Patents

Literature

1041 results about "Protein fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In general, protein fibers are fibers of moderate strength, resiliency, and elasticity. They have excellent moisture absorbency and transport characteristics. They do not build up a static charge. Example of some these fibers is Wool, Silk, Mohair, Cashmere etc.

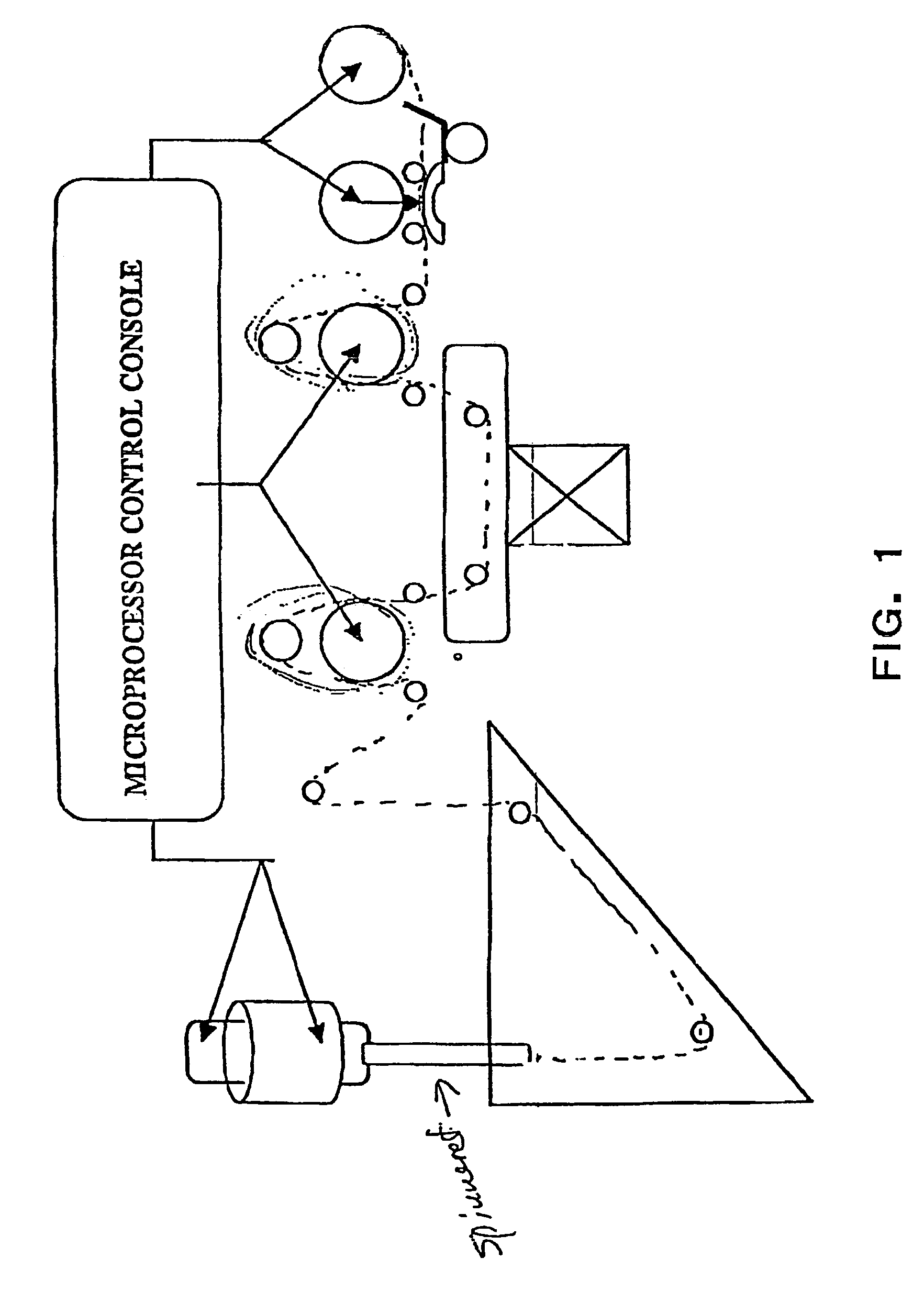

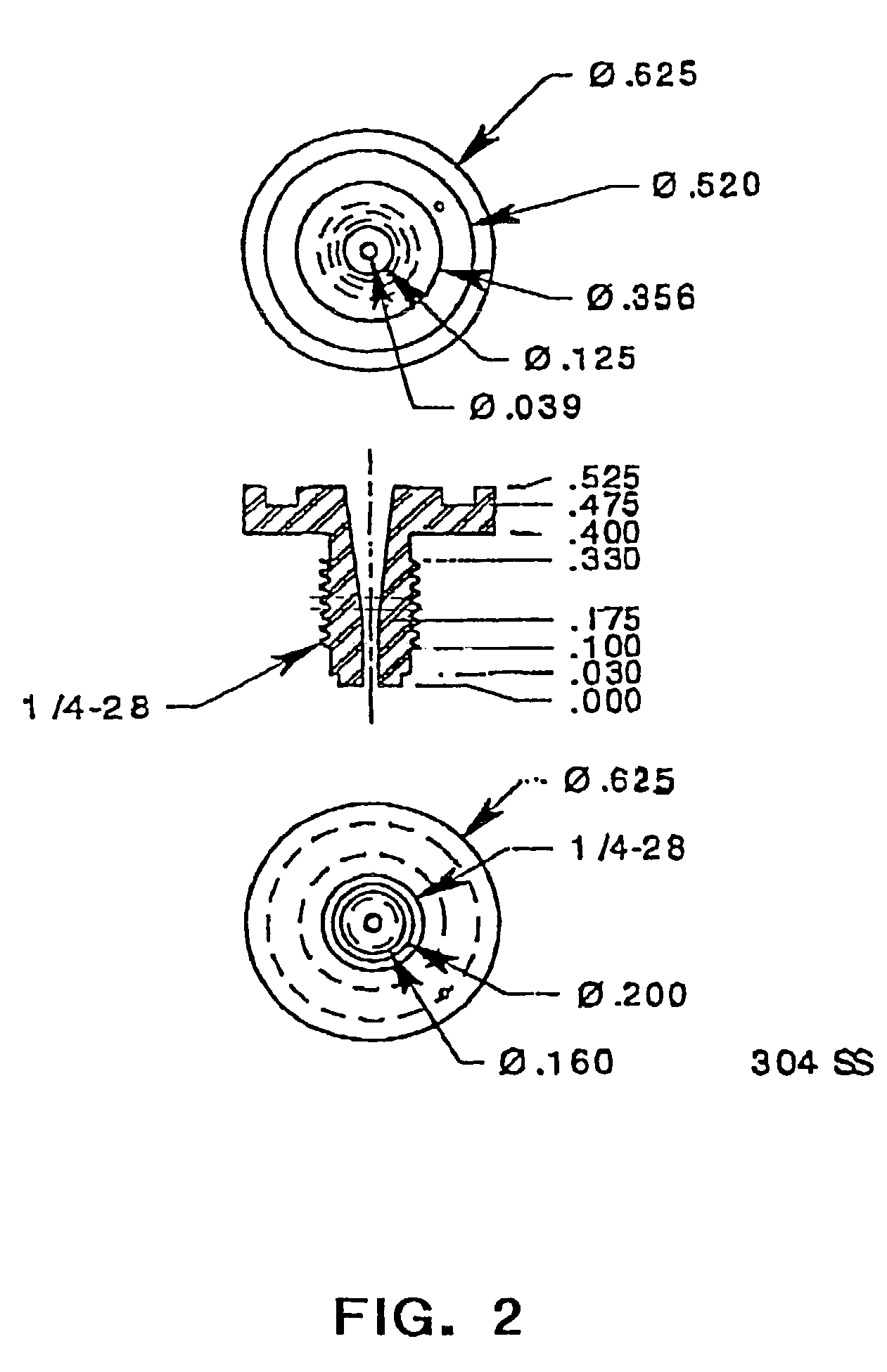

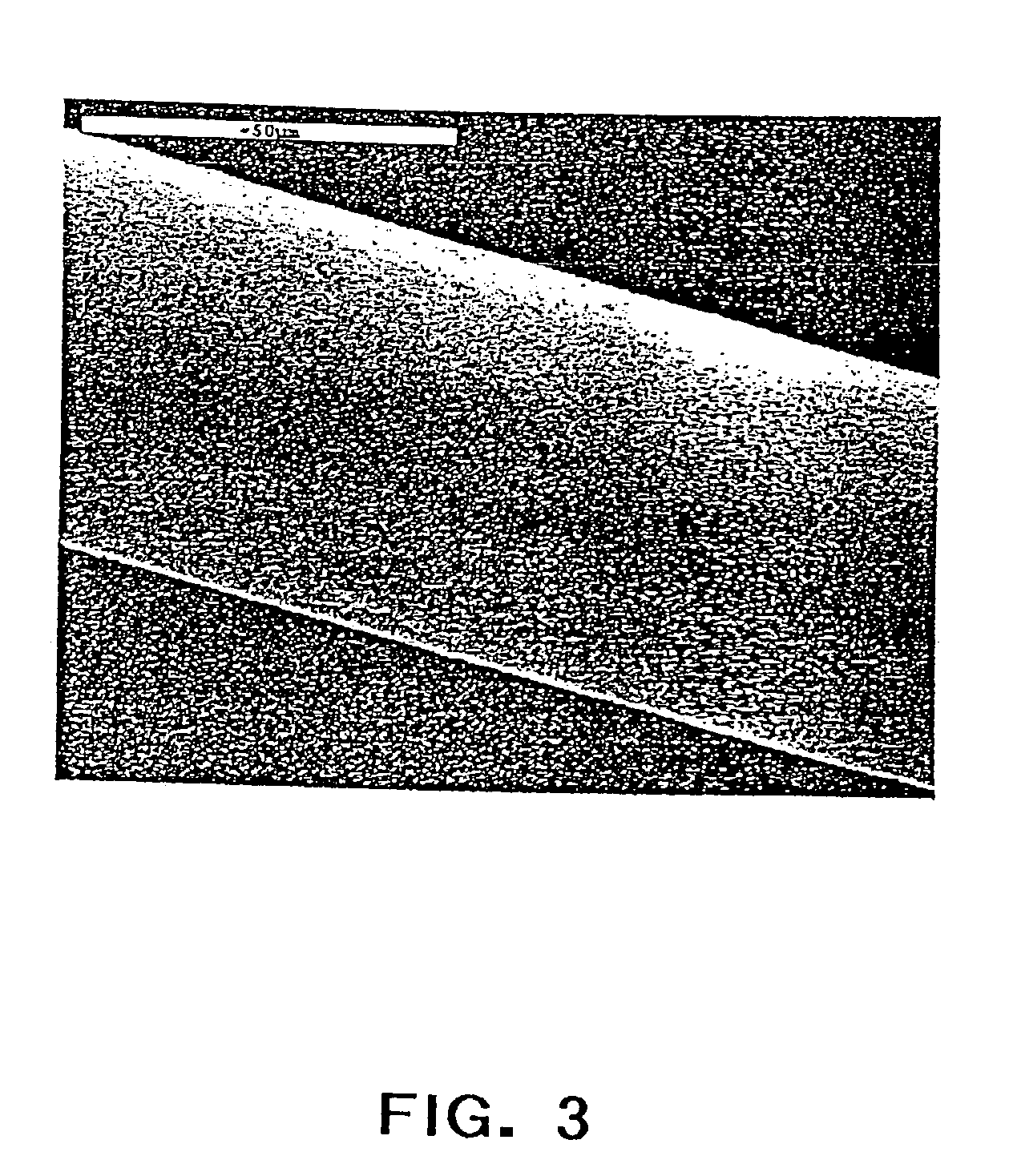

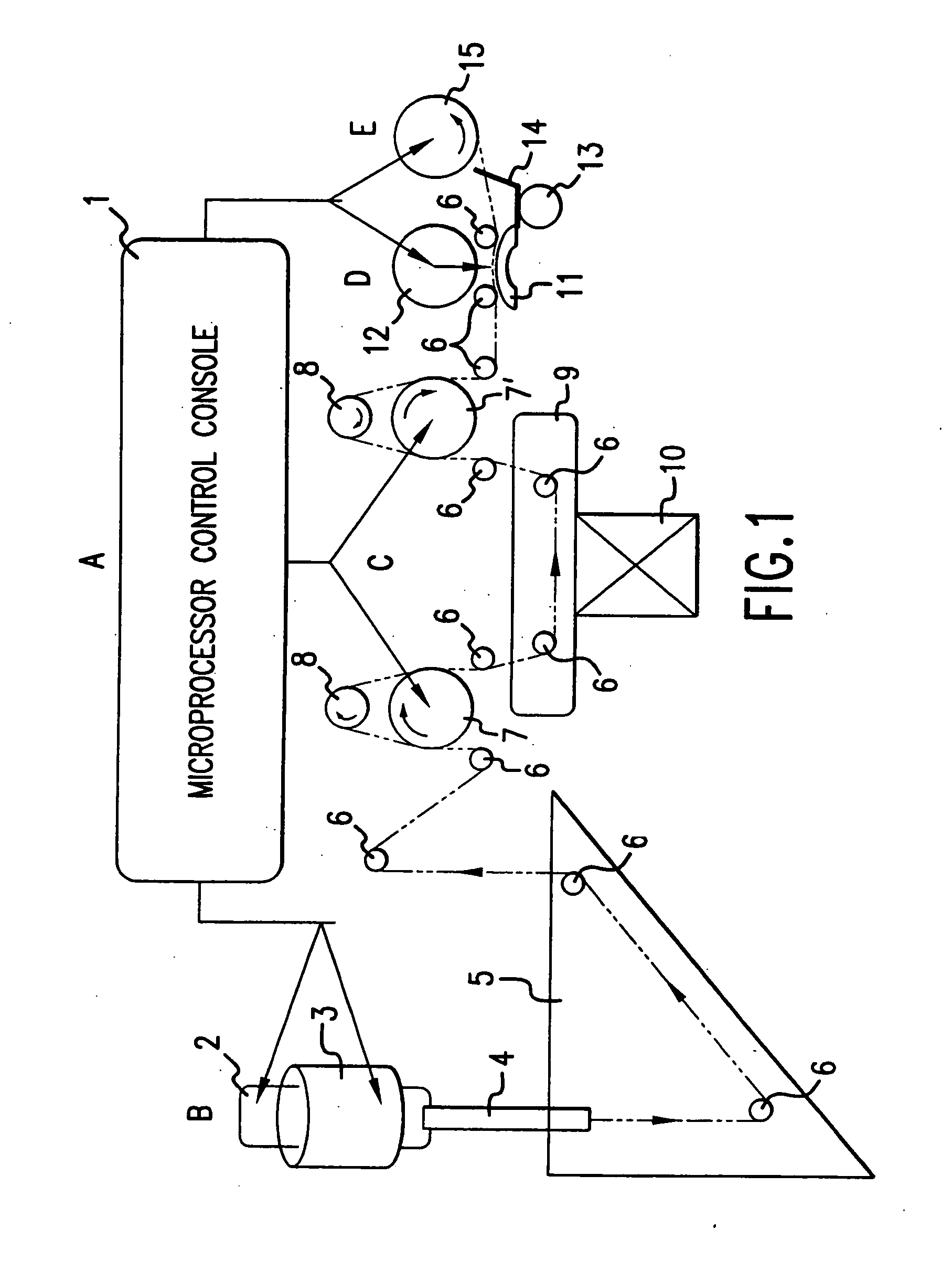

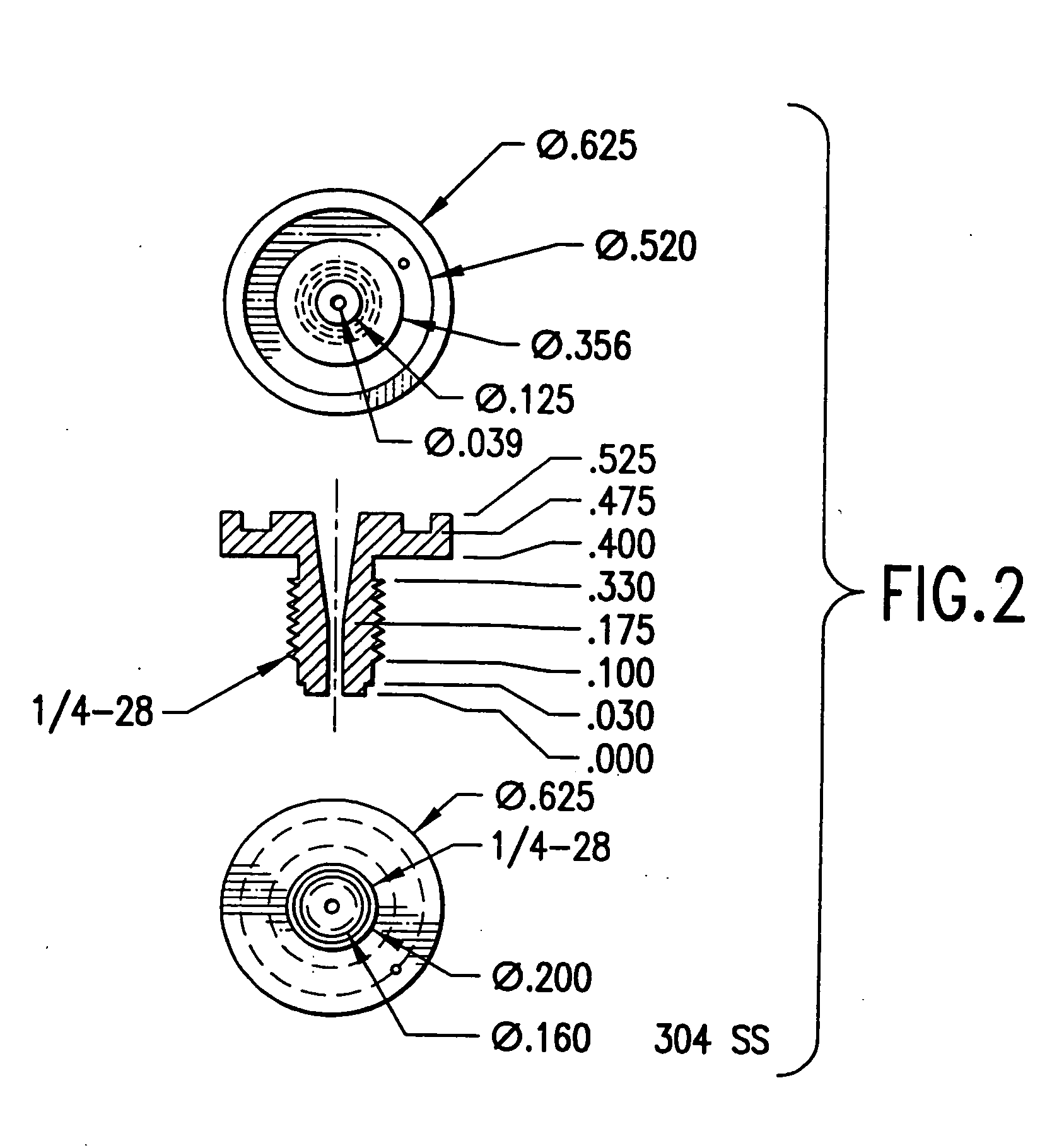

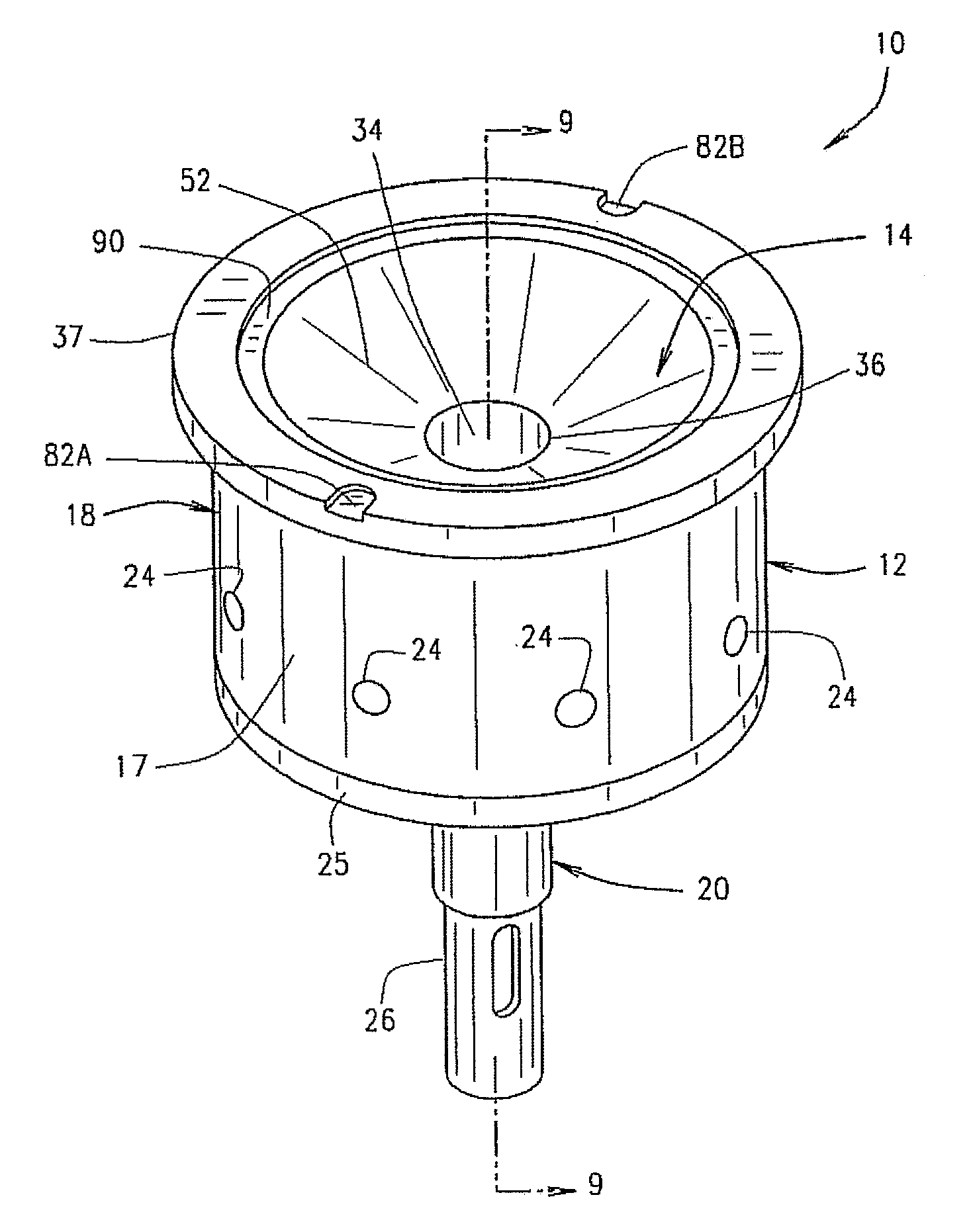

