Patents

Literature

177results about How to "Good blackness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic toner

To provide a magnetic toner which is excellent in durability and developability even in the case of being applied to high-speed developing process or being used in a large-capacity process cartridge amount of toner in which is increased, and which has high degree of blackness. Provided is a magnetic toner having magnetic toner particles containing at least a binder resin and magnetic material particles each comprising a predetermined amount of a titanium compound, characterized in that:1) the magnetic material particles have a predetermined amount of adsorbed moisture at a relative vapor pressure of 50%; and2) a difference between the amount of moisture adsorbed to the magnetic material particles in an adsorbing process for increasing a relative vapor pressure and the amount of moisture adsorbed to the magnetic material particles in a desorbing process for reducing a relative vapor pressure is reduced.

Owner:CANON KK

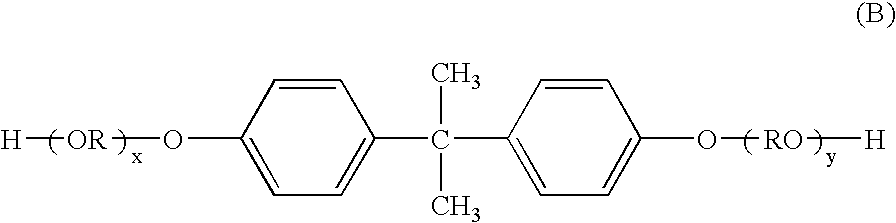

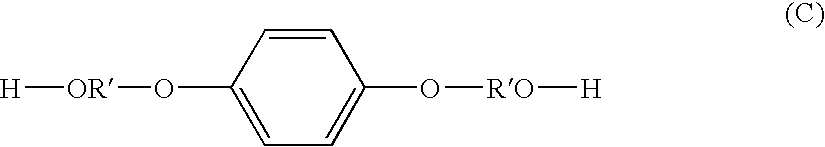

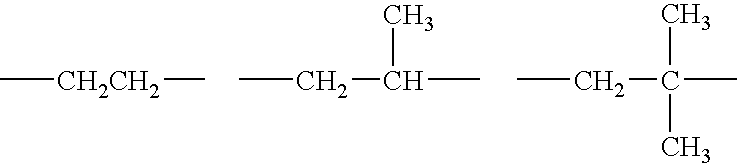

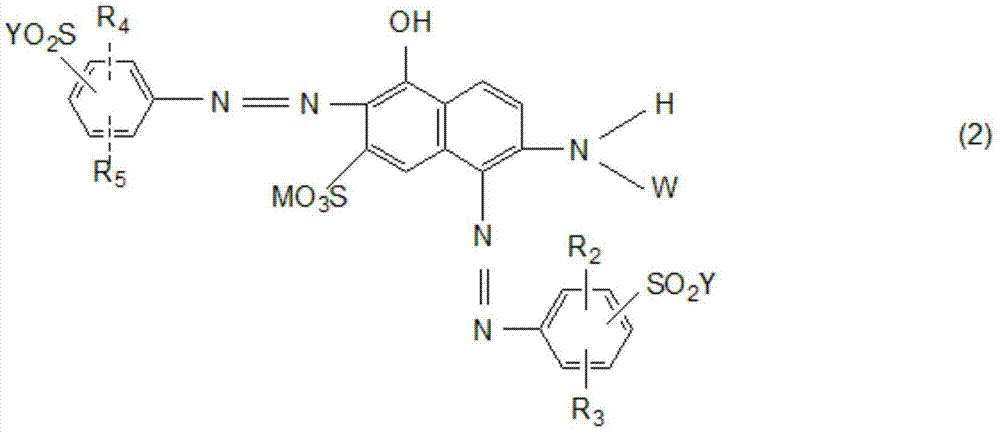

Compound black reactive dye composition, and applications thereof and fiber or fiber textile made thereby

ActiveCN104059387AImprove dyeing effectGood blacknessOrganic dyesDyeing processCellulose fiberProtein fiber

The invention relates to a compound black reactive dye composition, and applications thereof and a fiber or fiber textile made thereby, belonging to the field of reactive dyes. Particularly, the invention relates to a compound black reactive dye composition applicable to printing and dyeing cotton, rayon, hemp, regenerative fiber or textiles thereof, or to printing and dyeing polyamide fiber, cellulose fiber, protein fiber or textiles thereof. The invention further relates to applications of the compound black reactive dye composition, and fiber or fiber textile made by the compound black reactive dye composition.

Owner:ZHEJIANG RUIHUA CHEM

Preparation of nano black carbon and use of nano black carbon in fabric dyeing

InactiveCN101348618ASimple preparation processLow costInorganic pigment treatmentDyeing processPigment dispersionCellulose fiber

The invention relates to a nano-carbon black preparation method and an application of nano-carbon black in fabric dyeing, belonging to the technical field of textile chemical engineering. The preparation method is characterized in that an ultrasonic technique is utilized to prepare the nano-carbon black, so as to obtain a nano-carbon black pigment dispersion system with good dispersivity and high stability; the prepared nano-carbon black pigment dispersion system can be used for dyeing natural cellulose fiber and regenerated cellulose fiber fabrics; and the dyed fabrics are pure in color, good in jet-black degree and excellent in color fastness. The preparation method has the advantages of simple process, low cost and little pollution.

Owner:JIANGNAN UNIV

Composite black oxide particle, method for producing same, black coating material and black matrix

InactiveUS20070128438A1Good blacknessIncrease resistancePigmenting treatmentMolten spray coatingManganeseCopper

Disclosed is a composite black oxide particle which is composed of oxide of cobalt, copper and manganese. The copper / cobalt molar ratio is 0.1-0.5, and the manganese / cobalt molar ratio is 0.2-1.0. The composite black oxide particle further contains silicon, and the silicon content to the total oxide particle is 0.1-3 mass %. The surface of the composite black oxide particle is coated with aluminum oxide. The Al content in the surface coating to the entire particle is 0.05-3 mass %.

