Patents

Literature

3888 results about "Stacker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stacker is a large machine used in bulk material handling. Its function is to pile bulk material such as limestone, ores and cereals on to a stockpile. A reclaimer can be used to recover the material.

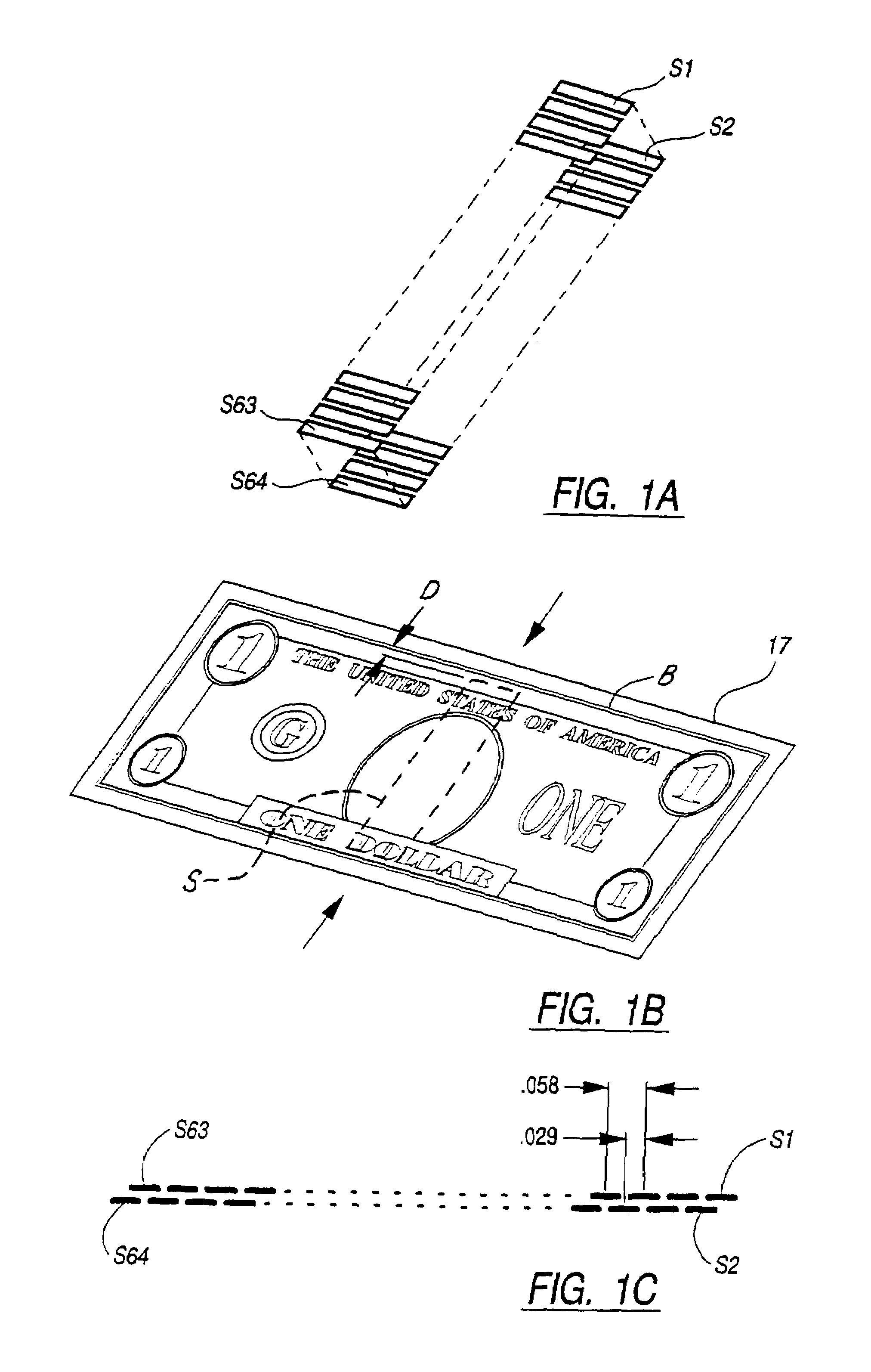

Method and apparatus for currency discrimination

InactiveUS20050117792A2Efficient countingEfficient discriminationComplete banking machinesImage analysisEngineeringStacker

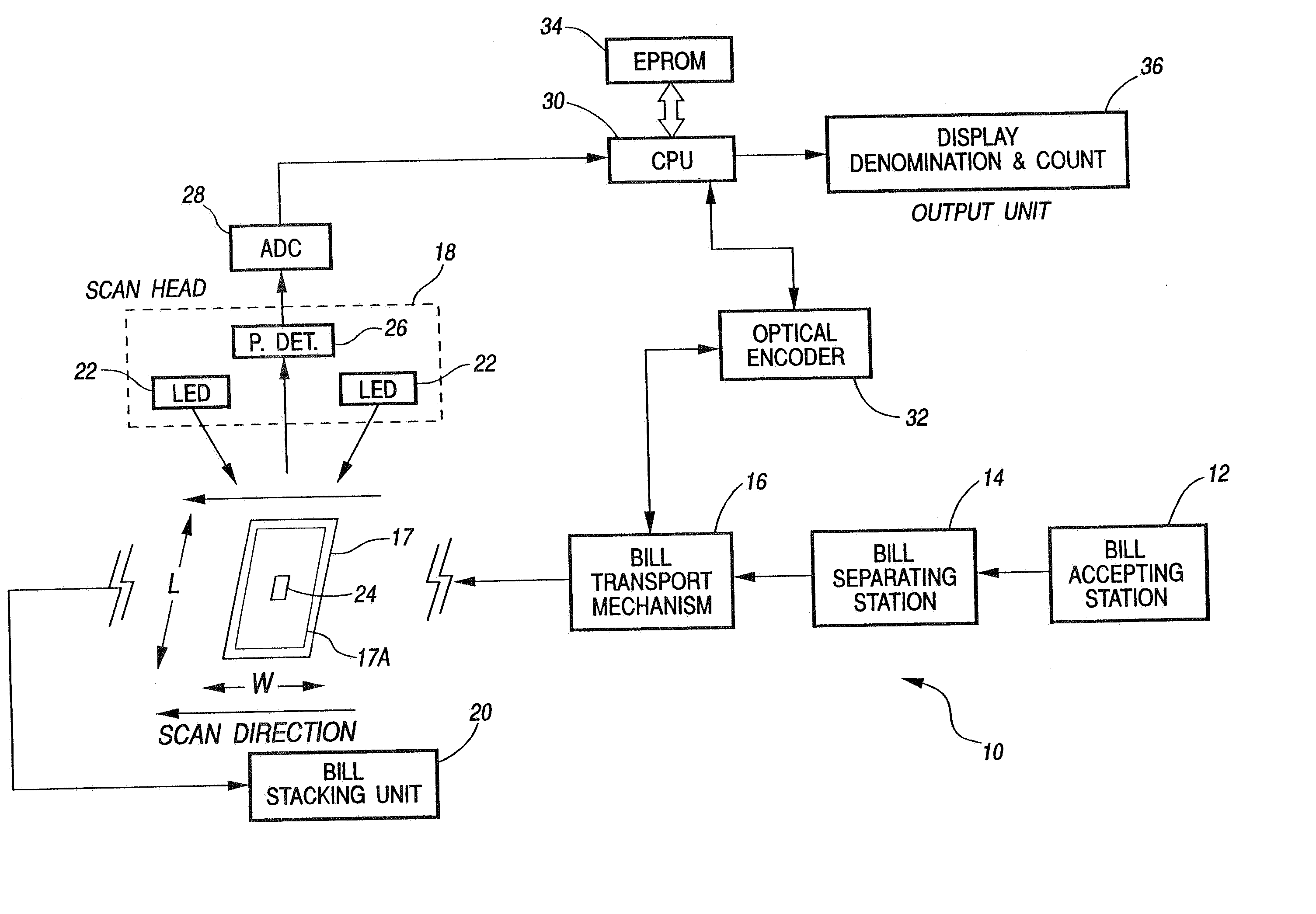

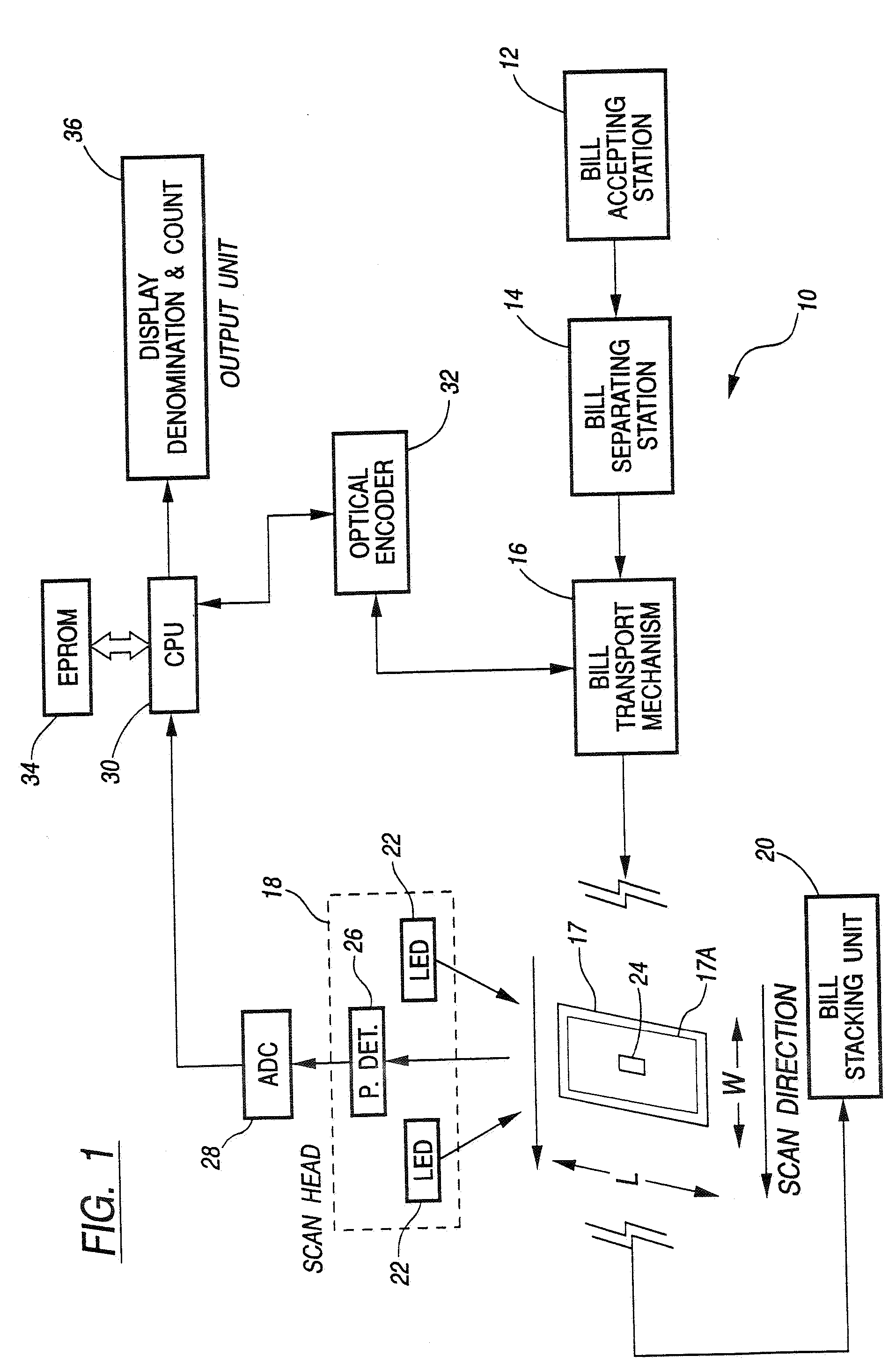

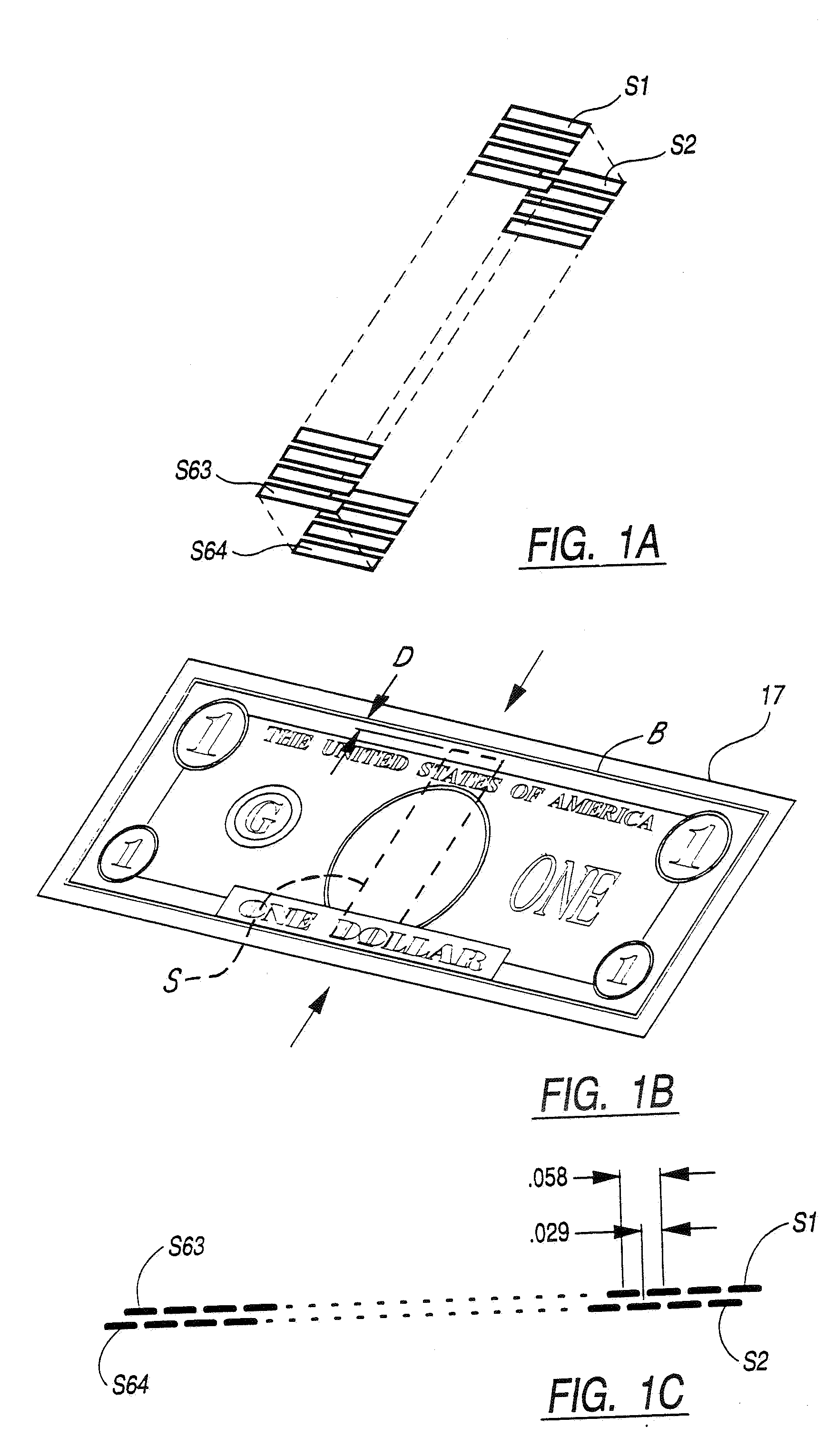

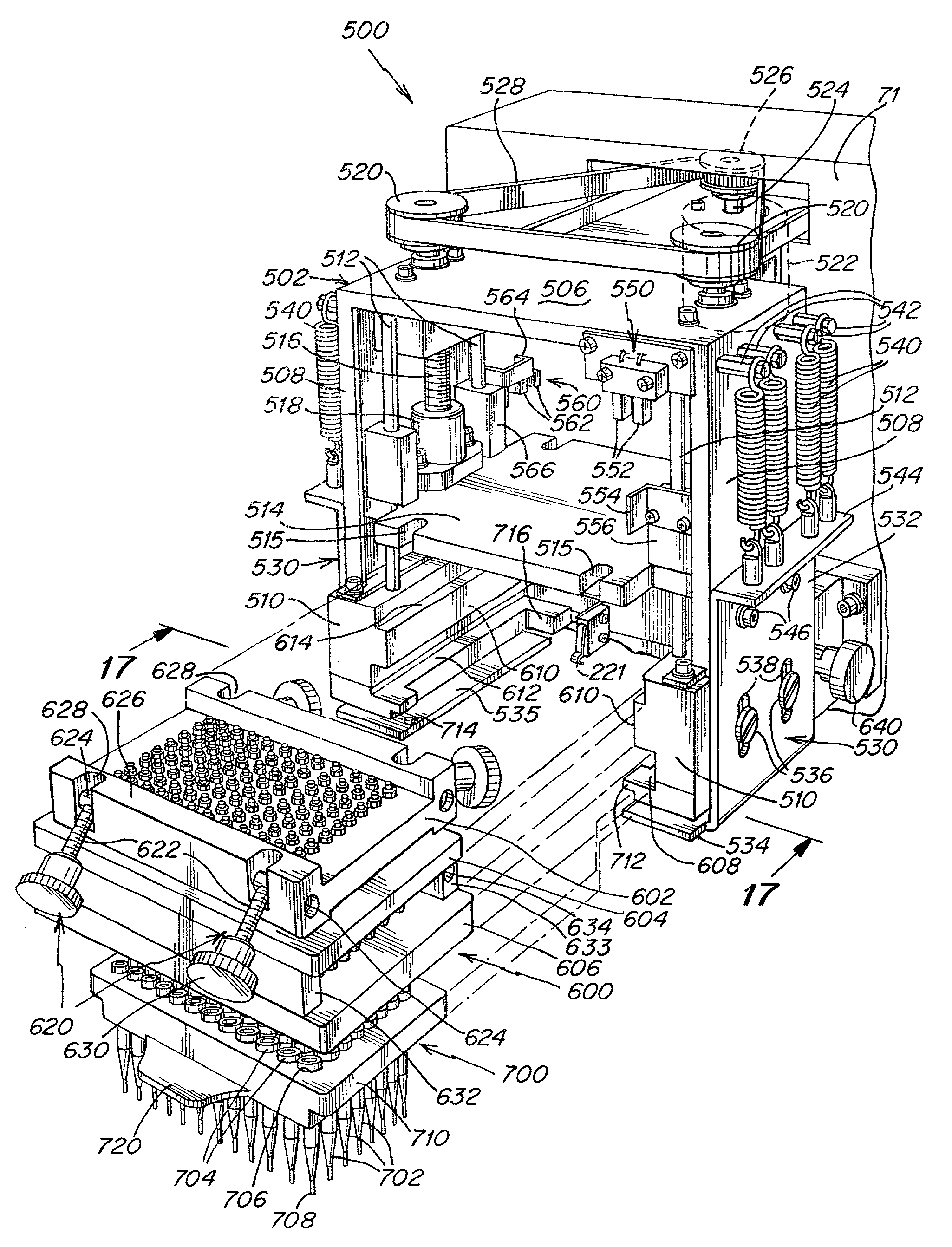

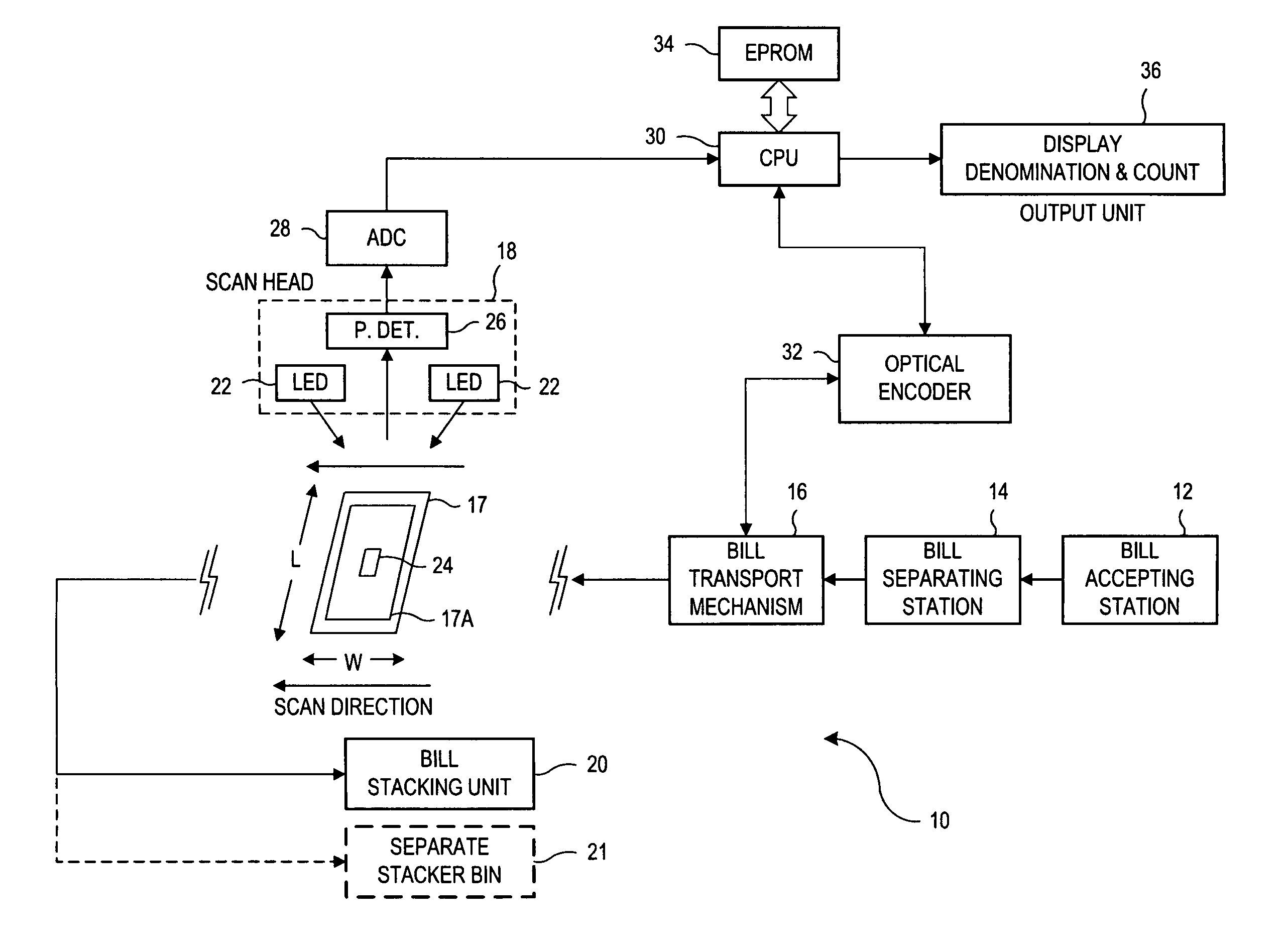

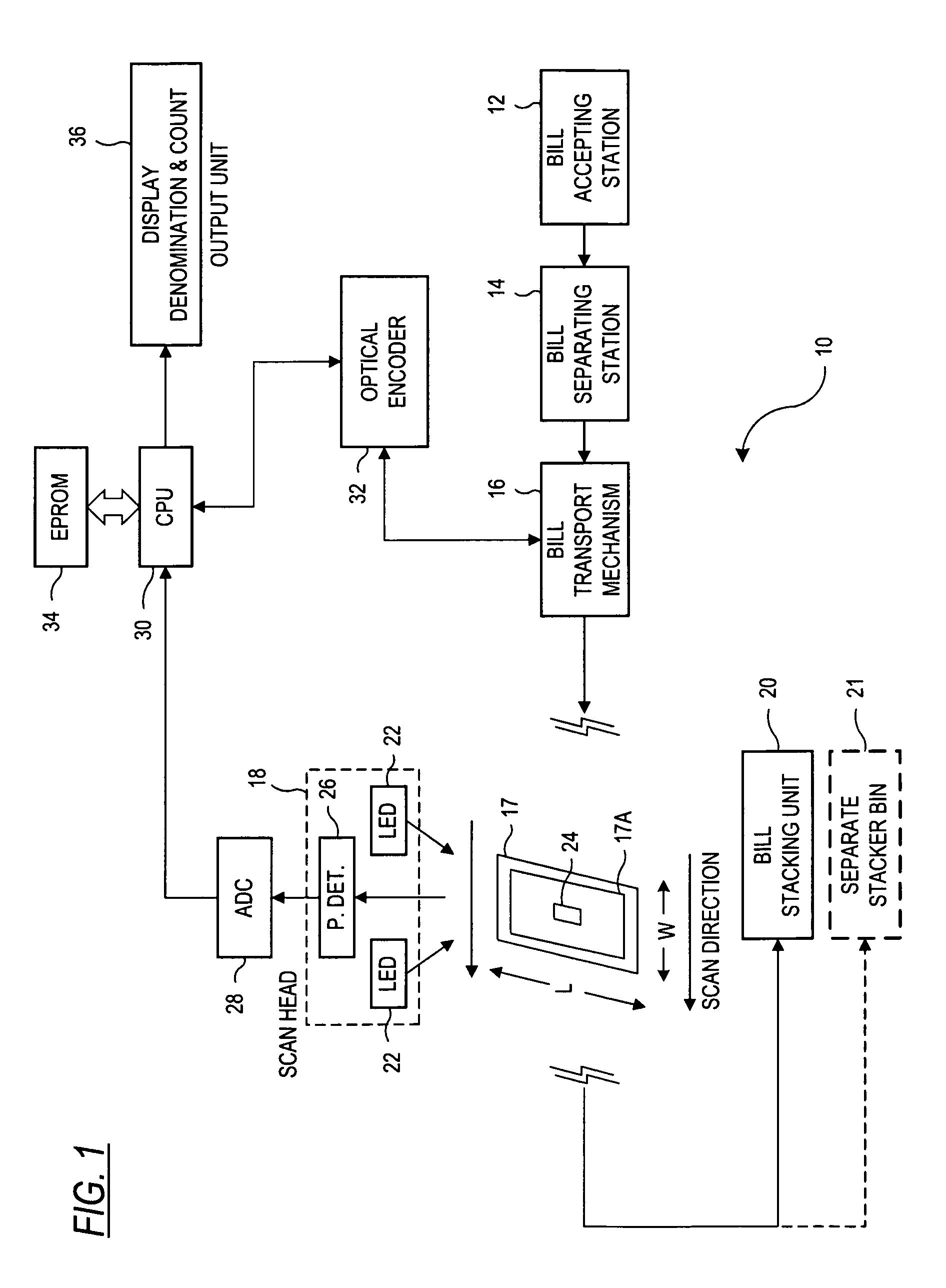

Abstract of the DisclosureA currency evaluation device for receiving a stack of U.S. currency bills and rapidly evaluating all the bills in the stack comprises an input receptacle adapted to receive a stack of U.S. currency bills of a plurality of denominations to be evaluated. According to one embodiment, a transport mechanism transports the bills, one at a time, from the input receptacle along a transport path at a rate of at least about 800 bills per minute. A denomination discriminating unit which includes a detector positioned along the transport path evaluates the bills. The device comprises a single denominated bill output receptacle positioned to receive bills whose denomination have been determined by the discriminating unit including bills of a plurality of denominations. A separate stacker bin is provided and a diverter positioned along the transport path routes bills whose denomination cannot be determined to the separate stacker bin.

Owner:CUMMINS-ALLISON CORP

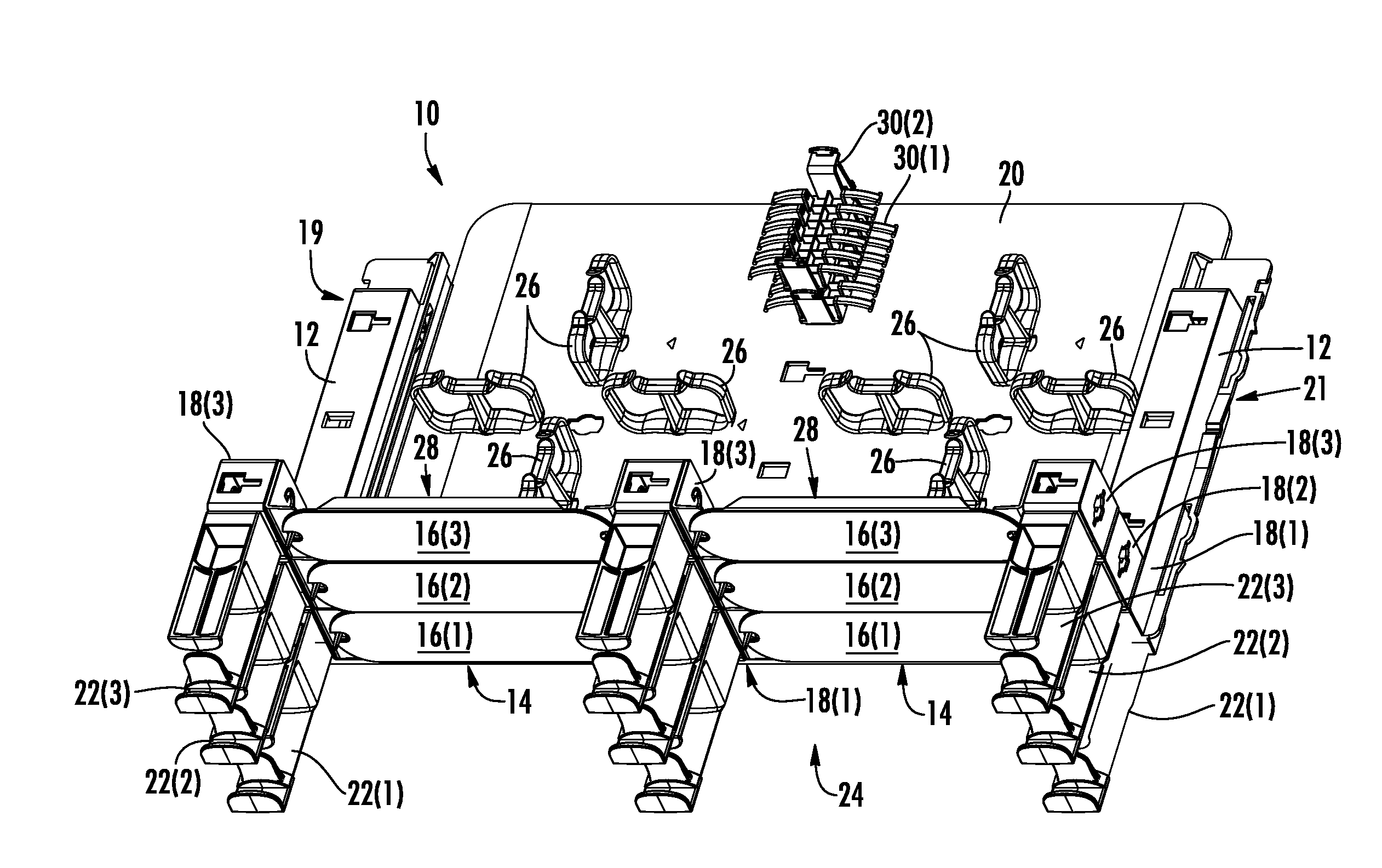

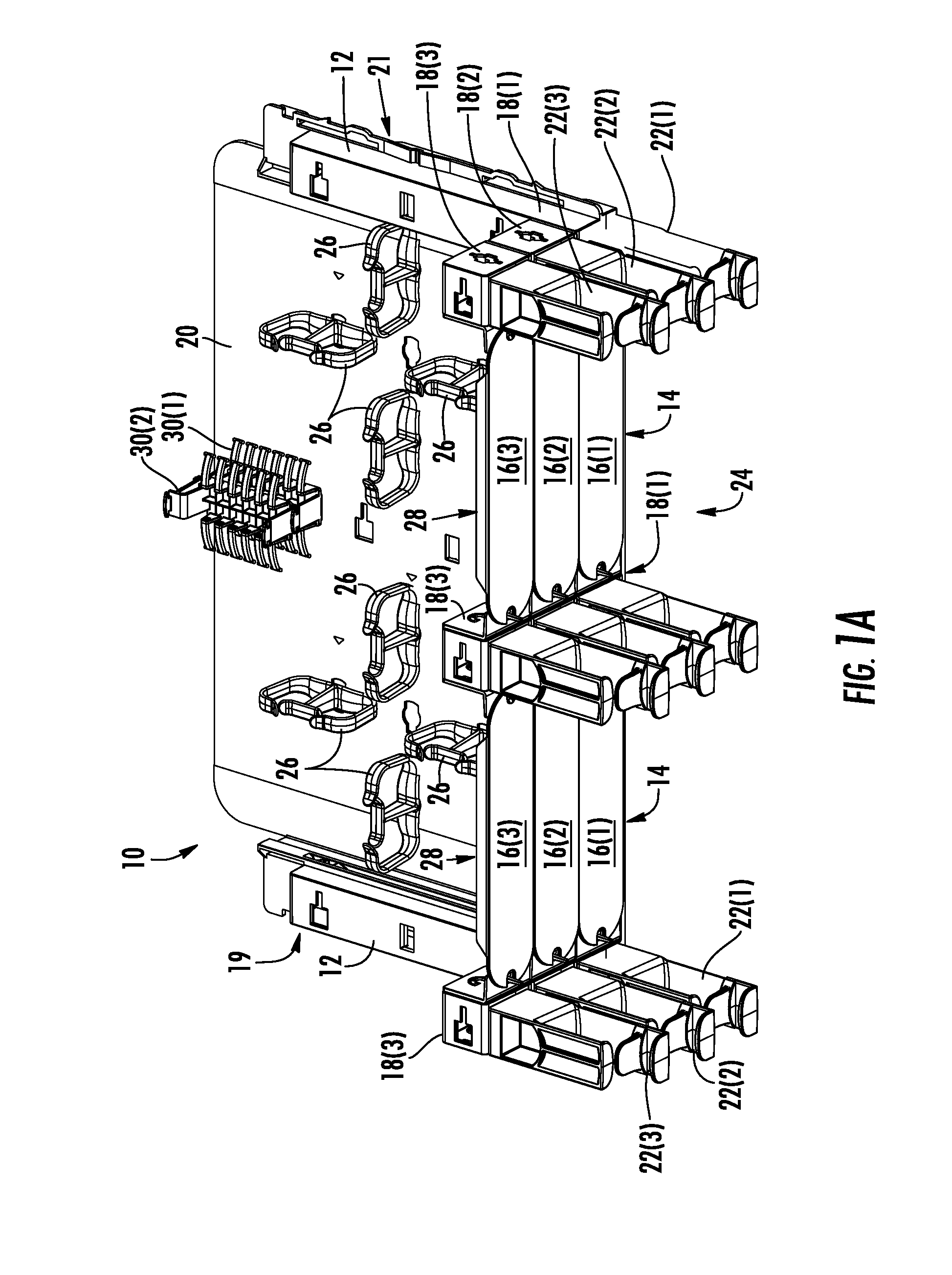

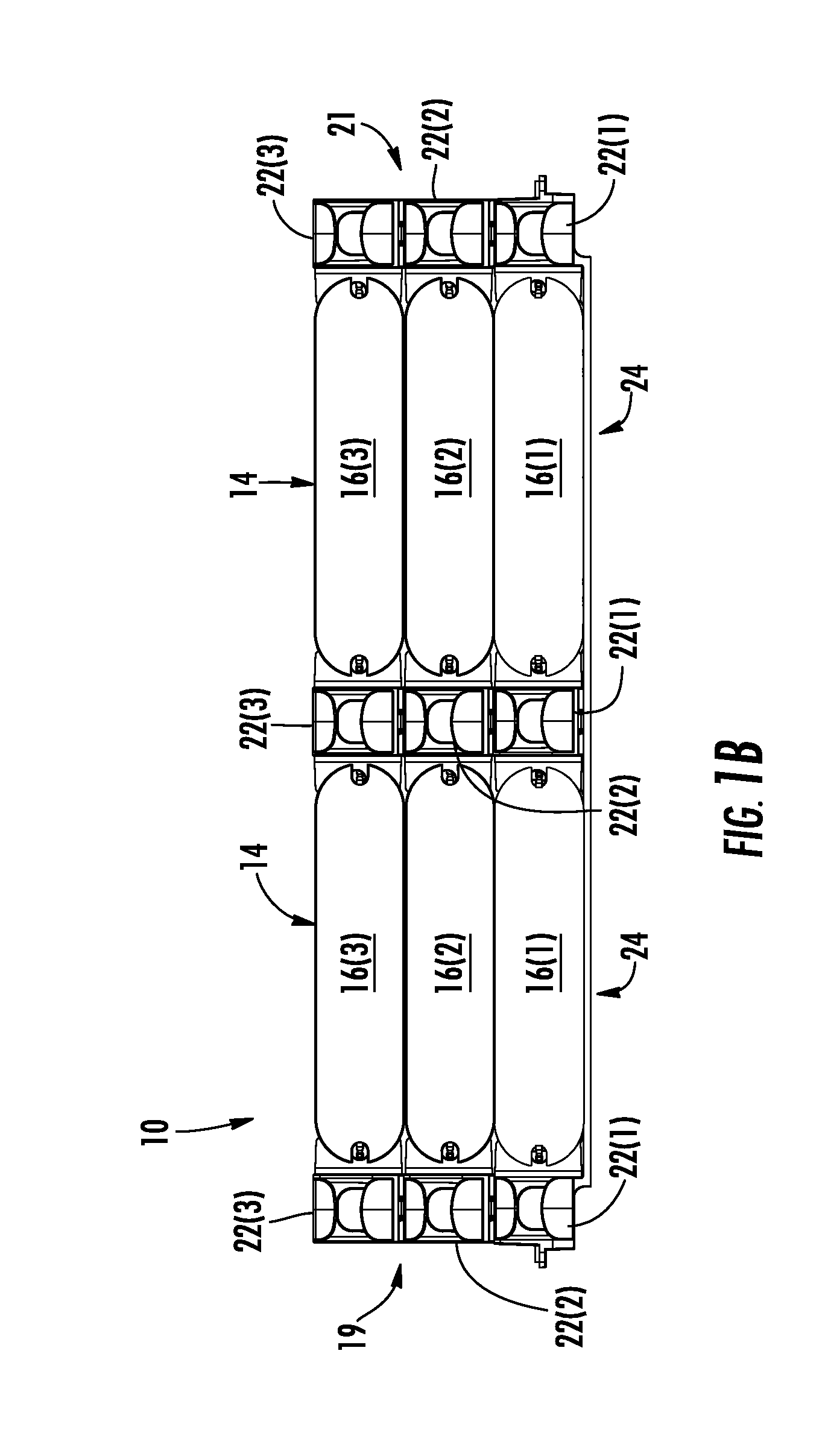

Automated pipetting system

InactiveUS6982063B2Good flexibilityImprove throughputChemical analysis using titrationWithdrawing sample devicesMechanical pipetteManual insertion

