Patents

Literature

200results about How to "Increase laser power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

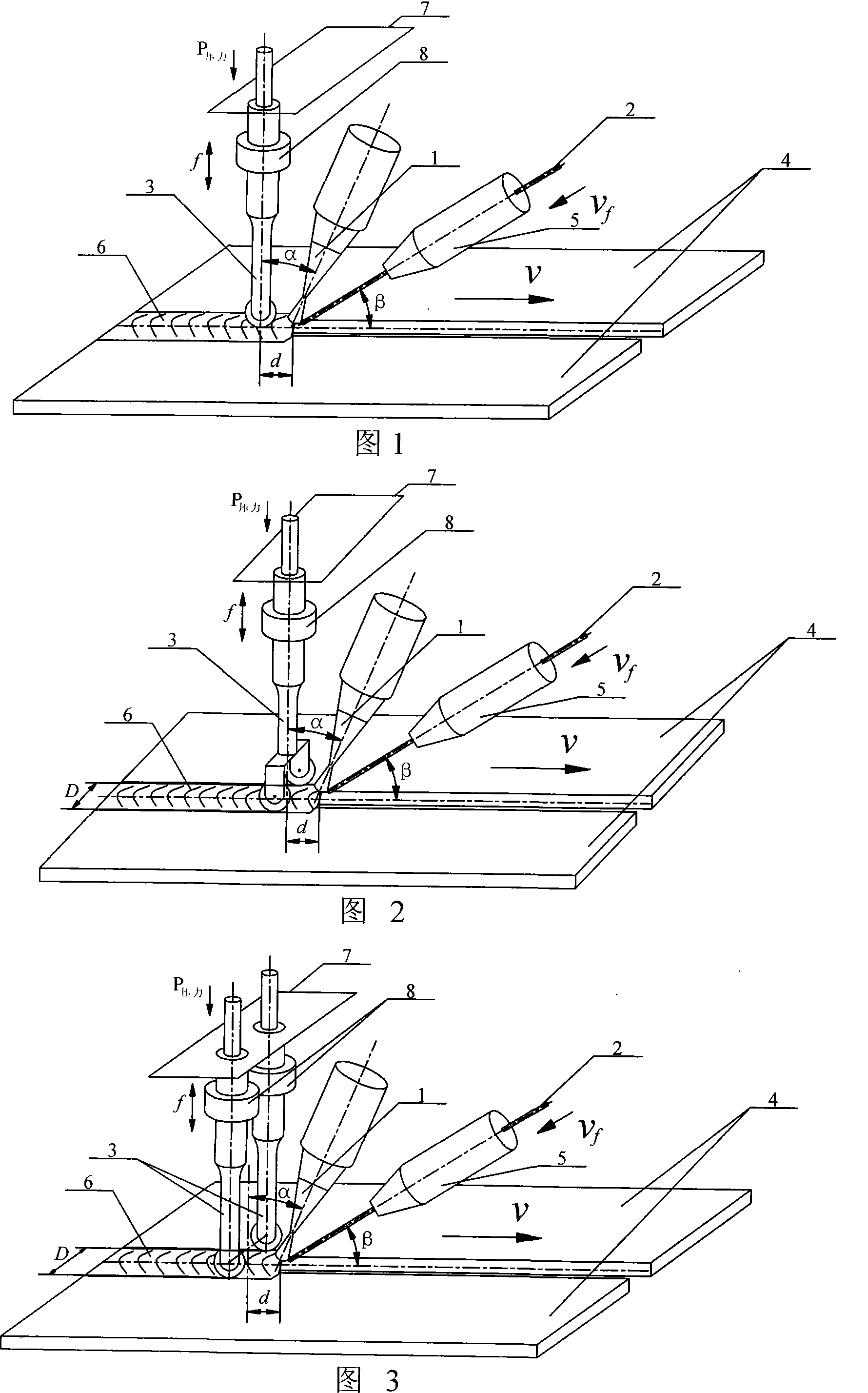

Ultrasound wave auxiliary laser braze (fuse) welding method

InactiveCN101195183AIncrease the amount of weld fillerImproved weld formationSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedWeld strength

Owner:HARBIN INST OF TECH

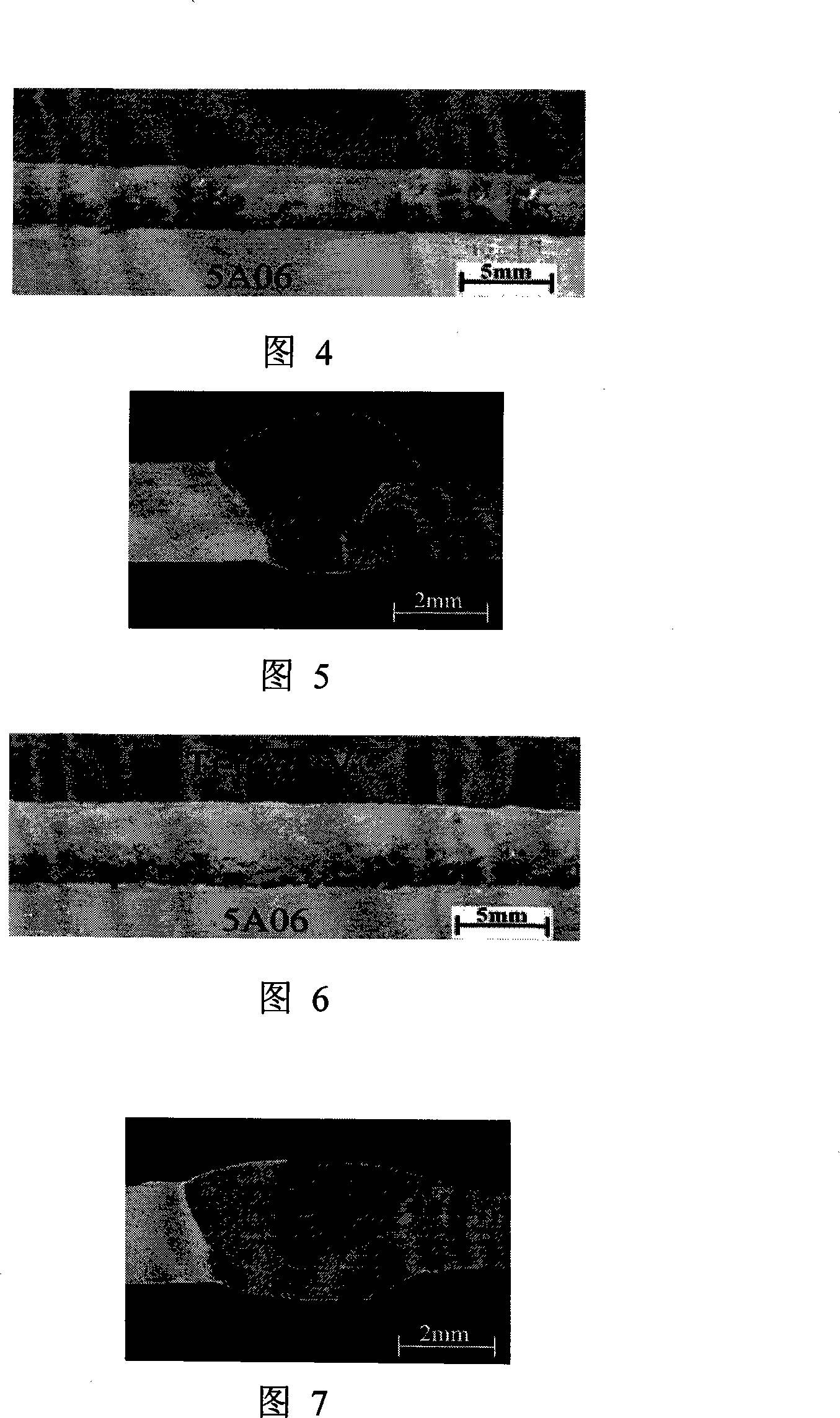

Apparatus for generating light in the extreme ultraviolet and use in a light source for extreme ultraviolet lithography

InactiveUS20060039435A1Increase powerIncrease laser powerNanoinformaticsPhotometryLithographic artistUltraviolet

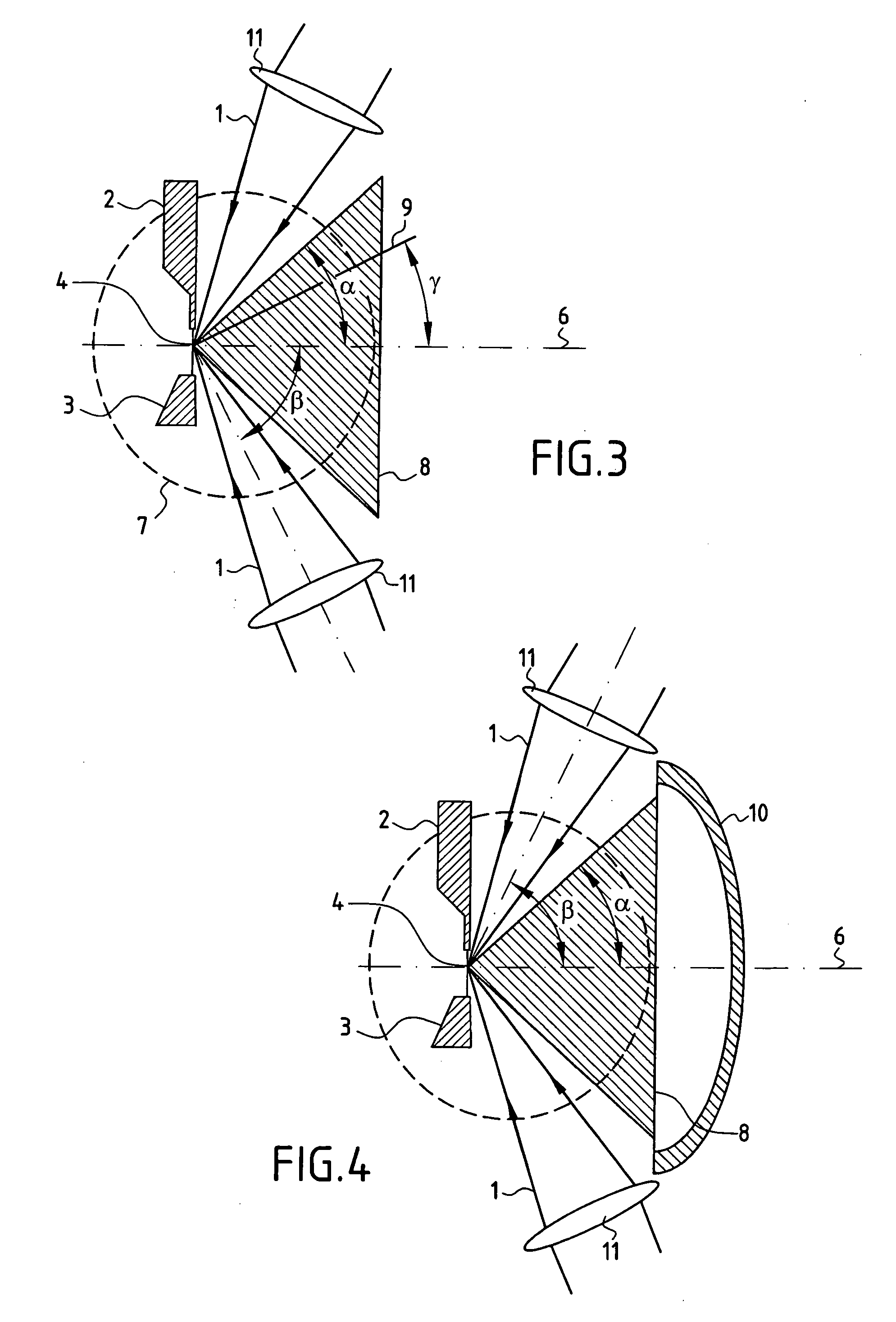

The device comprises a device (2) for creating an essentially linear target (4) in an evacuated space where laser beams (1) are focused, the target being suitable for interacting with the focused laser beams (1) to emit a plasma emitting radiation in the extreme ultraviolet. A receiver device (3) receives the target (4) after it has interacted with the focused laser beams (1), and a collector device (110) collects the EUV radiation emitted by the target (4). The focusing elements (11) for focusing the laser beams on the target (4) are arranged in such a manner that the laser beams (1) are focused on the target (4) laterally, being situated in a common half-space relative to the target (4) and being inclined at a determined angle lying in the range about 60° to about 90° relative to a mean collection axis (6) perpendicular to the target (4). The collector device (110) is disposed symmetrically about the mean collection axis (6) in the half-space containing the laser beams (1) focused on the target (4) and inside a conical space (8) centered on the mean collection axis (6) with a vertex situated at the target (4) and a half-angle at the vertex that is less than the angle of inclination of the focused laser beams (1) relative to the mean collection axis (6). The device is suitable for use as a source for EUV radiation in lithography for fabricating integrated circuits.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Low absorption coatings for infrared laser optical elements

InactiveUS6020992AEffective and practical low absorptionReduce absorptionMirrorsOptical filtersOptoelectronicsOptic system

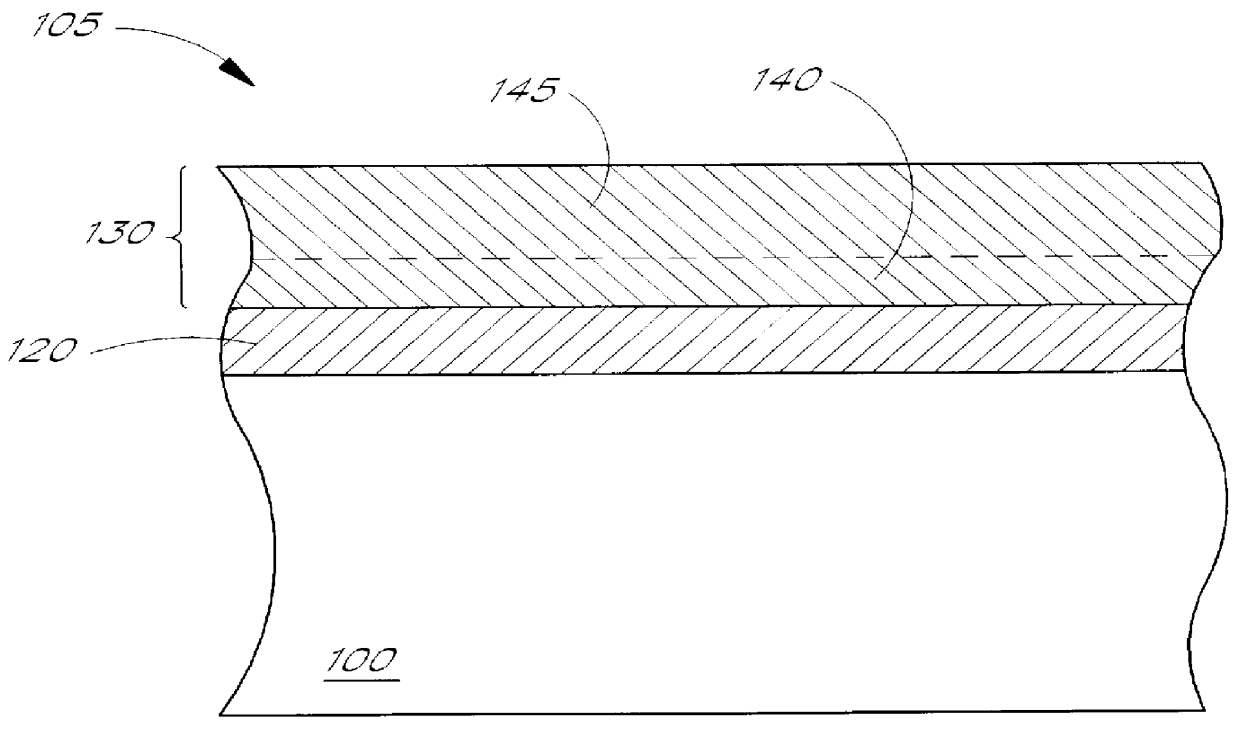

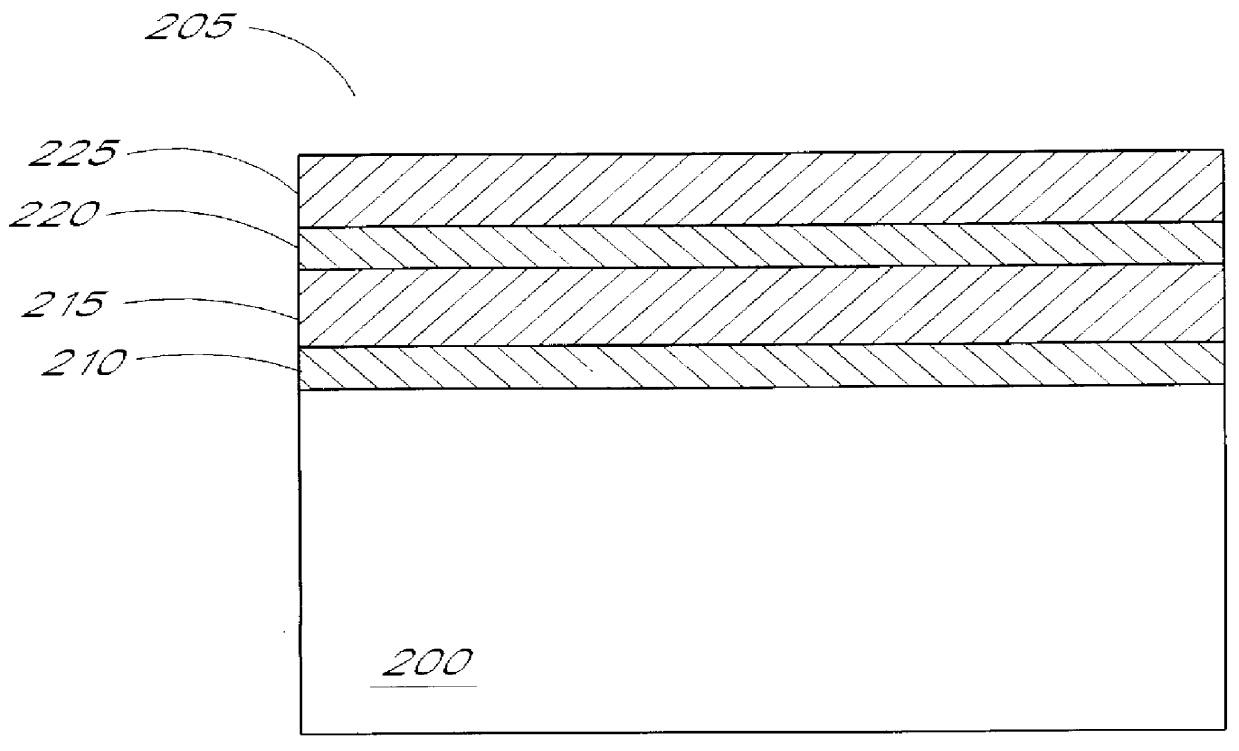

A thorium-free low absorption coating for infrared CO2 laser optics comprises an interior BaF2 layer formed on a substrate and an exterior layer formed over the interior layer to a predetermined thickness sufficient to substantially prevent water adsorption by the interior layer. Generally, the predetermined thickness is greater than about 11000 ANGSTROM , and in one embodiment of a two-layer low absorption coating designed for antireflection at 10.6 microns, the exterior layer has a physical thickness in a range between about 24600 ANGSTROM and 22800 ANGSTROM , and preferably about 24000 ANGSTROM . In the preferred two-layer AR coating embodiment, the exterior layer defines a cover layer and an absentee layer, and the interior layer is relatively thin. The preferred exterior layer and the preferred substrate consist essentially of ZnSe. Multilayer stacked coatings of more than two layer can also be formed to provide low absorption partially reflective or totally reflective coatings as well as AR coatings.

Owner:II VI

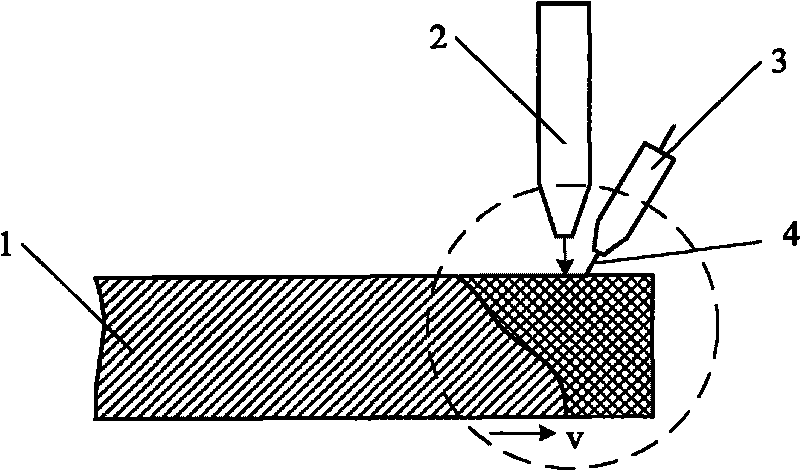

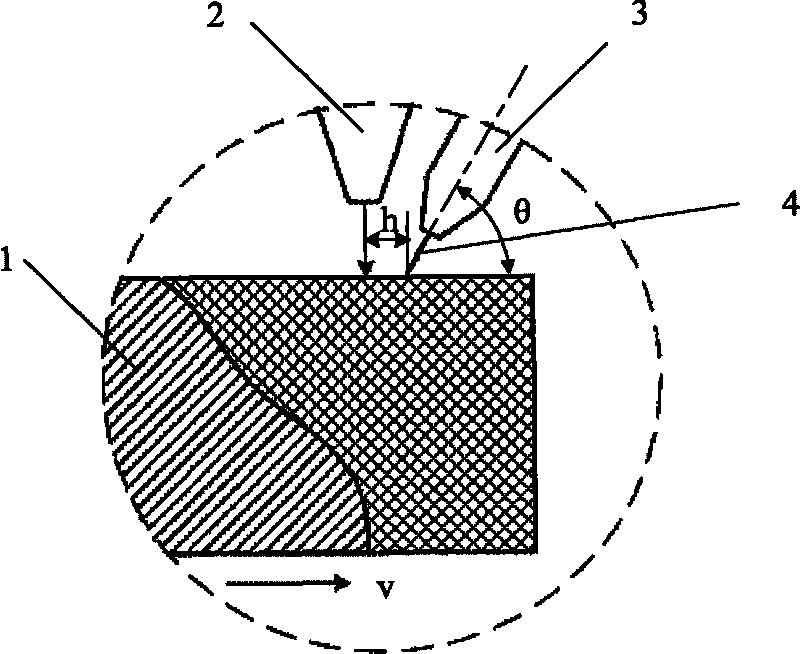

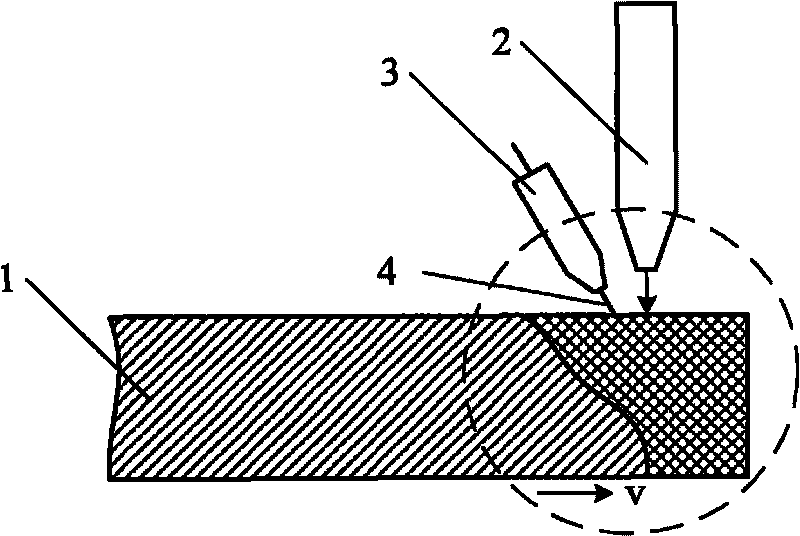

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

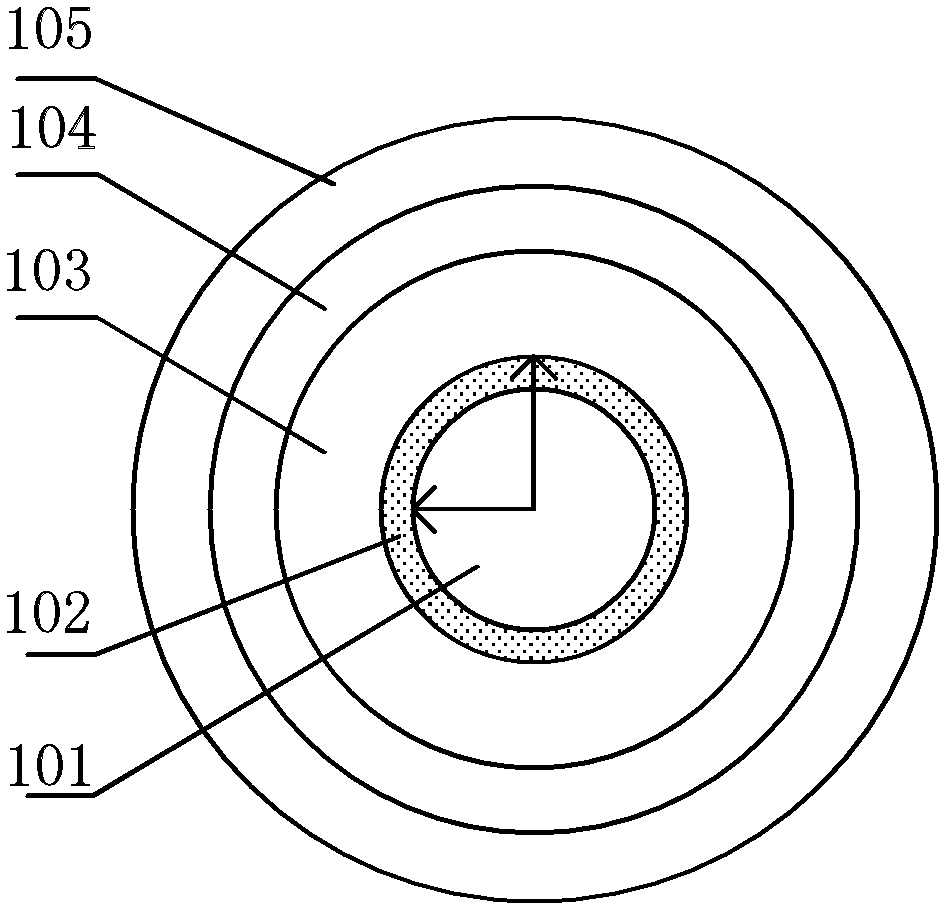

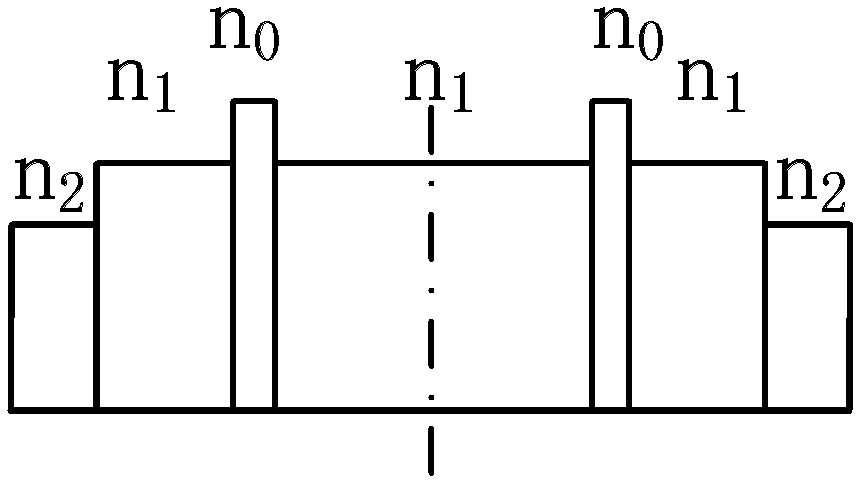

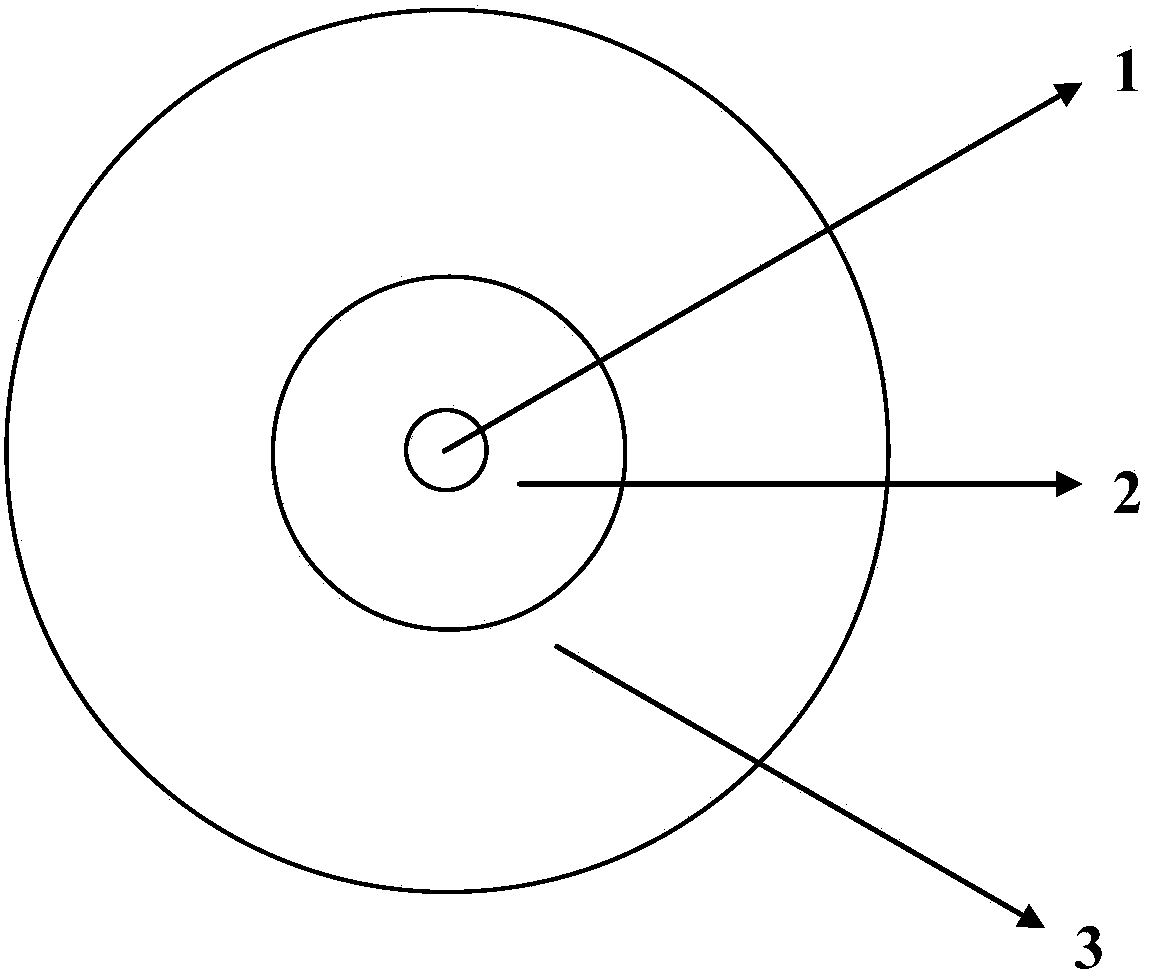

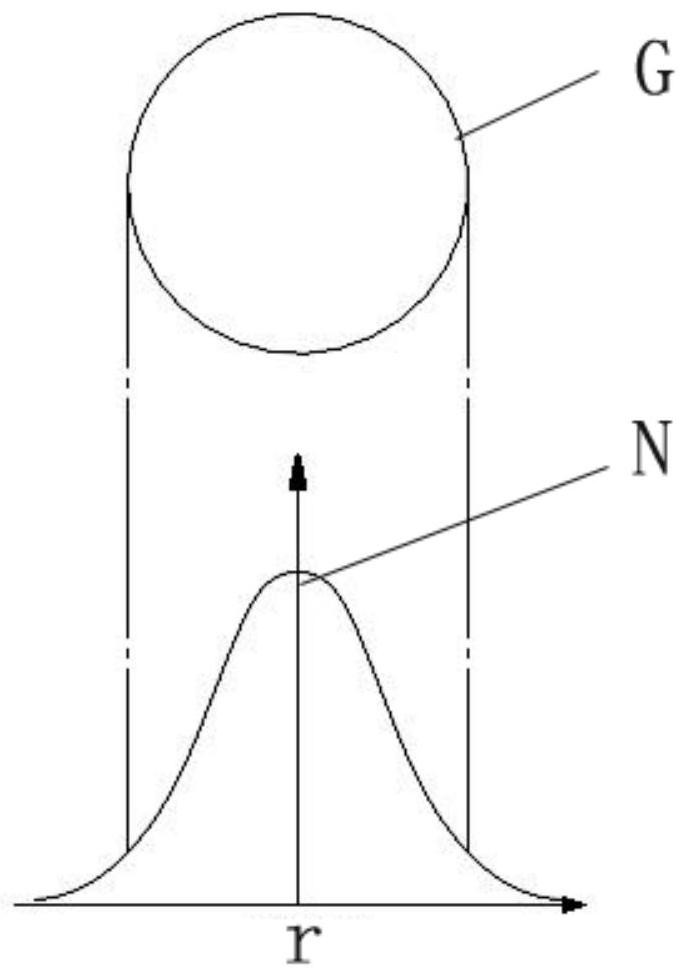

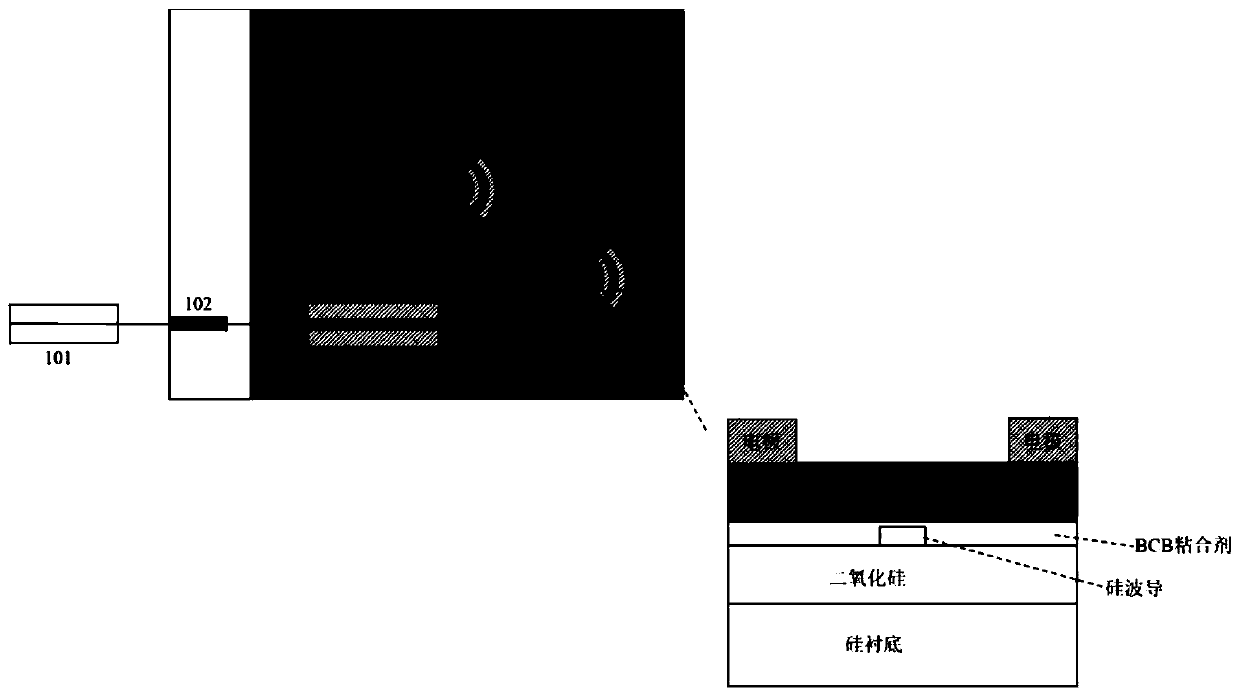

Optical fiber with ring-shaped doped layer and preparation method thereof and laser containing optical fiber