Owner:MITSUI MINING & SMELTING CO LTD

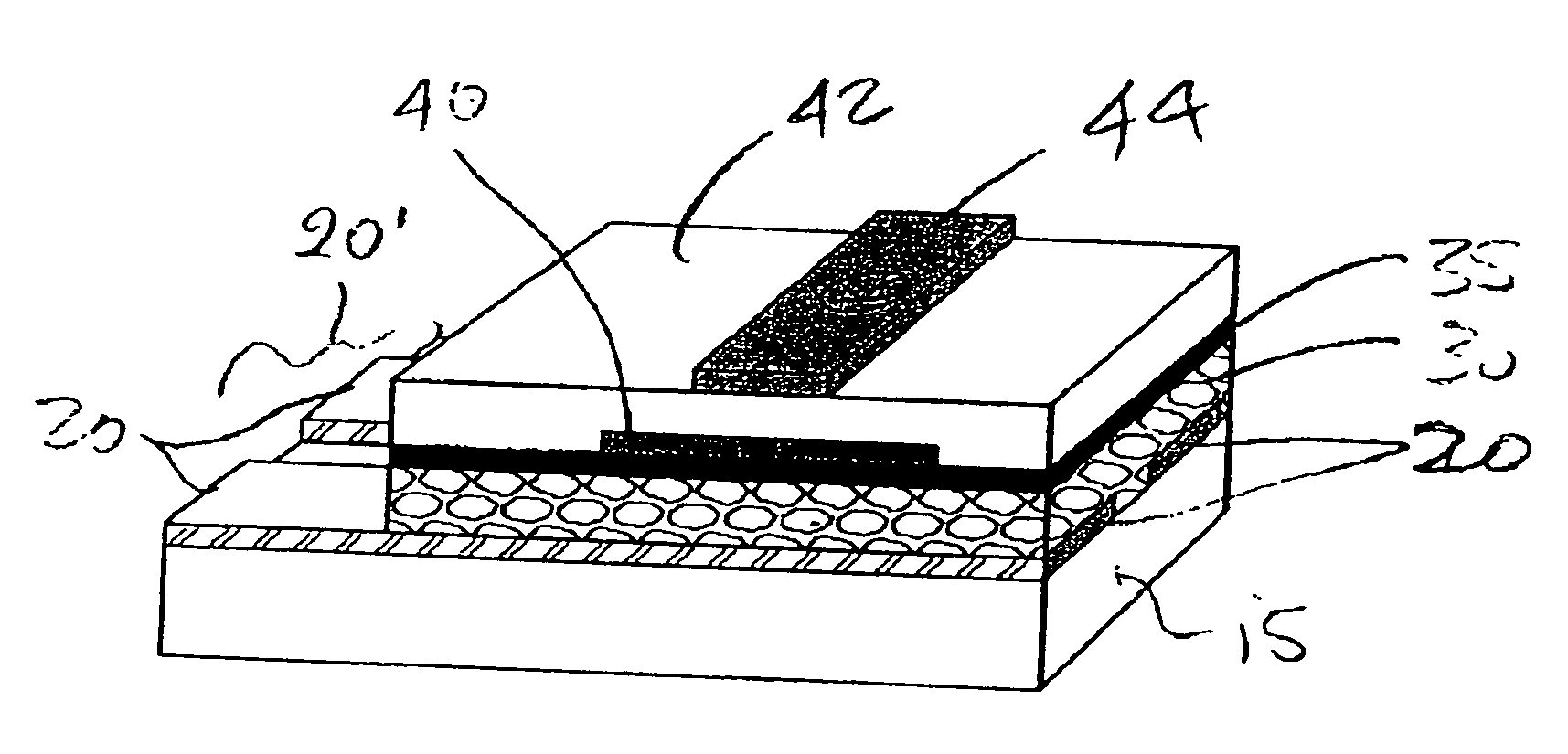

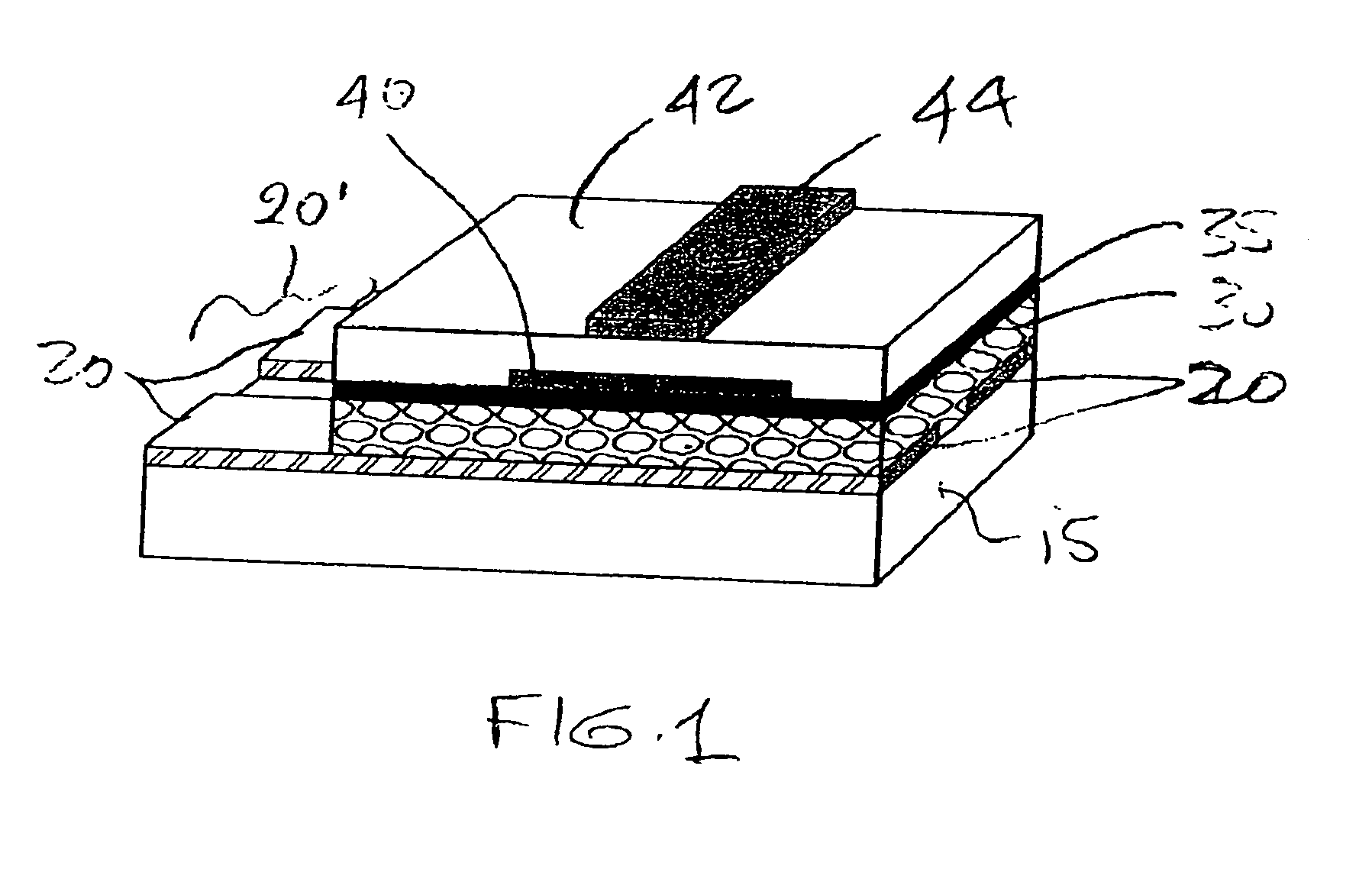

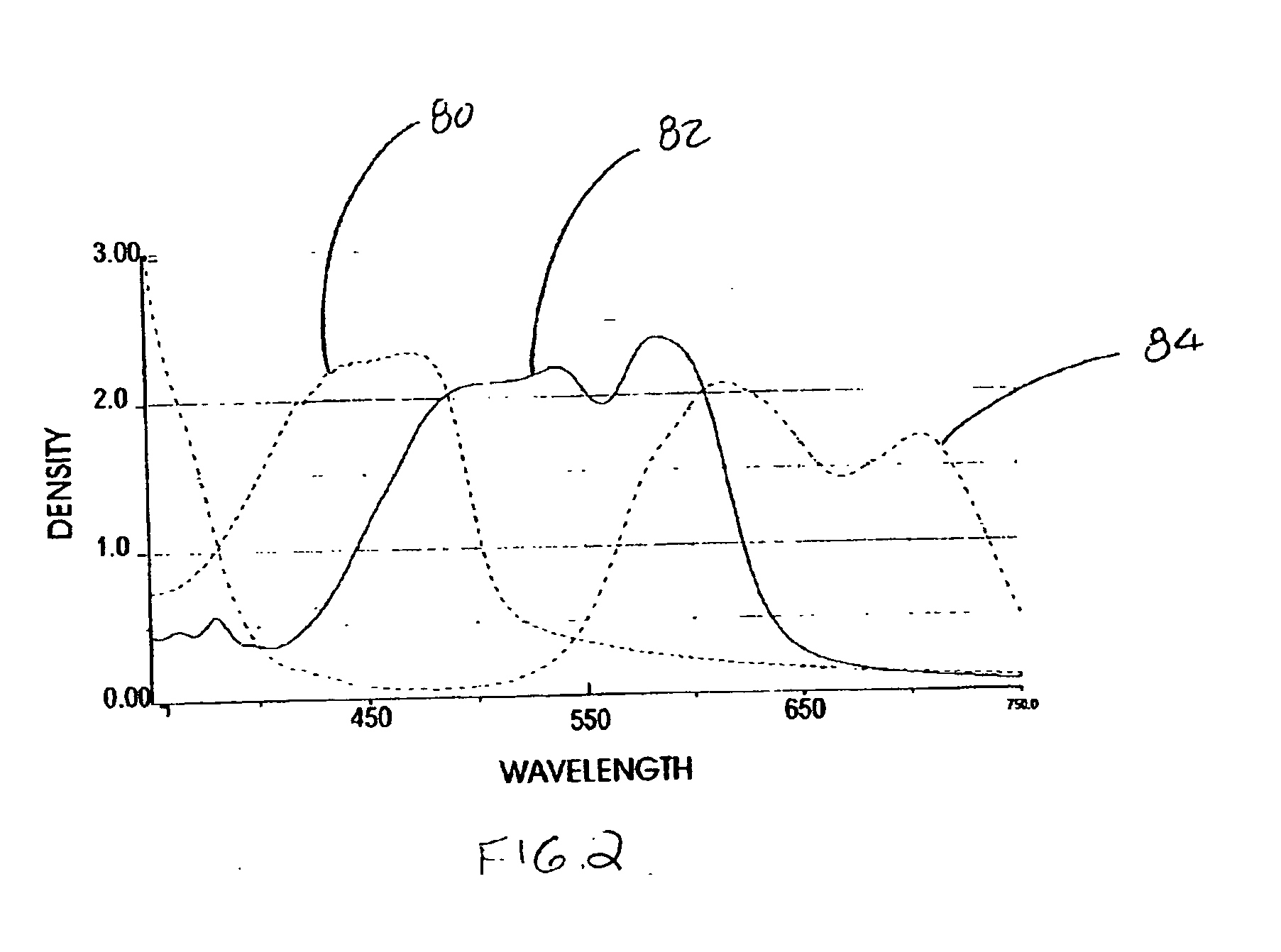

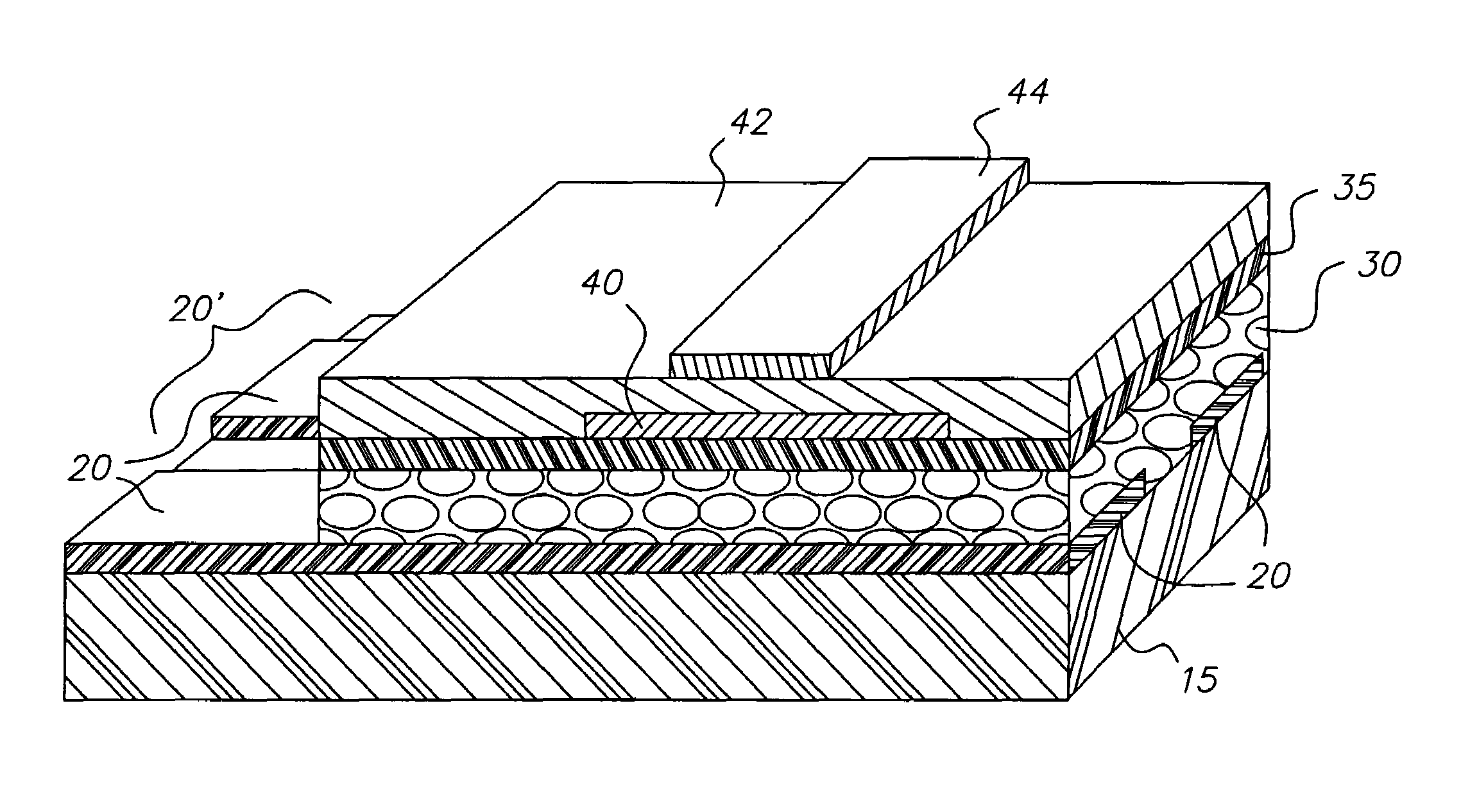

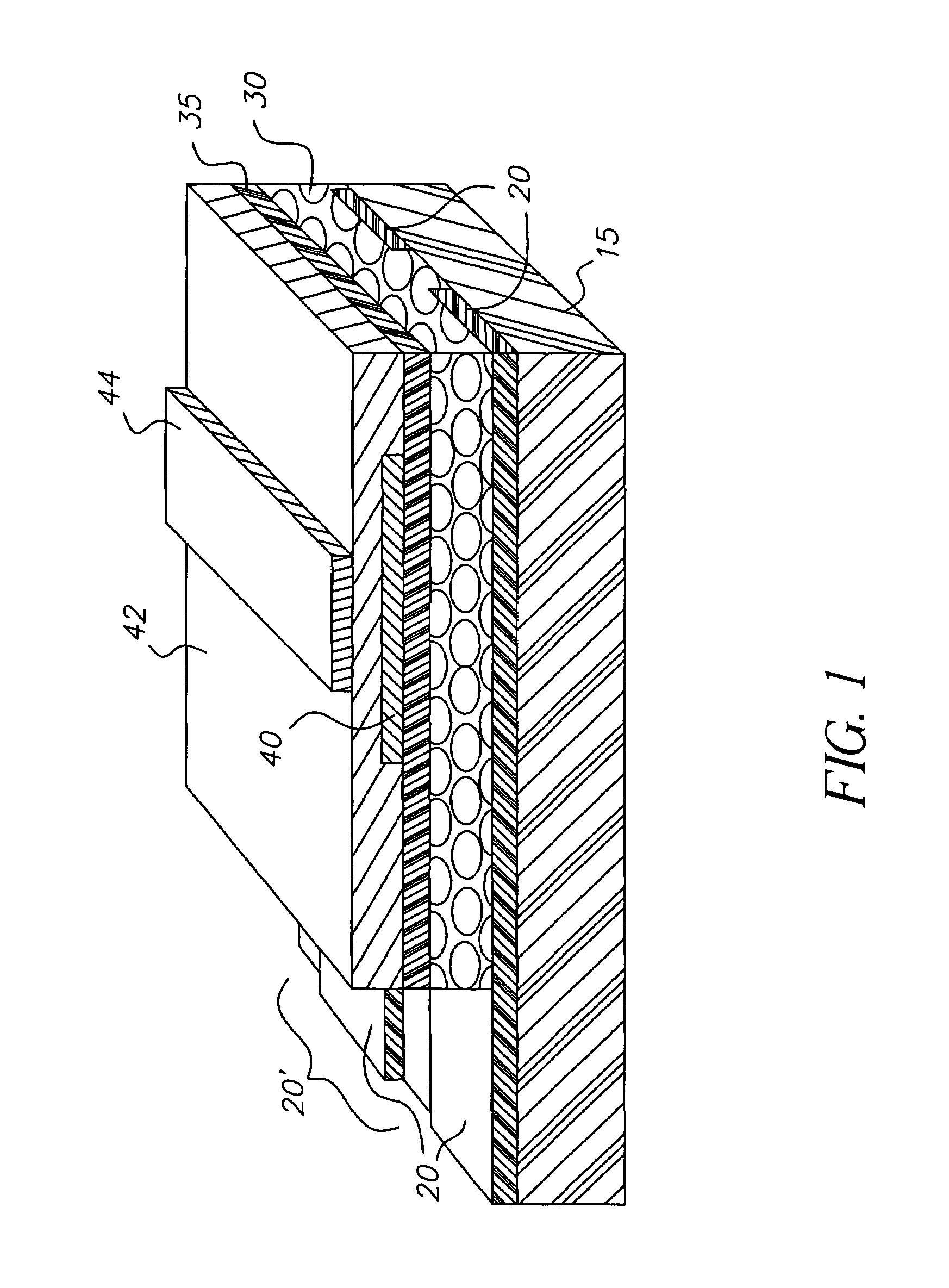

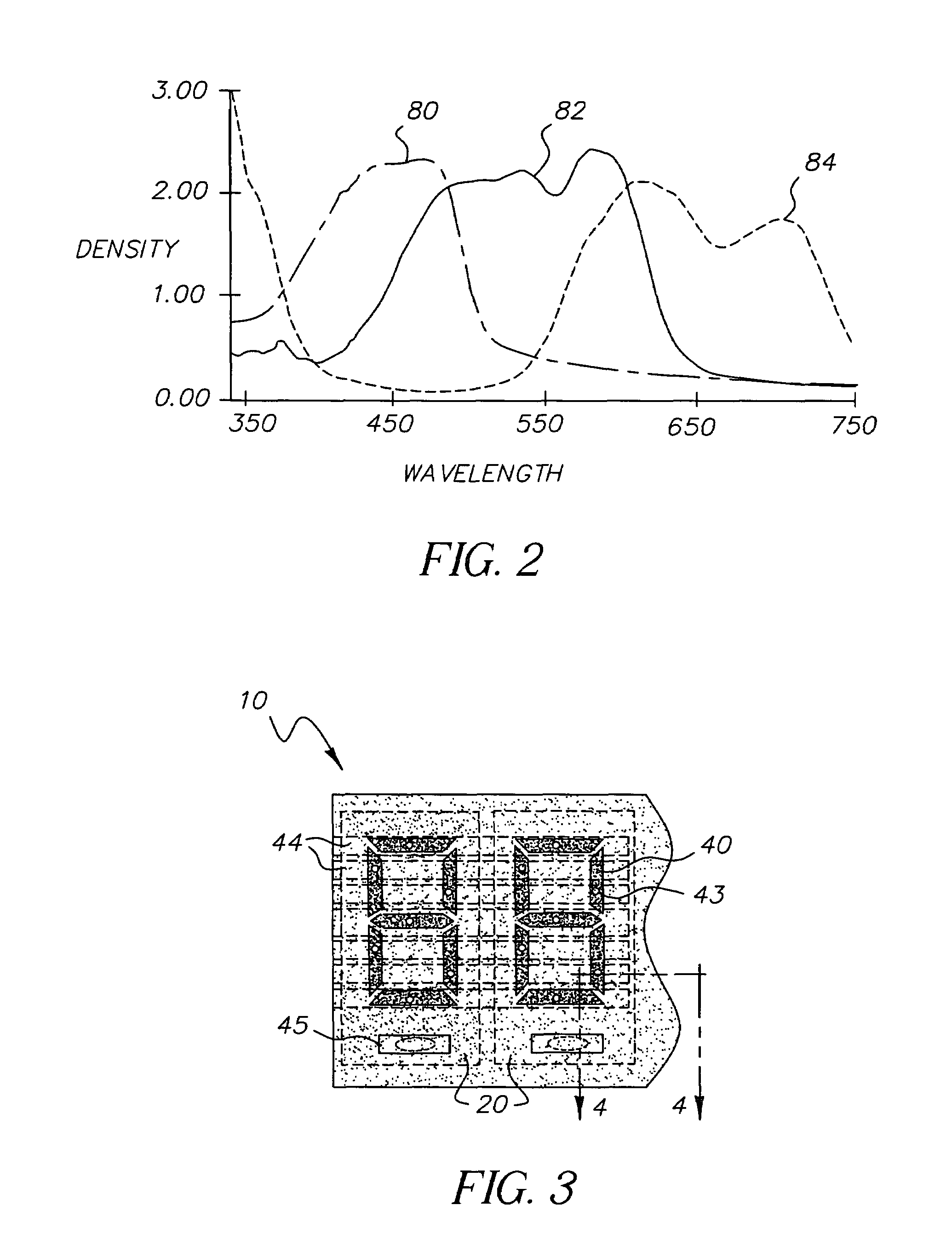

Mixed absorber layer for displays

ActiveUS20050259300A1Good blacknessAvoid excessive absorptionLiquid crystal compositionsLiquid surface applicatorsElectricityOptoelectronics

Owner:IRIS OPTRONICS CO LTD +1

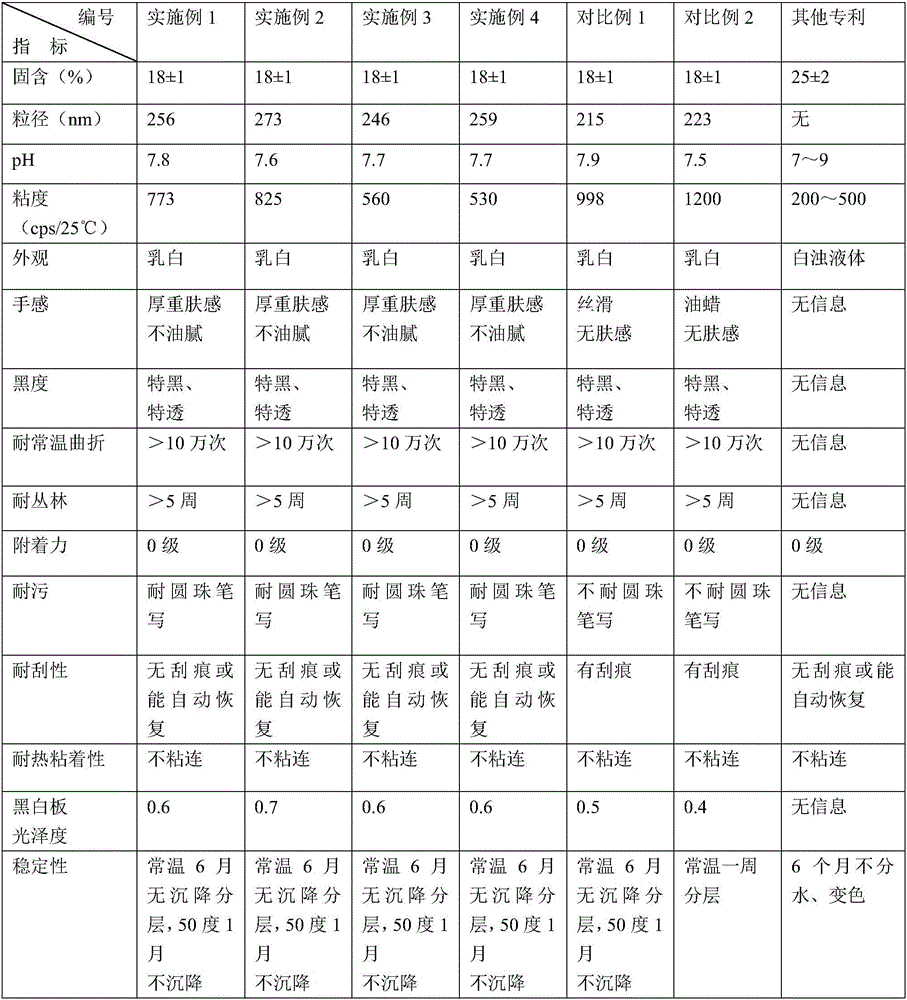

Aqueous matt surface finishing agent for PVC (Polyvinyl Chloride) leather and preparation method thereof

ActiveCN106349914AImprove performanceNo adverse phenomena such as whiteningAntifouling/underwater paintsPaints with biocidesWaxSurface finish

The invention relates to an aqueous matt surface finishing agent for PVC (Polyvinyl Chloride) leather and a preparation method thereof. The aqueous matt surface finishing agent is prepared from the following components: aqueous polyurethane resin, water, silicon dioxide matting powder, polysiloxane water