Patents

Literature

2355 results about "Air heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

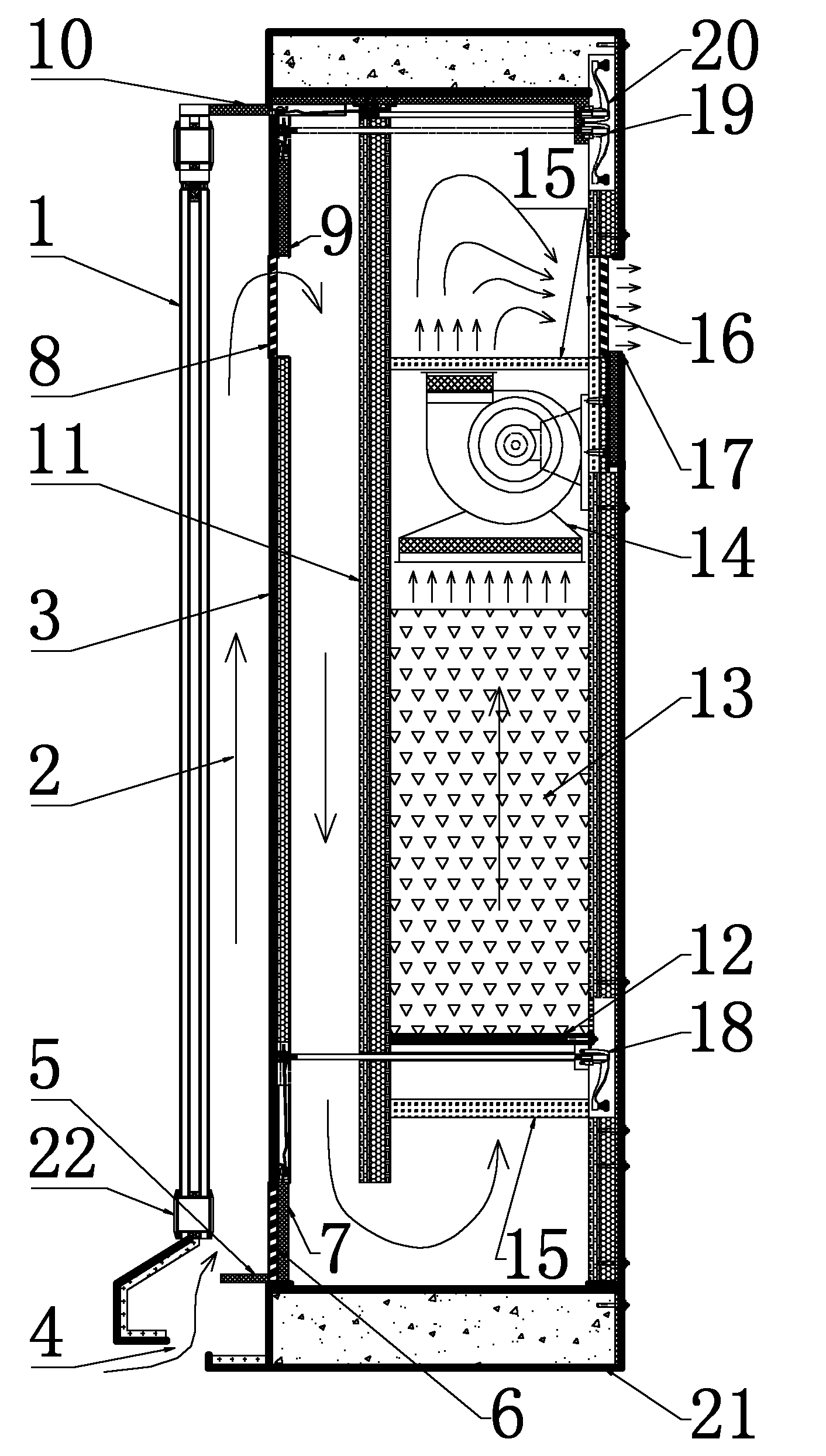

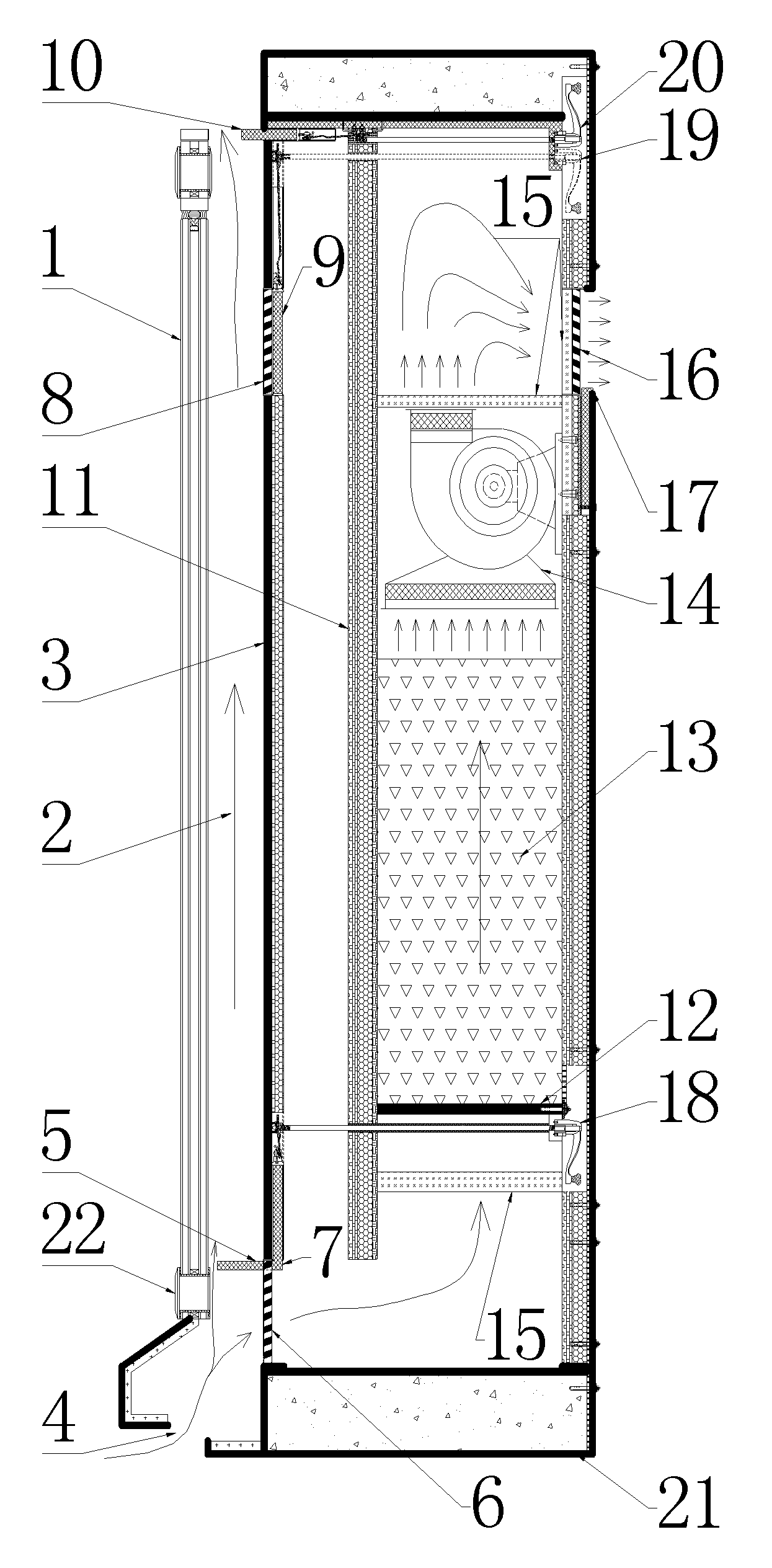

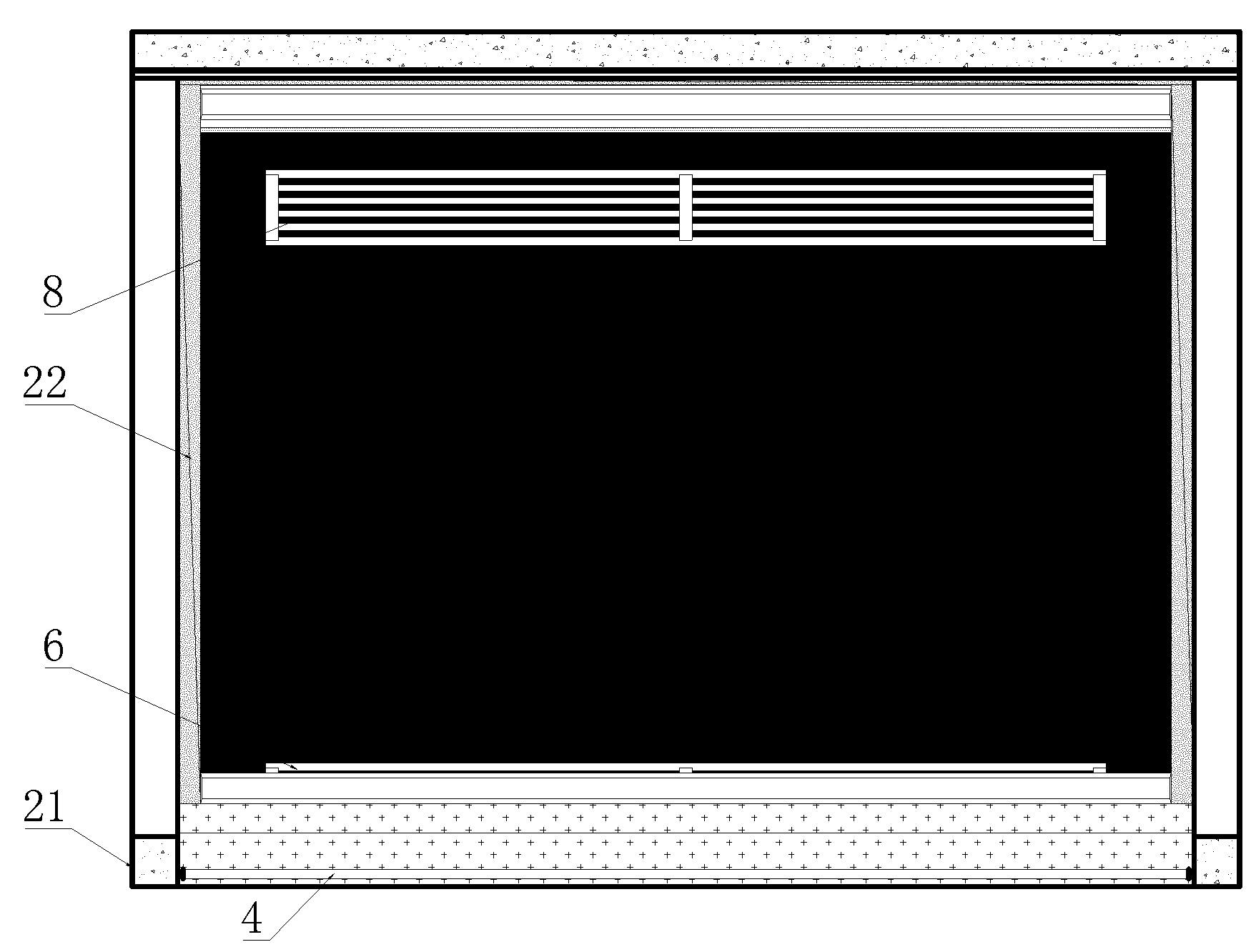

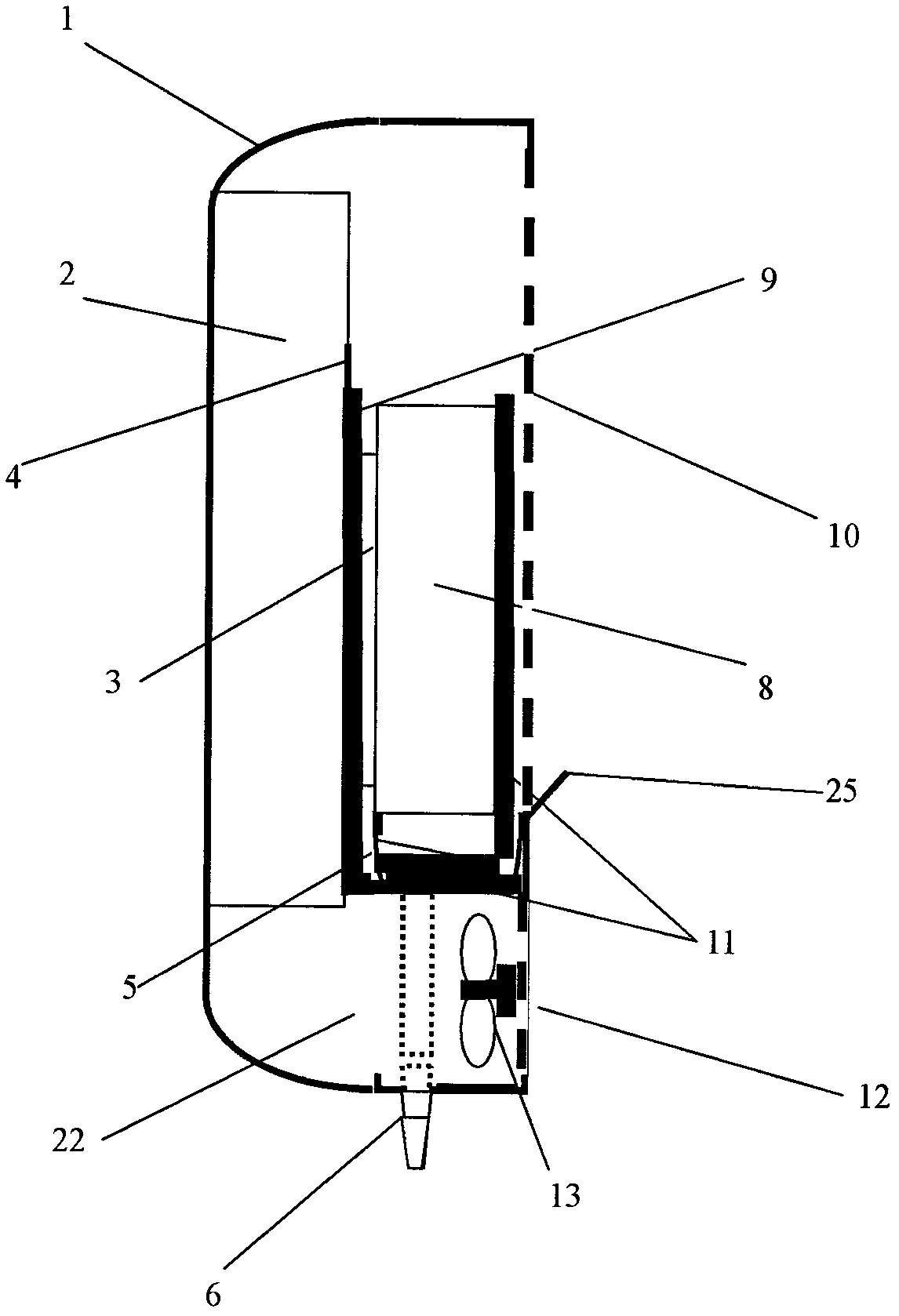

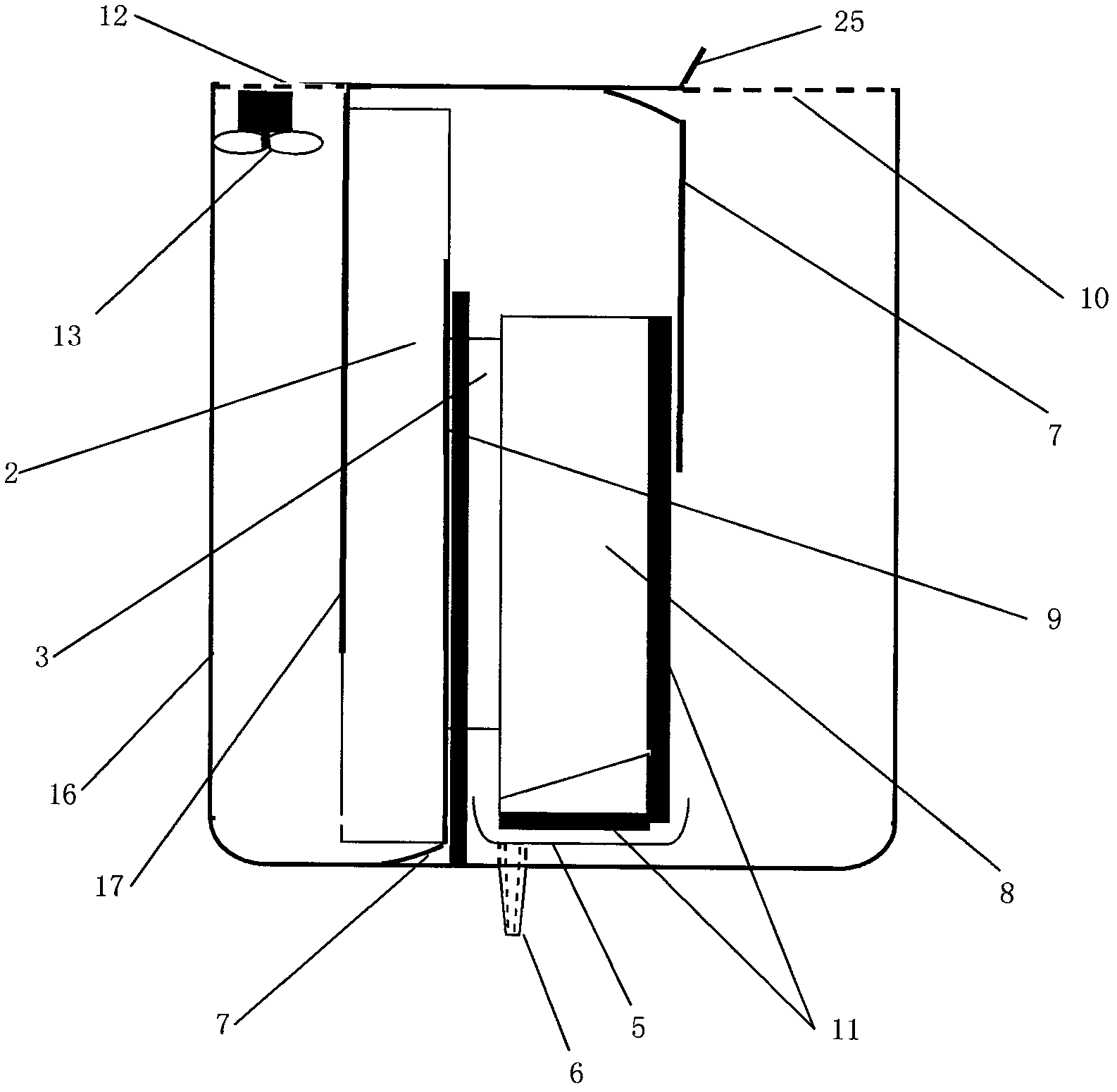

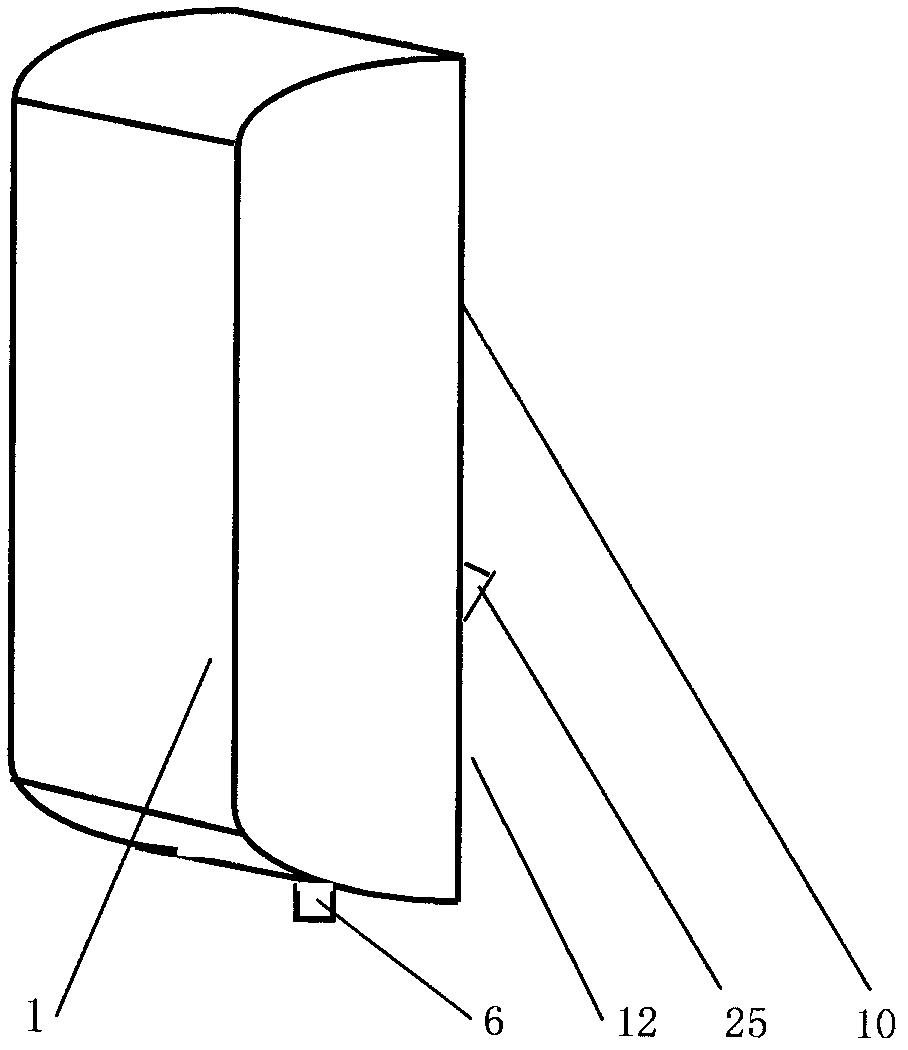

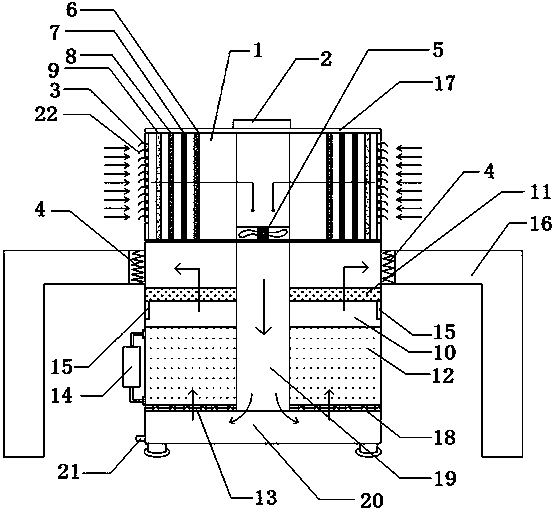

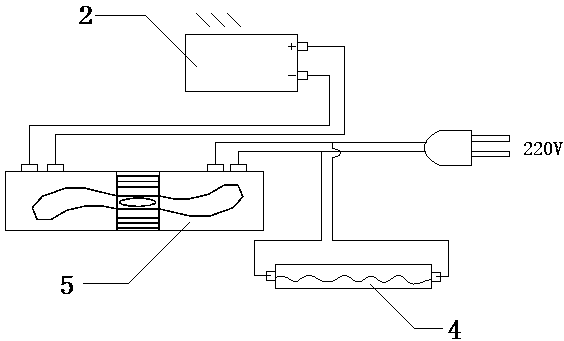

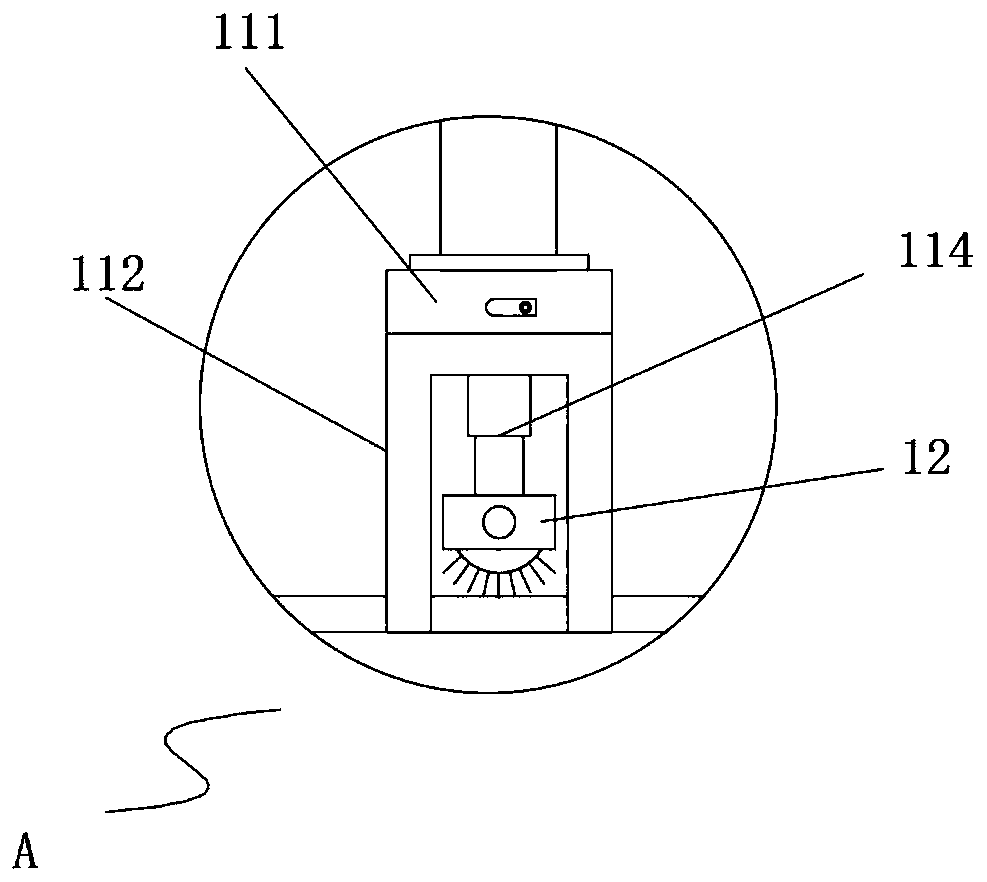

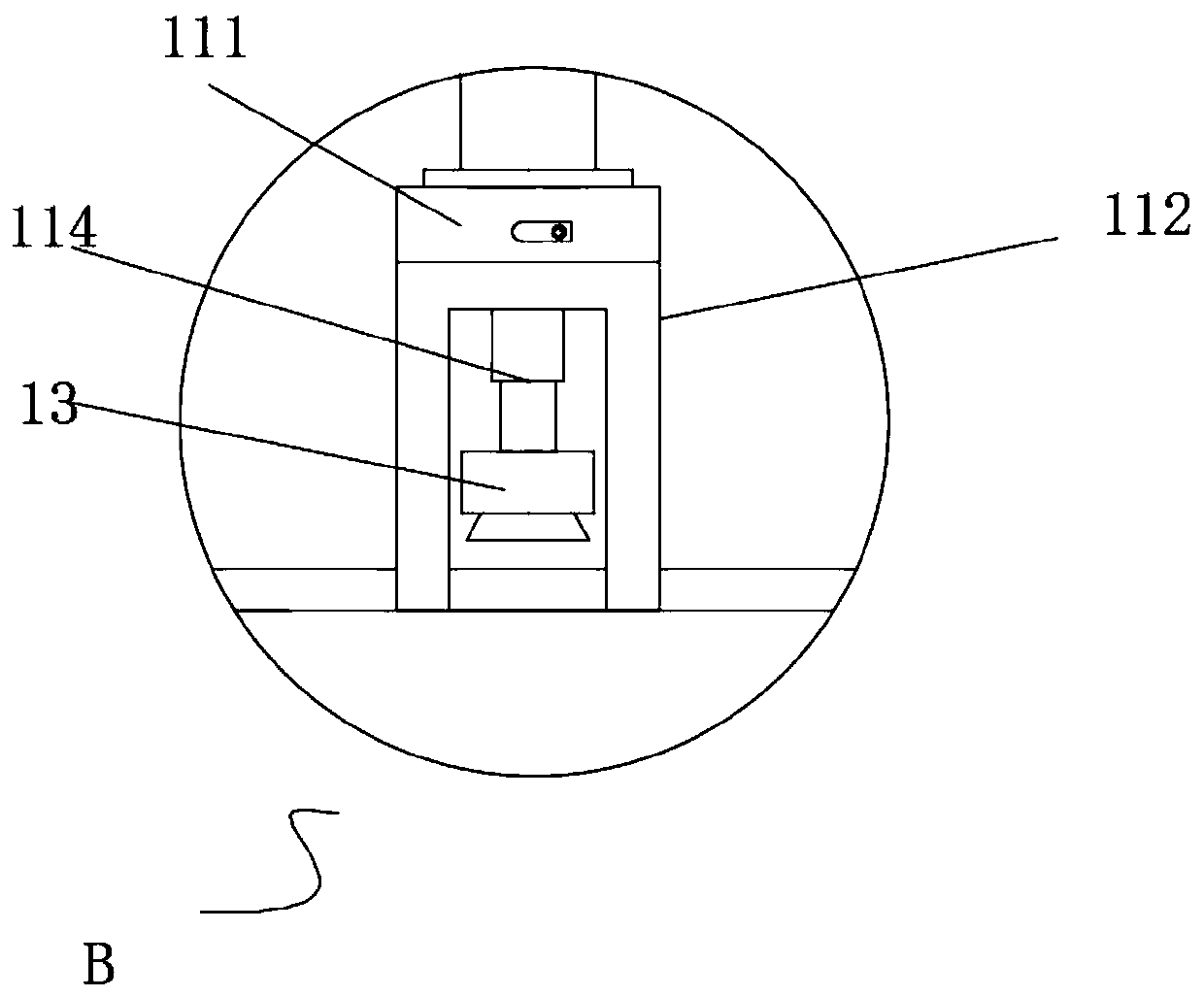

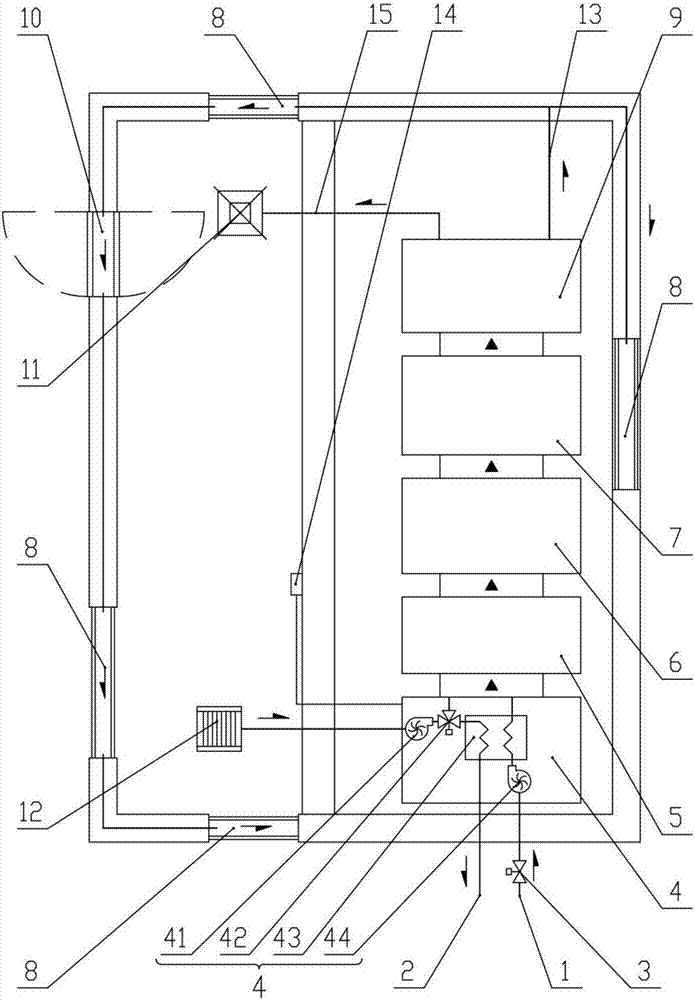

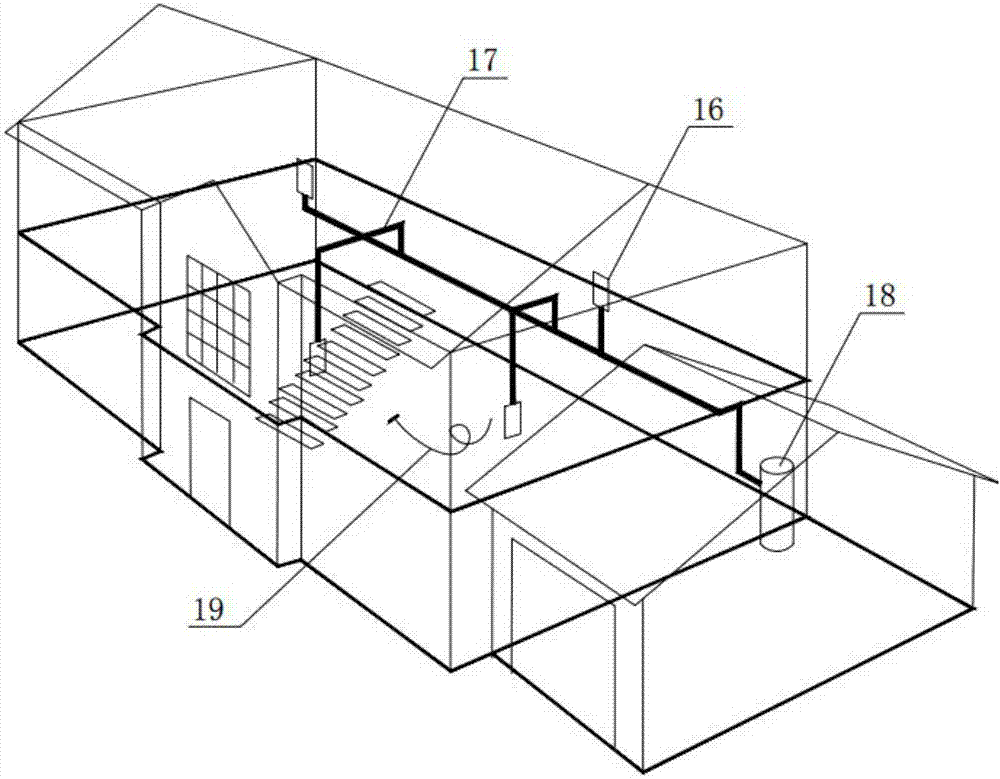

Constant-temperature, constant-humidity and constant-cleanliness silent indoor air system

