Patents

Literature

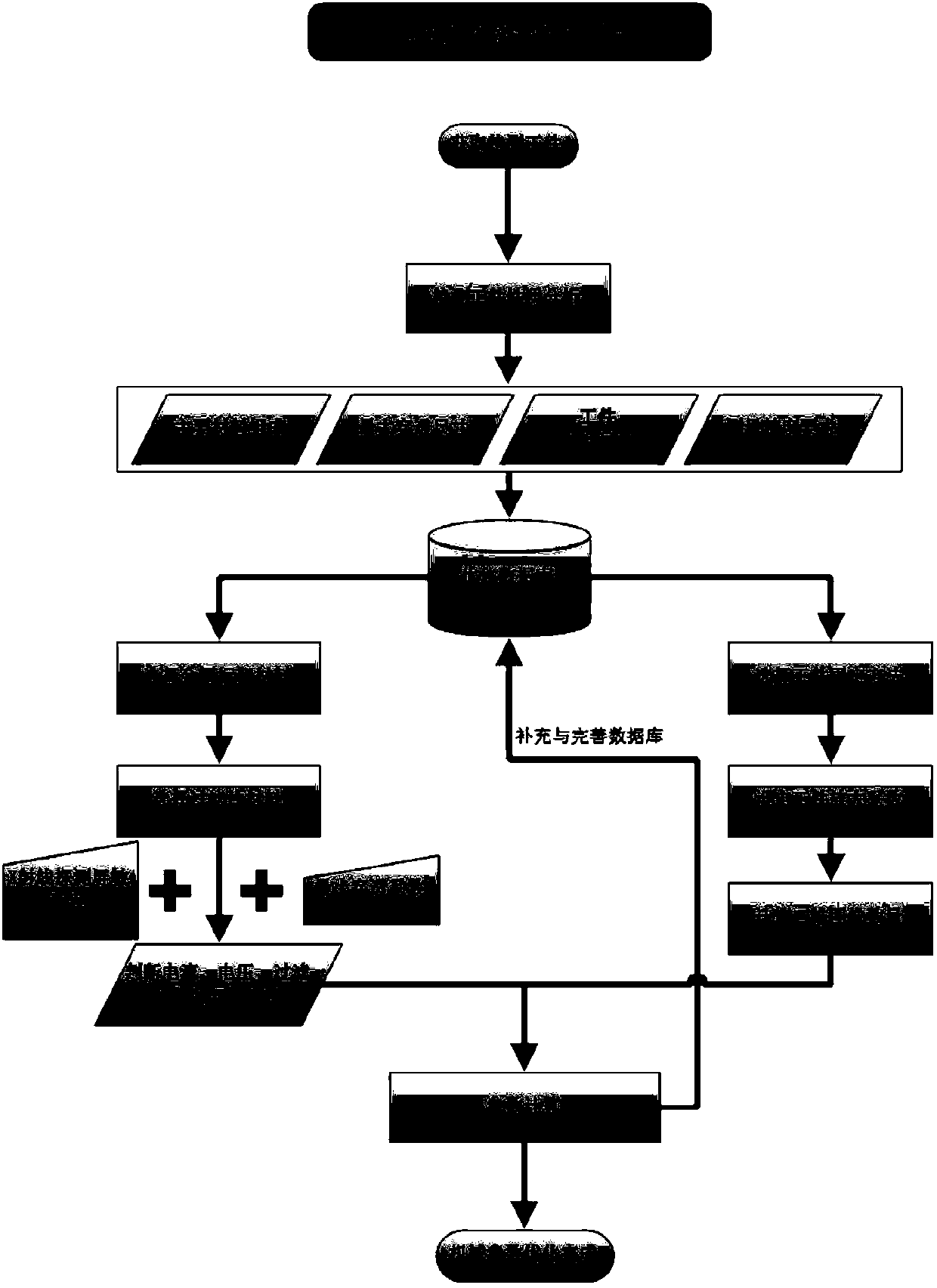

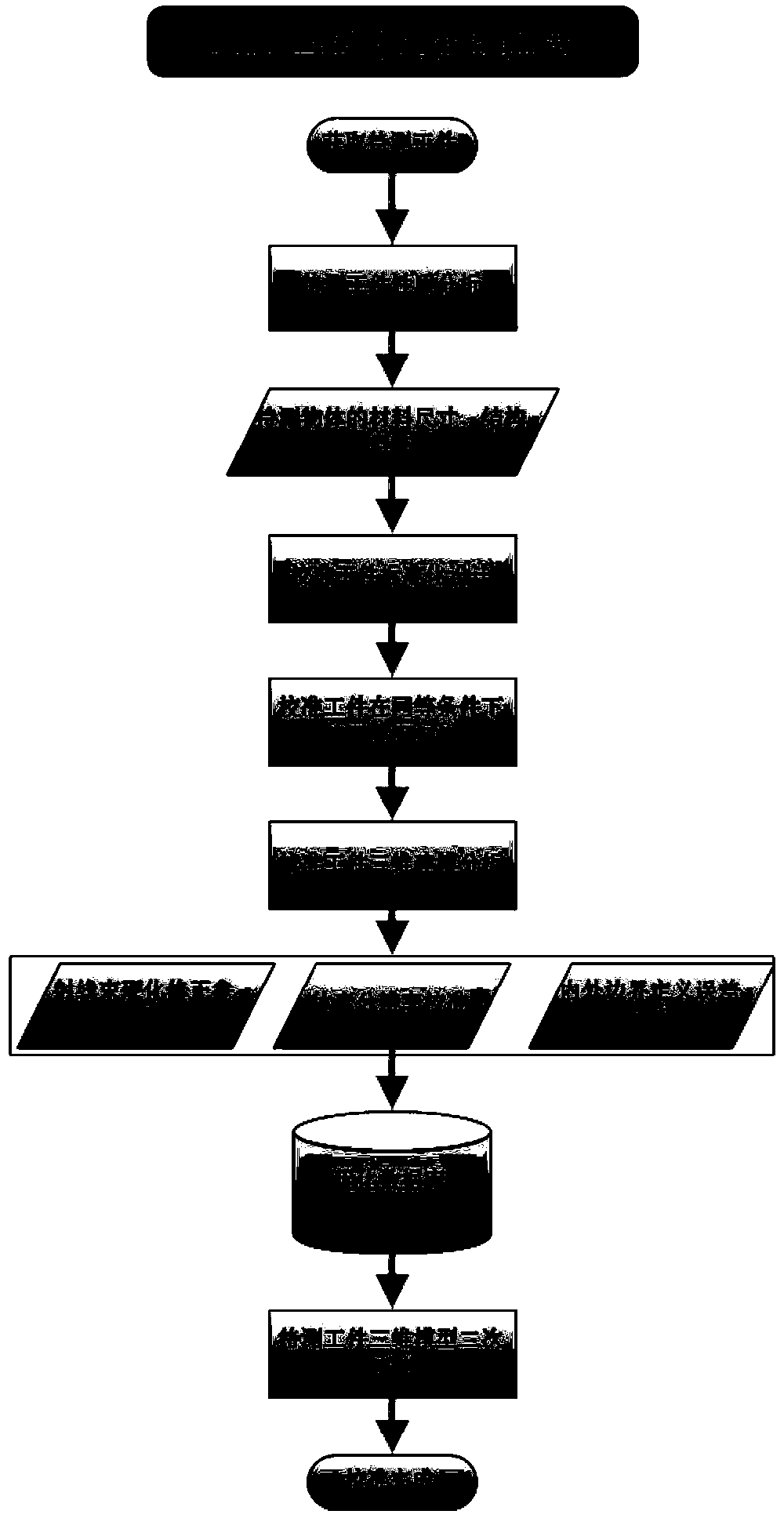

438 results about "Laboratory research" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

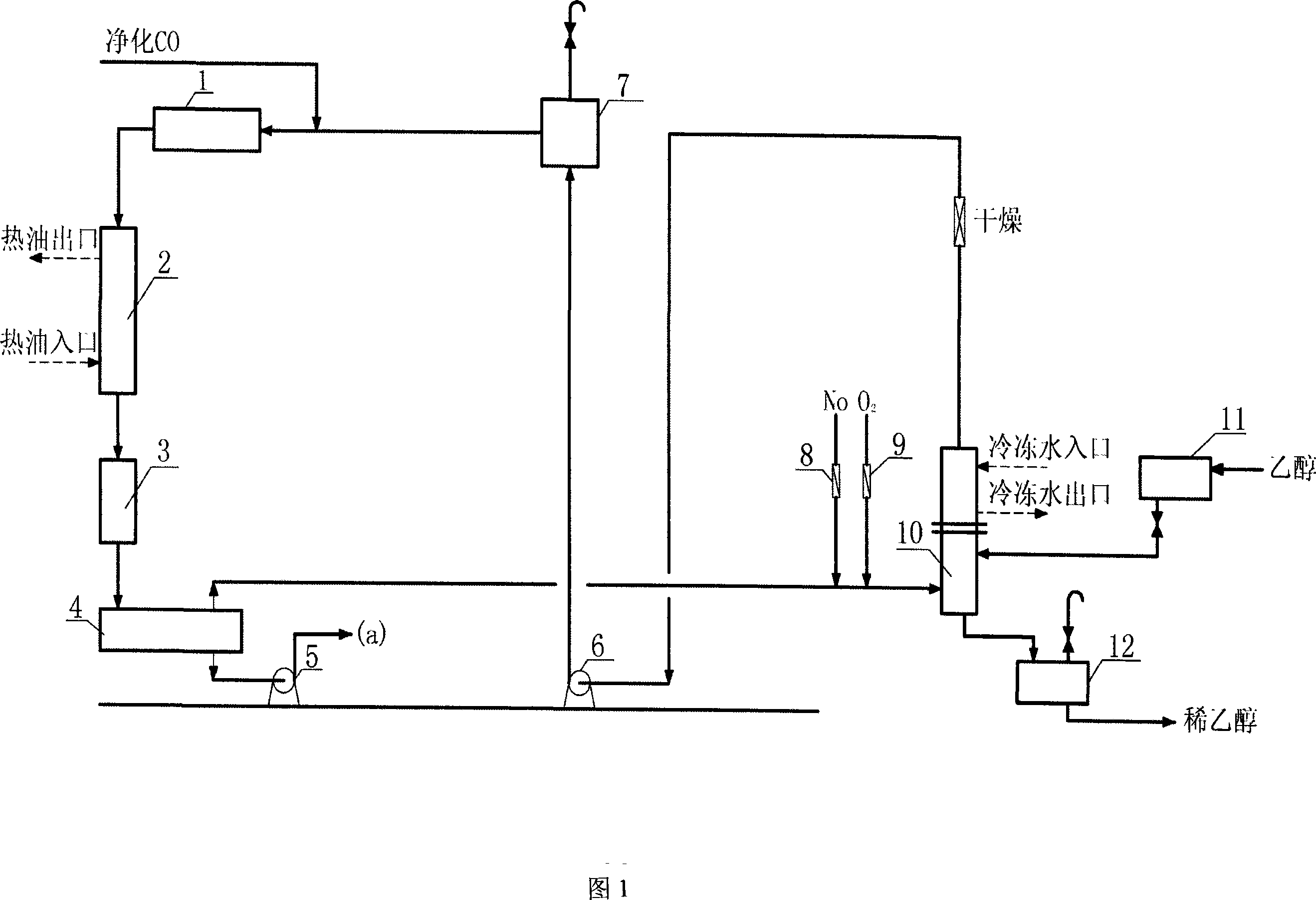

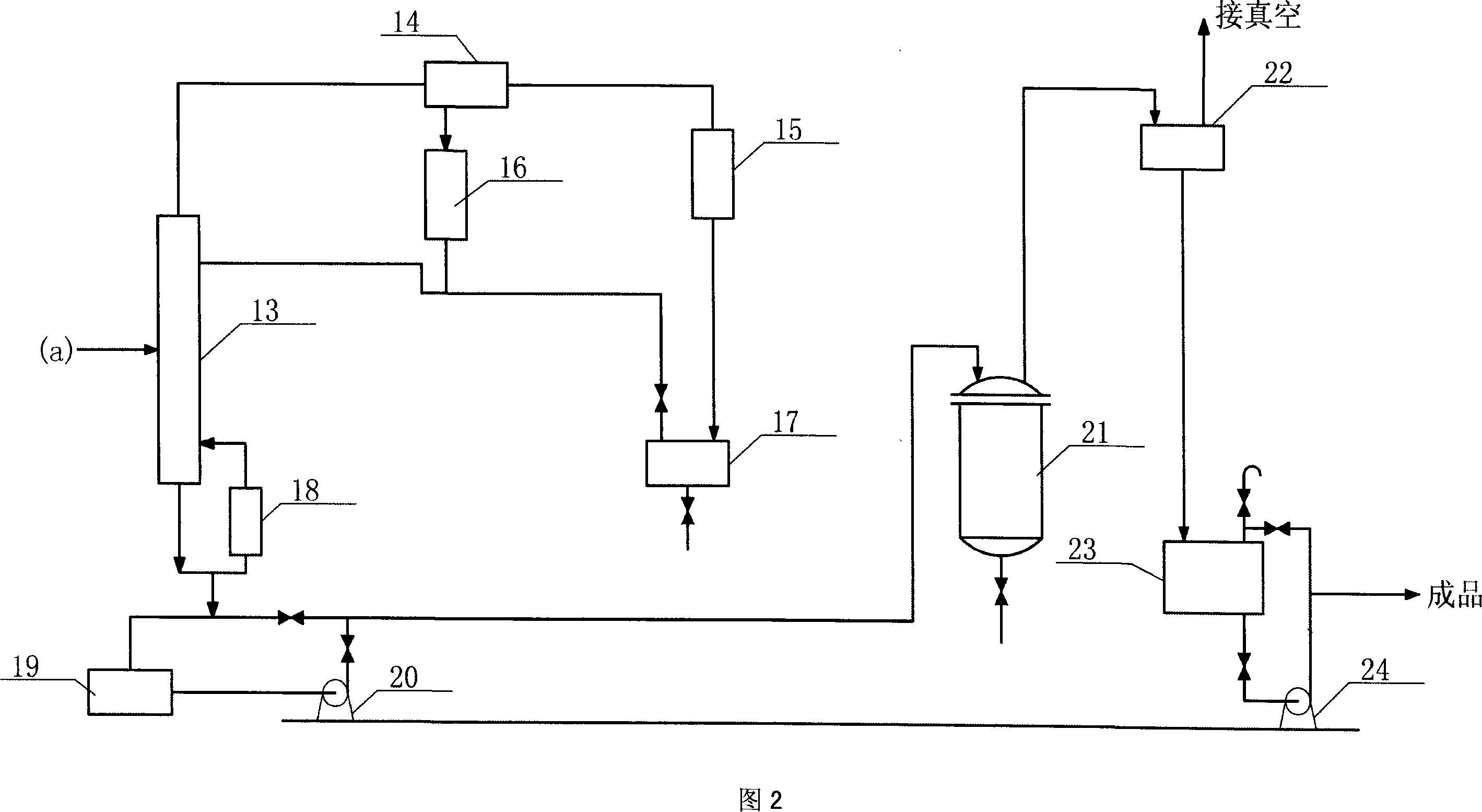

Method for preparing diethyl oxalate by coupling CO

ActiveCN101143821ANo pollution in the processImprove efficiencyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCyclic processContinuous use

The invention discloses a method for preparing diethyl oxalate by CO coupling reaction. By applying a gas phase method, CO is coordinated with ethyl nitrite and is catalyzed by bimetallic supported catalyzer to couplingly generate crude diethyl oxalate, the reaction is a self-sealing circulation process, the CO gas mixed with the ethyl nitrite coming from a regeneration reactor is preheated and then enters into a coupling reactor, after the reaction, the gas is separated by condensation, so that the colorless and transparent condensed diethyl oxalate liquid is produced, and the uncondensed gas containing NO enters into the regeneration reactor to react with ethanol and oxygen in order to generate ethyl nitrite which is again circulated back to the coupling reactor for continuous use. The invention is carried out on the basis of previous laboratory research and under the background of industrial production and fulfils the continuous run examination of the bench scale test and pilot magnification under the condition of industrial operation, the temperature of the coupling reaction is low, and the concentration of products is increased. The method has the advantages of more energy saving, no pollution and high benefit. The total conversion rate of the CO generated by reaction is one hundred percent, and the selectivity of diethyl oxalate is over ninety six percent.

