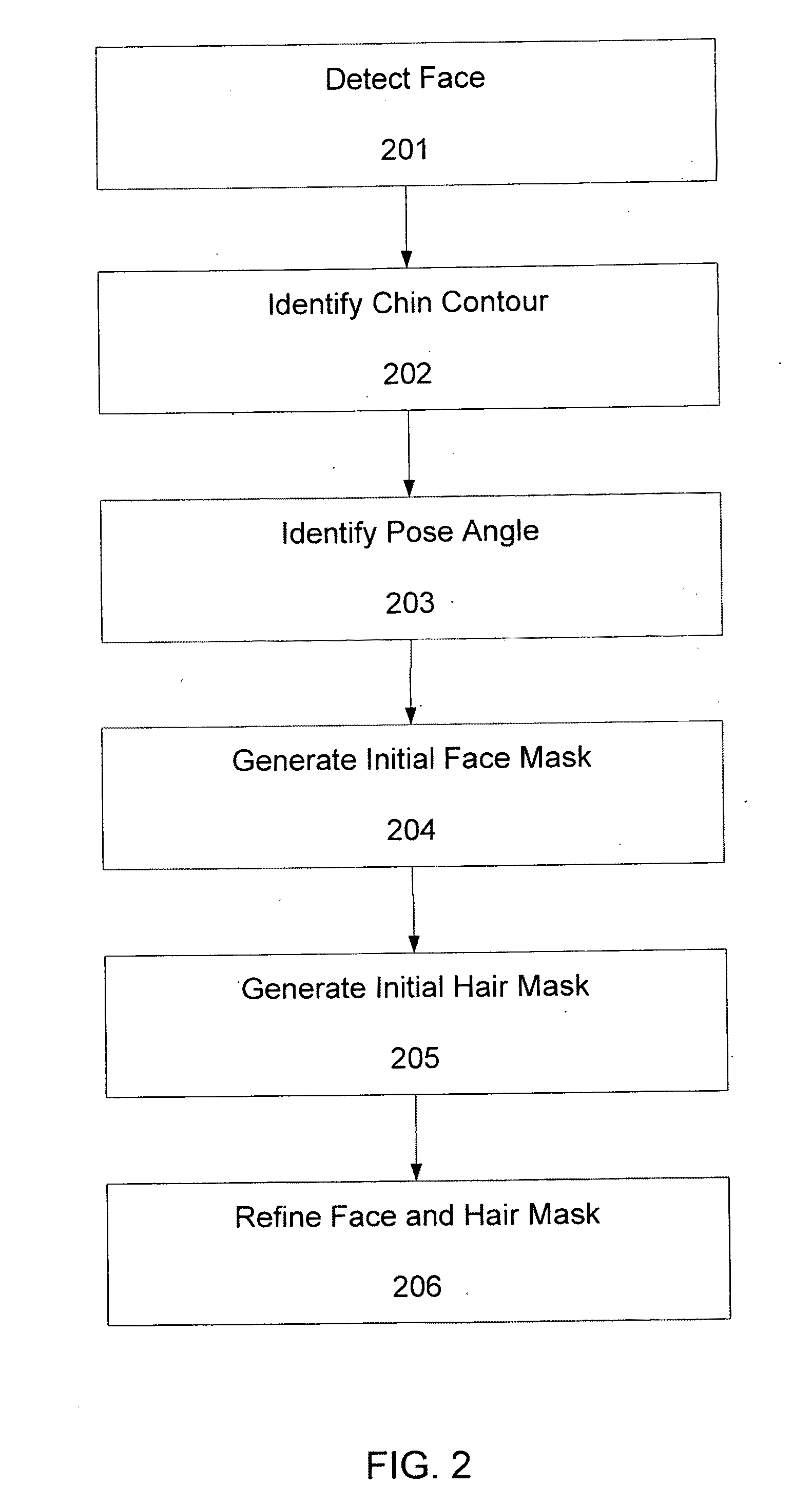

Systems and methods for segmenting human hairs and faces in color images

InactiveUS20110299776A1Ability to easilyCharacter and pattern recognitionPattern recognitionColor image

Systems for segmenting human hairs and faces in color images are disclosed, with methods and processes for making and using the same. The image may be cropped around the face area and roughly centered. Optionally, the illumination environment of the input image may be determined. If the image is taken under dark environment or the contrast between the face and hair regions and background is low, an extra image enhancement may be applied. Sub-processes for identifying the pose angle and chin contours may be performed. A preliminary mask for the face by using multiple cues, such as skin color, pose angle, face shape and contour information can be represented. An initial hair mask by using the abovementioned multiple cues plus texture and hair shape information may be created. The preliminary face and hair masks are globally refined using multiple techniques.