dispersoid, aqueous wax emulsion, an aqueous wetting agent, an aqueous de-foaming agent and a thickening agent. The invention further relates to a preparation method of the aqueous matt surface finishing agent for the PVC leather. The aqueous matt surface finishing agent for the PVC leather, disclosed by the invention, has an excellent matt surface effect, a good heavy and skin feeling and a pollution-resisting performance and is aqueous and environment-friendly; meanwhile, the aqueous matt surface finishing agent has the advantages of good adhesive force, scratching resistance, bending resistance and forest resistance, and can meet the higher and higher requirements on skin feeling and pollution resistance of home decorations, electric appliances, furniture, automobile interiors and the like.

Owner:WANHUA CHEM GRP CO LTD +1

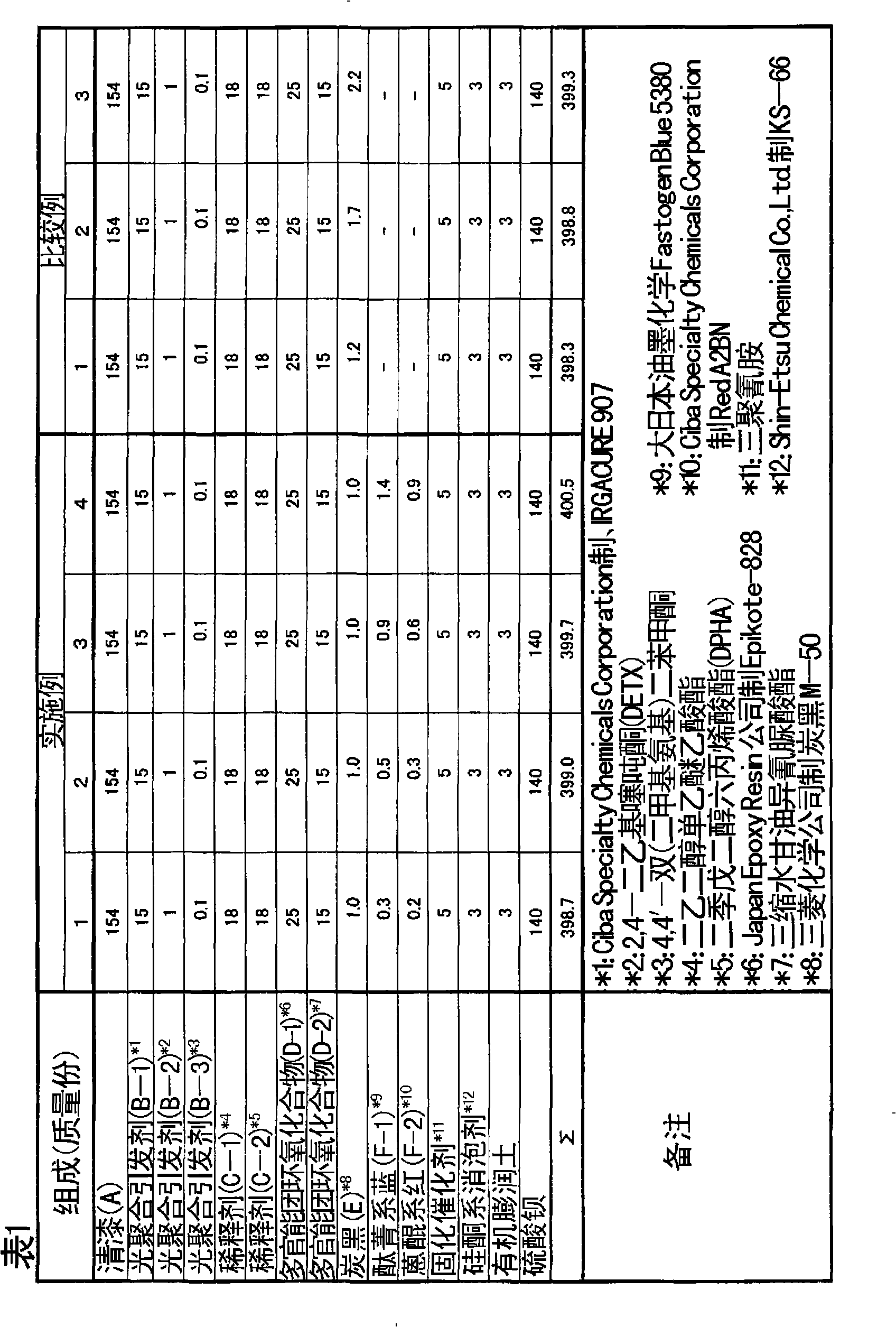

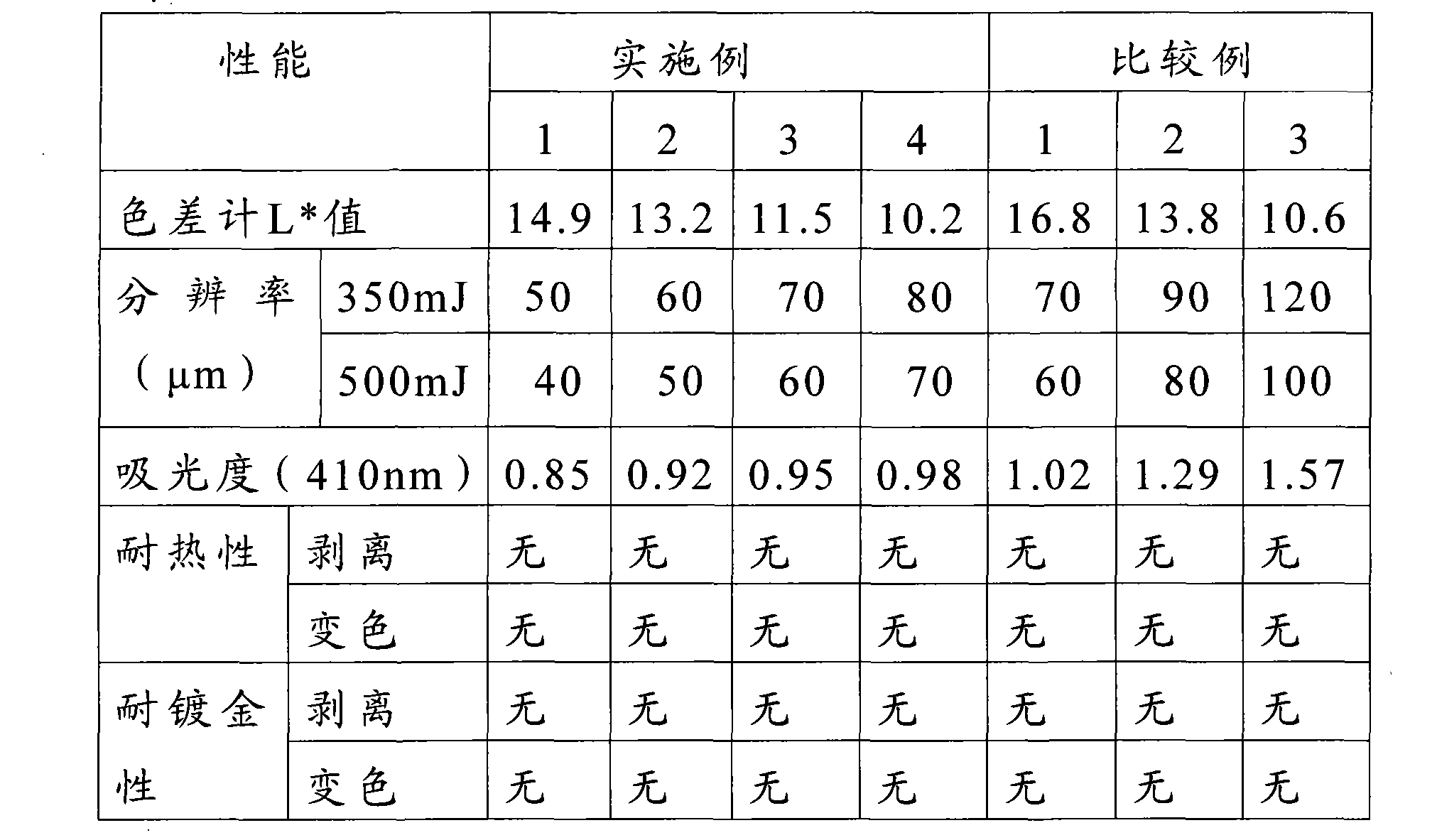

Black solder resist compound and cured product thereof

ActiveCN101281368AGood blacknessHigh resolutionPhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationResistEpoxide

