Patents

Literature

1734 results about "Angle of inclination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Angle of Inclination of a Line. The angle between a line and the x-axis. This angle is always between 0° and 180°, and is measured counterclockwise from the part of the x-axis to the right of the line.

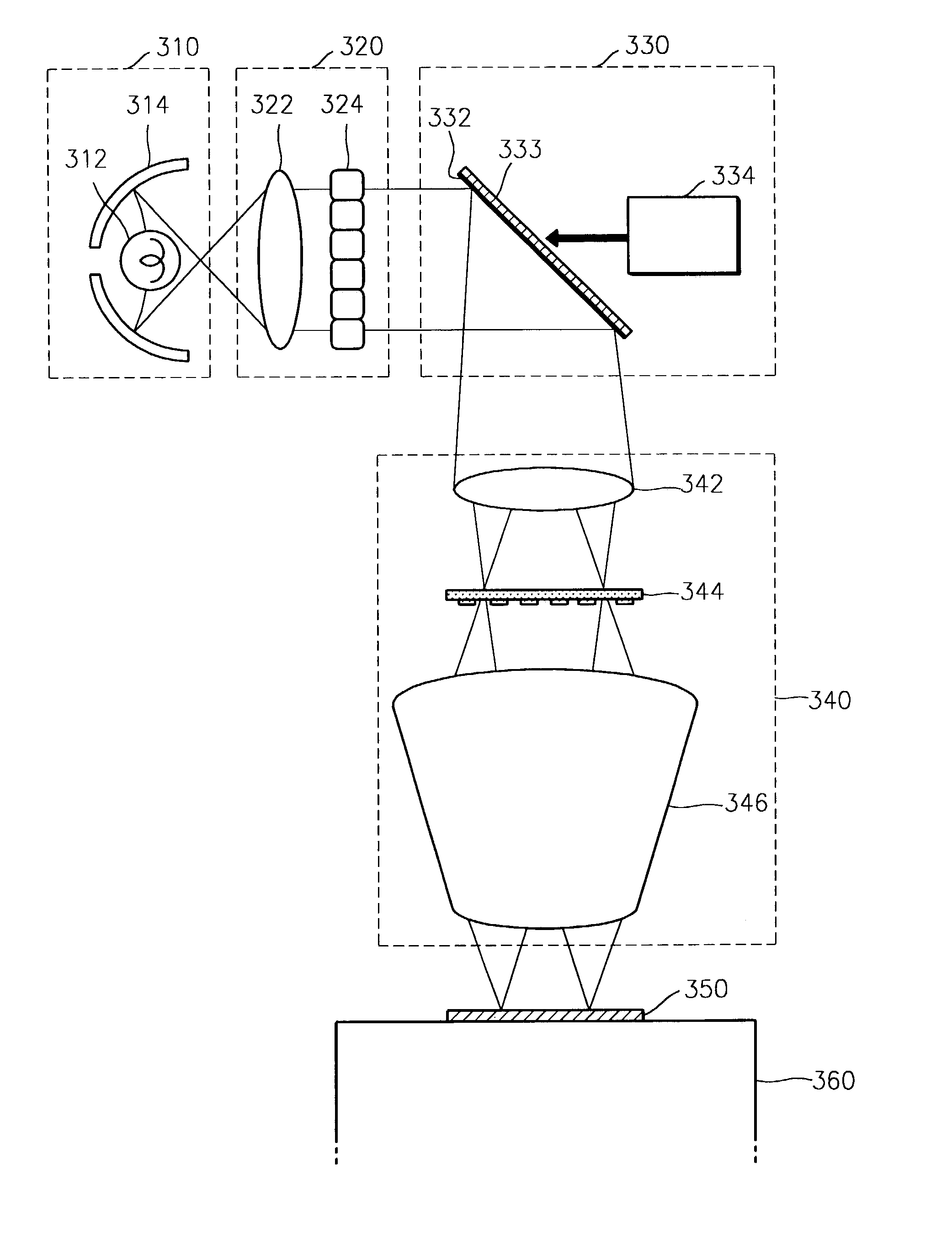

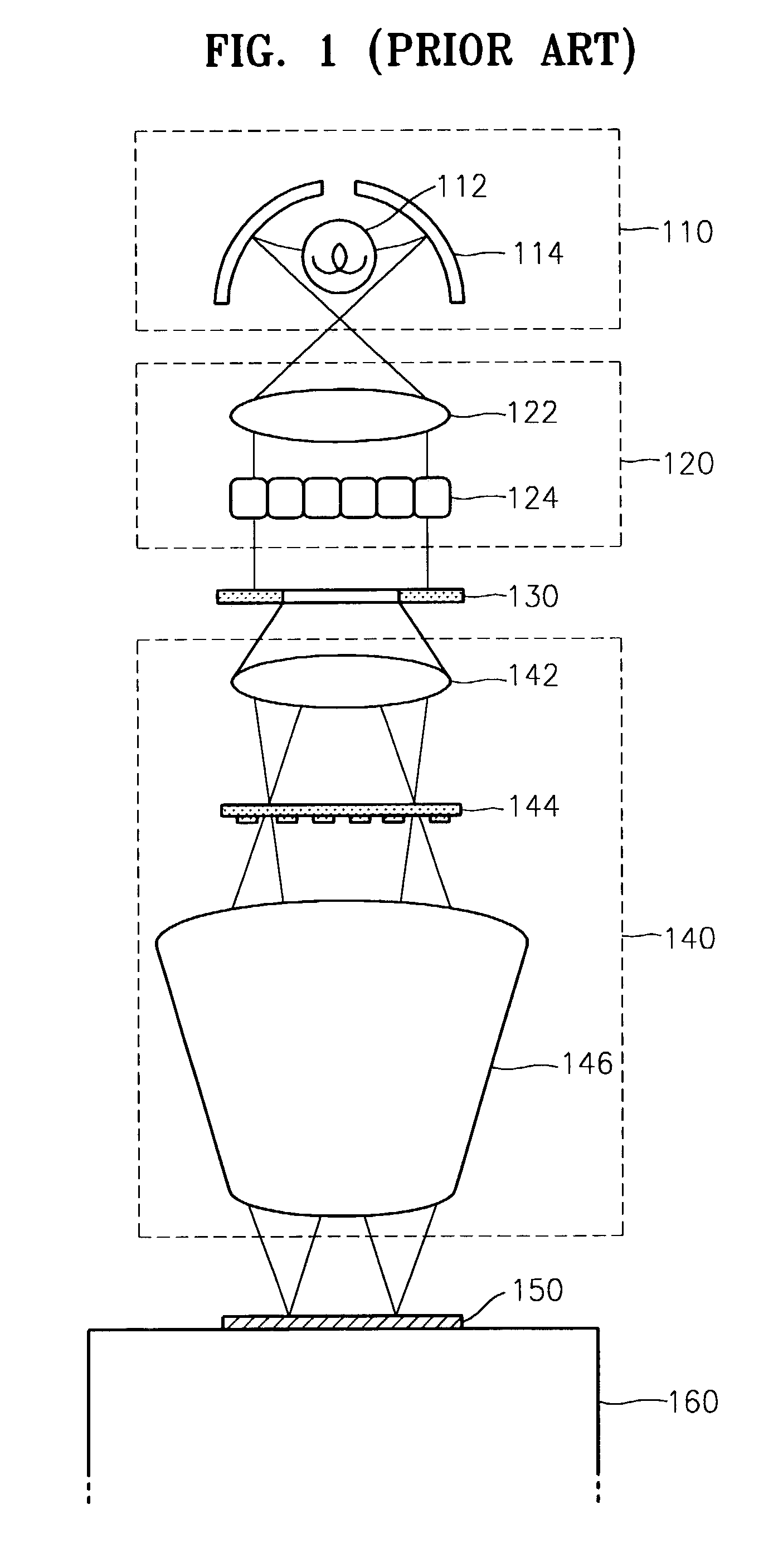

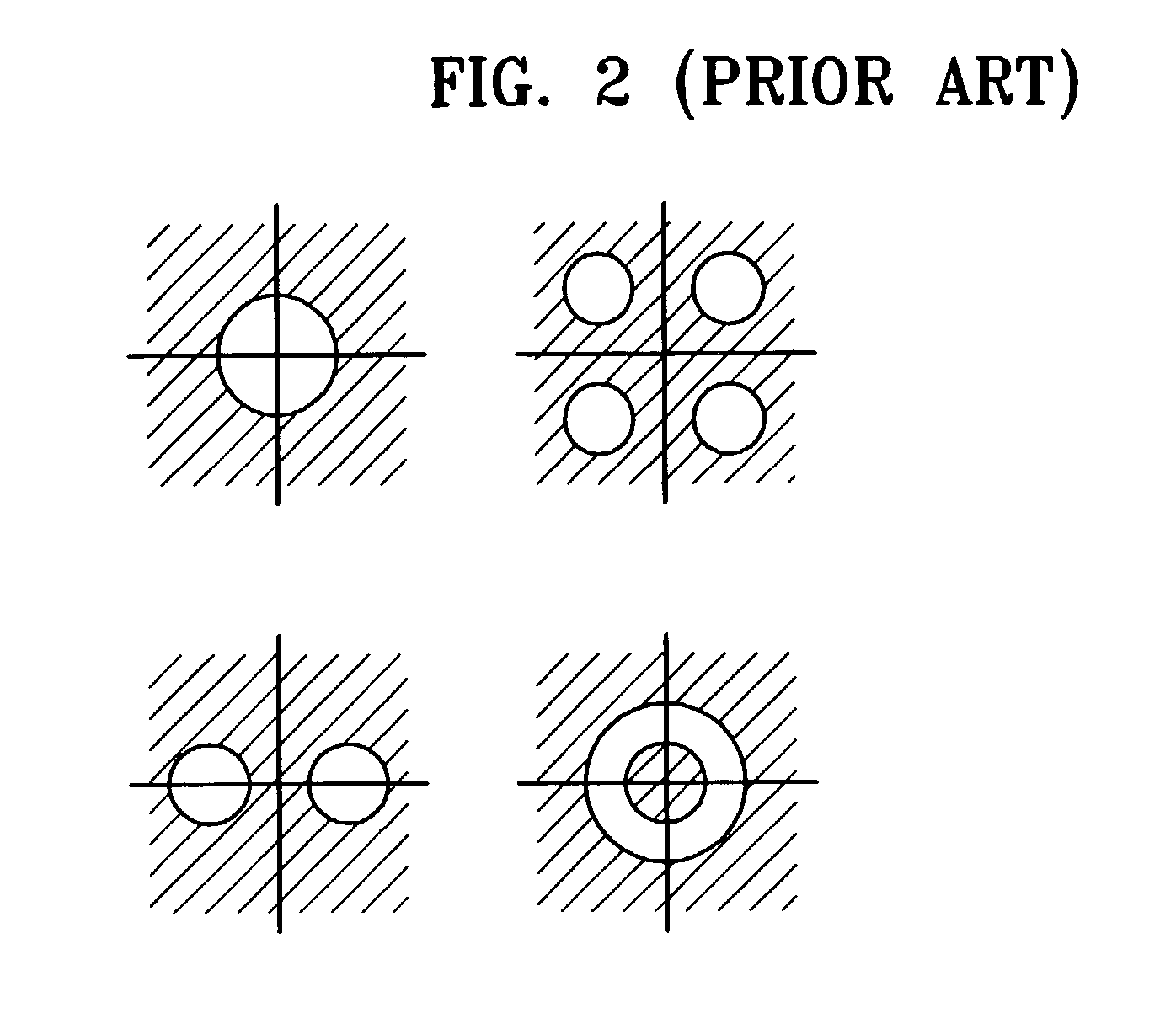

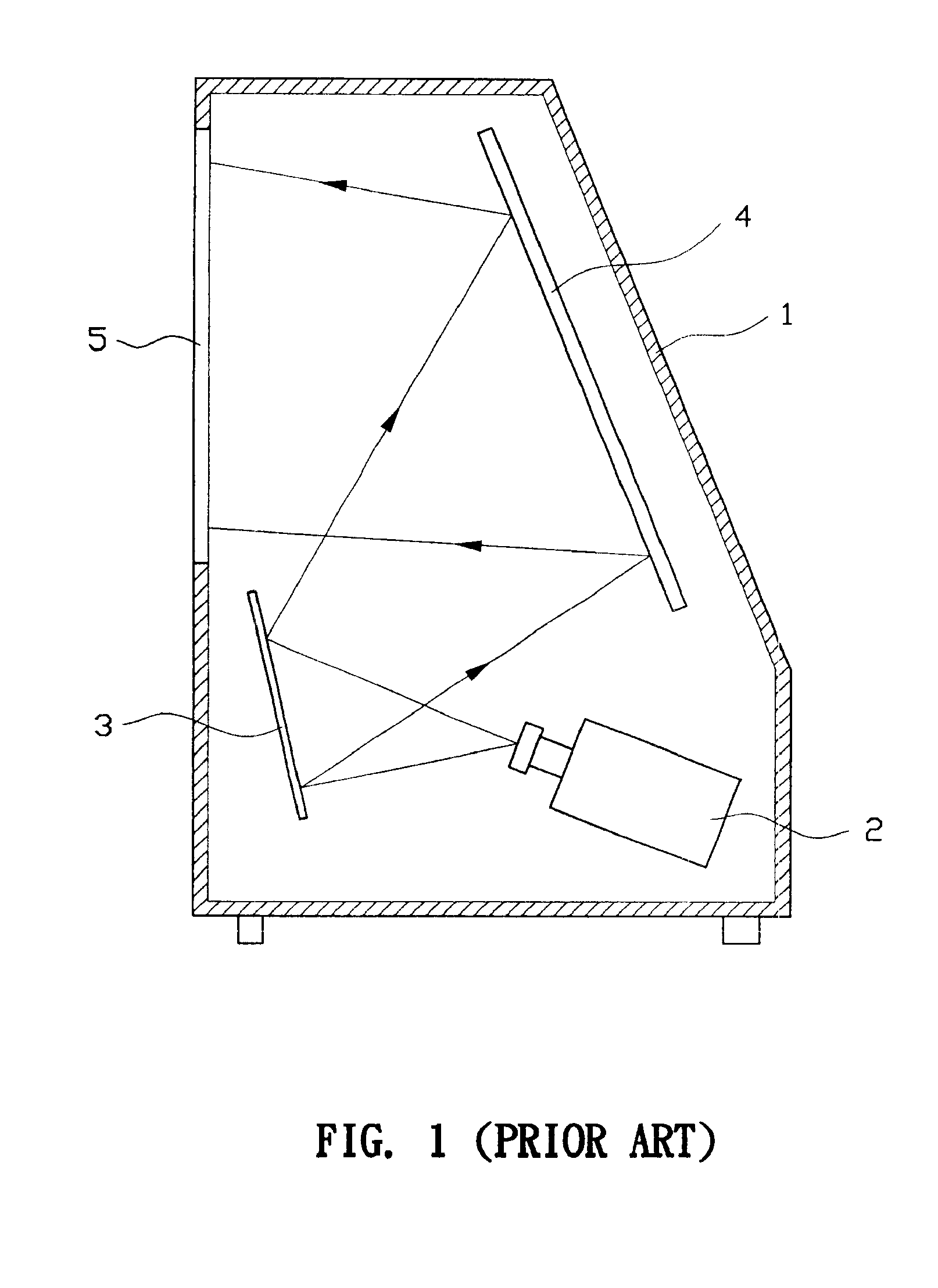

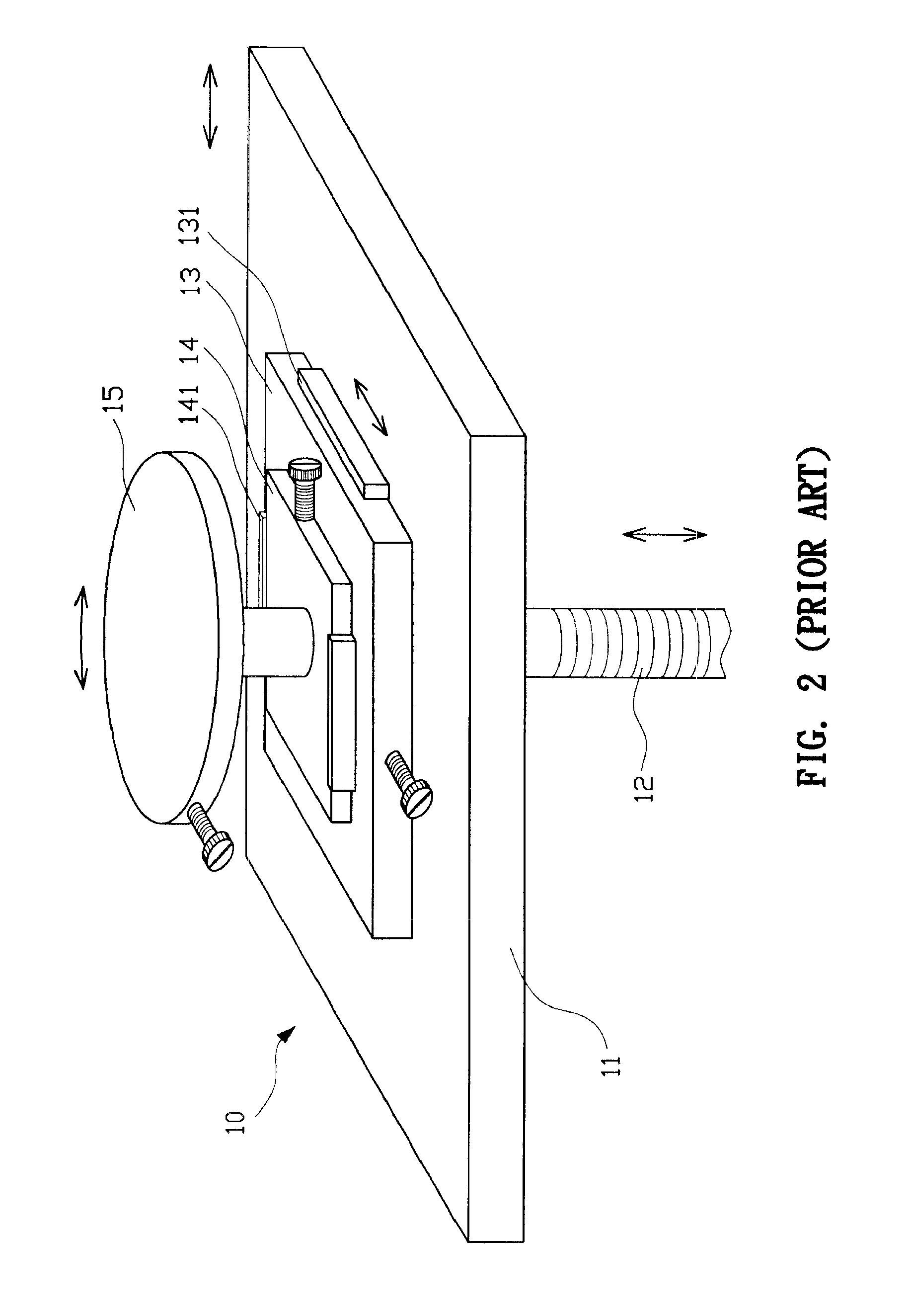

Exposure apparatus including micro mirror array and exposure method using the same

InactiveUS7061582B2High resolutionShort amount of timeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistImage resolution

An exposure method and apparatus for use in exposing a photoresist on a semiconductor wafer do not employ an aperture for shaping the exposure light. The exposure apparatus includes a light source unit, a reflecting mirror unit having a micro mirror array (MMA) and a control unit that controls the MMA, and a pattern transfer unit that transfers the pattern of a photomask onto the photoresist. The angles of inclination of the respective mirrors of the MMA are adjusted to reflect incident light in a manner that shapes the incident light. Accordingly, it is possible to form a pattern having the highest degree of resolution and optimum depth of focus (DOF) in the shortest amount of processing time.

Owner:SAMSUNG ELECTRONICS CO LTD

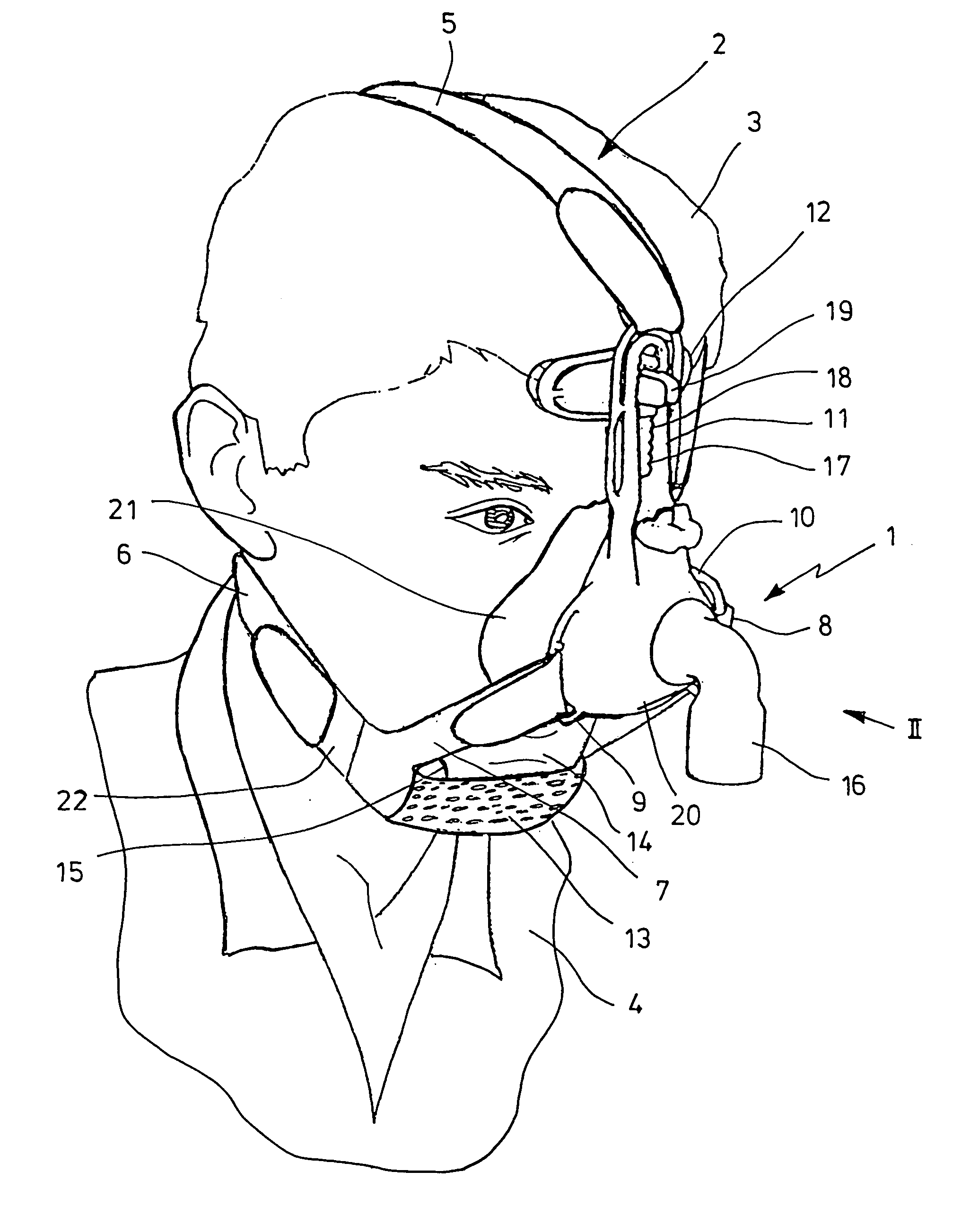

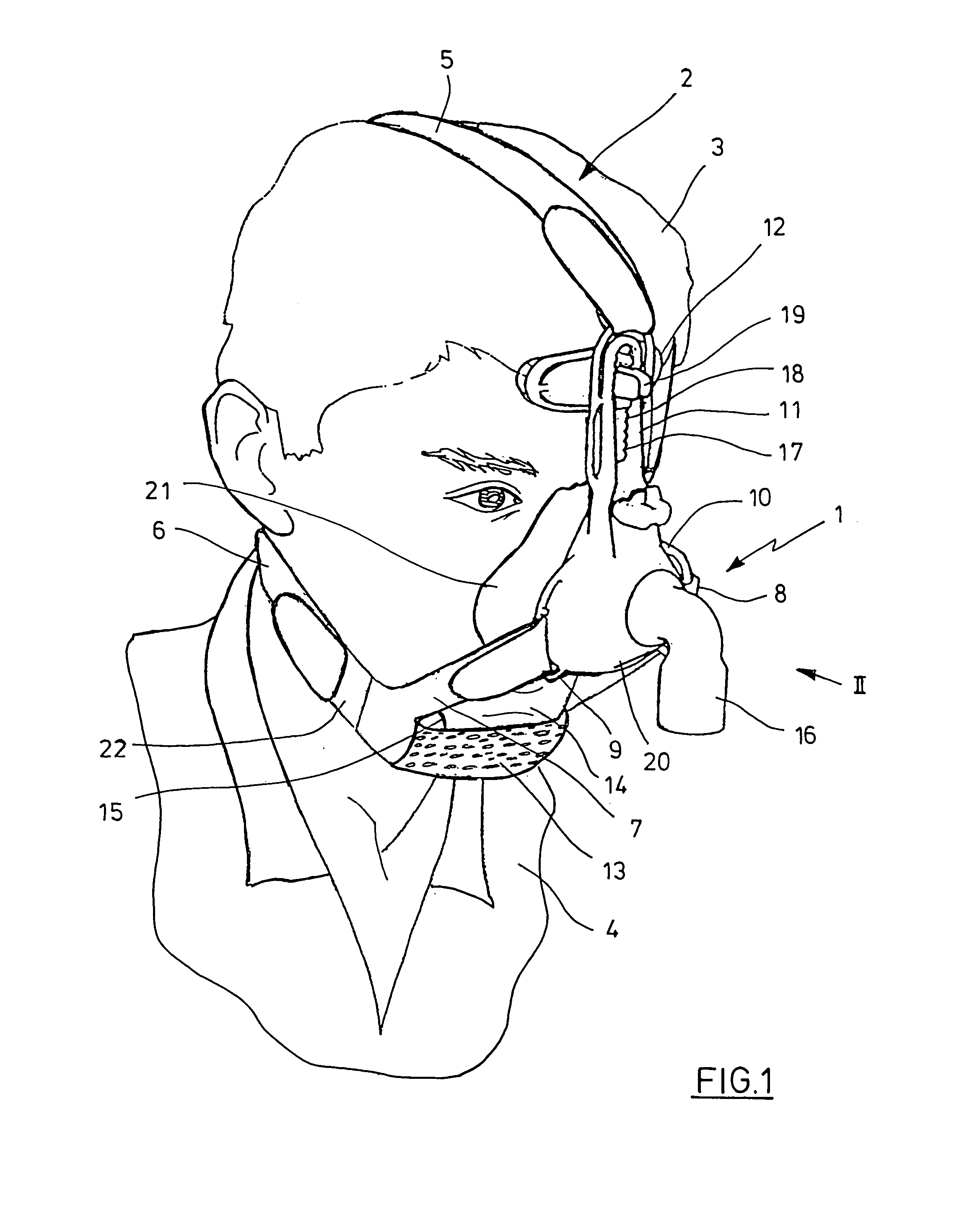

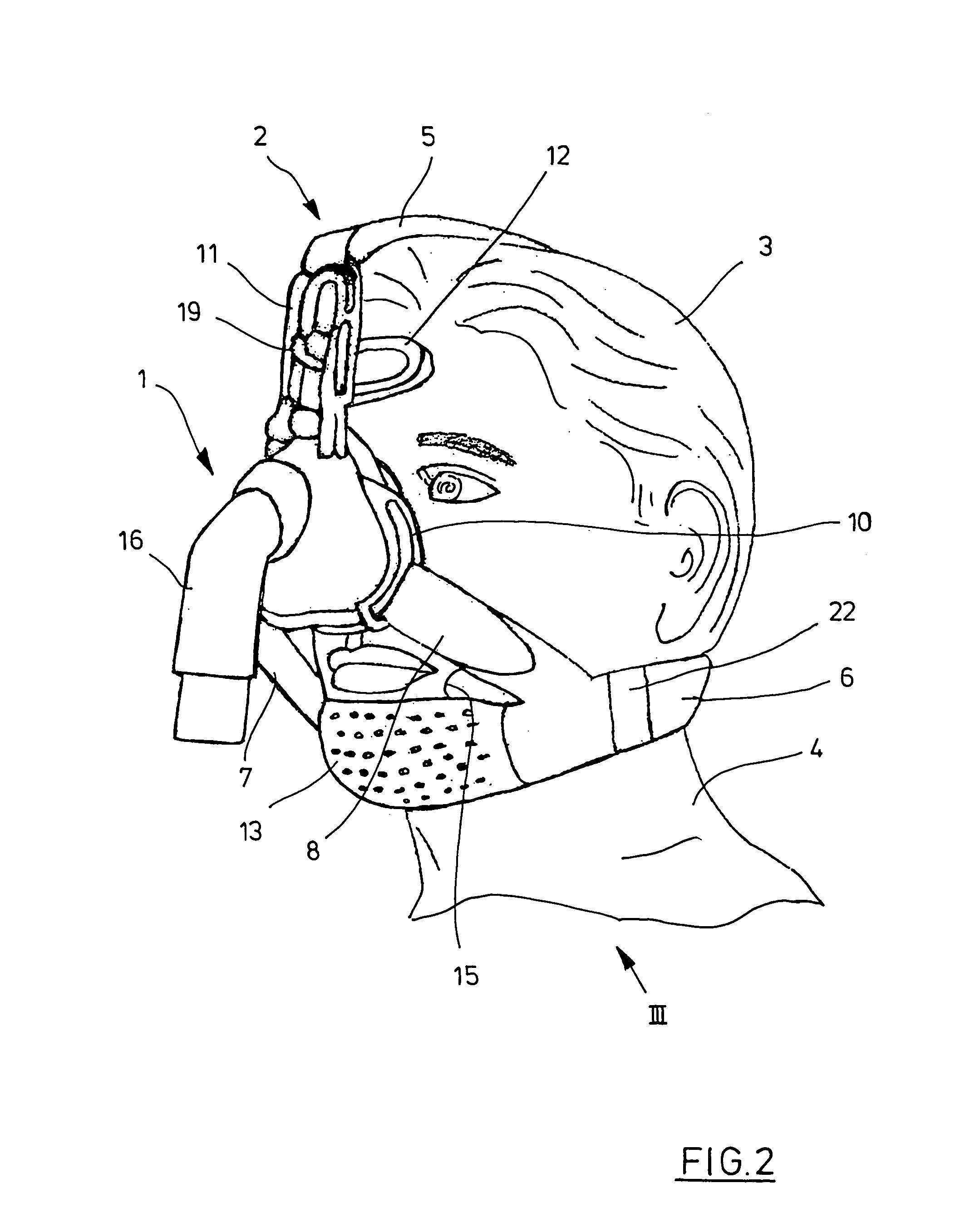

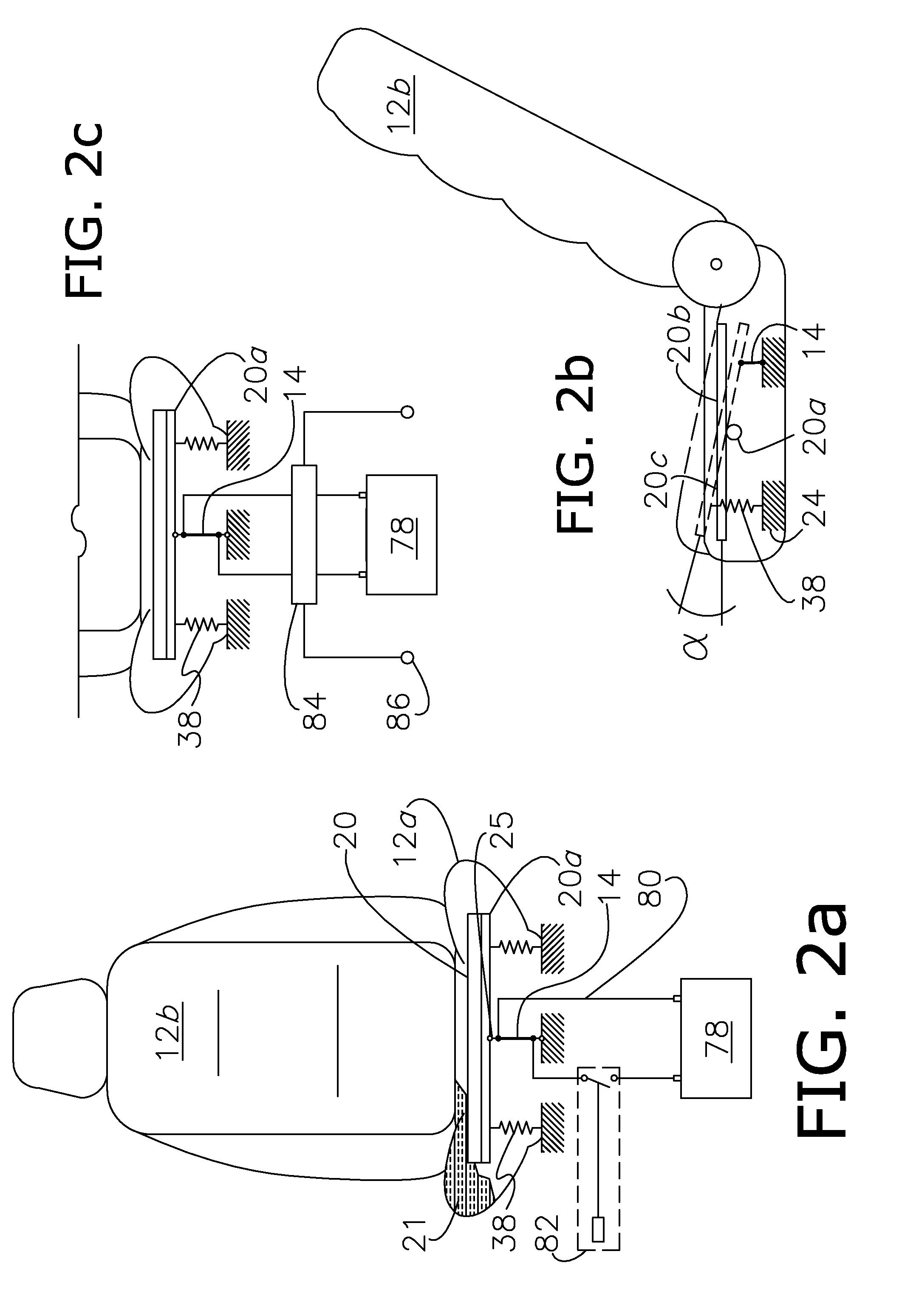

Breathing mask with a head fastening device

A breathing mask is joined with a head fastening device that has at least one headstrap and at least one neckstrap. The headstrap and the neckstrap are connected with each other in the area of their extensions away from the breathing mask. The headstrap is fastened to the breathing mask at the top, and the neckstrap is fastened to the breathing mask at the sides in the orientation of the breathing mask when it is being worn. Regions of the neckstrap that are located next to the breathing mask are connected with one another by a chinstrap. The chinstrap extends essentially in the longitudinal direction of the neckstrap. End segments of the neckstrap, which are arranged between the breathing mask and the places at which the neckstrap is connected with the chinstrap, run towards the breathing mask at an angle of inclination relative to the chinstrap, so that they move farther and farther away from the chinstrap as they approach the breathing mask.

