Patents

Literature

292 results about "Spider Proteins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

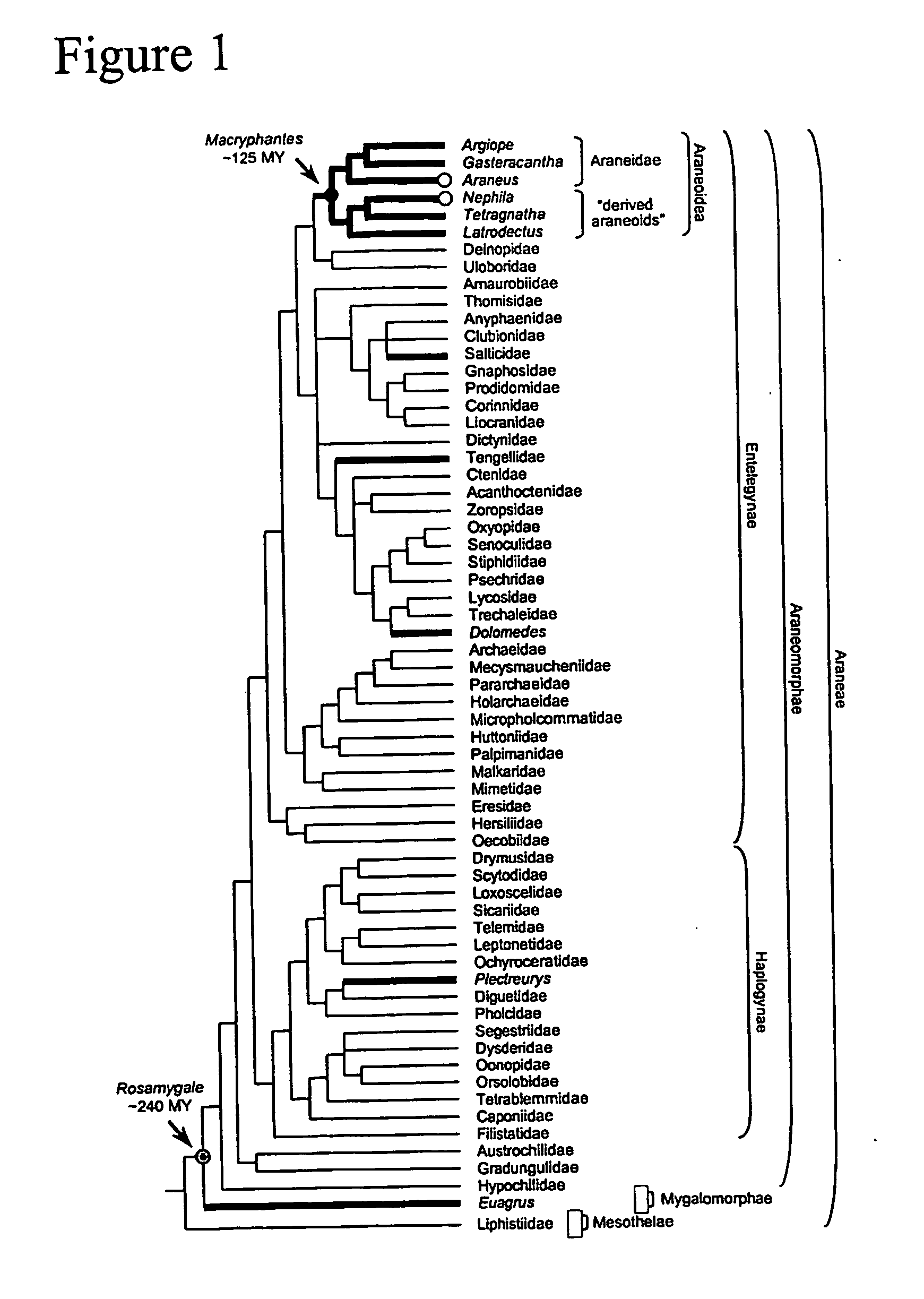

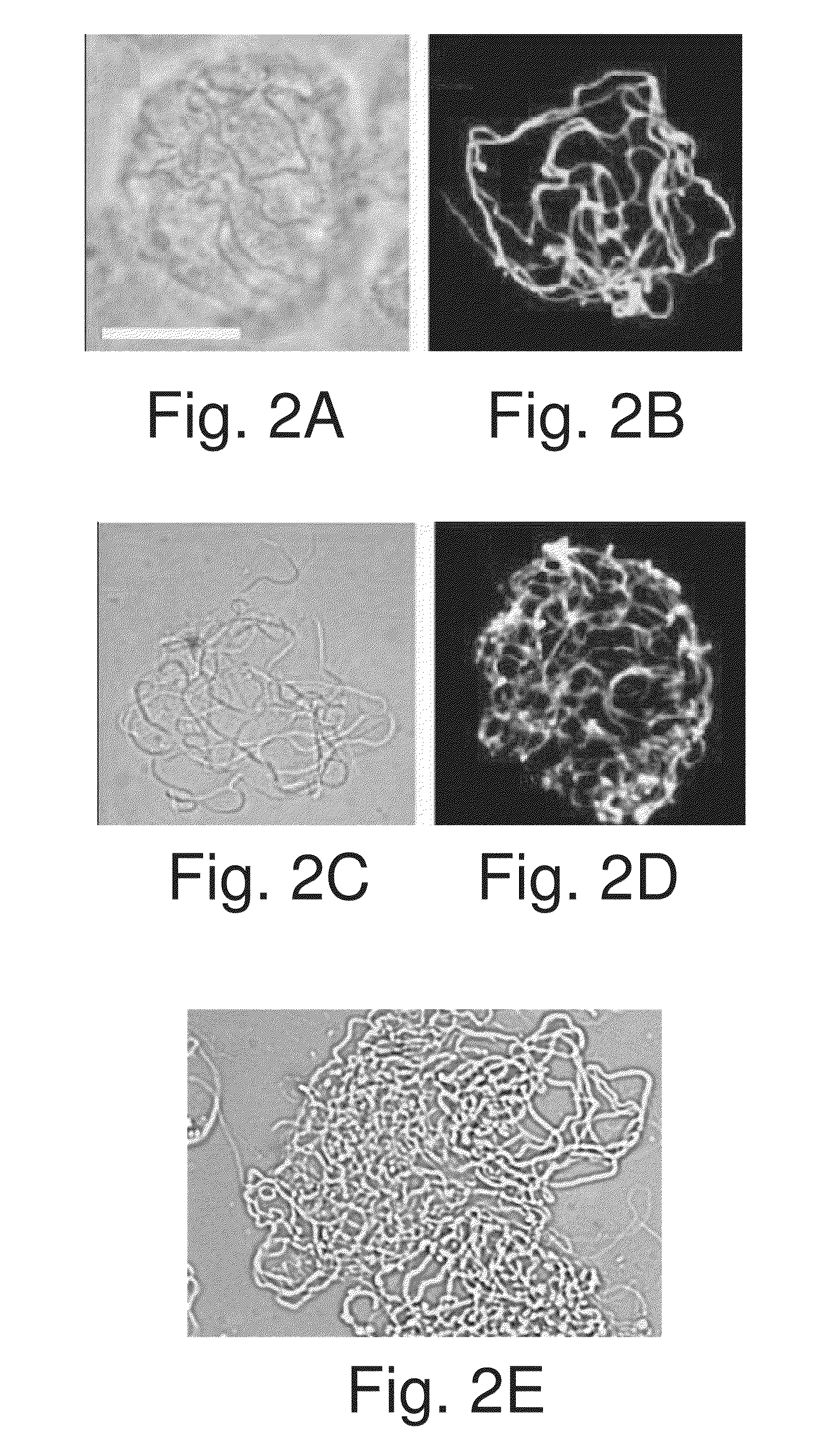

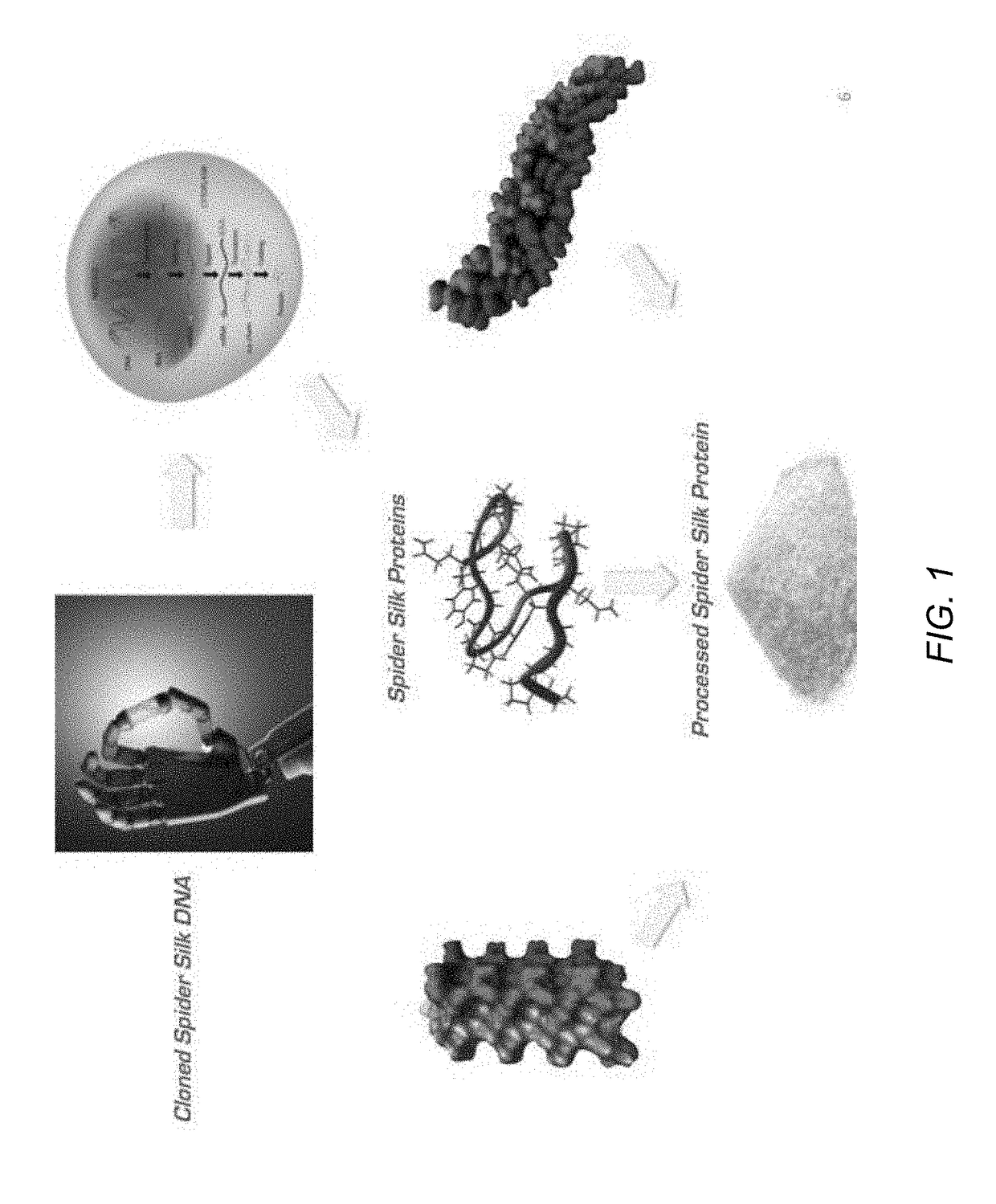

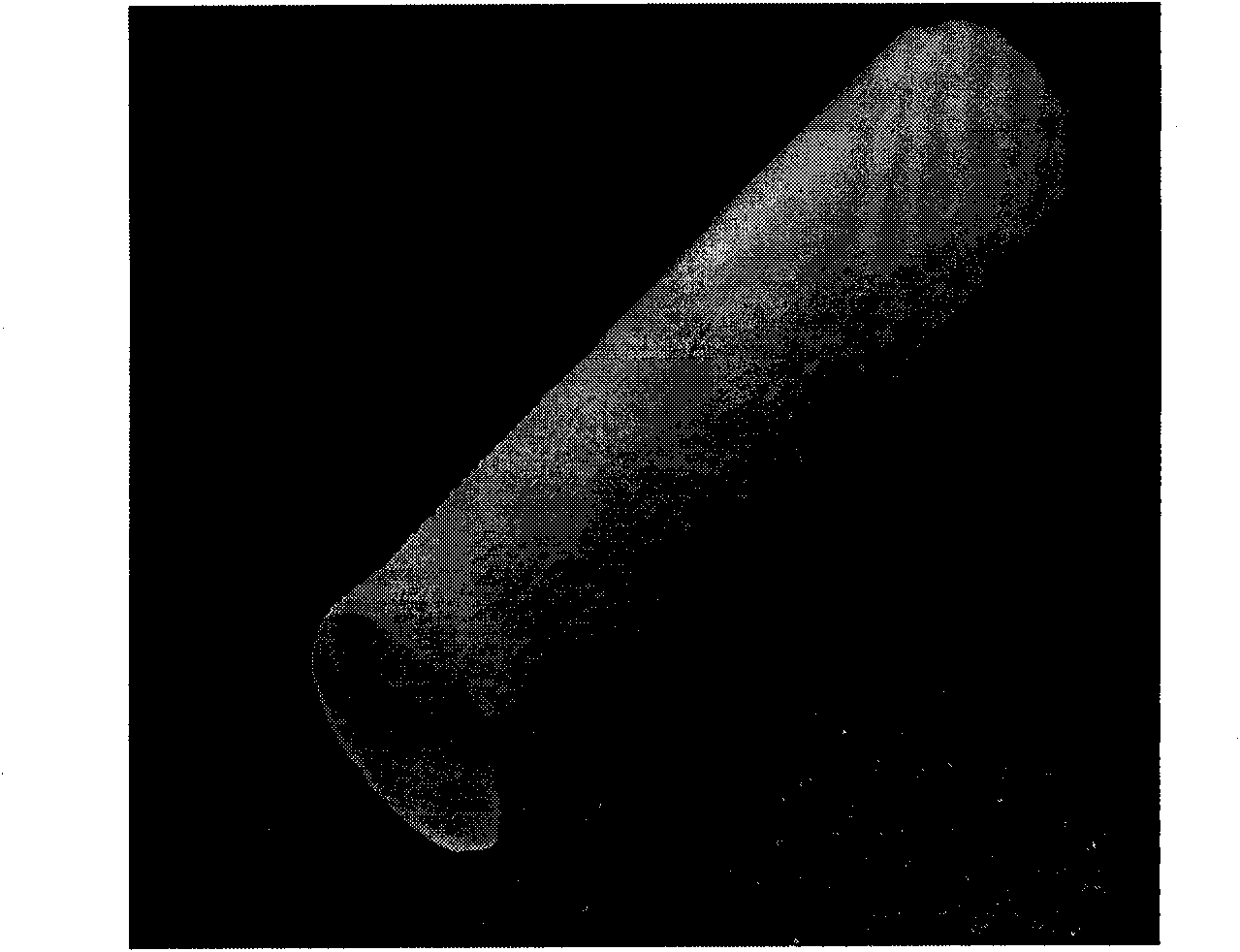

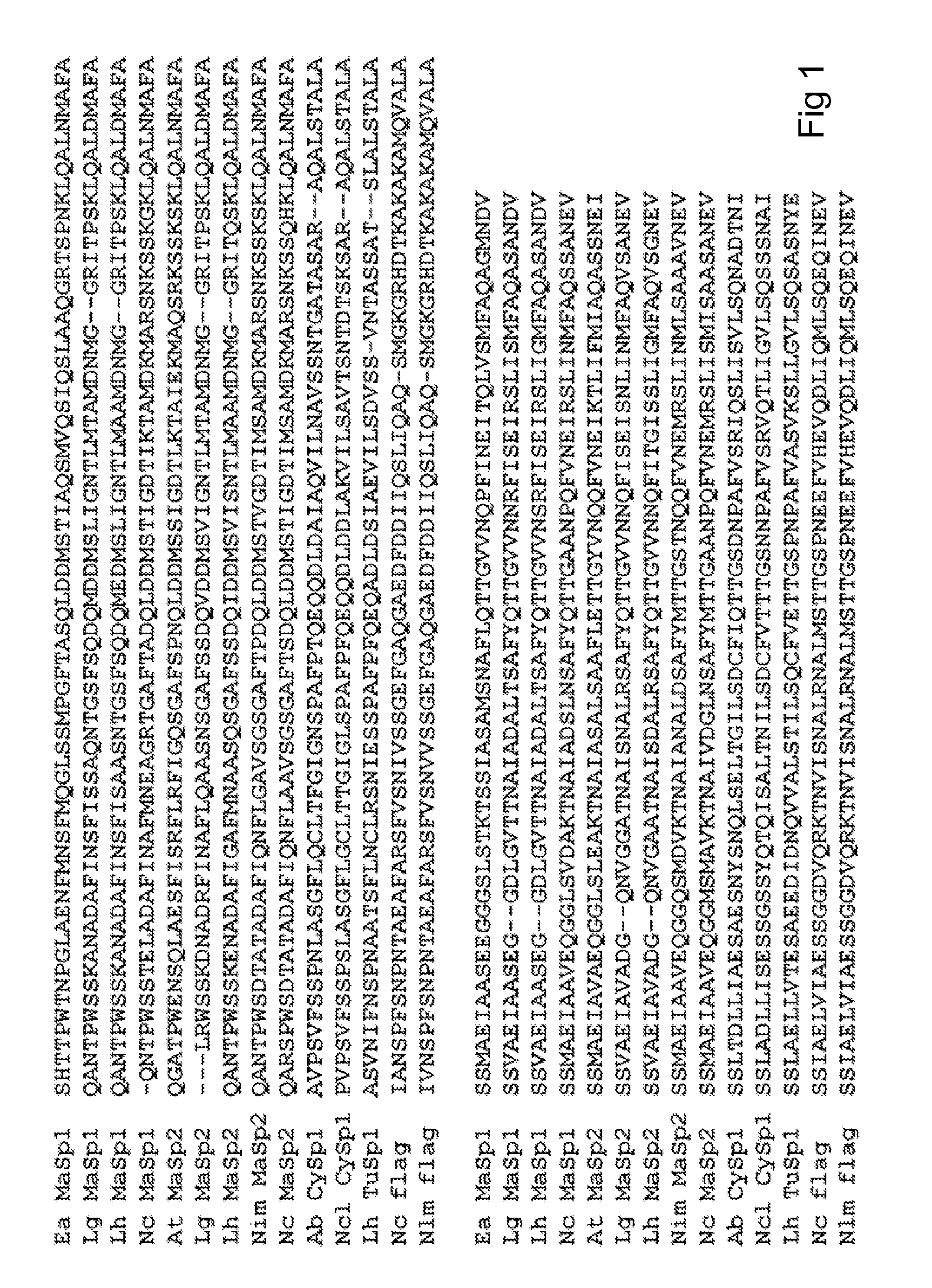

Spider cocoon. Spider silk is a protein fibre spun by spiders. Spiders use their silk to make webs or other structures, which function as sticky nets to catch other animals, or as nests or cocoons to protect their offspring, or to wrap up prey.

