Patents

Literature

150results about How to "Effective stress relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

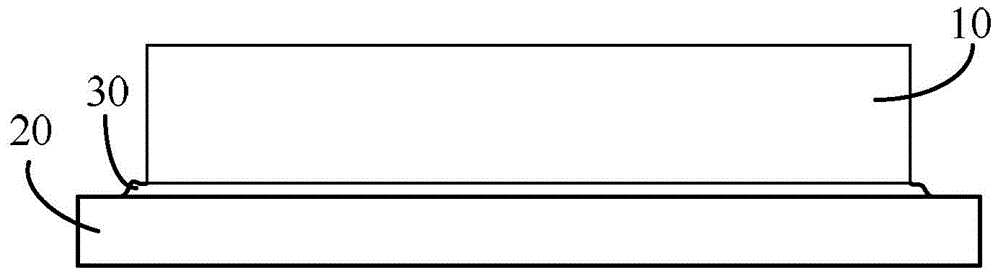

Foldable display device

The invention provides a foldable display device which comprises a shell, a middle frame, a display panel and a surface frame. The shell comprises a shell bending device, the middle frame is mounted to the shell, the middle frame comprises a middle frame bending device opposite to the shell bending device, the display panel is mounted to the middle frame and comprises a panel bending area oppositeto the middle frame bending device, the surface frame is mounted to the shell, and the display panel is clamped into an opening. When the display panel is bent, the middle frame bending device and the shell form a cavity, and the panel bending area is bent and then placed into the cavity.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

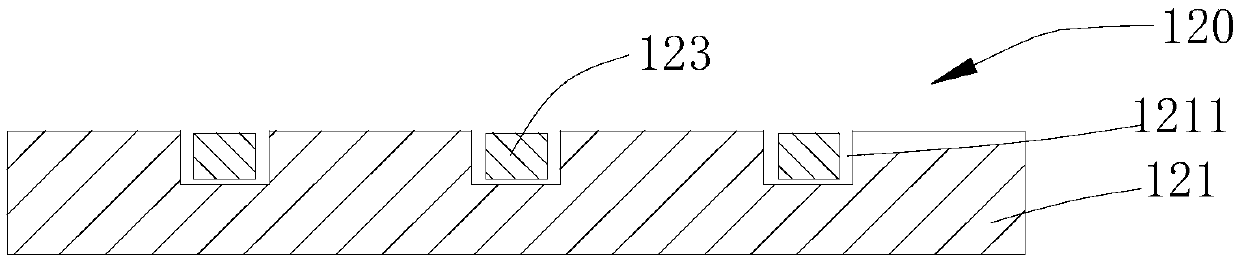

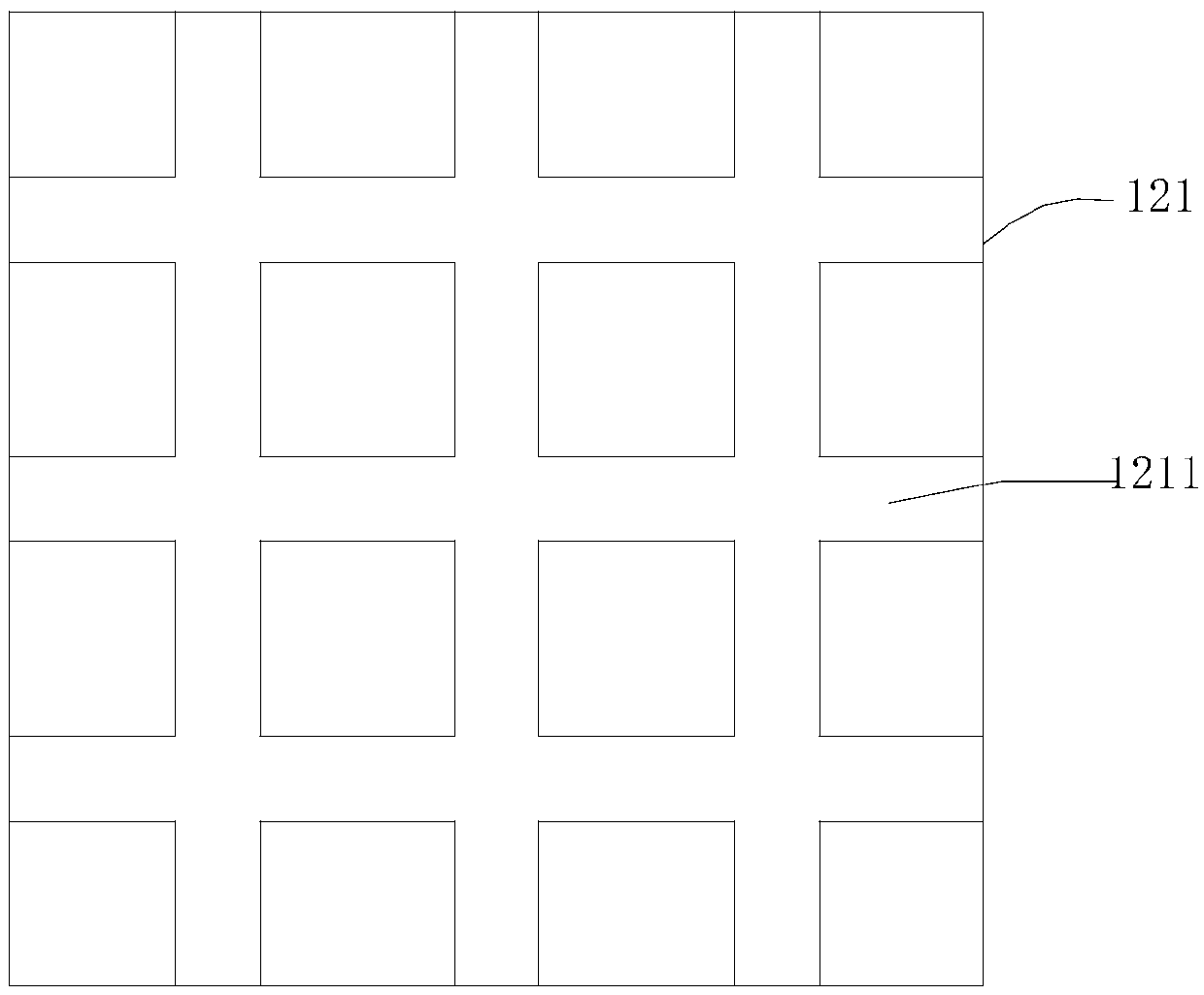

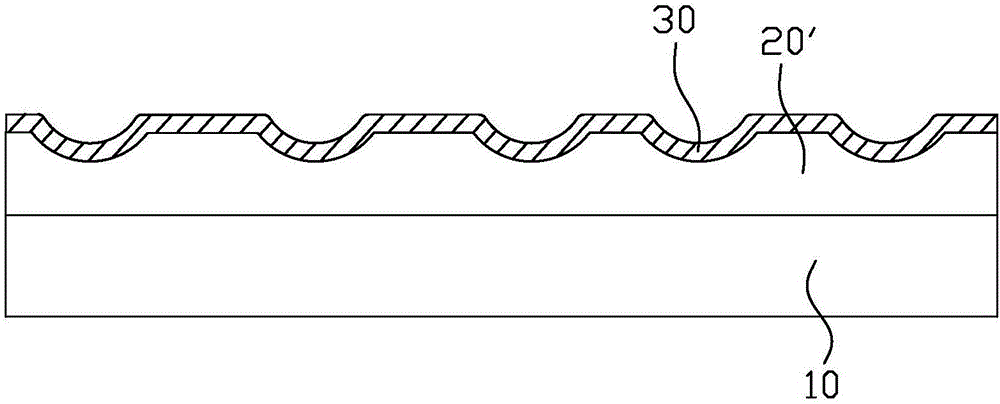

Array substrate and manufacturing method thereof, and display screen

ActiveCN107910336AExtended service lifeAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

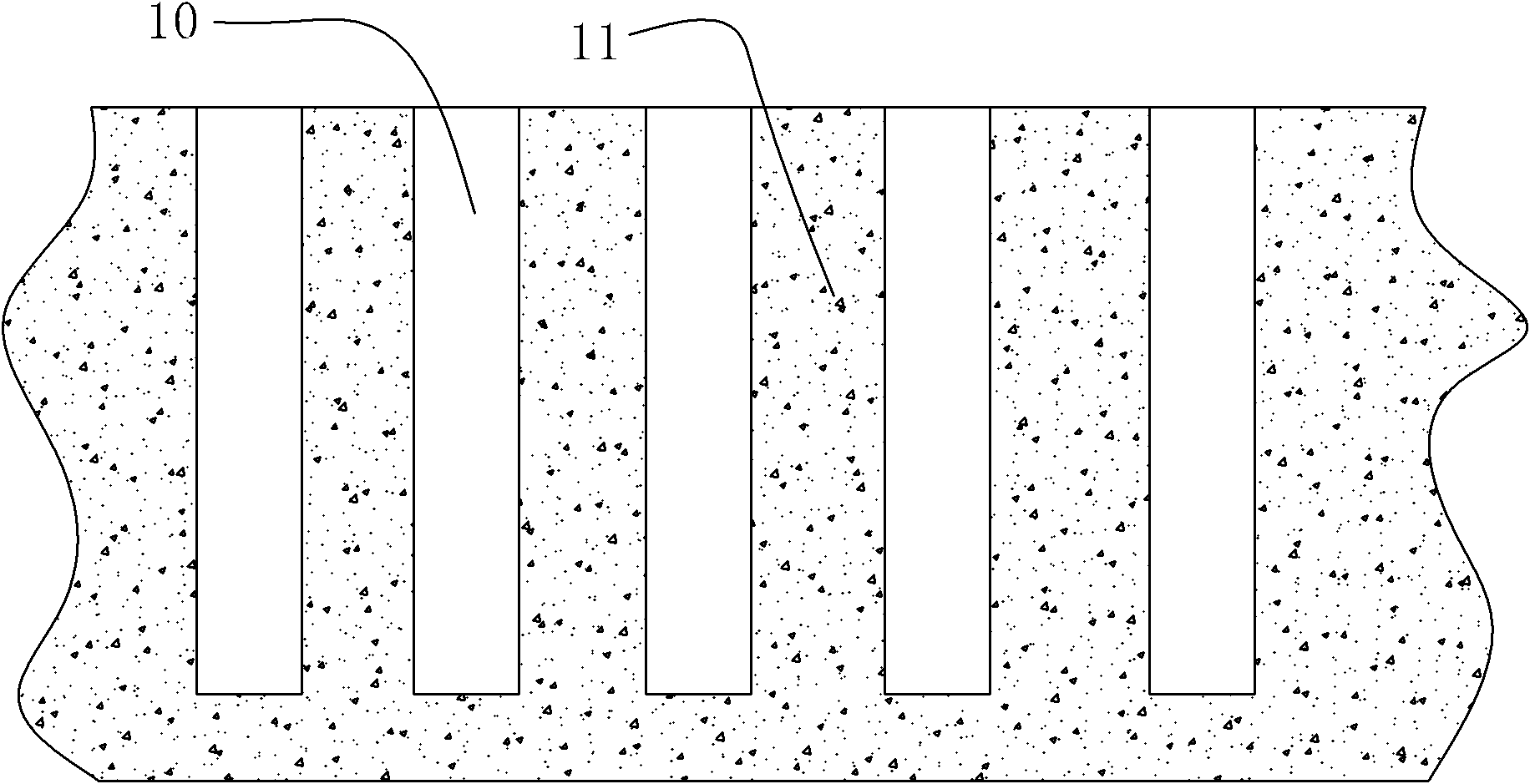

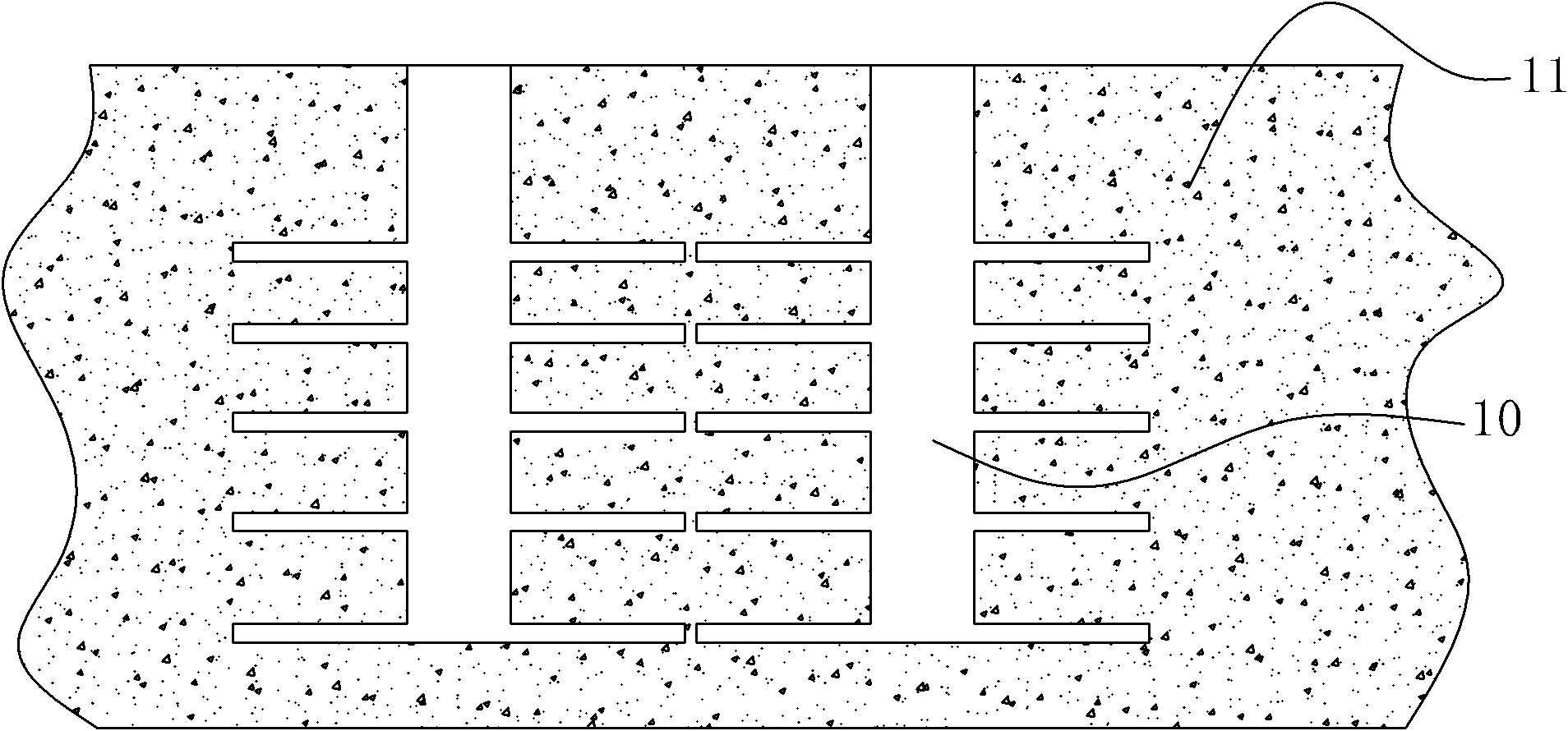

The invention relates to an array substrate. The array substrate comprises a display region and a non-display region positioned on the outer side of the display region; and the non-display region comprises a flexible substrate with multiple grooves in the surface, and peripheral metal lines positioned in the grooves. According to the array substrate, the grooves are formed in the surface of the substrate, and the peripheral metal lines are positioned in the grooves, so that the thickness, in the peripheral metal lines, of the flexible substrate is reduced, and extrusion of the flexible substrate on the peripheral metal lines is reduced in a bending process; and in addition, by virtue of setting of the grooves, the stress of the flexible substrate can be effectively released in bending, thereby effectively preventing cracking of the peripheral metal lines and improving reliability of the array substrate. The invention also provides a display screen and a manufacturing method of the array substrate.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