Owner:WEINMANN GERATE FUR MEDIZIN

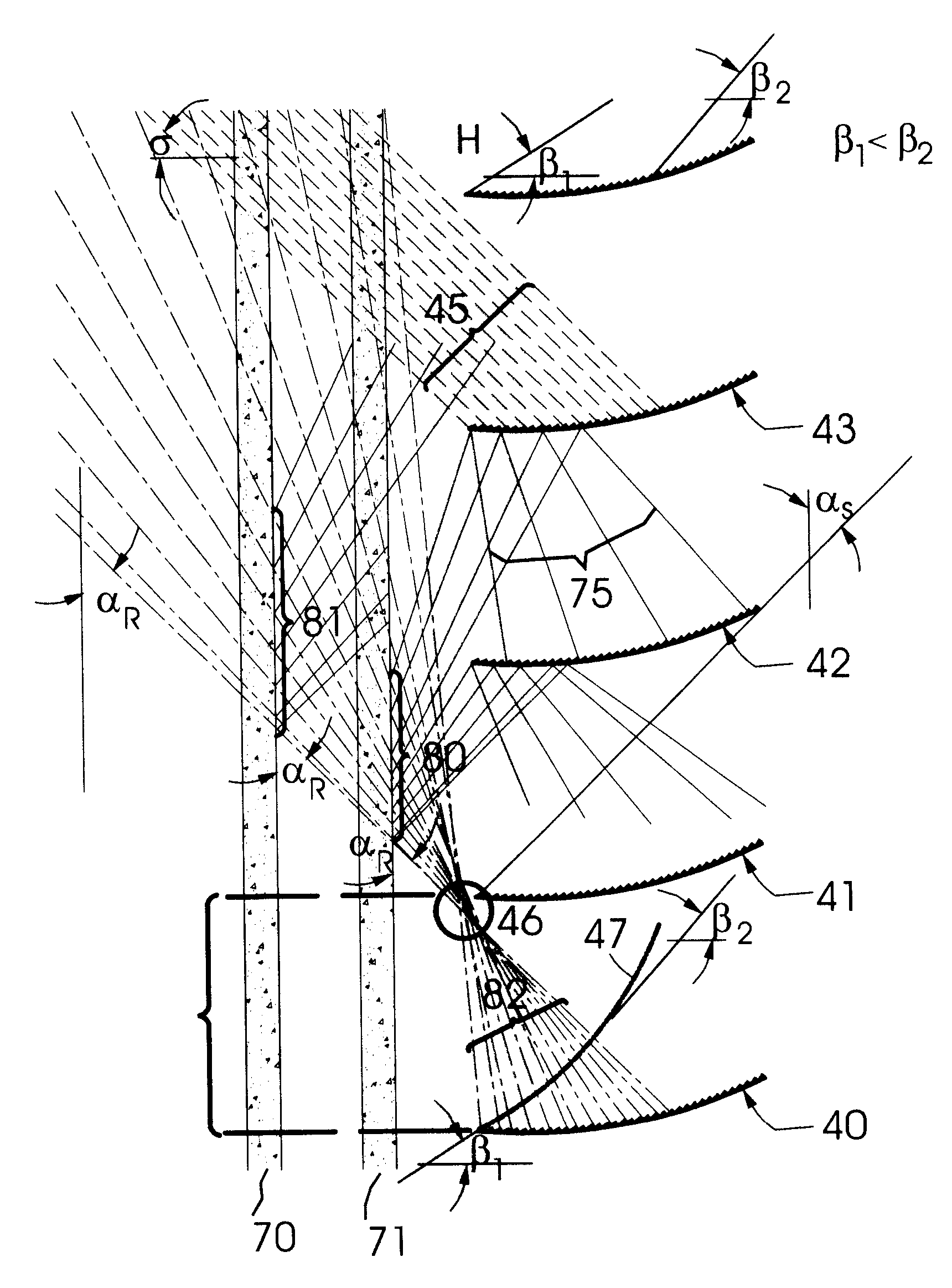

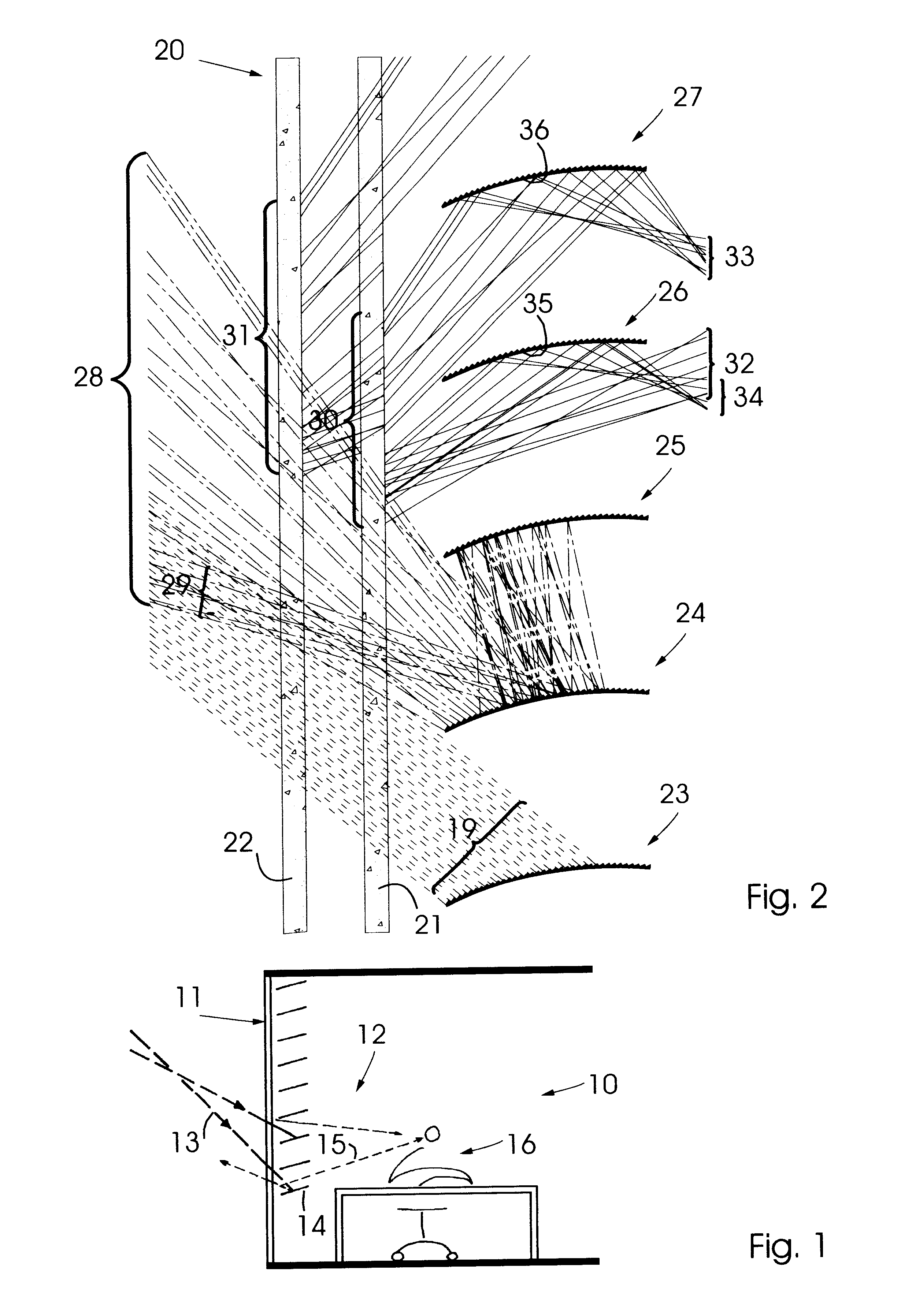

Toothed daylight blinds

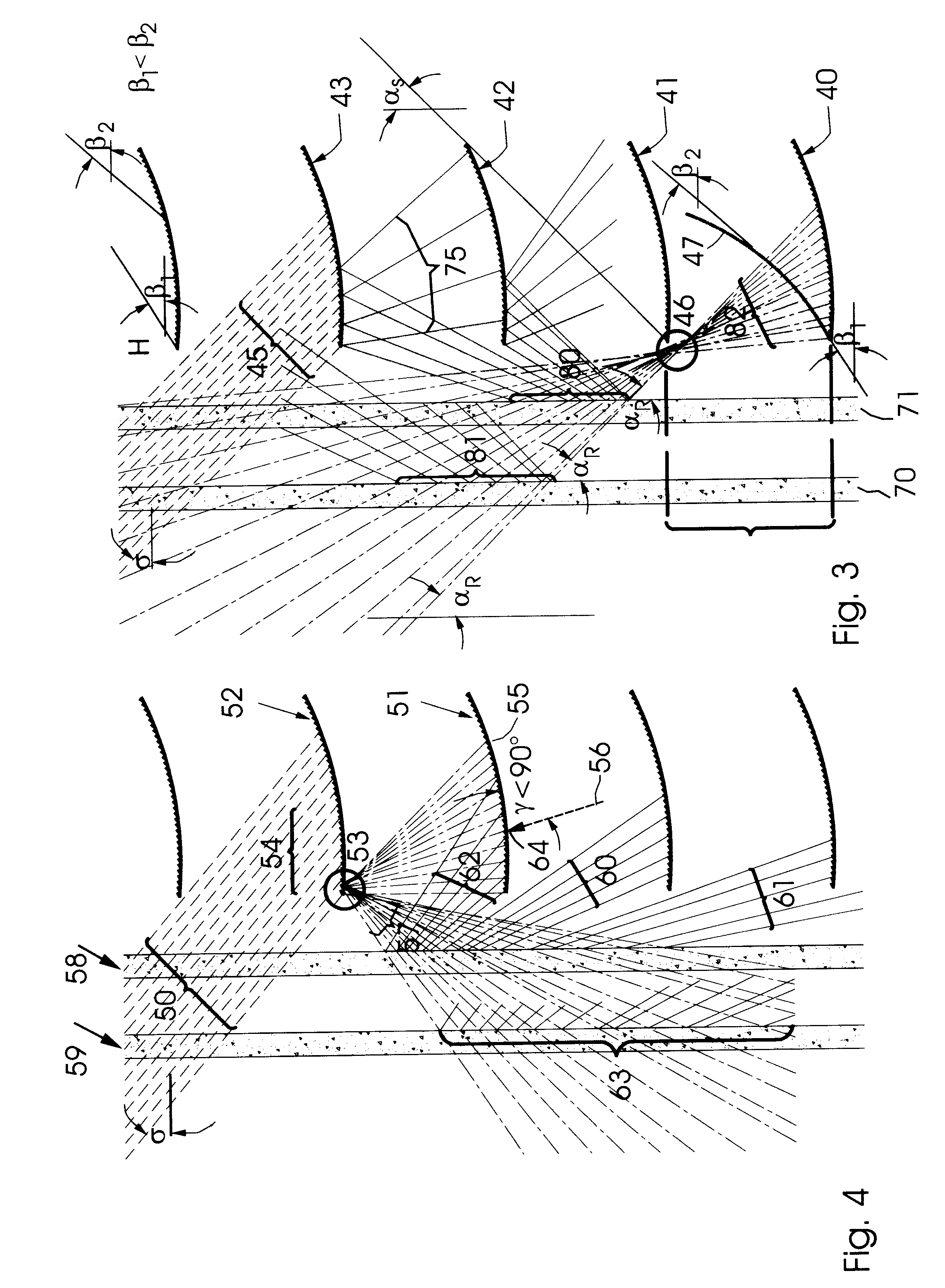

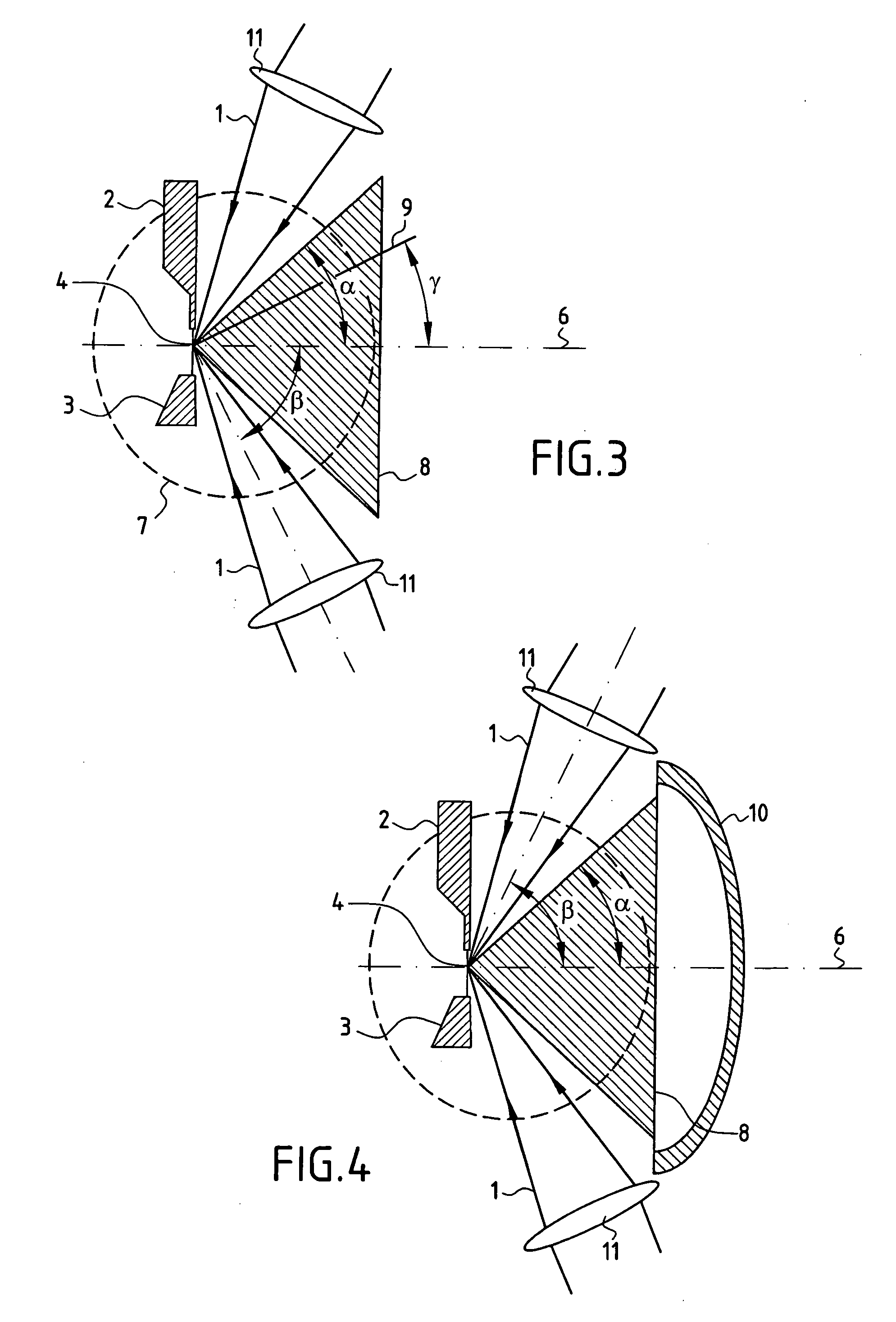

InactiveUS6845805B1Eliminate glareGlare in the outer panes is extensively excludedLight protection screensWing framesLight guideDaylight

The flight guiding blinds of this invention are characterized in that the tooth sides showing towards sun incidence have an angle of inclination β essentially smaller in the area of the irradiation portion and larger at a larger distance from the irradiation portion, and the angles of inclination β increase following a concave curve path increasingly ascending from the irradiation area towards the reflection area, and at the upper side of light guiding blinds retro-reflected reaction is concentrated and a concentration zone is formed near irradiation portion and the concentration zone is disposed either in front of blind in the irradiation portion and / or on the underside of upper blind behind the irradiation portion, and on the upper side of a light guiding blind light radiation may be reflected at the individual teeth at and angle αR<αS.

Owner:KOSTER HELMUT

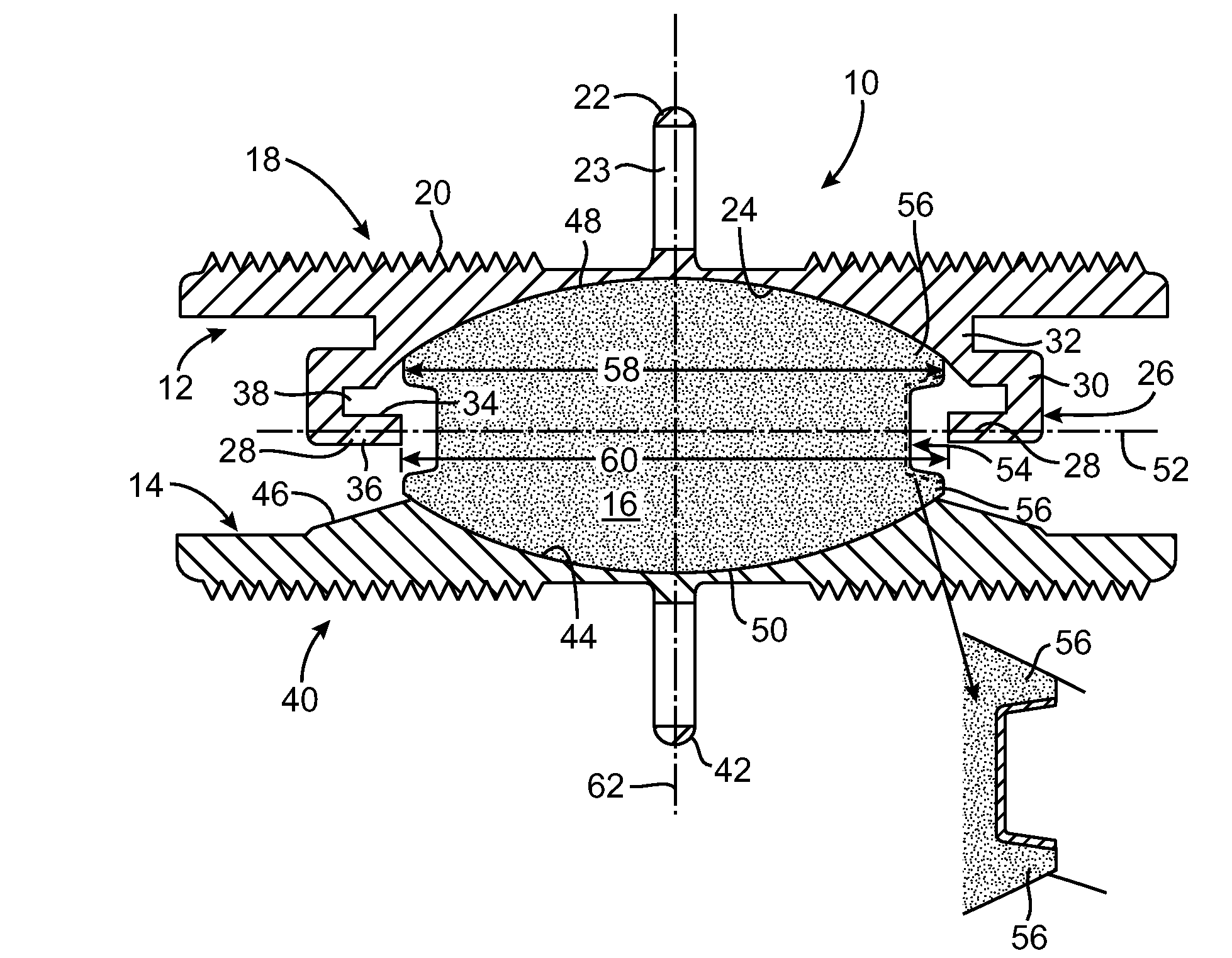

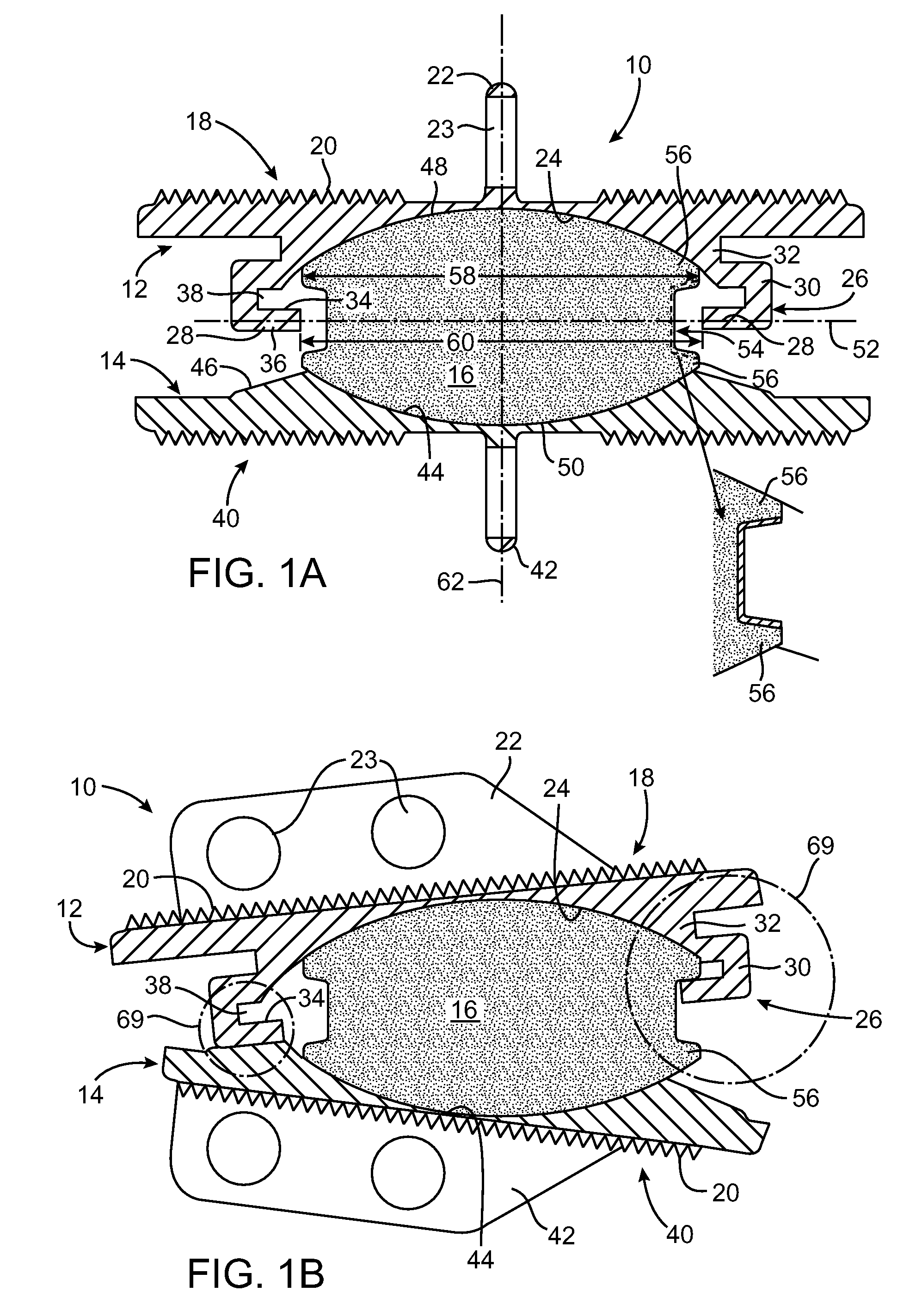

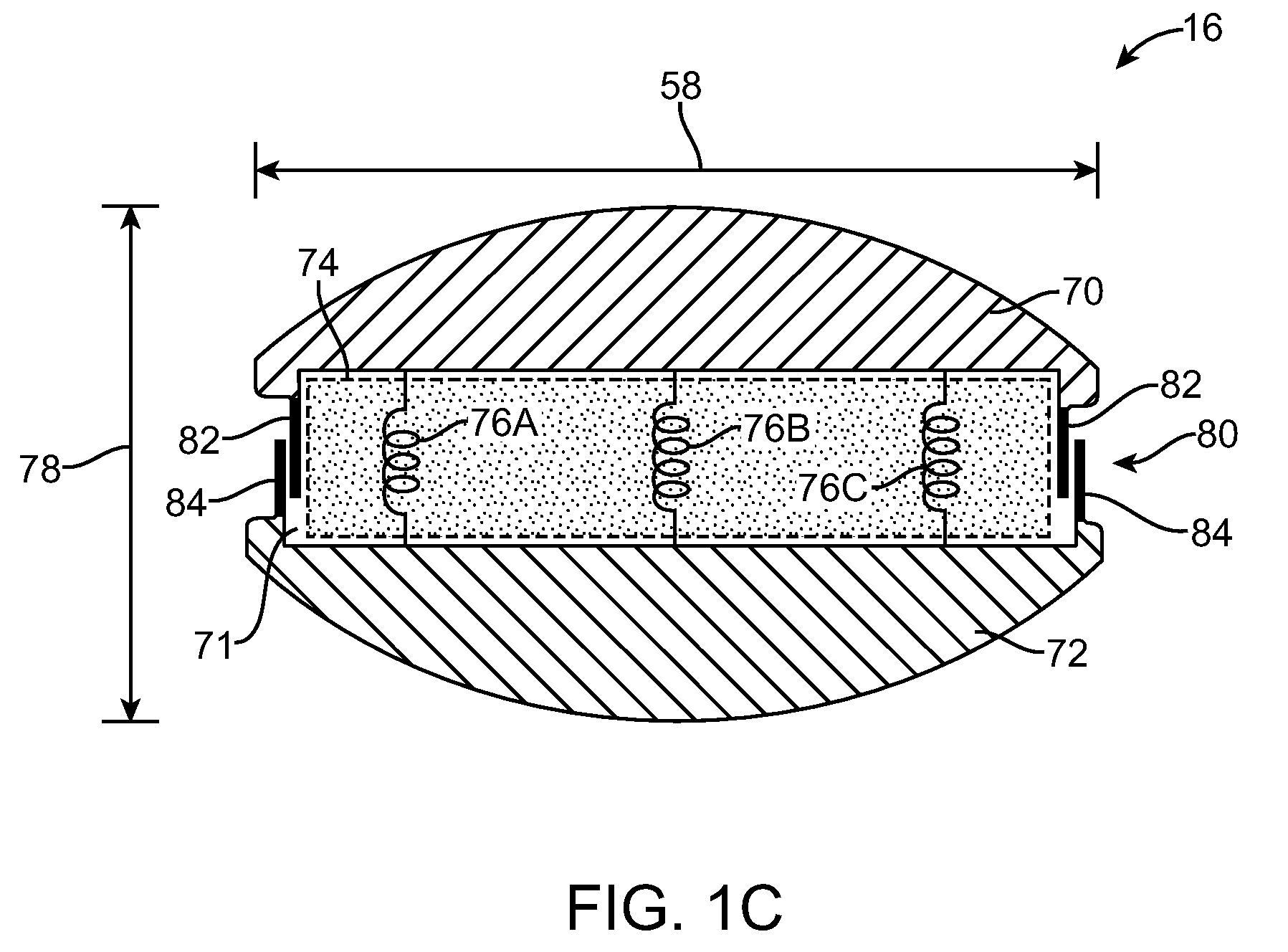

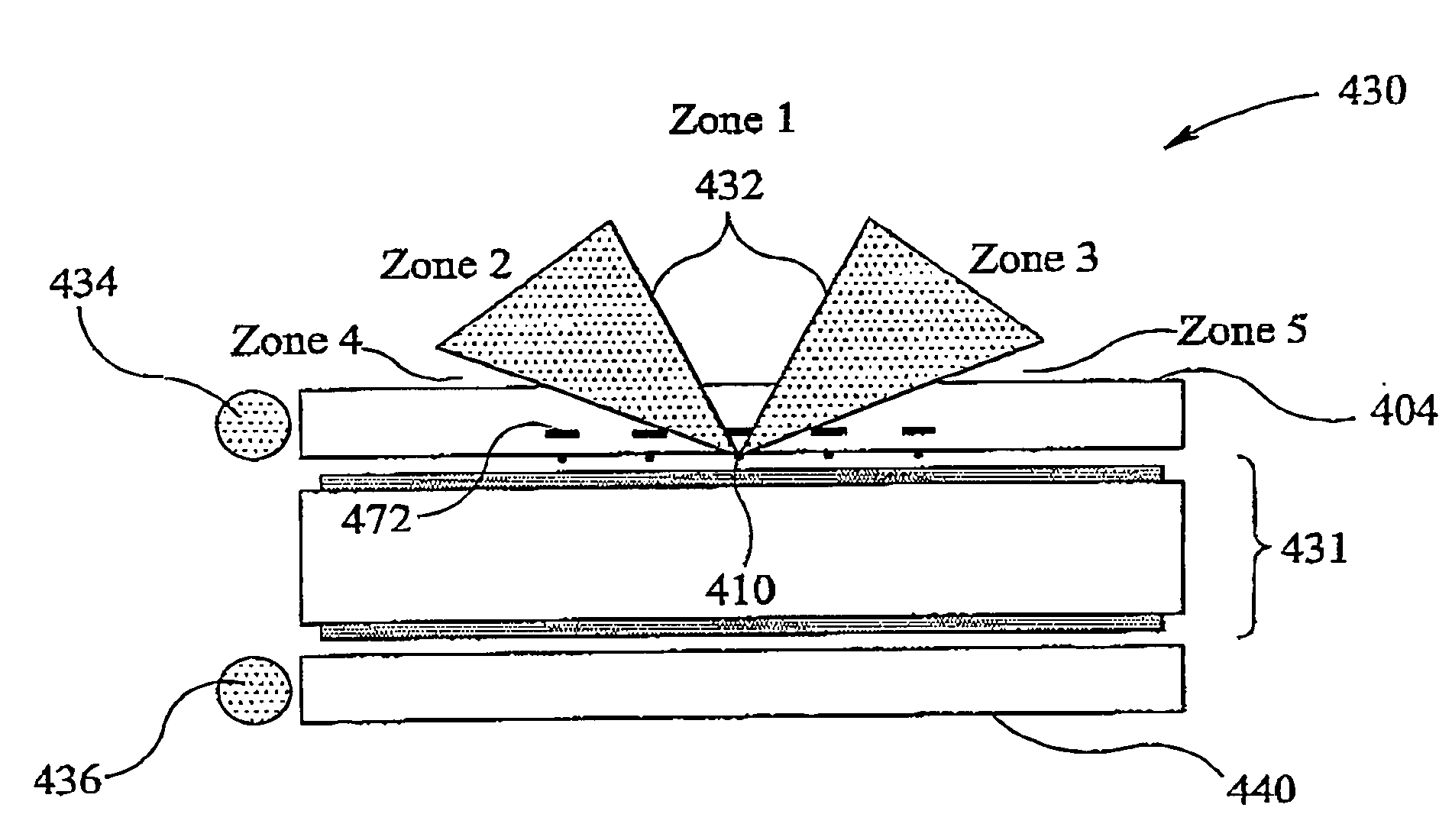

Customized Intervertebral Prosthetic Disc with Shock Absorption

InactiveUS20090043391A1Minimize distractionMinimizing invasivenessSpinal implantsCoatingsPatient characteristicsMedicine

A prosthesis system comprises plates that can be positioned against vertebrae and a selected resilient core that can be positioned between the plates to allow the plates to articulate. The selected resilient core can be chosen from a plurality of cores in response to patient characteristics, such as age and / or intervertebral mobility, such that the prosthesis implanted in the patient is tailored to the needs of the patient. The plurality of cores may comprise cores with different resiliencies, and one of the cores can be selected such that the upper and lower plates articulate with the desired shock absorbing resiliency and / or maximum angle of inclination when the one selected core is positioned between the plates.

Owner:SIMPLIFY MEDICAL PTY LTD

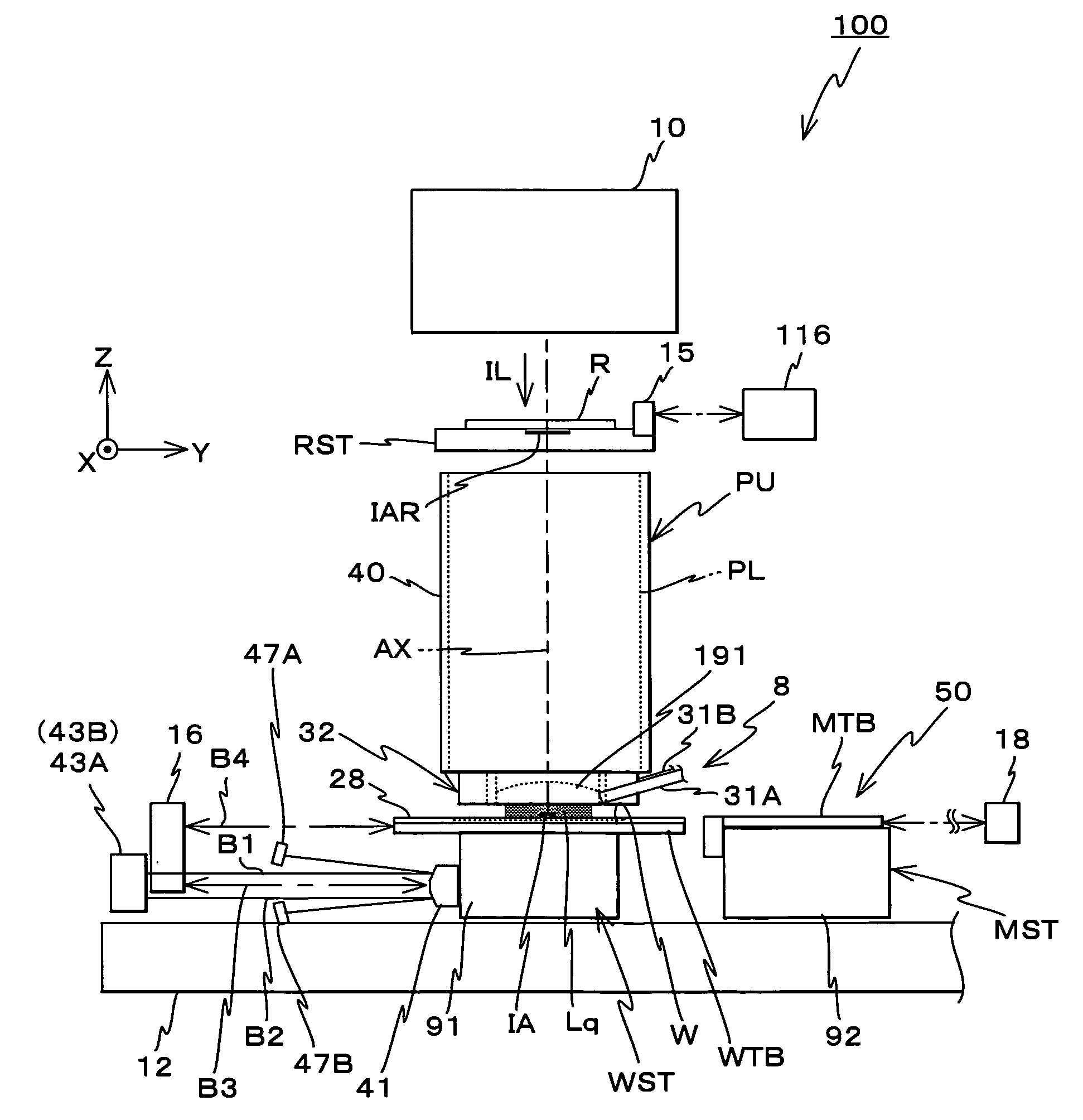

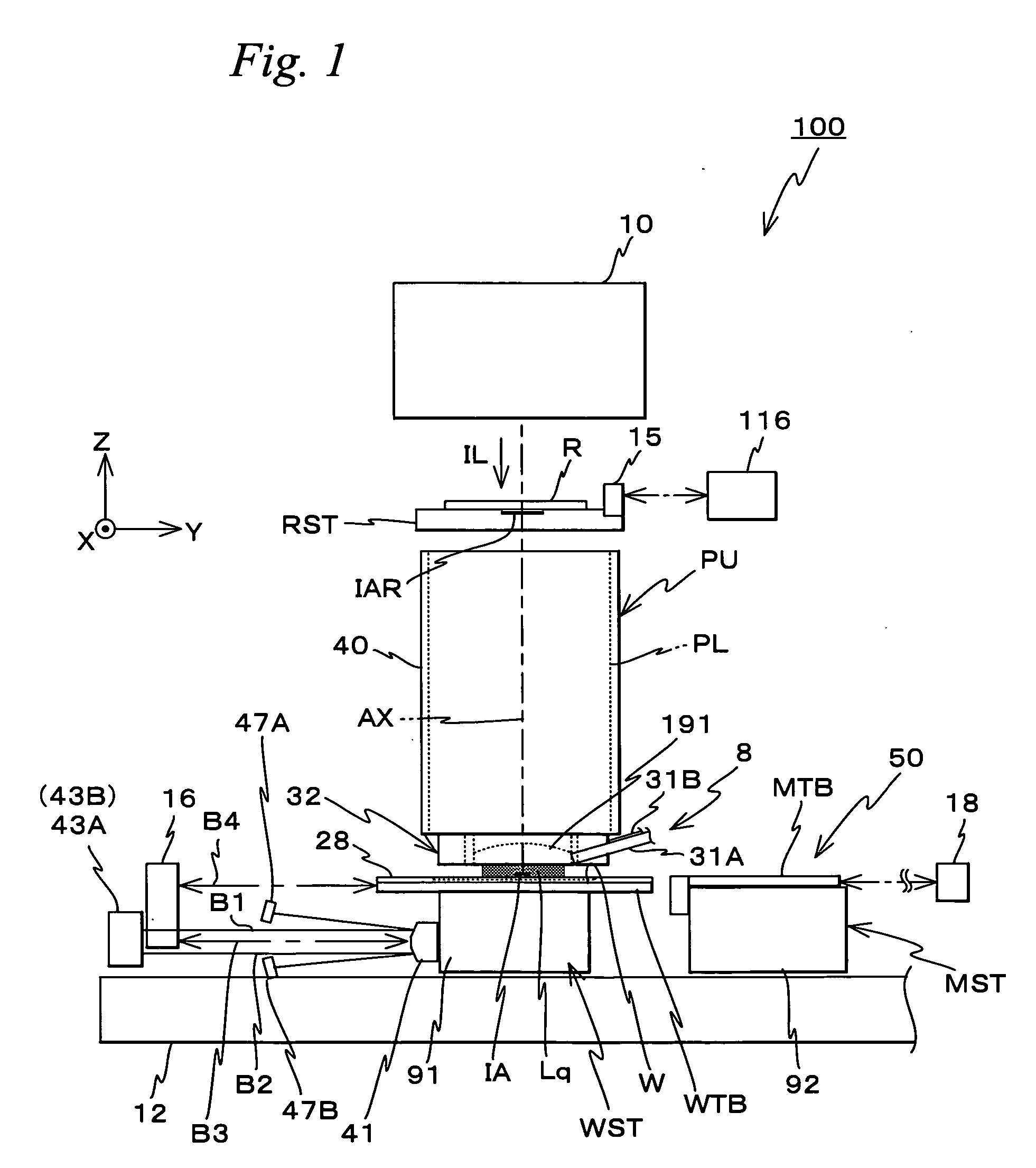

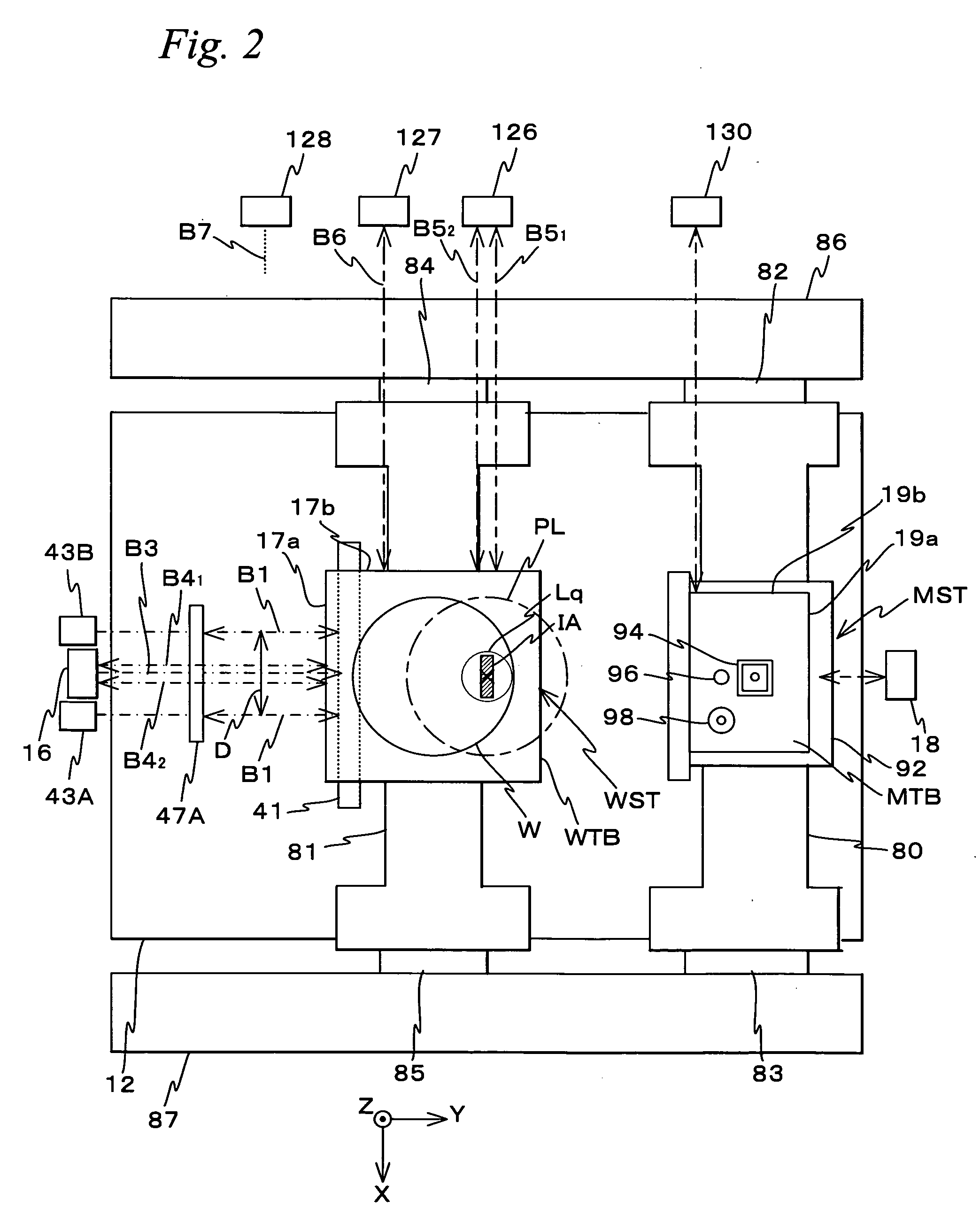

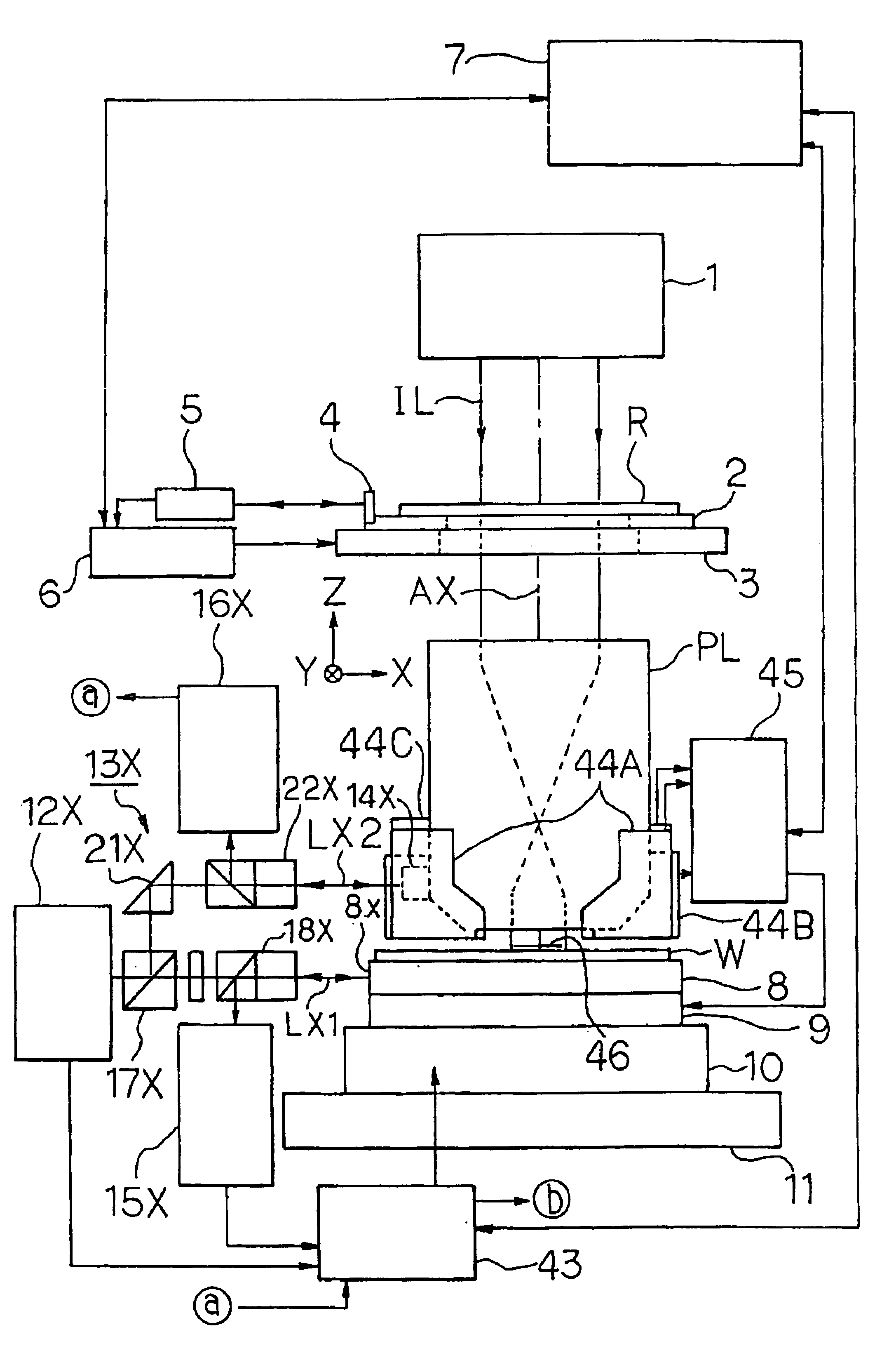

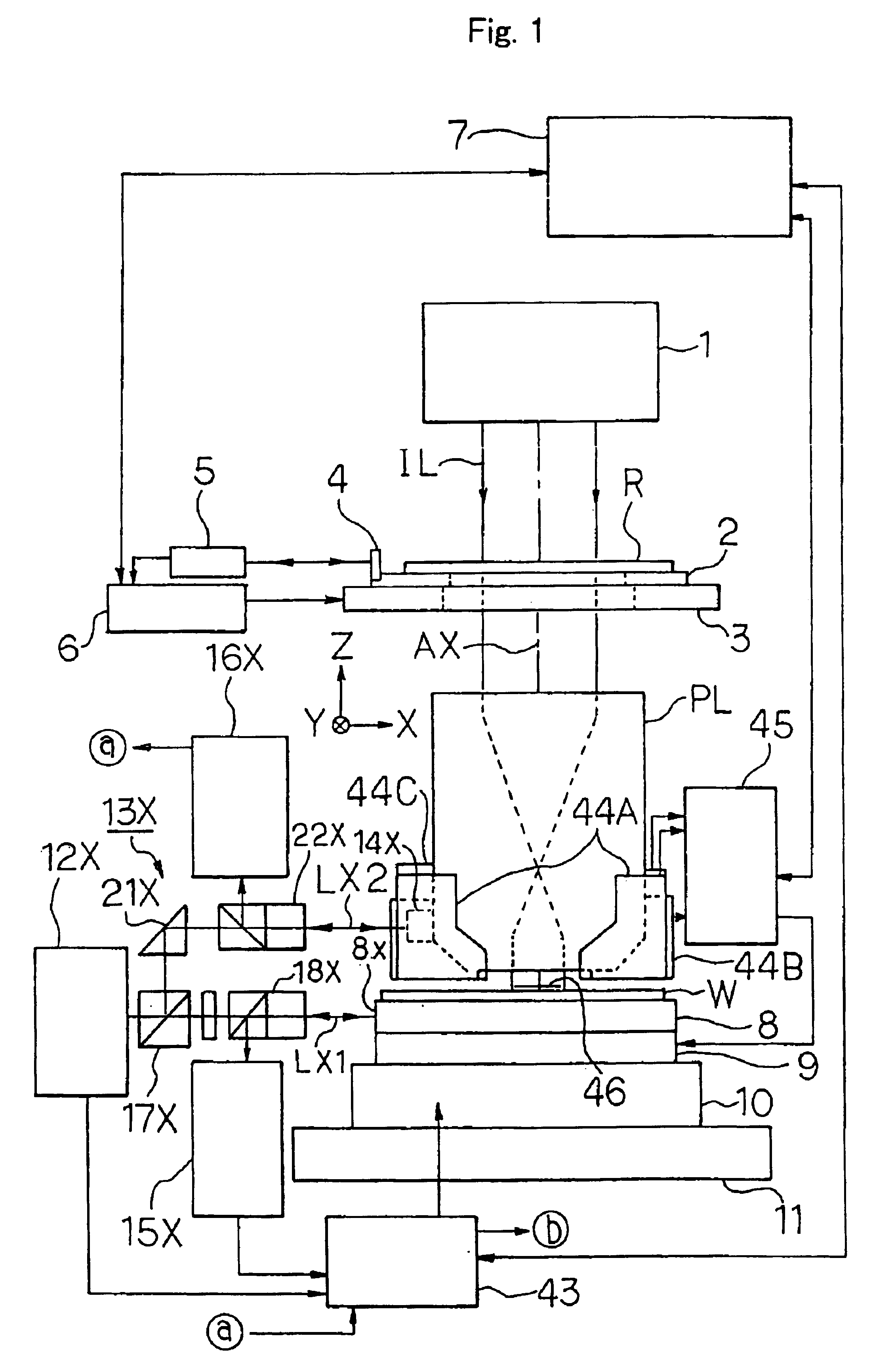

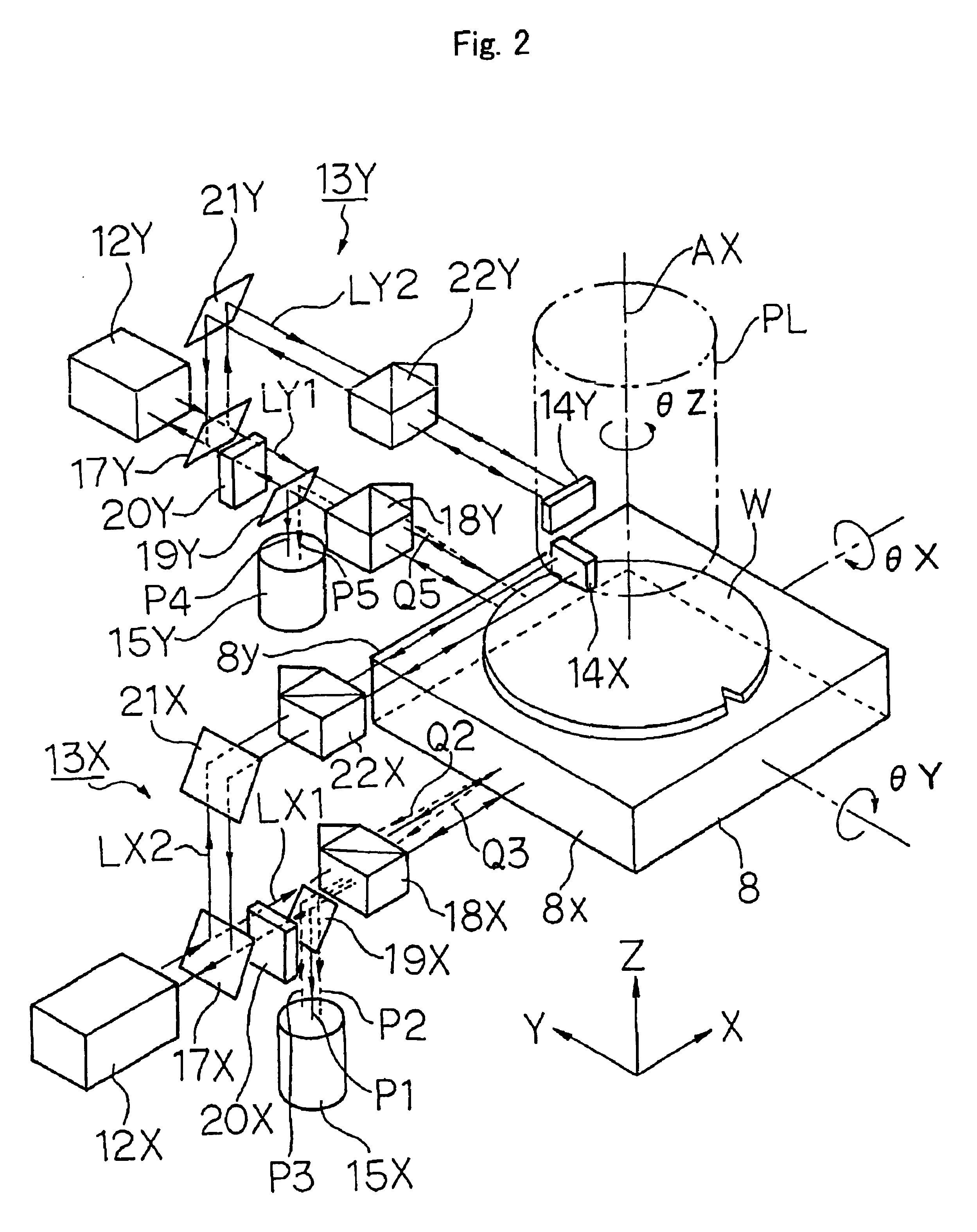

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, and device manufacturing method

InactiveUS20080094604A1Good precisionImprove accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGratingEngineering

A controller inclines a movable body with respect to an XY plane at an angle α in a periodic direction of a grating, based on a measurement value of an interferometer which measures an angle of inclination of the movable body to the XY plane, and based on a measurement value of an encoder system and information of angle α before and after the inclination, and computes an Abbe offset quantity of the grating surface with respect to a reference surface (e.g., an image plane of a projection optical system) which serves as a reference for position control of the movable body in the XY plane. Then, the controller drives the movable body, based on positional information of the movable body in the XY plane measured by the encoder system and a measurement error of the encoder system corresponding to an angle of inclination of the movable body to the XY plane due to the Abbe offset quantity of the grating surface.