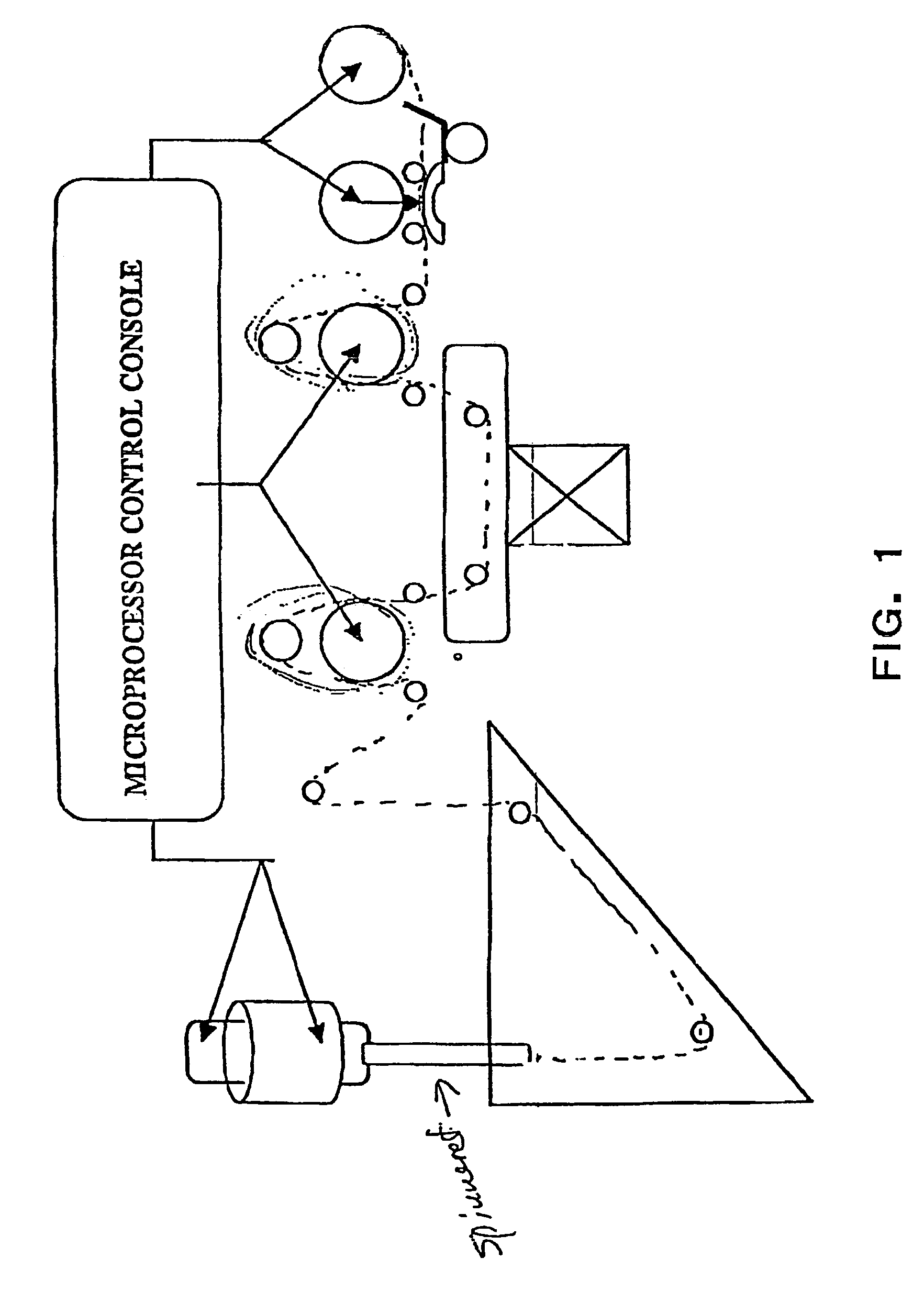

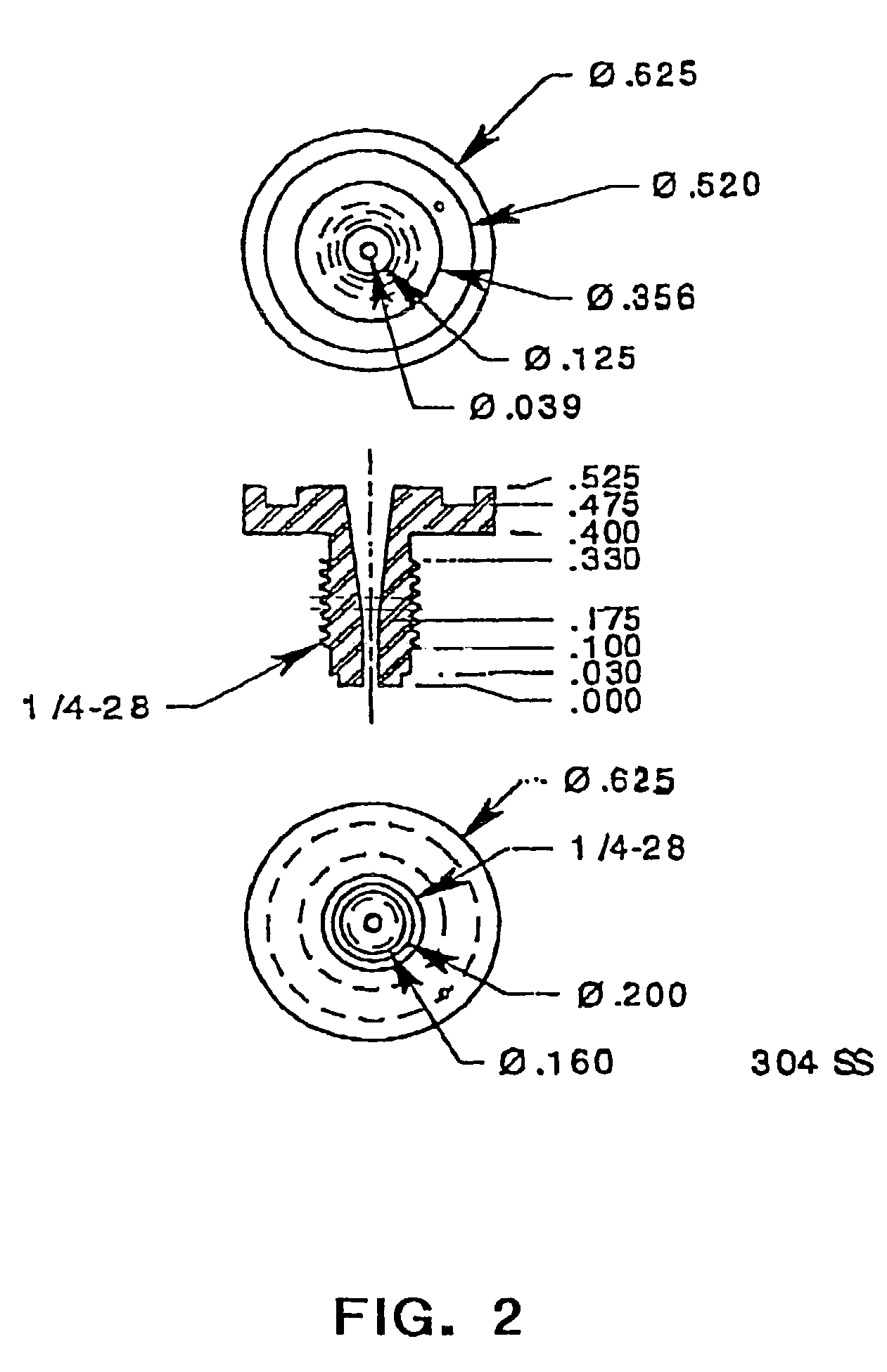

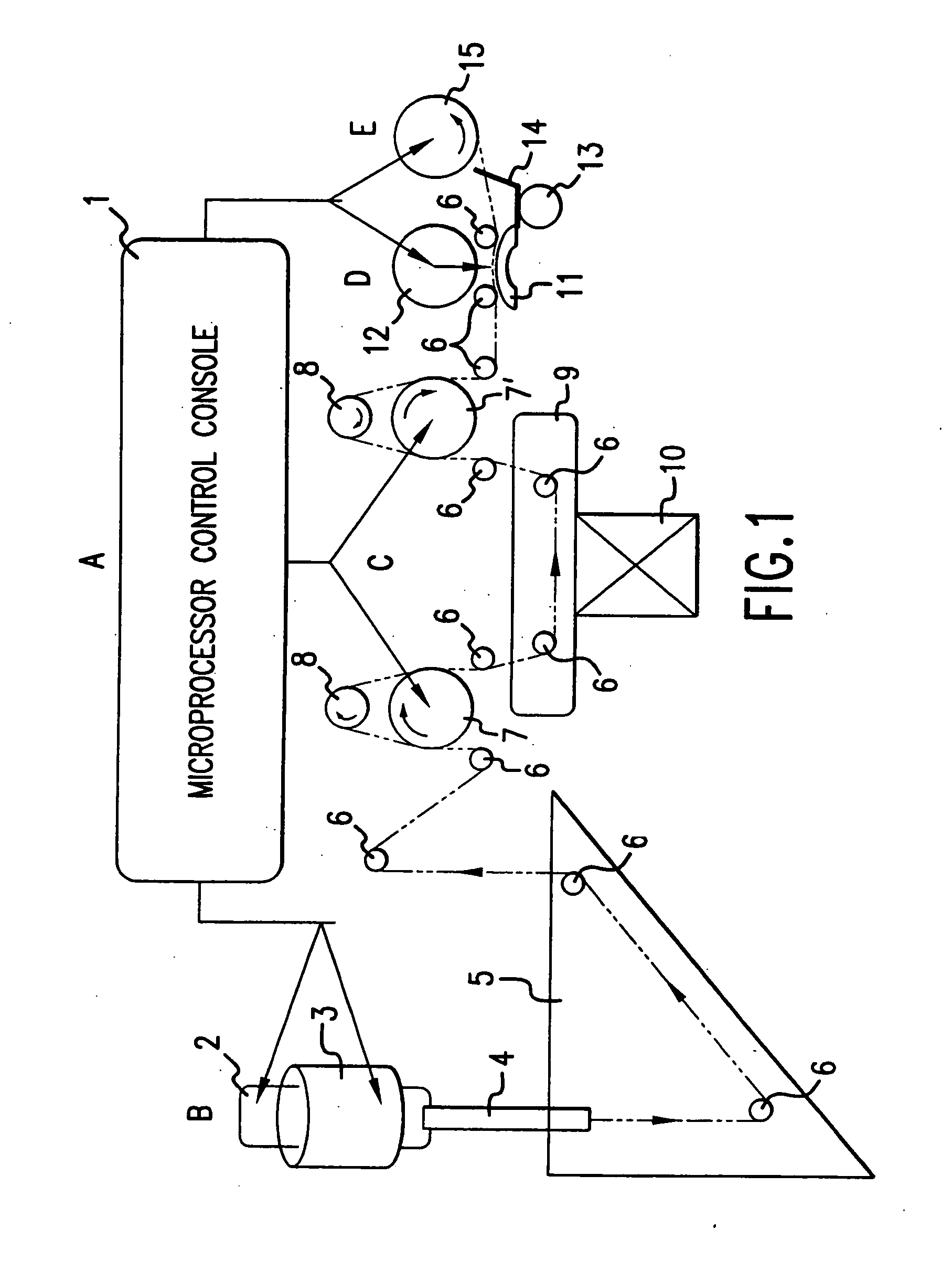

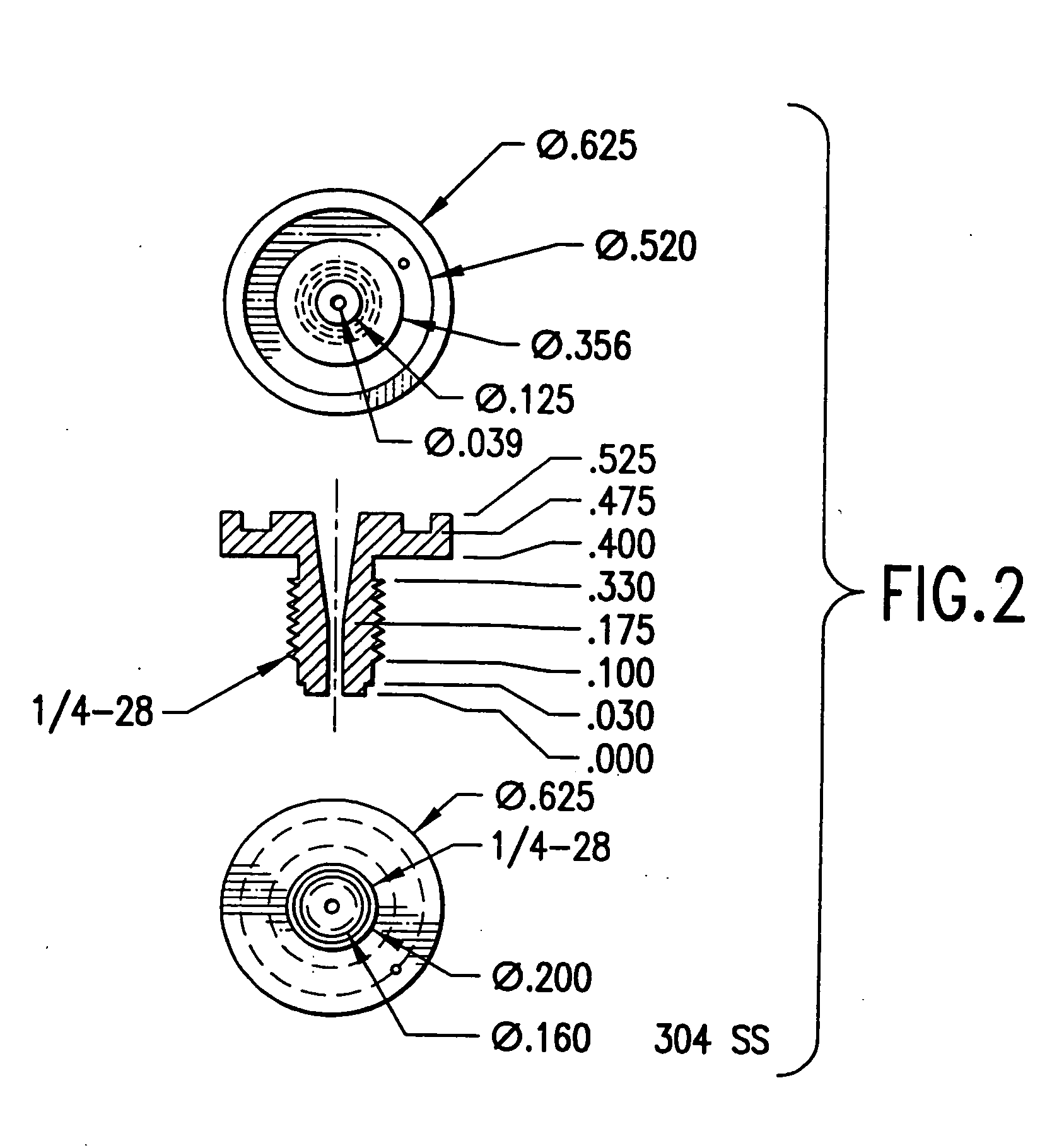

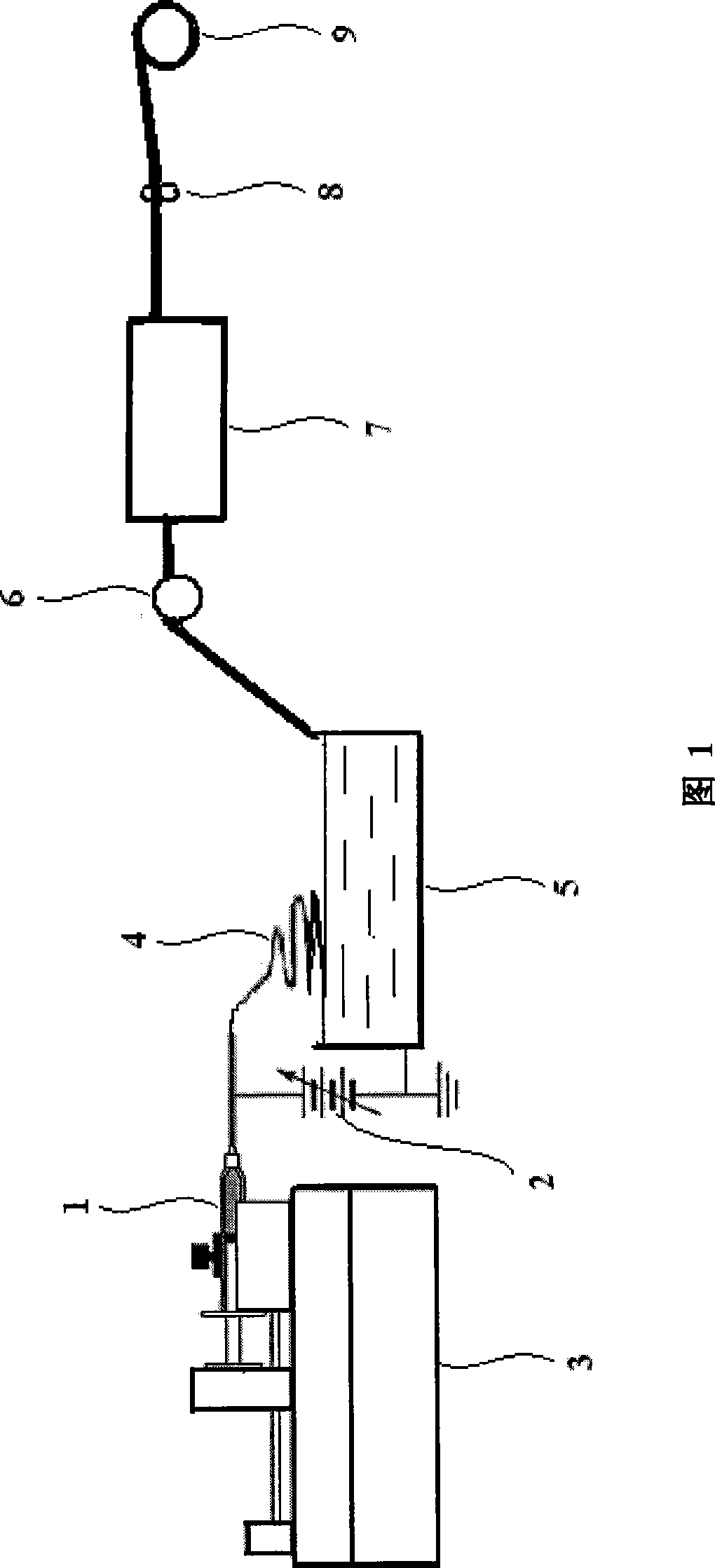

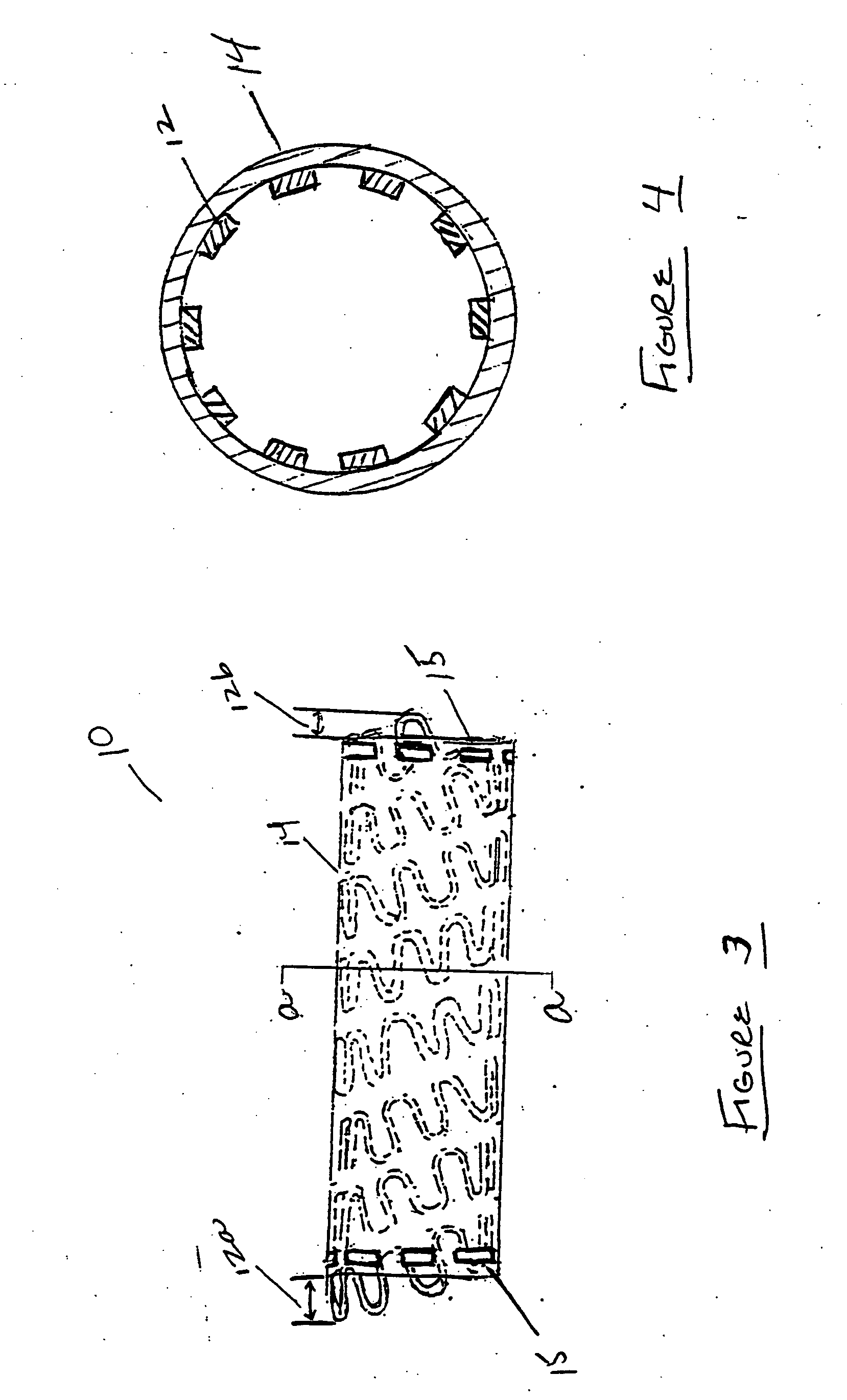

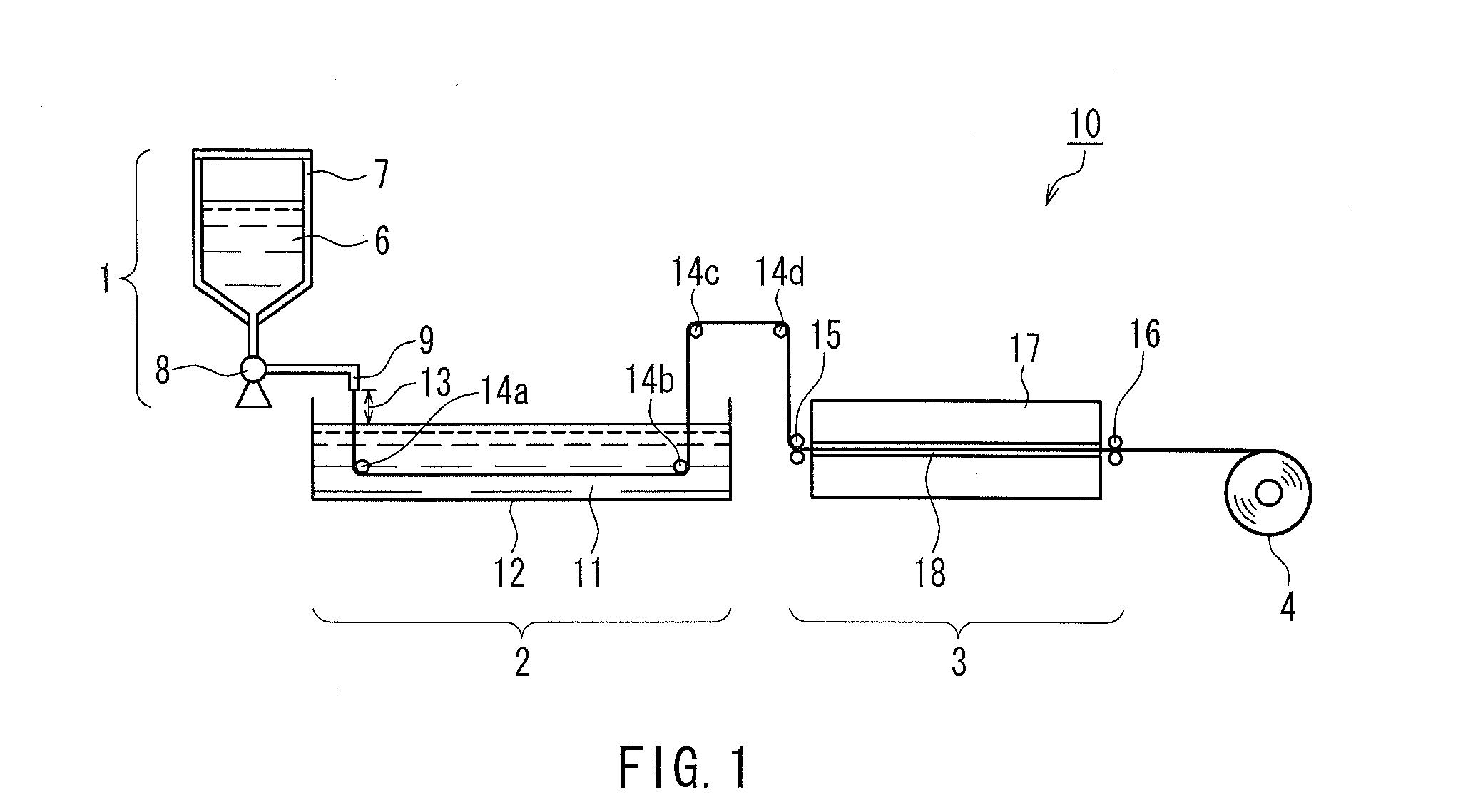

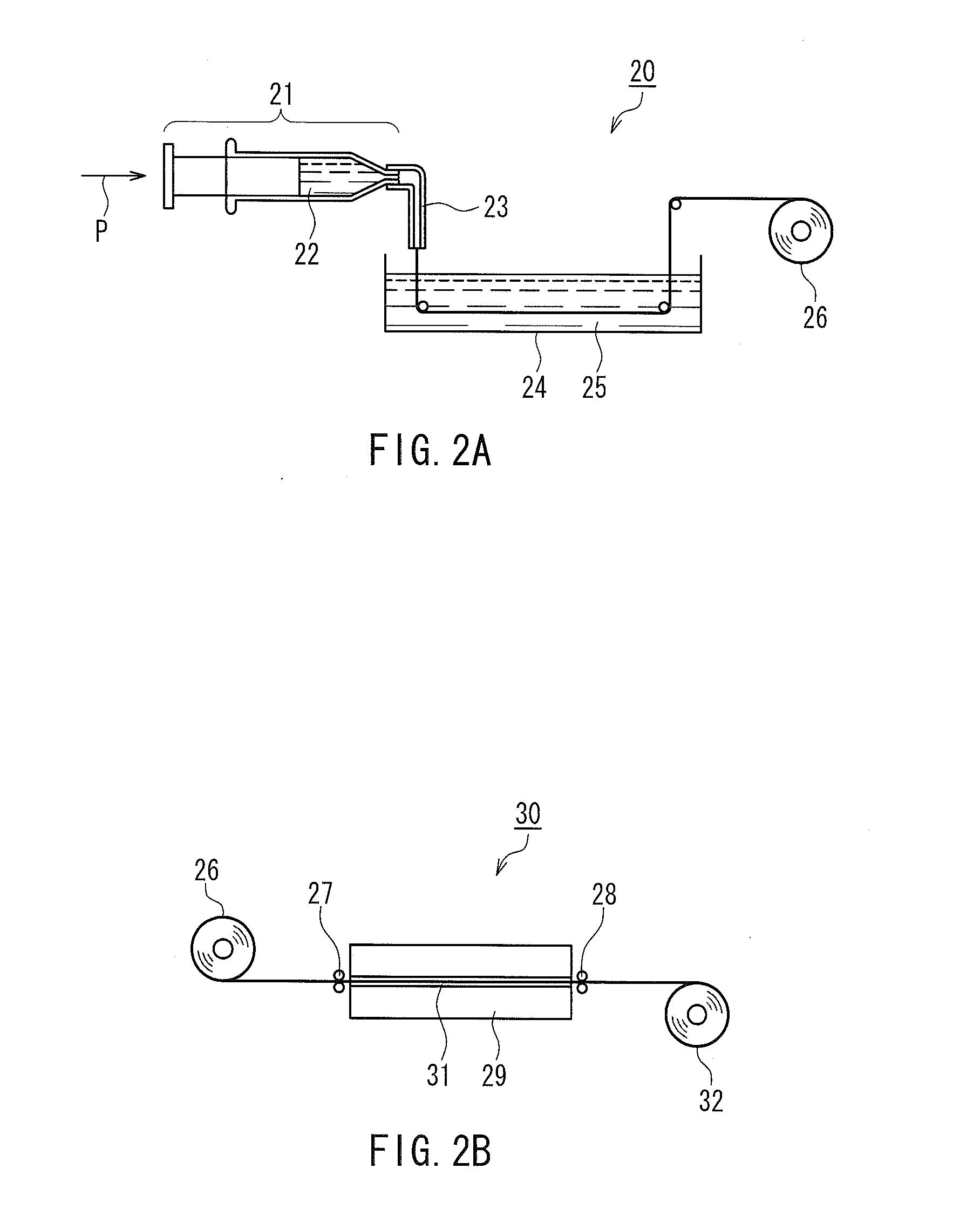

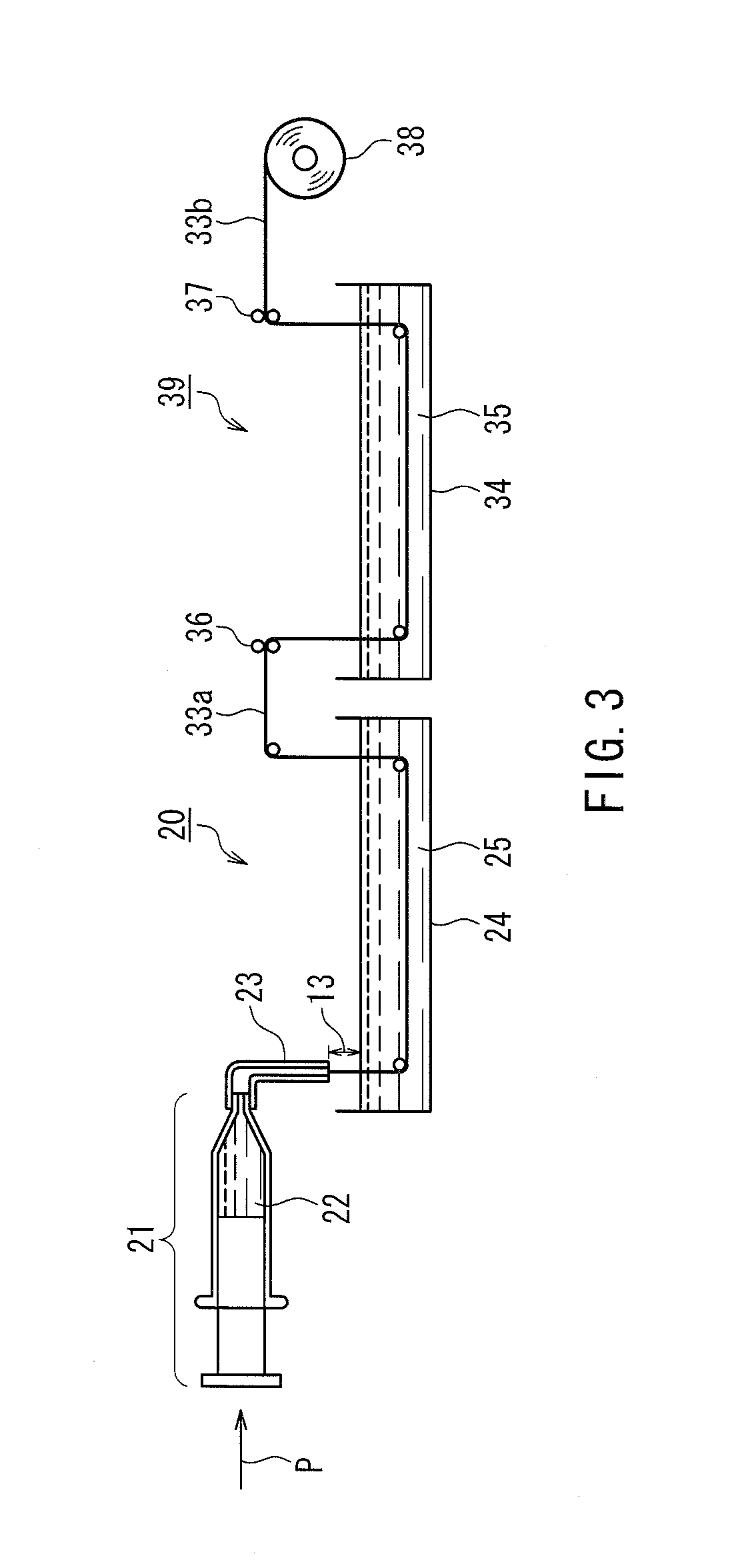

Methods and apparatus for spinning spider silk protein

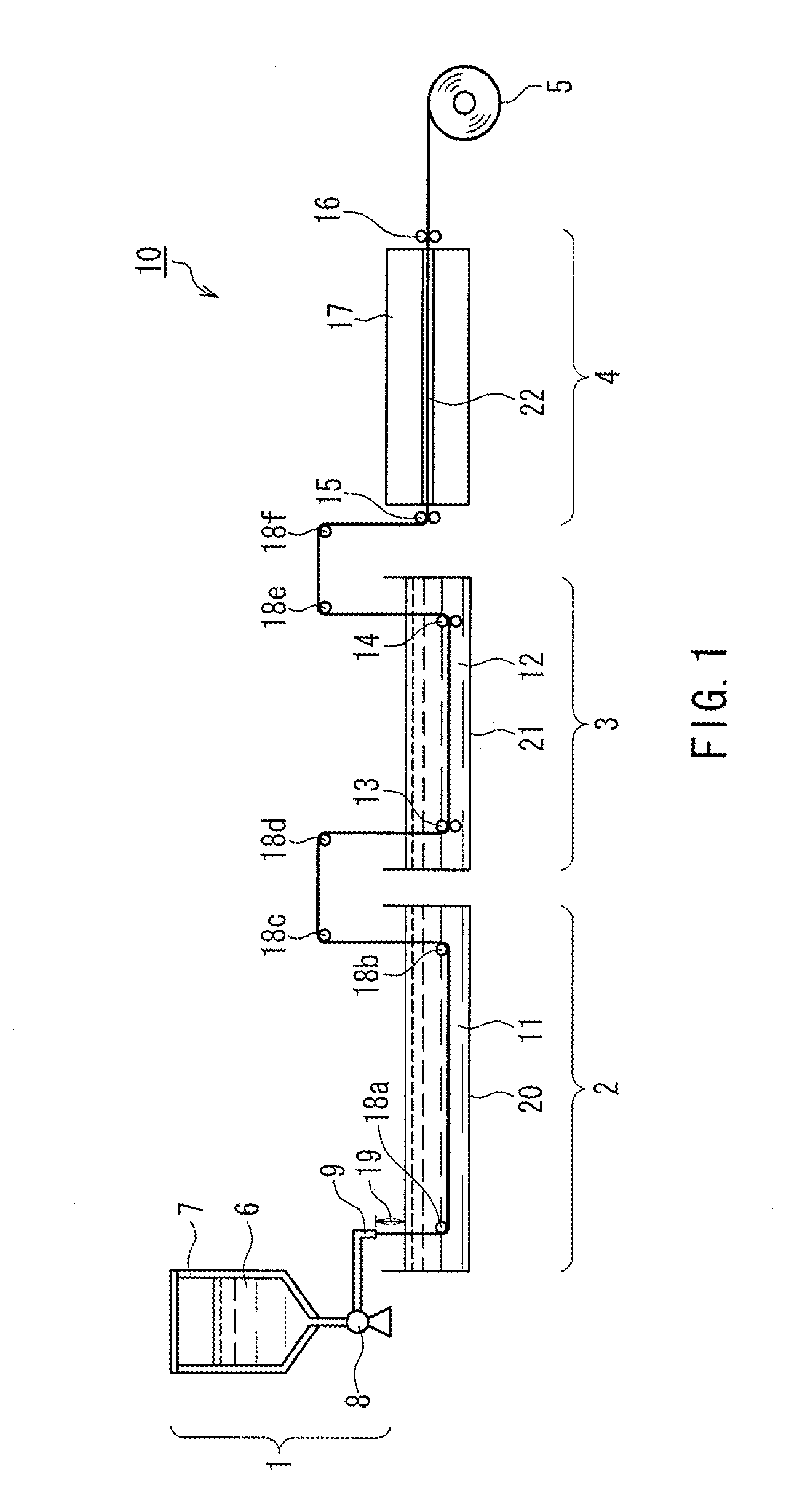

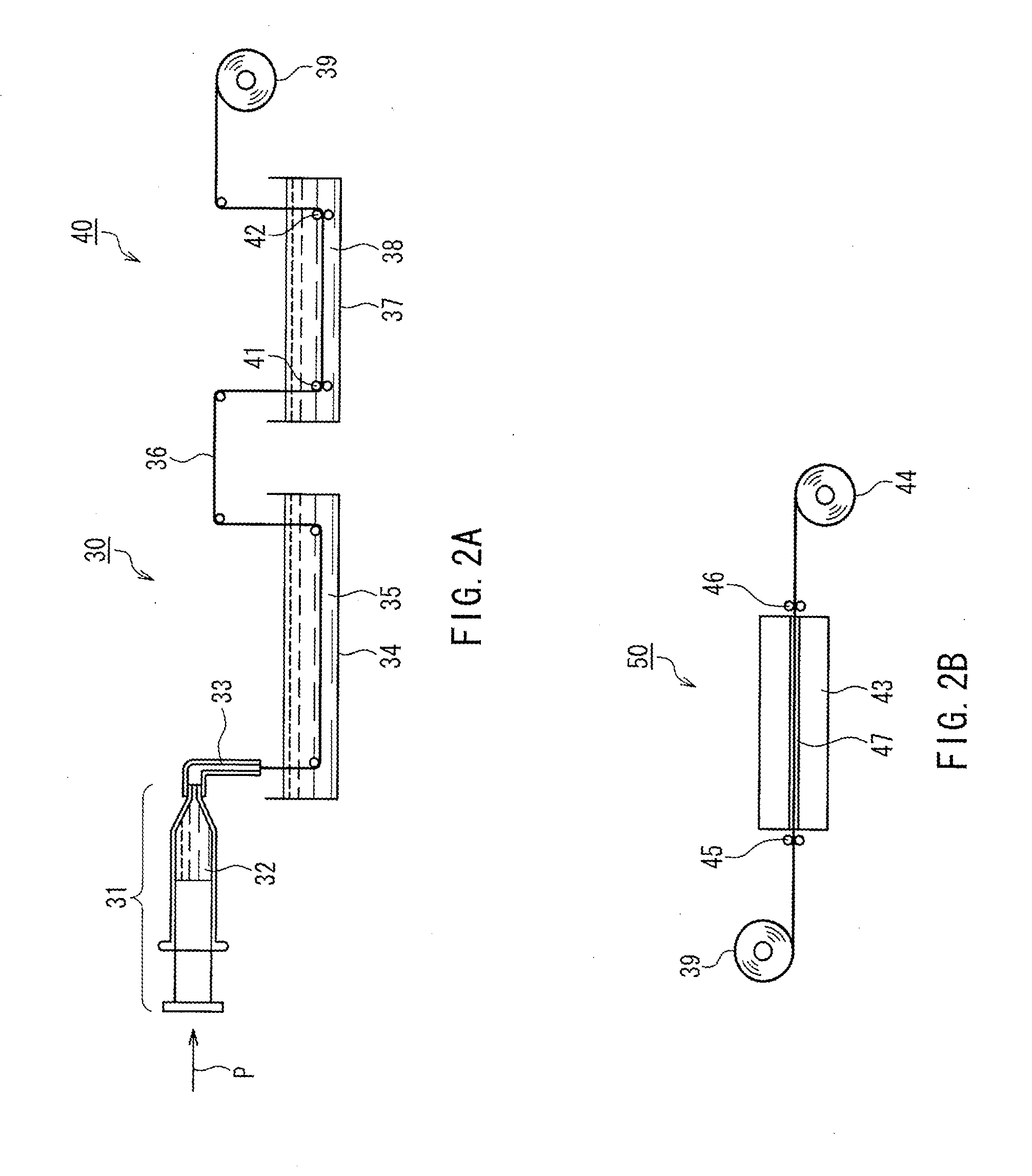

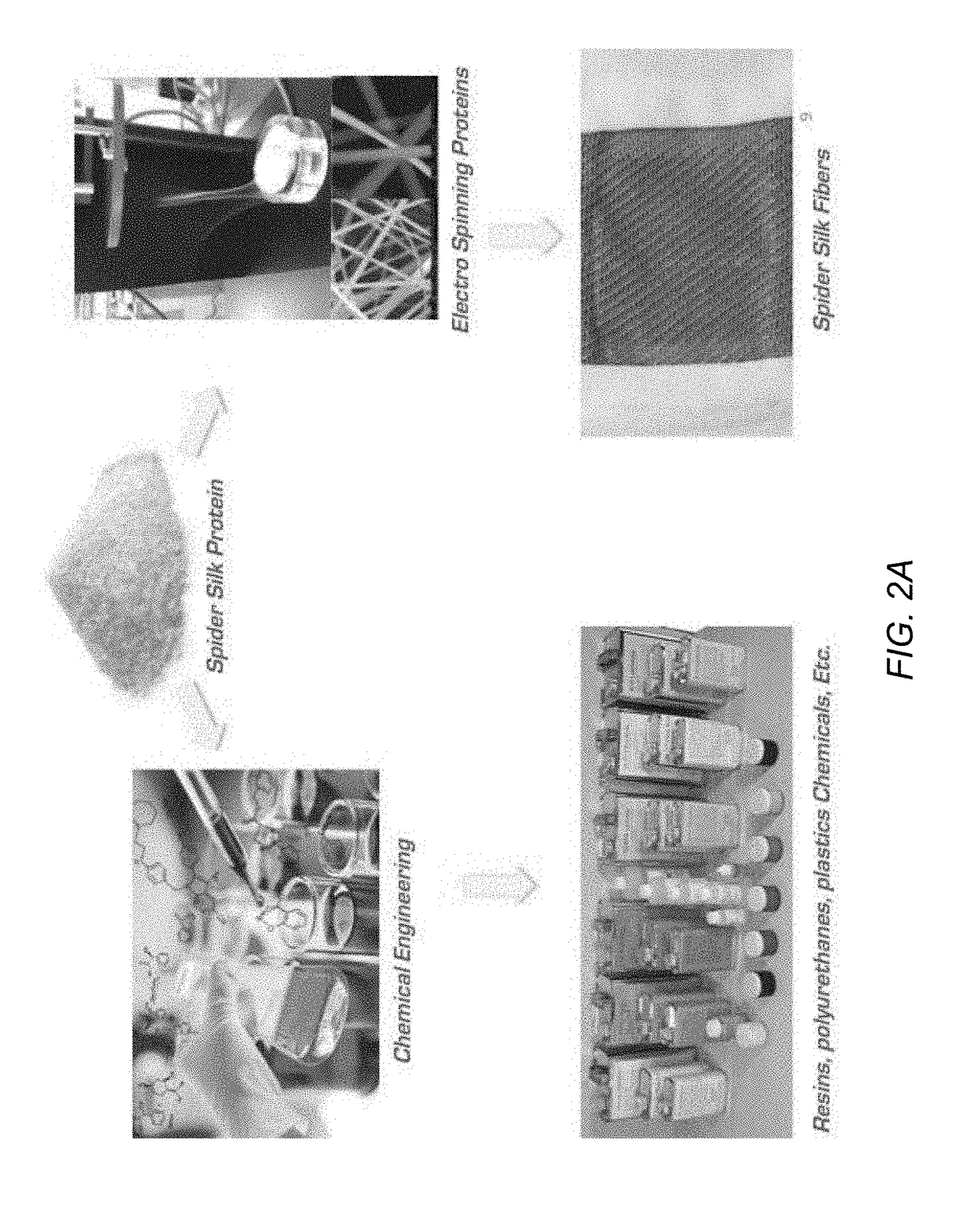

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:SANTE BIOMATERIALS

Methods and apparatus for spinning spider silk protein

InactiveUS20050054830A1Peptide/protein ingredientsMonocomponent fibroin artificial filamentBiotechnologySpider Proteins

