Patents

Literature

6810results about How to "Reduce defective rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

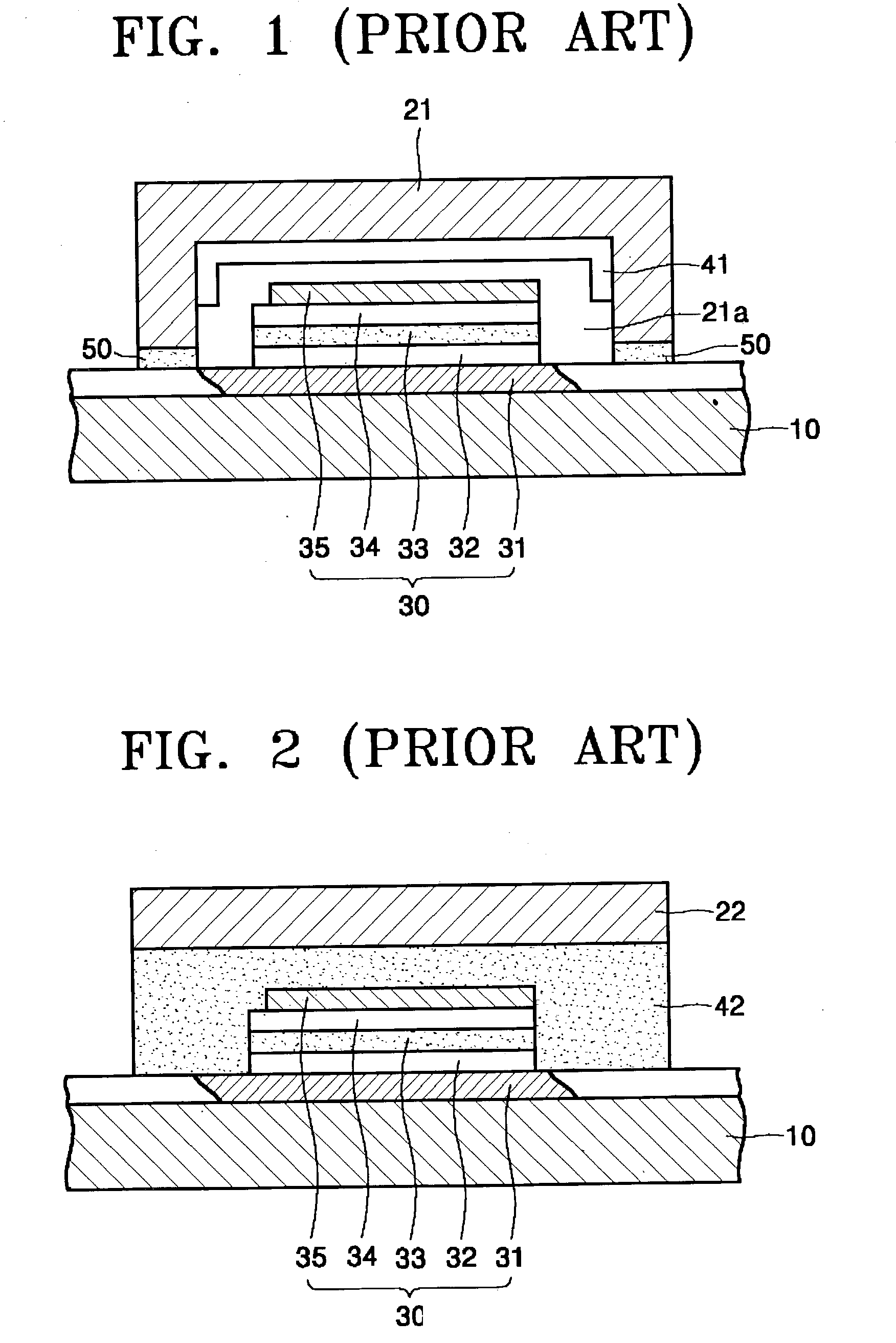

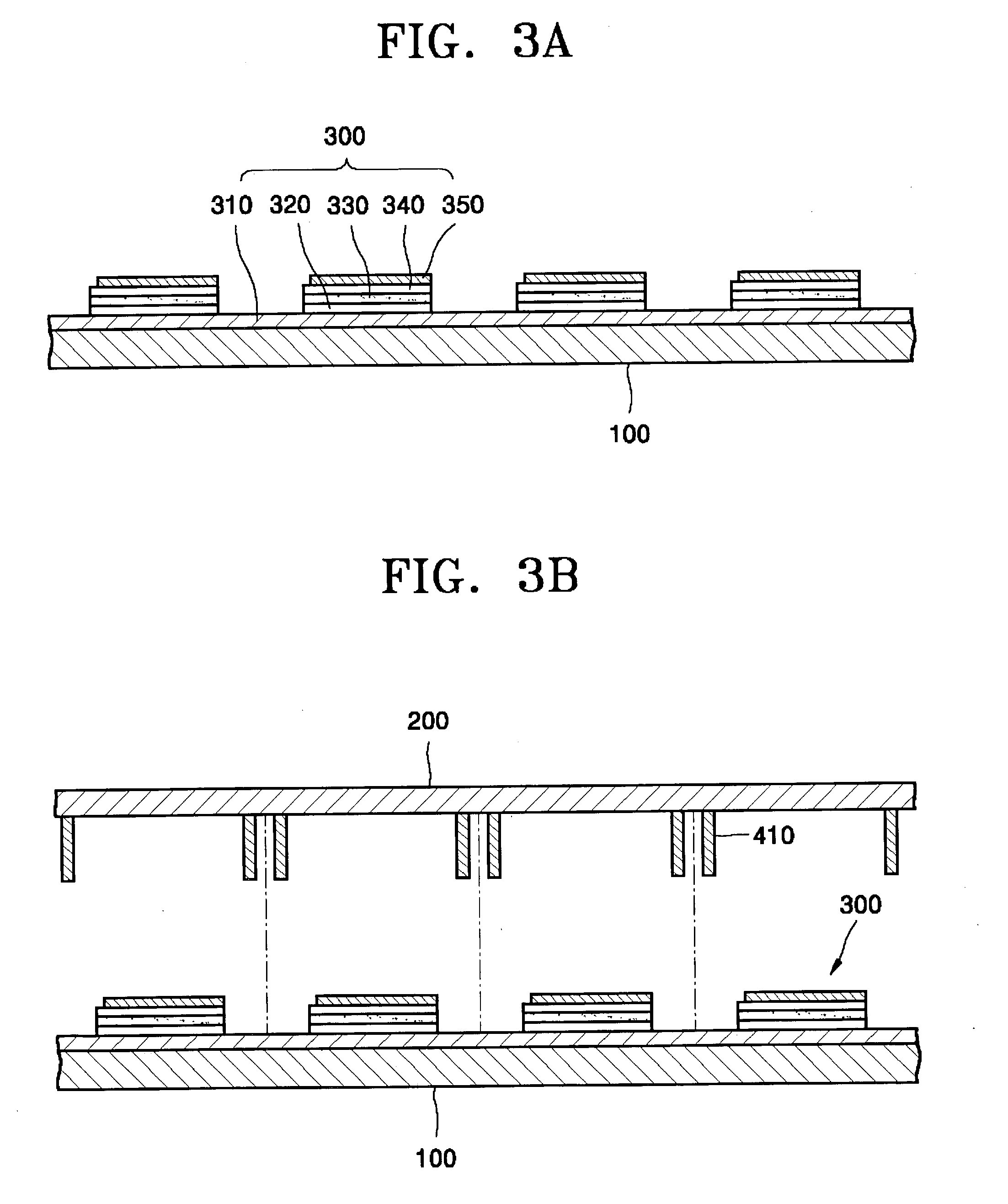

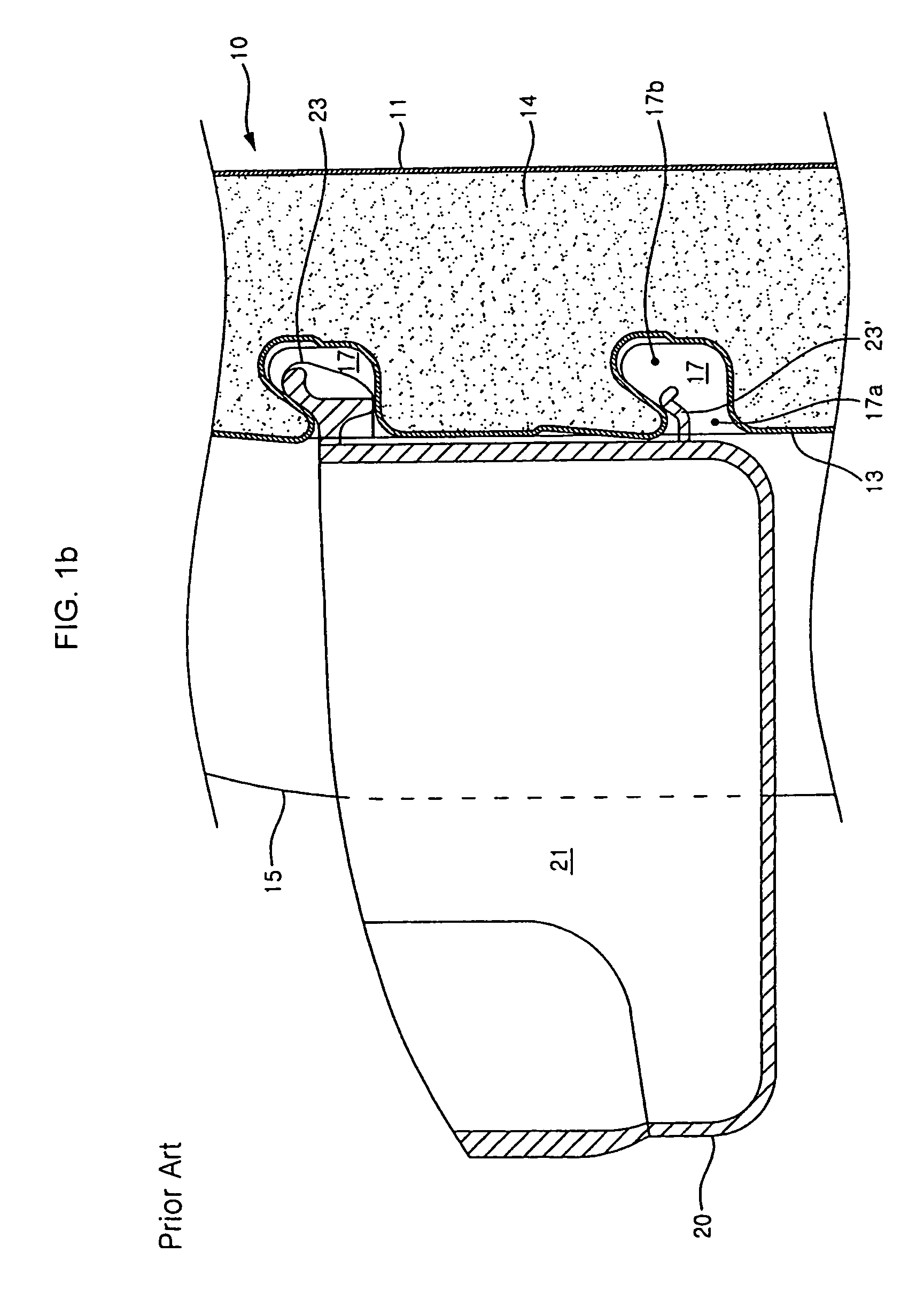

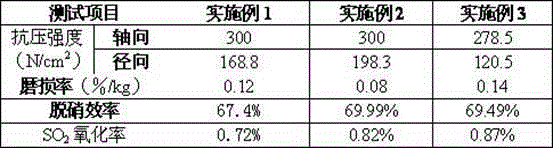

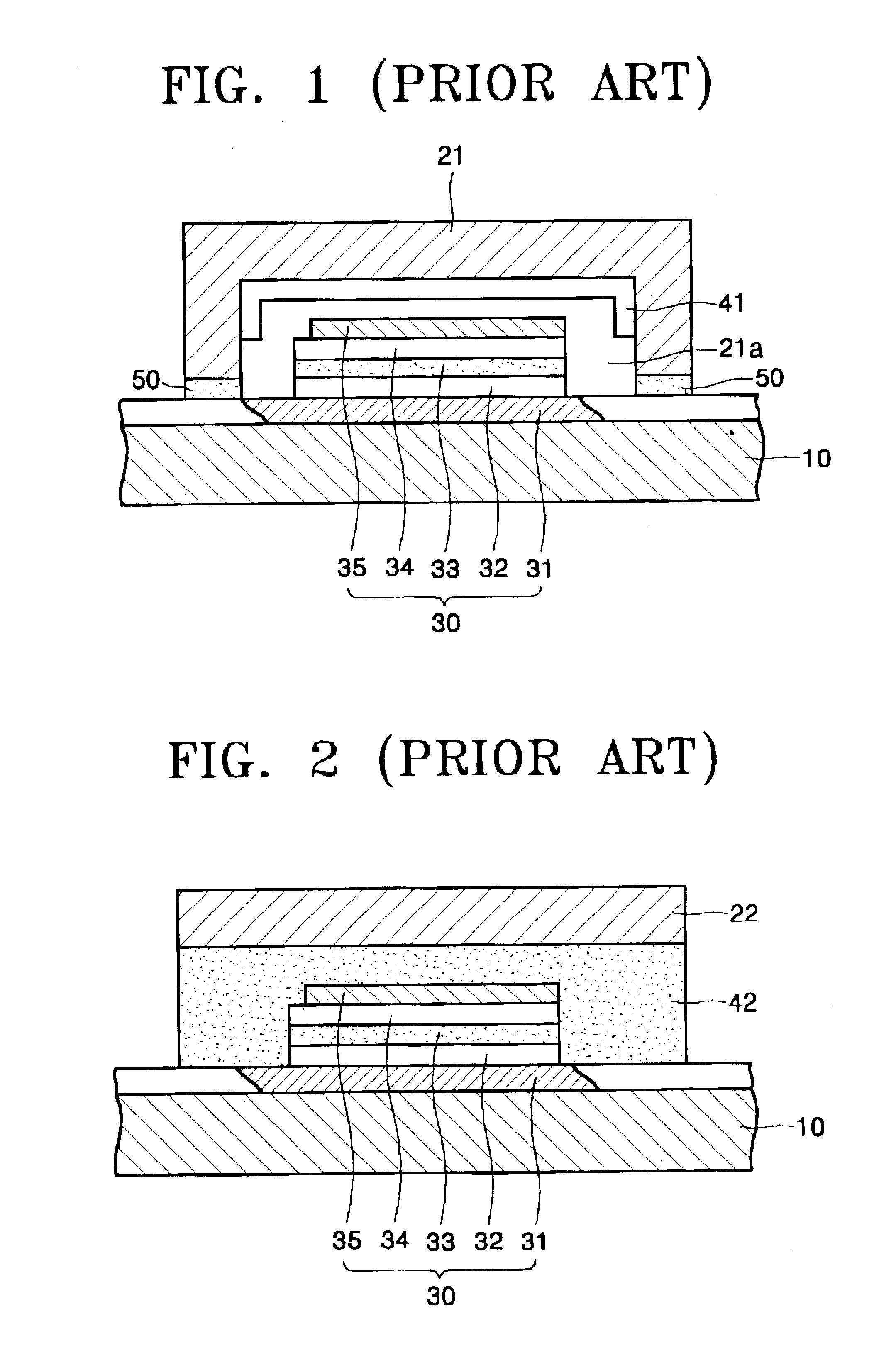

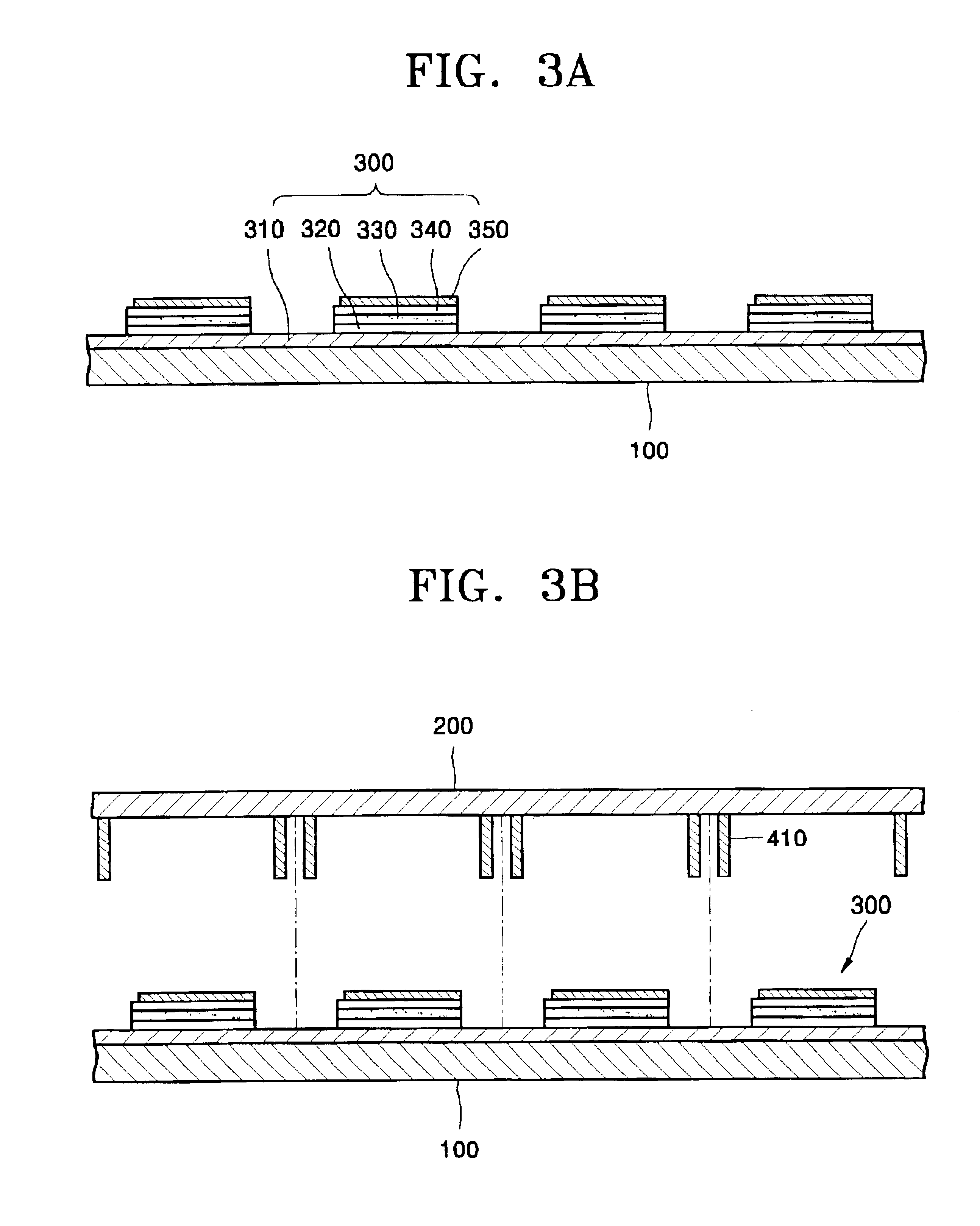

Method for encapsulating organic electroluminescent device and an organic electroluminescent panel using the same

InactiveUS20030218422A1Improve manufacturabilityReduce defective rateDischarge tube luminescnet screensElectroluminescent light sourcesDevice formOrganic layer

A method of encapsulating an organic electroluminescent (EL) device. The method includes applying a first sealant to a portion of an encapsulation plate facing a substrate to define one selected from a plurality of organic EL devices formed on the substrate, each including a first electrode layer, organic layers, and a second electrode layer. A space produced by the encapsulation plate and the first sealant and having an open face is filled with a second sealant. The substrate and the encapsulation plate are bonded together by applying pressure. The first sealant and the second sealant are then cured. The substrate and the encapsulation plate are cut into a plurality of independent organic EL panels.