InactiveCN106895521AAgainst intrusionAvoid damageMechanical apparatusSpace heating and ventilation safety systemsFiltrationFresh air

The invention provides a constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, belongs to the field of indoor intelligent adjustment, and relates to multiple techniques including indoor air pressure control, indoor air purification, an indoor central dedusting system, supercharging and compensation functions for interlayers of double windows and double doors, an outdoor haze isolating system, an indoor air internal-circulation cleaning method, air heat exchange, air heating, refrigeration, dehumidification and the like. According to the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, the pressure of fresh air is made positive through the interlayers of the double doors and the double windows, the air pressure in the interlayers of the double doors and the double windows is made higher than outdoor air pressure, and outdoor air is prevented from invading indoor air; a small primary-efficiency, medium-efficiency and high-efficiency filtering system is used for filtration, various types of automatic adjustment and control including heating, refrigerating, dehumidifying and the like are conducted on air, pollutant dust generated indoors is removed through the central dedusting system, and the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system is an omnidirectional intelligent air control system.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

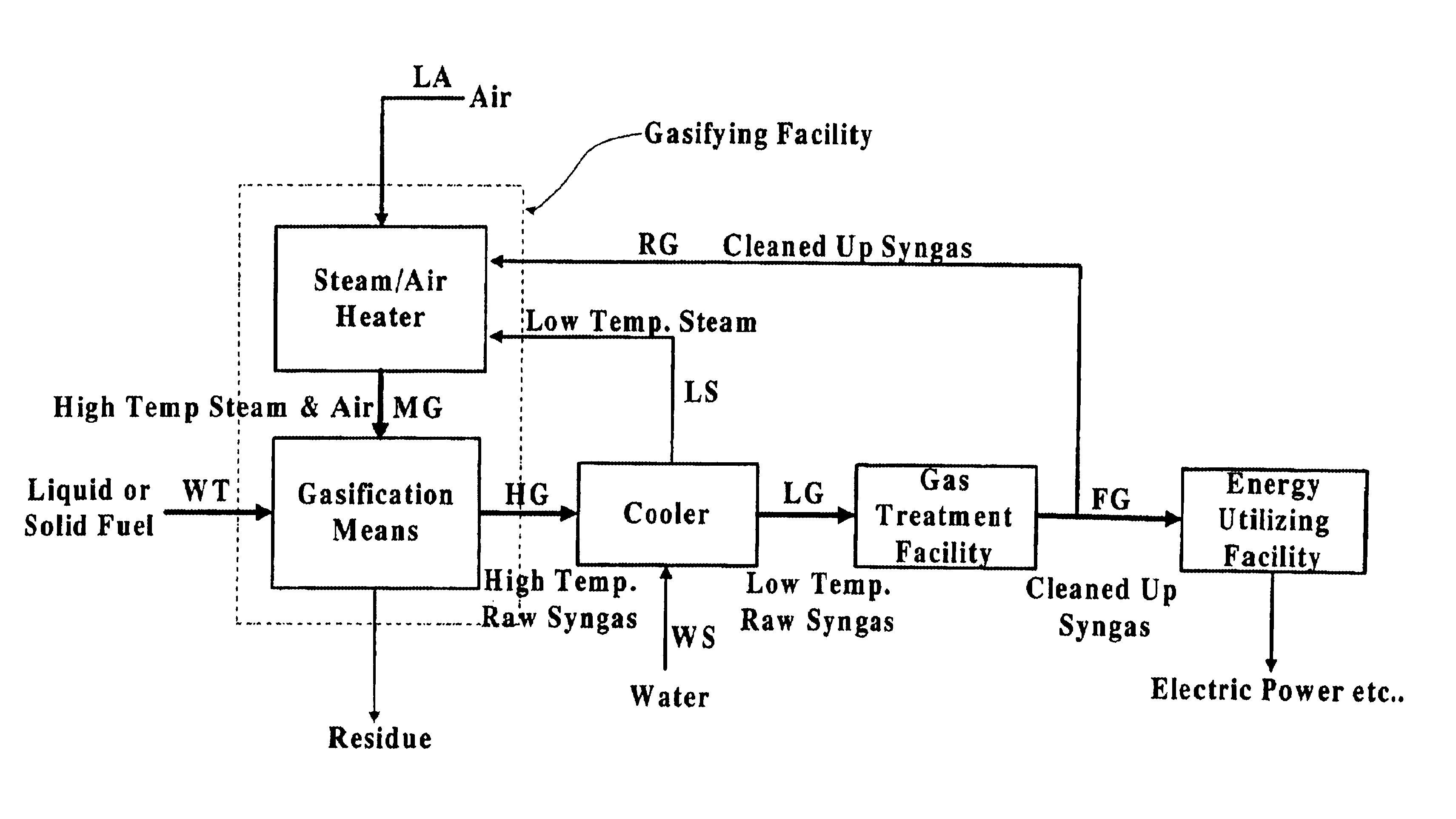

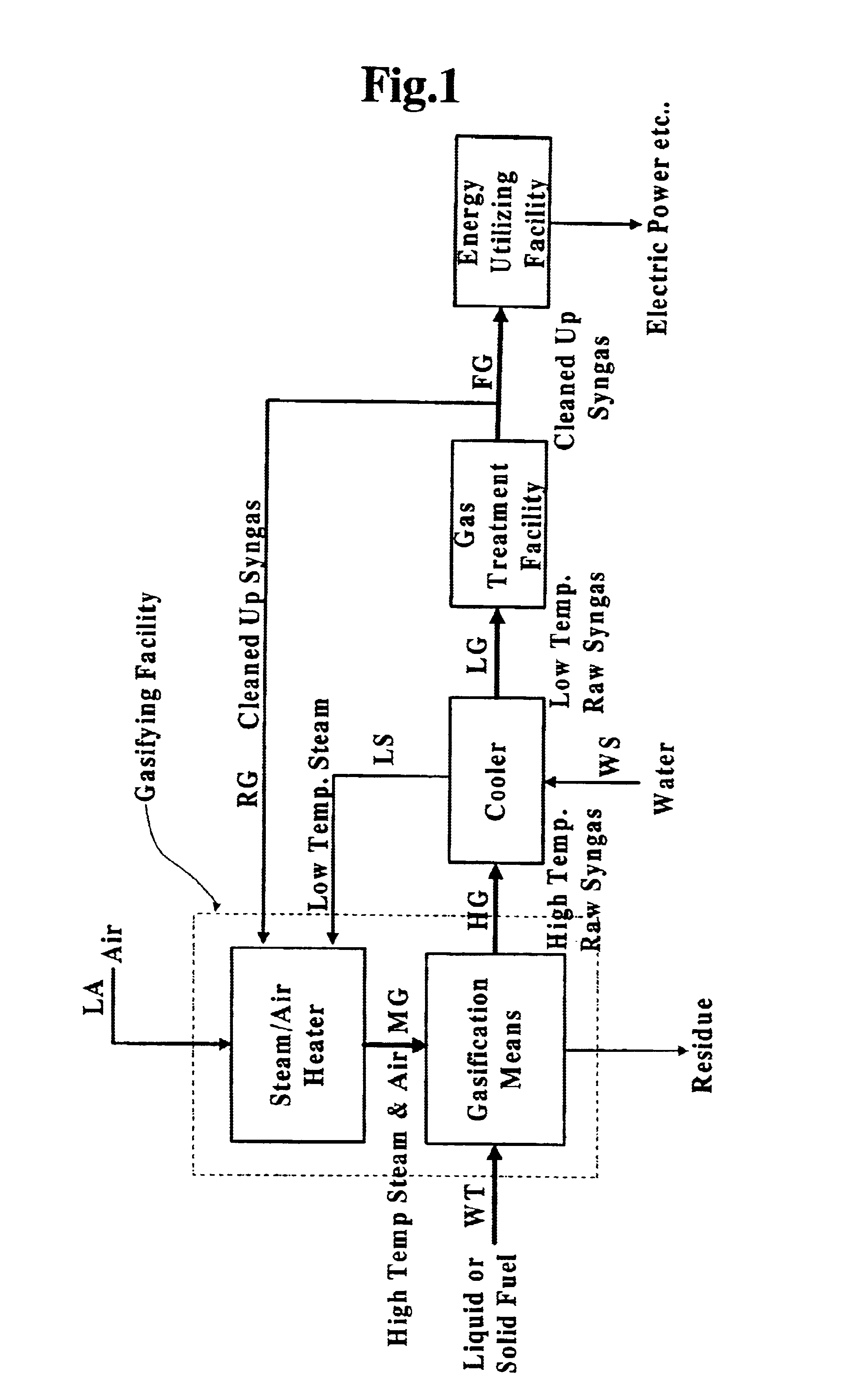

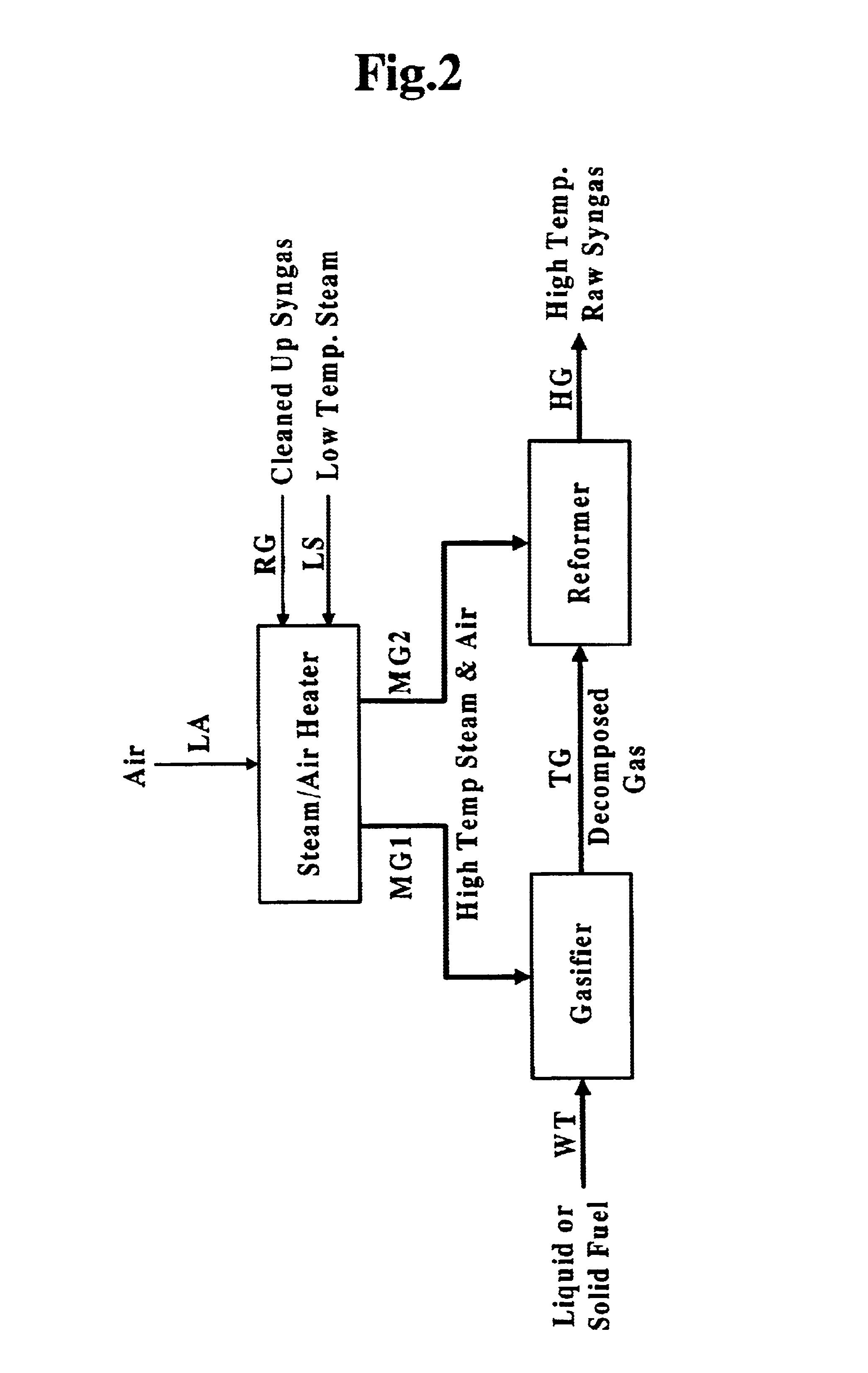

Apparatus and method for gasifying liquid or solid fuel

InactiveUS6837910B1Quality improvementAmount of heat can be ensuredHydrogenGaseous fuelsSyngasExothermic reaction

A gasifying apparatus comprises a gasifier, a reformer and a heating device. The gasifier produces a thermal decomposed gas with use of a thermal decomposition reaction of a liquid or solid fuel such as waste or coal, and the heating device heats a low-temperature steam and air so as to be a high-temperature steam and air, which have a temperature equal to or higher than 700 deg. C. The gasifying apparatus has feeding means including fluid passages for feeding the high-temperature steam and air to the gasifier and the reformer. In a thermal decomposition area of the gasifier, the liquid or solid fuel is thermally decomposed to produce the thermal decomposed gas with sensible heat of the high-temperature steam and air and with the heat generated by an exothermic oxidation reaction between the high-temperature air and the liquid or solid fuel. In the reformer, the thermal decomposed gas is reformed in the existence of the high-temperature steam so as to be a high-temperature syngas. The steam reforming reaction of the liquid or solid fuel is carried out with an exothermic reaction between the high-temperature air and hydrocarbon contained in the thermal decomposed gas and with an endothermic reaction between the hydrocarbon and the high-temperature steam.

Owner:NIPPON FURNANCE IND KAISHA +1

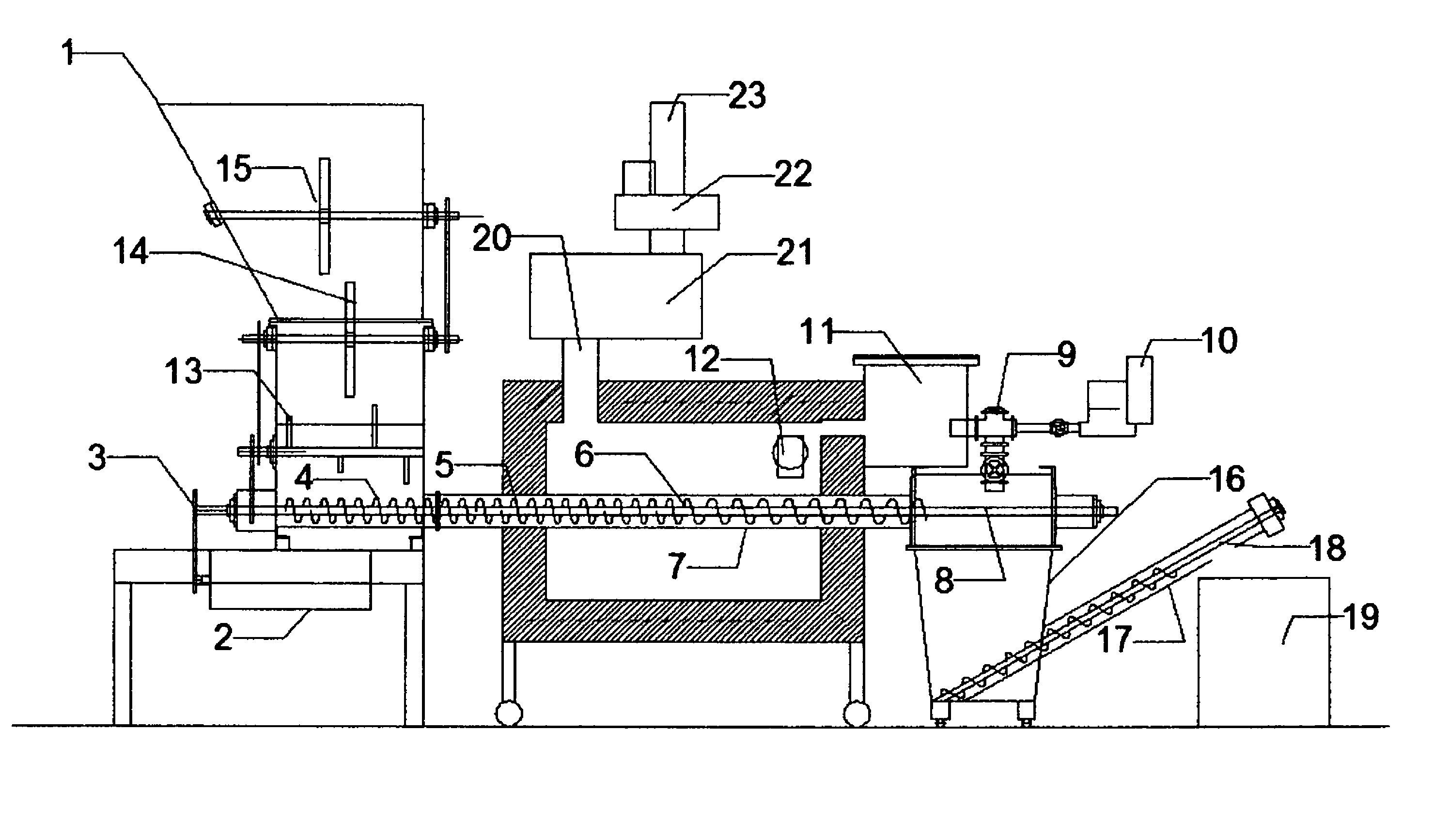

Process and device for the pyrolysis of feedstock

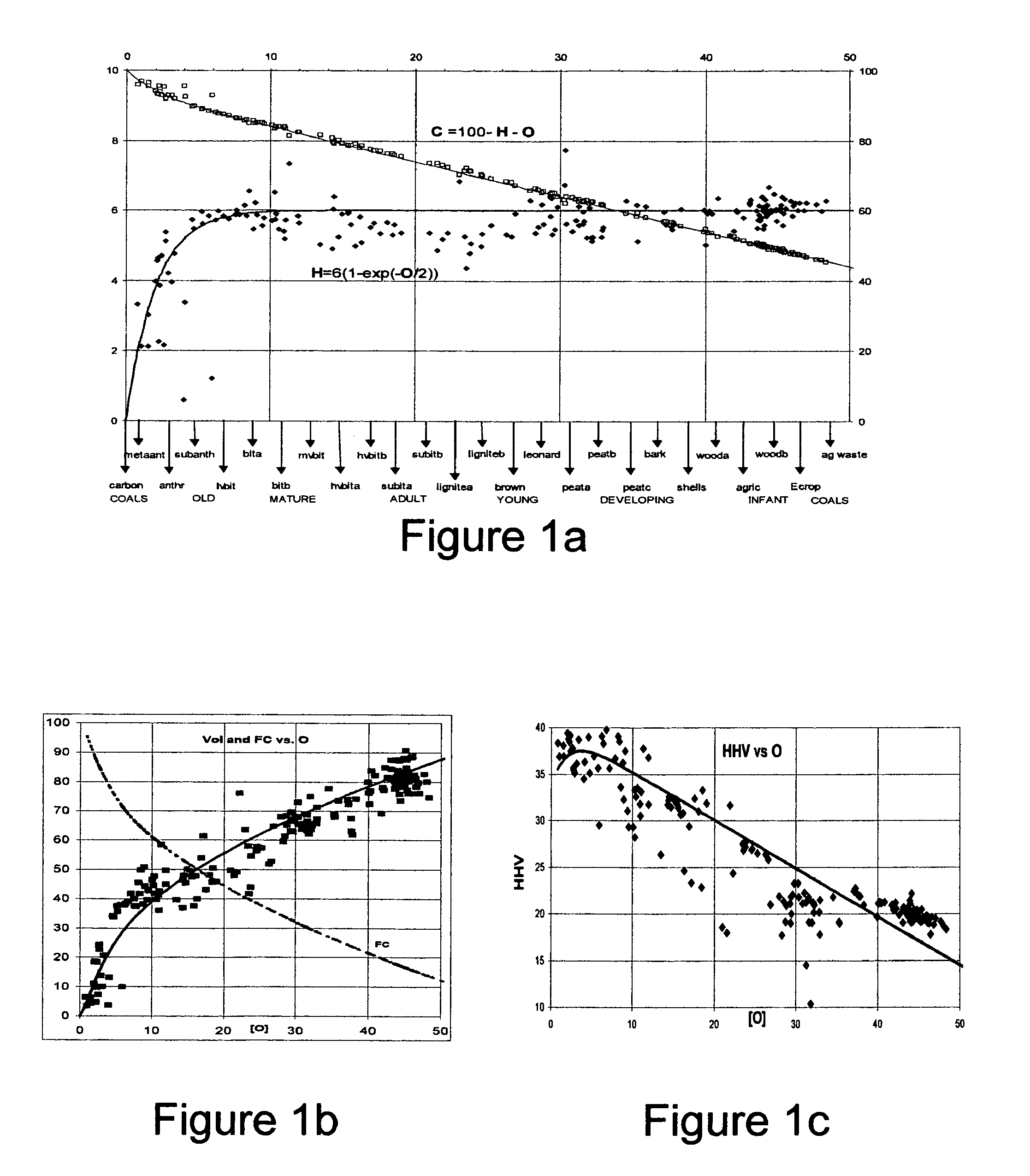

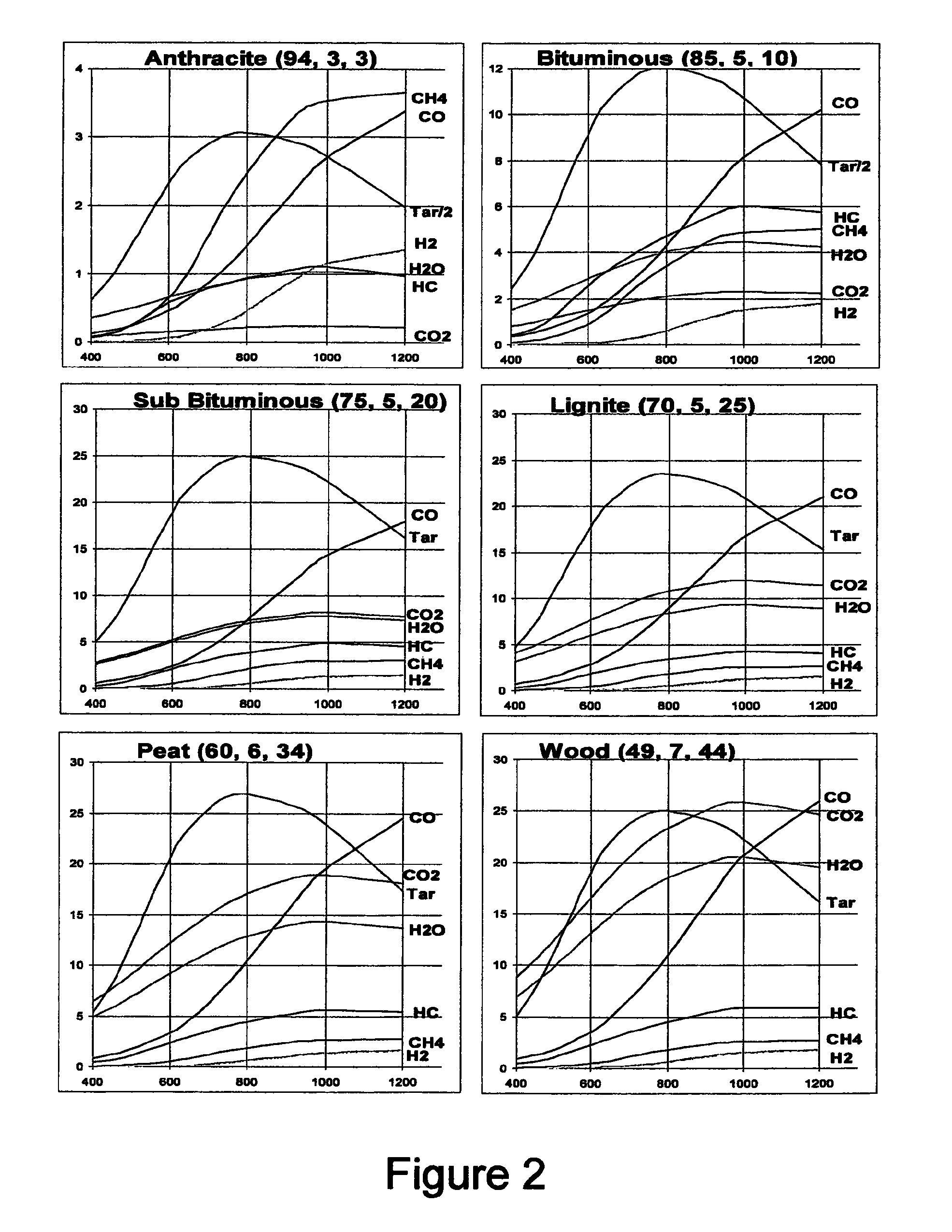

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

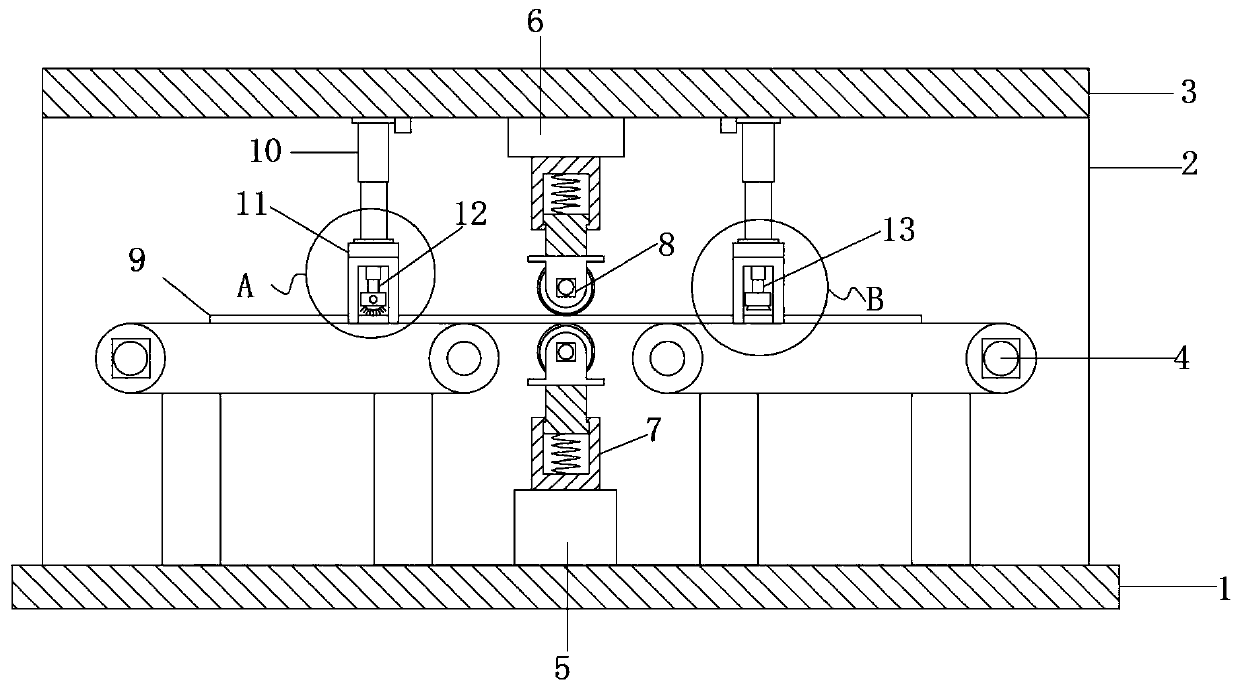

Apparatus for preparing food having a drawer with a sliding mechanism

ActiveUS20160192808A1Easy accessPrevent leakageFood preservationRoasting apparatusEngineeringMechanical engineering

