Patents

Literature

224results about How to "Slow movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

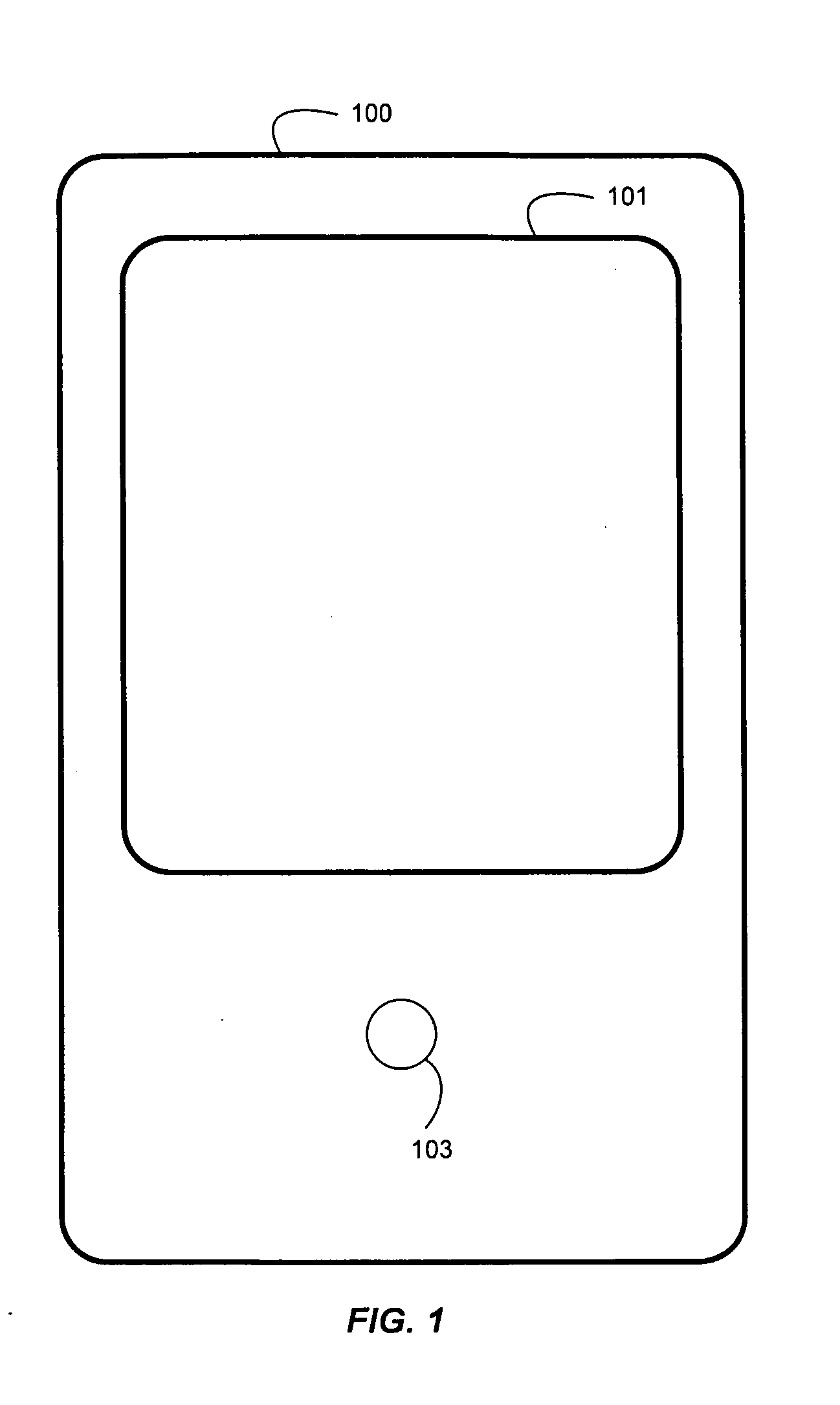

Touch-Sensitive Display Screen With Absolute And Relative Input Modes

InactiveUS20100156813A1Slow down movementSlow movementInput/output processes for data processingJoystickMotion direction

Owner:QUALCOMM INC

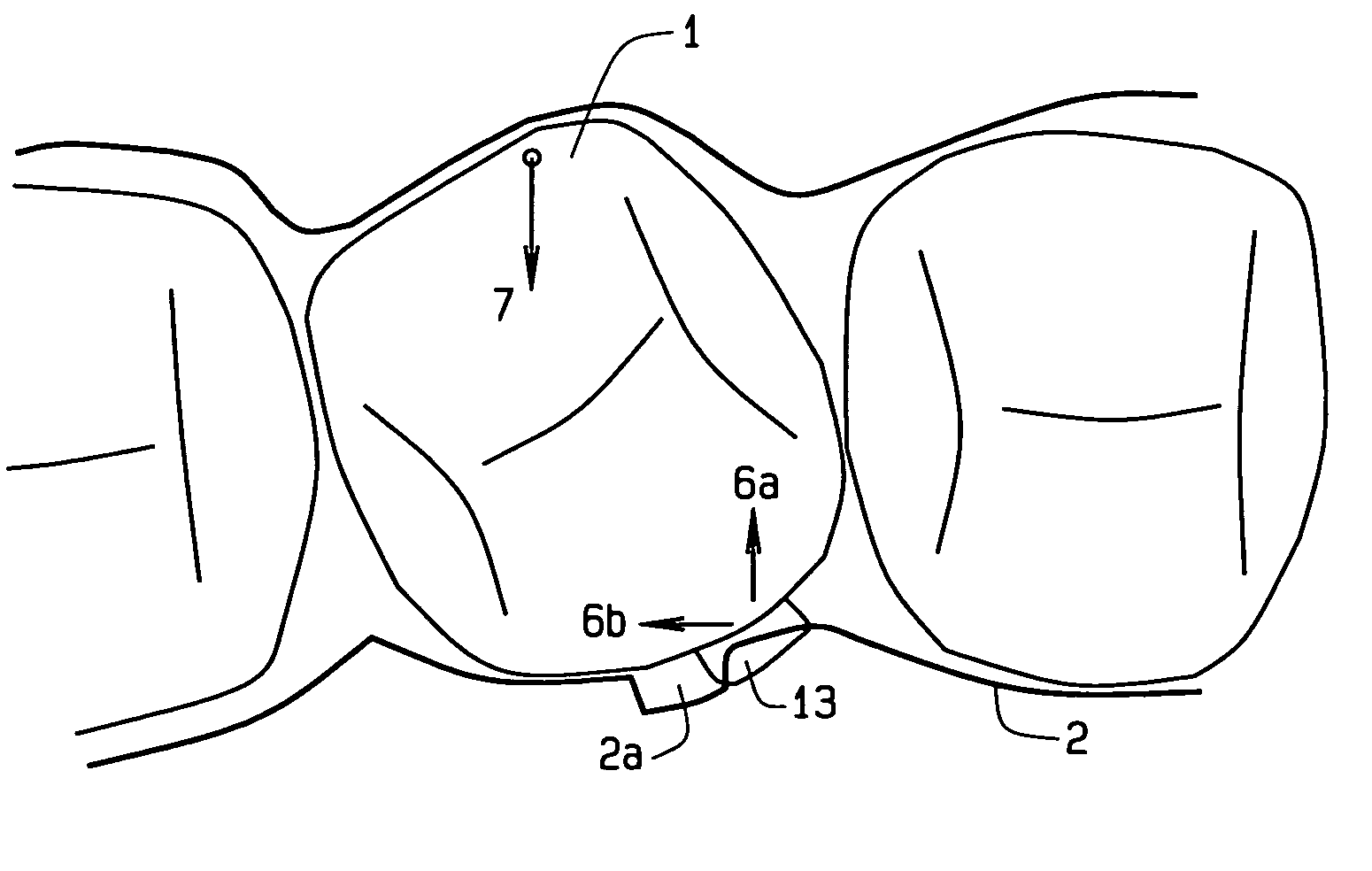

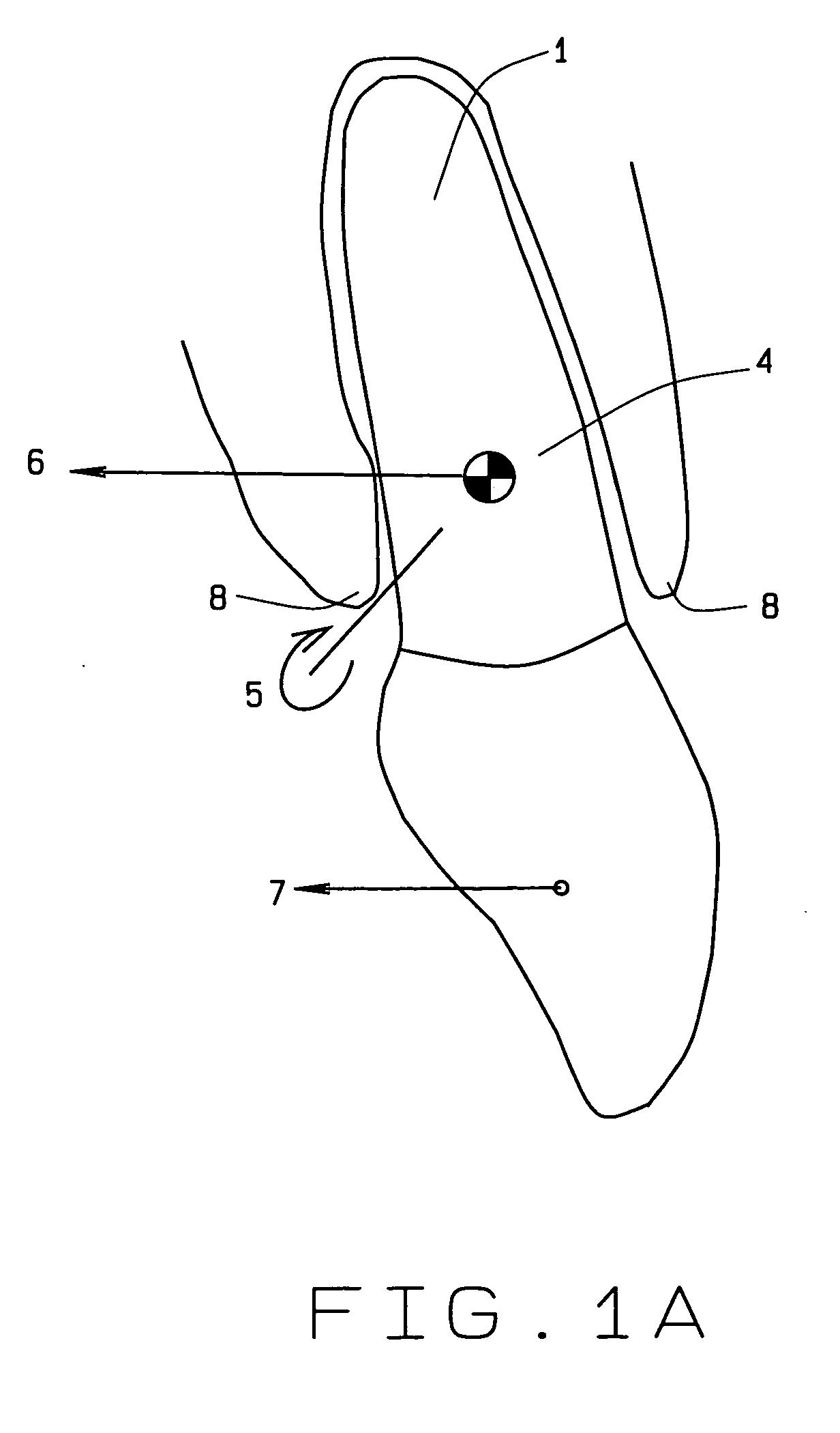

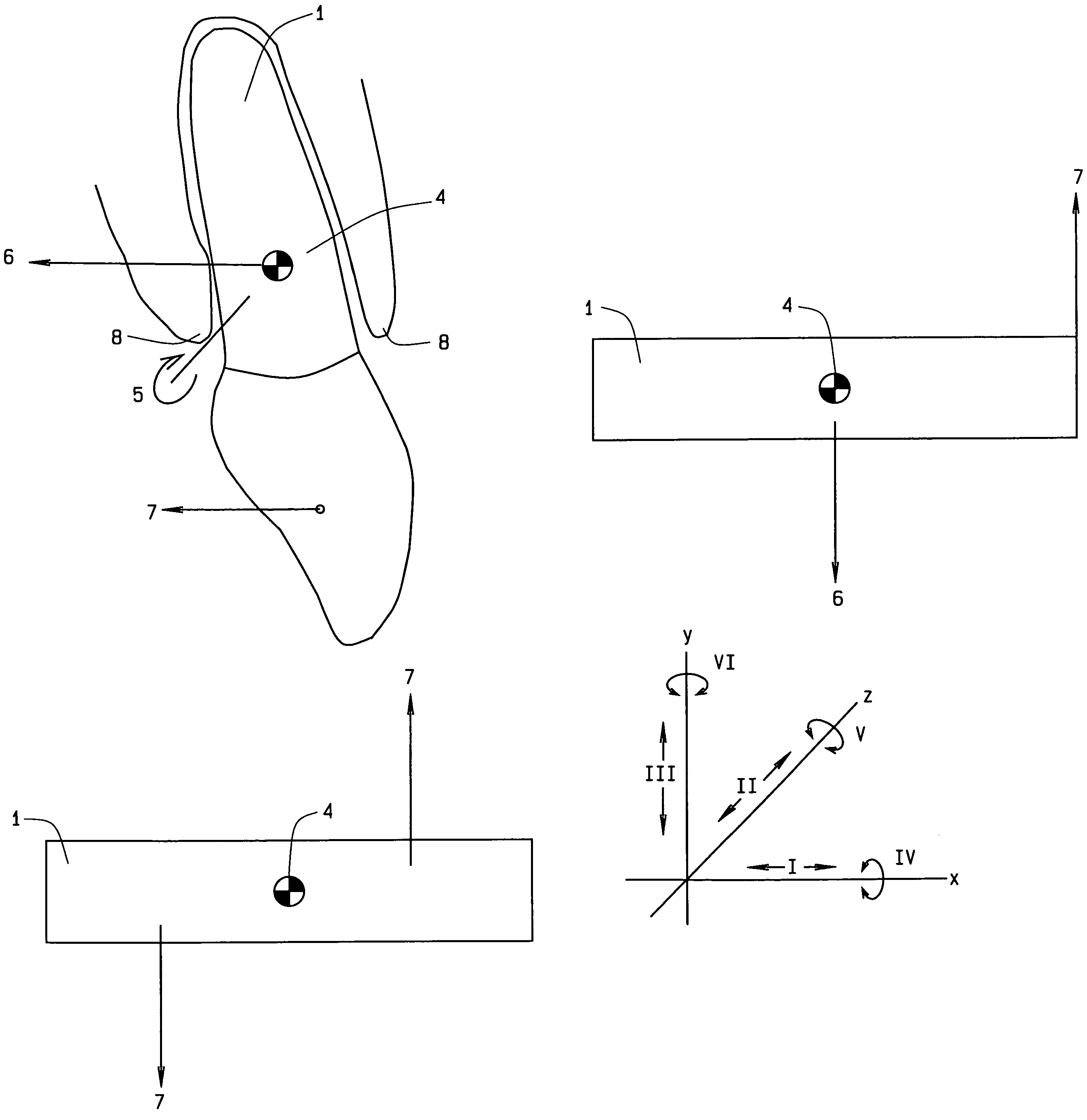

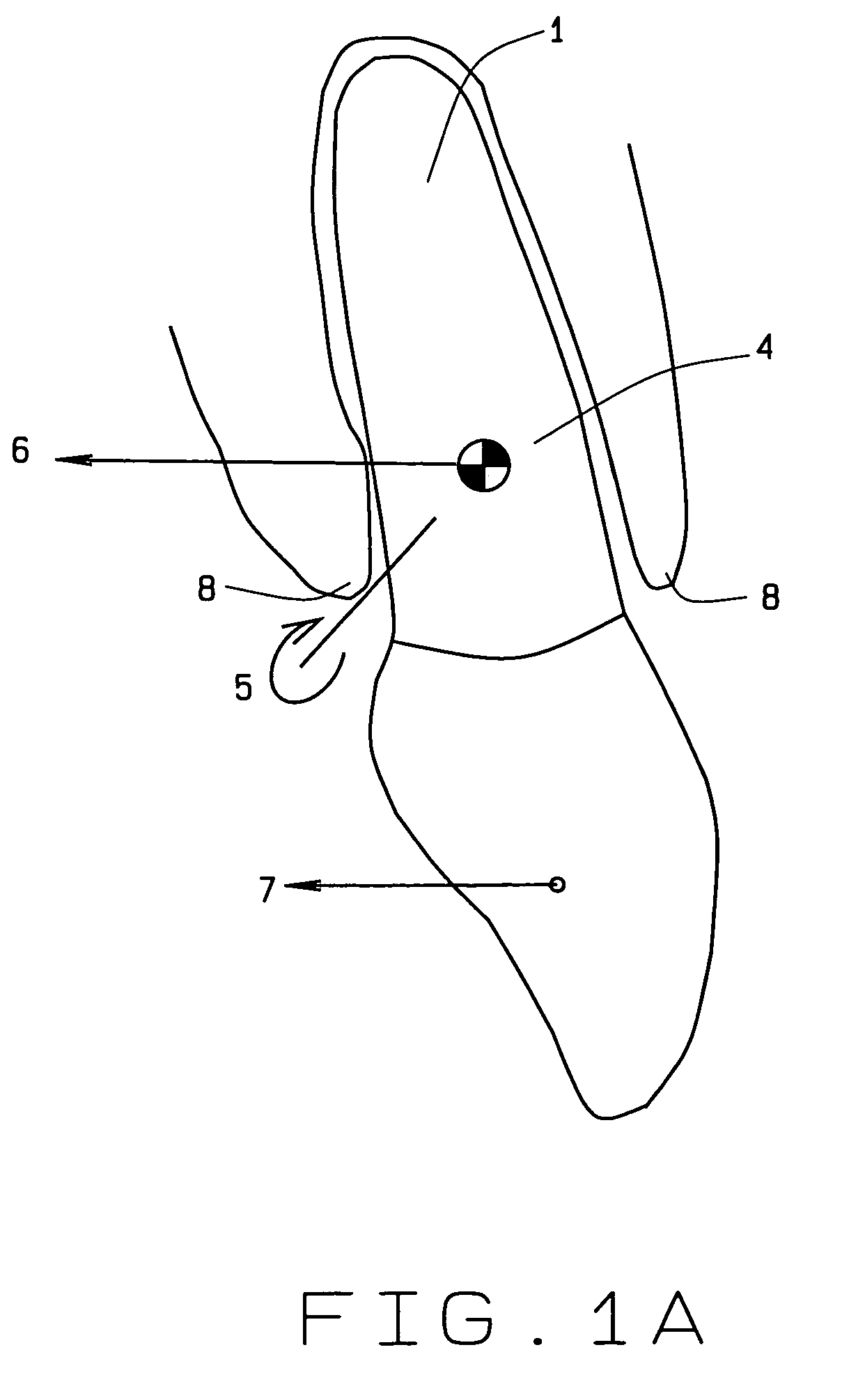

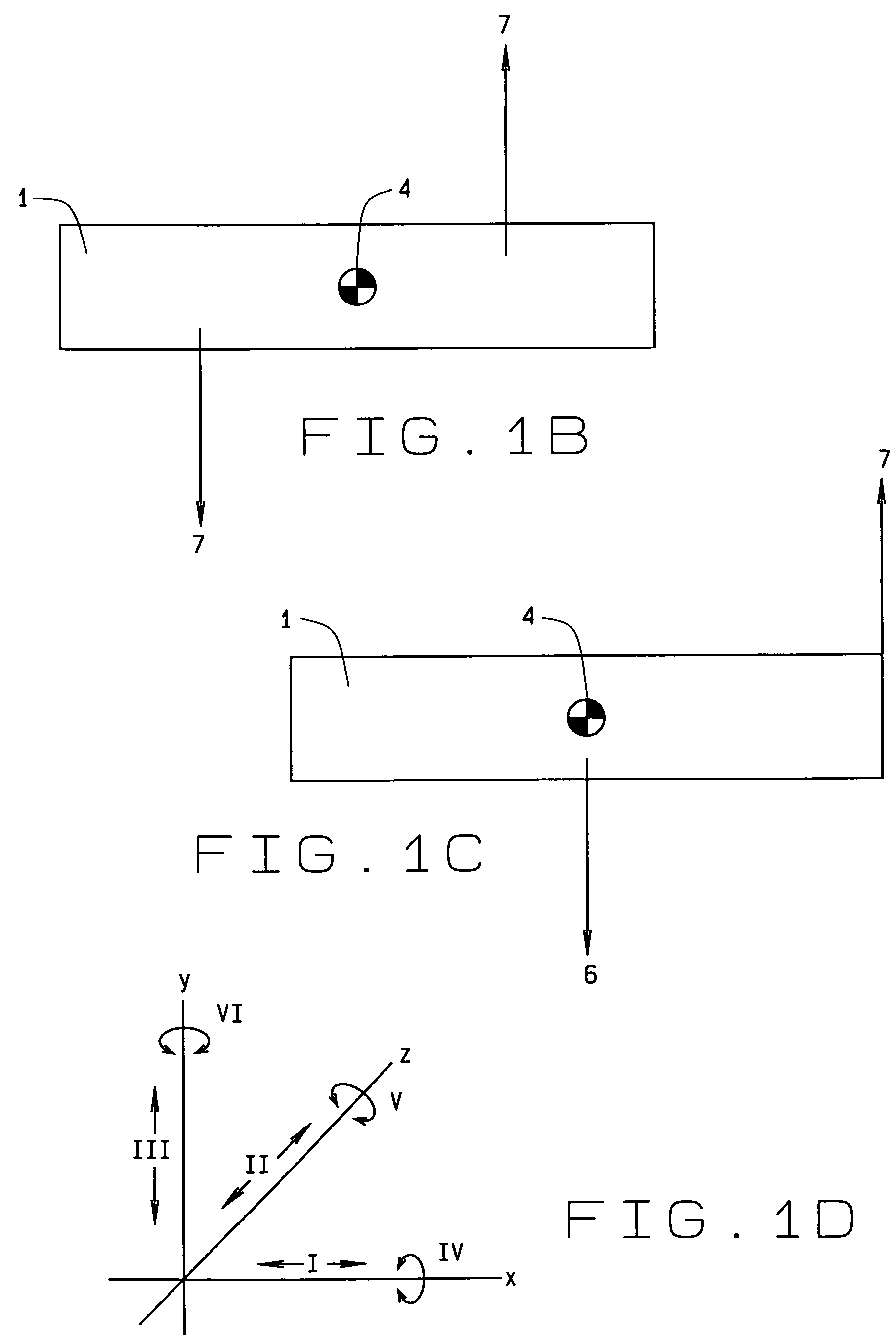

System and method for improved control of tooth movement with elastic repositioning appliances

InactiveUS20060223022A1Easy to controlGood tooth alignmentOthrodonticsDental toolsElectrical resistance and conductanceCoupling

Micro-regional force application improves the control of the orthodontic movement of teeth in all six degrees of freedom. Micro regional force application utilizes an elastic repositioning appliance, a tooth positioner, a polymeric shell, or preprogrammed series of polymeric shells. The key components of the invention are the envelope of freedom, the force applicators, force couplers, counterpart coupling, vector modifiers, seating guides, decouplers, and forced balance points. Further, computerized finite element analysis determines the center of resistance and the center of rotation for each tooth to be moved. The present invention gently rotates and translates one or more teeth to a desired straight position within a treatment plan.

Owner:SOLOMON FREDERICK

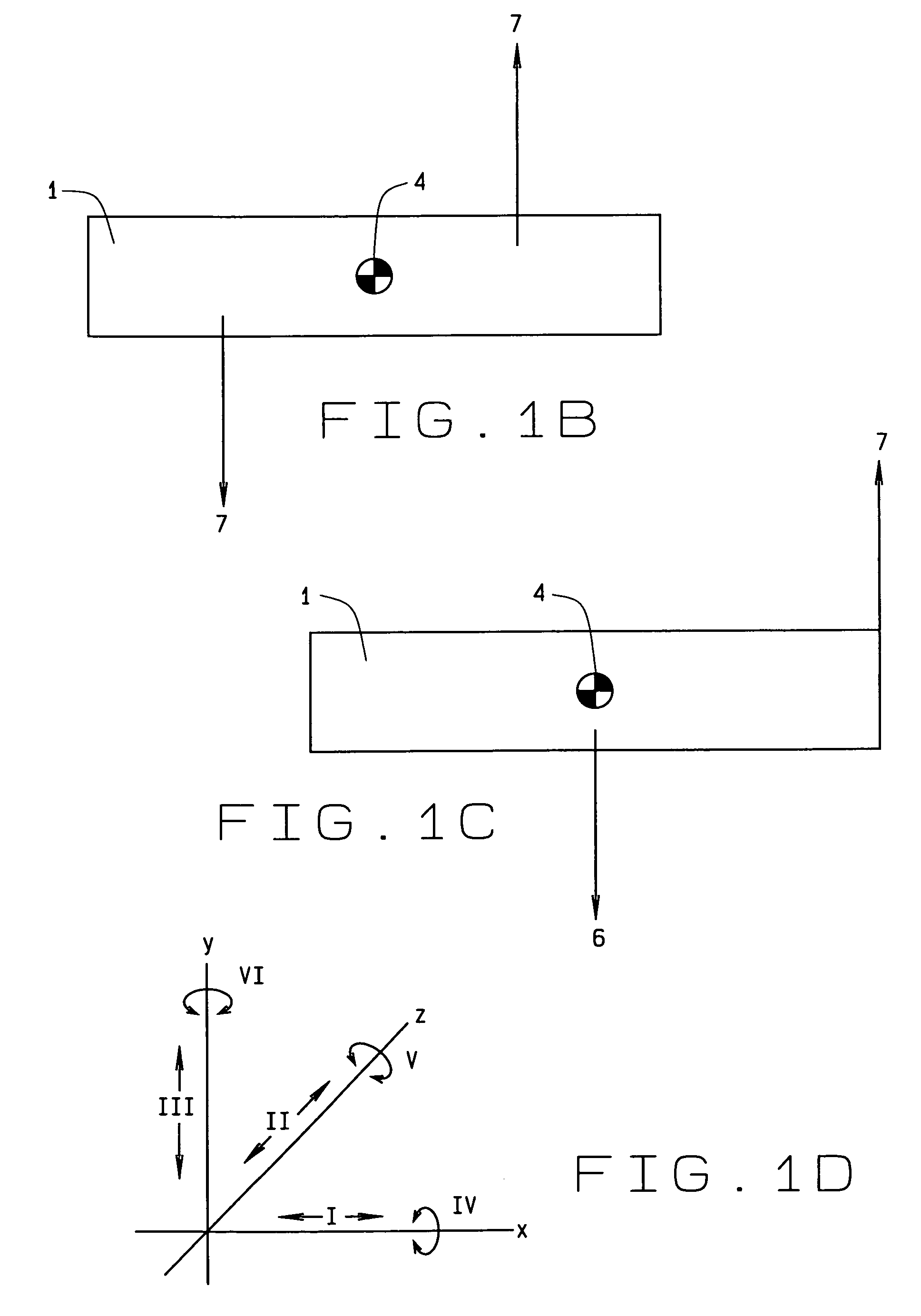

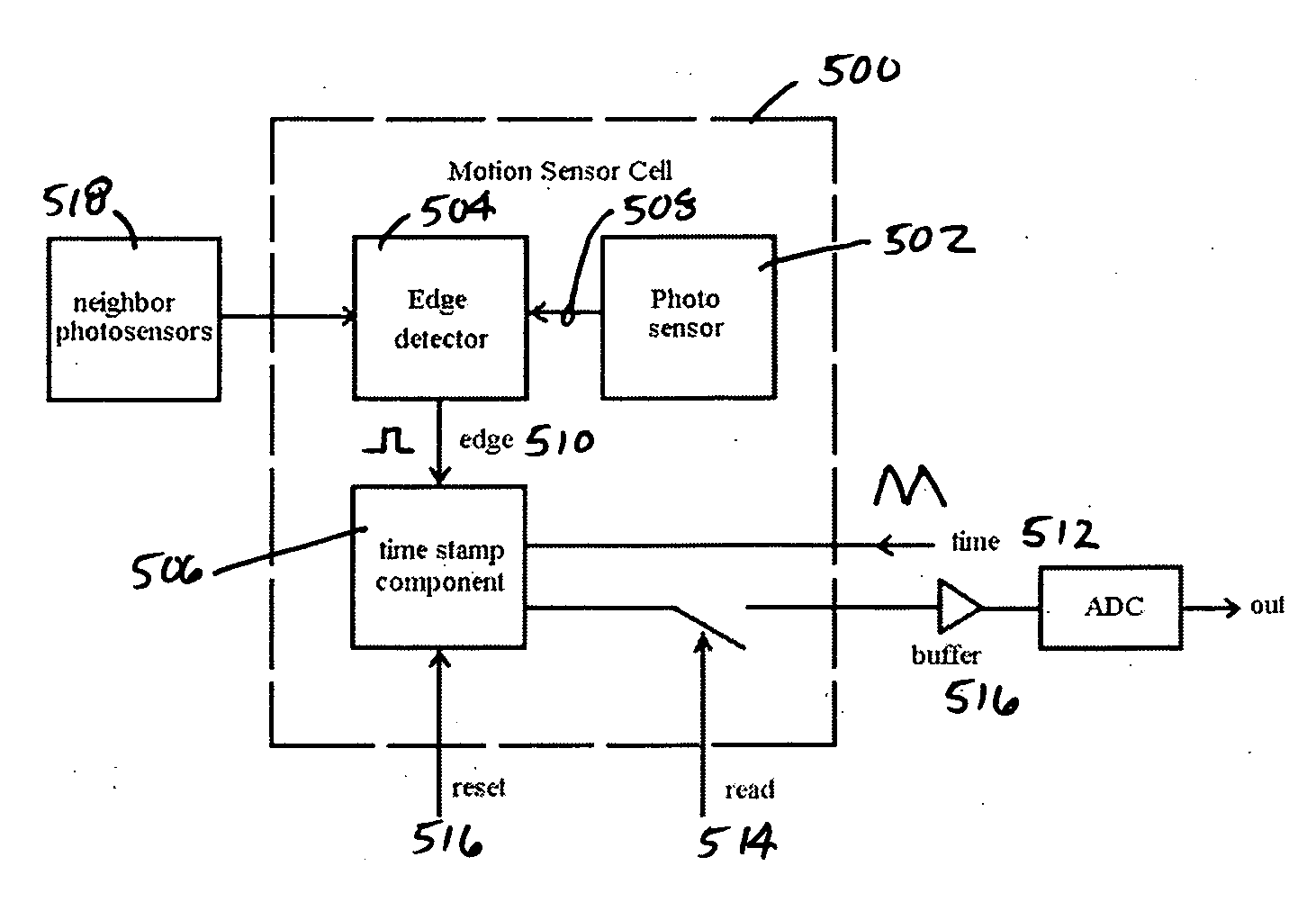

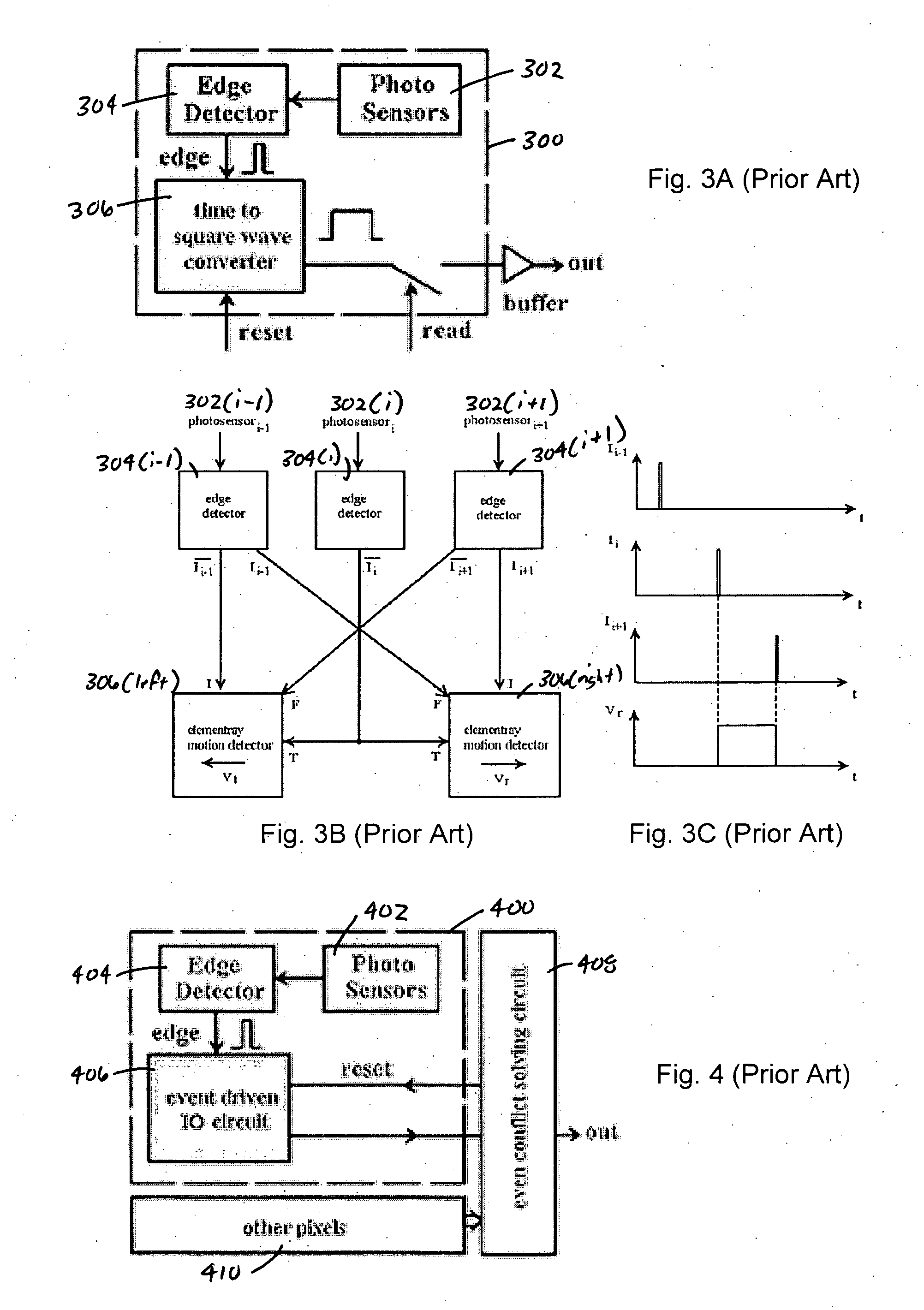

Method, system and apparatus for a time stamped visual motion sensor

InactiveUS20060197664A1Improve accuracyHigh detectionImage analysisMicrobiological testing/measurementData transmissionComputer science

The present invention provides a method, system and apparatus for a time stamped visual motion sensor that provides a compact pixel size, higher speed motion detection and accuracy in velocity computation, high resolution, low power integration and reduces the data transfer and computation load of the following digital processor. The present invention provides a visual motion sensor cell that includes a photosensor, an edge detector connected to the photosensor and a time stamp component connected to the edge detector. The edge detector receives inputs from the photosensor and generates a pulse when a moving edge is detected. The time stamp component tracks a time signal and samples a time voltage when the moving edge is detected. The sampled time voltage can be stored until the sampled time voltage is read. In addition, the edge detector can be connected to one or more neighboring photosensors to improve sensitivity and robustness.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