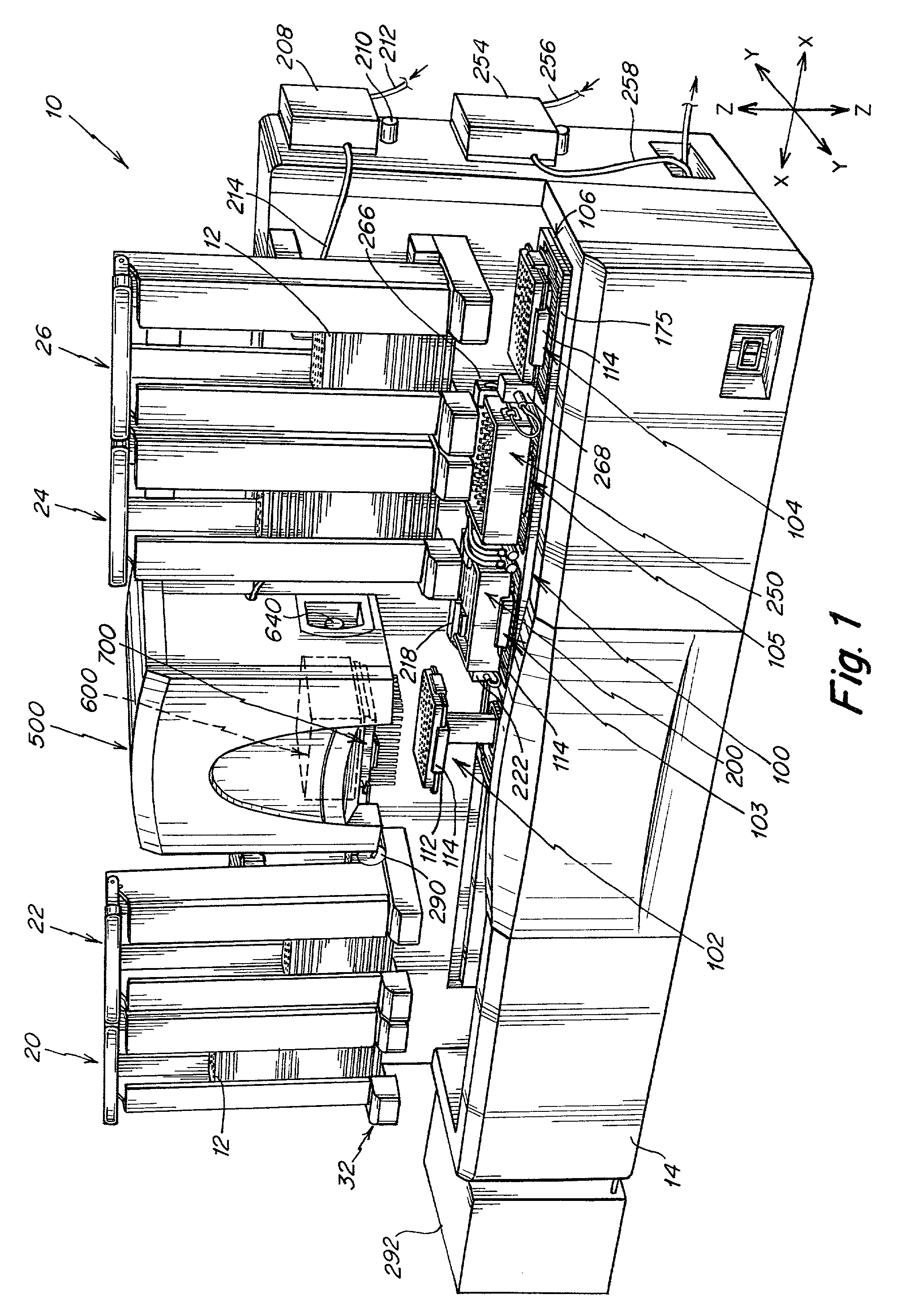

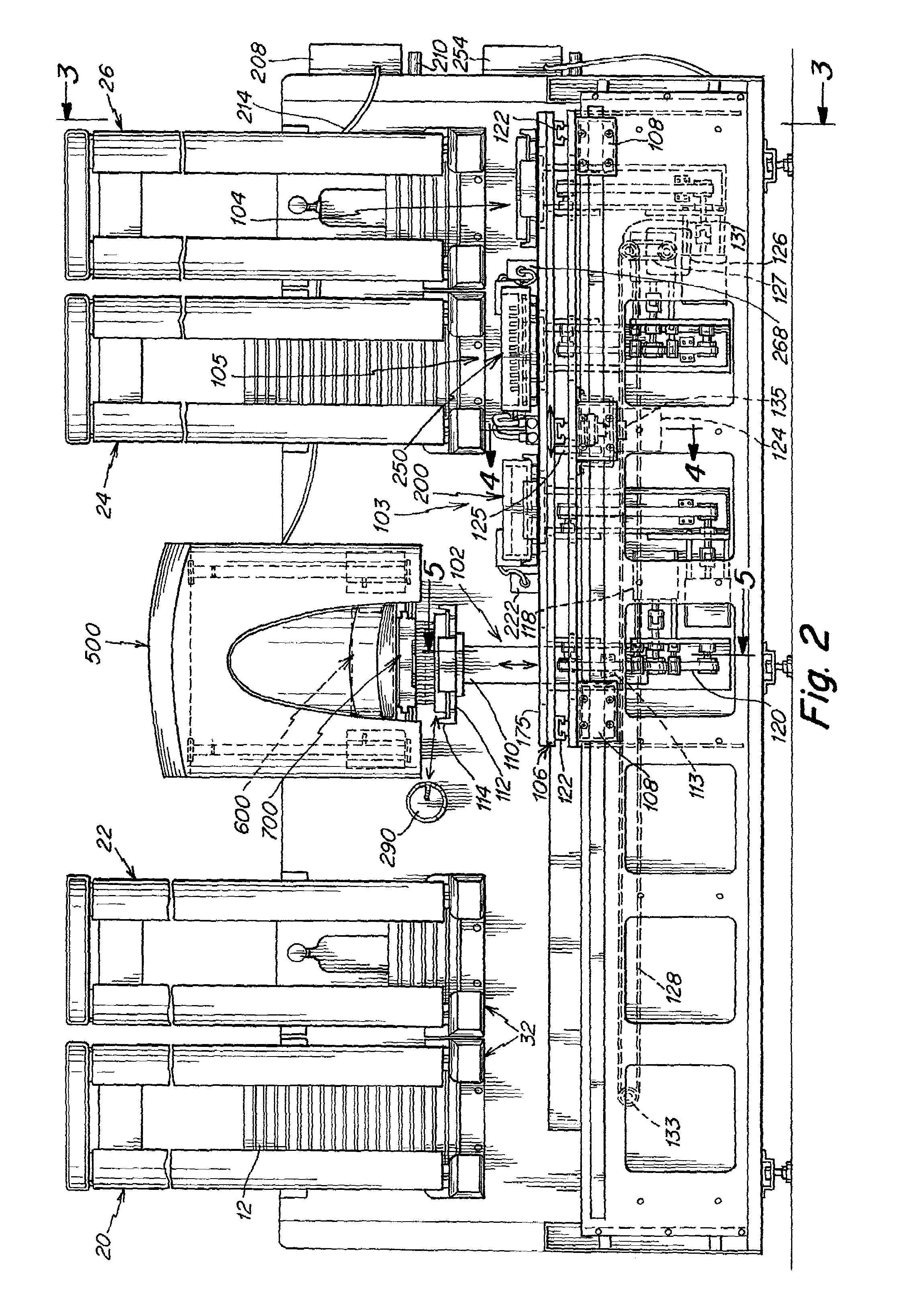

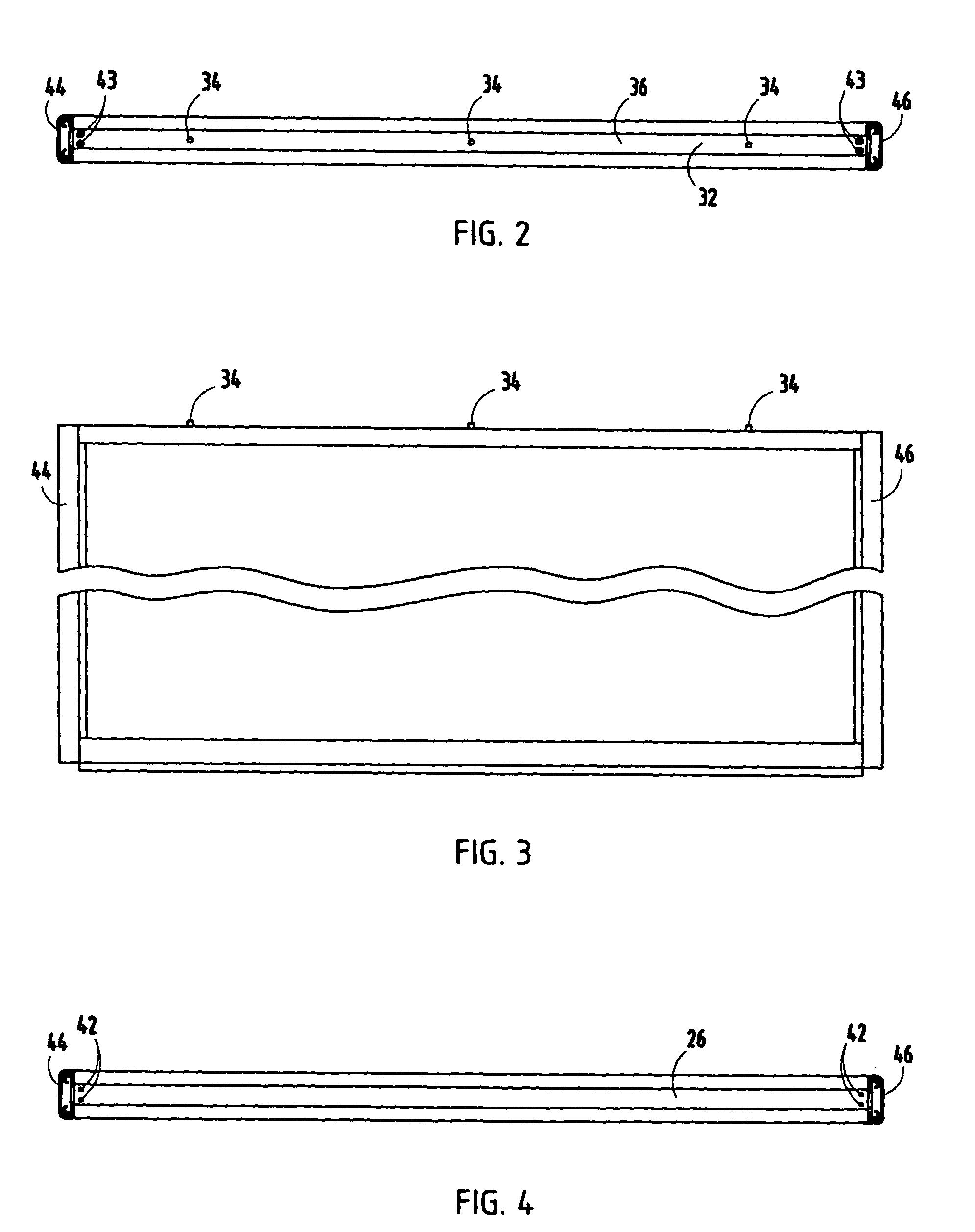

A highly automated, high volume multichannel pipetting system which transfers liquid from mother plates to daughter plates, or from a fill station to daughter plates. The mother plates are stacked in one set of stacker assemblies, while the empty daughter plates are stacked in another stacker assembly. A plate handling assembly which is capable of moving the plates in three orthogonal directions retrieves the plates from the stacker assemblies, carries them to the pipetting head, and returns them to other stacker assemblies. The pipetting head is removable for replacement or repair thereof, or for insertion of another head assembly having a different number of pipetting channels. The head slides into the housing on slideways, and is retained in place by manually operable, threaded knobs mounted on shafts. The stacker assemblies include a chimney which is removable from a base. The plates may be stacked in the chimney and then inserted on the base. The base includes solenoids whose arms are retractable to permit plates to be retrieved or replaced one at a time. The chimneys contain flaps which serve to retain the plates within the chimney if manually removed from the base. Doors in the stacker chimneys allow manual insertion and replacement of plates. Methods of operation of the pipetting system are also disclosed.

Owner:MATRIX TECH +1

Method and apparatus for currency discrimination and counting

InactiveUS7536046B2Efficient countingEfficient discriminationComplete banking machinesImage analysisStackerBank note

A currency evaluation device for receiving a stack of U.S. currency bills and rapidly evaluating all the bills in the stack comprises an input receptacle adapted to receive a stack of U.S. currency bills of a plurality of denominations to be evaluated. According to one embodiment, a transport mechanism transports the bills, one at a time, from the input receptacle along a transport path at a rate of at least about 800 bills per minute. A denomination discriminating unit which includes a detector positioned along the transport path evaluates the bills. The device comprises a single denominated bill output receptacle positioned to receive bills whose denomination have been determined by the discriminating unit including bills of a plurality of denominations. A separate stacker bin is provided and a diverter positioned along the transport path routes bills whose denomination cannot be determined to the separate stacker bin.

Owner:CUMMINS-ALLISON CORP

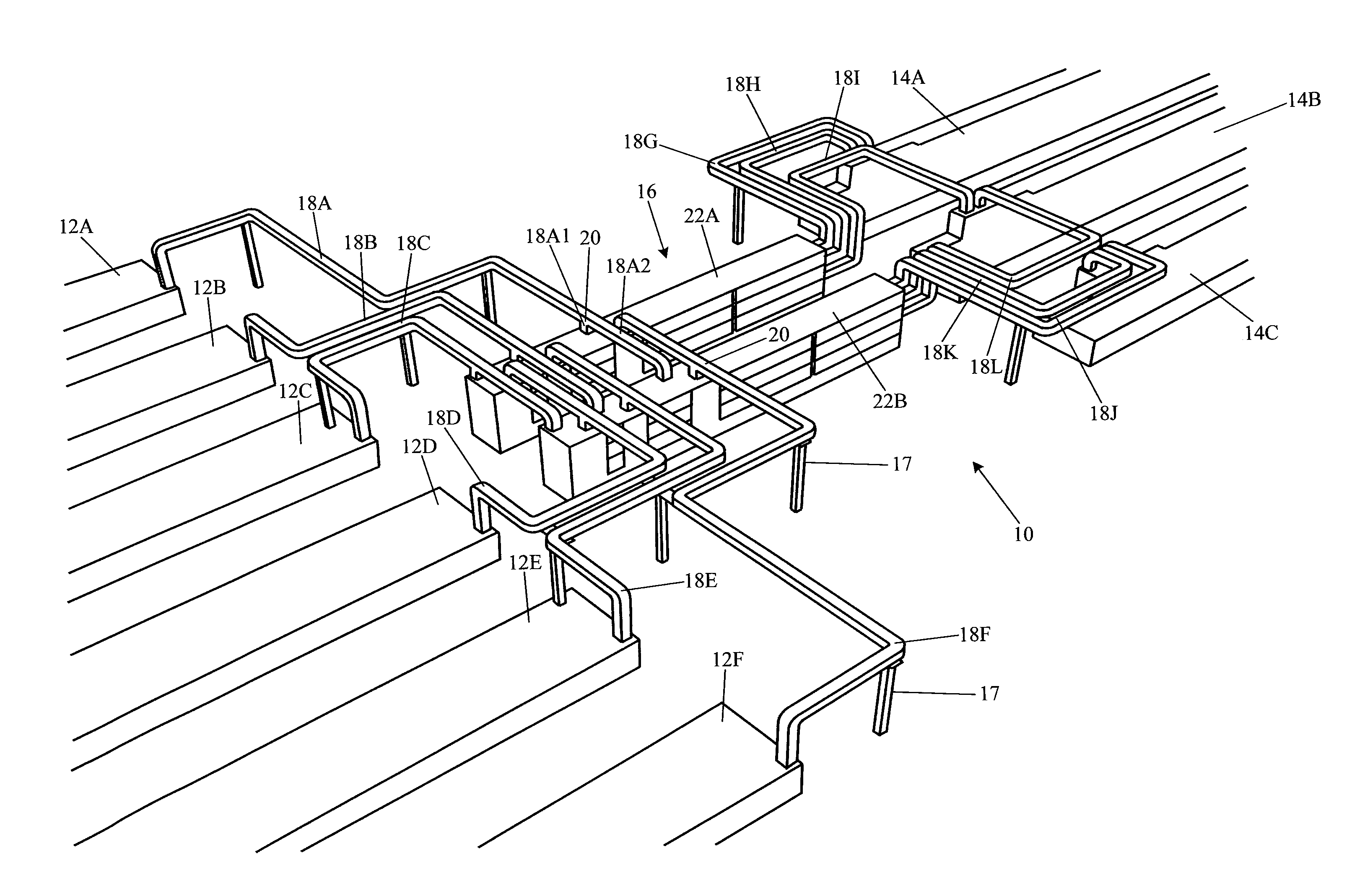

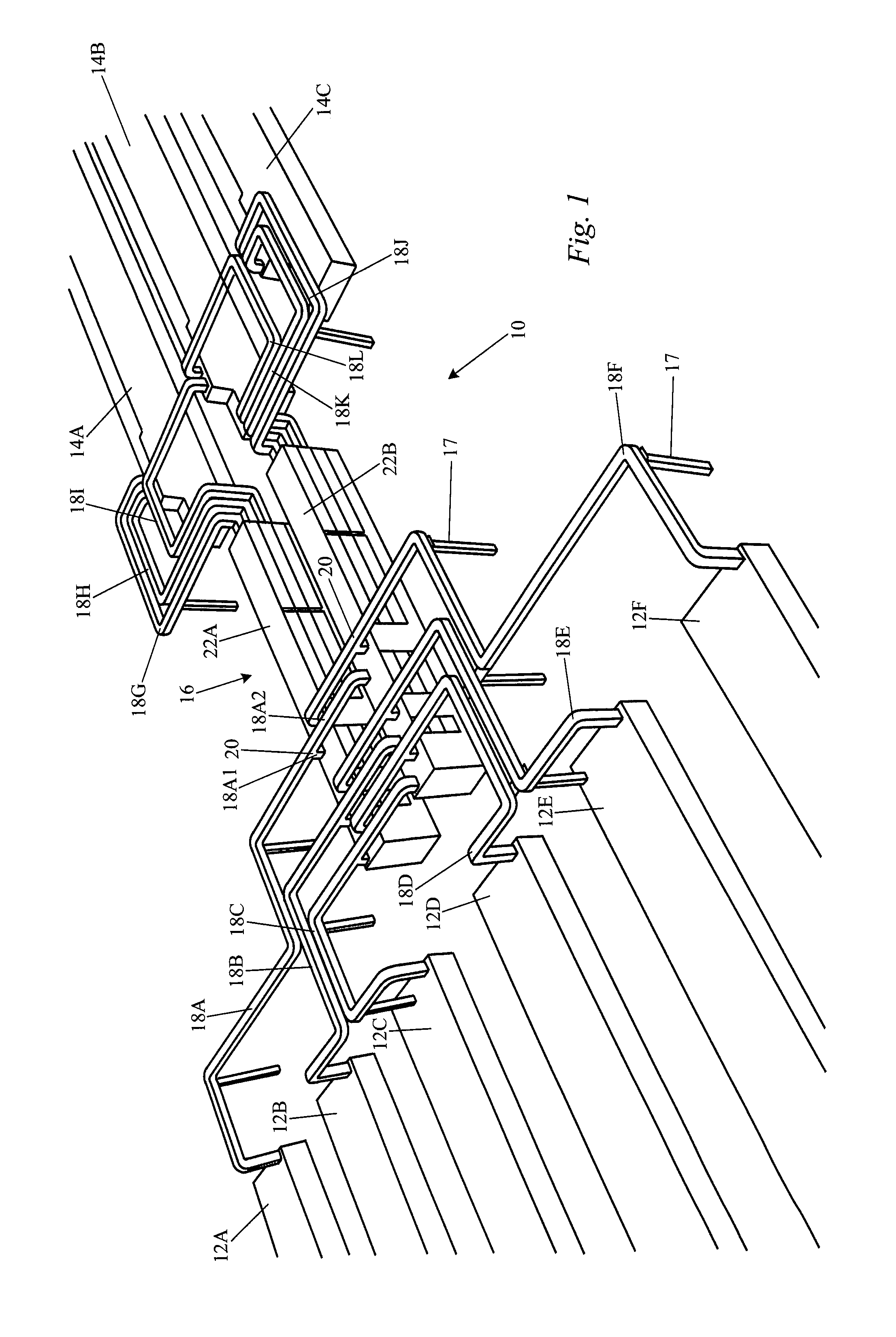

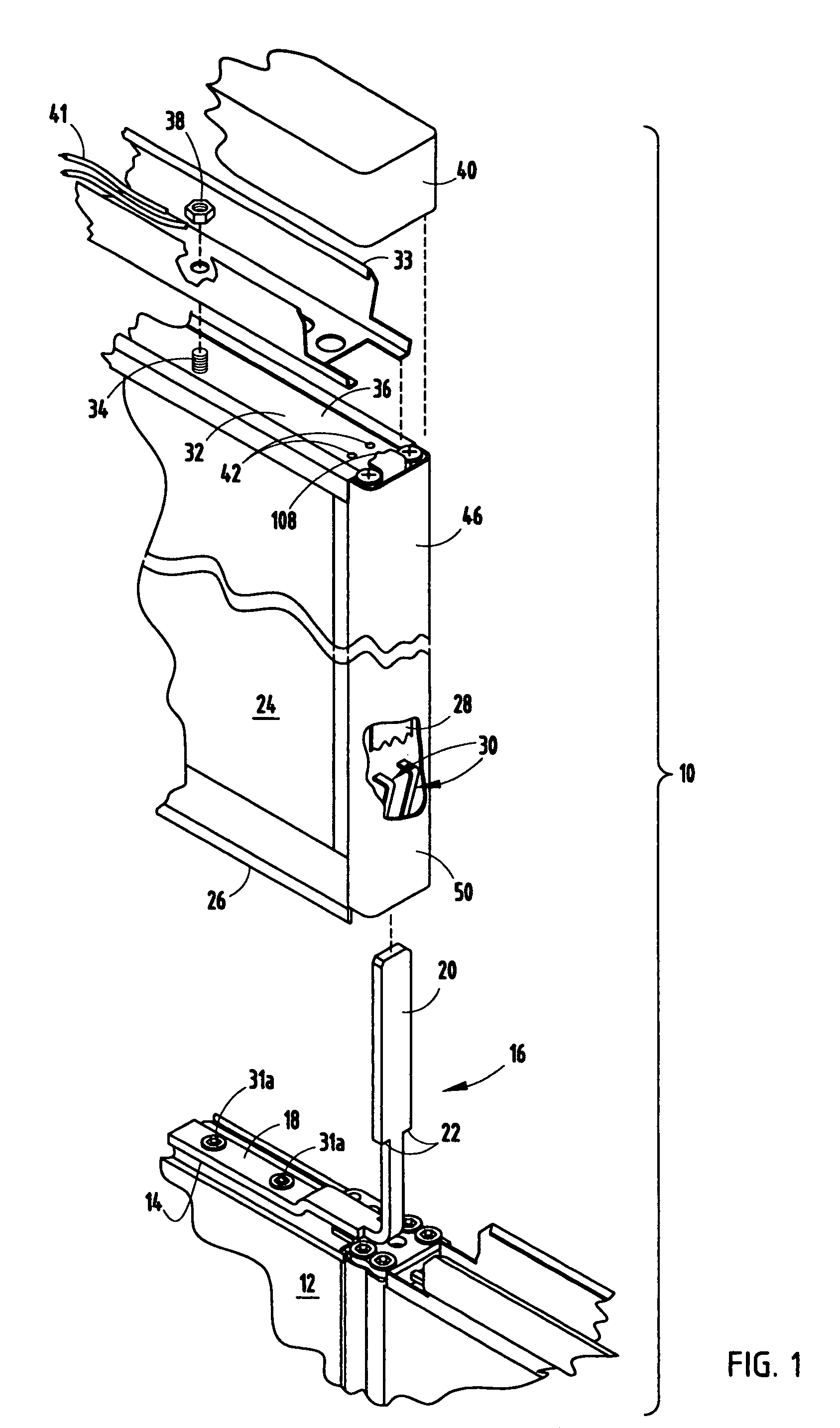

Stackable shelves for a fiber optic housing, and related components and methods

Stackable shelves for a fiber optic housing and related components and methods are disclosed. In one embodiment, a stackable shelf for a fiber optic housing is provided. The stackable shelf comprises a mounting surface and one or more stacker assemblies stacked above the mounting surface, each configured to support fiber optic equipment in one or more height spaces. The one or more stacker assemblies are further configured to support one or more additional removable stacker assemblies each configured to support fiber optic equipment at one or more additional height spaces. In another embodiment, a removable stacker assembly configured to support fiber optic equipment in a stackable shelf is provided. Related methods are also disclosed.