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:NEXIA BIOTECH

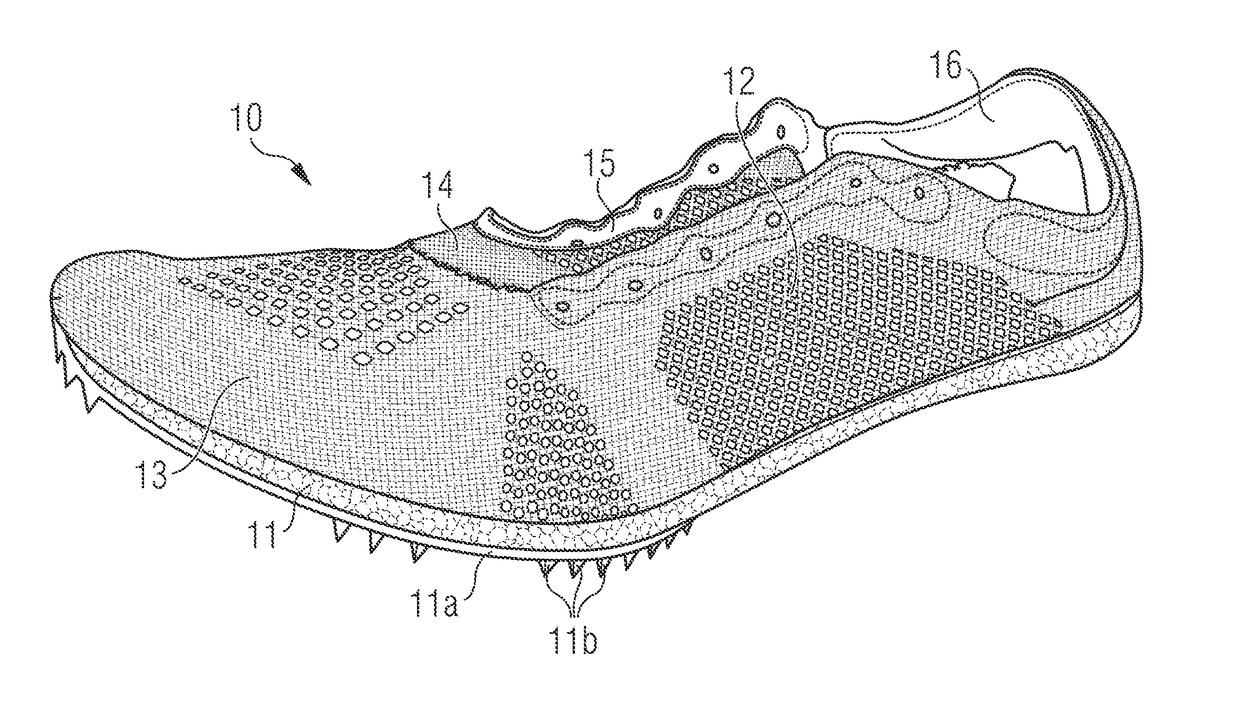

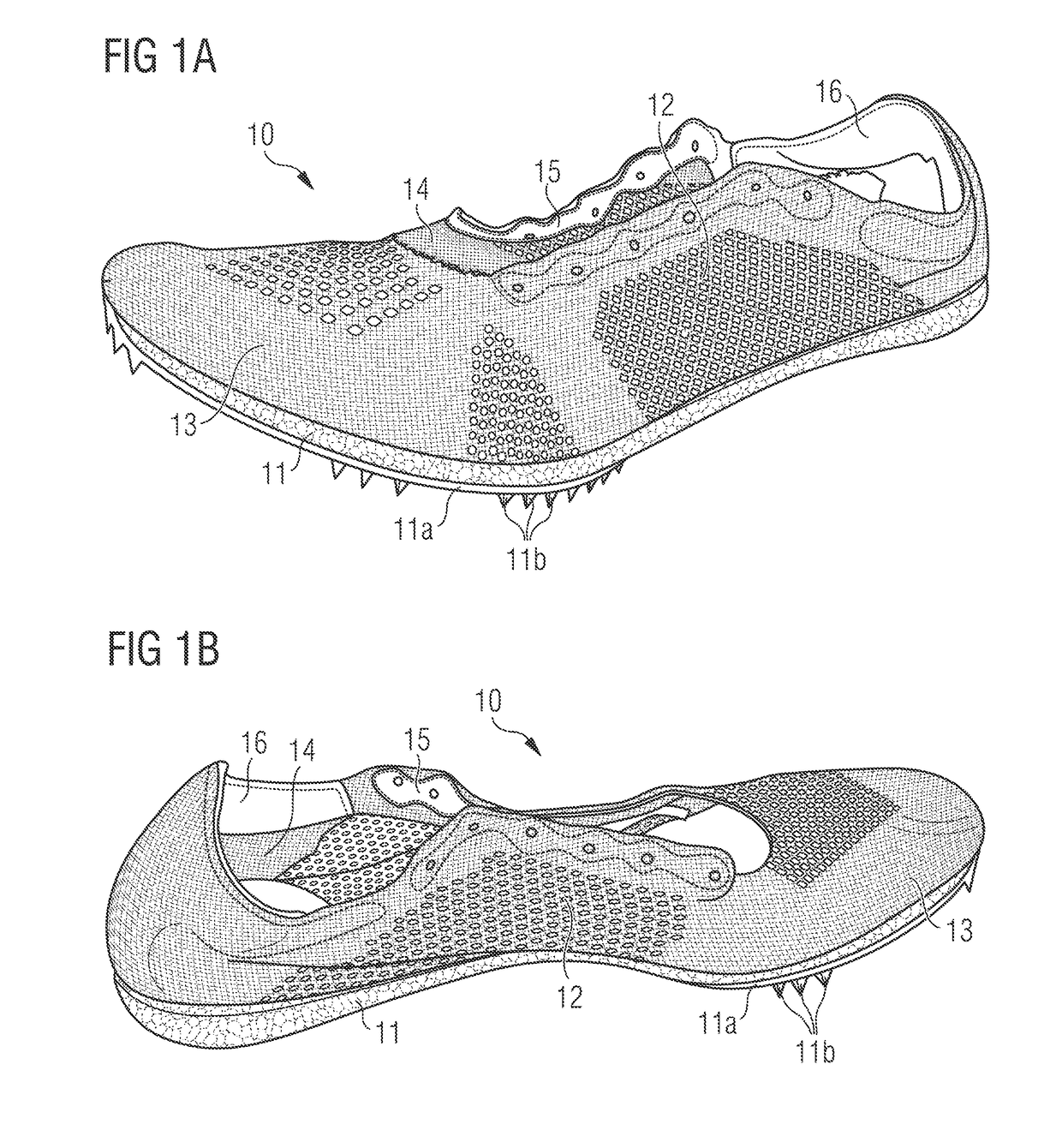

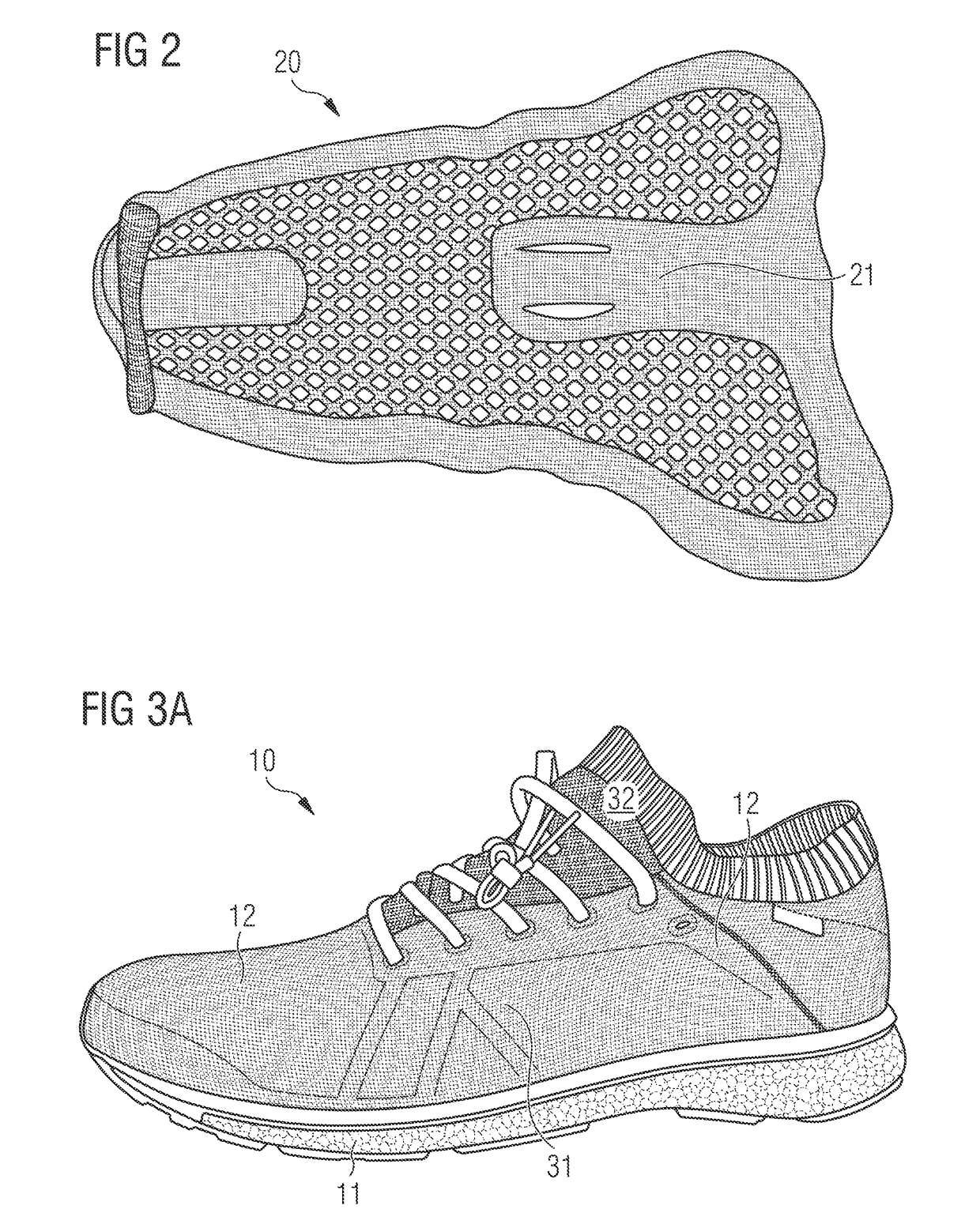

Clothing item comprising spider silk

Described are spider silk articles of wear. The article of wear, which may be apparel or shoes, includes an inner surface, wherein the inner surface includes an area including spider silk. The spider silk of the article of wear may be arranged to contact the skin of a wearer when the article of wear is worn.

Owner:ADIDAS

Method for purifying and recovering silk proteins using magnetic affinity separation

A method for the purification of recombinant silk proteins from a sample using magnetic affinity separation is described. The recombinant silk protein is expressed with an affinity tag which has a high binding affinity for an affinity ligand immobilized on magnetic particles. In the method, the processes of clarification of the crude silk protein extract, concentration of the product and purification of the product are combined in a single step involving the affinity capture of the spider silk protein onto the magnetic particles directly from the extract. The product yields are improved due to the reduced number of steps in the purification process.