Owner:TIANJIN UNIV

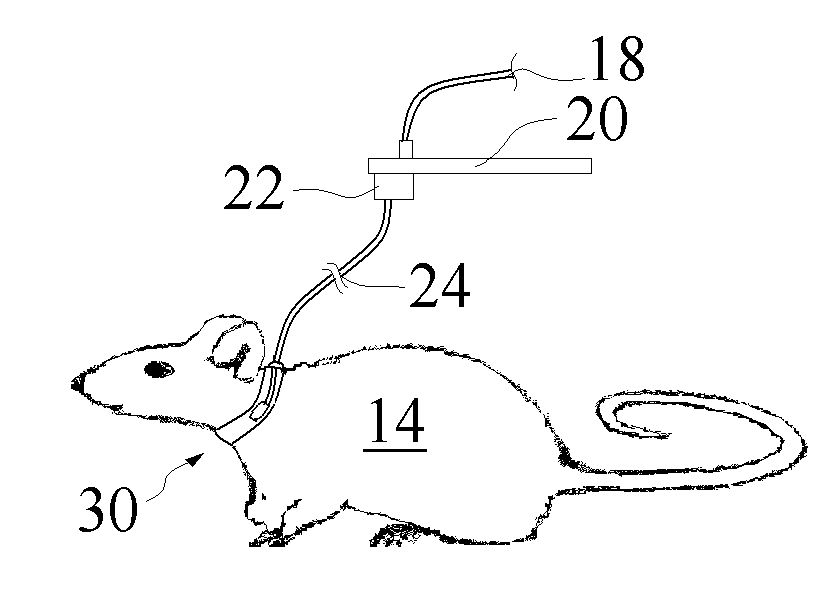

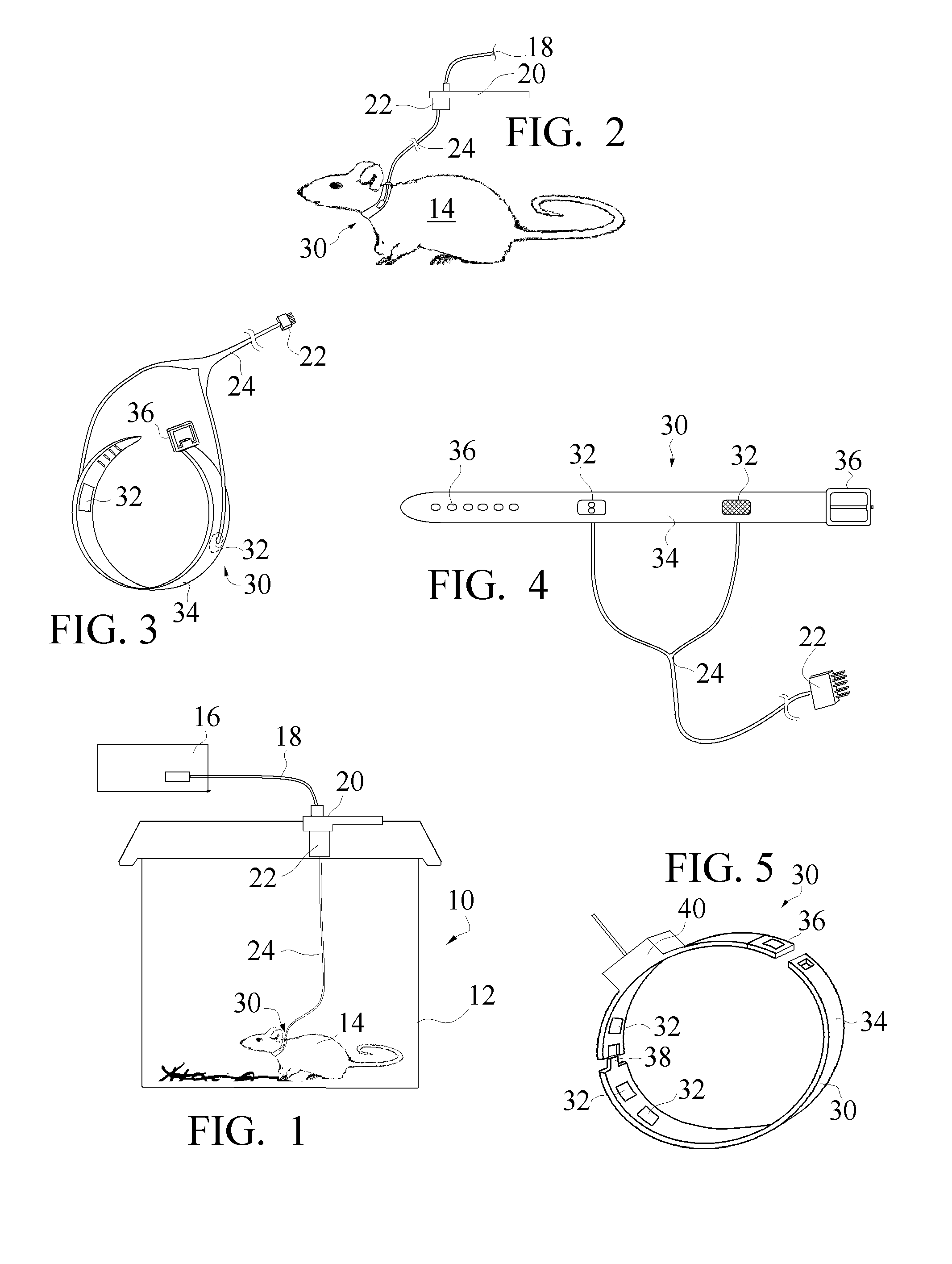

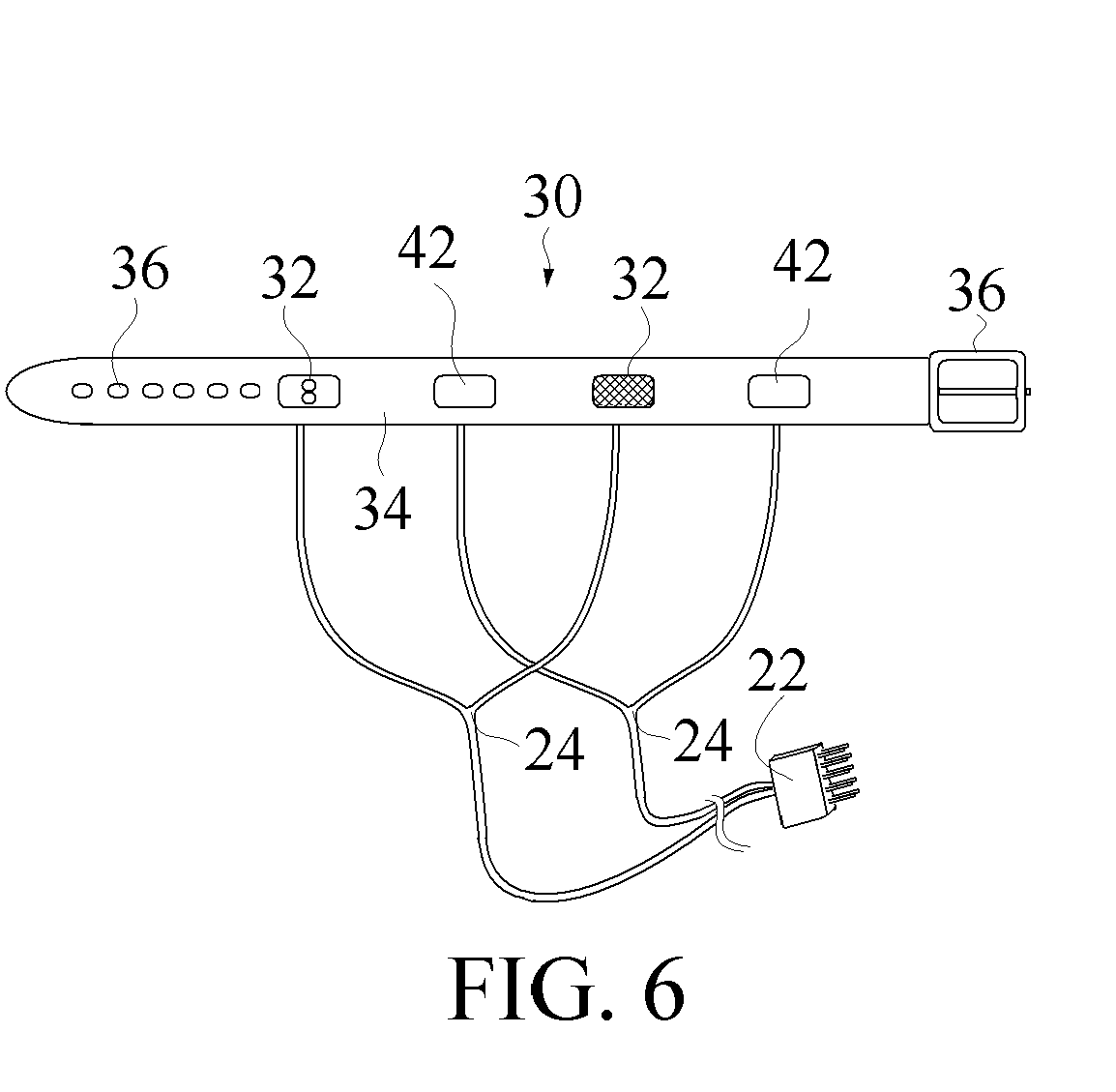

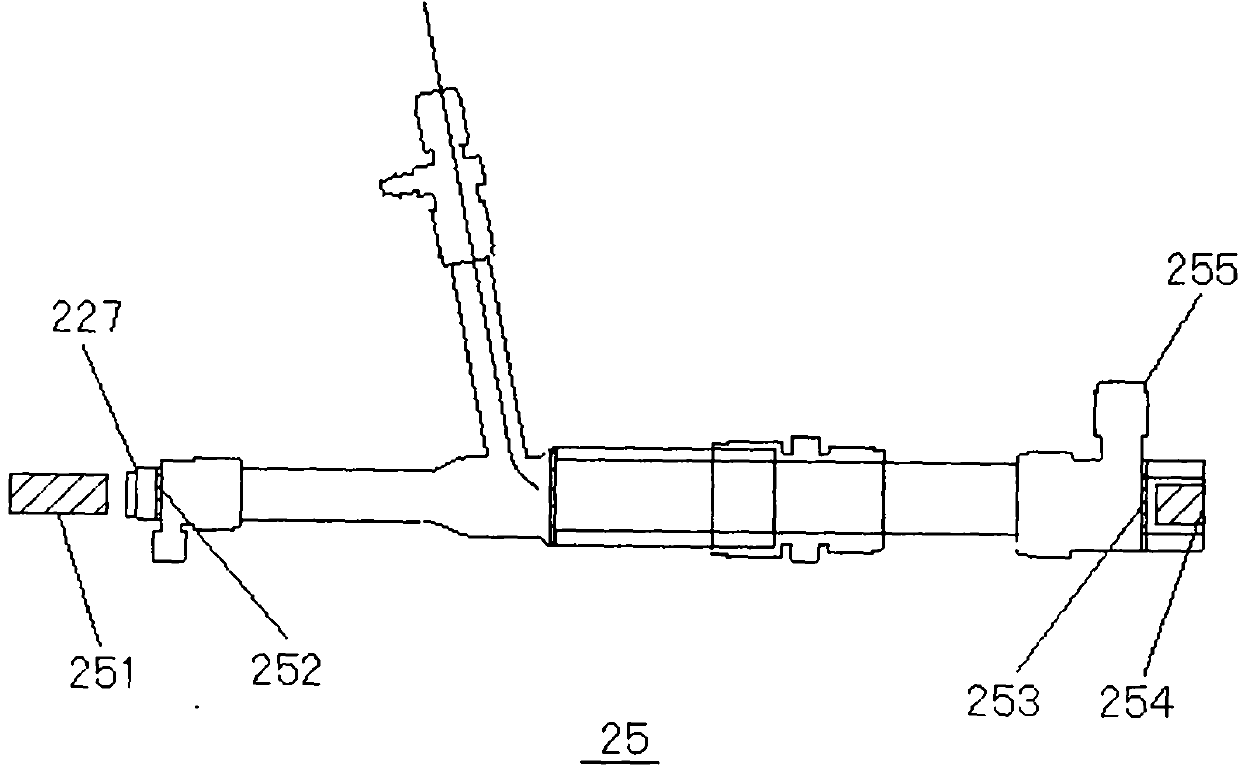

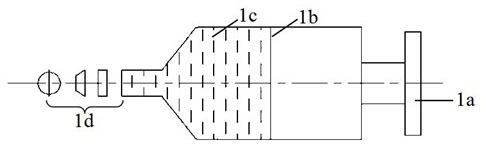

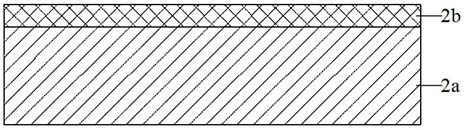

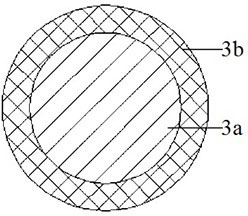

Noninvasive Photoplethysmographic Sensor Platform for Mobile Animals

ActiveUS20090149727A1Easily affixedSignificant blood flowDiagnostic recording/measuringSensorsTransmittanceEngineering

A noninvasive photoplethysmographic sensor platform for mobile animals such as small rodents, namely rats and mice is useful such as in a laboratory research environment. The noninvasive photoplethysmographic sensor platform may be a collar which provides an easily affixed, adjustable attachment mechanism that encircles the animal, such as the neck. The neck of the animal provides several particular advantages as a sensor mounting platform for photoplethysmographic sensors. For pulse oximetry, the neck location will provide significant blood flow under all conditions. For small mammals, such as rats and mice, transmittance pulse oximetry through the neck of the subject remains possible. The neck mounted collar also offers inherent bite resistance to the sensor platform.

Owner:STARR LIFE SCI

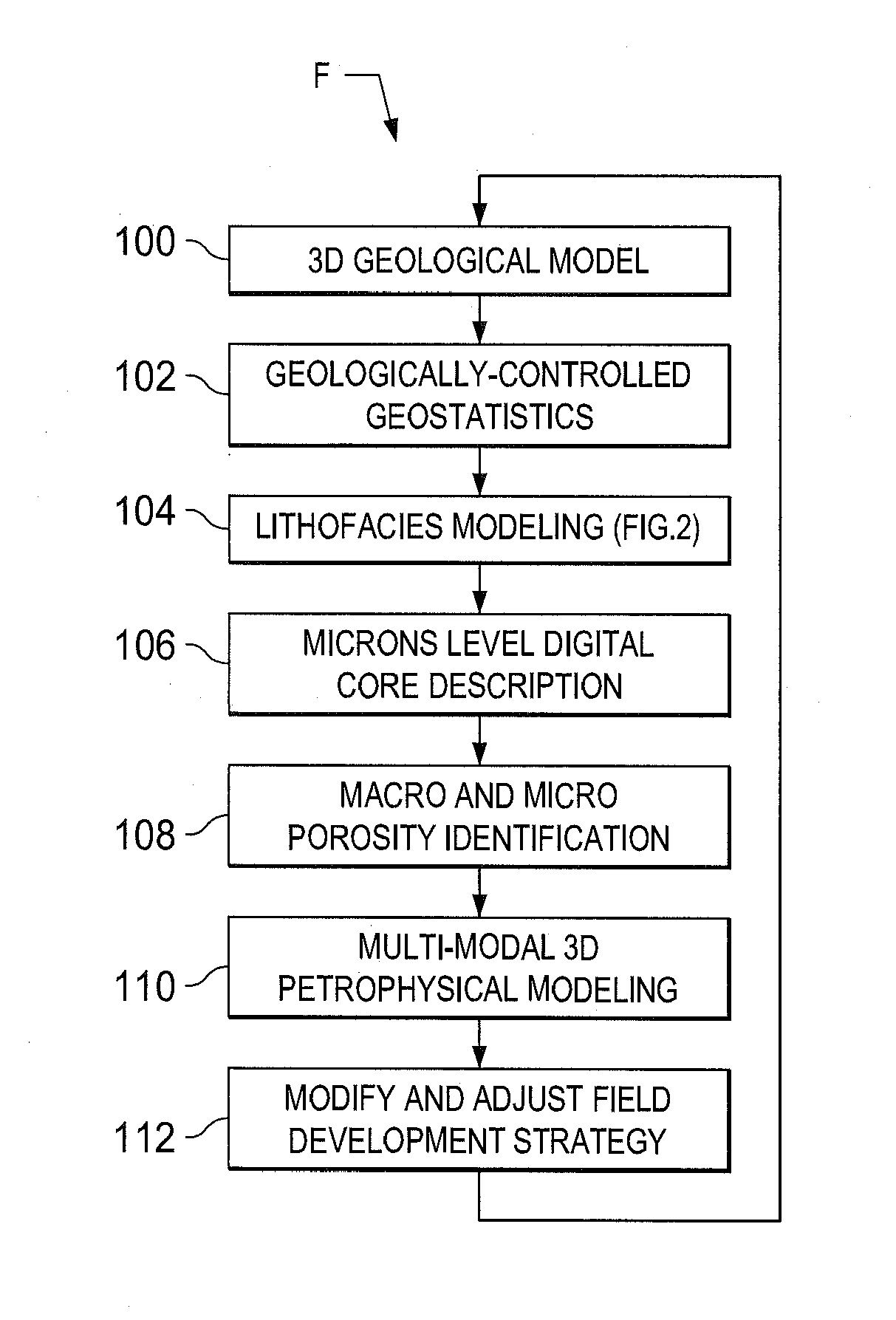

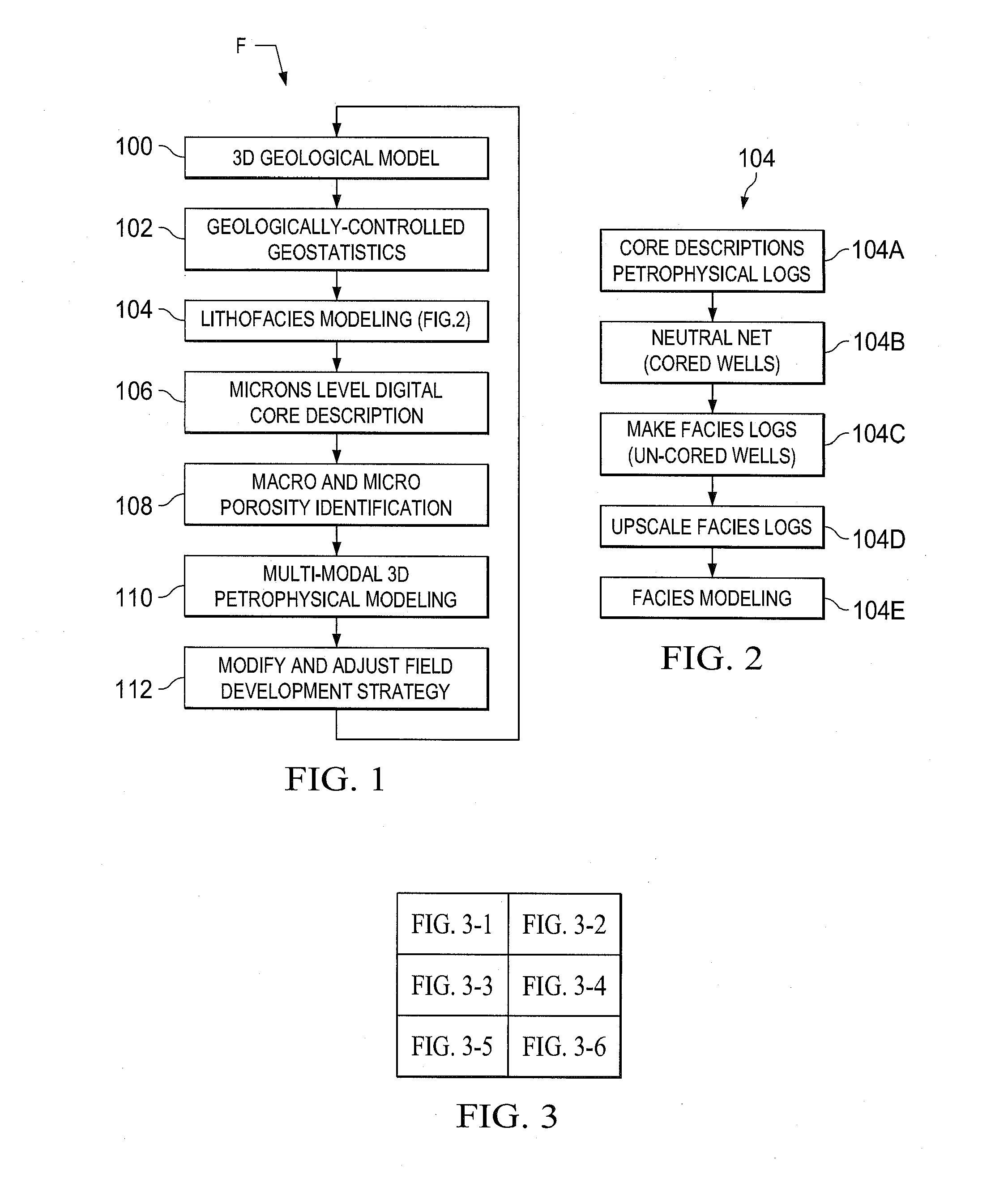

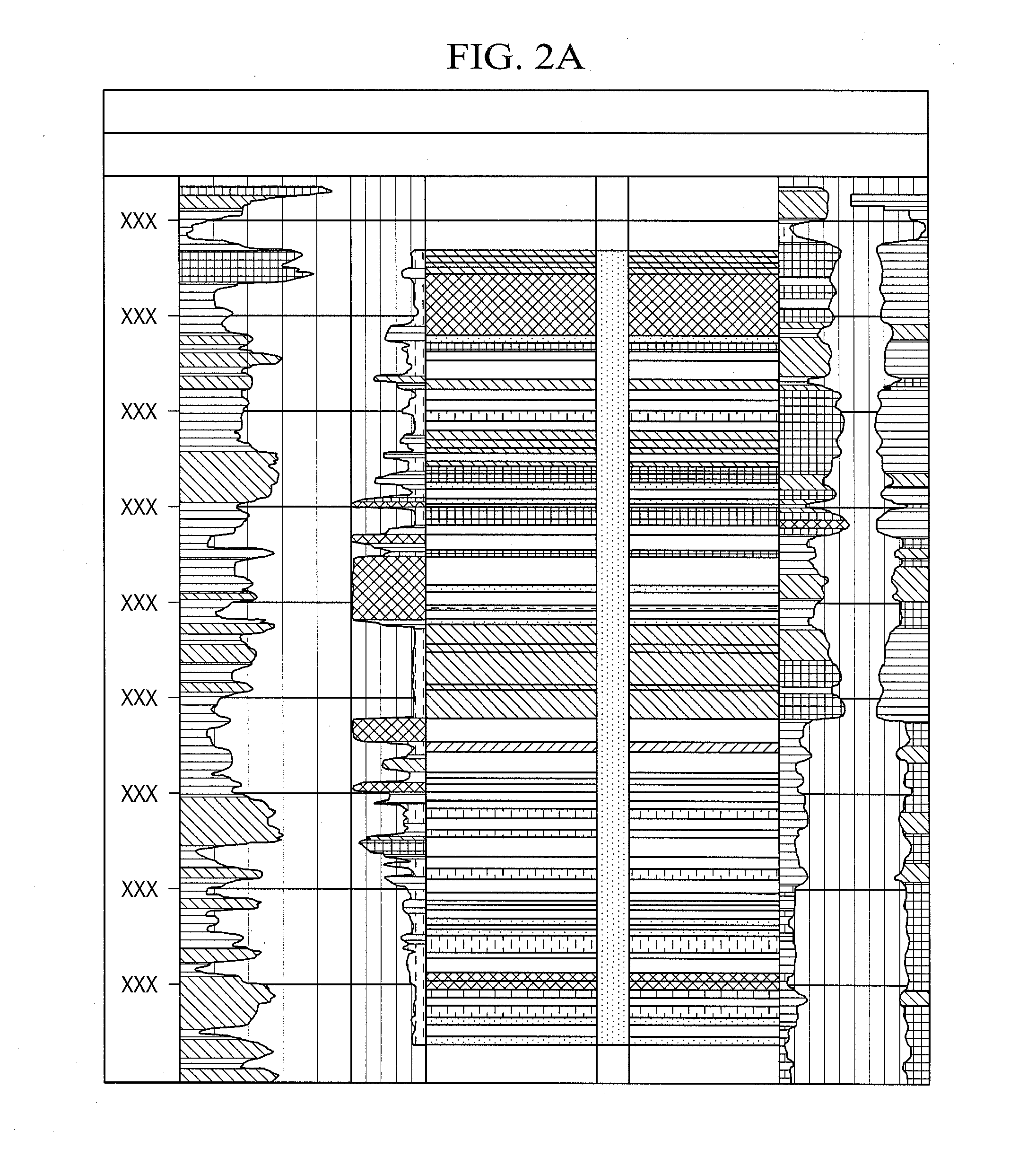

Three-dimensional multi-modal core and geological modeling for optimal field development

A roadmap for a field development strategy for optimal recovery is provided in a high quality 3D geological model. This geological model combines geological attributes, pore and rock properties for an optimum 3D representation of the reservoir thousands feet beneath the surface. The model is based on the pertinent geological facies, derived from well core description and detailed studies of rock, as well as fluid and pore properties (Full Pore System) obtained from laboratory analyses of core material and well log data. These data differentiate various important pore throat and pore body regions and relationships, i.e., macroporosity and microporosity. Understanding hydrocarbon volumes in the various pore type groups and then establishing proper recovery techniques through focused laboratory studies yields a field development strategy that can significantly increase hydrocarbon recovery from a reservoir.