InactiveCN102621628AMature preparation technologyIncrease laser powerGlass making apparatusOptical fibre with multilayer core/claddingOptical fiber cableWaveguide

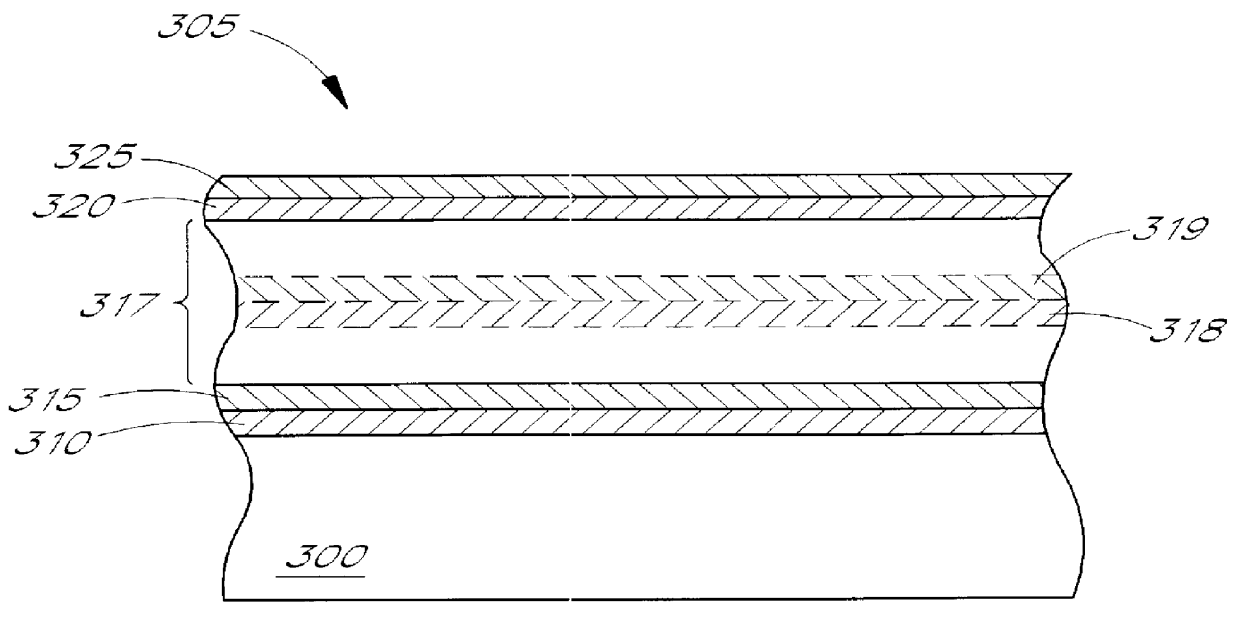

The invention discloses an optical fiber with a ring-shaped doped layer, which is used in an optical fiber laser and composed of an inner clad layer (101), a ring-shaped doped layer (102), a middle clad layer (103), an outer clad layer (104) and a protective layer (105), wherein the ring doped layer (102), the middle clad layer (103), the outer clad layer (104) and the protective layer (105) are, from inside to outside, sequentially clad on the inner clad layer (101), and the inner clad layer (101) is an undoped optical fire core. The invention also discloses a method for preparing the optical fiber with a ring-shaped doped layer, and a laser taking the optical fiber with a ring-shaped doped layer as a gain medium. According to the invention, the traditional fiber core doping is changed into a ring-shaped doped layer, so that the laser oscillation is actually performed in a ring-shaped waveguide, and then through reasonably designing the thickness of the ring-shaped waveguide, a single-mode operation can be kept; meanwhile, because the cross section area of the doped layer is large, the optical fiber with a ring-shaped doped layer is suitable to high-power output, therefore, the output power of the optical fiber laser using the optical fiber can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

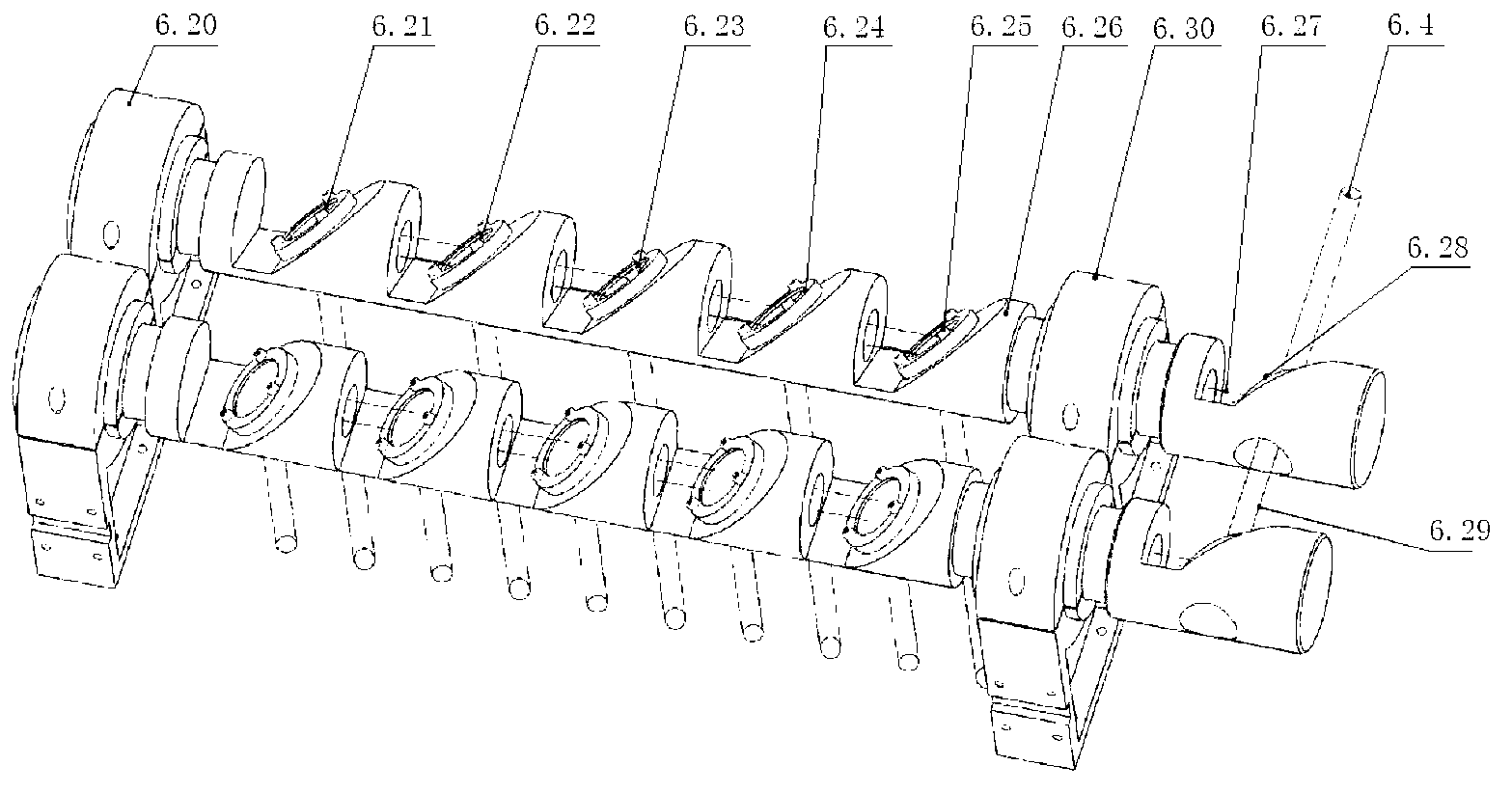

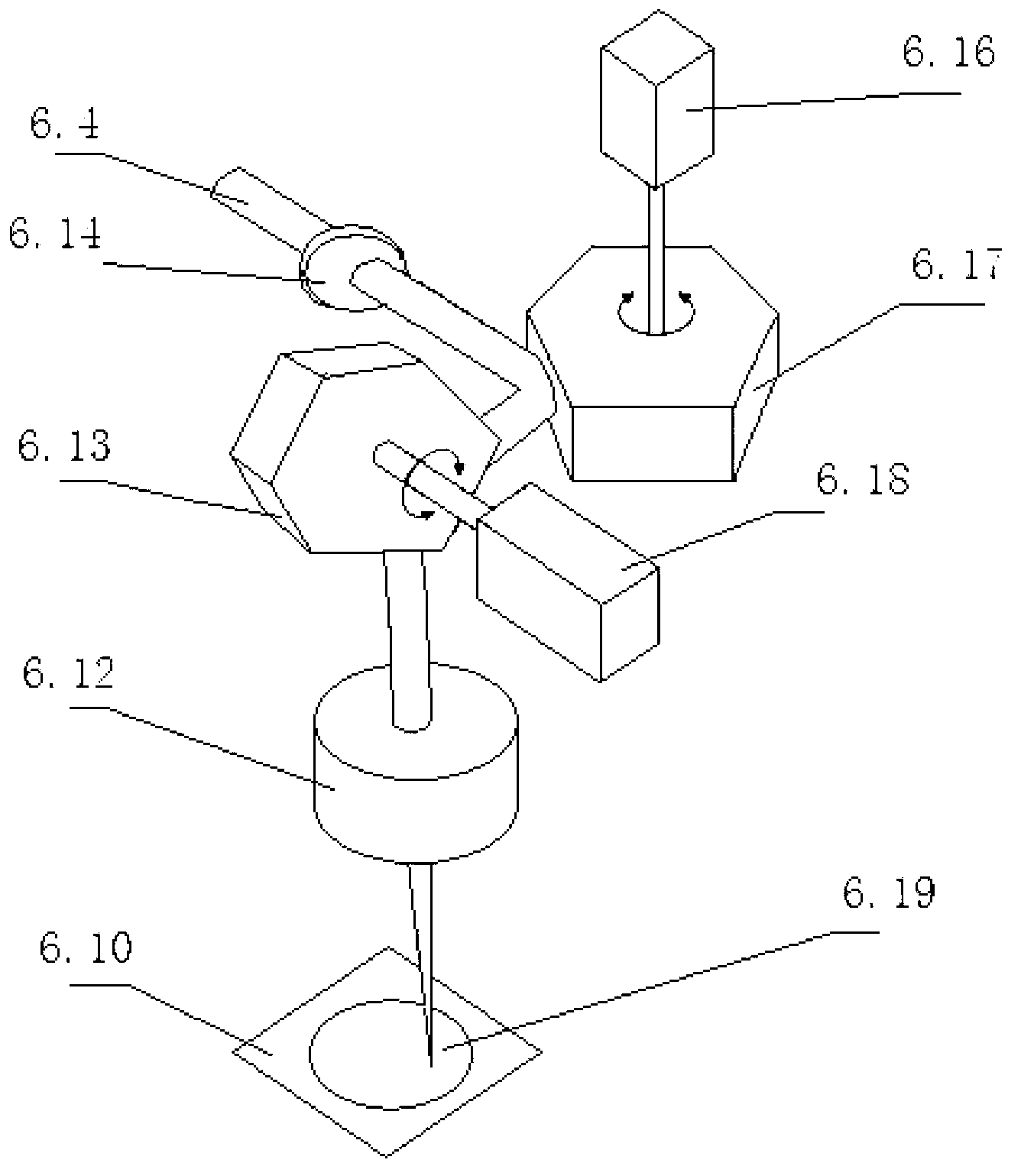

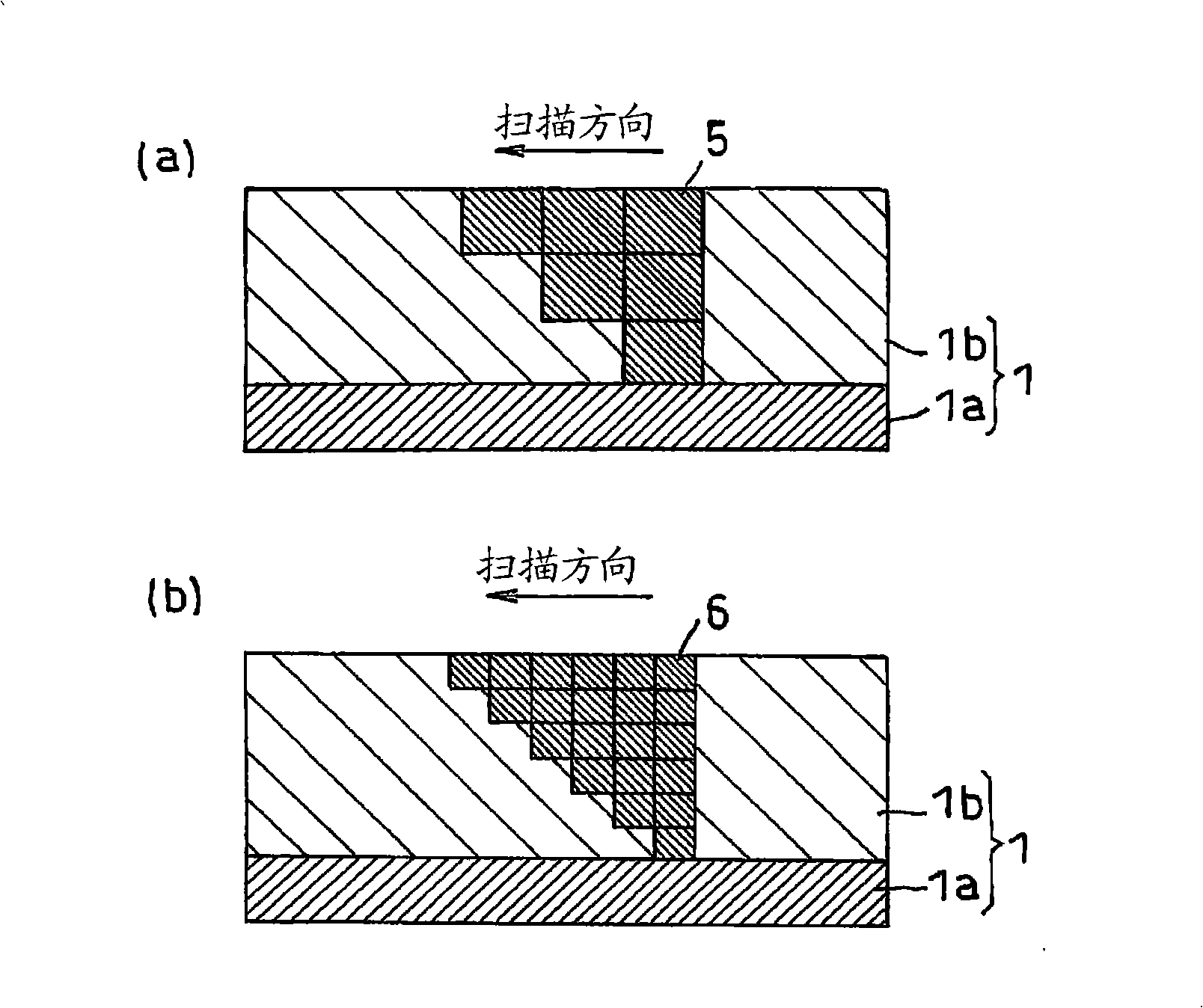

Multi-irradiation laser quenching method and device

The invention discloses a laser quenching method and device. According to the method, single heating in the conventional laser quenching technology is changed into multi-irradiation heating, or even high-frequency multi-irradiation heating by combining multi-irradiation heating with a quick scanning function of a rotating mirror; the heat conduction process caused by input of laser energy is injected into the surface of a workpiece within short heating time in a multi-stacking mode, so that the accumulation of the laser energy absorbed by a metal base body is increased, and the accumulation of the heat conduction depth is also increased. The device comprises a laser device, a control system, a light guide system, a mechanical motion device and a laser processing head. Even if technical parameters adopt high laser power, and when the scanning speed is high, and an irradiation interval exists, the surface temperature of the metal is always controlled to be below a melting point, and heat can be effectively and continuously expanded from the surface of the workpiece into the workpiece; and therefore, on the premise that the surface of the metal is prevented from being melted, the depth of an austenitizing region on the surface of the workpiece is increased, and the laser quenching efficiency is obviously improved.

Owner:WUHAN HIVALUE INTELASER LTD

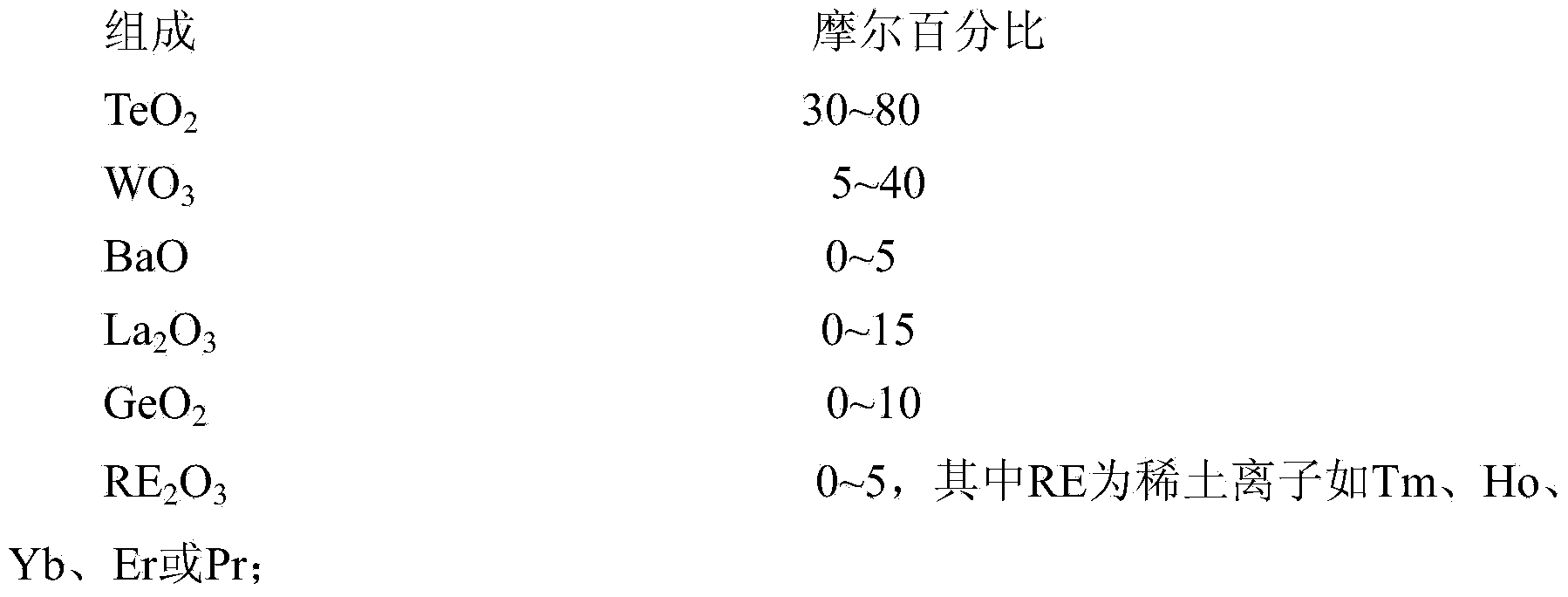

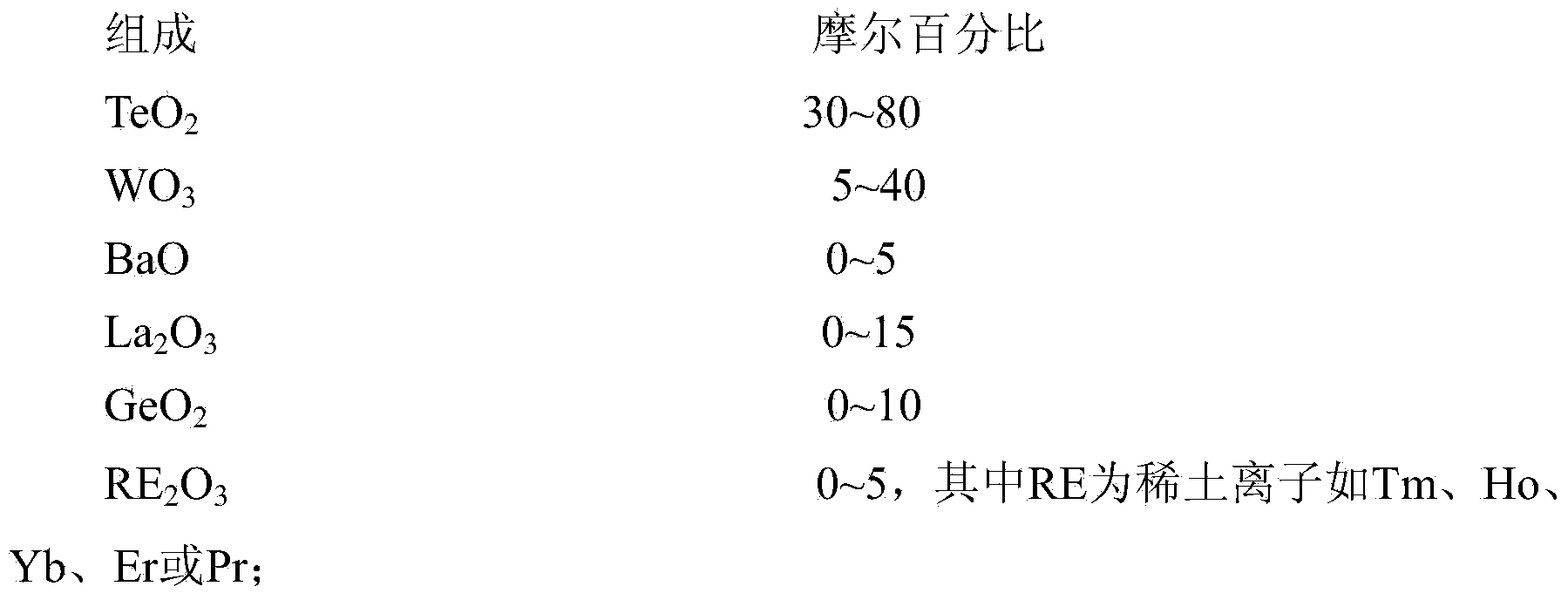

Preparation method for tellurate glass compound optical fibers

ActiveCN103771717AHigh mechanical strengthEasy to operateGlass making apparatusMiddle infraredLead silicate

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

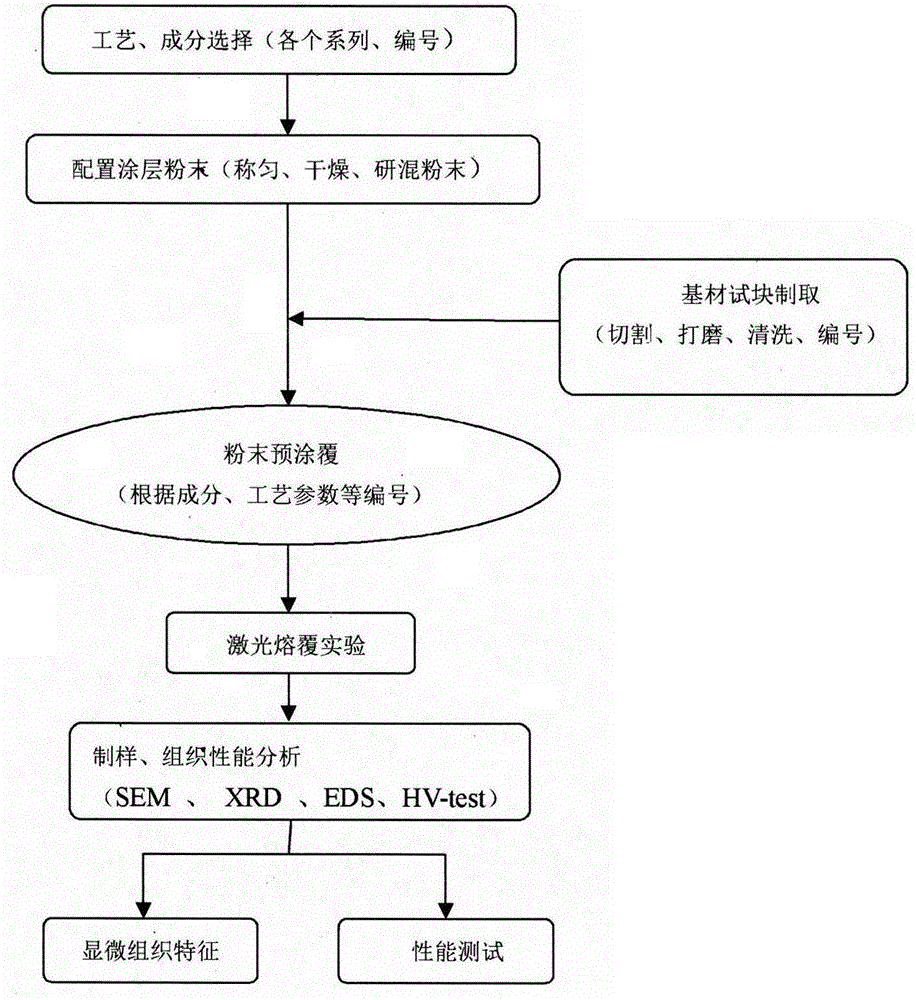

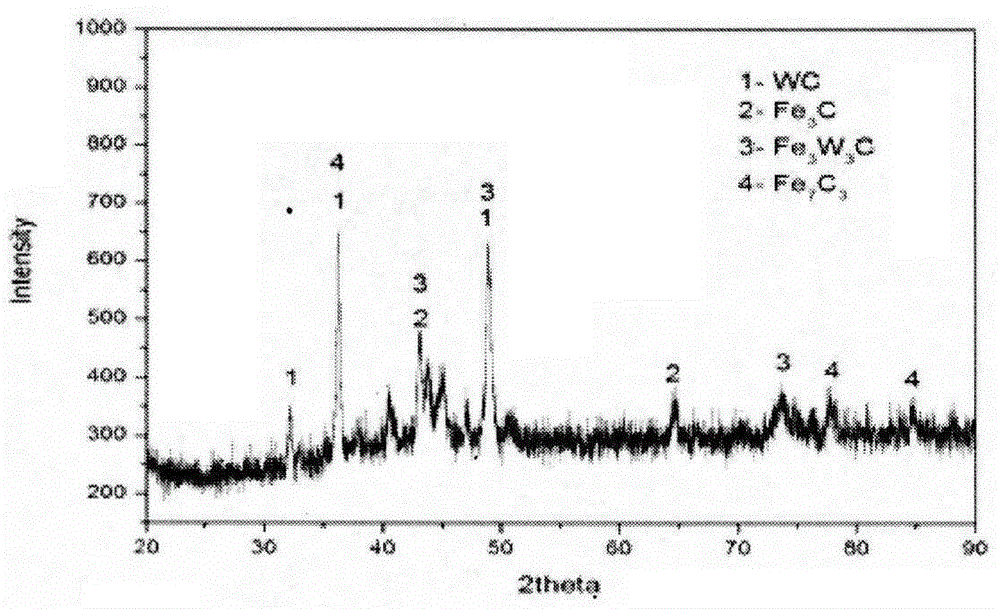

Laser-cladding tungsten carbide ceramic particle reinforced metal-based coating and processing method thereof

ActiveCN105112908AImprove bindingImprove wettabilityMetallic material coating processesAlloyMetallic Nickel

The invention discloses a laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. The coating comprises alloy powder; the alloy powder comprises tungsten powder and graphite with the mole ratio of 2:1 and further comprises reduced iron powder, chromium powder, nickel powder, boron powder, silicon powder and copper powder; further, the alloy powder preferentially comprises the following components in percentage by mass: 55-60% of tungsten powder, 7-9% of graphite, 23-30% of reduced iron powder, 0-3% of chromium powder, 2-6% of nickel powder, 0.3-1% of boron powder and 0.4-1% of silicon powder. The invention further discloses a processing method for the laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. According to the invention, a tungsten carbide particle reinforcing phase for reinforcing the iron-based composite is successfully prepared through a laser cladding in-situ synthesis technology, and a transition layer is arranged between the coating and the matrix, so that atom binding between the coating and the matrix is realized and the bonding strength is relatively high.

