Patents

Literature

5542results about "Non-metallic protective coating application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

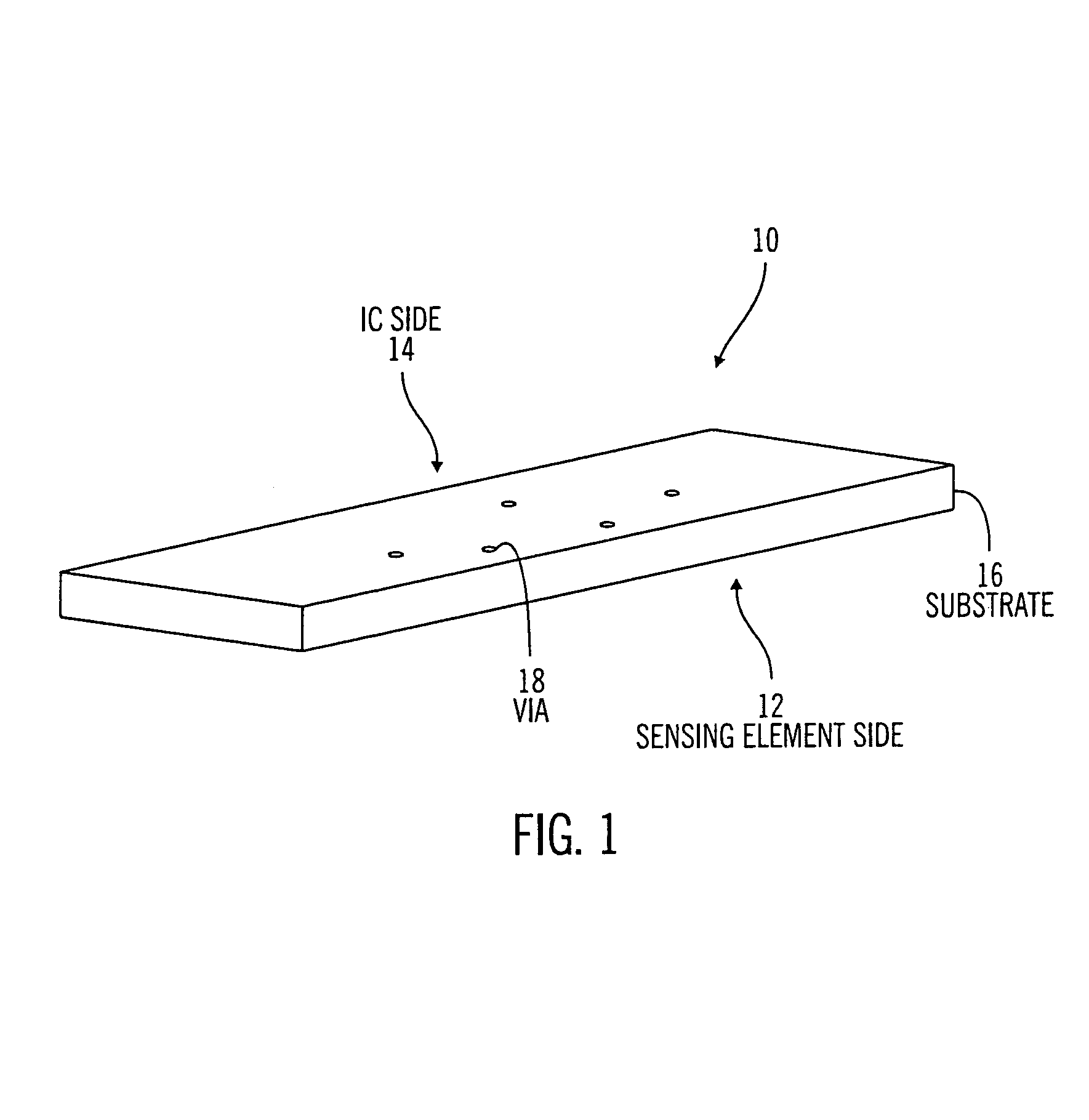

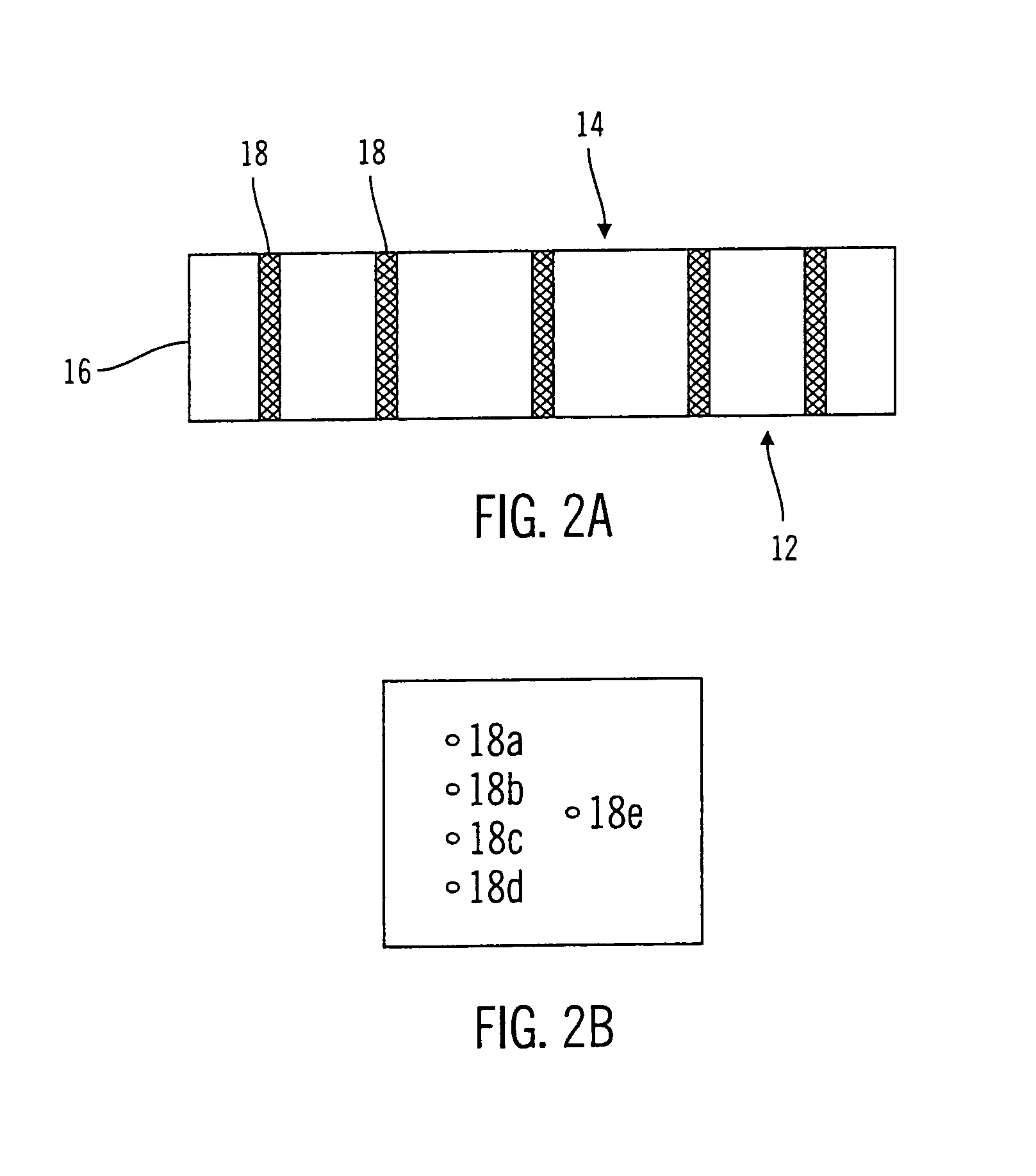

Sensor substrate and method of fabricating same

A substrate with hermetically sealed vias extending from one side of the substrate to another and a method for fabricating same. The vias may be filled with a conductive material such as, for example, a fritless ink. The conductive path formed by the conductive material aids in sealing one side of the substrate from another. One side of the substrate may include a sensing element and another side of the substrate may include sensing electronics.

Owner:MEDTRONIC MIMIMED INC

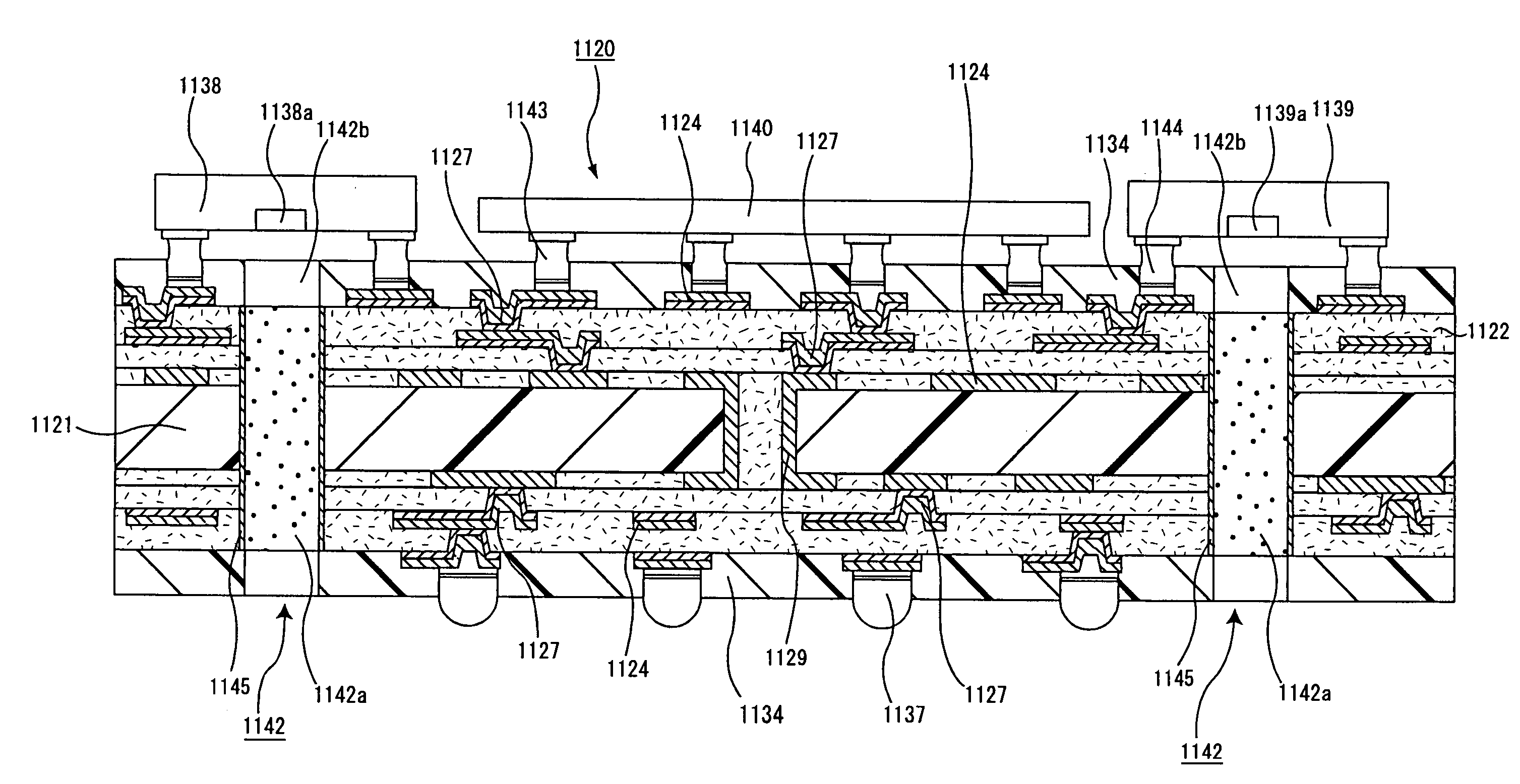

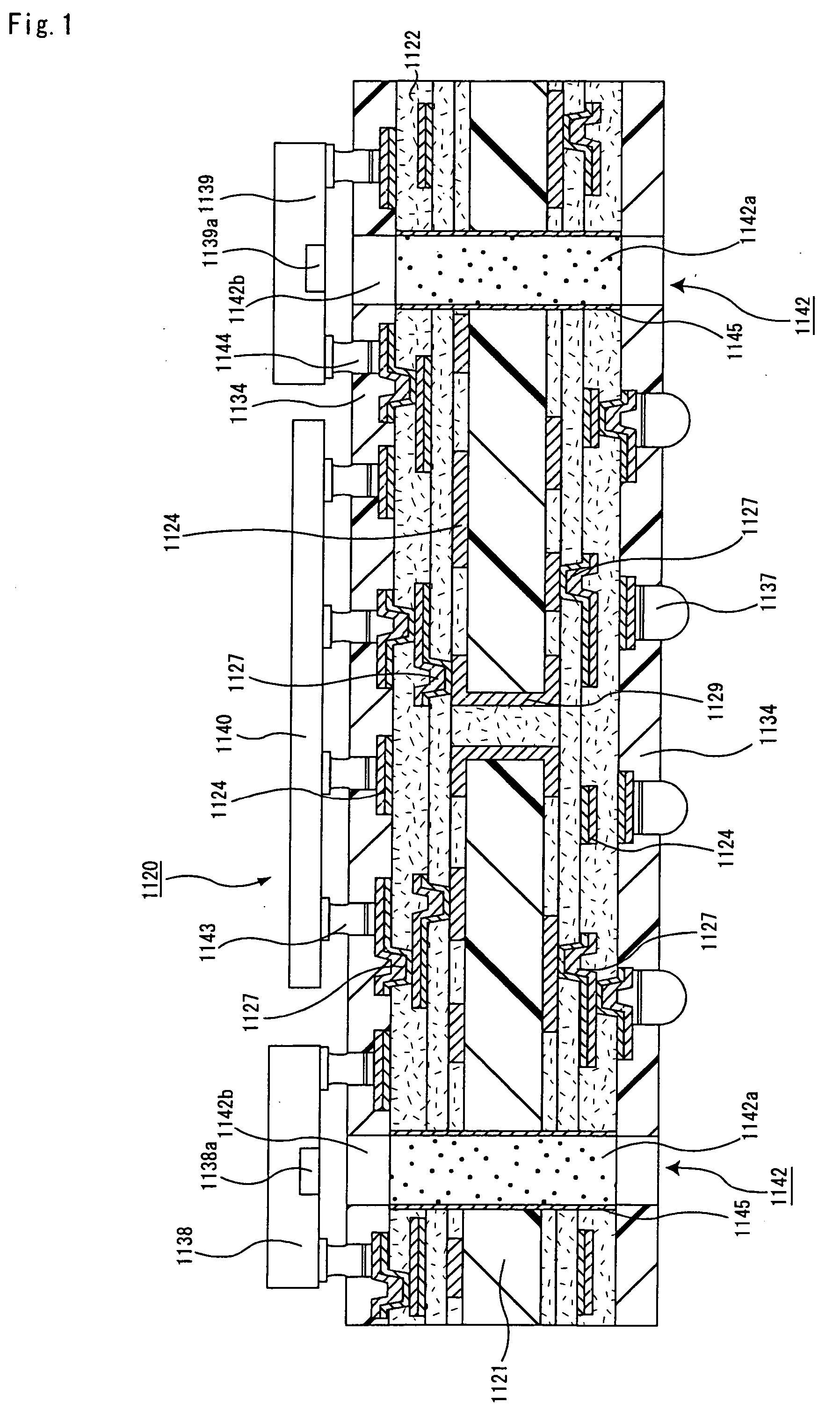

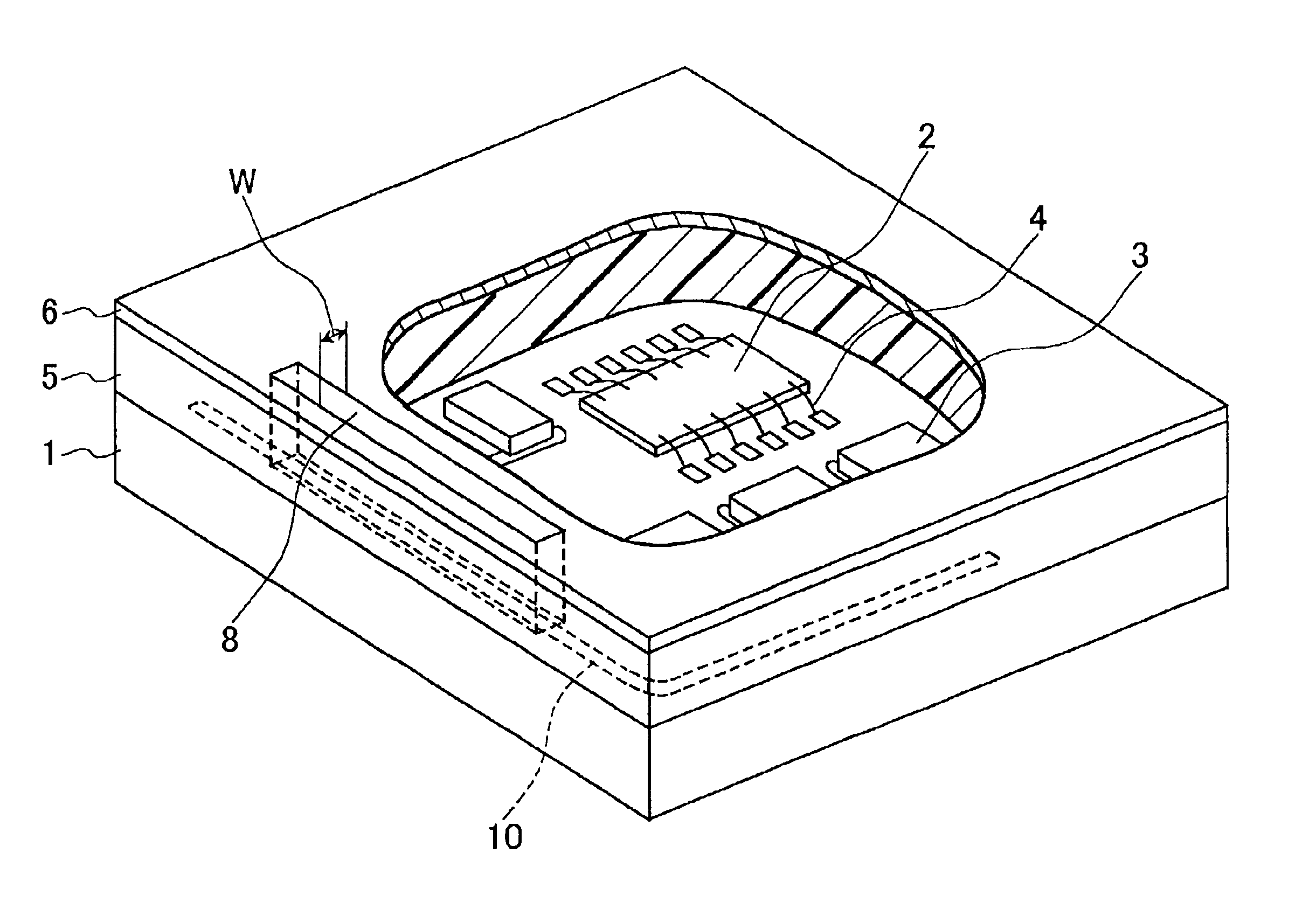

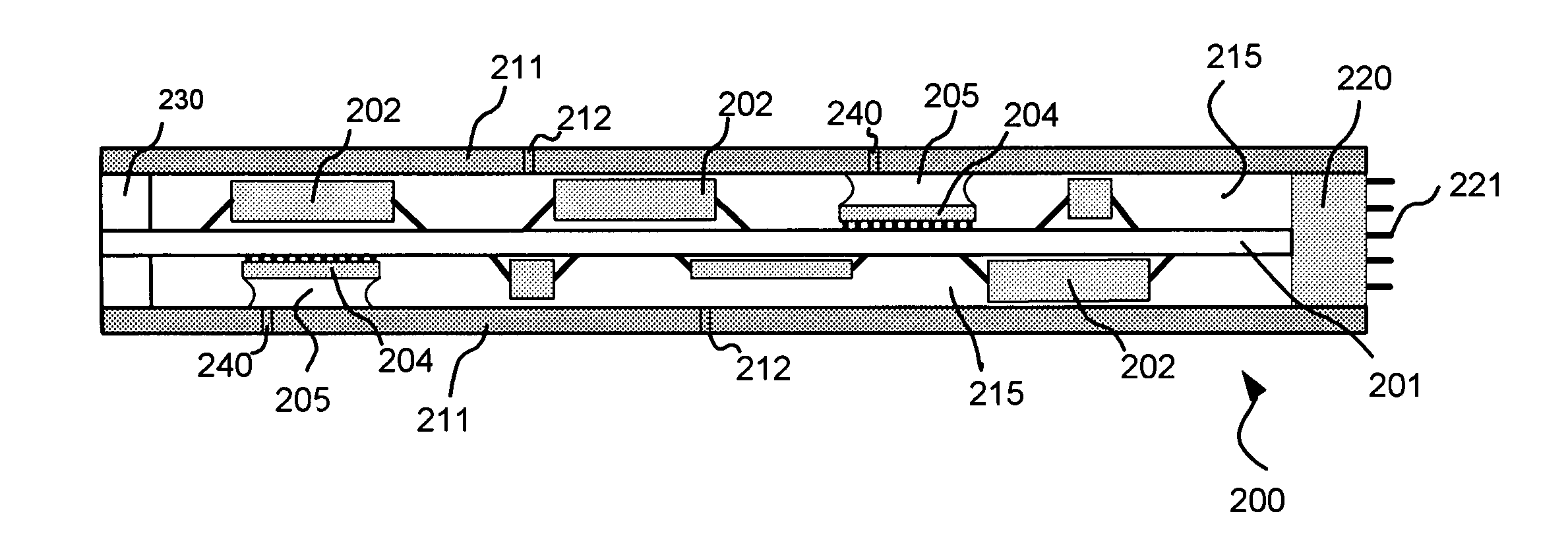

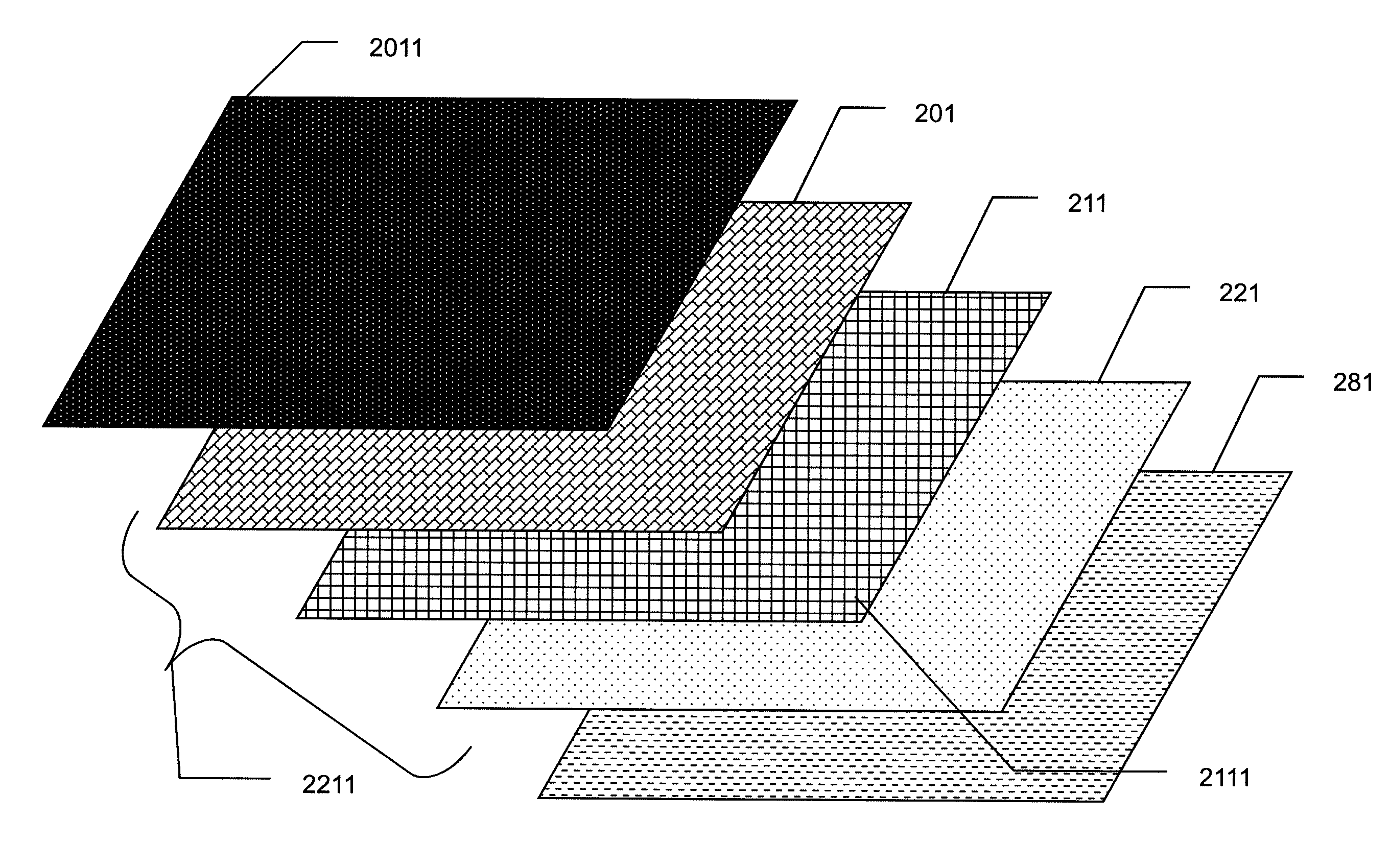

Ic chip mounting substrate, ic chip mounting substrate manufacturing method, optical communication device, and optical communication device manufacturing method

InactiveUS20060012967A1Improve connection reliabilitySmall sizeCircuit optical detailsSolid-state devicesResistElectrical conductor

An object of the present invention is to provide a substrate for mounting an IC chip which is a component for optical communication having an IC chip and an optical component integrally provided thereon, which can ensure a short distance between the IC chip and the optical component, which is excellent in electric signal transmission reliability and which can transmit optical signal through an optical path for transmitting optical signal. The substrate for mounting an IC chip of the present invention is a substrate for mounting an IC chip comprising: a substrate and, as serially built up on both faces thereof, a conductor circuit and an interlaminar insulating layer in an alternate fashion and in repetition; a solder resist layer formed as an outermost layer; and an optical element mounted thereto, wherein an optical path for transmitting optical signal, which penetrates the substrate for mounting an IC chip, is disposed.

Owner:IBIDEN CO LTD

Apparatus and methods for plasma enhanced chemical vapor deposition of polymer coatings

Apparatuses and methods are described that involve the deposition of polymer coatings on substrates. The polymer coatings generally comprise an electrically insulating layer and / or a hydrophobic layer. The hydrophobic layer can comprise fused polymer particles have an average primary particle diameter on the nanometer to micrometer scale. The polymer coatings are deposited on substrates using specifically adapted plasma enhanced chemical vapor deposition approaches. The substrates can include computing devices and fabrics.

Owner:LIQUIPEL IP

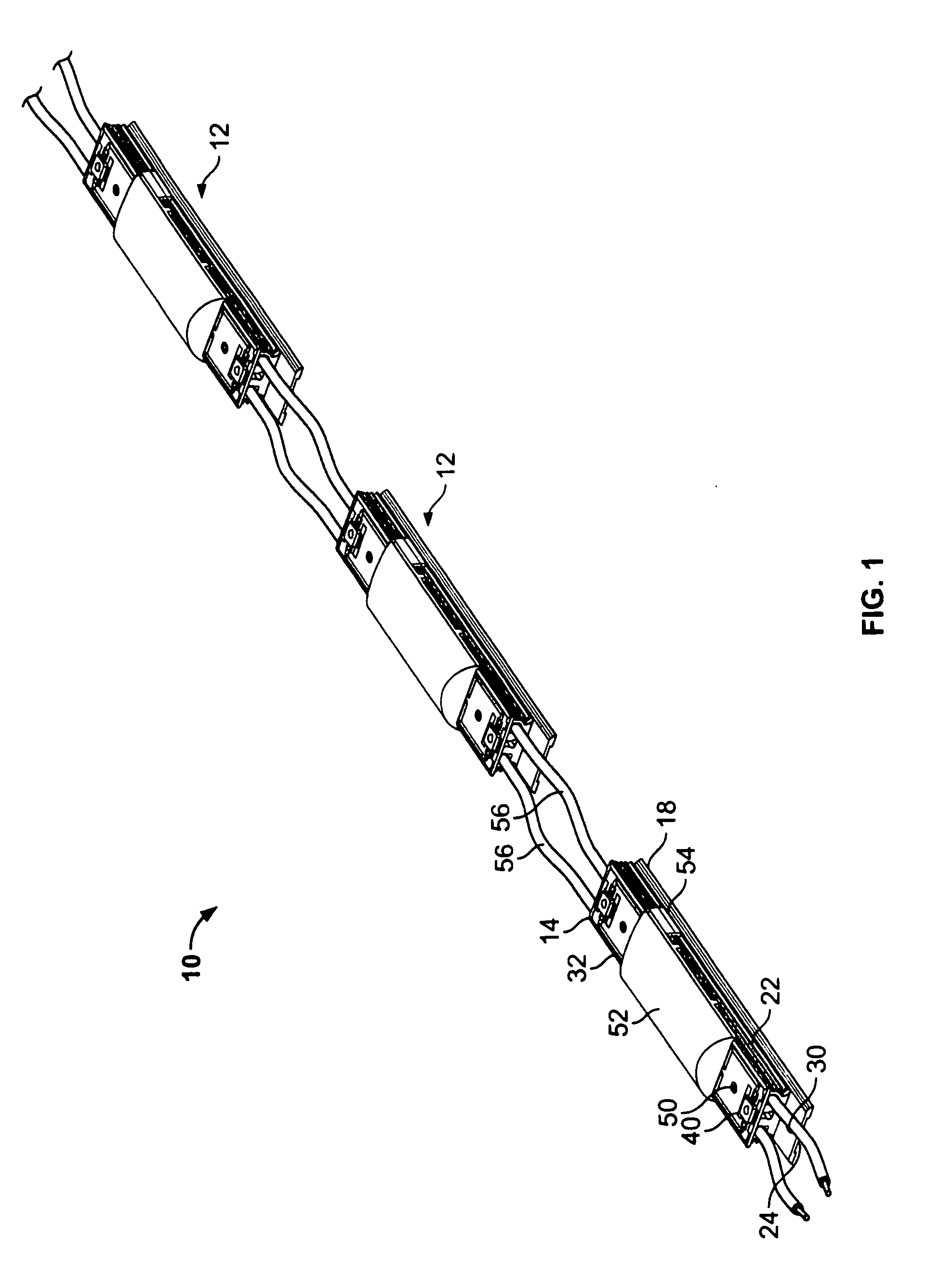

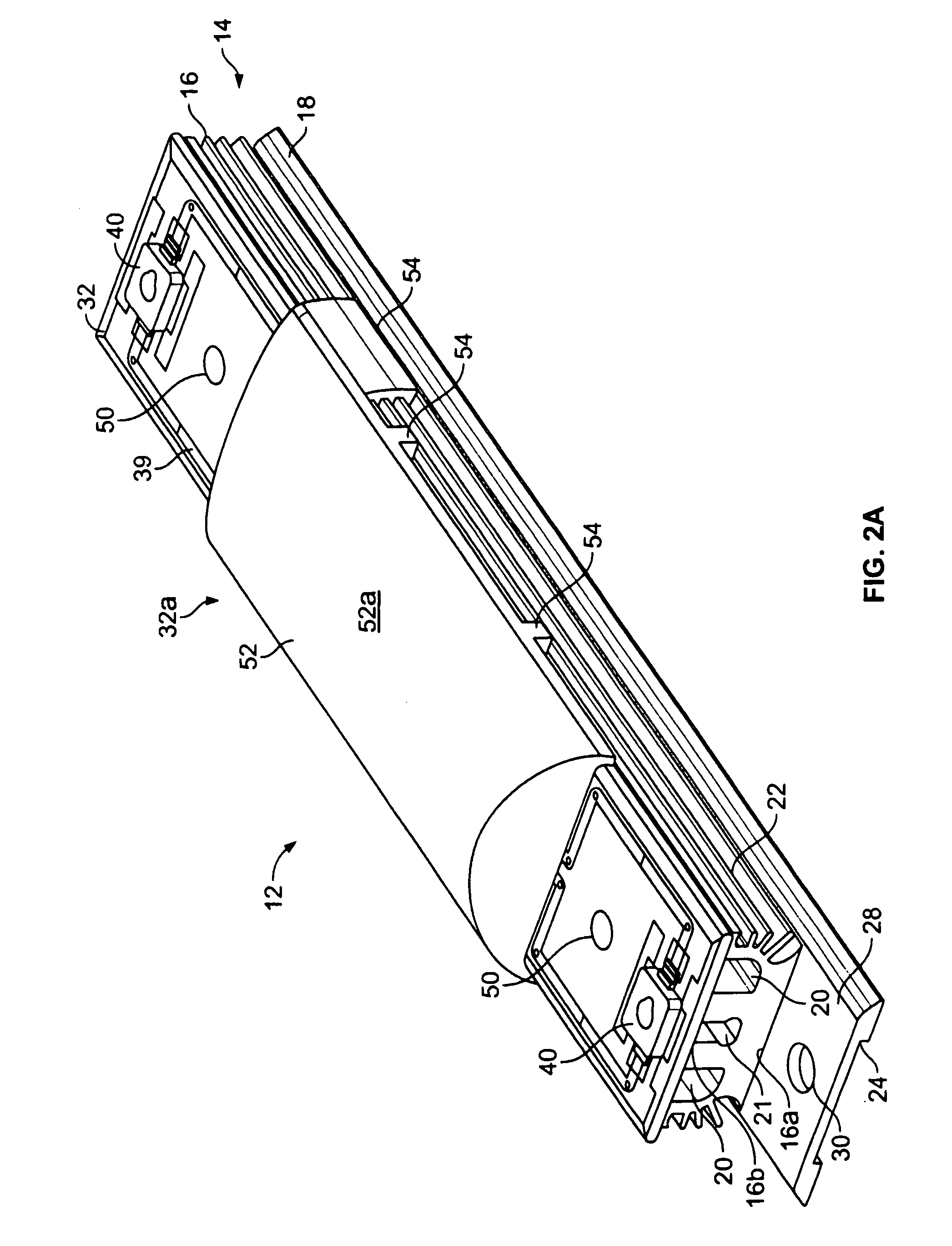

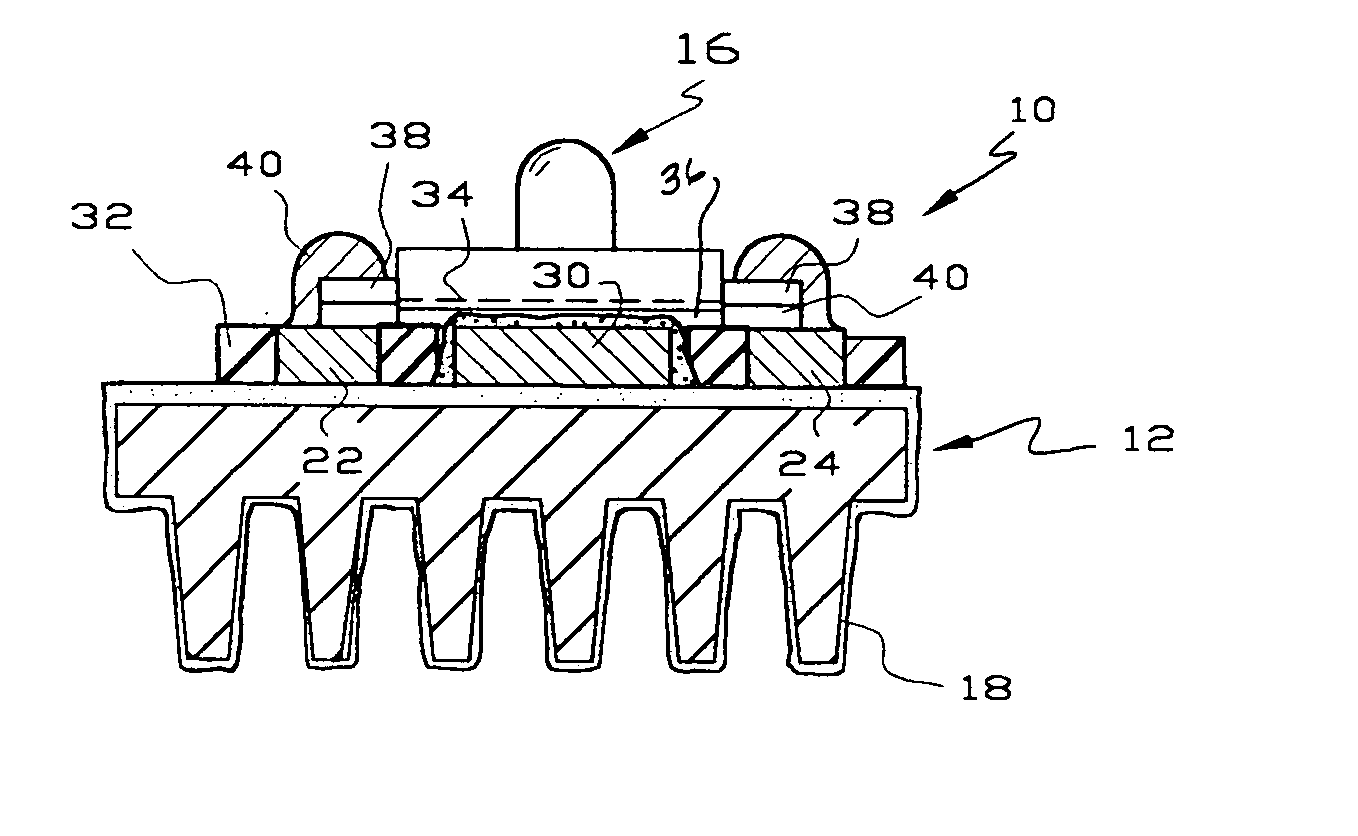

Illumination system

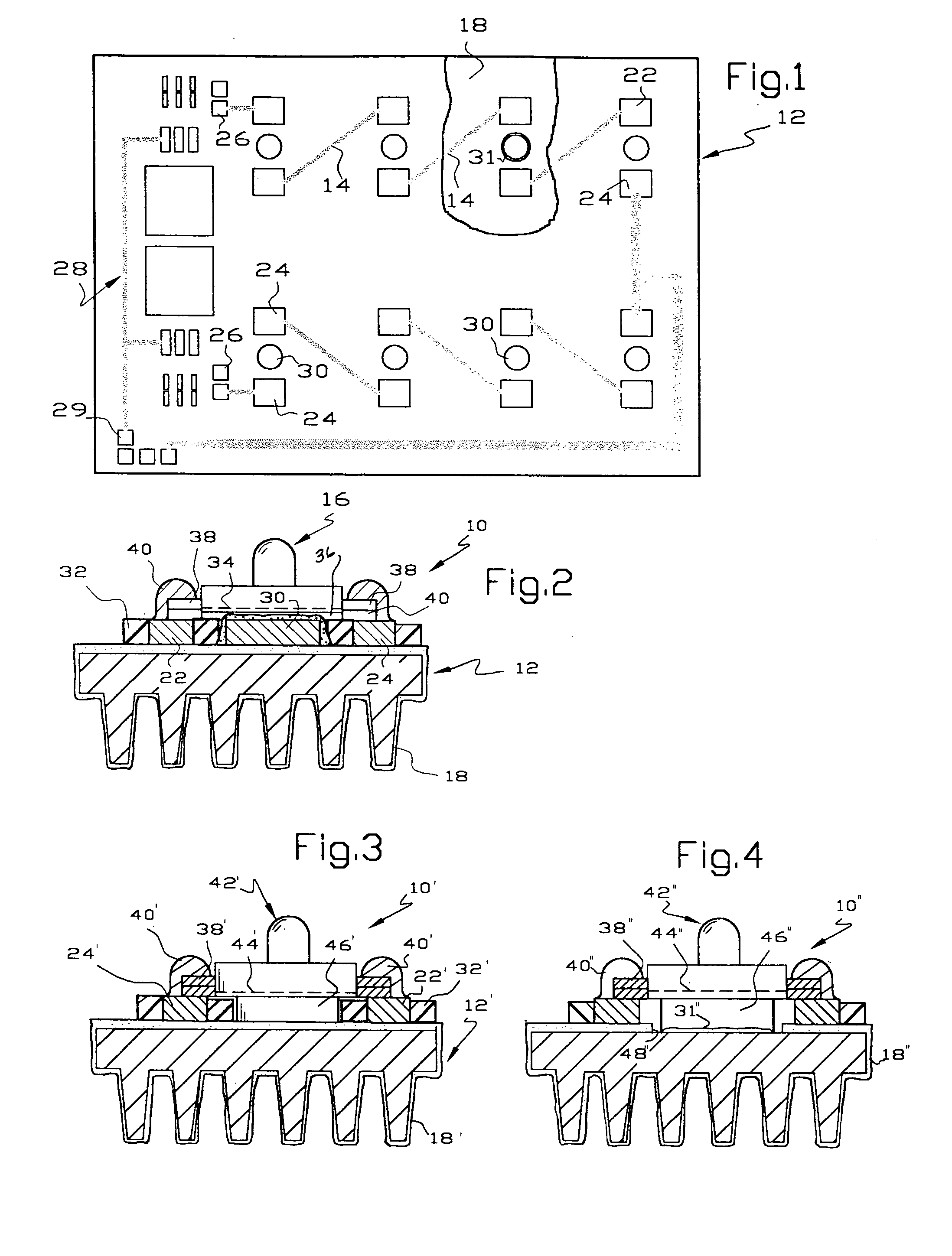

ActiveUS7165863B1Easily and efficiently manufactured and marketedDurable and reliable constructionPoint-like light sourceLighting support devicesLighting systemElectronic component

A module has a metallic mass with an upper surface having laterally spaced wiring channels and outwardly extending fins. A circuit board is mounted on the module and fabricated of an insulating bottom layer with trace patterns thereon. A plurality of electrical components, including at least one light emitting diode, are coupled to the trace patterns of the circuit board. A pair of continuous conductor wires couple the electrical components with each wire and extend through the wiring channels of the module. At least one pair of connectors extend through the circuit board with upper ends coupled with the trace patterns and lower ends extending downwardly to electrically couple with the wires.