Owner:NIKON CORP

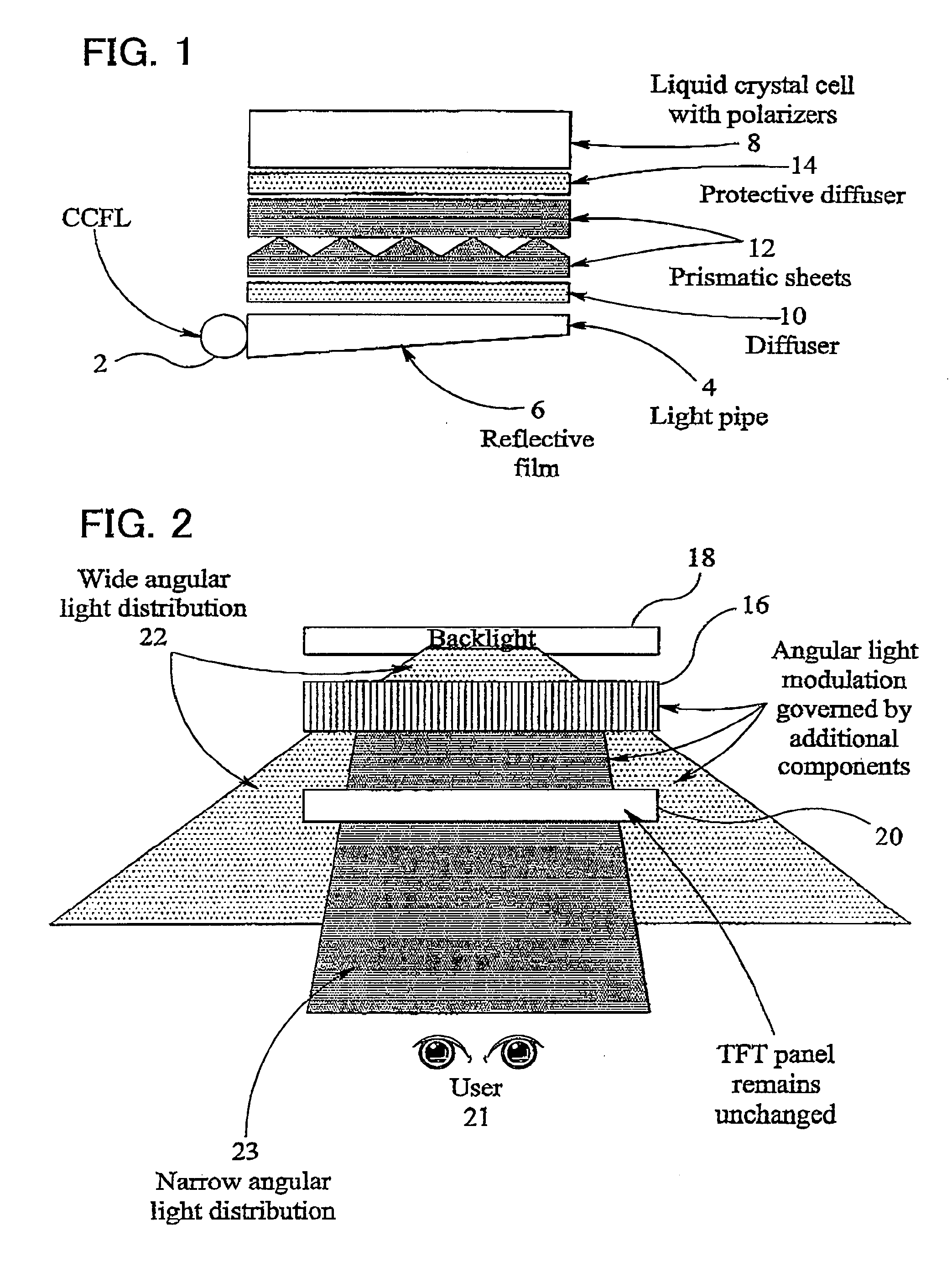

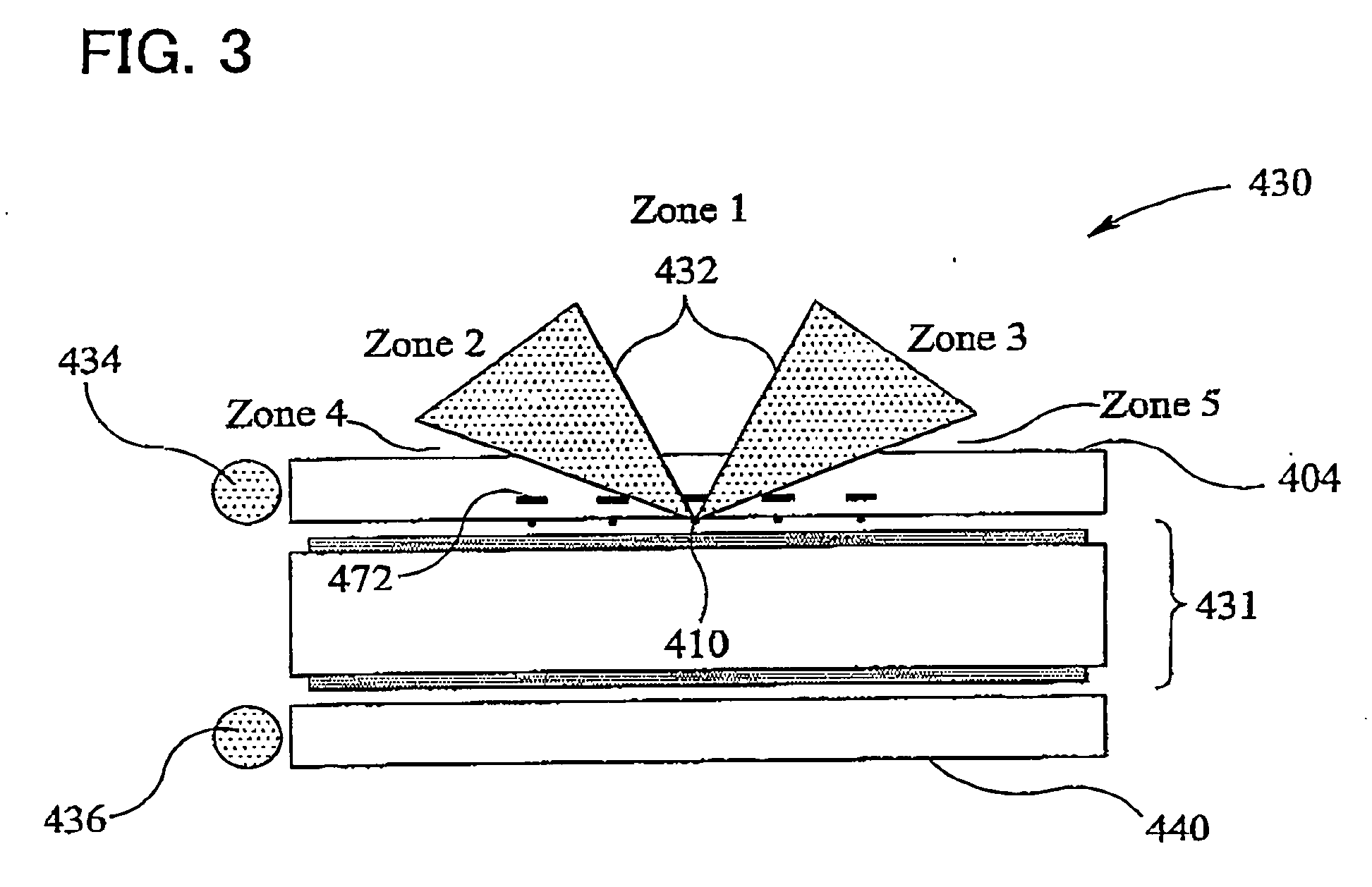

Illumination system and a display incorporating the same

InactiveUS20070008456A1Effective privacyMechanical apparatusStatic indicating devicesDisplay deviceLighting system

An illumination system is providing comprising a first waveguide having a plurality of light-directing surfaces on its lower surface. These surfaces direct light through an output surface of the waveguide into at least one angular range while directing substantially no light into a different angular range. Each surface comprises a plurality of portions having different angles of inclination to a normal to the waveguide.

Owner:SHARP KK

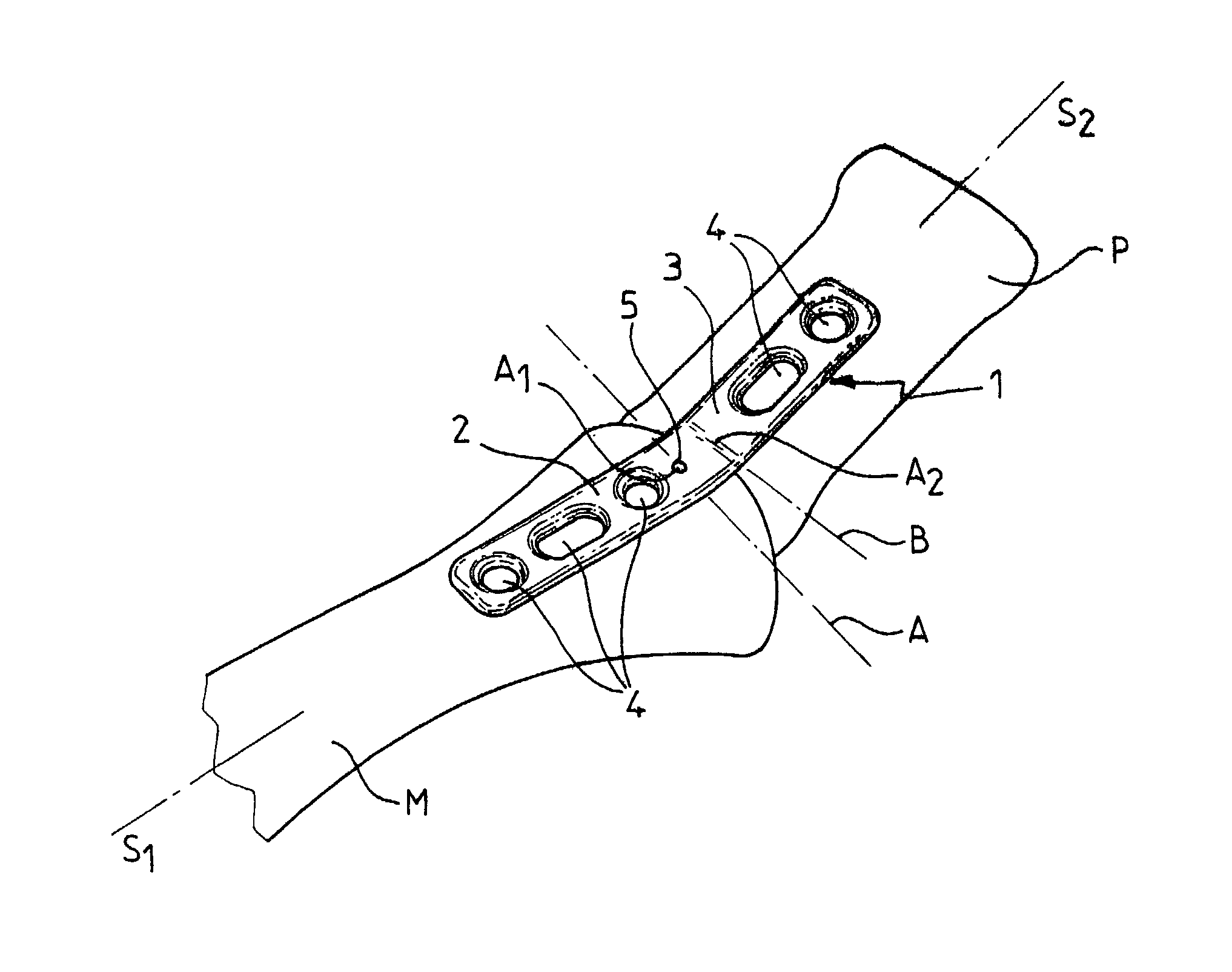

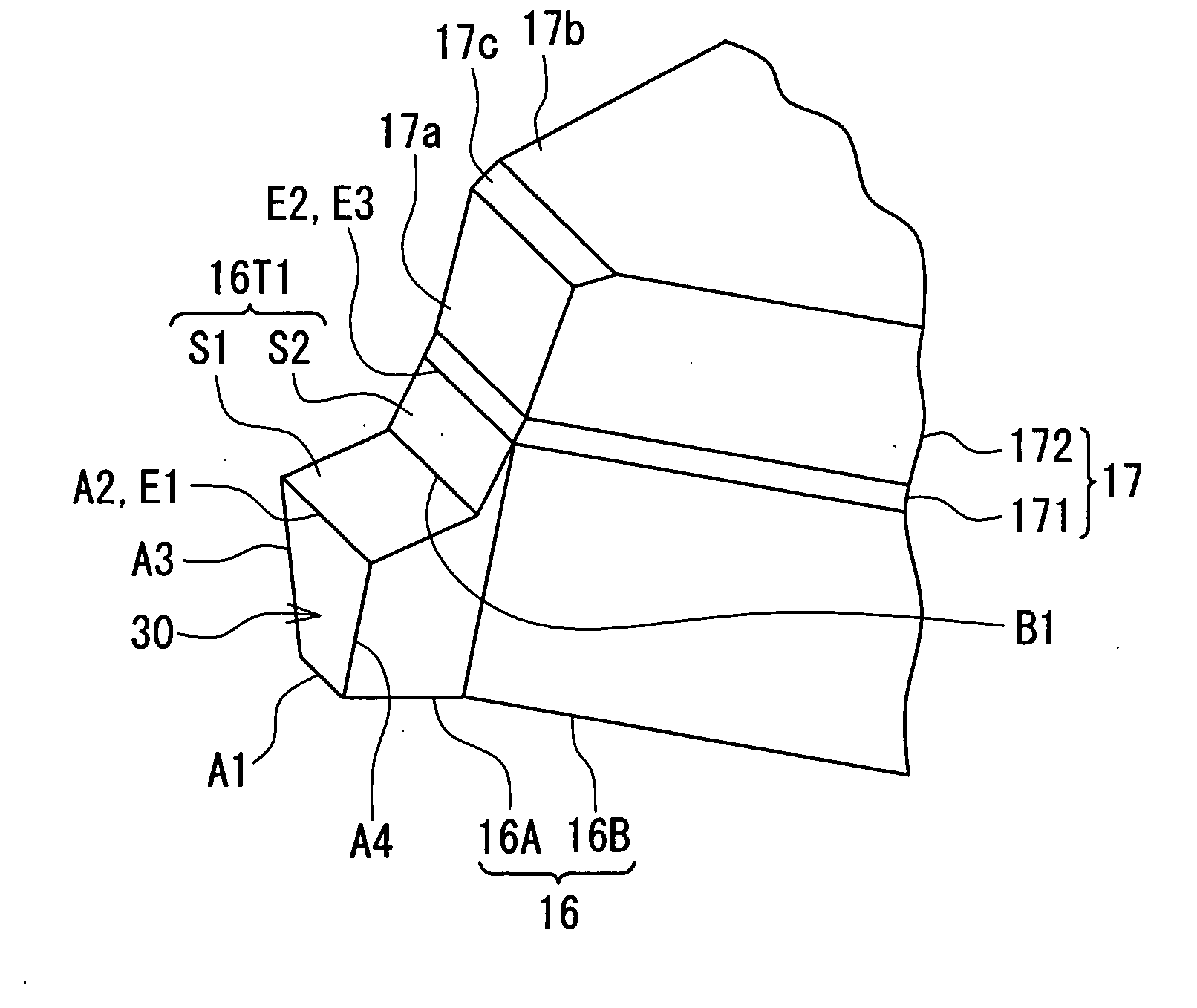

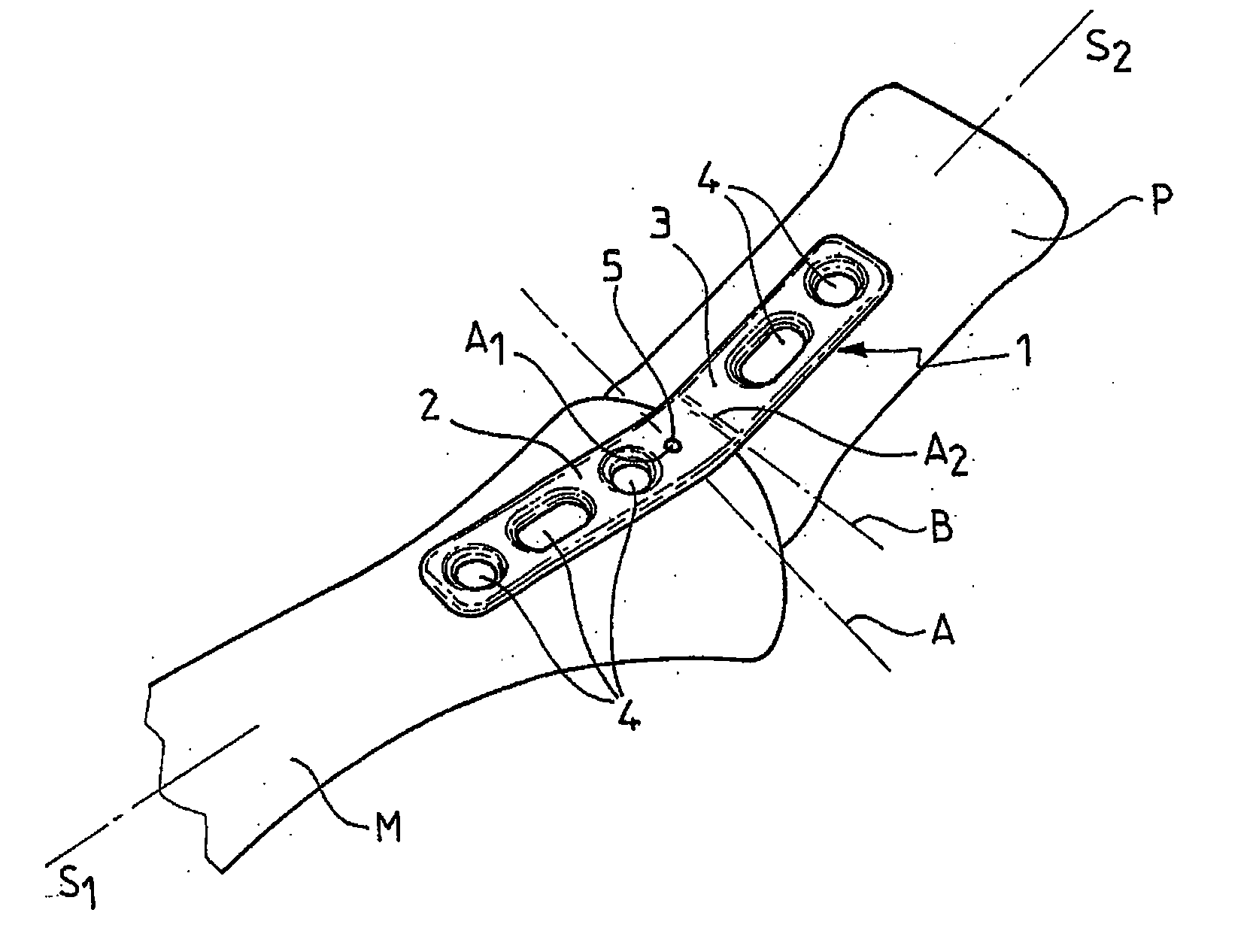

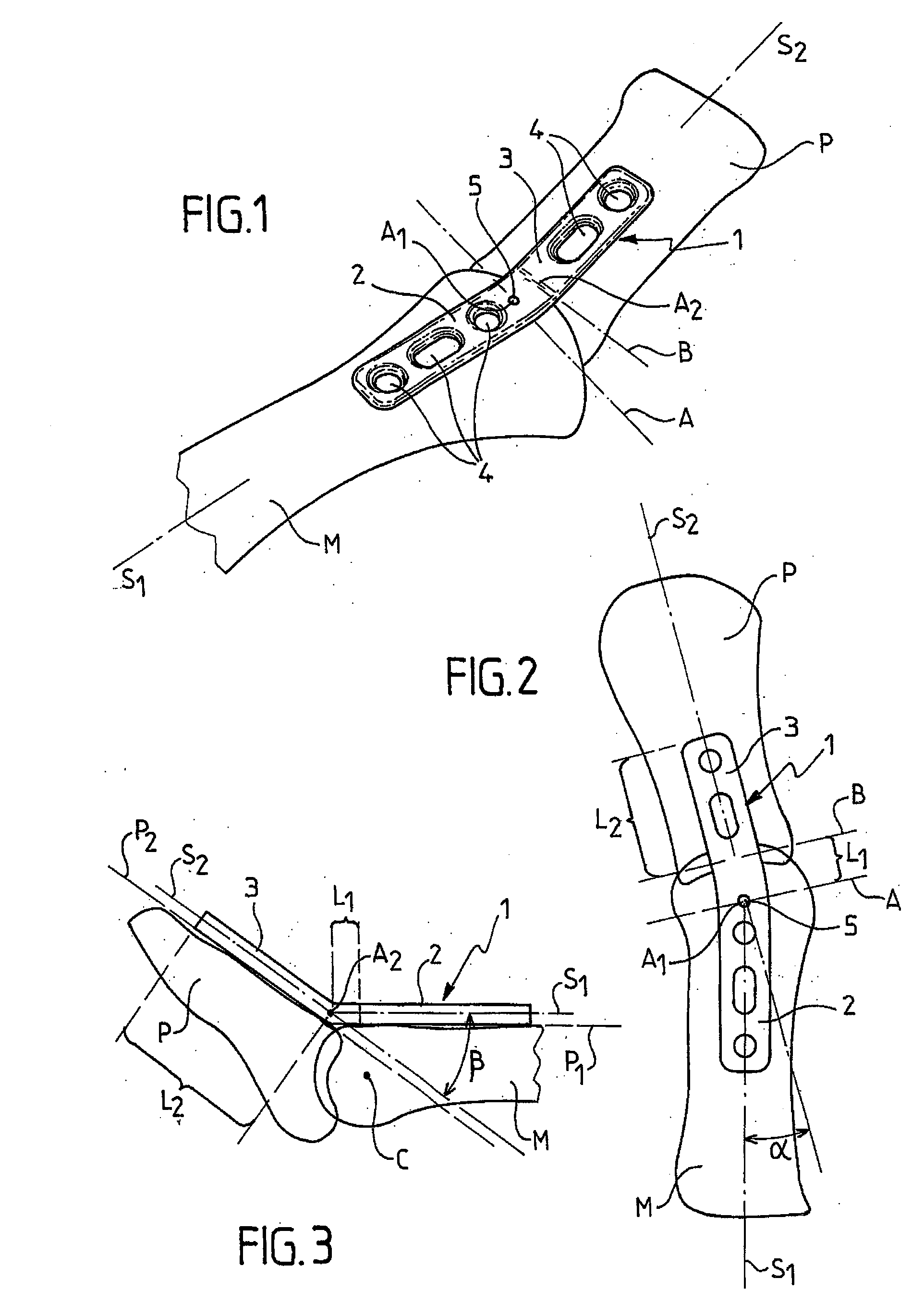

Plate for fixing the bones of a joint, in particular a metatarso-phalangeal joint

InactiveUS20030060827A1Improve accuracyEasy to placeJoint implantsBone platesJoint arthrodesisVertical plane

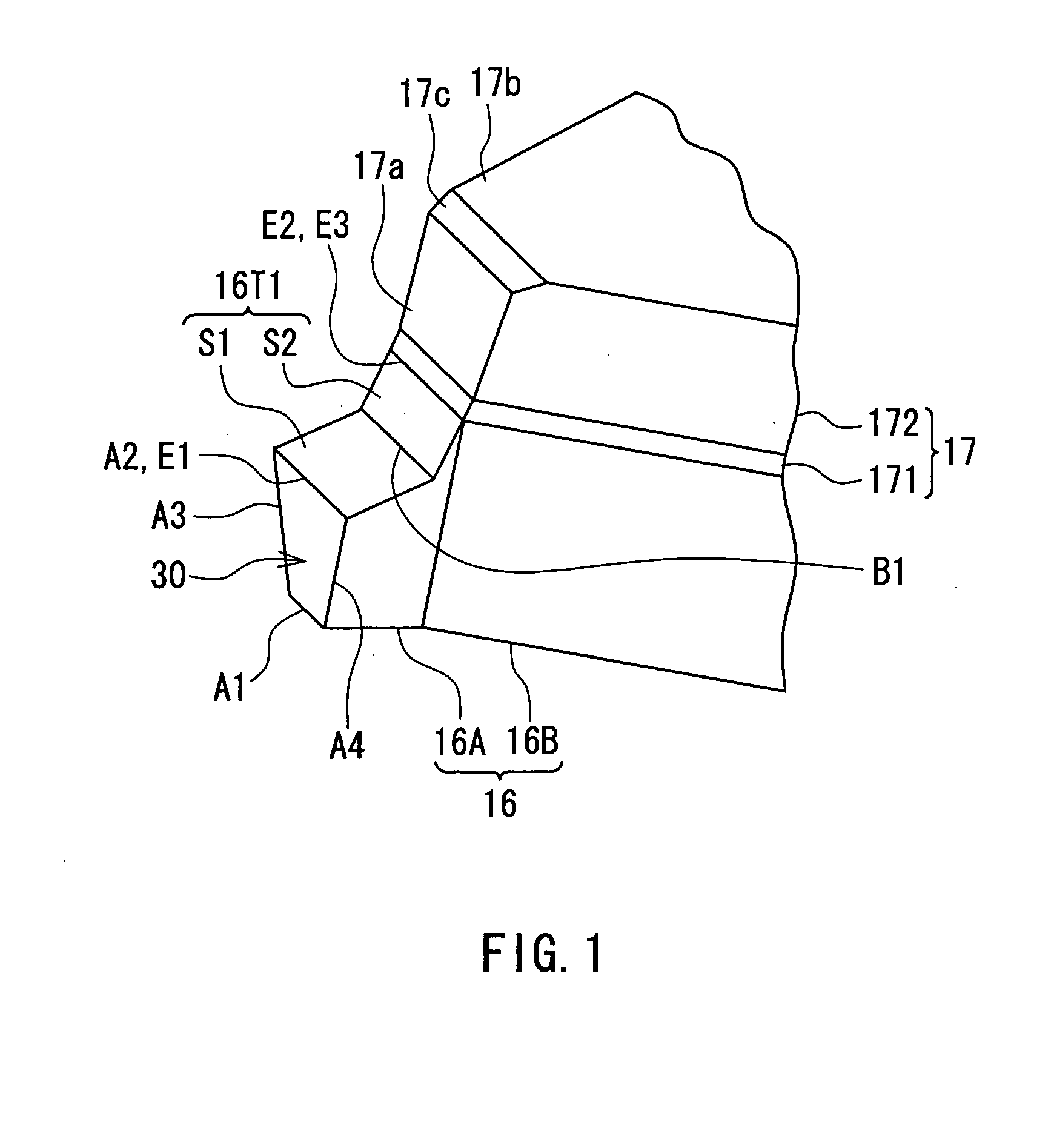

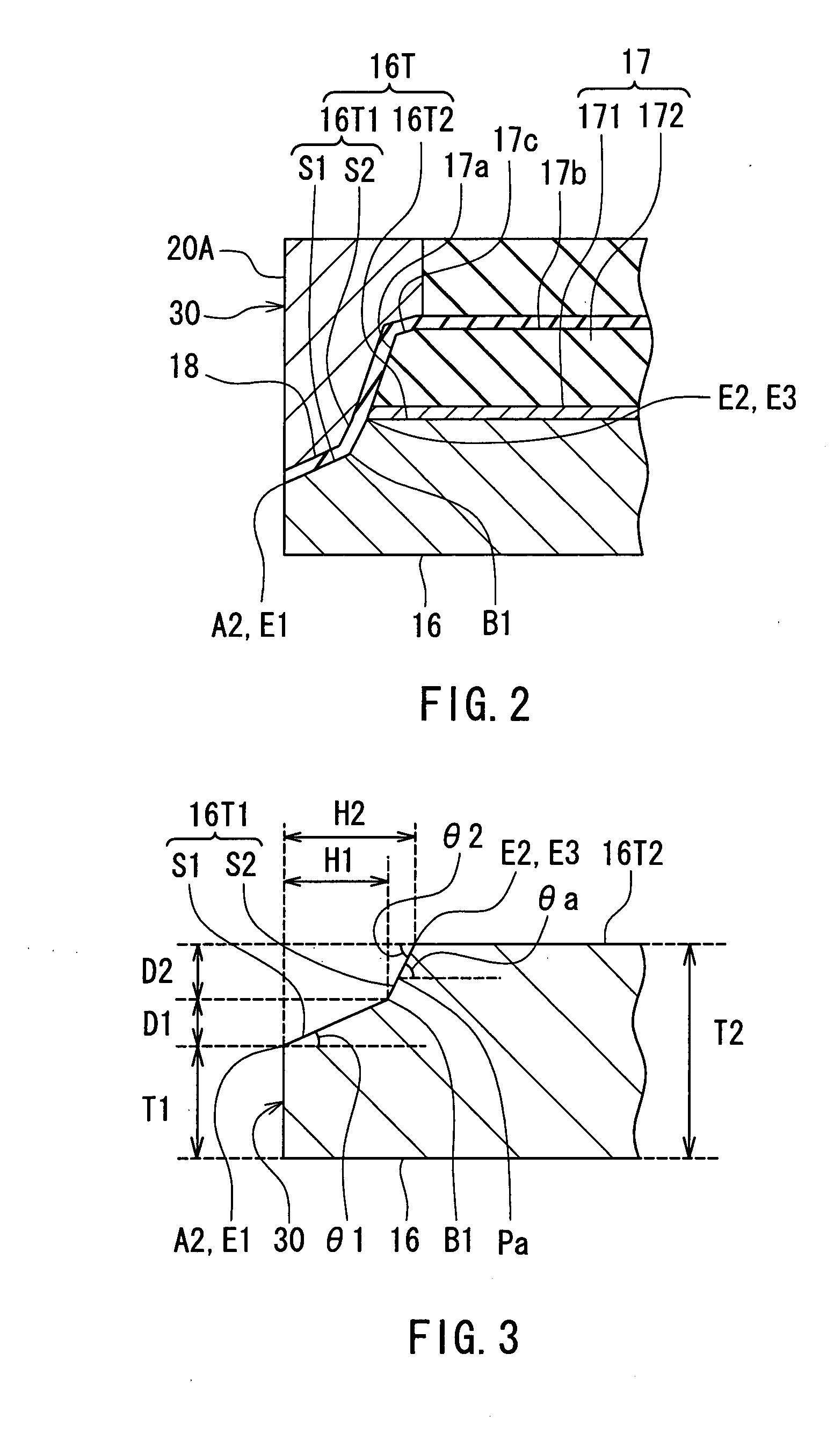

The invention relates to a plate for fixing the bones of a joint, in particular of a metatarso-phalanageal joint, for the purpose of performing arthrodesis, wherein: the plate comprises two sections, respectively a proximal section and a distal section, each section having a respective longitudinal axis of symmetry S1, S2 such that the projection onto a horizontal plane of tie axis of symmetry S2 of the distal section presents an angle of inclination relative to the projection of the axis of symmetry S1 of the proximal portion, the projections intersecting at a point A; and the projection onto a vertical plane of the axis of symmetry S2 presents an angle of inclination relative to the projection of the axis of symmetry S1, their intersection taking place at a point A2 which is distinct from the point A1