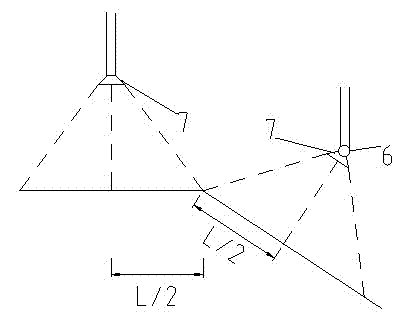

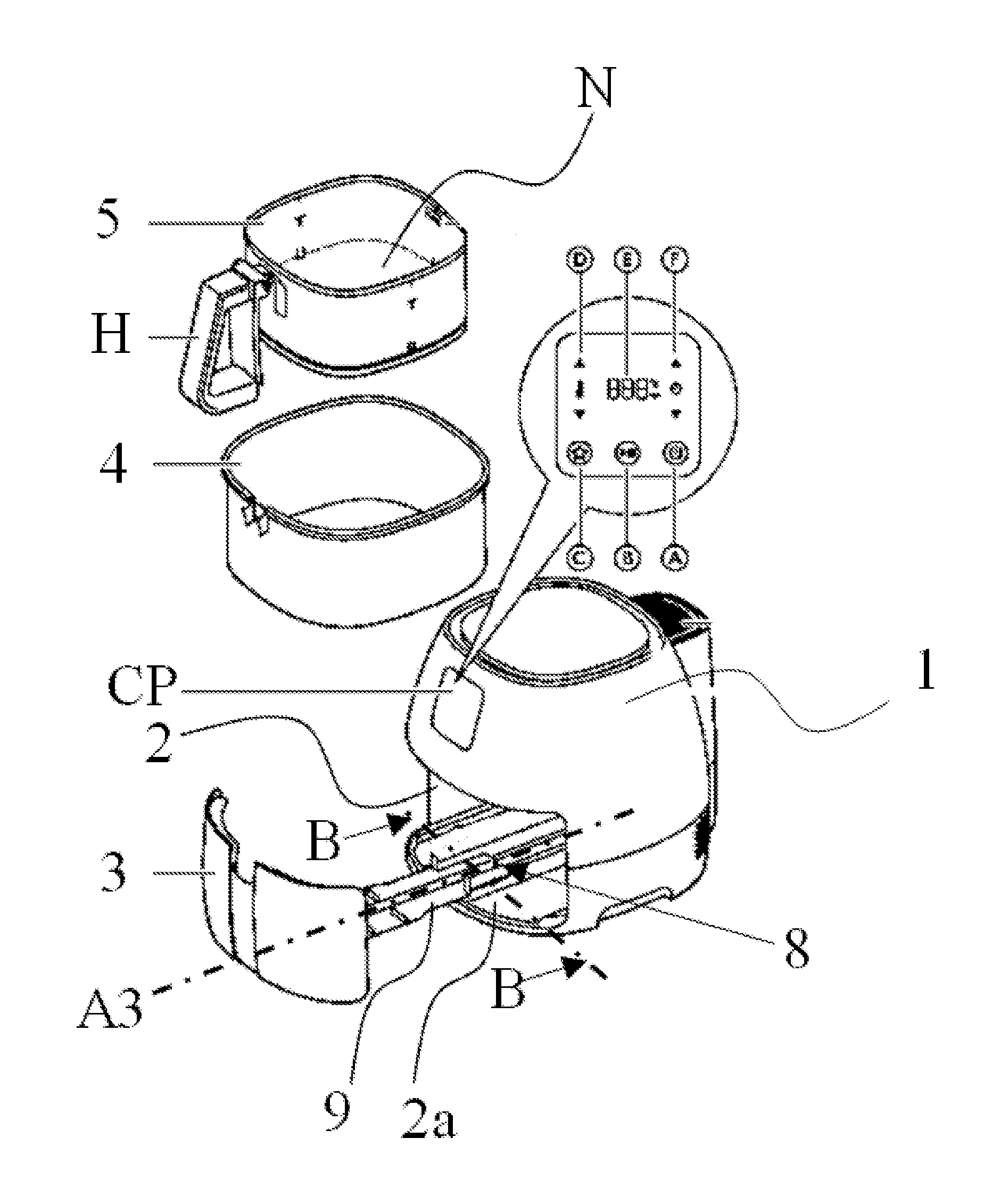

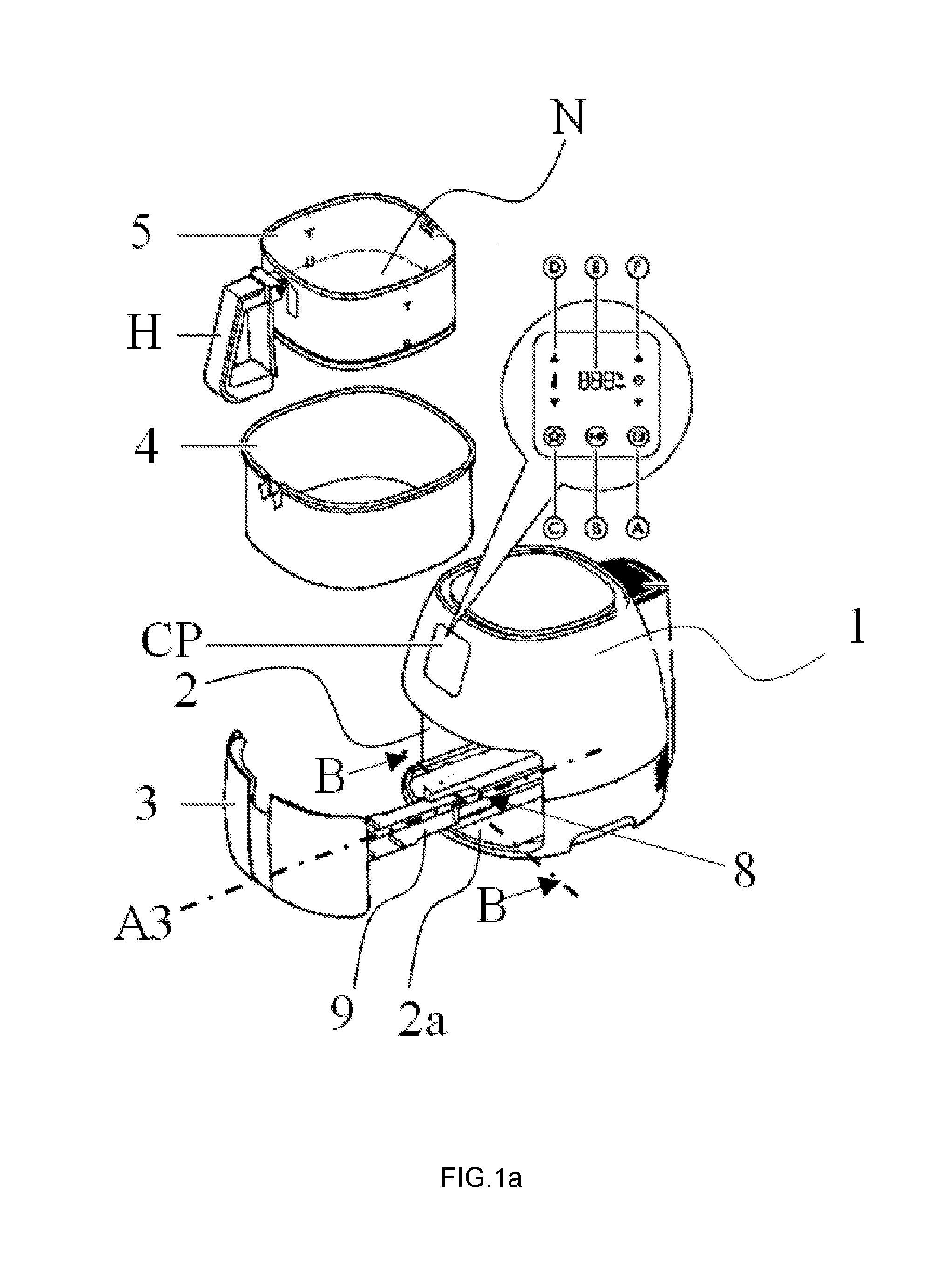

The present invention relates to an apparatus for preparing food, said apparatus comprising: —a shell (1) having internal walls (2), —a drawer (3) placed inside the shell (1), the drawer comprising a pan (4) and a food basket (5), the food basket (5) being placed inside the pan (4), —an air heating system (6) and an air fan (7) placed inside the shell (1), —a sliding mechanism (8) placed between the internal walls (2) and the drawer (3). The sliding mechanism allows to correctly position the drawer inside the apparatus, and reduces efforts of use to manipulate the drawer.

Owner:KONINKLJIJKE PHILIPS NV

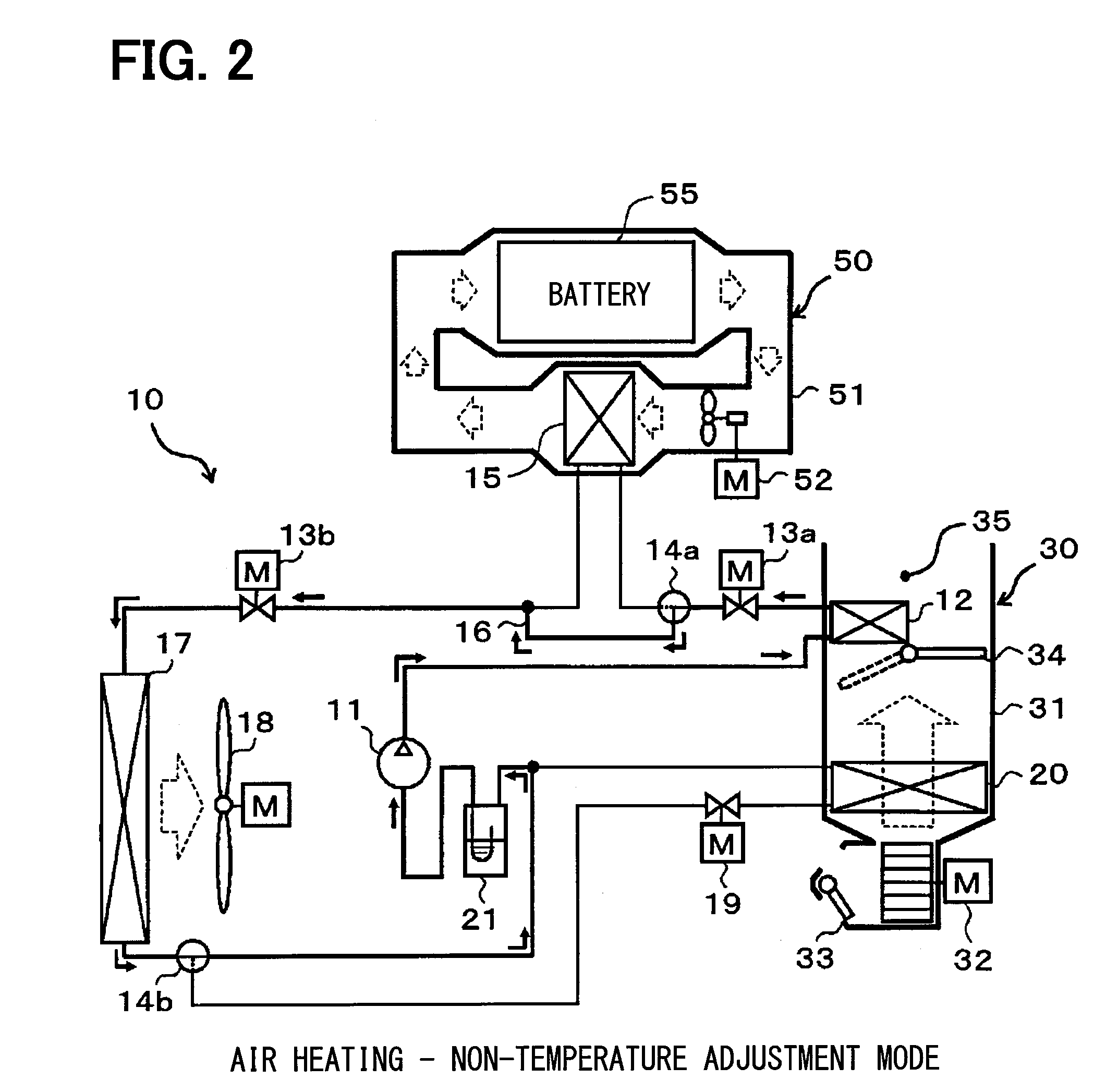

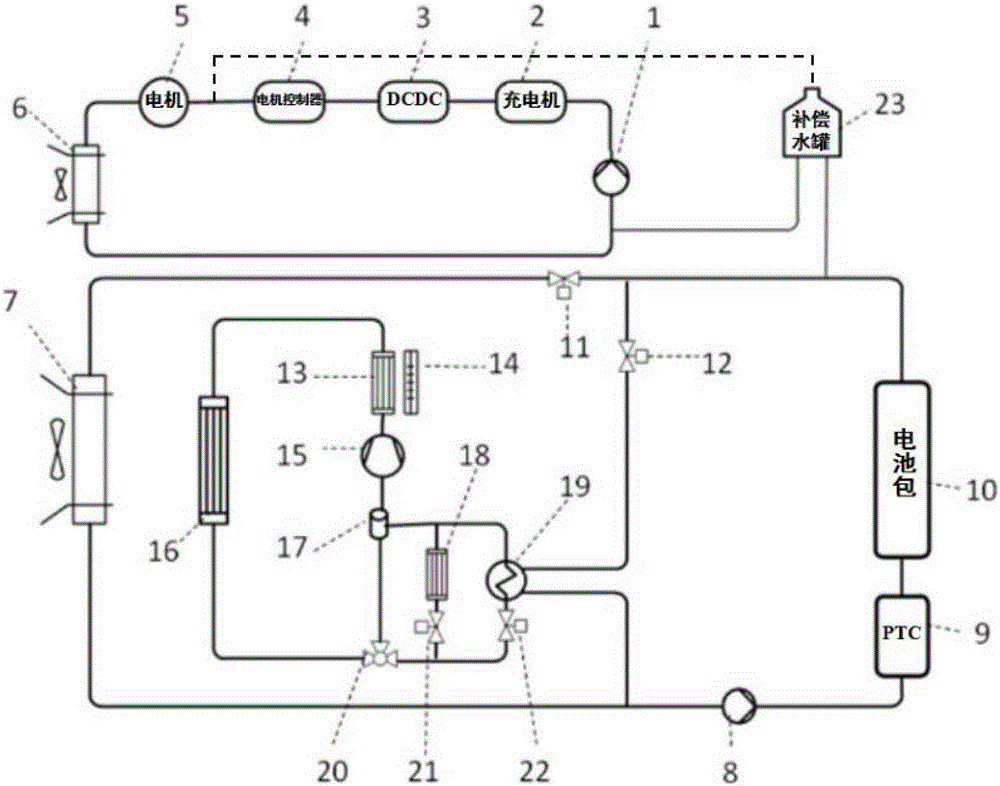

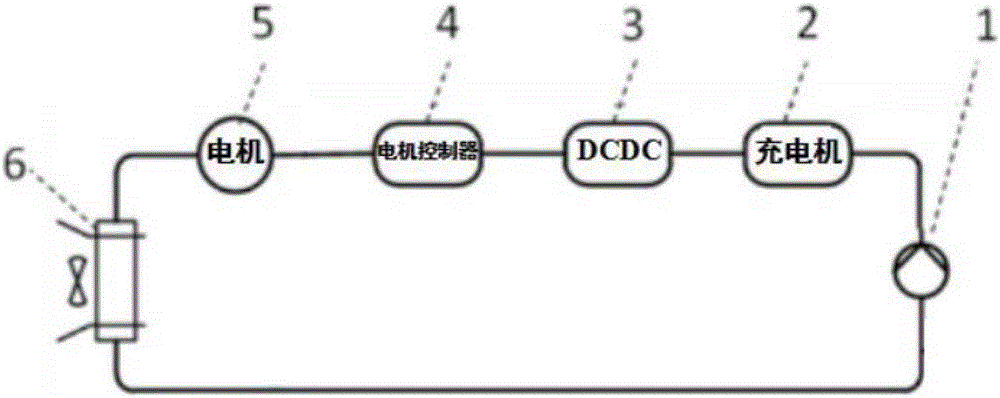

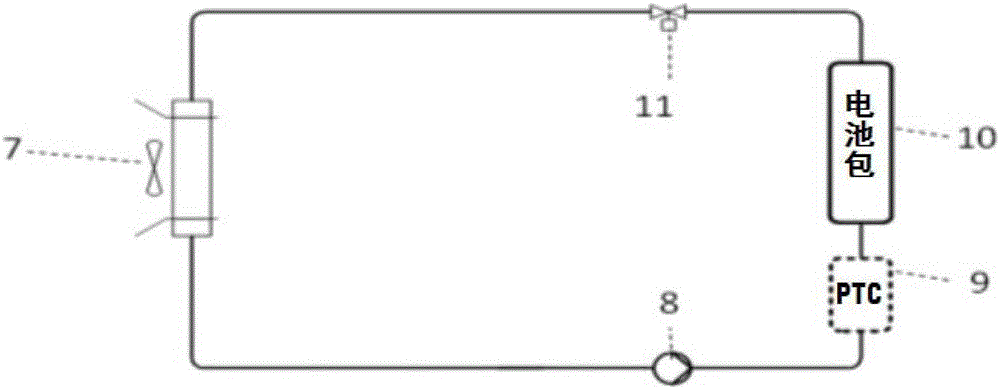

Electric vehicle thermal management system and control method thereof

ActiveCN106183789AAchieve mutual integrationExtend your lifeAir-treating devicesCell temperature controlElectrical batteryElectric cars

The invention provides an electric vehicle thermal management system comprising a motor cooling system, a battery thermal management system and an air conditioning system; the motor cooling system comprises a motor system radiator, a motor, a motor controller, a charger, a DCDC, and a motor water pump; the battery thermal management system comprises a battery system radiator, a cell pack, a heat exchanger, a water heating heater, and a battery water pump; the air conditioning system is a heat pump type air conditioner with an air heating PTC. The electric vehicle thermal management system can cool down the motor system, the battery system and a passenger cabin when the environment temperature is high, can heat up the cell pack and the passenger cabin when the temperature is low, thus satisfying high demands on usage temperature of the motor system and battery system, and improving motor system and battery system life and efficiency.

Owner:CHINA FIRST AUTOMOBILE

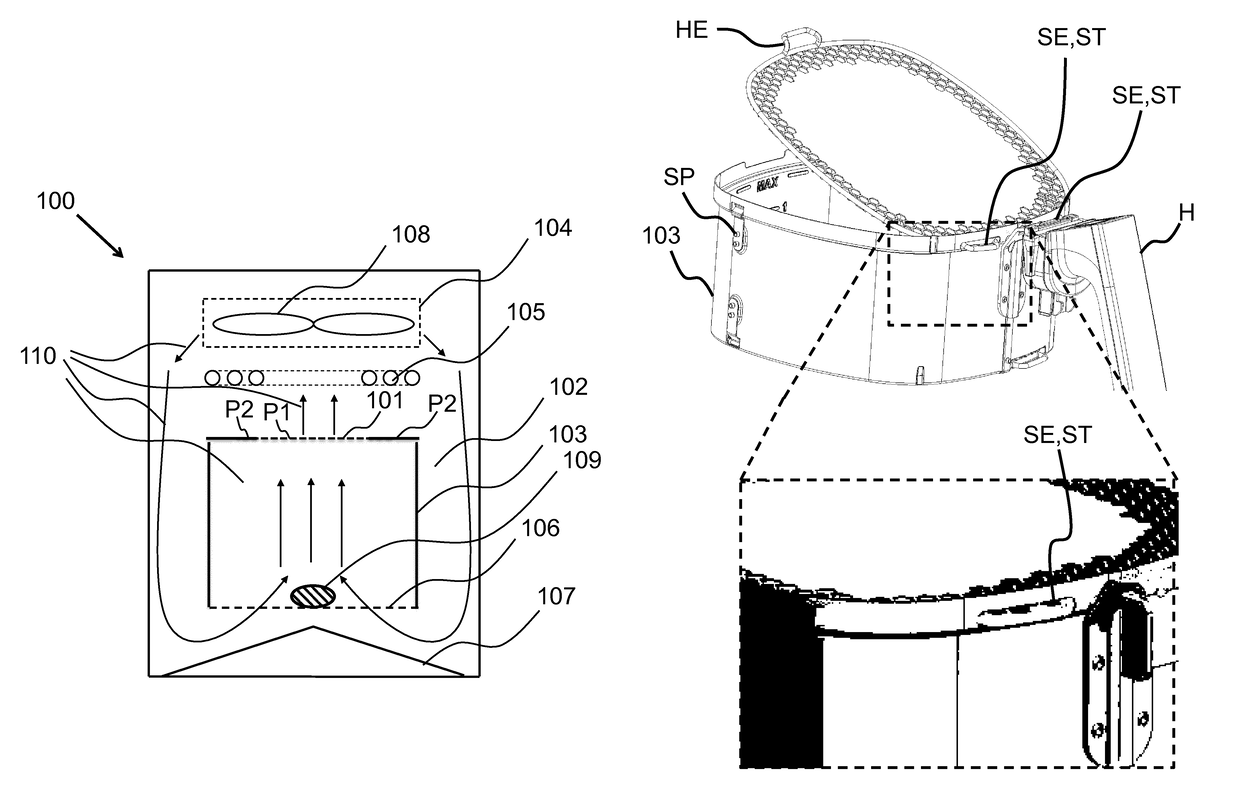

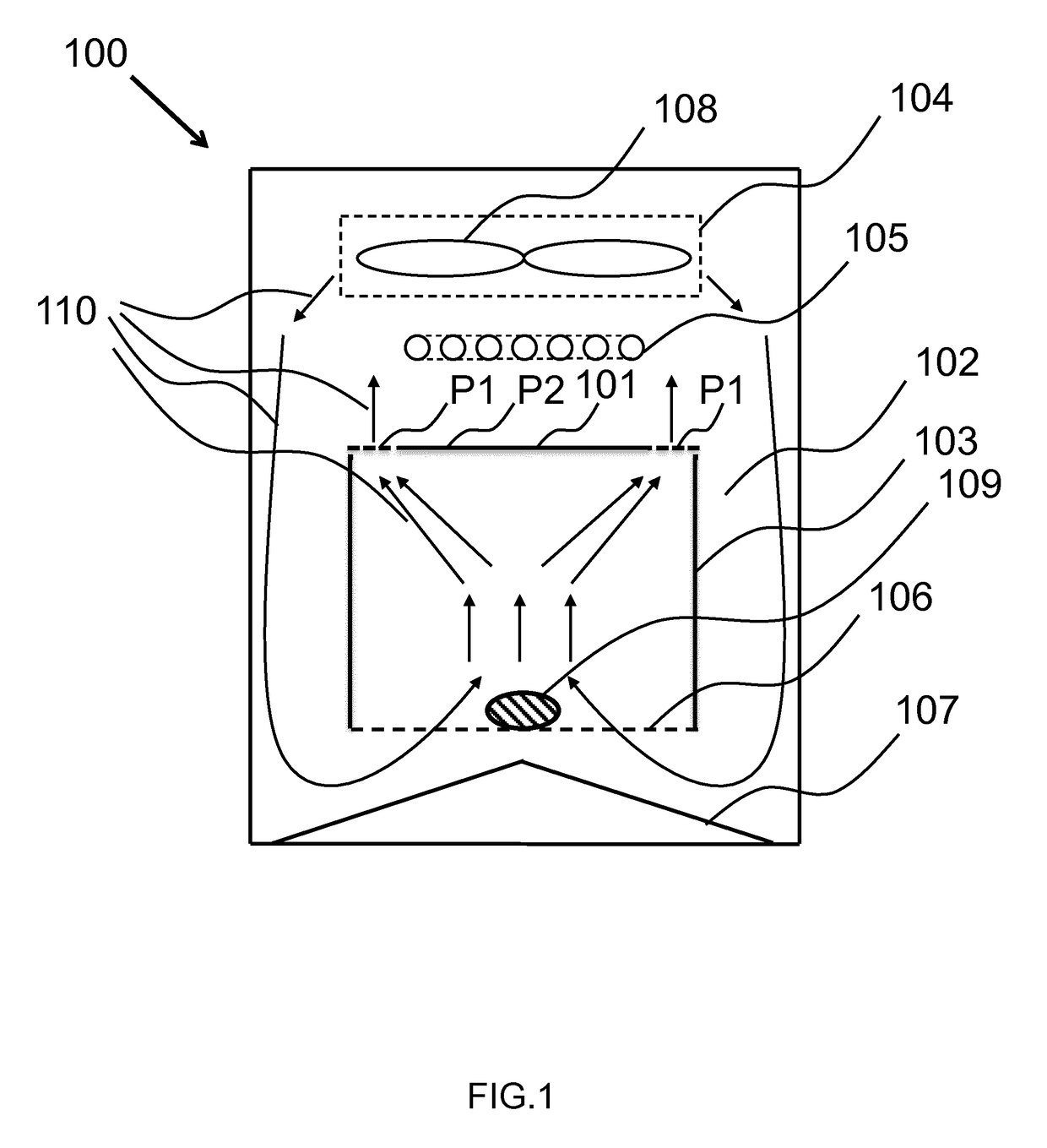

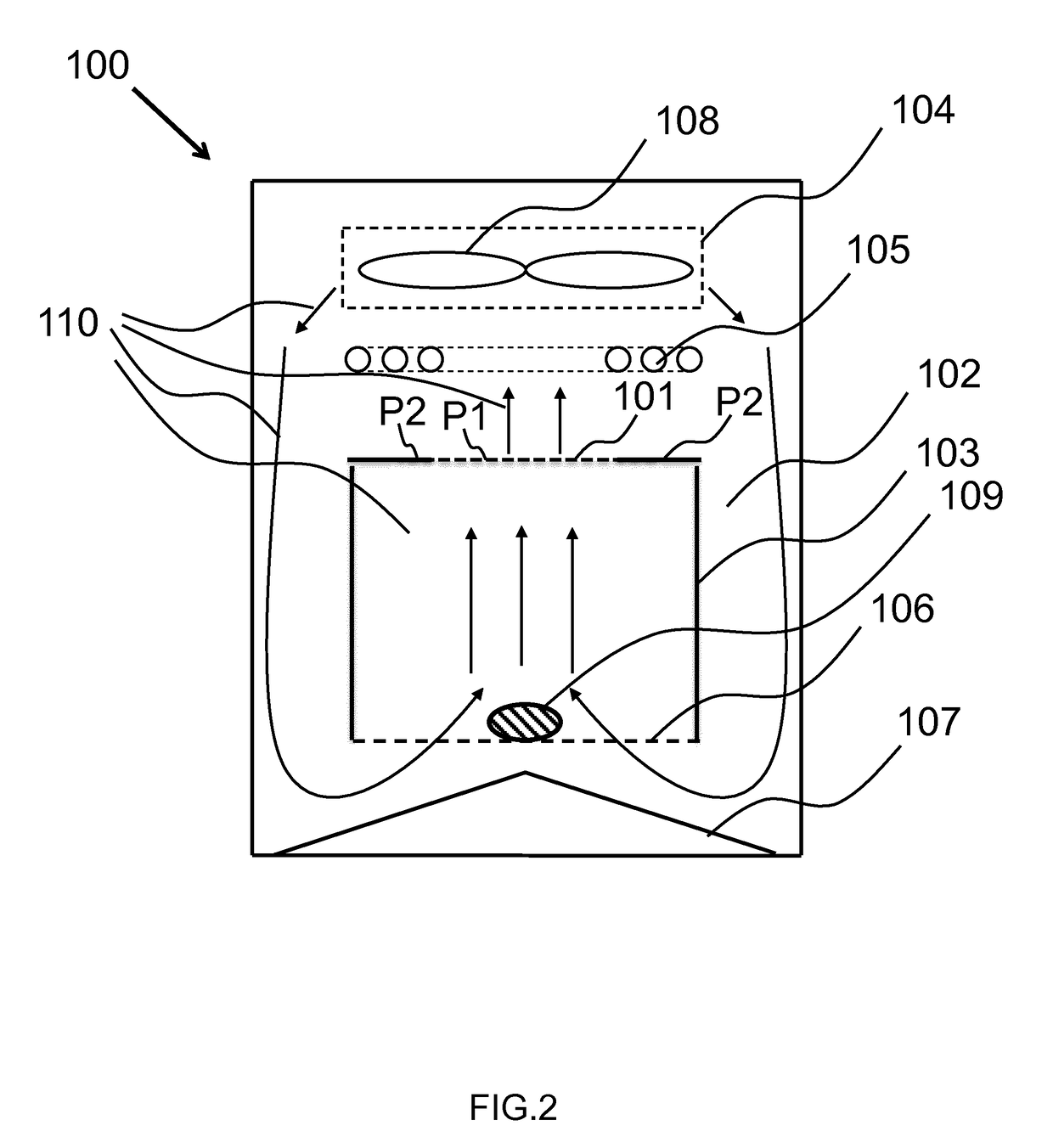

Lid for reducing fumes in an air-based fryer

ActiveUS9854941B2Reduce the amount requiredCooking-vessel materialsDomestic stoves or rangesThermodynamicsCooking process

The invention relates to an air-based flyer apparatus (100) for preparing food. The apparatus comprises a food preparation chamber (102), a food basket (103) placed in said food preparation chamber (102), a system (104) for circulating an upward flow of hot air inside said food basket (103), a heating element (105) placed above said food basket (103) to generate said hot air, a lid (101) placed below the heating element for covering the food basket. The lid (101) comprises a first part (P1) being air-permeable, and a second part (P2) facing said heating element (105) being air-impermeable. The invention allows reducing fumes generated by an air-based flyer during cooking process.

