High-frequency coil structure capable of simultaneous producing four silicon cores and other crystal material

A high-frequency coil and crystal material technology, which is applied in coil device, crystal growth, single crystal growth and other directions, can solve the problems of high current running in the middle inner hole, the current running can not be reached, the number of defective products increases, etc. The effect of energy utilization, reducing defective rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to these examples.

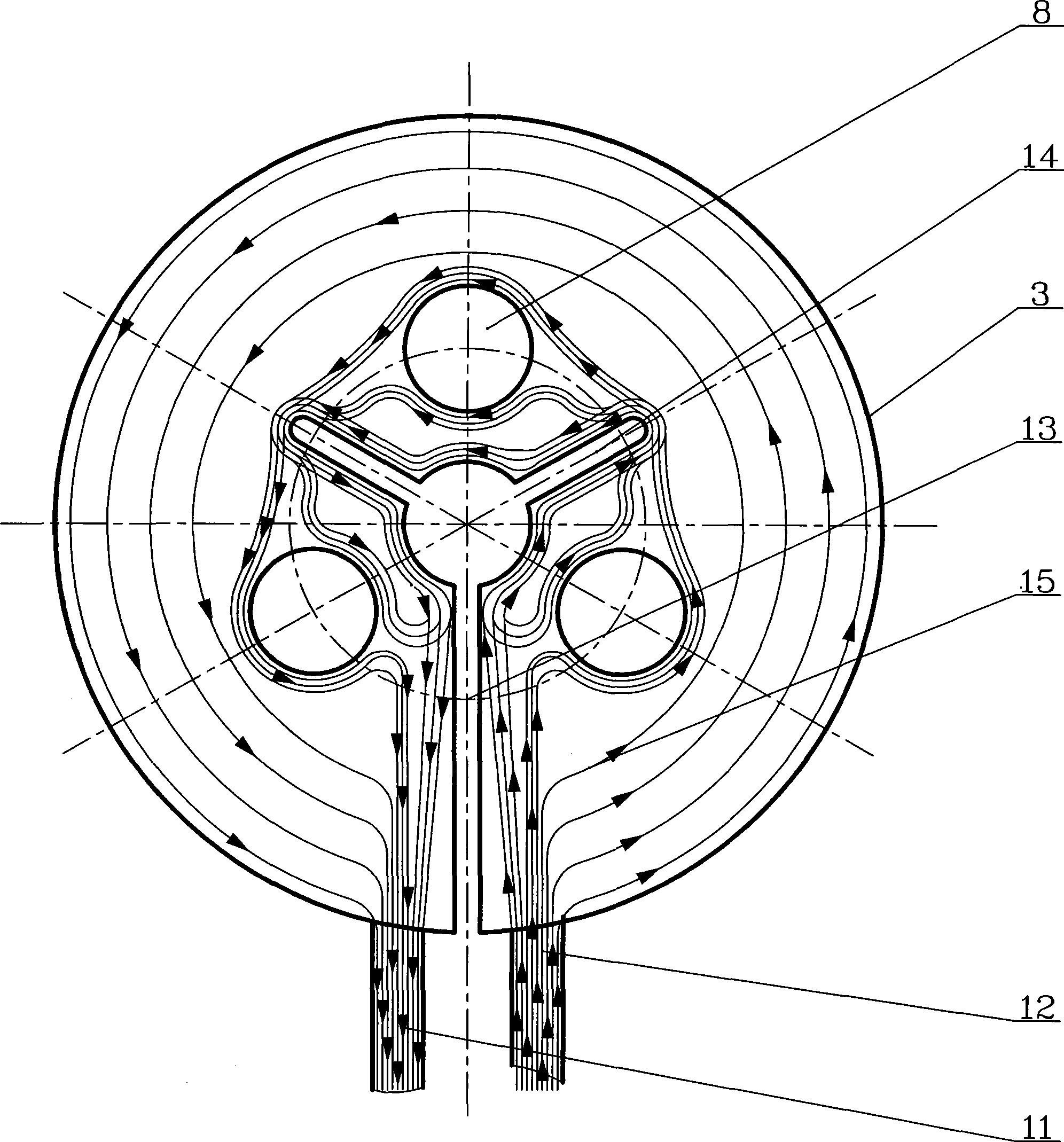

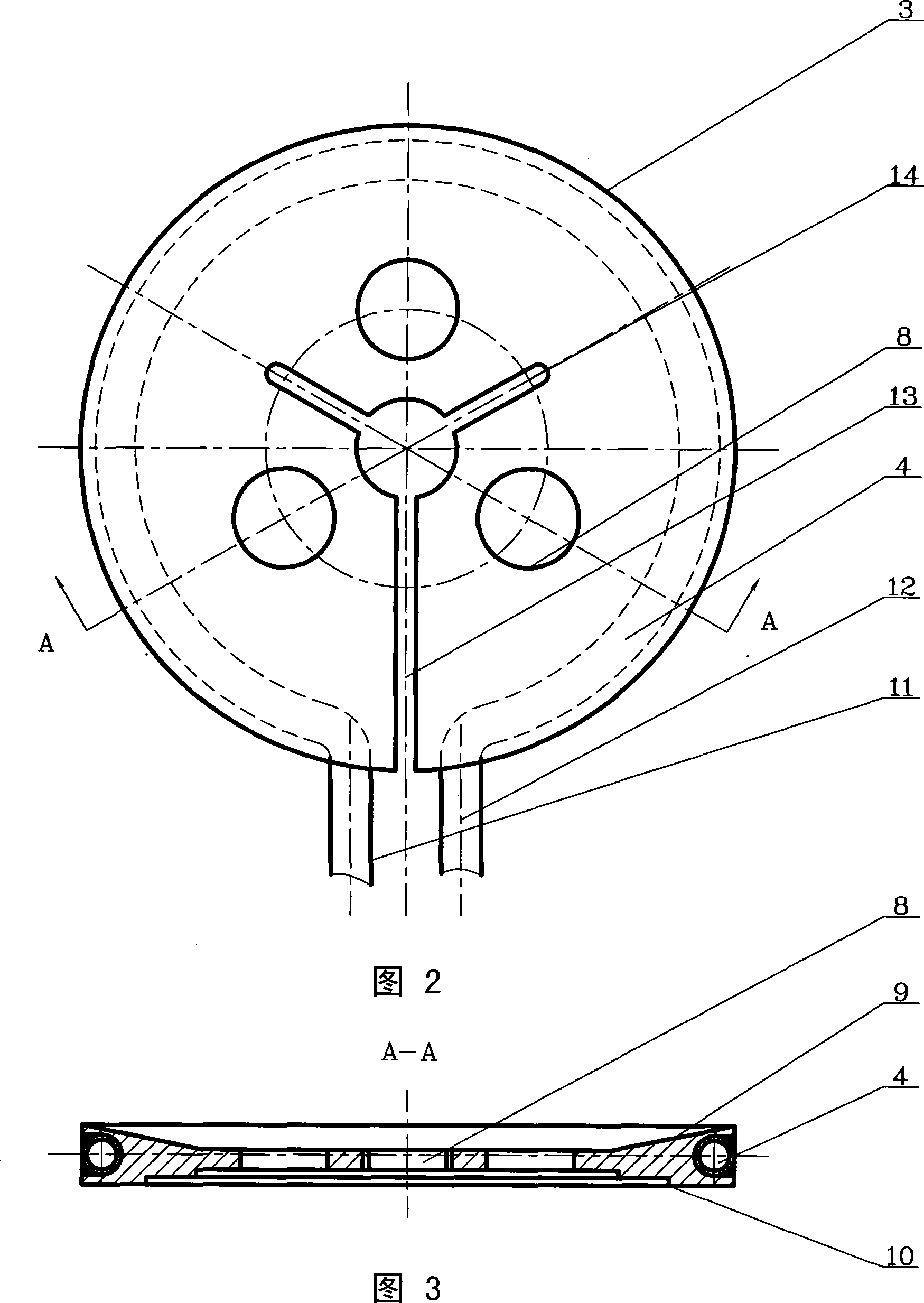

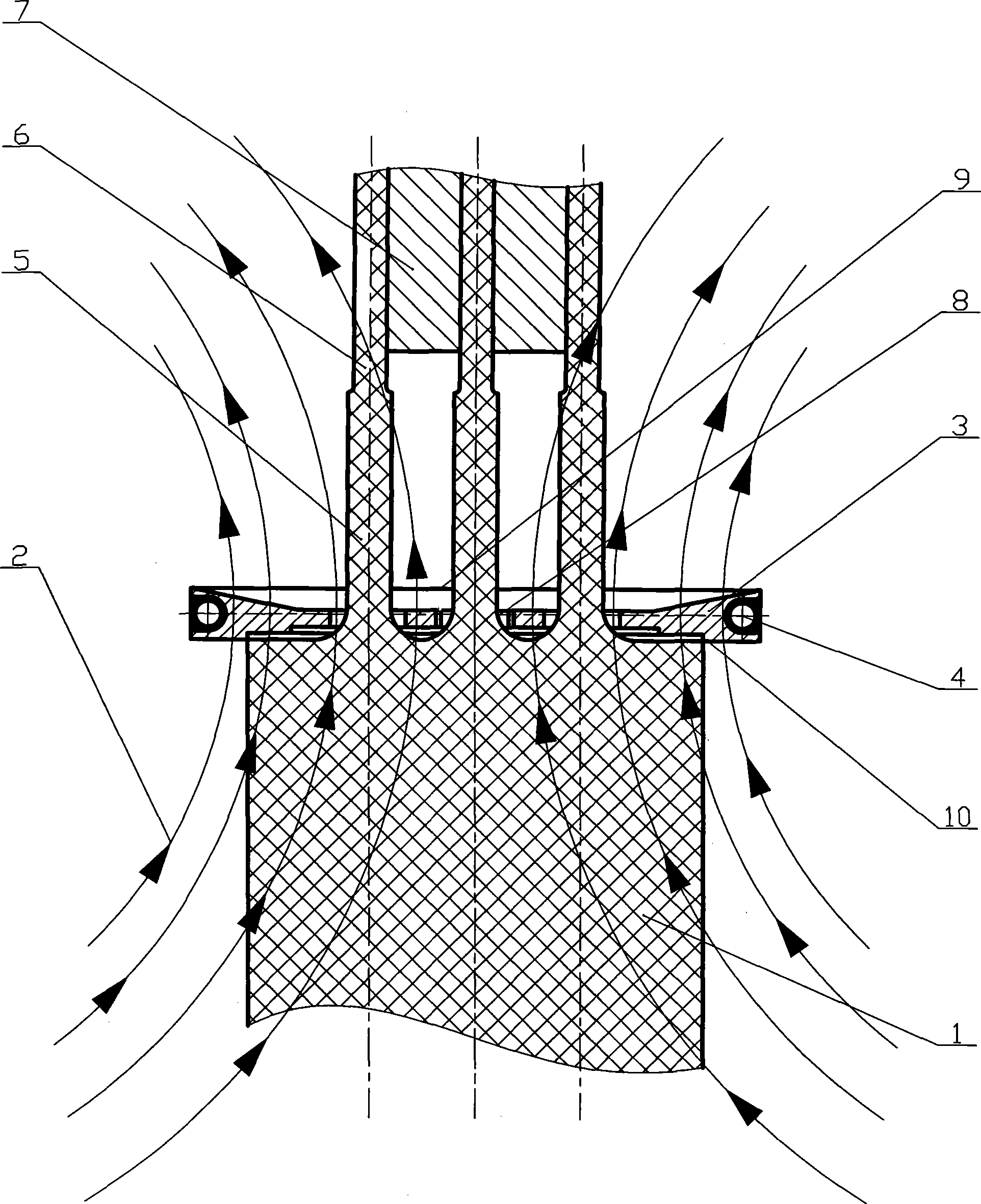

[0019] exist figure 1 , 2, 3, and 4; a high-frequency coil structure that can simultaneously produce four silicon cores and other crystal materials, the high-frequency coil structure is provided with a current delivery and cooling water delivery copper pipe at the bottom of the high-frequency coil A11 and copper pipe B12 for current transmission and cooling water transmission. The top 9 of the high-frequency coil of the high-frequency coil is a slope that sinks toward the center. The bottom of the high-frequency coil of the high-frequency coil is provided with a trapezoid that sinks toward the center. 4 rings are embedded in the outside of the high-frequency coil 3; the high-frequency coil structure includes a shunt groove 14 for current 15 diversion, four inner holes 8 are provided with an inner hole 8 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com