Patents

Literature

4751 results about "Water delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

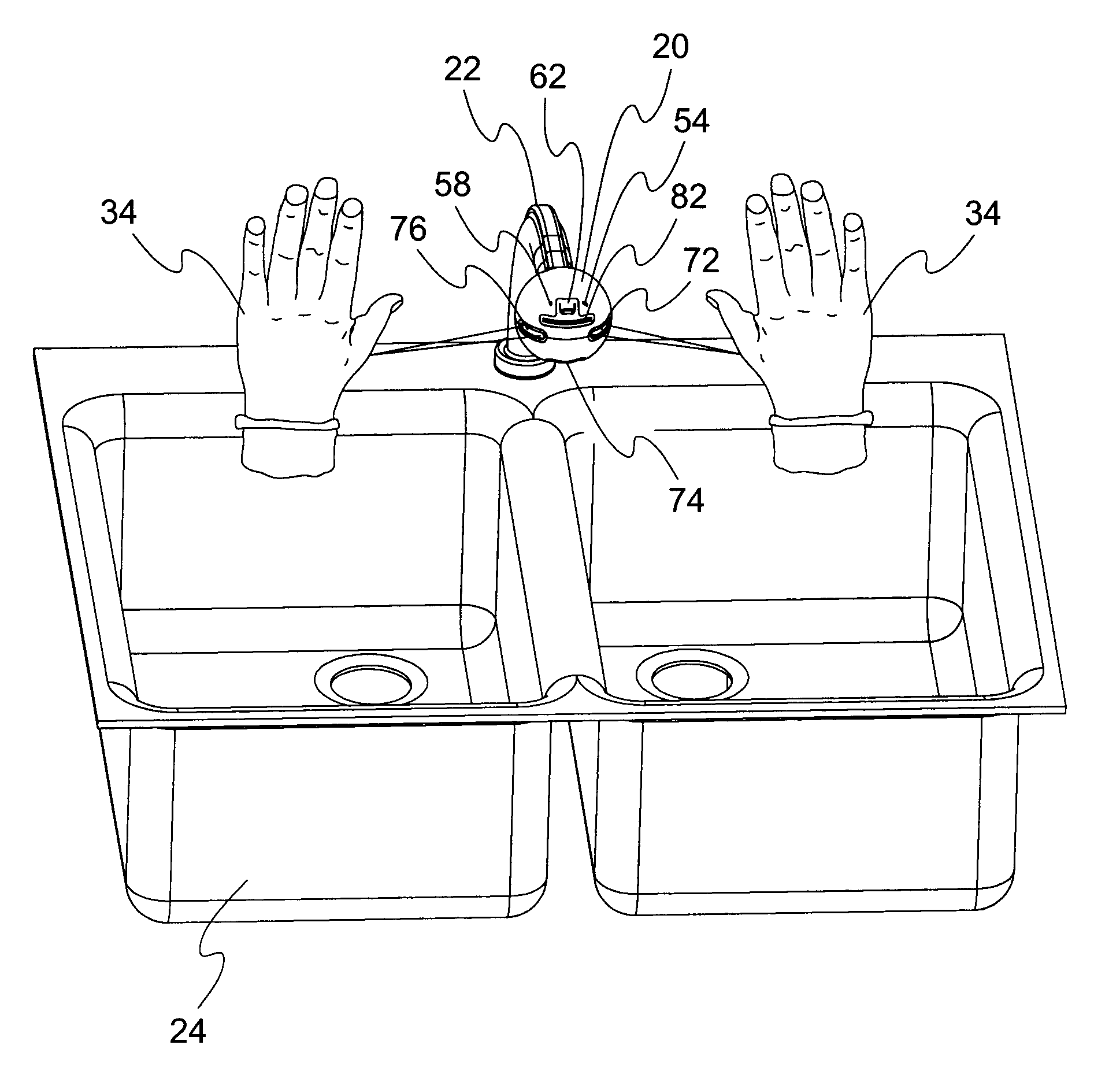

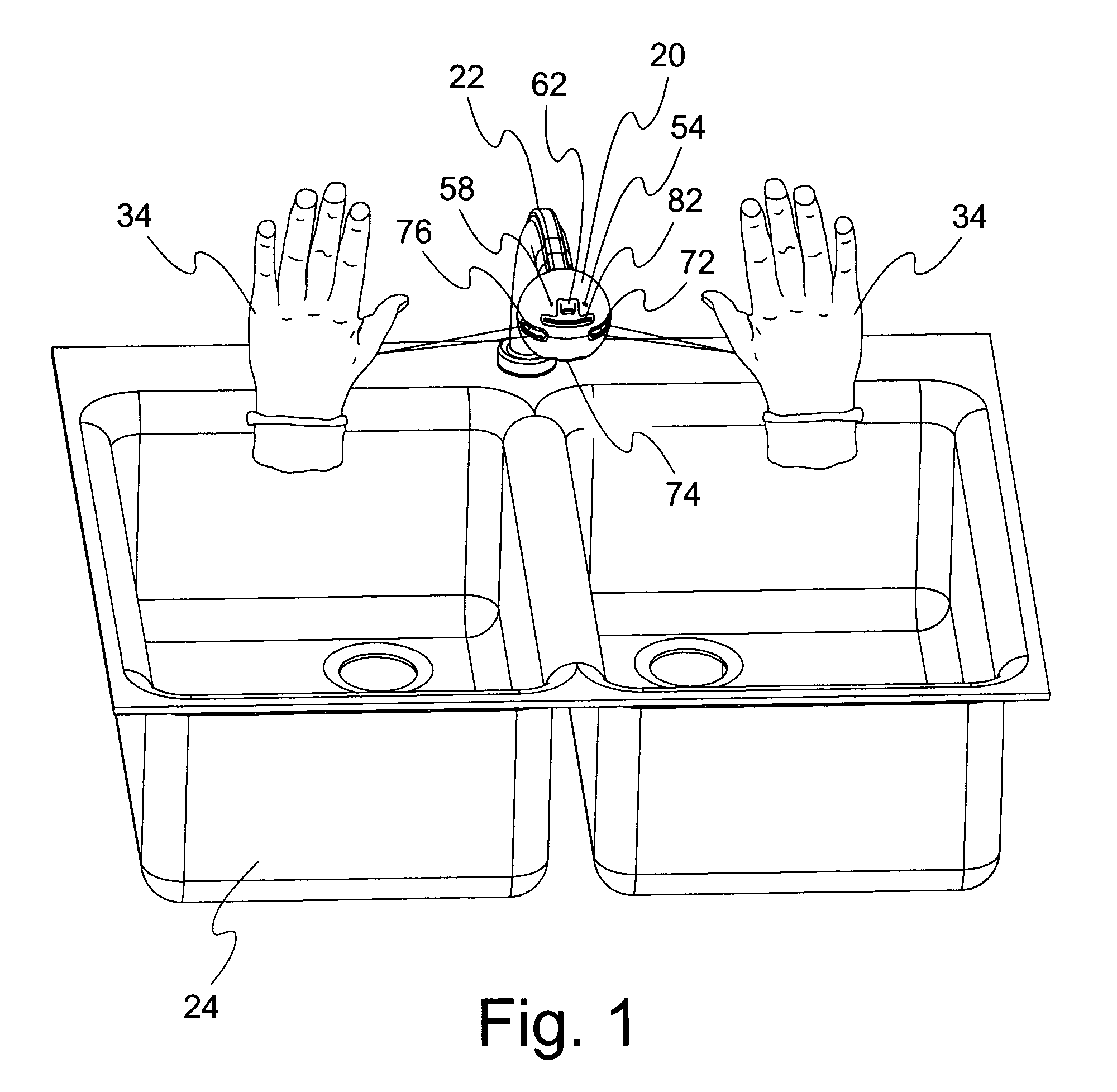

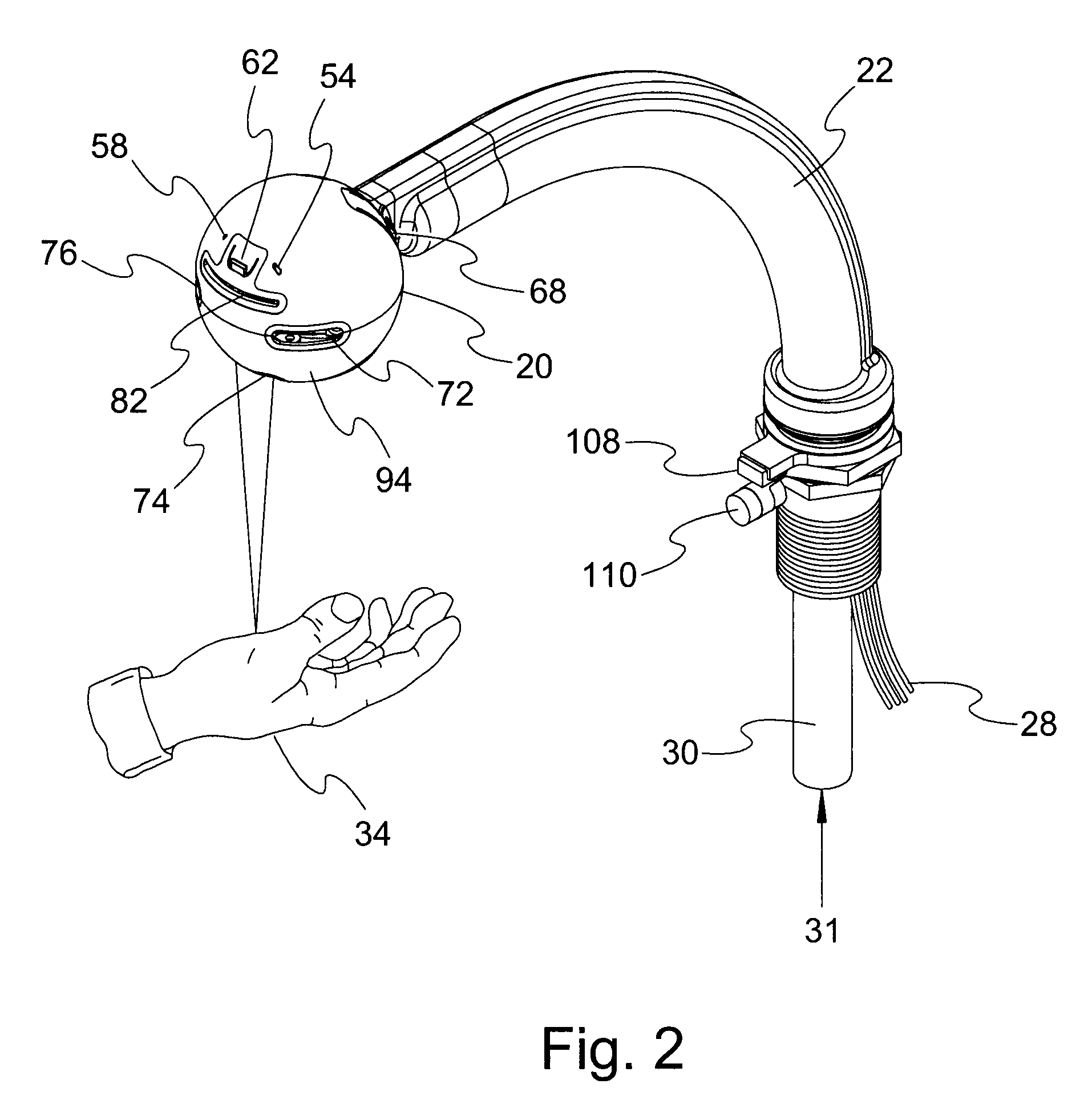

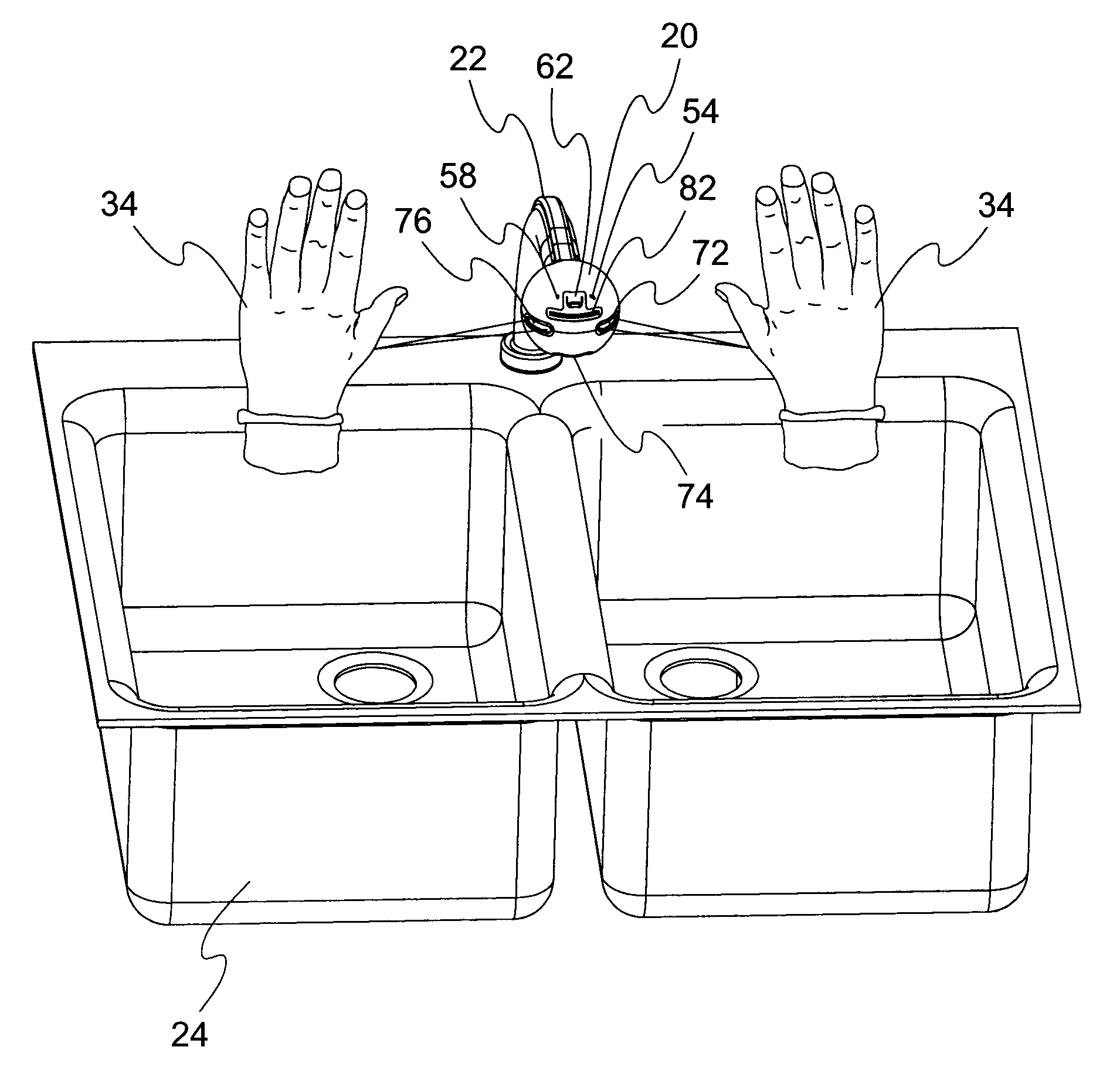

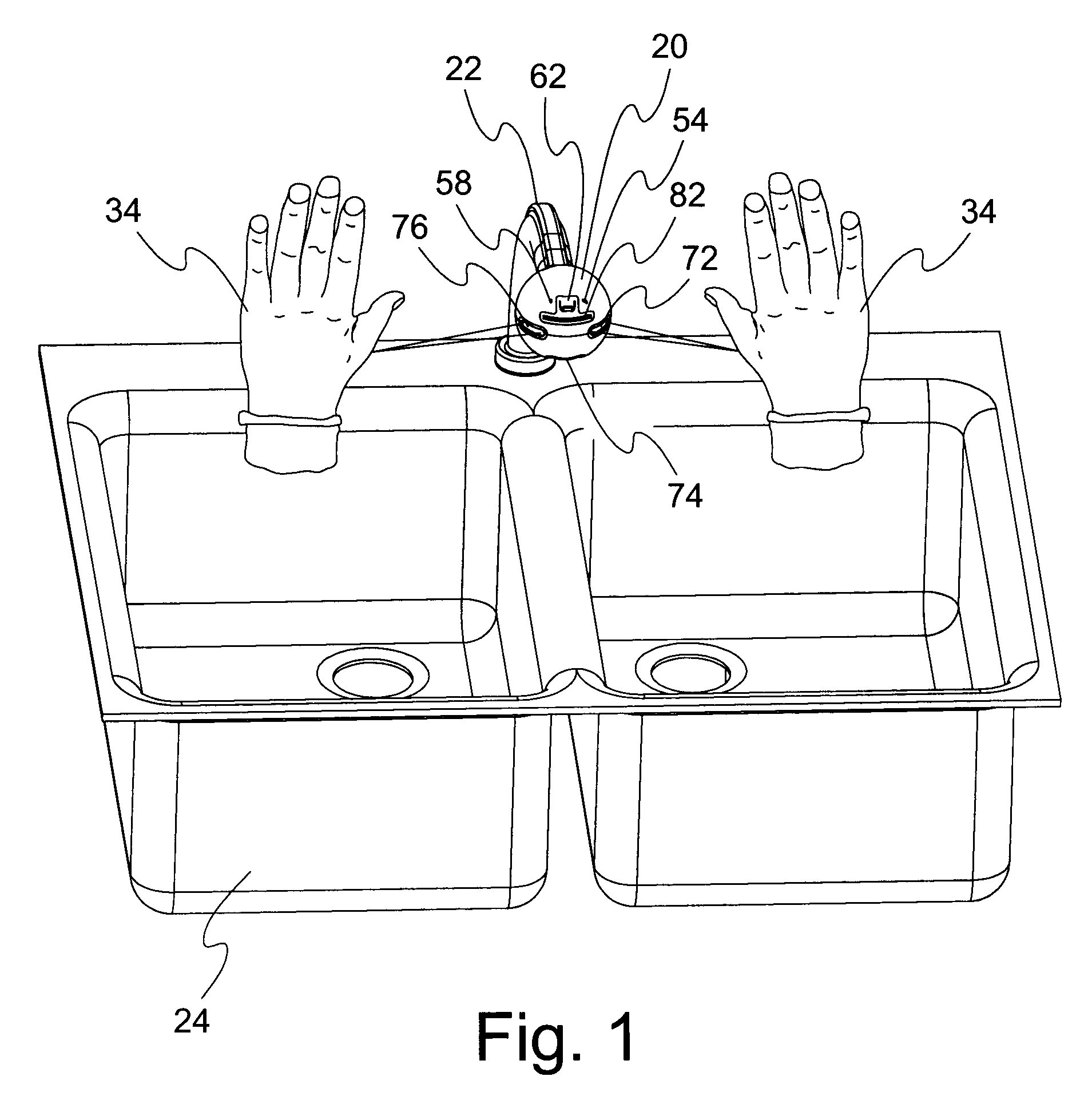

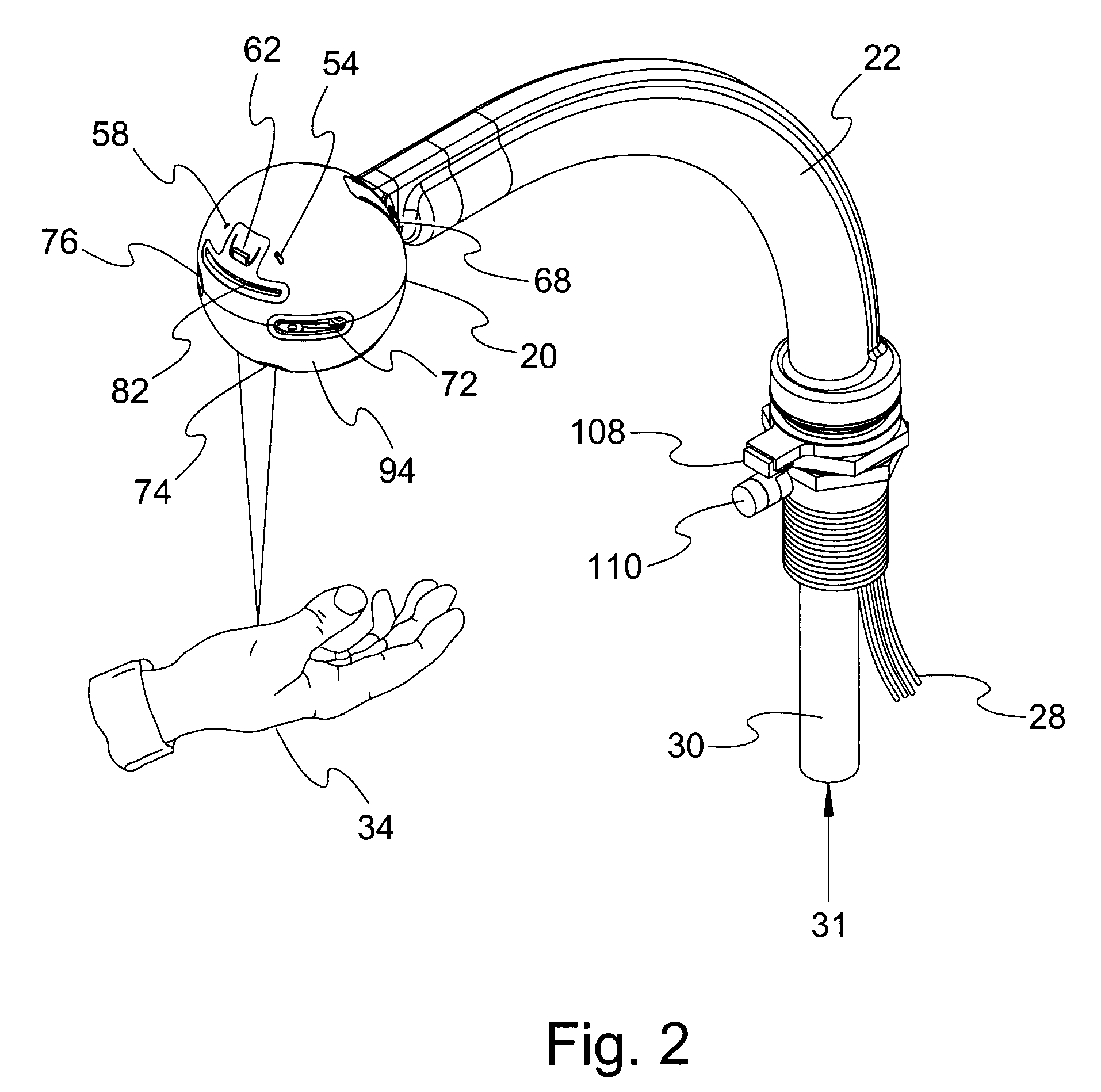

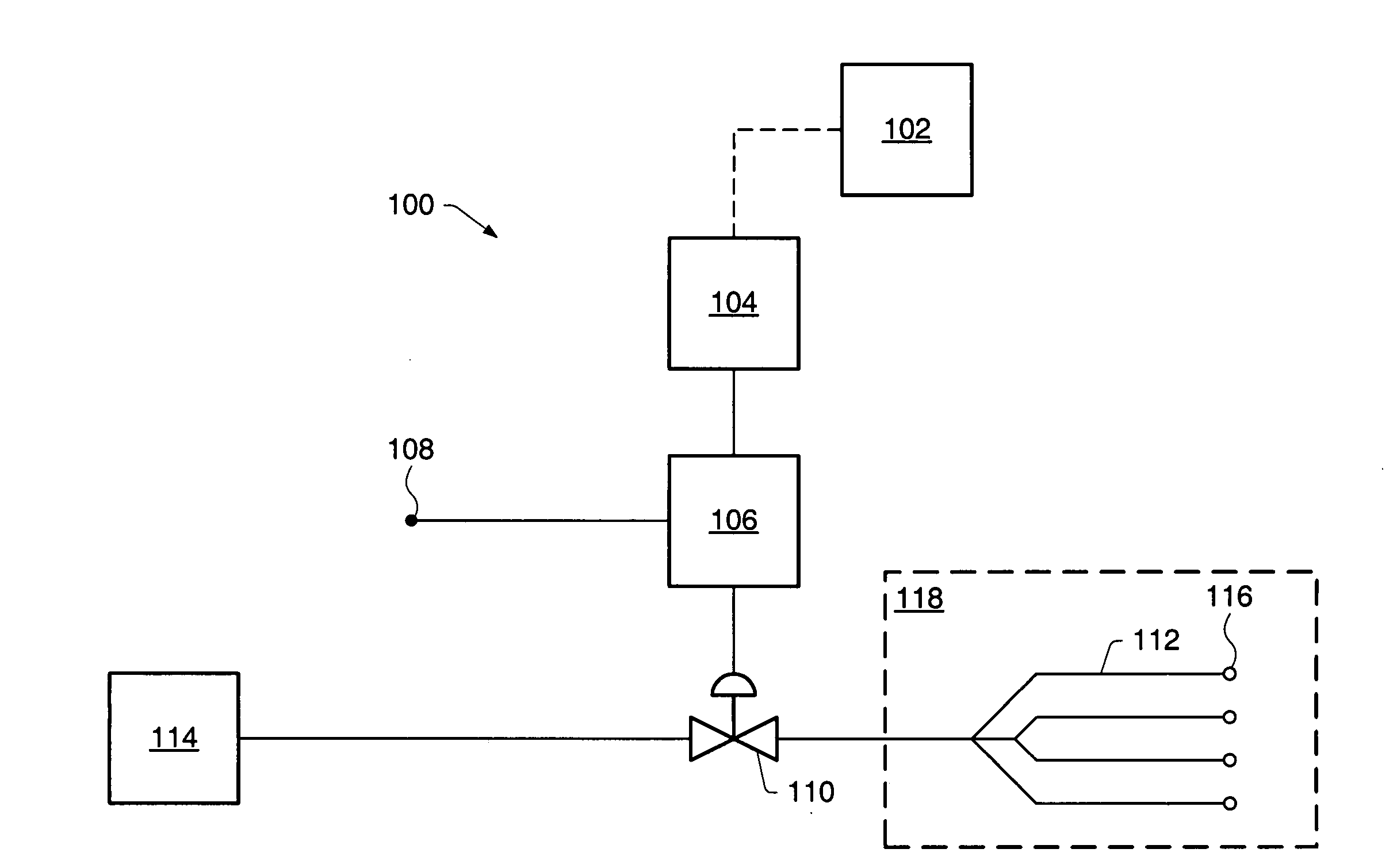

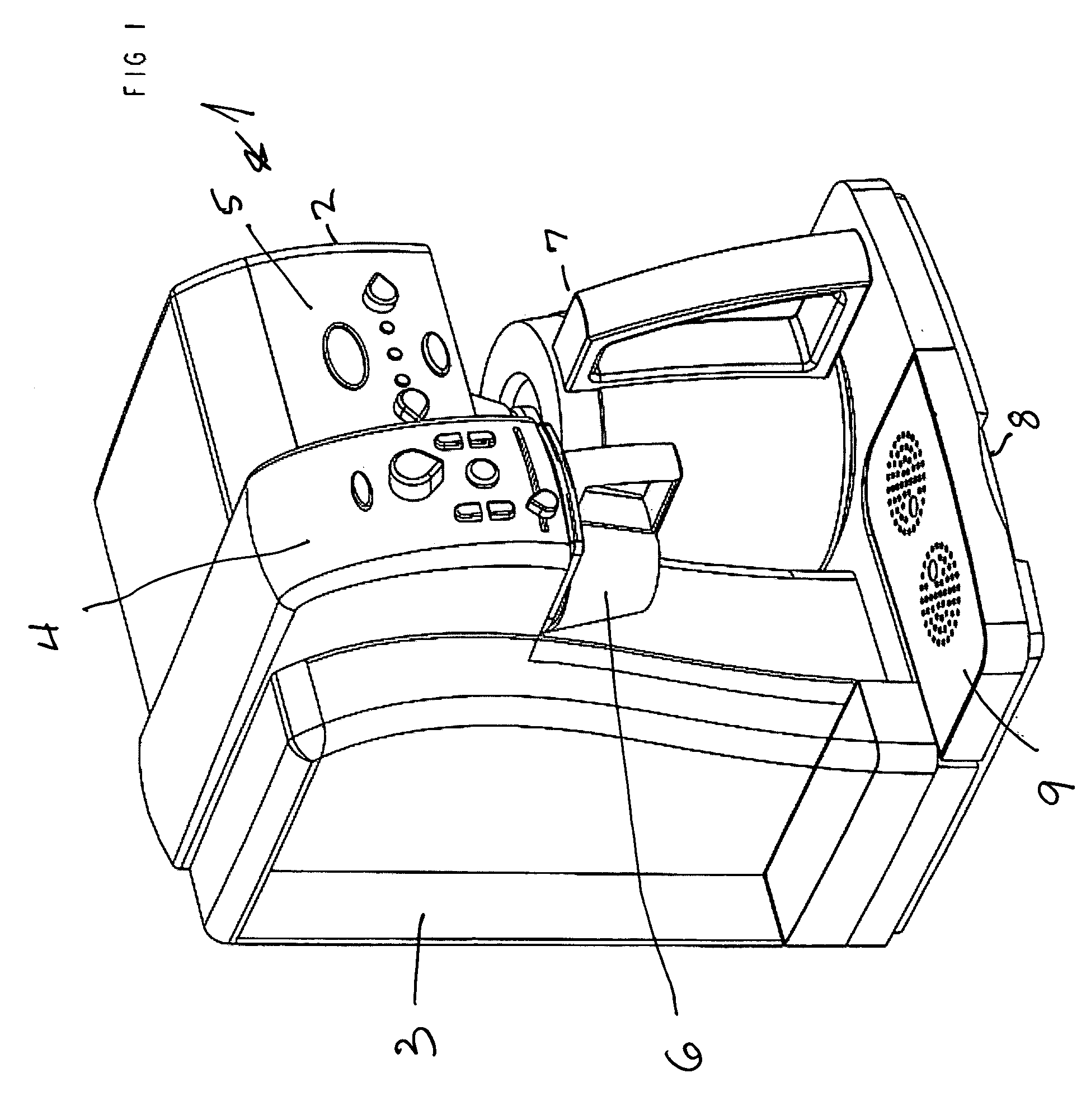

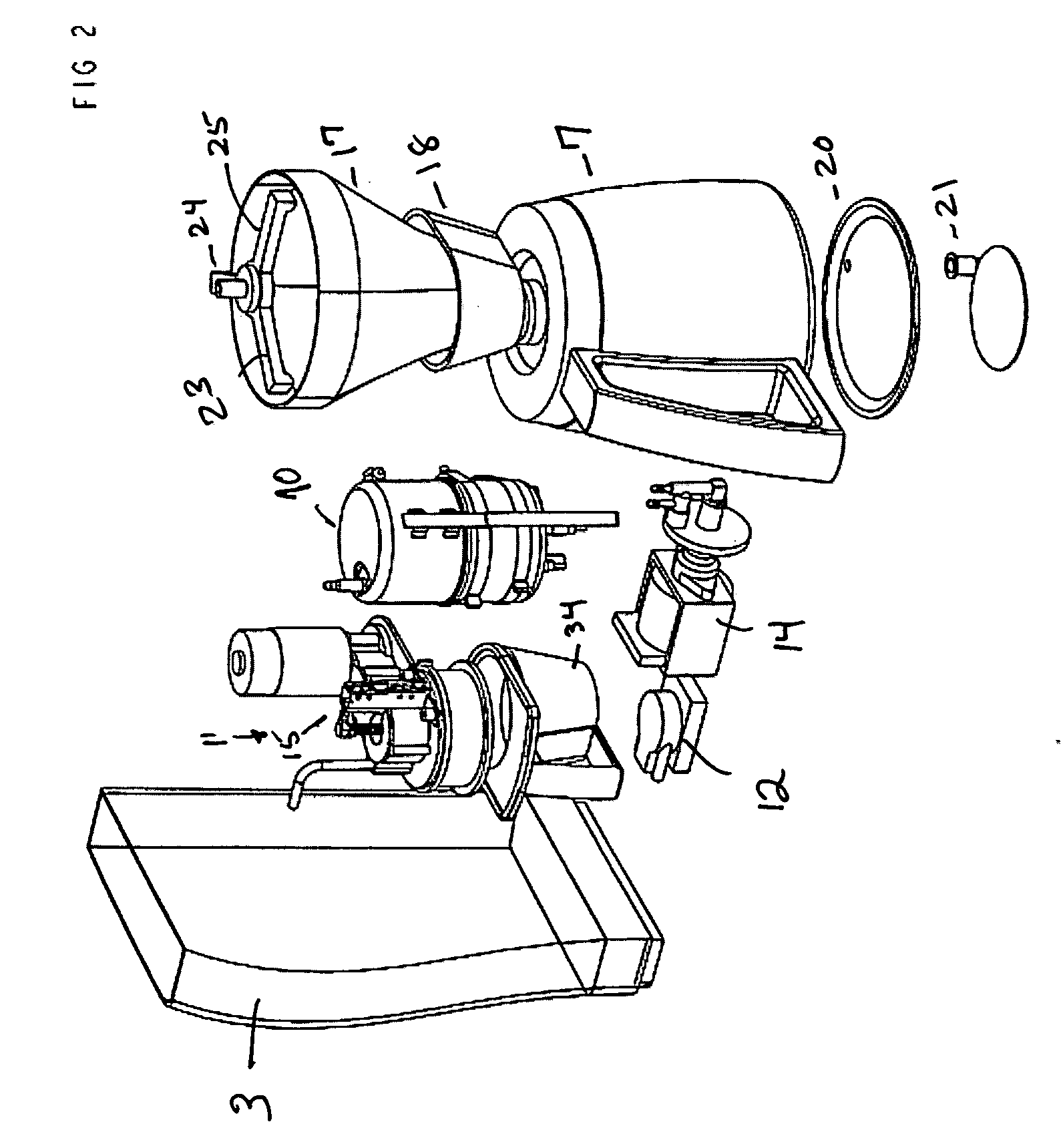

Electronic Faucet with Voice, Temperature, Flow and Volume Control

An ergonomic water conserving faucet assembly that pivots around a cognitive central point providing touchless water temperature, flow rate, volume control and spray pattern adjustment through multiple, hygienic means. The assembly comprises a pivotable, ergonomic, ball-shaped spout that may be used statically or hand held; a retractable water delivery hose connecting the spout to a water source; a water mixing valve at the water source delivering water of preselected temperature; solenoid valves controlling flow; proximity and object detection sensors mapping the sink area and detecting input signals; speech sensors with microphone for voice control; an LED display of water temperature; internal speakers delivering audible prompts; and an electronic controller recognizing speech and supervising operations.