The present invention provides a black optical resistance flux with sufficient blackness degree and excellent resolving capability and condensate thereof. The black soldering inhibitor composition contains (A) carboxy group resin, (B) initiators for photopolymerization, (C) fluidifying agent, (D) multi- function epoxides at least having two epoxy radicals in one molecule, (E) blackness colorant, (F) more than one colorant except black colorant.

Owner:TAIYO INK MFG

Mixed absorber layer for displays

ActiveUS7195813B2Good blacknessAvoid excessive absorptionLiquid crystal compositionsLiquid surface applicatorsDisplay deviceOptoelectronics

Owner:IRIS OPTRONICS CO LTD +1

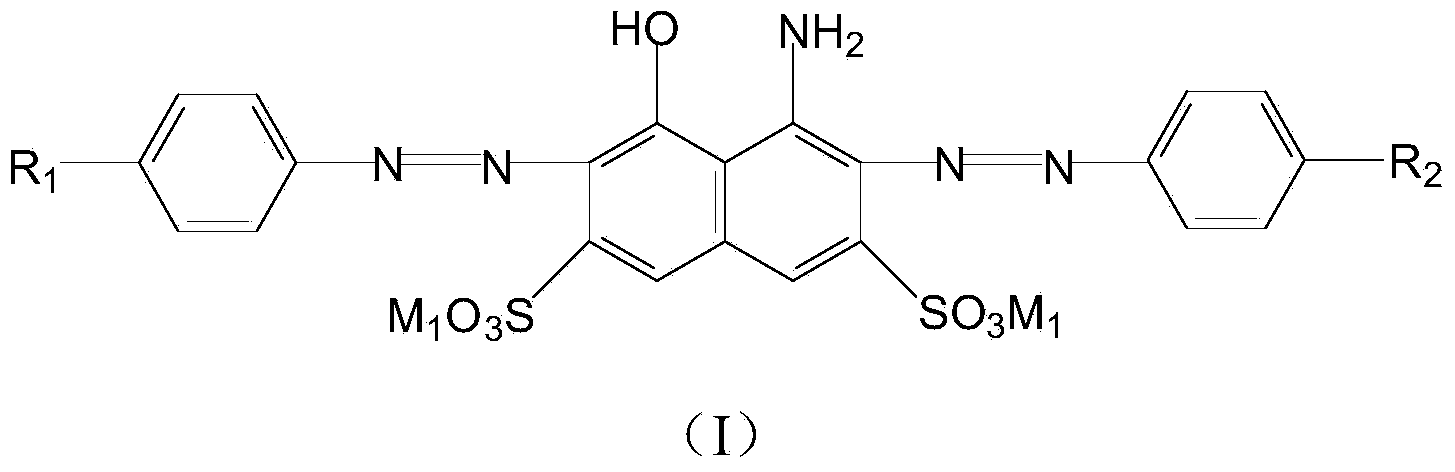

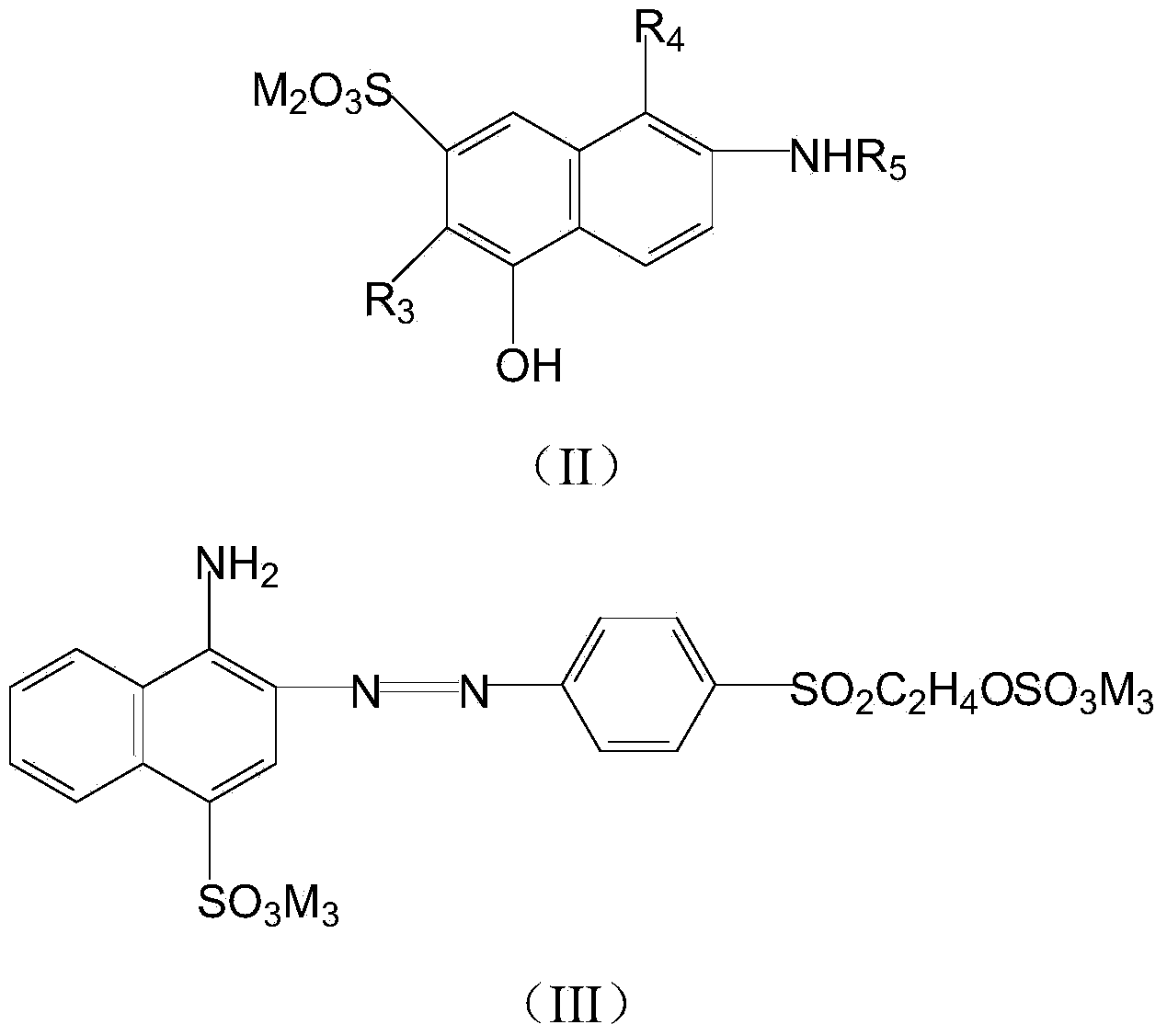

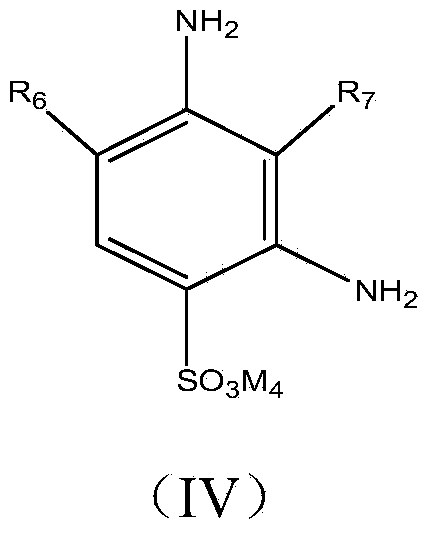

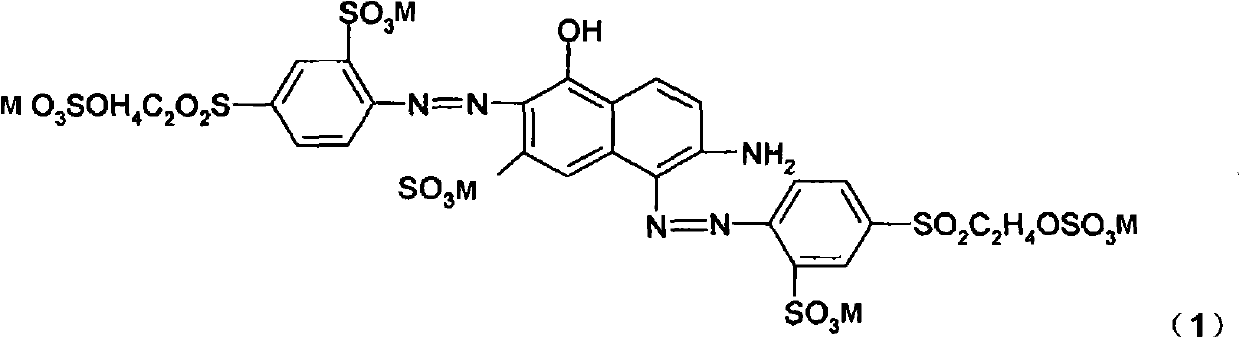

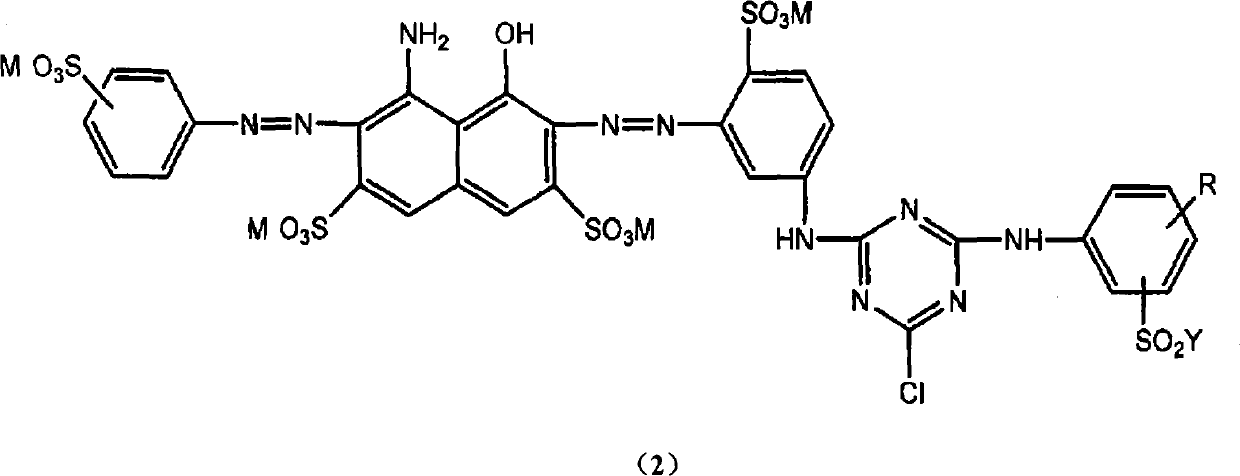

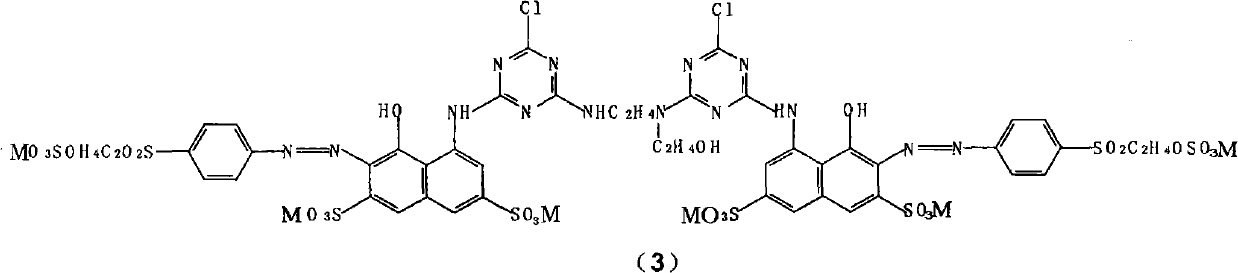

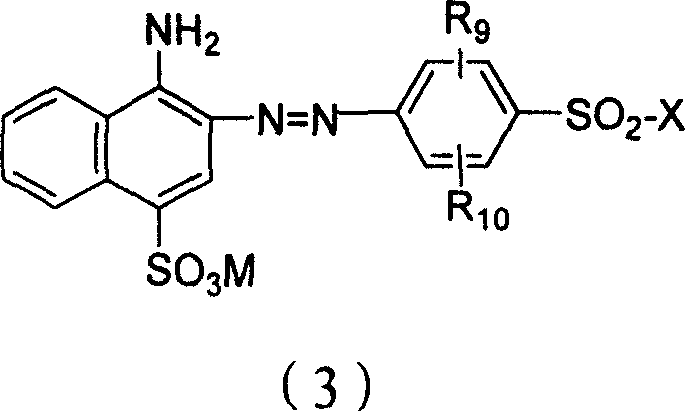

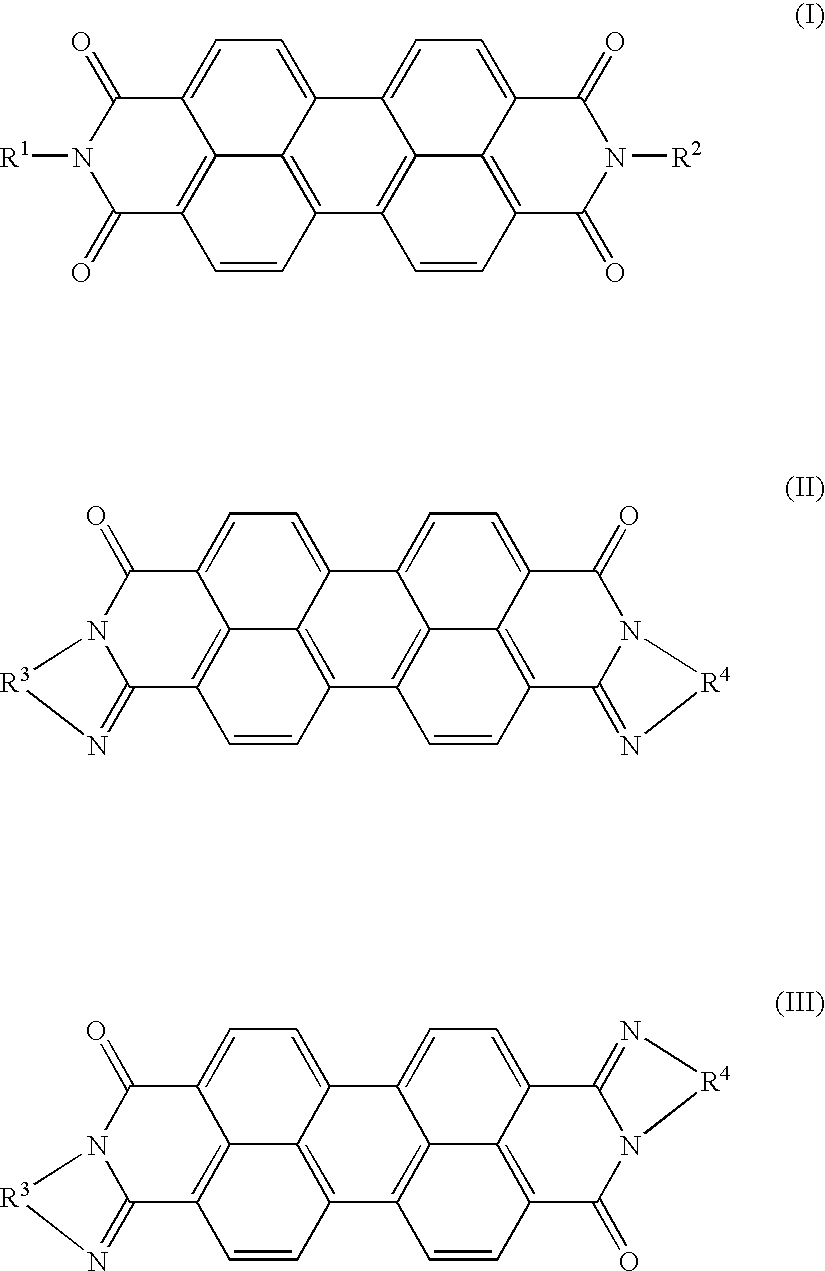

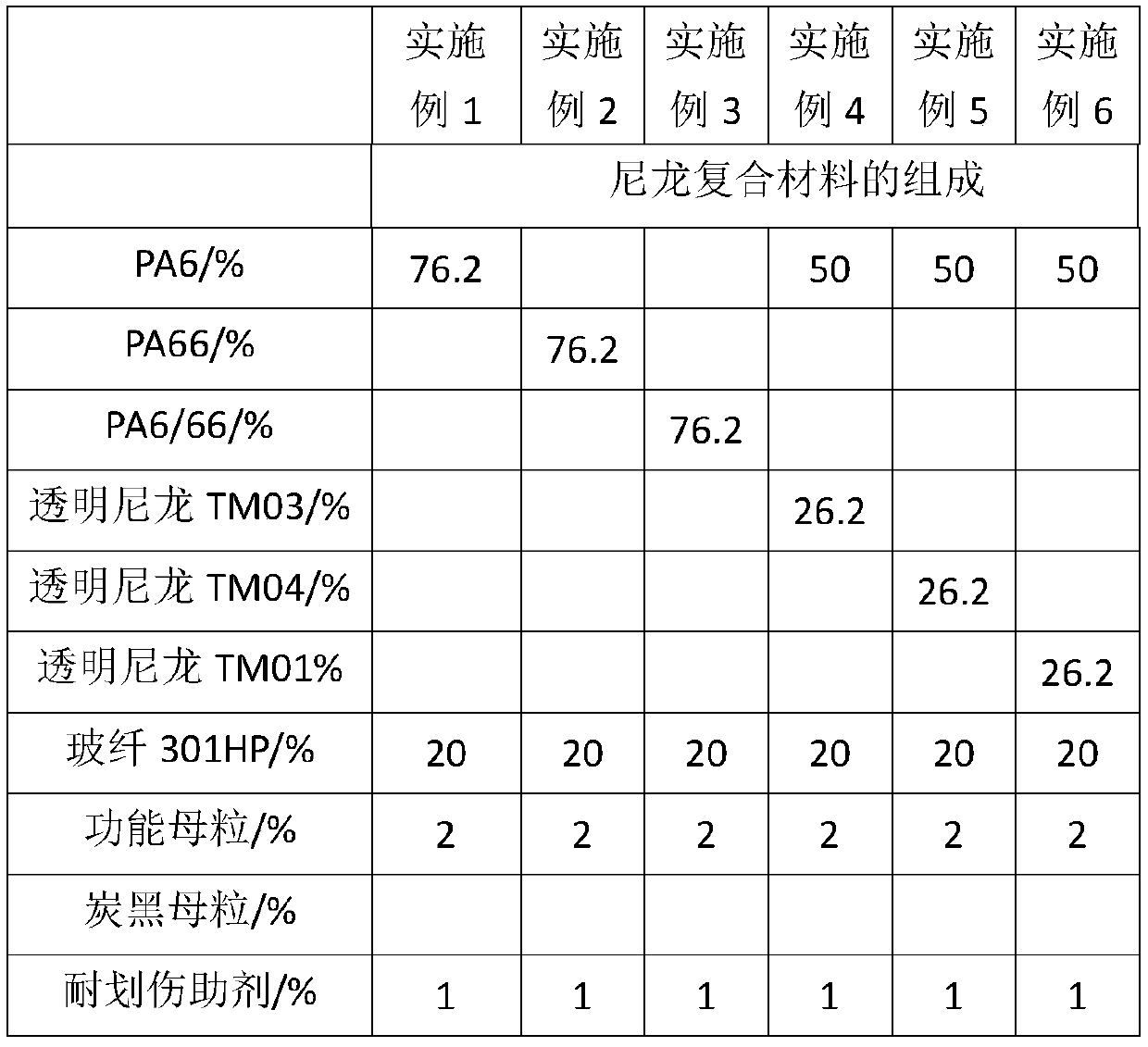

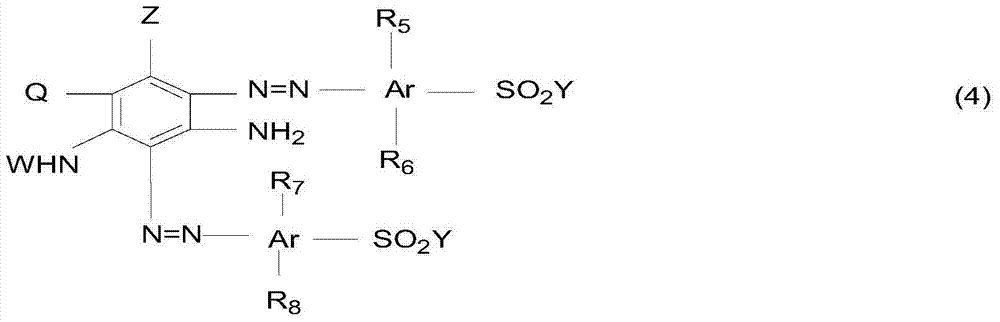

Composite active black dye

The invention relates to a composite active black dye and preparation and use thereof, in particular to a composite active black dye for dyeing cellulose or protein fibers. The composite active black dye has high fastness to washing, lifting power, dyeing uniformity, dyeing reproducibility and dye-uptake. The composite active black dye mainly contains dye compounds of formula (I), formula (II) and formula (III).

Owner:WUJIANG YISHENG TEXTILE

Phosphating liquid of high corrosion resistance black phosphating production process

ActiveCN101864563ACrystal fineFirmly attachedMetallic material coating processesO-Phosphoric AcidOptical instrumentation

The invention relates to phosphating liquid of a phosphating process, in particular to phosphating liquid of a high corrosion resistance black phosphating production process for steel piecec, which is characterized in that: the phosphating liquid comprises the following components: 25 to 35 g / L zinc oxide (ZnO), 120 to 135 g / L phosphoric acid H3PO4, 100 to 150 g / L zinc nitrate Zn(NO3)2.6H2O, 5 to 8 g / L nitric acid HNO3, 3 to 5 g / L citric acid, 0.5 to 1 g / L tartaric acid and 5 to 10 g / L nickel nitrate. The phosphating liquid ensures the fineness and smoothness of the phosphating film crystal of the steel piece, has firm attachment, good blackness and high abrasion resistance, and is particularly applicable to the steel components of the optical instrument.

Owner:西安北方光电有限公司

One-step preparation method for synthesizing black expandable polystyrene particles

InactiveCN101560308AReduce polymerization inhibitionAvoid the defect of poor compatibilityReaction temperaturePolystyrene particle

The invention relates to a one-step preparation method for synthesizing black polystyrene particles. The preparation method uses surfactant to pretreat carbon black so as to ensure that the carbon black is uniformly dispersed in suspending medium water instead of agglomerating; the carbon black is partially coated with organic dispersant so as to reduce the polymerization inhibition effect of the carbon black during polymerization; and as the polymerization proceeds, monomer phase viscosity increases, and carbon black particles are fixed inside a small ball. Therefore, the preparation method avoids the problem that the carbon black is poor in compatibility with polymers, and overcomes the disadvantages of poor black chromaticity, non-uniform carbon black dispersion and the like. The preparation method has the double function of protecting colloidal particles and reducing the polymerization inhibition effect of the carbon black, overcomes the polymerization inhibition effect of the carbon black in the process of polymerizing styrene, avoids the problem that the carbon black is poor in compatibility with polystyrene during a technological process, and simplifies the process of preparing black polystyrene. The preparation method has the advantages of low reaction temperature, simple process, convenient operation, friendliness to environment and low cost.

Owner:吉林省吉盛源泡塑材料科技有限公司

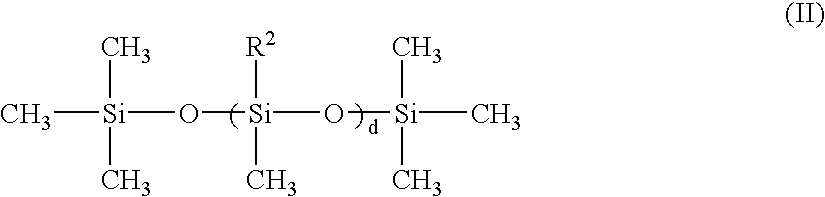

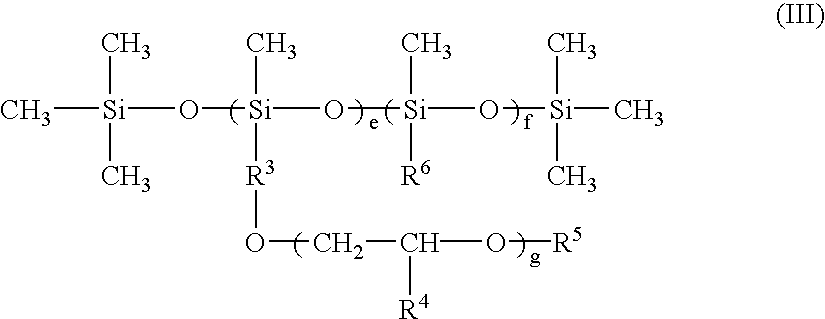

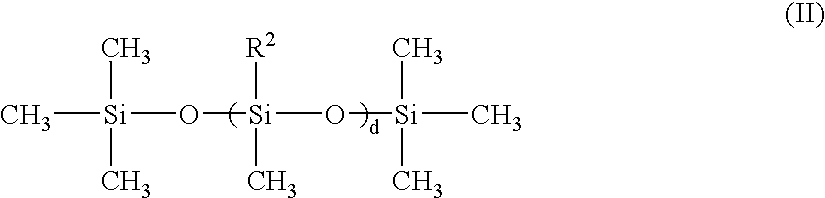

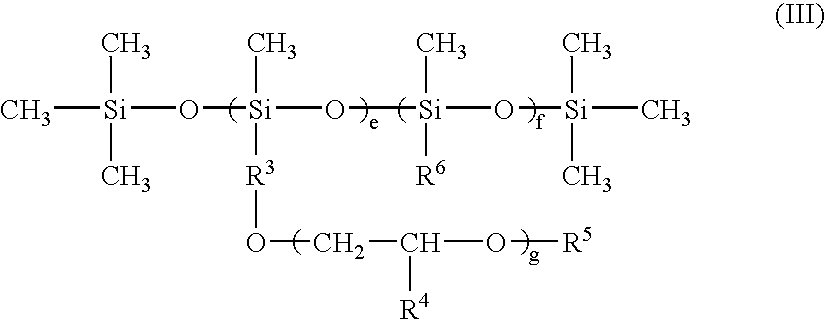

Black magnetic acicular composite particles for magnetic recording medium and magnetic recording medium using the same

InactiveUS20030027018A1Flat surfaceSmall light transmittanceMagnetic materials for record carriersSynthetic resin layered productsMetal particleCobalt

A magnetic recording medium using black magnetic acicular composite particles produced by forming a single carbon black coat between the surface of magnetic acicular cobalt-coated iron oxide particle or magnetic acicular metal particle and a coating comprising at least one organosilicon compound, in an amount of from more than 10 to 40 parts by weight based on 100 parts by weight of the magnetic acicular particles, exhibits not only a smooth surface, a smaller light transmittance and a lower surface electrical resistivity value, but also a small friction coefficient and an excellent running durability.