Owner:CORNING OPTICAL COMM LLC

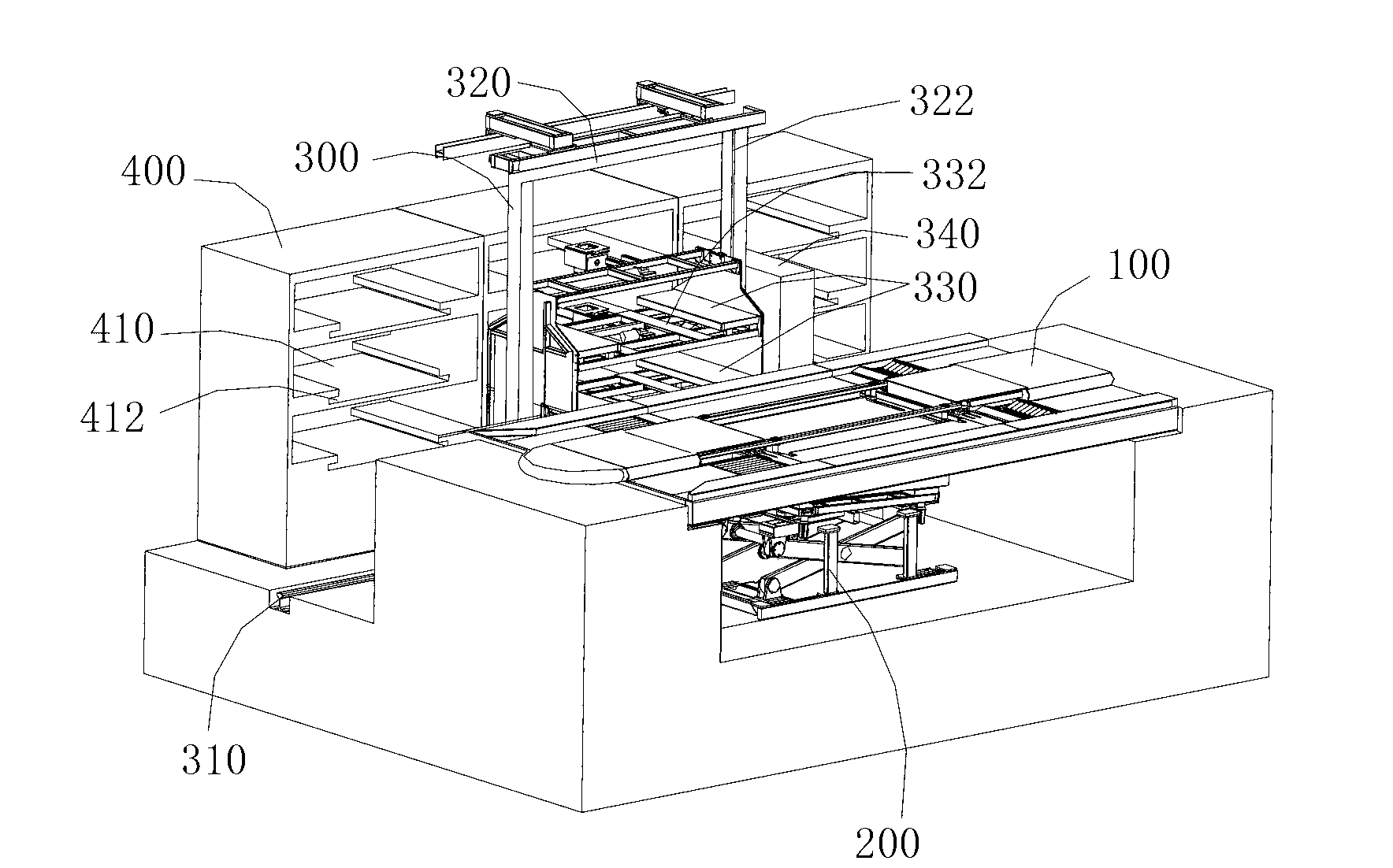

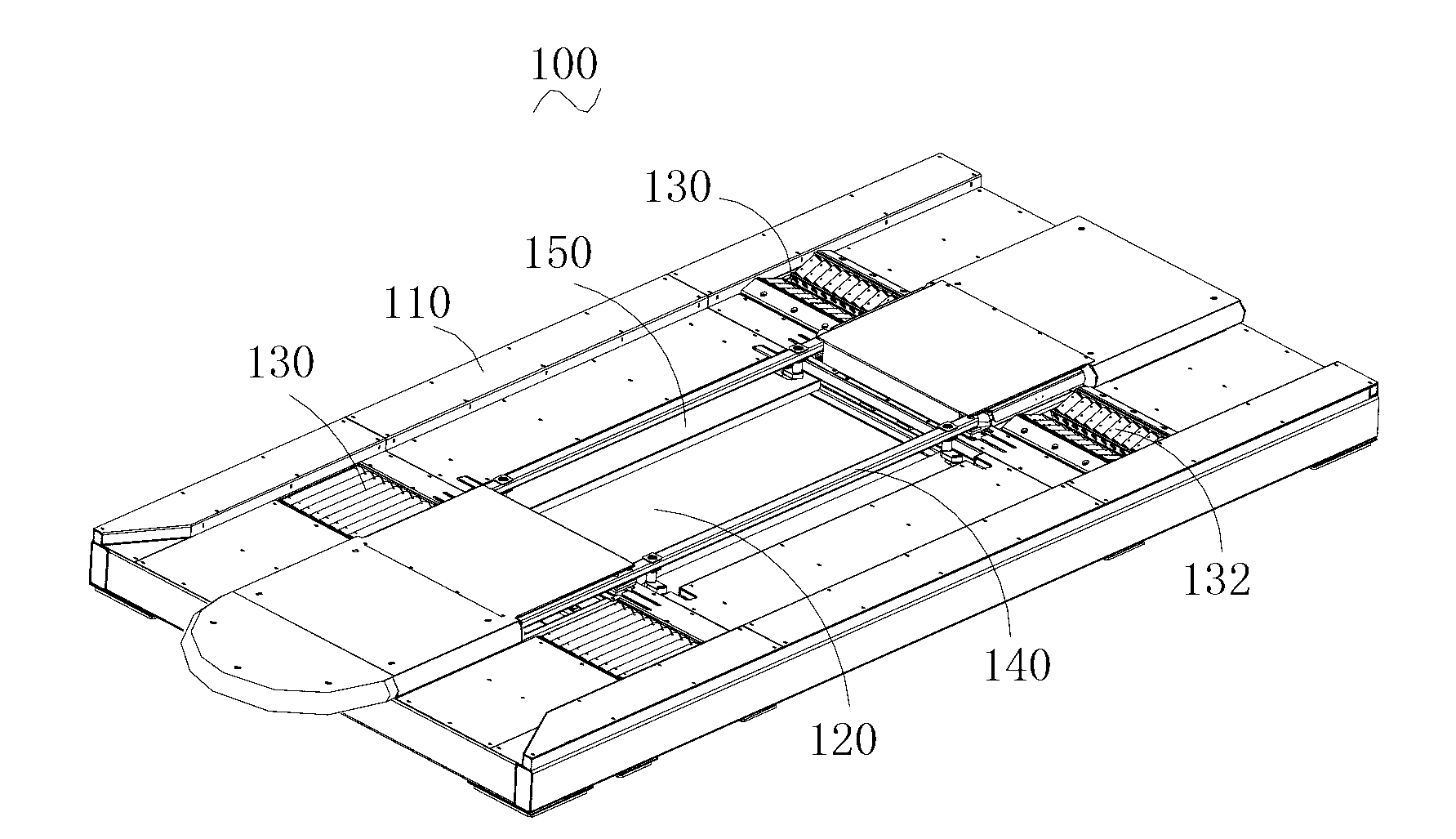

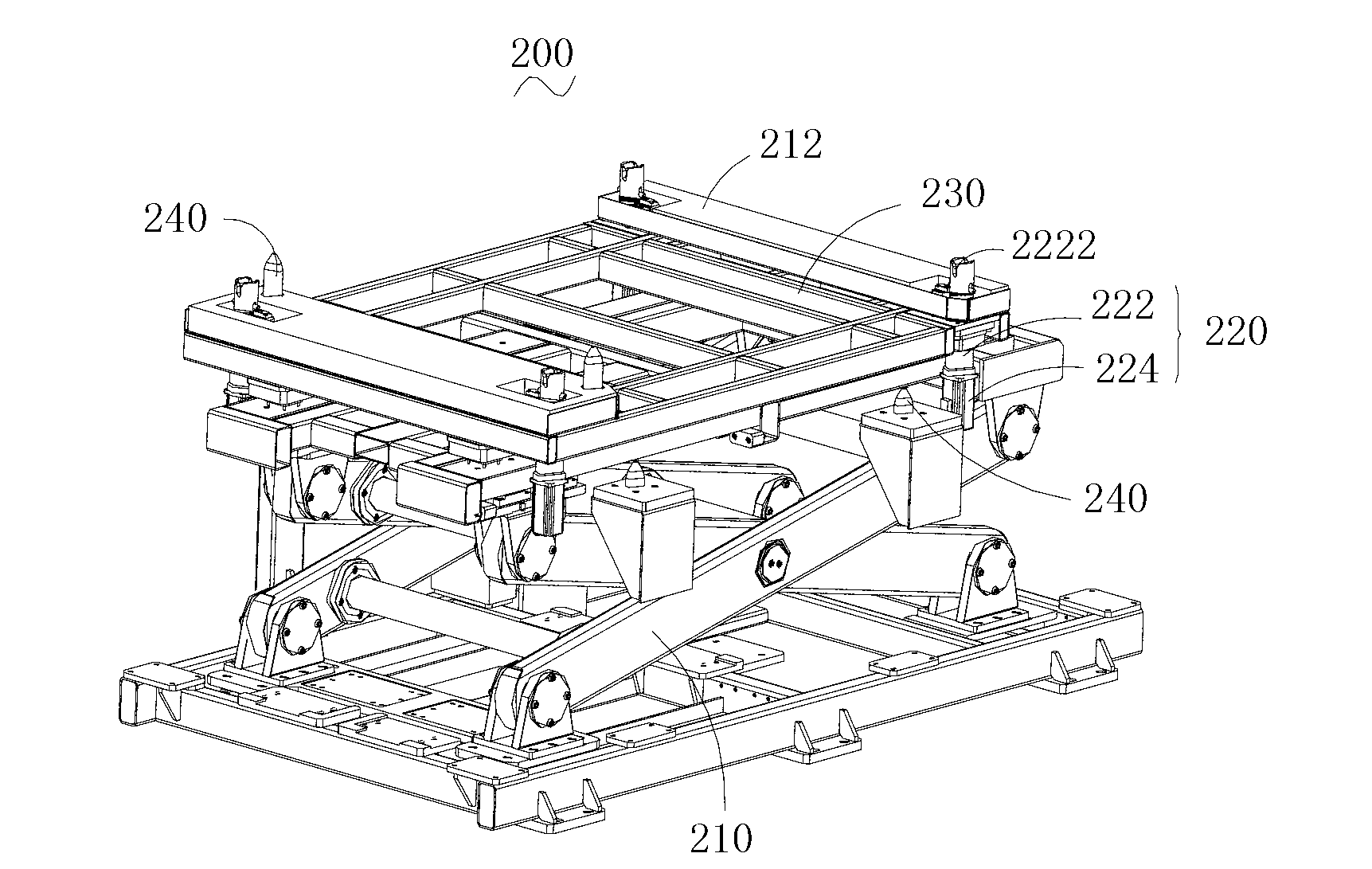

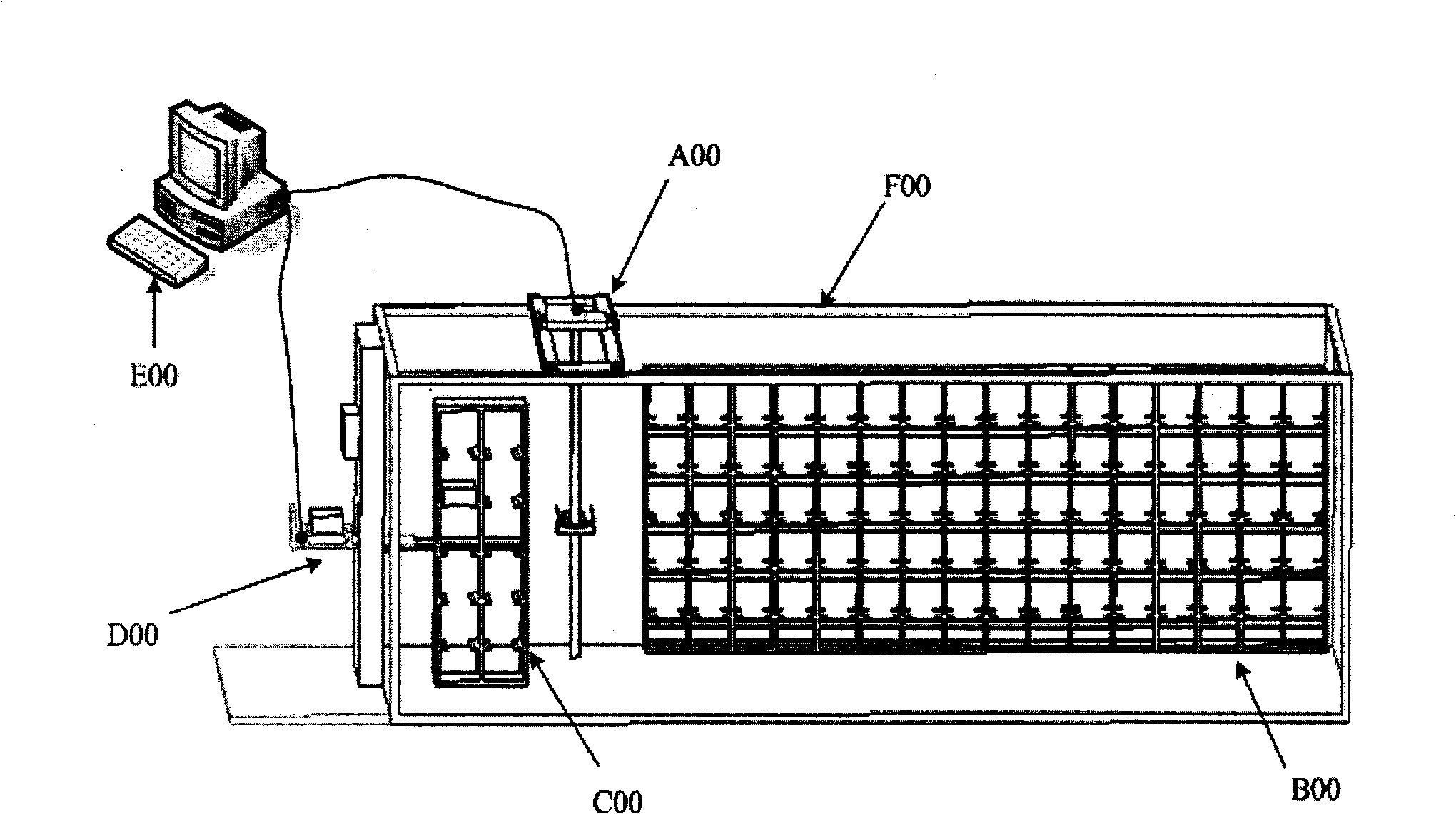

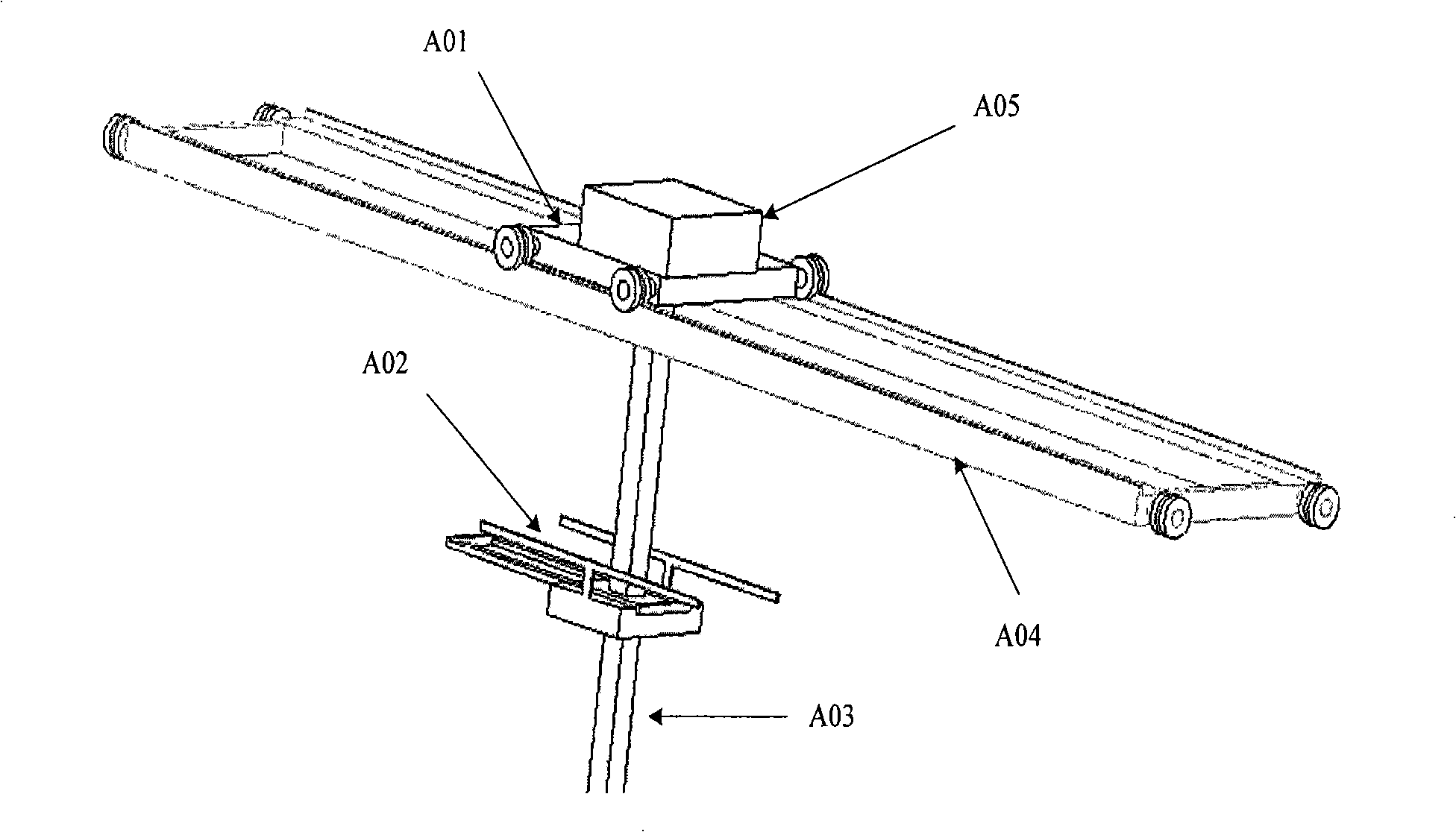

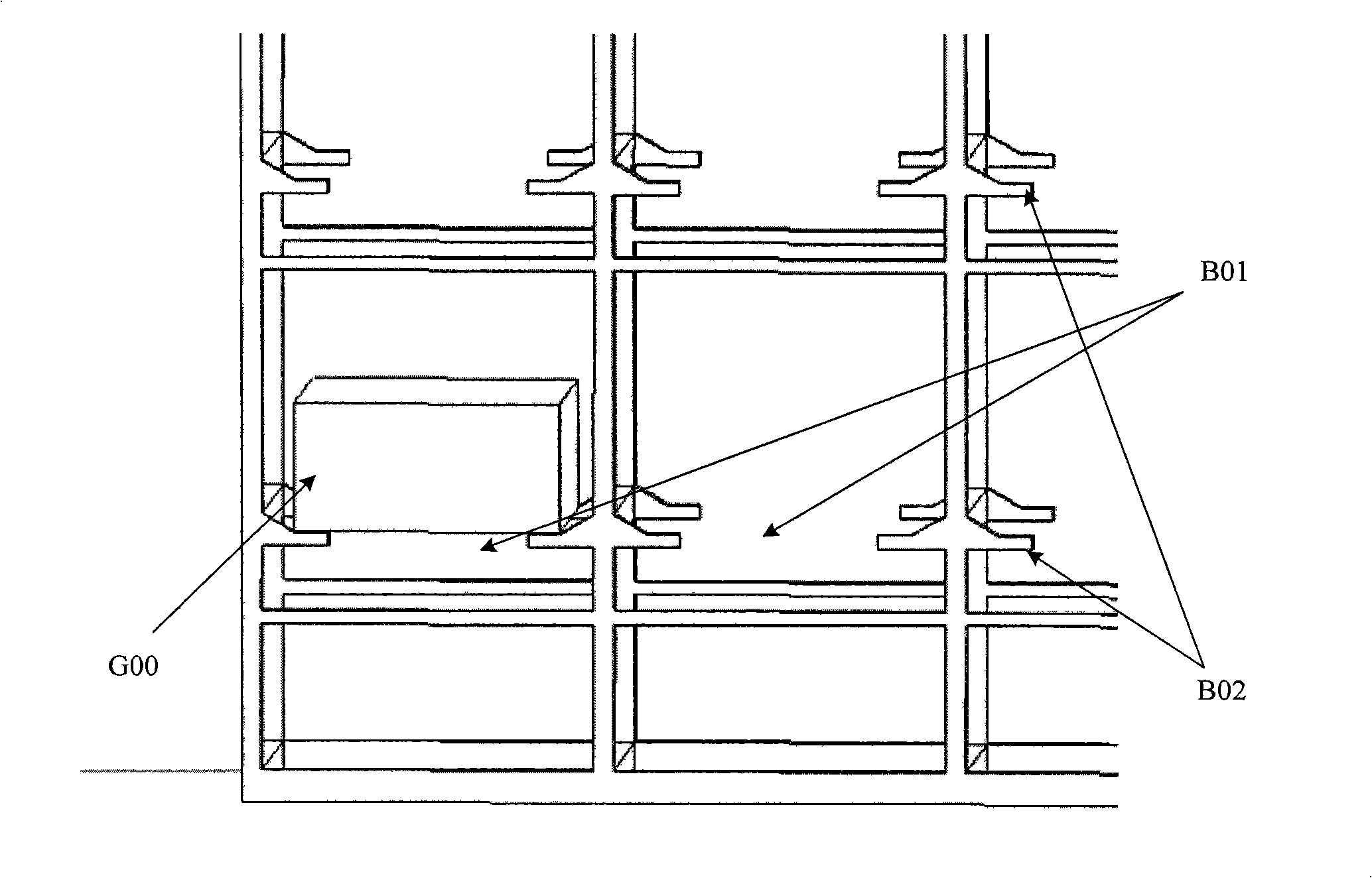

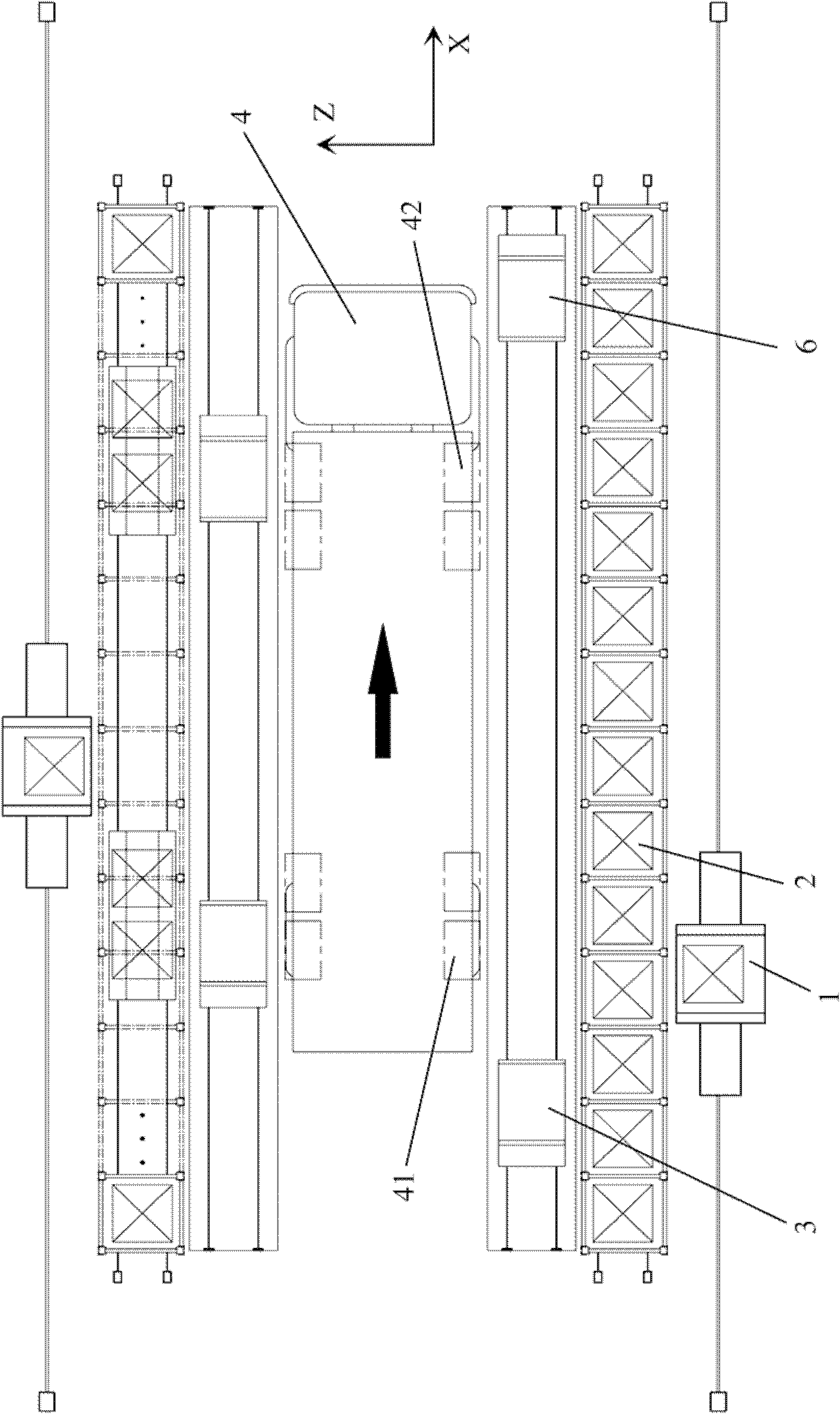

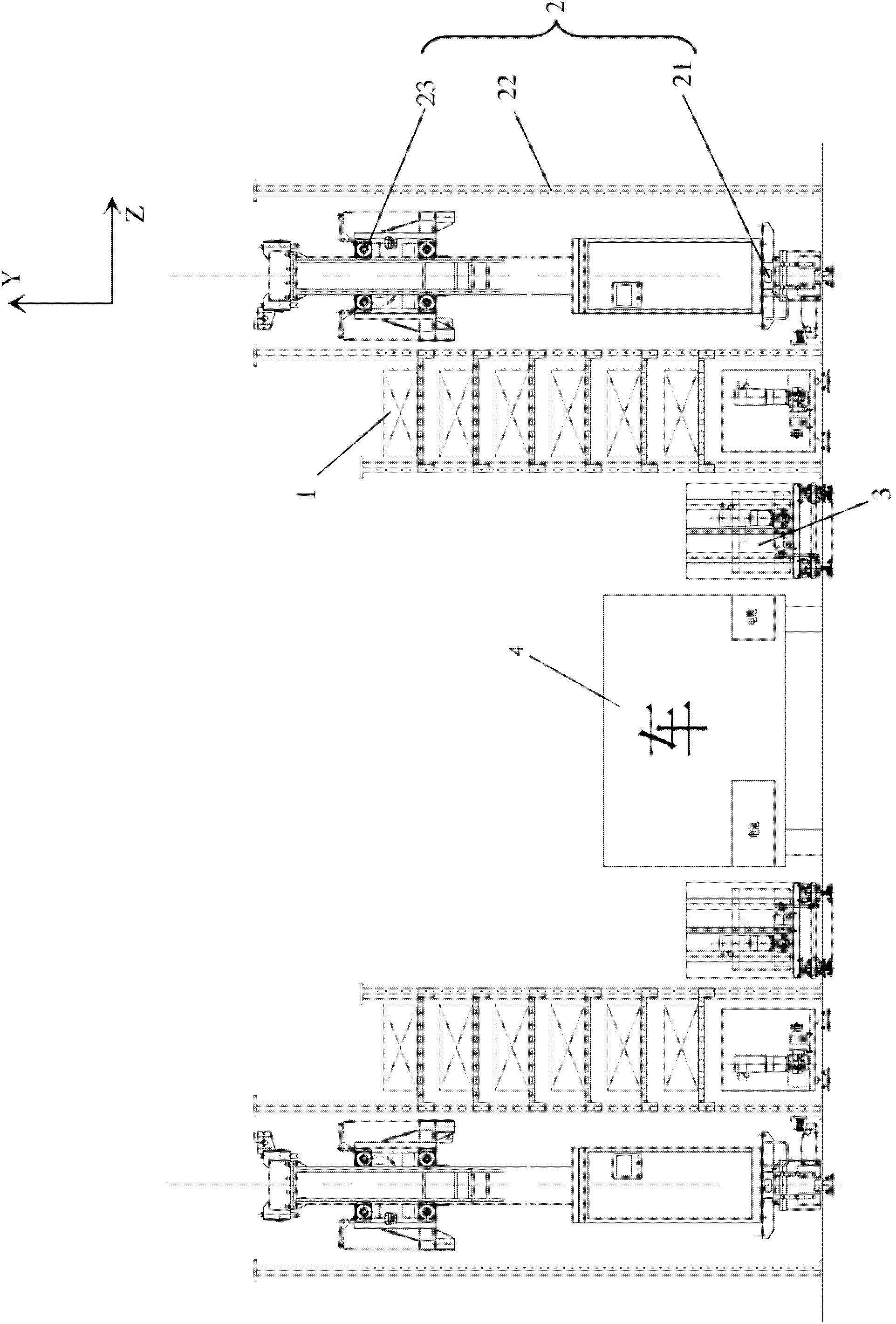

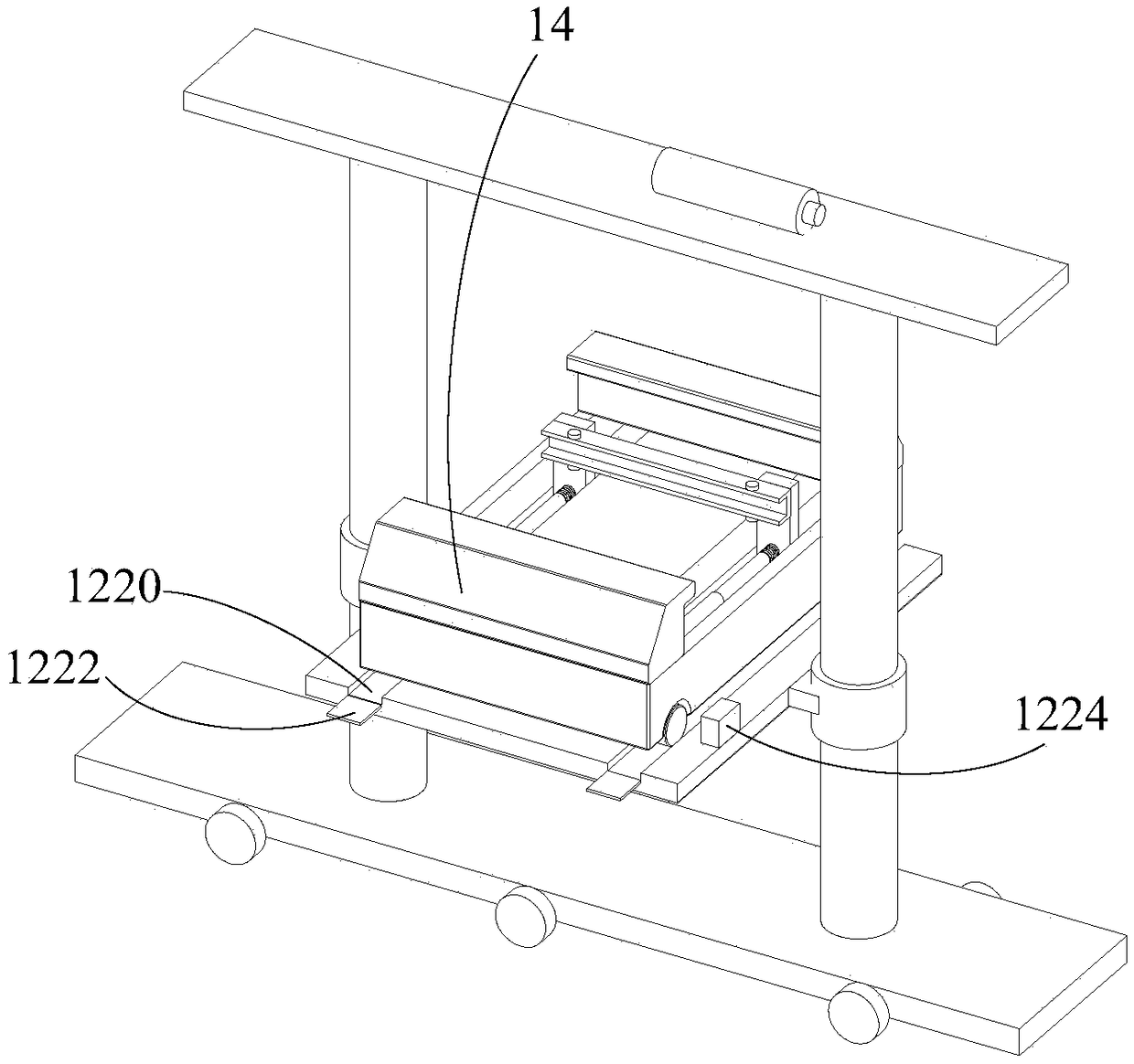

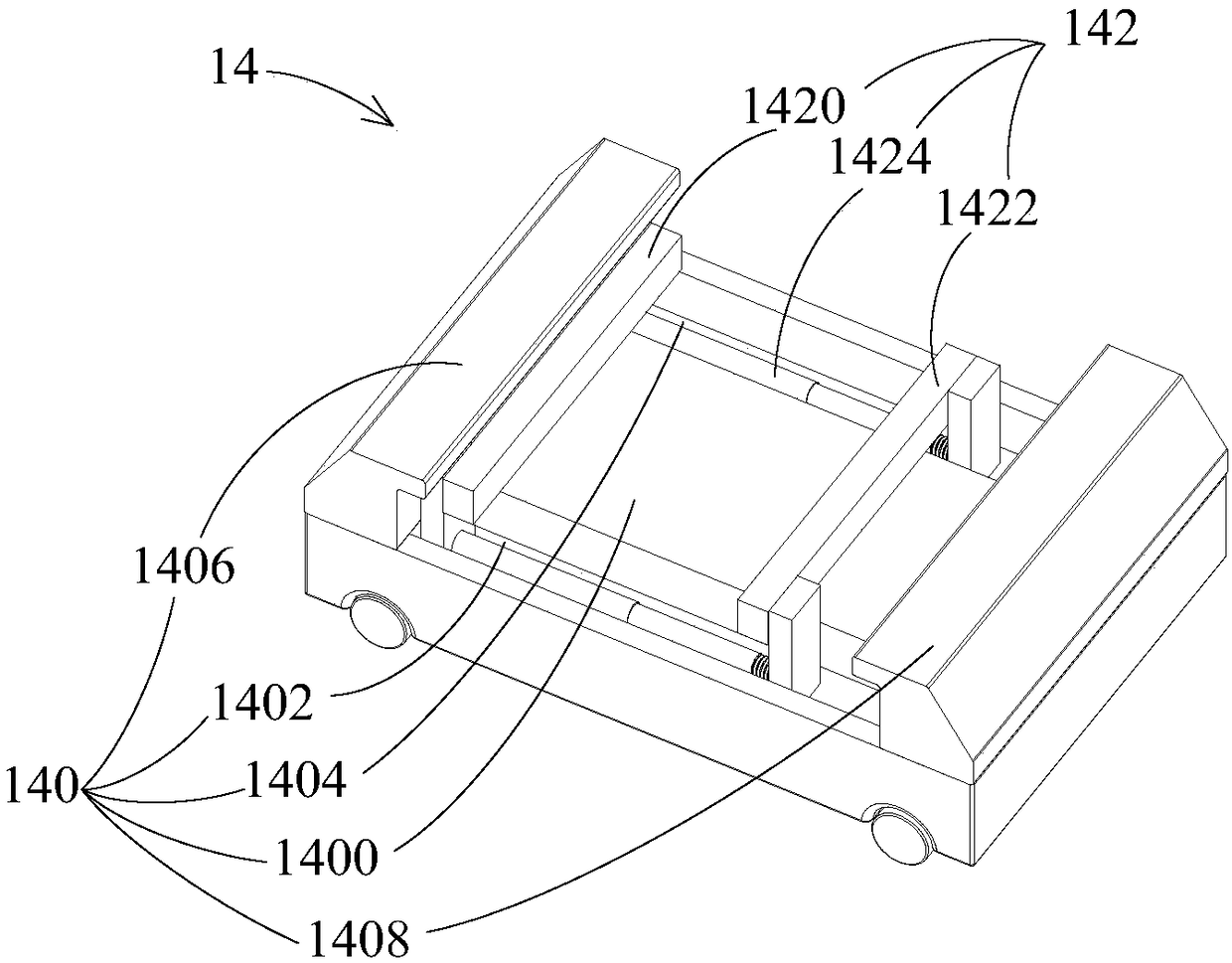

Electric car chassis battery charging and replacing station and battery replacing method using same

The invention provides an electric car chassis battery charging and replacing station. The electric car chassis battery charging and replacing station comprises a car centering device, a battery lifting and replacing device, a track-type laneway stacking machine, a battery storage frame, a battery carrying device and a battery charging device. The battery carrying device is moved among the battery lifting and replacing device, the track-type laneway stacking machine and the battery storage frame by the movement of the track-type laneway stacking machine, so that a battery can be transported without a conveying line, thereby guaranteeing the electric car chassis battery charging and replacing station to have higher space utilization rate. In addition, the invention further provides a battery replacing method.

Owner:SHENZHEN JINGZHI MACHINE

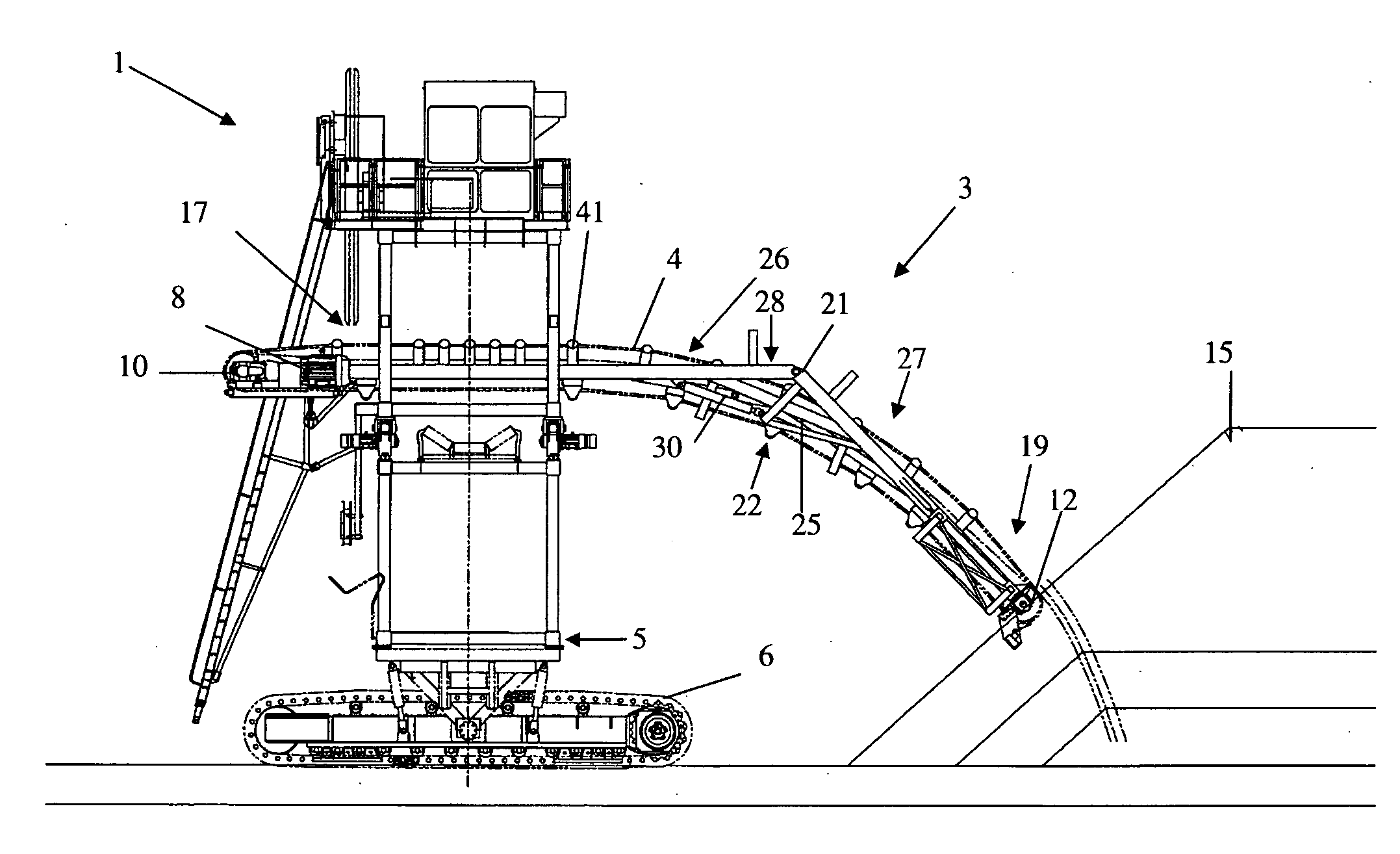

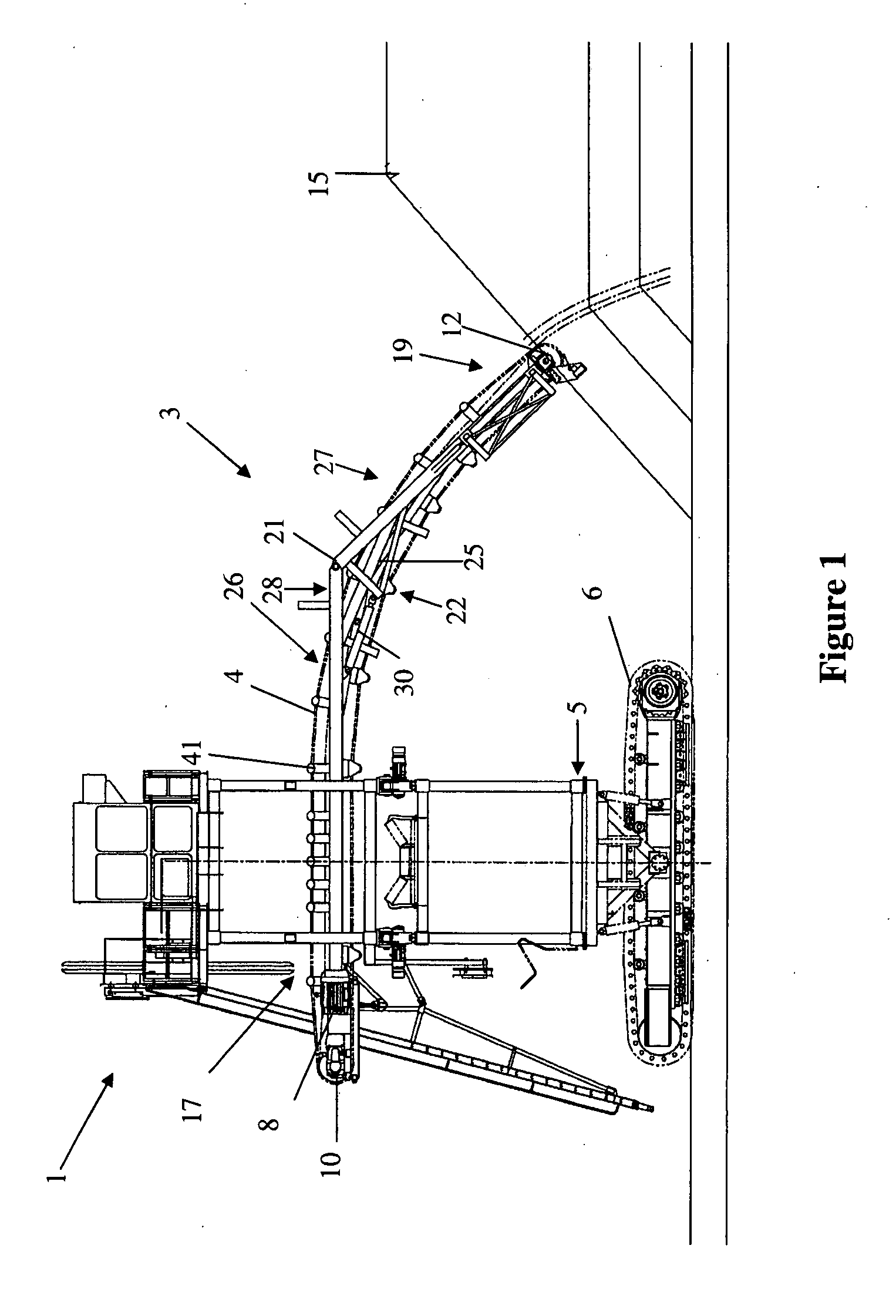

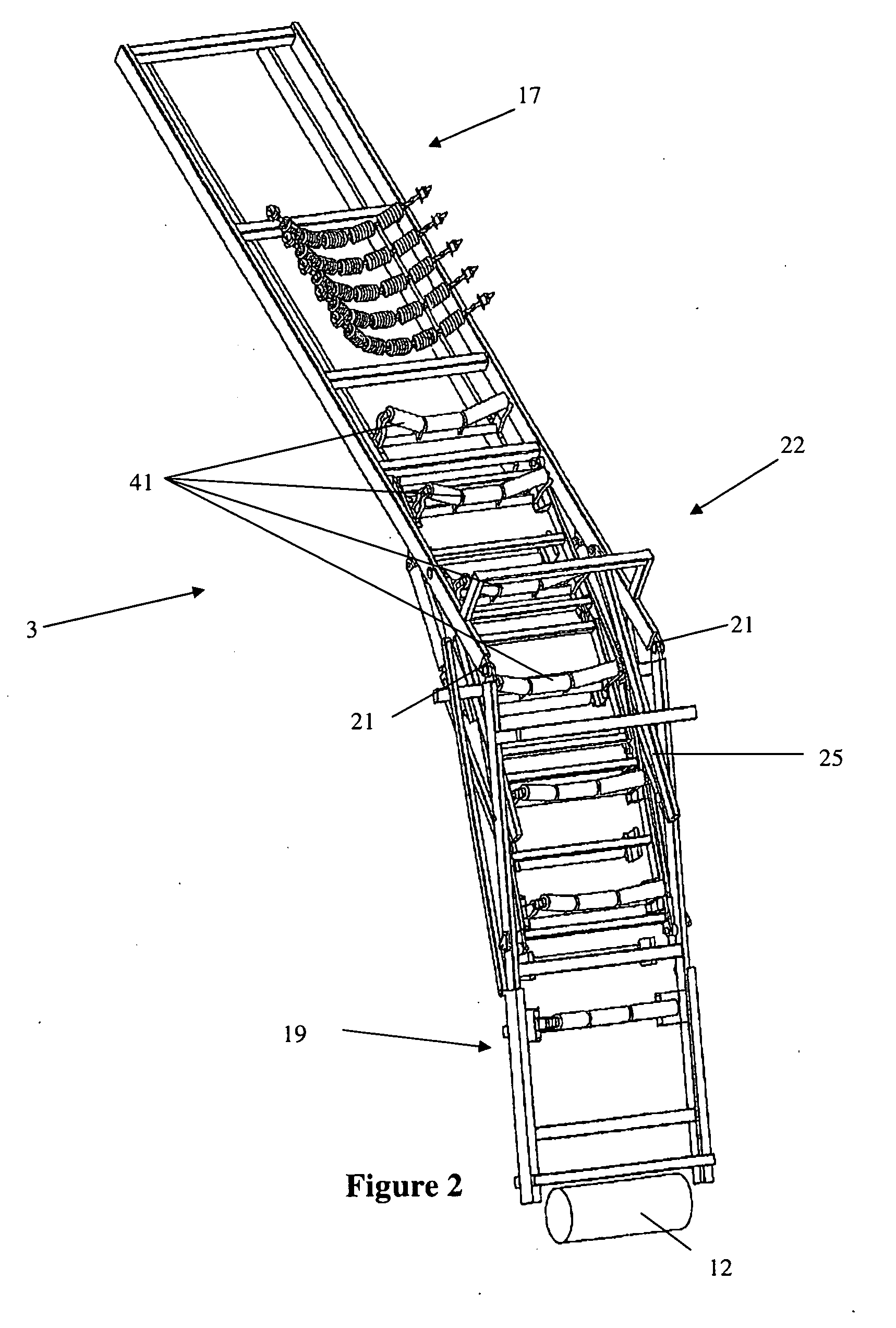

Conveyor Apparatus

A conveyor apparatus includes a tail portion connected to a head portion such that the head portion is moveable relative to the tail portion from a first position to a second position located lower than the first position. It should be appreciated that such movement of the head portion can permit the drop height of the conveyor apparatus to be adjusted. At least one frame portion is moveably positioned between the tail portion and the head portion. A stacker is also provided that includes the conveyor apparatus.