Owner:SMITH & NEPHEW INC

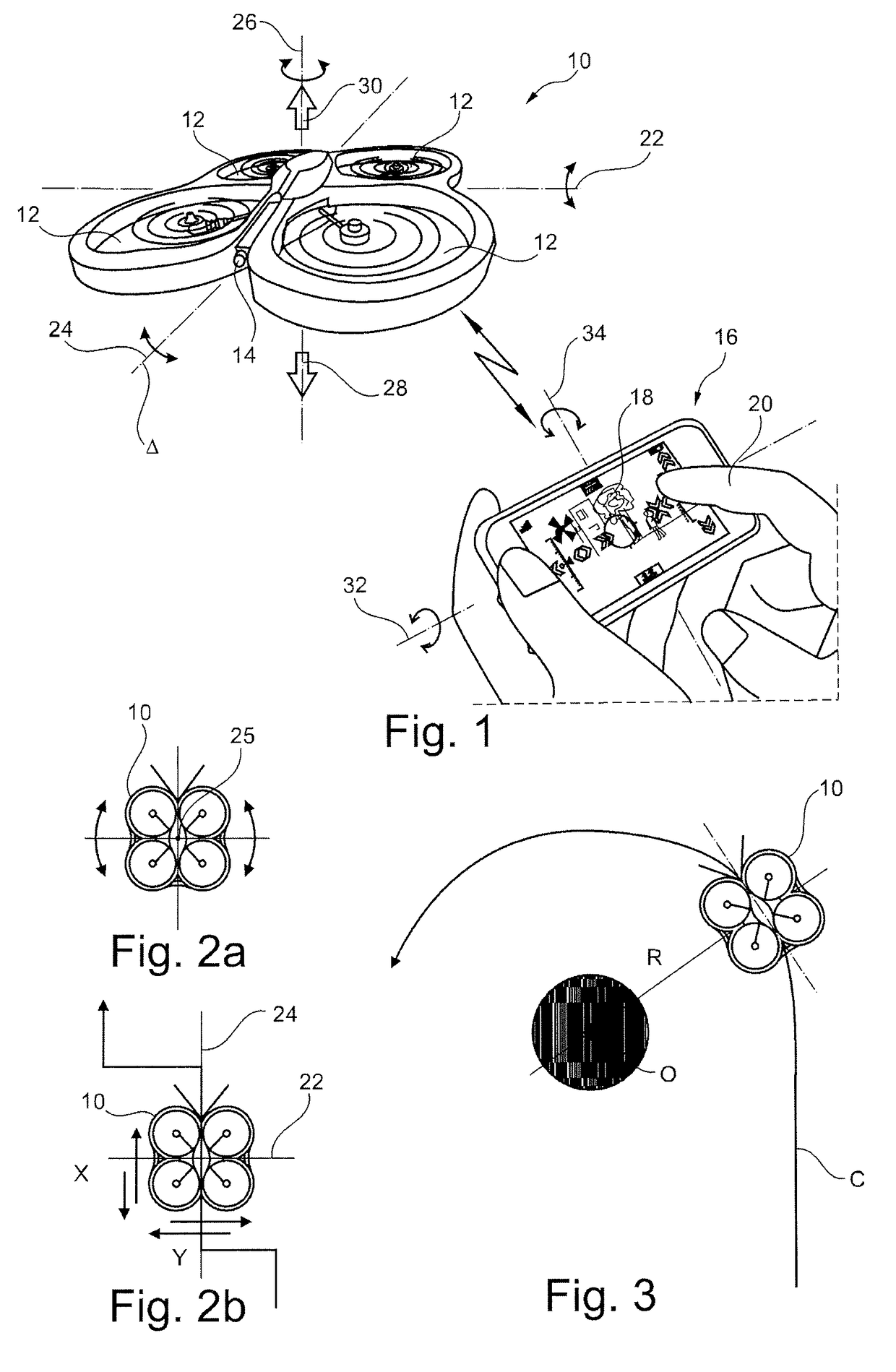

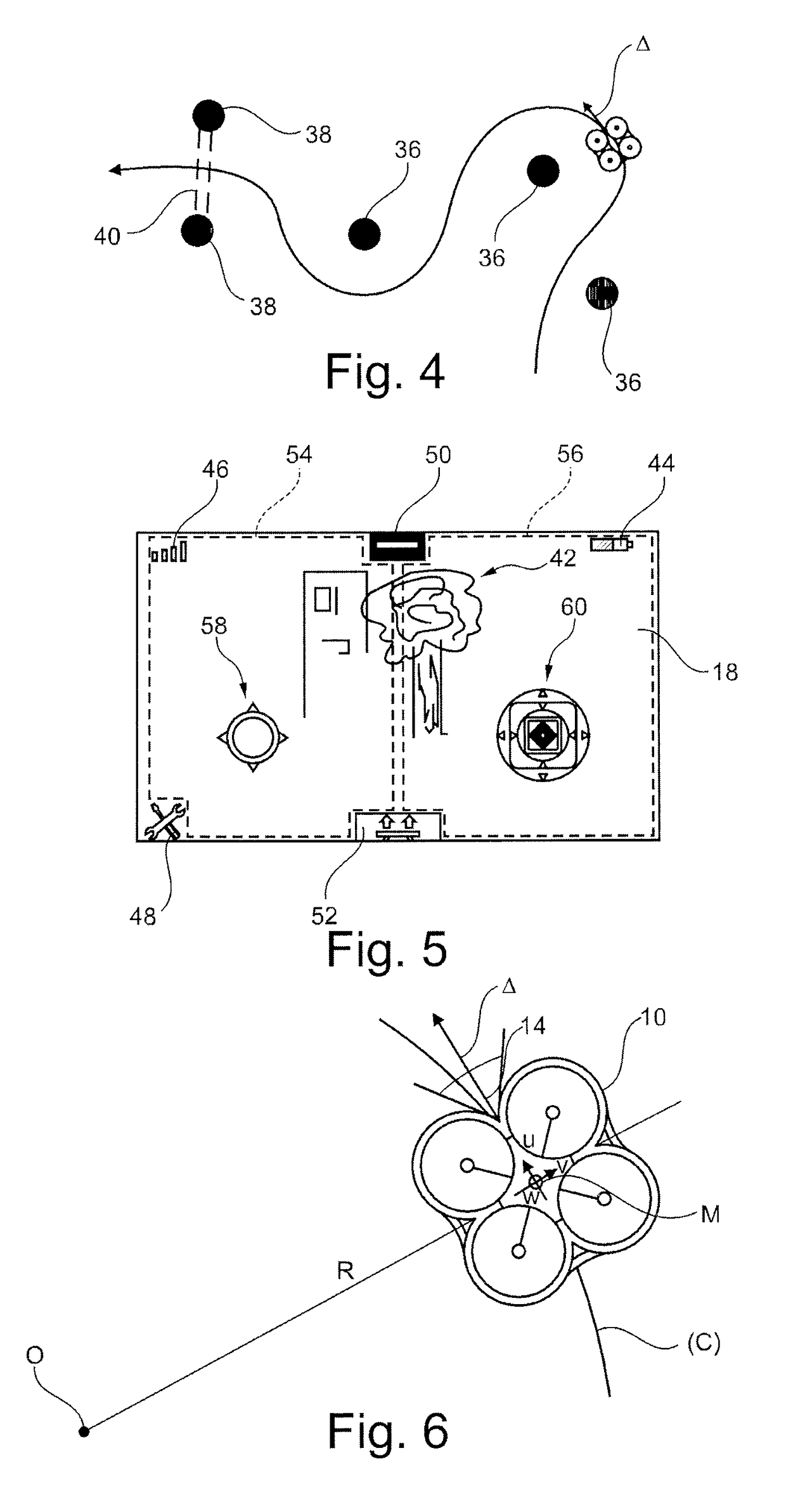

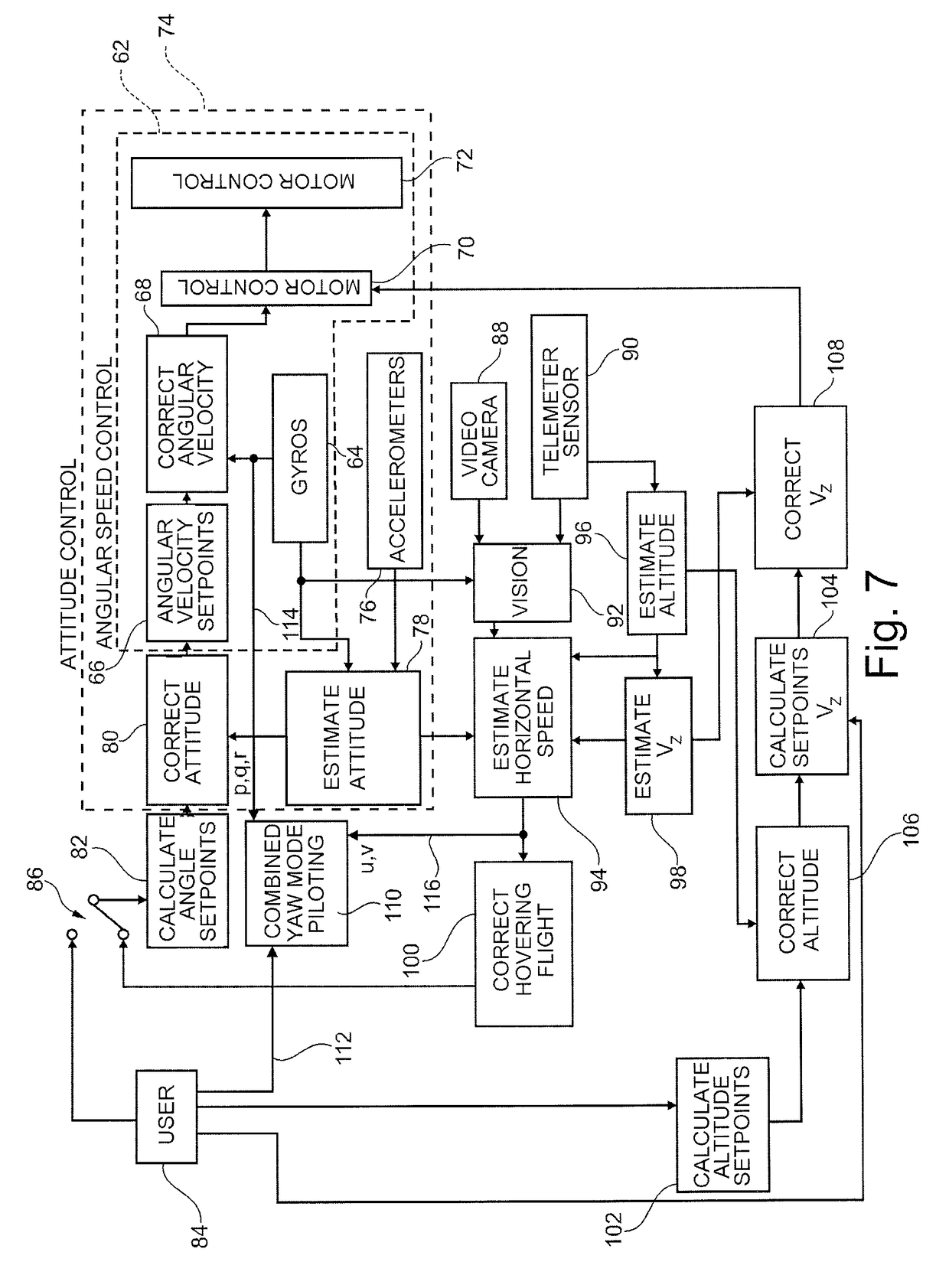

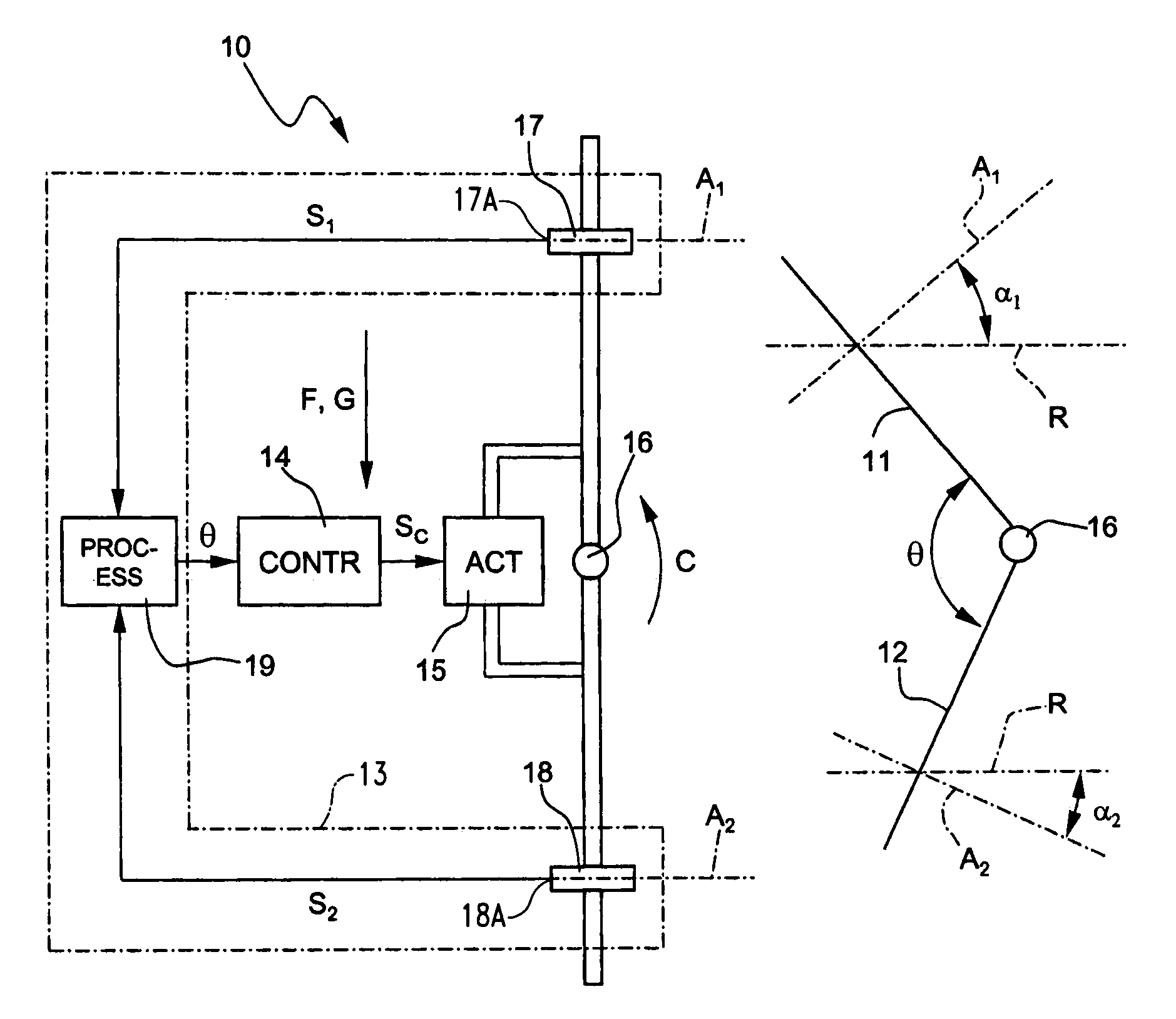

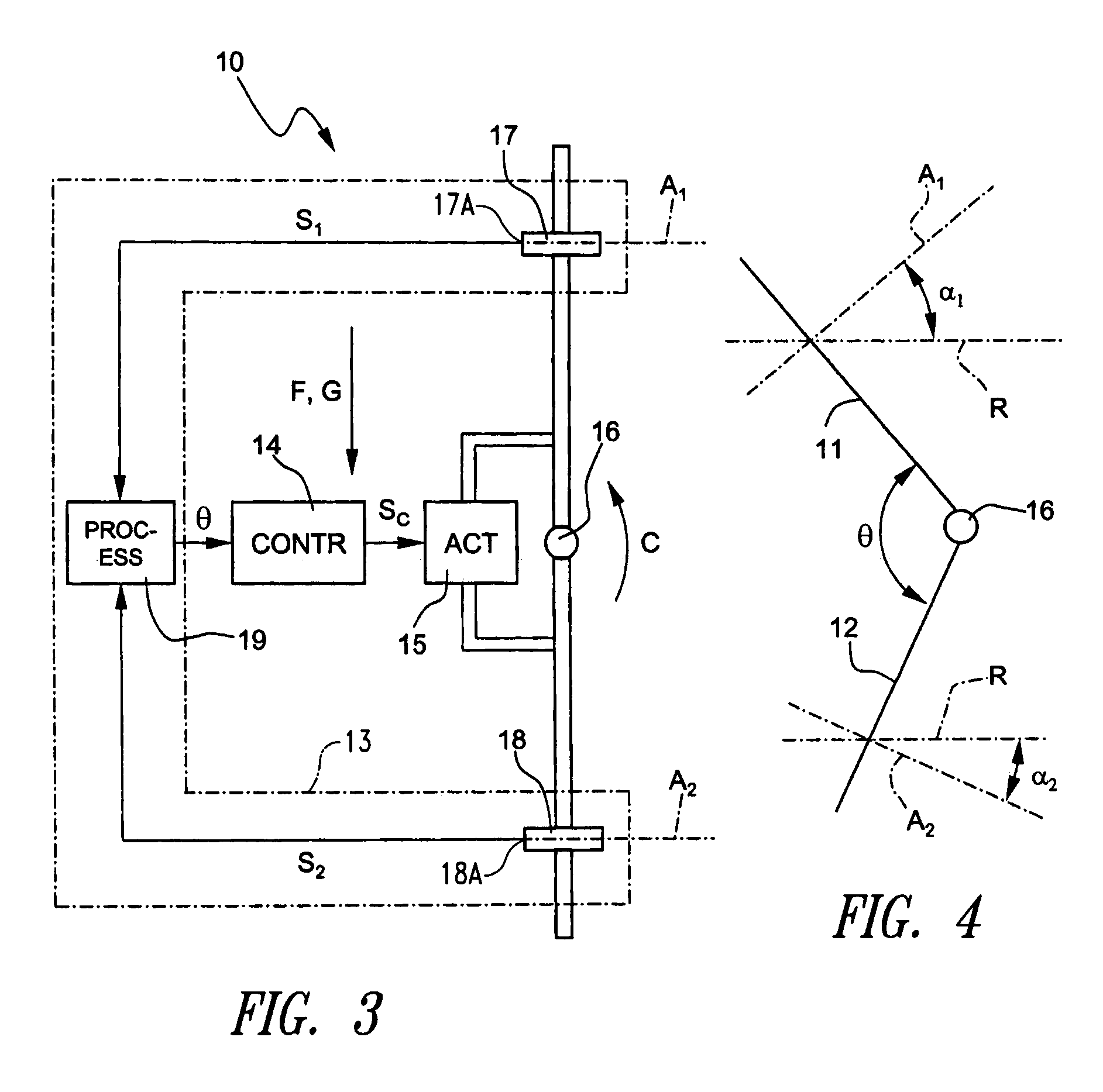

Method of piloting a multiple rotor rotary-wing drone to follow a curvilinear turn

InactiveUS8473125B2Reduce number of degree of freedomModel aircraftPropellersRemote controlUncrewed vehicle

The respective motors of the drone (10) can be controlled to rotate at different speeds in order to pilot the drone both in attitude and speed. A remote control appliance produces a command to turn along a curvilinear path, this command comprising a left or right turning direction parameter and a parameter that defines the radius of curvature of the turn. The drone receives said command and acquires instantaneous measurements of linear velocity components, of angles of inclination, and of angular speeds of the drone. On the basis of the received command and the acquired measurements, setpoint values are generated for a control loop for controlling motors of the drone, these setpoint values controlling horizontal linear speed and inclination of the drone relative to a frame of reference associated with the ground so as to cause the drone to follow curvilinear path (C) at predetermined tangential speed (u).

Owner:PARROT

Magnetic head for perpendicular magnetic recording and method of manufacturing same

ActiveUS20090059426A1Avoid problemsImprove featuresElectrical transducersRecord information storageEngineeringAngle of inclination

A top surface of a pole layer of a magnetic head includes: a first portion having a first edge located in a medium facing surface and a second edge opposite thereto; and a second portion located farther from the medium facing surface than the first portion and connected to the first portion at the second edge. The distance from a substrate to an arbitrary point on the first portion increases with increasing distance from the medium facing surface to the arbitrary point. The angle of inclination of the first portion taken at the arbitrary point with respect to a direction perpendicular to the medium facing surface increases stepwise or continuously with increasing distance from the medium facing surface to the arbitrary point. The angle of inclination taken at the first edge is greater than zero degree. The second portion extends in a direction substantially perpendicular to the medium facing surface.

Owner:HEADWAY TECH INC

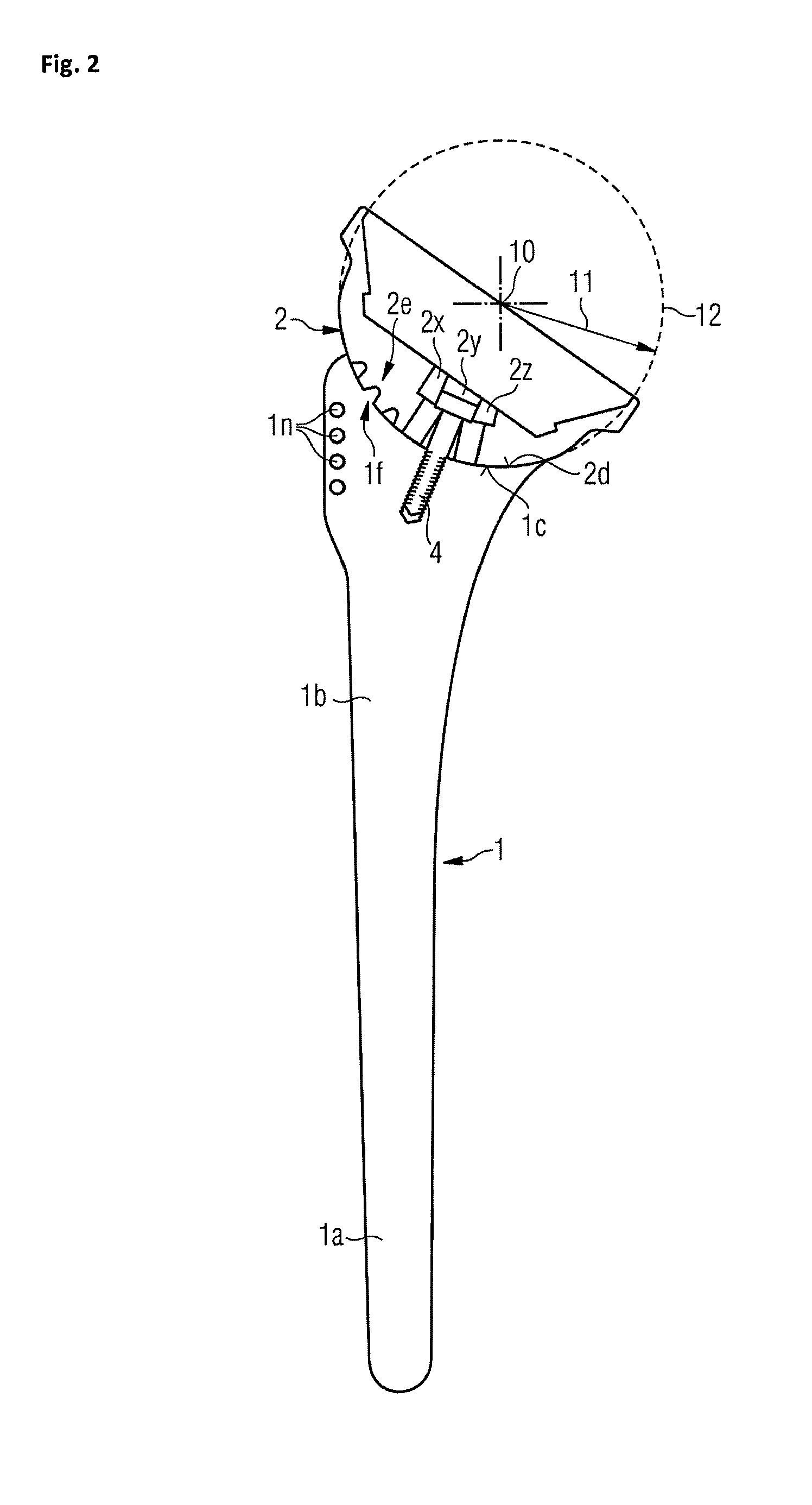

Method of shoulder arthroplasty with adjustable angle of inclination

ActiveUS8663333B2Increase frictionPrevent movementJoint implantsShoulder jointsHumerusSacroiliac joint

Owner:ARTHREX

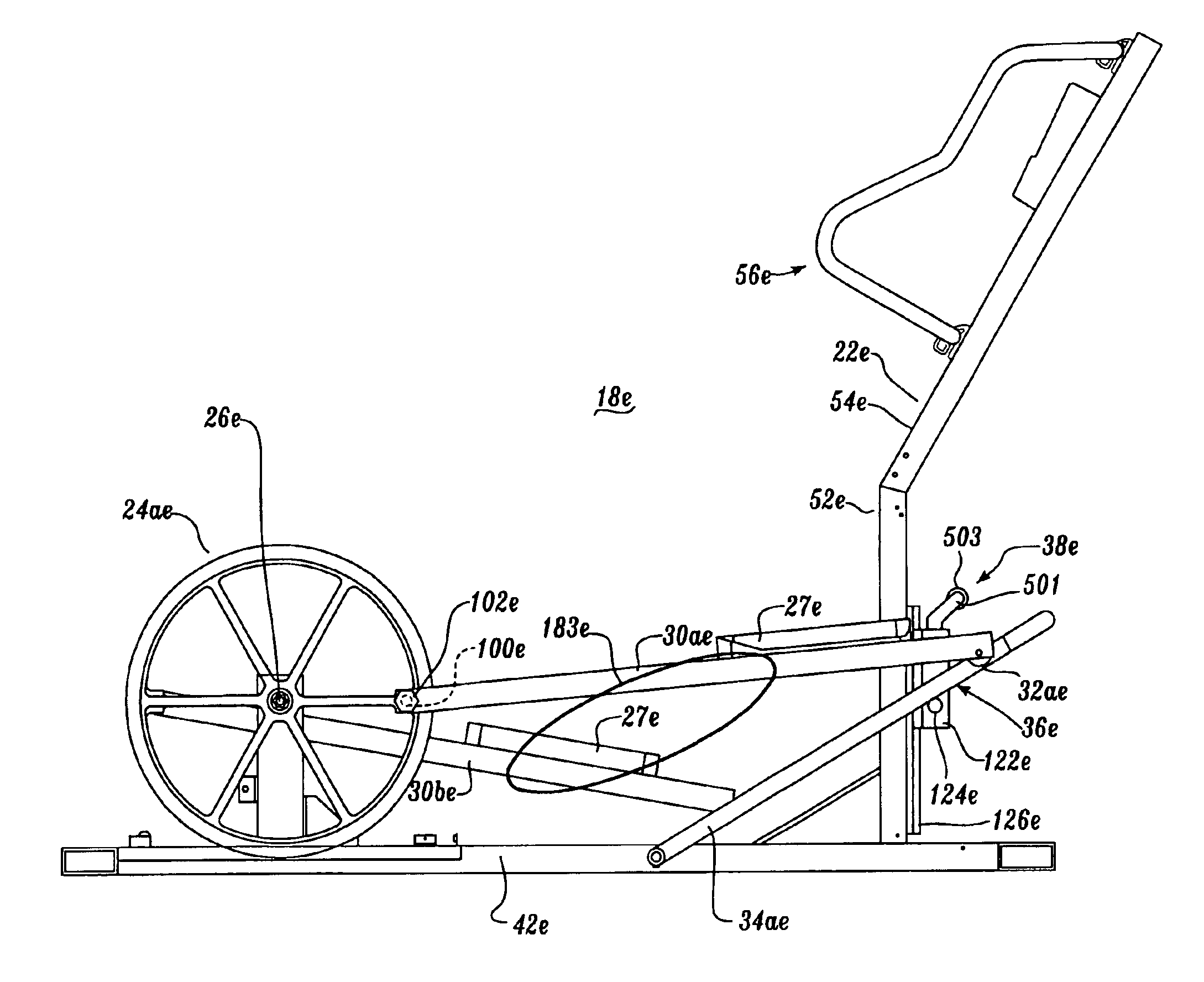

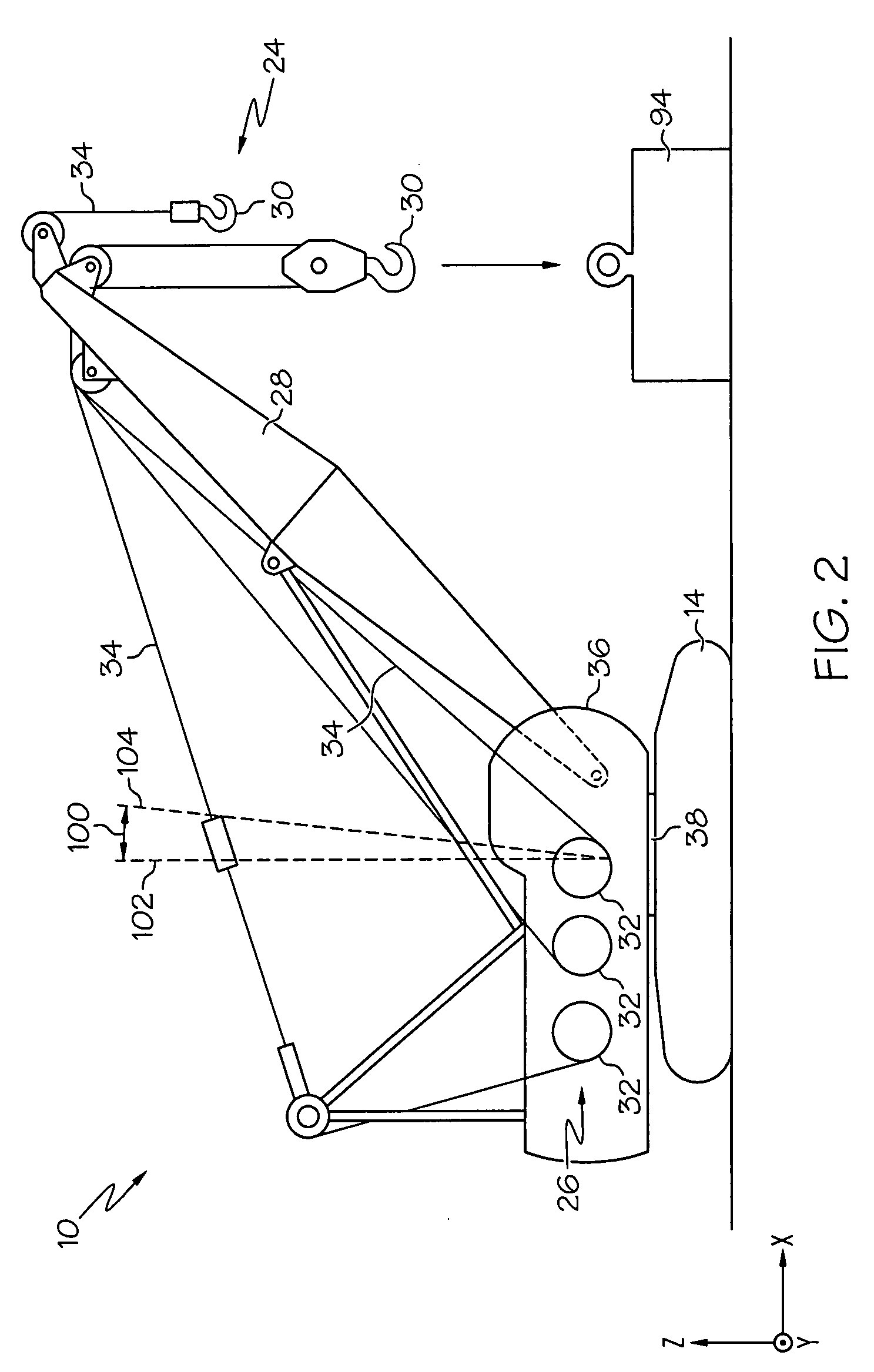

Crosstraining exercise device

InactiveUS6939271B1Low pour pointStepping motion harder or easier to achieveFrictional force resistorsMovement coordination devicesEngineeringCross country

An exercise device includes a pair of foot engaging links (30a, 30b). The rearward ends of the foot links are supported for arcuate motion about a pivot axis (26), and the forward ends of the foot links travel back and forth along a guide (36). The combination of these two foot link motions permits the users feet to travel along an elliptical path of travel. The inclination of the foot links may be selectively altered to vary the nature of the stepping motion experienced by the user. At flatter inclinations of the foot links, the stepping motion may resemble cross country skiing. At progressively greater angles of inclination of the foot links, the stepping motions may simulate walking, jogging, running and climbing.

Owner:PRECOR

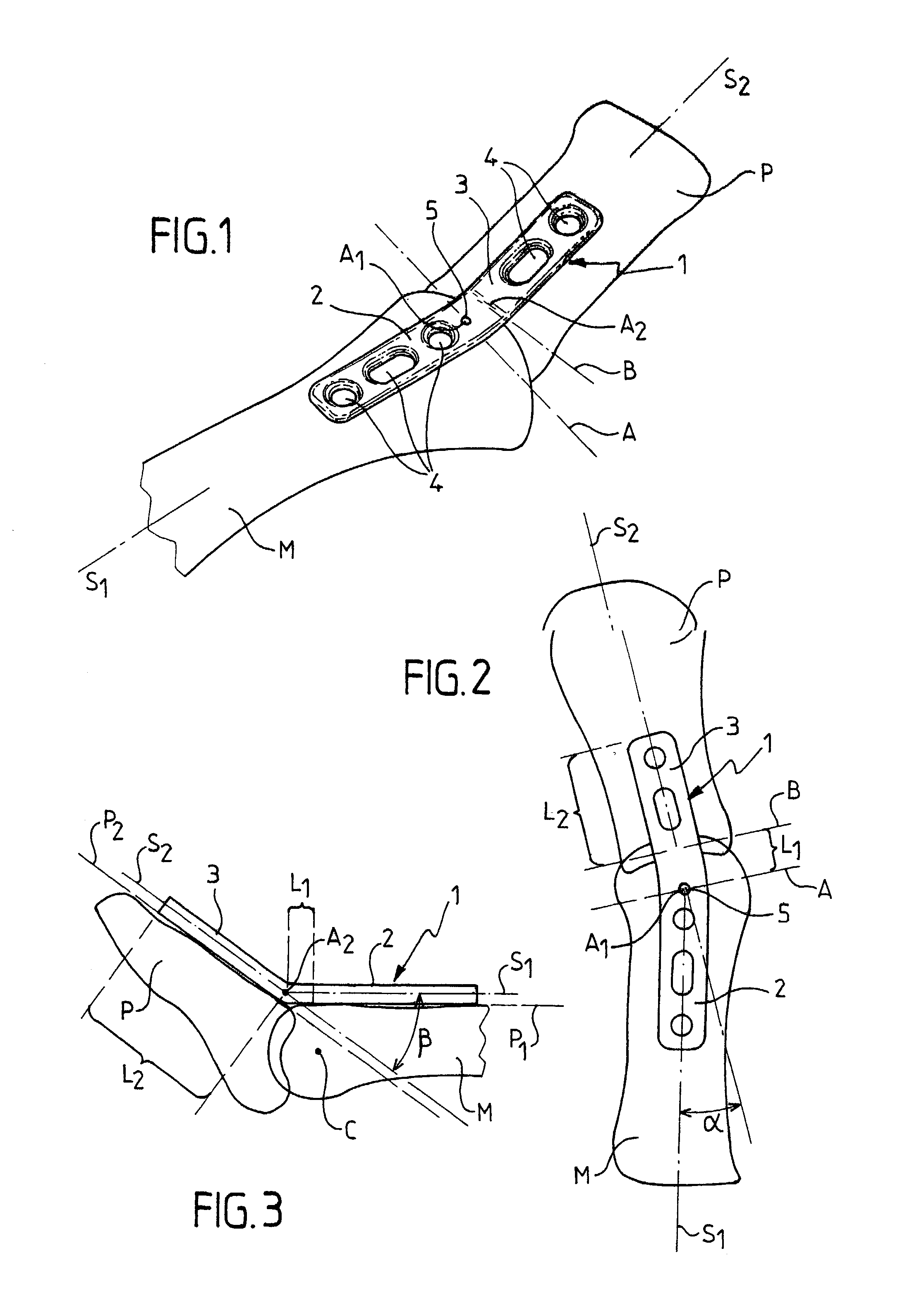

Plate for fixing the bones of a joint, in particular a metatarso-phalangeal joint

InactiveUS20080091197A1Improve accuracyEasy to placeJoint implantsBone platesAxis of symmetryVertical plane

A plate for fixing the bones of a joint, in particular of a metatarso-phalangeal joint, for the purpose of performing arthodesis. The plate comprises two sections, respectively a proximal section and a distal section, each section having a respective longitudinal axis of symmetry S1, S2 such that the projection onto a horizontal plane of the axis of symmetry S2 of the distal section presents an angle of inclination relative to the projection of the axis of symmetry S1 of the proximal portion, the projections inserting at a point A. The projection onto a vertical plane of the axis of symmetry S2 presents an angle of inclination relative to the projection of the axis of symmetry S1, their intersection taking place at a point A2 which is distinct from the point A1.

Owner:NEWDEAL

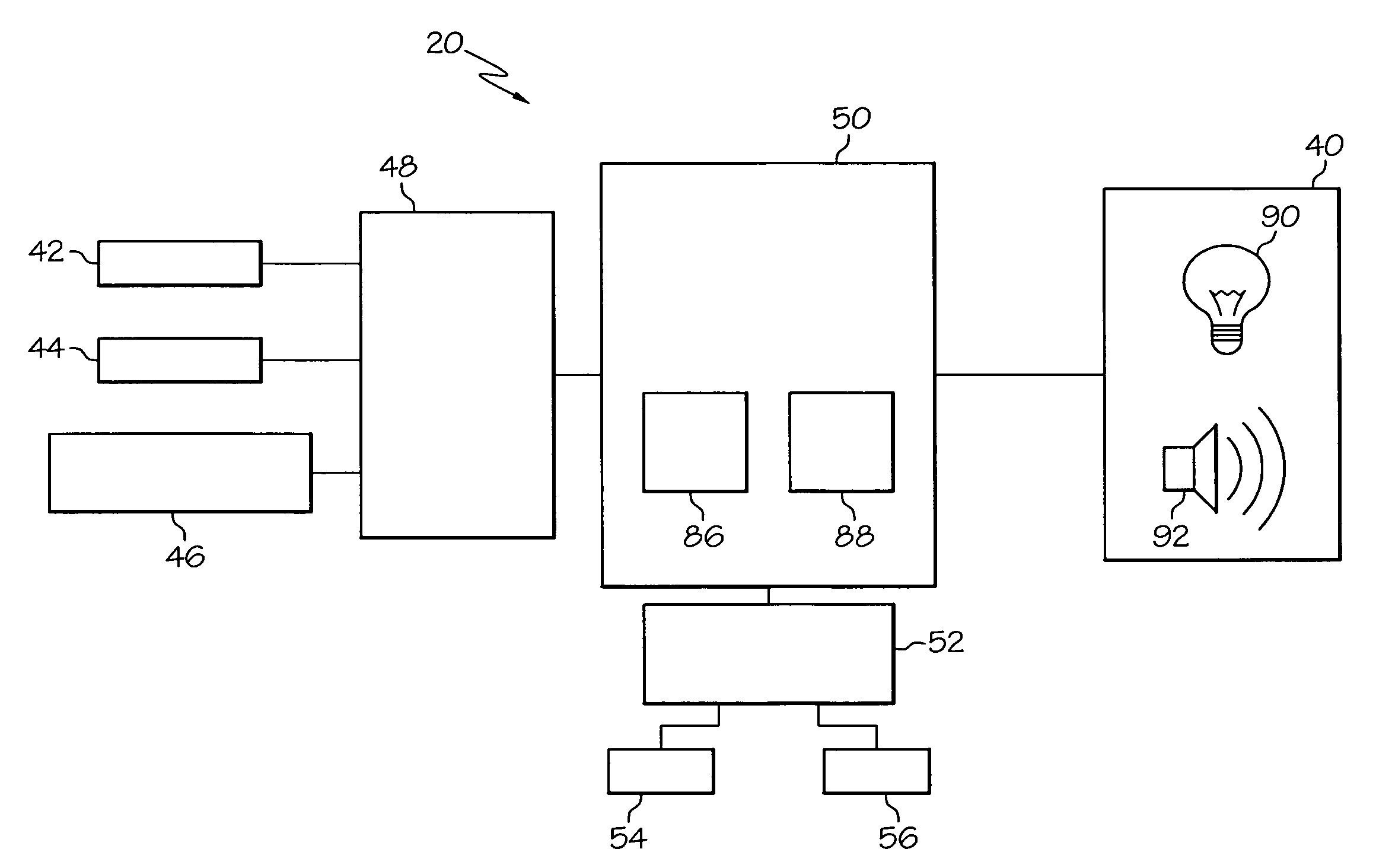

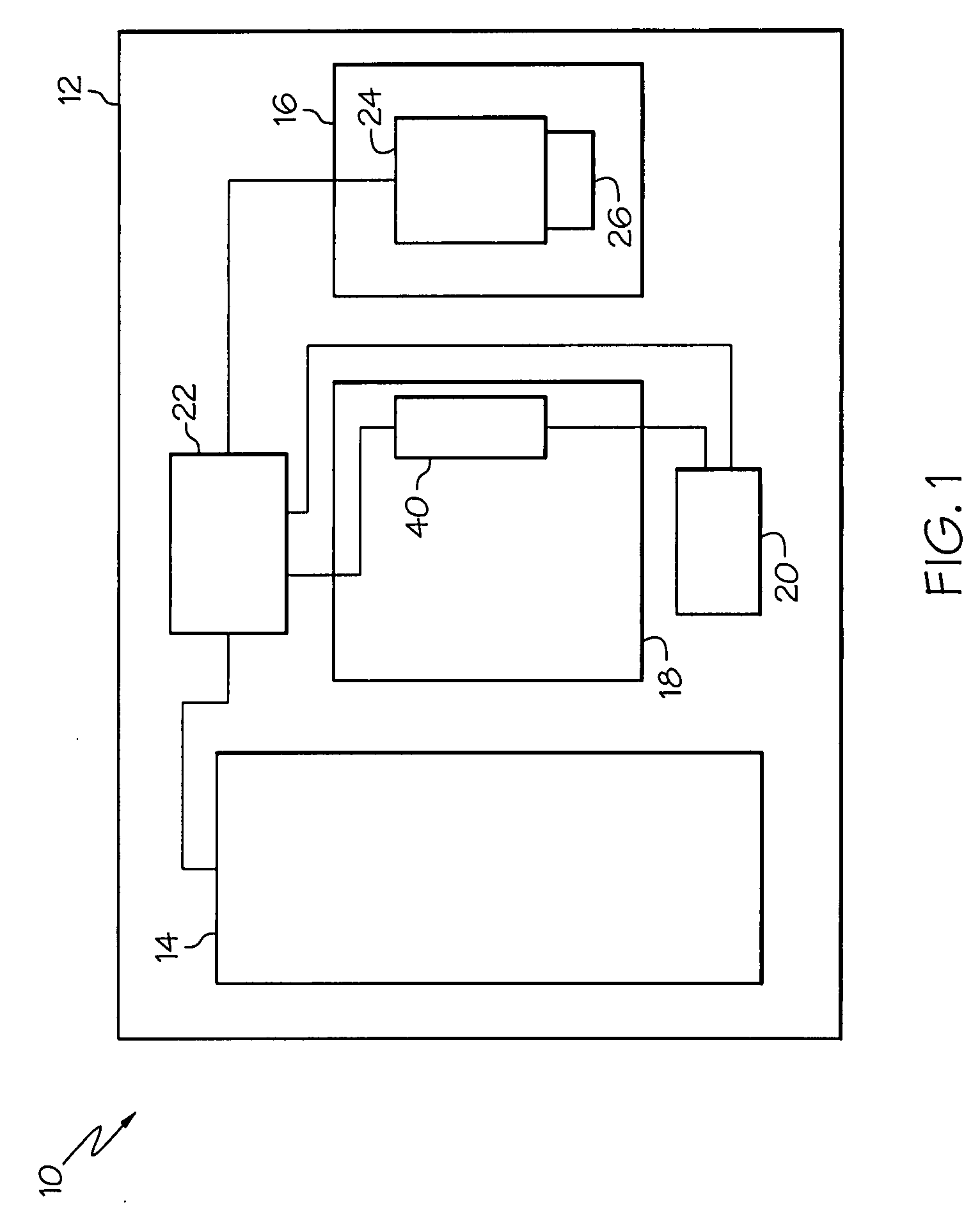

Apparatus and method for monitoring the stability of a construction machine

InactiveUS20090125196A1Mechanical apparatusAnalogue computers for trafficGyroscopeMechanical stability

Systems and methods for monitoring the stability of a construction machine are provided. A gyroscope is configured to detect an angle of inclination of the construction machine relative to a vertical axis and generate an inclination signal representative thereof. A processor in operable communication with the gyroscope is configured to receive the inclination angle and generate a warning signal when the angle of inclination exceeds a predetermined threshold. An alarm device in operable communication with the processor is configured to generate an alarm to indicate to a user of the construction machine when the angle of inclination has exceeded the predetermined threshold.