Owner:VERSUNI HLDG BV

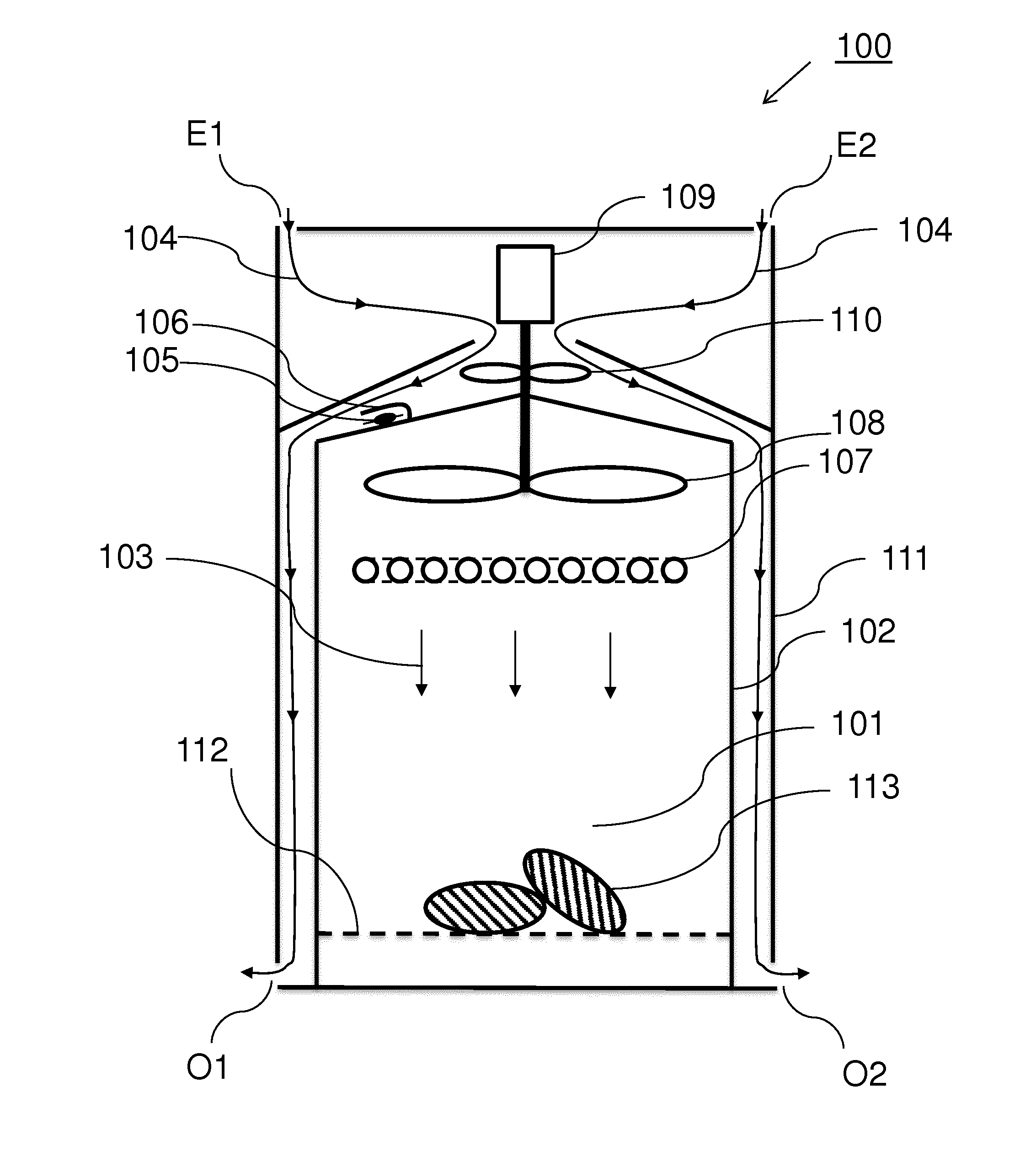

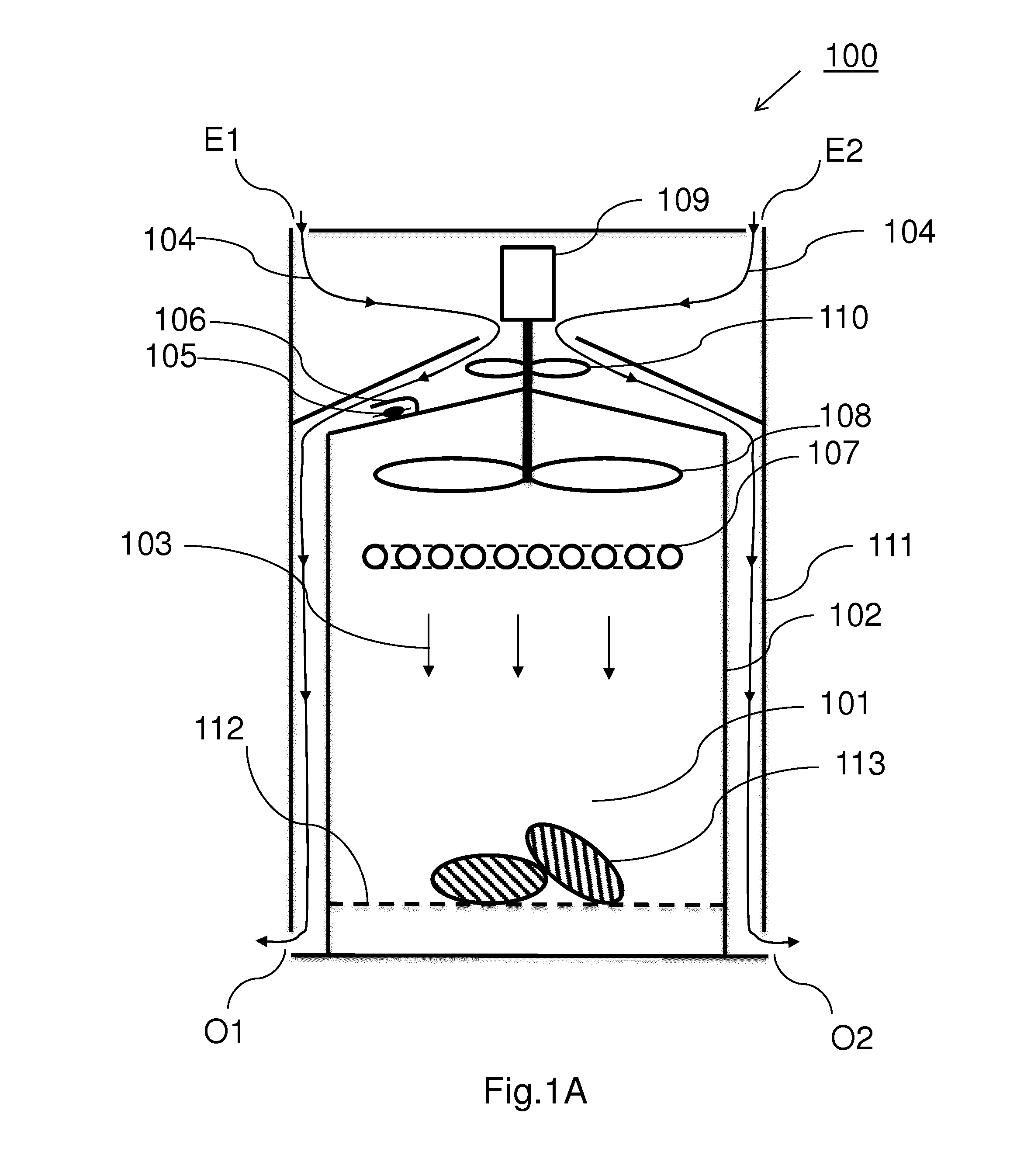

Apparatus for preparing food having an improved thermal protection

The invention relates to an apparatus (100) for preparing food. The apparatus comprises a food preparation chamber (101) having an outer wall (102), an air heating system to circulate hot air (103) inside the food preparation chamber (101), air cooling system to circulate cool air (104) on said outer wall (102) outside the food preparation chamber (102), a thermal fuse system (105) to cut the electrical supply of said apparatus when the temperature of the thermal fuse system (105) exceeds a given threshold (TH), the thermal fuse system (105) being attached to said outer wall (102) outside the food preparation chamber (101), a cover element (106) placed at the proximity of said thermal fuse system (105) to protect the thermal fuse system (105) from the cool air. This invention improves the thermal protection of the apparatus.

Owner:KONINKLJIJKE PHILIPS NV

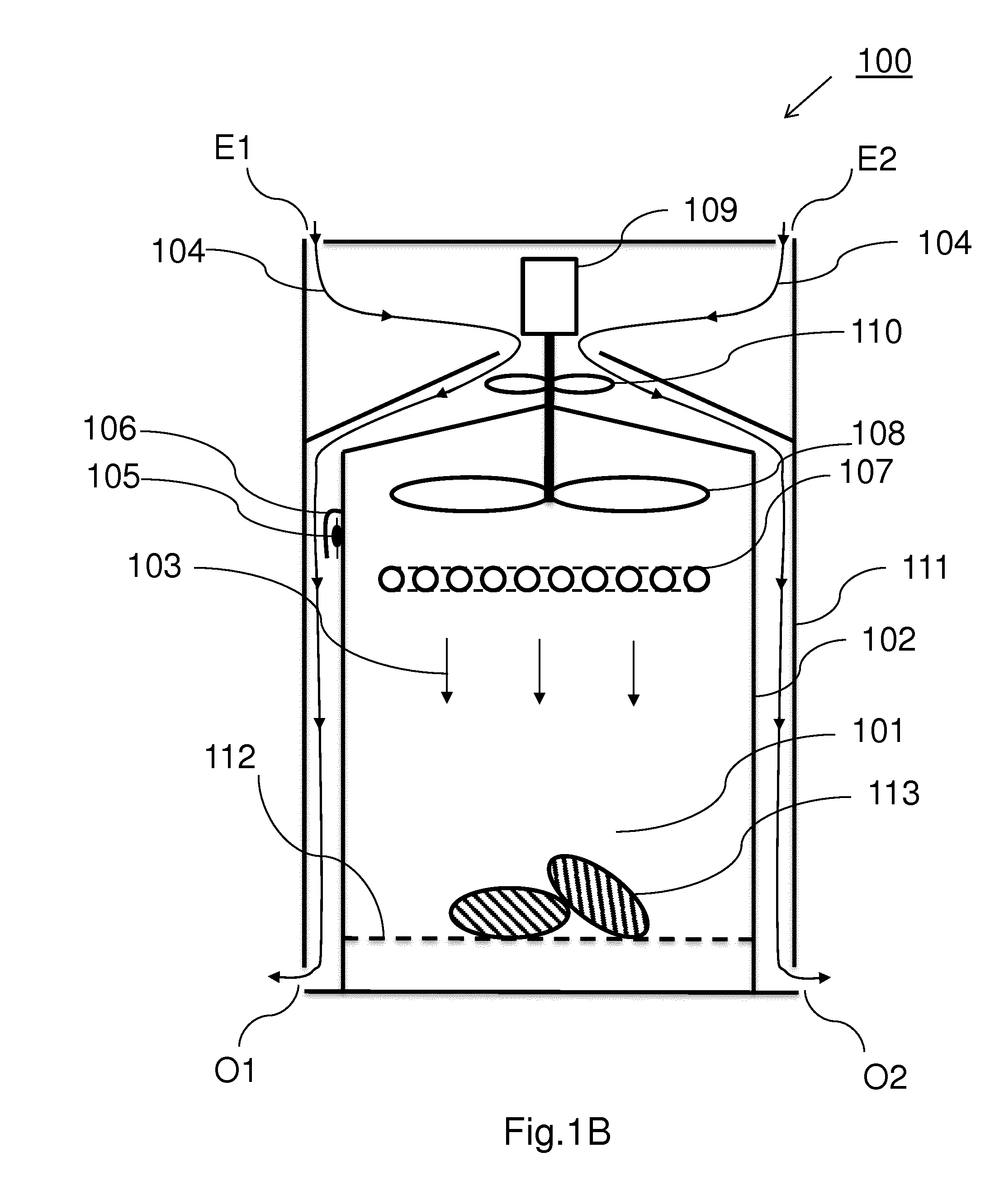

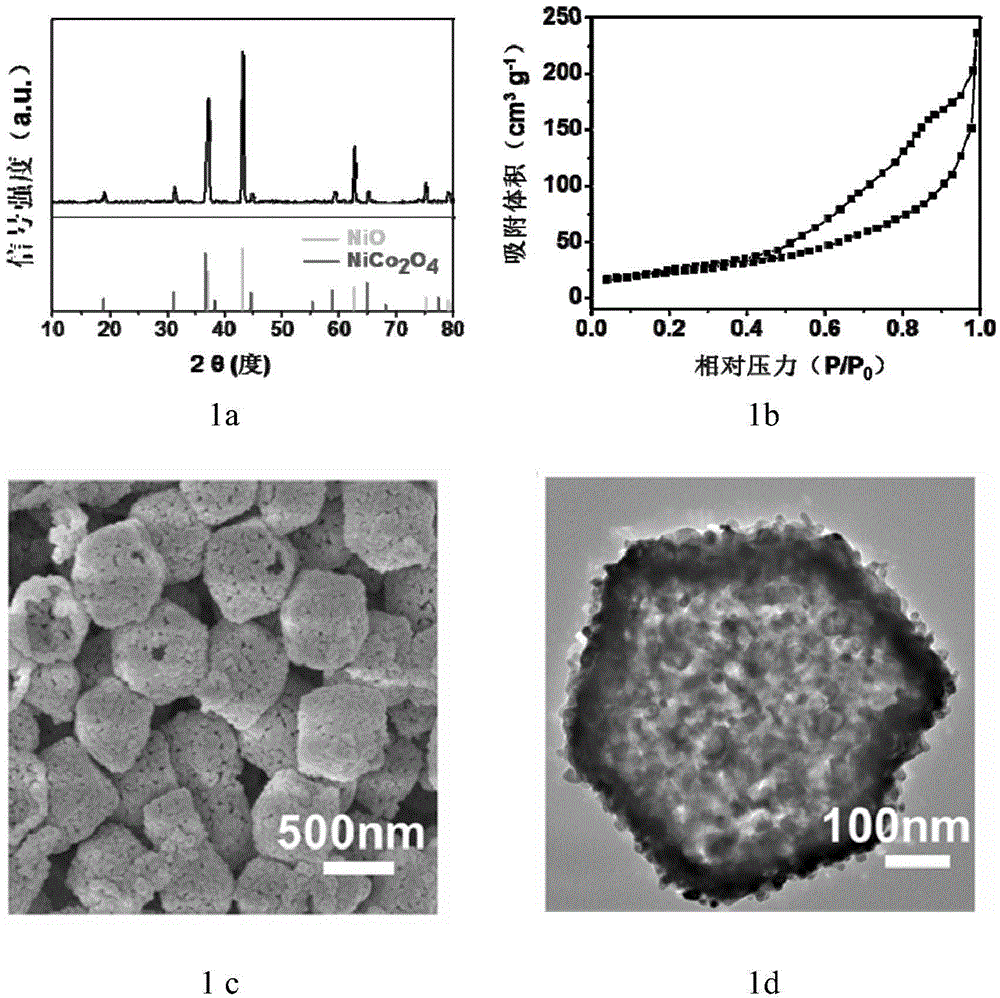

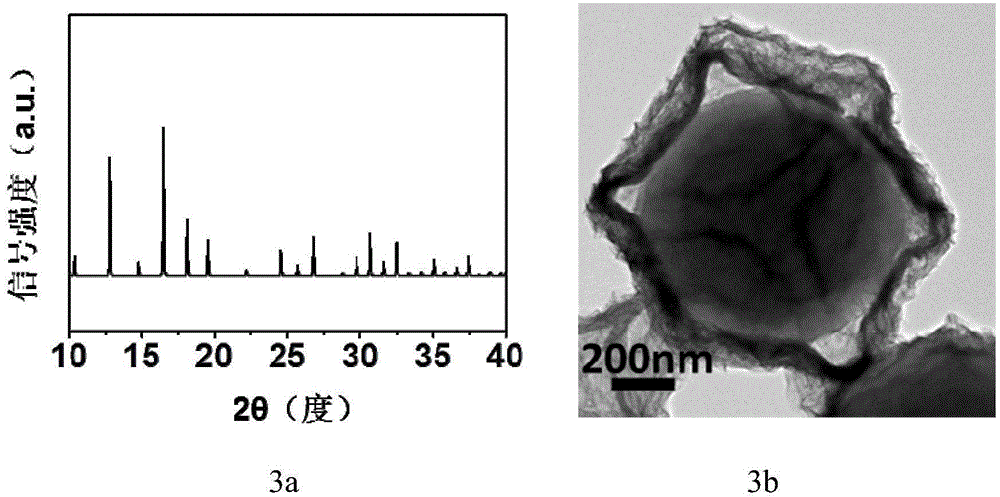

Preparation method of hollow nickel cobaltate nano polyhedron

The invention discloses a preparation method of a hollow nickel cobaltate nano polyhedron. The method comprises the following steps: (1) mixing an organic metal framework complex ZIF-67 and an alcoholic solution of nickel nitrate uniformly, and reacting at the temperature condition of 80-100 DEG C; (2) cooling to room temperature after reaction, collecting precipitate, cleaning by ethyl alcohol or other non-polar solvents, centrifuging, removing the solvents, and carrying out vacuum drying so as to obtain a hollow nickel cobalt hydroxide polyhedron; and (3) annealing the hollow nickel cobalt hydroxide polyhedron in air heating so as to obtain the porous nickel cobaltate nano hollow polyhedron. The method is simple to operate, and is environmentally friendly, and the mold plate removing process is omitted; the hollow obtained nickel cobaltate nano polyhedron has the relatively high specific surface area, relatively low mass transfer resistance and relatively excellent structure stability; as an electrode material of the lithium ion battery, the hollow nickel cobaltate nano polyhedron is superior to an existing transition metal oxide electrode material in cost and performance.

Owner:NANJING UNIV OF TECH

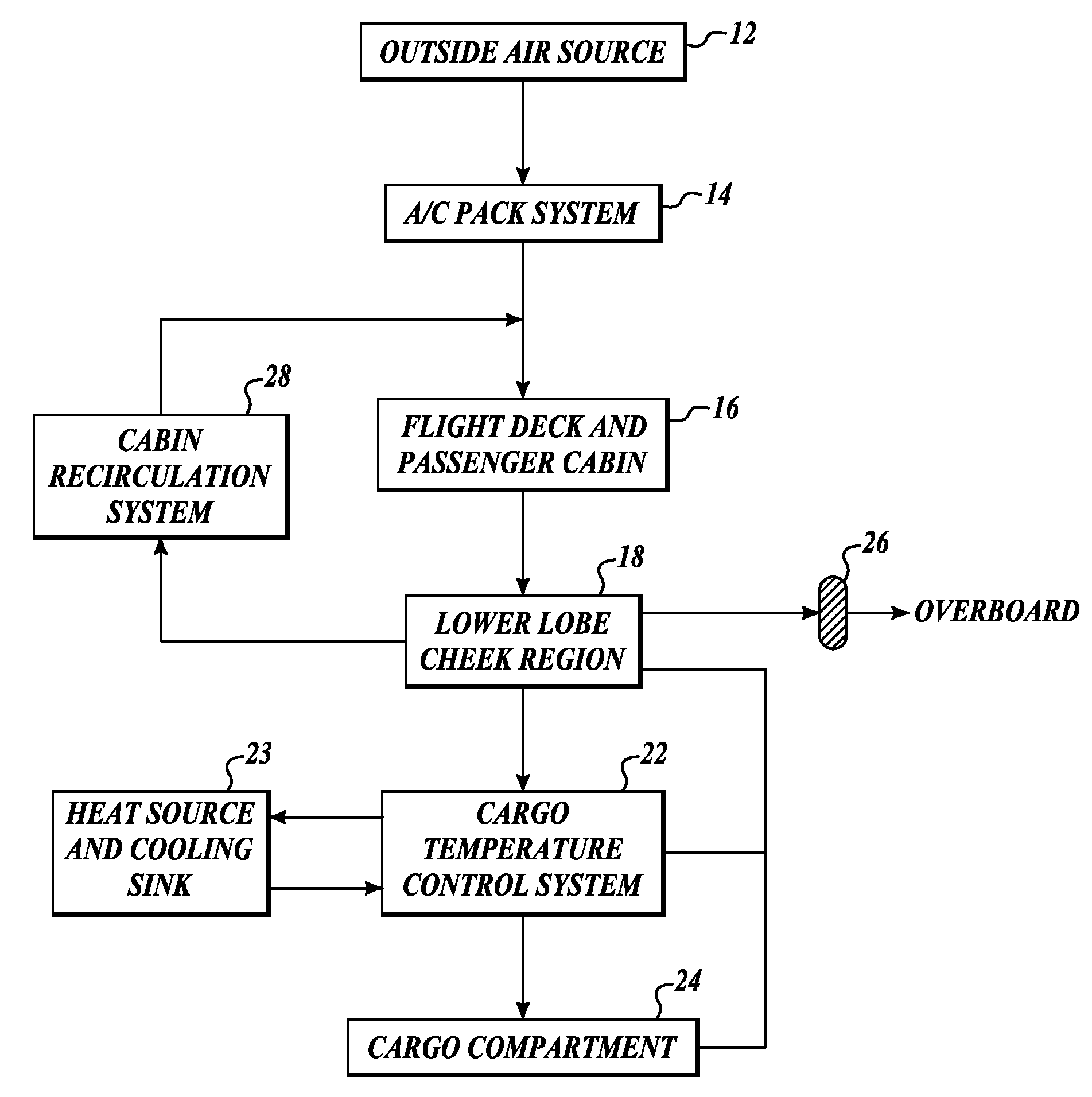

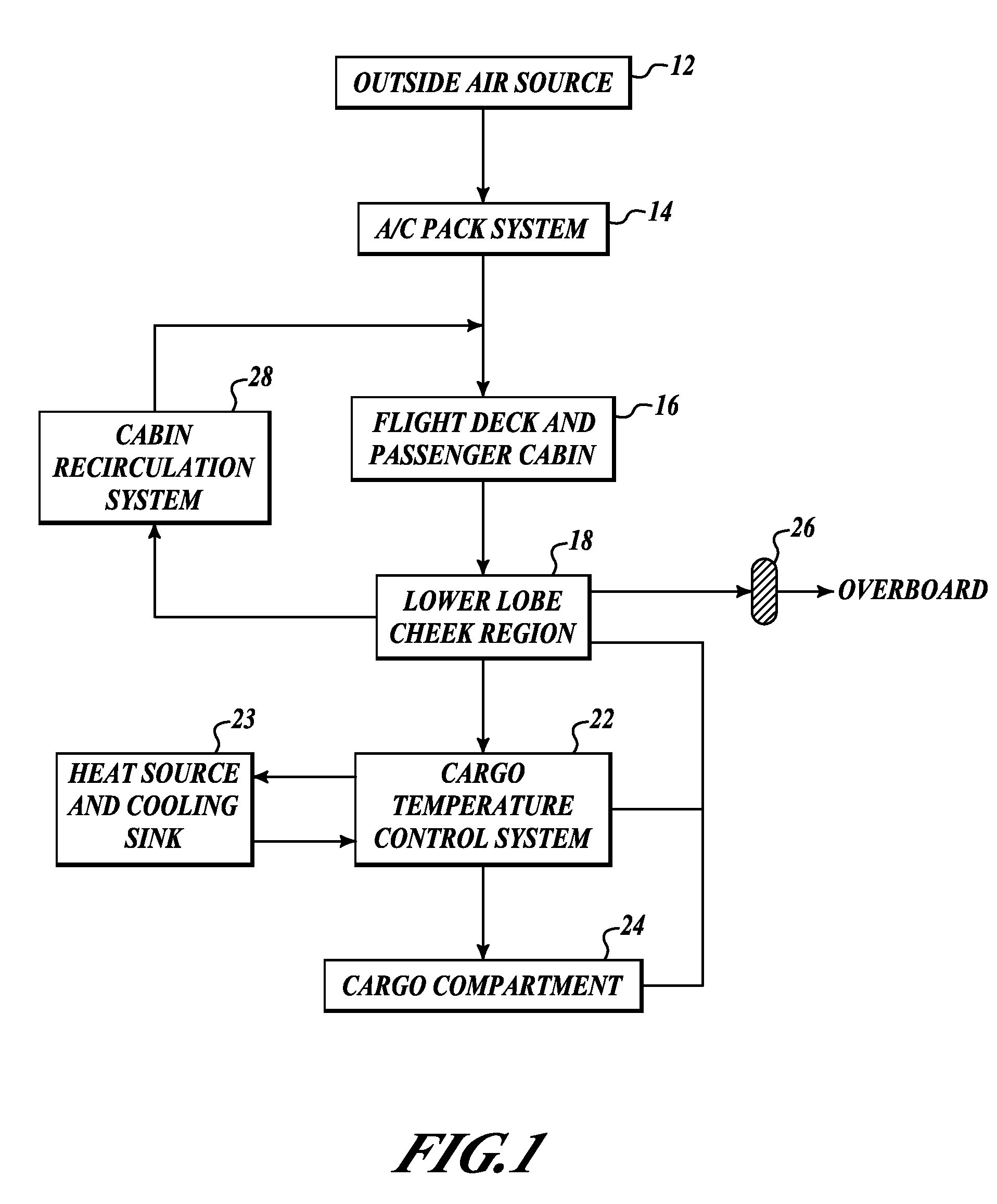

Systems and methods for cargo compartment air conditioning using recirculated air

ActiveUS20060219842A1Air-treatment apparatus arrangementsEnergy efficient board measuresTemperature controlControl system

The present invention comprises systems and methods for providing conditioned air to a selected portion of an aircraft cabin. In one embodiment, a system includes a cargo compartment air recirculation system fluidly coupled to the cargo compartment and having an air moving device to extract air from the compartment and to transport the air to an air heating device and an air cooling device fluidly coupled to the cargo compartment. Air may be supplied from an air source. Extracted air maybe discharged overboard. A temperature control system is operably coupled to the air heating device and the air cooling device, the control system being configured to maintain a predetermined air temperature within the compartment in response to a sensed compartment temperature.

Owner:THE BOEING CO

Device and method for keeping food warm

A food warming device having a bin for holding food products. The bin has an air delivery port and an air intake port located at first and second end walls that are disposed at first and second opposite edges of the bottom portion. The regions above the bottom portion and along the third and fourth opposite edges between the first and second walls are substantially open whereby the food products are clearly visible to customers. The bottom portion has a heated surface for receiving food products to be warmed. An air circulating means forms a stream of circulating heated air that moves from the air delivery port over the heated surface to the air intake port. The food products are warmed by heat emanating from the heated surface and by warm air from the stream of circulating heated air. A balancing system maintains the circulating air in balance by diverting a portion of the return air to ambient atmosphere through a bleed exhaust port.

Owner:THE FRYMASTER CORP LLC

Exhaust system of image forming device

ActiveUS20040096229A1Electrographic process apparatusPhotographic printingLow voltageImage formation

A low-voltage power source circuit board is provided downstream in relation to the flow of air introduced through an intake hole and exhausted by a power source fan. Heat sinks are provided on the low-voltage power source circuit board on electronic parts that generate a large amount of heat, the plate surfaces of the heat sinks being arranged along the direction of airflow, thereby minimizing their resistance to the airflow. Air including heat generated from these electronic parts is exhausted by the power source fan without the air heating the high-voltage power source circuit board or engine circuit board that are disposed upstream in relation to the direction of airflow.

Owner:BROTHER KOGYO KK

Three-phase separation and waste water purification standard treatment device of kitchen waste including 'waste oil' and solid waste and kitchen waste water

InactiveCN103159362AEfficient separationIncrease temperatureFatty oils/acids recovery from wasteFatty/oily/floating substances removal devicesNumerical controlWater quality

The invention discloses a three-phase separation and waste water purification standard treatment device of kitchen waste including 'waste oil', solid waste and kitchen waste water. The three-phase separation and waste purification standard treatment device of the kitchen waste including the 'waste oil', the solid waste and the kitchen waste water is mainly composed of a shell body, a solid-liquid separation chamber, a filtering bag with meshes, a liquid level displayer, an oil-water interface detector, a numerical control electric valve which discharges the 'waste oil', a flowmeter of the 'waste oil', a collection tank of the 'waste oil', a blower, an air heating device, a filtering tank, a drug adding tank and the like. According to the three-phase separation and waste water purification standard treatment device of the kitchen waste including the 'waste oil', the solid waste and the kitchen waste water, oil and water separation and waste water purification are carried out in the same device, an equipment structure is simplified, the water quality after being purified is in line with each indicator of 'water quality standard of sewage discharged into the city sewer' (CJ3082-1999), The three-phase separation and waste purification standard treatment device of the kitchen waste including the 'waste oil', the solid waste and the kitchen waste water has the advantages that the size is small, the investment is low, either manual or automatic operation is available and the like, and obvious creativity, novelty and good industrial applicability are provided.