Owner:ELECTRALED

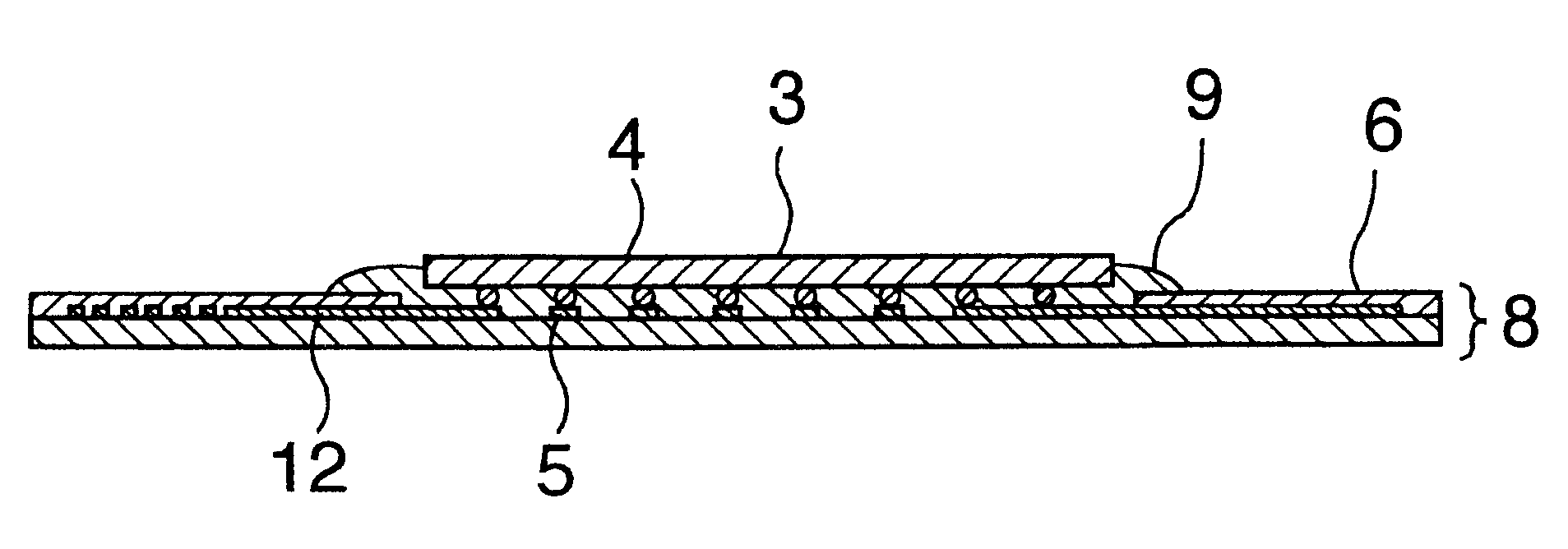

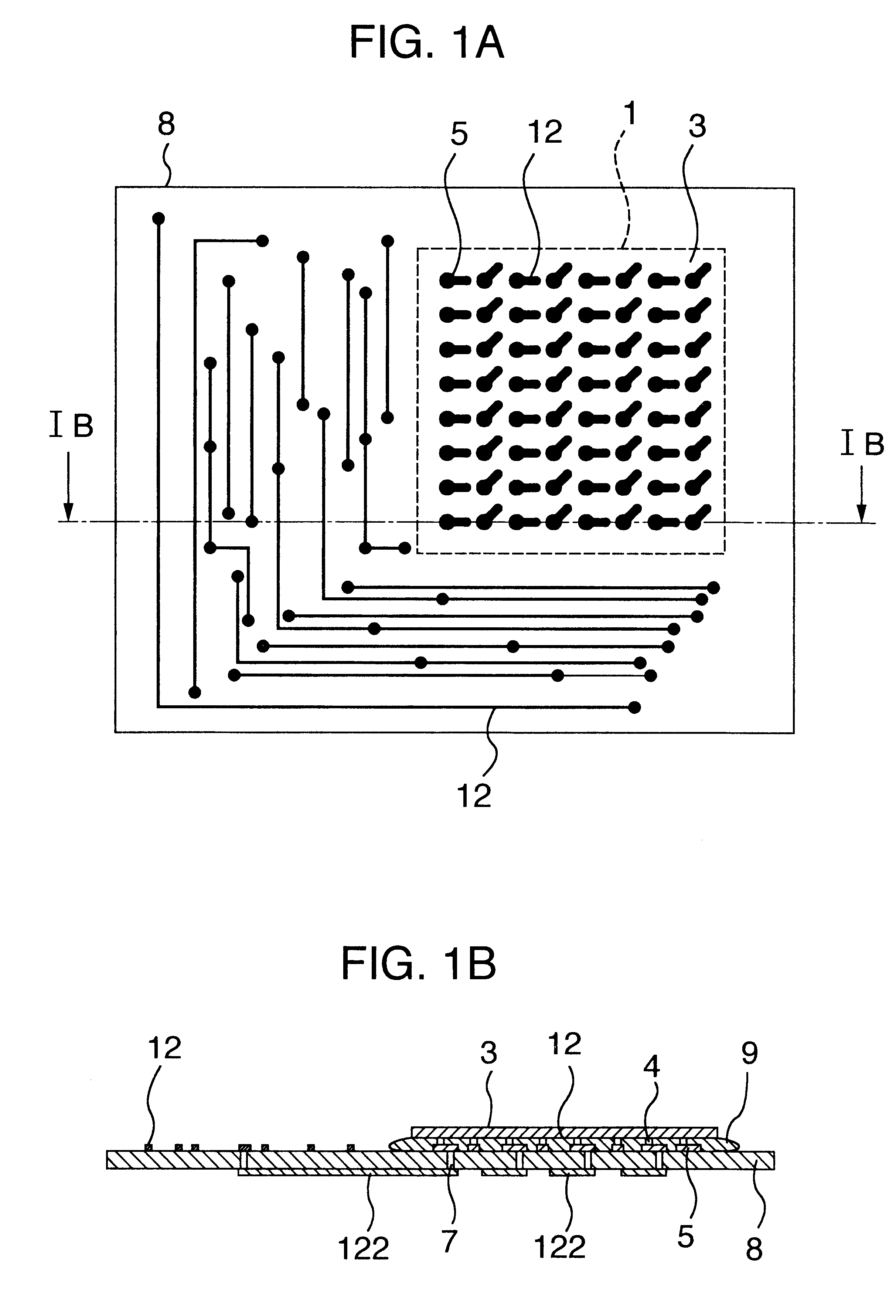

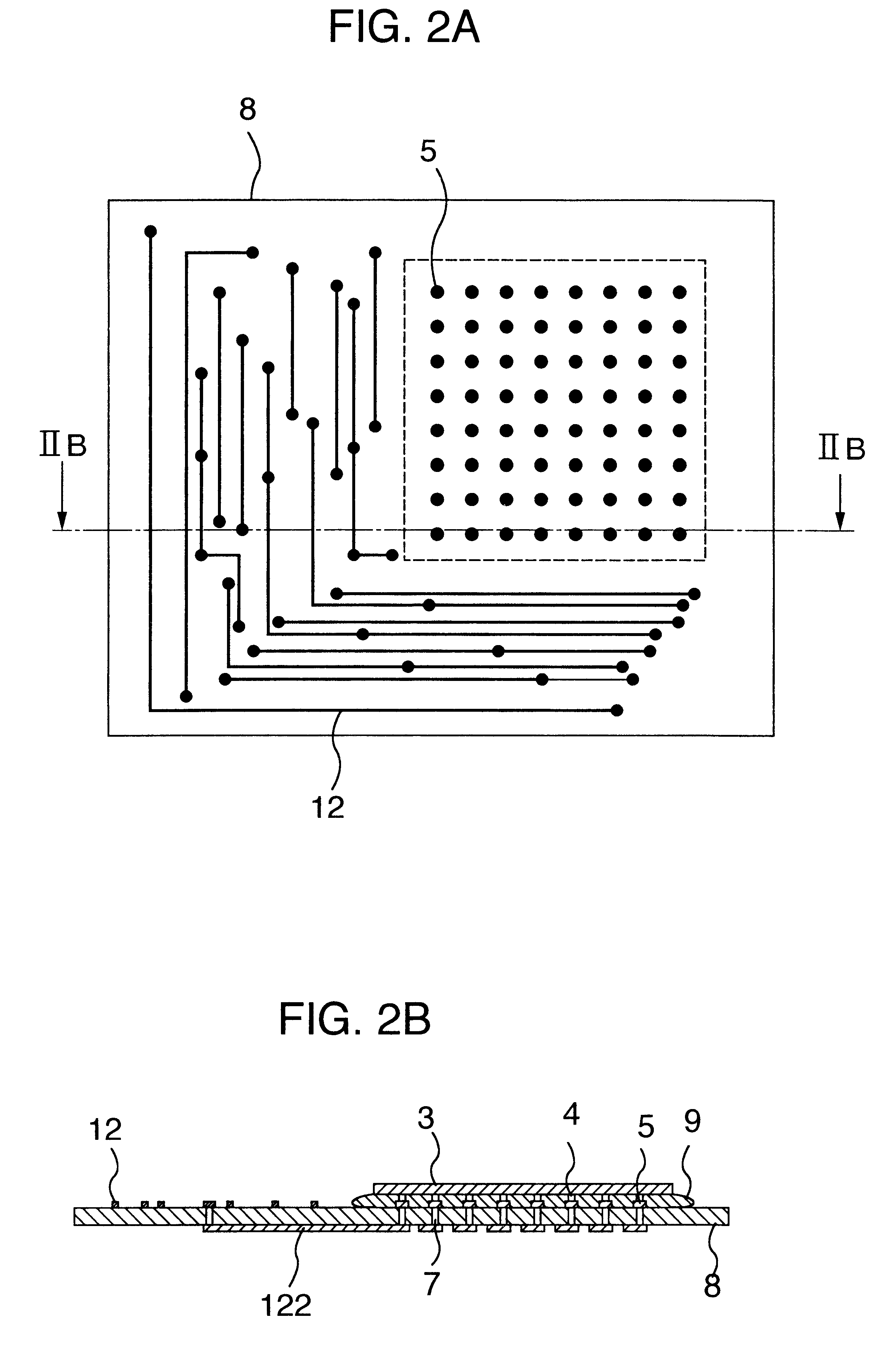

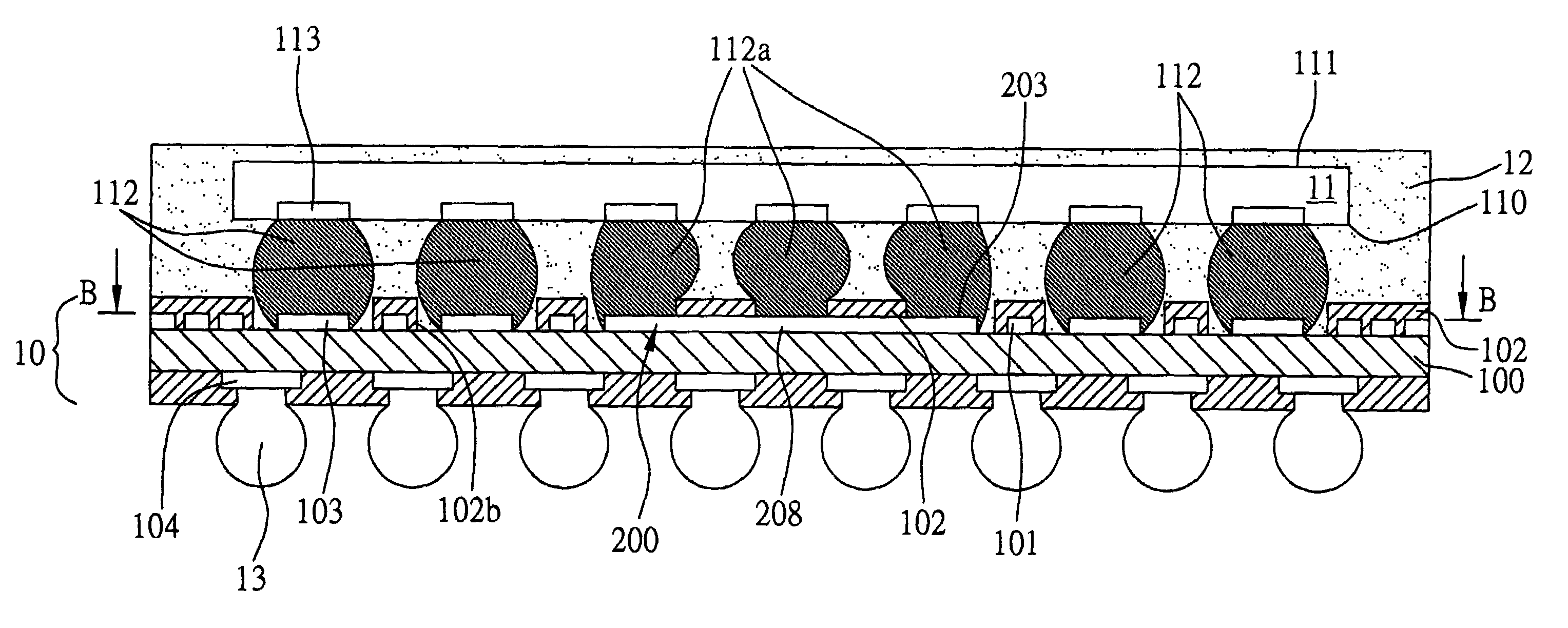

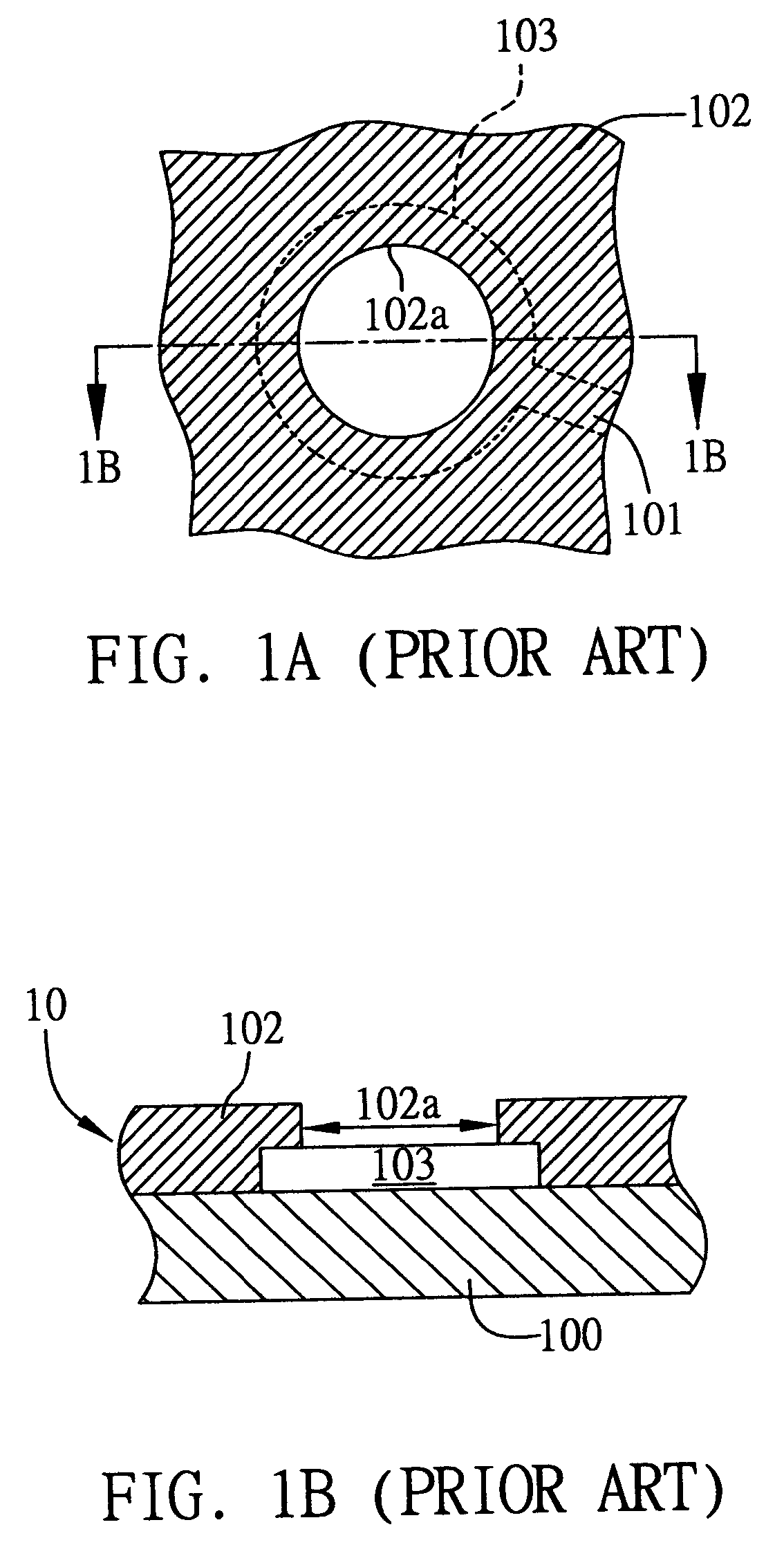

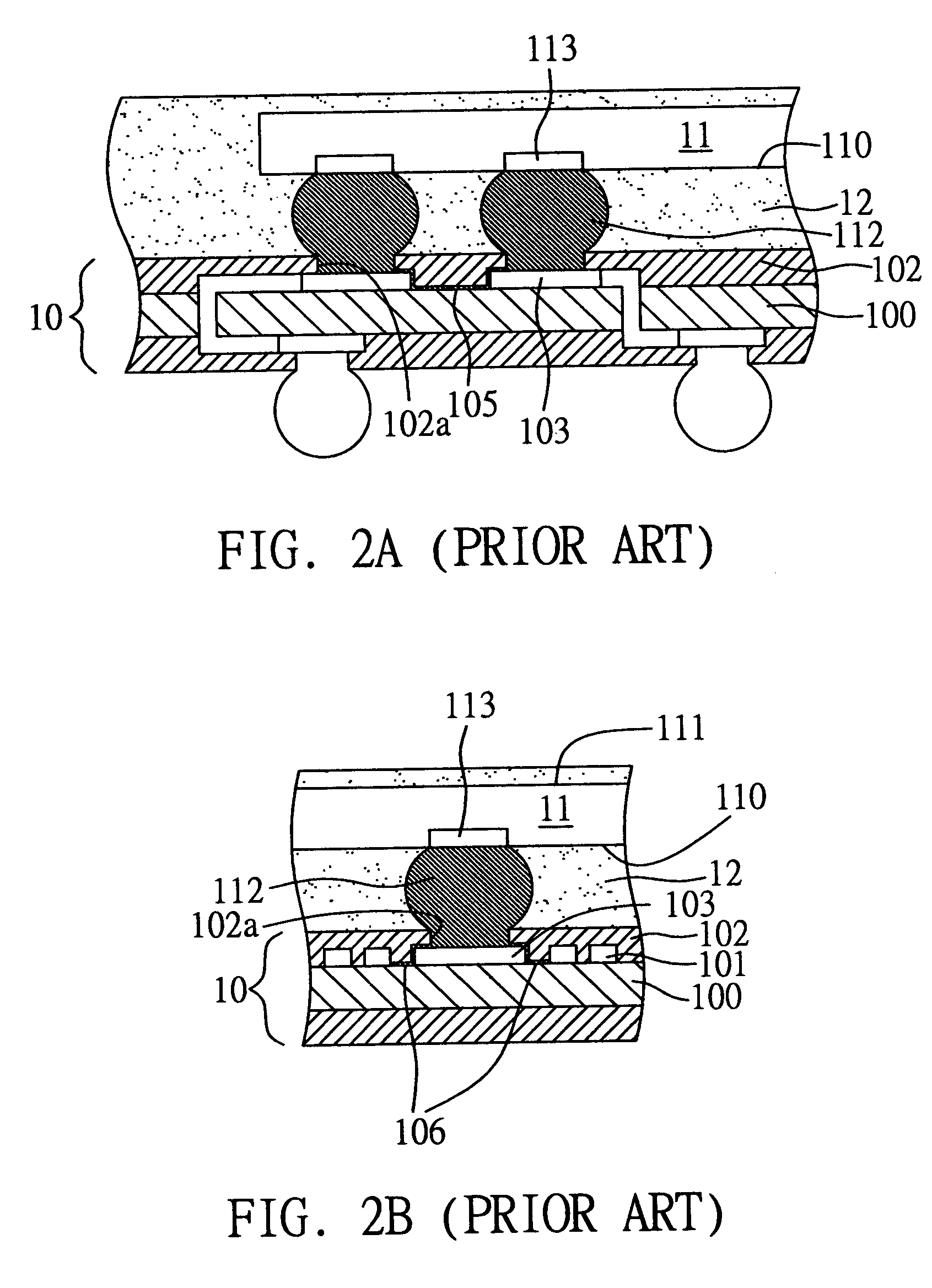

Substrate for mounting semiconductor chips

InactiveUS6281450B1Improve connection reliabilityImprove batch productivitySemiconductor/solid-state device detailsSolid-state devicesProduction rateElectrical conductor

A substrate for mounting a semiconductor chip having bumps using an adhesive thereon, said substrate being, for instance, provided with an insulating coating having an opening in the semiconductor chip mounting area so that the wiring conductors will not be exposed to the substrate surface near the boundary of the semiconductor chip mounting area, is improved in connection reliability and has high mass productivity.

Owner:HITACHI CHEM CO LTD

High-frequency module and method for manufacturing the same

InactiveUS7081661B2Reduce electromagnetic influencePliability problemMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectronic component