Owner:HONEYWELL INT INC

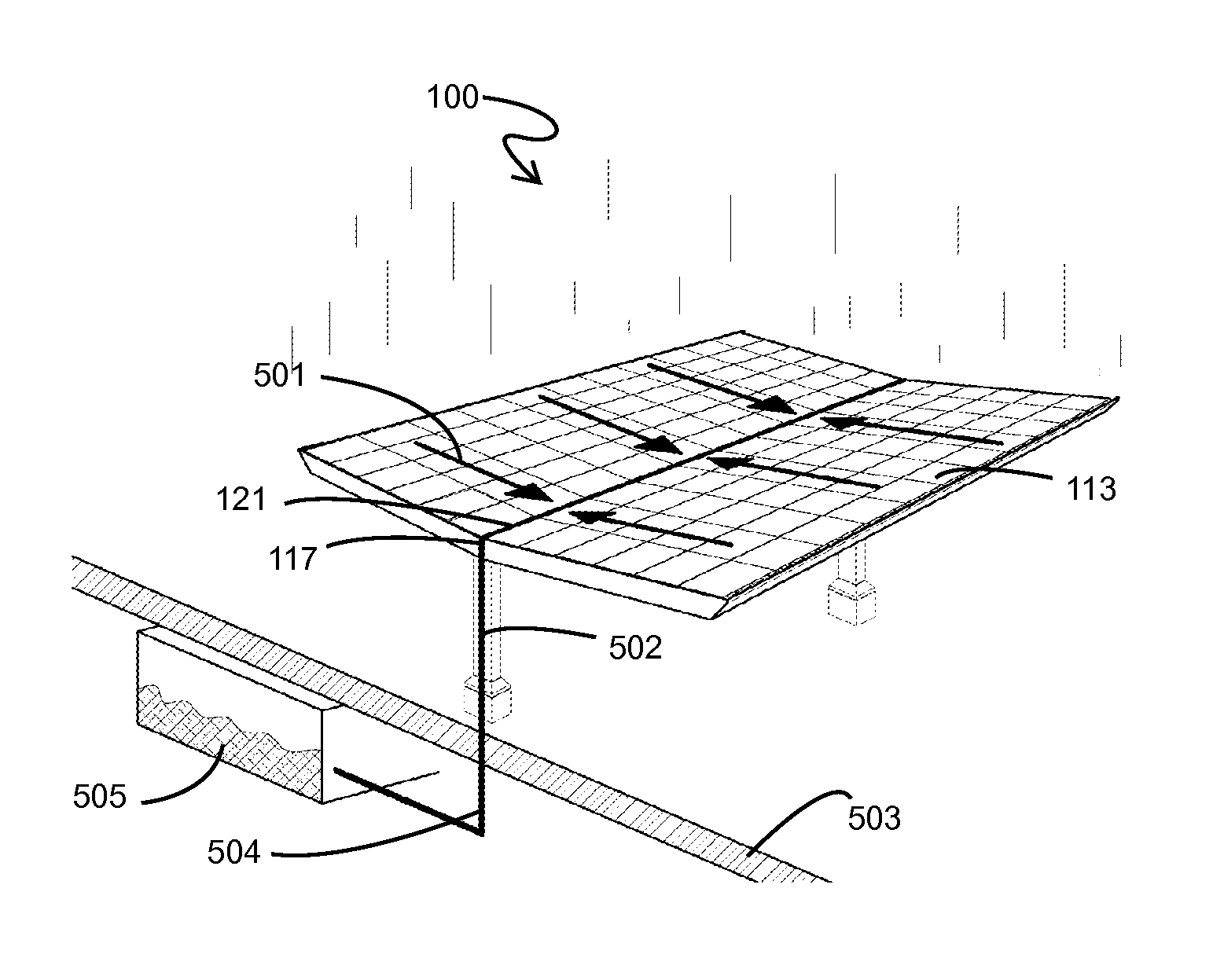

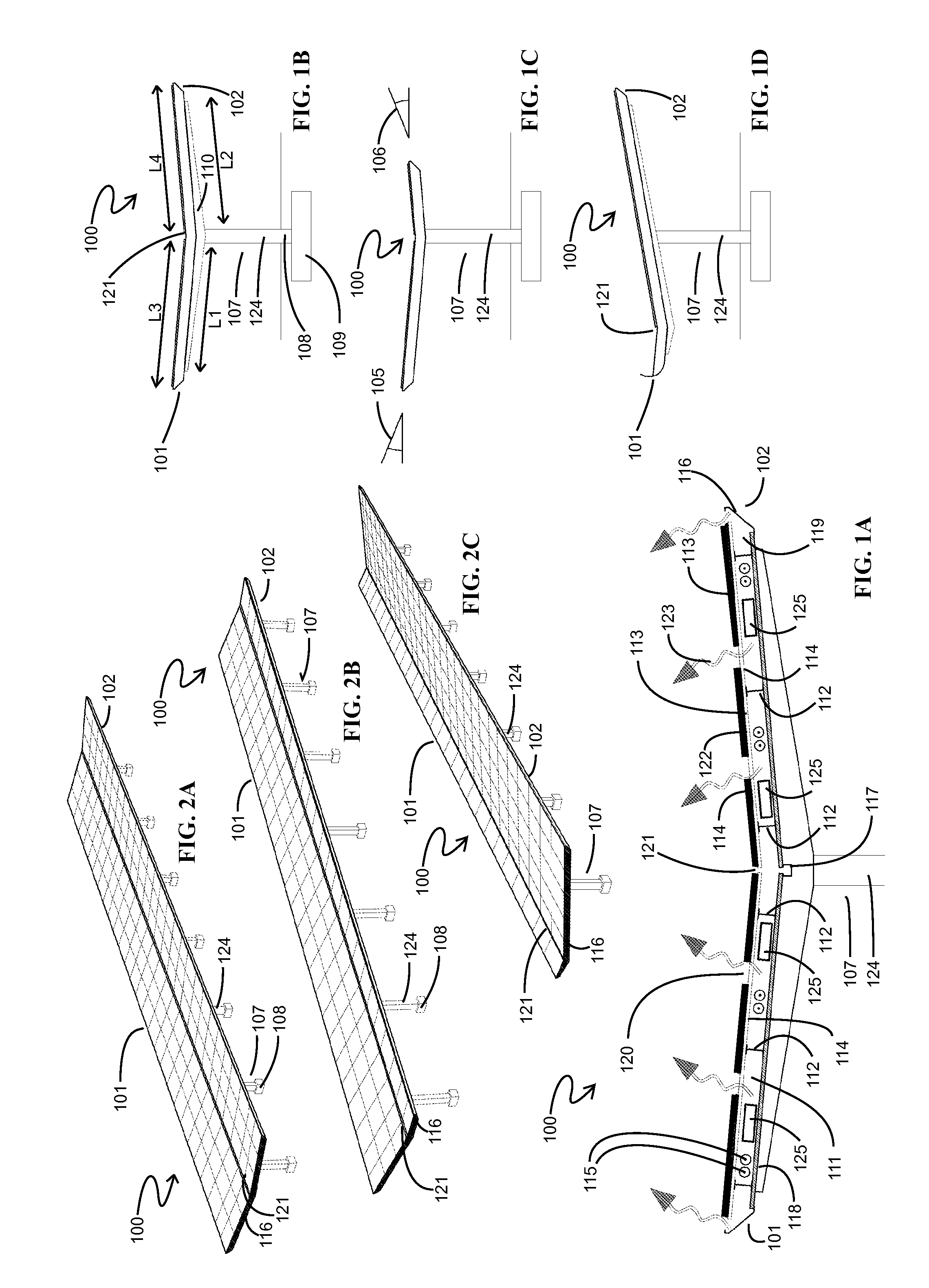

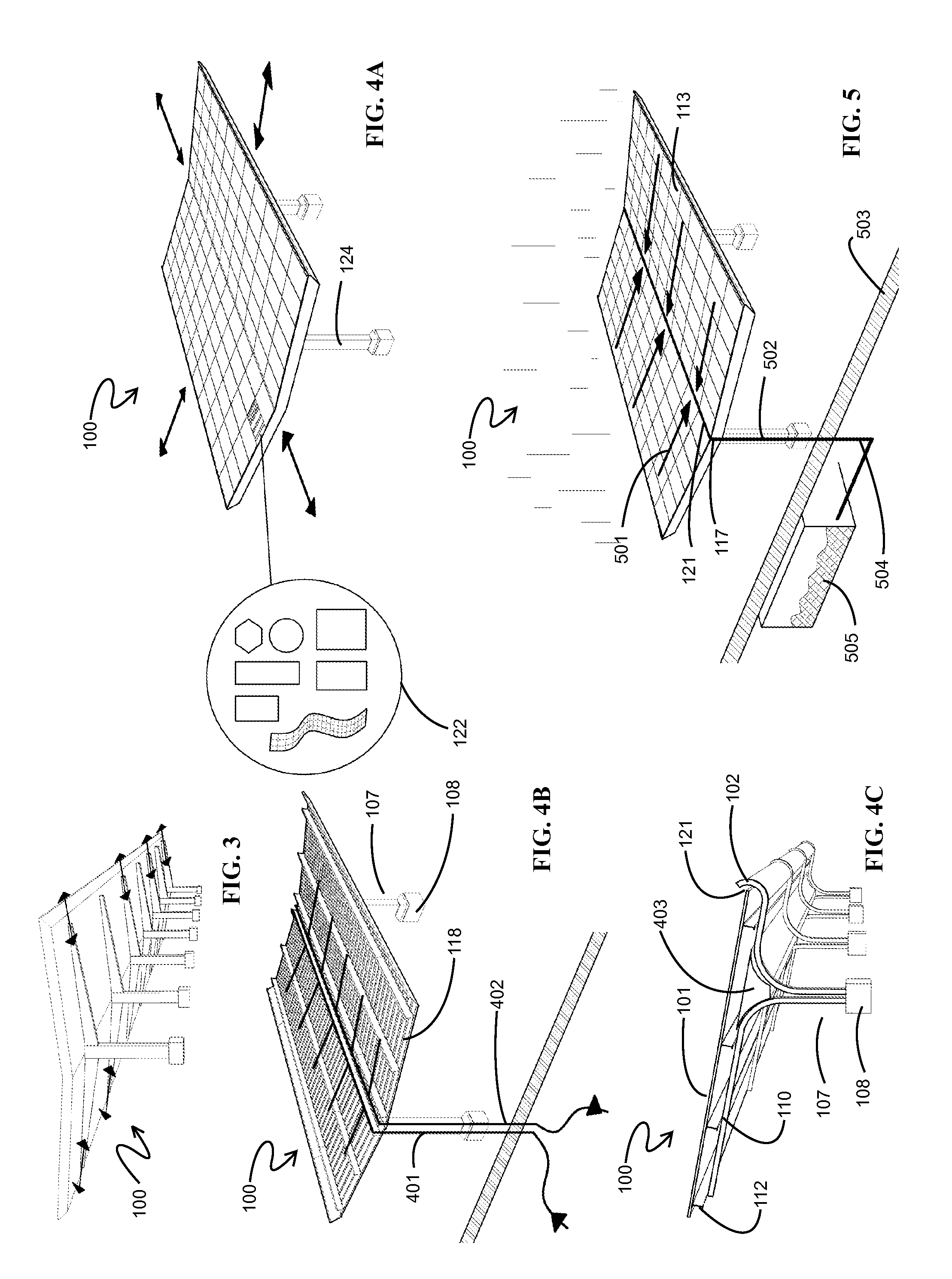

Solar Power Generation Assembly and Method for Providing Same

ActiveUS20100000596A1Solve low usageIncrease valuePhotovoltaic supportsSolar heating energyHigh energyModularity

The present invention relates to a solar power generation assembly and method for providing same involving an array of solar generating modules on a dual-incline structure, which can achieve high energy yields over a wide range of azimuths / orientations. The assembly consists of canopy wings providing for the dual-incline structure, where, depending on specifications, the canopy wings can differ in length, width, angle of inclination, structural material and solar module or other material mounted on the surface. The canopy wings may be pivoted or hinged to enhance the energy generation and / or other functional benefits of the assembly or system, including display elements, advertising, rainwater / precipitation and snow drainage and collection and energy transmission. The assembly or system is modular and may be assembled in a long continuous configuration in which the inclination, width and tilt of the canopy wings may vary of a long distance to maintain substantially consistent energy yields as the assembly or system orientation changes.

Owner:TOTALENERGIES ONETECH

Device for measuring the relative angular position of two bodies with respect to a point, and articular prosthesis provided therewith

A device for measuring the relative angular position of two bodies with respect to a point is provided with a first measuring element and a second measuring element, relatively movable with respect to one another and connectable to a first body and a second body, respectively; the first measuring element includes a first inclination sensor, which has a first detection axis and supplies a first inclination signal, correlated to a first angle of inclination of the first detection axis with respect to a reference axis, and the second measuring element includes a second inclination sensor, which has a second detection axis and supplies a second inclination signal, correlated to a second angle of inclination of the second detection axis with respect to the reference axis.

Owner:STMICROELECTRONICS SRL

Exposure method and apparatus

InactiveUS6813000B1Highly accurately conform surface of substrateImprove accuracyUsing optical meansPhotomechanical exposure apparatusSemiconductorImage plane

An exposure method is disclosed, in which a surface of a wafer can be conformed to an image plane highly accurately even when an angle of inclination of a running surface of a wafer stage is varied when a pattern for a semiconductor device or the like is transferred onto the wafer in accordance with the scanning exposure system. The focusing is performed in an exposure area on the basis of a focus position detected in a pre-reading area in which the focus position can be detected highly accurately although the detection range is narrow, disposed in front of the exposure area on the wafer in the scanning direction. In order to allow the surface of the wafer to be included in the detection range of the focus position in the pre-reading area, the focus position of the wafer is roughly conformed to the image plane on the basis of a result of detection at a rough detecting point for roughly detecting the focus position in front of the pre-reading area with a wide detection range.

Owner:NIKON CORP

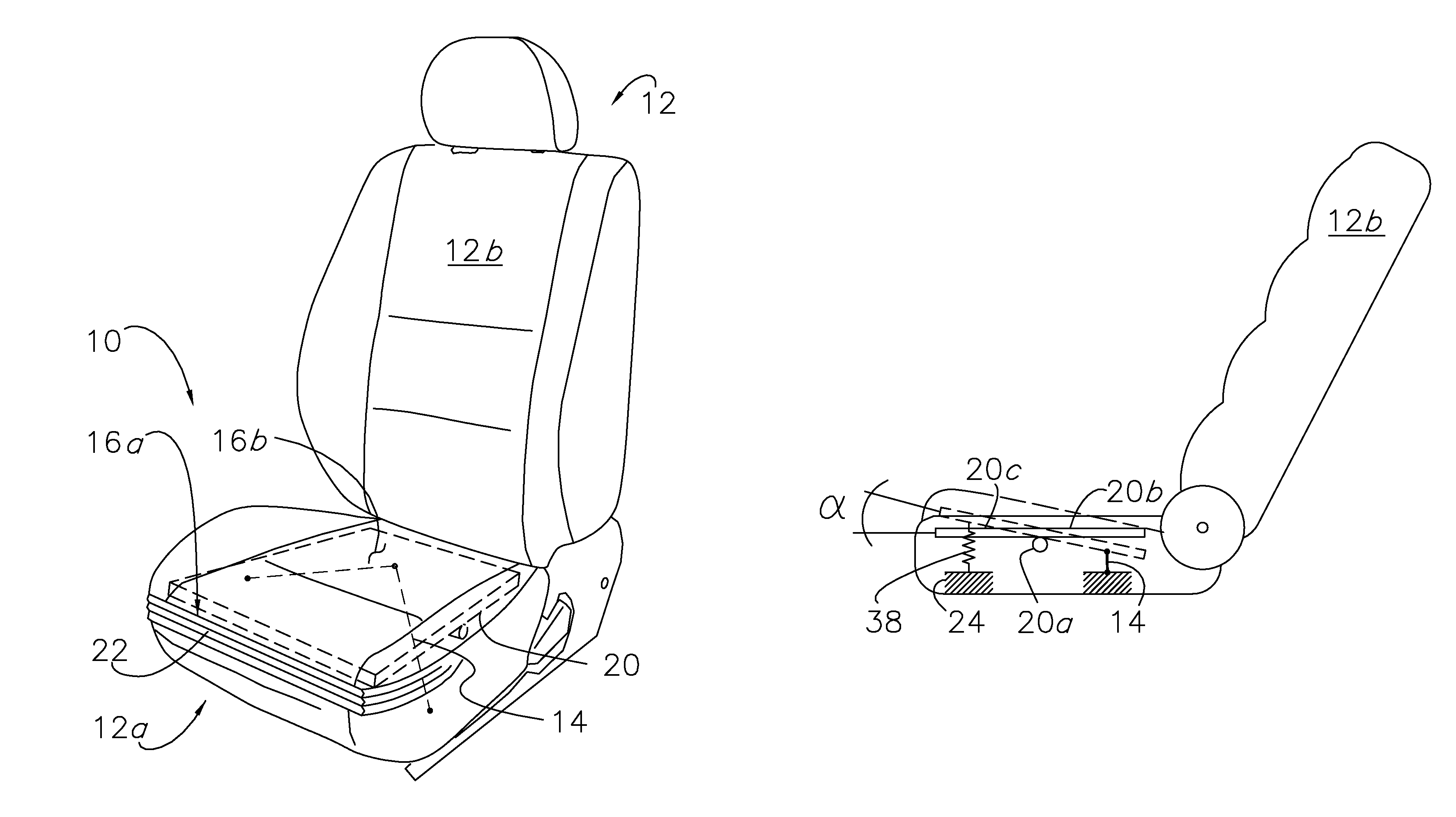

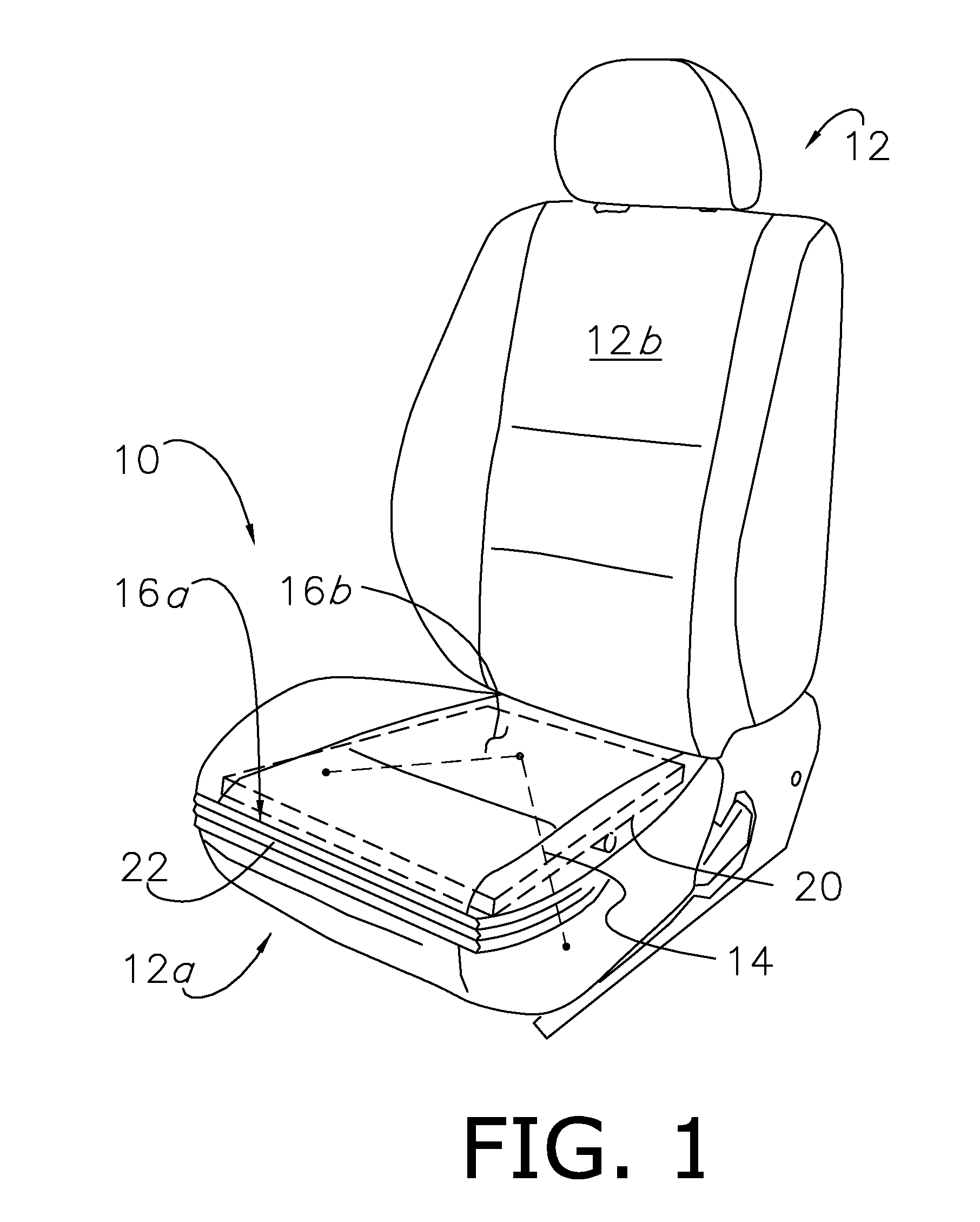

Adjustable seat ramp utilizing active material actuation

InactiveUS8100471B2Effective regulationImproving occupant kinematics, ergonomics, and comfortOperating chairsPedestrian/occupant safety arrangementEngineeringActuator

An adjustable seat ramp adapted for use with a seat base and defining a first angle of inclination, includes a structure translatably disposed within or integrally formed with the base and presenting a first position, and further includes an actuator employing a shape memory material element and configured to cause the structure to translate to a second position, wherein a second angle of inclination is defined.

Owner:GM GLOBAL TECH OPERATIONS LLC

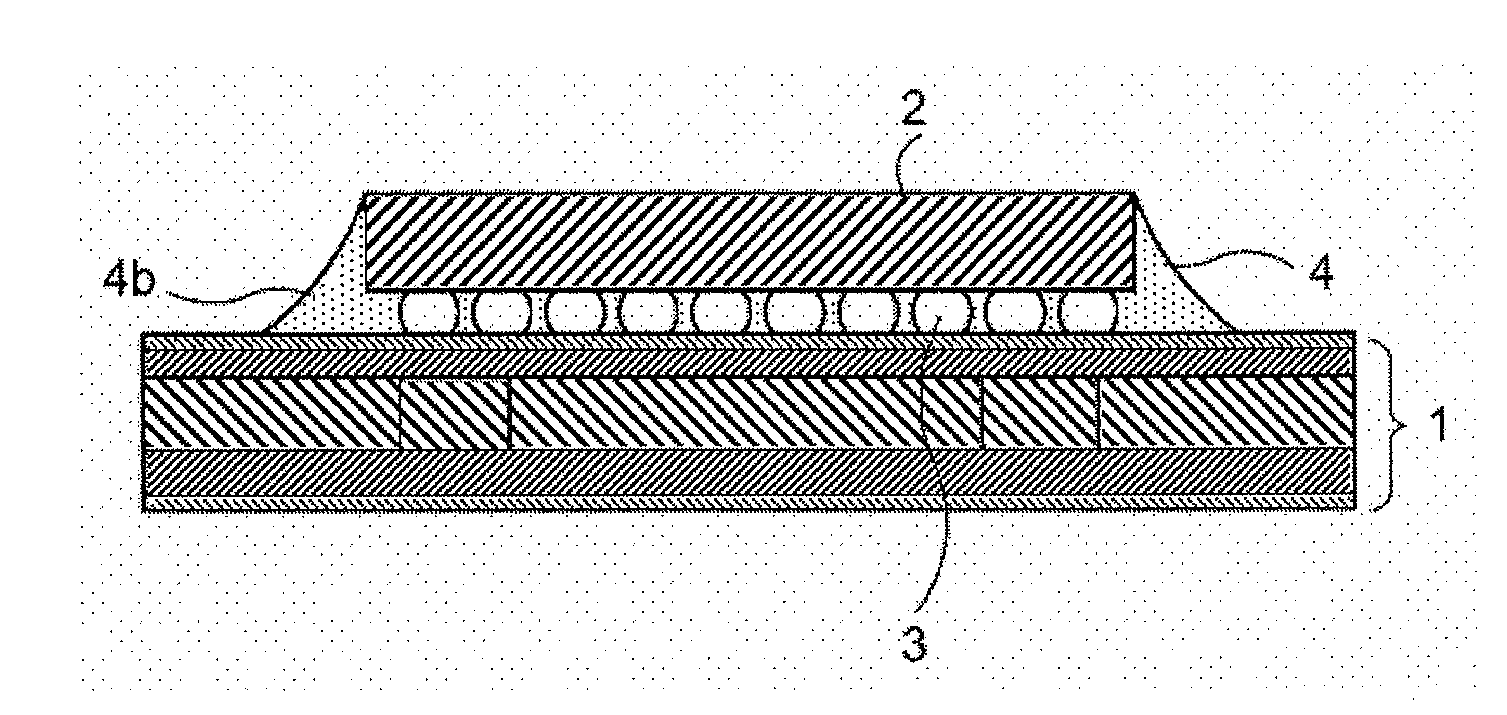

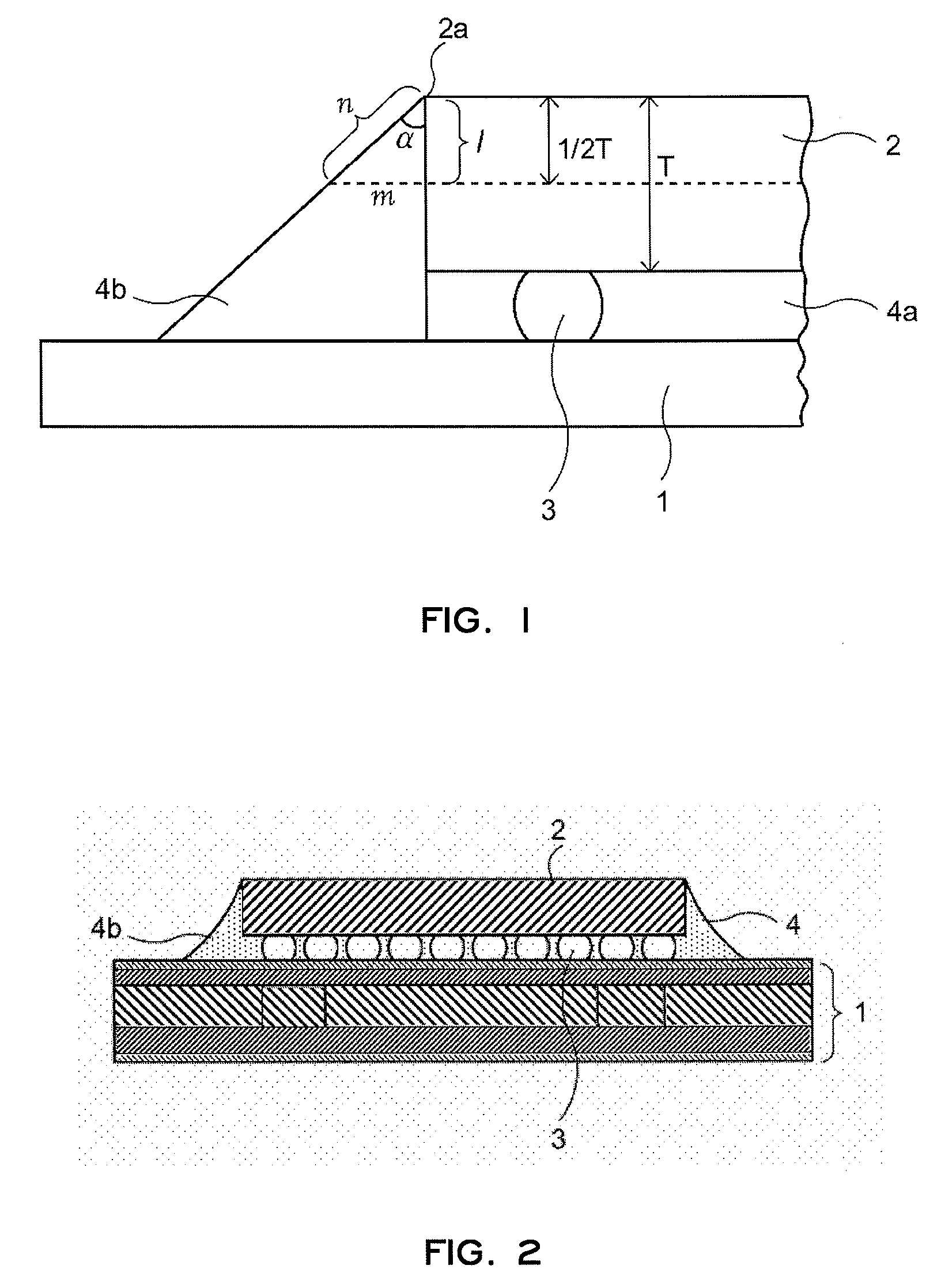

Semiconductor package, method of production thereof and encapsulation resin

InactiveUS20080036097A1Crack can be prevented and reducedImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A flip-chip semiconductor package and method of manufacture thereof, the flip-chip semiconductor being highly reliable due to suppression of cracking. The flip-chip semiconductor package is formed by flip-chip bonding of a semiconductor chip-connecting electrode surface of a circuit board 1 and an electrode surface of a semiconductor chip 2, dispensing of an encapsulation resin 4 between the circuit board 1 and the semiconductor chip 2, and formation of fillet 4b by providing the encapsulation resin 4 on peripheral side portions of the semiconductor chip, the fillet 4b having inclined surfaces extending from upper edges 2a of the peripheral side portions of the semiconductor chip 2 outward toward the circuit board, wherein the angle of inclination formed between the inclined surfaces and the peripheral side portions of the semiconductor chip 2 is 50 degrees or less in the vicinity of the upper edges of the peripheral side portions 2a of the semiconductor chip.

Owner:SUMITOMO BAKELITE CO LTD

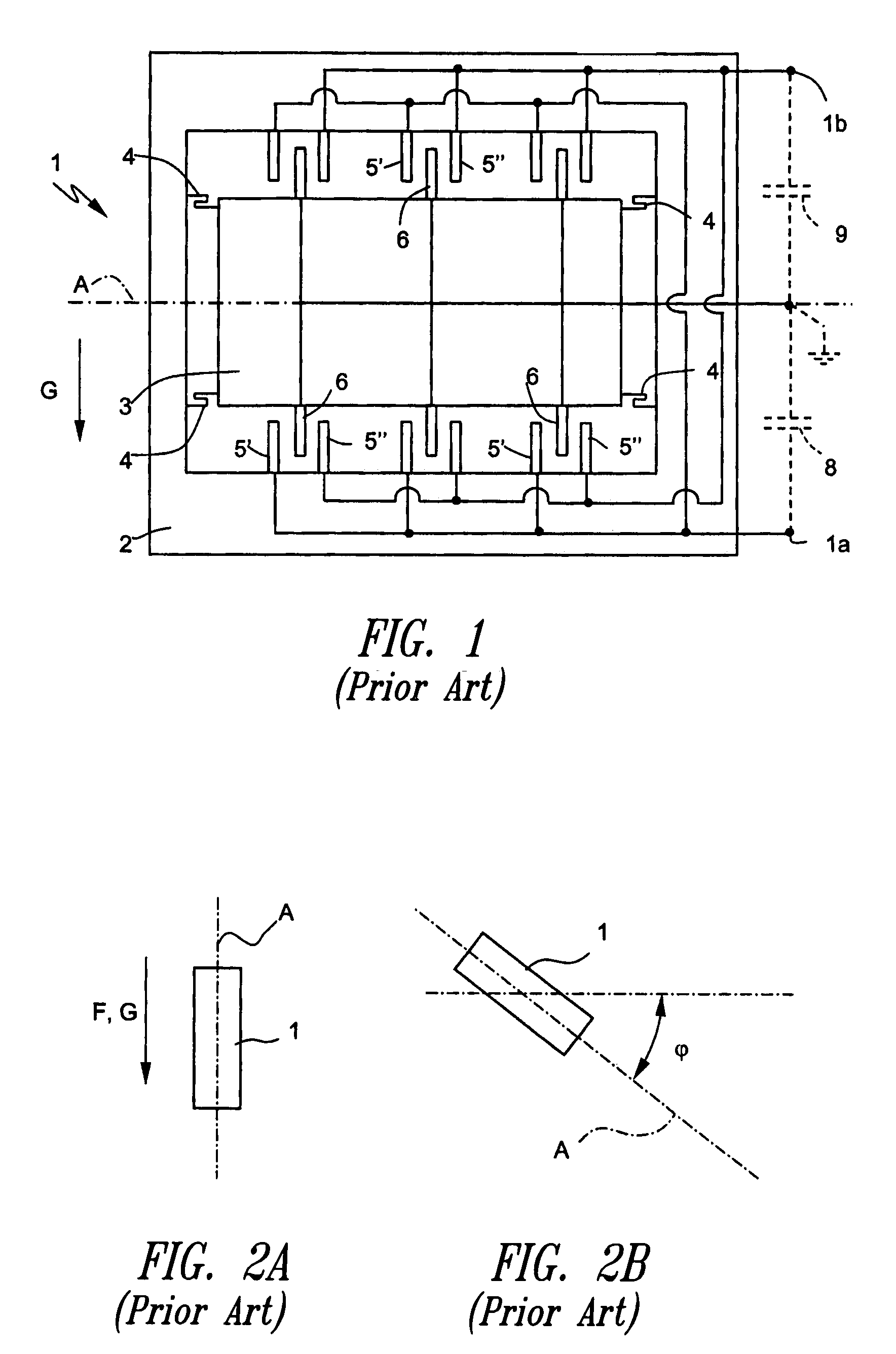

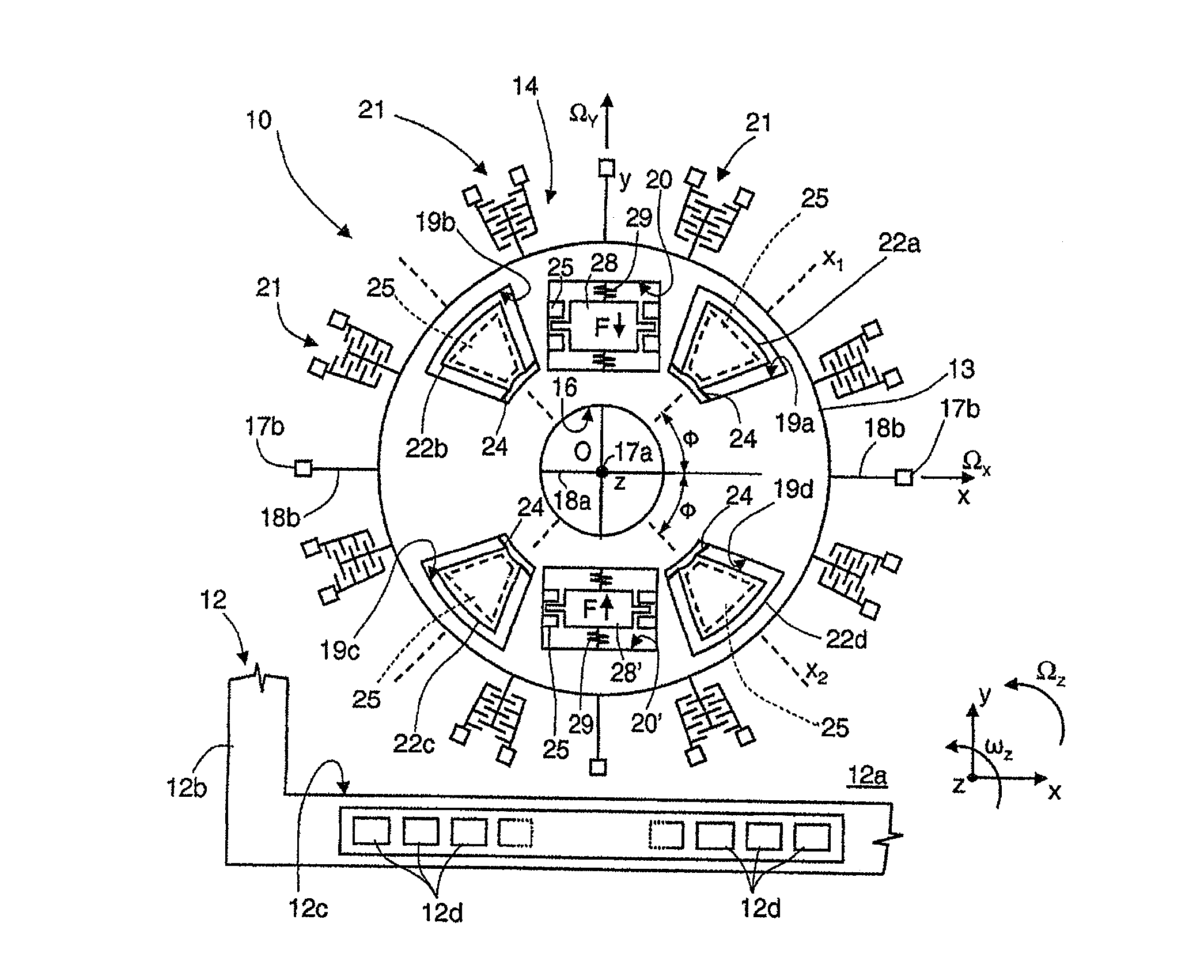

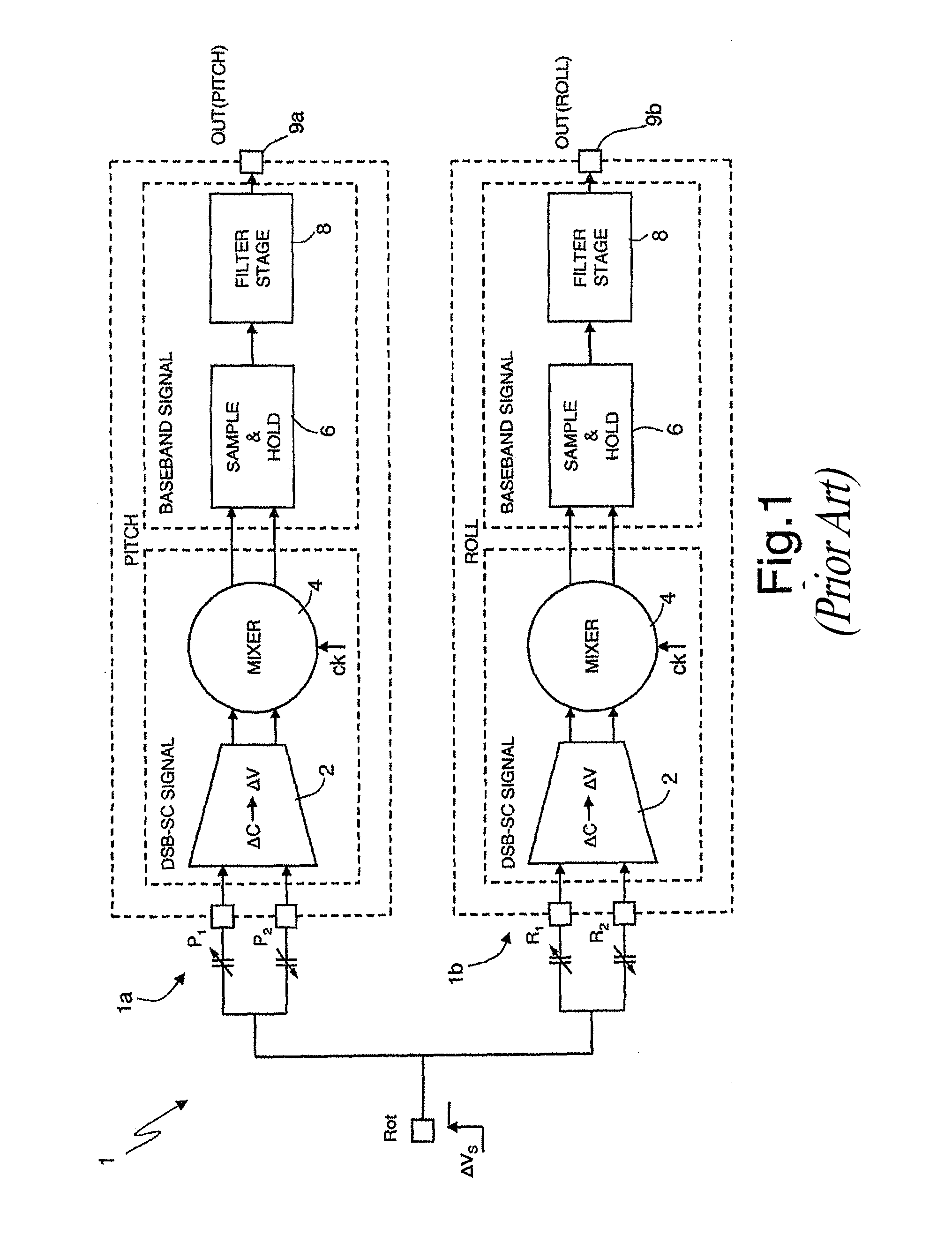

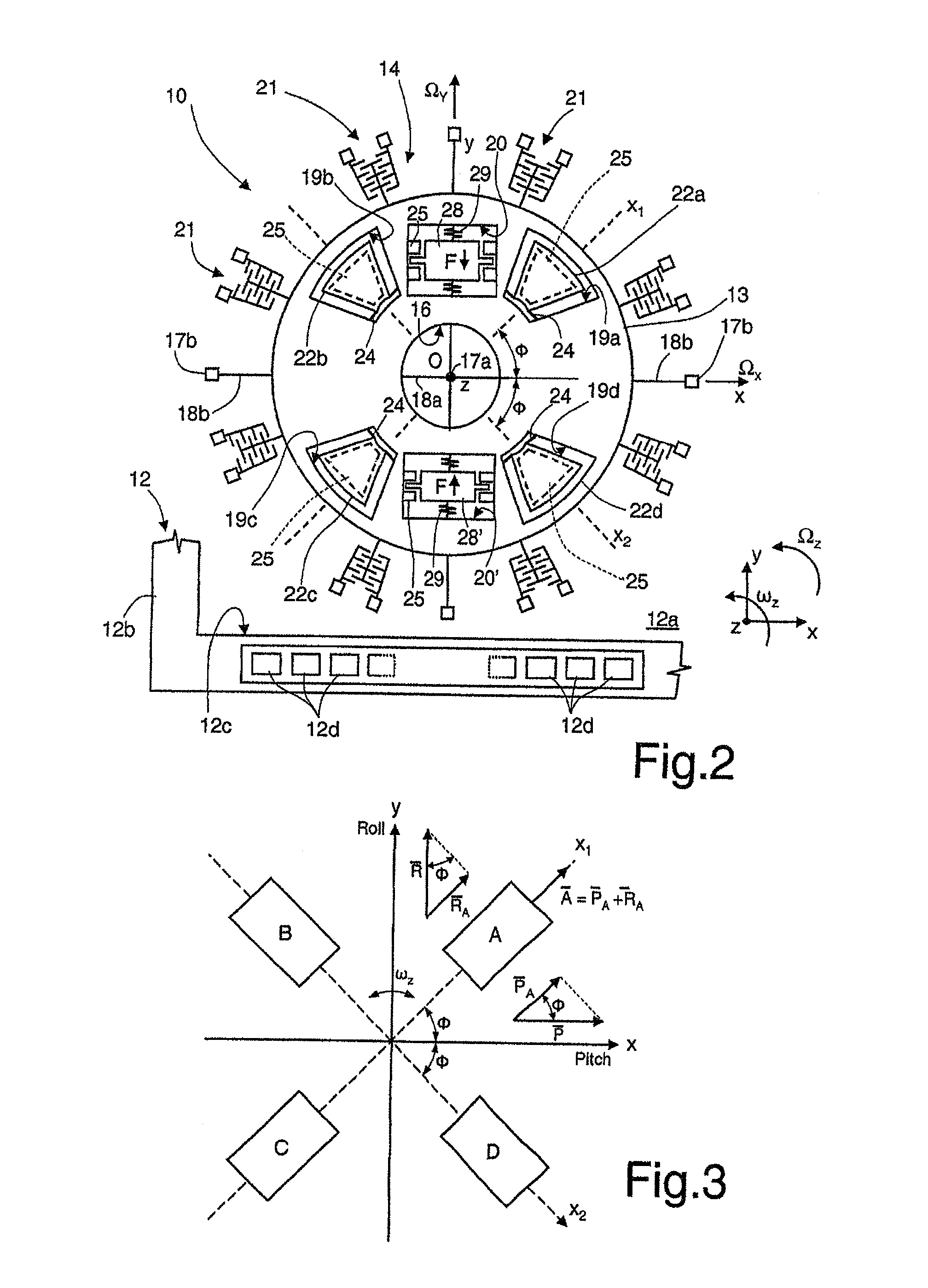

Reading circuit for a multi-axis MEMS gyroscope having detection directions inclined with respect to the reference axes, and corresponding multi-axis MEMS gyroscope

ActiveUS20100132463A1Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsElectricityGyroscope

A multi-axis gyroscope includes a microelectromechanical structure configured to rotate with respective angular velocities about respective reference axes, and including detection elements, which are sensitive in respective detection directions and generate respective detection quantities as a function of projections of the angular velocities in the detection directions. The gyroscope including a reading circuit that generates electrical output signals, each correlated to a respective one of the angular velocities, as a function of the detection quantities. The reading circuit includes a combination stage that combines electrically with respect to one another electrical quantities correlated to detection quantities generated by detection elements sensitive to detection directions different from one another, so as to take into account a non-zero angle of inclination of the detection directions with respect to the reference axes.