Owner:WOLF JAMES L +1

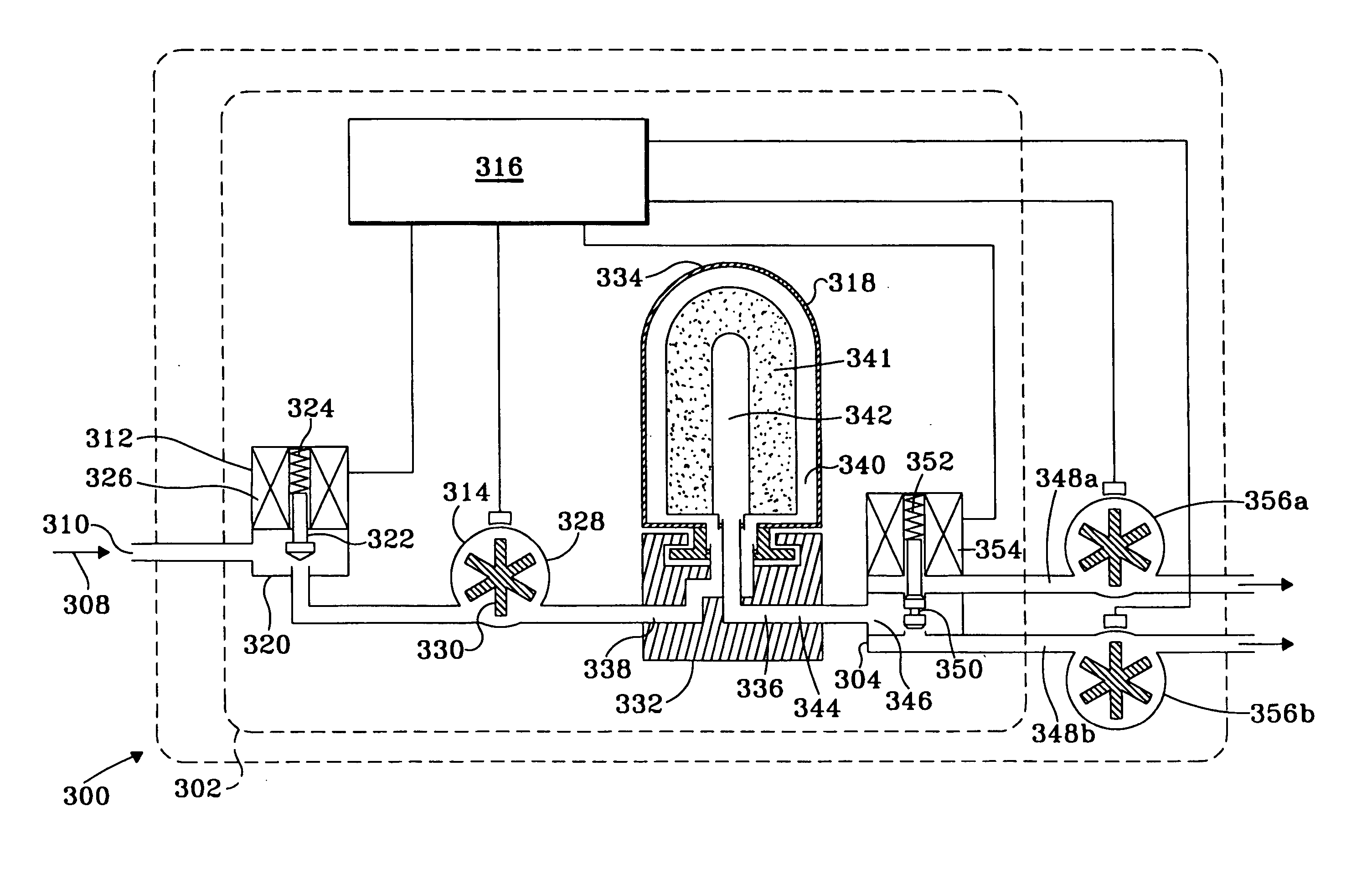

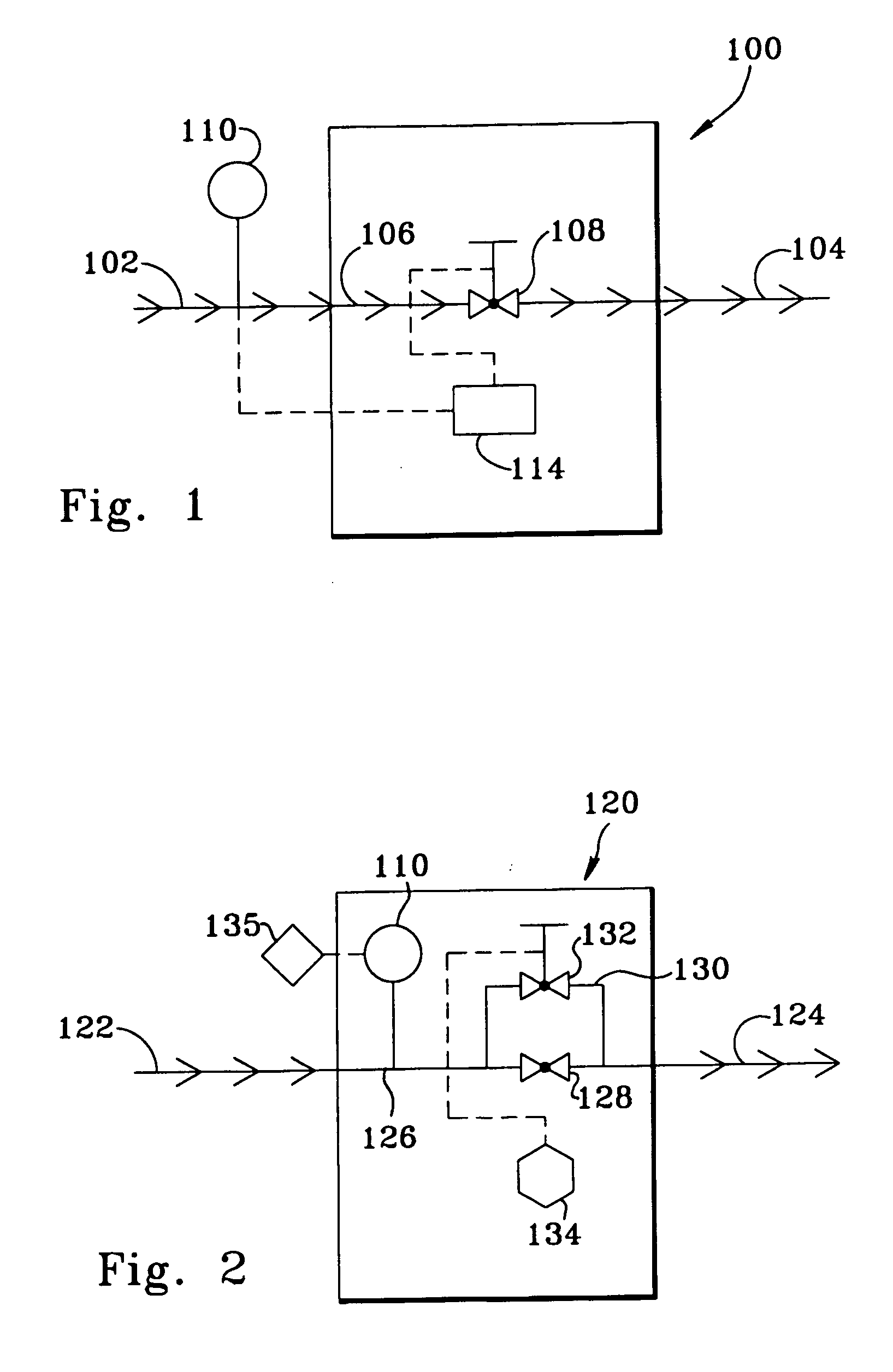

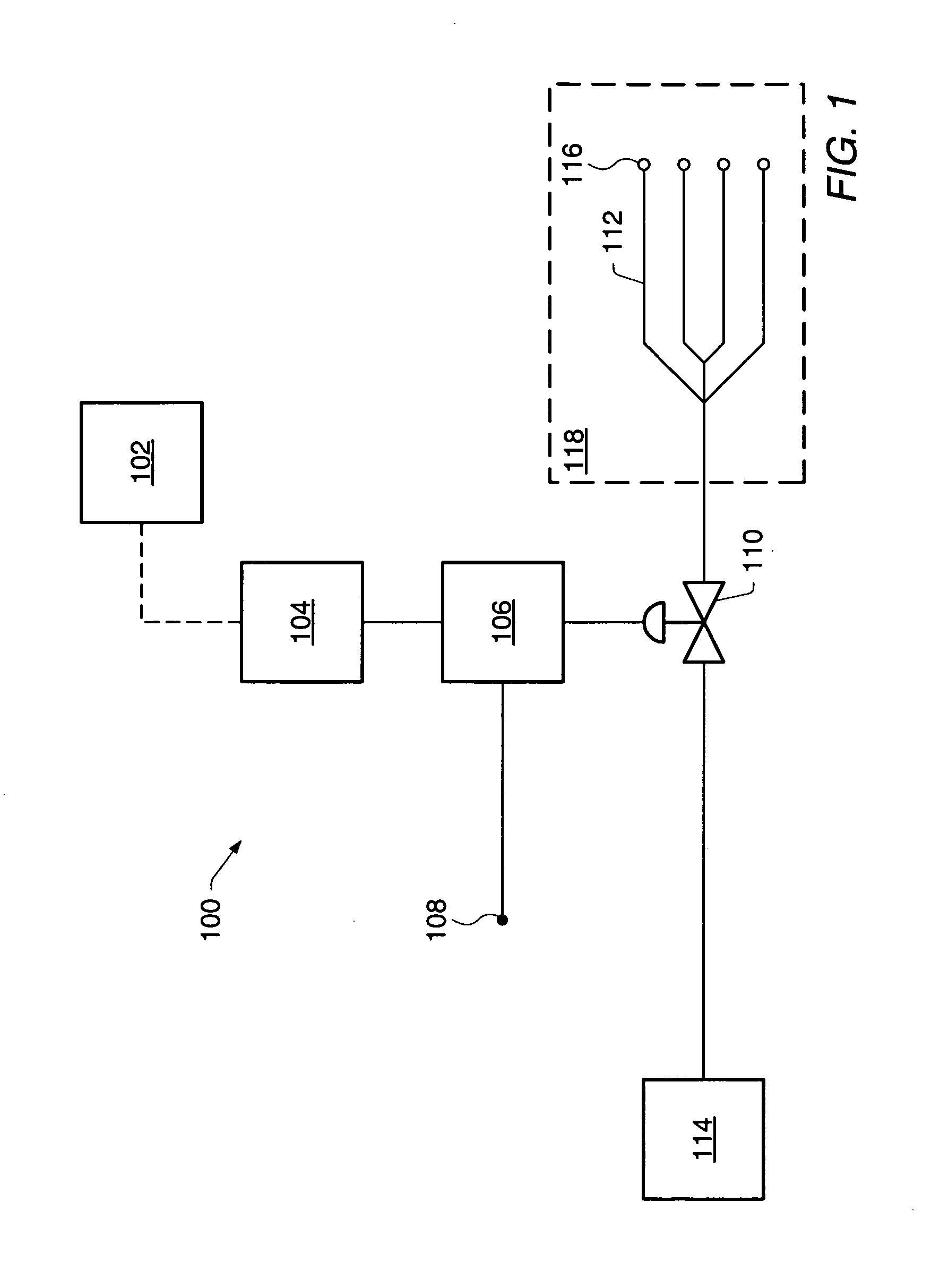

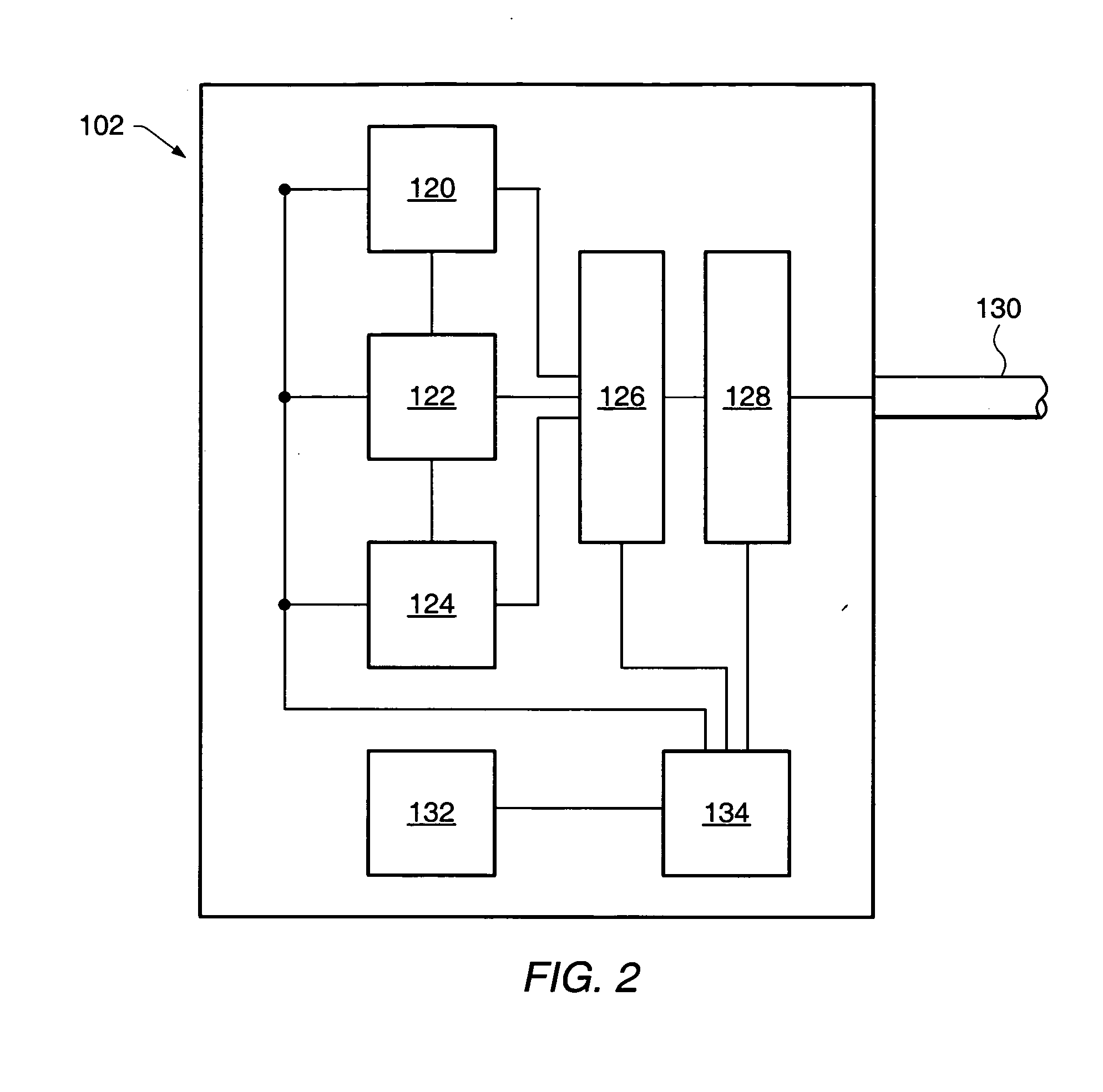

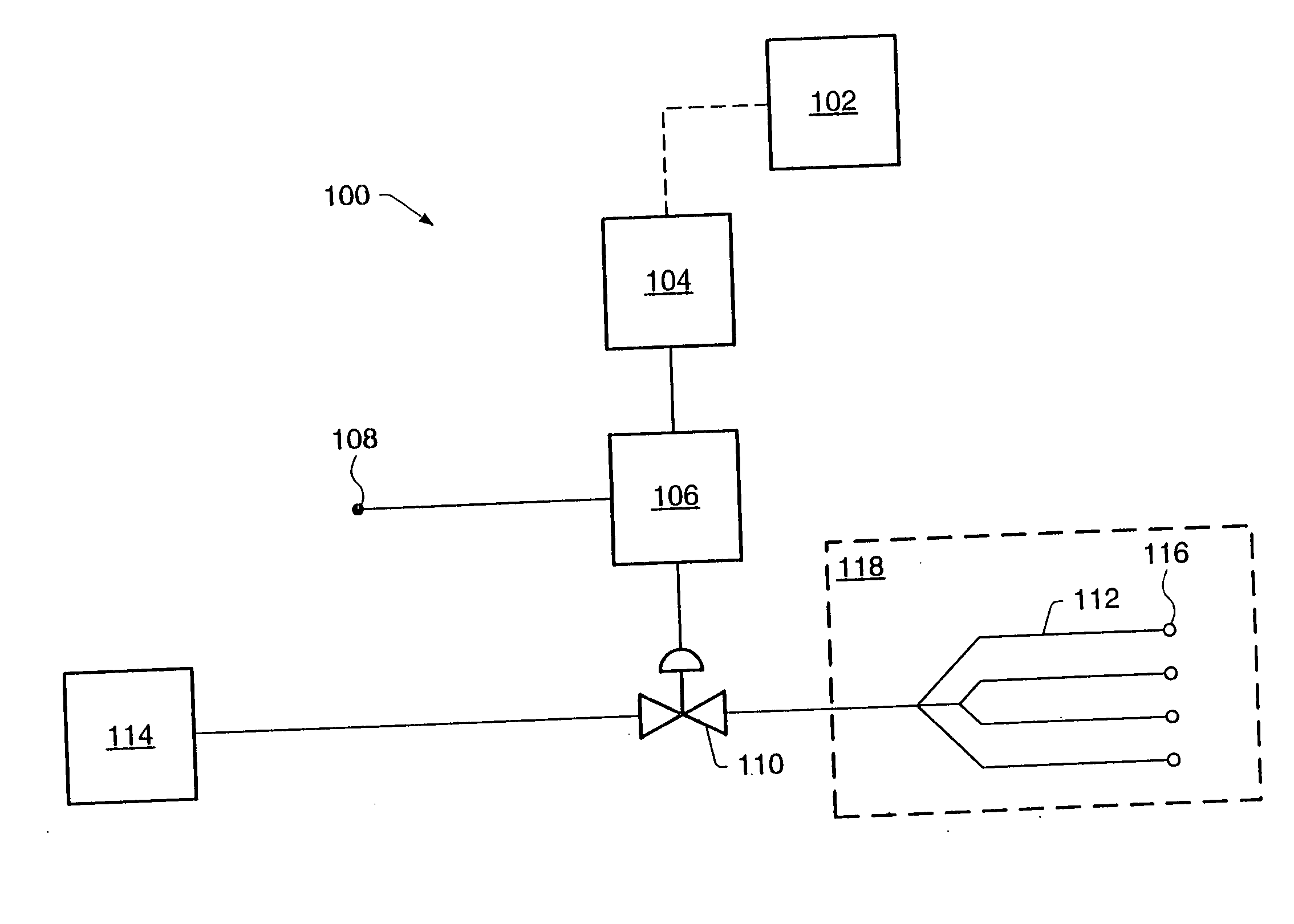

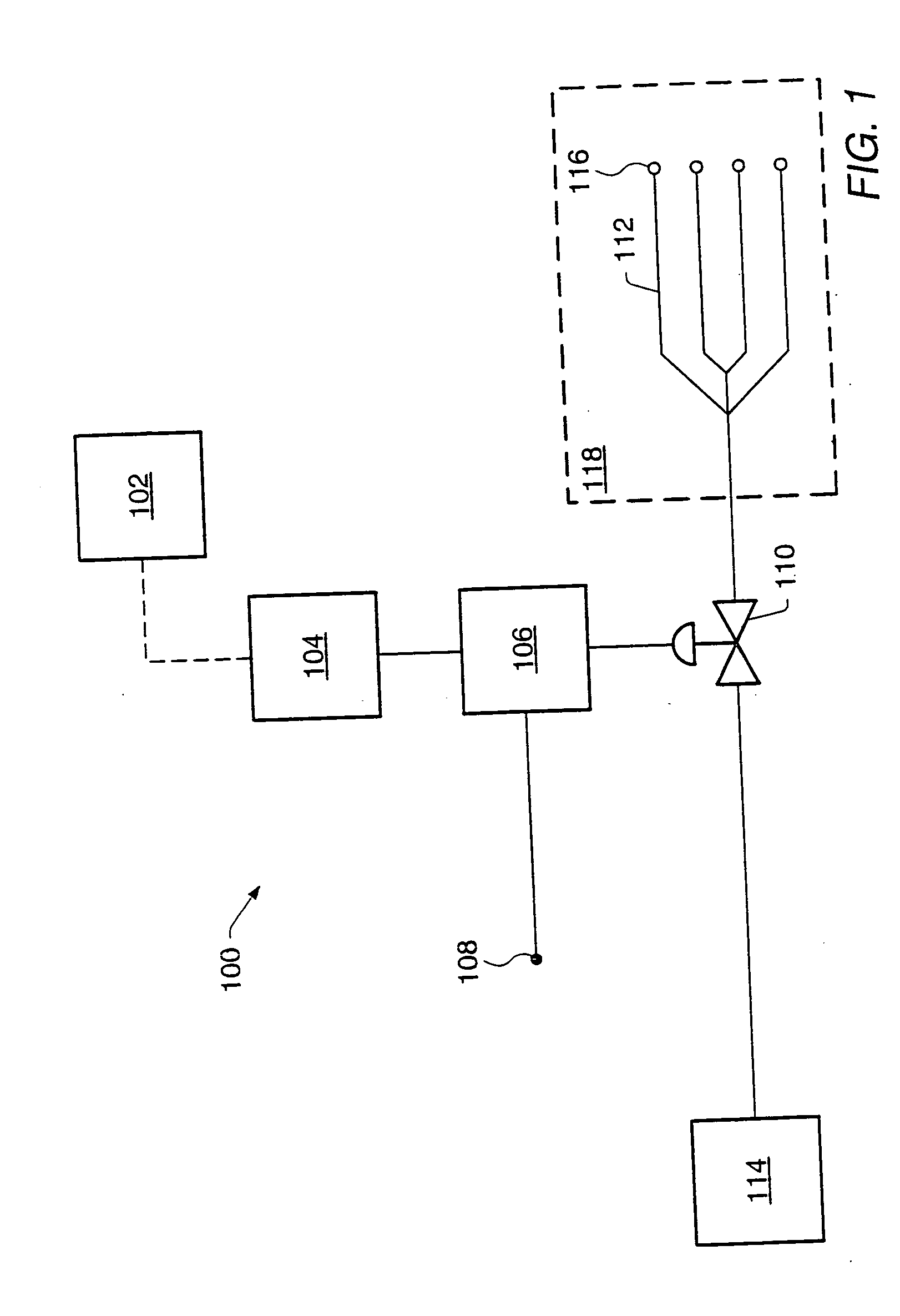

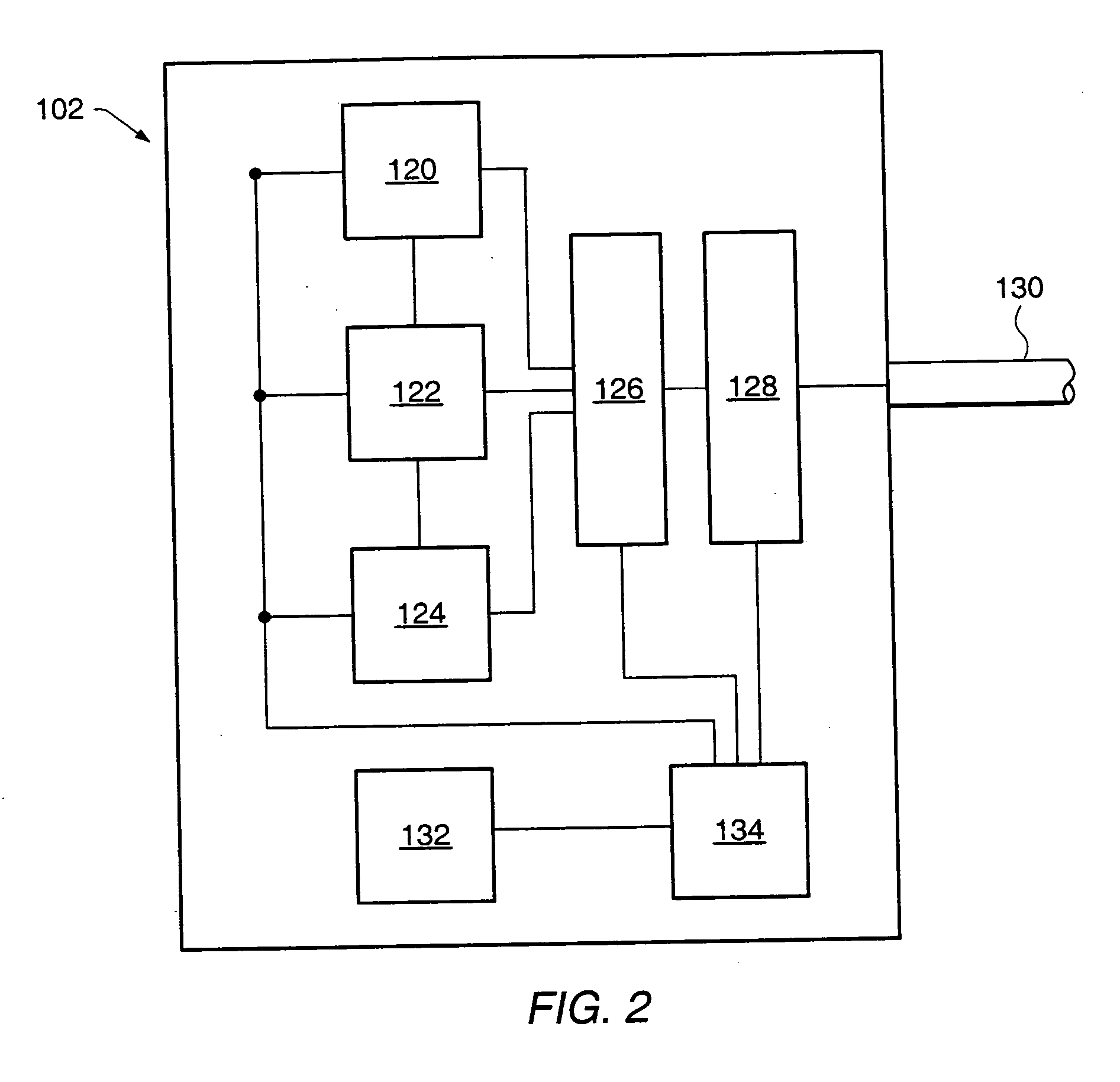

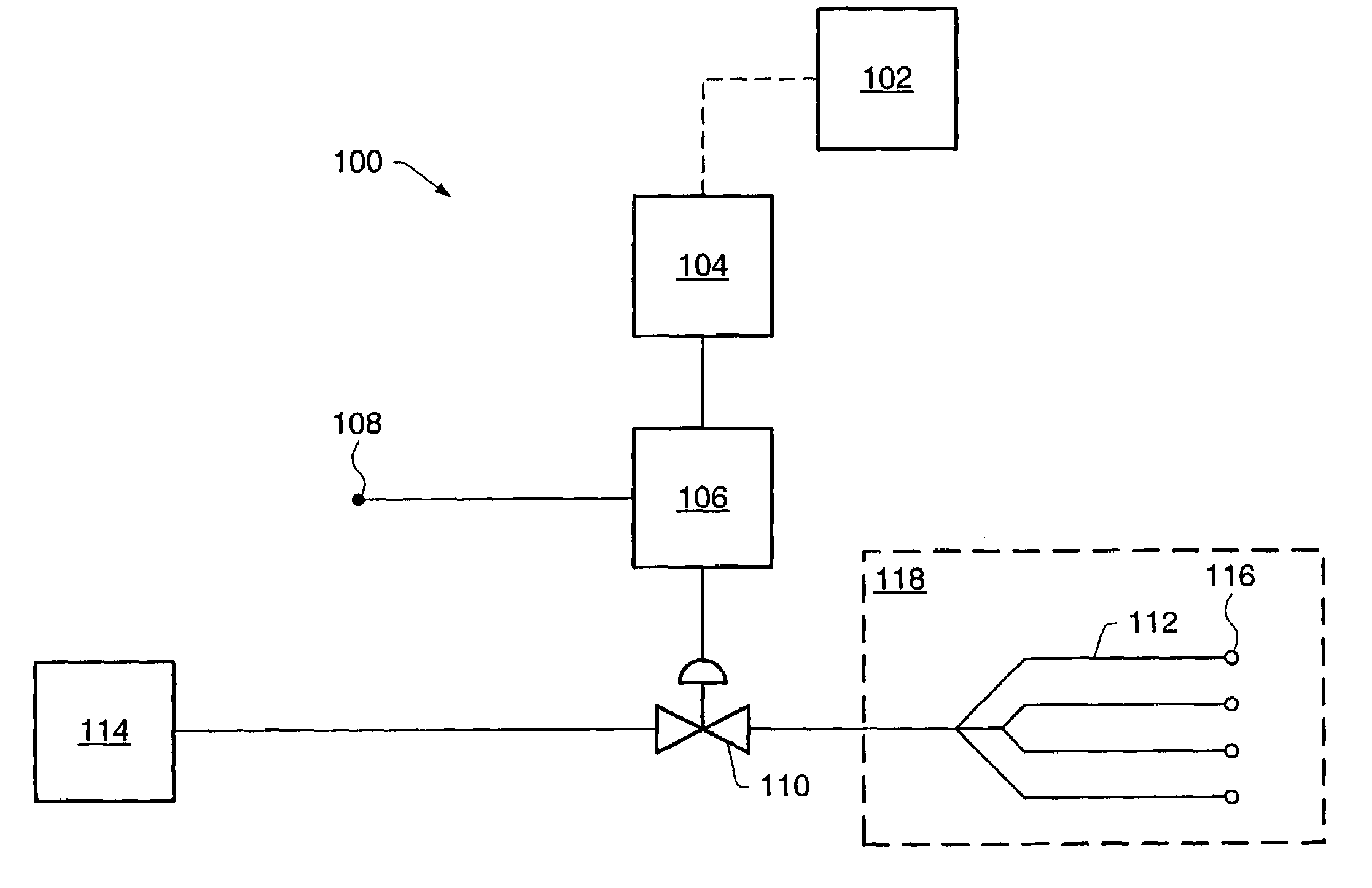

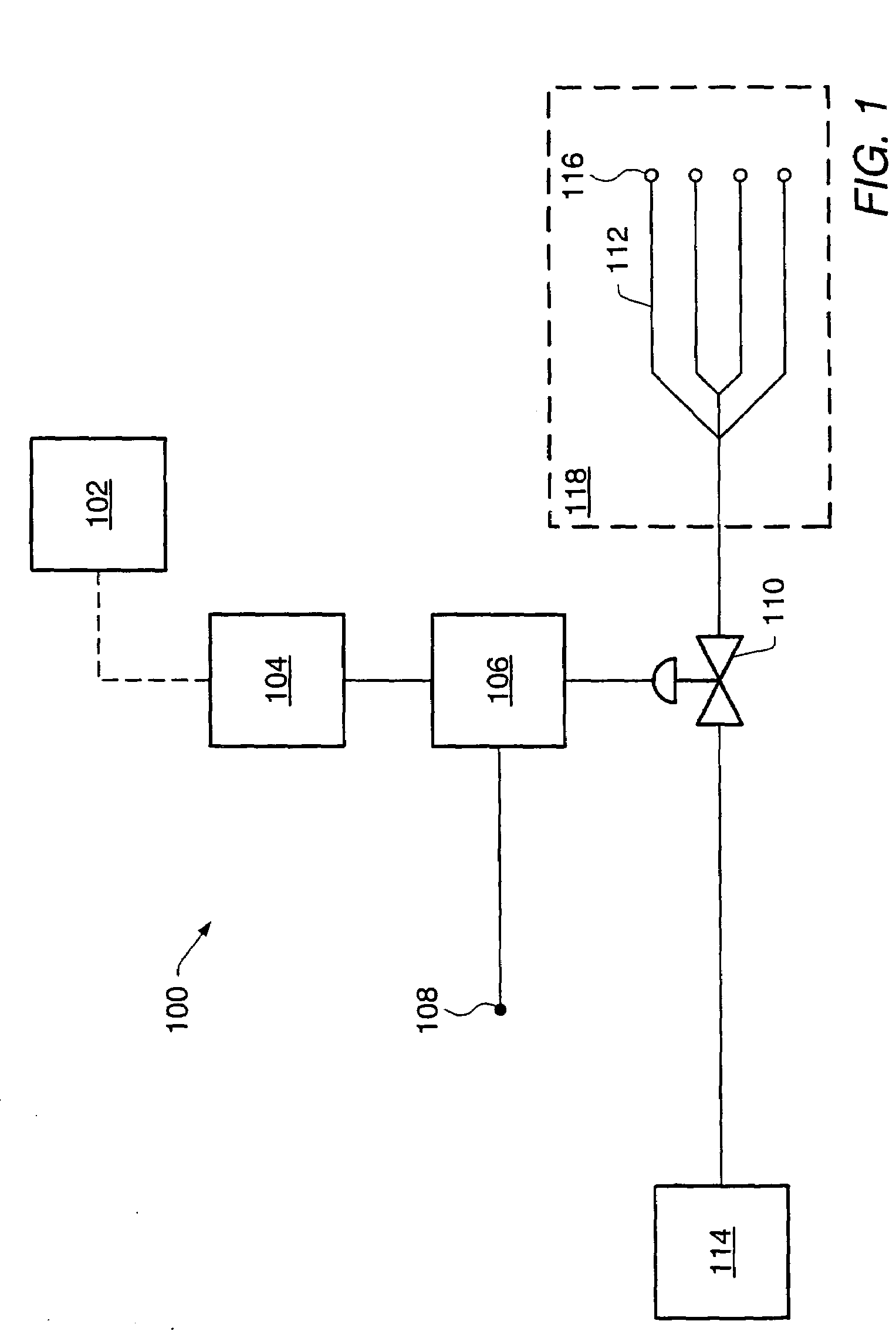

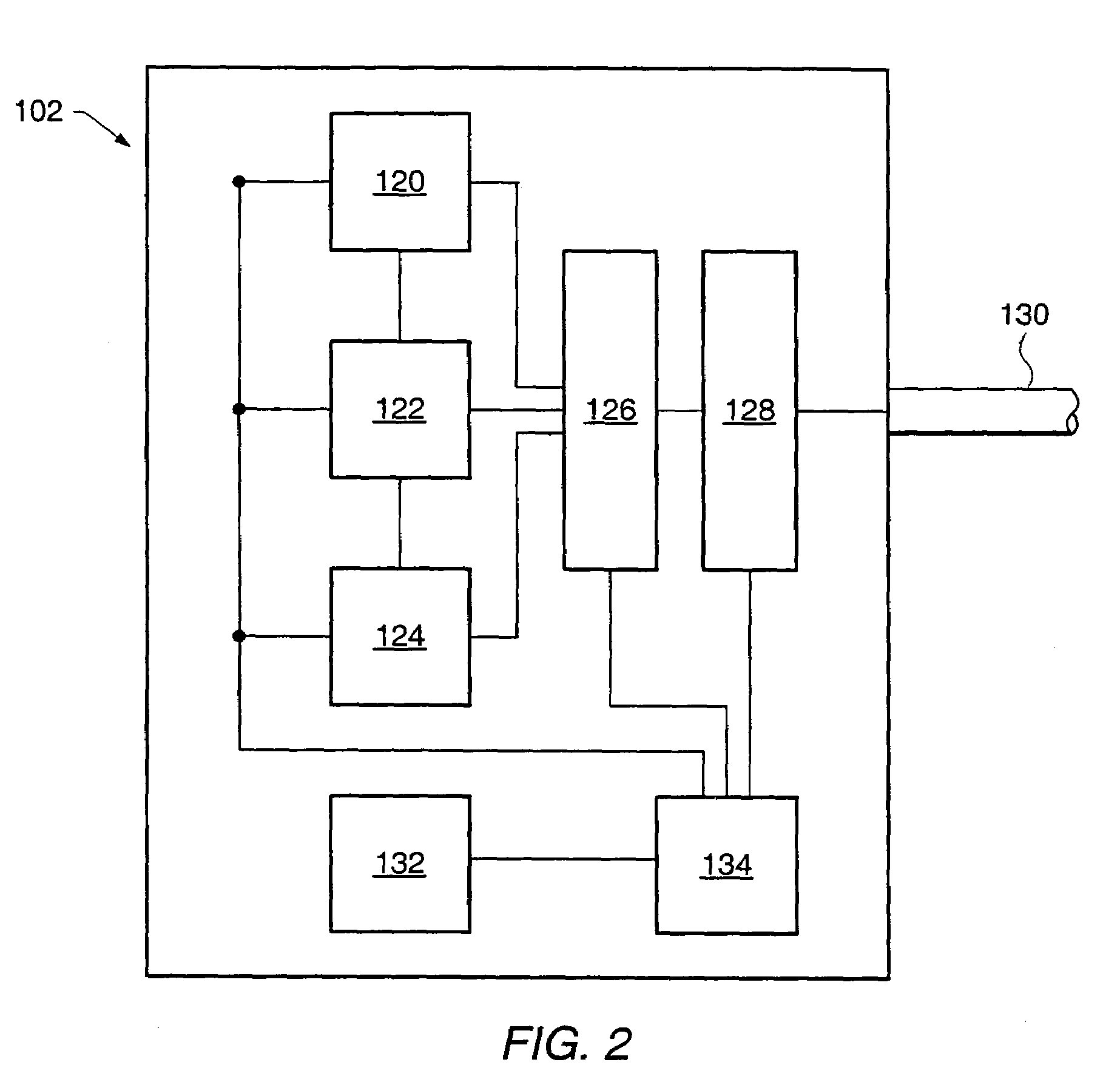

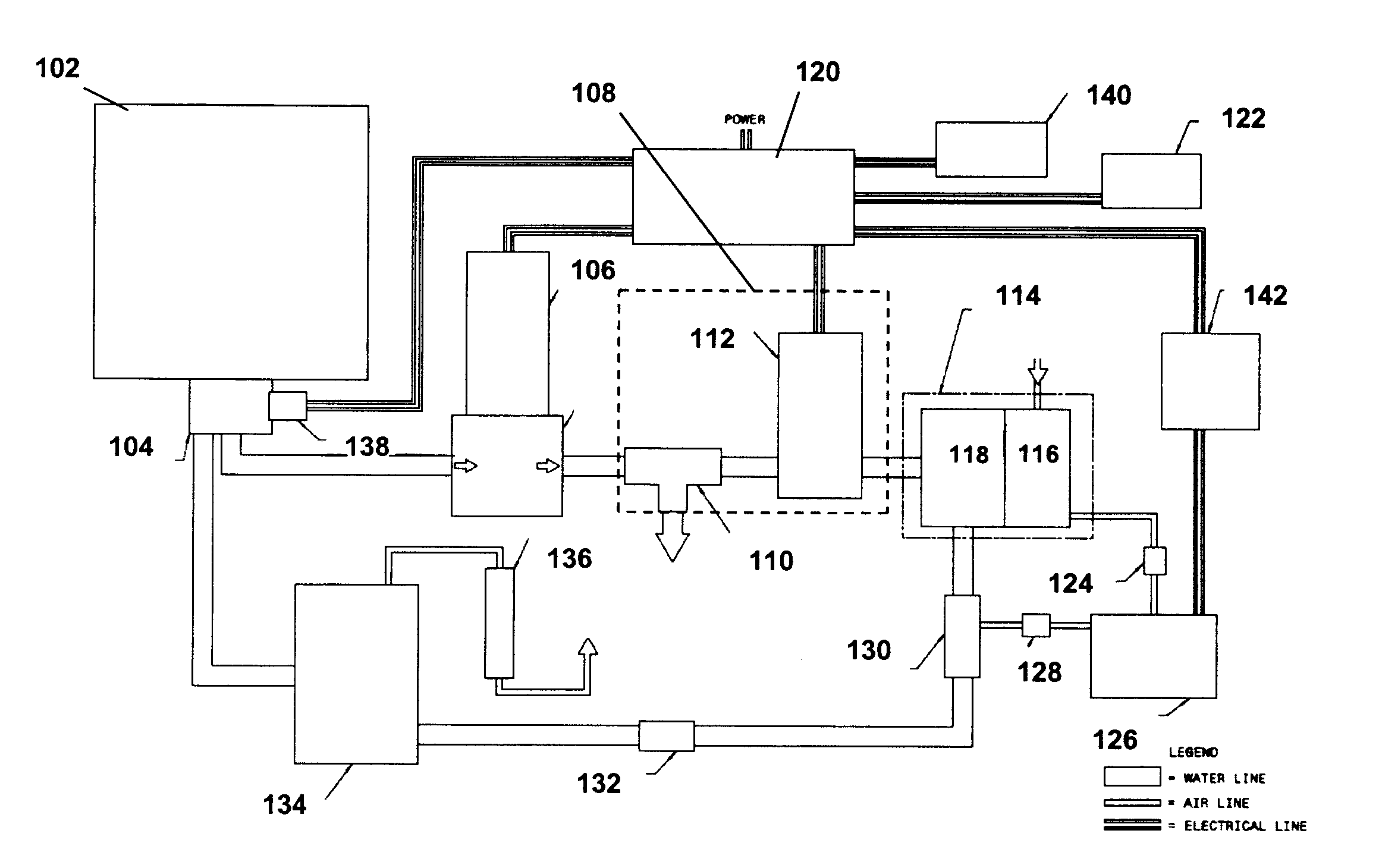

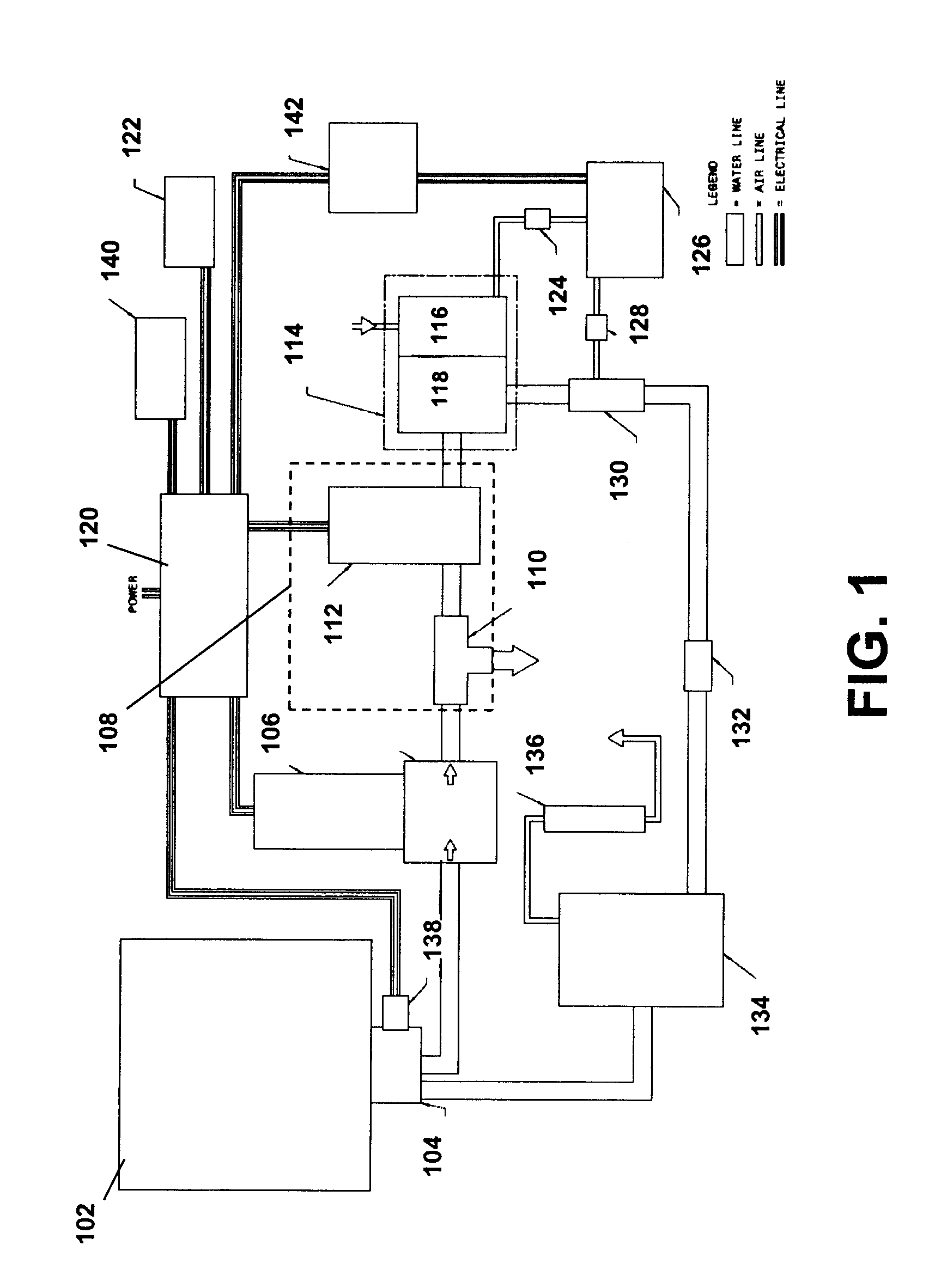

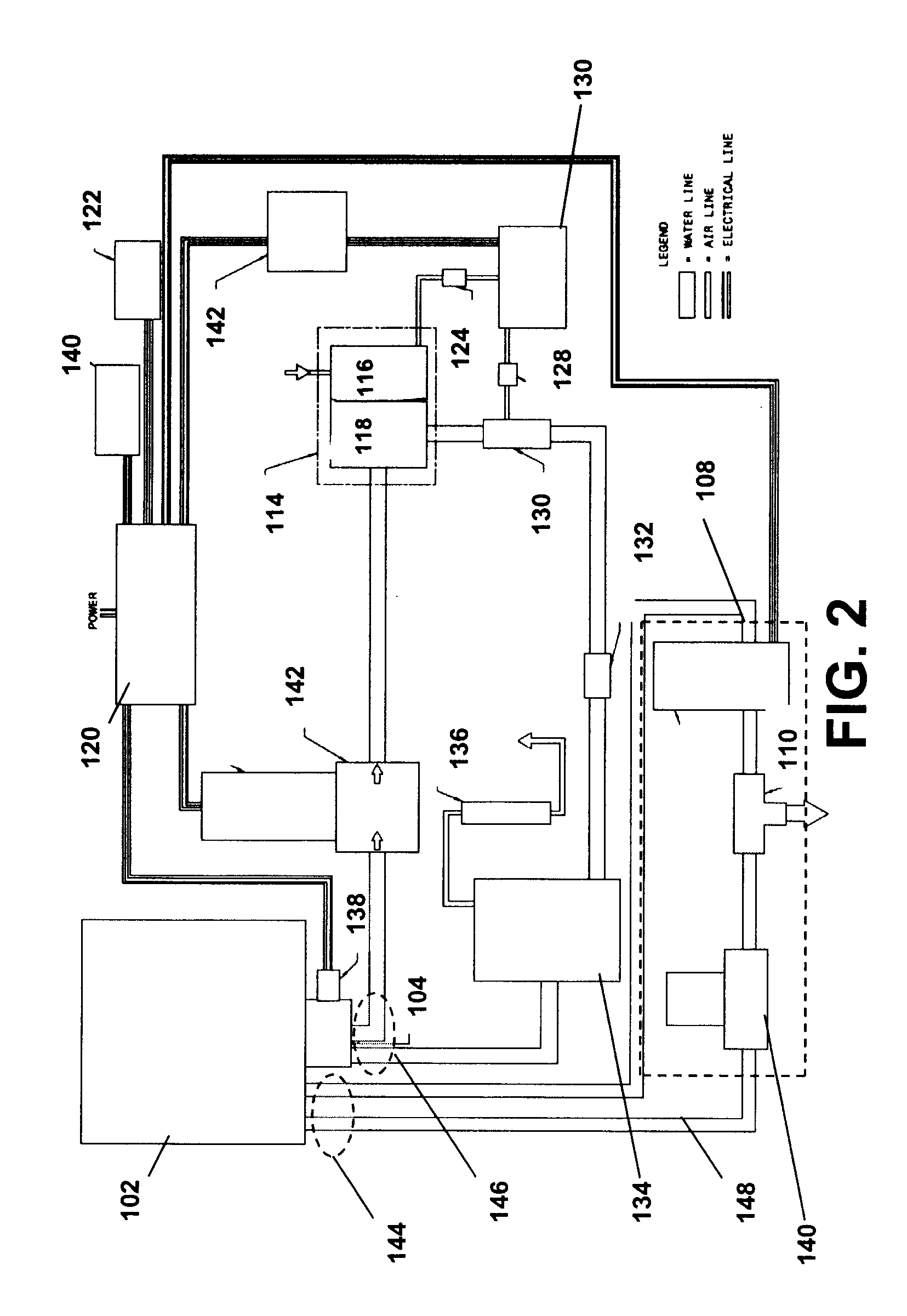

Systems and methods for detecting and eliminating leaks in water delivery systems for use with appliances

InactiveUS20060027267A1Prevent water flowQuick installationOperating means/releasing devices for valvesLighting and heating apparatusFlow transducerIsolation valve

Apparatus and methods for detecting and eliminating water flow leakage conditions within appliances having integral water filtration systems. Leak free water delivery systems for use with an appliance can include an isolation valve and flow sensor for providing a response mechanism for possible water leakages within the integral water filtrations system. The appliance makes use of a flow sensor to sense water flow rates within a preselected flow range. When water flow rates outside the preselected flow range are sensed, the isolation valve is closed to prevent non-transient water flow through the water system. The isolation valve can be remotely located on an inlet line or can be as a part of the integral water filtration system. The integral water filtration system can include a manual or automatic reset mechanism such that a user can restore water flow after a low flow or high flow situation has been rectified.