Owner:SAMSUNG DISPLAY CO LTD

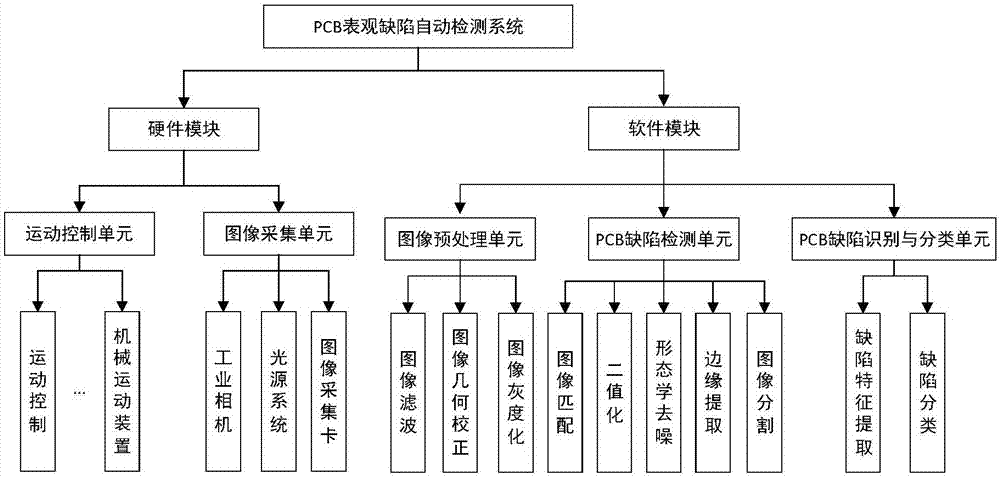

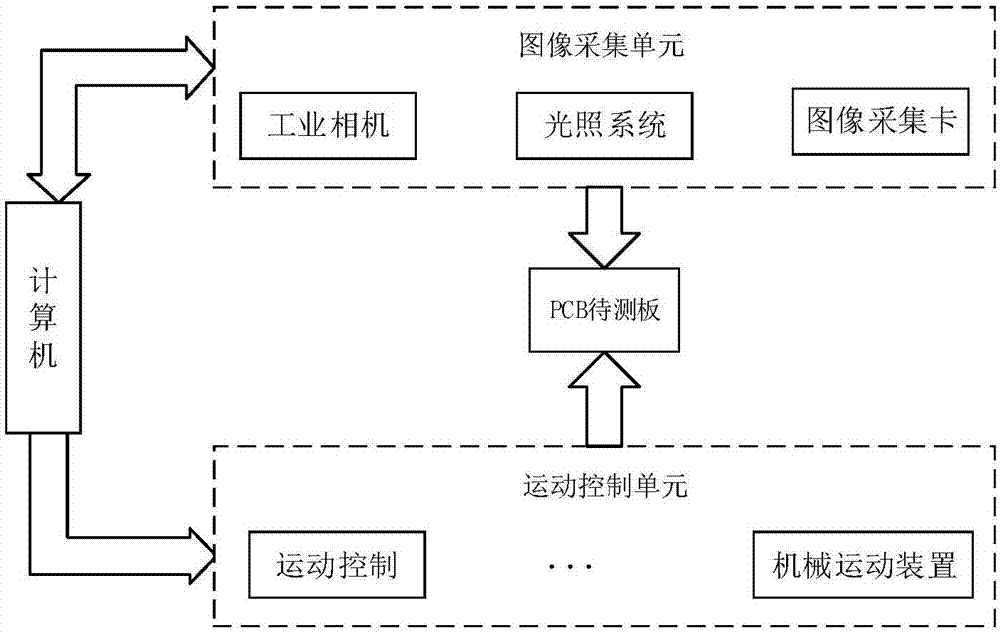

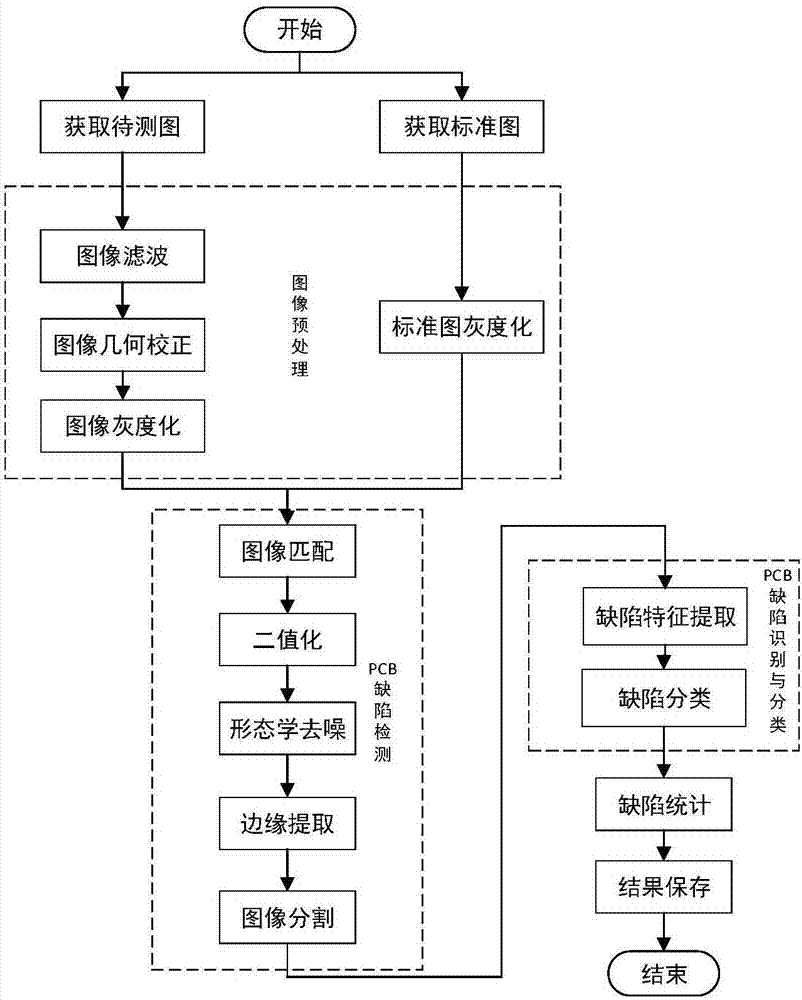

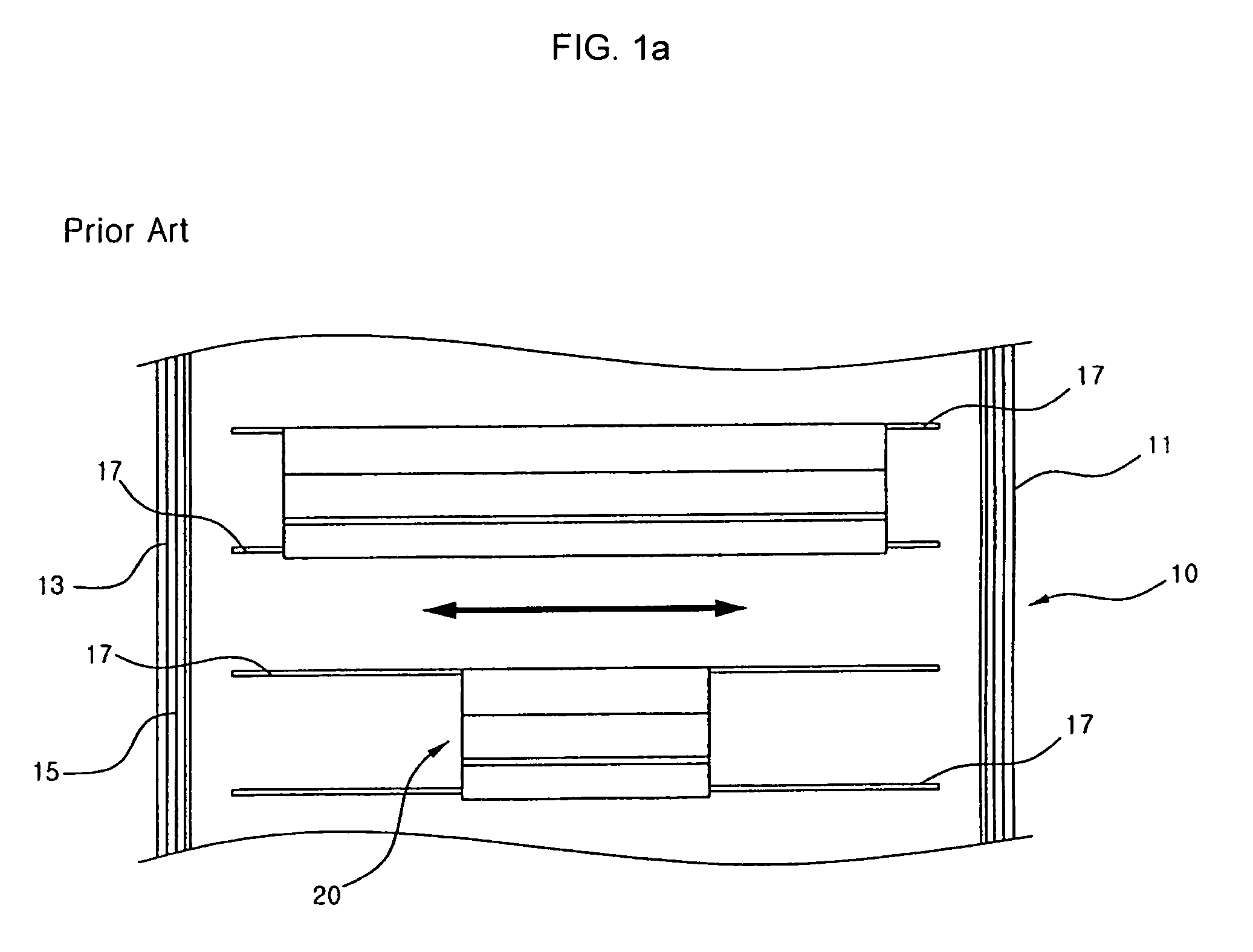

PCB apparent defect automatic detection system and method based on image

InactiveCN107389701AImprove detection efficiencyReduce false detection rateImage enhancementImage analysisMovement controlAutomatic testing

The invention provides a PCB apparent defect automatic detection system and method based on an image and aims at solving the problems that detection efficiency is low and misjudgment rate is high. The method comprises the following steps: firstly transmitting a to-be-detected PCB to a specified position by virtue of a motion control unit; acquiring an image of the to-be-detected PCB by utilizing image acquisition equipment such as an image acquisition card and an industrial camera; then sequentially carrying out a series of operation such as image preprocessing, PCB defect detection and PCB defect identification and classification on the acquired image, so that PCB defect automatic detection is completed; and finally realizing real-time automatic sorting of an unqualified PCB and timely reporting a defect position and a defect analysis result to an operator. The system and method which are provided by the invention can automatically detect the PCB defect and identify the defect type to a great extent, and false detection rate is reduced, so that enterprise cost is reduced, and the system and method which are provided by the invention have stronger practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

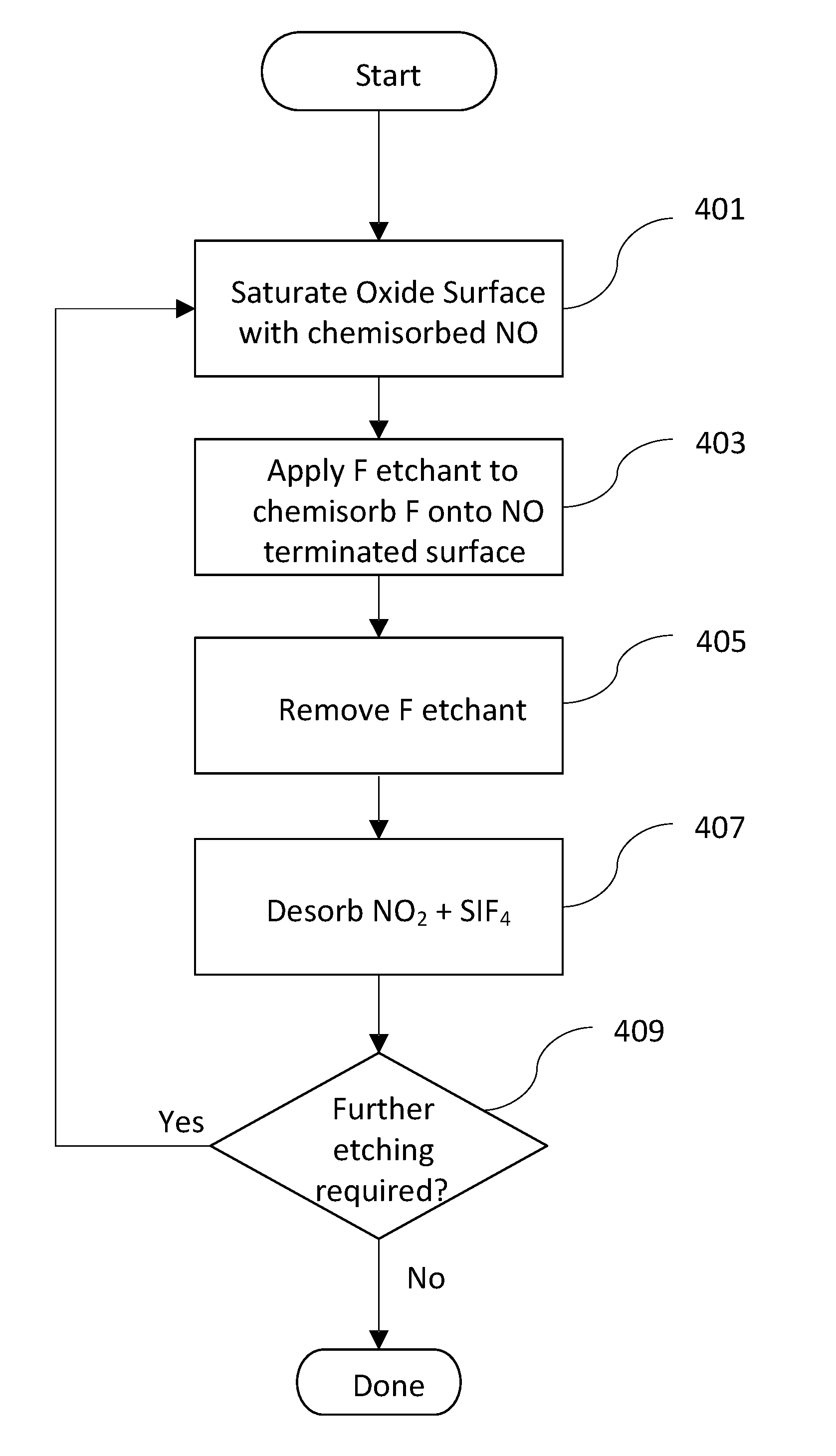

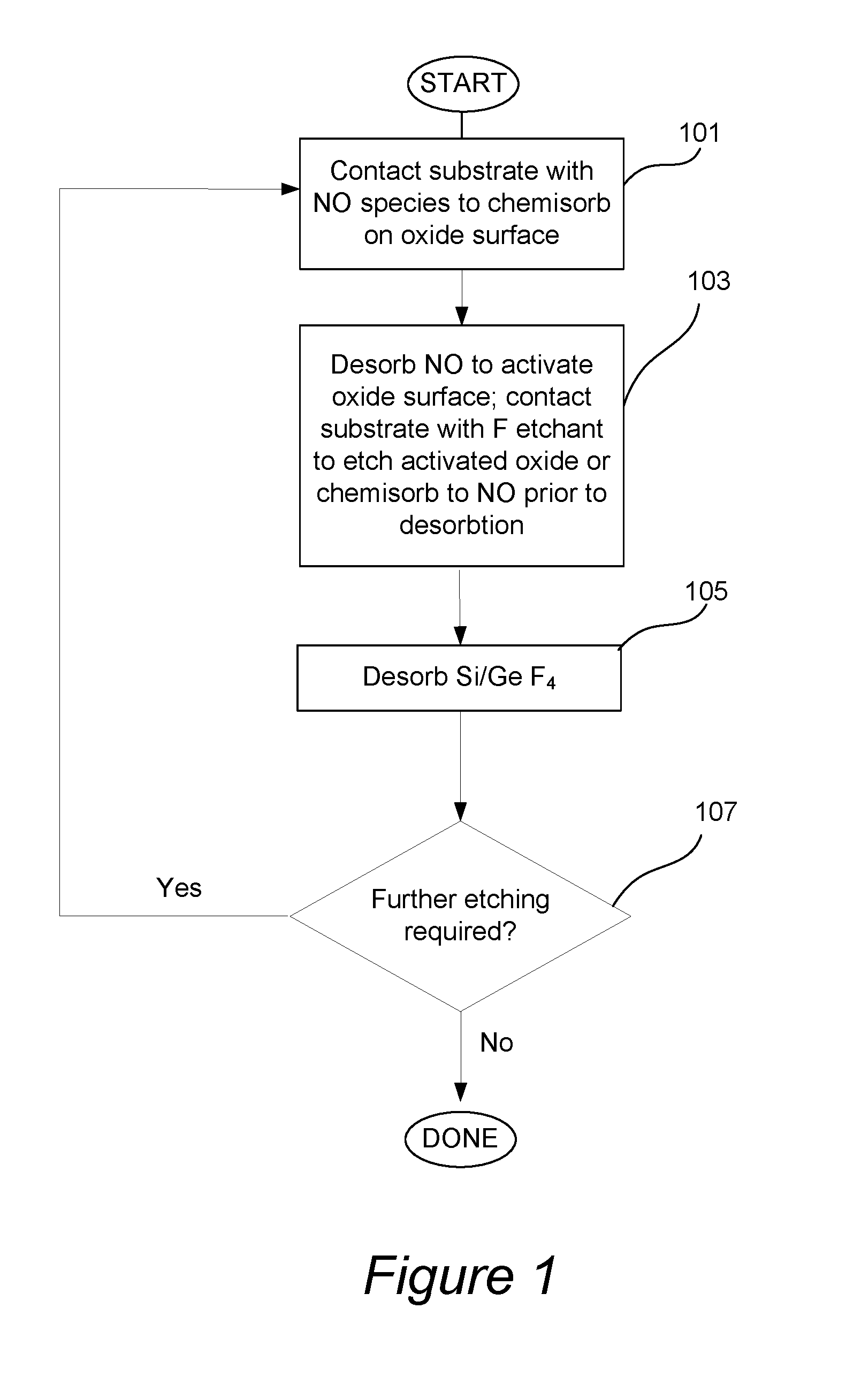

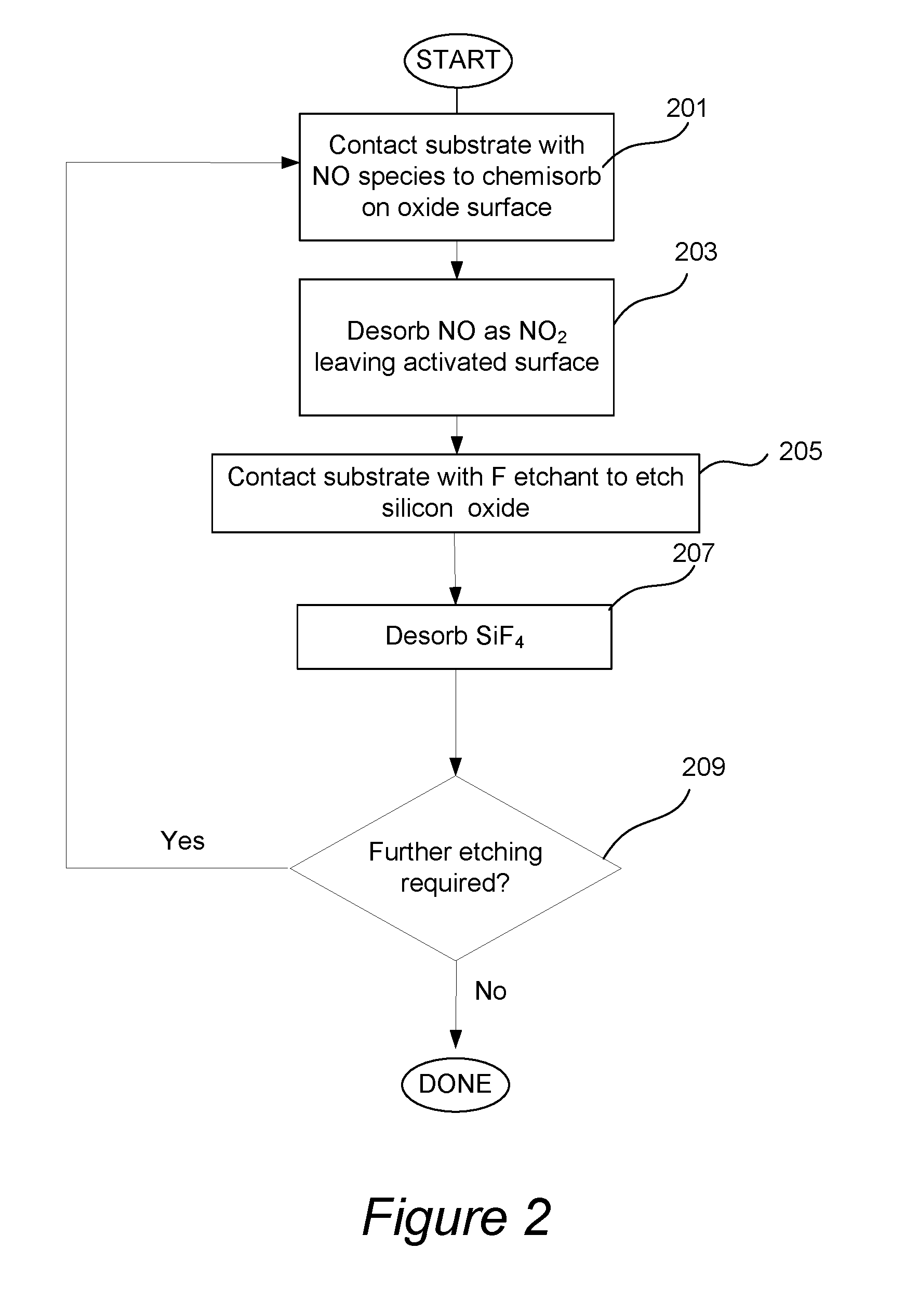

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS9425041B2High selectivityReduce defective rateElectric discharge tubesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