Owner:WENZHOU UNIVERSITY

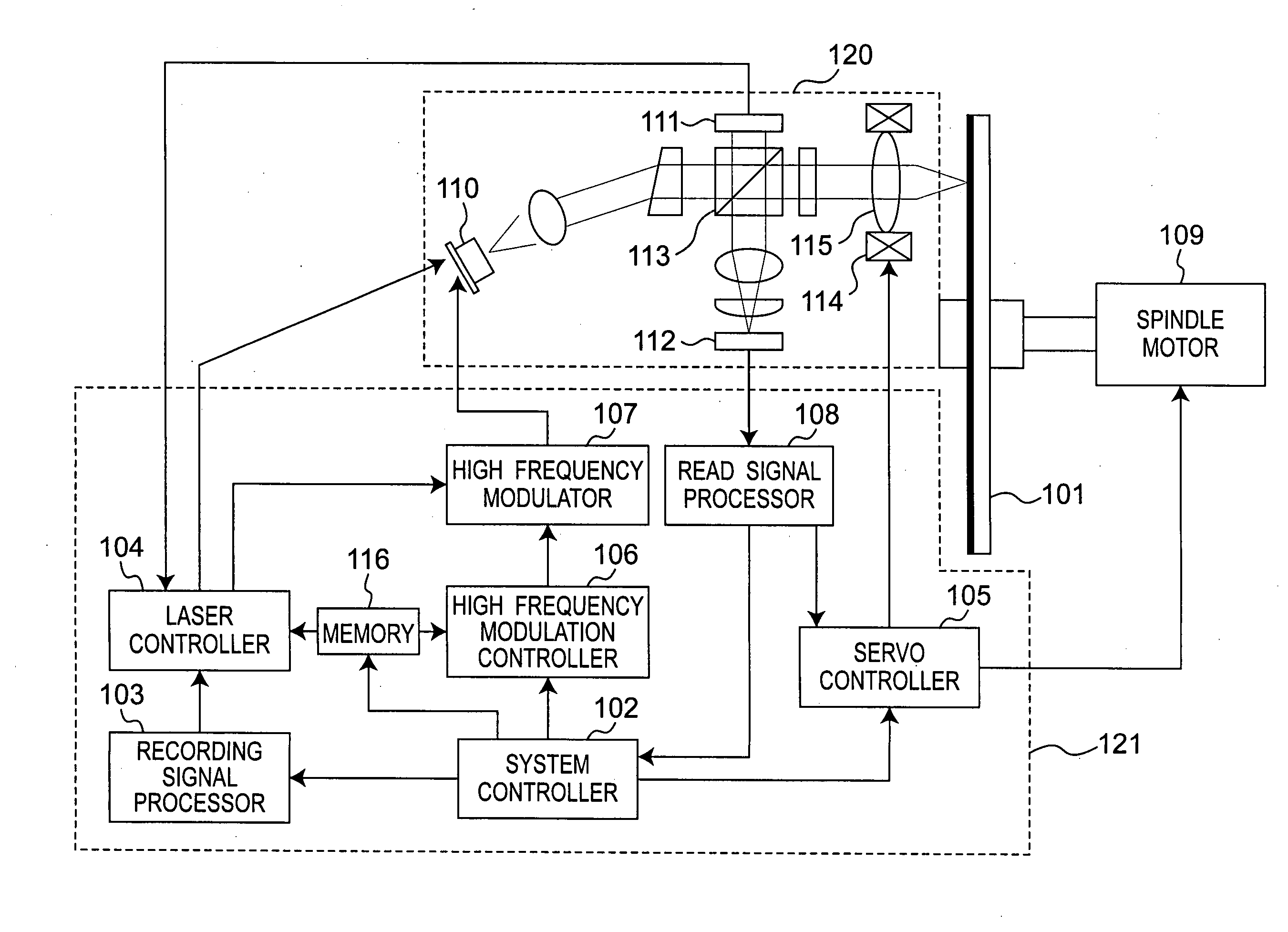

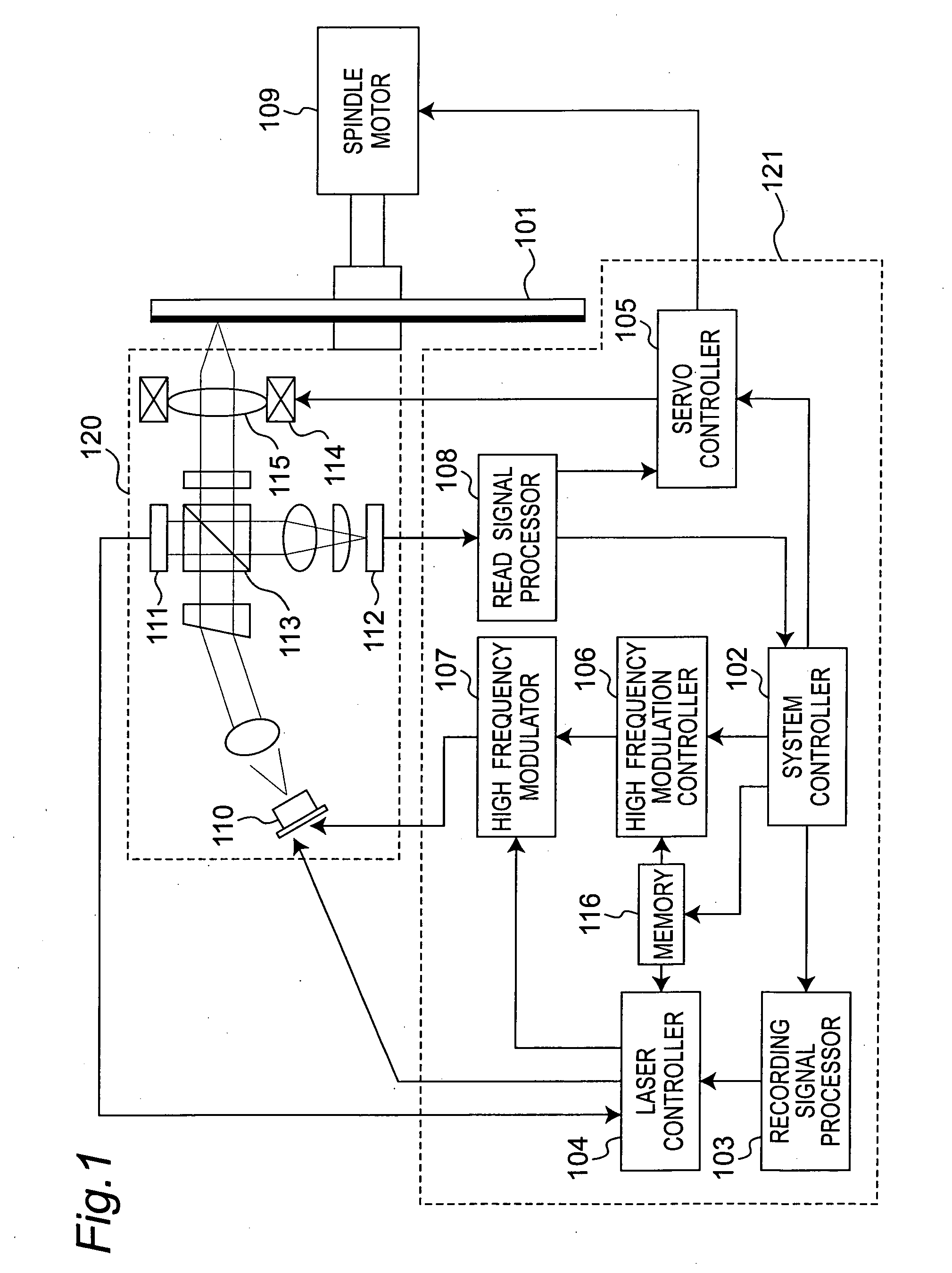

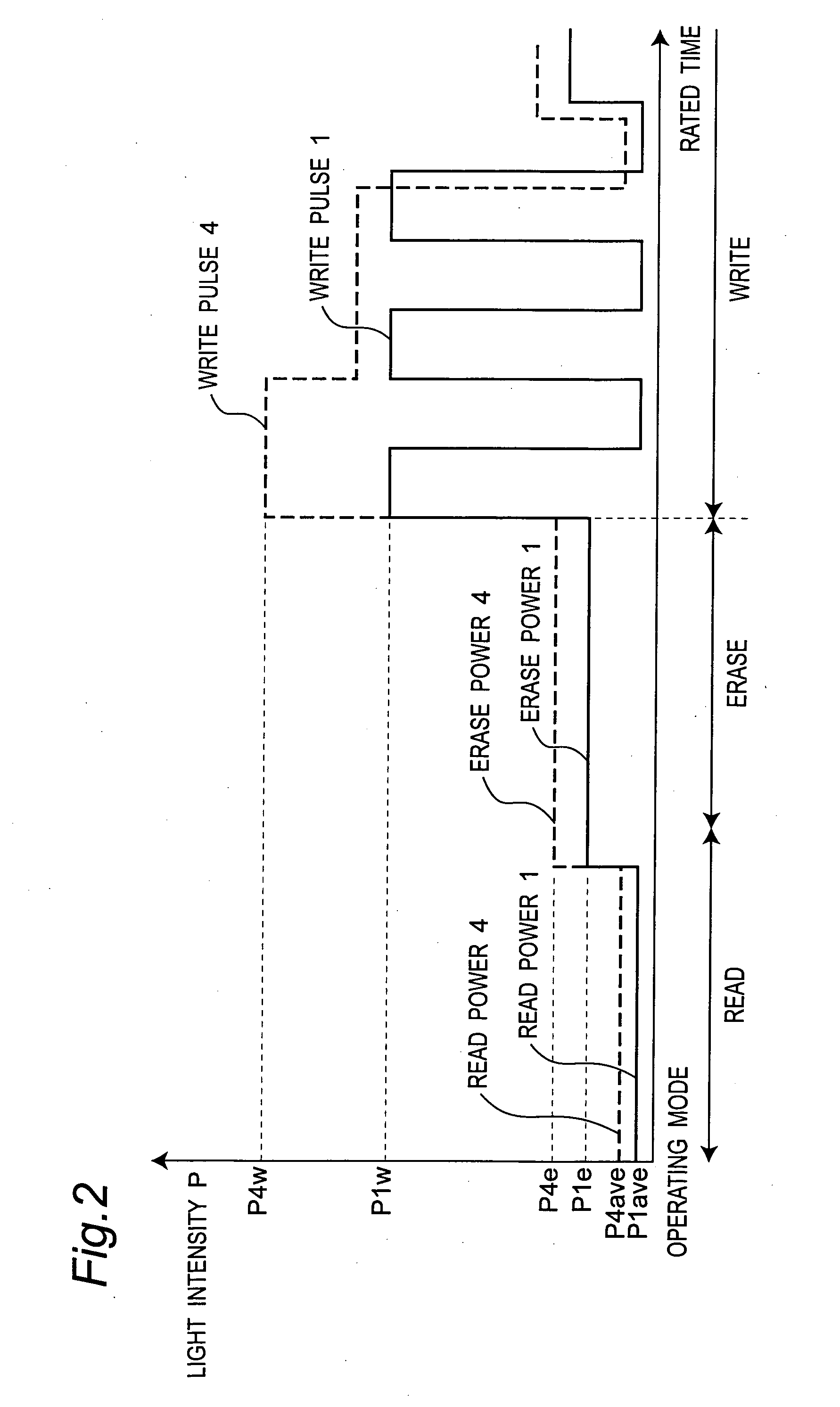

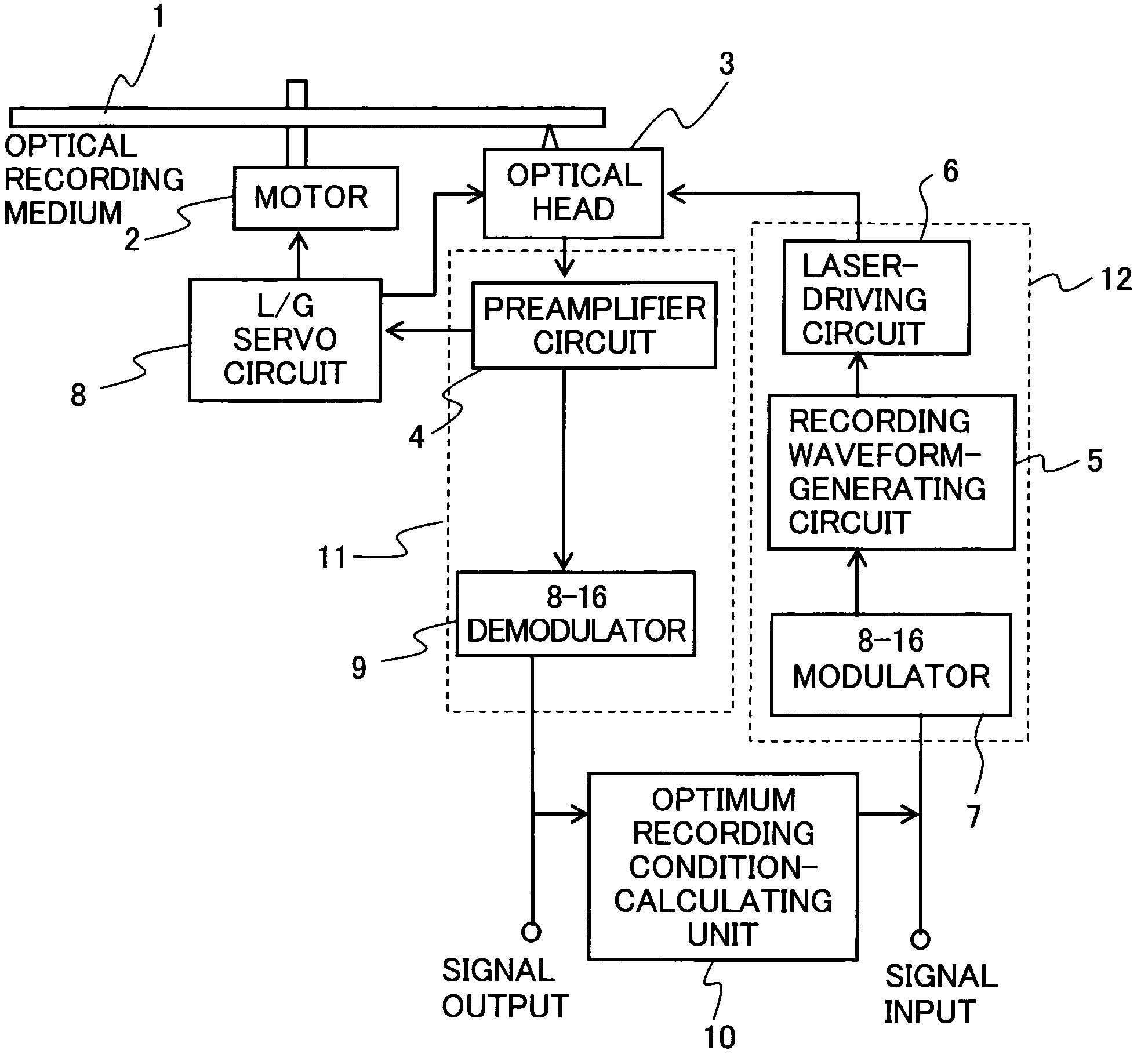

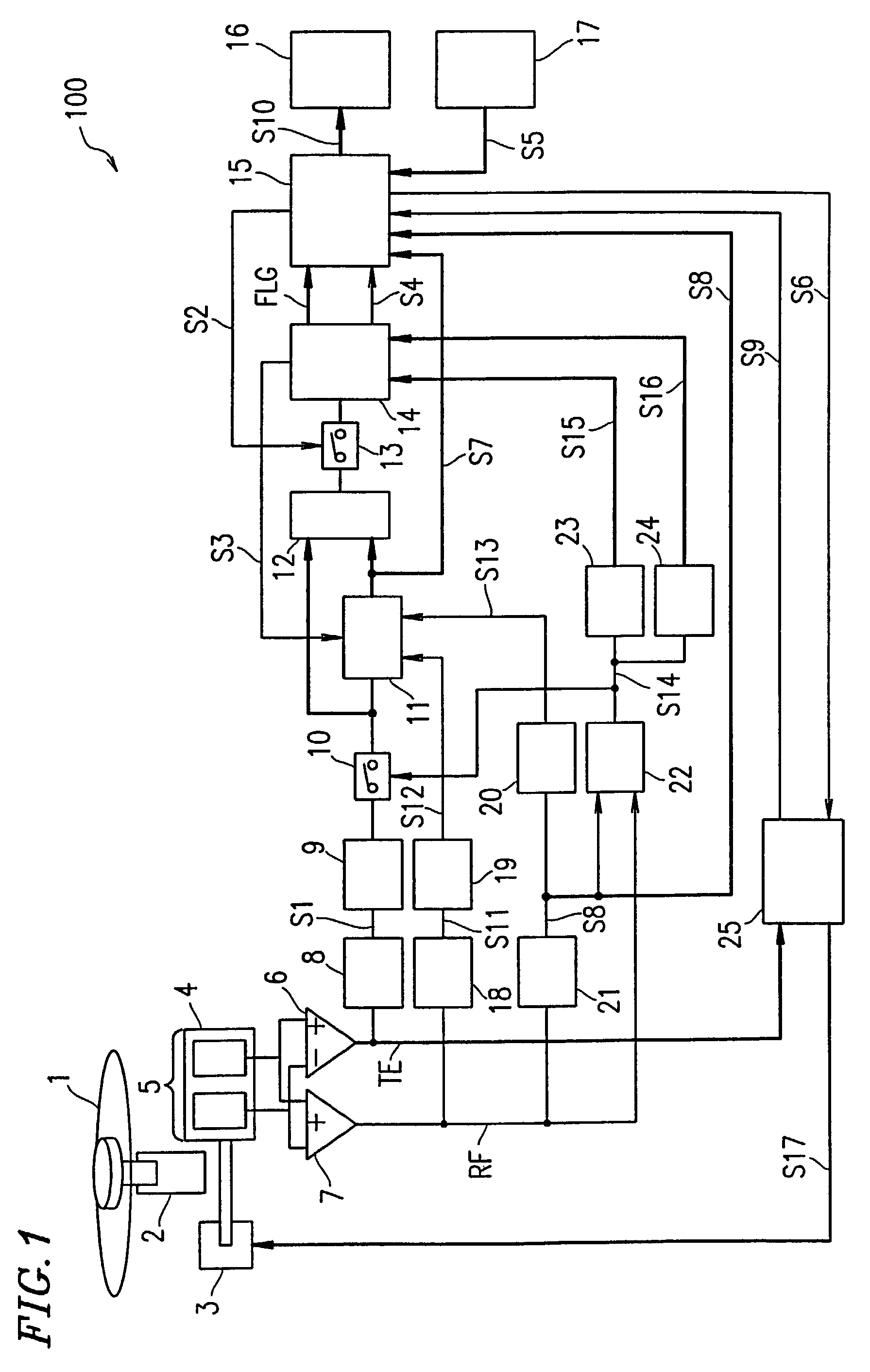

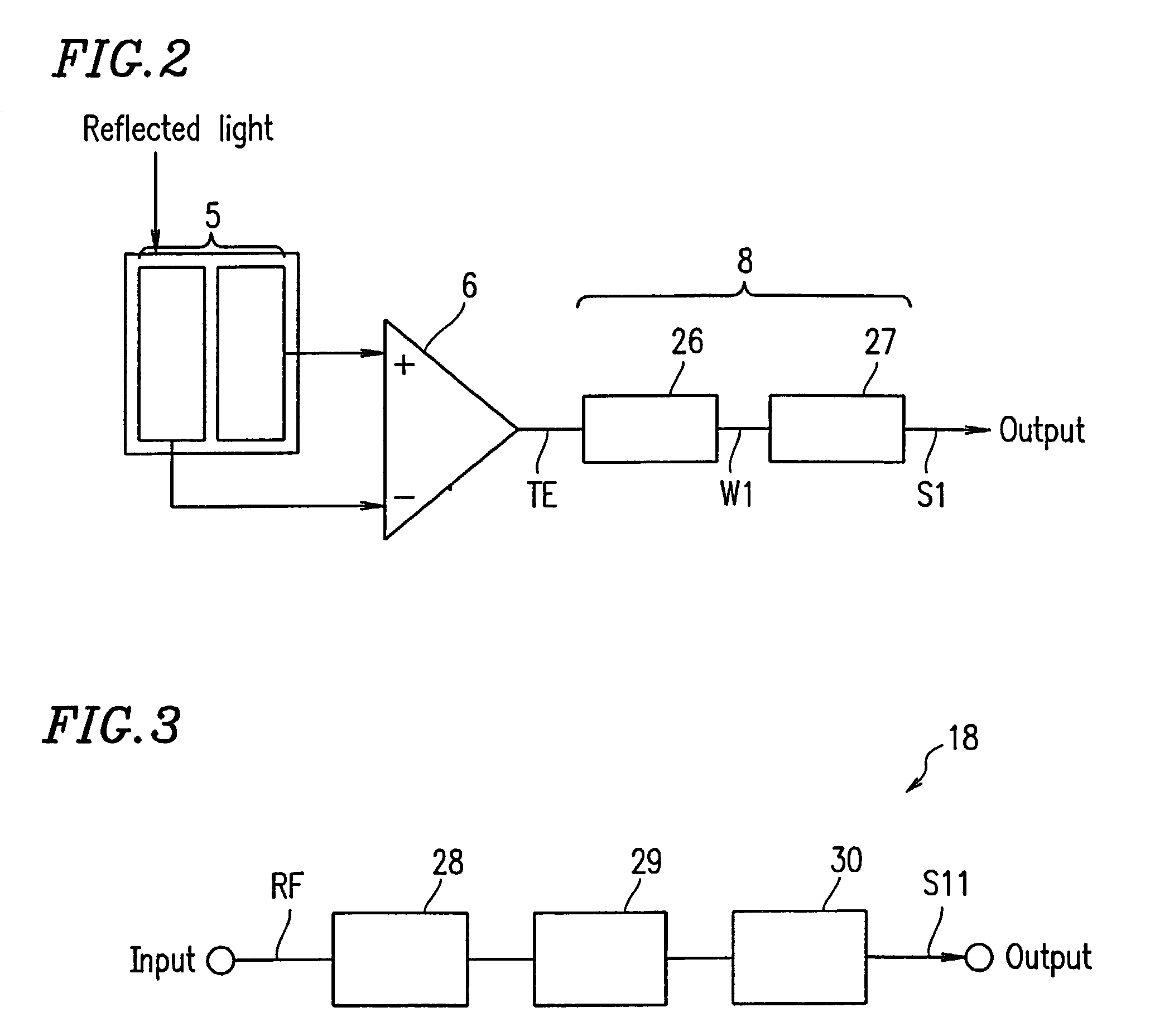

Reading device and reading method for an optical data recording medium

ActiveUS20100226218A1Prevent problematic drop in S/N ratioImprove signal qualityFilamentary/web record carriersOptical beam sourcesDriving currentHigh density

A reading devices suppresses deterioration of the recording marks caused by increasing the output laser power to compensate for a drop in the S / N ratio when reading at a high speed information recorded to a high density recording medium. To read information recorded to an optical data recording medium that is written and read using a laser beam output from a semiconductor laser, the reading method modulates a high frequency current on the drive current of the semiconductor laser to output the laser beam, and changes the light modulation rate according to the selected linear velocity used for reading. The light modulation rate is the ratio Pp / Pave between the peak power Pp and the average read power Pave of the light intensity of the high frequency modulated laser beam.

Owner:PANASONIC CORP

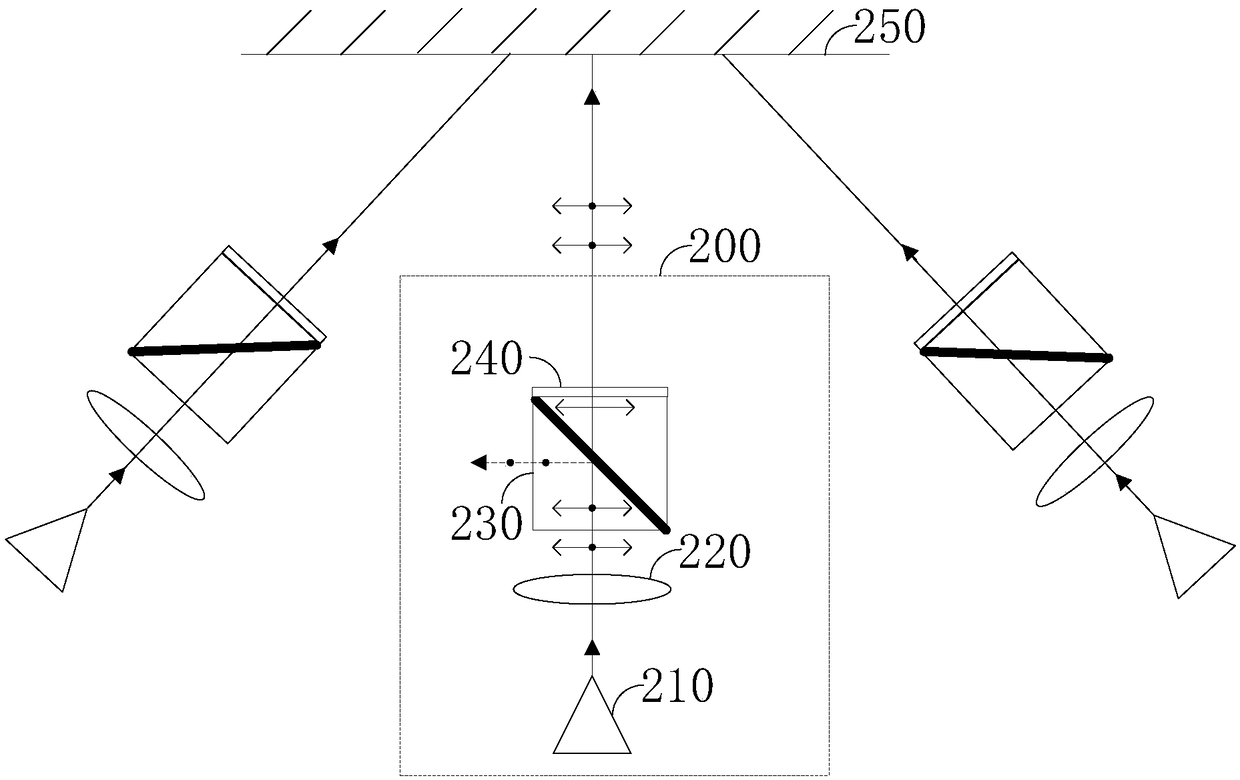

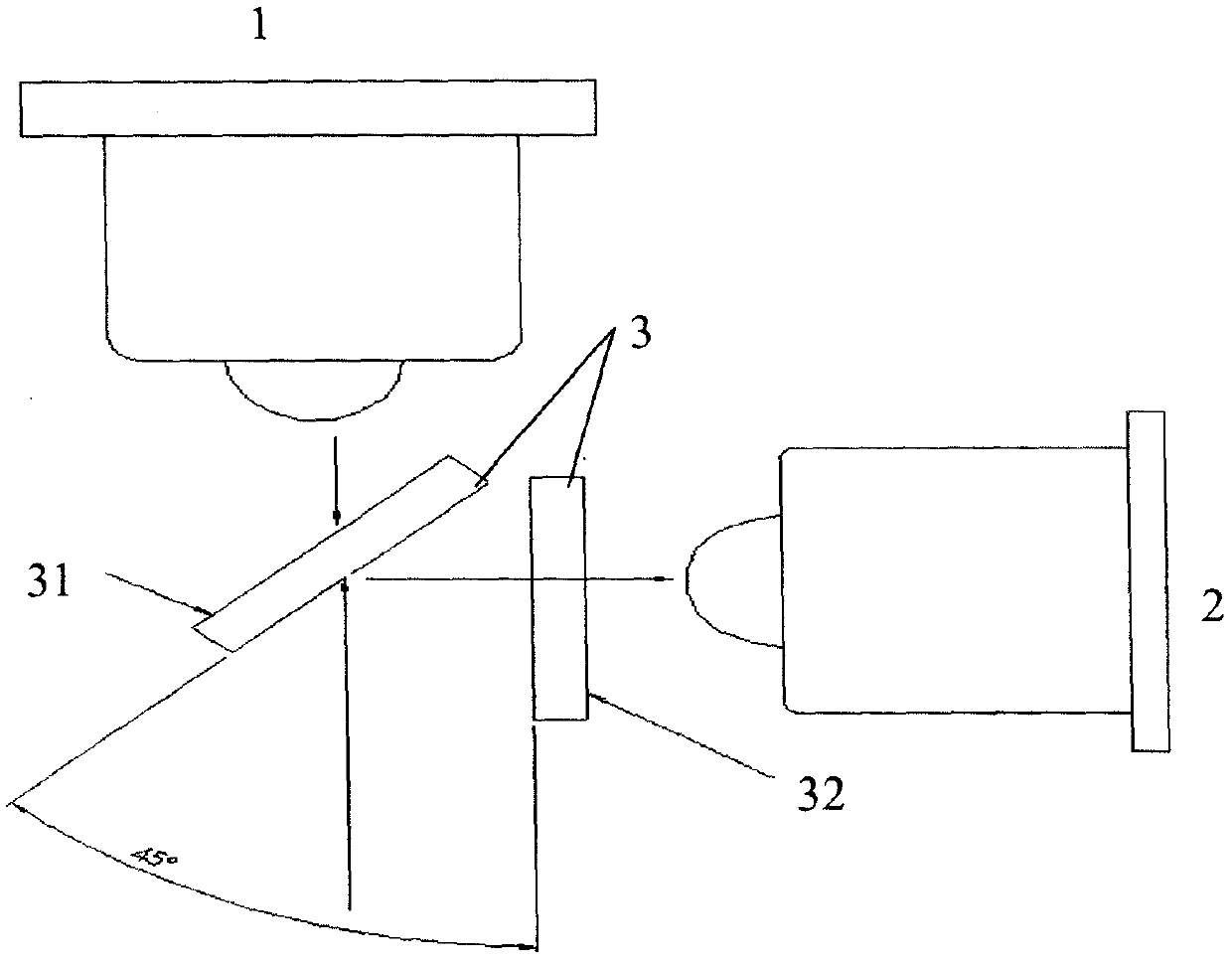

Laser radar and laser radar control method

PendingCN108761424AExtend the scan rangeImprove signal-to-noise ratioElectromagnetic wave reradiationImage resolutionBeam splitting

The embodiment of the invention discloses a laser radar and a laser radar control method. The laser radar comprises two or more than two detection units, each detection unit comprises: one emitter configured to emit an emergent laser; one emitting terminal collimation unit configured to perform collimation of the emergent laser emitted by the emitter; one polarizing beam-splitting unit configuredto allow the emergent laser after collimation to enter from a first light port of the polarizing beam-splitting unit to allow the P polarized light in the emergent laser after collimation to be emergent from the emitting terminal collimation unit; a quarter-wave plate configured to allow the P polarized light emergent from the second light port of the emitting terminal collimation unit to become circular polarized light; and a galvanometric scanner configured to change the emergent direction of the circular polarized light to become the emergent laser. The laser radar and the laser radar control method can enhance the scanning range of the laser radar and improve the resolution and precision of the laser radar.

Owner:SUTENG INNOVATION TECH CO LTD

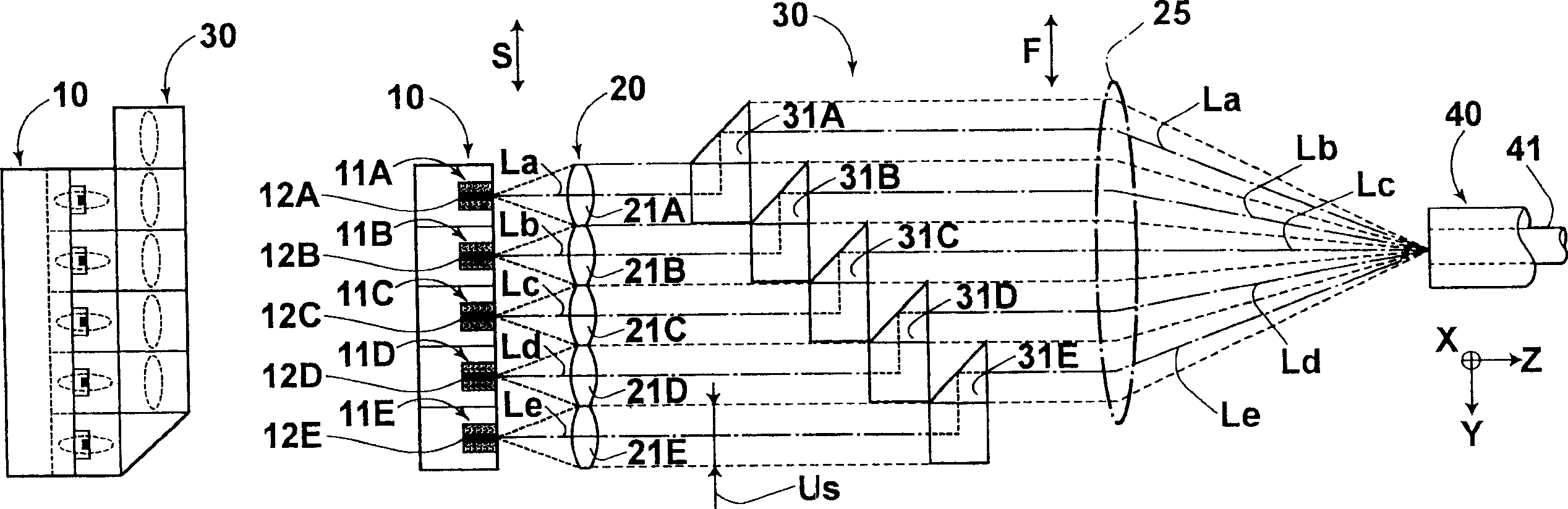

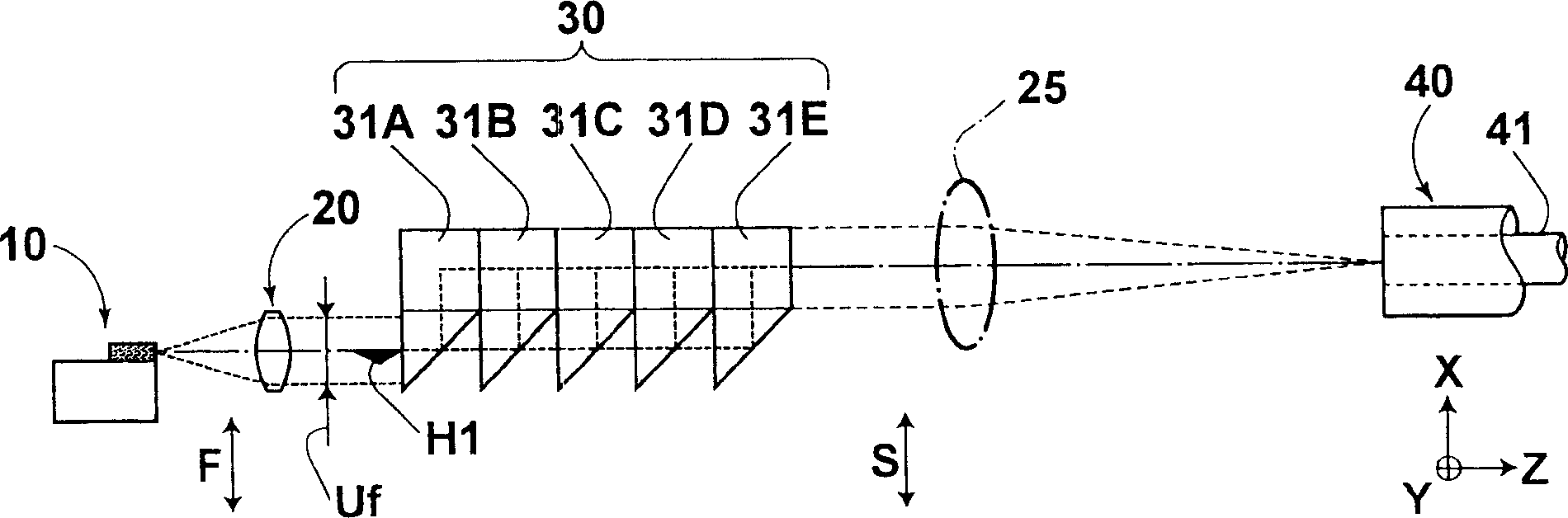

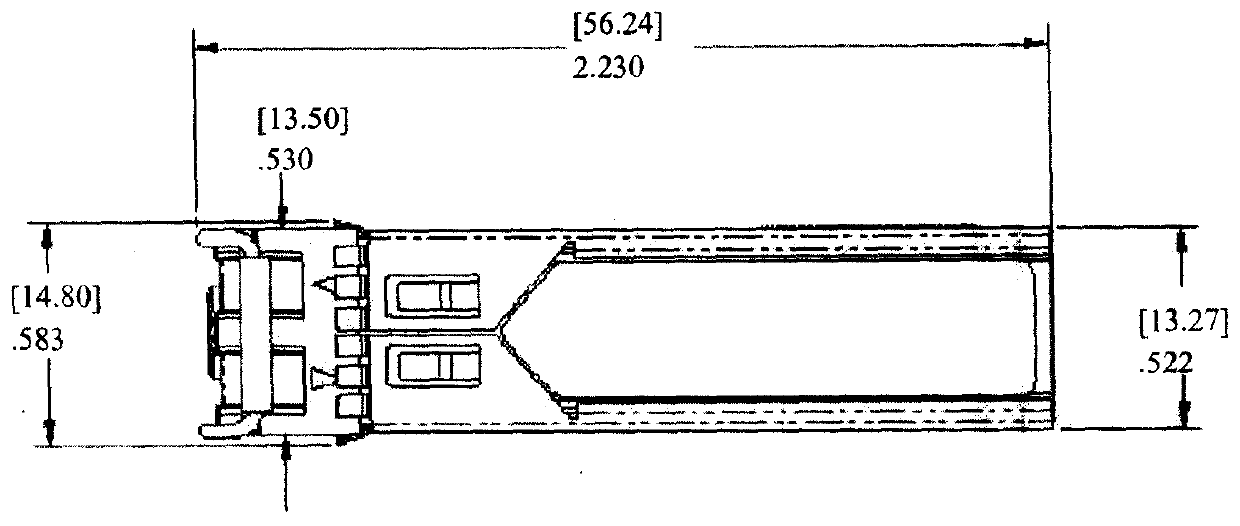

Laser multiplex transmission apparatus

In a laser light multiplexing apparatus: a collimating optical system collimates light beams emitted from semiconductor lasers so that the slow axes of the light beams become coplanar, and optical axes of the light beams become parallel to each other; a light beam rearrangement optical system constituted by prisms respectively arranged in correspondence with the light beams rearranges the light beams in such a manner that directions of the fast axes of the light beams are changed at different locations along a direction in which the light beams propagate, and the fast axes of the light beams become coplanar; and a convergence optical system converges a bundle of the light beams rearranged by the light beam rearrangement optical system, in directions of the fast axes and the slow axes of the light beams, and makes the converged bundle of the light beams enter an optical fiber.