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

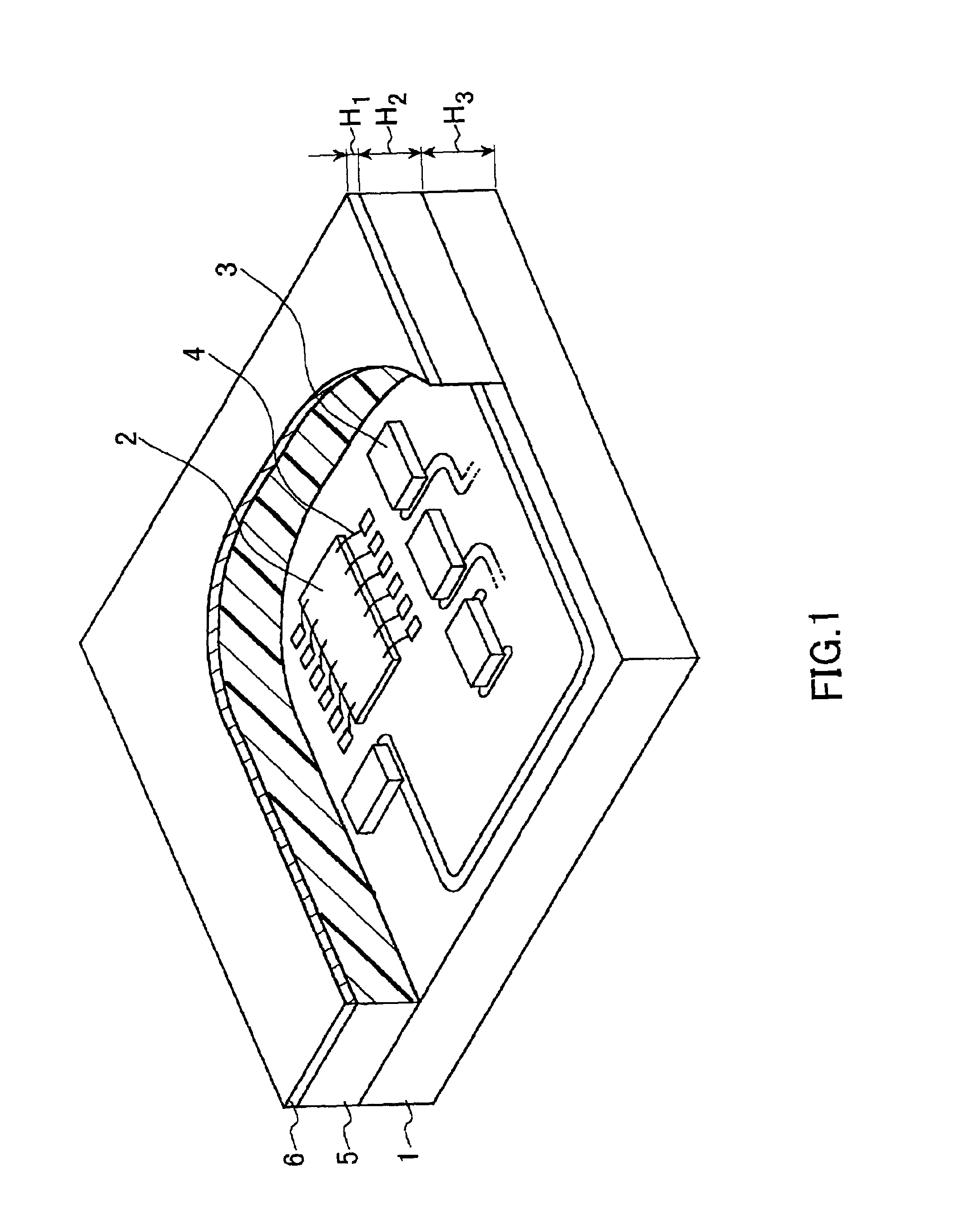

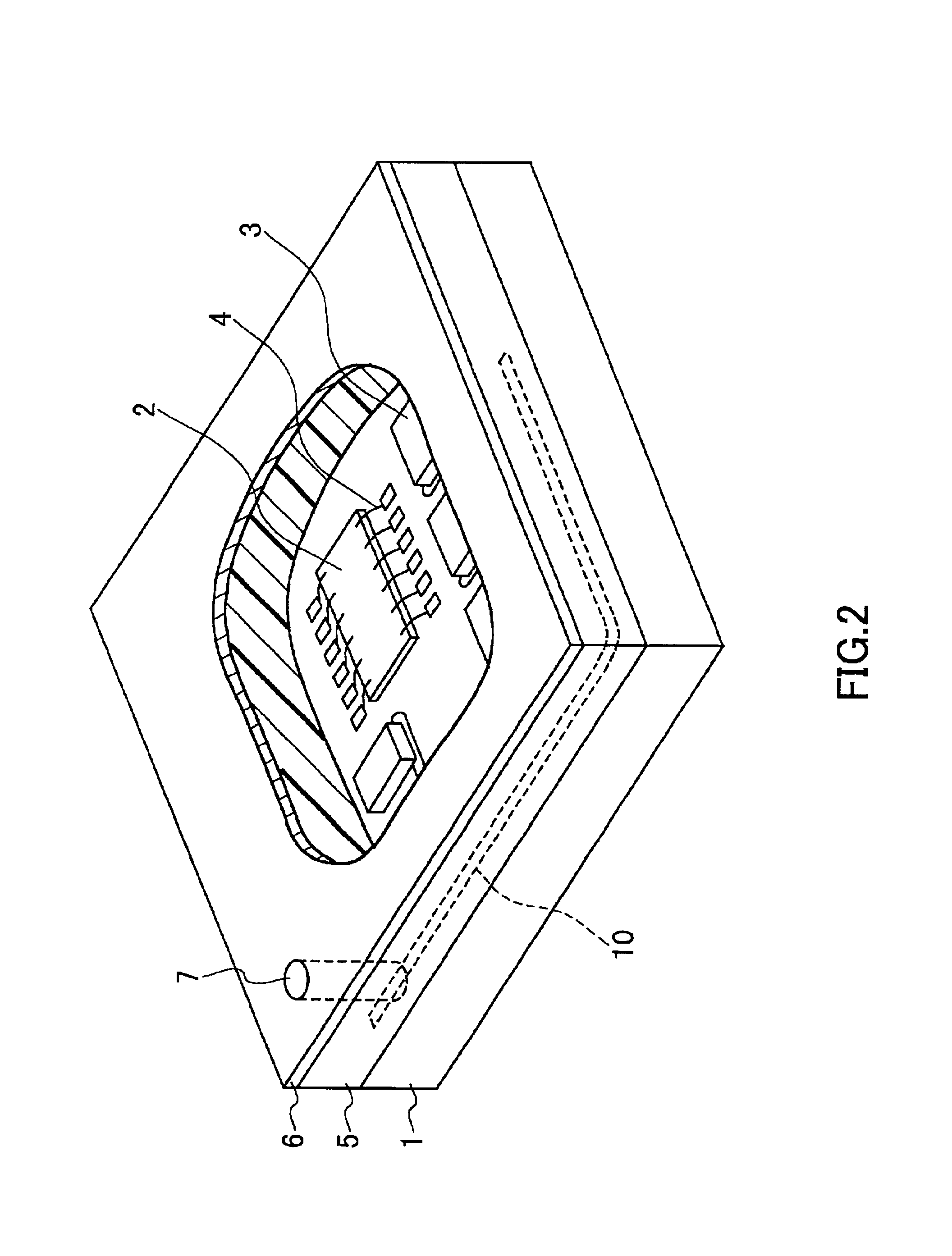

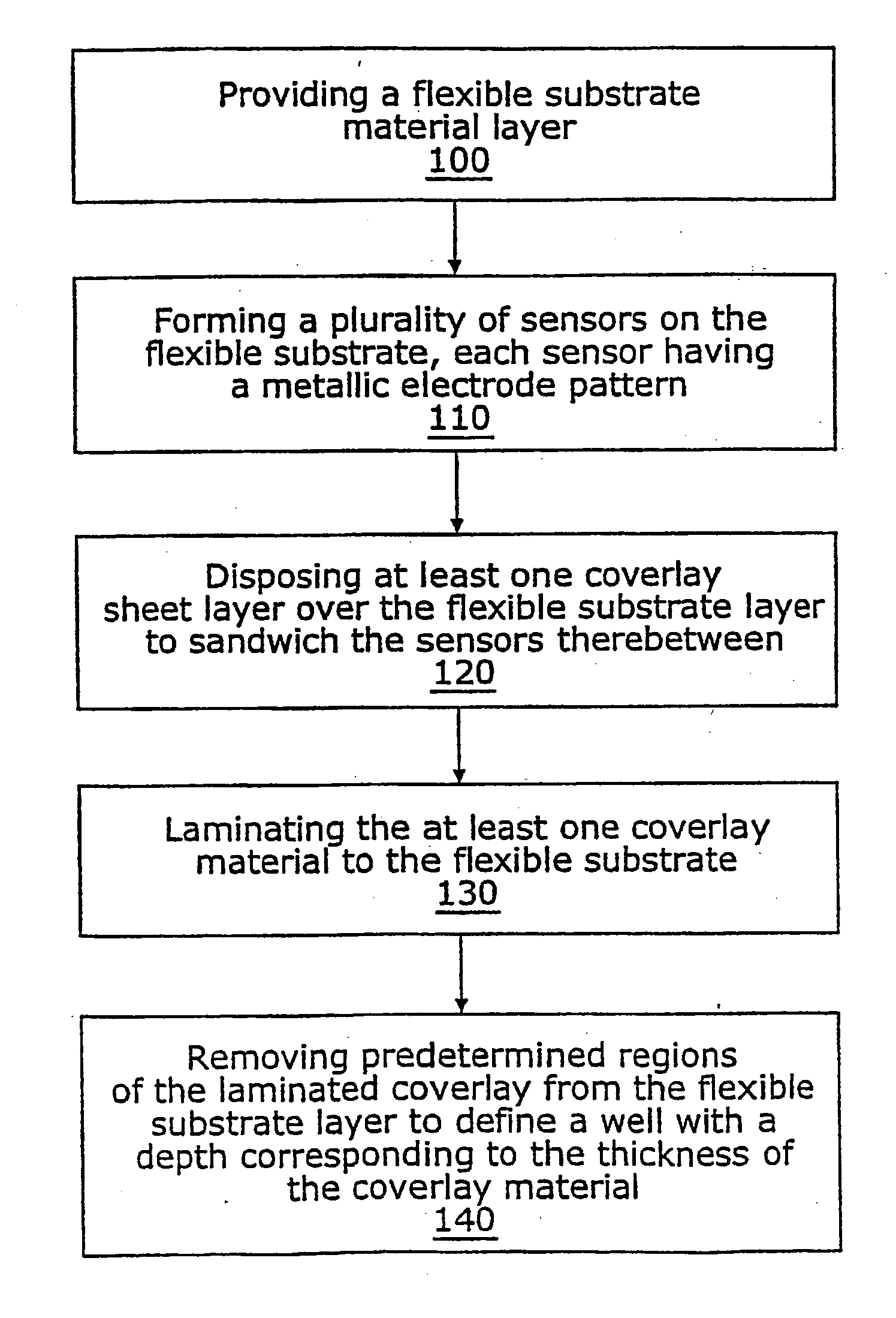

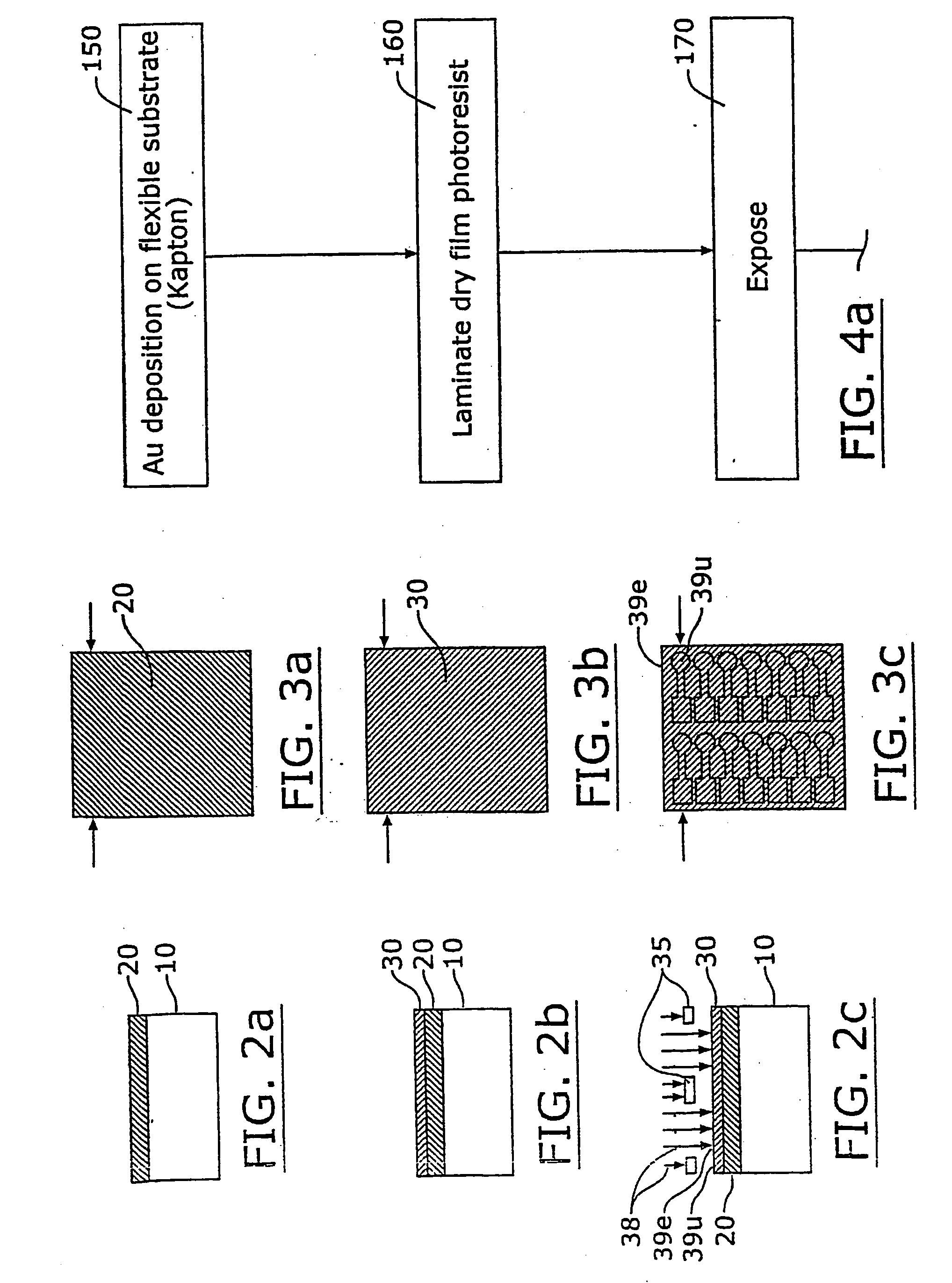

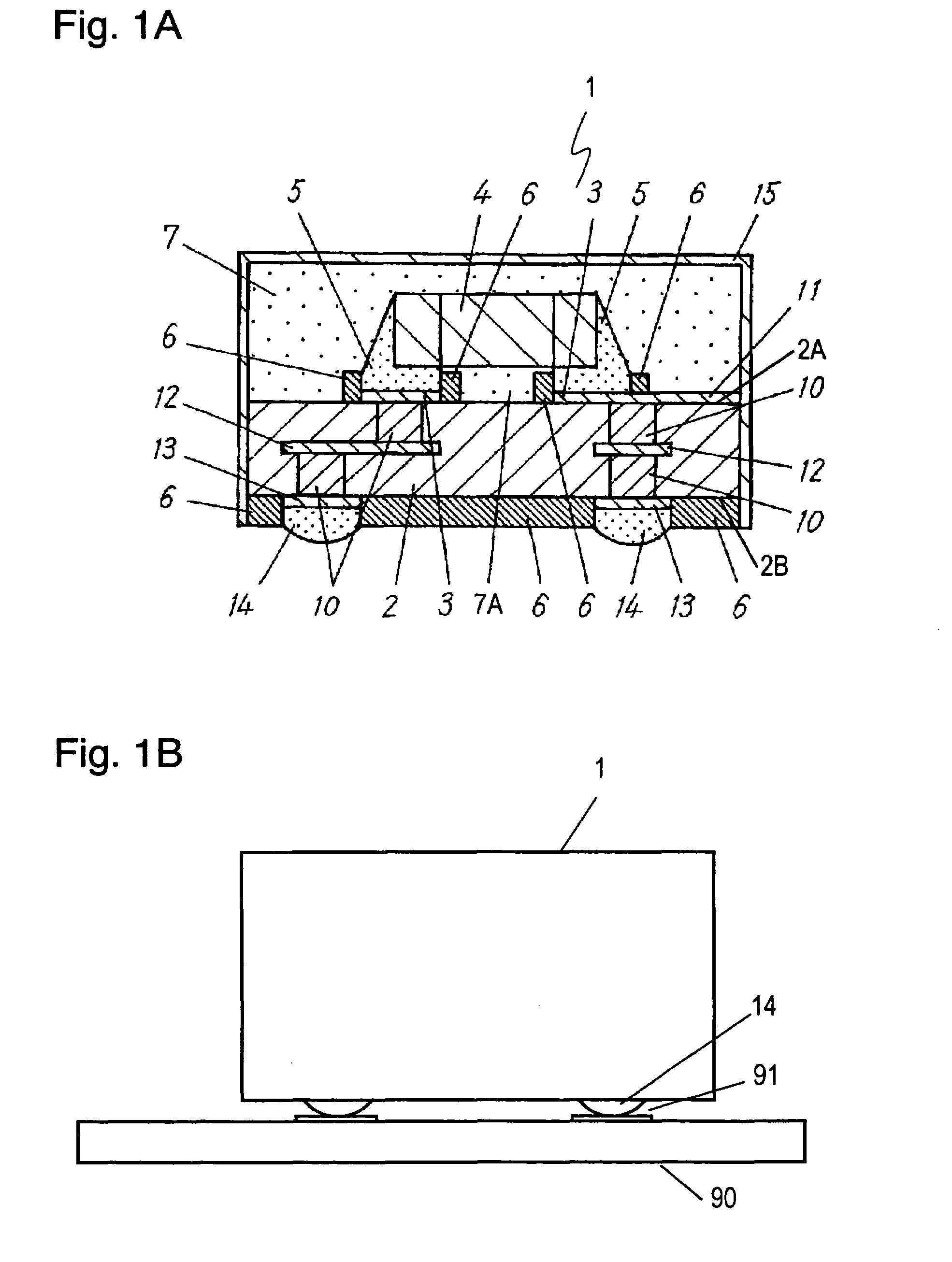

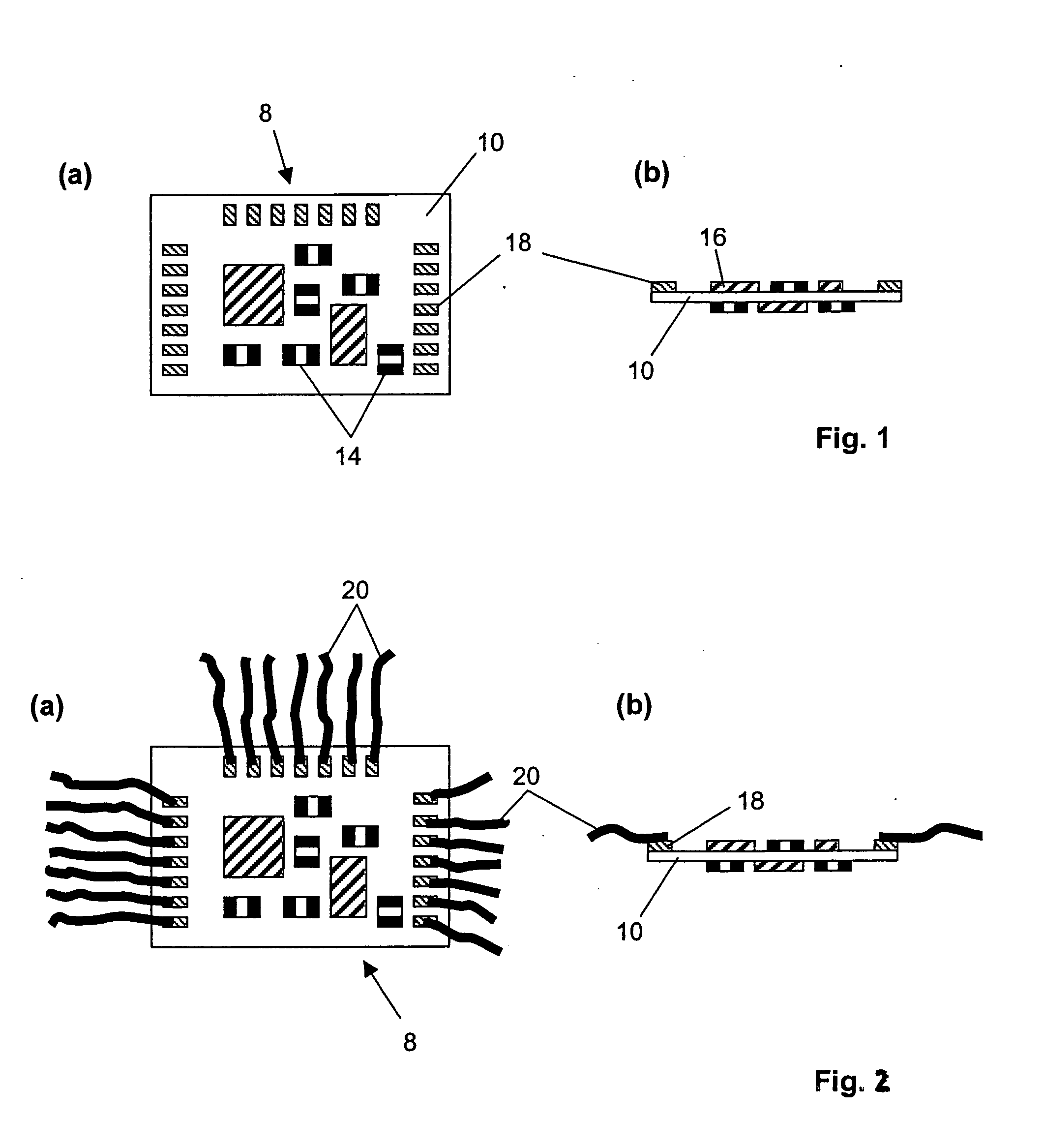

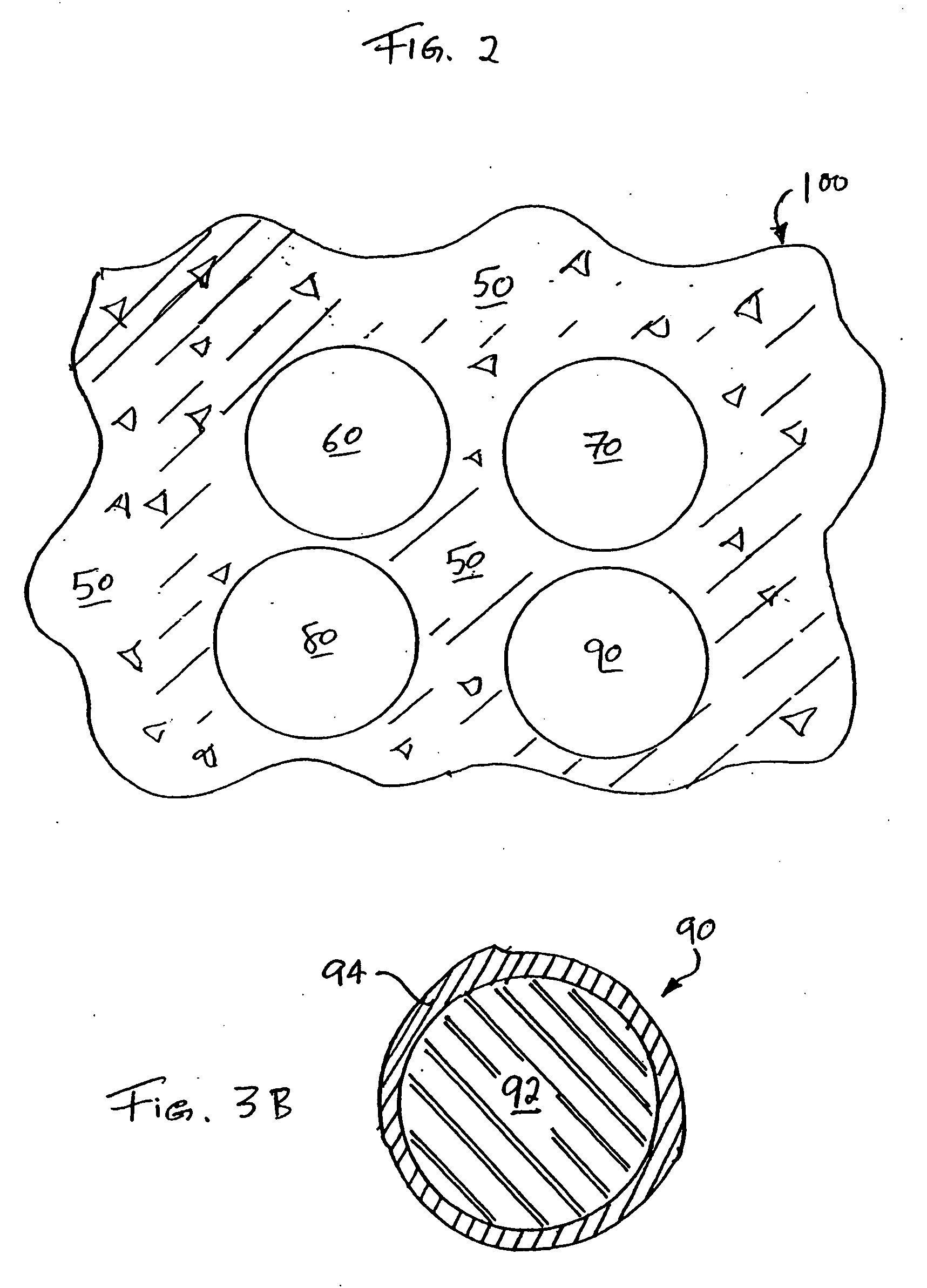

Biomedical electrochemical sensor array and method of fabrication

InactiveUS20050236361A1Decorative surface effectsSemiconductor/solid-state device manufacturingSensor arrayMetallic electrode

Methods for fabricating a plurality of sensors on a flexible substrate, with each sensor having associated electrodes and at least one well include (a) providing a flexible substrate material layer having a surface area defined by a length and width thereof; (b) forming a plurality of sensor elements onto the flexible substrate material layer, each sensor element comprising at least one metallic electrode; (c) disposing at least one coverlay sheet layer over the flexible substrate sandwiching the sensor elements therebetween; (d) laminating the at least one coverlay sheet layer having an associated thickness to the flexible substrate; and (e) removing predetermined regions of the laminated coverlay sheet layer from the flexible substrate layer to expose a portion of the underlying metallic pattern of each sensor element and to define a well with a depth corresponding to the thickness of the coverlay sheet layer. The disclosure also describes multi-layer laminated flexible sensors and arrays of sensors with wells having enhanced well capacity and / or depth.

Owner:ROCHE DIABETES CARE INC

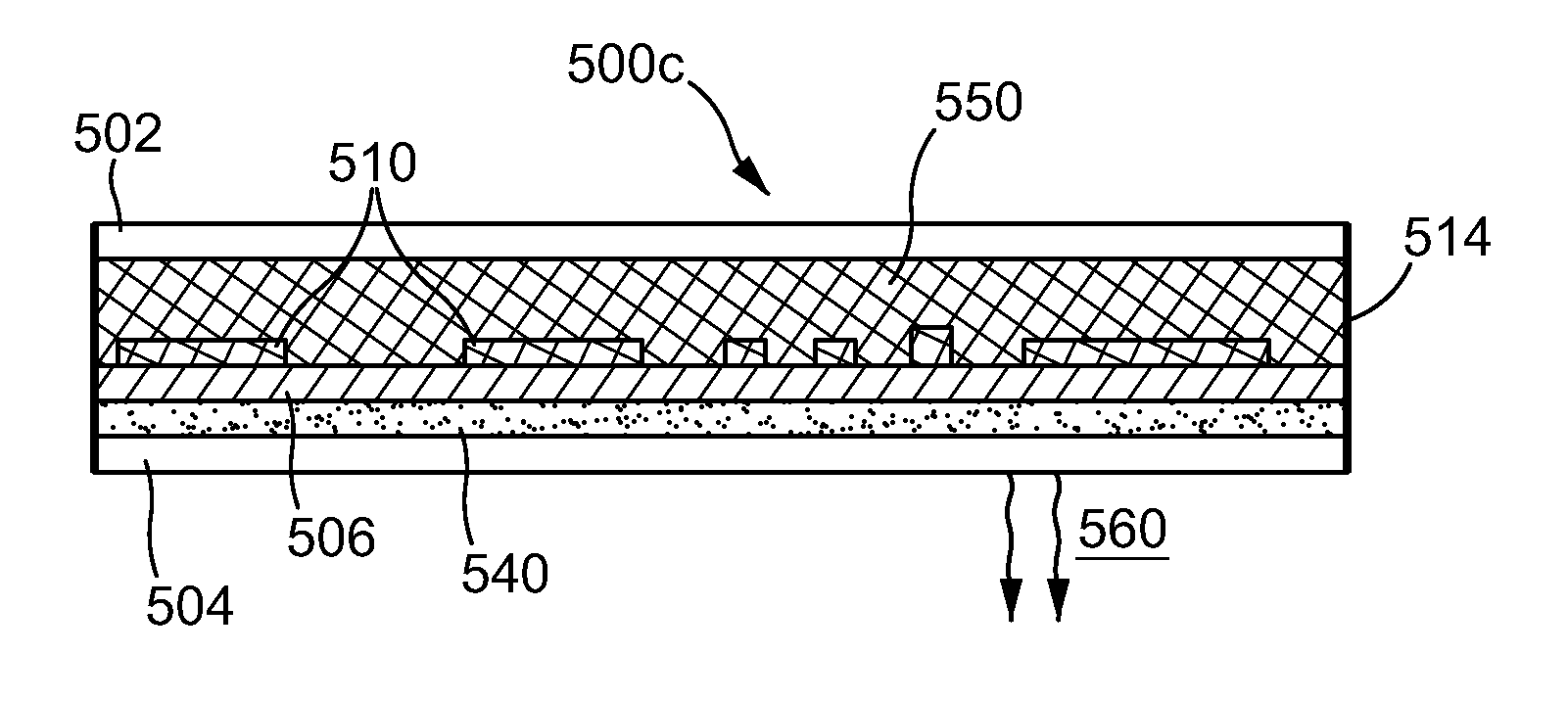

Systems structures and materials for electronic device cooling

An electronic device having one or more components that generate heat during operation includes a structure for temperature management and heat dissipation. The structure for temperature management and heat dissipation comprises a heat transfer substrate having a surface that is in thermal communication with the ambient environment and a temperature management material in physical contact with at least a portion of the one or more components of the electronic device and at least a portion of the heat transfer substrate. The temperature management material comprises a polymeric phase change material having a latent heat of at least 5 Joules per gram and a transition temperature between 0° C. and 100° C., and a thermal conductive filler.

Owner:LATENT HEAT SOLUTIONS LLC

Semiconductor device structural body and electronic device

InactiveUS20050029666A1Prevent outflowPrinted circuit assemblingFinal product manufactureDevice materialMetal powder

A semiconductor device, in which a solder layer bonding chip parts and wiring members are enclosed with the resin layer, and the solder layer is comprised of a compound body in which metal powder is distributed in the matrix metal, is disclosed. When a semiconductor device in which the chip parts are installed in the wiring member with the solders, the soldering part is sealed with the resin is mounted secondly on the external wiring member, the outflow of the solders and the short circuit due to the outflow, the disconnections, and the displacement of the chip parts can be prevented.

Owner:HITACHI LTD +1

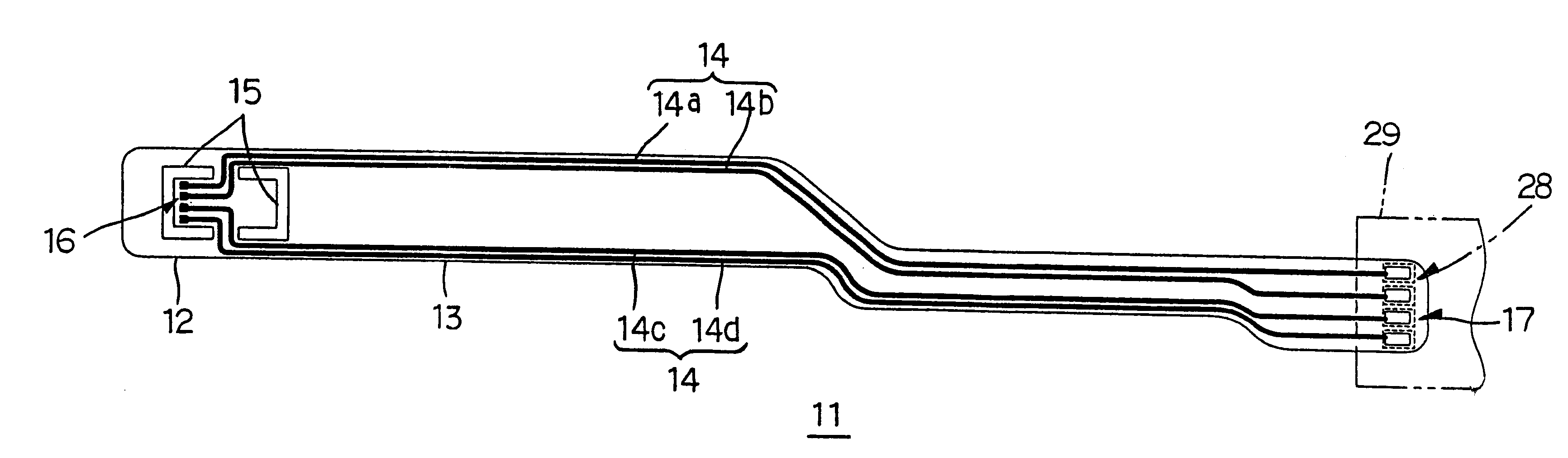

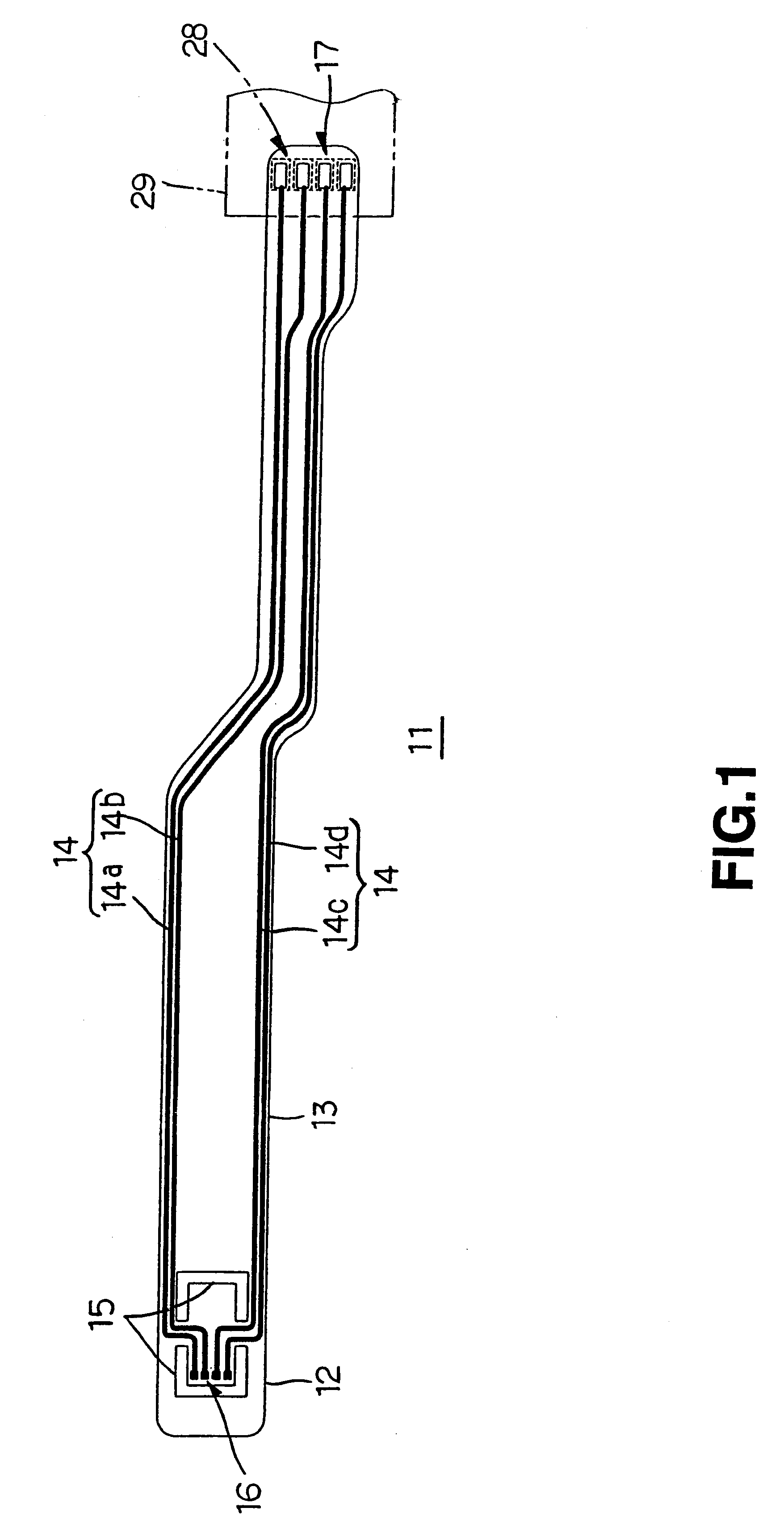

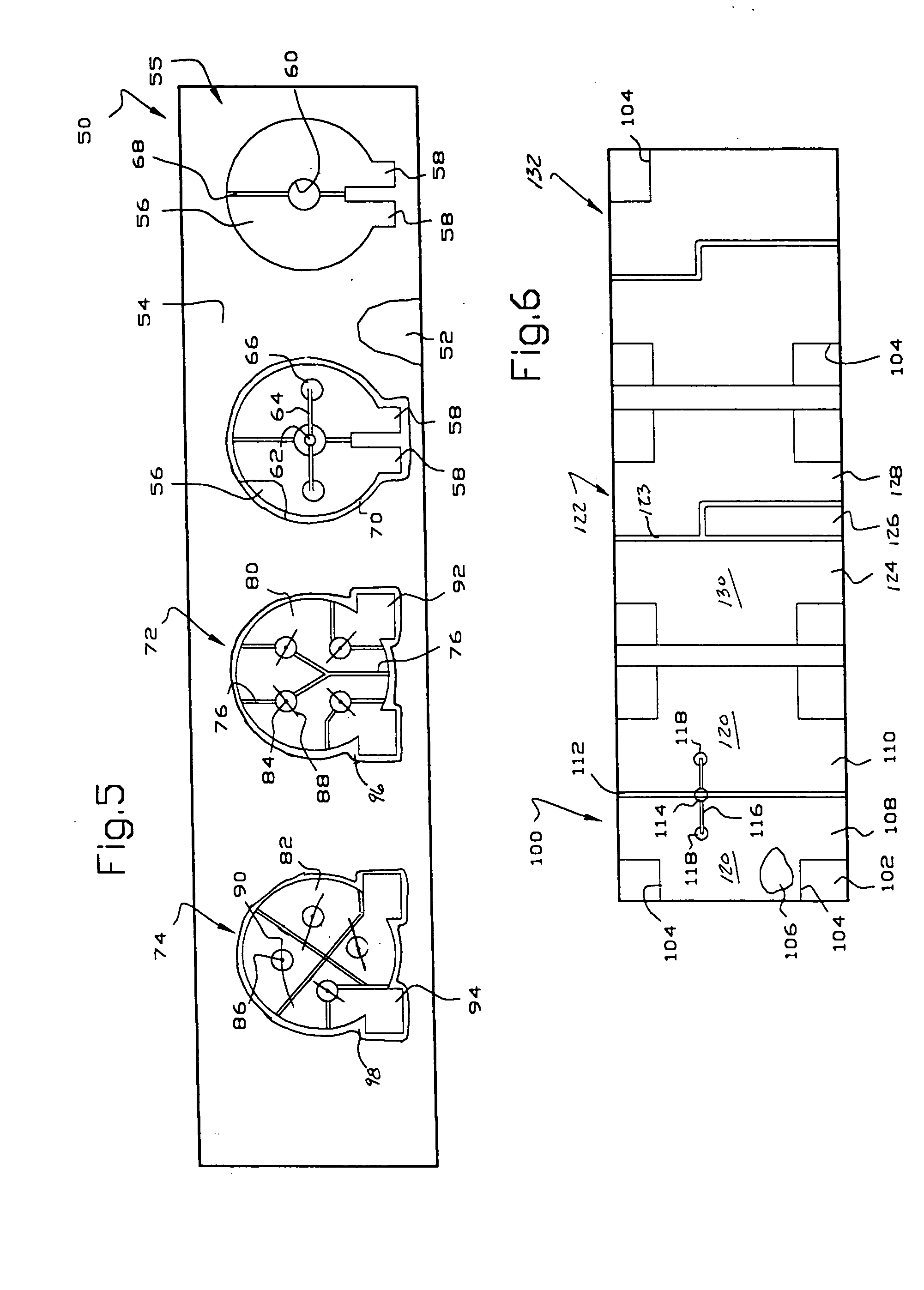

Suspension board with circuit

InactiveUS6399899B1High strengthSimple structureRelieving strain on wire connectionRecord information storageExternal connectionEngineering

To provide a suspension board with circuit that enables its terminals to be bonded to the other terminals with sufficient strength with simple structure, to ensure sufficient bonding reliability, the suspension board with circuit 11 includes a suspension board 12, a base layer 13 formed on the suspension board 12, and a conductive layer 14 formed on the base layer 13 and a cover layer 18 with which the conductive layer 14 is covered, wherein external connection terminals 17 to be bonded to terminals 28 of a read / write board 29 are formed without the suspension board 12 and / or the base layer 13 being formed.