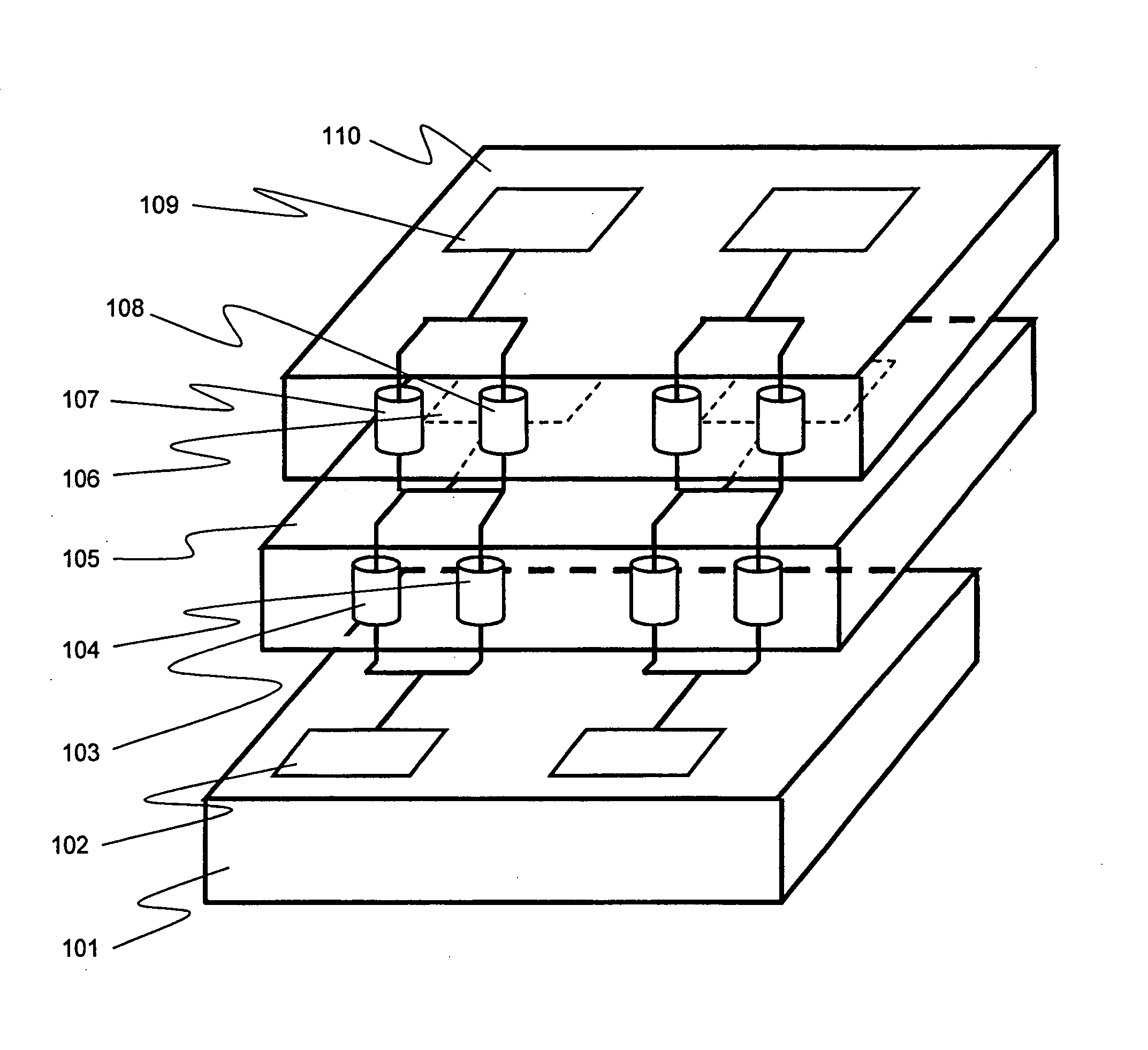

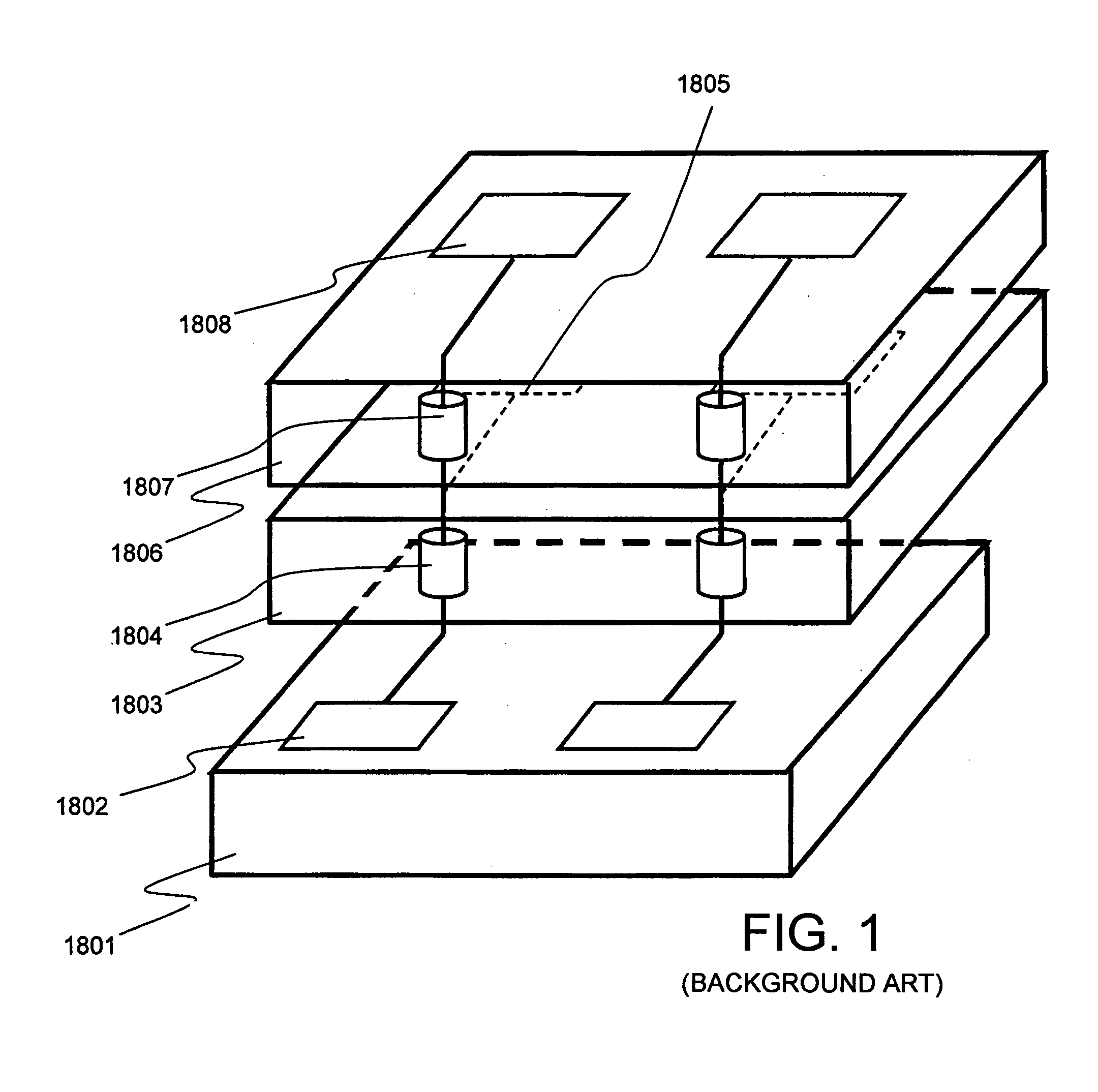

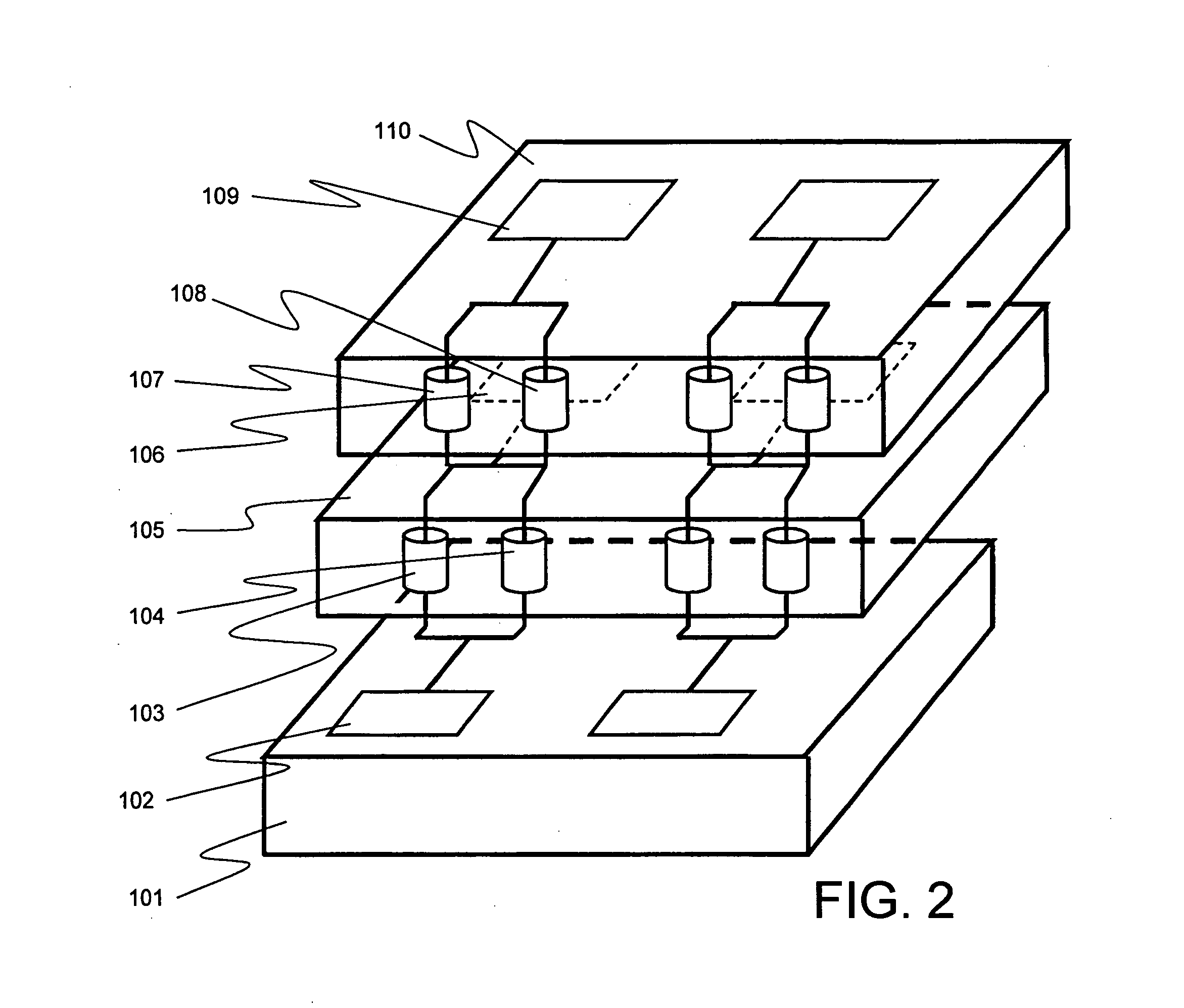

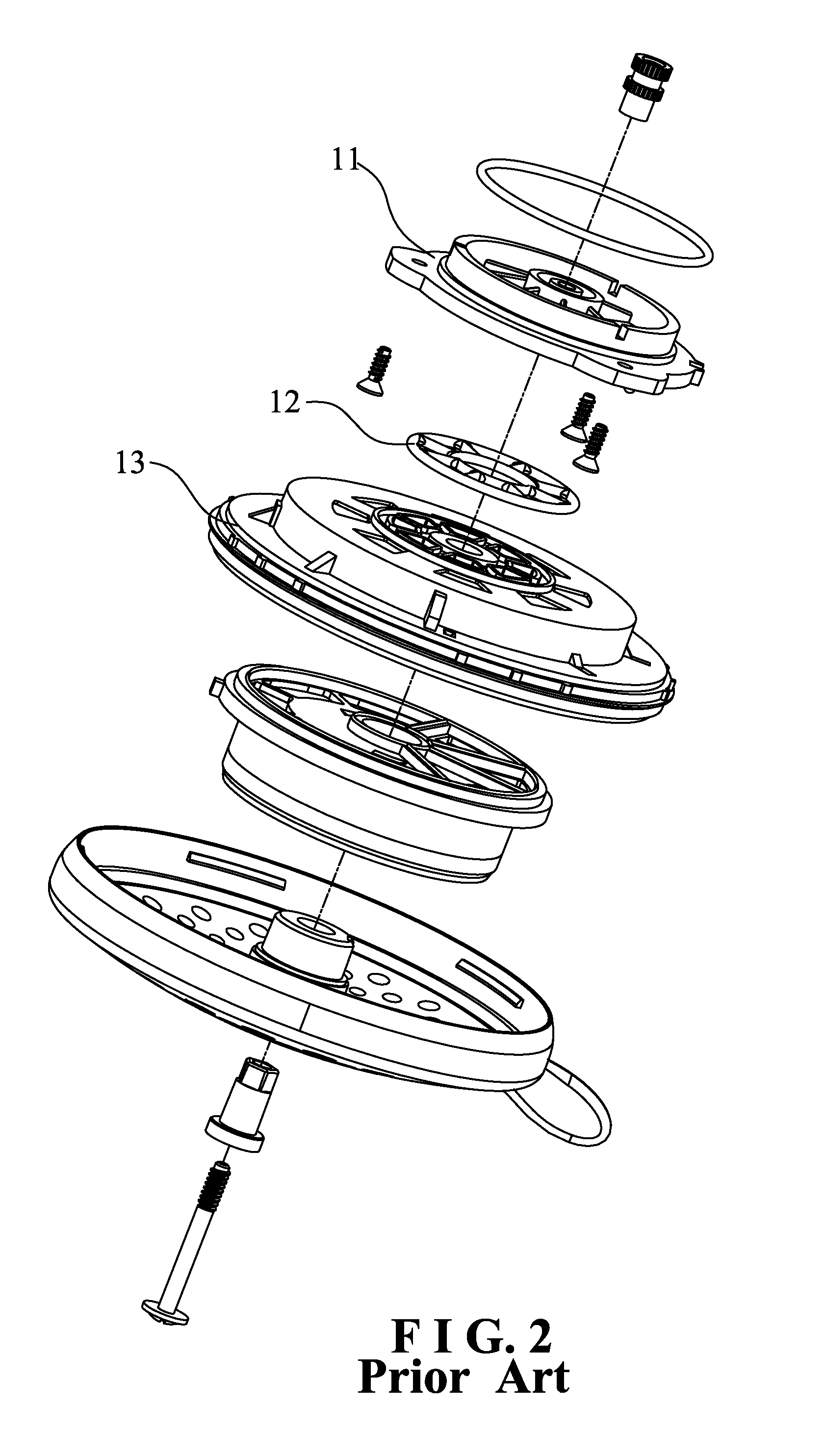

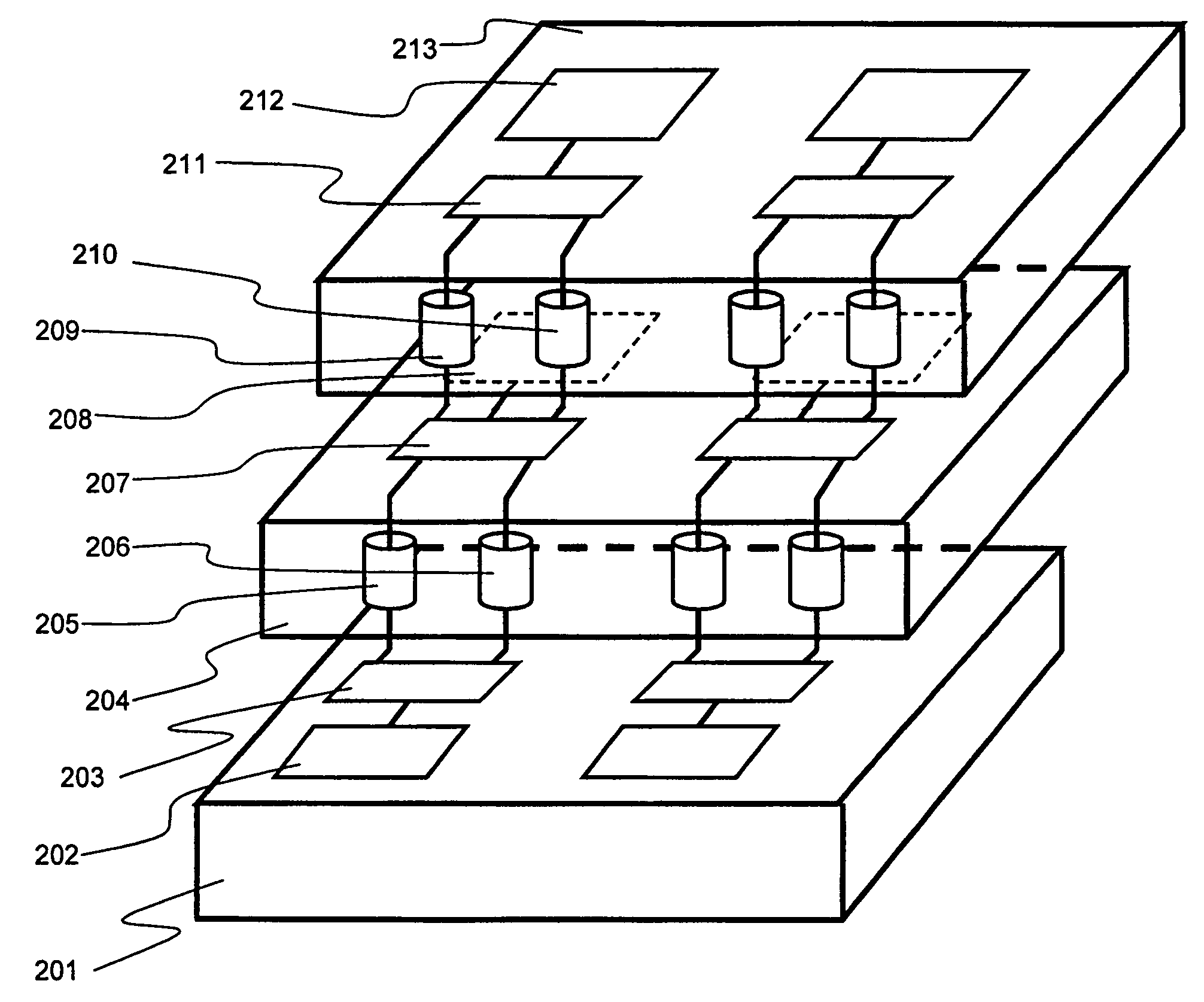

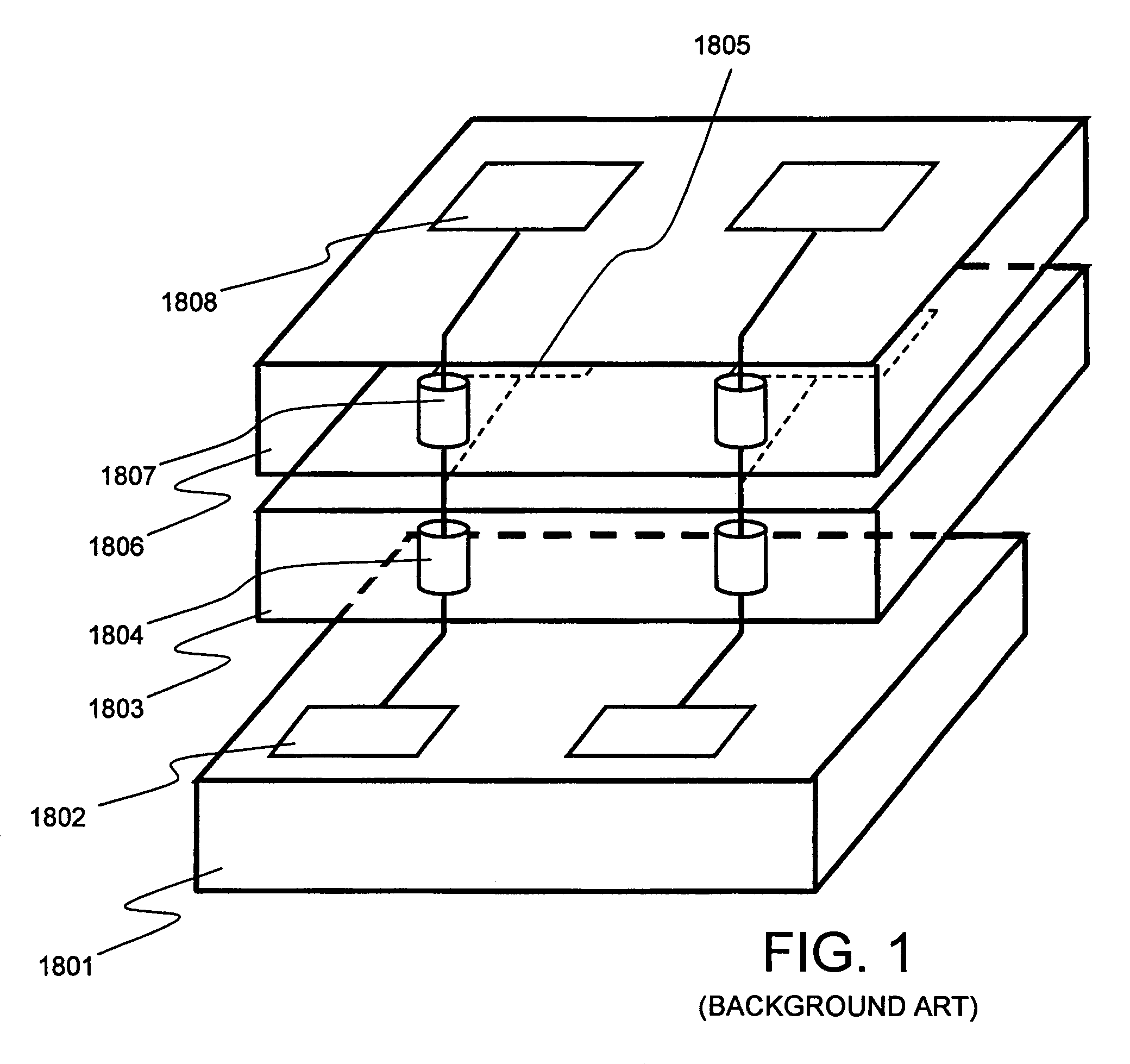

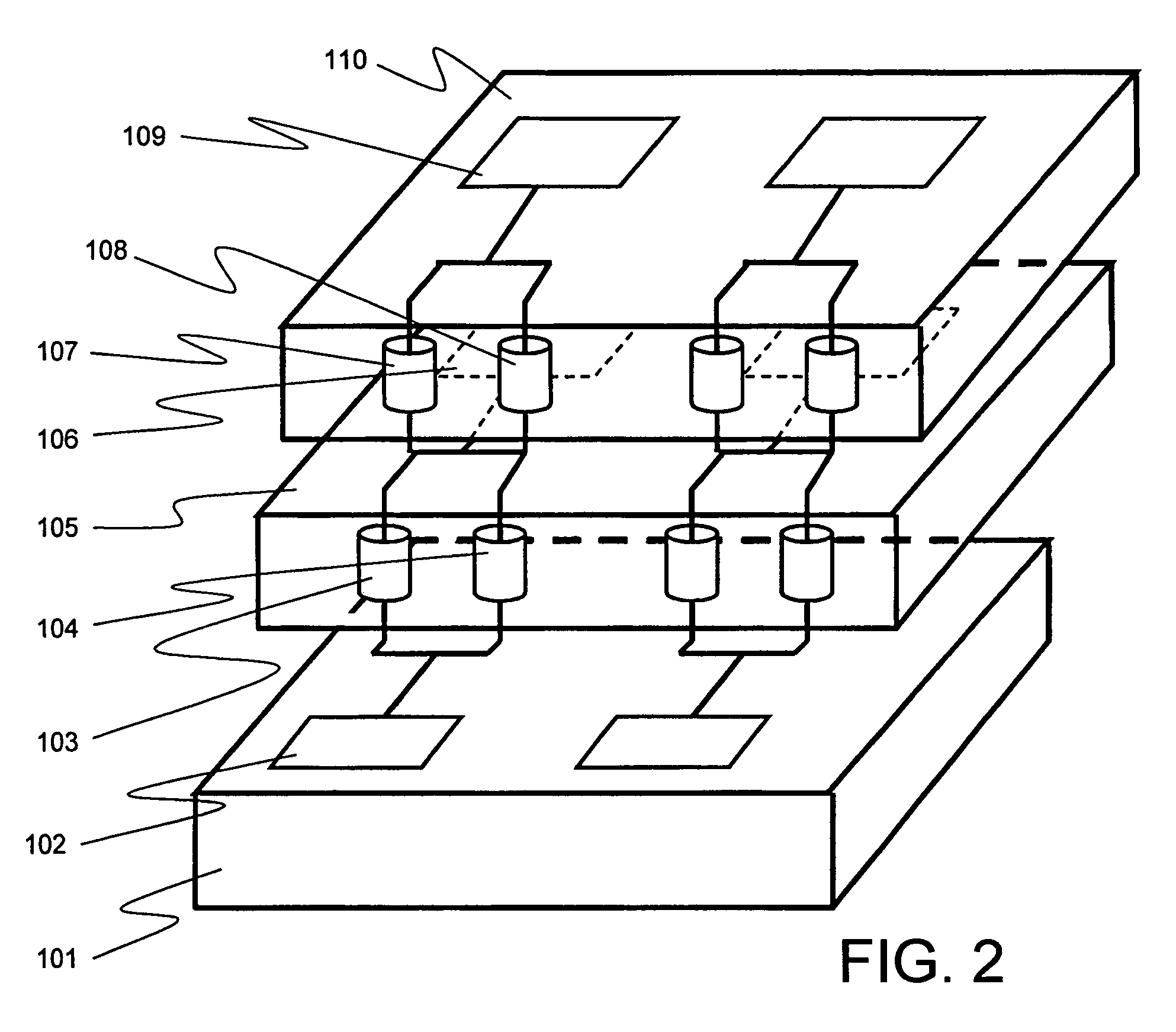

Stacked semiconductor device

ActiveUS20060001176A1High yieldReduce defective rateSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A stacked semiconductor device includes a plurality of semiconductor chips and a conductive path extending through at least one of the semiconductor chips. The semiconductor chips are stacked together. The semiconductor chips are electrically connected by the conductive path, and the conductive path has a plurality of through-connections extending through the corresponding semiconductor chip.