Owner:FUJIFILM CORP

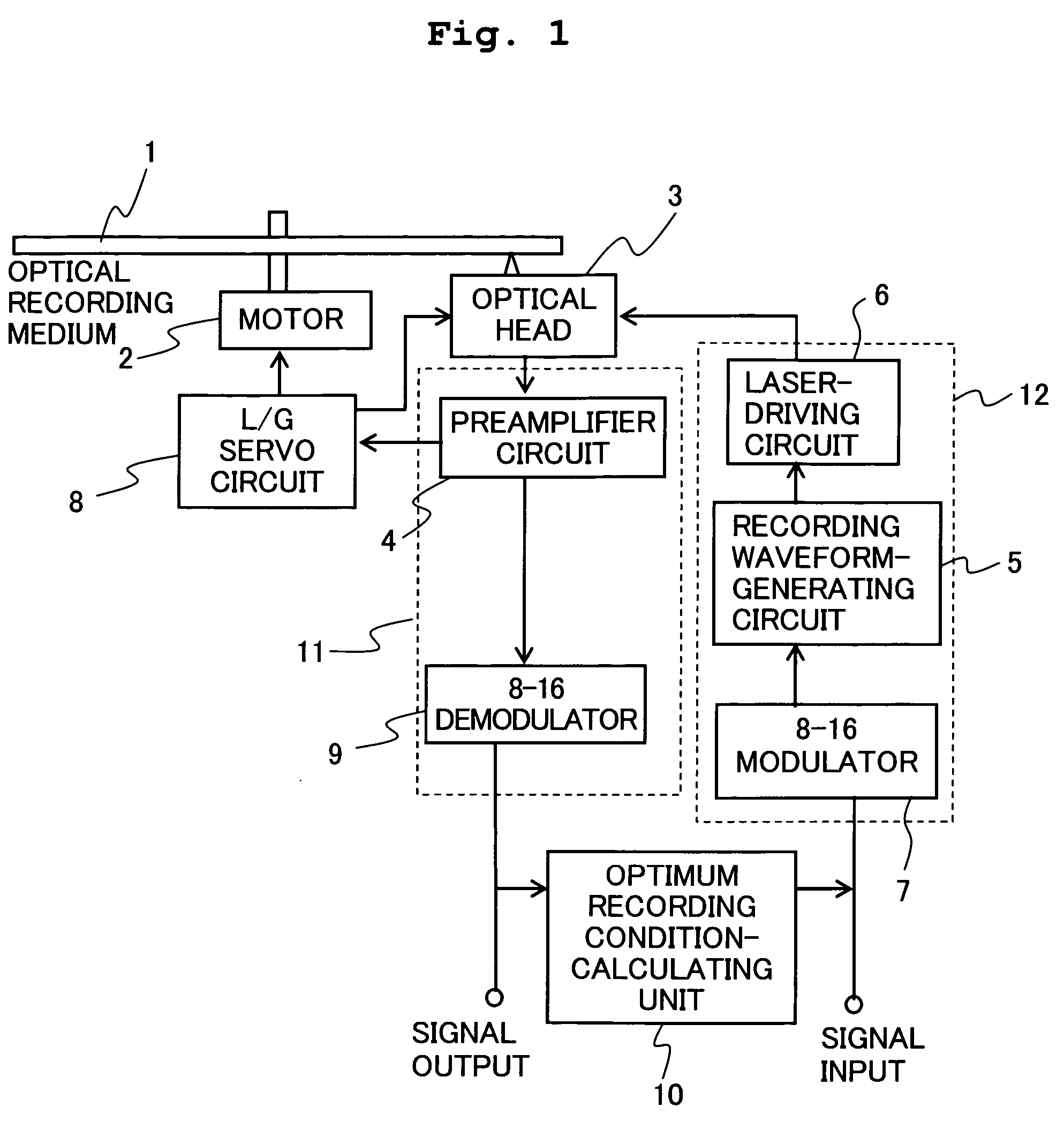

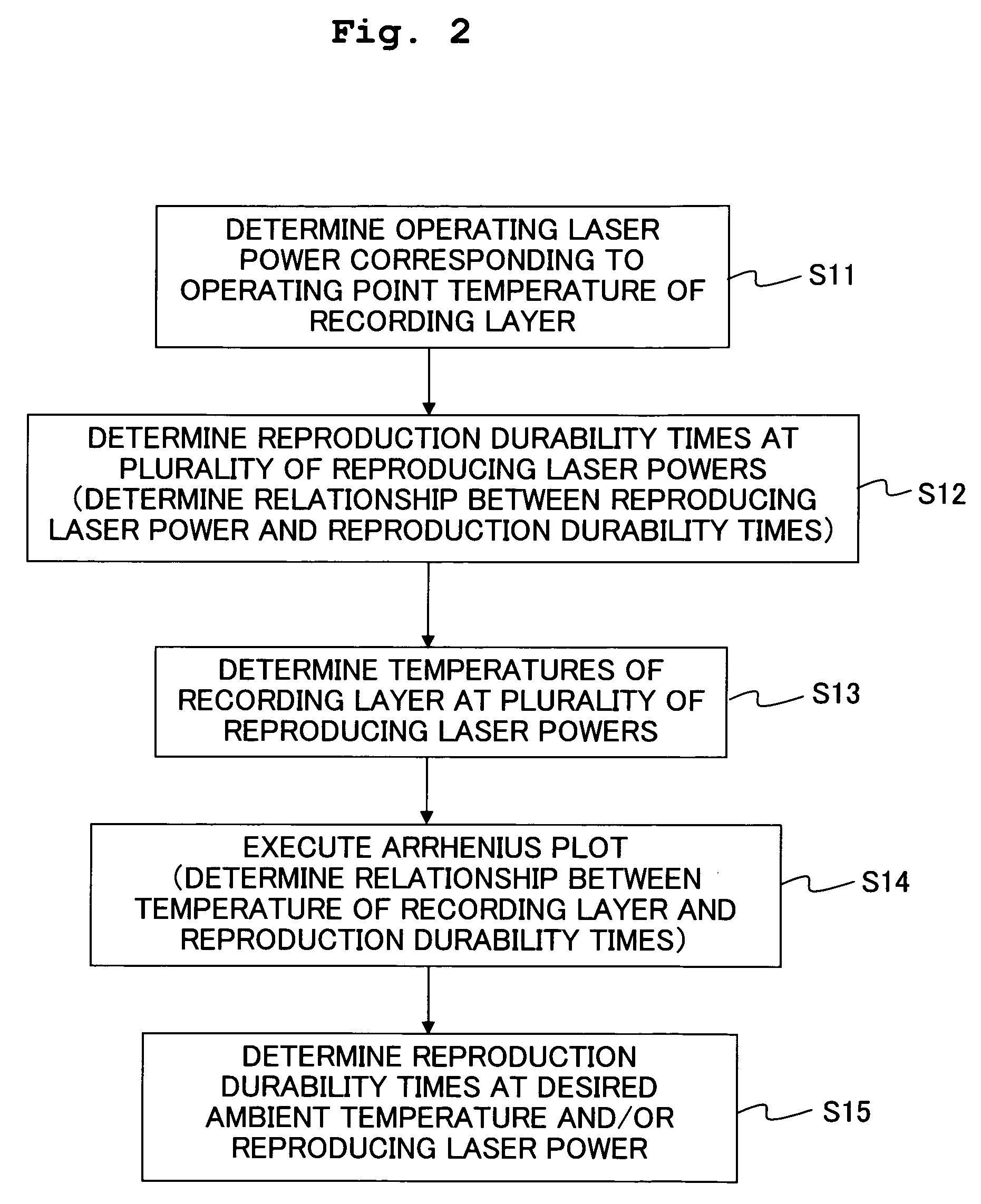

Method for evaluating optical recording medium, optical recording medium, and information-recording/reproducing apparatus

InactiveUS20060221787A1Reliable reproductionInhibit deteriorationCombination recordingFilamentary/web record carriersOptical recordingRecording layer

The reproduction durability of an optical recording medium is evaluated highly accurately in a short period of time by providing a method for evaluating the optical recording medium, the method including determining an operating laser power for heating a recording layer to a recording operating temperature; determining a temperature of the recording layer when a laser beam having a predetermined reproducing laser power is radiated during a data reproduction; determining a relationship between the reproducing laser power during the data reproduction and a reproduction durability times at the reproducing laser power; and determining a relationship between the temperature of the recording layer during the data reproduction and the reproduction durability times from the relationship between the reproducing laser power during the data reproduction and the reproduction durability times.

Owner:HITACHT MAXELL LTD

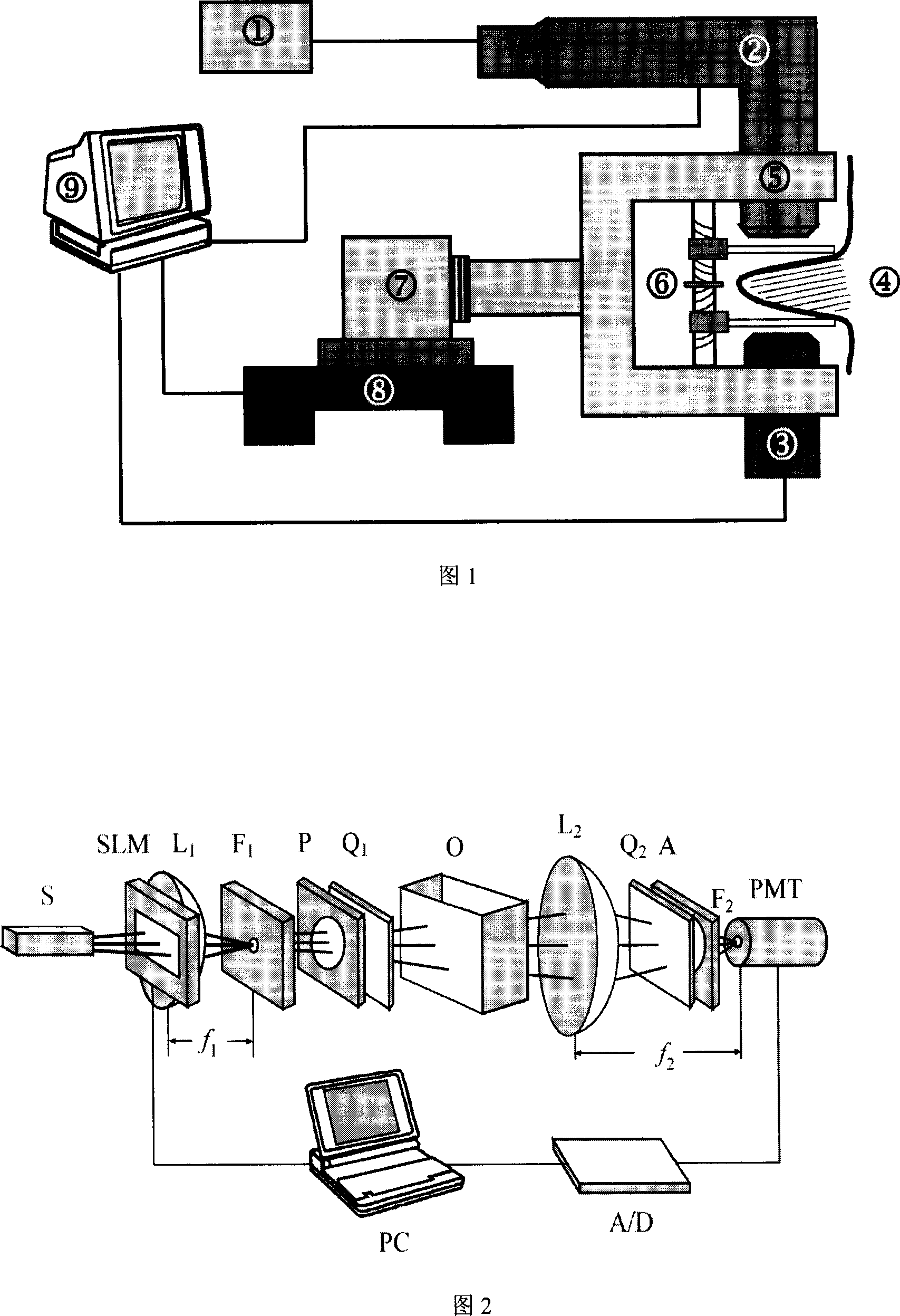

3-D high-definition mammary gland imager

InactiveCN101015446AAccurate reconstructionReduce volumeSurgeryDiagnostic recording/measuringDiseaseMammary gland structure

The invention discloses a three-dimensional high-definition mammary gland imager in the biological medical imaging domain, which is characterized by the following: judging pathologic position and degree of mammary gland tissue according to optical parameter according to grey, tissue structure and size semi-quantitatively or qualitatively; adopting infrared (600-900nm) as light source; modulating space of irradiated light through coded aperture without harmful detecting; forming digital infrared optical scanning hologram; utilizing digital decoded technique to extract the information of galactophore tissue; displaying three-dimensional high-definition image.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

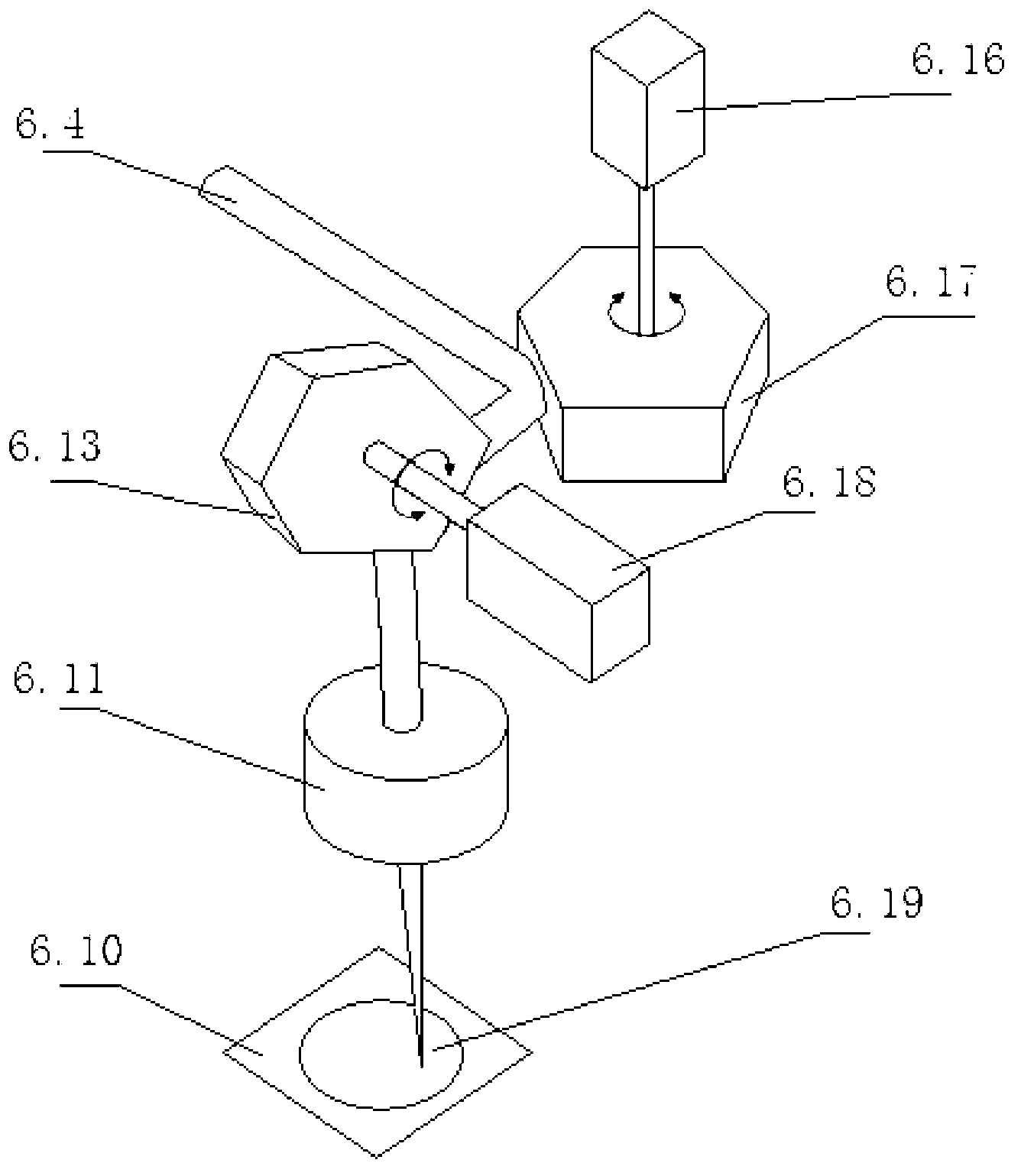

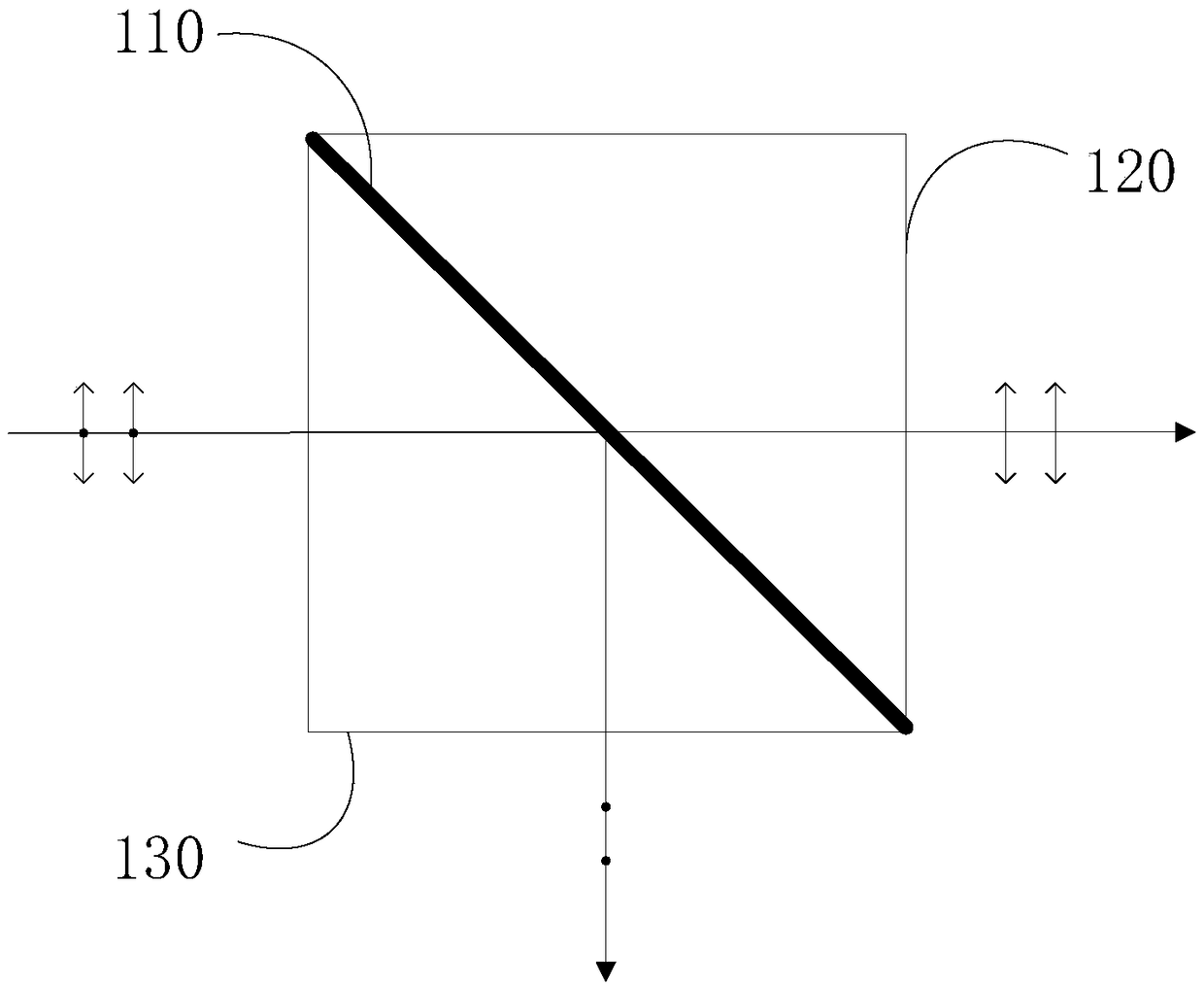

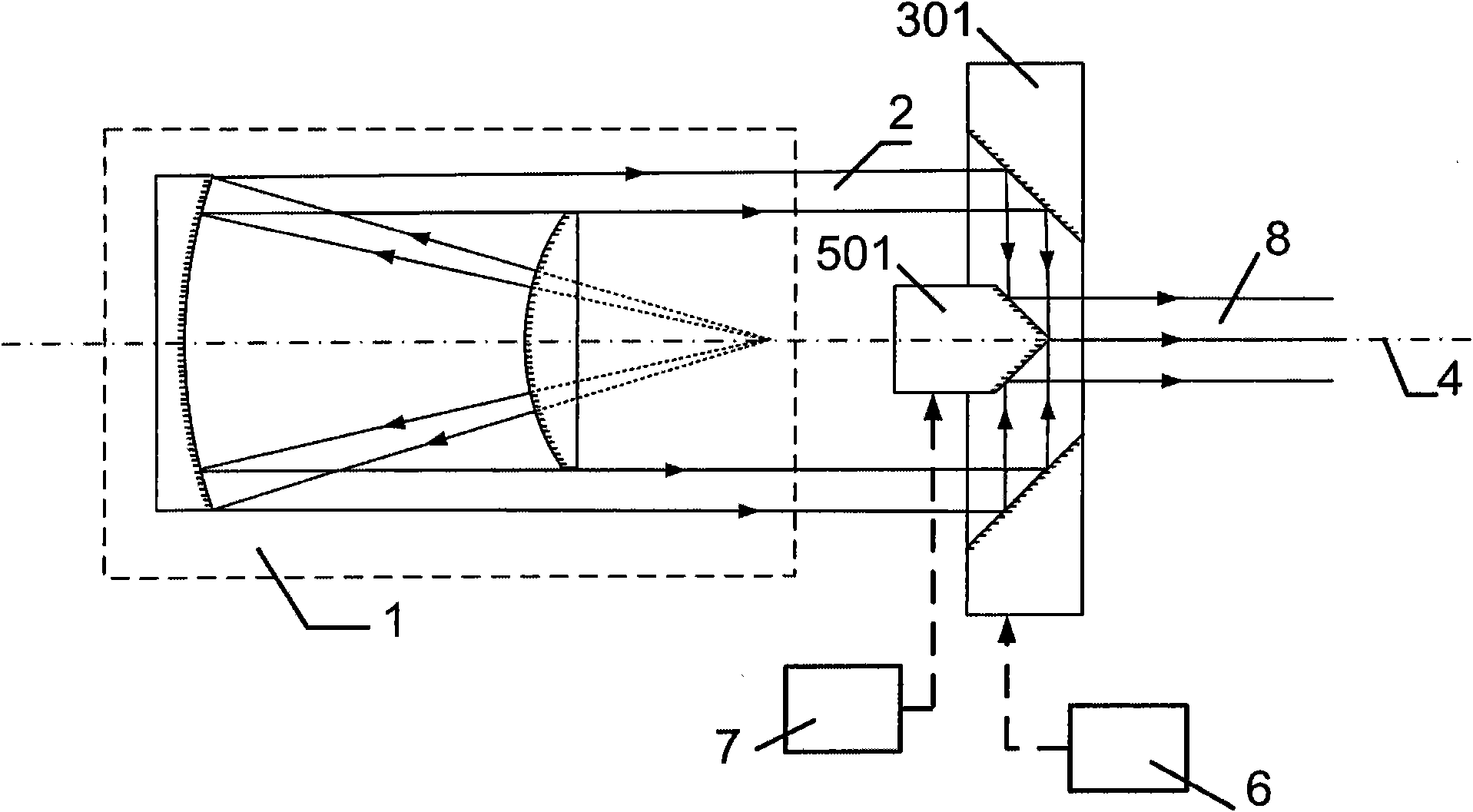

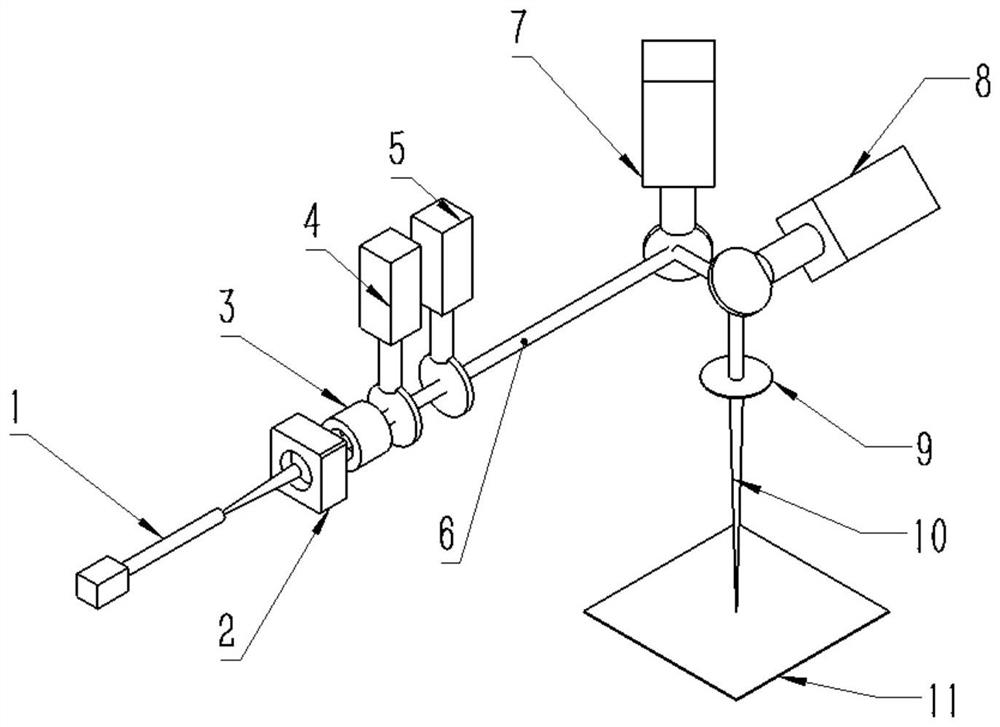

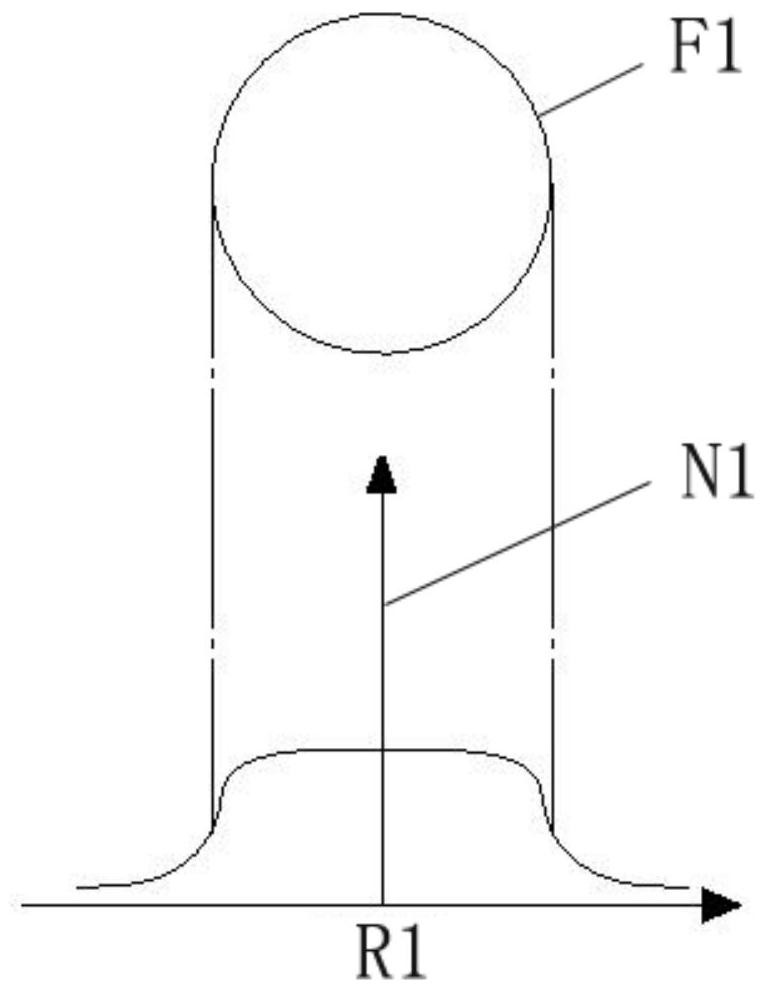

Central part reconstruction method and device of unstable resonator laser annular beam

InactiveCN101806958ASuitable for plastic surgeryIncrease laser powerOptical elementsSolid lightOptical axis

The invention provides a central part reconstruction method and a device of an unstable resonator laser annular beam. The method comprises: an annular beam output by an unstable resonator laser is guided by an inner round table surface annular reflecting mirror and is gradually concentrated towards the optical axis position of the laser; the light beam concentrated on the periphery of the optical axis is reguided by utilizing an external cone surface reflecting mirror to obtain a reshaped light beam output along the optical axis direction; and the relative position of the inner round table surface annular reflecting mirror and the external cone surface reflecting mirror along the optical axis direction is precisely adjusted to realize the circular solid reshaping light beam output along the optical axis direction. The device comprises the unstable resonator laser, the inner round table surface annular reflecting mirror, the external cone surface reflecting mirror, a precise displacement mechanism of the inner round table surface annular reflecting mirror and a precise displacement mechanism of the external cone surface reflecting mirror. Compared with the prior art, the method can utilize an extracavity optical element to change the annular beam output by the unstable resonator laser and obtain circular solid light beam output. The provided device has simple structure and stable operation.