Owner:NITTO DENKO CORP

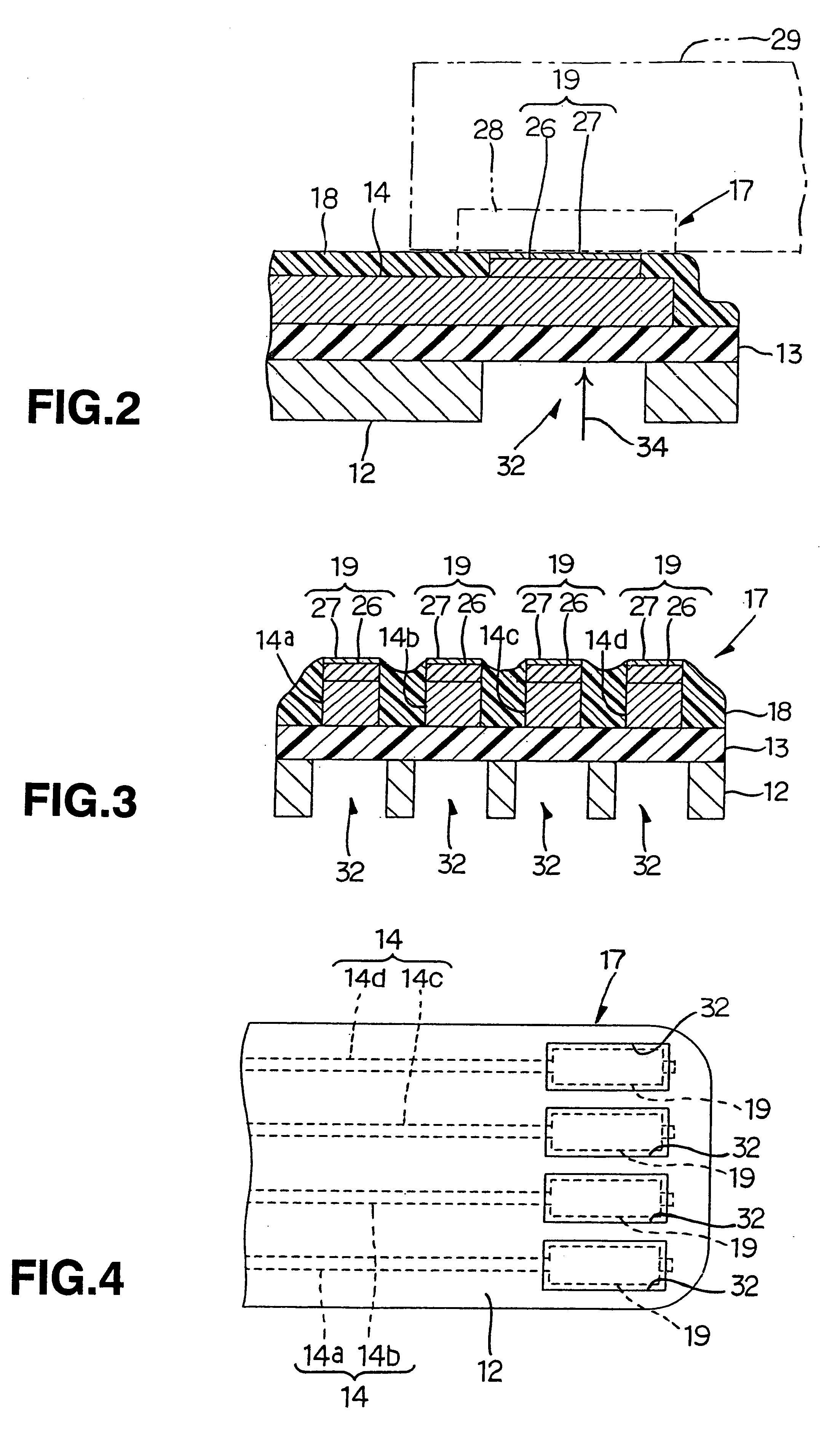

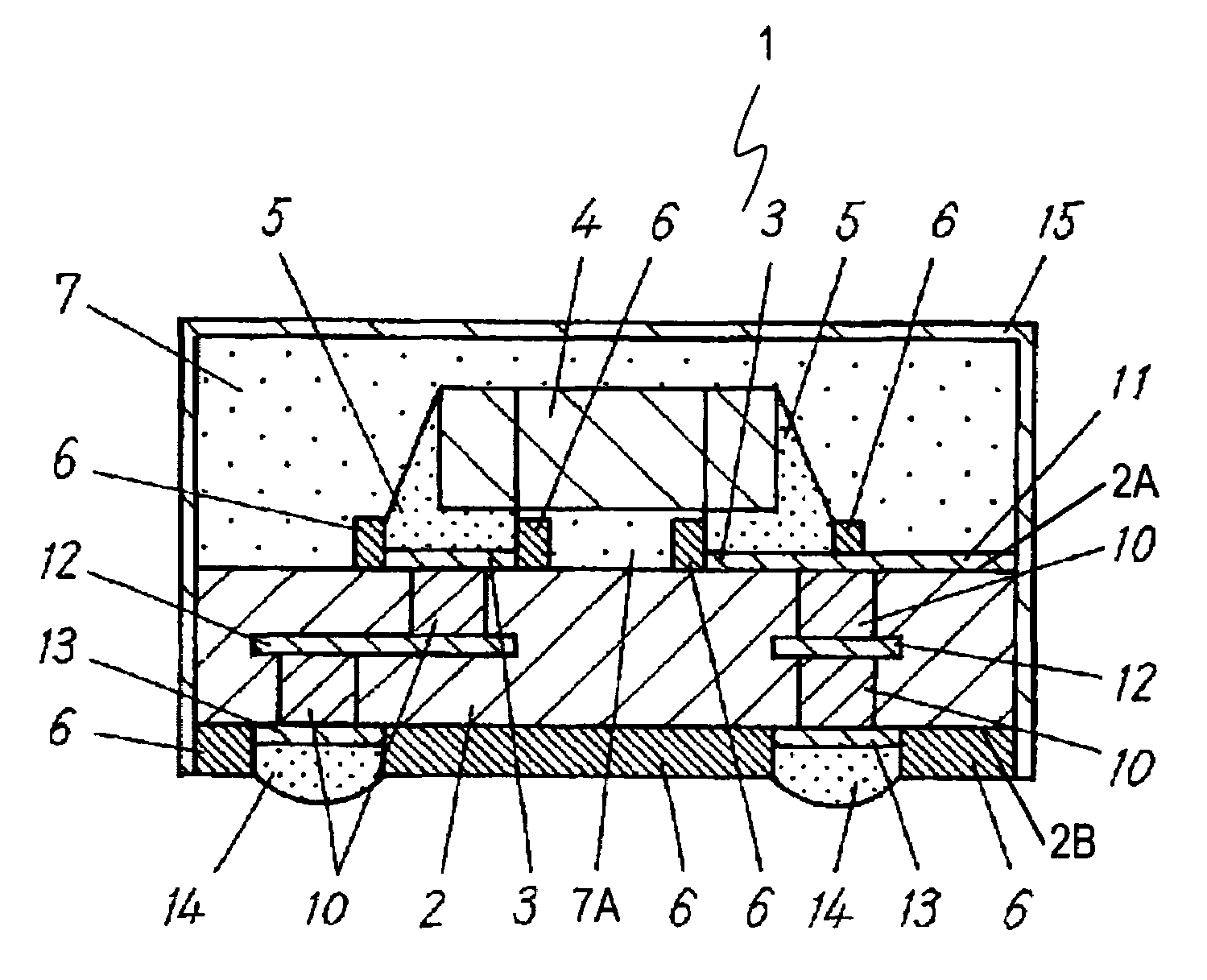

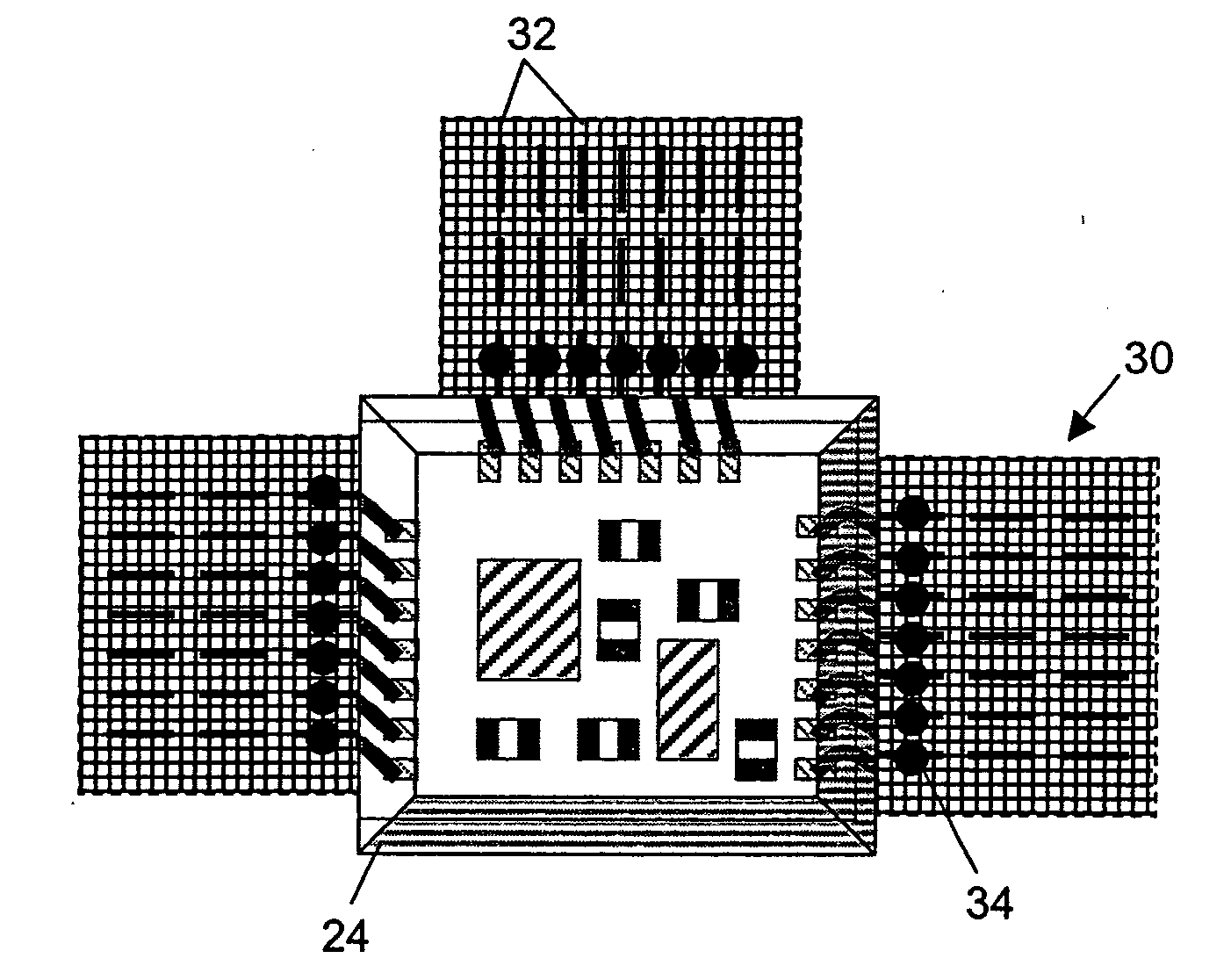

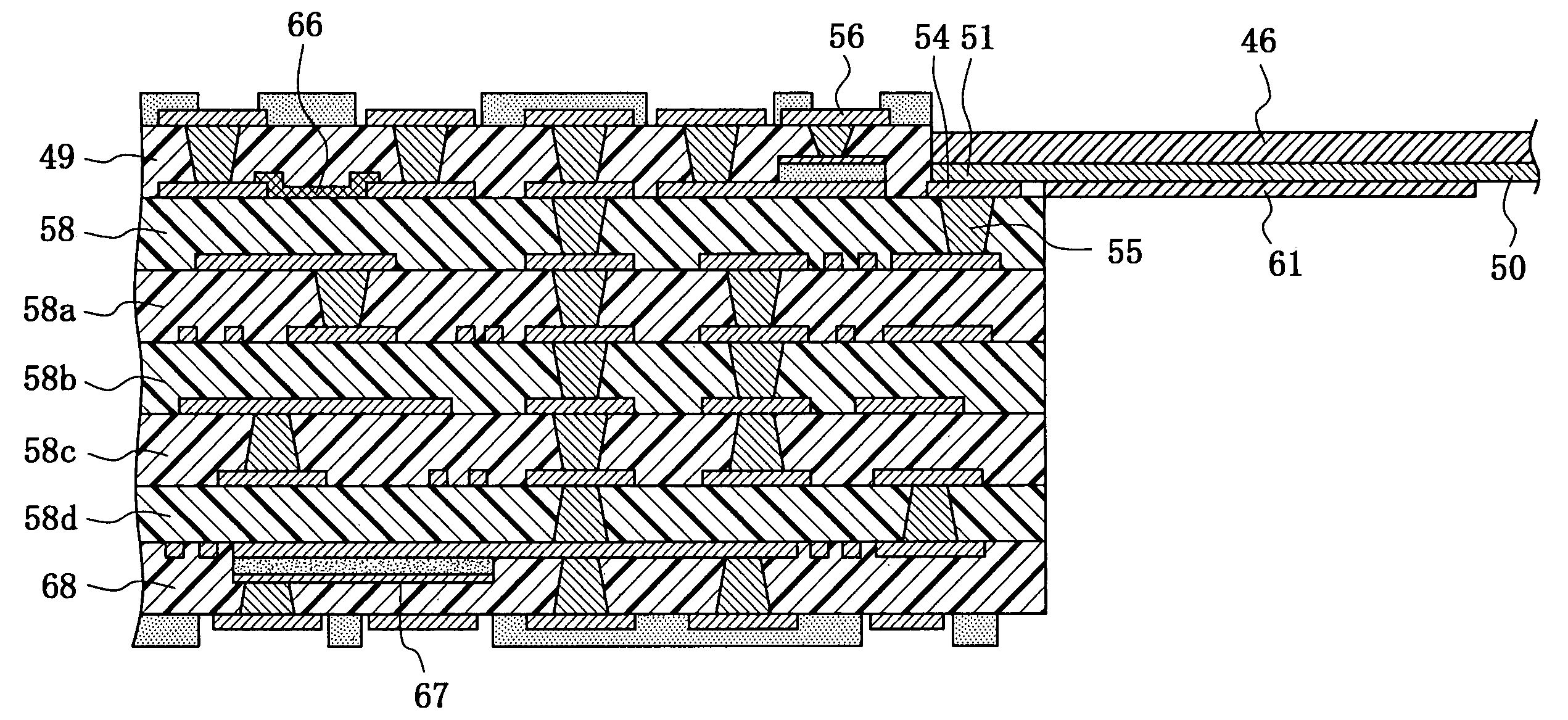

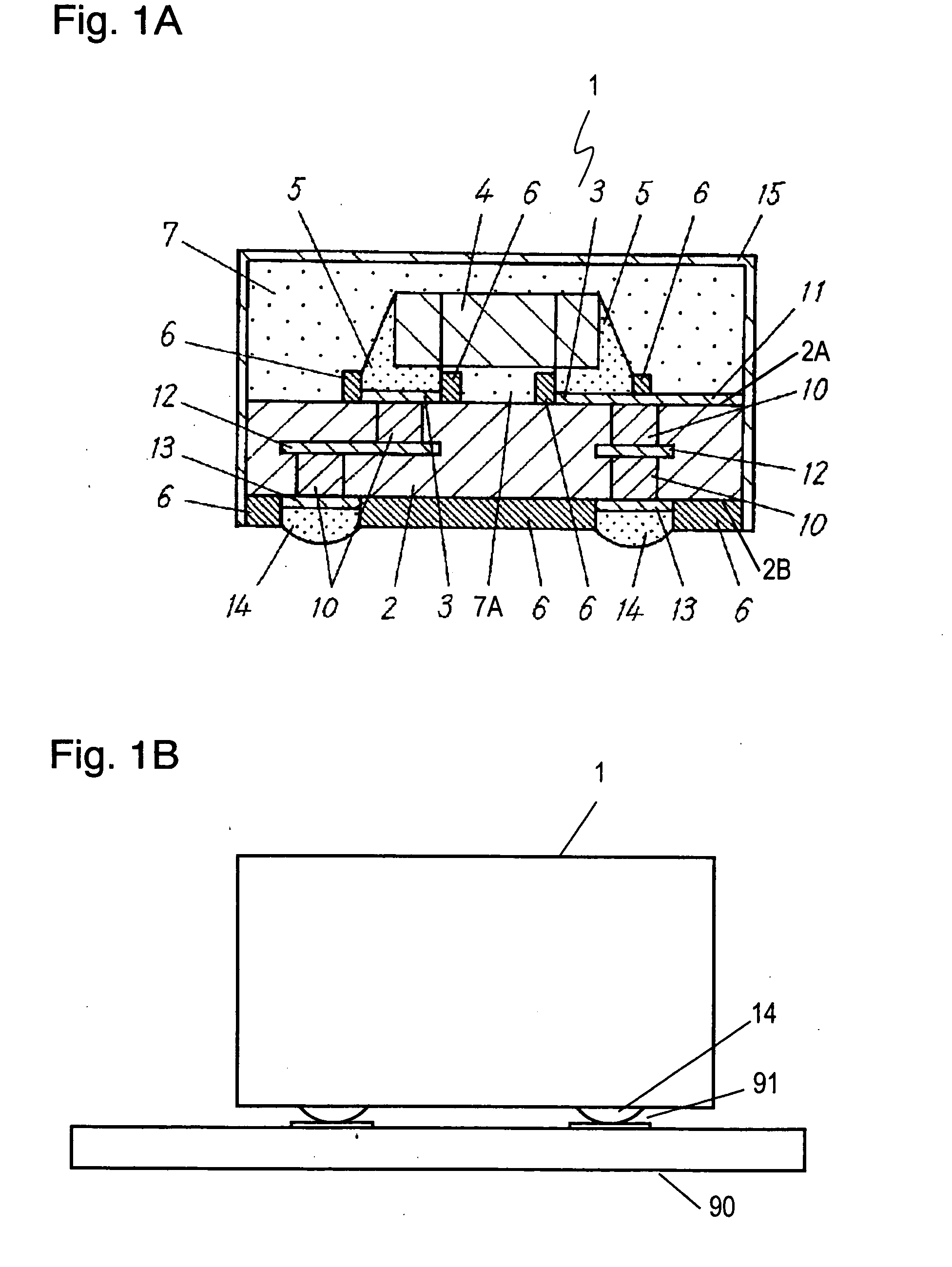

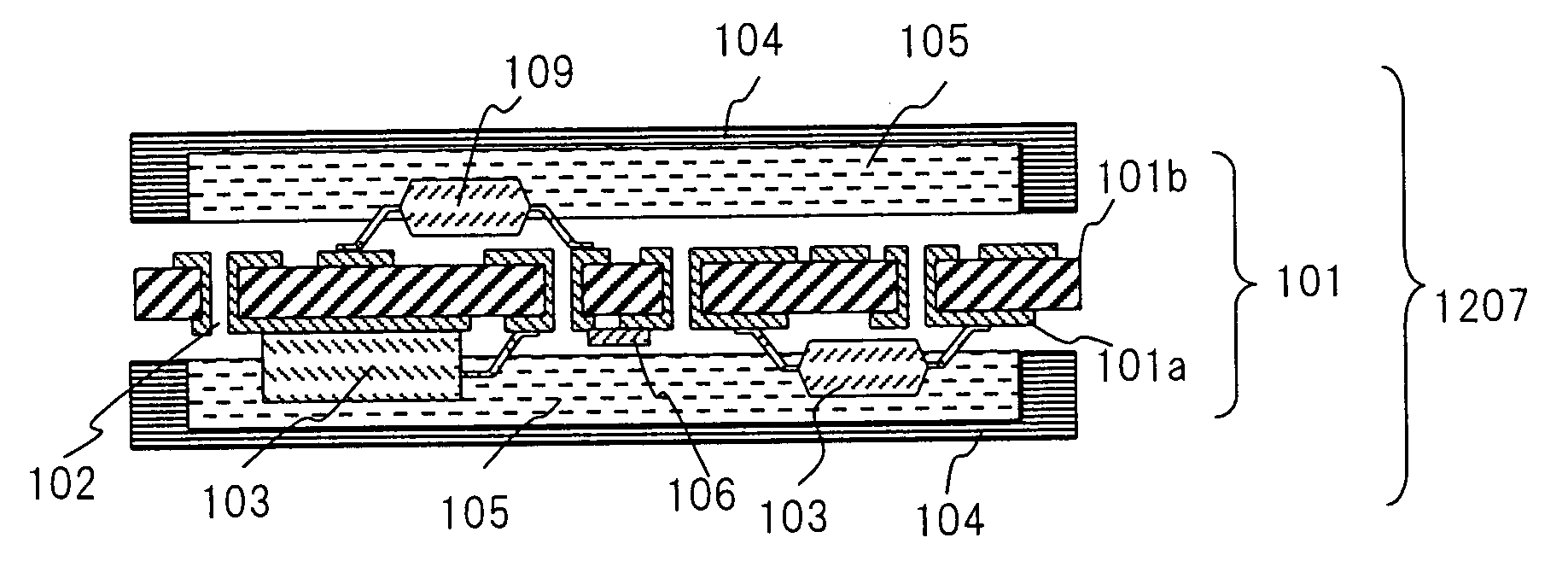

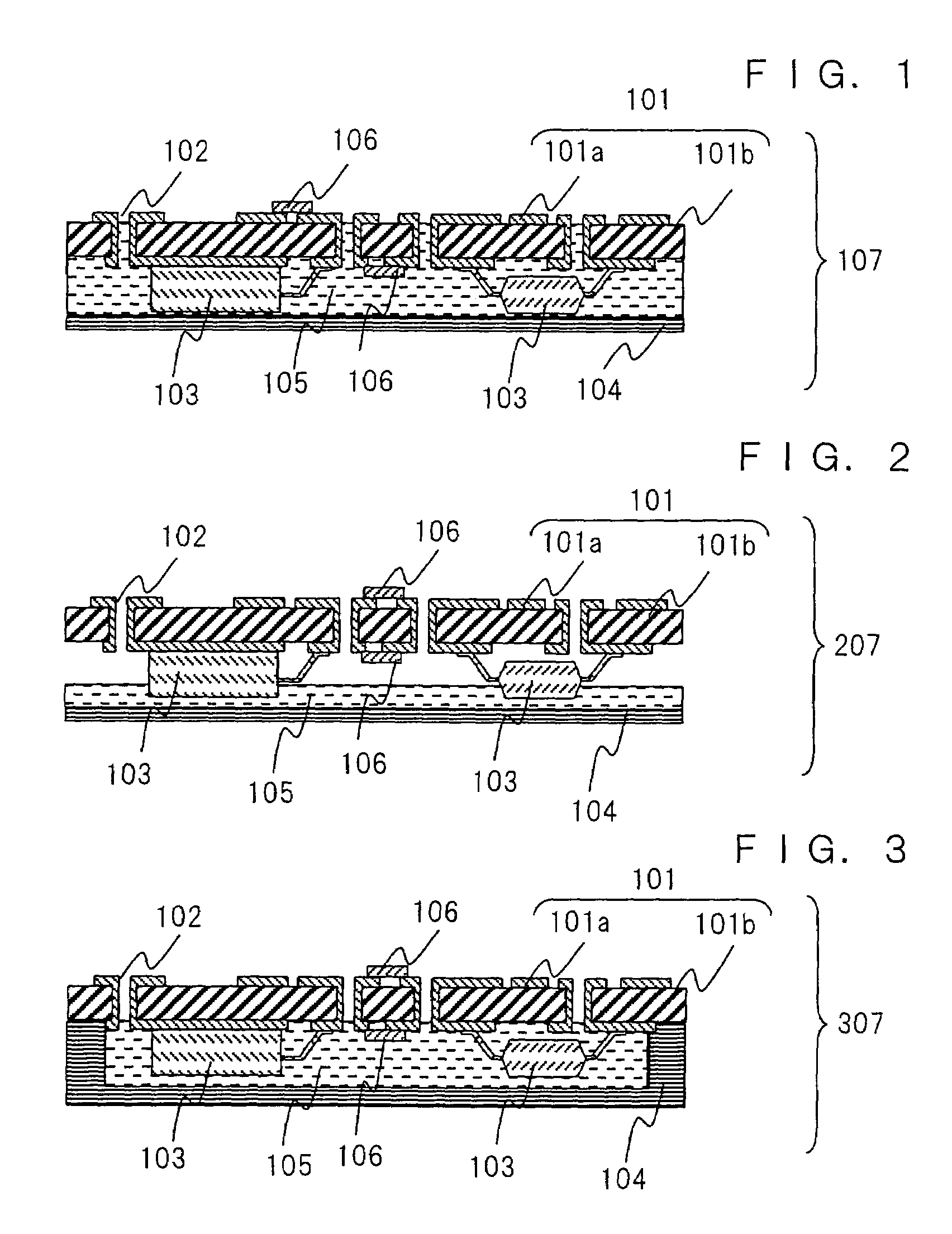

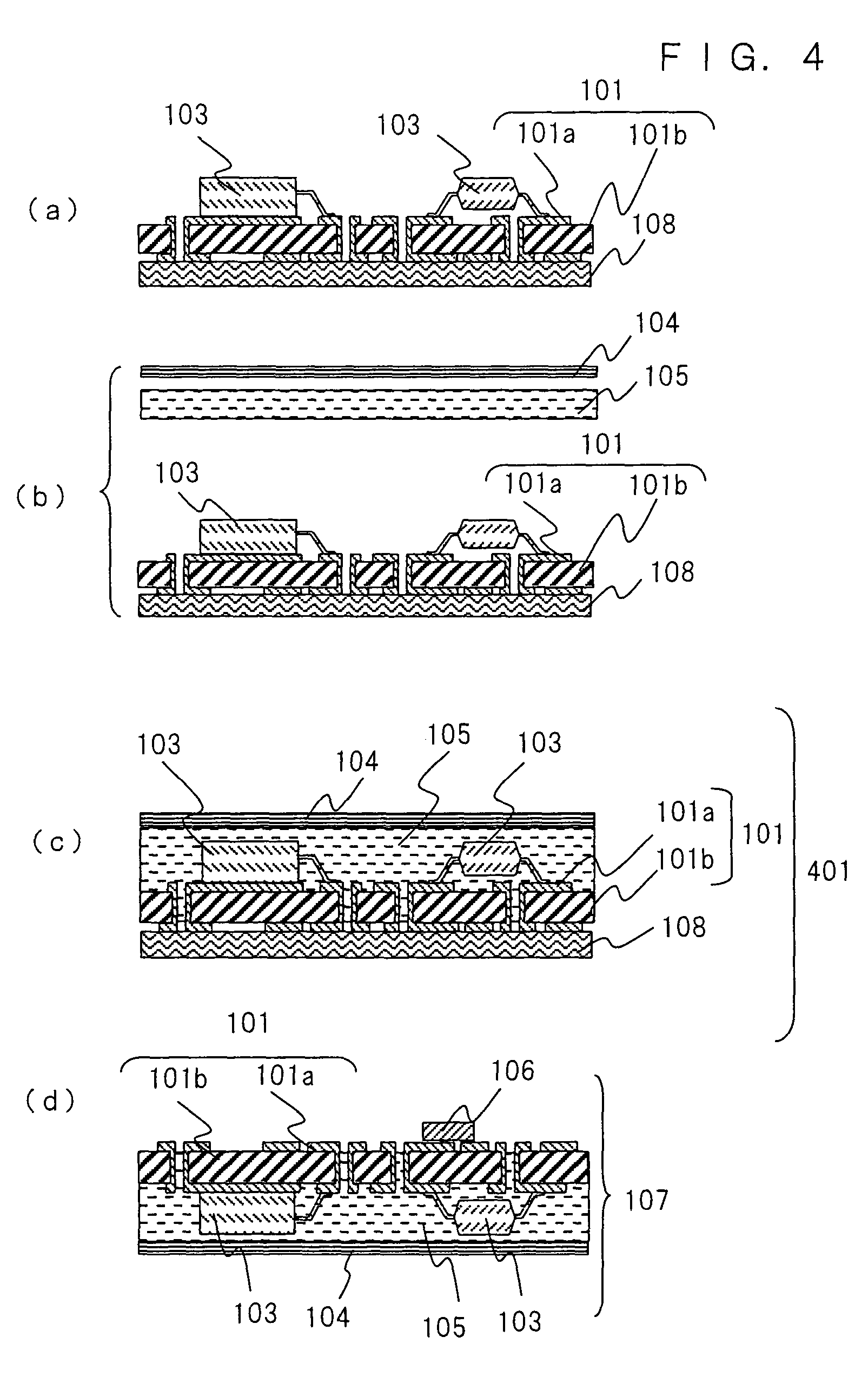

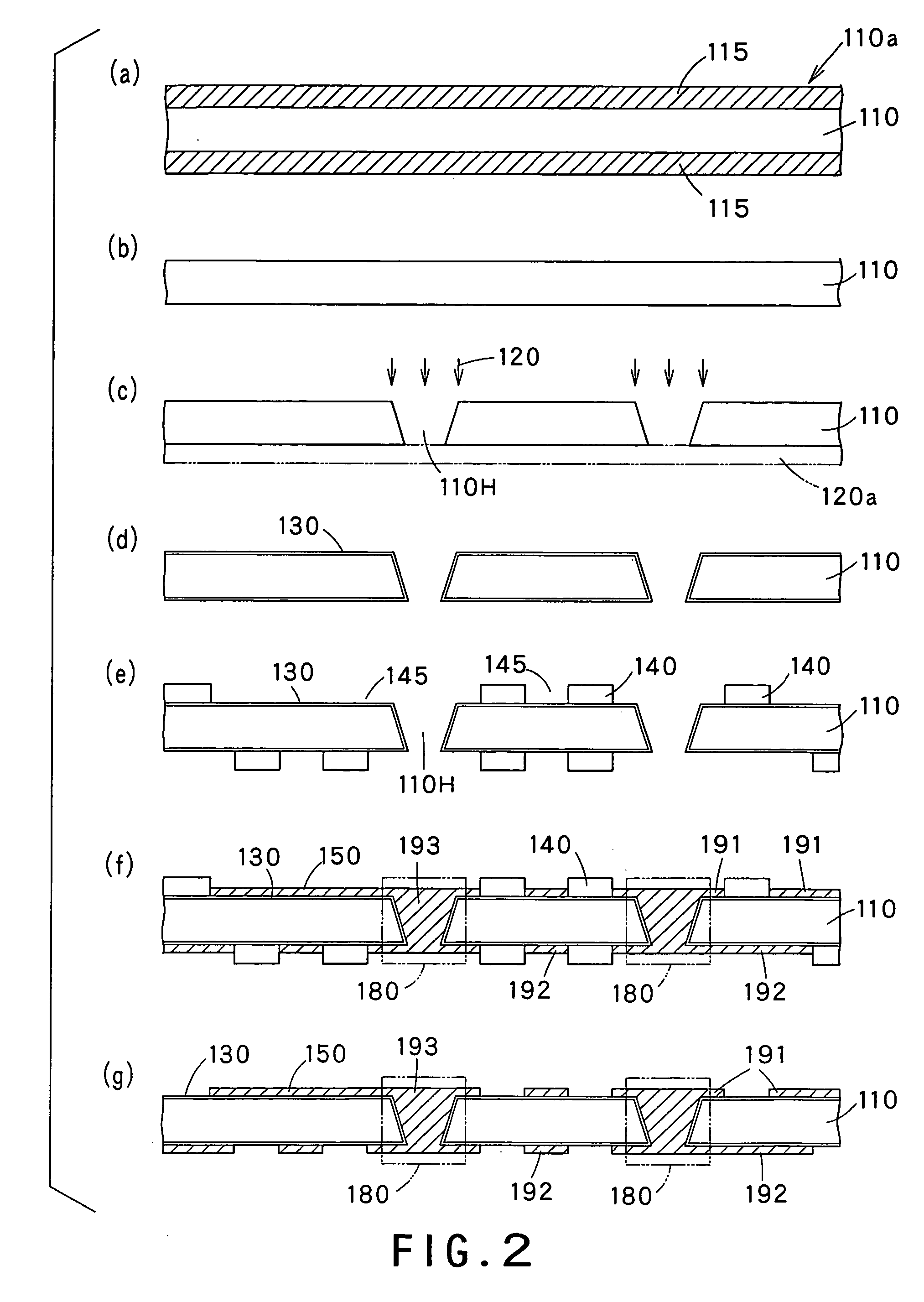

Electronic component-built-in module

InactiveUS6998532B2Final product manufactureSemiconductor/solid-state device detailsResistEngineering

A module includes an electronic component having at least two electrodes, a board having electrodes on its surface to be connected to the electrodes of the electronic component, respectively, solders for connecting the electrodes of the electronic component to the electrodes of the board, respectively, an insulating resin covering the electronic component, the surface of the board, the solder, and the electrodes, and solder resists provided on the surface of the board and around the electrodes of the board, respectively. One of the solder resists is separated from the other electrode at a portion between the electronic component and the board. When this module is mounted on a motherboard, the solder does not flow out of the electrodes even when the solder in the insulating resin melts.

Owner:PANASONIC CORP

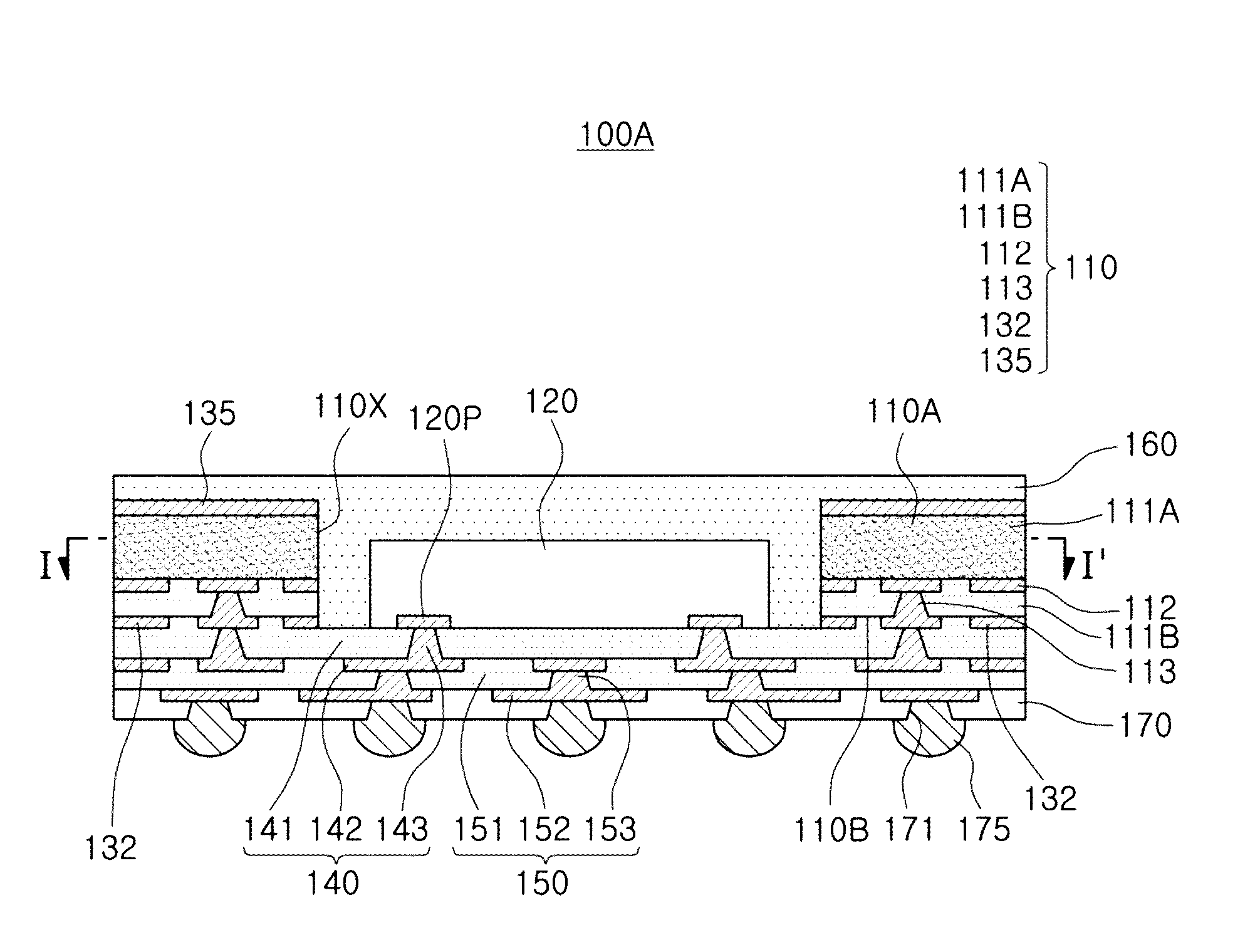

Electronic component package and method of manufacturing the same

ActiveUS20160338202A1Reduce yieldPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringElectronic component

An electronic component package and a method of manufacturing the same are provided. The electronic component package includes a frame having a through-hole, an electronic component disposed in the through-hole of the frame, and a redistribution part disposed at one side of the frame and the electronic component. One or more first wiring layers of the frame are electrically connected to the electronic component through the redistribution part.