Owner:FLASHFOTO

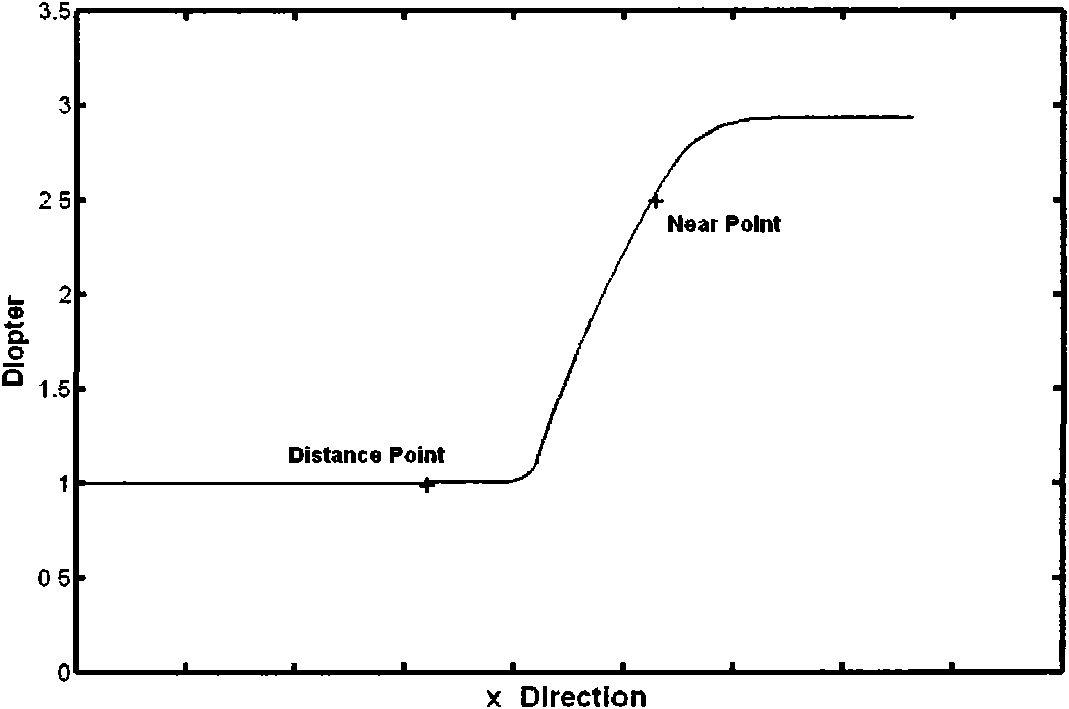

Method for designing ophthalmic progressive additional lens by utilizing meridian

The invention relates to a method for designing a lens, in particular to a method for designing an ophthalmic progressive additional lens by utilizing meridian. The method mainly comprises the following steps of: a) designing a meridian diopter variation curve of the ophthalmic progressive additional lens; and b) determining the surface shape of the ophthalmic progressive additional lens accordingto the meridian diopter variation curve. According to the visual demands of a wearer, the diopter distribution of the ophthalmic progressive additional lens is designed along the meridian, therefore,the method can be used for the design of multifunctional ophthalmic progressive additional lens; in addition, according to the meridian diopter variation curve, the method can determine the surface shape, the diopter and astigmation distribution of the ophthalmic progressive additional lens to better satisfy the needs of wearers.