Owner:FLSMIDTH RAHCO +1

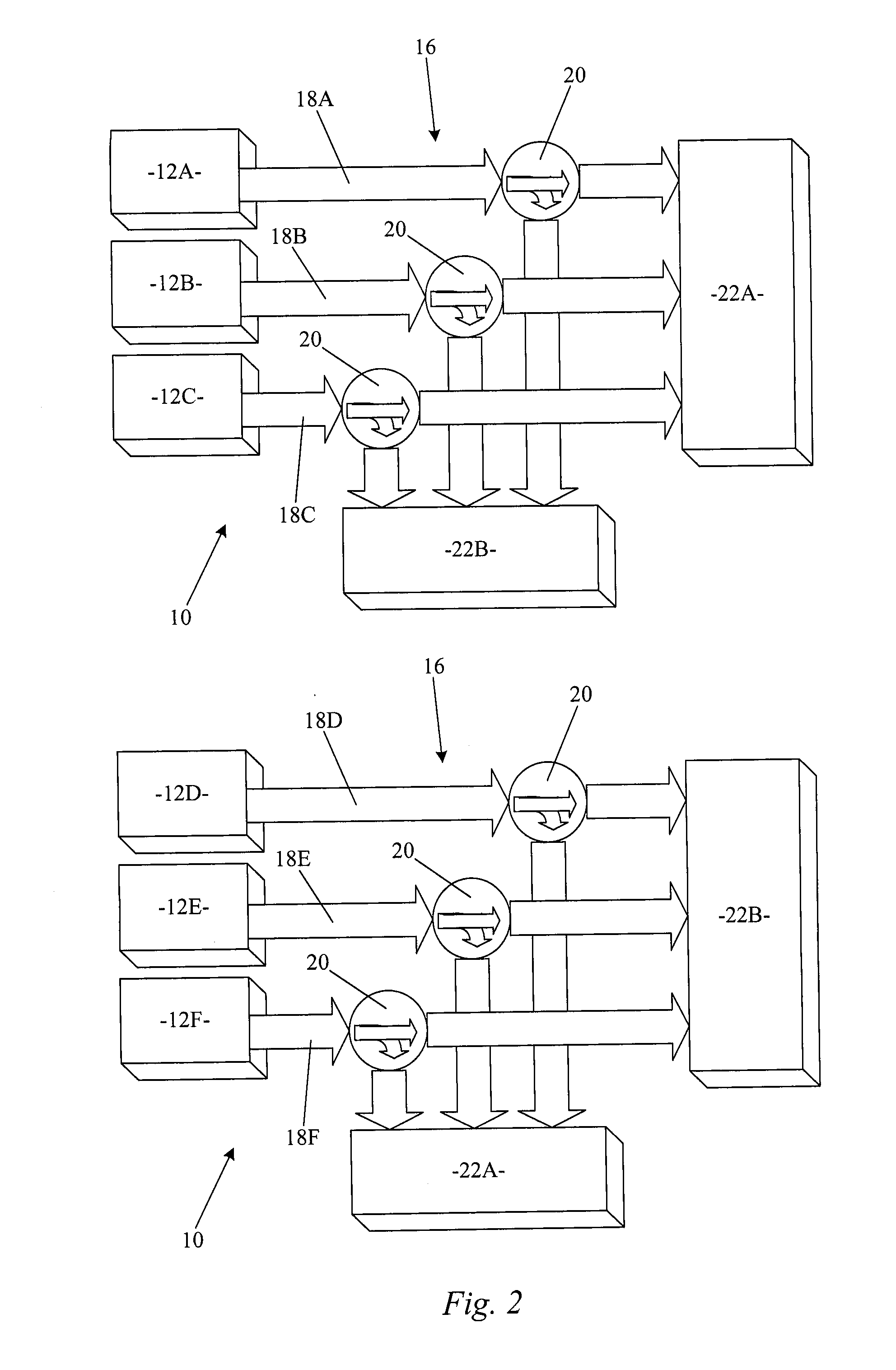

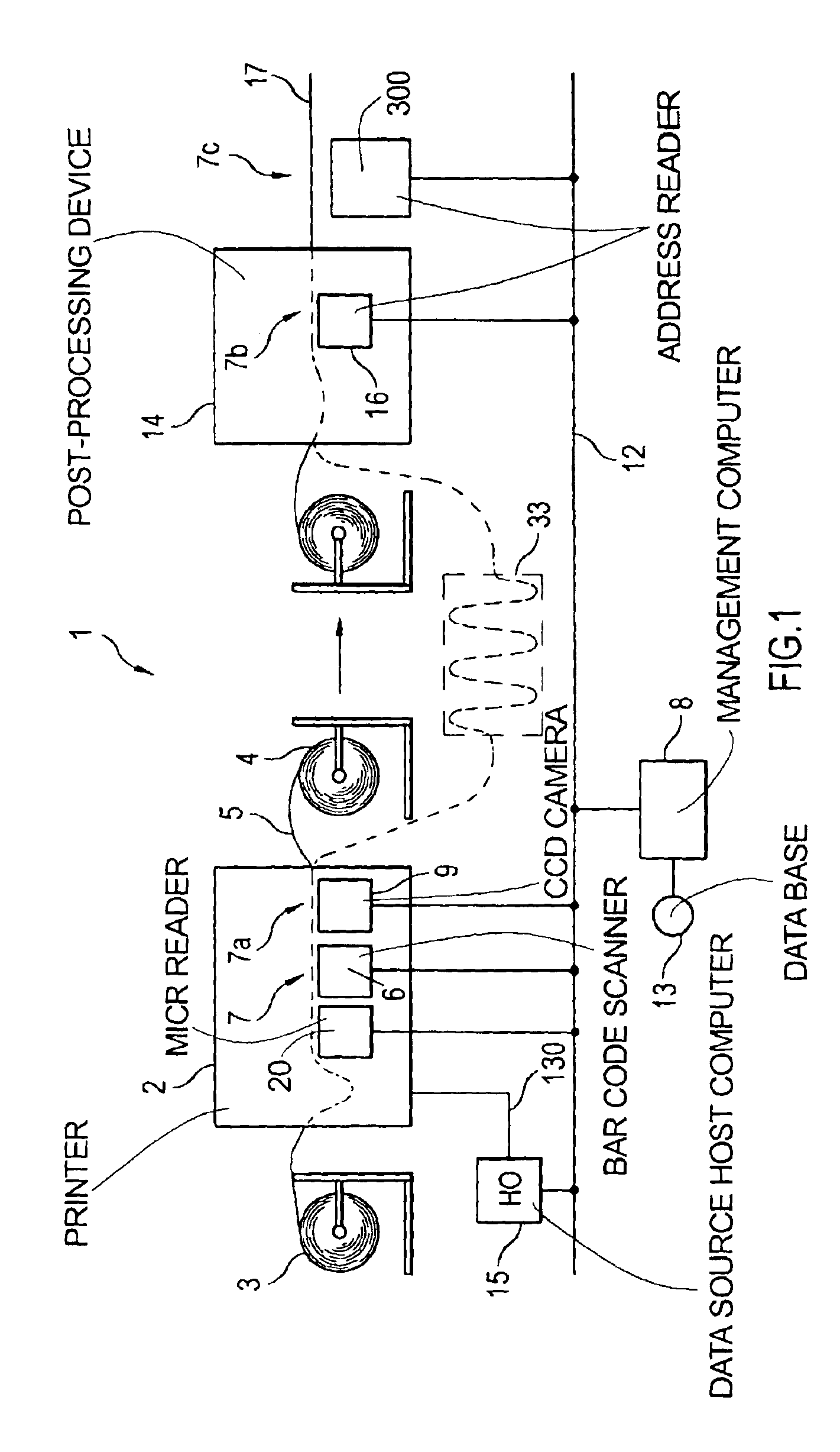

Multi-Machine Mail Sorting System

InactiveUS20100122942A1Slow movementSpeed up the contractionFunction indicatorsCharacter and pattern recognitionMulti machineControl system

A sorting system for postal mail has a plurality of input sections capable of operating in parallel, each including a feeder that takes in mail pieces one at a time and a scanner that scans each mail piece for destination indicia. The system further includes a plurality of stackers each comprising at least one row of pockets in which mail is stacked, and a routing section or switch network effective to route mail in accordance with a sort scheme from any input section to any pocket of a stacker. The routing section uses diverts and merges so that mail can be conveyed to each stacker in accordance with a sort scheme implemented by a control system.

Owner:SIEMENS LOGISTICS LLC

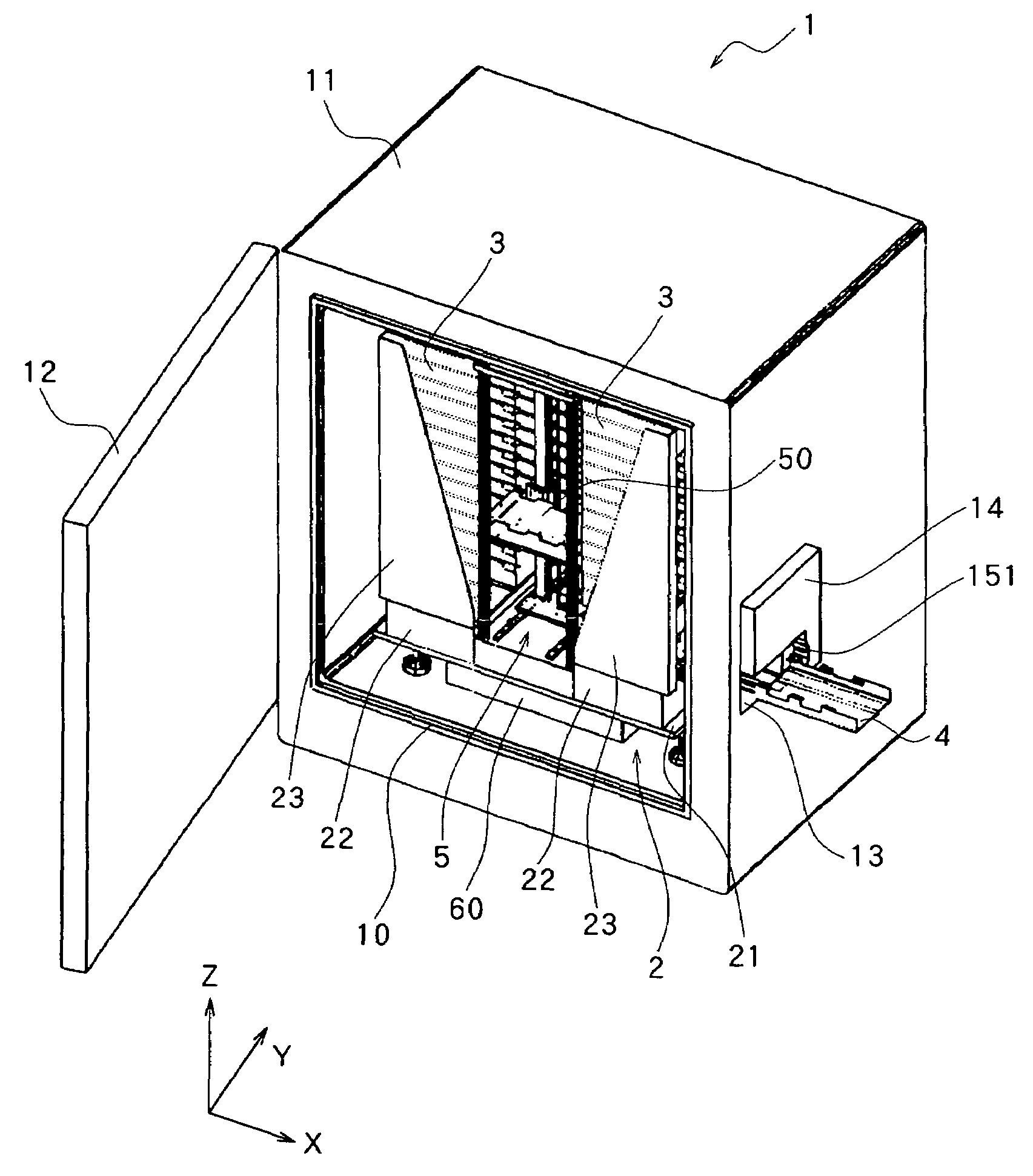

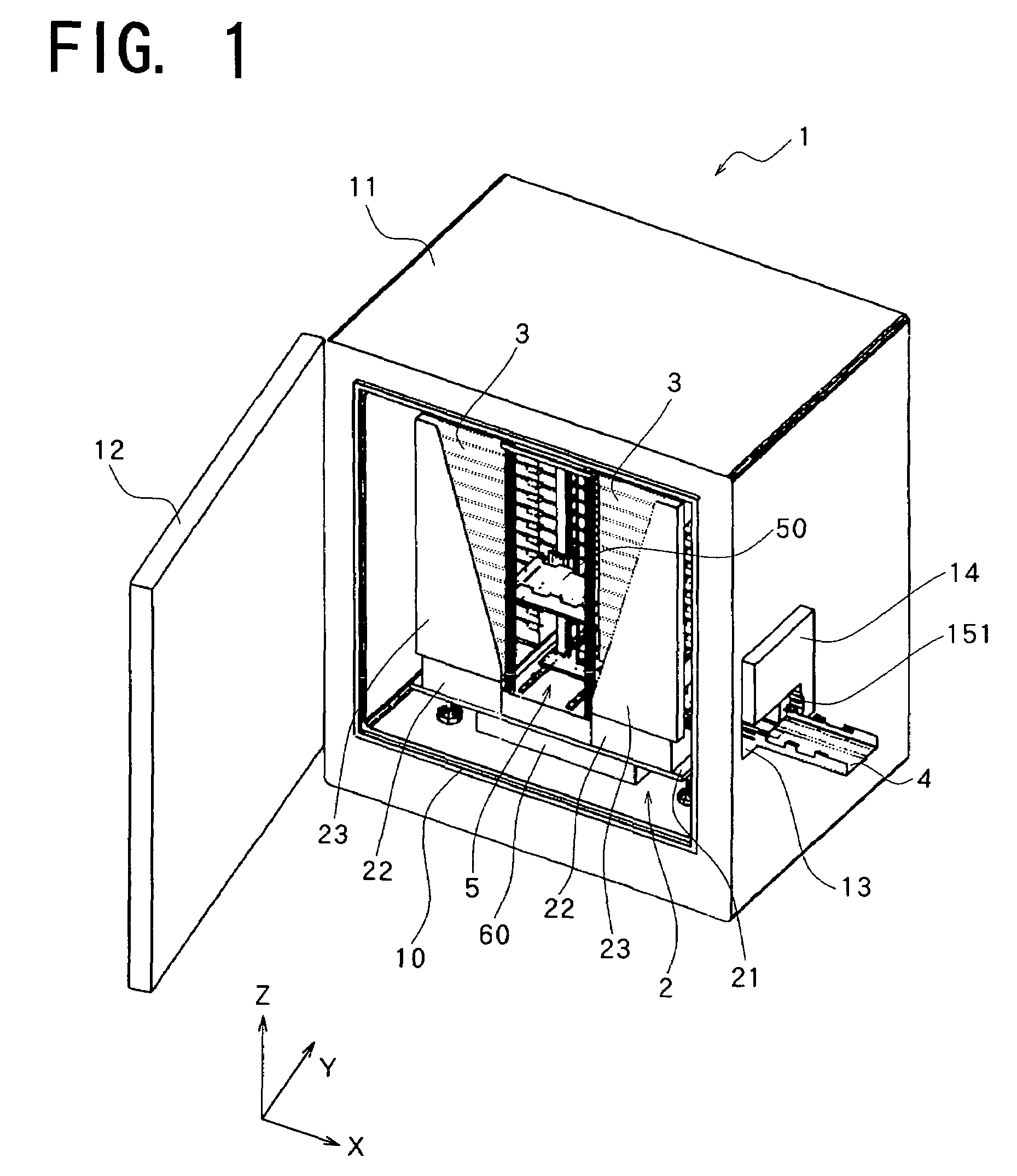

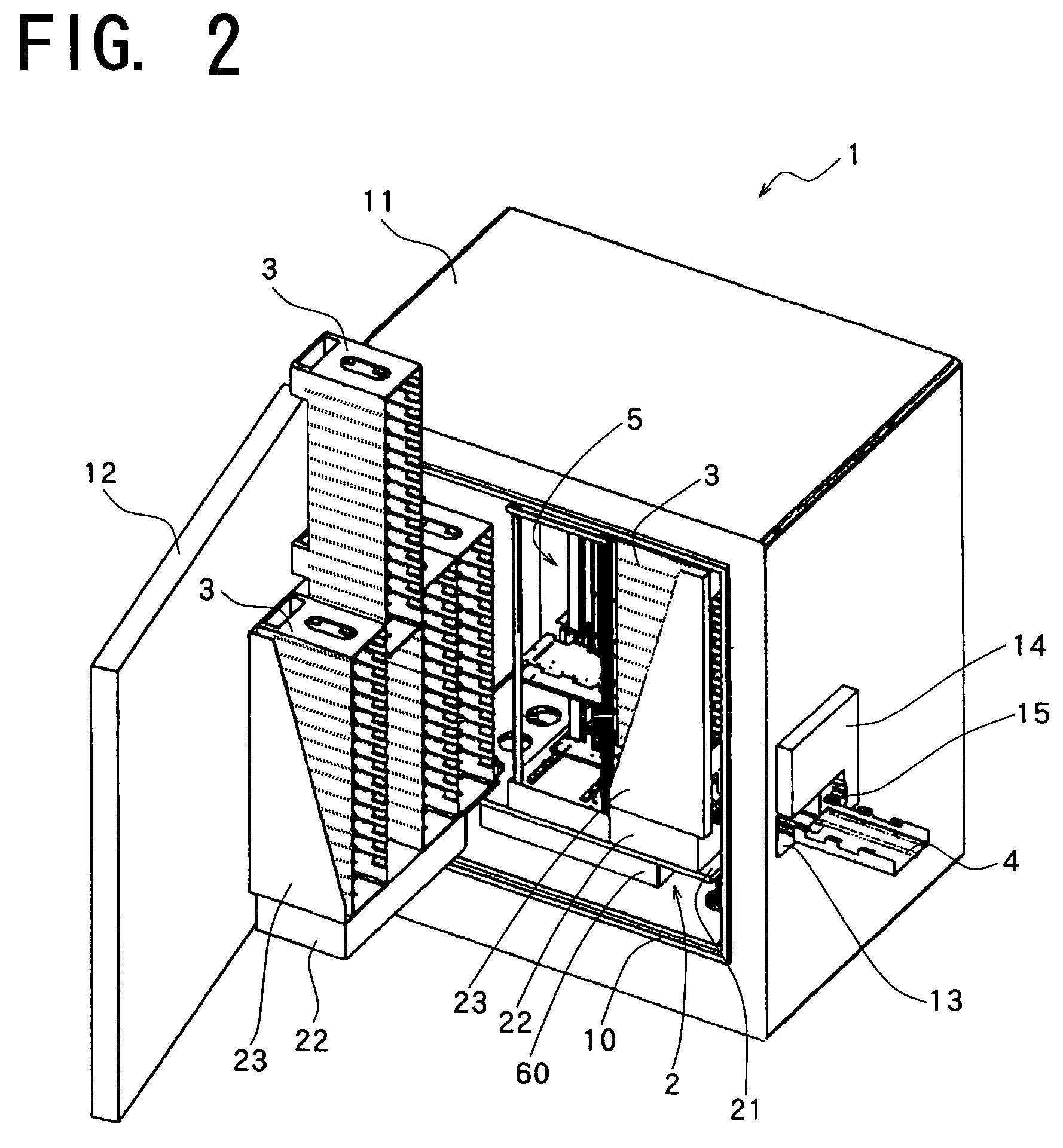

Storage apparatus

ActiveUS7326565B2Easy constructionEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsStackerEngineering

The invention provides an incubator 1 wherein a microplate transport device 5 is disposed inside a chamber 11 centrally thereof. The transport device 5 comprises a transport table 50 for placing a microplate thereon and is capable of driving the table 50 along the directions of three axes, i.e., X-axis, Y-axis and Z-axis. A plurality of stackers 3 are arranged in the direction of Y-axis at each of opposite sides of the transport device 5 along the direction of X-axis. Each of the stackers 3 has a plurality of microplate accommodating portions arranged in the direction of Z-axis. The microplate is movable into or out of the desired accommodating portion by the transport device 5.

Owner:PHC HLDG CORP

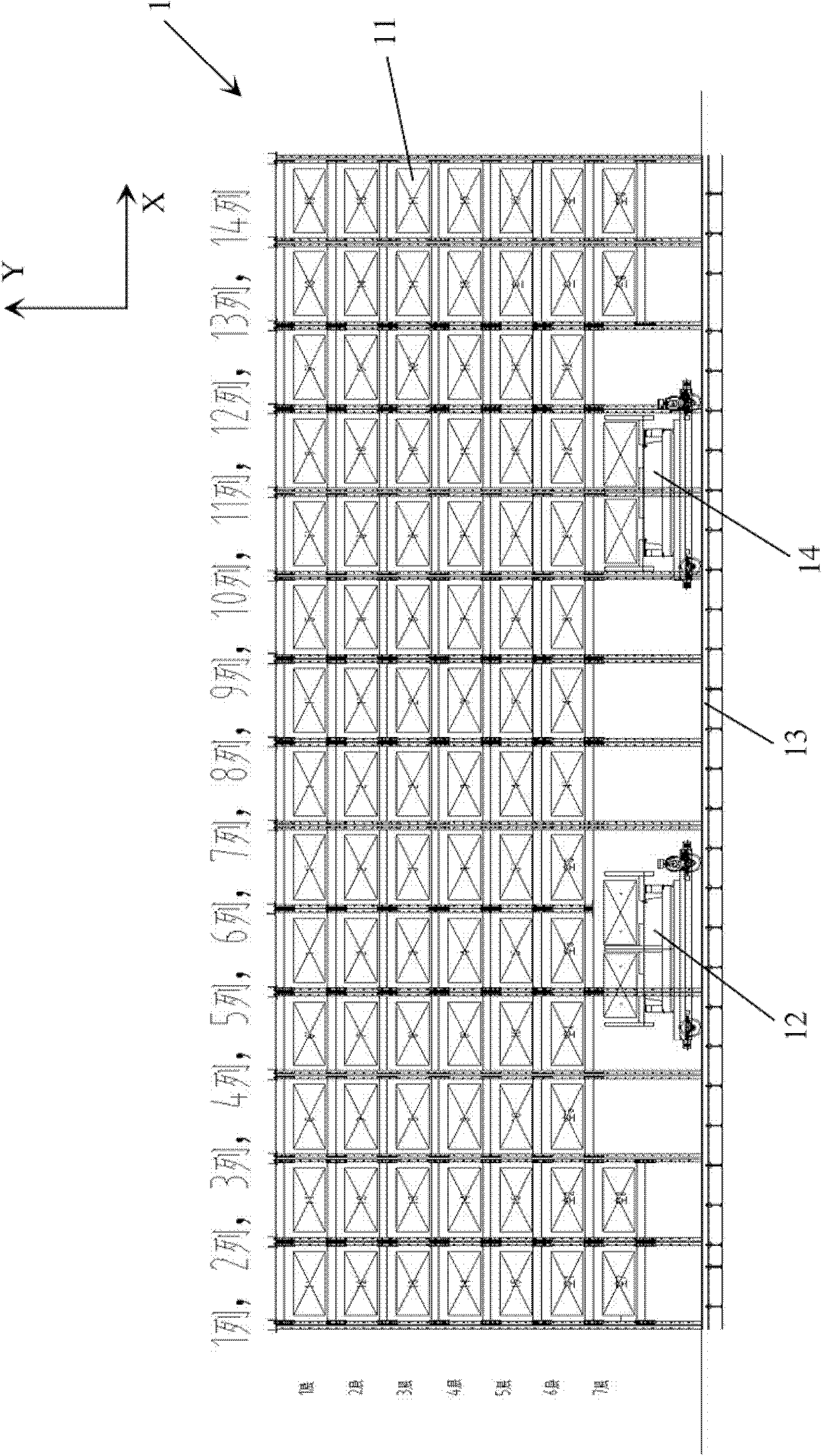

Automatic three-d storehouse frame construction

InactiveCN101407271AReduce workloadReduce work intensityStorage devicesQuick FreezeAutomatic transmission

The invention discloses a frame construction of an automatic stereowarehouse, a piler is positioned on a guide rail and used for loading and unloading and transporting goods; a plurality of aisle racks are positioned under the guide rail and used for storing the goods loaded by the piler; a buffering shelf is positioned between the in-out window of the warehouse and the aisle racks and used for the temporary storage of the incoming and outgoing goods; an automatic incoming and outgoing mechanism is positioned between the in-out window of the warehouse and the buffering shelf and used for incoming and outgoing the goods; and a computer is in communication connection with the servo-control system and the automatic incoming and outgoing mechanism of the piler and used for controlling and managing the goods of the warehouse. The piler which takes a crown block and the linear guide rail as the basis is matched with the buffering technique and the automatic transmission mechanism to realize the automatic stereowarehouse which can adapt to deep cooling environment. The frame construction has the advantages of high degree of automation, low energy consumption and low cost, is applicable to middle-size and small-size deep cooling quick-freeze warehouses, and has positive realistic meaning and social and economic profits for saving energy, improving the working conditions of workers and guaranteeing food security.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

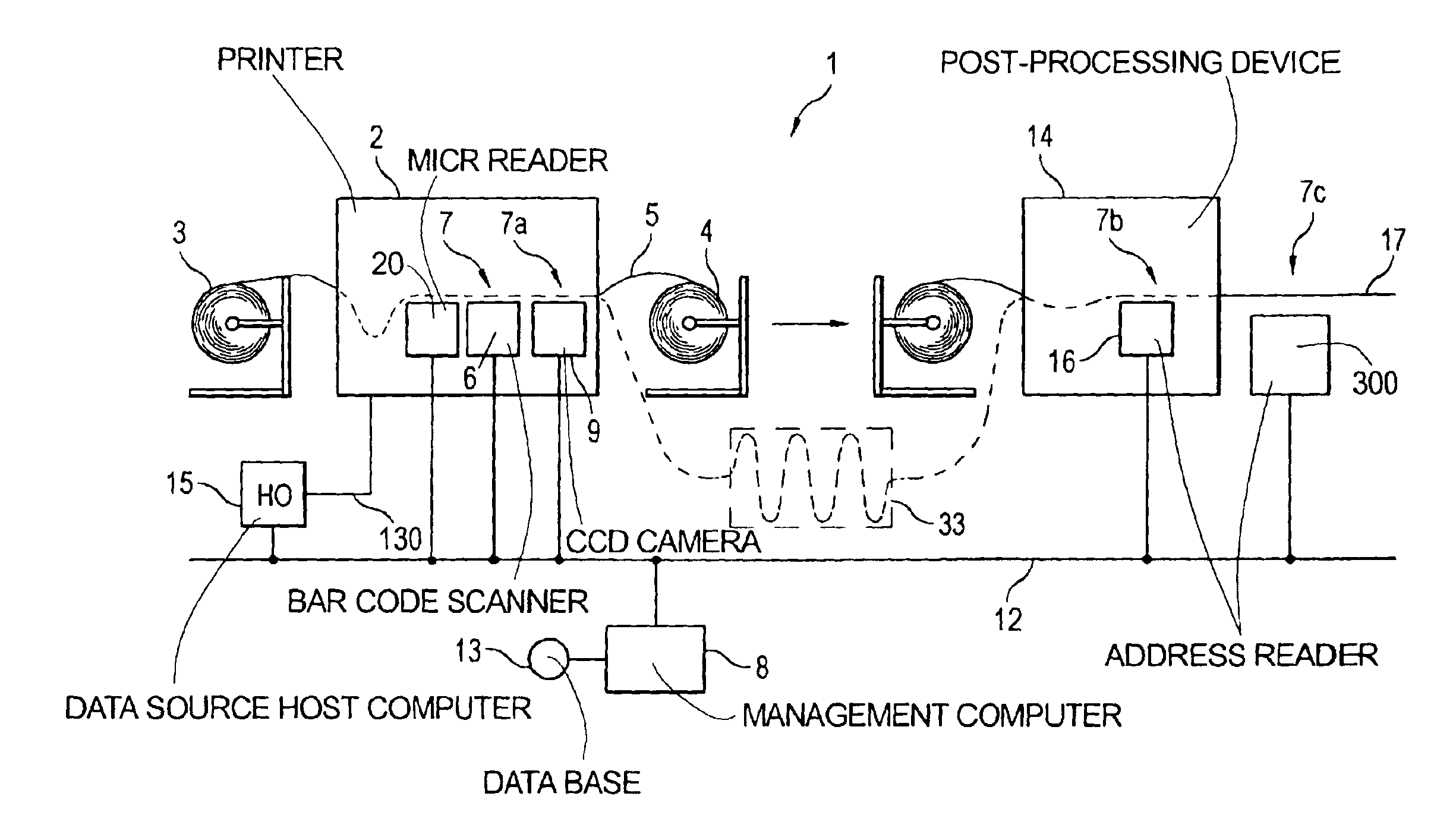

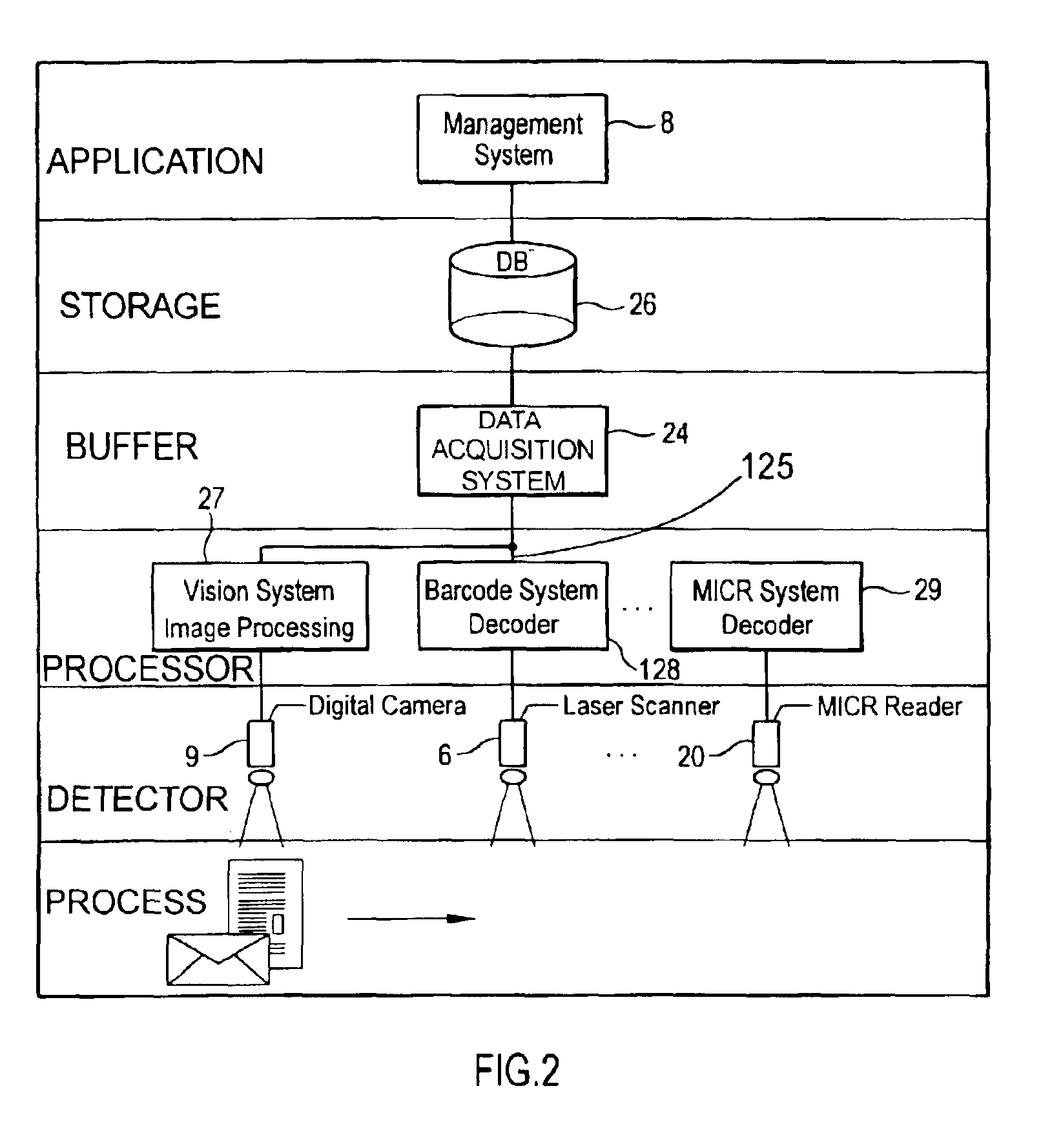

Document verification and tracking system for printed material

InactiveUSRE38957E1Co-operative working arrangementsCharacter and pattern recognitionOptical testBarcode

In a multifunctional printing method and printing system, printed material is checked, verified and tracked. For that purpose different test equipments are located in-line with a printing line. Magnetic information being printed by a printing station onto the recording carrier using magnetic ink character readable toner may be in-line tested by a magnetic test equipment, which reads information from the magnetic recording zone on the carrier. Optical information may be tested by an in-line mounted optical test equipment, respectively. Further in-line test equipment is proposed such as a leaser bar code scanner and an address reader. The printing line may have additional devices such as print preprocessing unwinders or print postprocessing stackers, folders or cutters.

Owner:OCE PRINTING SYST

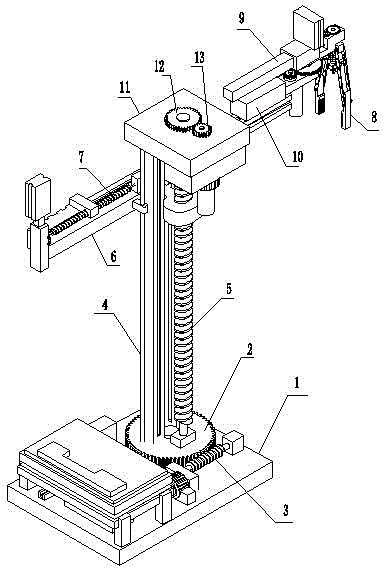

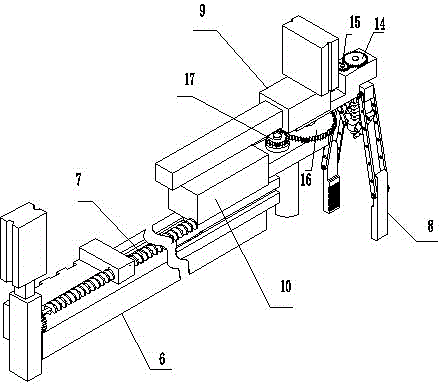

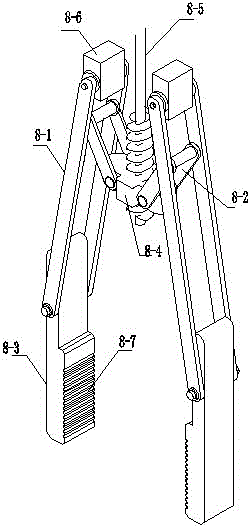

Full-automatic bidirectional stacker robot

InactiveCN104786214ASave palletizing spaceStrong packing effectProgramme-controlled manipulatorGripping headsGear wheelEngineering

The invention relates to a full-automatic bidirectional stacker robot which comprises a base. The base is rotatably connected with a gear disc, a propelling screw rod which is meshed with the gear disc and can drive the gear disc to rotate is arranged at the position, on one side of the gear disc, of the base, a lifting lead screw and a stand column with a lifting sliding rail are vertically arranged on the gear disc, the lifting lead screw is in thread fit with a telescopic cross arm, a horizontal movement sliding rail and a horizontal movement lead screw are arranged on the telescopic cross arm in parallel, the horizontal movement lead screw is in thread fit with a sliding block, the front end of the sliding block is connected with a supporting plate, the supporting plate is rotatably connected with a driven gear I and a driving gear I, the upper portion of the driven gear I is fixedly connected with a rotary arm, a holder is arranged at the front end of the rotary arm, the screw rod, the lifting lead screw, the horizontal movement lead screw and the driving gear I are connected with a drive motor, and the drive motor is in signal connection with a controller. The full-automatic bidirectional stacker robot has the advantages of being simple in structure and free of manual assistance, improving production efficiency and lowering production cost.

Owner:SHANDONG JIAOTONG UNIV

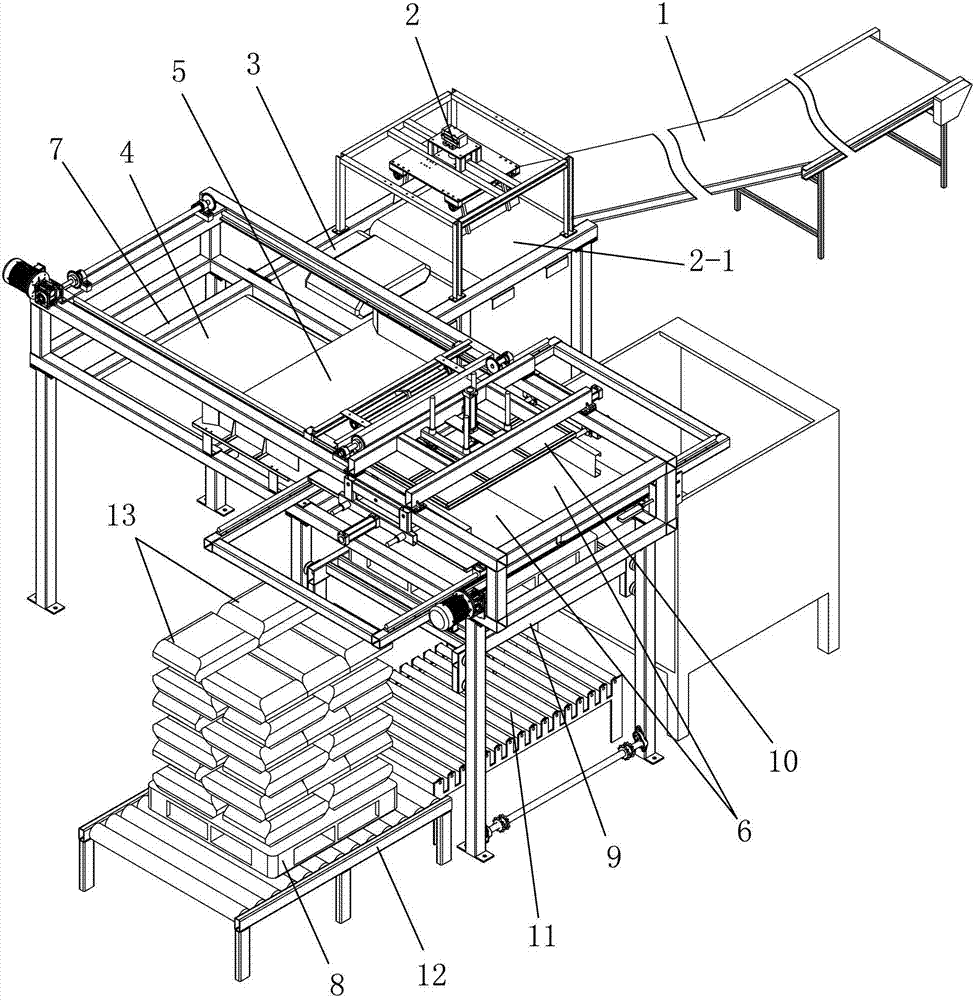

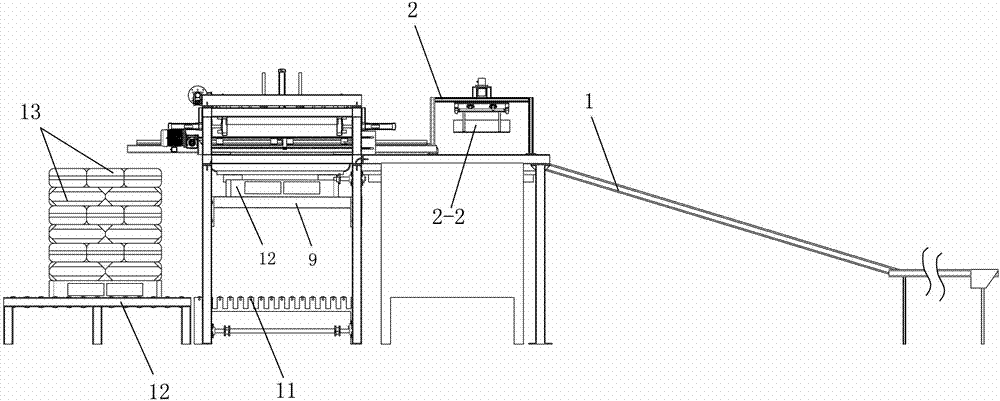

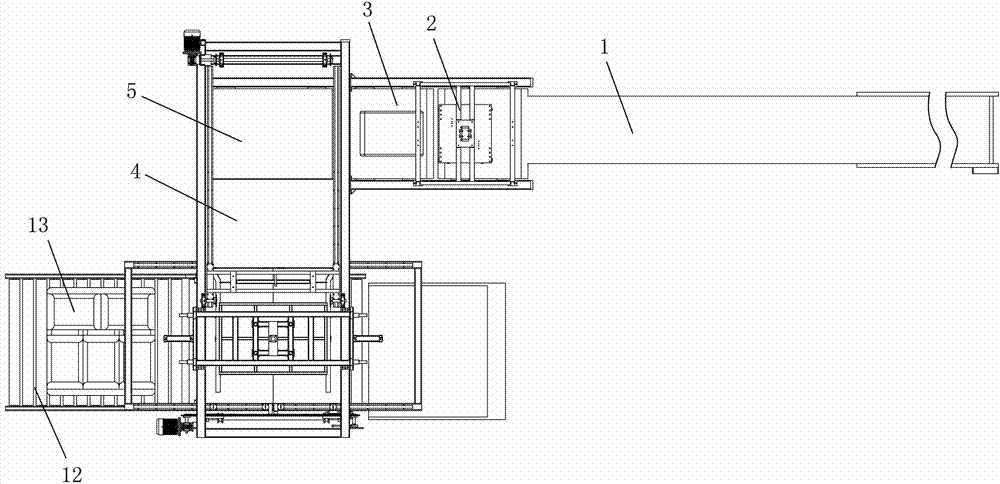

Automatic stacker crane

InactiveCN102774660AHigh degree of automationLow costControl devices for conveyorsStacking articlesEngineeringConveyor belt

The invention relates to an automatic stacker crane which is high in automation degree and stacking efficiency. The stacker crane comprises a first conveyor belt, a pocket steering mechanism, a middle conveyor belt, a transition conveyor belt, a pair of sliding blanking plates, a pushing plate, a lifting platform, a driving roller assembly and a downhill roller table, wherein the pocket steering mechanism is arranged at the tail end of the first conveyor belt and is used for rotating pockets horizontally at an angle of 90 degrees and continuing to convey pockets, the middle conveyor belt is arranged at the rear end of the pocket steering mechanism, the transition conveyor belt is arranged at the rear end of the middle conveyor belt, one of the pair of sliding blanking plates is arranged on a middle platform which is arranged on the right side of the transition conveyor belt, the other one of the pair of sliding blanking plates is arranged on the right side of the middle platform, the pushing plate is arranged on the left side of the transition conveyor belt and is used for pushing pockets on the transition conveyor belt to the middle platform and the pair of sliding blanking plates in succession, the lifting platform is arranged on the lower portion of the pair of sliding blanking plates and is used for arranging a tray, the driving roller assembly is arranged on the lower portion of the lifting platform and the downhill roller table is arranged on one side of the driving roller assembly. By the aid of the stacker crane, packages are grouped in accordance with a preset mode, and the pockets are stacked on the tray in layers, so that the production and conveying capabilities are improved.

