Central part reconstruction method and device of unstable resonator laser annular beam

A ring beam and central part technology, applied in the field of reconstruction of the central part of the ring beam output by the unstable cavity laser, can solve the problems of high cost and difficult design of oblique axis reflecting telescope, and achieve low manufacturing cost, simple and convenient processing, The effect of job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

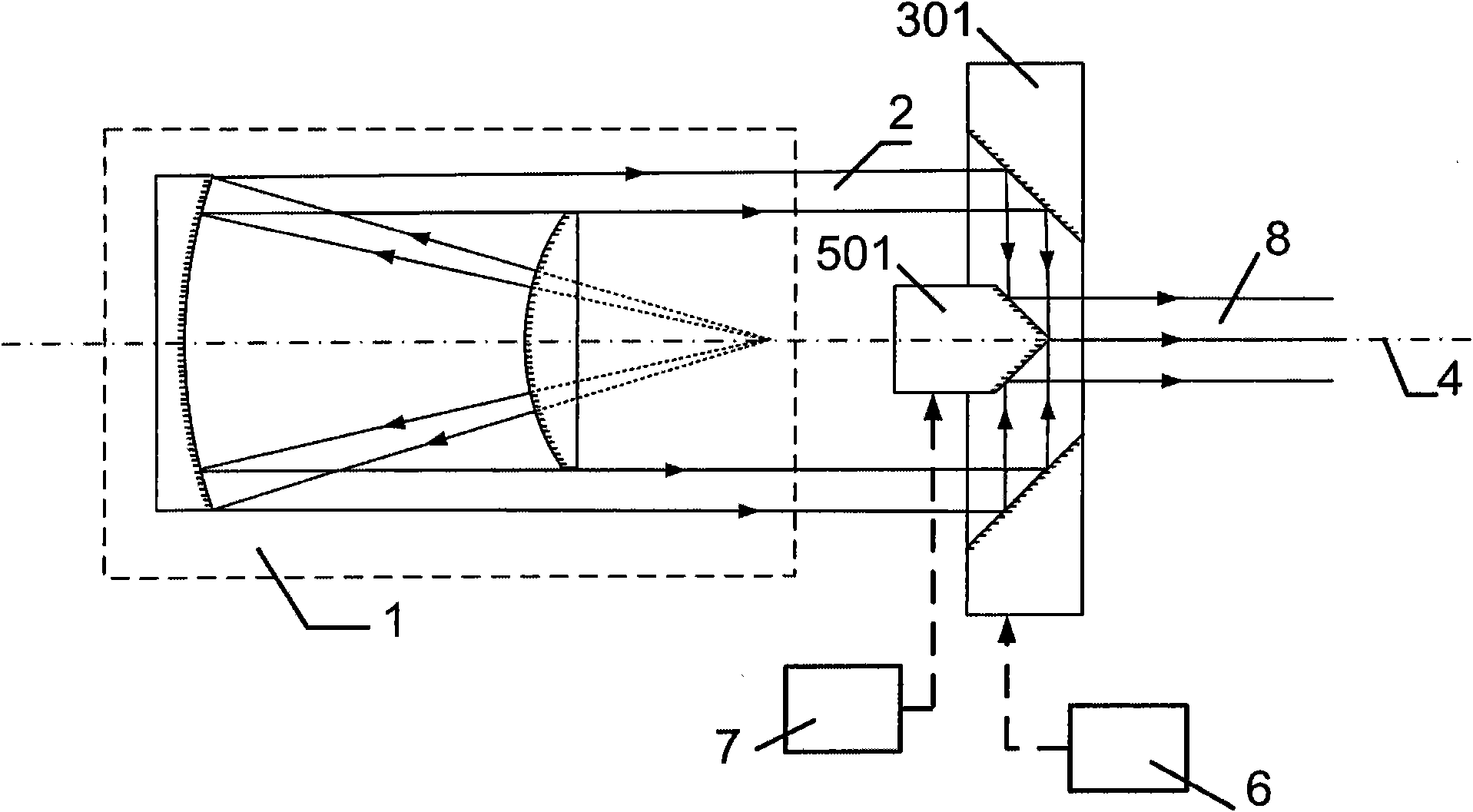

[0040] Such as figure 1 As shown, the reconstruction device for the central part of the output ring beam of the unstable cavity laser based on the extra-cavity beam shaping technology provided in this embodiment is mainly composed of the unstable cavity laser 1, the right-angled inner circular mesa ring mirror 301, and the right-angled outer conical surface reflector The mirror 501, the precision displacement mechanism 6 of the right-angle inner circular table-top annular reflector and the precision displacement mechanism 7 of the right-angle outer conical surface reflector are composed.

[0041] The right-angle inner circular mesa annular reflector 301 and the right-angle outer conical reflector 501 are metal reflectors with a rotationally symmetrical structure, which are easy to manufacture and can be directly processed by ultra-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com