Owner:HUAZHONG UNIV OF SCI & TECH

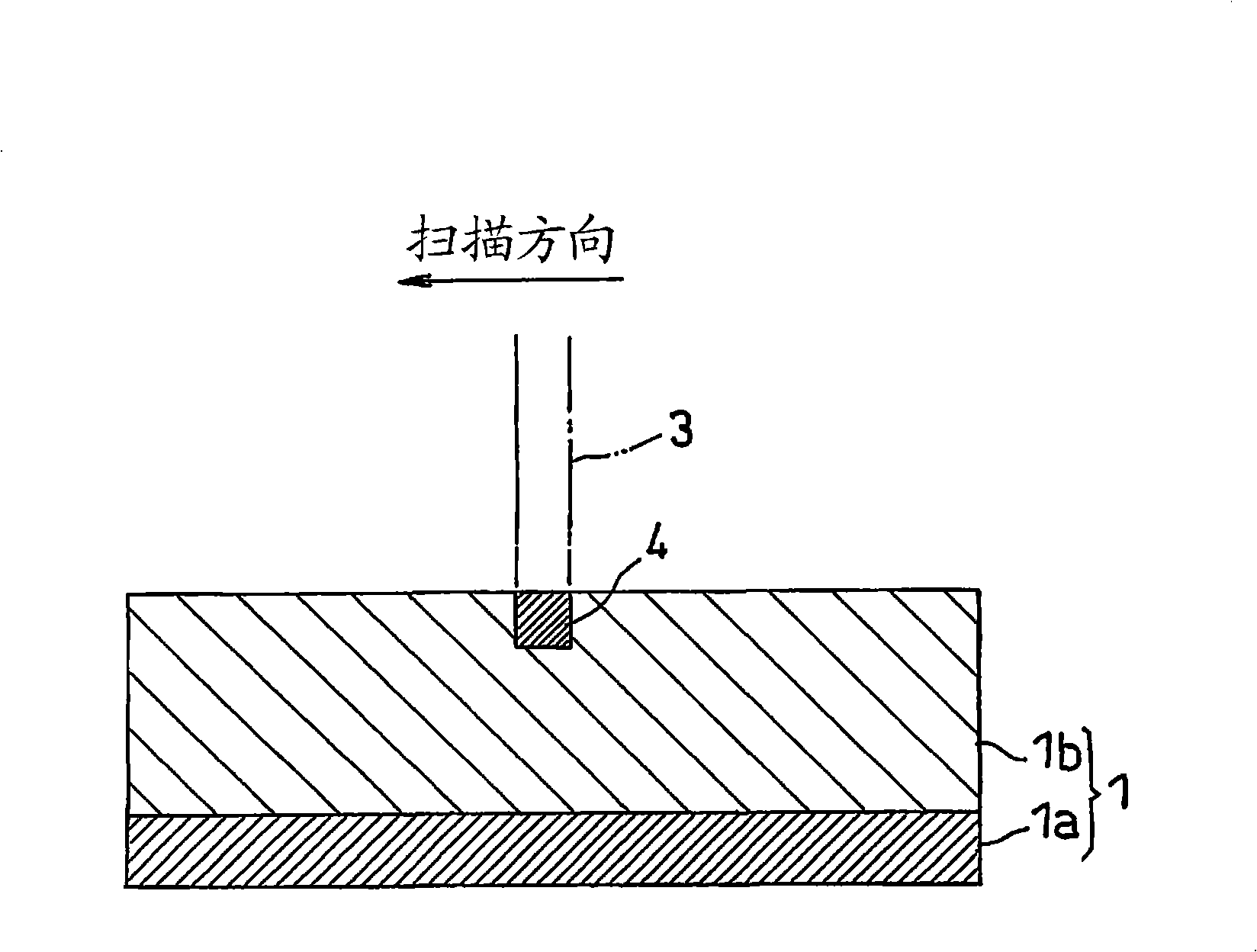

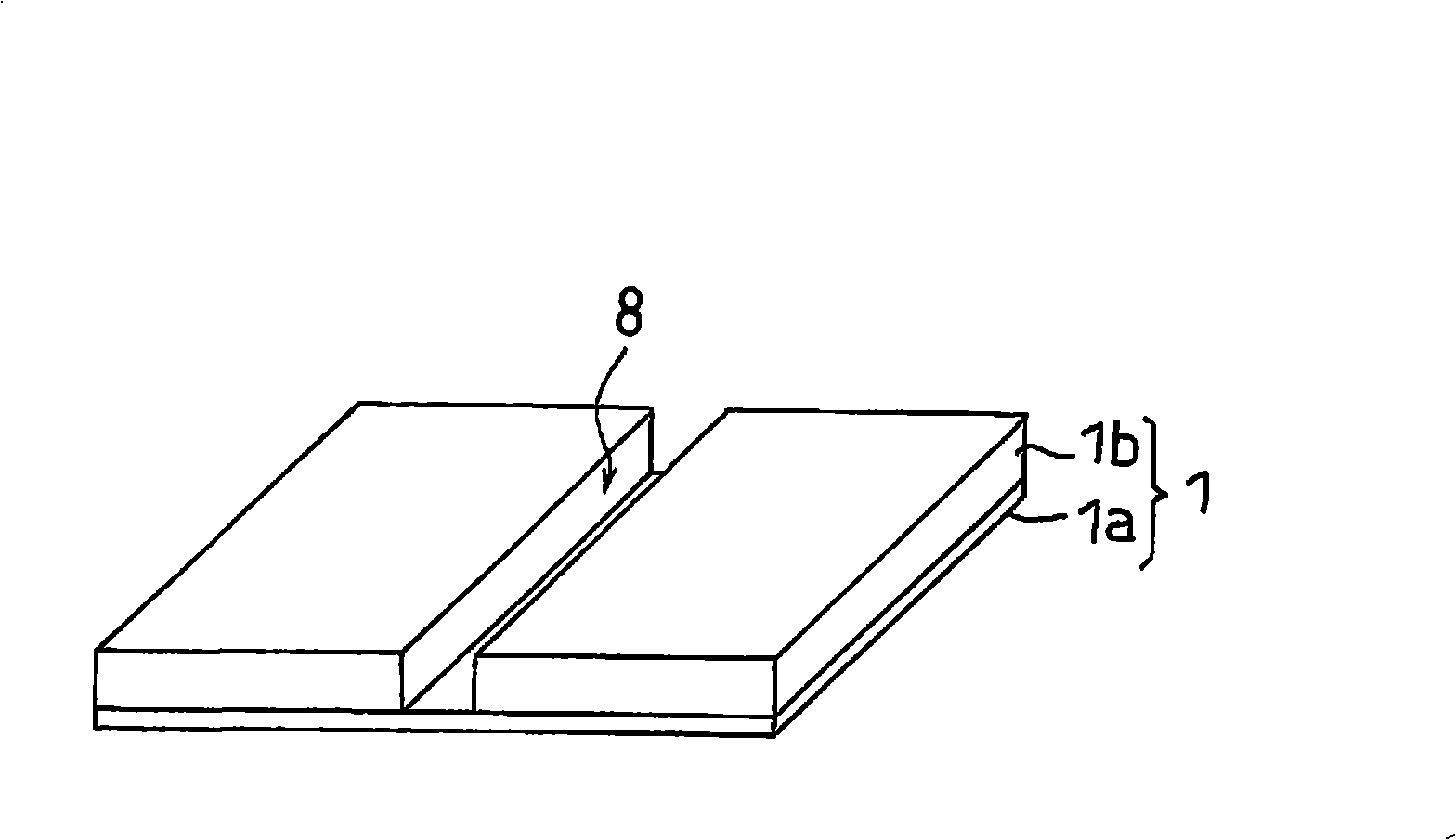

Laser beam processing method

ActiveCN101347869AIncrease laser powerIncrease movement speedPrinted circuit manufactureWelding/soldering/cutting articlesLaser processingEnergy control

The laser beam processing method according to the present invention is a laser beam processing method that performs shape processing on a work to a designated depth position using a laser beam, and is characterized in that the laser power of the laser beam and the relative moving speed between the work and the laser beam are made to be large, and the number of times of irradiation that is necessary for laser beam processing is made to be small so that the energy per unit length of the laser beam that is optimally set depending on the work is within an energy range that does not allow the work to be pierced even when the laser power increases due to a power fluctuation in the laser beam oscillator.

Owner:NITTO DENKO CORP

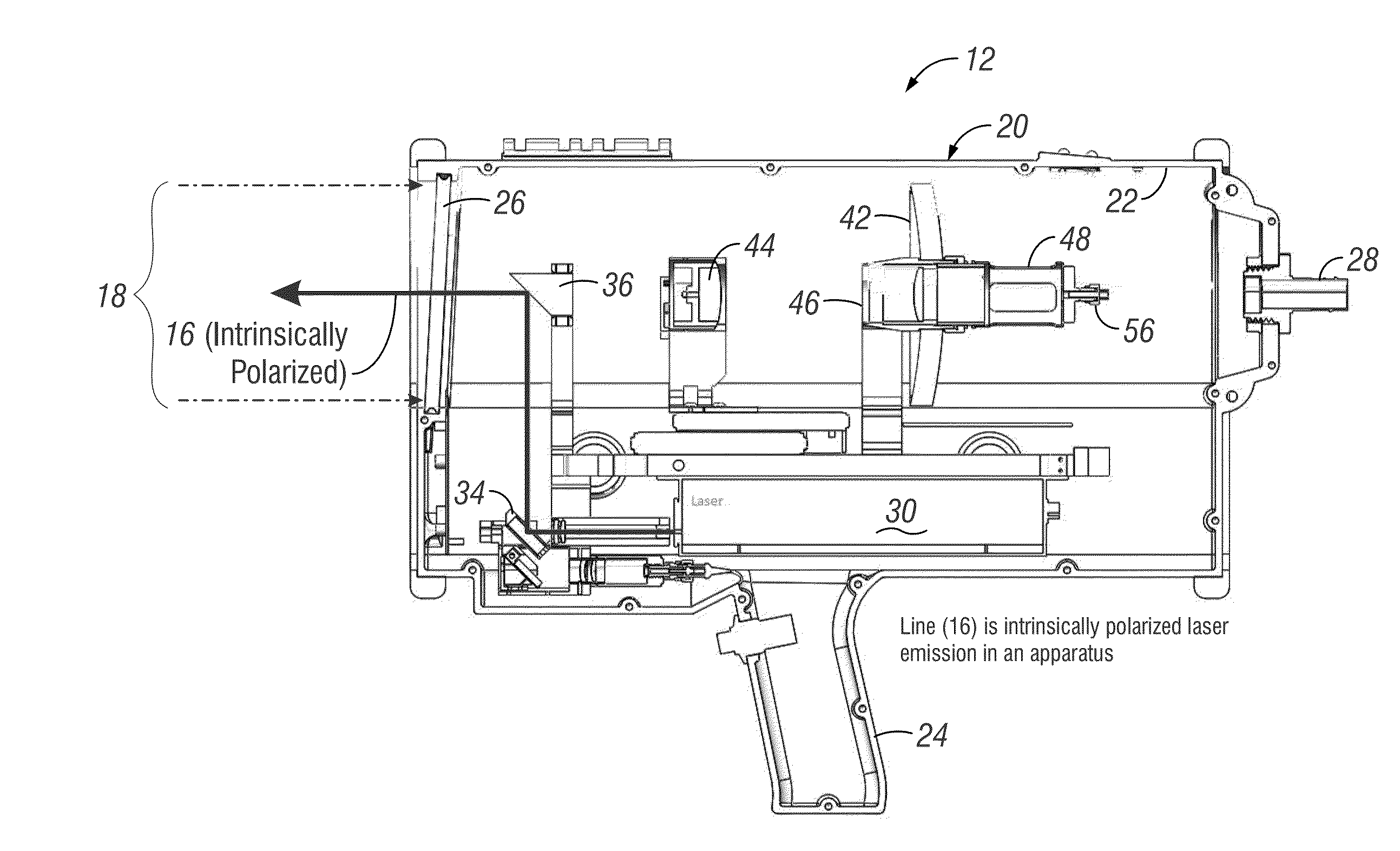

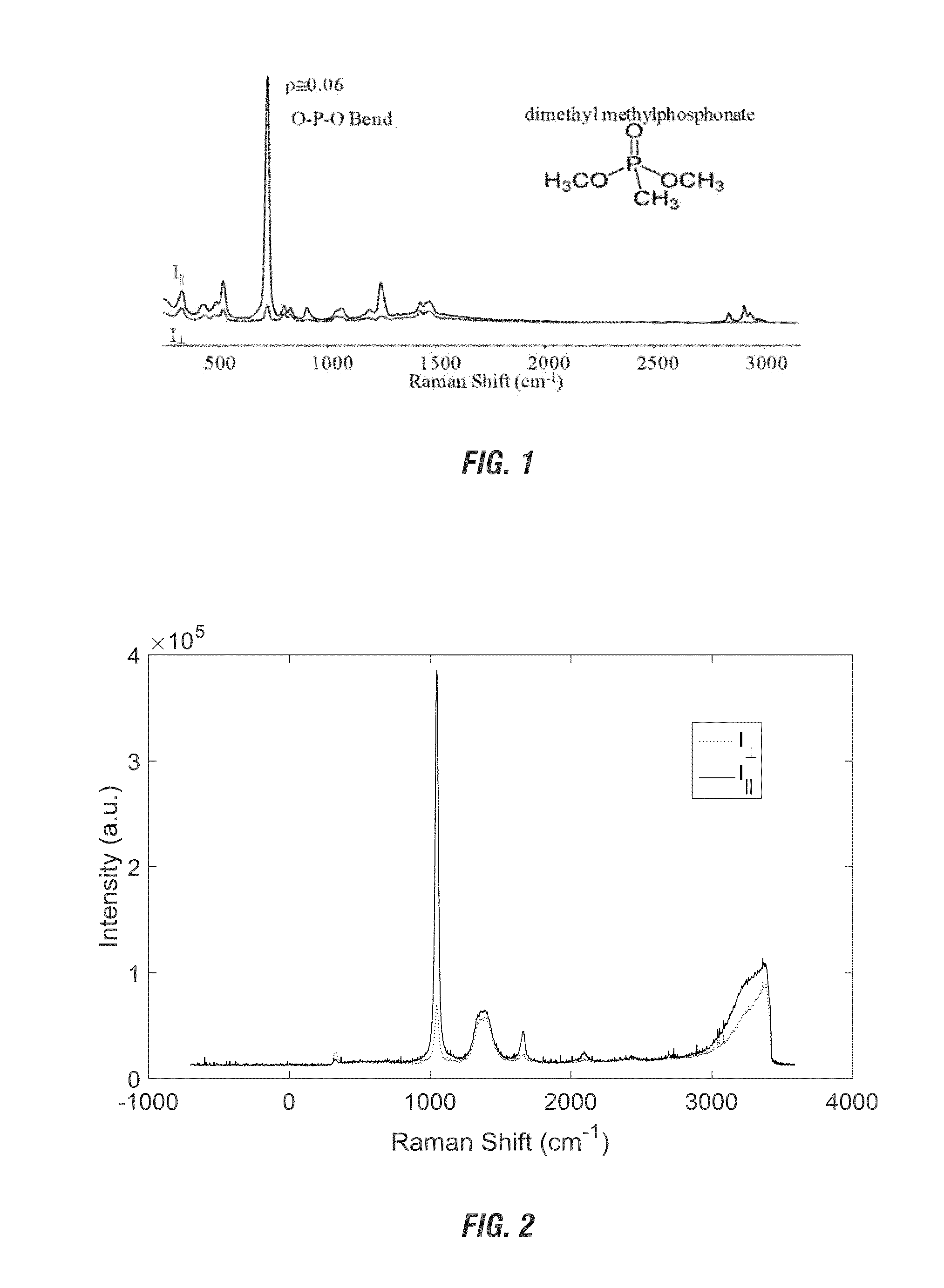

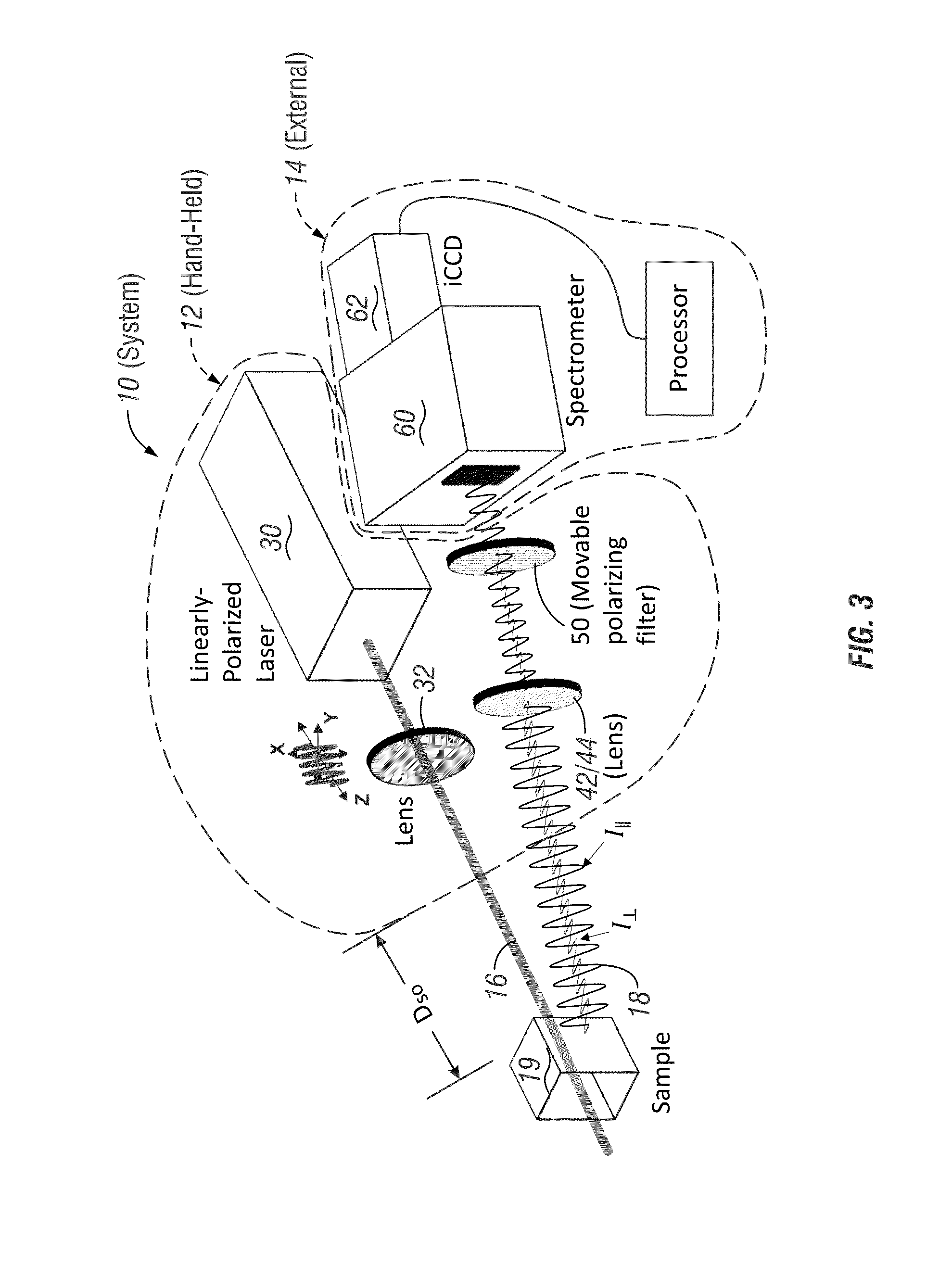

Fluorescence removal from raman spectra by polarization subtraction

InactiveUS20160103073A1Accurate detectionEasy to adjustRaman/scattering spectroscopyRadiation pyrometryFluorescenceUltraviolet

A method for utilizing polarization as a scheme for fluorescence removal from UV Raman spectra collected in a standoff detection scheme has been invented. In this scheme, a linearly polarized ultraviolet (UV) laser interacts with a material on a surface or in a container. The material generates Raman scattering with polarization contributions relative to that of the laser. The material possibly fluoresces as well, but the fluorescence is generally unpolarized. By subtracting a scaled version of the perpendicular component from the parallel component of the returned signal both relative to the laser source polarization—it is possible to generate a spectrum that is fluorescence free and contains the strongest features of the Raman scattered light.

Owner:ALAKAI DEFENSE SYST

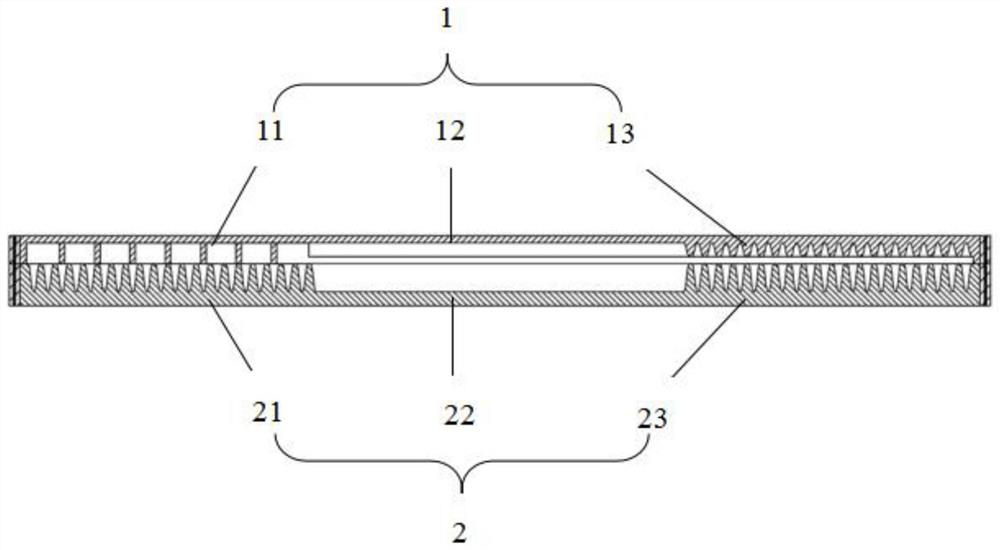

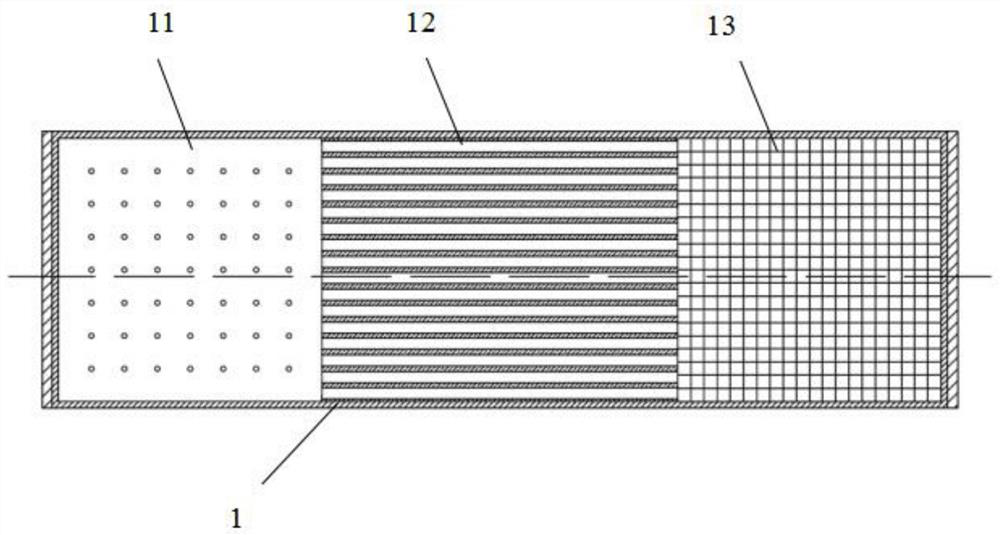

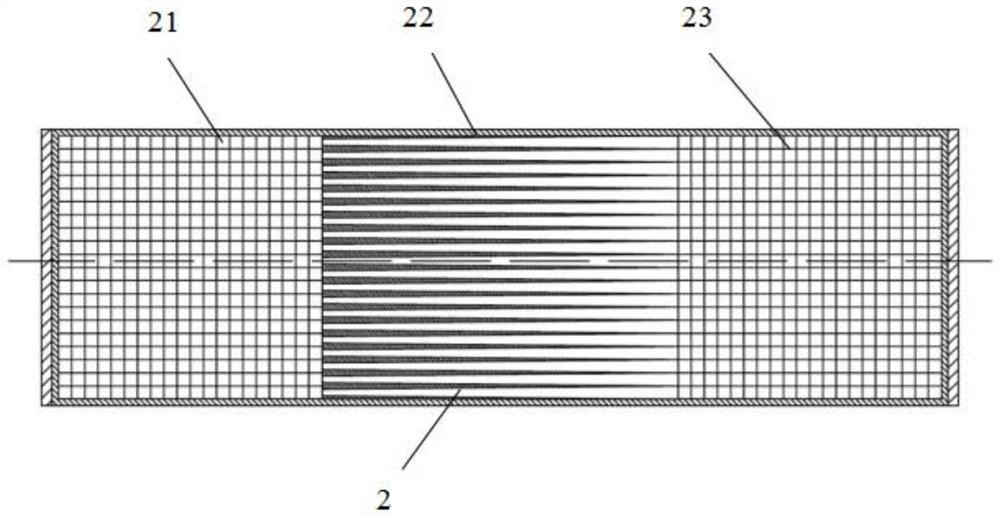

Partition-optimized ultrathin VC with thickness of 0.1-0.4 mm and preparation method

PendingCN111879158AEmission reductionSpeed up distributionIndirect heat exchangersMicro nanoNano structuring

The invention discloses a partition-optimized ultrathin VC with the thickness of 0.1-0.4 mm and a preparation method. The ultrathin VC comprises an upper cover plate and a lower cover plate, and the upper cover plate and the lower cover plate are welded. Each of the upper cover plate and the lower cover plate comprises an evaporation section, a heat insulation section and a condensation section; the surface of the evaporation section of the upper cover plate is of a super-hydrophilic cavity-shaped micro-nano structure, the surface of the heat insulation section of the upper cover plate is of asuper-hydrophilic equal-width groove micro-nano structure, and the surface of the condensation section of the upper cover plate is of a super-hydrophobic conical micro-nano structure; and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the evaporation section of the lower cover plate, a super-hydrophilic cactus-like wedge-shaped groove micro-nano structure is arranged on the surface of the area of the heat insulation section, and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the condensation section. The invention further discloses a preparation method of the ultrathin VC. A steam cavity structure, a liquid cavity structure and volume distribution in a heat pipe can be optimized, and good capillary water absorption performance and low water resistance and heat resistance of the heat pipe can be guaranteed.

Owner:绍兴镭纳激光科技有限公司

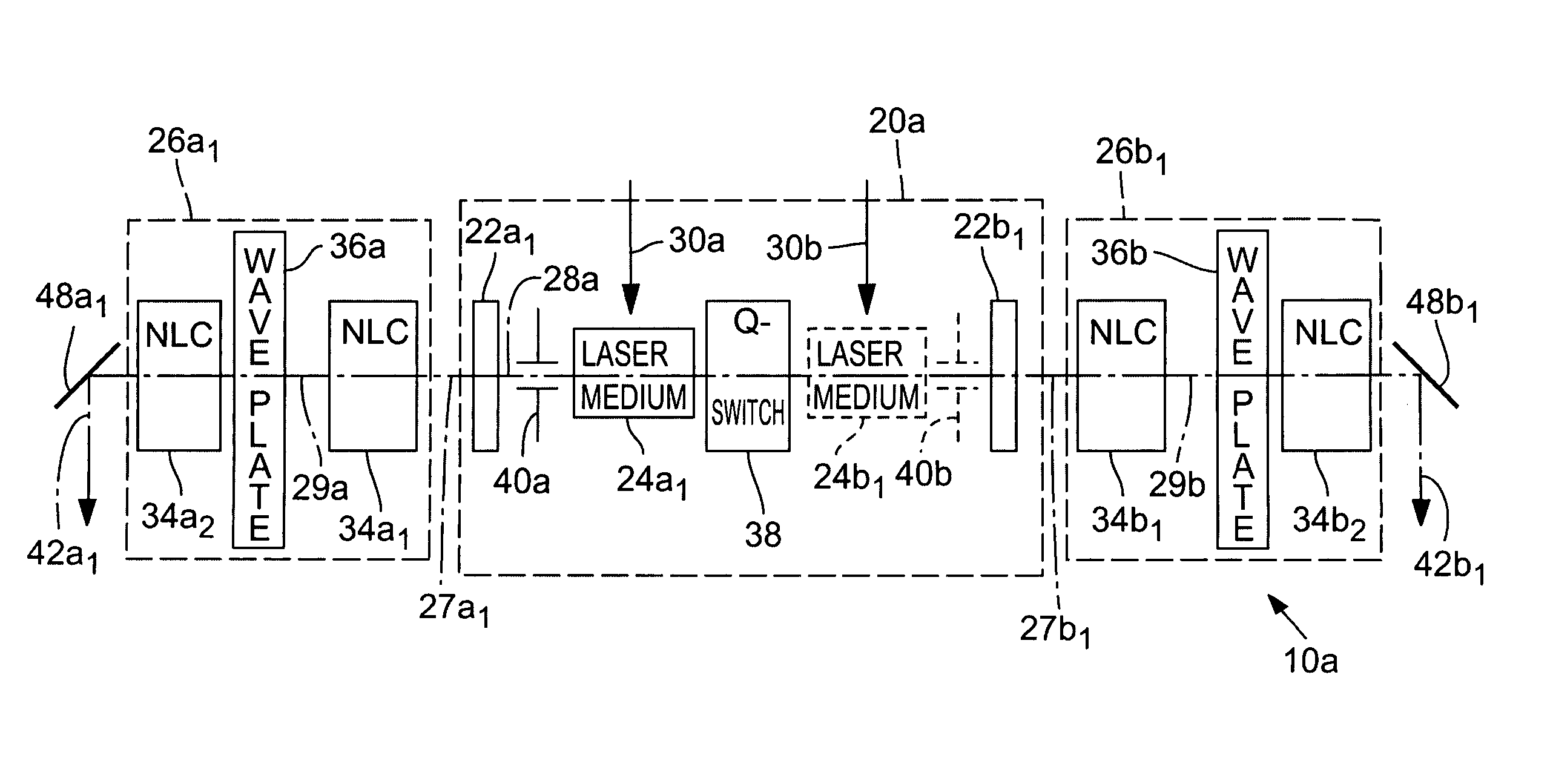

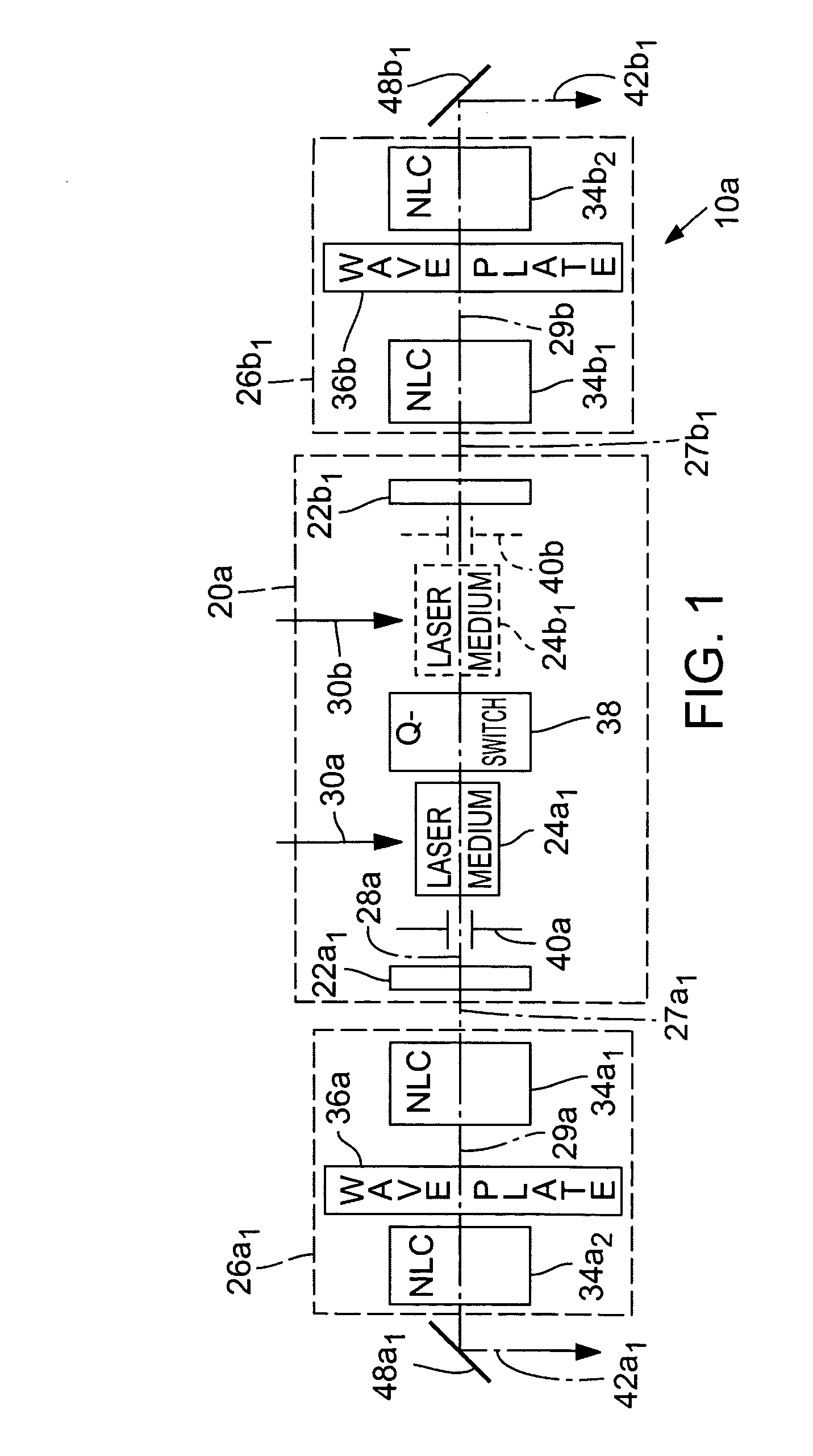

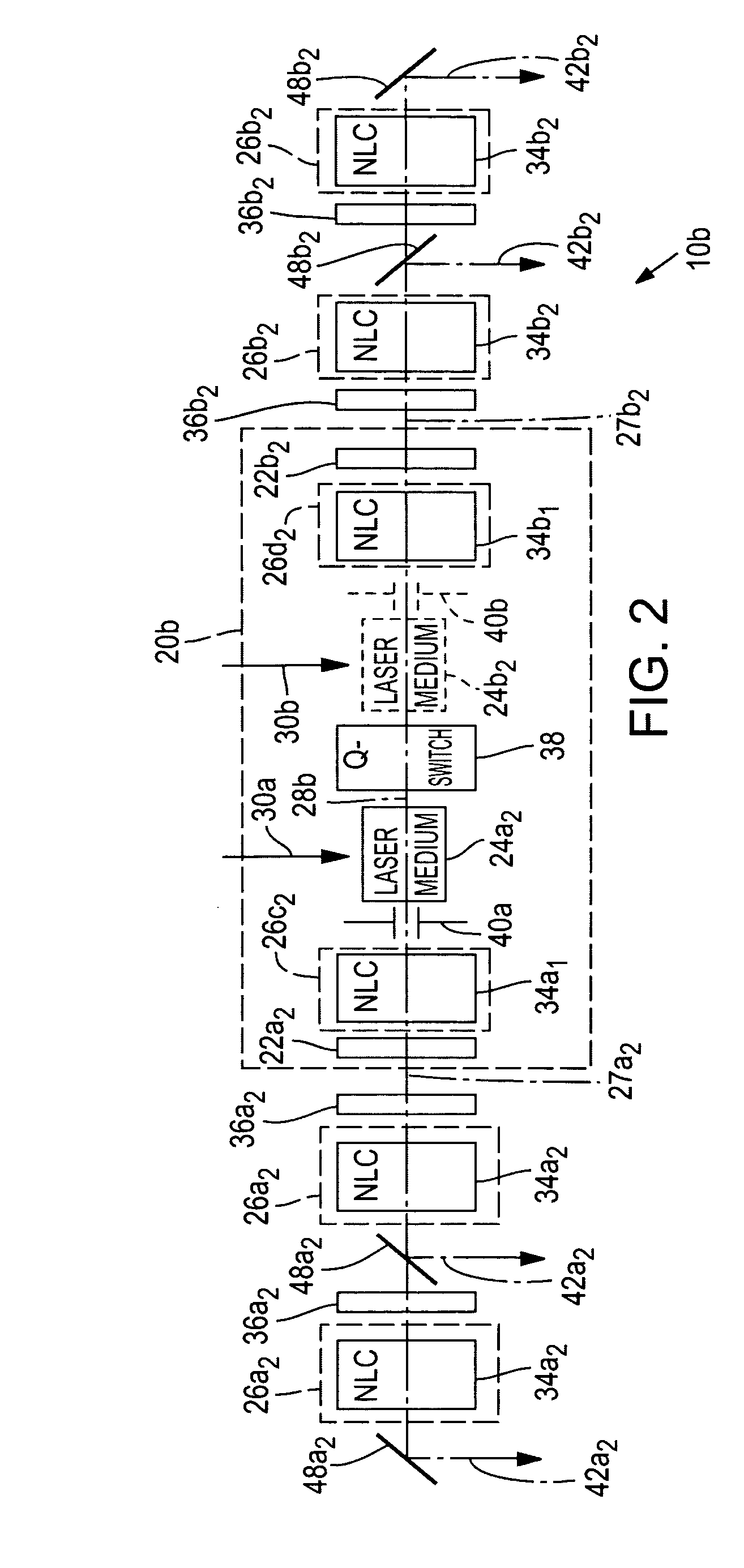

Multi-output harmonic laser and methods employing same

InactiveUS20050254530A1Less riskLow costOptical resonator shape and constructionActive medium shape and constructionHarmonicLength wave

A solid-state laser (10) has a laser resonator (20) with output ports (22) at both ends to provide two separate laser micromachining beams (42). A set of wavelength converters (26) can be employed to convert the laser machining beams (42) to harmonic wavelength outputs, thus reducing the risk of damage to the wavelength converters and enabling higher total average harmonic power to be generated from a single laser. The laser machining beams (42) can be different to perform different laser operations independently or can be adapted to have substantially identical parameters to permit simultaneous parallel high-quality laser operations on substantially identical workpieces (54), or the laser machining beams (42) can be combined to provide a single laser system output (42e). The two laser machining beams (42) can be further split or multiplexed to suit particular applications.