Owner:TODA IND

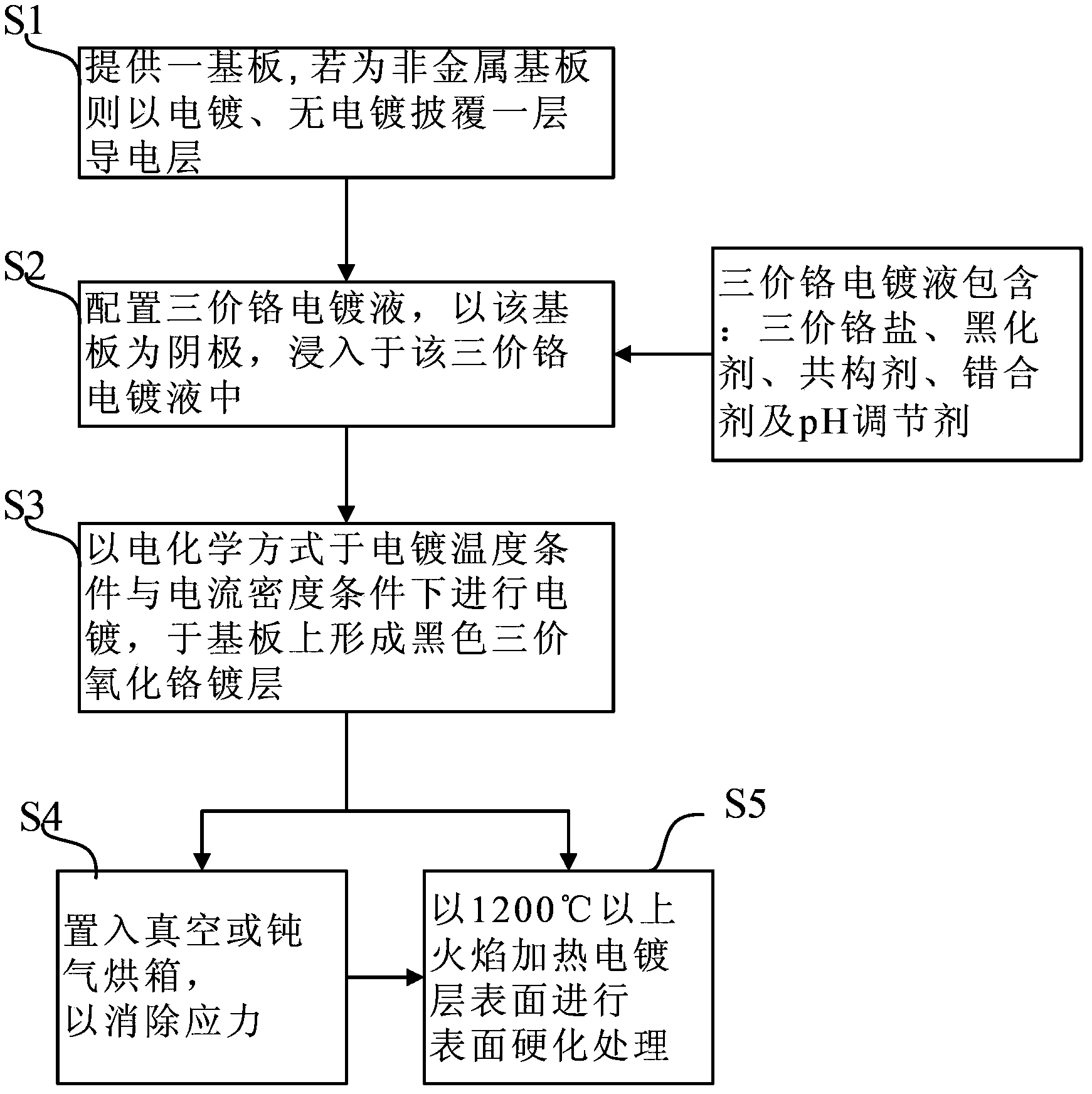

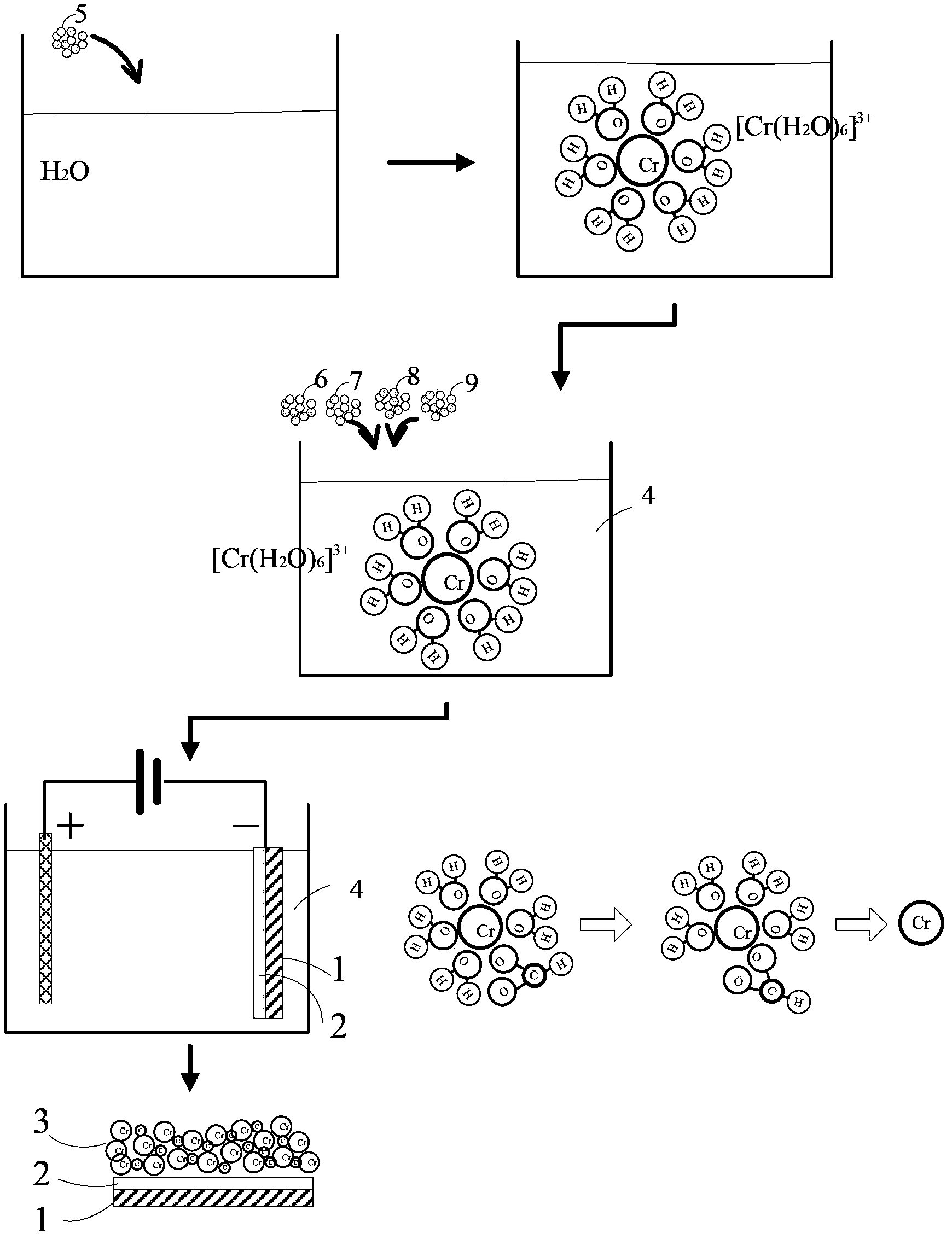

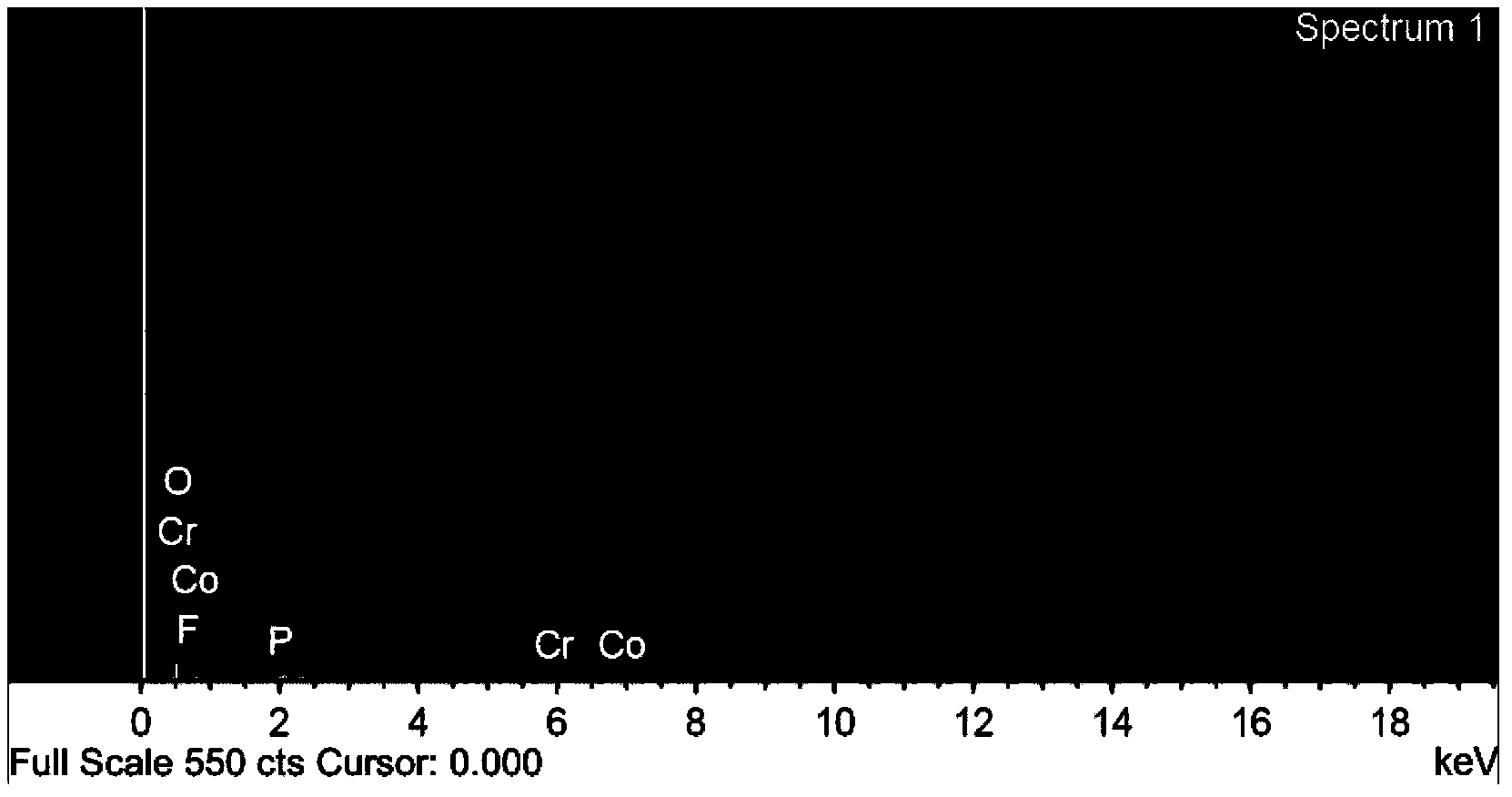

Electrochemical method of forming black trivalence chromic oxide coating and black trivalence chromic oxide coating

ActiveCN103510131AReduce the burden on the environmentReduce the difficulty of wastewater treatmentCorrosionInorganic salts

The invention discloses an electrochemical method of forming black trivalence chromic oxide coating and the black trivalence chromic oxide coating; a black trivalence chromic oxide electroplating layer is formed on the surface of the substrate through the electroplating method; black trivalence chromic oxide electroplating liquid comprises chromic salt, darkening agent containing nitrate, co-deposition agent containing cobalt salt, complexing agent of inorganic salt, and water solution formed by PH modifier of inorganic acid salt. The thickness of the black trivalence chromic oxide electroplating layer formed under the set electroplating operation condition is between 0.5-15 micrometers, the gray-scale value of the darkening degree is below 45%, and the requirements of corrosion resistance, high surface hardness and good wear resistance are satisfied so as to be applied on tools needing high precision, high hardness and wear resistant property, such as a slide rail and a screw rod.

Owner:DEXNANO CHEM TECH

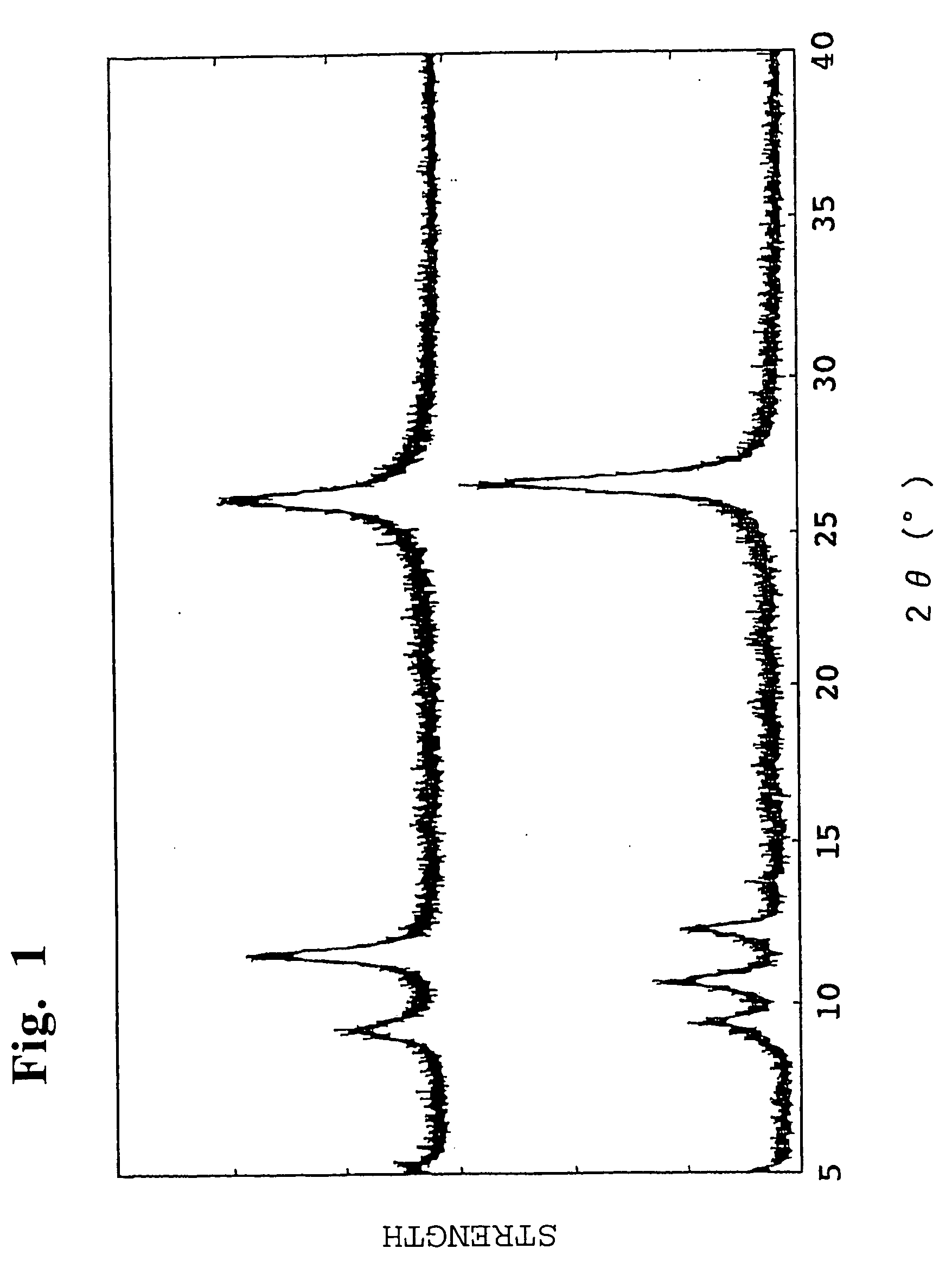

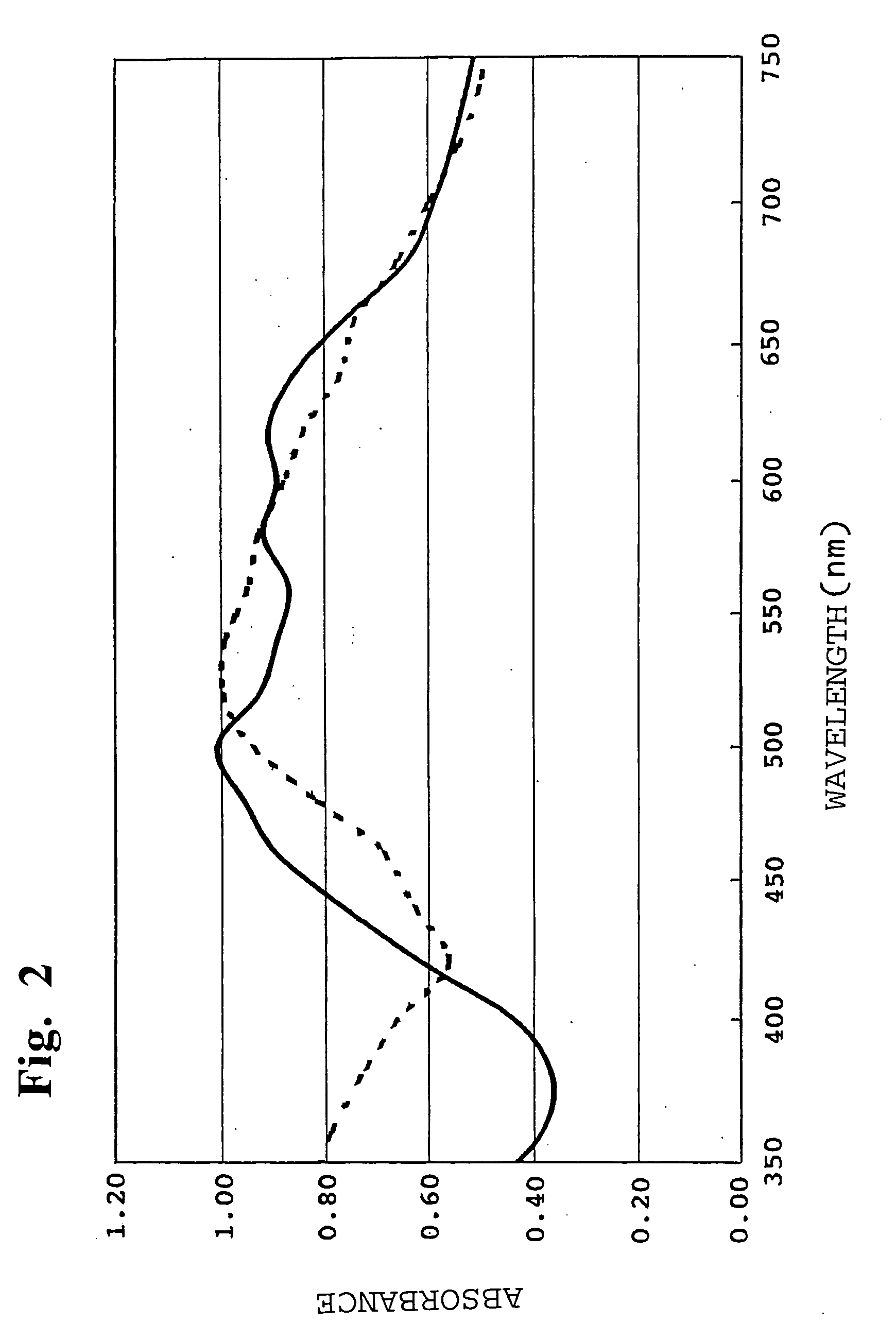

Black perylene pigment and process for producing the same

InactiveUS20050016420A1Improve thermal stabilitySuitable change in molecular arrangementArtificial dyesAnthracene dyesHigh resistancePerylene

A black perylene-based pigment produced by calcining at least one compound selected from the group consisting of diimide derivatives of perylene tetracarboxylic acid and diimide derivatives of perylene diiminodicarboxylic acid, at a temperature of 200 to 600° C. in vacuum or in an inert gas atmosphere, exhibits an excellent blackness, an excellent heat resistance and an excellent weather fastness as well as a high resistance and a high safety.

Owner:BASF AG

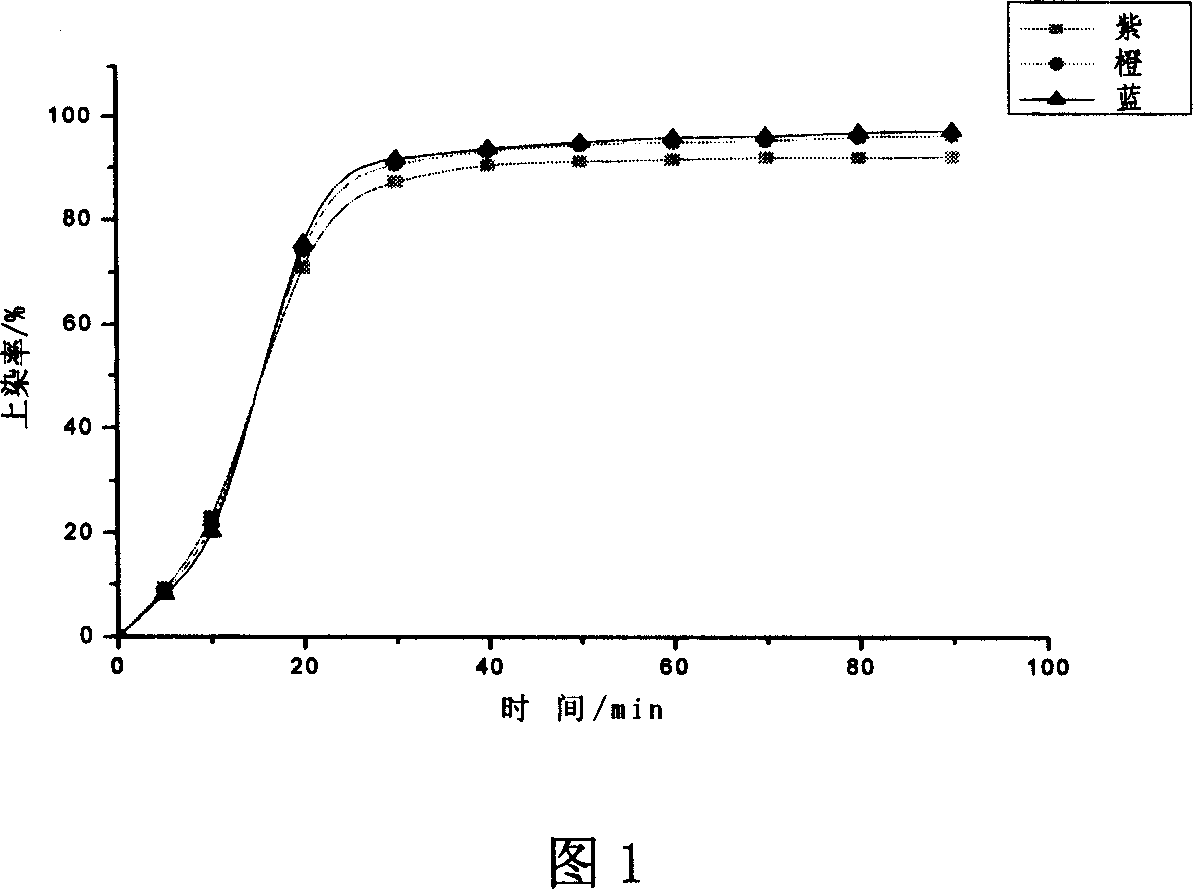

Microcapsule disperse black, its preparing method and dyeing method for superfine synthesized fiber and fabric

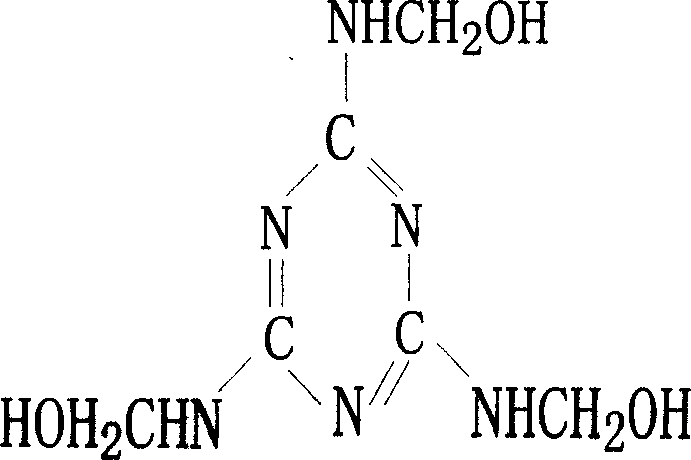

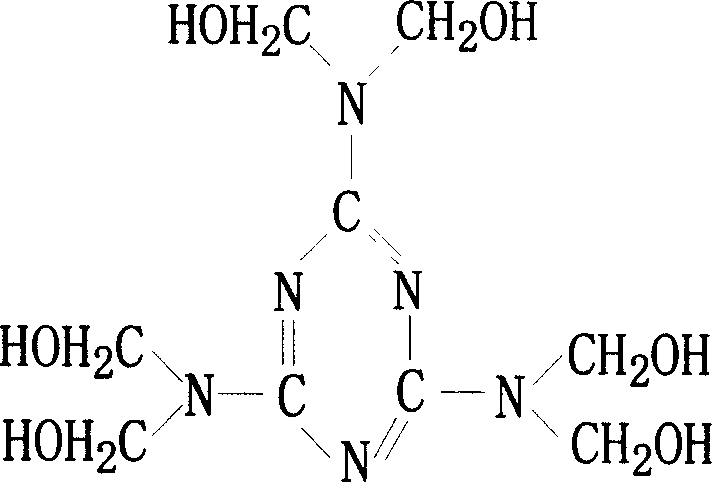

The invention relates to a microcapsule disperse black and the manufacture method and the coloring method for superfine synthetic fiber and the fabric. It uses etherification melamine resin as microcapsule wall material monomer, blue, purple, orange three dispersing primary color as core material to make blue, purple, and orange three microcapsule dispersing dye, and mixing the dyes according to 1-0.5:1-0.5:1-0.5 to form microcapsule disperse black. The invention could dye to gain pure black, and the dyed waste water could be recycled after simple filtering.