Owner:NEC CORP +1

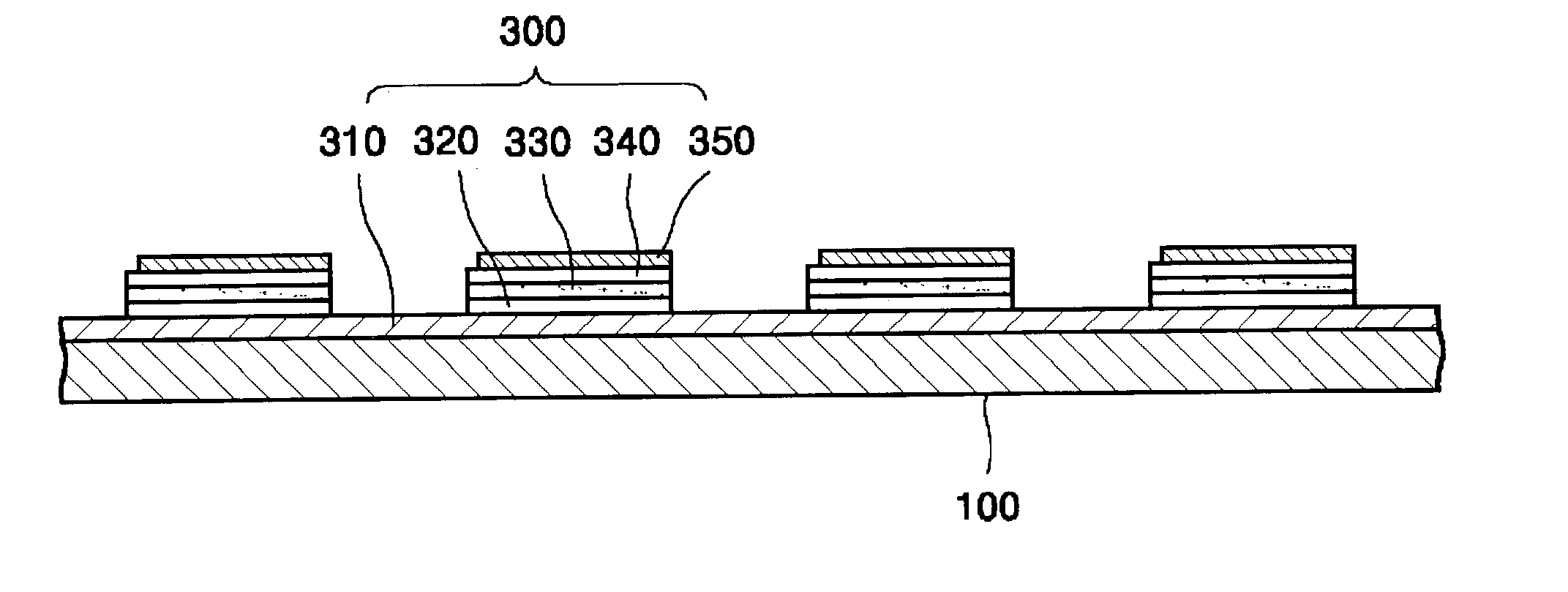

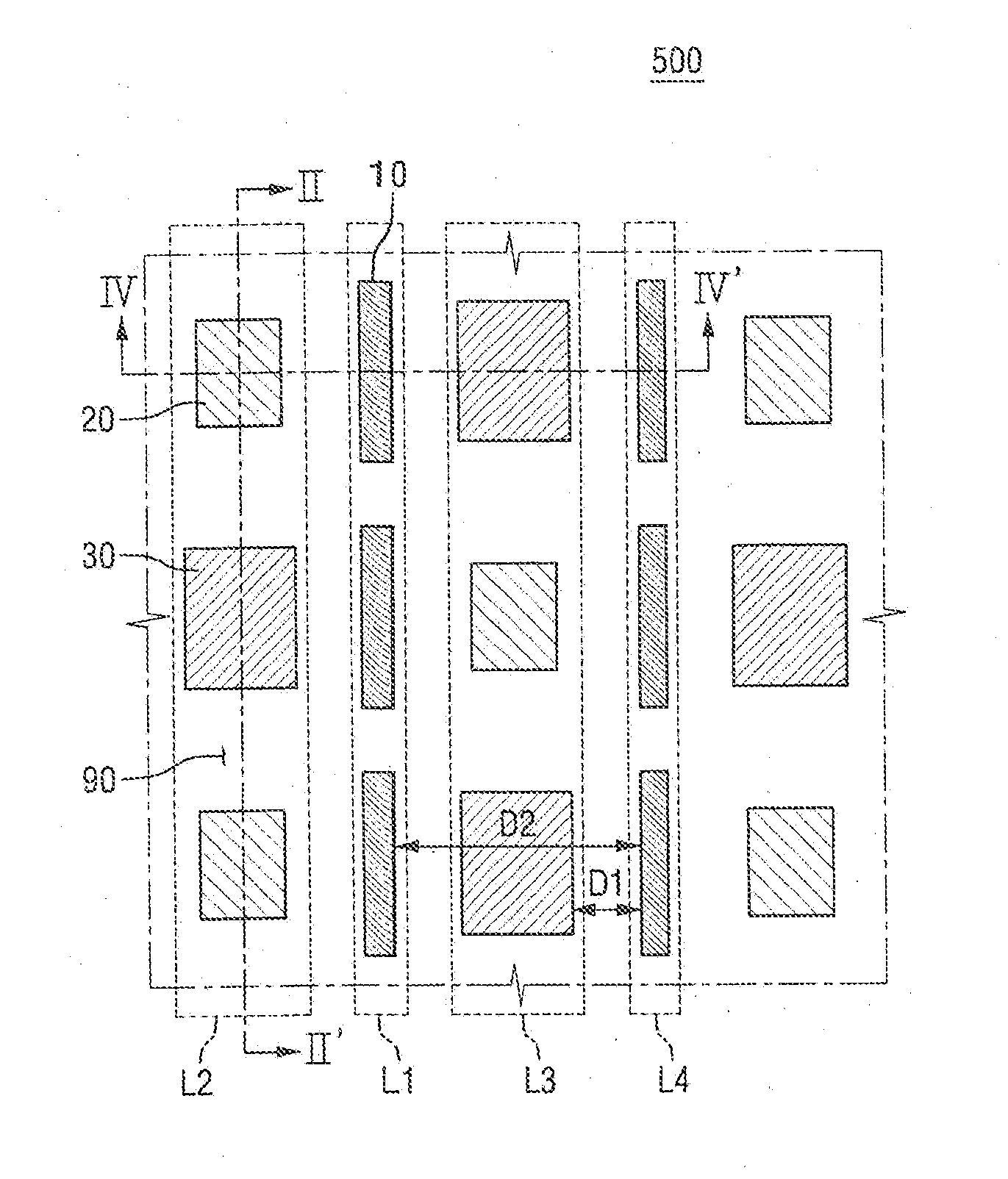

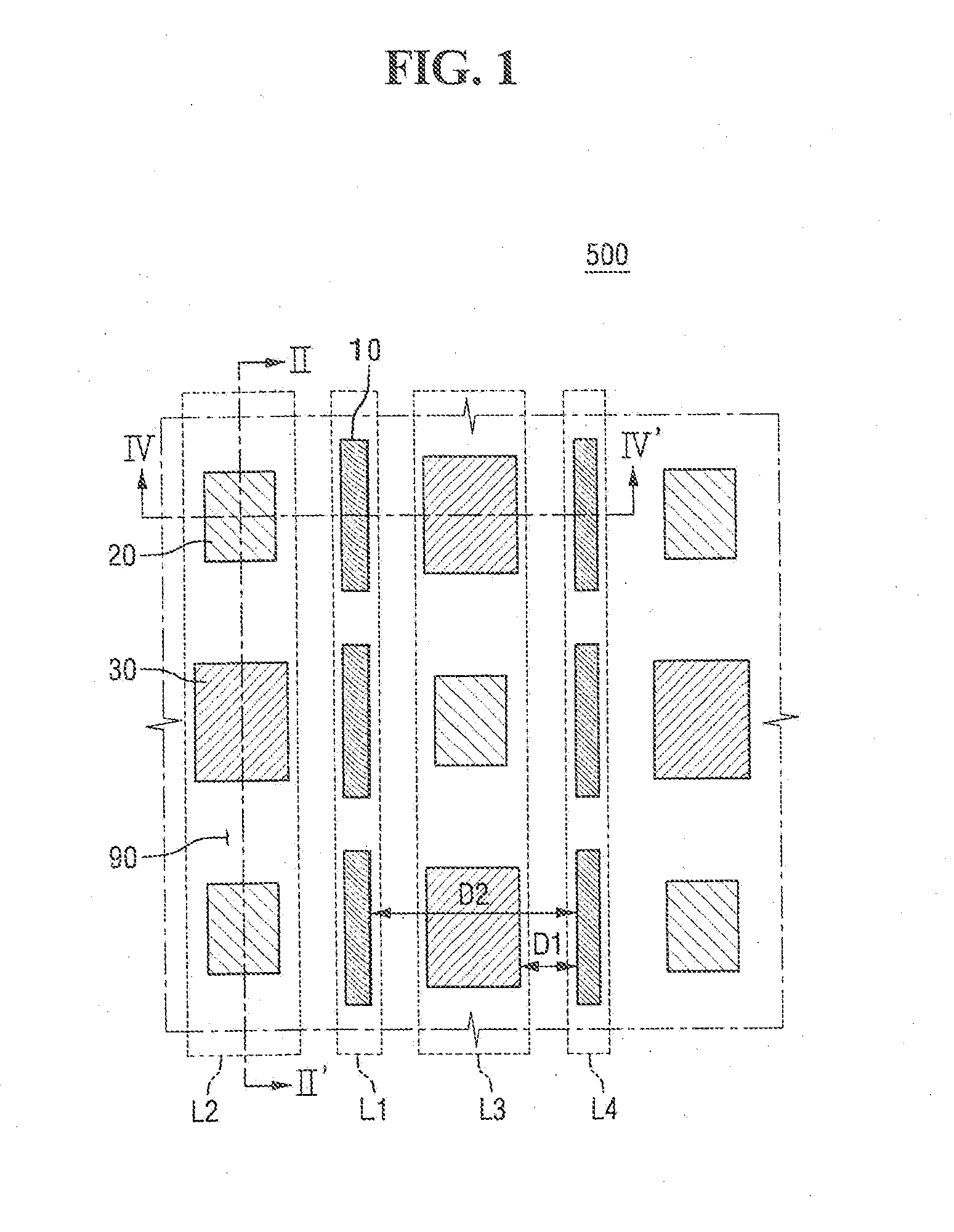

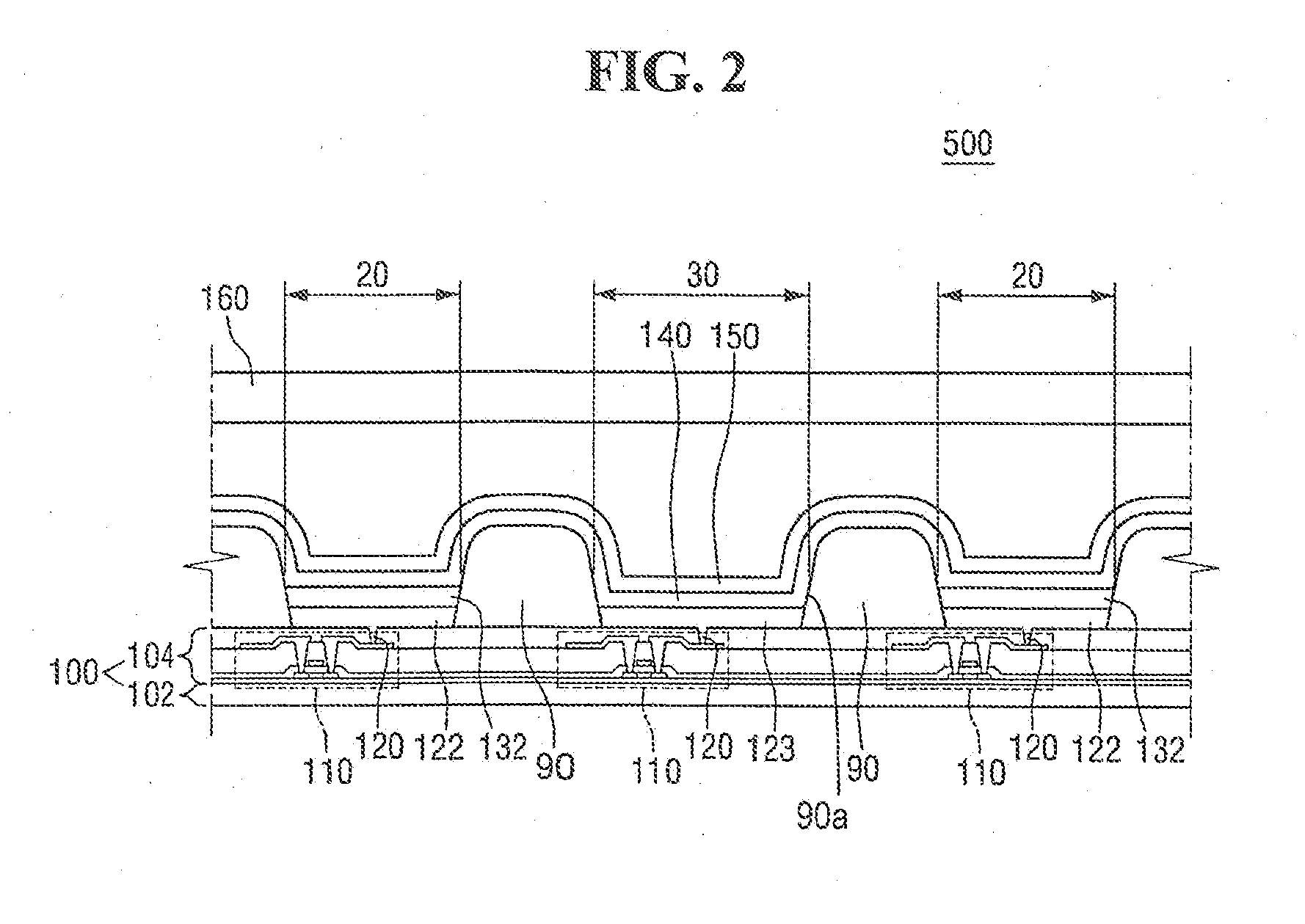

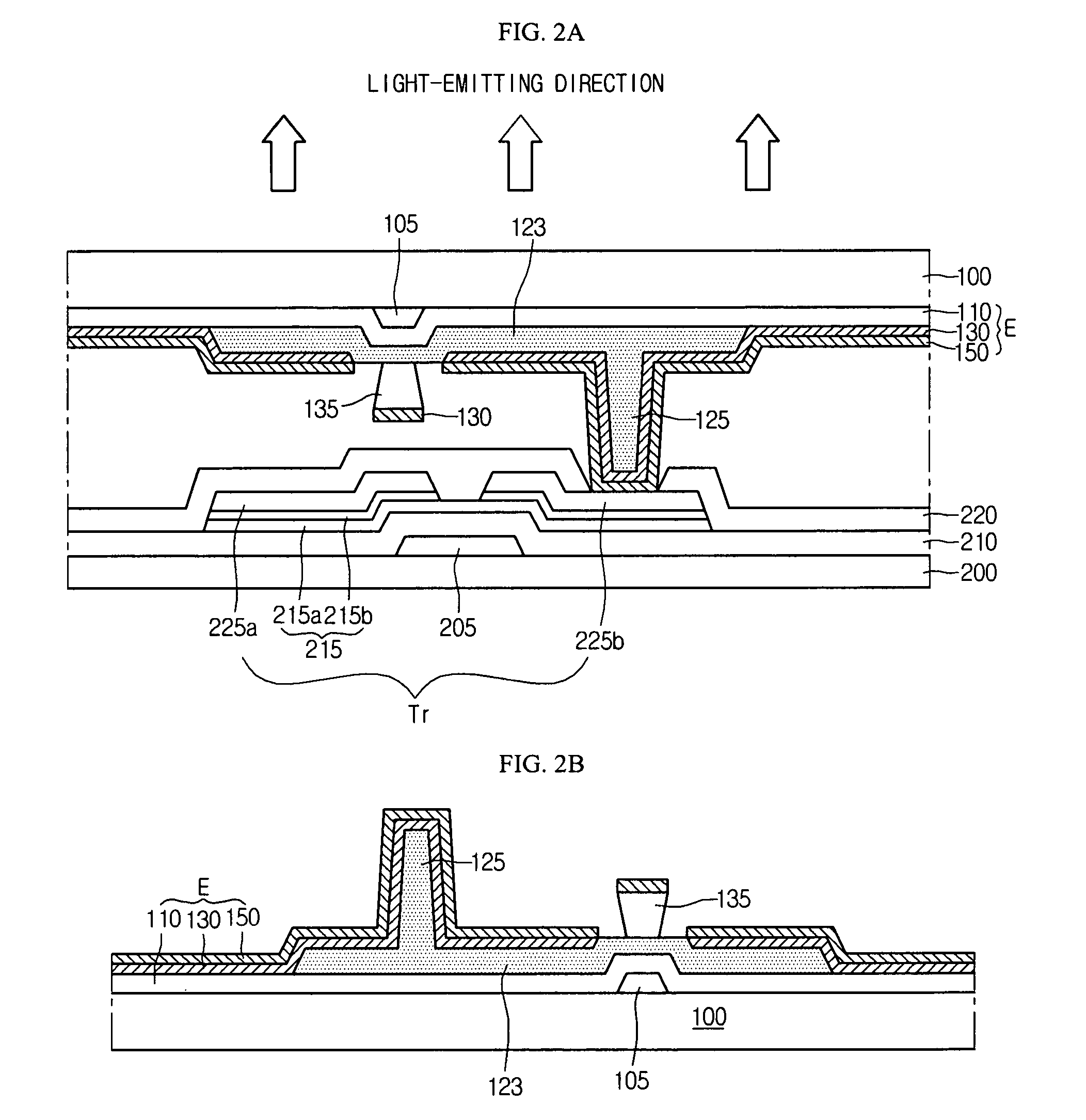

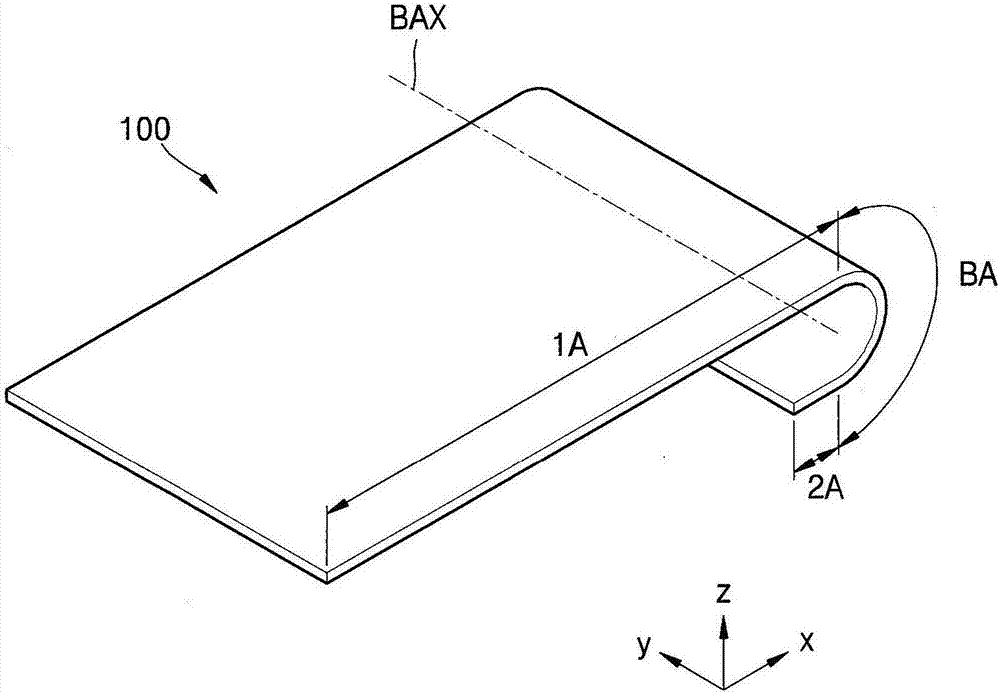

Organic light-emitting display device and method of manufacturing the same

ActiveUS20120313844A1Reduce in quantityReduce defective rateStatic indicating devicesElectroluminescent light sourcesDisplay deviceMaterials science

An organic light-emitting display device includes a substrate, a plurality of pixel electrodes arranged in a matrix on the substrate, and an organic common layer covering the pixel electrodes. The pixel electrodes include a plurality of first pixel electrodes, a plurality of second pixel electrodes, and a plurality of third pixel electrodes. An n-th pixel column includes the second pixel electrodes and the third pixel electrodes arranged alternately, an (n+1)-th pixel column which is adjacent to the n-th pixel column includes the first pixel electrodes, and an (n+2)-th pixel column which is adjacent to the (n+1)-th pixel column includes the second pixel electrodes and the third pixel electrodes arranged alternately, wherein n is a natural number. One of the second and third pixel electrodes is disposed in the n-th pixel column in a row and the other one of the second and third pixel electrodes is disposed in the (n+2)-th pixel column in the same row.

Owner:SAMSUNG DISPLAY CO LTD

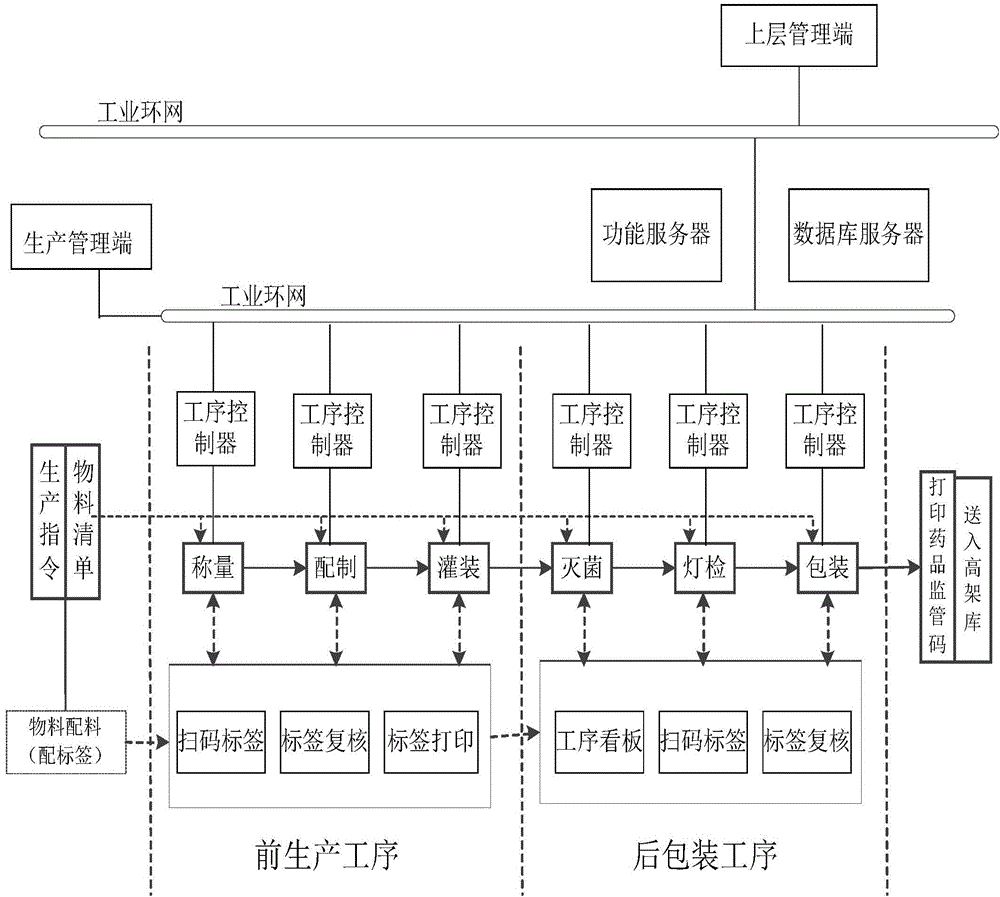

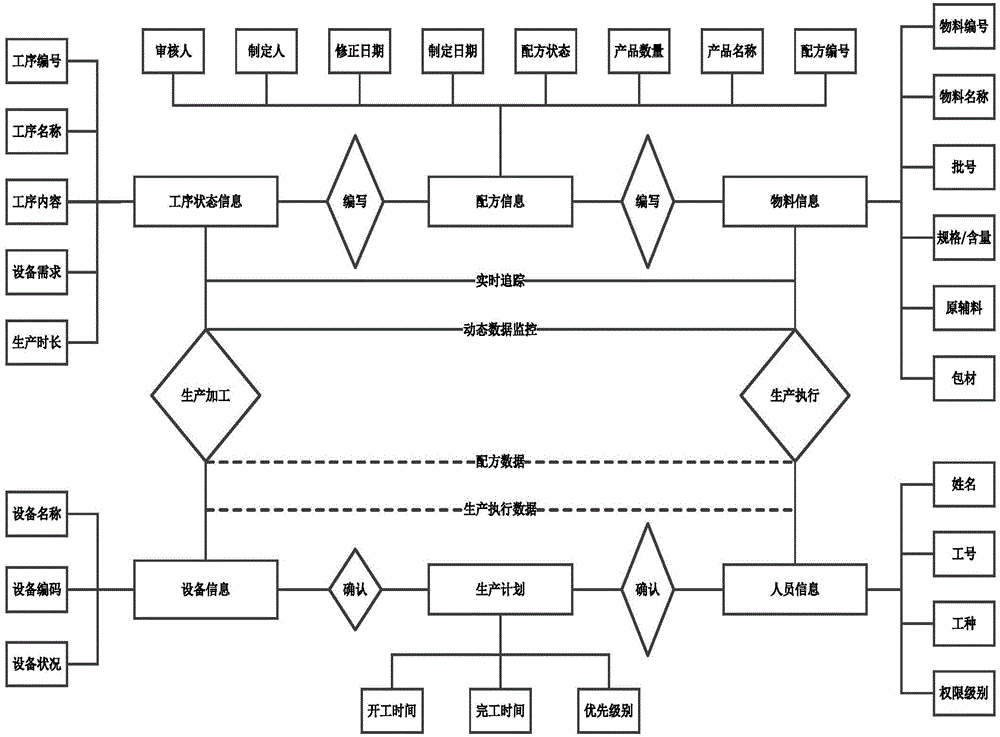

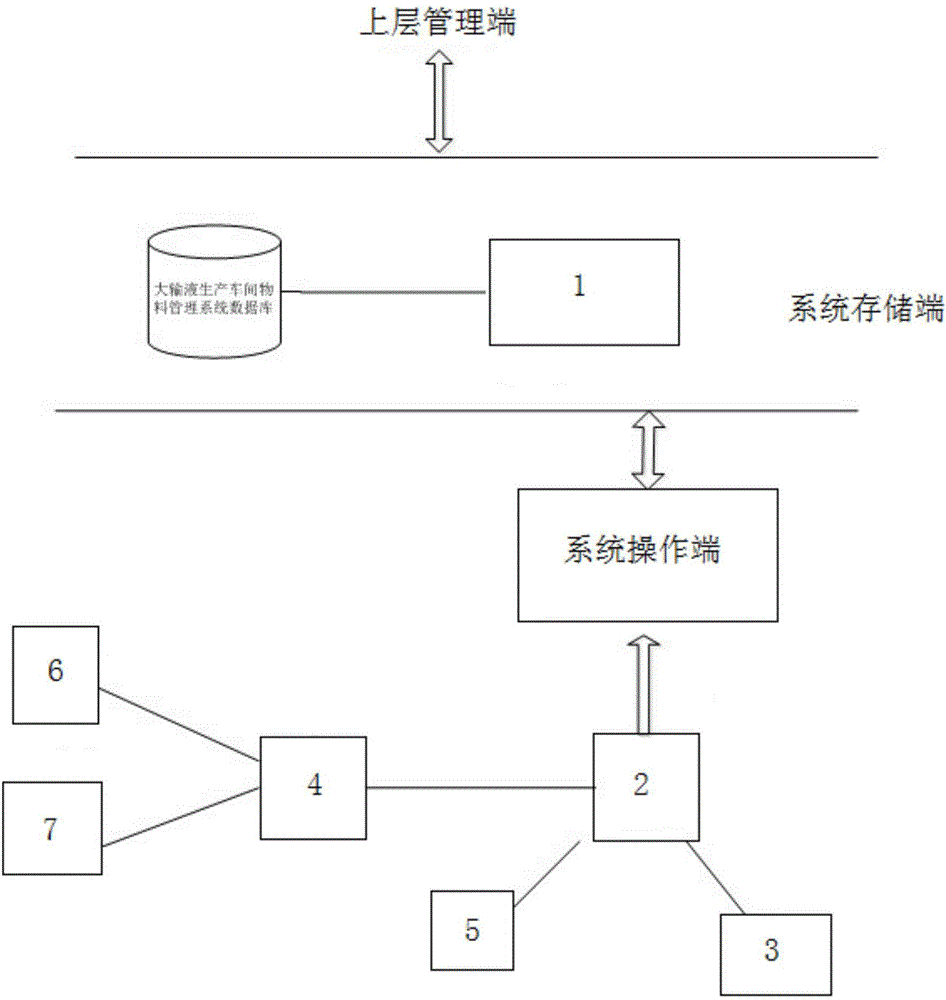

Pharmaceutical product manufacturing execution system and method

InactiveCN104808639AImprove development efficiencyImprove maintainabilityTotal factory controlProgramme total factory controlDatabase serverManufacturing execution system

