Flexible display panel and manufacturing method thereof

A flexible display and flexible substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the limitation of the application scope and bending method of flexible OLED screens, partial peeling of OLED light-emitting layers, and uneven screen stress. problem, to avoid local peeling, improve packaging effect, and improve bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

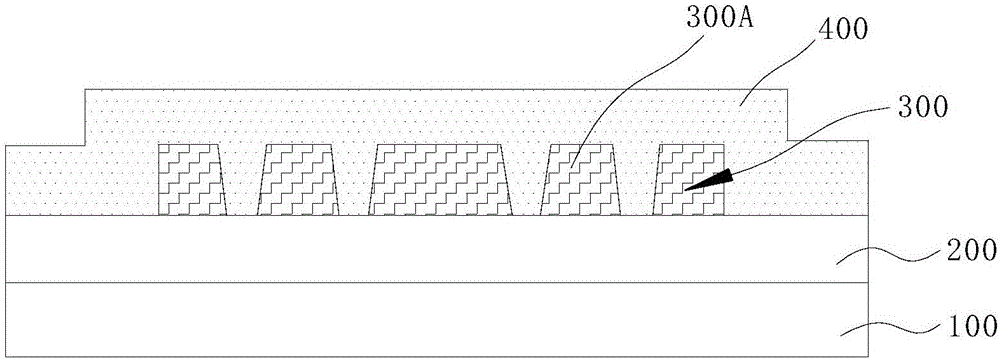

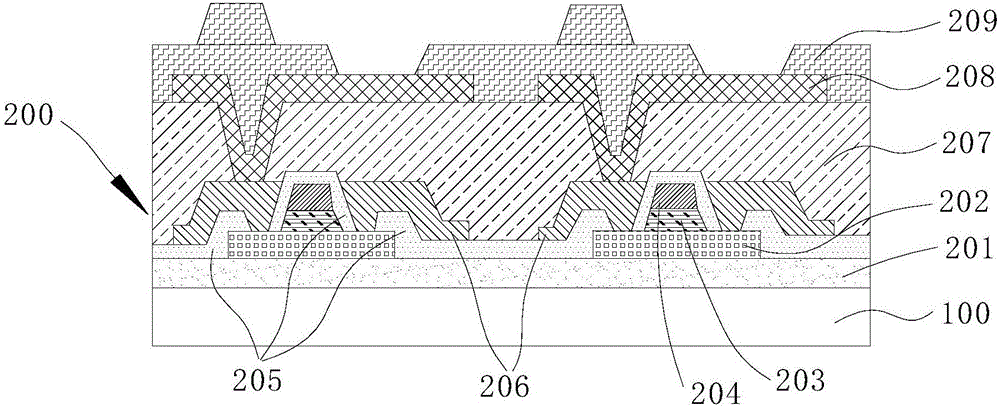

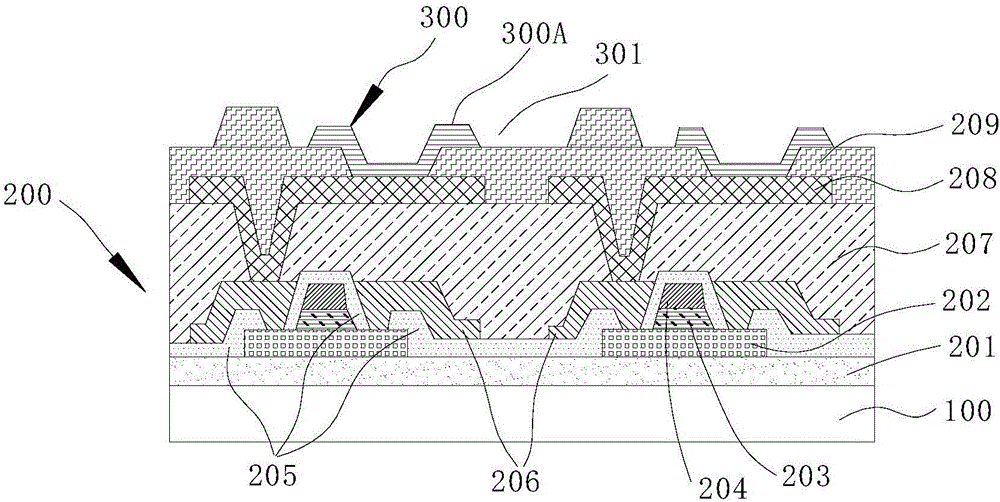

[0034] refer to figure 1 , the flexible display panel of this embodiment includes a flexible substrate layer 100, an array substrate layer 200, an organic light-emitting layer 300, and a thin-film encapsulation layer 400 stacked vertically in sequence, wherein the effective display area of the organic light-emitting layer 300 includes a light-emitting area with sub-pixels 300A and the non-light-emitting area (not shown) next to the light-emitting area 300A, that is, the area between two adjacent light-emitting areas 300A is the non-light-emitting area. combine image 3 As shown, the non-light-emitting area is provided with a recessed portion 301 with a hole structure, and the thin film encapsulation layer 400 is deposited on the surface of the organic light-emitting layer 300 and in the recessed portion 301 .

[0035] Preferably, the thin film encapsulation layer 400 is alternately deposited on the surface of the flexible OLED layer 300 using polymer organic films and inorg...

Embodiment 2

[0046] like Figure 7 As shown, as another implementation manner, the recessed portion 301 further extends through the pixel defining layer 209 to the anode layer 208 , and the thin film encapsulation layer 400 is deposited on the surface of the anode layer 208 or the planar layer 207 .

[0047] The difference from the fabrication method in Example 1 is that specifically in the fabrication step (2) of the flexible display panel, it is necessary to further etch the array substrate layer 200 when fabricating the recessed portion 301 so that the recessed portion 301 further penetrates the pixel defining layer 209 , and then, the thin film encapsulation layer 400 may be deposited on the surface of the anode layer 208 or the planar layer 207 .

Embodiment 3

[0049] like Figure 8 As shown, as yet another embodiment, the depth of the recessed portion 301 is further extended relative to the embodiment 1, sequentially passing through the pixel defining layer 209, the anode layer 208, the planar layer 207 to the interlayer insulating layer 205, and the thin film encapsulation layer 400 is deposited on the surface of the interlayer insulating layer 205 .

[0050] The difference from the fabrication method in Example 1 is that, specifically in the fabrication step (2) of the flexible display panel, it is necessary to further etch the array substrate layer 200 when fabricating the recessed portion 301 so that the recessed portion 301 further penetrates the pixel defining layer 209 , the anode layer 208 , the flat layer 207 to the interlayer insulating layer 205 , and then, the thin film encapsulation layer 400 may be deposited on the surface of the interlayer insulating layer 205 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com