Owner:常州汉诺斯生物科技有限公司

Particle of carbon-containing modified polystyrene resin, expandable particle of carbon-containing modified polystyrene resin, expanded particle of carbon-containing modified polystyrene resin, molded

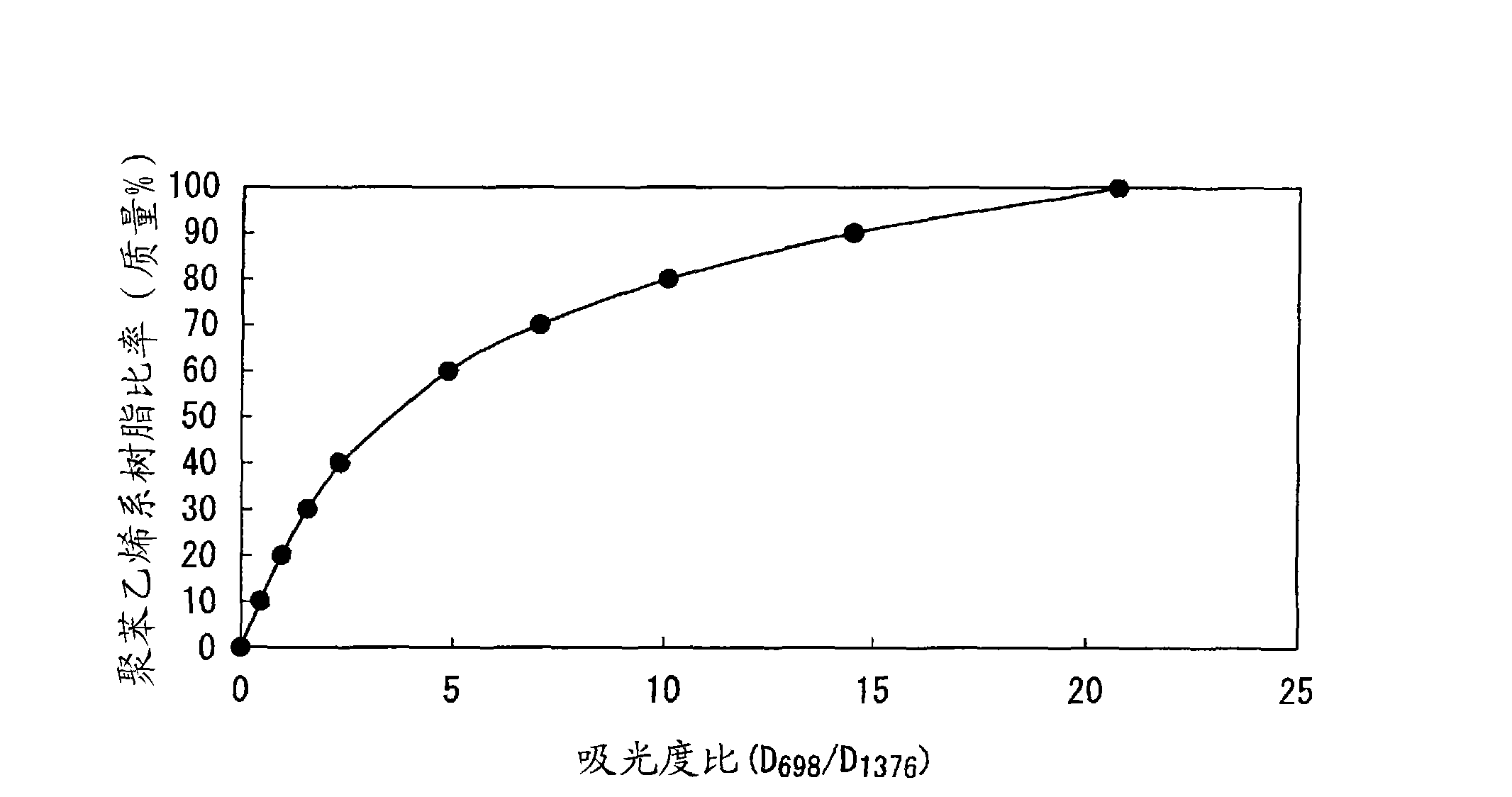

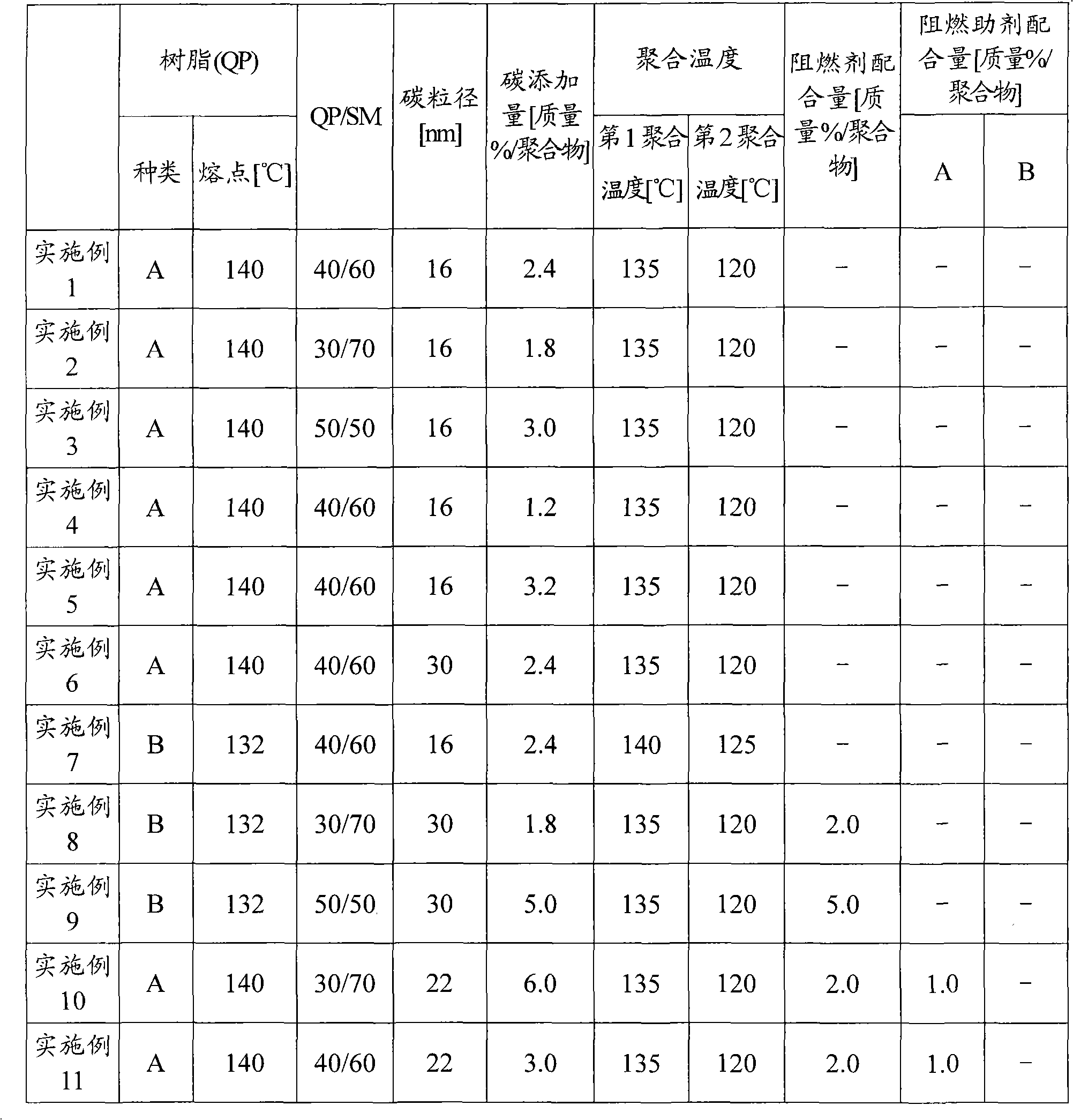

Carbon-containing modified polystyrene resin particles which contain a carbon-containing polypropylene resin and contain a polystyrene resin in an amount of 100-400 parts by mass, excluding 400 parts by mass, per 100 parts by mass of the carbon-containing polypropylene resin. The polystyrene resin proportion in a central part of each particle as calculated from the ratio between absorbances at 698 cm<-1> and 1,376 cm<-1> (D698 / D1376) obtained from an infrared absorption spectrum for the central part in infrared spectroscopic analysis by the ATR method is at least 1.2 times the polystyrene resin proportion in the whole particle.

Owner:SEKISUI PLASTICS CO LTD

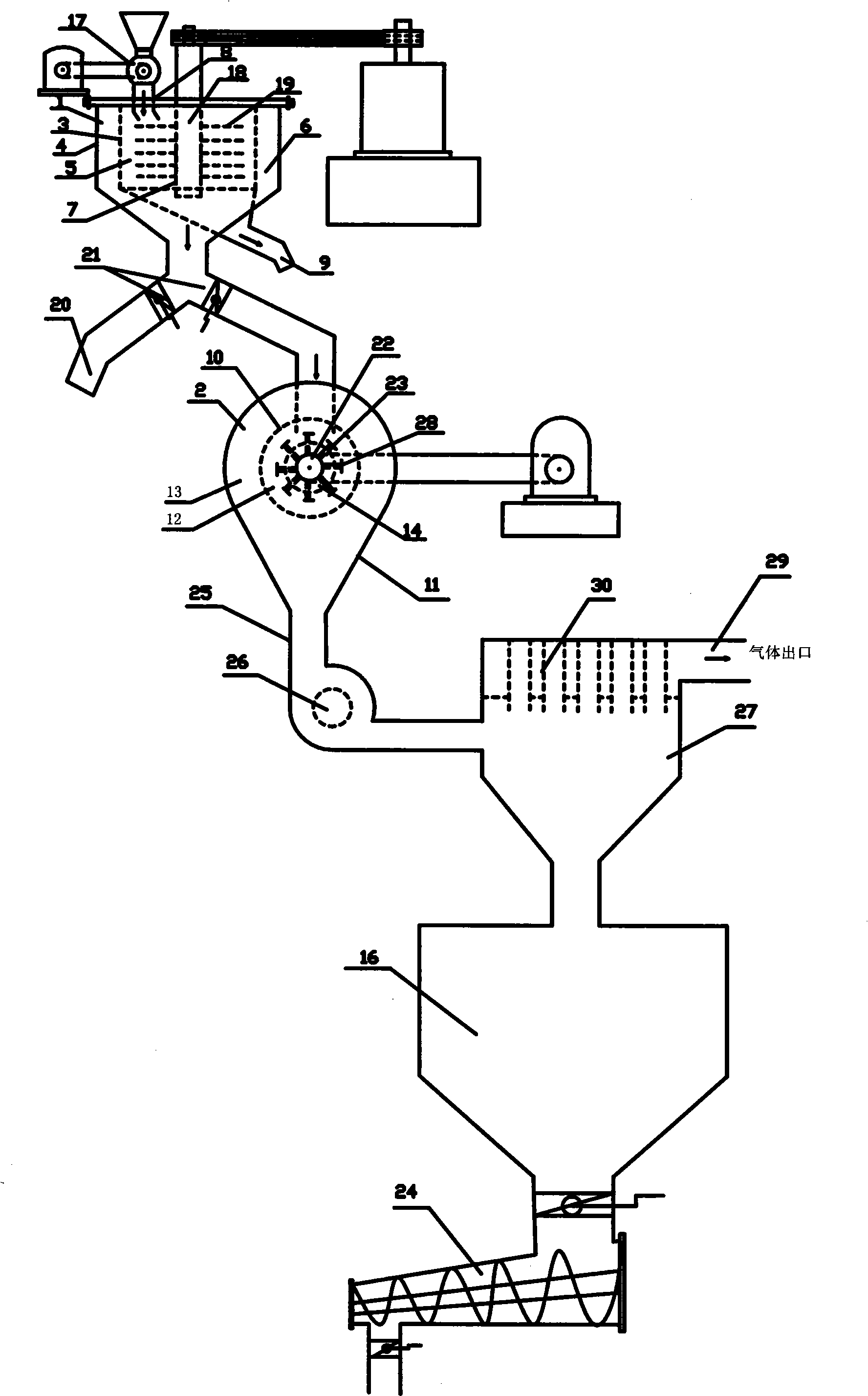

Black carbon crushing machine

InactiveCN101337198AGood dispersionImprove liquidityDispersed particle filtrationGrain treatmentsFiltrationEngineering

The invention relates to a carbon black crusher which is characterized in that a frame, a main powdering chamber and a secondary powdering chamber are included, wherein, the main powdering chamber and the secondary powdering chamber are arranged on the frame sequentially; the main powdering chamber is divided into a main powdering cavity and a filtration cavity by a main screen which is vertically arranged and a breathable layer which is vertically arranged at the periphery of the main screen; a disintegrated powder mixer is vertically arranged in the main powdering cavity; a granular carbon black inlet and a granular carbon black outlet are formed on the main powdering cavity; the material outlet of the filtration cavity communicates with the secondary powdering chamber; the secondary powdering chamber is also divided into a secondary powdering cavity and a secondary filtration cavity by a secondary screen which is horizontally arranged and an outer casing baffle plate which is arranged at the periphery of the secondary screen; a secondary disintegrated powder mixer is horizontally arranged in the secondary powdering cavity; a material discharging pipe is arranged on the secondary powdering cavity; through a blower, carbon black is fed into a bag filter for filtering and collecting; and the filtered and collected carbon black enters a storage hopper. The carbon black product ground and crushed by the crusher of the invention has the advantages that the particle size is small, the particle size distribution is narrow, the surface of the carbon black has a lot of oxygen-containing functional groups, and the dispersion property and the flow property of the carbon black are good.

Owner:陈智贤

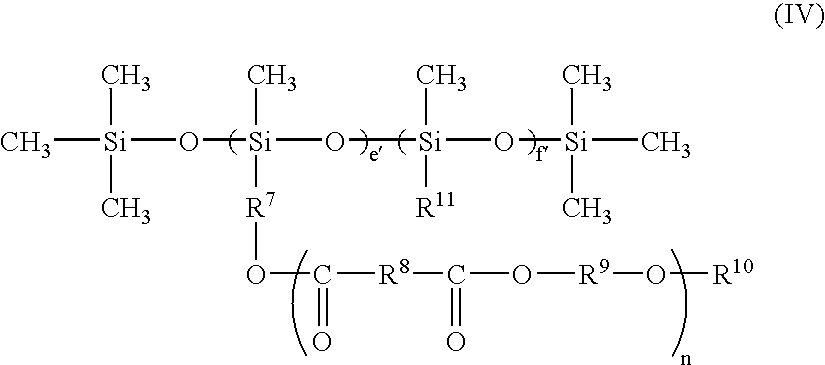

Cationic self-matting resin, and preparation method and application thereof

ActiveCN108546323ASmall particle size fluctuationEasy to movePolyurea/polyurethane coatingsEmulsionAlcohol

The invention discloses a cationic self-matting resin, and a preparation method and application thereof. The cationic self-matting resin comprises isocyanate, a diamine cationic hydrophilic chain extender, macropolyol, monohydric alcohol and / or dihydric alcohol with the main chain and / or the side chain containing a polyoxyethylene chain, a small molecular diamine chain extender, a catalyst, a solvent and a neutralizing agent. The preparation method has the advantages of simple process, convenience in operation, safety and non-toxicity, and the obtained cationic self-matting resin has the advantages of small particle size fluctuation, good emulsion stability and resistance, good adhesion to anionic leather, glass and other substrates, and bringing of soft and smooth hand feeling and naturalrich appearance for leather, and can be widely applied to the fields of leather finishing, wood plastics, paper printing, printing and dying inks, printing coatings, packaging coatings and matt nailpolish.

Owner:WANHUA CHEM GRP CO LTD

Black Polytetrafluoroethylene Porous Film, Production Process for the Same, and Uses of the Same