Owner:EI DU PONT DE NEMOURS & CO

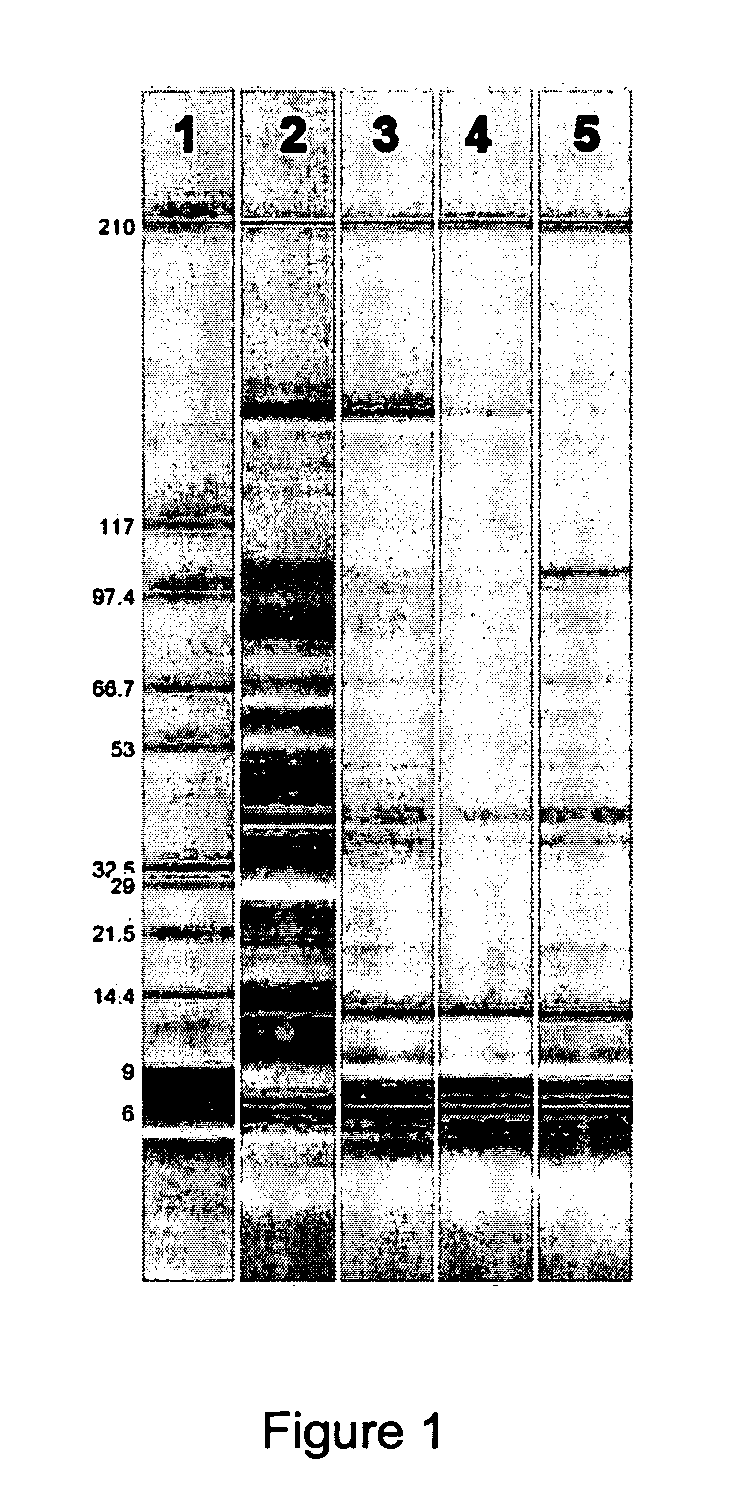

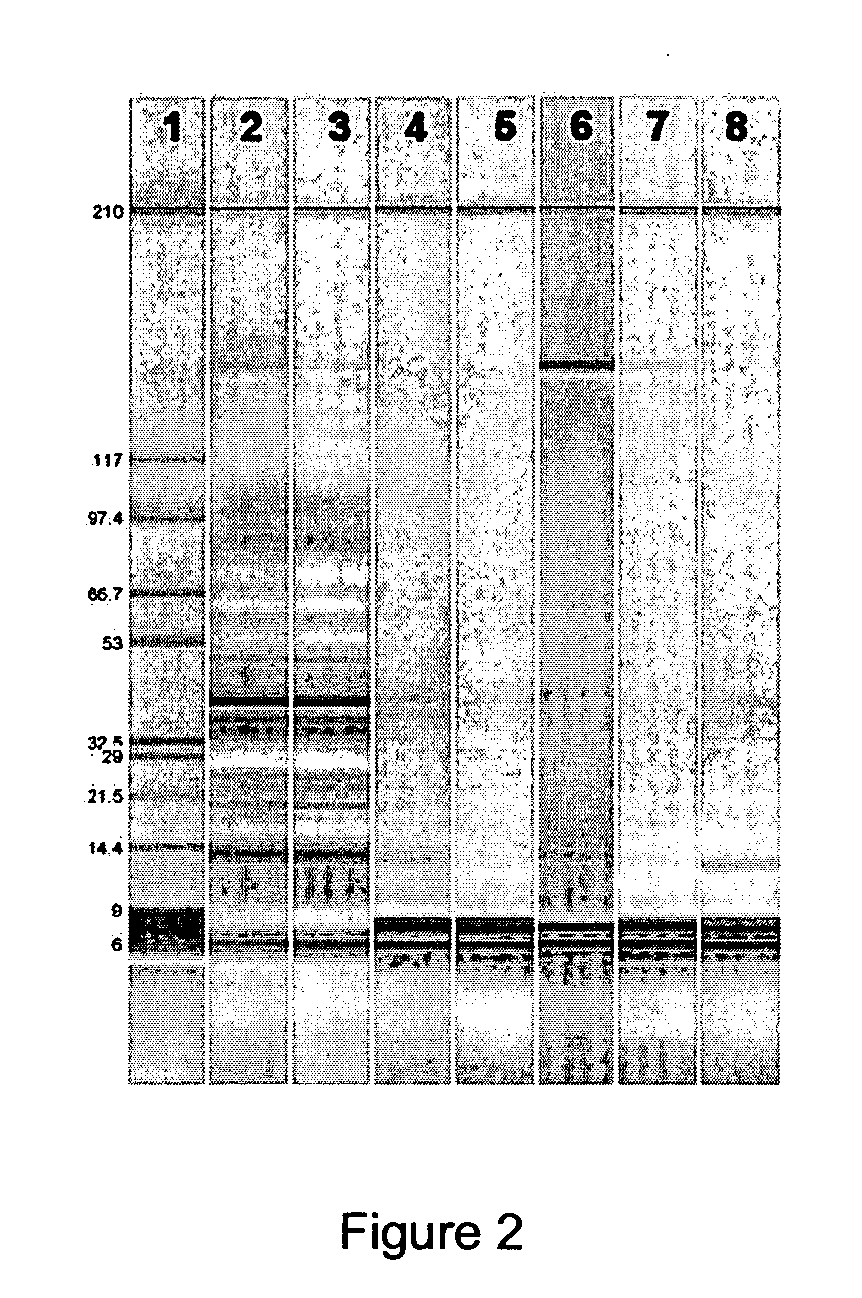

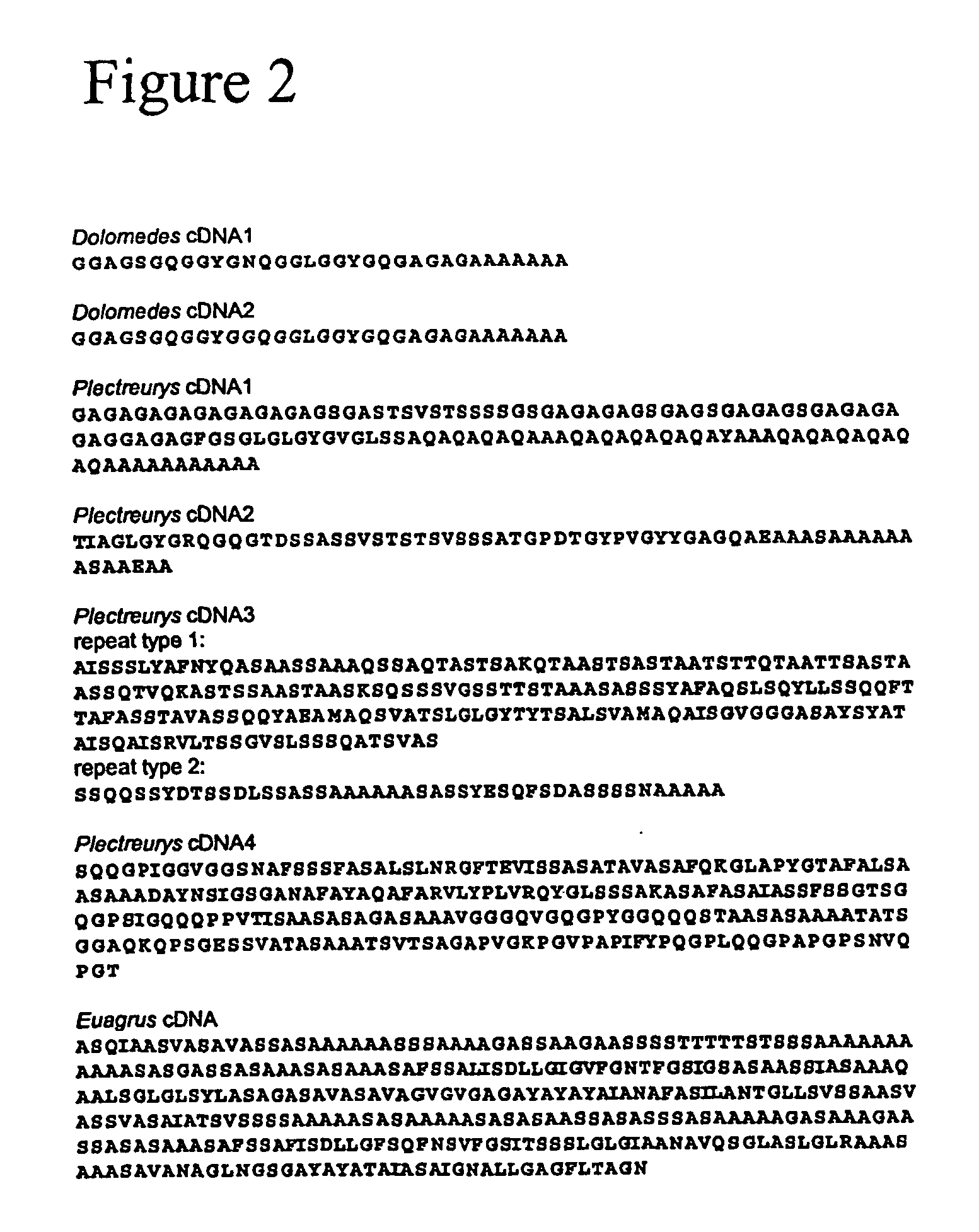

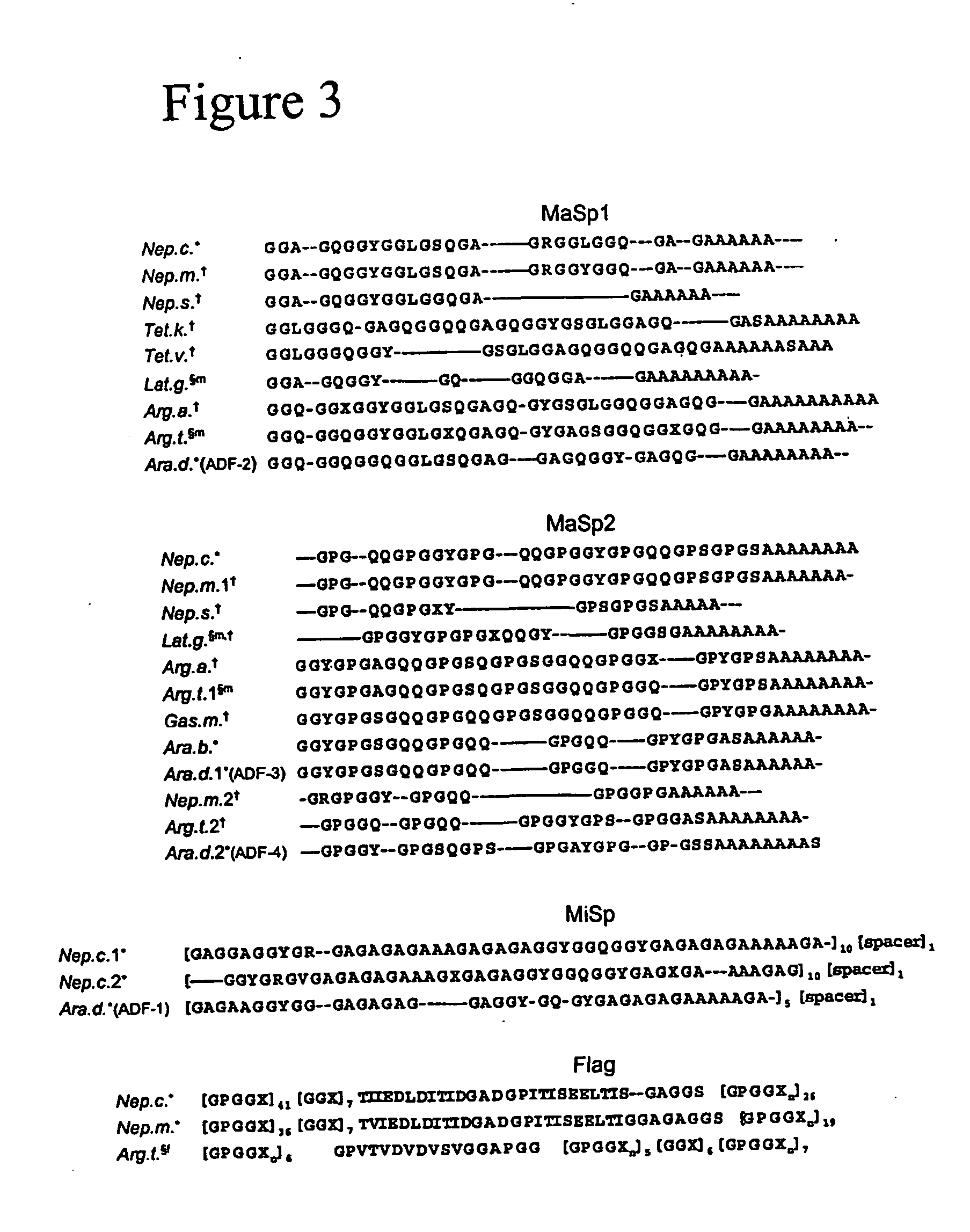

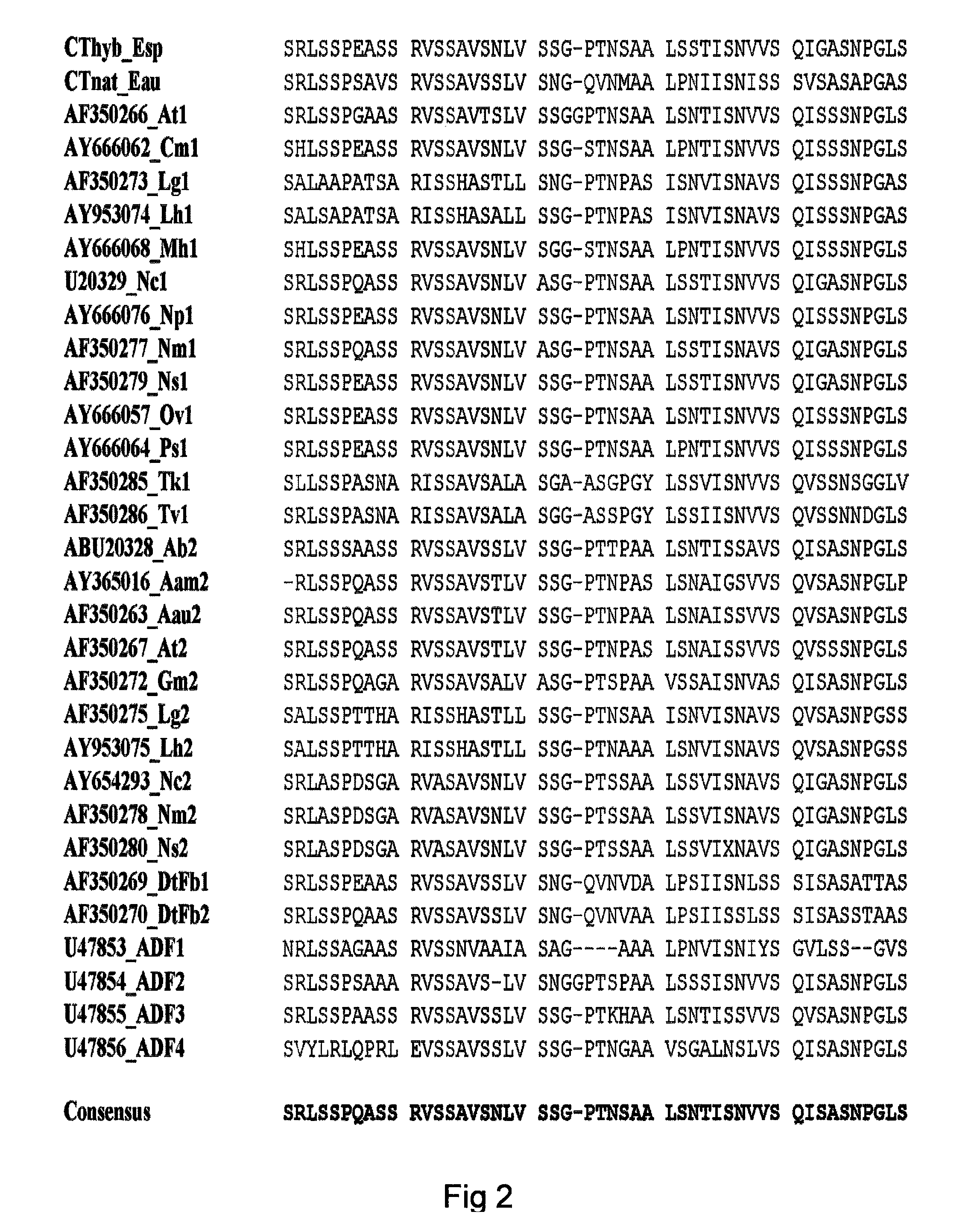

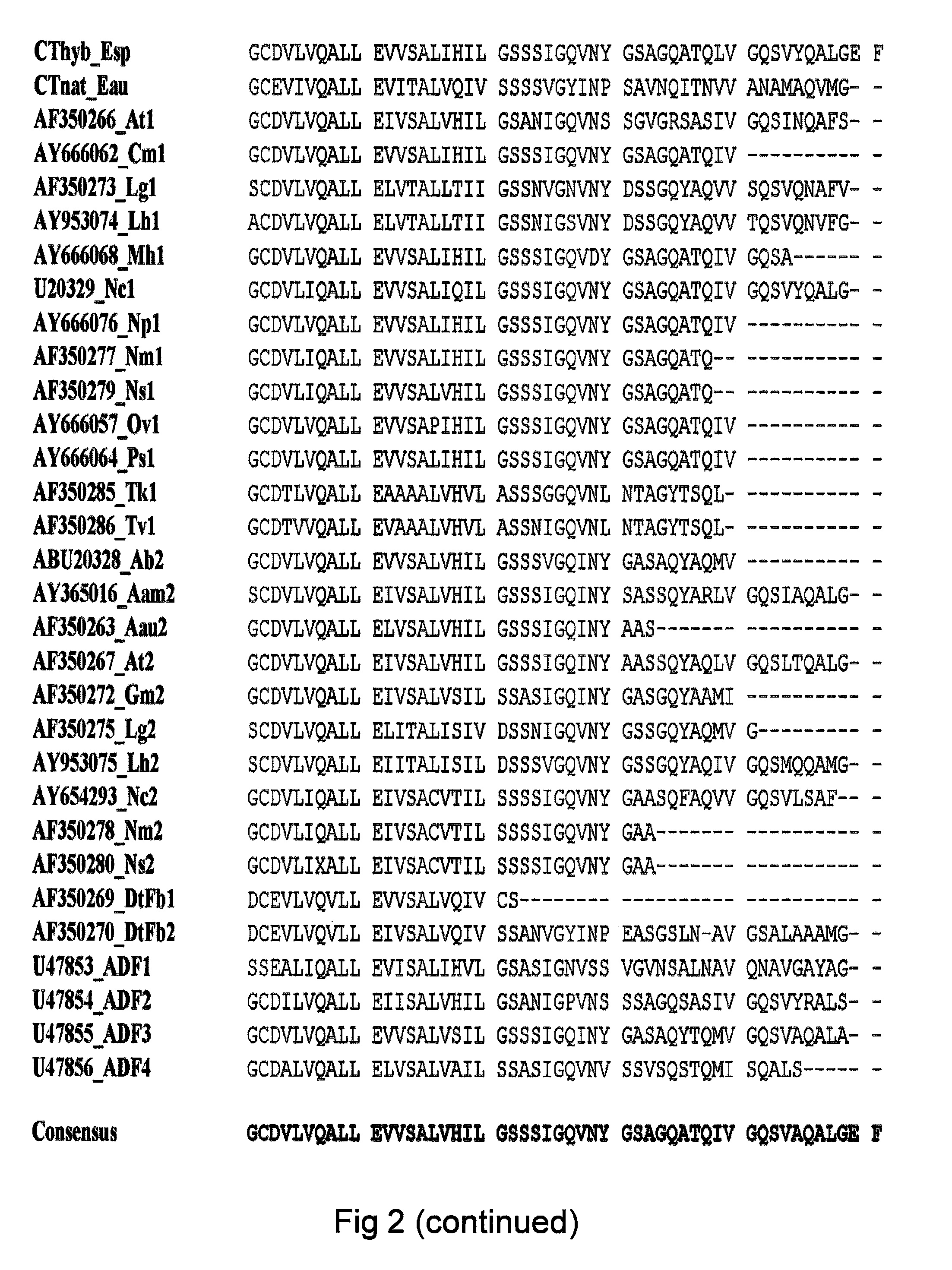

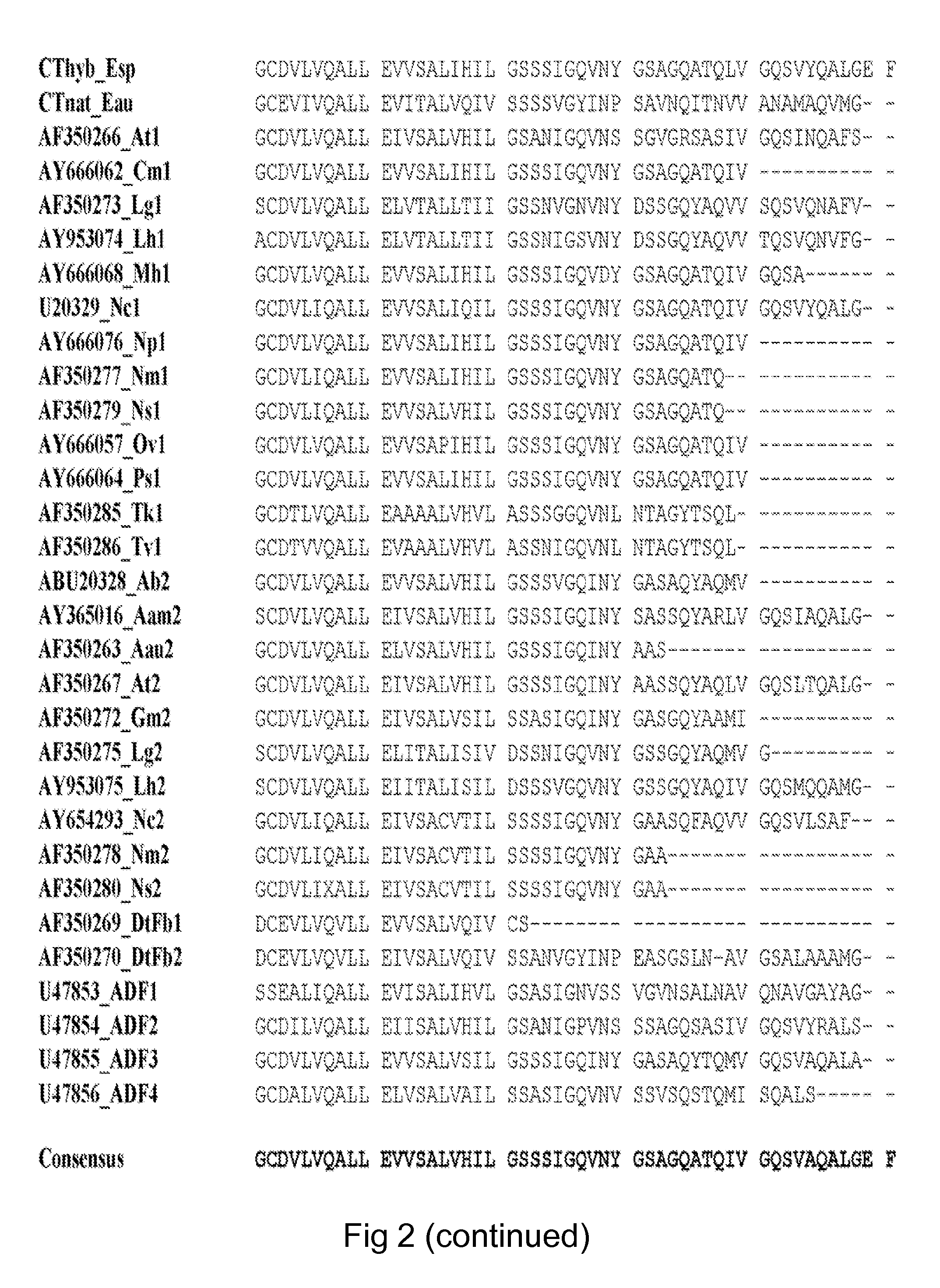

Spider silk protein encoding nucleic acids, polypeptides, antibodies and methods of use thereof

Spider silk proteinencodingnucleic acids, polypeptides and antibodies immunologically specificthereforeare disclosed. Methods of use therefore are also provided.

Owner:WYOMING THE UNIV OF

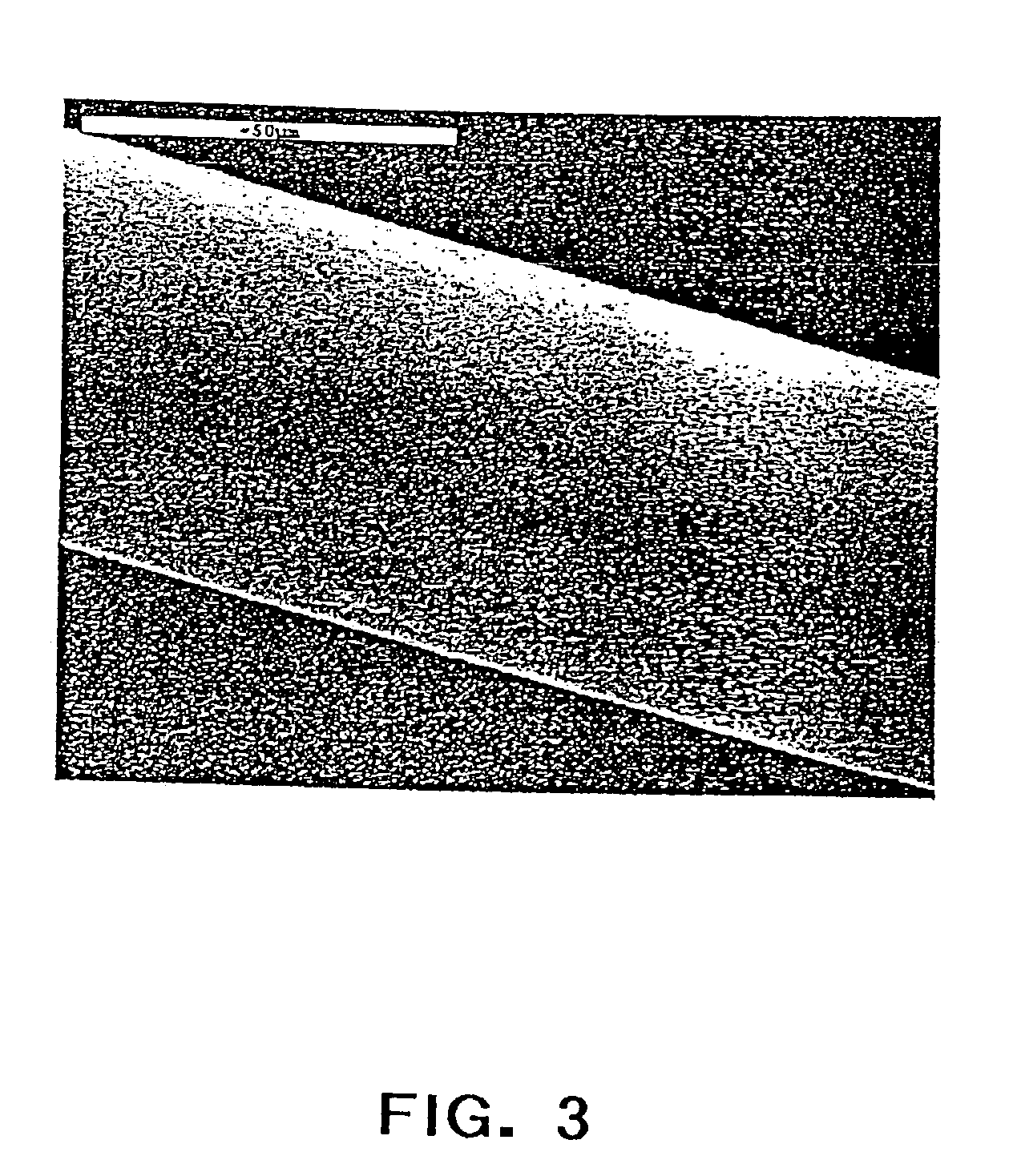

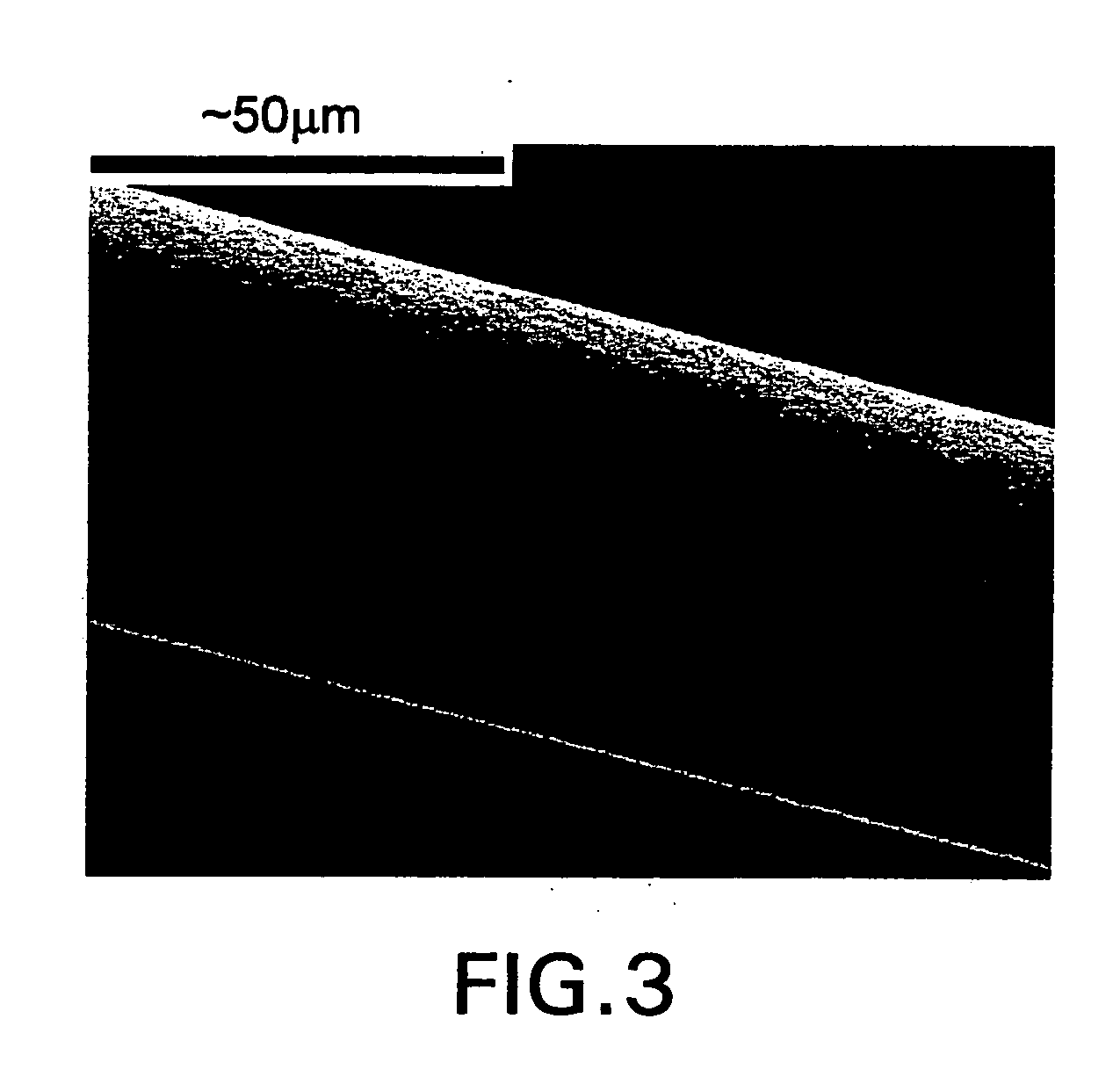

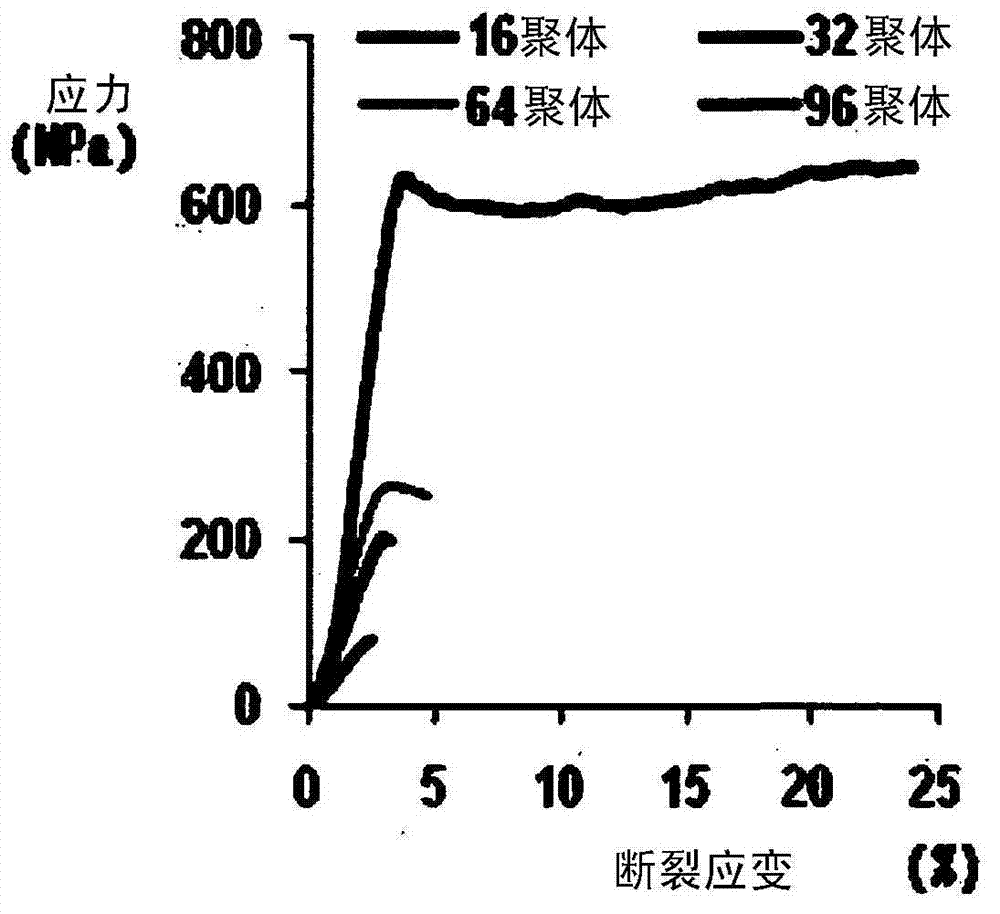

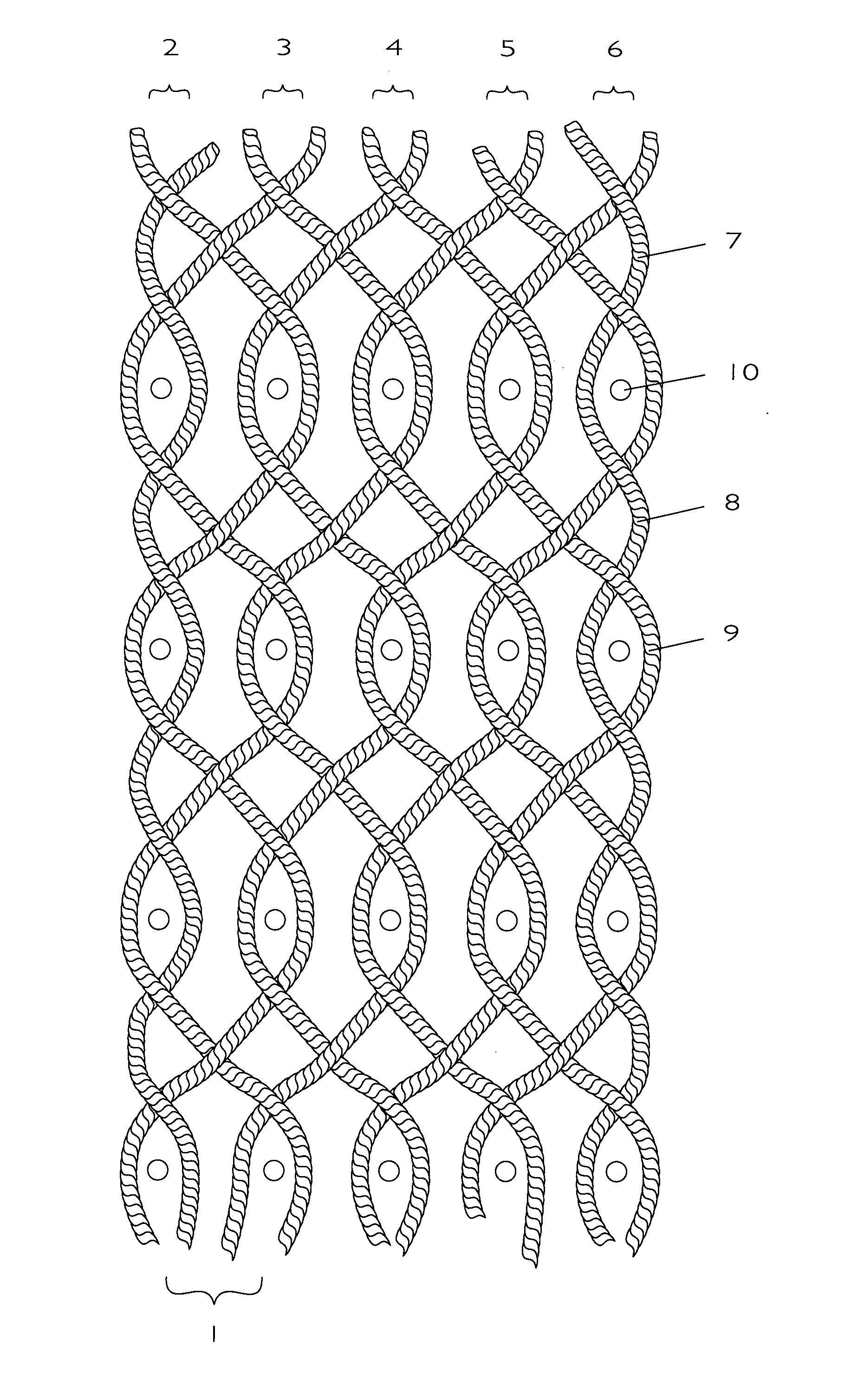

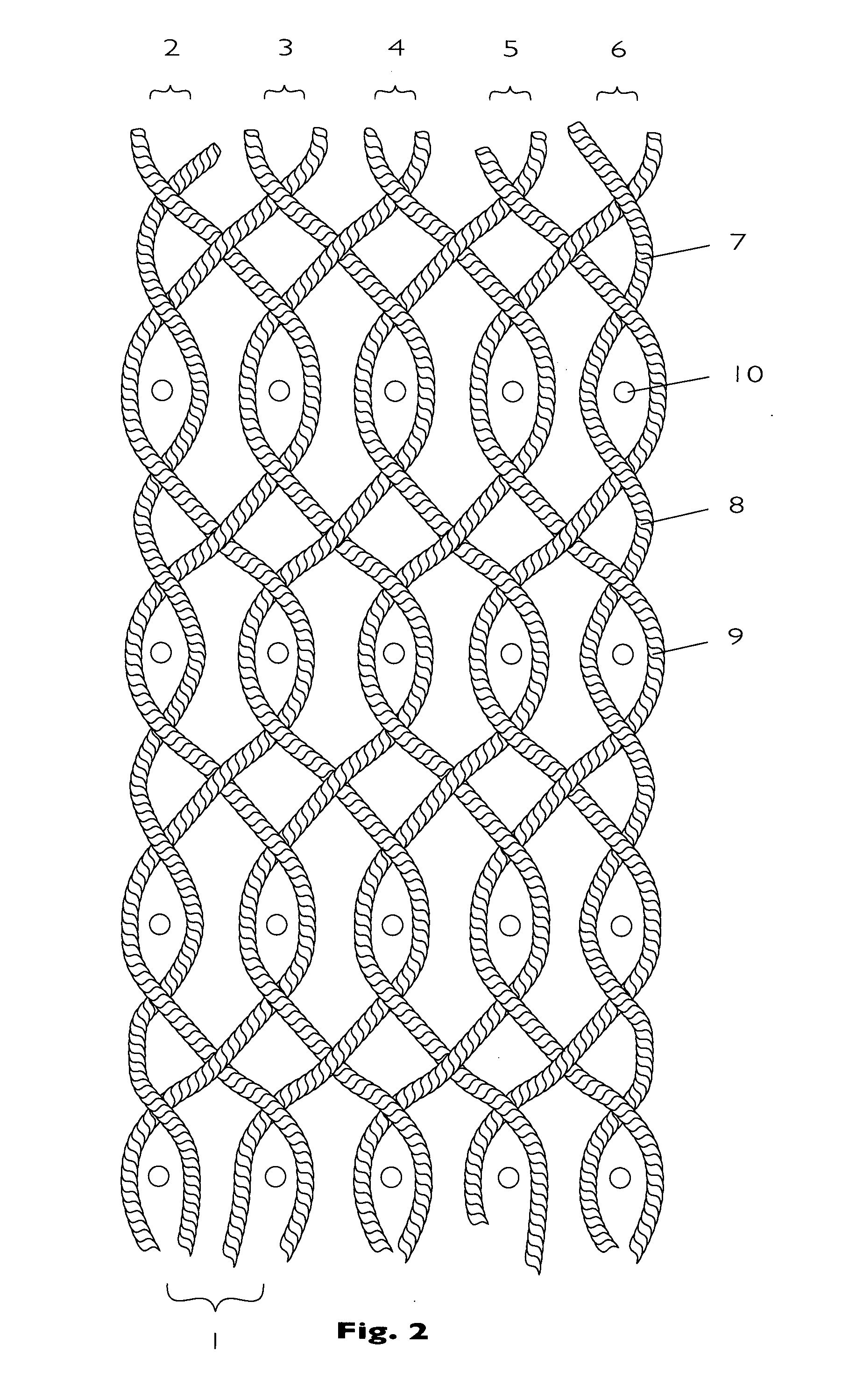

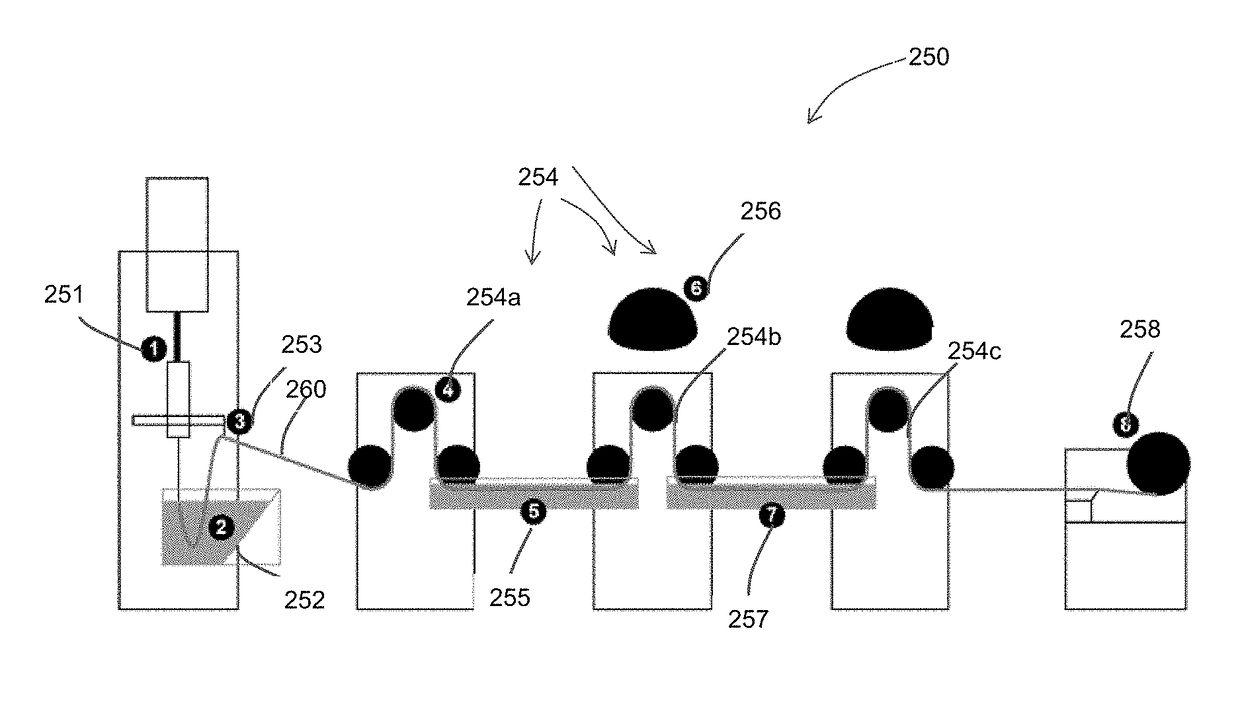

Artificial polypeptide fiber and method for producing the same

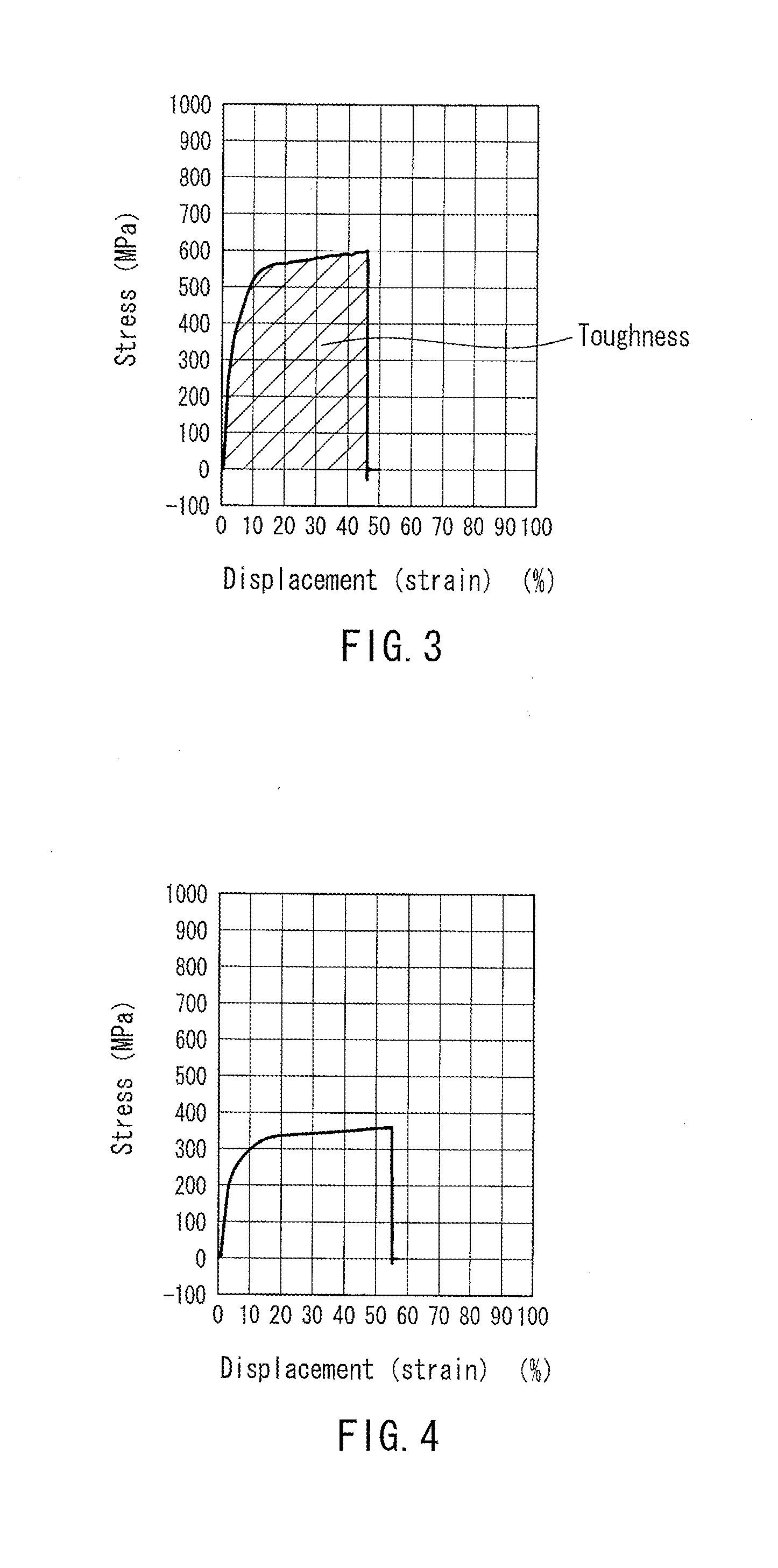

ActiveUS20140058066A1High stressImprove toughnessPeptide/protein ingredientsMonocomponent polypeptides artificial filamentFiberSpider Proteins