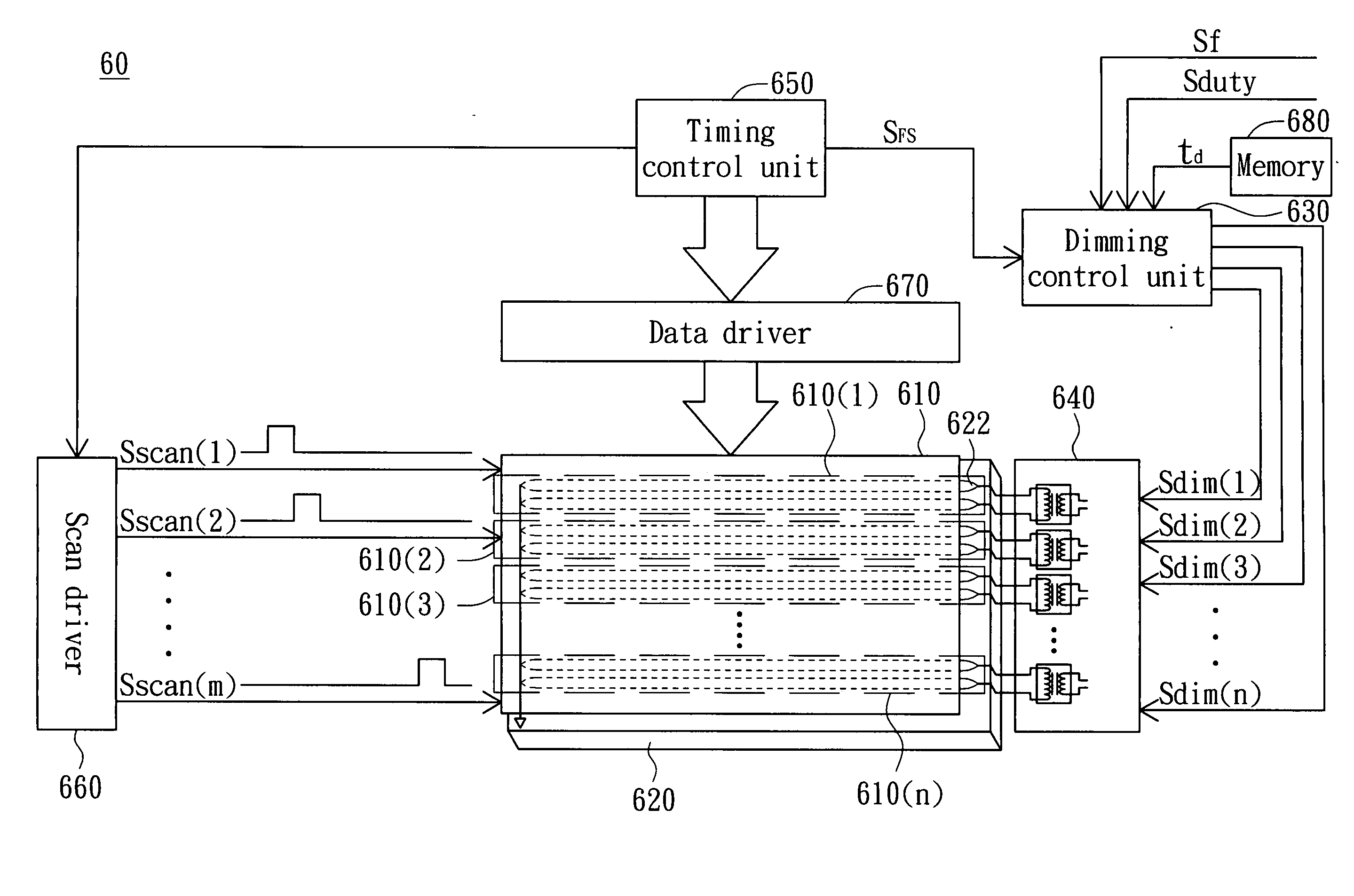

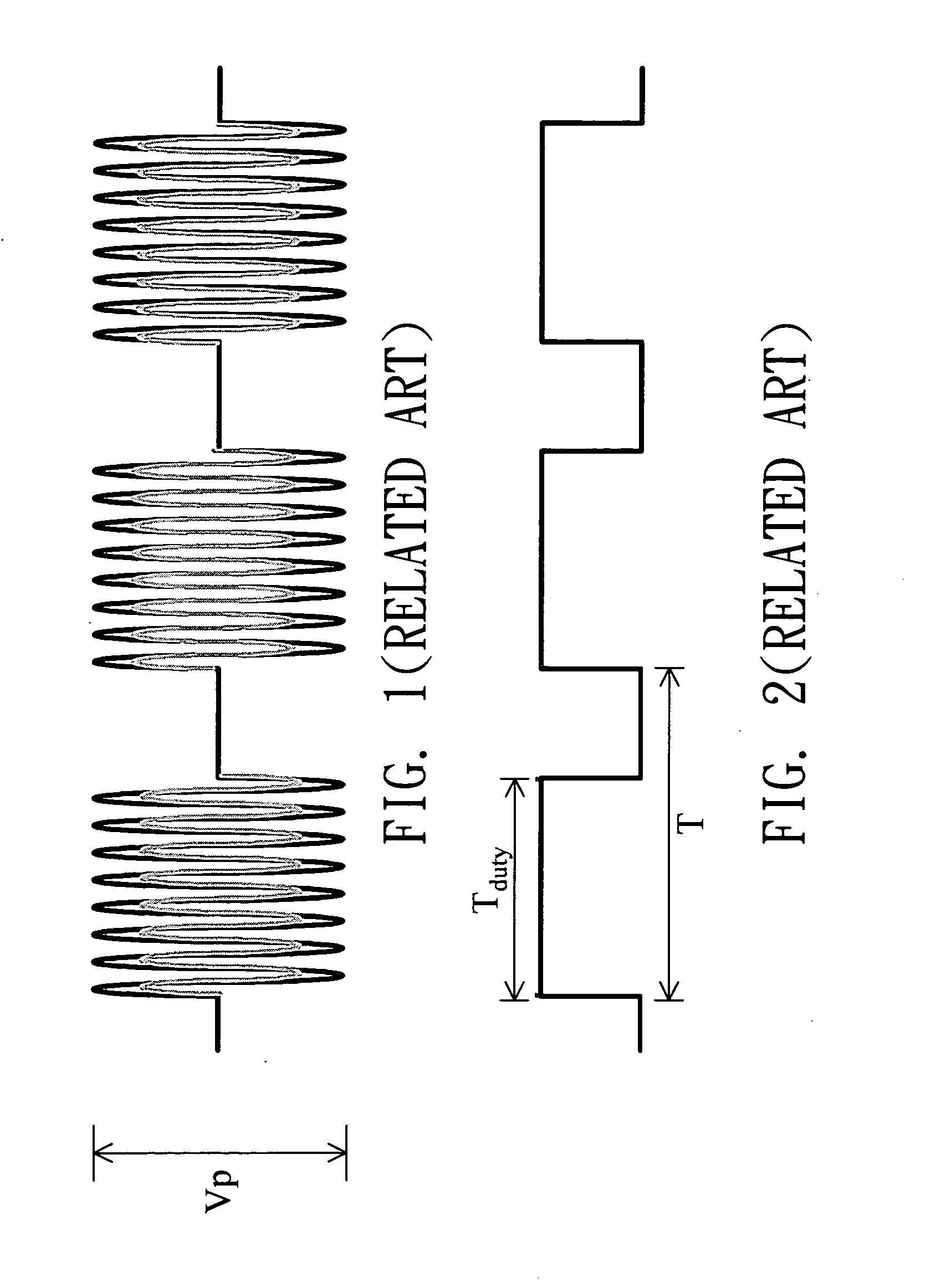

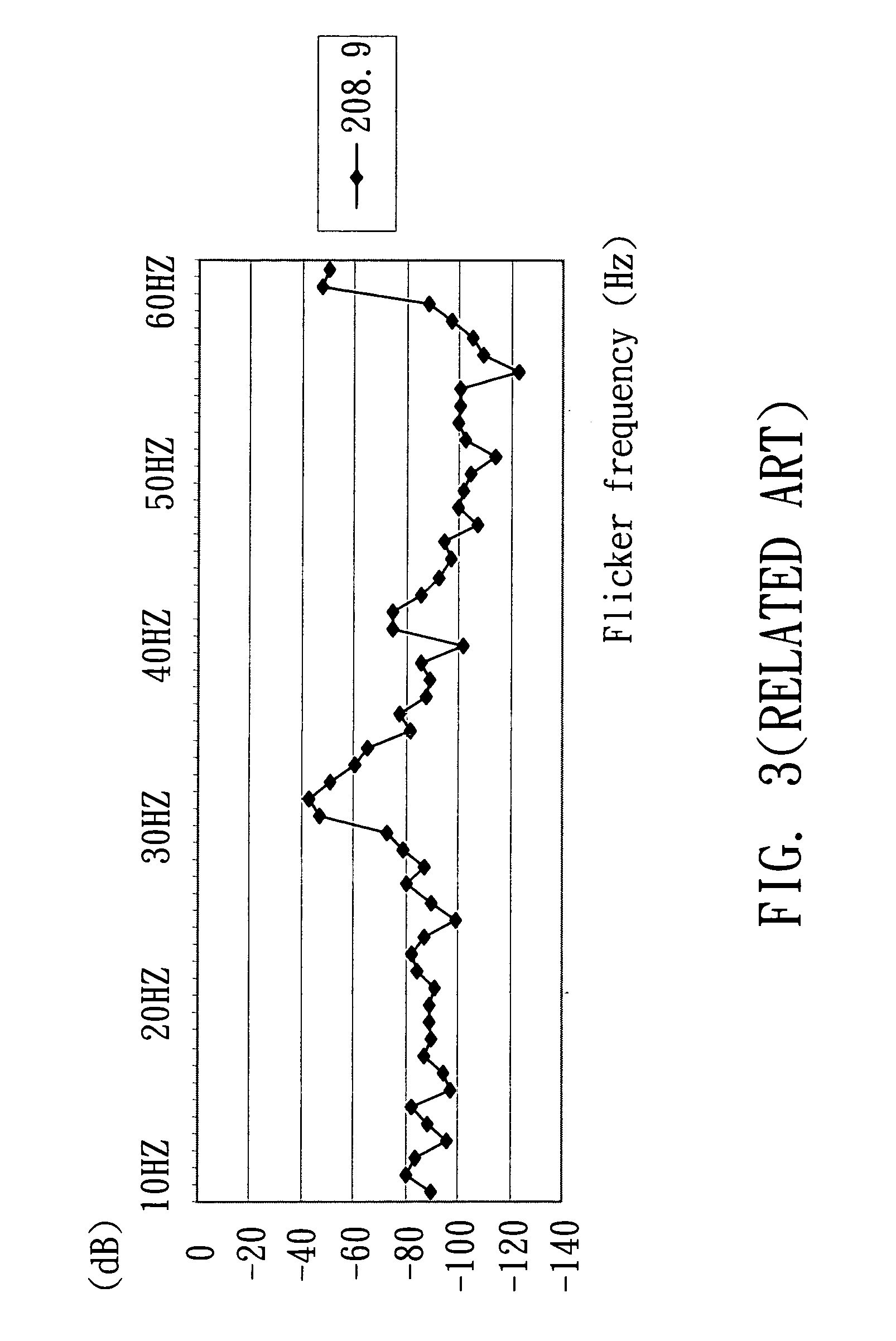

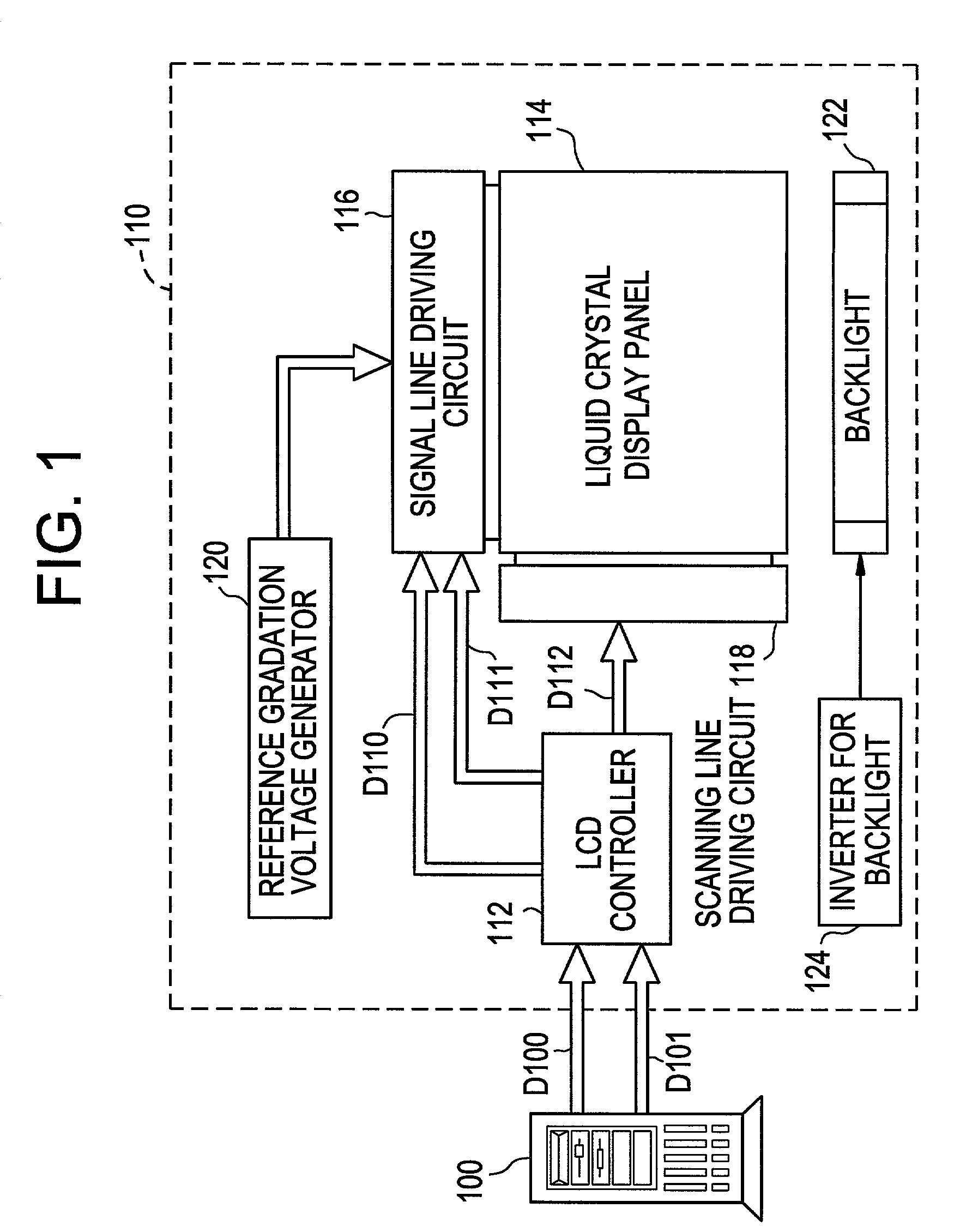

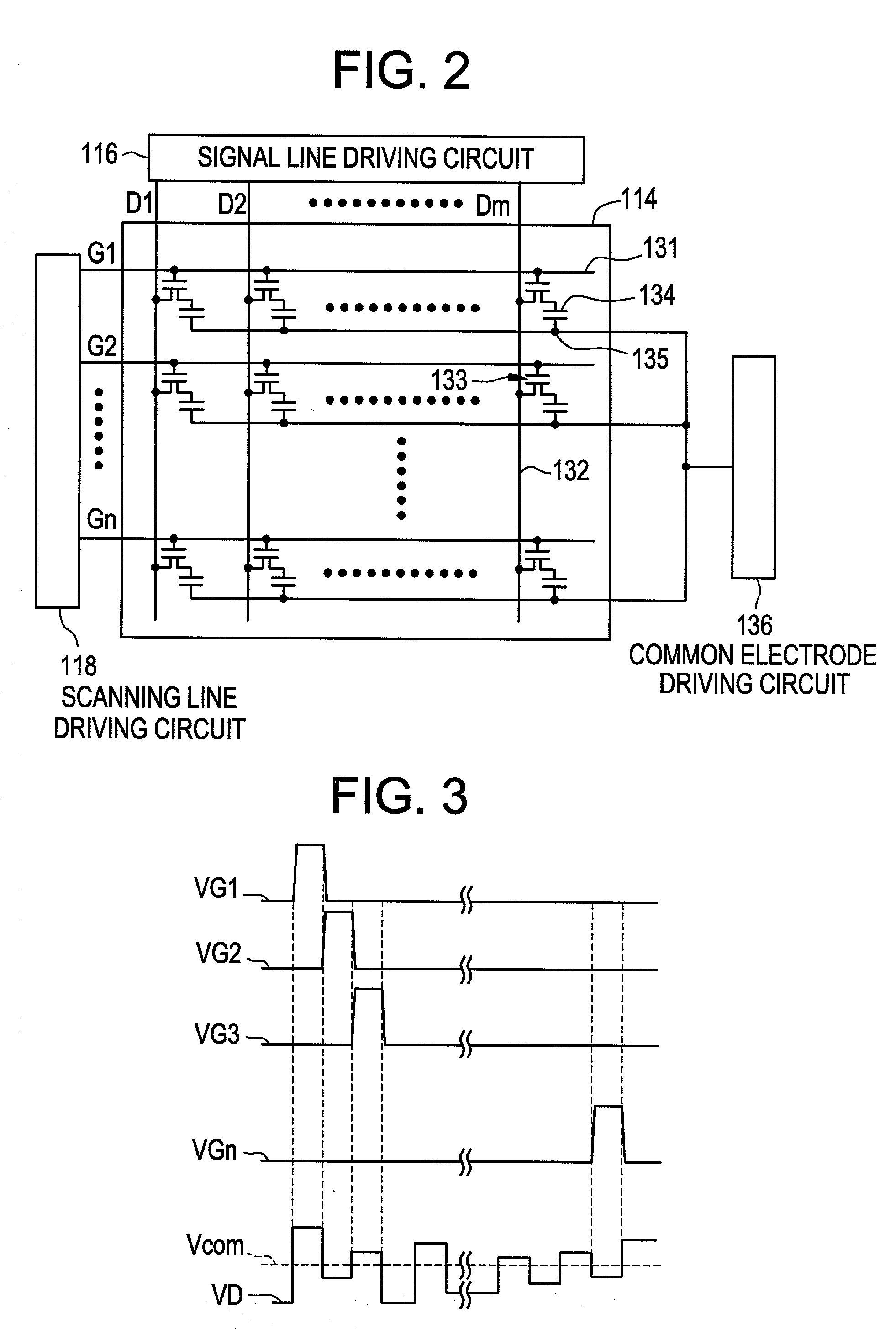

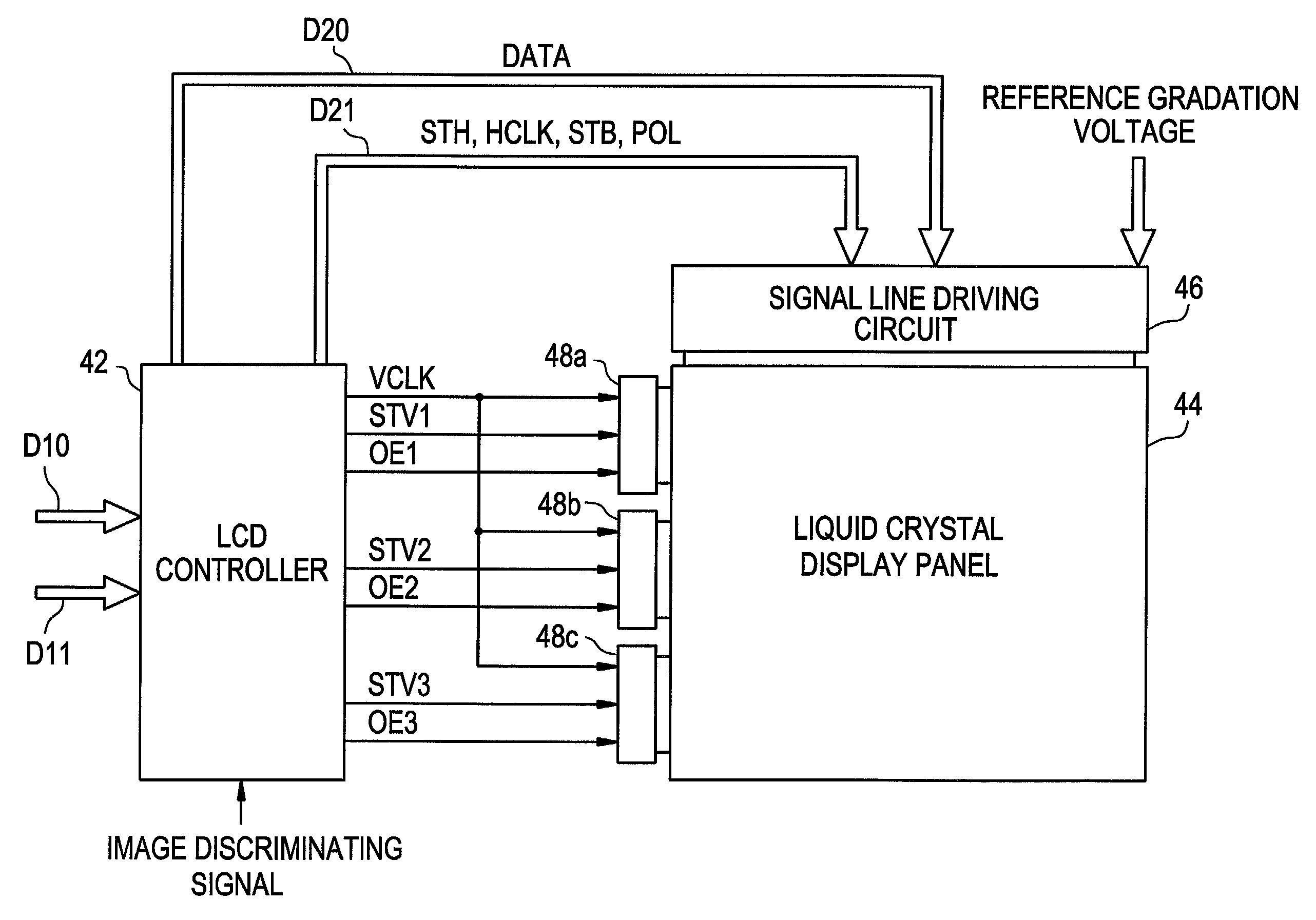

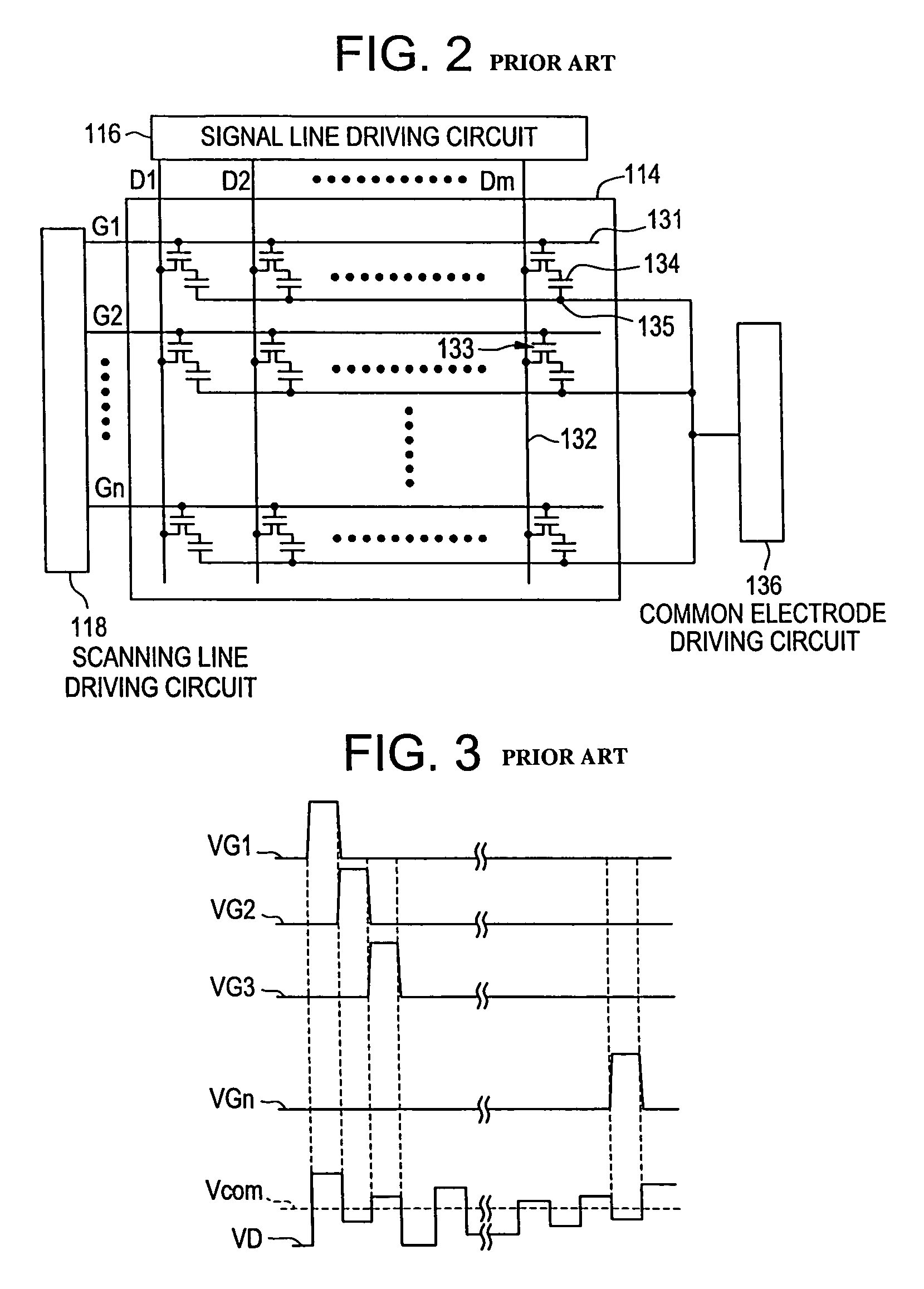

Liquid crystal display and driving method thereof

ActiveUS20070176883A1Slow movementImprove liquid qualityStatic indicating devicesNon-linear opticsLiquid-crystal displayControl signal

A liquid crystal display and a driving method thereof. The liquid crystal display includes a liquid crystal display panel, a backlight module, a dimming control unit and a backlight module driving circuit. The liquid crystal display panel has a first display area and a second display area. The backlight module includes a plurality of lighting devices respectively corresponding to pixels in the first display area and the second display area. The dimming control unit generates at least one dimming control signal having a dimming frequency which is a multiple of a frame rate of the liquid crystal display panel. The backlight module driving circuit periodically drives the lighting devices in sequence according to the dimming control signal.

Owner:AU OPTRONICS CORP

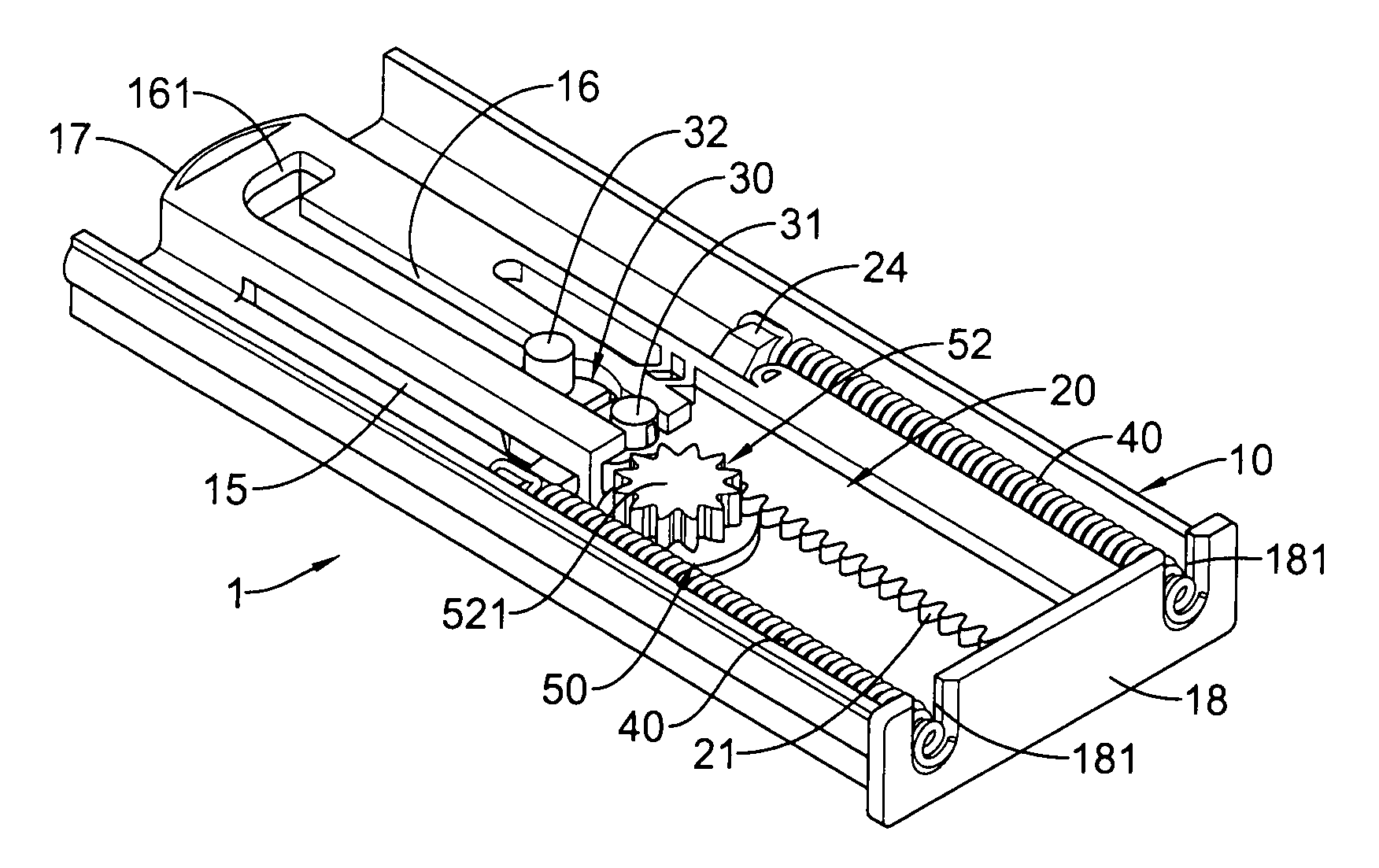

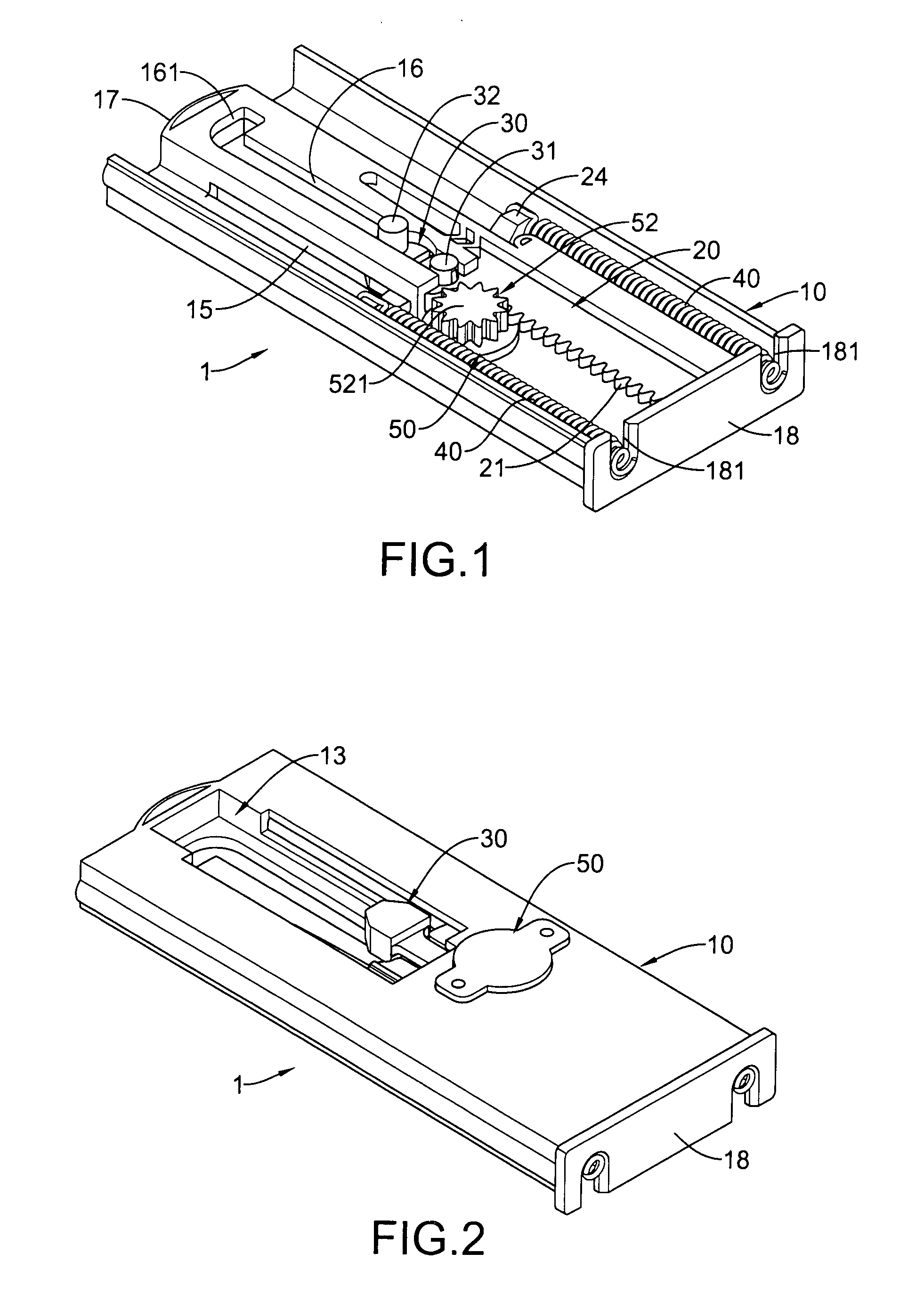

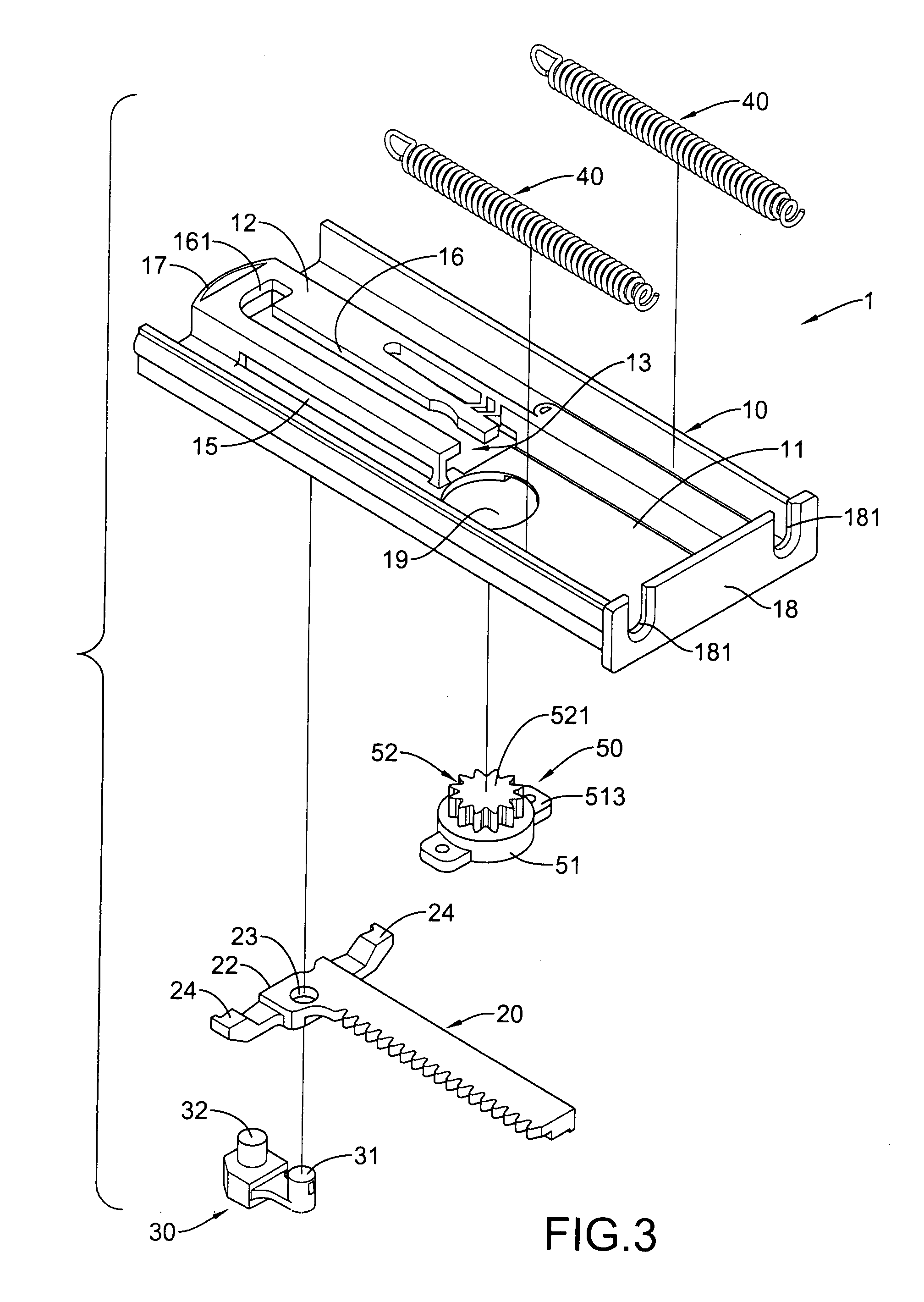

Auto-returning assembly with mechanical damper

An auto-returning assembly with mechanical damper is used in conjunction with a drawer rail and has a body, a rack, a locking protrusion, at least one spring and a damper. The body has a base and a guiding mount. The guiding mount is formed on the base and has a guide slot. The rack is mounted slidably on the body. The locking protrusion is mounted rotatably on the rack and slidably in the guiding slot and has a pivoting protrusion and a locking post. The at least one spring is connected to the body and the rack. The damper is connected securely to the body and engages the rack and has a casing and a buffering wheel. When the spring pulls the drawer rails back, rack forces the damper wheel to turn that encounters high resistance and slows the movement of the drawer rail.

Owner:CHUNG CHIN HSIANG

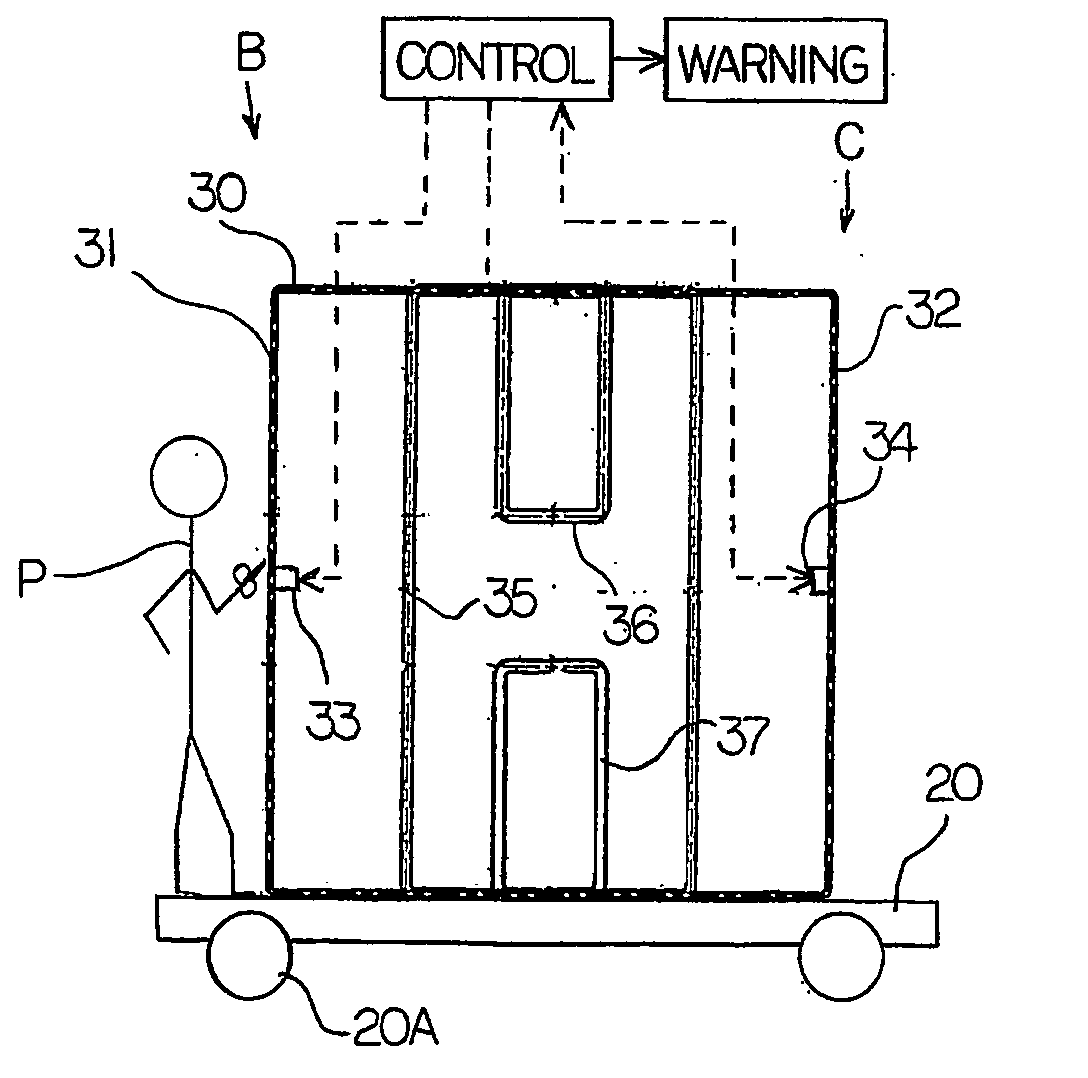

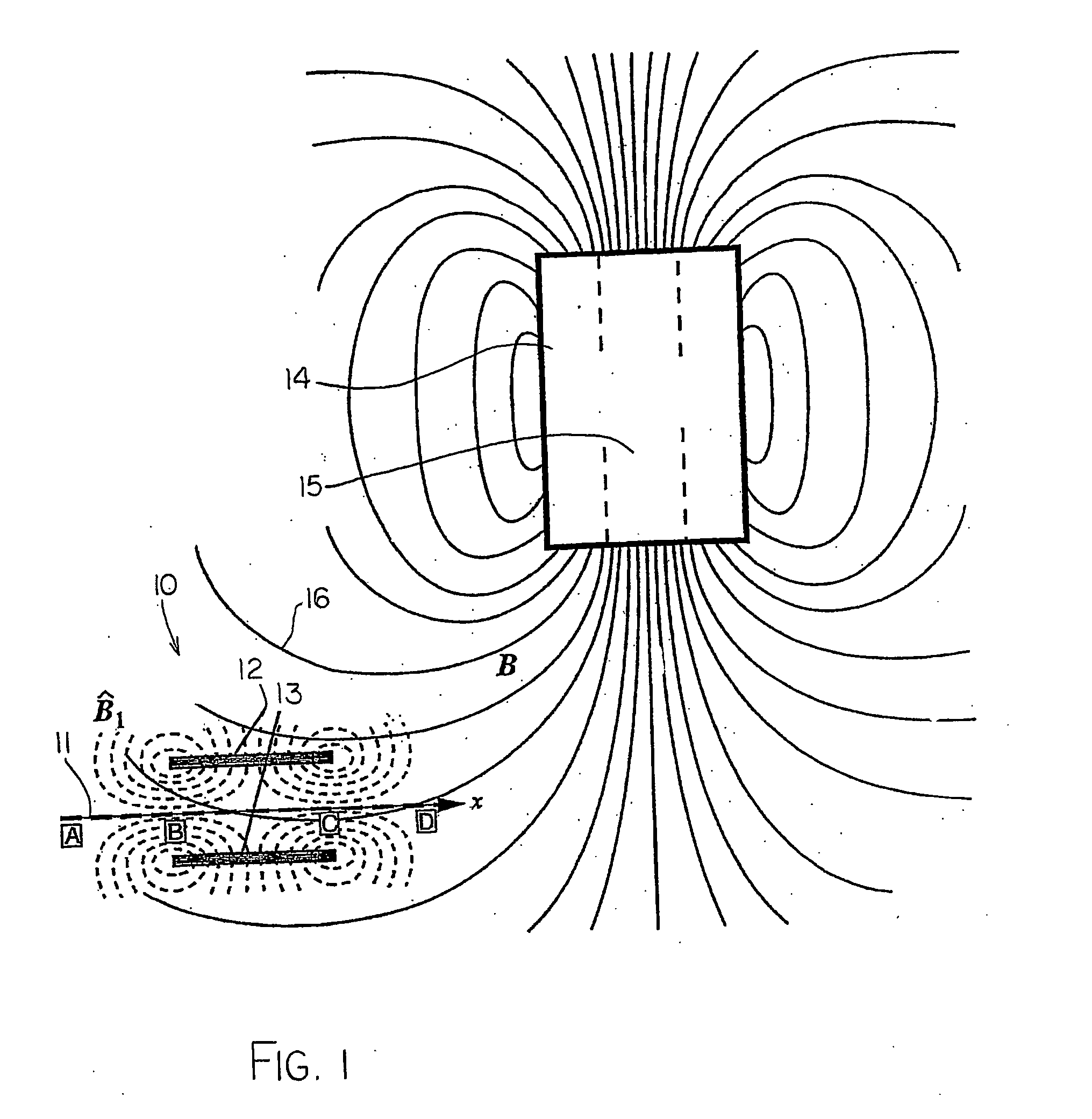

Detection of ferromagnetic objects approaching a magnet

InactiveUS20050242817A1Minimise false signalMove fastElectric ignition installationMagnetic property measurementsMagnetVoltage

An apparatus for detecting a potentially dangerous ferromagnetic object carried inadvertently by a person approaching the magnet of a magnetic resonance imaging system (14) uses the fringe field (16) of the magnet and provides guide members (11) defining a path along which the person is prescribed to pass. The path (11) is generally or approximately parallel to the field at the path. At least one sense coil and generally two sets of sense coils (12, 13) are located on respective sides of the path (11) so that the movement of the ferromagnetic object in the field of the magnet causes a voltage to be generated in the sense coil.