Owner:SAUDI ARABIAN OIL CO

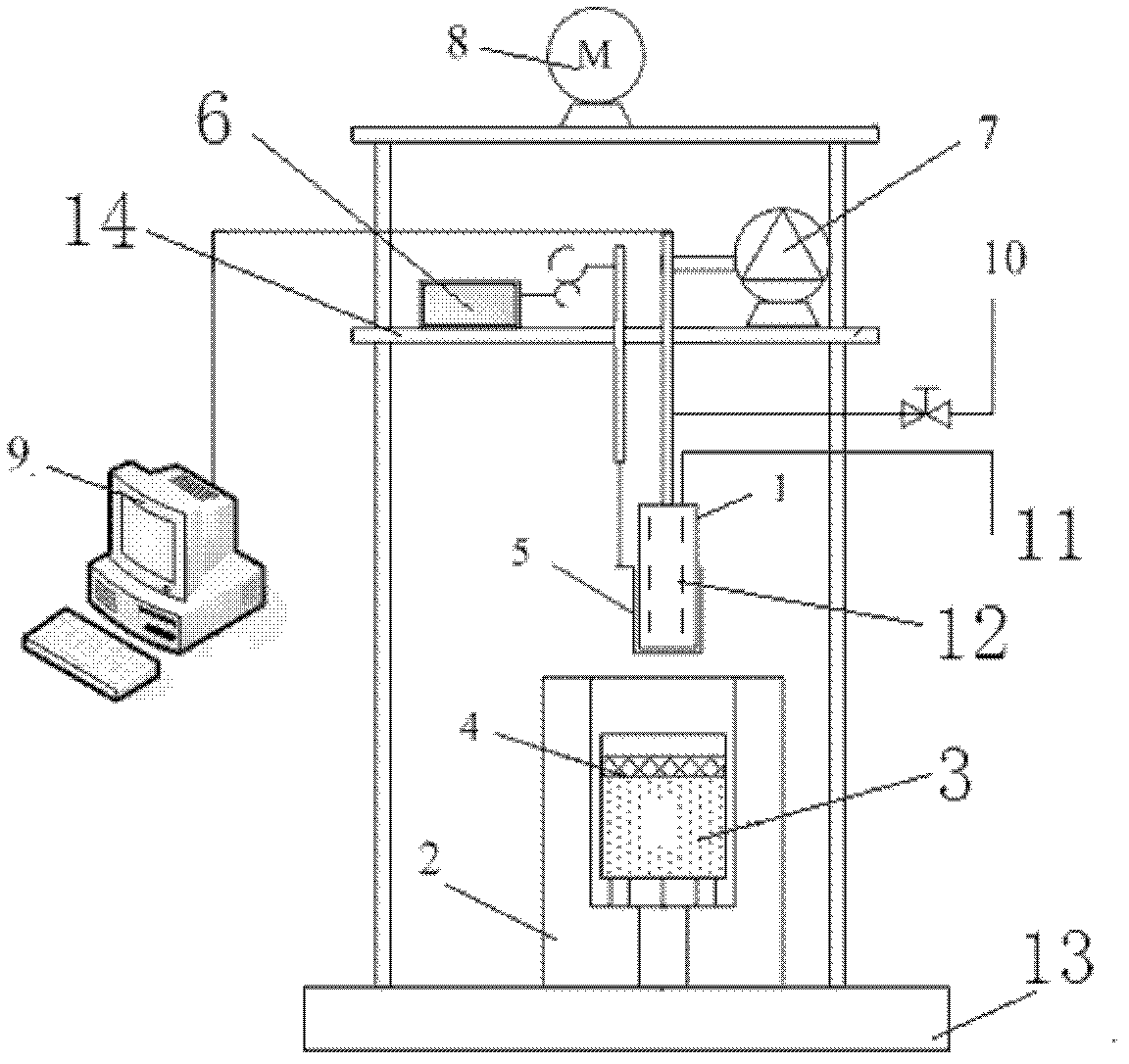

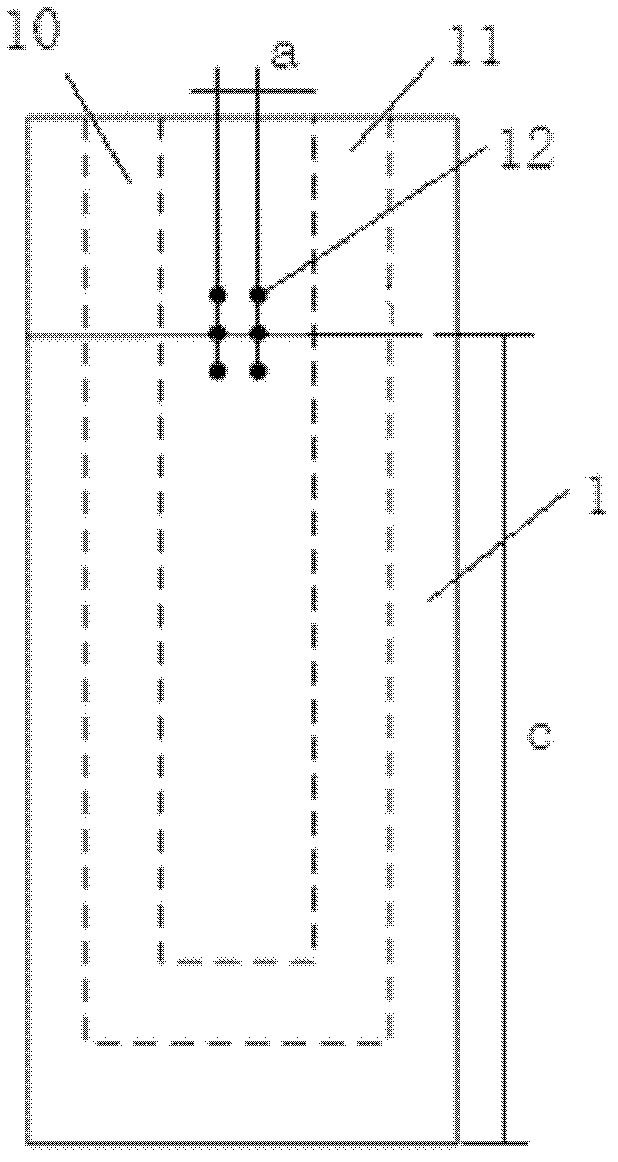

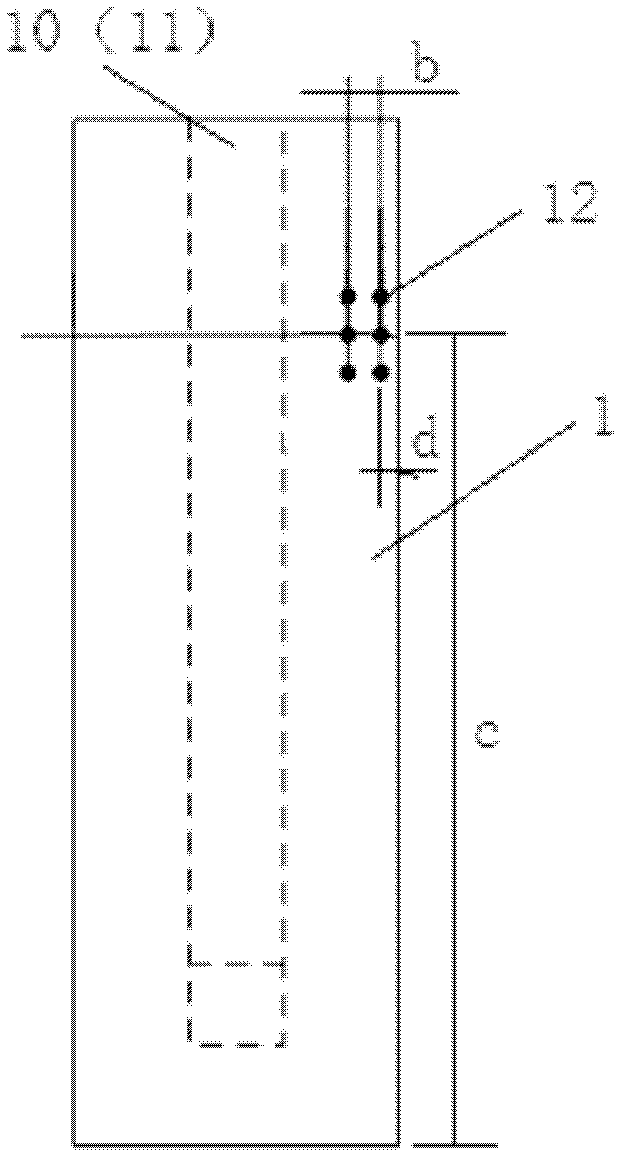

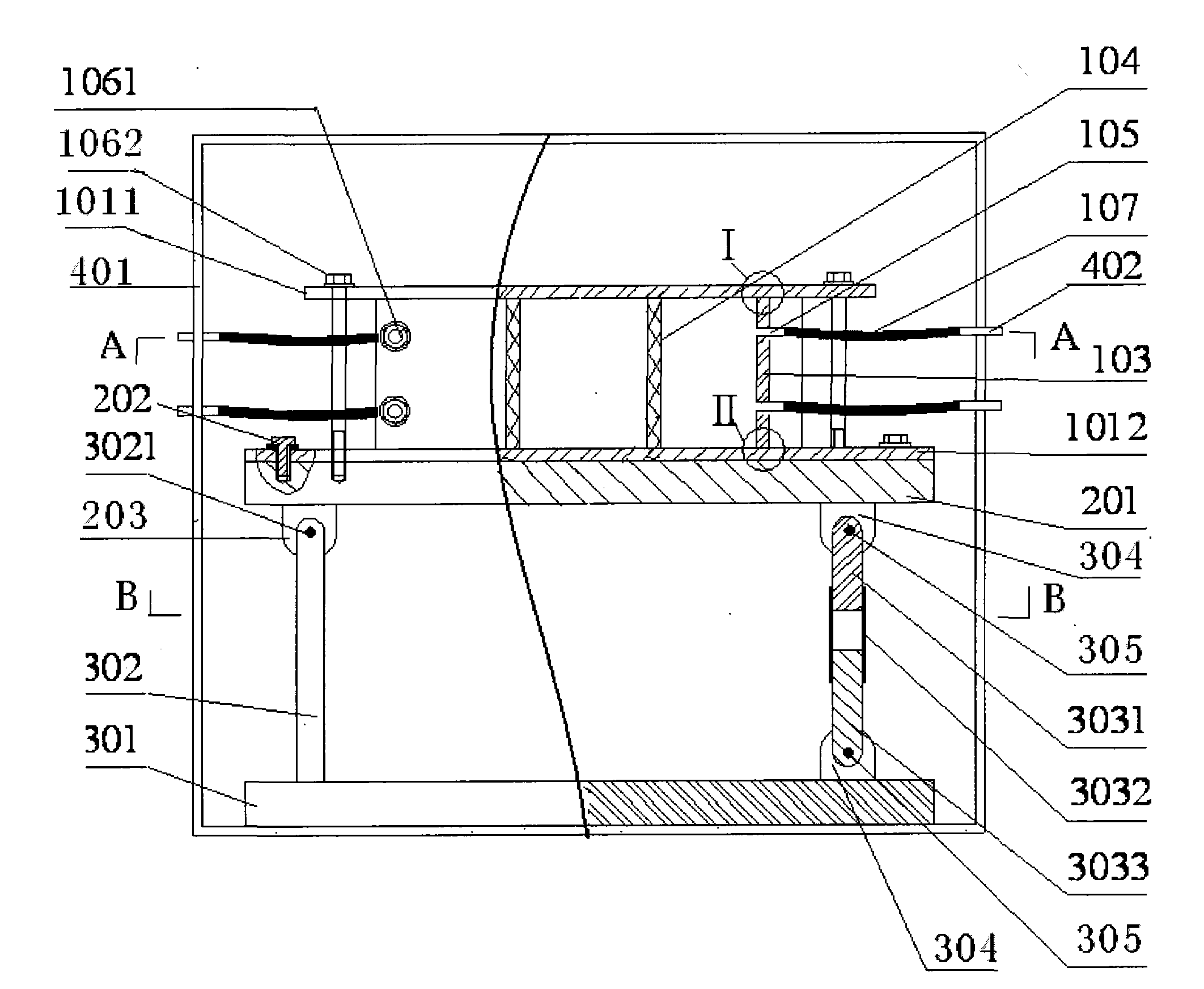

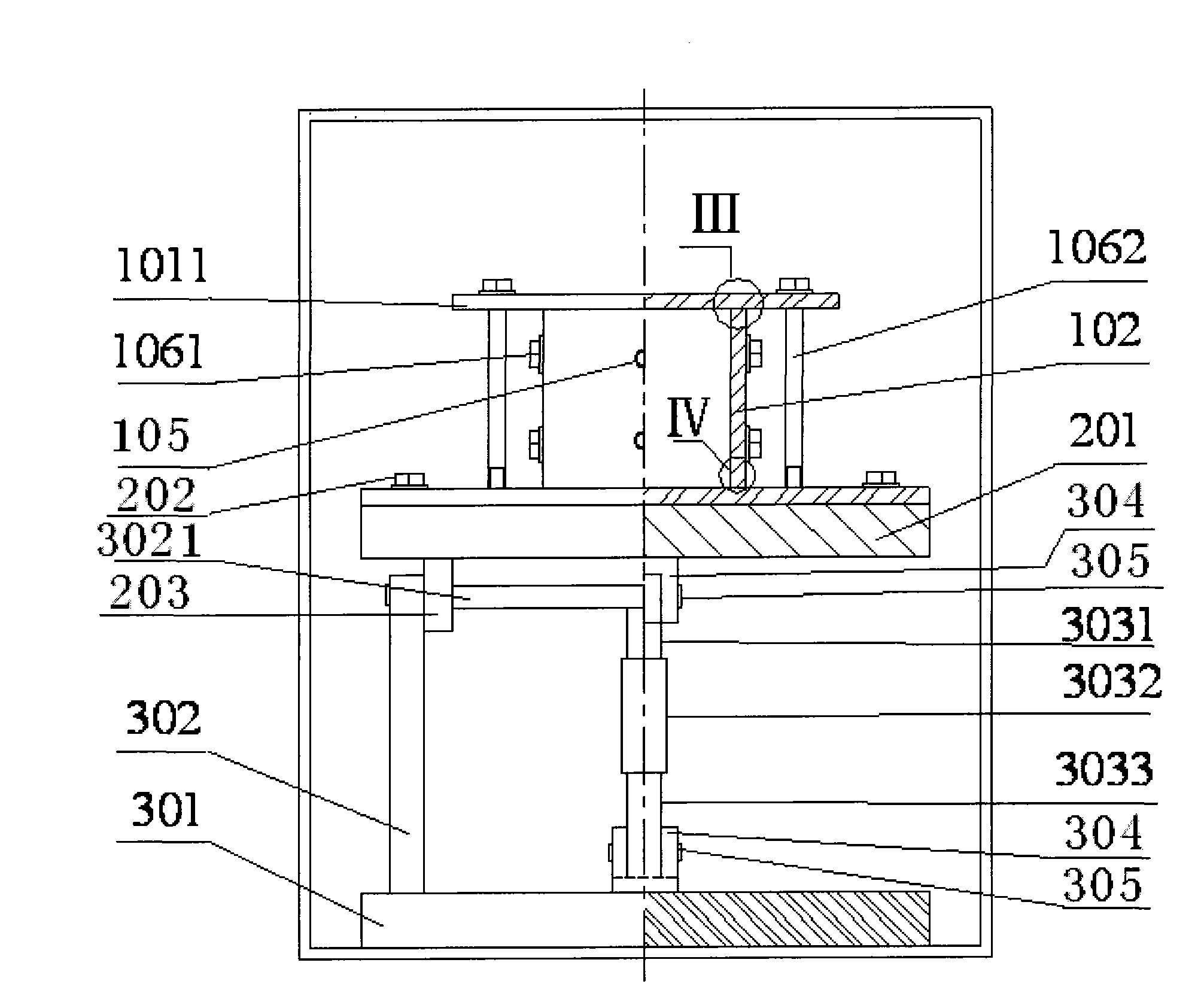

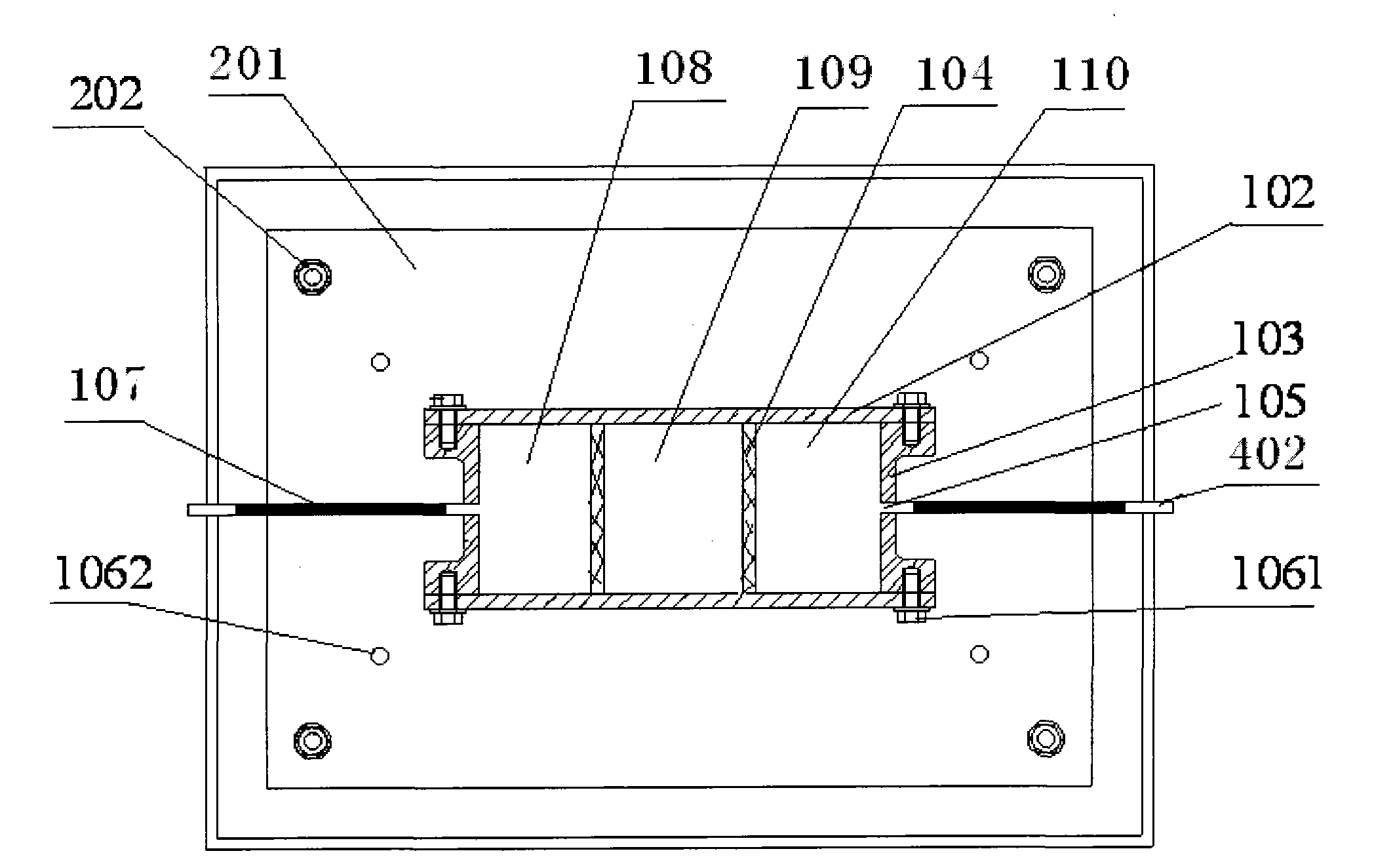

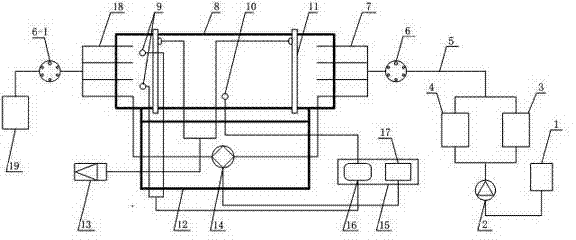

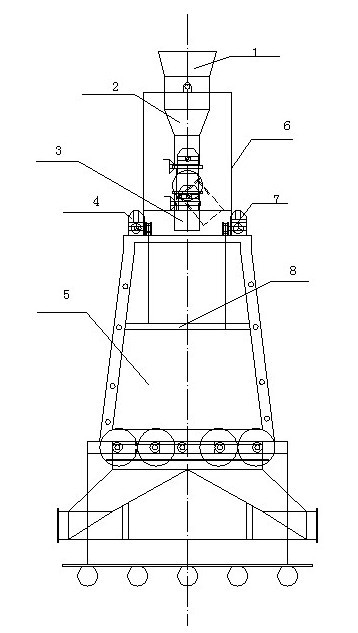

Steel liquid solidification simulator in continuous casting crystallizer

InactiveCN102357650AAchieve mechanical propertiesResearch on Vibration Waveform OptimizationHeat fluxMotor drive

A steel liquid solidification simulator in a continuous casting crystallizer comprises a machine seat, a steel furnace, a crystallizer, a throwing motor, a vibration motor, a cooling water channel and a data acquisition system. Two lead screws are arranged on the machine seat, one ends of the lead screws are perpendicular to the plane of the machine seat, and the other ends of the lead screws areconnected with a motor driving device. A lifting bracket is arranged on the lead screws. The steel furnace is arranged on the machine seat. Both the throwing motor and the vibration motor are arranged on the lifting bracket, the crystallizer is driven by the vibration motor to vertically vibrate, the throwing motor drives a throwing board, and the throwing board is located below the crystallizer.By simulating practical production process of continuous casting, the steel liquid solidification simulator in the continuous casting crystallizer measures heat flux change curves at meniscus positions in the crystallizer under different continuous casting process parameters, obtains a steel liquid solidification shell with characteristics of practical casting blank, and achieves research on initial solidification performance of steel liquid in the crystallizer and influence of the continuous casting process parameters on steel liquid initial solidification performance, and is convenient to operate, low in test cost and suitable for serving as a device for laboratory to research various process conditions of the continuous casting crystallizer.

Owner:CENT SOUTH UNIV

Strong inhibition type anti-collapse foam liquid for drilling

InactiveCN101798499AIncreased water carrying capacityPrevent immersionDrilling compositionFoaming agentCarrying capacity

The invention relates to foam liquid for drilling, in particular to strong inhibition type anti-collapse foam liquid for drilling, which is characterized by being prepared with the following components in parts by weight: 0.09-0.11 part of foam stabilizer, 0.36-0.44 part of foaming agent, 2.34-2.86 parts of anti-collapse agent, 2.7-3.3 parts of fluid loss additive and 94.51-93.29 parts of water. When complex situations such as formation water occur to gas drilling, the foam liquid of the invention can effectively improve the rock carrying capacity and the water carrying capacity and simultaneously protect the stability of the upper well wall. Laboratory studies shown that the foam liquid has high foaming capacity, the foaming capacity is more than or equal to 500 percent, the half-life is moderate, and the foam liquid can be easily controlled and is conducive to drilling engineering construction.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

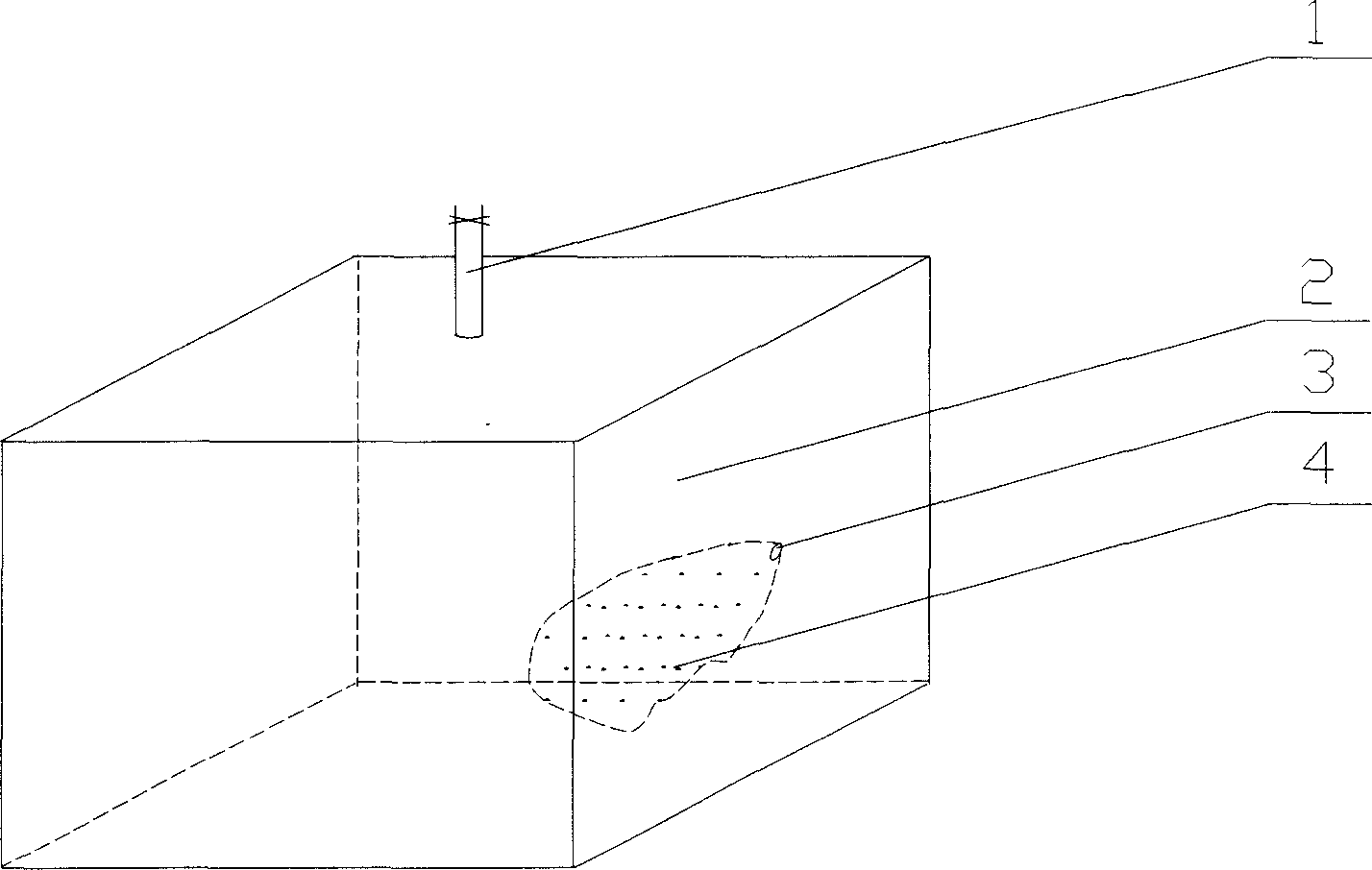

Scouring model experimental device of underground silt and method

InactiveCN101666720AWith mechanical propertiesThe principle is clearHydrodynamic testingPreparing sample for investigationPorositySmall sample

The invention relates to scouring model experimental device of underground silt and method, which belong to the technical field of characteristic tests of hydraulics, river dynamics and soil and rockmechanics. The device comprises a scouring tank, a fixing table, a tilting device and a freezing tank. The method comprises the following steps: putting or stacking experimental soil samples or sand samples in the scouring tank; closing the scouring tank; starting a water flow for scouring the underground silt in a model experiment; shooting and recording a scouring process; closing the water flowand maintaining original water pressure when the scouring reaches a certain experimental state; then, freezing the scouring tank and the scouring samples by the freezing tank; labeling, positioning and cutting frozen scouring sample grids; and individually measuring, thawing, weighing and screening second-state frozen small samples to obtain the graduation of scouring models of the underground silt and the distribution of porosity in a scouring state. The scouring model experiment of the underground silt is carried out in a laboratory. The invention provides a reference and a theory for mutually stacking the silt, damming by sand stone and banking for preventing flood for river ways and is applied to the laboratory research of scouring the underground silt.