Owner:周鼎力

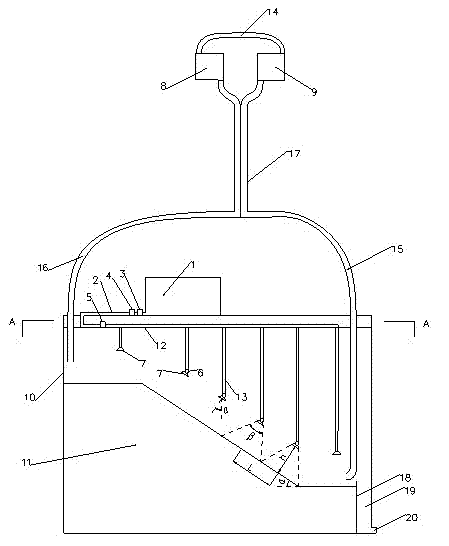

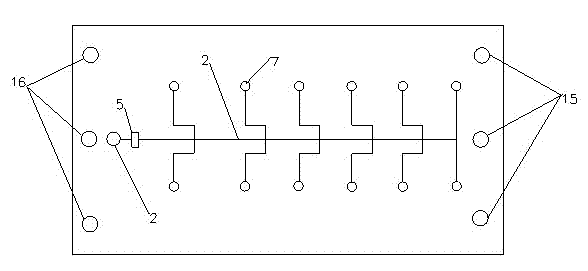

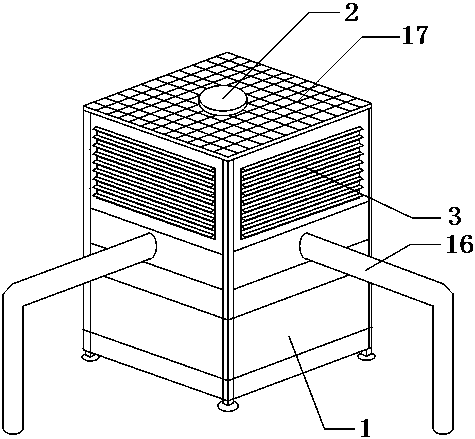

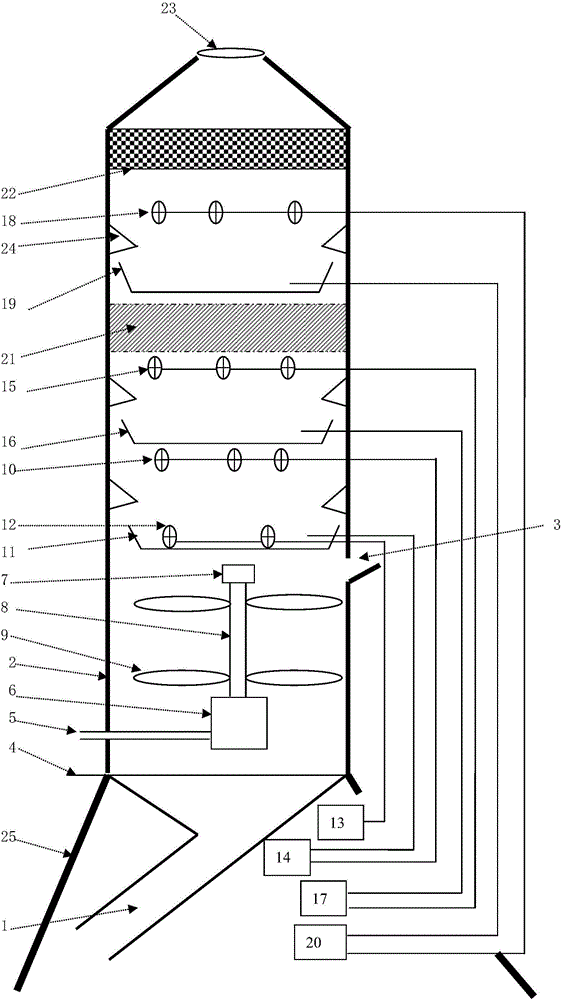

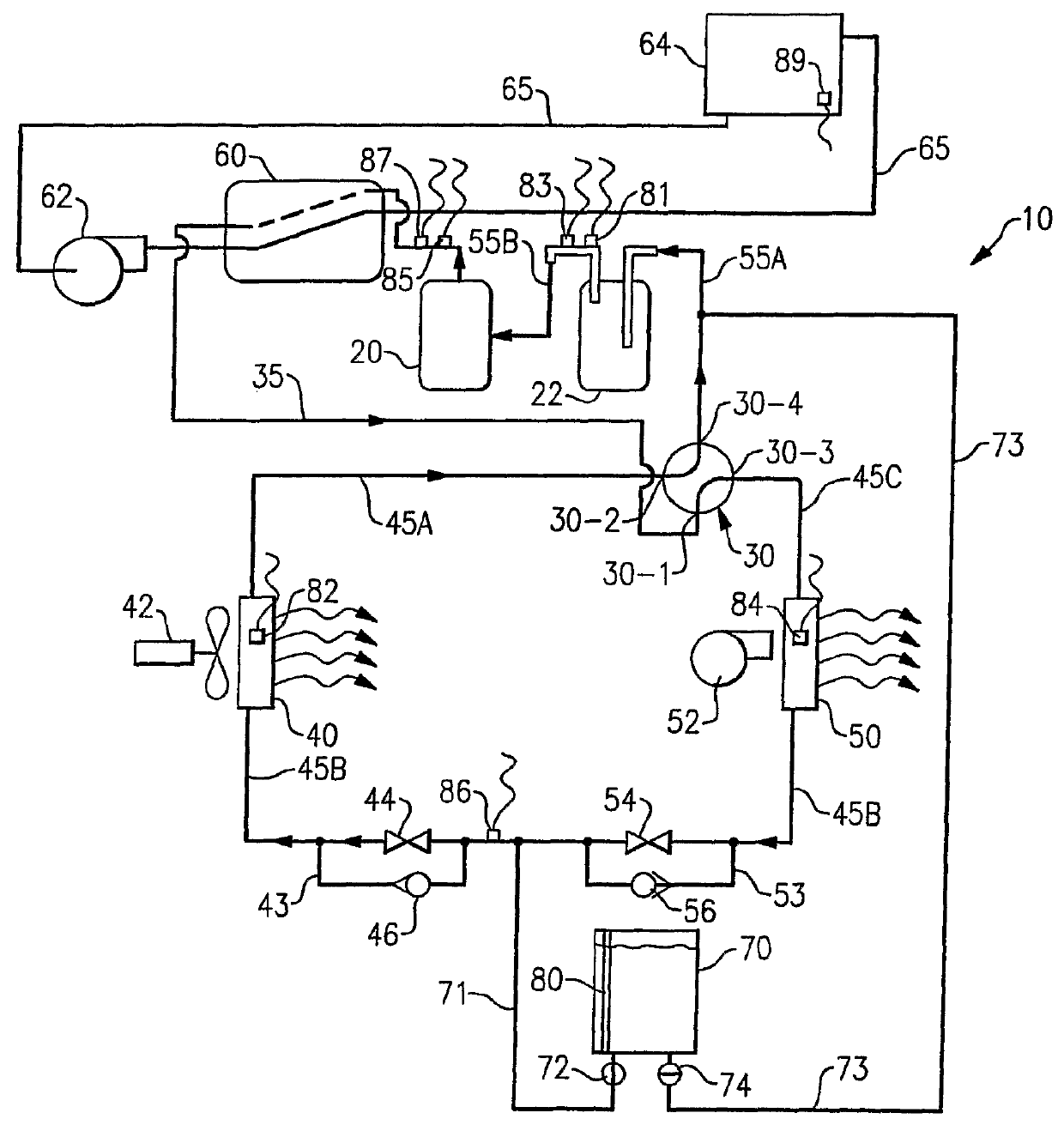

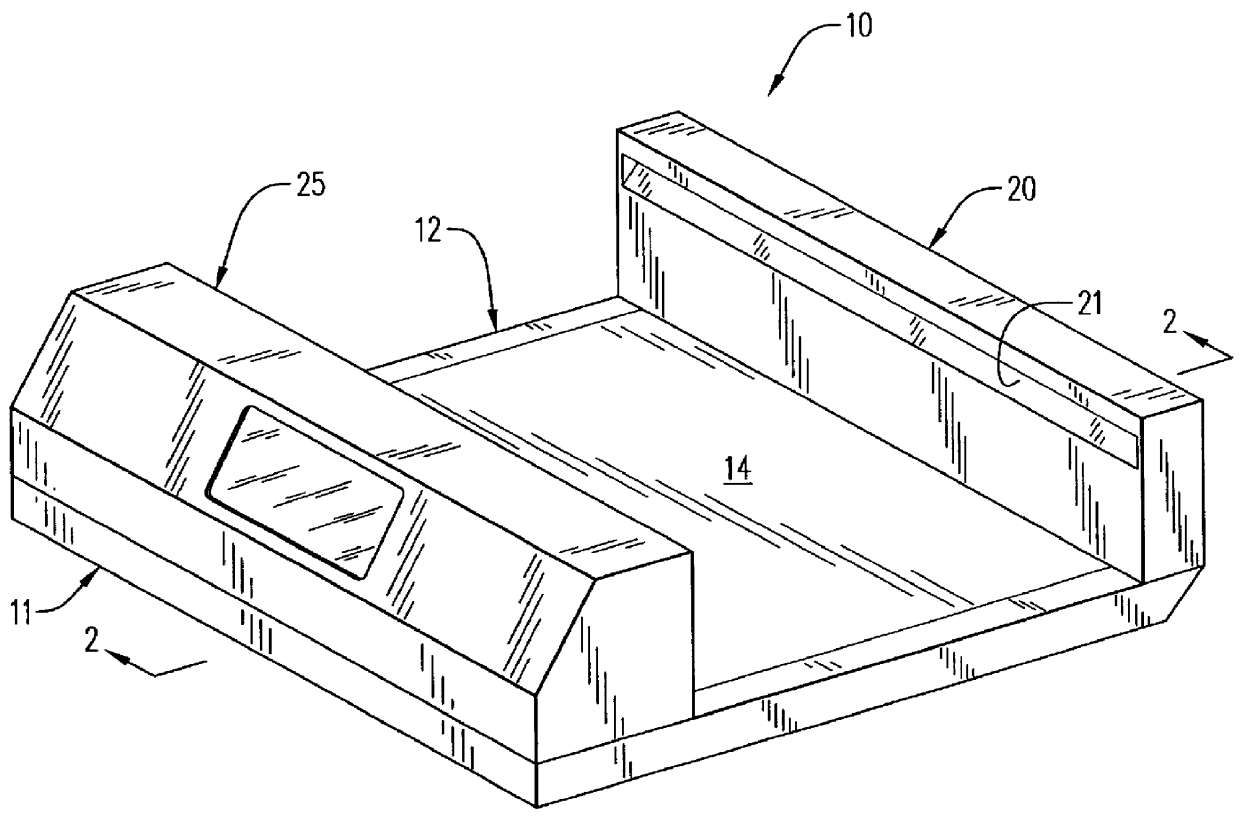

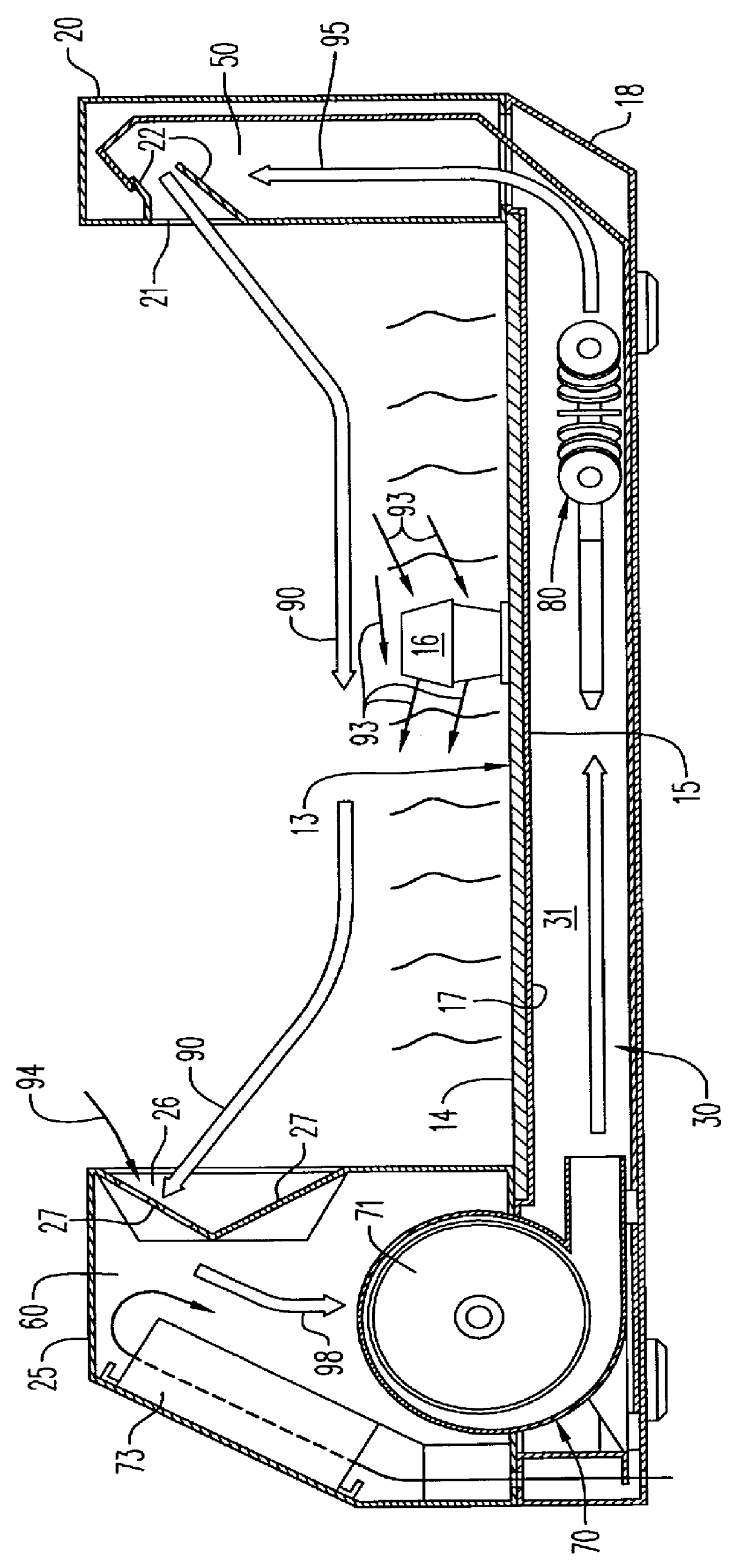

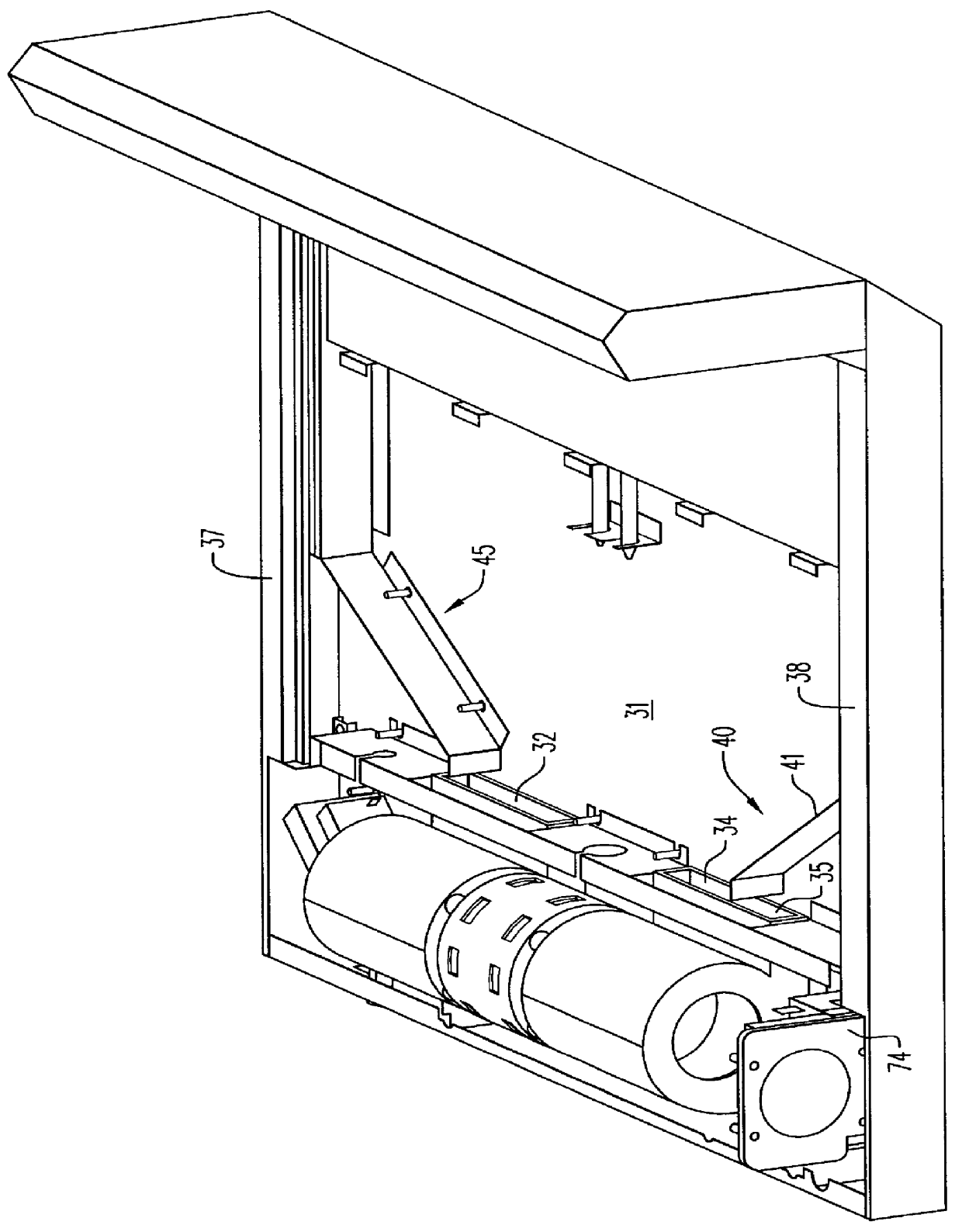

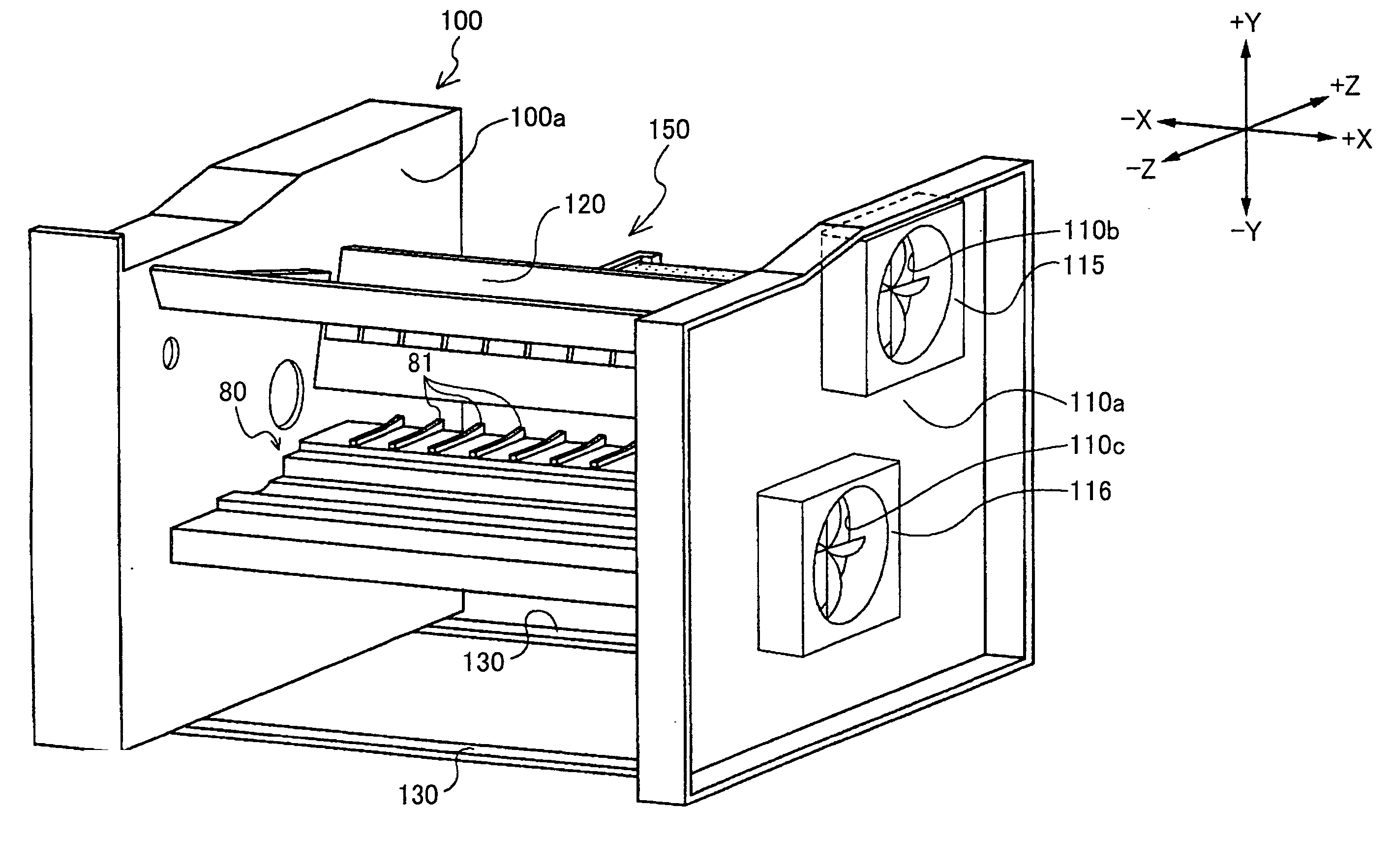

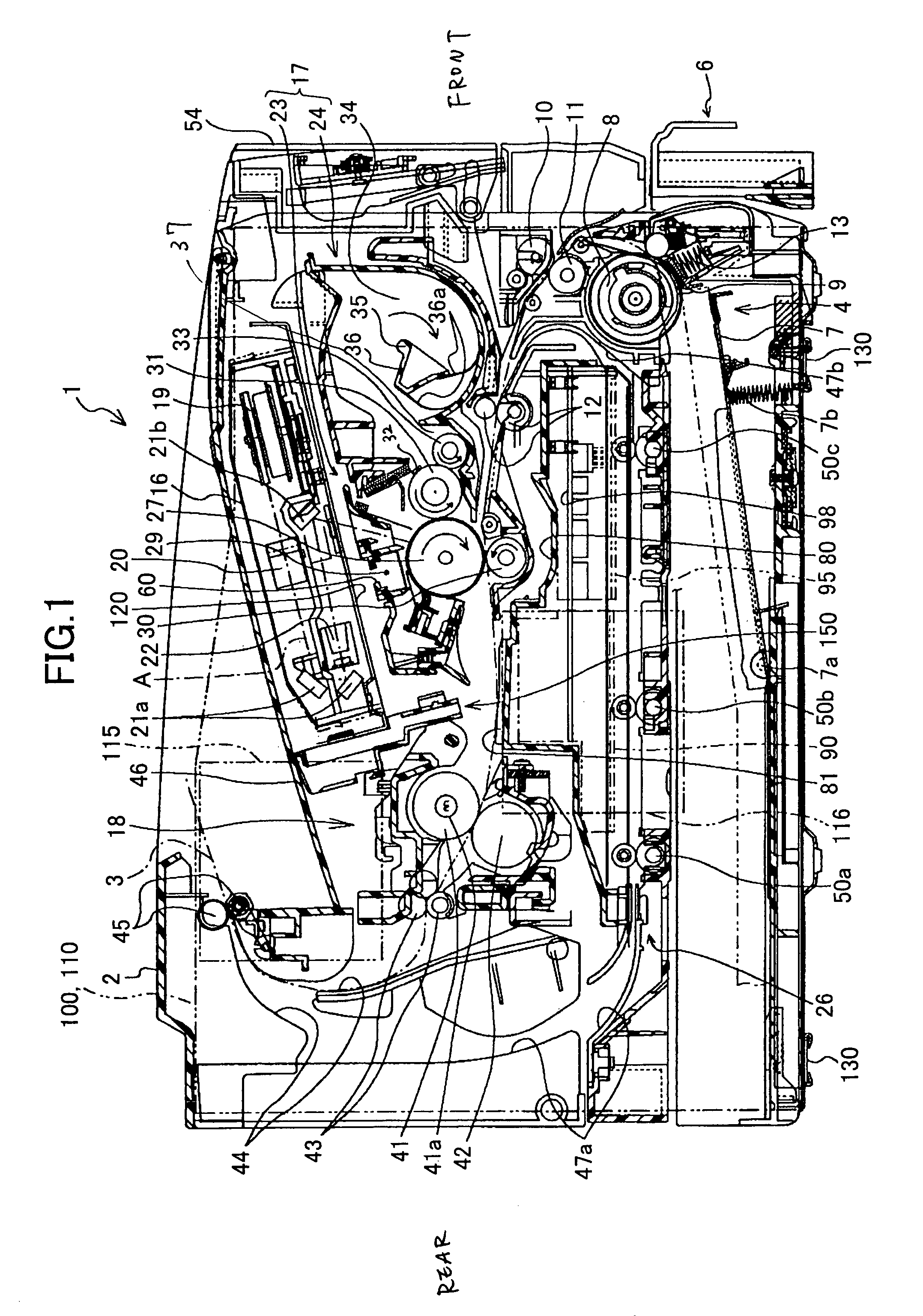

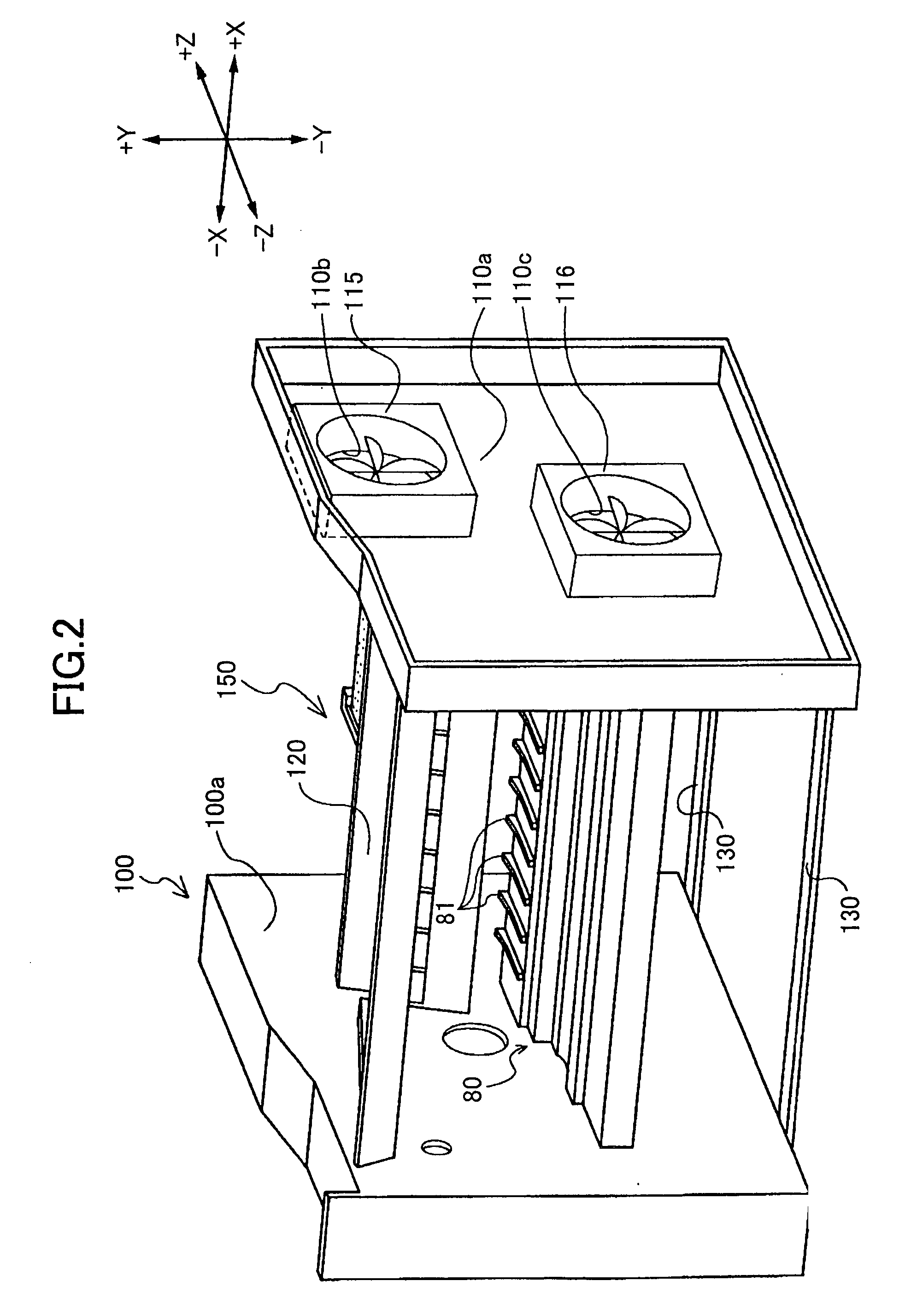

[Air and Water Conditioning System and Filter Media]

InactiveUS20050274663A1Efficiently exchange heatSimple self-regulatingLiquid separation auxillary apparatusSolvent extractionCelluloseWater filter

Disclosed is an air-water-catalyst-UV light contacting, air heating and cooling, humidifying and dehumidifying CHAMBER, which receives water that continuously recirculates through the water filtering, heating and cooling, (and deionizing) loop, which gets fresh outdoors air through the energy-efficient heat exchanger, which generates water from the atmospheric moisture, which stores and recirculates pure water through potable water holding tank, and to which is connected a novel design energy-efficient self-regulating steam distillation apparatus. Also, a water filtration system utilizing zwitterionic polymers as ion exchange and salt-absorbing and filtration media. Also disclosed are novel ionic and zwitterionic polymers, derived from cellulose.

Owner:ROITMAN LIPA LEON

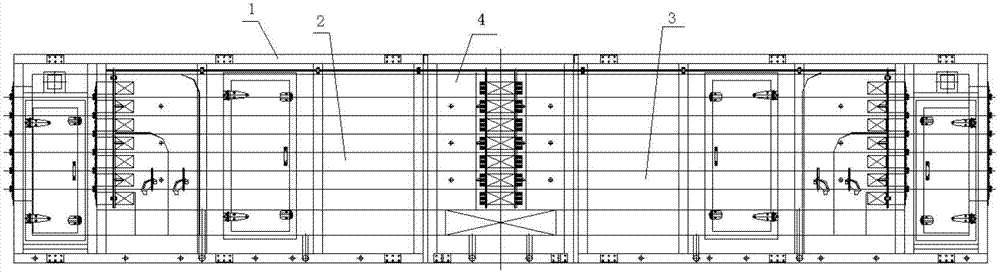

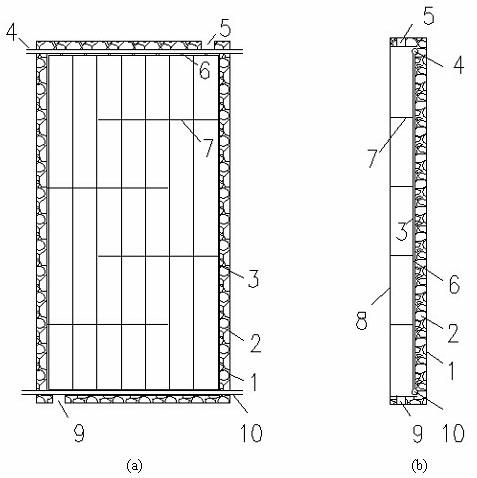

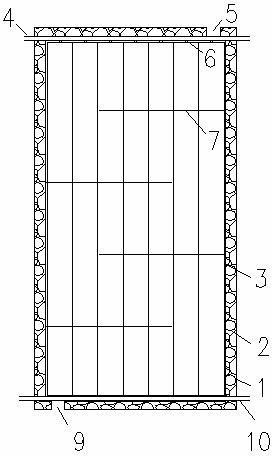

Energy-saving environmental-friendly multifunctional double-skin facade

InactiveCN101974953AReduced indoor heating energy demandEasy to disassembleSolar heating energyCombination devicesNoise controlPorous medium

The invention relates to an energy-saving environmental-friendly multifunctional double-skin facade which belongs to the fields of solar utilization, air purification, noise control and building wall body development. The energy-saving environmental-friendly multifunctional double-skin facade is characterized by comprising two layers of transmission glass, an air heating cavity, a solar radiant heat absorbing plate, a total air inlet, a total inlet guide baffle plate, a lower inlet louver, a lower inlet baffle plate, an upper inlet louver, an upper inlet baffle plate, an air cavity top baffle plate, an intra-wall guide plate, a filtering unit support plate, a porous medium filtering unit, a cross flow fan, a noise elimination net, an outlet louver, an air outlet openness regulating baffle plate, a lower inlet baffle opening and closing control connecting rod, an upper inlet baffle plate opening and closing control connecting rod, a cavity top baffle plate opening and closing control connecting rod, a wall body base, a glass panel fixing frame, and the like. The invention is suitable for supplying fresh air for rooms in buildings in a downtown area with low air quality and large noise, inhibits outdoor noise, creates a silent, healthy and comfortable indoor environment for the rooms of the building, and reduces the energy resource requirements on the buildings.

Owner:DALIAN UNIV OF TECH

High-performance carbon fiber pre-oxidation furnace

ActiveCN102758270AAvoid burnsPrevention of legitimate discharge problemsFibre chemical featuresFiberCarbon fibers

The invention discloses a high-performance carbon fiber pre-oxidation furnace which is specially designed for carrying out heat treatment on a high-performance carbon fiber material at a temperature below 350 DEG C. A furnace body is designed into a building block structure and is convenient to assemble and disassemble. For the design of the furnace, the requirements of a preparation process of the high-performance carbon fiber material are fully considered and understood and the key special requirements of the preparation process of the high-performance carbon fiber material are met to the greatest extent. According to the requirements of the preparation process of the material, a circulating hot air heating mode is adopted for the pre-oxidation furnace; for a circulating air traveling mode, air is blown to two ends of the furnace body from the middle of the furnace body; and a plurality of heat treatment cavities are connected in series and in parallel to form a system with a certain temperature gradient. An anticorrosion stainless steel structure is adopted for an inner hearth totally; a full-fiber superlight material is adopted as a heat insulating material to carry out heat insulation; a PLC (Programmable Logic Controller) temperature control module is used for temperature control and has the characteristics of high temperature control accuracy, high temperature stability and the like; and according to the pre-oxidation furnace, in a pre-oxidation process, the problems of low heat treatment efficiency, inaccurate temperature control and unideal temperature uniformity in the heat treatment cavities are solved, protofilament combustion is prevented, sufficient supplementation of the oxygen content in the hearth is realized and waste gas is reasonably discharged. The integral high-performance carbon fiber pre-oxidation furnace has relatively low energy consumption and is durable.