Owner:ELECTRO SCI IND INC

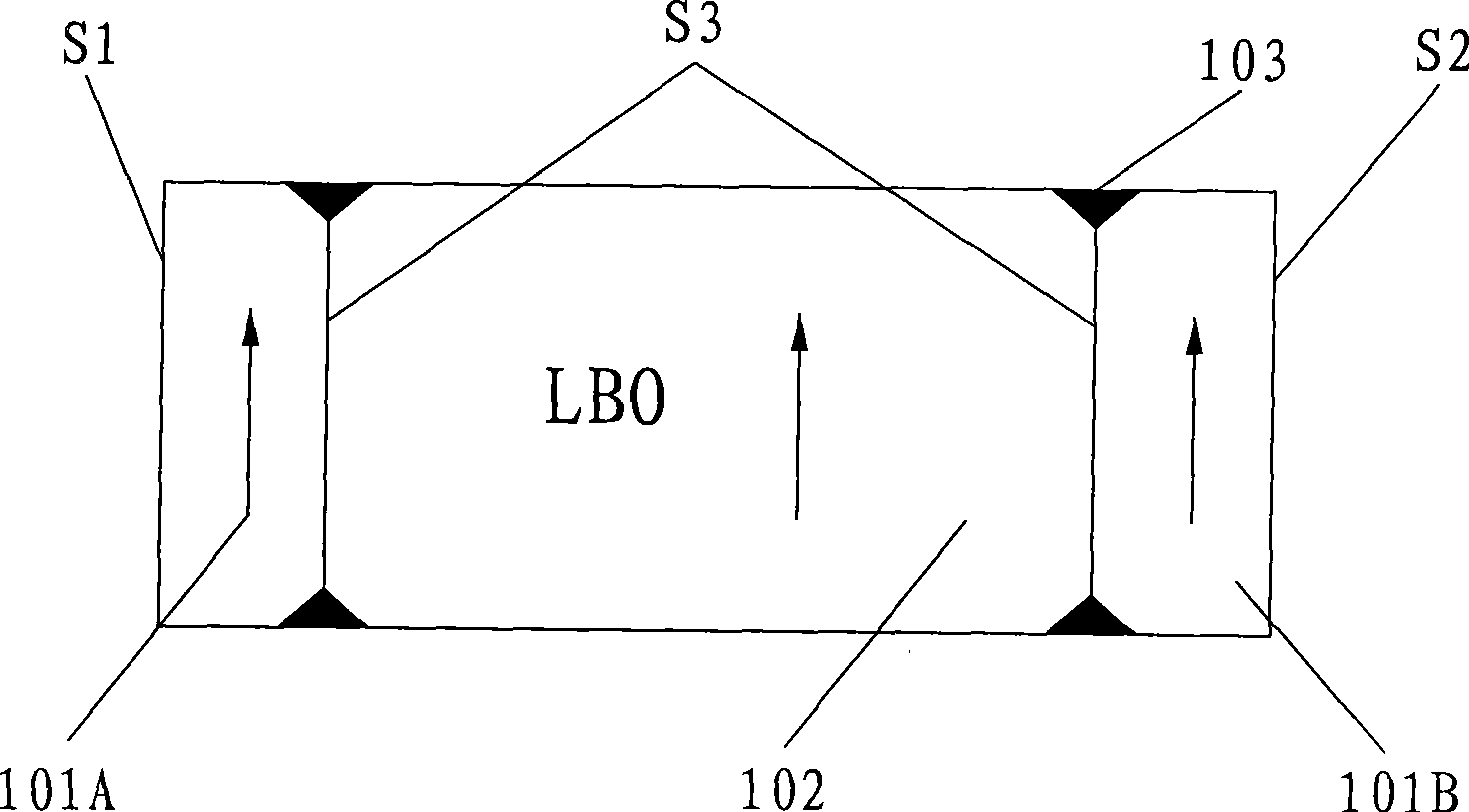

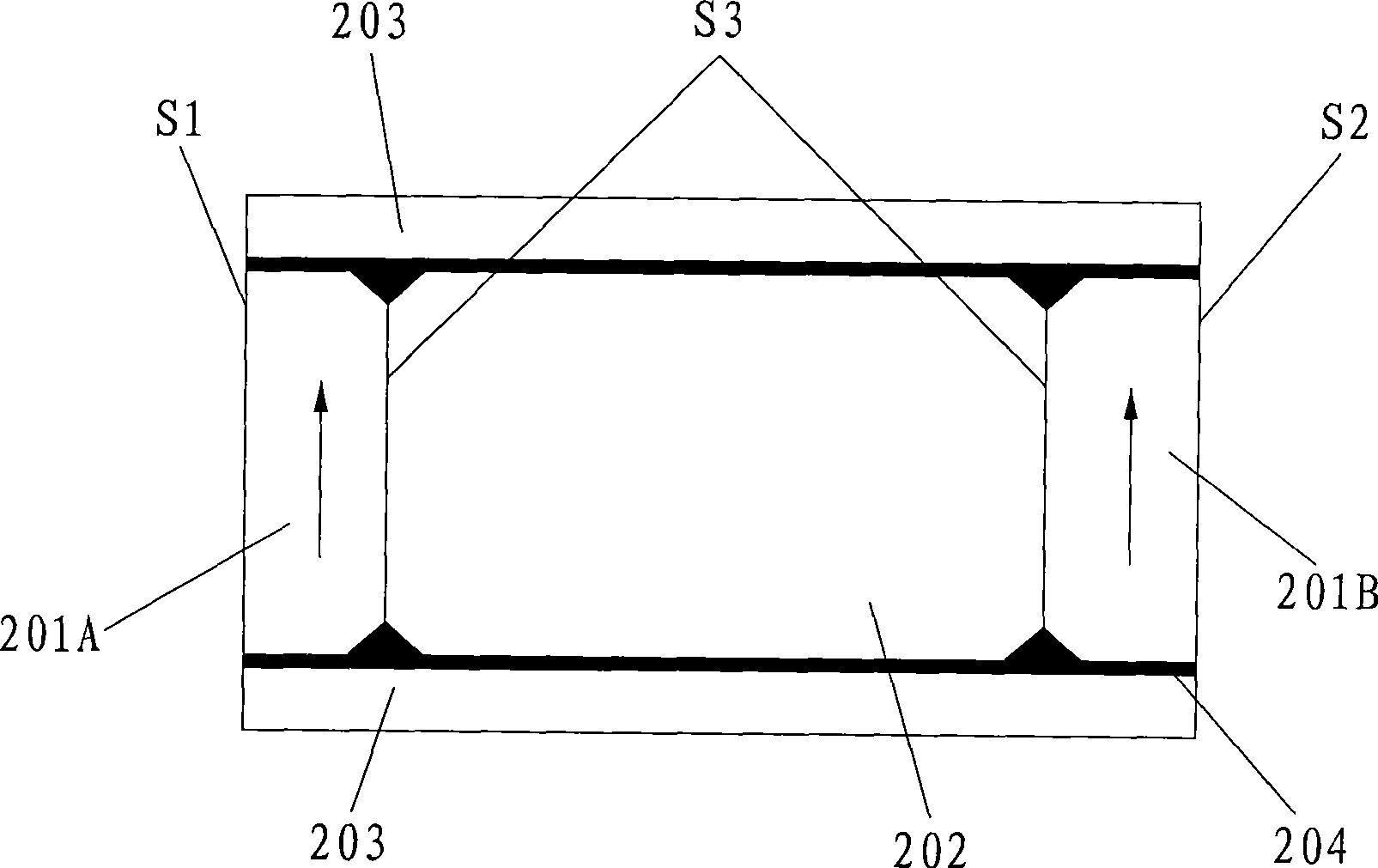

A crystal device

InactiveCN101499605AAvoid film damageIncreased damage threshold and laser powerActive medium shape and constructionAdhesiveRefractive index

The invention relates to the field of the optics and laser, in particular to a structure of optics or laser crystal. The crystal device comprises a crystal, a first window diaphragm and a second window diaphragm, wherein, the first window diaphragm is glued with an incident optical surface of the crystal; and the second window diaphragm is glued with an emergent optical surface. The first window diaphragm or the second window diaphragm is plated by a dielectric film. The side surfaces of the contact surfaces among the crystal, the first window diaphragm and the second window diaphragm are adhered by UV adhesive; the non-light through an upper bottom surface and a non-light through lower bottom surface of the crystal are respectively provided with a protection plate, and the protection plates are adhered with the crystal by the UV adhesive. The refractive indexes of the first window diaphragm and the second window diaphragm are identical or similar to the refractive index of the crystal. Due to the technical proposal, the invention can prevent the film damage from influencing the performances of the laser, or prevent the deliquescence of the crystal or prevent the direct plating on the surface of the optical crystal from causing the film damage or shedding and the like, thereby improving the damage threshold and the laser power of the laser and broadening the application range of certain crystals.

Owner:SHANGHAI BRANCH FUZHOU GAOYI COMM CO LTD

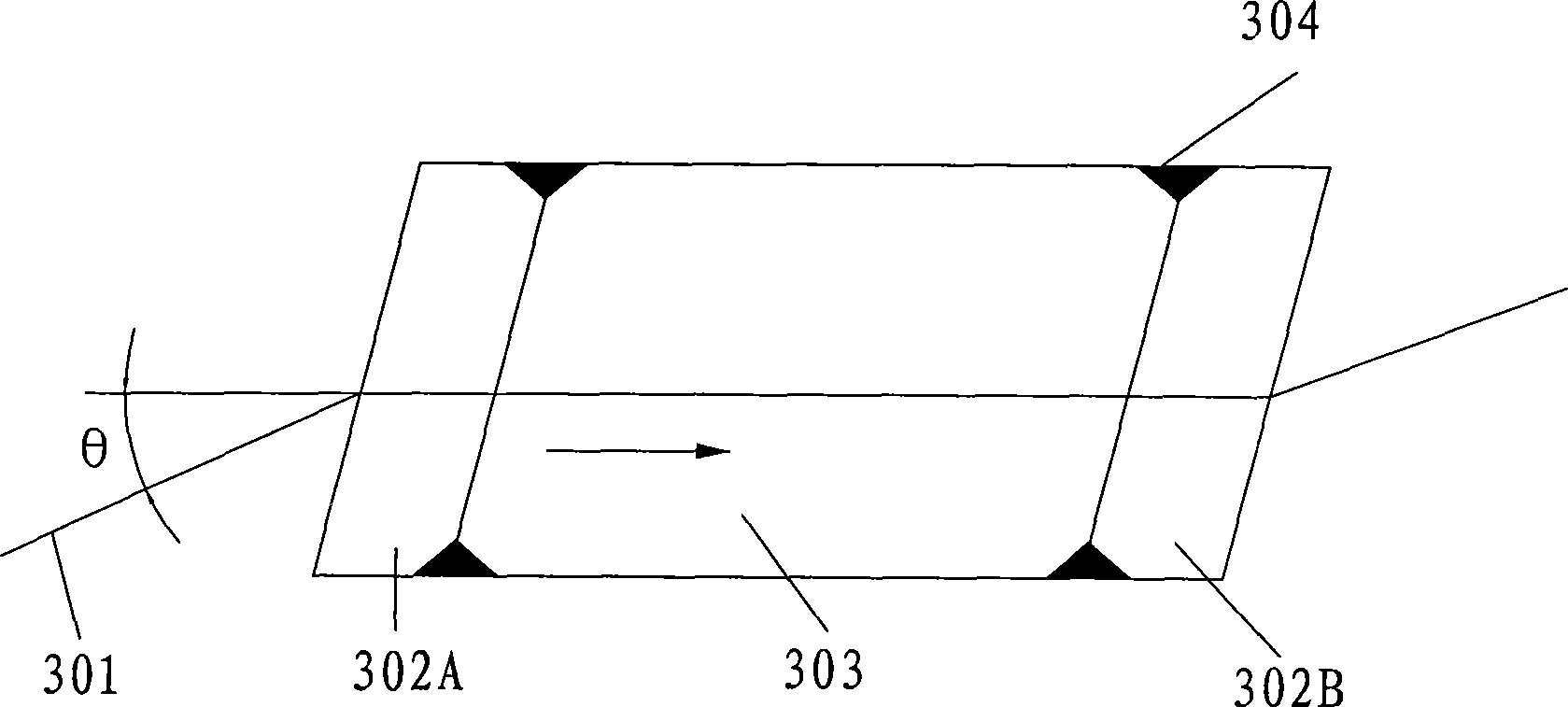

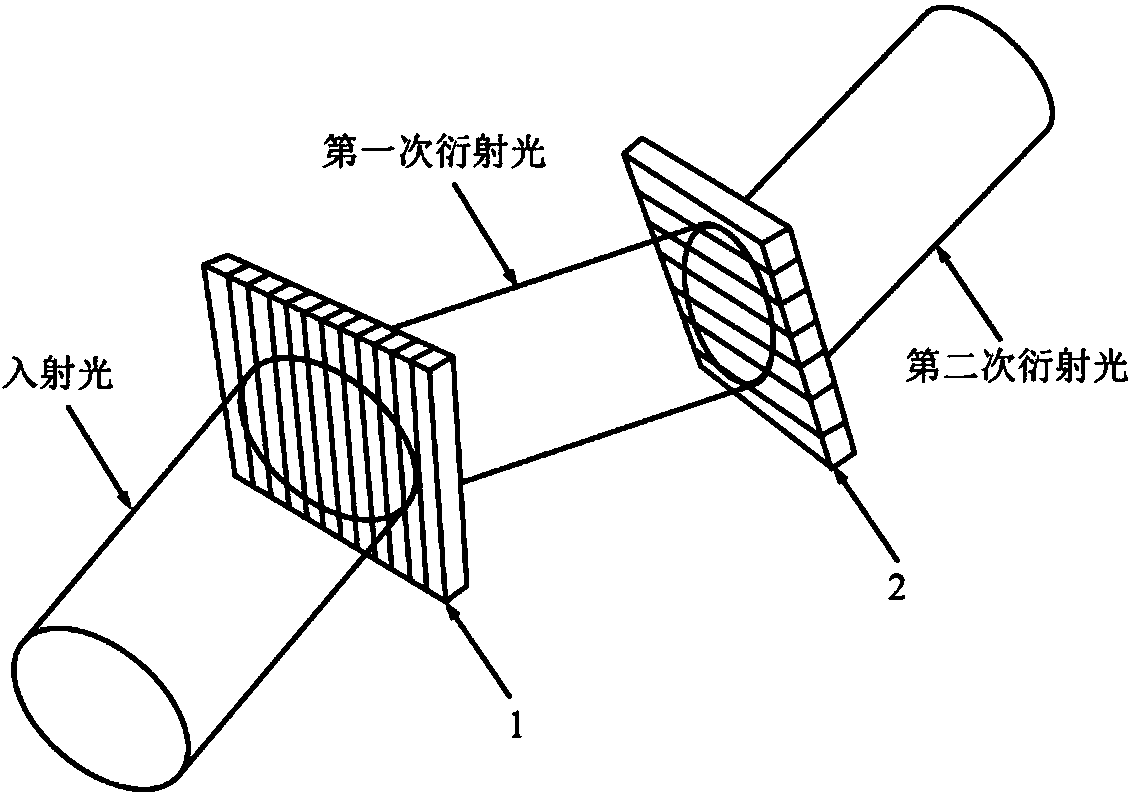

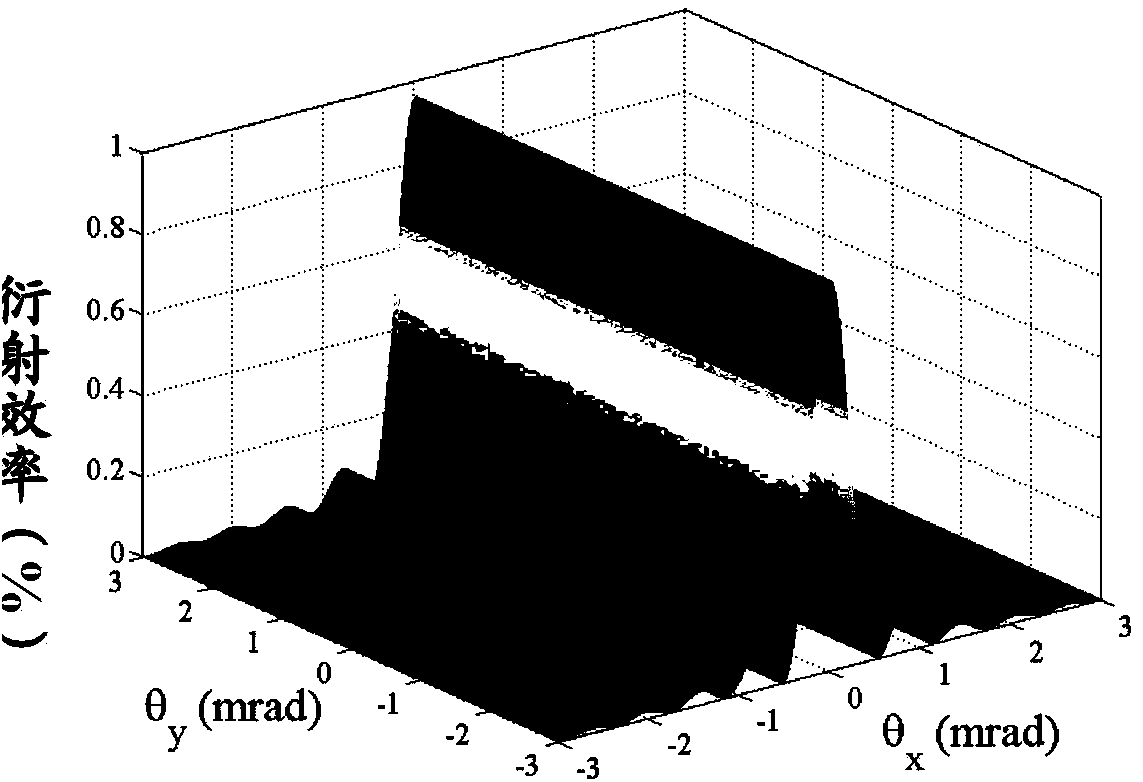

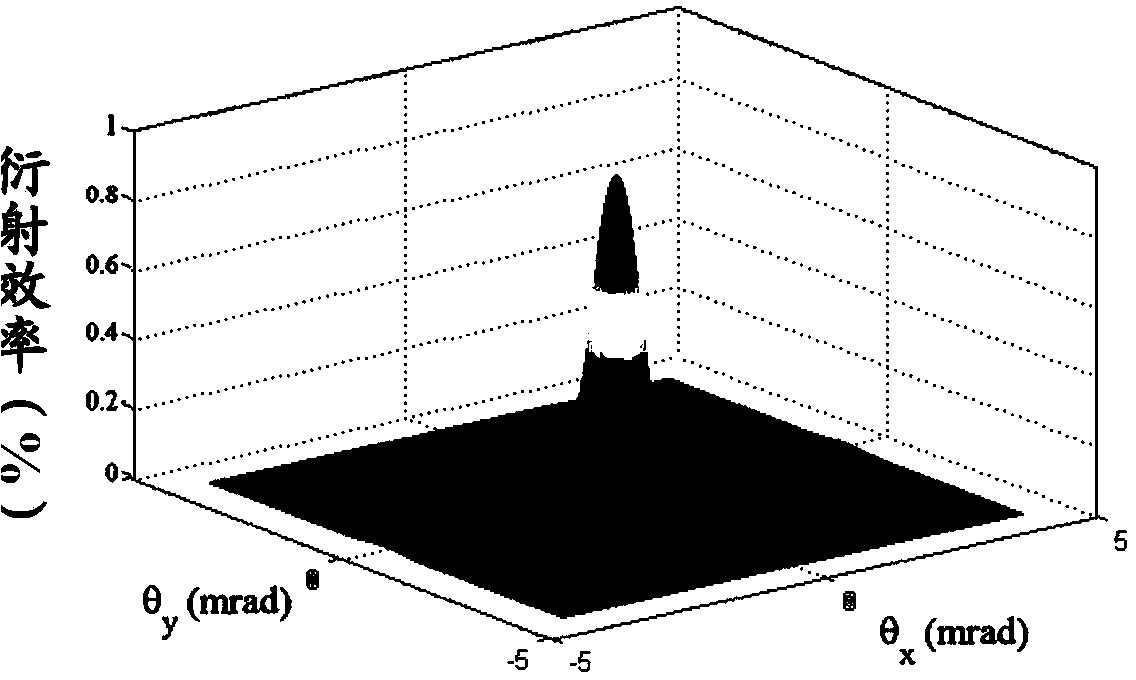

Two-dimensional angle selecting laser filter

The invention discloses a two-dimensional angle selecting laser filter. The two-dimensional angle selecting laser filter comprises a first volume Bragg grating for performing first-time diffraction on incident light and a second volume Bragg grating for performing second-time diffraction on the diffracted light emerging from the first volume Bragg grating, wherein grating vectors of the first volume Bragg grating and the second volume Bragg grating are mutually orthogonal. The two-dimensional angle selecting laser filter is completely different from a traditional spatial filter provided with a lens and a pin hole, and the high-quality spatial filtering is directly achieved in a laser transmission near field. The two-dimensional angle selecting laser filter is compact in structure, has excellent lowpass filtering capacity on spectral components and is high in bearable laser power.

Owner:SUZHOU UNIV

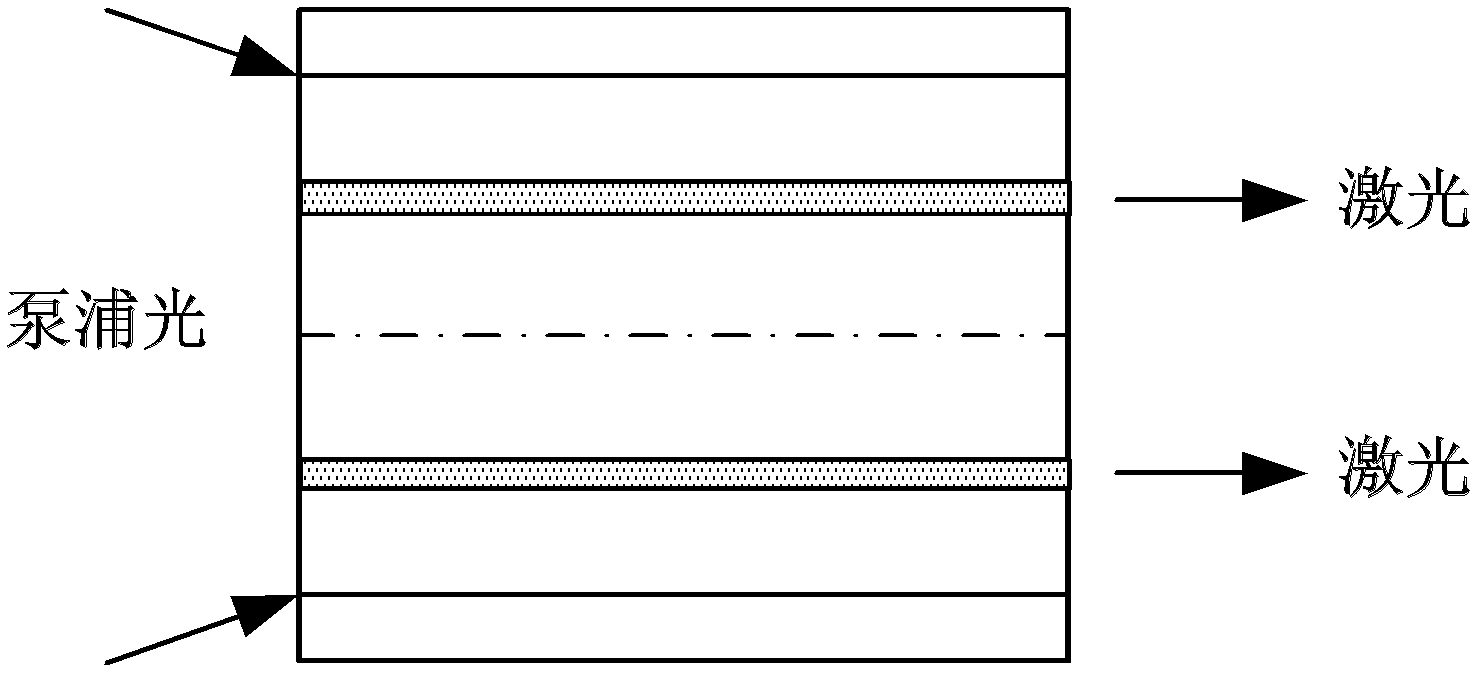

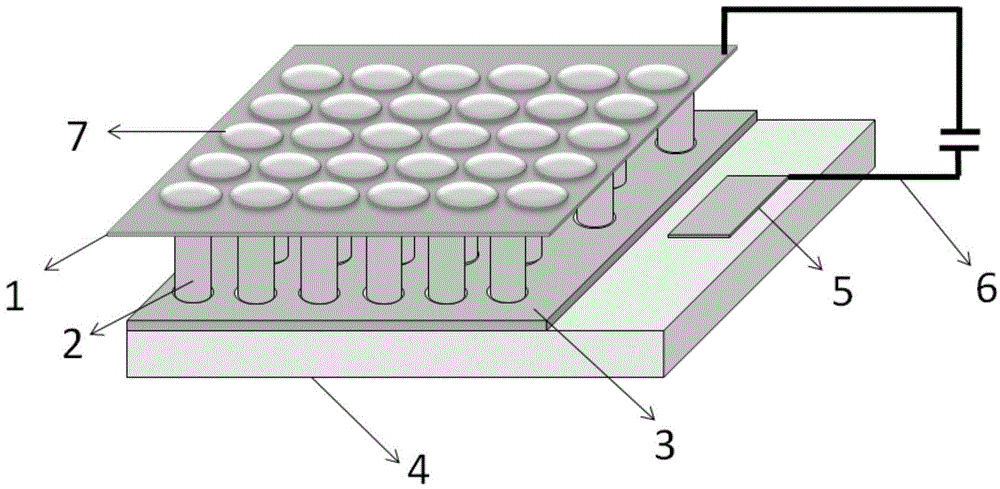

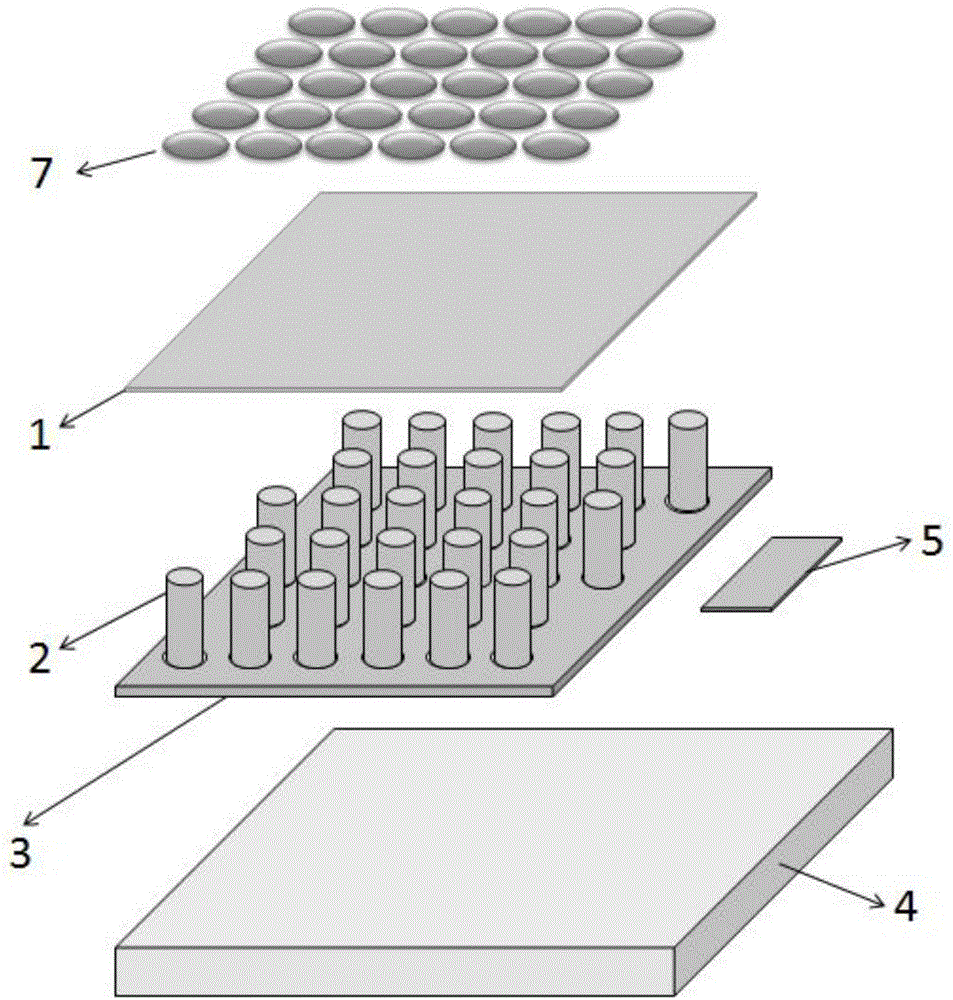

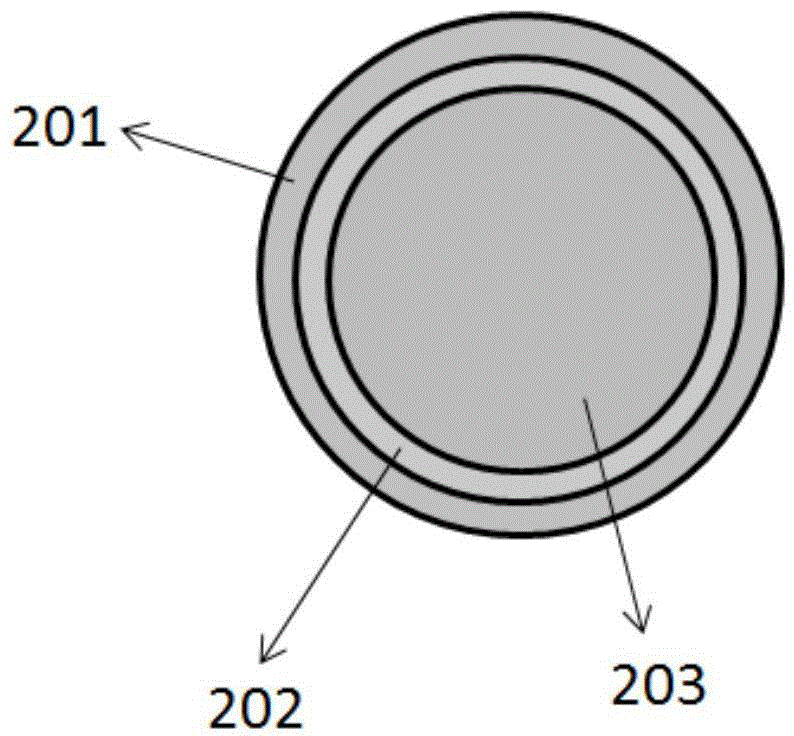

Nanometer plasma array laser device and manufacturing method thereof

InactiveCN104538837AAchieve laser emissionIncrease laser powerOptical wave guidanceExcitation process/apparatusDielectricResonant cavity

The invention provides a nanometer plasma array laser device and a manufacturing method of the laser device and belongs to the technical field of optics. According to the method, photons excited by an electrical pump semiconductor nanowire p-n junction array are utilized for interacting with surface metal-dielectric films to generate surface plasmon polaritons (SPP), and then photon beams generated in a nanowire resonant cavity are restrained and regulated. According to the method, the double advantages of semiconductor nanometer structure geometric limitation and limitation and constraint of a surface plasma mode field to beams are combined, a semiconductor nanowire is utilized for integrating a working substance and the resonant cavity and achieving mode field constraint on surface plasmas, and finally the nanometer plasma laser device is formed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