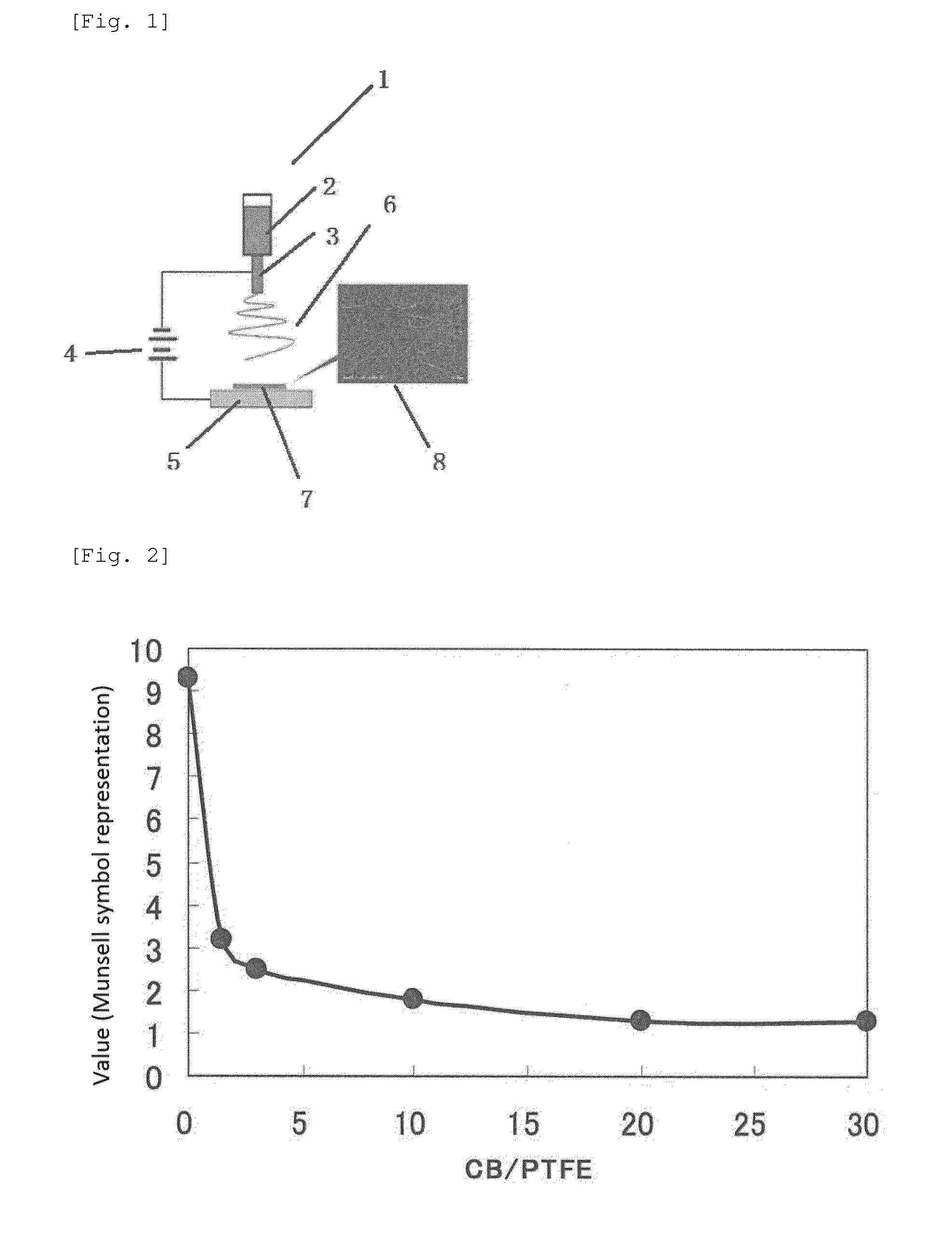

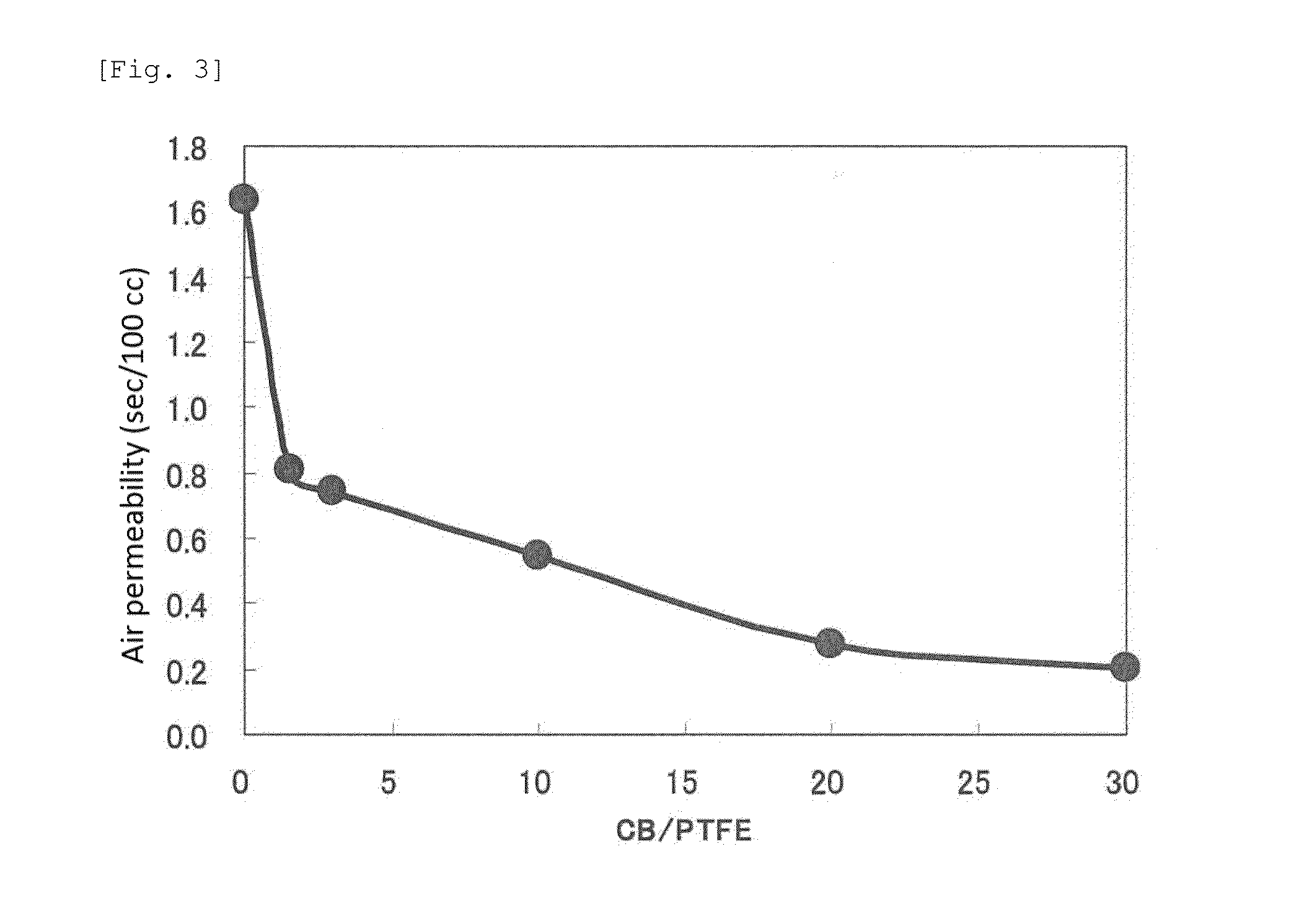

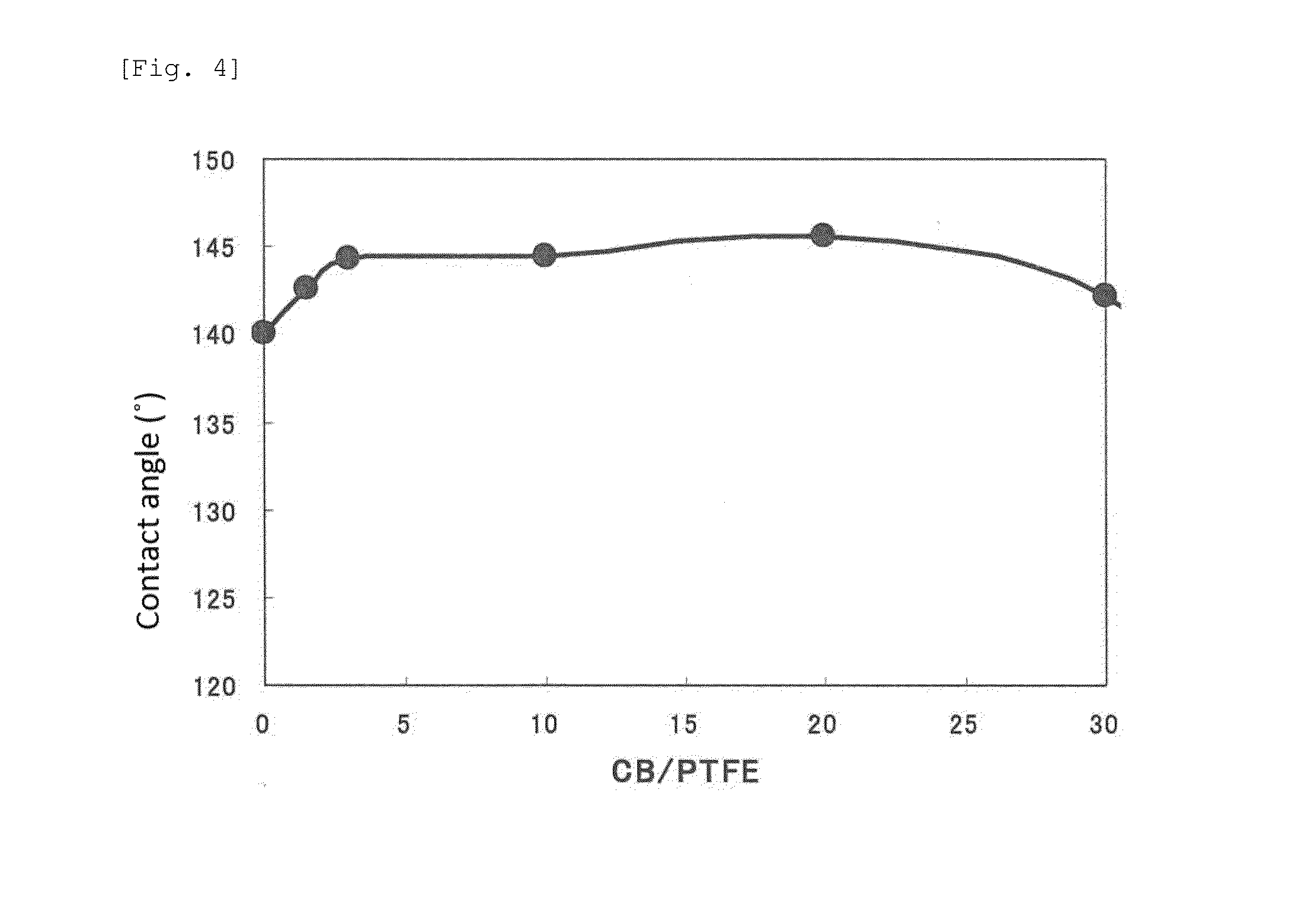

InactiveUS20160075838A1Good blacknessImpair performanceSemi-permeable membranesElectric discharge heatingElectrospinningNanofiber

Provided is a black PTFE porous film which comprises a black colorant-containing PTFE nanofiber (D) containing a polytetrafluoroethylene (PTFE) nanofiber (E) and a black colorant (B) and has a value (V), as represented by a Munsell symbol in accordance with JIS Z 8721, of not more than N2.5, wherein the black colorant-containing PTFE nanofiber (D) is obtained by subjecting a spinning solution containing at least PTFE or modified PTFE (A) to an electrospinning method.

Owner:NIPPON VALQUA IND LTD

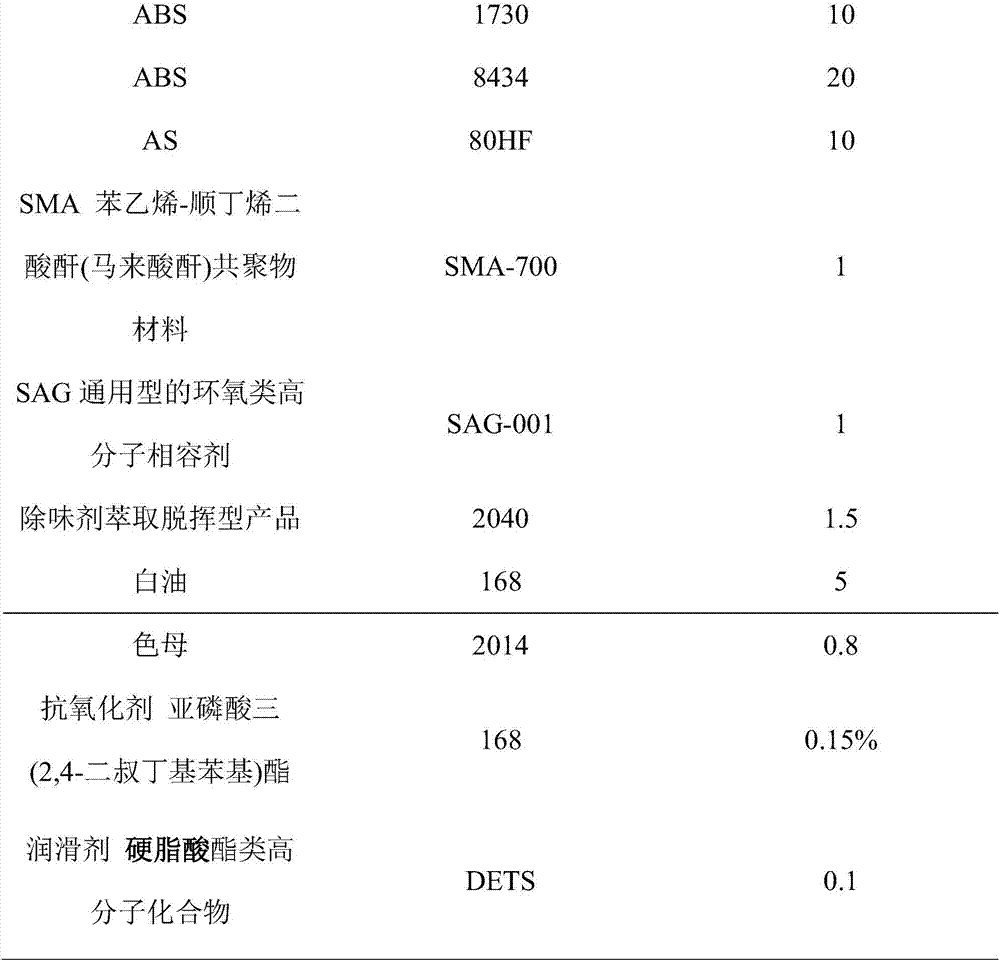

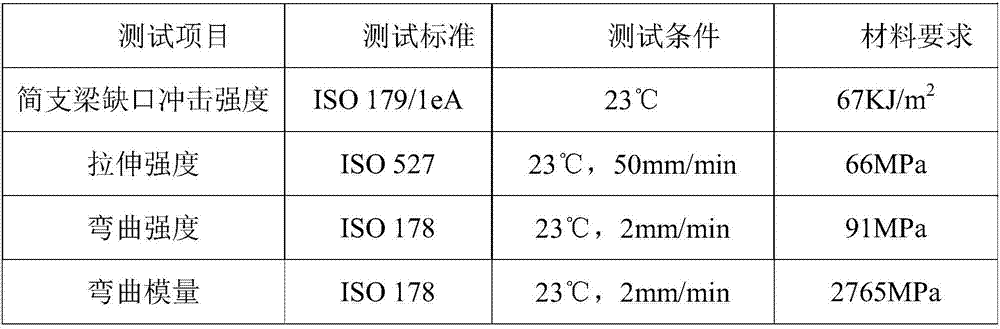

Low-odor spray-coating-free PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

The invention discloses a low-odor spray-coating-free PC / ABS (polycarbonate / acrylonitrile butadiene styrene) material and a preparation method thereof. The material is prepared from the following ingredients including 40 to 80phr of PC, 20 to 60phr of ABS, 5 to 10phr of AS, 0 to 1phr of lubricating agents, 1 to 1.5phr of deodorants, 0.5 to 1phr of heat stabilizers, 0.5 to 1phr of color masterbatch, 0 to 10phr of compatibilizers, 0 to 5phr of processing auxiliary agents, 0.1 to 0.5phr of antioxidants and 0 to 5phr of ultraviolet light absorbers. The material has the low odor and spray-coating-free appearance requirements; the odor grade is lower than or equal to 3.0; the appearance luster is good; the blackness is high; the thermal stability is high; the defects of flowing marks, melting and connecting wires, silver silks and the like cannot be easily generated; the spraying work procedure is omitted; the good spray-coating-free effect is achieved; through the creative selection on raw materials and auxiliary agents and the process innovation, a low-odor spray-coating-free PC / ABS material is produced, and is obviously superior to similar products in the market.