Owner:NAT RES COUNCIL OF CANADA

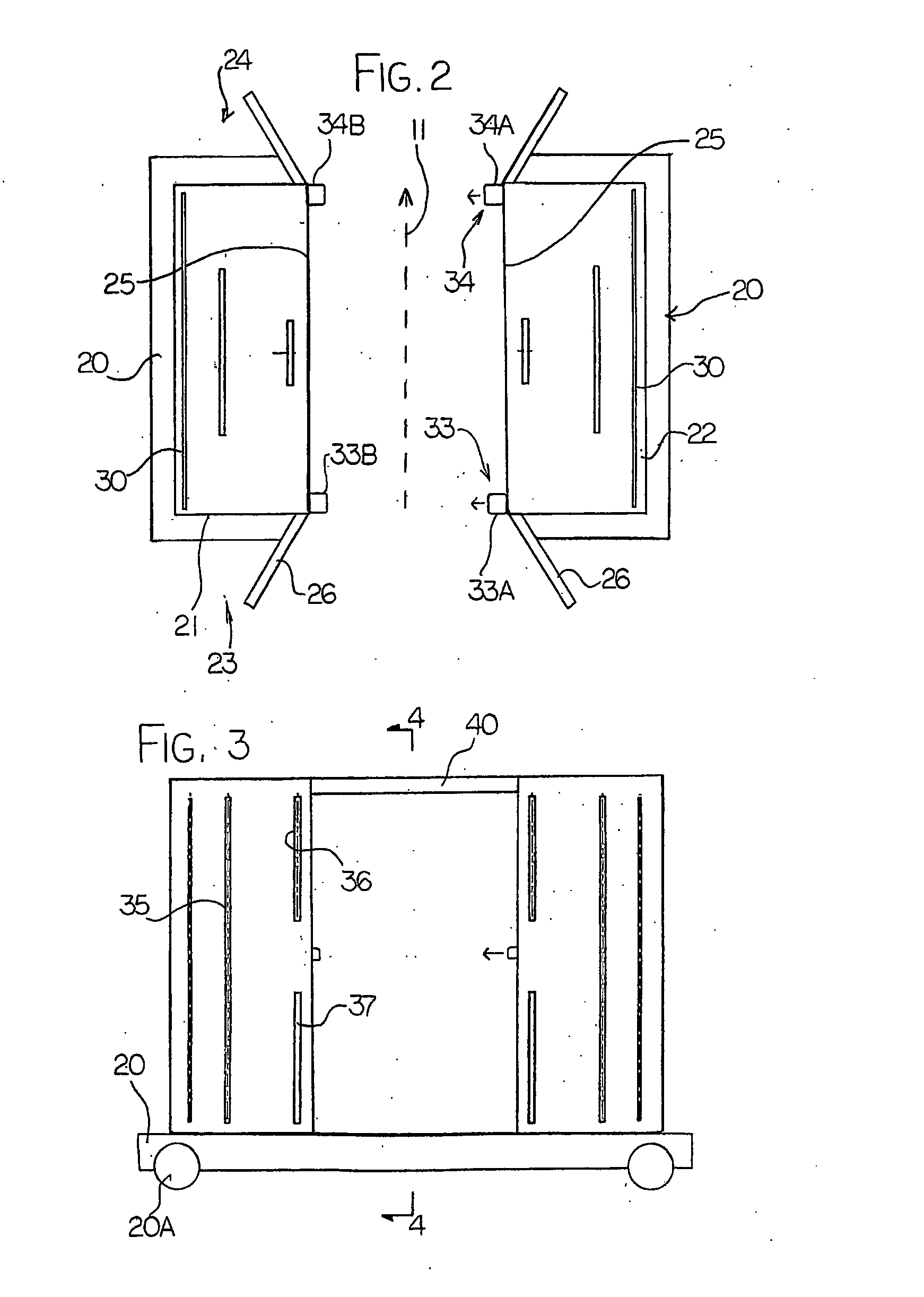

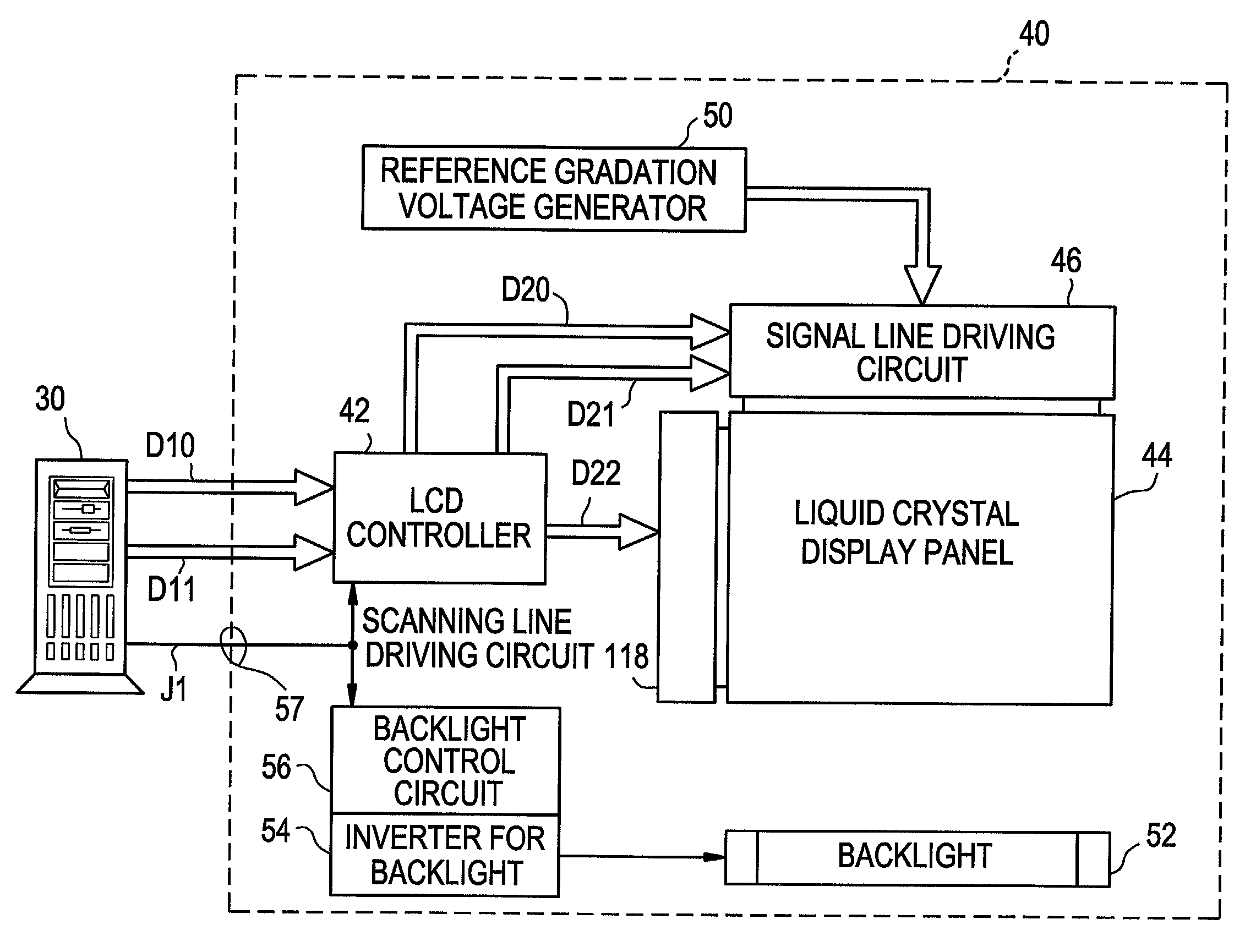

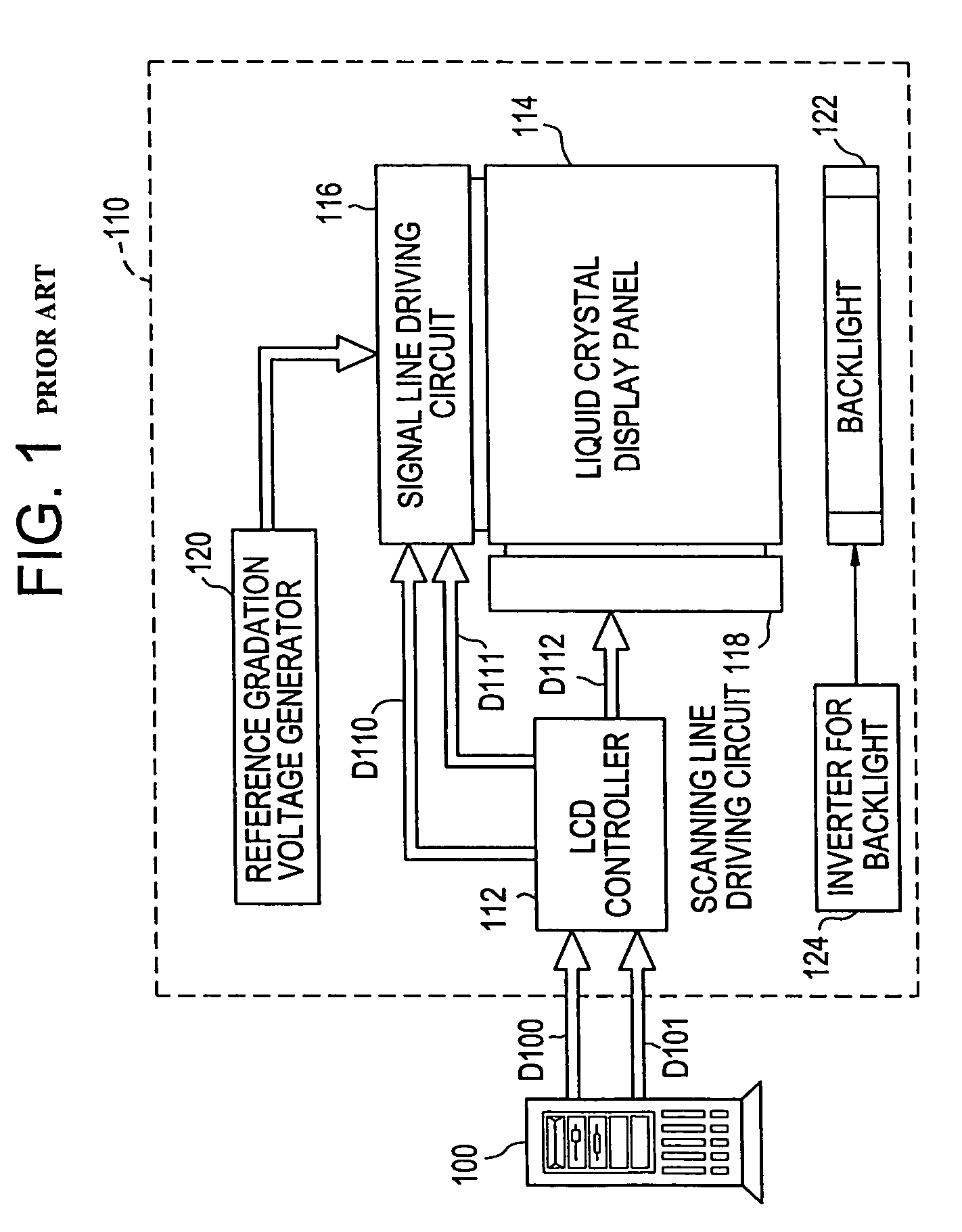

Liquid crystal display and computer

InactiveUS20030001983A1Slow movementInhibit deteriorationTelevision system detailsStatic indicating devicesLiquid-crystal displayControl circuit

A backlight control circuit that variably controls the display luminance of a liquid crystal display panel by controlling the luminance of a backlight based upon whether an image displayed on the liquid crystal display panel is a dynamic image or a static image, and an LCD controller that controls so that a part or the whole of a dynamic image is displayed by using a single color for a predetermined time in case an image displayed on the liquid crystal display panel is a dynamic image are provided.

Owner:RENESAS ELECTRONICS CORP

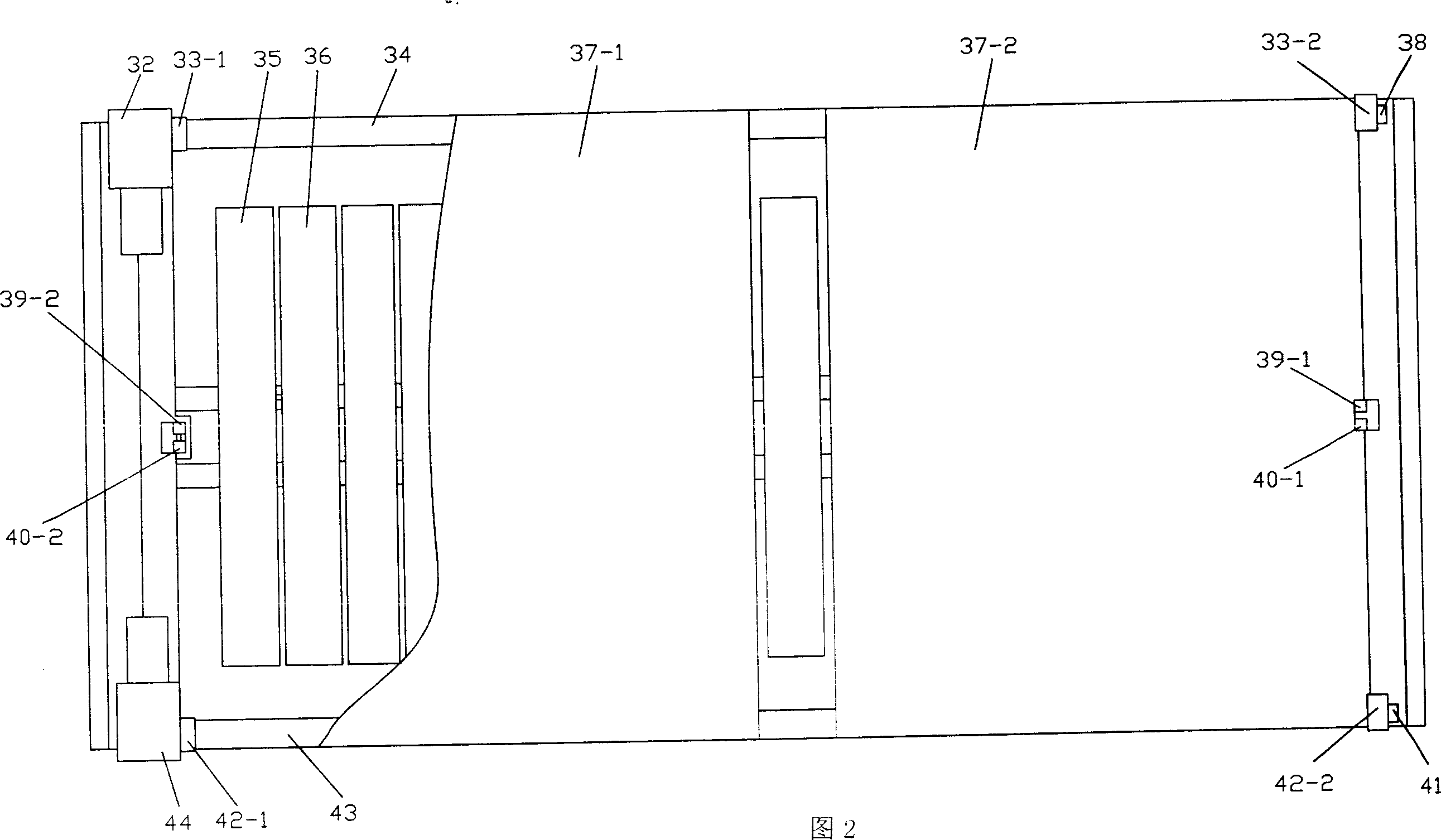

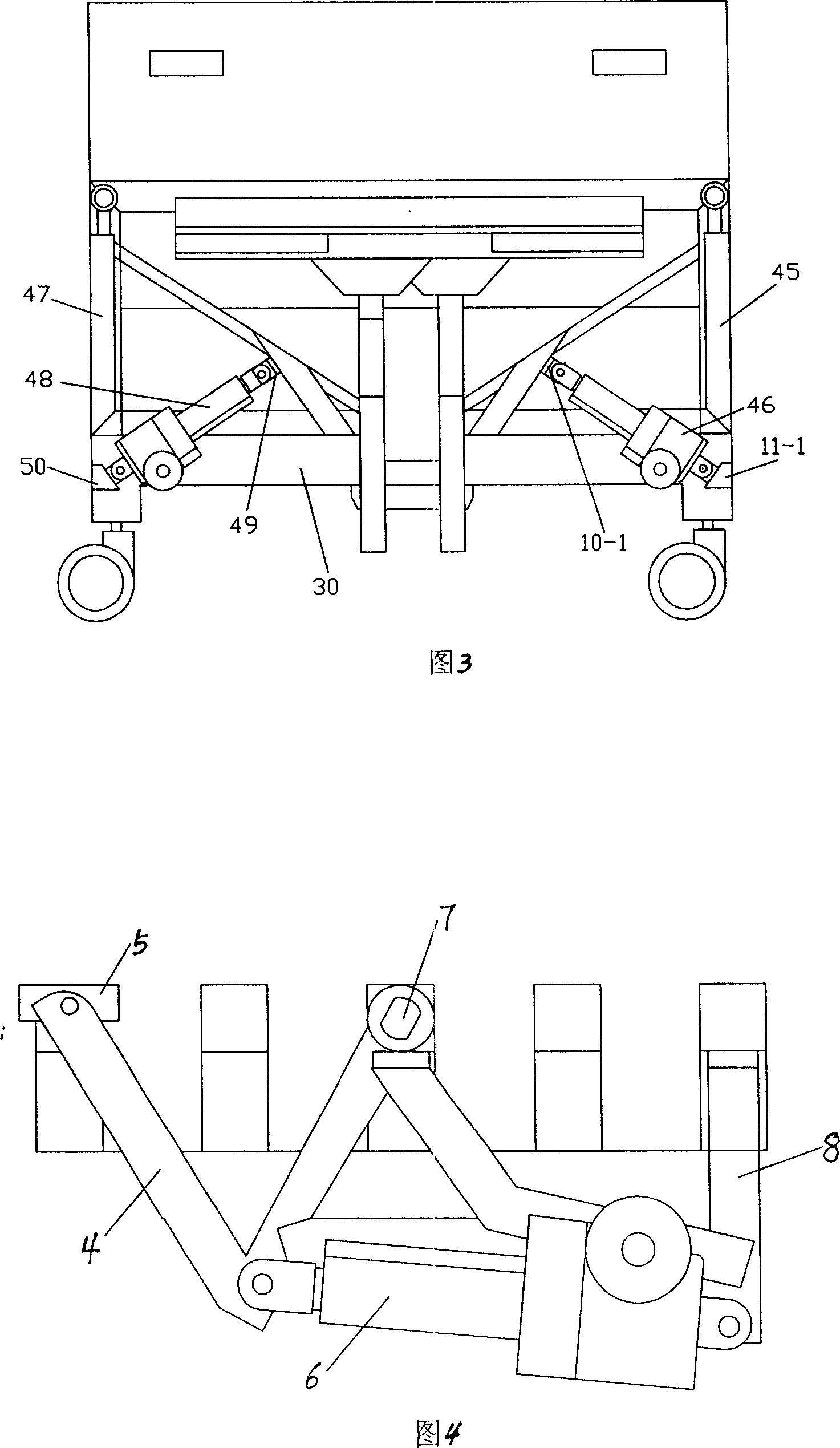

Multifunctional bedsore-proof nursing bed

The invention relates to a multifunctional anti-bedsore bed, which comprises a bed support, lifting plates, a stern lifter and a turnover device, wherein, the support is mounted with two lifting plates separated distributed; the stern lifter is mounted under one lifting plate; the turnover device is mounted at two sides of support. The invention uses the alternative motion of lifting plates, to move the back of patient, to prevent bedsore. And the invention can lift up the stern of patient to discharge dirt, without drawing out the plate, to reduce the friction on the stern. And the invention can draw the flexible cloth to turnover the body. The invention has simple structure and the anti-bedsore function.

Owner:莫之民 +1

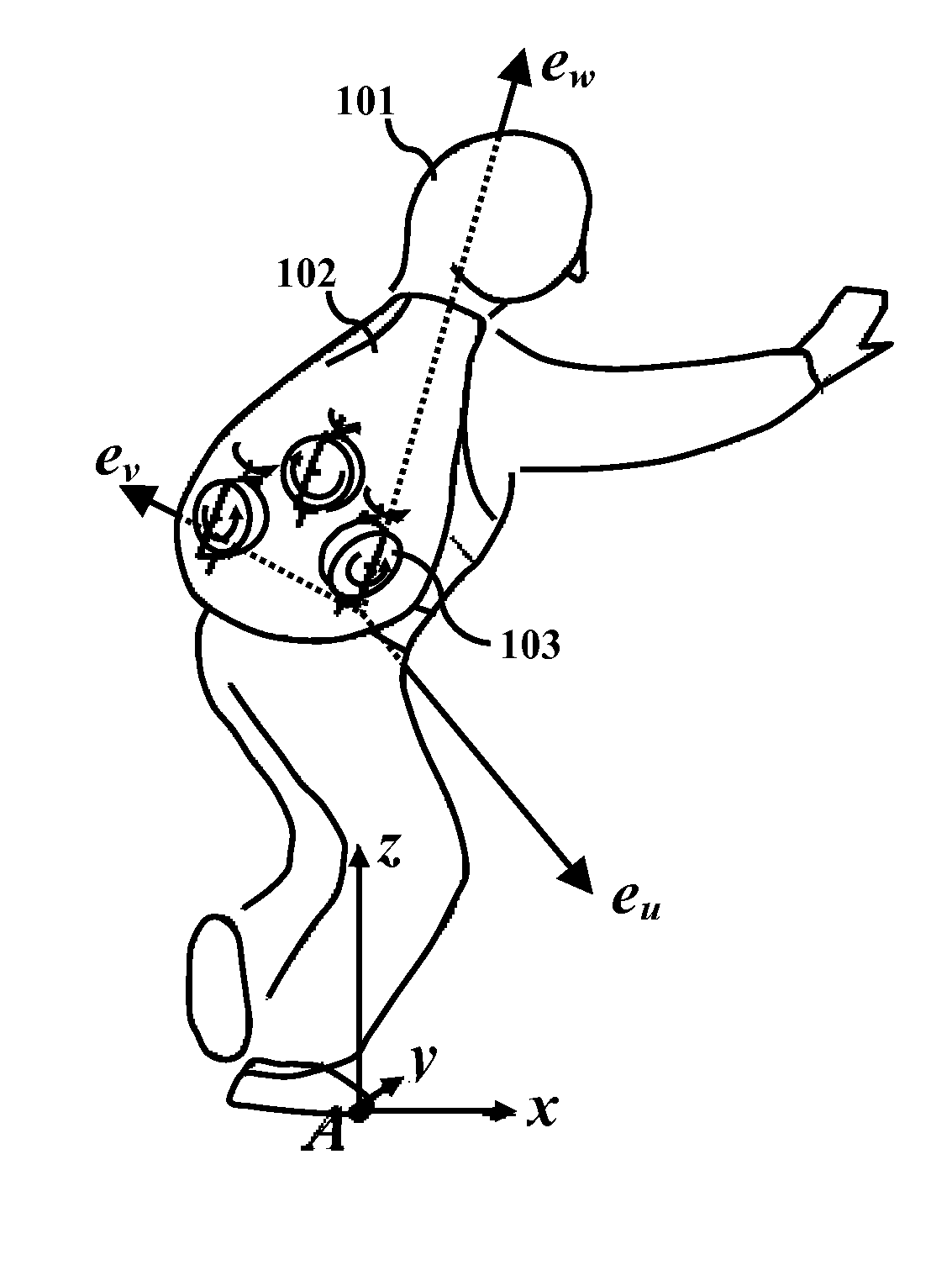

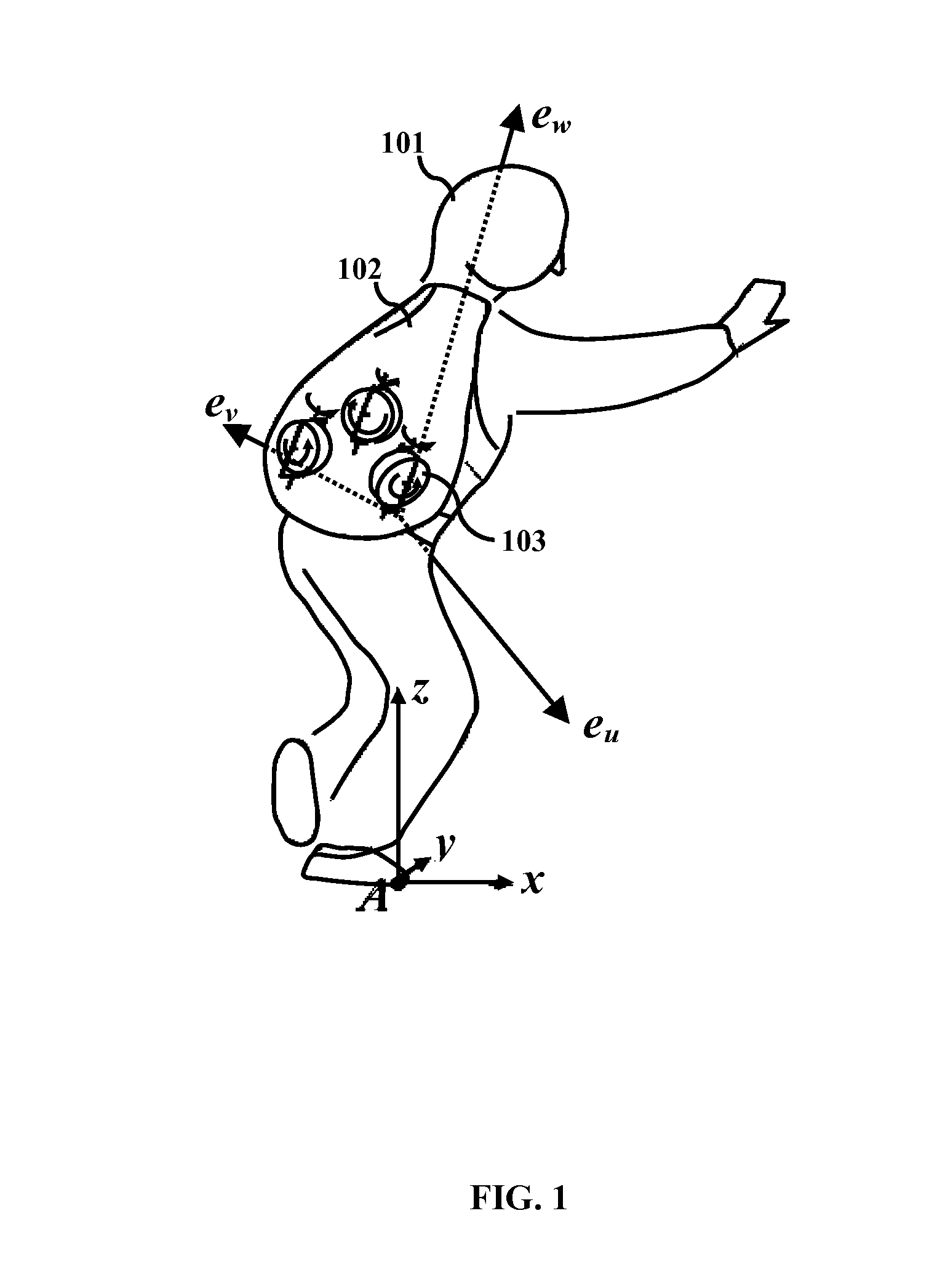

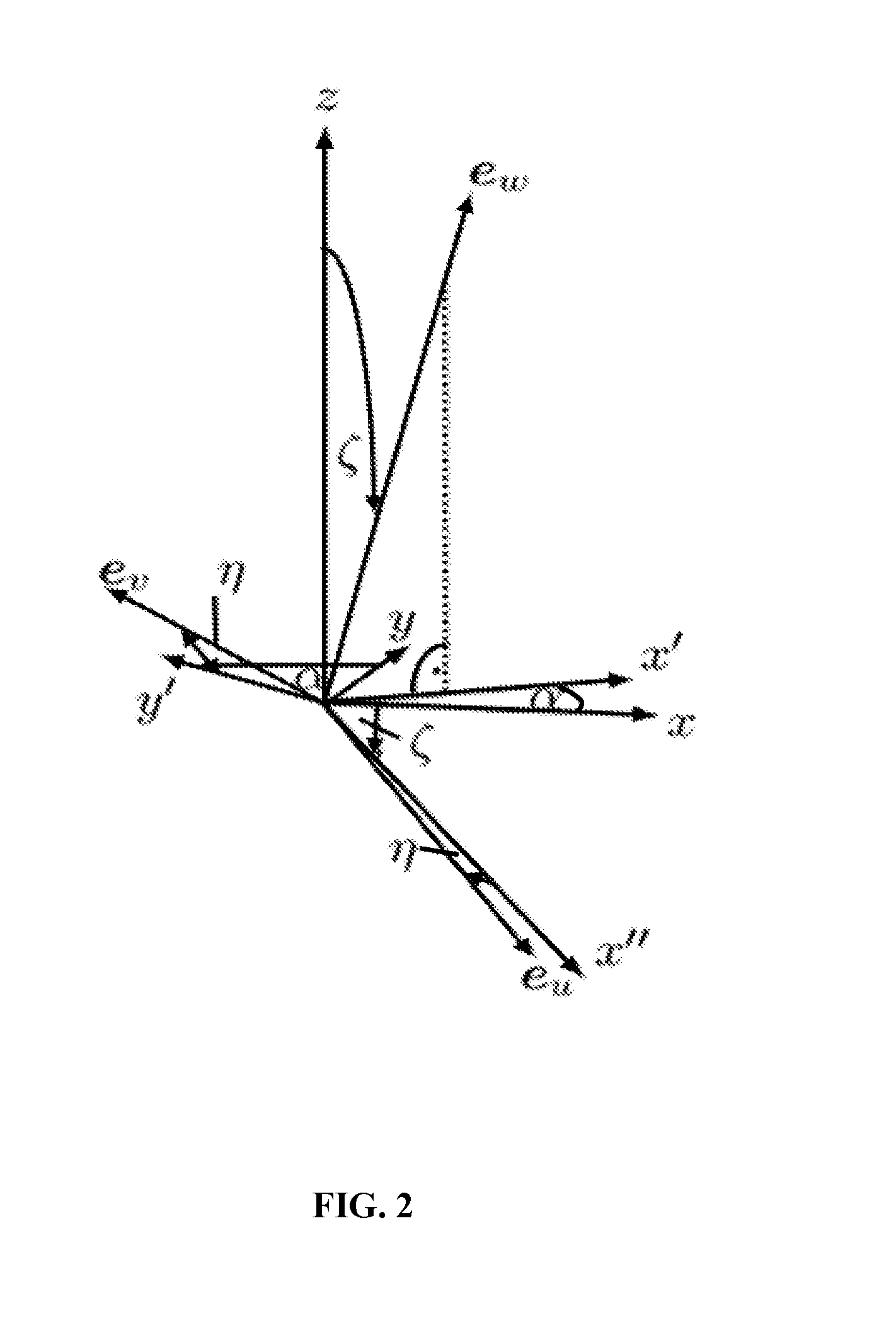

Gyroscopic-assisted device to control balance

InactiveUS20140260714A1Prevent fallingSlow movementMechanical apparatusWalking aidsGyroscopeEngineering

The embodiment herein generally relates to a system to apply moments to a user, particularly during gait. The system is a portable gyroscopic-assisted system, mounted on a user's body, particularly the upper body, particularly to influence orientation of users having difficulty with balancing during gait. The system comprises a plurality of variable-speed control moment gyroscopes (VSCMGs). The VSCMGs generate moments, particularly to counteract a fall to any direction. The VSCMGs are placed close to the center of mass of the user. The couple moments of the VSCMGs are transmitted to the user through a support structure that is tightly attached to the user. Particularly, the system controls moments based on detecting pre-fall conditions.