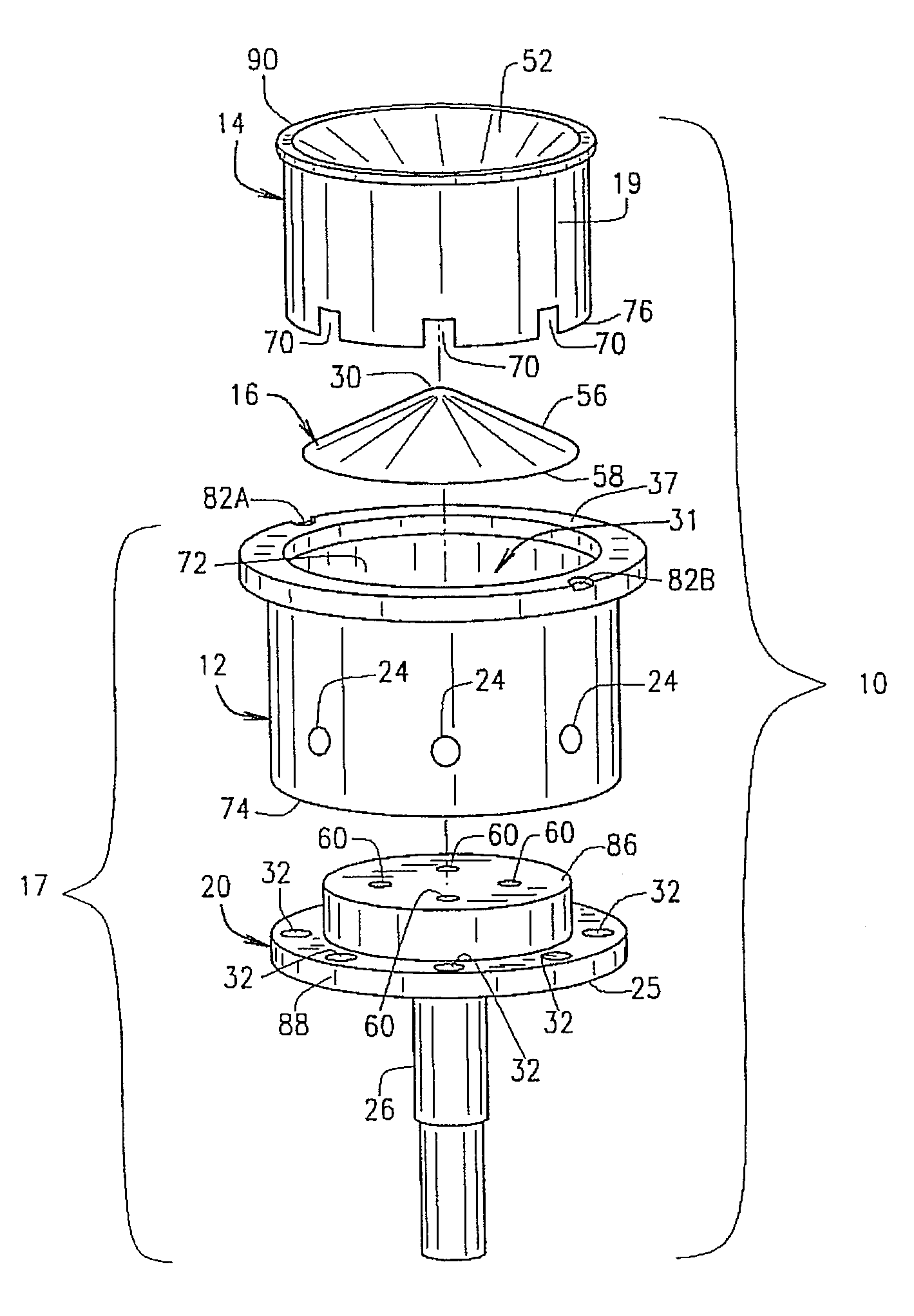

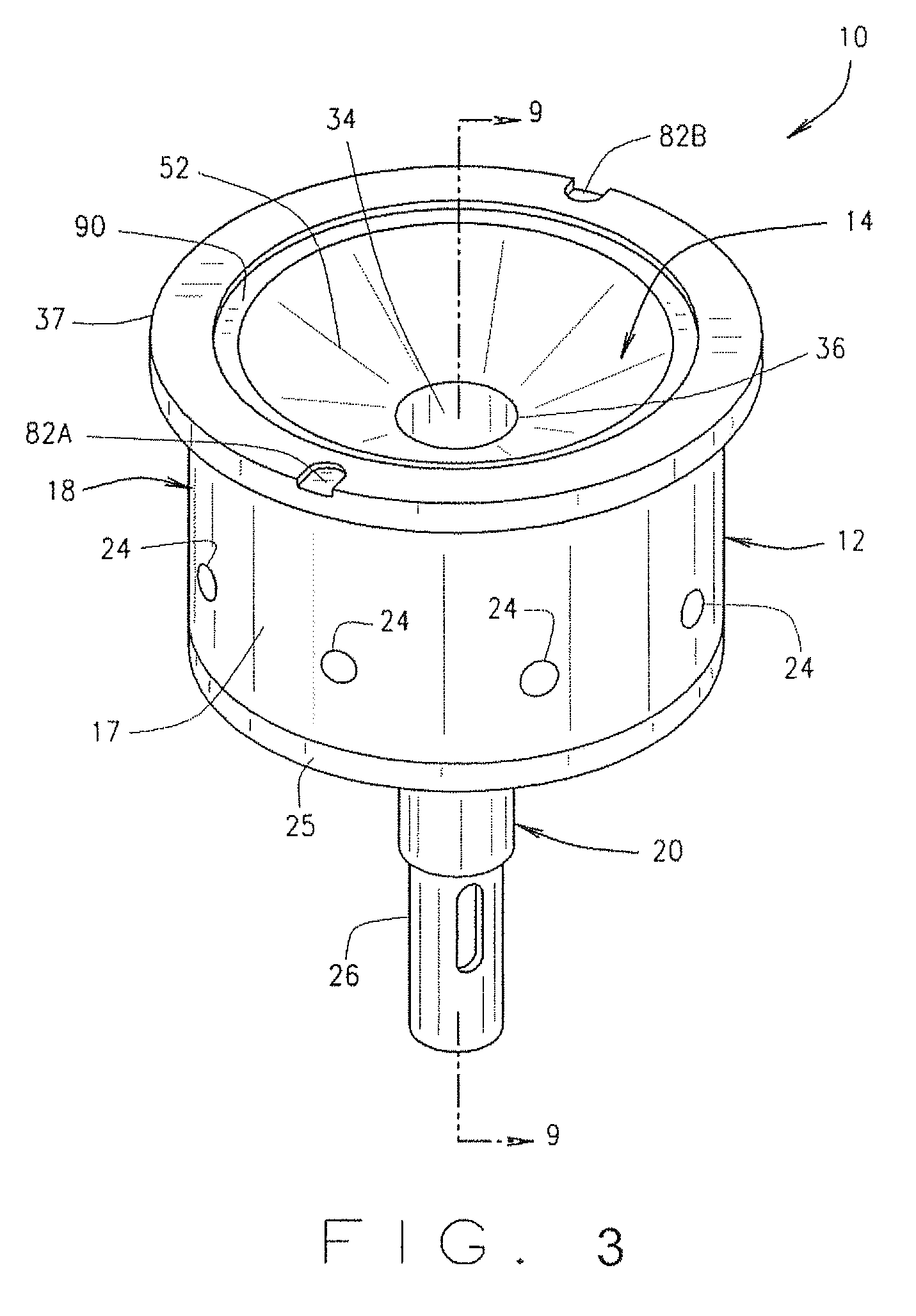

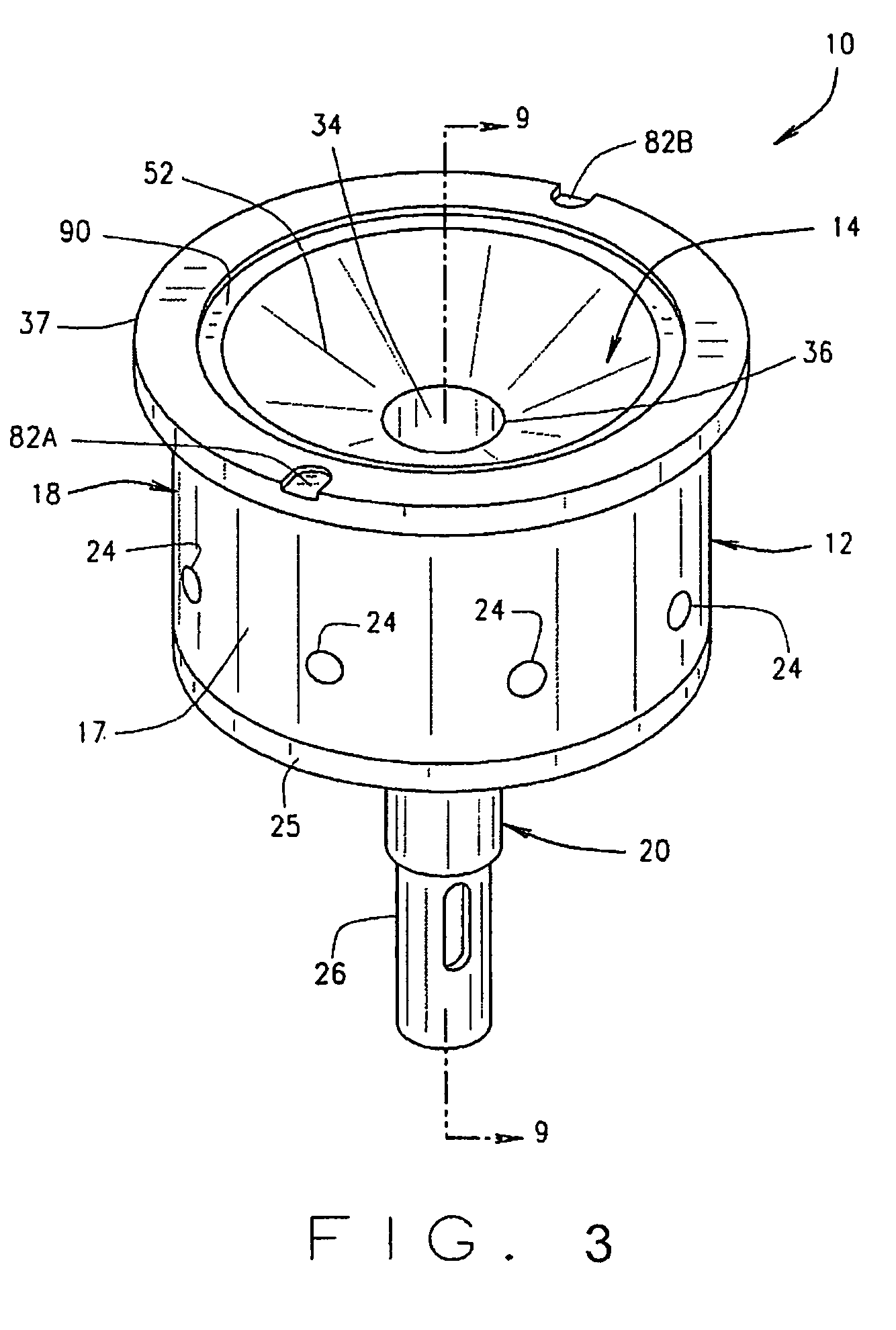

Methods and apparatus for spinning spider silk protein

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:SANTE BIOMATERIALS

Methods and apparatus for spinning spider silk protein

InactiveUS20050054830A1Peptide/protein ingredientsMonocomponent fibroin artificial filamentBiotechnologySpider Proteins

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:NEXIA BIOTECH

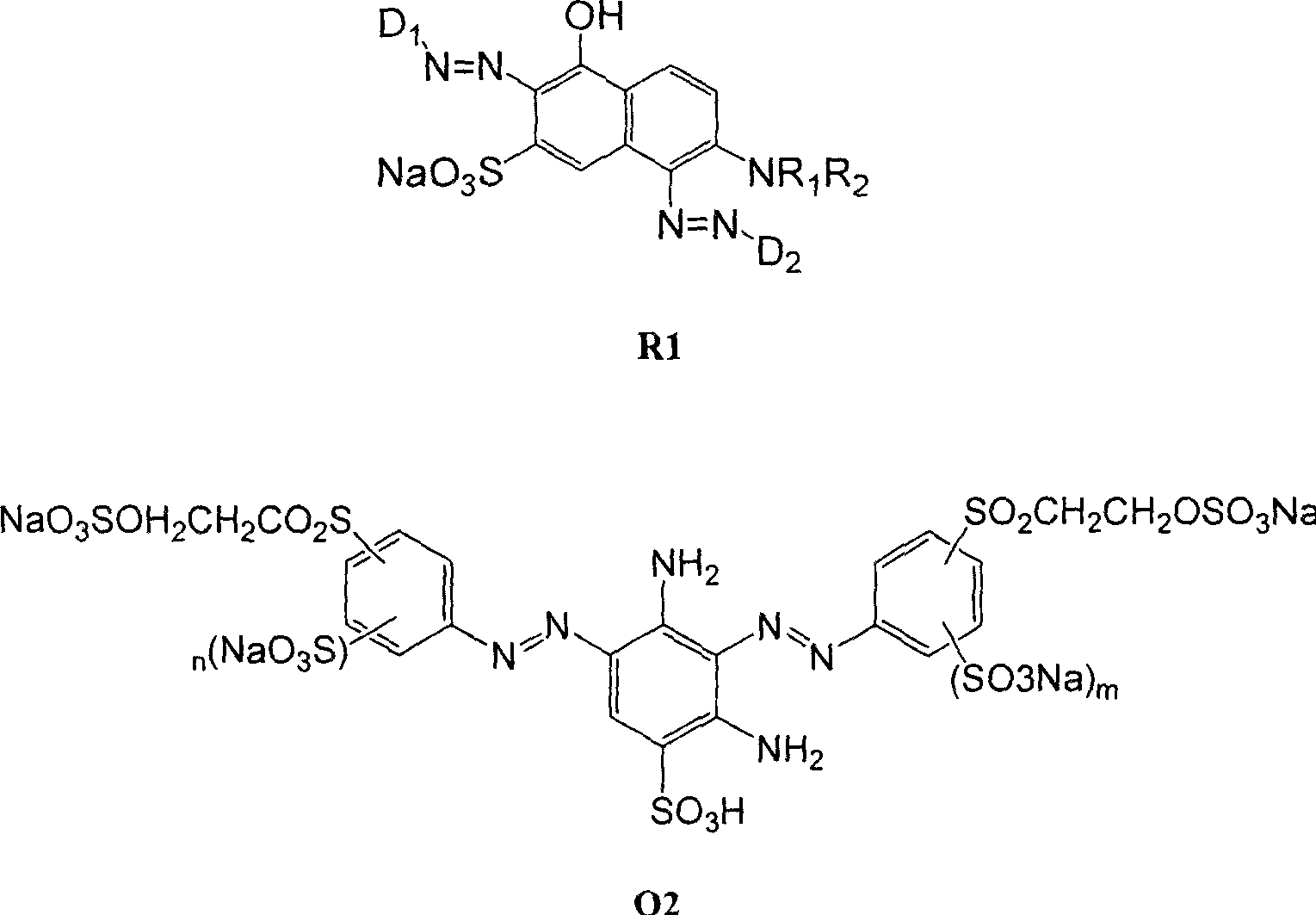

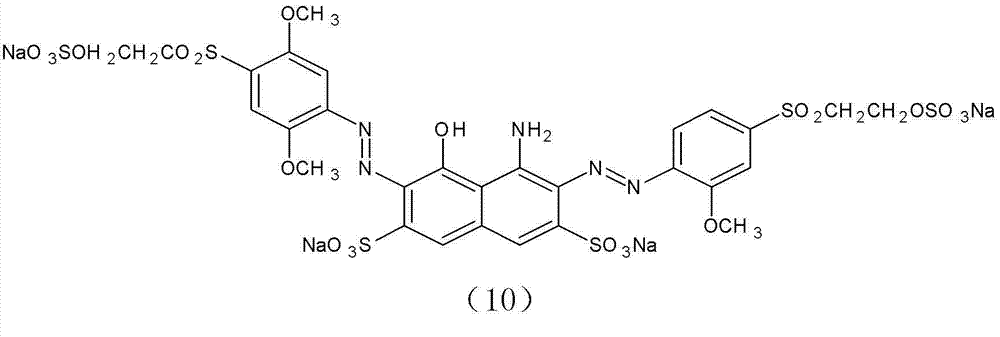

Black and active dye

The invention provides a black composite reactive dye having three primary color constituents comprising, green disazo dye employing ethylene sulfone series arylamine or aniline derivative as diazo component and H acid as coupling component, one ore more red disazo dyes employing sulfoalkyl J acid or carboxymethyl J acid derivatives as coupling components, one ore more yellow bisazo or polyazo dyes employing sulfochlorinated 3,5-diaminobenzoic acid or sulfoalkyl derivatives as coupling components. The dye can be applied to intermittent and continuous dyeing for cellulose fiber, protein fiber, poly nylon and their fiber mixed fabrics.