Owner:HEFEI RISINE HEATEK

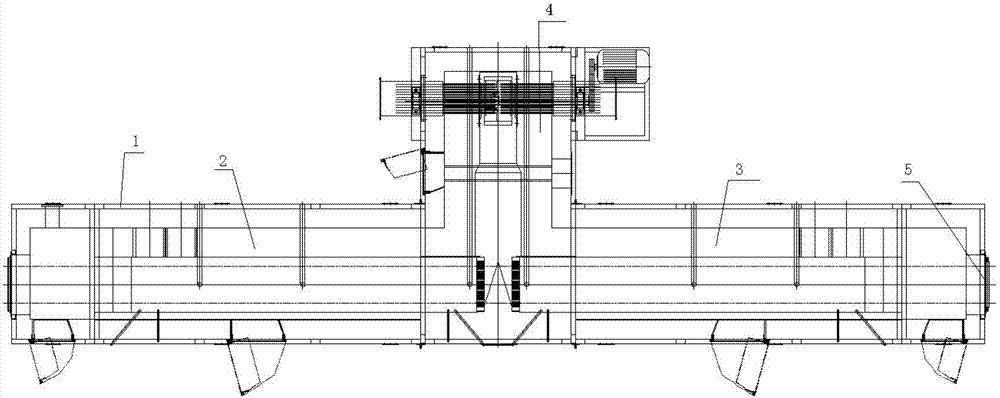

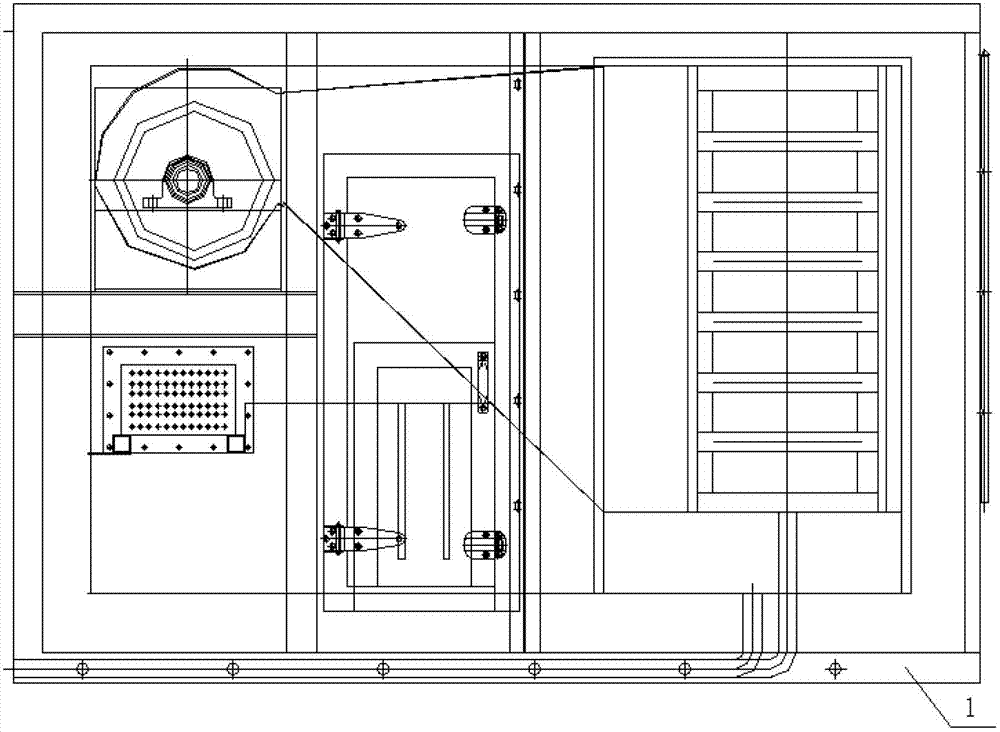

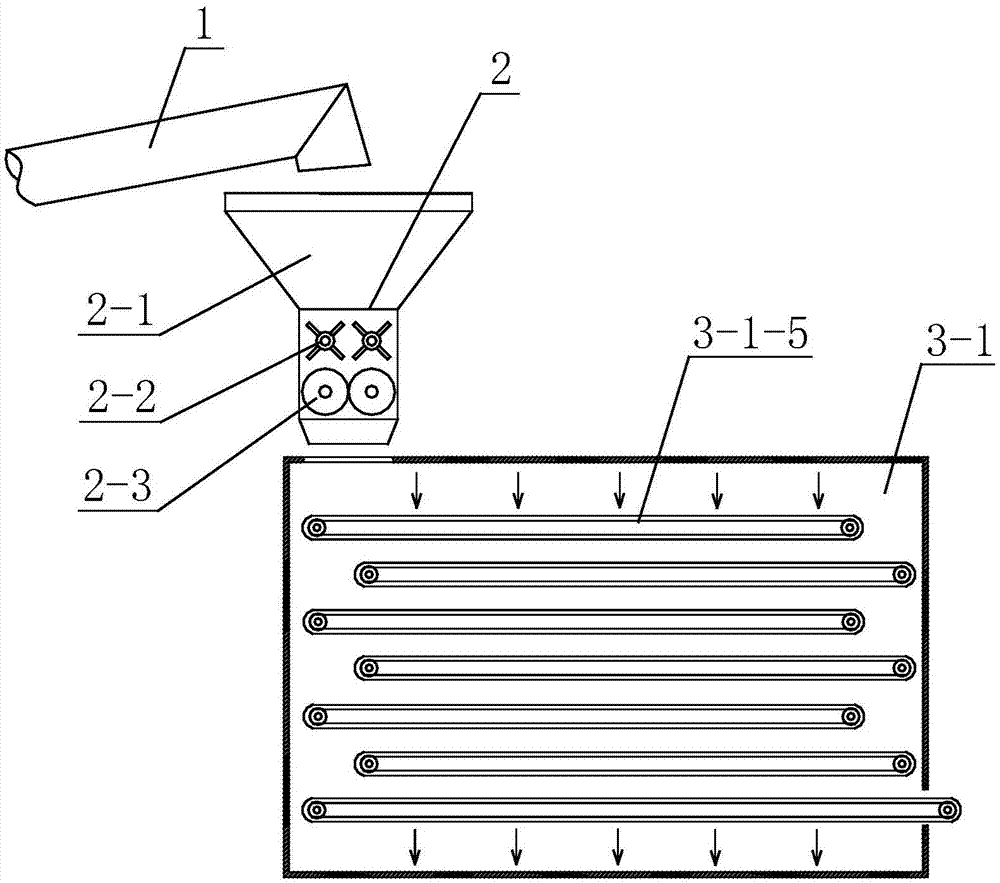

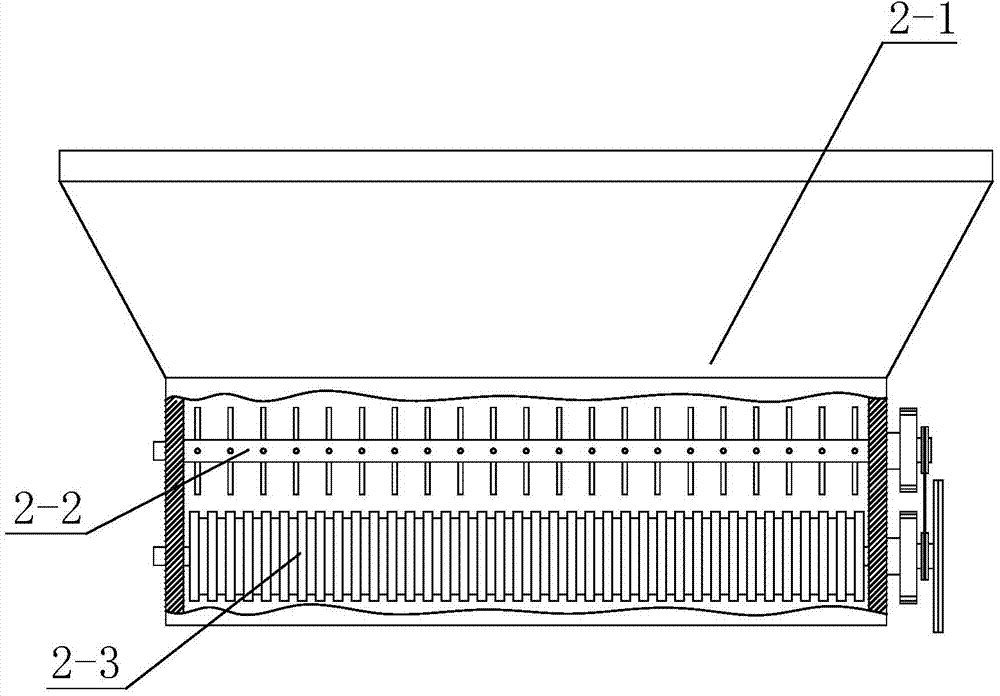

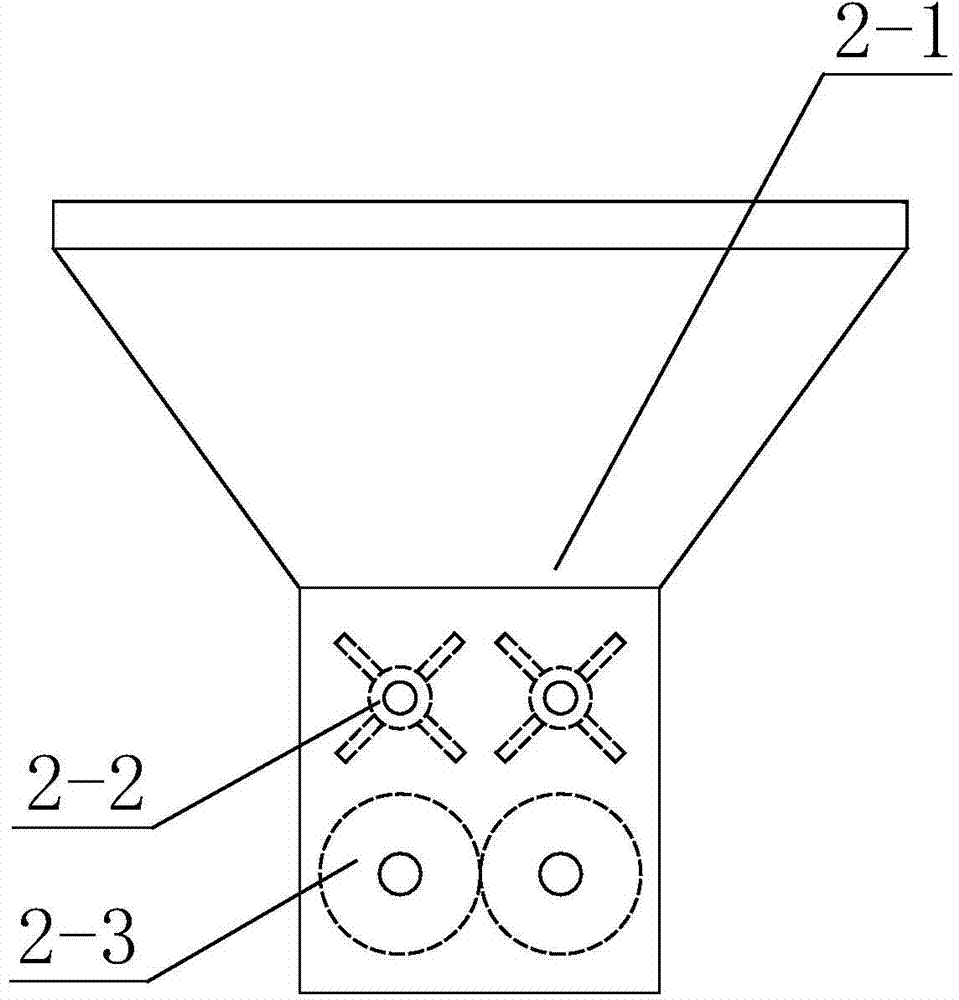

Sludge treatment equipment and process

InactiveCN103693829AIncrease contact areaSmall flow resistanceSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentCompression moldingSocial benefits

The invention relates to sludge treatment equipment and a sludge treatment process. The equipment comprises a sludge conveyor, a sludge crushing former and a sludge dryer, wherein a pair of sludge crushing rollers and a pair of sludge strip compression molding rollers driven by a variable-frequency motor are arranged from top to bottom in a sludge hopper of the sludge crushing former; the inner cavity of the drying cabin of the sludge dryer is partitioned into a drying chamber and a circulating air heating chamber; a plurality of layers of stainless steel mesh belt conveying tables are formed in the drying chamber; the discharging hole of the sludge hopper of the sludge crushing former is positioned above the conveying start end of the topmost layer stainless steel mesh belt conveying table in the drying cabin. When applied to an urban domestic sludge treatment process, the sludge treatment equipment and the process have the remarkable advantages of high durable treatment capacity, short period, high efficiency, good treatment effect, avoidance of secondary pollution, environmental friendliness, stability and safety in equipment running, low energy consumption, high degree of automation and the like. The sludge treatment equipment and the process are high in input-output ratios and have good popularization and application prospects, and good social benefit can be achieved.

Owner:CHANGZHOU XINGANG THERMOELECTRICITY

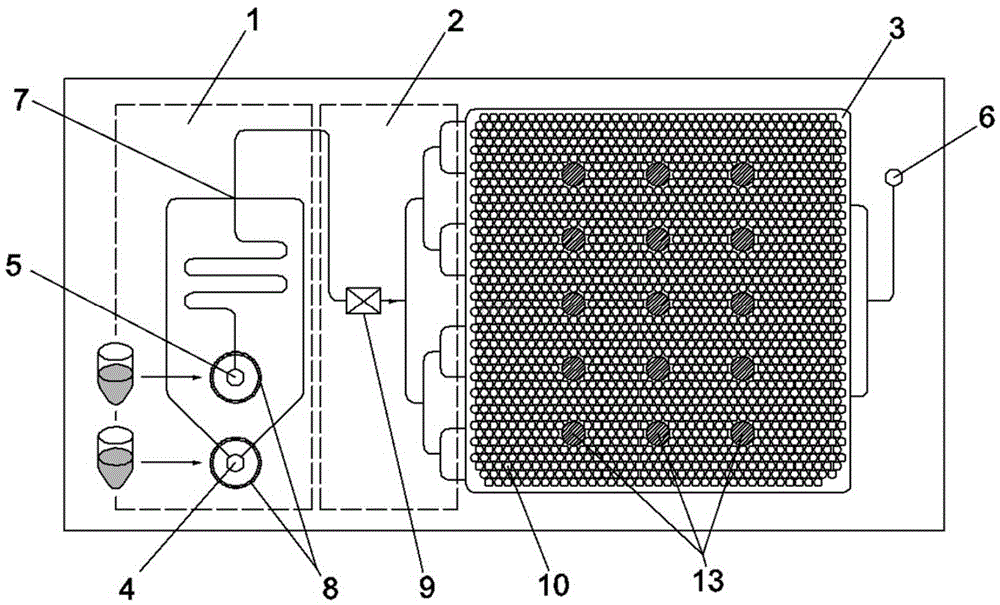

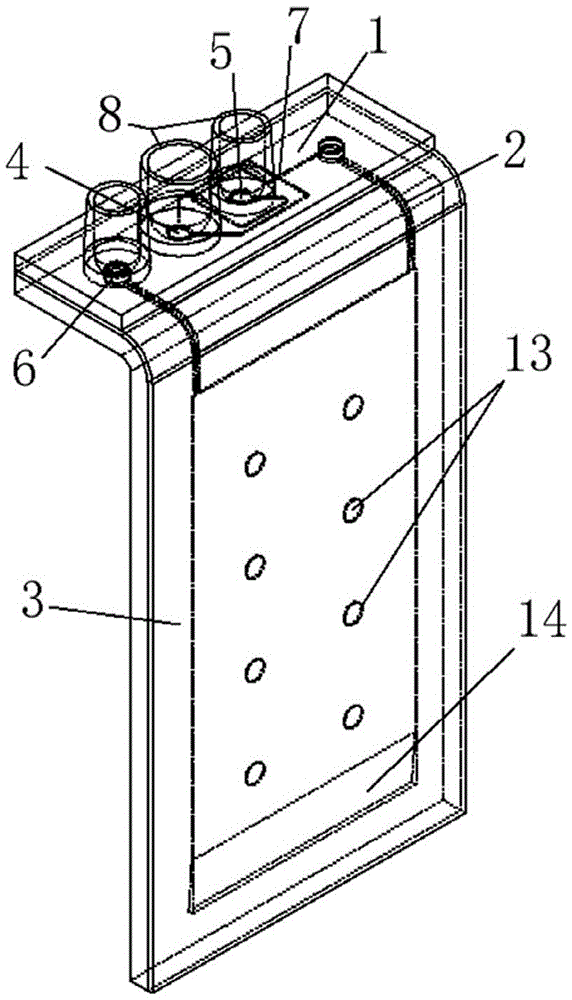

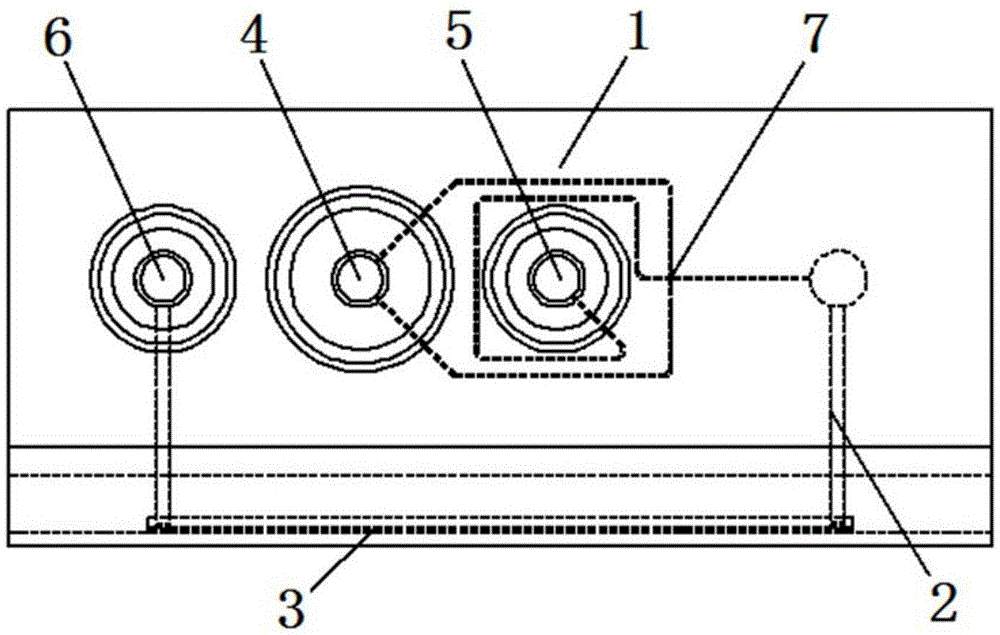

Integrated liquid drop microfluidic chip

InactiveCN105567560ASmall sizeReduce transferBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOil phase

An integrated liquid drop microfluidic chip comprises one or more liquid drop generation structures, every liquid drop generation structure is connected with a corresponding collection cavity structure through a corresponding connection channel, a water phase reagent and an oil phase reagent respectively go through the one or more liquid drop generation structures to generate liquid drops with uniform dimension, an emulsion including the liquid drops goes through the connection channel and directly or indirectly enters the collection cavity structure, and is adaptively arranged to form a regular liquid drop array in the collection cavity structure, the liquid drop array undergoes a biochemical reaction under constant temperature control or temperature circulation control in an air heating refrigeration or Peltier semiconductor heating refrigeration mode, and real time monitoring or timed optical detection is also carried out. The integrated liquid drop microfluidic chip reduces the sample transfer process, can be conveniently integrated with a thermometric module and an optical detection module, greatly improves the reaction and detection speed, and also simplifies the complex degree of a whole apparatus system.

Owner:XI AN JIAOTONG UNIV

Sealed structure of mini-type electronic dehumidifying and cooling machine

InactiveCN102545080AEnsure safe operation and reliabilityReduce power consumptionSubstation/switching arrangement cooling/ventilationWater collectionWater pipe

The invention provides a sealed structure of a mini-type electronic dehumidifying and cooling machine. A heat radiation face and a refrigerating face of a vertical electronic refrigerating sheet are sealed to be a wet air heating channel and a wet air condensing channel, which are mutually independent and are provided with vertical communicated upper parts. One end of a wet air leading channel is communicated with the lower part of the wet air heating channel, and the other end of the wet air leading channel is provided with a mini-type blower. The lower end opening of the wet air condensing channel is sealed, and a refrigerating face of the wet air condensing channel aligns to a dried cool air discharge hole which is arranged at a vertical position. A water collection hopper is arranged below a condensing sheet of the refrigerating face. A drain pipe of the water collection hopper is communicated to the outside of a shell box of the sealed structure of the mini-type electronic dehumidifying and cooling machine through leading of the water collection hopper. The installation on the lateral face or the bottom face outside an indoor armor switch cabinet or various terminal bins of an electric system with a 6-kV or above voltage class is met. The inside spaces of the armor switch cabinet and the terminal bins are not occupied. No interferences of a high voltage and a strong magnetic field exist. The equipment operation inside the armor switch cabinet and the terminal bins is not influenced by the maintenance and repair of the mini-type electronic dehumidifying and cooling machine.

Owner:叶秋诗 +2

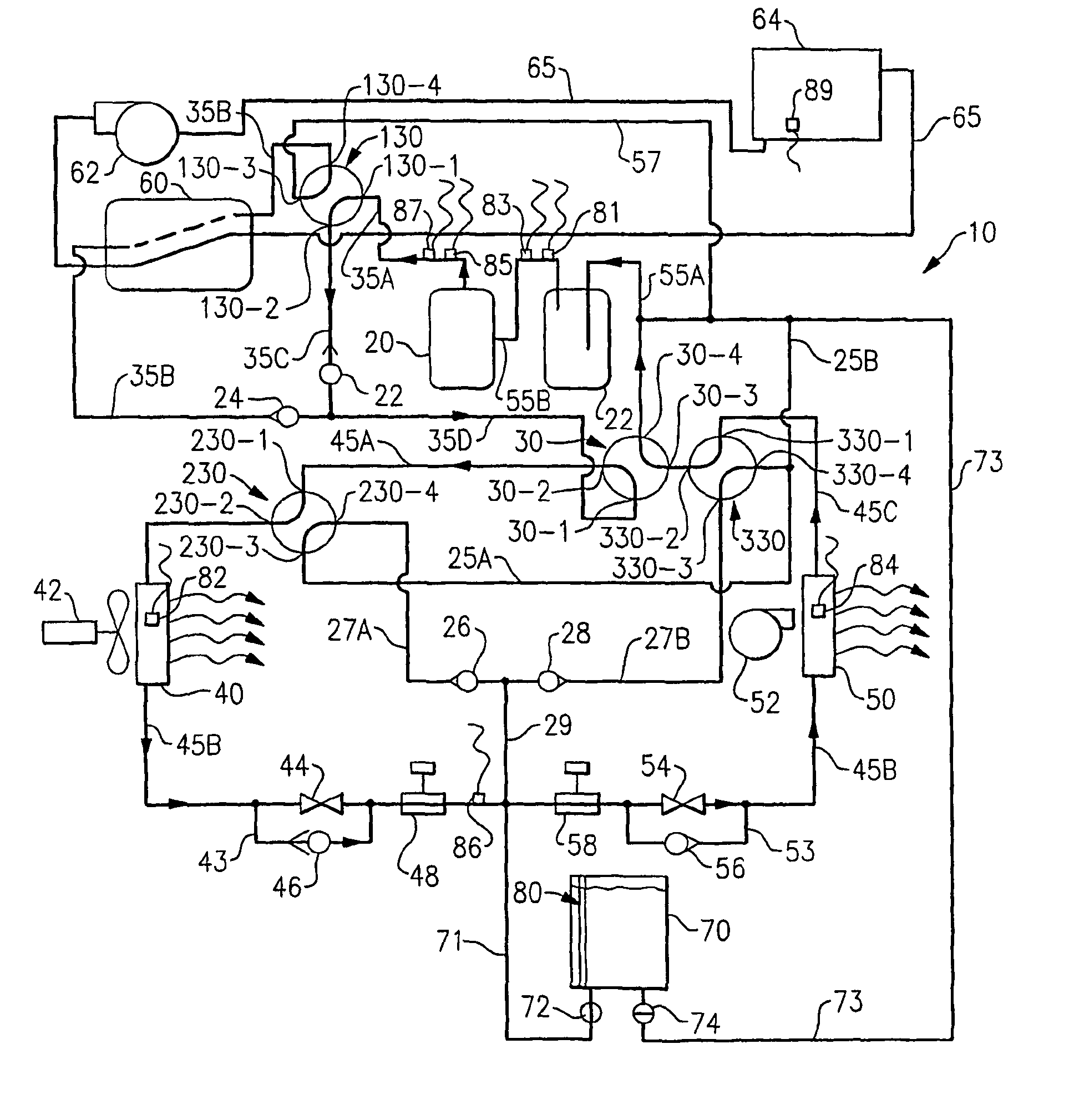

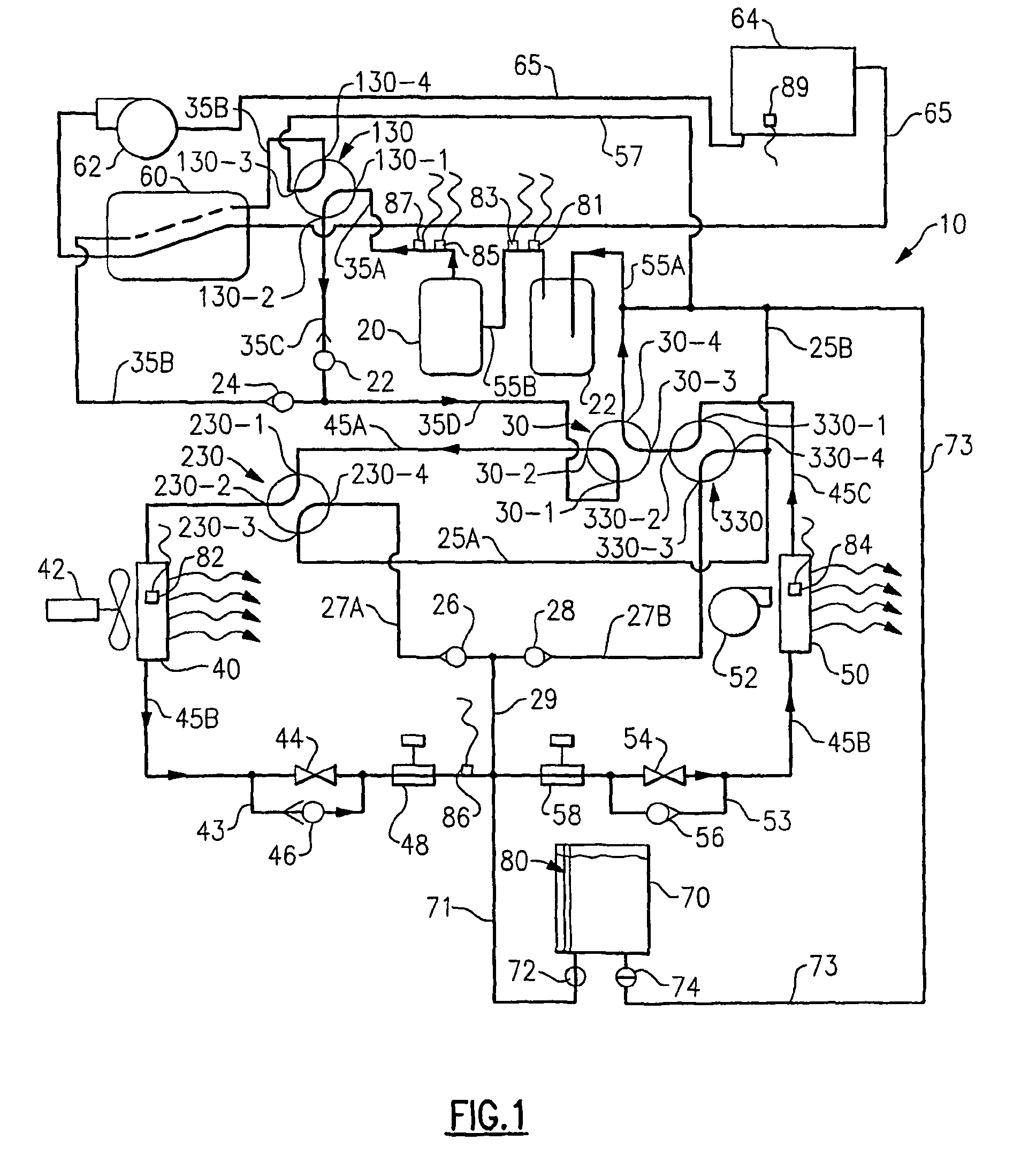

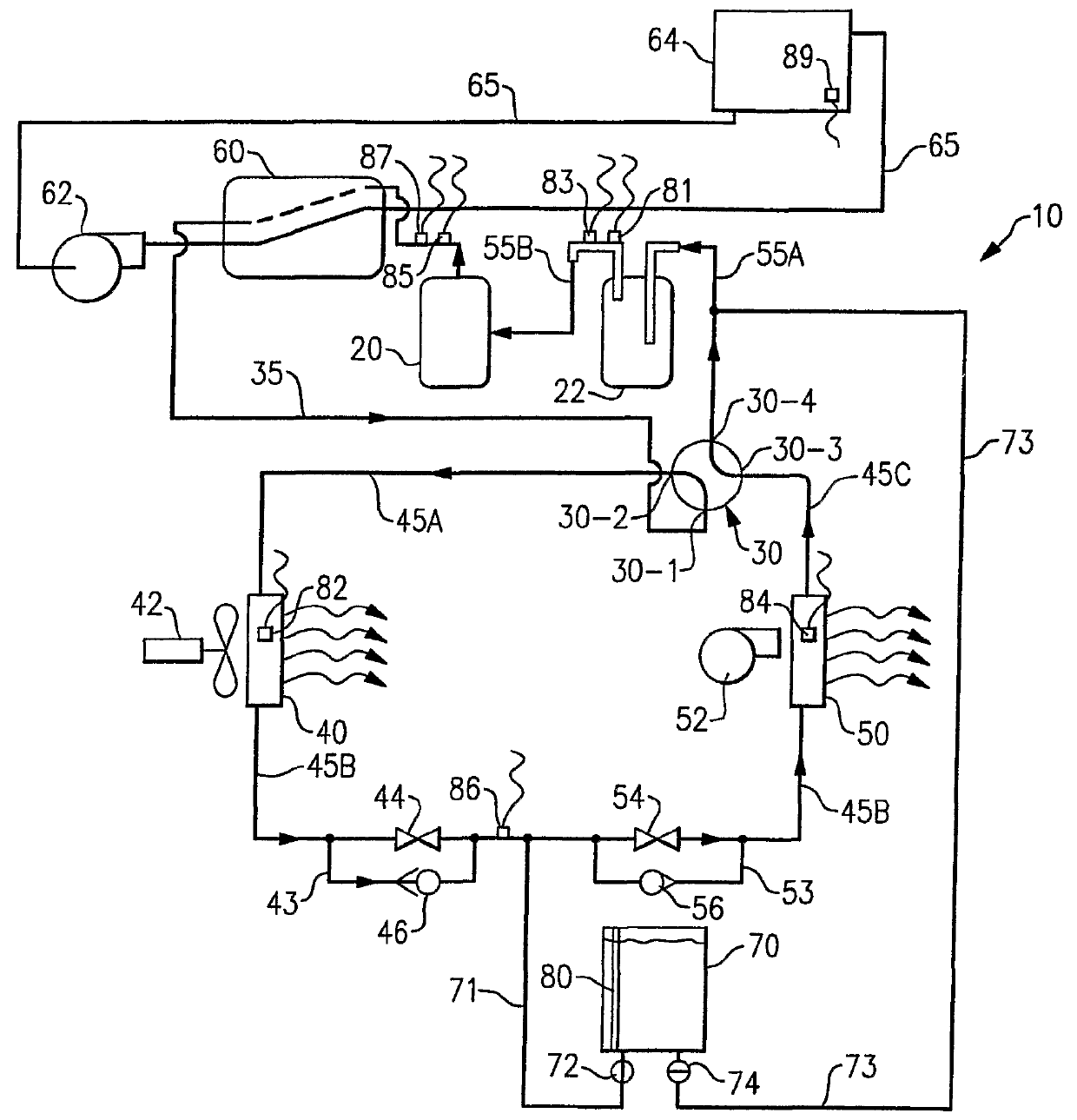

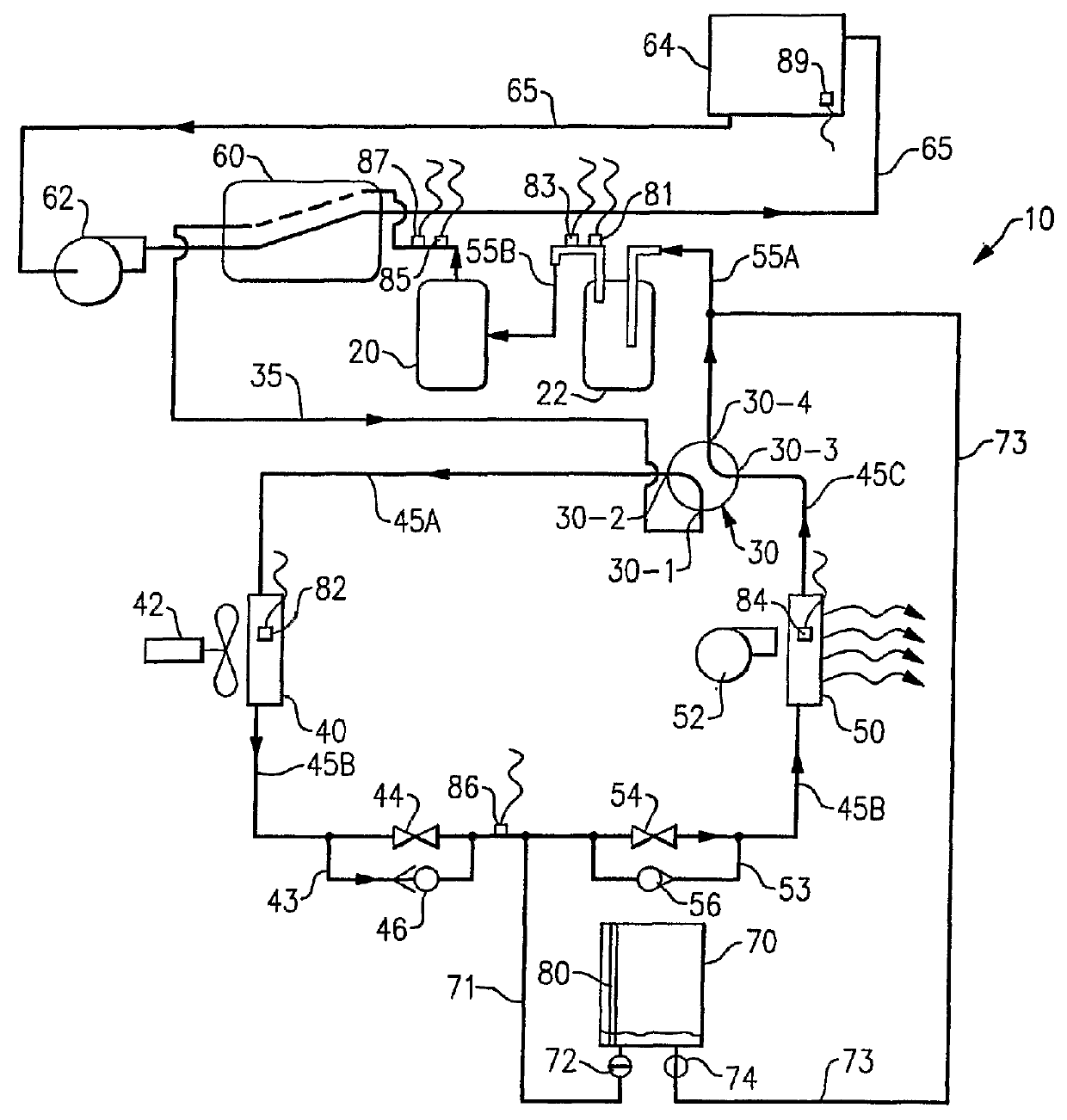

Heat pump system having auxiliary water heating and heat exchanger bypass

InactiveUS8074459B2Evaporators/condensersCompression machines with reversible cycleEngineeringRefrigeration

A heat pump system (10) includes a compressor (20), a reversing valve (30), an outdoor heat exchanger (40) and an indoor heat exchanger (50) coupled via refrigerant lines (35, 45, 55) in a conventional refrigeration circuit, a refrigerant to liquid heat exchanger (60), a refrigerant to liquid heat exchanger bypass valve (130), an outdoor heat exchanger bypass valve (230), and an indoor heat exchanger bypass valve (330). A controller (100) is provided to selectively control the respective positioning of the valves (30, 130, 230 and 330) between their respective open and closed positions so as to selectively configure the refrigerant circuit for operation in one of an air cooling only mode, an air cooling with liquid heating mode, an air heating only mode, an air heating with liquid heating mode, and a liquid heating only mode.