The invention discloses a pharmaceutical product manufacturing execution system and method. The method includes connecting a manufacturing execution system function server and a manufacturing execution system database server to an upper-level management terminal through an industrial loop network; allowing the manufacturing execution system function server to perform data exchange with a production management terminal through the industrial loop network; allowing the production management terminal to connect to a bottom procedure controller through the industrial loop network; allowing the production management terminal to receive a production planning instruction from the upper-level management terminal, divide the production planning instruction into a production instruction and a material list and transmit the production instruction to the bottom procedure controller, and allowing the bottom procedure controller to control corresponded production procedures and acquire staff producing operation information and corresponded equipment information. The method has the advantages that the corresponded material is encoded correspondingly and respectively, the workshop producing material data management and tracking are implemented, the statistical graph and report support is provided, and the material management is simplified.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Mounting structure of door basket for refrigerator

ActiveUS7300120B2Low production costReduce defective rateLighting and heating apparatusFurniture partsMechanical engineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

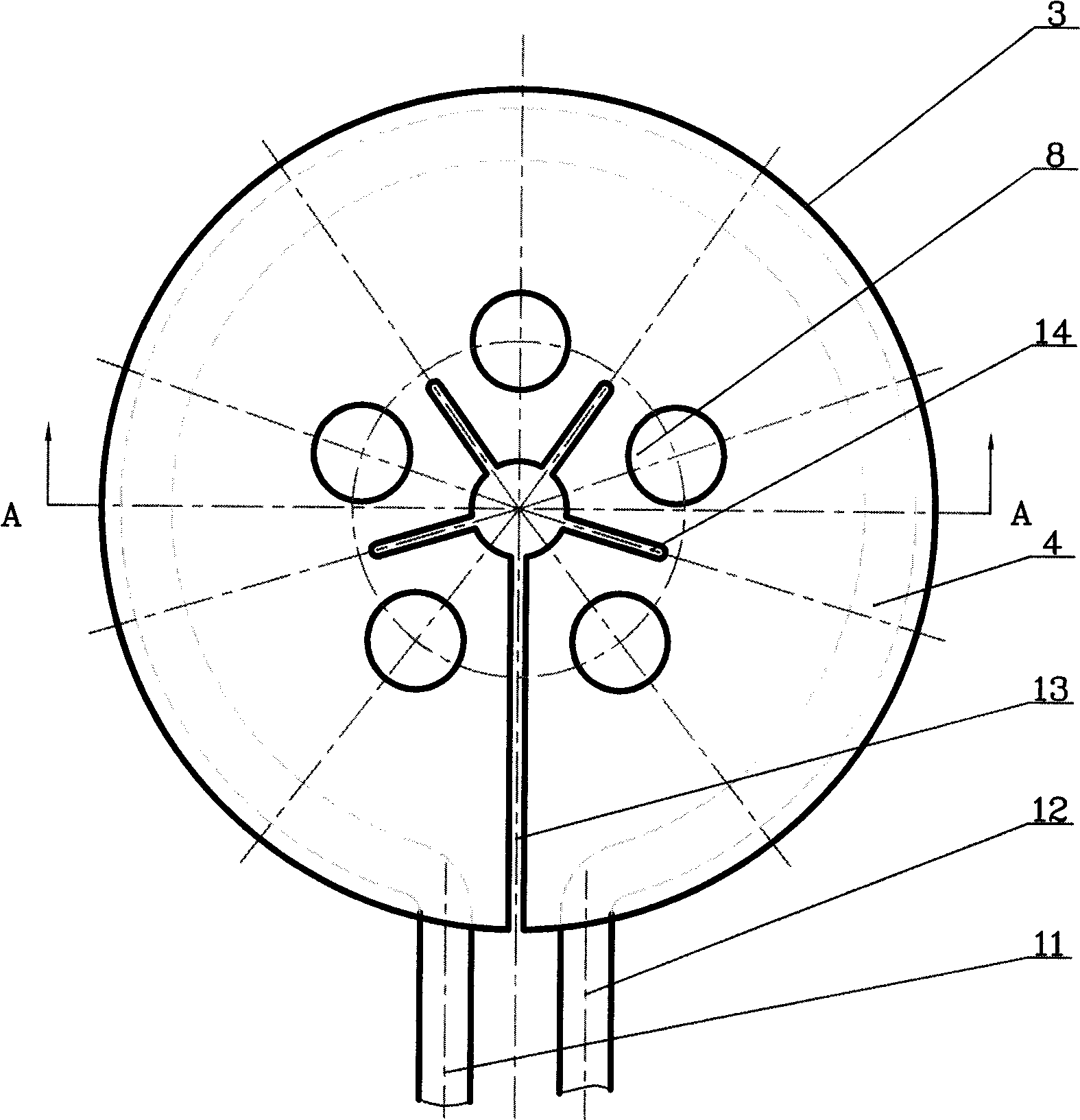

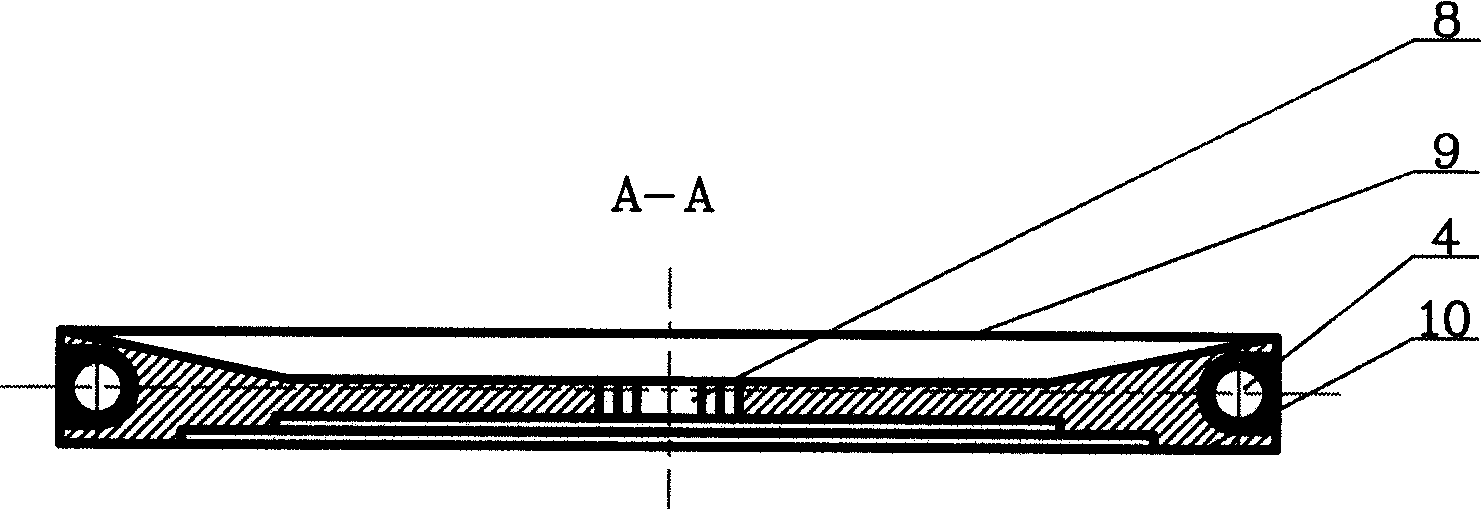

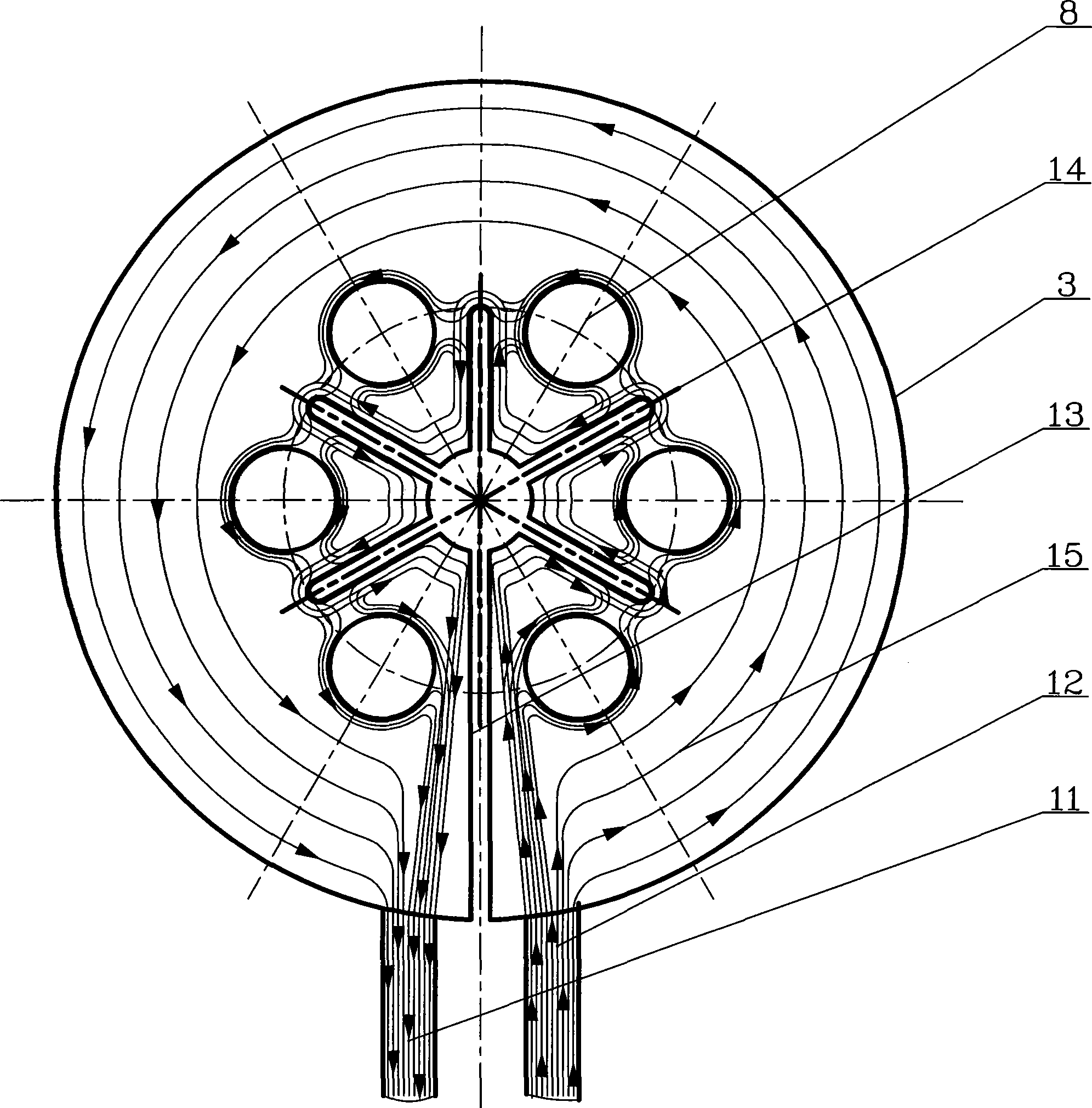

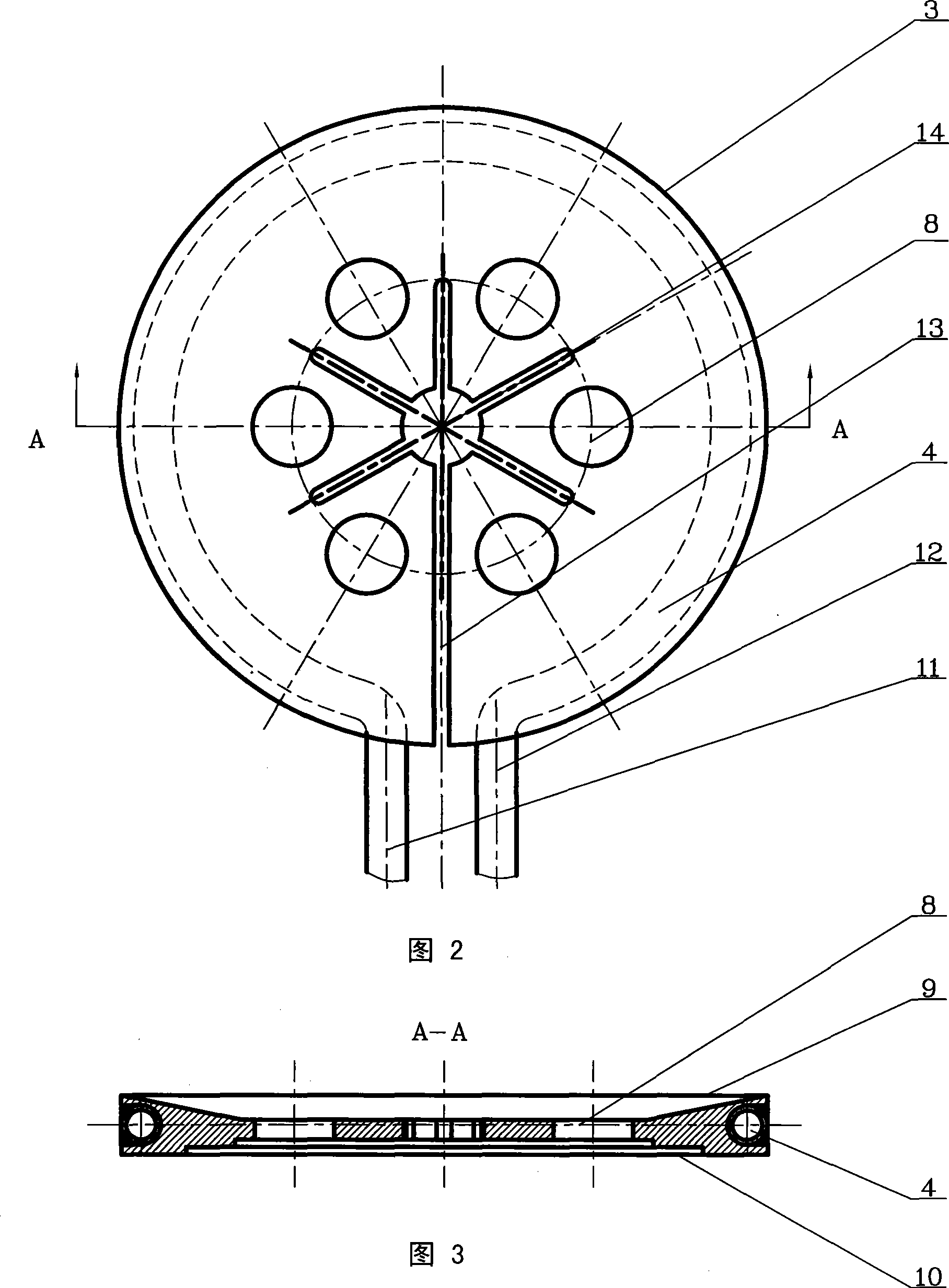

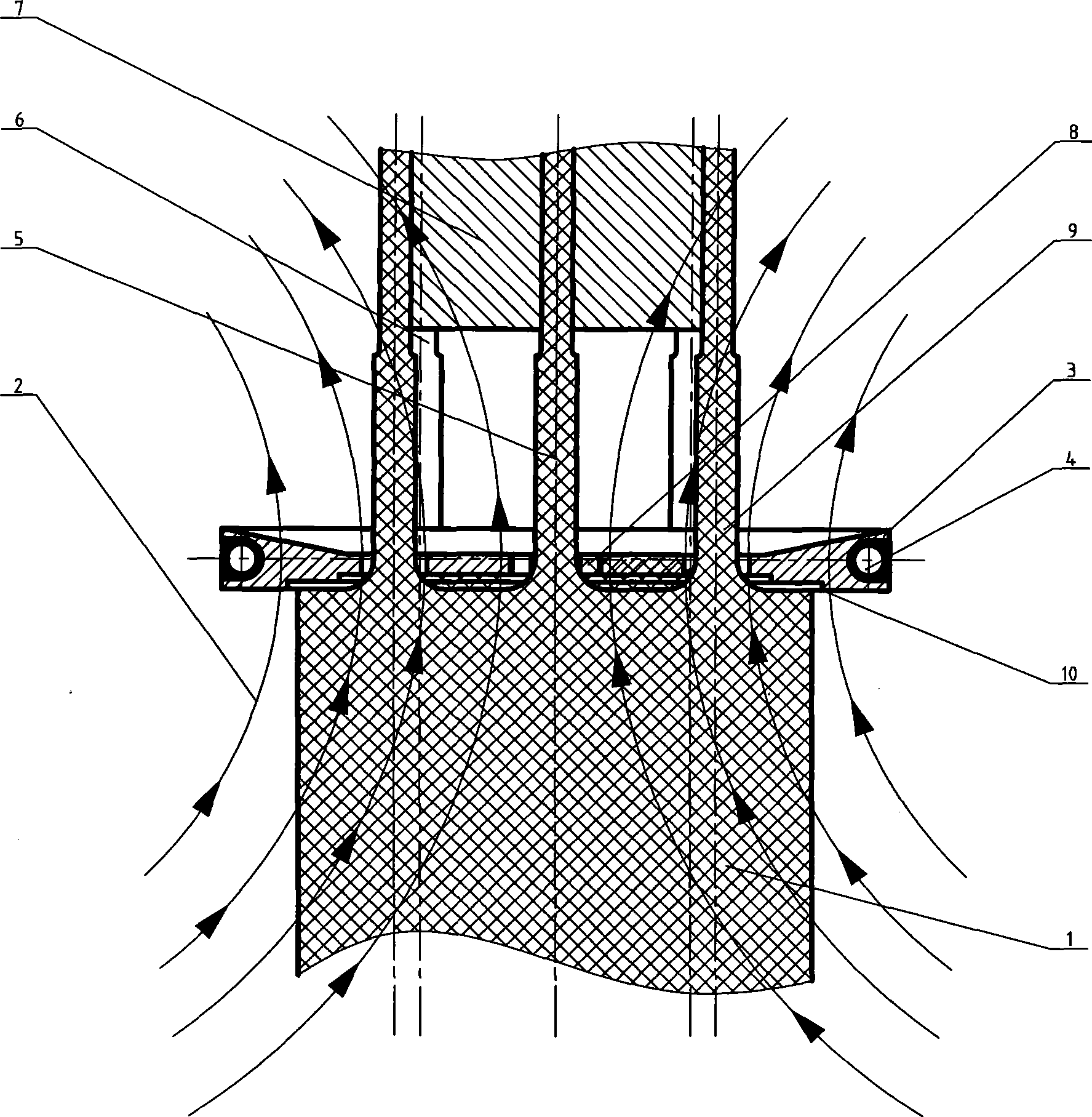

High-frequency coil structure capable of producing six silicon cores and other crystal material at the same time

ActiveCN101487136AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsEngineeringCopper

The invention provides a high-frequency coil structure which can produce six silica cores and other crystal materials simultaneously, relating to the technical field of high-frequency coils. The high-frequency coil structure comprises a radial shunt trough (14) which is used for diversion of current (15), and six internal holes (8), wherein, one internal hole is arranged at the middle part and other five internal holes are uniformly distributed around the middle internal hole in a petal-shape; an inclined opening (13) at one side of a copper pipe A(11) for conveying current and cooled water and a copper pipe B(12) for conveying current and cooled water is connected and communicated with the middle internal hole; the radial shunt trough extends out from the middle internal hole to a position between every two internal holes except the inclined opening; the inclined opening is connected with the middle internal hole; and the radial shunt trough is radially distributed between every two peripheral internal holes by the middle internal hole, thus leading the current to uniformly run by surrounding the six internal holes under the shunt effect of the shunt trough during the running process and achieving the objects that the current is uniformly distributed around the six internal holes.