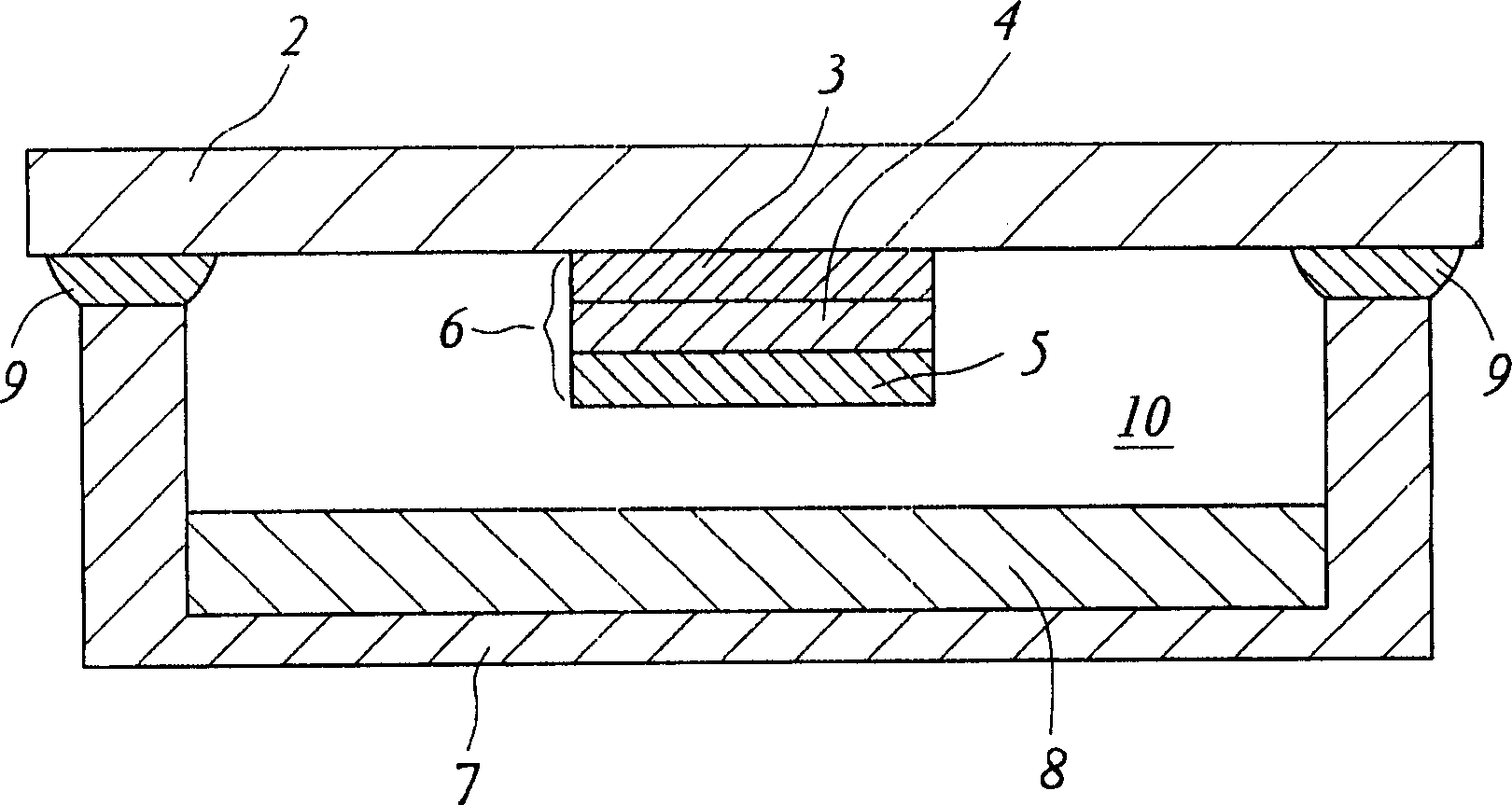

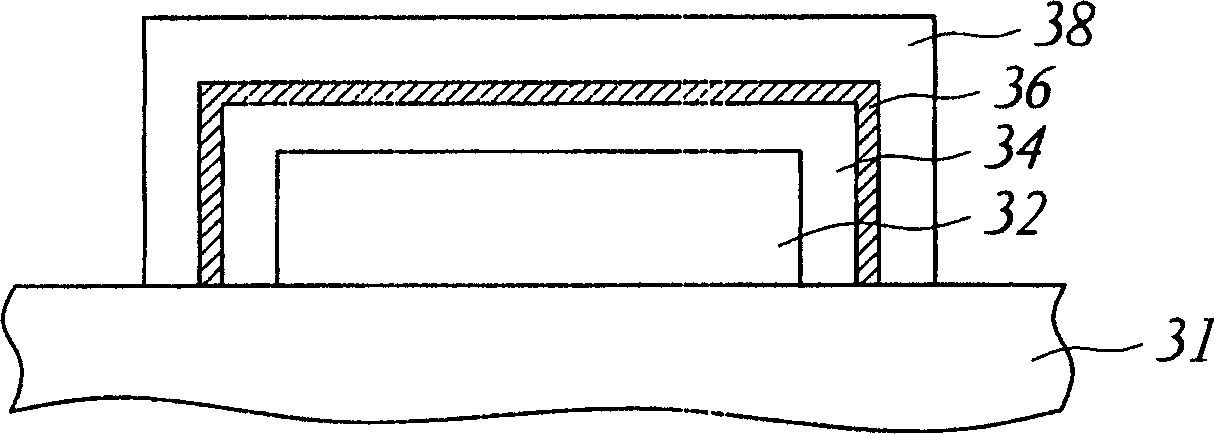

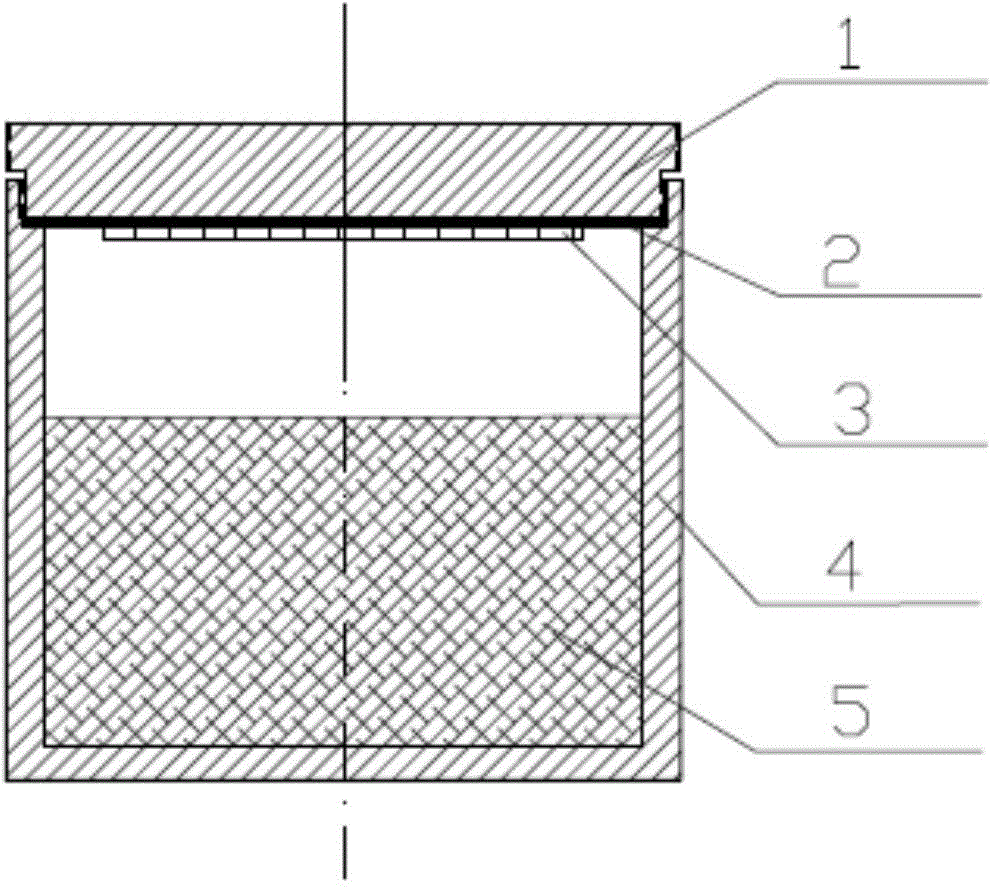

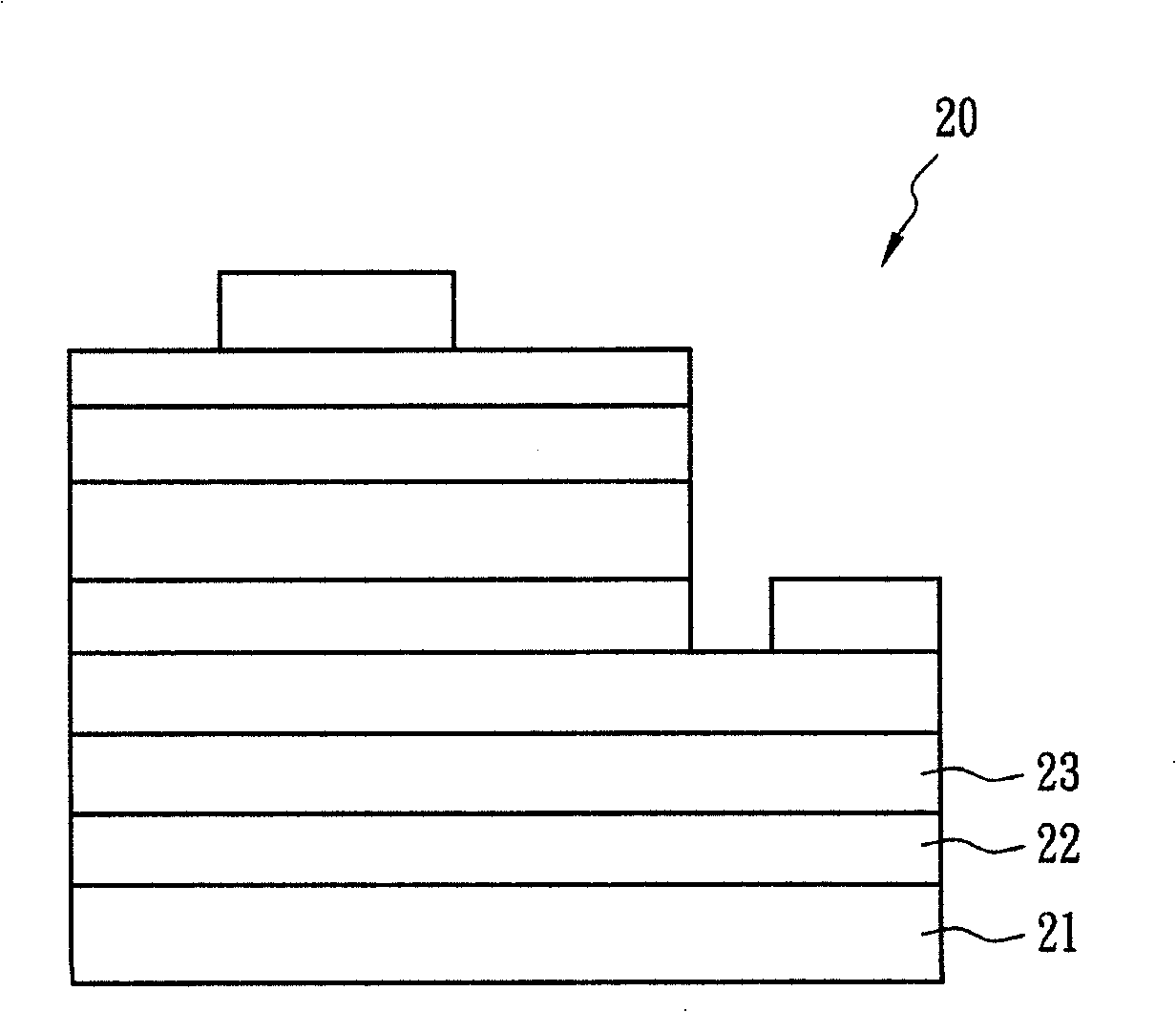

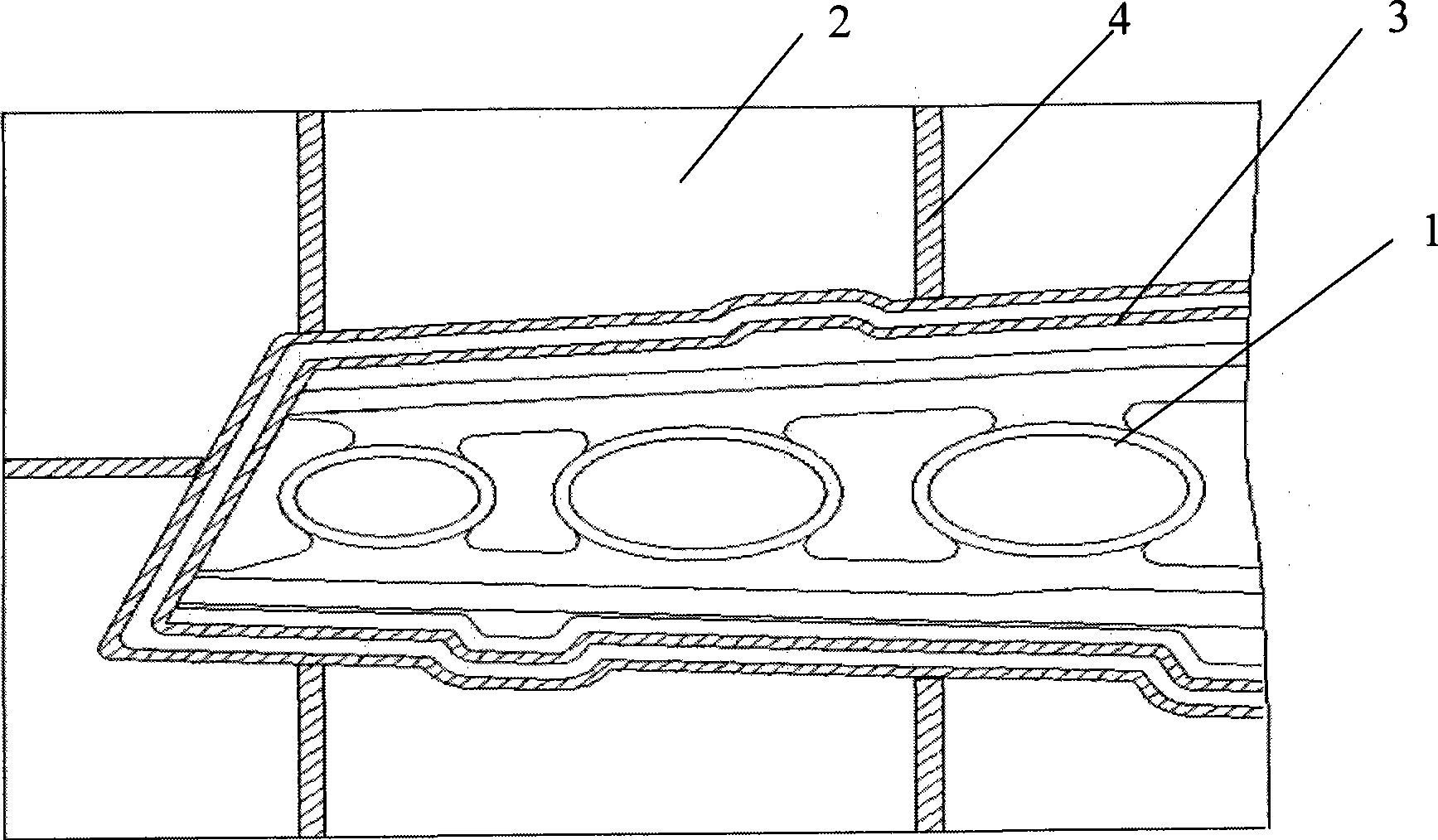

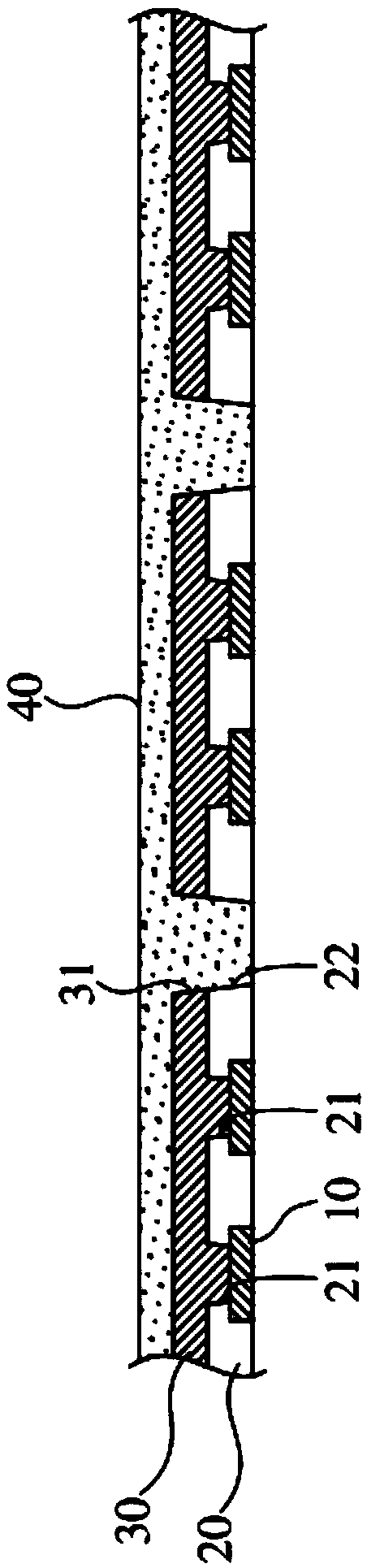

Structure for packaging organic electroluminescence element

InactiveCN1652646APrevent intrusionEffective stress reliefElectrical apparatusElectroluminescent light sourcesMoisture absorptionEngineering

Encapsulation structure for organic electroluminescence device (OELD) includes a base plate, an OELD, a soft protective layer, a moisture absorption layer, and a rigid protective layer. The OELD is setup on the base plate. The soft protective layer is on the base plate and covers on the OELD. The moisture absorption layer covers on the soft protective layer, and the rigid protective layer covers on the moisture absorption layer.