Owner:KHALIFA UNIV OF SCI & TECH & RES KUSTAR

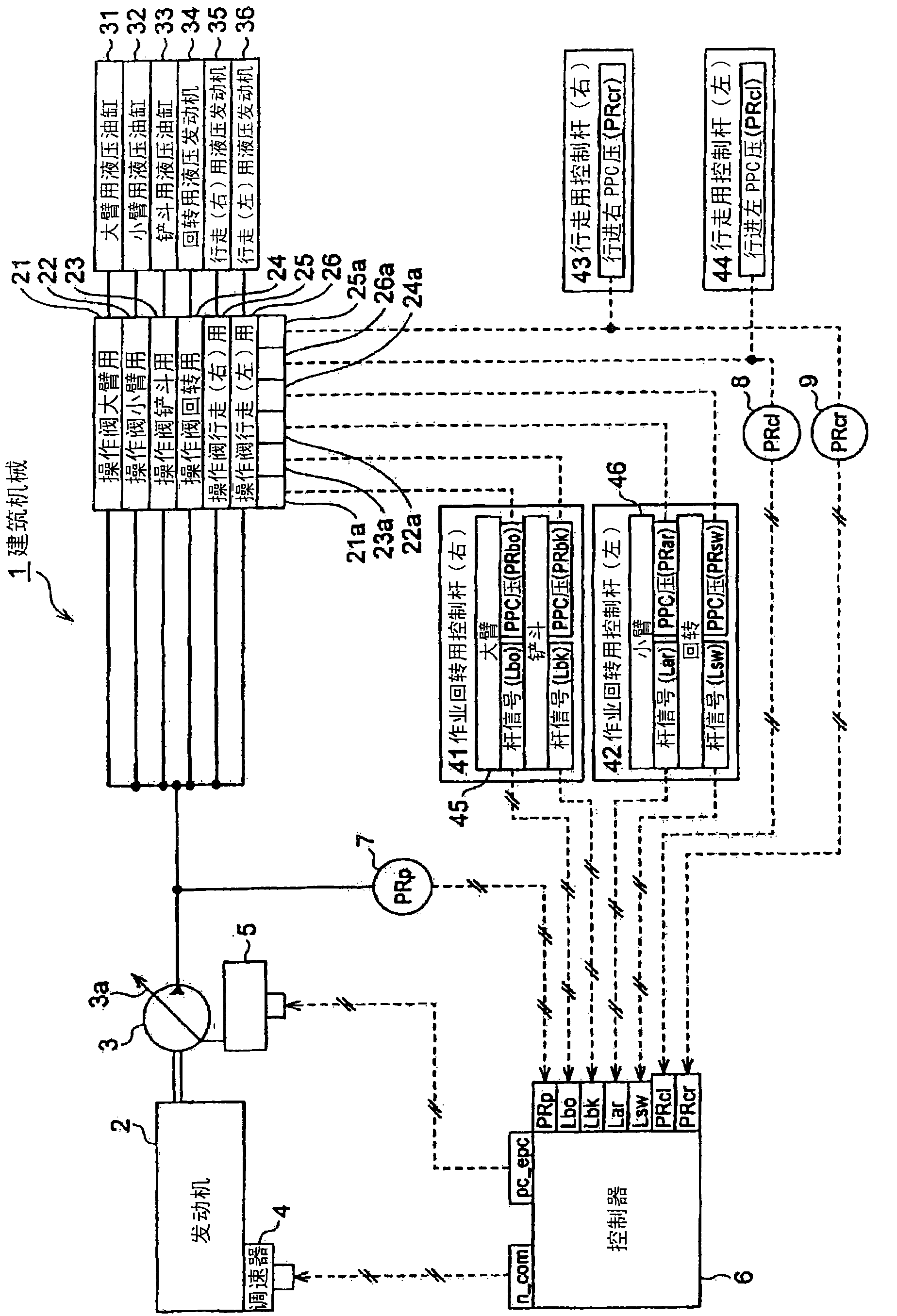

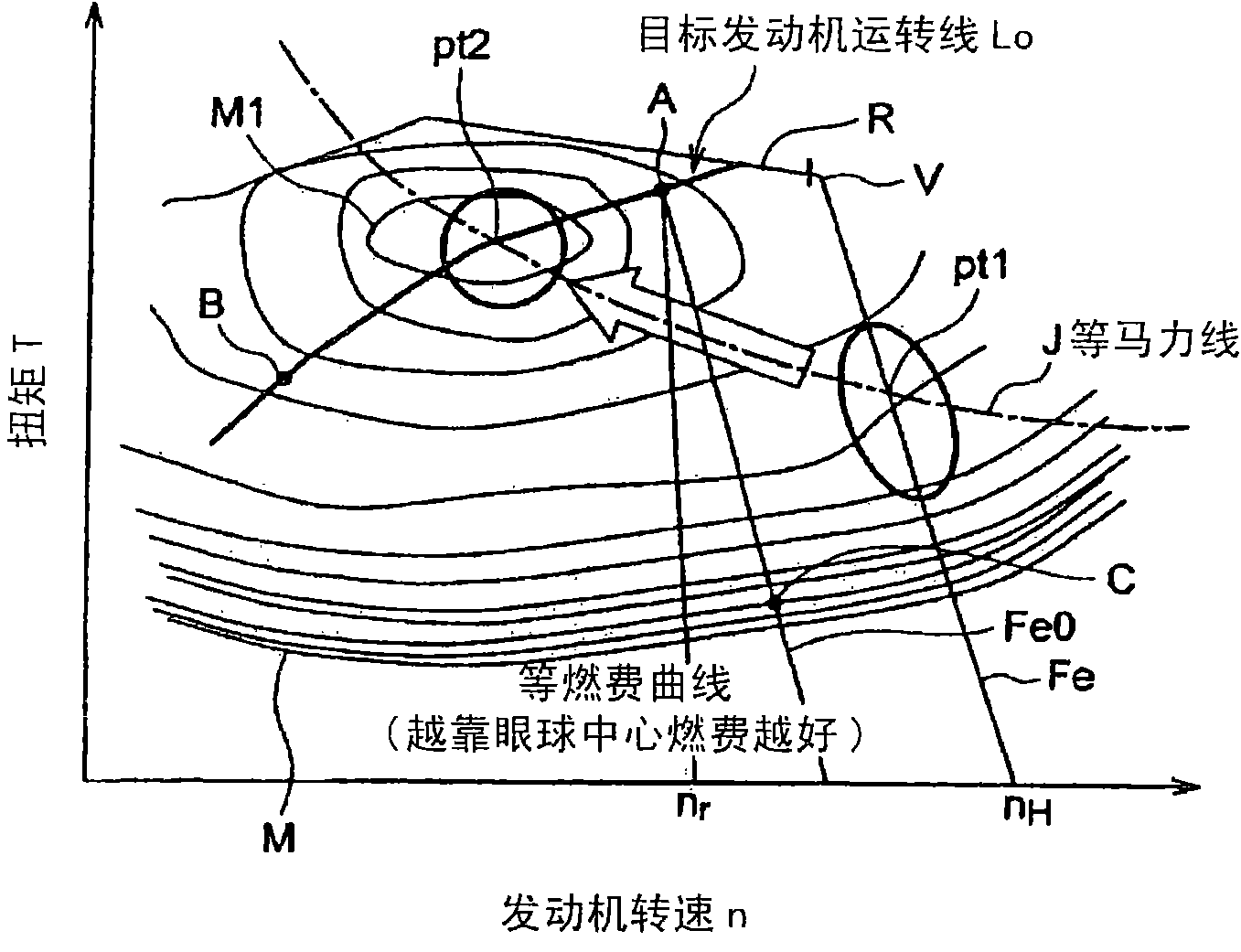

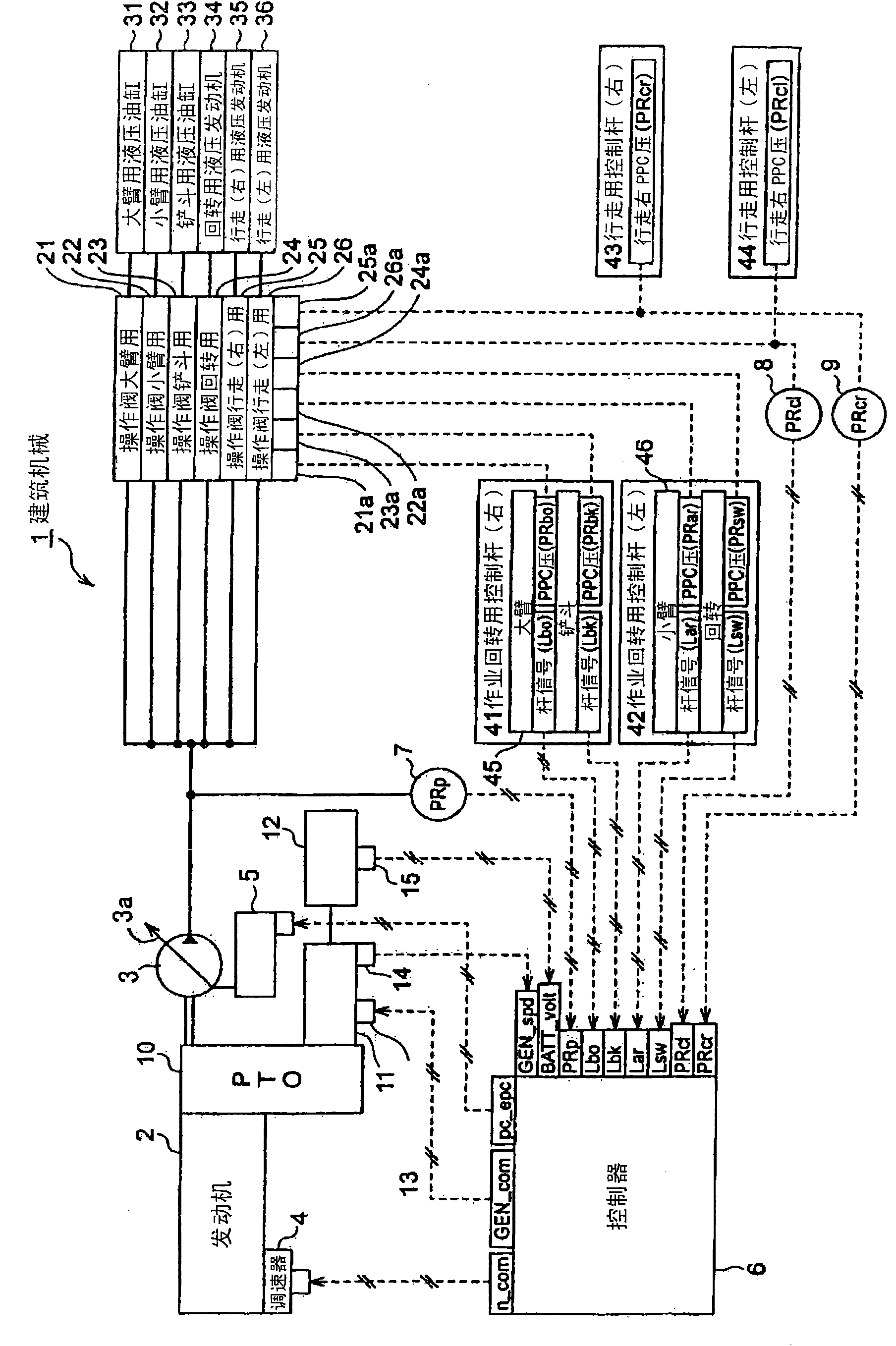

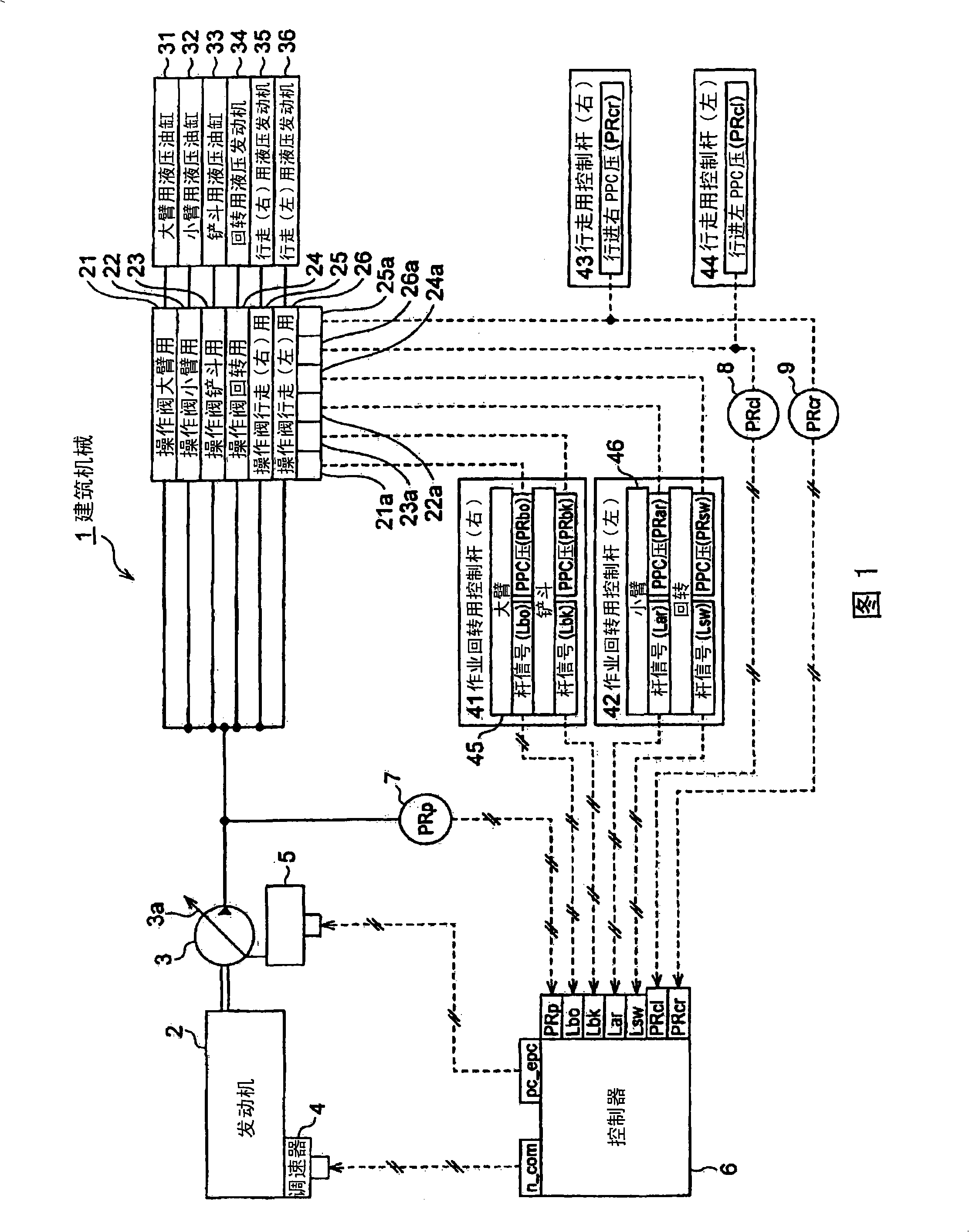

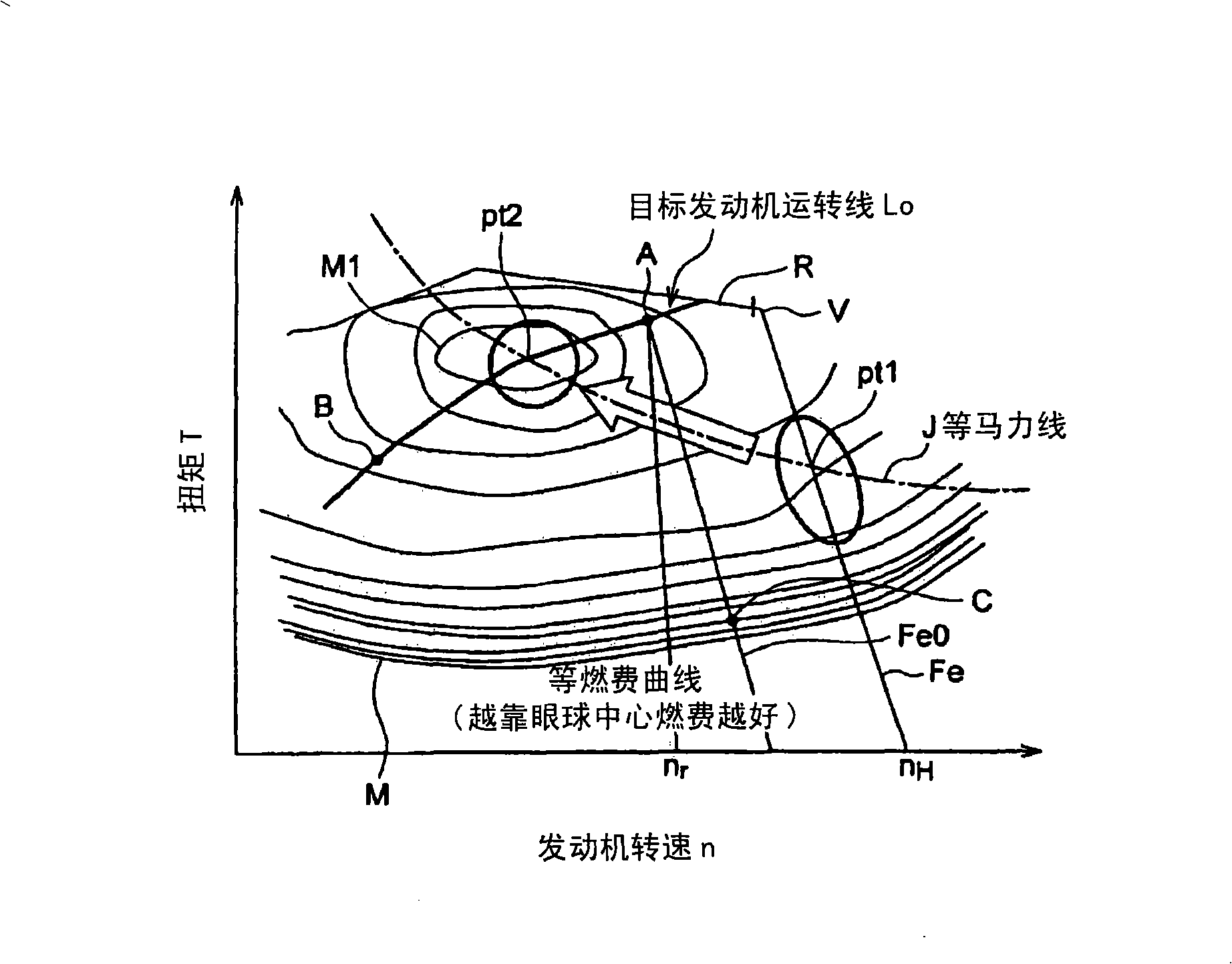

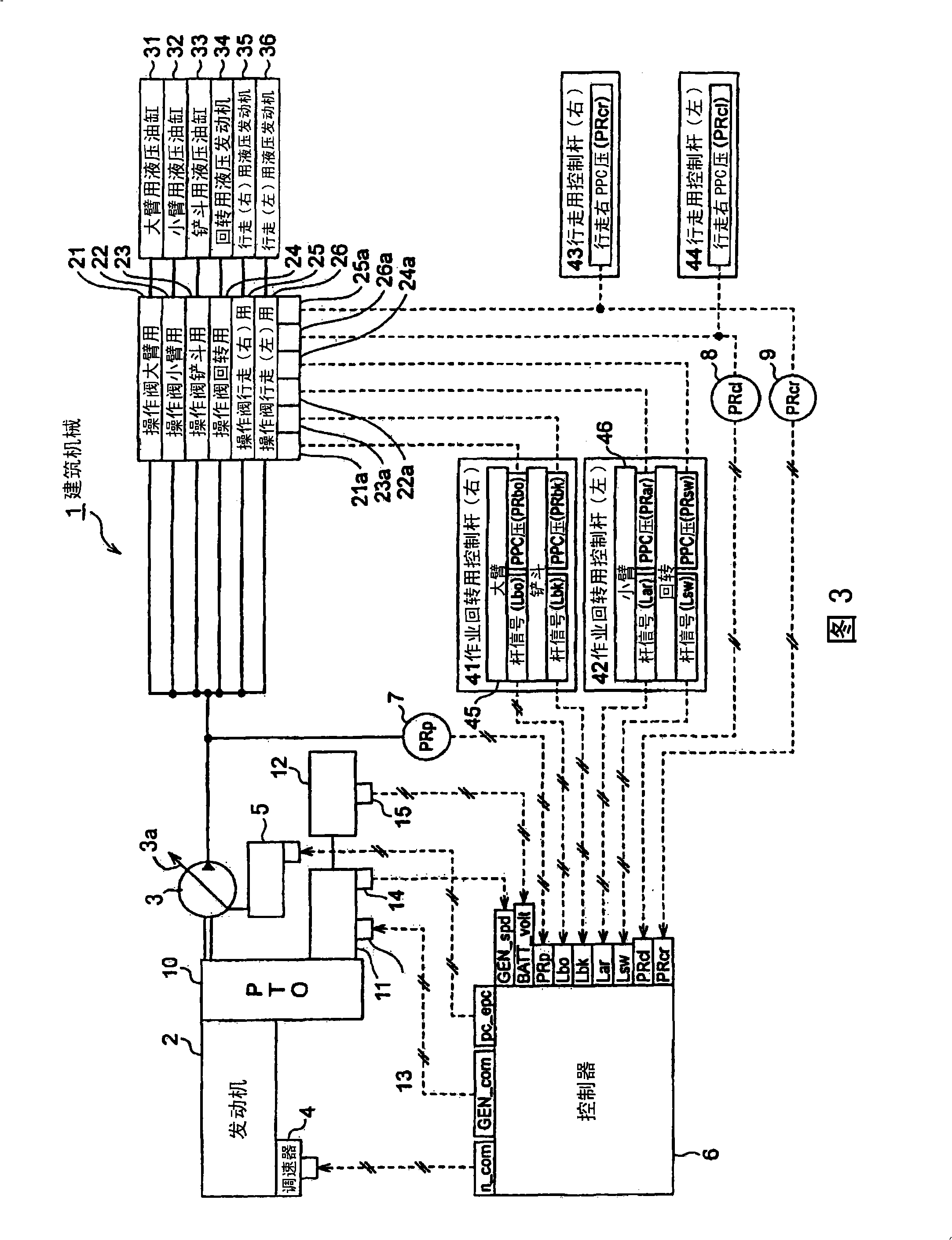

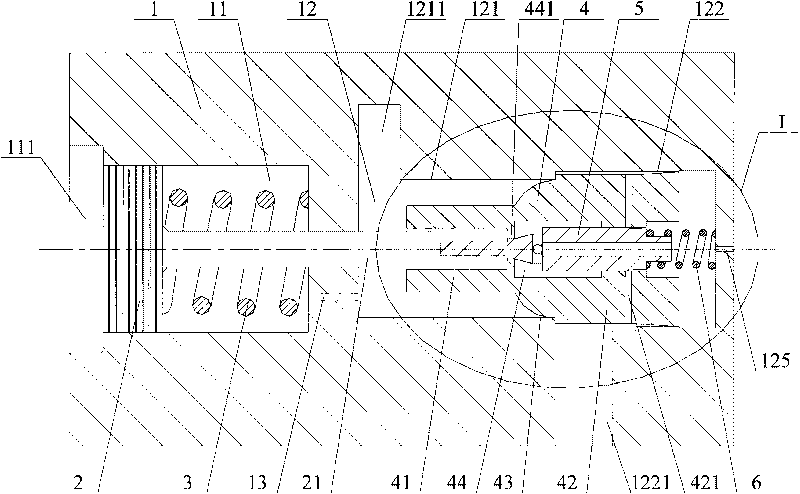

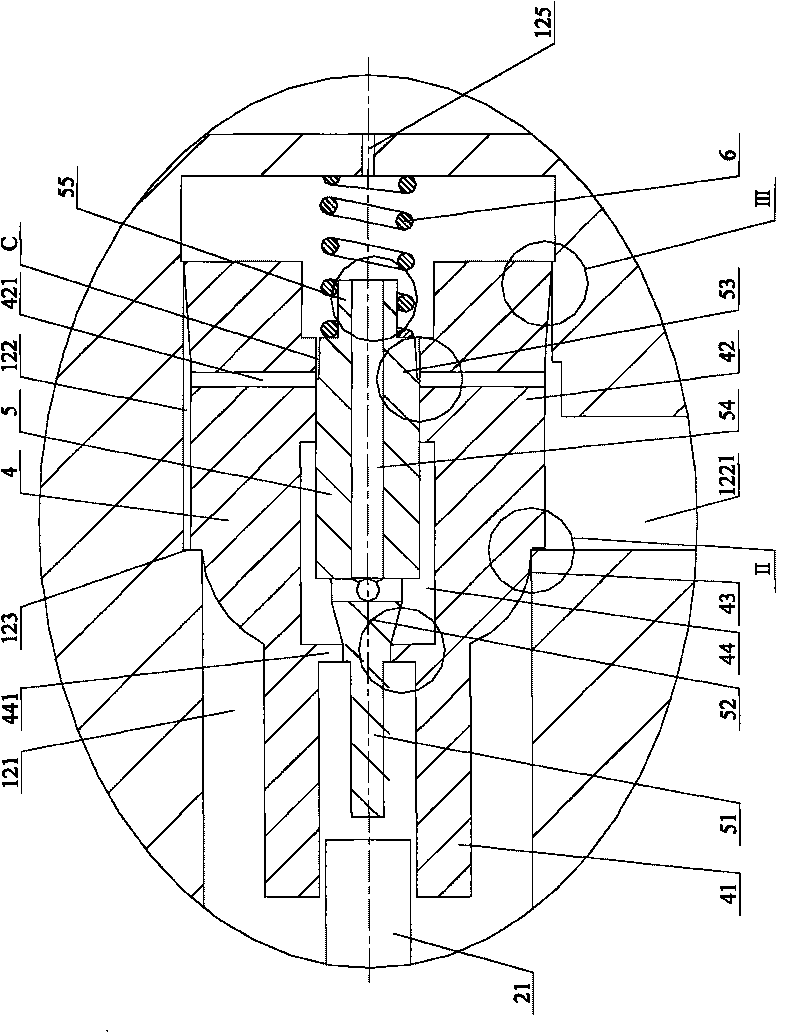

Control device of engine, control device of engine and hydraulic pump, and control device of engine, hydraulic pump, and generator motor

The invention provides a control device of engine, a control device of engine and hydraulic pump, and a control device of engine, hydraulic pump and generator motor. A working machine is operated as intended by an operator with good response and with enhanced engine efficiency, pump efficiency, and the like. A first engine target speed of rotation ncom1 conforming to a current pump target delivery flow rate Qsum is set, and when a decision is made that the current pump target delivery flow rate Qsum is higher than a predetermined flow rate (e.g. 10 (L / min)), a decision is made that operating means (41-44) are switched from nonoperating state to operating state, and a speed of rotation nM (e.g. 1400 rpm) higher than the engine idle speed of rotation nL is set as a second engine target speed of rotation ncom2. If the second engine target speed of rotation ncom2 is higher than the first engine target speed of rotation ncom1, engine speed of rotation is controlled to attain the second engine target speed of rotation ncom2.

Owner:KOMATSU LTD

System and method for improved control of tooth movement with elastic repositioning appliances

InactiveUS7374421B2Quality improvementControl over tooth movementOthrodonticsDental toolsCouplingElement analysis

Micro-regional force application improves the control of the orthodontic movement of teeth in all six degrees of freedom. Micro regional force application utilizes an elastic repositioning appliance, a tooth positioner, a polymeric shell, or preprogrammed series of polymeric shells. The key components of the invention are the envelope of freedom, the force applicators, force couplers, counterpart coupling, vector modifiers, seating guides, decouplers, and forced balance points. Further, computerized finite element analysis determines the center of resistance and the center of rotation for each tooth to be moved. The present invention gently rotates and translates one or more teeth to a desired straight position within a treatment plan.

Owner:SOLOMON FREDERICK

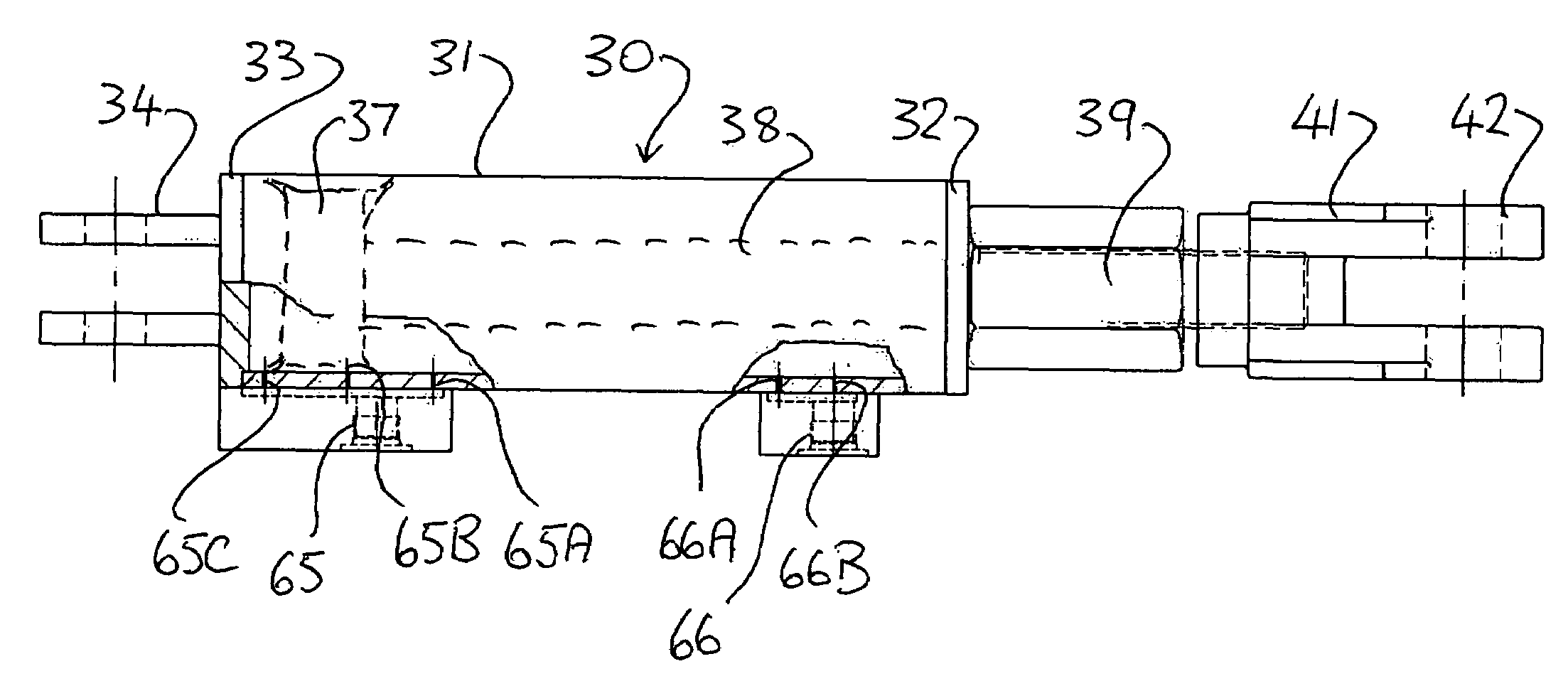

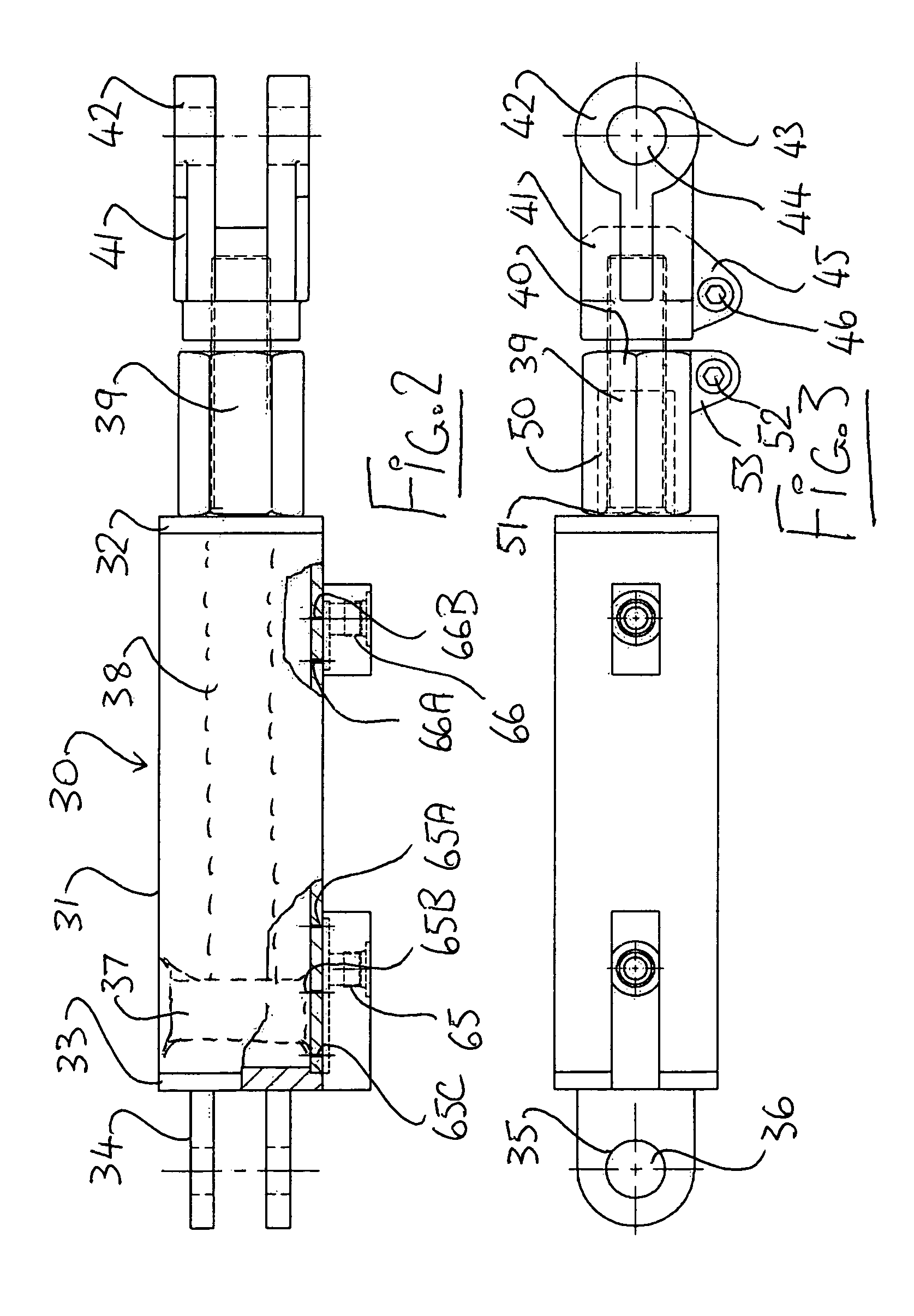

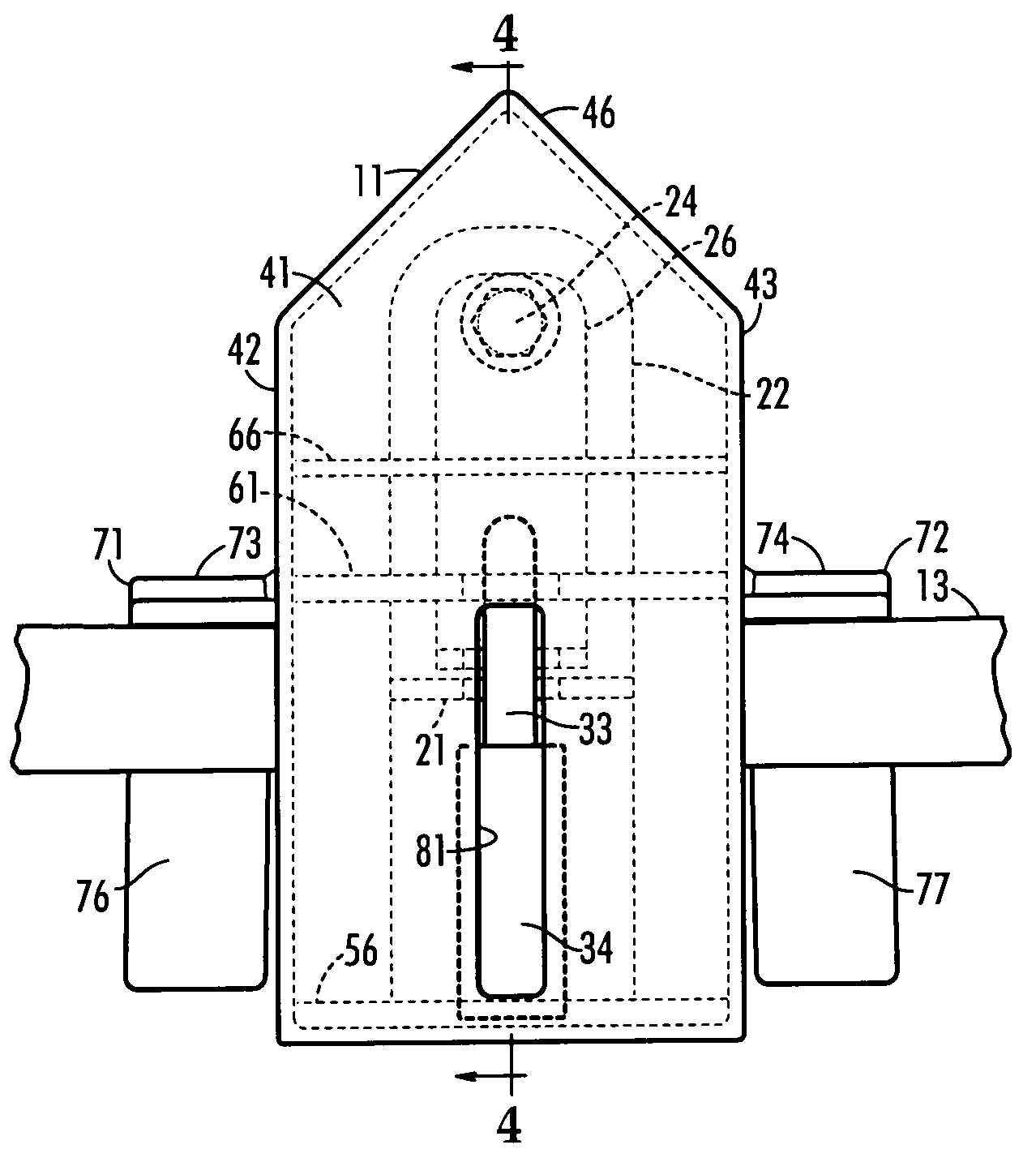

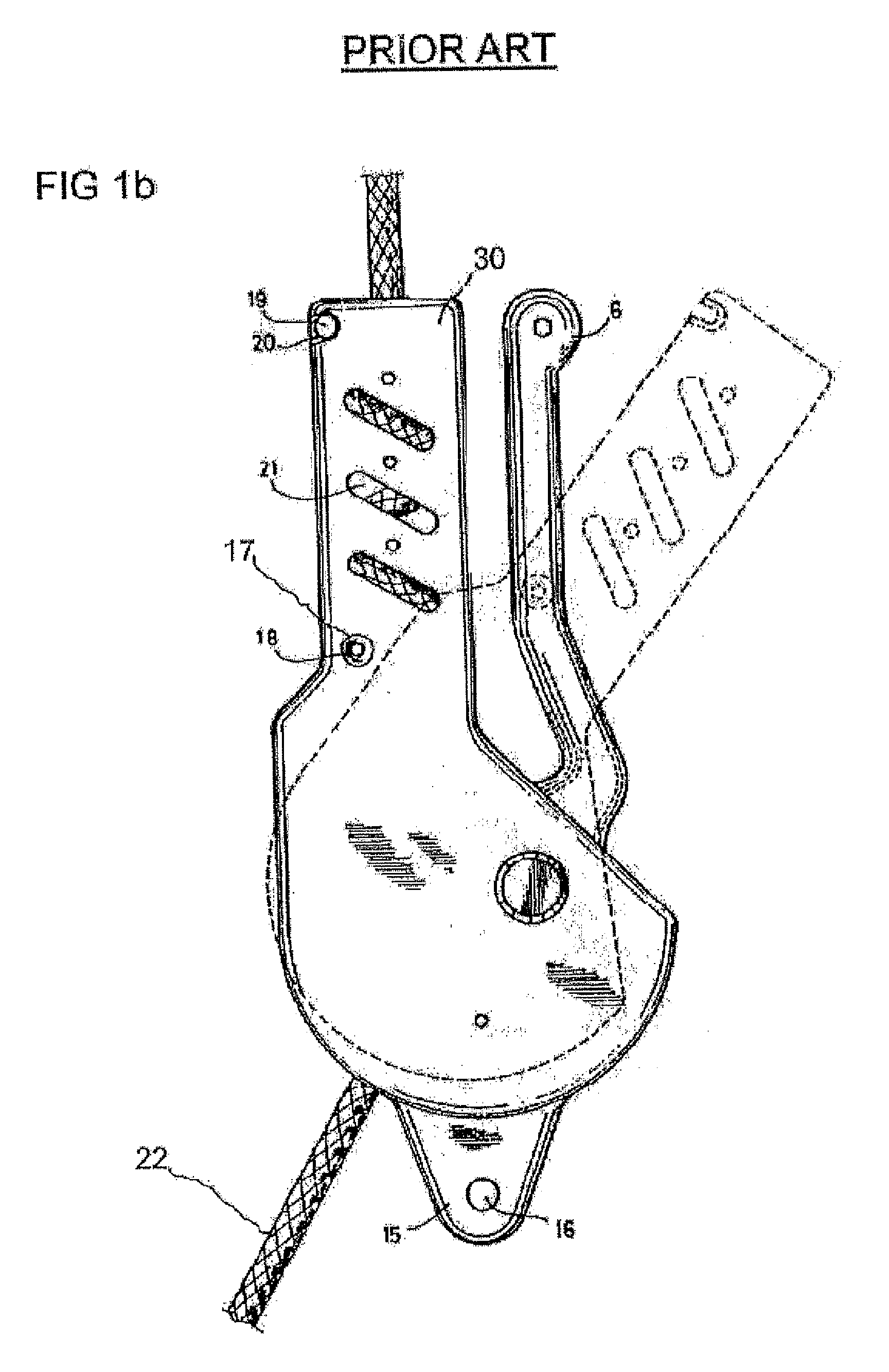

Adjustment of the hitch arm of a pull-type crop harvesting machine

A pull-type crop harvesting machine has a header carried on a frame mounted on ground wheels with a hitch arm extending from the frame over the header to a hitch coupling of a tractor. The hitch arm is mounted for pivotal movement about a generally upright axis such that in a first position the tractor tows the frame in echelon to one side and in a second position the tractor tows the frame in echelon. The movement is actuated by a hydraulic cylinder and stopped at one end of the movement by the piston with a rod coupling being adjustably mounted on the rod to adjust the end position. At the other end of the movement, the position is defined by a stop member mounted on the piston rod and adjustable relative thereto. Each end of the cylinder includes a cushion effect by using separate orifices for the fluid ports which slow fluid flow as the piston approaches the ends of the cylinder.