Owner:3M INNOVATIVE PROPERTIES CO

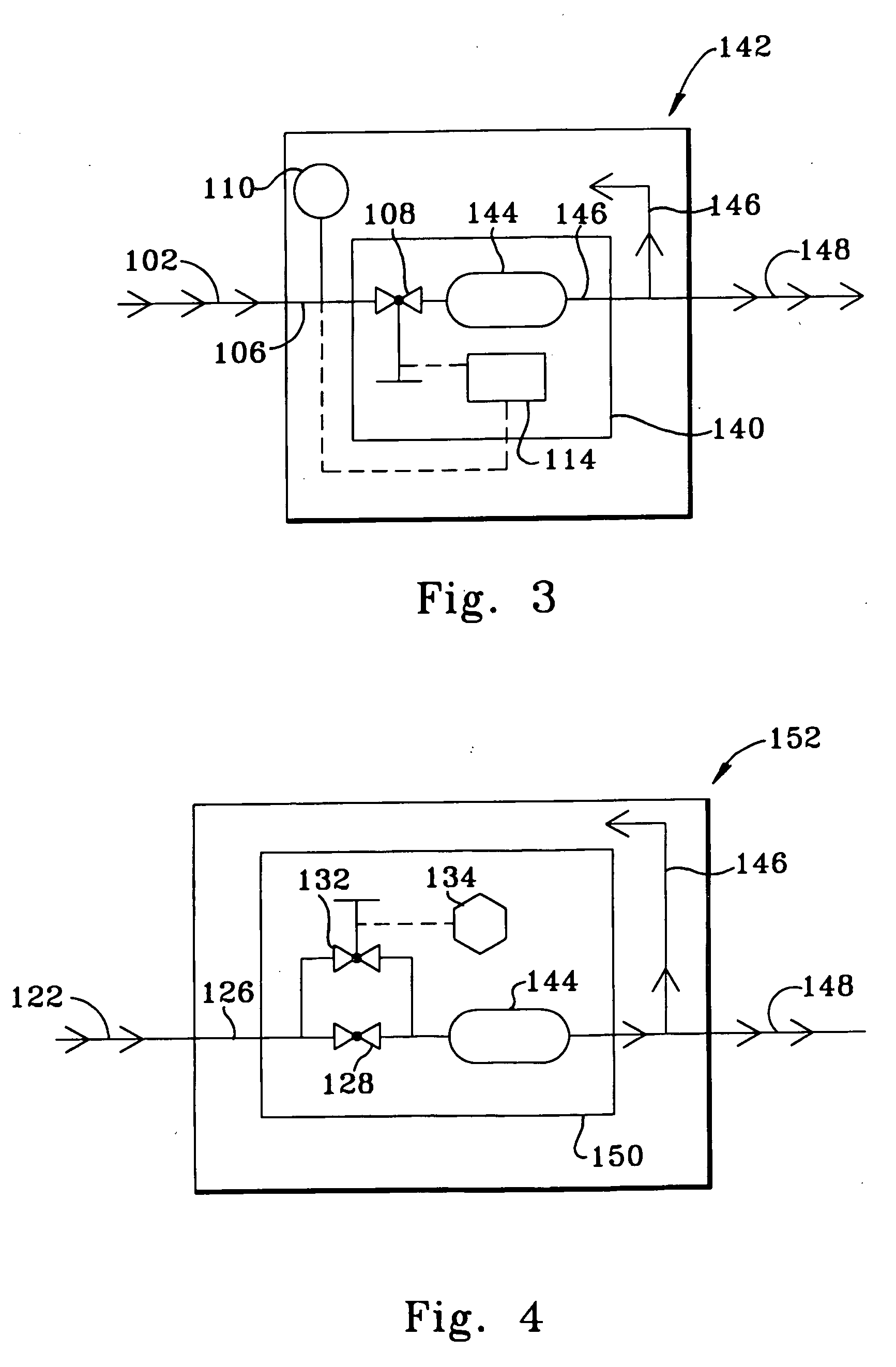

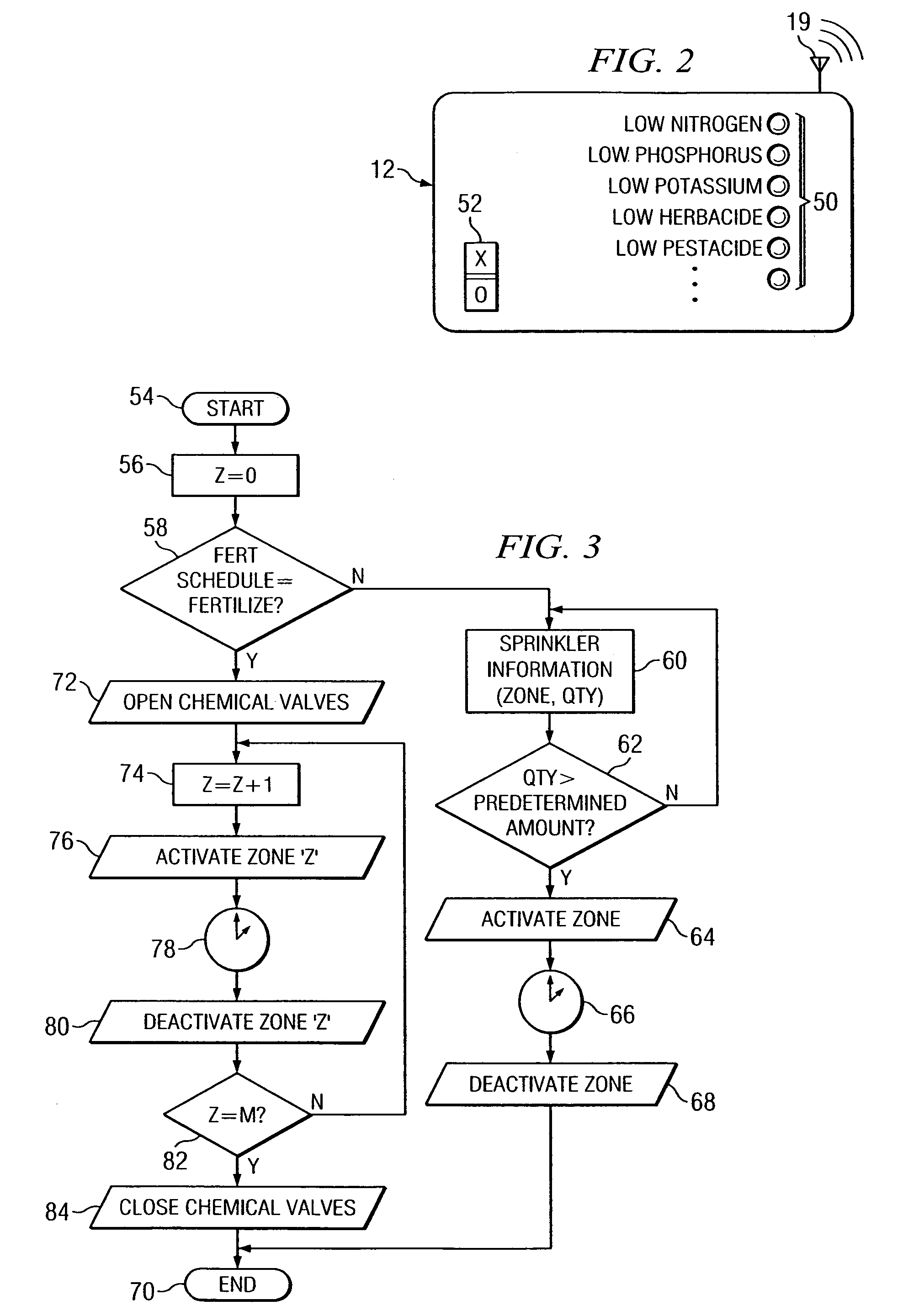

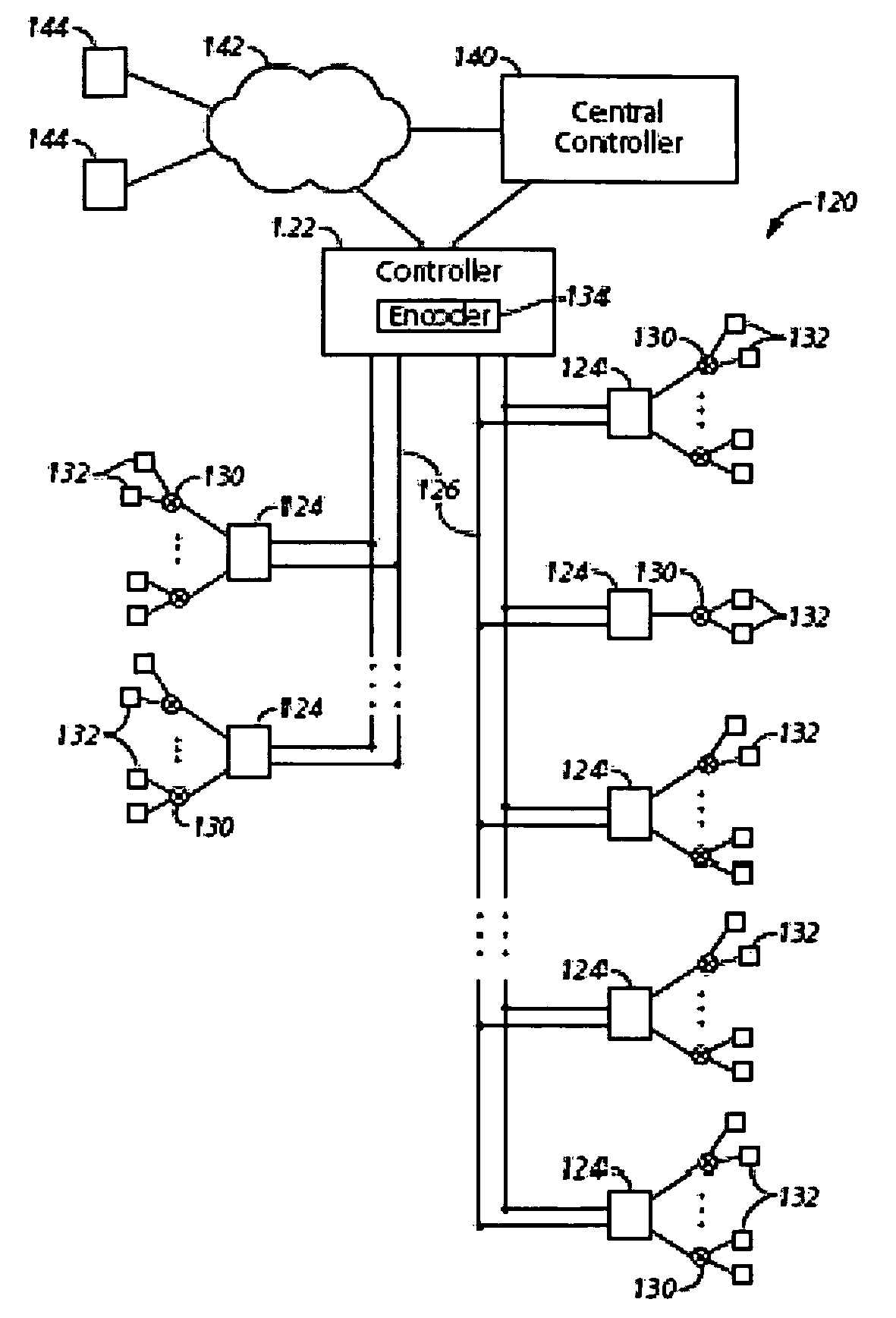

Methods, systems and apparatuses for automated irrigation and chemical treatment

InactiveUS7264177B2Easy programmingLow costSelf-acting watering devicesLiquid fertiliser distributionChemical treatmentWireless transceiver

An automated irrigation and chemical treatment system comprising a user input device adapted to communicate with a control unit; a mixing chamber adapted to communicate with the control unit and connected to a water supply and chemical canisters, wherein each canister has a sensor to monitor fluid level therein, and control valves for connecting the mixing chamber to a network of pipes. Sprinkler heads connected to the network of pipes each include, a control valve adapted to control fluid flow to a water delivery nozzle by an electro magnet controlled rubber coated ferric ball closure member. The sprinkler heads include water and chemical saturation sensors and the sprinkler heads also communicate with the control unit via wireless transceivers. Multiple zones covered by the system may be treated according to predetermined schedules.

Owner:INTELLIGENT LAWN SYST

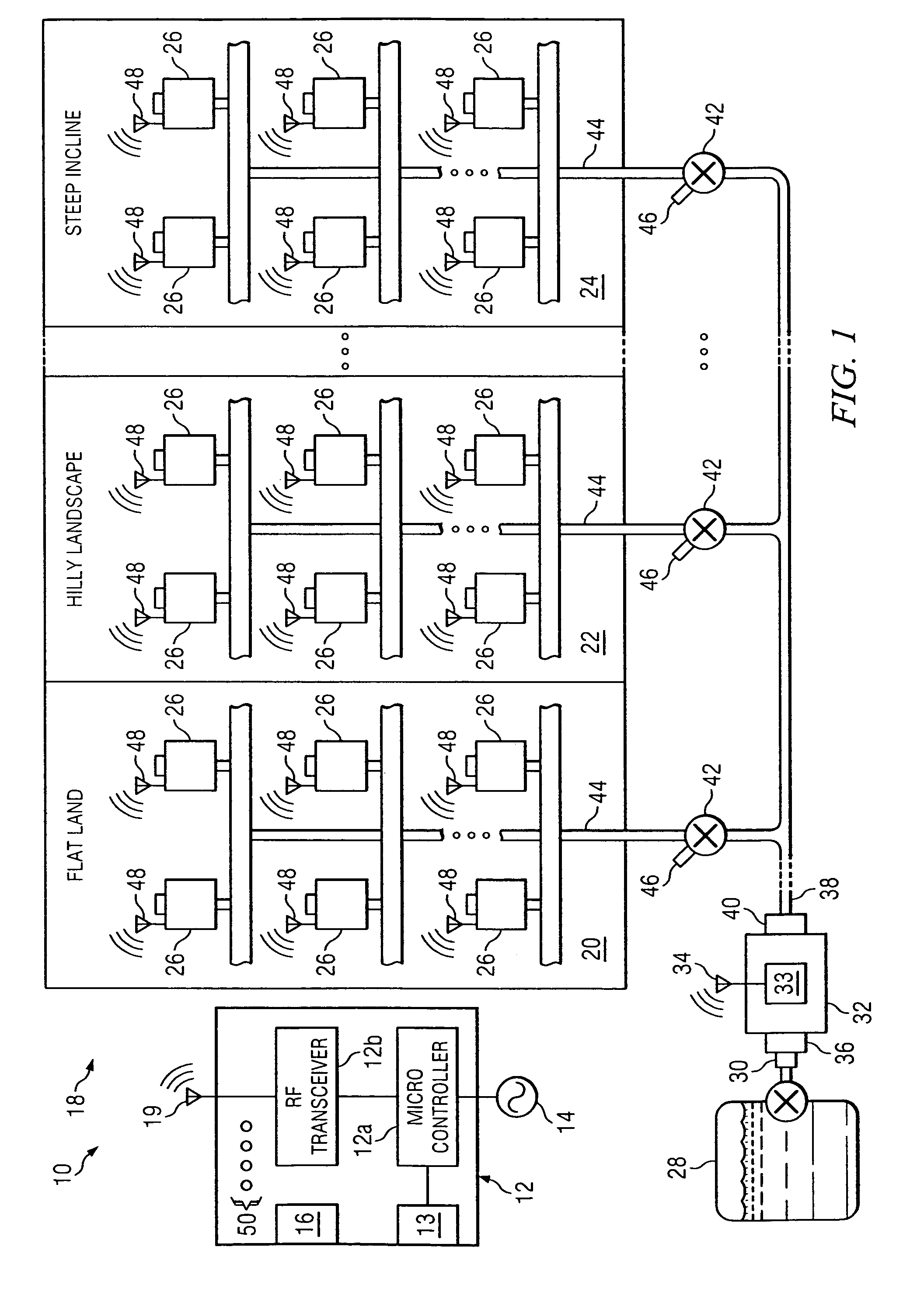

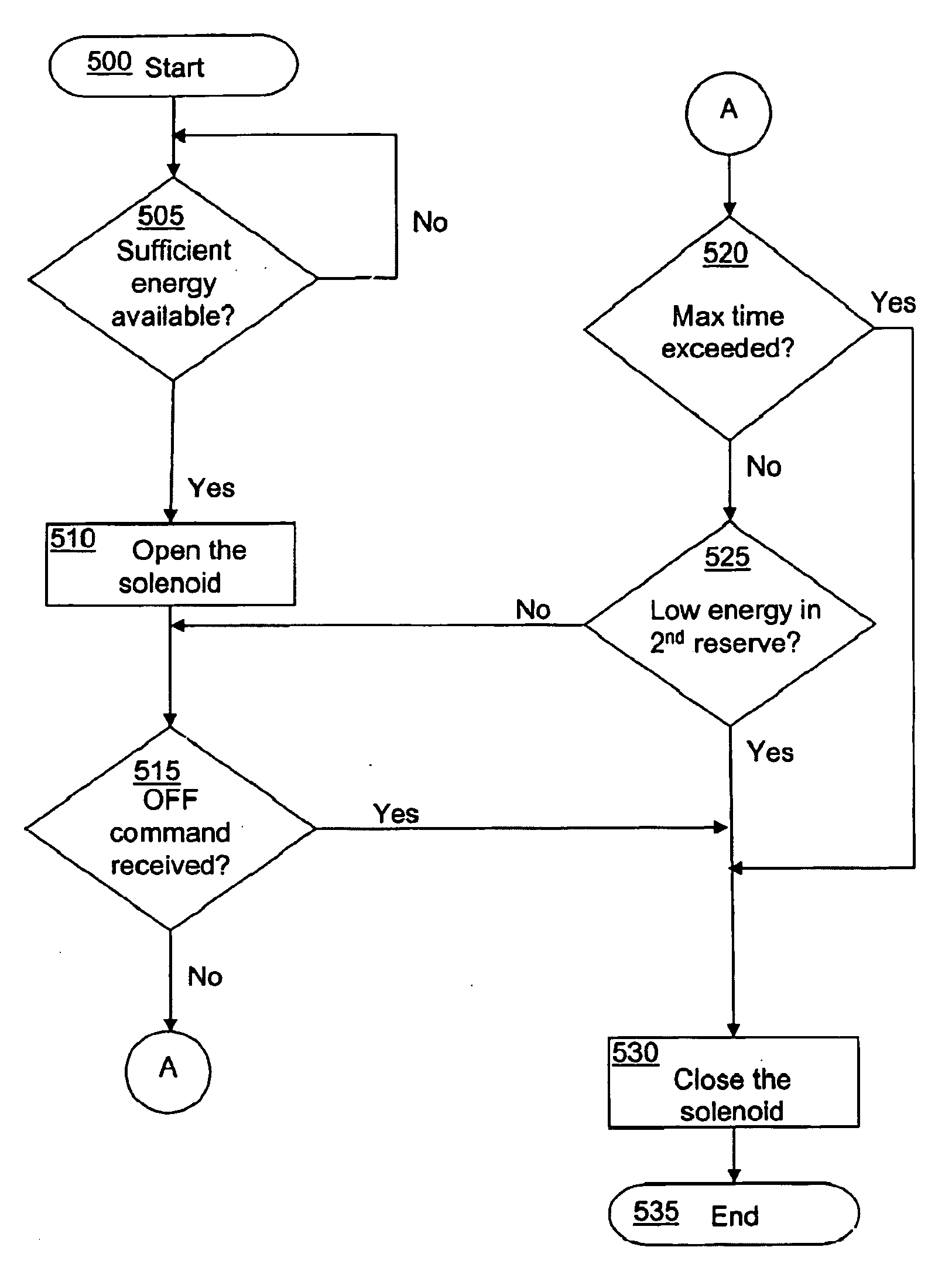

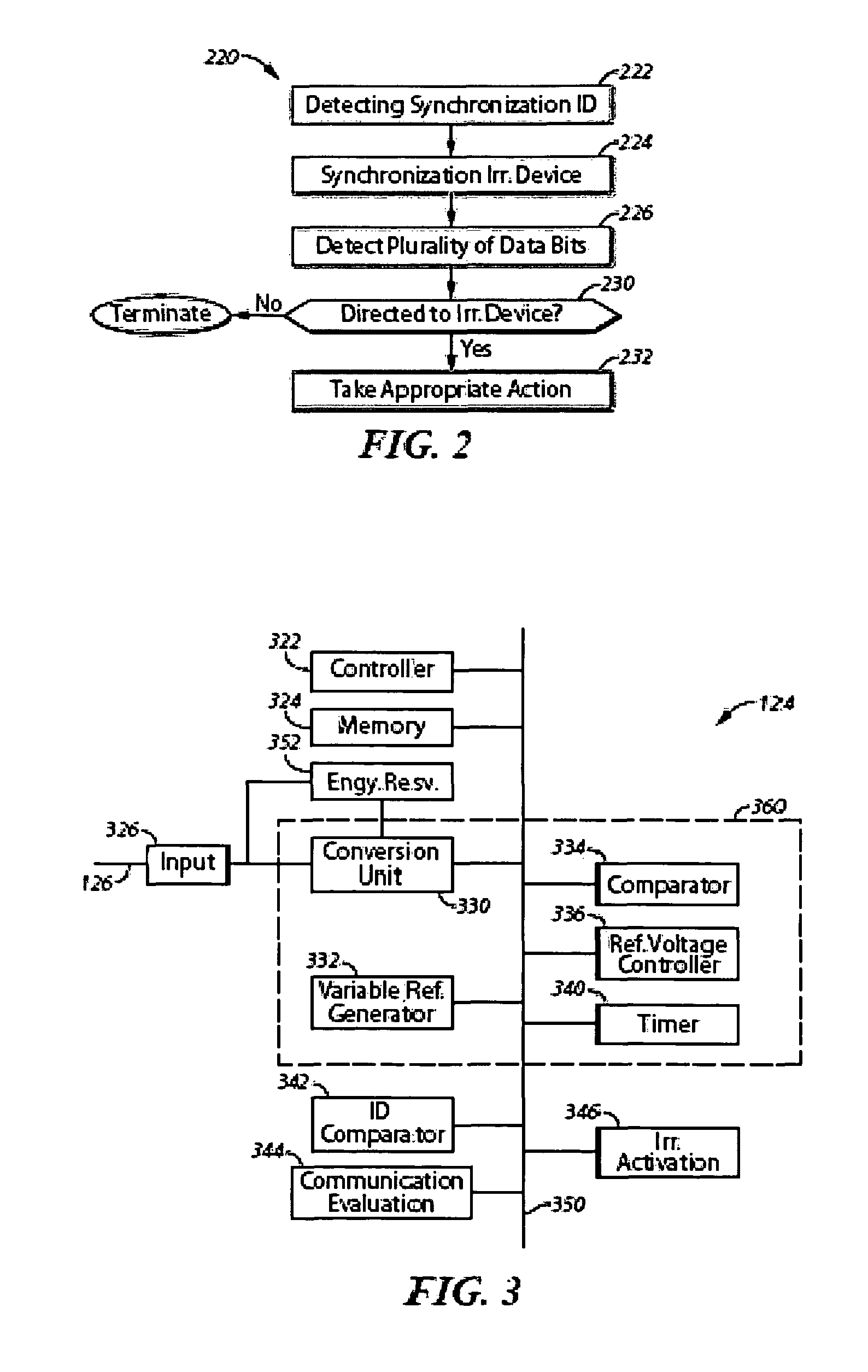

Latching solenoid energy reserve

ActiveUS20100161144A1Increase system costSmall power demandOperating means/releasing devices for valvesWatering devicesStored energySolenoid valve

An irrigation device including an actuator configured to control water flow to at least one water delivery device, a first stored energy source configured to power the actuator to effect irrigation via the at least one water delivery device, and a second stored energy source which is separate from the first stored energy source, wherein the second stored energy source is configured to power the actuator to terminate the irrigation via the at least one water delivery device. The irrigation devices further includes a controller configured to cause the first stored energy source to power the actuator to effect the irrigation, responsive to an instruction to provide irrigation, and to cause the second stored energy source to power the actuator to terminate the irrigation responsive to a termination condition.

Owner:RAIN BIRD CORP

Electronic faucet with voice, temperature, flow and volume control

An ergonomic water conserving faucet assembly that pivots around a cognitive central point providing touchless water temperature, flow rate, volume control and spray pattern adjustment through multiple, hygienic means. The assembly comprises a pivotable, ergonomic, ball-shaped spout that may be used statically or hand held; a retractable water delivery hose connecting the spout to a water source; a water mixing valve at the water source delivering water of preselected temperature; solenoid valves controlling flow; proximity and object detection sensors mapping the sink area and detecting input signals; speech sensors with microphone for voice control; an LED display of water temperature; internal speakers delivering audible prompts; and an electronic controller recognizing speech and supervising operations.