Owner:TSINGHUA UNIV

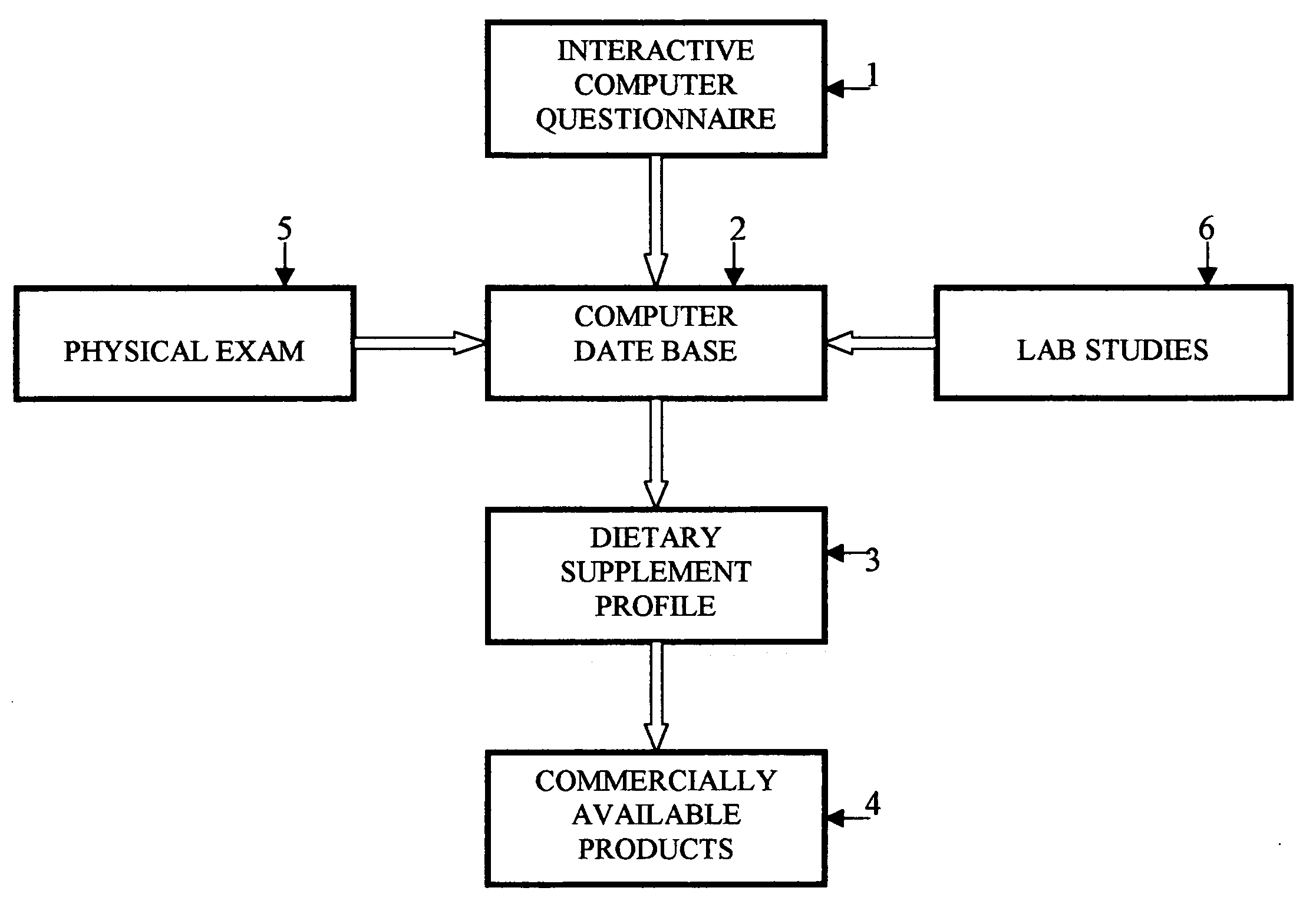

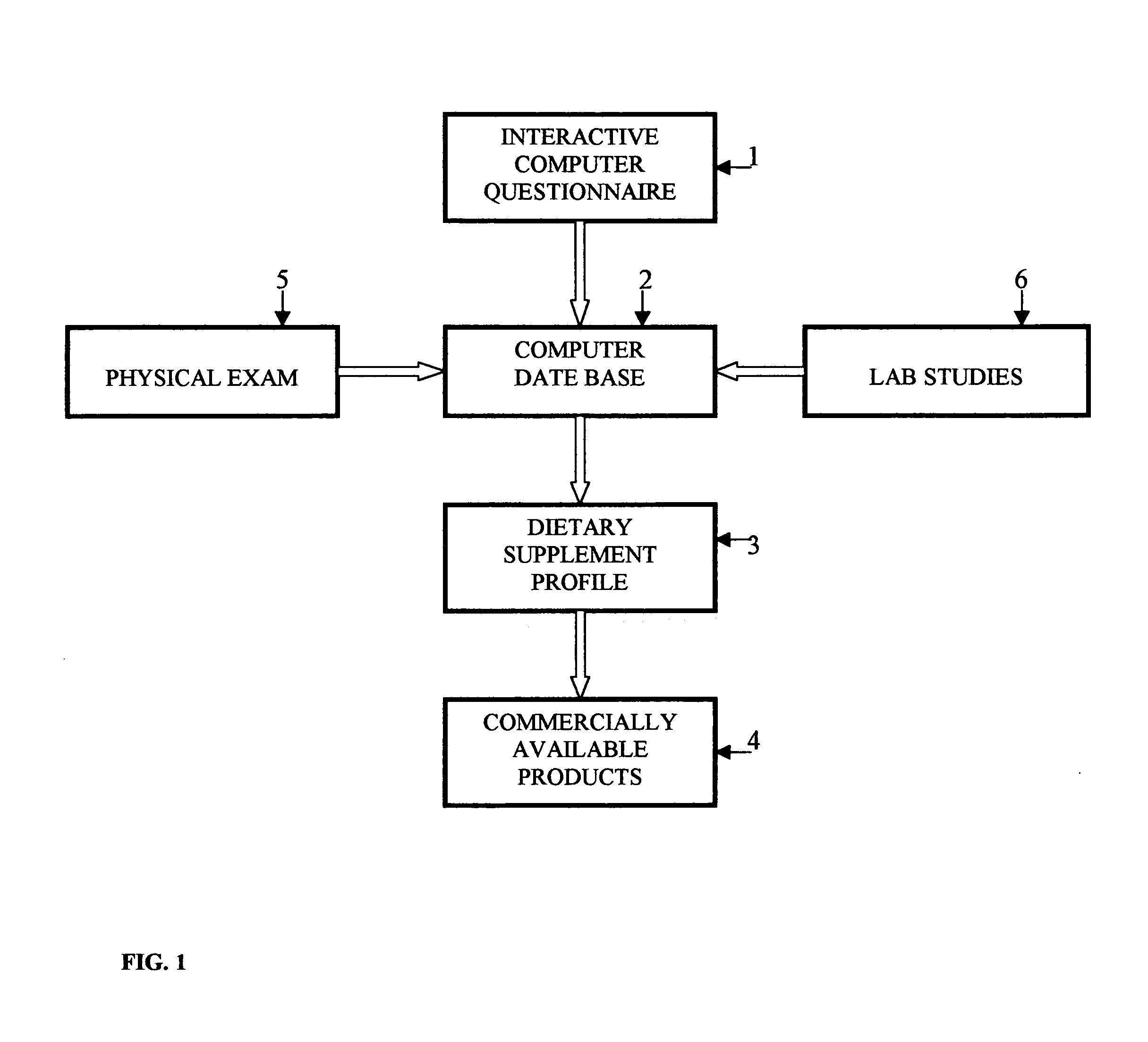

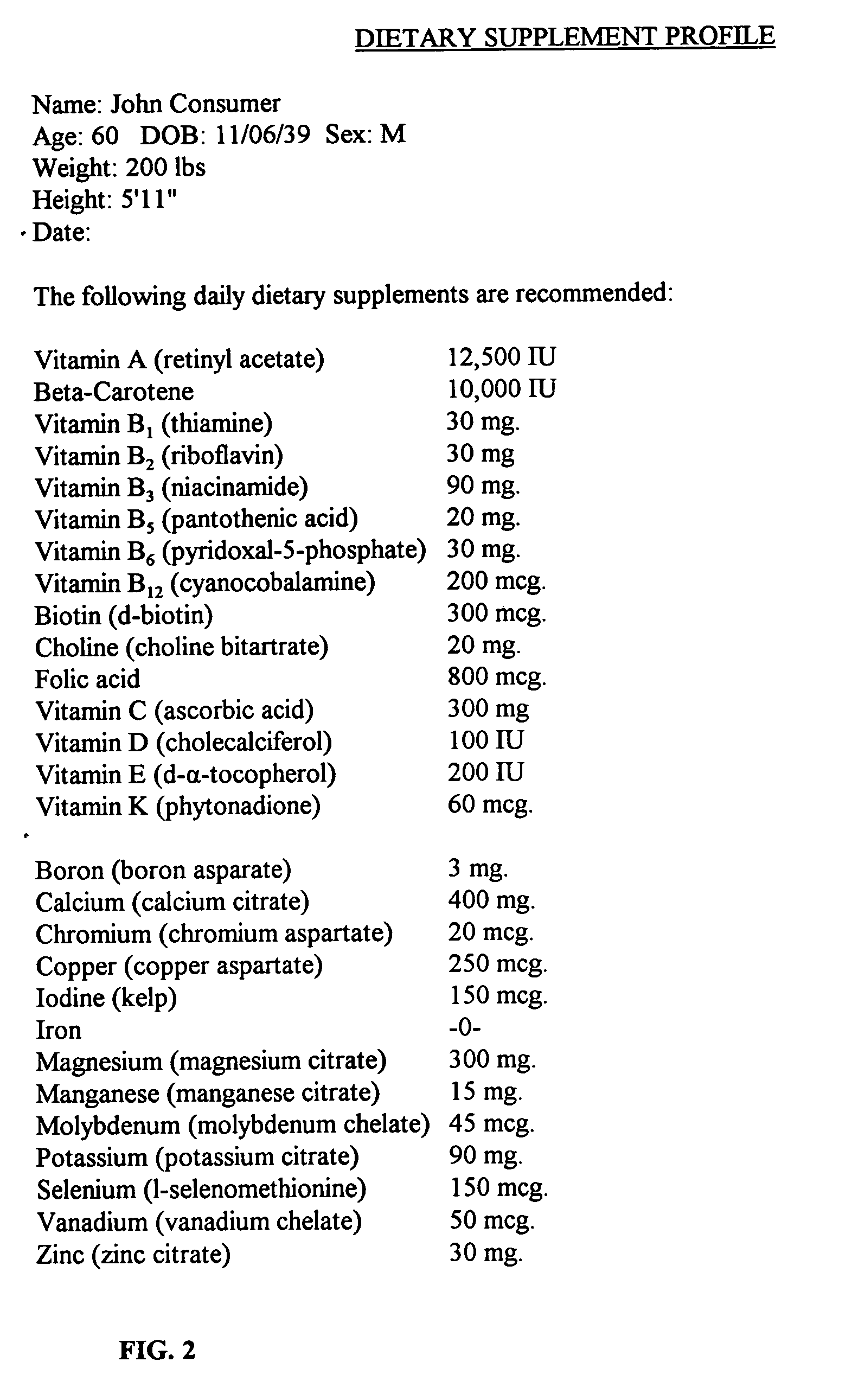

Method/process of determining a personal dietary supplement profile and recommending dietary supplements for an individual

InactiveUS7136820B1Enhance the imageData processing applicationsNutrition controlDietary supplementNutritional Supplementation

This invention provides a method / process of determining a personal dietary supplement profile of vitamins, minerals, amino acids, enzymes, herbs, and other nutritional supplements for an individual based on information from a health questionnaire and comparing the individual's health information to an ideal health profile in a computer data base. Optionally, information provided by physical examination and laboratory studies can be incorporated into the method / process of determining the dietary supplement profile. The profile can be further defined by listing commercially available products that provide the suggested dietary supplements.

Owner:ADVANCED MEDICAL INSTR

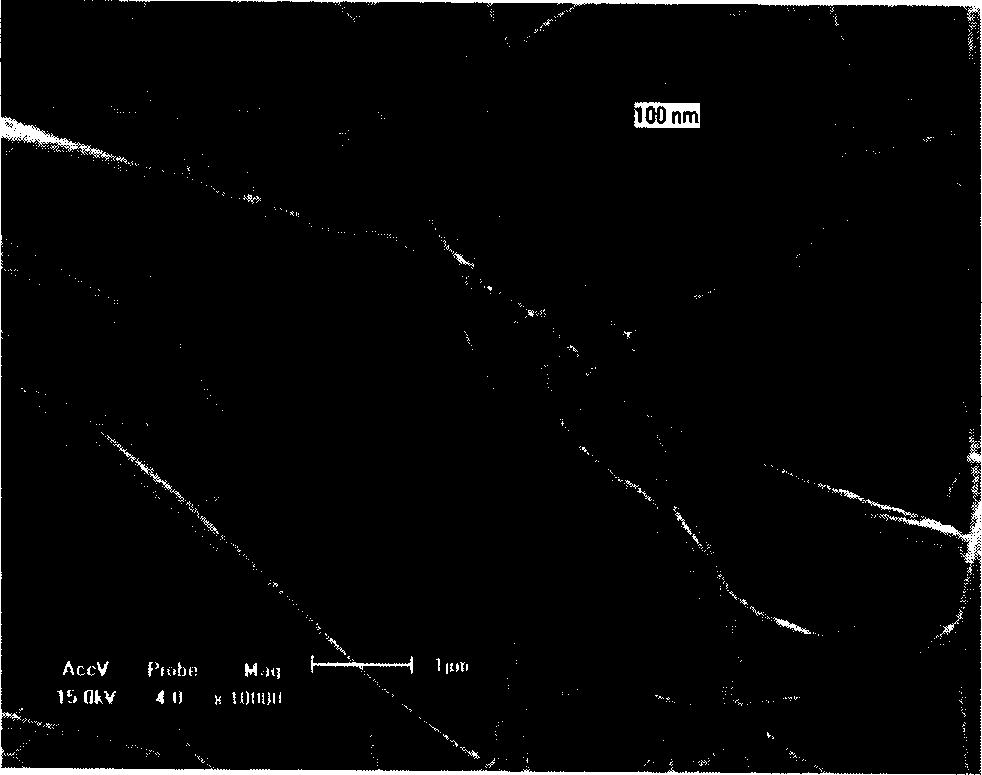

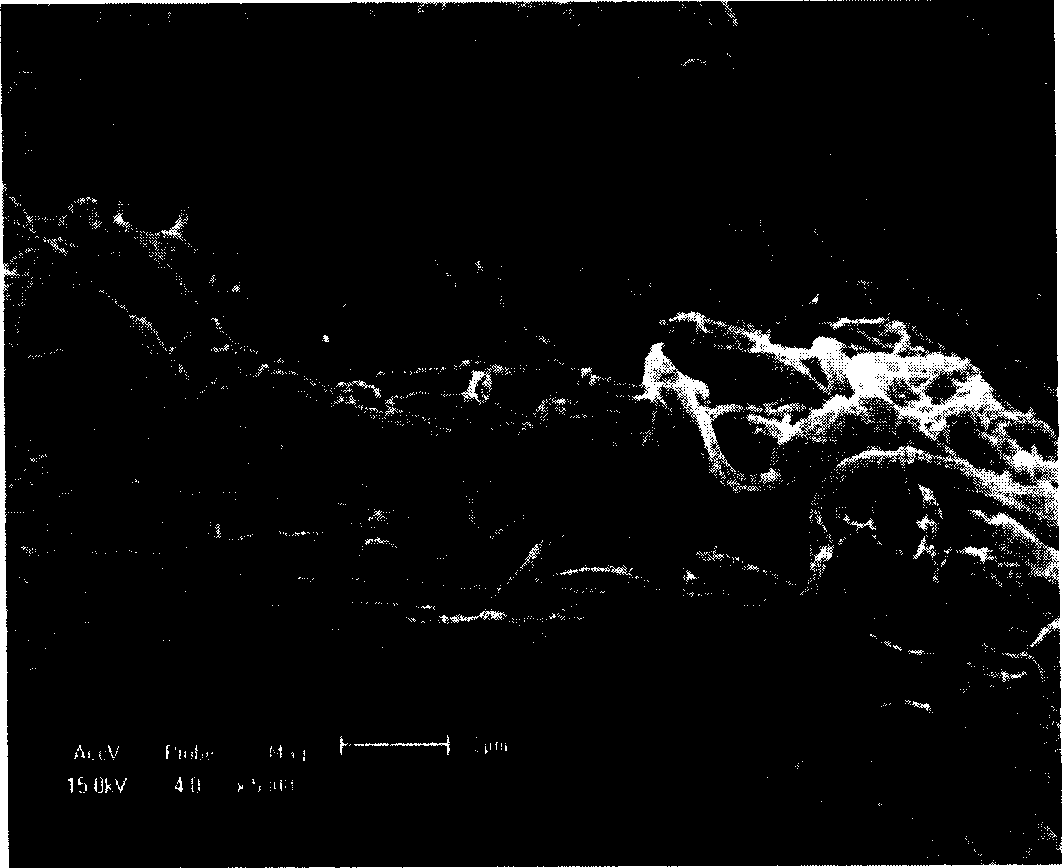

Natural nanometer fiber preparation method

InactiveCN1730734ASuitable for a wide rangeControllableMonocomponent fibroin artificial filamentFilament/thread formingSpider ProteinsLaboratory research

The present invention relates to the preparation process of natural nanometer fiber for tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material, and is especially the preparation process of natural nanometer spider silk fiber and cocoon silk fiber. Through soaking in certain solution and ultrasonic dissociation, natural nanometer fiber of diameter 30-100 nm may be prepared. The prepared natural nanometer fiber may find its wide application in tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material. The present invention has simple operation, simple equipment, low power consumption and low cost, and is suitable for both lab preparation and industrial production.

Owner:TSINGHUA UNIV

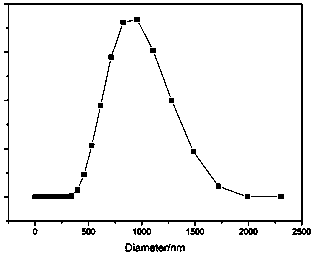

Preparation method for small-size graphene

ActiveCN104003375AHigh monolayer ratioAvoid destructionMaterial nanotechnologyGrapheneCentrifugationGraphite

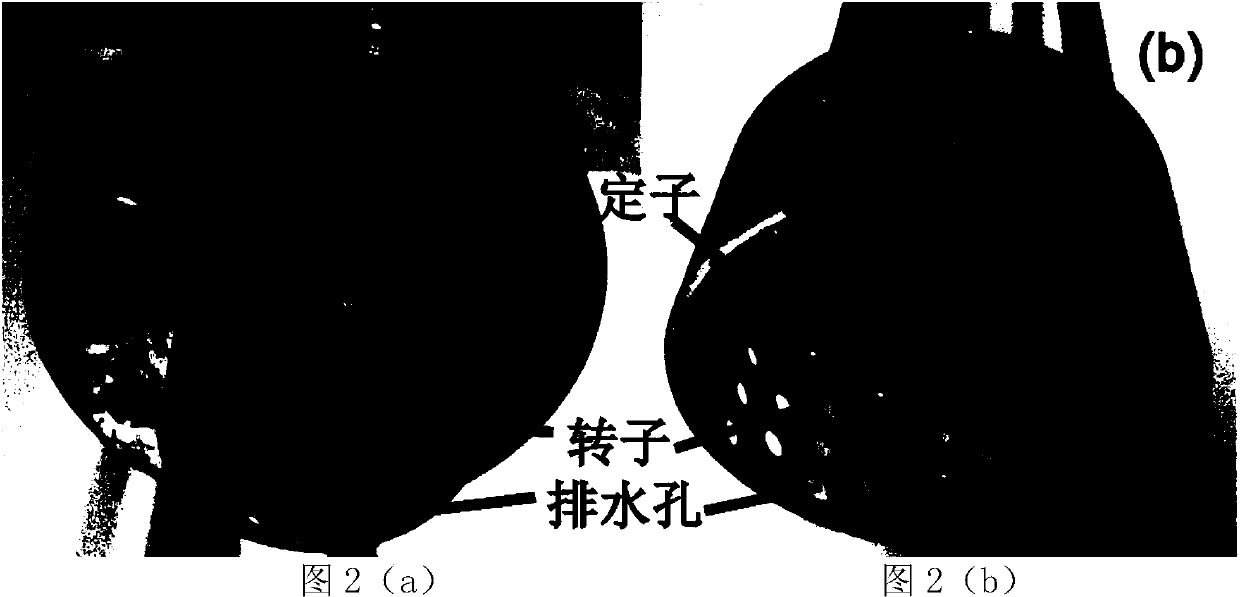

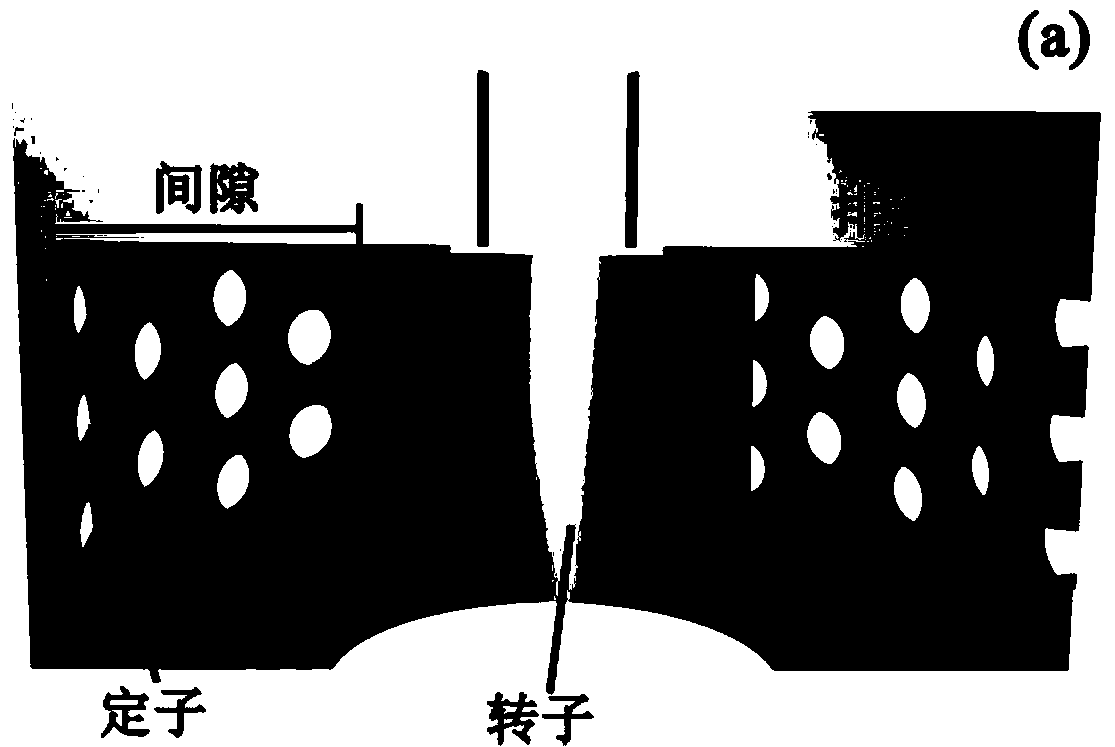

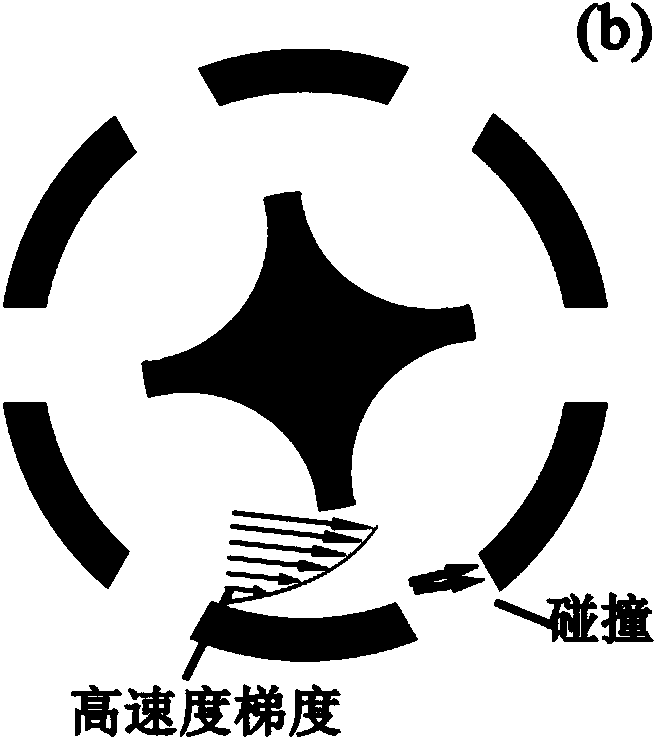

A disclosed preparation method for small-size graphene comprises the steps: step 1, mixing a graphite powder raw material and a solvent to obtain a graphite mixed solution; step 2, putting the solution in a container, and fixedly arranging a homogenizing head of a stator-rotor apparatus of a stator-rotor mixer below the liquid level; step 3, starting a cooling system and the stator-rotor mixer for processing; and step 4, performing standing processing or centrifugation separation on the prepared solution to remove incompletely-peeled particles, and collecting the supernatant to obtain a stable dispersion solution of small-size graphene. According to the preparation method, a rotor rotating with a high speed drives a fluid to have a high-speed motion, so that high velocity gradient and high shear force are generated, and also graphite sheets are subjected to peeling and refining because the high-speed fluid bumps bosses of a hole wall of a stator, and the prepared graphene is small in dimension, concentrated in distribution and high in single-layer ratio. The method has the characteristics of small equipment investment, low raw material cost, simple, easy and practicable operation and impressive output, and is suitable for large-scale industrialized production as well as laboratory research.

Owner:BEIHANG UNIV

Movable LED lighting circulation plant water-culture device

InactiveCN104082119APromote growth and developmentEasy to operateAgriculture gas emission reductionCultivating equipmentsTemperature controlEngineering

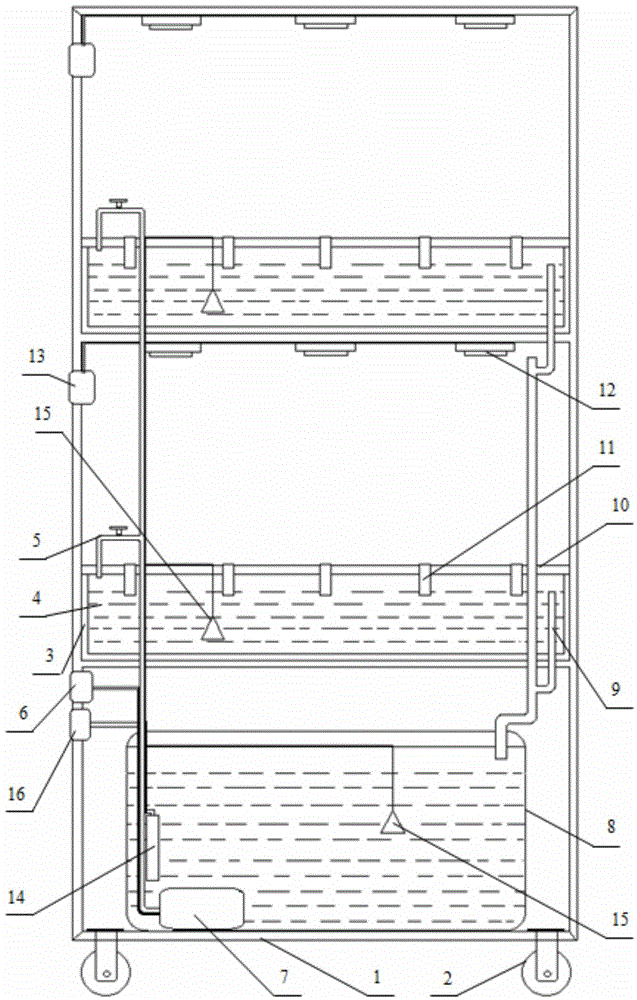

The invention discloses a movable LED illumination circulation plant water-culture device. The movable LED illumination circulation plant water-culture device mainly comprises a multilayer support, a planting device, a lighting system, a temperature control system and a water, fertilizer and air integrated circular supplement system. The movable LED illumination circulation plant water-culture device can be moved to a proper place to perform water culture according to natural lighting conditions and space sizes, fixed in a room for use, and moved out of the room or moved to a corridor for use. The movable LED illumination circulation plant water-culture device is simple in structure and convenient to operate, so that the movable LED illumination circulation plant water-culture device is applicable to homes and laboratories for researches. Furthermore, the movable LED illumination circulation plant water-culture device is suitable for planting of nursery stocks of multiple plants, branch planting and seed sowing. By controlling lighting time and the temperature of water culture liquor and supplementing water, fertilizers and air (oxygen) in a circular mode, growth and development of the plants are promoted, and therefore, plant water culture which is low in power consumption, easy to operate, rapid in growth and high in efficiency is achieved. The movable LED illumination circulation plant water-culture device has high practical value and wide market prospects.

Owner:广西壮族自治区蚕业技术推广总站

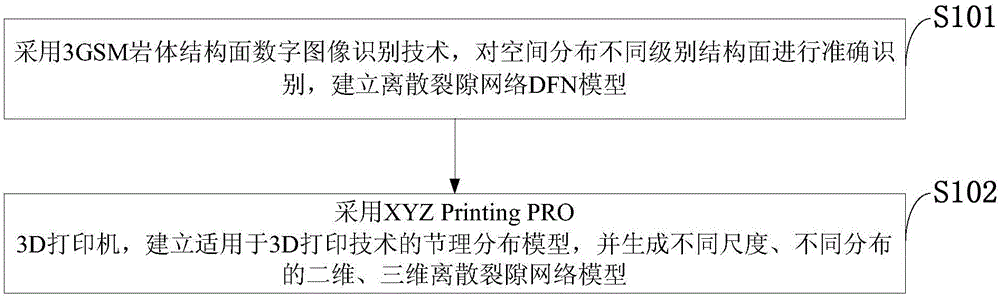

Complex fractured rock mass physical model manufactured based on 3D printing productionand modeling method

InactiveCN106447776ALow costSmall scaleDetails involving processing stepsAdditive manufacturing apparatusModel reconstructionPhysical model

The invention discloses a complex fractured rock mass physical model manufactured based on 3D printing production and a modeling method. By using 3D printing, a complex fractured network model entity is reconstructed and a model suitable for an indoor analog simulation experiment is established; the complex fractured rock mass physical model comprises a discrete fracture network DFN model and an entity discrete joint network DFN model. Based on the 3D printing, the complex fractured network model entity can be reconstructed and the model suitable for the indoor analog simulation experiment is established, and an effective method can be provided for an indoor laboratory research on complex fractured rock mass mechanical behaviors. A reliable and effective method is provided for the rock mechanical test field by adopting fractured rock mass model reconstruction and fractured network entity model construction through the 3D printing; with the help of the 3D printing technology, the problems that modeling is difficult to conduct and the cost is high in the current complex fractured rock mass physical model indoor experiment can be effectively solved.