Owner:JIANGSU ZHONGKE YOUTE ROBOT TECH

Container transport system and measurement container

ActiveUS20080156069A1Low costSave spaceDetection of fluid at leakage pointTesting/calibration apparatusTransport systemProcess engineering

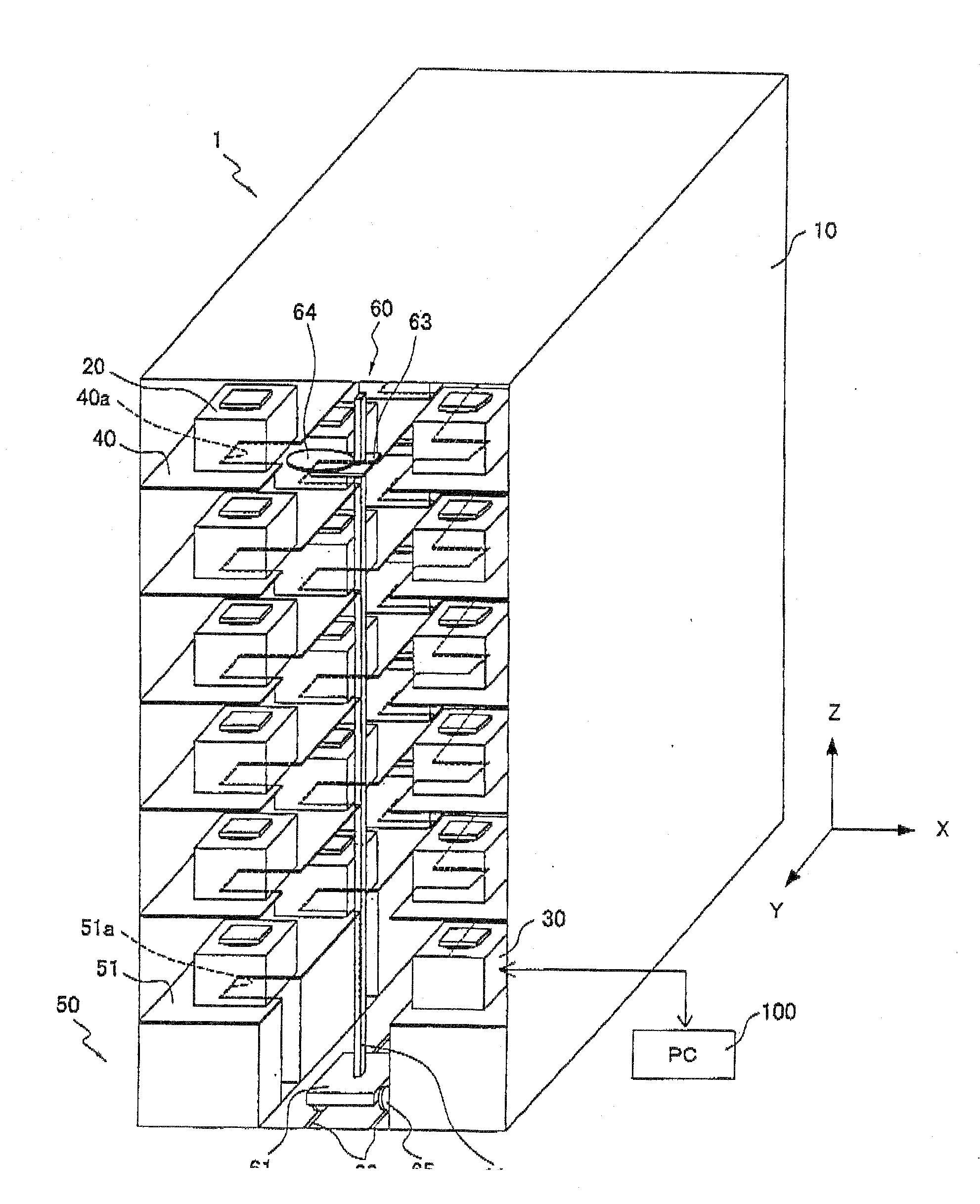

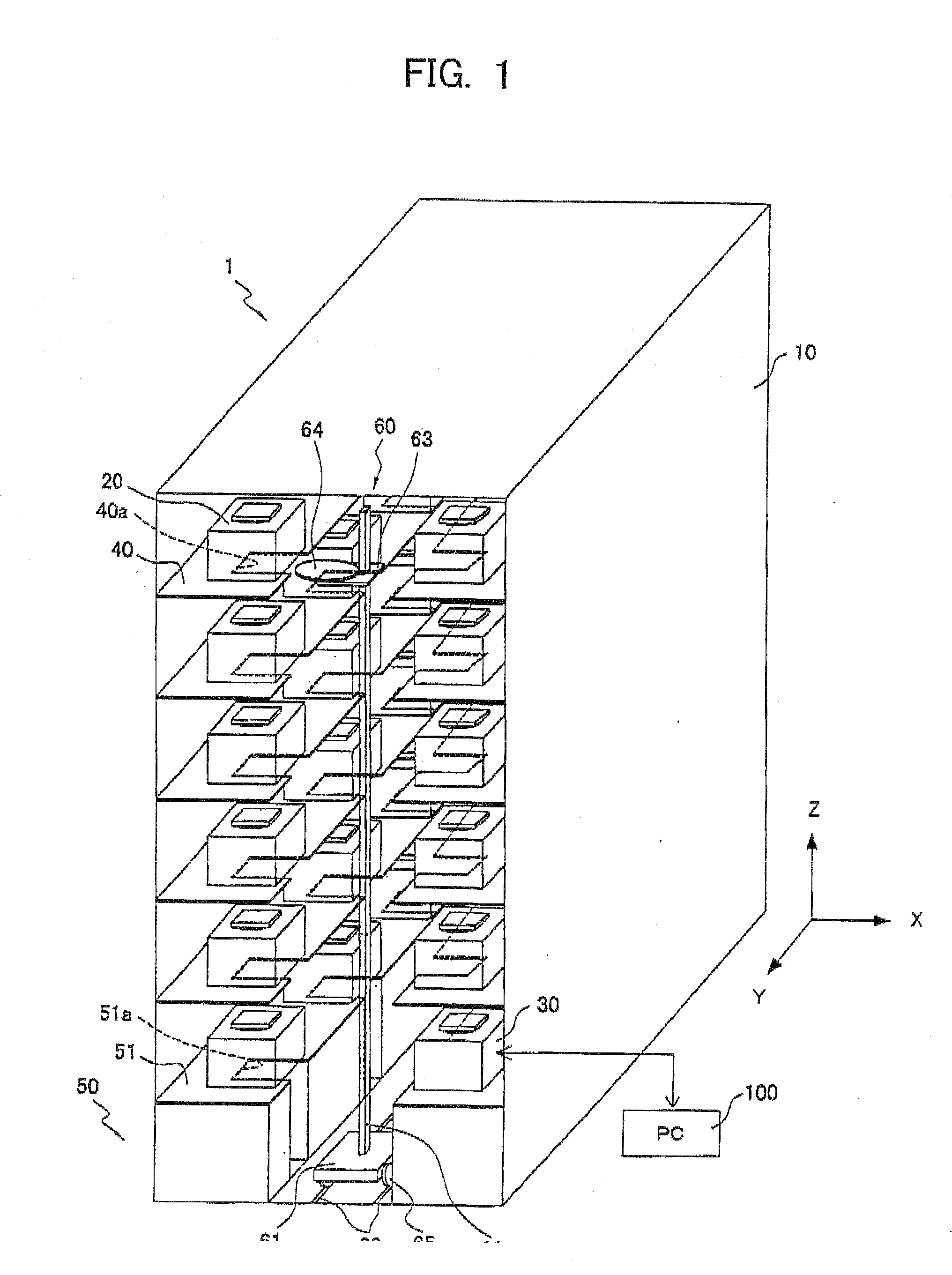

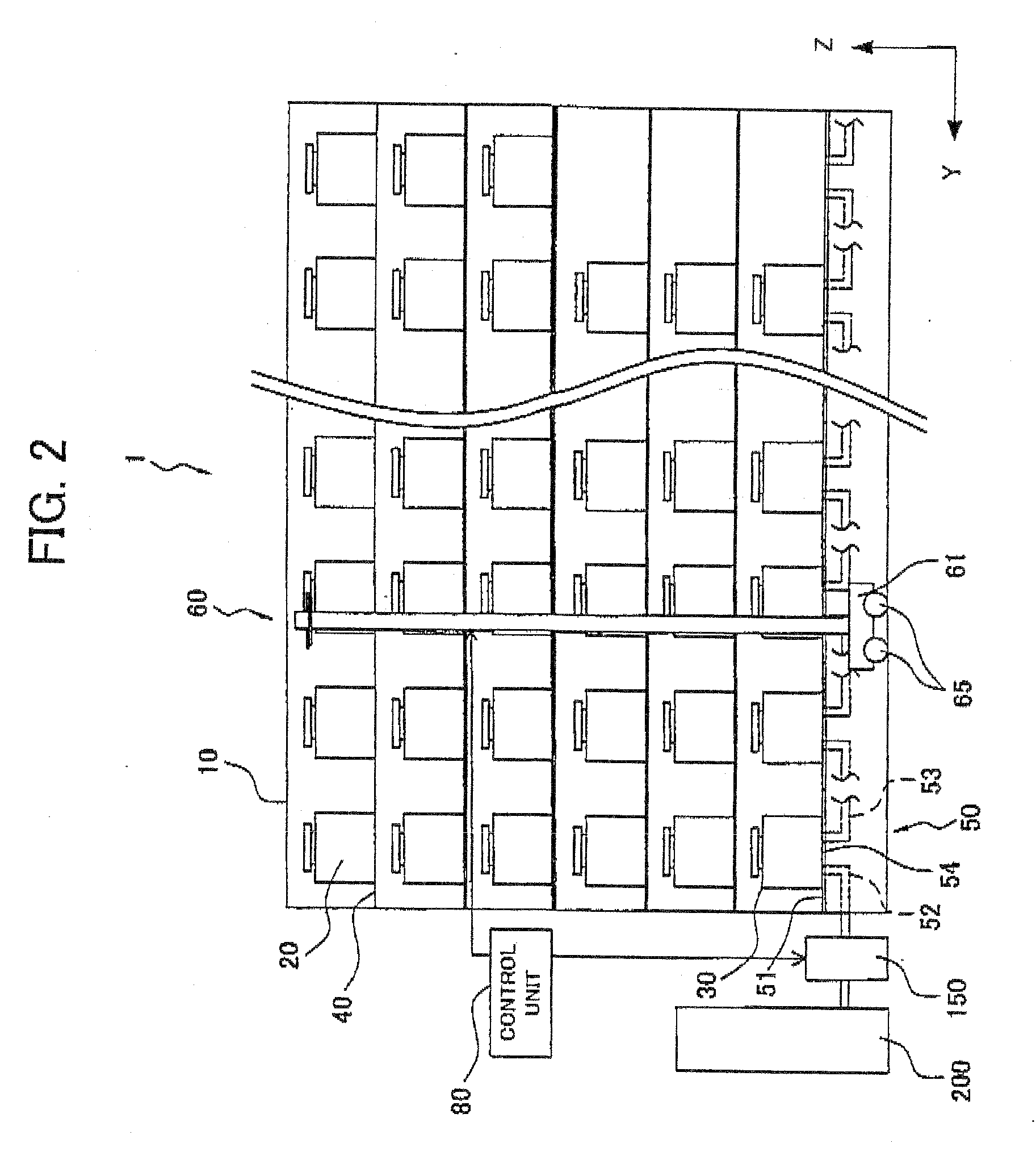

A stocker 1 includes a storage FOUP 20, plural purge units 50, a measurement FOUP 30 and a stacker crane 60. The storage FOUP 20 stores a semiconductor wafer inside. The measurement FOUP 30 includes a flow meter inside. The purge unit 50 includes a purge shelf 51 having plural purge tables 54 for placing the storage FOUP 20, and a nitrogen gas is supplied into the storage FOUP 20 placed on the purge table 54. The stacker crane 60 transports the storage container 20 onto the purge table 54, and the measurement FOUP 30 is transported between the plural purge tables 54.

Owner:MURATA MASCH LTD

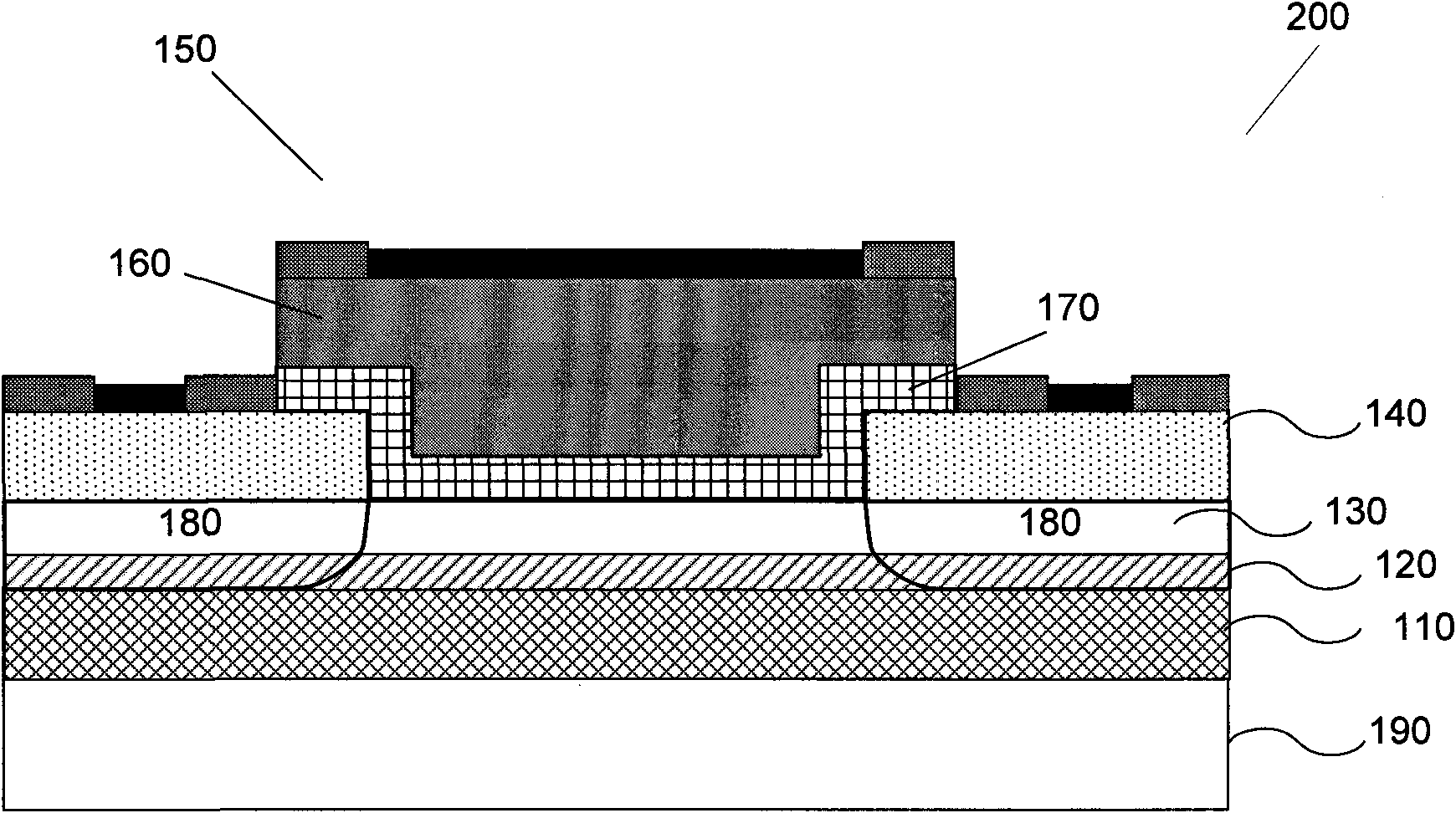

Semiconductor device structure and forming method thereof

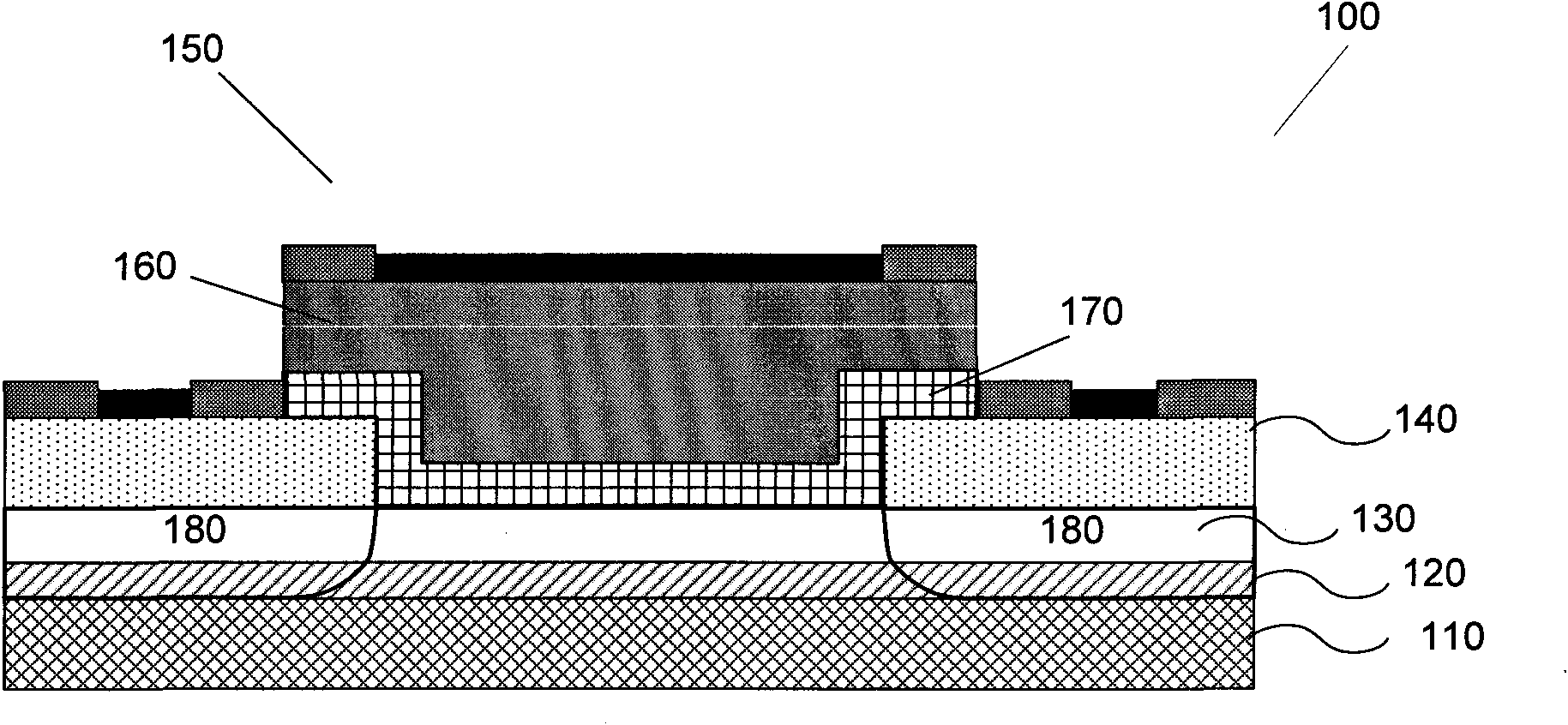

ActiveCN101834206AHigh speedSmall feature sizeSemiconductor/solid-state device manufacturingSemiconductor devicesCarbon layerMetal silicide

The invention provides a semiconductor device structure and a forming method thereof. The semiconductor device structure comprises a substrate layer, a silicon carbon layer, a carbon base material layer, a gate stacker, a source, a drain and a metal silicide layer, wherein the silicon carbon layer is formed on the substrate layer; the carbon base material layer is formed on the silicon carbon layer; the gate stacker is formed on the carbon base material layer; the source and the drain are formed in the carbon base material layer; and the metal silicide layer is formed on the source and the drain. In the invention, the carbon base material layer, such as graphene, is used as a channel layer, and therefore, the speed of the device is greatly increased.

Owner:TSINGHUA UNIV

Palletless loading structure for storage system

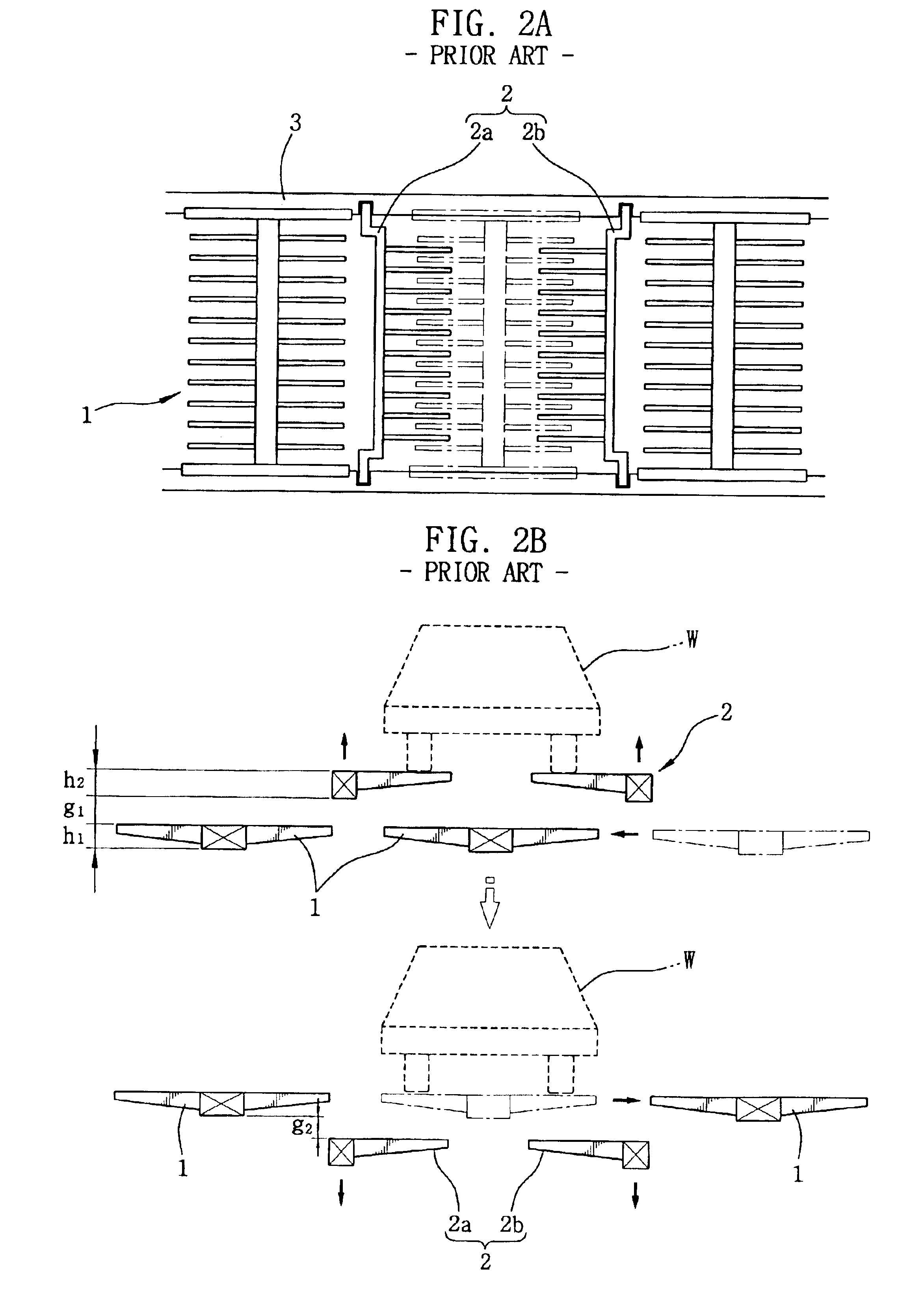

InactiveUS6948899B2Quickly and safely taken intoEasily and simply and safely storeStorage devicesLoading/unloadingEngineeringStacker

The invention provides a palletless loading structure for a storage system which comprises a plurality of storage forks including a first support beam and a plurality of storage fork bars mounted in regular interval to cross the first support beam at a right angle; a stacker crane and a including a plurality of transporting fork bars horizontally arranged in a regular interval to be alternatively positioned between the storage fork bars and a third support beam supporting the lower middle portion of the transporting fork bar, wherein any one height of the storage fork bar transporting fork bar is set to be relatively higher than the other one, and the fork bar of a relatively lower height includes a projecting tap mounted on the lower portion thereof, the projecting tap being mounted on the supporting beam.

Owner:LEE WAN YOUNG

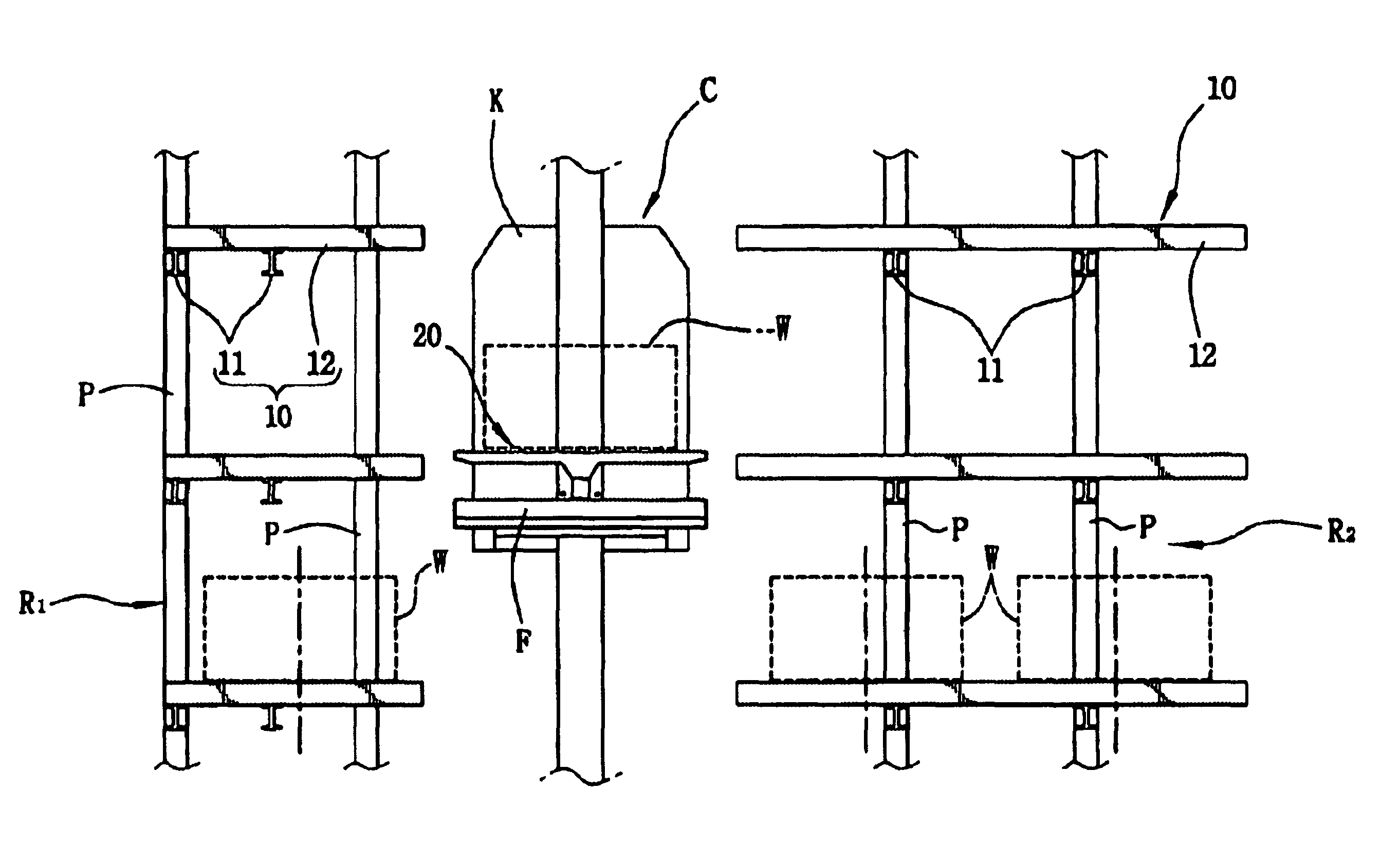

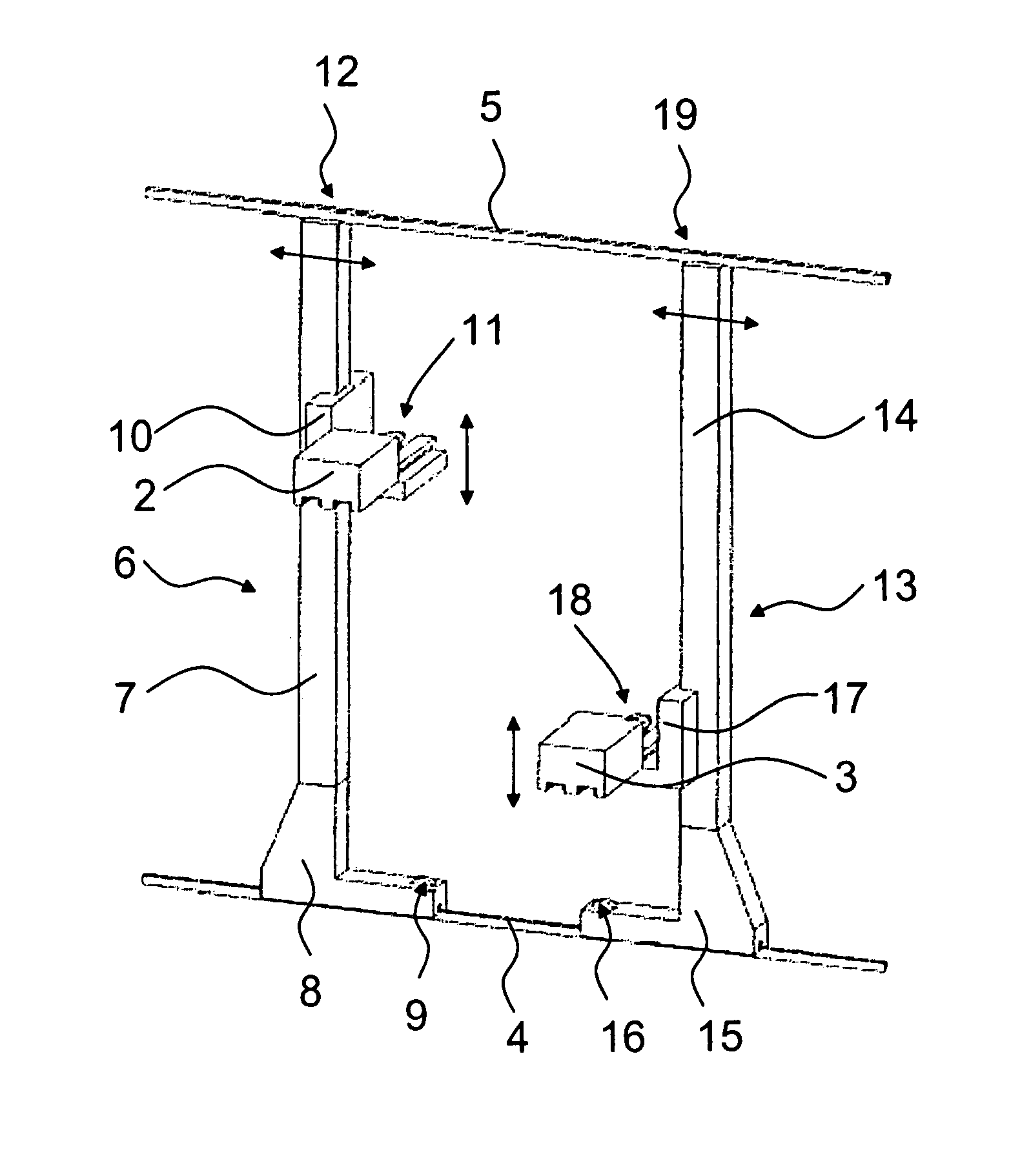

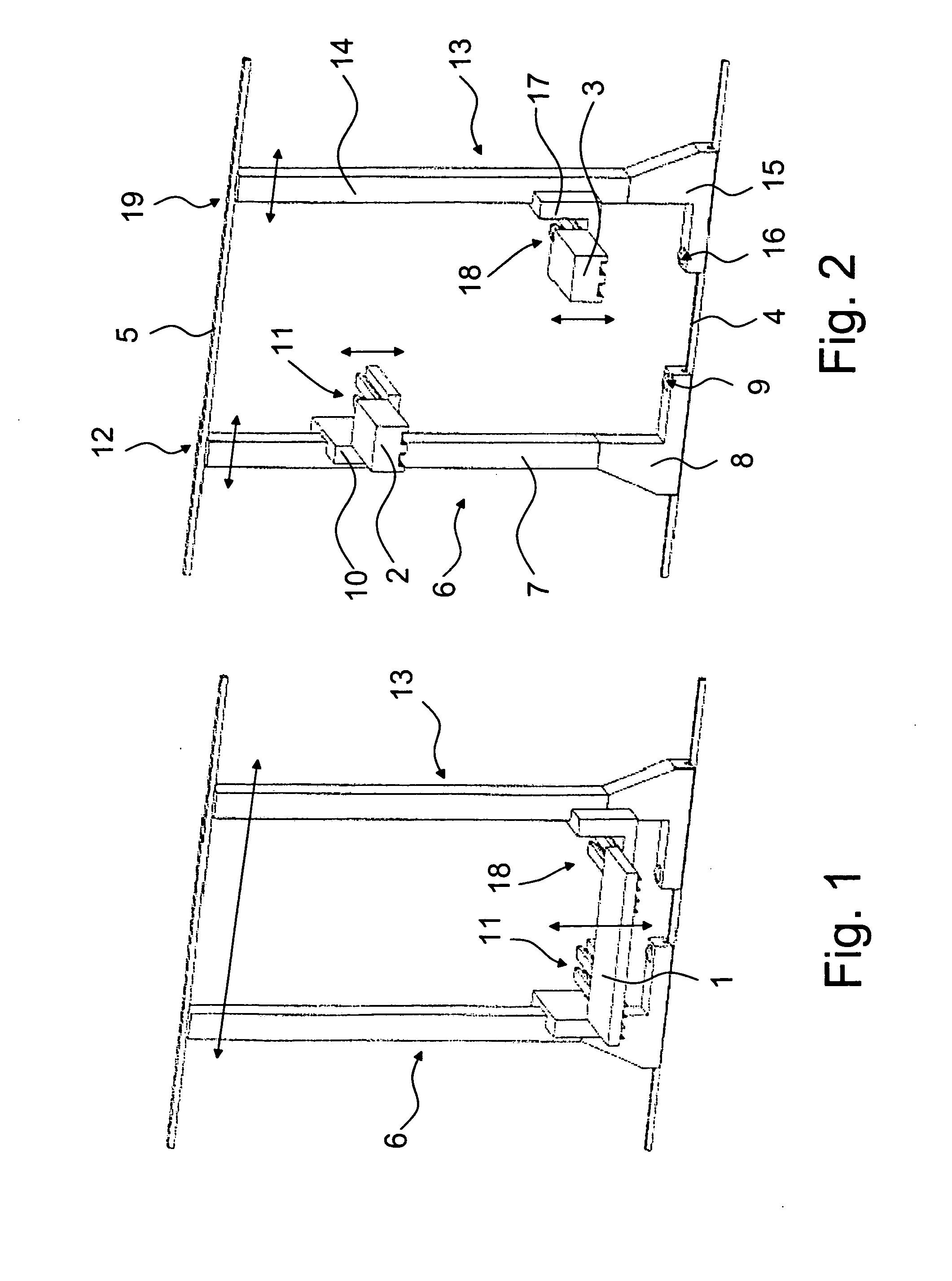

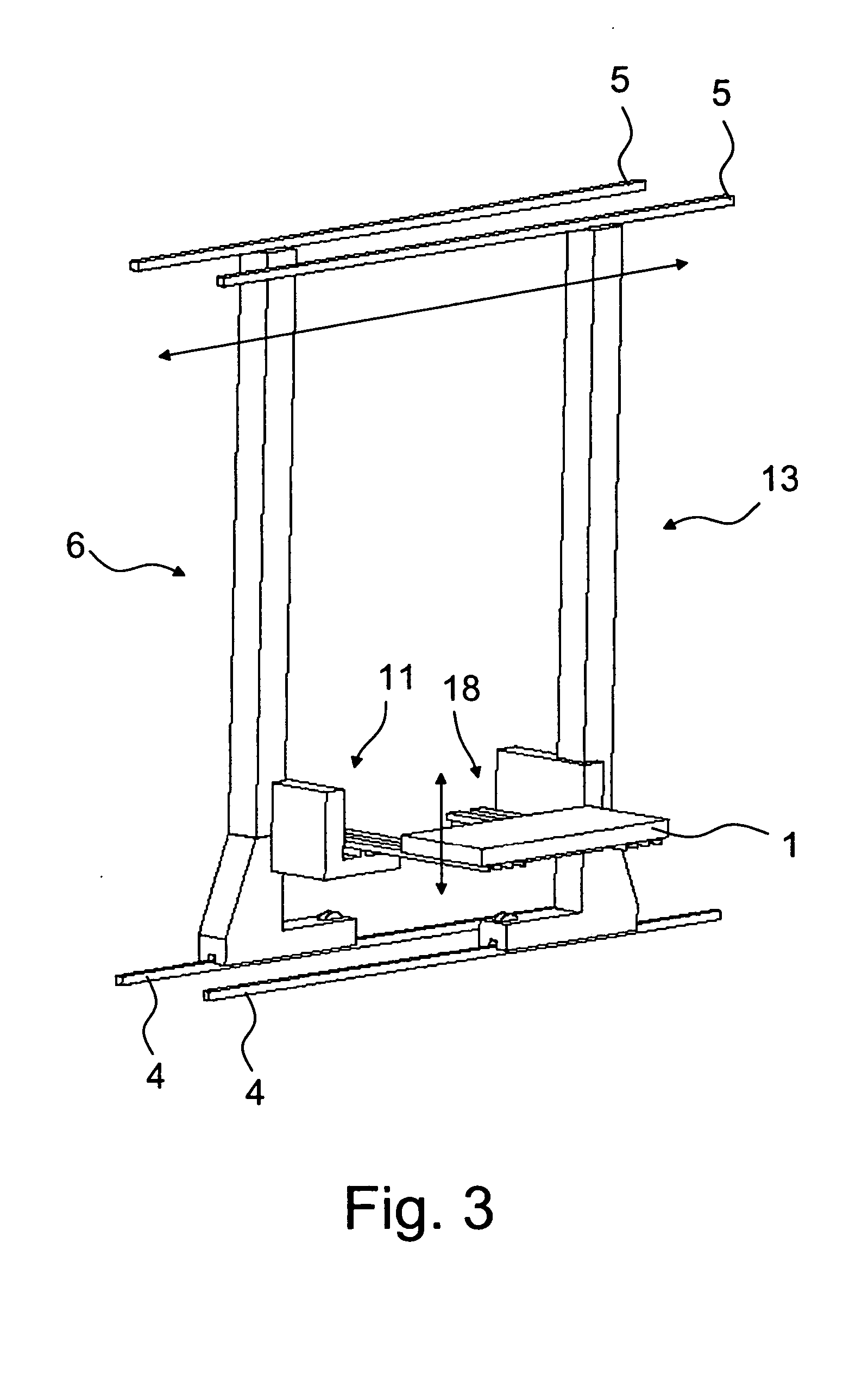

System of several stacker cranes, and a method for controlling the same

InactiveUS20050053450A1Increase capacityMore efficientLifting devicesStorage devicesVehicle frameEngineering

A method and a system utilizing the same, comprising two or more stacker cranes, of which each is intended to transfer at least one load independently, comprising a horizontally movable driving carriage and a lifting carriage arranged therein and intended for the manipulation and vertical transfer of said load. At least two stacker cranes are arranged to move, when necessary, to such a relative position in which it is possible to manipulate and transfer a load resting on the support of both lifting carriages simultaneously and to perform the movements of the driving carriages and the lifting carriages in a synchronized manner.