Owner:WOLF JAMES L +1

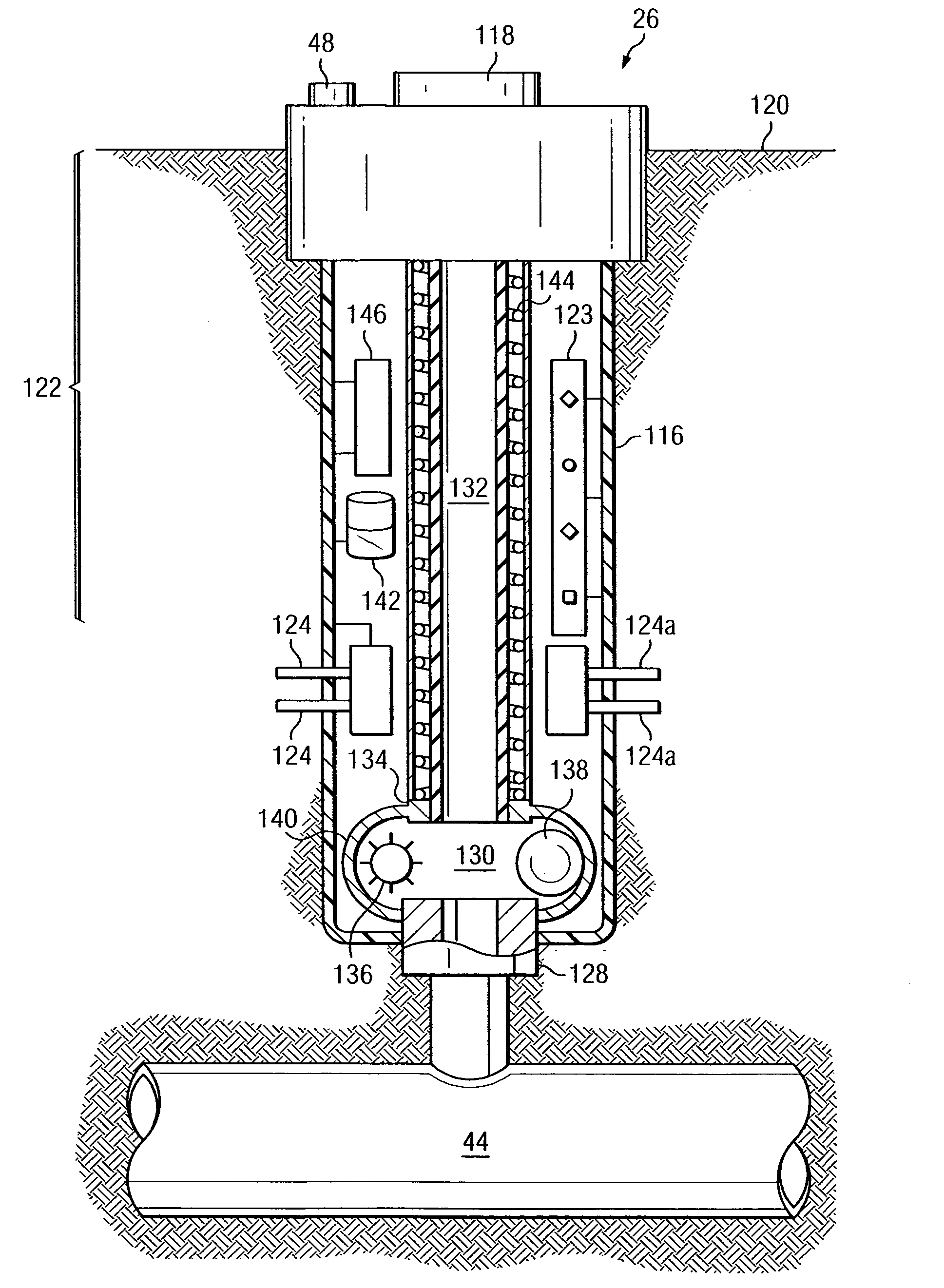

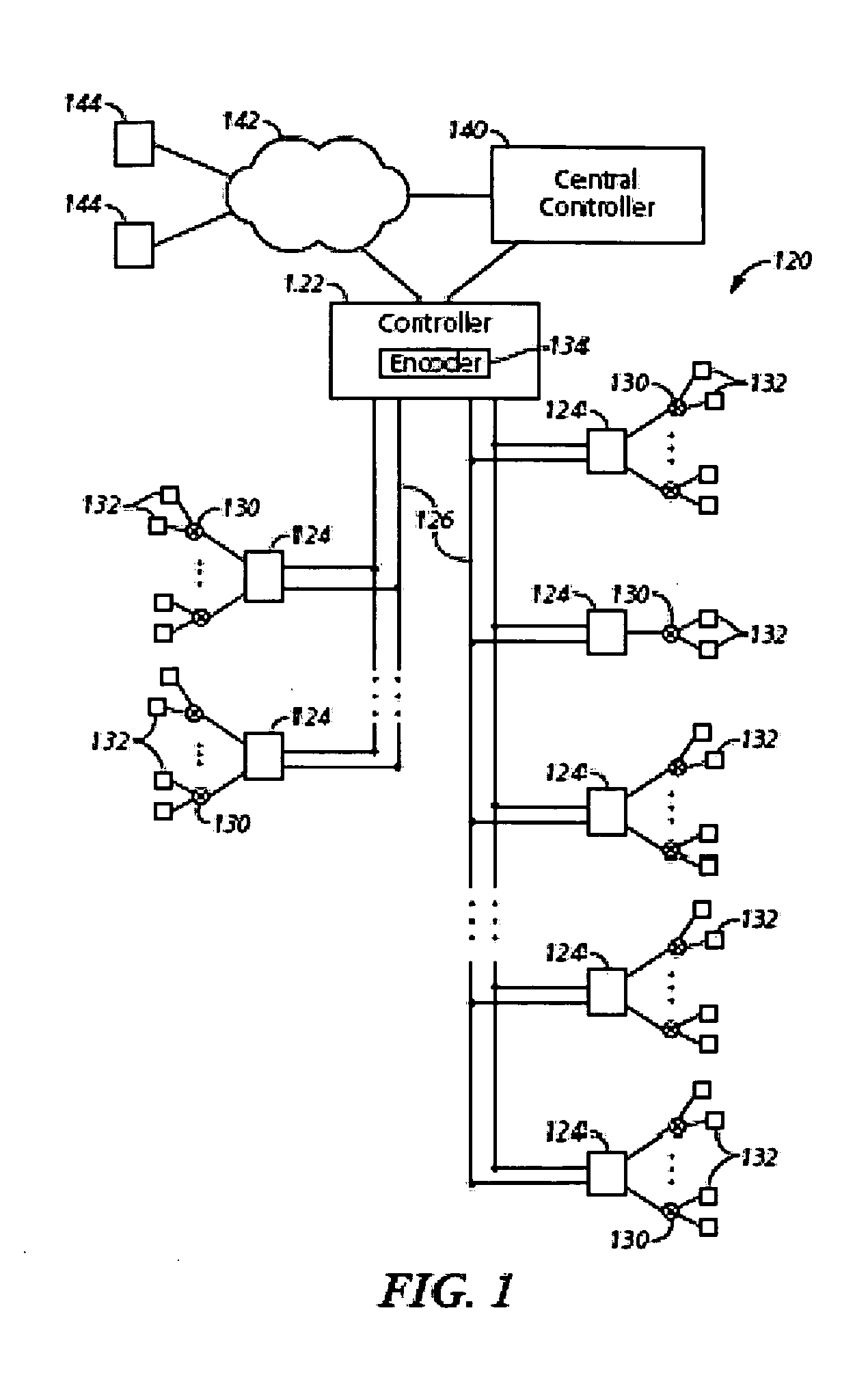

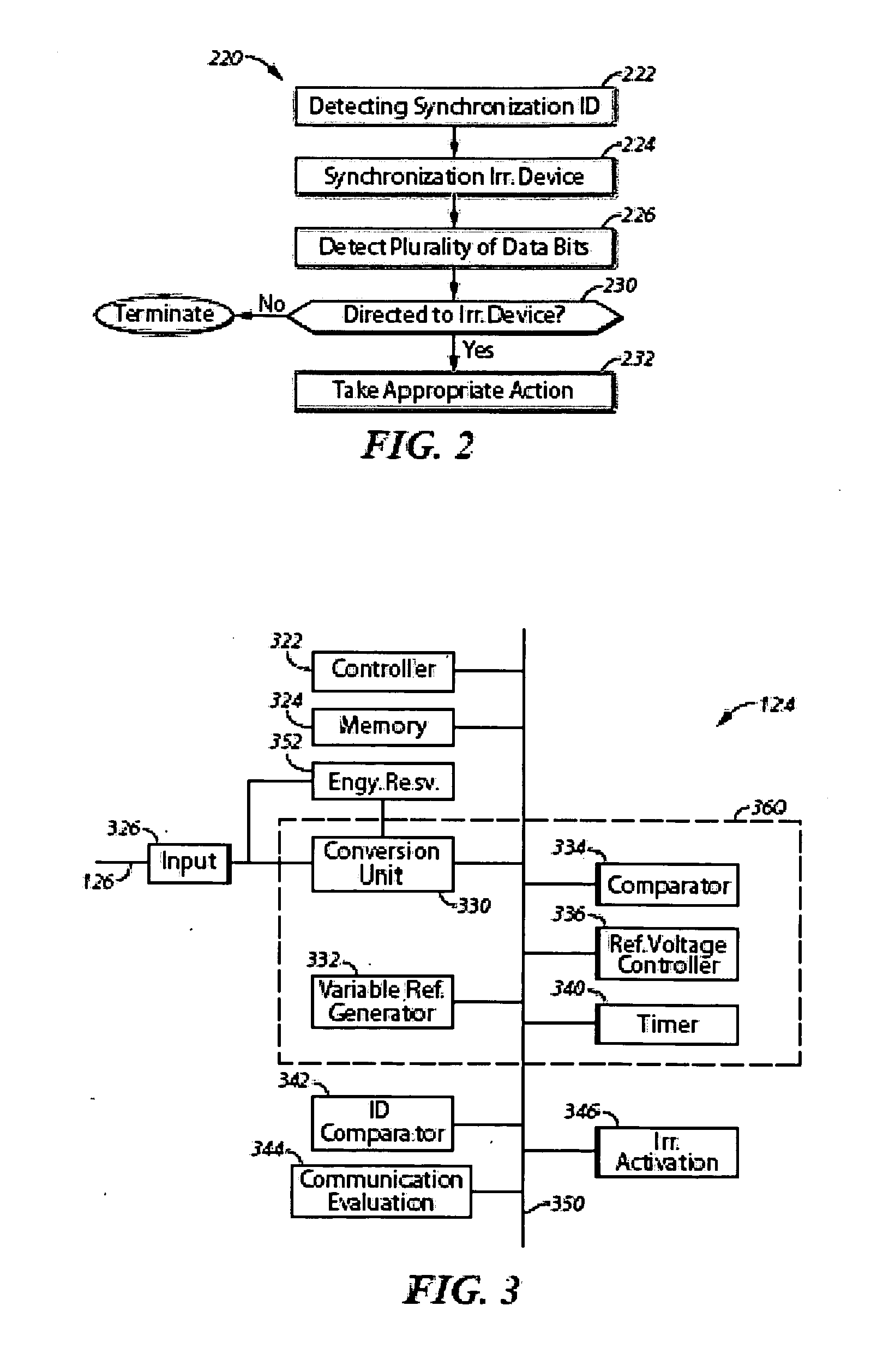

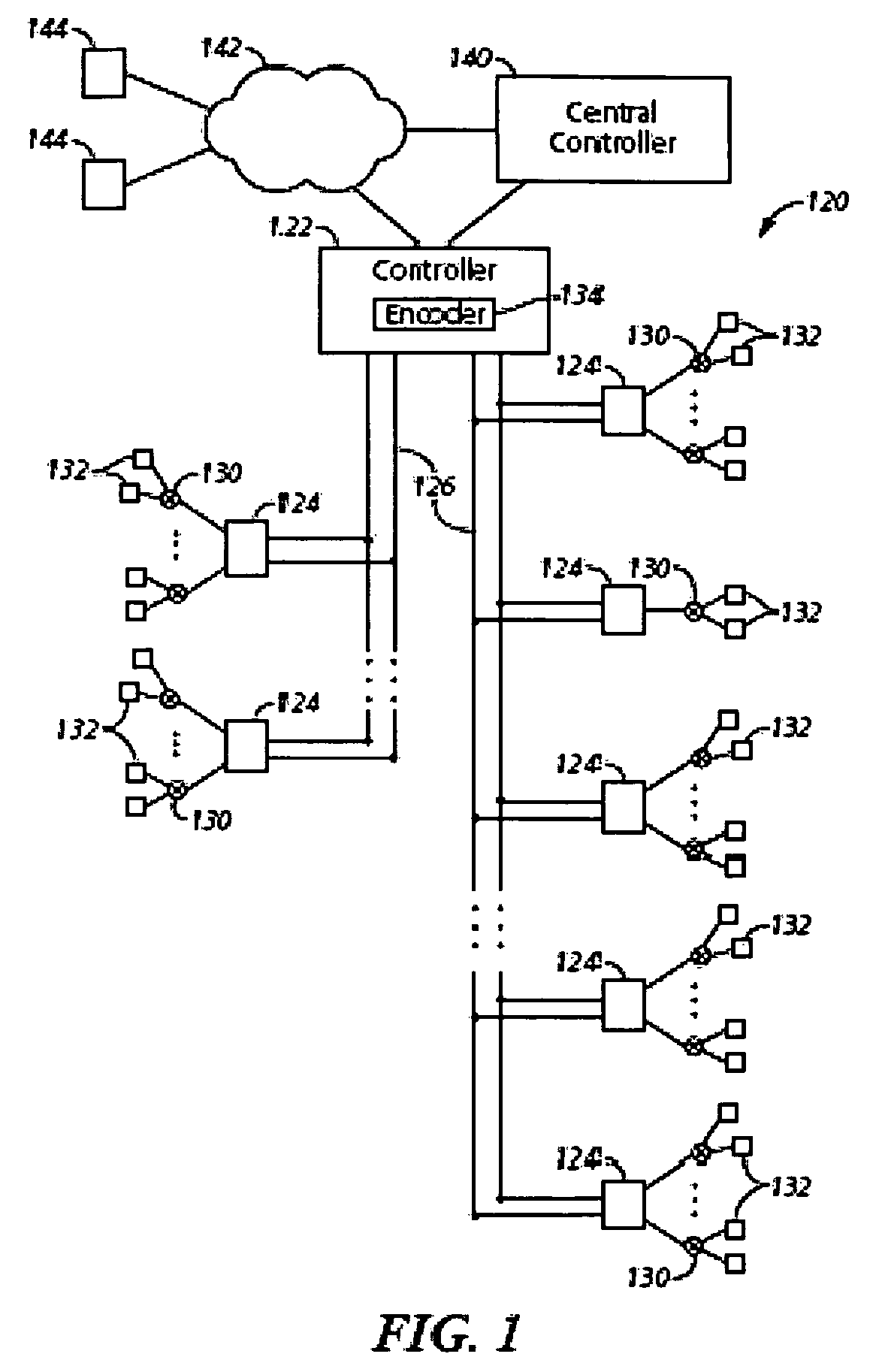

Water irrigation system with wireless communication and method of controlling irrigation

A water irrigation system may include a computer system, a sensing unit, an irrigation controller, and / or a water delivery system. The computer system may include an infrared receiver. An operator may use a portable device with an infrared transmitter to provide a signal to the infrared receiver of the computer system. The signal may include instructions for the water irrigation system. The computer system may control irrigation of a zone to be irrigated at least partially based on the infrared signal from the portable device. A method of controlling irrigation may include allowing an infrared receiver of a computer system to receive infrared output from a portable device and controlling irrigation of a zone to be irrigated at least partially based on the infrared output. The method may include controlling irrigation of a zone to be irrigated at least partially based on the infrared output received from the portable device.

Owner:CLARK JAMES JOLLY

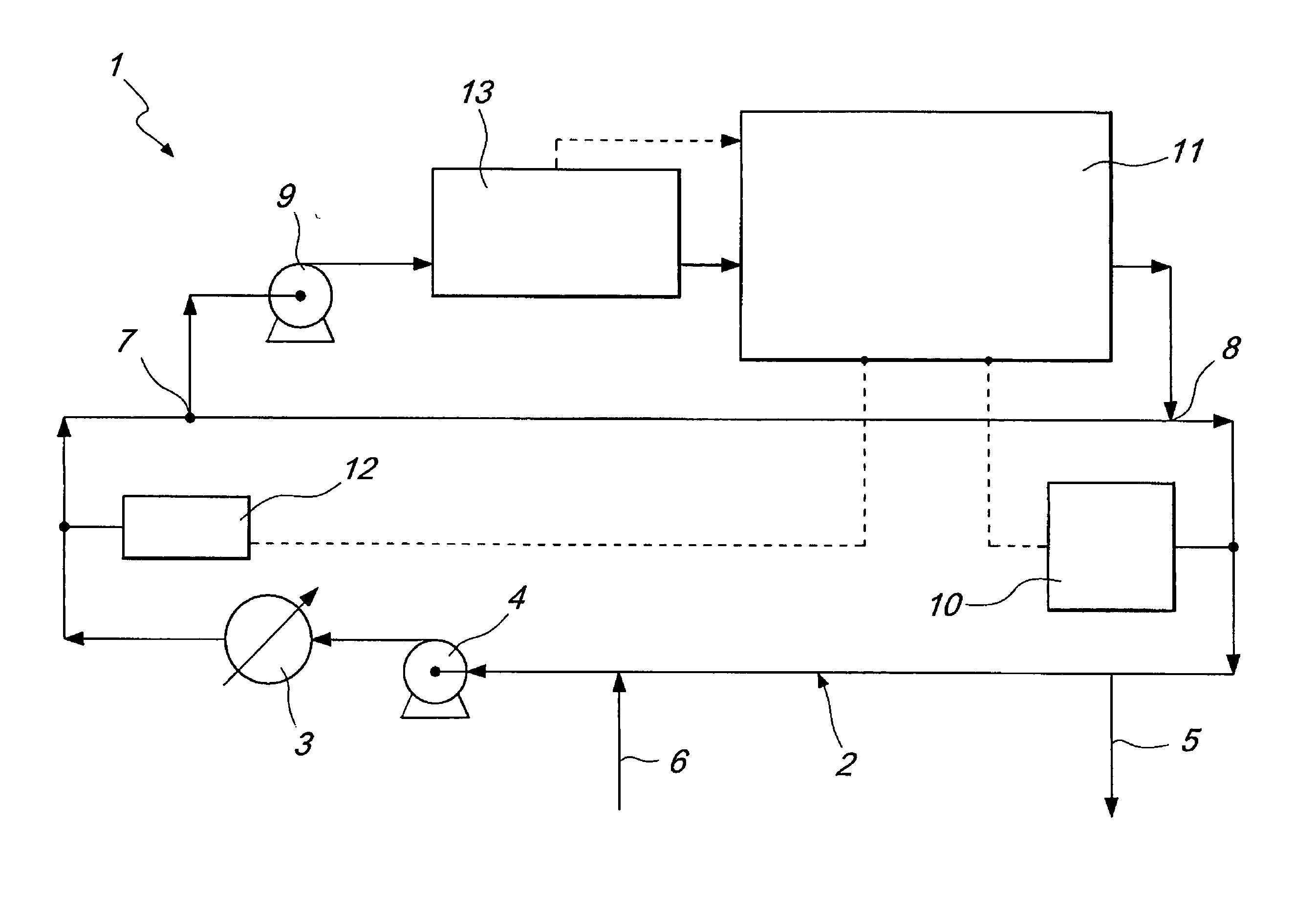

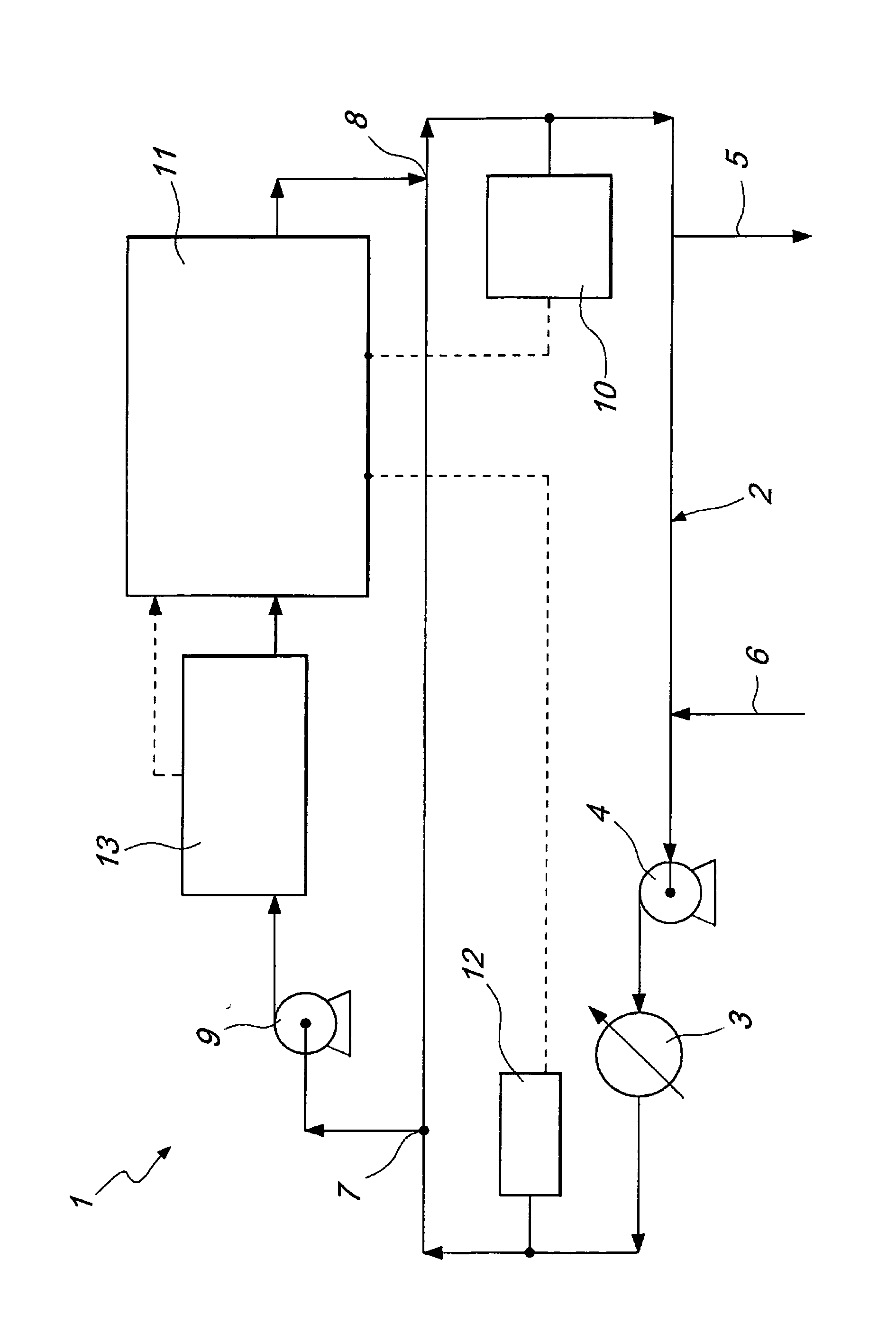

Method and apparatus for disinfecting hot water

ActiveUS20100206815A1Avoid accumulationReliable and safe methodWater treatment parameter controlIon-exchanger regenerationWater volumeEngineering

A method for disinfecting hot water, in recirculating systems, includes producing monochloramine directly in hot water, at a temperature higher than 30° C. in a hot water circulating system The method is implemented by an apparatus for disinfecting hot water, in recirculating systems, having a main hot water circuit, one or more water delivery points and a water feed point, adapted to maintain the circulating water volume constant, a drawing point, where a portion of water of the main circuit is drawn and an intake point where water added with monochloramine is reintroduced into the main circuit; and an adding circuit formed between the drawing point and the intake point; the adding circuit has a control and adding system, adapted to add monochloramine producing reagents to the hot water.

Owner:SANIPUR

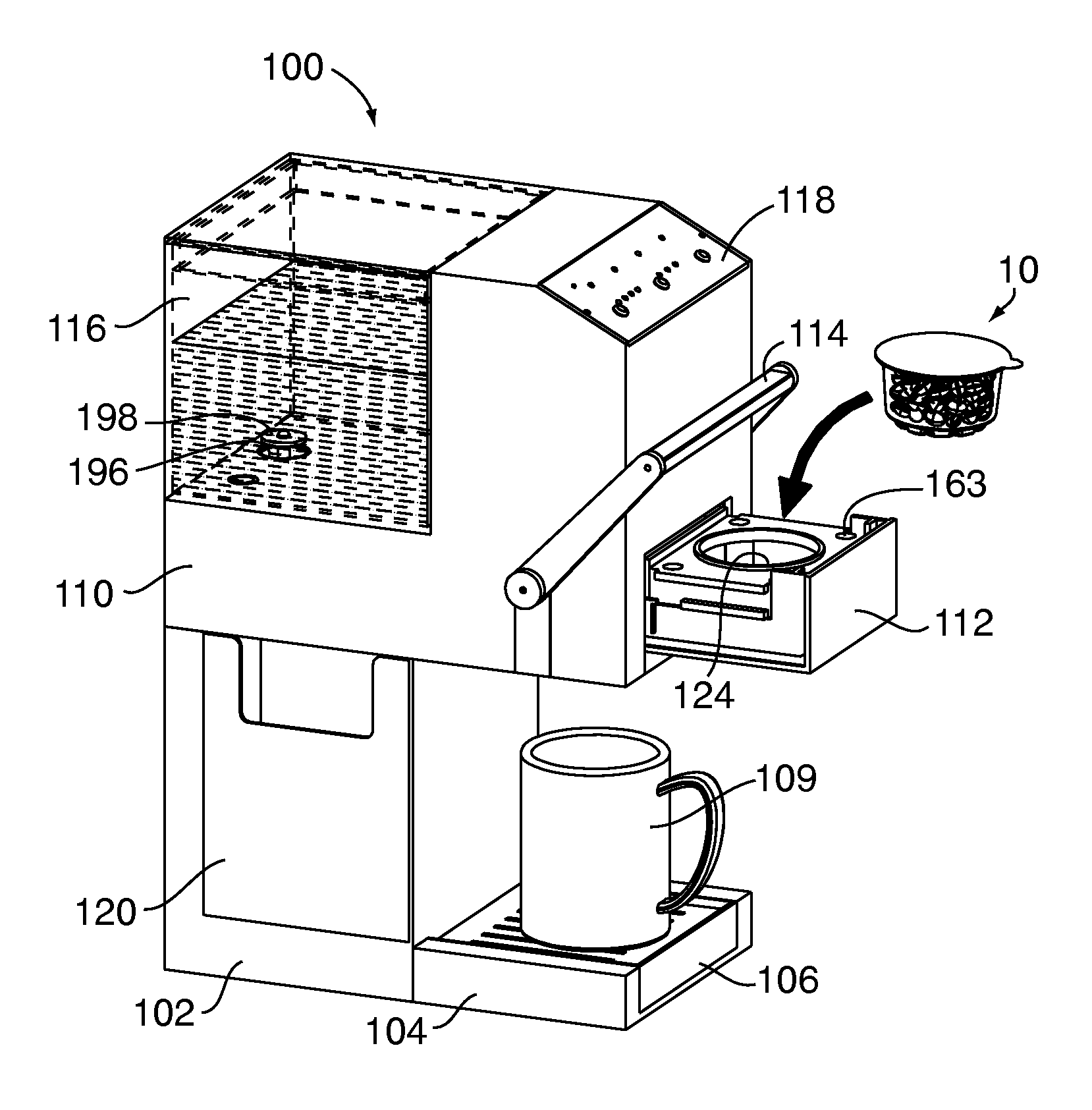

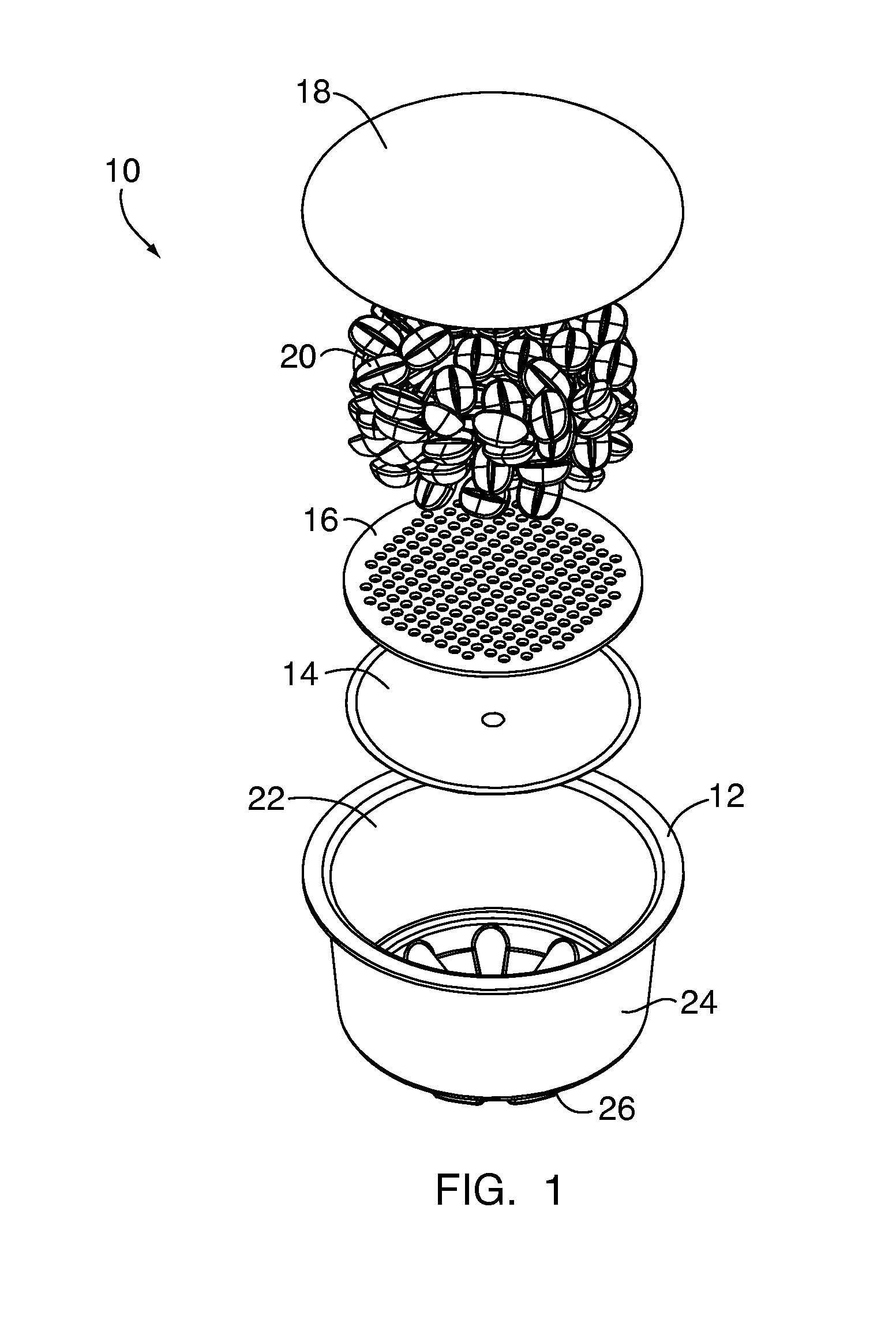

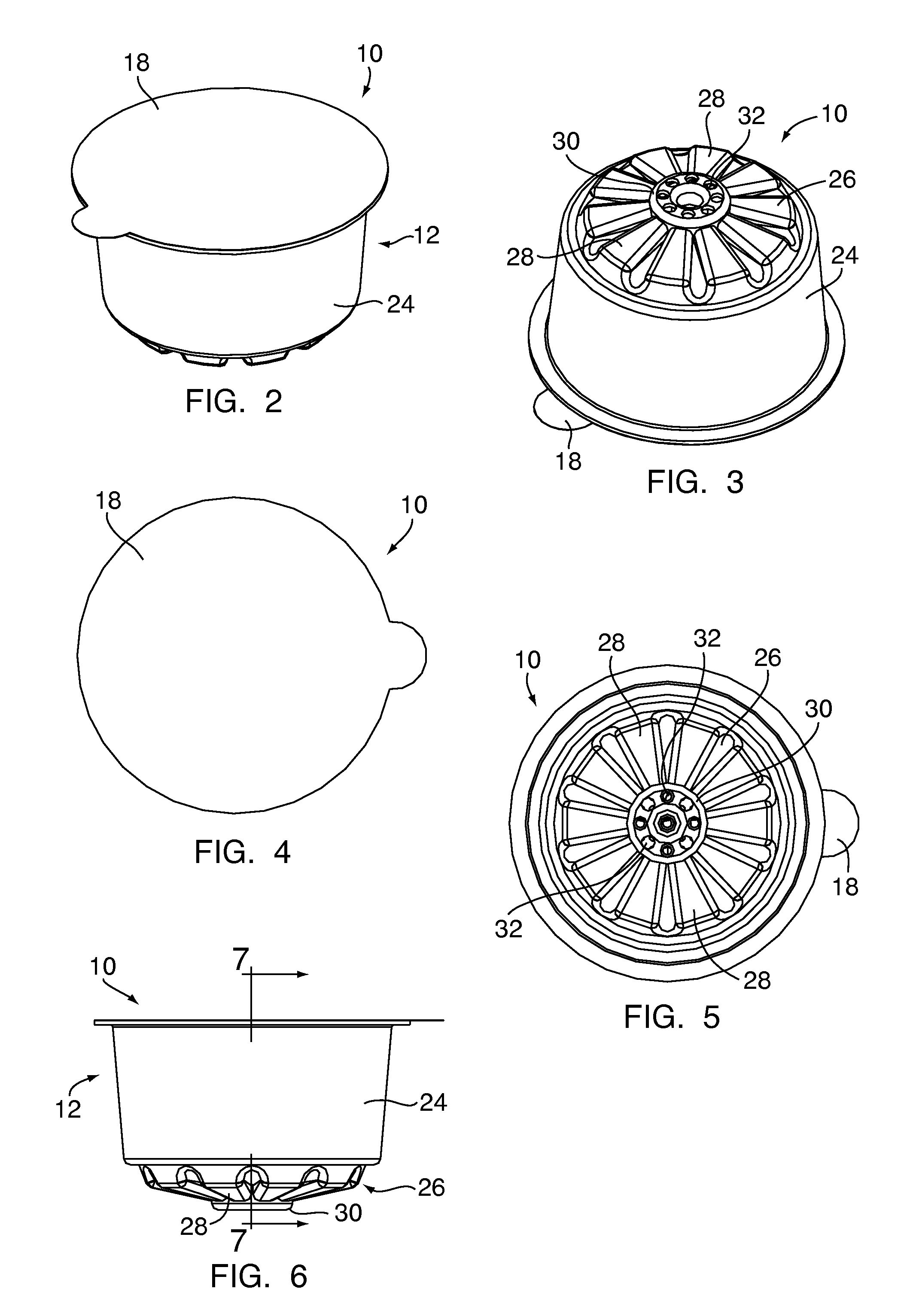

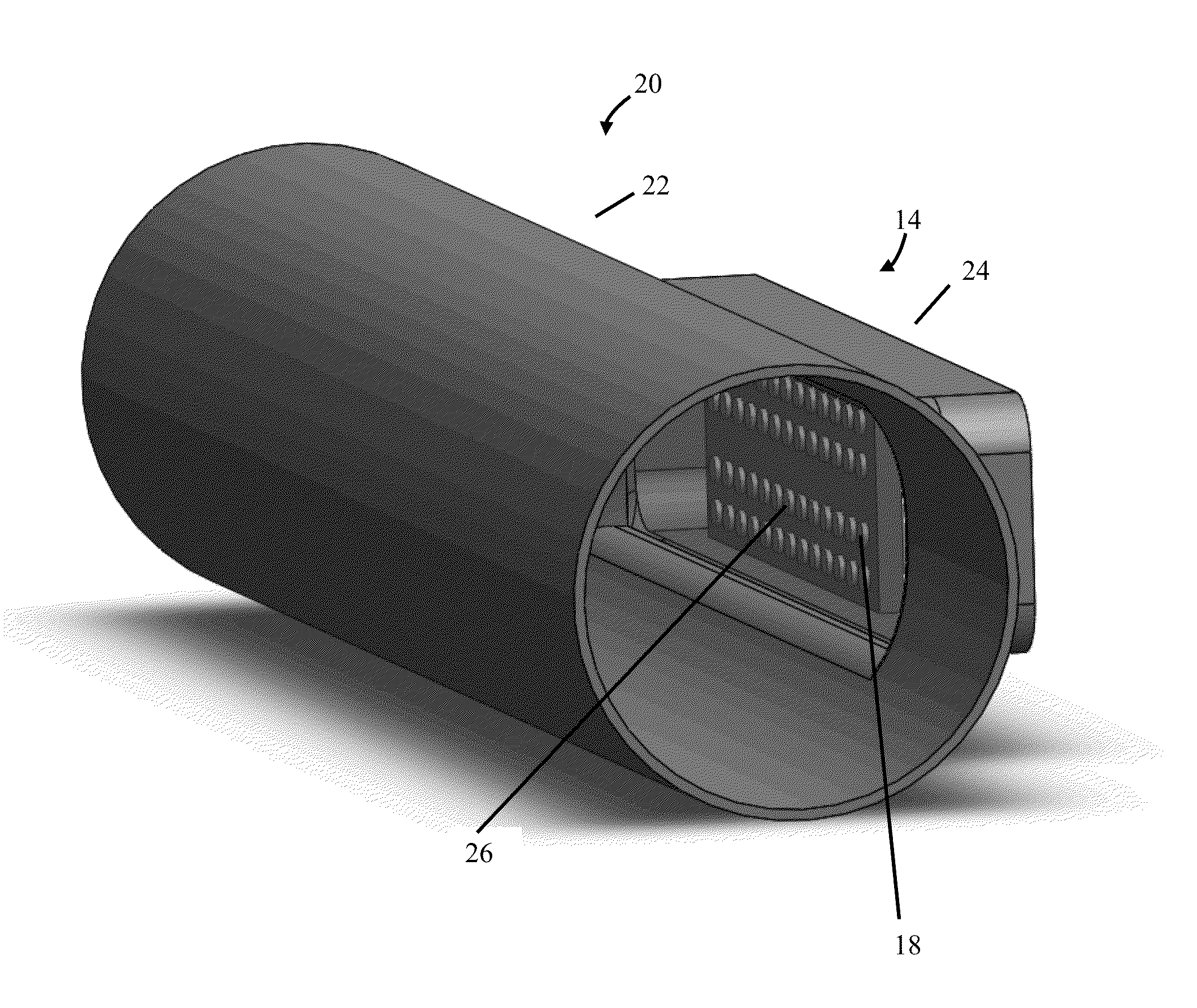

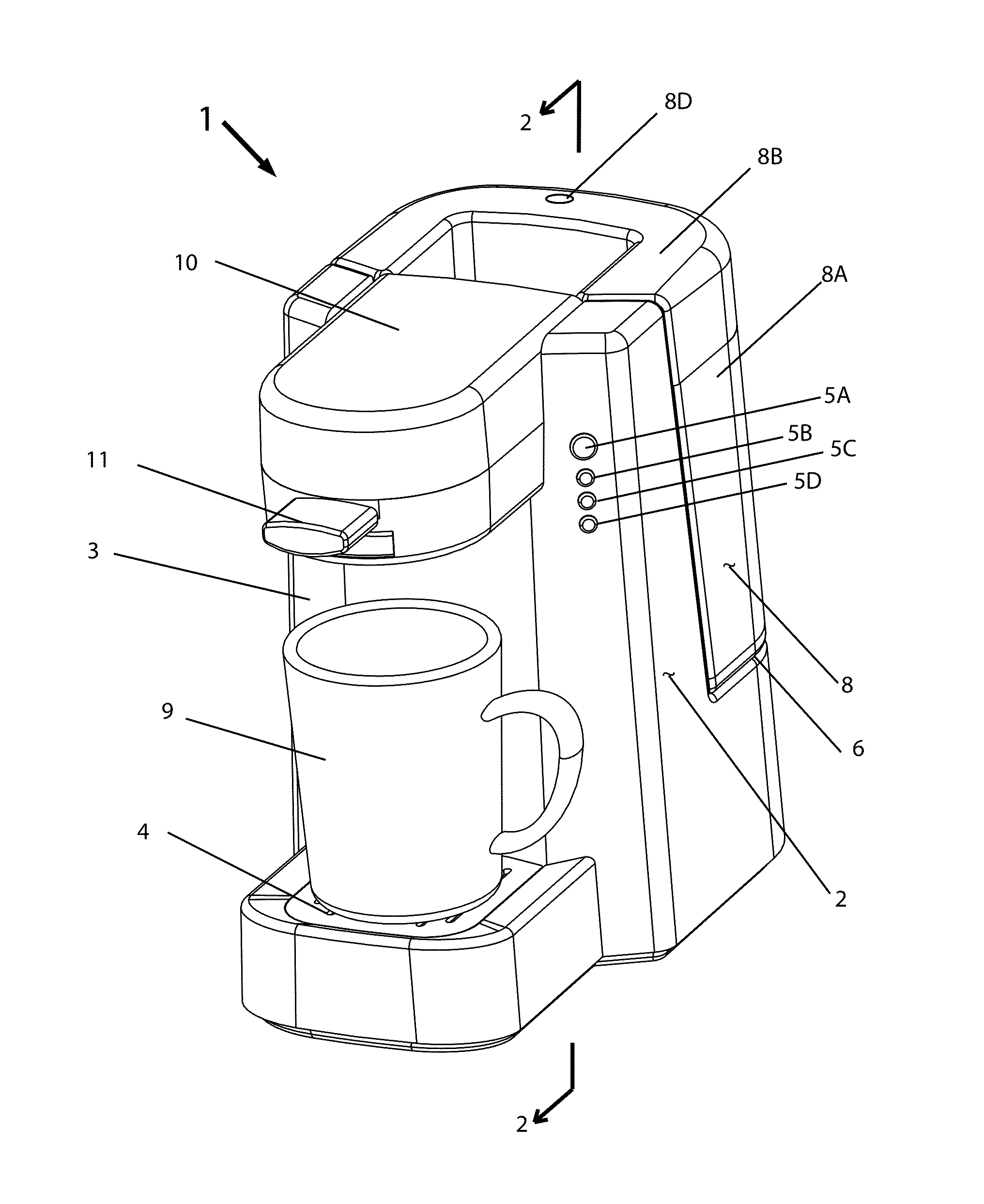

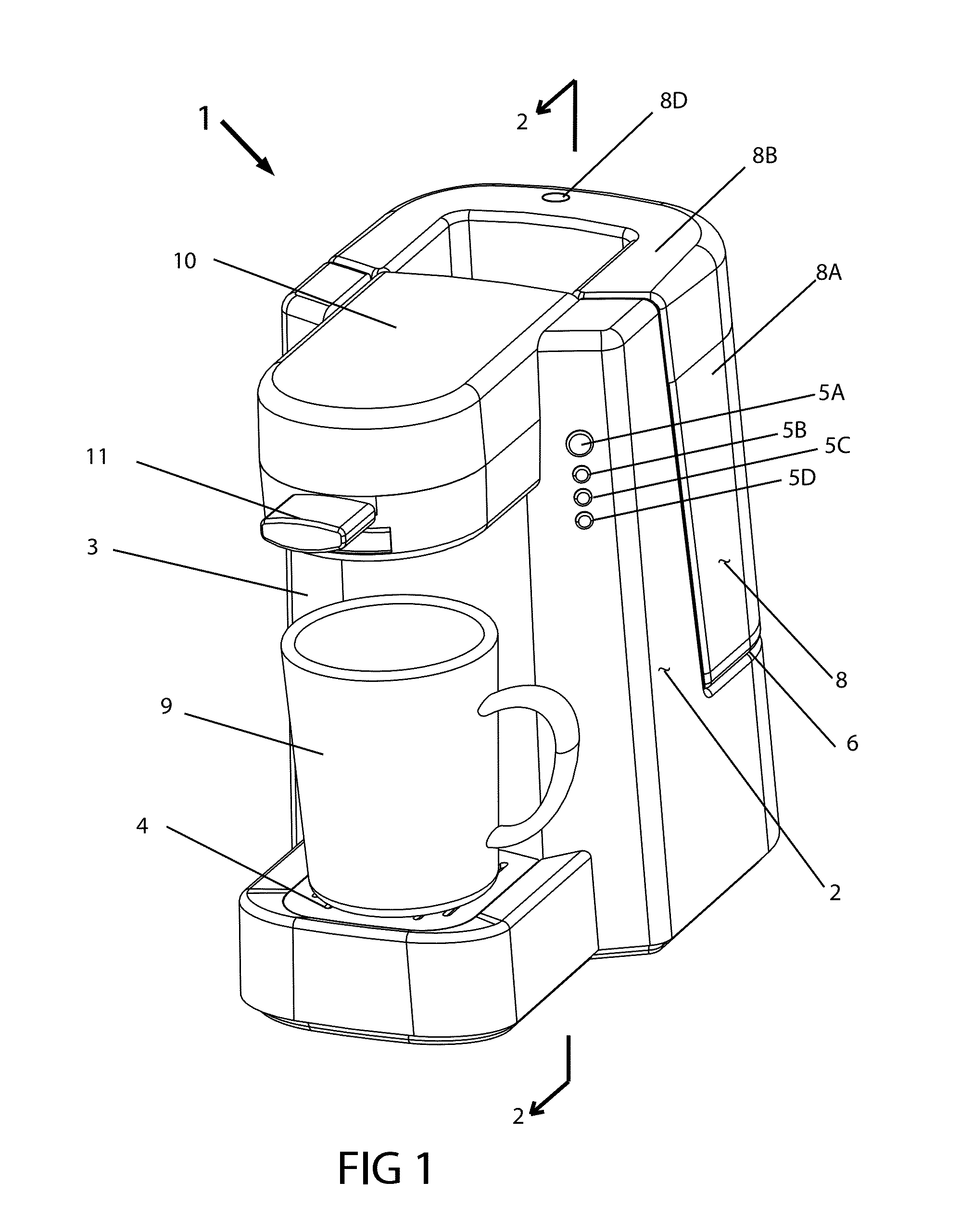

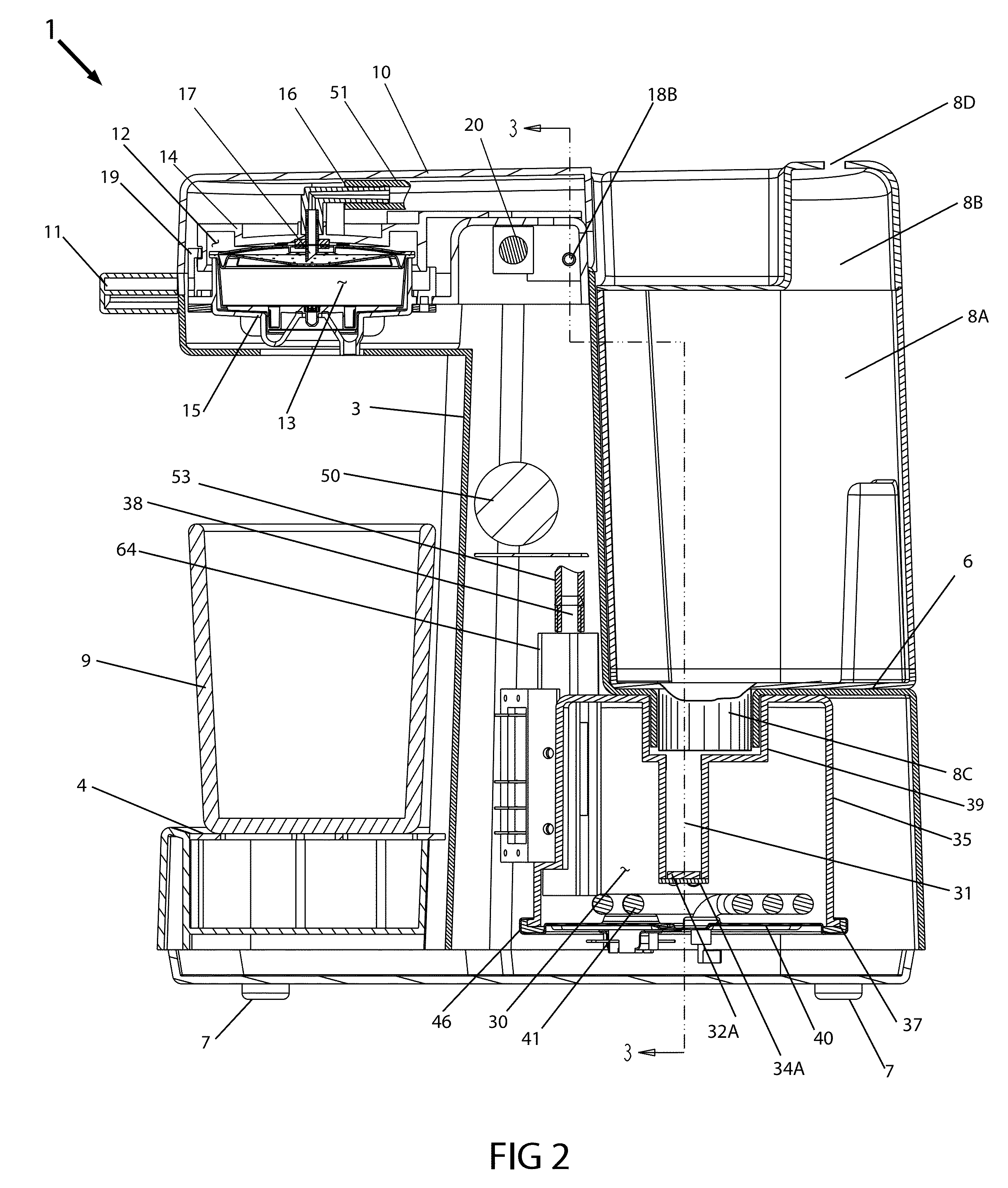

Brewed beverage appliance and method

A beverage making appliance uses a specialized beverage container and a related method of brewing a beverage. The container includes a cup-shaped body having a floor, a circumferential wall, and a top opening, a filter element positioned above the floor, at least one aperture formed in the floor, and a cover releasably attached to the cup body and covering the top opening. The appliance includes a base adapted to receive a beverage receptacle, a reservoir, a housing, a brewing tray in mechanical communication with the housing and dimensioned to receive a container containing at least one drink ingredient having particles of a first size, a grinding mechanism and a water delivery mechanism to selectively deliver water from the reservoir to one of a brewed beverage outlet in fluid communication with the receptacle, and a hot-water outlet.