Owner:MACDON INDS

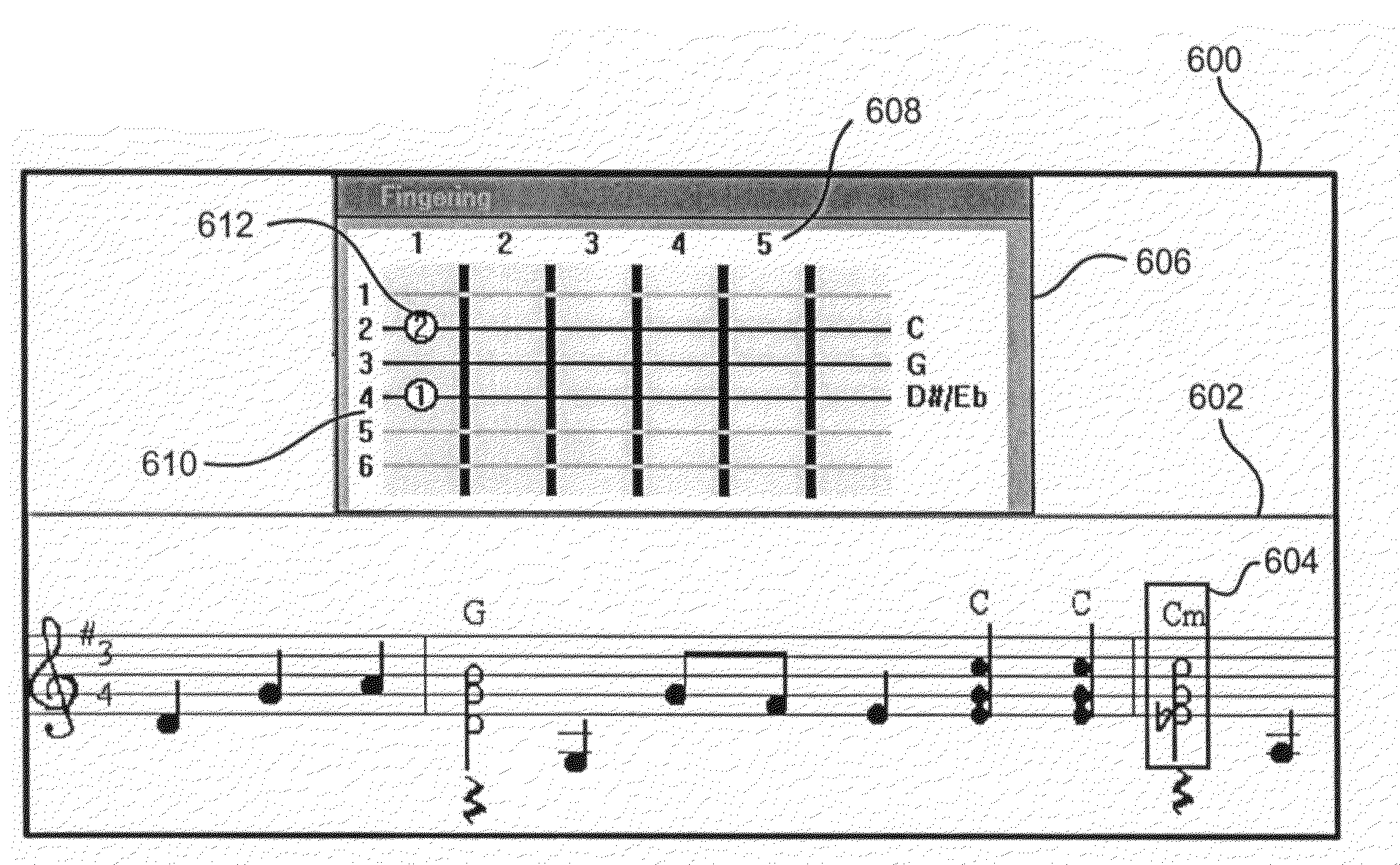

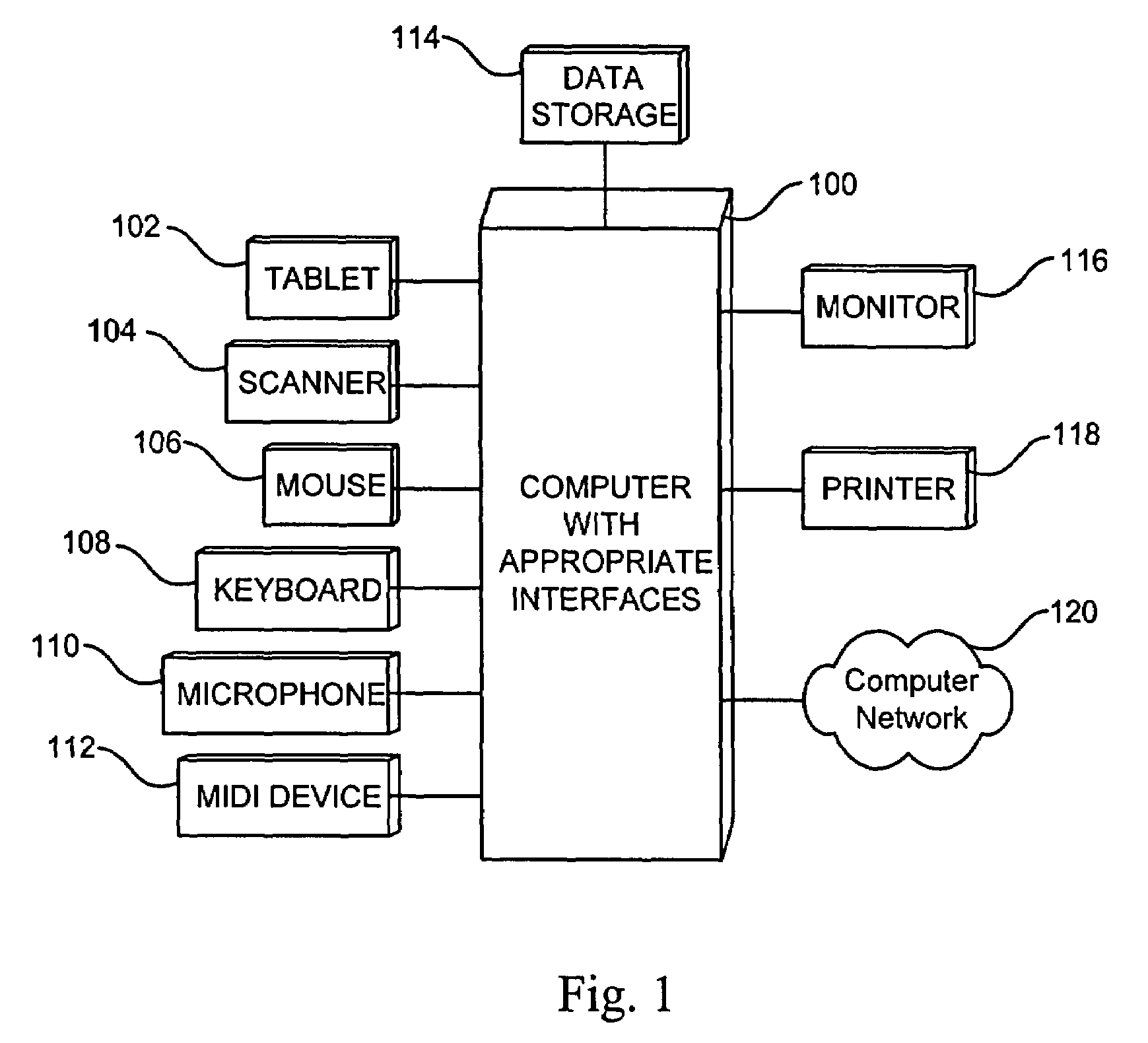

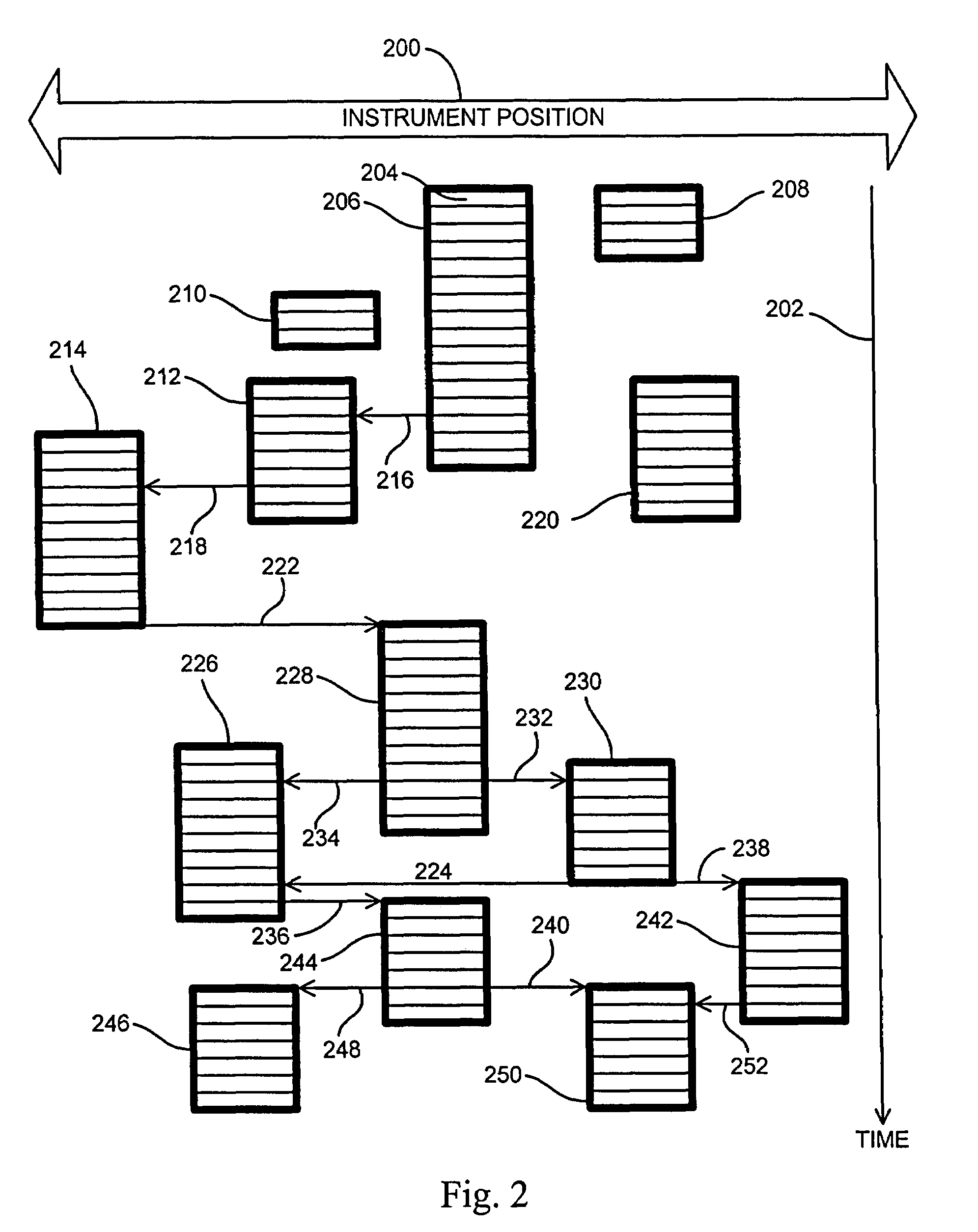

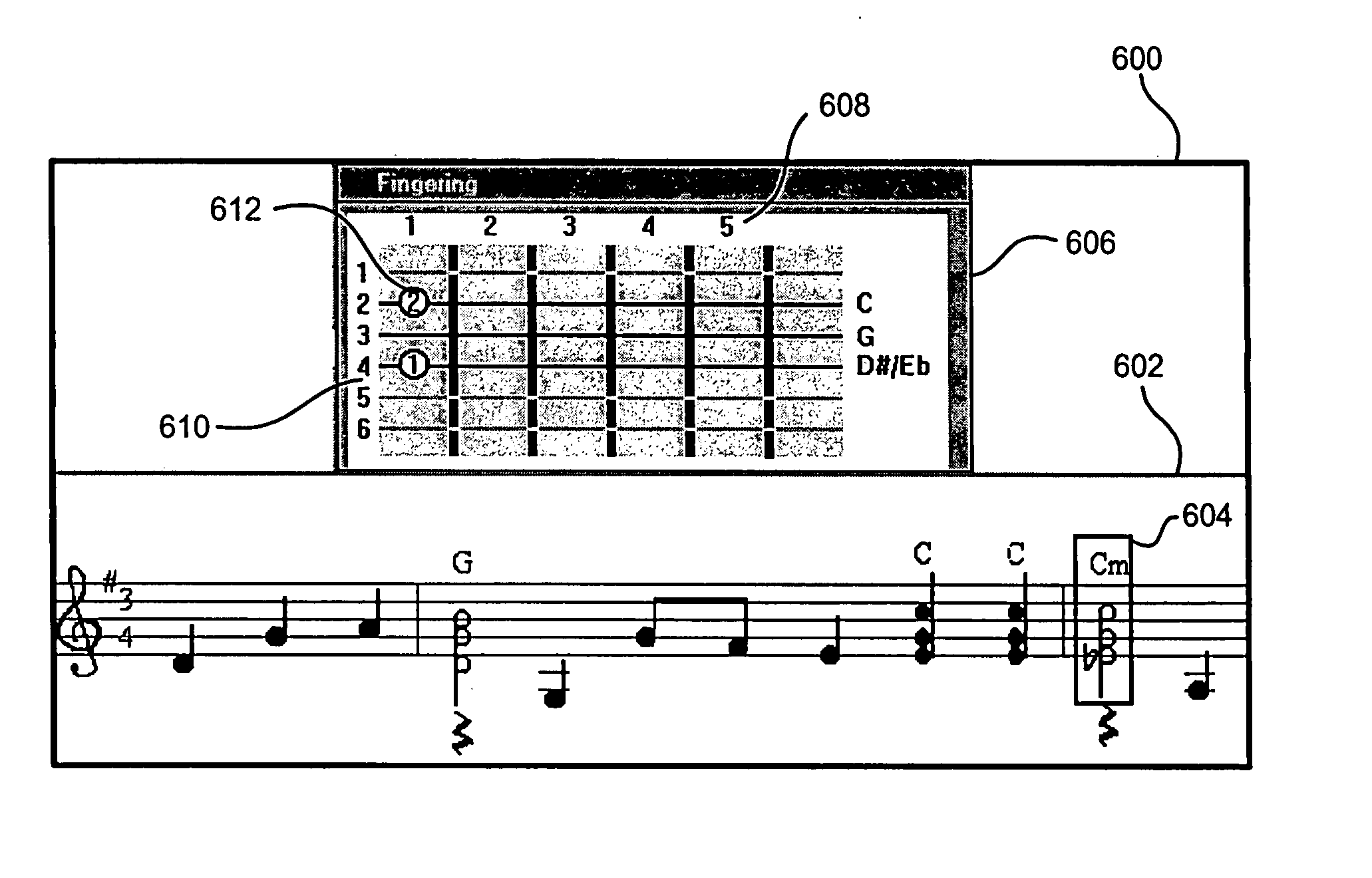

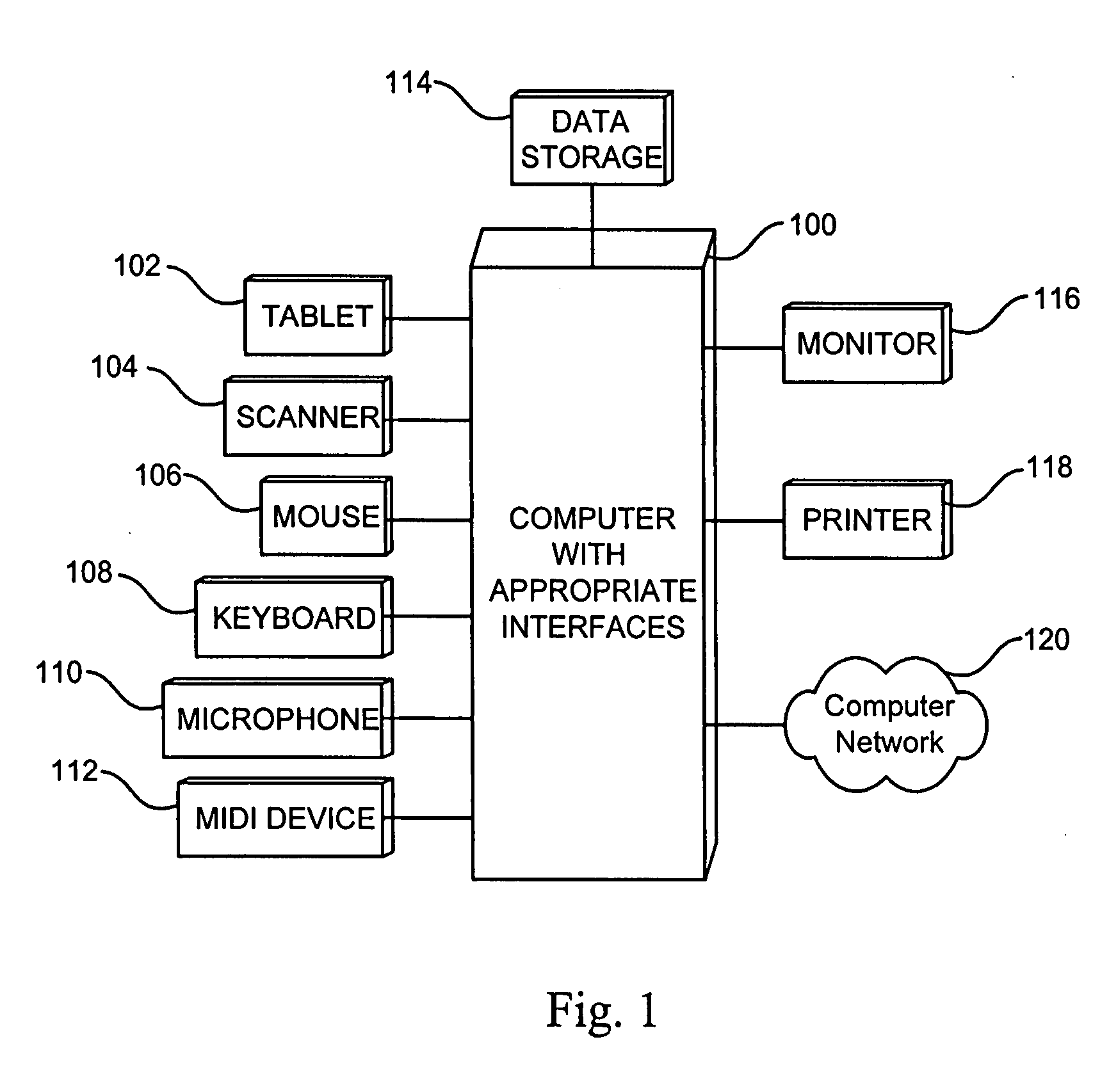

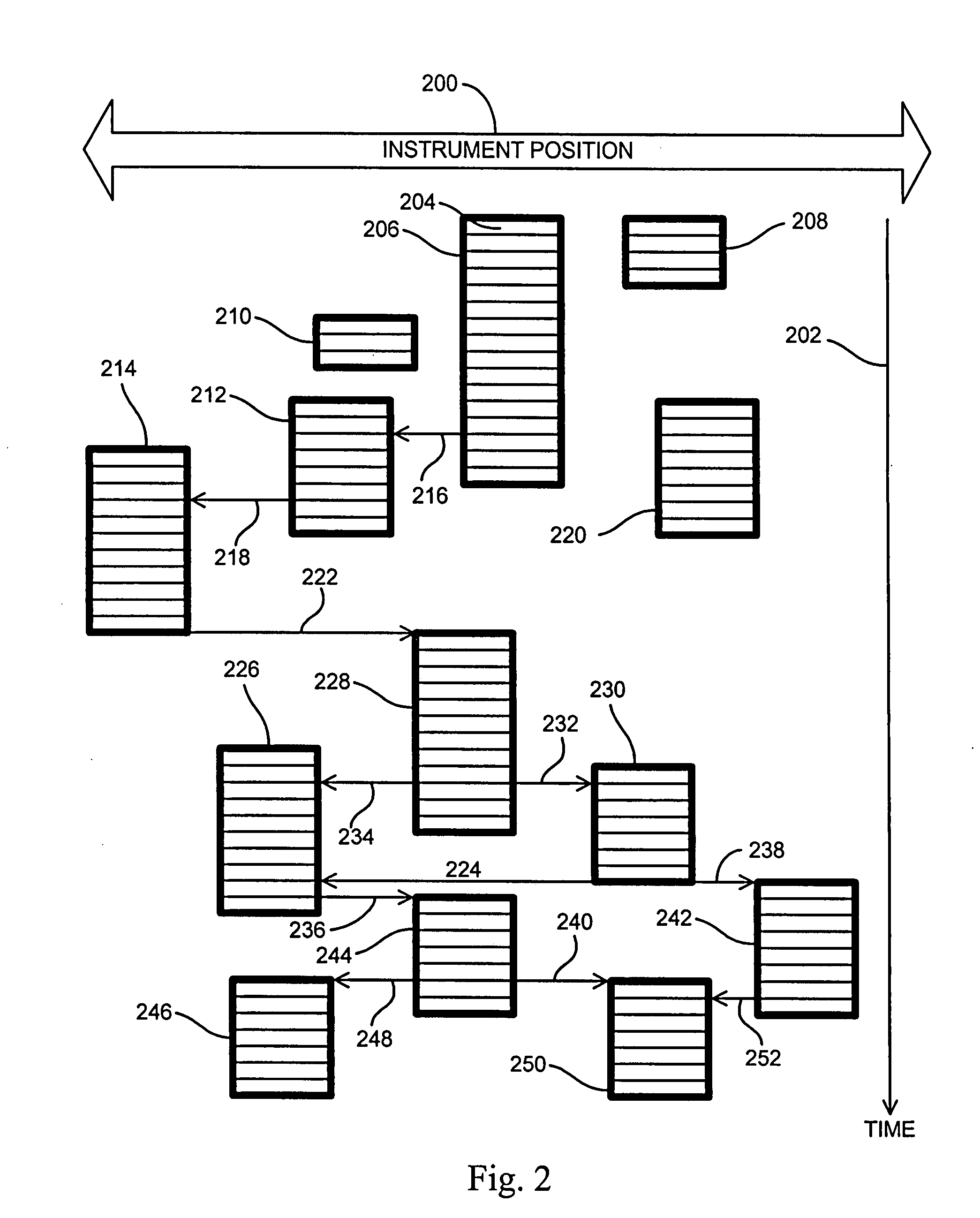

Method of automated musical instrument finger finding

InactiveUS7345236B2Slow movementEase of performanceElectrophonic musical instrumentsMusicHand movementsSkill sets

An automated computing system and method for determining fingering of musical instruments from digitized scored music or tablature. The computerized automated finger finder system and method analyzes a musical composition and determines hand and / or fingering positional information such that the musical composition can be efficiently played on a musical instrument of choice with minimal hand movement. The method and computing system also provide alternate or secondary fingering choices such that the musician can play with a different tonal stylization or with greater or lesser ease depending on his skill level.

Owner:WEB2INTRANET CORP

Liquid crystal display and computer

InactiveUS7218305B2Slow movementInhibit deteriorationTelevision system detailsStatic indicating devicesLiquid-crystal displayControl circuit

A backlight control circuit that variably controls the display luminance of a liquid crystal display panel by controlling the luminance of a backlight based upon whether an image displayed on the liquid crystal display panel is a dynamic image or a static image, and an LCD controller that controls so that a part or the whole of a dynamic image is displayed by using a single color for a predetermined time in case an image displayed on the liquid crystal display panel is a dynamic image are provided.