Owner:AU OPTRONICS CORP

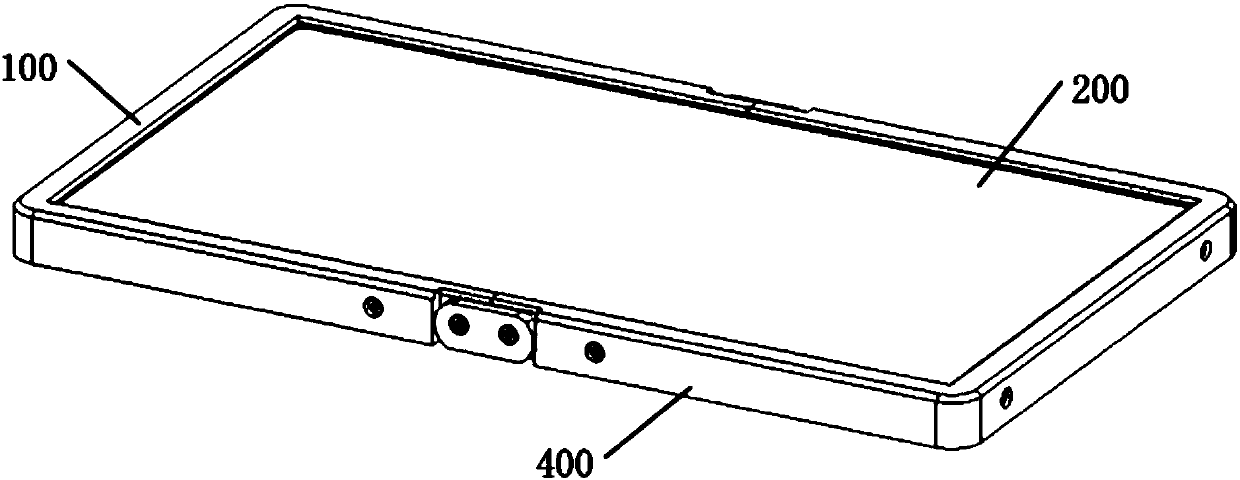

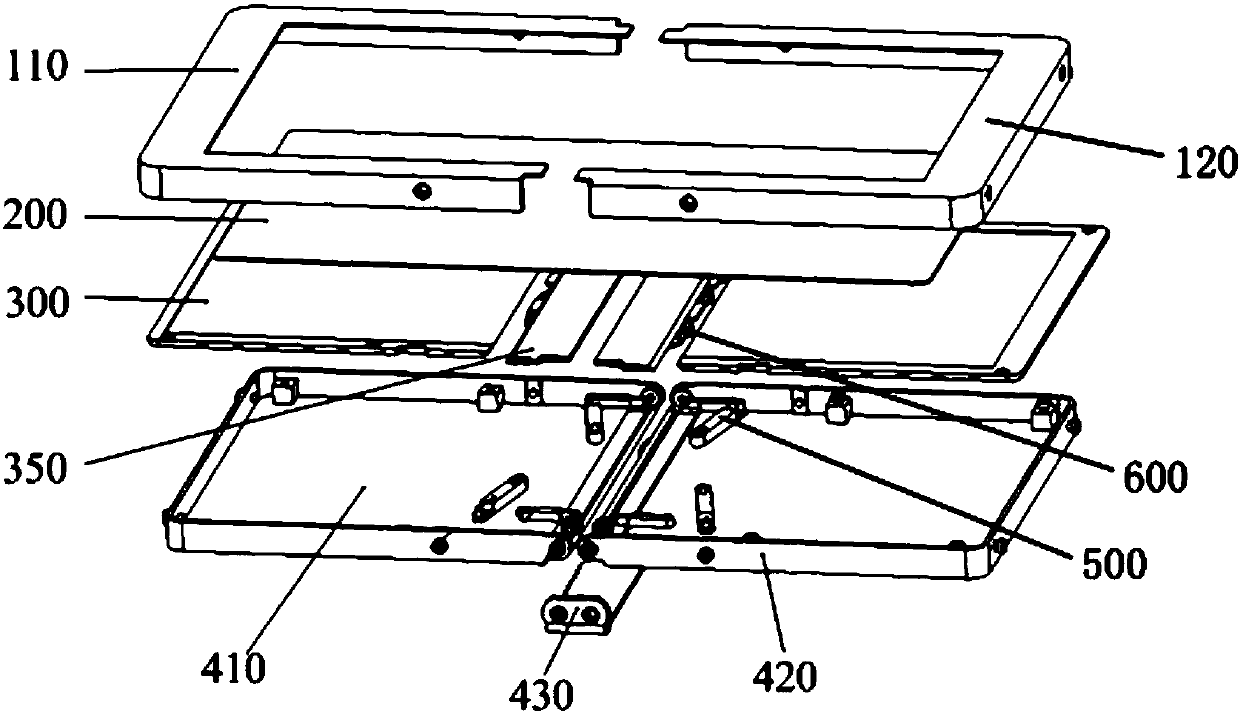

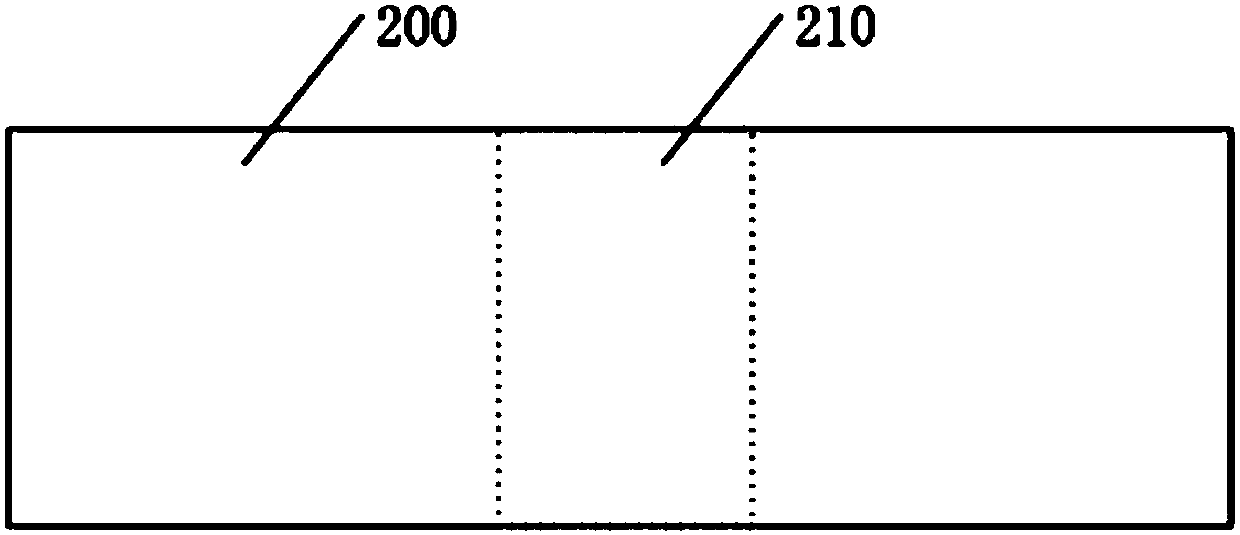

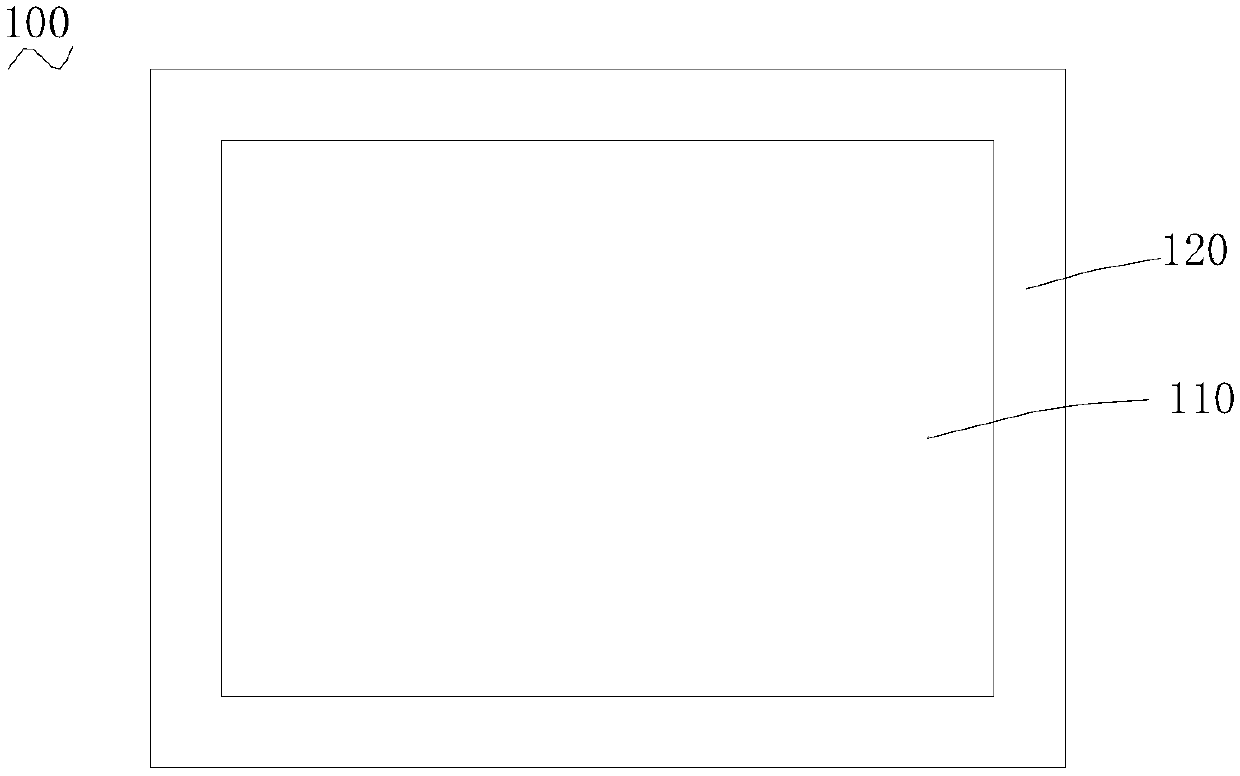

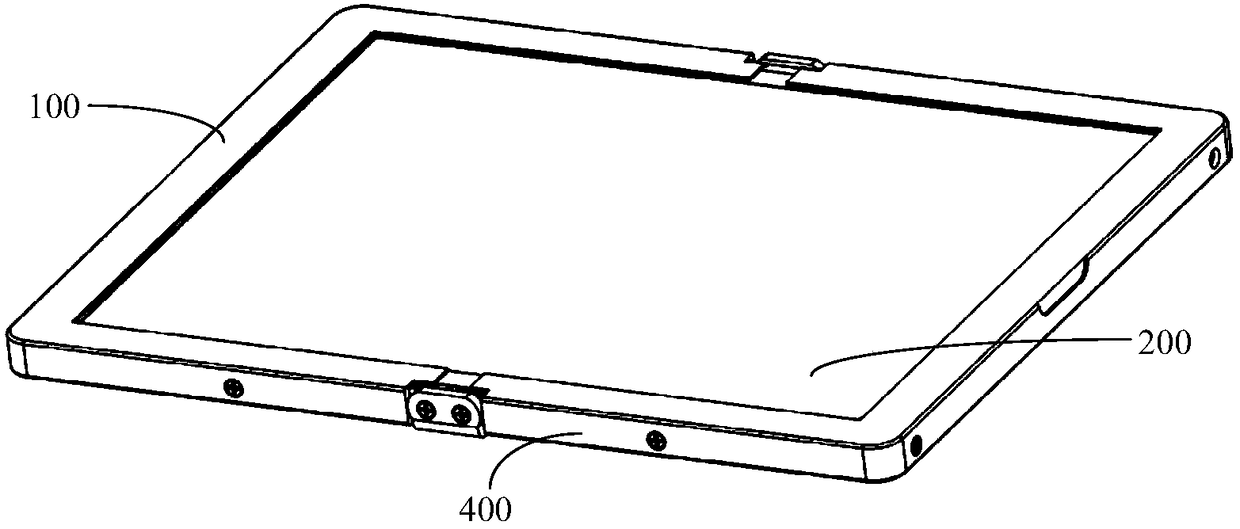

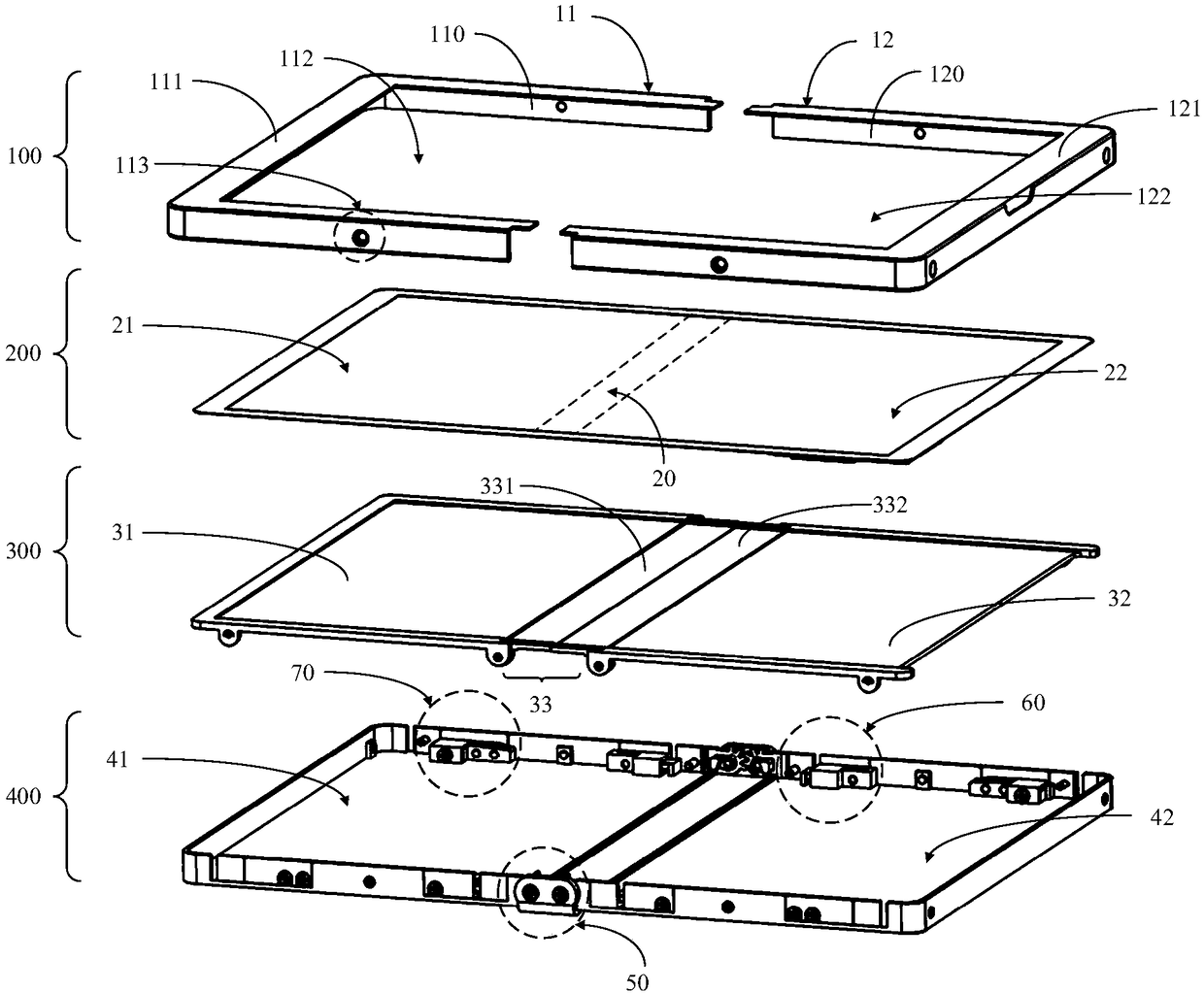

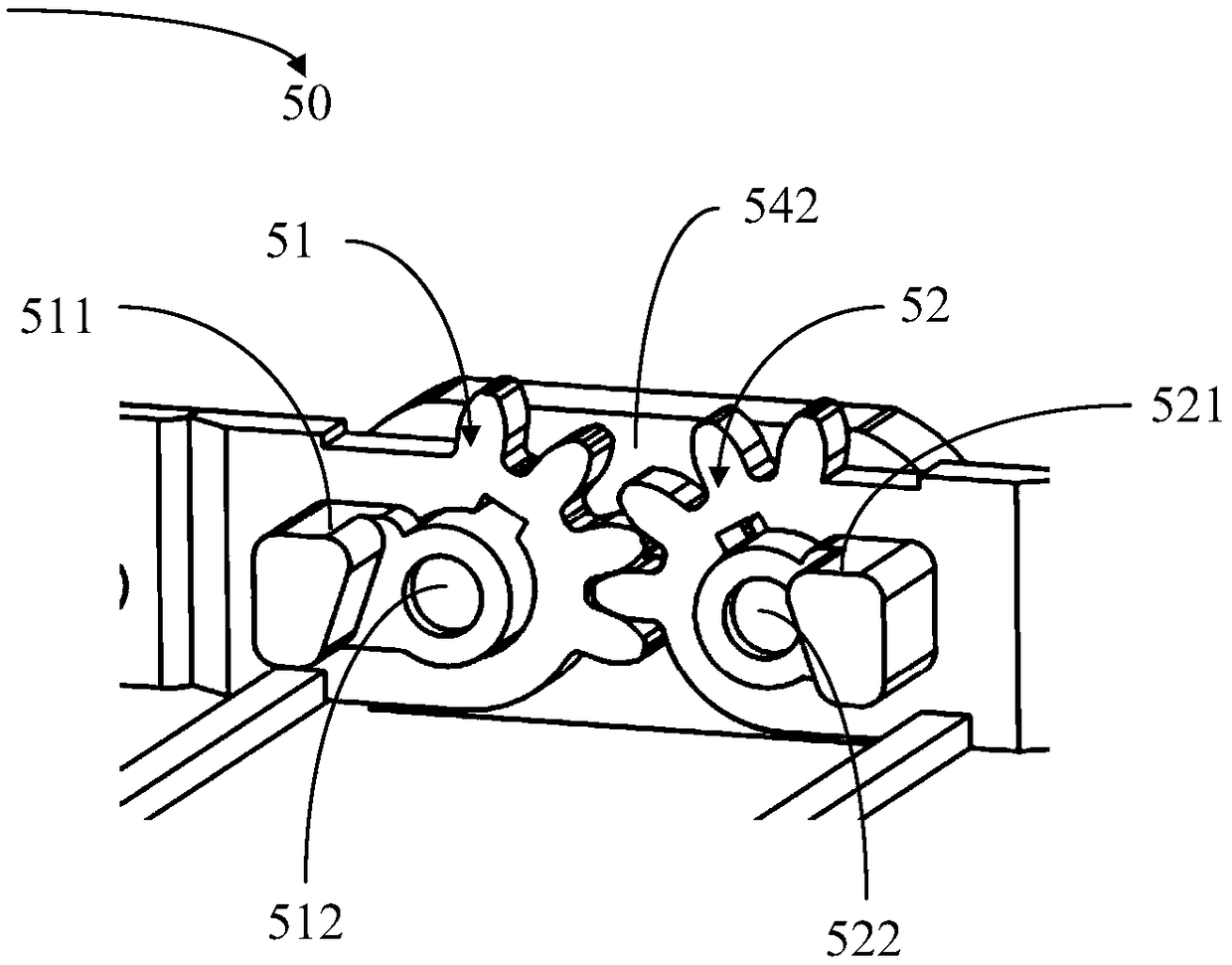

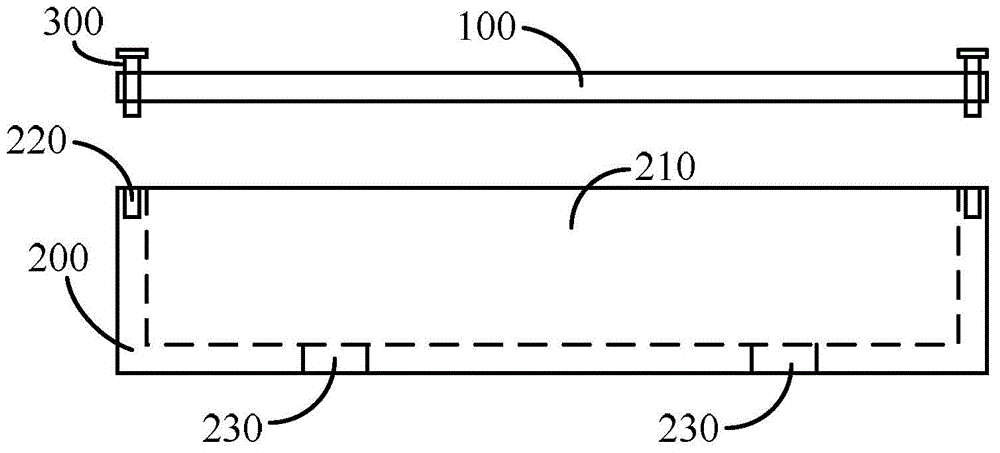

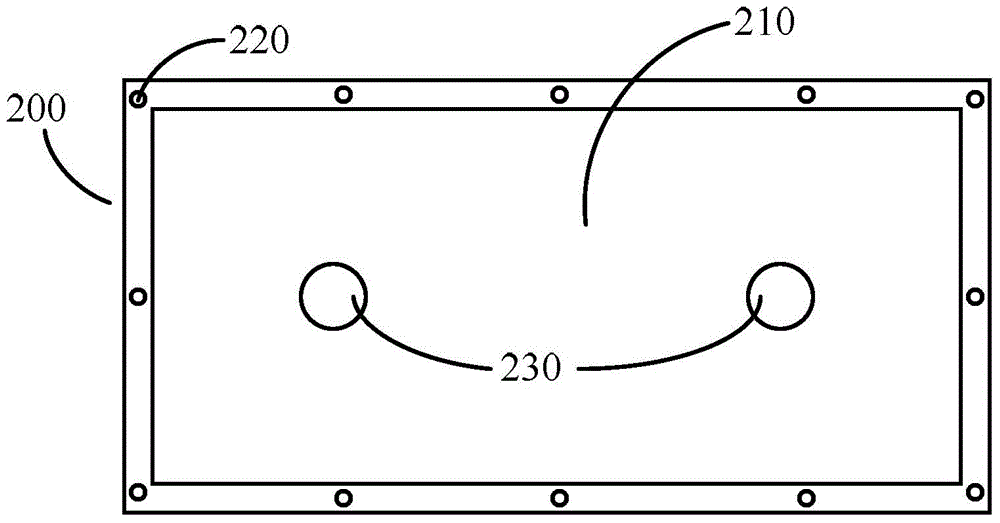

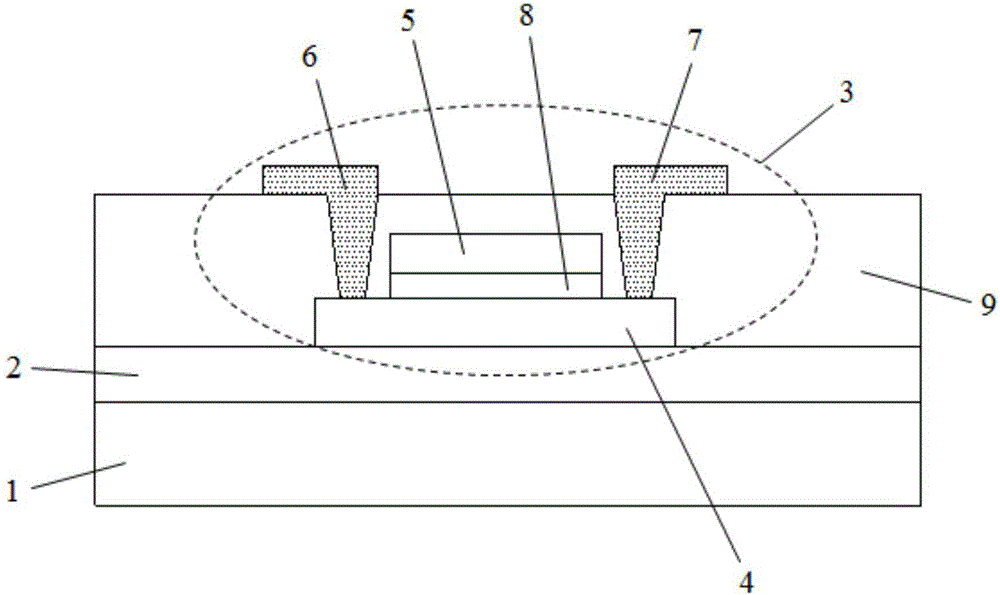

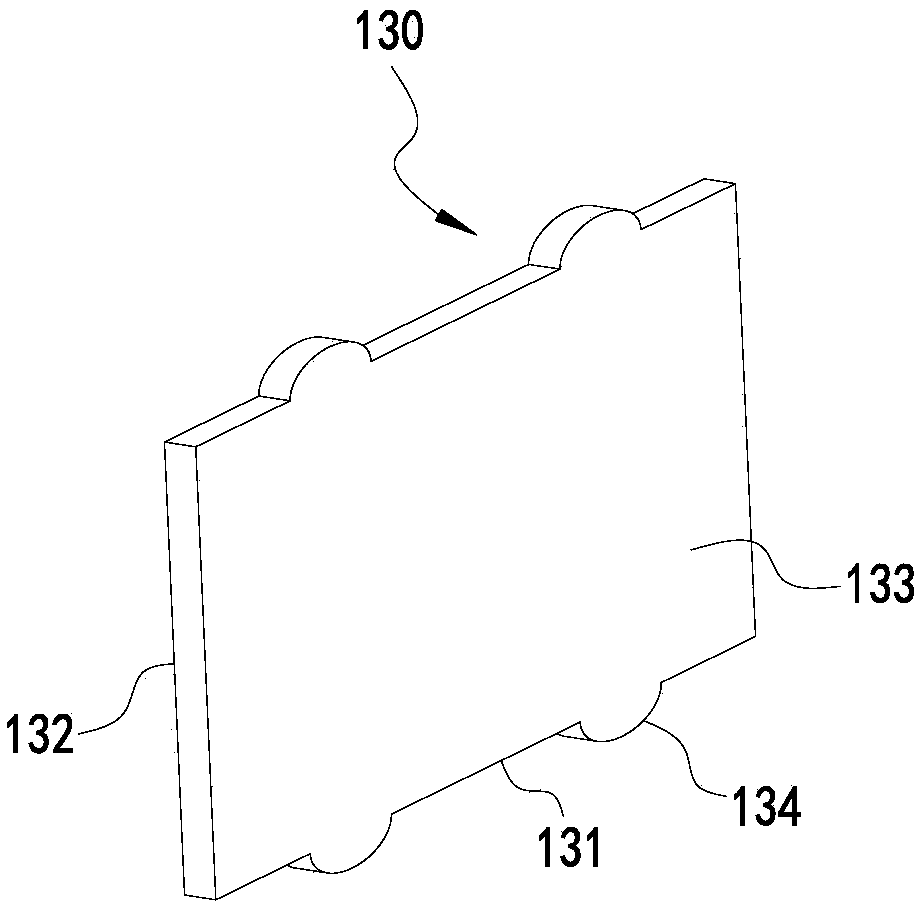

Foldable display device

ActiveCN109461383ABending stabilityEffective stress reliefDigital data processing detailsPin hingesWrinkle skinDisplay device

The invention provides a foldable display device, which comprises a shell; the middle frame comprises a middle frame bending device; a display panel including a panel bending region; the face frame device comprises a face frame provided with an opening, a face frame bending device, a face frame sliding device and a face frame elastic device. When the display panel is in a bending state, the middleframe bending device and the face frame bending device form a first cavity, and the panel bending area is bent into the first cavity; when the display panel is in a non-bending state, the surface frame bending device enables the panel bending area to be in a flattening state by supporting the middle frame bending device. According to the invention, the combined action of the face frame bending device, the face frame sliding device and the face frame elastic device, can effectively release the stress when the foldable display device is in a bending state, thereby the display panel can be smoothly bent and rolled, and avoid wrinkles and fracture damage.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Target welding clamp and target welding method

ActiveCN104551309AAvoid deformationAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to a target welding clamp and a target welding method. The target welding clamp comprises a cover plate and a substrate. The substrate comprises a groove with open upper end; the cover plate covers the groove and a fixing mechanism is arranged between the cover plate and the substrate. In the process of welding a target by using a target welding clamp, a backboard is placed in the groove of the substrate and the welding face of the backboard faces upward, the welding face of a target blank is adhered to the welding face of the backboard, the cover plate covers the groove and presses the target blank, and then a welding process is carried out for forming a target component. According to the technical scheme, the backboard and the target blank can be firmly fixed between the substrate and the cover plate, so that in the welding process, the structures of the backboard and the target blank are retained so as to effectively prevent a sputtering face of the target blank from deformation. Therefore, after welding process, a subsequent leveling treatment process for the target component is not needed, so that the target component is formed in one time, and the target component is prevented from being damaged by the leveling treatment process.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

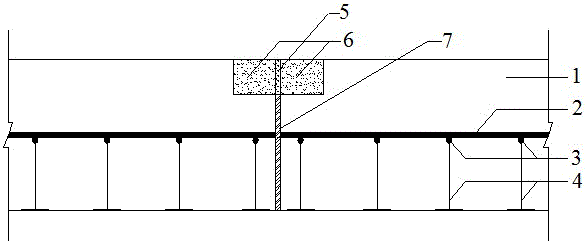

Silicon carbide seed crystal bonding device

InactiveCN103603037AEffective stress reliefPolycrystalline material growthFrom condensed vaporsOptoelectronicsGraphite

The invention provides a silicon carbide seed crystal bonding device comprising a graphite cover and a seed crystal bonding plate, wherein a seed crystal is bonded together with the seed crystal bonding plate, the graphite cover is fixedly connected with the seed crystal bonding plate, and the thickness of the seed crystal bonding plate is smaller than or equal to 2mm. According to the invention, the original seed crystal bonding graphite plate is divided into two parts, the seed crystal is bonded by using the seed crystal bonding plate with smaller thickness, and after the crystal growth is finished and the temperature is reduced, the seed crystal bonding plate is thinner and can deform, so that the stress in the crystal can be effectively released, and the breakage rate of the crystal and a wafer can be reduced.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

Method for improving drop of tube cores in GaAs-based LED chip cutting process

ActiveCN107068820AEffective stress reliefReduce deformation tensionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringElectrical and Electronics engineering

The invention relates to a method for improving drop of tube cores in a GaAs-based LED chip cutting process. The method comprises the steps of: (a), semi-cutting the surface of an LED chip by utilizing a saw blade; (b), baking the semi-cut LED chip; (c), performing blue film lamination of the baked LED chip; (d), performing secondary baking of the blue film laminated LED chip; (e), fully cutting the secondarily baked LED chip; and (f), performing film expansion after cleaning the fully cut LED chip. With the help of a heater, the chip is baked before being laminated; the stress of the chip itself can be effectively released; the deformation tension of the chip itself can be reduced; simultaneously, the laminated chip together with a blue film is baked; therefore, the malleability of the blue film is improved; therefore, the film is thoroughly expanded; the viscidity of the blue film is improved; the method for effectively improving drop of the tube cores in the GaAs-based LED chip cutting process is simple to work and high in effectiveness; the drop problem of the tube cores can be effectively solved; and thus, the product throughput can be increased.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

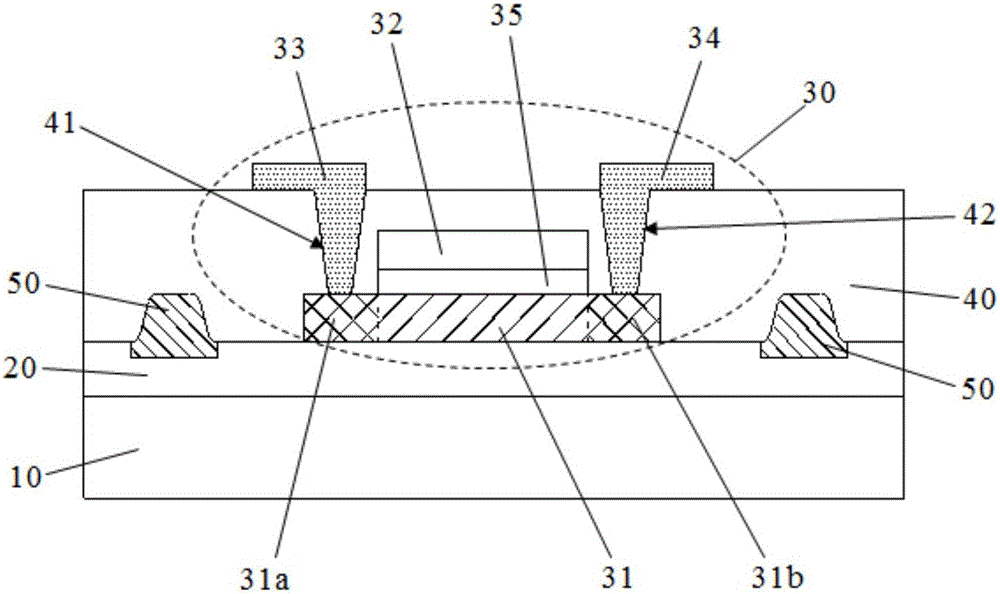

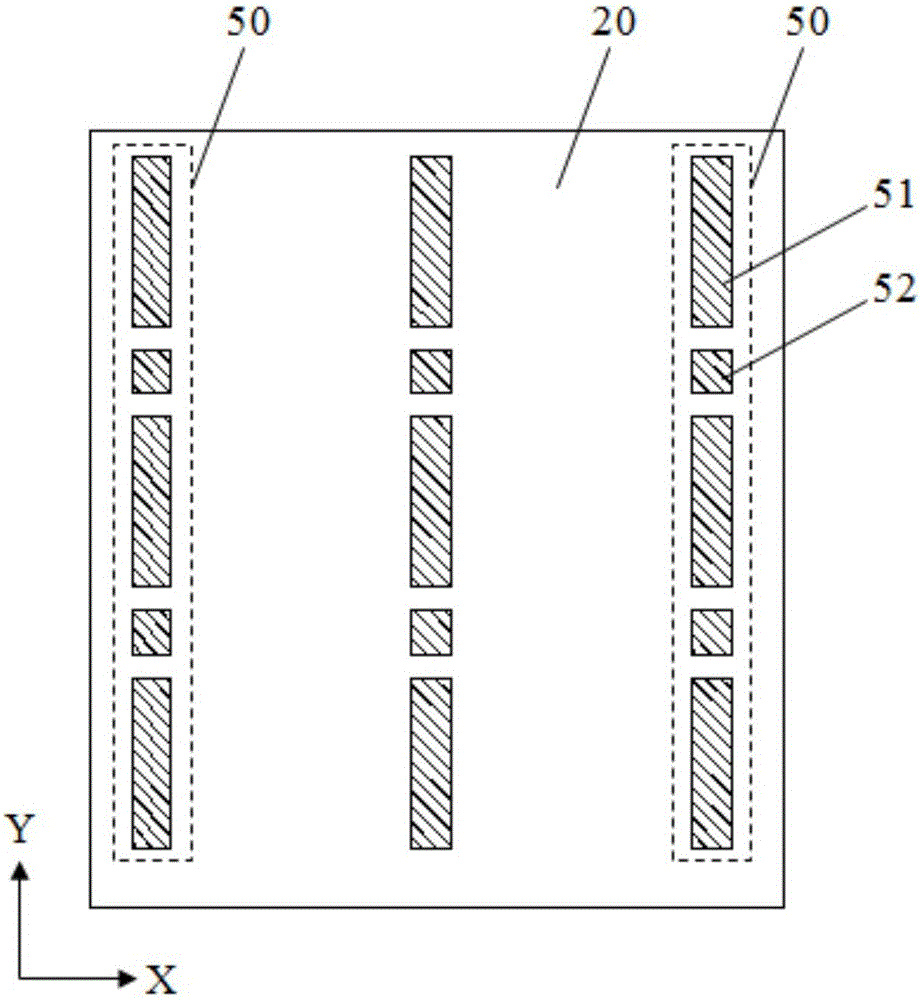

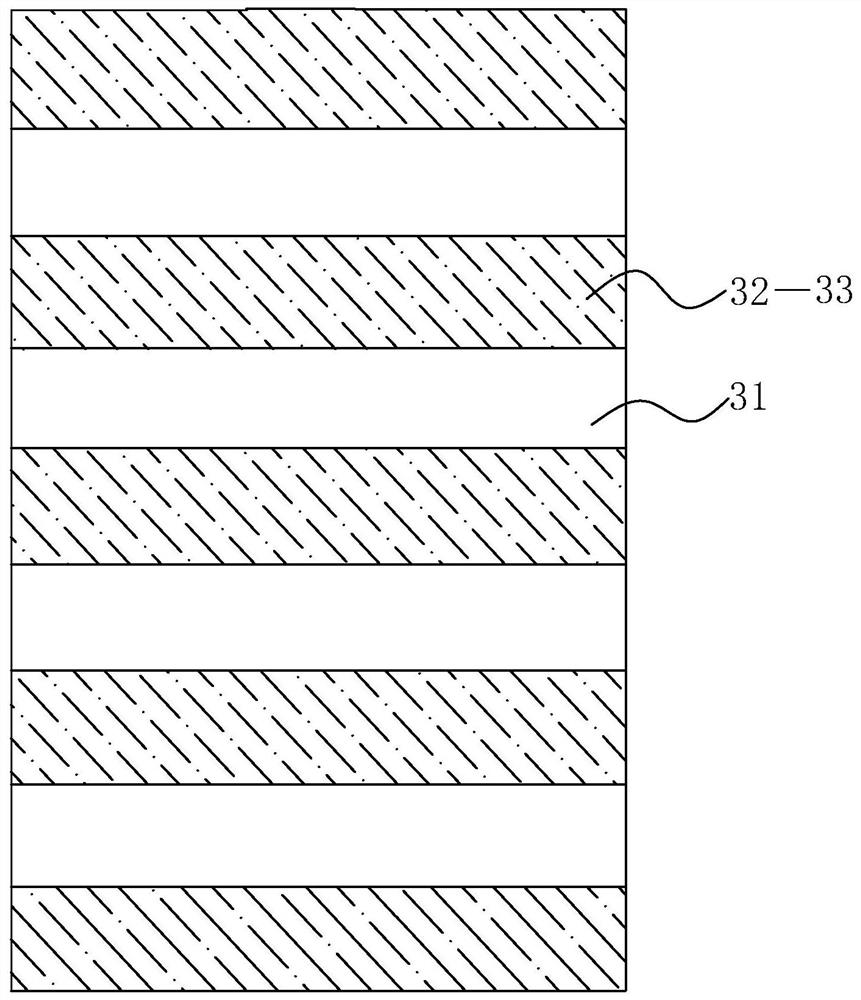

Flexible array substrate and preparation method thereof, and flexible display device

ActiveCN106169481AImprove qualityGood flexibilityFinal product manufactureSolid-state devicesDielectricInter layer

