Patents

Literature

1251 results about "Thin film encapsulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

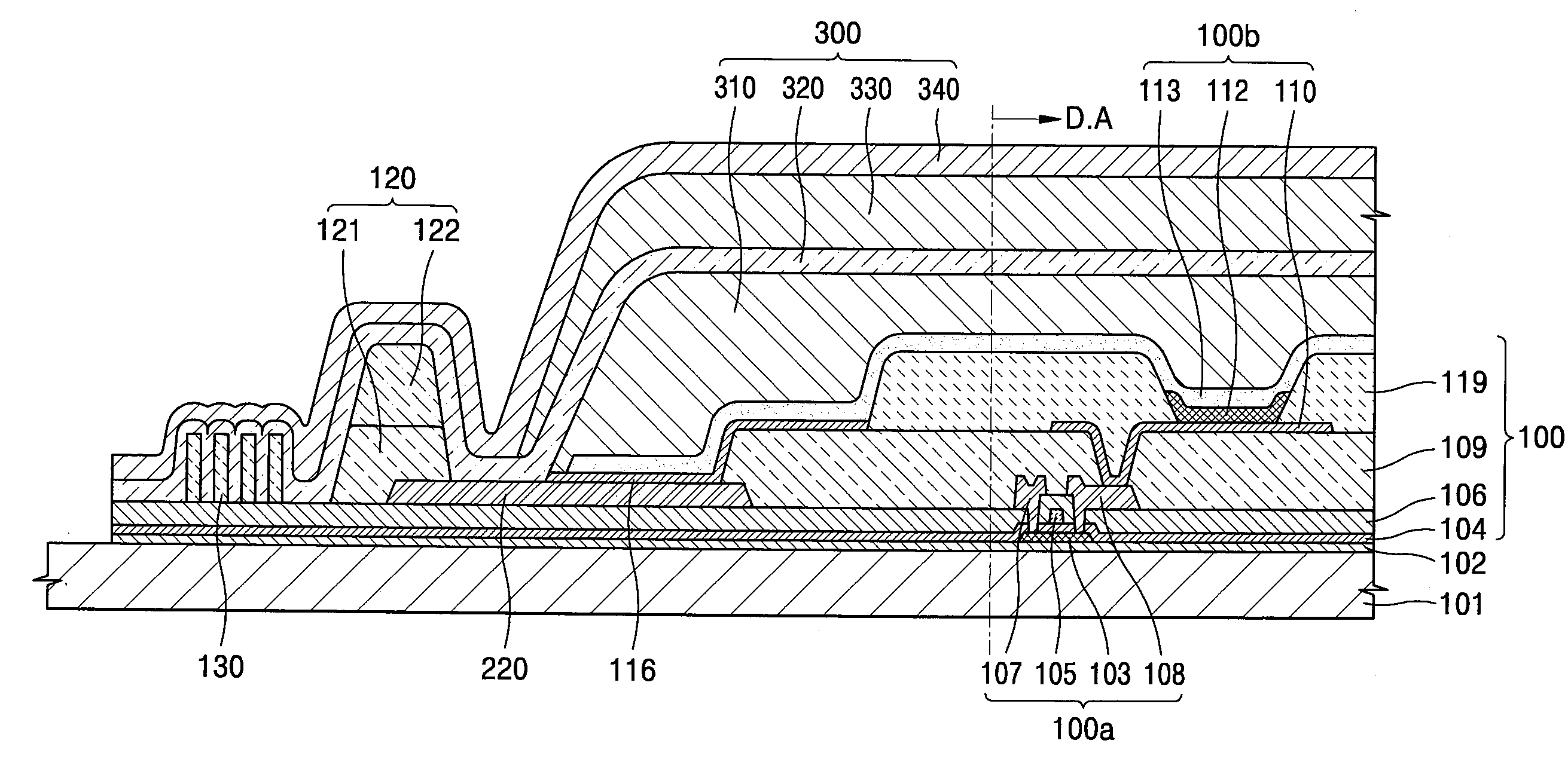

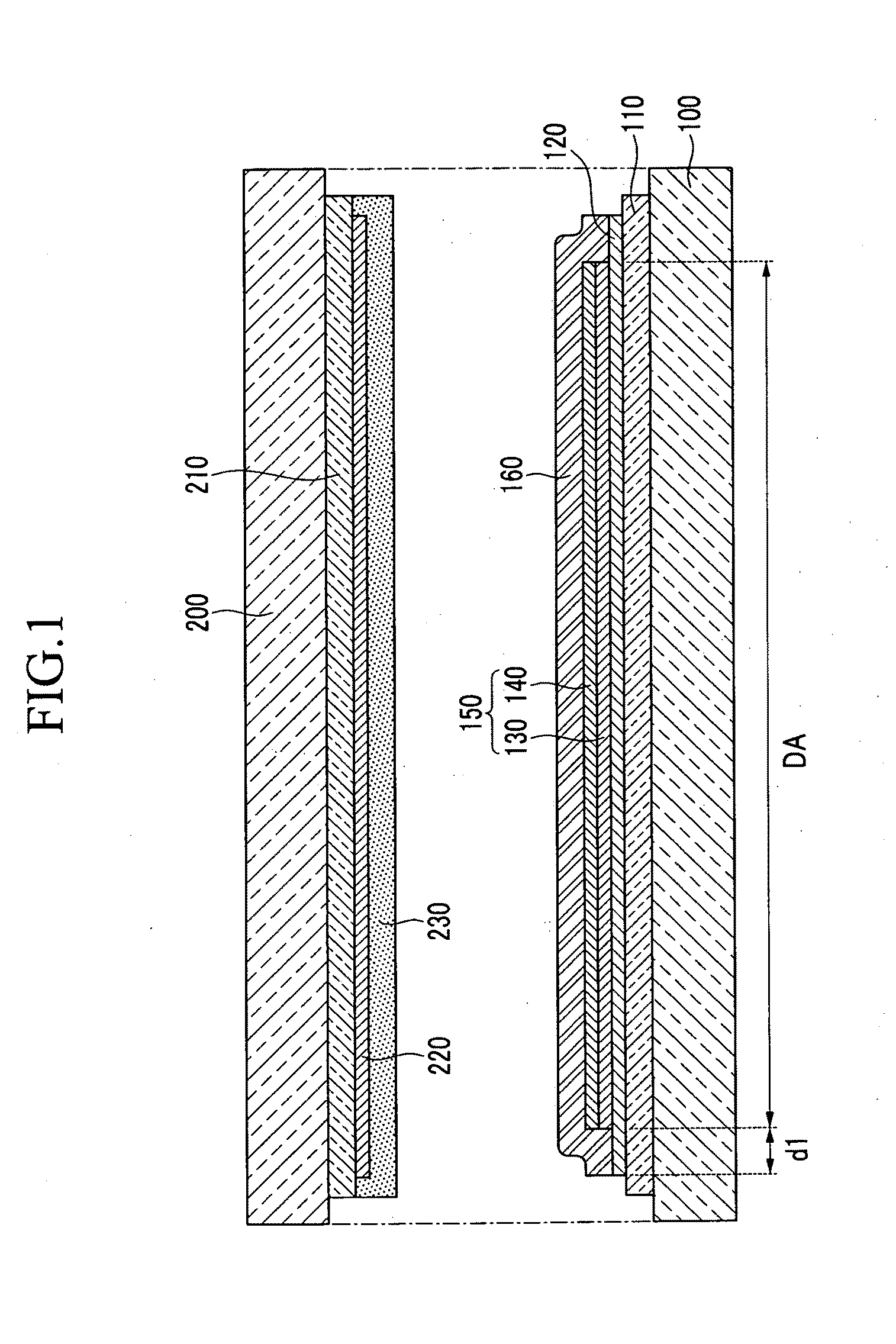

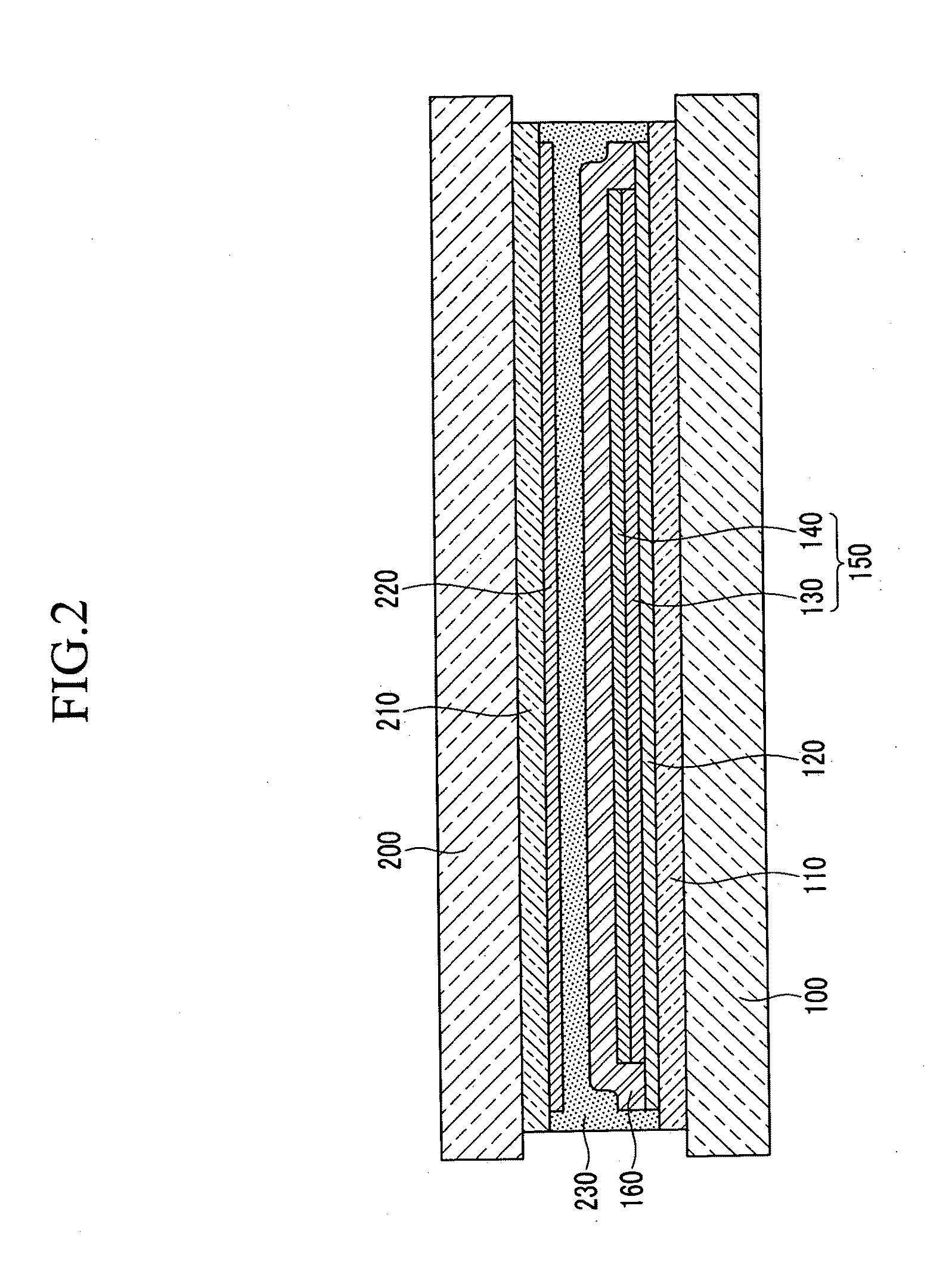

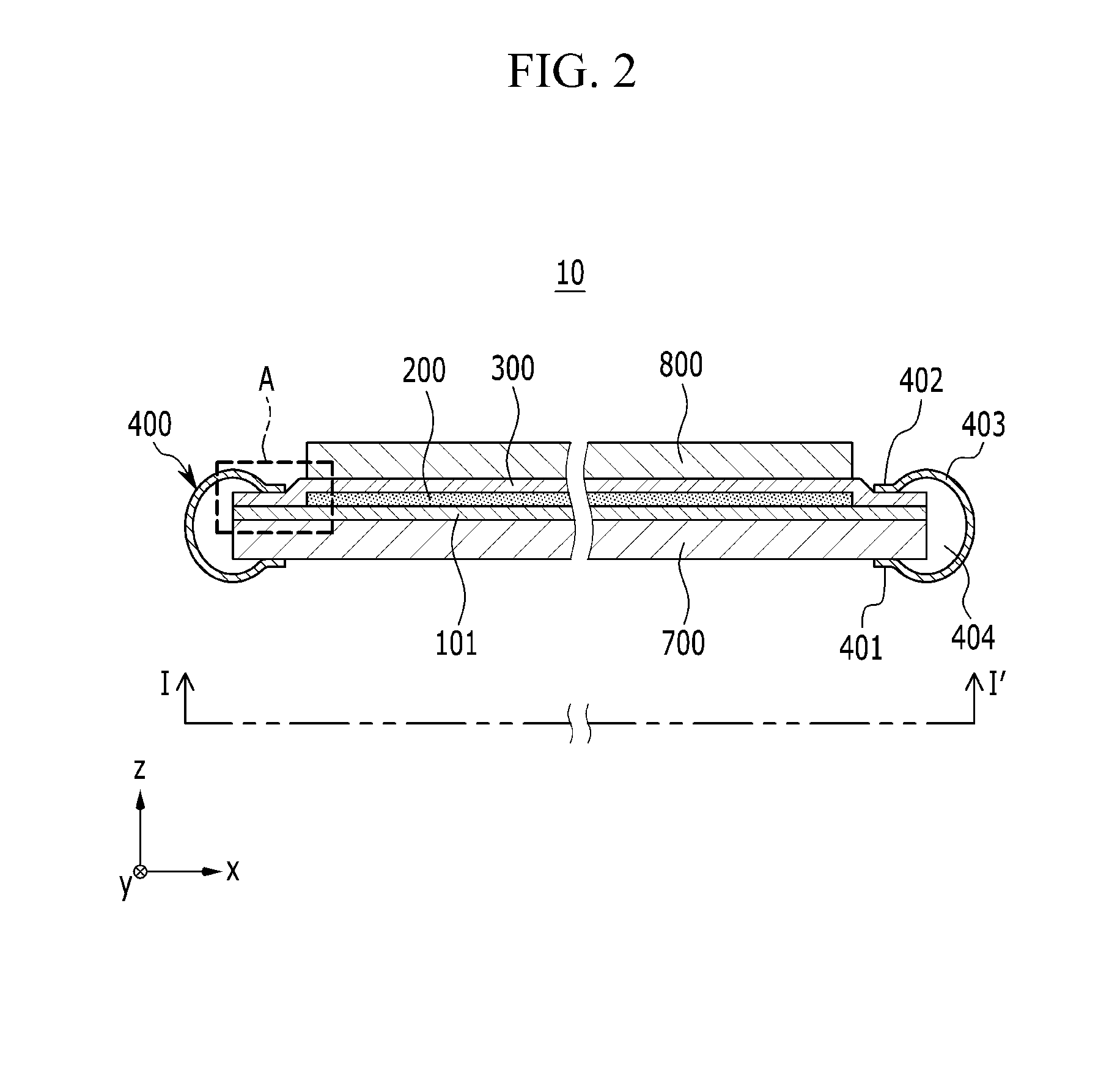

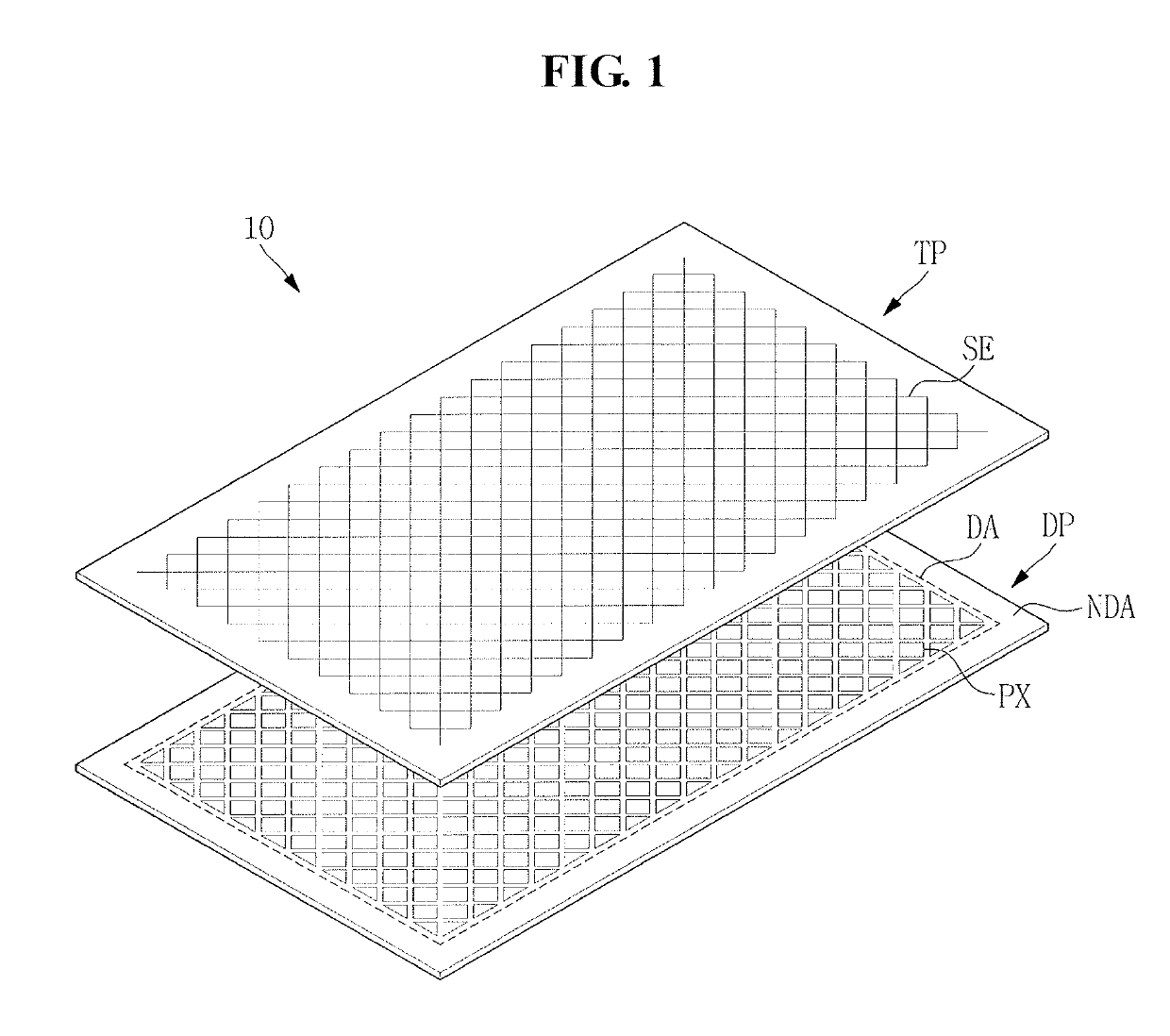

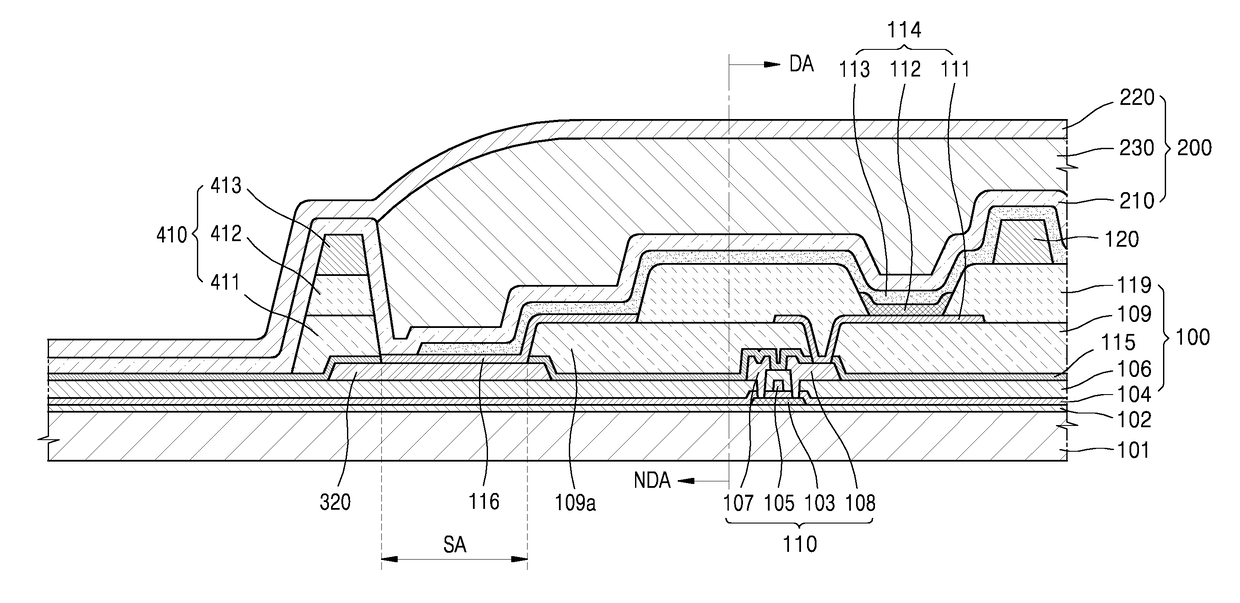

Organic light emitting display apparatus and method of manufacturing the same

ActiveUS20140145979A1Electrical apparatusElectroluminescent light sourcesTouch SensesLight-emitting diode