Owner:RENESAS ELECTRONICS CORP

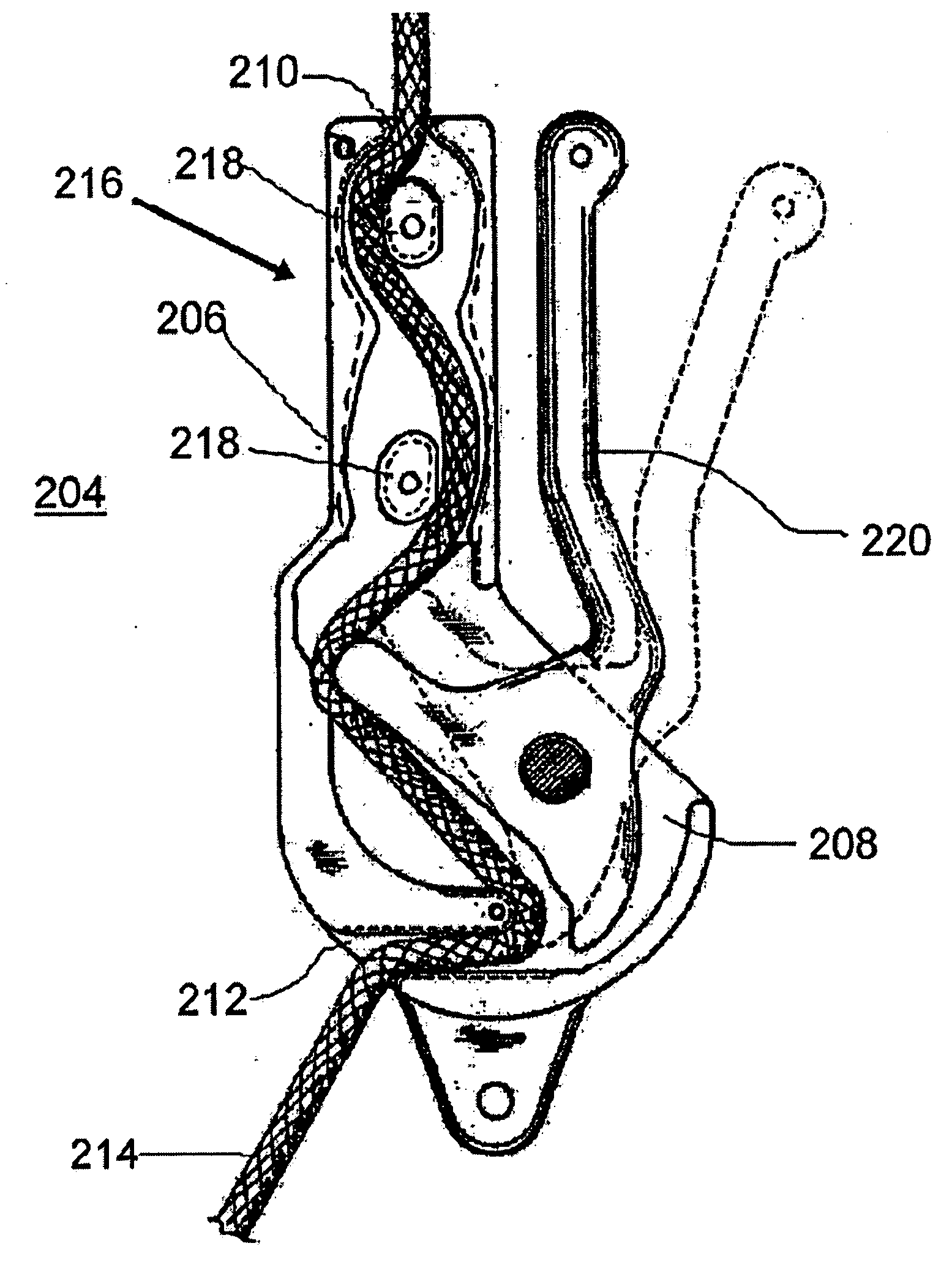

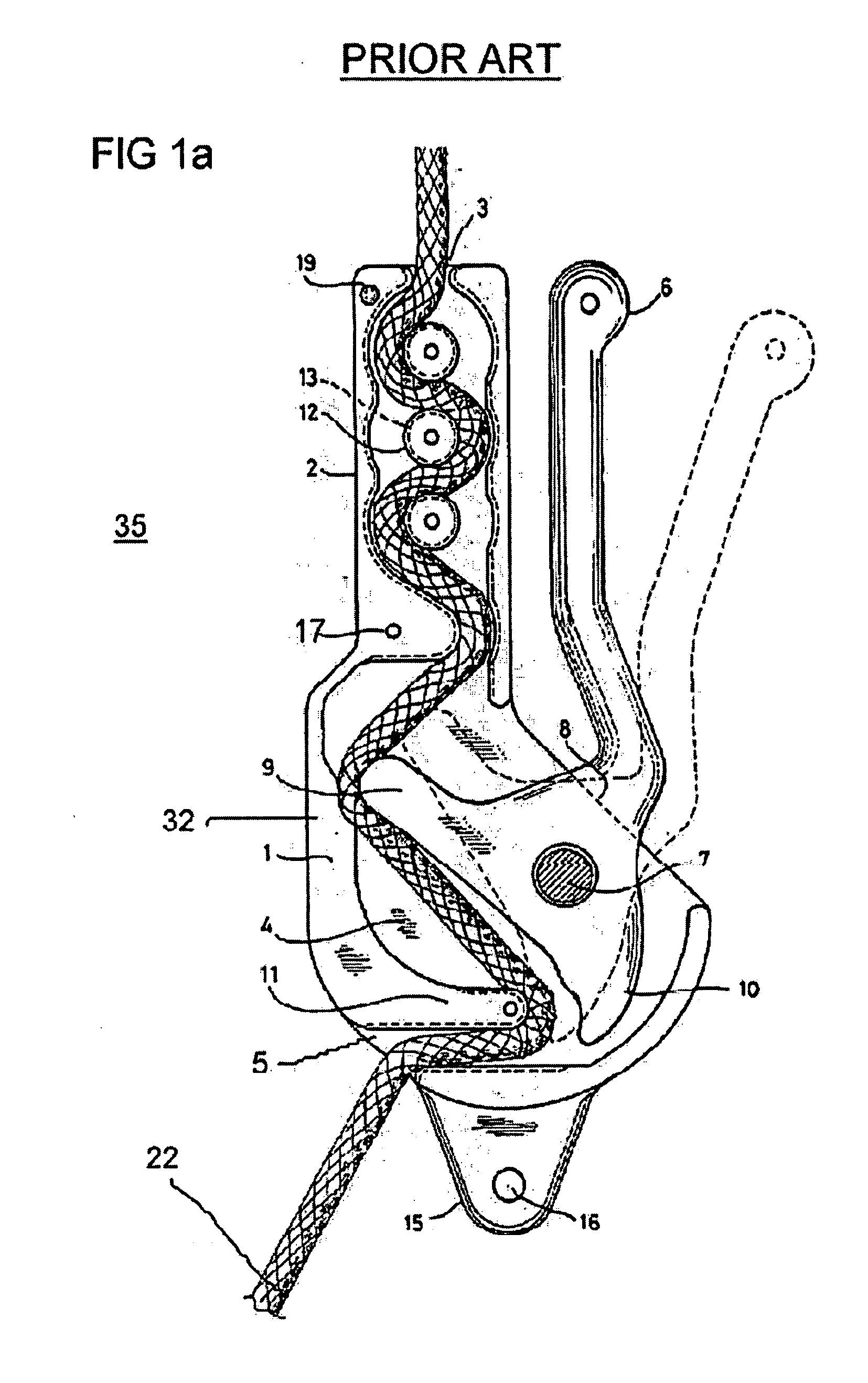

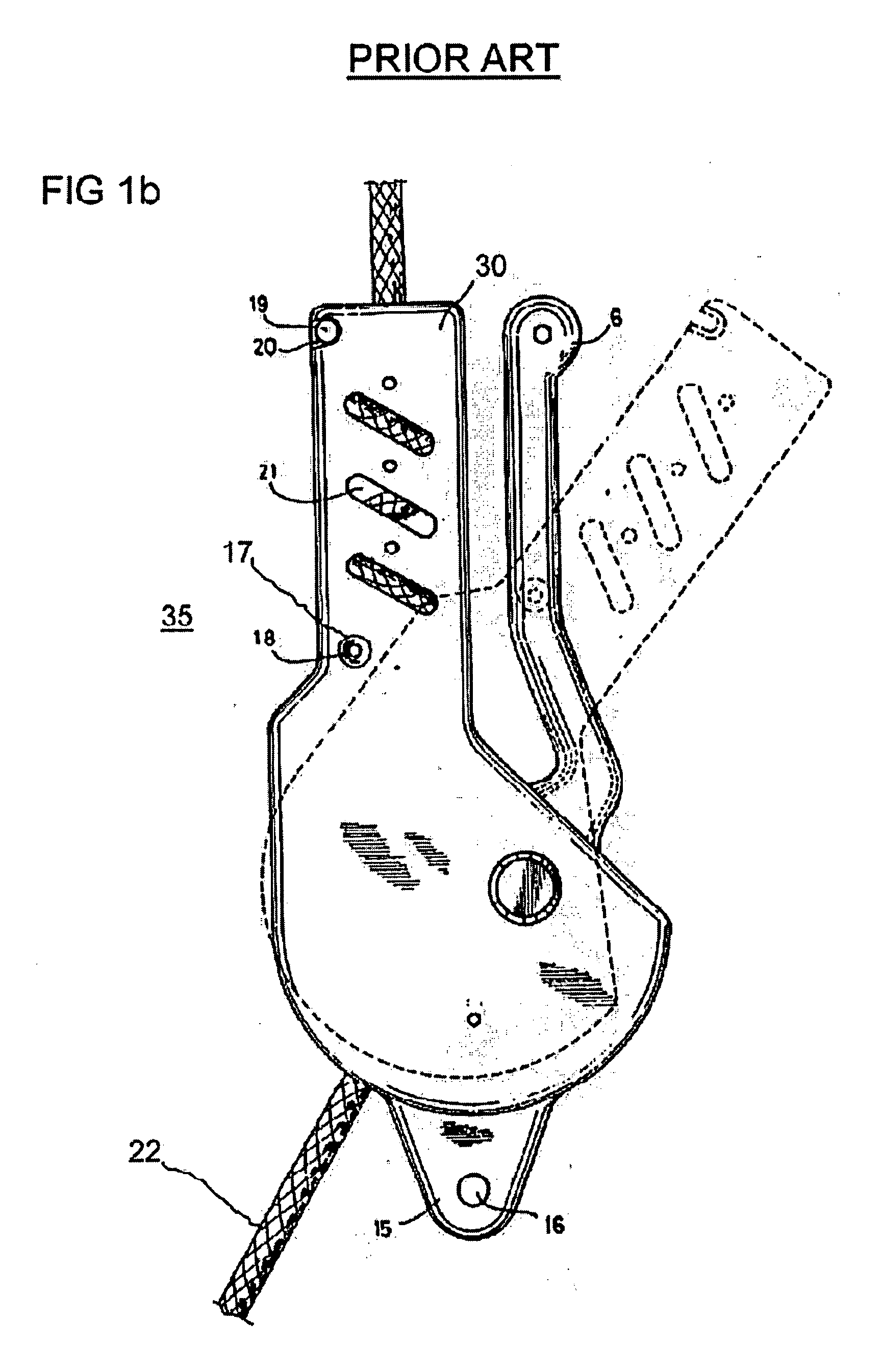

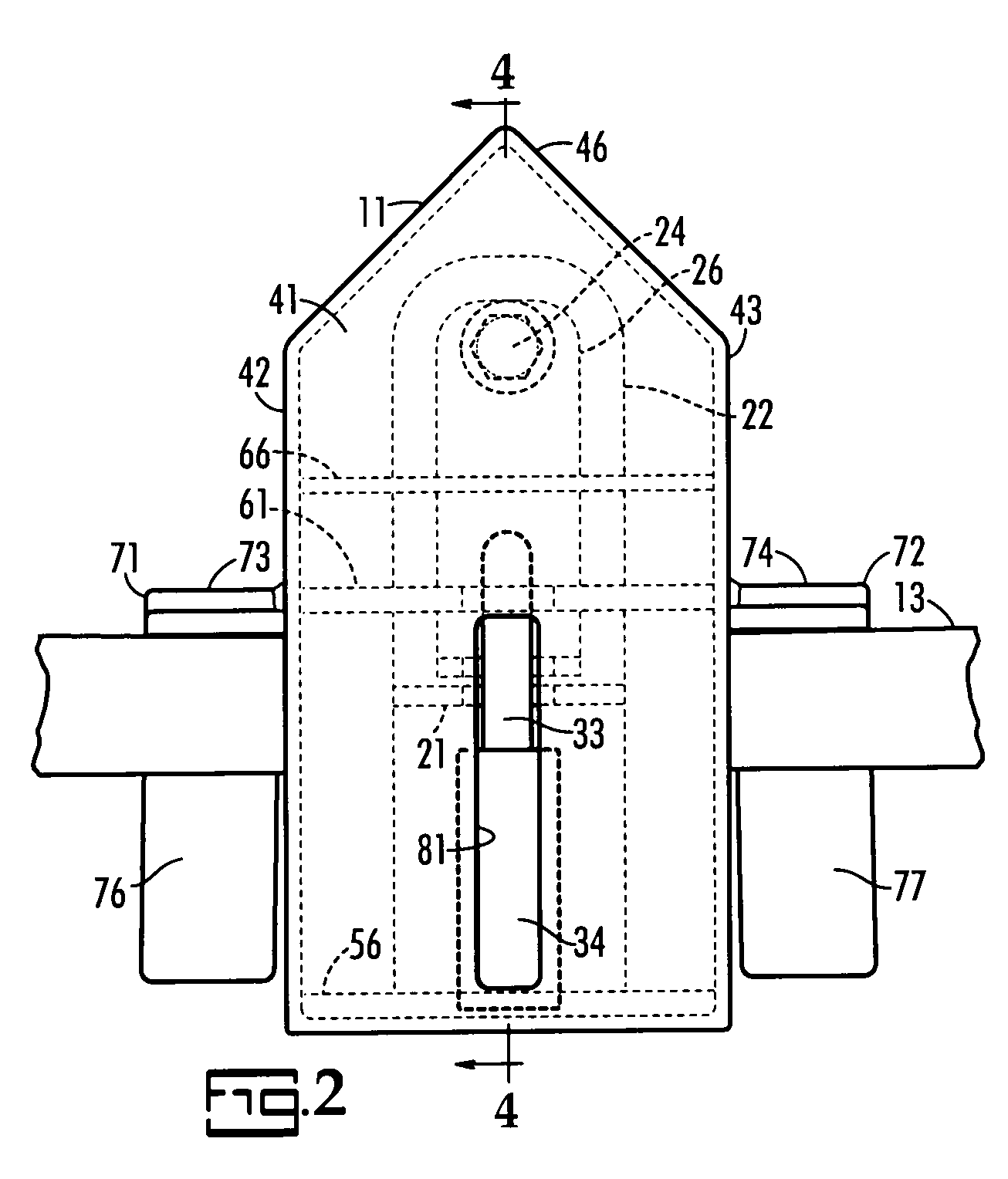

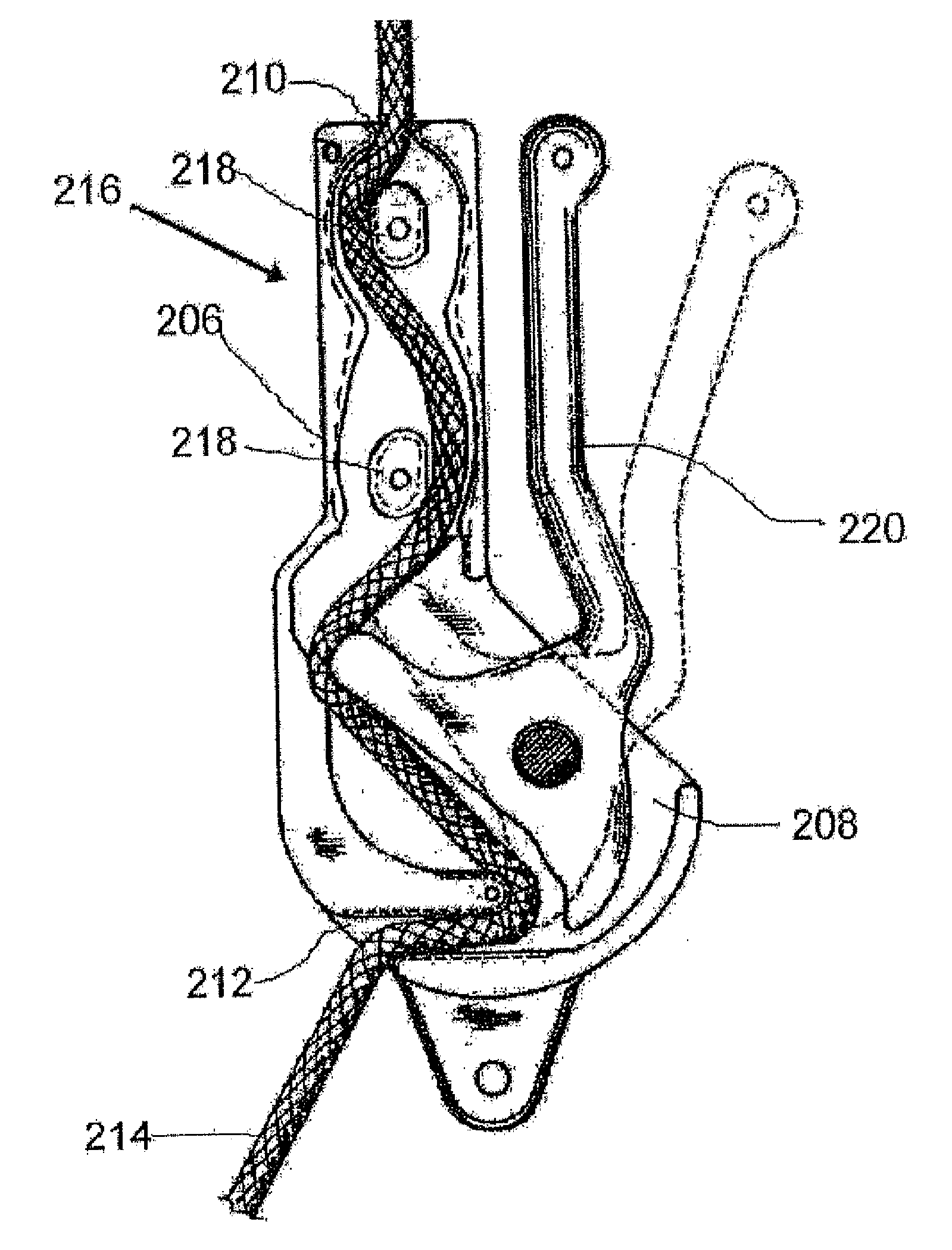

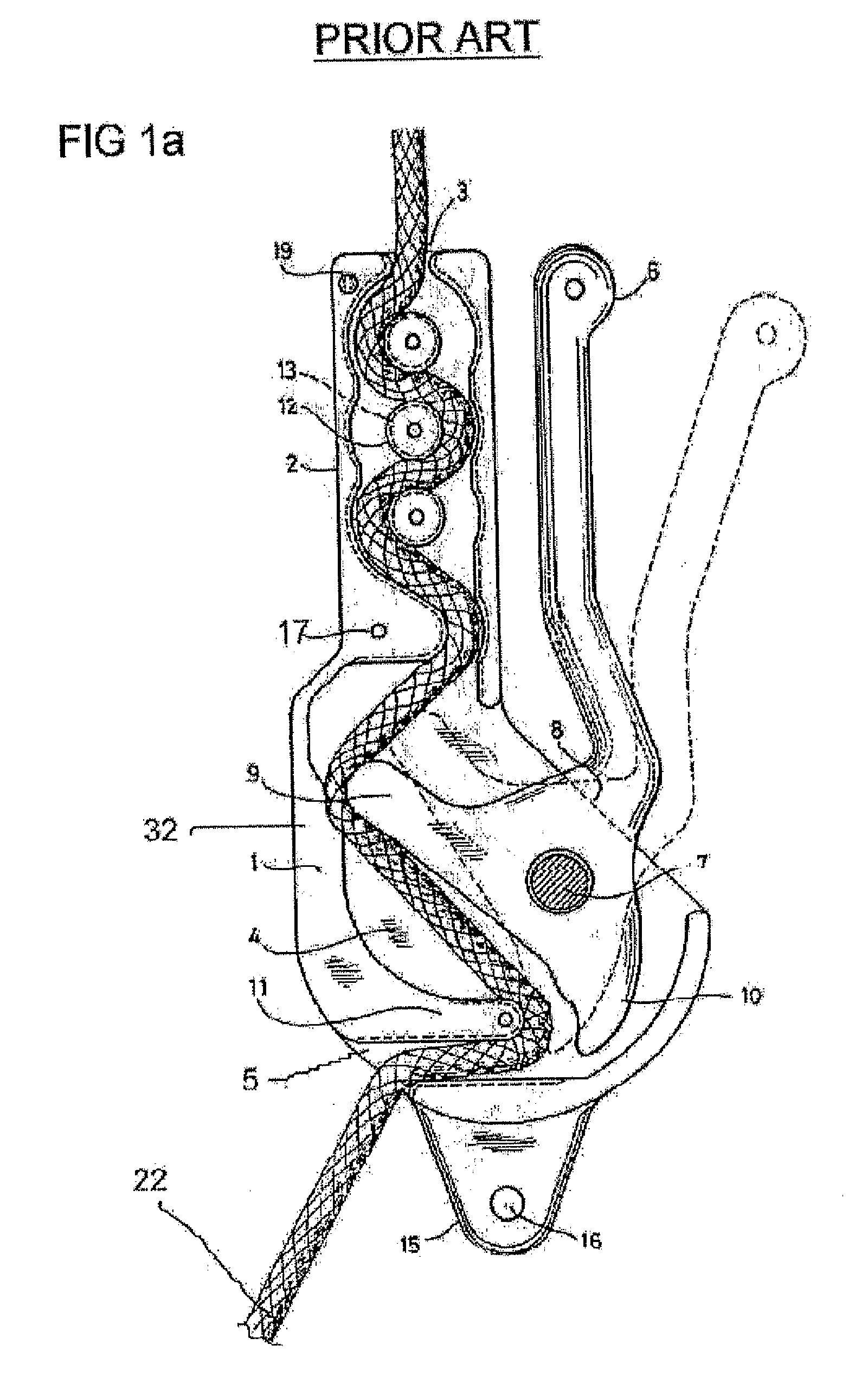

Advanced "Omer" rescue system

InactiveUS20060070809A1Slow movementSafety beltsMountaineeringBiomedical engineeringClassical mechanics

An escape system for moving a person on a cord on the exterior of a building. The building has a first surface and a second surface. The first surface and the second surface are substantially perpendicular to each other. The system comprises a control device for controlling the movement of the person on the cord and an anchoring device for reversibly mechanically attaching the control device to the building. The control device is substantially irreversibly mechanically connected to the anchoring device. The anchoring device has a first elongated element and a second elongated element. The first elongated is mechanically connected to the second elongated element. The first elongated element and the second elongated element are configured such that, the first elongated element at least partially rests against the first surface of the building and the second elongated element at least partially rests against the second surface of the building.

Owner:BARZILAI YOAV

Method of automated musical instrument finger finding

InactiveUS20070234878A1Improve performanceEasy fingeringElectrophonic musical instrumentsMusicHand partsHand movements

An automated computing system and method for determining fingering of musical instruments from digitized scored music or tablature. The computerized automated finger finder system and method analyzes a musical composition and determines hand and / or fingering positional information such that the musical composition can be efficiently played on a musical instrument of choice with minimal hand movement. The method and computing system also provide alternate or secondary fingering choices such that the musician can play with a different tonal stylization or with greater or lesser ease depending on his skill level.

Owner:WEB2INTRANET CORP

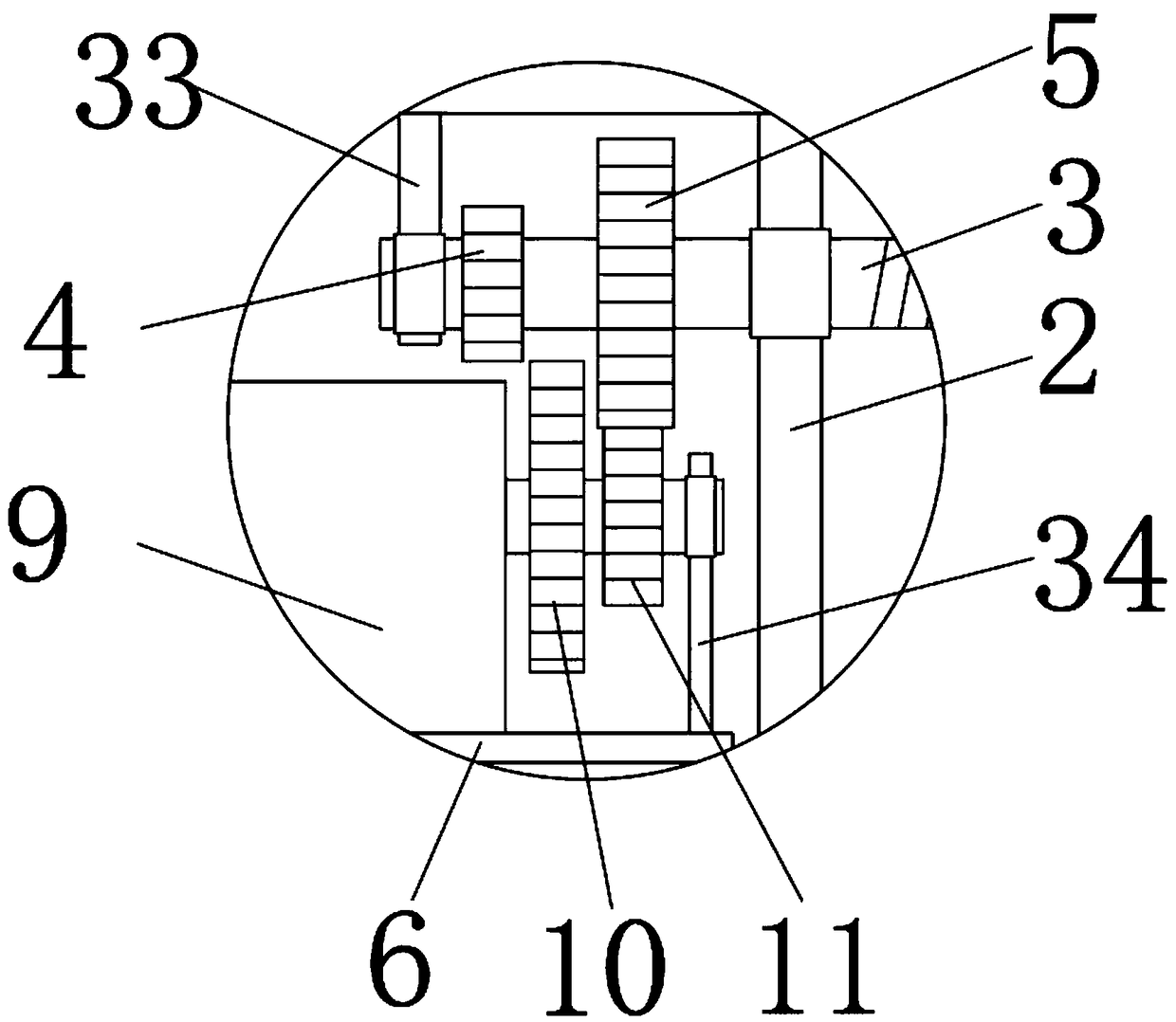

Automatic anesthetic injection device

The invention discloses an automatic anesthetic injection device. The device comprises a box body. A partition plate is vertically and fixedly connected between the top and the bottom of the inner wall of the box body, and a screw is connected between two opposite sides of the partition plate and the inner wall of the box body in a sliding mode. A first gear and a second gear are sequentially andfixedly connected to one end of the screw extending to the other side of the partition plate, one side of the top of the box body is fixedly connected with a fixed bottom plate, and the top of the fixed bottom plate is fixedly connected with a tube. One end of the tube is fixedly connected with a support sleeve, and a push rod is connected to the center of the support sleeve in a sliding mode. Oneend of the push rod in the tube is fixedly connected with a fixed block, the surface of the fixed block is fixedly connected with a piston, and the top of one side of the tube away from the support sleeve is fixedly connected with a liquid level switch through a first connecting pipe. The automatic anesthetic injection device relates to the technical field of anesthesia. The automatic anestheticinjection device solves problem that the anesthetic dosage accuracy of the existing artificial operation injector is difficult to control, ensures the safety of a patient, and reduces the workload ofan anesthesiologist.

Owner:刘斐

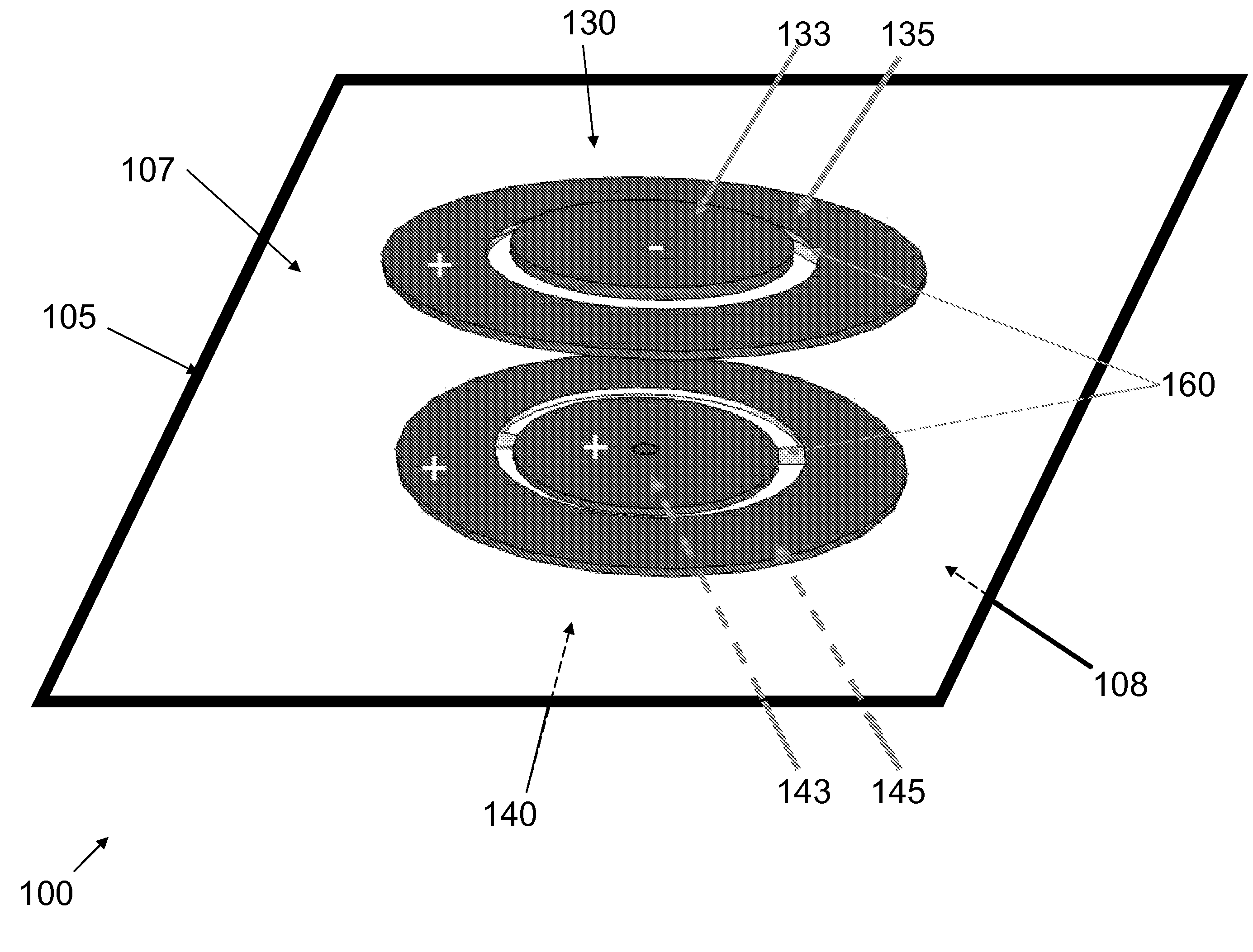

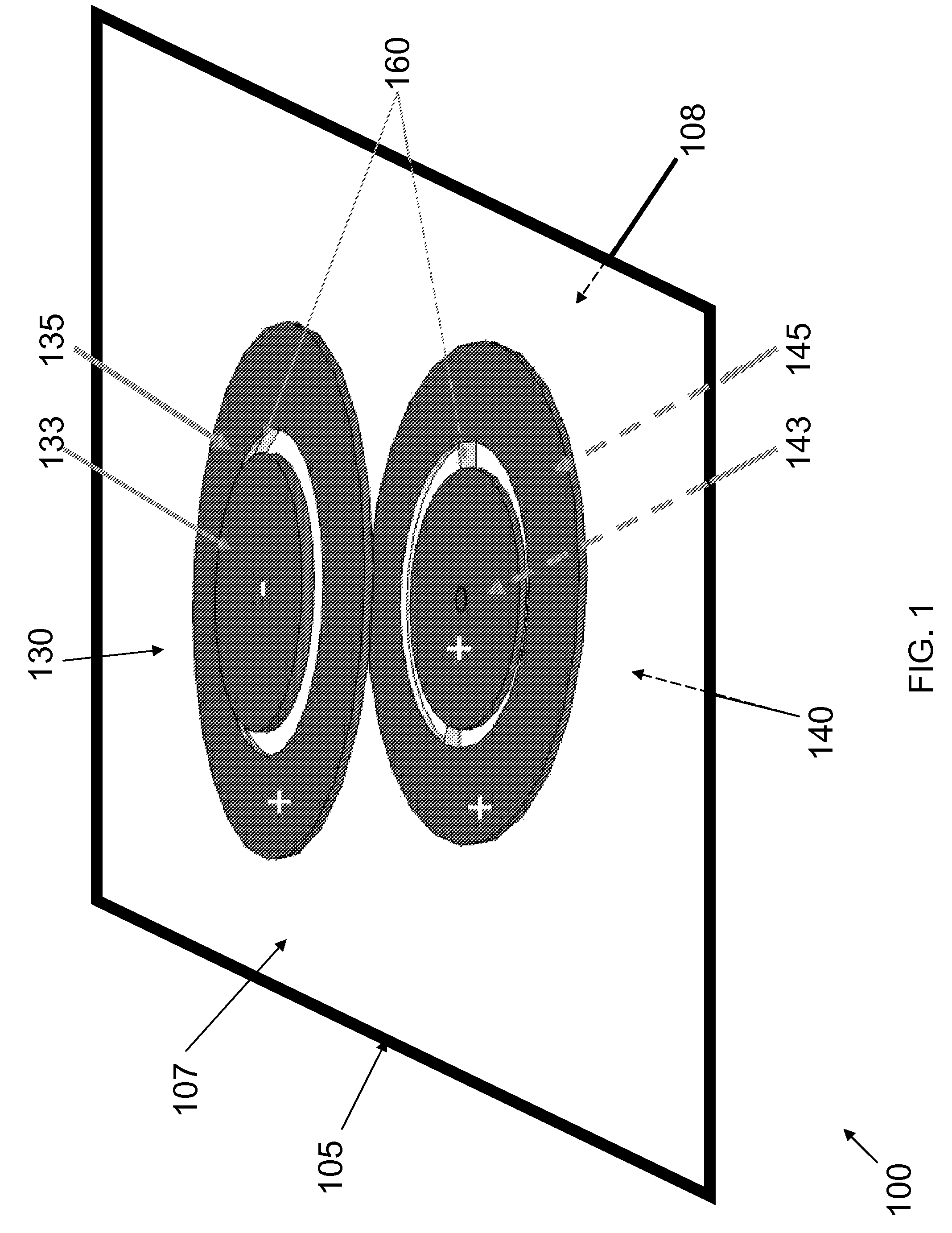

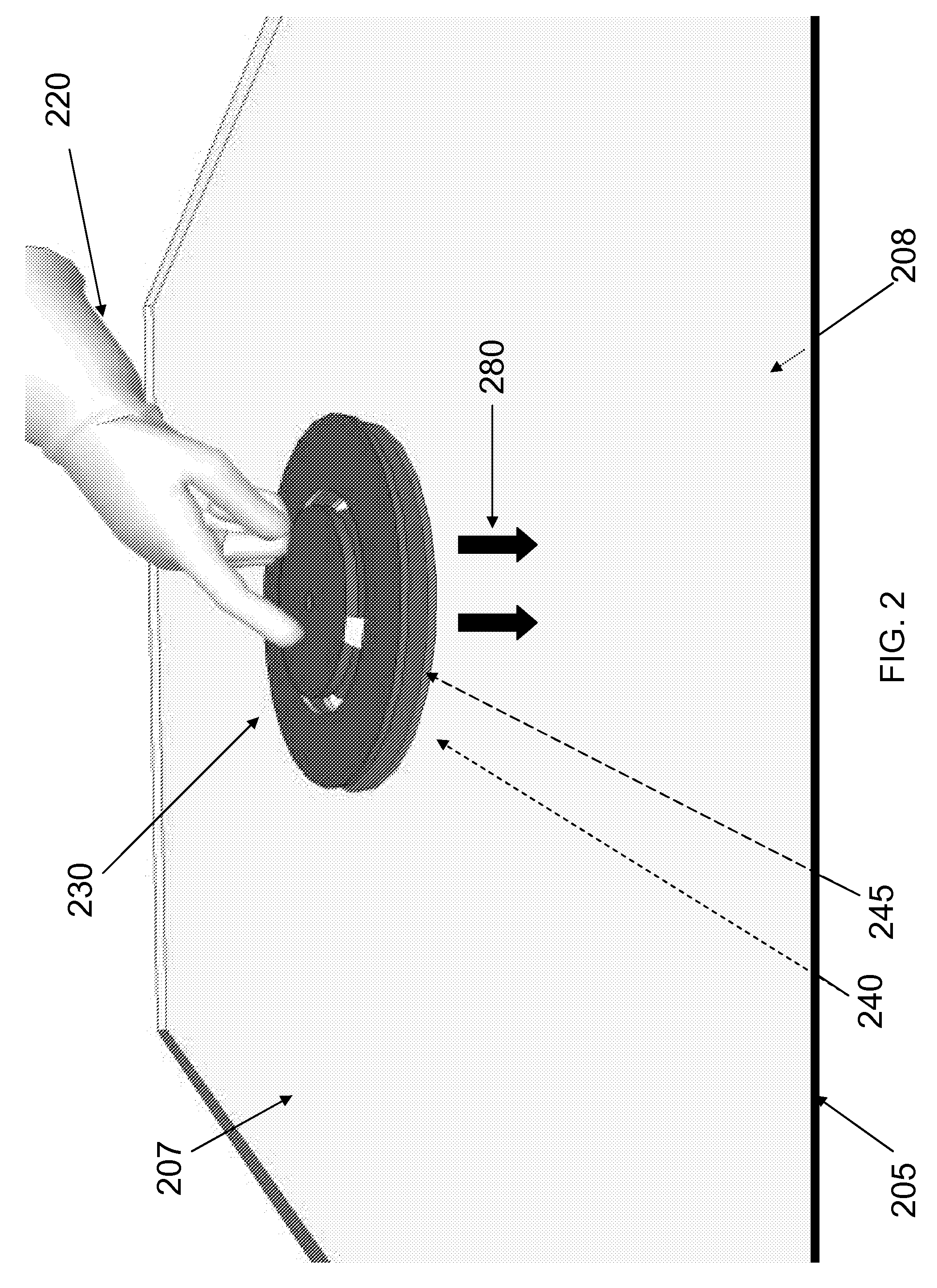

Method for protecting a touch-screen display

InactiveUS8671553B1Easy to viewAvoid damagePrinted circuit assemblingLine/current collector detailsMagnetEngineering

The invention discloses methods for transferring a tactile signal through an inert piece of material. In some embodiments, clear, impact resistant covers are employed with devices including touch-sensitive screens. The instant invention, in some embodiments, describes a method for employing a plurality of magnets to allow a user to input information on a touch-sensitive screen through the inert cover. Contact of a magnet pair above the cover may allow for a signal to be delivered to the touch-sensitive display via a second magnet pair that includes a stylus adapted to activate the surface of the display.

Owner:RAISCH NETANEL

Engine controller, controller of engine and hydraulic pump, and engine, hydraulic pump and controller of generator motor

InactiveCN101297106ASlow movementElectrical controlSoil-shifting machines/dredgersDriver/operatorEngine efficiency

A working machine is operated as intended by an operator with good response and with enhanced engine efficiency, pump efficiency, and the like. A first engine target speed of rotation ncom1 conforming to a current pump target delivery flow rate Qsum is set, and when a decision is made that the current pump target delivery flow rate Qsum is higher than a predetermined flow rate (e.g. 10 (L / min)), a decision is made that operating means (41-44) are switched from nonoperating state to operating state, and a speed of rotation nM (e.g. 1400 rpm) higher than the engine idle speed of rotation nL is set as a second engine target speed of rotation ncom2. If the second engine target speed of rotation ncom2 is higher than the first engine target speed of rotation ncom1, engine speed of rotation is controlled to attain the second engine target speed of rotation ncom2.