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

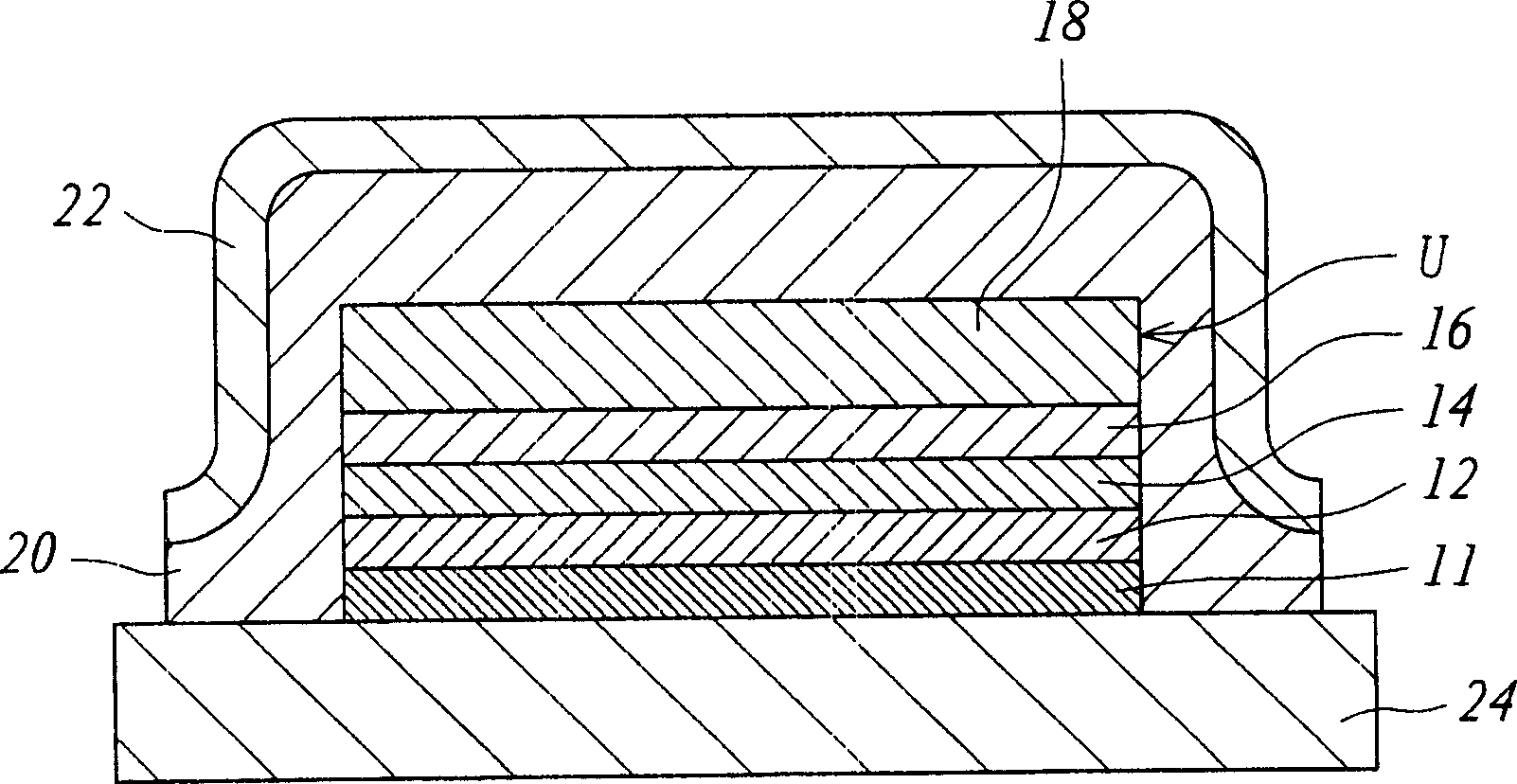

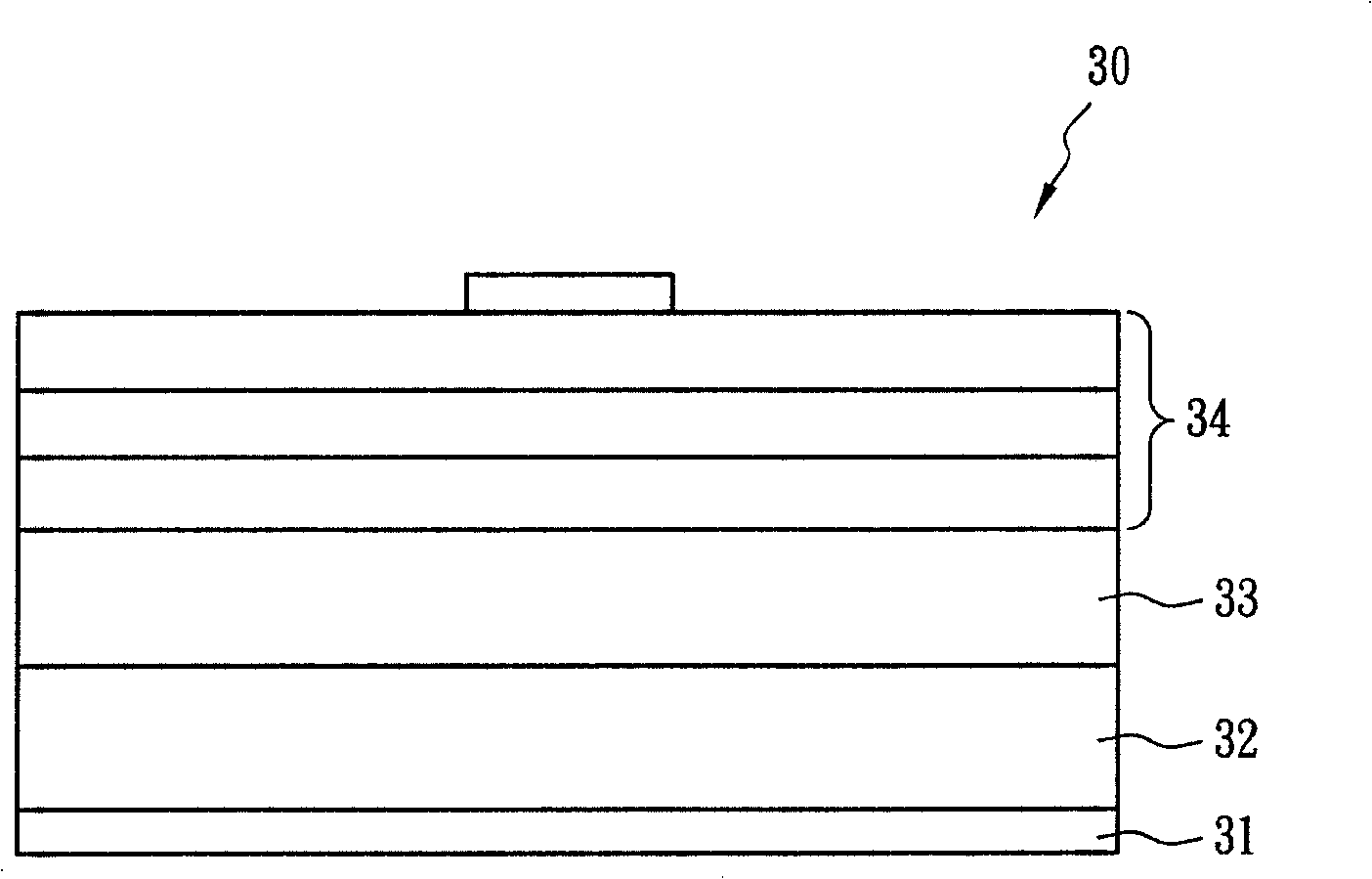

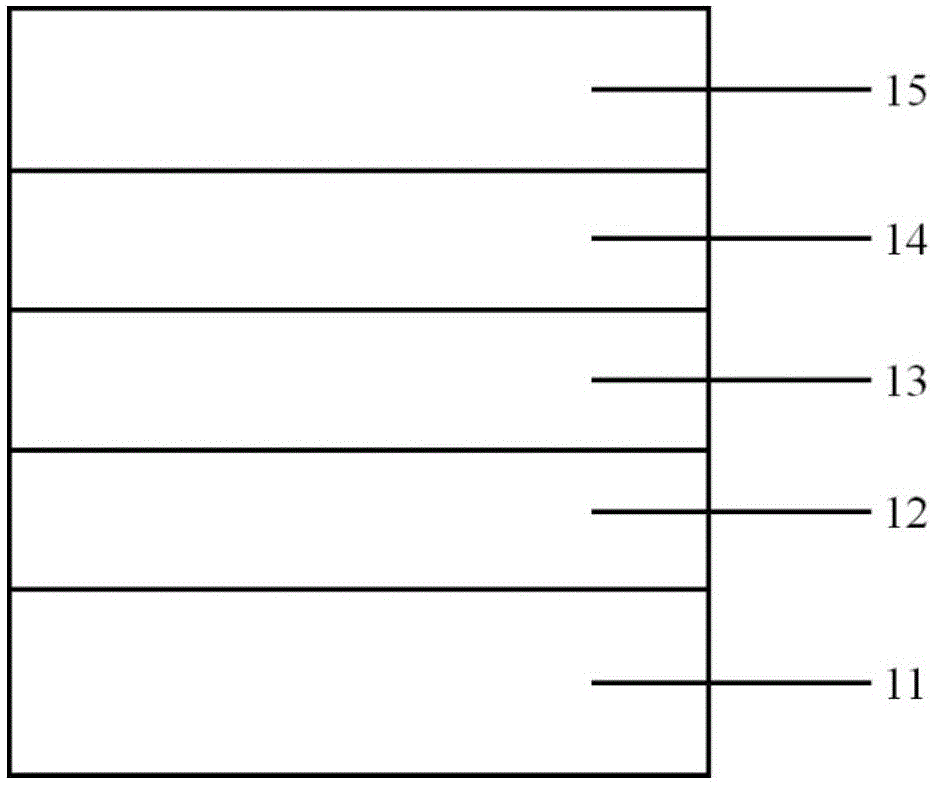

Photoelectrical semiconductor component with 3-familty Ni compound semiconductor buffer layer and its making method

InactiveCN101267008AEffective stress reliefAvoid crackingSemiconductor devicesNitrogenCompound semiconductor

A photoelectric semiconductor component with three families nitrogen compound semiconductor buffer layers is provided, which comprises a substrate, and at least two InGa<1-x>N layers and at least two InGa<1-y>N layers which superimposes on the substrate alternately, wherein the x not equals to the y. A luminescent epitaxial structure is located on the surface of the InGa<1-y>N layer which is at the upper layer. A superlattice buffer layer is formed by the InGa<1-x>N layer which is between the substrate and the luminescent epitaxial structure and the InGa<1-y>N layer to reduce stress.

Owner:ZHANJING TECH SHENZHEN +1

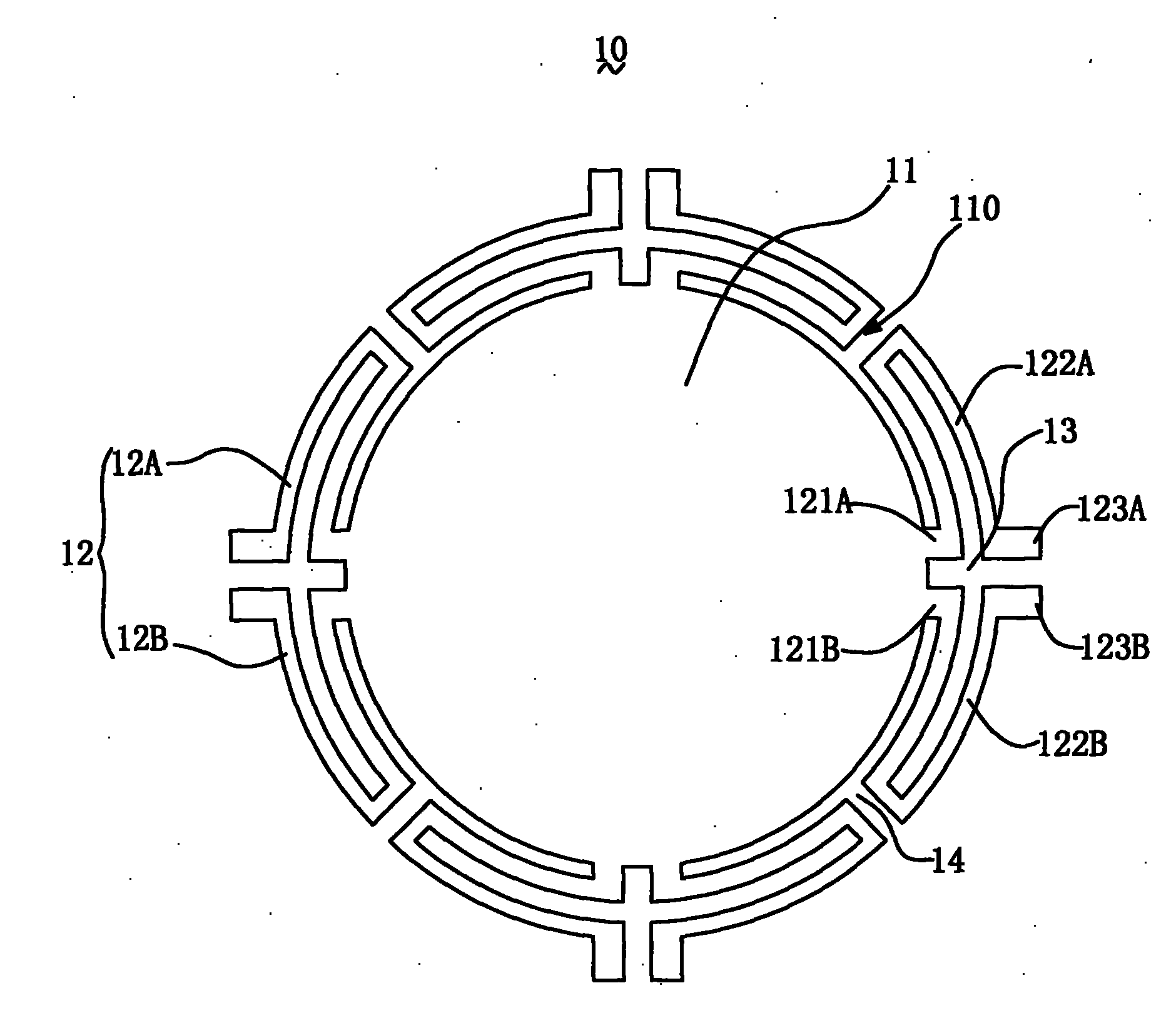

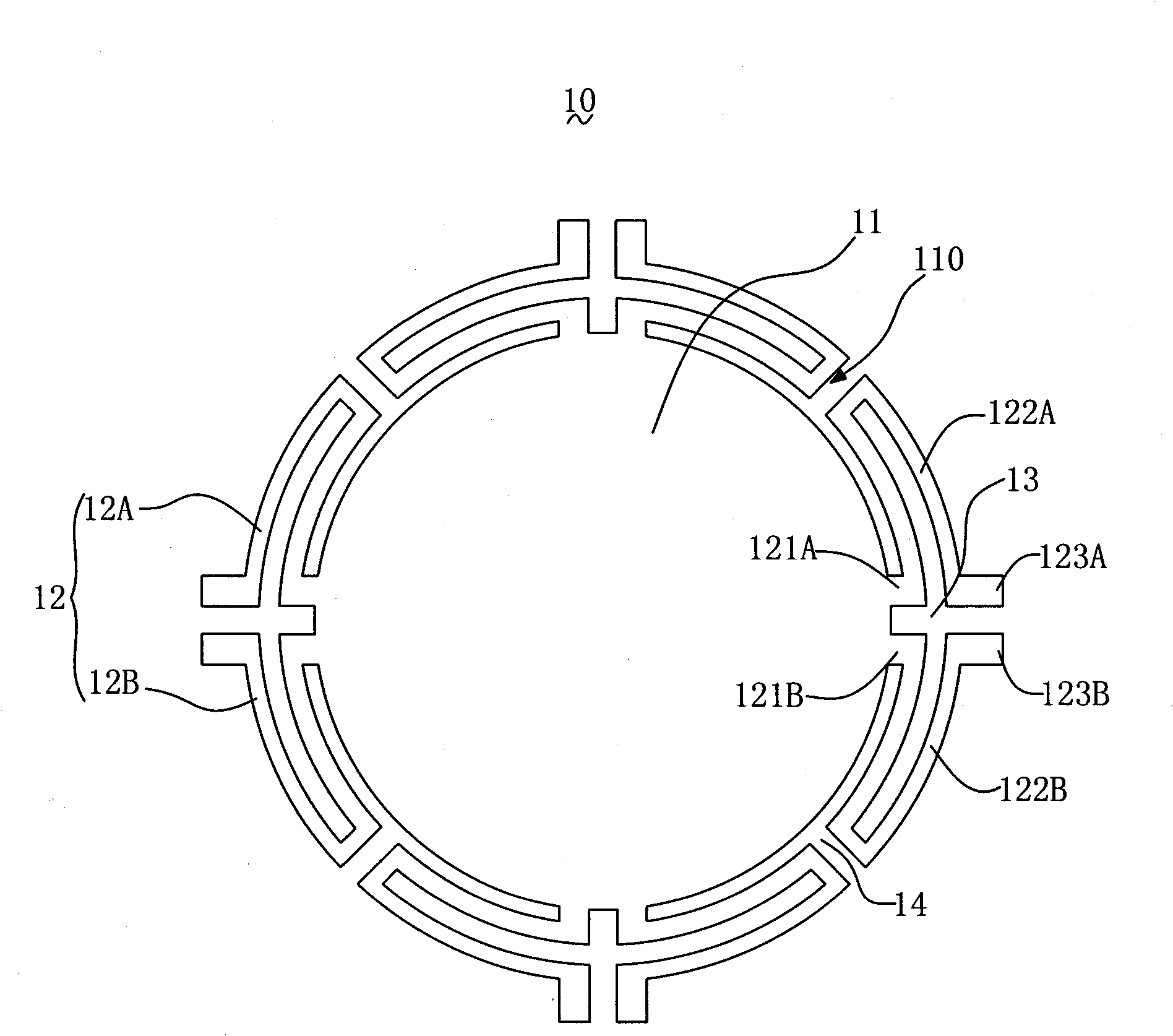

Capacitor MEMS (Micro-Electro-Mechanical System) microphone diaphragm

InactiveCN101883307AImprove stabilityPrevent plane twistingMicrophonesLoudspeakersCapacitanceMems microphone

The invention relates to the field of microphones, in particular to a capacitor MEMS (Micro-Electro-Mechanical System) microphone diaphragm with sensitivity applied on electronic equipment. The capacitor MEMS microphone diaphragm comprises a diaphragm unit forming a capacitor system together with a backboard, wherein the diaphragm unit comprises an inner diaphragm piece suspended in a center position and an outer diaphragm piece, wherein the outer diaphragm piece comprises at least four pairs of uniformly distributed annular bending beams formed by outwards deviating and extending the edge of the inner diaphragm piece to reduce the restriction of an insulating layer to the edge part at the peripheral side of the diaphragm unit, thereby effectively improving the sensitivity. Meanwhile, the diaphragm unit can prevent plane torsion when the diaphragm unit shakes and effectively release the stress, thereby further improving the stability of the microphone property.

Owner:AAC TECH PTE LTD +1

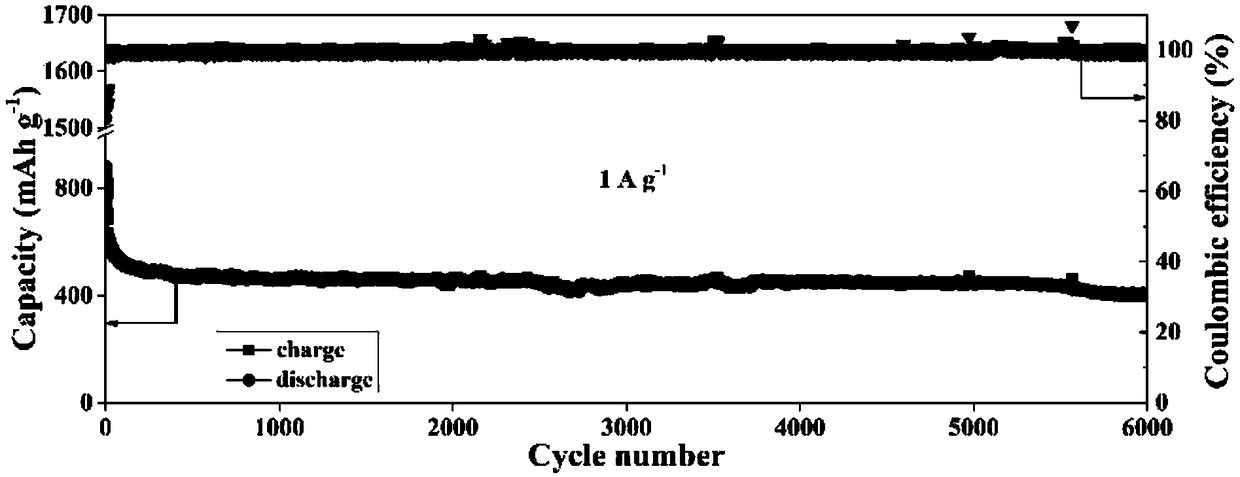

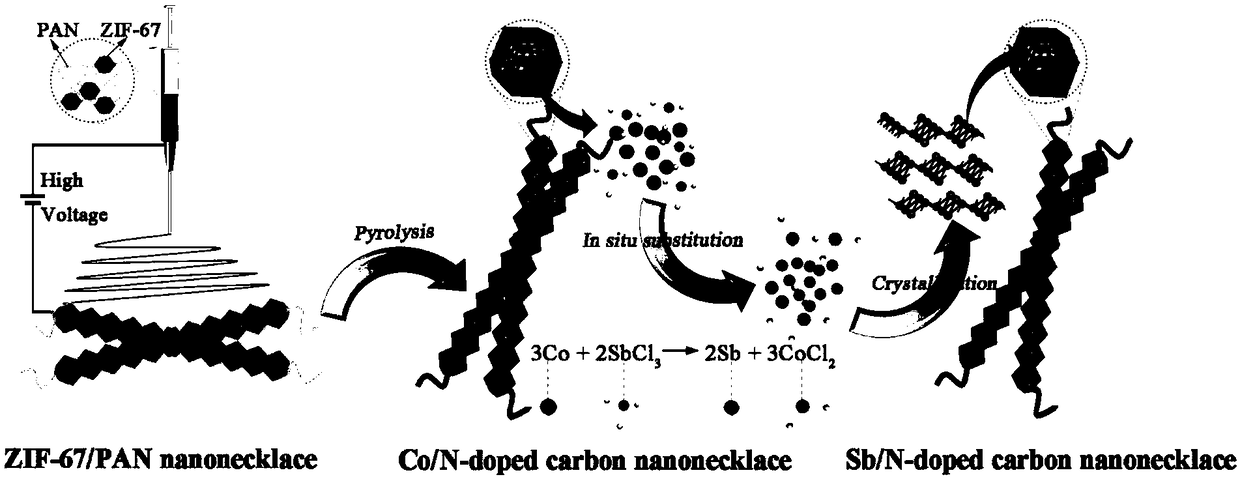

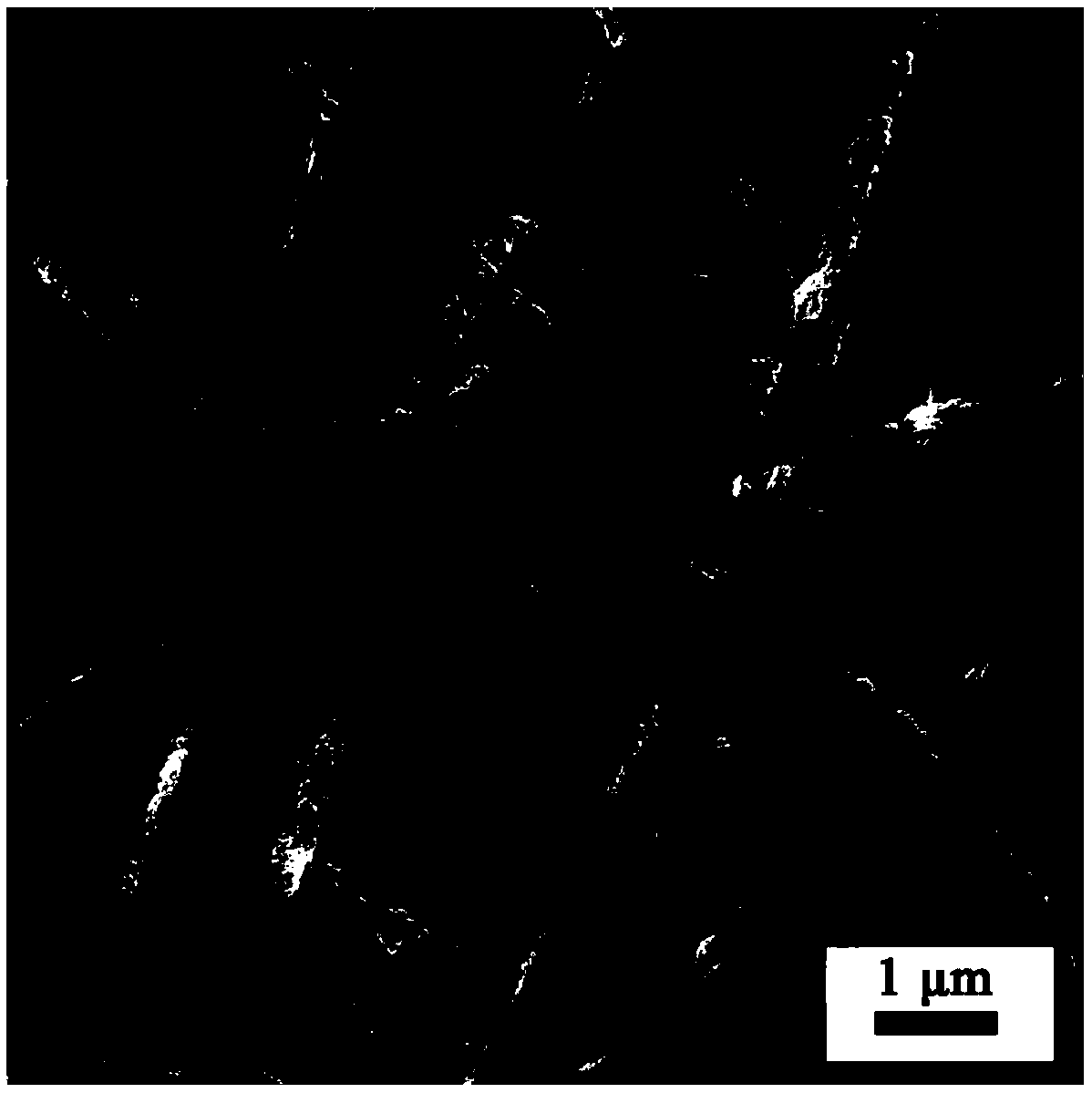

Preparation method and application of antimony nanoparticle/nitrogen-doped carbon nano necklace composite material (Sb/N-CNN)

InactiveCN109473655AImprove conductivityLarge specific surface areaCell electrodesSecondary cellsSodium-ion batteryCobalt

The invention relates to a preparation method of an antimony nanoparticle / nitrogen-doped carbon nano necklace composite material (Sb / N-CNN), and an application thereof serving as a negative electrodematerial of a sodium ion battery. The preparation steps of the composite material are as follows: a, preparing ZIF-67; b, preparing a ZIF-67 / PAN- nano chain by electrospinning of ZIF-67 and polyacrylonitrile (PAN); c, annealing the ZIF-67 / PAN- nano chain in a 5% H2 / Ar atmosphere to obtain a cobalt / nitrogen-doped carbon nano necklace (Co / N-CNN); d, performing a replacement reaction on the preparedCo / N-CNN and SbCl3 in a hydrothermal environment, and then performing annealing in an Ar atmosphere to obtain a Sb / N-CNN composite material. Serving as the negative electrode material of the sodium ion battery, the Sb / N-CNN has a capacity of 579 mAh g-1 after being circulated for 100 circles at the current density of 0.1 A g-1, the Sb / N-CNN has a capacity of 401 mAh g-1 after being circulated for6000 circles at the current density of 1 A g-1, and the Sb / N-CNN has a capacity of 314 mAh g-1 at the current density of 20 A g-1. The invention provides a new idea for the development of electrode materials of high-performance sodium ion batteries.