Owner:LUOYANG JINNUO MECHANICAL ENG

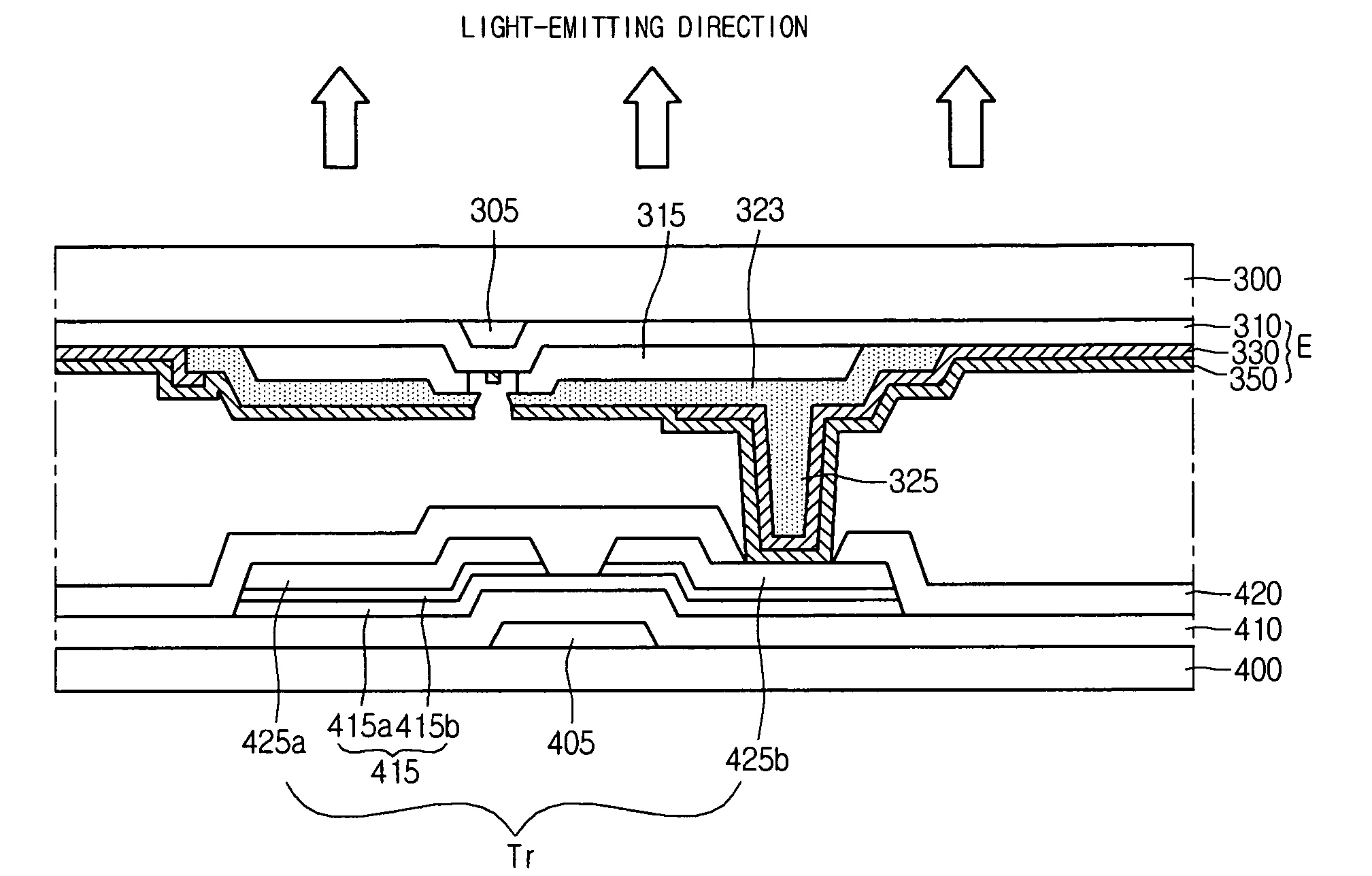

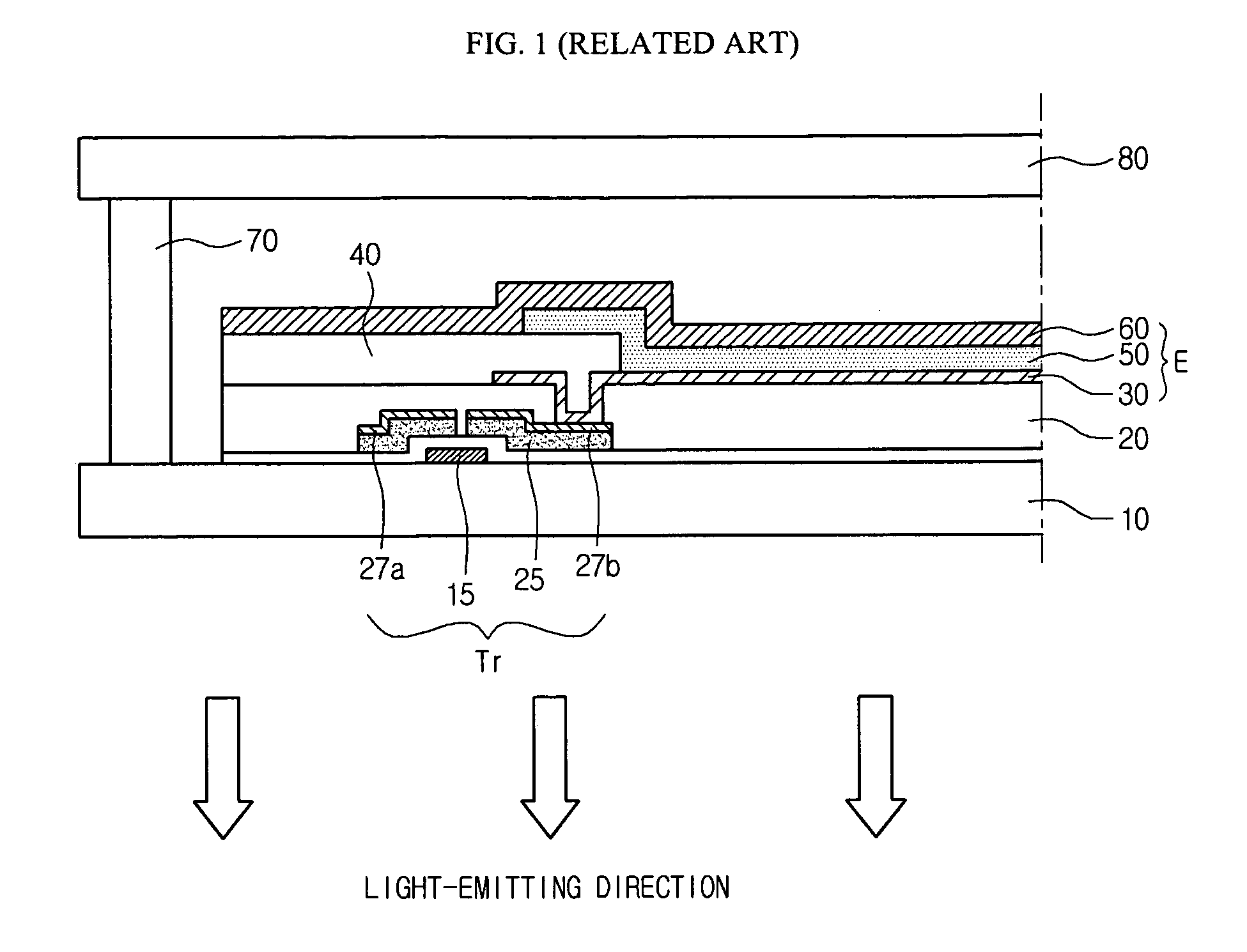

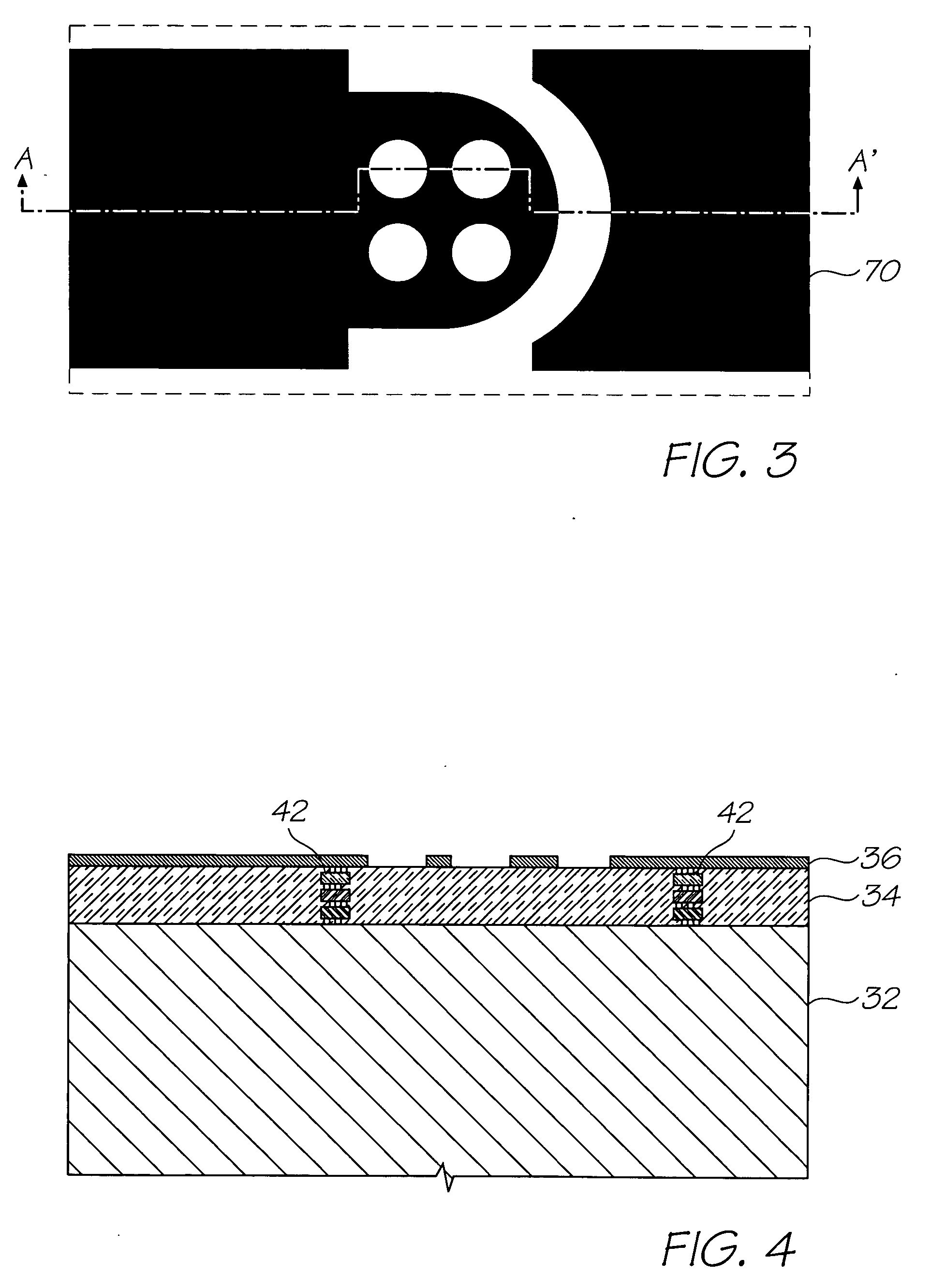

Organic electro-luminescence display device and method for fabricating the same

ActiveUS20070132374A1Increase product yieldReduce defect rateDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceDisplay device

An organic electro-luminance display device includes a first substrate including a plurality of sub-pixels, a first electrode on the first substrate, a buffer layer on the first electrode of a region that partitions each of the sub-pixels, a spacer on the buffer layer, the buffer layer and the spacer being integrally formed, an organic light-emitting layer on the first electrode that corresponds to each of the sub-pixels and the spacer, and a second electrode on the organic light-emitting layer.

Owner:LG DISPLAY CO LTD

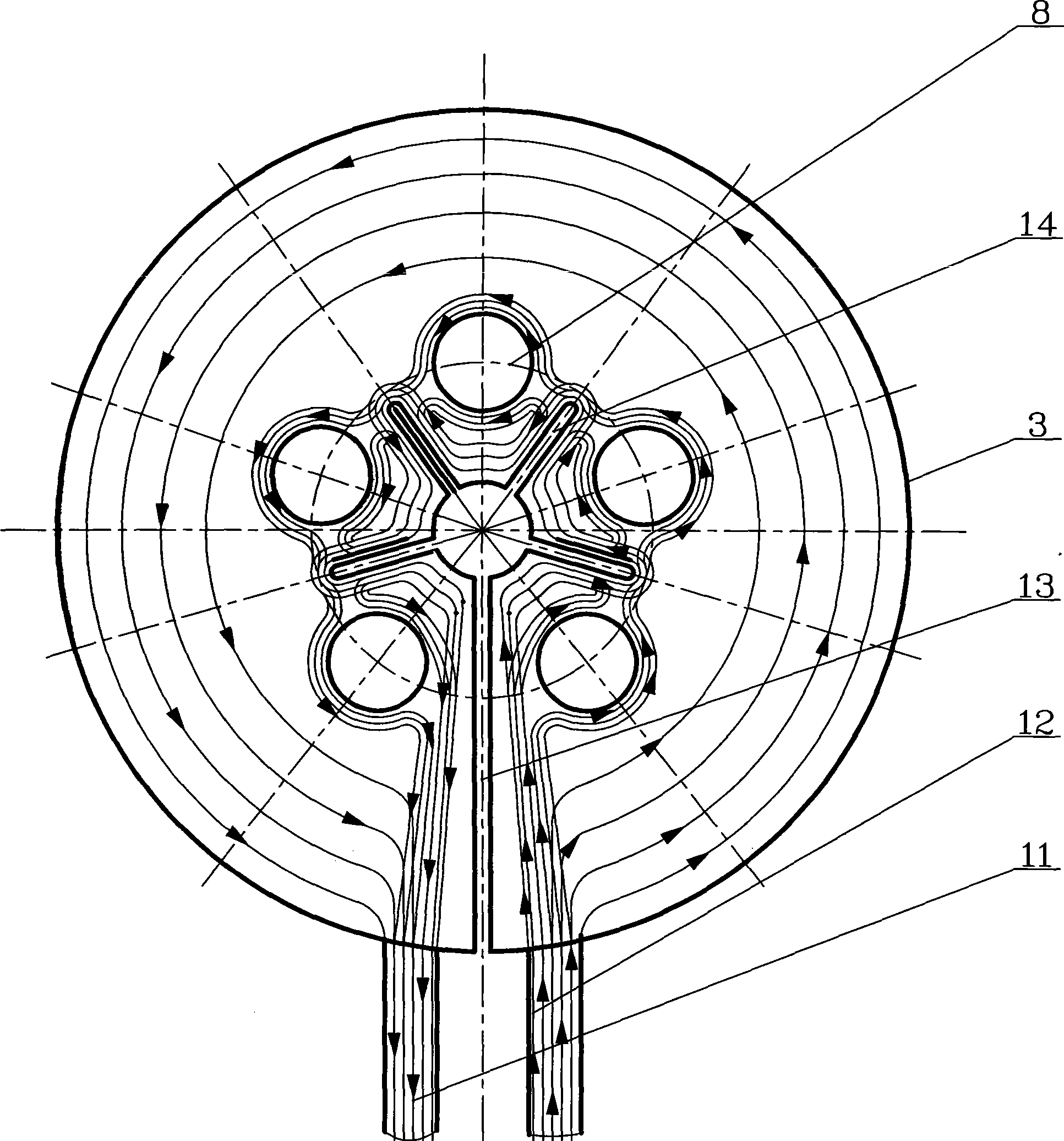

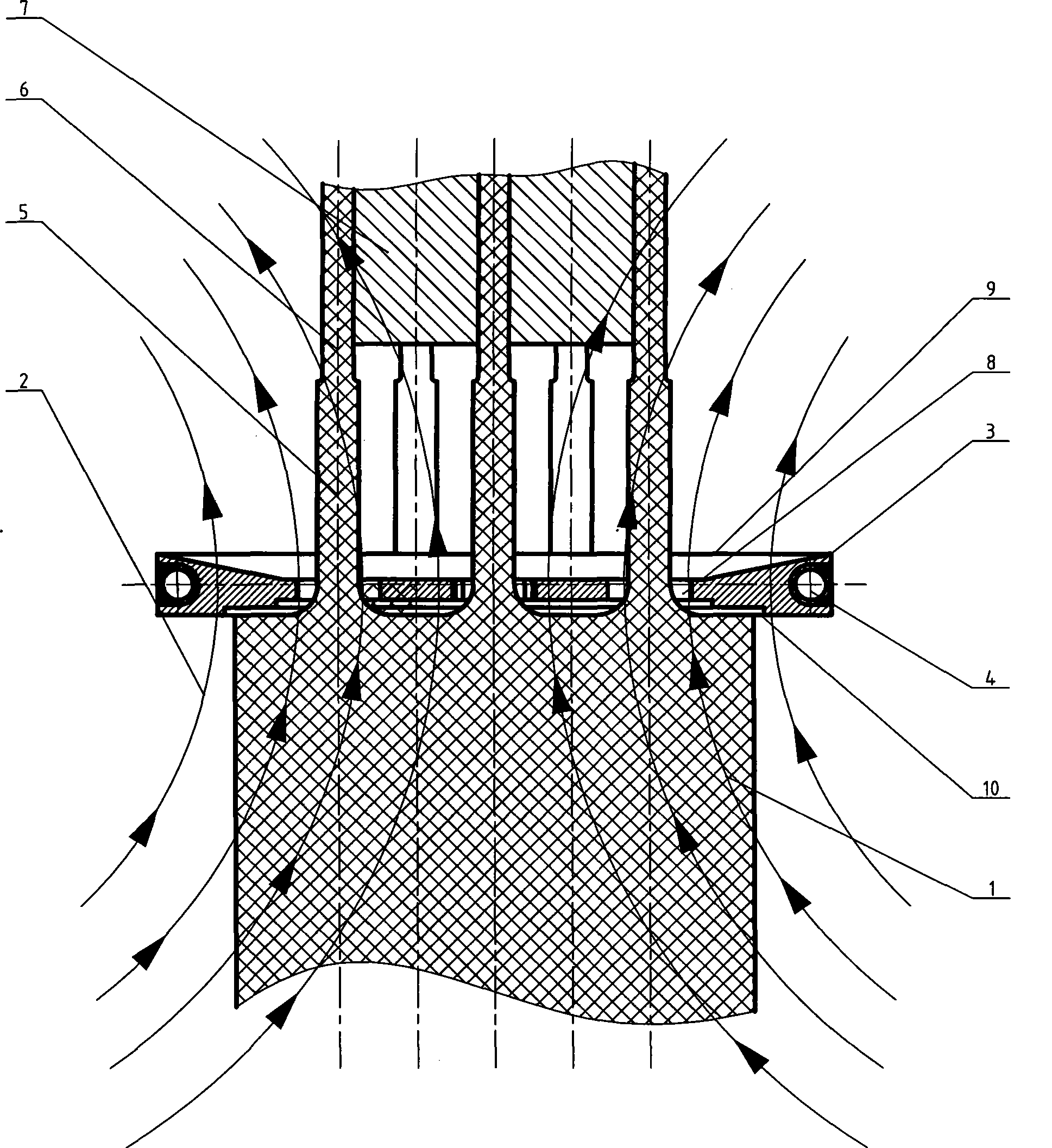

High-frequency coil structure capable of simultaneous producing seven silicon cores and other crystal material

ActiveCN101457389AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing seven silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and seven inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and six inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the seven inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the seven inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

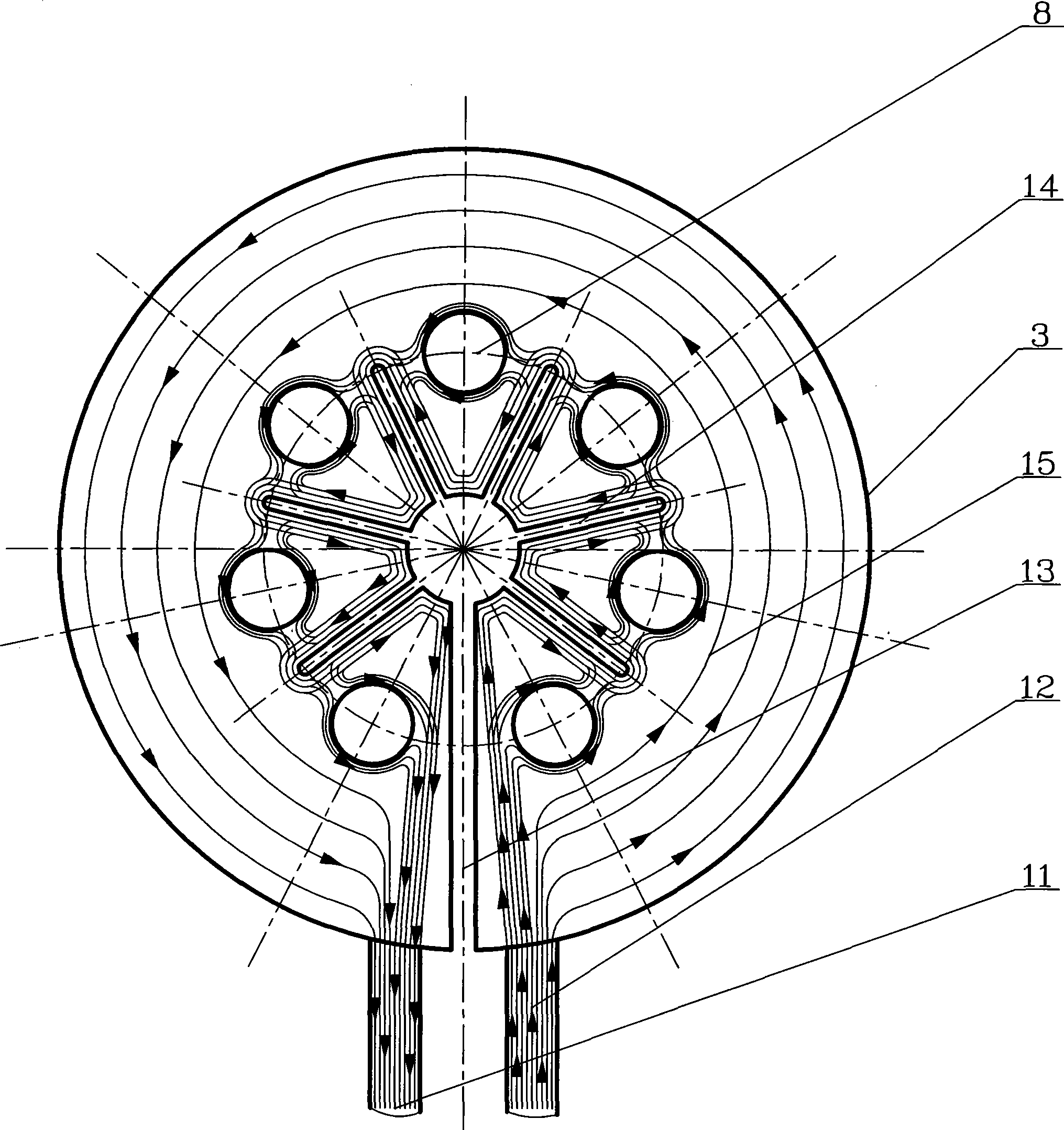

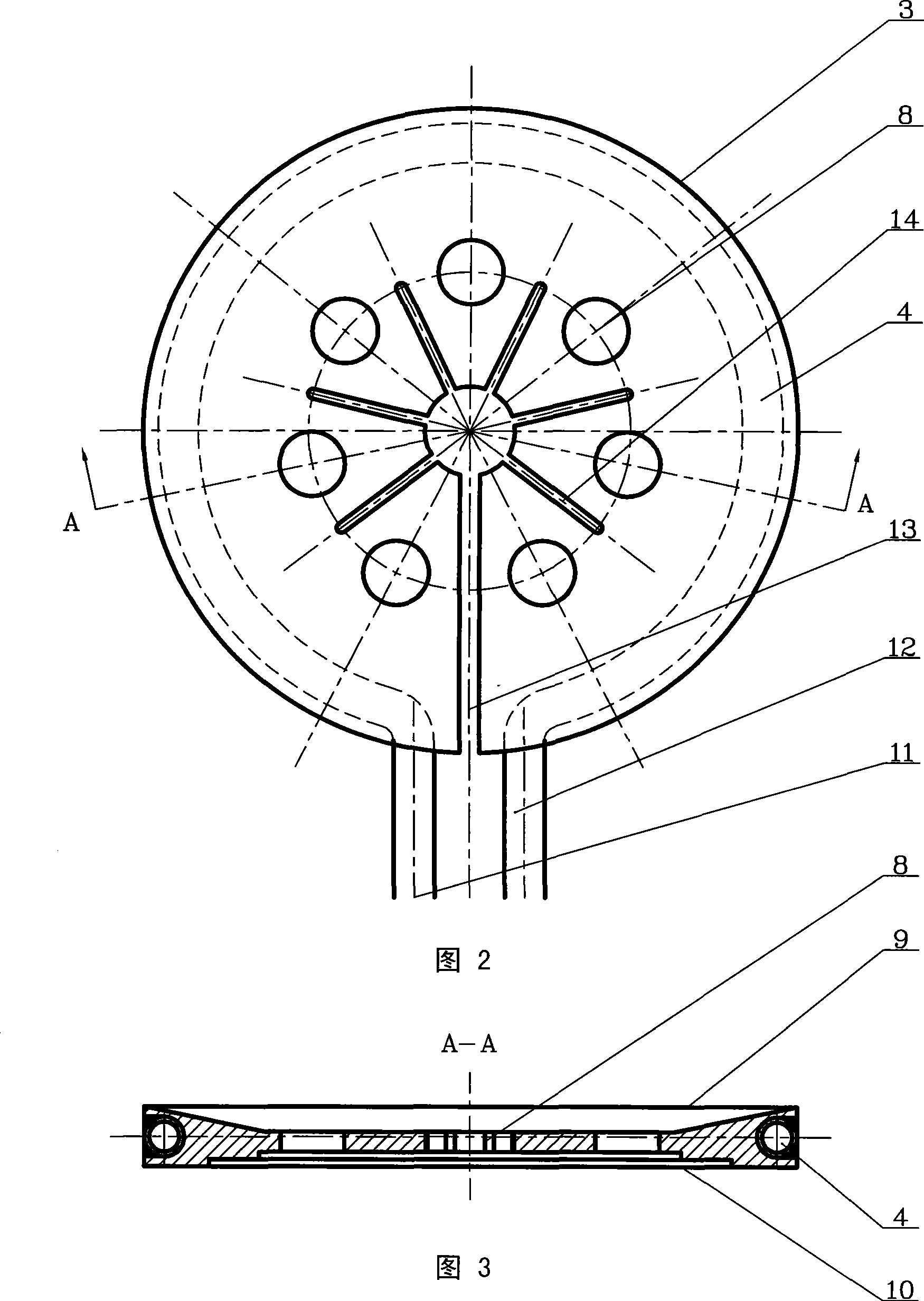

High-frequency coil structure capable of simultaneous producing eight silicon cores and other crystal material

ActiveCN101457390AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing eight silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and eight inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and seven inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape, an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the eight inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the eight inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