Owner:CONAIR CORP

Inline UV LED water disinfection and heating

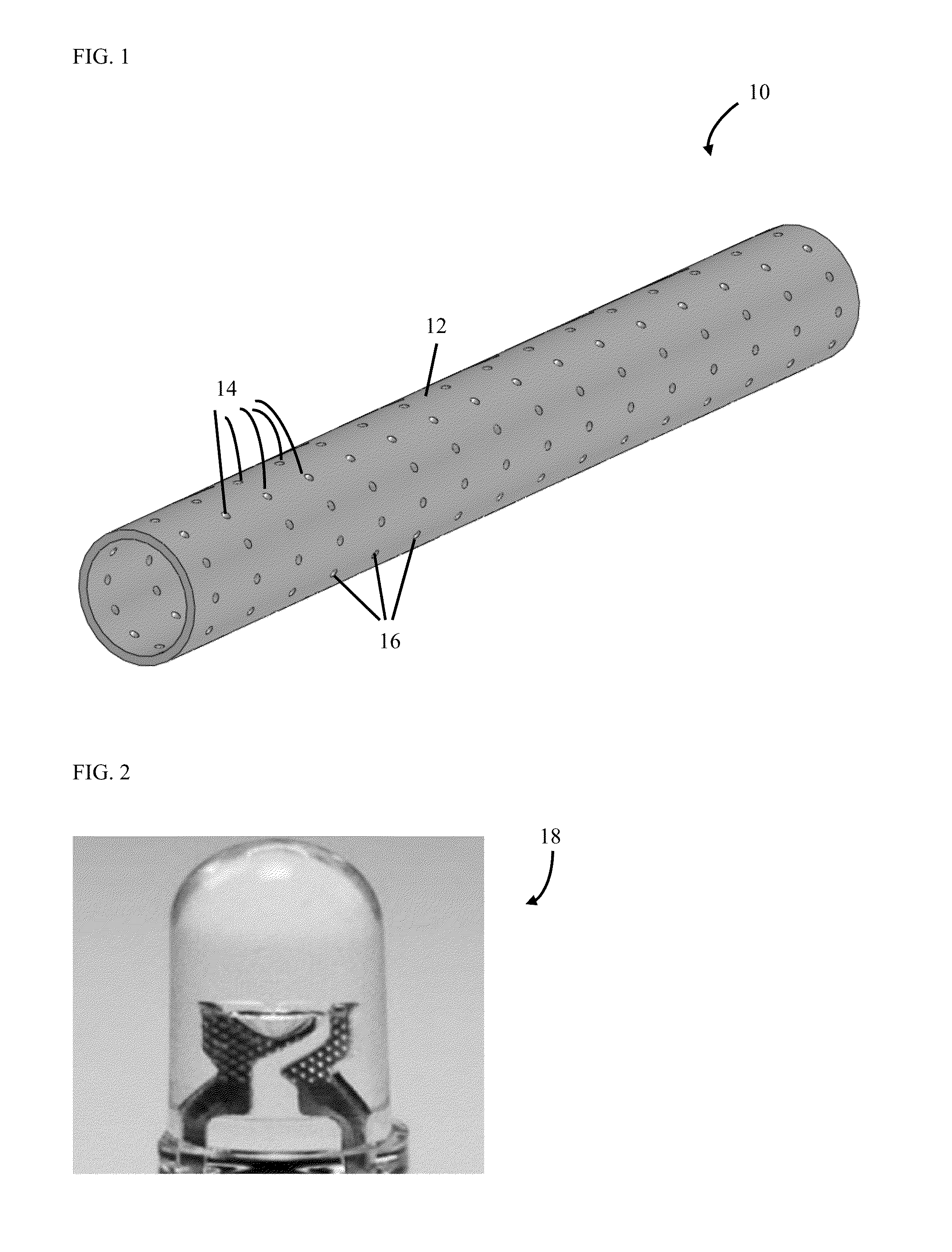

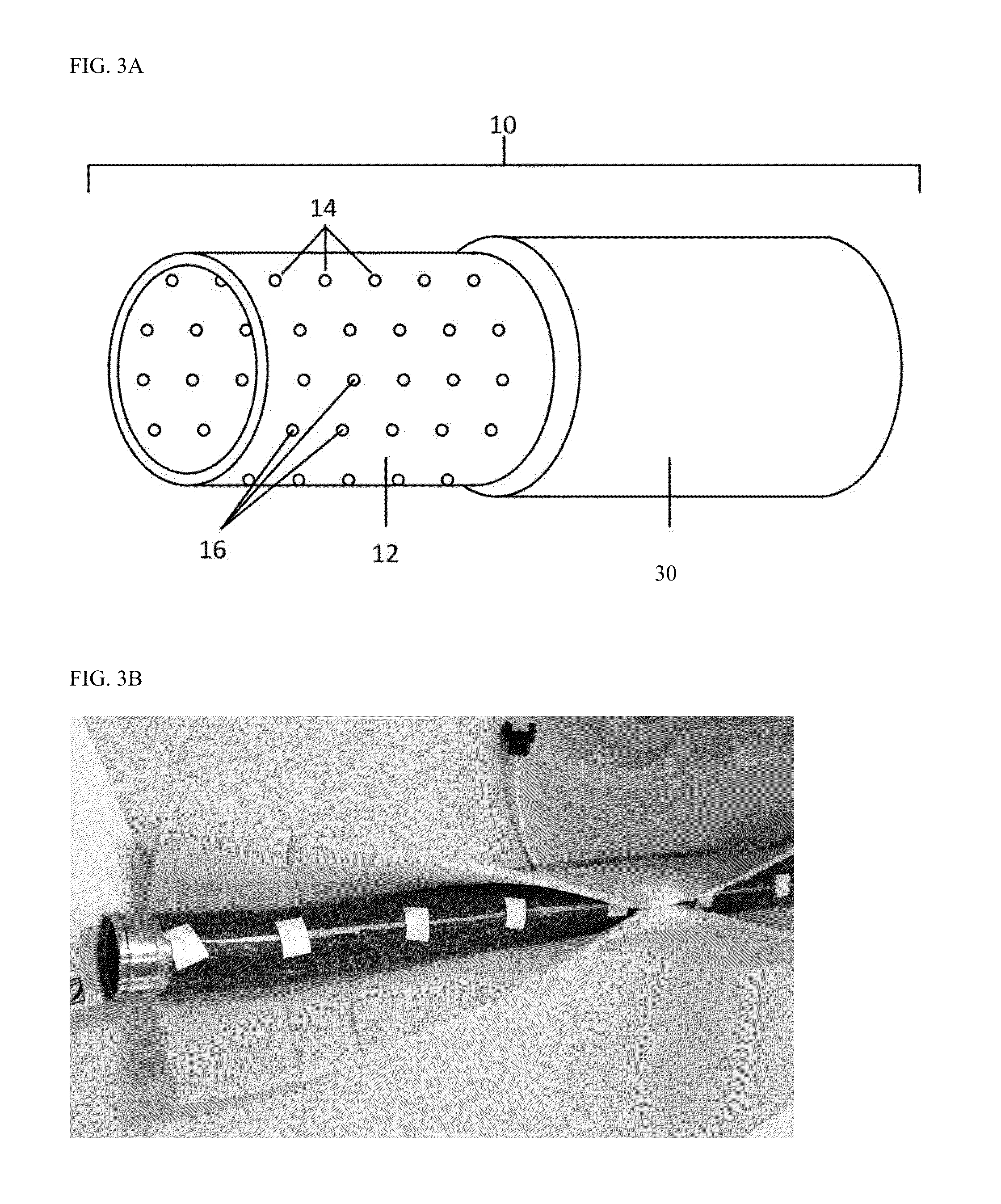

ActiveUS20130146783A1Water/sewage treatment by irradiationSpecific water treatment objectivesWater deliveryLight source

Embodiments of the present invention relate generally to on-aircraft potable water disinfection with UV LED light sources that are positioned in-line with the water delivery system. Further embodiments relate to using the scavenged heat generated by the LEDs to deliver heat back to the water supply tube for temperature stabilization and to prevent water freezing.

Owner:MAG AEROSPACE IND INC

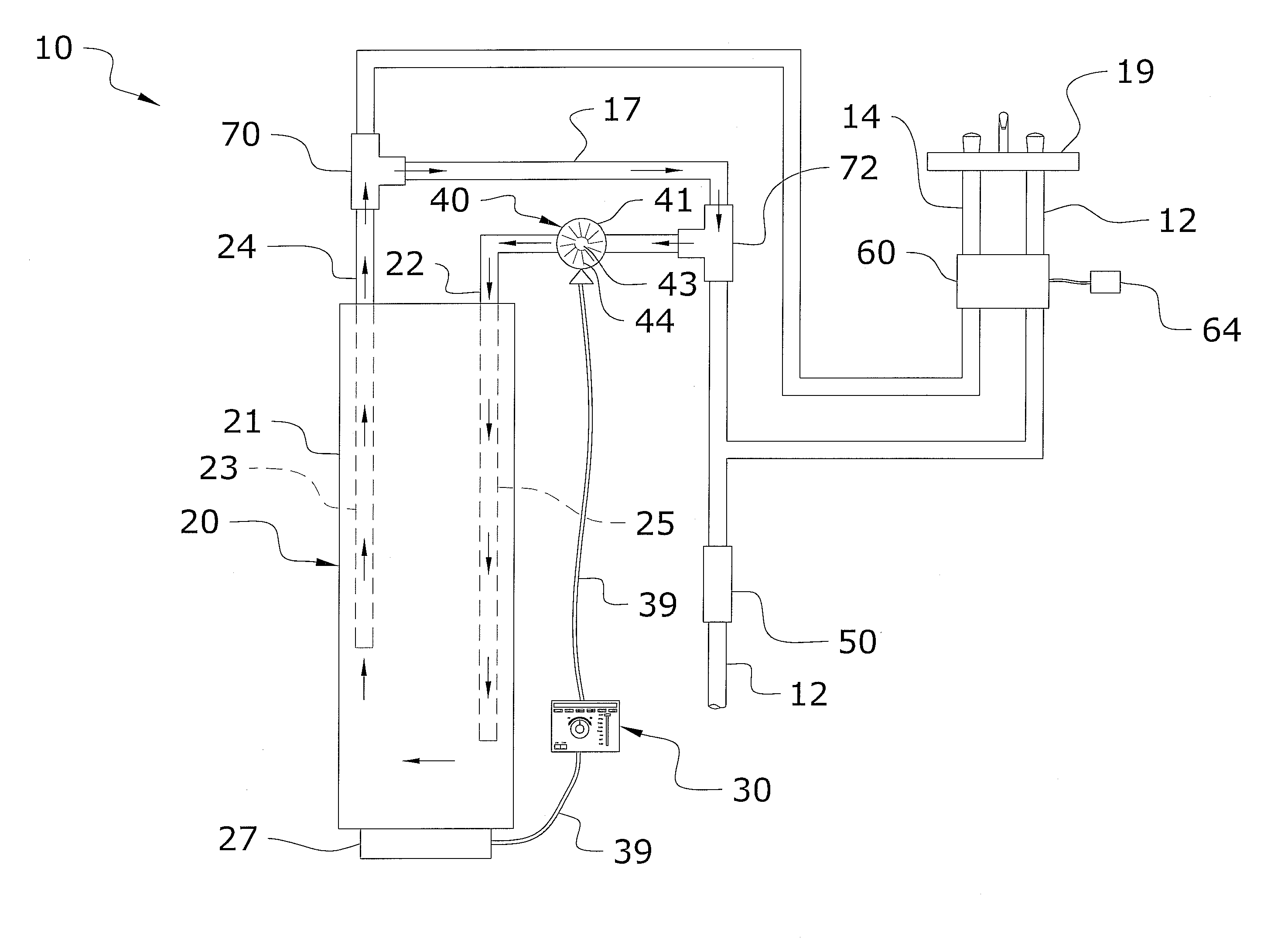

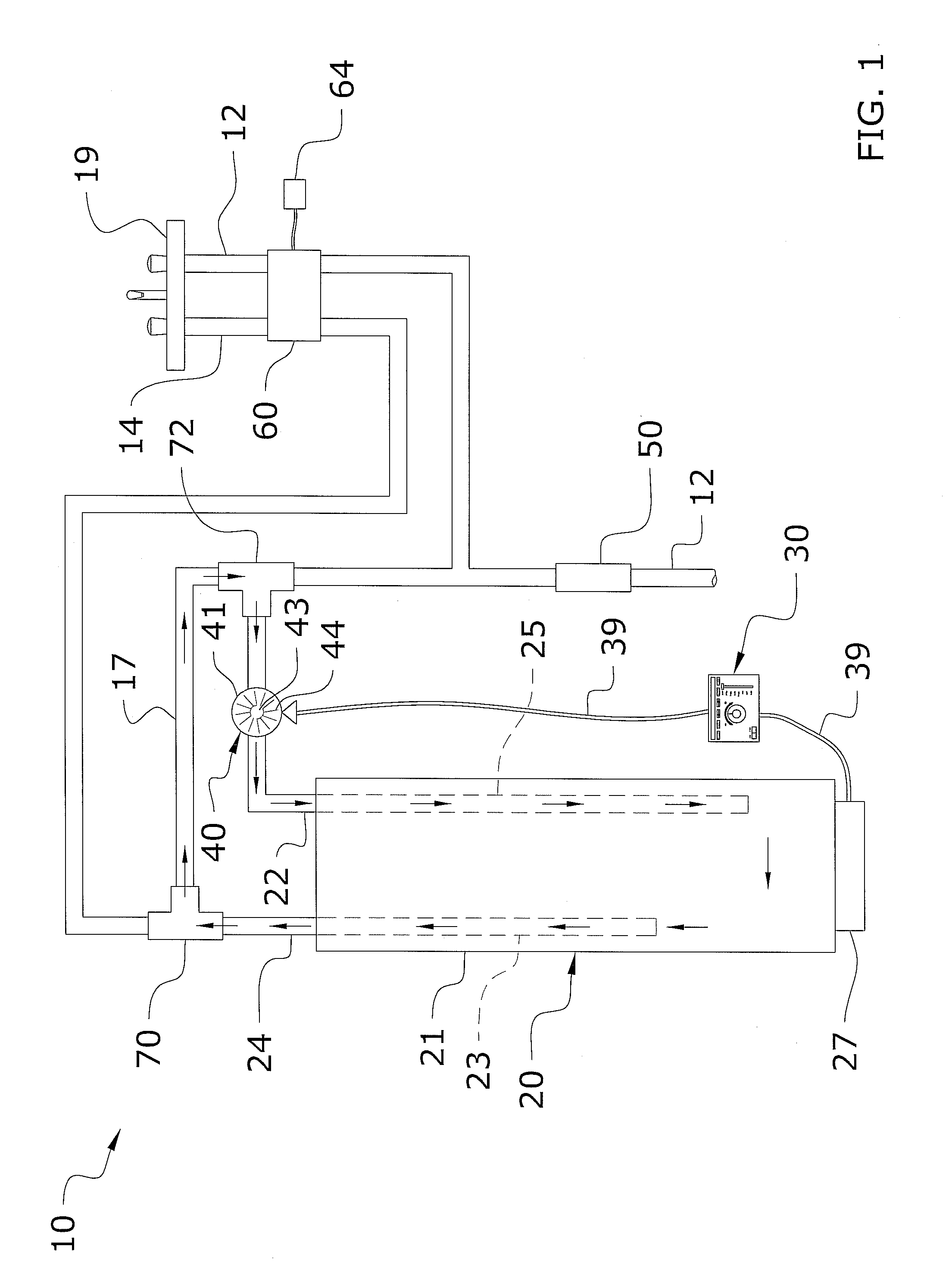

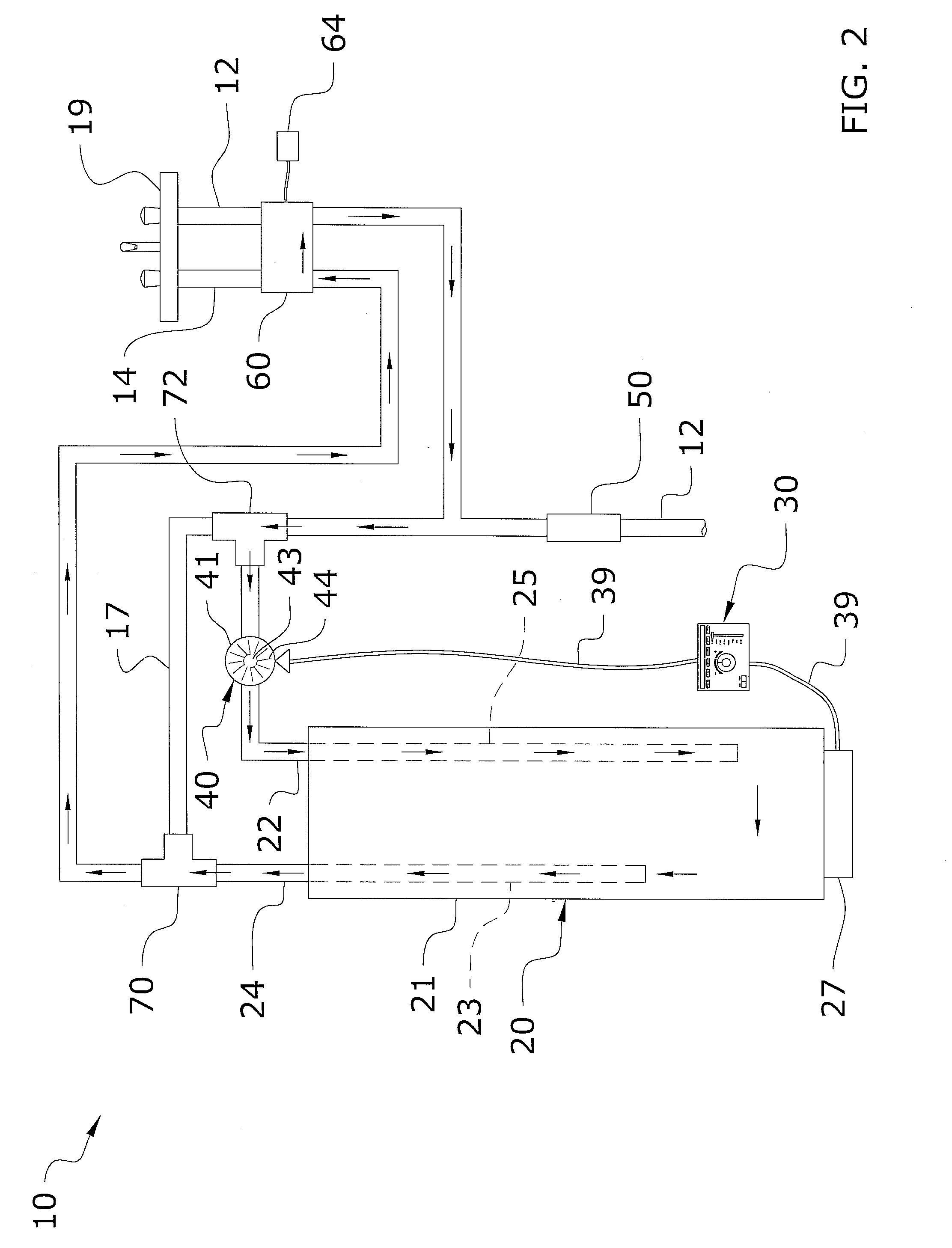

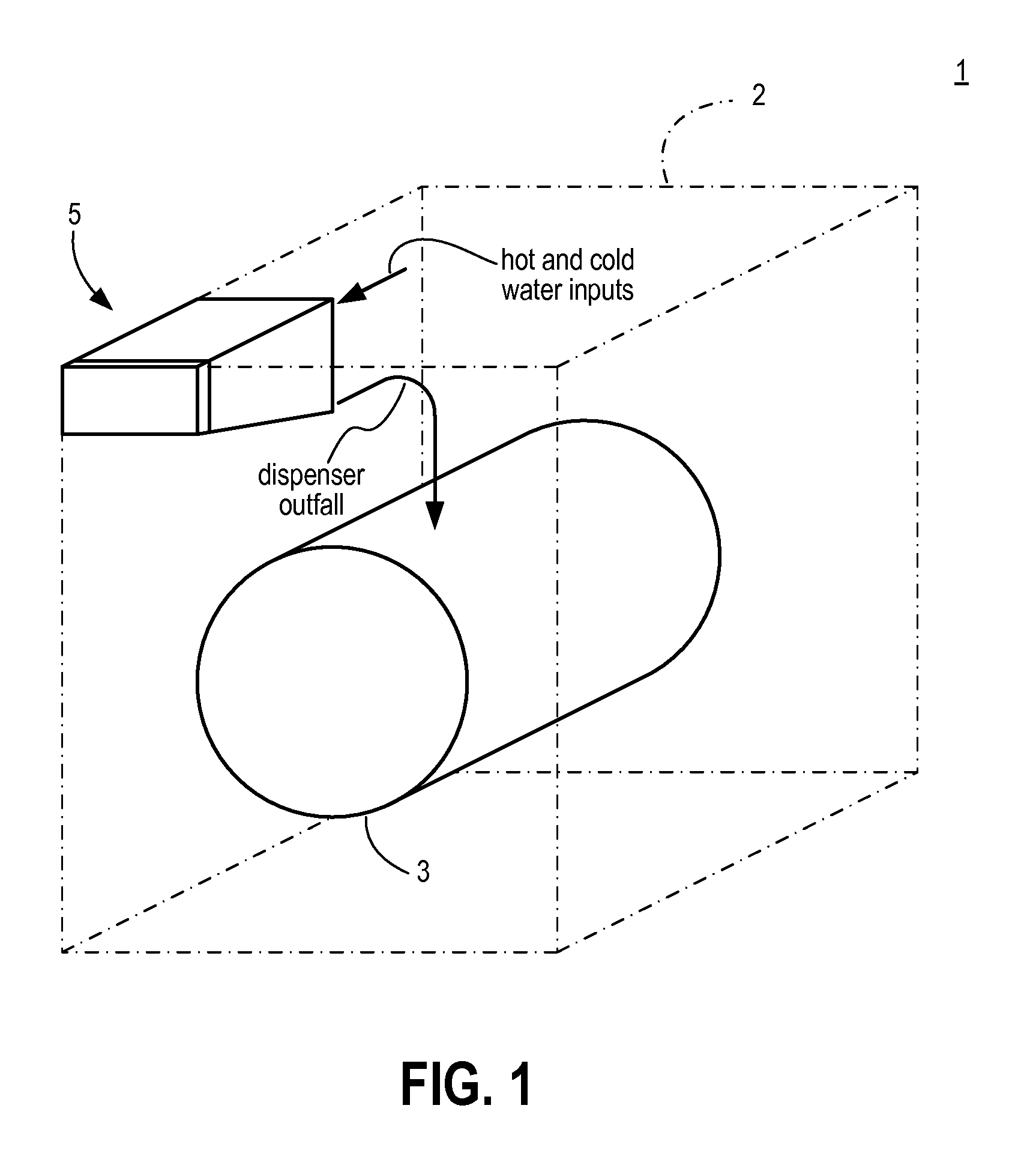

Instant Hot Water Delivery System

InactiveUS20090211644A1Efficiently heating waterReduce energy consumptionValve members for heating/coolingPipe heating/coolingEngineeringThermal water

An instant hot water delivery system for efficiently heating water when necessary to provide instant hot water to a faucet. The instant hot water delivery system generally includes a water heater including an inlet and an outlet, a cold water supply line introducing cold water into the inlet, a hot water supply line connecting the outlet to a faucet and a recirculation line connected to the hot water supply downstream of the outlet and the cold water supply line upstream of the inlet. The recirculation line forms a first recirculation loop for water within the water heater to flow during a first water heating process. A recirculation pump is connected to the cold water supply line between the local recirculation line and the inlet for circulating the water during the water heating process.