Owner:JILIN UNIV

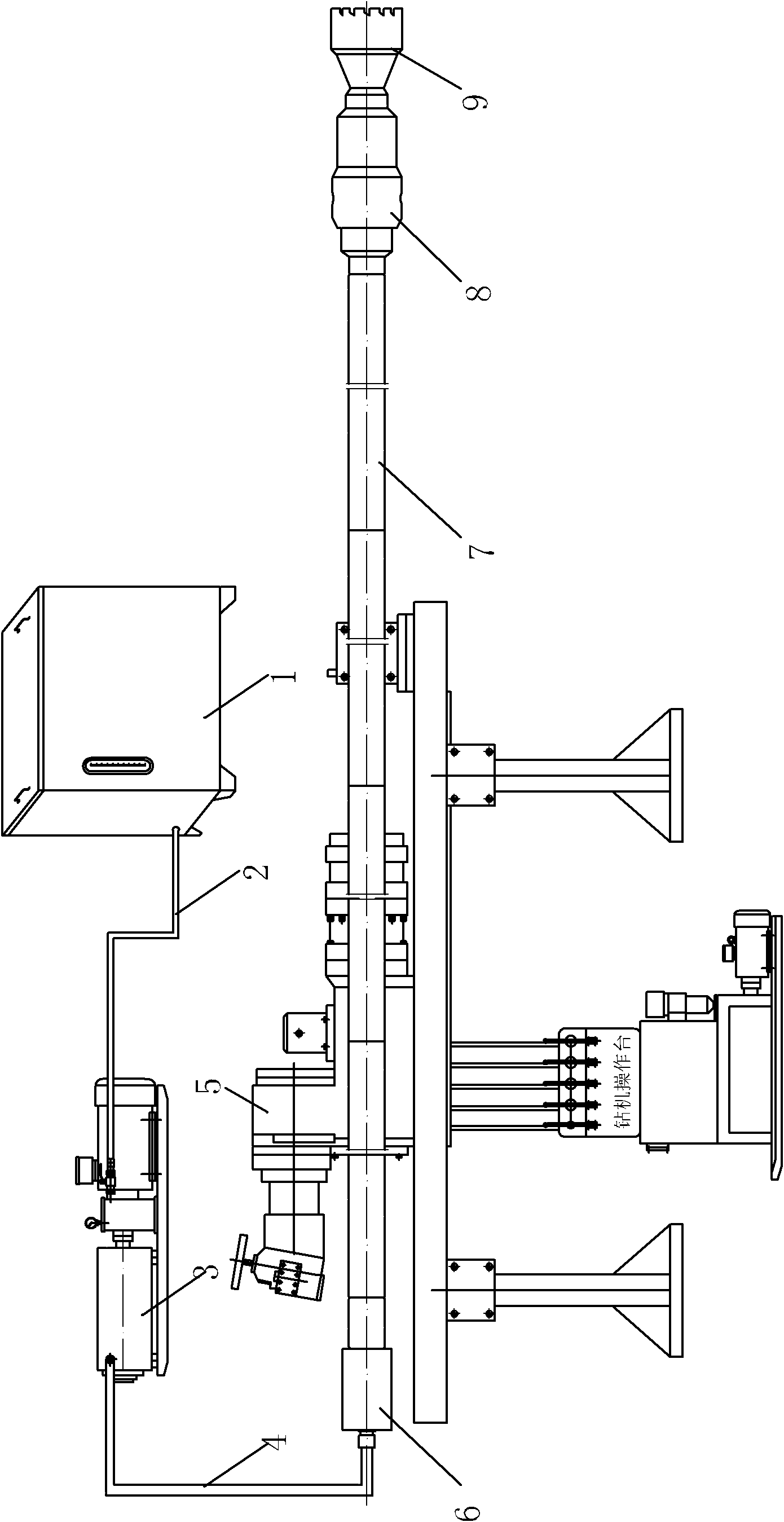

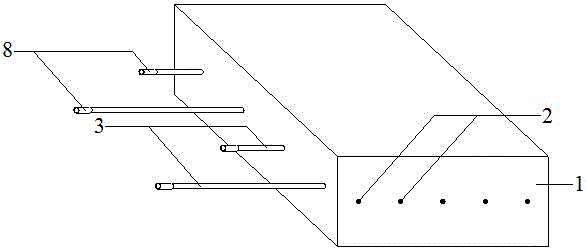

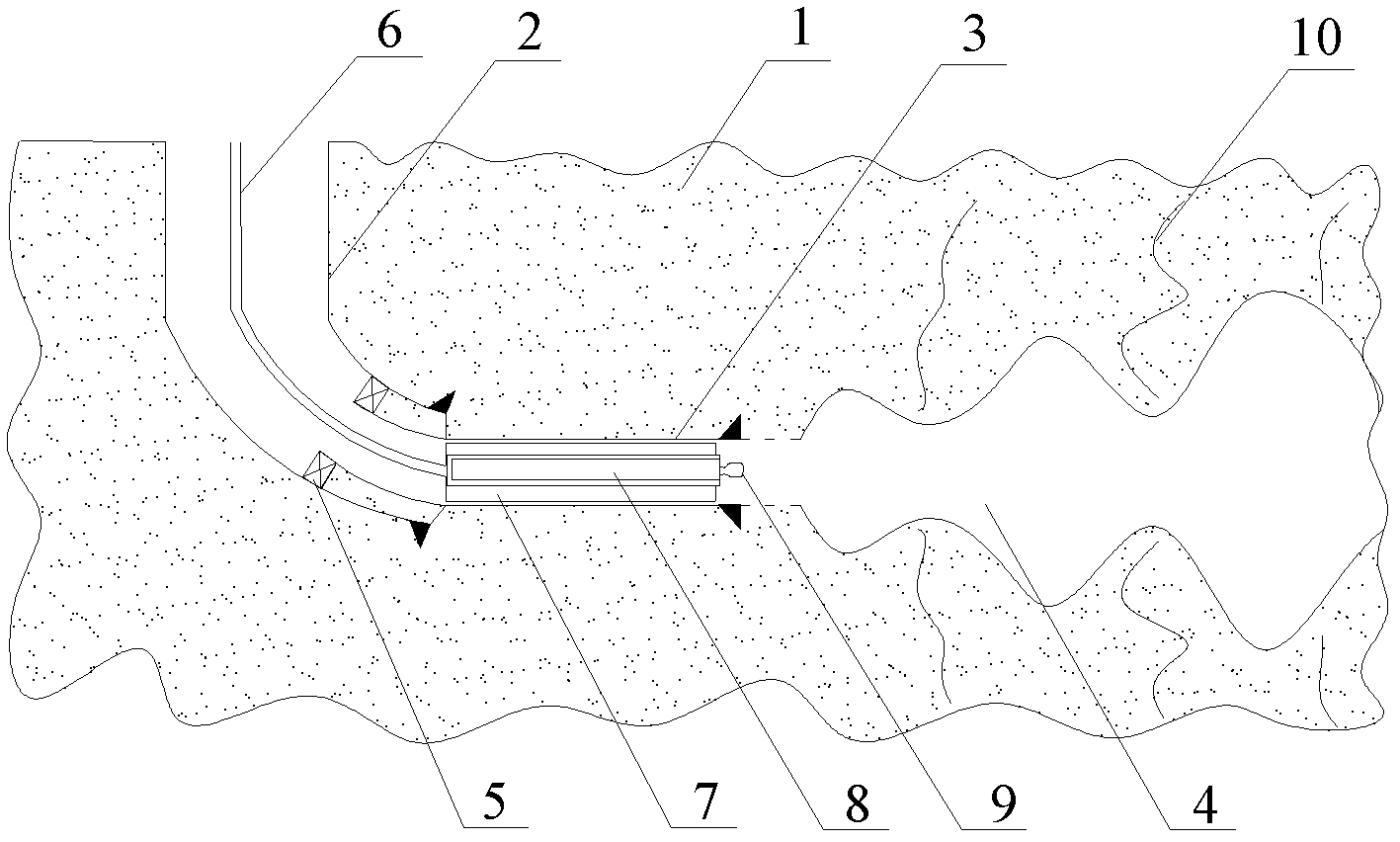

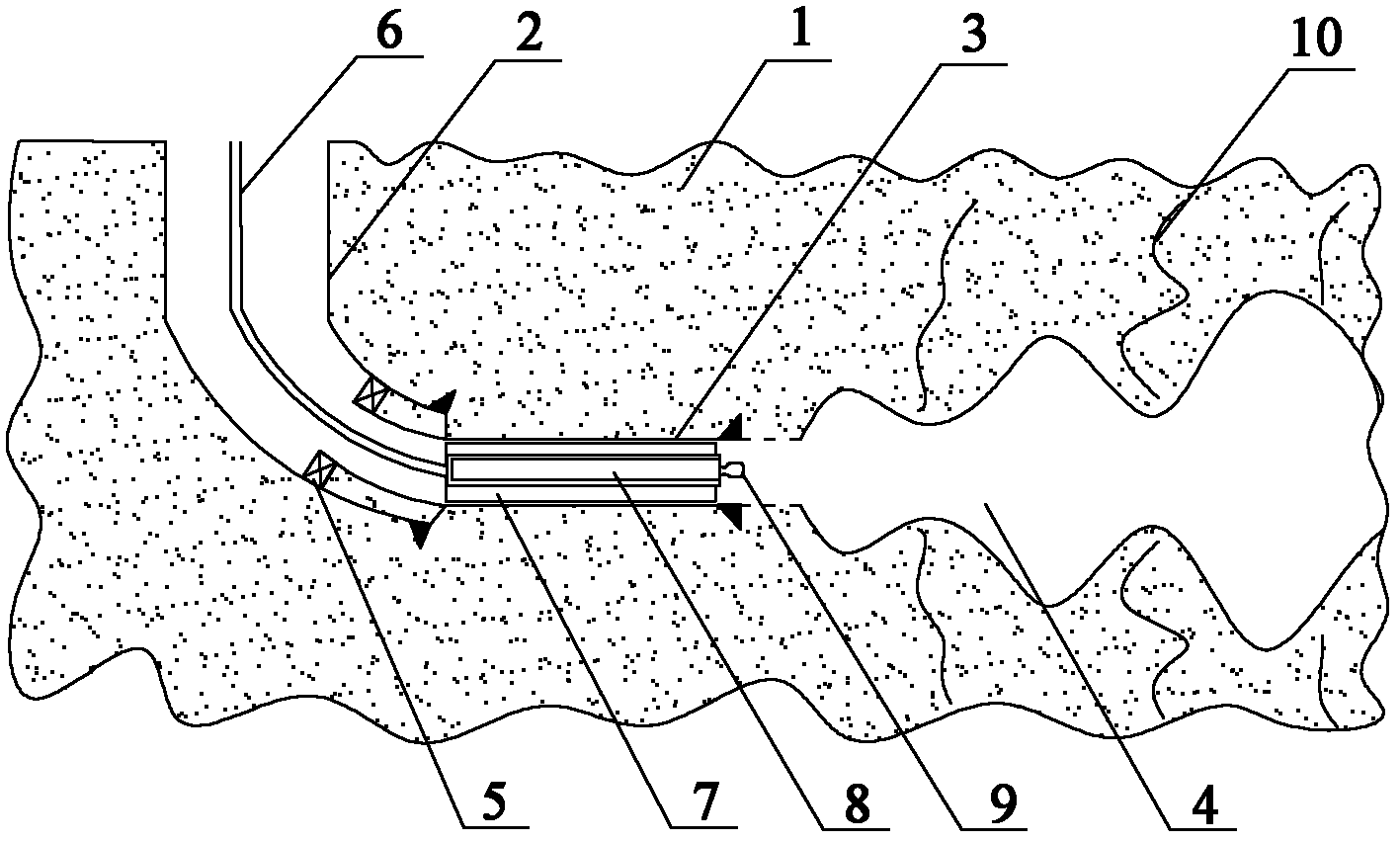

Drilling-cutting-linked coal layer gas drainage and outburst prevention system and method based on ultra-long drilling and high-pressure water jetting

InactiveCN102465712AIncrease the exposed areaExpand the scope of the releaseOperating means/releasing devices for valvesMultiple way valvesPressure senseHigh pressure water

The invention discloses a drilling-cutting-linked coal layer gas drainage and outburst prevention system and method based on ultra-long drilling and high-pressure water jetting. The system comprises a drill bit, a pressure sensing valve, a drill stem, a drill machine, a high / low-pressure water delivery and rotation device, a high-pressure pump and a water tank, wherein the pressure sensing valve is mounted at the front end of the drill stem; the drill bit is mounted at the front end of the pressure sensing valve; a nozzle is mounted at the outer side of the pressure sensing valve; the drill machine drives the drill stem to rotate; and water in the water tank is delivered to the high / low-pressure water delivery and rotation device through the high-pressure pump, input to the drill stem through the high / low-pressure water delivery and rotation device and delivered to the pressure sensing valve through the drill stem. In the drill withdrawing process, the coal layer is cut by the high-pressure water, thereby realizing the drilling-cutting linkage and improving the working efficiency. The invention is simple and delicate in structure; and by using the invention, the cutting diameter can be up to 3 meters or above, thereby increasing the gas exposure area to more than 6 times of the traditional gas exposure area and effectively widening the gas release range by more than 3 times. Thus, the invention solves the drainage and outburst prevention problems of coal mine gas.

Owner:湖南汉寿中煤科技有限公司

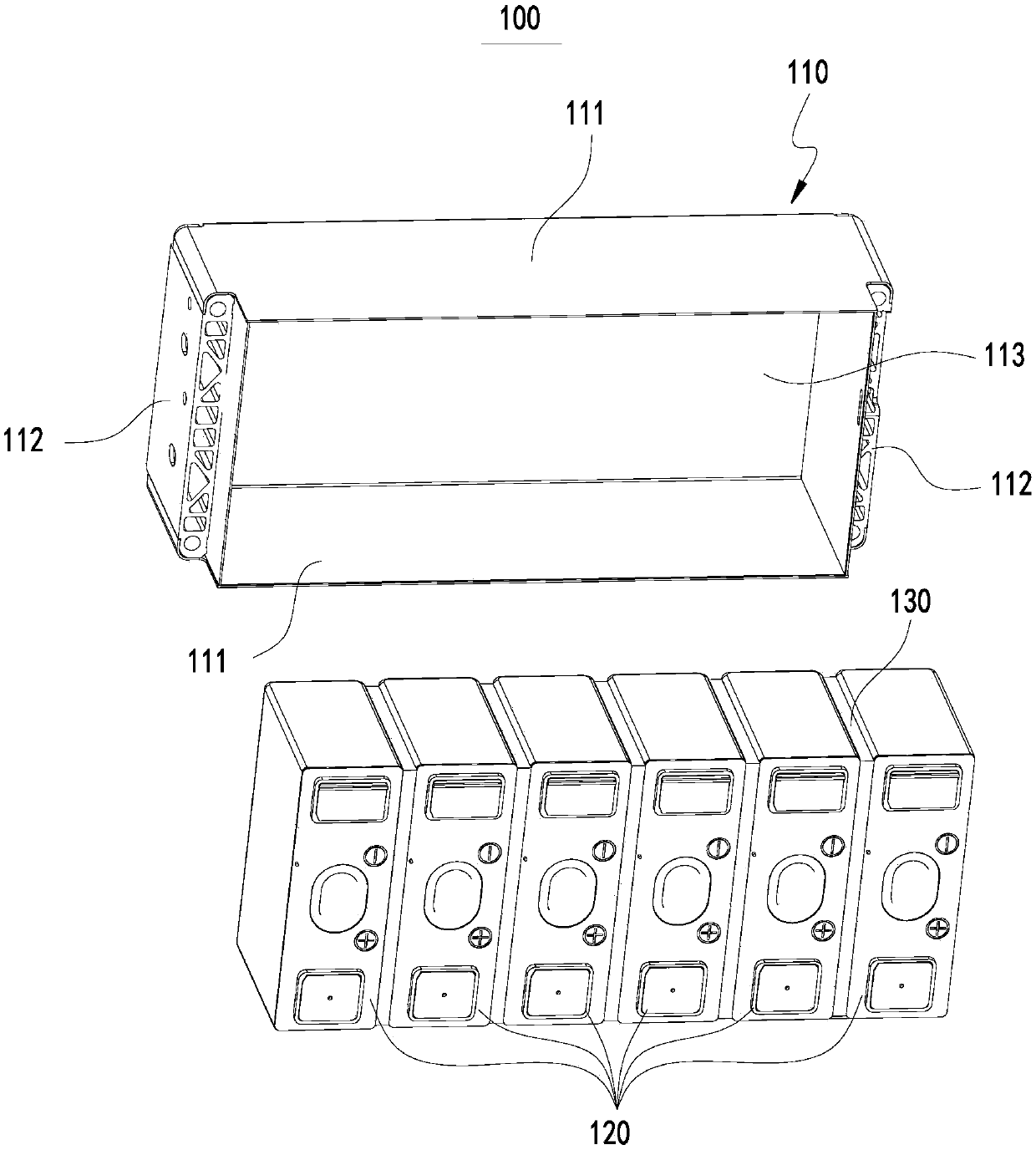

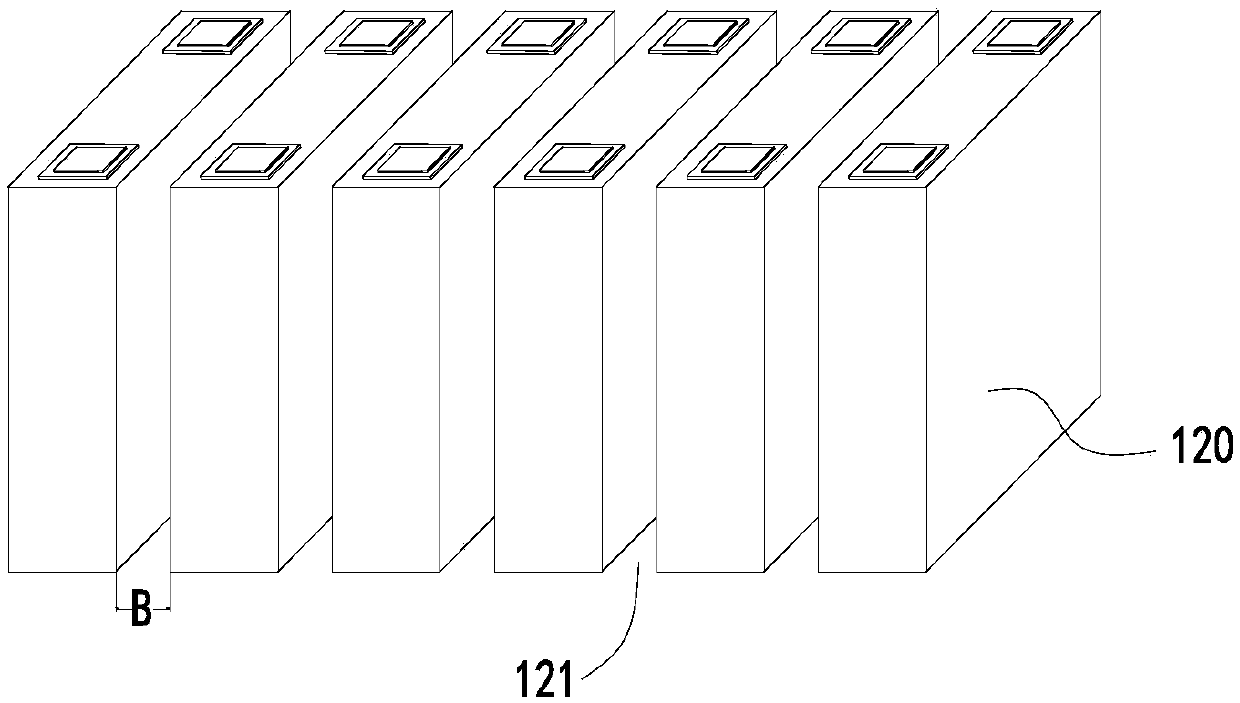

Battery module

ActiveCN110265591APromote circulationCompressibleFinal product manufactureSecondary cellsEngineeringCompressibility

The invention discloses a battery module and belongs to the technical field of energy storage. The battery module includes: a frame having a receiving space; a plurality of battery units which are successively arranged in the receiving space of the frame along the thickness direction of the battery units, wherein separating plates are disposed between adjacent battery units and have compressibility, and a compression ratio [delta]1 of the separating plates at a pressure less than or equal to 2MPa satisfies a condition of C0*[delta]1 <= A0*0.2, wherein C0 is the initial thickness of the separating plates, and A0 is the initial thickness of the battery units. The battery module provided by the invention has excellent cycle performance.