Owner:SAMSUNG ELECTRONICS CO LTD

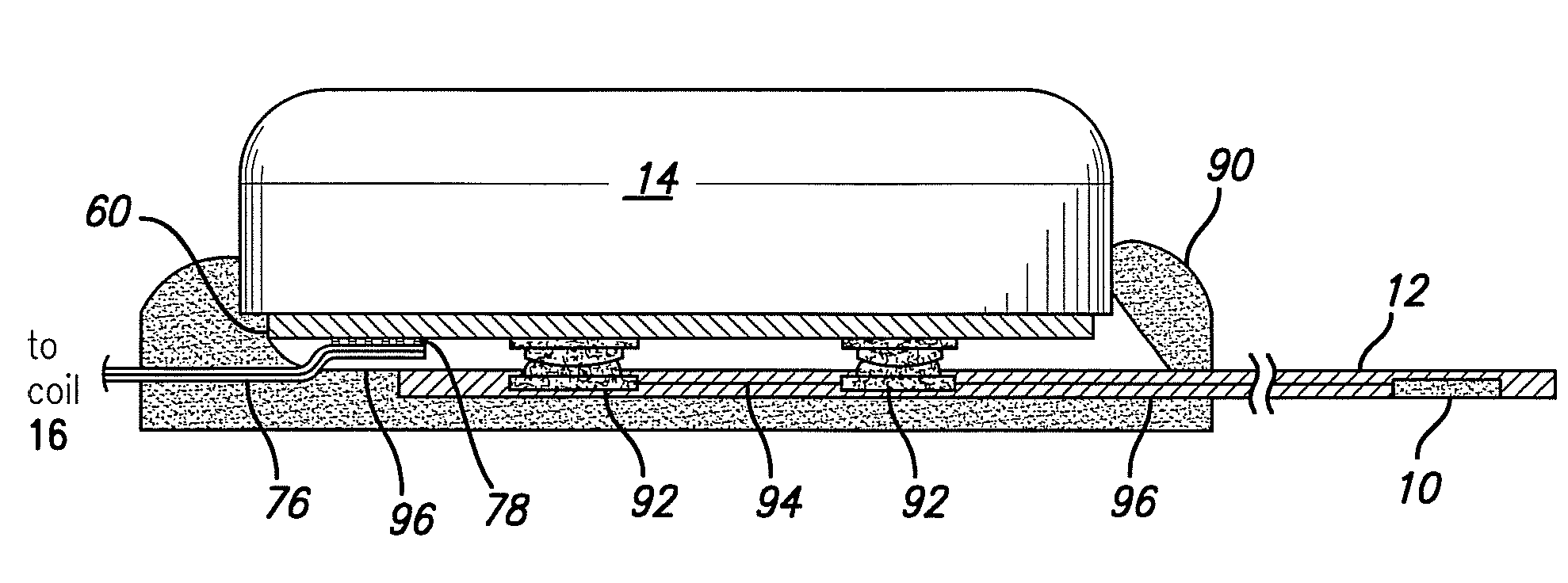

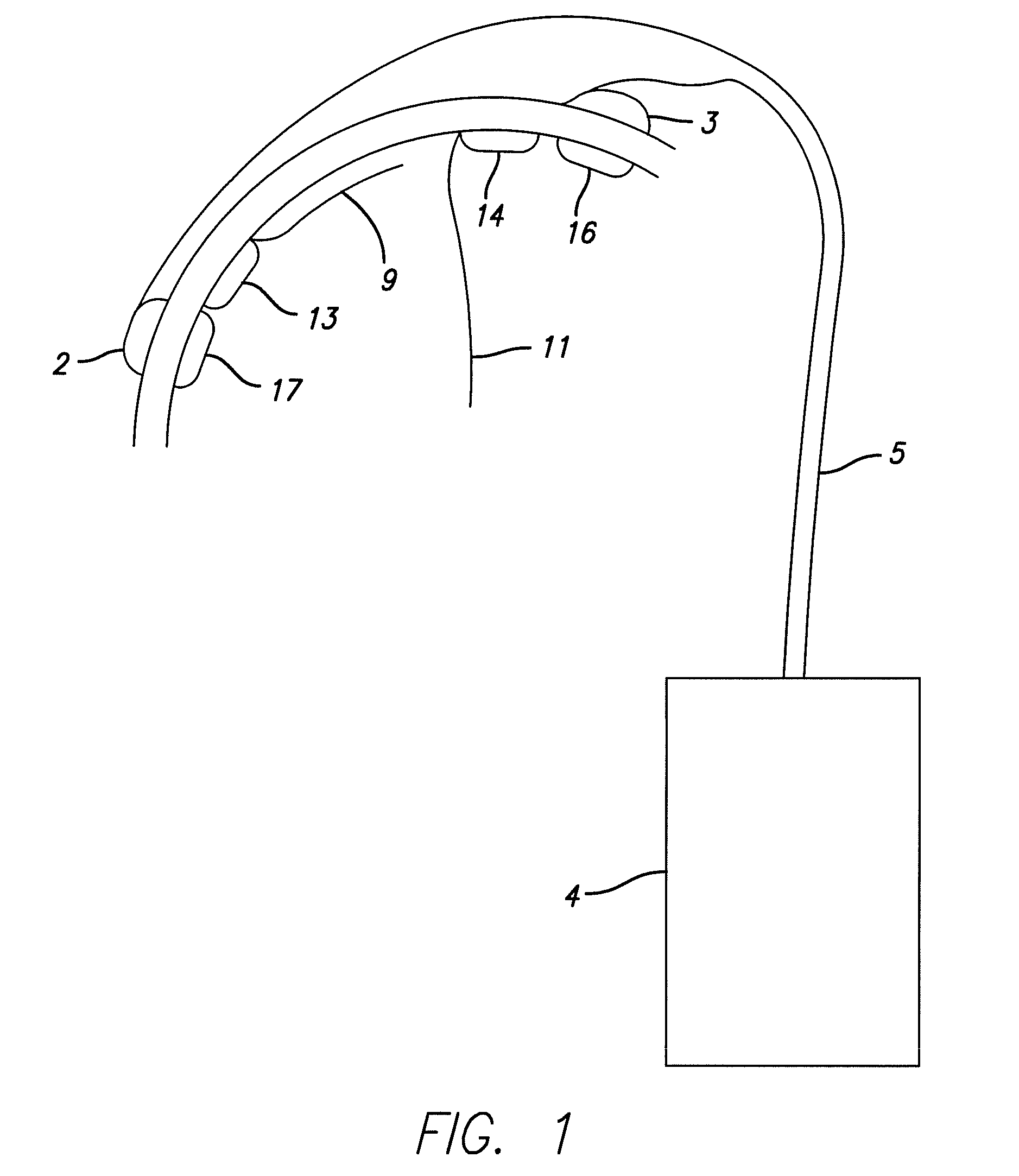

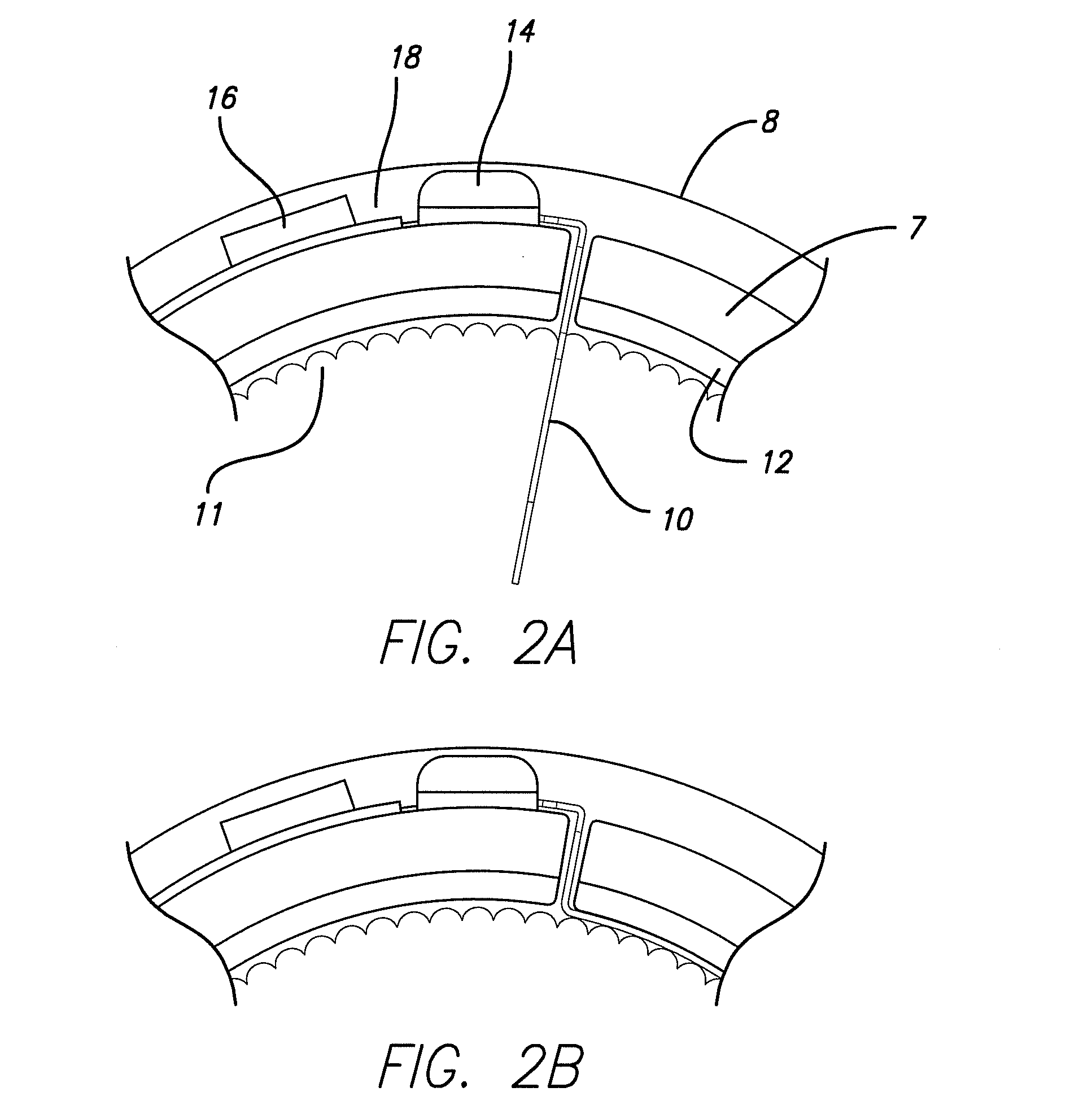

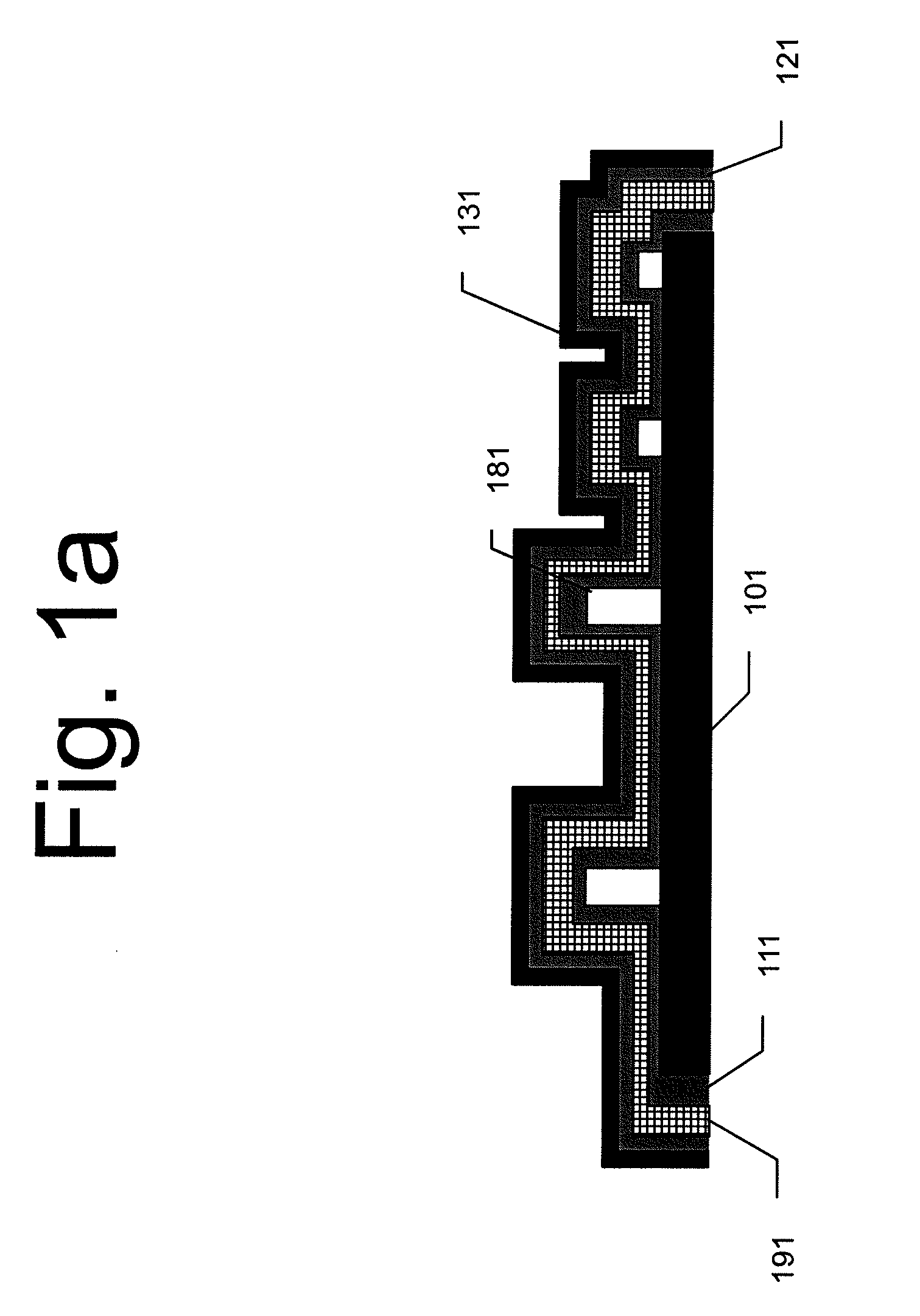

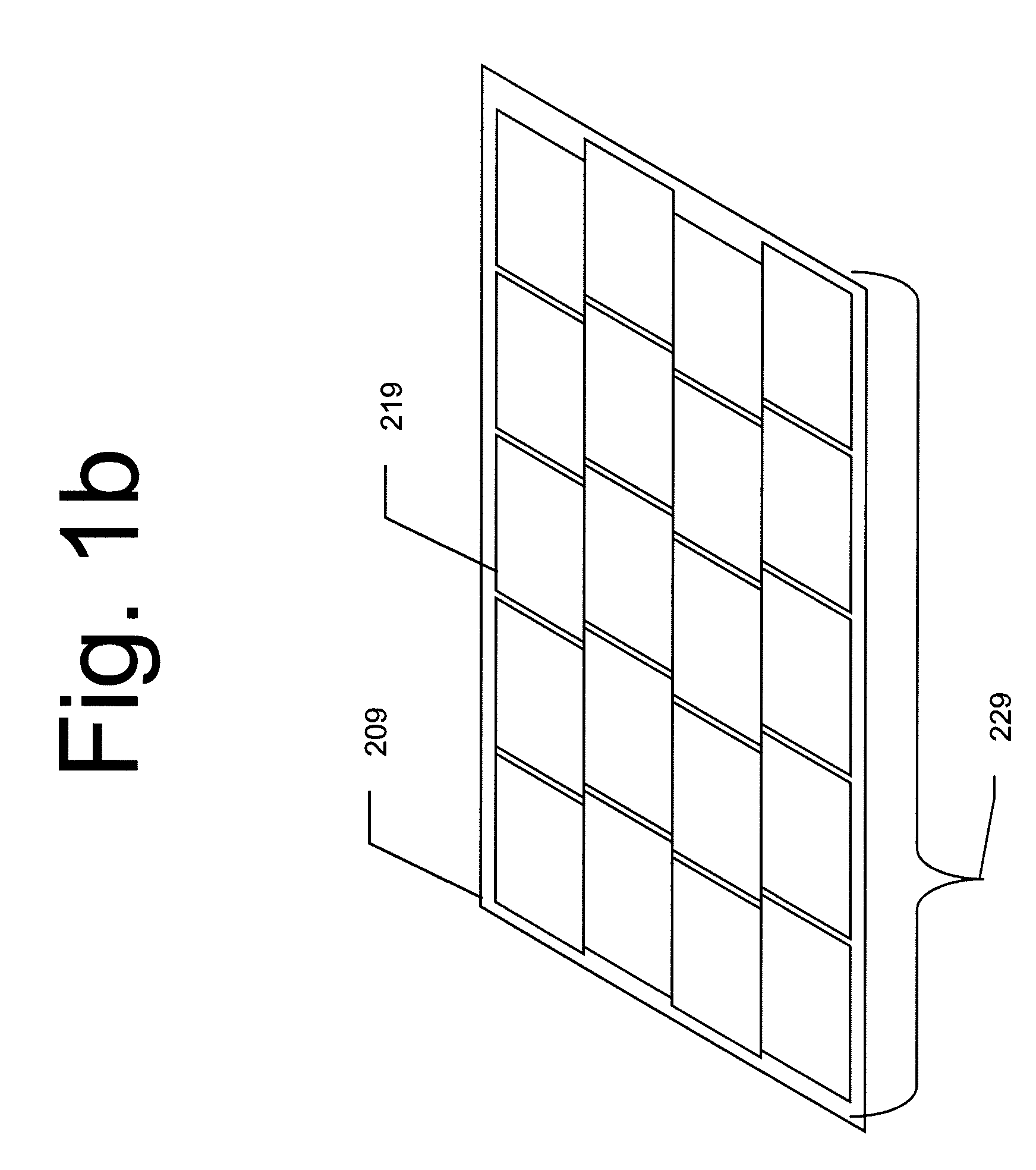

Cortical Implant System for Brain Stimulation and Recording

ActiveUS20150157862A1Shorter electrode arraysLess distortionSemiconductor/solid-state device detailsLaminating printed circuit boardsDiseaseEngineering

The present invention consists of an implantable device with at least one package that houses electronics that sends and receives data or signals, and optionally power, from an external system through at least one coil attached to at least one package and processes the data, including recordings of neural activity, and delivers electrical pulses to neural tissue through at least one array of multiple electrodes that are attached to the at least one package. The device is adapted to electrocorticographic (ECoG) and local field potential (LFP) signals. A brain stimulator, preferably a deep brain stimulator, stimulates the brain in response to neural recordings in a closed feedback loop. The device is advantageous in providing neuromodulation therapies for neurological disorders such as chronic pain, post traumatic stress disorder (PTSD), major depression, or similar disorders. The invention and components thereof are intended to be installed in the head, or on or in the cranium or on the dura, or on or in the brain.

Owner:CORTIGENT INC

Light emitting assembly with heat dissipating support

InactiveUS20050122018A1Low costImprove cooling effectPoint-like light sourceDischarge tube main electrodesLight reflectionEngineering

A light emitting assembly includes a metal substrate for dissipating heat from the assembly. The metal substrate includes an electrically insulating layer or coating on at least one side. Circuit traces are applied to the electrically insulating layer using either thick or thin film techniques. At least the ends of the circuit traces include a metallic section to which leads of light emitting elements are soldered or wire-bonded. A metallic section is provided adjacent the light emitting element to transfer heat to the underlying substrate and / or to reflect light from the element away from the substrate. A clear finish retards tarnishing of the reflecting metallic section.

Owner:INT RESISTIVE OF TEXAS

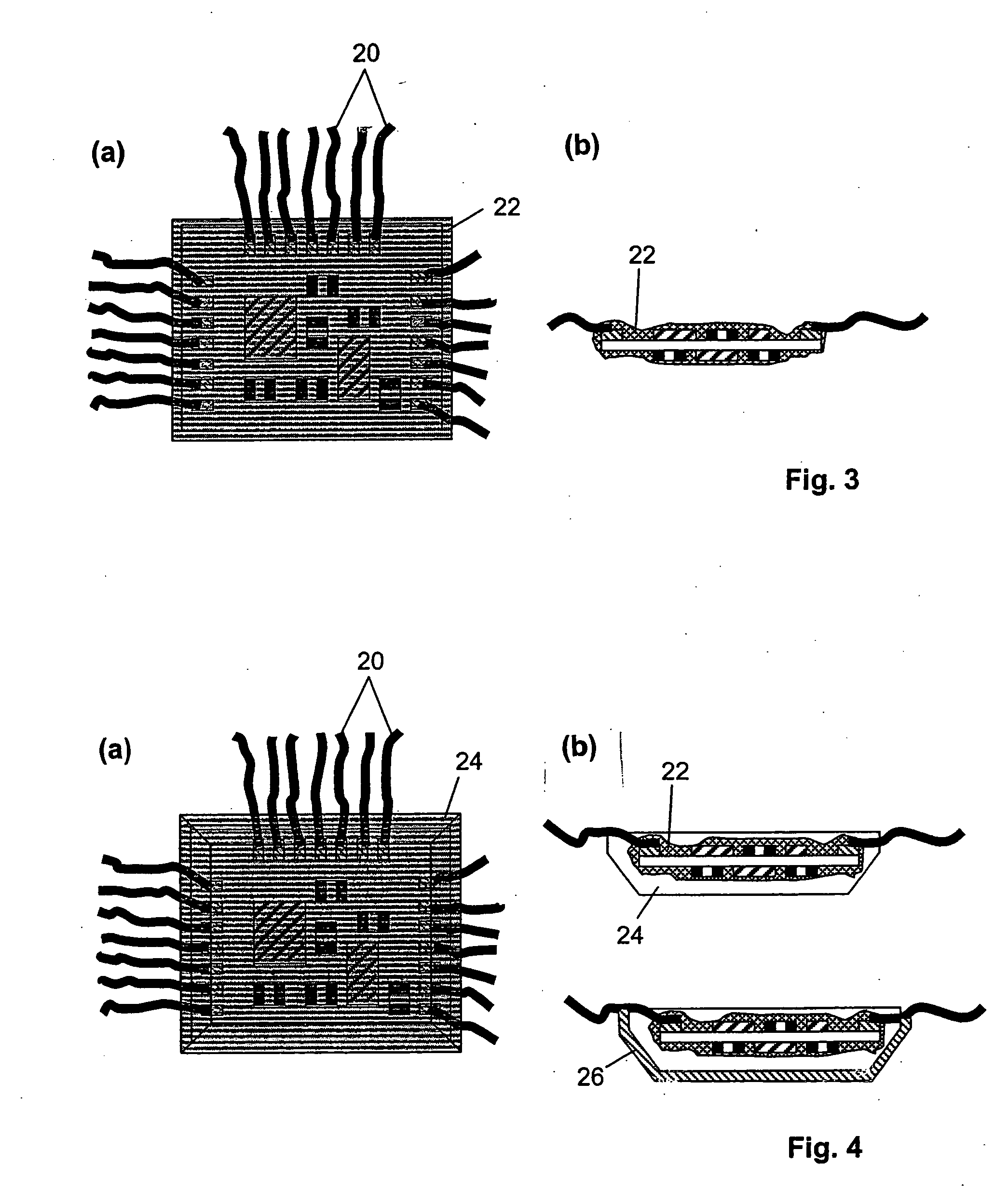

Method and apparatus for the integration of electronics in textiles

InactiveUS20050029680A1Simple and secure mechanical connection of componentGood chemical resistanceSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorAdhesive

Apparatus having at least one textile material in which at least one flexible, wire-like and / or thread-like electric conductor is arranged, at least one electronic component which has at least one electrically conductive contact point which is connected electrically to the conductor, at least a first hard encapsulation which covers and mechanically stabilizes at least the contact point of the component, and at least a second encapsulation, which is designed such that it permits a mechanical connection of the component to the textile material, wherein the second encapsulation comprises a silicone, a polyurethane and / or a textile adhesive.

Owner:INFINEON TECH AG

Ground pad structure for preventing solder extrusion and semiconductor package having the ground pad structure

ActiveUS7173828B2Reduce generationQuality improvementPrinted circuit assemblingFinal product manufactureSolder maskSemiconductor package

A ground pad structure for preventing solder extrusion and a semiconductor package having the ground pad structure are disclosed, wherein the ground pad structure has the ground pads located along the circumference of its ground plane be formed in a non-solder mask defined manner. Accordingly, a good grounding quality is maintained, and the occurrence of the electrical bridging among the adjacent conductive traces can be avoided as the extrusion of the molten solder bumps from the ground pads located along the ground pad structure's circumference toward their adjacent conductive traces is effectively prevented.

Owner:SILICONWARE PRECISION IND CO LTD

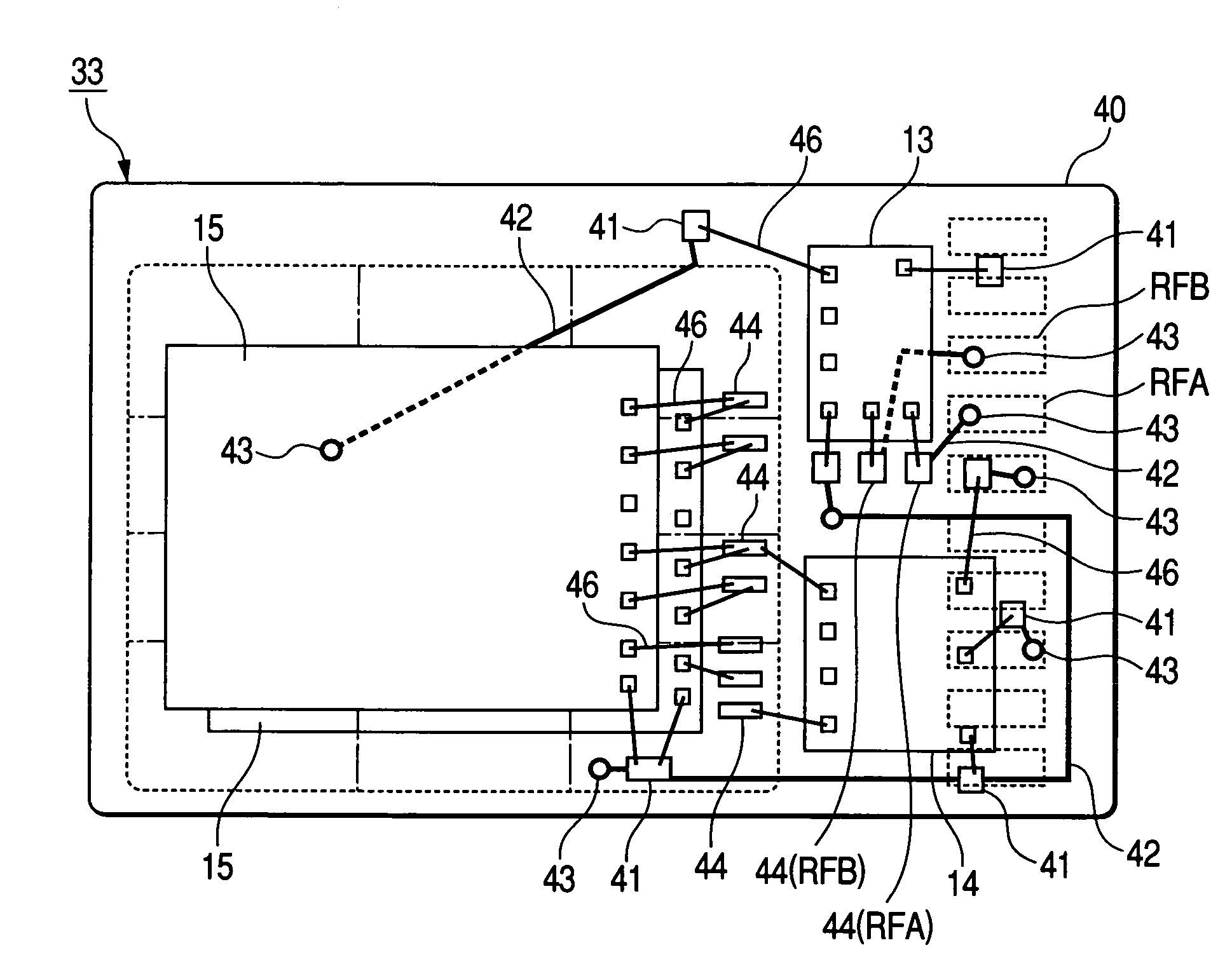

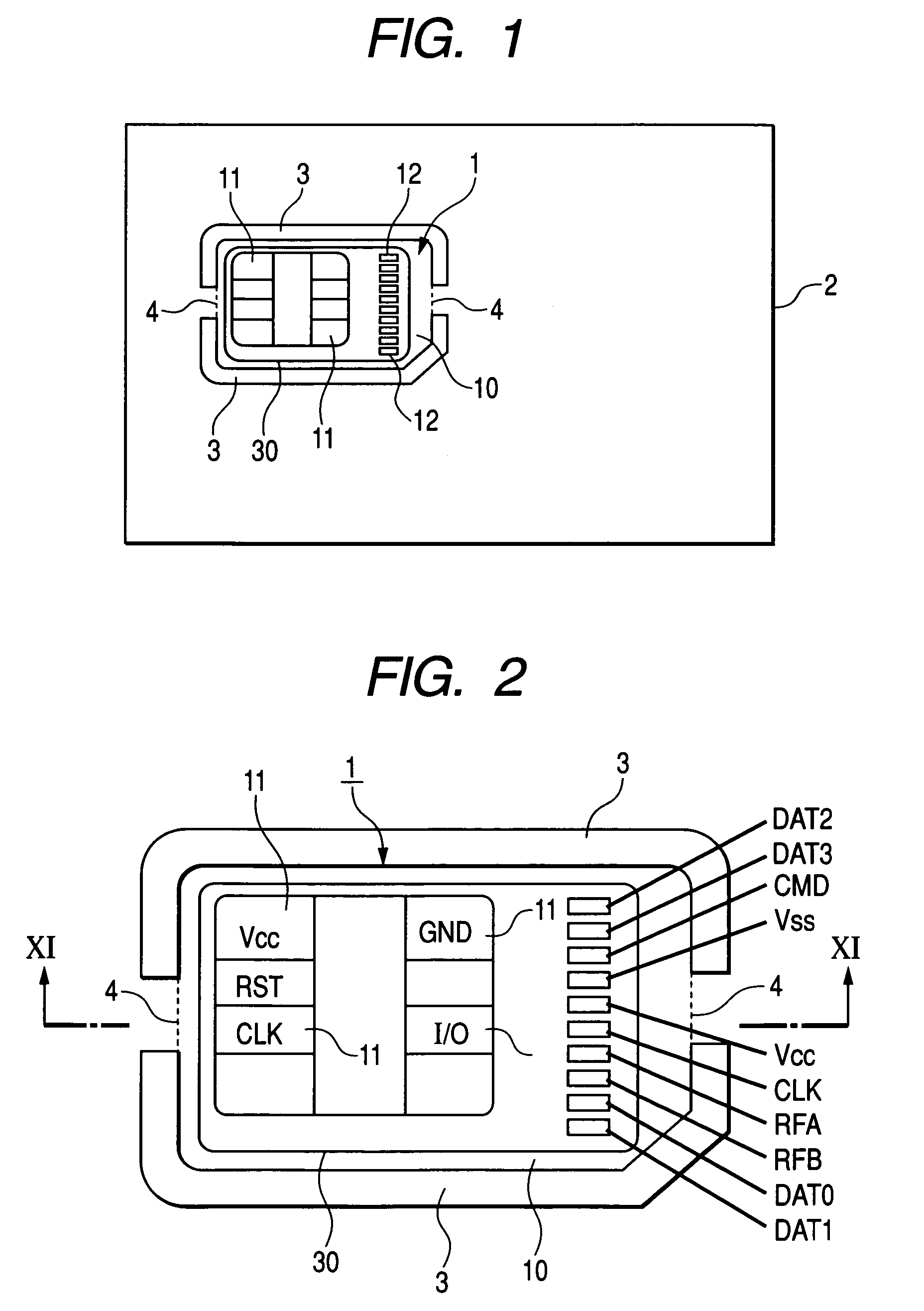

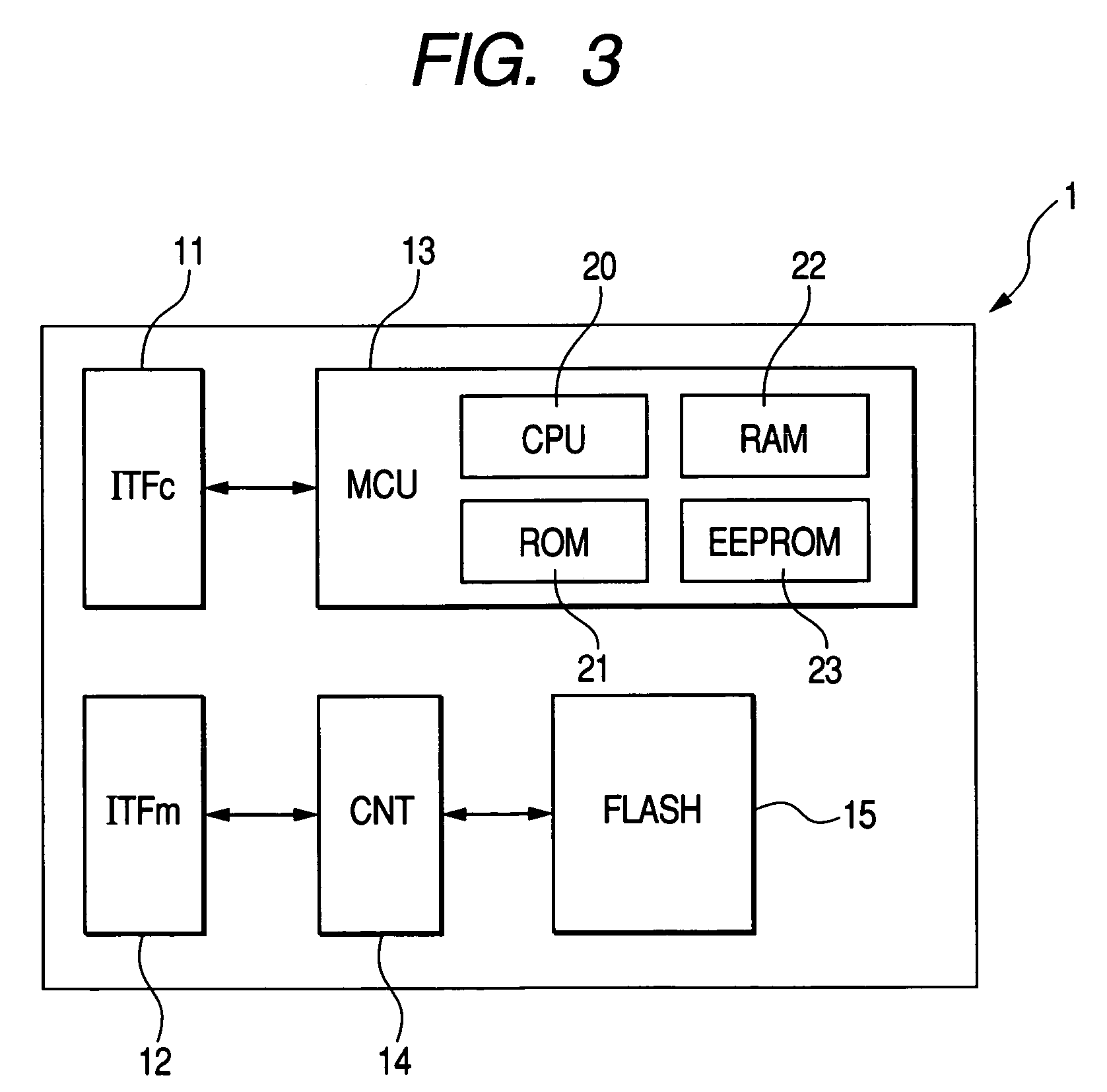

IC card module

InactiveUS7296754B2Improve reliabilitySolid-state devicesRead-only memoriesMicrocomputerComputer module

An IC card module includes first external connecting terminals and second external connecting terminals both exposed to one surface of a card substrate, a microcomputer connected to the first external connecting terminals, a memory controller connected to the second external connecting terminals, and a volatile memory connected to the memory controller. The shape of the card substrate and the layout of the first external connecting terminals are based on a standard of plug-in UICC of ETSI TS 102 221 V4.4.0 (2001-10). The second external connecting terminals are disposed outside the minimum range of the terminal layout based on the standard for the first external connecting terminals. The first and second external connecting terminals include signal terminals electrically separated from one another.

Owner:RENESAS ELECTRONICS CORP

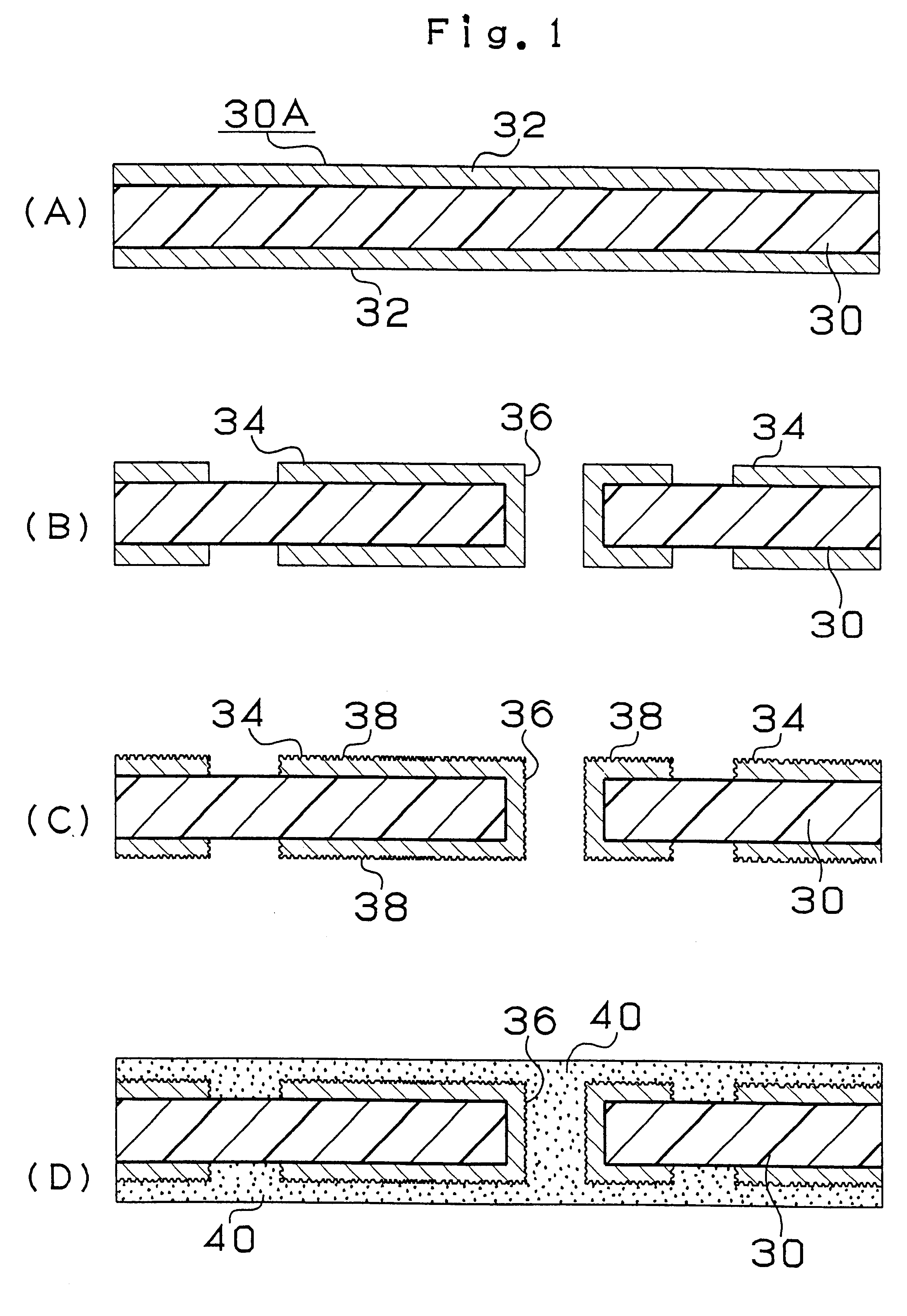

Manufacturing method of a multilayered printed circuit board having an opening made by a laser, and using electroless and electrolytic plating

InactiveUS6591495B2Satisfactory productivityAvoid separationSolid-state devicesInsulating layers/substrates workingCopper foilPulse shaping

An opening is formed in resin by a laser beam so that a via hole is formed. Copper foil, the thickness of which is reduced to 3 mum by etching to lower the thermal conductivity, is used as a conformal mask. Therefore, an opening is formed in the resin and the number of irradiation of pulse-shape laser beam is reduced. Thus, occurence of undercut of the resin, which forms an interlayer insulating resin layer, can be prevented and the reliability of the connection of the via holes can be improved.

Owner:IBIDEN CO LTD

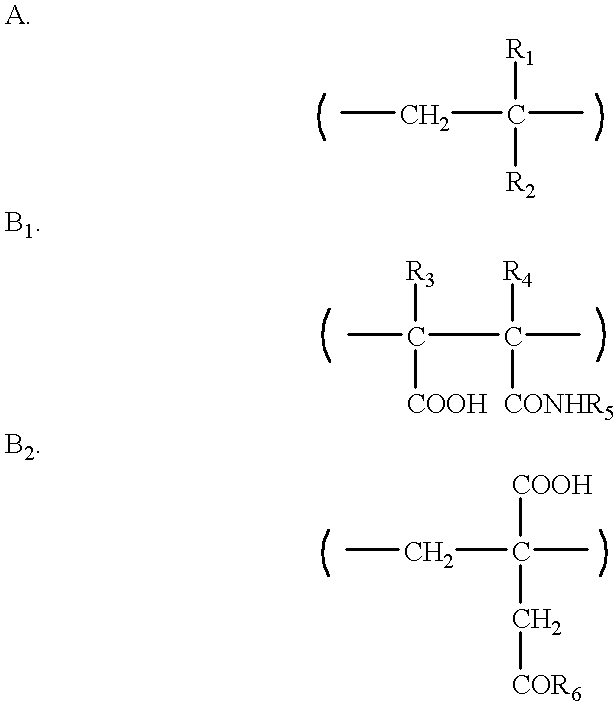

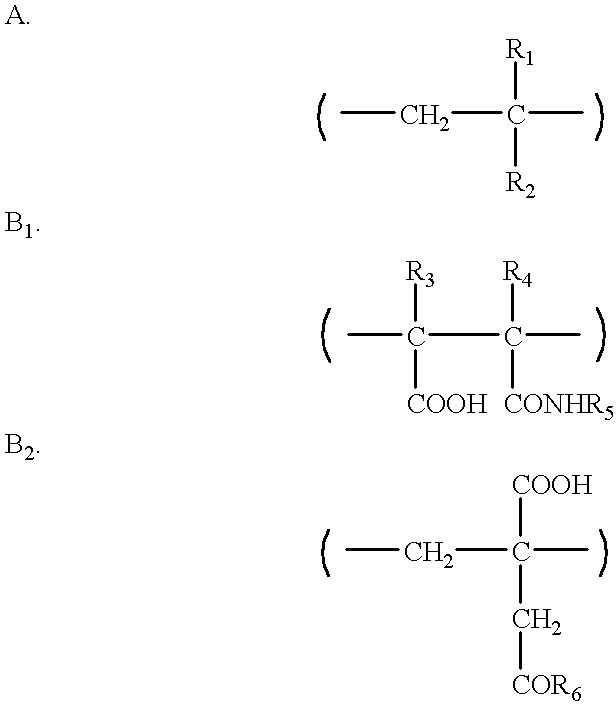

Flexible, flame-retardant, aqueous-processable photoimageable composition for coating flexible printed circuits

A flexible, flame-retardant, aqueous processable, photoimageable resin composition for forming a permanent, protective coating film for printed circuitry and a multilayer photoimageable element containing a layer of the photoimageable resin composition in combination with a low tack photoimageable resin sublayer and a temporary support film are disclosed. The photoimageable resin composition has excellent aqueous developability and provides a cured coating film having good flexibility, adhesion, solvent resistance, surface hardness, thermal resistance, electrical insulating properties and flame retardancy.