Owner:DALIAN UNIV OF TECH

Processed Meat Products Comprising Structured Protein Products

InactiveUS20080248167A1Meat/fish preservationProteins working-up by texturisingProtein fiberChemistry

The present invention provides processed meat compositions comprising structured protein products having substantially aligned protein fibers and reprocessed meat products. The processed meat products of the invention have improved nutritional profiles and favorable textural characteristics.

Owner:SOLAE LLC

Protein composition and its use in restructured meat and food products

This invention relates to a protein containing composition, comprising;a protein composition, wherein at least about 75 weight % of the protein composition contains at least about 15 weight % of large pieces comprised of protein fibers at least about 4 centimeters long, protein strands at least about 3 centimeters long, and protein chunks at least about 2 centimeters long andwherein at least about 75 weight % of the protein composition has a shear strength of at least about 1400 grams.The invention also relates to a process for preparing the protein composition.The invention further relates to a restructured meat product, or a vegetable product, or a fruit product comprising;a vegetable protein composition;a comminuted meat, or a comminuted vegetable, or a comminuted fruit, respectively; andwater;wherein at least about 75 weight % of the protein composition contains at least about 15 weight % of large pieces comprised of protein fibers at least about 4 centimeters long, protein strands at least about 3 centimeters long, and protein chunks at least about 2 centimeters long andwherein at least about 75 weight % of the protein composition has a shear strength of at least about 1400 grams.In another embodiment, the invention discloses a process for preparing the restructured meat product, or the vegetable product, or the fruit product, respectively.

Owner:SOLAE LLC

Colored Structured Protein Products

InactiveUS20080254199A1Monocomponent protein artificial filamentConfectioneryProtein fiberColoring agents

The present invention provides a process for producing a colored structured protein product with protein fibers that are substantially aligned and the resultant product. Specifically, the plant protein is combined with a colorant and extruded, forming a colored structured protein product with protein fibers that are substantially aligned and the resultant product.

Owner:SOLAE LLC

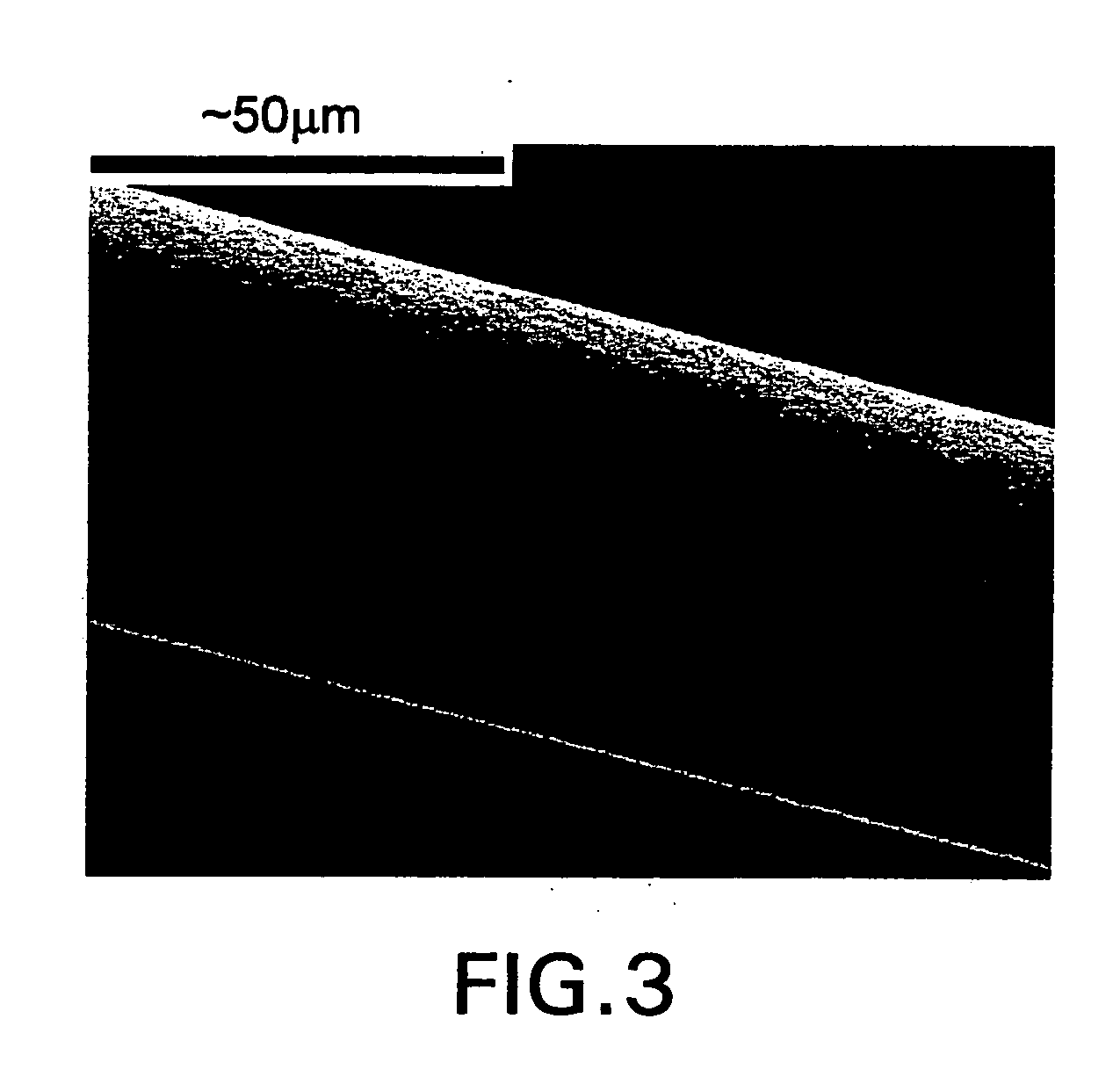

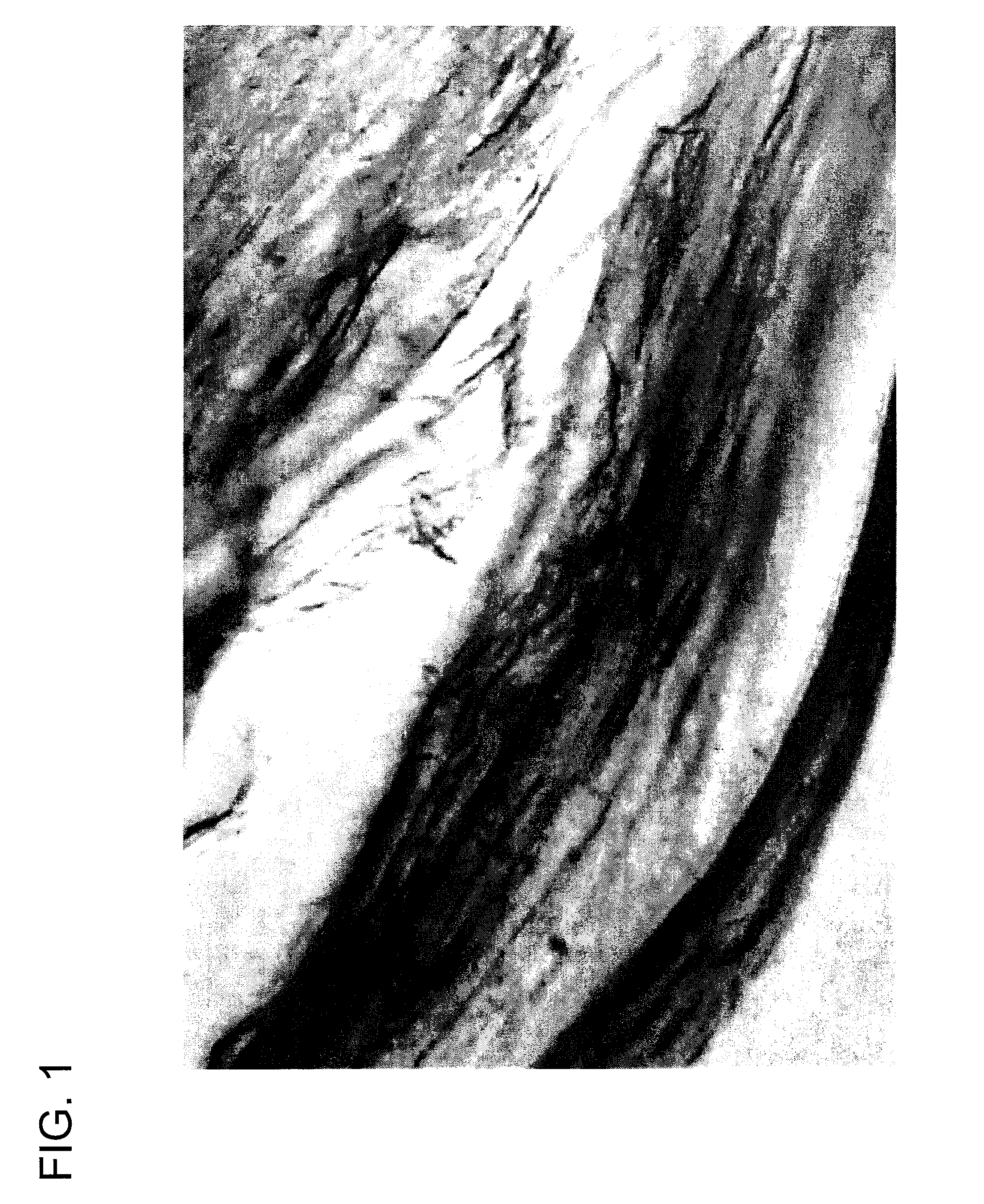

Biomimetic preparation method of high-strength regenerated silk protein fiber

ActiveCN103498210AHigh crystallinityHigh strengthConjugated cellulose/protein artificial filamentsWet spinning methodsMechanical propertyProtein fiber

The invention discloses a biomimetic preparation method of a high-strength regenerated silk protein fiber. The method takes high crystallization degree, high strength, high modulus nano cellulose whiskers with a large length-diameter ratio to simulate the beta-fold microcrystal in the natural silk fiber, then mixes the nano cellulose whiskers with a regenerated silk fibroin solution, and finally prepares the high-strength regenerated silk protein fiber through a wet spinning method. The characteristic that a large amount of hydroxyl groups in the molecular chains of the rigid nano cellulose whiskers can form intermolecular hydrogen bonds with polar groups such as carboxyl groups, amino groups, and the like, in the molecular chains of silk protein is utilized to achieve the structural bionics of the regenerated silk protein fiber, and thus improves the mechanical properties of the regenerated silk protein fiber. The preparation method is simple, and does not pollute the environment. The mechanical properties of the obtained regenerated silk fiber are equal to or even better than those of natural silk, and the regenerated silk fiber has the similar micro-structure and configuration as the natural silk.

Owner:浙江枫翎新材料科技有限公司

Seafood Compositions Comprising Structured Protein Products

InactiveUS20080254167A1Edible oils/fats ingredientsMeat/fish preservationBiotechnologyAdditive ingredient

Owner:SOLAE LLC

Vat dye dyeing method using supercritical CO2 fluid

The invention is applicable to the field of dyeing technologies, and provides a vat dye dyeing method using a supercritical CO2 fluid. The vat dye before a reduction reaction is dissolved by a supercritical CO2 fluid; polyester fiber, cellulosic fiber, protein fiber and fabric thereof are dyed; meanwhile, a cosolvent is added to improve the solubility of the vat dye in the supercritical CO2 fluid, the dyeing depth and the like; moreover, a natural fiber swelling agent is added for the vat dye to enter the fiber for dyeing, thereby greatly saving the water resources and realizing a perfect dyeing effect.

Owner:CHENGDU TEXTILE COLLEGE

Modified chemical fiber using natural protein fiber superfine powder and production process thereof

InactiveCN1594682AMeet the processing performanceGood hygroscopicityConjugated synthetic polymer artificial filamentsProtein fiberMelt spinning

The object of the invention is to provide a modified chemical fiber using natural protein fiber superfine powder and production process thereof. The modified chemical fiber is processed by superfine protein powder and chemical fiber material, in which the protein powder is 5-10%, fiber material is 90-95%. The modified chemical fiber using natural protein fiber superfine powder has an improved wettability, a good anti-static property, a good dyeing performance, and has the effects of wool-like and silk-like. The material is natural protein fiber material with a low price and broad source. The melt spinning and wet spinning will not change the processing craft of the traditional chemical fiber and has a good economic performance.

Owner:WUHAN TEXTILE UNIV

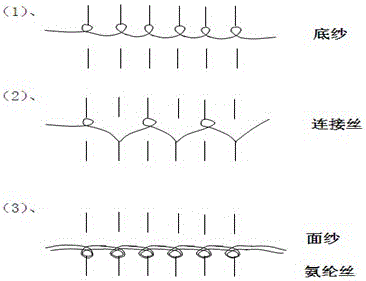

Method for producing stretch knit warm fabric with high shape preservation property

ActiveCN105970462ANo damage such as melting cracks was foundLess hairyWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention relates to a fabric production method, in particular to a method for producing a stretch knit warm fabric which is small in fiber damage, stable in elasticity, small in shrinkage degree and high in shape preservation property. The method comprises the steps of gray fabric knitting, gray fabric scutching, presetting, dyeing, water pressing and drying, fleecing, setting, lustring and shearing. During gray fabric knitting, ecotype fiber and single-component or multi-component blended yarn containing protein fiber or cellulosic fiber are used as surface yarn, DTY fine-denier polyester interlaced low-stretch long filament subjected to yarn steaming setting at 130 DEG C in a vacuum environment is used as bottom yarn, DTY polyester interlaced low-stretch yarn is used as middle connecting yarn, and 2.5 times drafting 20D spandex yarn is fed together with the surface yarn. In this way, the fabric is high in elasticity and shape preservation property. By reducing presetting temperature and machine speed, the degree of damage to spandex yarn is reduced to the minimum, and it is ensured that the elasticity of spandex yarn is stable.