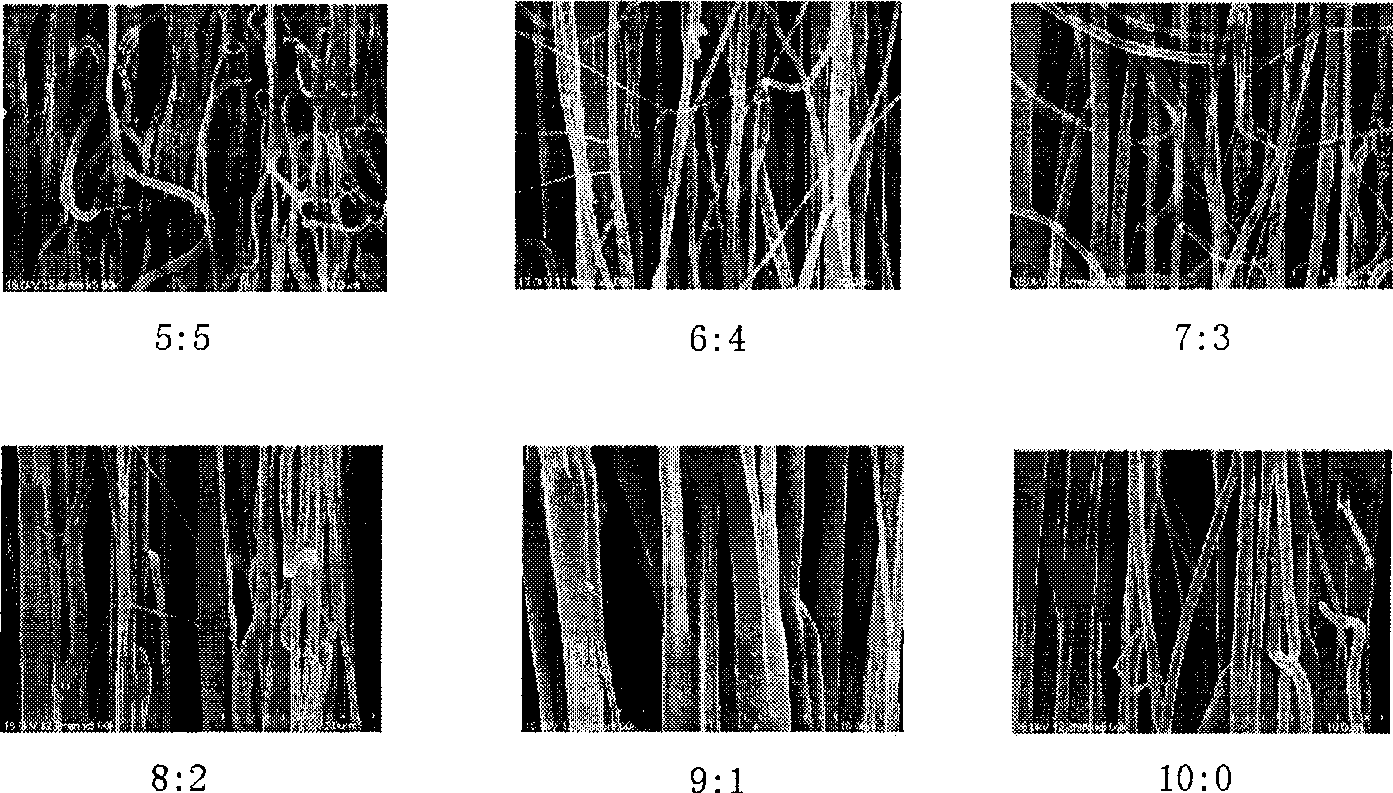

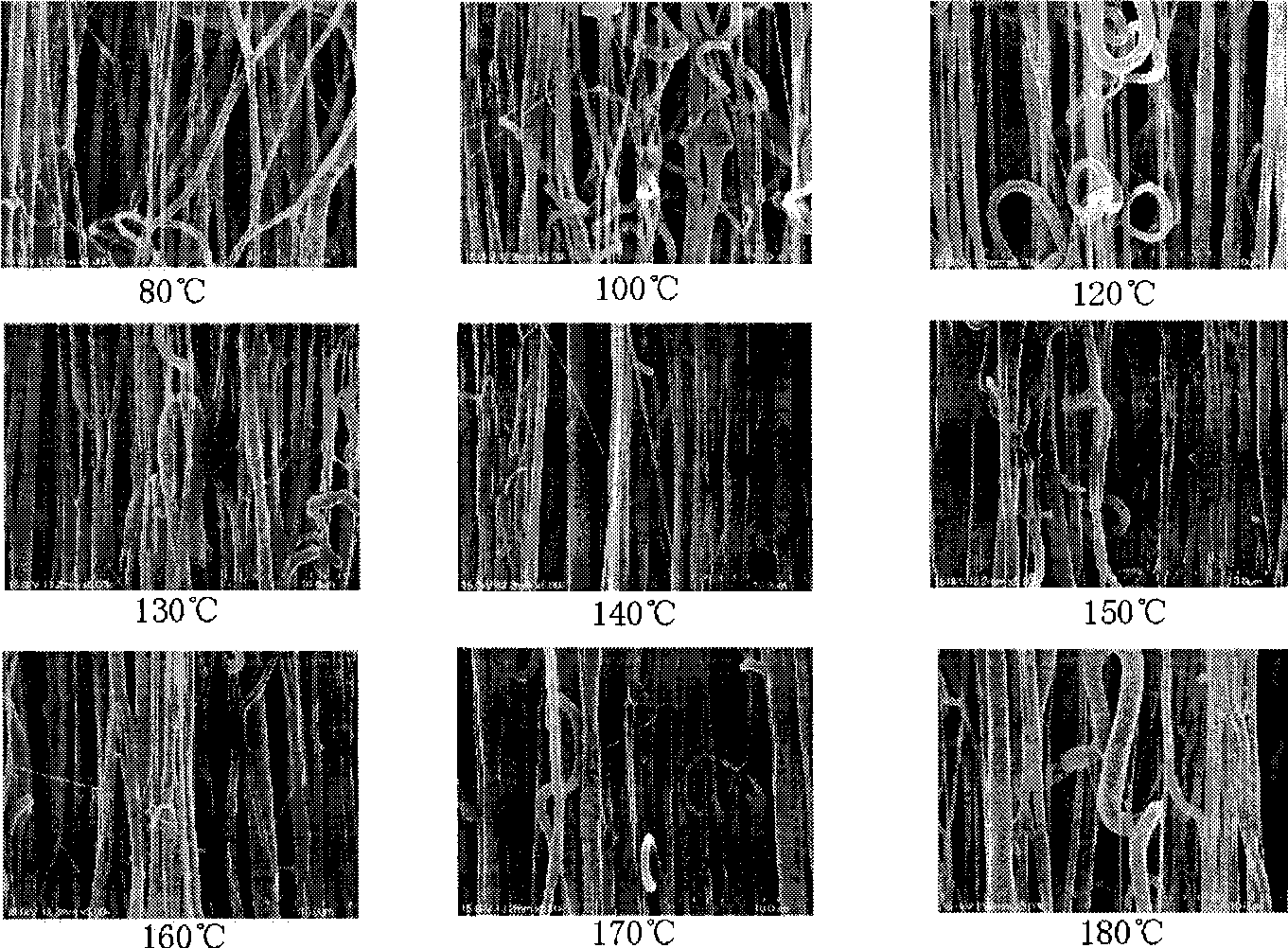

An artificial polypeptide fiber of the present invention is an artificial fiber containing a polypeptide as a main component, and has a stress of 350 MPa or more and a toughness of 138 MJ / m3 or more. A method for producing an artificial polypeptide fiber of the present invention is a method for producing the artificial polypeptide fiber obtained by spinning a spinning solution (6) containing a polypeptide derived from natural spider silk proteins and performing drawing of at least two stages. The drawing of at least two stages includes a first-stage drawing (3) in wet heat and a second-stage drawing (4) in dry heat. Thereby, the present invention provides high-toughness artificial polypeptide fibers having favorable stress and rupture elongation, and a method for producing the same.

Owner:SPIBER INC

Water-collecting polymer filament imitating spider silk structure and preparation method thereof

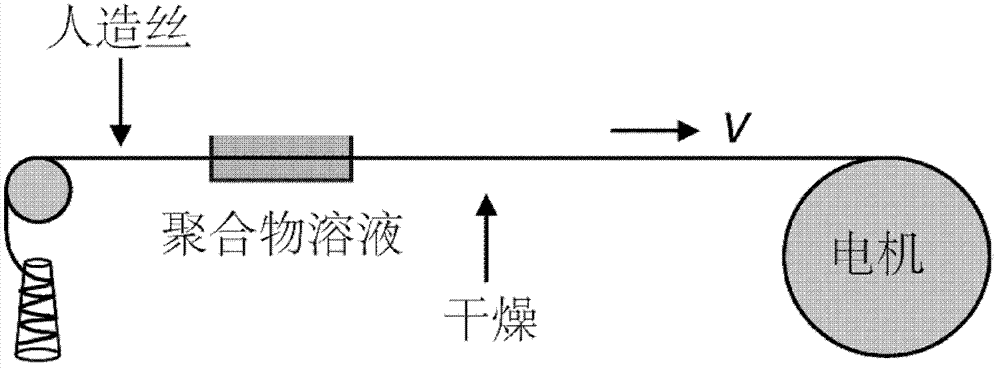

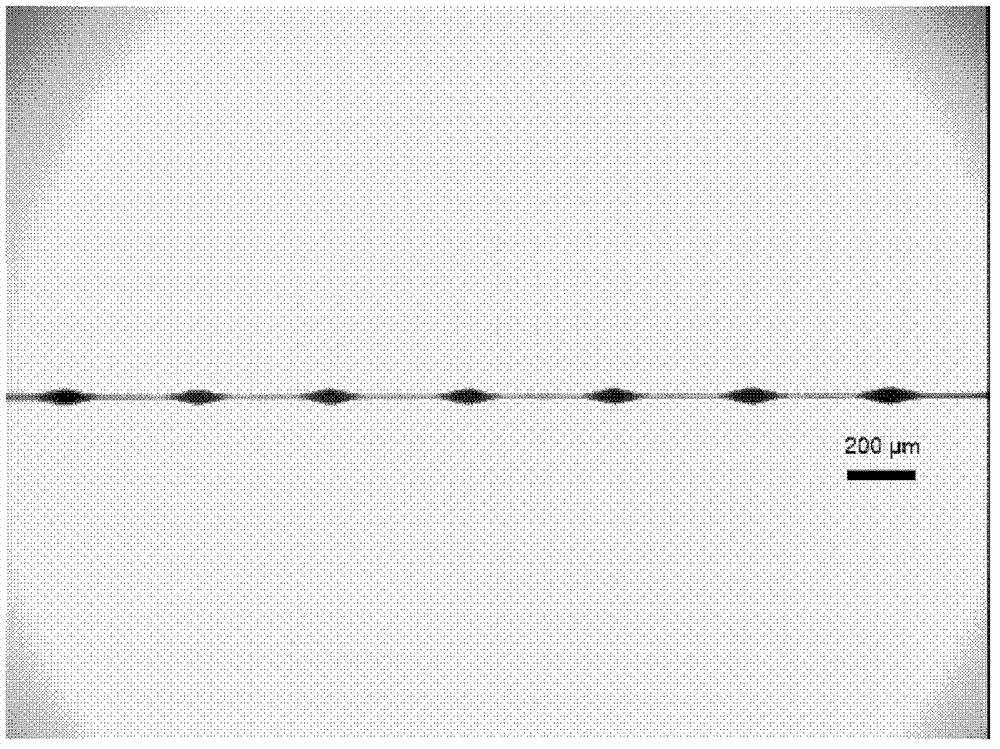

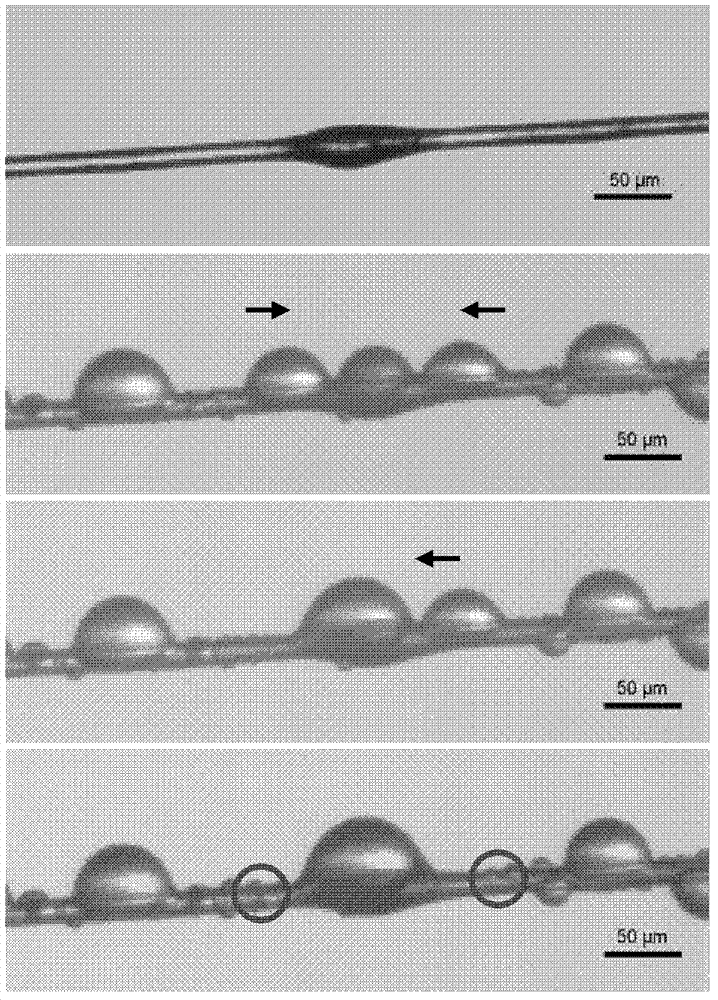

ActiveCN102776785AHigh affinityHigh fog water collection efficiencyFibre treatmentSpider ProteinsPolymer science

The invention relates to water-collecting polymer filament imitating the spider silk structure and a preparation method thereof. The preparation method comprises the following steps of: immersing common artificial silks into polymer solution mixed by a good solvent and a poor solvent containing polymer, then horizontally pulling out the artificial silks from the polymer solution along the axial direction of the artificial silks, and further enabling the polymer solution to wrap the surfaces of the artificial silks to form a liquid film; then due to Rayleigh instability, causing that the liquid film of the polymer solution on the surfaces of the artificial silks evolutes (break) into a string of liquid drops hung on the artificial silks; by adjusting the humidity and the temperature of the environment, drying the polymer liquid drops hung on the artificial silks so as to form spindle knots with periodic arrangement and a spindle-shaped structure on the surfaces of the artificial silks; and enabling the spindle knots which are in alignment along the axial direction of the artificial silks to form a coarse structure on the surfaces of the artificial silks, and further obtaining the water collecting polymer silks with the similar spider-silk structure by biomimetic synthesis.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Spider silk protein/polylactic acid composite nano fibre yarn and preparation method thereof

InactiveCN101418472AAvoid difficultiesHigh breaking strengthConjugated cellulose/protein artificial filamentsFilament/thread formingYarnFiber

The invention discloses a method for preparing spider silk protein / polylactic acid composite nano-fiber yarn. The method comprises the following steps of preparing a spinning solution, preparing a bath solution and then adopting an improved electrostatic spinning method to guide, heat, wind and shape bunched fibers, so as to obtain the spider silk protein / polylactic acid composite nano-fiber yarn. The composite nano-fiber yarn of the invention can be continuously spun for more than 10 hours and have no broken ends, and a certain amount of spider silk protein effectively reduces the diameter of the fibers and improves the strength of the yarn. In addition, the fracture strength and flexibility of the composite nano-fiber yarn can be further improved through secondary stretching and combined twisting, so that the composite nano-fiber yarn can be applied in biomedical materials and other fields better.

Owner:SUZHOU UNIV

Spider silk dental floss

Owner:YERUSHALMY ISRAEL

Natural nanometer fiber preparation method

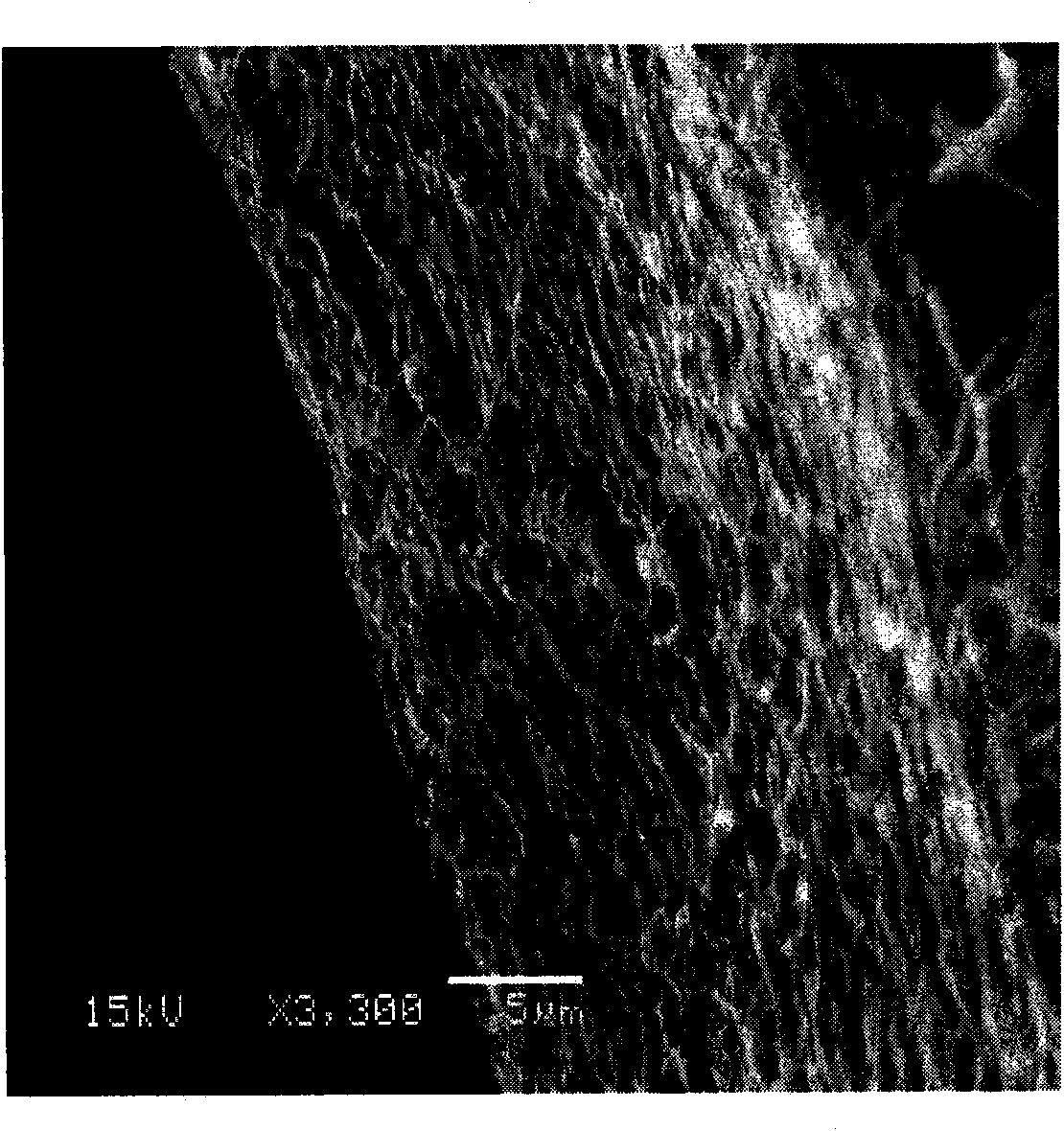

InactiveCN1730734ASuitable for a wide rangeControllableMonocomponent fibroin artificial filamentFilament/thread formingSpider ProteinsLaboratory research

The present invention relates to the preparation process of natural nanometer fiber for tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material, and is especially the preparation process of natural nanometer spider silk fiber and cocoon silk fiber. Through soaking in certain solution and ultrasonic dissociation, natural nanometer fiber of diameter 30-100 nm may be prepared. The prepared natural nanometer fiber may find its wide application in tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material. The present invention has simple operation, simple equipment, low power consumption and low cost, and is suitable for both lab preparation and industrial production.