Owner:STMICROELECTRONICS SRL

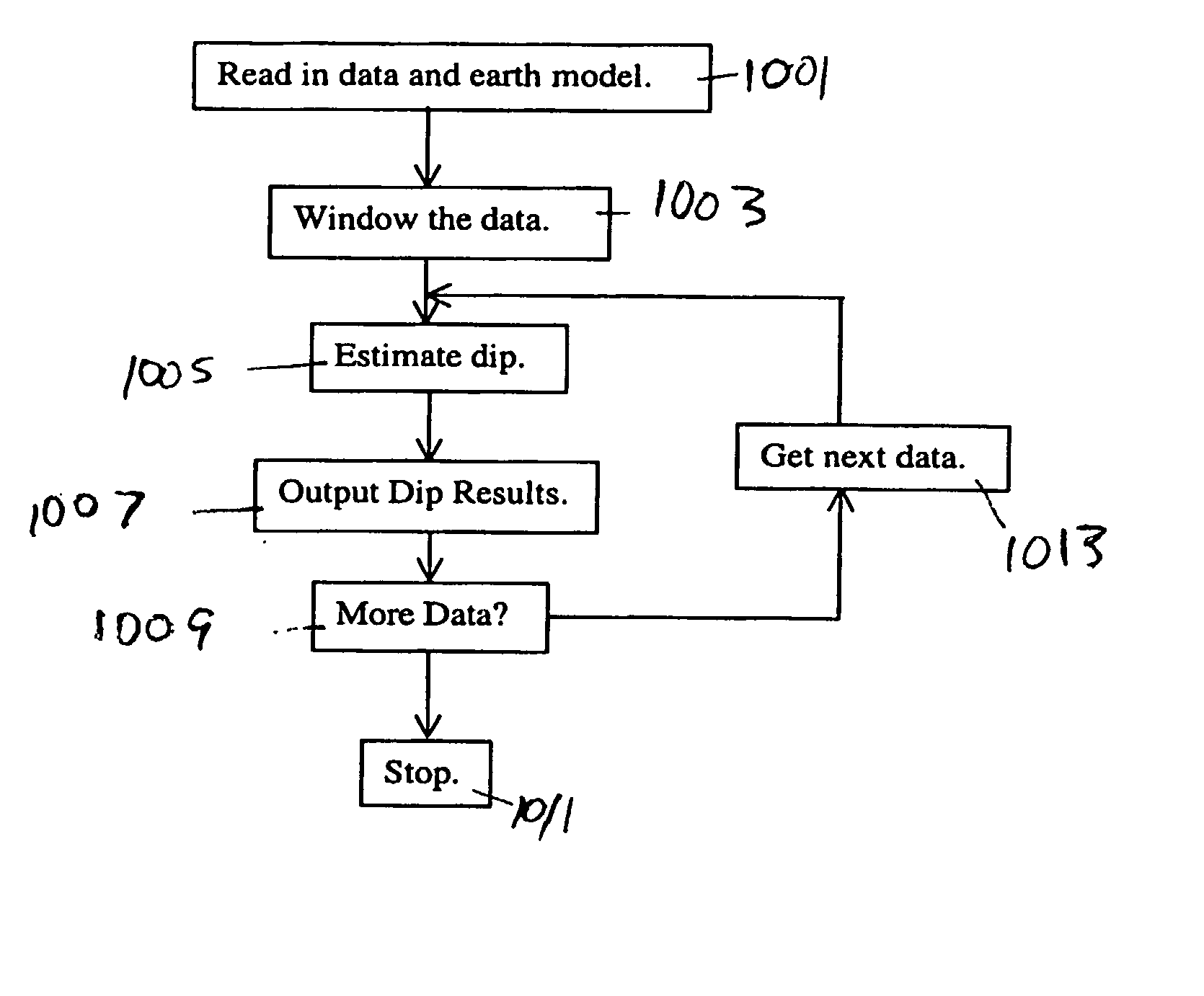

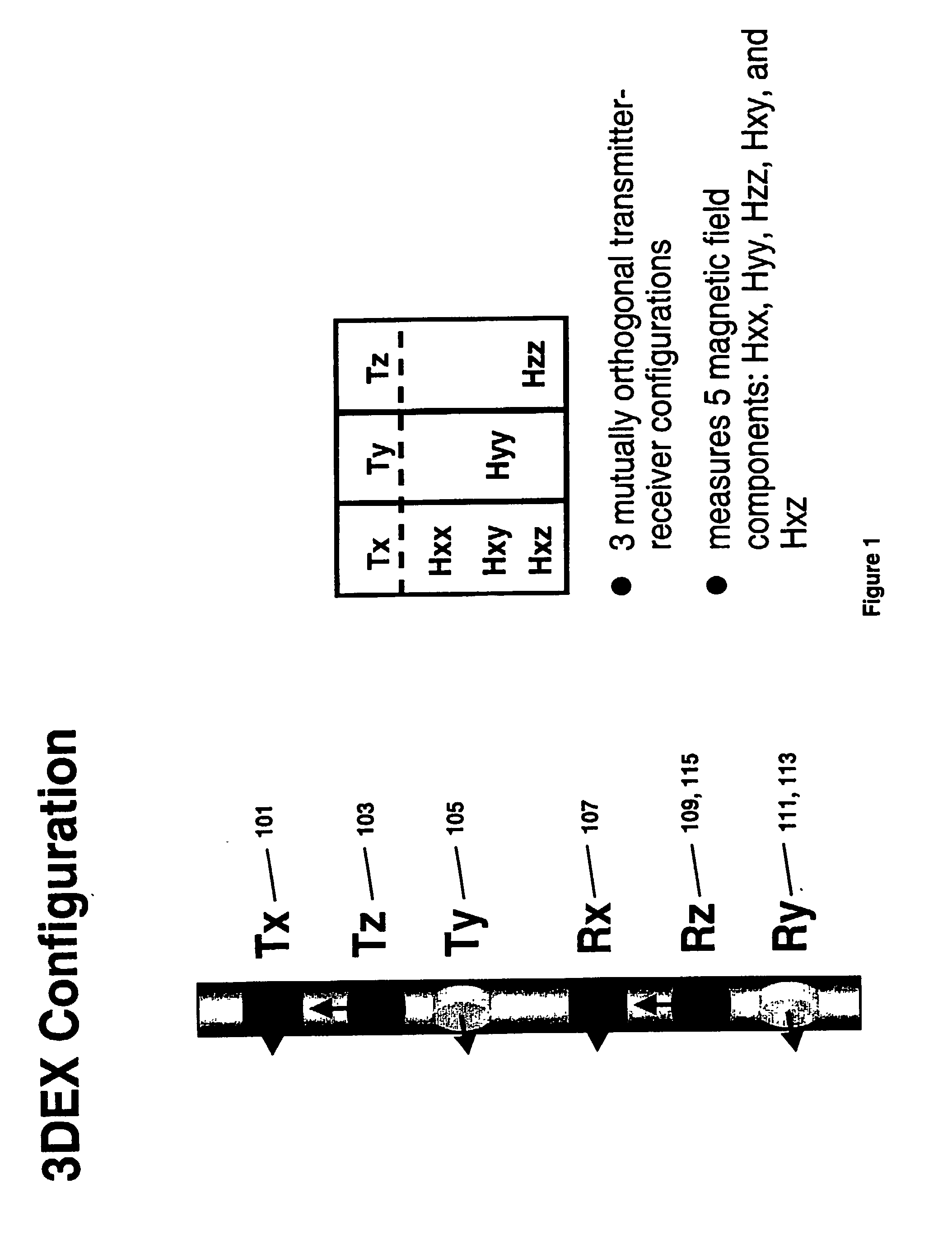

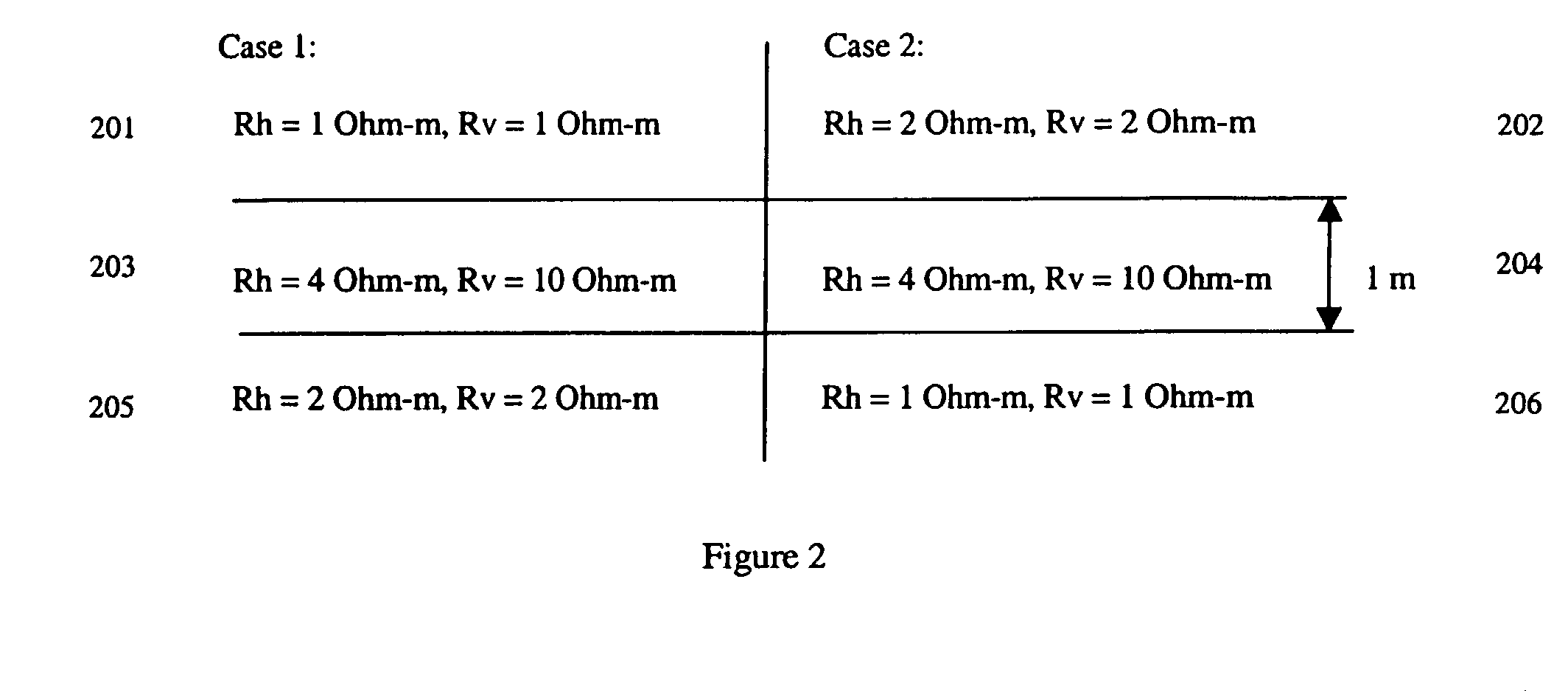

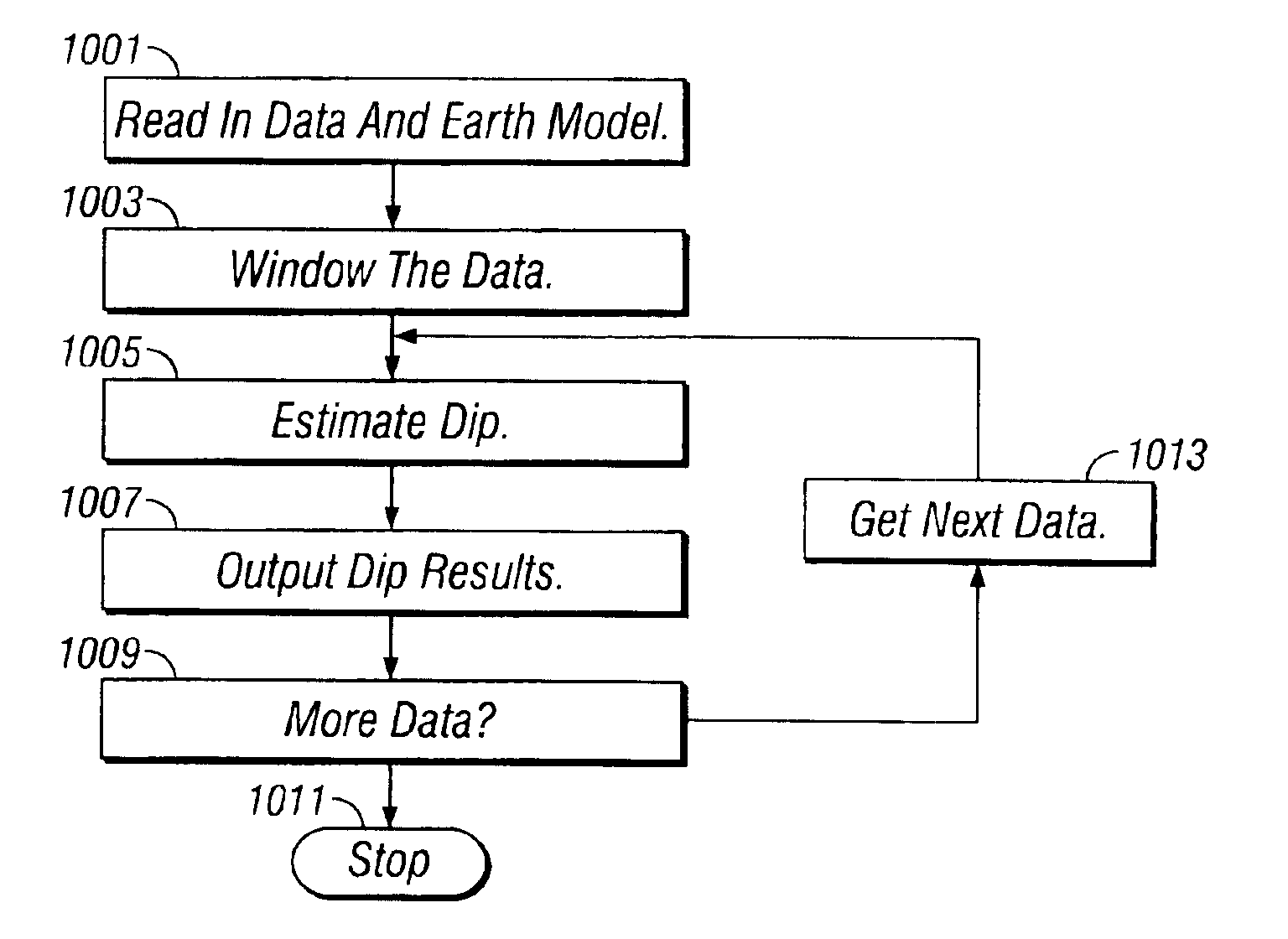

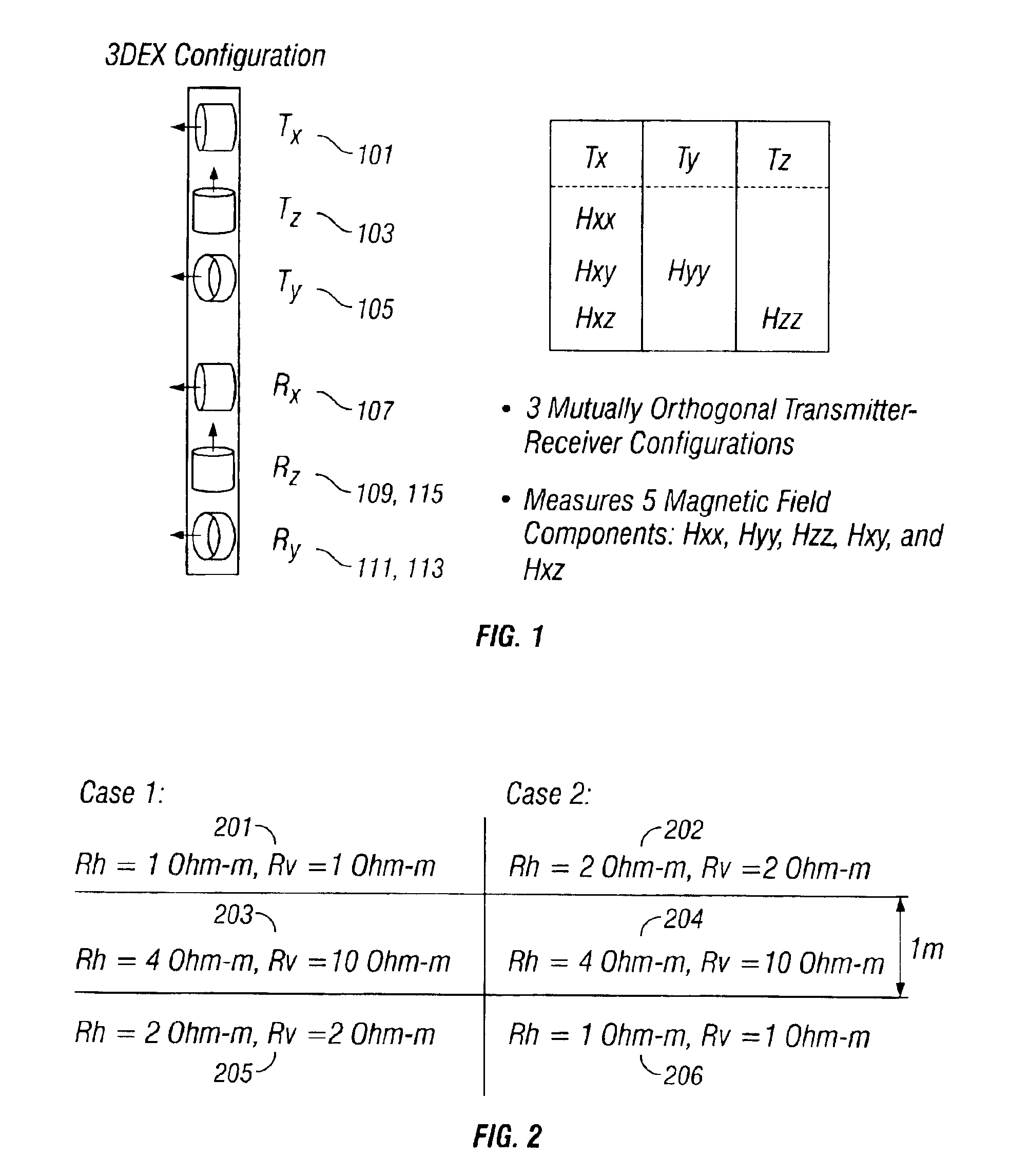

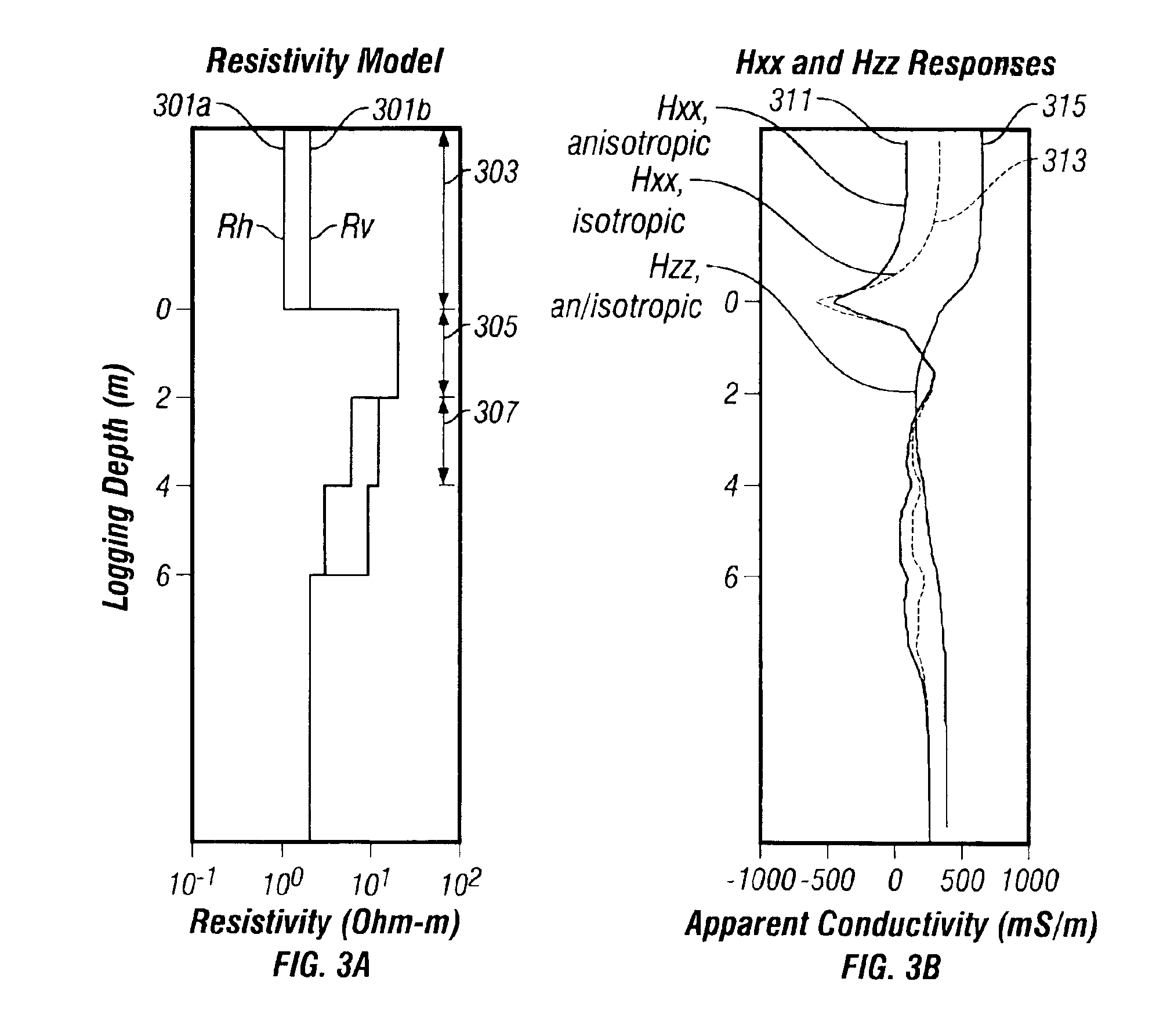

Method for joint interpretation of multi-array induction and multi-component induction measurements with joint dip angle estimation

InactiveUS20030028324A1Electric/magnetic detection for well-loggingSeismic signal processingCorrelation coefficientClassical mechanics

Data are acquired using multi-array logging tool in a borehole having an angle of inclination to a normal to the bedding plane of earth formations. The multi-array measurements are filtered using angle dependent filters to give a filtered curve corresponding to a target one of the multi-array measurements using angle dependent filters. Correlation coefficients are determined for a set of possible dip angles and a relative dip angle is estimated from the correlation coefficients. This dip angle estimate together with bed boundaries obtained from the multi-array measurements are used for inverting multi-component measurements alone or jointly with multi-array measurements to refine the relative dip angle interpretation and give horizontal and vertical formation resistivity.

Owner:BAKER HUGHES INC

Method for joint interpretation of multi-array induction and multi-component induction measurements with joint dip angle estimation

InactiveUS6885947B2Electric/magnetic detection for well-loggingSeismic signal processingCorrelation coefficientAngular correlation

Data are acquired using multi-array logging tool in a borehole having an angle of inclination to a normal to the bedding plane of earth formations. The multi-array measurements are filtered using angle dependent filters to give a filtered curve corresponding to a target one of the multi-array measurements using angle dependent filters. Correlation coefficients are determined for a set of possible dip angles and a relative dip angle is estimated from the correlation coefficients. This dip angle estimate together with bed boundaries obtained from the multi-array measurements are used for inverting multi-component measurements alone or jointly with multi-array measurements to refine the relative dip angle interpretation and give horizontal and vertical formation resistivity.

Owner:BAKER HUGHES INC

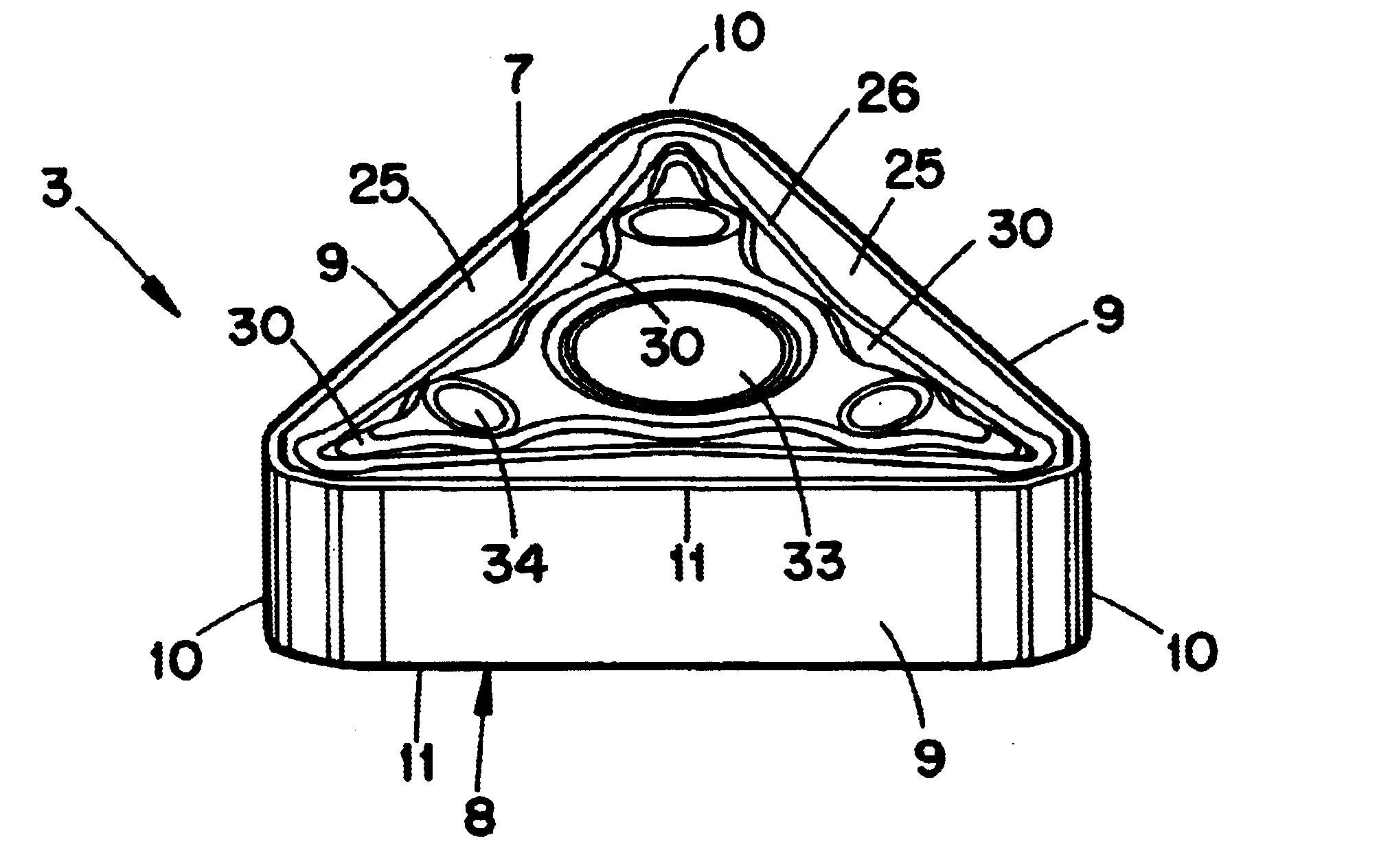

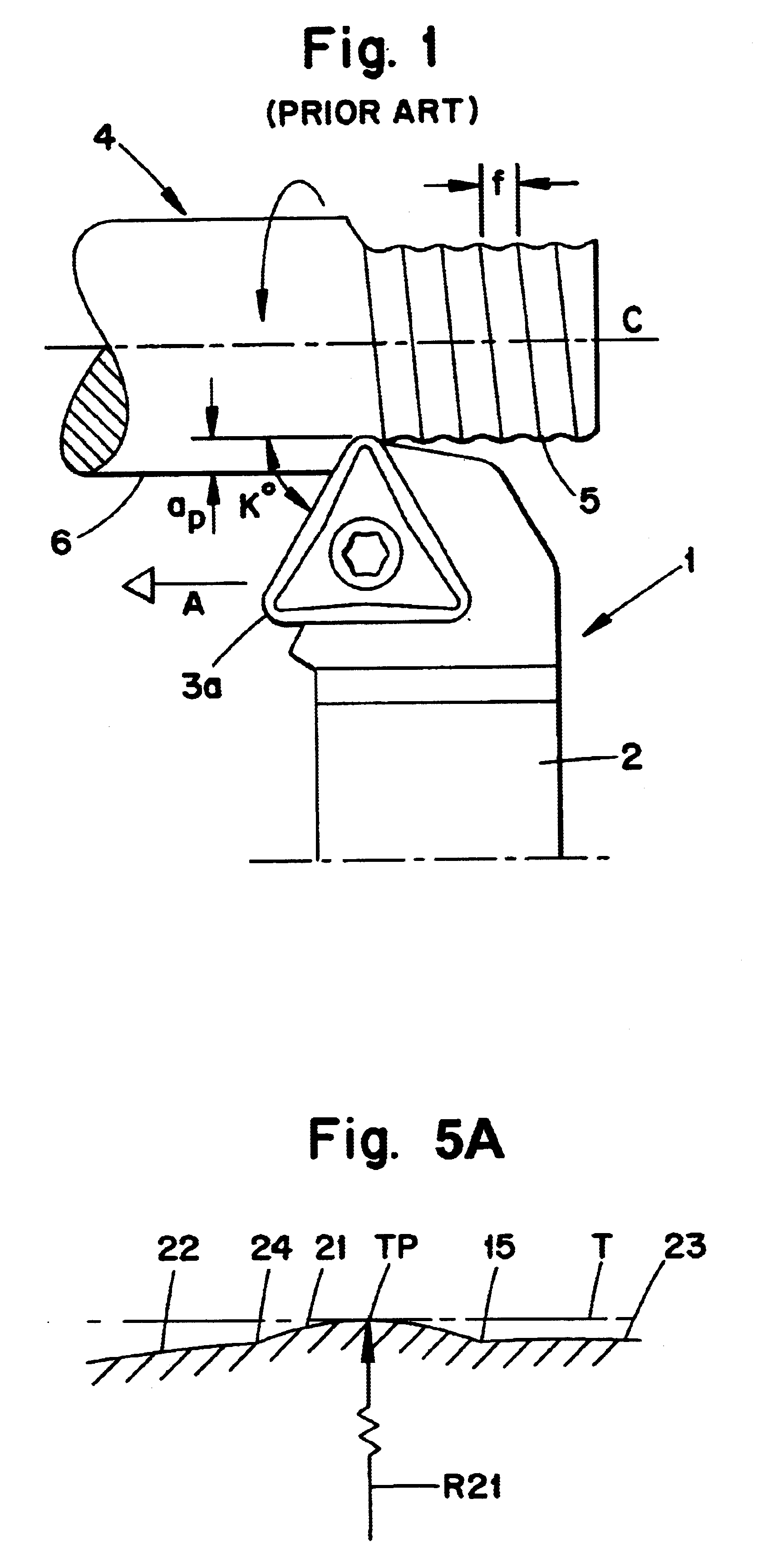

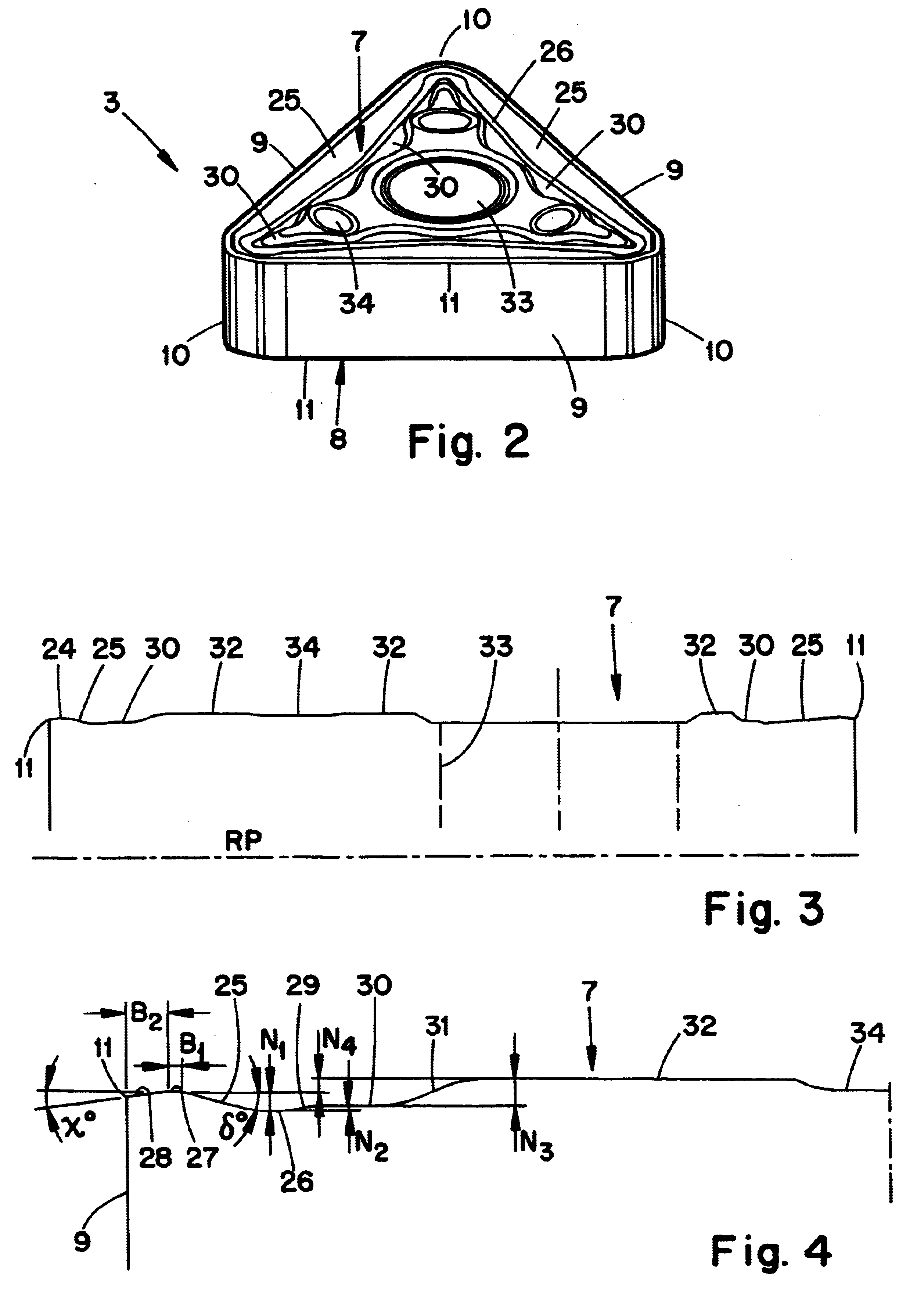

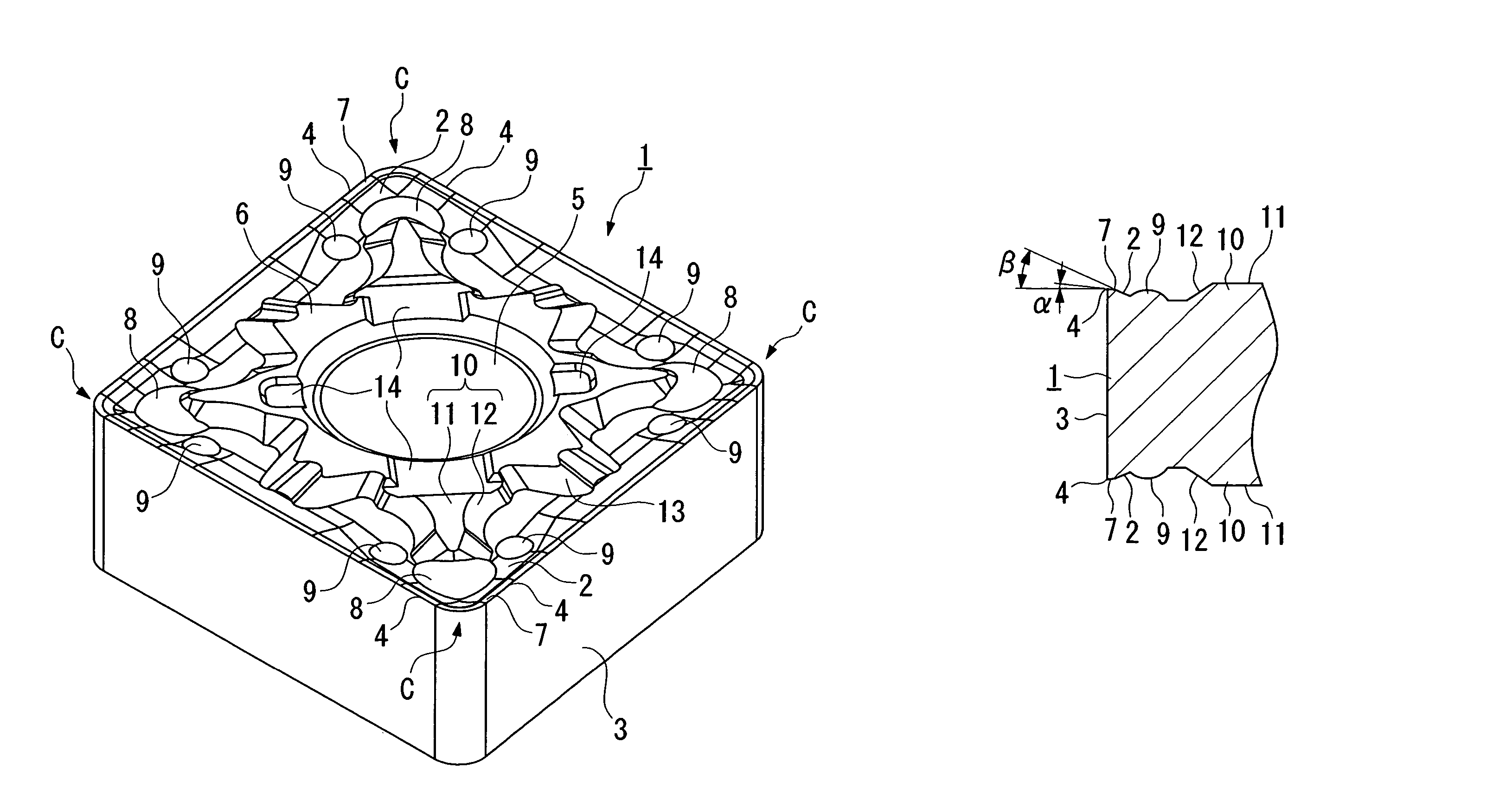

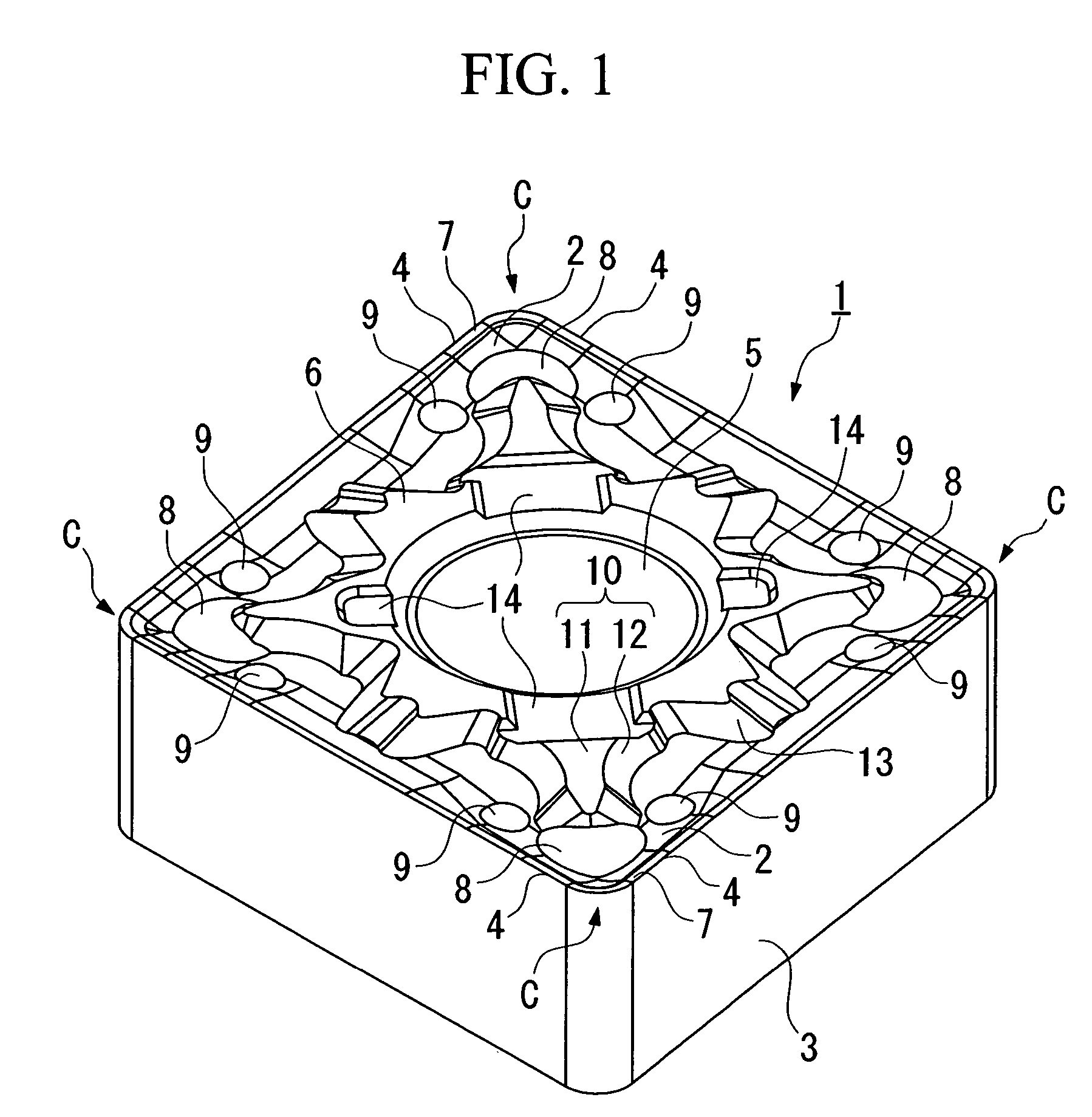

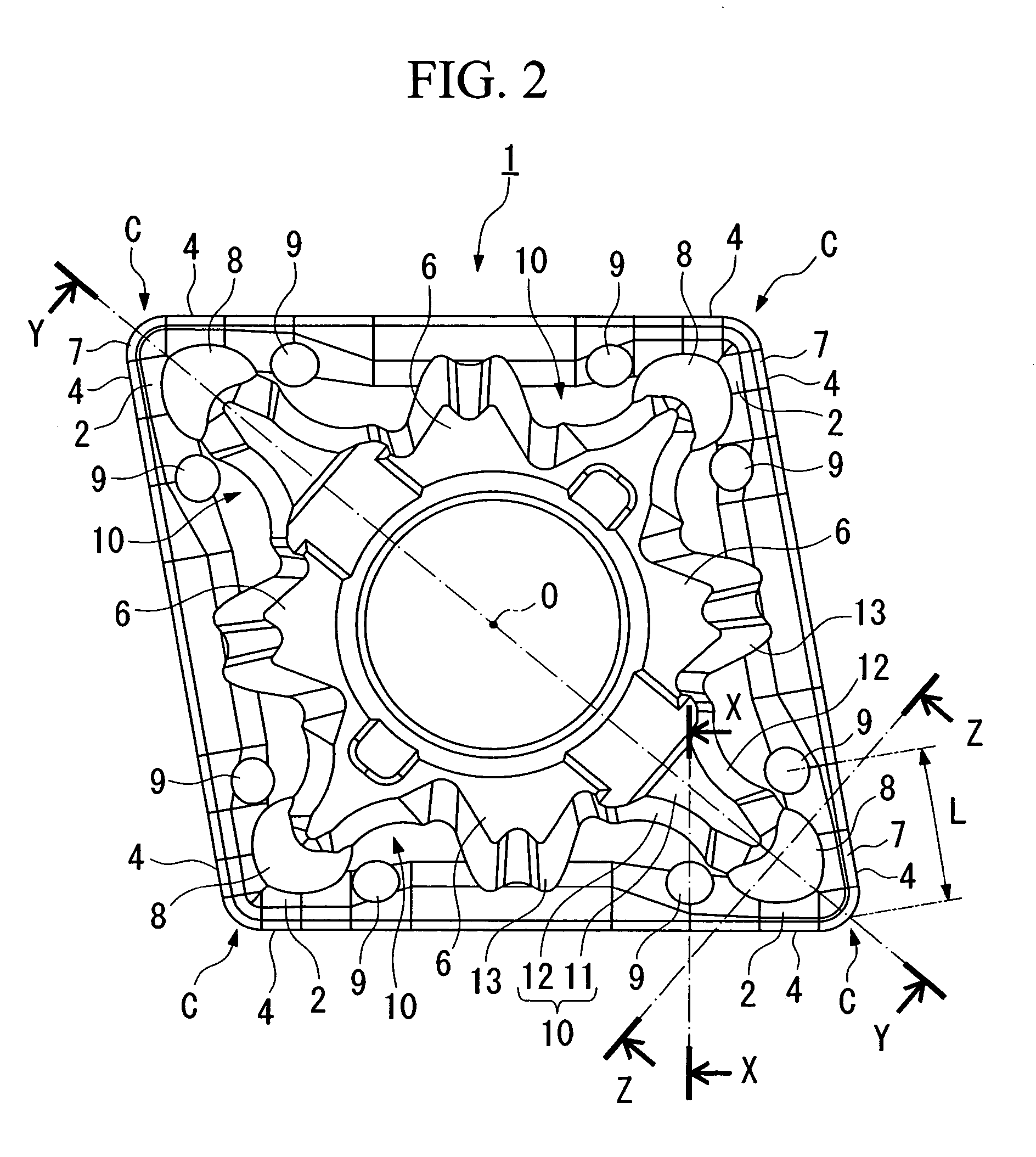

Cutting insert for chip removing machining

InactiveUS6715967B2Risk minimizationHigh surface finishCutting insertsTurning toolsEngineeringMachining

