Integrated liquid drop microfluidic chip

A microfluidic chip, integrated technology, applied in enzymatic/microbiology devices, biochemical instruments, biochemical equipment and methods, etc. High-sensitivity and high-throughput qualitative and quantitative detection, avoiding the formation of air bubbles, and reducing the effect of sample transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

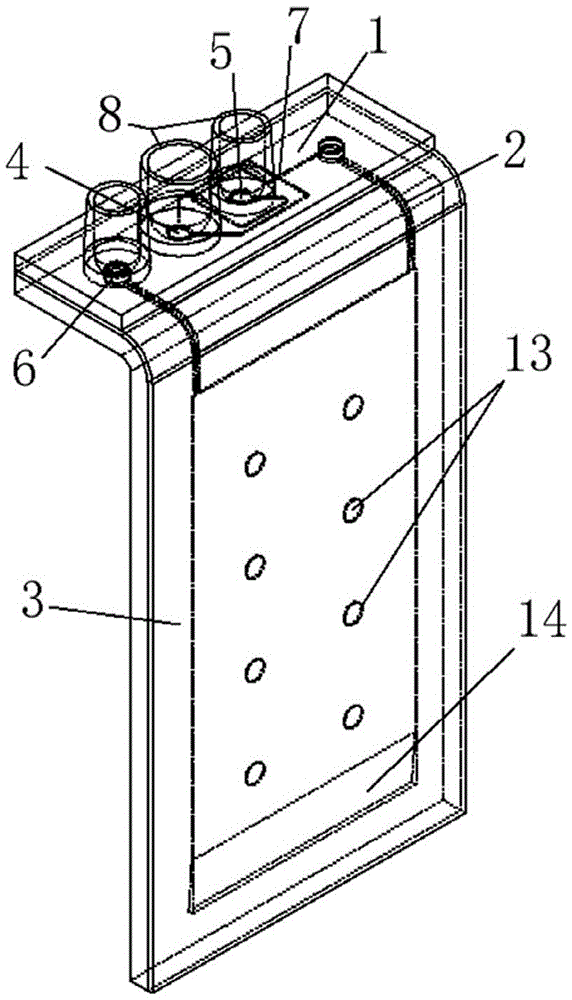

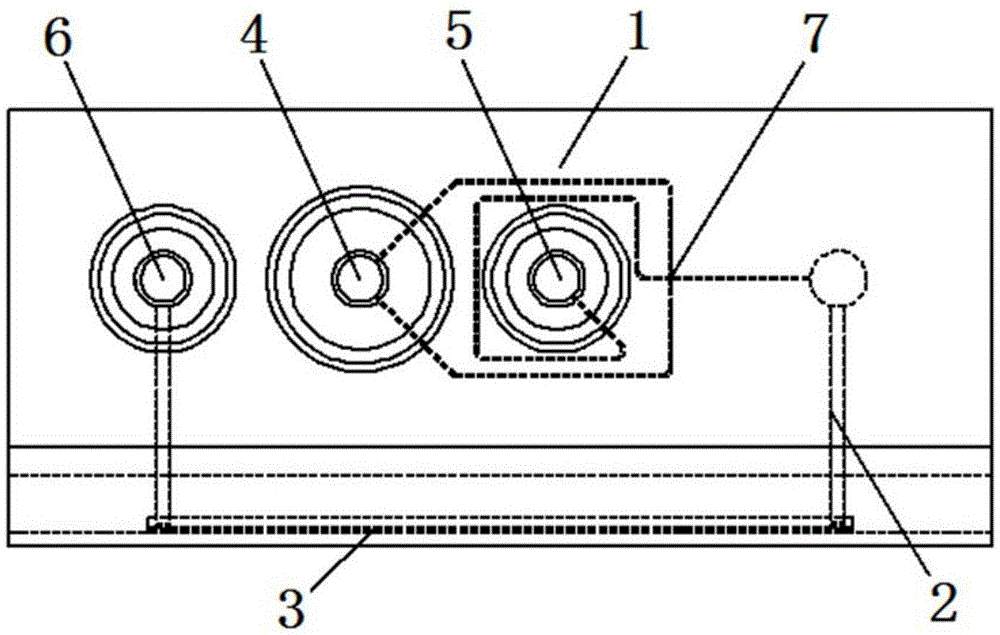

[0030] Example 1, three-dimensional single-channel droplet microfluidic chip: refer to figure 2 3(a), the three-dimensional single-channel droplet microfluidic chip includes a droplet generation structure 1, the droplet generation structure 1 communicates with the collection cavity structure 3 through the connecting channel 2, and the droplet generation structure 1 is provided with a first inlet 4. The second inlet 5 and the microchannel 7, the first inlet 4, the second inlet 5 and the microchannel 7 are connected to each other, the first inlet 4 and the second inlet 5 are respectively integrated with a liquid storage tank 8, connecting the channel 2 Consists of a channel, the outlet of the micro flow channel 7 is connected to the inlet of the collection chamber structure 3 through the connecting channel 2, and the collection chamber structure 3 is provided with an exhaust outlet 6; referring to Fig. 3(b) and Fig. 3(c), the collection The cavity structure 3 includes two oppos...