Owner:SCHOOL OF OPHTHALMOLOGY & OPTOMETRY WENZHOU MEDICAL COLLEGE +2

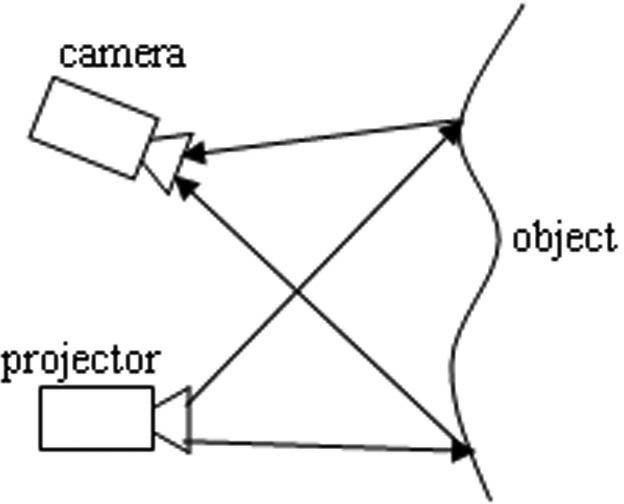

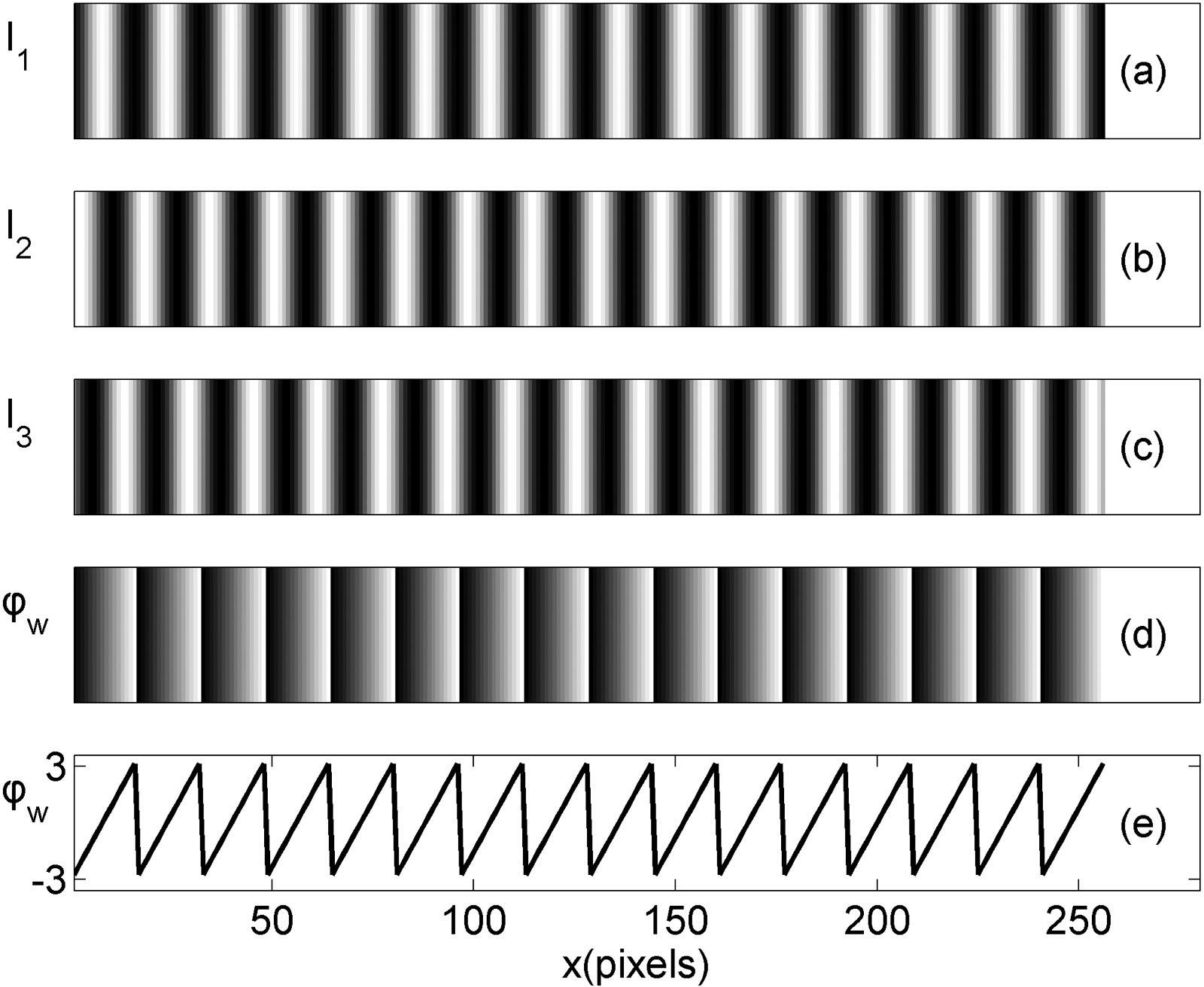

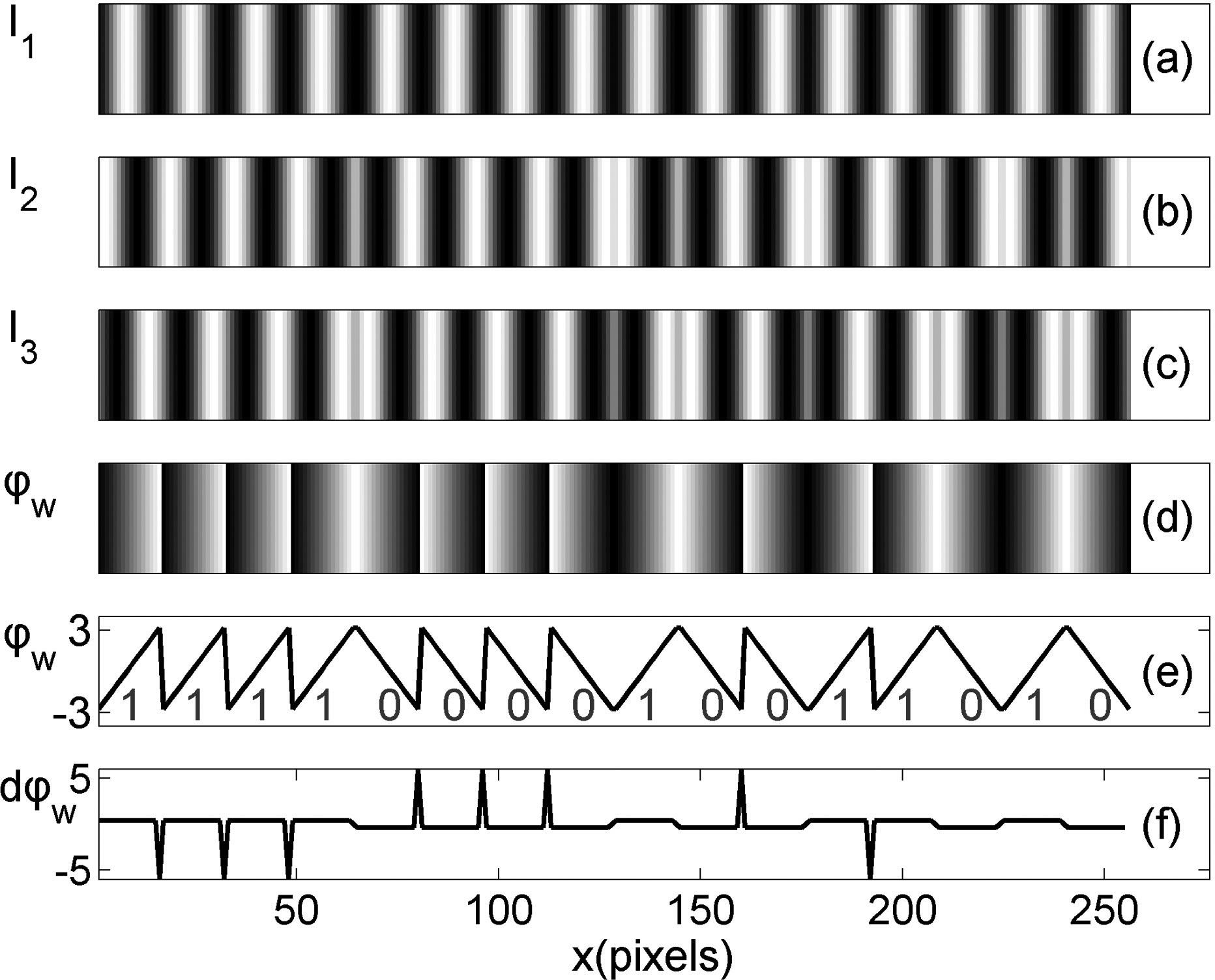

Phase grade self-coding-based optical three-dimensional measurement method

InactiveCN102322823AGet the absolute phase distributionRealize measurementUsing optical meansThree dimensional measurementFace shape