Owner:UNIV OF SCI & TECH BEIJING

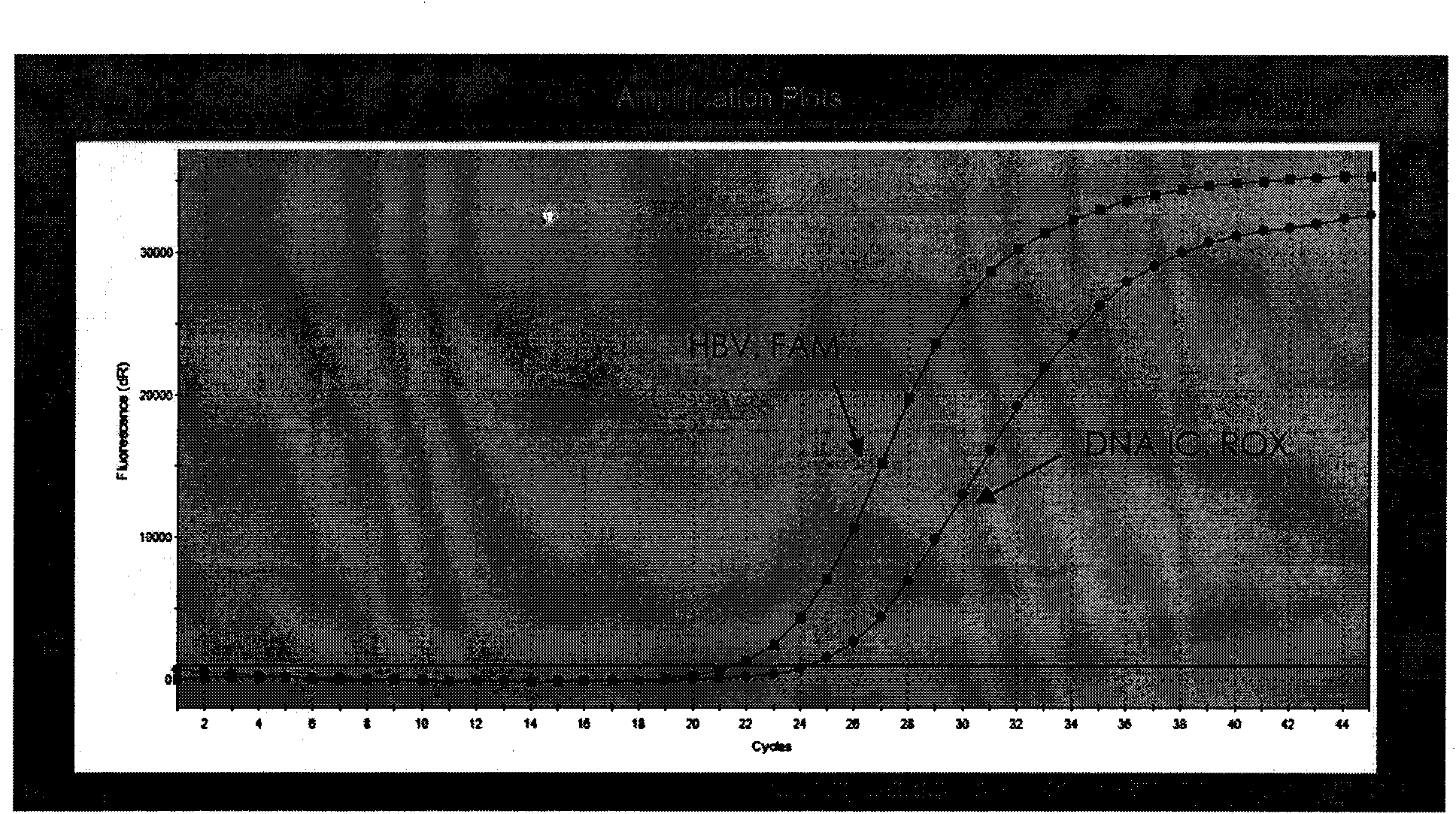

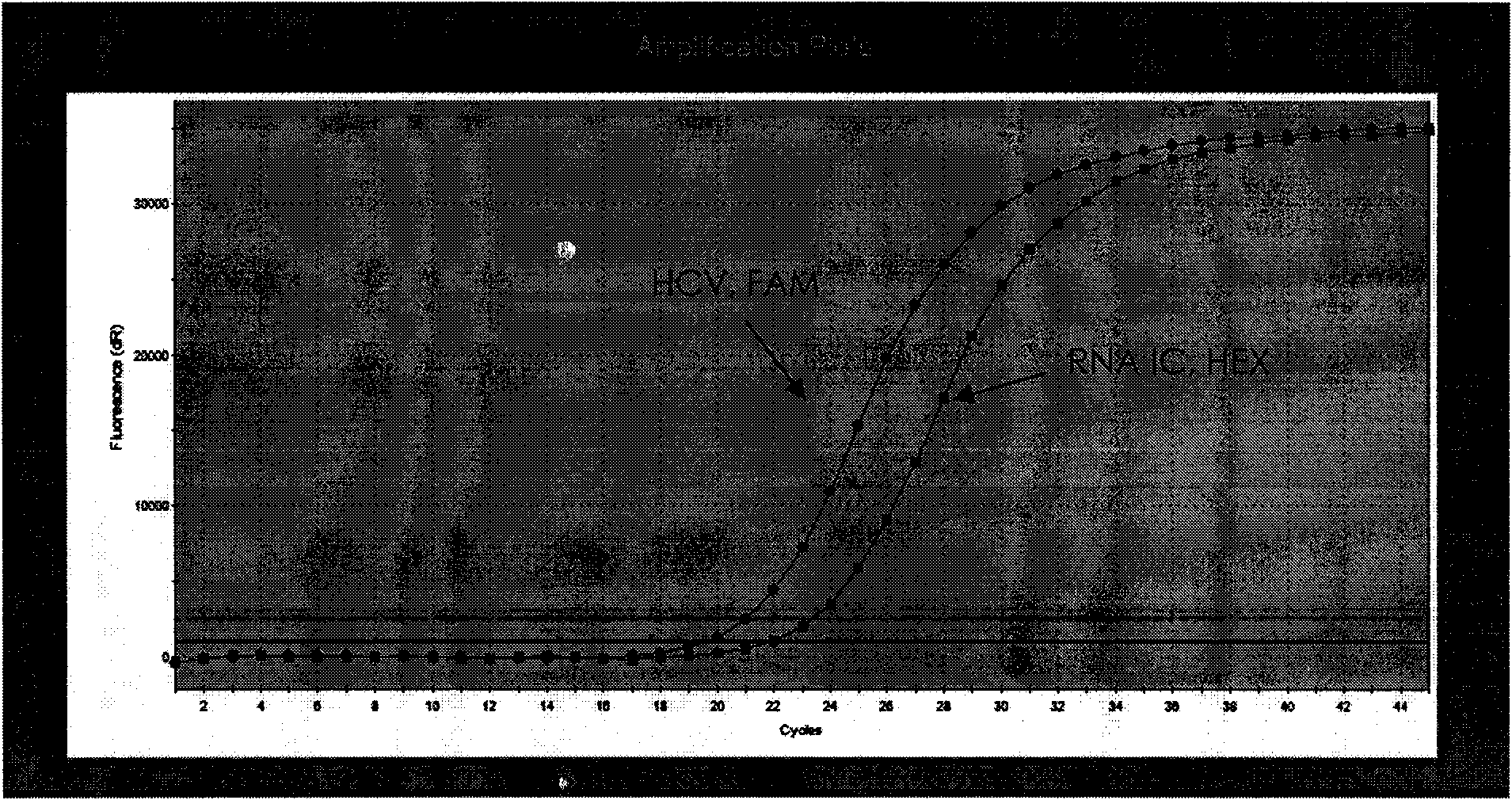

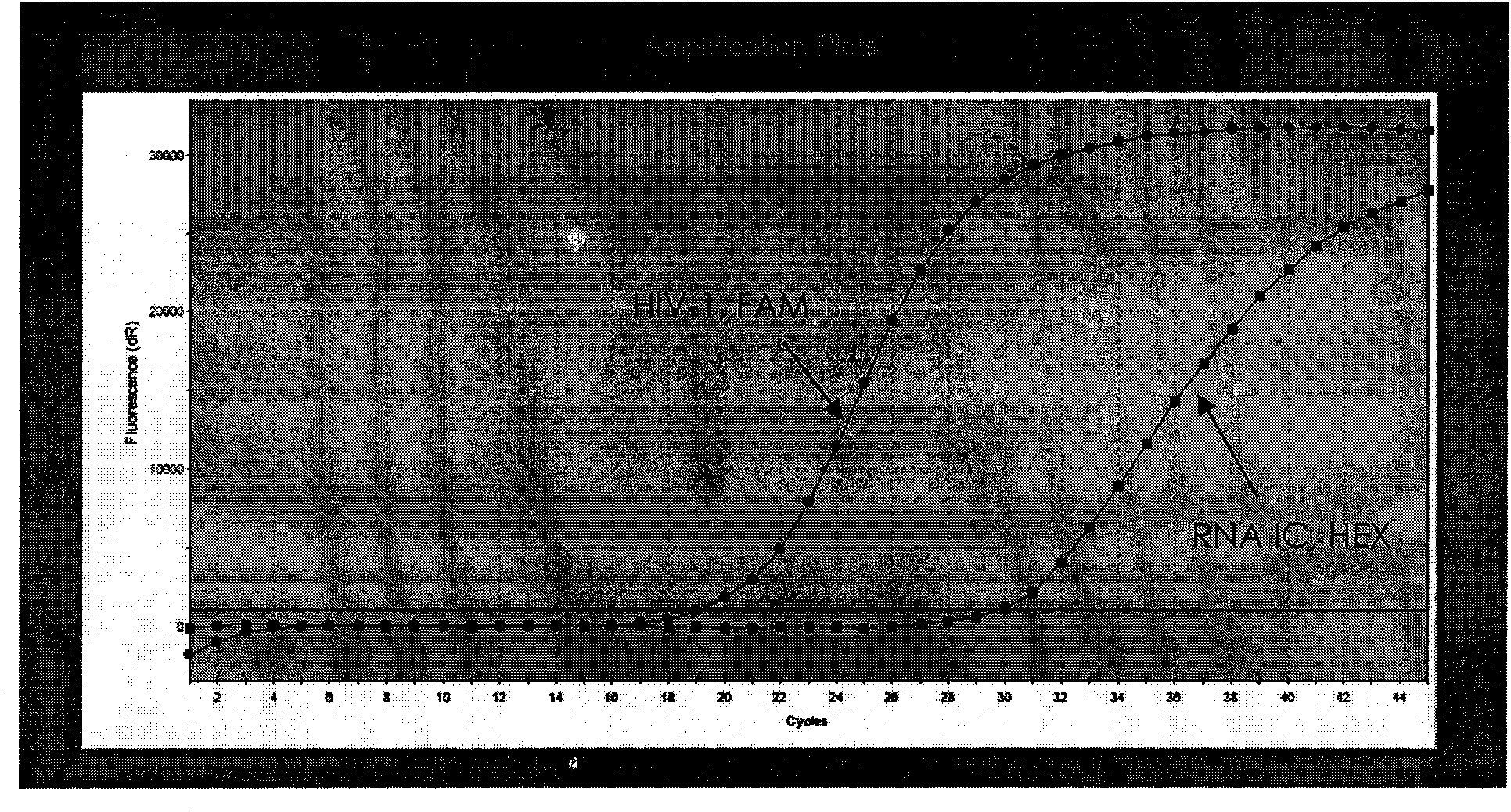

PCR detection method of multiple-target nucleic acid in single pipe and kit thereof

ActiveCN101624629AMicrobiological testing/measurementMicroorganism based processesFluorescenceLaboratory research

The invention relates to a real-time PCR method of one or more kinds of target nucleic acid in multiple-detection samples in a signal PCR reaction vessel, which comprises the following steps: (1) mixing a sample, DNA polymerase, dNTP, internal contrast nucleic acid, a target nucleic acid primer pair, an internal contrast nucleic acid primer pair, one or more kinds of target nucleic acid probes and internal contrast nucleic acid probes in the signal PCR reaction vessel, wherein the probes are marked with fluorescent groups and quenching groups, and moreover, the fluoroscopic detection wavelengths of the fluorescent groups marked by various probes are different; (2)detecting fluorescent light with different wave lengths in real time to carry out the PCR reaction; (3) calculating a Ct value according to a fluorescent light detecting result to judge whether one or more kinds of target nucleic acid is stored in the sample; in additon, the invention also discloses a detection kit for the method and preparation, application, and the like of the corresponding detection kit. The multiple-detection method does not need special devices and can be widely used in the fields of laboratory investigation, food security, medicine, hygiene, and the like.

Owner:SUZHOU SYM BIO LIFESCI CO LTD

Method for pre-measuring volume of lithium ion battery

InactiveCN102608535AOvercoming the cumbersome steps of research capacity testingOvercoming complexityElectrical testingPhysicsLaboratory research

The invention belongs to the technical field of lithium ion batteries, in particular to a method for pre-measuring the volume of a lithium ion battery. The method comprises the steps of: taking at least two batteries to be formulated, measuring the volumes of the two batteries and calculating the average value Cm of the volumes; after the batteries are formulated and aged, charging the batteries to a preset SOC (stage of charge) and standing still to measure the OCV (open-circuit voltage); and determining the volume of the batteries according to the OCV and Cm. The method takes the OCV value of the special SOC of the batteries as input, calculates the pre-measuring volume according to a pre-measuring formula, and can be applied to pre-measuring the volume of lithium ion batteries of different types and volumes, wherein the average pre-measuring error is within 3%, which is smaller than 5% permitted in application of industrial production. The method, on the one hand, solves the problems of long volume test period, large energy consumption, occupancy of a large number of plants and staffs and high production cost in existing industrial application, and on the other hand, overcomes the deficiencies that the volume test steps are miscellaneous with complex and profound theories in laboratory studies and are not appropriate for industrial application.

Owner:NINGDE AMPEREX TECH +1

Method of sampling greenhouse gas by utilizing gas balance bag

InactiveCN1563932AReduce measurement errorEasy to implementWithdrawing sample devicesMaterial weighingEngineeringProduct gas

A gas balance bag is put into a closed box in use for measuring gas flux discharged by soil or plants. An amount of air is filled into the gas balance bag from small hole in the closed box, making the gas balance bag expand so as to take up certain volume in the closed box. Then, extracting gas measuring and calculating processed result are carried out according to traditional method suitable to closed box. The gas balance bag adjusts consistent air pressure between inside box and outside box. Comparing with measuring in site or in lab, the invention measures gas flux discharged by soil or plants accurately and reduces error.

Owner:SHANGHAI JIAO TONG UNIV

Kiwi fresh fruit preservation technique

InactiveCN101223906ANo pollution in the processEasy to operateFruits/vegetable preservation by freezing/coolingVacuum pumpingActinidia

The invention relates to a preservative technique for fresh kiwifruit, which comprises technique processes of cold storage disinfection, precooling, bagging, air regulate case vacuum pumping, air distribution, preservation and unhouse packaging. The technique of the invention carries out laboratory study test on the storage of the fresh kiwifruit, the test shows that the kiwifruit can be preserved for more than 200 days with average fruit firmness more than or equal to 3.0kg / cm<2>, fruit firmness rate more than or equal to 90 percent, commercial fruits rate more than or equal to 95 percent, Vc keeping-rate more than or equal to 80 percent and freshness index more than or equal to 0.90. Pilot scale study was carried out in an air conditioned storehouse in Zhouzhi County Shanxi Province in 2006 by the technique of the invention to store 50 tons of Hayward kiwifruit for 215 days with commercial fruits rate of 96 percent. The invention has the advantages of simple operation, long preservation period, good preservation effect, no environmental pollution, obvious economic benefit, etc., which can be widely applied.

Owner:SHAANXI NORMAL UNIV

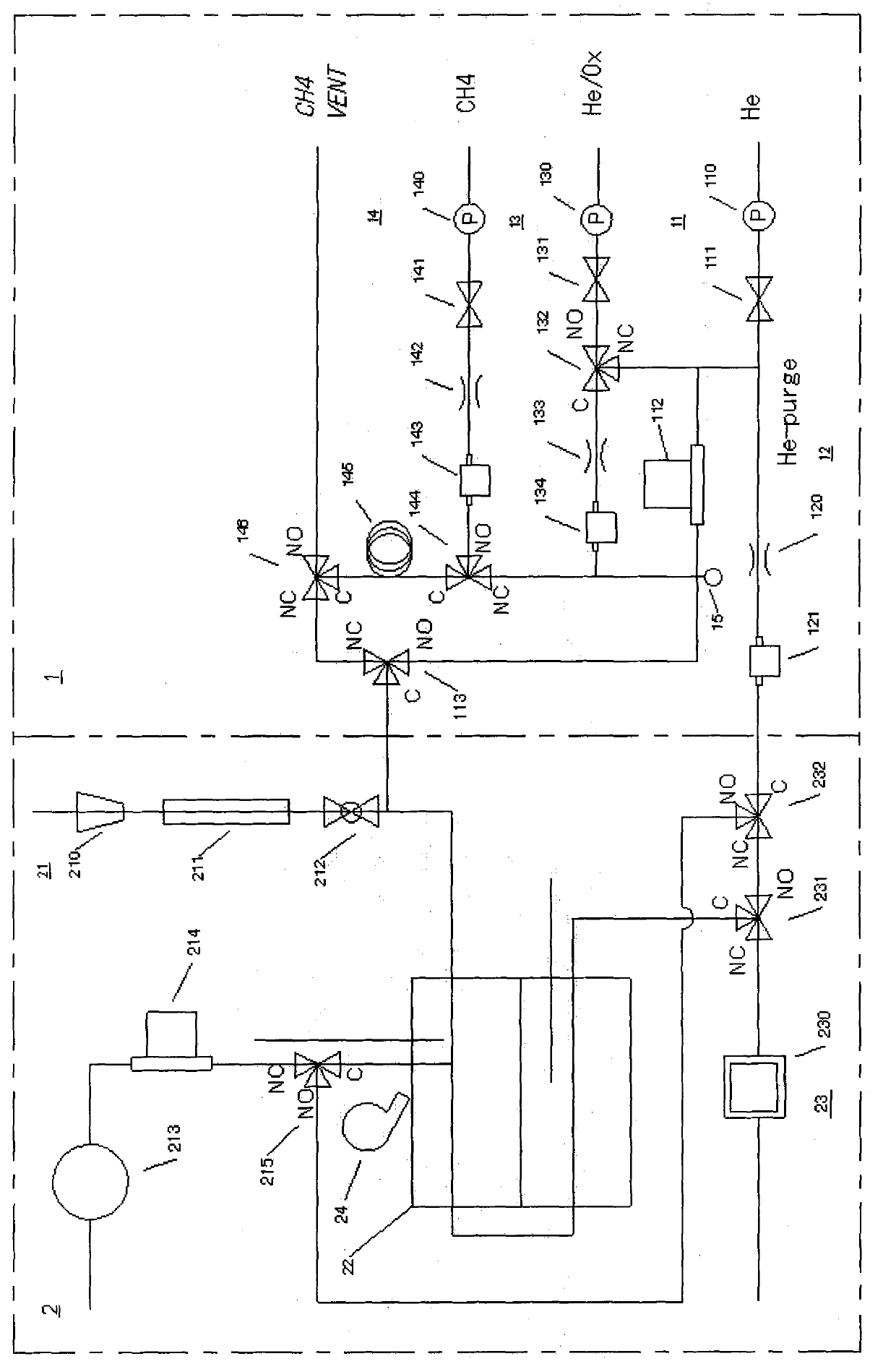

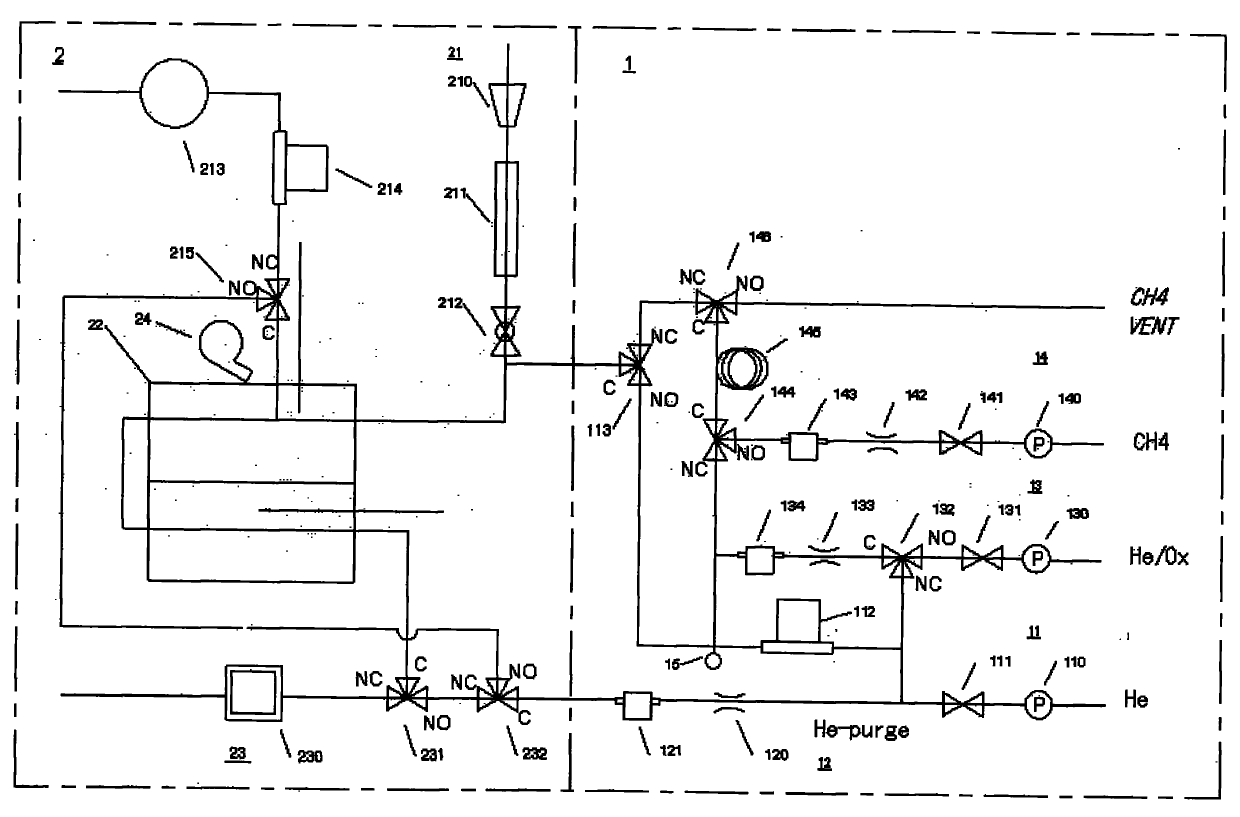

On-line aerosol carbon component collecting analyser

ActiveCN101949835AFlexible controlAutomate controlWithdrawing sample devicesColor/spectral properties measurementsProcess engineeringAtmospherics

The invention relates to an on-line aerosol carbon component collecting analyser. The analyser is characterized by comprising two parts, namely a carrier gas circuit system and a sampling-analyzing gas circuit system, wherein the carrier gas circuit system comprises a He gas circuit, a He-purge gas circuit, a He / Ox gas circuit and a He / CH4 gas circuit; and the sampling-analyzing gas circuit system comprises a sampling gas circuit, an analyzing-oxidizing furnace and an analyzing gas circuit. The on-line aerosol carbon component collecting analyser can continuously collect an atmospheric aerosol sample on line, chooses or automatically sets a temperature rise program according to needs and analyzes carbon components in the atmospheric aerosol by using a laser transmission method and a correction method. Besides, the on-line aerosol carbon component collecting analyser has the advantages of strong practicability, low running cost, convenient management, suitability for laboratory researches and environment-protection automatic monitoring stations all over China and capability of acquiring realer and more accurate carbon component data of the atmospheric aerosol.