Owner:EI DU PONT DE NEMOURS & CO

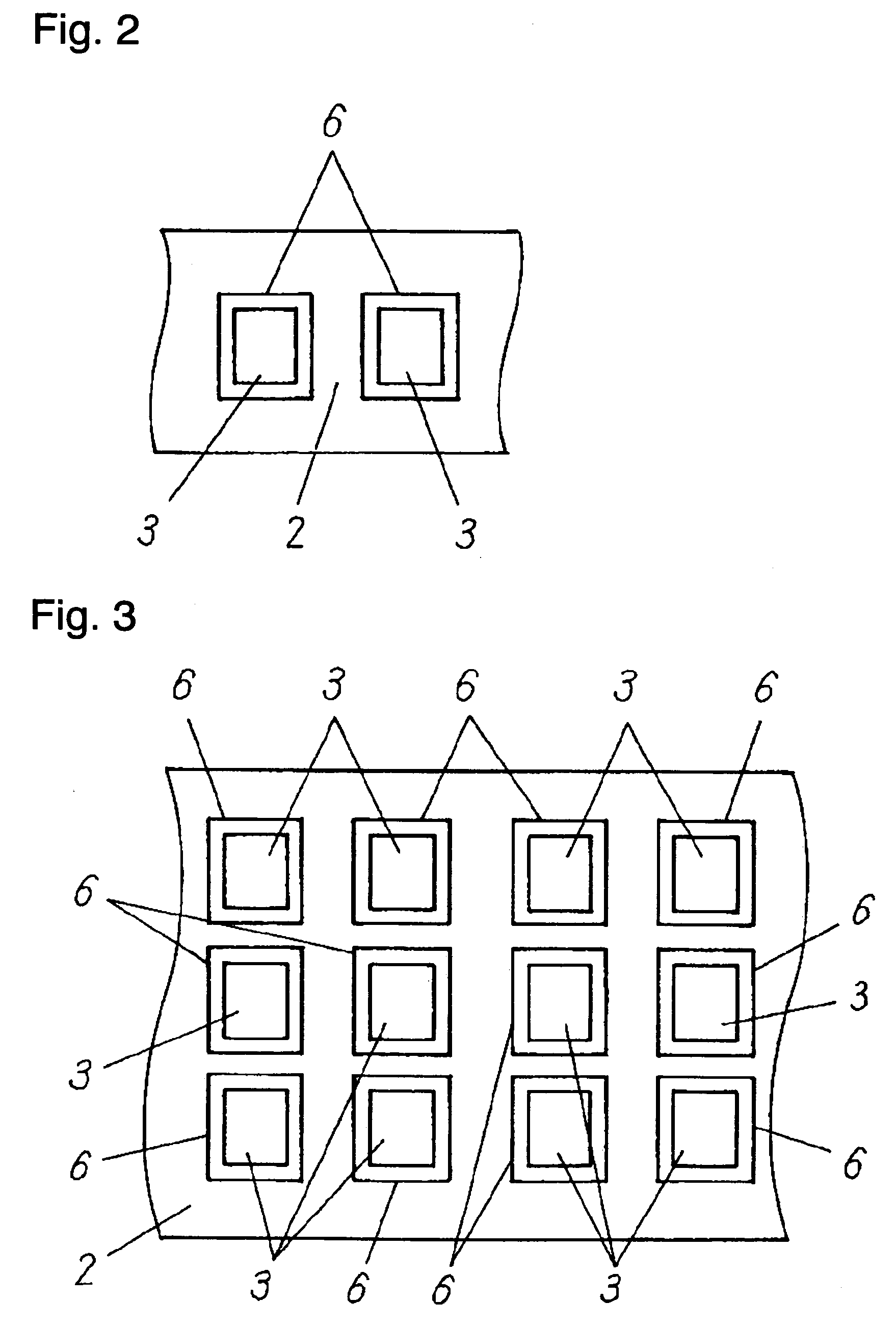

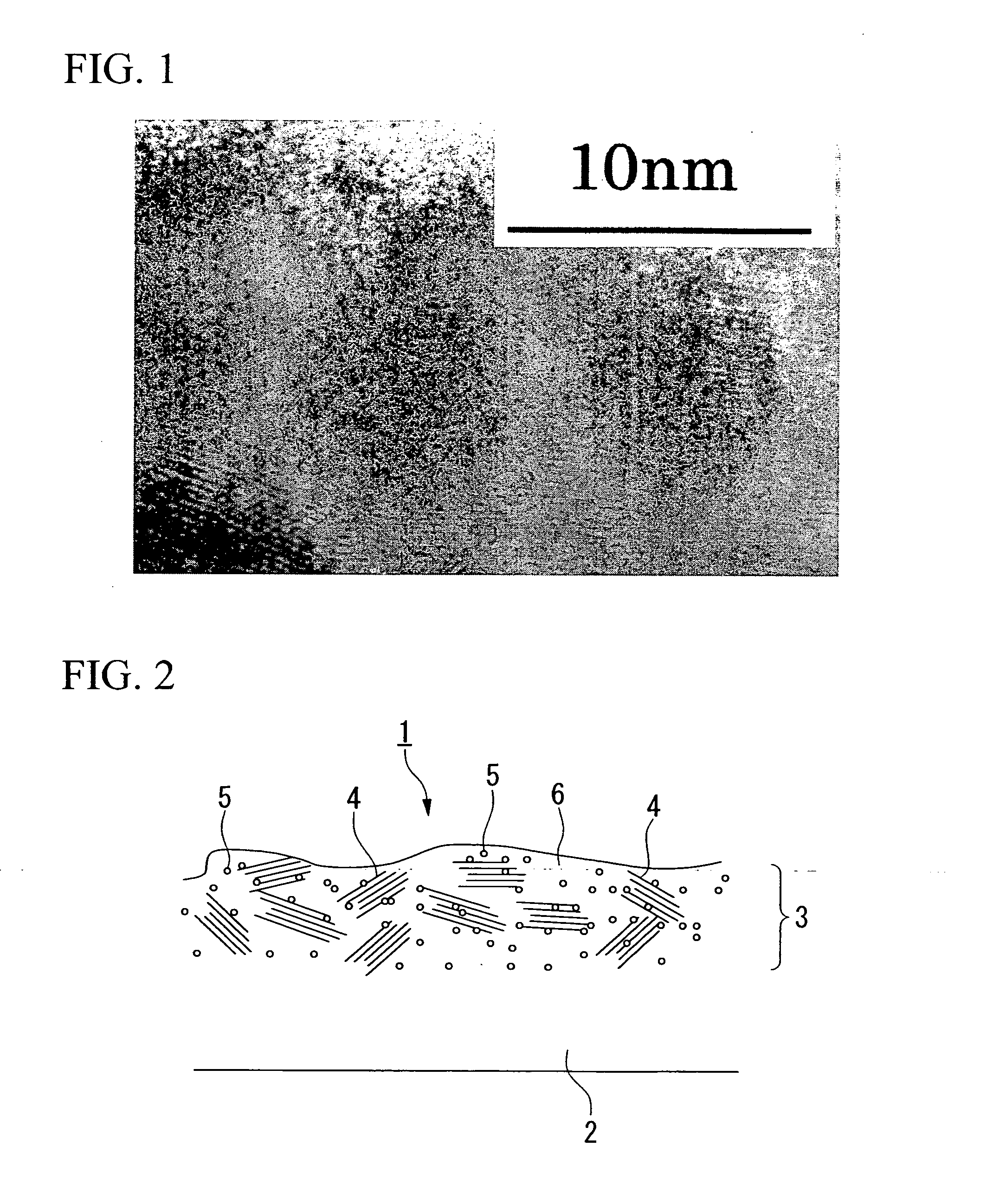

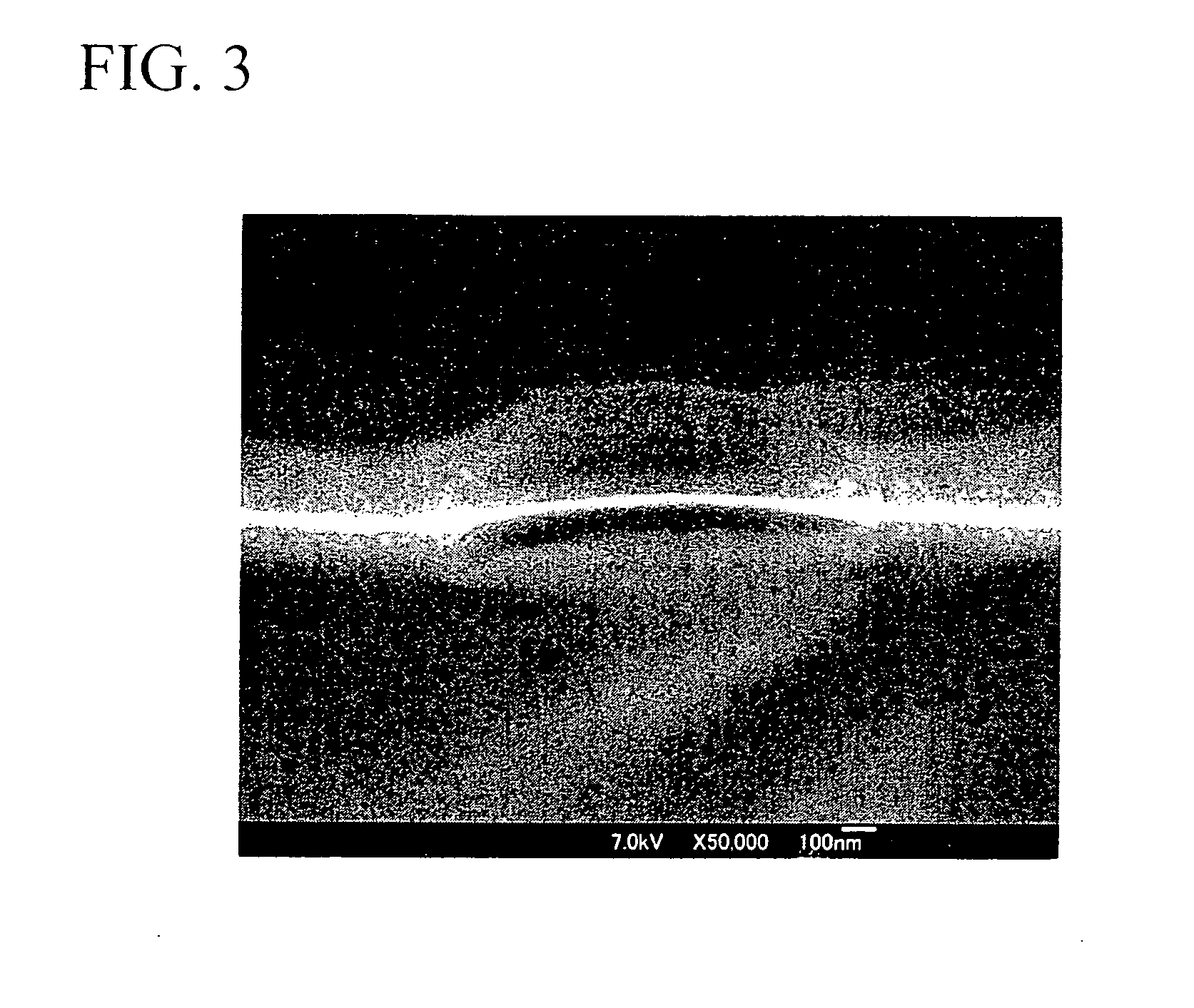

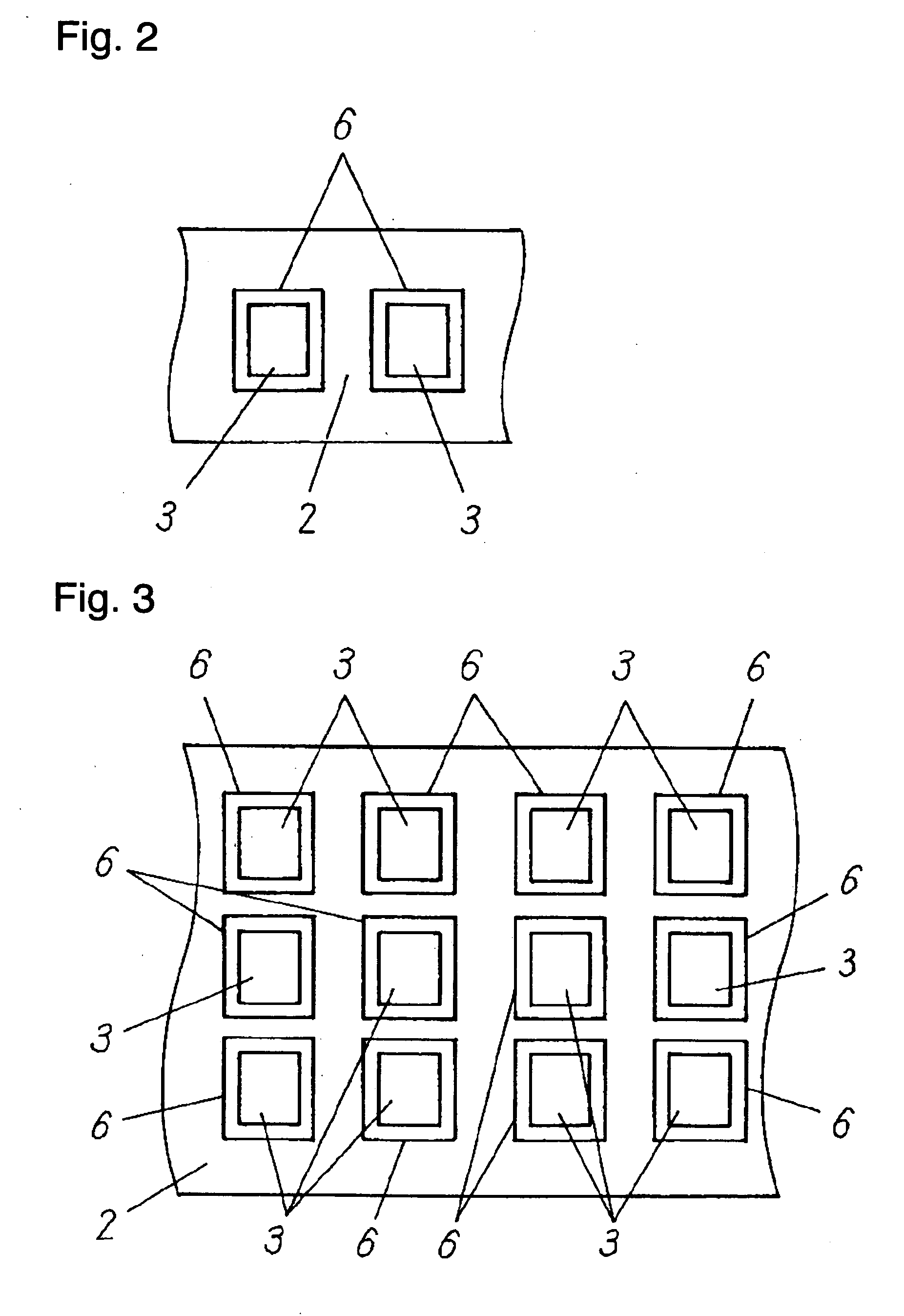

Electromagnetic noise suppressor, article with electromagnetic noise suppressing function, and their manufacturing methods

InactiveUS20060083948A1Eliminate the effects ofMeet cutting requirementsMagnetic/electric field screeningCross-talk/noise/interference reductionGas phaseSuppressor

An electromagnetic noise suppressor of the present invention includes a base material 2 containing a binding agent and a composite layer 3 formed by integrating the binding agent that is a part of the base material 2 and the magnetic material. This electromagnetic noise suppressor has high electromagnetic noise suppressing effect in the sub-microwave band, and enables it to reduce the space requirement and weight. The electromagnetic noise suppressor can be manufactured by forming the composite layer 3 on the surface of the base material 2 by physical vapor deposition of the magnetic material onto the surface of the base material 2. The article with an electromagnetic noise suppressing function of the present invention is an electronic component, a printed wiring board, a semiconductor integrated circuit or other article of which at least a part of the surface is covered by the electromagnetic noise suppressor of the present invention.

Owner:SHIN-ETSU POLYMER CO LTD

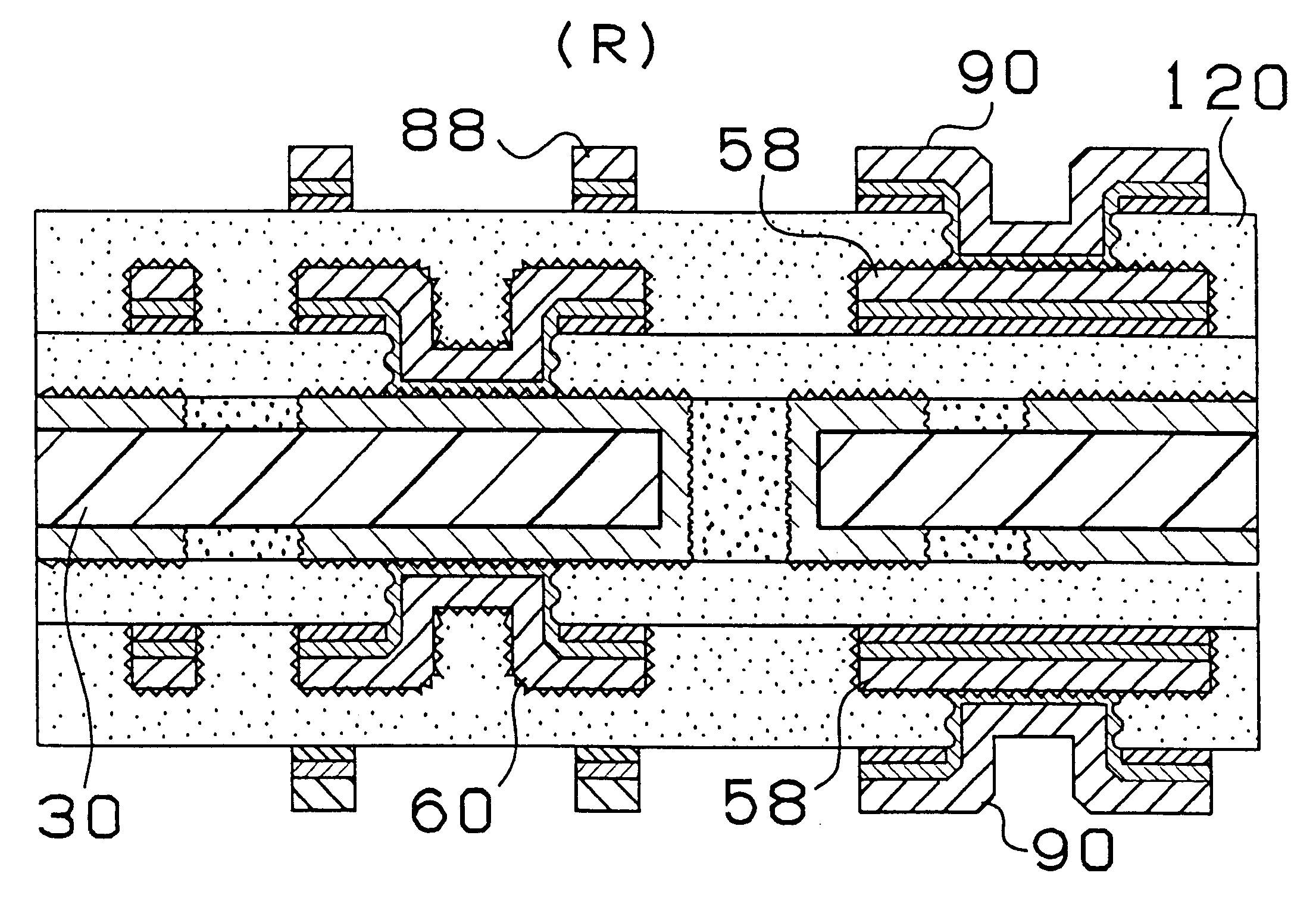

Rigid-flex wiring board and method for producing same

InactiveUS20070012475A1Signal transmission is stableImprove electrical performancePrinted circuit assemblingIncandescent ignitionAnisotropic conductive adhesiveElectrical connection

In a flex-rigid wiring board in which a rigid substrate formed from a rigid base material and a flexible substrate formed from a flexible base material are stack-joined and electrically connected to each other, the flexible substrate including a conductive layer having interconnecting electrode pads provided on at least one surface thereof, and the rigid substrate including a conductive layer having interconnecting electrode pads provided on at least one surface thereof in a position opposite to the interconnecting electrode pads on the rigid substrate, are locally connected electrically to each other with an anisotropic conductive adhesive layer interposed between conductive layers of substrate portions each including at least the interconnecting electrode pads. In this flex-rigid wiring board, transmission of high-frequency signals can be prevented from being delayed, noises can be suppressed, and an excellent electrical connection and connection reliability be assured.

Owner:IBIDEN CO LTD

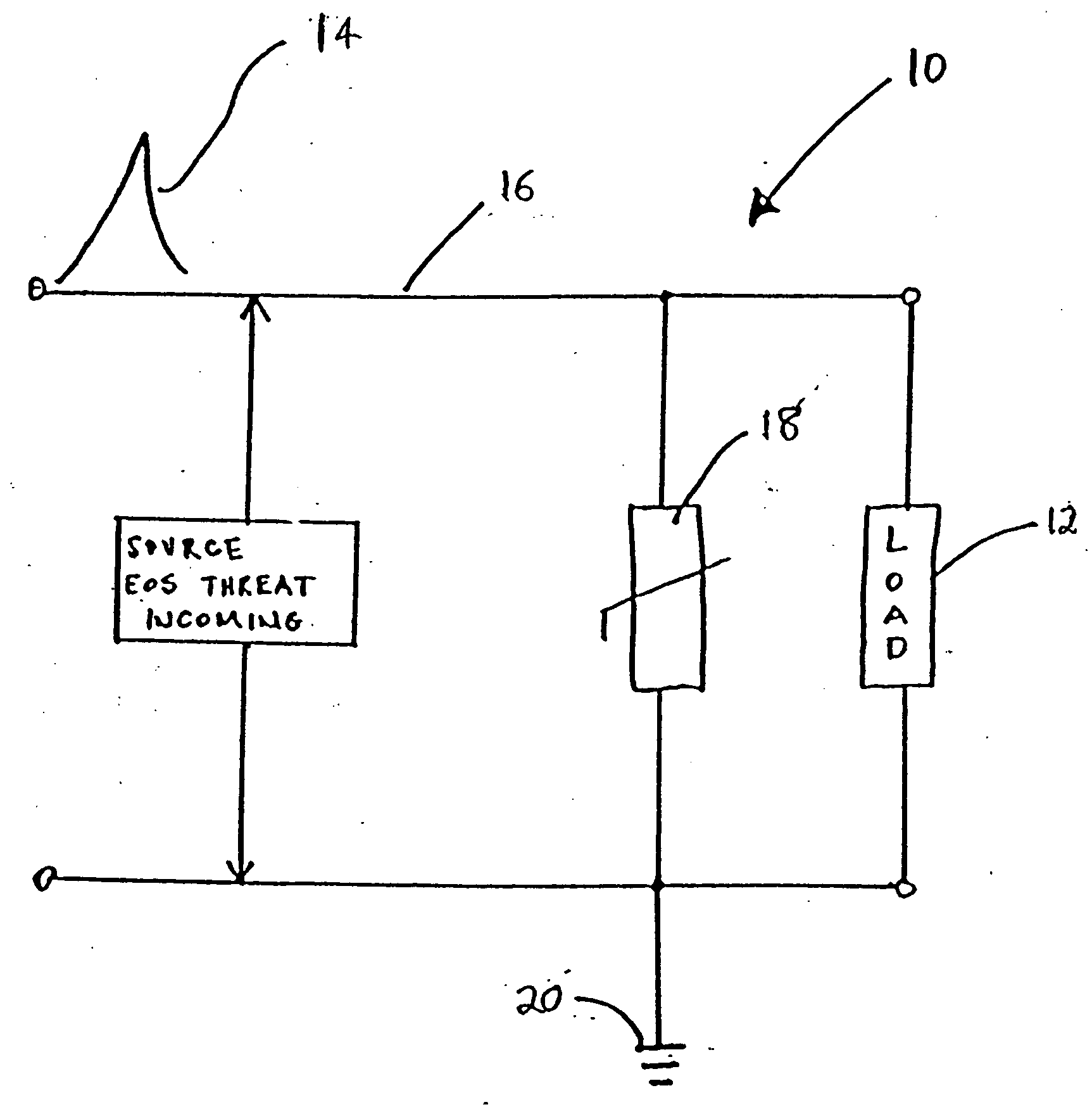

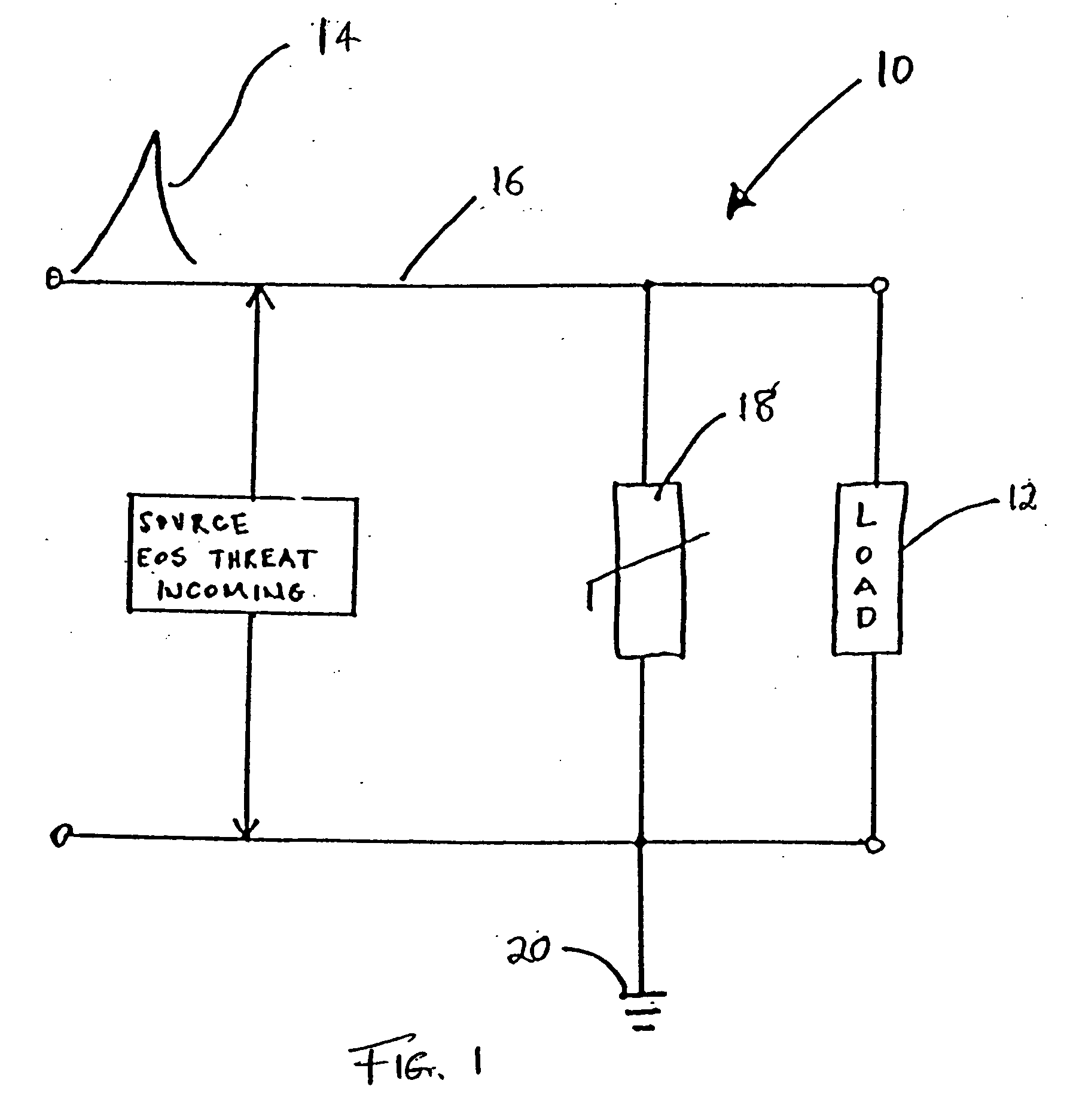

Direct application voltage variable material, devices employing same and methods of manufacturing such devices

ActiveUS20050057867A1Directly appliedCurrent responsive resistorsPrinted circuit aspectsStencil printingMechanical engineering

A voltage variable material (“VVM”) including an insulative binder that is formulated to intrinsically adhere to conductive and non-conductive surfaces is provided. The binder and thus the VVM is self-curable and applicable in a spreadable form that dries before use. The binder eliminates the need to place the VVM in a separate device or to provide separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid FR-4 laminate, a polyimide, a polymer or a multilayer PCB via a process such as screen or stencil printing. In one embodiment, the VVM includes two types of conductive particles, one with a core and one without a core. The VVM can also have core-shell type semiconductive particles.

Owner:LITTELFUSE INC

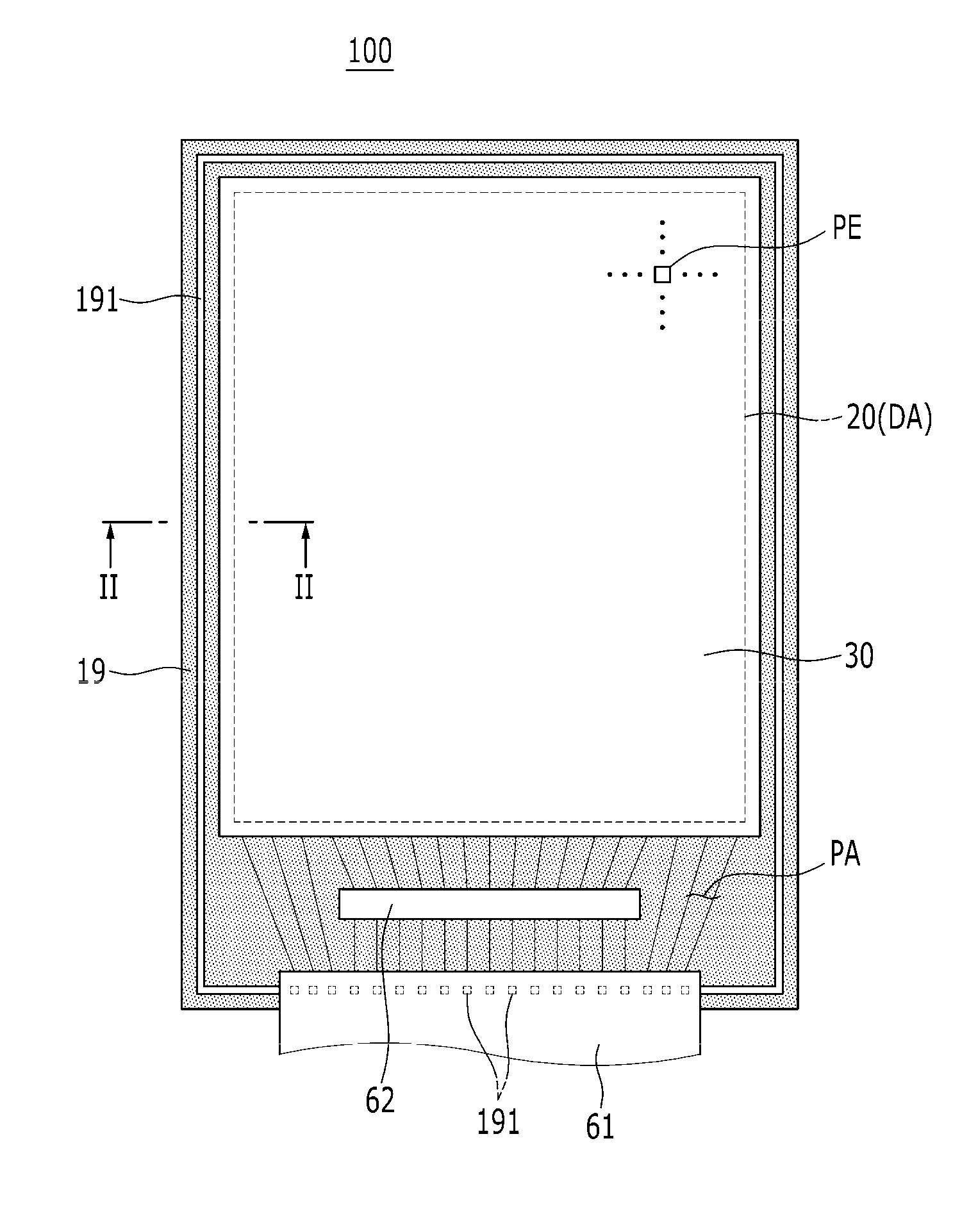

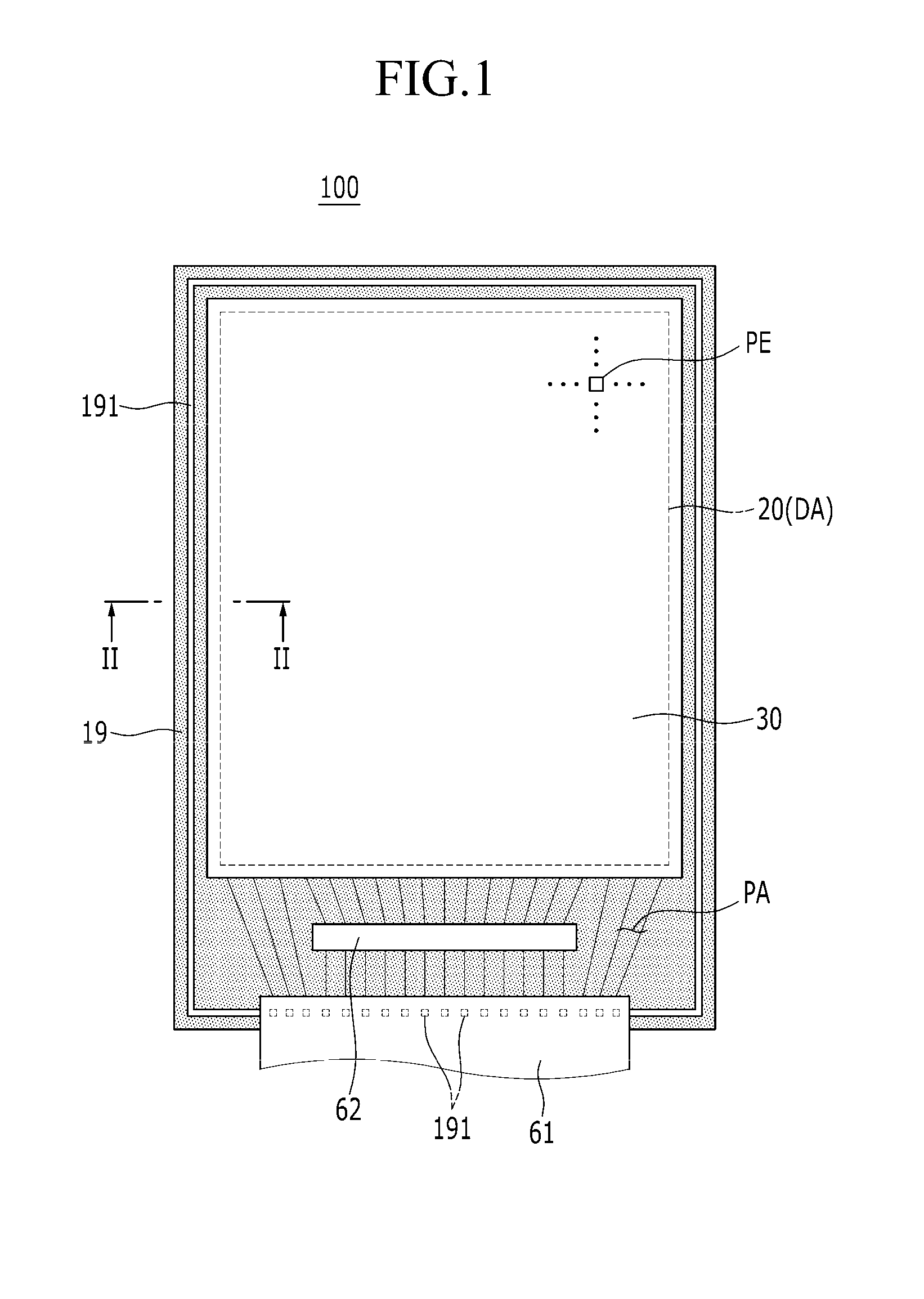

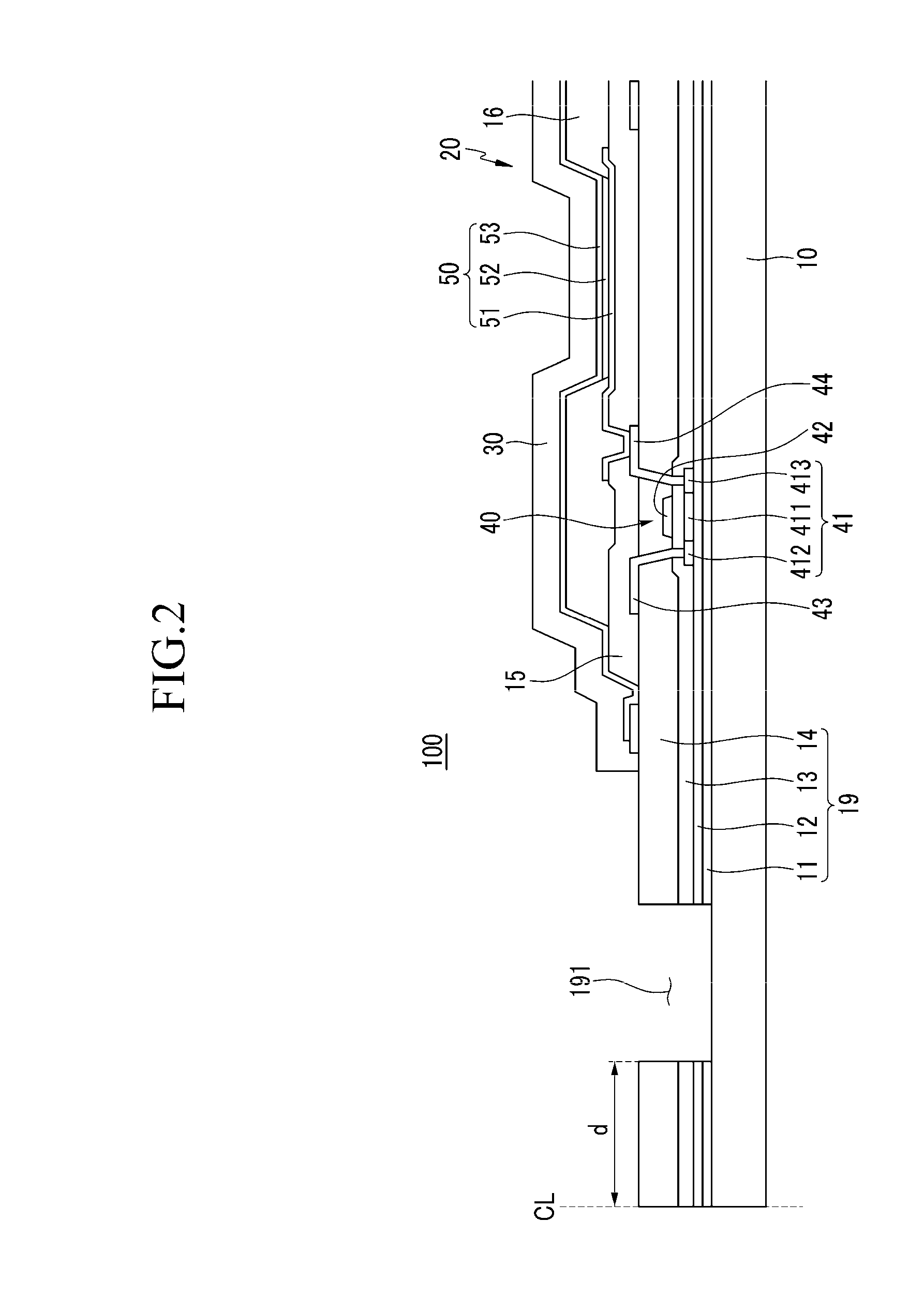

Flexible display device

ActiveUS20150036299A1Improve production yieldSuppressing panel shrinkageFinal product manufactureFlexible printed circuitsFlexible displayComputer science

A flexible display device that can suppress spread of cracks of an inorganic layer is provided. A flexible display device includes a flexible substrate including a display area and a periphery surrounding the display area, an inorganic layer formed on the flexible substrate, a display unit formed on the display area, and a thin film encapsulation layer covering the display unit. The inorganic layer includes an opening disposed on a periphery between edges of the flexible substrate and the thin film encapsulation layer.