Owner:KOMATSU LTD

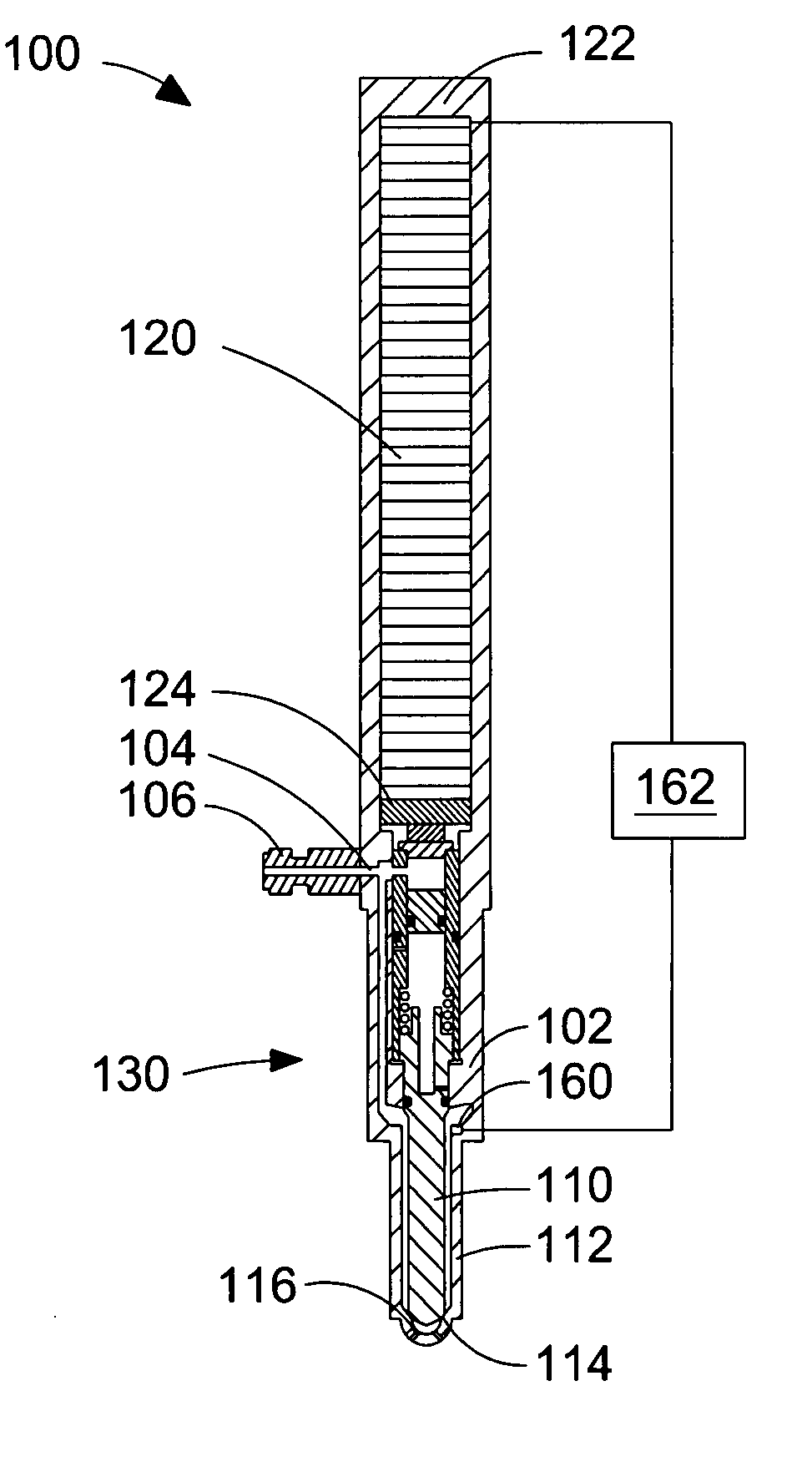

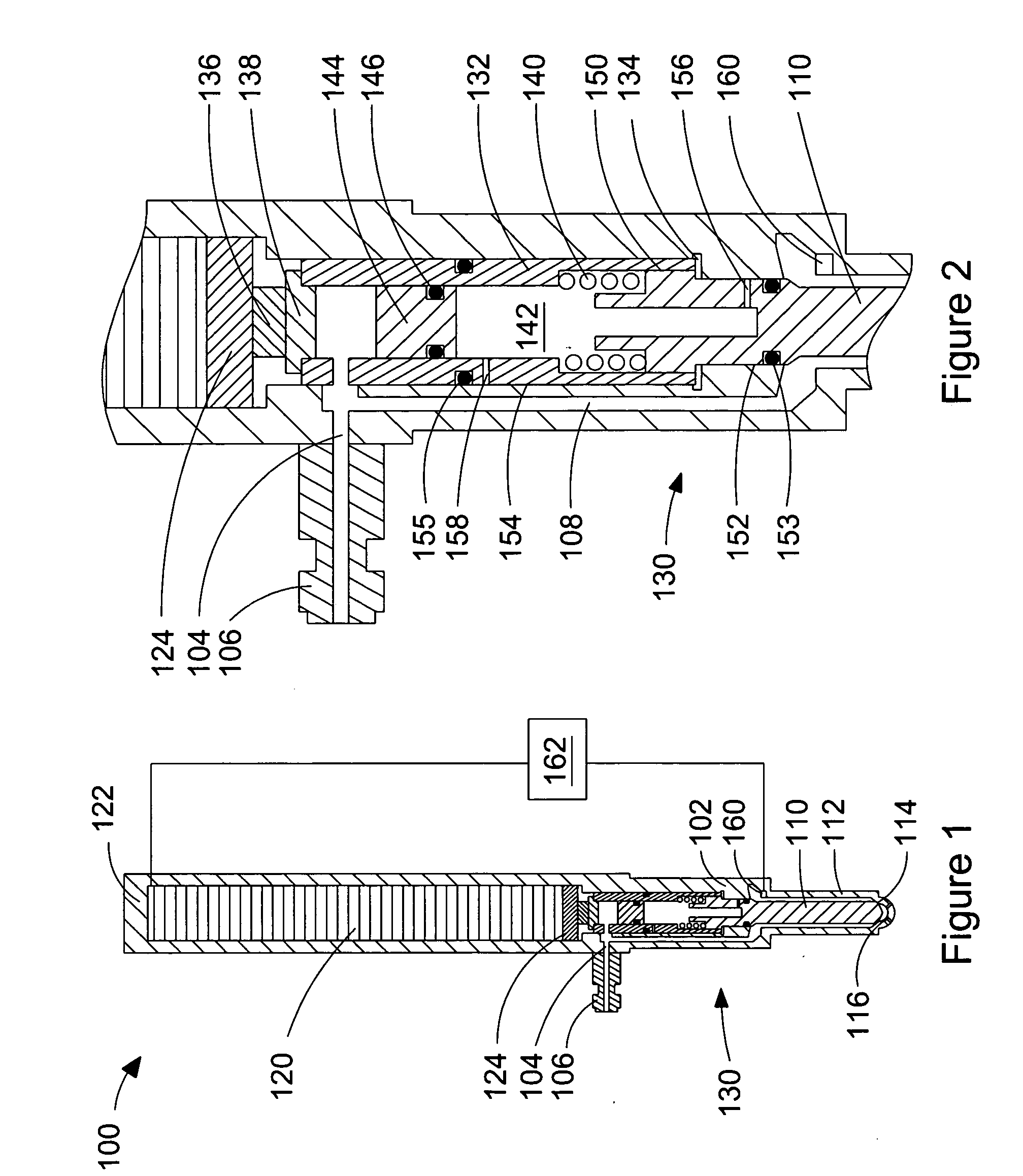

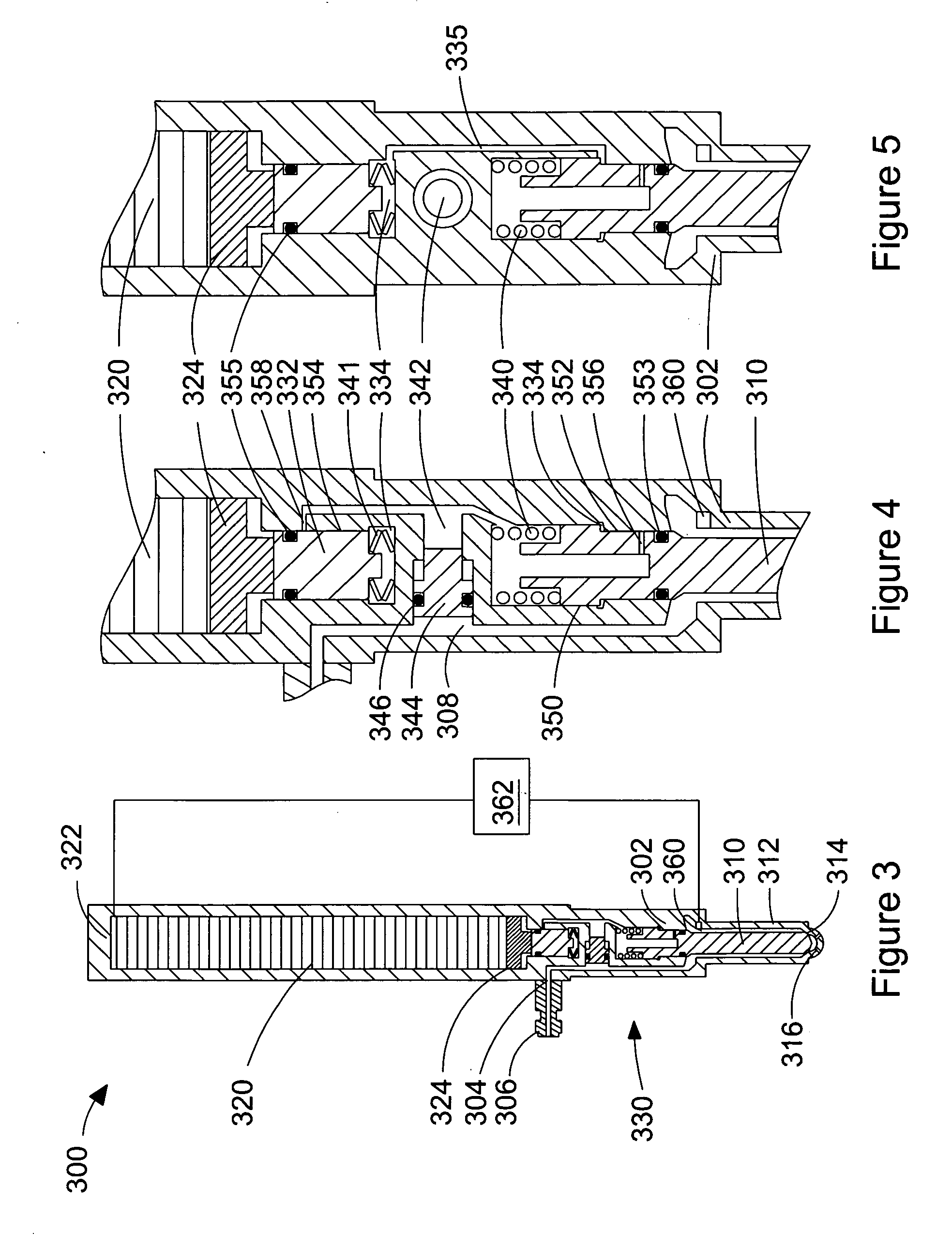

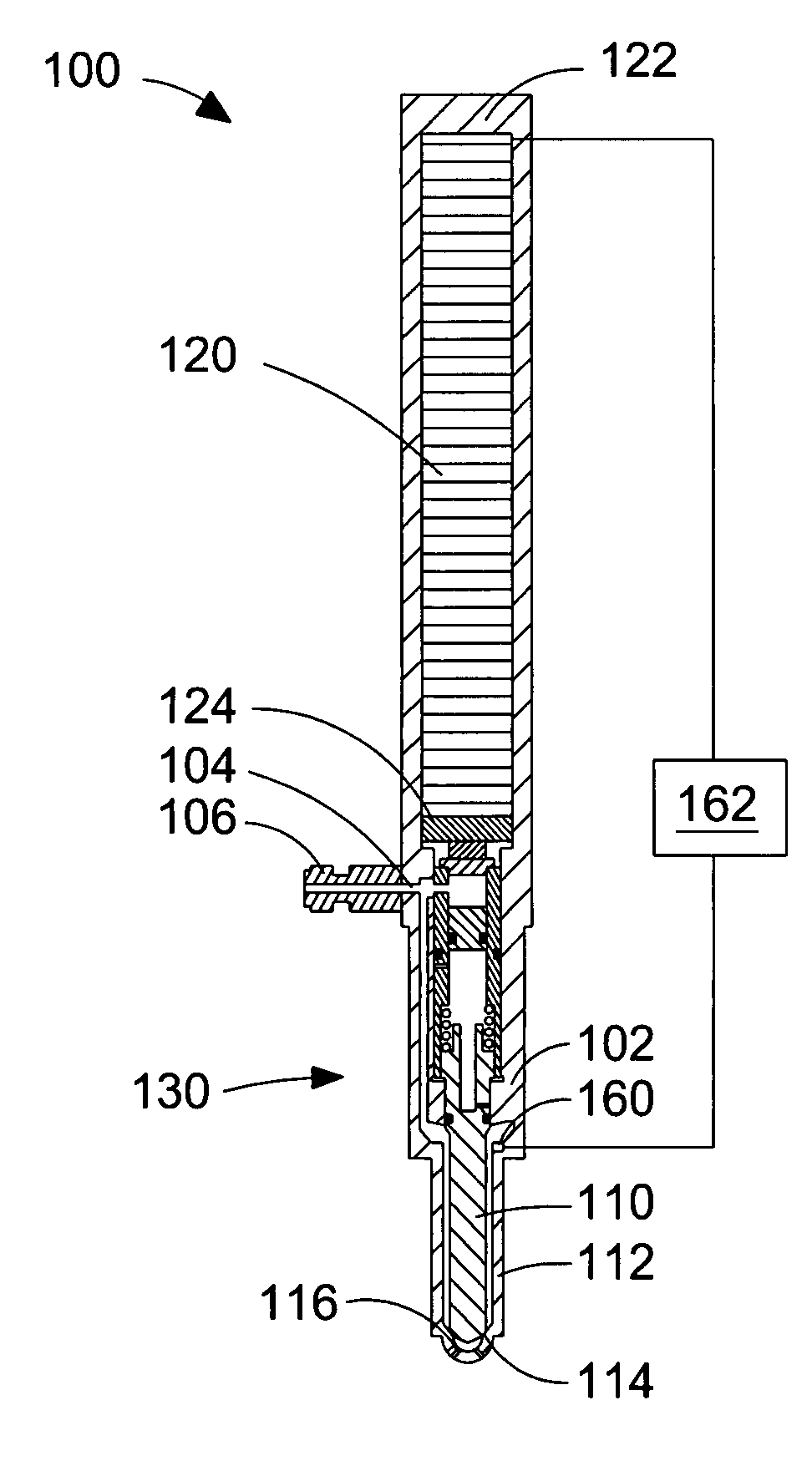

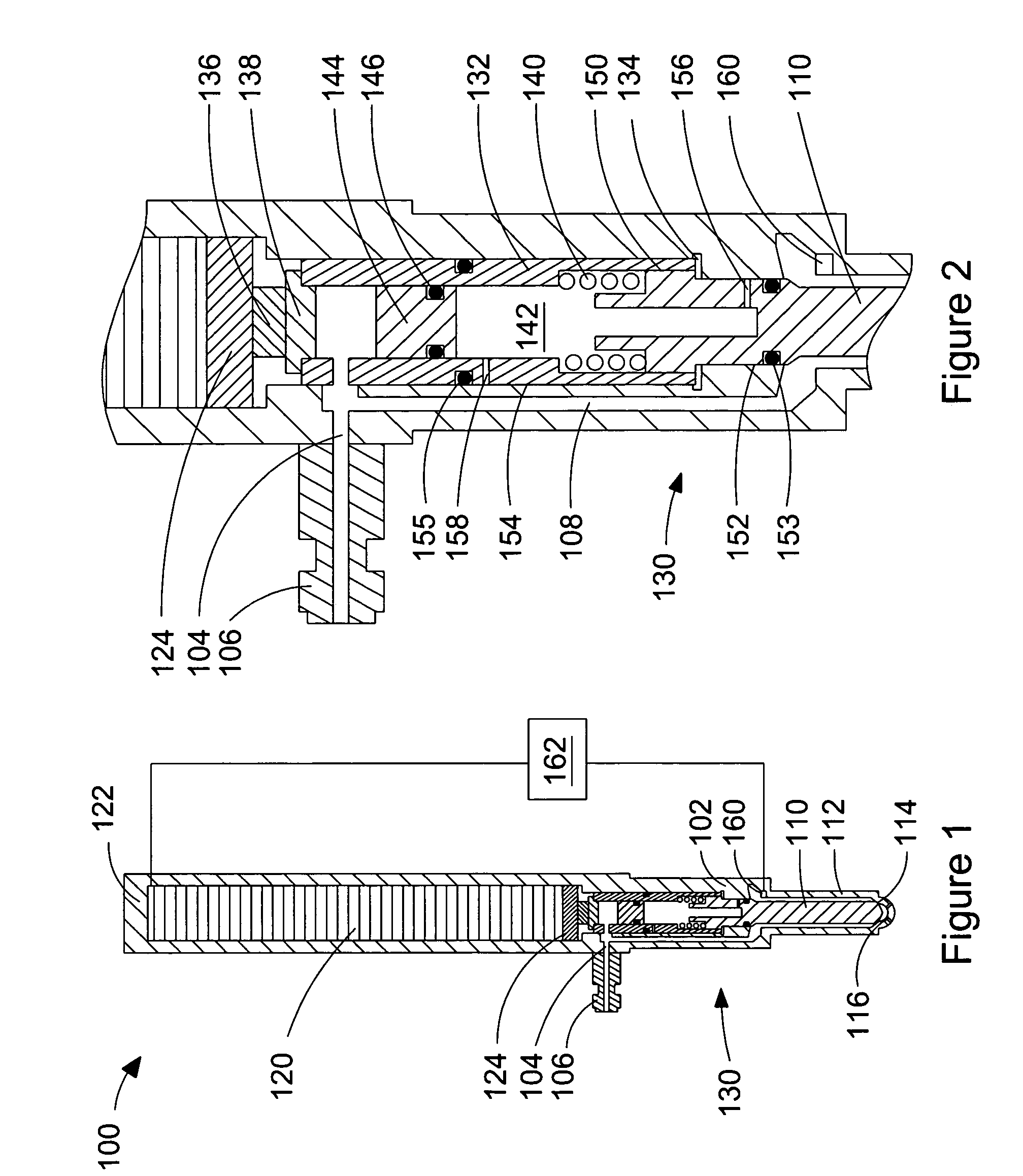

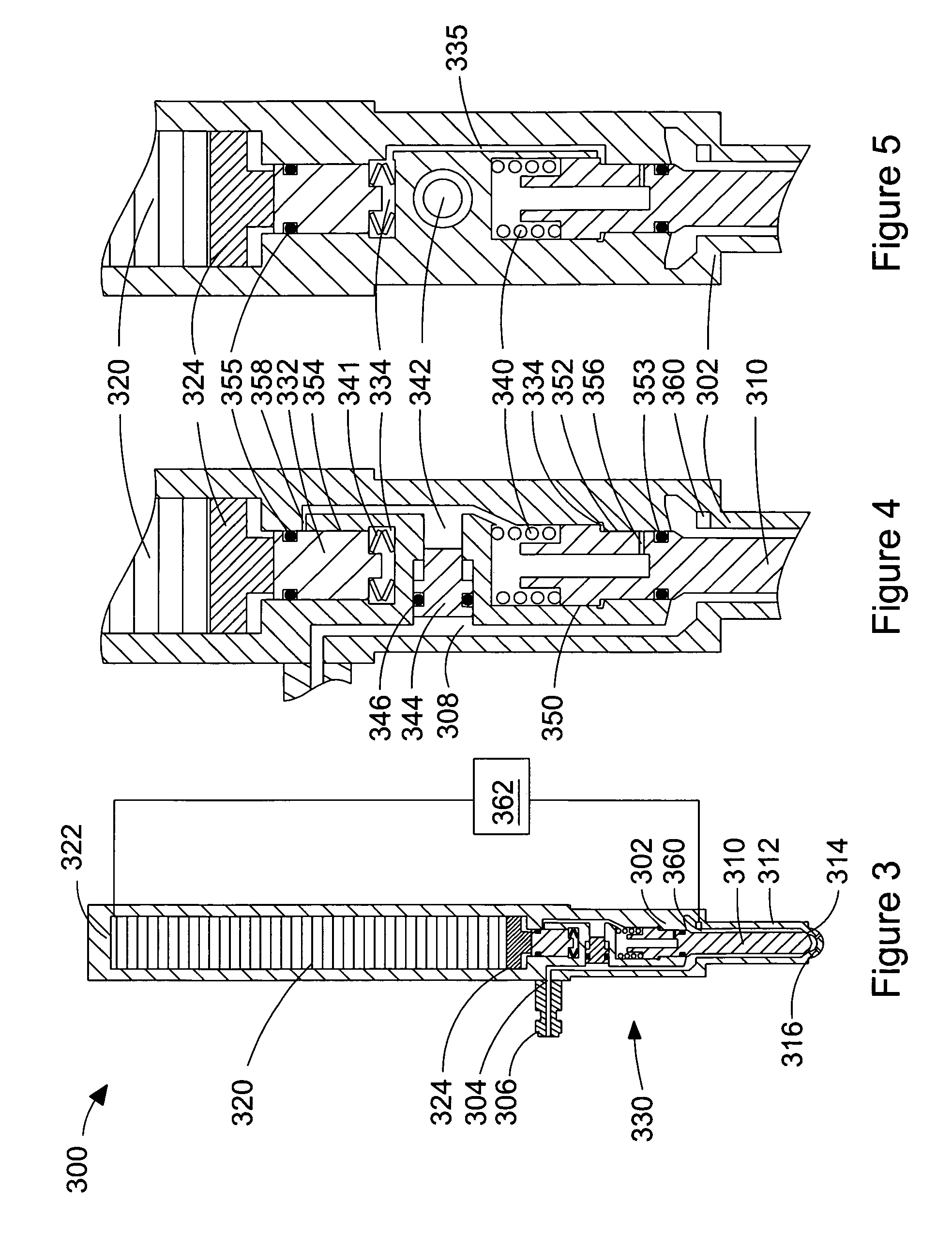

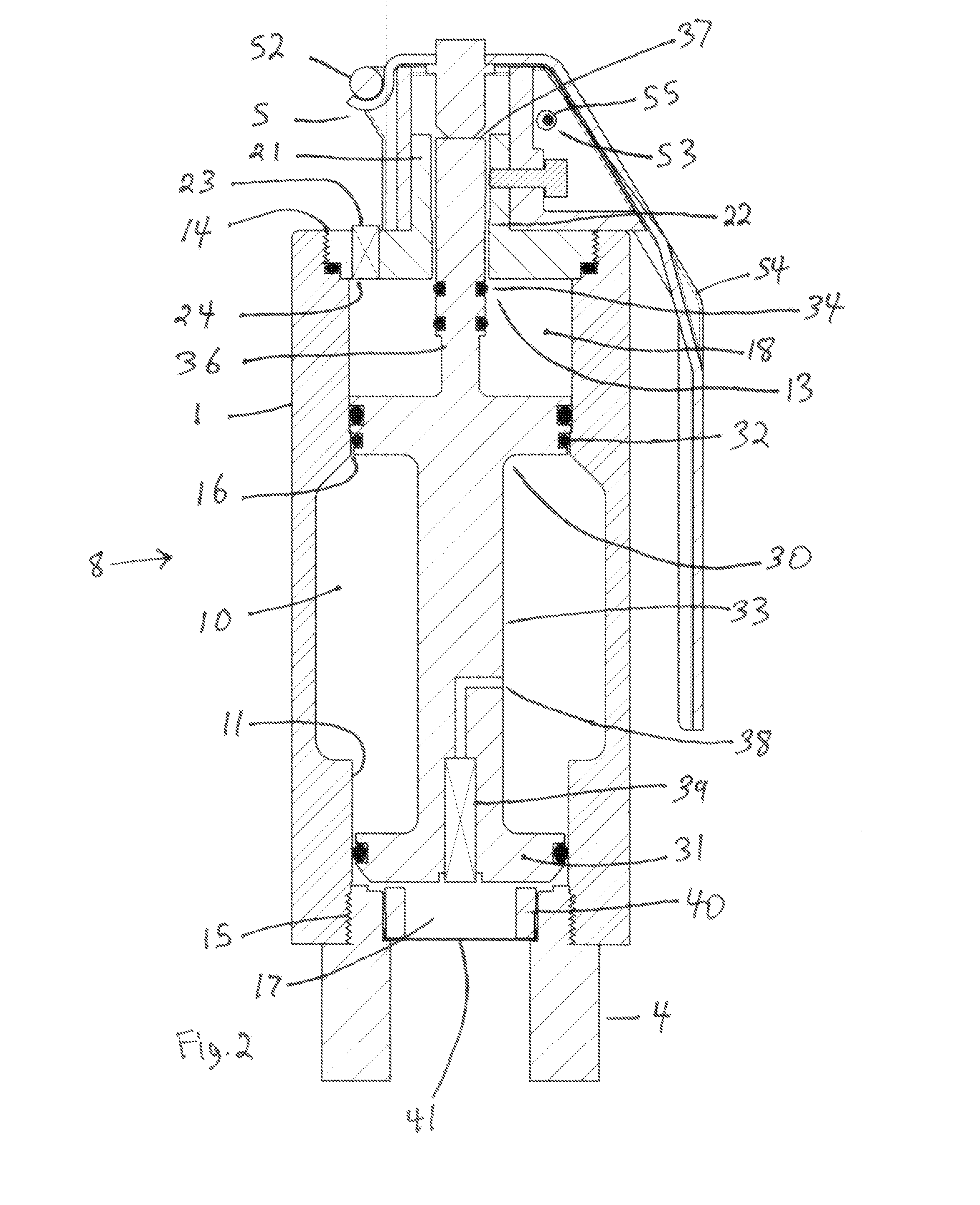

Common rail directly actuated fuel injection valve with a pressurized hydraulic transmission device and a method of operating same

ActiveUS20050274360A1Improve manufacturabilityLow costElectrical controlOperating means/releasing devices for valvesDifferential pressureCommon rail

A common rail directly actuated fuel injection valve is disclosed with a hydraulic transmission device that is fluidly isolated from the fuel so that the hydraulic fluid can be different from the fuel. This arrangement is particularly suitable for valves that inject a gaseous fuel, but can also be beneficial for use with liquid fuels. According to the method, the hydraulic fluid is pressurizable by the fuel pressure to reduce differential pressures and leakage, in addition to assisting with operation of the hydraulic transmission device. The method further comprises detecting the position of the valve needle for more accurate control of rate of fuel injection during an injection event.

Owner:WESTPORT FUEL SYST CANADA INC

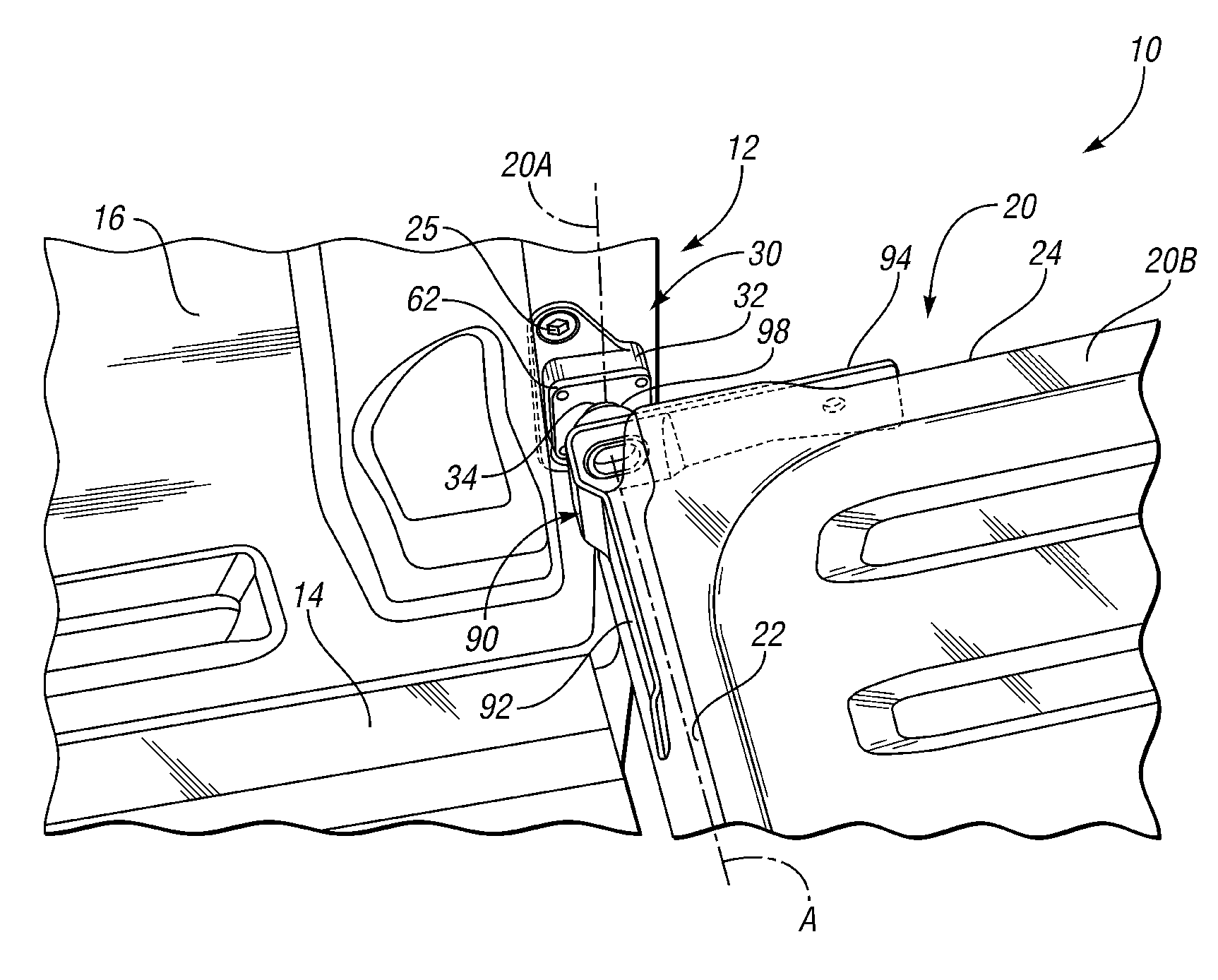

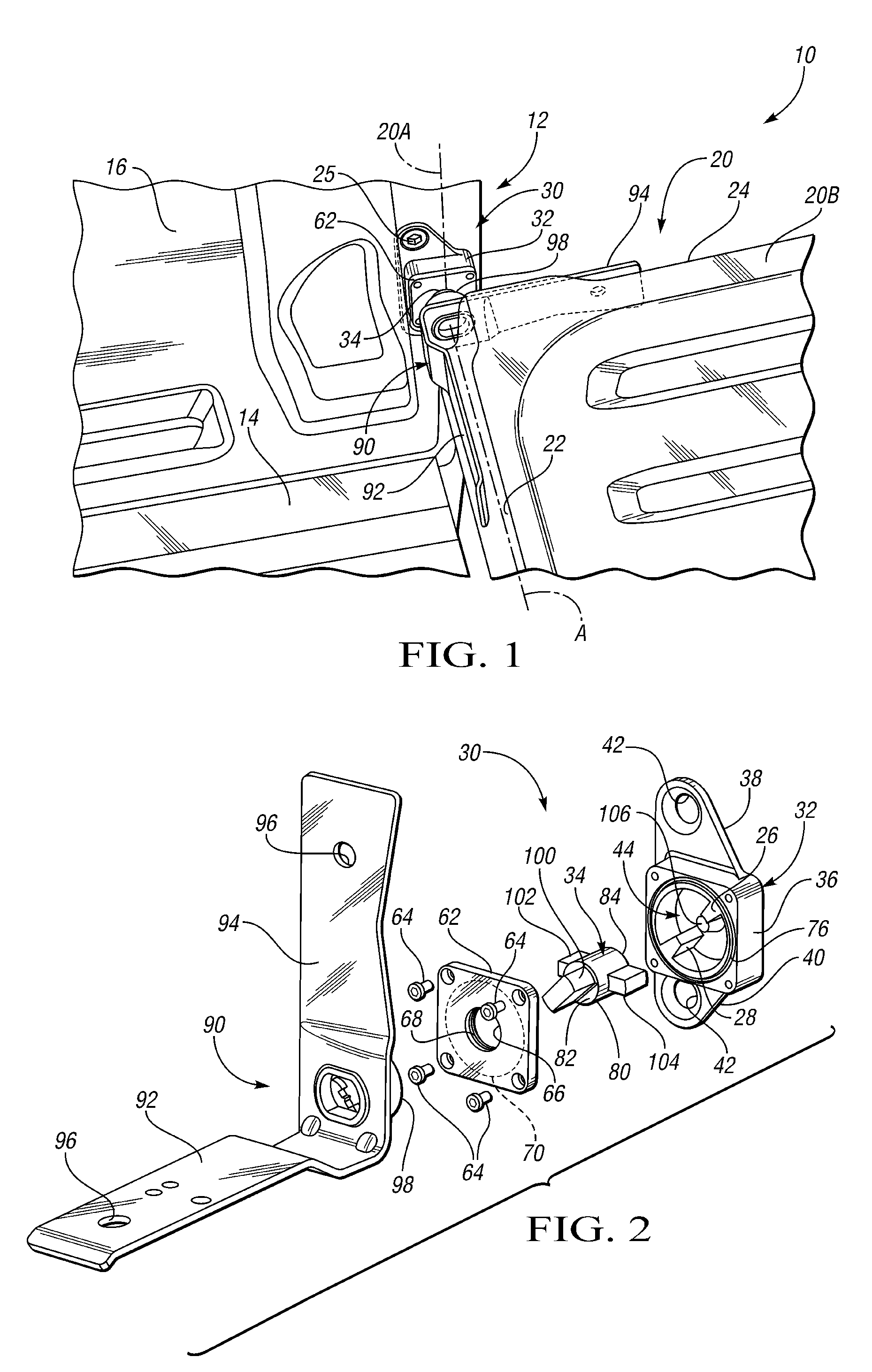

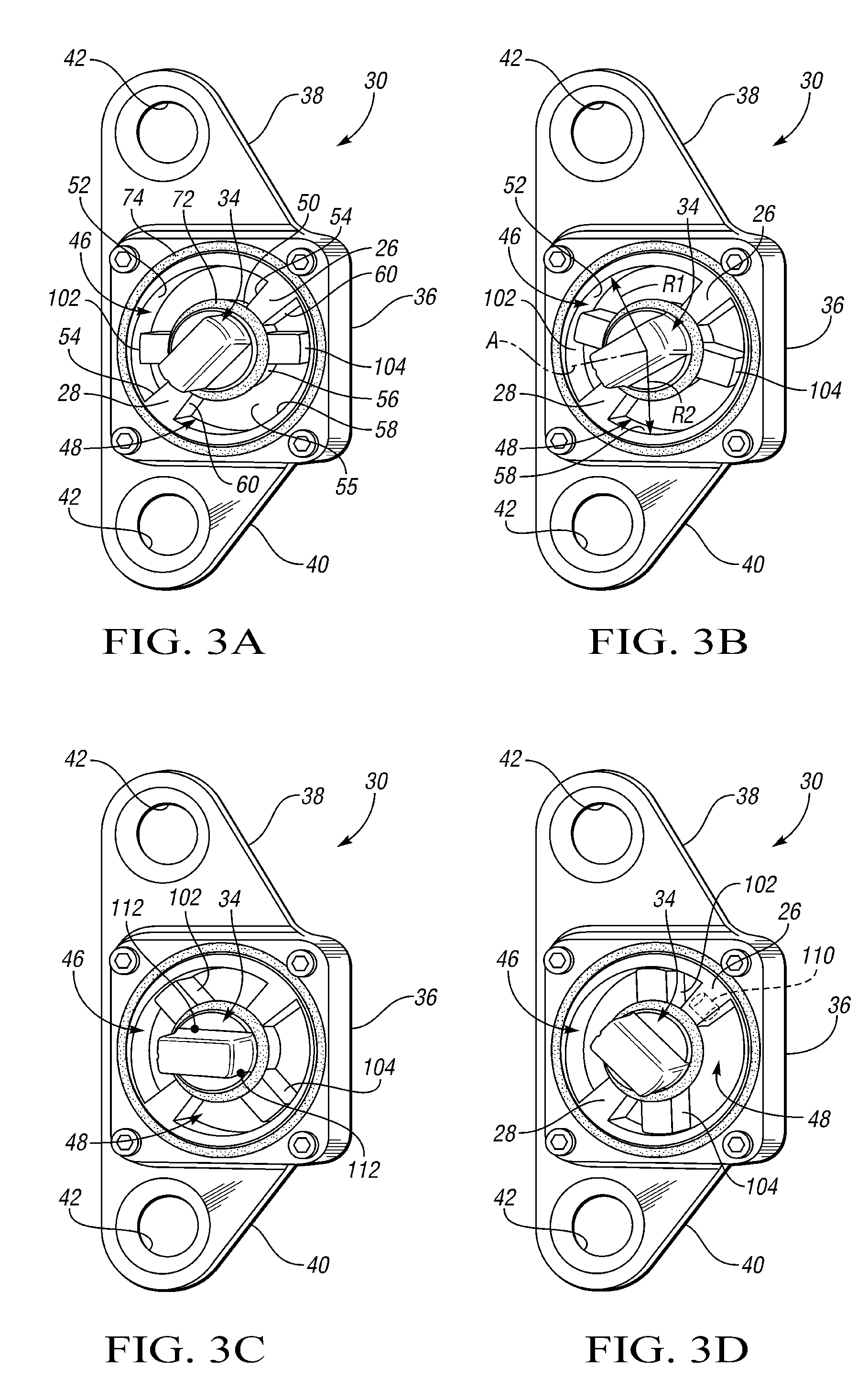

Viscous Rotary Damper for Vehicle End Gate Assembly

ActiveUS20100084885A1Dissipate kinetic energySlow movementBuilding braking devicesSuperstructure subunitsImpellerEngineering

A viscous rotary damping device for a vehicle end gate assembly is provided. The damping device includes a housing member configured to operatively attach to the vehicle body or the end gate assembly. The housing member defines a fluid chamber having viscous fluid therein. The damping device also includes an impeller member having a mast with a first end configured to operatively attach to the other of the vehicle body and the end gate assembly, and a second end having one or more blades projecting outward therefrom. The second end of the mast is rotatably received in the fluid chamber such that the impeller member dissipates kinetic energy generated by the end gate assembly when transitioning between a first, closed position and a second, open position. A cover plate member is preferably coupled to the housing member, and configured to fluidly seal the fluid chamber.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lock guard for long shackle padlock over handle

InactiveUS7412856B1Slow movementThwart excessive movementAnti-theft cycle devicesVehicle locksEngineeringShackle

Owner:MCGRAW ENTERPISES

Common rail directly actuated fuel injection valve with a pressurized hydraulic transmission device and a method of operating same

ActiveUS7100577B2Reduce leakageSlow movementOperating means/releasing devices for valvesElectrical controlThermodynamicsCommon rail

A common rail directly actuated fuel injection valve is disclosed with a hydraulic transmission device that is fluidly isolated from the fuel so that the hydraulic fluid can be different from the fuel. This arrangement is particularly suitable for valves that inject a gaseous fuel, but can also be beneficial for use with liquid fuels. According to the method, the hydraulic fluid is pressurizable by the fuel pressure to reduce differential pressures and leakage, in addition to assisting with operation of the hydraulic transmission device. The method further comprises detecting the position of the valve needle for more accurate control of rate of fuel injection during an injection event.

Owner:WESTPORT FUEL SYST CANADA INC

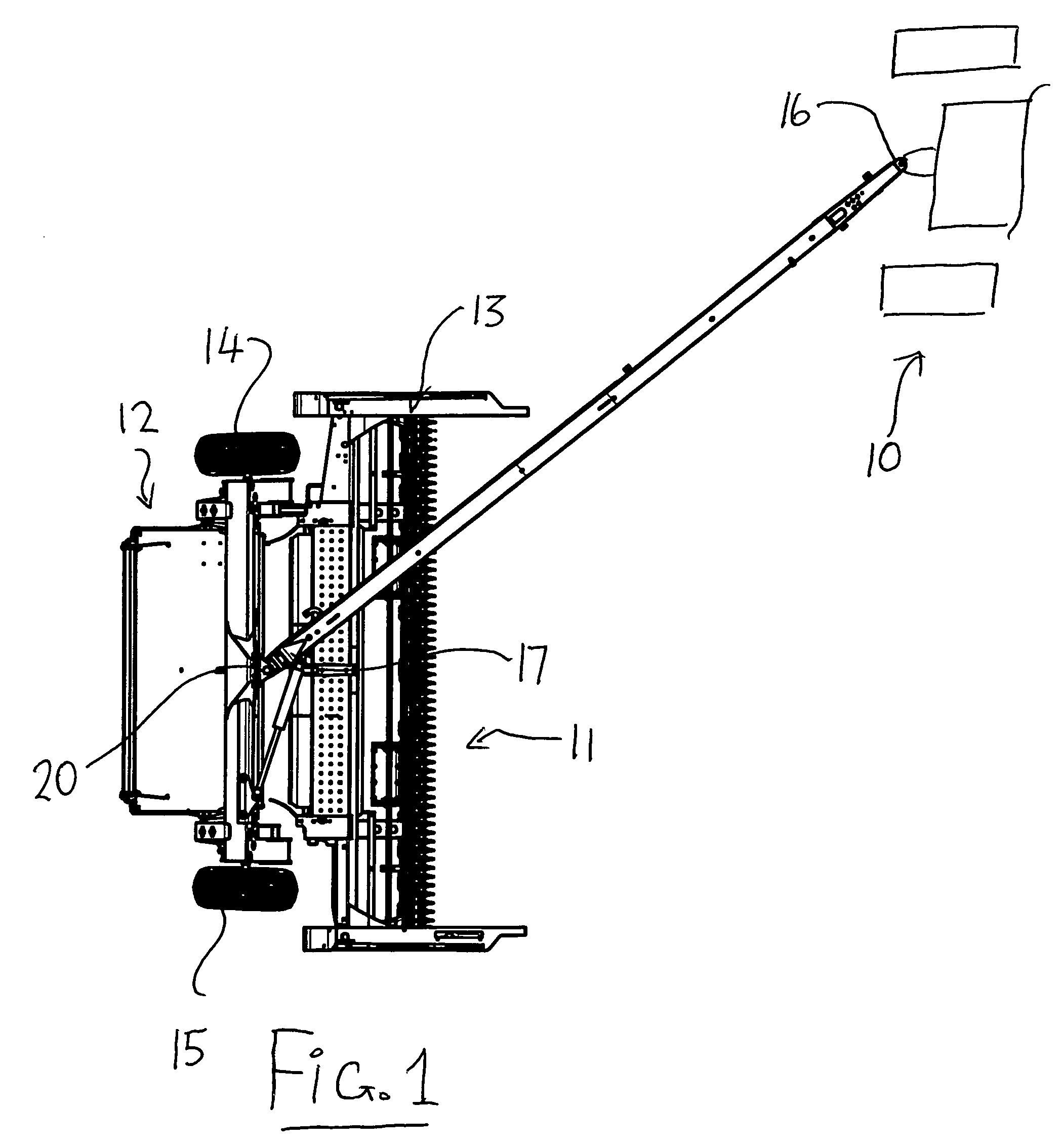

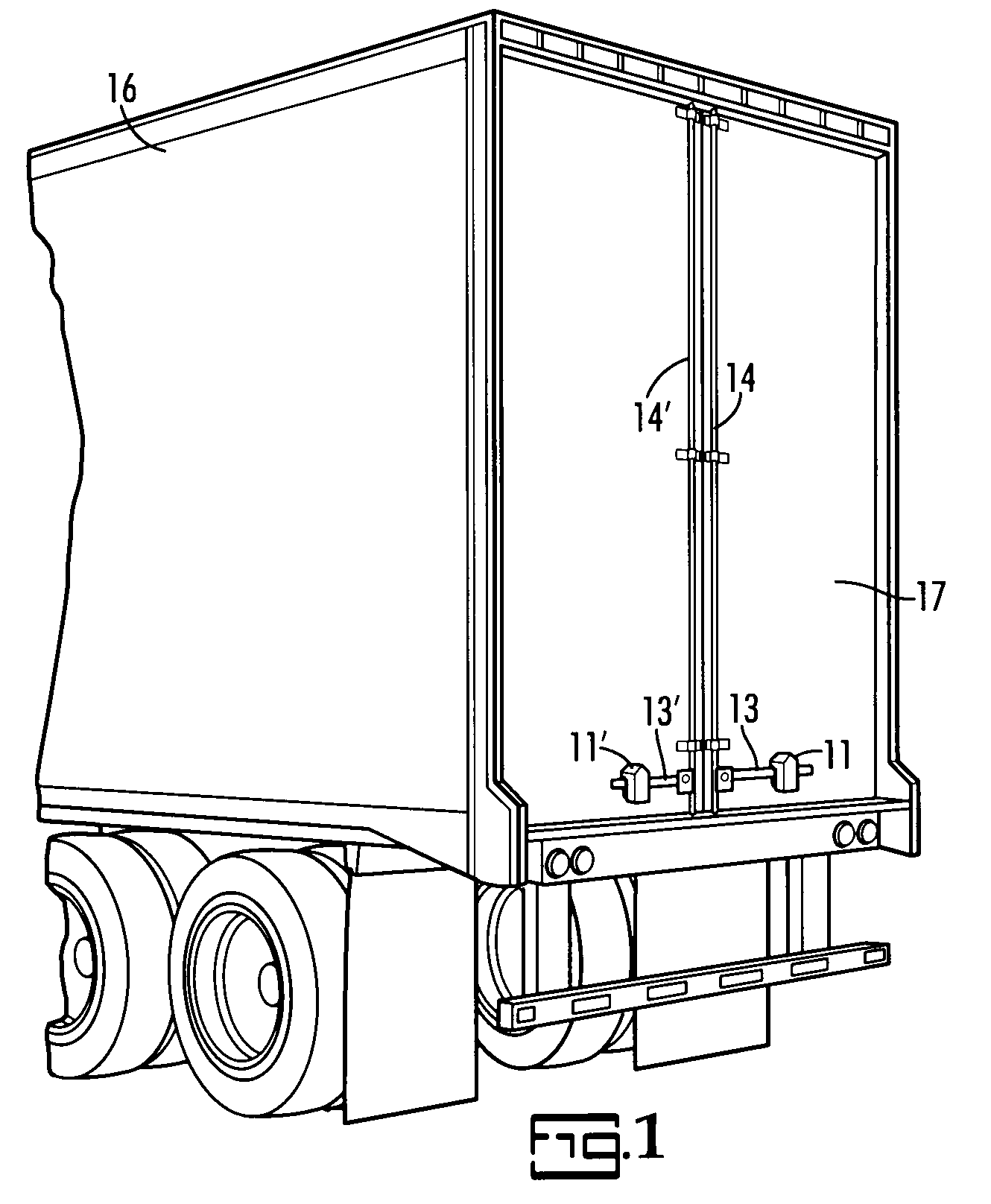

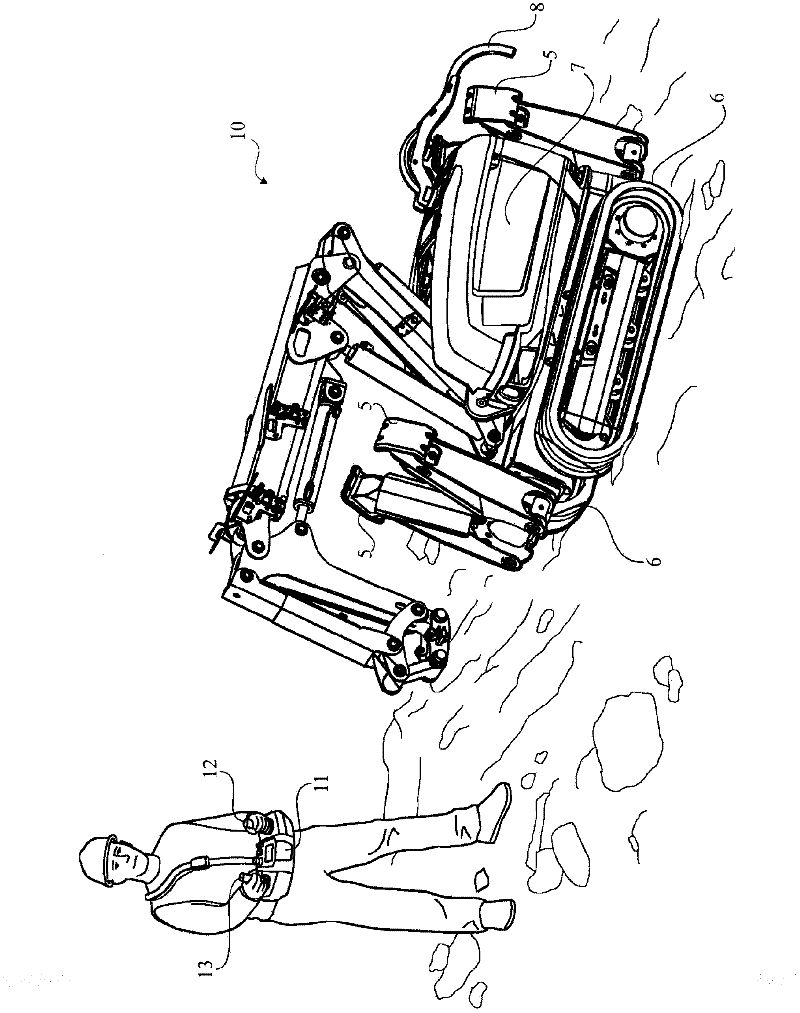

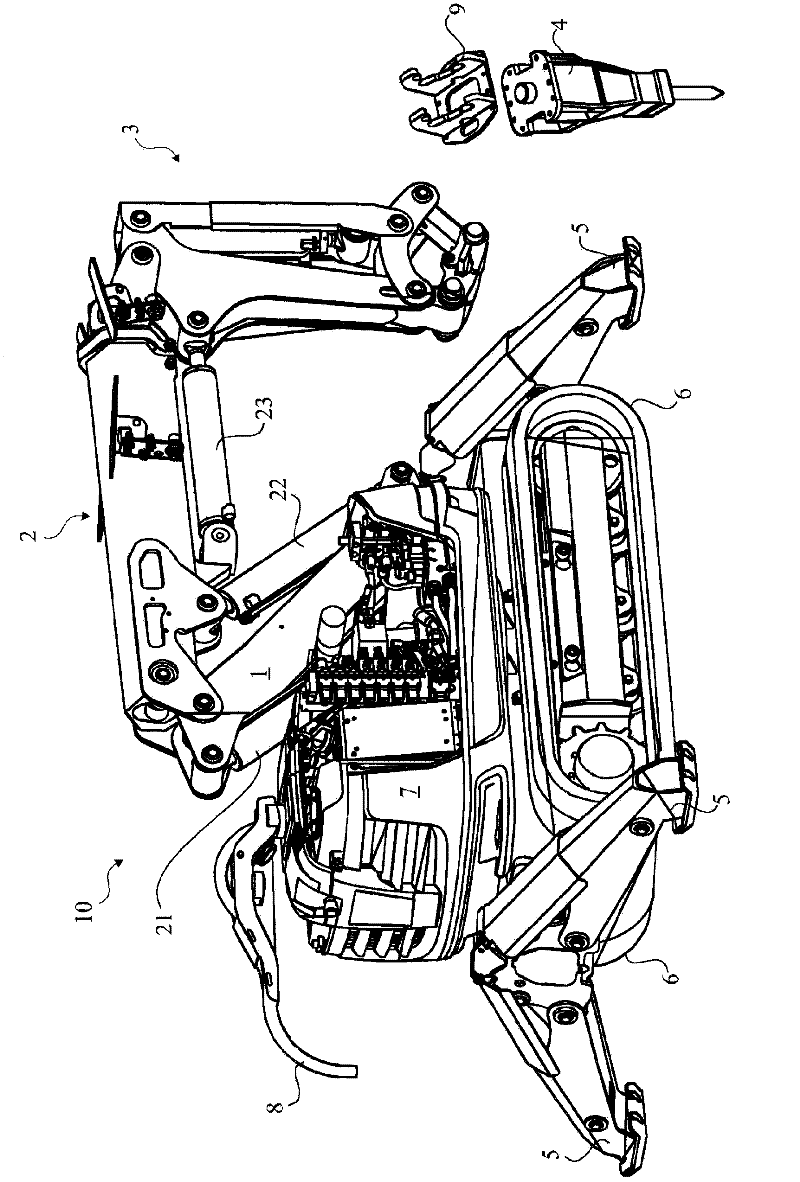

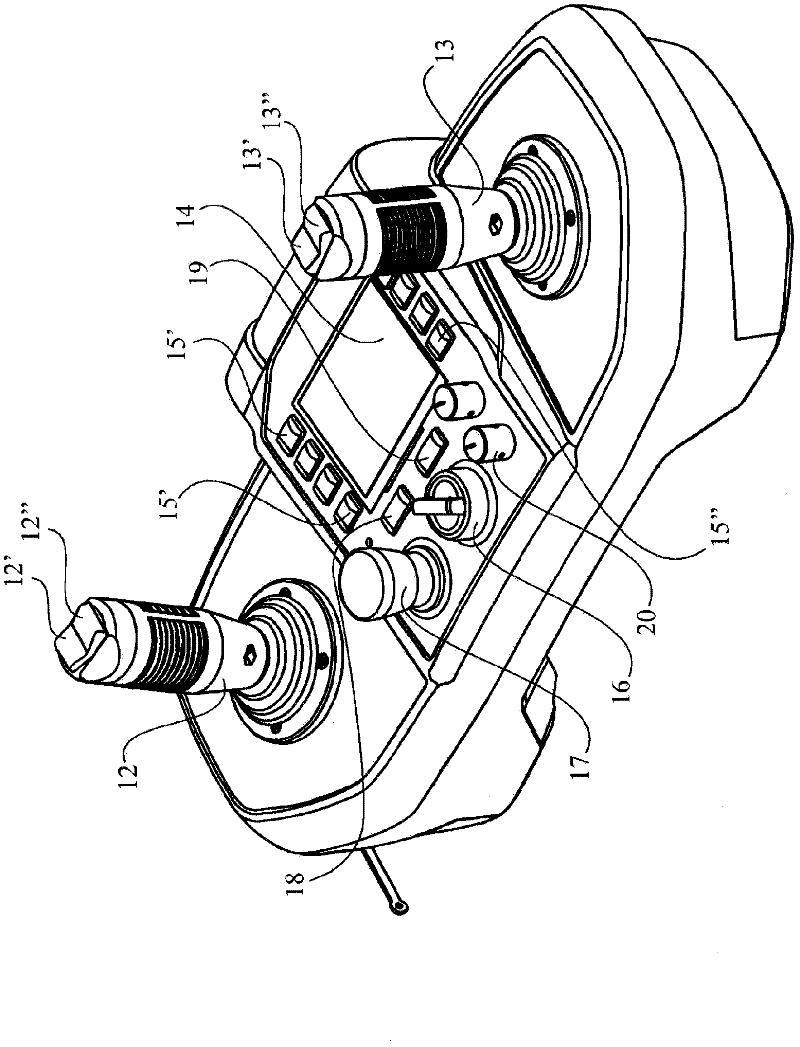

Control system for remote working machines

ActiveCN102282321ASlow movementMove quicklyManual control with multiple controlled membersControlling membersTravel modeJoystick

Control system for a remote-controlled working machine (10) provided with caterpillar tracks (6) or the like for the travel thereof, e.g. a demolition robot intended for demolition work, etc., the said control system including a remote control (11) intended to be carried by an operator situated beside the machine (10), the said remote control (11) being connected wirelessly, e.g. via Bluetooth, or by means of a cable to at least one electronic unit in the machine, and having at least one control stick or joystick (12, 13) and a number of buttons, levers and / or knobs for operating the different travel and working functions of the machine. The machine furthermore has one or more different setting modes or positions, wherein its control sticks and / or certain buttons have different functions in different modes. In a travel mode, also referred to as a transport position, travel of the machine is handled entirely by one control stick (12, 13), advantageously the left control stick (12), such that the caterpillar tracks (6) of the machine are operated as follows: - if the control stick is moved forwards or backwards, both caterpillar tracks (6) are driven forwards or backwards so that the machine moves forwards or backwards; - if the control stick is moved straight to the left, the right caterpillar track is driven forwards and the left caterpillar track is driven backwards so that the machine turns to the left; - if the control stick is moved straight to the right, the left caterpillar track (6) is driven forwards and the right caterpillar track is driven backwards so that the machine turns to the right. The operator's other hand is thus free for other tasks during travel of the machine.