Owner:PEKING UNIV

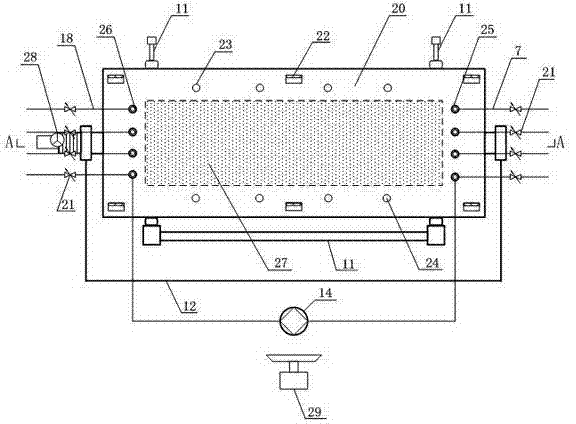

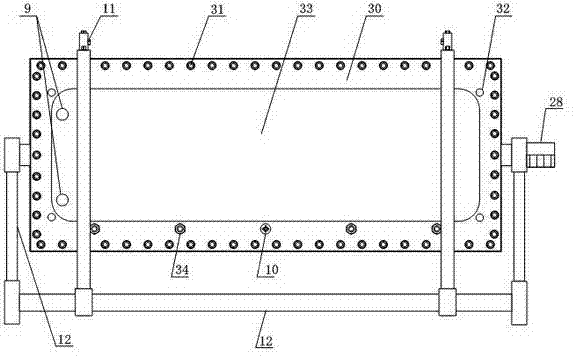

Device and method for large-size visual physical simulation of fingering of acid liquid in acid fracturing crack

InactiveCN102928556AFast heatingIn line with the real environmentFluid removalMaterial analysisAcid fracturingDifferential pressure

The invention relates to a device and a method for large-size visual physical simulation of fingering of an acid liquid in an acid fracturing crack in an oilfield chemistry and acid fracturing laboratory and a research laboratory. The device and the method can simulate flowing and reaction conditions of an acid liquid in an acid fracturing crack, can be used for observation of fingering of an acid liquid, and can determine associated parameters. The device is characterized in that a high-pressure constant-flow pump of a liquid pumping unit is connected to a liquid storage tank; a liquid outlet of the high-pressure constant-flow pump is connected to middle containers; the middle containers are connected to a six-way valve; the six-way valve is connected to a liquid inlet of a crack simulation unit; a stainless steel front frame is connected to a rear cover by fastening bolts; exhaust holes and drainage holes are arranged respectively at an upper part and a low part of the stainless steel front frame; liquid inlet holes and liquid outlet holes are arranged respectively at a left end and a right end of the stainless steel front frame; an observation window is arranged in the center of the stainless steel front frame; a rock plate is arranged between the stainless steel front frame and the rear cover; an electric heating panel and a heating probe are embedded in an outer side of the rear cover; a temperature sensor is arranged in the center of the rear cover; the liquid inlet holes and the liquid outlet holes of the stainless steel front frame are provided with a differential pressure transducer; and an image gatherer is installed right in front of the crack simulation unit. The device and the method improve a degree of mechanization and automation. A simulation experiment carried out by the device satisfies storage layer real-environment requirements, and is safe and fast.

Owner:SOUTHWEST PETROLEUM UNIV

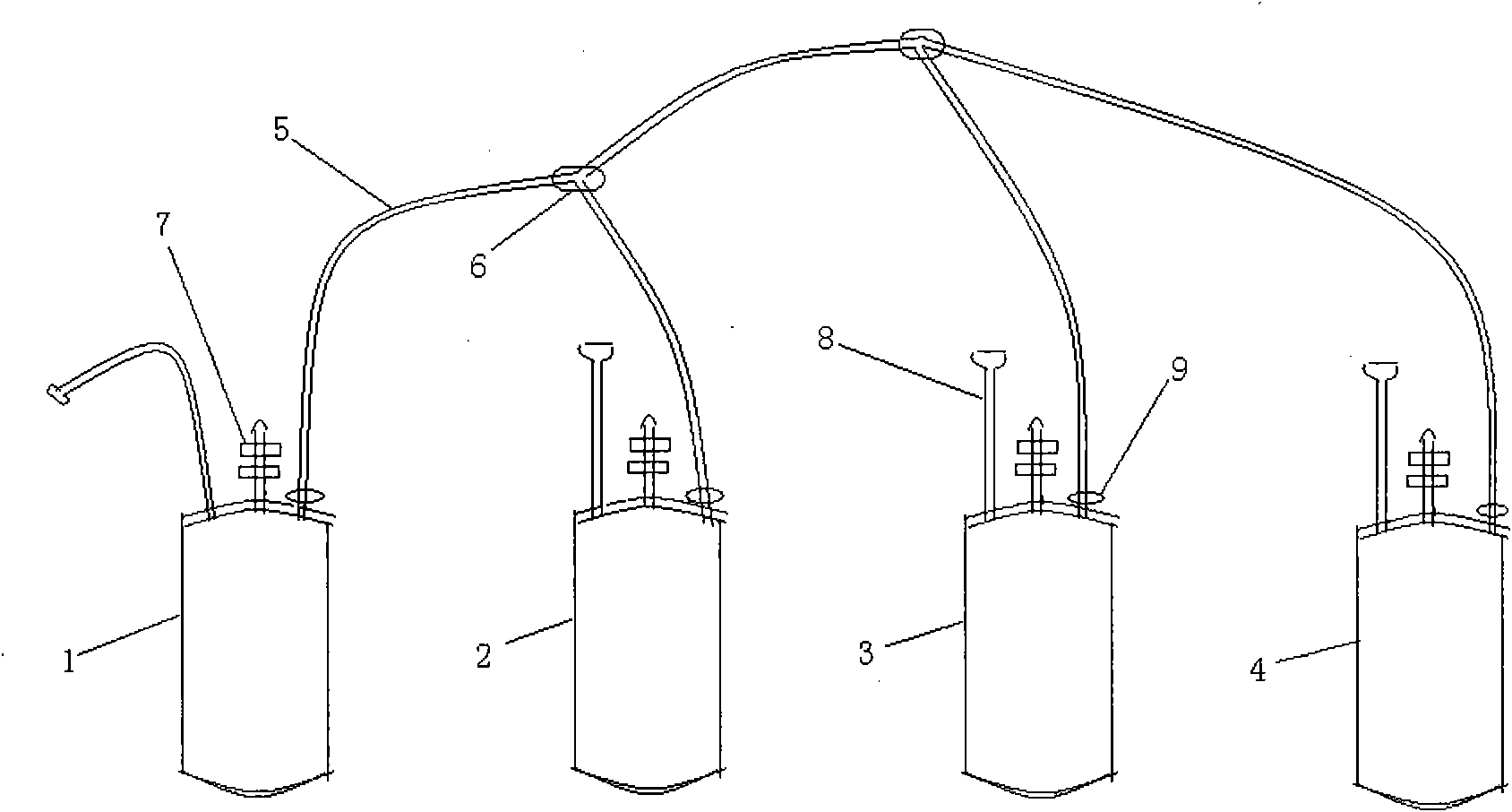

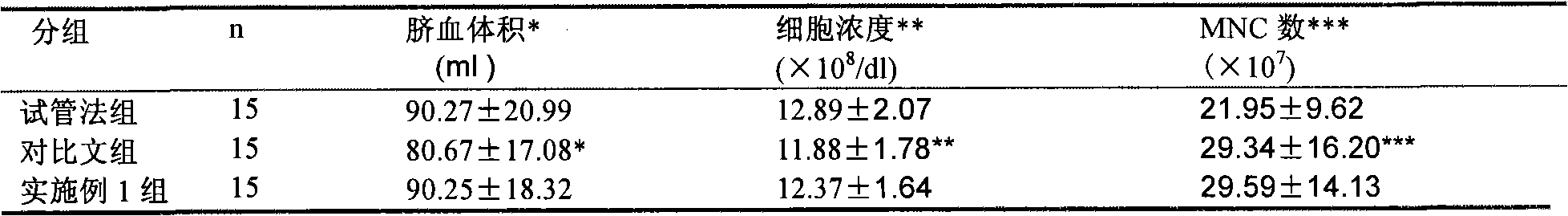

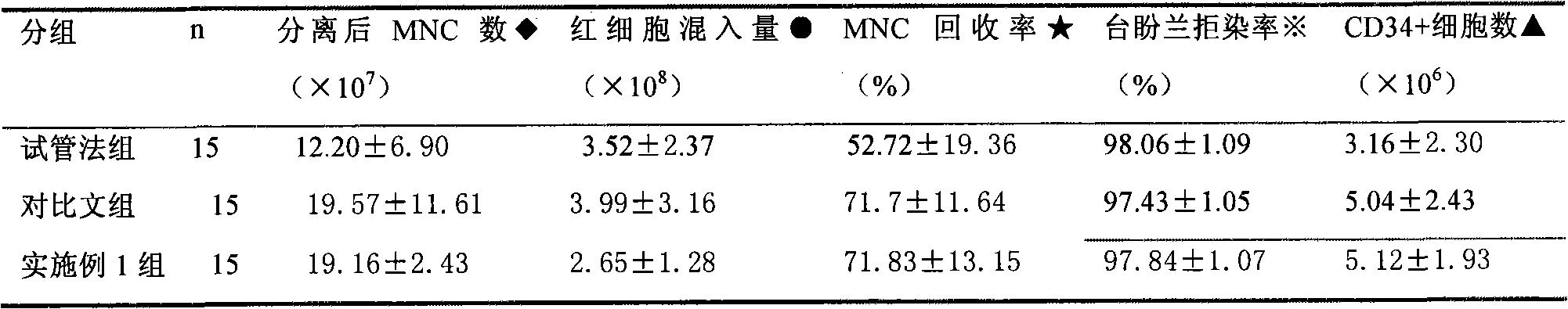

Method and device for separating single karyocyte

ActiveCN101560495ASolve pollutionReduce the amount of mixingBioreactor/fermenter combinationsBiological substance pretreatmentsHuman bodyCord blood stem cell

The invention provides a method and a device for separating a single karyocyte, in particular a method and a device for separating single karyocyte of cord blood, marrow and peripheral blood. The single karyocyte can be separated without a hundred grades purification environment, and the method and the device are not limited by sample numbers and volumes, and has high efficiency, simple structure and no pollution, thereby being applied to laboratory research and human body treatment, and being easy to produce in batch.

Owner:SHENZHEN BEIKE BIOTECH +1

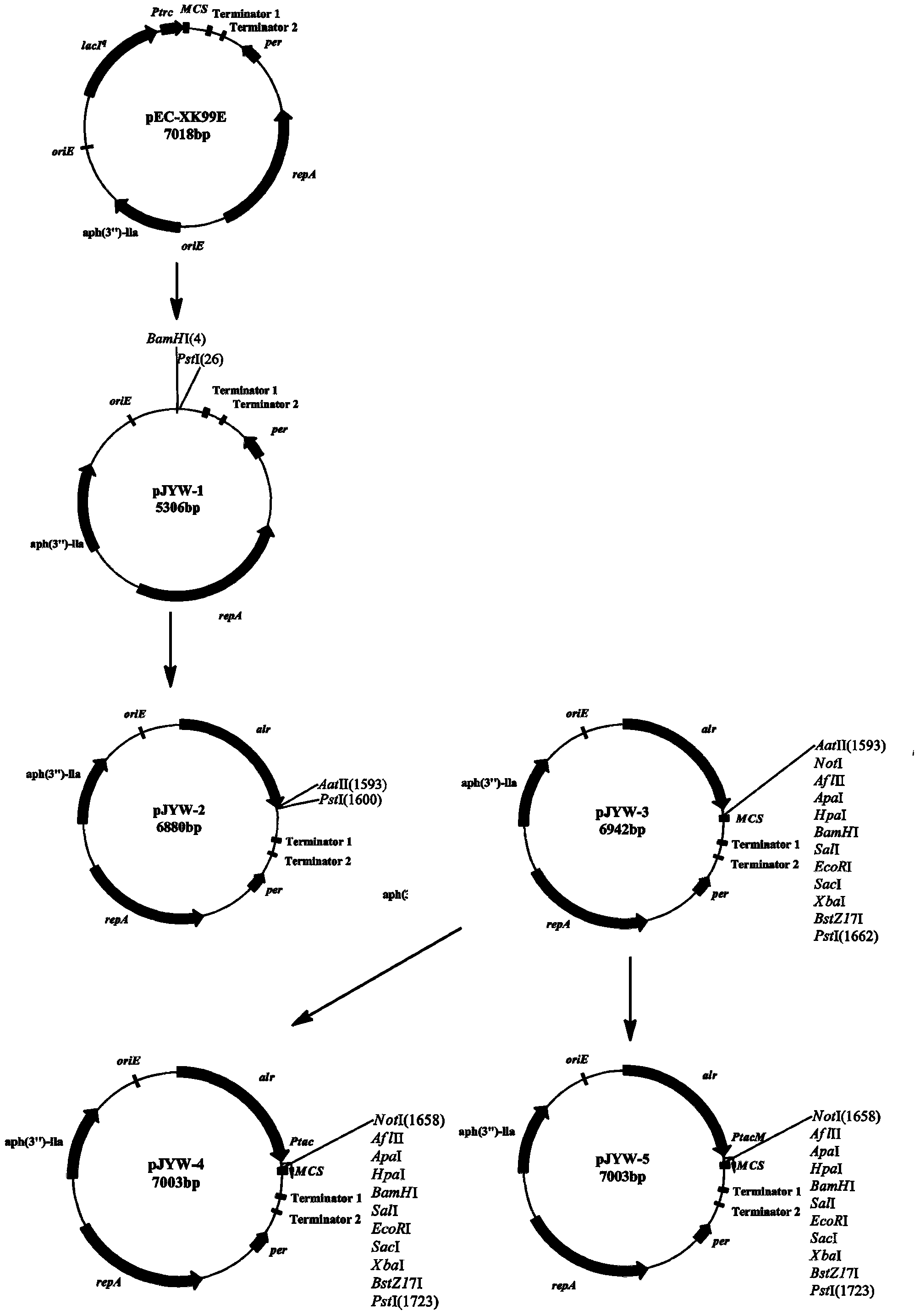

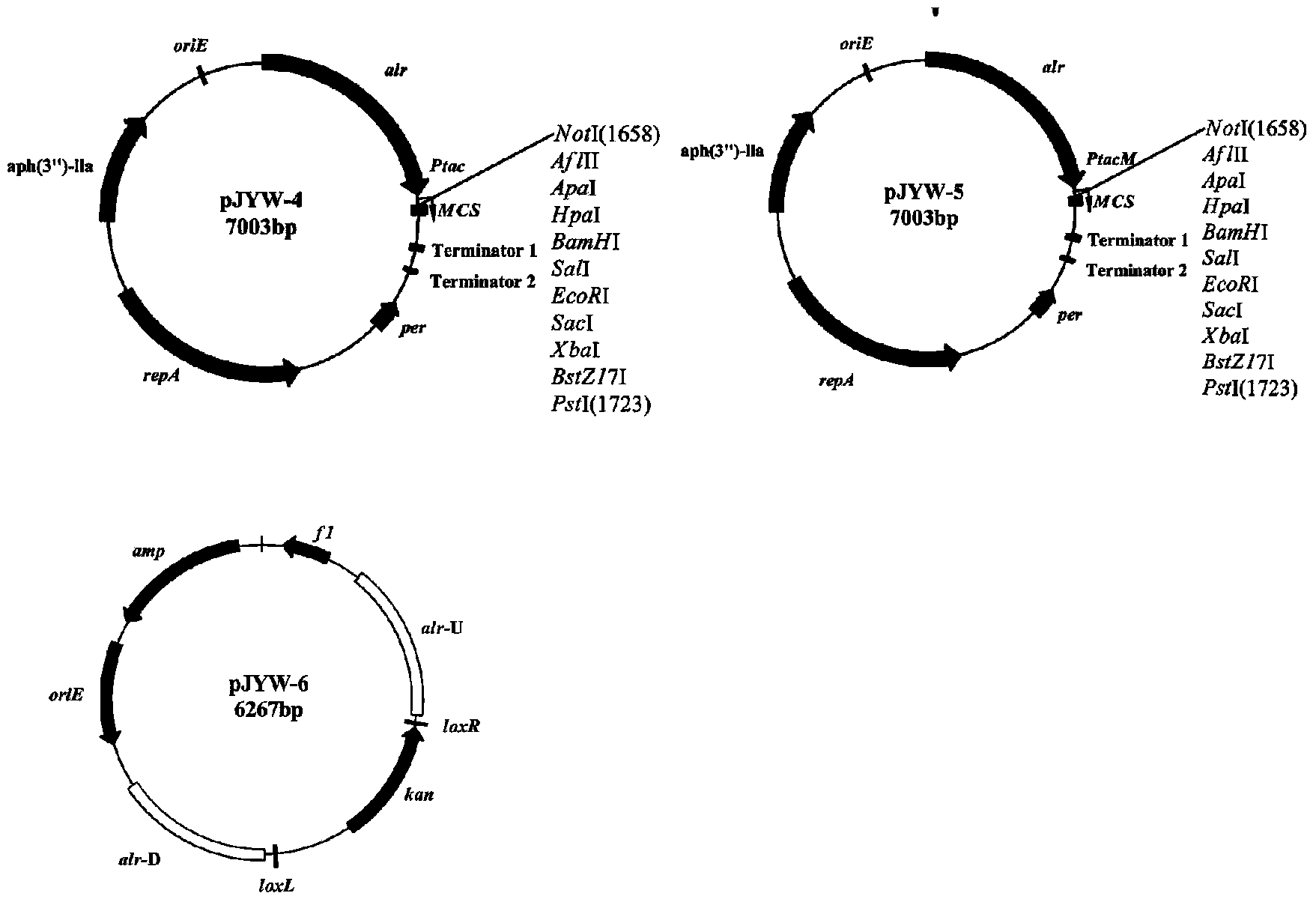

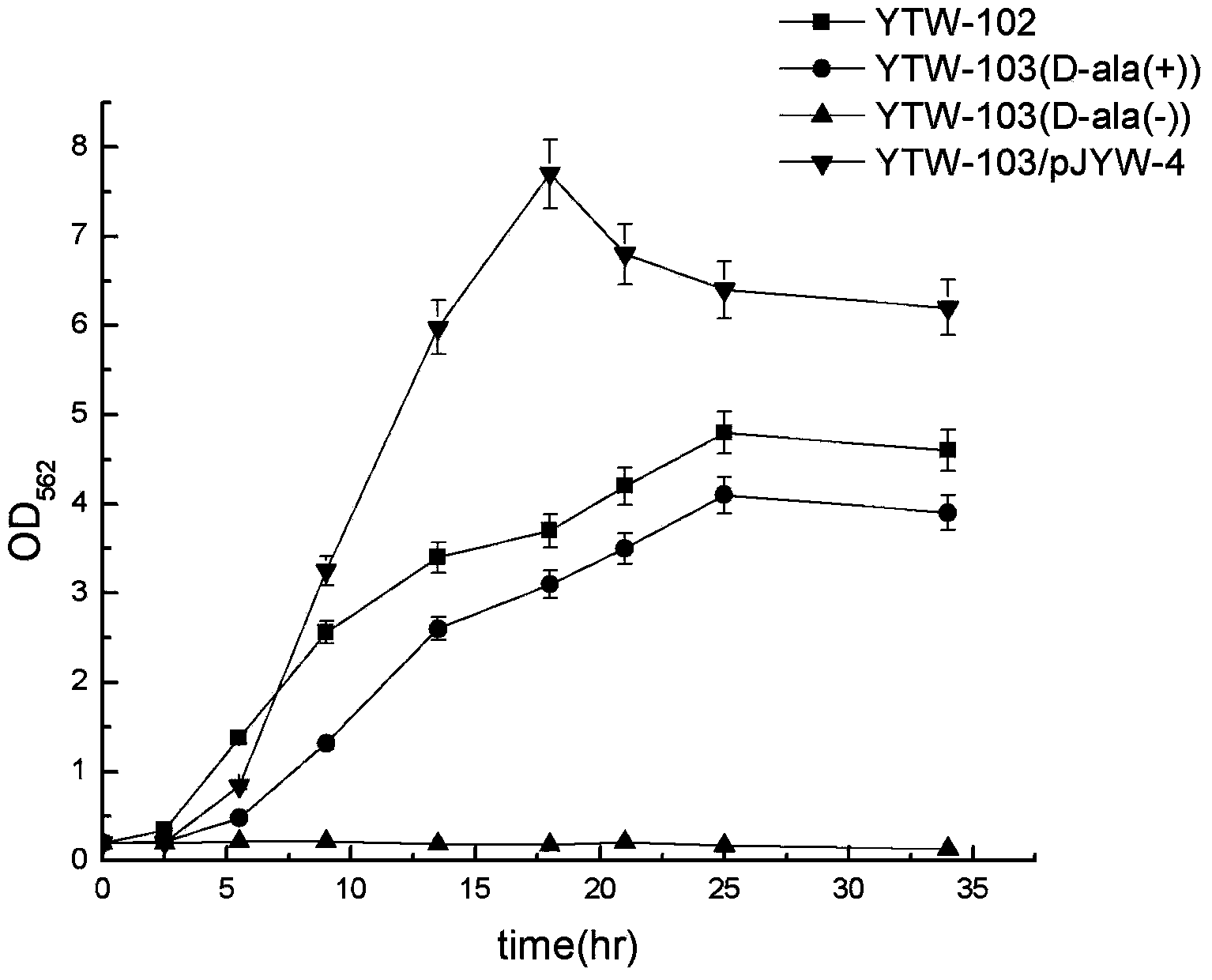

Corynebacteria expression system without depending on antibiotic being selection pressure

ActiveCN103834679AFacilitate scientific researchEase of industrial applicationBacteriaMicroorganism based processesMicroorganismGene engineering

The invention discloses a corynebacteria expression system without depending on antibiotic being selection pressure, and belongs to the microbe gene engineering field. Alr knock out carrier and expression carrier used for plasmid anaplerosis are constructed to bring conveniences for lab research and utilization, and a fermentation process no longer needs antibiotic. Through test results, the expression system realizes thalline inner plasmid stability in fermentation without adding the antibiotic; when the expression system is used to construct overexpression vector of branched chain amino acid-valine synthesis path main gene ilvBNC, valine output can be obviously improved; the corynebacteria expression system has wide application value.

Owner:JIANGNAN UNIV

Hydrocracking catalyst and preparation method thereof

InactiveCN103007999AHigh activitySmall cell constantMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveHazardous substance

The invention relates to a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst consists of hydrogenation active metal and a carrier structured by a modified composite molecular sieve and amorphous aluminium silicate; the hydrogenation active metal is molybdenum and / or tungsten, and / or cobalt, and / or nickel; the molybdenum and / or the tungsten accounts for 15.0-30.0% of the weight of the catalyst as weighed by oxide; the cobalt and / or the nickel accounts for 4.0-8.0% of the weight of the catalyst as weighed by oxide; the balance is the carrier structured by the modified composite molecular sieve and amorphous aluminium silicate; and the modified composite molecular sieve accounts for 10-20% and the amorphous aluminium silicate accounts for 80-90% by metering as the weight of the catalyst. The catalyst has the advantages that the raw materials are cheap and easy to buy; the preparation process is simple and easy to operate and has no generation of poisonous and harmful substances; the adaptability directing at the feature change of the raw materials; and the catalyst is suitable for experiment research on the existing hydrocracking process technology, can effectively solve the laboratory research difficulty and provides a reliable guarantee for the research and implementation of the hydrocracking process technology.