Owner:TSINGHUA UNIV

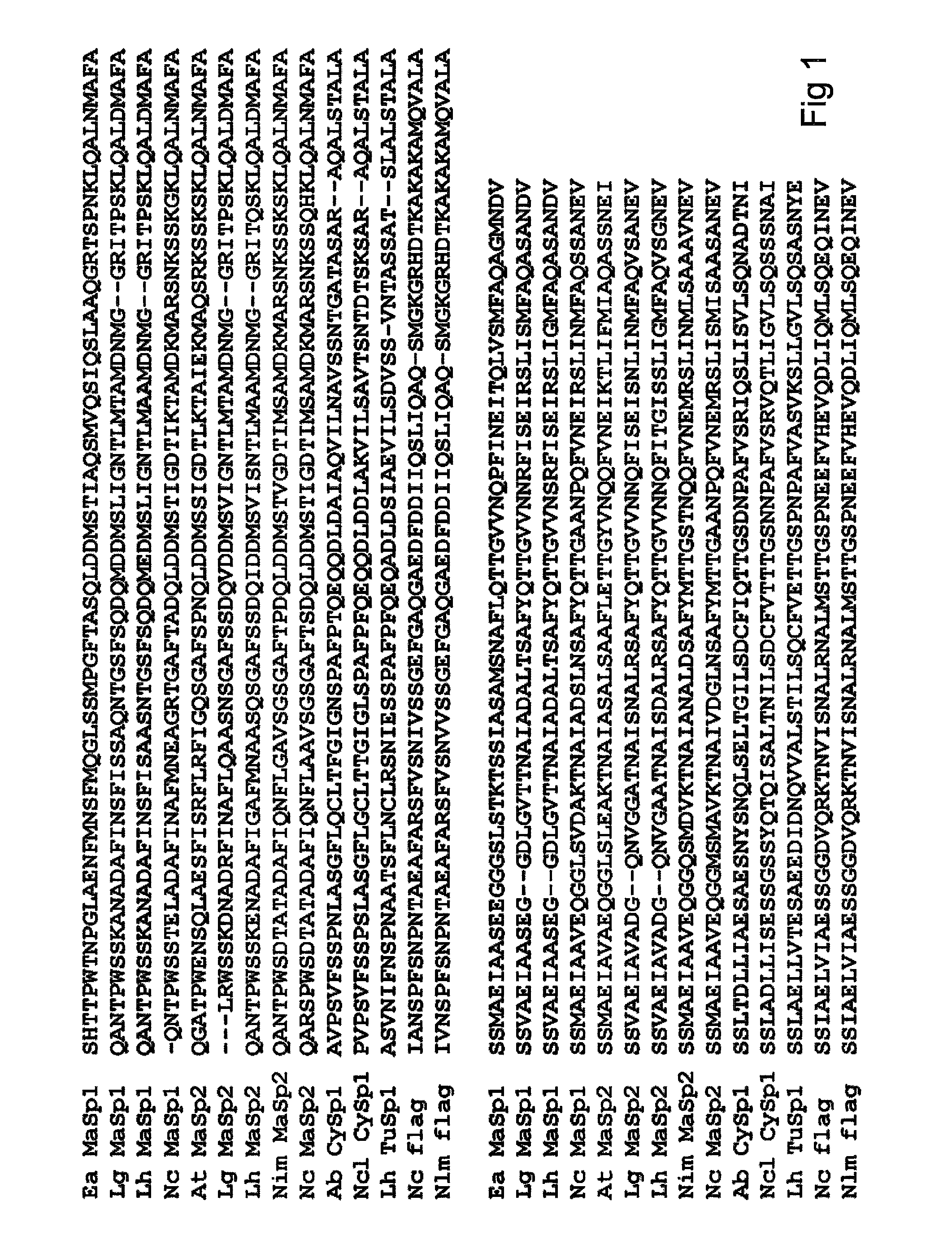

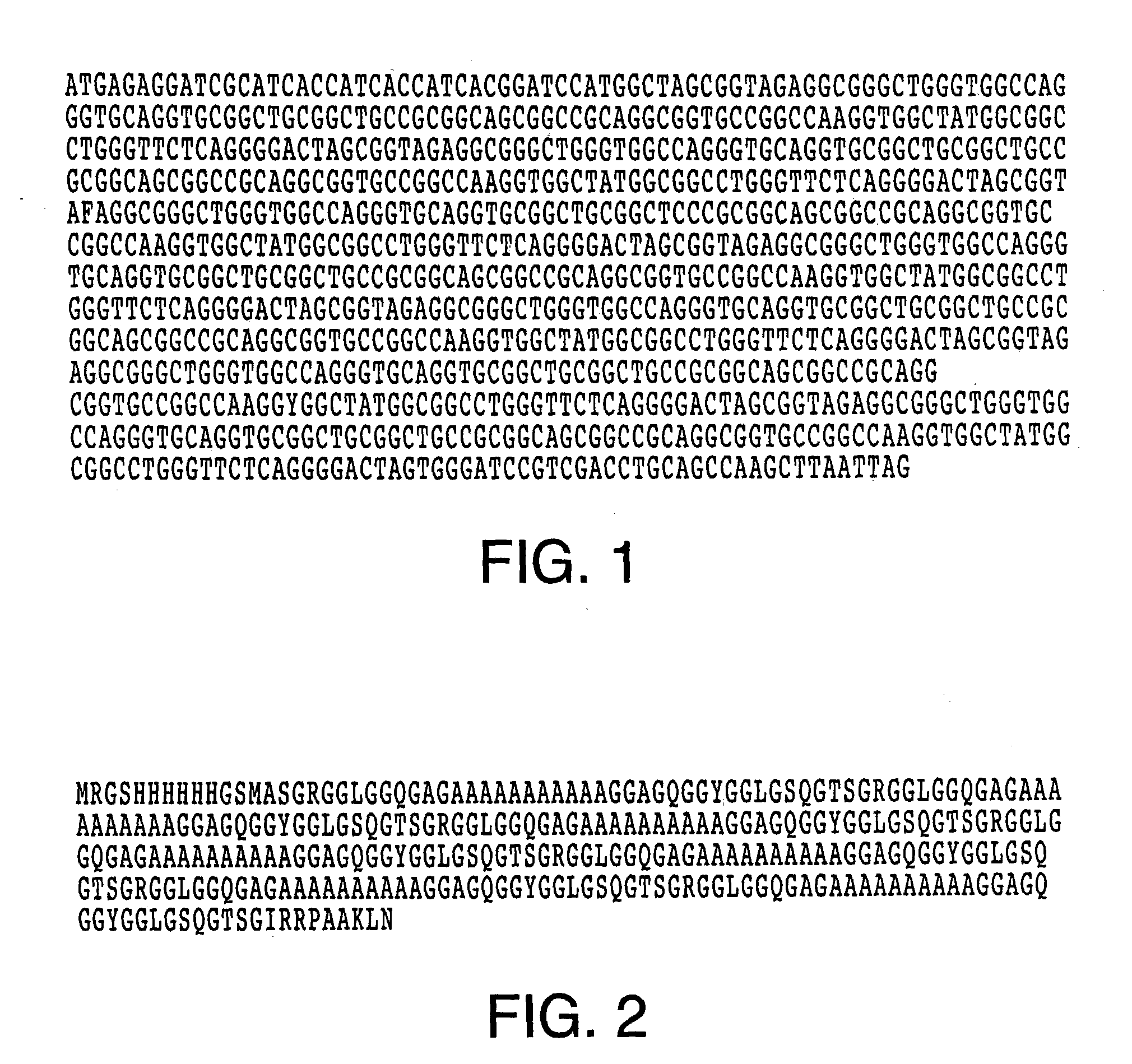

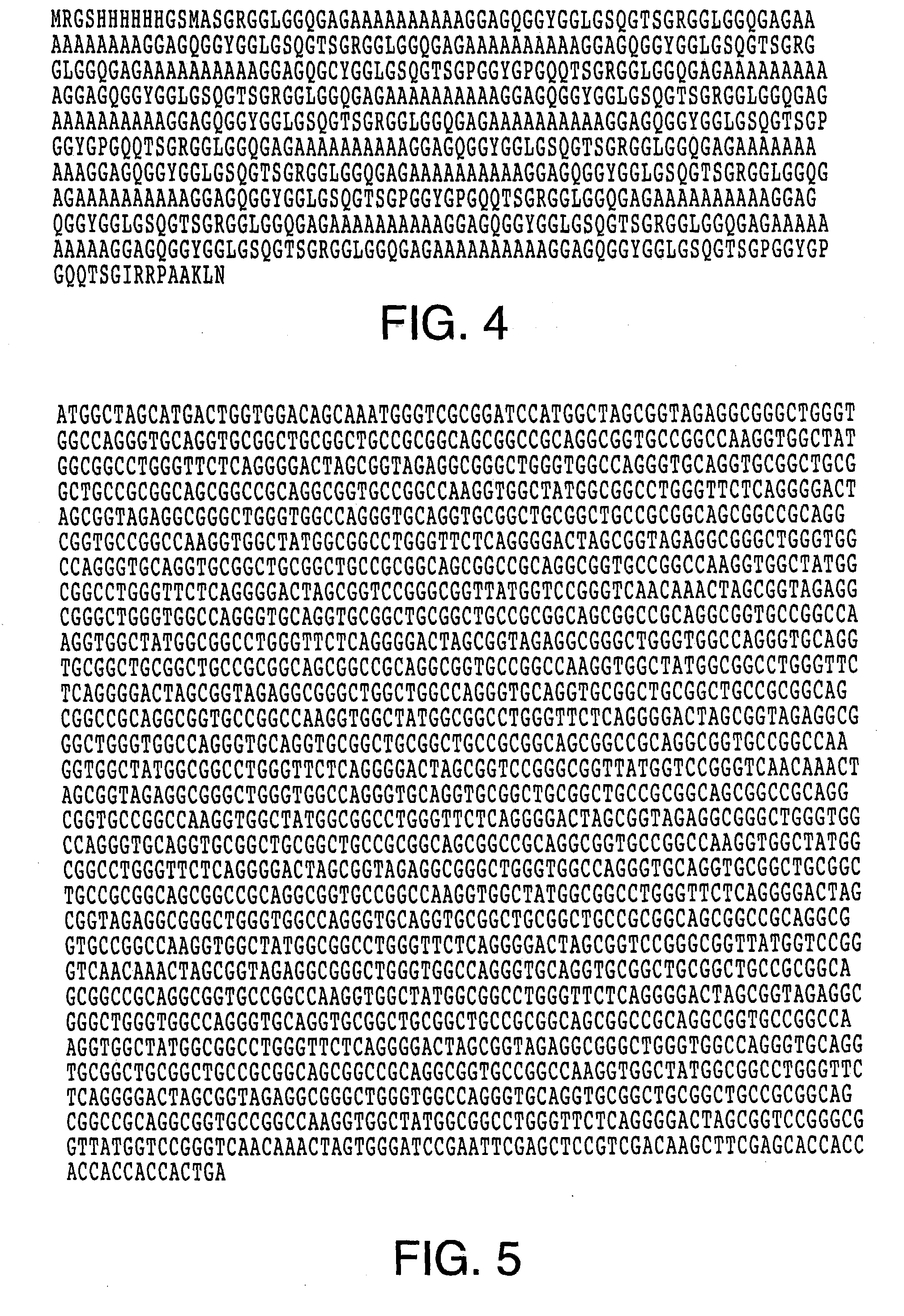

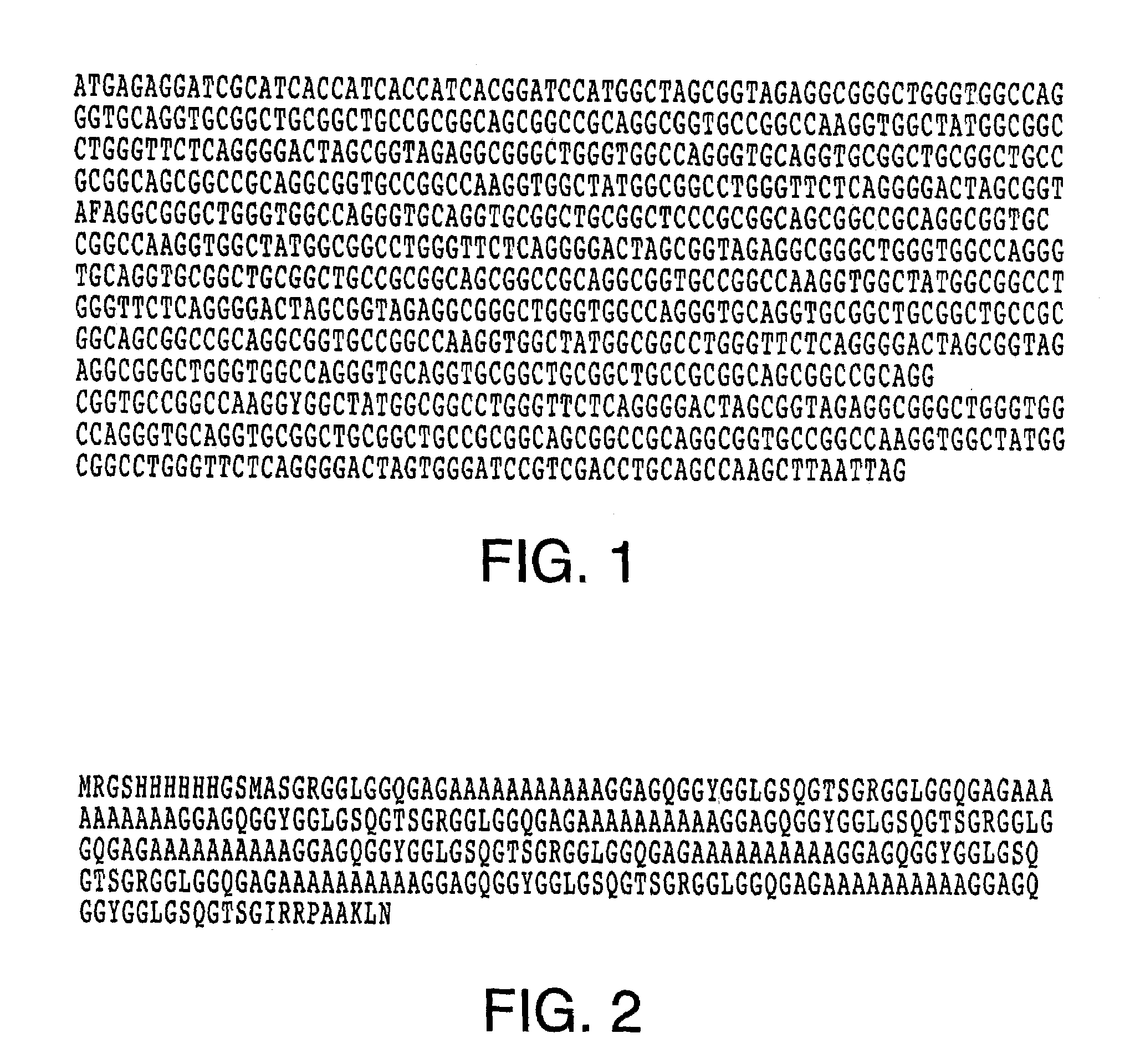

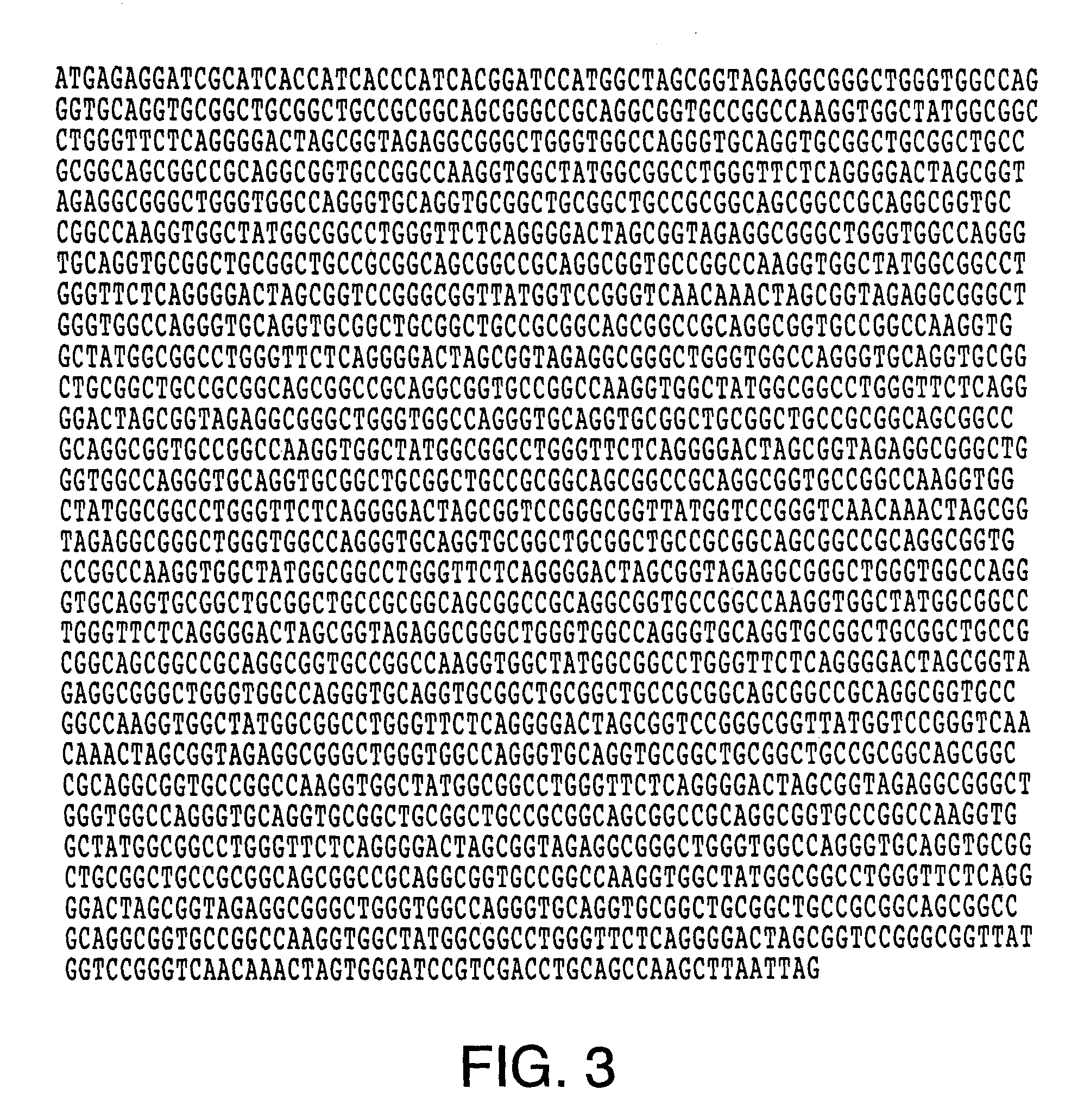

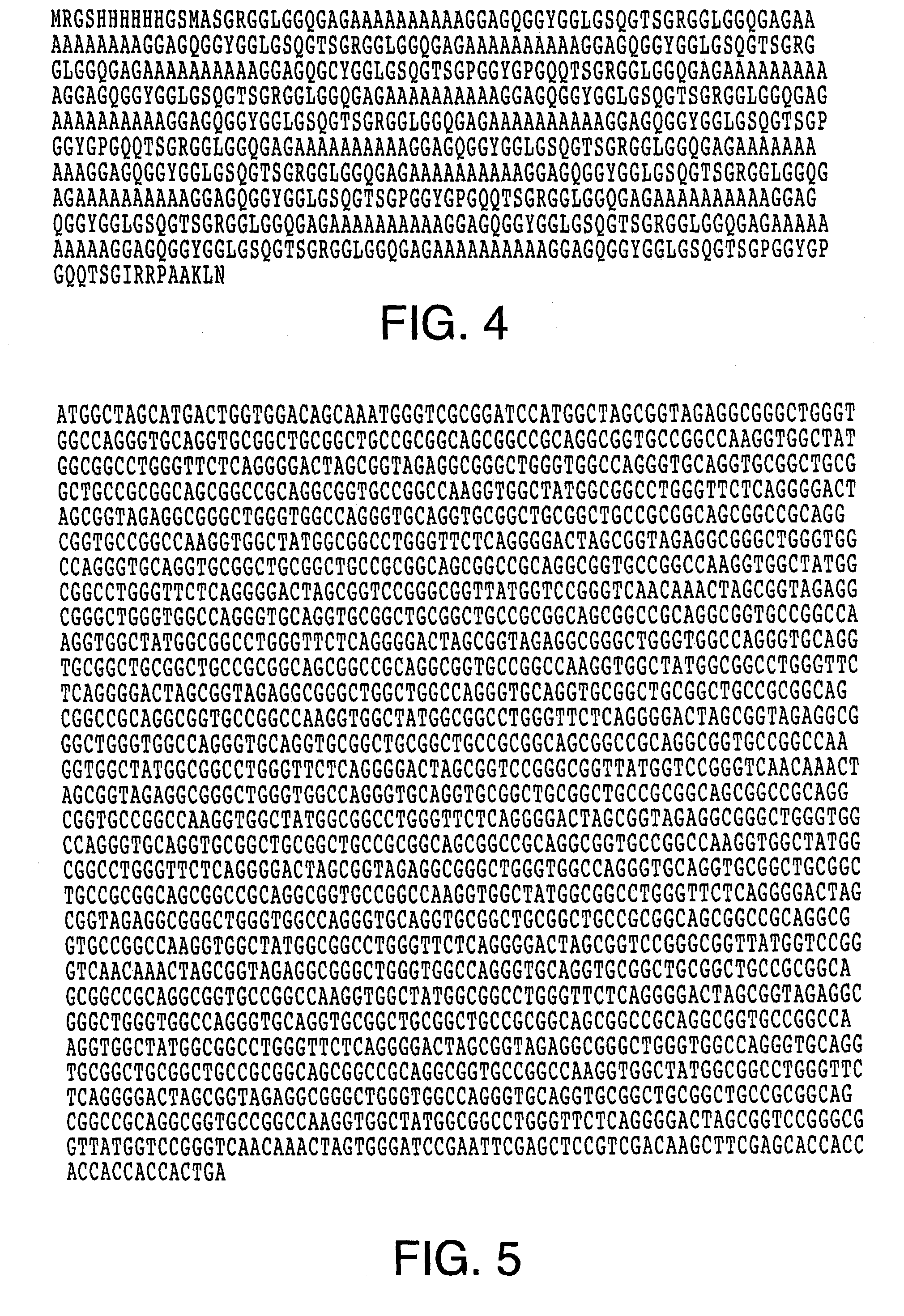

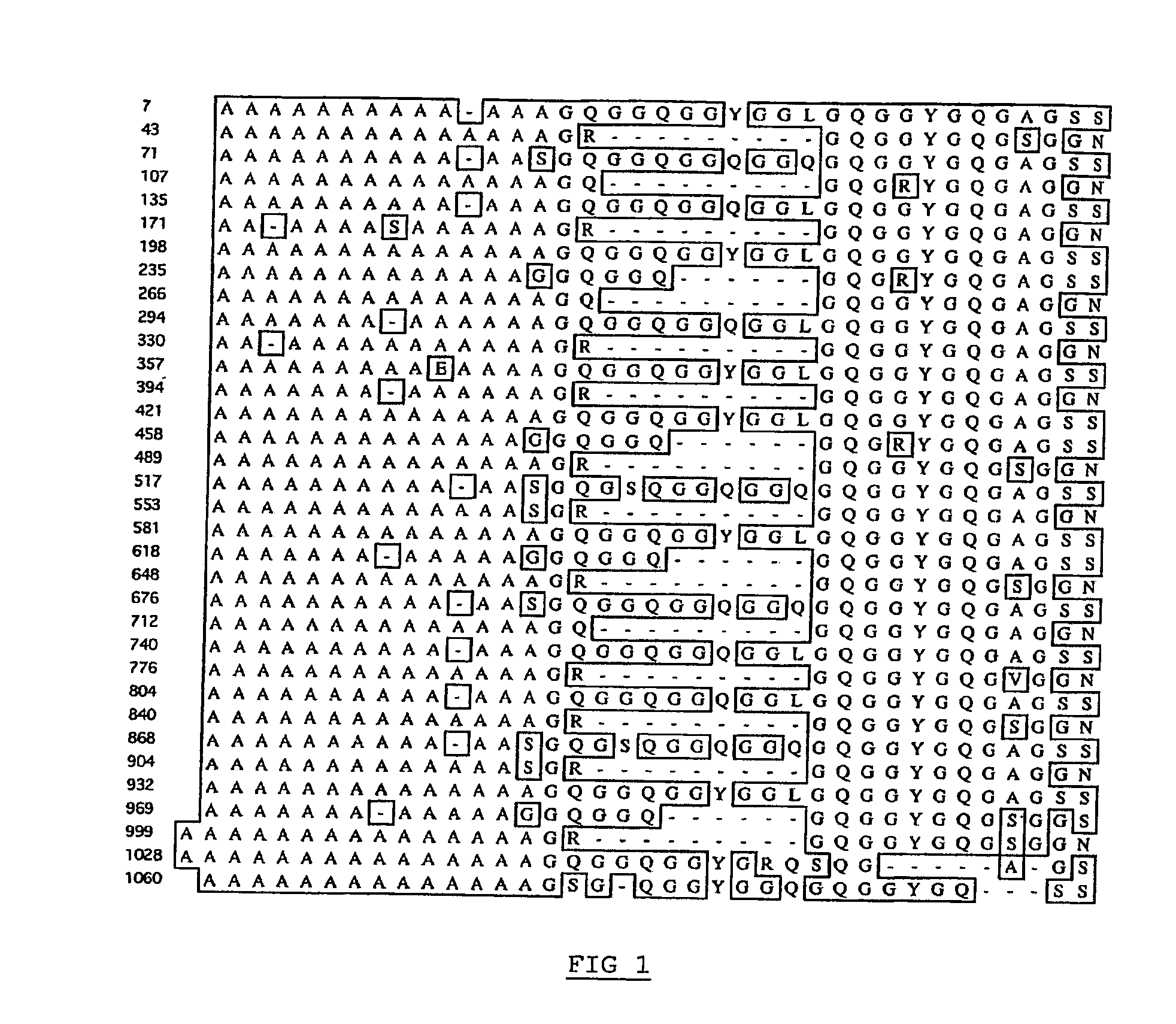

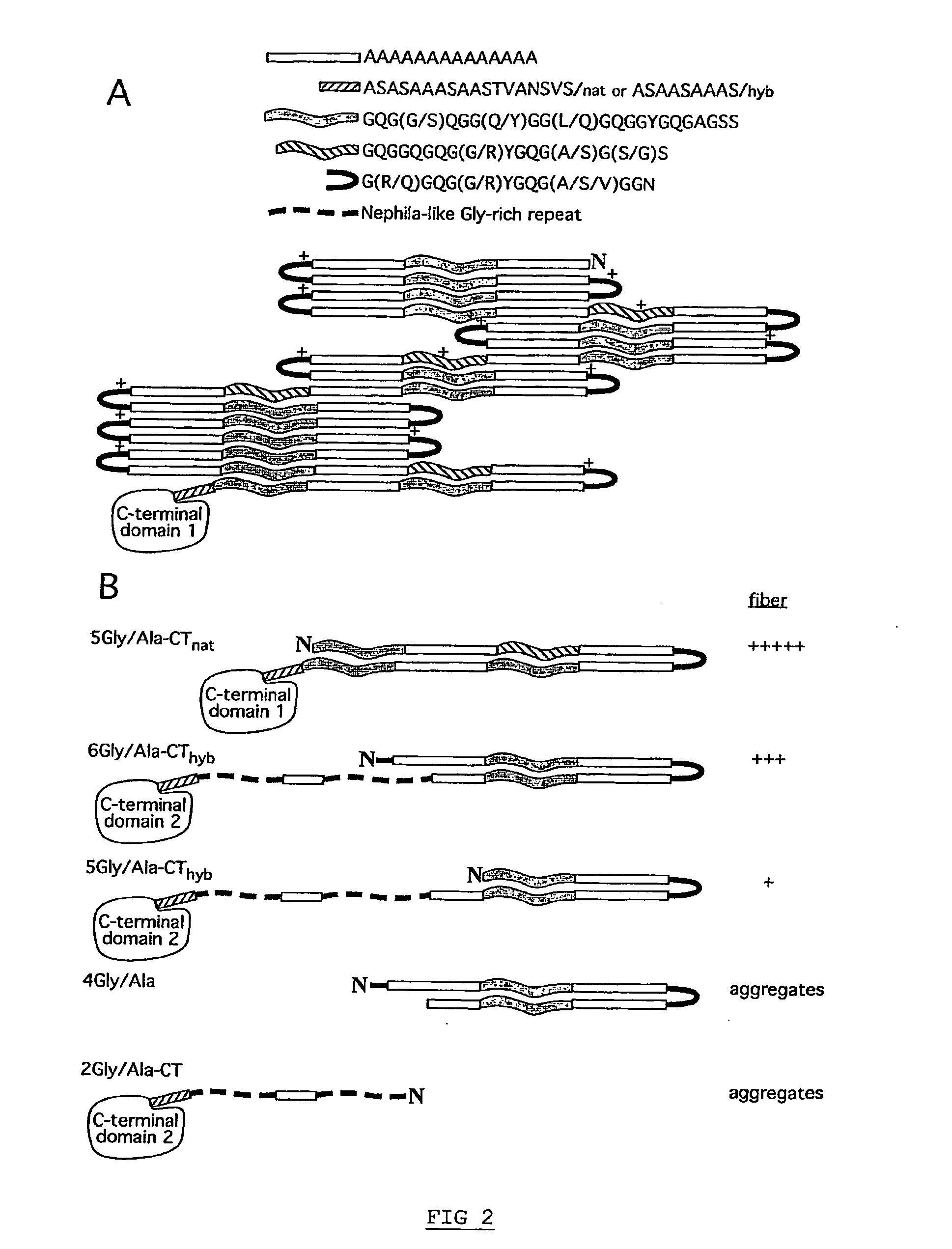

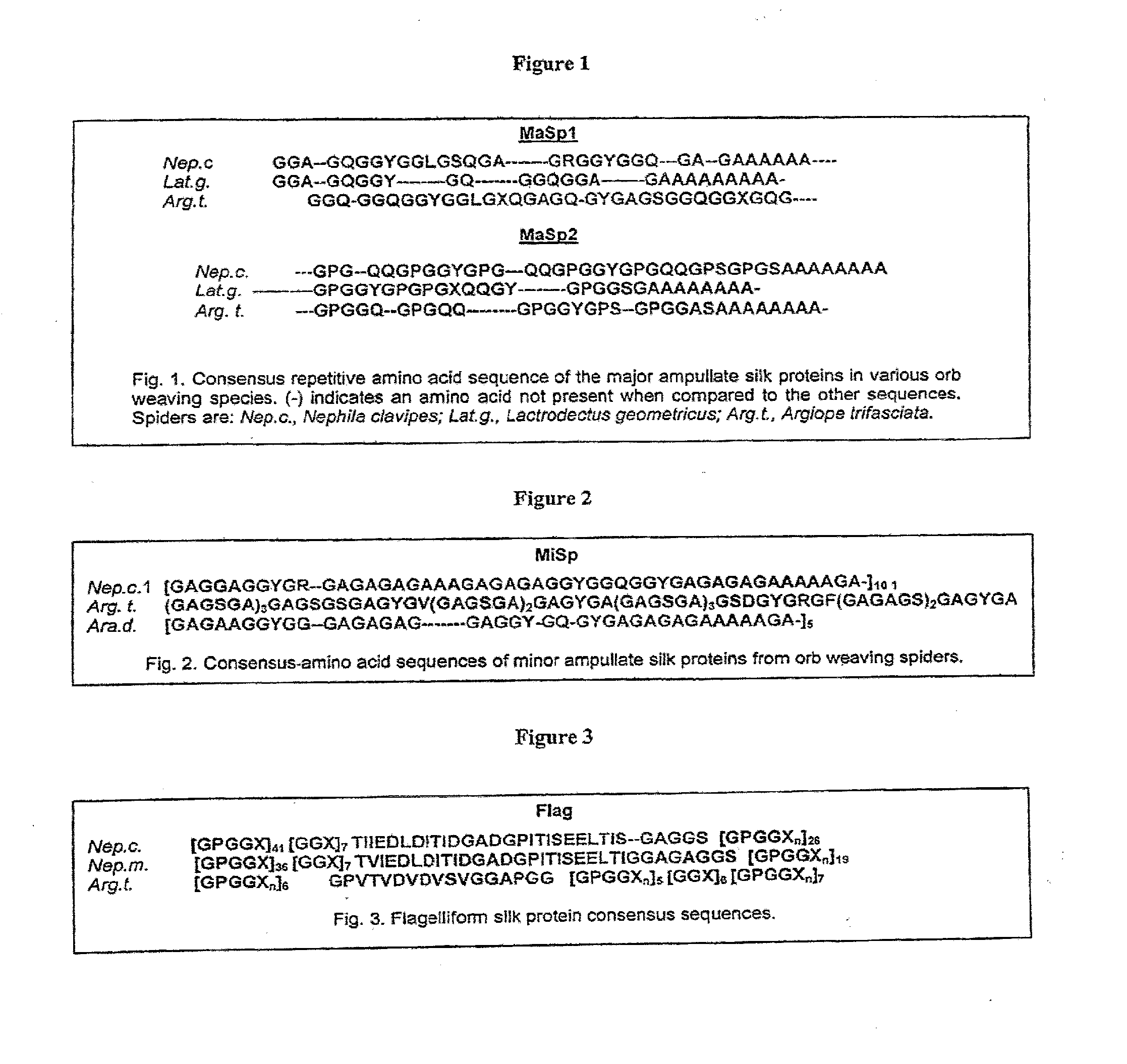

Synthetic Dragline Spider Silk-Like Proteins

The present application relates to isolated amino acid sequence comprising multiple repeats of a semi-synthetic spider silk protein domain, or any functional homolog, variant, derivative, fragment or mutant thereof. The amino acid sequence of the invention further comprises an N-terminal region and a C-terminal region. The invention further provides a nucleic acid encoding the amino acid sequence of the invention, an expression vector comprising said nucleic acid, a host cell transformed with said expression vector, a recombinant spider silk protein thus produced and a fiber composed of the recombinant spider silk protein. The invention further encompasses a composition comprising as an active ingredient said amino acid sequence or any said recombinant protein or fiber comprising the same. Lastly, the invention relates to an article comprising at least one fiber composed of said recombinant spider silk protein.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Preparation method of recombinant spider silk protein/silver nano biological wound membrane

InactiveCN103041440AImprove antibacterial propertiesSimple preparation processAbsorbent padsBandagesArginineProtein materials

The invention relates to a preparation method of a recombinant spider silk protein / silver-bearing nano wound membrane. The preparation method comprises the steps of dissolving PVA (Polyvinyl Acetate) in H2O to prepare a PVA aqueous solution, conducting electrostatic spinning to prepare PVA nanofiber membrane, uniformly spraying a silver nitrate weak solution onto the PVA nanofiber membrane, drying, dissolving pNSR 16 in formic acid to prepare a formic acid solution of RGD (Arginine-Glycine-Aspartate)-spider silk protein, electrically spinning the formic acid solution of the RGD-spider silk protein into the PVA nanofiber membrane by an electrostatic spinning technology to form a pNSR 16 composite silver-bearing PVA nanofiber membrane, dyring, and obtaining the silver-bearing nano biological wound membrane. The membrane adopts natural protein materials and has bioactivity; as silver nitrate antibacterial components are introduced, the membrane has a significant antibacterial property and can kill most gram-negative bacteria and gram-positive bacteria; with the adoption of the electrostatic spinning technology, the preparation process is simple; and compared with medical gauze, the number of days required by complete healing of animal skin is reduced by approximately one third.

Owner:FUJIAN NORMAL UNIV

Spider silk protein encoding nucleic acids, polypeptides, antibodies and methods of use thereof

Spider silk protein encoding nucleic acids, polypeptides and antibodies immunologically specific therefore are disclosed. Methods of use thereof are also provided.

Owner:WYOMING THE UNIV OF

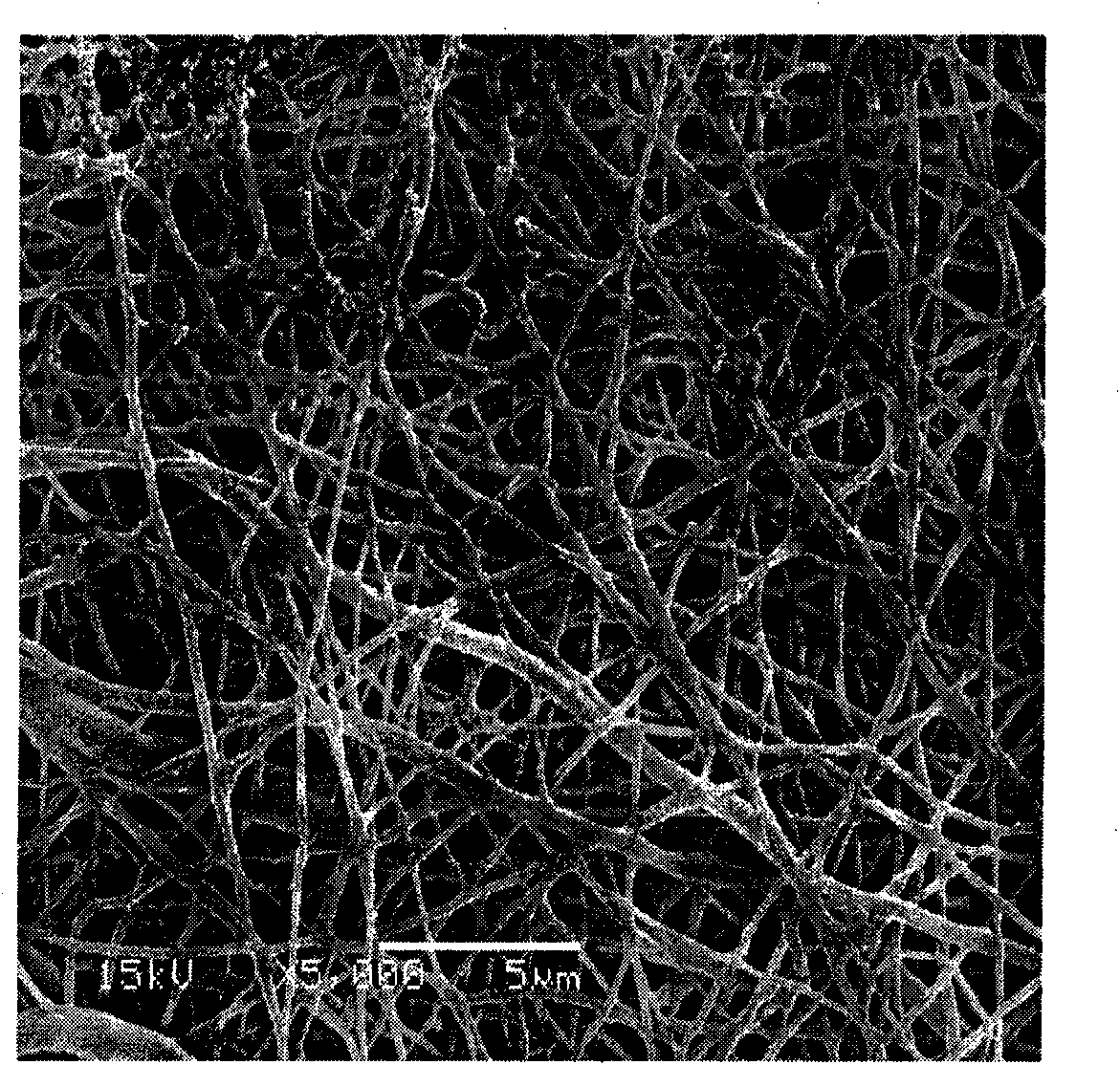

Electrospun carbon nanotube reinforced silk fibers

InactiveUS20070082197A1Material nanotechnologyElectroconductive/antistatic filament manufactureSpider ProteinsFibril

Strong and tough synthetic fibrils of carbon nanotube and spider silk are provided. Methods for production of these synthetic fibrils and methods for their use in biomedical devices, including those requiring electroconductivity, and areas of blast and ballistic protection are also provided.