Owner:WYLIE JACOB E +1

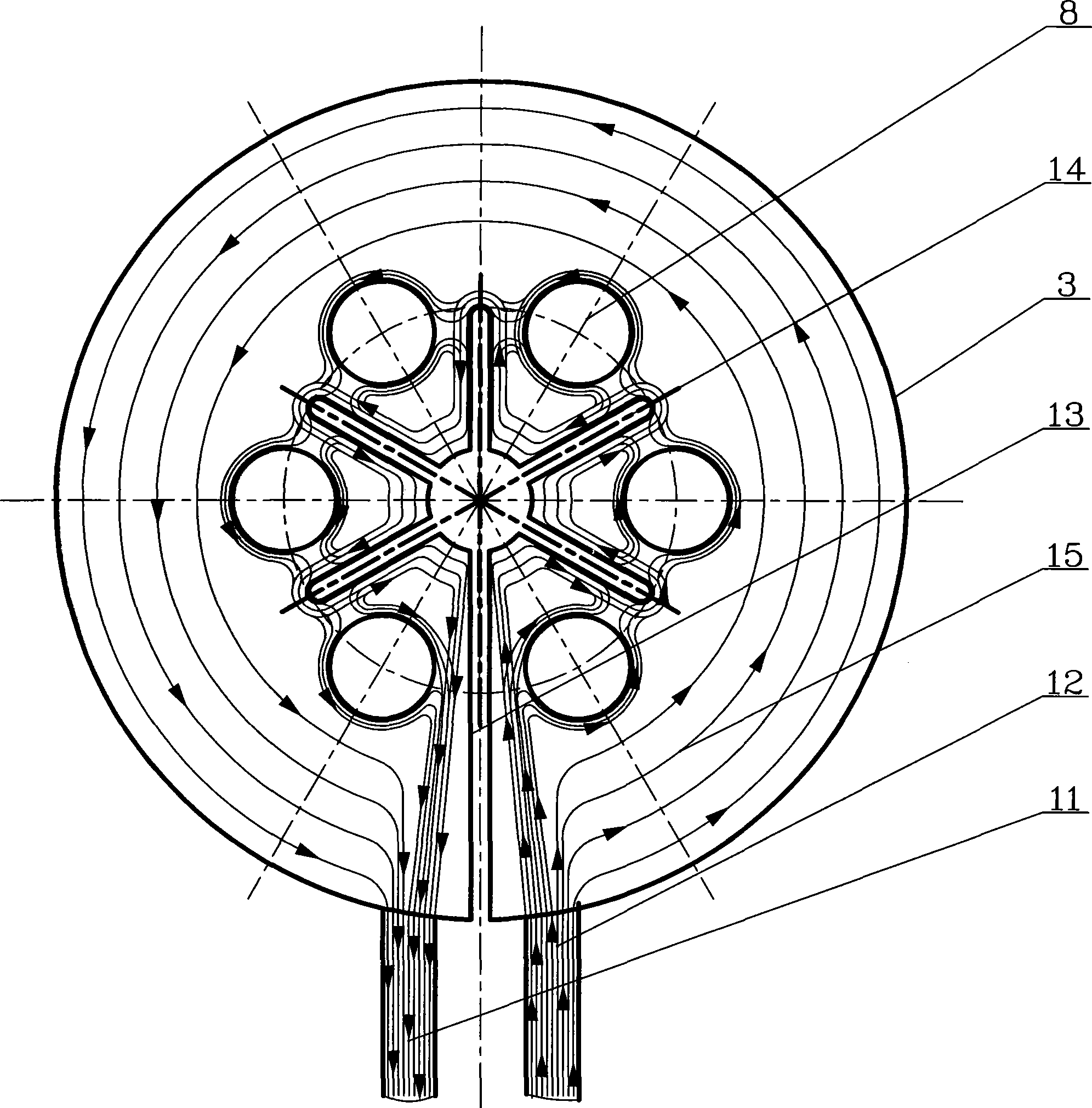

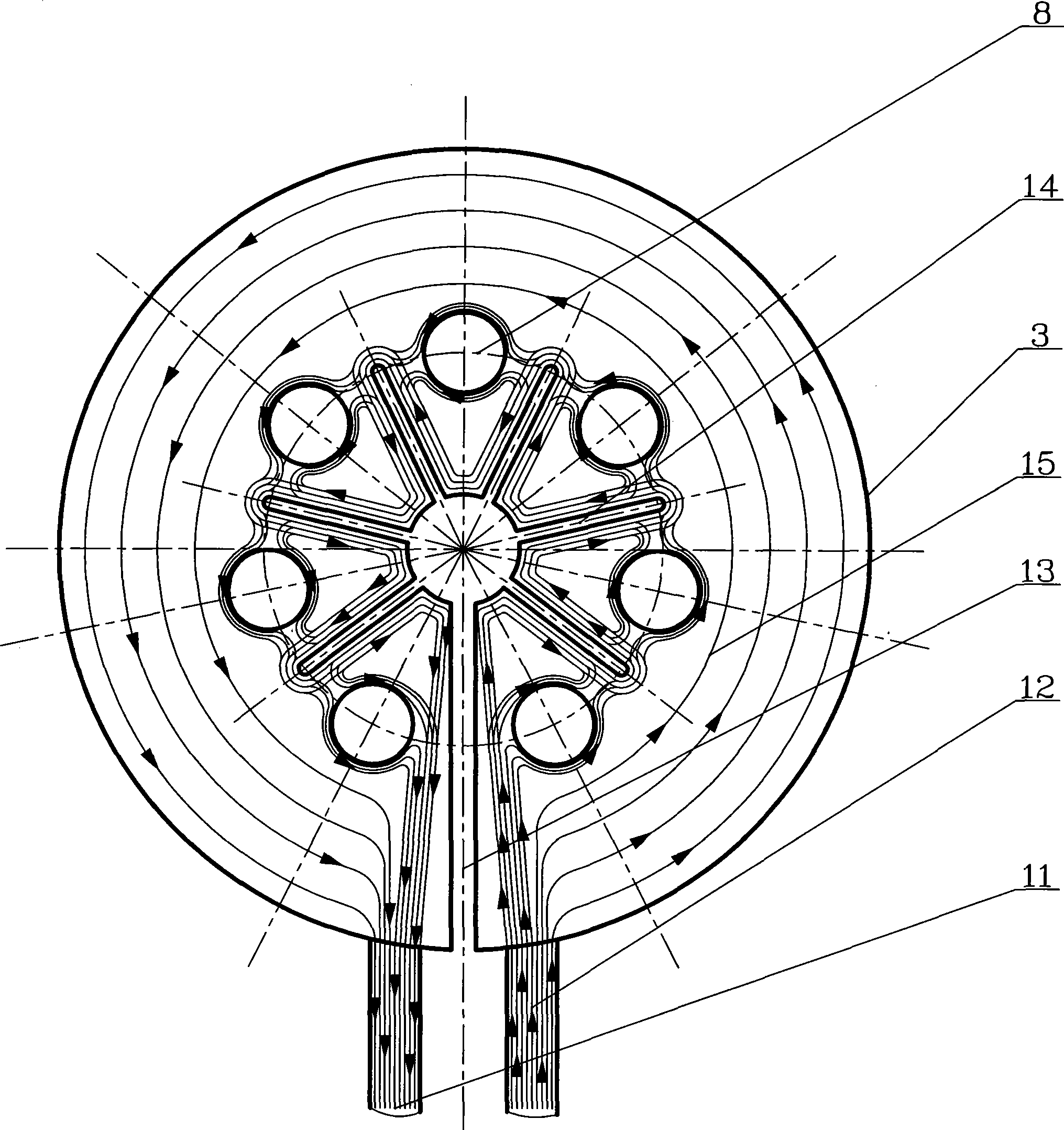

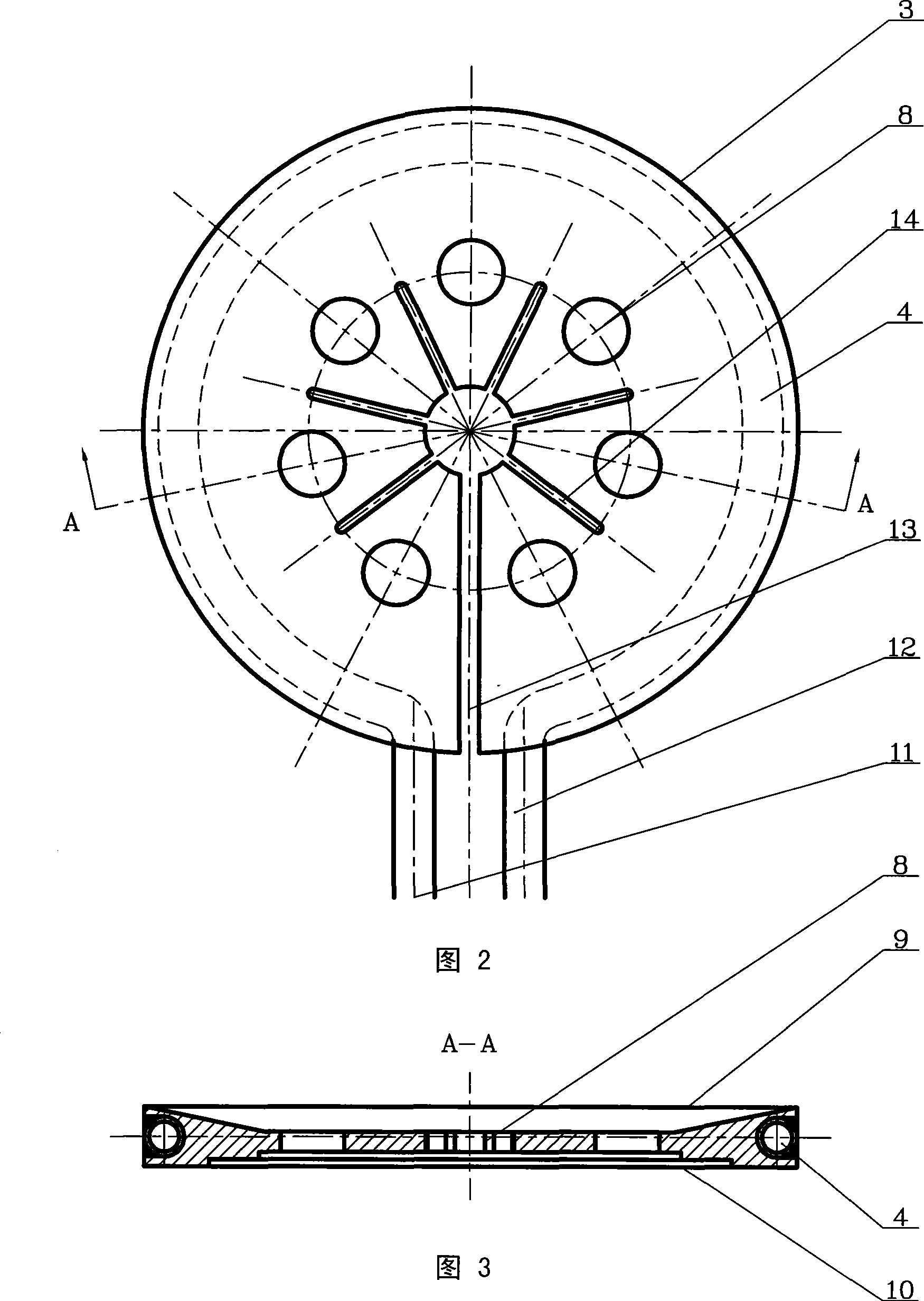

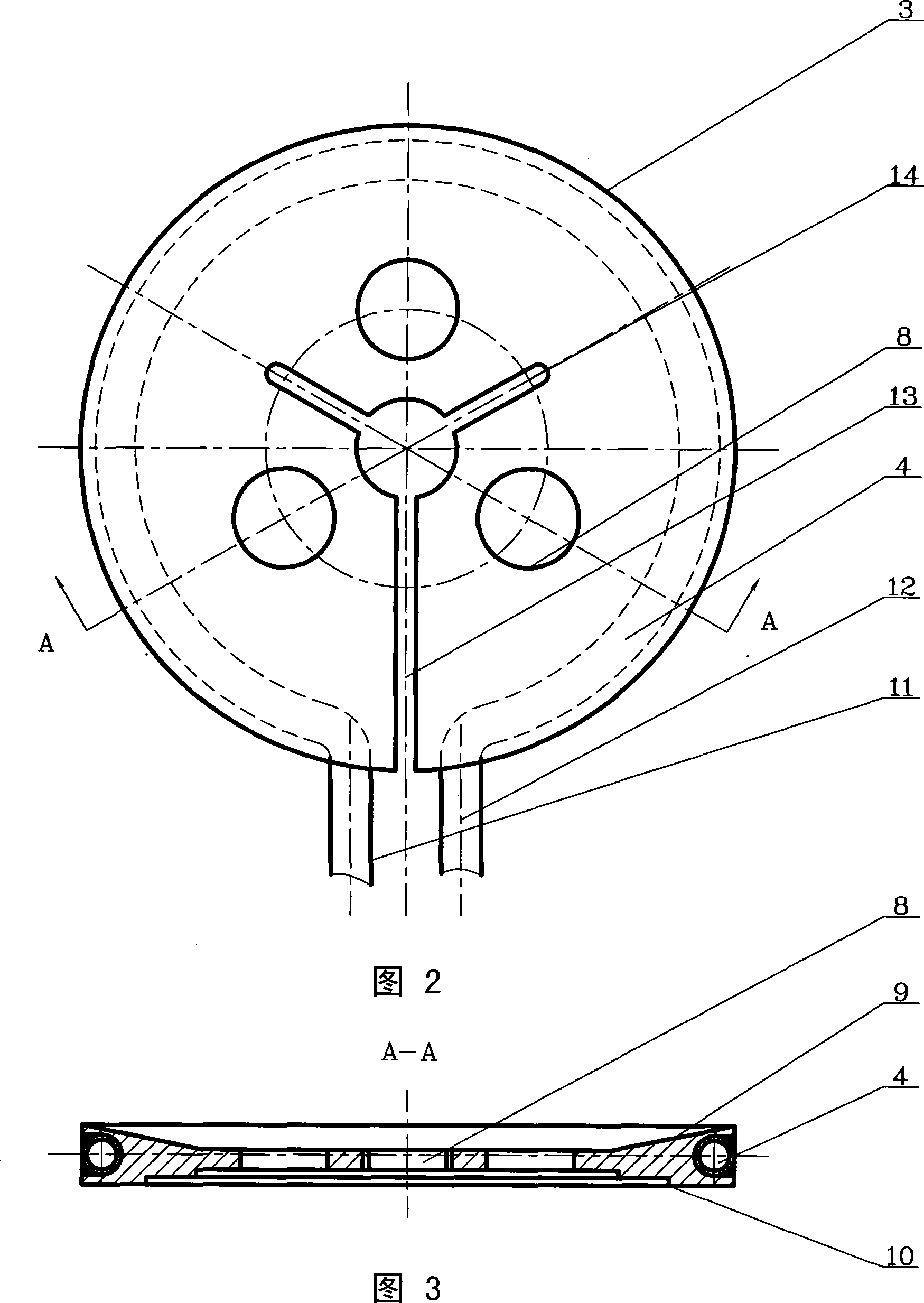

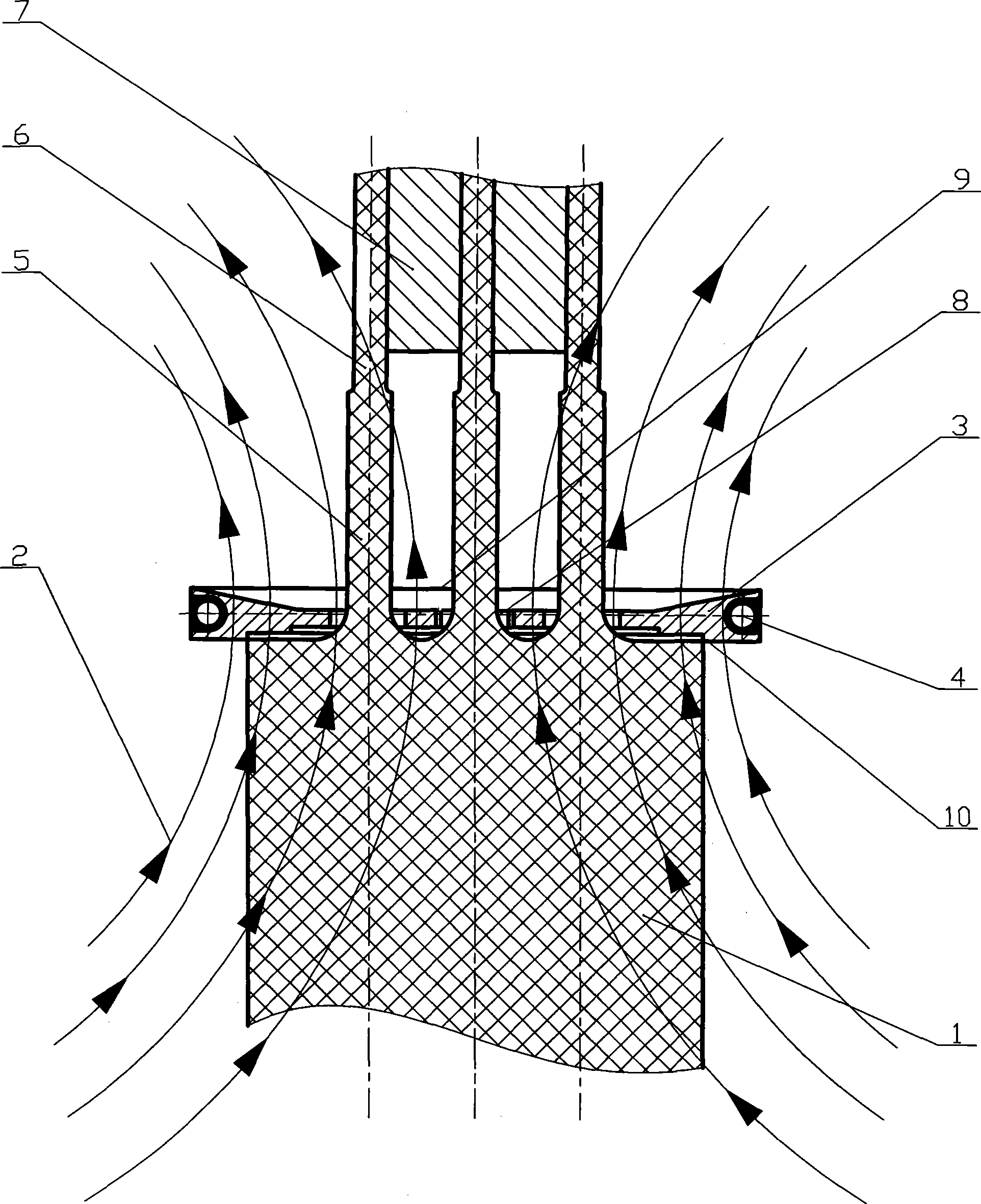

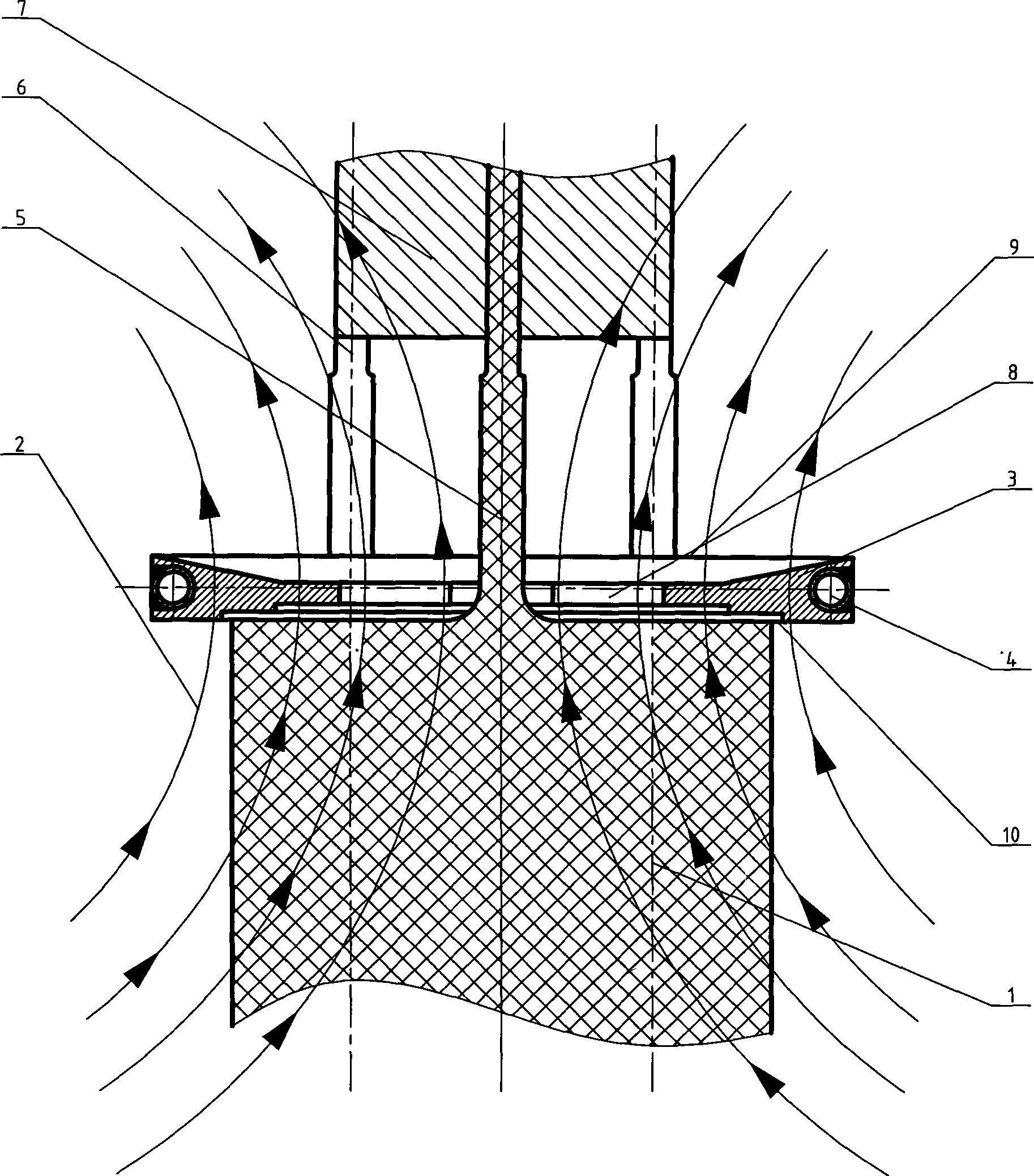

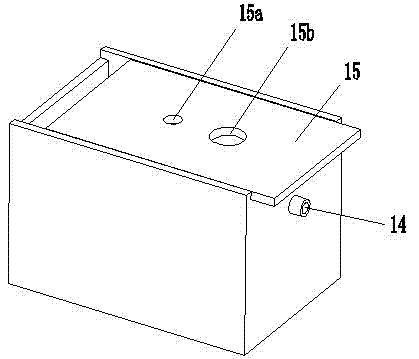

High-frequency coil structure capable of simultaneous producing seven silicon cores and other crystal material

ActiveCN101457389AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing seven silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and seven inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and six inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the seven inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the seven inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

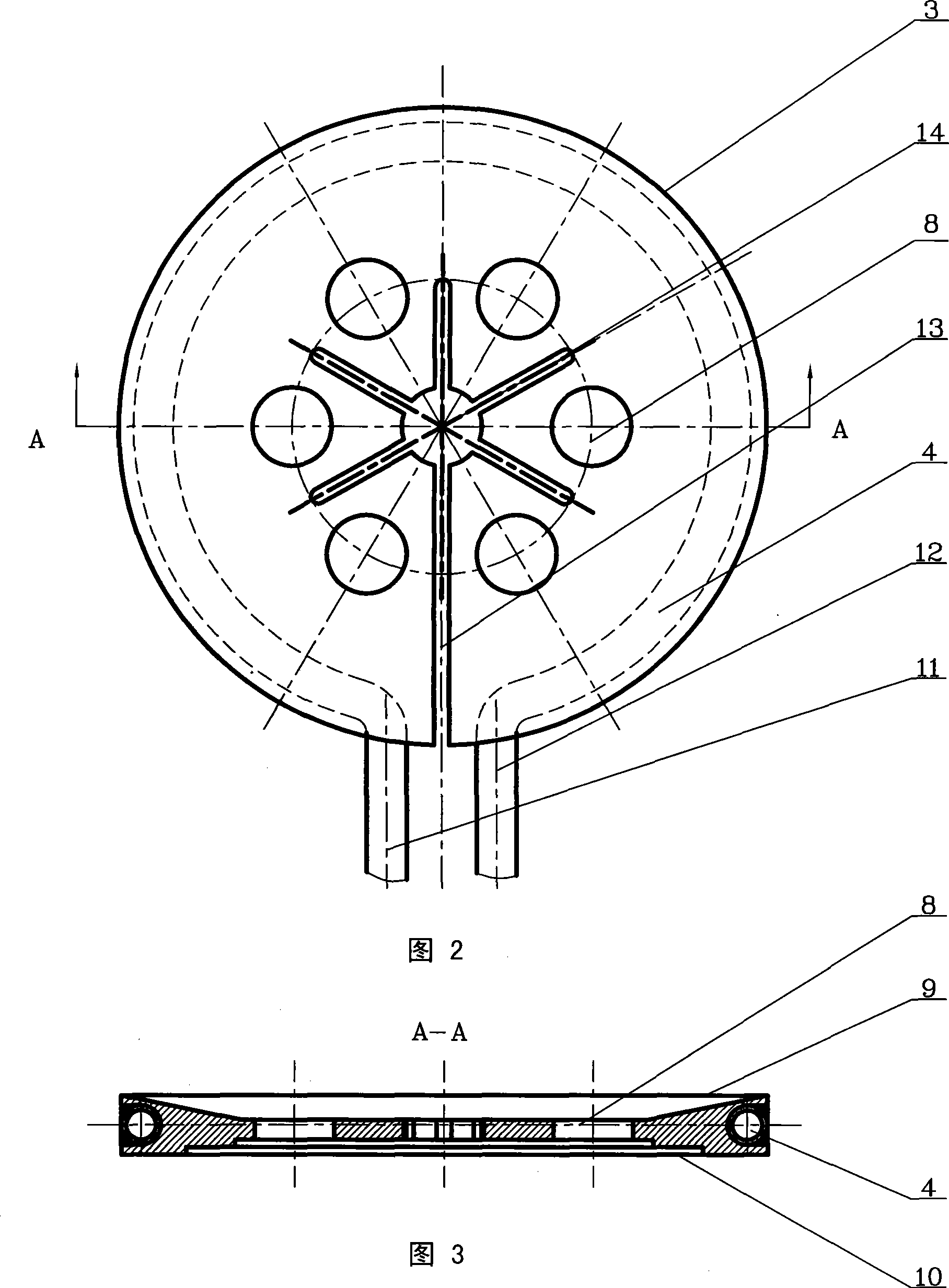

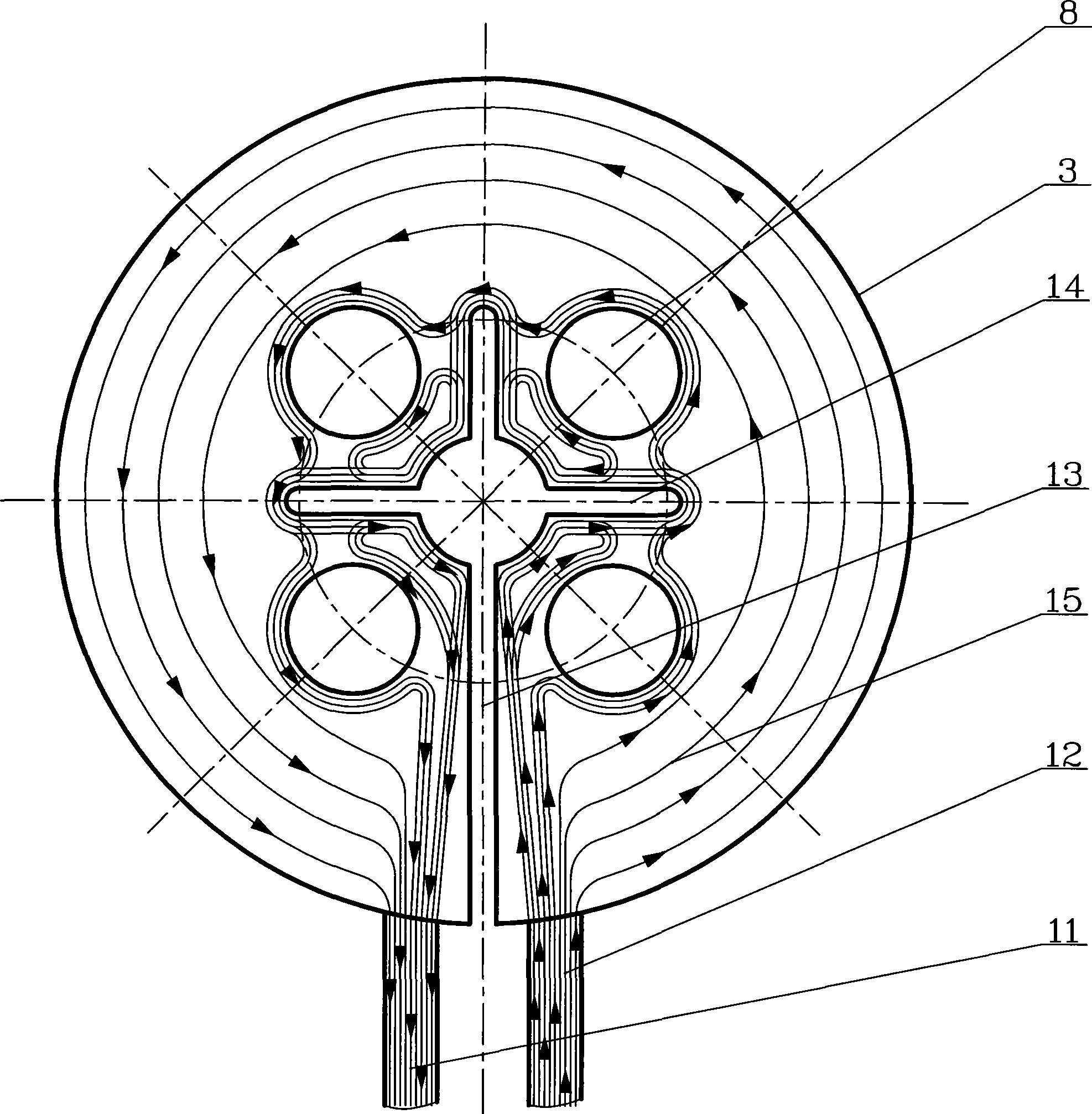

High-frequency coil structure capable of simultaneous producing eight silicon cores and other crystal material

ActiveCN101457390AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing eight silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and eight inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and seven inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape, an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the eight inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the eight inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

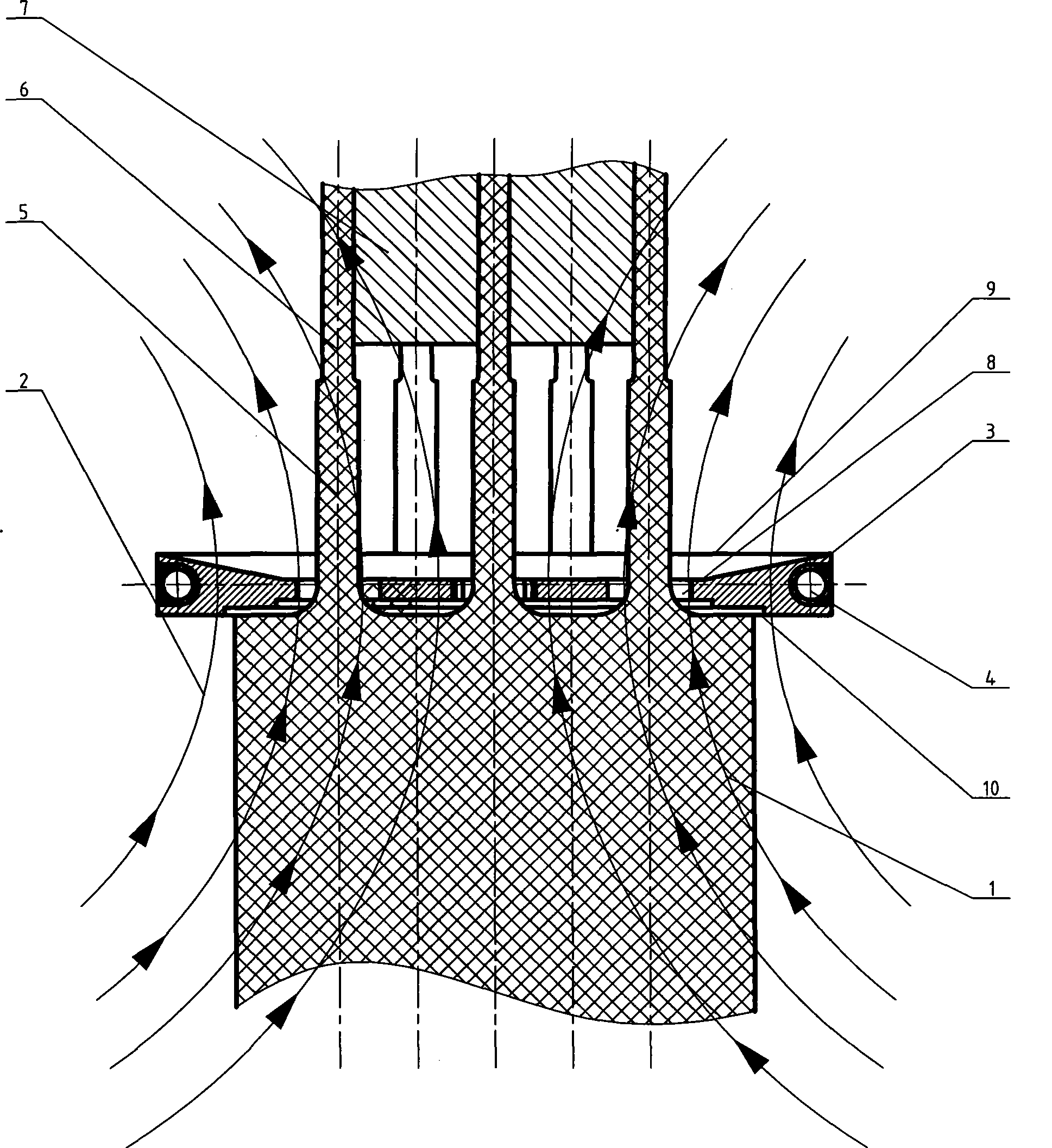

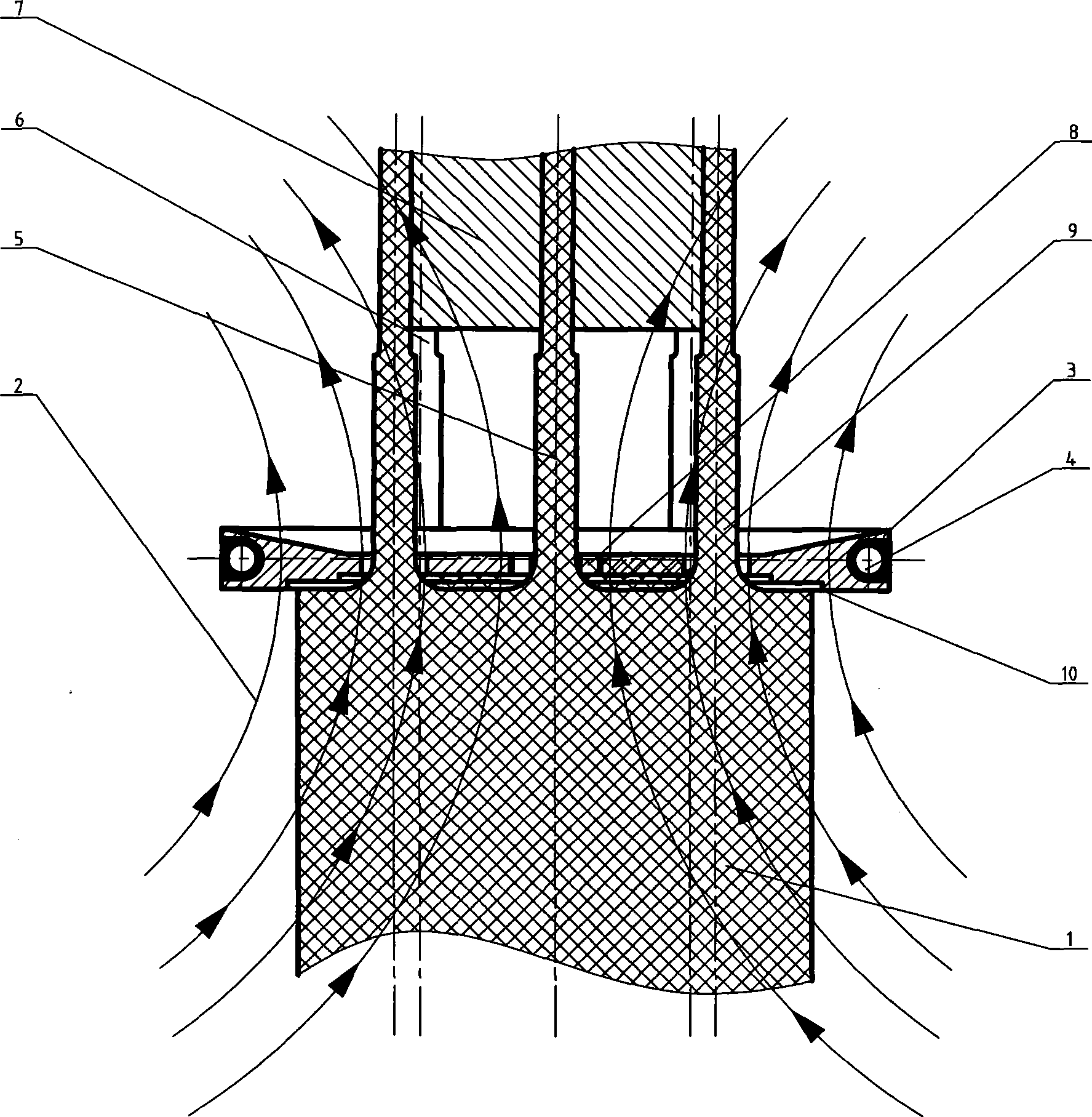

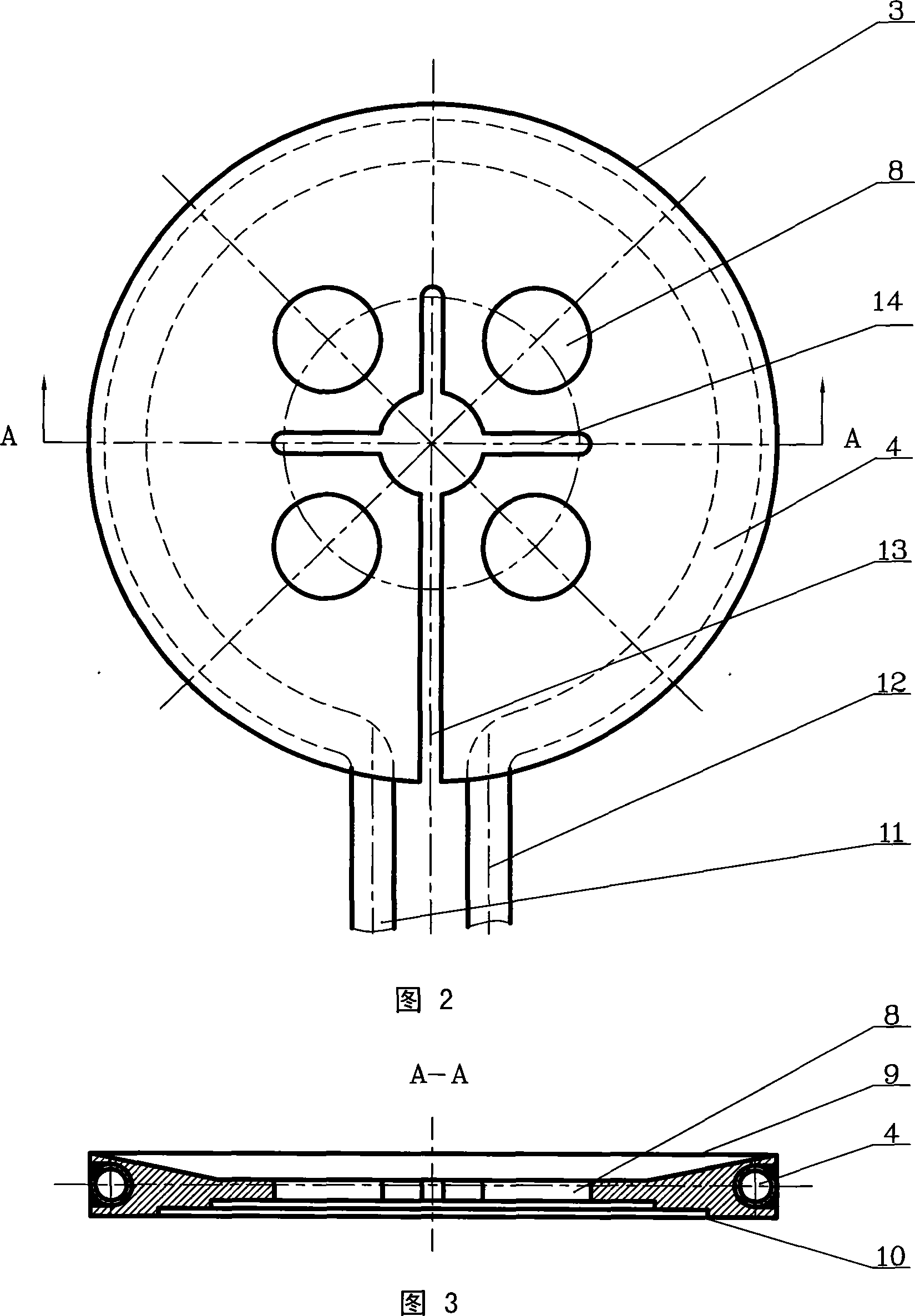

High-frequency coil structure capable of simultaneous producing four silicon cores and other crystal material

InactiveCN101457391AEvenly distributedHeating evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing four silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises splitter boxes (14) for guiding current (15), and four inner bores one inner bore (8) of which is arranged at the middle part of the high-frequency coil and three inner bores of which are evenly distributed around the inner bore at the middle part; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the splitter boxes extend outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the two splitter boxes extend upwards to the position between two inner bores without the oblique openings from the inner bore at the middle part, which causes the current to evenly surround the four inner bores for running under the current splitting action of the splitter boxes while the current is running, thus realizing the purpose that the current is evenly distributed around the four inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

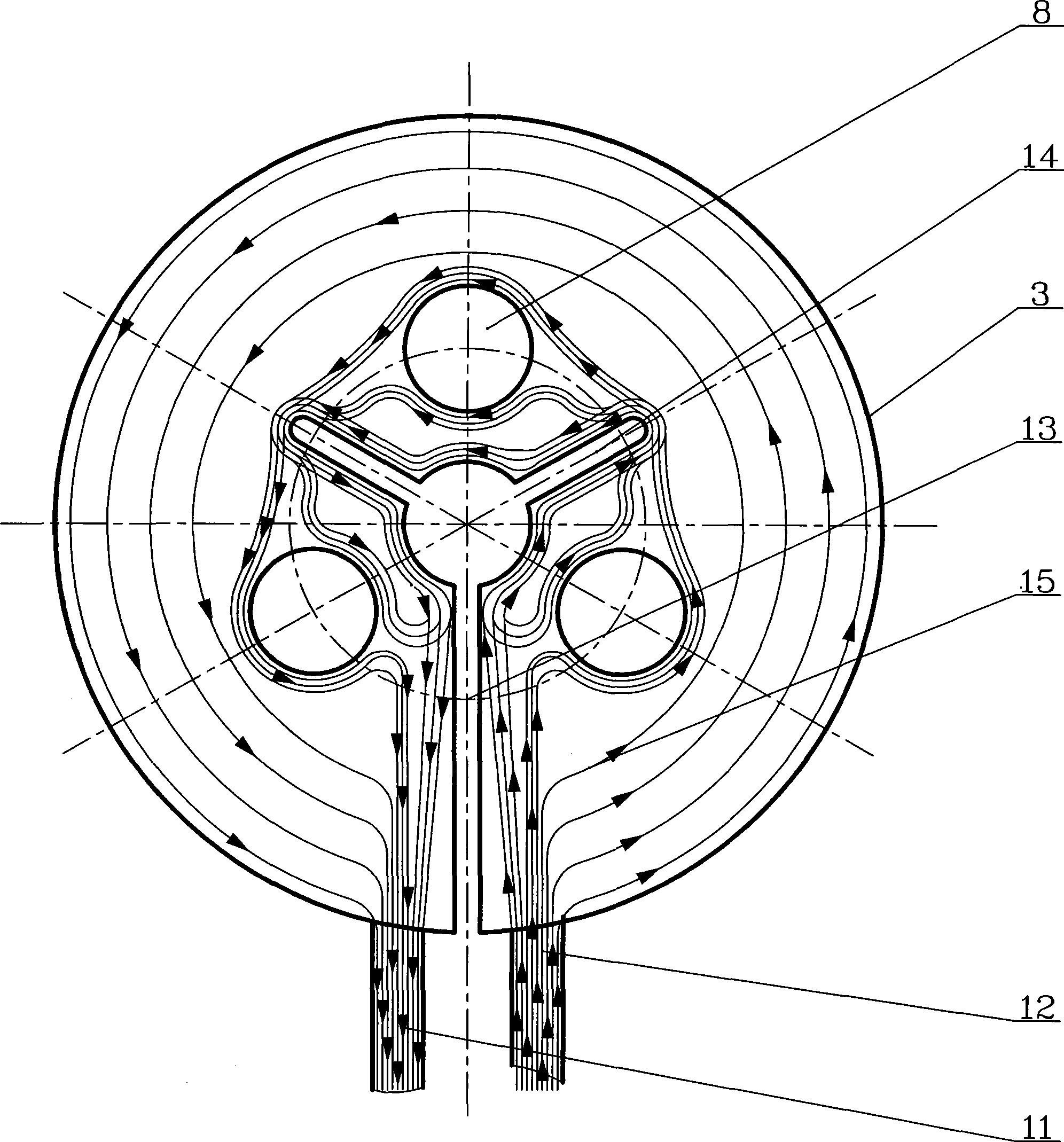

High-frequency coil structure capable of simultaneous producing five silicon cores and other crystal material

InactiveCN101457392AEvenly distributedHeating evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing five silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a splitter box (14) for guiding current (15), and five inner bores (8) one inner bore (8) of which is arranged at the middle part of the high-frequency coil and four inner bores (8) of which are evenly distributed around the inner bore at the middle part in a 'cross' shape; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore (8) at the middle part; and the splitter box (14) extends outwards to the position between every two inner bores (8) except for the oblique opening (13) from the inner bore (8) at the middle part. The high-frequency coil structure can cause the current to evenly surround the five inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the five inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

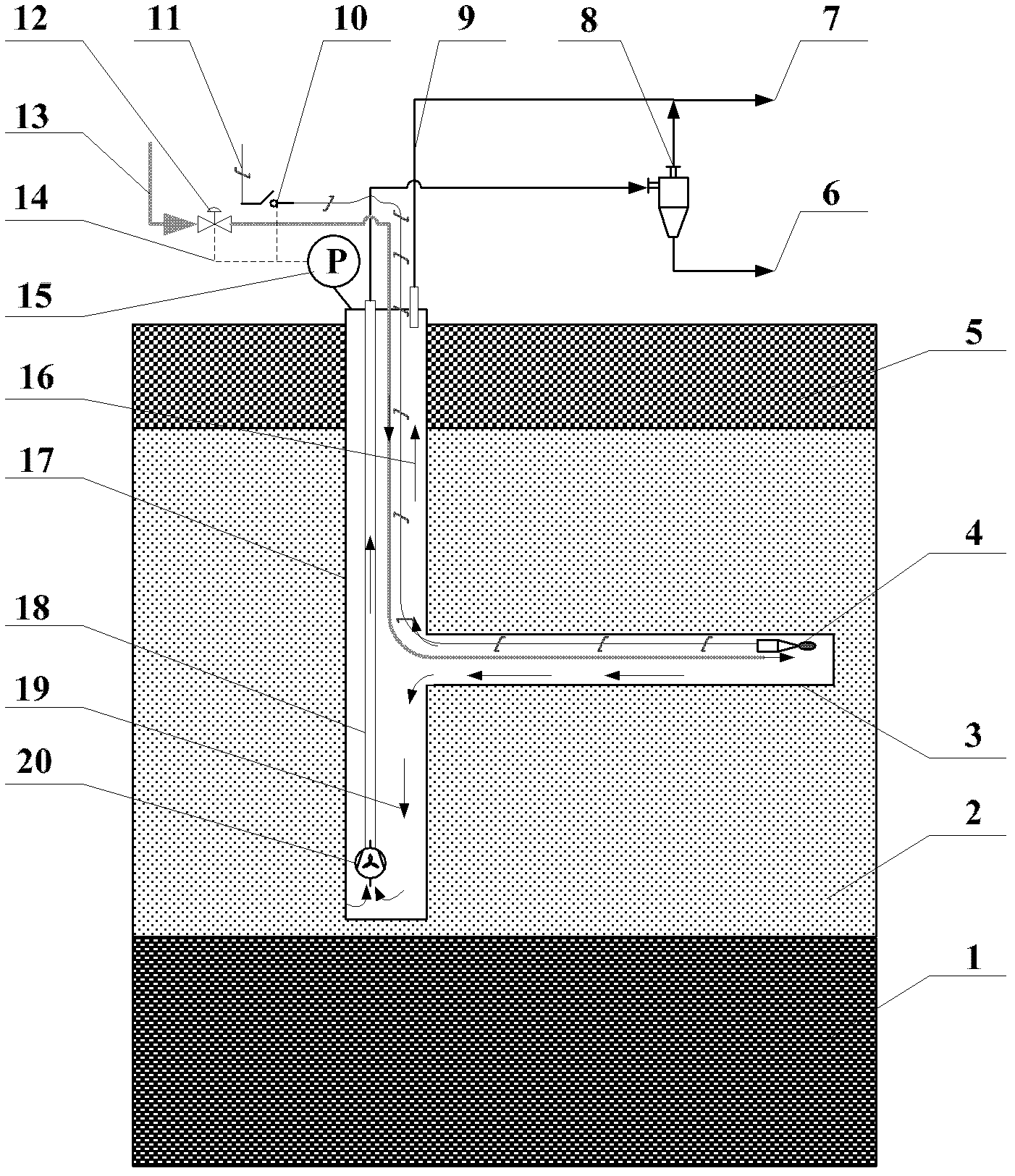

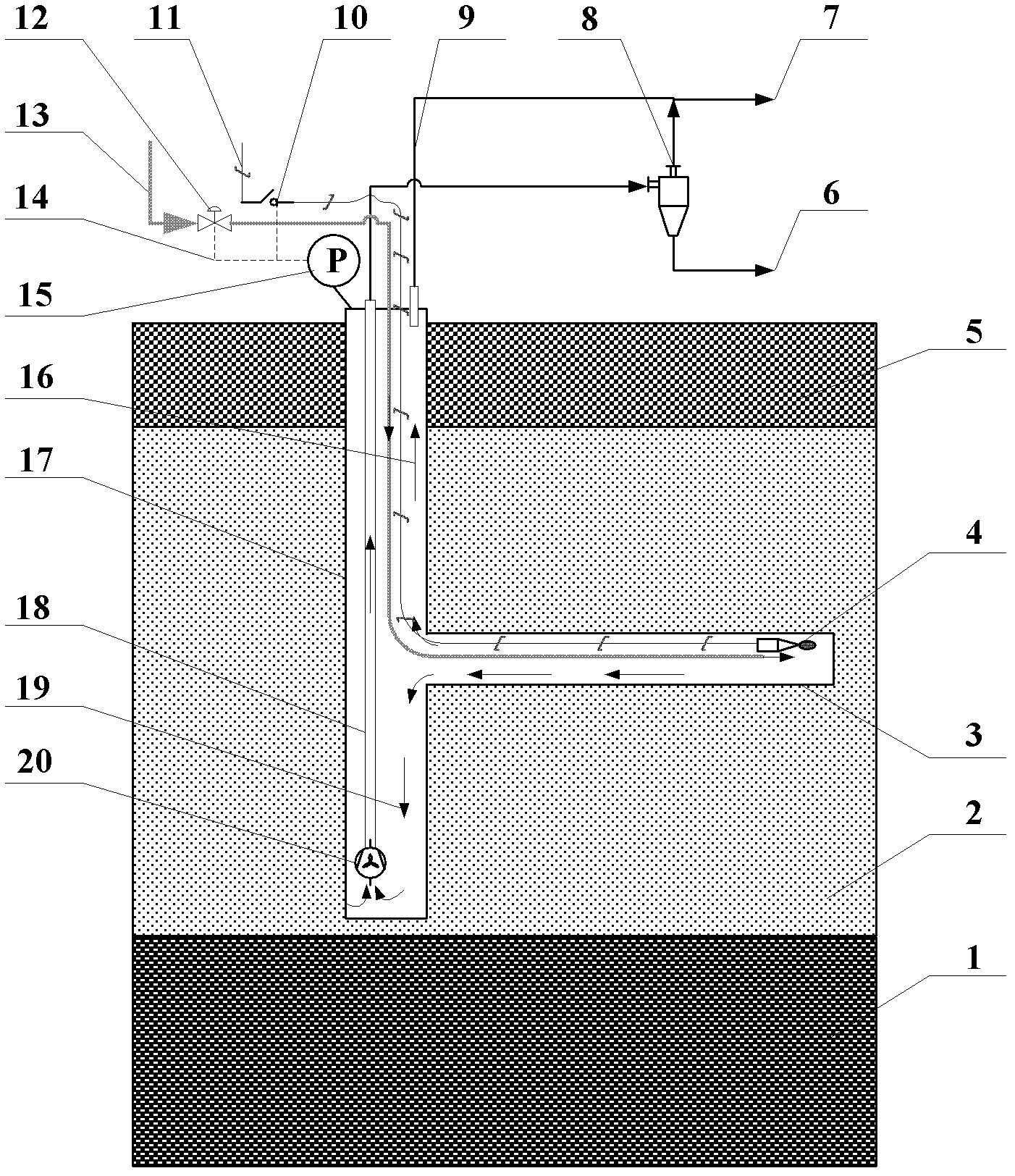

Method and device for exploiting natural gas hydrate in permafrost region

ActiveCN102213090APromote decompositionLower the water levelConstructionsFluid removalCollection systemOxygen

The invention discloses a method and a device for exploiting natural gas hydrate in a permafrost region. The device comprises a water-pumping depressurization system, an underground in-situ combustion heating system, a gas collection system and a control system. The water pumping depressurization system comprises a water delivery pipe, a deep-well pump and a gas-liquid separator, wherein the deep-well pump is arranged at the bottom of a vertical well; and the gas-liquid separator is connected with the deep-well pump by the water delivery pipe. The underground in-situ combustion heating system comprises an electronic ignition device and an oxygen-containing gas conveying pipe, wherein the electronic ignition device is connected with a ground power supply by a power switch; and the oxygen-containing gas conveying pipe is connected with an external gas supply system and paved from the ground to the electronic ignition device through the vertical well. The gas collection system comprises a gas collection pipe which is arranged at a well head of the vertical well. The control system comprises a pressure sensor, the power switch and a regulation valve, wherein the regulation valve is arranged on the oxygen-containing gas conveying pipe; and the control system controls the aperture of the regulation valve and the on and off of the power switch according to a pressure, which is measured by the pressure sensor, of the vertical well. By the invention, the synchronous continuous exploitation of depressurization and underground in-situ combustion heating can be realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

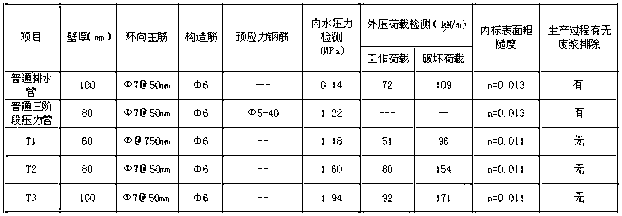

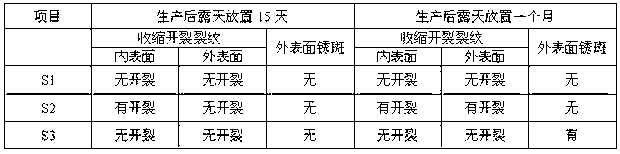

Green environmentally-friendly powder reinforced concrete water delivery pipe

ActiveCN103224356ALow costReduce pollution treatment costsCeramic shaping apparatusSlagMesh reinforcement

The invention belongs to the field of water delivery engineering and relates to a green environmentally-friendly powder reinforced concrete water delivery pipe. The green environmentally-friendly powder reinforced concrete water delivery pipe is manufactured by uniform distribution of concrete on a reinforcement mat. The concrete is prepared from 450 to 500 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 90 to 130 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 130 to 160 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 520 to 600 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 800 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 12 to 20 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 45 to 50 weight parts of a high-efficiency expanding agent, 130 to 150 weight parts of water, 0.8 to 1.2 weight parts of polypropylene fibers, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The reinforcement mat is manufactured by weaving hard-drawn wires having the diameter of 4.0 to 6.0 millimeters as reinforcements and cold-rolled ribbed bars having the diameter of 5.0 to 10.0 millimeters as hoop reinforcements.

