Automatic logistics stacking system

A logistics code and automatic technology, applied in the field of palletizing system, can solve the problems of inappropriate matching of palletizing and single function, and achieve the effect of low manufacturing cost and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

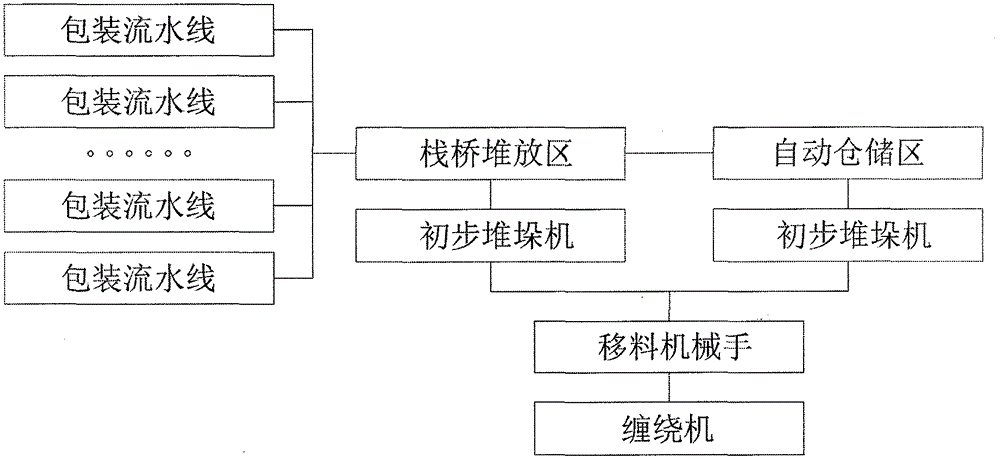

[0015] As shown in Figure 1, the automated logistics palletizing system includes several packaging lines, and all packaging lines correspond to racks. The frame is provided with a trestle stacking area corresponding to the position of the packaging line, and an automatic storage area for the corresponding use. The trestle stacking area and the automatic storage area are respectively connected with preliminary stackers. The primary stacker is connected to the material shifting mechanism through the main transport line. The material shifting mechanism is connected to the palletizing and packaging area through the auxiliary transportation line. Wrapping equipment is provided in the palletizing and packaging area, and transport equipment corresponding to the winding equipment is provided on the side of the palletizing and packaging area.

[0016] The material-moving mechanism is a material-moving manipulator installed on the frame and corresponding to the main conveying line; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com