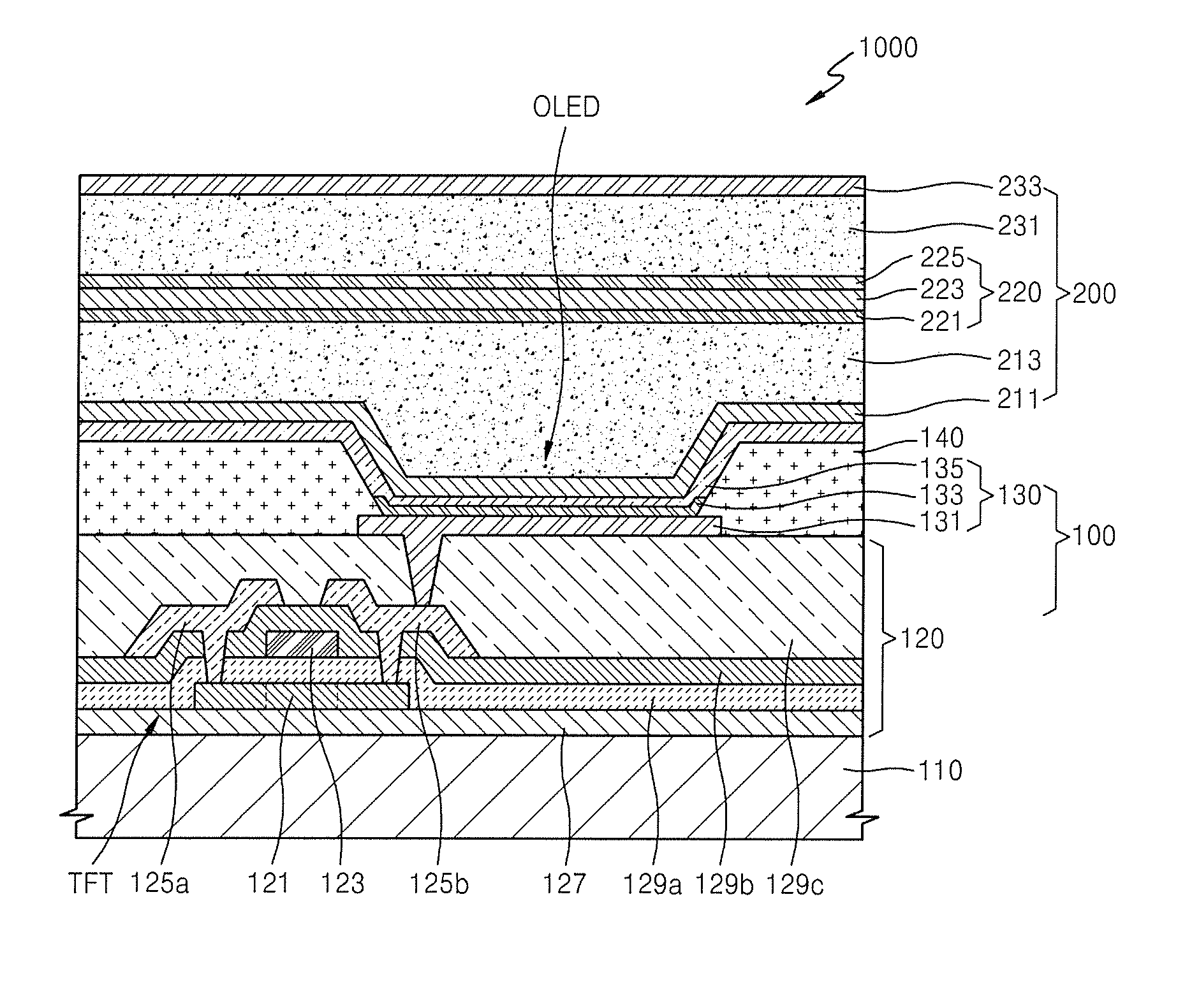

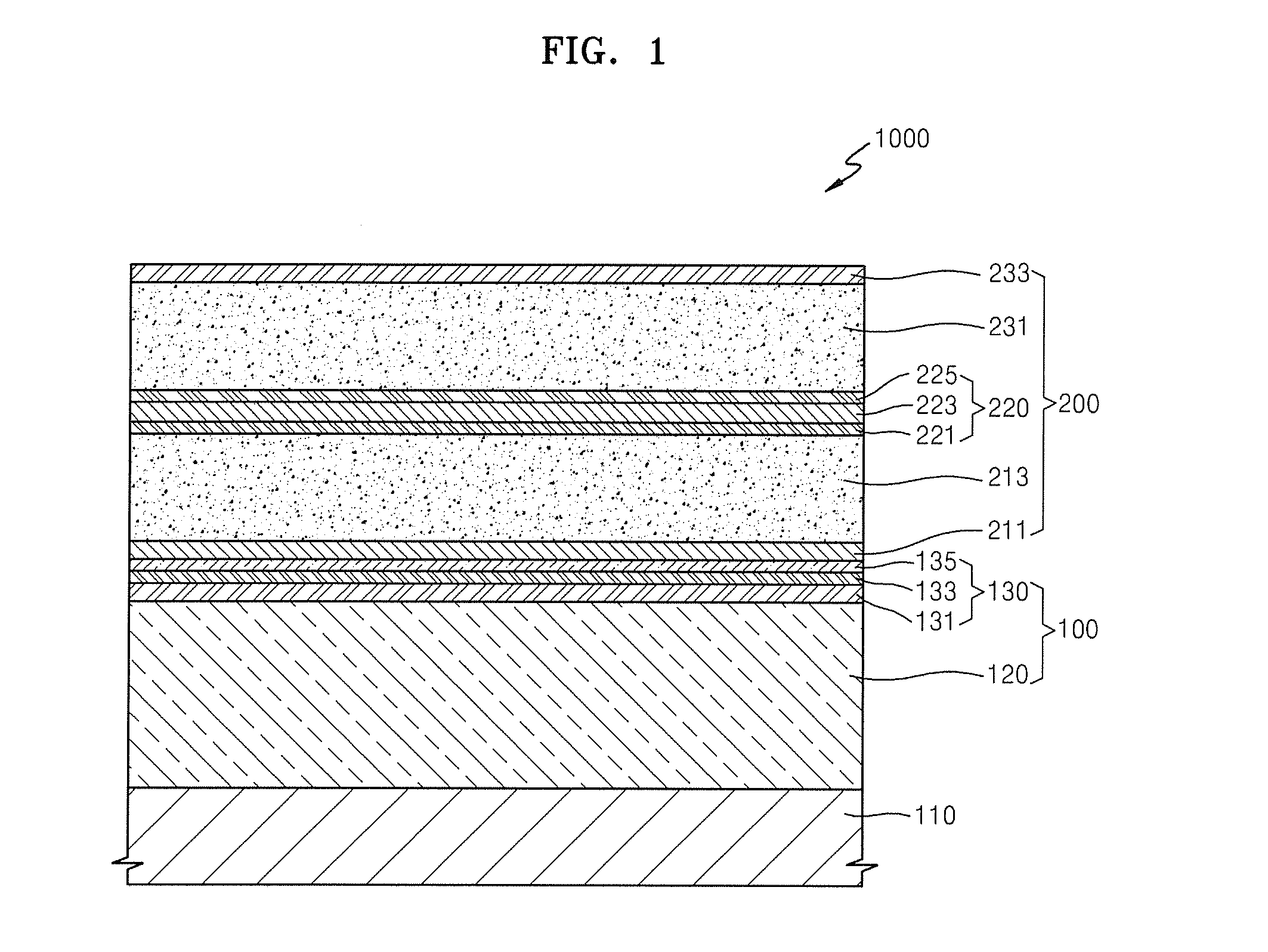

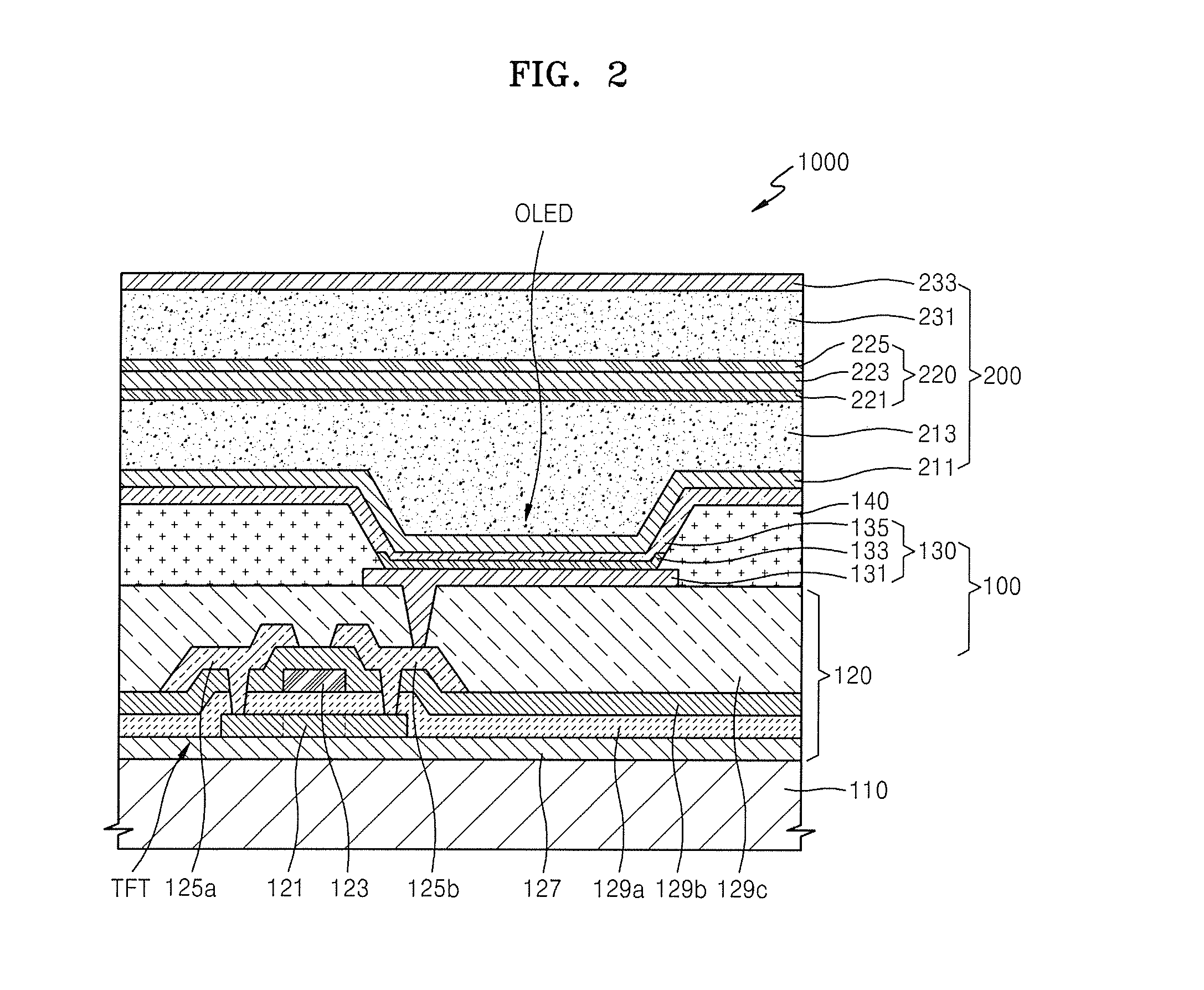

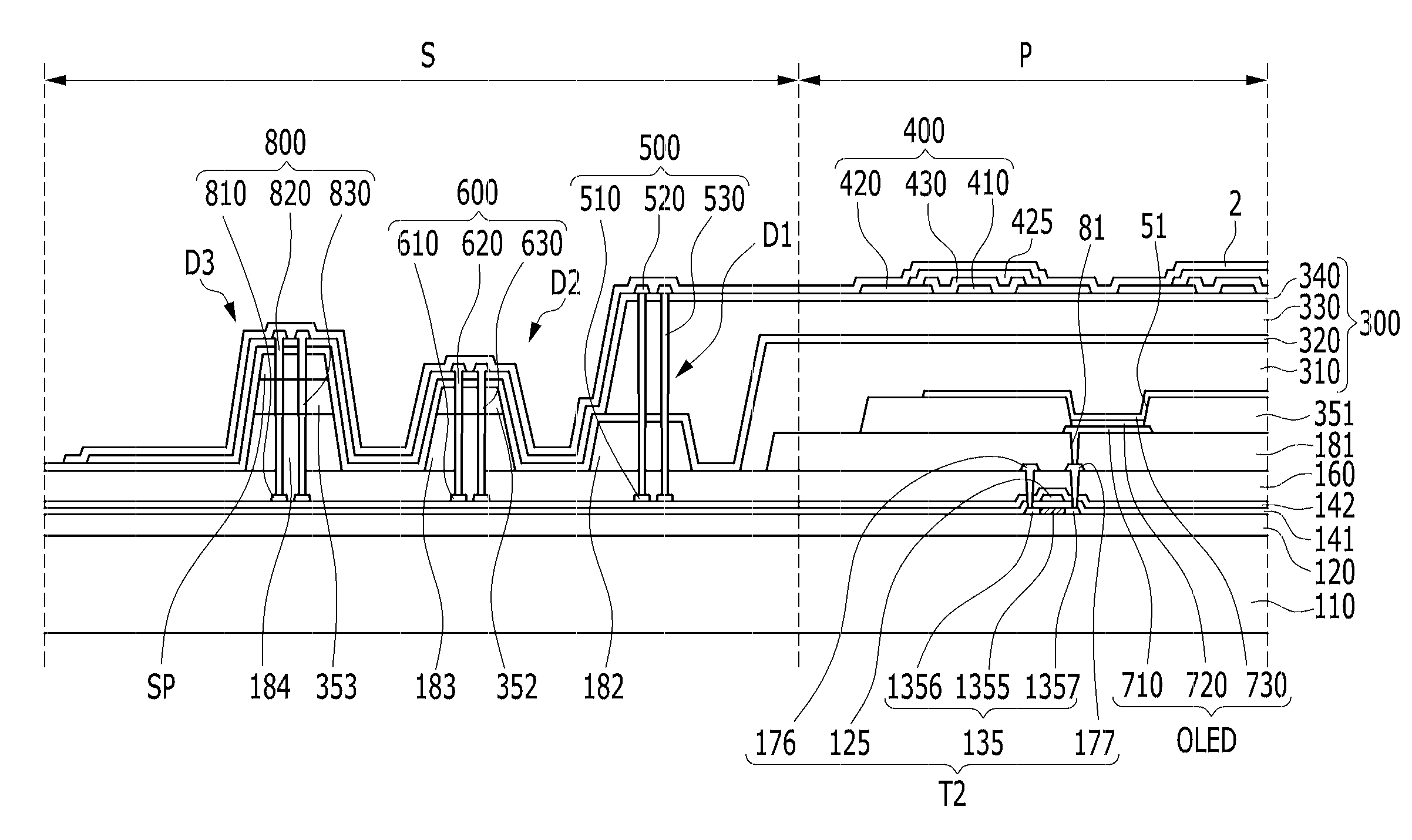

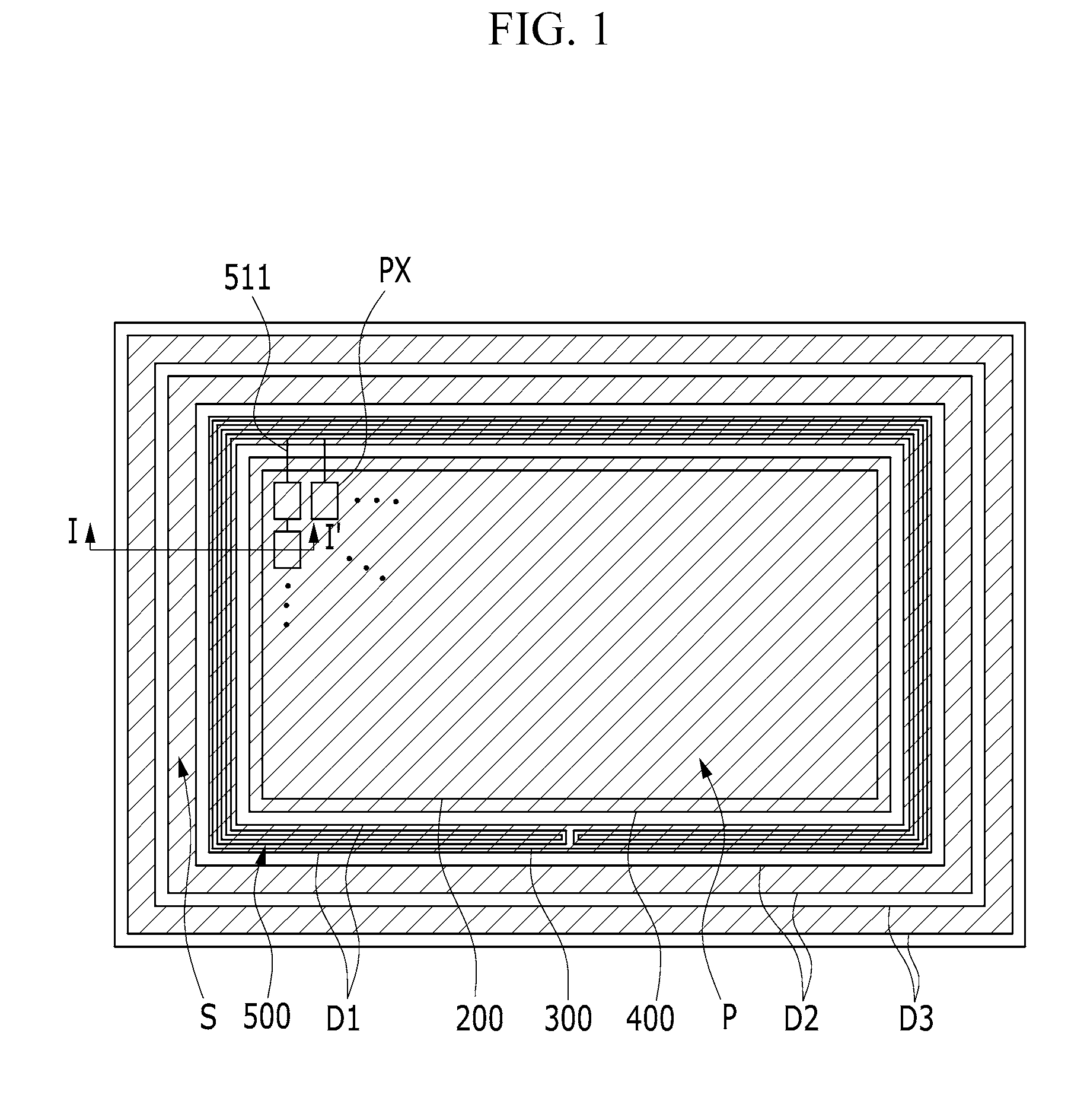

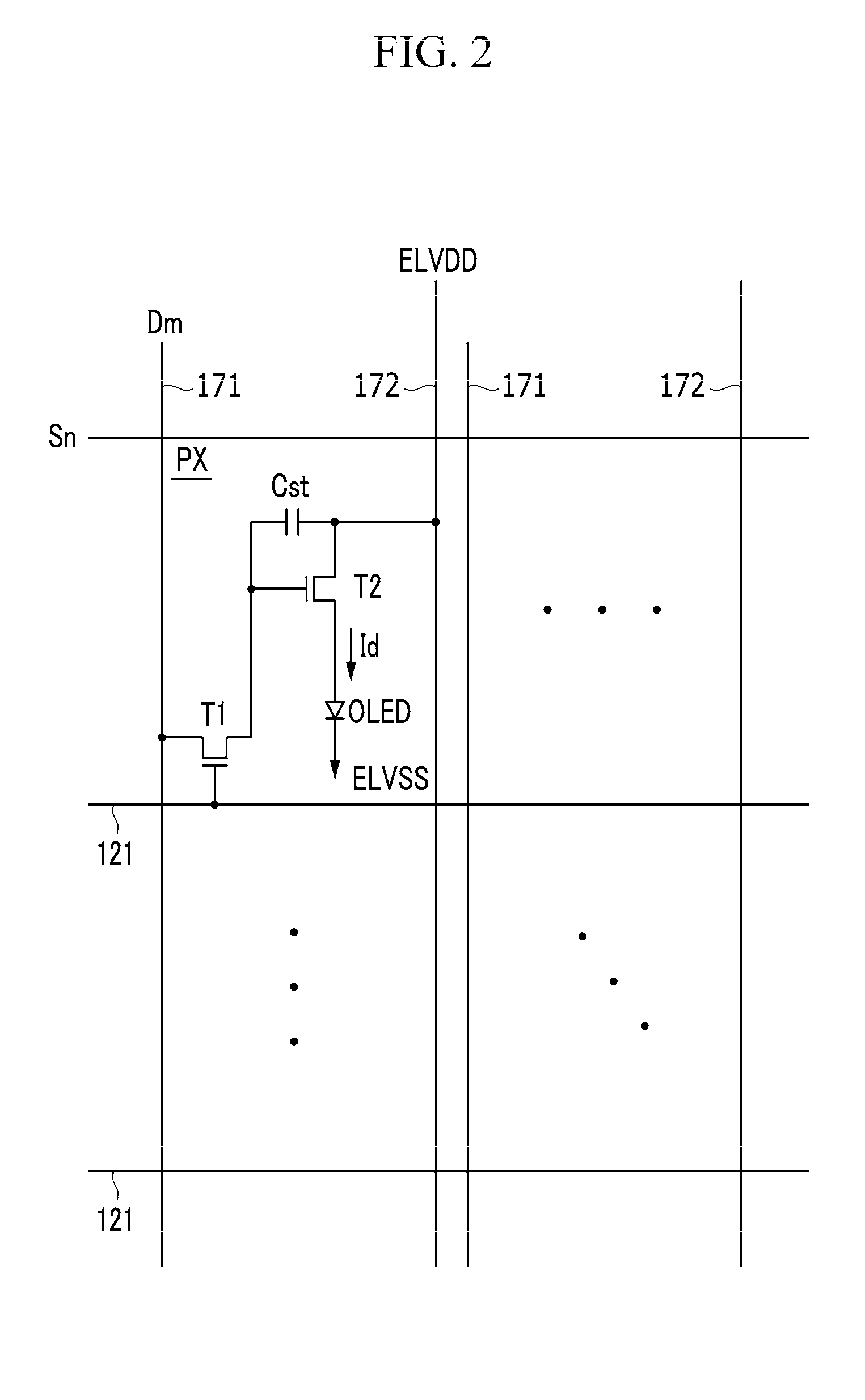

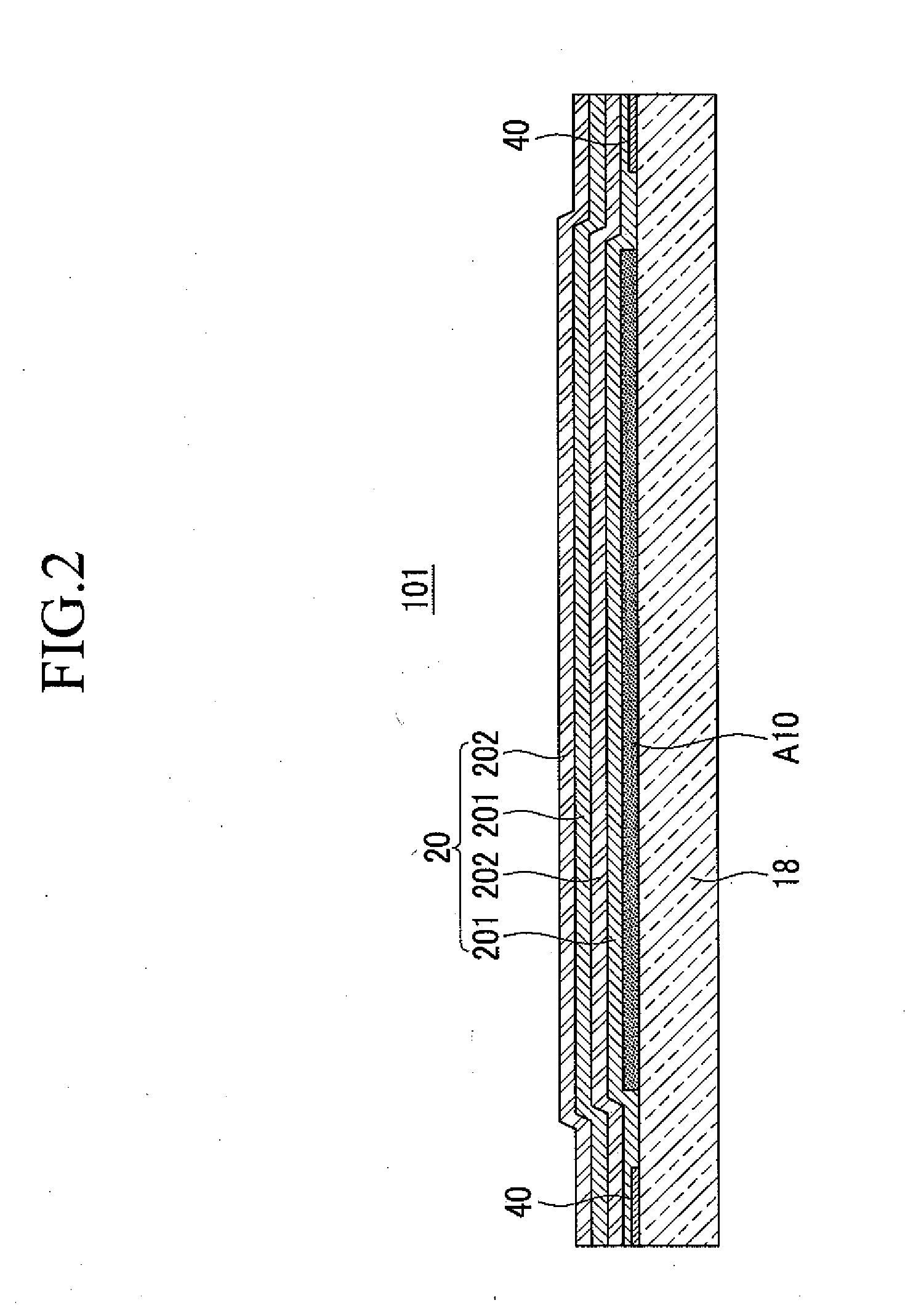

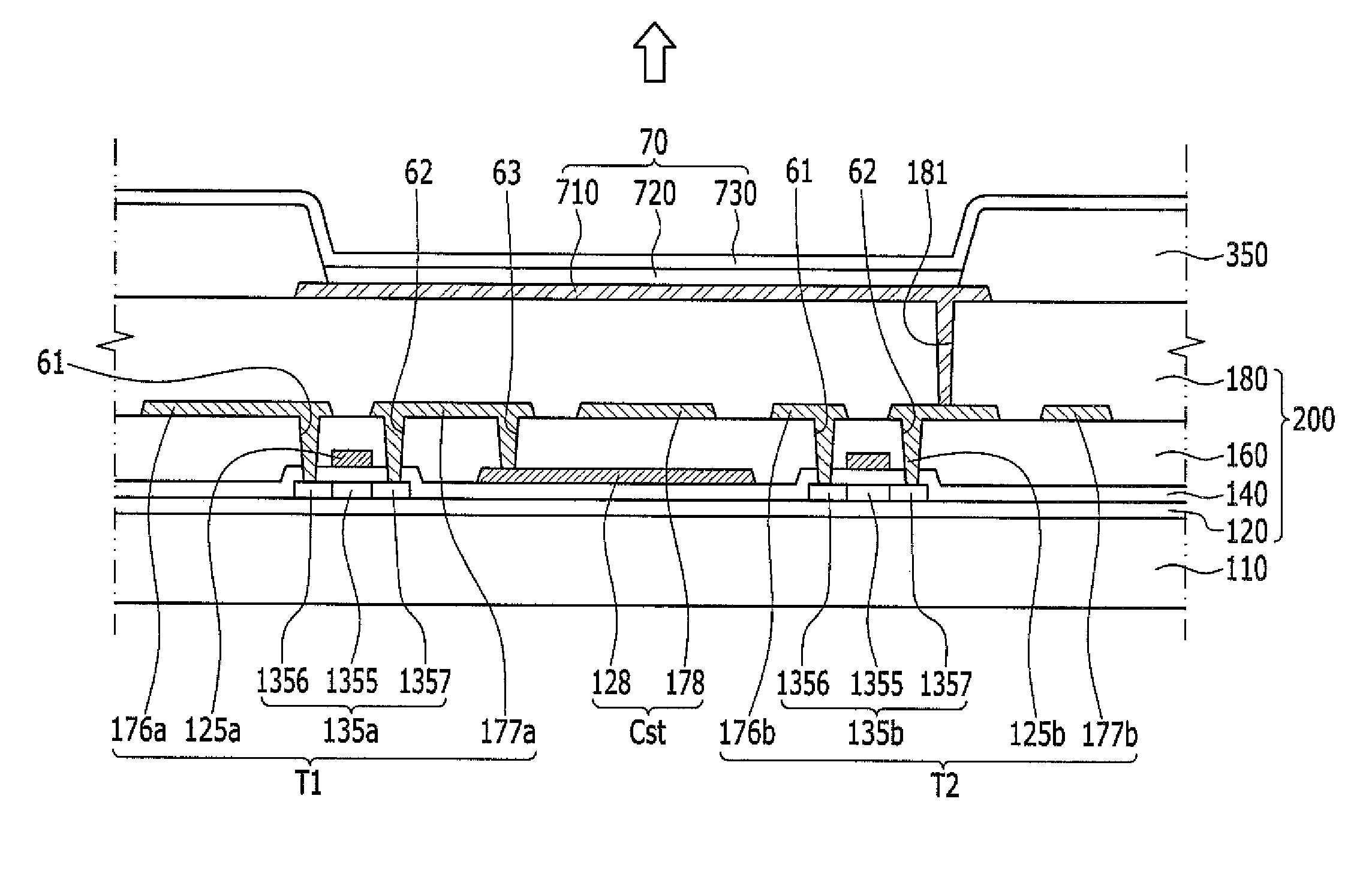

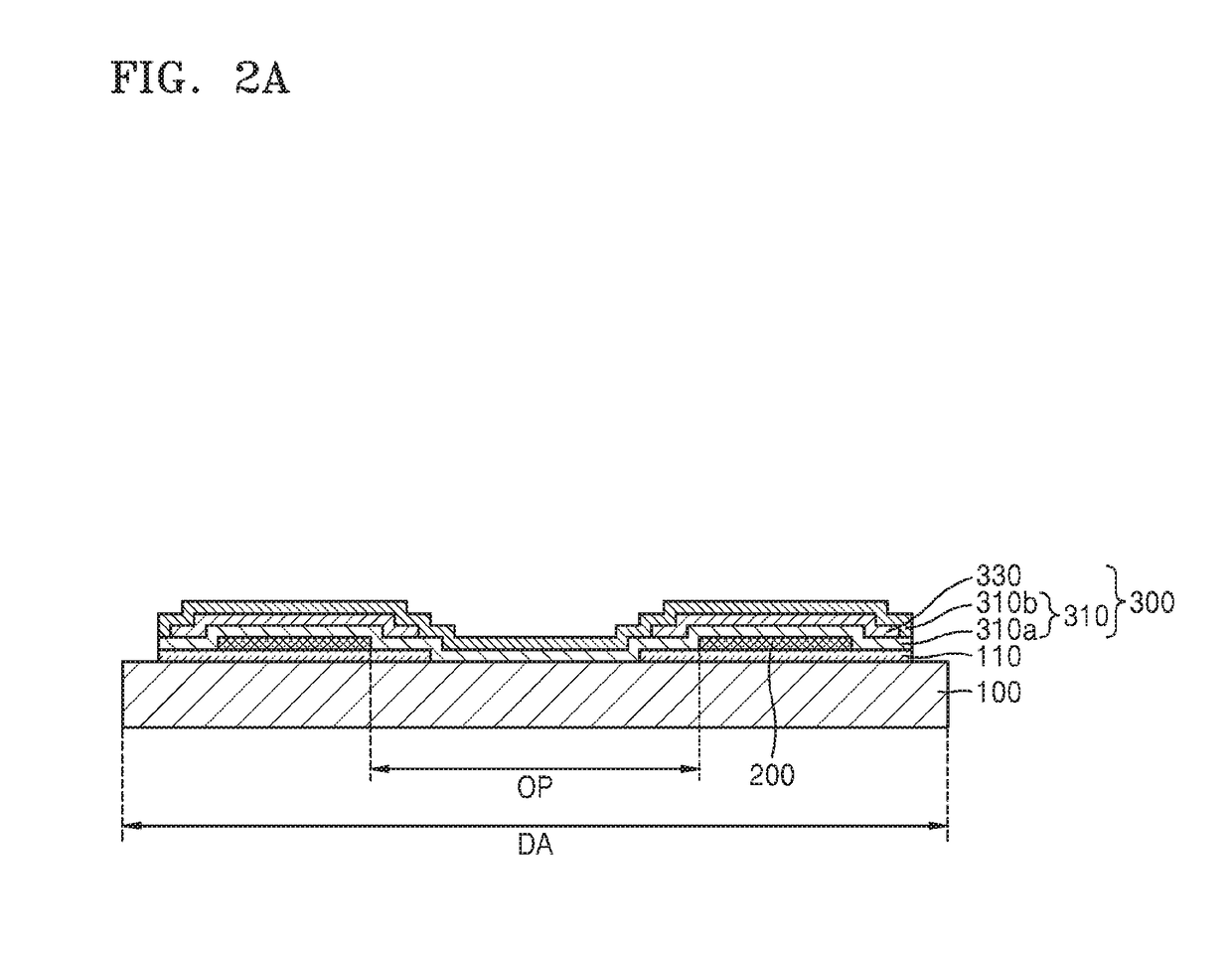

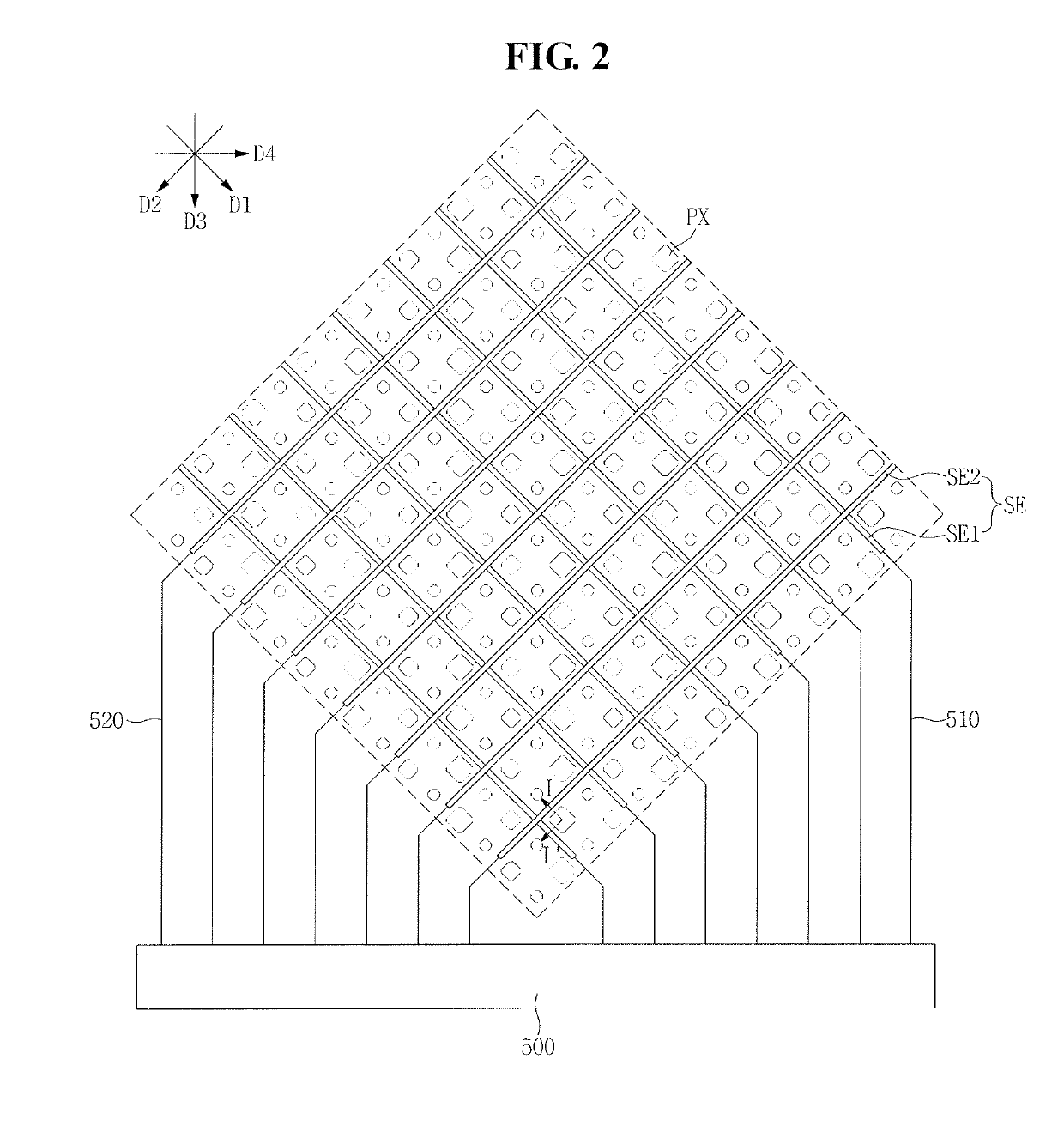

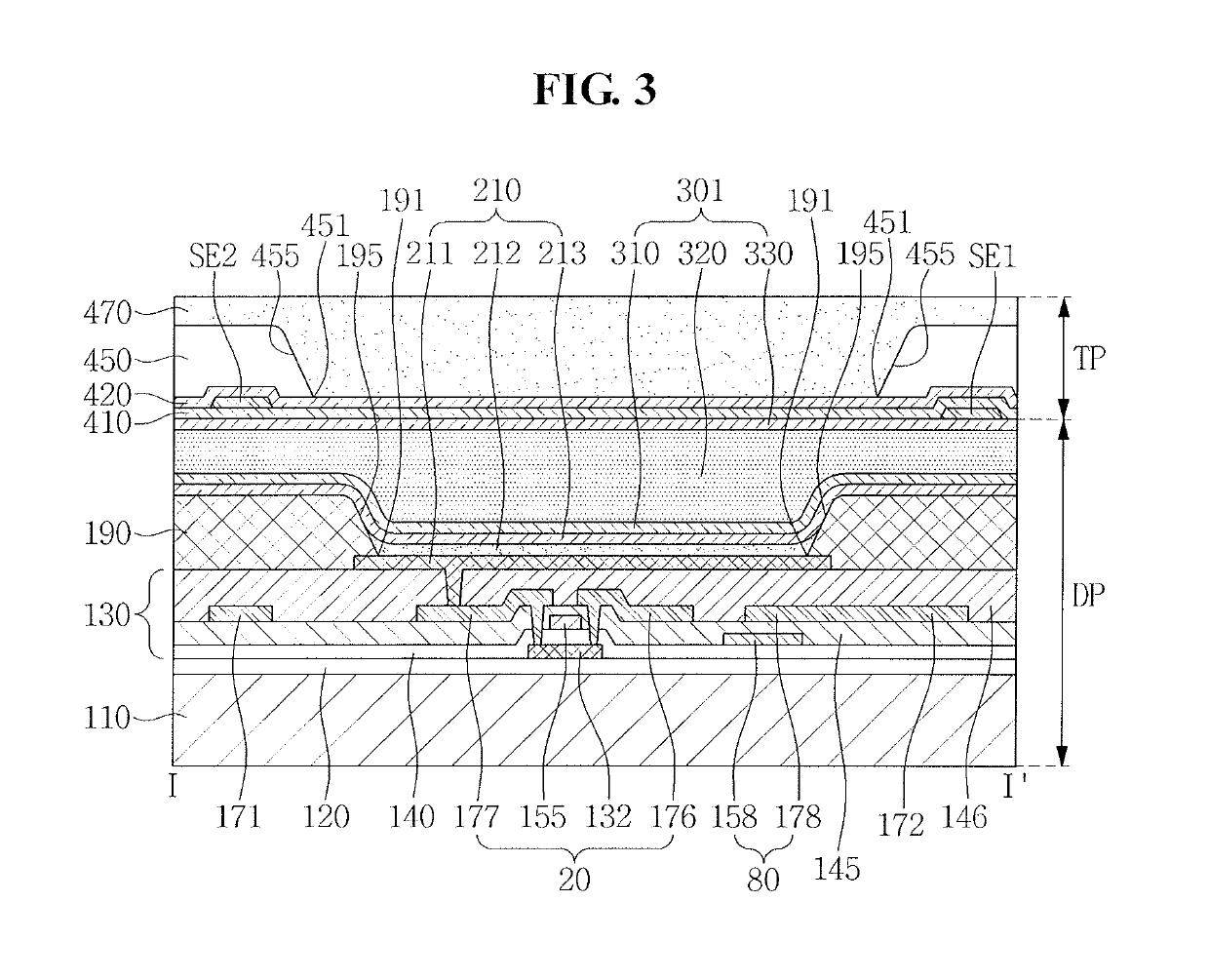

An organic light emitting display apparatus including a thin film encapsulation layer having a touch screen structure. The organic light emitting display apparatus includes a substrate; an organic light emitting diode (OLED) layer on the substrate; a thin film encapsulation layer on the OLED layer, and comprising a plurality of inorganic layers and a plurality of organic layers that are alternately stacked; and a touch sensing layer in the thin film encapsulation layer, wherein the touch sensing layer includes: a first touch conductive layer; a touch inorganic layer on the first touch conductive layer; and a second touch conductive layer on the touch inorganic layer, wherein the touch inorganic layer is one of the plurality of inorganic layers included in the thin film encapsulation layer.