Owner:黄贺明

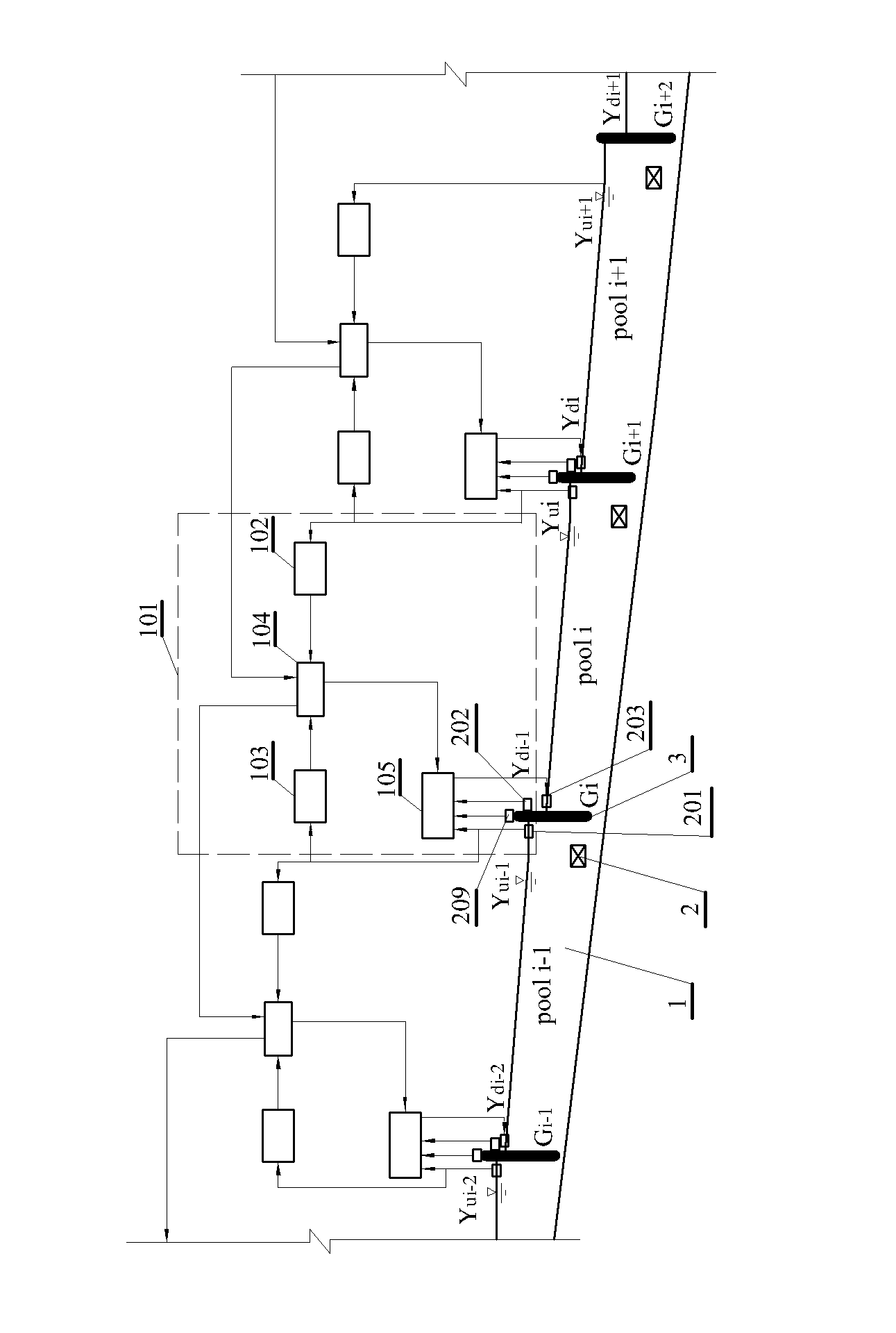

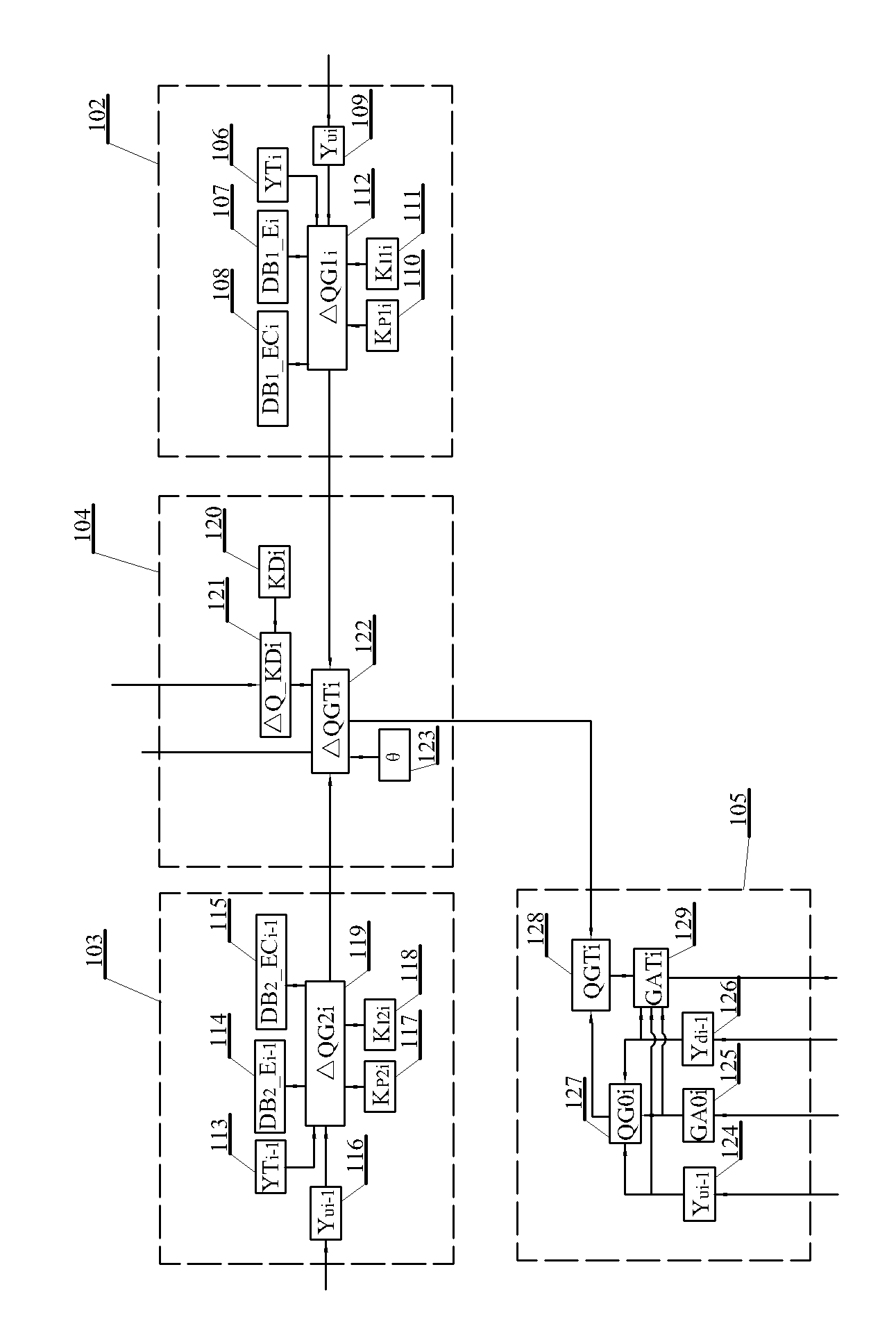

Method and device for automatically controlling water levels of multiple channel sections

InactiveCN101935996AReduce the impactOvercome timeConstructionsIrrigation ditchesStreaming dataAutomatic control

The invention relates to a method and a device for automatically controlling water levels of multiple channel sections. The device comprises a water delivery open channel and a plurality of gates, wherein a water-dividing opening is reserved at a place close to the upstream of each gate; a gate opening and closing mechanism of each gate is connected with a control unit of each gate; and the control units are connected through a network. The control unit comprises a gate-front water level sensor, a gate-rear water level sensor and a gate open degree sensor, wherein the gate-front water level, gate-rear water level and the gate open degree sensors are connected with a low pass filter; the low pass filter is connected with an A / D converter; the A / D converter is connected with a data acquisition unit; the data acquisition unit is connected with an industrial control computer; the industrial control computer is connected with a PLC; and the PLC is connected with the gate opening and closing mechanism. Due to the adoption of upper and lower stream data acquisition, gate and water flow control simultaneously, the method and the device avoid the influences of long time delay and coupling effect of the long-distance large-scale water delivery open channel and give full play to the advantages of the upstream control and the downstream control method in the water level regulation and water quantity regulation.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Water irrigation system with solar panel and method of controlling irrigation

A water irrigation system may include a computer system, a sensing unit, an irrigation controller, and / or a water delivery system. The sensing unit may include one or more sensors and a solar panel. Electricity produced by the solar panel may be supplied to the sensors of the sensing unit. The sensing unit may provide output to the computer system that is a function of the received sunlight. The computer system may assess solar insolation as a function of the output from the sensing unit. The computer system may control irrigation of a zone to be irrigated at least partially based on the assessed solar insolation. A method of controlling irrigation may include assessing solar insolation from output provided by a solar panel near or in a zone to be irrigated and controlling irrigation at least partially based on the assessed solar insolation.

Owner:CLARK JAMES JOLLY

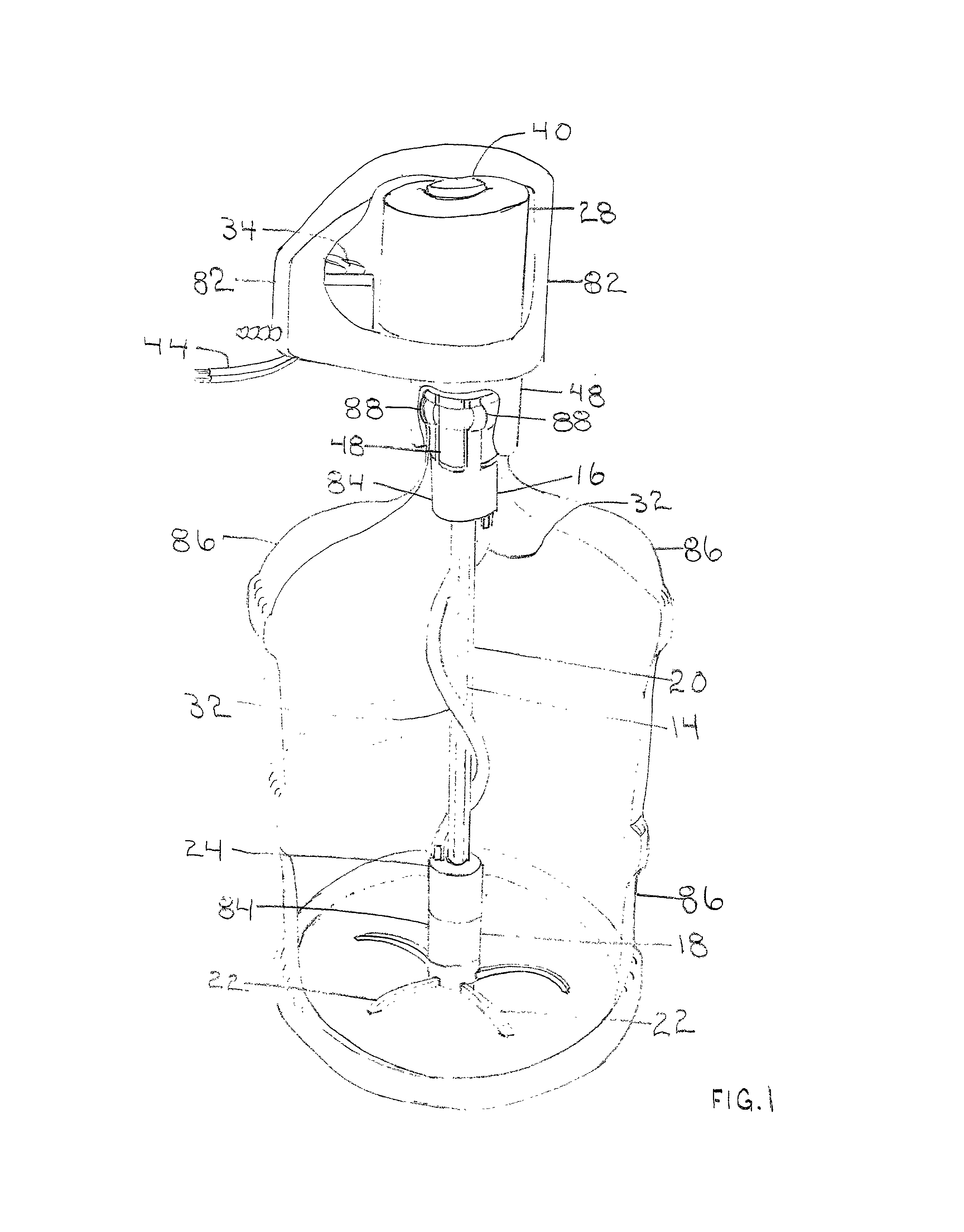

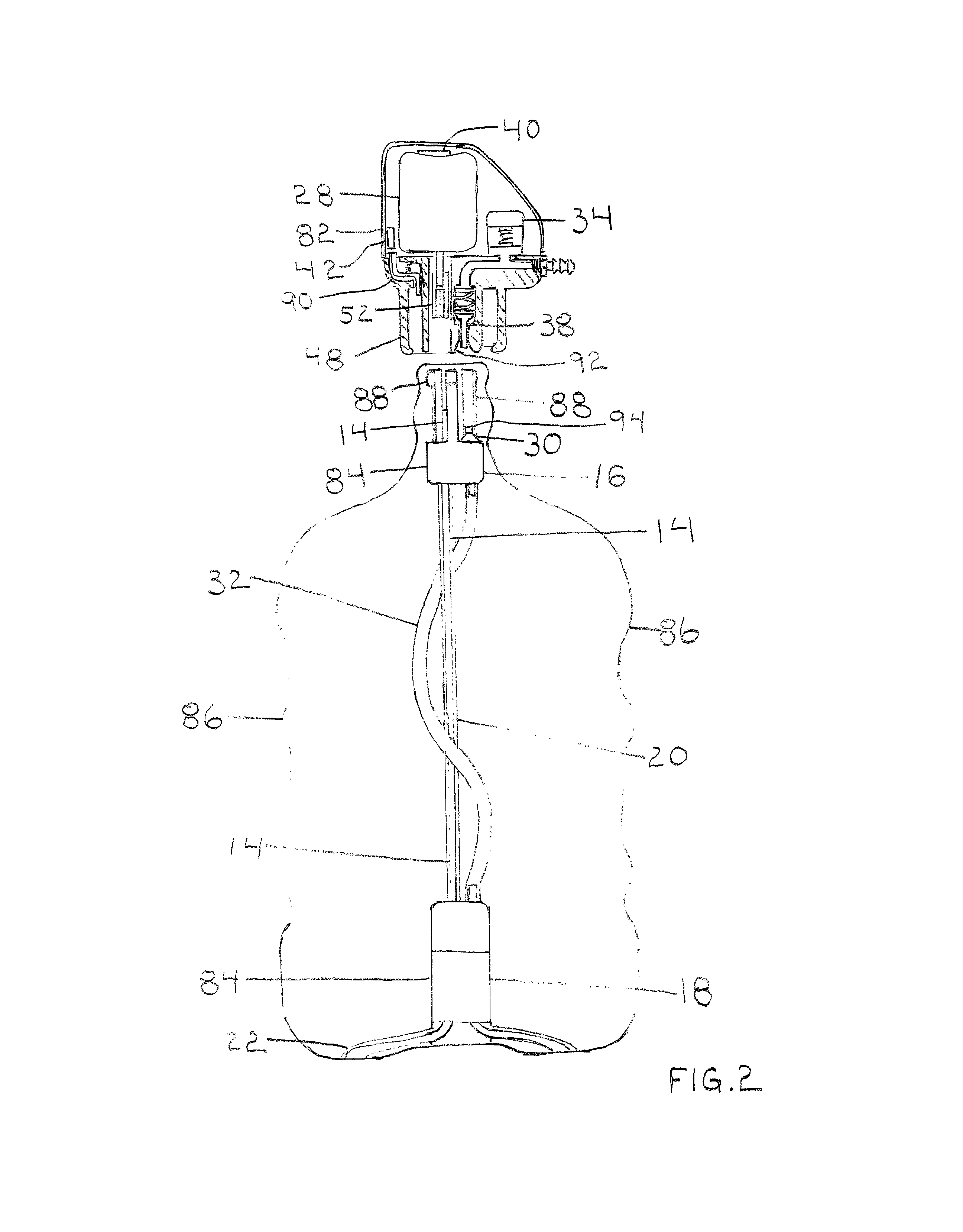

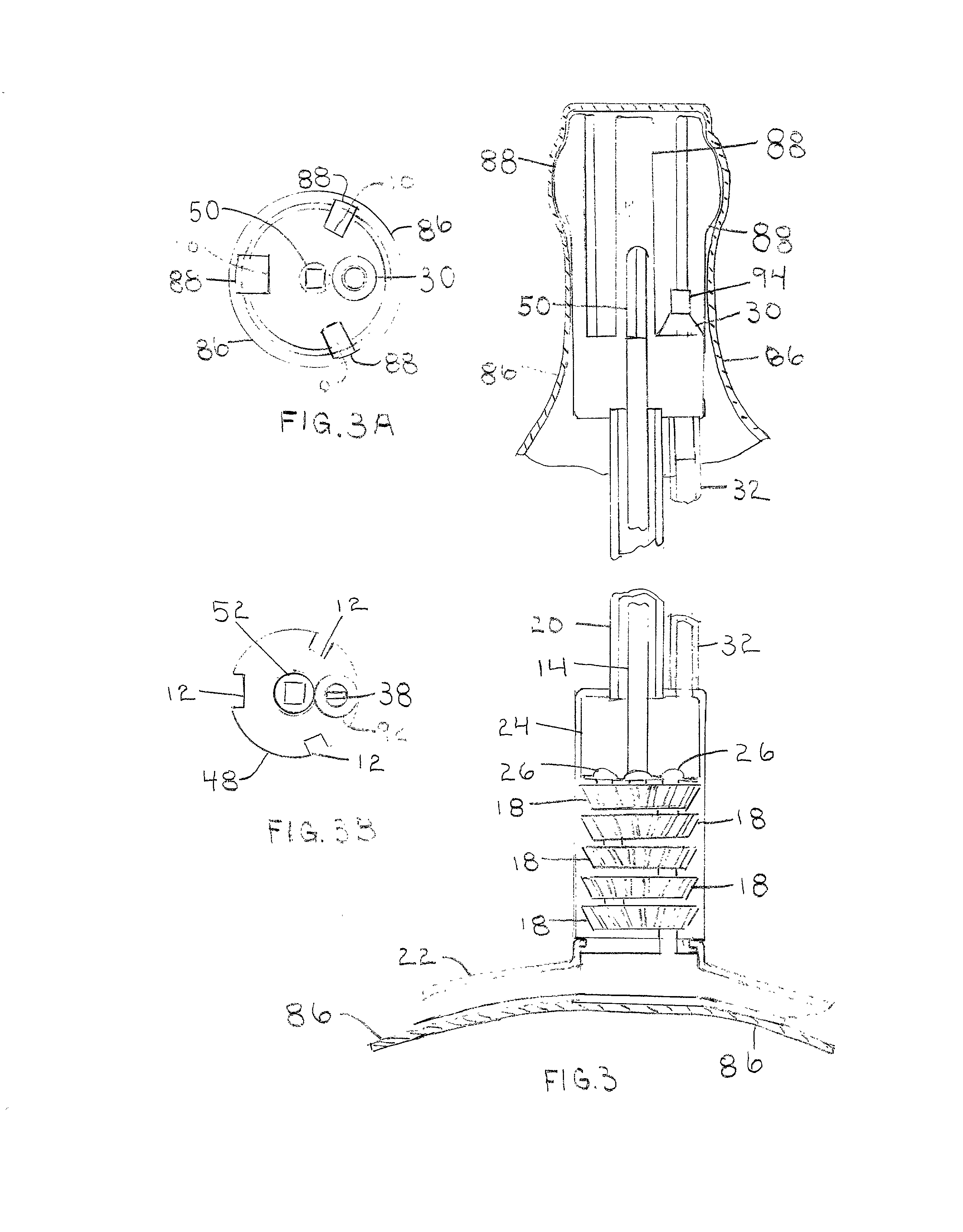

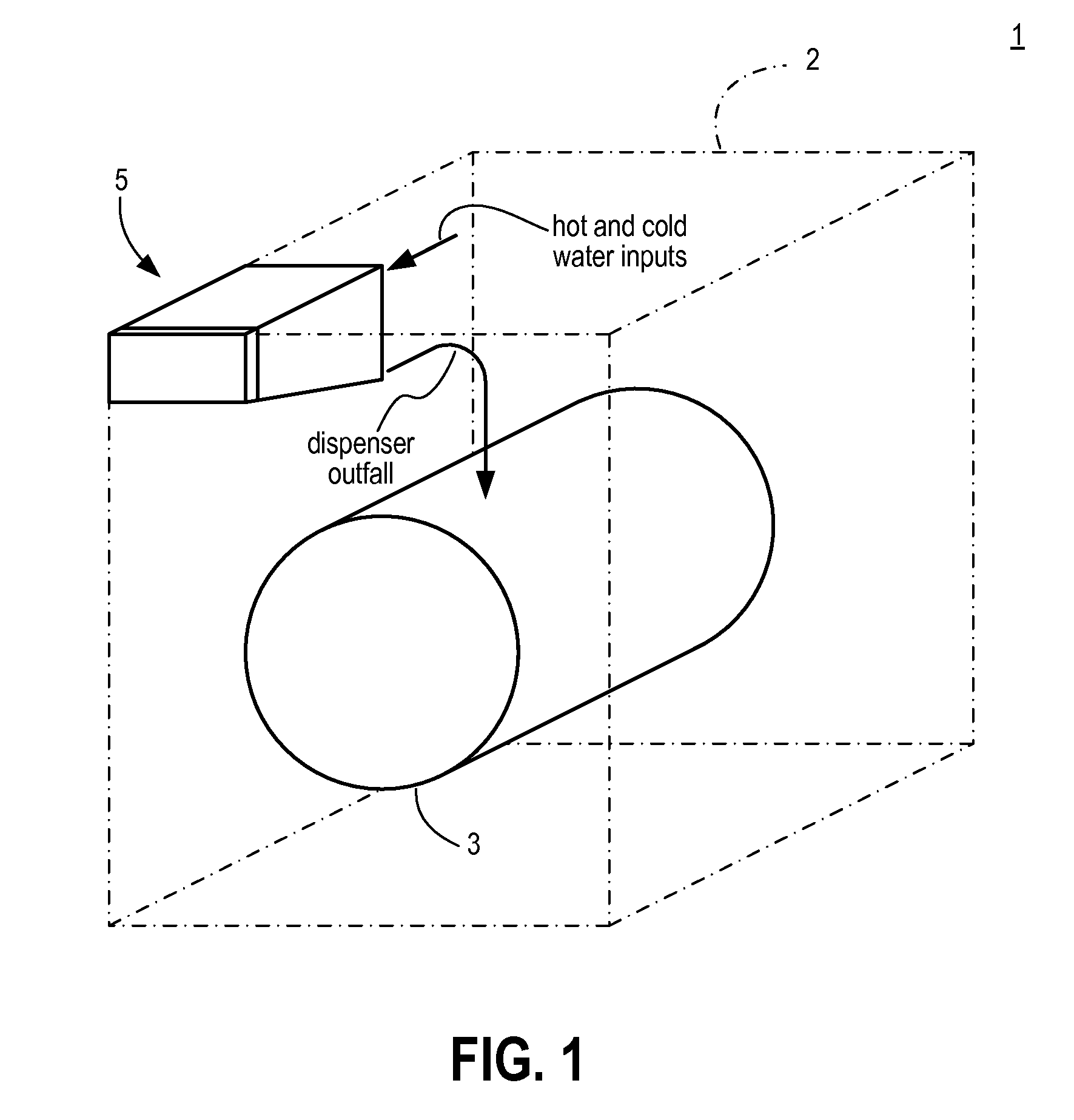

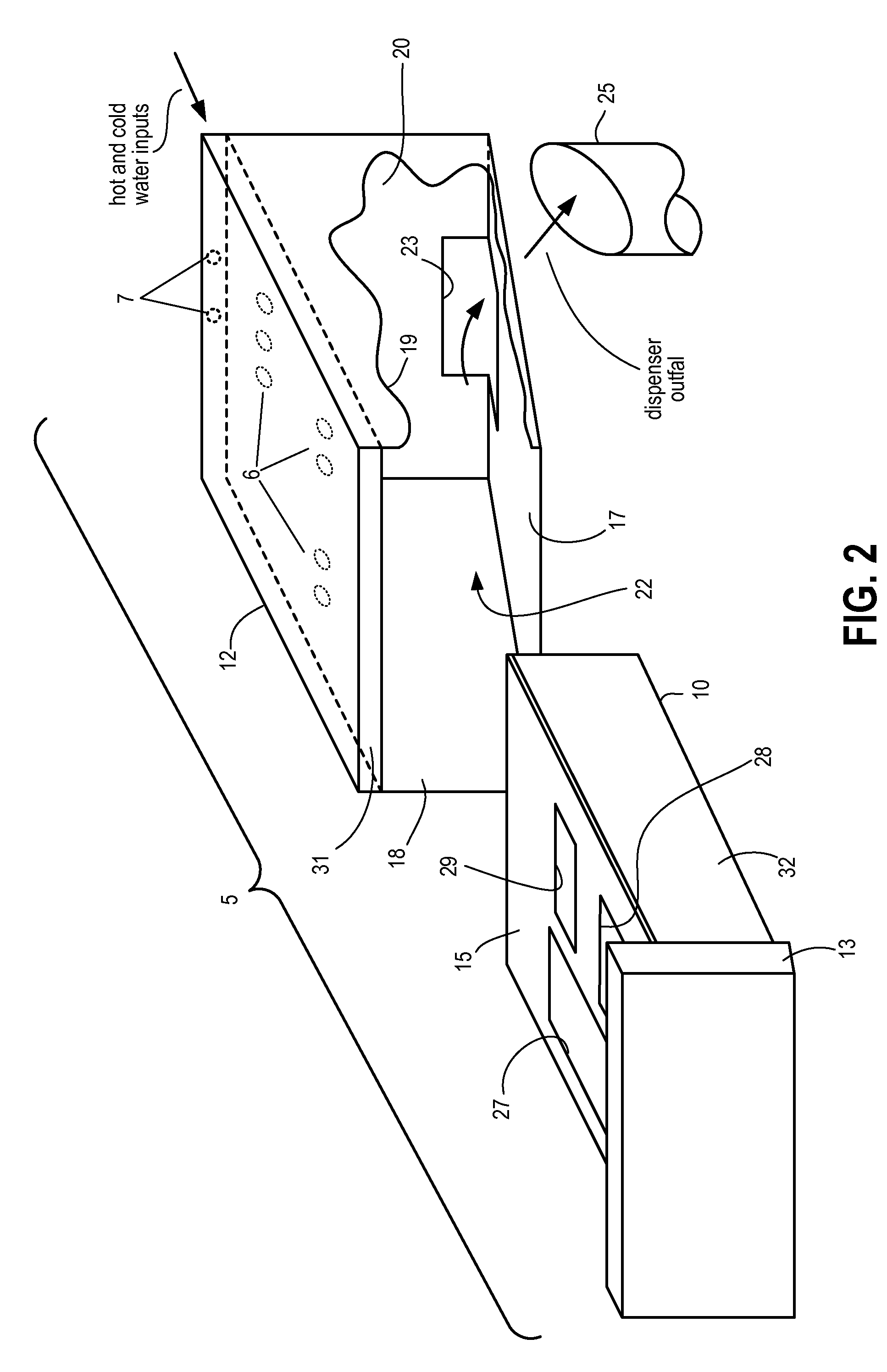

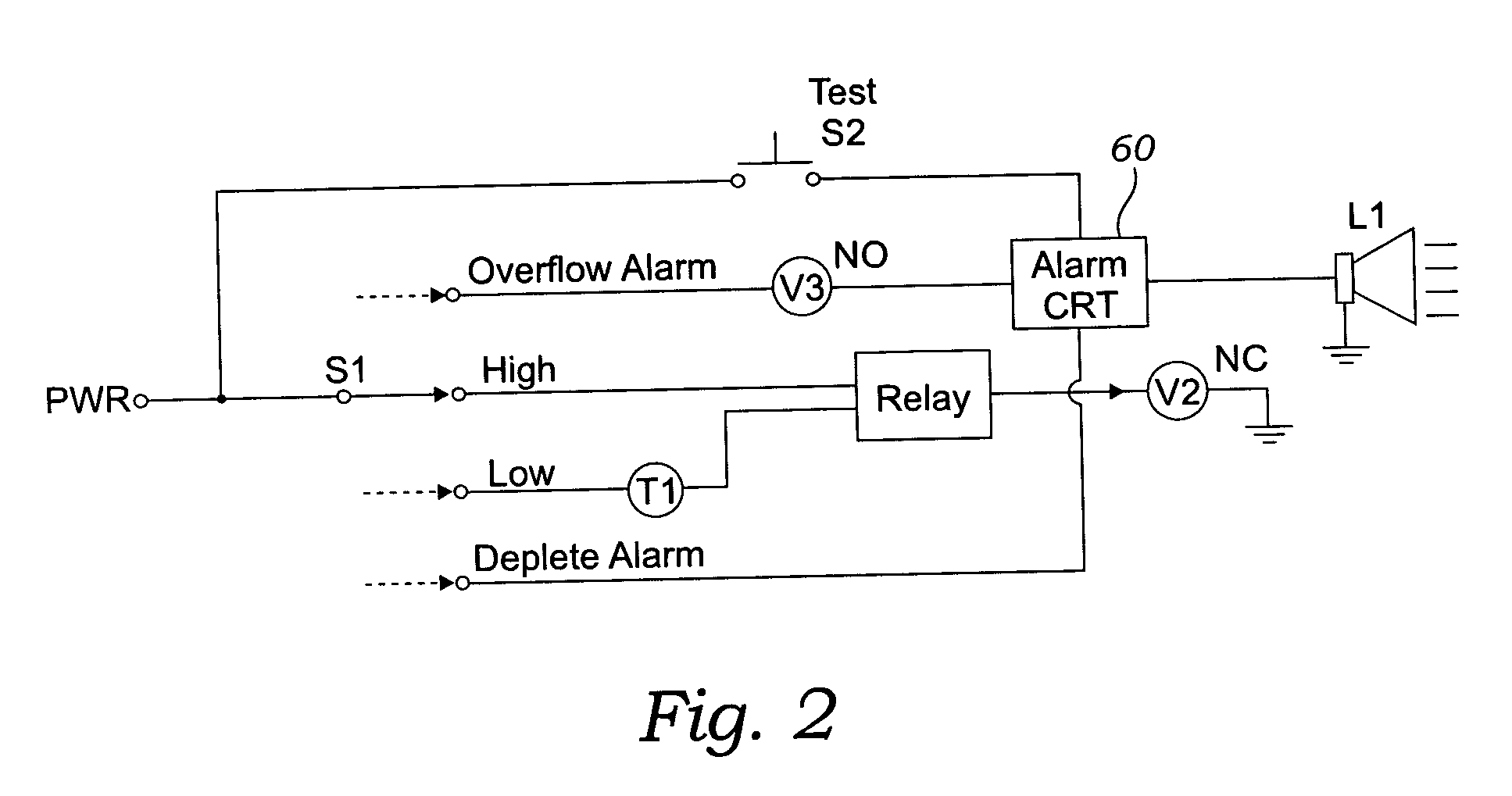

Water delivery 7 dispensing system

A two-part bottle water delivery system. A separate pump unit (84) snaps into a typical commercial water bottle (86). The bottom draw pump (18) is shaft driven (14). The separate placement of pump (18), feedline (32), drive shaft (14), and drawlines (22) into the bottle (86) allows all water contact items to be submitted to the commercial bottle cleaning and sterilization process. This assures maximum purity within the typical sealed plastic cap. The corresponding control / motor (82) automatically activates by switch (42) upon insertion into bottle (86). Water flow control is upon demand by pressure switch (34). Control / motor (82) and pump unit (86) are designed with exact one position alignment. Dispensing is accomplished by a reversible mounting (78) self-adhering (68) valve (80) incorporating a flat tube (54) capable of bypassing the typical magnet seal (56) on a conventional refrigerator. The seal is maintained and tube protected by a bridge (66).

Owner:GERHARDT JOHN MARVIN

Apparatus and method for infusing hot beverages

ActiveUS20140242224A1More volumeReduce manufacturing costBeverage vesselsAvicultureAtmospheric airWater flow

A hot beverage brewing apparatus including a pressurized hot water delivery system to provide liquid under pressure within a range of acceptable infusion temperatures without a water pump. A fresh water tank is situated above a water heater in liquid communication to maintain the water heater filled. Water in the water heater is kept at a pre-infusion temperature. When infusion process is to commence the user selects volume of water to be dispensed into infusion material, water is rapidly heated to infusion temperature and displaced from water heater by pressurised air from air pump. At the end of the brew cycle the air pump is stopped and a valve connects the water heater to atmospheric pressure to facilitate water flow from the fresh water tank into the water heater. After the infusion process an air valve may direct air from the air pump to the infusible material to dry it for ease of disposal.

Owner:APPLIANCE DEVMENT

Water irrigation system with moisture gauge and method of controlling irrigation

A water irrigation system may include a computer system, a sensing unit, an irrigation controller, and / or a water delivery system. The sensing unit may include a moisture gauge. The moisture gauge may include a capacitor coupled to a collector. The sensing unit may assess an amount of moisture in the collector and provide output that is a function of the amount of moisture in the collector to the computer system. The computer system may control irrigation of a zone to be irrigated at least partially based on the assessed amount of moisture in the collector. A method of controlling irrigation may include assessing an amount of moisture in a collector near or in a zone to be irrigated and controlling irrigation at least partially based on the assessed amount of moisture in the collector.