The invention discloses a phase grade self-coding-based optical three-dimensional measurement method. In the traditional phase measurement technology, generally additional coding patterns need to be projected to realize three-dimensional profile measurement of an isolated object. The method comprises the following steps of: providing sinusoidal stripes, the digital projection of which has phase grade coding information; constructing a code sequence, the total length of which is equal to the projected stripe period sum, by using the differential value or the slope value of phase distribution as a coding channel and using each stripe period as a coding unit; constructing a code sub sequence by using a plurality of adjacent periods; searching the position of the code sub sequence in the total code sequence to determine the phase grade of the period so as to obtain absolute phase distribution of the object to be measured; and finally, reconstructing a three-dimensional profile of the object to be measured according to the phase height relationship. The method can complete three-dimensional information acquisition of the object without projecting the additional coding patterns, and is particularly suitable for quick three-dimensional profile measurement of the isolated object.

Owner:SICHUAN UNIV

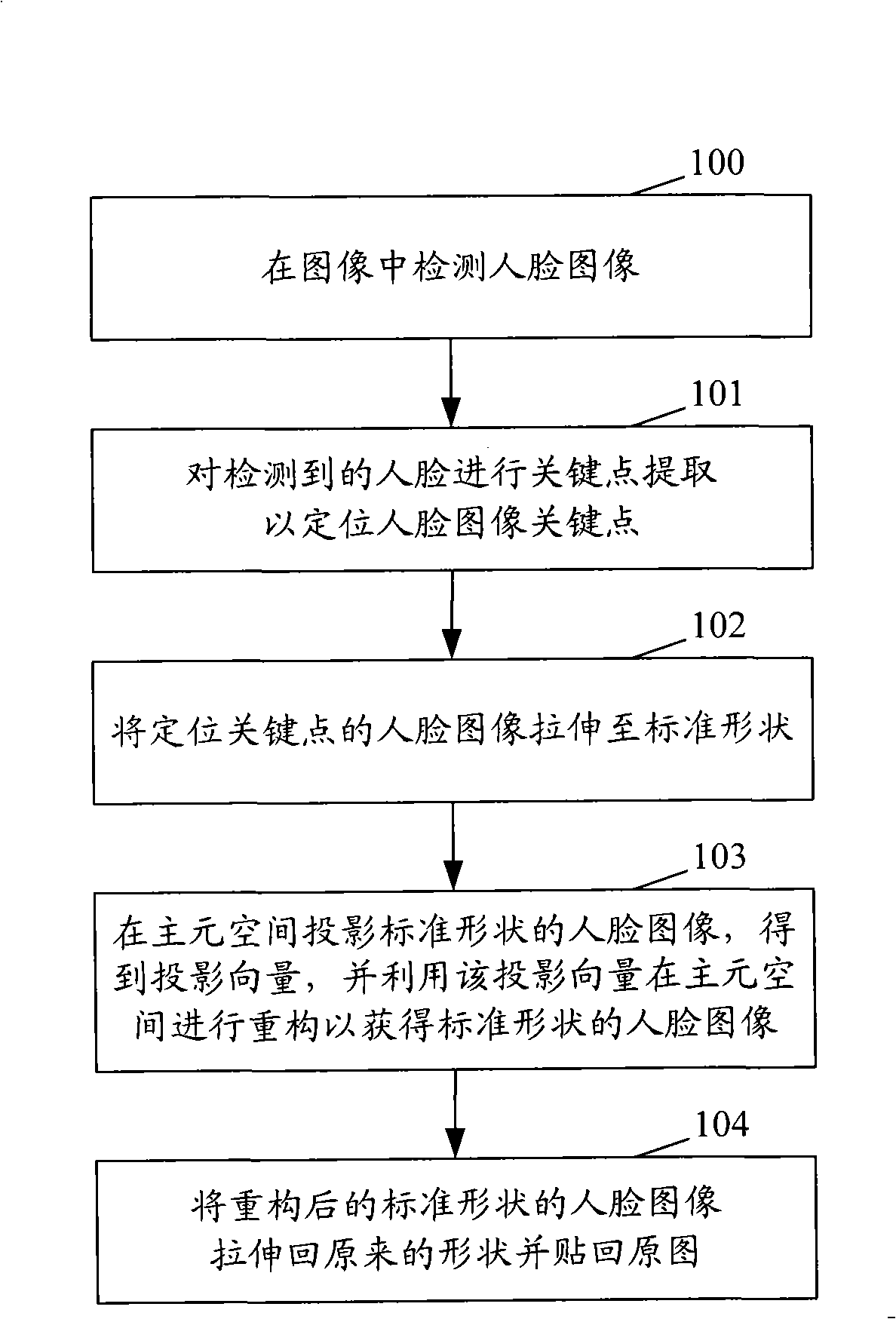

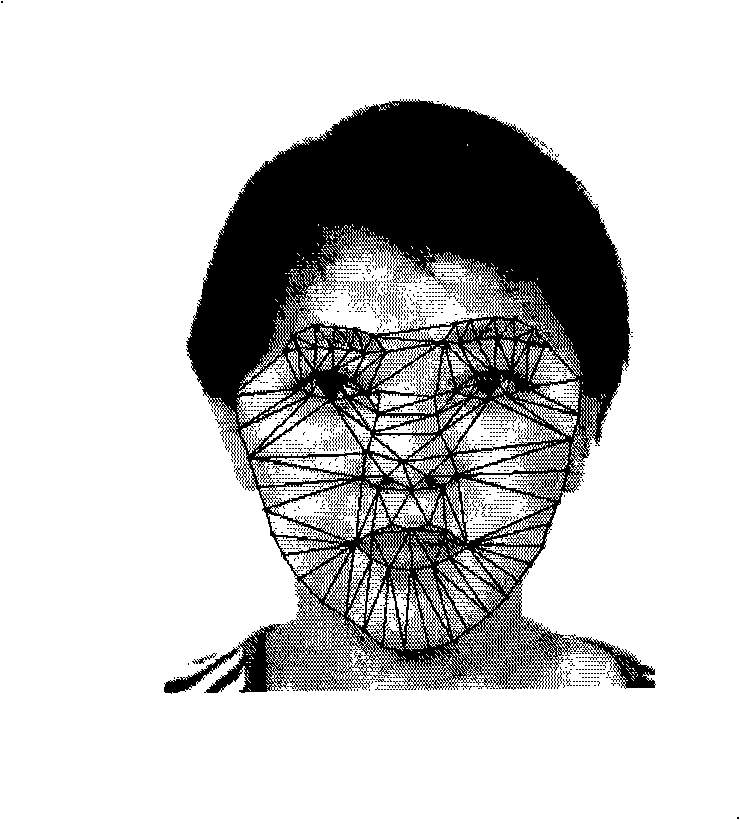

Method and device for processing human face image

InactiveCN101299267AWill not affect the effectSmooth textureImage enhancementPattern recognitionVein

The present invention discloses a face image processing process and apparatus. The scheme of the invention will project the face region of the image in the beforehand disciplinary pivot space, and reconstructs according to the projection result. As the beforehand disciplinary pivot space only reserves the low frequency partial component of the face image and removes the high-frequency part, thereby the reconstructed face image only