Owner:SAMSUNG DISPLAY CO LTD

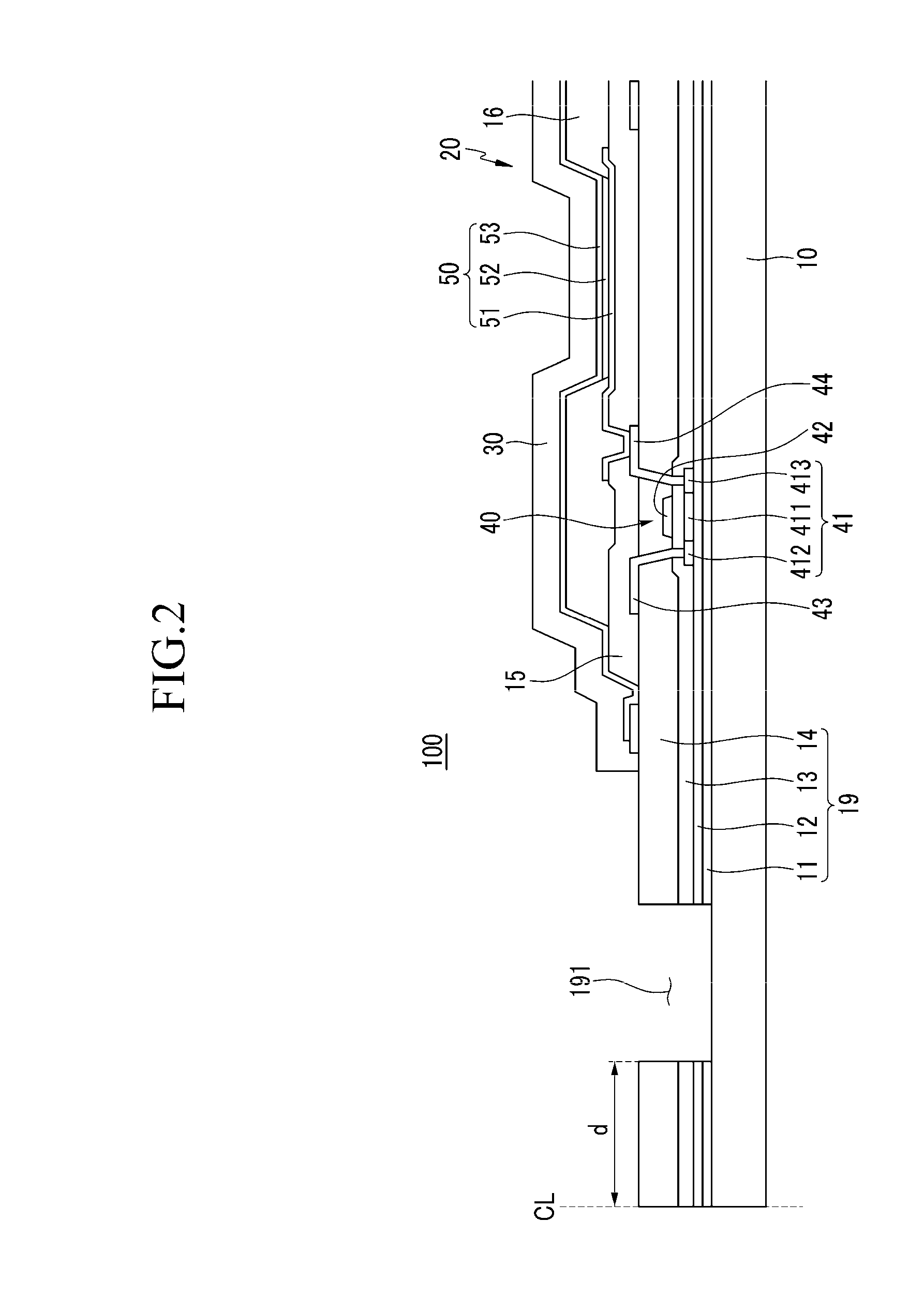

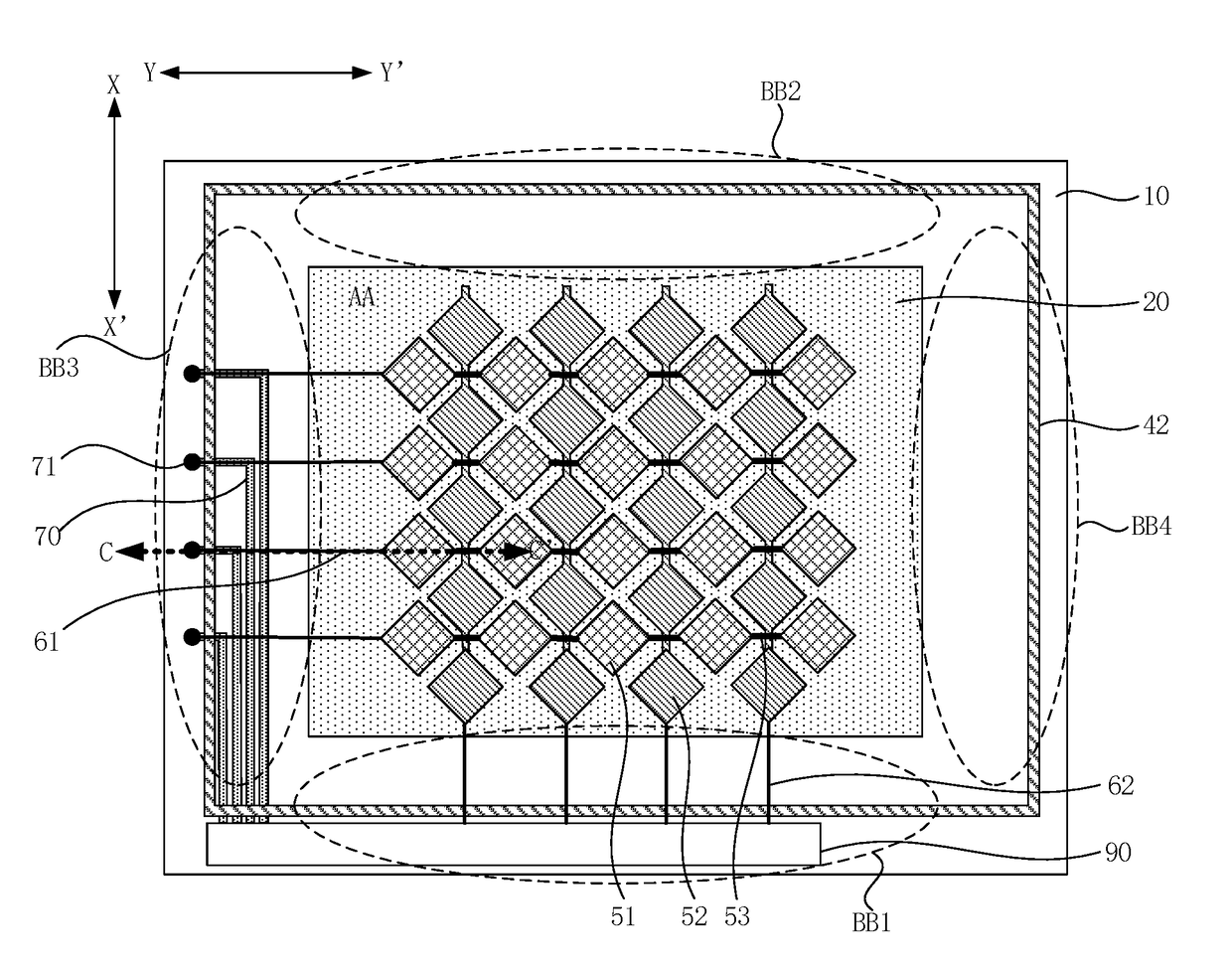

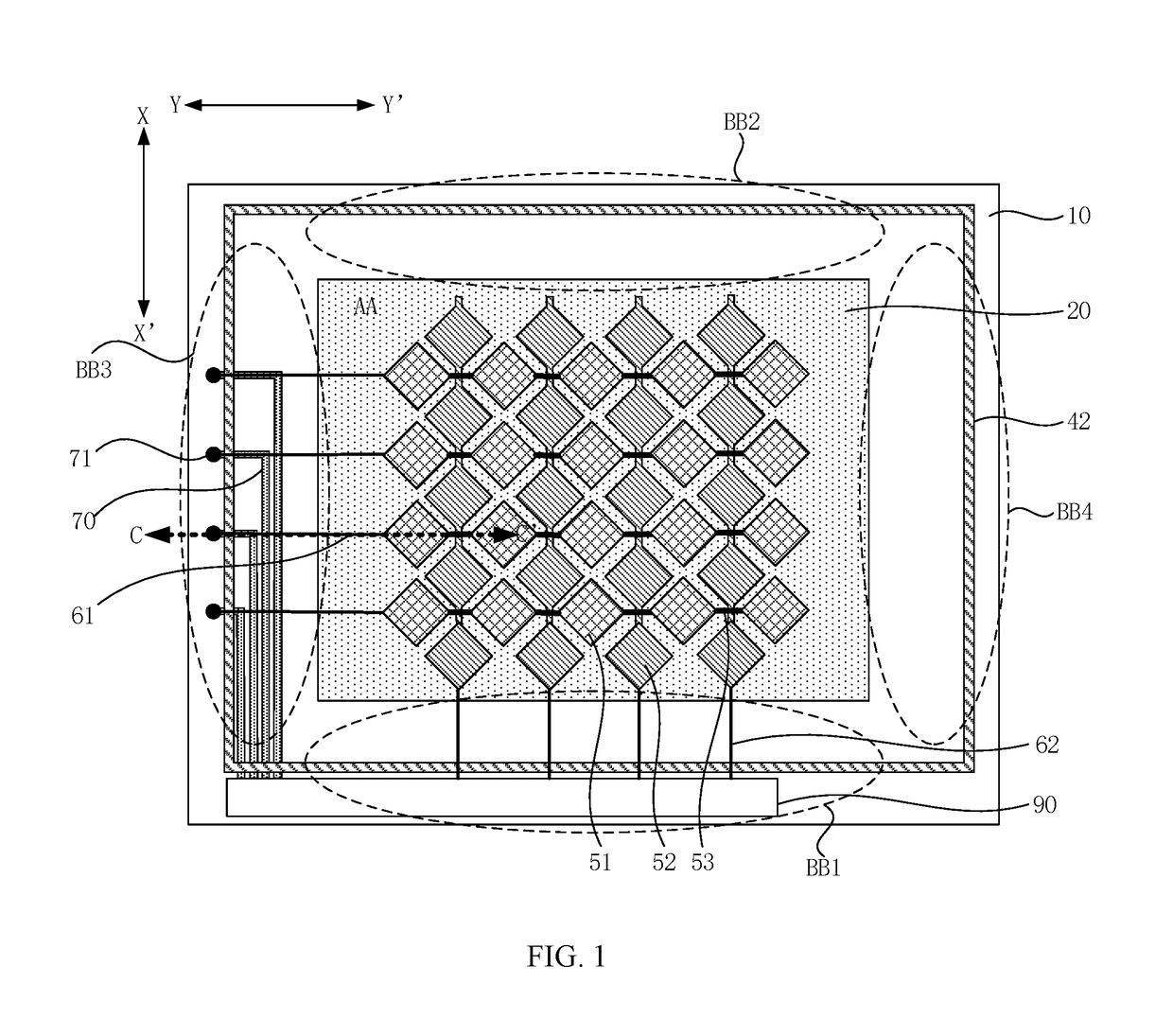

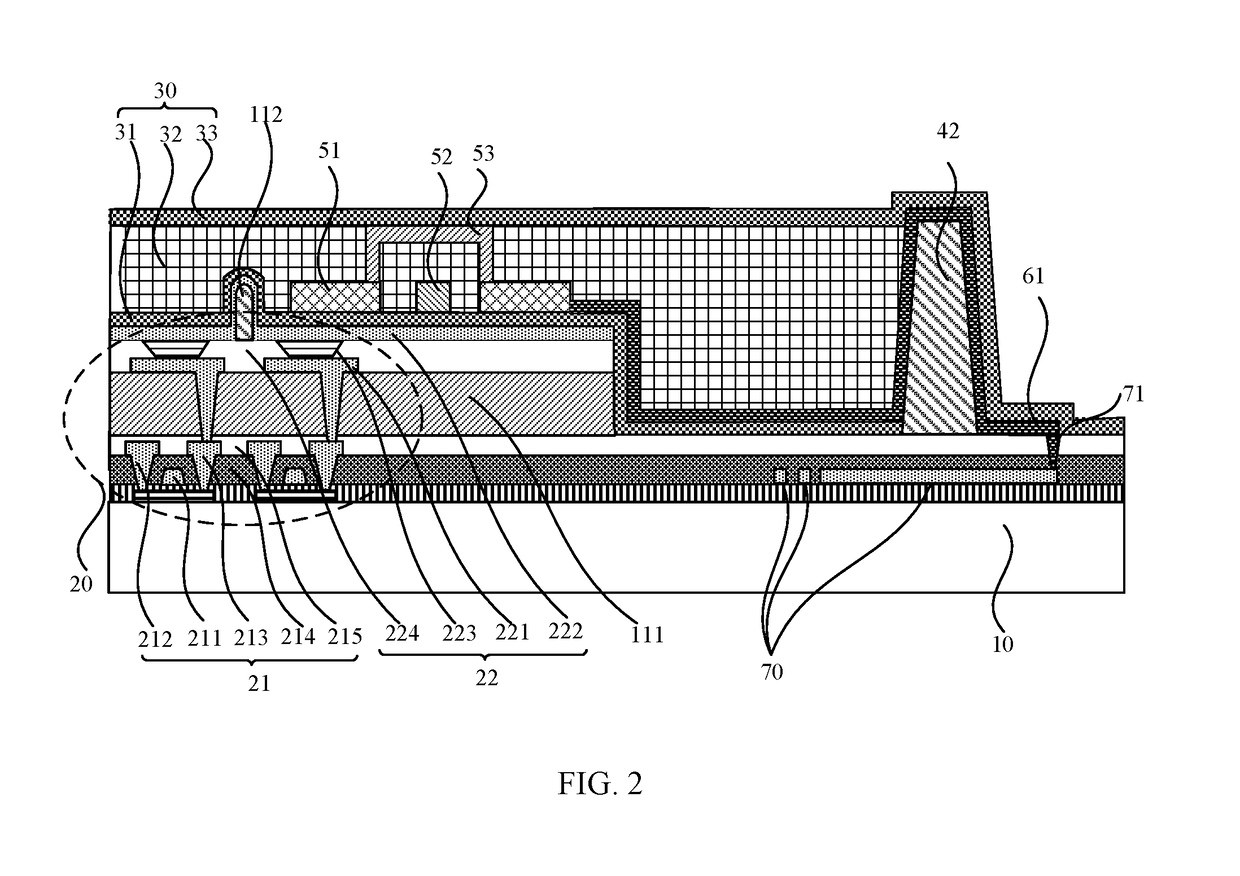

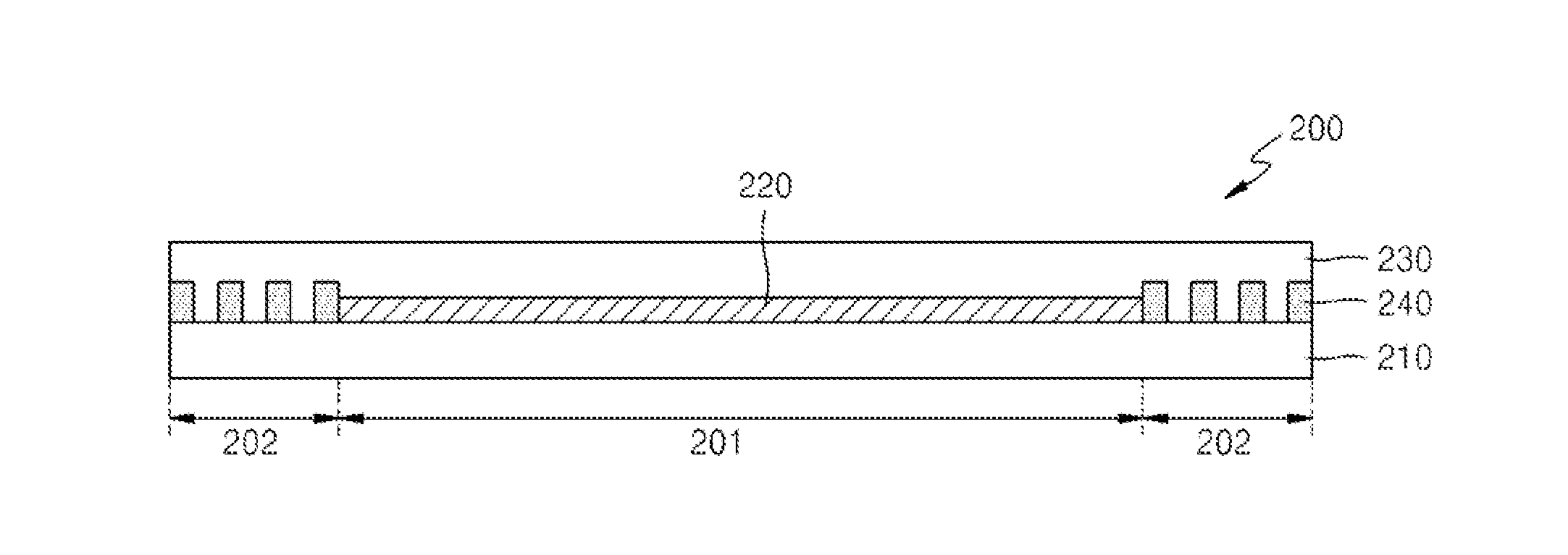

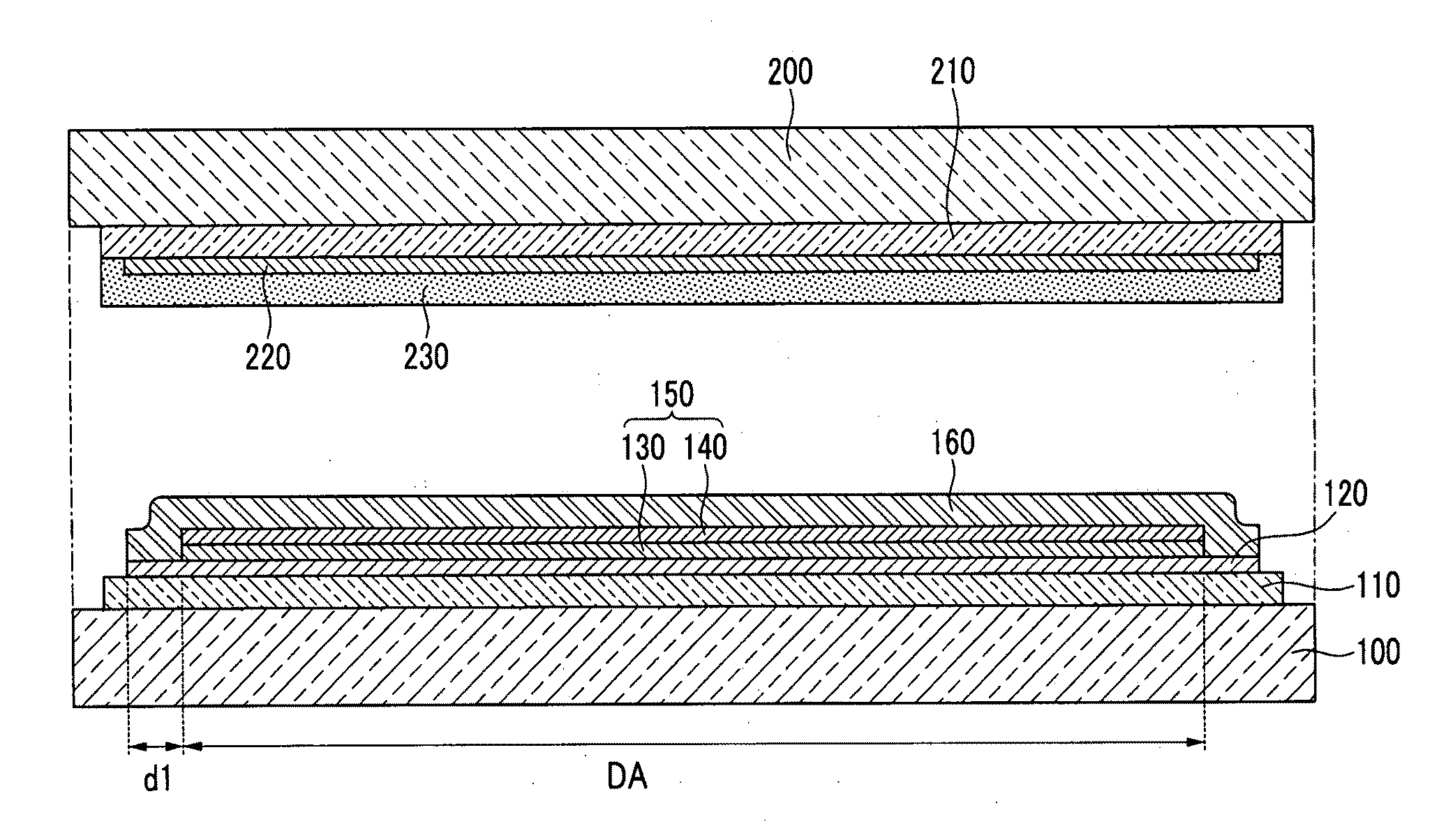

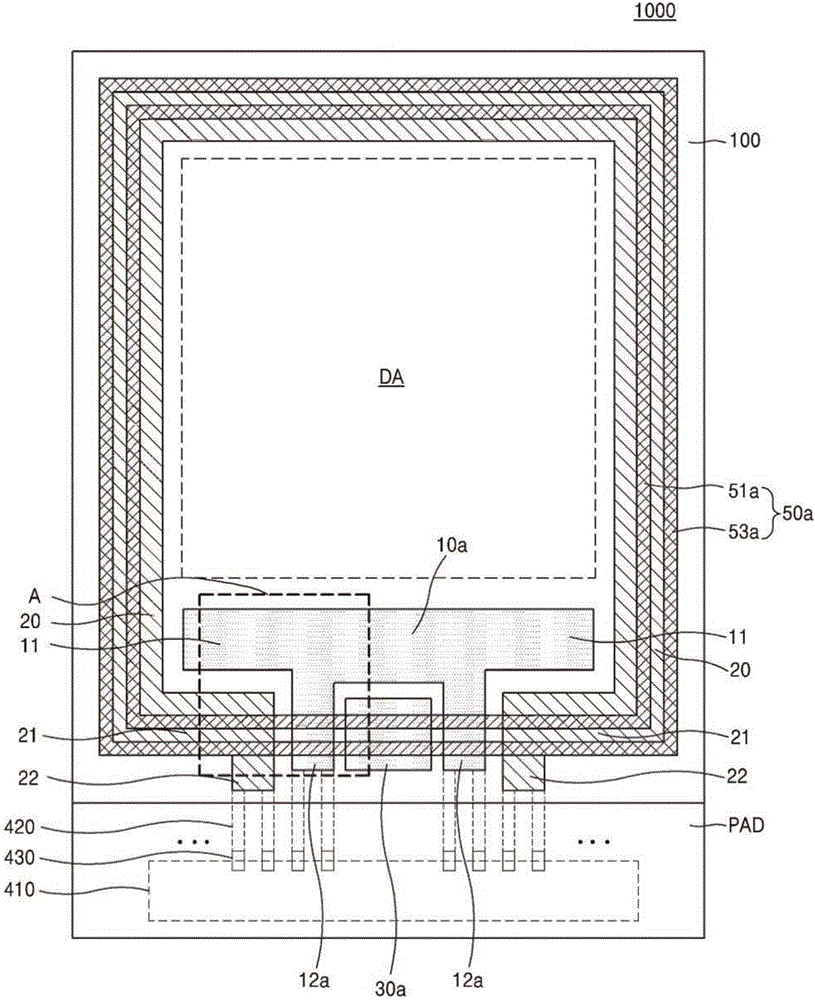

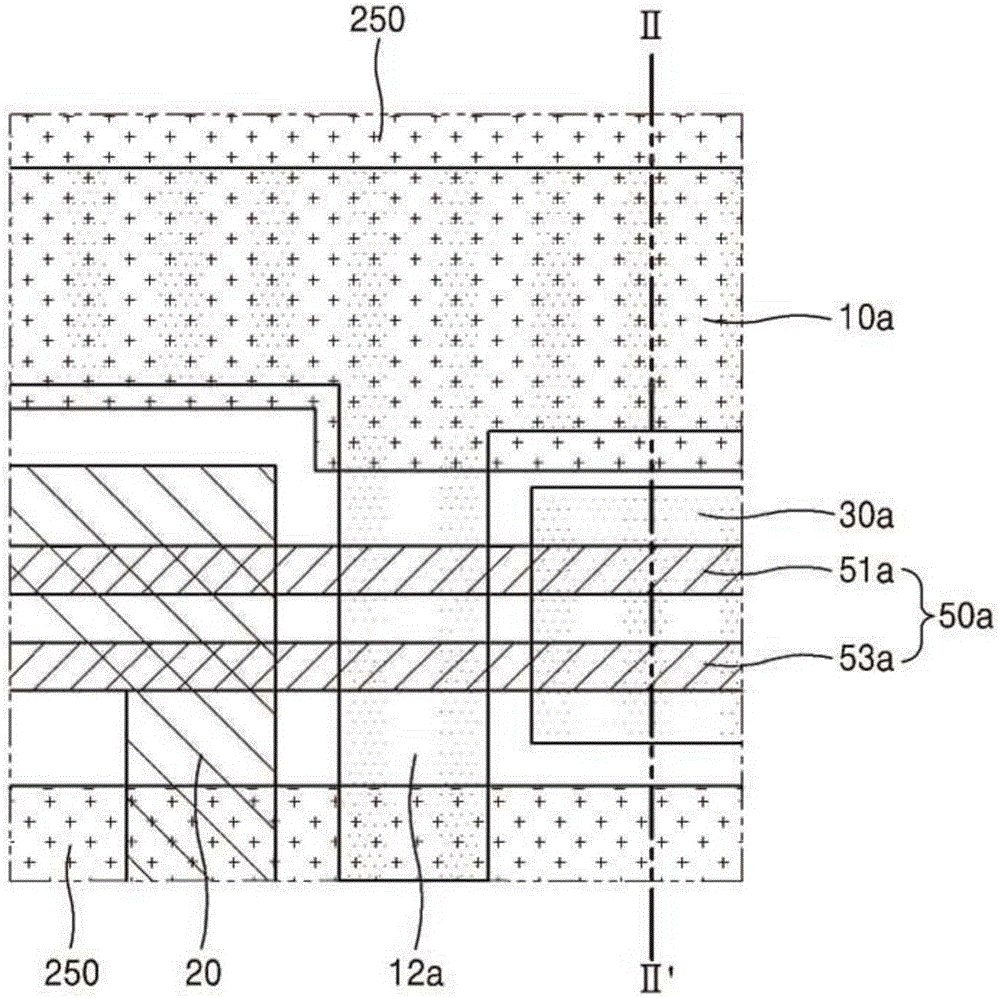

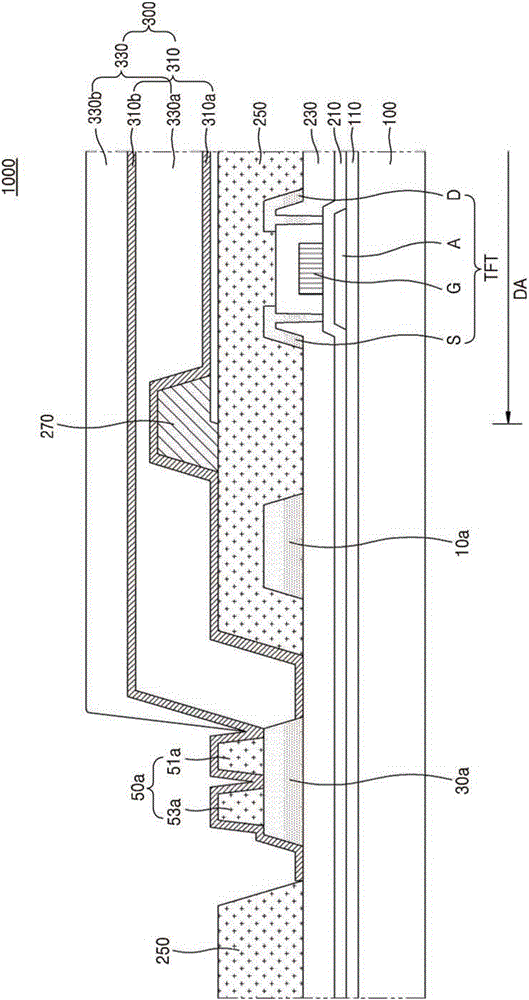

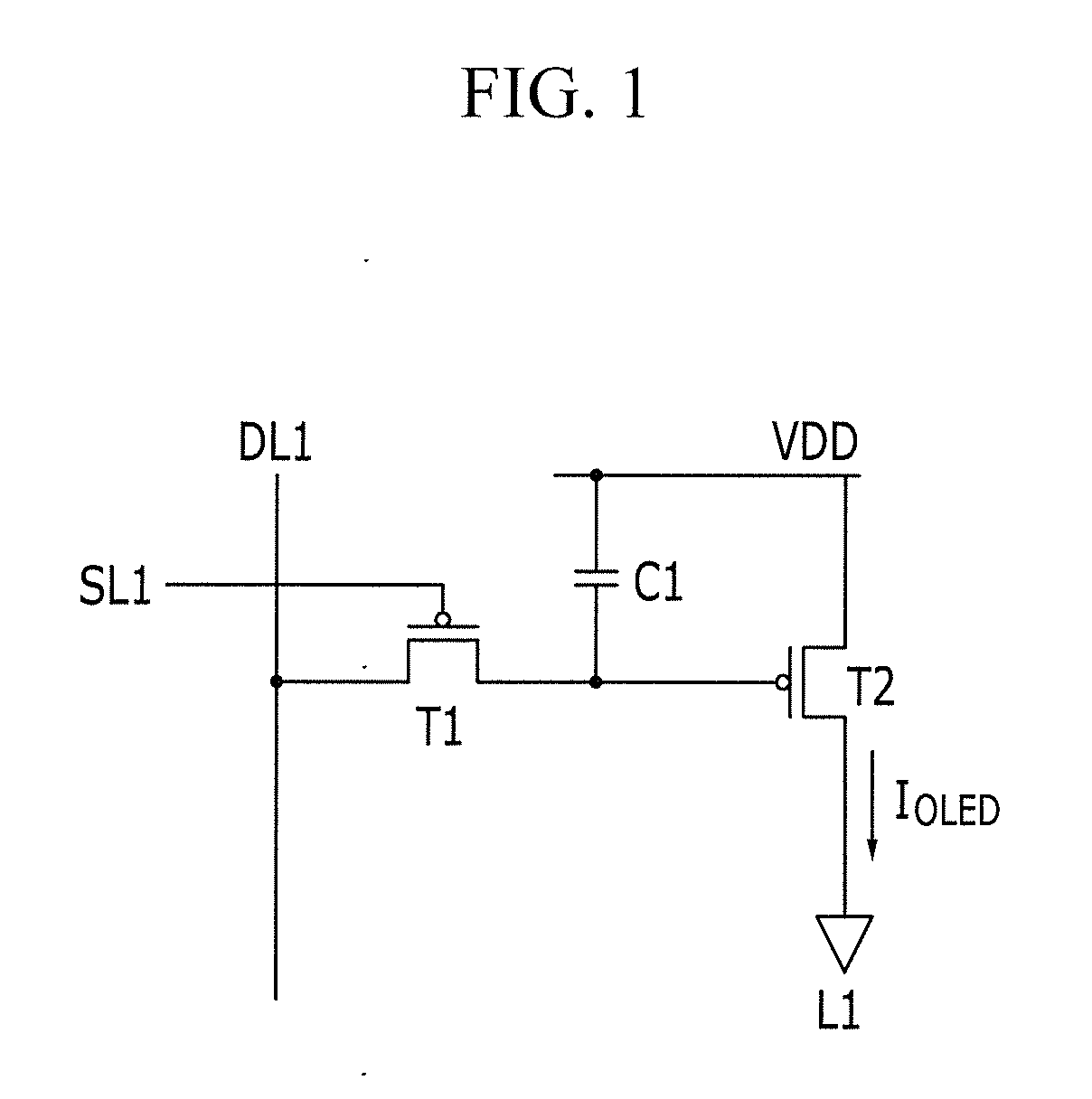

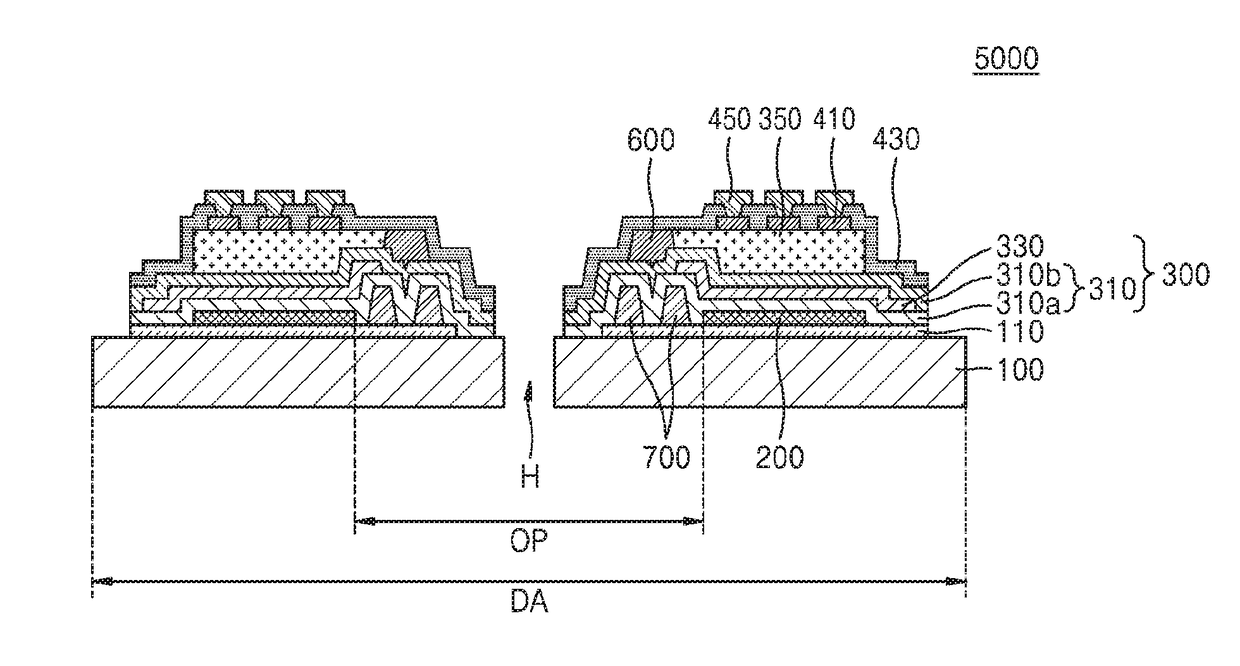

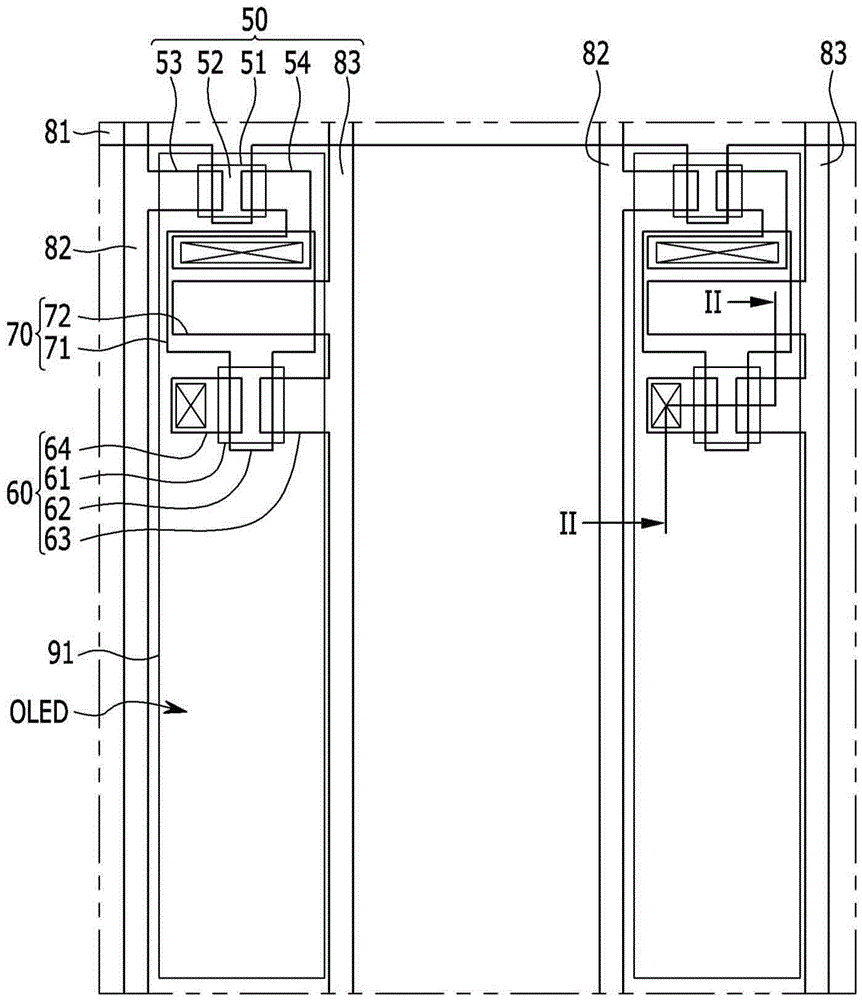

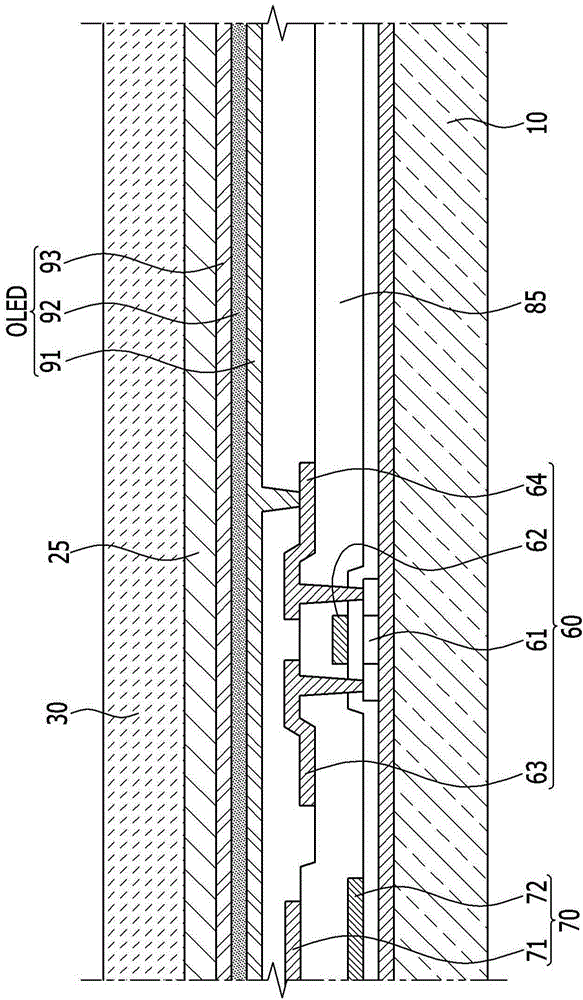

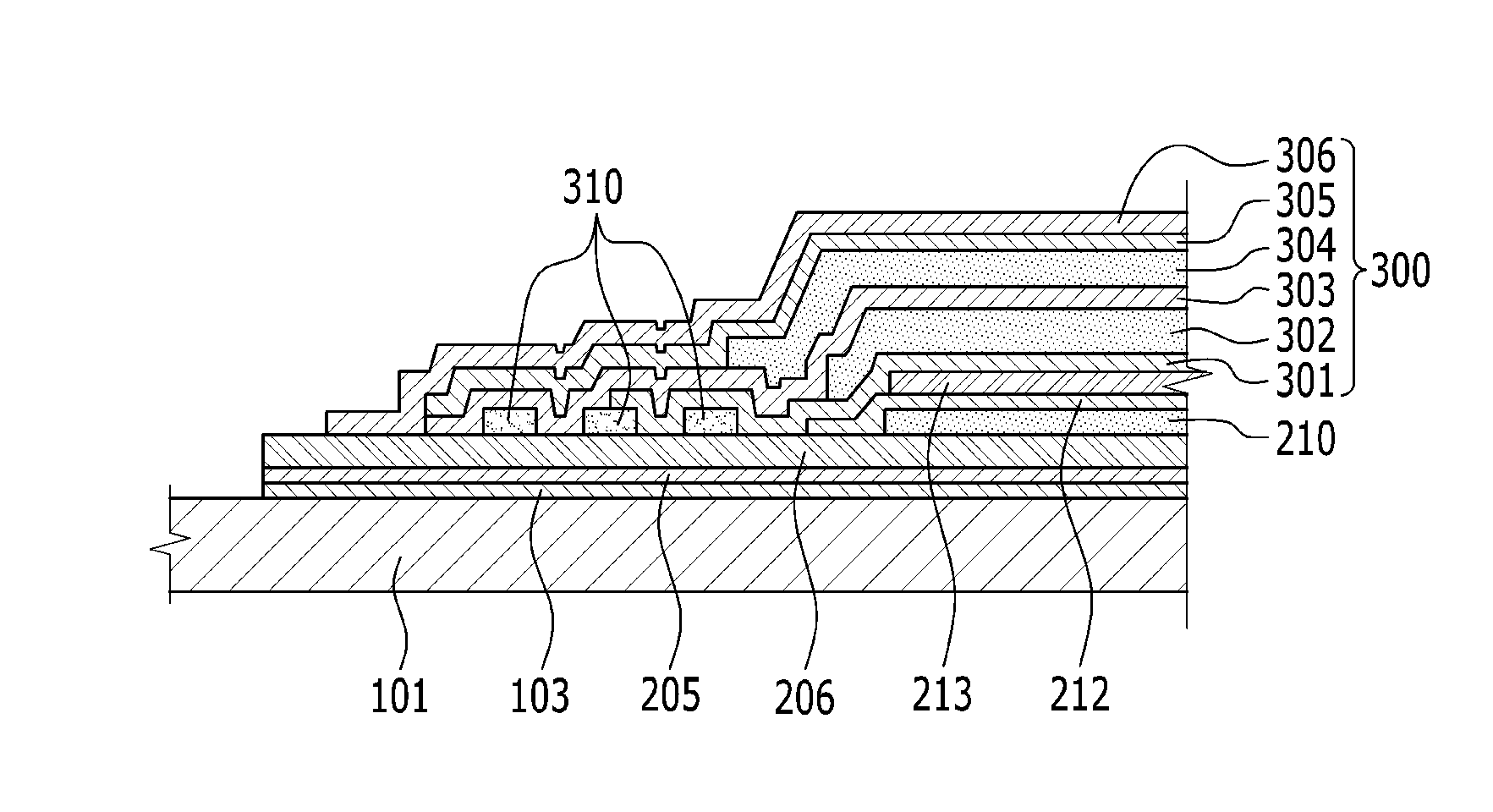

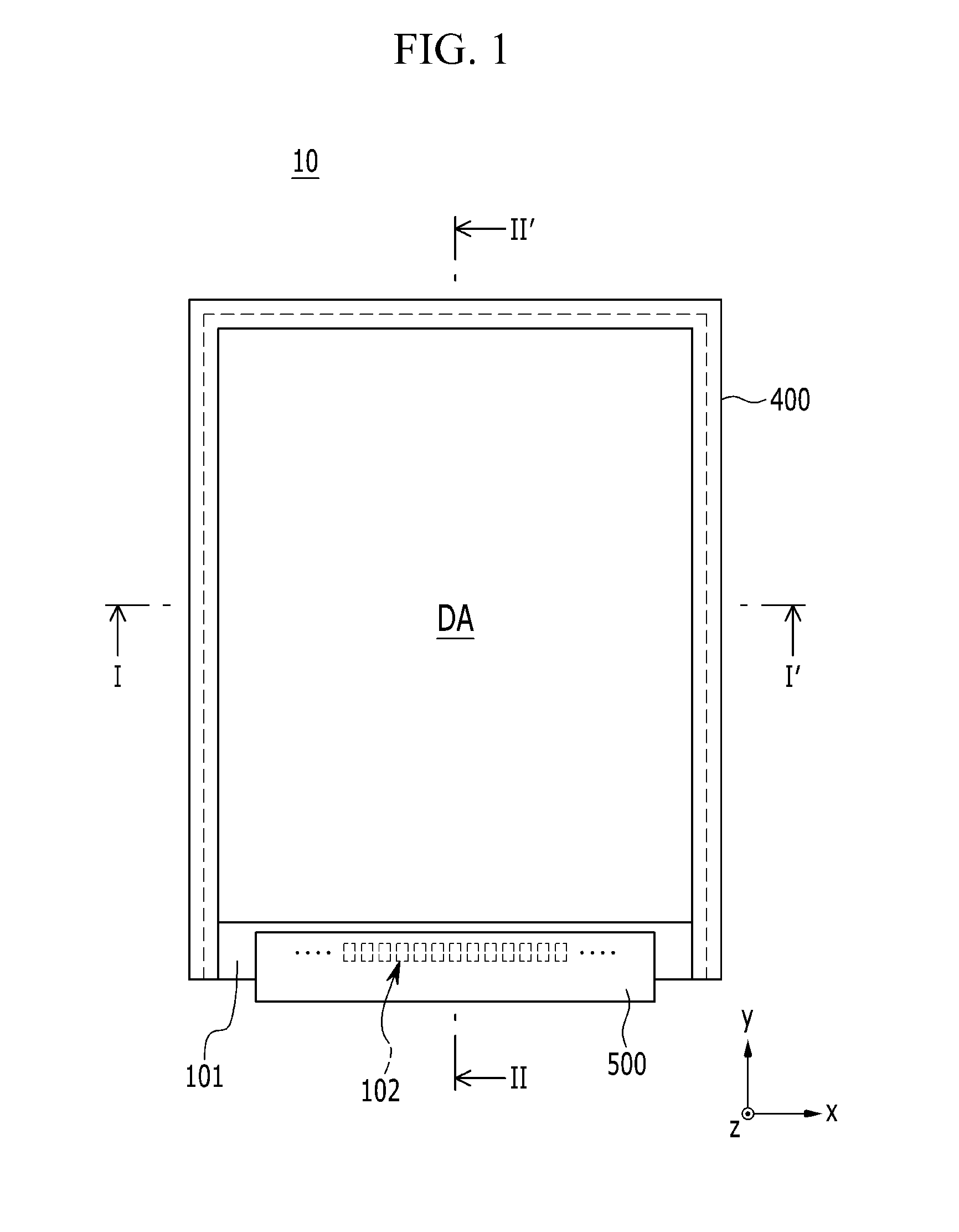

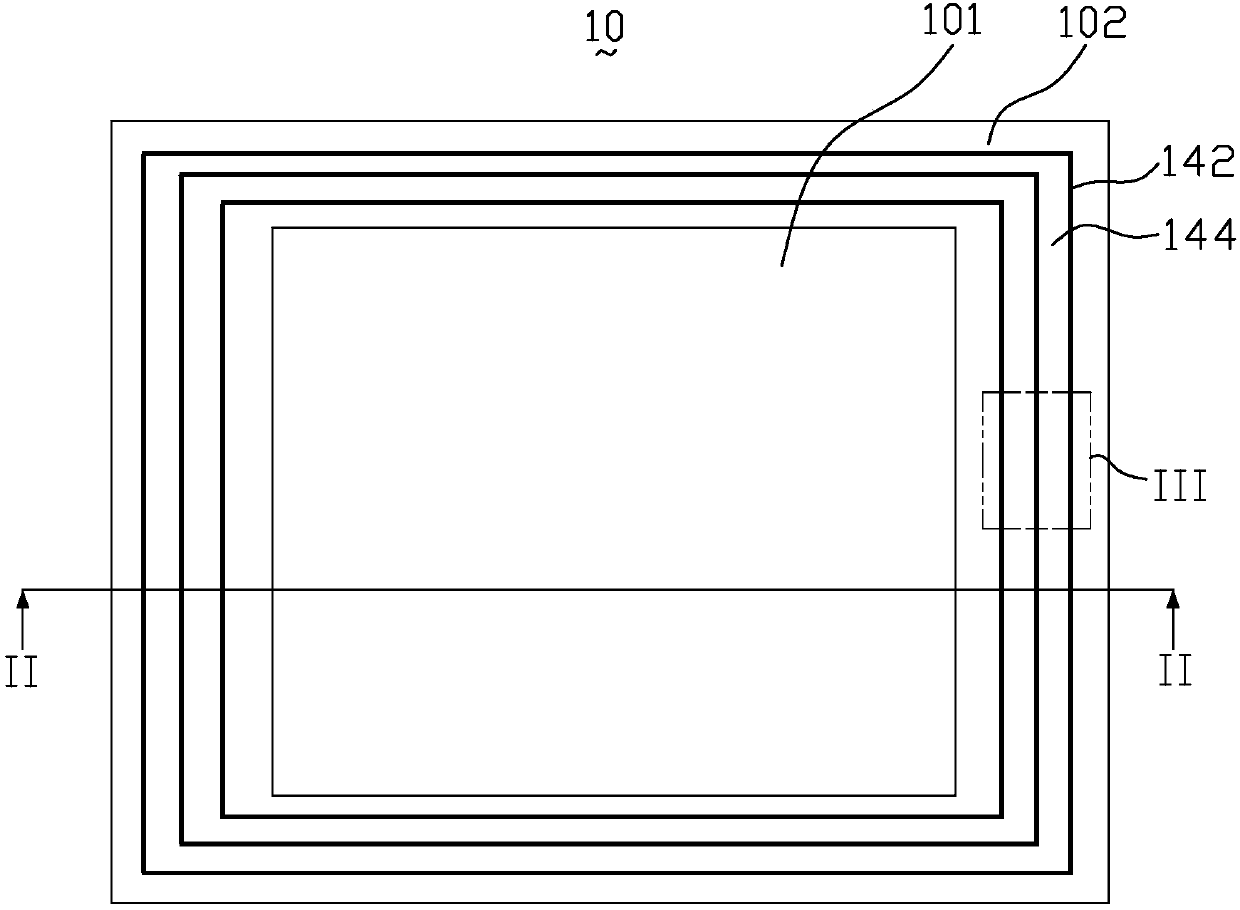

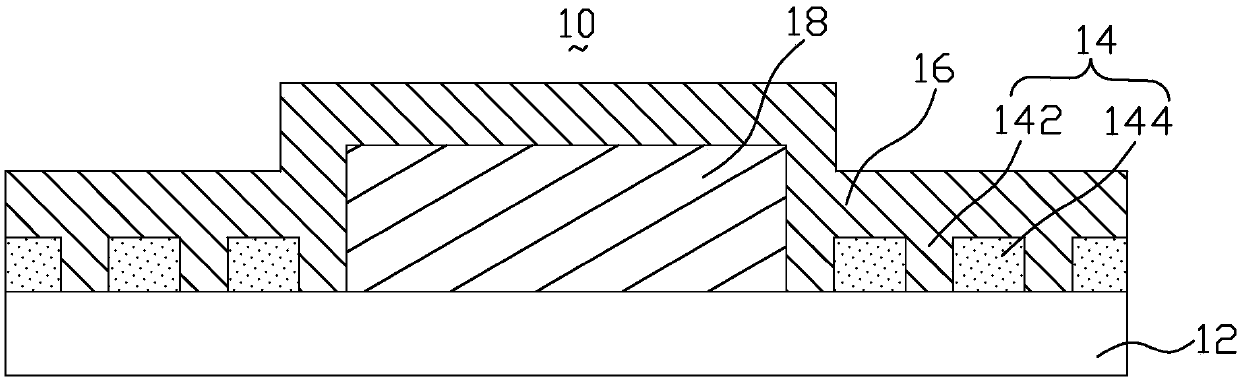

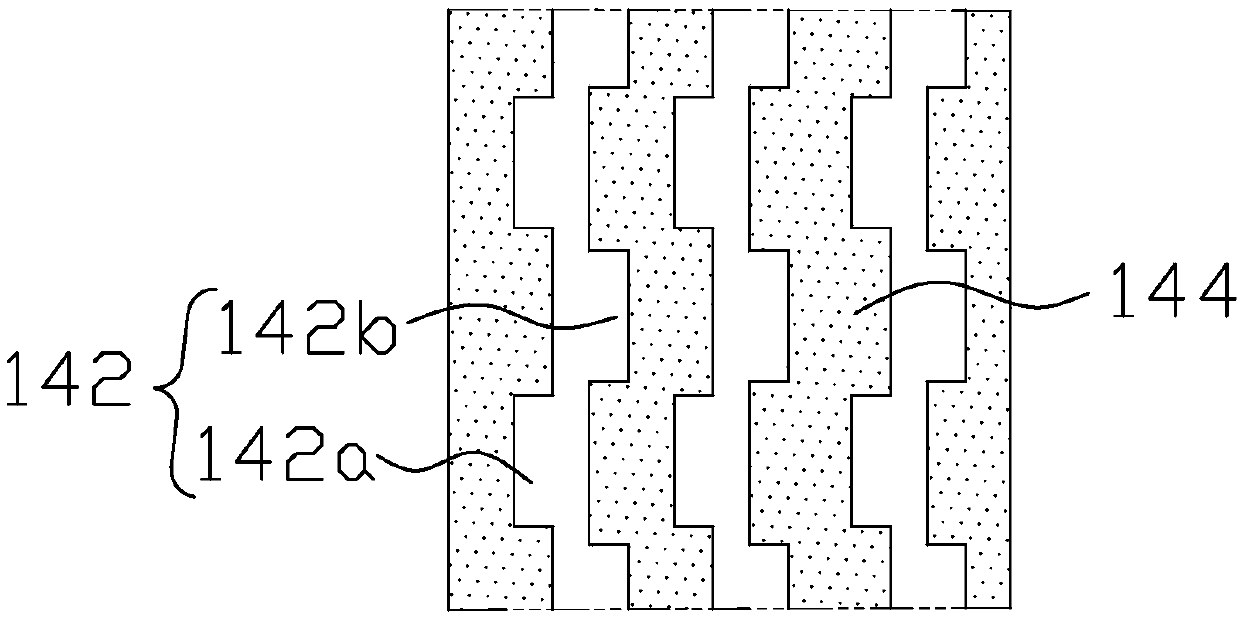

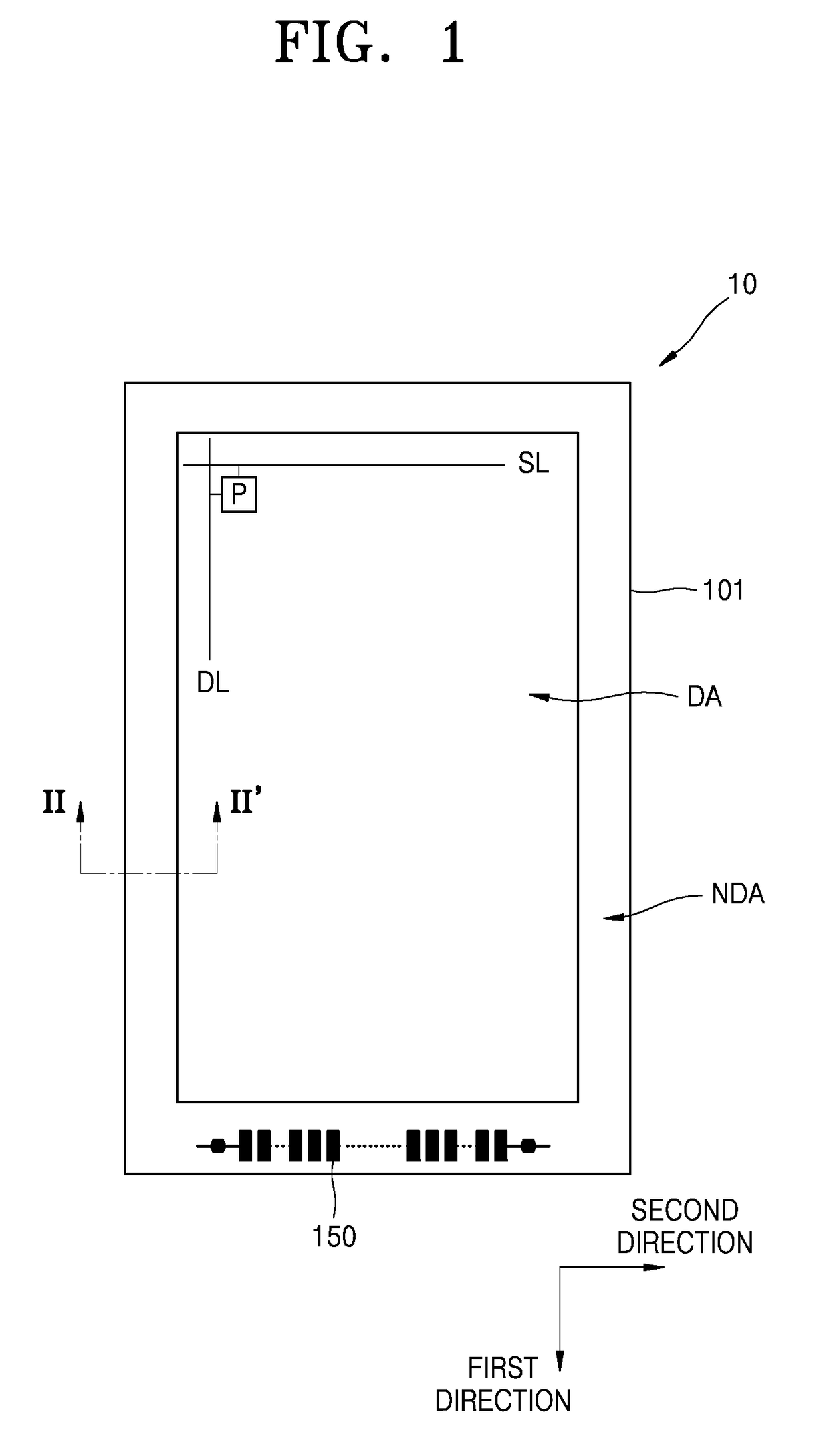

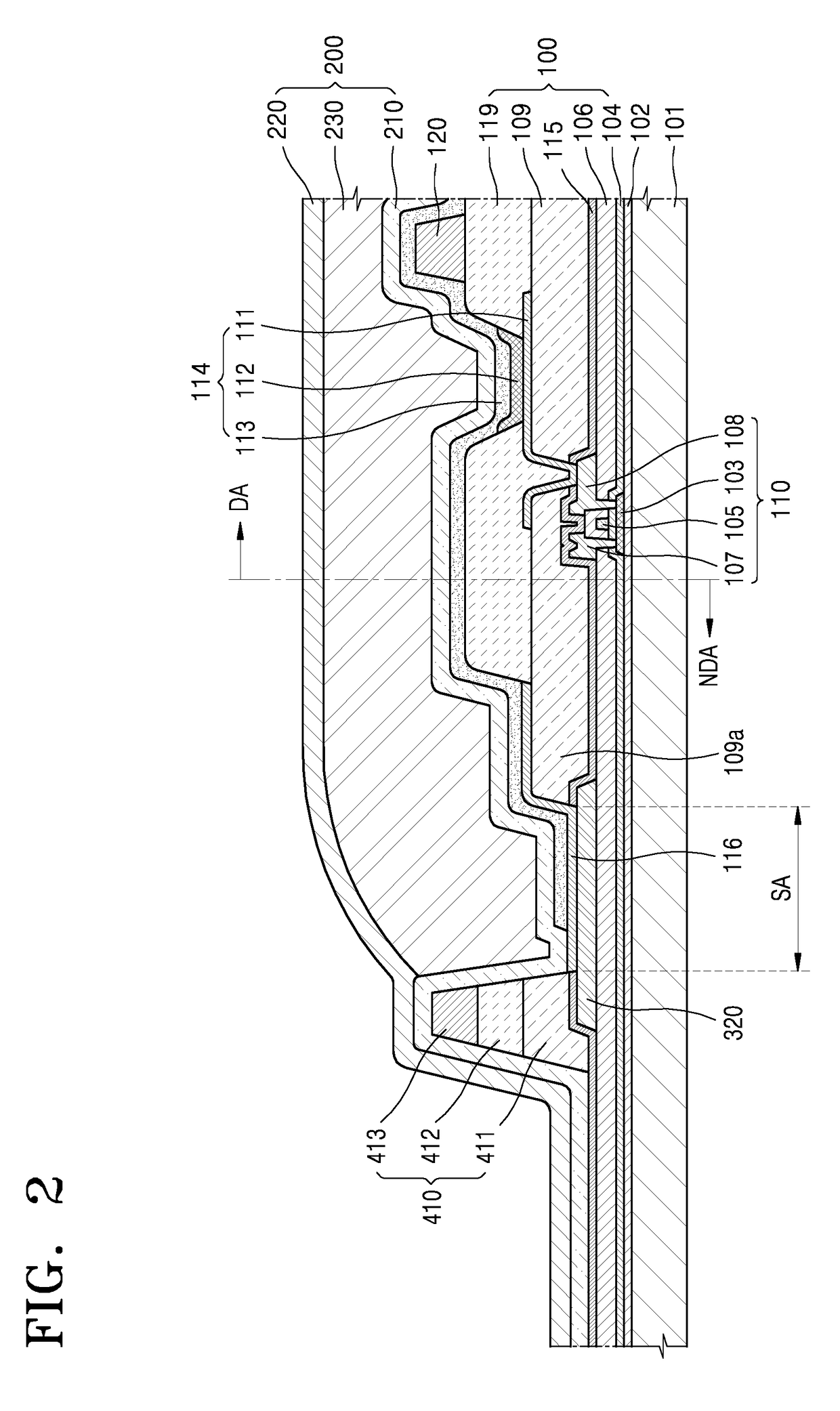

Organic light emitting diode display

ActiveUS20160307971A1Minimizes failure ratioSemiconductor/solid-state device testing/measurementStatic indicating devicesTouch SensesDisplay device

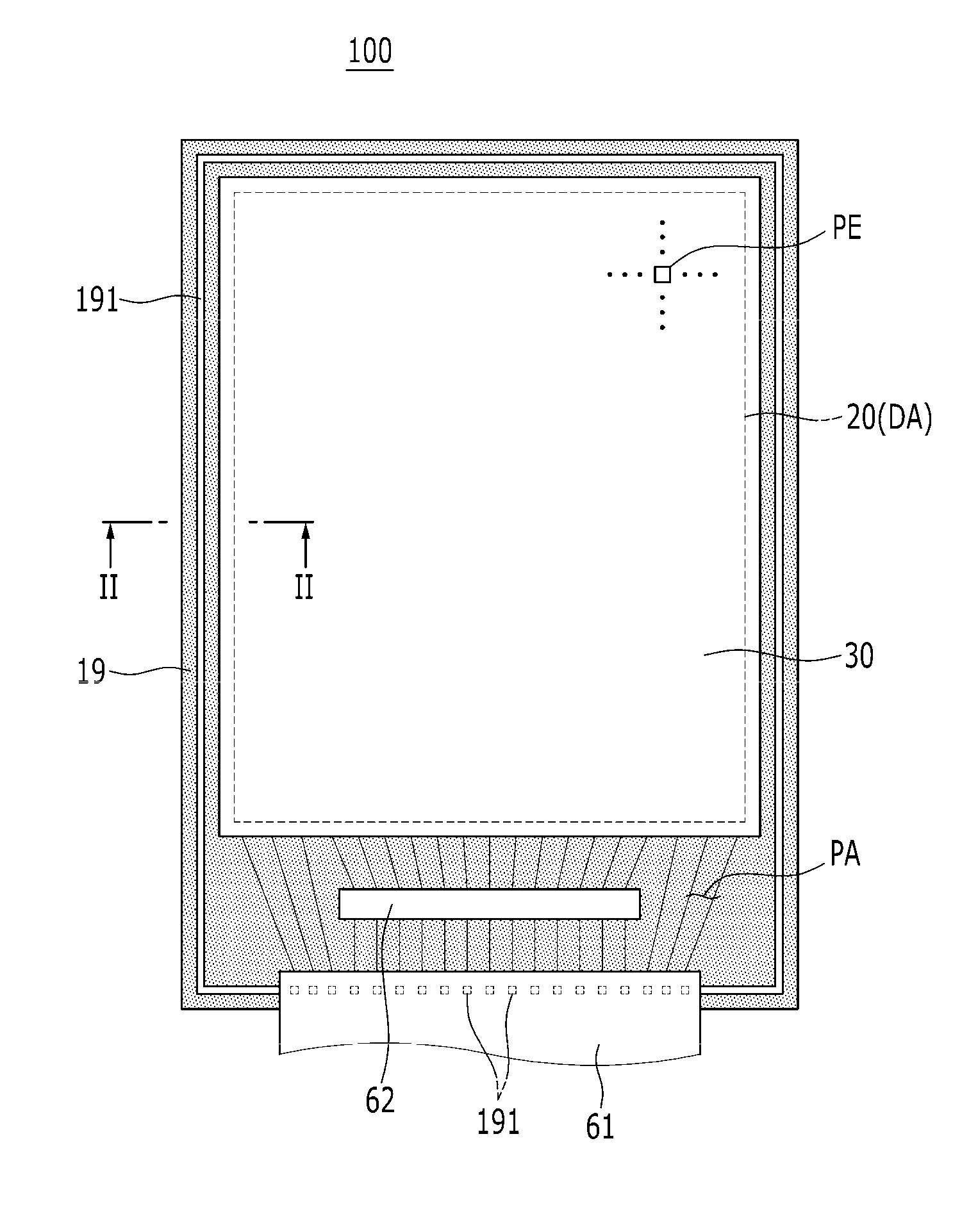

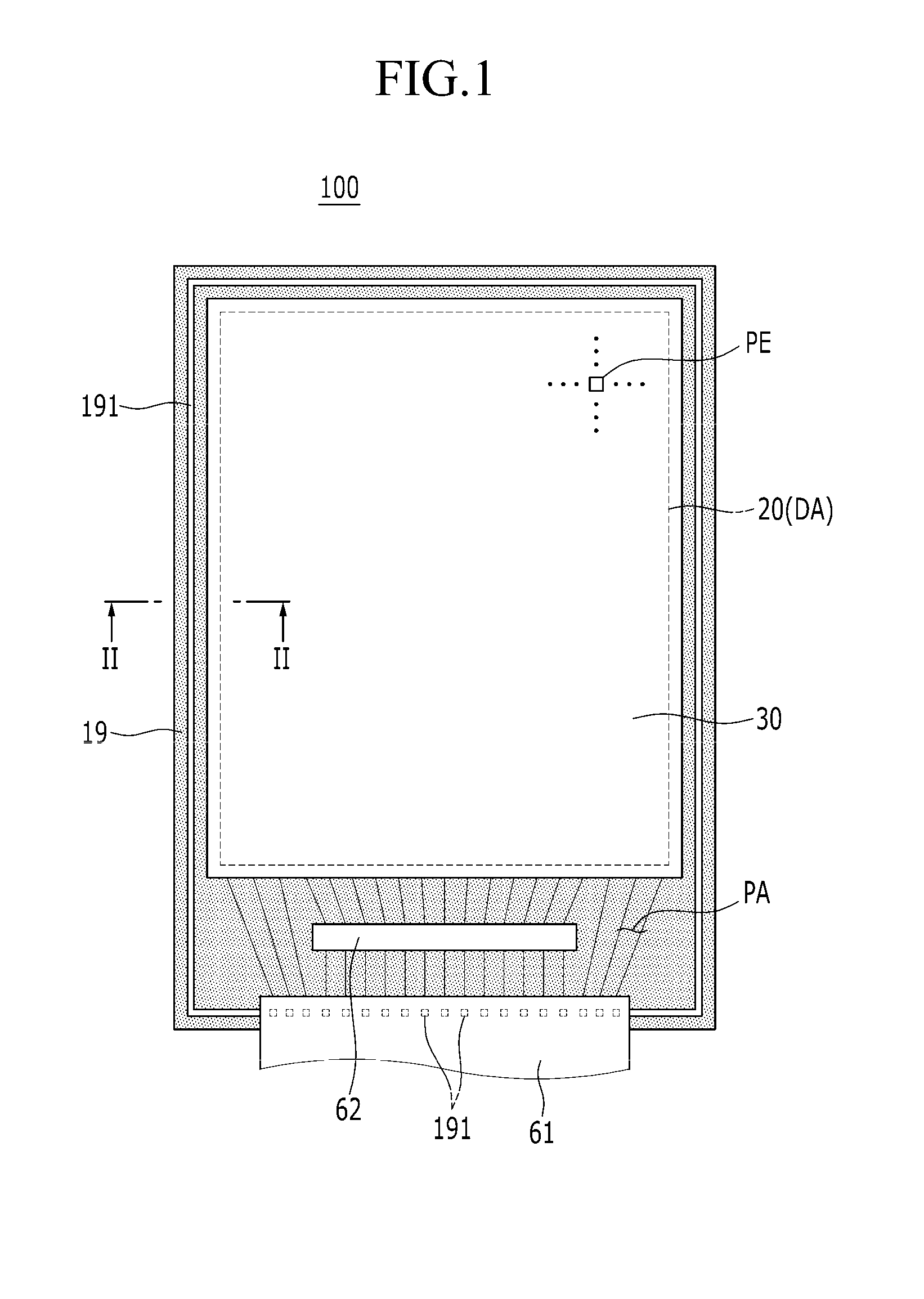