Owner:ZHEJIANG JIAMING DYEING & FINISHING CO LTD

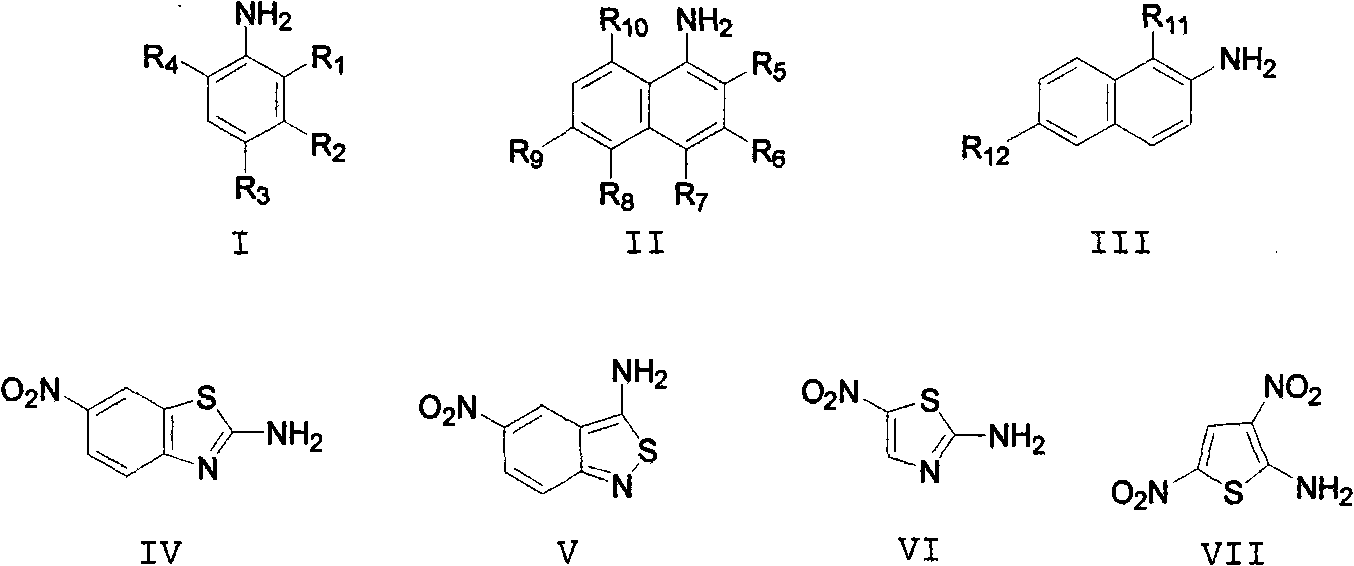

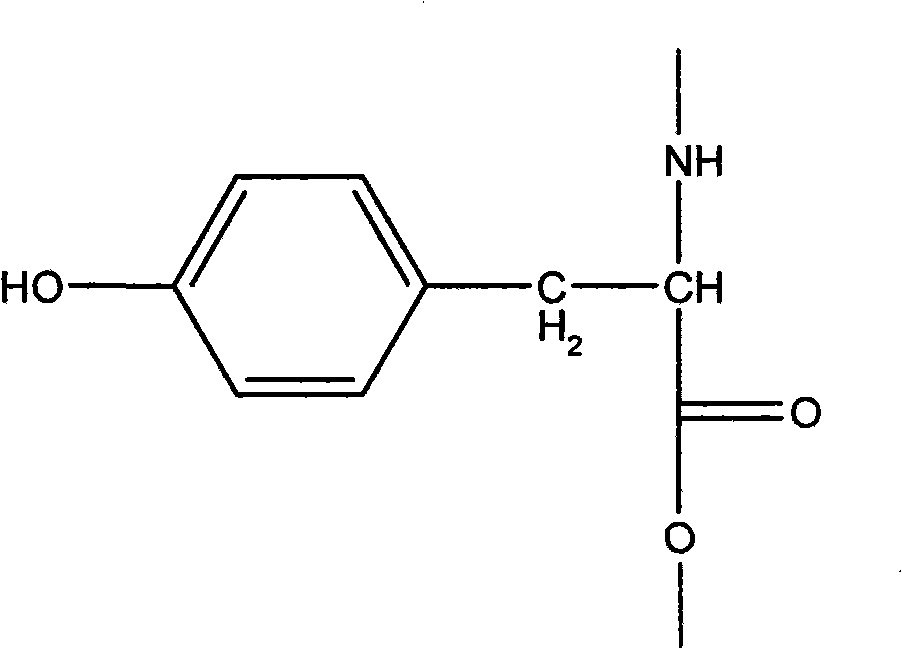

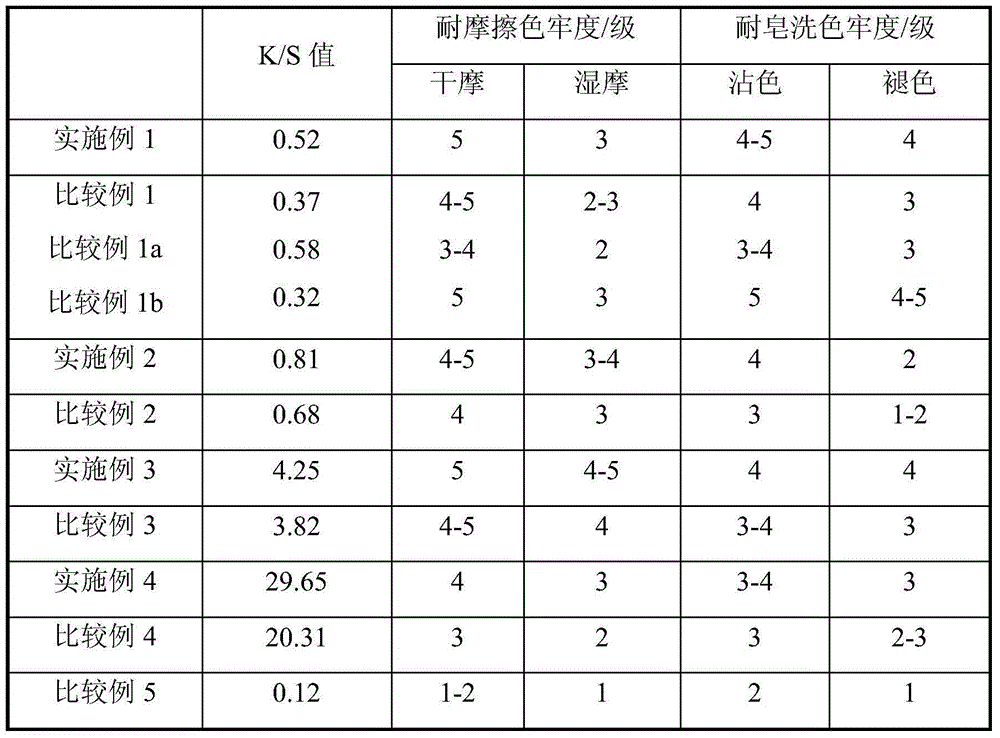

Dyeing method of protein material

The invention discloses a dyeing method of protein material. Arylamine compound is diazotized and then is directly coupled with tyrosine segment in protein molecule, so as to generate coloured substance containing azo bond; dosage of arylamine compound is equivalent to 0.1-5% of weight of protein material, and dyeing bath ratio is 1:20-100. Arylamine compound is taken as colour base and diazotized and then is directly coupled with tyrosine segment in protein molecule, and coloured substance connected with main chain by covalent bond in protein molecule, thus realizing dyeing on protein material and obtaining various colours by selecting arylamine colour bases in different structures. The dyeing method has the advantages of low energy consumption, less pollution and high colour fastness. The protein fiber fabric obtained by the method has higher wet-processing fastness; and the dyed protein powder also has higher fastness. The invention also provides a new dyeing method for protein material.

Owner:ZHEJIANG SCI-TECH UNIV

Air conditioning fiber blended yarn and spinning method thereof

InactiveCN101580987AOvercoming uneven blendingOvercome the phenomenon of color shift on the cloth surfaceYarnTextile fiberYarn

The invention provides an air conditioning fiber blended yarn and a spinning method thereof. The blended ratio of each component of the air conditioning fiber blended yarn is as follows: 30%-70% of the air conditioning fiber content, 5%-45% of the protein fiber content, and 25%-65% of other textile fiber content. The number of the blended yarn is 10-50. The spinning method of the air conditioning fiber blended yarn uses conventional cotton spinning blowing equipment, and the manufacturing procedure of loosing and coiling, carding, drawing, roving, yarn and cheese winding is carried out on the blended fiber. In the invention, an intelligent tempering yarn for variously blended fiber with high quality and high performance is provided, so is a creative processing method of variously blended fiber of the intelligent tempering yarn.

Owner:上海第三十六棉纺针织服装厂有限公司

Bamboo pupa protein fiber long-short yarn and method for making same

ActiveCN101117737AConjugated cellulose/protein artificial filamentsStaple fibre formationYarnCellulose

The present invention belongs to the spinning field and provides a long or short filament of bamboo pupa protein fiber. The long or short filament comprises 10-40wt percent silkworm pupa protein spinning liquid and 60-90wt percent bamboo cellulose viscose as the raw materials. The present invention also provides a method for preparing of the long or short filament. With bamboo cellulose as the raw material, the present invention can still meet the quality standard. Since bamboo cellulose can be acquired easily, the present invention provides a new choice for spinning product-pupa protein fiber.

Owner:YIBIN GRACE

Preparation method and application of chitosan-natural plant pigment macromolecular dye solution

ActiveCN104087020AImprove adsorption capacityAchieve purificationOrganic dyesDyeing processColour fastnessCellulose fiber

The invention belongs to the field of new materials, and particularly relates to a preparation method and application of a chitosan-natural plant pigment macromolecular dye solution. The preparation method comprises the following steps: firstly purifying a natural plant dye by utilizing the electrostatic attraction and the intermolecular force between the amido of chitosan and a negative ion natural plant pigment to obtain a chitosan-natural plant pigment macromolecular dye; and then preparing the chitosan-natural plant pigment macromolecular dye into a dye solution for textile coloration. Compared with the original natural plant dye, the obtained chitosan-natural plant pigment macromolecular dye has heavier molecular weight and has very high coloring capacity on natural fibers, such as cotton, hemp, silk and fur, because the chitosan has high affinity with cellulose fibers and protein fibers; a dyed fabric obtained by the chitosan-natural plant pigment macromolecular dye solution not only has deep color, but also has good color fastness.

Owner:临泉县嘉鸿装饰工程有限公司

Process for producing regenerated silk protein super fine fiber

InactiveCN1587459AWide range of choicesImprove performanceMonocomponent fibroin artificial filamentWet spinning methodsHigh concentrationInorganic salts

The production process of superfine regenerated silk protein fiber features that silk protein is first dissolved in inorganic salt, the solution is desalted and concentrated to produce high concentration and high spinnability regenerated silk protein aqua, and the aqua is electrostatically spun directly into the superfine regenerated silk protein fiber. The fiber has excellent performance, has stable silk protein-II crystal structure without need of post-treatment. The present invention uses water without toxicity and harm as solvent to make the superfine fiber good in biocompatibility and suitable for use as biomedicine material. The present invention has wide material source including common silk and silk leftover, and the product of superfine regenerated silk protein fiber has its specification regulated with the use.

