Coiled material shaping and cutting machine

A cutting machine and coil technology, which is applied in the direction of coiling strips, metal processing, sending objects, etc., can solve the problems of low efficiency and quality, and achieve the effect of efficient assembly, quality assurance, and convenient cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

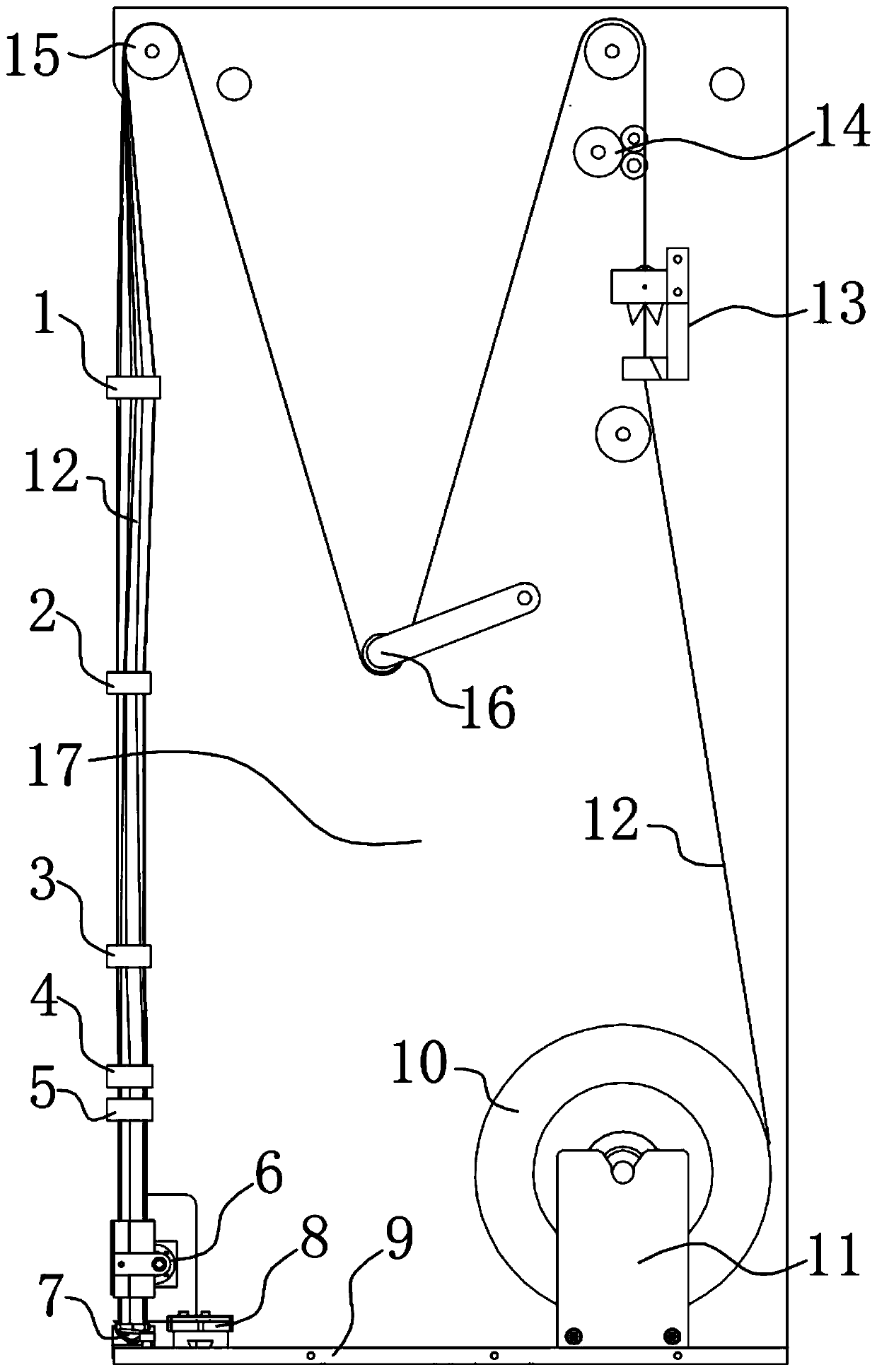

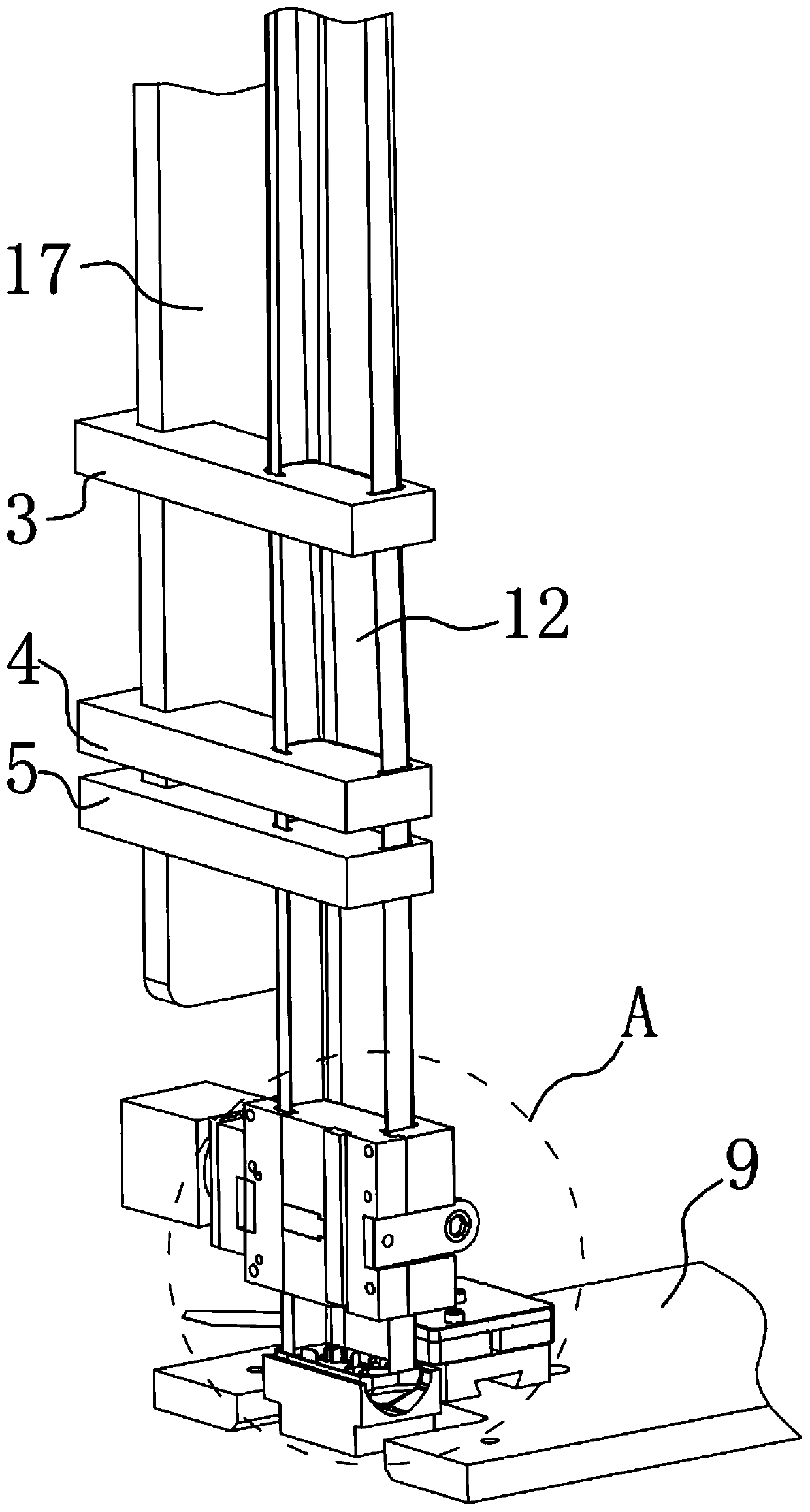

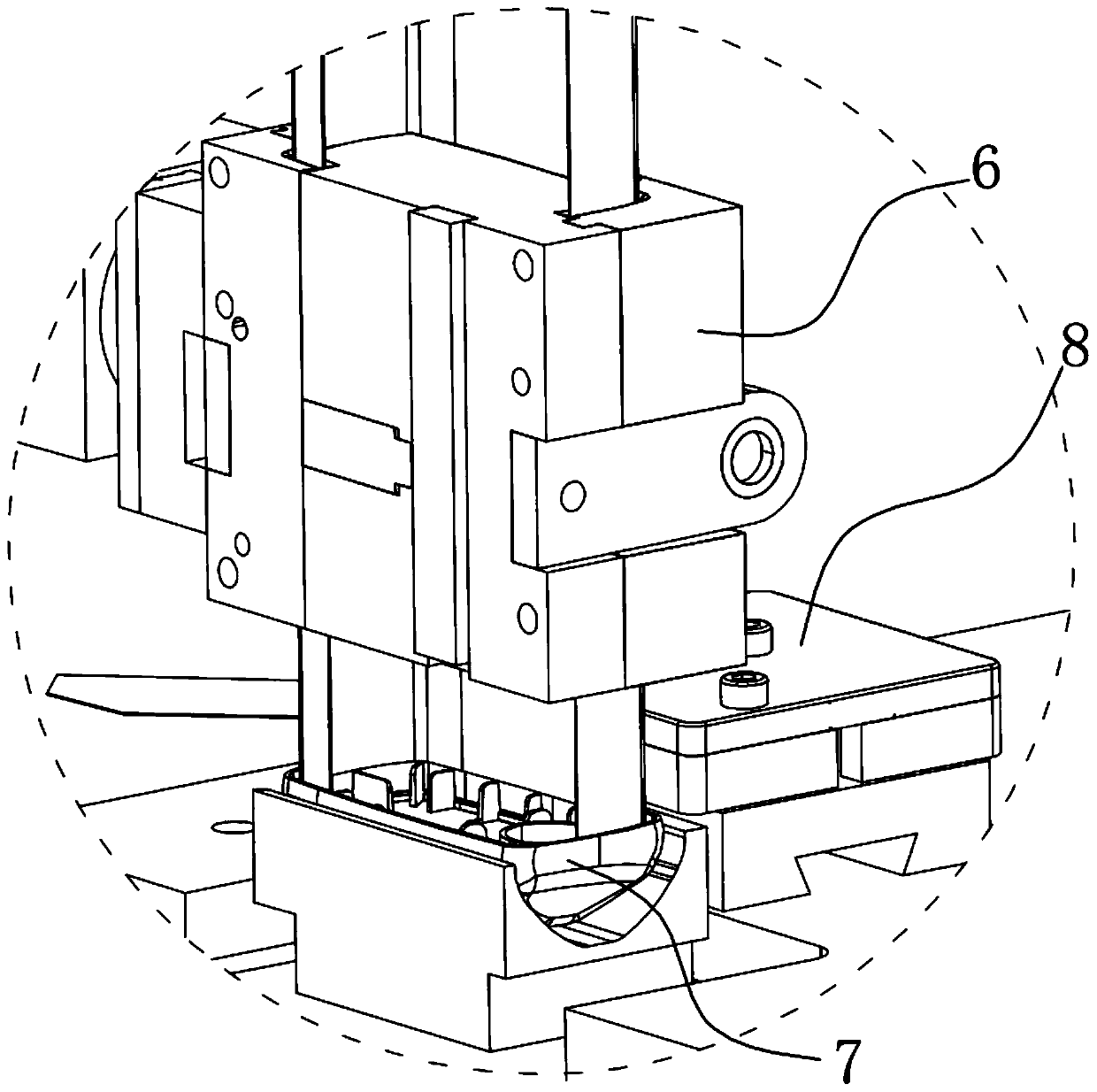

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0033] In order to achieve the purpose of the present invention, a coil shaping and cutting machine includes: a discharge mechanism, including a coil 12 wound on a reel 10, and the coil 12 on the reel 10 protrudes and contacts a driving coil 12 The initial driving wheel 14 that is transmitted, the coiled material 12 cross-sectional profile at the initial driving wheel 14 places is a line segment; Several shaping fixtures, each shaping fixture has a shaping seam for the coiled material 12 to pass through, along the conveying direction of the coiled material 12, the coiled material 12 after passing through the shaping seam is finally docked with the product 7, and each shaping The curvature of the trajectory of the shaping seam on the tool gradually increases, and the trajectory of the shaping seam of the shaping jig closest to the product 7 coincides with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com