Owner:HUSQVARNA AB

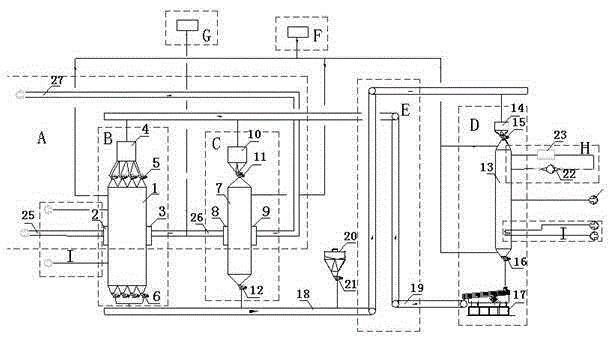

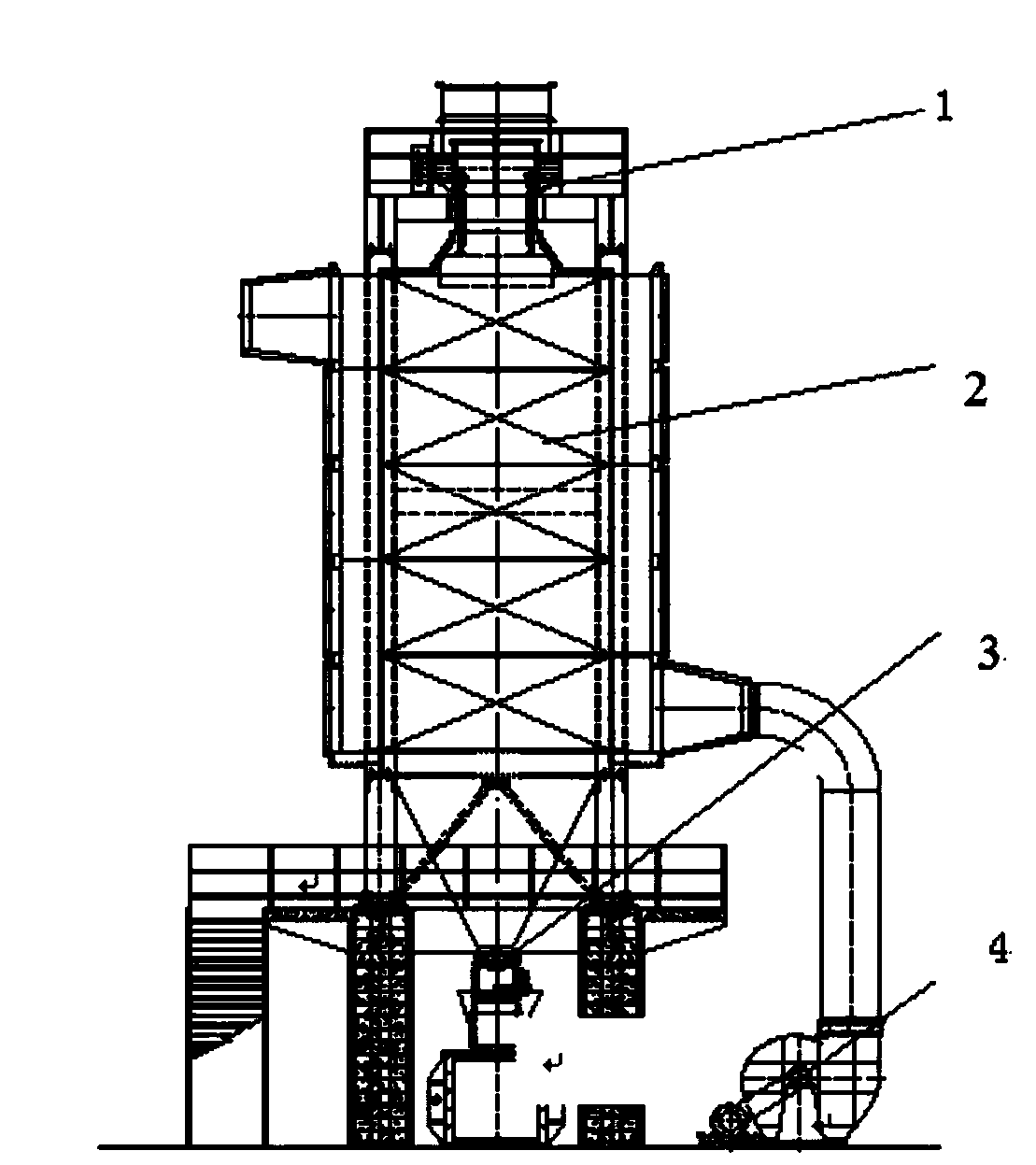

Carbon-based catalyst desulfurization and denitrification system and method

ActiveCN105233673ASlow movementReduce wearDispersed particle separationPtru catalystProcess engineering

The invention provides a carbon-based catalyst desulfurization and denitrification system and method. The carbon-based catalyst desulfurization and denitrification system comprises a fume system (A), a desulfuration adsorption system (B), a denitrification adsorption system (C), a carbon-based catalyst conveyer system (E), a nitrogen system (F), an ammonia gasification dilution system (G), a cooling water system (I), a carbon-based catalyst regeneration system (D) and an air heating system (H), wherein all the systems are connected through a pipeline. Boiler fume enters a chimney to be discharged after reaching the standard by being processed through the carbon-based catalyst desulfurization and denitrification system, the adsorbed carbon-based catalyst is heated, desorbed and regenerated and then returns to an adsorption tower, and high-concentration SO2 obtained through desorption is used for resource recovery. According to the system, SO2 and NOx are removed through two-stage movement adsorption, adaptability to the fume condition characterized in high sulfur content, variable sulfur content and large fume amount change is high, and the foundation can be laid for large-scale application and popularization of the carbon-based catalyst fume purification technique in the thermal power industry.

Owner:GUODIAN SCI & TECH RES INST

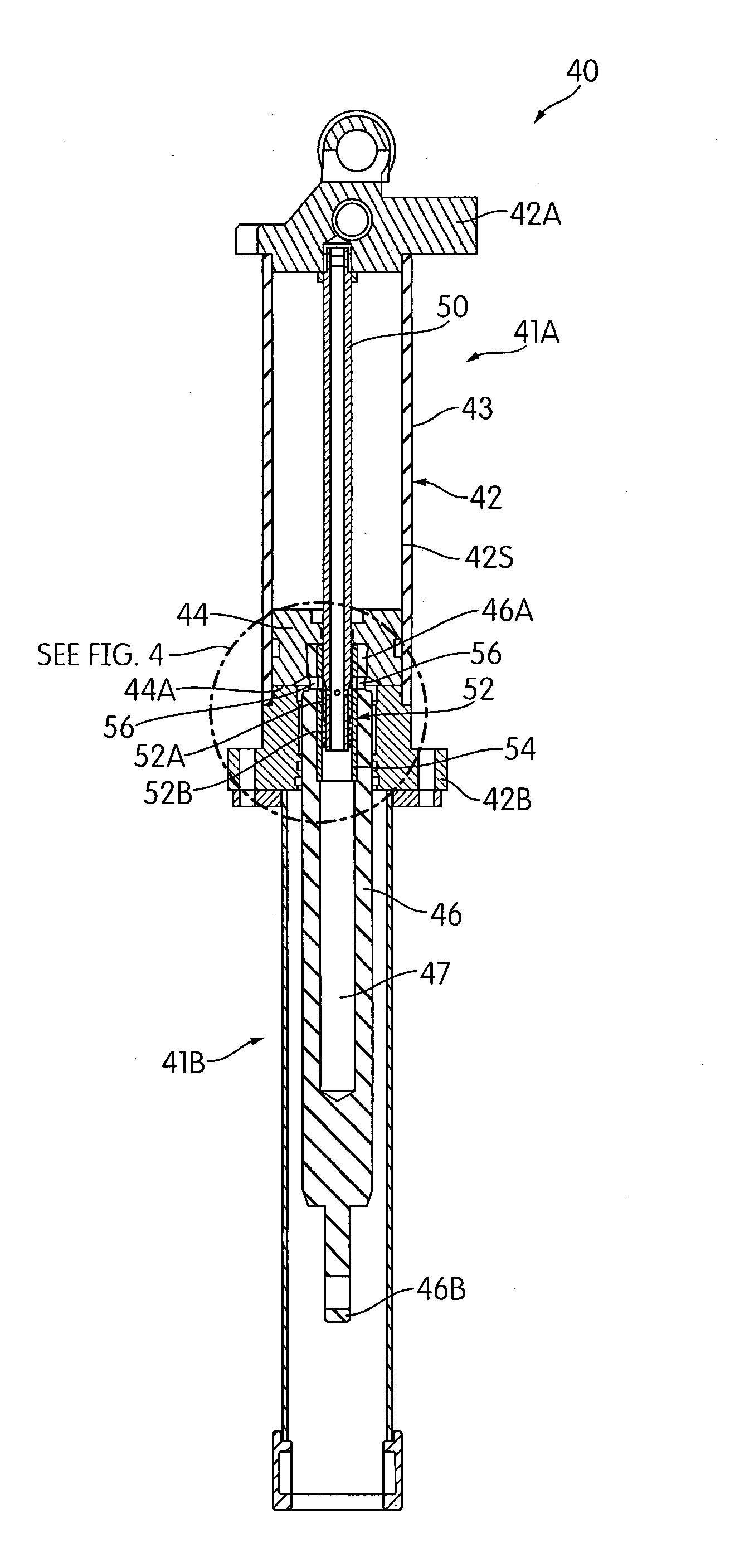

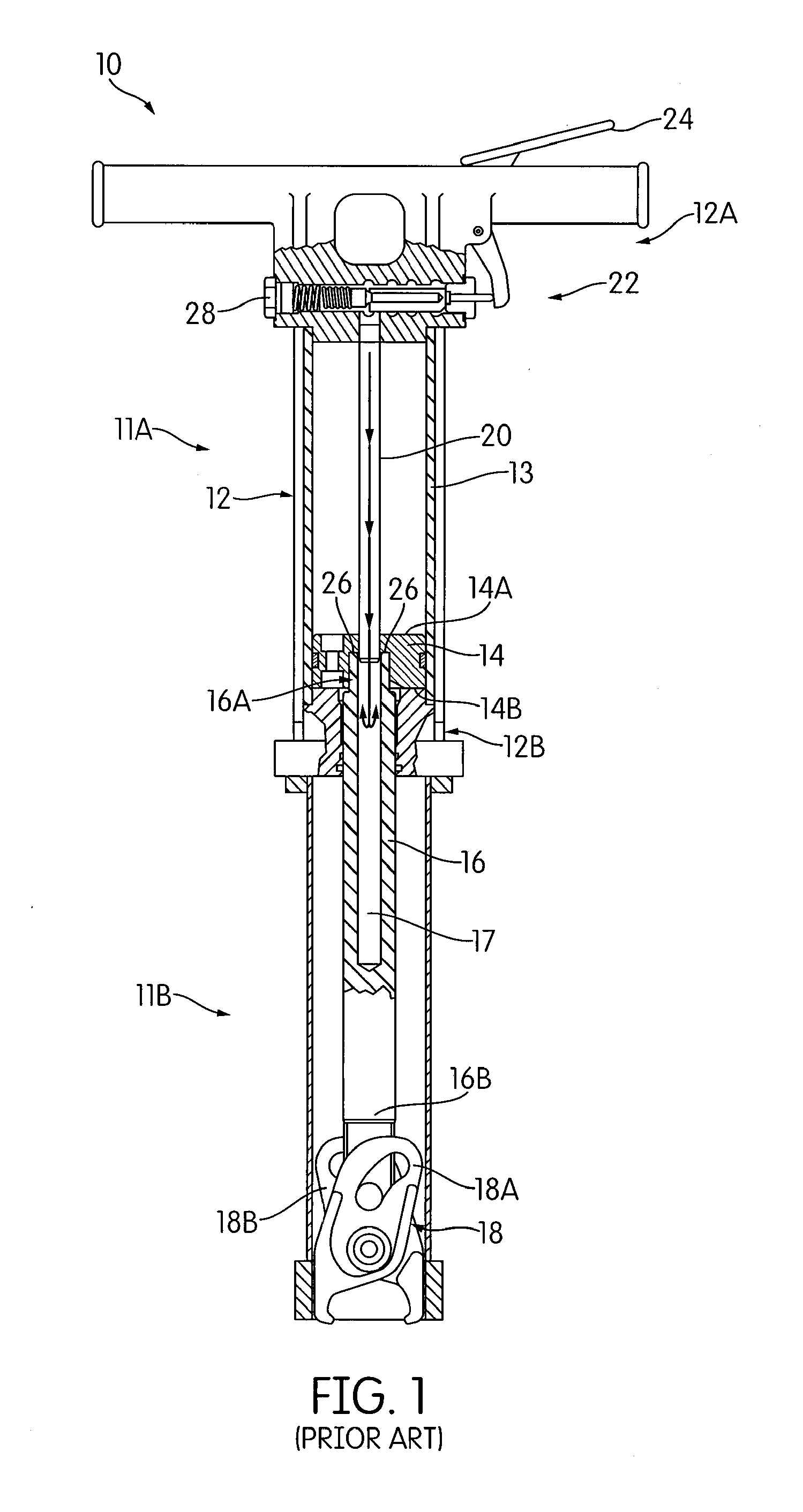

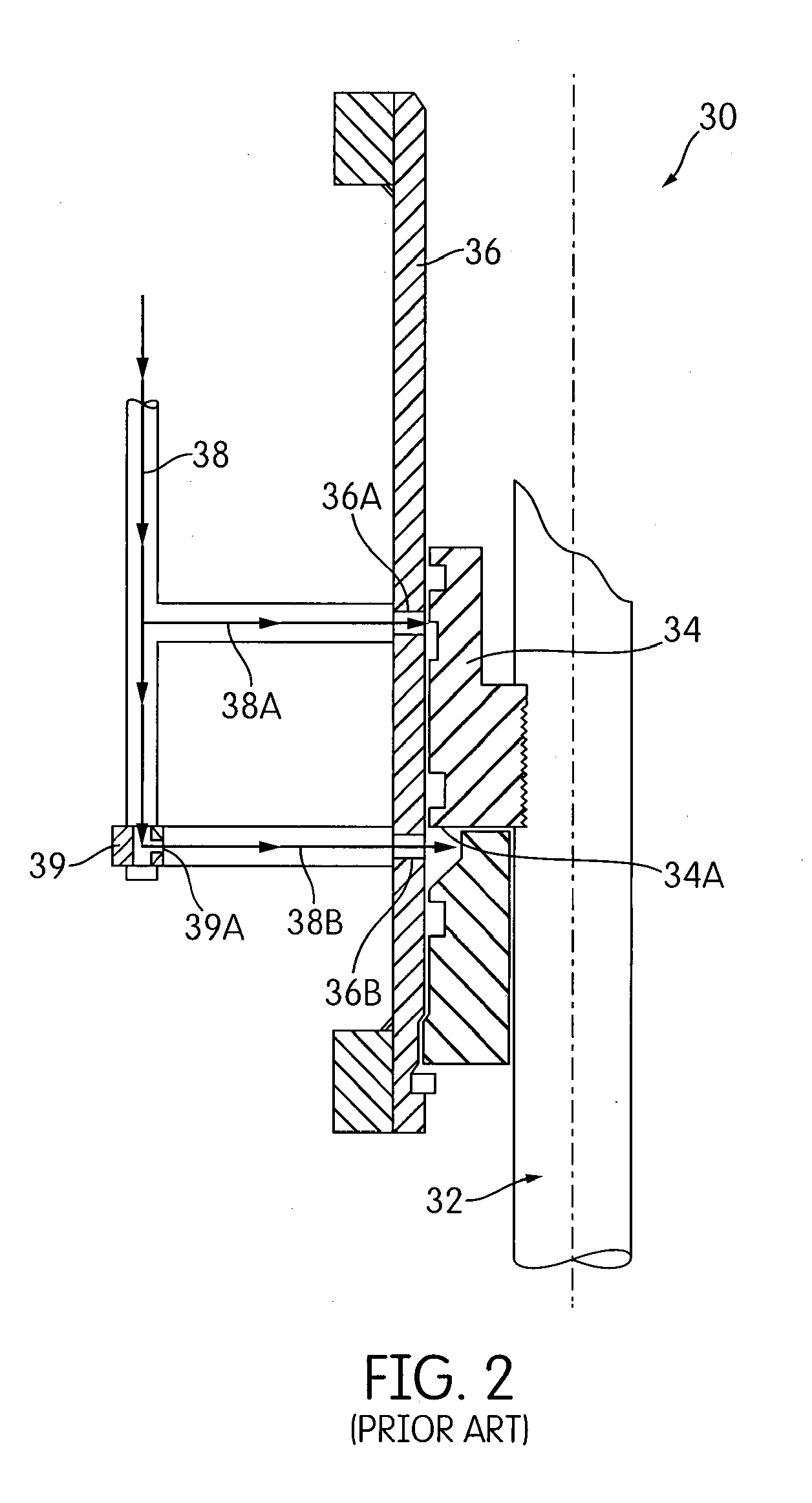

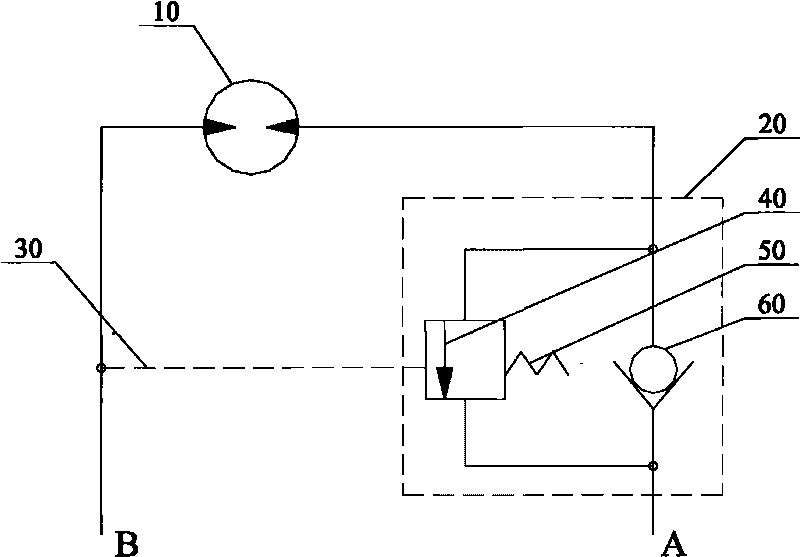

Hydraulic spike puller

A pulling tool includes a housing and a tube disposed within the housing, the tube configured to supply hydraulic fluid. The spike puller further includes a piston rod connected to a piston. The piston rod has a hollow axial bore, and the piston and the piston rod are axially moveable relative to the tube. The spike puller has a passage communicating fluid from the tube to the piston. The passage is contained within the housing. The passage is variable between a first configuration in which hydraulic fluid flows at a first restricted flow so as to provide a slower retraction of the piston rod and a second configuration in which hydraulic fluid flows at a second less restricted flow so as to provide a faster retraction of the piston rod.

Owner:STANLEY WORKS THE

Balance valve

InactiveCN101725743ACompact designReduce outflowOperating means/releasing devices for valvesServomotor componentsEngineeringControl valves

The invention discloses a balance valve. In the balance valve, a main valve core and a control piston are placed in two cavities of a valve body respectively; a control valve core is arranged in a cavity of the main valve core in an embedded mode; when working pressure oil liquid enters the valve body from a second oil opening, the control piston moves to the right to pull the control valve core to move to the right, a second segment of the control valve core is separated from a ring-shaped protrusion of the cavity of the main valve core; the working pressure oil liquid acts on the protruding surface of the outer edge of the main valve core, the main valve core moves to the right, namely the transitional surface of the main valve core is separated from the transitional surface of a second cavity, and the working pressure oil liquid passes the second cavity of the valve body and flows out of the valve body by a first oil opening; because the control valve core needs to be opened before the main valve core is opened and in fine adjustment, the main valve core is still at a closing state and relatively smoothly moves, so that the vibration caused by loading operation is eliminated; and when the control pressure continuously increases, the main valve core moves to the right under an action of the working pressure of the second oil opening, the opening is free from the influence of control pressure, a heavy article can smoothly fall at a controlled speed, and the control accuracy is improved.

Owner:XUZHOU HEAVY MASCH CO LTD

Advanced "Omer" rescue system

InactiveUS20080087498A1Slow movementBuilding rescueSpecial door/window arrangementsBiomedical engineering

An escape system for moving a person on a cord on the exterior of a building. The building has a first surface and a second surface. The first surface and the second surface are substantially perpendicular to each other. The system comprises a control device for controlling the movement of the person on the cord and an anchoring device for reversibly mechanically attaching the control device to the building. The control device is substantially irreversibly mechanically connected to the anchoring device. The anchoring device has a first elongated element and a second elongated element. The first elongated is mechanically connected to the second elongated element. The first elongated element and the second elongated element are configured such that, the first elongated element at least partially rests against the first surface of the building and the second elongated element at least partially rests against the second surface of the building.

Owner:BARZILAI YOAV

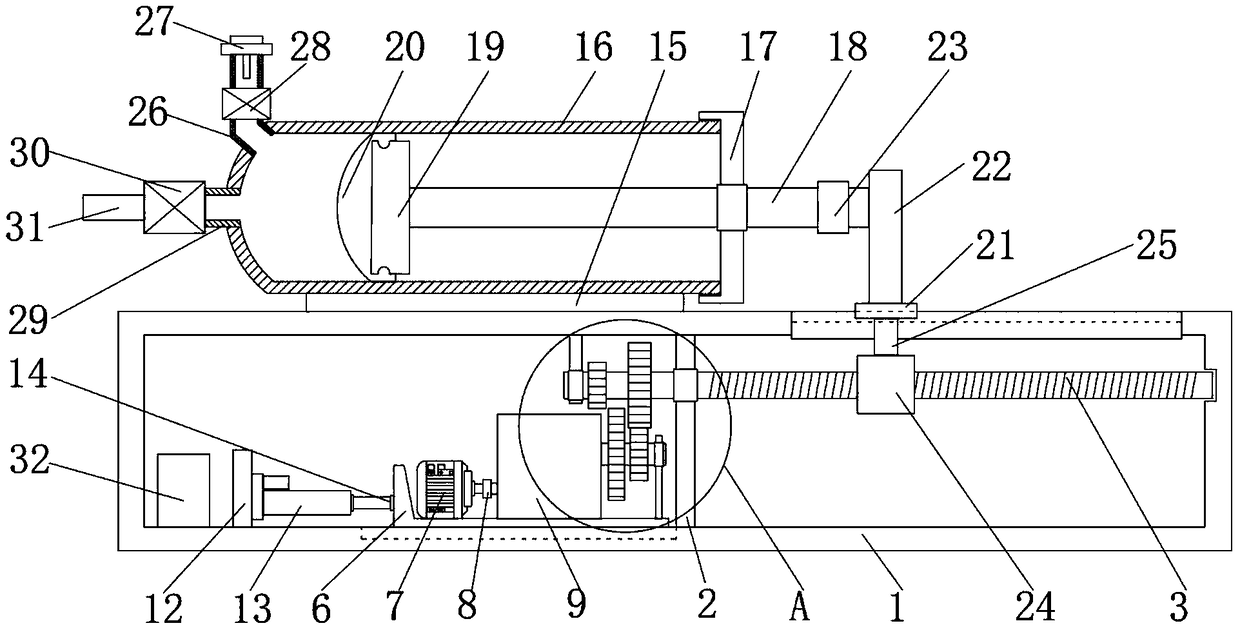

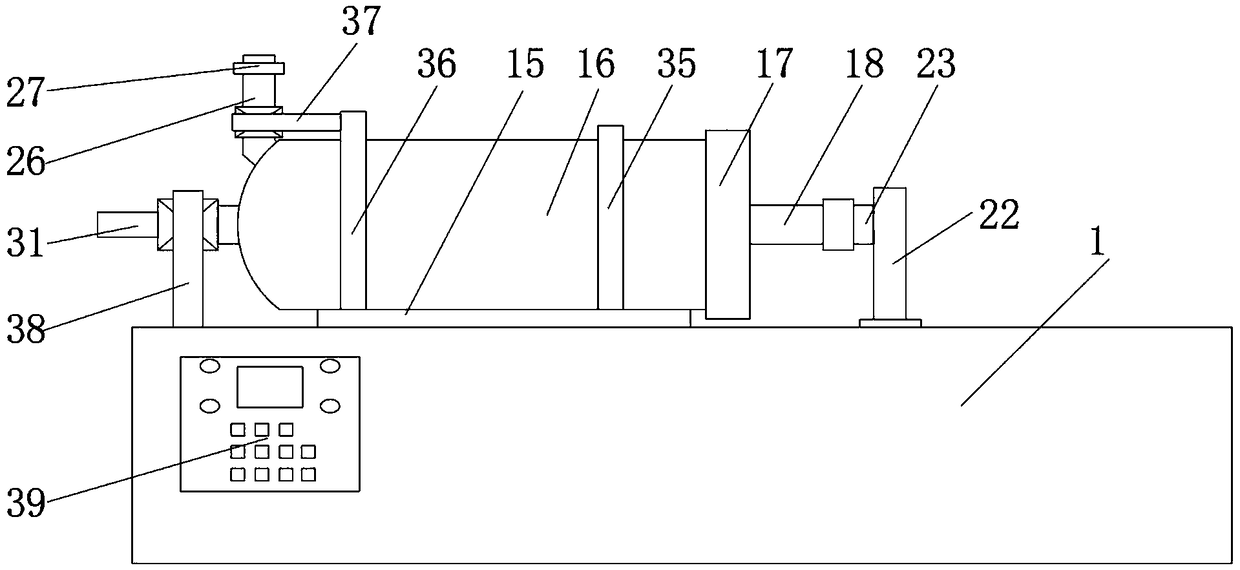

Self-pulverization clinker indirect cooling equipment for fly ash limestone calcined alumina

The invention relates to self-pulverization clinker indirect cooling equipment for fly ash limestone calcined alumina. The self-pulverization clinker indirect cooling equipment for the fly ash limestone calcined alumina comprises a cooling machine body, an air inlet channel, an air blower and an air outlet channel. The cooling machine body is provided with a plurality of cooling modules, the cooling modules comprise a plurality of cooling pipes, the cooling modules are arranged in parallel in the vertical direction, the cooling pipes of all of the cooling modules are communicated with one another, the cooling module at the lowest end of the cooling machine body is connected with one end of the air inlet channel, the air blower is connected with the other end of the air inlet channel, the upper end of the cooling module at the top end of the cooling machine body is connected with one end of the air outlet channel, and the other end of the air outlet channel is communicated with the external world. The self-pulverization clinker indirect cooling equipment for the fly ash limestone calcined alumina has the advantages that efficient indirect cooling is adopted, no dust is discharged, the time of clinker in a cooling machine is long, material pulverization effects are good, the clinker moves slowly in the cooling machine, the equipment is small in abrasion and discharges no dust, cooling air can be recycled to serve as secondary air and third air, moving parts are small, faults are few, and maintenance workload is small.

Owner:内蒙古蒙西鄂尔多斯铝业有限公司

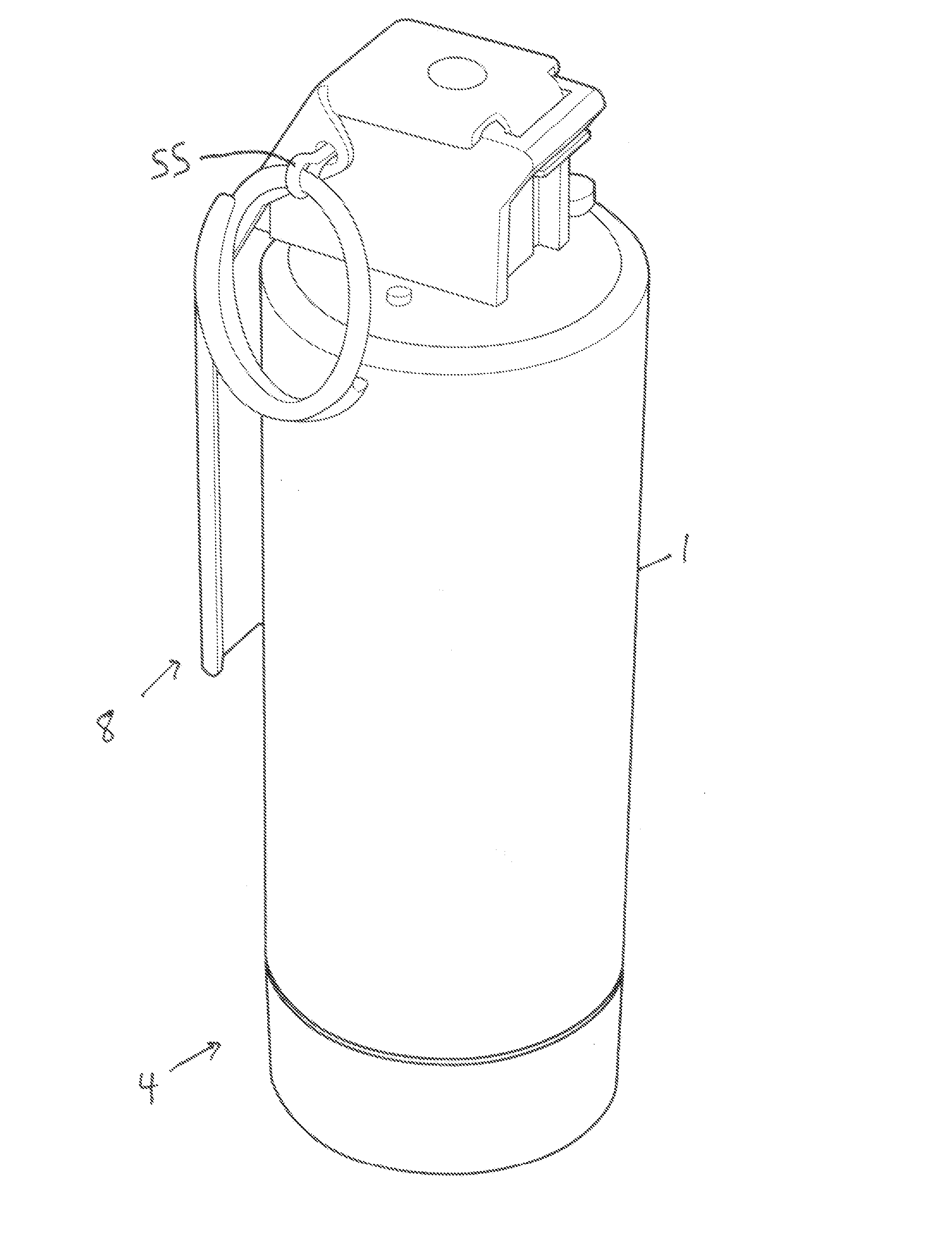

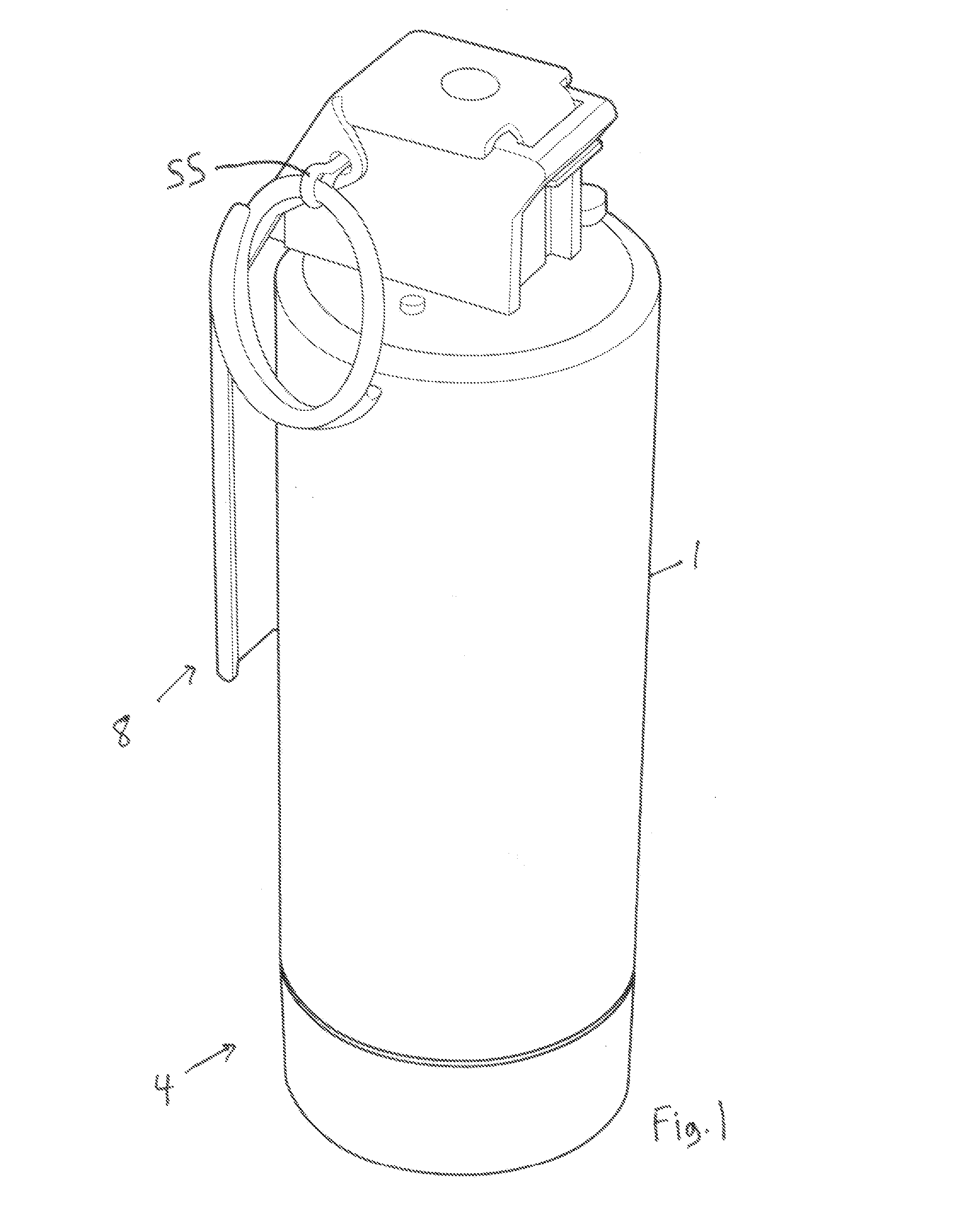

Reusable Distraction Device Simulator

InactiveUS20140130695A1Convenient and economical and safe to useOpening can be delayedAmmunition projectilesTraining ammunitionDistractionEngineering

Here is disclosed a reusable pneumatic distraction device having a housing which encloses a first and a second gas reservoir which are configured to contain a quantity of high and low pressure gas, respectively. A valve member seals off an exhaust in the first gas reservoir, the valve member movable between a closed position sealing the exhaust and an open position. The device also includes a pneumatic drive for urging the valve towards its opened position. The pneumatic drive configured to apply a lower urging force followed by a larger urging force as the valve opens. The device is also provided with a lock pin releasably coupled to the valve for preventing the valve from moving towards its open position. Finally, the device includes a delay mechanism to delay the opening of the piston when the lock pin is released.

Owner:CHONG CARLTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com