contains low-frequency components in the image and removes the high-frequency components. In the face images, the low frequency part usually includes brightness, skin color, gesture, face shape, face expression and the like information, while the high-frequency part usually includes flecks, wrinkles, thickness veins and other details. As a result, by the projection and reconstruction of facial image in the pivot space, the skin color and veins of the face images become uniform, wrinkles decrease, spots disappear, and so on, so as to achieve the goal of the human face image improvement and face beautification. Since the scheme of the invention only process the part of the face image, which will not affect the whole image.

Owner:VIMICRO CORP

Interferometric method using partial compensation lens to realize nno-spherical surface shape

A interference measuring method of inspherical face form realized by using partial compensating lens belongs to electrooptical technical field, having no requirement that large aberration wave front of inspherical face form has to be compensated completely by compensating lens, but allowing residual wave difference not larger than fifty wavelengthes exists, changing traditional small wave difference interference measuring system into large wave difference by using digit Mohr phase shift phase shift method. The invention has the structure of compensating lens simplified. The difficulty of design, processing of which decreased and the measuring range of which extended; by using refraction principle, interference fringe is very clean because of no perturbance from other light created by holographic element, and which has little lose; the measuring accuracy is high and stability is good; it can be used to measure varies of rotational symmetric aspheric surface especially for aspheric surface with large relative aperture and convex inaspheric surface with large inaspheric ratio.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com