Owner:太仓市华鼎塑料有限公司

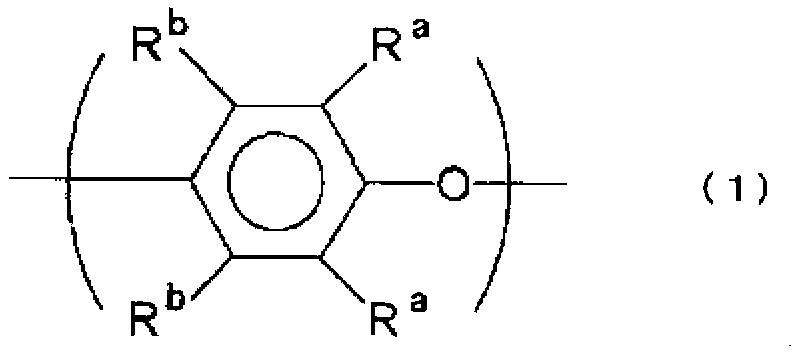

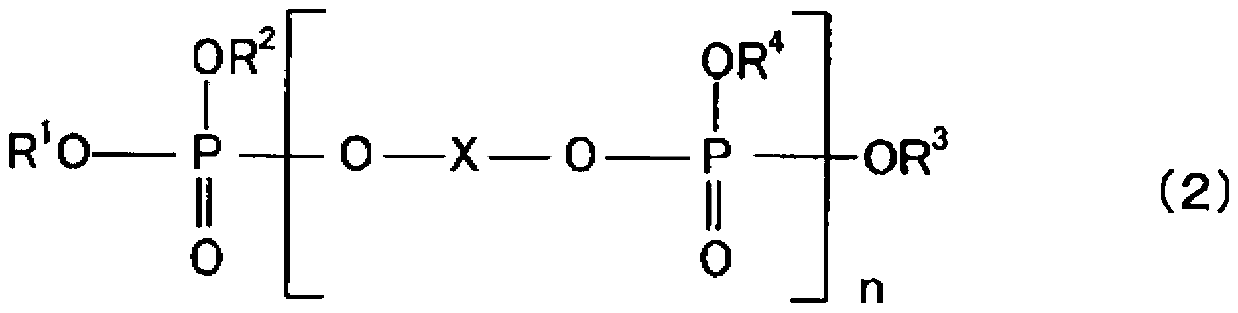

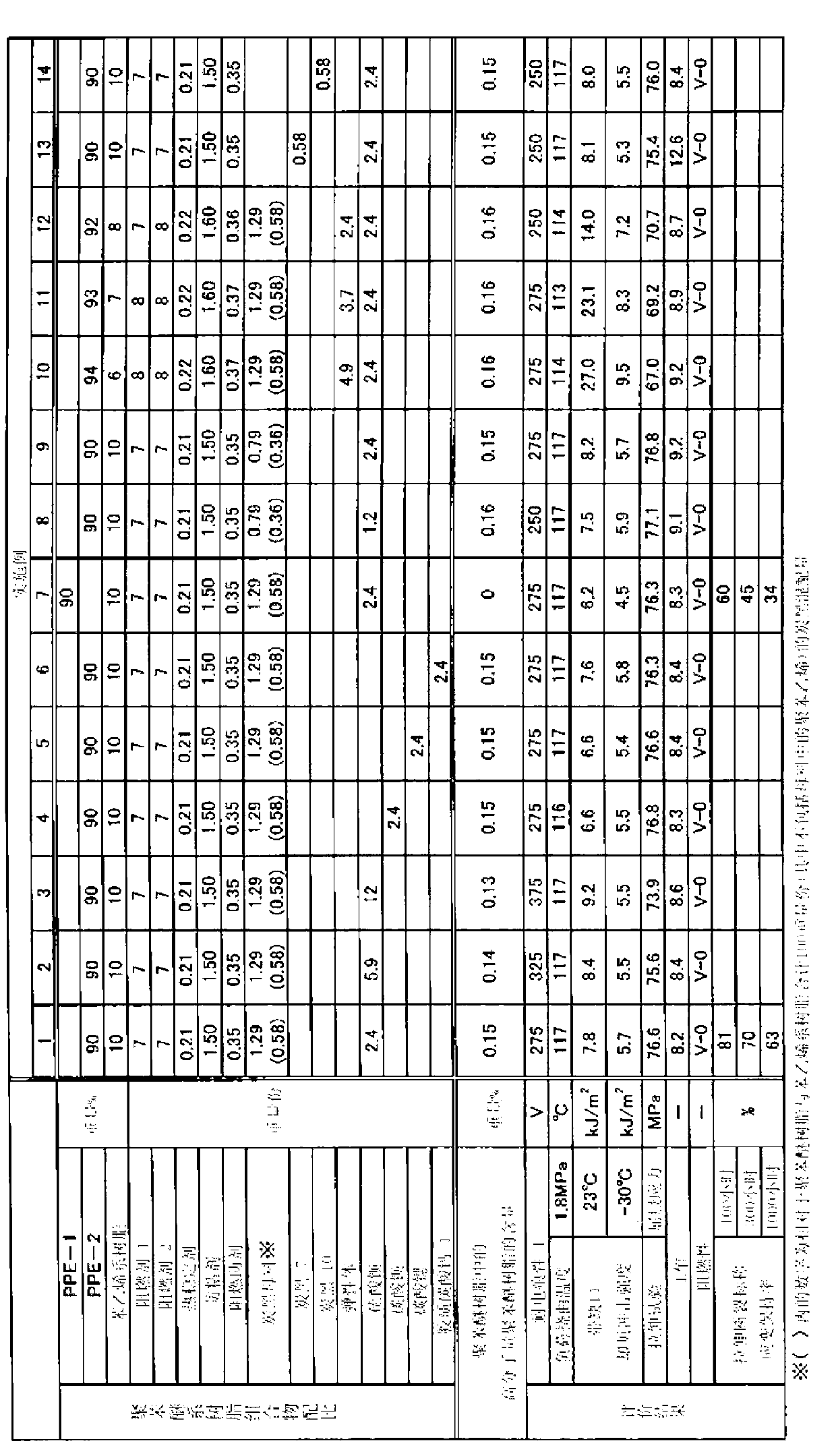

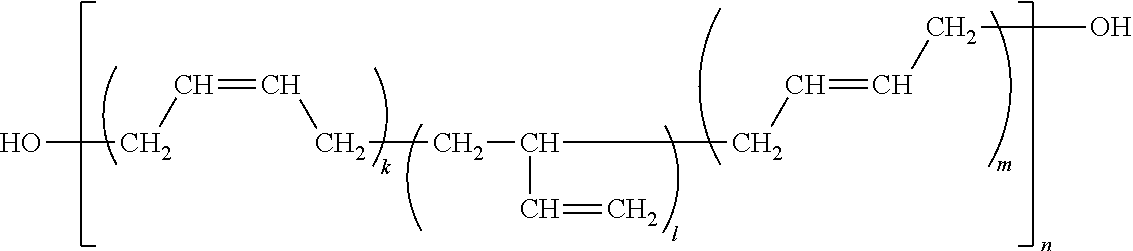

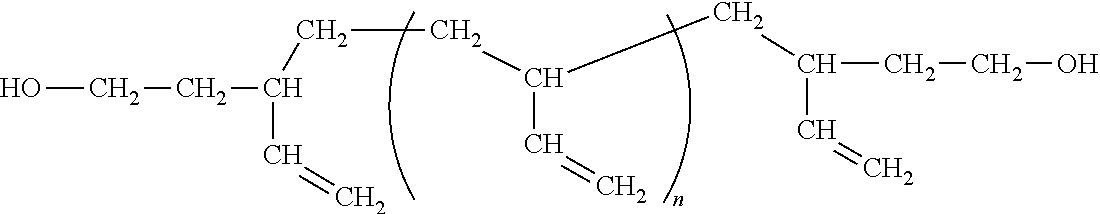

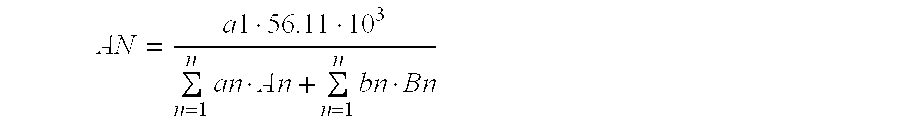

Polyphenylene ether resin composition and molded article of same

ActiveCN103108917AImprove heat resistanceImprove impact resistanceAlkaline earth metalShock resistance

To provide a polyphenylene ether resin composition which has excellent mechanical properties such as shock resistance and heat resistance, and has a high degree of blackness, excellent weather resistance, and excellent tracking resistance. [Solution] A polyphenylene ether resin composition formed by including 0.01-5 parts by weight of carbon black (B) and 0.1-20 parts by weight of an alkali earth metal carbonate and / or sulphate (C) per 100 parts by weight of a resin component (A) which has polyphenylene ether resin (a1) as the main component thereof. By combining, in a prescribed proportion, an alkali earth metal carbonate and / or sulphate in a polyphenylene ether resin composition containing carbon black, tracking resistance and shock resistance can be improved.

Owner:MITSUBISHI ENG PLASTICS CORP

Preparation method for aqueous polyurethane resin-pigment dispersion, aqueous polyurethane resin-pigment dispersion, and ink composition

ActiveUS20120190789A1Good dispersibilityHigh image densityDuplicating/marking methodsInksPolyurethane dispersionEnd-group

A method of producing a polyurethane resin-bonded pigment aqueous dispersion includes causing (I) a pigment having a surface acidic group to come in contact with (II) a basic compound having two or more amino groups selected from a primary amino group and a secondary amino group in its molecule in an aqueous medium so that the pigment has an unreacted surface amino group, and causing the pigment to come in contact and react with (III) a polyurethane resin having an isocyanate end group. A polyurethane resin-bonded pigment aqueous dispersion produced by the method exhibits excellent image density, dispersibility, and storage stability.

Owner:TOKAI CARBON CO LTD

Black composite particles for semiconductor sealing material use and semiconductor sealing material

InactiveCN1436819AImprove moisture resistanceGood blacknessOther chemical processesInorganic pigment treatmentHeat resistanceFlexural strength

The invention relates to a black composite particles for semiconductor sealing material and a semiconductor sealing material using the same. Black composite particles for semiconductor sealing material, comprise: an extender pigment as a core particle; and a black pigment provided on the surface of the extender pigment in an amount of 1 to 100 parts by weight per 100 parts by weight of the extender pigment. Such black composite particles not only exhibit enhanced blackness, moisture resistance, fluidity and tinting strength but also show an excellent dispersibility in binder resins. The resulting semiconductor sealing material is capable of exhibiting a high volume resistivity as well as excellent blackness, moisture resistance, soldering heat resistance, flowability and flexural strength.

Owner:TODA IND

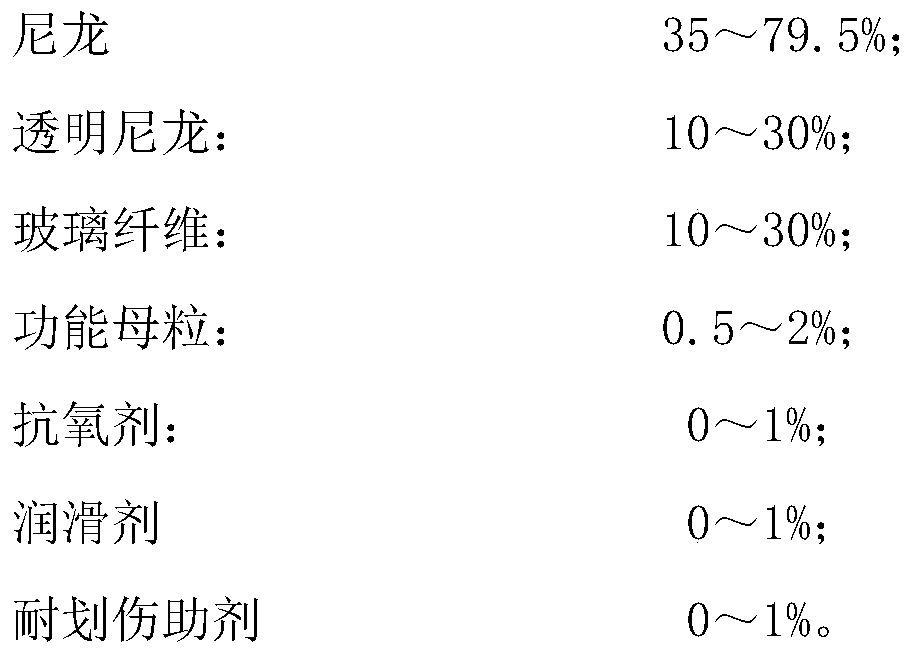

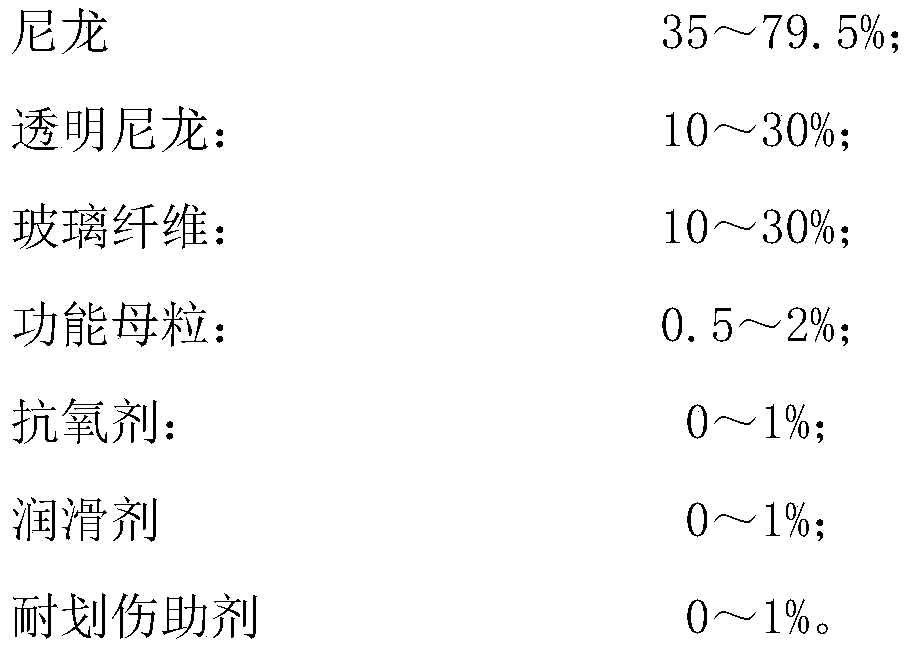

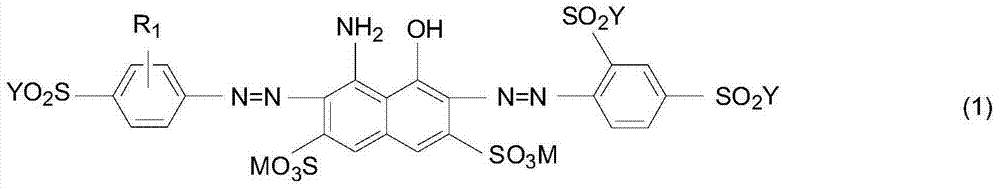

High-strength, high-brightness black and glass fiber reinforced nylon material and preparation method thereof

The invention discloses a high-strength, high-brightness black and glass fiber reinforced nylon material and a preparation method thereof. The material is prepared from the following components in percentage by mass: 35-79.5% of nylon, 10-30% of transparent nylon, 10-30% of glass fibers, 0.5-2% of a functional master batch, 0-1% of an antioxidant, 0-1% of a lubricant, and 0-1% of a scratch-resistant auxiliary agent. The glass fiber reinforced nylon material has the beneficial effects that the crystallinity of the nylon material is controlled and an injection molding process is adopted to ensure that the material has higher glossiness, and the self-made functional master batch is added, so that the reinforced nylon material is covered with the glass fibers, and the blackness and the glossiness are improved. The nylon composite material prepared by the invention not only meets the requirements of parts on the mechanical properties of the material, but also meets the requirement that theappearance effect of high brightness black can be achieved without spraying, and solves the problem that the strength and the appearance cannot be considered at the same time.

Owner:ZHEJIANG PRET NEW MATERIALS

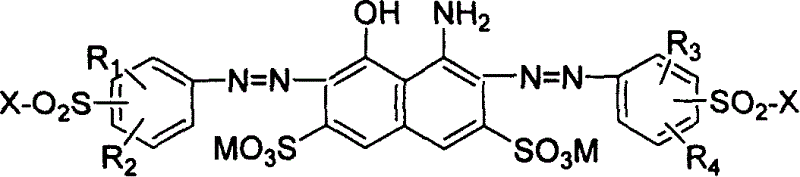

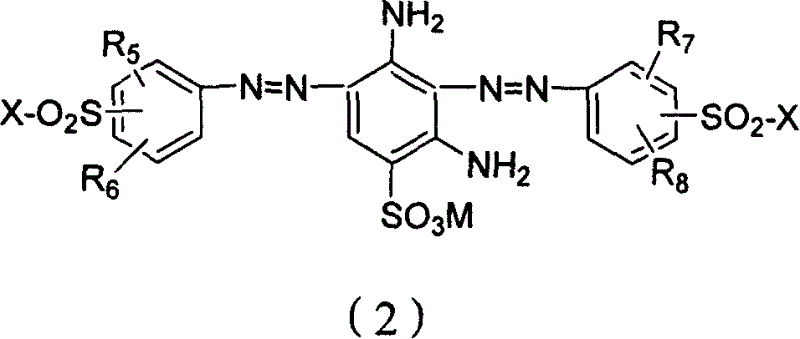

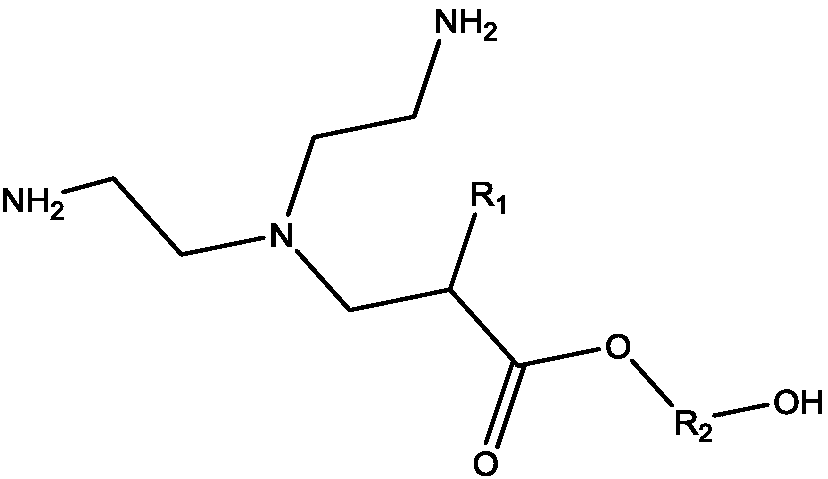

Dark colored reactive dye with high fixation rate

The invention relates to a dark colored reactive dye with high fixation rate, belonging to the technical field of chemical dyestuff. The dark colored reactive dye consists of dark blue, red and yellow reactive dyes. The dye is characterized by comprising dark blue, red and yellow components in structures shown in general formulae. The three-primary-color reactive dye comprises the following components in ratio by weight: dark blue: red: orange=(50-80):(6-25):(6-20). The dark colored reactive dye provided by the invention is applicable to dyeing natural fibers such as cotton, hemps and regenerated fibers and is also applicable to dyeing protein fibers and polyamide fibers. The textile fibers can be in various forms such as fibers, yarns, fabrics or knitted goods. Dip dyeing means that the dyed object is absorbed in a dye bath with an appointed formula and then is fixed by alkali treatment, wherein the dyeing and fixing temperature is 50-70 DEG C. The leveling property of the dye is better promoted, the three components are good in compatibility, the colored light in a dyeing process is relatively stable, and the dye has good pitch-black degree.

Owner:褚平忠

Bismuth oxide-based addictive for laser marking

The present invention is directed to a bismuth oxide-based additive for laser marking containing oxygen-deficient bismuth oxide represented by the general formula: Bi2O(3-x) (provided that x is 0.01 or more and 0.3 or less and x represents the amount of oxygen deficiency calculated according to the formula: x=3−O1s / Bi4f×2 from the ratio (O1s / Bi4f) of the peak area attributed to the 1s electrons of oxygen bonded to bismuth to the peak area attributed to the 4f electrons of bismuth obtained by X-ray photoelectron spectrometry), which enables marking with excellent blackness and contrast without causing undesirable coloration of a resin composition regardless of the type or shape of a resin to be used.

Owner:TOMATEC CO LTD

High-temperature corrosion-resistant phosphating solution

InactiveCN102817023AImprove corrosion resistanceFirmly attachedMetallic material coating processesPhosphoric acidZinc nitrate

The invention provides a high-temperature corrosion-resistant phosphating solution. The phosphating solution is a mixture comprising the following components by weight in per liter mixture: 320-330g of 80% phosphoric acid, 120-125g of zinc oxide, 5-7g of sodium molybdate, 12-13g of citric acid, 100-150g of zinc nitrate, 4-6g of nitric acid, 4-6g of nickel nitrate, 2.0-2.5g of chromic acid, and the balance of water. The phosphating solution provided by the invention can treat a variety of metal workpiece materials with a short working time. The phosphating film formed on the surface of the workpieces is thick and dense and has the characteristics of good adhesion, good blackness, high corrosion resistance and high stability. The phosphating solution can be widely used for motors, gears, a variety of high strength carbon steels, alloy steel works and the like, and is suitable to be used in a high temperature environment with a stable operation.

Owner:BENGBU FUWOTE WHEEL MFG TECH

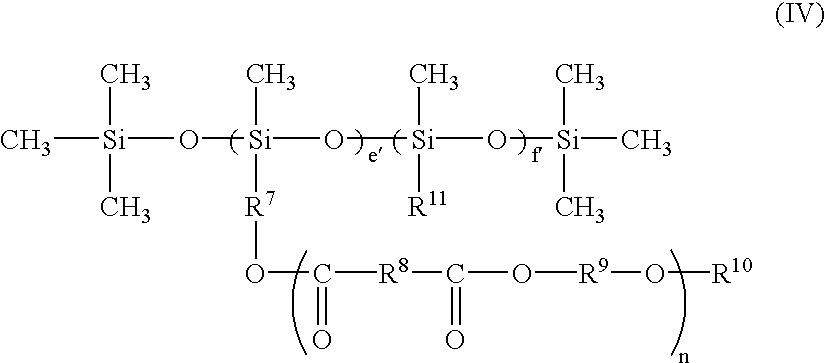

Black magnetic acicular composite particles for magnetic recording medium and magnetic recording medium using the same

InactiveUS6863966B1Flat surfaceSmall light transmittanceMagnetic materials for record carriersSynthetic resin layered productsMetal particleNon magnetic

A magnetic recording medium comprises:a non-magnetic base film; anda magnetic recording layer comprising a binder resin and black magnetic acicular composite particles having an average particle diameter of 0.051 to 0.35 μm, comprisingmagnetic acicular cobalt-coated iron oxide particles or magnetic acicular metal particles containing iron as a main component,a coating formed on surface of the magnetic acicular particles, comprising at least one organosilicon compound selected from the group consisting of:(1) organosilane compounds obtainable from alkoxysilane compounds, and(2) polysiloxanes or modified polysiloxanes, anda carbon black coat formed on the coating layer comprising said organosilicon compound, in an amount of from more than 10 to 40 parts by weight based on 100 parts by weight of said magnetic acicular particles.Such a magnetic recording medium exhibits not only a smooth surface, a smaller light transmittance and a lower surface electrical resistivity value, but also a small friction coefficient and an excellent running durability.

Owner:TODA IND

Plastic color master batch and preparation method thereof

The invention discloses a plastic color master batch and a preparation method thereof. The plastic color master batch comprises, by mass, 10-30% of a carrier, 50-80% of carbon black, 3-10% of a lubricant and 0.1-1% of an antioxidant. The plastic color master batch has the advantages of very good blackness, good dispersibility, less consumption, no untoward influences on the mechanical performances on plastic products, production technology simplification, convenient use, environmental pollution avoiding and time saving when the plastic color master batch is used in the coloring of the plastic products.

Owner:QINGDAO XINZHAN PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com