An organic light emitting diode display including a substrate includes a display area and a peripheral area surrounding the display area, an organic light emitting member disposed in the display area, dams disposed in the peripheral area, a thin film encapsulation layer covering a portion of a first dam among the dams and the organic light emitting member, a touch sensing member disposed on the thin film encapsulation layer of the display area, and a first crack sensing member disposed at a position corresponding to the first dam.

Owner:SAMSUNG DISPLAY CO LTD

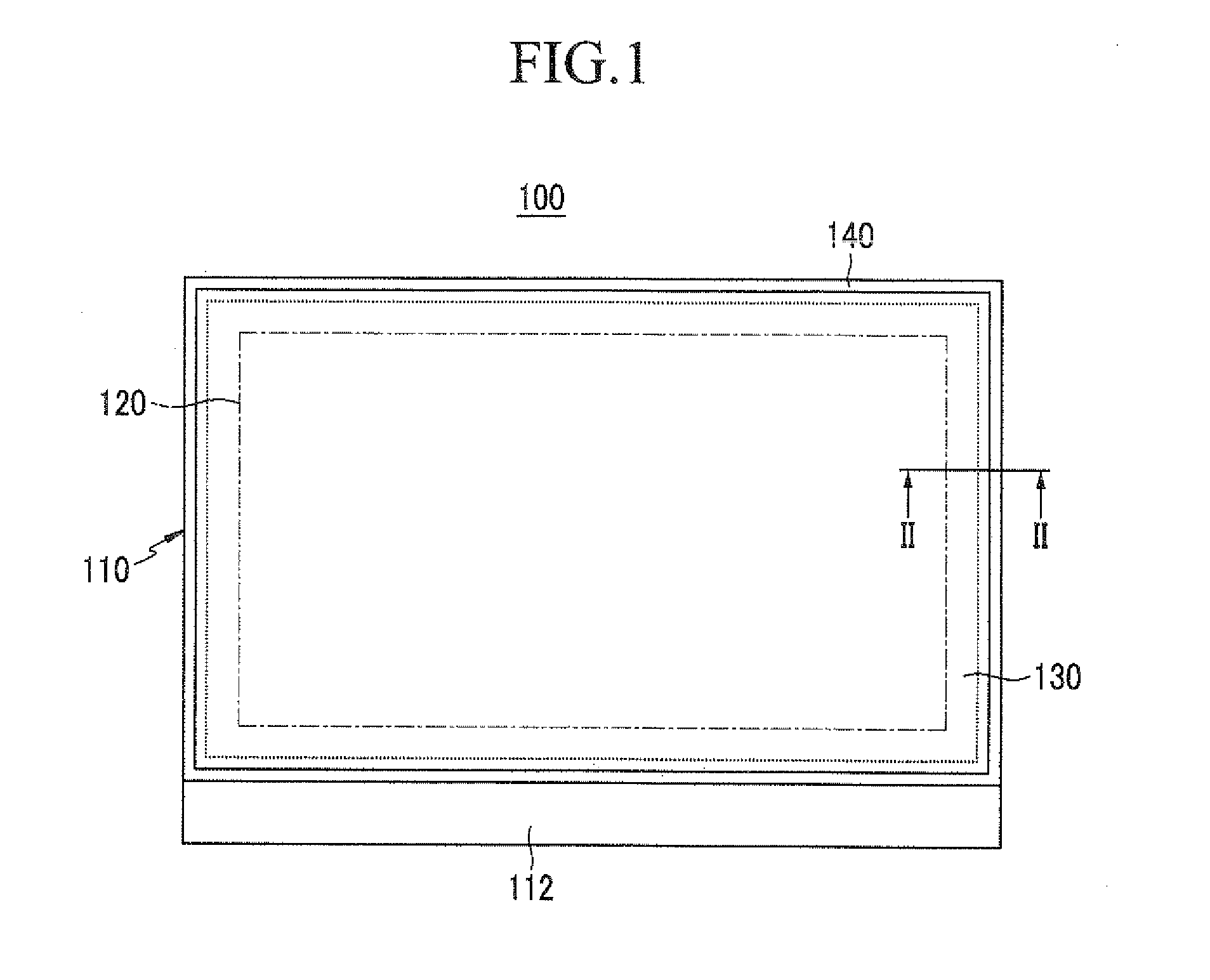

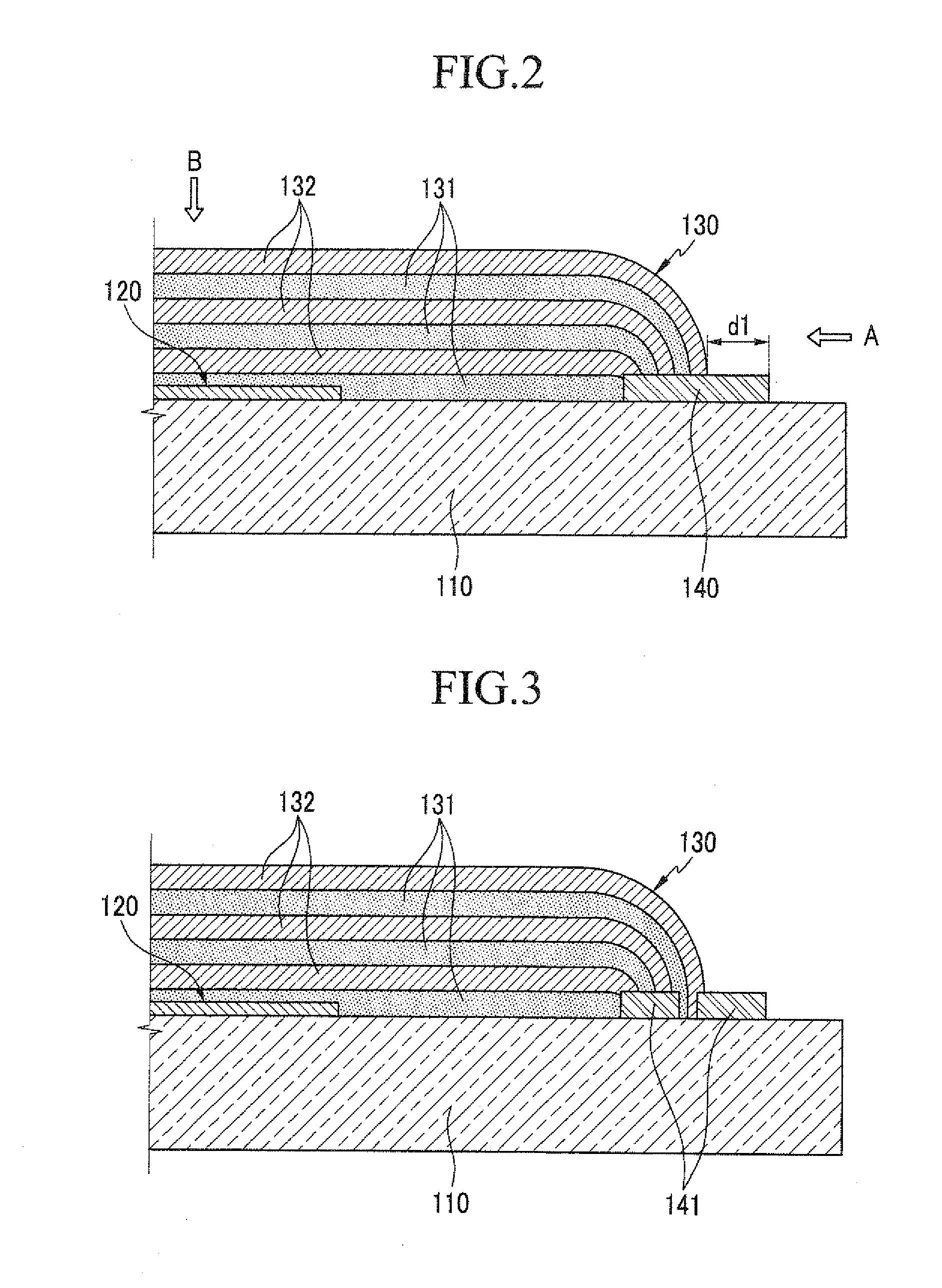

Flexible display device

ActiveUS20150036299A1Improve production yieldSuppressing panel shrinkageFinal product manufactureFlexible printed circuitsFlexible displayComputer science

A flexible display device that can suppress spread of cracks of an inorganic layer is provided. A flexible display device includes a flexible substrate including a display area and a periphery surrounding the display area, an inorganic layer formed on the flexible substrate, a display unit formed on the display area, and a thin film encapsulation layer covering the display unit. The inorganic layer includes an opening disposed on a periphery between edges of the flexible substrate and the thin film encapsulation layer.