Owner:CARRIER CORP

Dry and wet cycle climate hypergravity simulation system

ActiveCN102297834AGreat advantageAdjustable spray angleWeather/light/corrosion resistanceOutfallWater transport

The invention discloses a dry-wet circulation climate hypergravity simulation system. According to the present invention, an air heating dehumidifier, an air blower and a water tank are arranged in the external of a hypergravity centrifuge-carried model box; a gas outlet of the air heating dehumidifier is connected with a gas inlet of the air blower through gas guiding pipes; a gas outlet of the air blower is connected with a gas inlet pipe; a gas inlet of the air heating dehumidifier is connected with a gas outlet pipe; the water tank is fixed on the top of the model box; the gas inlet pipe and the gas outlet pipe both extend to the internal of the model box; a rock-soil mass model is arranged on the bottom of the internal of the model box; an earthwork separator is arranged between the rock-soil mass model and a side wall of the model box, and the left space between the earthwork separator and the side wall of the model box is provided for a water collecting area; a water outlet is arranged on the bottom of the water collecting area; quadrate rain-fog nozzles are arranged above the rock-soil mass model, wherein the quadrate rain-fog nozzles are distributed in matrix; each quadrate rain-fog nozzle is communicated with the water tank through water transporting pipes; pressure sensors, pressure reducing valves and rain controlling switches are arranged on the water transportingpipes; the pressure sensors and the pressure reducing valves are arranged outside the model box.

Owner:ZHEJIANG UNIV

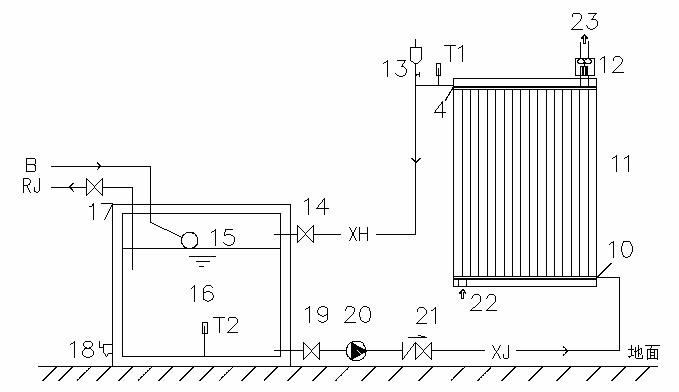

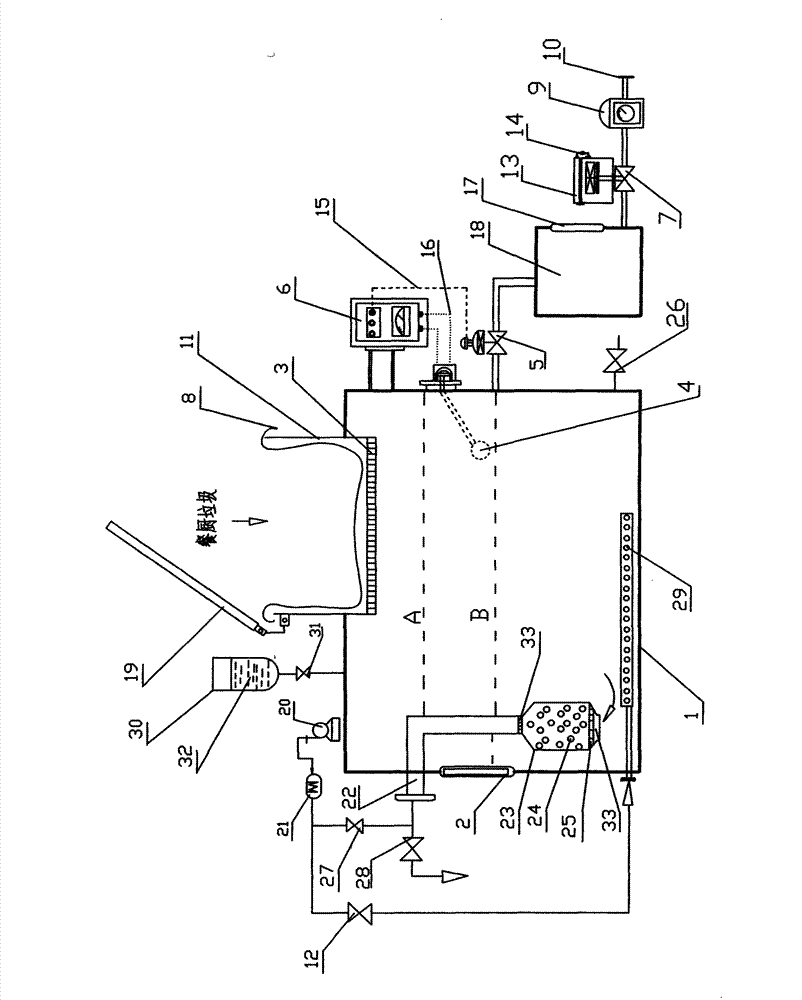

Mud drying system and use method thereof

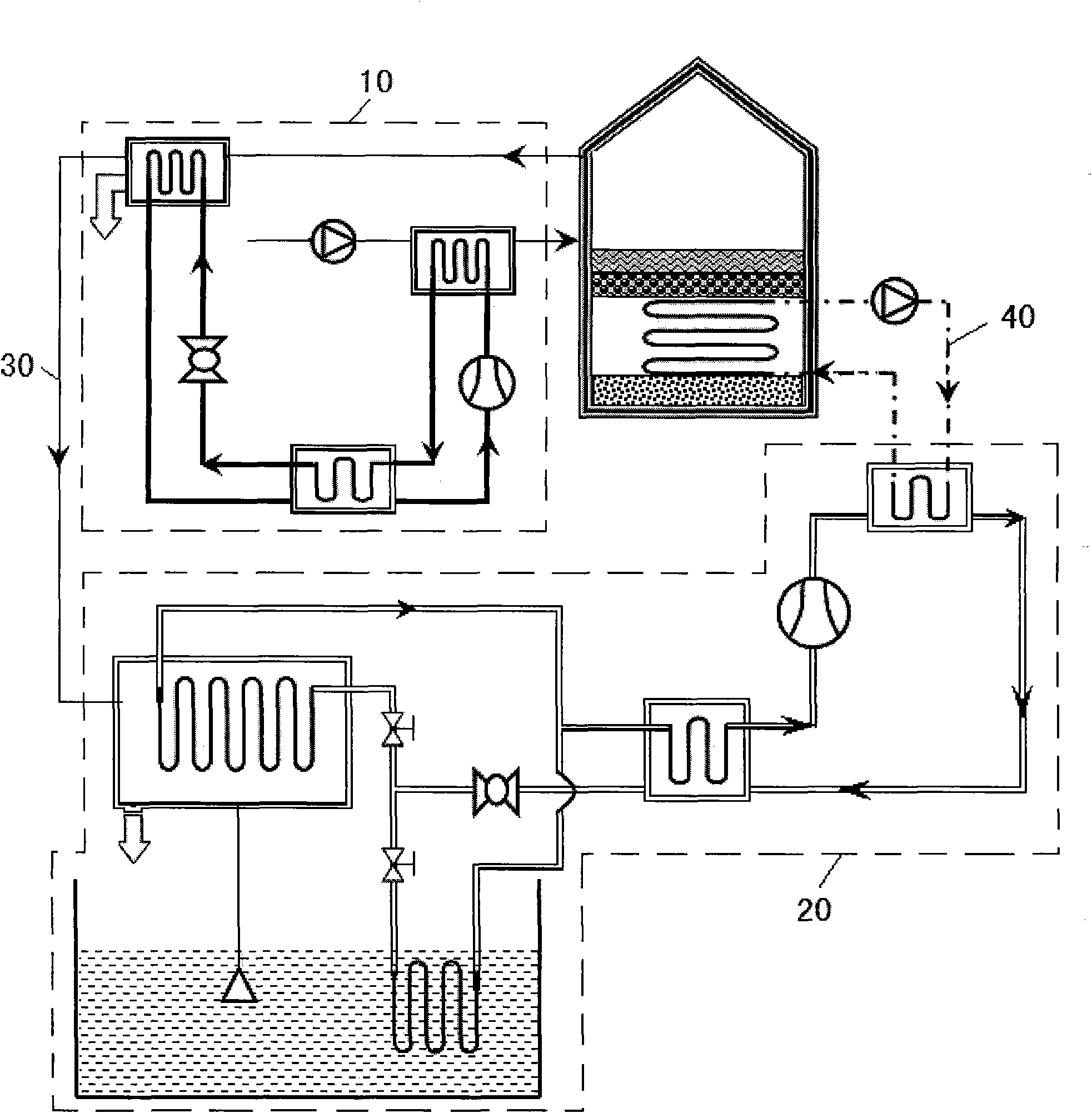

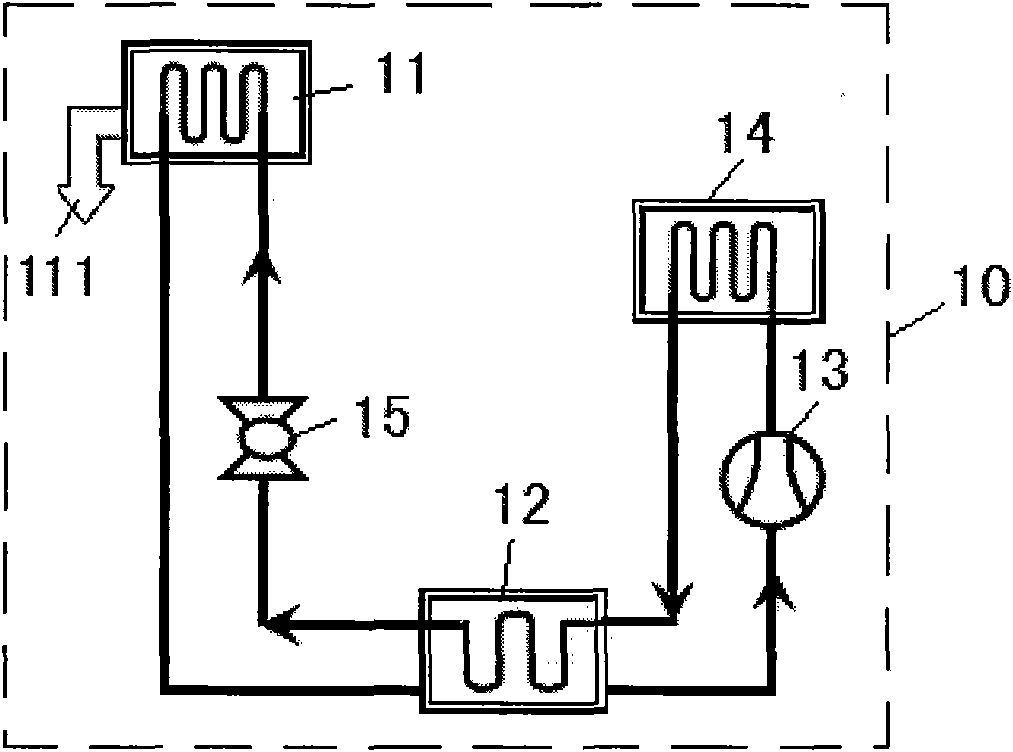

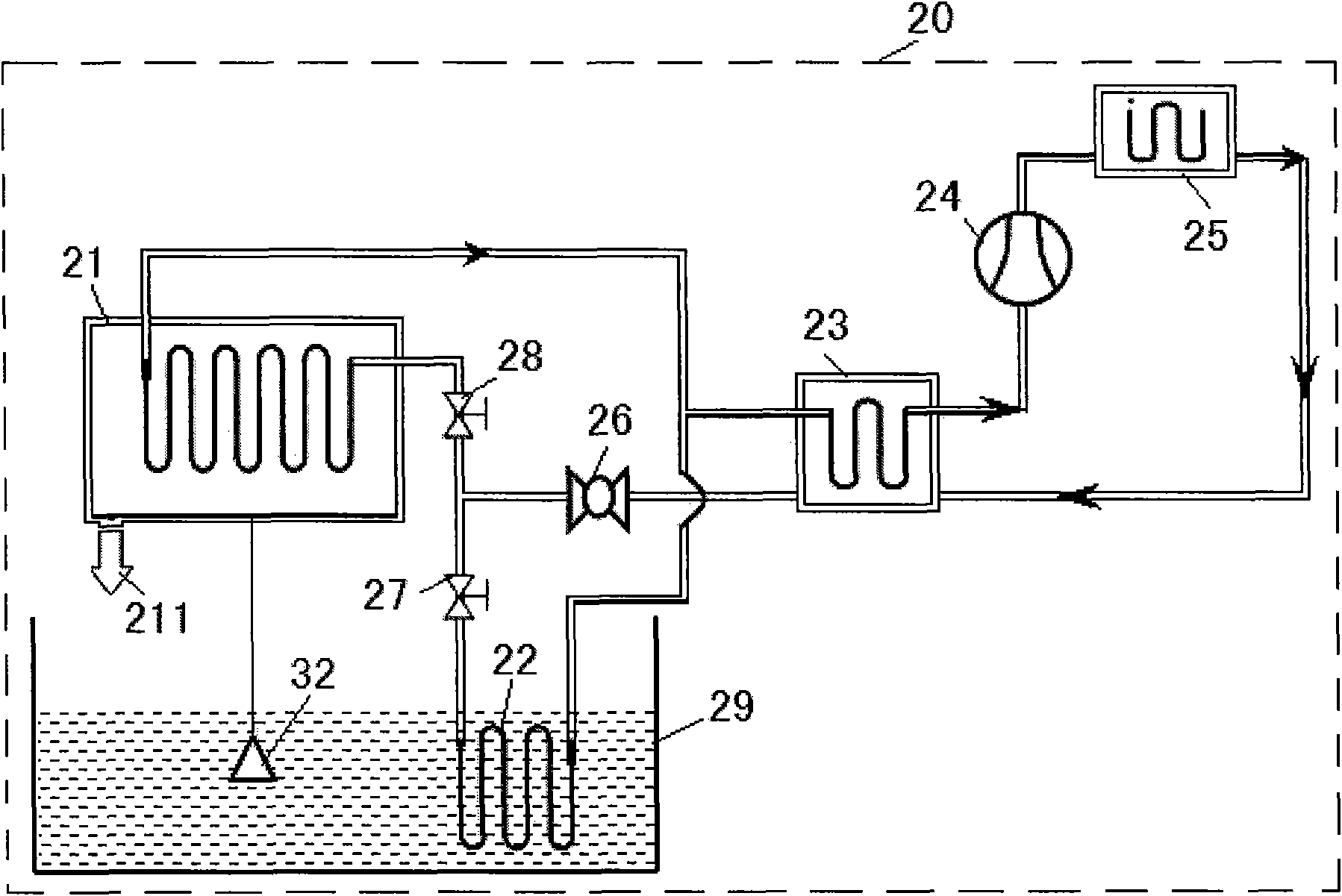

ActiveCN101618930AHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port, a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

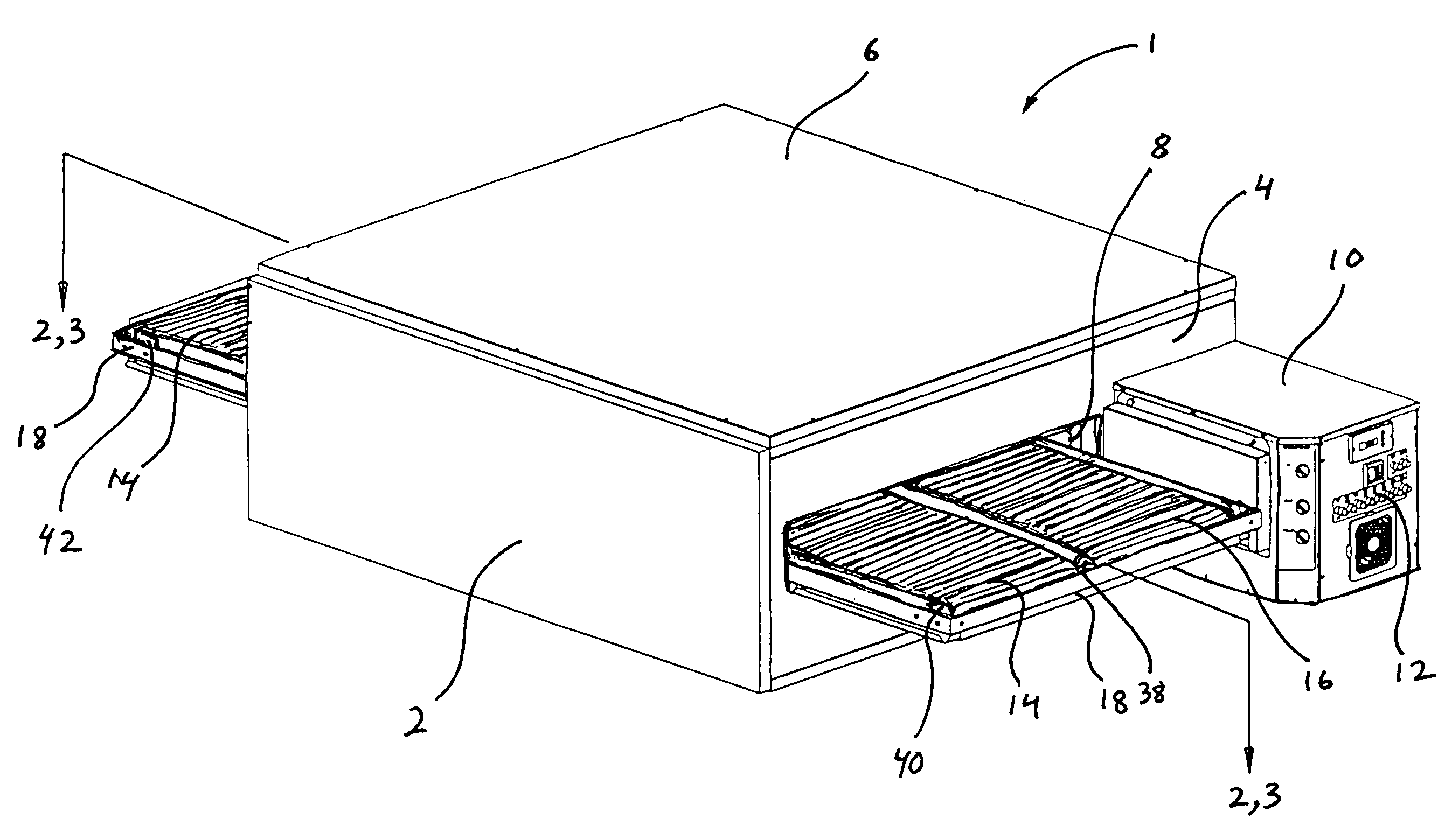

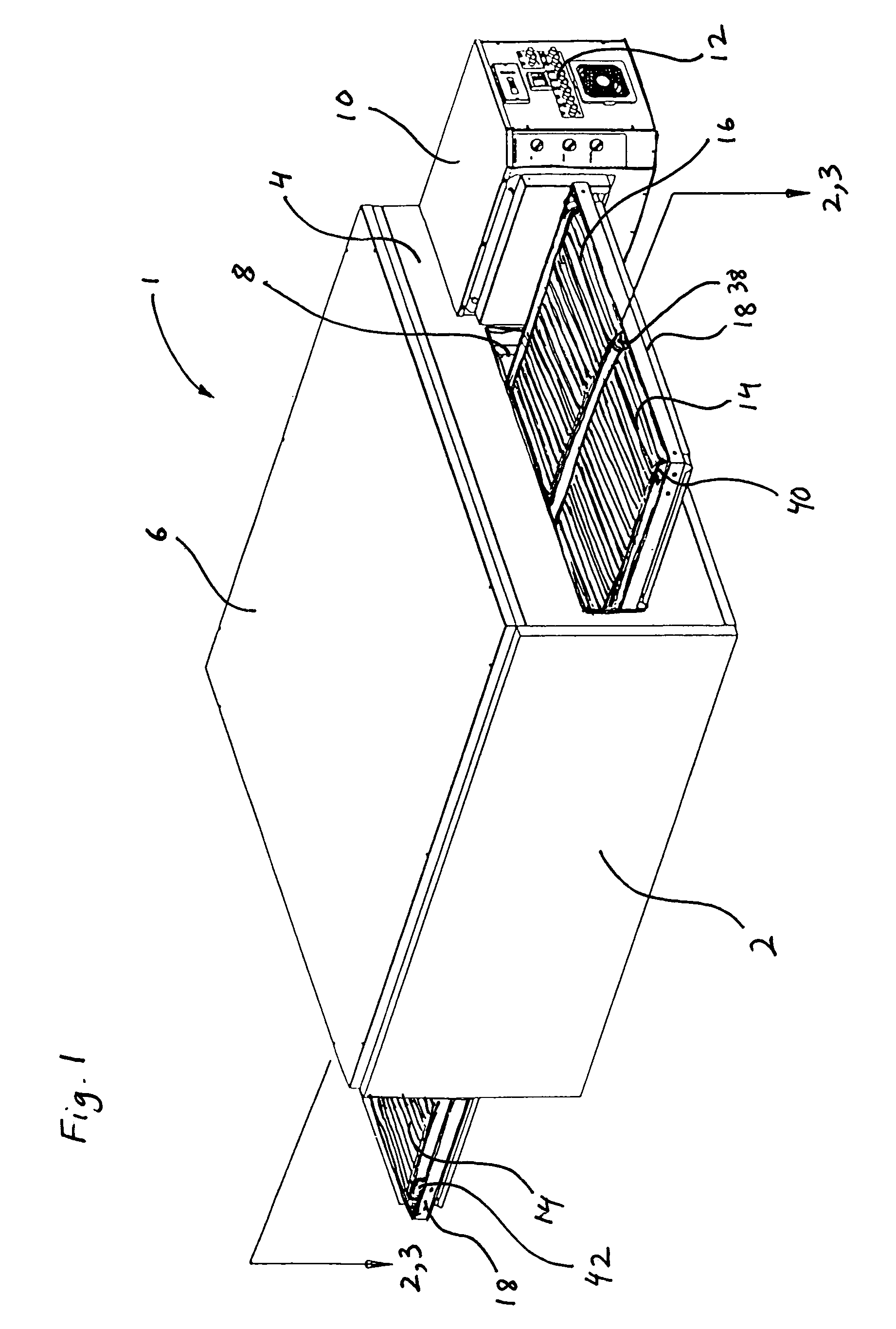

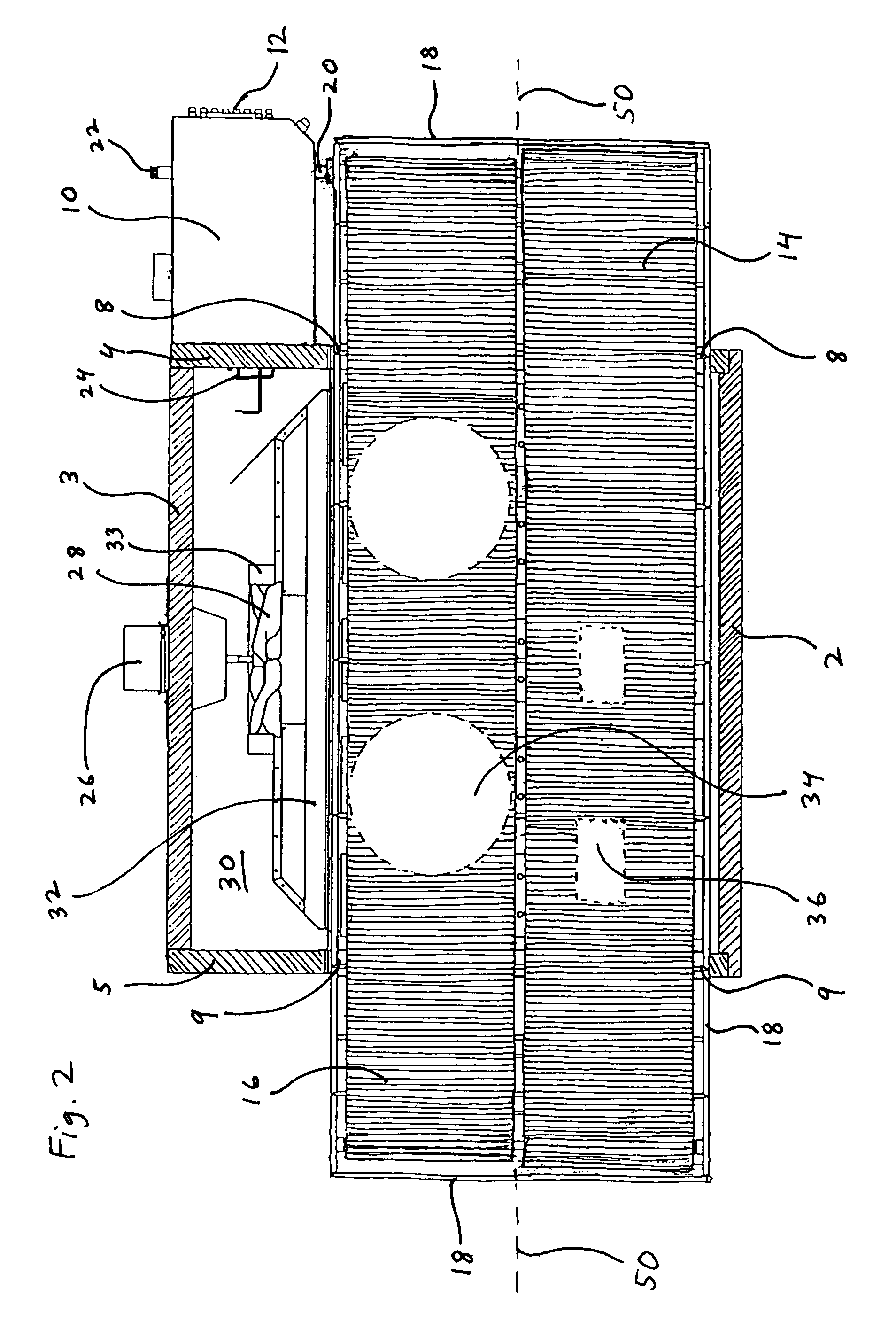

Dual belt conveyor oven

ActiveUS7340992B1Easy maintenanceIncrease frictionDomestic stoves or rangesLighting and heating apparatusInterior spaceAir blower

An air impingement conveyor oven including a baking case having an interior space, a food input port, a food output port, and having a longitudinal axis extending from the food input ports to the food output port; an air heating gas burner connected operatively to the baking case for heating air within the interior space; a plurality of air registers mounted within the baking case's interior space, the air registers being positioned longitudinally along the baking case's longitudinal axis; an air blower mounted within the baking case's interior space; a network of air ducts interconnecting the air registers and the air blower; left and right conveyor belts extending along the baking case's longitudinal axis and being respectively positioned leftwardly and rightwardly from the longitudinal axis; a first roller mounted intersectingly across the baking case's longitudinal axis, the first roller being frictionally engaged with the left and right conveyor belts, the first roller being annularly coffered at said axis; and an electric motor connected operatively to the first roller.

Owner:WOLFE ELECTRIC

Water filtering air purifier

InactiveCN103721507AWith air heating functionTake advantage ofCombination devicesHEPAActivated carbon filtration

The invention relates to the technical field of air purification, in particular to a water filtering air purifier. An exhaust fan sucks outdoor air, the outdoor air is filtered by a hair dust pre-filter screen, a harmful gas formaldehyde filter screen, an activated carbon filter screen and an HEPA filter screen, the filtered outdoor air is conveyed to a seventh ventilation layer, the air pressure of the seventh layer is increased, a one-way air valve layer is opened through pressure, the filtered outdoor air enters a water filtering layer, and reaches the fourth ventilation layer after water filtering, air contains moisture, and is dehumidified by a third humidify filter screen layer, and the dehumidified air enters a second ventilation layer, an exhaust hole is connected to the second ventilation layer, and the purified air is conveyed indoors through the exhaust hole. The air purifier also has the air heating function, and provides warm air while enabling indoor air to be purified.