Owner:FASTEMS

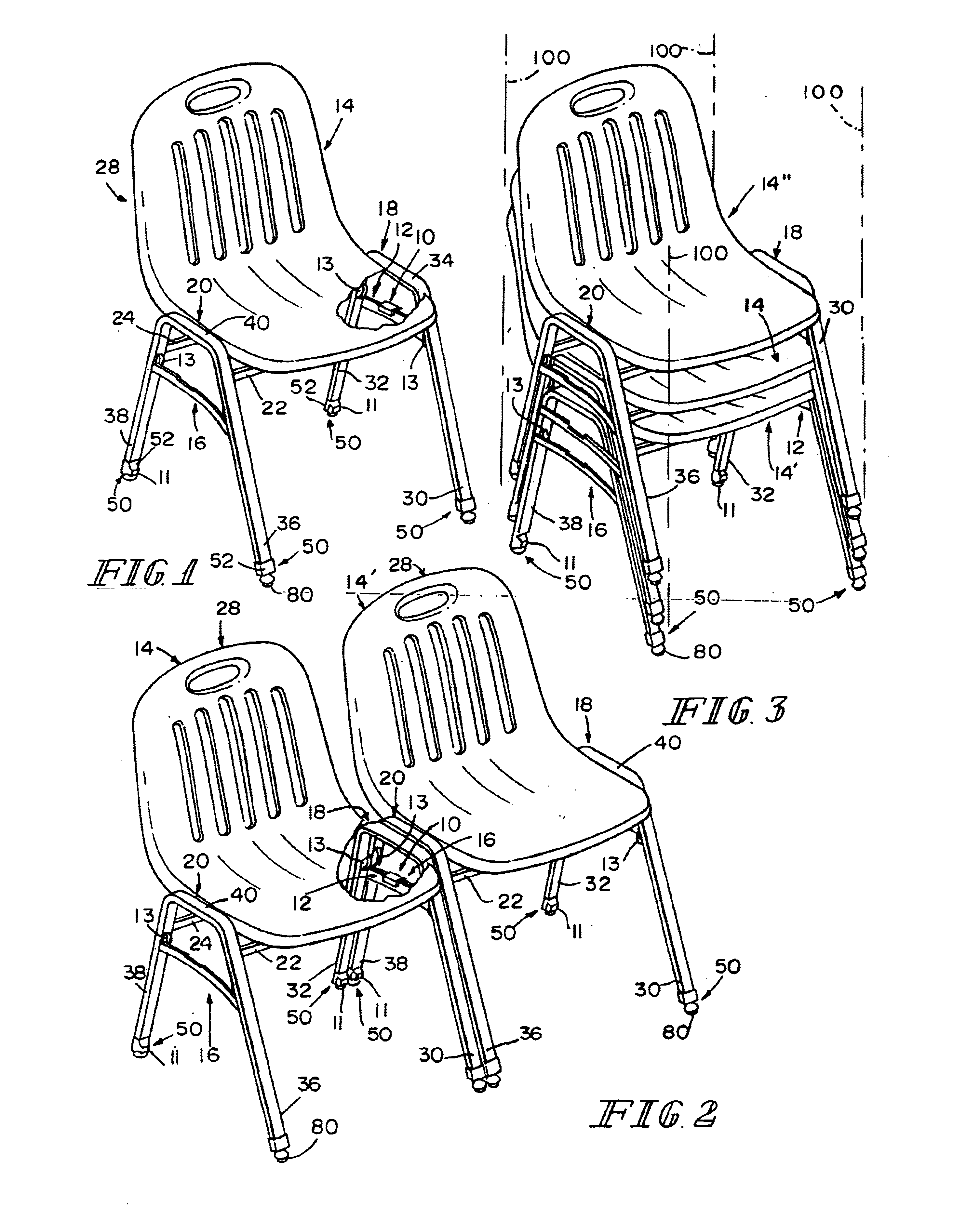

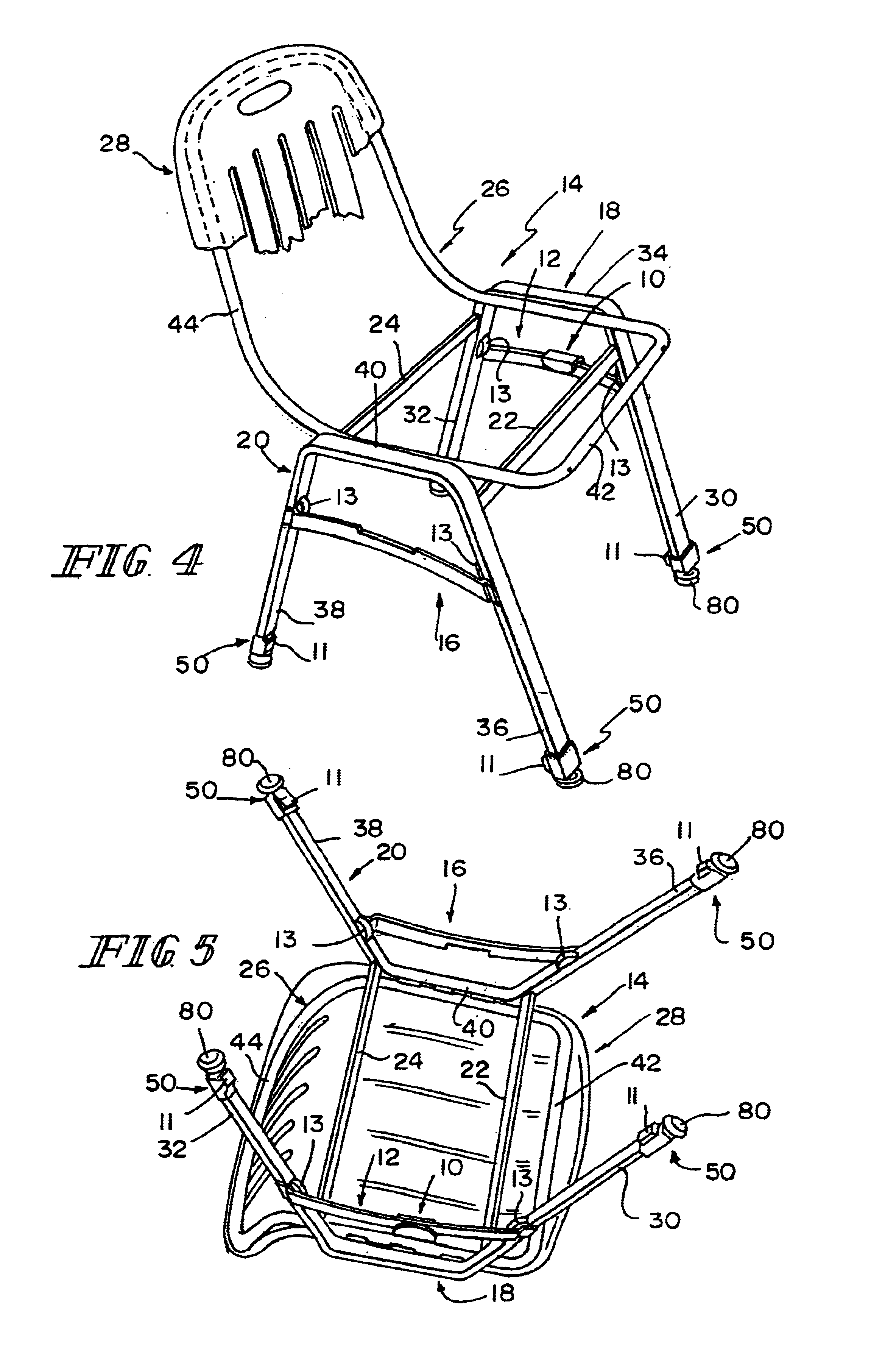

Chair stacker apparatus

InactiveUS6866338B2Facilitate creation of an upright vertical stack of chairsCastorsStoolsEngineeringStacker

Owner:DOREL HOME FURNISHINGS INC

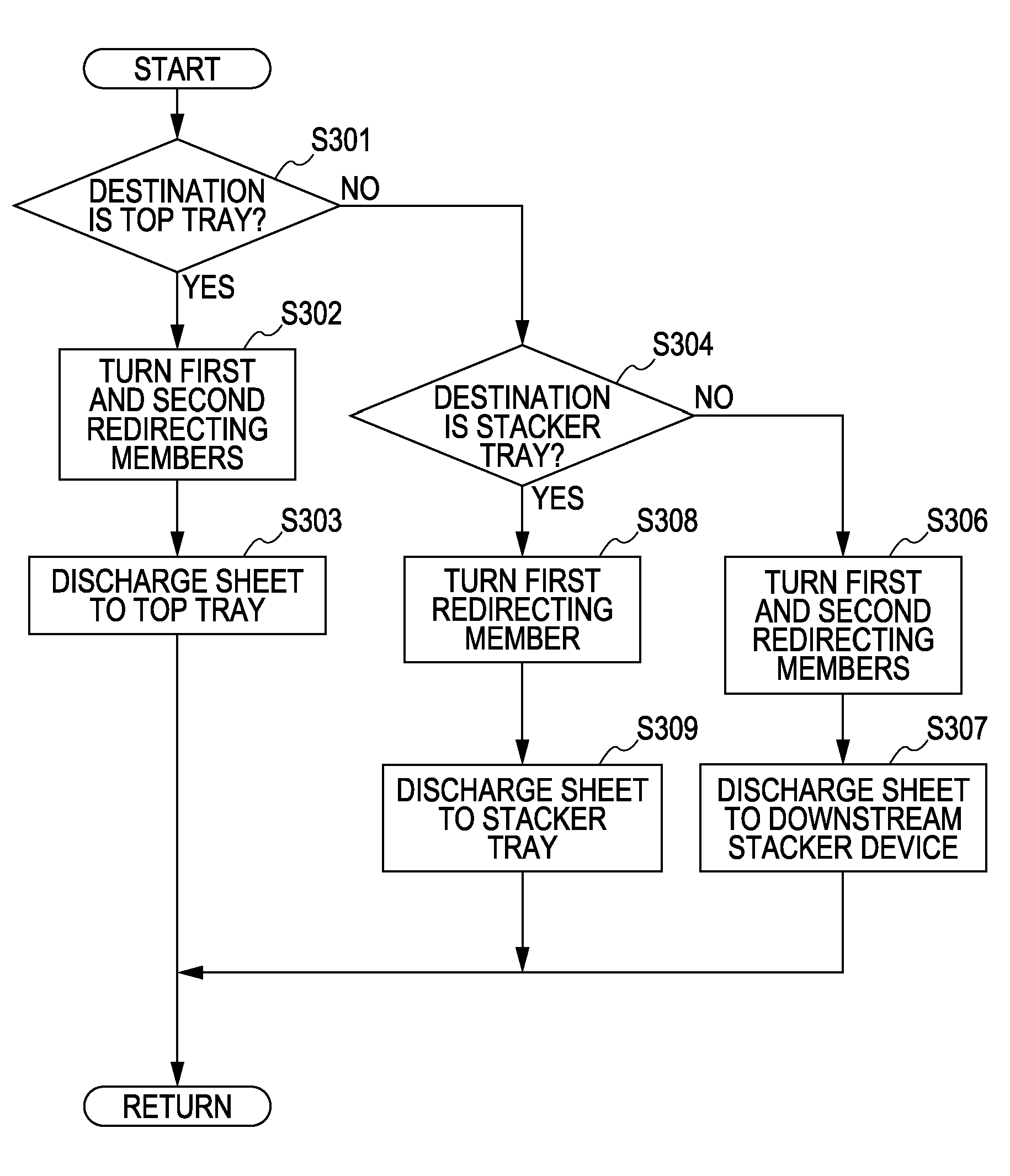

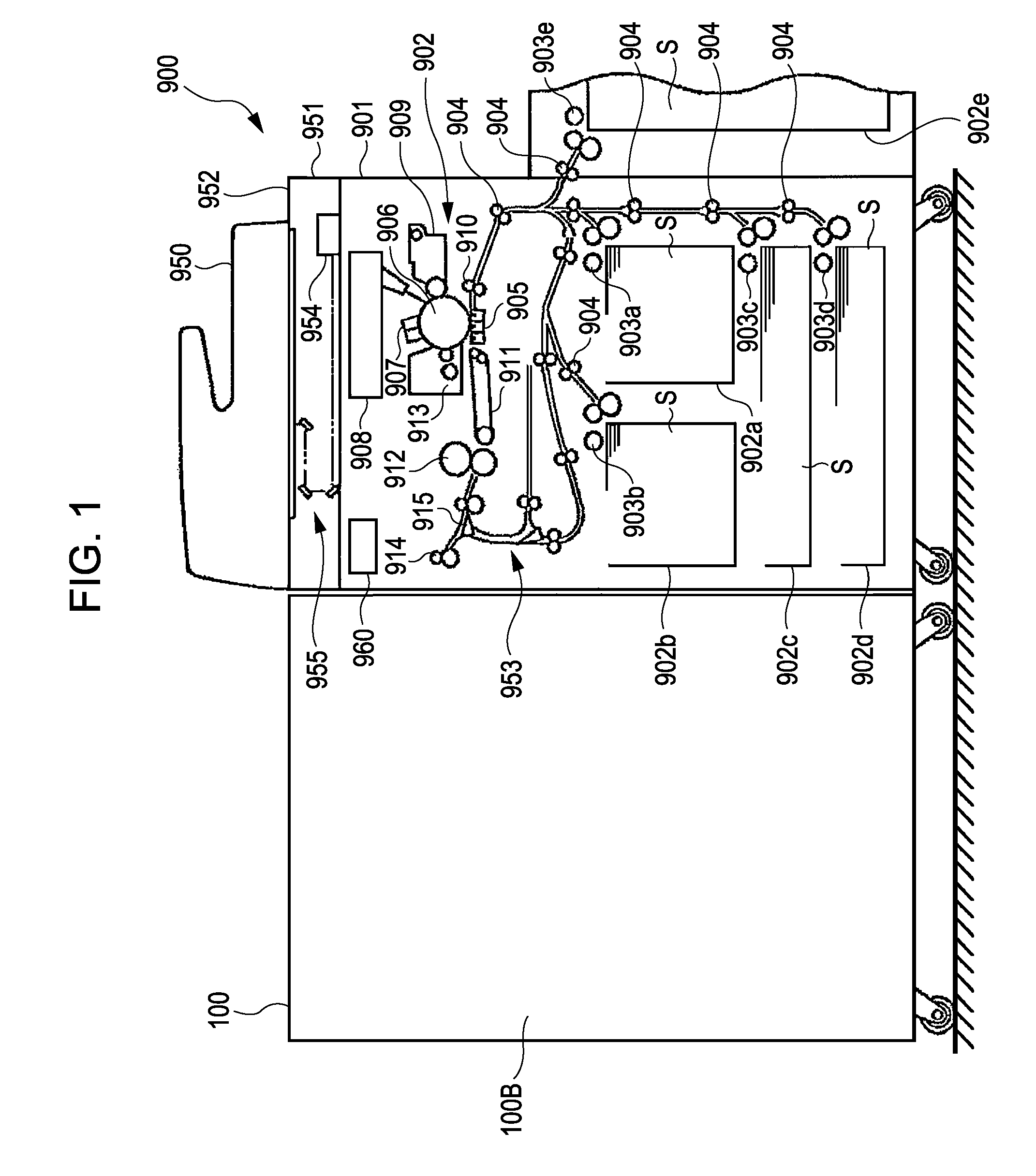

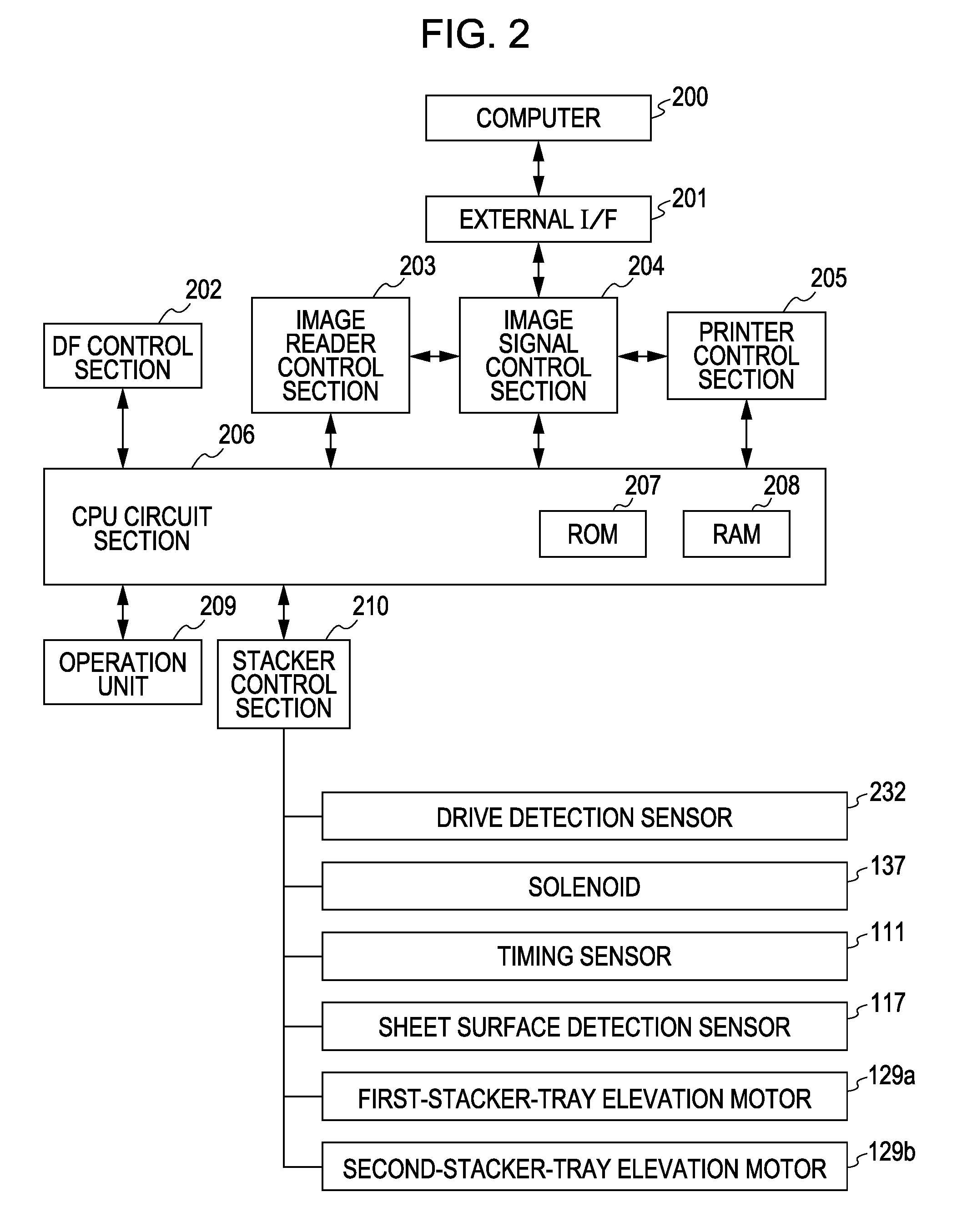

Sheet stacking device and image forming apparatus

A stacker includes a plurality of sheet stacking units individually movable upward and downward. Sheets are selectively stacked onto either of the stacker trays. To remove the sheets stacked on one of the stacker trays, a door is opened. In a state where the door is open, the stacker trays moved by respective elevation units are movable only downward. In this manner, accidental upward movement of each of the stacker trays caused by a malfunction of a motor or the like is regulated, whereby damage to the stacker is prevented.