Owner:SAMSUNG DISPLAY CO LTD

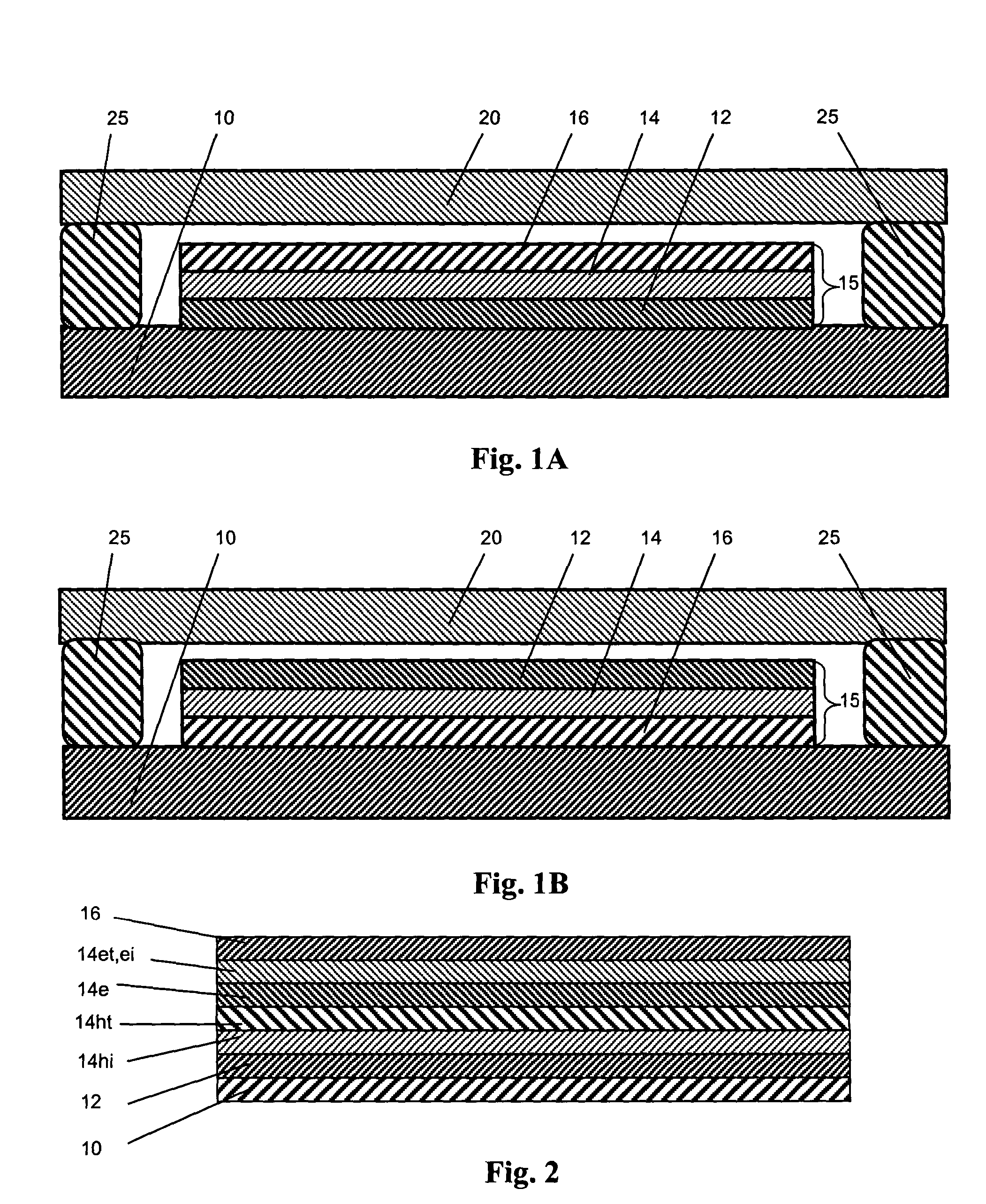

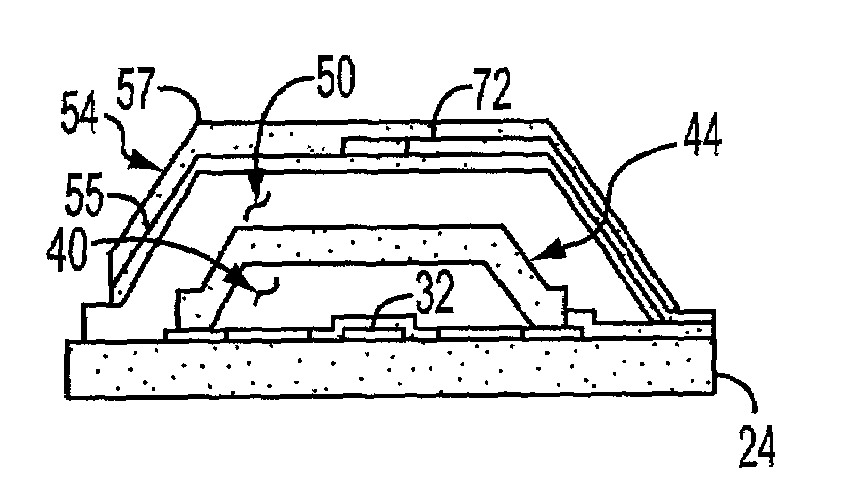

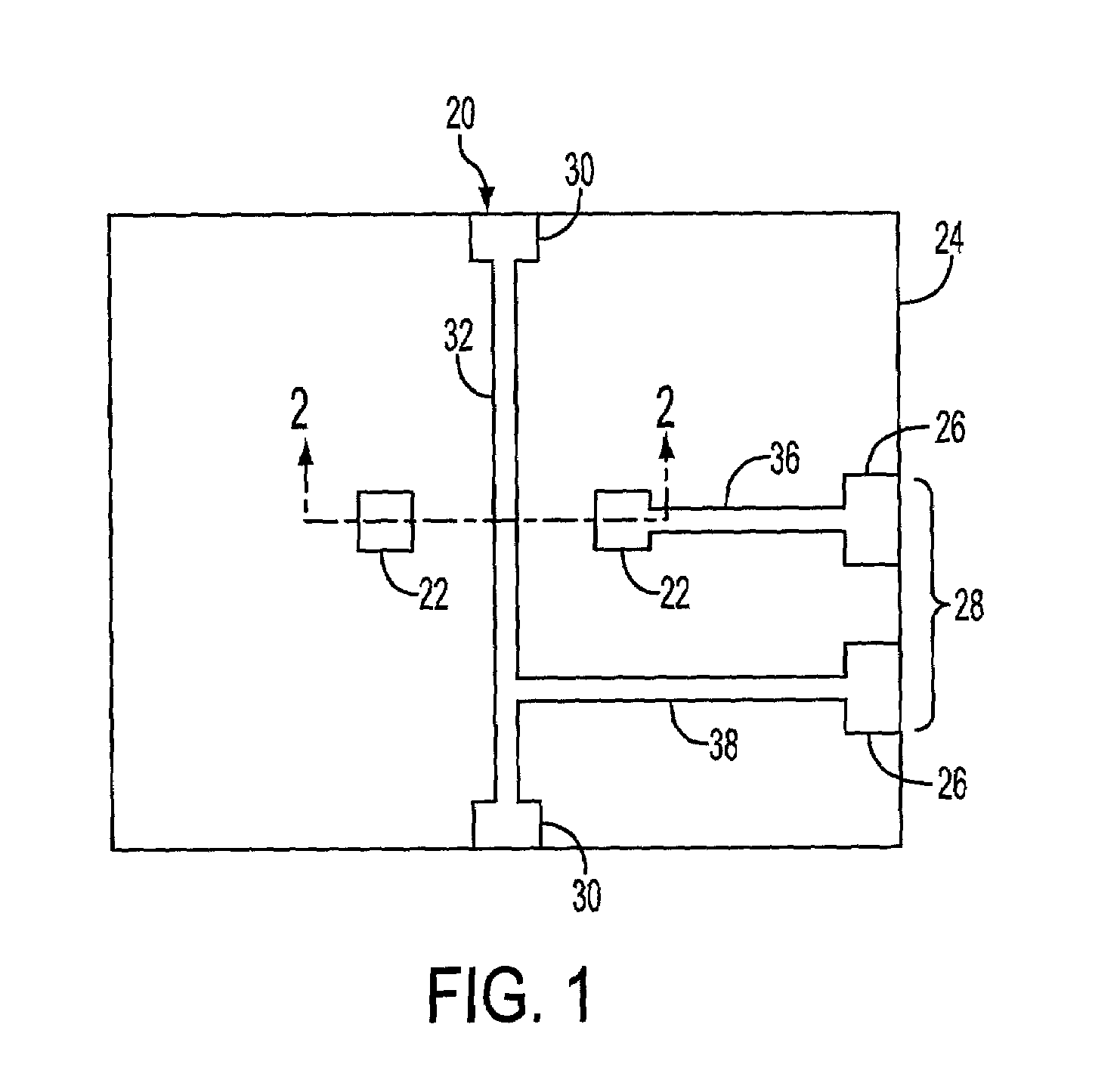

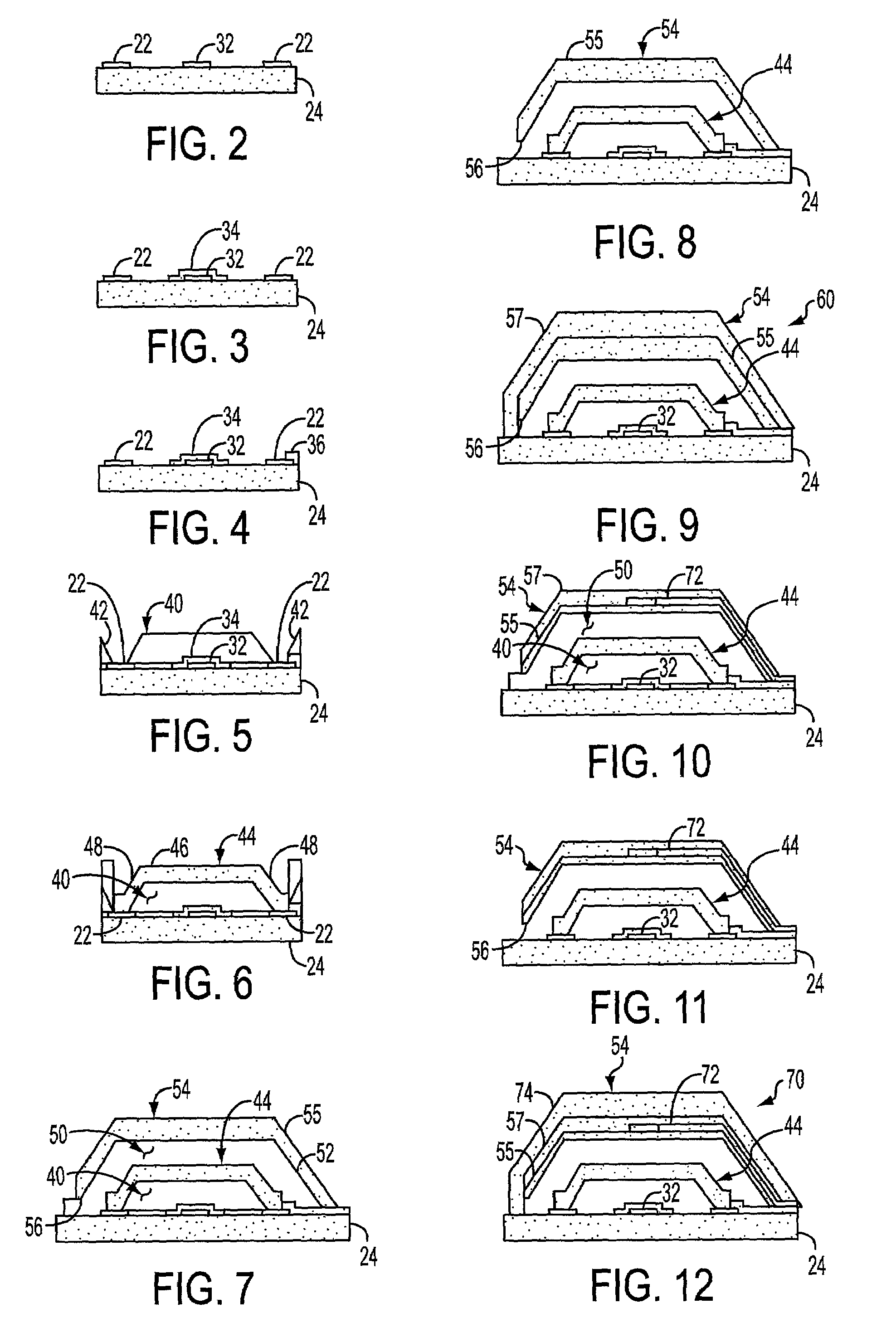

Protected organic electronic devices and methods for making the same

InactiveUS20050023974A1Avoid Display DamageImprove production yieldDischarge tube luminescnet screensLamp detailsHole injection layerConductive polymer

An organic light emitting device structure is provided, which comprises: (a) a substrate; (b) a first electrode disposed over the substrate; (c) a polymeric layer comprising a conductive polymer disposed over the first electrode; (d) an organic layer consisting essentially of small molecule material disposed over and in direct contact with said polymeric layer; (e) a second electrode disposed over the organic layer; and (f) a thin film encapsulation region disposed over the second electrode. An organic light emitting device is also provided, which comprises: (a) a polymer layer comprising a hole injecting conductive polymer and (b) a small molecule layer comprising an emissive small molecule material. In certain embodiments, the small molecule layer further comprises a small molecule hole injection layer.

Owner:UNIVERSAL DISPLAY

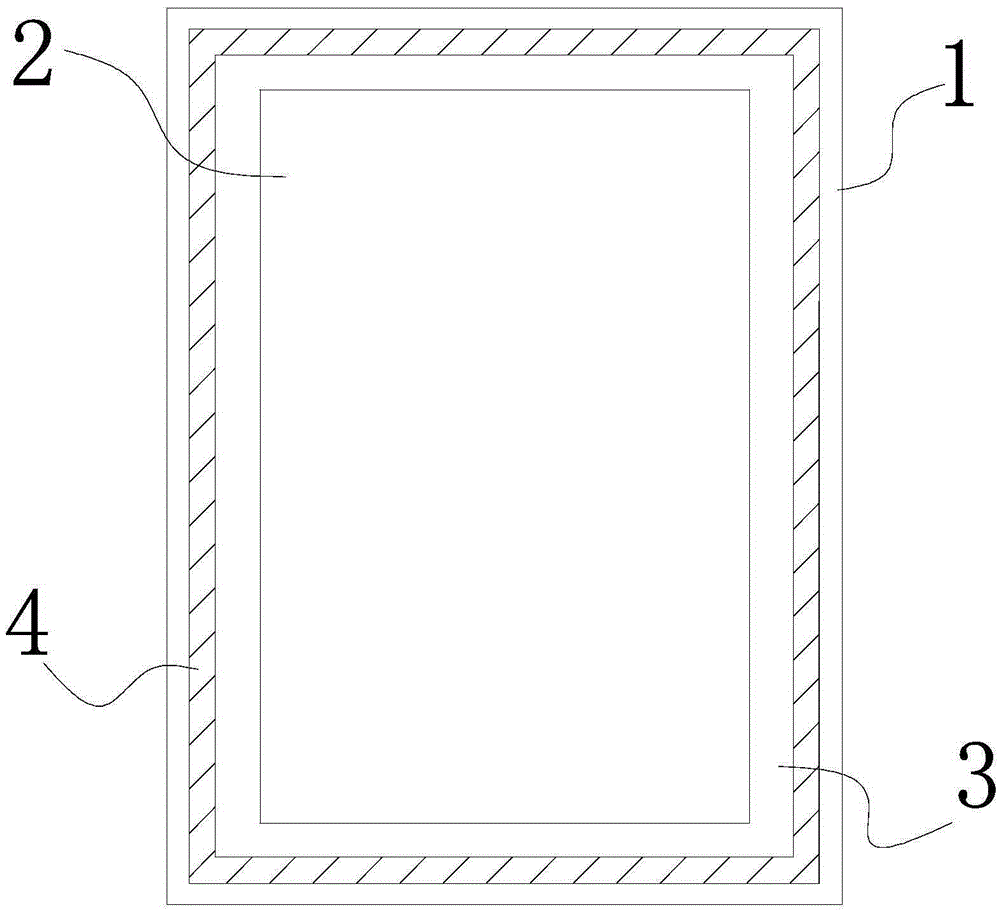

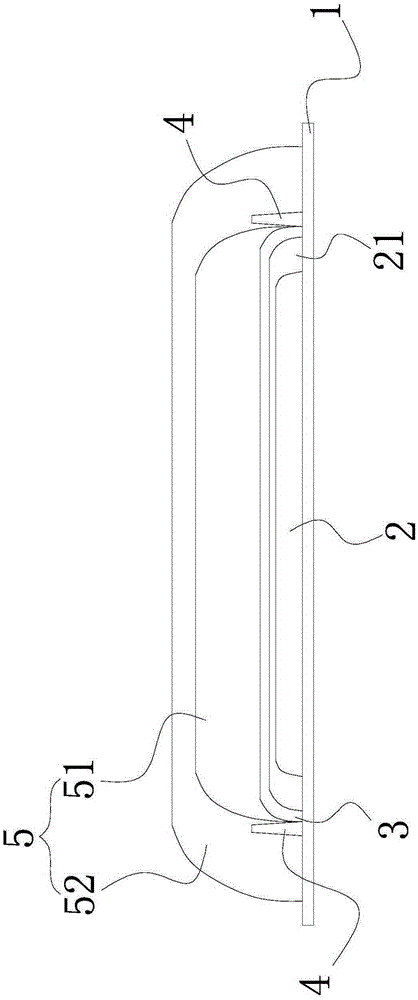

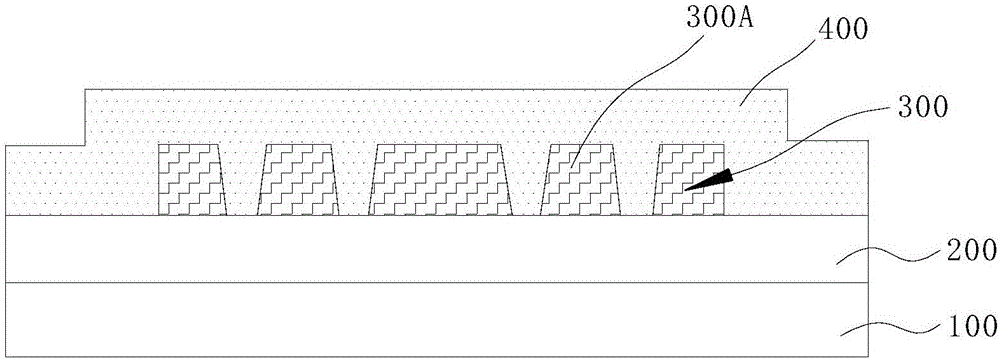

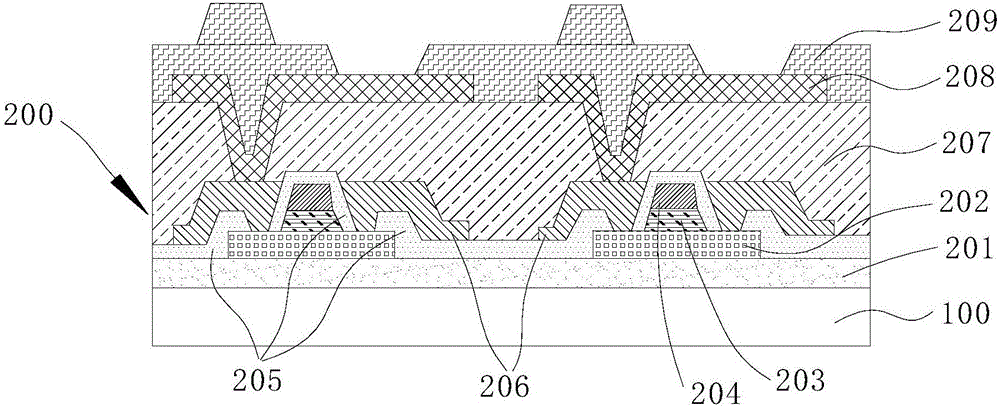

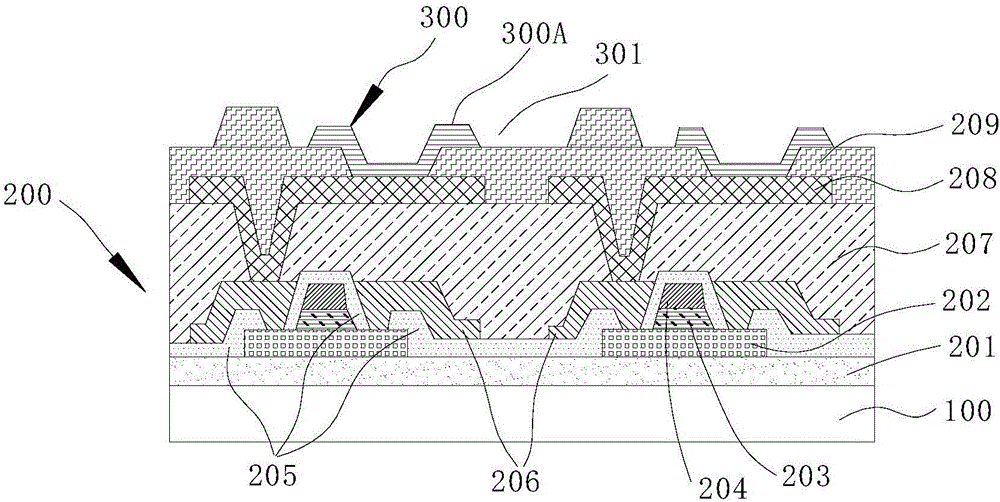

Display panel, display apparatus and preparation method for display panel

ActiveCN106653818AIncrease stressImprove packaging effectSemiconductor/solid-state device detailsSolid-state devicesOrganic light emitting deviceOptoelectronics

The invention discloses a display panel, a display apparatus and a preparation method for the display panel. The display panel comprises a substrate, an organic light emitting device, a thin film packaging layer, and a metal layer, wherein the substrate comprises a display region and a non-display region; the organic light emitting device is arranged in the display region of the substrate; the thin film packaging layer covers the organic light emitting device; the metal layer is positioned in the non-display region of the substrate; grooves are formed in the metal layer; and the grooves are filled with an organic layer. By virtue of setting the metal layer in the non-display region of the substrate, forming the grooves in the metal layer and filling the grooves with the organic layer, bending stress resistance and cutting stress resistance of an edge region are improved, so that risk of cracks on the edge is relieved, and crack expansion can be effectively prevented.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Organic Light Emitting Diode Display

ActiveUS20120091477A1Avoid failureExtend the lifespanSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmDisplay device

An organic light emitting diode (OLED) display comprises: a substrate; a display unit formed on the substrate and including an organic light emitting element; an interception layer positioned at the outside of the display unit on the substrate; and a thin film encapsulation layer which is formed with a stacked film of an inorganic film and an organic film, which has an end portion contacting the interception layer, and which covers the entire display unit and at least a part of the interception layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Organic light-emitting display apparatus

ActiveUS20160285038A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

Owner:SAMSUNG DISPLAY CO LTD

Touch control display panel and touch control display device

A touch control display panel and a touch control display device are provided. The touch control display panel comprises a substrate including a display region and a non-display region; an organic light-emitting structure; a thin film encapsulation layer having a first side facing the substrate; a first retaining wall; first and second touch control electrodes; first and second touch control lines disposed in the non-display region; and conductive leads disposed on the first side of the thin film encapsulation layer. At least one first touch control line steps across the first retaining wall to be electrically connected to a corresponding conductive lead, and further electrically connected to a driving chip or a flexible printed circuit disposed in a first non-display region through the corresponding conductive lead. A connection region of the at least one first touch control line and the corresponding conductive lead is arranged outside the first retaining wall.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

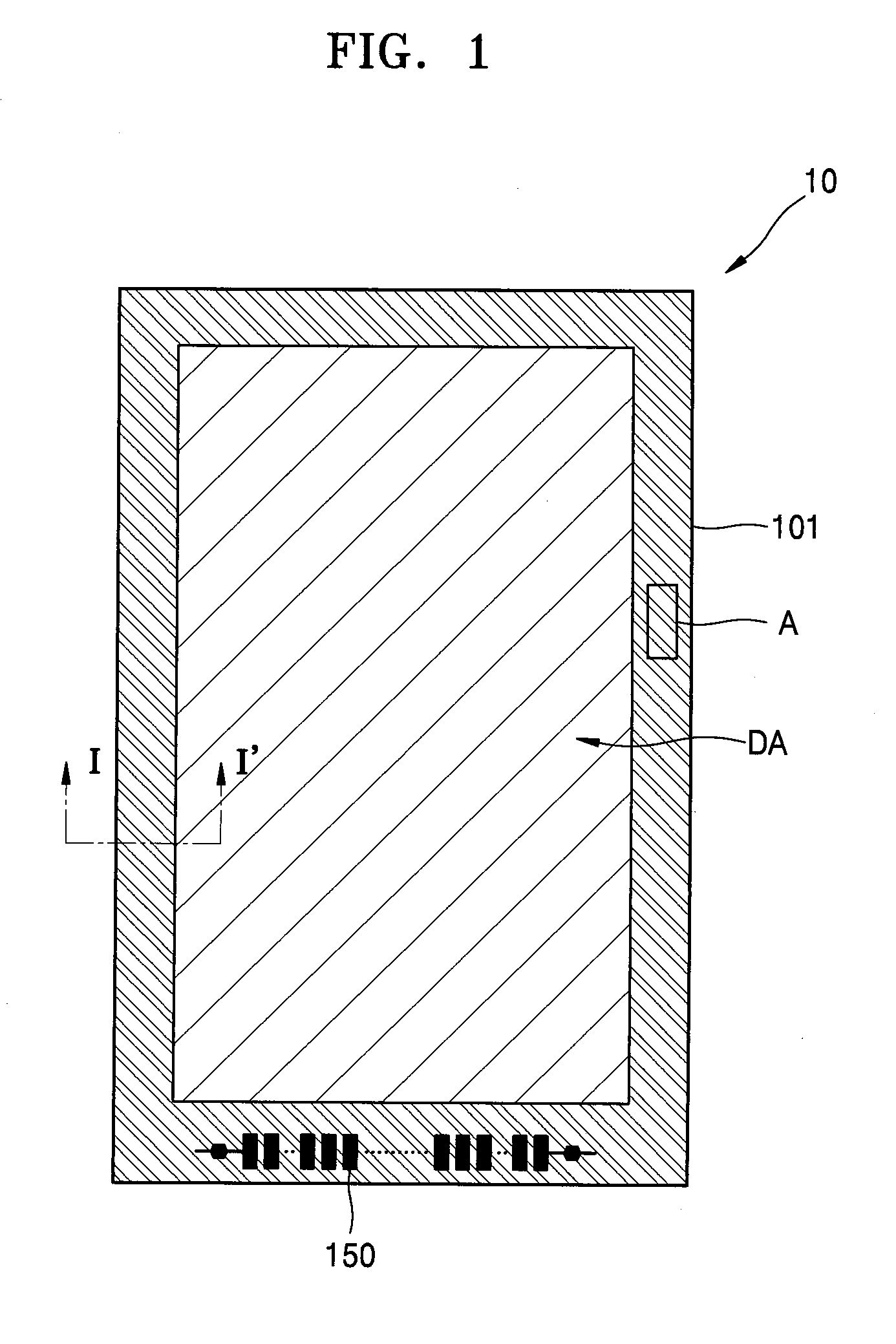

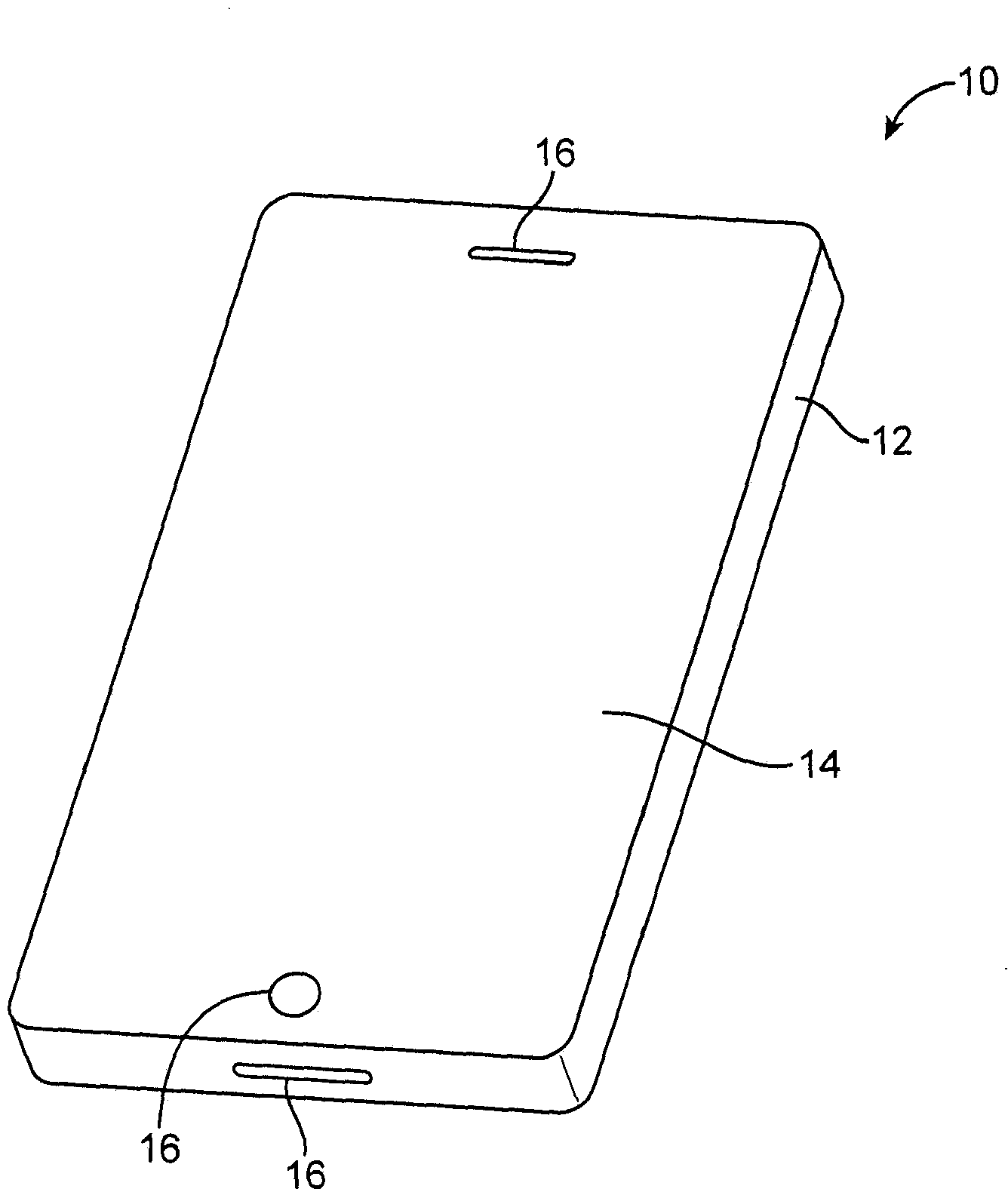

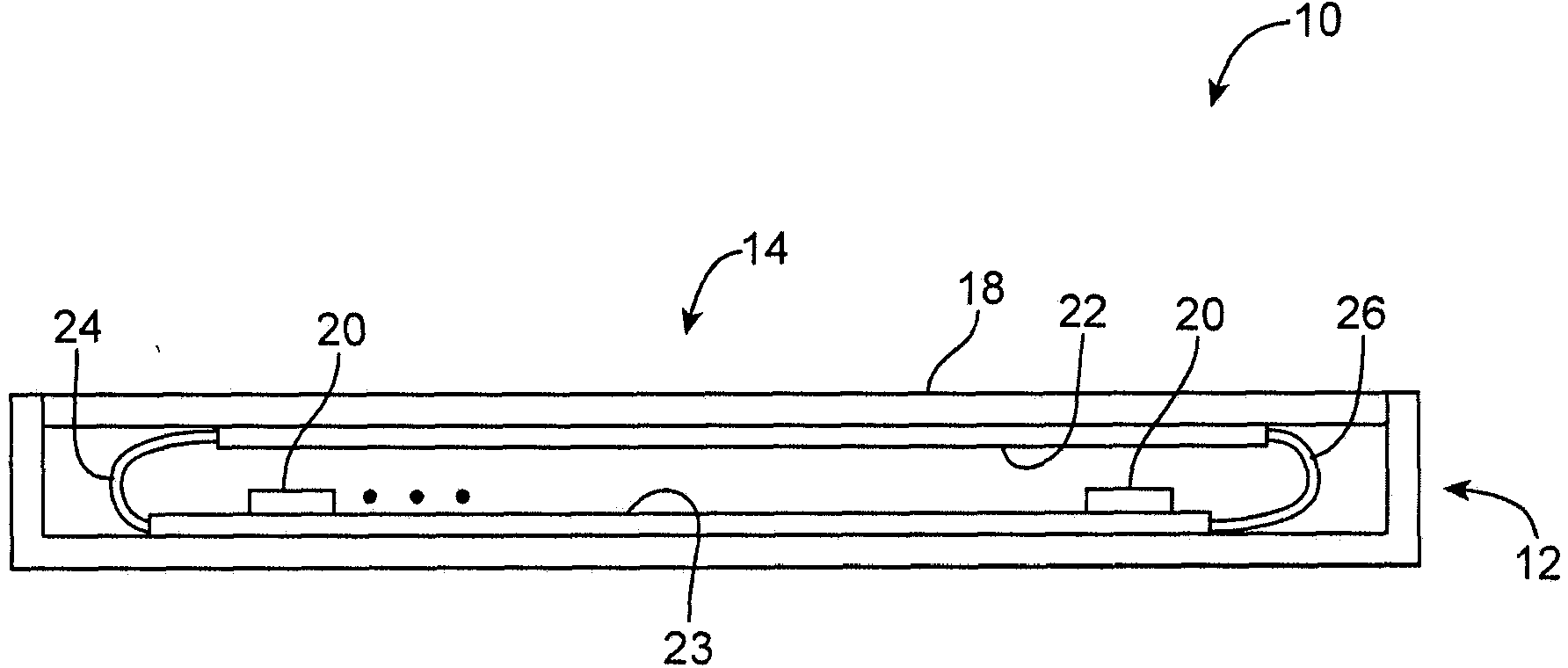

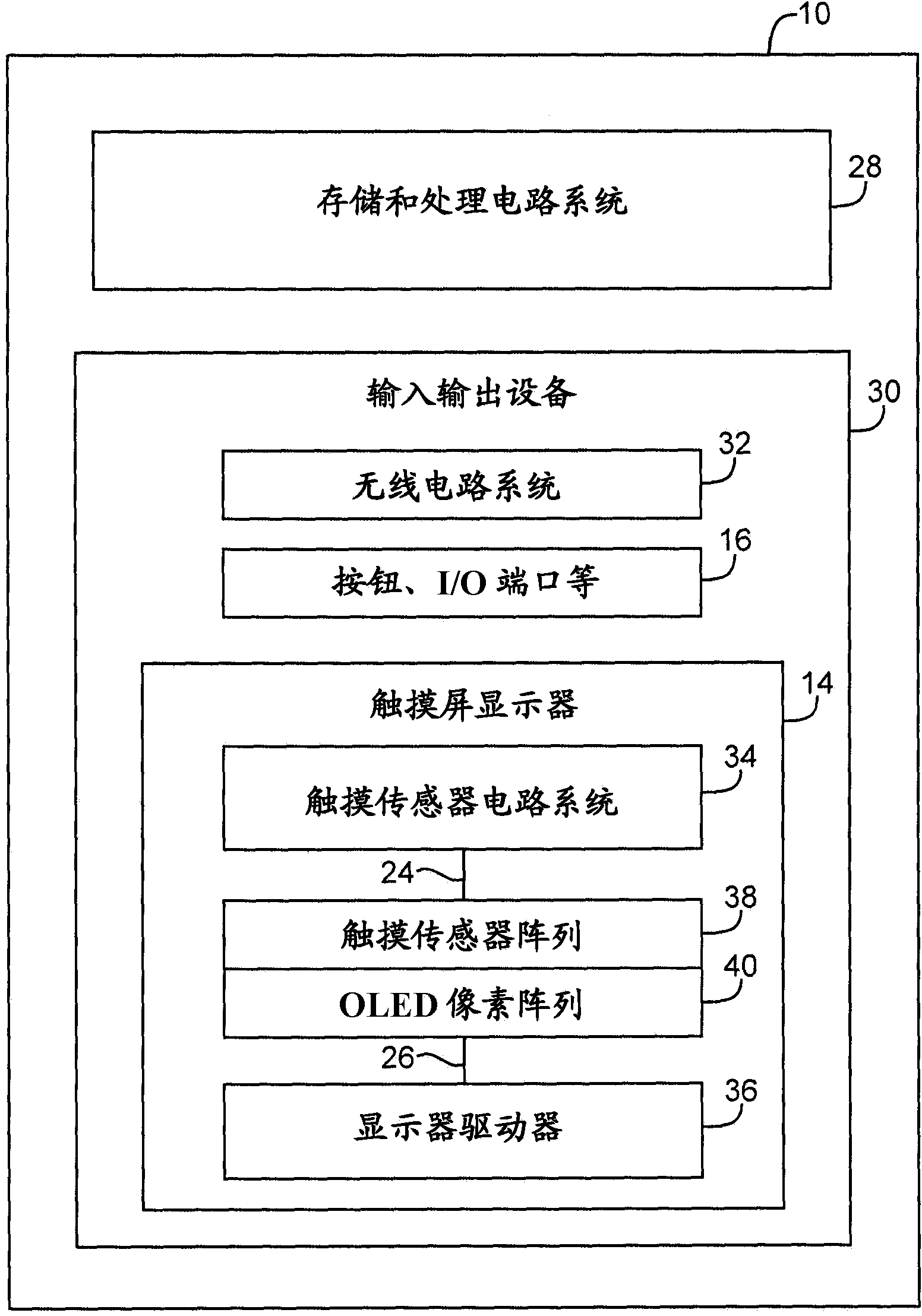

Touch sensitive displays

ActiveCN103748538ADigital data processing detailsInput/output processes for data processingControl signalTouch Senses

Displays such as organic light-emitting diode displays may be provided with touch sensing capabilities. A touch sensor (14) may be formed from electrodes (44) located on a thin-film encapsulation layer (84) or one or more sides of a polarizer. A single-sided or double-sided touch sensor panel may be attached to the upper or lower surface of a polarizer. Control circuitry (36) may be used to provide control signals to light-emitting diodes (50) in the display using a grid of control lines. The control lines and transparent electrode structures such as indium tin oxide structures formed on a thin-film encapsulation layer (84) or polarizer may be used as electrodes for a touch sensor. Displays (14) may have active regions (A) and inactive peripheral portions (IR). The displays (14) may have edge portions that are bent along a bend axis (122) that is within the active region (A) to form a borderless display. Virtual buttons (VB) may be formed on the bent edge portions.