Owner:CONTEMPORARY AMPEREX TECH CO

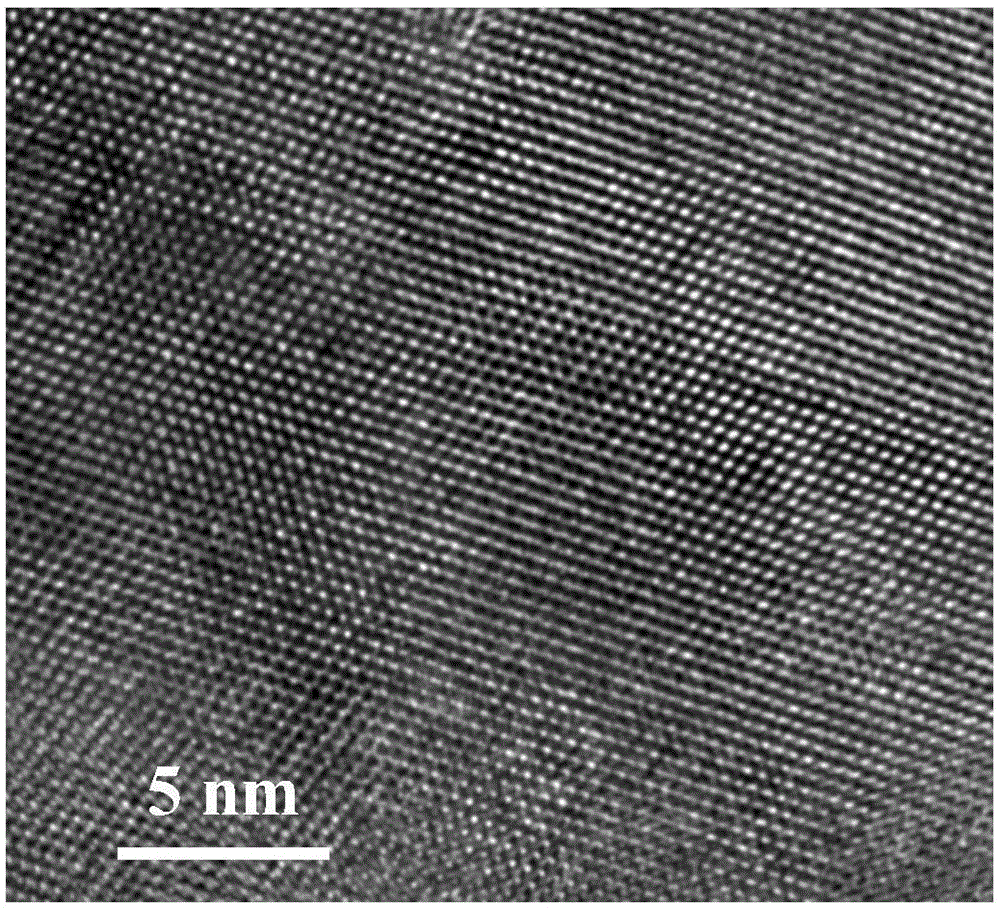

GaAs film growing on Si substrate and preparation method thereof

ActiveCN105023962AChanging the Surface Reconstruction ProcessInhibition formationPolycrystalline material growthSemiconductor/solid-state device manufacturingSolar cellSemiconductor

The invention discloses a preparation method of a GaAs film growing on a Si substrate. The method comprises the following steps: (1) cleaning the Si substrate (111); (2) pretreating the Si substrate (111); (3) deoxidizing the Si substrate (111); (4) growing a first In<x>Ga<1-x>As buffer layer; (5) annealing the first In<x>Ga<1-x>As buffer layer on situ; (6) growing a GaAs buffer layer; (7) annealing the GaAs buffer layer in situ; (8) growing a second In<x>Ga<1-x>As buffer layer; (9) annealing the second In<x>Ga<1-x>As buffer layer; and (10) growing a GaAs epitaxial film. The invention also discloses the GaAs film growing on the Si substrate. The obtained GaAs film is good in crystal quality and flat in surface, and has positive promoting significance to the preparation of semiconductors and the field of solar cells.

Owner:SOUTH CHINA UNIV OF TECH

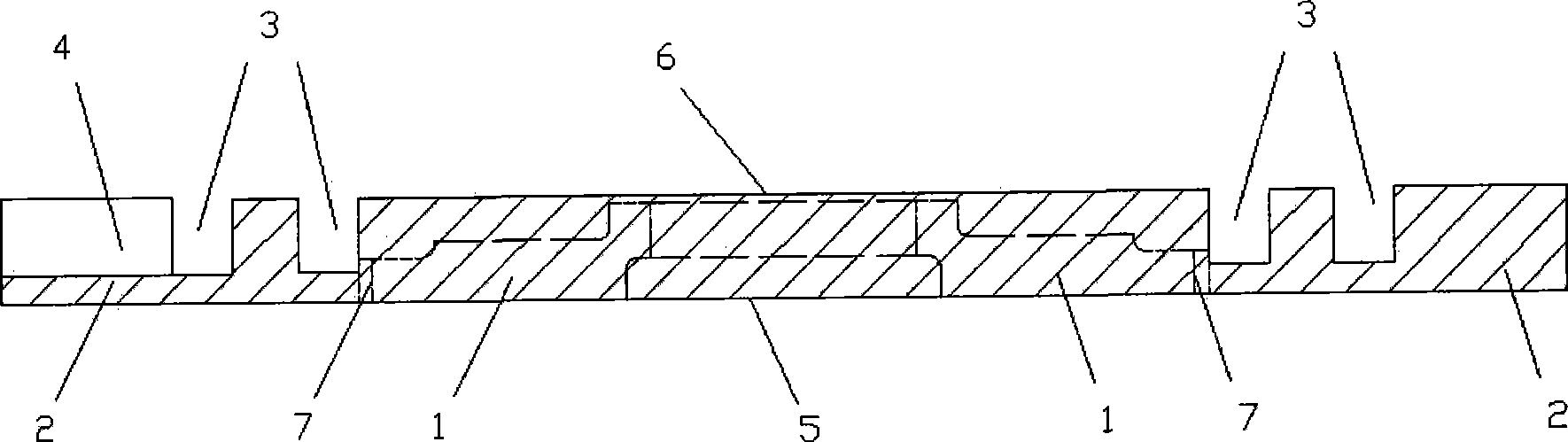

Control method for numerical control machining deformation of wall panel parts

ActiveCN101412188AEffective stress reliefRelease stress deformationPositioning apparatusMetal-working holdersNumerical controlMachining deformation

The invention relates to a processing method for providing stress grooves at outside outline of the periphery of a large-sized wall plate part. The method effectively releases stress deformation generated by a wall plate material in a numerical control machining process, and achieves the aim of controlling processing deformation of the wall plate part.

Owner:XIAN AIRCRAFT IND GROUP

Joints and construction method suitable for continuous reinforced concrete pavement structure

ActiveCN105714642AExtended service lifeImprove driving comfort and safetyPaving detailsRebarTransverse reinforcement

The invention discloses joints and a construction method suitable for the continuous reinforced concrete pavement structure. The joints include the transverse joints, the pre-cutting joints traversing well lids and the longitudinal construction joints. One transverse joint is arranged every 150 m, the width of the transverse joints ranges from 1.0 cm to 1.5 cm, and each transverse joint is divided into an upper part and a lower part, wherein the depth of the upper part of the transverse joint ranges from 5.0 cm to 8.0 cm, is filled with silicone adhesive, epoxy mortar is poured at the portions, within 8-15 cm, of the two sides of the upper part of the transverse joint, the lower part of the transverse joint is filled with a polyethylene blind-hole foam joint filling plate, and longitudinal reinforcing steel bars transversely penetrate through the joint filling plate. The depth of the pre-cutting joints traversing the well lids ranges from 3 cm to 4 cm, the width ranges from 3 mm to 5 mm, and the pre-cutting joints are filled with silicone adhesive. Transverse reinforcing steel bars at the longitudinal construction joints are connected with direct thread sleeves, and the reservation length of the transverse reinforcing steel bars is 60 cm and 20 cm. By means of the joints, the problem in the arrangement of joint of a continuous reinforced concrete pavement can be solved, and the traffic safety and comfort are improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

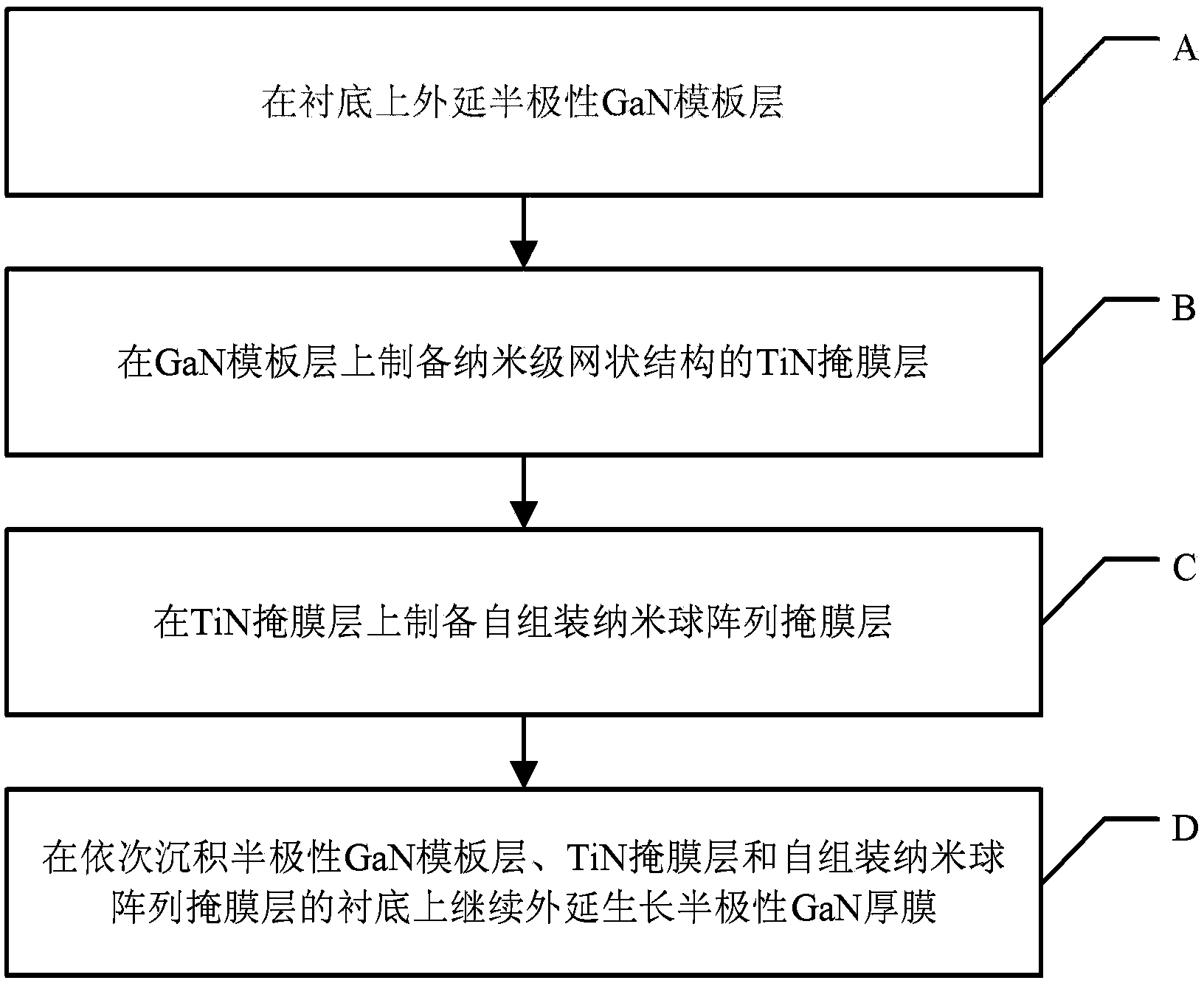

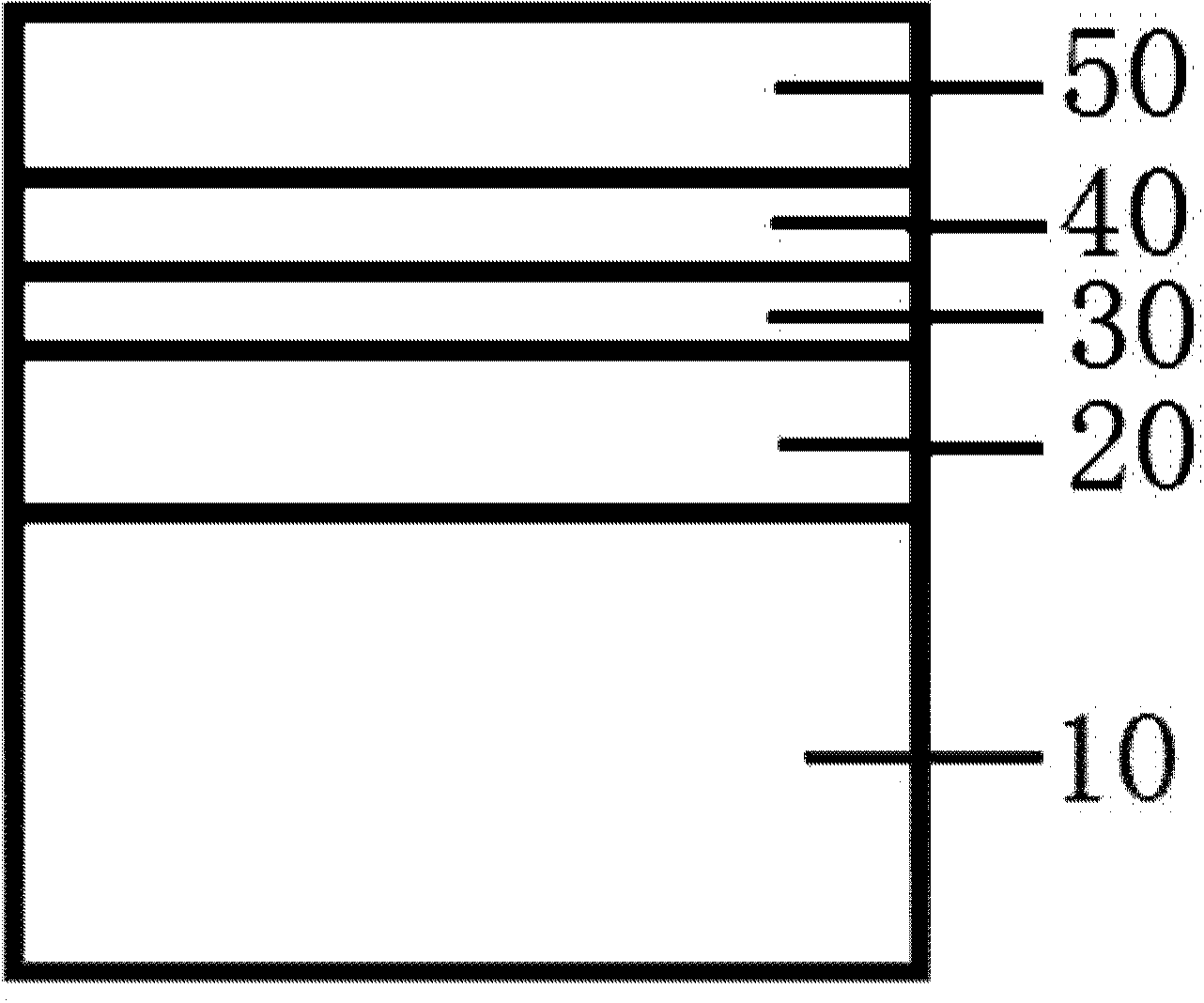

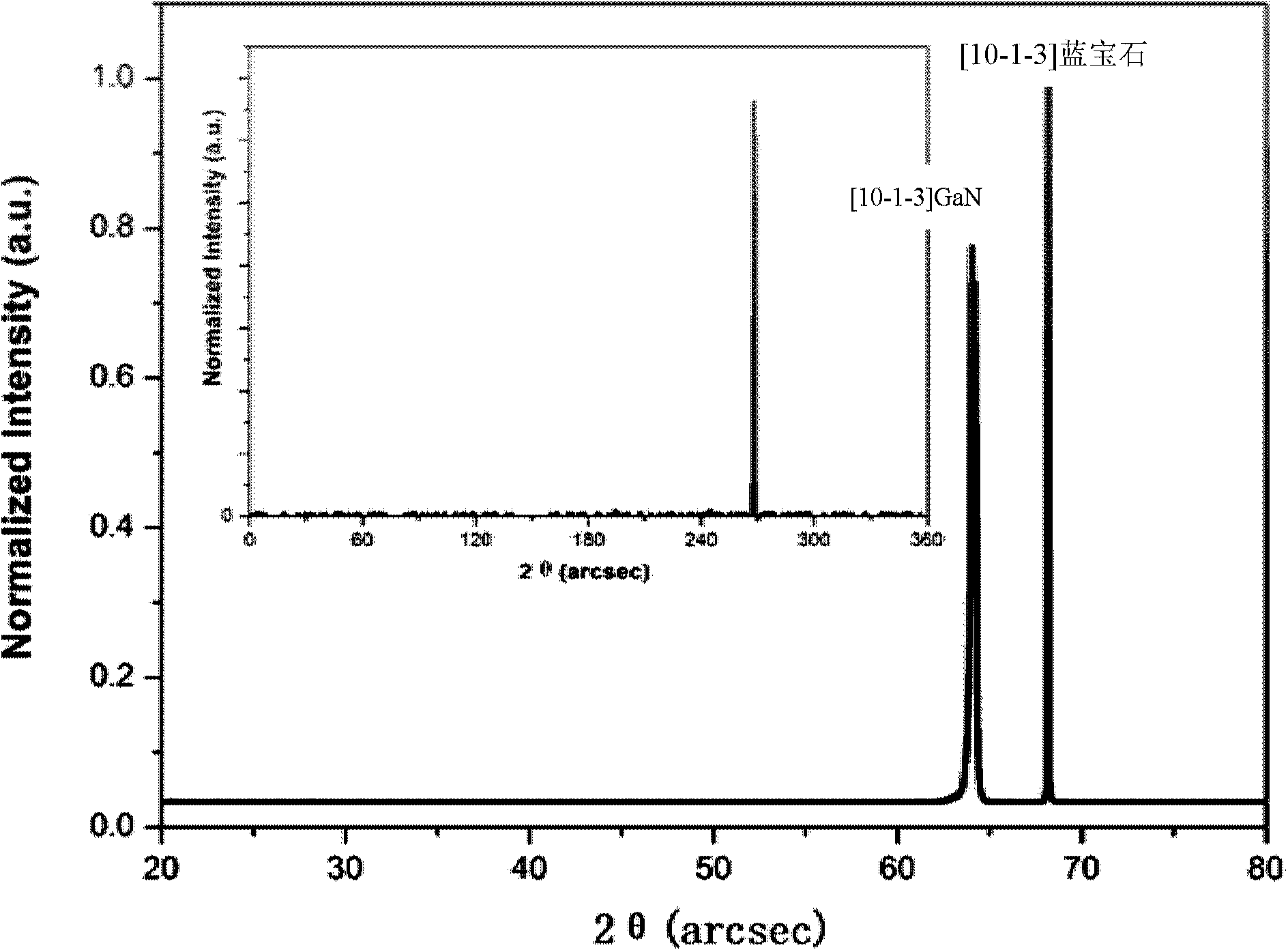

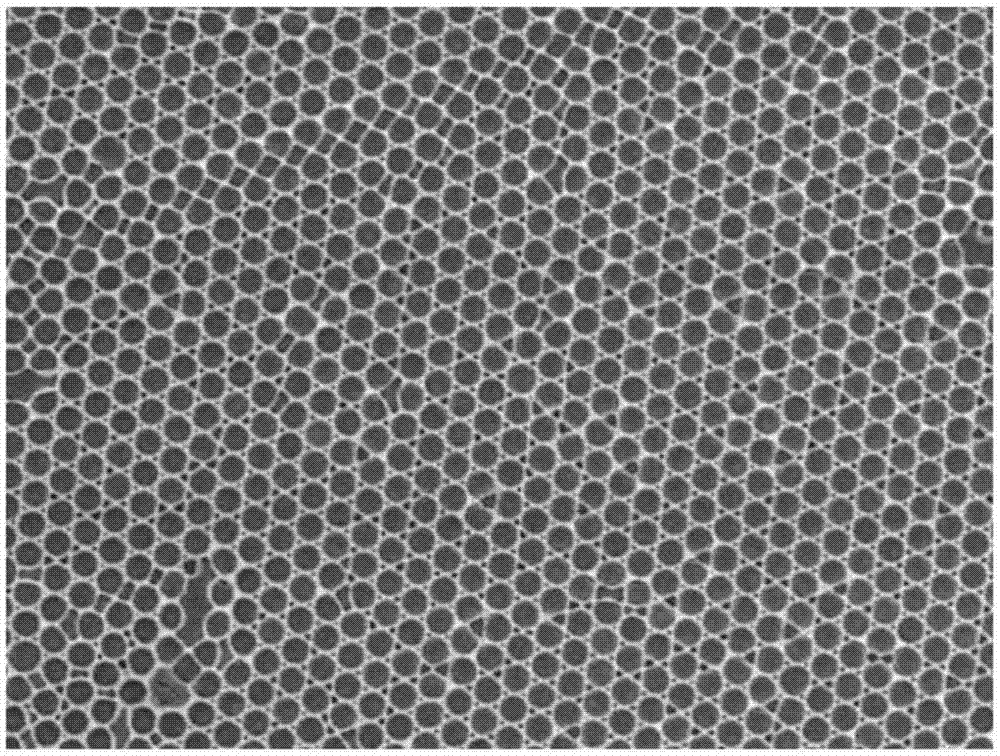

Method for growing semi-polarity GaN (gallium nitride) thick film

ActiveCN103647008AReduce dislocationEffective stress reliefSemiconductor devicesTitanium nitrideGallium nitride

The invention provides a method for growing a semi-polarity GaN (gallium nitride) thick film. The method comprises the following steps of step A, extending a substrate to form a semi-polarity GaN template layer; step B, preparing a TiN (titanium nitride) mask layer with a nano-grade net structure on the GaN template layer; step C, preparing a self-assembling nano-spherical mask layer on the TiN mask layer; and step D, continuing to extend the substrate, which is sequentially deposited with the semi-polarity GaN template layer, the TiN mask layer and the self-assembling nano-spherical mask layer, to form the semi-polarity GaN thick film. By adopting the method, the stress in the semi-polarity GaN thick film can be effectively released, and the heteroepitaxy of the high-quality and large-area semi-polarity GaN thick film is realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