A cutting insert, intended for chip removing machining includes a cutting geometry surface having a cutting edge from which extends a primary chamfer that transforms into a chip removing surface. The chip removing surface is inclined in a inwards / downwards direction in order to permit sinking of a chip being formed, and transforms into a deflection surface arranged to initiate deflection of the chip from the cutting insert. The angle of inclination of the chip removing surface does not exceed 18°. The level difference in elevation between the primary chamfer and the chip deflection surface amounts to maximally 0.20 mm.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

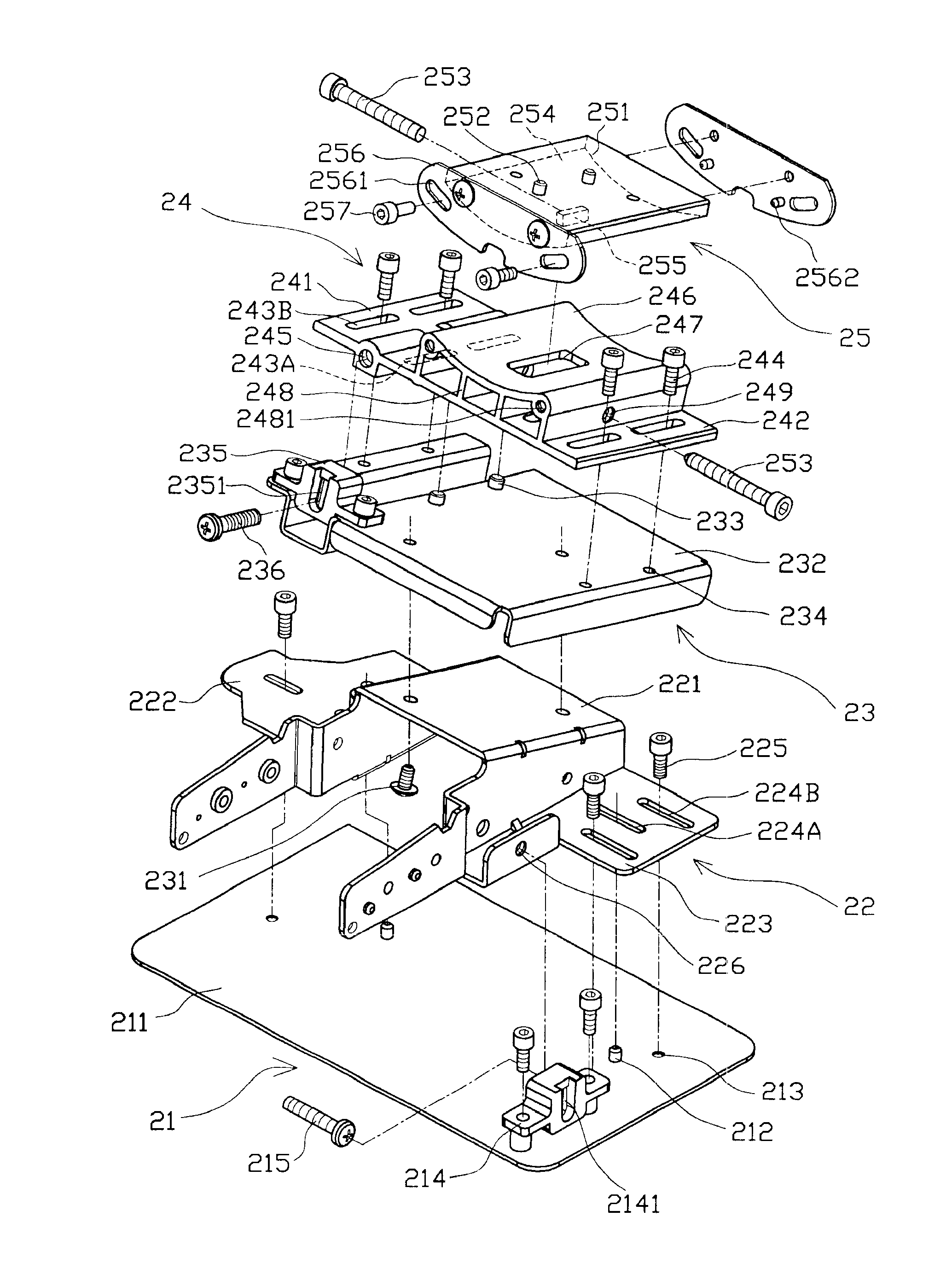

Adjusting apparatus

An adjusting apparatus comprises a base, and a supporting frame, a fixed plate, a sliding stand, and a carrier, which are sequential stacked on the base. An optical engine is fixed on the carrier. By rotating the adjusting device, the axis position of optical engine can be adjusted along sliding slots guided by bulges. By using arc surfaces of the sliding stand and the carrier, the adjusting apparatus clips and pushes the blocks of the carrier to adjust the left and right angle of inclination of optical engine. Therefore, the light beam provided by optical engine could project on a screen precisely and reach the optimum projection performance.

Owner:PURAC BIOCHEM +1

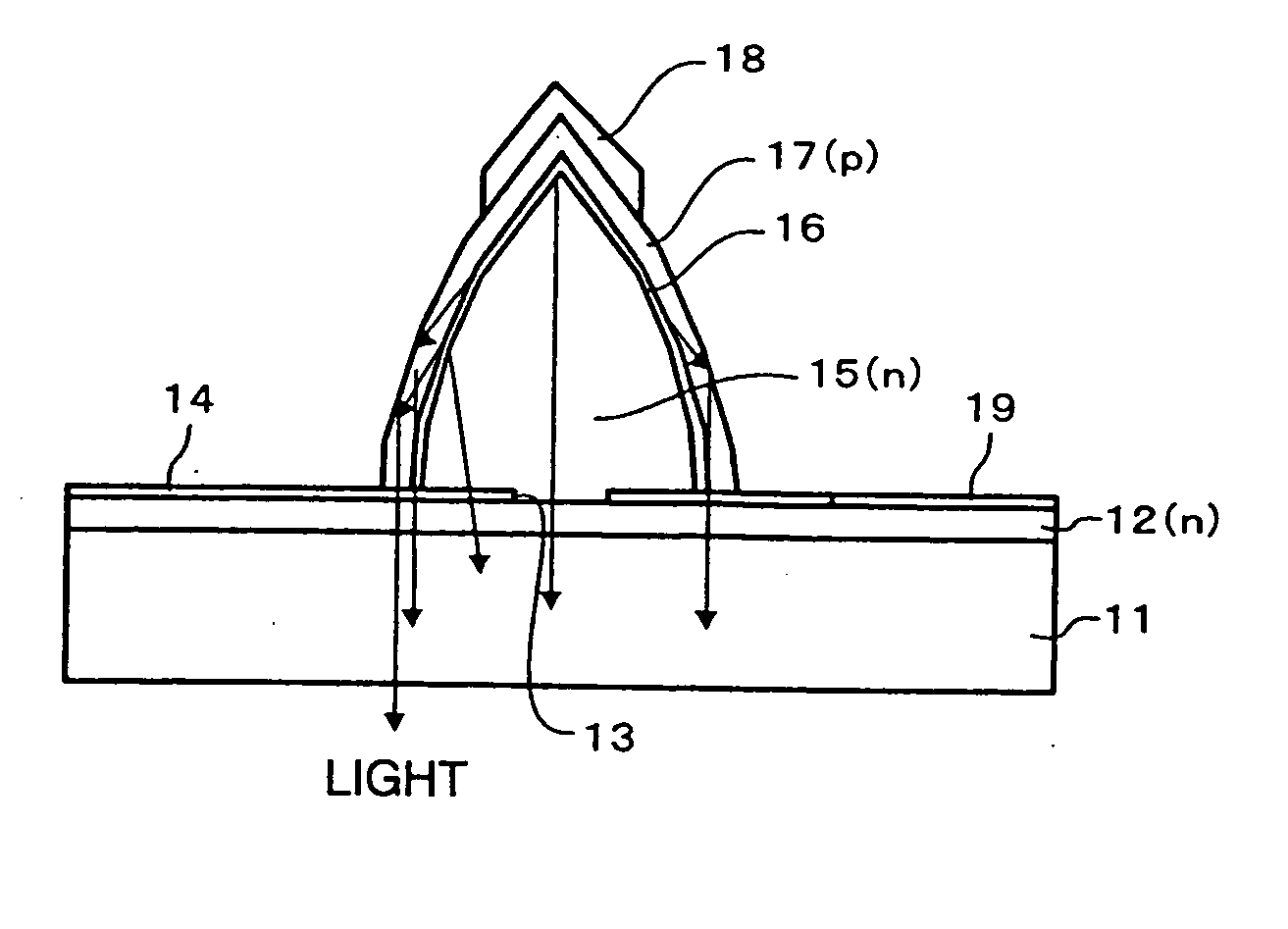

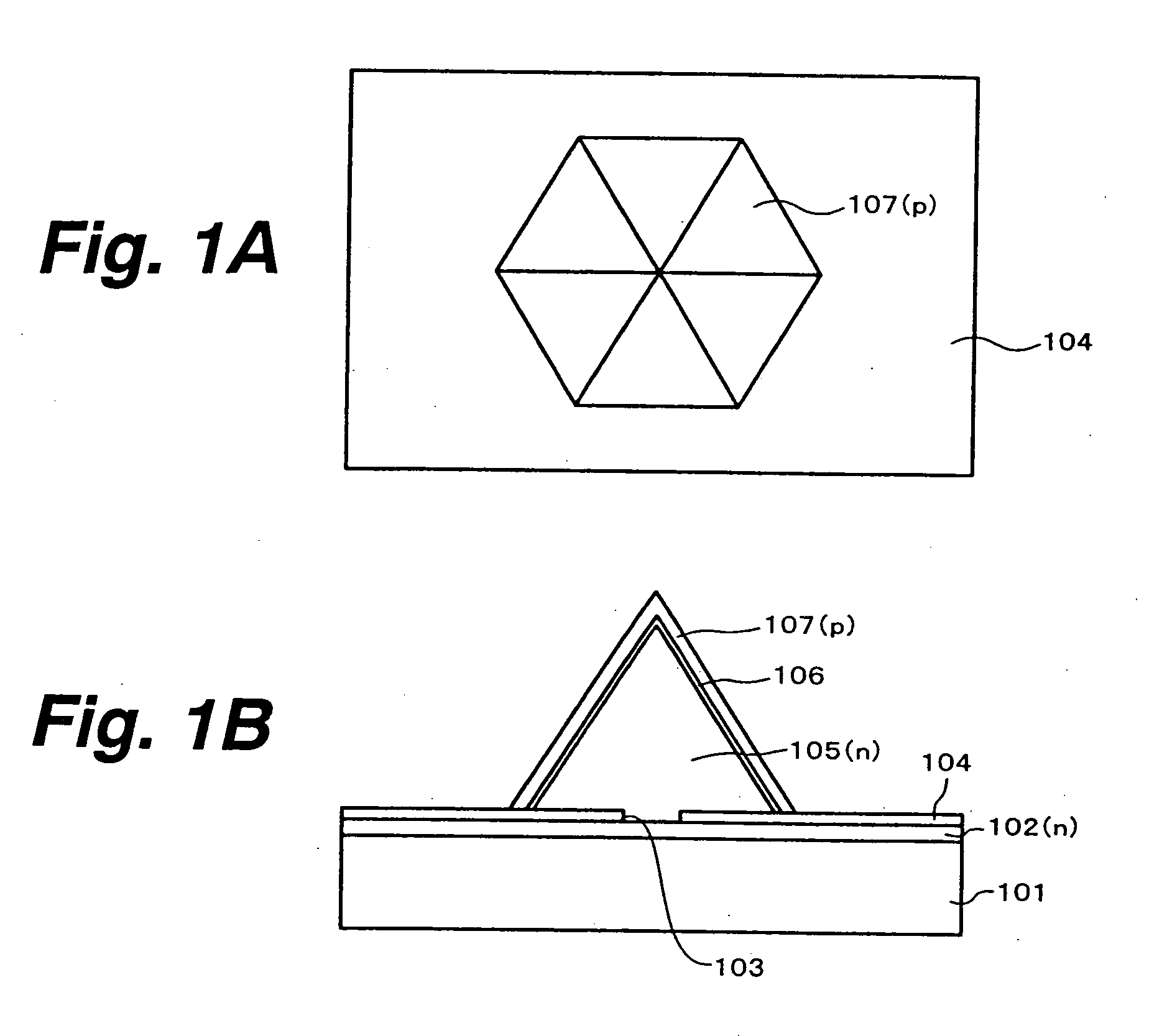

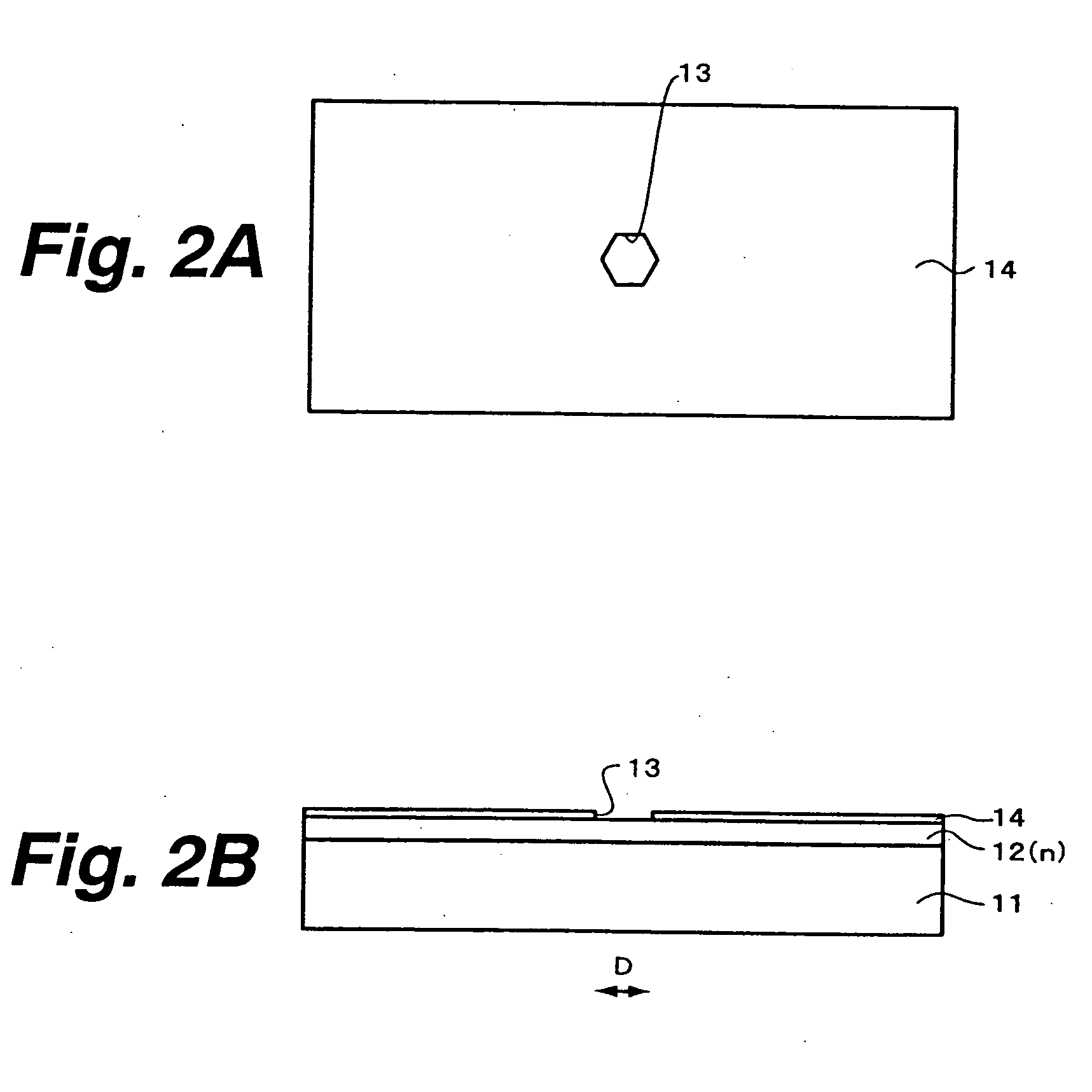

Semiconductor light emitting element and method for manufacturing same, integrated semiconductor light-emitting device and method for manufacturing same, image display and method for manufacturing same, and illuminating device and method for manufacturing same

InactiveUS20050145865A1Small sizeLess subjectWater treatment parameter controlFatty/oily/floating substances removal devicesDisplay deviceCrystal plane

A semiconductor light emitting element, manufacturing method thereof, integrated semiconductor light emitting device, manufacturing method thereof, illuminating device, and manufacturing method thereof are provided. An n-type GaN layer is grown on a sapphire substrate, and a growth mask of SiN, for example, is formed thereon. On the n-type GaN layer exposed through an opening in the growth mask, a six-sided steeple-shaped n-type GaN layer is selectively grown, which has inclined crystal planes each composed of a plurality of crystal planes inclined from the major surface of the sapphire substrate by different angles of inclination to exhibit a convex plane as a whole. On the n-type GaN layer, an active layer and a p-type GaN layer are grown to make a light emitting element structure. Thereafter, a p-side electrode and an n-side electrode are formed.

Owner:SONY CORP

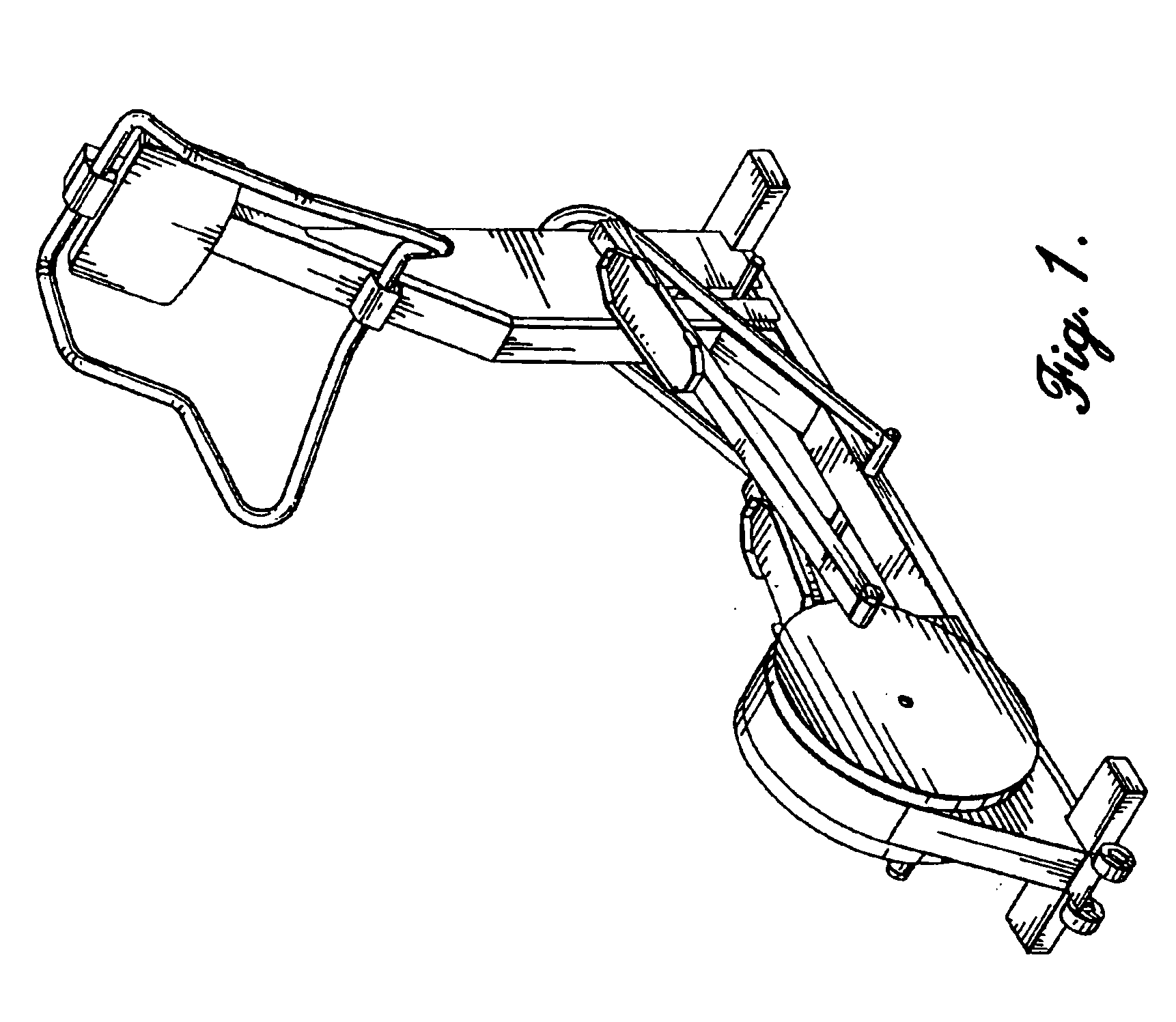

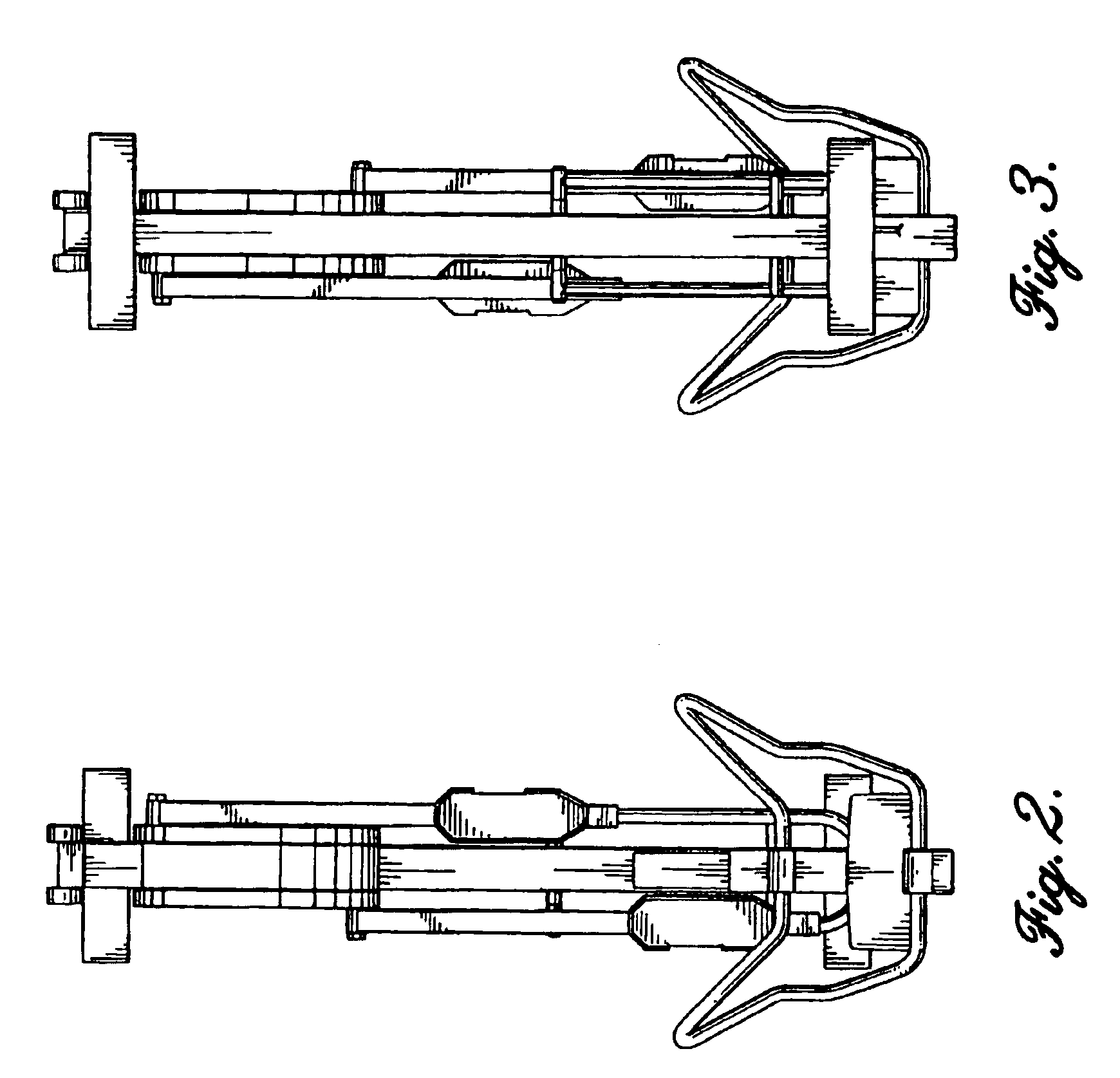

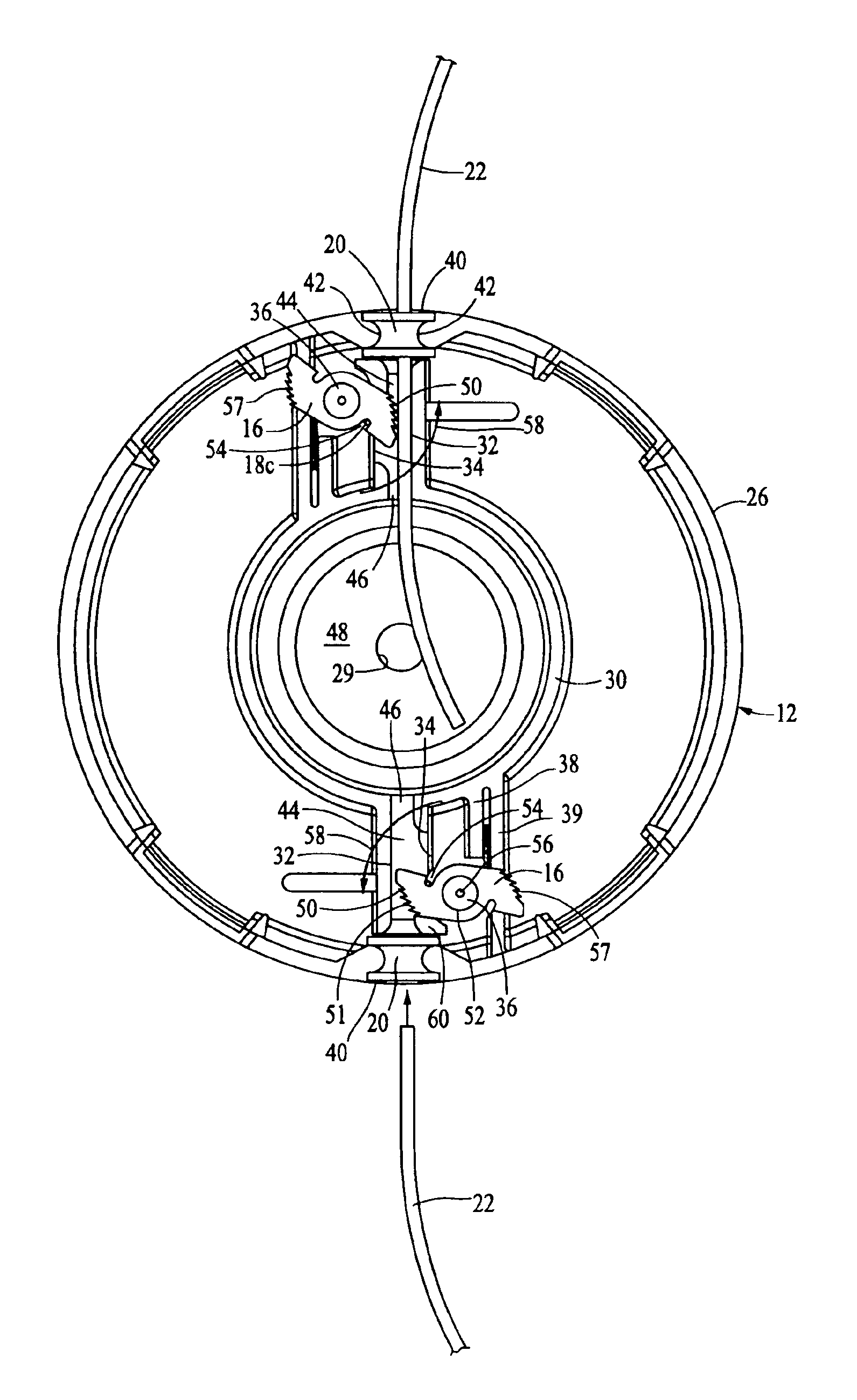

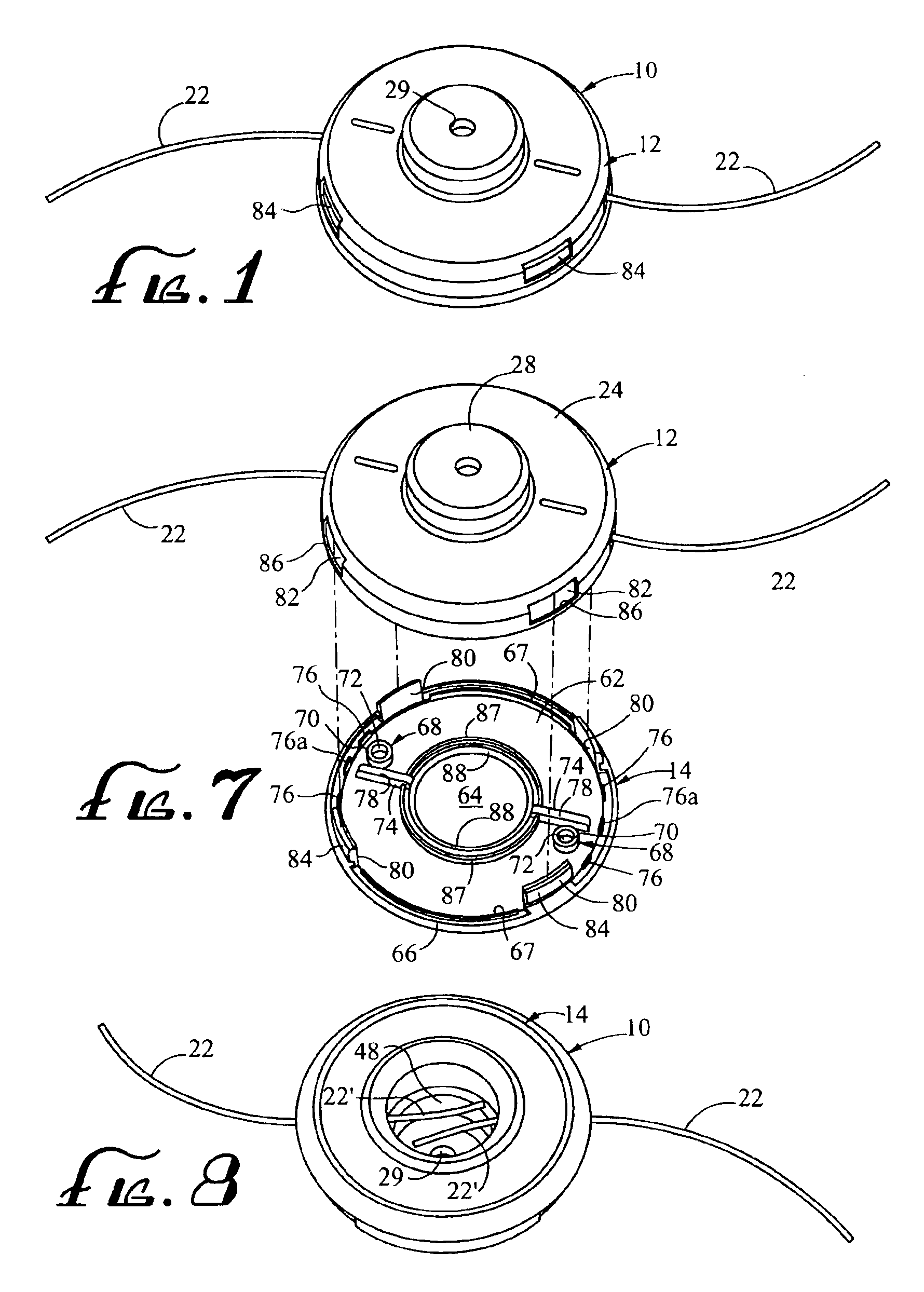

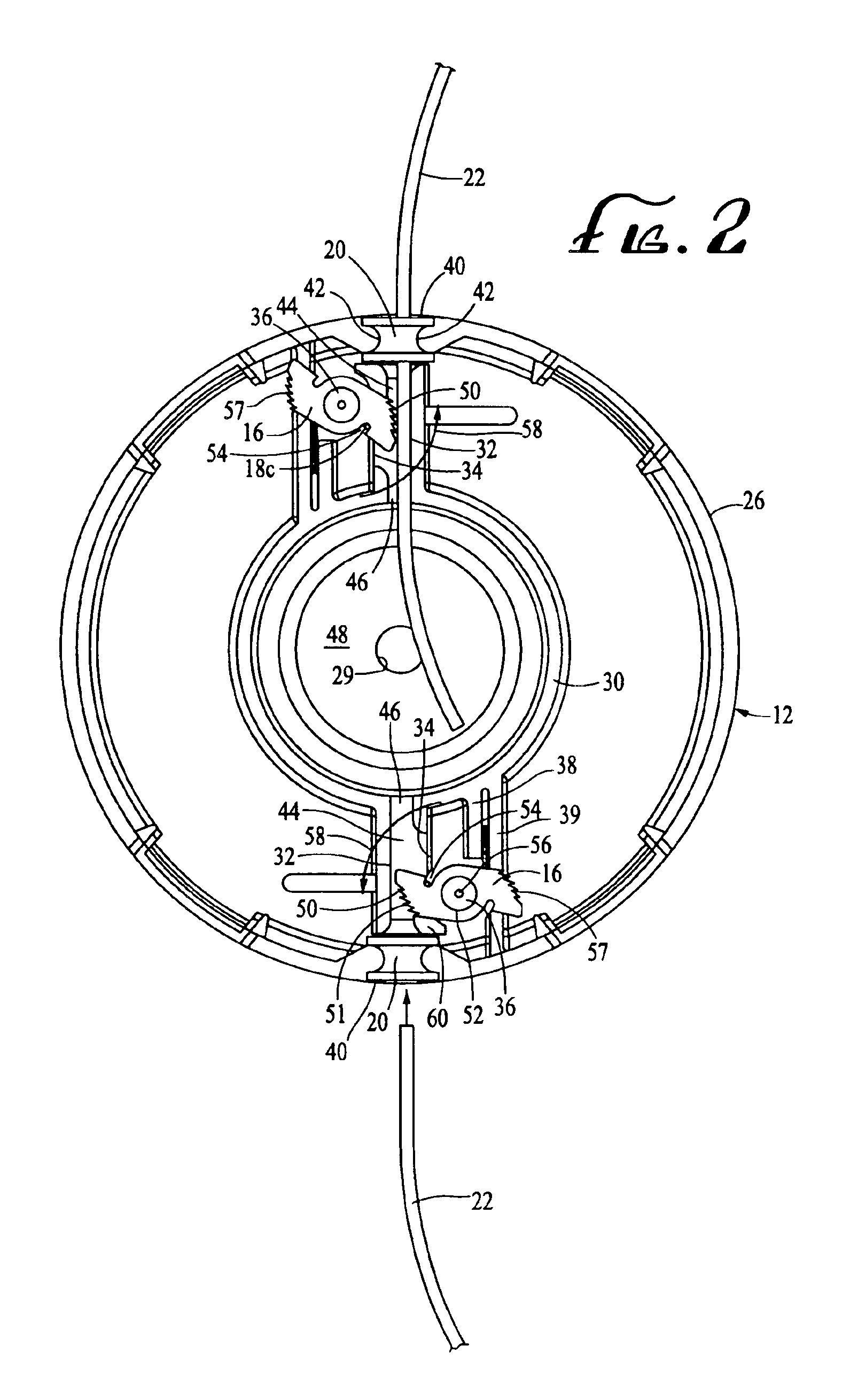

Fixed line head for flexible line rotary trimmers

InactiveUS6928741B2Simplifies line removalSolve the complicated replacementMowersMetal working apparatusSpacing toothCam

A cutting head for rotary trimmers in which at least one, and preferably two relatively short fixed lengths of flexible cutting line are inserted into opposed channels in the head and are secured in place by a pair of spring biased toothed cams. Each of the cams is pivotally mounted on a post within the housing adjacent one of the channels and defines a curvilinear camming surface having a plurality of uniformly spaced teeth thereon that project into the channels at increasing angles of inclination from the outermost tooth to the innermost tooth for engaging the line. A pair of torsion springs bias the cams to pivot on their mounting teeth such that the backsides of the teeth are continually urged toward the openings to the channels thereby allowing line to be inserted inwardly into the head past the toothed cams but retained by the cams against any outwardly directed forces acting on the line. The cams are symmetrically balanced about their axes of rotation so as to be unaffected by centrifugal force acting thereon during use.