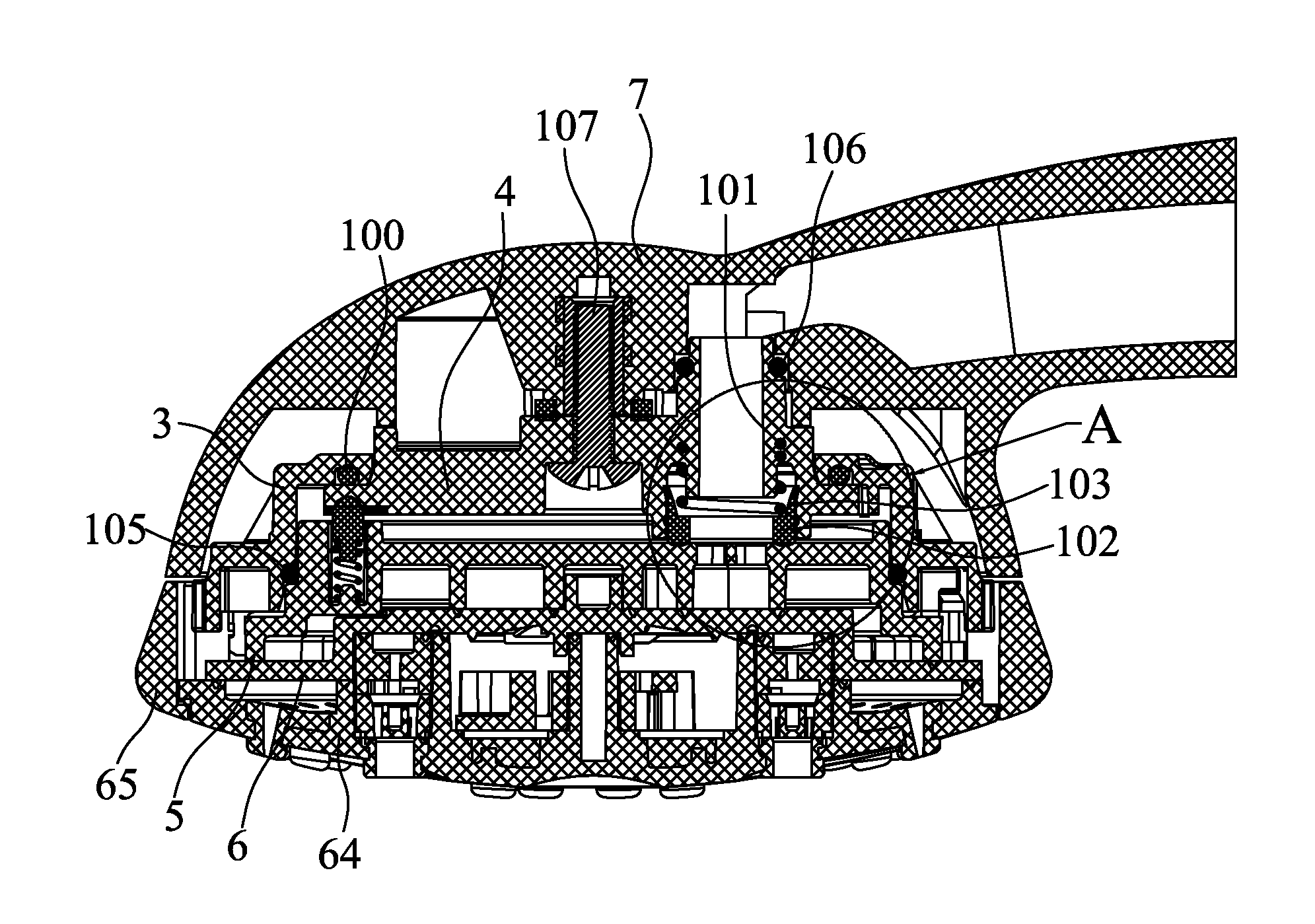

Shower Head

ActiveUS20130126646A1Improve sealingReduce defective rateSpray nozzlesFire rescueRotation flapEngineering

A shower head includes a main body seal seat fixed to a main body. The main body seal seat is fitted in a rotation seat in a rotation way and located above a cover seal seat. The cover seal seat is fixed to a cover unit. The joint of the main body seal seat and the rotation seat has a groove to receive a first seal ring. The main body seal seat has at least one water inlet. The water inlet is provided with a spring and a second seal ring therein. The spring is located between the second seal ring and the water inlet of the main body seal seat. The cover seal seat has at least one through hole corresponding in position to the water inlet. The cover unit has at least one water outlet.

Owner:WU WEI SHENG

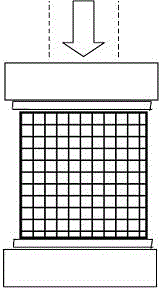

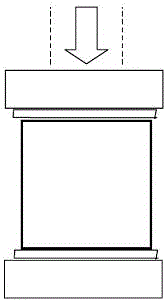

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

Preparation process of semiconductor wafer

InactiveUS6159827AEasy to peelShorten operation timeSolid-state devicesSemiconductor/solid-state device manufacturingWarm waterEngineering

An object of the invention is to provide a preparation process of a semiconductor wafer, in which breakage of the wafer on grinding the back surface of the wafer and on peeling the adhesive tape is prevented, and the operation time can be reduced. The preparation process of a semiconductor wafer comprises the steps of: adhering an adhesive tape on a front surface of a semiconductor wafer; grinding a back surface of the semiconductor wafer by a grinding machine; peeling the adhesive tape; and cleaning the front surface of the semiconductor wafer, wherein an adhesive tape having heat shrinkability is used as the adhesive tape, and after grinding the back surface of the semiconductor wafer, warm water at a temperature of from 50 to 99 DEG C. is poured to peel the adhesive tape in a wafer cleaning machine, and the front surface of the semiconductor wafer is cleaned in the wafer cleaning machine.

Owner:MITSUI CHEM INC

Method for encapsulating organic electroluminescent device and an organic electroluminescent panel using the same

InactiveUS6896572B2Improve manufacturabilityReduce defective rateElectroluminescent light sourcesSolid-state devicesDevice formOrganic layer

Owner:SAMSUNG DISPLAY CO LTD

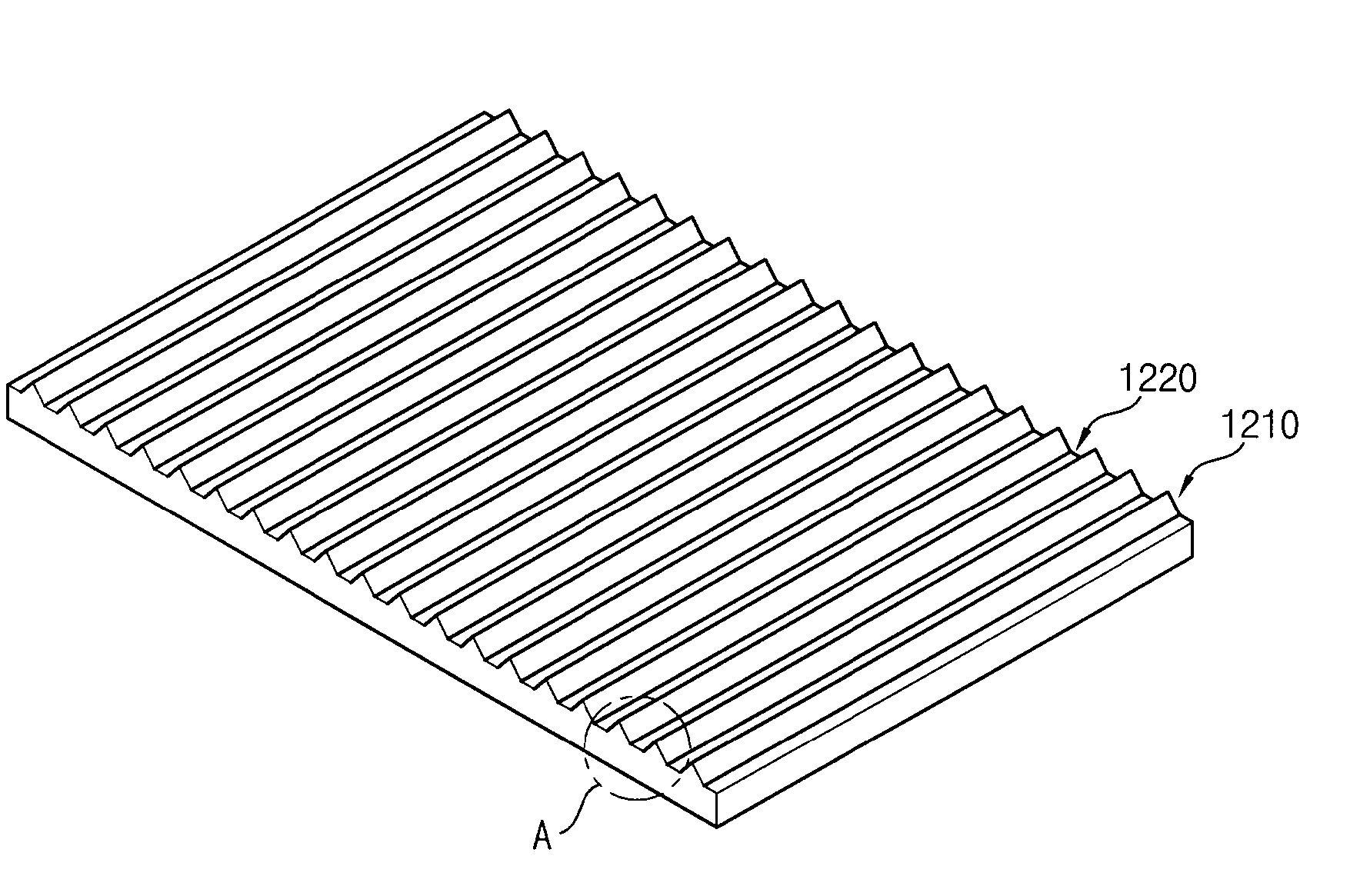

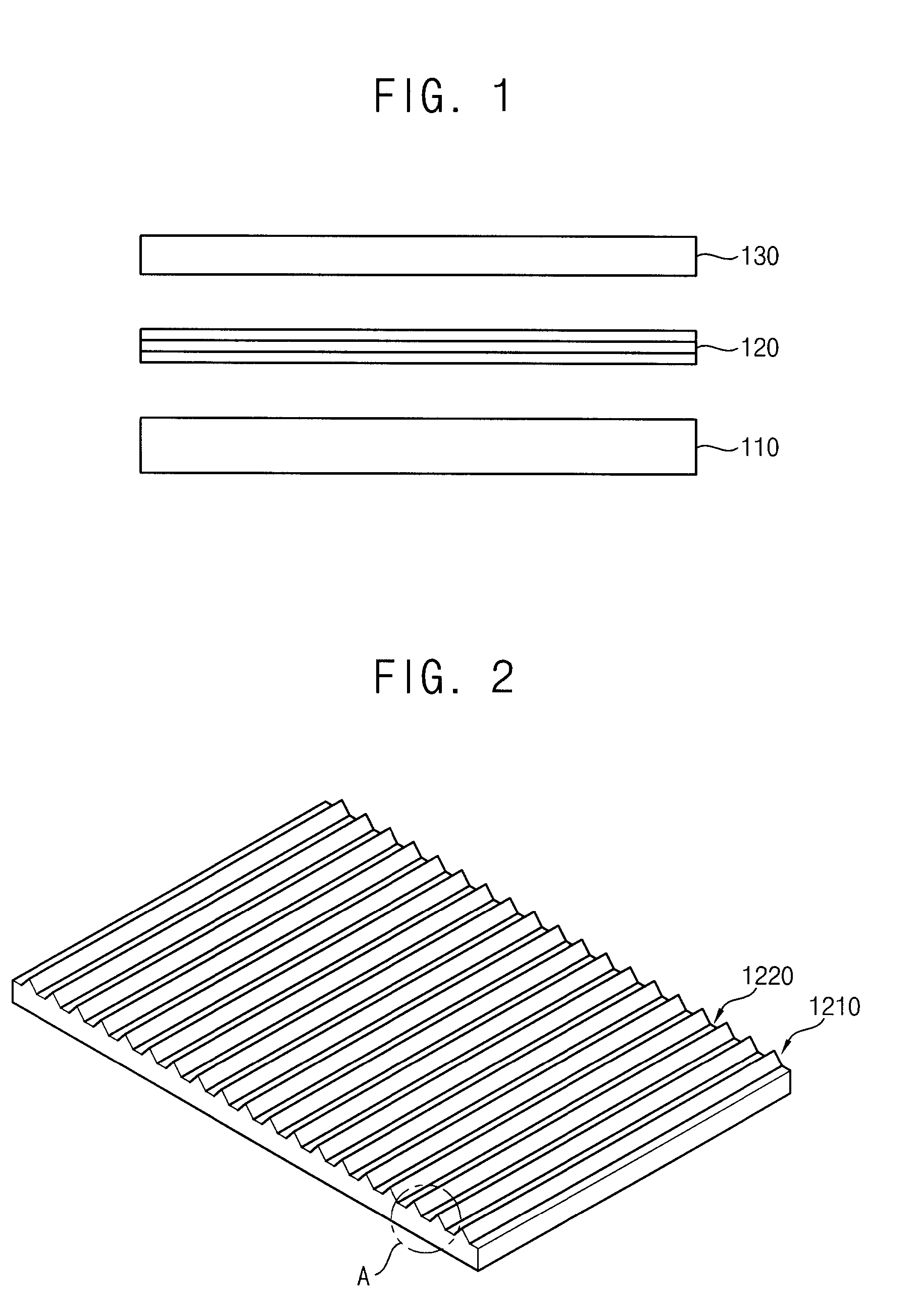

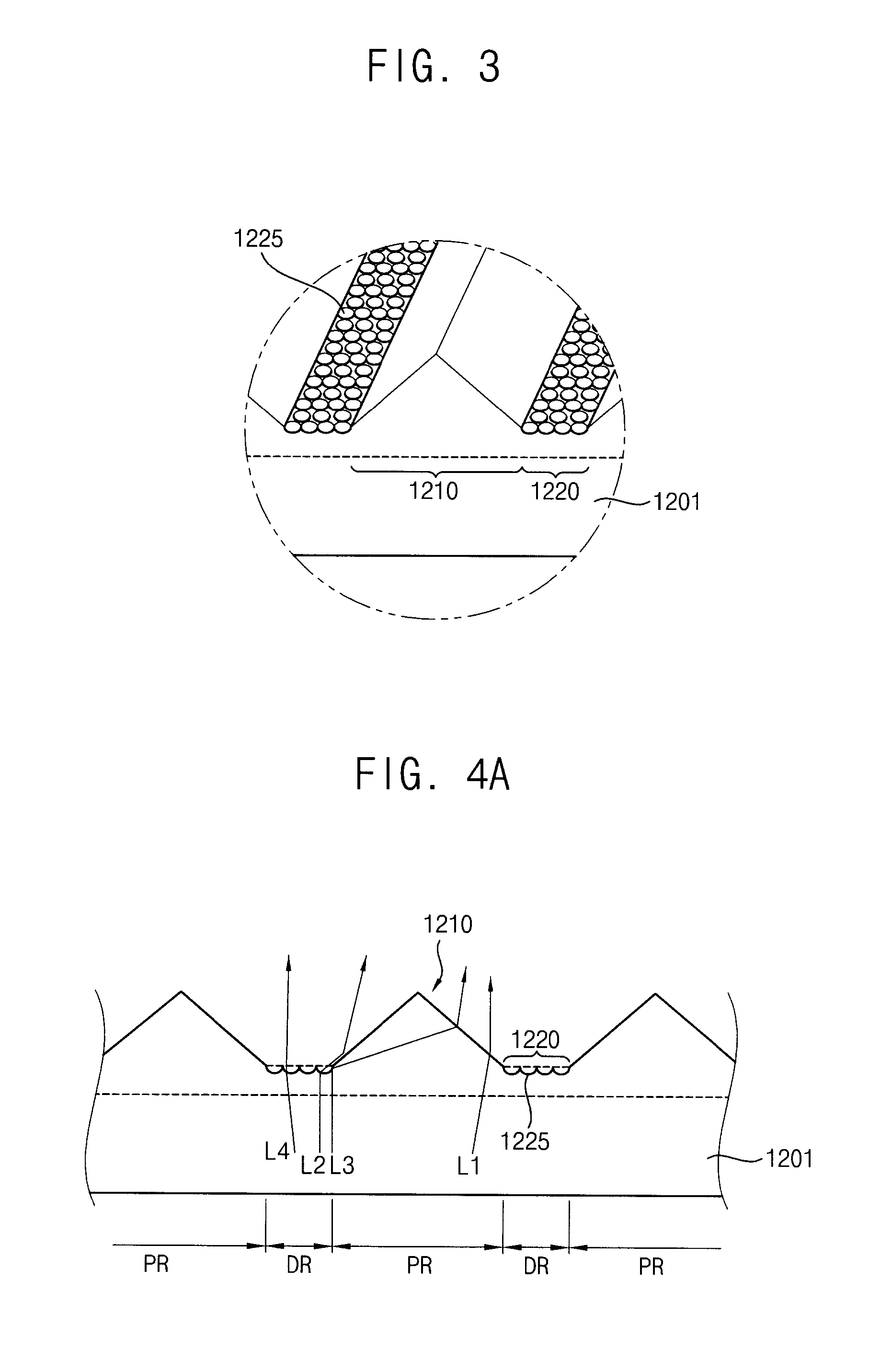

Optical sheet and method of manufacturing the same

ActiveUS20100027294A1Increase front brightnessImprove display qualityDiffusing elementsVessels or leading-in conductors manufacturePrismEngineering

An optical sheet includes a base film in which light is incident from a lower side, a plurality of prism patterns and a diffusion member. The prism patterns are protruded to be spaced apart from each other on the base film to enhance the front luminance of light incident from the lower side of the base film. The diffusion member is disposed between prism patterns to have a diffusion surface in parallel with the base film. The diffusion member includes a plurality of diffusion dots capable of enhancing the luminance uniformity of light incident from the lower side of the base film. Thus, front luminance and luminance uniformity may be enhanced due to a juxtaposition of the prism patterns and the diffusion portion, and the viewing angle of the LCD device may be enhanced.