Owner:PETROCHINA CO LTD

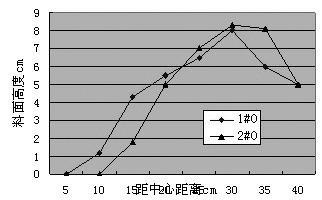

Model testing method for adjustment of ore-coke ratio distribution in blast furnace

InactiveCN102559963AOperational metrics improved and improvedEasy to operateBlast furnace detailsModel testingReduced size

The invention relates to a model testing method for adjustment of ore-coke ratio distribution in a blast furnace, belonging to the technical field of test research in the industry of metallurgy. The technical scheme includes the steps as follows: a blast furnace burden-distributing model is manufactured by the 10-time reduced size of the upper part of the actual blast furnace body, a clapboard is arranged inside the blast furnace burden-distributing model and the clapboard is moved up and down by a pulley system on the framework at the upper part of the blast furnace burden-distributing model so as to imitate burden distribution; and after burden distribution according to on-site burden, the thickness values of ore and coke distributed on the clapboard are measured, the height of the radial burden surface is measured, and then the curve of the shape of the burden surface is drawn, so that the ore-coke ratio of the burden is calculated. The model testing method has the beneficial effects of being simple in operation, correct in measurement, convenient and visualized, saving not only test materials but also test furnace burden and reducing test workload; and the model testing method has the advantage of analyzing the reasonable ore-coke ratio distribution on the bell-less top of the blast furnace as well as radial relevant parameters in an aiming way, therefore the model testing method is a practical method for researching the burden distribution law of the blast furnace and guiding on-site operation in a metallurgical laboratory.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

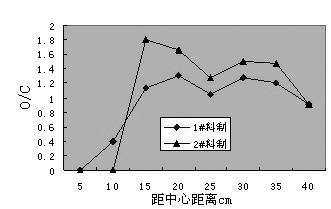

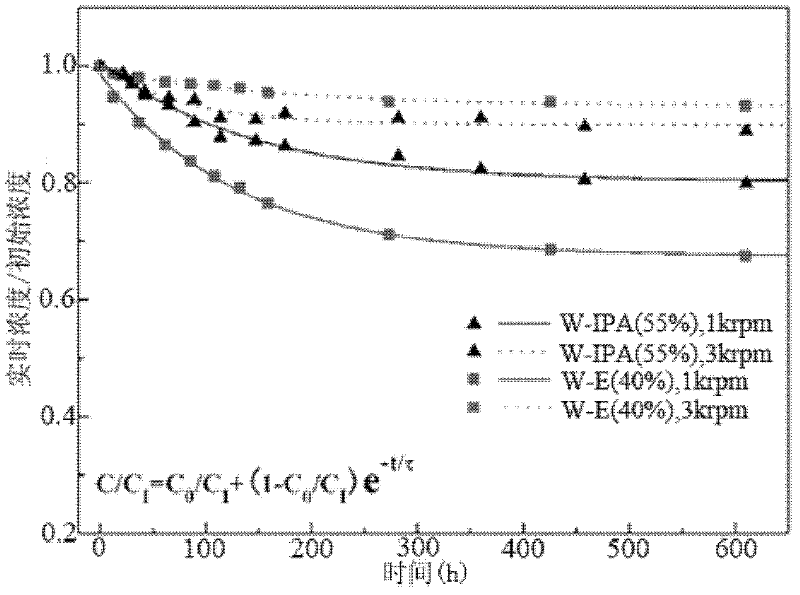

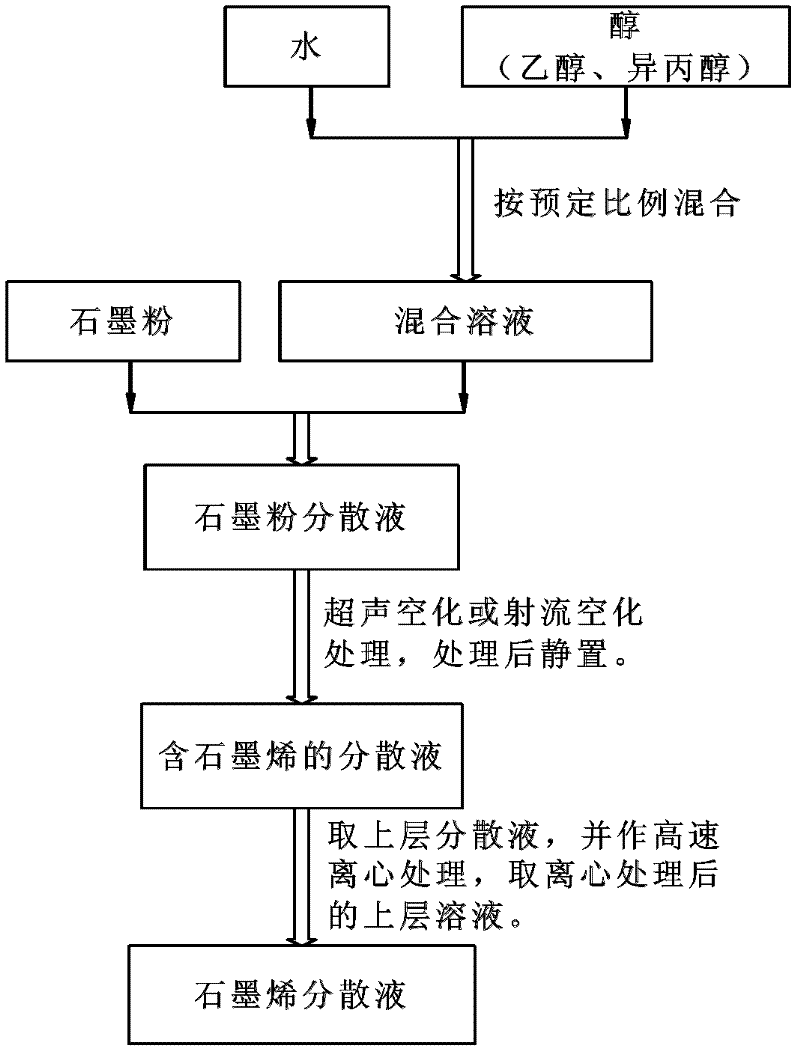

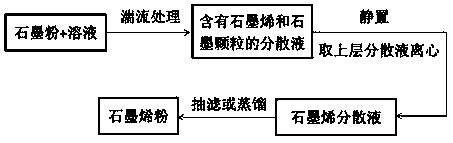

Technology and method for preparing solution used for preparing graphene in liquid phase

InactiveCN102583332ASimple preparation processEasy to prepareMaterial nanotechnologyGrapheneUltrasonic cavitationSolvent

The invention provides a technology and method for preparing solution used for preparing graphene in a liquid phase, comprising the following six steps of: firstly, directly mixing water and alcohol in predetermined proportion, thus the solution used for preparing graphene in the liquid phase can be obtained; secondly, dispersing graphite powder into the solution, thus graphite dispersion is obtained; thirdly, treating by adopting ultrasonic cavitation or jet flow cavitation; fourthly, standing the treated solution, and taking the solution at the upper layer; fifthly, carrying out high-speed centrifugal separation on the solution at the upper layer; and sixthly, collecting supernate at the upper layer after the high-speed centrifugal separation is carried out, thus stable graphene dispersion is obtained. By adopting the solution directly mixed by the water and the alcohol in the invention, the graphene can be prepared in non-toxic pollution-free green solvent with low boiling point, equipment investment is less, raw materials are available, production safety is high, operation is simple and convenient, environmental protection can be realized, yield is considerable, reproducibility is good, and the technology and method provided by the invention are applicable to laboratory study and are also applicable to large-scale industrial production.

Owner:BEIHANG UNIV +1

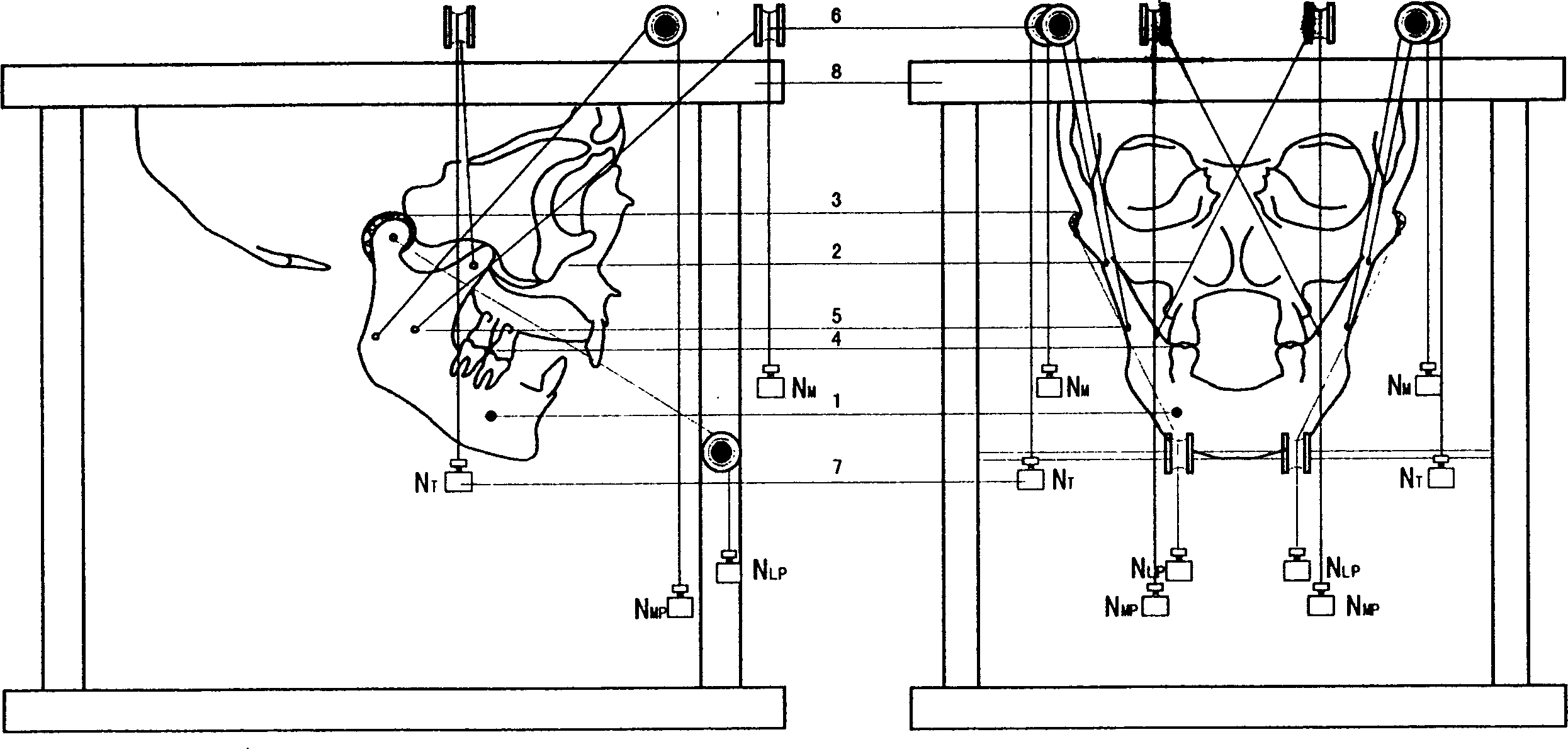

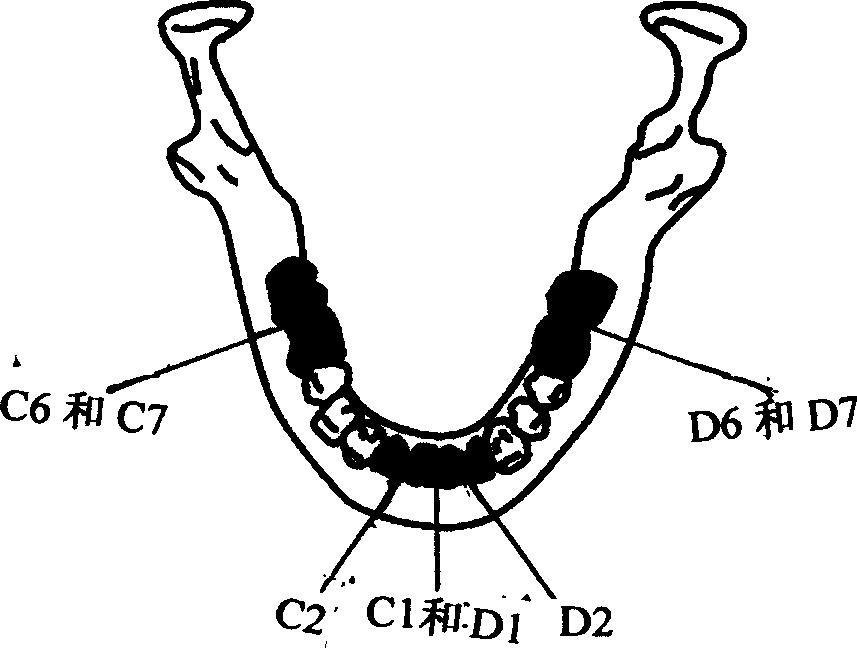

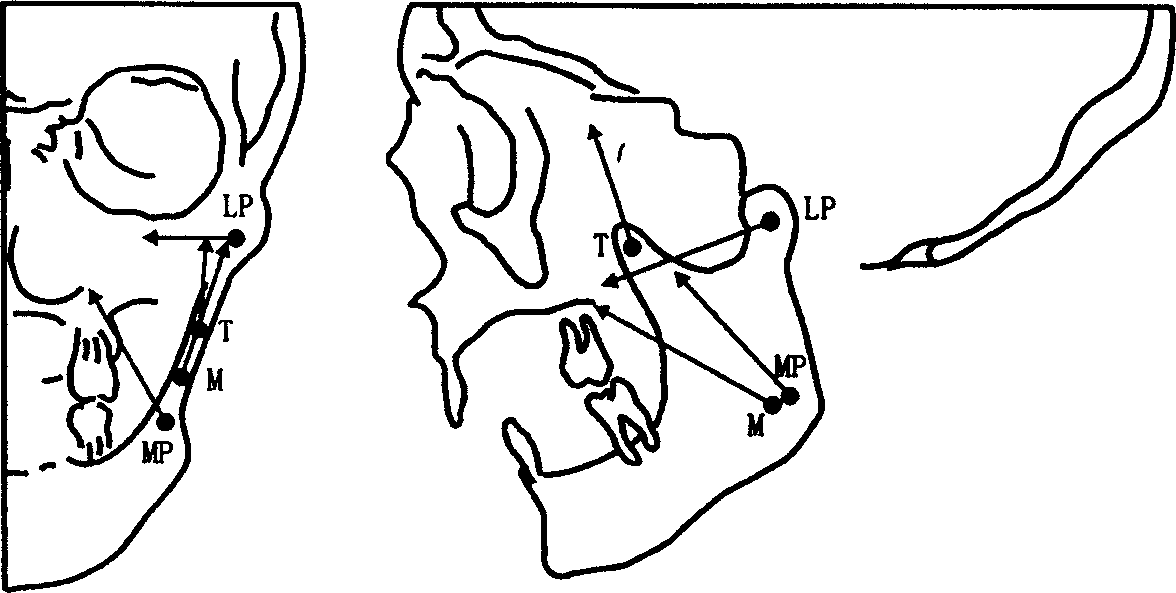

Biomechanical model of human lower jawbone

InactiveCN1527255AOvercoming Shortcomings of Simplified Loading ModelingIntuitive stress stateEducational modelsMaxillofacial oral surgeryHuman body

The present invention relates to the biomechanical model of human lower jawbone in oral cavity masticatory surface surgery, and aims at forming one kind of experimental biomechanical model of human lower jawbone approaching the functional state. The biomechanical model includes lower jawbone, upper jaw model, temporomandibular joint model, occlusion platform, loading myodynamia and loading device. The model can be used in simulating the action of masseter, temporal muscle, musculus pterygoideus internus and musculus pterygoideus externus, and is superior to available simplified model. The biomechanical model of the present invention is accurate, objective and complete in simulating lower jawbone in functional state and is significant for relevant laboratory research and clinical application.

Owner:SICHUAN UNIV

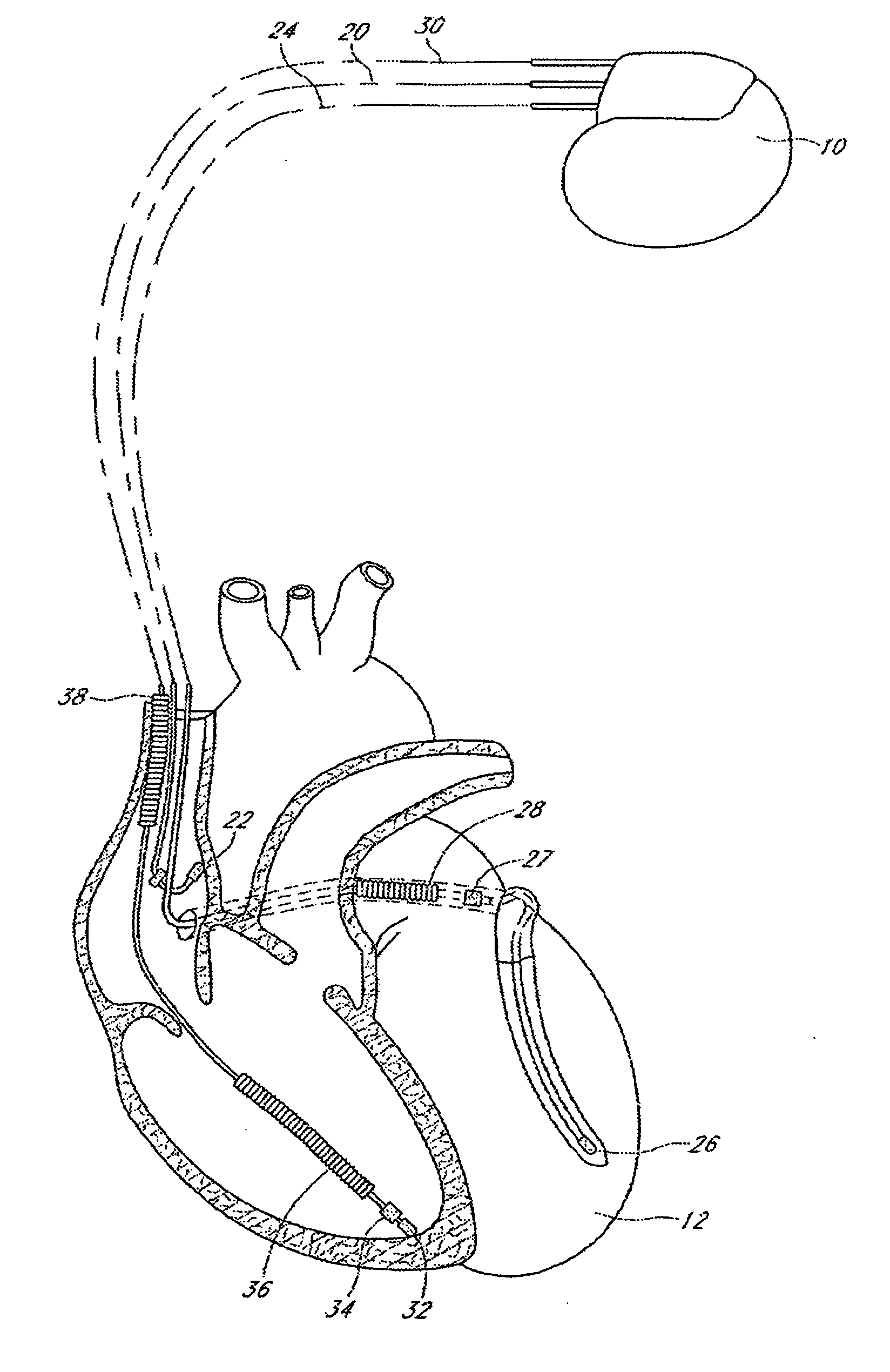

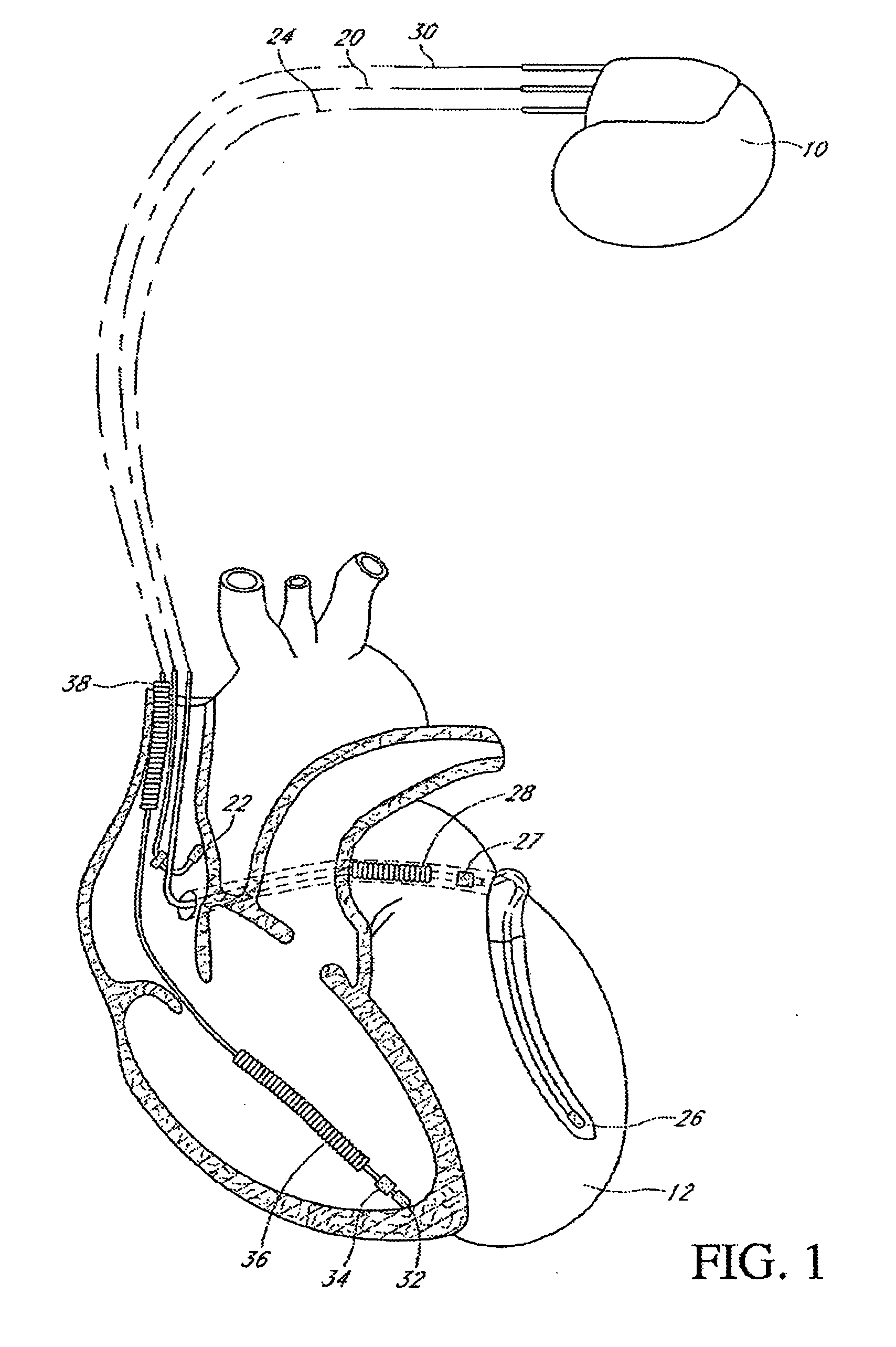

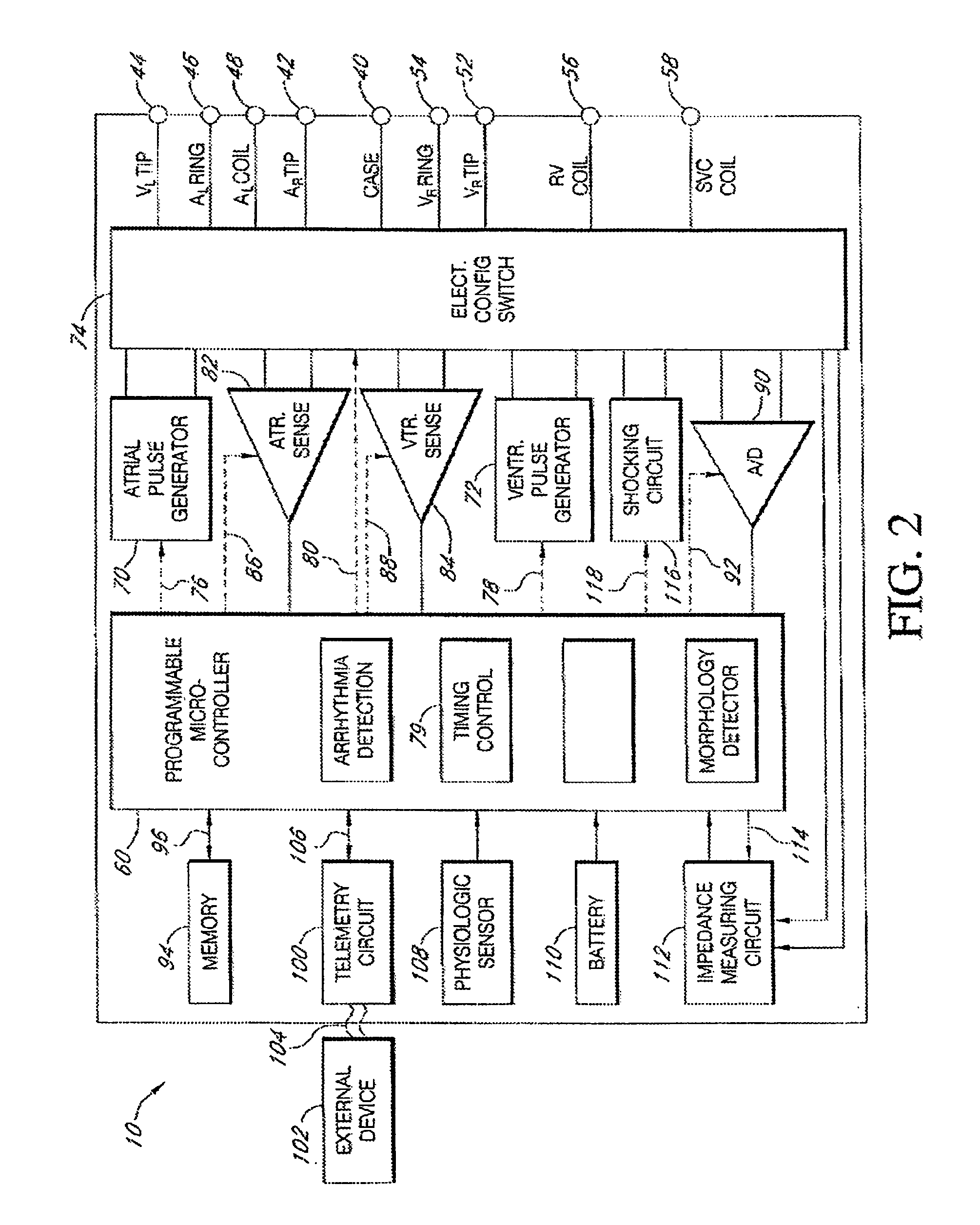

High Voltage Confirmation System Utilizing Impedance Data

Systems and methods for providing high voltage confirmation are disclosed. In various embodiments, impedance data can be used as a basis for determining the operation of a high voltage confirmation system. In some embodiments, measurements of impedance associated with the high voltage lead(s) can provide indication as to the condition of the lead(s). In some embodiments, faulty leads can yield impedance values that exceed a known threshold value. In some embodiments, such threshold value can be determined from a laboratory study of the leads under conditions that are similar to the operating conditions of implantable cardiac devices.