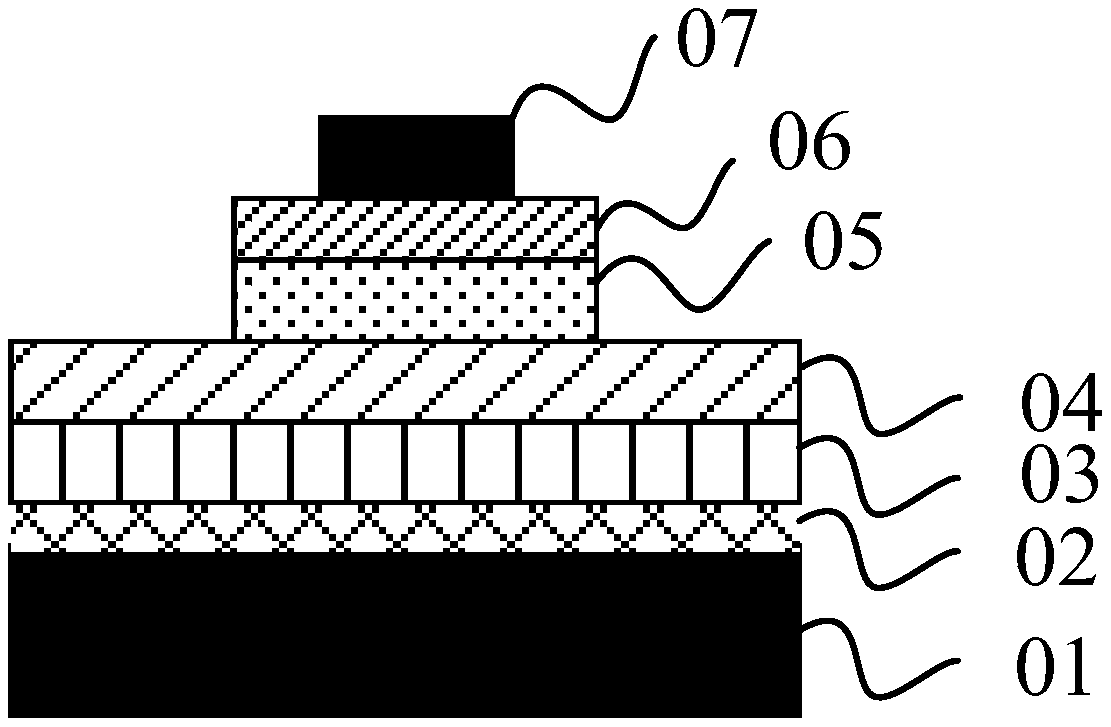

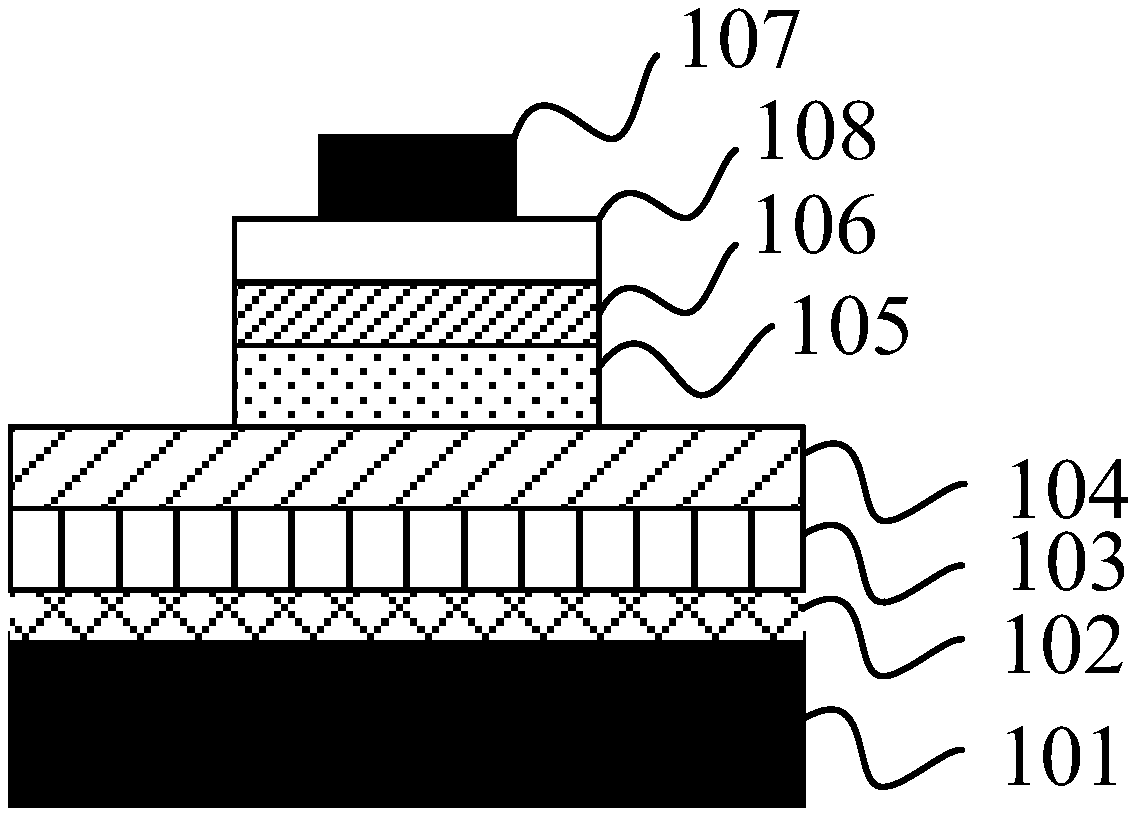

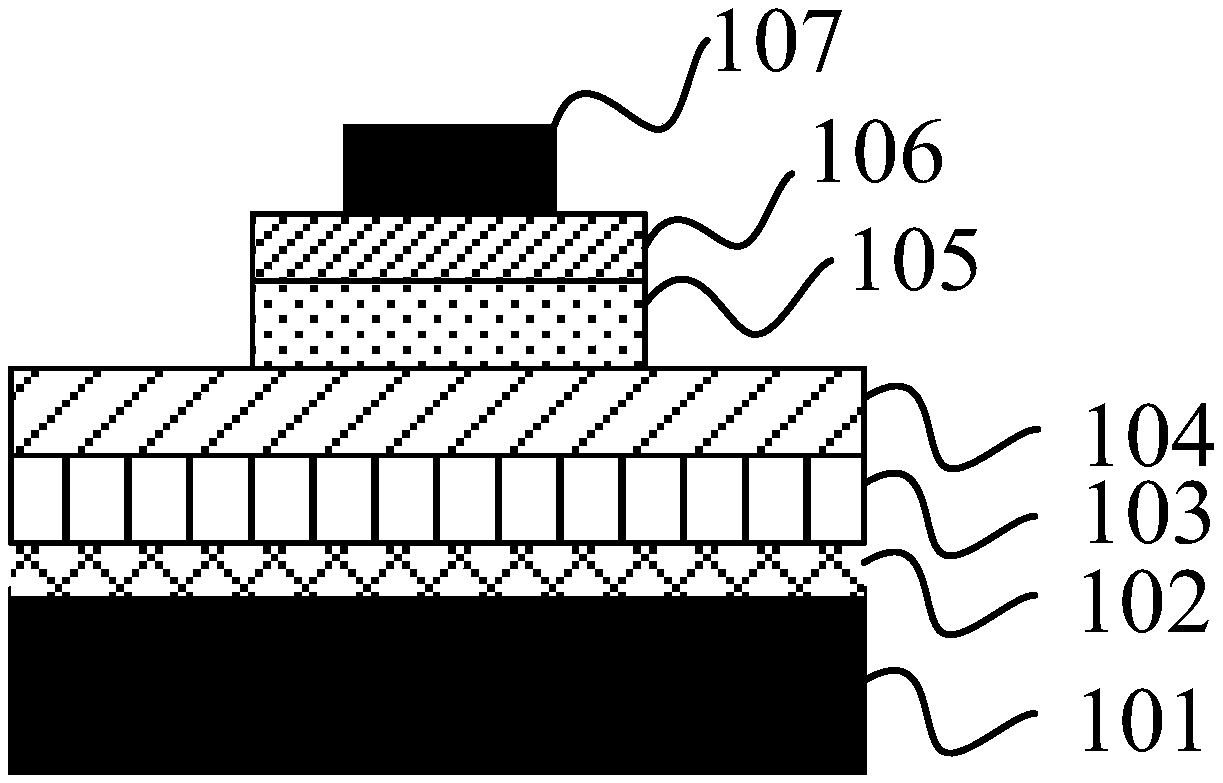

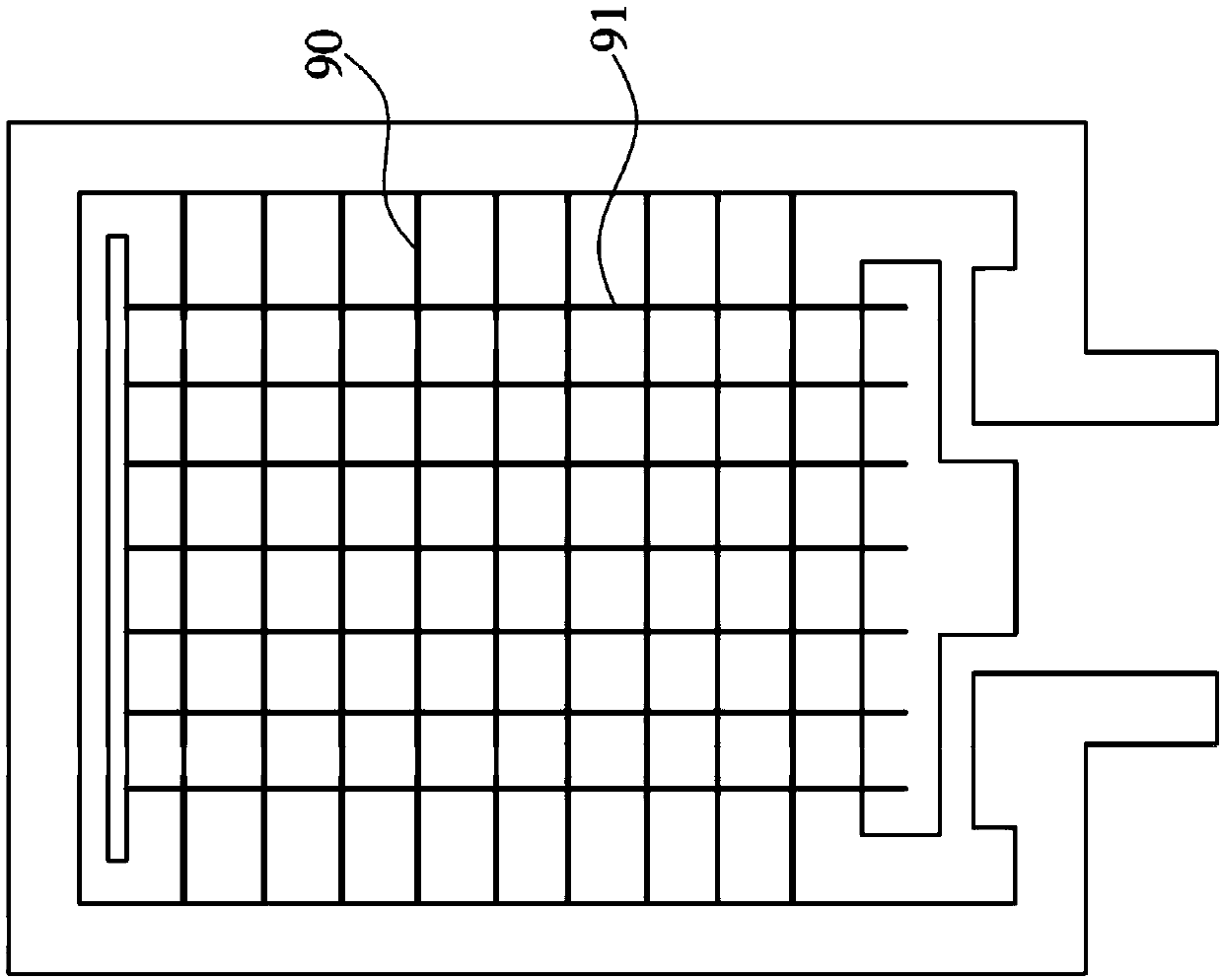

AlGaN-based ultraviolet detector and manufacturing method thereof

InactiveCN109346551AHigh sensitivityReduce dark currentFinal product manufactureSemiconductor devicesPower flowUltraviolet detectors

The invention discloses an AlGaN-based ultraviolet detector, which sequentially comprises an AlN template, an AlGaN / AlN superlattice, a first N type AlGaN layer, an intrinsic AlGaN layer, a P type AlGaN layer and an electrode in an outward direction from a substrate. The AlGaN-based ultraviolet detector comprises a second N type AlGaN layer; the second N type AlGaN layer is arranged between the first N type AlGaN layer and the intrinsic AlGaN layer; and the Al ingredient content of the second N type AlGaN layer from the contact surface with the first N type AlGaN layer to the contact surface with the intrinsic AlGaN layer is gradually reduced. Through the introduction of the second N type AlGaN layer with the gradually changed Al ingredient content, the polarization electric field of a heterogenous interface is regulated and controlled; dark current in the detector is reduced; the noise in the work process of the detector is reduced; and the detector response degree is improved. In addition, through the introduction of the layer with the gradually changed Al ingredient content, the stress of a light absorption layer is effectively released; and the crystal quality of the light absorption AlGaN material is improved. Meanwhile, the invention also provides a manufacturing method of the AlGaN-based ultraviolet detector with the beneficial effects.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Special quenching liquid for preparing large axial forgings from 35CrMo

The invention discloses special quenching liquid for preparing large axial forgings from 35CrMo, and belongs to the technical field of heat treatment quenching. The quenching liquid disclosed by the invention is composed of a mixture of polypropylene-methacrylic acid and polyacrylamide, an ethylene oxide and epoxypropane random copolymer, polyamide polyethylene glycol, a defoaming agent and water. The quenching liquid is mainly suitable for quenching large axial forgings prepared from 35CrMo steel, the process is simple, the traditional double-liquid and triple-liquid quenching processes are changed to effectively avoid quenching crack of the large axial forgings of 35CrMo steel, the quenching effect is good, and the defects of common quick quenching oil that the hardness after quenching is insufficient, the internal organizational form is non-uniform and cracking is liable to produce can be overcome.

Owner:马鞍山金泉工业介质科技有限公司

Method for preparing quenching liquid

ActiveCN104388643AOvercoming vulnerability to contaminationUniform cooling rate on the surfaceQuenching agentsPolypropyleneEpoxide

The invention discloses a method for preparing a quenching liquid, and belongs to the technical field of thermal treatment quenching. The quenching liquid consists of a mixture of polypropylene-methacrylic acid and polyacrylamide, a random copolymer of ethylene oxide and propylene epoxide, polyamide polyethylene glycol, a defoaming agent and water. The quenching liquid is mainly applicable to quenching of large-size 35CrMo steel forged shaft pieces, the process is simple, the conventional double-liquid / three-liquid quenching process is changed, by adopting the quenching liquid prepared by using the method disclosed by the invention, the large-size 35CrMo steel forged shaft pieces are effectively prevented from being cracked when being quenched, the quenching effect is good, the defects that the large-size 35CrMo steel forged shaft pieces are insufficient in hardness, not uniform in internal tissue form, easy to crack and the like when being quenched by using ordinary rapid quenching oil are overcome, and the prepared quenching liquid has the advantages of good dispersibility and high storage property.

Owner:马鞍山金泉工业介质科技有限公司

Silicon-based lithium ion battery negative electrode material and preparation method thereof

ActiveCN110707316AImprove electrochemical performanceIntegrity guaranteedSecondary cellsNegative electrodesSpray driedCarbon nanomaterials

The invention discloses a silicon-based lithium ion battery negative electrode material and a preparation method thereof, and belongs to the technical field of lithium ion batteries. The silicon-basedlithium ion battery negative electrode material sequentially comprises a silicon-based composite material and a carbon nano material / polymer mixed coating layer from inside to outside, wherein the mass ratio of the polymer to the silicon-based composite material is (0.05-0.6): 1, and the mass ratio of the carbon nano material to the silicon-based composite material is (0.001-0.1): 1. The composite material is prepared from a silicon-based composite material, a polymer, a carbon nano material, a binder, deionized water and other raw materials by a spray drying loading method or a fluidized bedloading method. The negative electrode material provided by the invention can effectively release the stress generated by volume expansion under the extremely high pole piece compaction density, caneffectively maintain the integrity of a conductive network and an adhesive network, and can improve the electrochemical performance of a battery cell.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

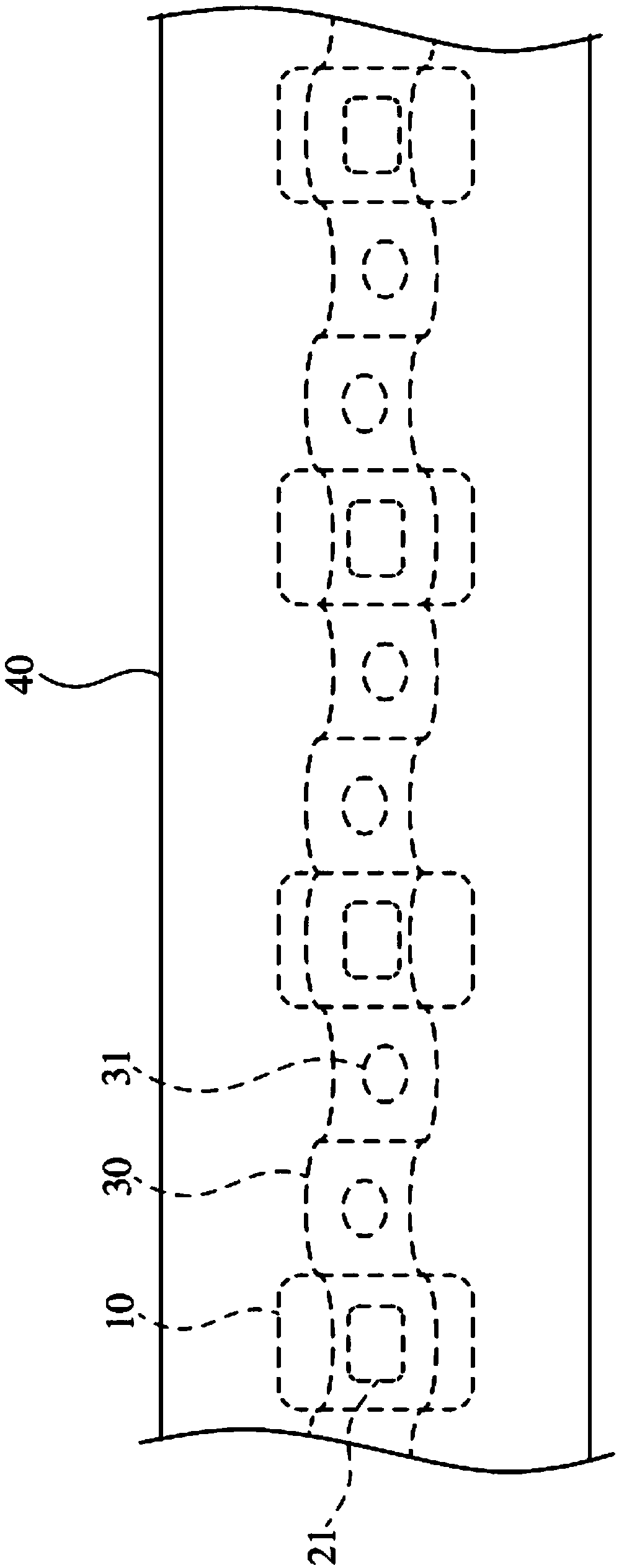

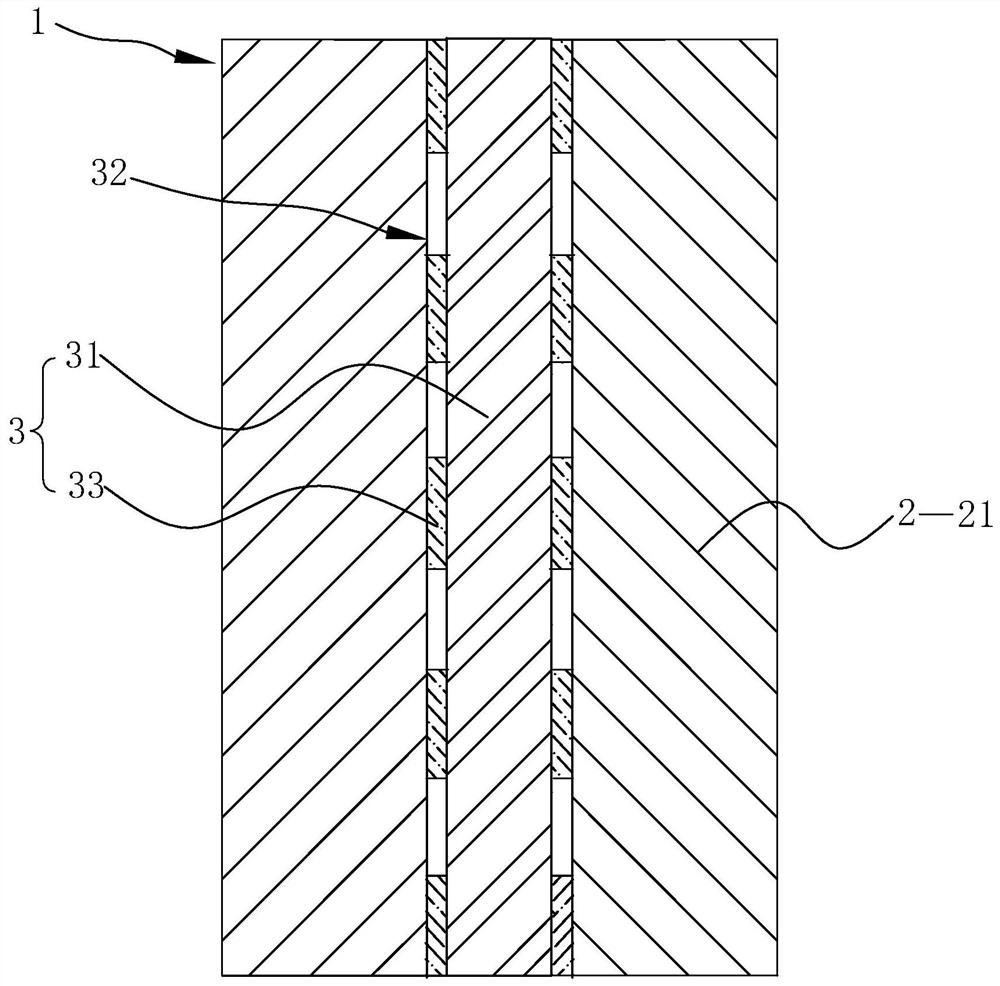

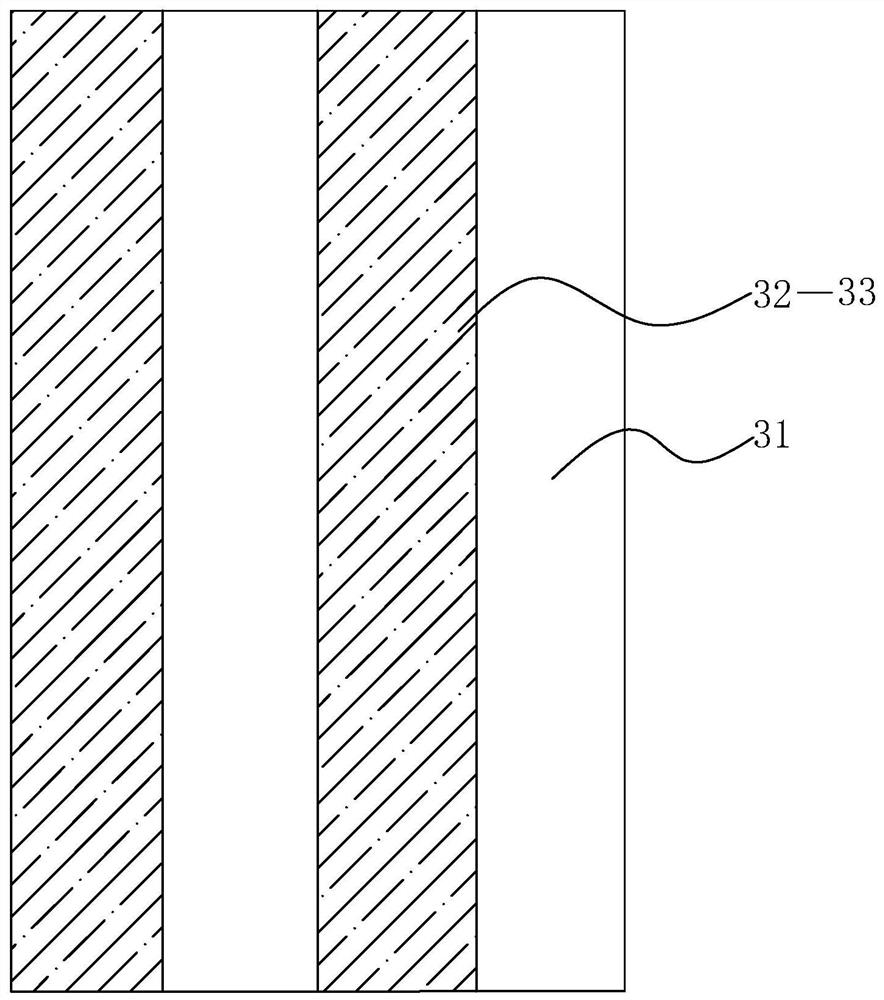

Flexible display panel with bending-resistant signal line

InactiveCN109256398AImprove stress toleranceExtended service lifeSolid-state devicesSemiconductor devicesFlexible displayMaterials science

A flexible display panel has a plurality of signal lines, at least one of which comprises a first metal layer, a first planar layer and a second metal layer. The first metal layer includes a pluralityof spaced apart metal pieces. The first flat layer is disposed on the first metal layer and includes a plurality of first through holes, and the first through hole positions correspond to the metal parts one by one to expose the metal parts. The second metal layer is disposed on the first flat layer, wherein the pattern shape of the second metal layer is a wavy shape, and the second metal layer is connected to the metal part through the first via hole.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

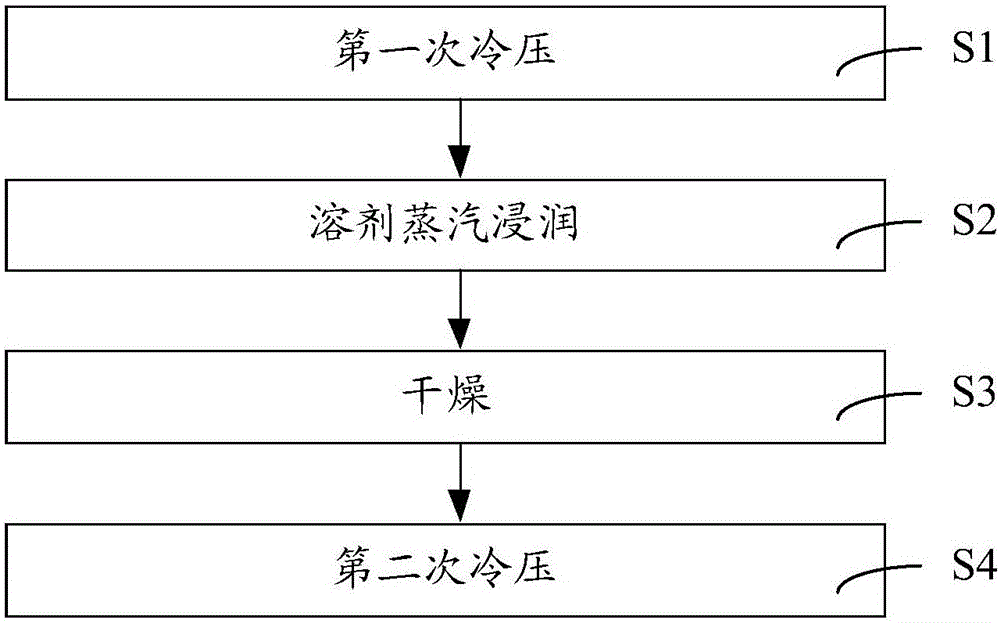

Pole piece and pressing method thereof

ActiveCN105810884AThe pressing method is simple and easyEffective stress reliefElectrode rolling/calenderingSolvent vaporPole piece

The invention relates to the field of batteries, in particular to a pressing method of a pole piece.The pressing method includes: performing first cold pressing on the pole piece; performing solvent vapor infiltration on the pole piece after the first cold pressing; drying the pole piece after the infiltration; performing second pressing on the dried pole piece.The pressing method has the advantages that the solvent vapor infiltration and the drying are added between the two pressing processes; during the solvent vapor infiltration, vapor enters the pole piece to allow the directions of the particles on the pole piece to be readjusted and effectively release the stress of the pole piece, and accordingly the bounce of the pole piece is lowered effectively, influence on the overall performance of a battery cell is reduced, and the overall performance of the battery cell is increased; the pressing method is simple and practicable and suitable for industrial large-scale production.The invention further discloses the pole piece.