Owner:APPLE INC

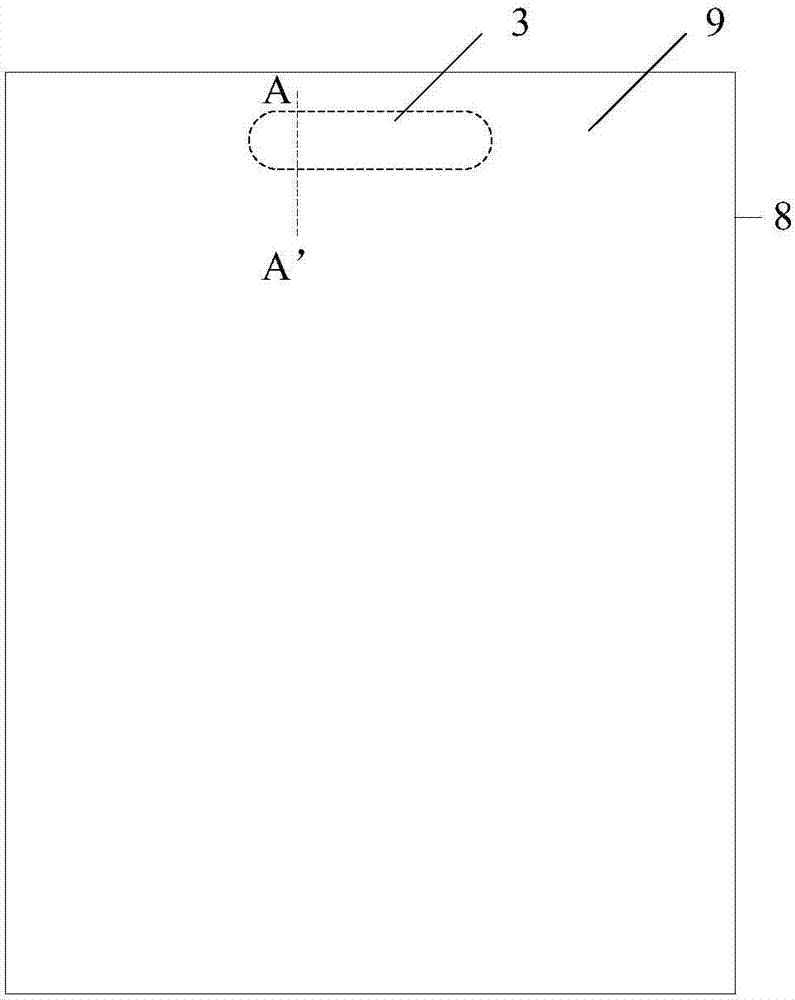

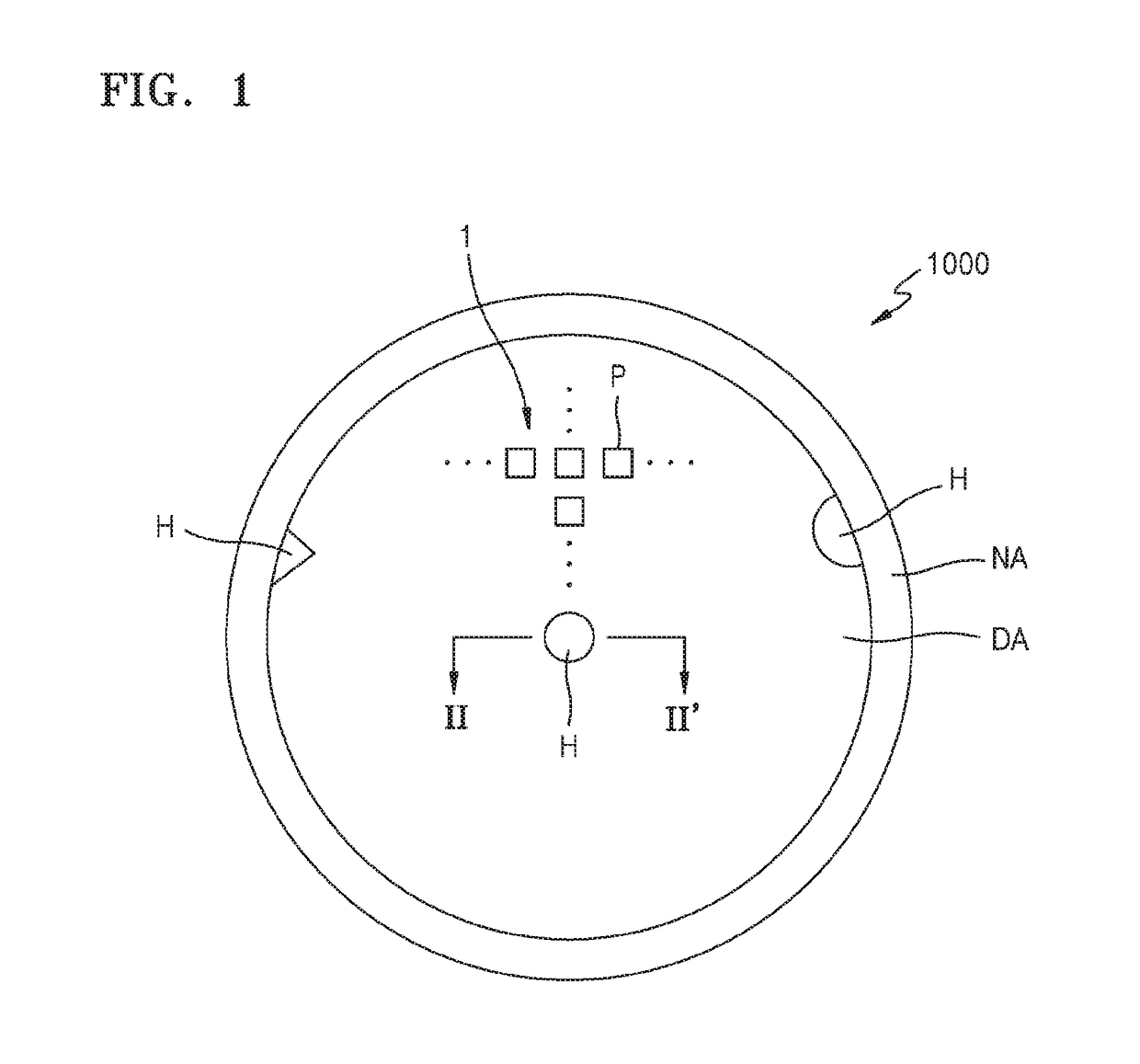

Display panel and display apparatus

ActiveCN107359185AAvoid thermal burnsAvoid process injuries such as thermal burnsSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsPhysics

The invention discloses a display panel and a display apparatus, and aims to lower technological difficulty in display panel thin film encapsulation and improve thin film encapsulation reliability. The display panel provided by the embodiments comprises an array substrate and a film layer structure positioned on the array substrate; the array substrate and the film layer structure both have transparent regions; the projection of the transparent region of the array substrate in a direction perpendicular to the display panel is overlaid with the projection of the transparent region of the film layer structure in a direction perpendicular to the display panel; the array substrate comprises a pixel structural layer and an encapsulation layer positioned on the pixel structural layer, wherein the pixel in the pixel structural layer is positioned outside the transparent region; and the forward projection of the transparent region in a direction perpendicular to the display panel just falls into the forward projection of the encapsulation layer in a direction perpendicular to the display panel.

Owner:BOE TECH GRP CO LTD +1

Organic light emitting diode display

ActiveUS20100200846A1Reduce failureImprove the display effectElectroluminescent light sourcesSolid-state devicesDisplay deviceLight-emitting diode

An organic light emitting diode display includes a substrate having organic light emitting diodes thereon. A thin film encapsulation layer is formed on the substrate such that the thin film encapsulation layer covers the organic light emitting diodes. A nonorganic layer is formed under the thin film encapsulation layer along the edge of the thin film encapsulation layer.

Owner:SAMSUNG DISPLAY CO LTD

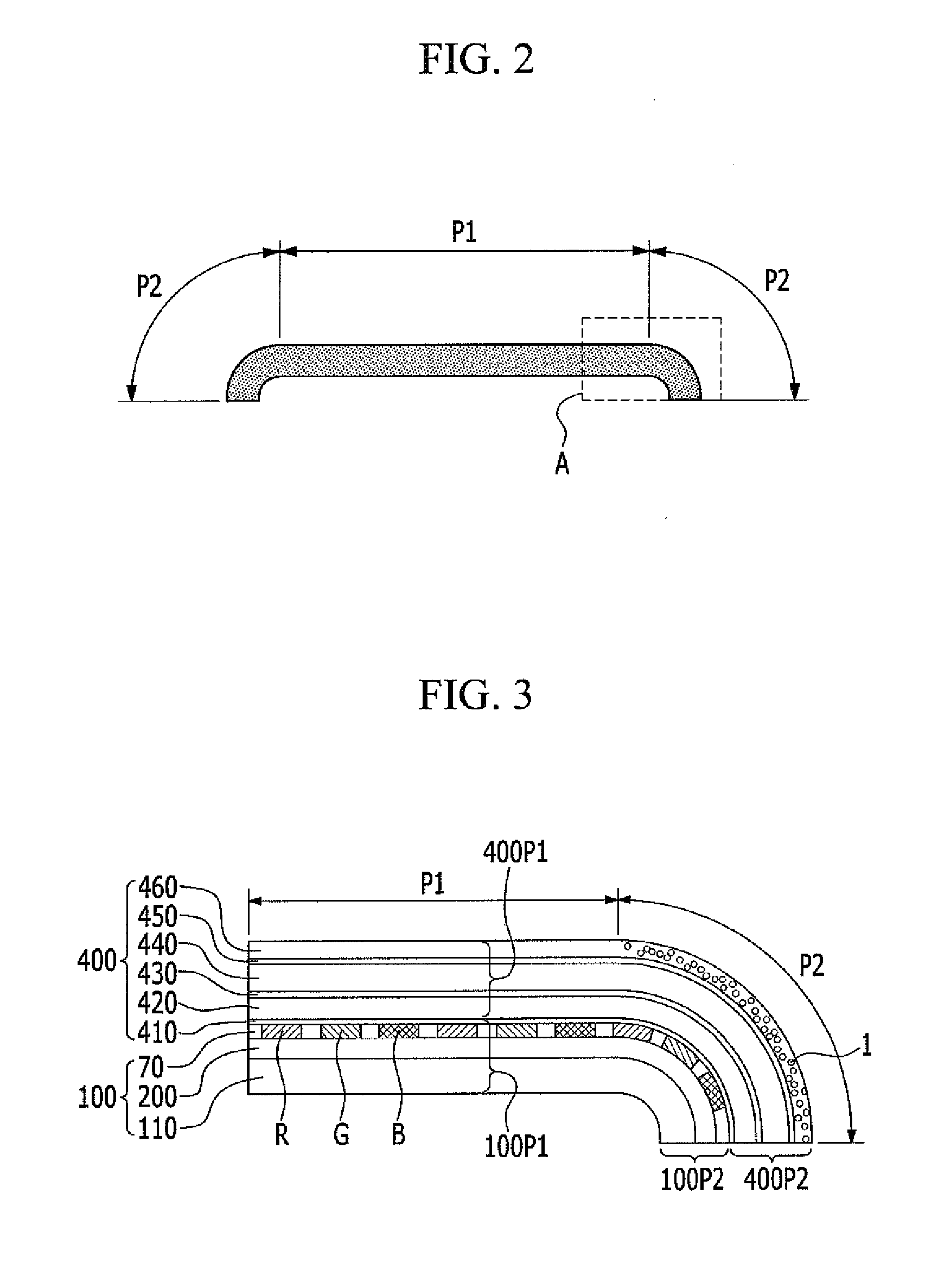

Organic light emitting diode display

ActiveUS20150001483A1Increase brightnessEasy to identifyStatic indicating devicesElectroluminescent light sourcesDisplay deviceLight-emitting diode

An organic light emitting diode (OLED) display includes: a display layer including a front display layer configured to display an image at a front of the OLED display and a bending display layer bent at an end of the front display layer, and a thin film encapsulation layer covering the display layer. The thin film encapsulation layer includes a front encapsulation layer disposed on the front display layer and a bending encapsulation layer disposed on the bending display layer and having a plurality of pores.

Owner:SAMSUNG DISPLAY CO LTD

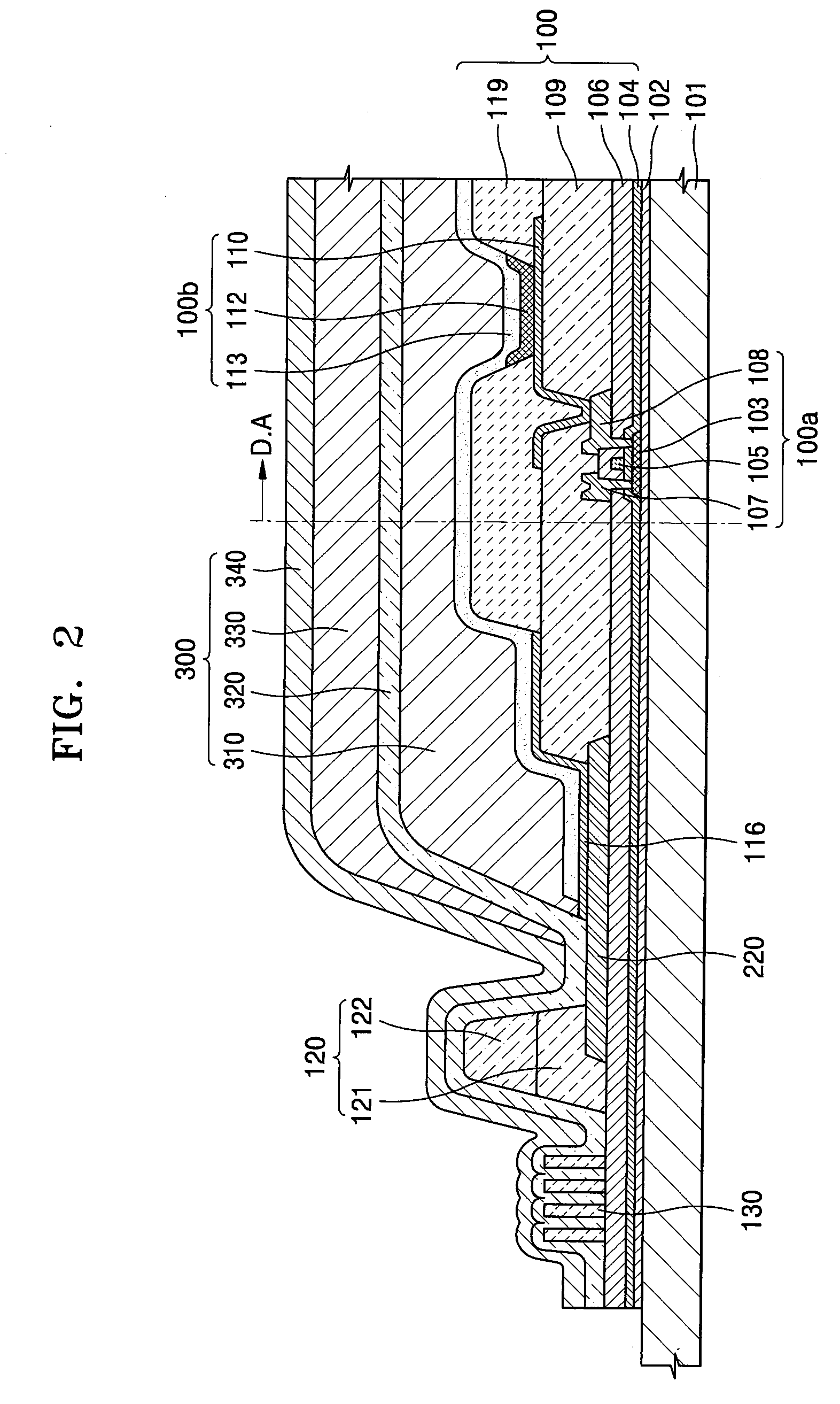

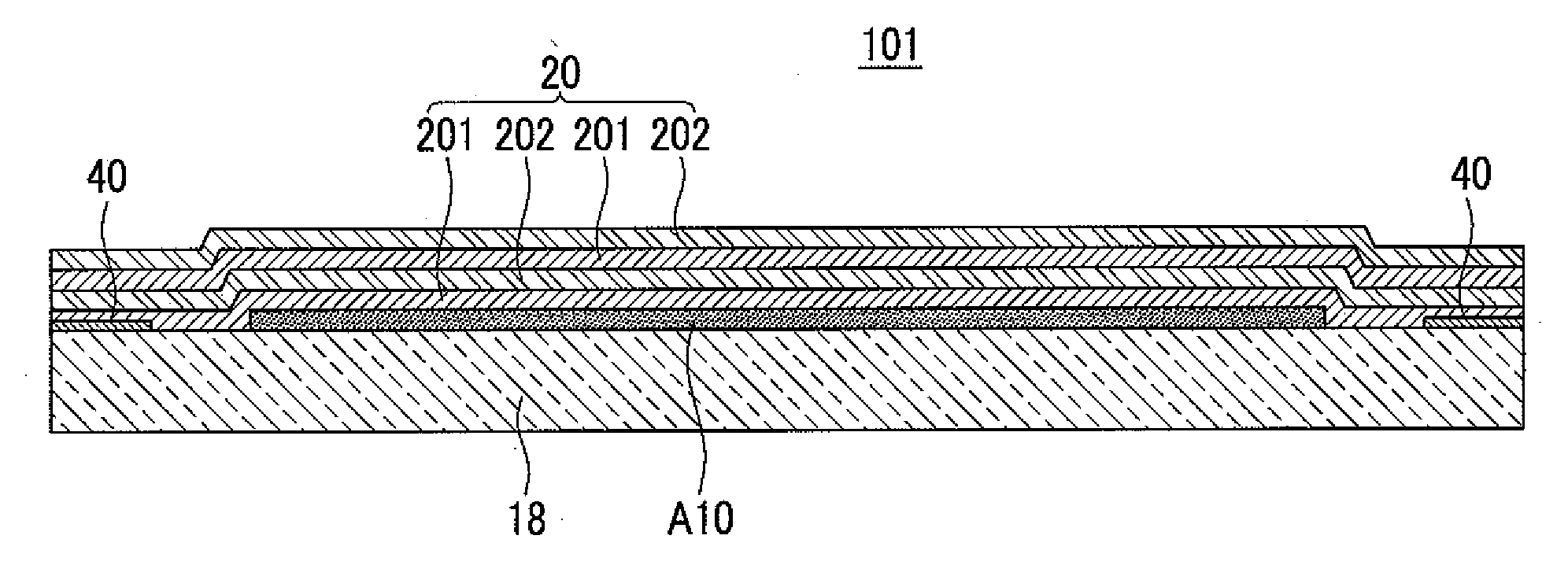

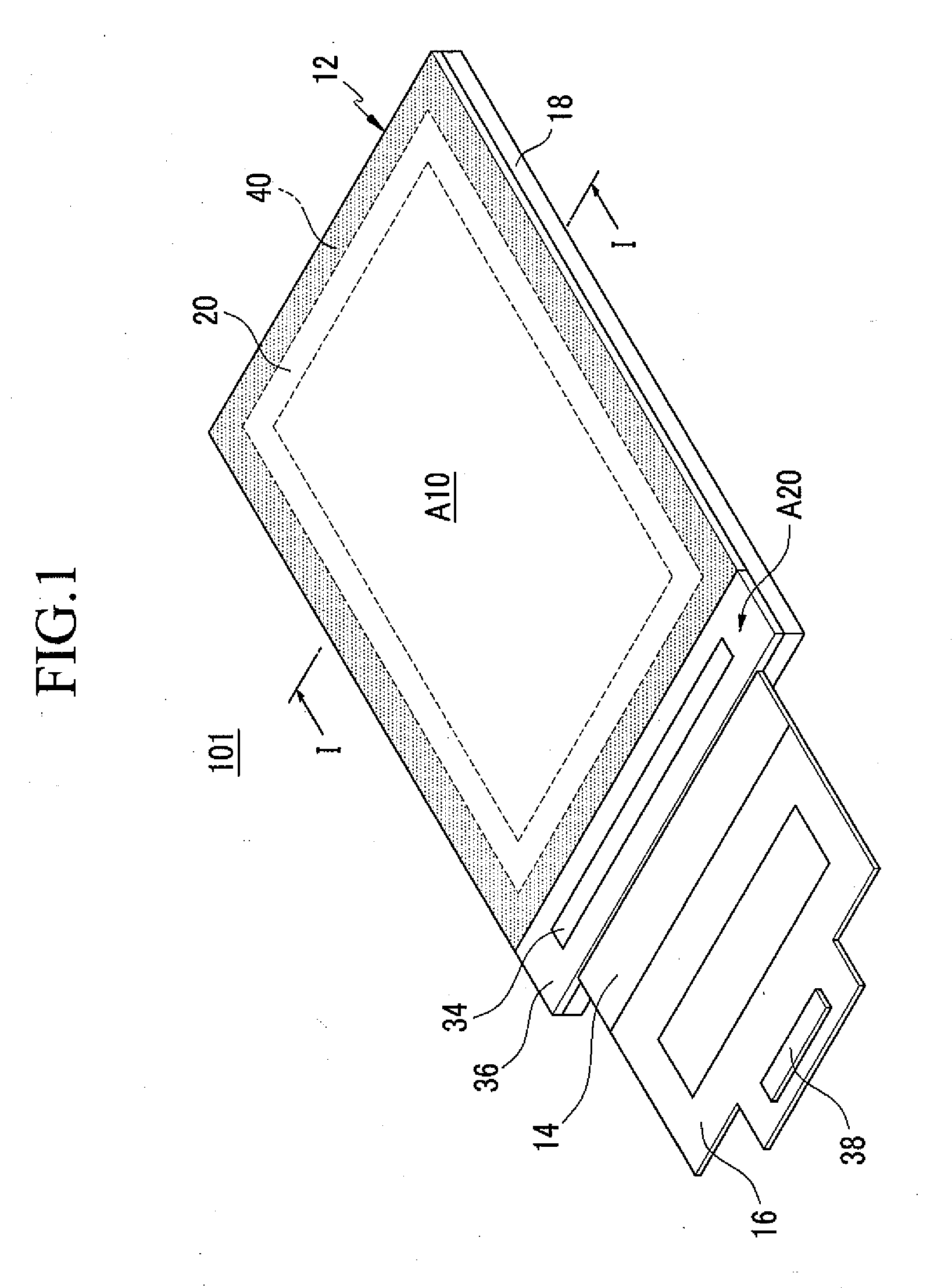

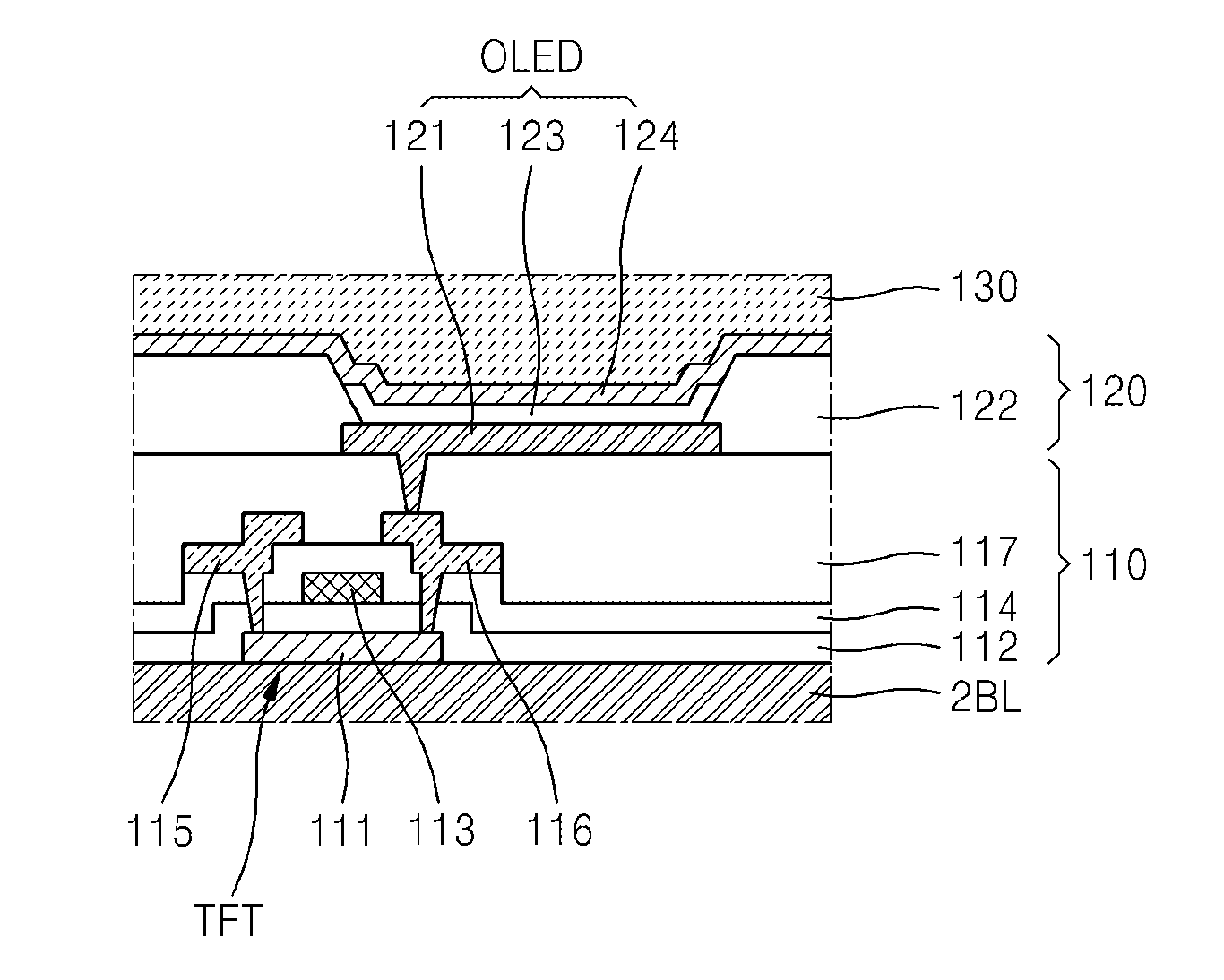

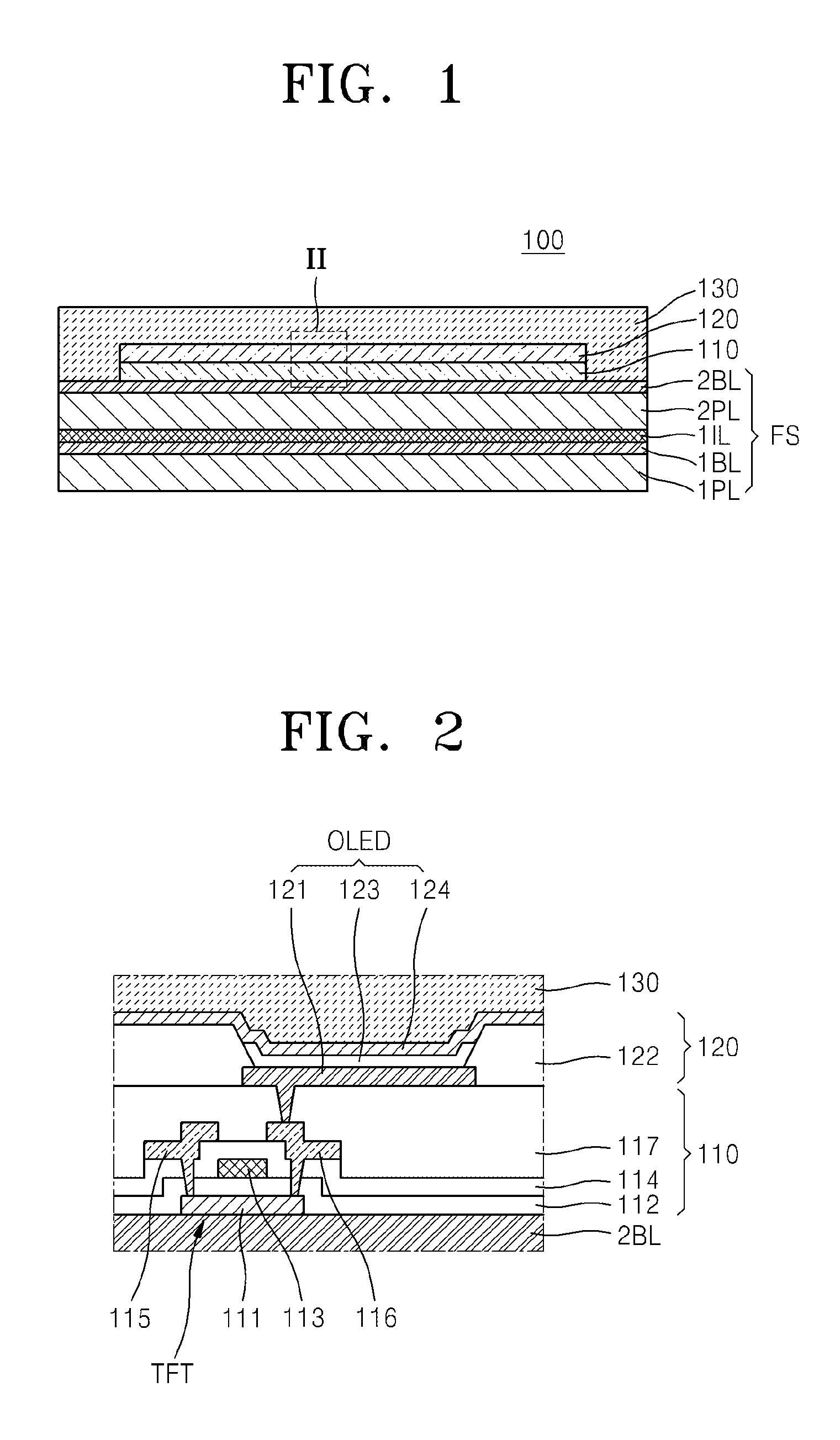

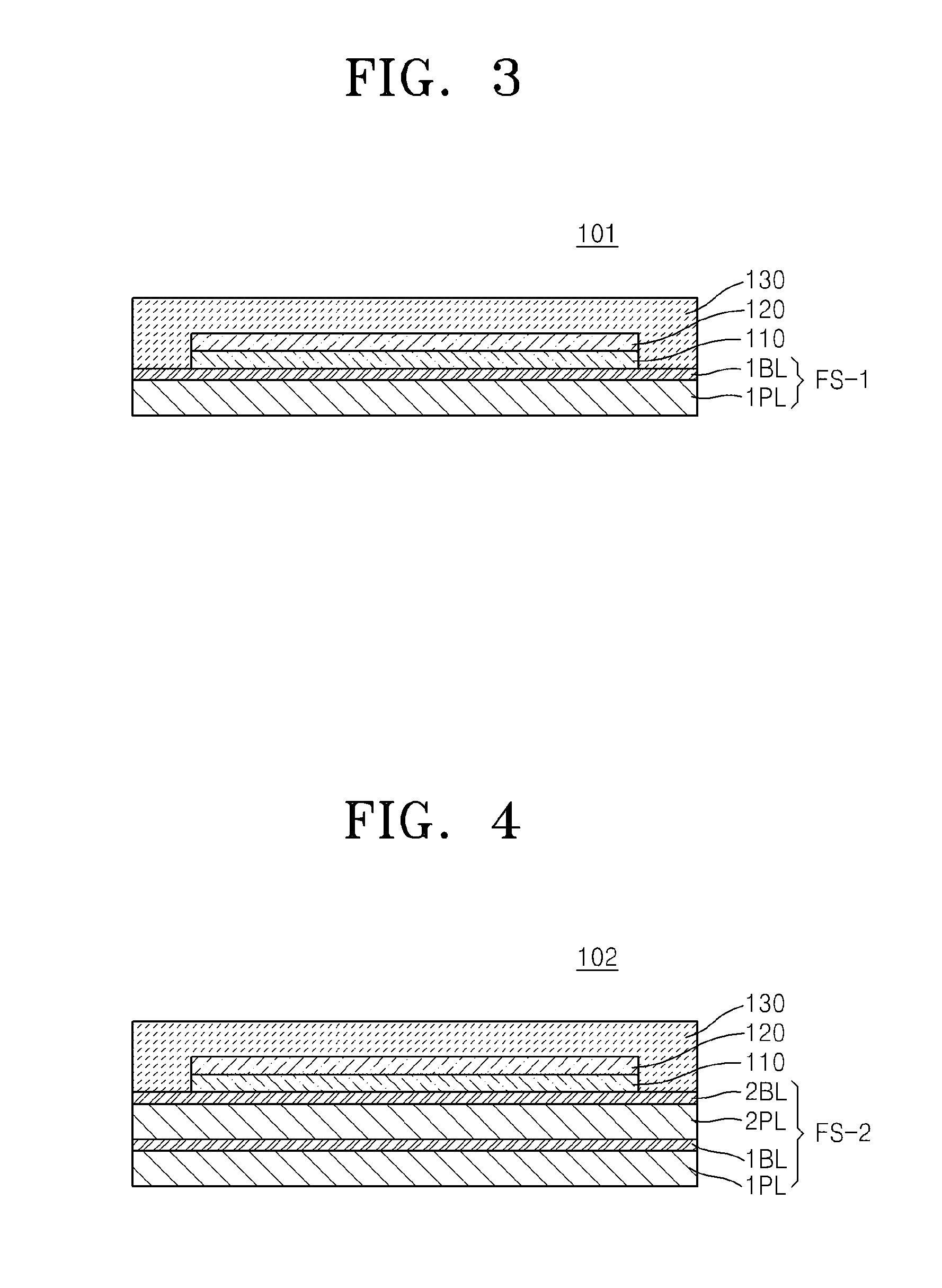

Organic light-emitting diode display, an electronic device including the same, and method of manufacturing said organic light-emitting diode display

ActiveUS20140339517A1Low water vapor transmission rateHigh bonding strengthFinal product manufactureElectroluminescent light sourcesInter layerDisplay device

Provided is an organic light-emitting diode (OLED) display including: a first plastic layer; a first barrier layer formed on the first plastic layer; a first intermediate layer formed on the first barrier layer; a second plastic layer formed on the intermediate layer; an OLED layer formed on the second plastic layer; and a thin-film encapsulation layer encapsulating the OLED layer.