Owner:DONGHUA UNIV

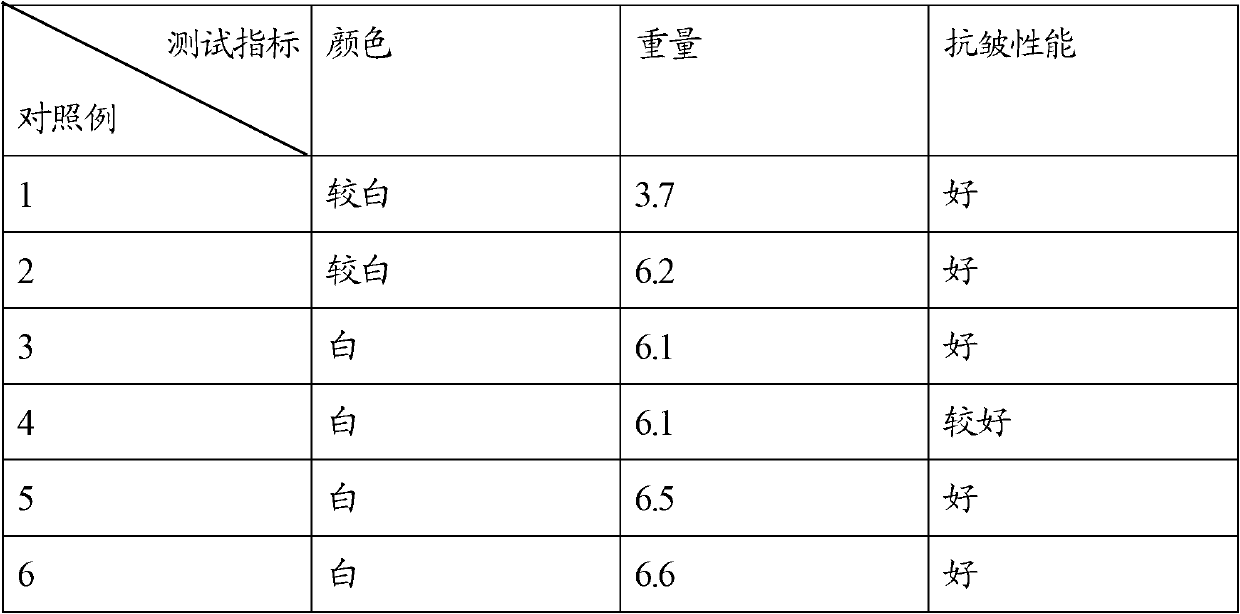

Feather protein fiber and method for preparing same

InactiveCN102733001AImprove wrinkle resistanceImprove toughnessConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentPotassium silicateAqueous solution

The invention discloses a feather protein fiber and a method for preparing the same. The feather protein fiber comprises the following components: 5-40 parts by weight of feather protein and 60-95 parts by weight of chemical fiber. The method for preparing the feather protein fiber comprises the following steps: A, feather protein spinning solution preparing: dissolving feather in an alkaline aqueous solution comprising sodium silicate and potassium silicate with the total mass concentration of 20-35%, and filtering to obtain the feather protein spinning solution, wherein the mass ratio of the sodium silicate to the potassium silicate is 1:(0.5-1); B, blending the feather protein spinning solution and the chemical fiber spinning solution, and spinning; and C, subjecting the feather protein fiber trickle to coagulation-bath treatment, pickling, washing and drying to obtain the feather protein fiber. The method for preparing the feather protein fiber can effectively ensure that the feather protein and the chemical fiber are fully and uniformly blended to achieve the purpose of spinning.

Owner:成都天之蚕生物科技有限公司

Supercritical carbon dioxide dyeing method for bulk fibers

InactiveCN101812809AAchieve direct dyeingImprove dyeing qualityDyeing processCellulose fiberNatural fiber

The invention relates to a supercritical carbon dioxide dyeing method for bulk fibers. The process flow comprises the following steps: placing dyes and bulk fiber materials in a supercritical carbon dioxide dyeing device, and dyeing under the condition of 70-150 DEG C and 20-30 MPa for 50-120 minutes; then releasing the pressure, and reclaiming carbon dioxide and the dyes under the condition of 4-5 MPa; and returning to the normal state to obtain stock-dyed fibers, wherein the bulk fibers are natural cellulose fibers, natural protein fibers and chemical fibers. The outstanding characteristics of the invention are as follows: the dyes directly carry out the supercritical waterless dyeing on the bulk fibers, and enable the fabric to obtain a special effect; the fabric is enabled to have the characteristics of good dyeing quality, cleaning production without waste products and environmental pollution, low comprehensive cost and obvious economic benefits and environmental benefits, especially waterless dyeing which conforms to the current low-carbon economic policy calling for water saving and energy saving; and the product comes up to GB18401-2003, National General Safety Technical Code for Textile Products.

Owner:DALIAN POLYTECHNIC UNIVERSITY

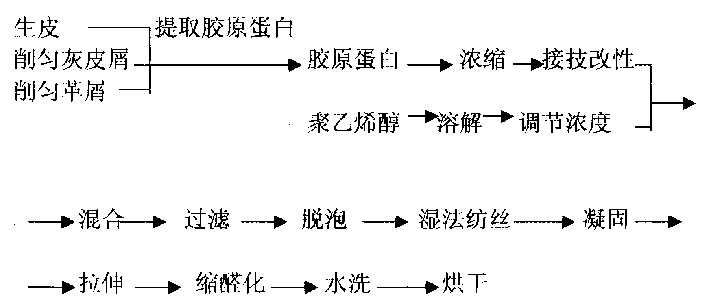

Compound protein fiber and preparation method thereof

ActiveCN102174720ASoft touchSoft lusterConjugated cellulose/protein artificial filamentsWet spinning methodsMoisture absorptionPVA - Polyvinyl alcohol

The invention relates to a compound protein fiber and a preparation method thereof. The compound protein fiber comprises the following components in percentage by mass: 10 to 45 percent of collagen, 10 to 45 percent of soybean protein and 10 to 80 percent of polyvinyl alcohol. The preparation method of the compound protein fiber comprises the following steps of: dissolving the collagen and the soybean protein in water, adding the polyvinyl alcohol, dissolving, and performing copolymerization modification to obtain spinning solution; and performing processes such as wet spinning, solidification molding, acetalation treatment and the like to obtain the compound protein fiber. The invention has the characteristics that: the compound protein fiber which has a high mechanical property, a high moisture absorption property, high air permeability, a high dyeing property, smooth handfeel, soft luster, skin intimate performance and health-care performance and is comfortably worn is manufactured by performing blending and copolymerization modification on the polyvinyl alcohol by using the collagen and the soybean protein; and the collagen and the soybean protein have wide raw material resources and low prices, a manufacturing process is relatively simple, and production cost is reduced.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

Biomass regenerated-fiber blended silky yarn and production method thereof

The invention provides a biomass regenerated-fiber blended silky yarn and a production method thereof. The biomass regenerated-fiber blended silky yarn is characterized in that blended yarn materials include pupa protein fibers and Levin bamboo fibers. The percentages of the pupa protein fibers and the Levin bamboo fibers, by weight, are 20-80% and 80-20%; the pupa protein fibers contain 18 kinds of amino acids and can fit and benefit skins and are noble in color and luster, and wastes are biodegradable; and the Levin bamboo fibers are high in wet-and-dry strength, are capable of bacteria resistance and bacteriostasis and are comfortable and soft and have silky color and luster, and wastes are biodegradable. One kind or a plurality of kinds of other biodegradable biomass regenerated fibers can be added into the blended yarn, the percentage of the sum of the other fibers by weight is 30-70%, and the percentage of the sum of the pupa protein fibers and the Levin bamboo fibers by weight is 30-70% (each fiber is no less than 15%). By processes of compact spinning and Siro compact spinning and Nu-Torque lower torsion moment spinning technology, the spun yarn is silky, has significant skin-benefit and comfortable functions, and is a novel ideal raw material for weaving woven or knitted superior fabrics.

Owner:RUGAO CITY DINGYAN TEXTILE

Regenerated chicken-feather protein viscose fiber as well as preparation method and application thereof

InactiveCN102304781AIncrease contentImprove washing resistanceConjugated cellulose/protein artificial filamentsArtificial filaments from viscosePolymer scienceEngineering

The invention discloses a regenerated chicken-feather protein viscose fiber which contains 10-30% of regenerated chicken-feather protein based on the mass percentage of fiber total dry basis in fibers. The preparation method comprises the following steps of: pre-treating waste chicken feathers; extracting chicken-feather proteins and preparing a regenerated chicken-feather protein stock solution;mixing, spinning and post-treating the regenerated chicken-feather protein stock solution and viscose; and finally obtaining finished-product regenerated chicken-feather protein viscose fibers. The regenerated chicken-feather protein viscose fiber disclosed by the invention has the advantages of pure natural property, degradability, softness, excellent dyeing property and the like, and further integrates the advantages of protein fiber and cellulose fibers; the interiors and the surfaces of the regenerated chicken-feather protein viscose fiber contain various amino acid which is necessary forhuman bodies, and the regenerated chicken-feather protein viscose fiber has unique skin-care healthcare functions; the fabric is soft and full of gloss, and the fabric is smooth in hand feeling, moisture-permeable and ventilating; and the fabric can be taken as a textile raw material with great weaving property and service performance, and is a kind of high-grade clothing fabric, in particular being suitable for material selection of clothing fabric, such as underwear, casual clothing and the like of women and children.