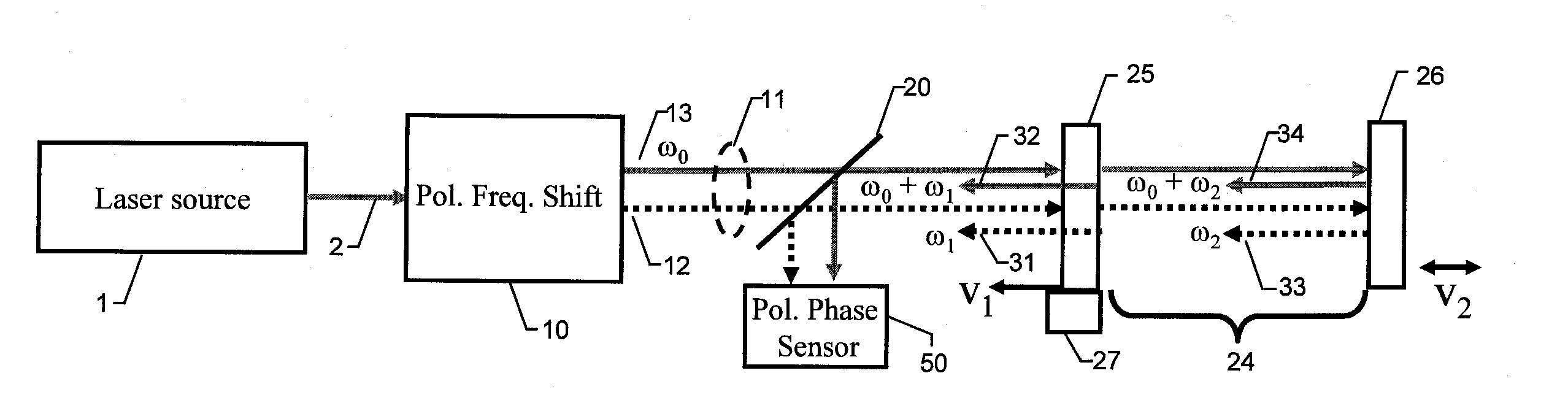

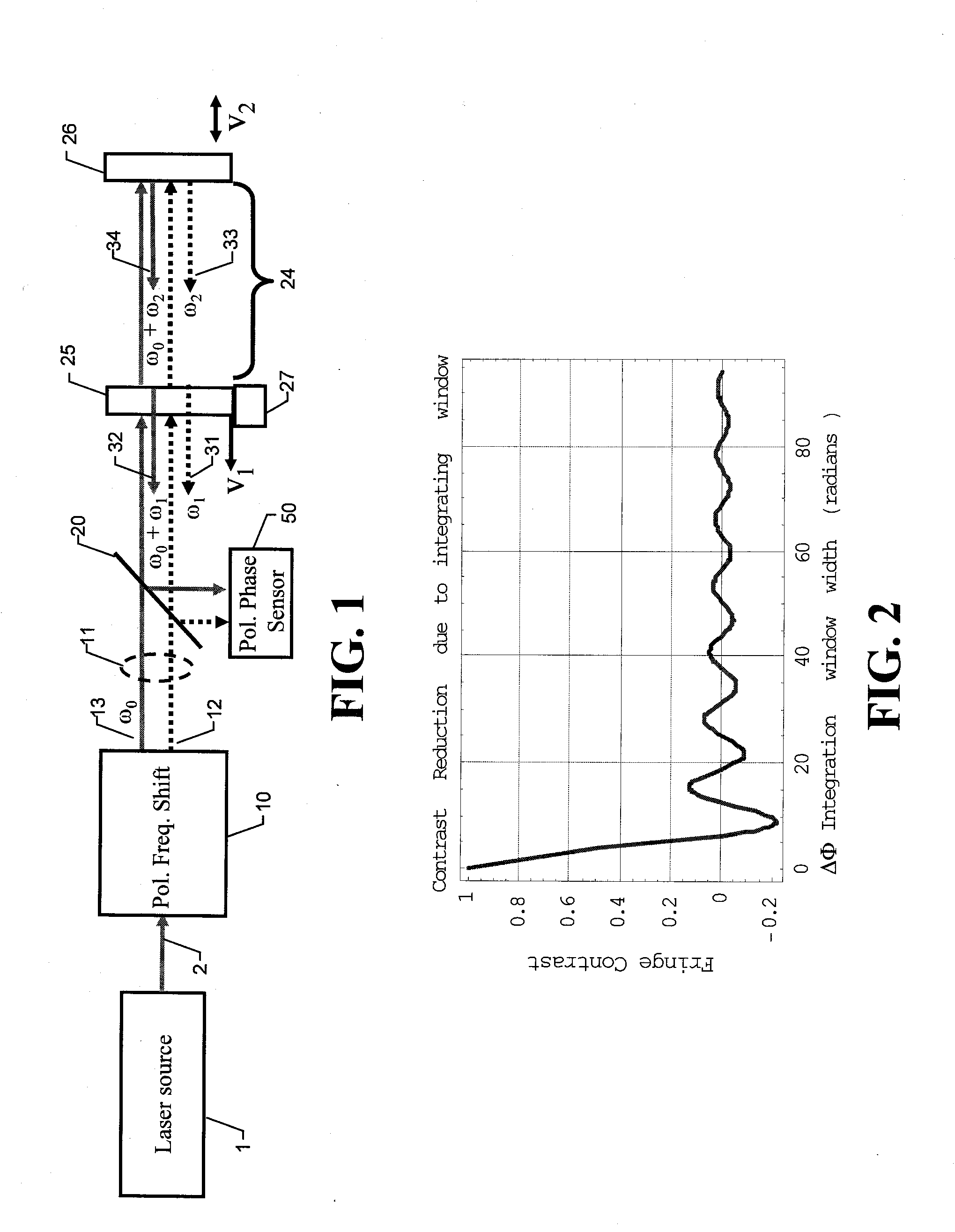

Synchronous frequency-shift mechanism in fizeau interferometer

ActiveUS20100134801A1Increase laser powerShort integration timeInterferometersUsing optical meansOptical cavityTest beam

An optical device for characterizing a test surface combines a Fizeau interferometer with a polarization frequency-shifting element. Two substantially collinear, orthogonally polarized beams having respective frequencies differing by a predetermined frequency shift are generated by the polarization frequency-shifting element and projected into the Fizeau optical cavity to produce a pair of test beams and a pair of reference beams, wherein the beams in each pair have orthogonal polarization states and have frequencies differing by the predetermined frequency shift. A second, substantially equal frequency shift is introduced in the Fizeau cavity on either one of the pairs of test and reference beams, thereby generating a four-beam collinear output that produces an interferogram without tilt or short-coherence light. The invention may also be implemented by reversing the order of the Fizeau cavity and the polarization frequency-shifting element in the optical train.

Owner:ONTO INNOVATION INC

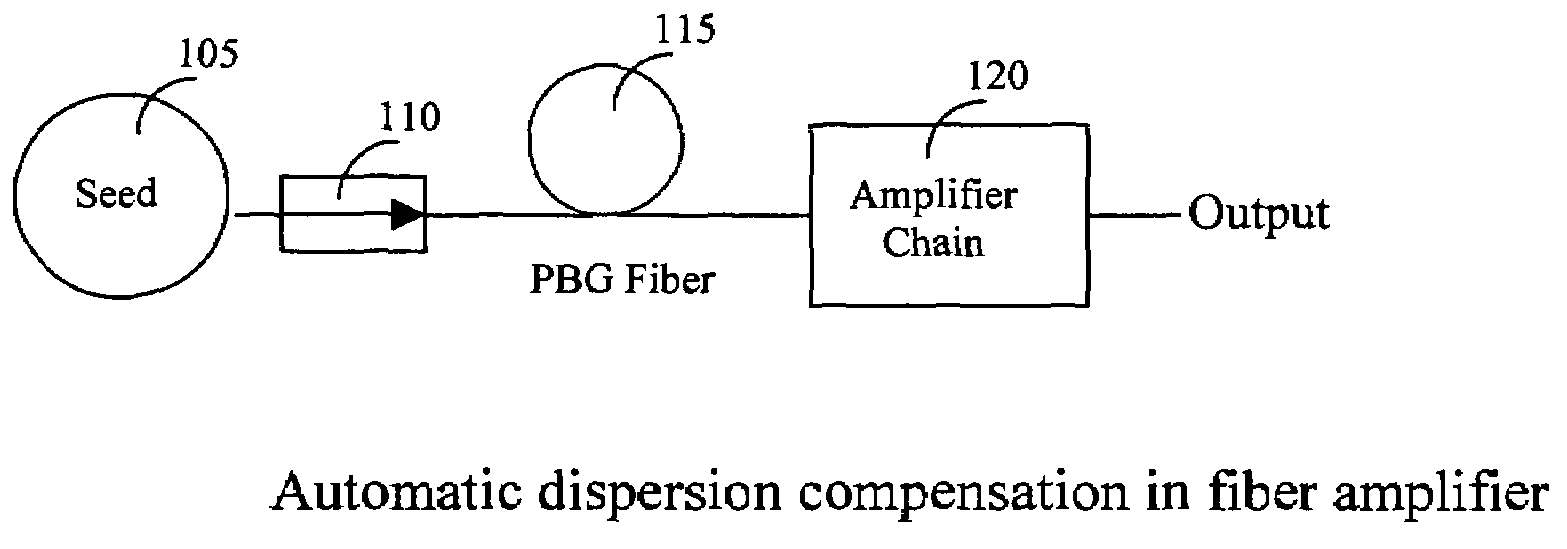

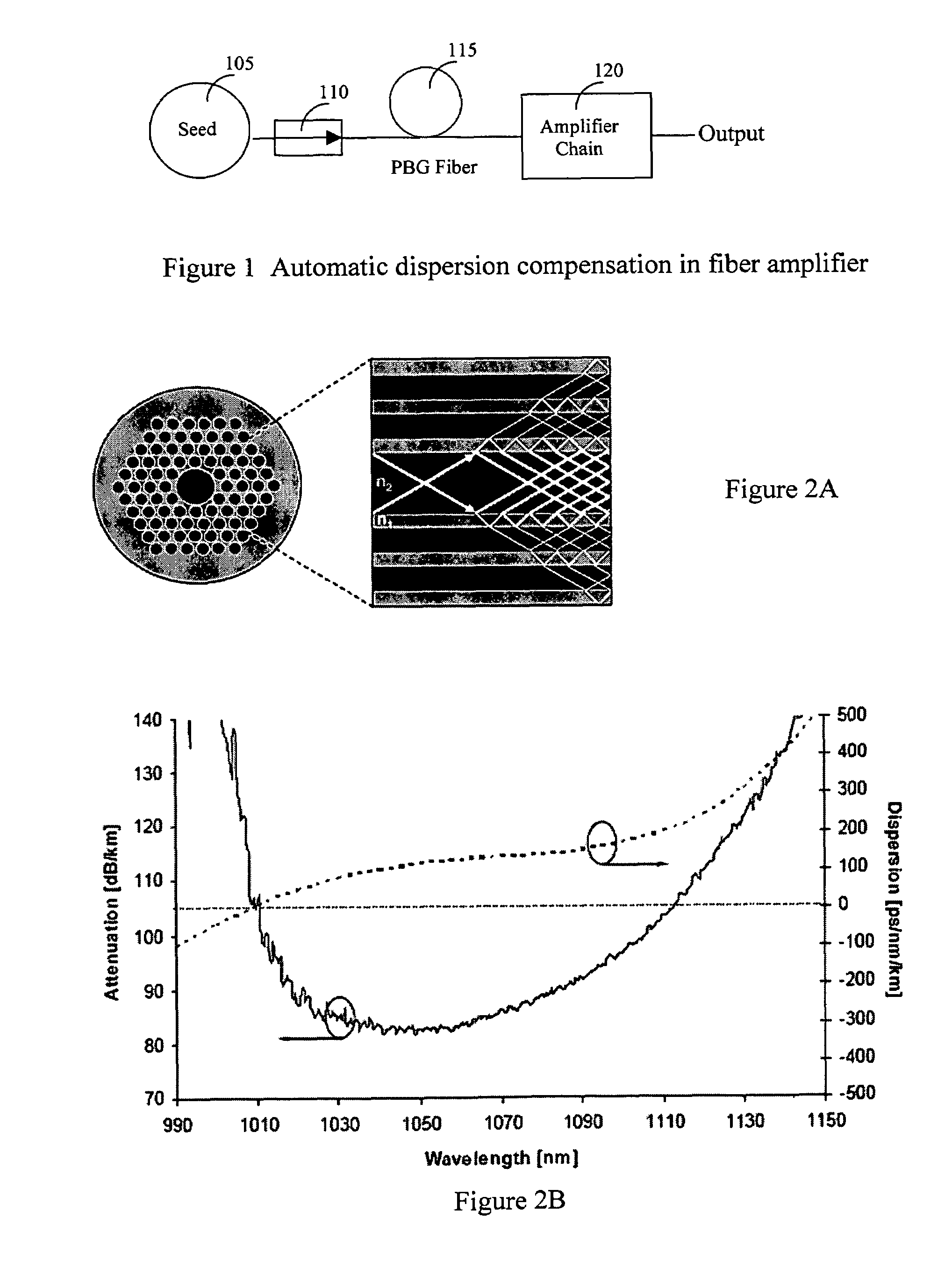

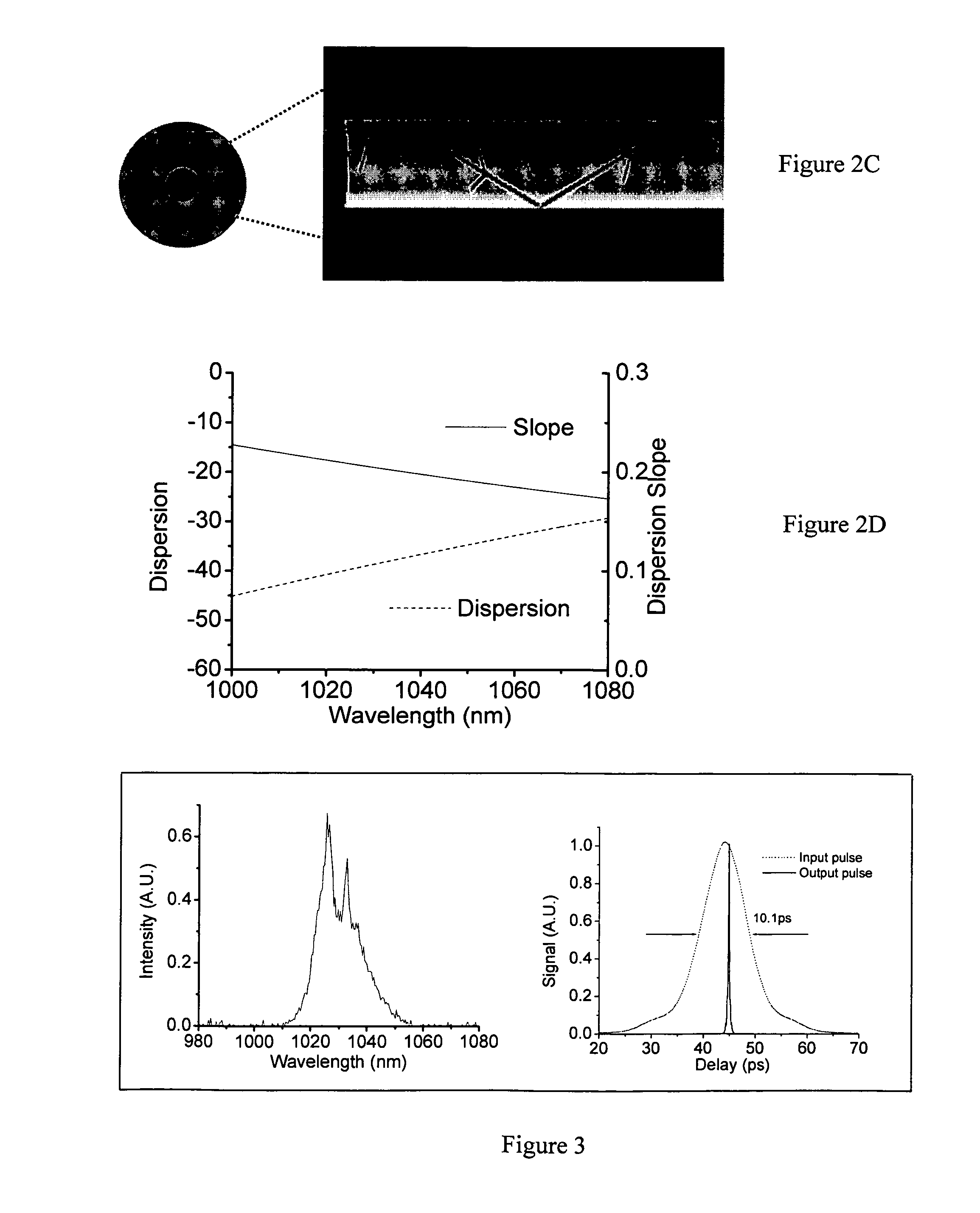

Automatic dispersion compensation in amplification for short pulse fiber laser system

ActiveUS7430224B2Increase laser powerLaser using scattering effectsGenerators/motorsAudio power amplifierPhotonic bandgap

A fiber Chirped Pulse Amplification (CPA) laser system includes a fiber mode-locking oscillator for generating a laser for projecting to a fiber stretcher for stretching a pulse width of the laser wherein the stretcher further comprising a Photonic Bandgap (PBG) fiber having a lower nonlinearity and an abnormal dispersion than a solid core fiber for connecting and transmitting a laser from the stretcher to a multistage amplifier for amplifying the laser into an output laser whereby a separate compressor is not required.

Owner:POLARONYX

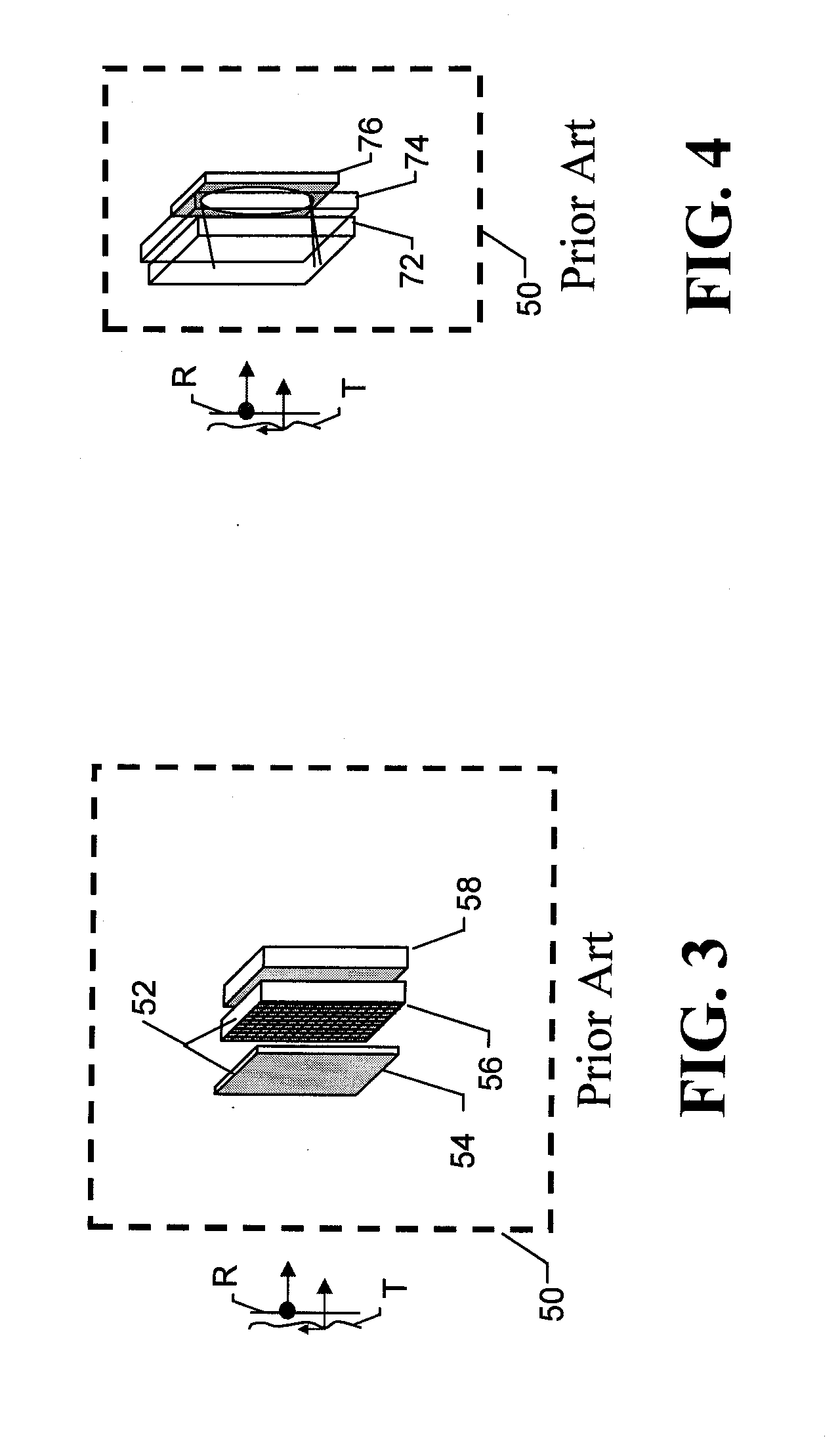

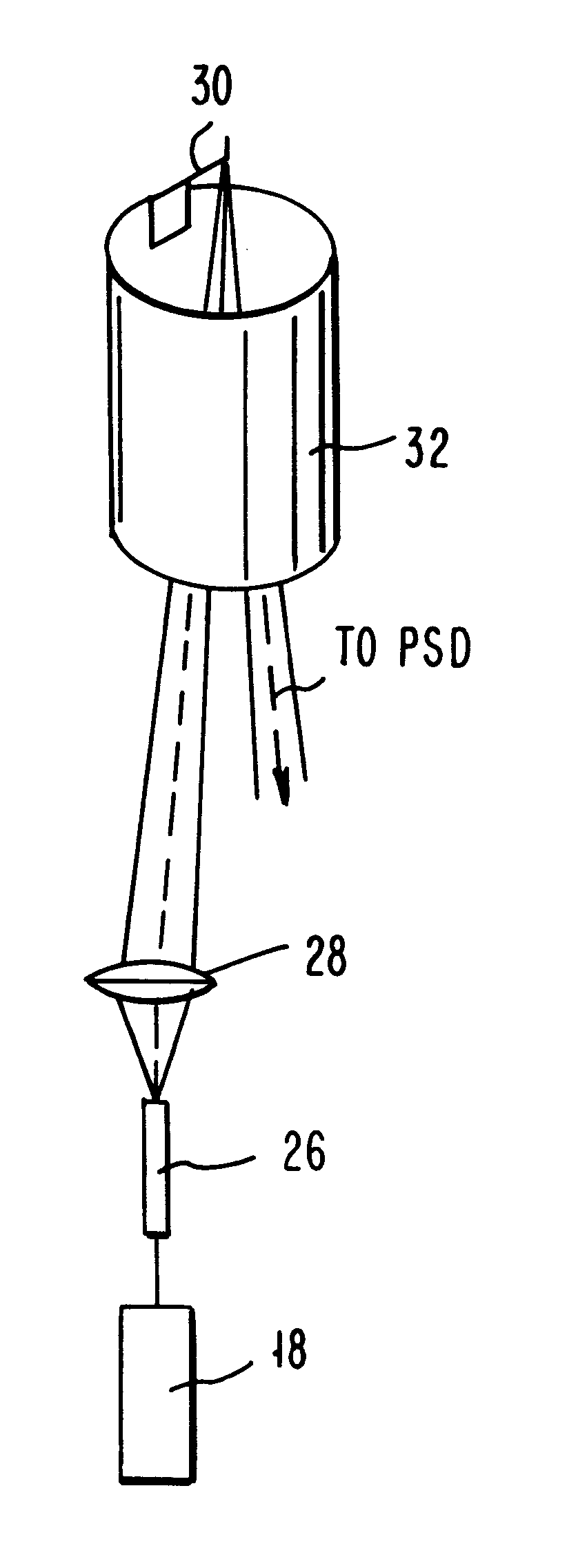

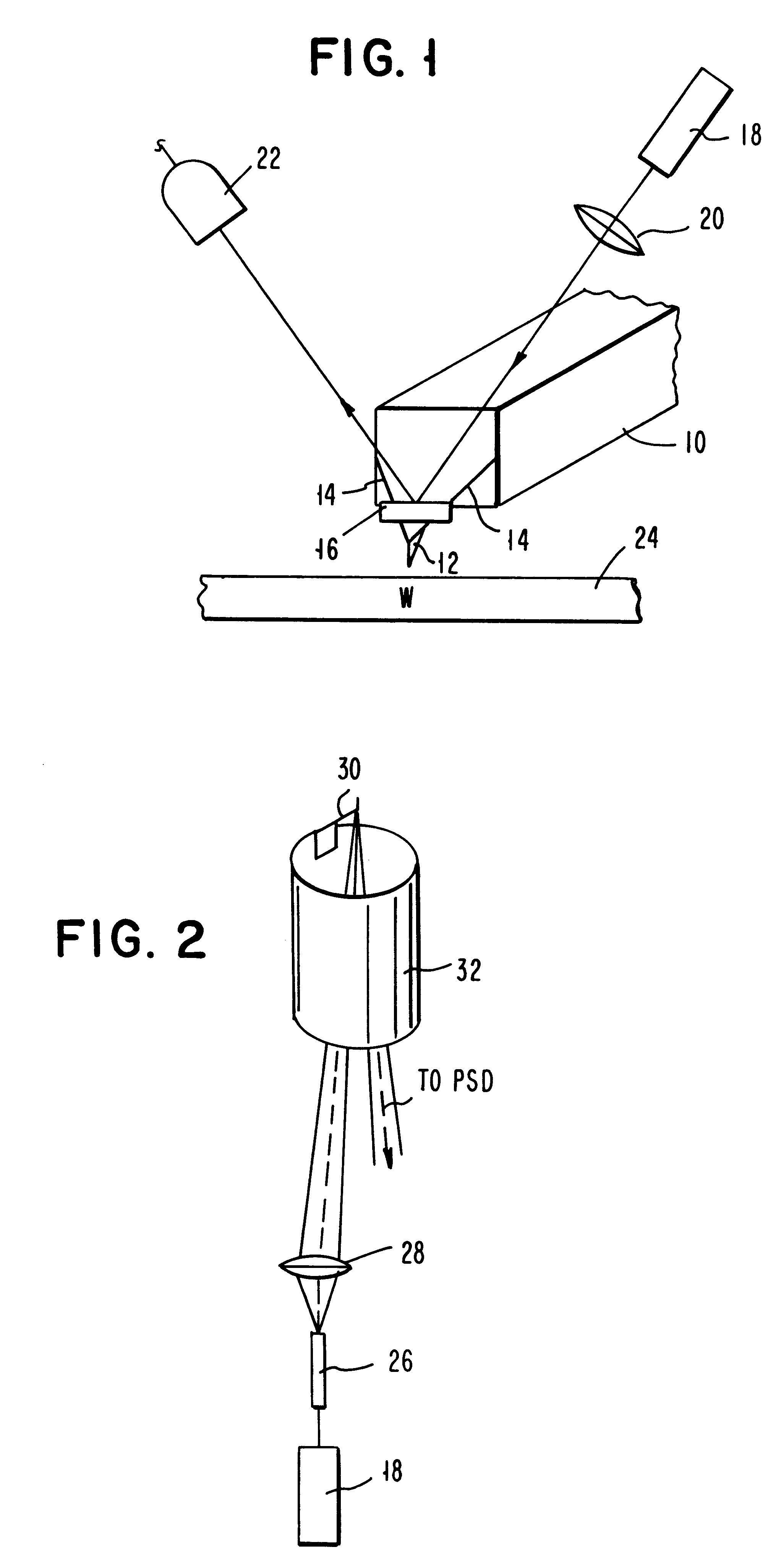

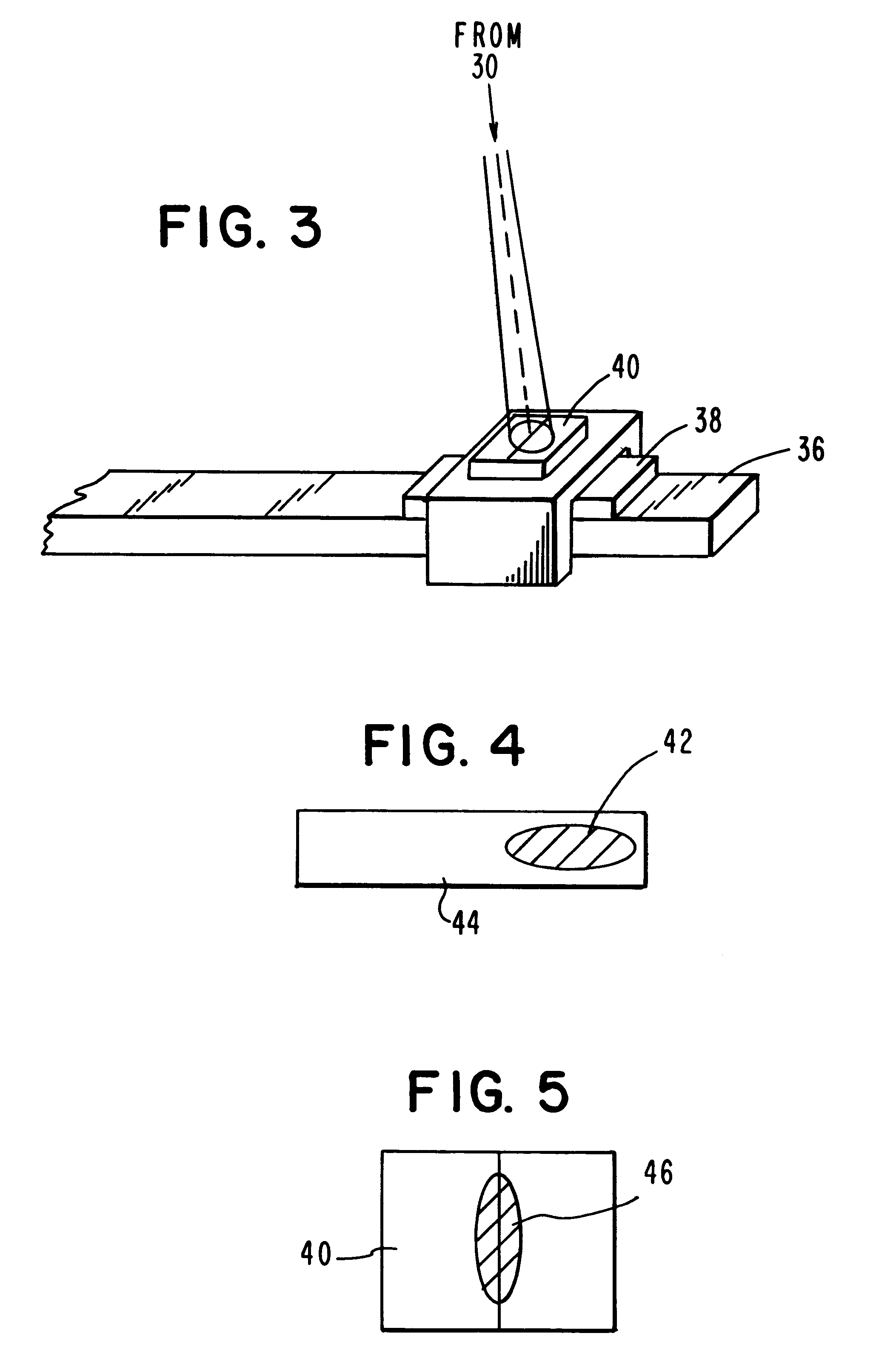

Atomic force microscopy

InactiveUSRE37299E1Convenient ArrangementMore compact designNanotechMaterial analysis using wave/particle radiationAtomic force microscopyImage resolution

An atomic force microscope includes a tip mounted on a micromachined cantilever. As the tip scans a surface to be investigated, interatomic forces between the tip and the surface induce displacement of the tip. A laser beam is transmitted to and reflected from the cantilever for measuring the cantilever orientation. In a preferred embodiment the laser beam has an elliptical shape. The reflected laser beam is detected with a position-sensitive detector, preferably a bicell. The output of the bicell is provided to a computer for processing of the data for providing a topographical image of the surface with atomic resolution.