Owner:肖美汉 +2

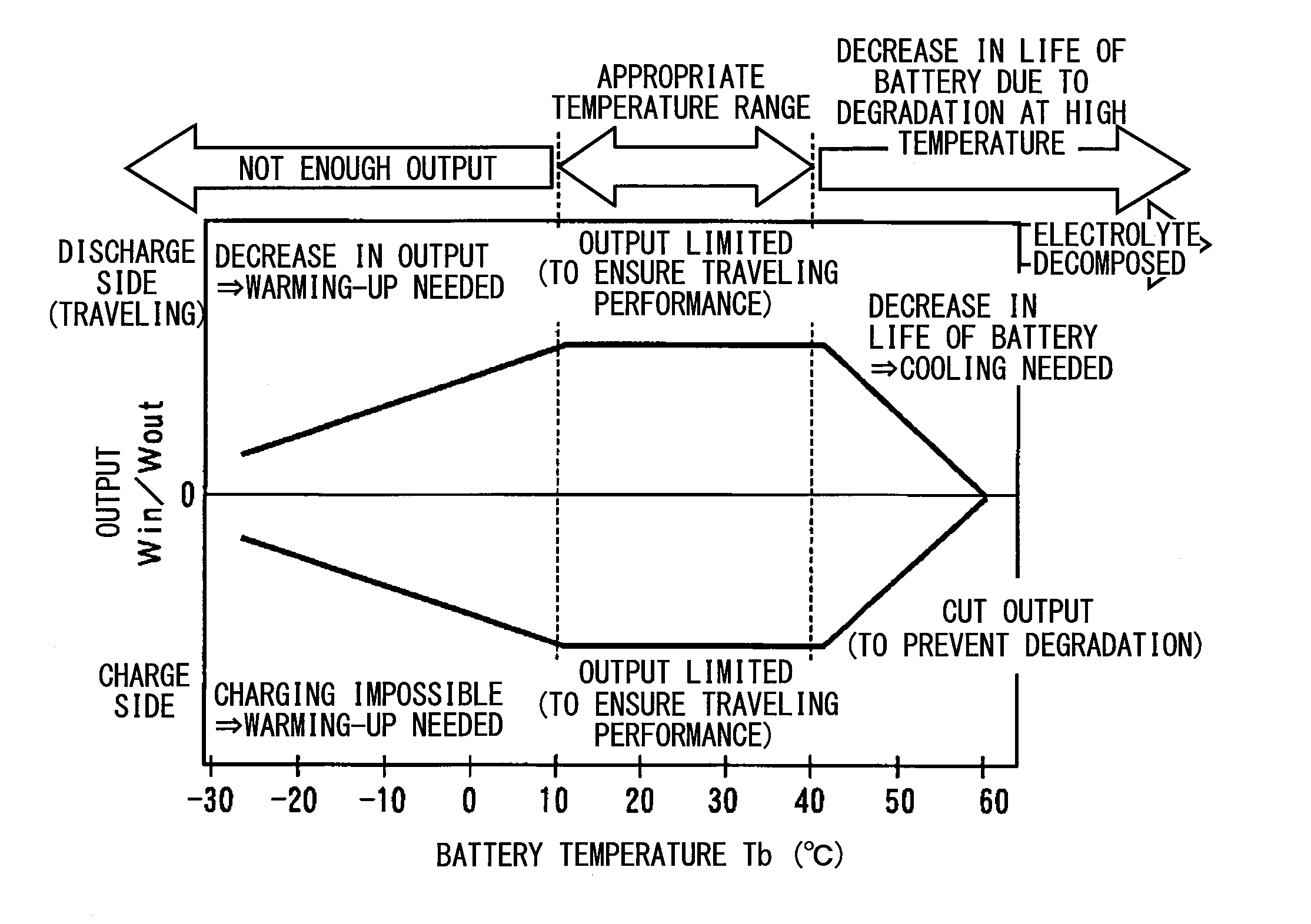

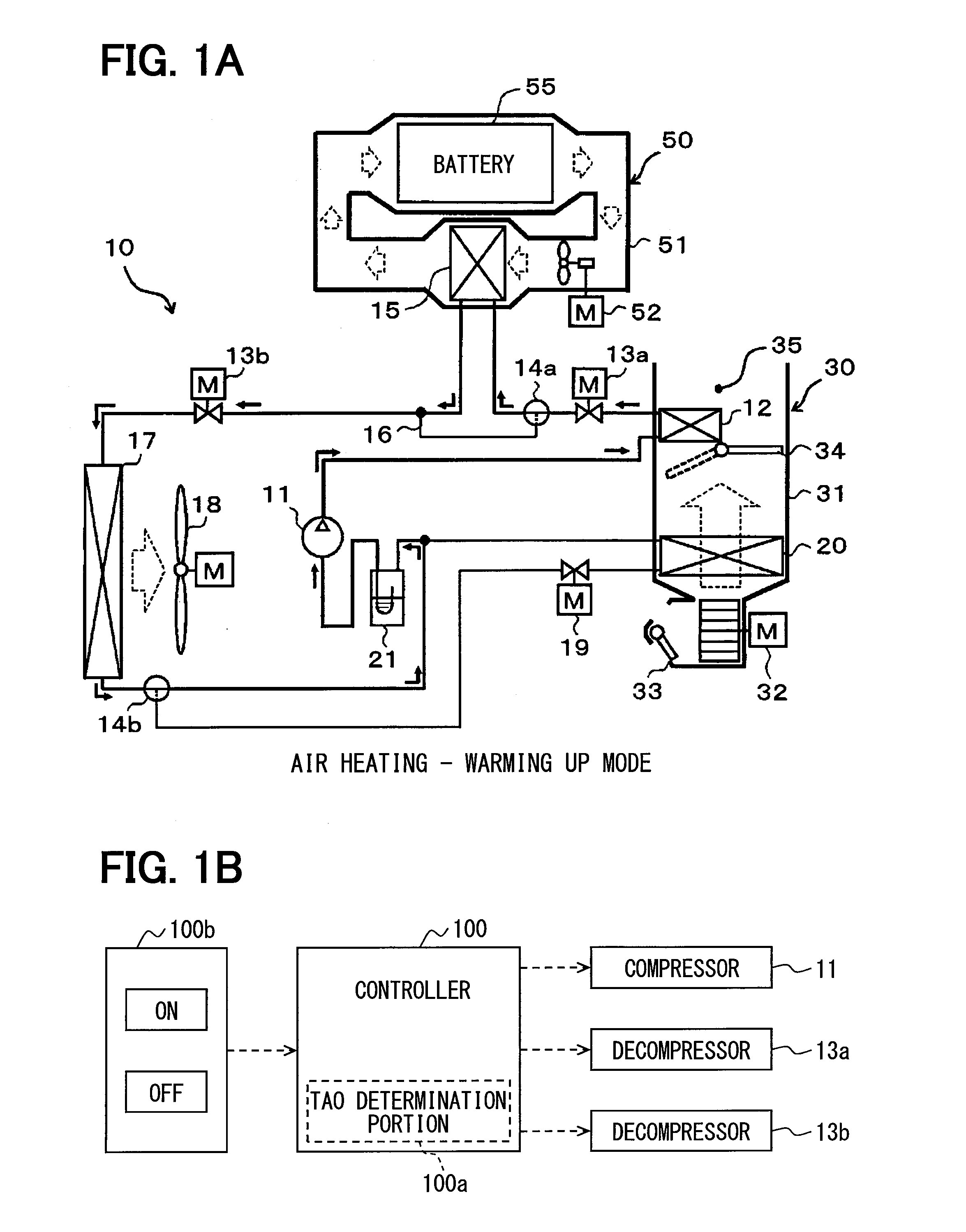

Refrigeration cycle device

ActiveUS20150191072A1Reduce the temperatureReduction in size of accumulatorMechanical apparatusEvaporators/condensersEngineeringAir conditioning

A refrigeration cycle device includes an air heat exchanger that heats air to be blown into an interior of a vehicle compartment using refrigerant discharged from a compressor, a high-stage side expansion valve decompressing the refrigerant flowing out of the air heat exchanger, and a battery heat exchanger that heats air to be blown to a battery using the refrigerant decompressed by the high-stage side expansion valve. In an air heating-warming up mode of heating the air for the interior and the air for the battery, a refrigerant discharge capacity of the compressor is controlled such that an air temperature for the interior approaches a target air temperature, and an opening degree of the high-stage side expansion valve is controlled such that a battery temperature becomes within a predetermined reference temperature range. A selector switch allows a passenger to select which operation of air conditioning or warming-up is prioritized.

Owner:DENSO CORP

Processing method for preparing phosphate rock powder into pellet yellow phosphorus charge

ActiveCN102701164AIncrease the content of phosphorus pentoxideHigh strengthPhosphorus compoundsPhosphateBall mill

The invention provides a processing method for preparing phosphate rock powder into pellet yellow phosphorus charge. For producing 1000kg of yellow phosphorus pellet charge, 1000kg of the phosphate rock powder, 100kg of humic acid and 20kg of sodium hydroxide are adopted. The preparation method comprises the following steps of: adding the phosphate rock powder (100 meshes) into a binding agent combined by the humic acid and the sodium hydroxide, uniformly stirring, pressing into pellets by a ball press, rolling by a disc pelletizer for ejection, entering an air heating furnace for preliminary drying, entering a vertical kiln for through drying, and then further entering a rotary kiln for performing high-temperature calcination treatment at the temperature of 1100 DEG C-1200 DEG C so as to obtain a yellow phosphorus charge finished product. According to the processing method provided by the invention, the phosphate rock powder is utilized, the 100-mesh phosphate rock powder is finely ground by a ball mill and pressed into the pellet-like yellow phosphorus charge finished product via the binding agent; and compared with lump ore charge, the removal rate of harmful carbonate impurities can be up to 95%, the power consumption per ton of yellow phosphorus is reduced by 35%, the discharge of pollutants is reduced, and the production cost is lowered. The processing method is the excellent processing method for producing yellow phosphorus by utilizing the phosphate rock powder in China at present.

Owner:瓮安烨烨磷化工实业有限公司

Severely-polluted soil remediation device

InactiveCN104307863AAchieve emission standardsEffective repair processDispersed particle separationContaminated soil reclamationPollution soilEnvironmental engineering

The invention provides a severely-polluted soil remediation device. The severely-polluted soil remediation device comprises a soil adding and discharging system, a soil heating and stirring system and a volatile waste gas purification system, wherein the soil adding and discharging system comprises a soil discharging inclined hopper, a soil barrel and a soil adding opening; the soil heating and stirring system comprises an air inlet pipe, an air heating system, a stirring motor, a stirring transmission shaft and stirring blades; the volatile waste gas purification system sequentially comprises a volatile waste gas oxidization and absorption region, a volatile waste gas alkalization and absorption region, a demister, a volatile waste gas acidification and absorption region, an active carbon adsorption layer and an exhausting fan from bottom to top; or the volatile waste gas purification system sequentially comprises the volatile waste gas oxidization and absorption region, the volatile waste gas acidification and absorption region, the demister, the volatile waste gas alkalization and absorption region, the active carbon adsorption layer and the exhausting fan from bottom to top.

Owner:CHANGZHOU UNIV

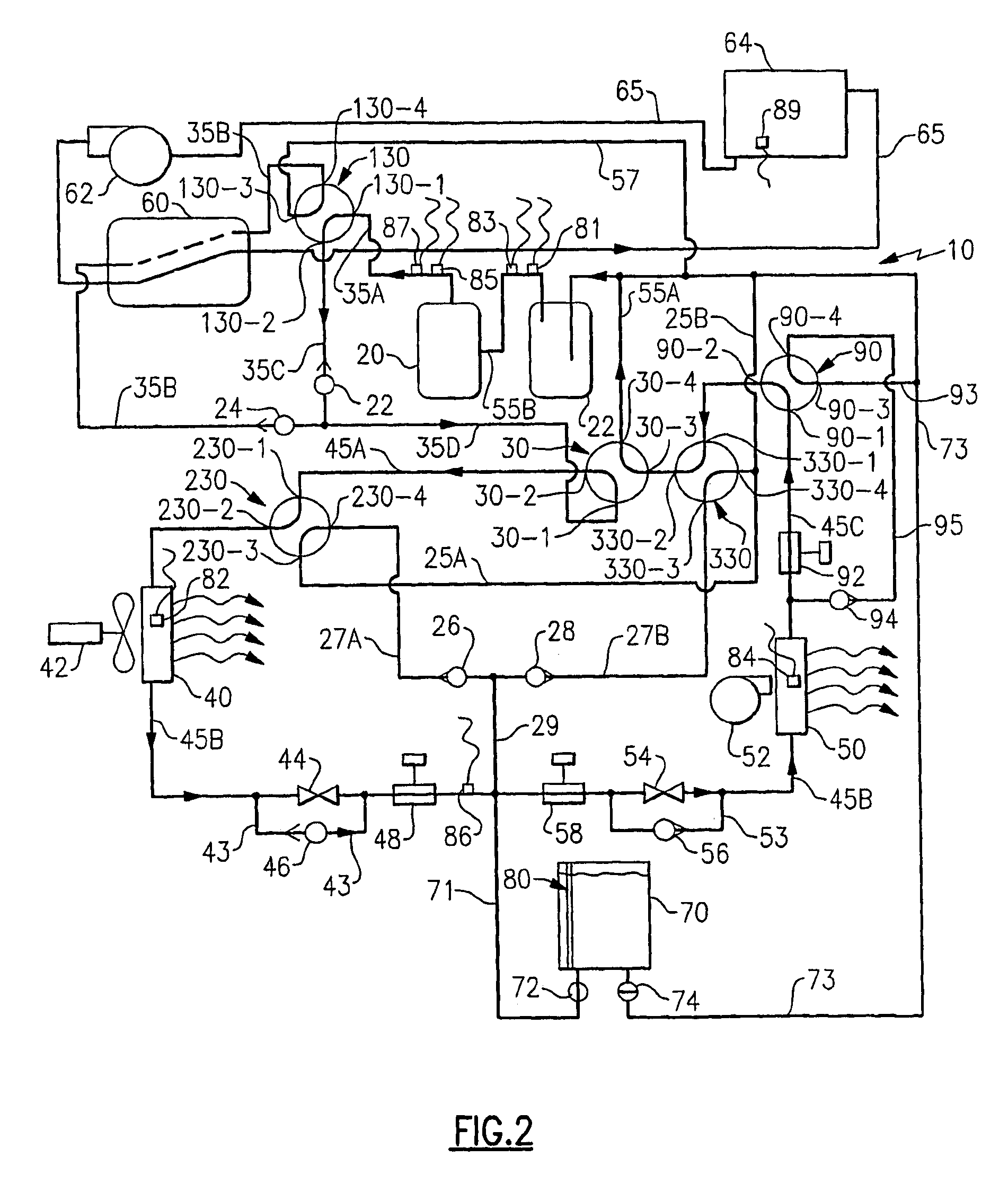

Heat pump system with auxiliary water heating

InactiveUS8220531B2Improved refrigerant charge controlLevel controlDesuperheatersEngineeringHeat pump

A heat pump system (10) includes a compressor (20), a reversing valve (30), an outdoor heat exchanger (40) and an indoor heat exchanger (50) coupled via refrigerant lines (35, 45, 55) in a conventional refrigeration circuit, and a refrigerant-to-water heat exchanger (60). In the air cooling with water heating mode, the air heating with water heating mode and the water heating only mode, water from a water reservoir (64), such as a storage tank or swimming pool, is passed through heat exchanger (60) in heat exchange relationship with refrigerant passing through line (35). A refrigerant reservoir (70) may be provided for use in refrigerant charge control. A refrigerant line (71) couples reservoir (70) to the refrigerant circuit intermediate the outdoor and indoor heat exchangers for directing liquid refrigerant into the reservoir (70) and a refrigerant line (73) couples the refrigerant circuit upstream of the suction inlet to the compressor (20) for returning refrigerant to the refrigerant circuit. A controller (100) controls flow into and from the refrigerant reservoir (70) through selective opening and closing of control valve (72) in line (71) and control valve (74) in line (73).

Owner:CARRIER CORP

Highly-efficient gas-water hybrid solar heat collector and application thereof

InactiveCN102141304AOvercome the shortcoming of single functionIncrease disturbanceSolar heating energySolar heat devicesGlass coverLow emissivity

The invention belongs to the field of energy conservation, and in particular relates to a highly-efficient gas-water hybrid solar heat collector and application thereof. In the invention, the form of a traditional panel type solar water heater is utilized, a full copper heat collecting plate is formed by splicing tube plate type heat collecting strips, a secondary tube at the back of each heat collecting strip is respectively connected with an upper main tube and a lower main tube, and a high-absorptivity and low-emissivity selective coating is sprayed on the front surface of each heat collecting strip. Simultaneously, a space between the heat collecting plate and a glass cover plate is taken as an air flow channel and is uniformly provided with four glass baffles such that the residence time of the air in the heat collector is prolonged and the air turbulence in a chamber is strengthened. When the highly-efficient gas-water hybrid solar heat collector is applied to a highly-efficient gas-water hybrid solar heat collecting system, hot water flows in copper tubes at the back of the heat collecting plate, the air flows in the chamber between the heat collecting plate and the glass cover plate, and the hot water and the air are not interfered mutually, thus the highly-efficient gas-water hybrid solar heat collector disclosed by the invention can be used for heating water for daily life in summer, heating the air for heating or drying in winter and simultaneously heating the water and the air in spring and autumn, and the annual utilization rate of the heat collector is increased; in addition, the problem that a solar air heating system is overheat in summer is solved at the same time.

Owner:TONGJI UNIV

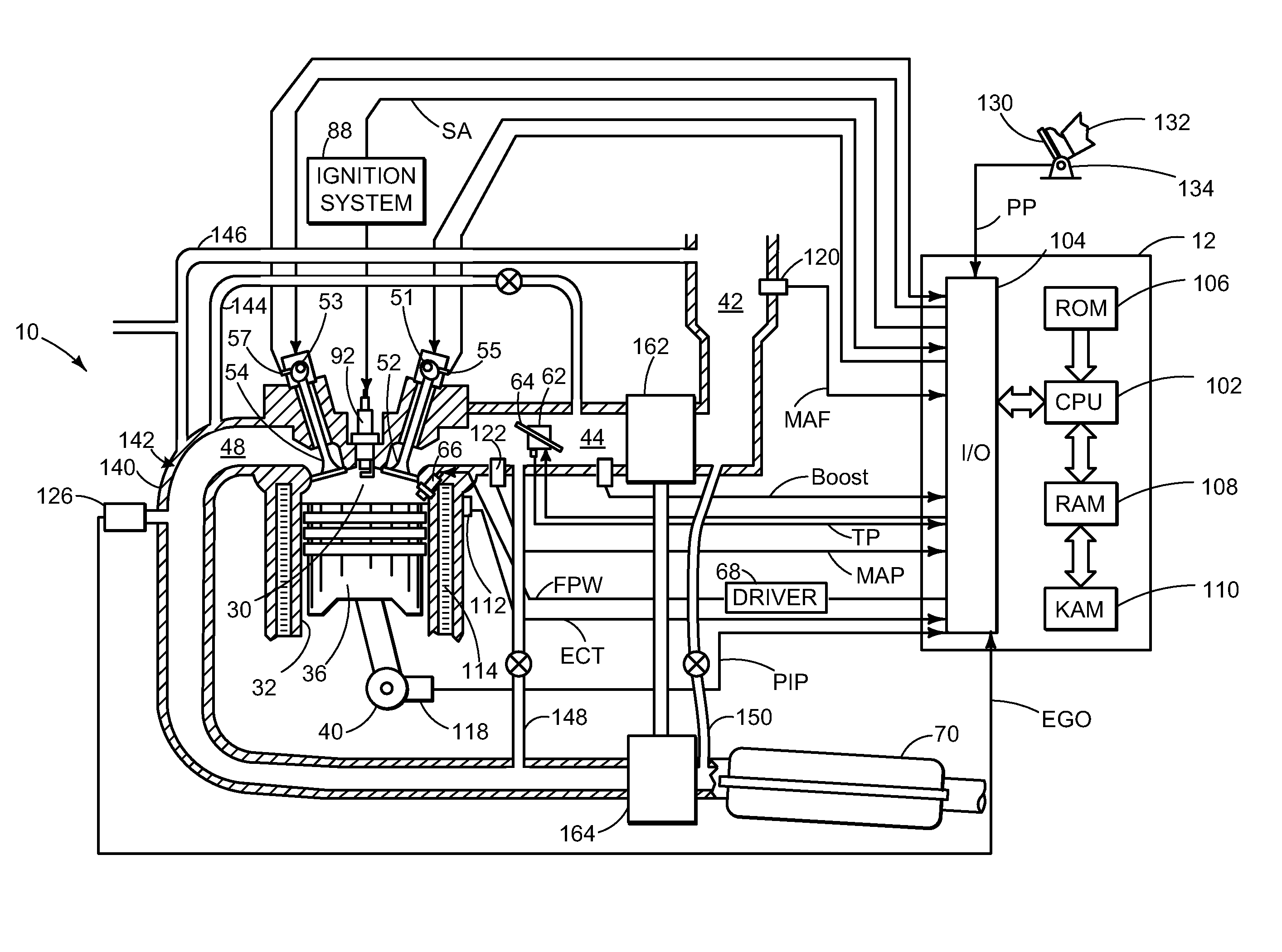

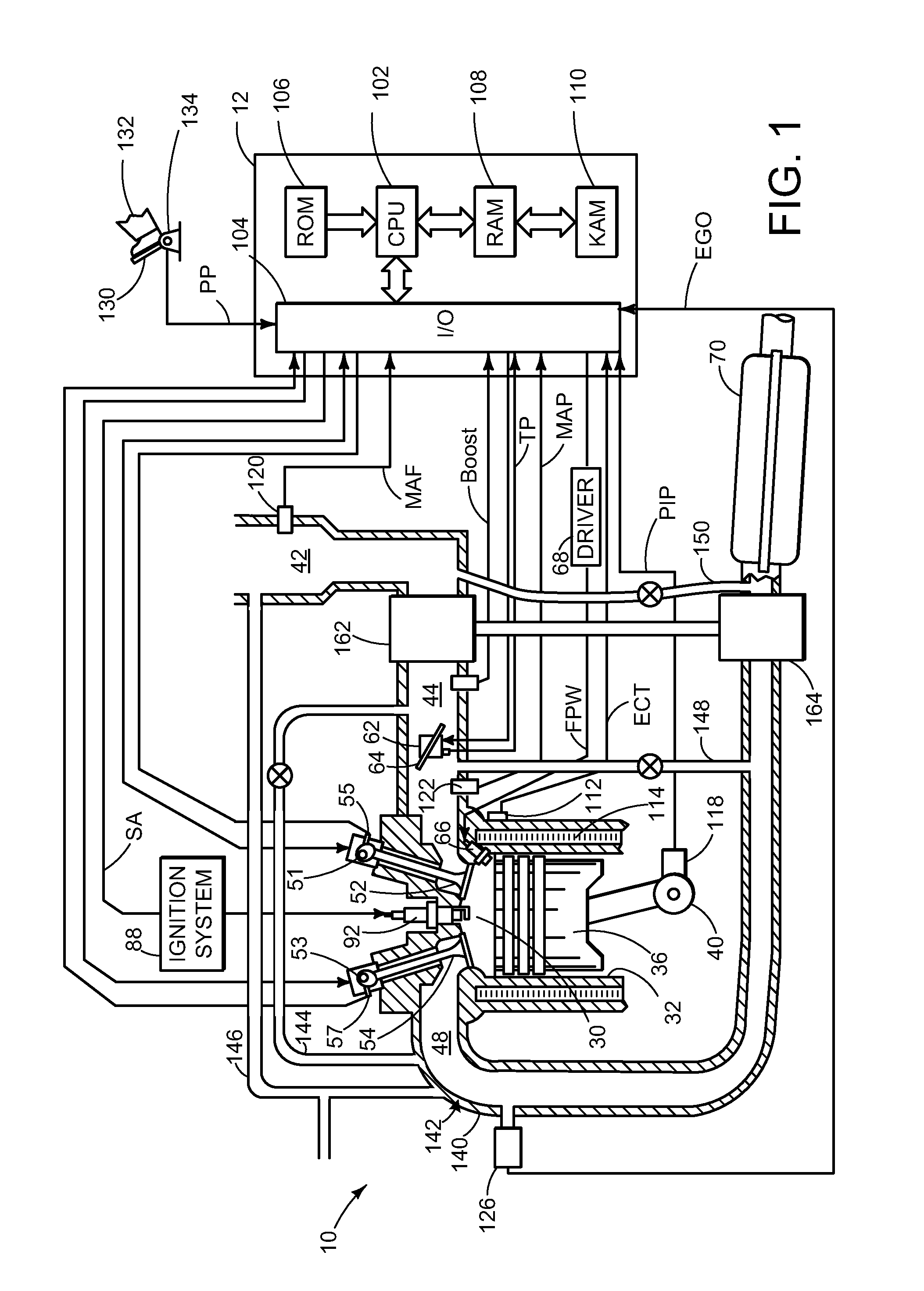

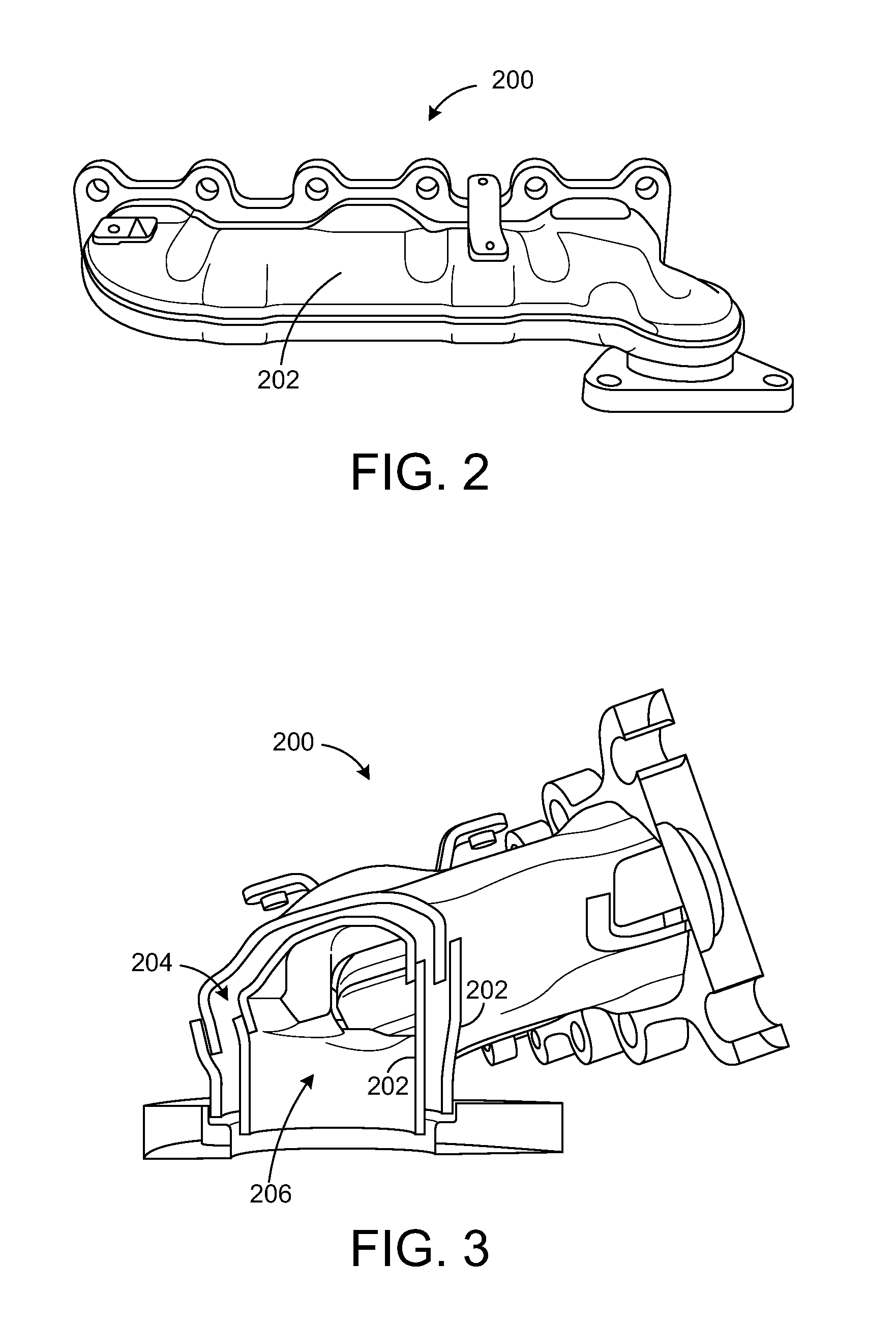

Intake air heating and exhaust cooling

ActiveUS20110138774A1Fuel economyReduced pumping lossesNon-fuel substance addition to fuelInternal combustion piston enginesDouble wallPlate fin heat exchanger

Intake air heating and exhaust cooling is provided by a double wall exhaust system serving as an exhaust-to-air heat exchanger, sourcing hot air to the intake manifold for intake stroke pumping benefit and cooling the exhaust system during high load operation by routing excess boost air through an interstitial space of the double wall.

Owner:FORD GLOBAL TECH LLC

Paperboard film laminating device for paperboard processing

ActiveCN110202907ASave lamination timeImprove production efficiencyLamination ancillary operationsLaminationPaperboardEngineering

The invention discloses a paperboard film laminating device for paperboard processing in the technical field of paperboard processing. The device includes a base. Vertical beams are arranged on the top end of the base. A crossbeam is arranged on the top ends of the vertical beams. The device can carry out film laminating on the upper and lower surfaces of a paperboard at the same time through double film laminating roller structures which are arranged upper-lower symmetric, which saves the film laminating time of the paperboard. The design of elastic connectors makes a film and the paperboardtighter after rolling. The limit mechanism arranged on the two sides of film laminating mechanisms can limit a movement track of the paperboard so as to avoid the problem of inaccurate alignment of the film and the paperboard during film laminating. The spacing of the limit mechanisms is adjustable, which can carry out limiting and righting of paperboards with different width. A roller brush cleaning mechanism can clean dust on the exposed surface of the paperboard before the film laminating, which improves the adhesion effect between the film and the paperboard. An arranged hot-air drying mechanism can carry out hot air heating on the film paper after the film laminating to make the adhesion effect better.

Owner:ZHEJIANG JUDING PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[Air and Water Conditioning System and Filter Media] [Air and Water Conditioning System and Filter Media]](https://images-eureka.patsnap.com/patent_img/7a12db92-c370-467d-80d1-4e4b53e06f22/US20050274663A1-20051215-D00000.png)

![[Air and Water Conditioning System and Filter Media] [Air and Water Conditioning System and Filter Media]](https://images-eureka.patsnap.com/patent_img/7a12db92-c370-467d-80d1-4e4b53e06f22/US20050274663A1-20051215-D00001.png)

![[Air and Water Conditioning System and Filter Media] [Air and Water Conditioning System and Filter Media]](https://images-eureka.patsnap.com/patent_img/7a12db92-c370-467d-80d1-4e4b53e06f22/US20050274663A1-20051215-D00002.png)