Owner:FUJIAN ZHONGHE

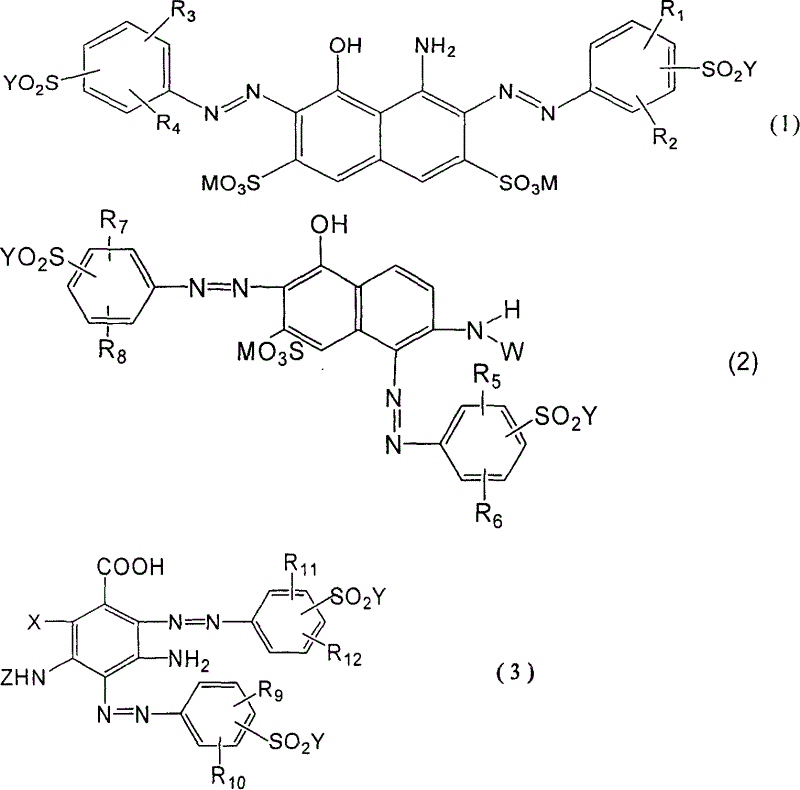

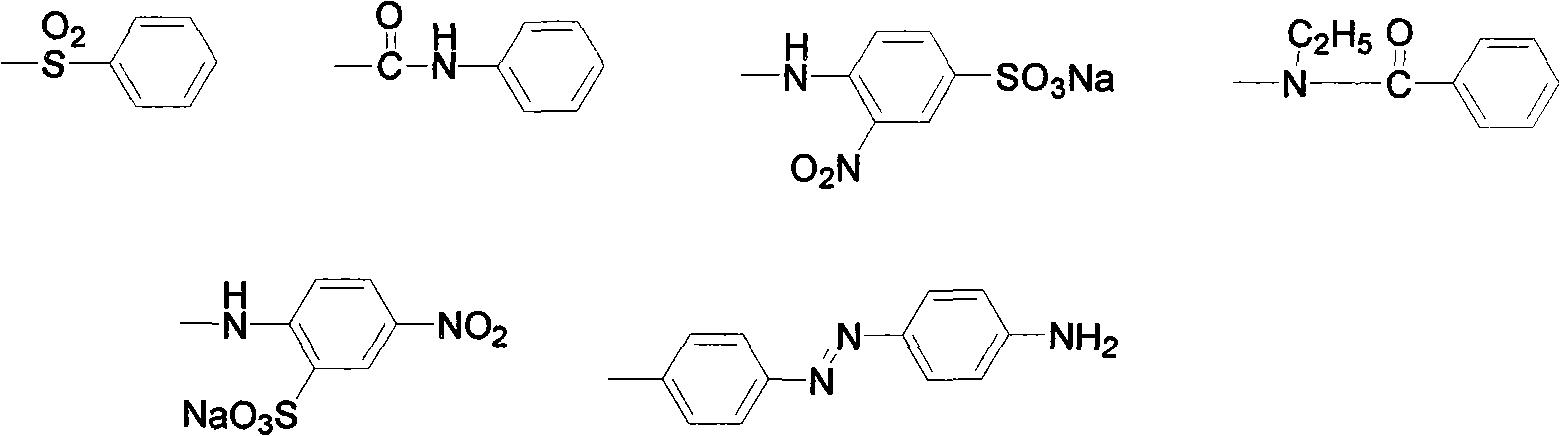

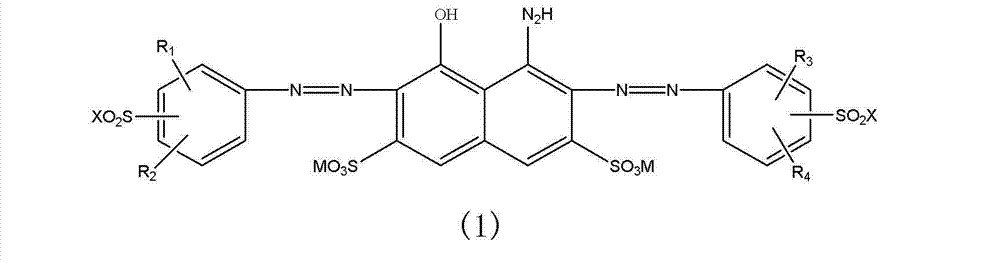

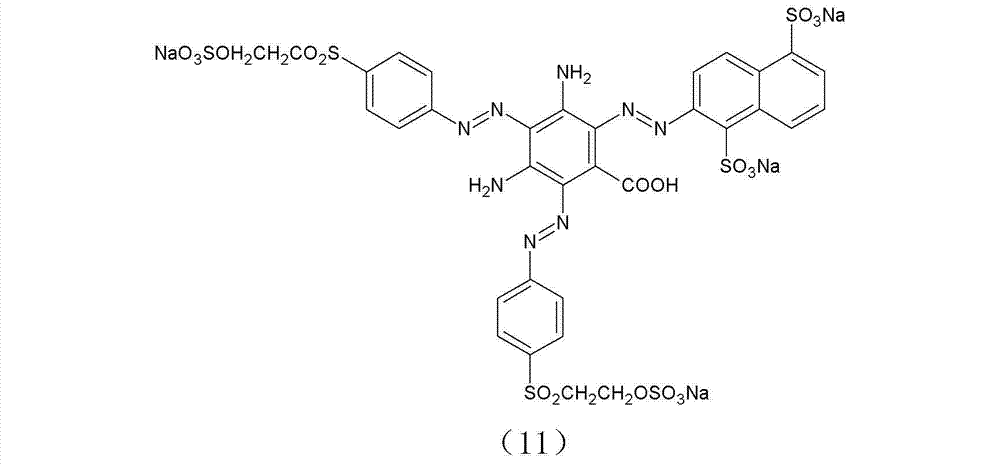

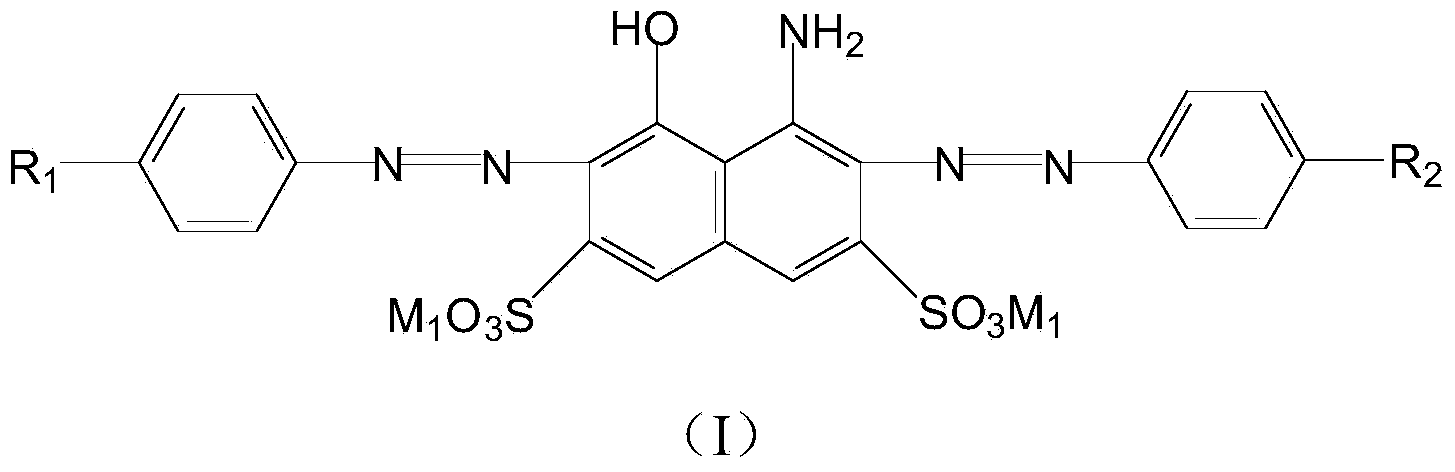

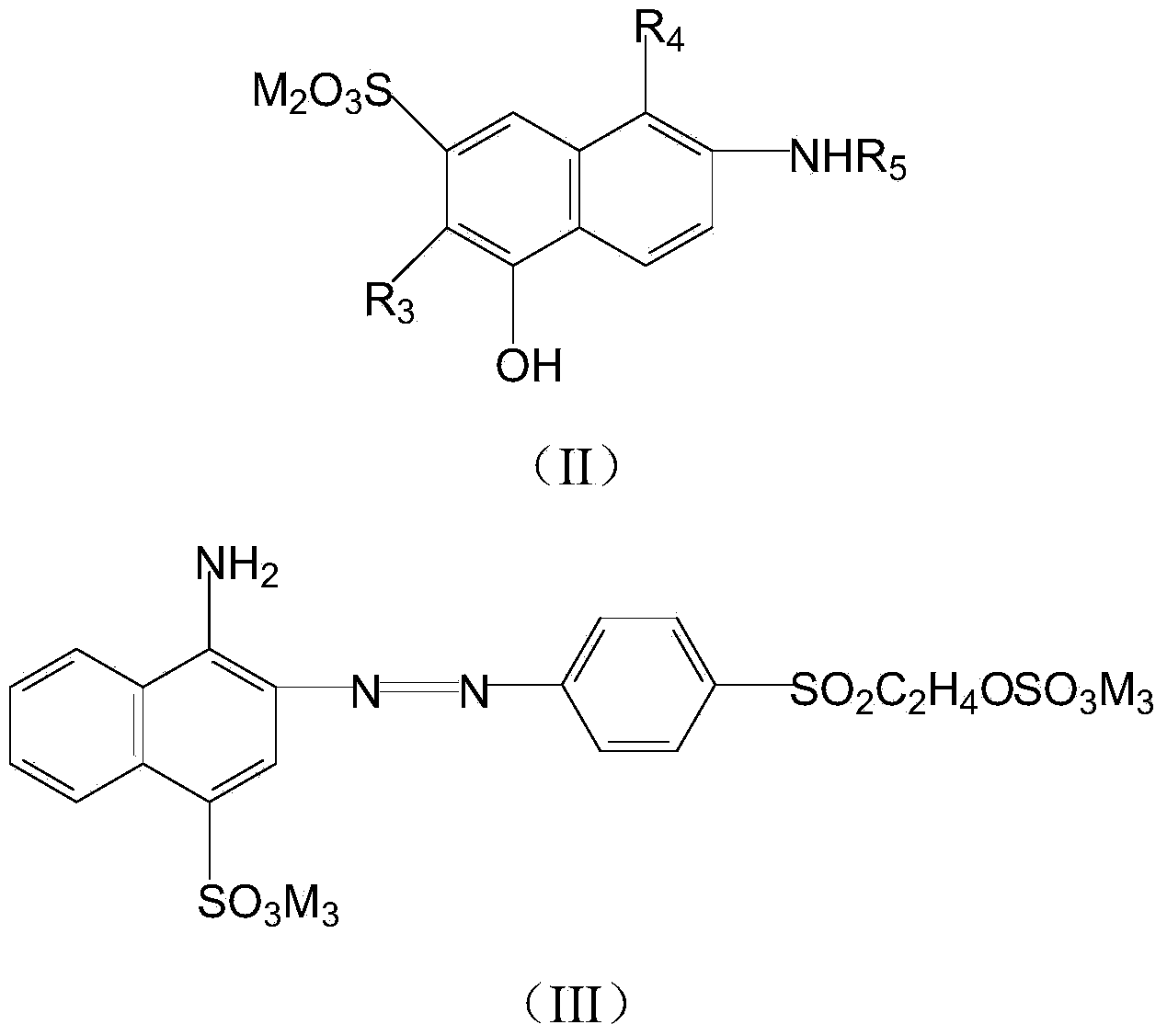

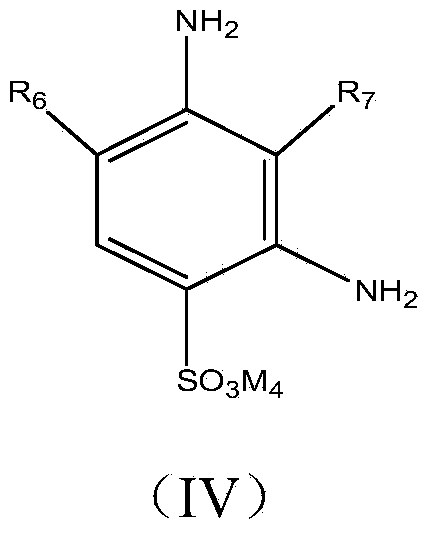

Composite dark black reactive dye

InactiveCN102898869AWide applicabilityHigh dyeing rateOrganic dyesDyeing processCellulose fiberProtein fiber

The invention discloses a composite dark black reactive dye. The dye is mixed by, by mass, reactive dyes of A, B and C, wherein the mass percent of the three dyes is 50-80% of A, 10-40% of B, 5-30% of C and the balance assistants, and the structural general formulas of A, B and C are presented in (1), (2) and (3). The composite dark black reactive dye is high in dye-uptake, fixation degree, alkali resistance and lifting power, low in substantivity, good in compatibility, easy to wash and wide in application; colors are guaranteed to be consistent before and after pad dyeing; and the dye is particularly suitable for dyeing of cellulosic fibers, protein fibers and polyamide fiber due to good leveling property.

Owner:ZHEJIANG YIDE CHEM

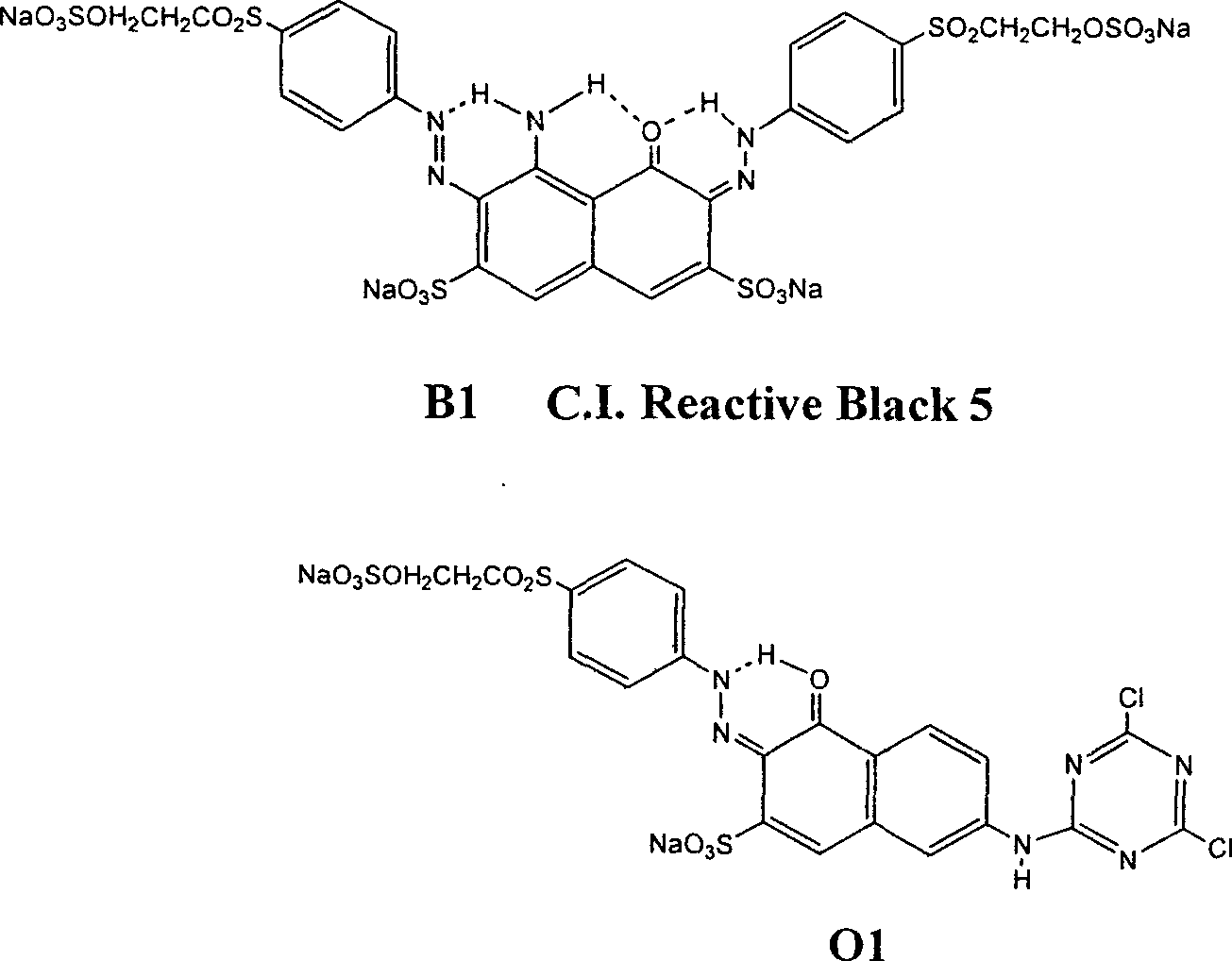

Compound black reactive dye composition, and applications thereof and fiber or fiber textile made thereby

ActiveCN104059387AImprove dyeing effectGood blacknessOrganic dyesDyeing processCellulose fiberProtein fiber

The invention relates to a compound black reactive dye composition, and applications thereof and a fiber or fiber textile made thereby, belonging to the field of reactive dyes. Particularly, the invention relates to a compound black reactive dye composition applicable to printing and dyeing cotton, rayon, hemp, regenerative fiber or textiles thereof, or to printing and dyeing polyamide fiber, cellulose fiber, protein fiber or textiles thereof. The invention further relates to applications of the compound black reactive dye composition, and fiber or fiber textile made by the compound black reactive dye composition.