Owner:JAMES JOLLY CLARK

Ozonated Water Dispenser

InactiveUS20080237368A1Reduce disadvantagesInhibited DiffusionWatering devicesSpray nozzlesTap waterWater flow

An ozonated water dispenser allows a user to kill bacteria and microbiological organisms on their hands or other objects. The dispenser includes a reservoir, a pump, and an ozonated water delivery means downstream from the pump to dispense pressurized ozonated water in a fine mist. The delivery means includes a mister and a control valve, such as a solenoid, to restrict water flow in a water line to build up water pressure between the pump and the control valve to overcome the mister's cracking pressure. A water ozonation means is provided downstream from the ozonated water delivery means, and in communication with an inlet of the reservoir to recirculate water. This dispenser uses regular tap water and can be employed as an alternative to a sanitizing gel, or when use of a gel is not practical or desirable, such as for sanitizing fresh produce after its purchase.

Owner:TERSANO INC

Latching solenoid energy reserve

ActiveUS8295985B2Increase system costSmall power demandOperating means/releasing devices for valvesWatering devicesStored energySolenoid valve

An irrigation device including an actuator configured to control water flow to at least one water delivery device, a first stored energy source configured to power the actuator to effect irrigation via the at least one water delivery device, and a second stored energy source which is separate from the first stored energy source, wherein the second stored energy source is configured to power the actuator to terminate the irrigation via the at least one water delivery device. The irrigation devices further includes a controller configured to cause the first stored energy source to power the actuator to effect the irrigation, responsive to an instruction to provide irrigation, and to cause the second stored energy source to power the actuator to terminate the irrigation responsive to a termination condition.

Owner:RAIN BIRD CORP

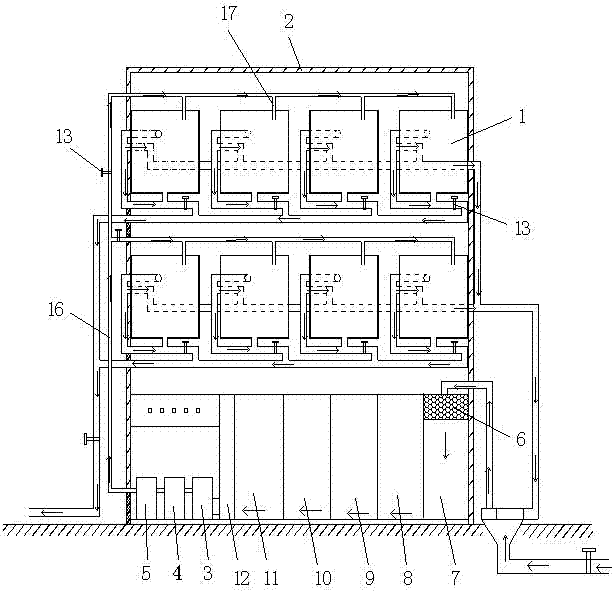

Efficient and economical indoor circulating aquaculture system

InactiveCN102177867AIncrease the amount of breedingImprove farming efficiencyPisciculture and aquariaAutomatic controlWater quality

The invention discloses an efficient and economical indoor circulating aquaculture system. The system comprises a culture tank, a solid multi-layer frame and a water treatment system, wherein the culture tank is arranged on the solid multi-layer frame; the water treatment system comprises a filter device, a sterilization device, a temperature controller and a circulation pump which are arranged along the water downstream direction in sequence; and a sewage outlet of the culture tank is connected with the filter device through a water delivery pipe, and a water outlet of the circulation pump is connected with the culture tank through a water delivery pipe. In the efficient and economical indoor circulating aquaculture system, a plurality of layers of culture tanks can be placed on the solid multi-layer frame, so that the indoor space is sufficiently utilized for solid culture, the culture quantity is increased, and the culture benefit is improved. The water treatment system can automatically drain sewage, independently oxygenate, independently control water flow level, and can automatically control water quality and water temperature, so that high-density safe culture is realized.

Owner:SOUTHWEST UNIVERSITY

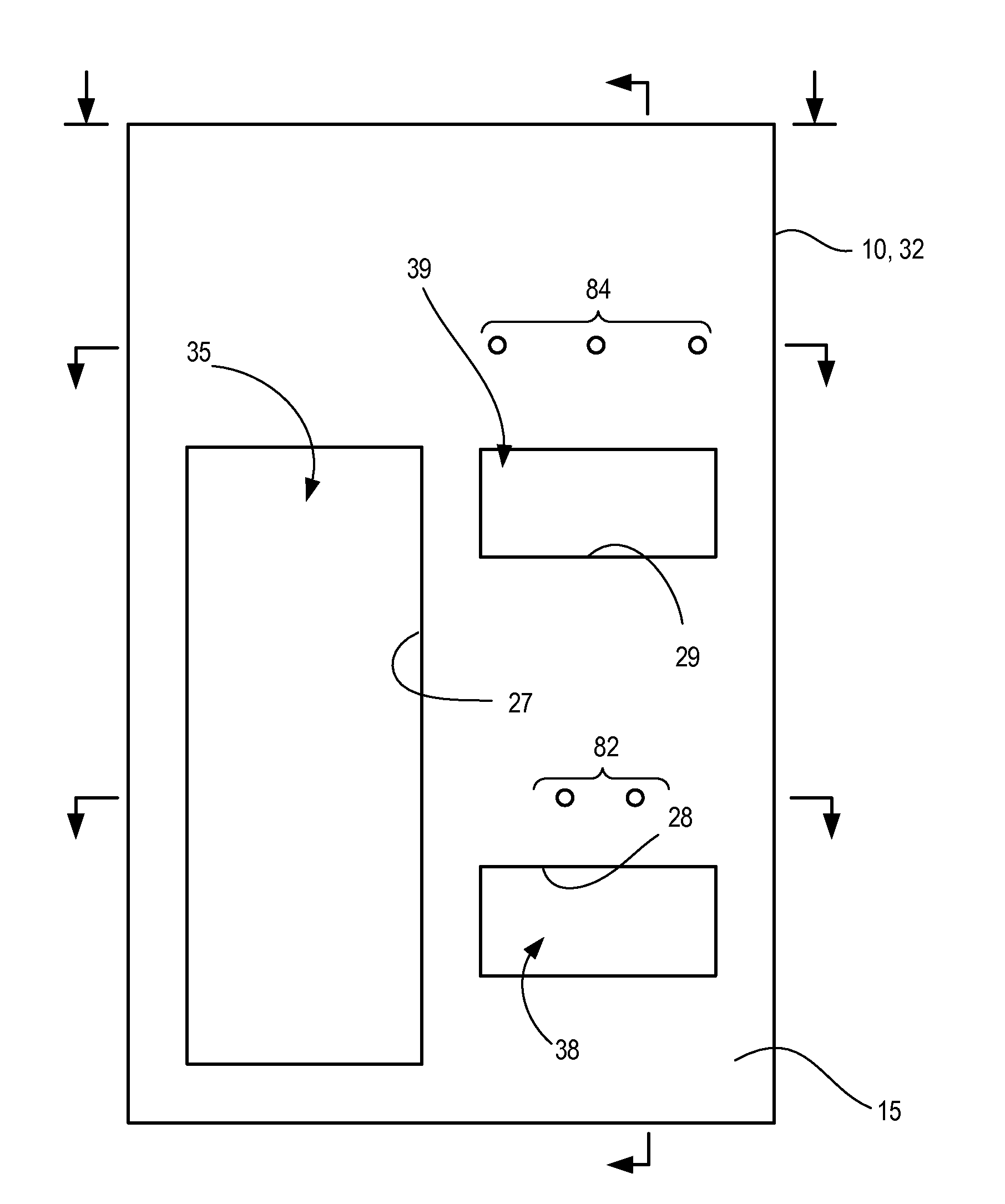

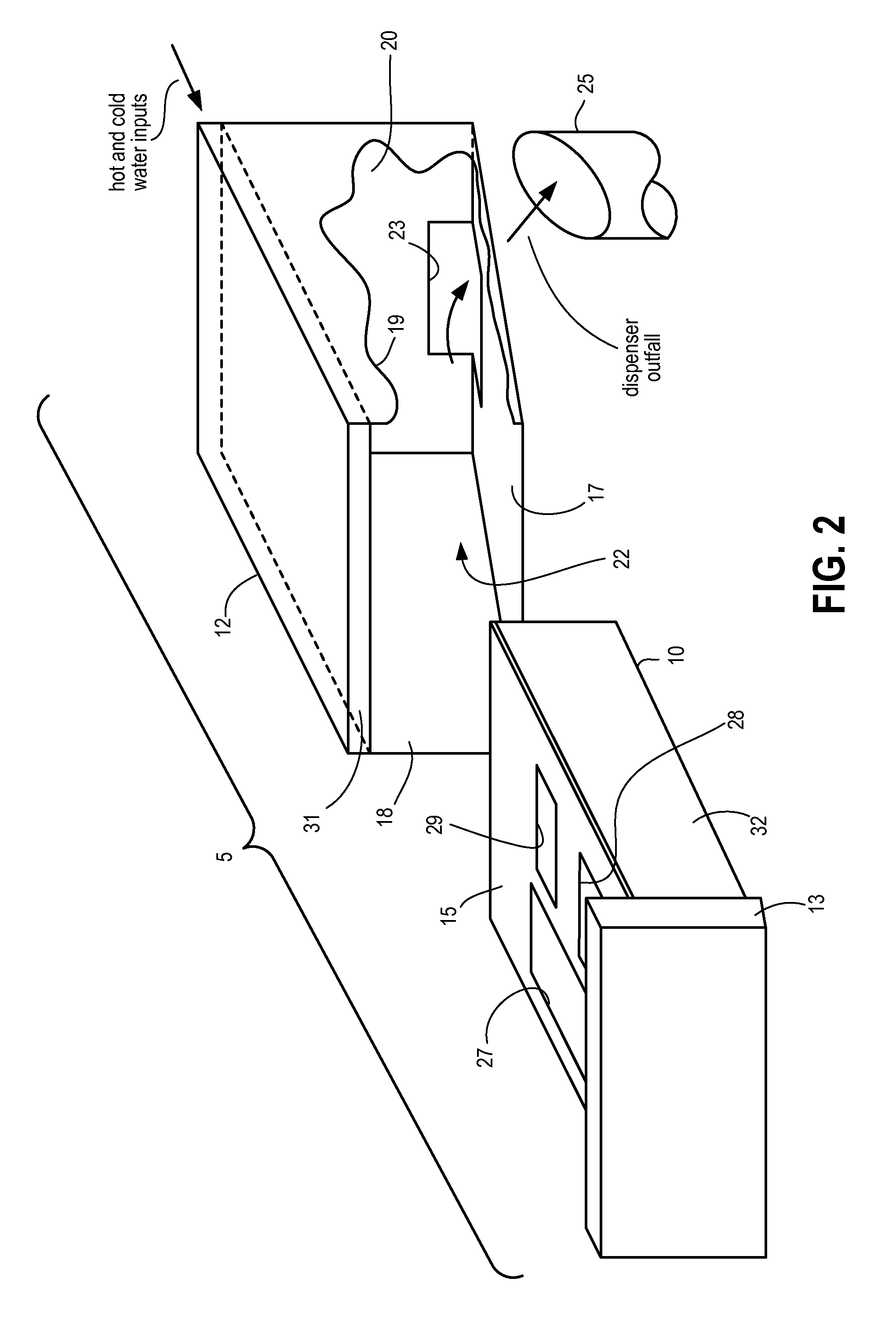

Methods and Systems for Water Delivery in an Additive Dispenser

ActiveUS20090158782A1Avoid residueSpeed up siphoningControl devices for washing apparatusMachines/enginesSiphonLaundry washing machine

A washing apparatus such as an automatic laundry washing machine includes a wash agent dispenser drawer including an additive compartment for storing various additives such as detergent, bleach and fabric softener. One or more water inflow tubes may extend downwardly into the additive compartment and may be configured to deliver water for diluting the additives contained in the compartment. The inflow tubes are of sufficient length to reach a sub-surface portion of additive held in the compartment. Water may simultaneously be delivered to the surface of the additive. Furthermore, inflow tubes have their outlets positioned adjacent to the base(s) of one or more siphon post / cap assemblies located in the additive compartments, such that a churning effect is produced from the injection of water through the tubes and the siphoning action of the siphon post, whereby mixing is enhanced and additive buildup may be avoided and / or removed.

Owner:ELECTROLUX HOME PROD CORP NV

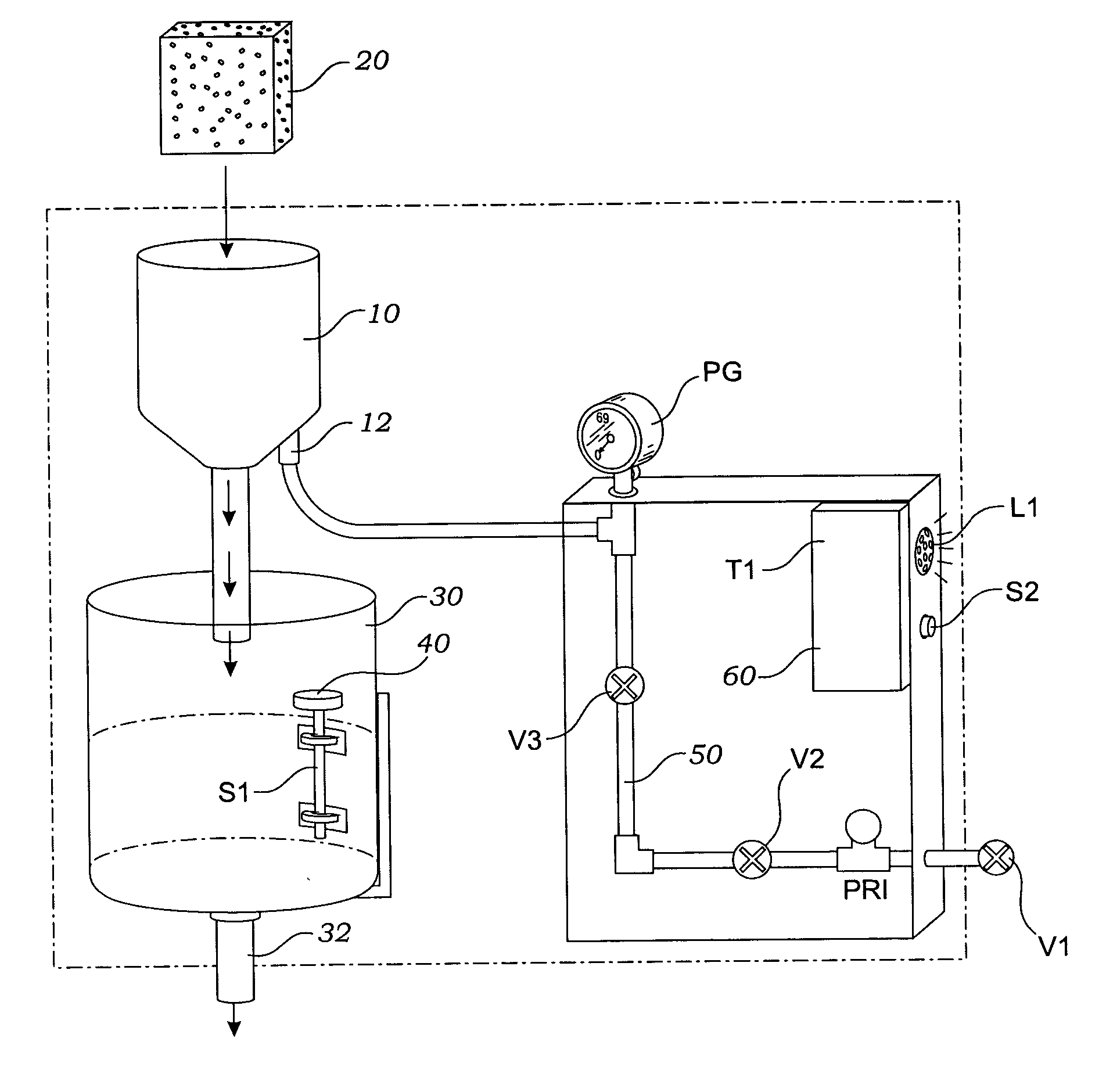

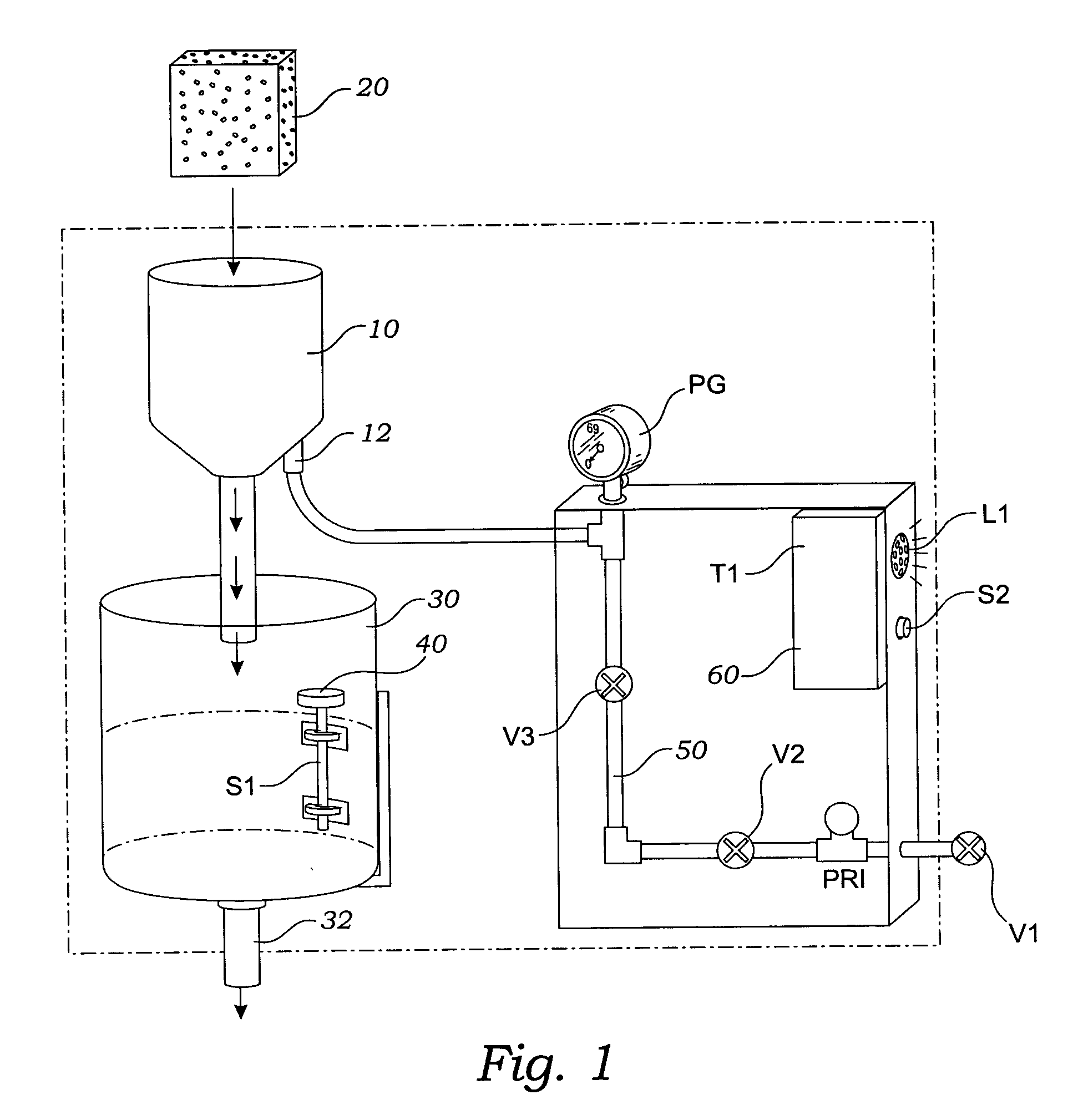

Automatic dilution system with overflow protection

ActiveUS20050201200A1Controlling ratio of multiple fluid flowsSolid sorbent liquid separationChemical solutionWater source

A chemical solution dispensing apparatus uses a dissolving tank to hold a solid chemical cake. The dissolving tank delivers the chemical solution into a holding tank by gravitational flow and then to a receiving system. A liquid level sensor in the holding tank senses the liquid level of the solution and calls for water delivery through a conduit into the dissolving tank. When the level reaches a low point a circuit opens a inlet flow valve to deliver water into the dissolving tank. When the level reaches a high point, the circuit closes a safety shutoff valve in the conduit line. A pressure regulator and control relay enable the conduit line to be properly pressurized by an inlet source of water through a shutoff valve that is normally open. When the level in the holding tank rises above the high point, an alarm signal is released to initiate an audible alarm.

Owner:FLEIG JOHN

Sequenced Water Delivery in an Additive Dispenser

ActiveUS20090119849A1Preventing situationOther washing machinesControl devices for washing apparatusEnvironmental engineeringWater delivery

An automatic washing machine includes a wash additive dispenser for dispensing detergent and one or more additives into a wash tub. Water is delivered to a first wash agent chamber in the wash additive dispenser for delivery into a wash tub during a wash cycle. Water is subsequently delivered to a second wash agent chamber to flush from that chamber any unintended collection of water or additive residue therein, as may result from the water delivery to the first wash agent chamber and / or from an earlier dispensing of additive from the second wash agent chamber.

Owner:ELECTROLUX HOME PROD CORP NV

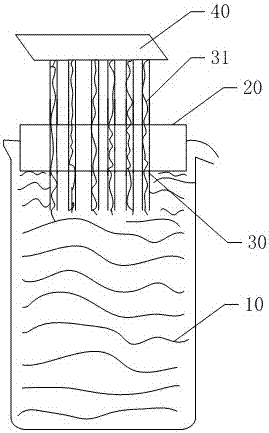

Automatic water delivery device for photo-thermal water treatment

InactiveCN107226504AReduce lossesIncrease profitGeneral water supply conservationWater/sewage treatment apparatusEnvironmental engineeringThermal water

The invention discloses an automatic water delivery device for photo-thermal water treatment. The automatic water delivery device comprises a fixed base suspending above water, a plurality of supporting columns with water absorption action and a photo-thermal converting layer located at top ends of the supporting columns, wherein bottom ends of the supporting columns are inserted in the fixed base and are in contact with water, and the photo-thermal converting layer generates energy under the action of lighting and is used for evaporating water which is continuously conveyed by the supporting columns from bottom to top. According to the automatic water delivery device, the photo-thermal converting layer is separated from the water, and moisture transport channels are established through the hydrophilic supporting columns, so that moisture can be continuously supplemented to the photo-thermal converting layer from bottom to top under the condition that energy is not required to be additionally consumed; and meanwhile, converted energy lost in heat conduction can be further reduced, and the converted energy is used for evaporating the water in a more centralized manner, so that the energy utilization ratio is increased.

Owner:SHENZHEN UNIV

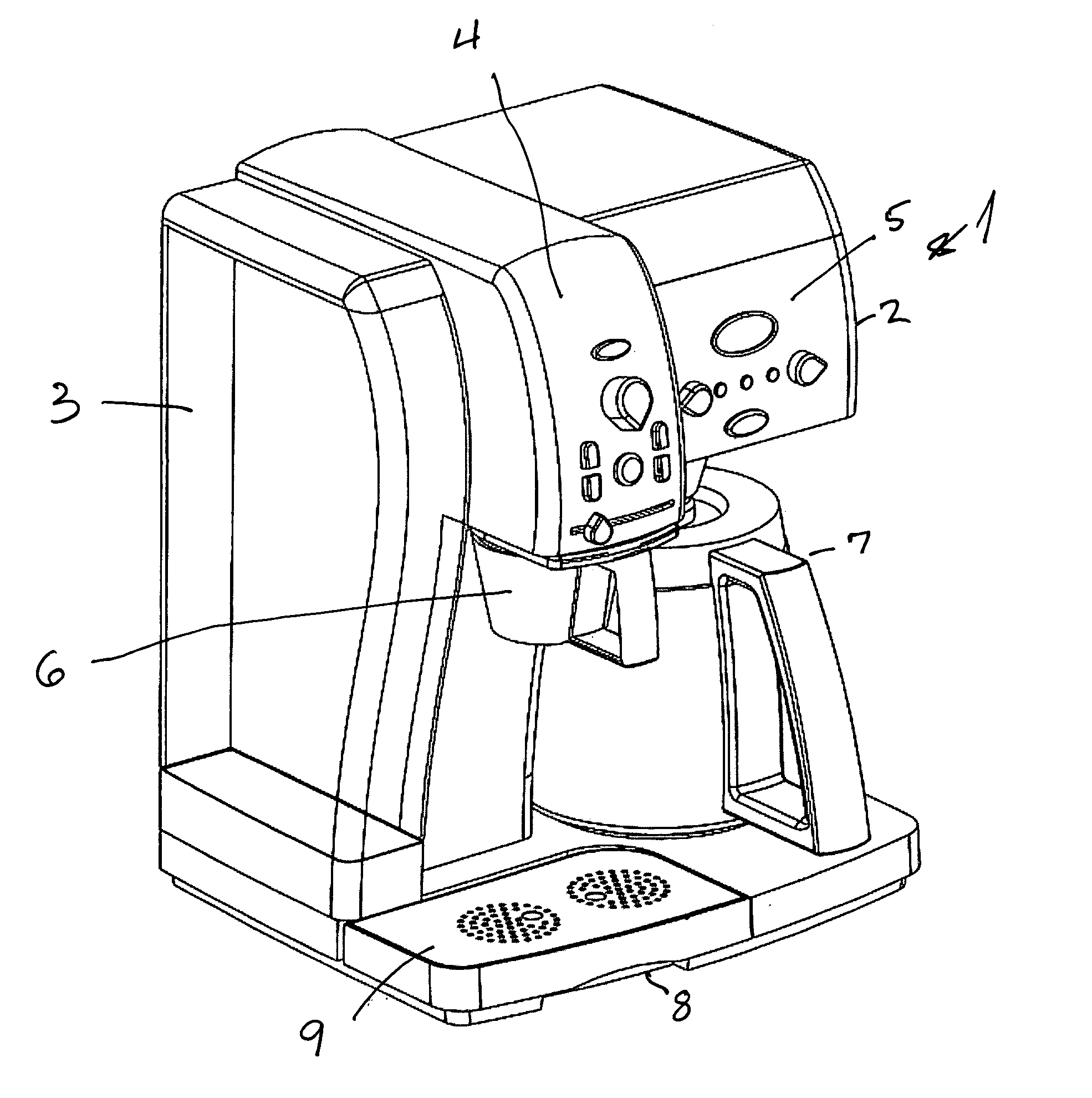

Hot beverage apparatus

InactiveUS20070119308A1Minimize changesAvoid flowBeverage vesselsLiquid dispensingEngineeringBrewing

A hot beverage brewing apparatus 1 has a plurality of heated water delivery nozzles 19 that direct heated water under pressure simultaneously to a specified point 26 within a brew basket 17 that, regardless of the amount or type of grounds in the basket 17, will ensure thorough mixing of the heated water and grounds to deliver optimally brewed beverage. Additionally, the present invention is directed to a heat sensor 31 and weight sensor 33 positioned in contact with a carafe 7 to sense whether or not the carafe is thermally-insulated or not to determine whether or not to automatically activate a warming plate 20.

Owner:GLUCKSMAN DOV +3

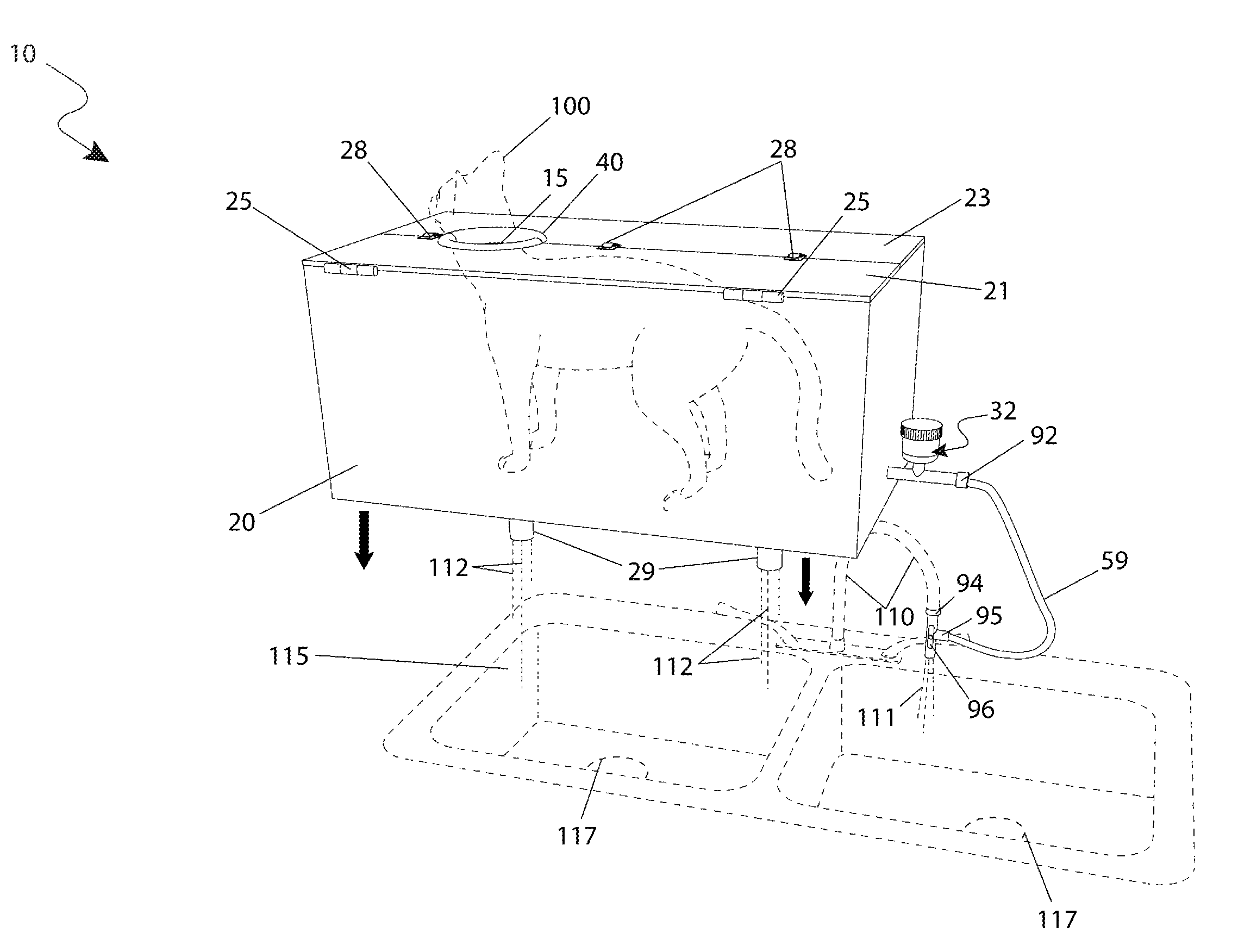

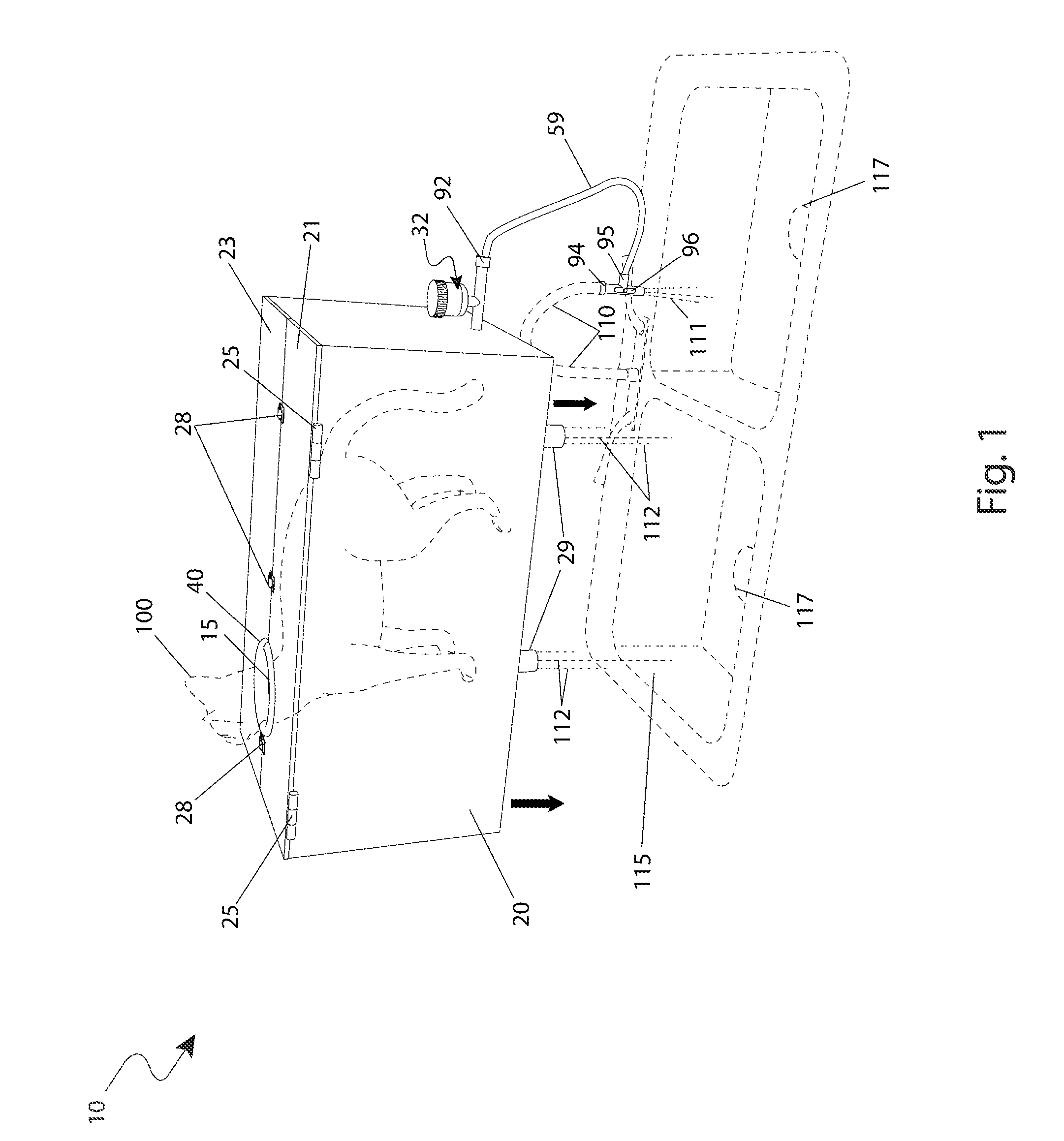

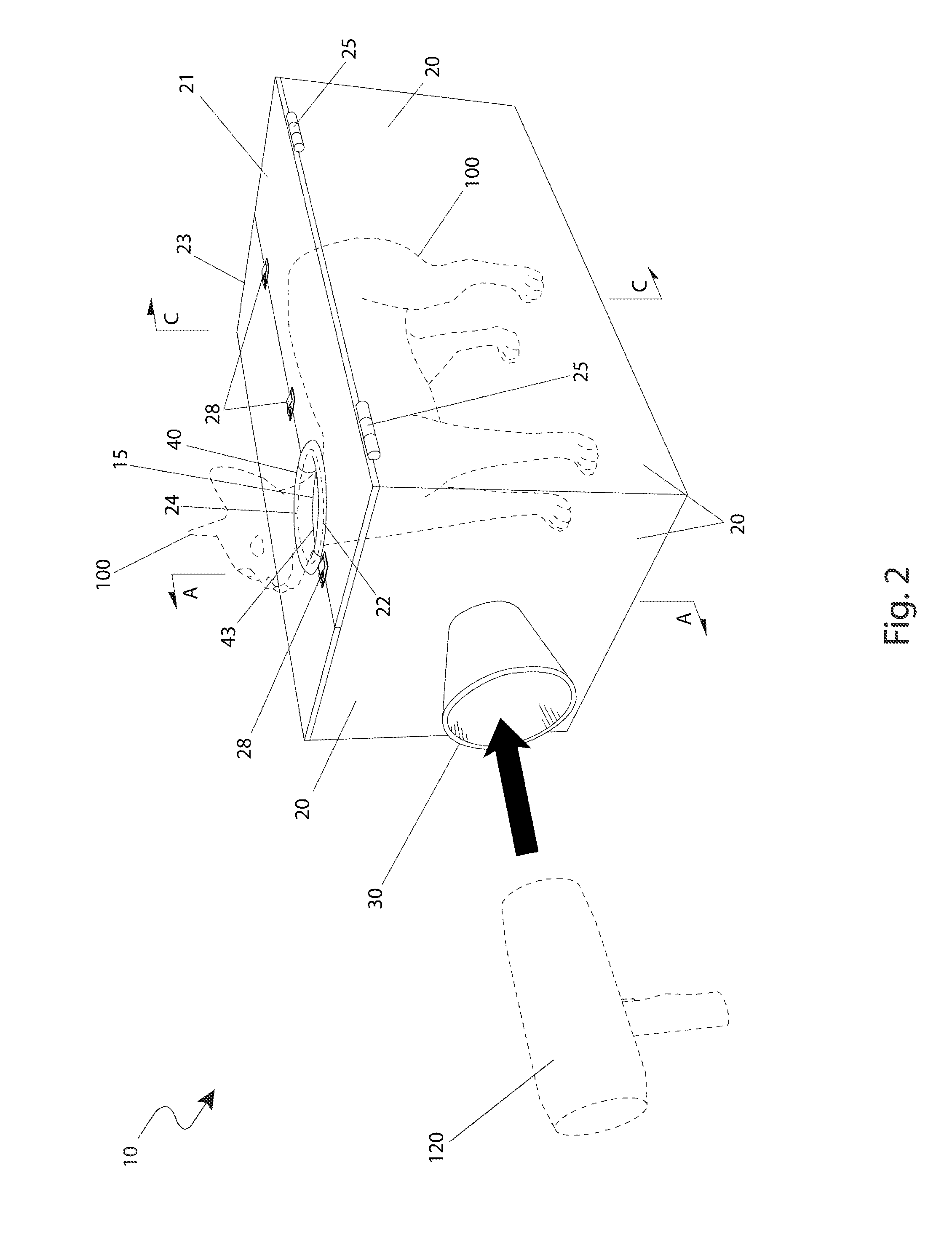

Small pet washing apparatus

InactiveUS8061304B1Increasing pressure of supplyOther apparatusGrooming devicesFoam rubberCompanion animal

An apparatus to aid in the bathing of cats, dogs, or similar small pets that is intended for countertop use over an existing a sink is herein disclosed, comprising a box-like structure with a hinged lid. The apparatus is designed such that the cat or dog can be secured within the enclosure with its head protruding from a foam rubber lined opening. A hose and valve connected thereto the apparatus are hooked up to a sink faucet providing a mixture of water and liquid soap which fills and pressurizes the hollow walls of the apparatus causing spraying of the pet from a plurality of water delivery apertures formed in the vertical walls. When completed, the pet is rinsed with clean water. Waste water from the washing process is strained and drained into the sink below. Finally, a dryer adapter coupling allows a user to dry the pet using a hair dryer while still inside the apparatus.

Owner:RAMSAY JENNIFER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com