Owner:PACESETTER INC

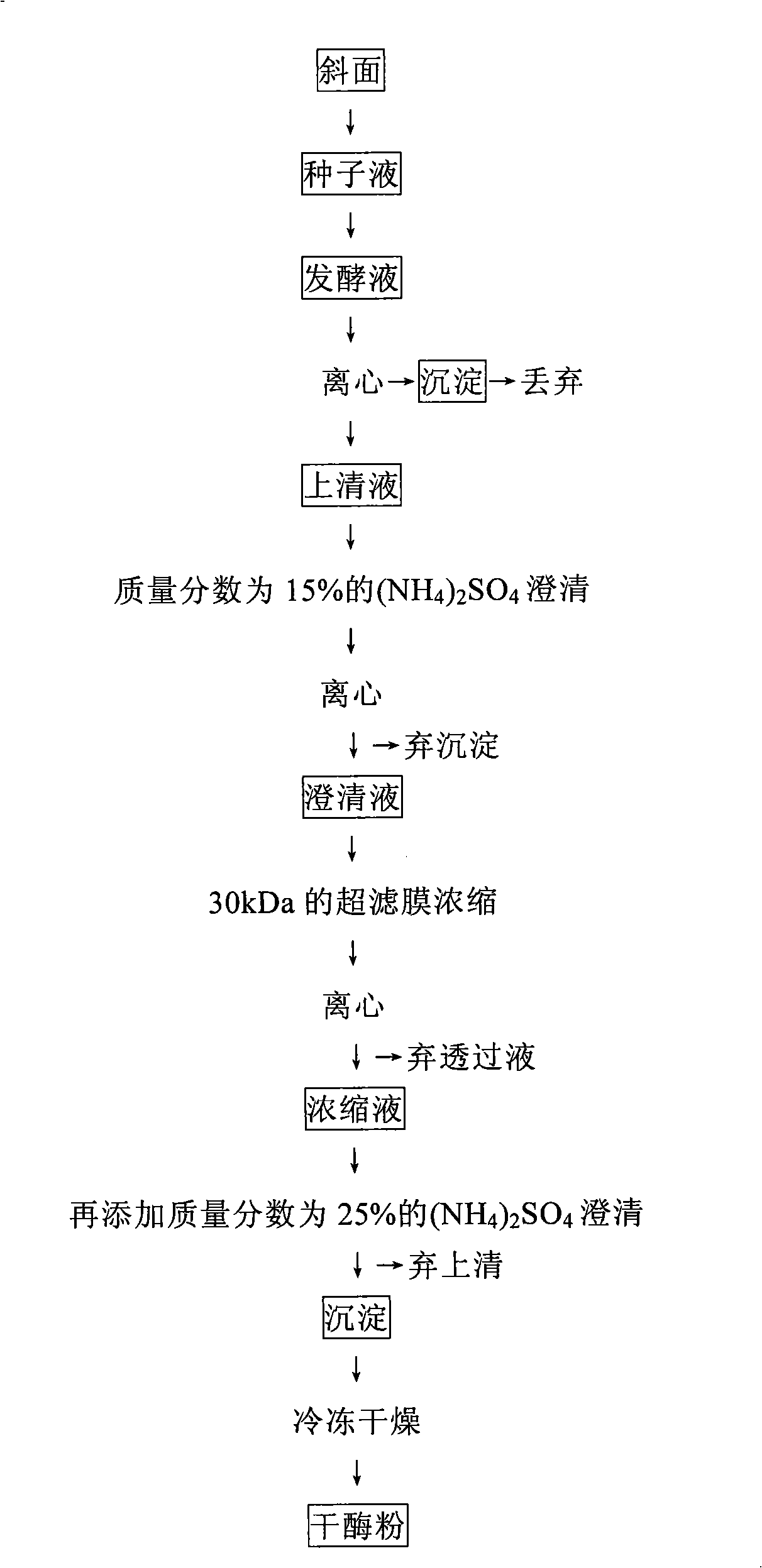

Fermentation preparation and extraction method for bacillus subtilis debitterized aminopeptidase

ActiveCN101492663ANo bitternessReduce or eliminate bitternessMicroorganism based processesEnzymesFood additiveDipeptide

The invention discloses a method for preparing and extracting Bacillus subtilis debittering aminopeptidase by fermentation, which belongs to the technical field of enzyme preparation and food additive. The invention uses the fermentation cylinder production condition of Bacillus subtilis Zj016 to collect fermentation liquor and obtain the product of debittering aminopeptidase by carrying out clarifying, ultrafiltration concentration and salting out on the fermentation liquor. The aminopeptidase produced by the selected Bacillus subtilis Zj016 is exopeptidase which can dissociate amino acid from a polypeptide chain amino terminal. Researched by the laboratory, the aminopeptidase cooperates with alkali protease to hydrolyze soybean protein isolate; the prepared soybean peptide does not have bitterness, and the contents of oligopeptide like dipeptide and tripeptide are higher. Besides, researches on the enzyme lines produced by the Bacillus subtilis show that the Bacillus subtilis only produces circumscribed prolease and does not have the activity of endo protease; moreover, the circumscribed prolease has a stronger hydrolysis capacity to the terminal amino acid with strong hydrophobicity. The research further explains that the invention can reduce or eliminate the bitterness generated during hydrolysis of the soybean protein.

Owner:江苏博立生物制品有限公司

Method for obtaining composite coating by means of laser cladding of extrusion preset powder

InactiveCN102618868ANo lossIncrease profitMetallic material coating processesOptoelectronicsVacuum drying

The invention relates to a method for obtaining a composite coating by means of laser cladding of extrusion preset powder. The method includes uniformly mixing cladding powder materials into paste or cream by the aid of prepared adhesive liquor; then presetting the paste or cream on the surface of a substrate material in an extrusion manner; naturally drying the paste or cream on the surface of the substrate material or placing the paste or cream on the surface of the substrate material in a vacuum drying tank for drying, and forming a preset layer; and finally realizing laser cladding so that the preset layer is in metallurgical bonding with the substrate material, and obtaining the required composite coating. The method has the advantages of wide application range, high powder utilization rate, low cost, simple process, simplicity and convenience in control, and the like. In addition, the method not only is applicable to laboratory research of laser cladding composite coatings, but also is applicable to fields of laser cladding composite coatings on surfaces of metal parts with complicated shapes and high technical requirements.

Owner:KUNMING UNIV OF SCI & TECH

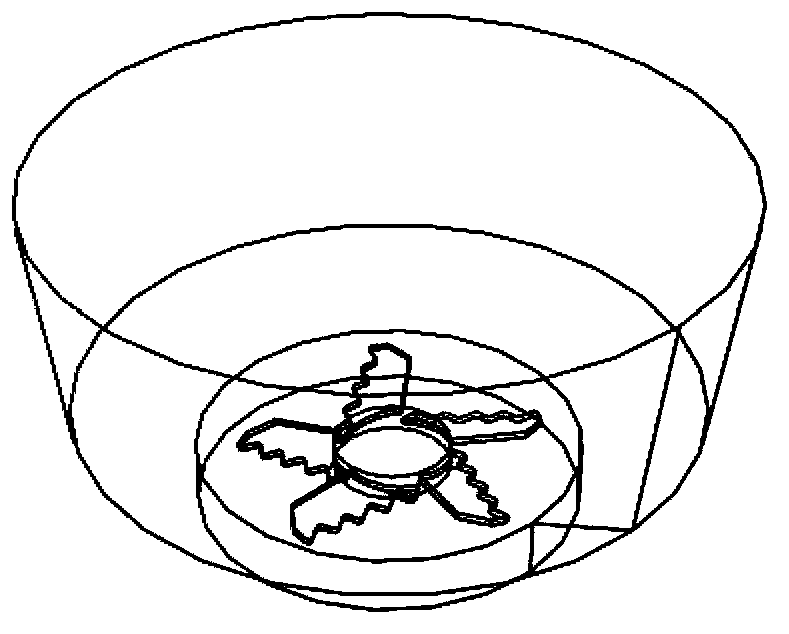

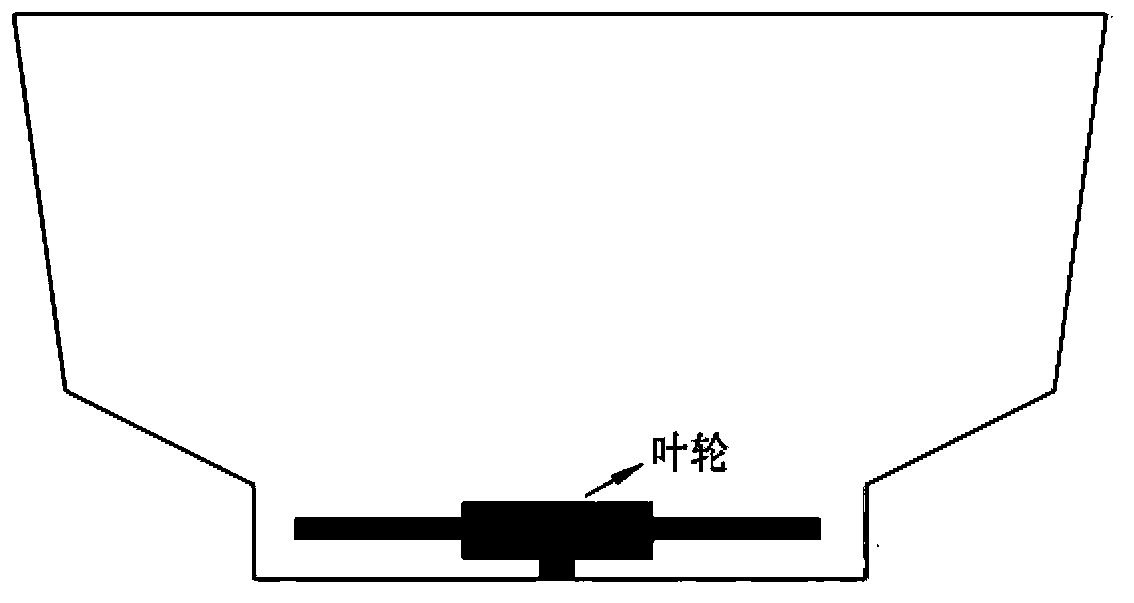

Turbulence method for preparing high-quality graphene

The invention discloses a turbulence method for preparing high-quality graphene. The turbulence method comprises seven steps: 1, dispersing graphite powder into a solution to obtain graphite dispersion liquid; 2, rotating the graphite dispersion solution in a container at high speed to obtain turbulence; 3, processing the graphite powder dispersion solution by using the turbulence; 4, standing the processed solution and taking the upper layer of solution; 5, performing centrifugal separation on the upper layer of solution; 6, collecting the upper layer of solution which is subjected to high-speed centrifugal separation to obtain a stable high-quality graphene dispersion solution; 7, performing suction filtration or distillation on the graphene dispersion solution to obtain graphene powder. The turbulence method is mild in preparation process, low in equipment investment, low in raw material cost, high in production safety, simple and convenient to operate, feasible, environmentally friendly, considerable in yield, high in reproducibility, applicable to laboratory research and suitable for large-scale industrialized production.

Owner:BEIHANG UNIV

Three-dimensional precision measurement and calibration method for industrial CT (computed tomography)

InactiveCN103558237AEasy to fixReduce refractionMaterial analysis by transmitting radiationVoxelDimensional modeling

The invention discloses a three-dimensional precision measurement and calibration method for industrial CT (computed tomography). The three-dimensional precision measurement and calibration method comprises two parts, namely industrial CT scanning parameter optimization and three-dimensional precision industrial CT measurement and calibration. According to the method, the conventional technology is innovatively optimized on the basis of a large quantity of laboratory researches and industrial applications aiming at three important processes, including setting of main scanning parameters, correction of a ray beam hardening phenomenon in a three-dimensional reconstruction process and voxel dimension and boundary definition calibration in a three-dimensional modeling and precision measurement process, which affect the three-dimensional industrial CT measurement quality. According to the method, the precision and the stability of the three-dimensional industrial CT measurement can be greatly improved, so that the applications of the three-dimensional industrial CT measurement in the fields of precision measurement and control, three-dimensional modeling, quantitative and qualitative analysis of internal and external structures of complicated machinery, reverse engineering and the like can be greatly expanded.

Owner:谭晔

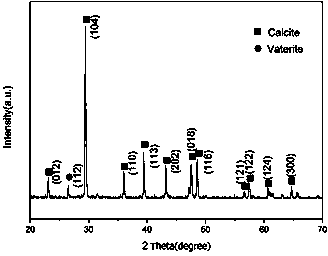

Method for preparing globular porous calcium carbonate granules

ActiveCN103351016AUniform sizeSmall sizeCalcium/strontium/barium carbonatesMaterial nanotechnologyPrillArginine

The invention discloses a method for preparing globular porous calcium carbonate granules and belongs to the technical field of a preparation method of nano calcium carbonate granules. The method comprises the following processing steps: respectively preparing arginine solution, calcium source solution and sodium carbonate solution; mixing the arginine solution with the sodium carbonate solution to obtain mixed solution; dropwise adding the mixed solution to the calcium source solution under the condition of vigorous stirring; then, continuing to vigorously stir after the dropwise addition, centrifugally collecting granule sediments after reaction is finished; and washing the granule sediments by deionized water and absolute ethyl alcohol, and then drying, so as to obtain nano calcium carbonate granule powder. The method disclosed by the invention is simple in preparation process, strong in laboratory maneuverability, low in production cost, high in product yield, and suitable for research and application of the laboratory and industrial production; and the prepared globular granules have the advantages of good dispersibility, large specific surface area and the like. Therefore, the prepared globular granules have great application potential in the fields of biomedicine and biological materials, such as controlled-release drug carriers, gene therapy vectors and the like.

Owner:ZHEJIANG SCI-TECH UNIV

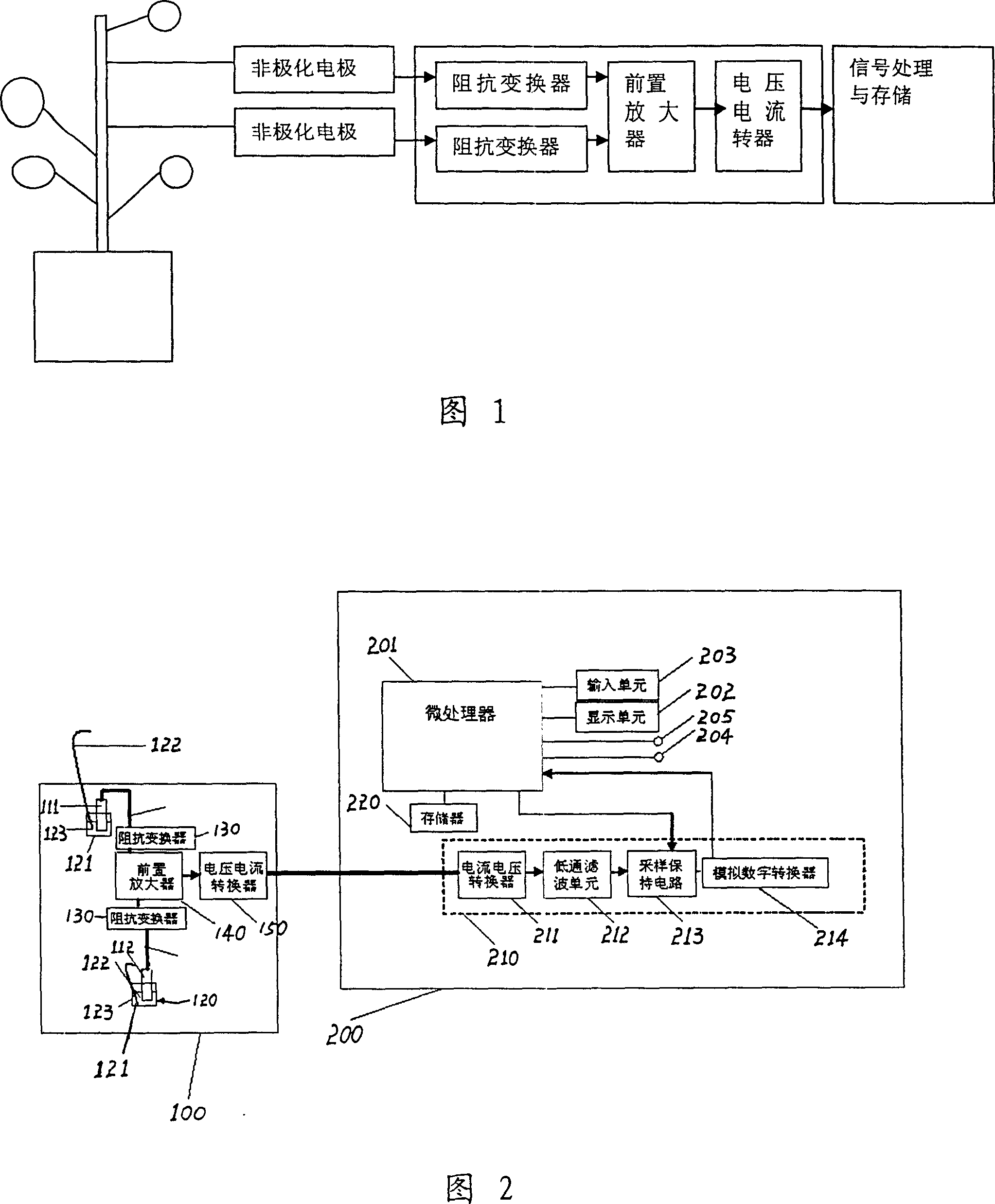

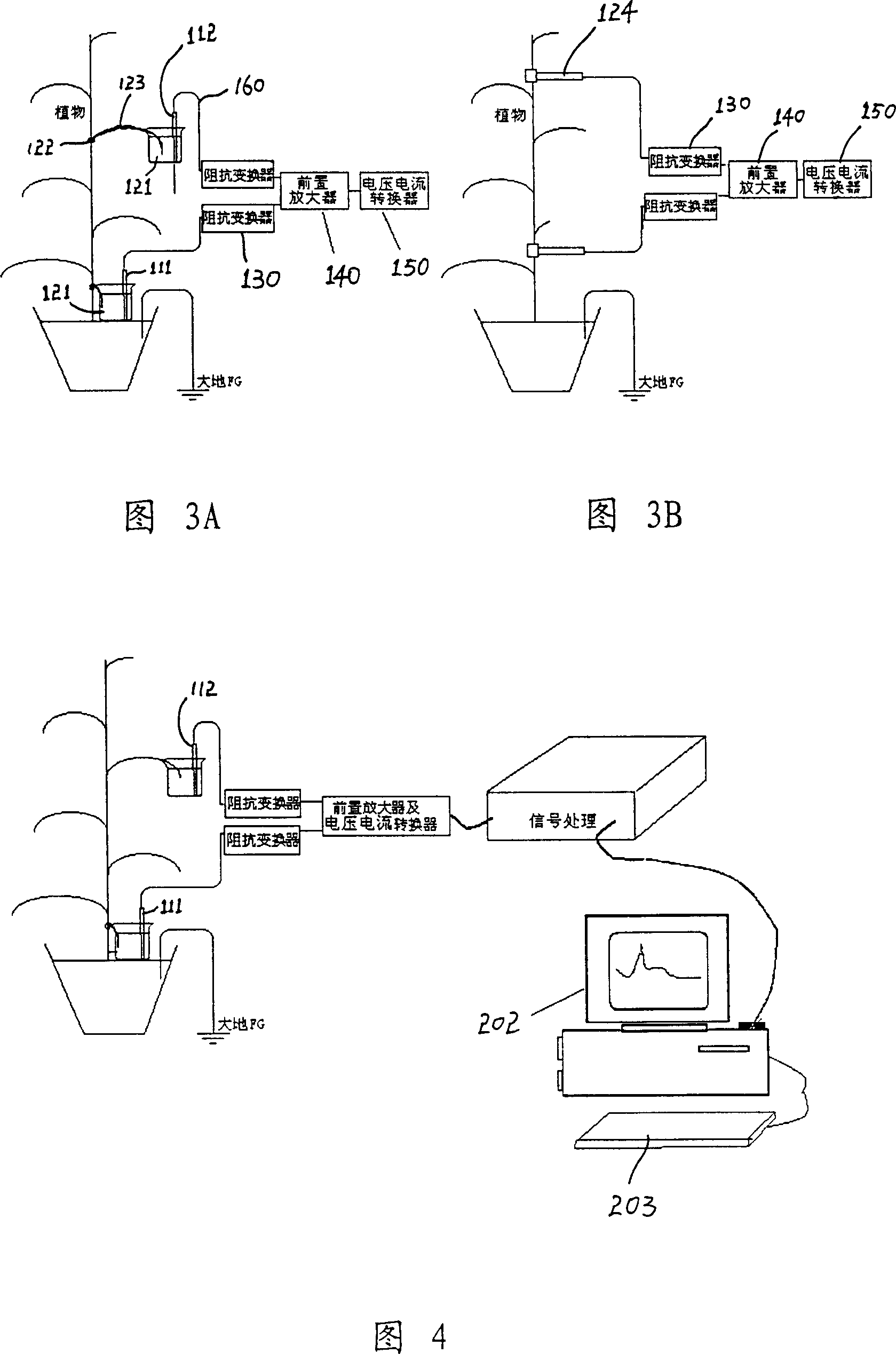

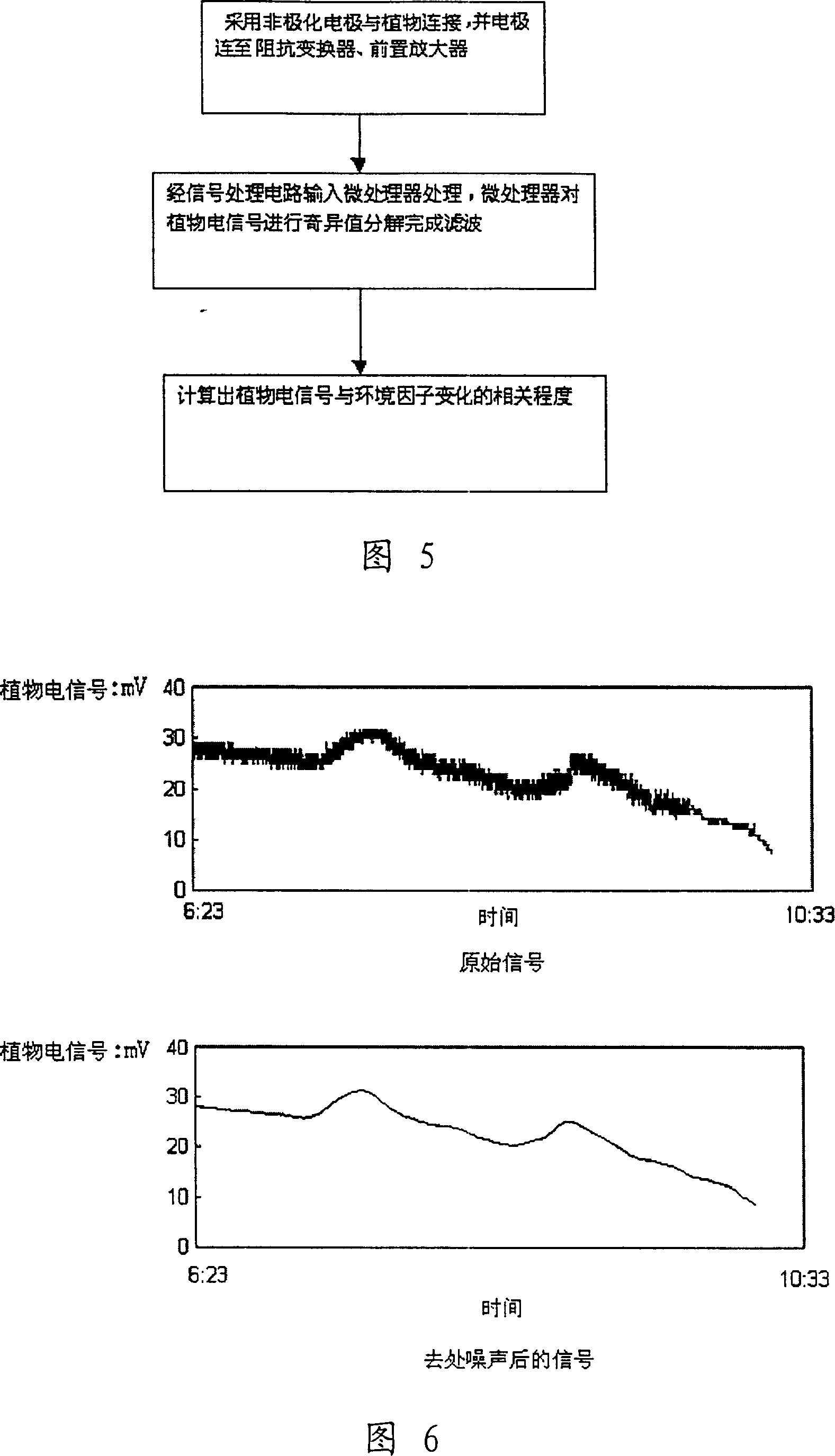

Method for detecting plant electric signal in green house and special equipment thereof

InactiveCN101021518ARealize long-distance transmissionMaterial analysis by electric/magnetic meansSpecial data processing applicationsImpedance transformerEngineering

The invention discloses a method and a special device to detect electric signal of greenhouse plant. Its steps are: (1) Takes unpolarized electrode as reference and measuring electrode. (2) Connects electrode and plant stems or leaves without consuming by electrode linkage unit. (3) Adopts impedance transformer with its input impedance greater than 1012Omega to connect with output port of electrode separately. Signal output port of each impedance transformer is connected with a preamplifier, whose output signal is transferred to current signal by a voltage-current converter sending to signal processing unit for processing. The invention can long-term detect change of plant electric signal without consuming, process weak plant electric signal to separate signal and noise. When environment factor changes, it can calculate and detect main factor causing changes of plant electric signal by some arithmetic, which provides premise condition for plant electric signal detecting transferring from lab research to service and production.

Owner:CHINA AGRI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com