Owner:CANON KK

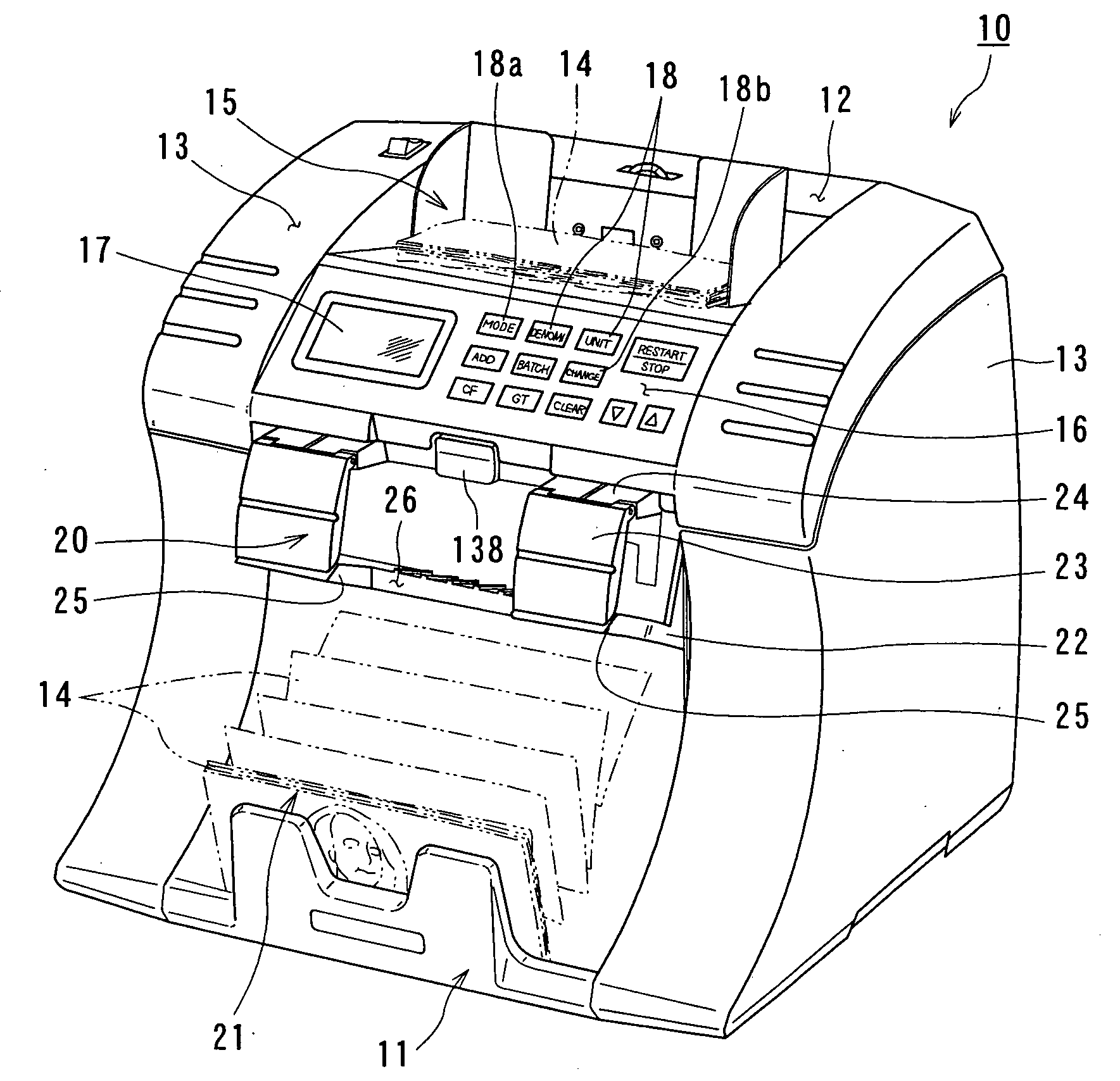

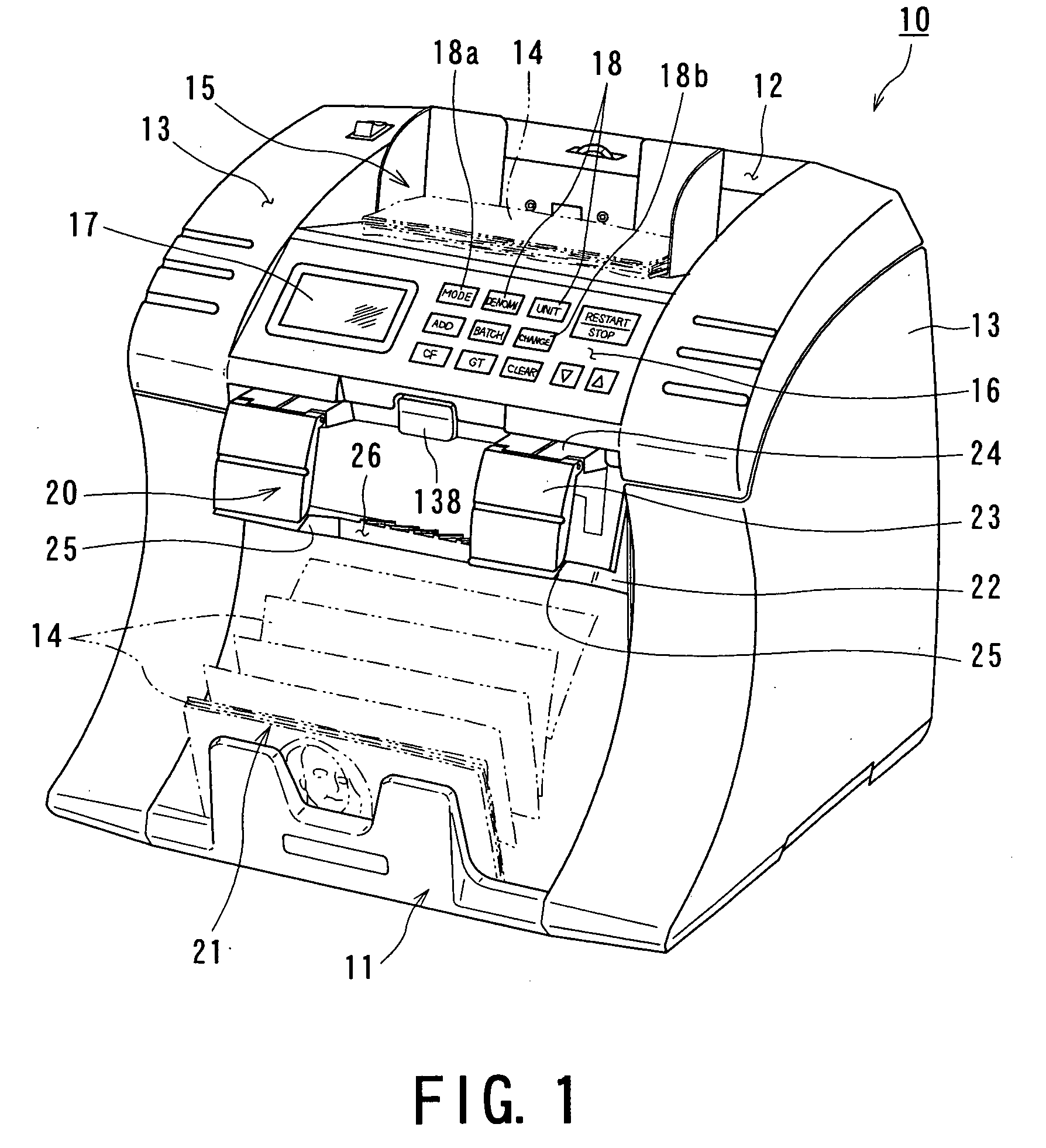

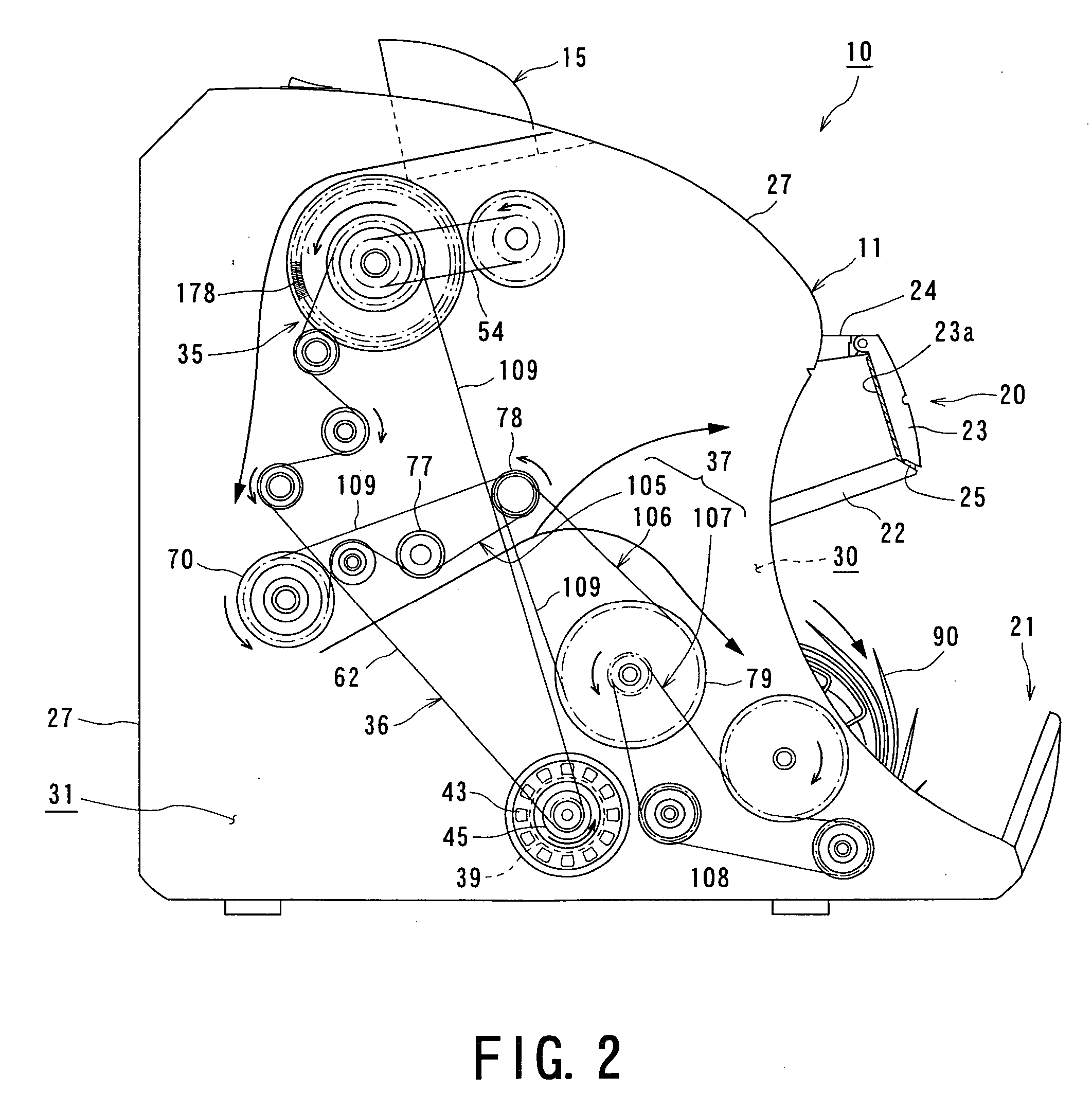

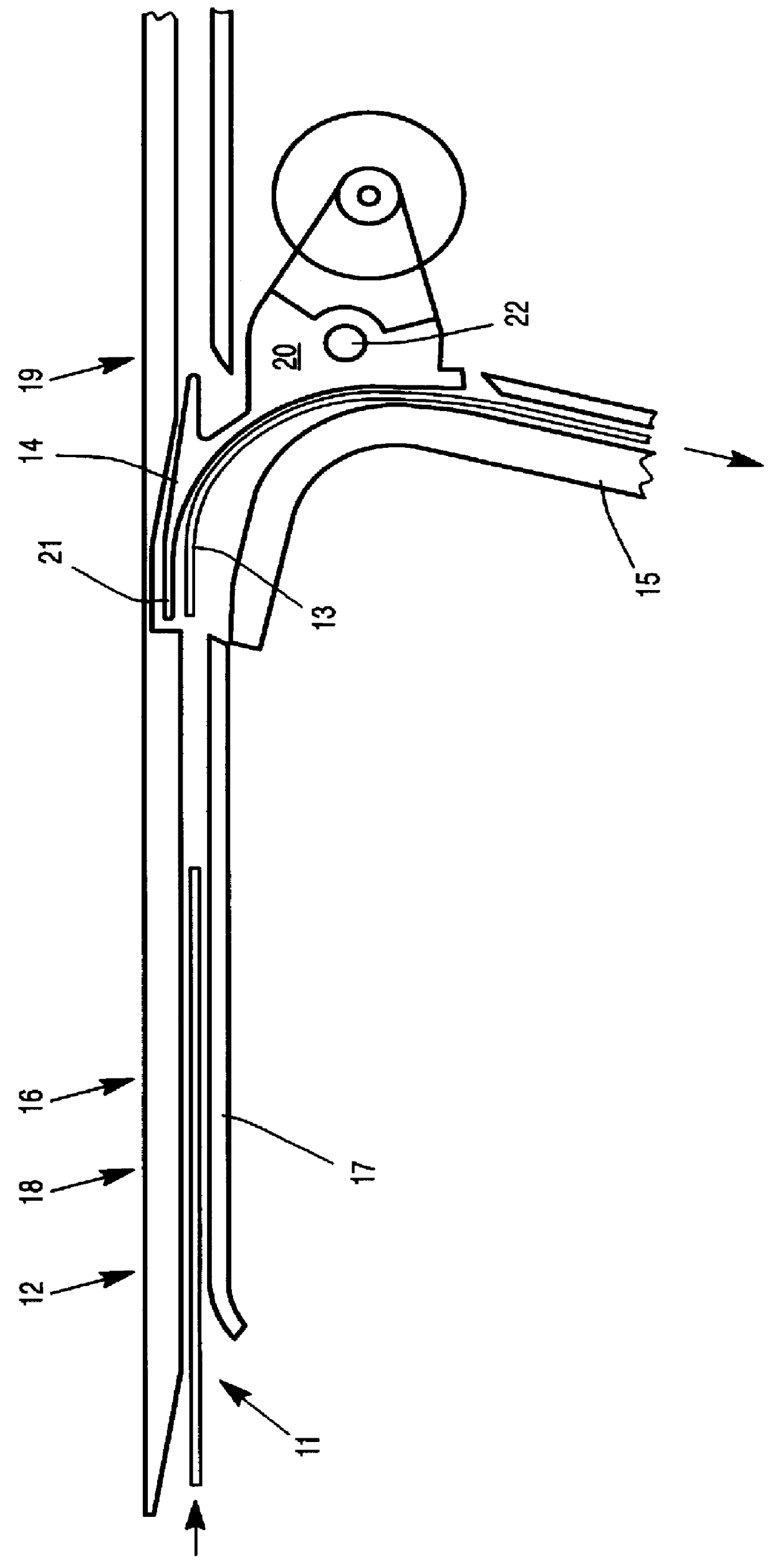

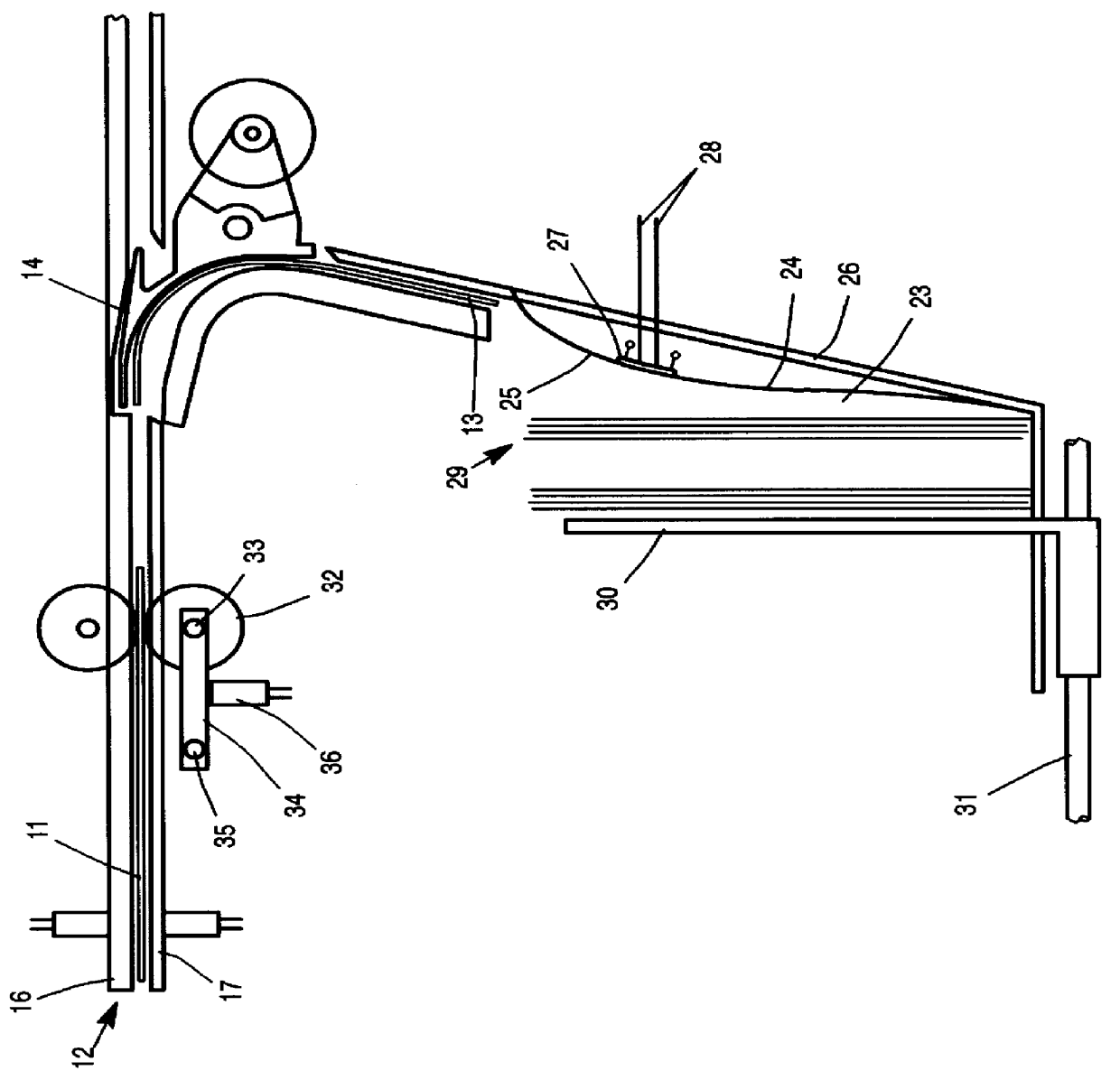

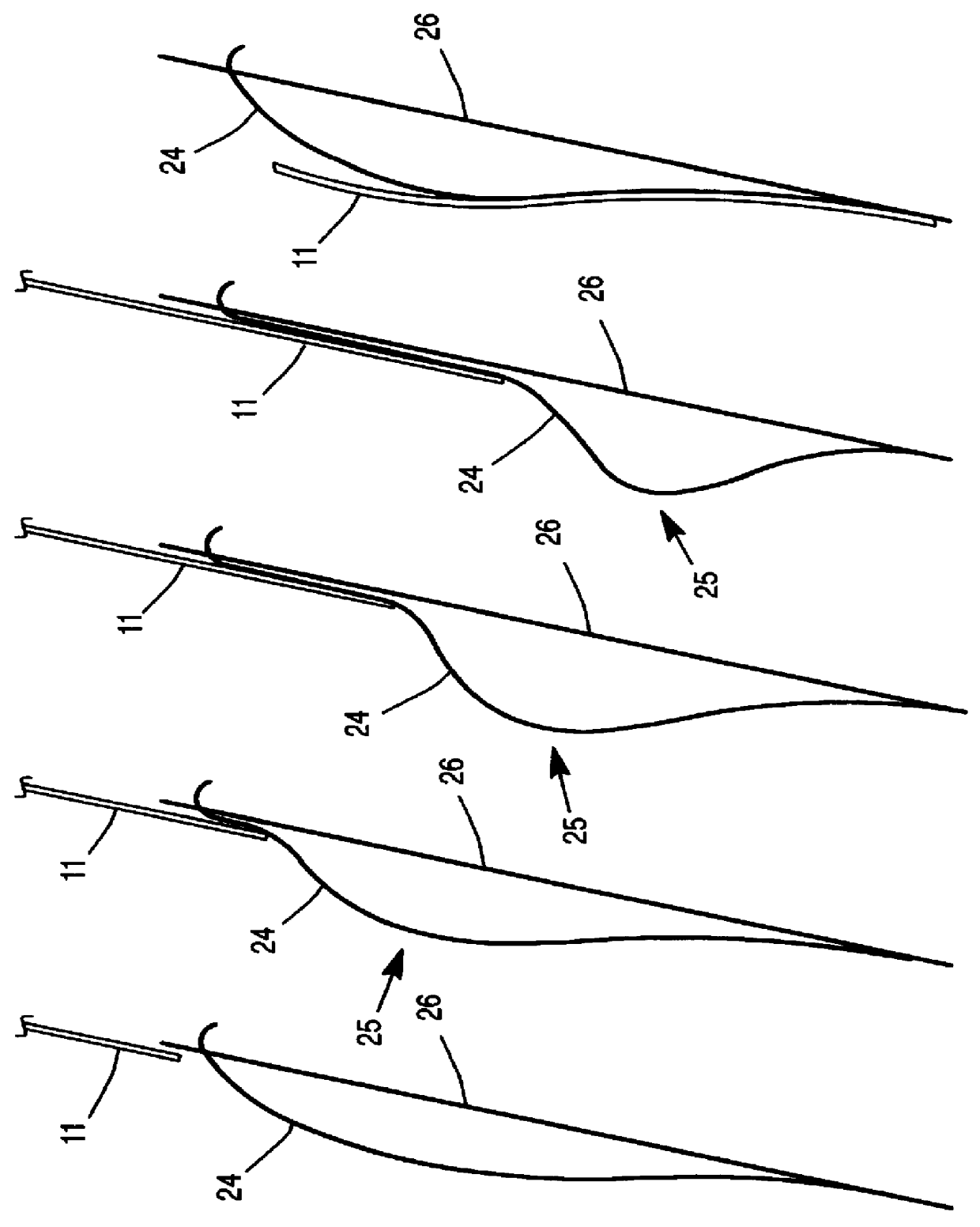

Paper sheet identifying and counting machine and method for identifying and counting paper sheet

InactiveUS20050053183A1Long processIncrease speedImage analysisPaper-money testing devicesPaper sheetStacker

A sheet discriminating / counting machine selects sheets to be discriminated of a predetermined country or region by discrimination object selecting means, transports the sheets to be discriminated at high speed along a transporting path, and performs sheet discriminating / counting processing at a sheet discriminating / counting unit disposed along the transporting path. The sheet discriminating / counting machine comprises: a hopper to which sheets to be discriminated are supplied; a sheet transporting device for transporting sheets supplied to the hopper one by one along a transporting path with the shorter side of each sheet parallel to the transporting direction; a sheet discriminating unit disposed along the transporting path for discriminating / counting sheets; and a stacker upon which sheets fed out from the transporting path are stacked. The transporting path is provided with a curved transporting region which is curved in a U-shape partway and has a reject transport path connected to a pocket from a the subsequent downstream side transporting path. The sheet discriminating / counting machine performs discrimination processing of 1200 sheets or more per minute and has one stacker and one pocket.

Owner:BILLCON

Apparatus and method of automatically adjusting a document deceleration rate

InactiveUS6065746AEnhance simple reliable selective decelerationQuickly and reliably selectively stopFunction indicatorsArticle feedersEngineeringPaper document

Apparatus and method for automatically adjusting a rate at which a document decelerates when entering a sort pocket of a document processing machine. The apparatus includes a track adapted for transporting the document, a guide wall, and a stacker flag spaced away from the guide wall to define the sort pocket therebetween. The sort pocket communicates with the track so that the document exits the track to enter the sort pocket. A wave spring is disposed proximate the guide wall so that the document engages the wave spring and is decelerated by the wave spring when the document enters the sort pocket. The weight of the document is calculated, and a signal is produced that represents the weight of the document. The wave spring is distorted according to this signal to vary a configuration of the wave spring depending on the weight of the document to decelerate the document at an optimal rate.

Owner:BURROUGHS CORP

Battery replacing method, battery replacing system and battery rack of electric vehicle

ActiveCN102180143ASingle actionFit closelyElectric propulsion mountingExternal framesElectrical batteryEngineering

The invention discloses a battery replacing method, a battery replacing system and a battery rack of an electric vehicle. In the invention, the battery replacing system comprises the fixed battery rack, a ferry vehicle, a stocker and a manipulator, wherein the ferry vehicle is movably arranged in the battery rack, a battery temporary storing place is arranged on the ferry vehicle, and the stockeris movably arranged at one side of the batter rack and the manipulator is movably arranged at the other side of the battery rack. The replacing method comprises the steps of: taking out a charged battery, moving to the ferry vehicle and putting the charged battery on the ferry vehicle by utilizing the stocker; taking out an uncharged battery on the electric vehicle and putting on the ferry vehicle by utilizing the manipulator; shifting the charged battery and the uncharged battery which are loaded on the ferry vehicle, for one station, aligning to the manipulator and placing the charged battery on the ferry vehicle on the electric vehicle by utilizing the manipulator so as to complete a replacing motion. In addition, a universal ball capable of autorotation and guide rolls arranged shapedlike a horn are arranged in a unit grid on the battery rack so that the battery can be more conveniently and rapidly guided to be put in the battery rack.

Owner:亿源动力(北京)科技有限公司

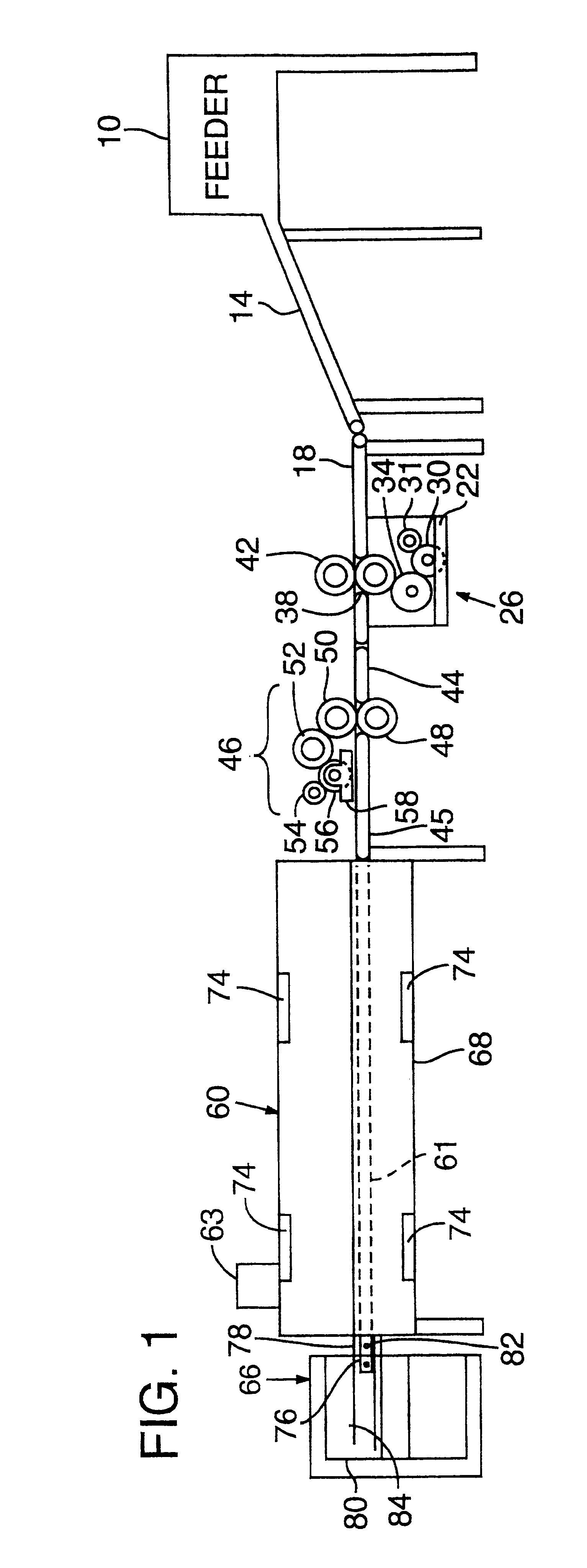

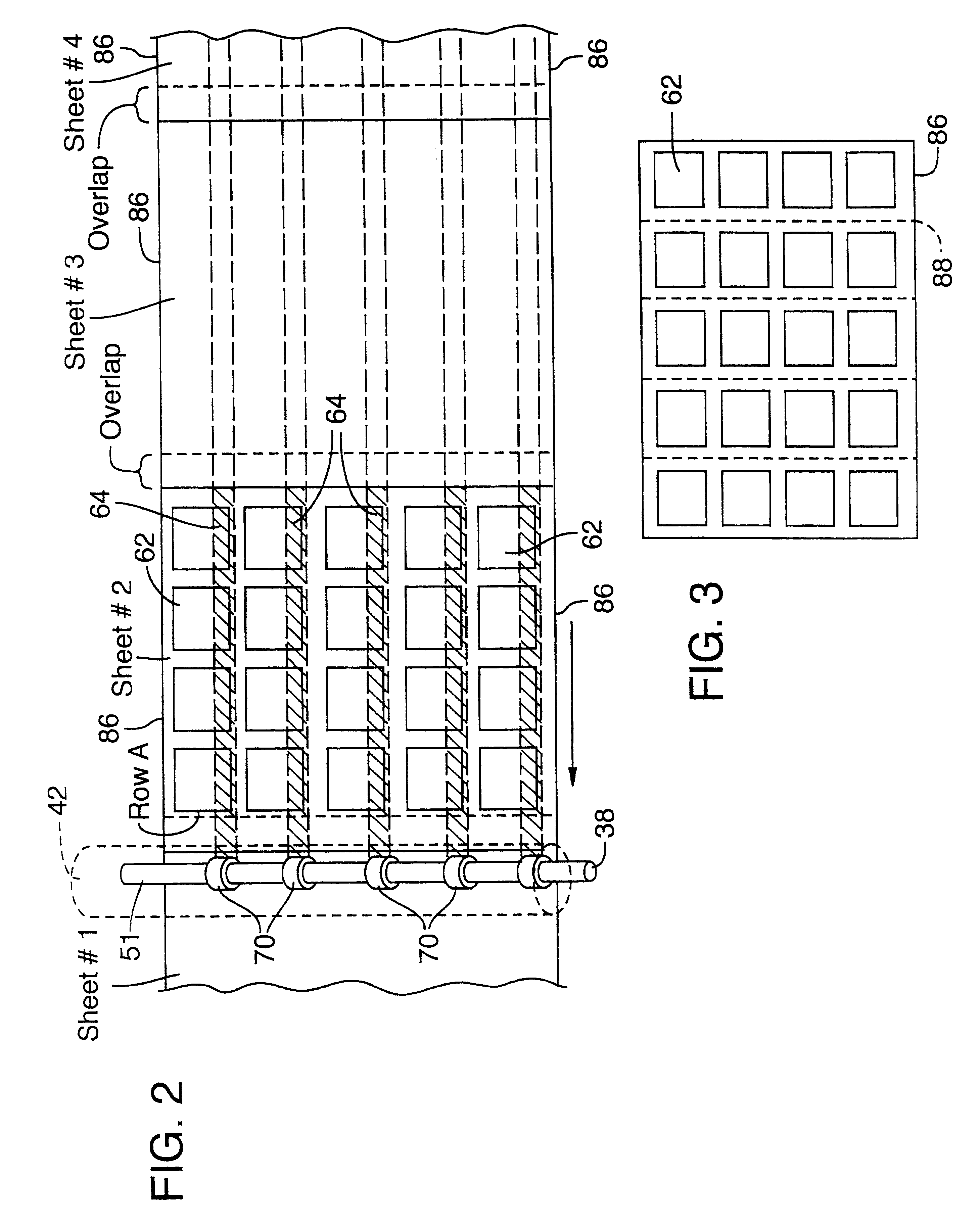

Pads of embossed, self-stick paper and process and apparatus for making same

A continuous process and apparatus are disclosed for applying an adhesive coating to one surface and a release coating to an opposite surface of sheets of previously embossed and optionally decoratively printed paper, and for drying the sheets and then stacking them for processing into individual pads of embossed, self-stick, removable sheets of notepaper. Individual sheets of embossed paper are fed onto a conveyor system, and the feed and conveyor speeds are regulated so that the sheets are in slightly overlapping relationship to form an artificial web as the sheets pass continuously through release coating and adhesive coating subassemblies which continuously apply release and adhesive coatings to opposite sides of the web. Conveyor speeds downstream of the coating subassemblies are regulated to separate the web into its individual coated and embossed sheets as they pass through a dryer. A relatively high-speed stacking conveyor downstream of the dryer delivers the dried sheets one-at-a-time into a stacker where the sheets are stacked and removed to other apparatus for collating with backing sheets, cutting and trimming into multiple note pads of embossed self-stick paper.

Owner:CAROL WILSON FINE ARTS

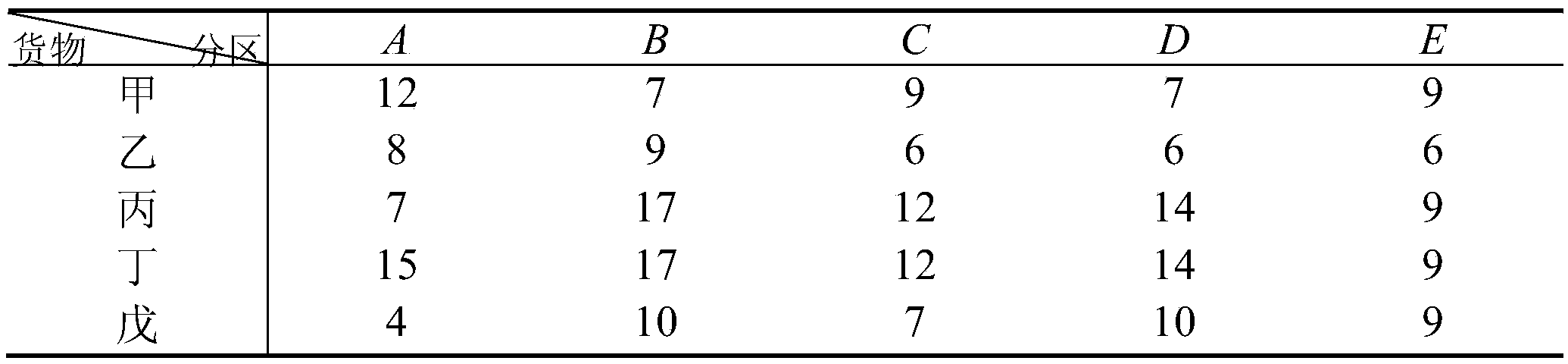

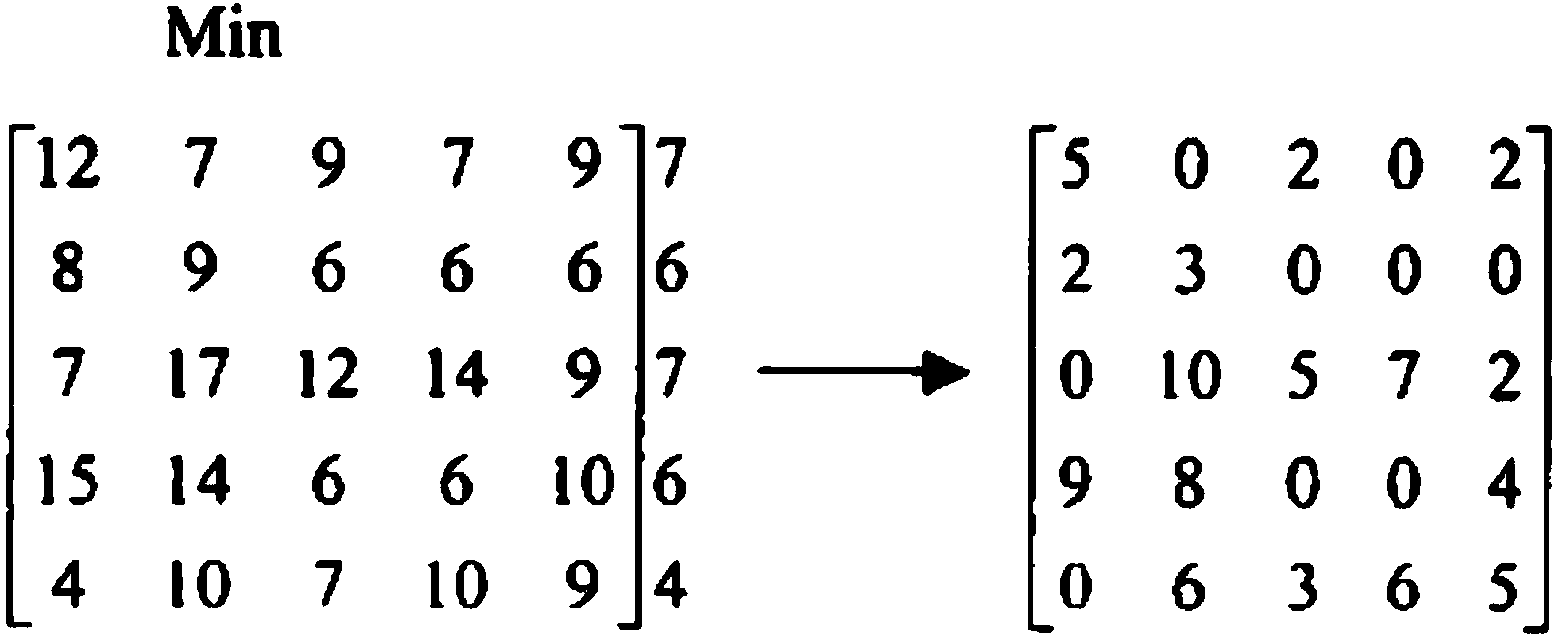

Intelligent stored cargo space distribution and optimization method

InactiveCN103942617AImprove operational efficiencyReduce inventory and other operationsForecastingLogisticsMathematical modelStack machine

The invention discloses an intelligent stored cargo space distribution and optimization method. The method comprises the following steps that 1, the frequency of cargo to leave from storage or be put into storage and the running speed of a stacking machine are counted, and a mathematic model is built; 2, two solutions are provided for different scales and include the Hungarian method and the genetic algorithm. By the intelligent stored cargo space distribution and optimization method, the utilization rate of cargo space is improved, the efficiency of cargo to leave from storage or be put into storage and the utilization rate of the stacking machine and other equipment are also improved, and the box shift operation and other operations can be reduced.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

Ultra-thin full-floating vehicle-taking apparatus by manipulator

ActiveCN101476402ASolve parking problemImprove the speed of access to the carParkingsDrive wheelElectric machinery

The invention relates to an ultra-thin device for parking and taking cars through full floating mechanical hands. Two sides of a longitudinal movement trolley are symmetrically provided with full floating mechanical hands, and the ultra-thin device consists of the longitudinal movement trolley and the full floating mechanical hands symmetrically arranged on the two sides, wherein the longitudinal movement trolley comprises an underframe, a running mechanism driving motor, a driving wheel, a driving wheel driving shaft, and a driving wheel driving gear; the full floating mechanical hand comprises a mechanical arm driving mechanism, a mechanical hand transition sliding plate, a mechanical arm, linear guide rails arranged on the inner and outer sides of a long beam on the underframe of the trolley respectively, and a swinging arm guide groove, wherein the mechanical hand transition sliding plate drives the mechanical arm to move. The device is ultra-thin, and two sets of independent full floating mechanical hands float freely in a set range, can be placed on a conveying trolley to form a horizontal movement type mechanical parking device, and can be placed on a stacker to form a laneway stacker type mechanical parking device without a carrying plate and a comb teeth rack; and the interbedded clear height is only 1.65 meters so that the construction investment is reduced, the structure is simple, the maintenance is convenient, and particularly the device is applicable to large mechanical garage.

Owner:HANGZHOU XIZI IUK PARKING SYST CO LTD

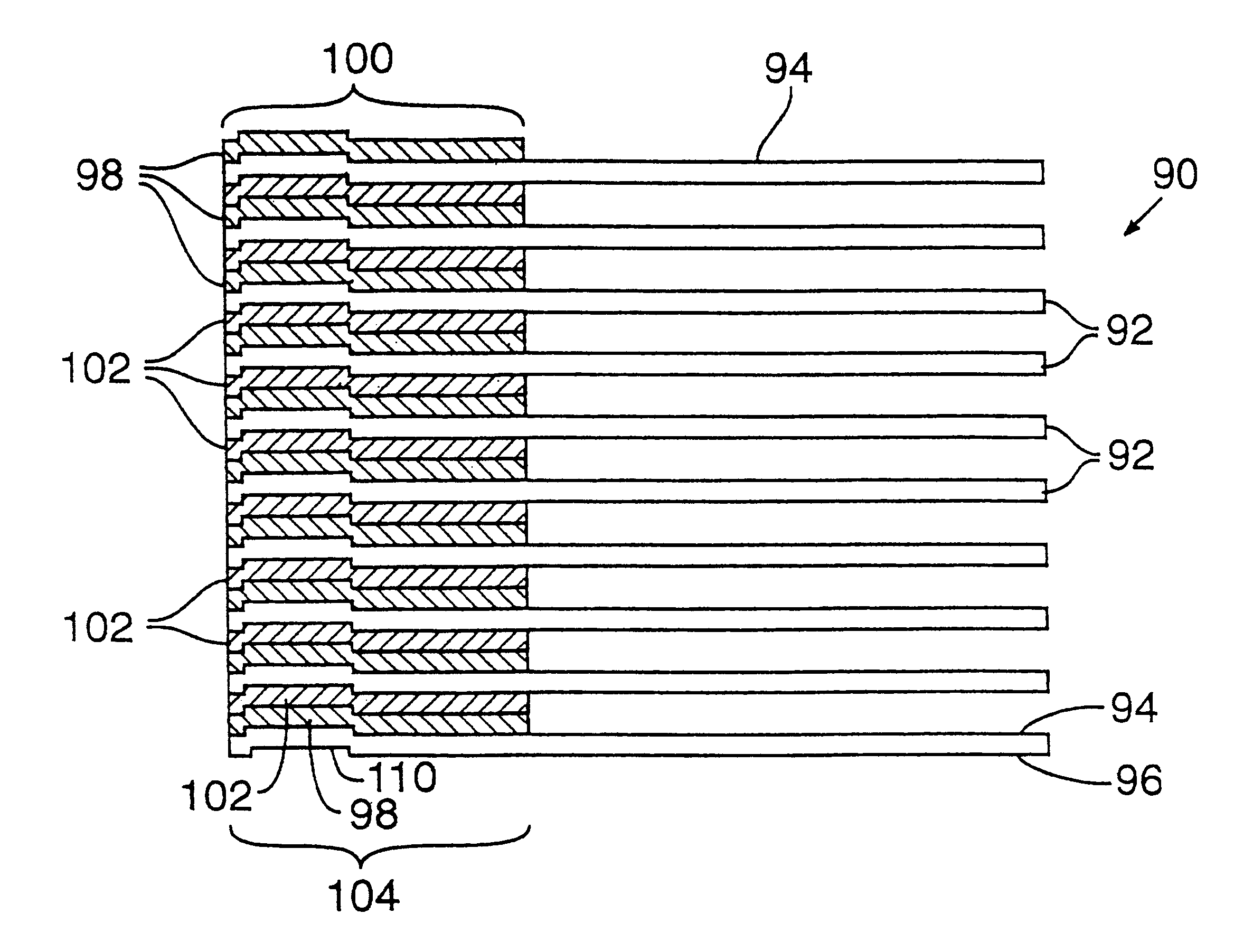

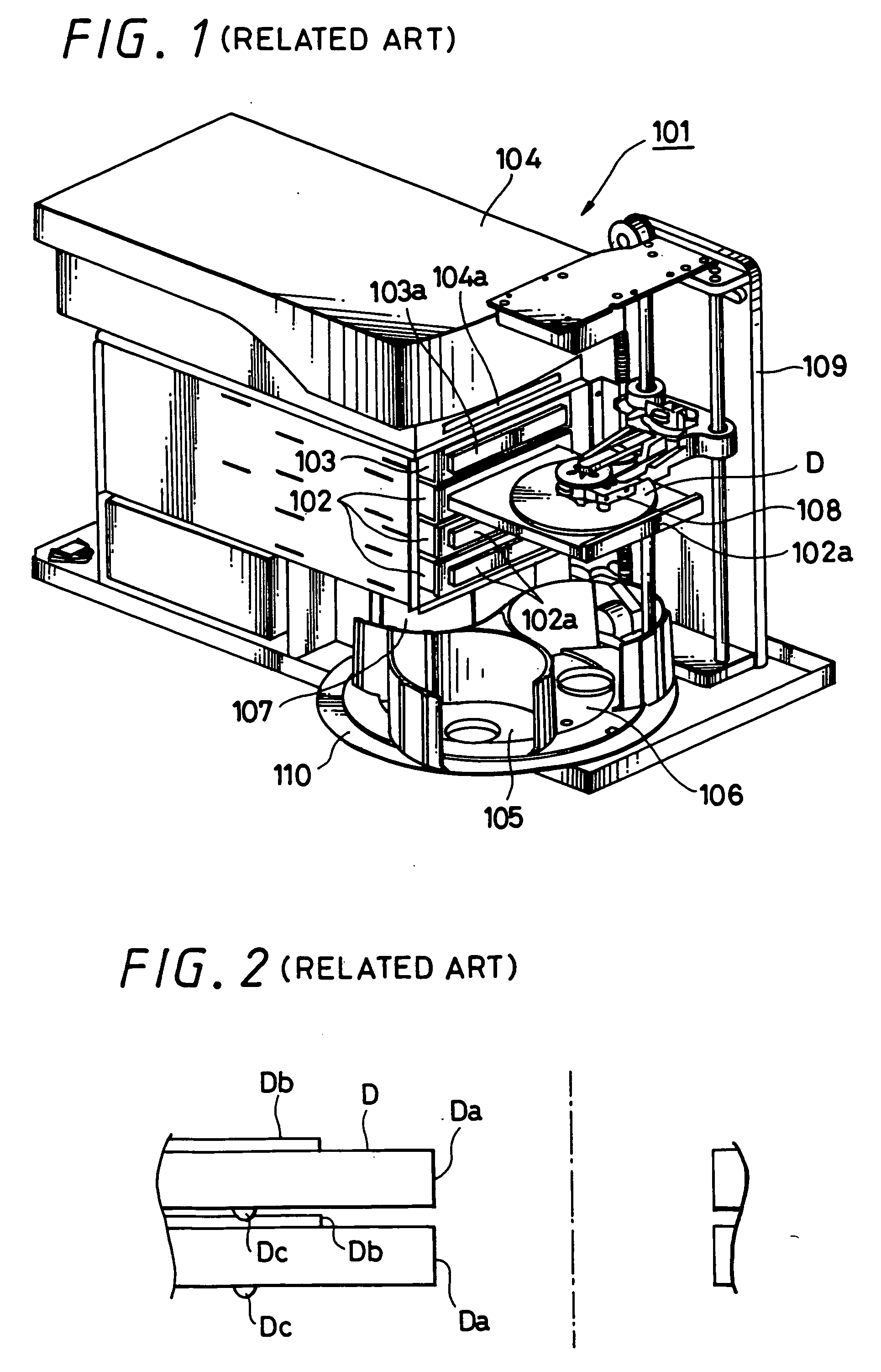

Plate stacker apparatus

A plate stacker is described for use in the field of sample analysis. The plate stacker increases the rate and ease with which sample carriers such as microwell plates may be interfaced with an automated system and includes a removable rack attached to a base to allow plates to be transported to and from an automated system. The stacker rack includes a door which allows for a compact stacker thus allowing manipulation of the microwell plates in a compact area. Generally, the plate stacker provides a means to allow a user to interface with an automated system. The rack portion of the stacker allows the user to load and unload microwell plates into the system in batches by loading or unloading multiple individual plates into or out of the rack. The base portion allows the automated system to load and unload individual microwell plates from the stacker.

Owner:GENESEE BIOMEDICAL +2

Stack-on panel assembly

A stack-on panel assembly for panel-based partition systems includes a connector bracket with a first portion shaped for connection with the top of an associated base panel, and a second portion upstanding from the first portion and having a first latch member. The stack-on panel assembly also includes a stacker panel having a bottom portion shaped for abutting support on top of the base panel, and a vertically extending slot disposed along one side to receive and retain therein the second portion of the connector bracket. A second latch member is disposed within the stacker panel at a location adjacent to the slot, and automatically engages and positively locks with the first latch member on the connector bracket when the stacker panel is lowered into place on top of the base panel to positively, yet detachably, connect the stacker panel on the base panel in a vertically stacked relationship.