Owner:SAMSUNG DISPLAY CO LTD

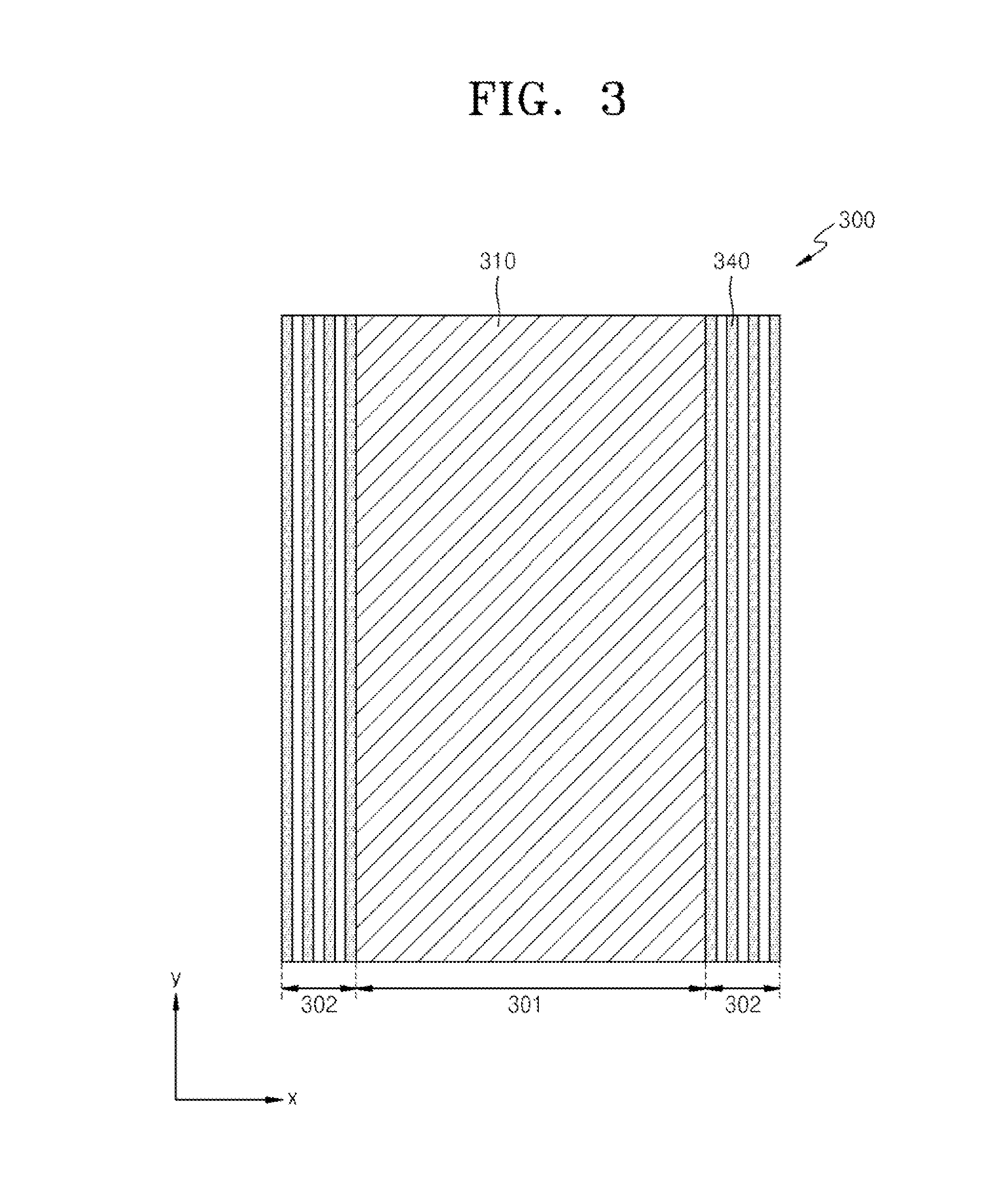

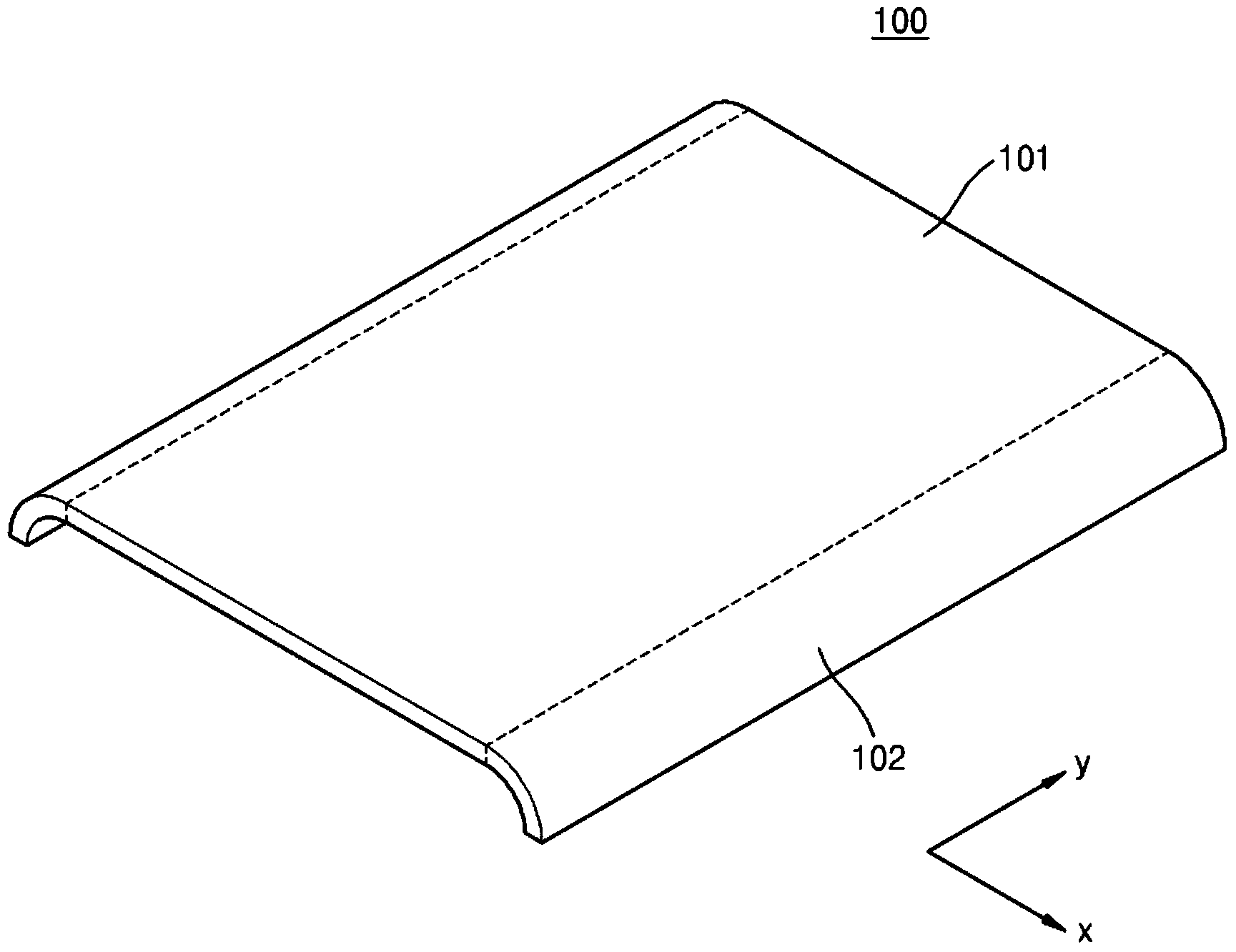

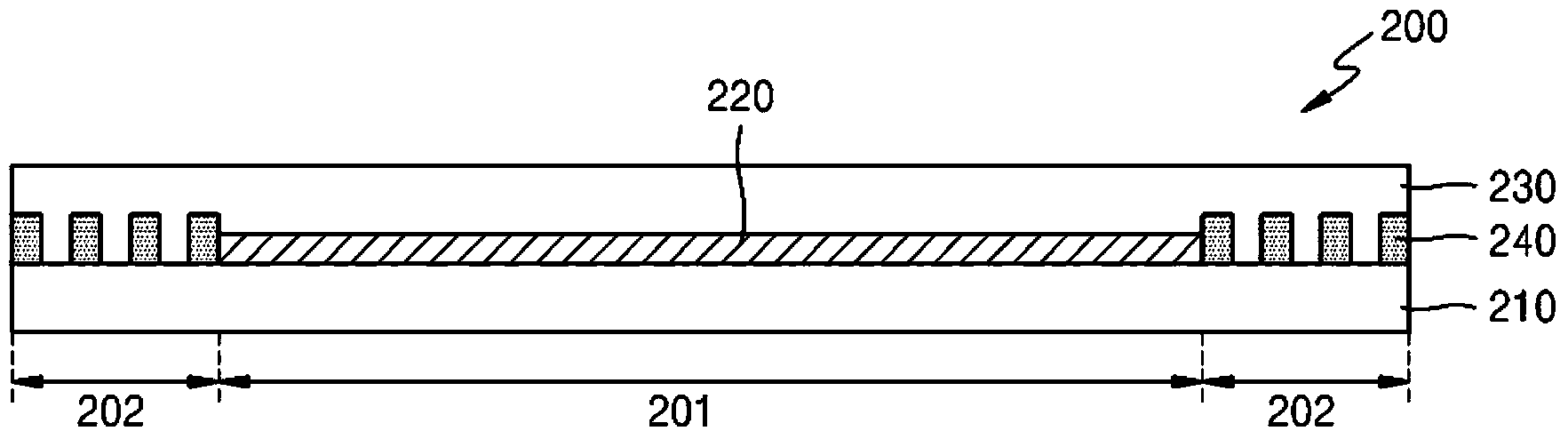

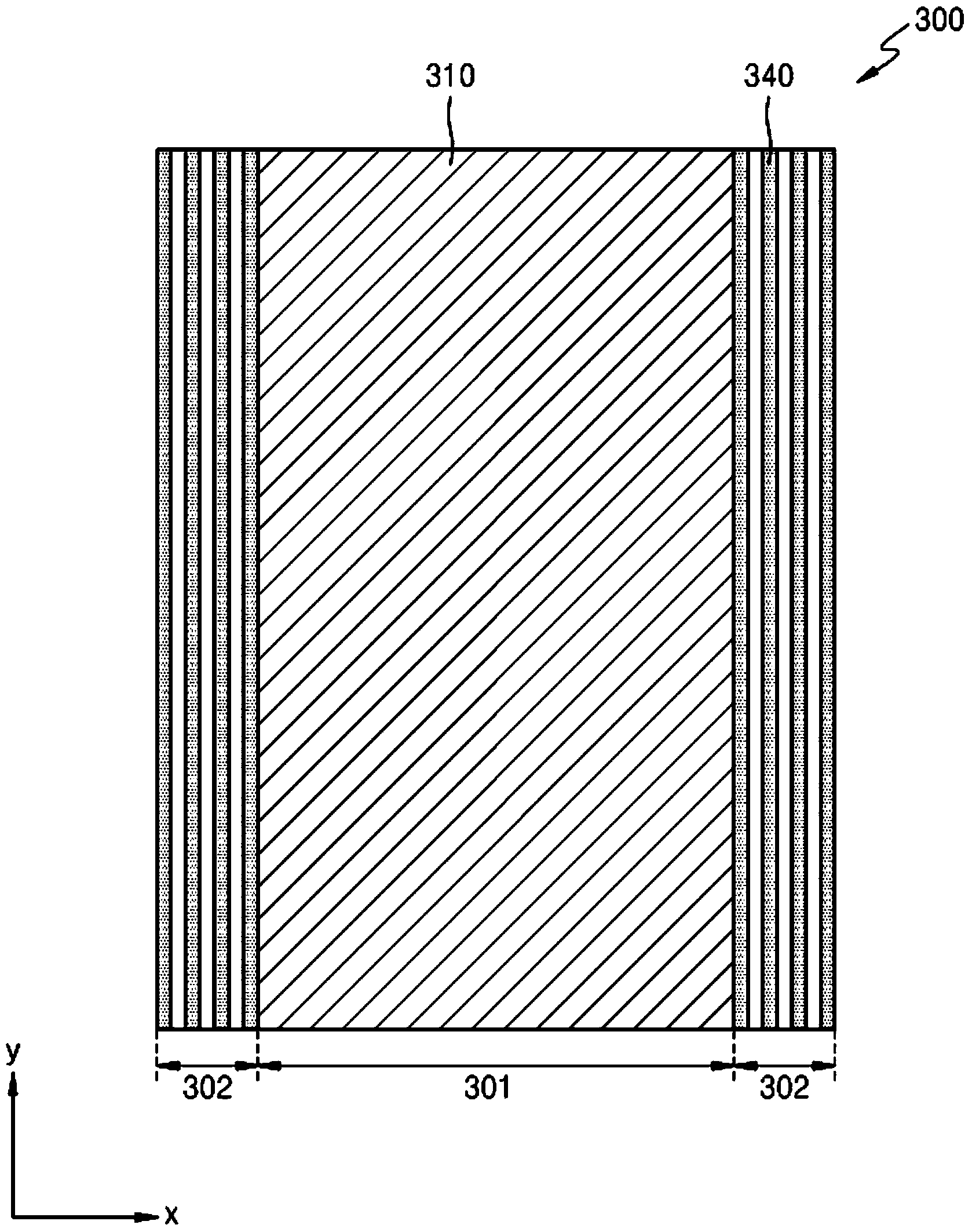

Display apparatus

ActiveUS20140319474A1Solid-state devicesSemiconductor/solid-state device manufacturingOrganic filmComputer science

Provided is a display apparatus that is bendable. The display apparatus includes: a substrate including a display region that includes a plurality of light-emitting devices and an edge region that surrounds the display region; and a thin-film encapsulation layer on the display region and the edge region of the substrate. The thin-film encapsulation layer includes a plurality of inorganic films and at least one organic film disposed between the plurality of the inorganic films. At least one of the plurality of the inorganic films of the thin-film encapsulation layer includes inorganic patterns.

Owner:SAMSUNG DISPLAY CO LTD

Display apparatus

Provided is a display apparatus that is bendable. The display apparatus includes: a substrate including a display region that includes a plurality of light-emitting devices and an edge region that surrounds the display region; and a thin-film encapsulation layer on the display region and the edge region of the substrate. The thin-film encapsulation layer includes a plurality of inorganic films and at least one organic film disposed between the plurality of the inorganic films. At least one of the plurality of the inorganic films of the thin-film encapsulation layer includes inorganic patterns.

Owner:SAMSUNG DISPLAY CO LTD

Organic light emitting diode display and manufacturing method thereof

ActiveUS20120007107A1Minimized increaseImprove sealingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen

An organic light emitting diode (OLED) display includes: a first substrate; a display portion that is formed on the first substrate and includes a driving circuit portion and an organic light emitting diode; a thin film encapsulation layer that covers the display portion; an adhesive layer that covers an upper surface and a side of the thin film encapsulation layer; an absorption functional layer that is formed on the adhesive layer and absorbs at least one of oxygen and moisture; and a second substrate that is formed on the absorption functional layer.

Owner:SAMSUNG DISPLAY CO LTD

Organic light-emitting diode display

An organic light-emitting diode display is disclosed. In one aspect, the display includes a display unit located on the substrate and including a display area and a non-display area surrounding the display area, and a thin film encapsulation layer sealing the display unit. The display also includes a voltage line formed in the non-display area and surrounding the display area, a metal layer formed of the same material as the voltage line, and a dam surrounding the display area and contacting the voltage line. The voltage line includes a first voltage line disposed in one side of the display area. The first voltage line includes a pair of first end portions and a pair of first connectors respectively connected to the pair of first end portions and extending away from the display area. The metal layer is disposed between the pair of first connectors. The dam contacts the metal layer.

Owner:SAMSUNG DISPLAY CO LTD

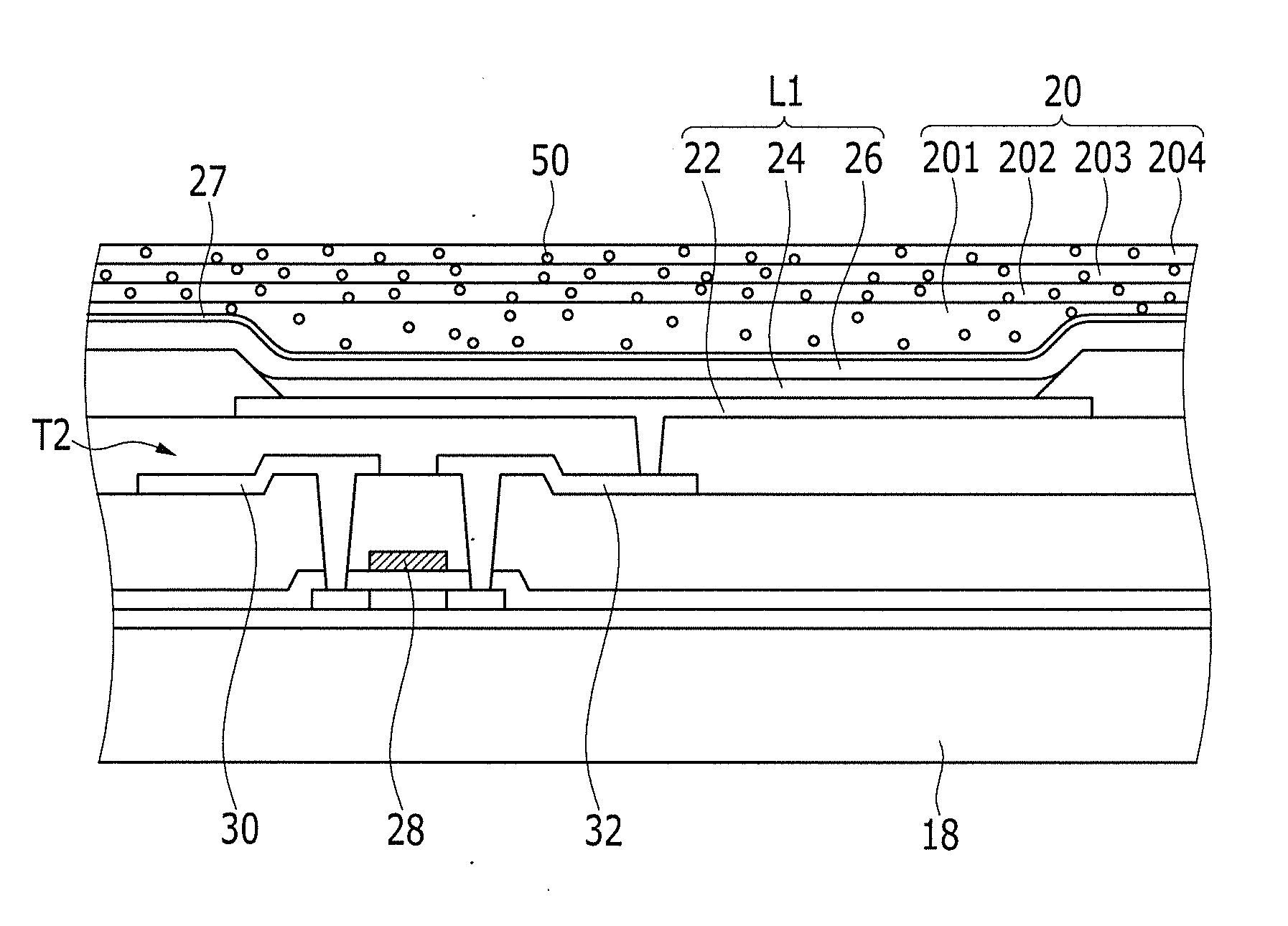

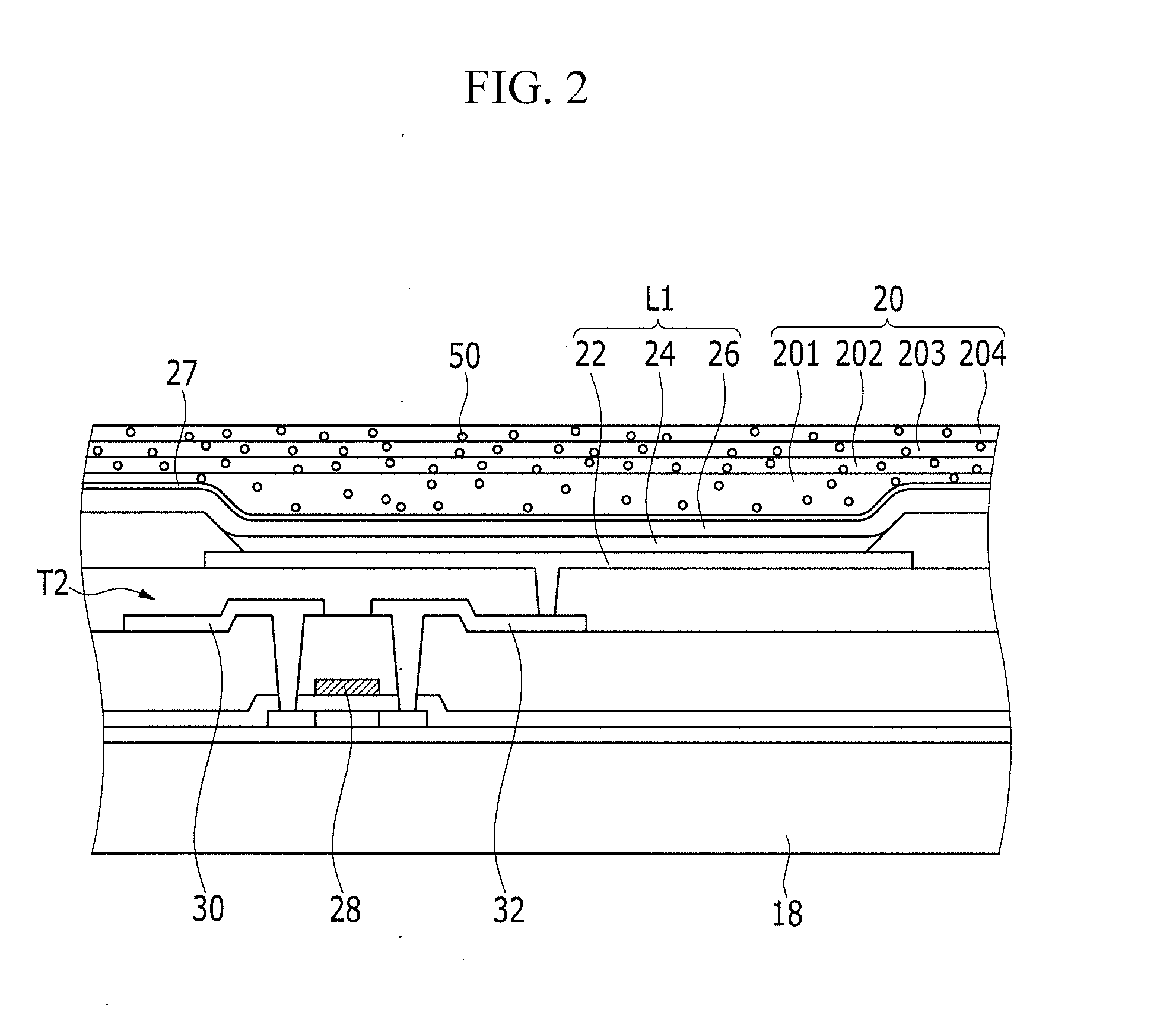

Organic light emitting diode display

ActiveUS20120256218A1Improve lighting efficiencyDiffusing elementsSolid-state devicesRefractive indexDisplay device

An organic light-emitting diode (OLED) display according to an exemplary embodiment may include: a substrate and an organic light emitting element on the substrate; a thin film encapsulation layer on the substrate and covering the organic light emitting element; and one or more scattering materials dispersed in the thin film encapsulation layer. According to the exemplary embodiment, light efficiency may be improved by dispersing scattering materials in at least one of an organic layer or an inorganic layer forming a thin film encapsulation layer with a large refractive index difference.

Owner:SAMSUNG DISPLAY CO LTD

Display apparatus and method of manufacturing the same

ActiveUS20170237037A1Avoid spreadingReduce crackingVisual indicationSolid-state devicesElectrical and Electronics engineeringContact hole

A method of manufacturing a display apparatus includes providing a substrate, forming a display unit defining an opening portion in a display region over the substrate, forming a thin film encapsulation layer to seal the display unit, forming a touch electrode over the thin film encapsulation layer, forming a touch insulating film covering the touch electrode such that the thin film encapsulation layer and the touch insulating film are sequentially stacked and formed over the substrate in the opening portion, forming a touch contact hole by removing a portion of the touch insulating film to expose a portion of the touch electrode, and removing a portion of the touch insulating film and a portion of the thin film encapsulation layer formed in the opening portion to expose a portion of the substrate during the forming of the touch contact hole.

Owner:SAMSUNG DISPLAY CO LTD

Touch control display panel and touch control display device

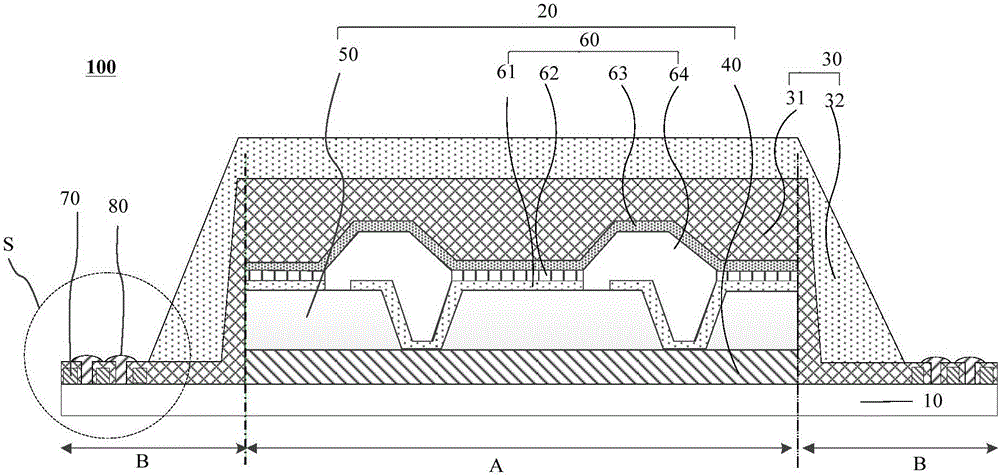

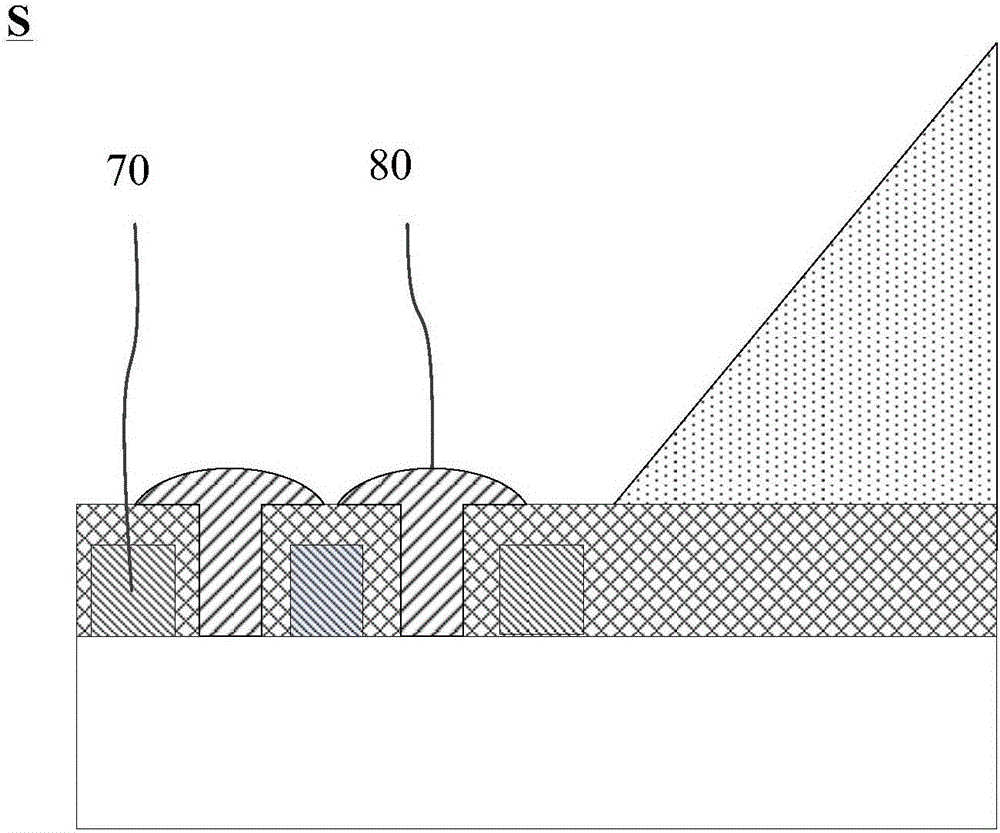

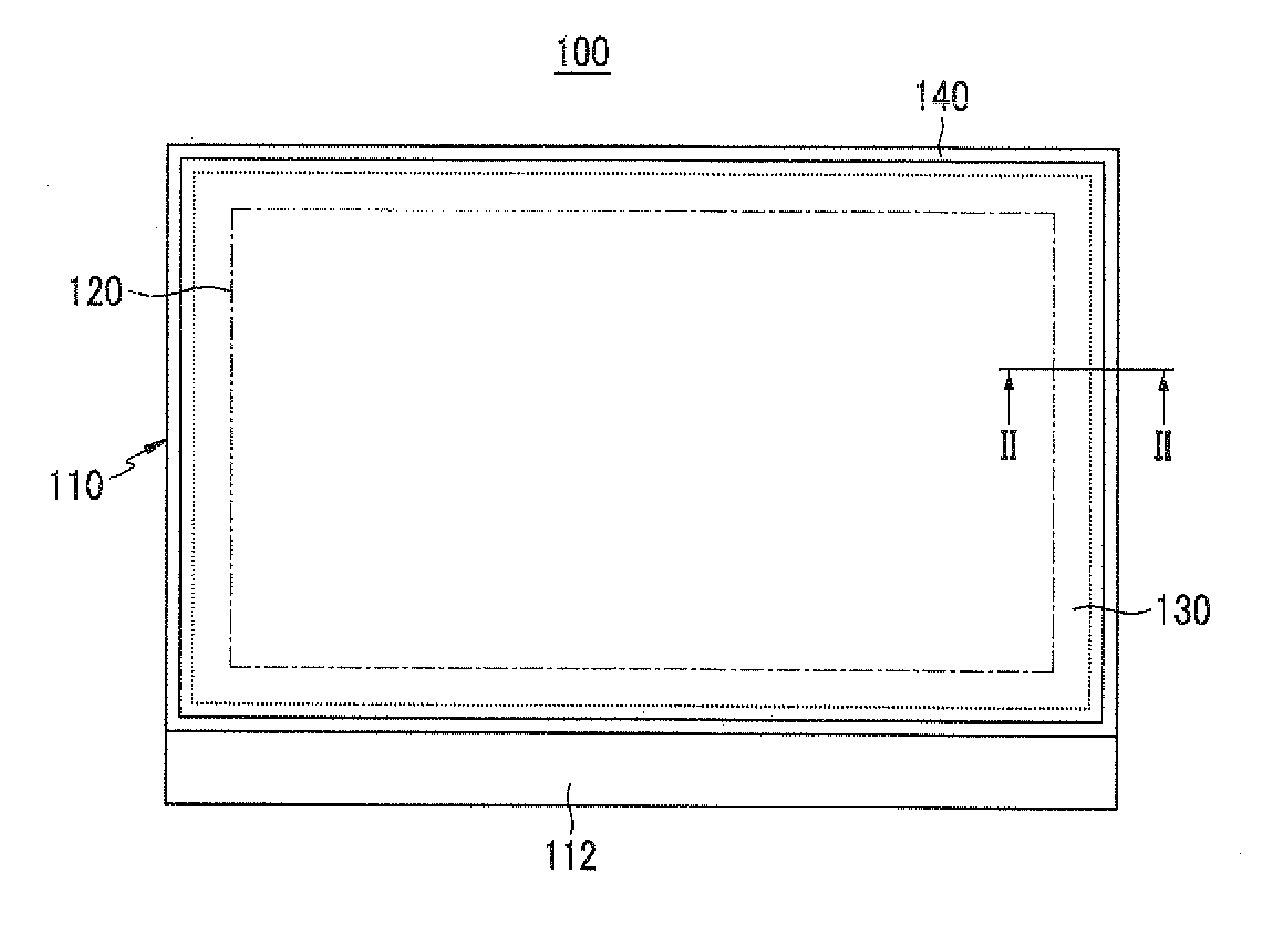

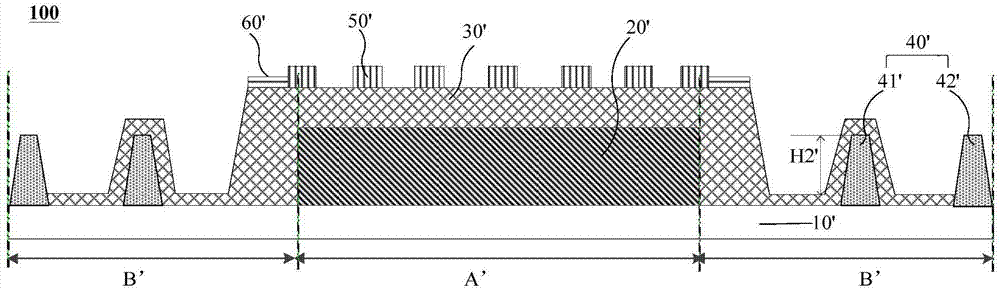

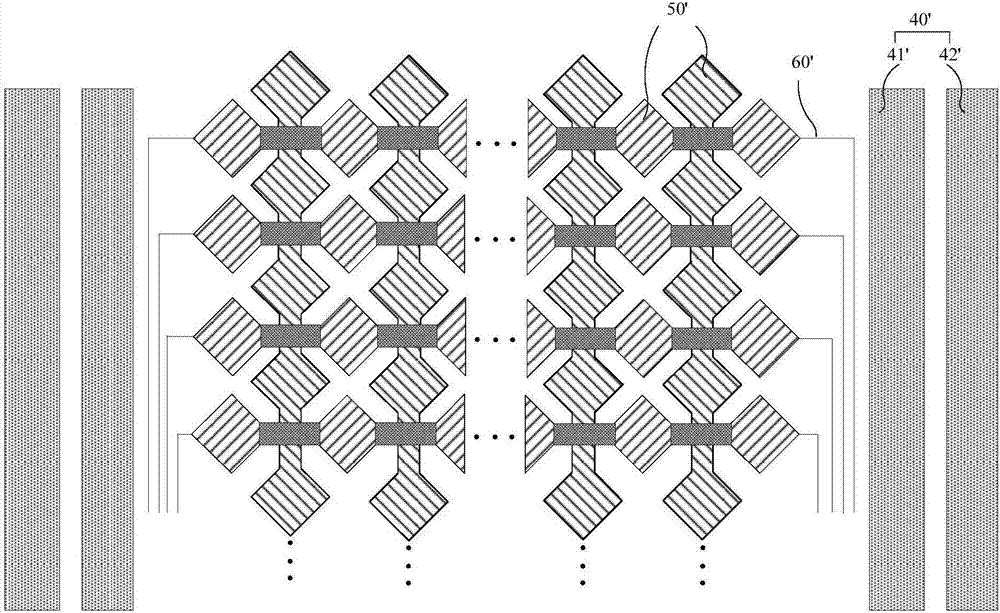

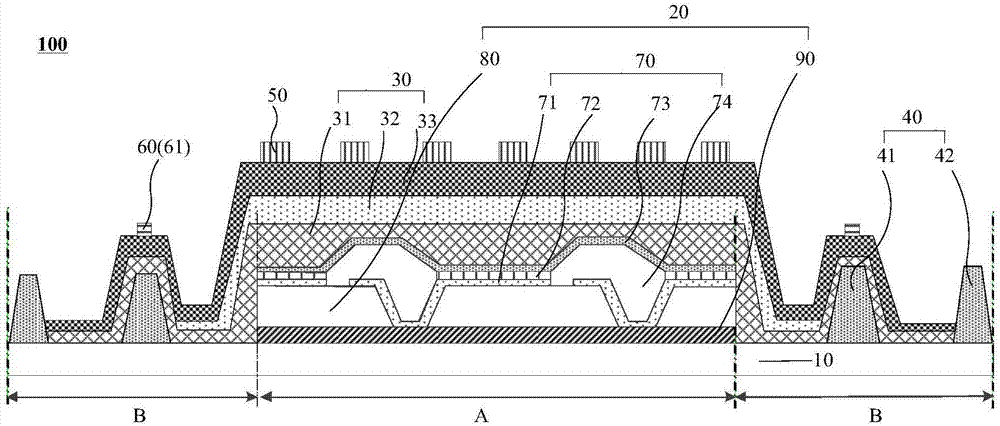

ActiveCN106873839AReduce border areaAchieving Narrow BezelsInput/output processes for data processingMicrometerOrganic light emitting device