Owner:SAMSUNG DISPLAY CO LTD

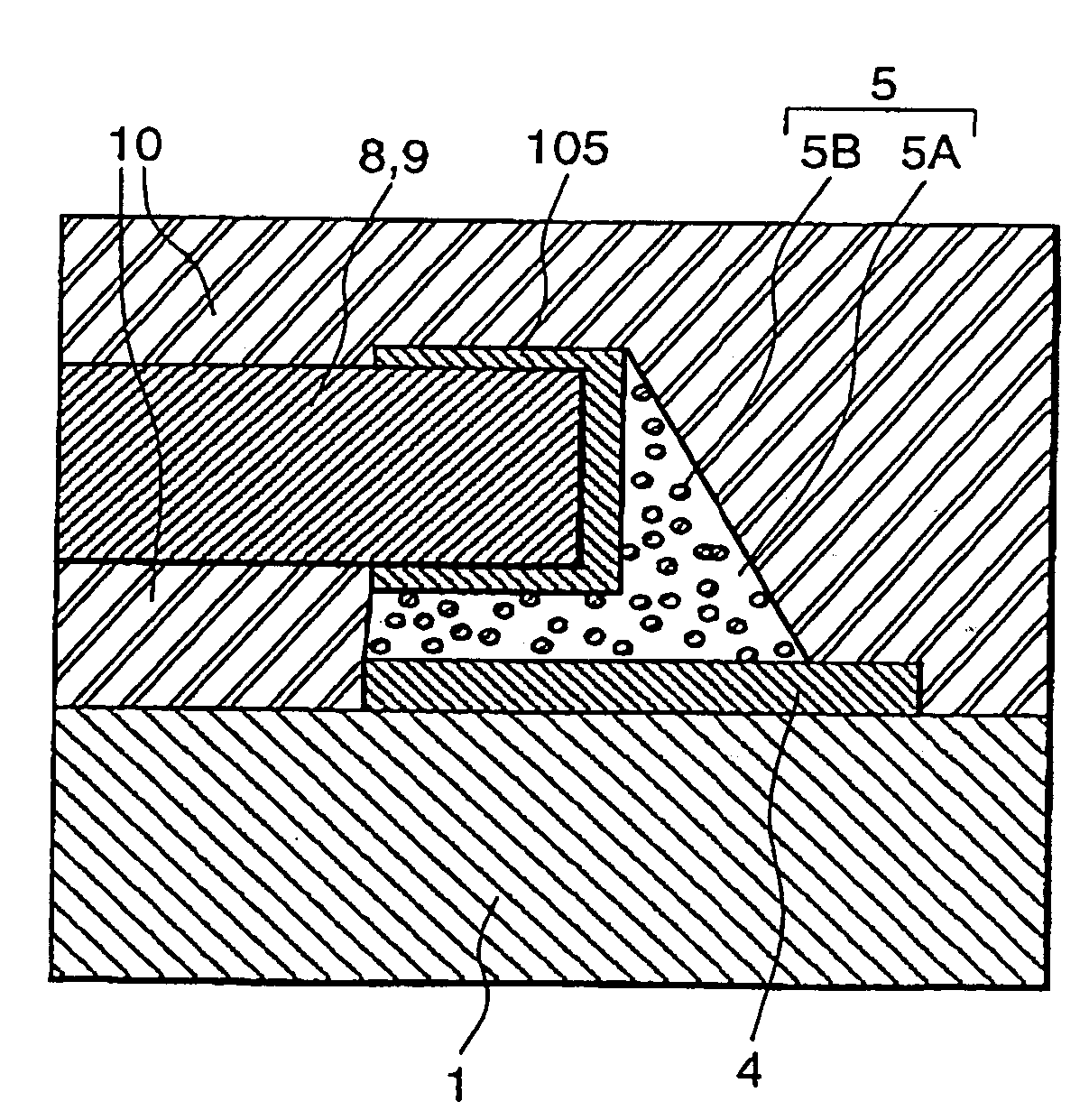

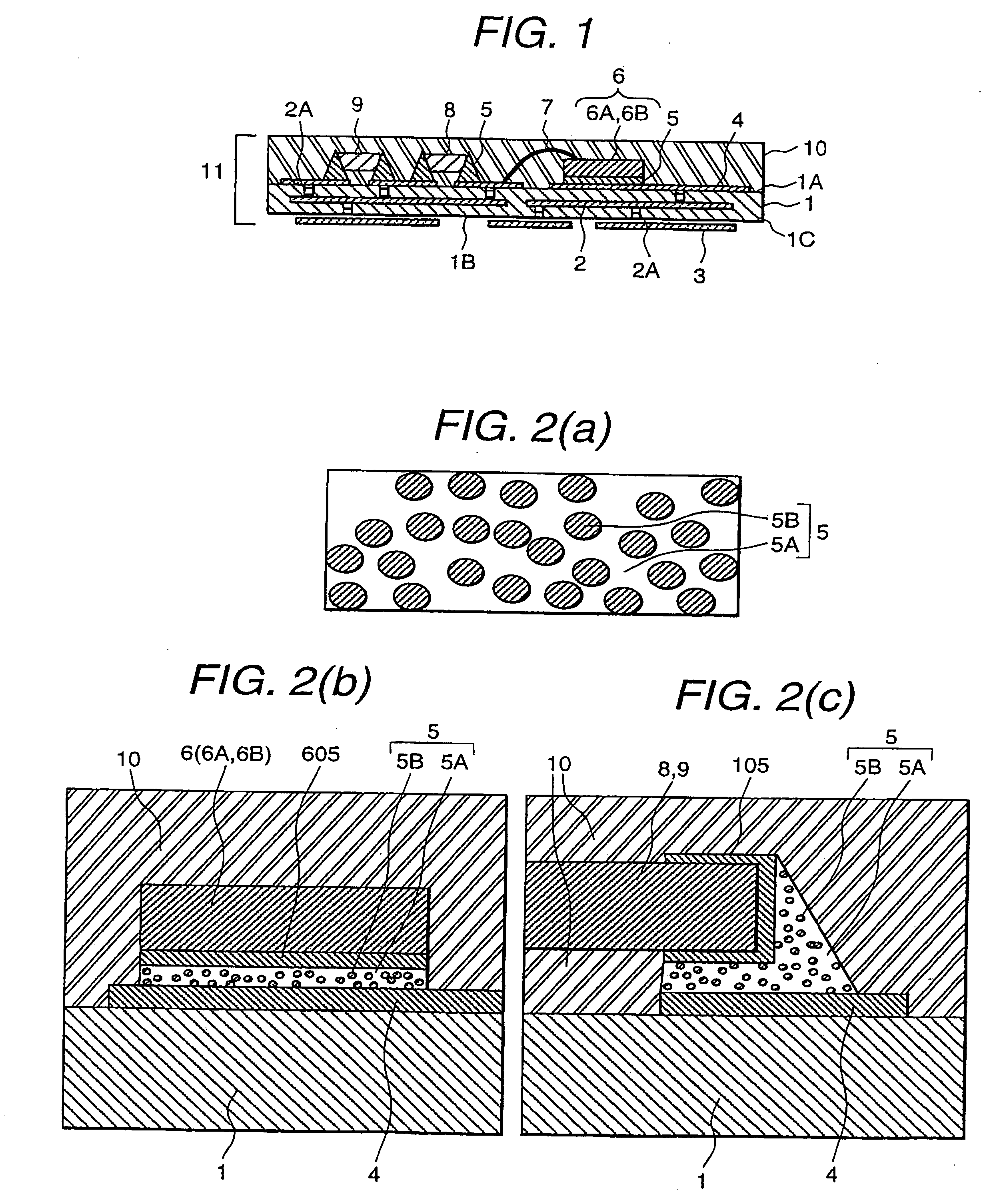

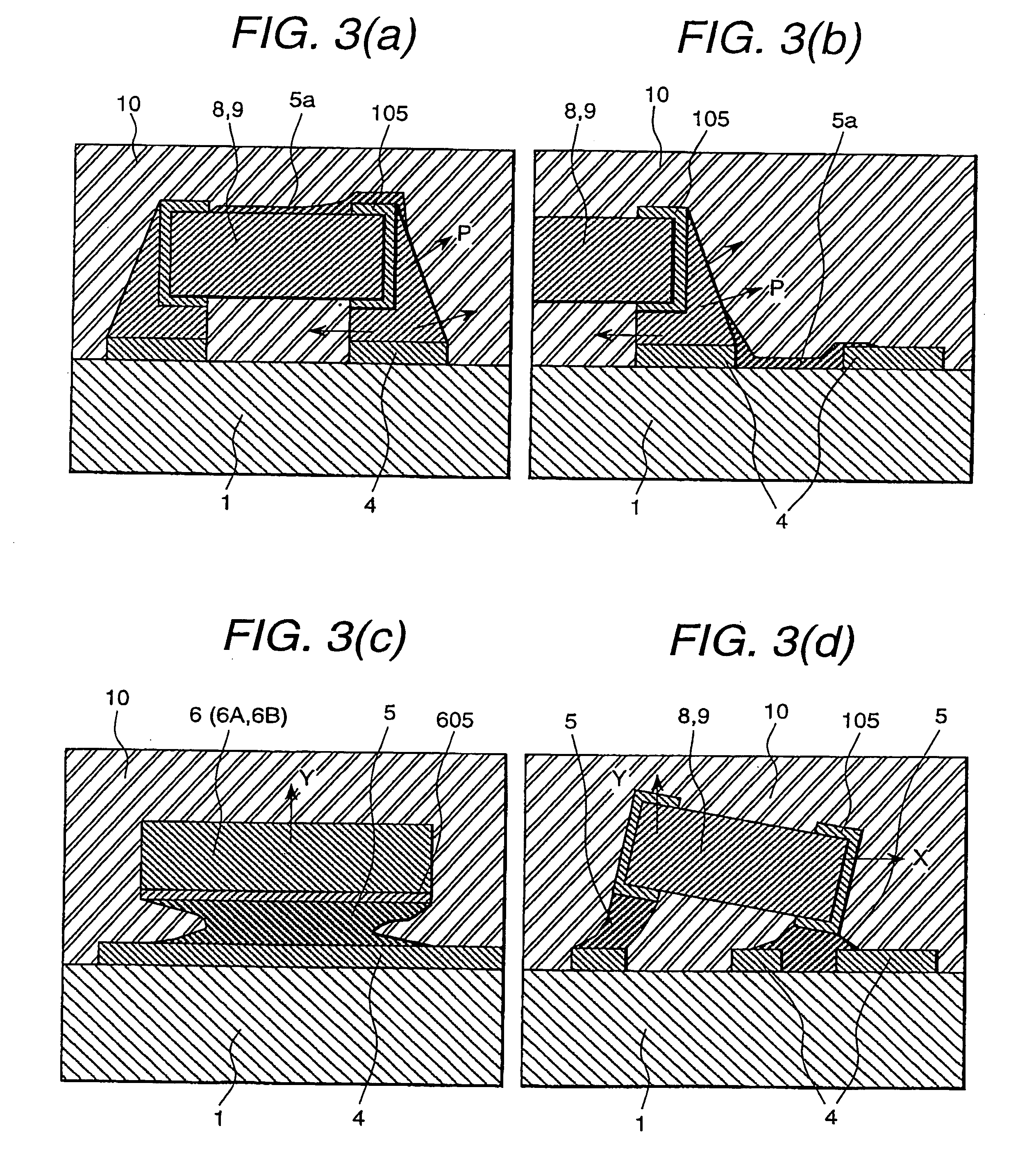

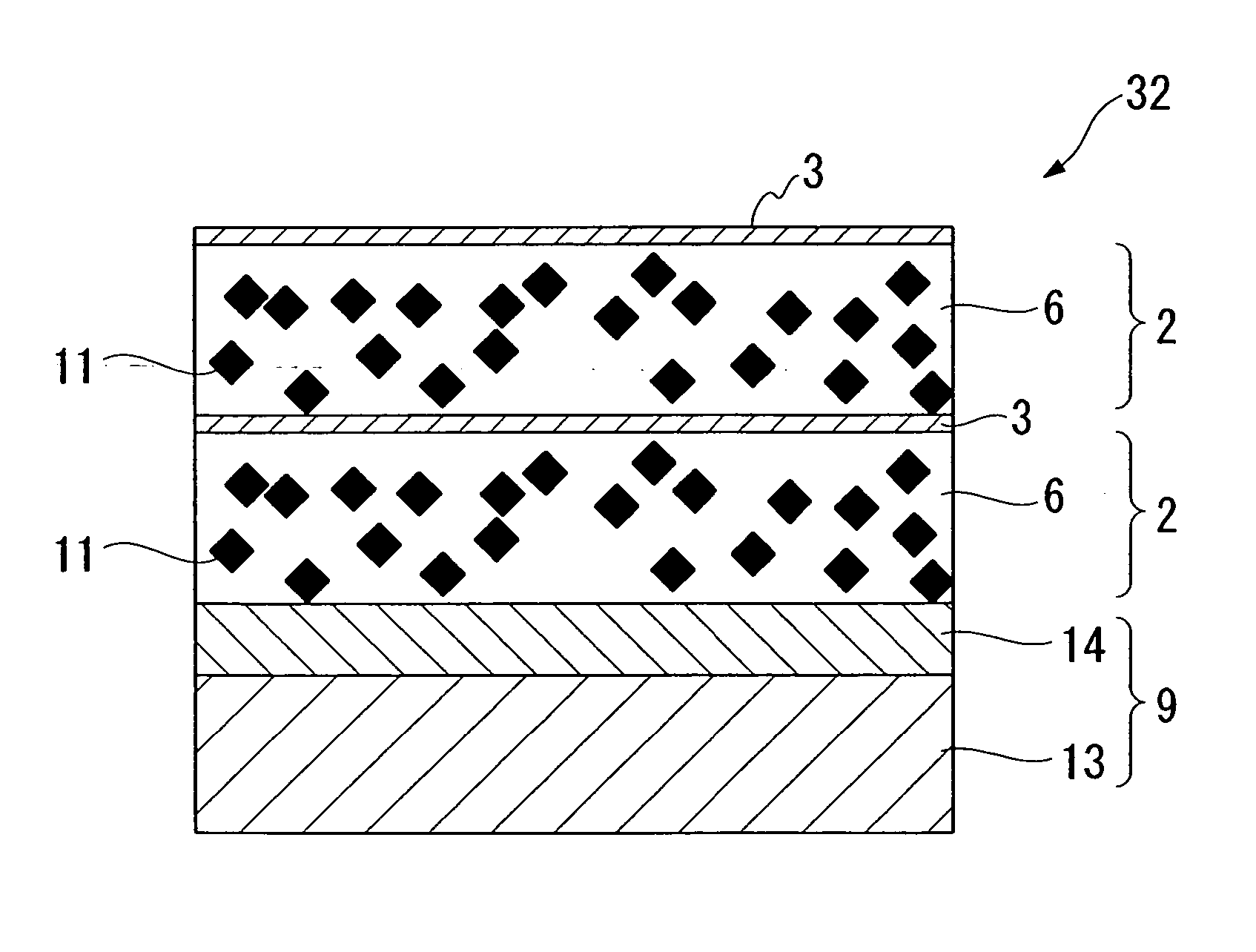

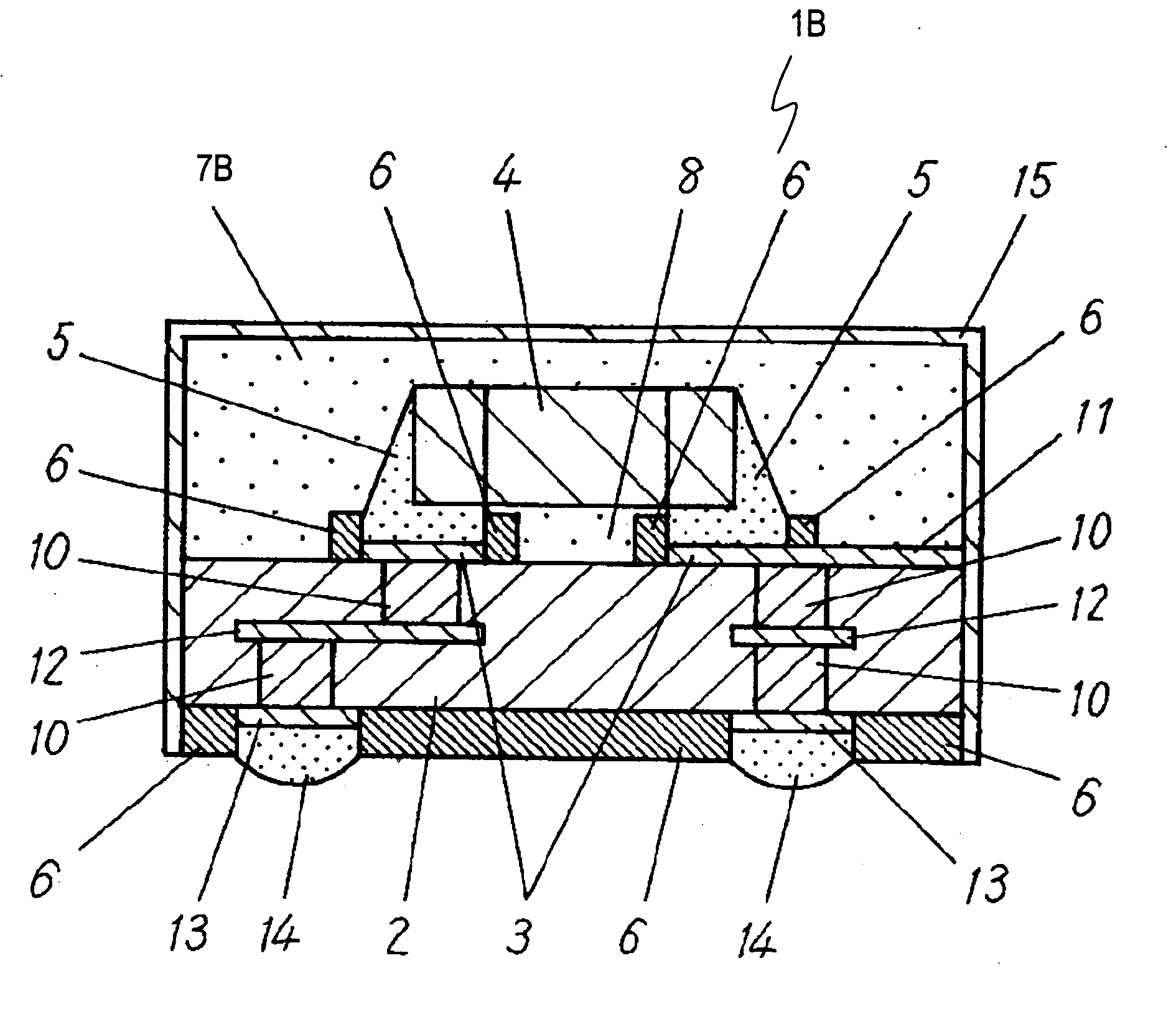

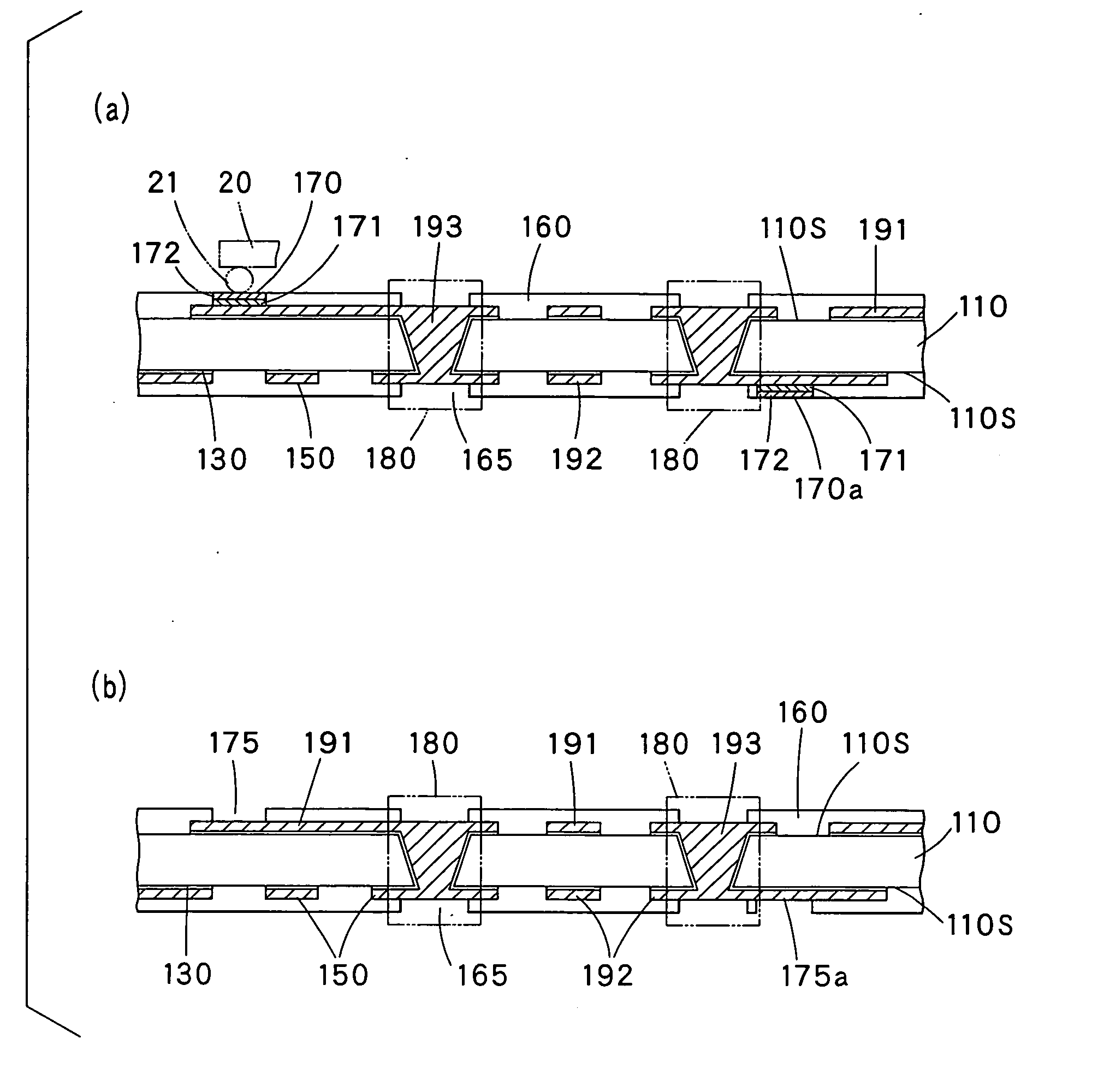

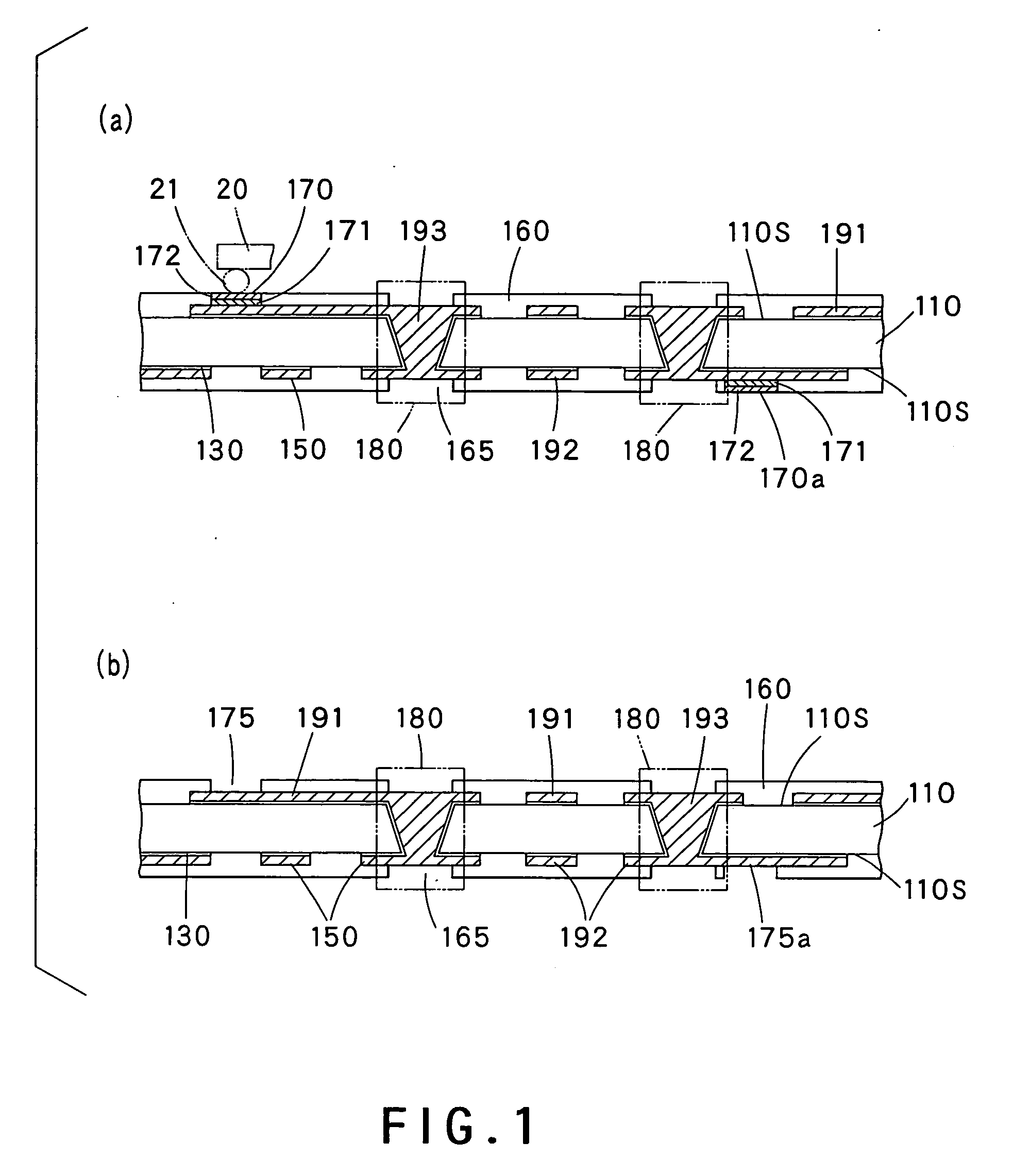

Electronic component-built-in module

ActiveUS20050013082A1Final product manufactureSemiconductor/solid-state device detailsResistElectronic component

A module includes an electronic component having at least two electrodes, a board having electrodes on its surface to be connected to the electrodes of the electronic component, respectively, solders for connecting the electrodes of the electronic component to the electrodes of the board, respectively, an insulating resin covering the electronic component, the surface of the board, the solder, and the electrodes, and solder resists provided on the surface of the board and around the electrodes of the board, respectively. One of the solder resists is separated from the other electrode at a portion between the electronic component and the board. When this module is mounted on a motherboard, the solder does not flow out of the electrodes even when the solder in the insulating resin melts.

Owner:PANASONIC CORP

Power module and production method thereof

ActiveUS7057896B2Improve reliabilityEfficient heatingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

A power module of the present invention mounts electronic components and comprises a circuit board that constitutes an electric power conversion circuit along with the above-mentioned electronic components; a heat sink; and a member with insulation characteristics and high thermal conductivity, which is disposed between plural devices with high heating value among the above-mentioned electronic components and the above-mentioned heat sink, embeds at least part of each of the above-mentioned plural devices with high heating value therein and transfers heat from the above-mentioned plural devices with high heating value to the above-mentioned heat sink.

Owner:PANASONIC CORP

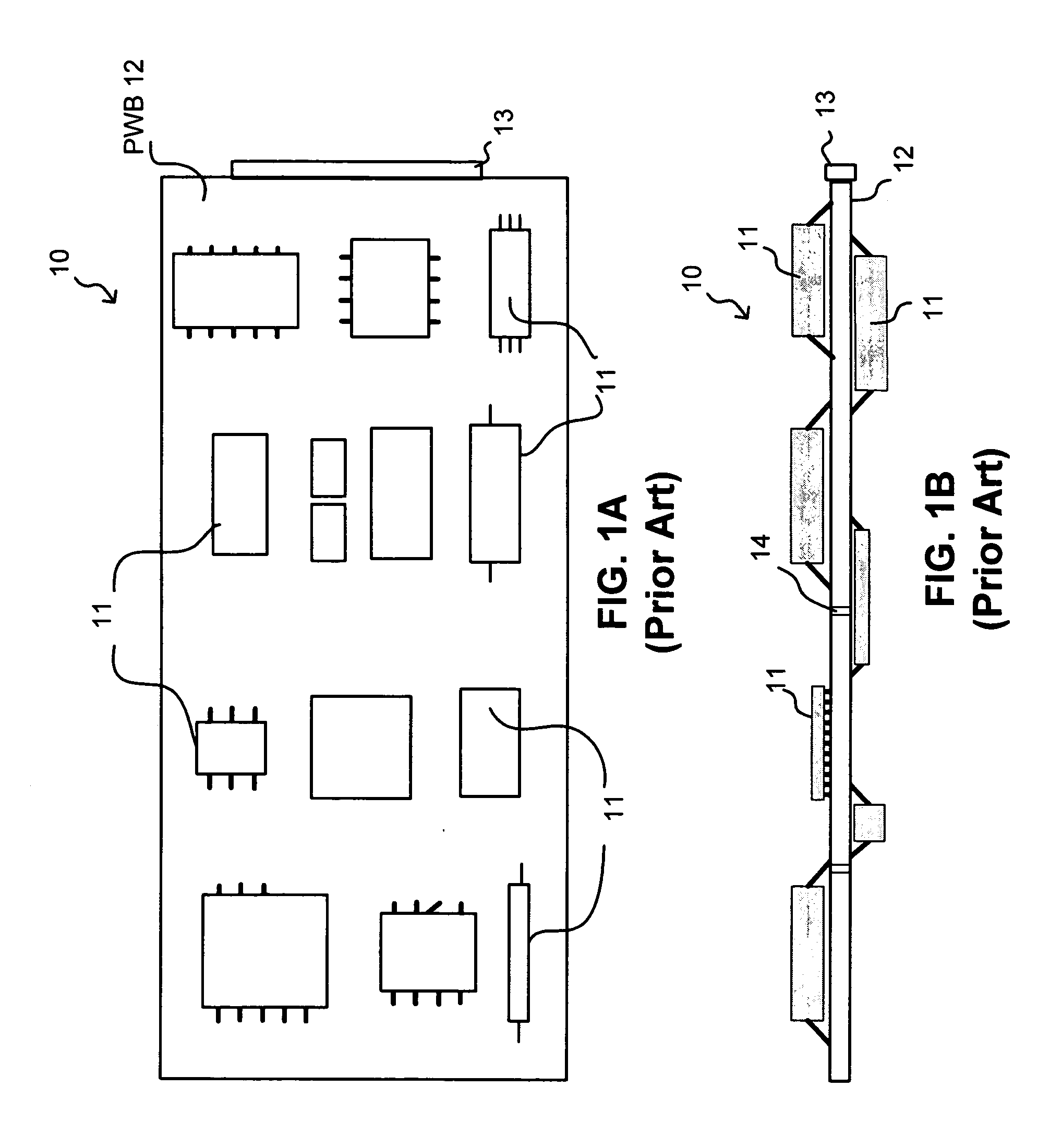

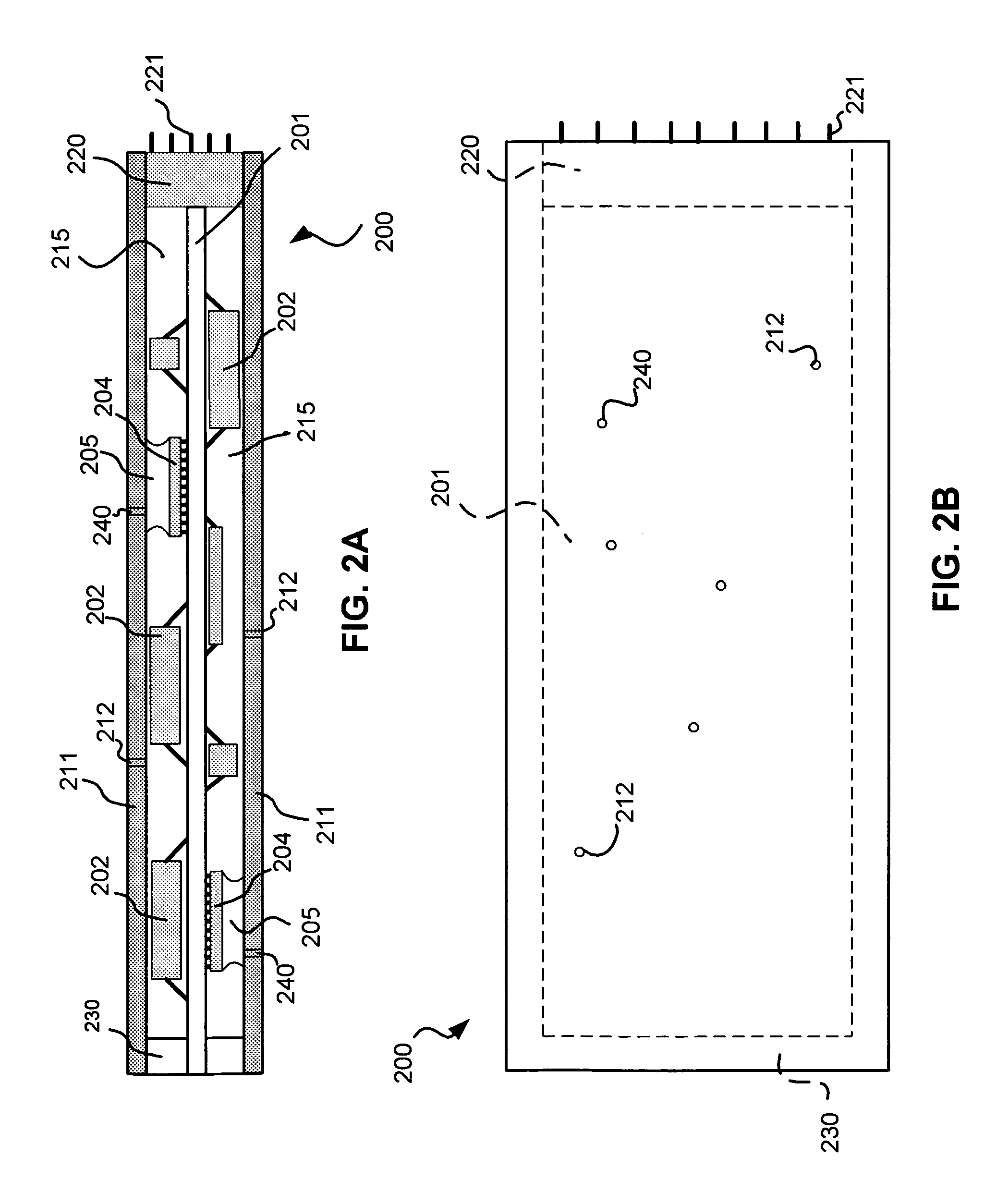

Environmentally tuned circuit card assembly and method for manufacturing the same

InactiveUS7095615B2Make up for deficienciesImprove rigiditySlidable card holdersCard stiffenersFilling materialsElectronic component

A circuit card assembly and a method for manufacturing the circuit card assembly are disclosed. The circuit card assembly includes a printed wiring board with electronic components bonded thereto. The printed wiring board and electronic components are placed in an outer shell made of lightweight stiff material. The spaces or voids between the outer shell and the printed wiring board and the electronic components are filled with lightweight filling material and thermal filler material. The outer shell and the filling material provide increased rigidity to the electronic components and the thermal filler material increases heat transfer from a given electronic component to outside the circuit card assembly.