Owner:IBM CORP

Method and system for active-illumination parallel raman microspectroscopy

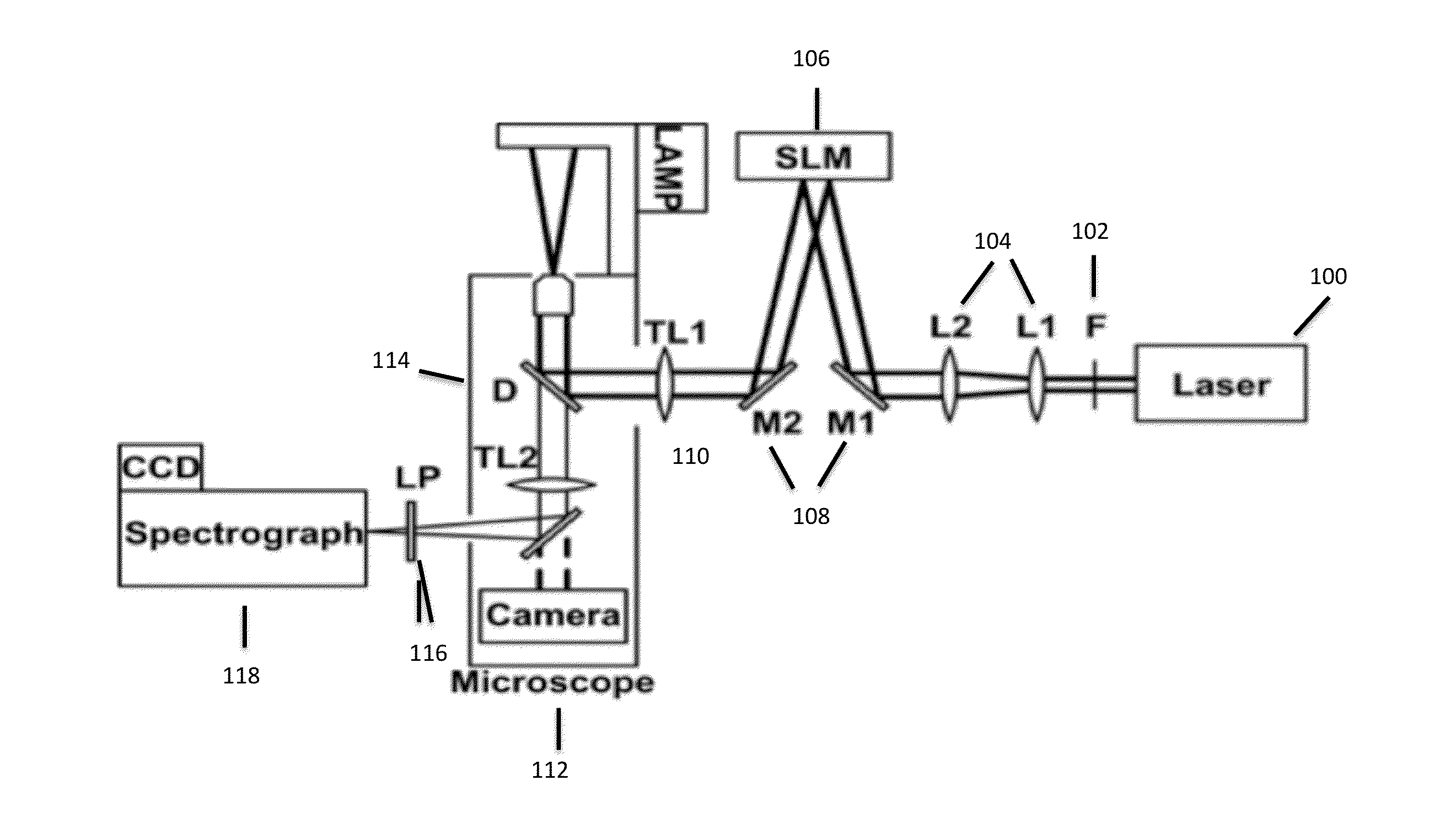

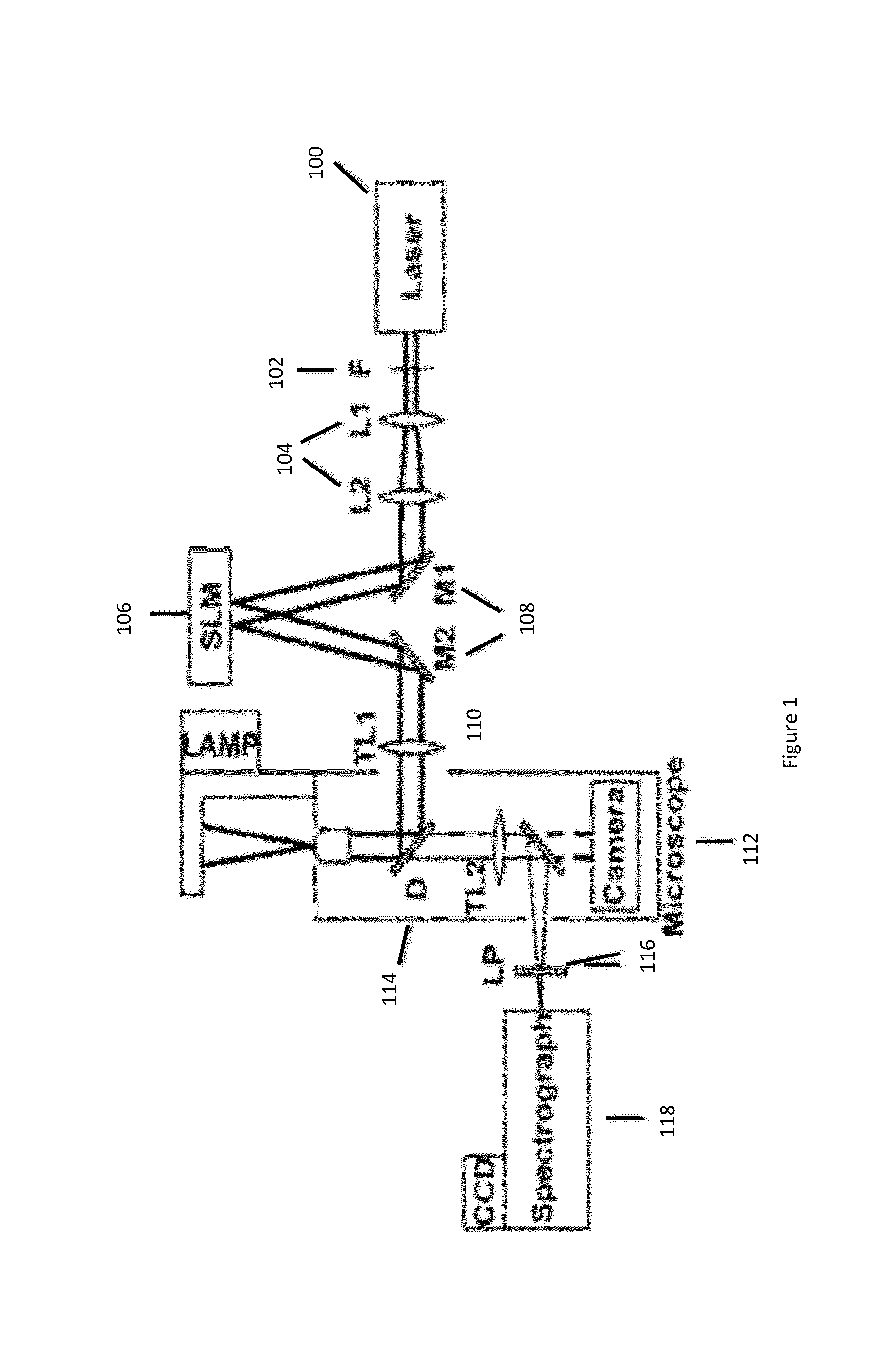

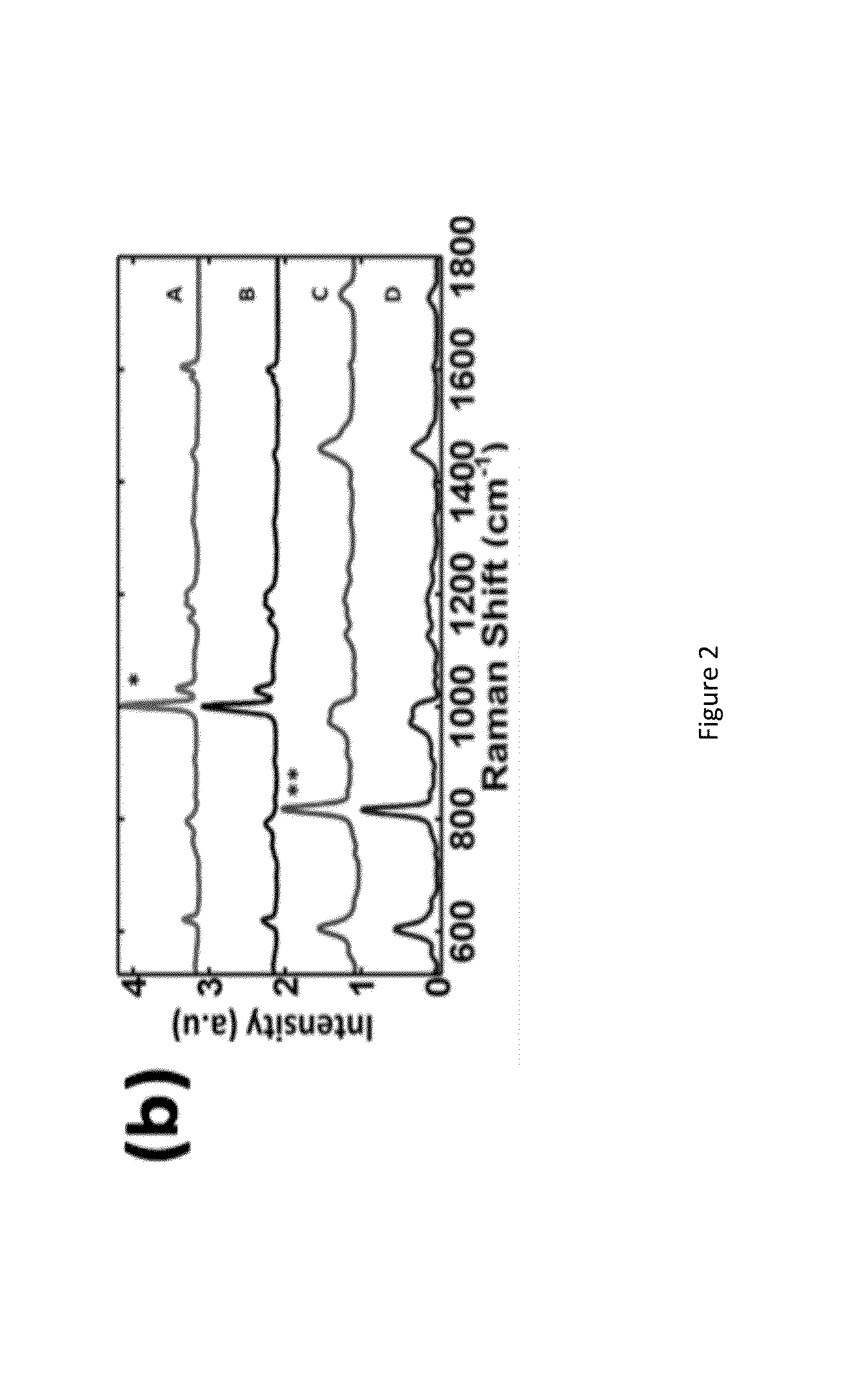

ActiveUS20140029003A1Improved sampling flexibilityHigh laser power duty cycleRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsRaman imagingWide field

An active-illumination parallel Raman microspectroscopy scheme for simultaneously collecting Raman spectra from multiple points in a full-spectra range. A combination of multi-point laser illumination with wide-field Raman imaging is employed in order to allow for simultaneous imaging of multiple points not aligned on a single line.

Owner:UNIV HOUSTON SYST

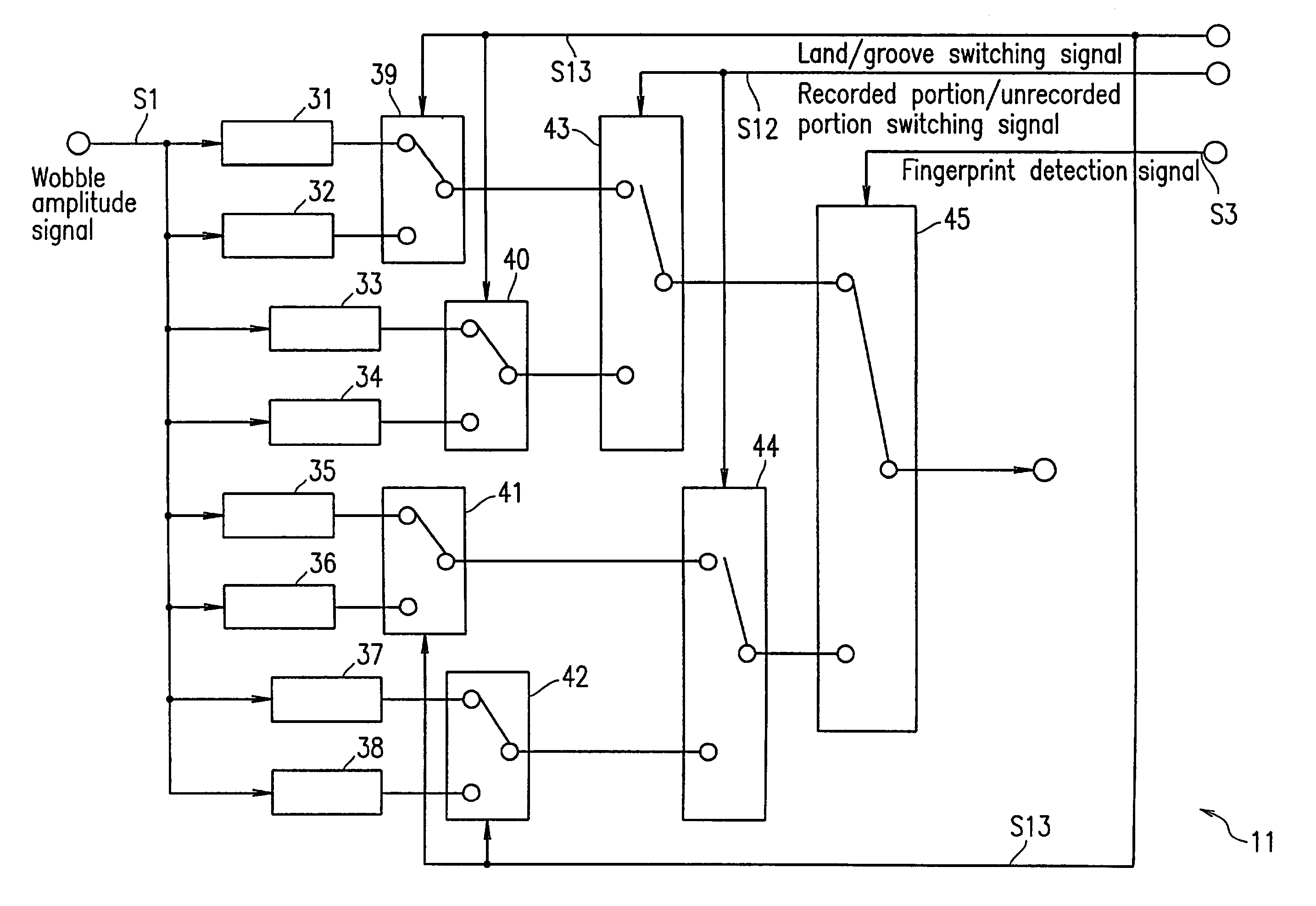

Optical disk recording/reproduction apparatus with a detection means for detecting dirt on the optical disk

InactiveUS7023777B2Misdetection be preventReduce amountCombination recordingRecord information storageLight detectionLight beam

An optical disc recording / reproducing apparatus includes: recording / reproducing means for recording / reproducing information by emitting a light beam onto a disc having a track which wobbles at a predetermined frequency; reflected light detection means for detecting the light beam reflected from the disc; wobble signal detection means for detecting a wobble amplitude signal which represents an amplitude of a signal generated from a component which is extracted from an output of the reflected light detection means and which wobbles at the predetermined frequency; and variation rate detection means for detecting dirt adhered on the disc based on a rate of a variation in the wobble amplitude signal, wherein the variation rate detection means detects the dirt based on the wobble amplitude signal before the recording / reproducing means records / reproduces the information.

Owner:PANASONIC CORP

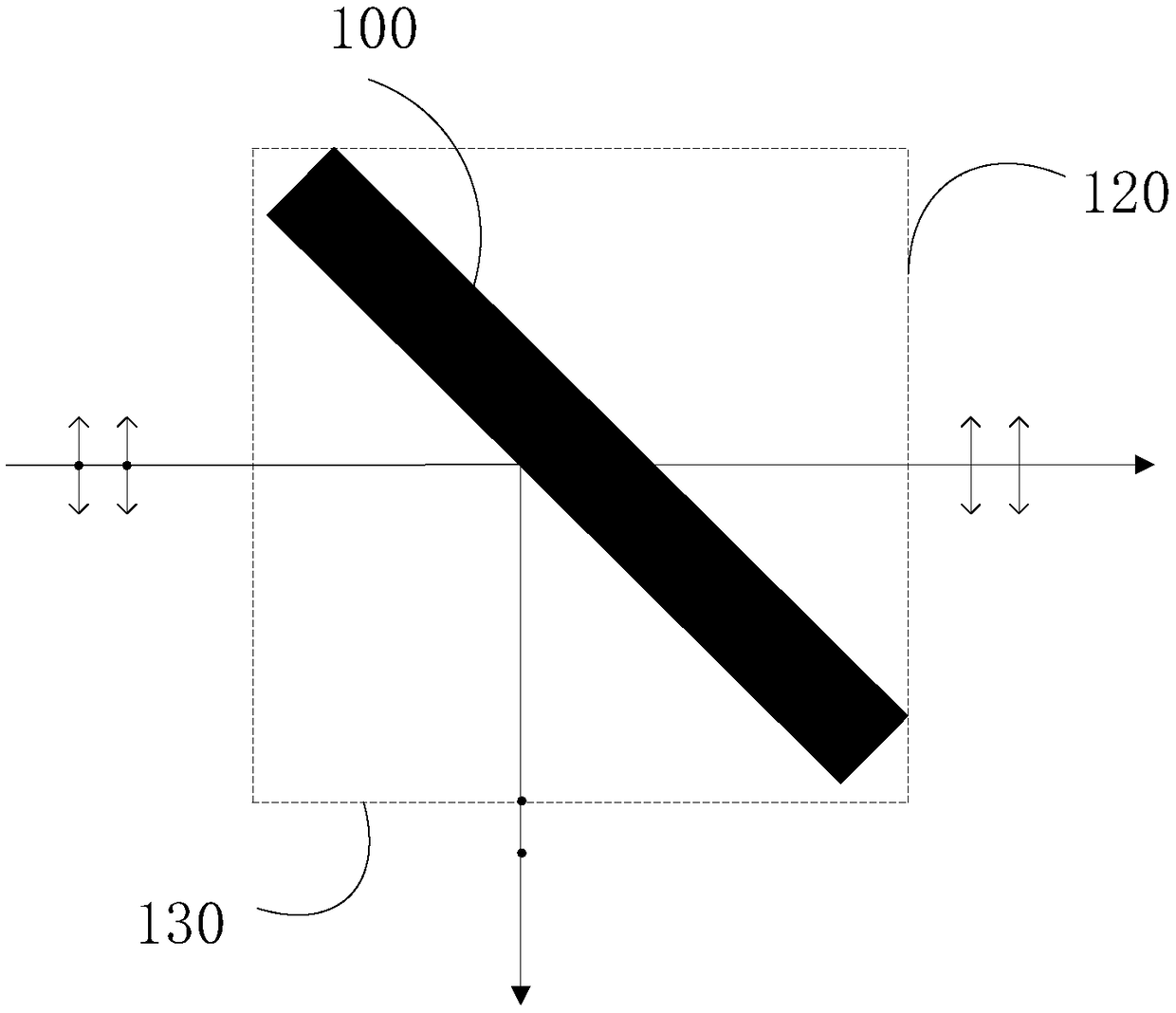

Beam shaping system for metal SLM printing

ActiveCN111796429AAuto switchMeeting Research Application NeedsAdditive manufacturing apparatusIncreasing energy efficiencyLight spotFacula

The invention provides a light beam shaping system for metal SLM printing. The system comprises a laser, and a collimator, a zoom beam expander, a beam shaping mechanism, a galvanometer system and a working platform which are sequentially arranged in the propagation direction of laser beams emitted by the laser. A laser beam emitted by the laser is transmitted through an optical fiber to the collimator with an optical fiber interface for collimation, and the spot size is adjusted through the zoom beam expander to meet the incident spot size requirement of the beam shaping mechanism, the incident spots are shaped through a beam homogenizer or a beam shaper and then converted into flat-topped spots, the flat-topped spots are focused through the galvanometer system to form gathered spots, andthen the gathered spots reach the working surface to machine the metal powder. According to the system, light beam energy is redistributed to obtain circular, rectangular and oval flat-topped light spots or flat-topped light spots of specific shapes are customized according to requirements, metal printing defects can be effectively reduced through shaping of the system, and meanwhile, efficient printing can be conducted by introducing a high-power laser system in cooperation with large-size light spots.

Owner:GUANGXI UNIV

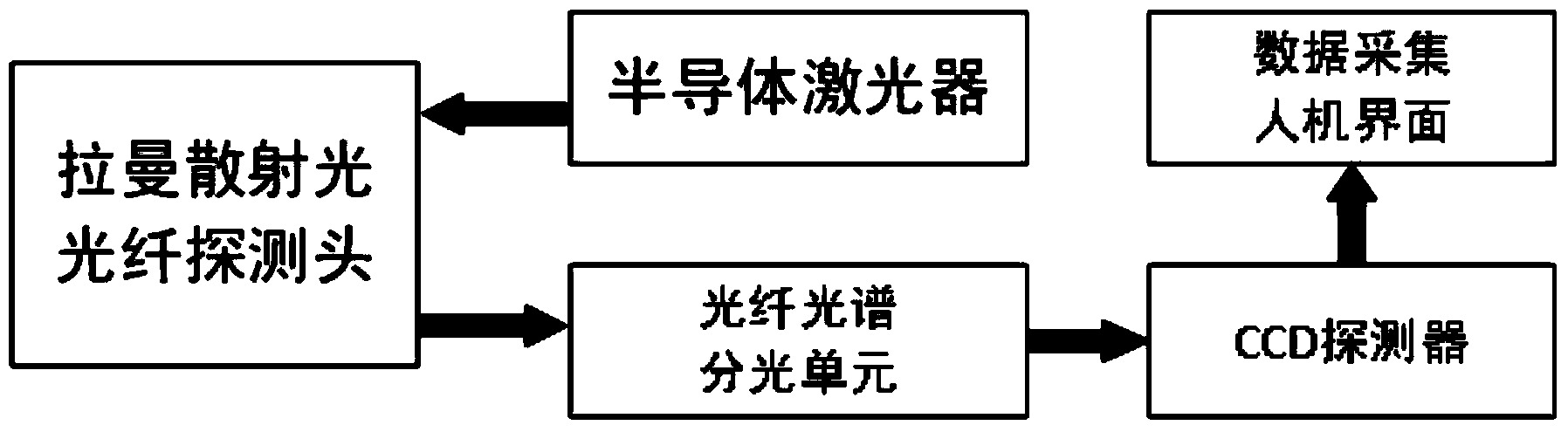

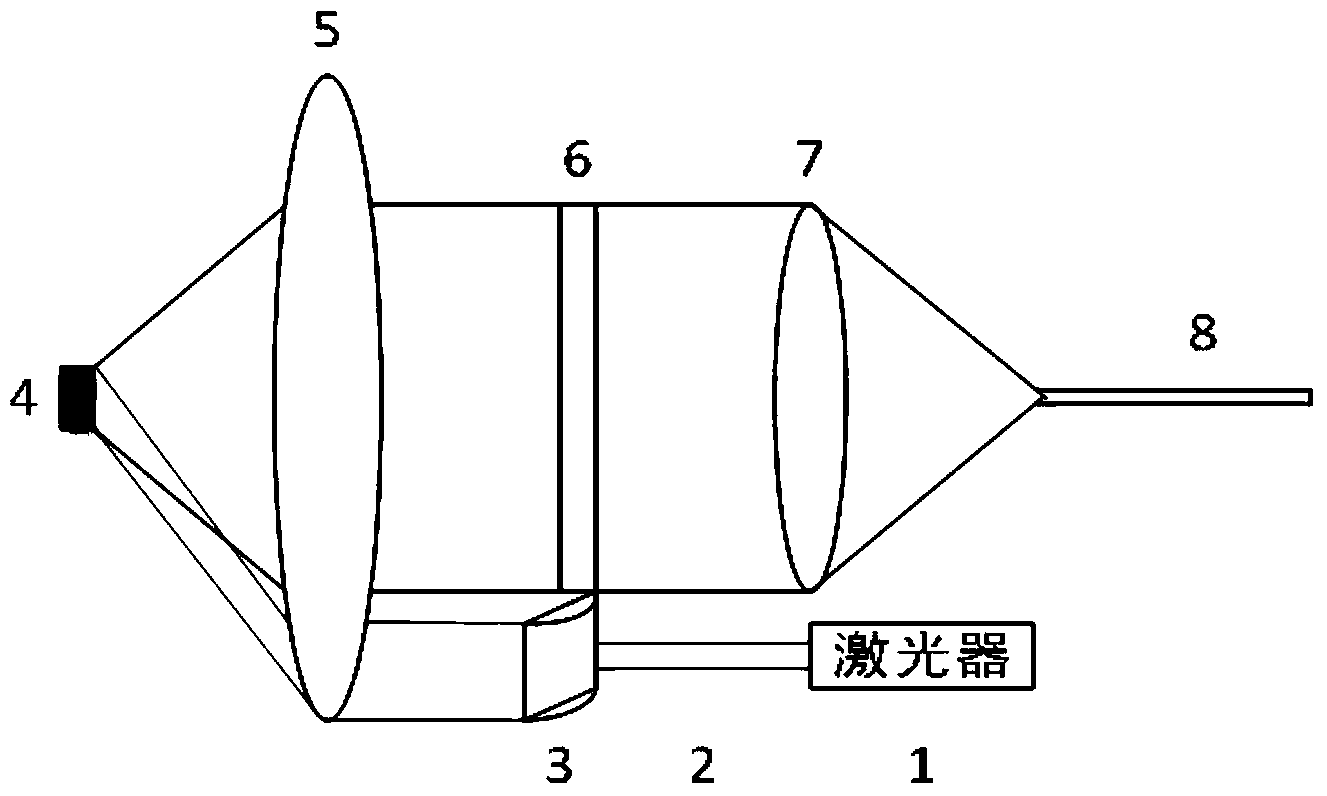

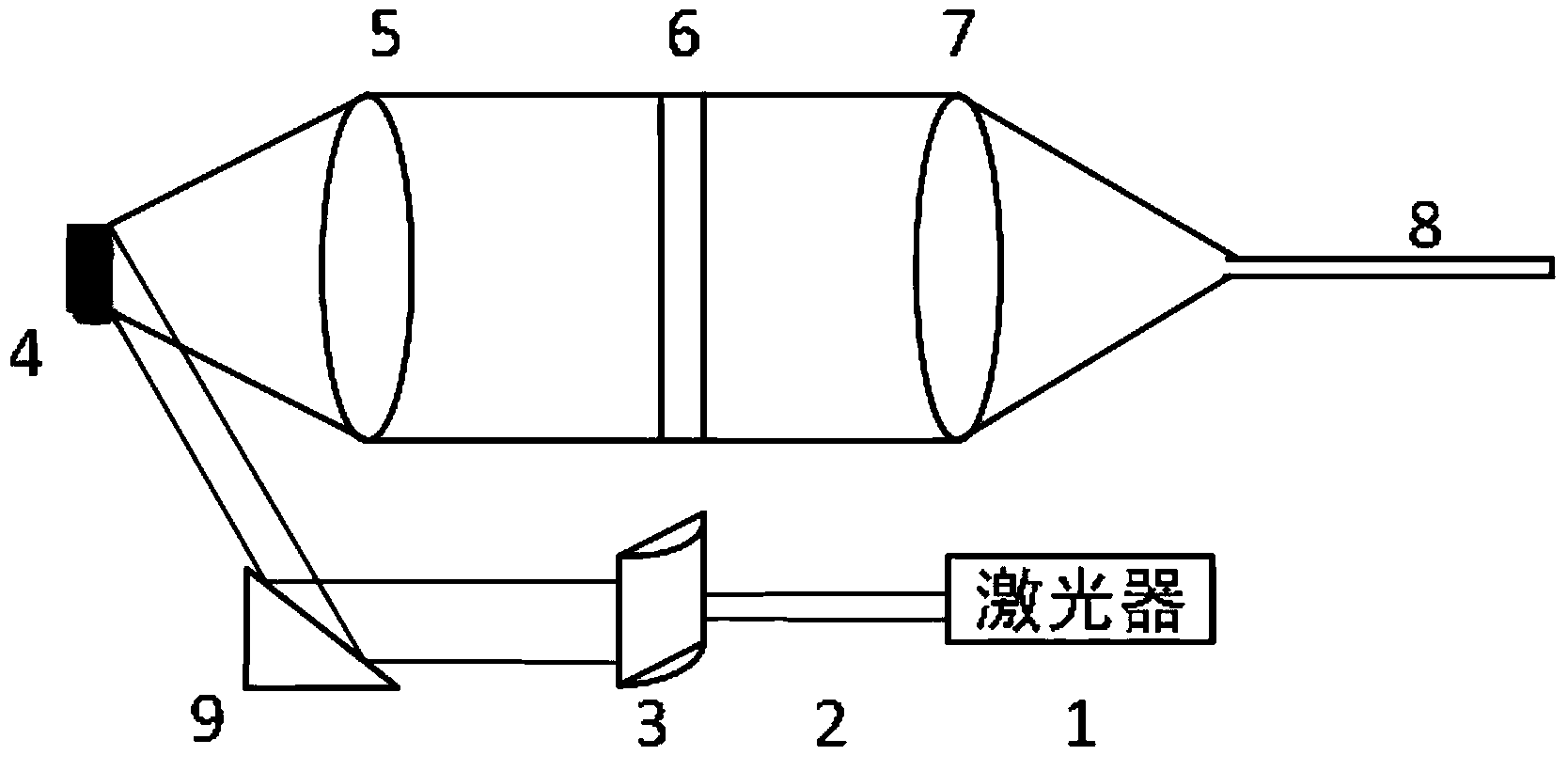

Linear focus Raman scattering probe

InactiveCN104390952ALarge scattering areaEnhanced Raman effectRaman scatteringLight filterSpectrometer

The invention discloses a linear focus Raman scattering probe. The linear focus Raman scattering probe comprises a laser conduction optical fiber 2, a linear cylindrical lens group 3, a scattered light collecting lens group 5, a narrowband resistance high-pass light filter 6, a parallel light converging lens group 7 and a scattered light conduction optical fiber 8, wherein laser is coupled to the linear cylindrical lens group 3 by the laser conduction optical fiber 2 and forms parallel linear laser through the linear cylindrical lens group 3; Raman scattered light is generated after the linear laser is reflected or converged to a sample; the scattered light collecting lens group 5 collects the scattered light from the surface of the sample; the scattered light enters the parallel light converging lens group 7 through the narrowband resistance high-pass light filter 6 and is coupled to the scattered light conduction optical fiber 8. According to the linear focus Raman scattering probe, Raman spectrum is guided in front of a slit of a spectrometer to form linear scattered light; the linear scattered light irradiates to the incident slit of the spectrometer is overlapped with the incident slit, so that the incident efficiency of the Raman spectroscopy is greatly improved; the sensitivity of a portable Raman spectrometer is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

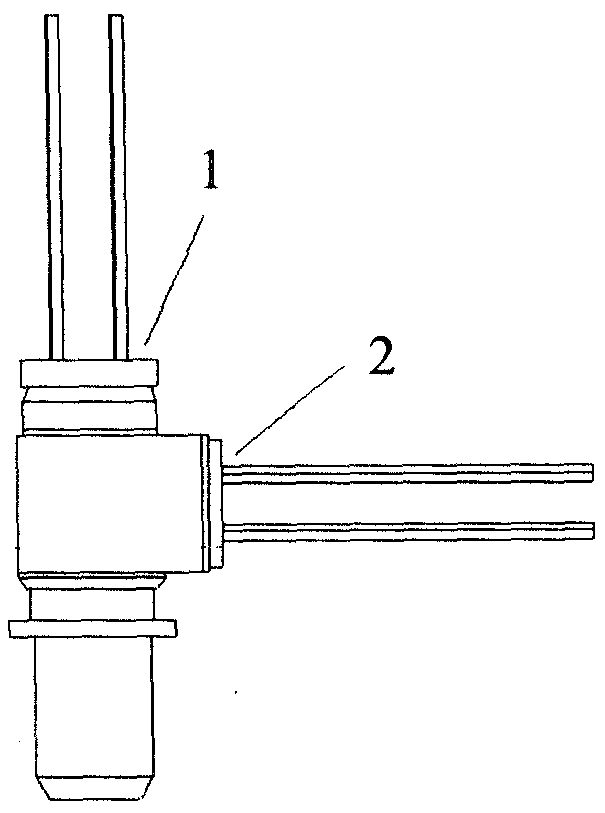

Photoelectric receiver-transmitter integrated module assembly of mono-optical fibre two-way

InactiveCN101030817AIncrease laser powerHigh sensitivityFibre transmissionElectromagnetic transceiversOptical pathOptoelectronics

Owner:深圳市华润通光电股份有限公司

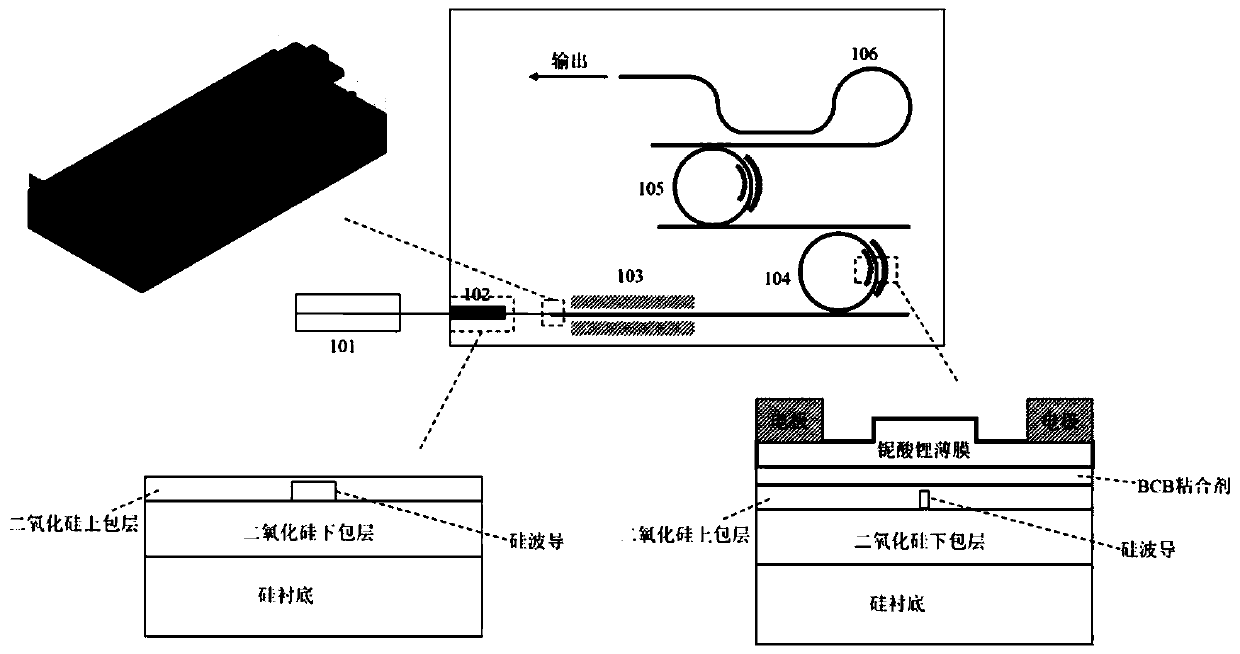

High-speed high-linearity silicon-lithium niobate external cavity frequency modulation laser

InactiveCN110911950AReduce lossIncrease laser powerActive medium materialConvertersExternal cavity laser

The invention discloses a high-speed and high-linearity silicon-lithium niobate external cavity frequency modulation laser. A reflective semiconductor optical amplifier of the external cavity laser isconnected to a phase shifter through a silicon-based light spot size converter; and then the output end of the phase shifter is connected with the input end of the first micro-ring filter, the outputend of the first micro-ring filter is connected with the input end of the second micro-ring filter, and the output end of the second micro-ring filter is connected with the input end of the reflector. And a lithium niobate film is bonded above the silicon waveguide. According to the invention, a filtering structure is formed through vernier effects of the two micro-ring filters, and laser with awide tuning range and a narrow line width can be obtained. By utilizing the advantages of low loss, strong linear electro-optic effect and high modulation speed of the lithium niobate film, the line width of the laser can be further compressed, the output laser power is improved, and high-speed linear frequency modulation is realized.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com