Owner:DREXEL UNIV

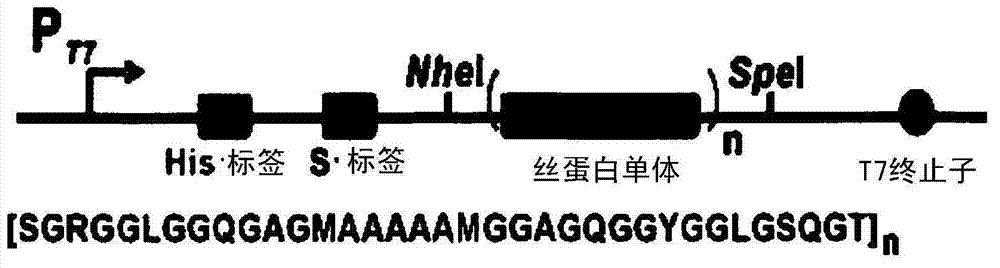

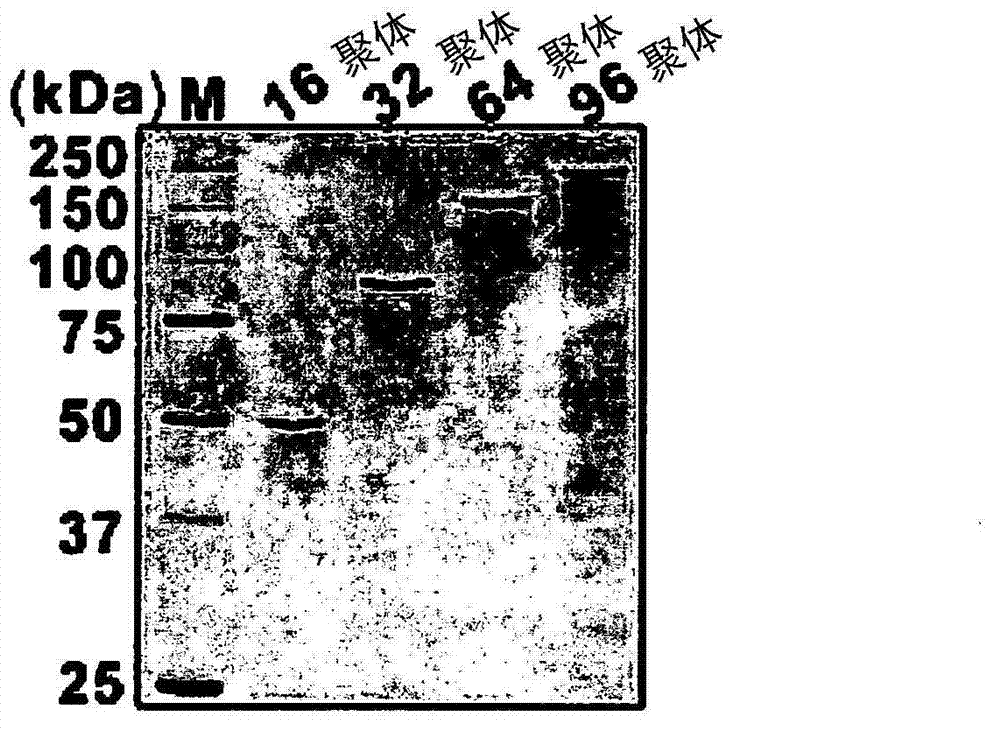

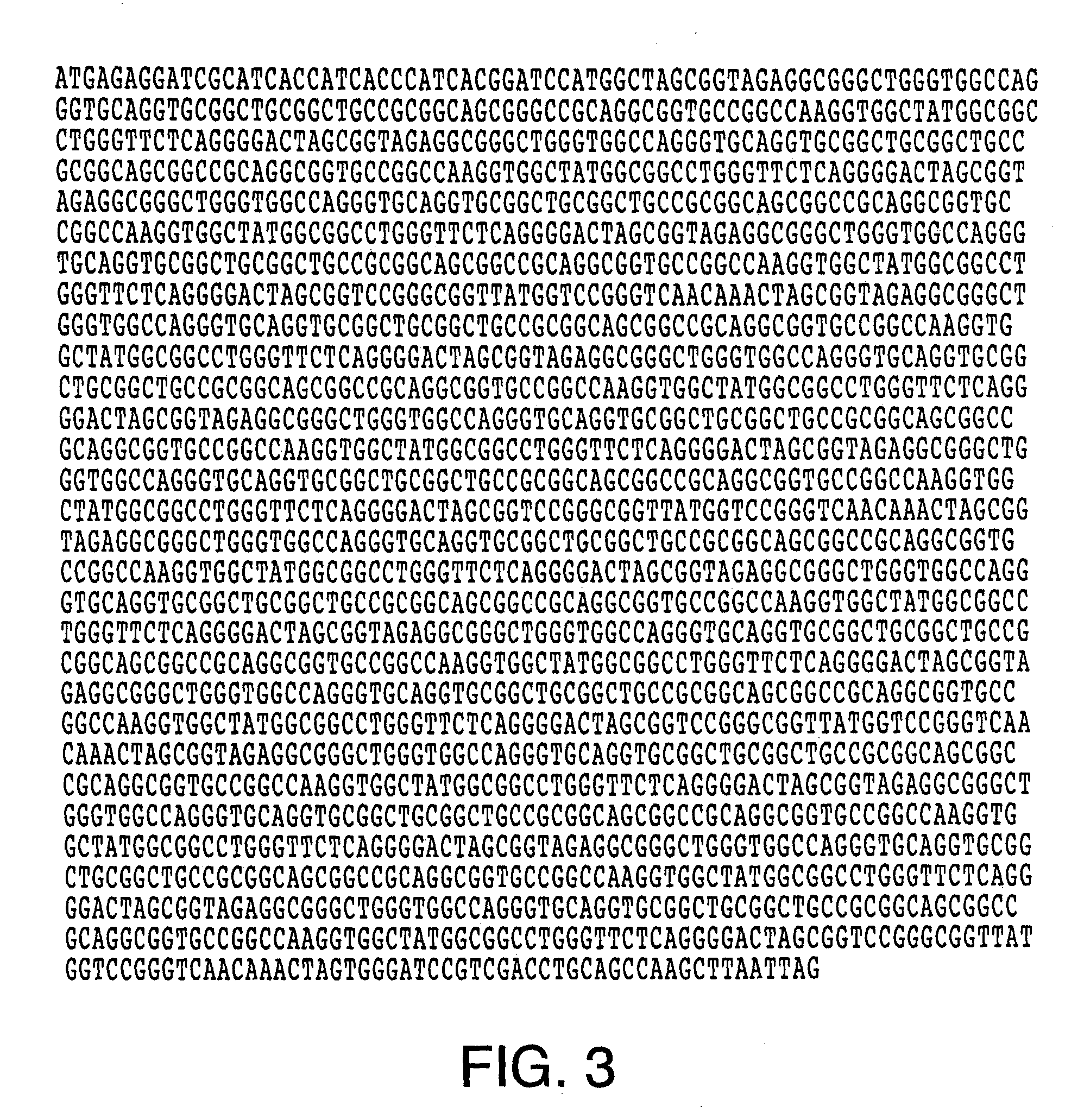

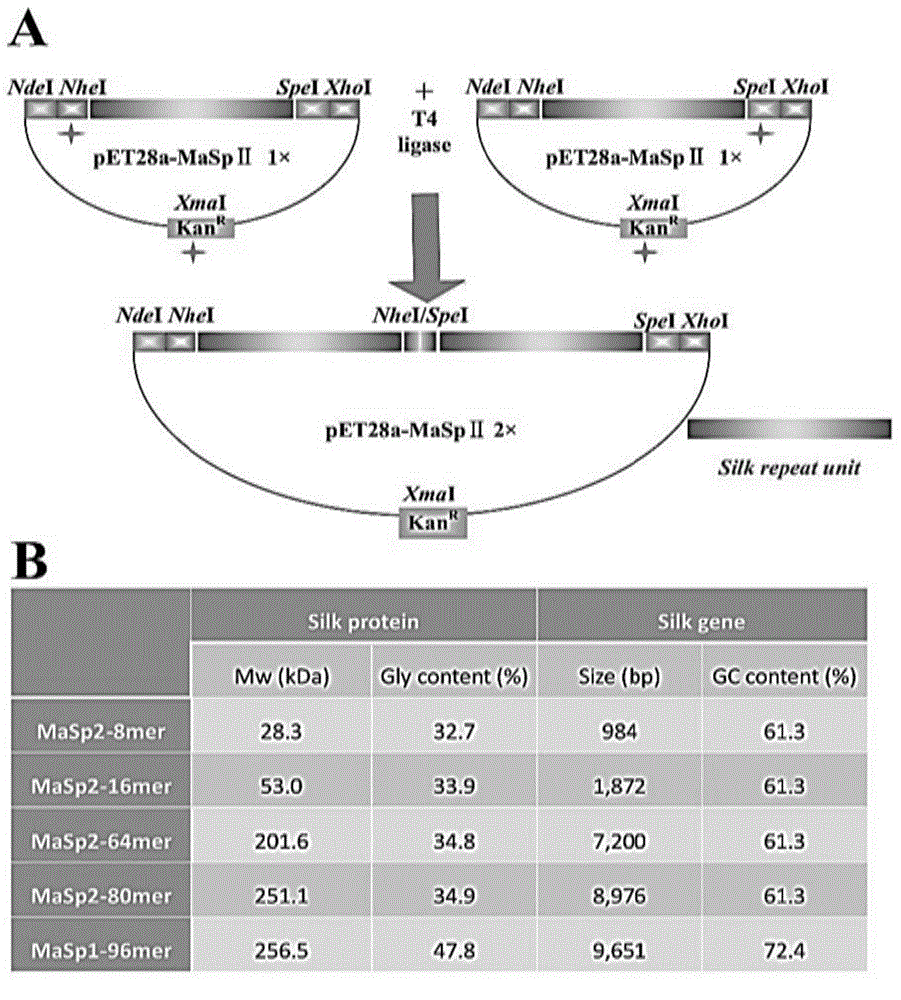

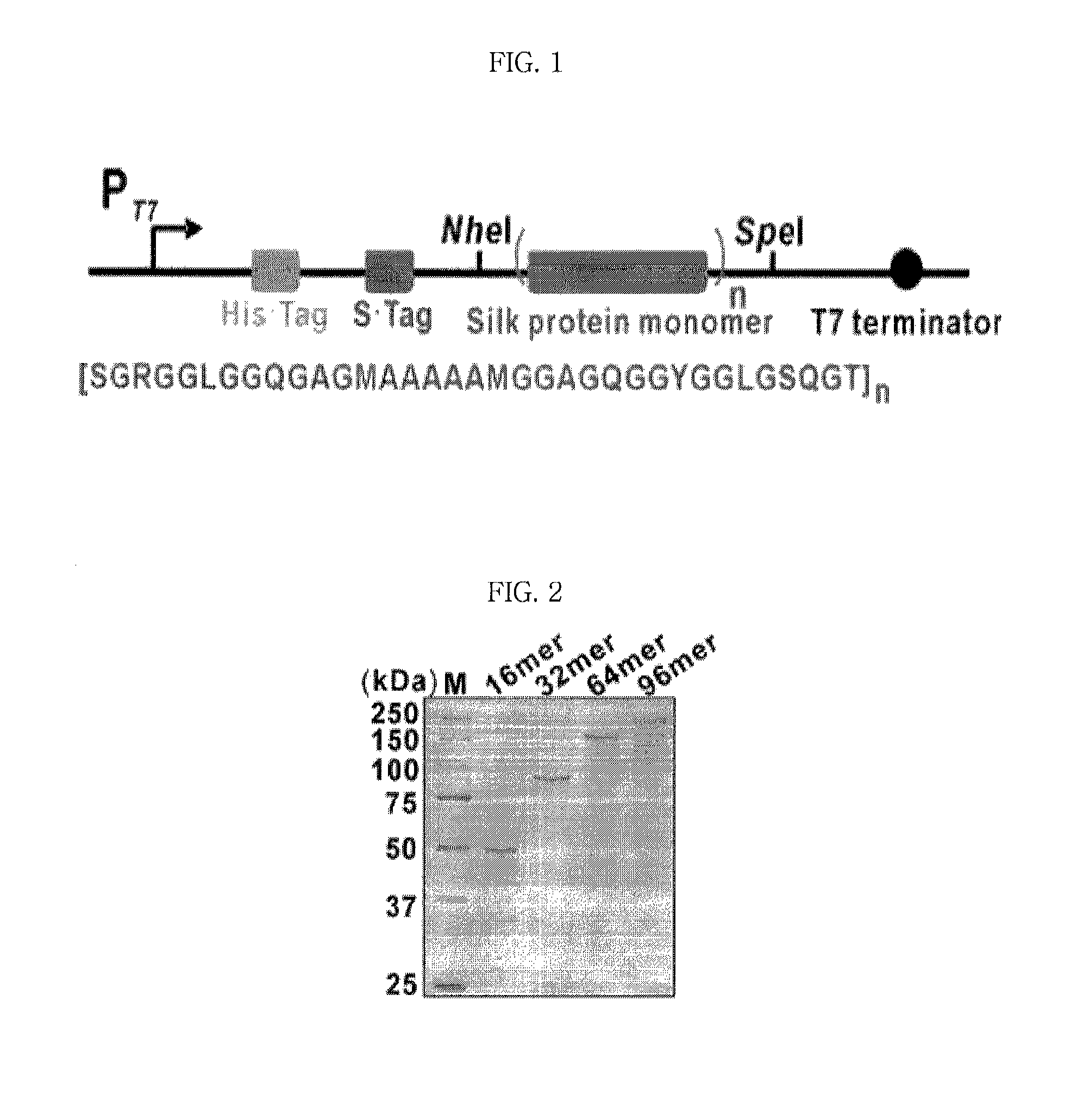

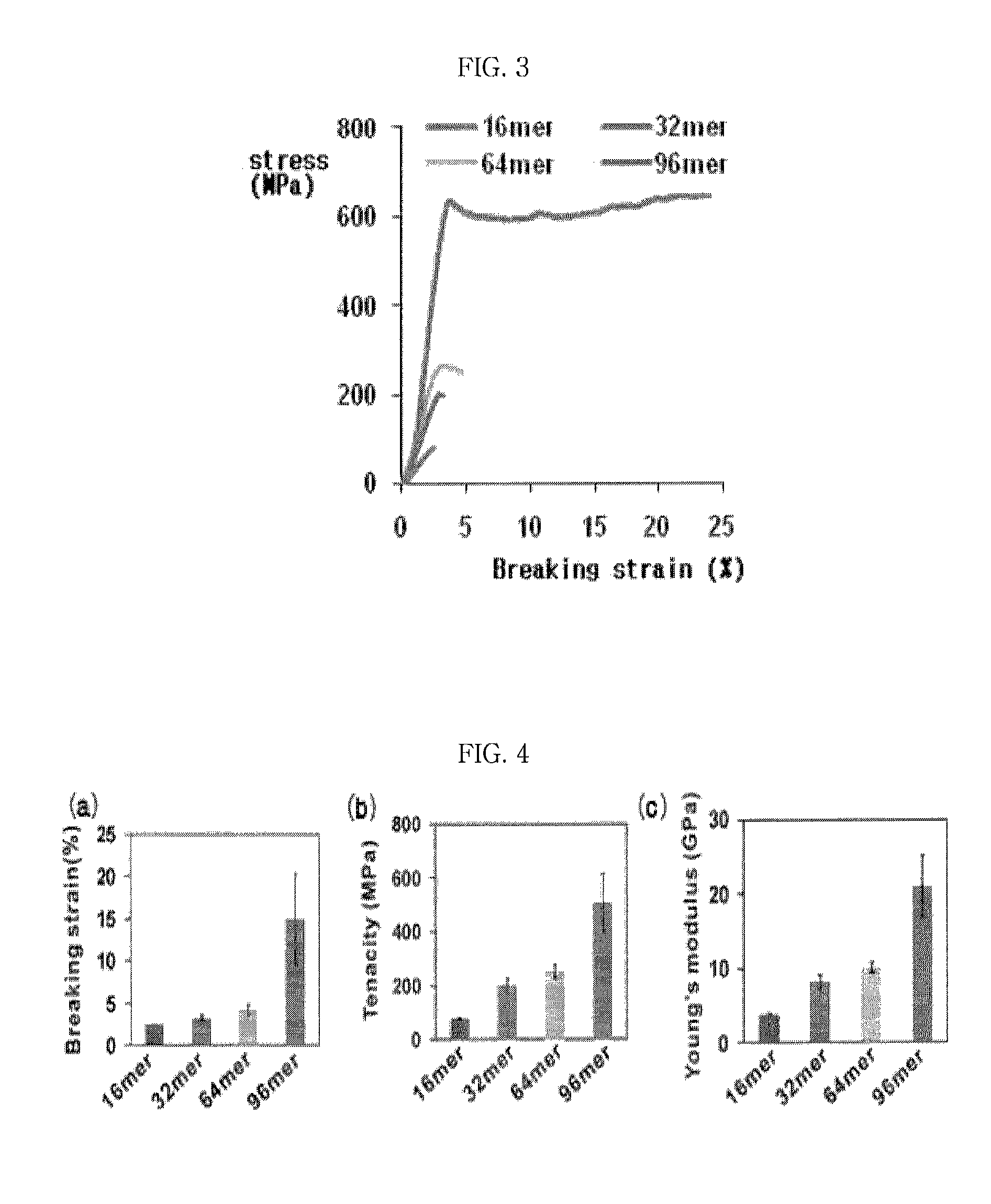

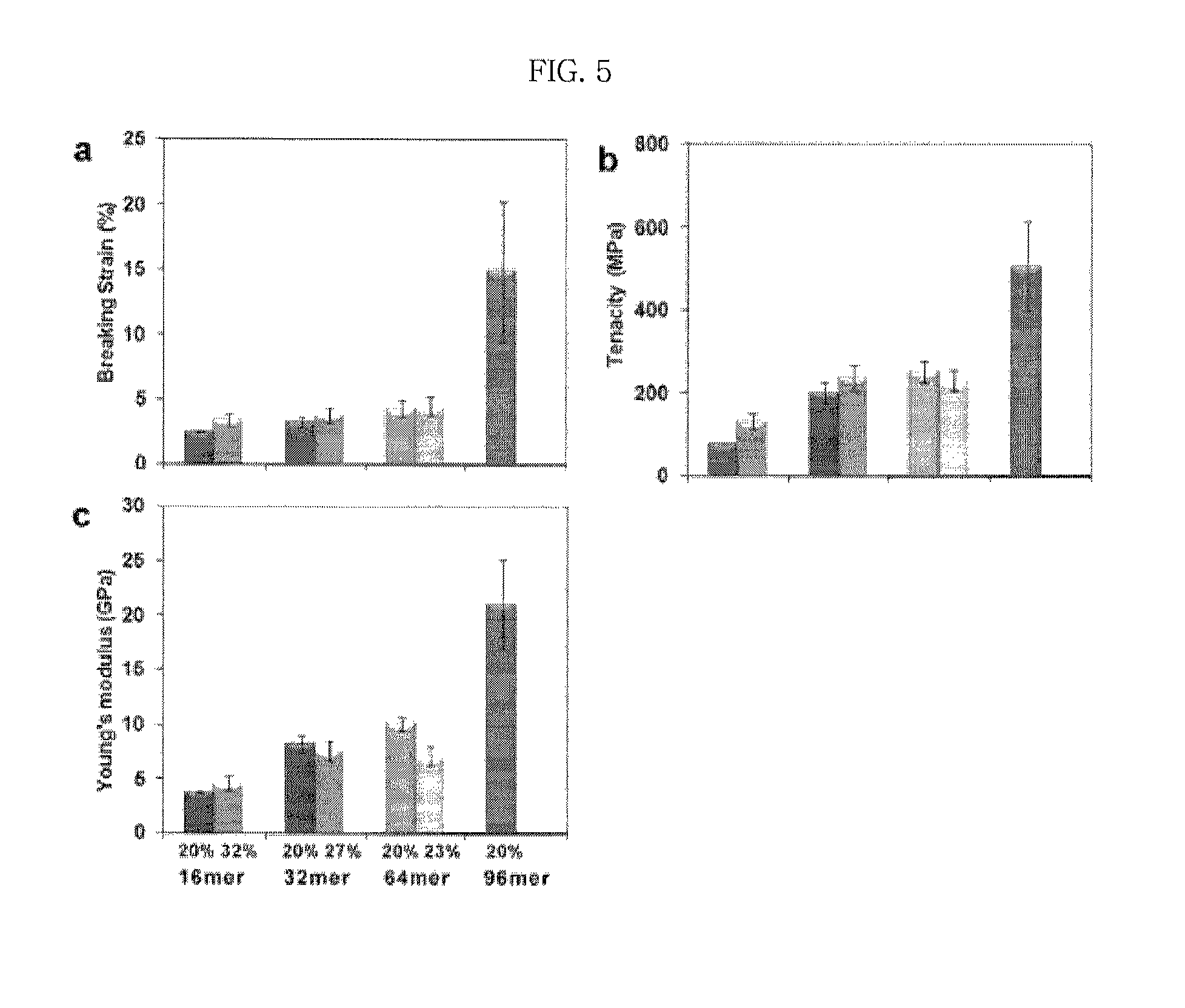

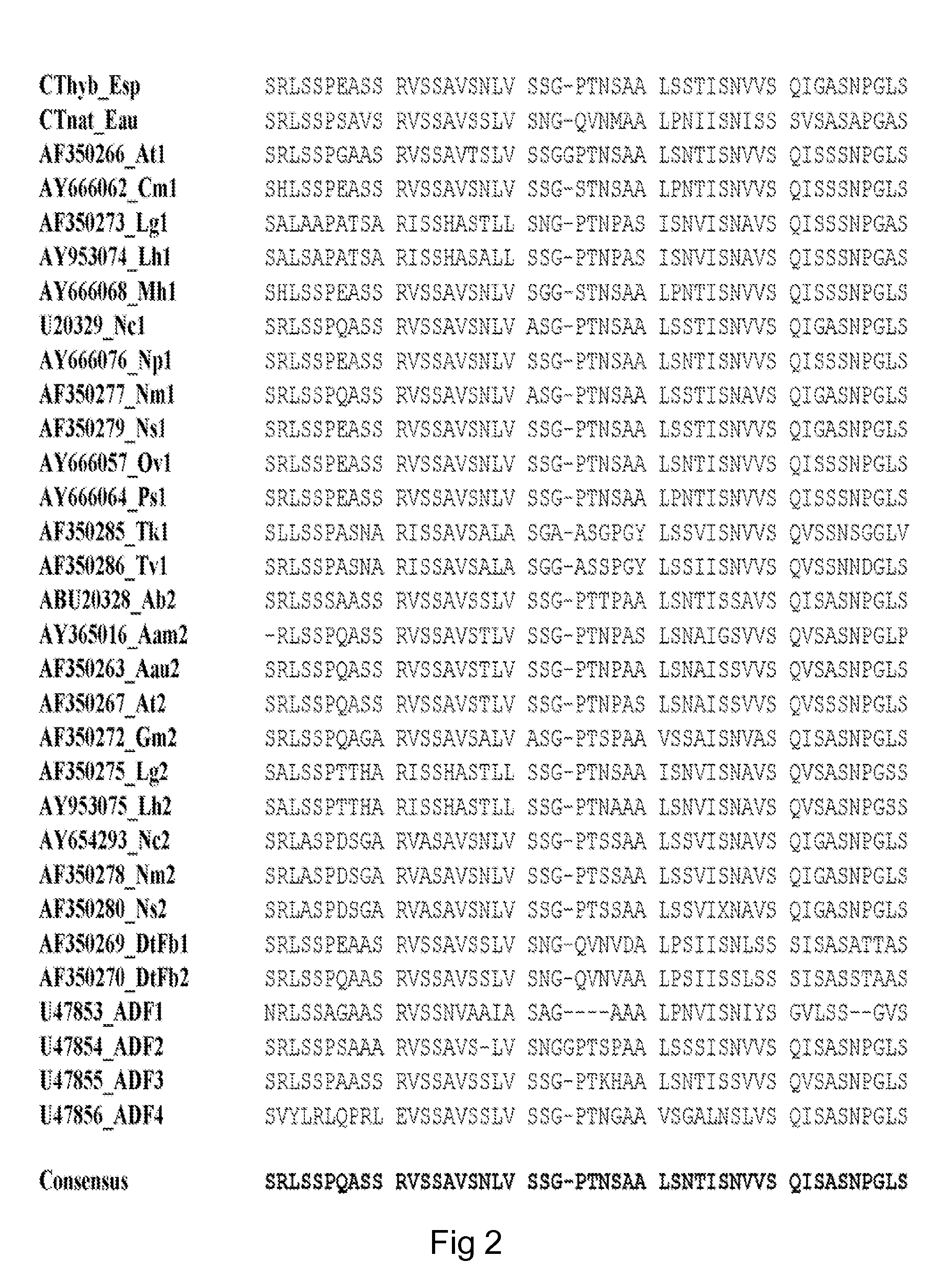

High molecular weight recombinant silk or silk-like protein, and micro- or nanoscale spider-web fiber or spider-web-like fiber produced using the recombinant silk or silk-like protein

The present invention relates to high molecular weight recombinant silk or silk-like protein, which has a molecular weight that is almost equivalent to that of natural silk protein, and to micro- or nanoscale spider-web fiber or spider-web-like fiber having improved physical properties produced using the recombinant silk of the silk-like protein. The recombinant silk or the silk-like protein according to the present invention is advantageous in that it has a high molecular weight like the dragline silk protein produced by a spider, and exhibits physical properties similar or superior to the natural silk protein when produced into fiber.; Therefore, the recombinant silk or the silk-like protein, and the spider-web fiber or spider-web-like fiber produced using the recombinant silk or silk-like protein according to the present invention can be significantly valuably used in a variety of industrial fields, such as the biotechnological fields and / or medicinal fields to which spider-web fibers are applicable.

Owner:MEDICOSBIOTECH INC

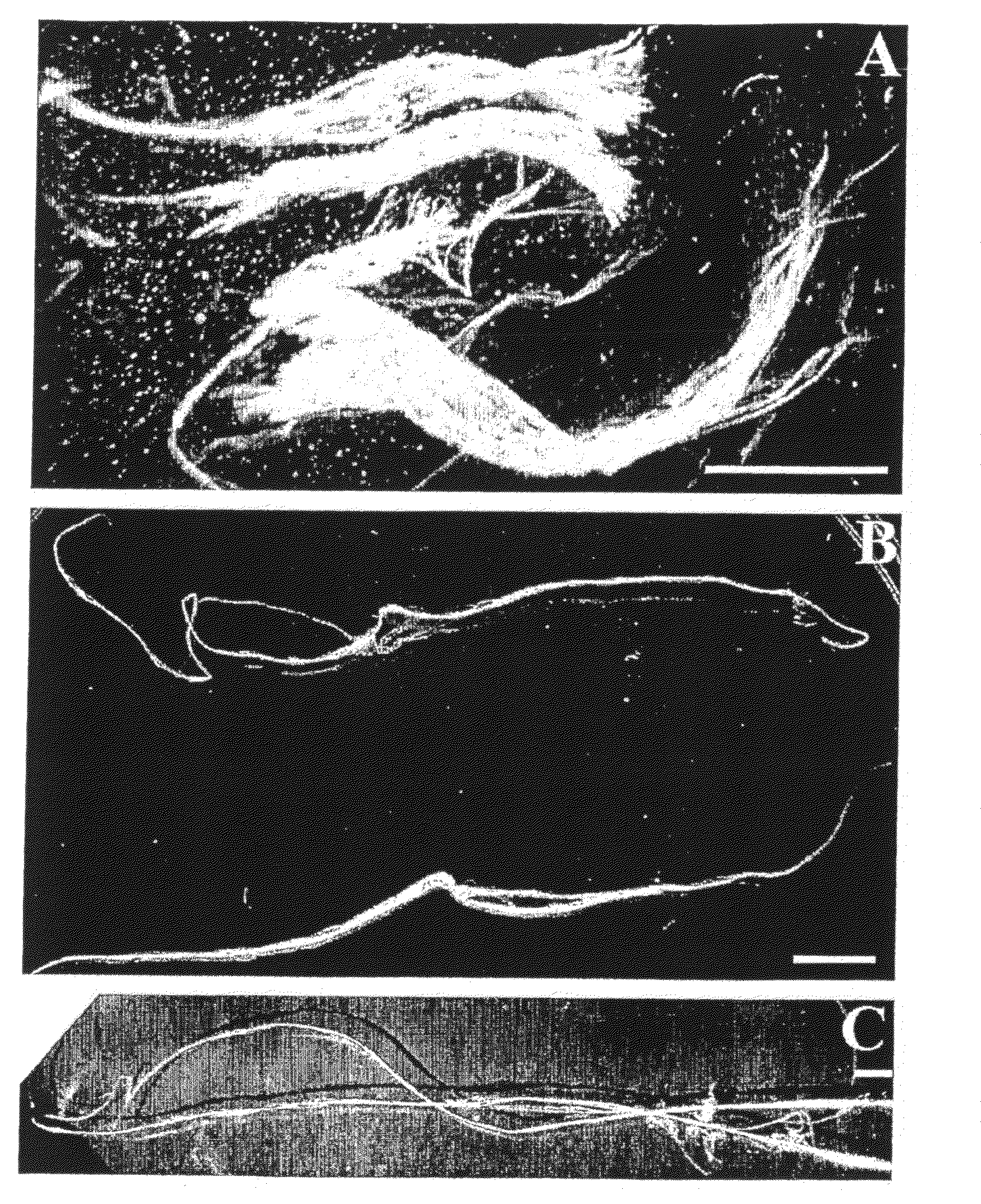

Method of producing polymers of spider silk proteins

ActiveUS20120041177A1Easy to operateReadily be manipulated to polymerise into fibersPeptide/protein ingredientsPeptide preparation methodsFiberLiquid medium

A method of producing polymers of an isolated spider silk protein involves providing a solution of said spider silk protein in a liquid medium at pH 6.4 or higher and / or an ion composition that prevents polymerisation of the spider silk protein. The properties of the liquid medium are adjusted to a pH of 6.3 or lower and an ion composition that allows polymerisation of the spider silk protein. The spider silk protein is allowed to form polymers in the liquid medium, and the resulting spider silk protein polymers are isolated from the liquid medium. The resulting polymers are useful as fibers, films, foams, nets or meshes.

Owner:SPIBER TECH

Methods for the purification and aqueous fiber spinning of spider silks and other structural proteins

InactiveUS20050158821A1Monocomponent protein artificial filamentPeptide/protein ingredientsOrganic acidLysis

Methods are described for the purification and spinning of recombinant and non-recombinant proteins. Specifically, the lysis of bacteria and purification of silk proteins occur in a single solution of organic acid. Bacterial proteins are hydrolyzed while the silk protein remains intact. Silk proteins remain soluble as they are concentrated into a aqueous-based mixture for fiber spinning.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Methods for the purification and aqueous fiber spinning of spider silks and other structural proteins

InactiveUS7335739B2Monocomponent protein artificial filamentPeptide/protein ingredientsOrganic acidLysis

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Method for treatment of spider silk-filament for use as thread or a composition in the manufacture of cosmetic, medical, textile or industrial applications such as bio-artificial cell tissue or skin based on (recombinant) spider silk

InactiveUS20150056256A1Reduced pathological immune responseImprove scalabilityCosmetic preparationsElectric discharge heatingAntioxidantMagnetite Nanoparticles

A method for the treatment of spider silk filament for use as a thread or composition in the manufacture of cosmetic, medical, textile, and industrial applications, wherein the spider silk filament, derived from genetically modified organisms, is treated with at least one component selected from the group consisting of vitamins, hormones, antioxidants, chelating agents, antibiotics, preserving agents, fragrances, dyes, pigments, magnetic nanoparticles, nanocrystals, cell adhesion enhancers, thermal insulators, shrinkage agents and cosmetic, medical or dermatological active substances. Textile fabrics obtained by this method are stronger, bio-compatible, bio-degradable and have a higher thermal conductivity. Treated spider silk filament can also be applied in an oil-in-water or water-in-oil protective cream that is hypoallergenic and ensures a firmer skin.