Embodiment 2

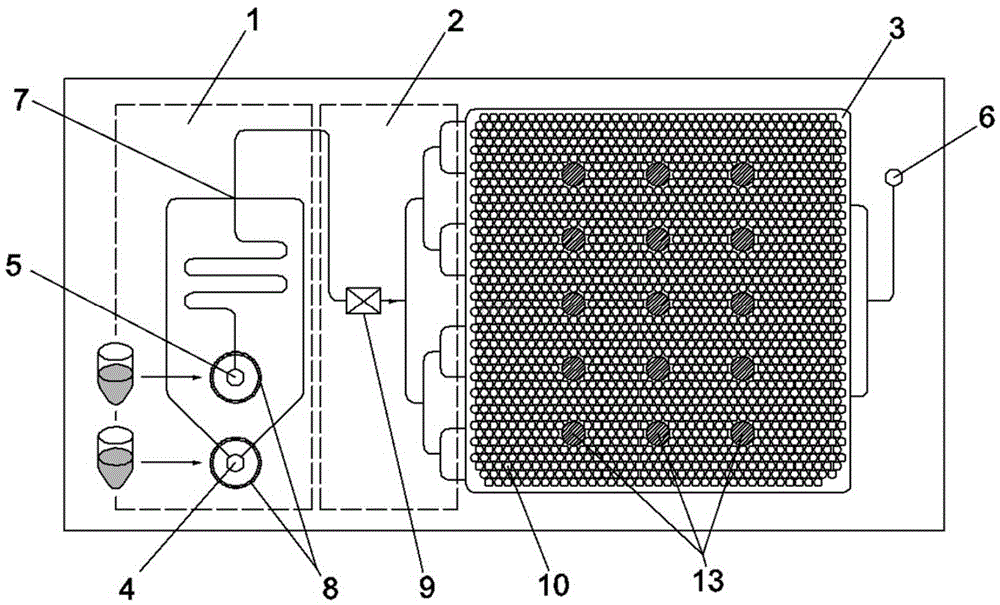

[0033] Example 2, planar multi-channel droplet microfluidic chip: refer to Figure 4 As shown in Figure 5, the planar multi-channel droplet microfluidic chip contains a parallel structure of 4 channels, which are distributed in four radial directions of the disc-shaped chip, and the angle between each other is 90°. The chip of each channel The structures all include a droplet generating structure 1, a connecting channel 2, and a collecting cavity structure 3. The droplet generating structure 1 communicates with the collecting cavity structure 3 through the connecting channel 2. The droplet generating structure 1 includes a first inlet 4, a second The inlet 5 and the microchannel 7 are respectively integrated with a liquid storage tank 8 at the first inlet 4 and the second inlet 5, and the connecting channel 2 is connected to the collection cavity structure 3 by a parallel flow path divided into two and divided into four, It is possible to keep the emulsion flowing synchronousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com