Owner:SUZHOU GCLSI SCI & TECH IND APPL RES INST CO LTD +3

Method for layering, stage multi-level blasting, hole expanding and crack expanding of oil-gas-bearing rock

The invention relates to a method for layering, stage multi-level blasting, hole expanding and crack expanding of an oil-gas-bearing rock. A drilling machine drills a vertical hole to the oil-gas-bearing rock, multilayer horizontal build-up is conducted in the oil-gas-bearing rock, and a casing pipe is contacted and fixed with an outer shale body and extends into a curve section; a light pipe is contacted and fixed with the outer shale body in a horizontal section, a packer is used for sealing the staggered position of the light pipe and the casing pipe, the light pipe with the preset length is arranged inside the horizontal section, and except the light pipe section, the residual horizontal section is an uncased hole; and a hydraulic expansion device is used for sending explosives to different positions of the horizontal uncased hole section, the explosive quantities increase gradually at the same position, stage blasting hole expanding and high-pressure gas explosion cracking at the position of the uncased hole are completed, and backwashing is conducted for different-stage blasting broken rocks to clear the uncased hole. Step-by-step blasting is conducted in a direction from the remote end of the uncased hole to the light pipe during blasting cracking, different levels of explosive quantities are adopted, the quantity at the remote end of the uncased hole is the most and the quantities are reduced gradually towards the curve section, so that the light pipe is protected, the backwashing of blasting broken rocks is facilitated, and big hole collapse and cracking are achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Amorphous composite brazing filler metal for brazing ceramic and alloy

PendingCN110153591AImprove mechanical propertiesImprove shear resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesUltimate tensile strengthFiller metal

The invention relates to a composite brazing filler metal layer for brazing ceramic and alloy, and belongs to the field of brazing filler metal. The brazing filler metal comprises a double-layer CuTiZrNi amorphous brazing filler metal and a foam Cu intermediate layer, and the foam Cu intermediate layer is filled between the double-layer CuTiZrNi amorphous brazing filler metal, and the atomic percentage of the CuTiZrNi brazing filler metal is Cu: 41.83, Ti: 30.21, Zr:19.76 and Ni:8.19. A foam Cu intermediate layer is added into the CuTiZrNi amorphous brazing filler metal, the brazing temperature is kept at 910 DEG c for 20 minutes, plastic deformation is generated between the brazing filler metal and the foam Cu intermediate layer,and the brazing filler metal and the foam cu intermediate layer are in close contact with each other, the surface of the base material is wetted, so that part of the base material is also dissolved in the molten brazing filler metal, a staggered structure isgenerated, so that the mechanical property of the ceramic and alloy connectivity is improved, the bonding strength of the interface is improved, the stress is effectively released, the cracking tendency is inhibited, so that the weld joint has good joint performance, and the negative influence of the hardening and the ductility of the braze welding head on the bonding strength is avoided;

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Piston with Ti-doping diamond multi-layer thick heat-insulating film on top face and preparation method and application of piston

ActiveCN106978593AEffective stress reliefImprove bindingVacuum evaporation coatingSputtering coatingTi dopingThermal impact

The invention relates to a piston with a Ti-doping diamond multi-layer thick heat-insulating film on the top face and a preparation method and application of the piston. The piston comprises a piston substrate, a transitional layer, n layers of TiC / DLC film layers and m buffer layers, wherein the outermost layer of the top face of the piston is the last TiC / DLC film layer. According to the preparation method of the piston, the transitional layer is prepared on the top face of the piston substrate; then the first TiC / DLC film layer is prepared; one buffer layer is formed on the first TiC / DLC film layer; the TiC / DLC film layers and the buffer layers are formed alternately, so that a middle layer is obtained, and then the last TiC / DLC film layer is prepared. According to the piston with the Ti-doping diamond multi-layer thick heat-insulating film on the top face has excellent abrasion resistance and thermal impact resistance and can meet the requirement of modern engines for high efficiency and low emission.

Owner:XIANGTAN UNIV

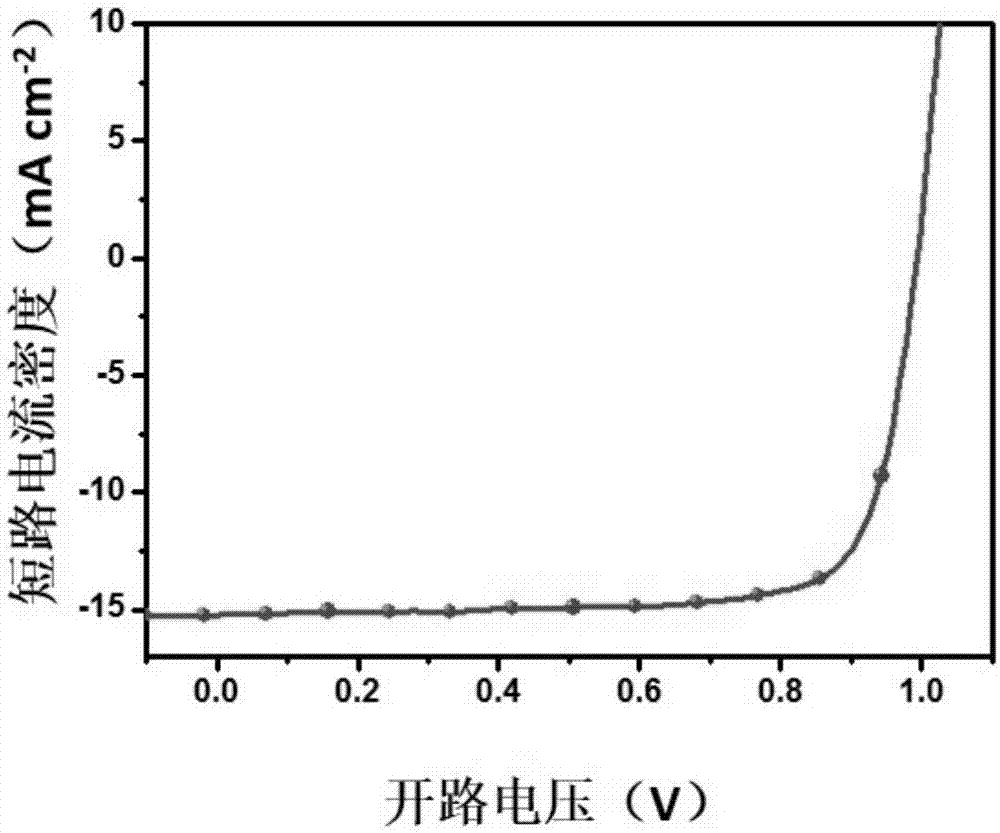

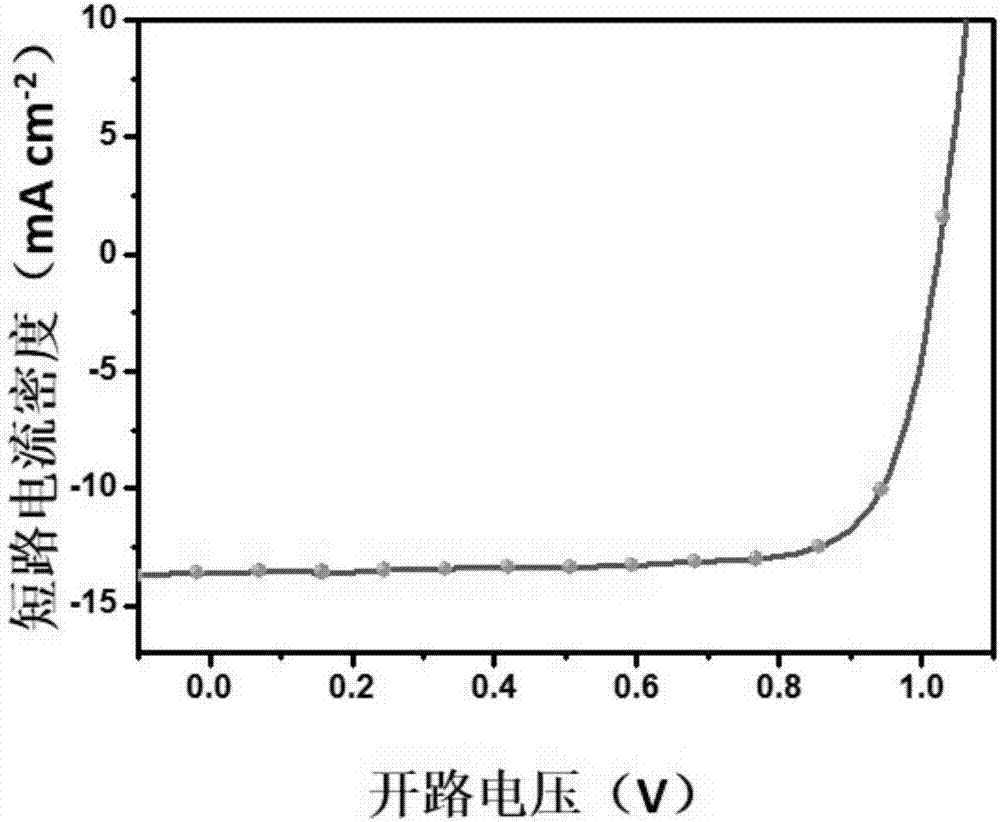

Large-area flexible perovskite solar cell and manufacturing method thereof

ActiveCN108011044AImprove spectral utilizationImprove mechanical stabilitySolid-state devicesSemiconductor/solid-state device manufacturingState of artPerovskite solar cell

The invention relates to the field of photoelectric energy, and discloses a large-area flexible perovskite solar cell and a manufacturing method thereof. The structure of the cell comprises a flexibletransparent electrode, a nano honeycomb bracket, a perovskite layer and a metal electrode layer sequentially from bottom to top. The invention also discloses a manufacturing method for the large-areaflexible perovskite solar cell. In comparison with the prior art, through introducing the nano honeycomb bracket, the spectral utilization rate of the cell device can be improved; the nano honeycombbracket can be used as an optical resonator, and the photoelectric conversion efficiency and the repeatability of the large-area device are improved; and the nano honeycomb bracket can also be used asa mechanical buffer layer, the stress produced during the bending process can be effectively released, the perovskite crystal layer is protected, and the mechanical stability of the cell device can be effectively improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Negative electrode current collector complex, preparation method thereof and lithium metal battery

ActiveCN113488659ALight in massLight weightElectrode carriers/collectorsSecondary cellsElectrical batteryLithium metal

The invention relates to the field of lithium batteries, in particular to a negative electrode current collector complex, a preparation method thereof and a lithium metal battery. The negative electrode current collector complex comprises a negative electrode and a current collector, the negative electrode is a lithium metal layer, the current collector comprises a polymer film, copper metal areas are arranged on the two side faces of the polymer film, copper metal layers are arranged on the copper metal areas, the lithium metal layer is attached to the side, away from the polymer film, of the copper metal layer, and the area of the copper metal layer is 20-70% of the area of the polymer film; the lithium metal layer and the polymer film coincide in size. The lithium metal battery provided by the invention adopts the current collector, so that the energy density of the lithium metal battery is improved, uneven lithium deposition on the surface of a negative electrode is also inhibited in the charging process of the battery, and the cycle life of the battery is further prolonged.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

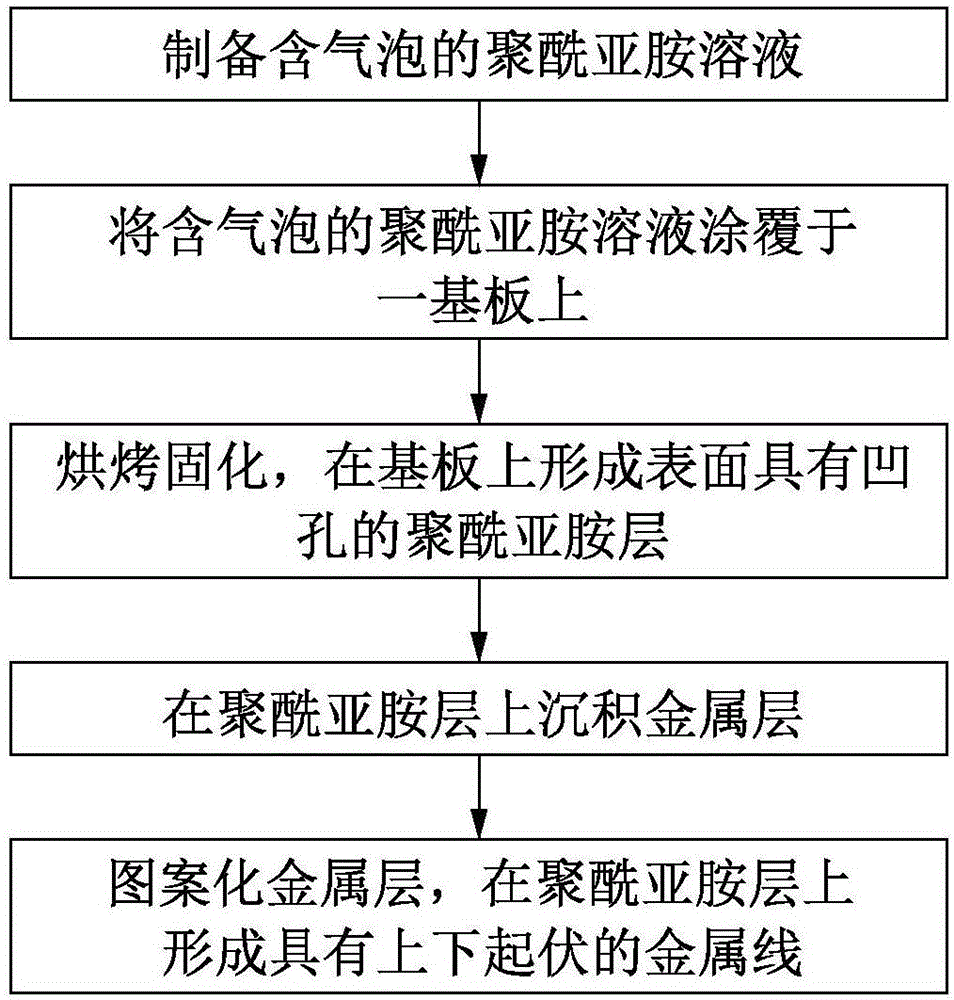

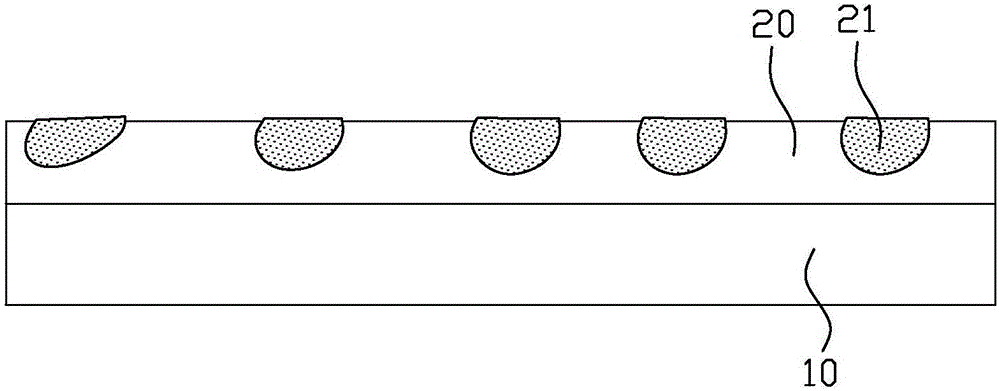

Metal wire manufacturing method of flexible substrate

ActiveCN106340460AIncreased durabilityEffective stress reliefSemiconductor/solid-state device detailsSolid-state devicesCooking & bakingOptoelectronics

The invention provides a metal wire manufacturing method of a flexible substrate. The method comprises a step of preparing a polyimide solution containing bubbles, a step of coating a substrate with the polyimide solution containing bubbles, a step of carrying out baking-curing and forming a polyimide layer with concave holes on the substrate, a step of depositing a metal layer on the polyimide layer, and a step of patterning the metal layer and forming wavy metal wires on the polyimide layer. According to the method, through simple steps, the wavy metal wires are formed on the substrate, the formed metal wires can release the stress of the formed metal wires in the bending of the flexible substrate, and the bending resistance and reliability of the flexible substrate are improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

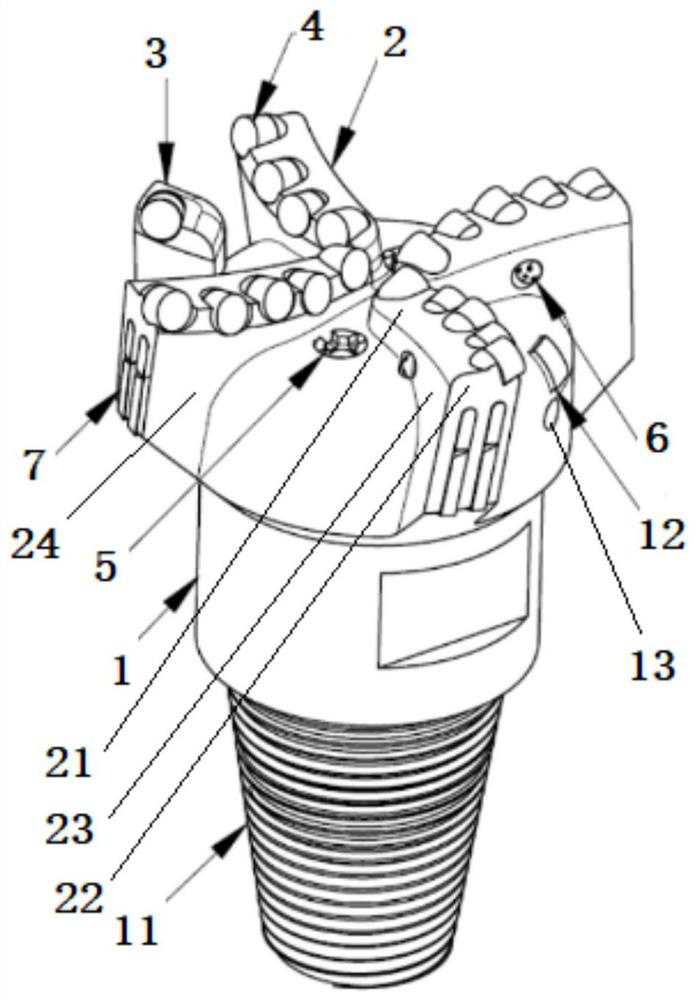

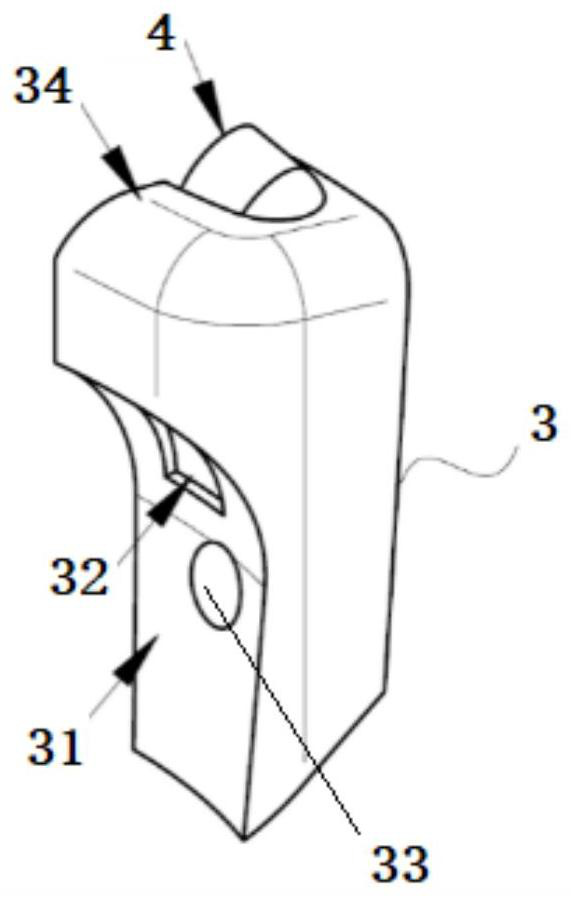

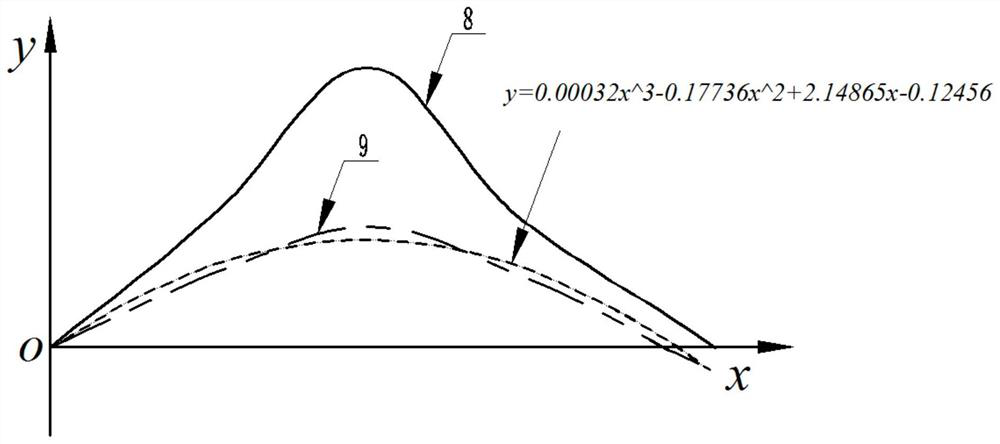

PDC drill bit for coal mine high-position directional drilling

ActiveCN111764831AStrong side cutting abilityWithout sacrificing build-up capabilityDrill bitsConstructionsMining engineeringStructural engineering

The invention discloses a PDC drill bit for coal mine high-position directional drilling. The PDC drill bit comprises a drill bit body, a plurality of fixed cutter wings, movable cutter wings and PDCcutting teeth, wherein the drill bit body and the fixed cutter wings are integrally formed, the movable cutter wings are detachably installed on the drill bit body, and the PDC cutting teeth are welded to the fixed cutter wings and the movable cutter wings. Fixed cutter wing tooth distribution faces extend to the edge of the front end of the drill bit body from the center close to the front end ofthe drill bit body in the radial direction, and gauge protection face connecting tooth distribution faces extend to the side face of the front end of the drill bit body; intersecting lines of the tooth distribution faces and the second side surface are designed according to a corrected mole front paw toe outline fitting curve, and the PDC cutting teeth are distributed along the intersecting lines; the movable cutter wings are arranged between the adjacent fixed cutter wings, and each movable cutter wing comprises a movable cutter wing tooth distribution face on which PDC cutting teeth can bemounted; the heights of the parts, higher than the front end of the drill bit body, of the fixed cutter wings and the movable cutter wings are consistent; and main runner nozzles are arranged on the drill bit body, and side blade nozzles are arranged on the fixed cutter wings. The directional deflecting capacity of a drill bit and the drilling adaptive capacity of the drill bit in a complex hard stratum can be improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com