Owner:ESSAIDI JALILA

Load-bearing composite panels, materials, products, and processes to make and use same

Load-bearing composite panels, materials, and products made by surrounding with a long fiber and / or fiber cloth reinforced polyurethane resin, an assembly containing one or more load-bearing members, graphene, a structural polyurethane / resin sandwich composite and / or spider silk protein fiber-cloth-continuous fibers. The composite structures can provide stronger, lighter-weight structural items such as vehicle floor and body panels, bullet-proof anti-ballistic panel products, vehicle bullet-proof anti-ballistic body panel structures and floors, bullet-proof vests, vehicle chassis, monocoque chassis, motor homes chassis-bodies, fuselage floors and frames for aircraft and / or UAV's, bicycle and motorcycle frames, wind turbine blades frames and structures, ship or boat haul body structures, shipment containers, pre-fabricated walls of buildings, train structure body or floor panels, solar panel supports, battery housings, mobile home walls, roof modules, truck beds, and truck trailer floors. Such composite panels, materials, and products can also be utilized in artificial organs, ligaments or tendons, artificial disc vertebrae, ropes, and 3D printing parts.

Owner:JEREZ ROBERTO VELOZZI

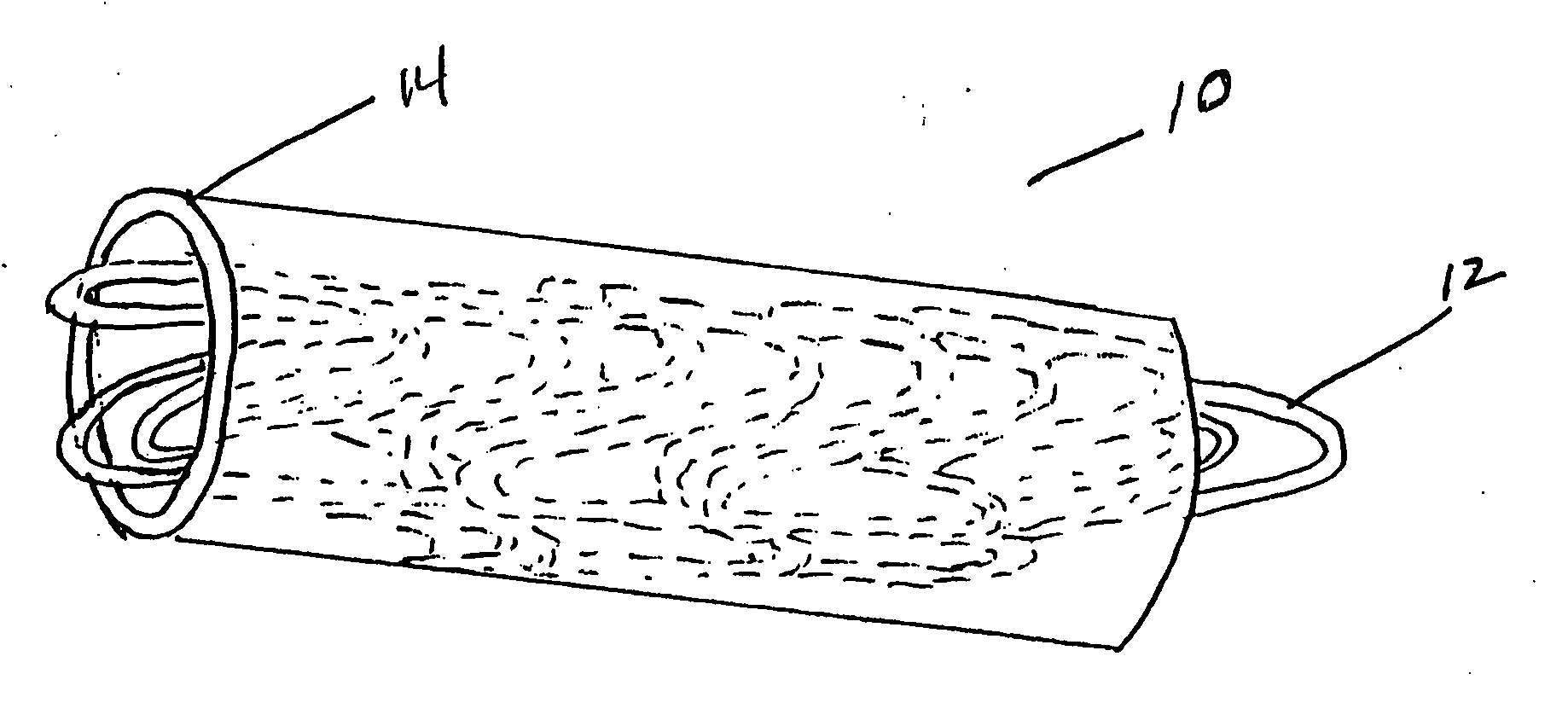

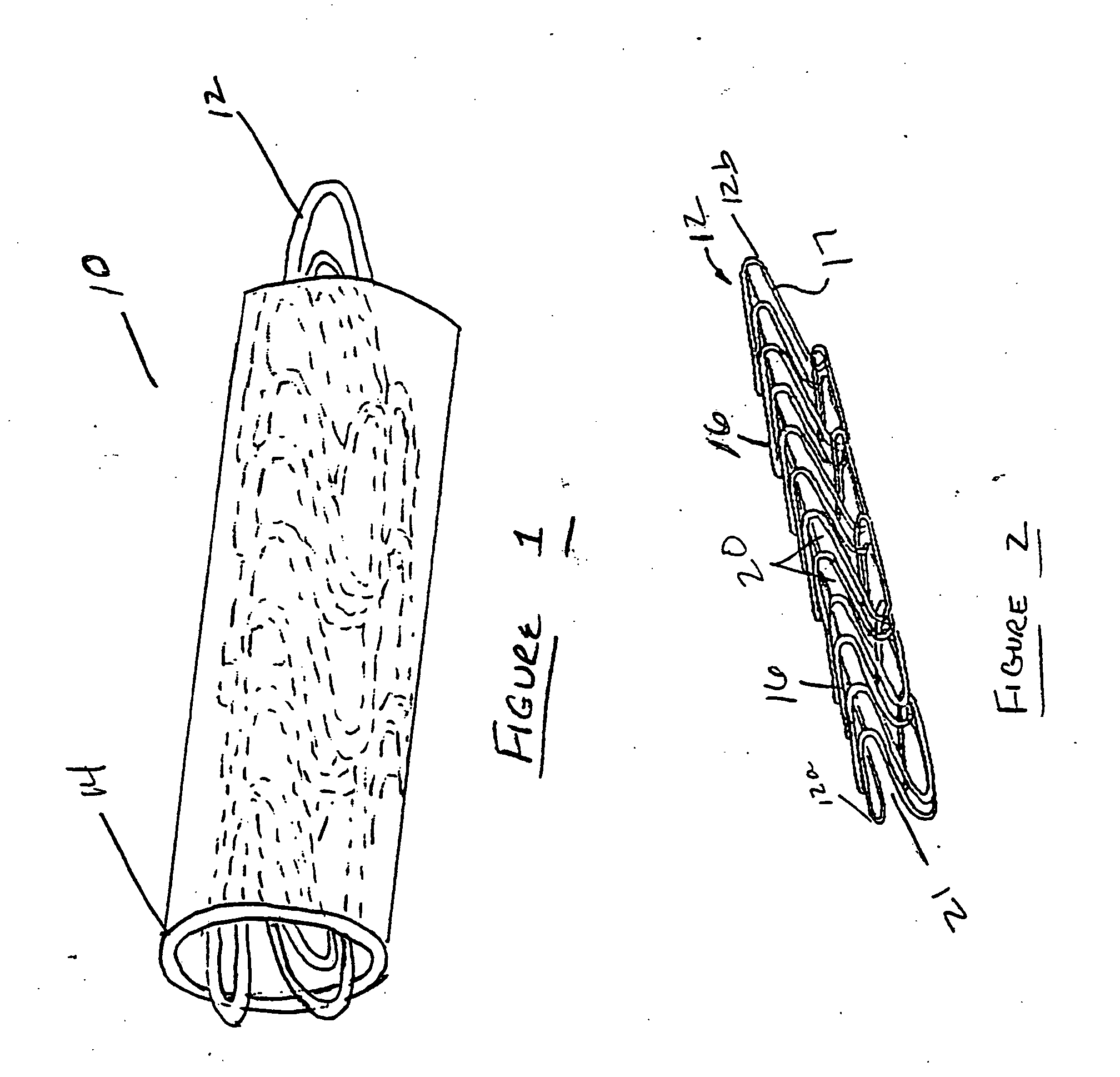

Thin-layered endovascular silk-covered stent device and method of manufacture thereof

InactiveUS20060030927A1Easy to optimizeEasy to manufactureStentsHydrolasesSpider ProteinsStent grafting

A stent-graft composite intraluminal prosthesis comprises an elongate radially adjustable tubular stent, defining opposed exterior and luminal stent surfaces and a polymeric stent sheath covering at least the exterior surface thereof. The stent can include a plurality of open spaces extending between the opposed exterior and interior surfaces so as to permit said radial adjustability. The stent has a polymeric material on its exterior surface, its interior surface, in interstitial relationship with the stent or any combination of the above. The polymer is preferably selected from the group of polymeric materials consisting of biological or genetically engineered spider silks, such as those derived from Nephila clavipes. The silk includes bioengineered spider silks as well as silk-like polymers manufactured using human proteins and blends of such silks with commonly used polymeric graft materials. If separate sheaths are placed on both the exterior and interior surfaces of the stent, the sheaths are secured to one another through said open spaces, such as by lamination, suturing or adhesion.

Owner:LIFESHIELD SCI

Spider Silk Proteins and Methods for Producing Spider Silk Proteins

ActiveUS20090226969A1Easy to operateReduce denaturationMonocomponent protein artificial filamentSugar derivativesSpider ProteinsProtein Fragment

The invention provides an isolated major ampullate spidroin protein, which consists of from 150 to 420 amino acid residues and is defined by the formula KEP-CT. KEP is a repetitive, N-terminally derived protein fragment having from 80 to 300 amino acid residues. CT is a C-terminally derived protein fragment having from 70 to 120 amino acid residues. The invention further provides an isolated fusion protein consisting of a first protein fragment, which is a major ampullate spidroin protein, and a second protein fragment comprising a fusion partner and a cleavage agent recognition site. The first protein fragment is coupled via said cleavage agent recognition site to the fusion partner. The invention also provides a method of producing a major ampullate spidroin protein and polymers thereof.

Owner:SPIBER TECH

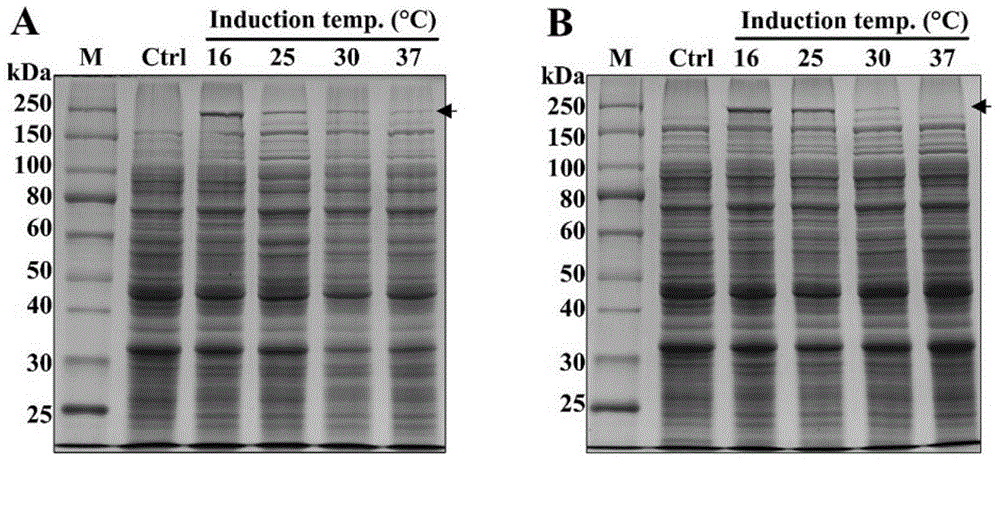

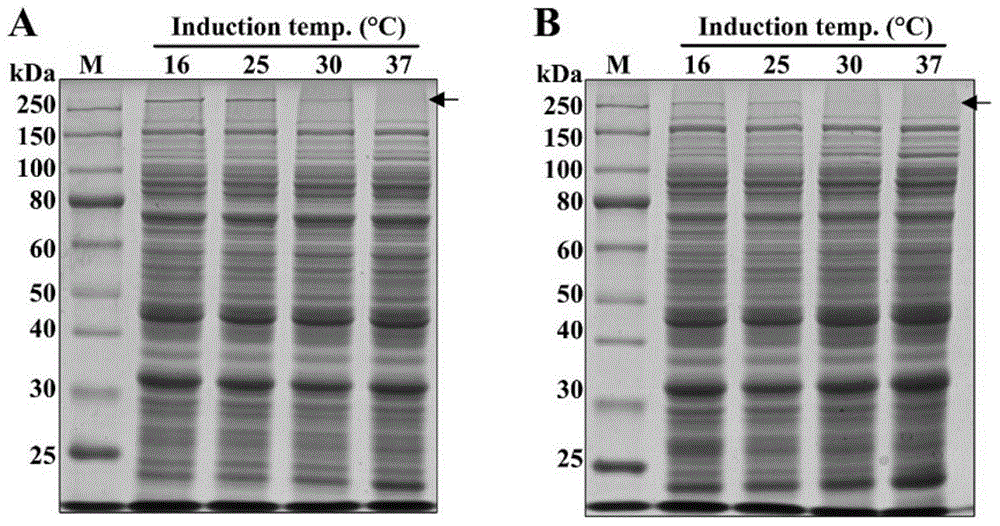

Spider dragline silk protein optimized expression method

InactiveCN104946710ALower culture temperatureOvercome the defect of low expressionFermentationBiotechnologyEscherichia coli

The invention relates to a spider dragline silk protein optimized expression method, belonging to the field of bioengineering. The method comprises the following steps: constructing high-molecular-weight recombinant spider dragline silk protein grains in Escherichia coli, and carrying out expression production, wherein the protein yield is enhanced by lowering the culture temperature in the protein expression production process; and by using the combined strategy of high-density fermentation and culture temperature lowering on the fermentation tank level, implementing the double enhancement of the cell quantity and expression level. The method can effectively overcome the defects of low expression level of the highly-repetitive recombinant spider dragline silk protein in the production fermentation process, and provides favorable reference meanings for fermentation production study and application of spider silk proteins and similar highly-repetitive sequence proteins.

Owner:SHANGHAI JIAO TONG UNIV

Solution-dyed protein fiber and method for producing same

ActiveUS20150141618A1Bright color toneLow costPeptide/protein ingredientsMonocomponent fibroin artificial filamentSpider ProteinsSolvent

A solution-dyed protein fiber of the present invention includes 0-100 mass % of silk fibroin and 100-0 mass % of a polypeptide derived from spider silk proteins when the protein fiber is assumed to be 100 mass %, wherein the solution-dyed protein fiber contains a solution-dyeing colorant. The fiber is obtained by: dissolving or dispersing a solution-dyeing colorant in a solvent used for a spinning solution or in dimethyl sulfoxide, thereby preparing a coloring liquid; adding a solvent to the coloring liquid in an amount necessary for a spinning solution; adding and dissolving protein powder into the solvent, thereby preparing a spinning solution; and subjecting the spinning solution to wet spinning or dry-wet spinning. Thereby, the present invention provides a low-cost solution-dyed protein fiber in which a solution-dyeing colorant is dispersed uniformly and that can exhibit bright color tone, and a method for producing the same.

Owner:SPIBER INC

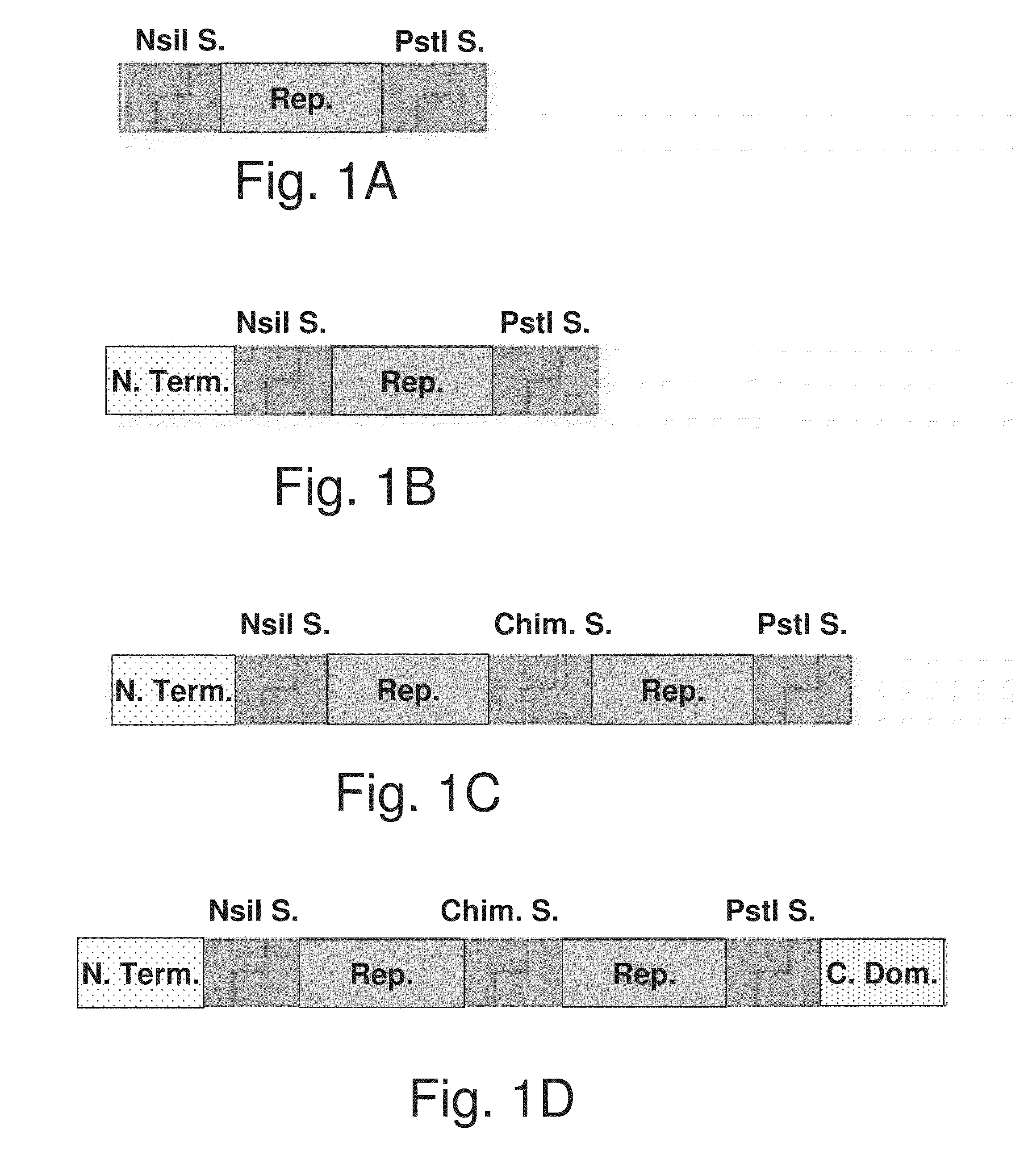

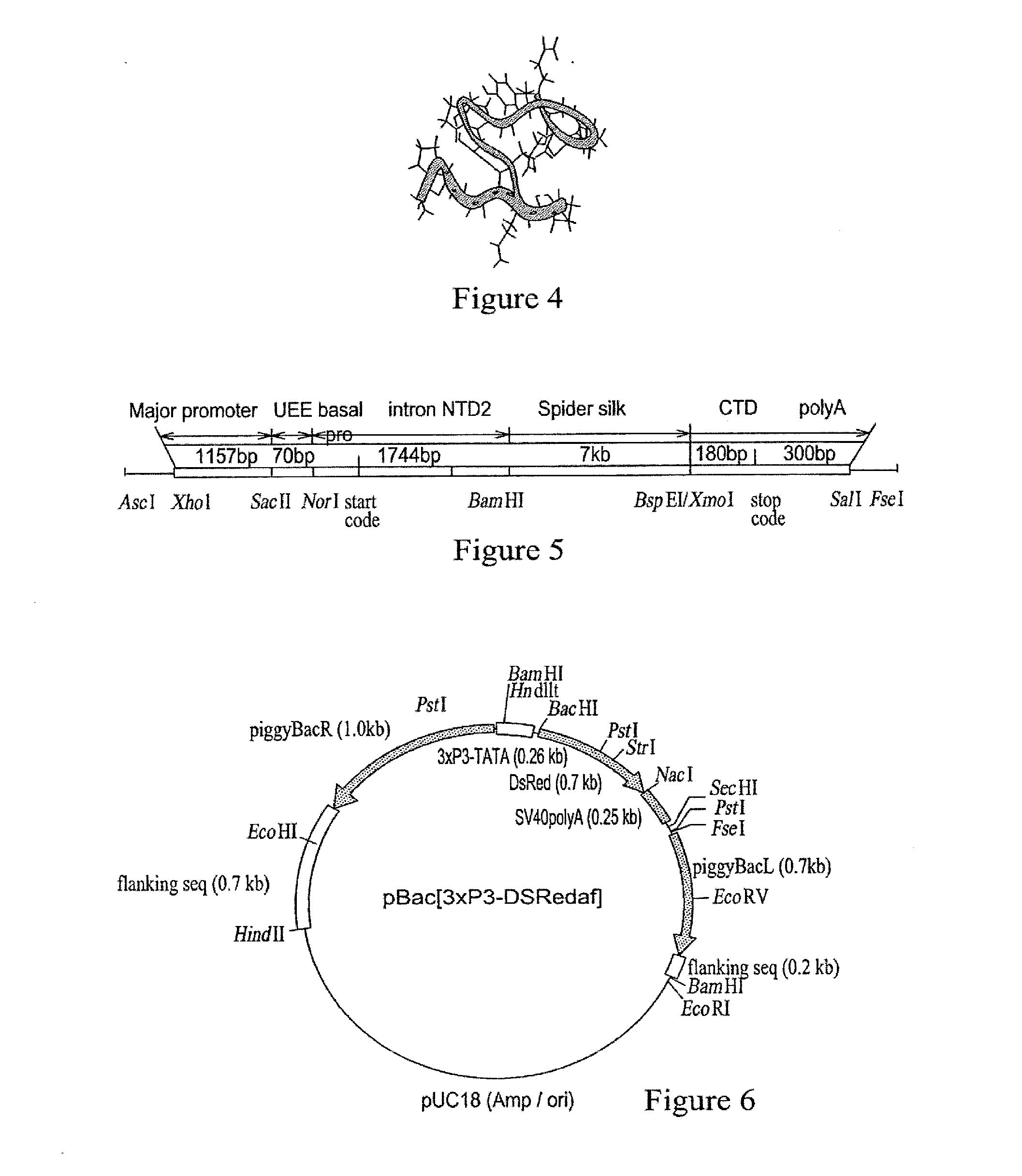

Chimeric spider silk and uses thereof

InactiveUS20130212718A1Easy to useEasy screeningPeptide/protein ingredientsAntibody mimetics/scaffoldsSpider ProteinsVector system

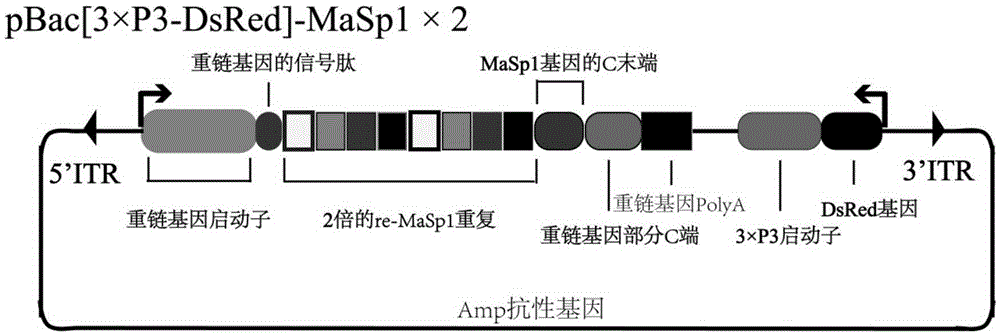

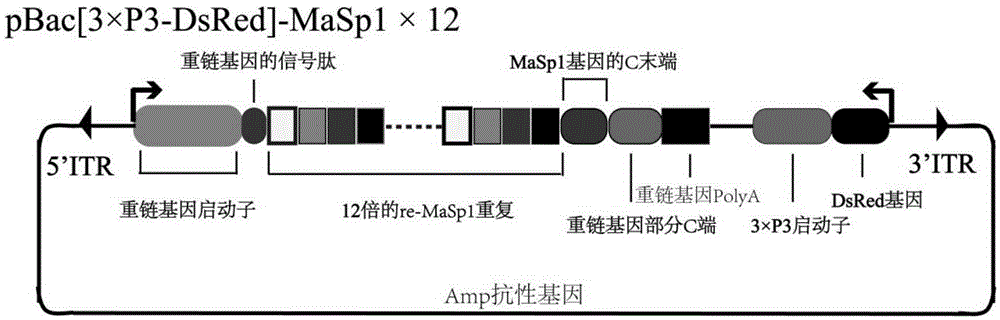

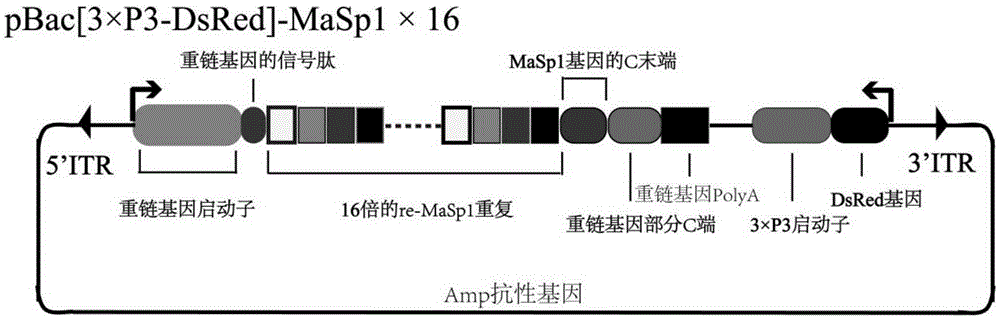

Transgenic silkworms comprising at least one nucleic acid encoding a chimeric silk polypeptide comprising one or more spider silk elasticity and strength motifs are disclosed. Expression cassettes comprising nucleic acids encoding a variety of chimeric spider silk polypeptides (Spider 2, Spider 4, Spider 6, Spider 8) are also disclosed. A piggyBac vector system is used to incorporate nucleic acids encoding chimeric spider silk polypeptides into the mutant silkworms to generate stable transgenic silkworms. Chimeric silk fibers having improved tensile strength and elasticity characteristics compared to native silkworm silk fibers are also provided. The transgenic silkworms greatly facilitate the commercial production of chimeric silk fibers suitable for use in a wide variety of medical and industrial applications.

Owner:KRAIG BIOCRAFT LAB

High-molecular-weight recombinant silk or silk-like protein and micro- or nano-sized spider silk or silk-like fiber produced therefrom

InactiveUS20120231499A1High molecular weightGood physical propertiesPeptide/protein ingredientsMonocomponent fibroin artificial filamentFiberSpider Proteins

A high-molecular-weight recombinant silk or silk-like protein having a molecular weight which is substantially similar to that of native silk protein, and a micro- or nano-sized spider silk or silk-like fiber having improved physical properties, produced therefrom. The recombinant silk or silk-like protein according to the invention has high molecular weight, like dragline silk proteins from spiders, while a fiber produced therefrom has excellent physical properties compared to a fiber produced from native silk protein. Thus, the recombinant silk or silk-like protein and the spider silk or silk-like fiber produced therefrom will be highly useful in various industrial applications, including bioengineering applications and medical applications.

Owner:KOREA ADVANCED INST OF SCI & TECH

Method for synthesizing and secreting black widow spider dragline silk protein 1 through bombyx mori silk gland bioreactor

ActiveCN105400815AImprove mechanical propertiesFunctionally activeVector-based foreign material introductionAnimal husbandrySelfingBiology

The invention discloses a method for synthesizing and secreting black widow spider dragline silk protein 1 through a bombyx mori silk gland bioreactor. The method includes the steps that firstly, pBac[3xP3-DsRed]-MaSp1 plasmids serving as a carrier for bombyx mori to synthesize and secrete black widow spider dragline silk protein 1 are established; then, plasmids and assistant plasmids are introduced into bombyx mori zygotes through microinjection, red fluorescence protein genes and black widow spider dragline silk protein 1 genes are introduced into bombyx mori genomes through the transposition characteristic of piggyBac transposons, stable inheritance and expression are performed, transgenic bombyx mori is obtained, mori moth selfing is performed to achieve homozygosis of black widow spider dragline silk protein 1 genes, and transgenic bombyx mori secreting black widow spider dragline silk protein 1 is bred. According to the method, transgenic bombyx mori is screened through fluorescence marker genes, and black widow spider dragline silk protein 1 is specifically synthesized and secreted through bombyx mori silk gland cells; the method is used for development and utilization of spider silk and can also be used for improving the mechanical performance of silk.

Owner:浙江超丝生物科技有限公司

Spider silk protein gene designed and synthesized by plant preference codon and its application

InactiveCN1390937AHigh strengthImprove practicalityFermentationVector-based foreign material introductionSAA proteinCellulose

The present invention relates to a spider silk crystal protein gene synthesized by plant preferance codon, its expression carrier, the plant cells transformed from it, and the transgenic plant and its descendant. Said gene can be effectively expressed in fibrous plant and the obtained protein moleculae can be combined with the cellulose of plant, so improving the strength of plant fibres.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of composite nanometer fiber small-diameter intravascular tissue engineering stent material

InactiveCN101653624AGood physical and mechanical propertiesGood chemical stabilityStentsProsthesisFiberCell adhesion

The invention relates to the field of tissue engineering, in particular to a preparation method of a composite nanometer fiber small-diameter intravascular tissue engineering stent material. The technical scheme is achieved as follows: formic acid is used as a common solvent; RGD-recombinant spider silk protein, polycaprolactone and chitosan are mixed in a mass ratio of 1:8:1 according to the requirements of an intravascular stent to prepare a spinning solution with the concentration of 20-30 percent (w / v); electrospinning process parameters are as follows: the diameter of a cross section of acylindrical rotating shaft is 3-6 mm, the rotating speed is 1,500-3,000rpm, the curing distance is 15-30 cm, the voltage is 50-150kV, the extrusion speed is 3-7ml / h and the temperature is 45-50 DEG C. The small-diameter intravascular stent has favorable cell adhesion-promoting capability, anticoagulant property and mechanical property for resisting physiological environment and can be clinicallyapplied as a small-diameter intravascular tissue engineering stent.

Owner:FUJIAN NORMAL UNIV

Production of proteins and polypeptides

ActiveUS20130065278A1Increase ionic strengthSugar derivativesPeptide/protein ingredientsSolubilitySpider Proteins

A method of producing a desired non-spidroin protein or polypeptide is comprising the steps of expressing in a suitable host a fusion protein, obtaining a mixture containing the fusion protein, and optionally isolating the fusion protein. The fusion protein is comprising at least one solubility-enhancing moiety which is derived from the N-terminal (NT) fragment of a spider silk protein. It is further comprising at least one moiety which is a desired non-spidroin protein or polypeptide. Each solubility-enhancing moiety is linked directly or indirectly to the desired protein or polypeptide moiety.

Owner:SPIBER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com