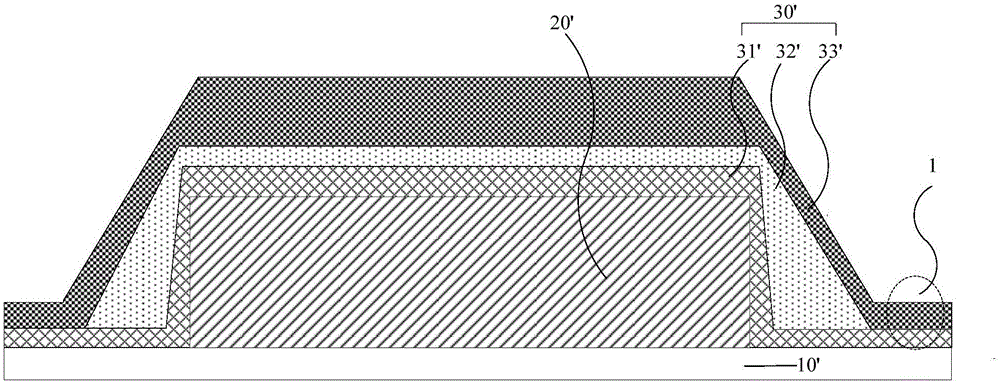

The invention discloses a touch control display panel and a touch control display device. The panel comprises a substrate, an organic luminescent device, at least one baffles, wherein the width of the at least one baffle is 30-200 micrometers, a thin film encapsulation layer, wherein the thin film encapsulation layer covers the at least one baffle, and difference between the baffle 30 and baffle 40 of the thin film encapsulation layer between the first baffle 41 and a display area A is 0-3 micrometers, electrode wires which are located at least at the non-display area of the substrate, and at least part of the electrode wires are located at the side away from the baffle, of the thin film encapsulation layer, and are arranged in the extension direction of the baffle. The projection of the electrode wires on the substrate is located in the range of the projection of the baffle on the substrate. According to the touch control display panel, at least part of electrode wires are located at the side away from the baffle, of the thin film encapsulation layer, and arranged in the extension direction of the baffle, therefore the side frame area of the baffle location is fully utilized to achieve narrow side frames and the lowering of wire cutting-off risk.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

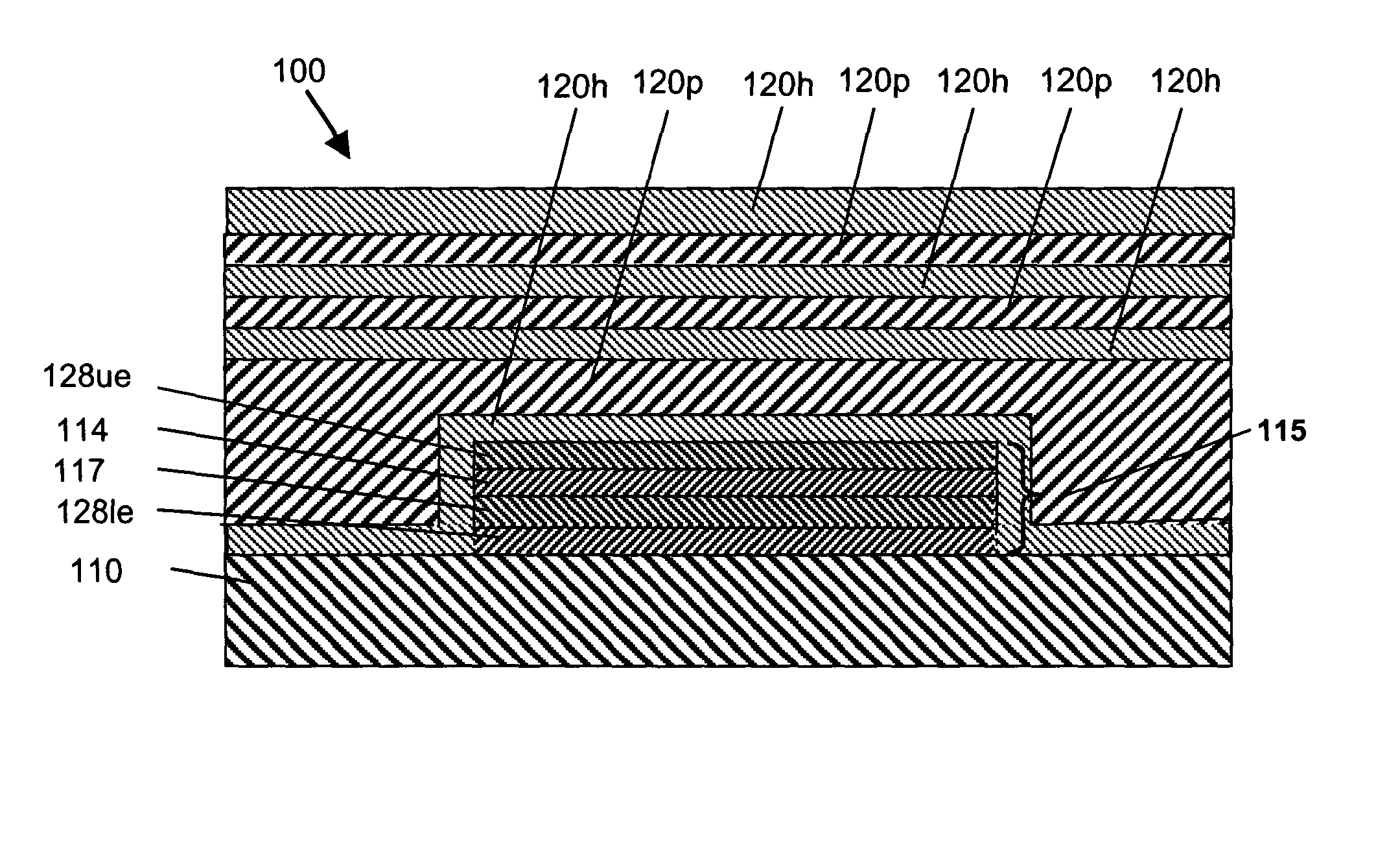

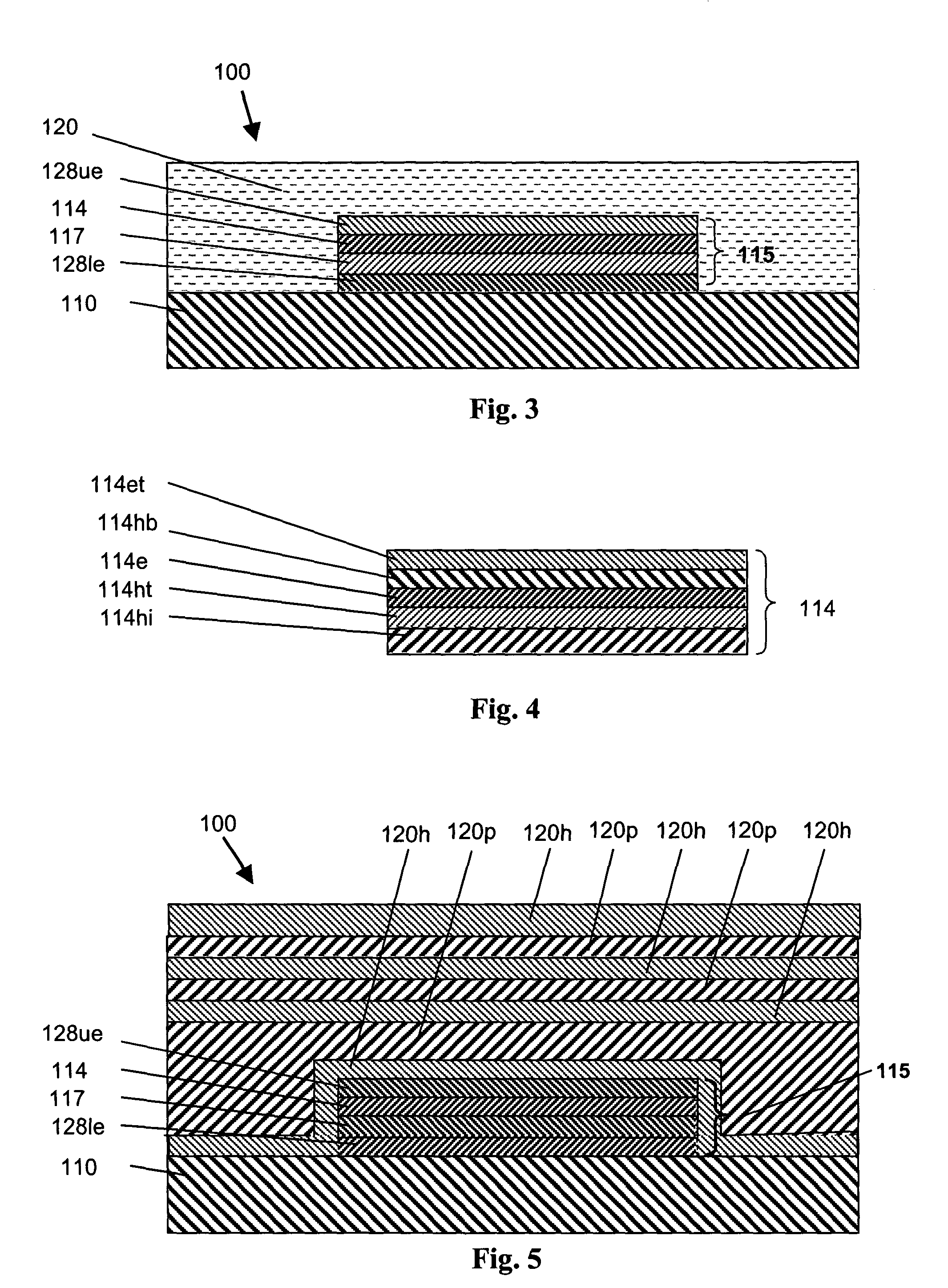

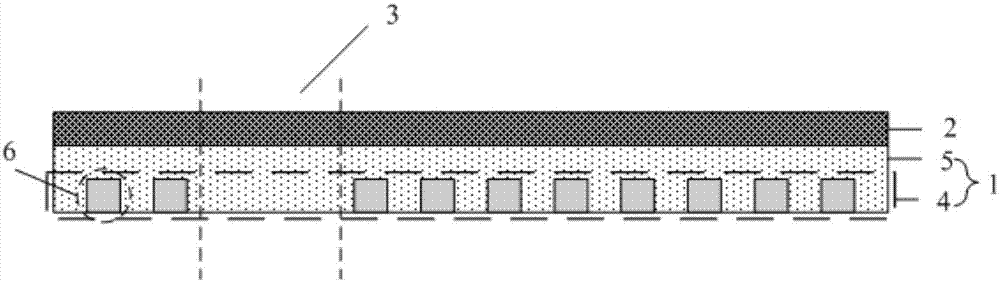

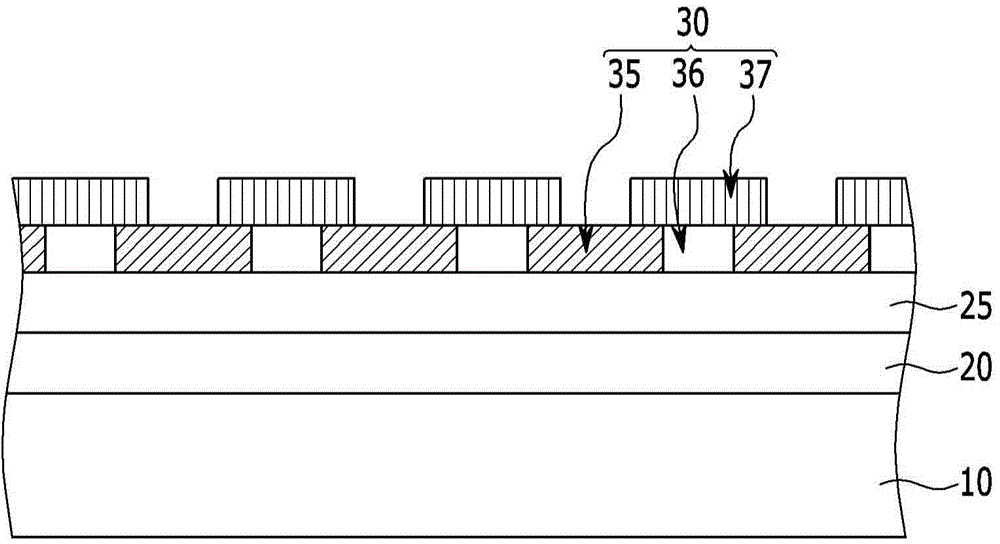

Flexible organic light emitting diode display and manufacturing method thereof

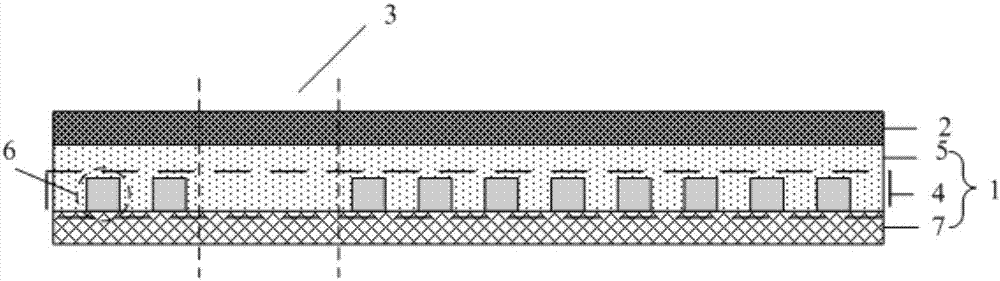

InactiveCN104576959APrevent infiltrationAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeDisplay device

A flexible organic light emitting diode display and a manufacturing method thereof are provided. The flexible organic light emitting diode (OLED) display according to an exemplary embodiment includes: a substrate; an organic light emitting diode (OLED) layer provided on the substrate; and a thin film encapsulation layer provided on the OLED layer. The thin film encapsulation layer includes a plurality of laminated inorganic layers, at least one inorganic layer of the plurality of inorganic layers includes a plurality of inorganic layer patterns that are disposed to be spaced apart from each other on a plane, and an organic layer is formed between the plurality of inorganic layer patterns.

Owner:SAMSUNG DISPLAY CO LTD

Thin film encapsulation of MEMS devices

InactiveUS7045459B2Small sizeLow costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesHermetic sealElectrical and Electronics engineering

A method of manufacturing a miniature electromechanical system (MEMS) device includes the steps of forming a moving member on a first substrate such that a first sacrificial layer is disposed between the moving member and the substrate, encapsulating the moving member, including the first sacrificial layer, with a second sacrificial layer, coating the encapsulating second sacrificial layer with a first film formed of a material that establishes an hermetic seal with the substrate, and removing the first and second sacrificial layers.

Owner:NORTHROP GRUMMAN SYST CORP

Organic light emitting diode display

ActiveUS20160254479A1Inhibit deteriorationImprove weaknessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

Provided is an organic light emitting diode display including a substrate; a display unit formed on the substrate and including a thin film transistor and an organic light emitting diode; a thin film encapsulation covering and encapsulating the display unit and formed by a laminated structure made of at least one first inorganic layer, a first organic layer, and a second inorganic layer; and a protective bezel fixed to the substrate and spaced apart from the side of the substrate to surround edges of the substrate and the thin film encapsulation.

Owner:SAMSUNG DISPLAY CO LTD

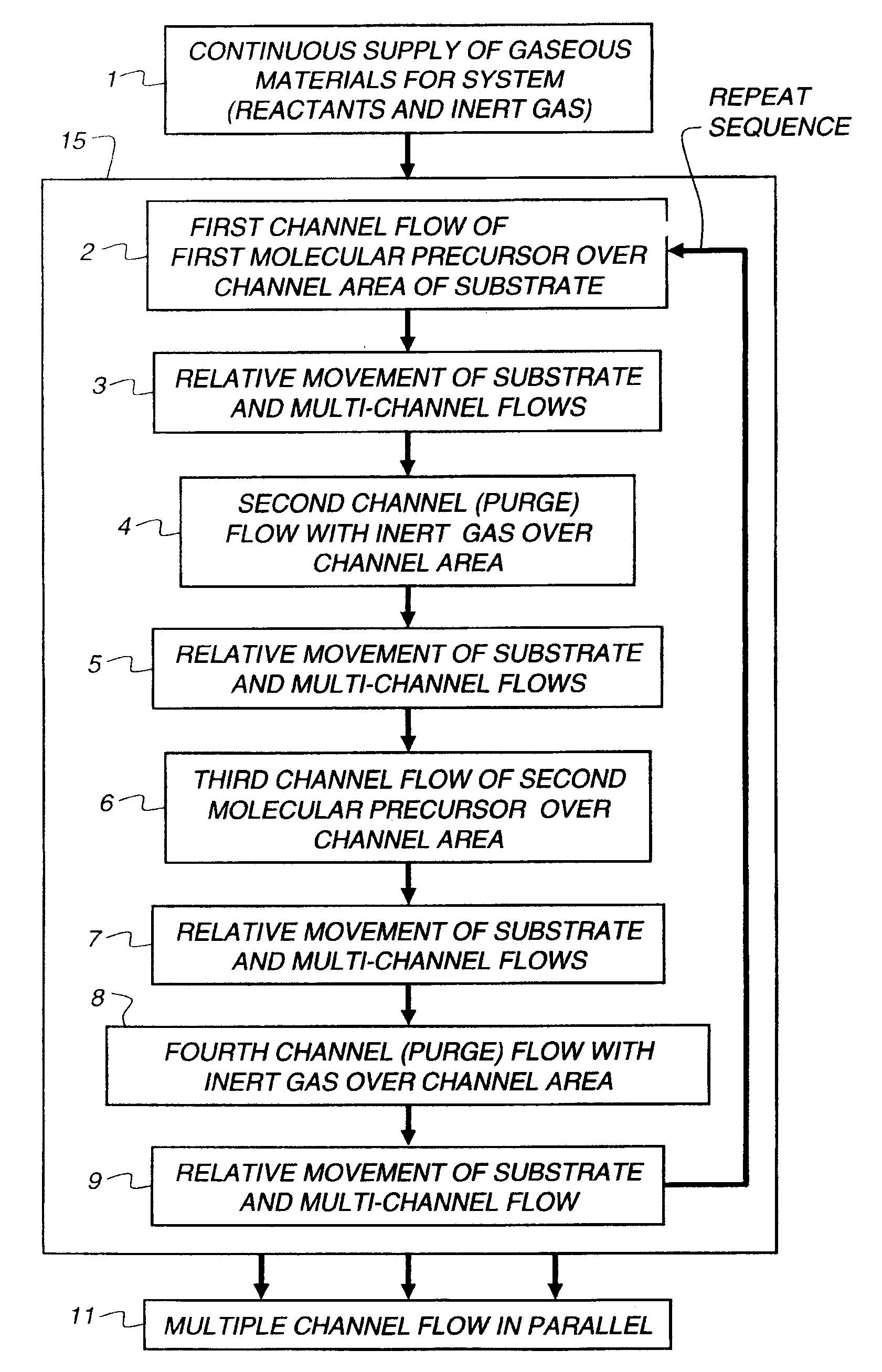

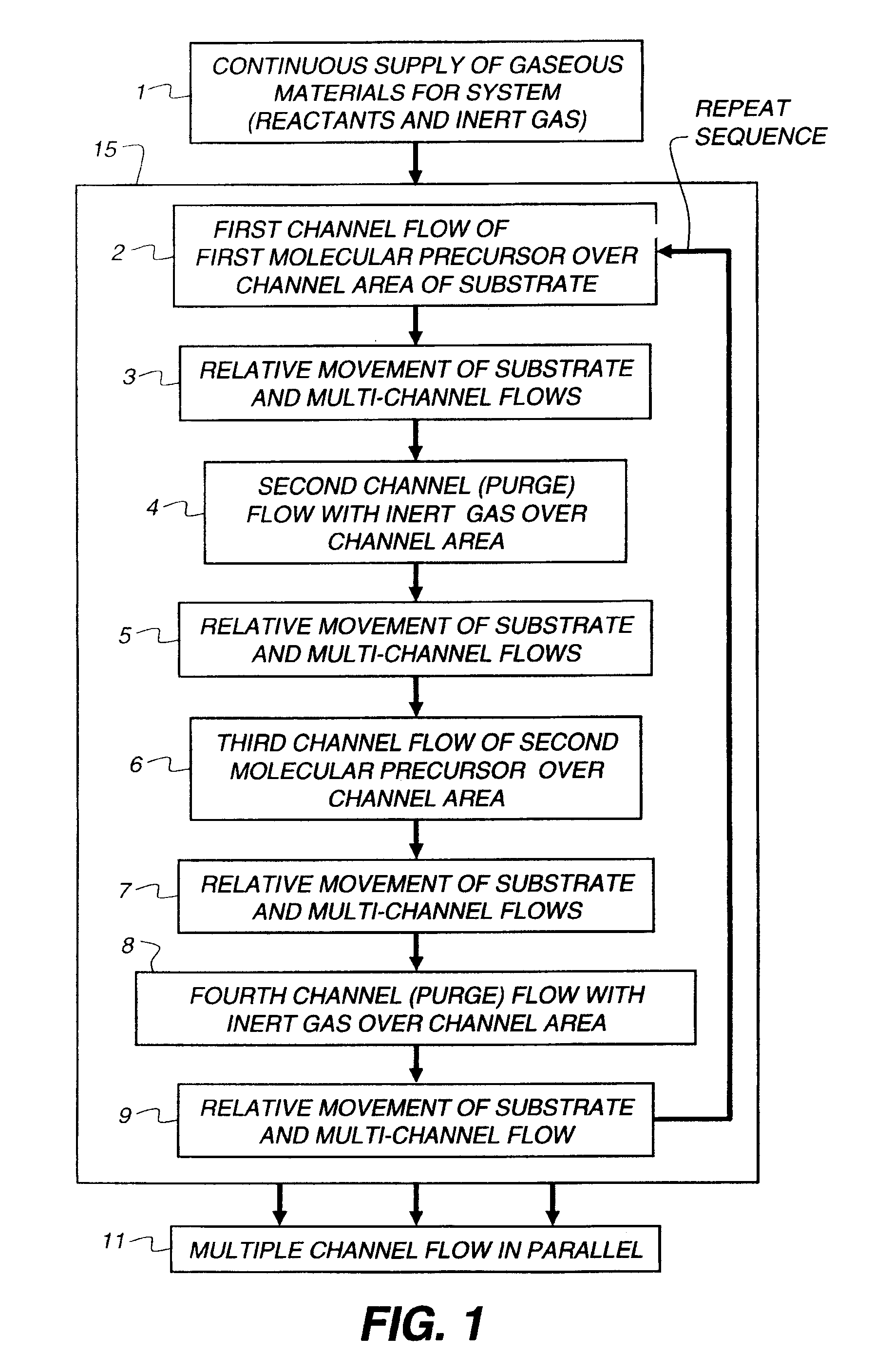

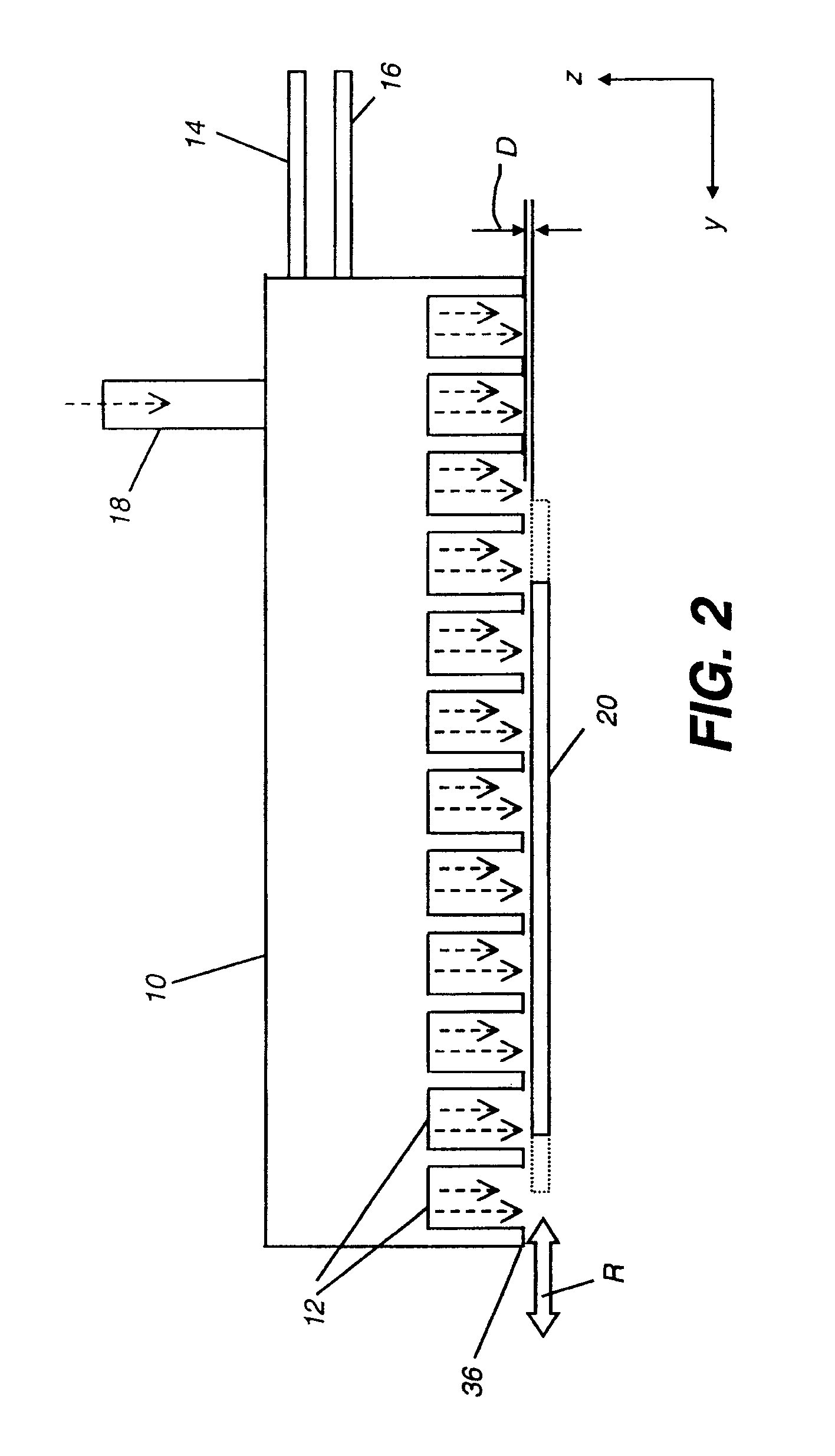

Process for forming thin film encapsulation layers

InactiveUS20090081356A1Suitable for processingSolid-state devicesSpecial surfacesSurface reactionReactive gas

A process is disclosed for making a thin film encapsulation package for an OLED device by depositing a thin film material on an OLED device to be encapsulated, comprising simultaneously directing a series of gas flows along substantially parallel elongated output openings, wherein the series of gas flows comprises, in order, at least a first reactive gaseous material, an inert purge gas, and a second reactive gaseous material, optionally repeated a plurality of times, wherein the first reactive gaseous material is capable of reacting with a substrate surface treated with the second reactive gaseous material to form an encapsulating thin film, wherein the first reactive gaseous material is a volatile organo-metal precursor compound. The process is carried out substantially at or above atmospheric pressure, and the temperature of the substrate during deposition is under 250° C.

Owner:EASTMAN KODAK CO

Thin-film packaging structure, thin-film packaging method and display panel

InactiveCN107689425ABy blockingImprove packaging effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

The invention relates to a thin-film packaging structure, a thin-film packaging method and a display panel. The thin-film packaging structure comprises a substrate base plate, an organic adhesive layer and a packaging film layer, wherein the packaging film layer covers the organic adhesive layer; the organic adhesive layer is made into groove structures and dam structures formed by limitation of the groove structure in a non-display area; the groove structures and the dam structures are arranged around a display area; at least one of the groove structures and the dam structures is of a windingextending structure or a latticed structure. The thin-film packaging structure, the thin-film packaging method and the display panel disclosed by the embodiment of the invention have the beneficial effects that the organic adhesive layer is arranged on the non-display area of the substrate base plate, and a plurality of groups of groove structures with winding extending or latticed structures aredesigned on the organic adhesive layer, so that the path of water-oxygen invasion is prolonged and the bending resistance of the edge area of the display panel also can be improved; simultaneously, due to embedding combination of the groove structures and the dam structures, the water-oxygen blocking capability is improved, simultaneously the occupied space is smaller and the narrow-frame designis realized.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Organic light emitting display device

ActiveUS20190165061A1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceRefractive index

An organic light emitting display device includes: a substrate; a first electrode on the substrate; a pixel defining layer on the substrate, the pixel defining layer defining a first opening which exposes at least a part of the first electrode; an organic light emitting layer on the first electrode; a second electrode on the organic light emitting layer; a thin film encapsulation layer on the second electrode; a sensing electrode on the thin film encapsulation layer; a low refractive index layer on the sensing electrode, the low refractive index layer defining a second opening which overlaps the first opening; and a high refractive index layer on the thin film encapsulation layer. A gap between an edge of the first opening and an edge of the second opening is constant irrespective of direction.

Owner:SAMSUNG DISPLAY CO LTD

Flexible OLED display panel

ActiveCN105261712AAvoid scratchesPrevent crushingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWater block

The invention discloses a flexible OLED display panel, which comprises a flexible substrate, an OELD device, a first encapsulation layer, a barrier layer and a second encapsulation layer, wherein the OLED device is arranged on the flexible substrate; the first encapsulation layer is arranged on the flexile substrate and covers the OLED device; the barrier layer is arranged on the flexible substrate, surrounds the periphery of the first encapsulation layer, and comprises a plurality of discontinuous barrier units; the plurality of barrier units are arranged in a chain form; and the second encapsulation layer is arranged on the flexible substrate and covers the first encapsulation material and the barrier layer. The flexible OLED display panel is capable of effectively blocking the diffusion effect of atomic deposition coating and enhancing the water blocking capacity of a thin-film encapsulation on the periphery of the flexible OLED display panel; meanwhile, the reelability of the barrier layer is increased; the development requirement of the flexible OLED display panel is relatively well met; and an important idea is also provided for development of the flexible OLED display panel.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

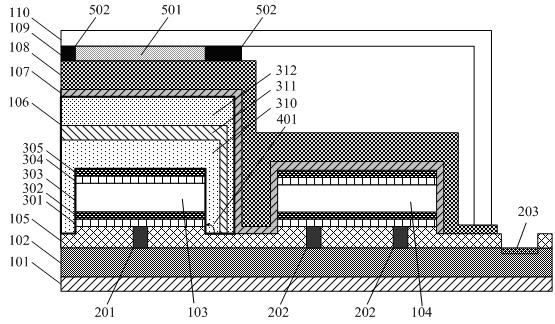

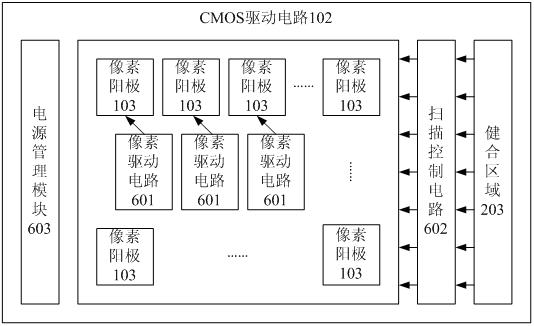

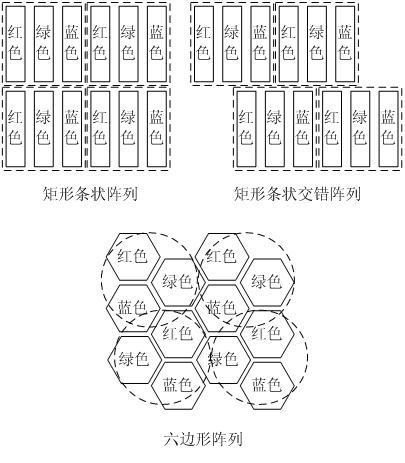

Silicon substrate top emission organic light emitting microdisplay and method for producing same

ActiveCN102629667AAvoid secondary processingSimple processStatic indicating devicesSolid-state devicesTitanium nitrideDisplay device

The invention relates to a silicon substrate top emission organic light emitting microdisplay and method for producing the same. An organic light emitting device is arranged on the surface of a silicon-based chip, and a driving circuit and a controlling circuit of the organic light emitting device are integrated in the silicon-based chip. The structure (from bottom to top) of the microdisplay is a monocrystalline silicon substrate, the driving circuit, a top through-hole layer and a top through-hole, a pixel anode and a common-cathode, an organic layer, a transparent cathode layer, a multi-layer film packaging layer, a color filtering layer and a glass sealing cap, wherein the pixel anode adopts a vertical five-layer structure and the five layers are titanium, titanium nitride, aluminum, titanium and titanium nitride; the organic layer comprises at least a hole transporting layer, a multi-layer organic light emitting layer and an electron transporting layer. The organic light emitting pixel unit area of the microdisplay is less than 100 square microns and the pixel resolution is more than 640*480. Besides, a processing procedure of chip cutting is performed before production of the organic light emitting layer and the film packaging layer, and various masks are used for producing organic displaying devices, so that laser etchers with high cost cannot be introduced.

Owner:LUMICORE MICROELECTRONICS SHANGHAI CO LTD

Display device having improved environmental tolerance

ActiveUS20170365814A1Increase air resistanceImprove moisture resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A display device includes a substrate including a display area and a non-display area surrounding the display area, a thin-film encapsulation layer disposed on the substrate, and a first blocking dam disposed outside the display area, the first blocking dam having at least one layer. Portions of the first blocking dam is removed, and thus, the divided pieces of the first blocking dam are spaced apart from each other, and a second blocking dam is disposed in at least one of a front portion and a rear portion of the first blocking dam corresponding to the spaced part.

Owner:SAMSUNG DISPLAY CO LTD

Flexible display panel and manufacturing method thereof

InactiveCN106783881AImprove bindingAvoid partial peelingSolid-state devicesSemiconductor/solid-state device manufacturingPath lengthContact position

The invention discloses a flexible display panel. The flexible display panel comprises a flexible substrate layer, an array substrate layer, an organic light emitting diode layer and a thin film encapsulation layer which are sequentially overlapped in the longitudinal direction. The effective display area of the organic light emitting diode layer comprises a luminous area with sub-pixels and a non-luminous area beside the luminous area, wherein the non-luminous area is provided with a recess unit, and the thin film encapsulation layer is deposited on the surface of the organic light emitting diode layer and inside the recess unit. The invention also discloses a manufacturing method of the flexible display panel. By increasing the contact area and the contact positions between the TFE (thin film encapsulation) layer and the Array layer, the flexible display panel can effectively enhance the bonding force between the TFE layer and the Array layer, avoids local peeling of the OLED (organic light emitting diode) layer of a screen under external force and further improve the impact resisting and bending resisting performance of the screen. Besides, the applied encapsulation manner of the flexible display panel can effectively release the internal stress of the TFE layer to further improve the bending resisting performance of the screen; meanwhile, the TFE structure prolongs the path length of water permeation and further enhances the encapsulation effects.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com