Owner:ZHEJIANG RUIHUA CHEM

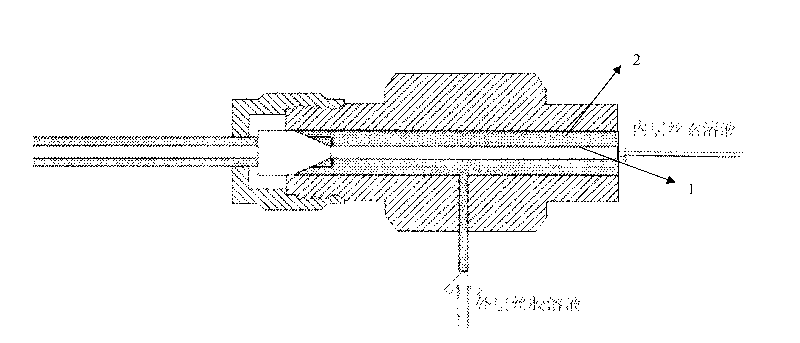

Preparation method of regenerative silk protein fiber with skin-core structure

ActiveCN101748504ANo pollution in the processEasy to prepareMonocomponent fibroin artificial filamentFilament/thread formingElectrospinningCarbon nanotube

The invention relates to a preparation method of regenerative silk protein fiber with skin-core structure, comprising the following steps: (1) silkworm cocoon is degummed and is dissolved in LiBr solution, a multi-wall carbon nano tube, a single-wall carbon nano tube or carbon black is added to obtain the solution with 20-35 percent of concentration; (2) sericin powder is prepared into the solution with 50-70 percent of concentration; (3) the solution is respectively poured into an inner pipe and an outer pipe of a coaxial spinning nozzle to carry out coaxial electrostatic spinning. The preparation method is simple, the operation is convenient, the cost is low, the method has no pollution to environment, and the obtained regenerative silk protein fiber has similar composition and skin-core structure with the natural silk.

Owner:DONGHUA UNIV

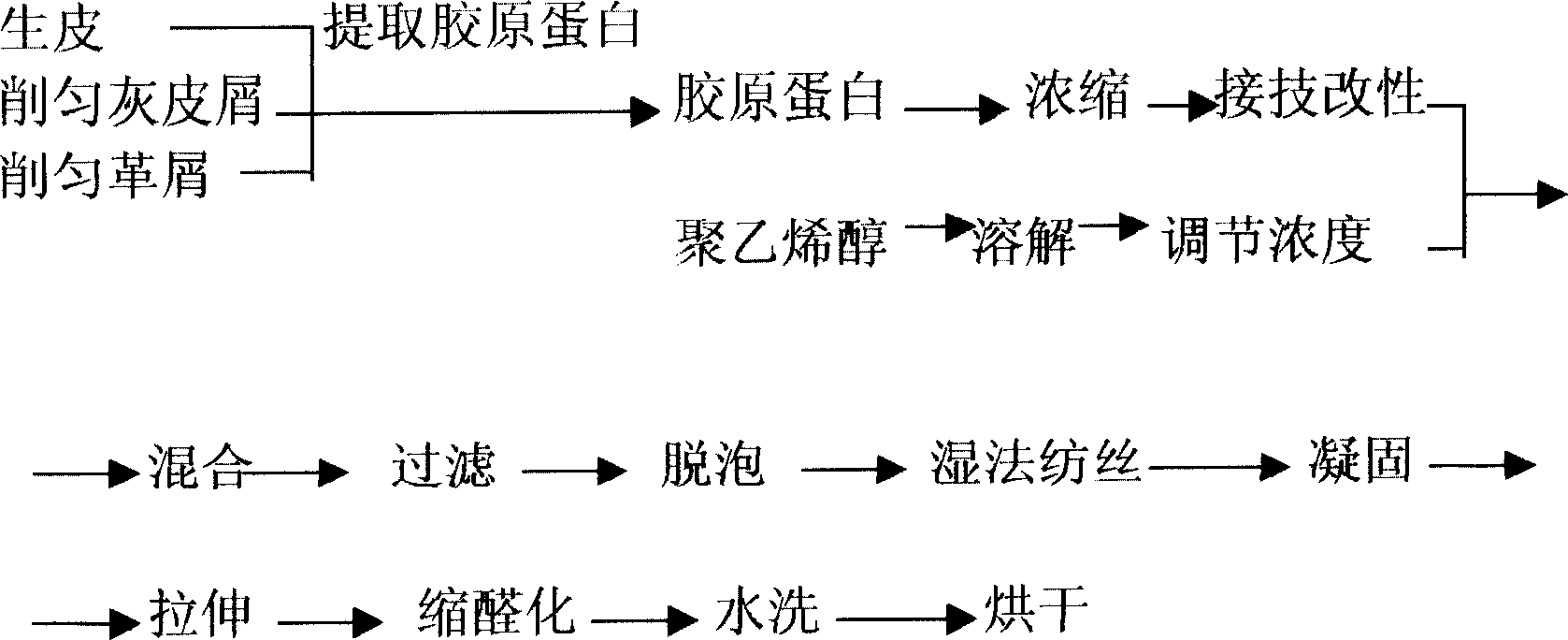

Collagen protein composite fiber and its producing method

InactiveCN1492087AComfortable to wearGood hygroscopicityConjugated artificial filamentsLeather industryPolyvinyl alcohol

The present invention relates to new material in textile industry. Collagen protein extracted from animal skin or leather industry leftover is grafting modified with olefin monomer and mixed with PVA to form spinning liquid with certain density and viscosity; and through further wet spinning, solidification, stretching and acetalization, the composite collagen protein fiber for textile industry is produced. The composite collagen protein fiber consists of collagen protein 10-45 wt%, olefin monomer modifier 5-20 wt% and PVA 50-85 wt%. The composite collagen protein fiber has excellent affinity to human skin, high hygroscopicity, wearing comfort and easy colorizing.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

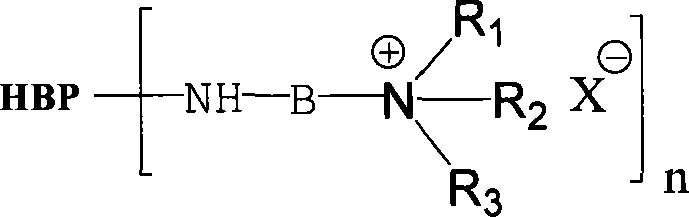

Amine-terminated hyperbranced compound quaternary ammonium salt and preparation method thereof

The present invention discloses amino end hyper-branched compound quaternary ammonium salt and the preparation method, pertaining to the art of macromolecular material technology. The method adopts the amino end hyper-branched compound as the matrix for quaternary ammoniation of the amido on the surface or grafting the quaternary ammonium salt, thus obtaining the polymerized quaternary ammonium salt. The preparation method is that the amino end hyper-branched compound is dissolved in deionized water and then a certain amount of quaternary ammoniation reagent is added; after being even mixed, the polymerized quaternary ammonium salt with characteristics of the hyper-branched compound and the polycation. The present invention has the advantages that the synthetic process is simple, the synthetic cost is relatively low, the product can be applied to cation modification of cellulose fiber and protein fiber, salt-free dyeing of active dyestuff, direct dyestuff, acid dyestuff, acid mordant dyestuff, etc., and the antiseptic performance and anti-UV performance of the fabric is enhanced. At the same time, the present invention is applied to sewage treatment agent, antibacterial agent, surface active agent, functional material forebody, medical carrier, etc.

Owner:SUZHOU UNIV

Method for producing pearl protein cellulose fibre

InactiveCN101487149AHigh in proteinTotal protein increaseConjugated cellulose/protein artificial filamentsWet spinning methodsCellulose fiberSingle type

The invention discloses a method for preparing pearl protein cellulosic fiber, which can prepare the pearl protein fiber with high protein content and rich amino acids; although the pearl contains pearl protein, the content of the pearl protein is extremely low and the amino acid has single type; and the fiber prepared by the method inherits the excellent performance of the pearl, contains relatively plenty of plant protein, and greatly improves the total quantity of the protein in the fiber. Various amino acids contained in the plant protein have the efficacy of caring skin on the human body, excellent softness and humidity adsorption performance and a certain ultraviolet resistance function; furthermore, the pearl powder and the plant protein powder have wide source in China and low production cost.

Owner:SUZHOU HENGGUANG CHEM FIBER +3

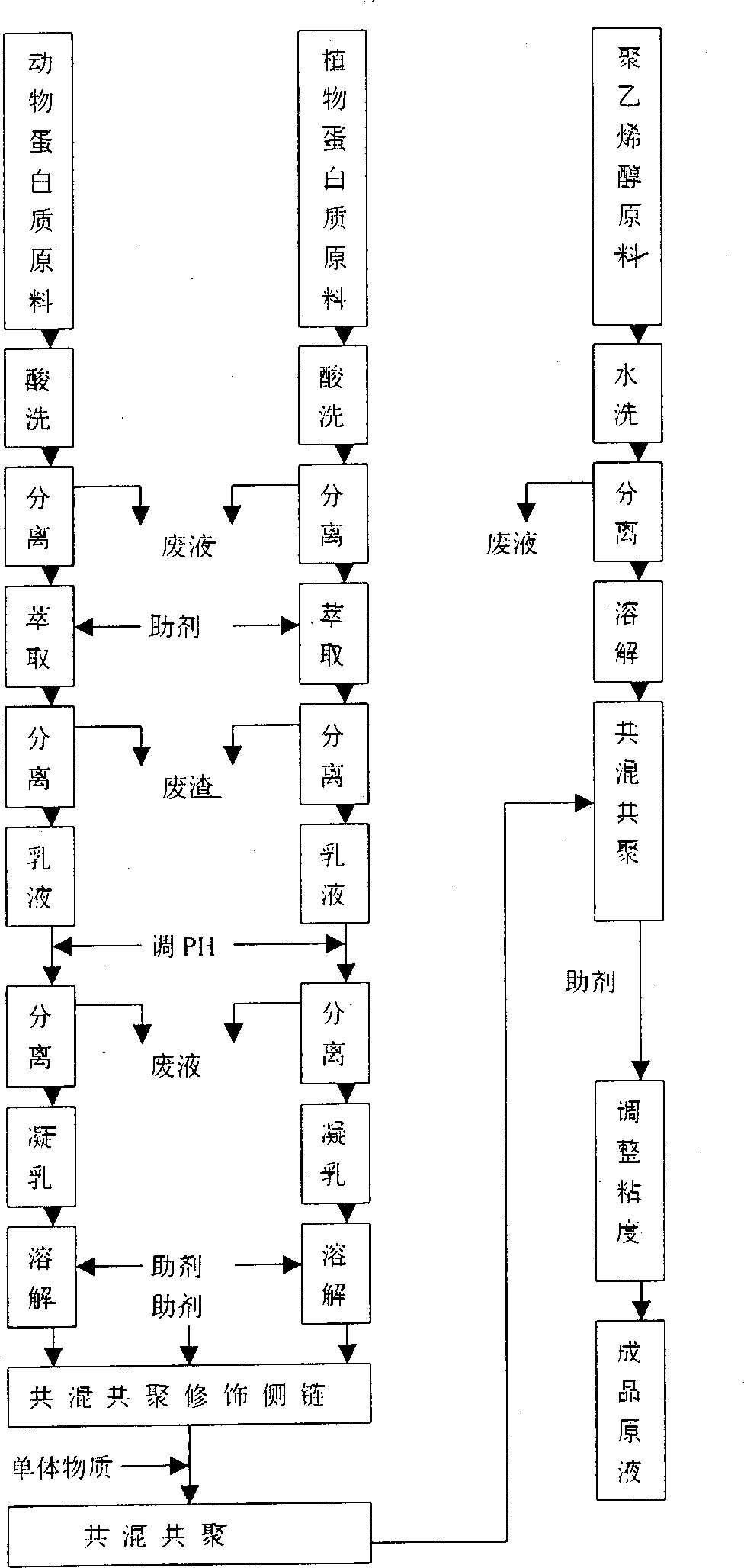

Protein synthetic fibre spinning solution and its producing method

InactiveCN1364948ASkin-friendlyBreathableConjugated cellulose/protein artificial filamentsPolymer scienceAmino acid side chain

The protein fiber spinning solution is produced by using animal and plant material and through the processes of acid pickling, extraction, pH regulation to obtain protein curd, dissolving with cosolvent to form water solution, mixing, modifying side chain of amino acid with modifying agent, copolymerization with coloring monomer, mixing with PVA water solution and addition crosslinking agent to regualte viscosity. It may be used in spinning fiber with the same strengt has chemical fiber, the skin friendship, air penetrability and hygroscopicity the same as natural protein fiber, and improved hot water resistance, shrinkage and color.

Owner:卓宝松 +1

PTT fiber and celluse fiber one-bath dyeing method

The invention discloses PTT and cellulose fibers one bath process dyeing method. It includes the following steps: adding dyeing assisted carrier into the bath; dying PTT fiber by disperse dyes; adding auxiliary agent to do reduction clearing; removing loose color; adding activated dye and auxiliary agent to dye cellulose fiber; soaping; washing; and fixing by fixing agent; mellowing; dehydrating; and drying. The invention solves the problem of blending PTT and protein fibers low temperature one bath process dyeing, and the production problem of no corresponding high temperature pressure dyeing device for enterprise, which is the key of deep processing for blending fiber product, the necessary condition for its market popularization and application.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com