Owner:STEELCASE INC

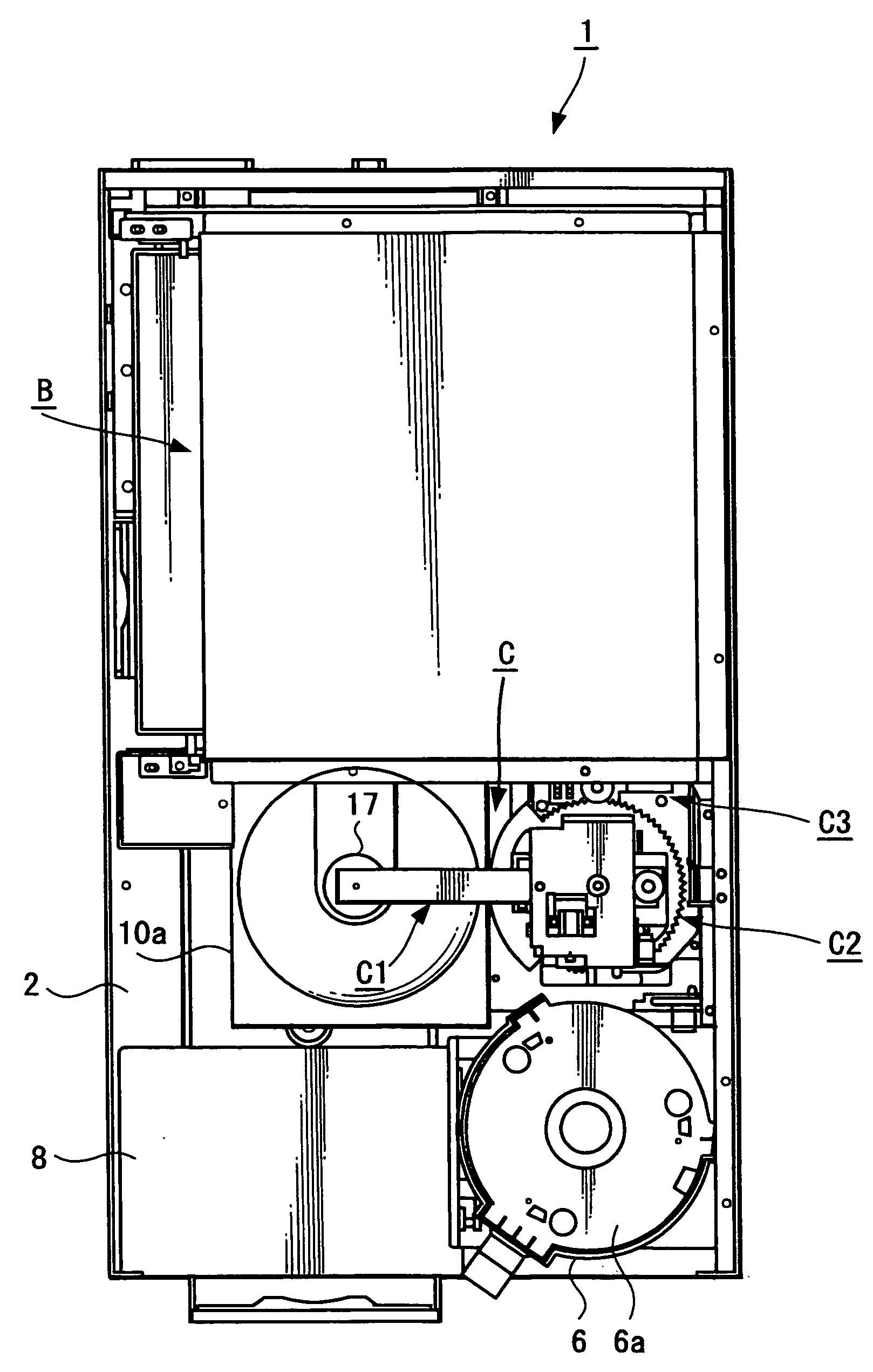

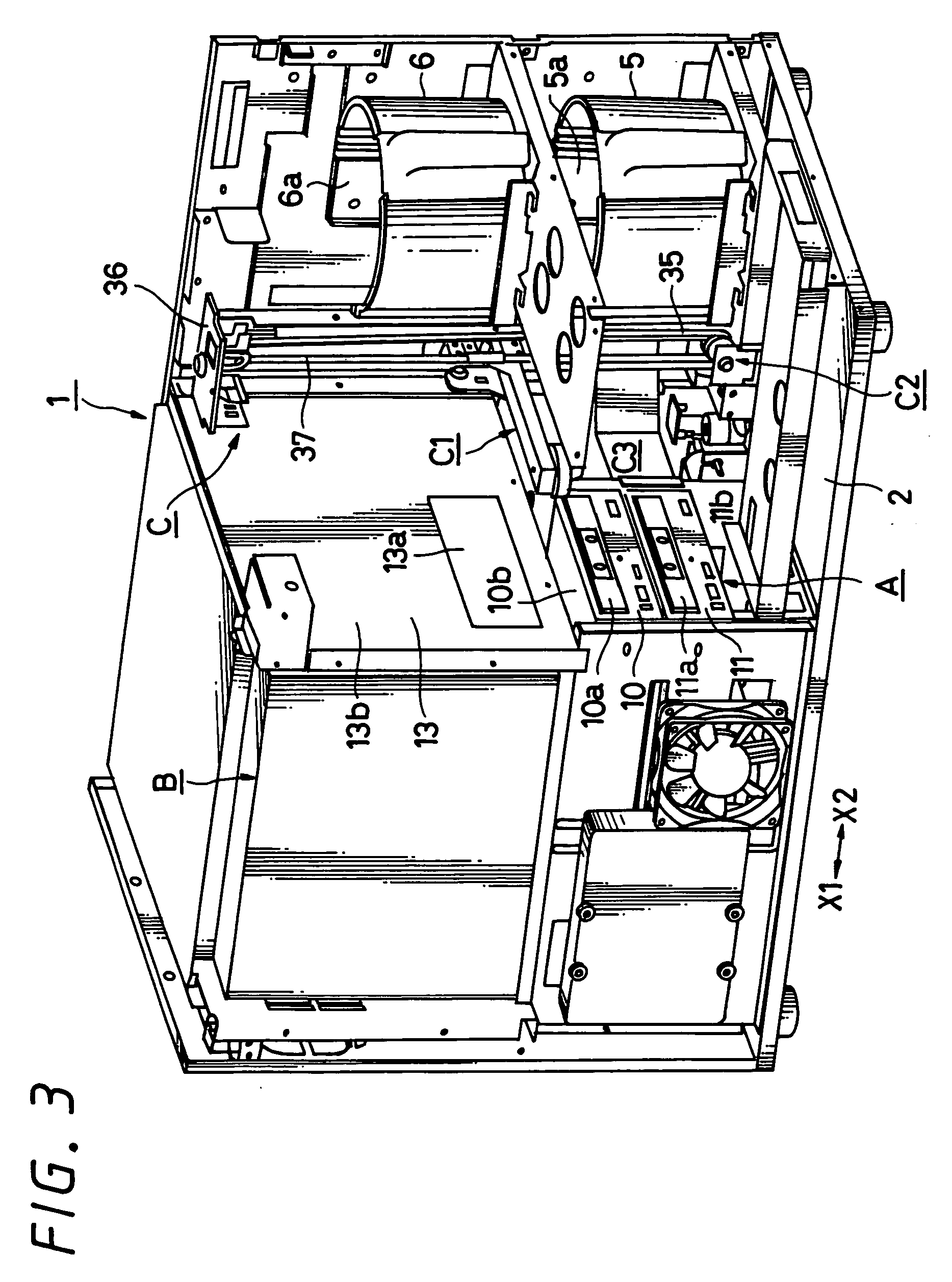

Disc processing apparatus

InactiveUS20070280057A1Precise processingRecord information storagePackagingCompact discCircular disc

In a disc processing apparatus capable of automatically carrying out processing work such as recording information on a plurality of optical discs and printing label surfaces on those optical discs, this disc processing apparatus is able to suppress by separating a conveyed optical disc from an optical disc located just under the conveyed optical disc the occurrence of a phenomenon in which a plurality of optical discs is simultaneously conveyed in the state in which they stuck together when a plurality of optical discs accommodated within a stacker in the stacked state stuck together. After a disc contact portion 17c of a disc holding mechanism C1 was brought in contact with an optical disc D, the disc holding mechanism C1 is lowered by a predetermined amount to urge the disc contact portion 17c to downwardly press the optical disc D to thereby apply force directed in the direction substantially perpendicular to the disc surface to the optical disc D. Thus, the optical disc D located at the uppermost portion of a stacker 5 can be separated from an optical disc D located just under the above-mentioned optical disc D.

Owner:TEAC CORP

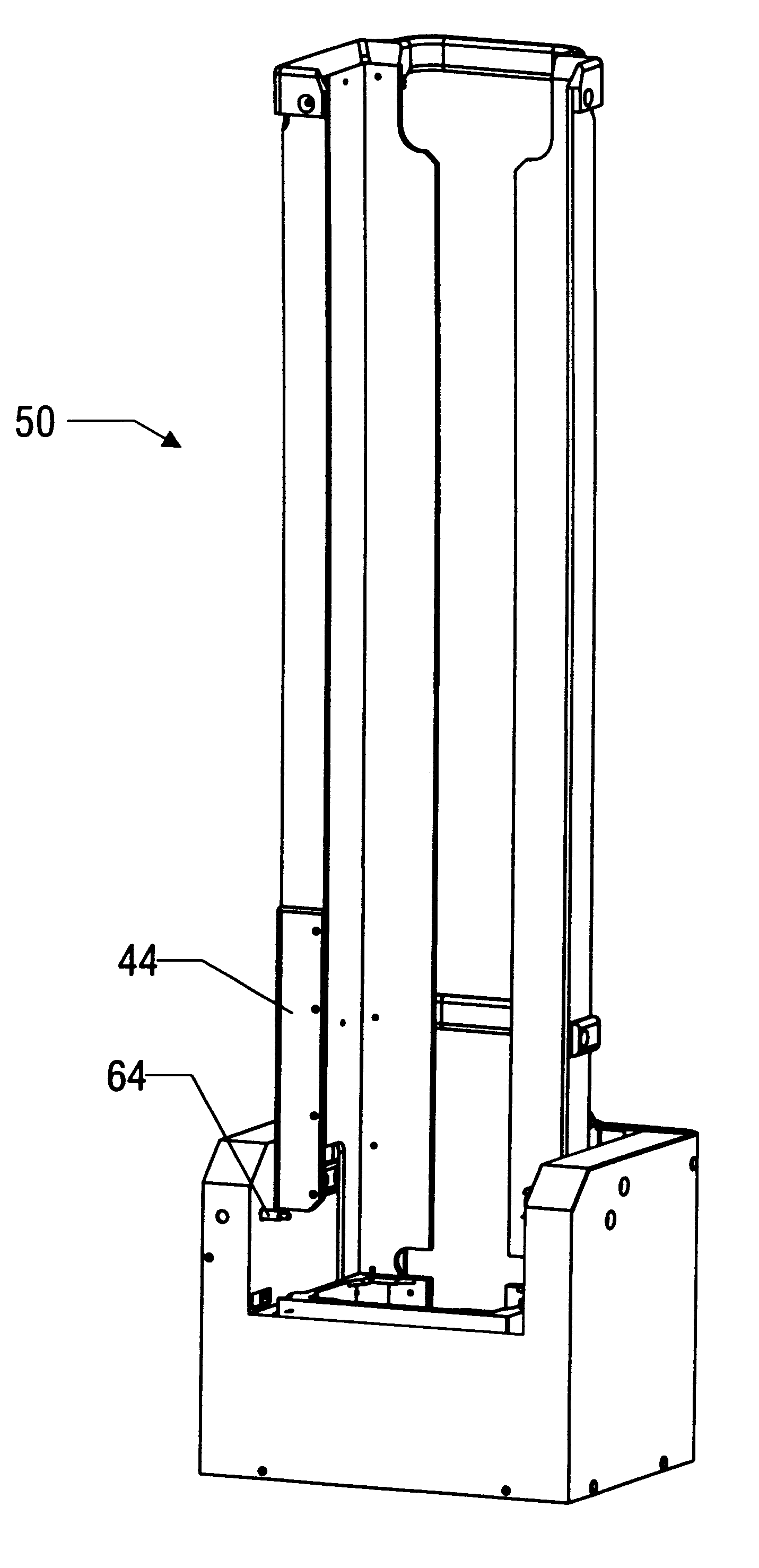

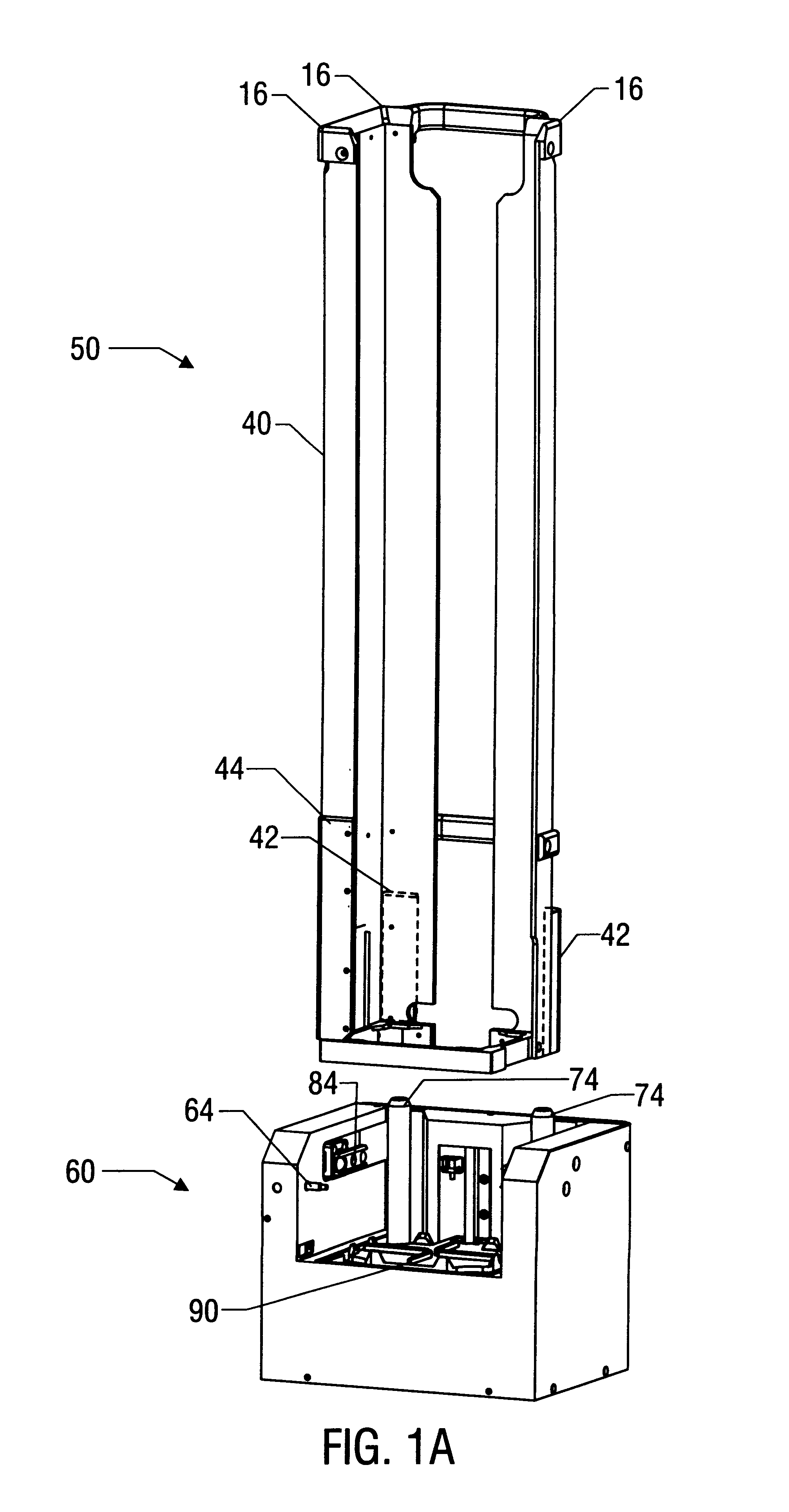

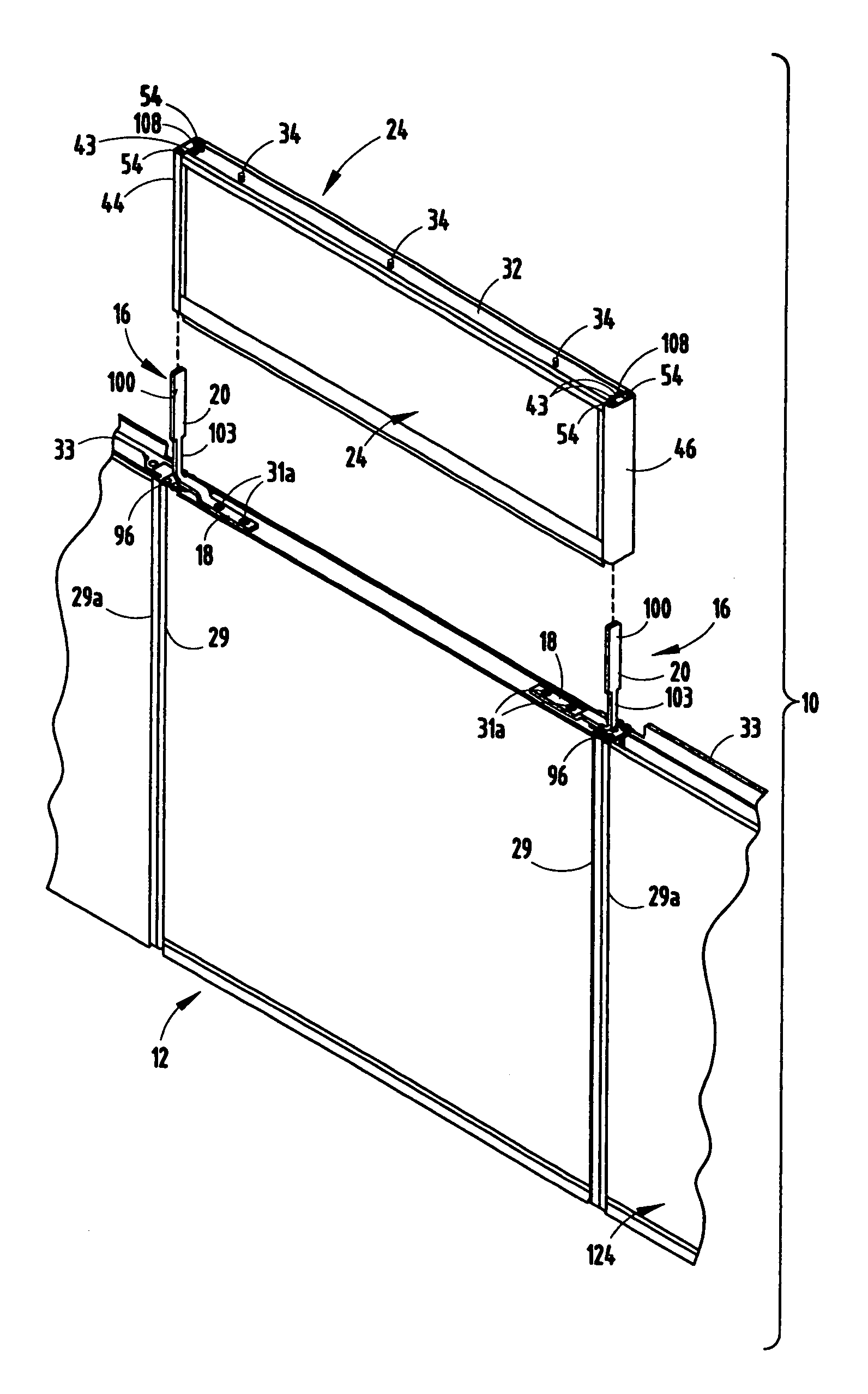

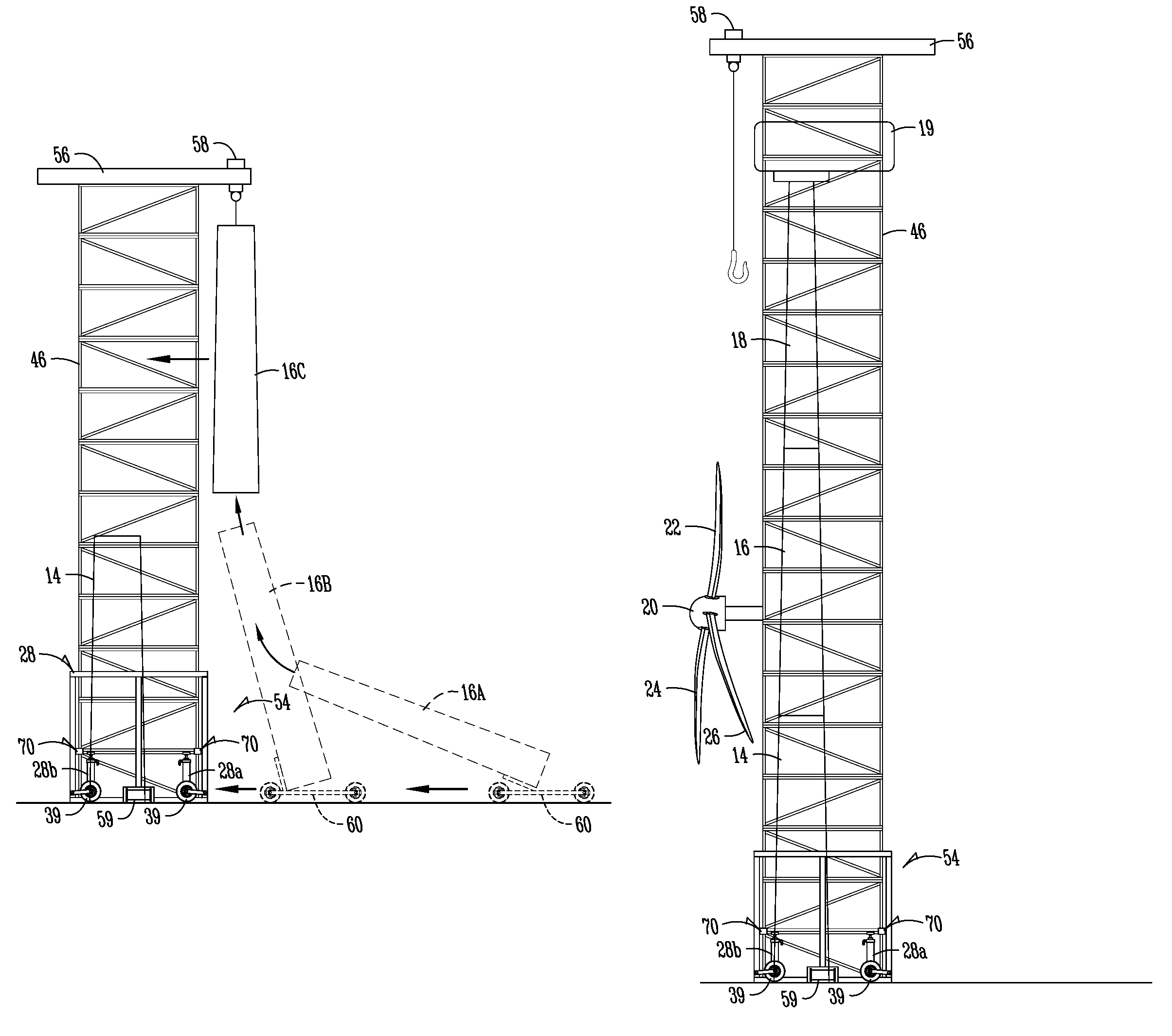

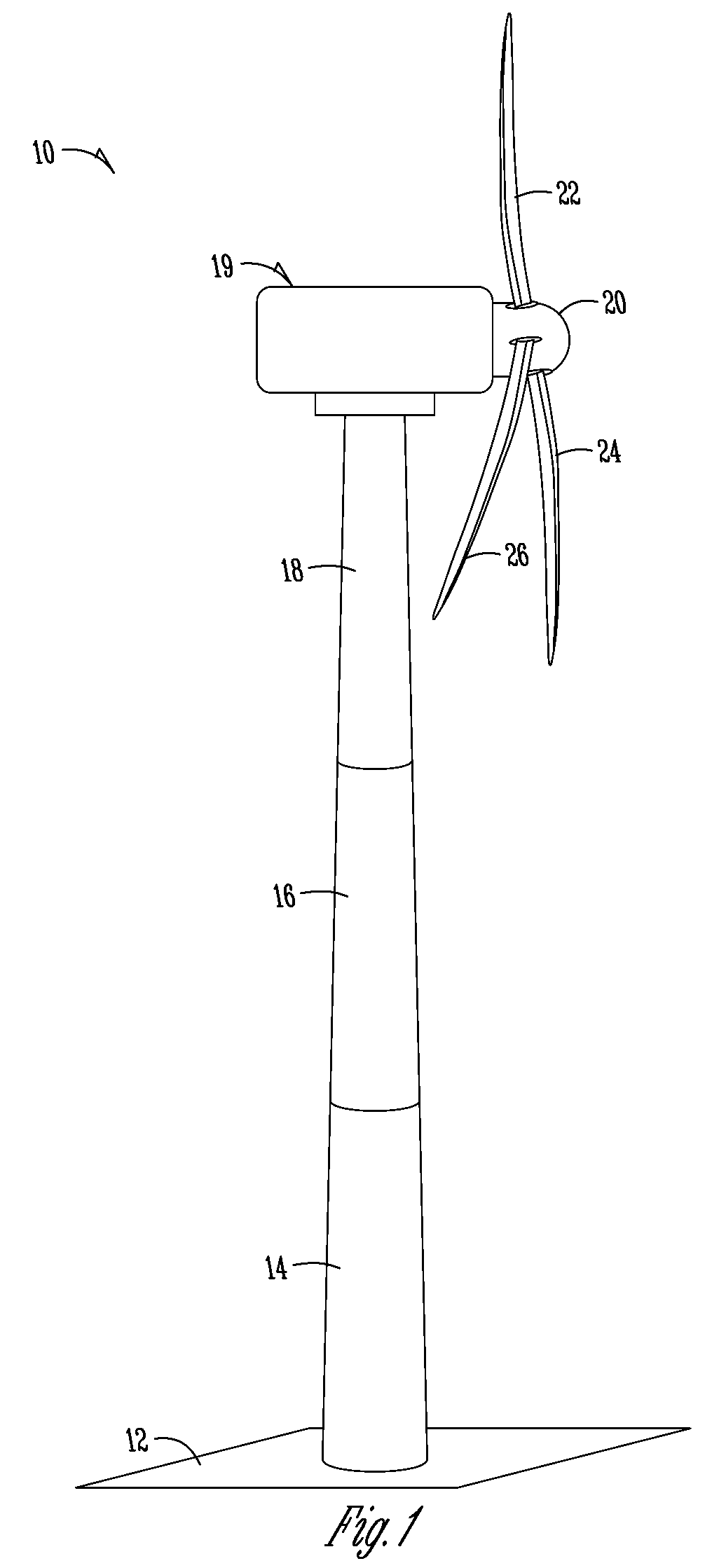

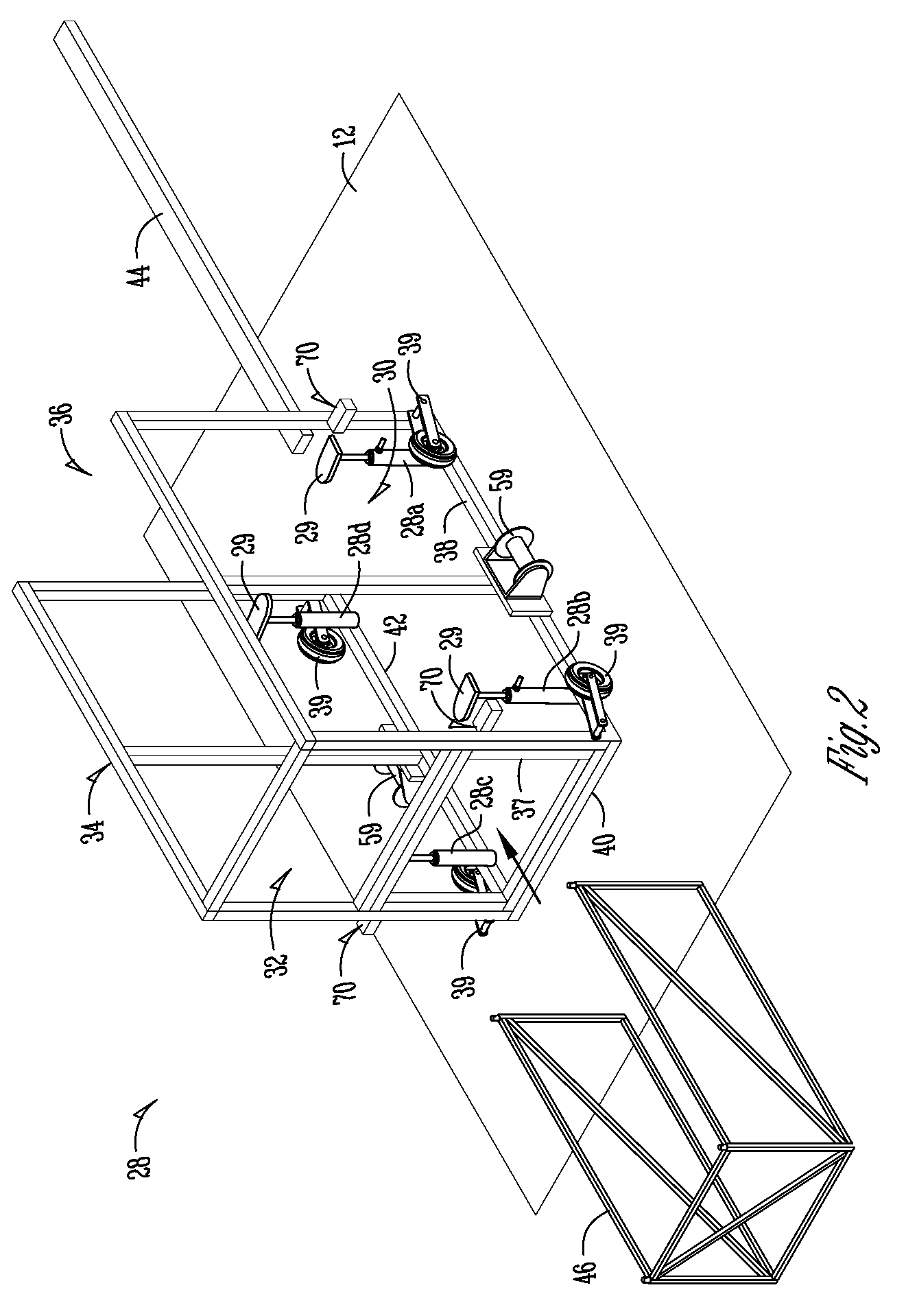

Wind turbine erector

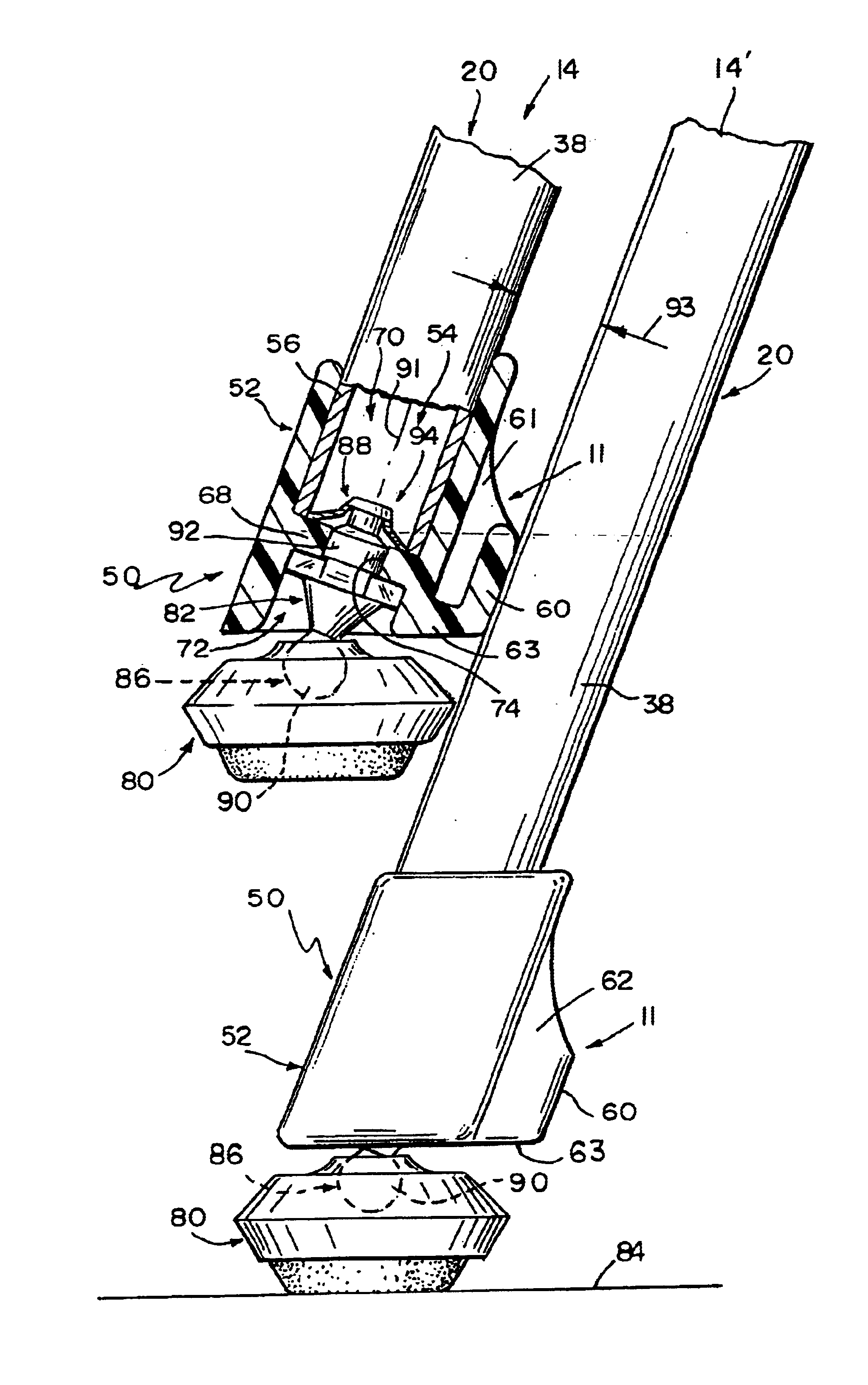

A wind tower erection device and method for erecting wind turbine towers which avoid the need for using expensive cranes. The device and method employs a stacker unit for anchoring to the wind turbine foundation, a plurality of intermediate modules, and a mechanical actuator for raising the intermediate modules vertically. The stacker unit has a receptacle allowing for lateral sliding of intermediate modules inside of the stacker unit. In one embodiment, the stacker unit has a receptacle for lateral sliding of intermediate modules inside of the stacker unit. The stacker unit and the intermediate modules each have at least one open side to for positioning of tower sections within the stacker unit and stacked intermediate modules. A bridge crane section is initially placed on top of the stacked intermediate modules. The bridge crane is raised vertically as additional intermediate modules are added at the bottom, thereby allowing wind tower sections to be winched into place using the crane, each being added on top of the other as the stacked intermediate modules increase to the necessary height.

Owner:VORHIES ROGER W

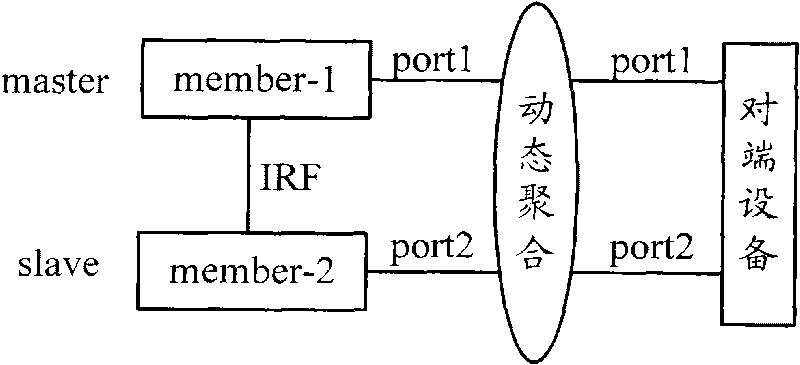

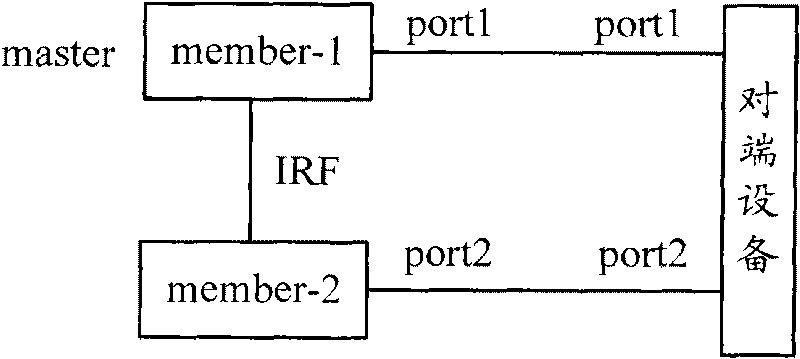

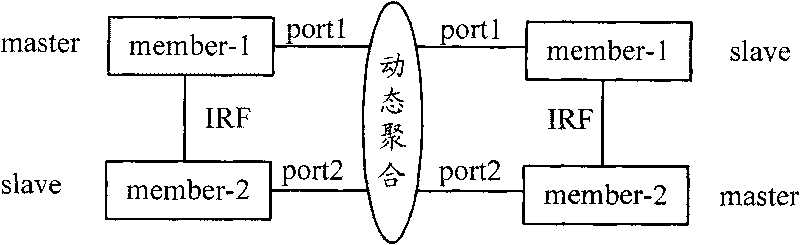

MAD testing method and device for IRF stacker

The invention discloses an MAD testing method for an IRF stacker, comprising the following steps: establishing an MAD region by an opposite terminal device according to MAD information distribution messages; and judging whether stacking fission occurs or not according to the MAD information distribution messages, if so, sending the MAD information reflection messages to member devices by the opposite terminal device, and closing the own device ports or maintaining the own device ports to be in an Active state by the member devices according to the MAD information reflection messages. In the invention, the MAD testing process is more efficient and the application range is not limited by networking.

Owner:NEW H3C TECH CO LTD

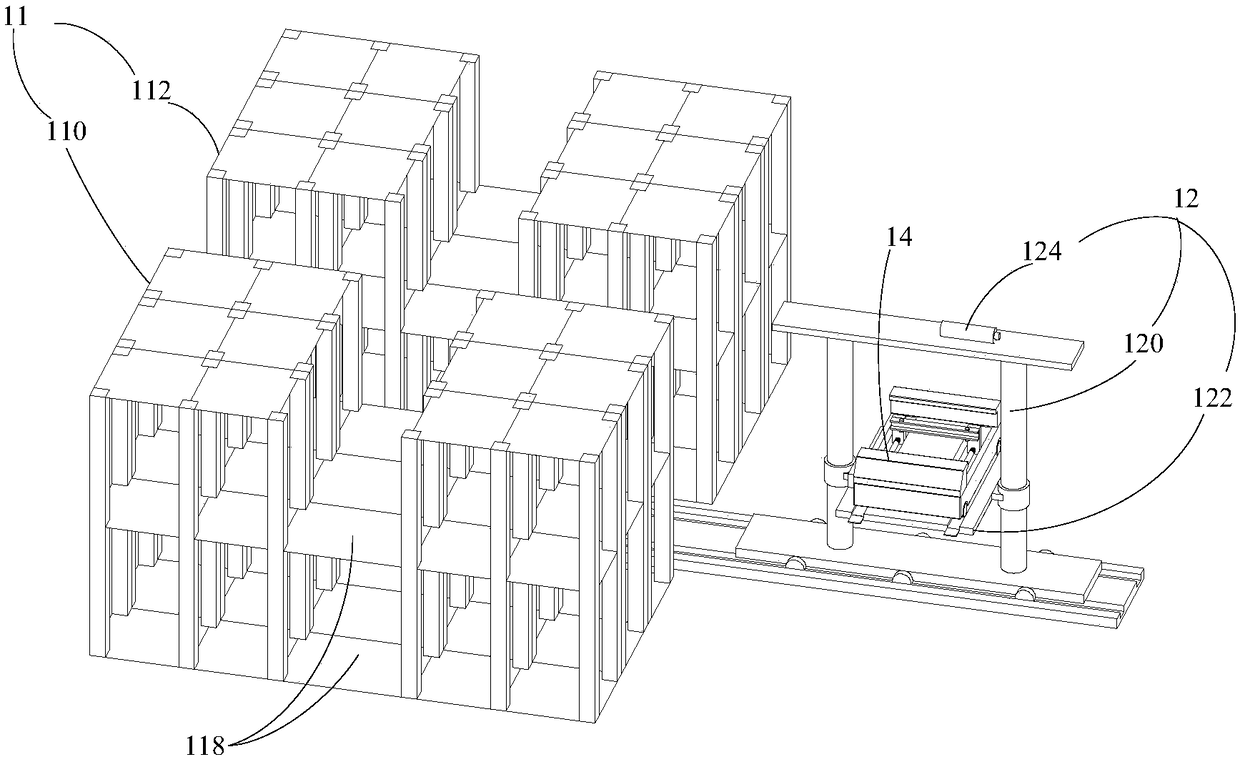

Automatic warehousing and stacker system

InactiveCN108820663AImprove work efficiencyIncrease flexibilityStorage devicesStackerAutomotive engineering

The invention discloses automatic warehousing and a stacker system. According to automatic warehousing, a storage goods shelf, a stacker and a shuttle vehicle are involved; the storage goods shelf isused for storing goods; the stacker comprises a main body frame, and at least one bearing table and a lifting device which are arranged on the main body frame, and the bearing table is used for bearing the shuttle vehicle; the shuttle vehicle comprises a vehicle main body, and a travelling mechanism and a storage device which are arranged on the lower portion of the vehicle main body; and the travelling mechanism is used for driving the shuttle vehicle to move within the storage goods shelf, and the storage device is used for placing cargoes on a goods carrying platform or taking cargoes to the storage goods shelf from the goods carrying platform. In this way, by means of automatic warehousing, the cargoes can be stored and taken through cooperation between the stacker and the shuttle vehicle, and accordingly, the operating efficiency, flexibility and reliability of the whole system are improved.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com