Owner:HONEYWELL INT INC

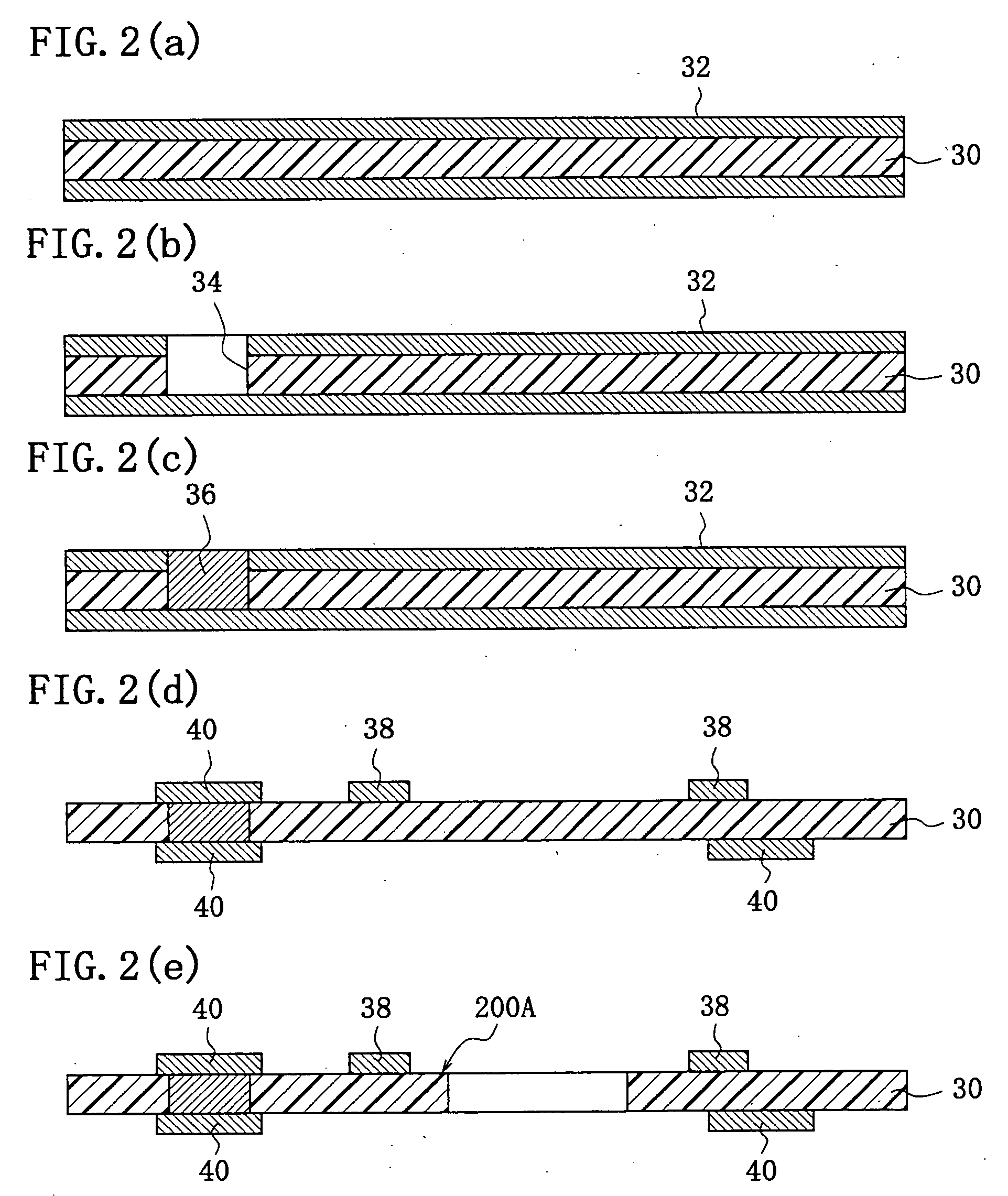

Double-sided wiring board, double sided wiring board manufacturing method, and multilayer wiring board

InactiveUS20060289203A1Improve productivitySemiconductor/solid-state device detailsPrinted circuit aspectsResistSolder mask

A single wiring layer is formed on each of both the roughened surfaces of a core substrate by a semiadditive method. The wiring layers formed on the surfaces of the core substrate are electrically connected through a through hole formed in the core substrate. The through hole is formed in the core substrate by laser machining. The through hole is filled up with conductive a plug. Both the surfaces of the core substrate are coated with solder resist layers, respectively, with predetermined terminal parts of the wiring layers exposed through openings formed in the solder resist layers. End surfaces of the conductive plug filling up the through holes, and the surfaces of the wiring layers are planarized by mechanical or chemical-mechanical polishing.

Owner:DAI NIPPON PRINTING CO LTD

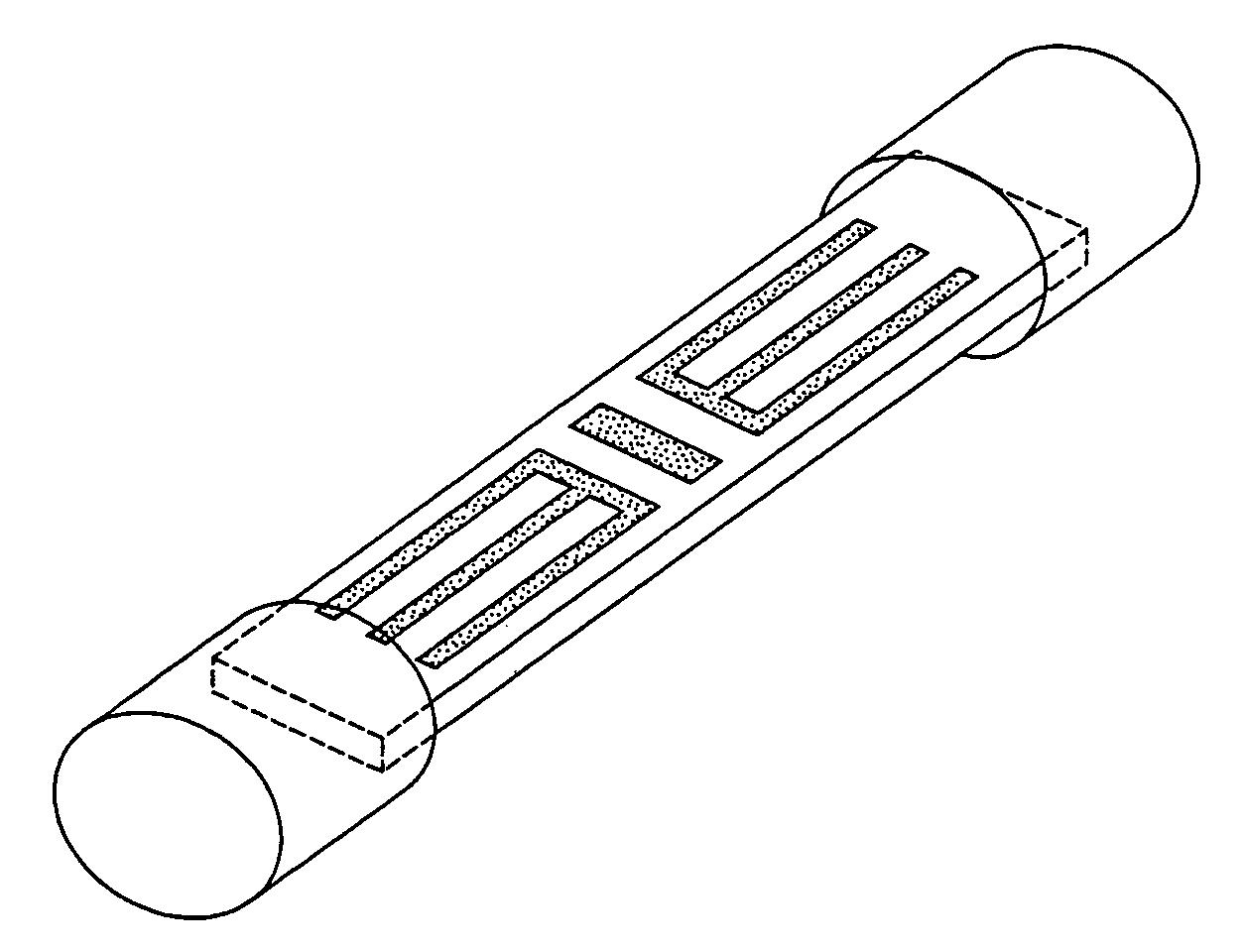

Conformal electromagnetic (EM) detector

InactiveUS8947889B2Efficient use ofEasy to disassembleMagnetic/electric field screeningCircuit security detailsArray data structureSingle element

Owner:LOCKHEED MARTIN CORP

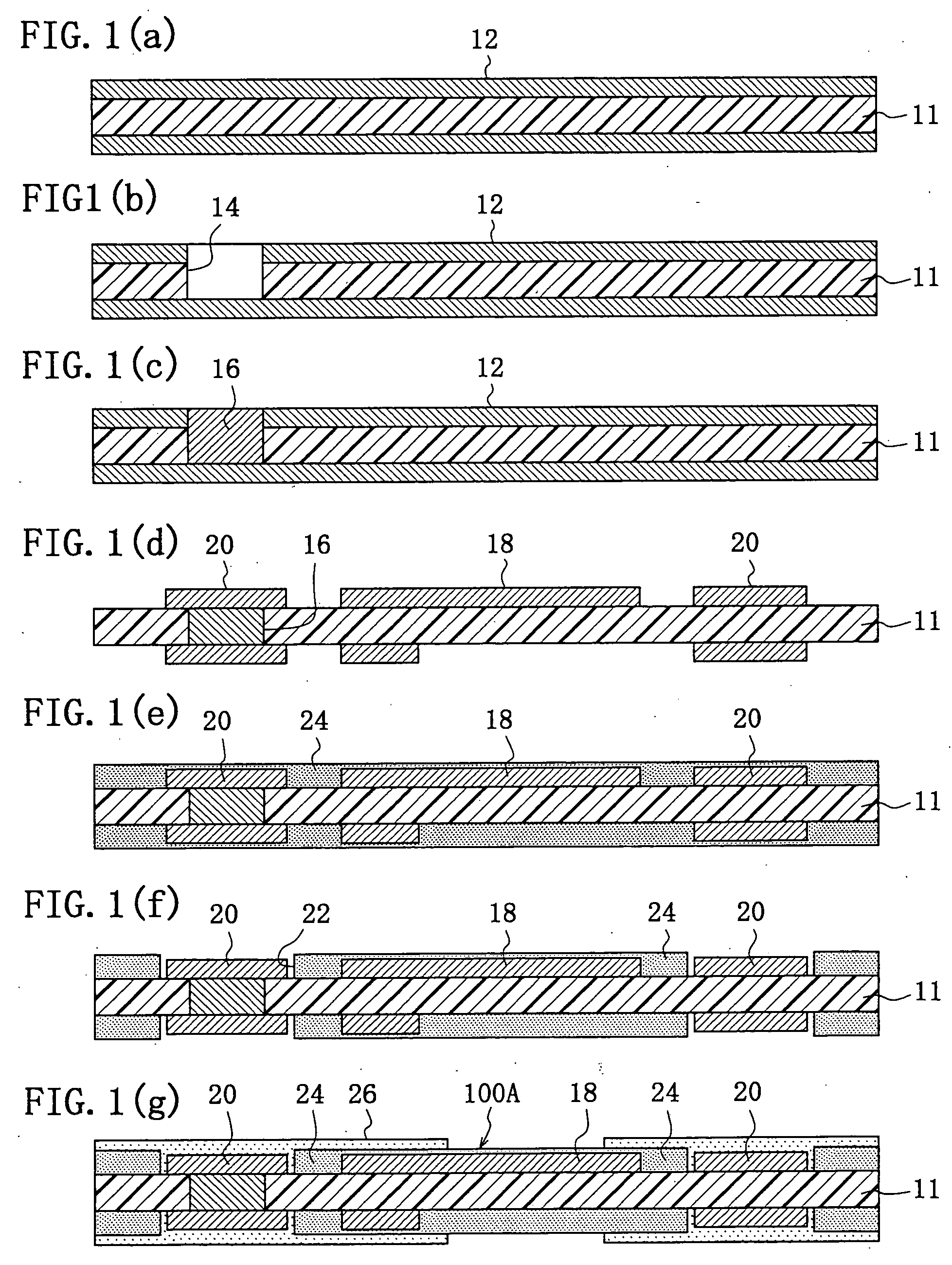

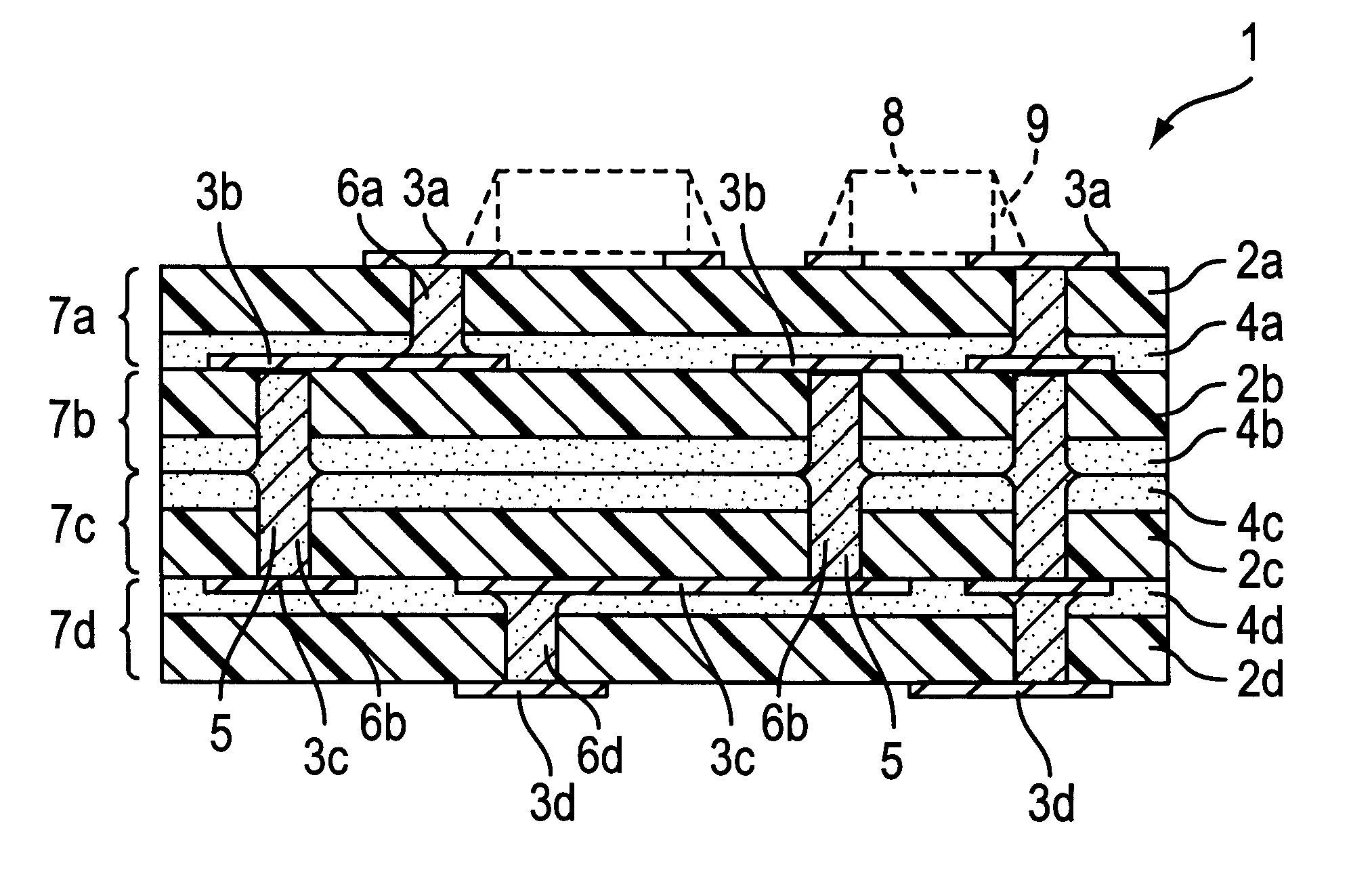

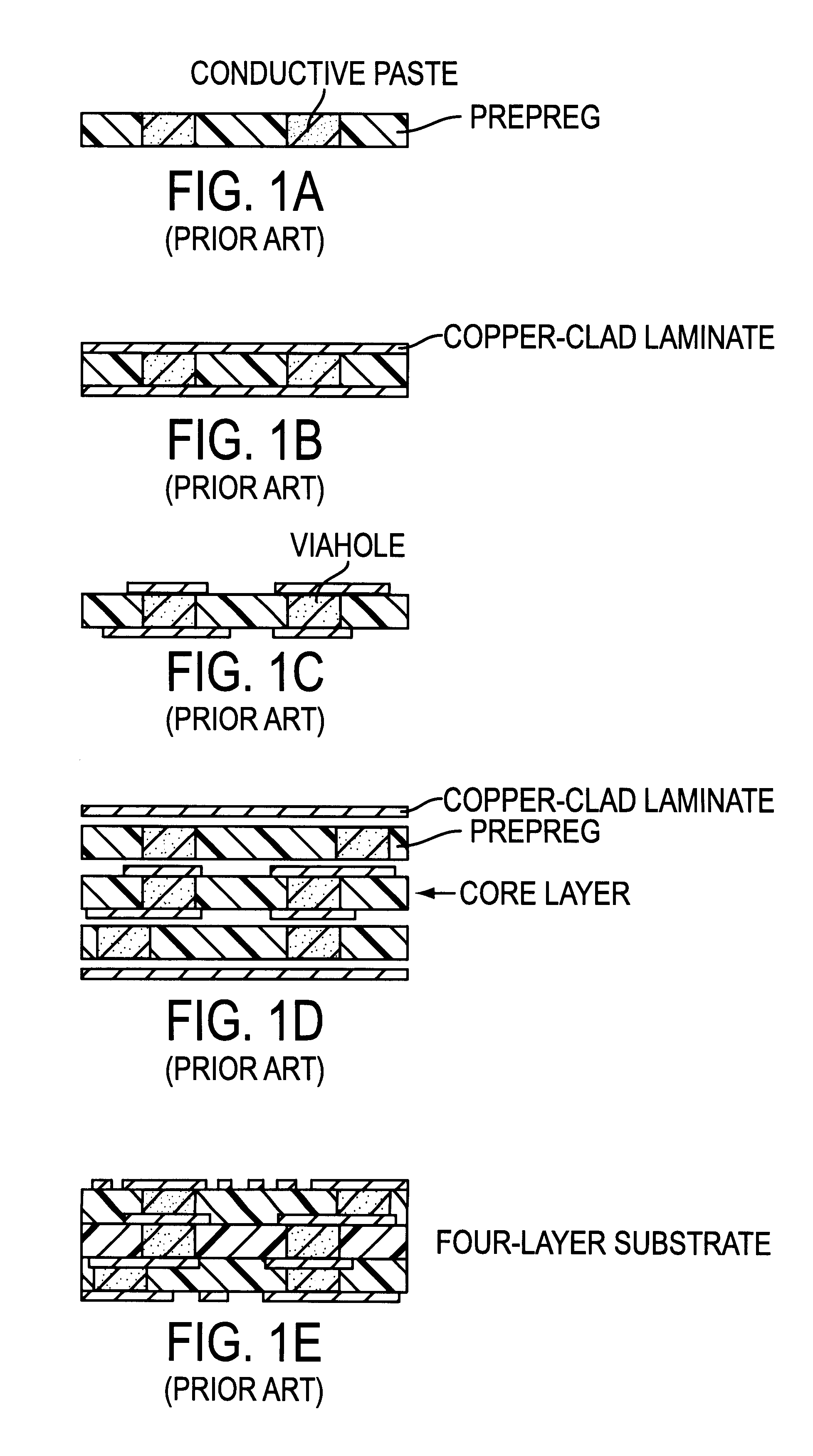

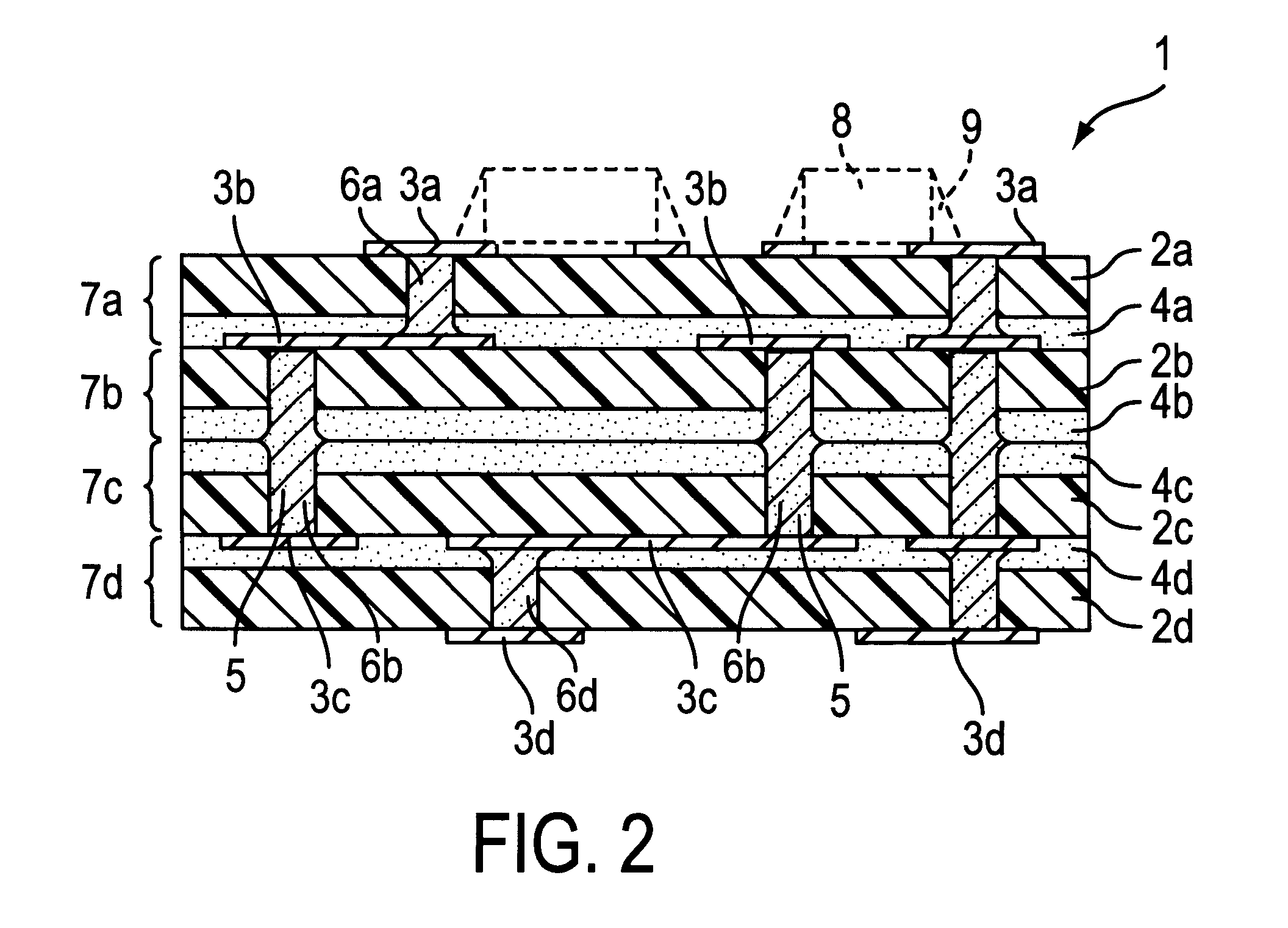

One-sided circuit board for multi-layer printed wiring board, multi-layer printed wiring board, and method of its production

InactiveUS6320140B1Printed circuit aspectsTwo-part coupling devicesConductive pastePrinted circuit board

A single-sided circuit substrate for a multilayer printed writing board has an insulating hard substrate, a conductor circuit formed on a surface of the substrate, an adhesive layer formed on the other surface, and at least one viahole through the substrate and the adhesive layer so as to pass these layers and contact with the conductor. The viaholes are filled with conductive paste. The invention also provides a multilayer printed wiring board having an IVH structure constituted with single-sided circuit hard substrates and a method of efficiently manufacturing the same with high yield.

Owner:IBIDEN CO LTD

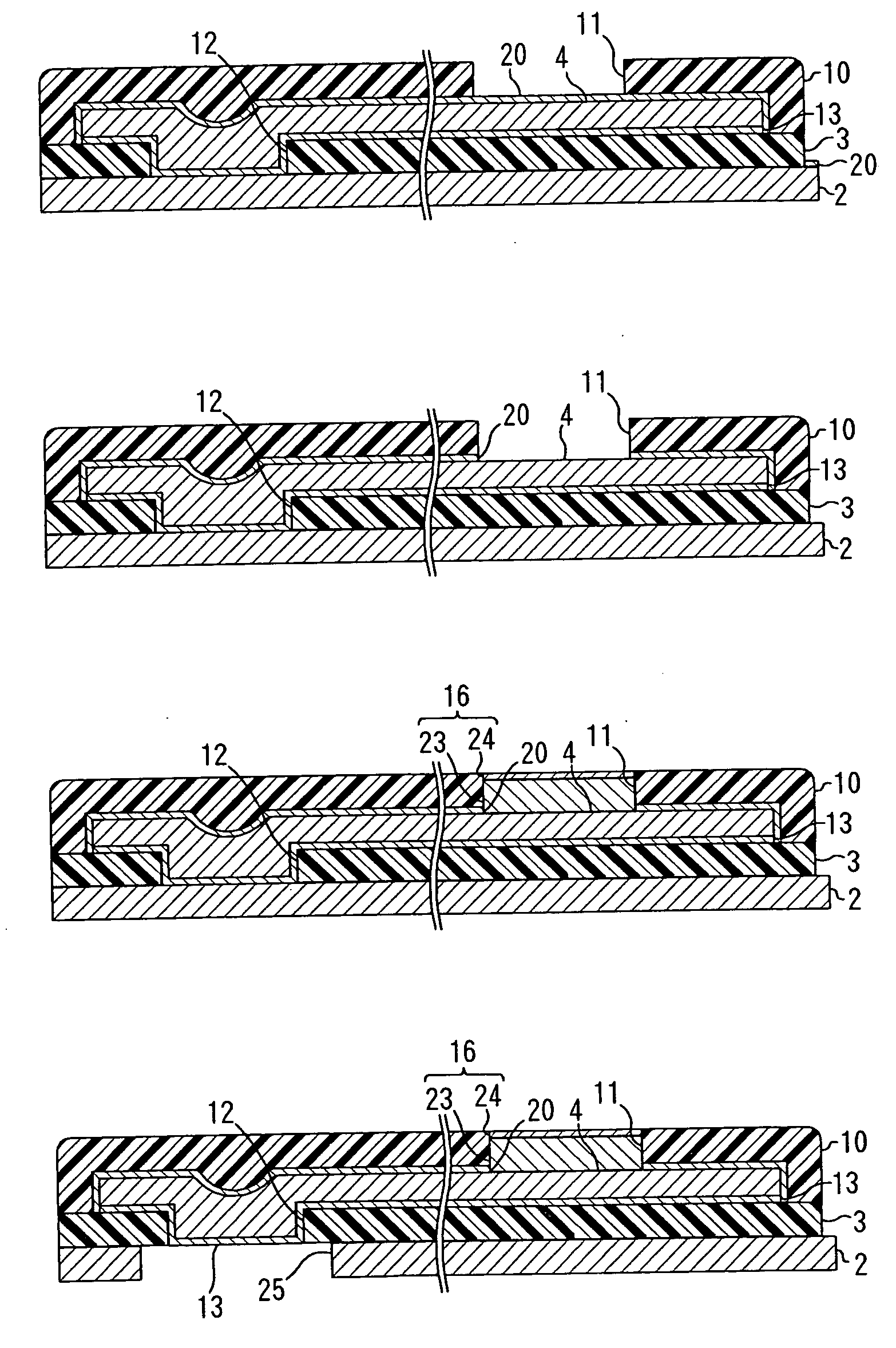

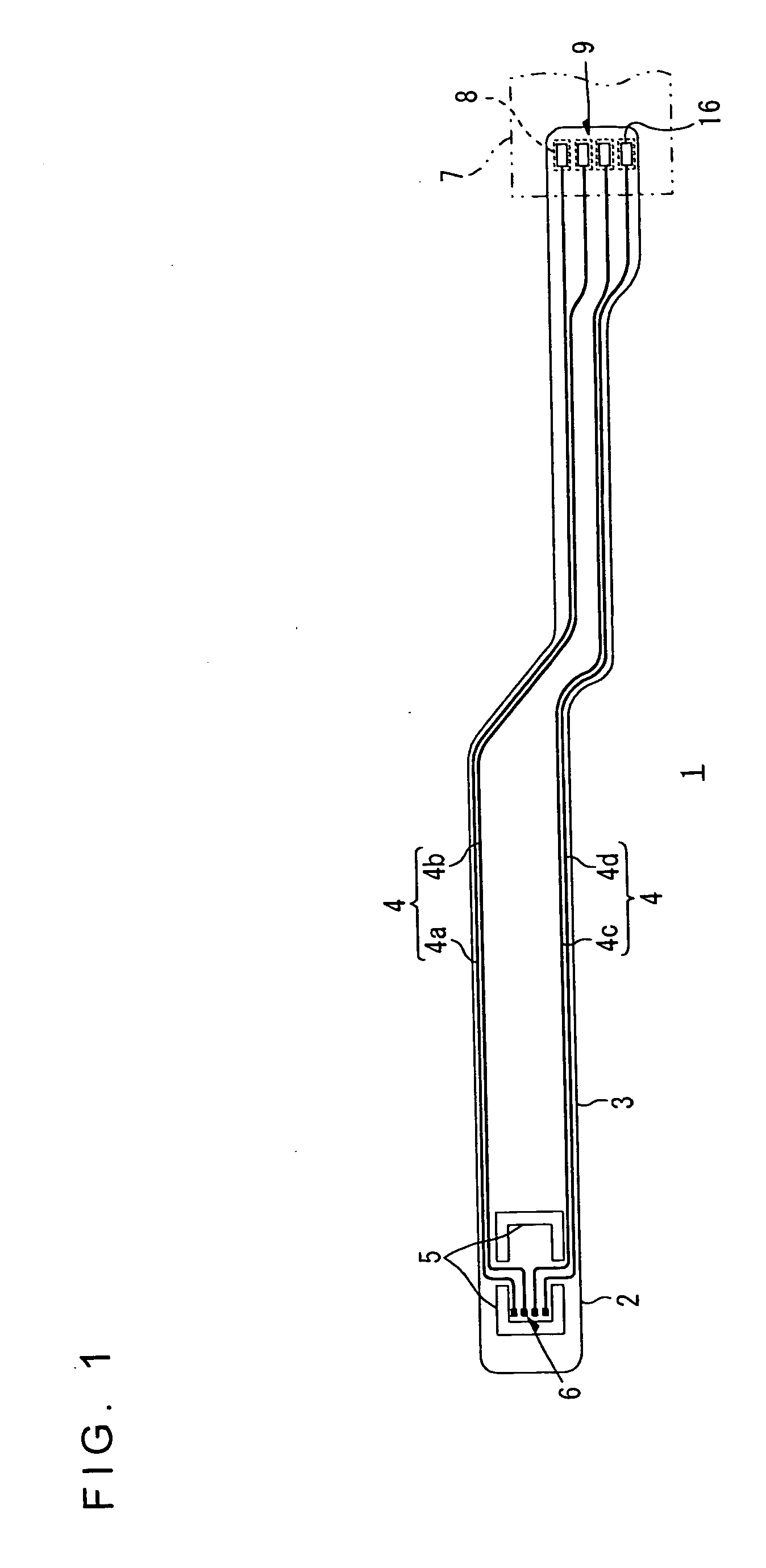

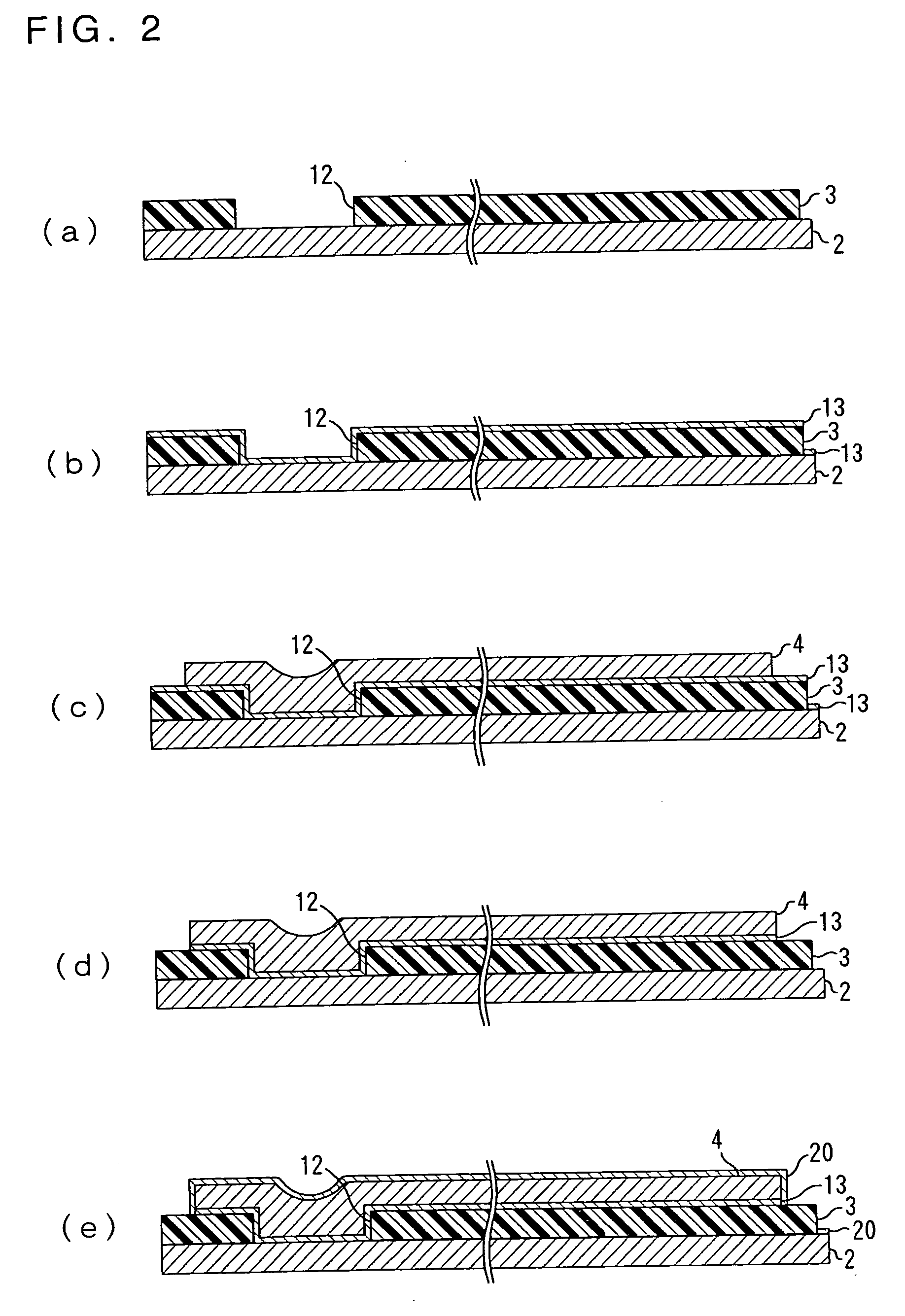

Suspension board with circuit and procuding method thereof

ActiveUS20050061542A1Increase productivityLow costInsulating substrate metal adhesion improvementCircuit arrangements on support structuresThin metalElectrical conductor

A producing method of a suspension board with circuit that can permit a terminal portion to be formed by electrolysis plating without exposing a conductor layer to outside and also can reduce the number of processes, and the suspension board with circuit produced by the same producing method. After an insulating base layer 3 is formed on a suspension board 2 in a specific pattern in which a second opening 12 is formed, a thin metal film 13 is formed on an entire surface of the insulating base layer 3 and on a surface of the suspension board 2 including the second opening 12 exposed from the insulating base layer 3.Then, a conductor layer 4 is formed in the form of a wired circuit pattern on the thin metal film 13. Thereafter, the insulating cover layer 10 is formed in such a manner that a pad opening 11 is formed in the insulating cover layer 10 and then a pad portion 16 is formed in the pad opening 11 using the suspension board 2 as a lead portion of the electrolysis plating. Thereafter, a first opening 25 larger than the second opening 12 is formed in the suspension board 2 at a portion thereof corresponding to the second opening 12.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com