Owner:PROULX MFG

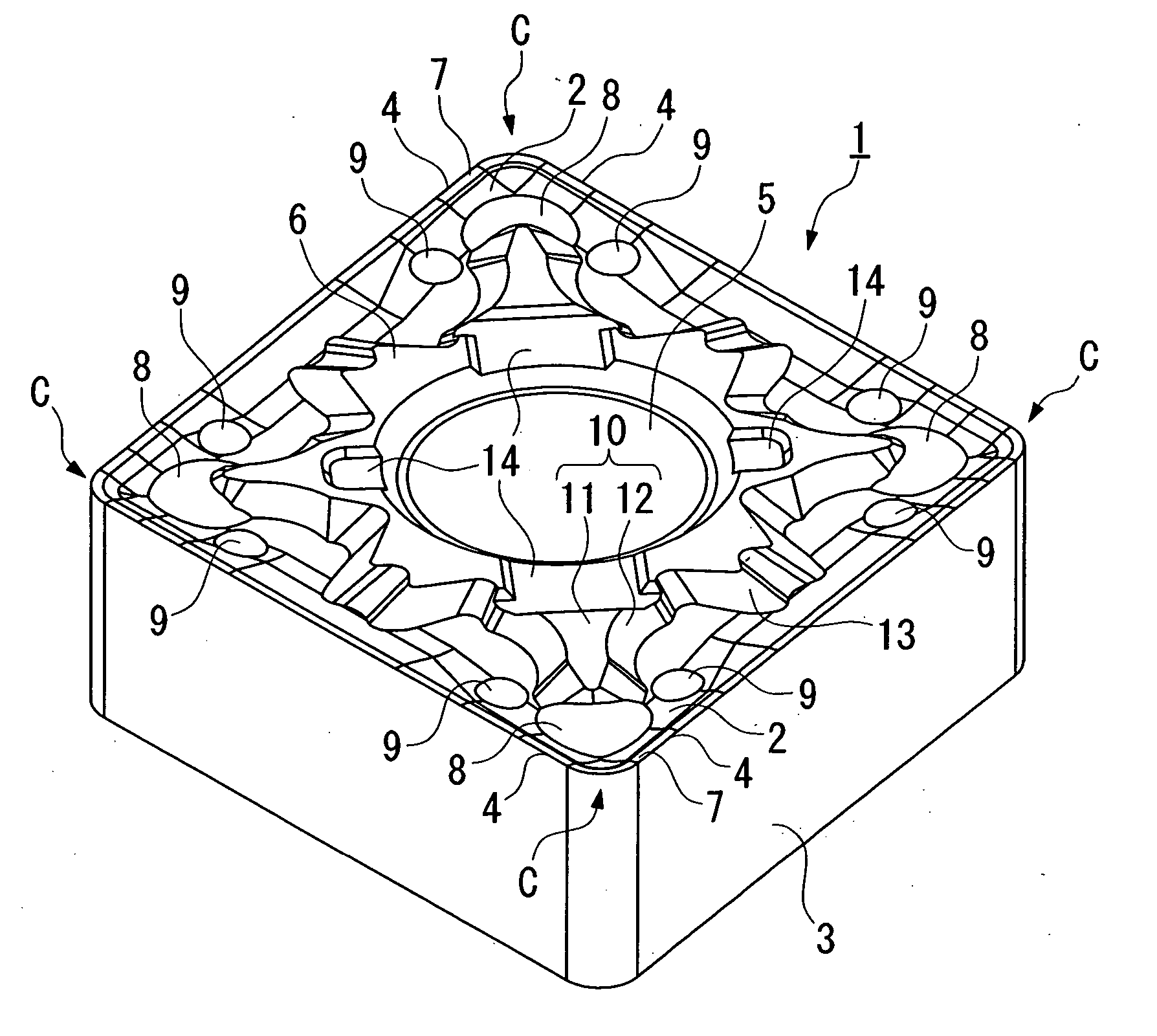

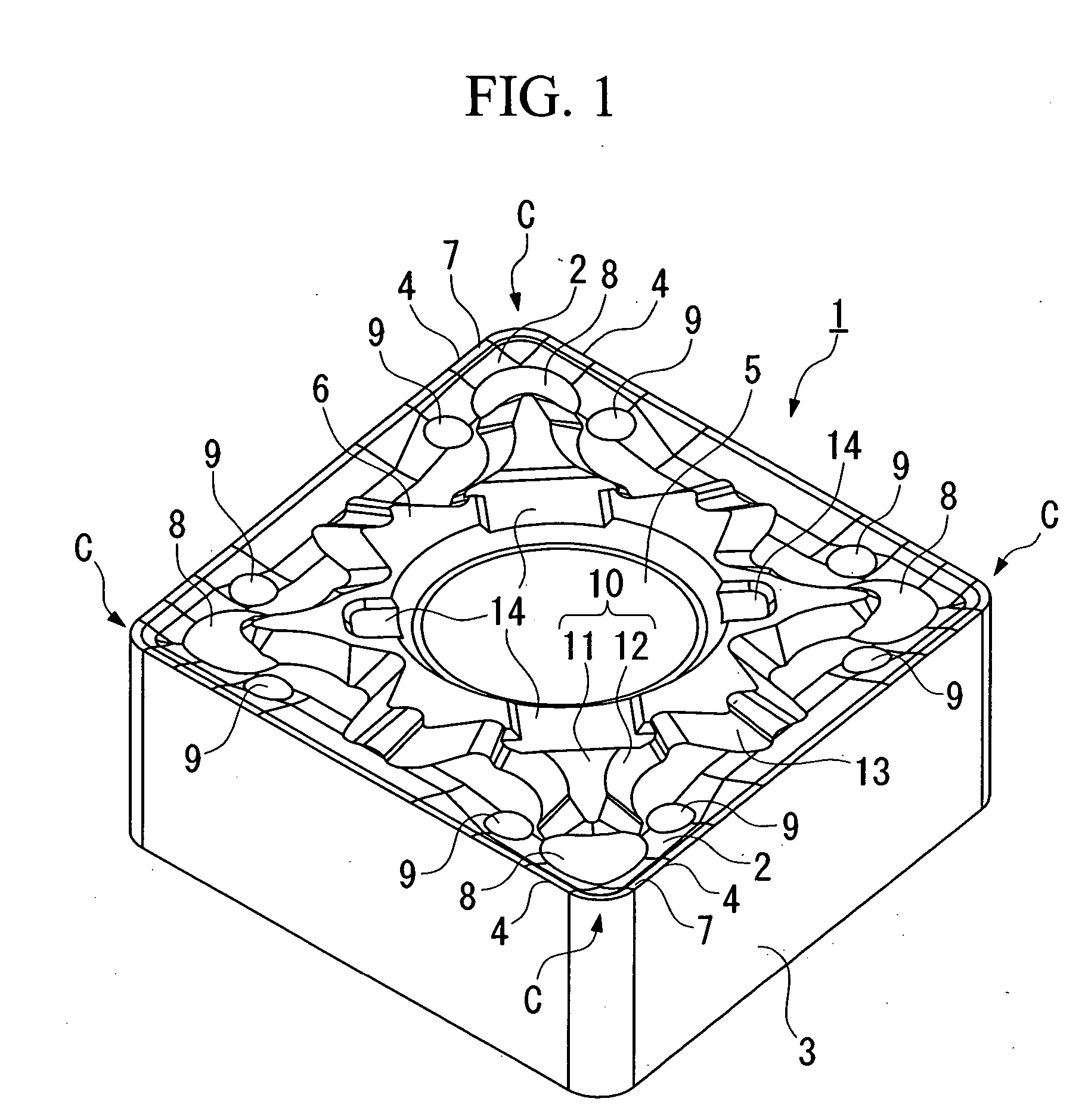

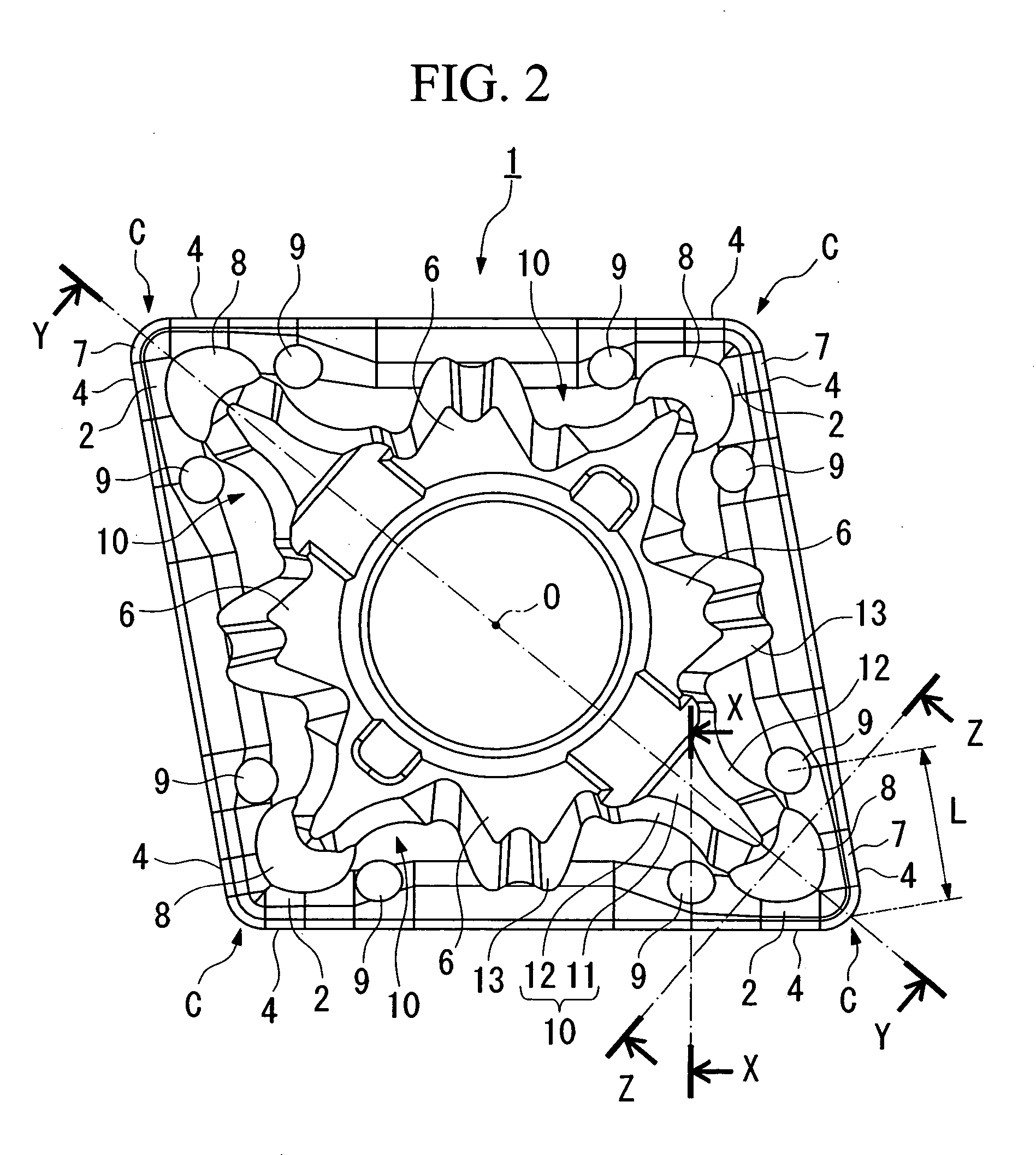

Throwaway tip

InactiveUS20050019111A1Reliable processing can be inhibitedSolve the broken effect is not goodCutting insertsTurning toolsConvex sideEngineering

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

Indexable insert

InactiveUS7182555B2Easily brokenReadily broken and processedCutting insertsTurning toolsEngineeringKnife blades

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

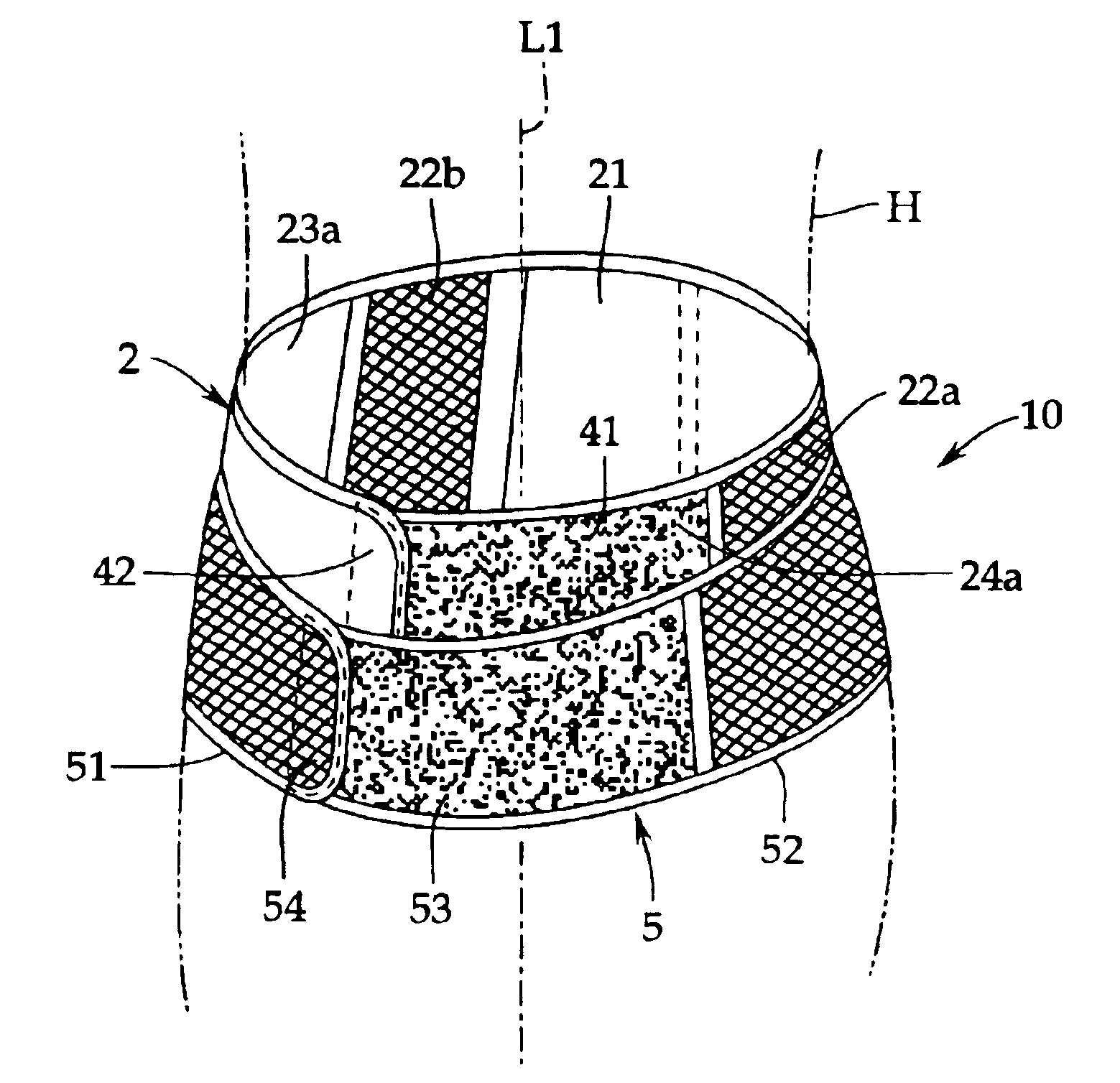

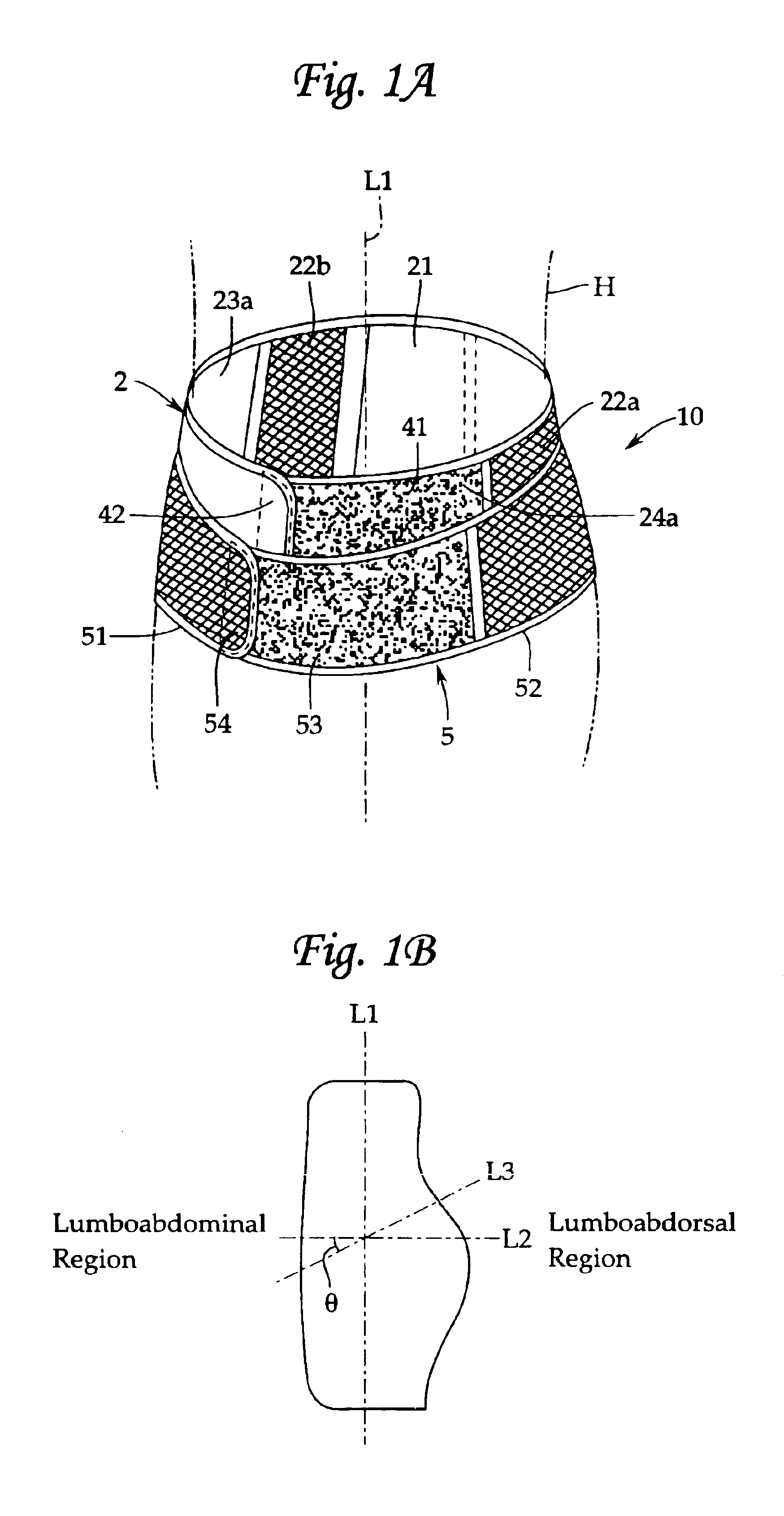

Lumbar supporter

A lumbar fixed belt that mainly holds a lumbar and a pelvic fixed belt that mainly holds the pelvis are integrally provided, and the pelvic fixed belt is inclined to the lumbar fixed belt 2 at 20° to 30° toward a lumboabdominal region, correspondingly to a physiological pelvic angle of inclination θ.

Owner:TAKETORA +1

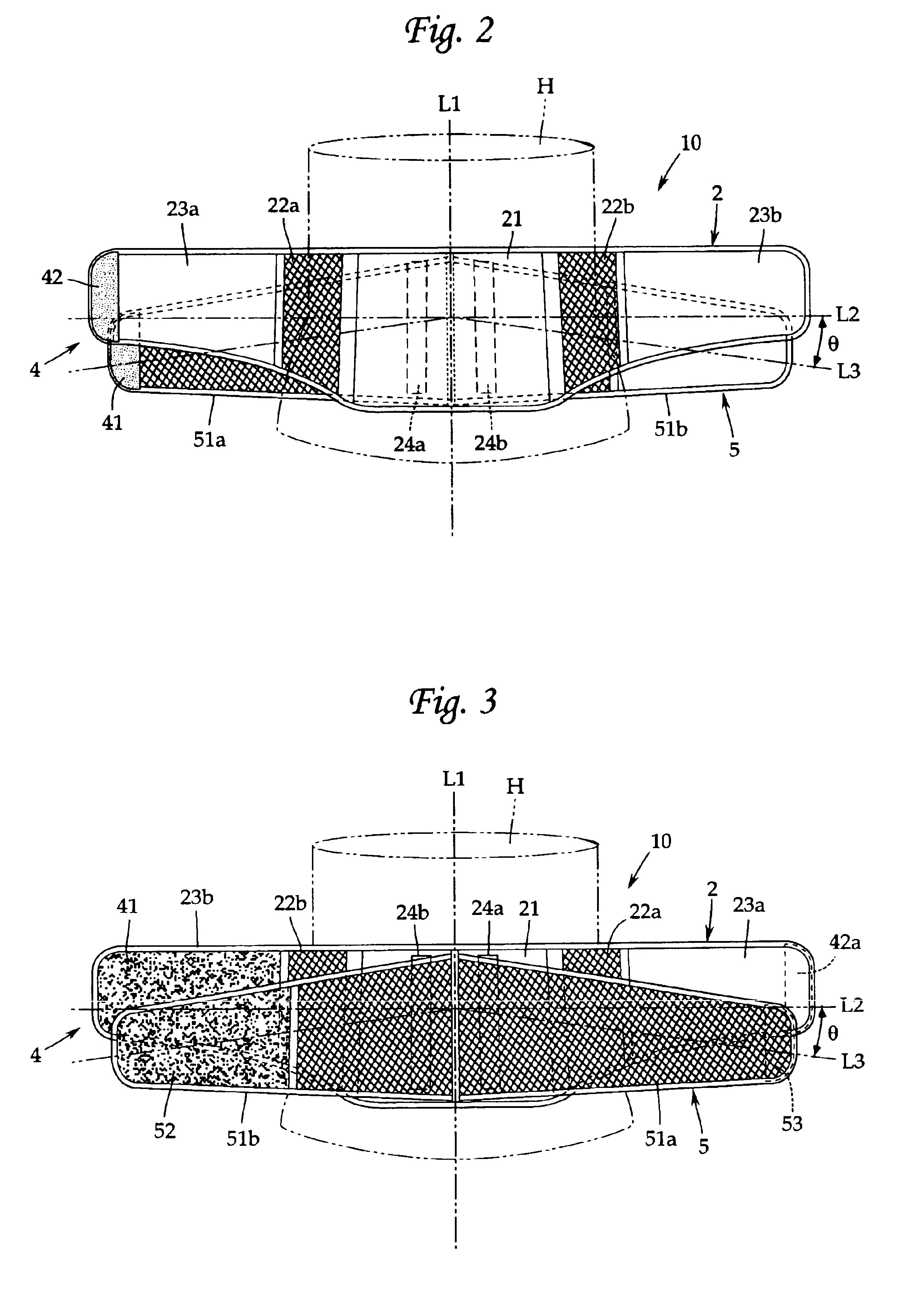

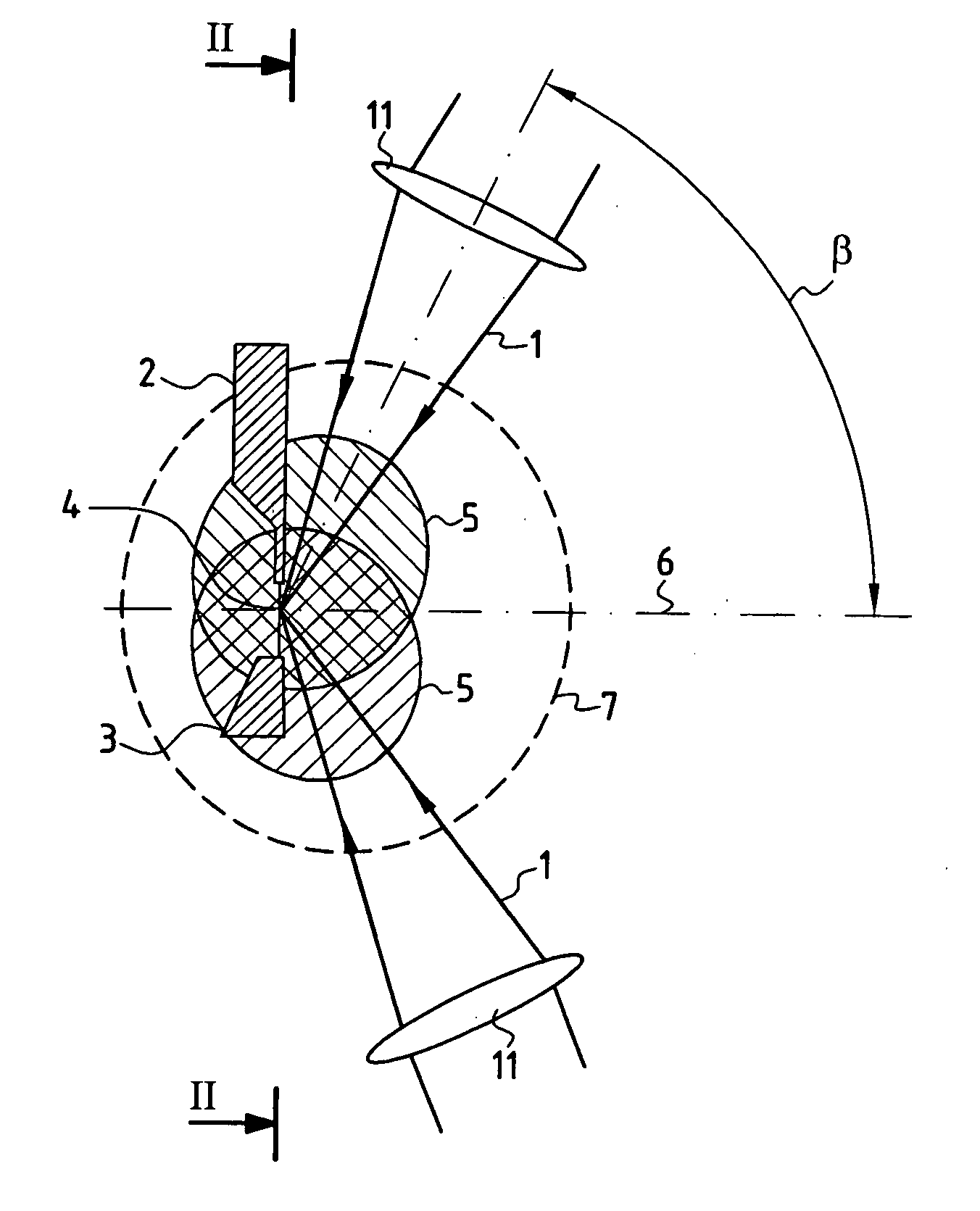

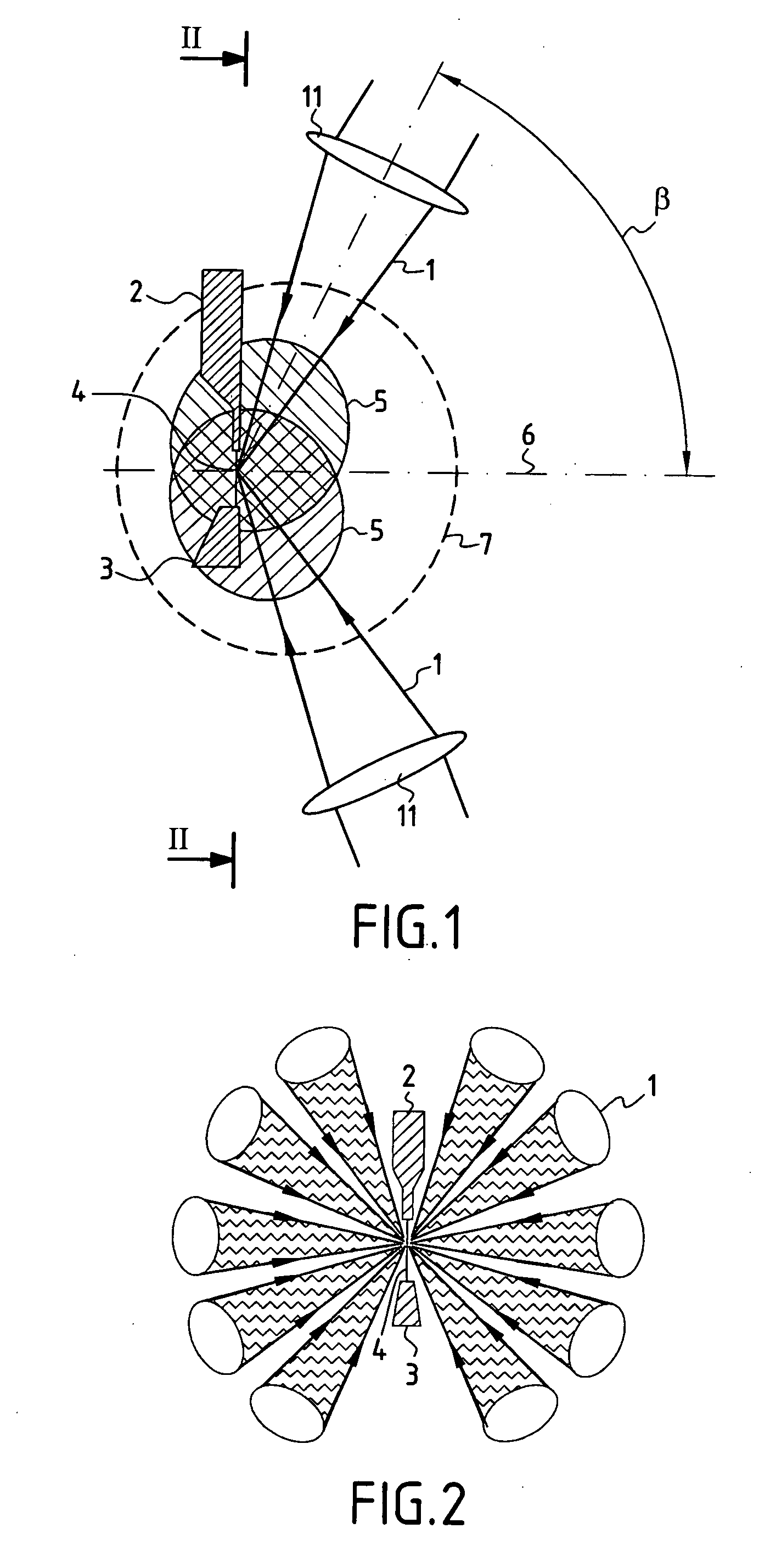

Apparatus for generating light in the extreme ultraviolet and use in a light source for extreme ultraviolet lithography

InactiveUS20060039435A1Increase powerIncrease laser powerNanoinformaticsPhotometryLithographic artistUltraviolet

The device comprises a device (2) for creating an essentially linear target (4) in an evacuated space where laser beams (1) are focused, the target being suitable for interacting with the focused laser beams (1) to emit a plasma emitting radiation in the extreme ultraviolet. A receiver device (3) receives the target (4) after it has interacted with the focused laser beams (1), and a collector device (110) collects the EUV radiation emitted by the target (4). The focusing elements (11) for focusing the laser beams on the target (4) are arranged in such a manner that the laser beams (1) are focused on the target (4) laterally, being situated in a common half-space relative to the target (4) and being inclined at a determined angle lying in the range about 60° to about 90° relative to a mean collection axis (6) perpendicular to the target (4). The collector device (110) is disposed symmetrically about the mean collection axis (6) in the half-space containing the laser beams (1) focused on the target (4) and inside a conical space (8) centered on the mean collection axis (6) with a vertex situated at the target (4) and a half-angle at the vertex that is less than the angle of inclination of the focused laser beams (1) relative to the mean collection axis (6). The device is suitable for use as a source for EUV radiation in lithography for fabricating integrated circuits.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

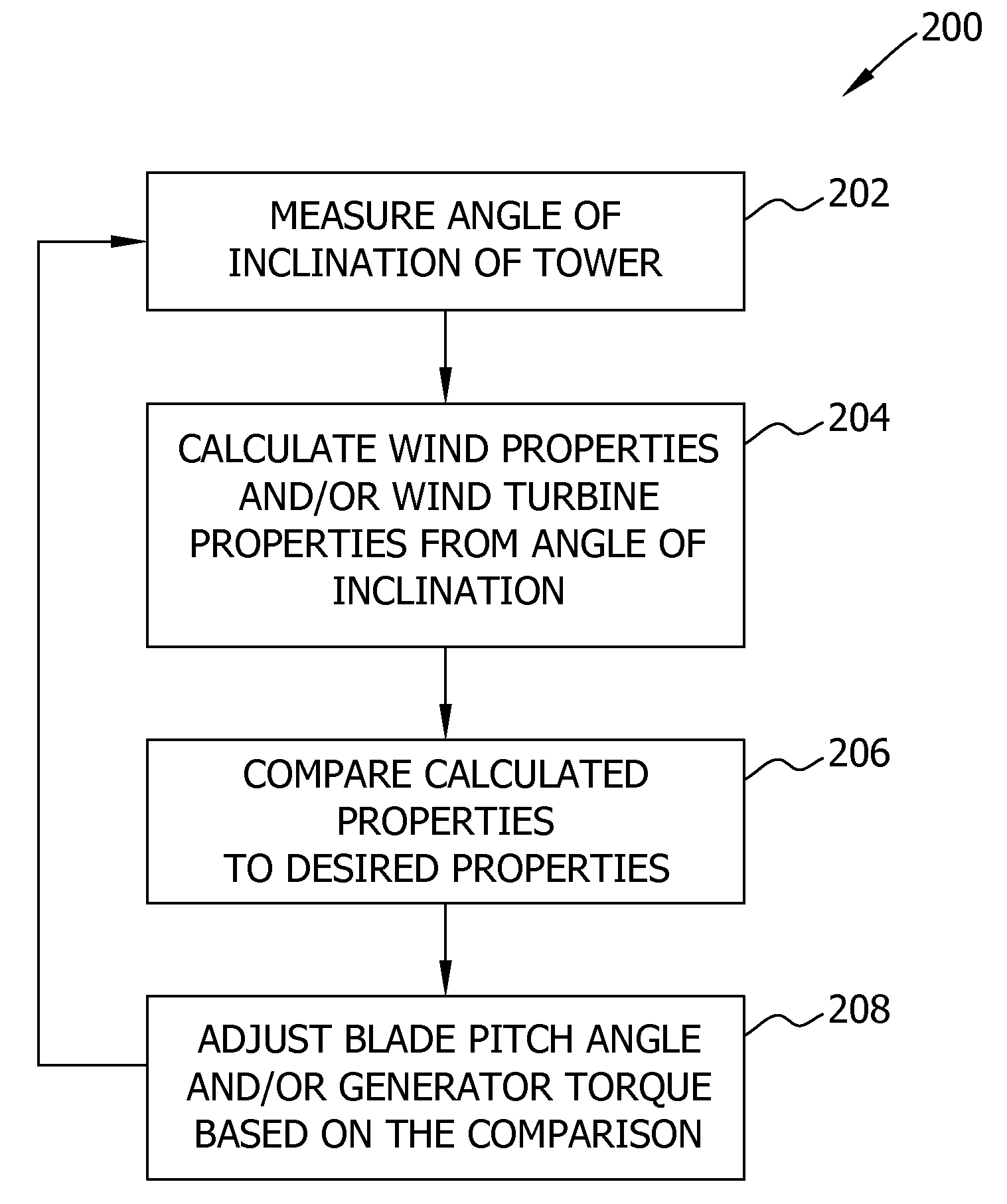

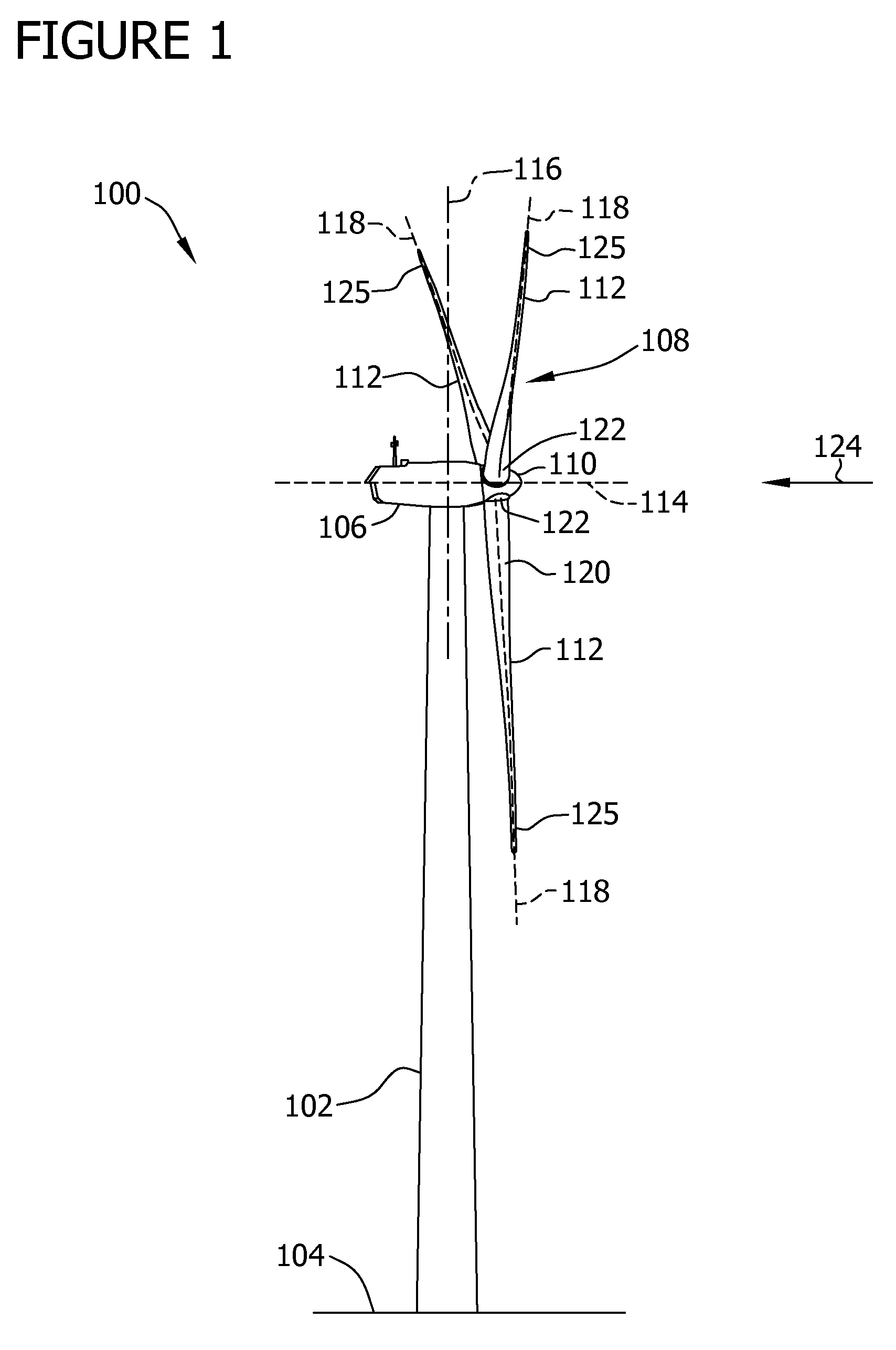

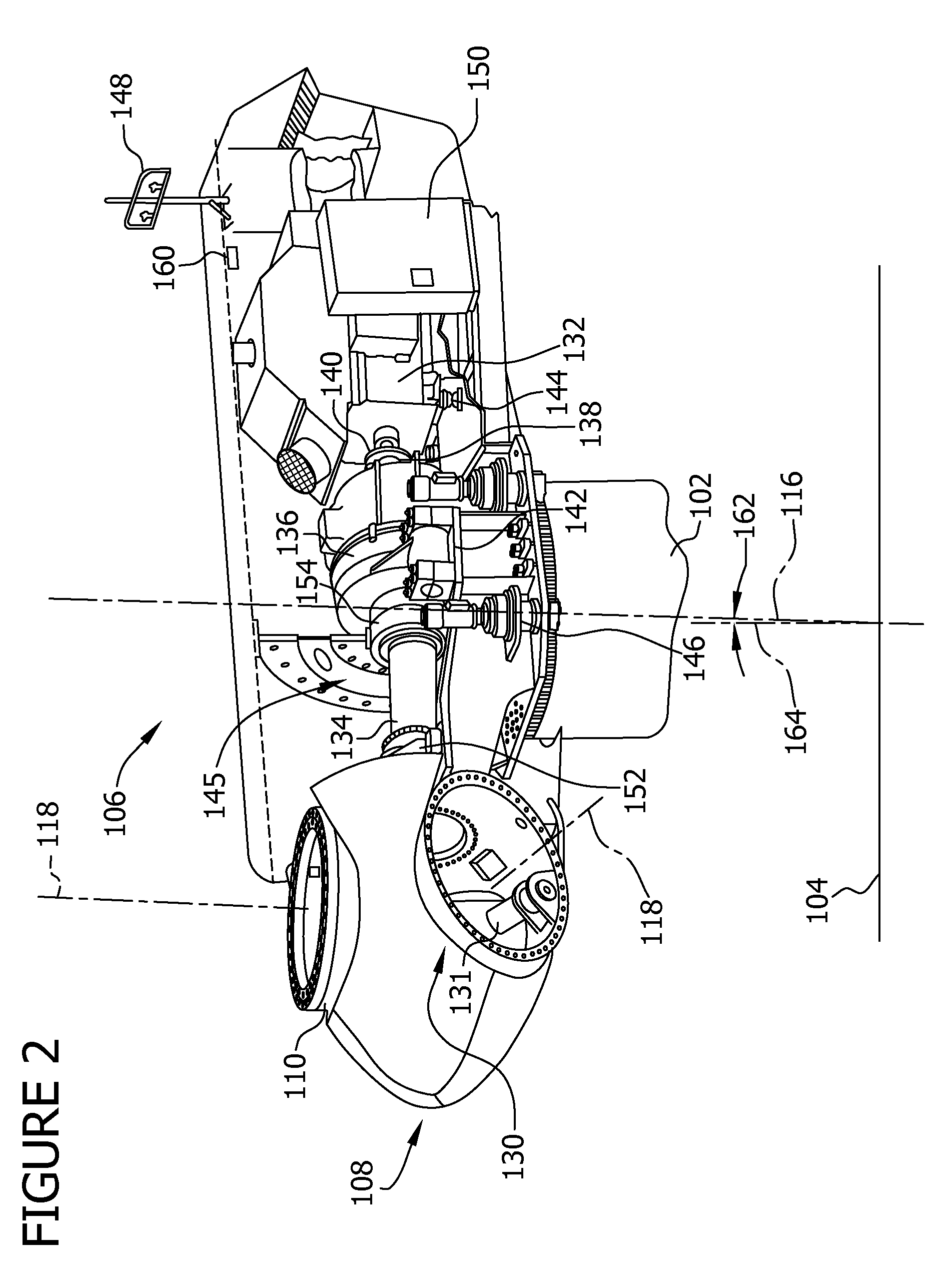

Method and system for controlling a wind turbine

A control system for a wind turbine having a tower, a generator, and at least one rotor blade. The control system includes a sensor configured to measure an angle of inclination of the tower with respect to a surface, at least one pitch assembly configured to adjust a pitch angle of the rotor blade, and a controller configured to control at least one of the pitch assembly and the generator based on the measured angle of inclination.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com