Owner:TSC OPTOS +1

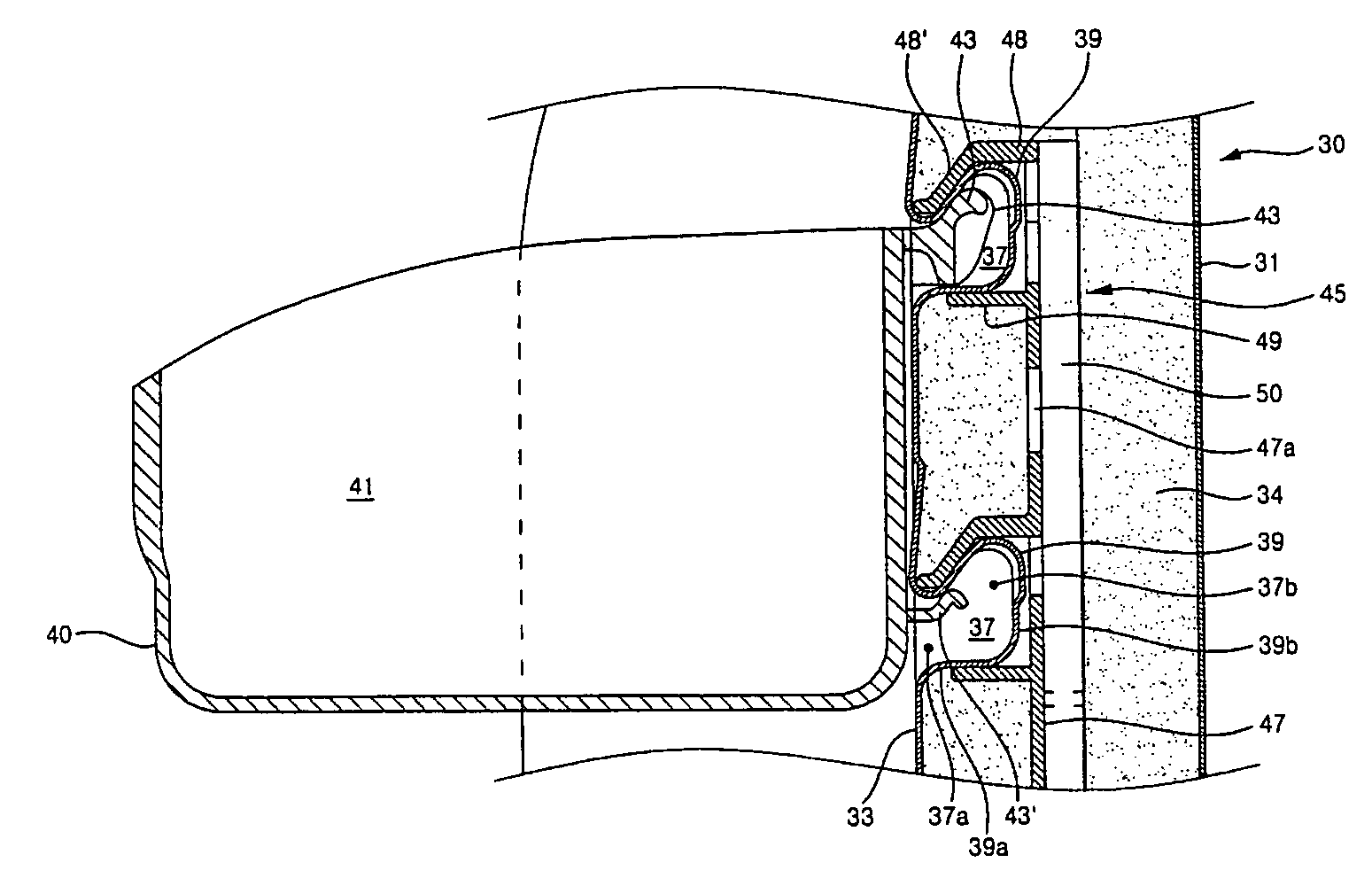

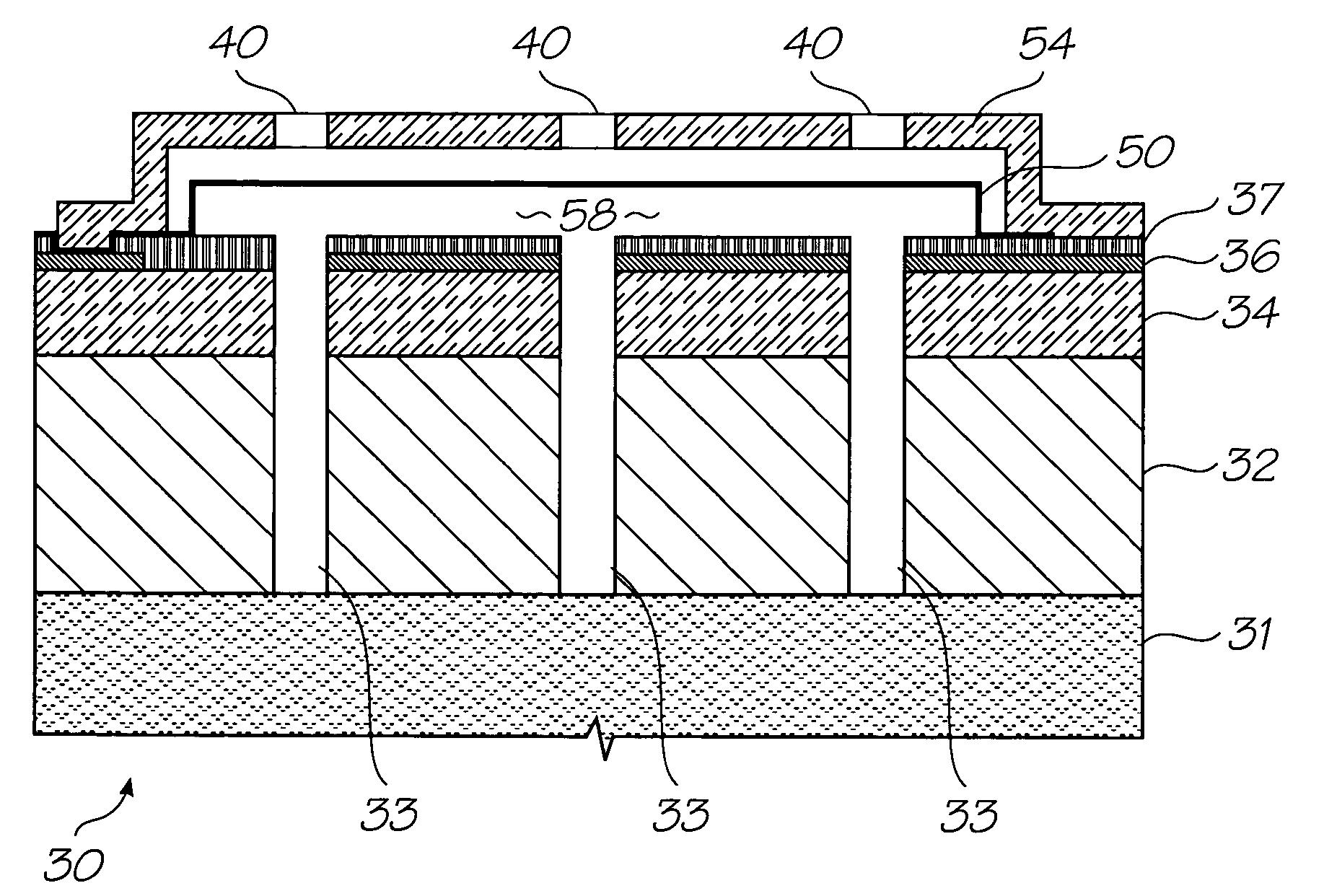

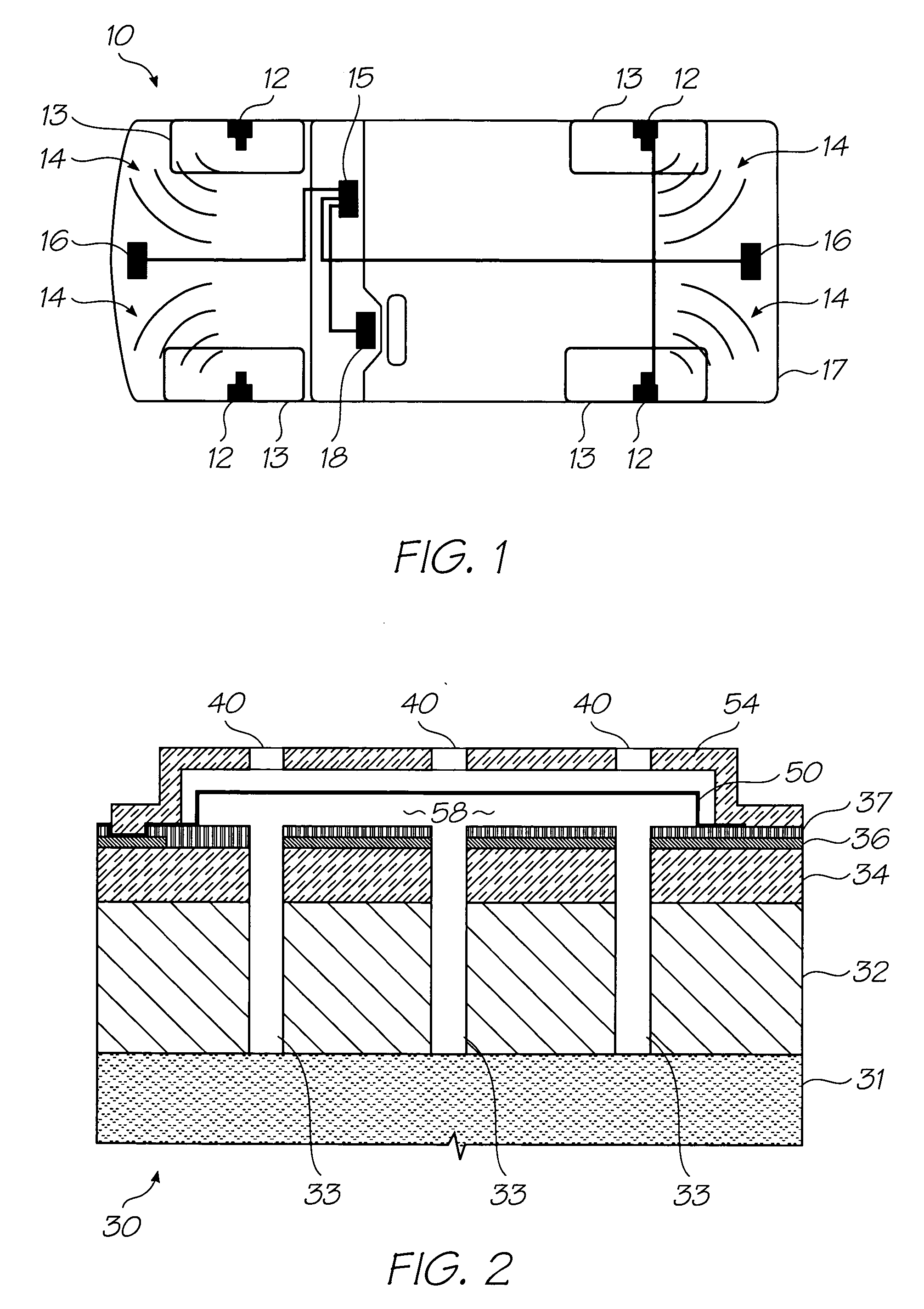

Wafer bonded pressure sensor

InactiveUS20060081062A1The material is lowAvoids high surface cleanlinessFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsHermetic sealEngineering

A pressure sensor (30) for sensing a fluid pressure in harsh environments such as the air pressure in a tire, by using a first wafer substrate (32) with a front side and an opposing back side, a chamber (58) partially defined by a flexible membrane (50) formed on the front side and at least one hole (33) etched from the back side to the chamber (58); a second wafer (31) on the back side of the first wafer (32) to seal the at least one hole (33); wherein, the chamber (58) containing a fluid at a reference pressure, such that the flexible membrane (50) deflects due to pressure differentials between the reference pressure and the fluid pressure; and, associated circuitry (34) for converting the deflection of the flexible membrane (50) into an output signal indicative of the fluid pressure; wherein, the second wafer (31) is wafer bonded to the first wafer substrate (32). Wafer bonding offers an effective non-adhesive solution. It provides a hermetic seal with only minor changes to the fabrication procedure. Skilled workers in this field will readily understand that the most prevalent forms of wafer bonding are: direct wafer, or silicon fusion, bonding; anodic, or electrostatic Mallory process bonding; and, intermediate layer bonding.

Owner:PRECISION MECHATRONICS

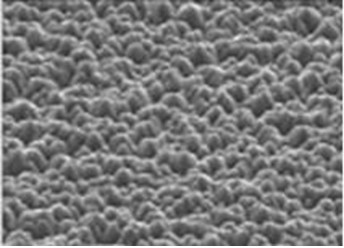

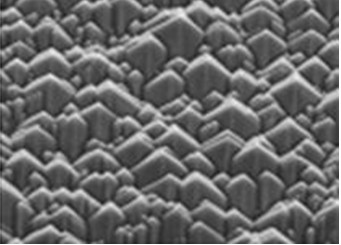

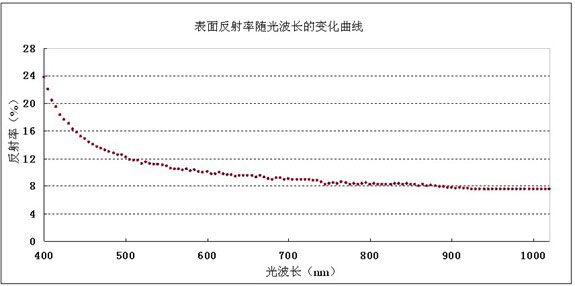

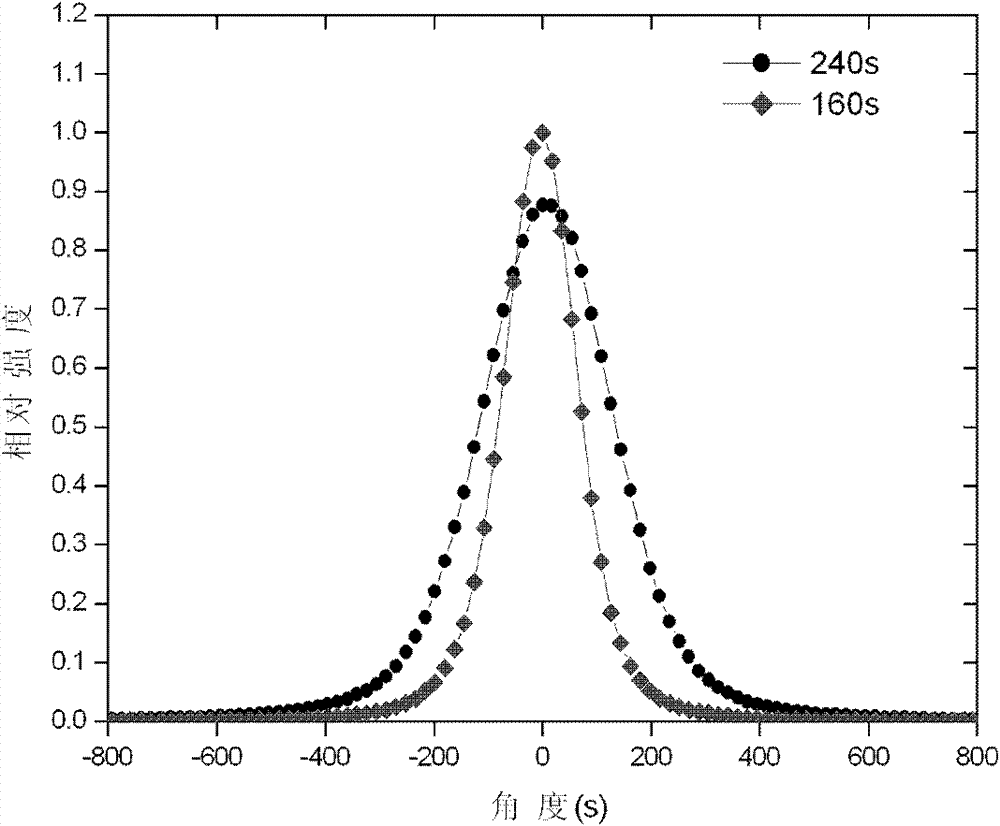

Single crystal silicon texture-making additive and single crystal silicon texture-making technology

InactiveCN102115915AIncrease productivityIncrease production capacityAfter-treatment detailsFinal product manufactureActive agentPotassium hydroxide

The invention relates to a single crystal silicon texture-making additive and a single crystal silicon texture-making technology. The single crystal silicon texture-making additive consists of a wetting agent and a defoaming agent. The additive is characterized in that the wetting agent is a nonionic surfactant. The single crystal silicon texture-making technology comprises the following steps: heating deionized water to 70-80 DEG C, adding sodium hydroxide or potassium hydroxide to obtain a single crystal silicon texture-making corrosive liquid, wherein the mass percentage of sodium hydroxide or potassium hydroxide is 1%-2%; adding the single crystal silicon texture-making additive in the single crystal silicon texture-making corrosive liquid to obtain a mixed solution, wherein the volume percentage of the additive is 0.3%-2%; and placing a precleaned raw silicon chip in the mixed solution for 600-1200s for texture-making. By adopting the additive and technology in the invention, the texture-making quality can be greatly increased, the cost is greatly reduced, the technological operation can be easier and the automatic solution preparation can be realized.

Owner:百力达太阳能股份有限公司

Structure using graphite alkene as buffer layer epitaxy GaN (gallium nitride) and preparation method of structure

InactiveCN102769081AReduce stressQuality improvementPolycrystalline material growthFrom chemically reactive gasesLattice mismatchThin layer

The invention relates to a structure using graphite alkene as buffer layer epitaxy GaN (gallium nitride) and a preparation method of the structure. The method comprises the following steps of: adopting a graphite alkene layer as a buffer layer between the substrate and a gallium nitride epitaxy layer; and inserting a nitride thin layer between the graphite alkene layer and a GaN layer so as to obtain a gallium nitride epitaxy layer with low stress and high quality. The defective rate of LED (light emitting diode) devices is reduced, the quality of the LED devices is increased, and the life cycle is prolonged. The problem of lattice mismatch and thermal expansion coefficient mismatch between the substrate and the gallium nitride are solved effectively.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

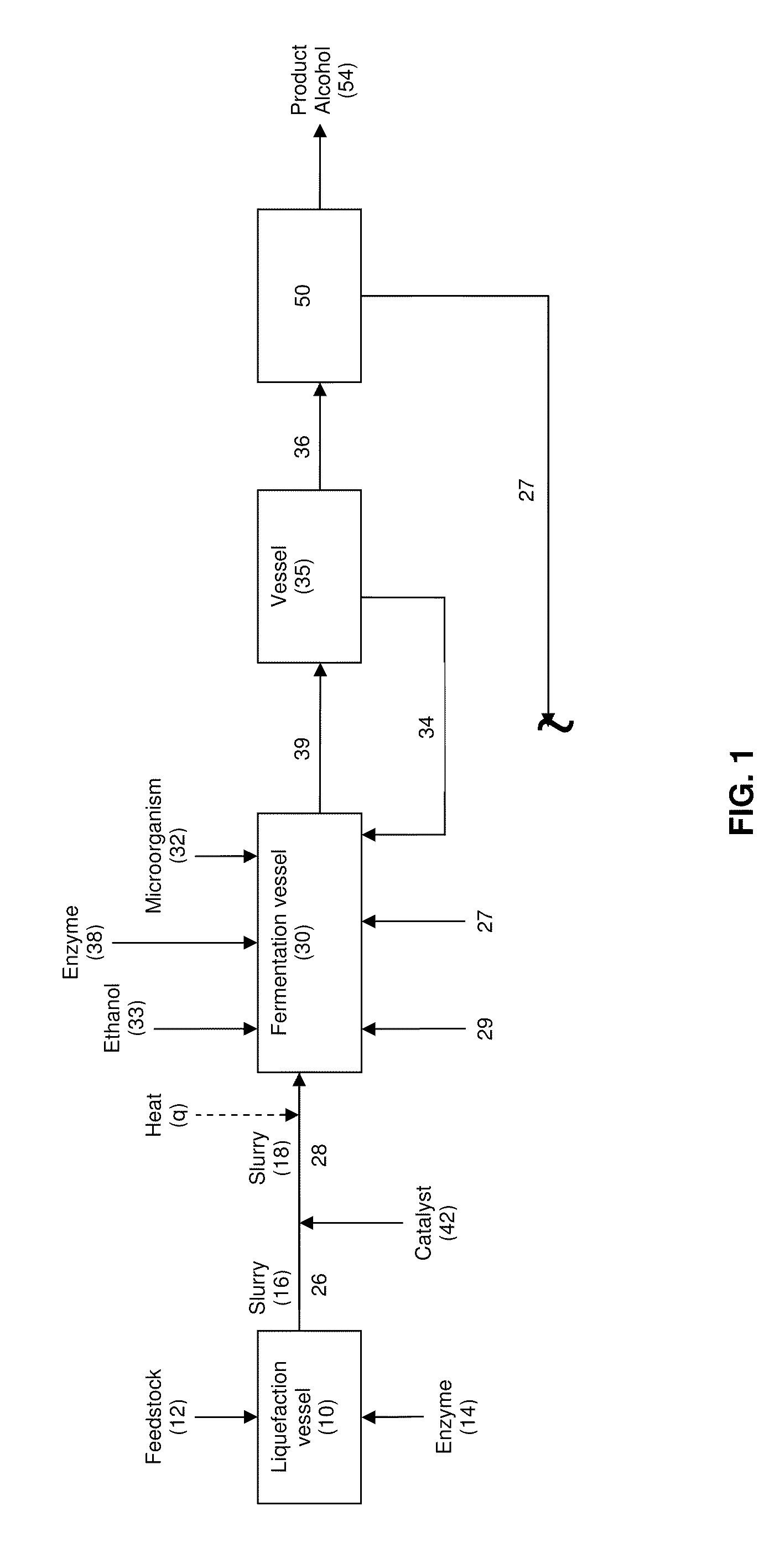

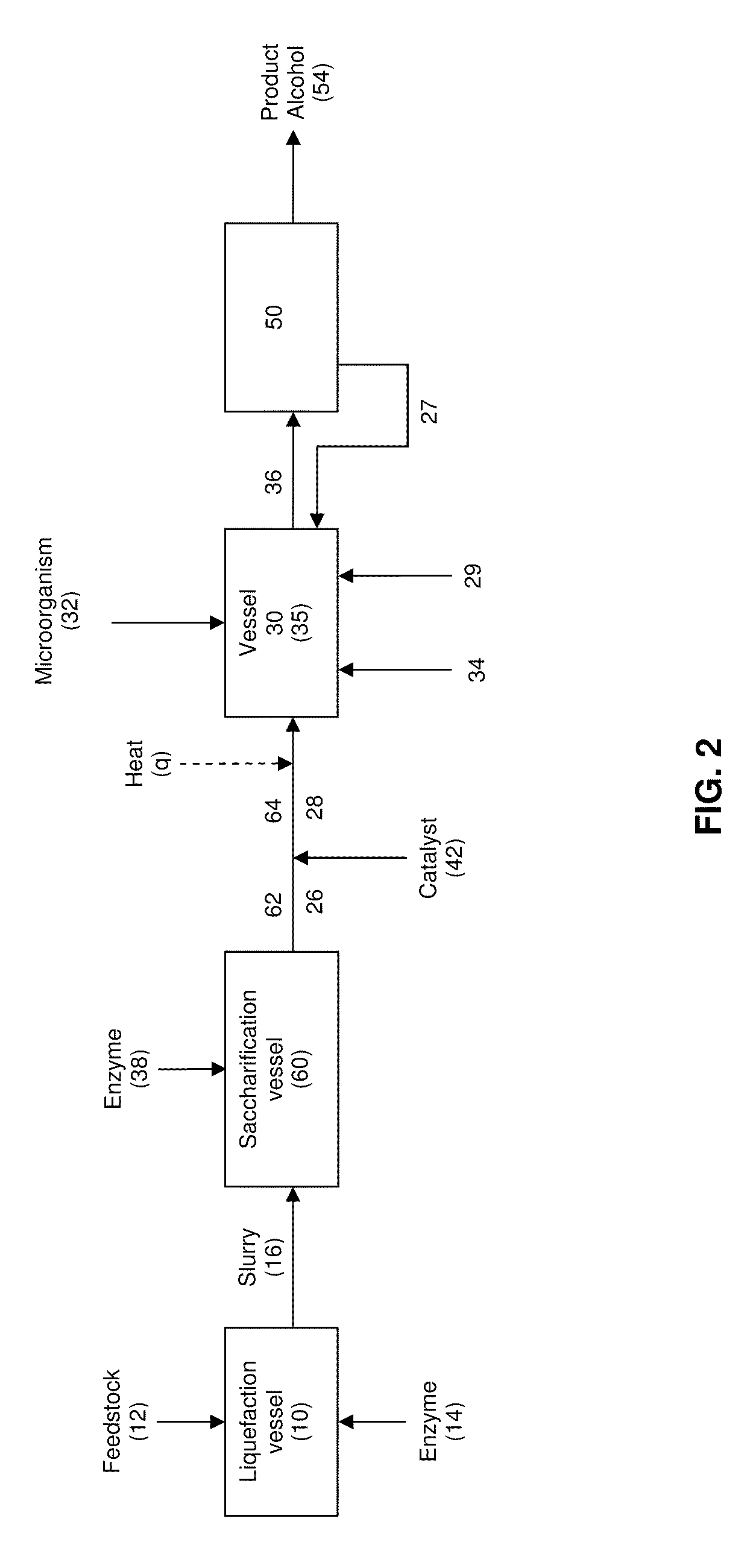

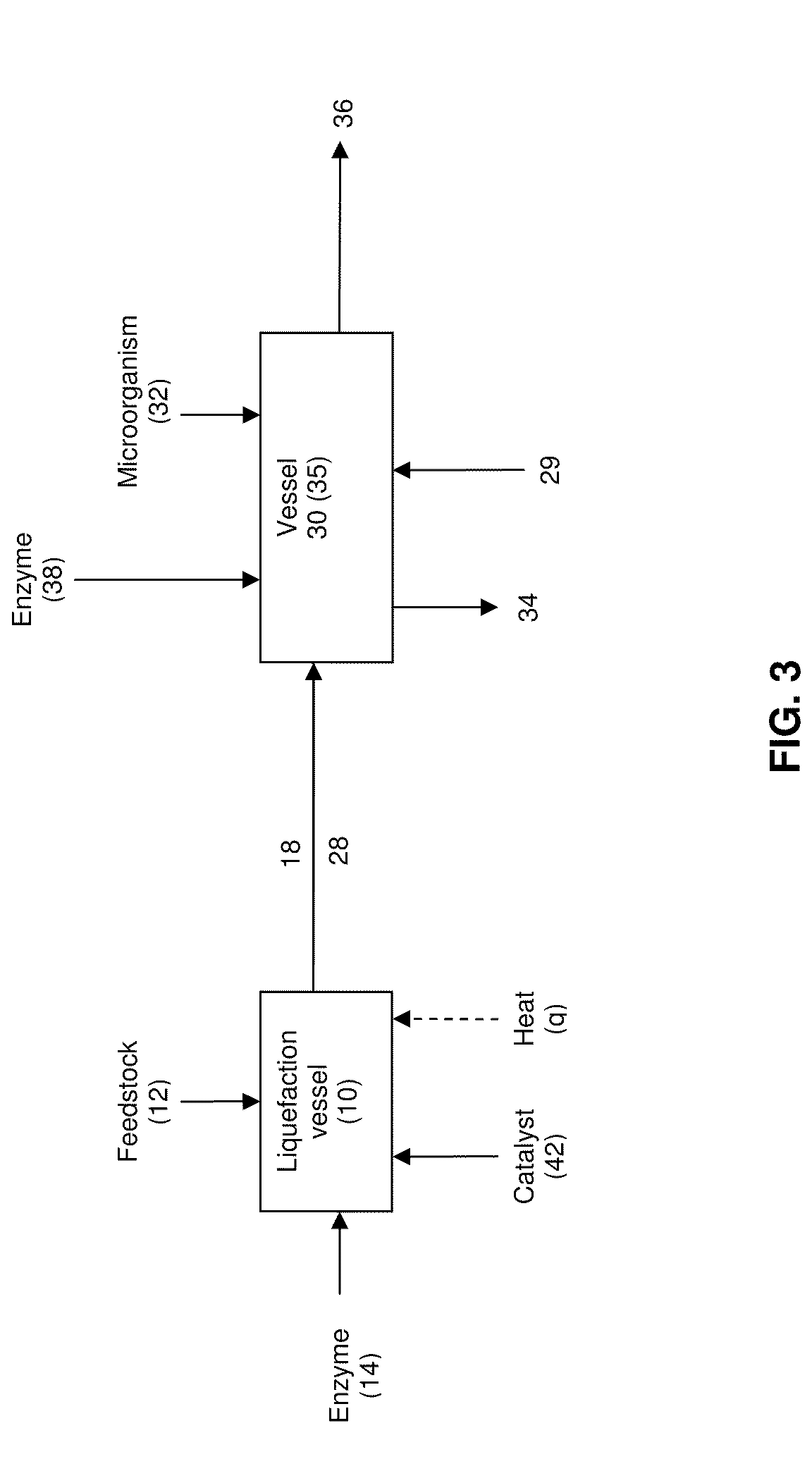

Extraction solvents derived from oil for alcohol removal in extractive fermentation

ActiveUS20110312043A1Reduce capacityPreventing lowering of partition coefficientFatty oils/acids recovery from wasteFungiAlcoholSolvent

In an alcohol fermentation process, oil derived from biomass is hydrolyzed into an extractant available for in situ removal of a product alcohol such as butanol from a fermentation broth. The glycerides in the oil can be catalytically (e.g., enzymatically) hydrolyzed into free fatty acids, which form a fermentation product extractant having a partition coefficient for a product alcohol greater than a partition coefficient of the oil of the biomass for the product alcohol. Oil derived from a feedstock of an alcohol fermentation process can be hydrolyzed by contacting the feedstock including the oil with one or more enzymes whereby at least a portion of the oil is hydrolyzed into free fatty acids forming a fermentation product extractant, or the oil can be separated from the feedstock prior to the feedstock being fed to a fermentation vessel, and the separated oil can be contacted with the enzymes to form the fermentation product extractant. The fermentation product extractant can be contacted with a fermentation broth for in situ removal of a product alcohol.

Owner:GEVO INC

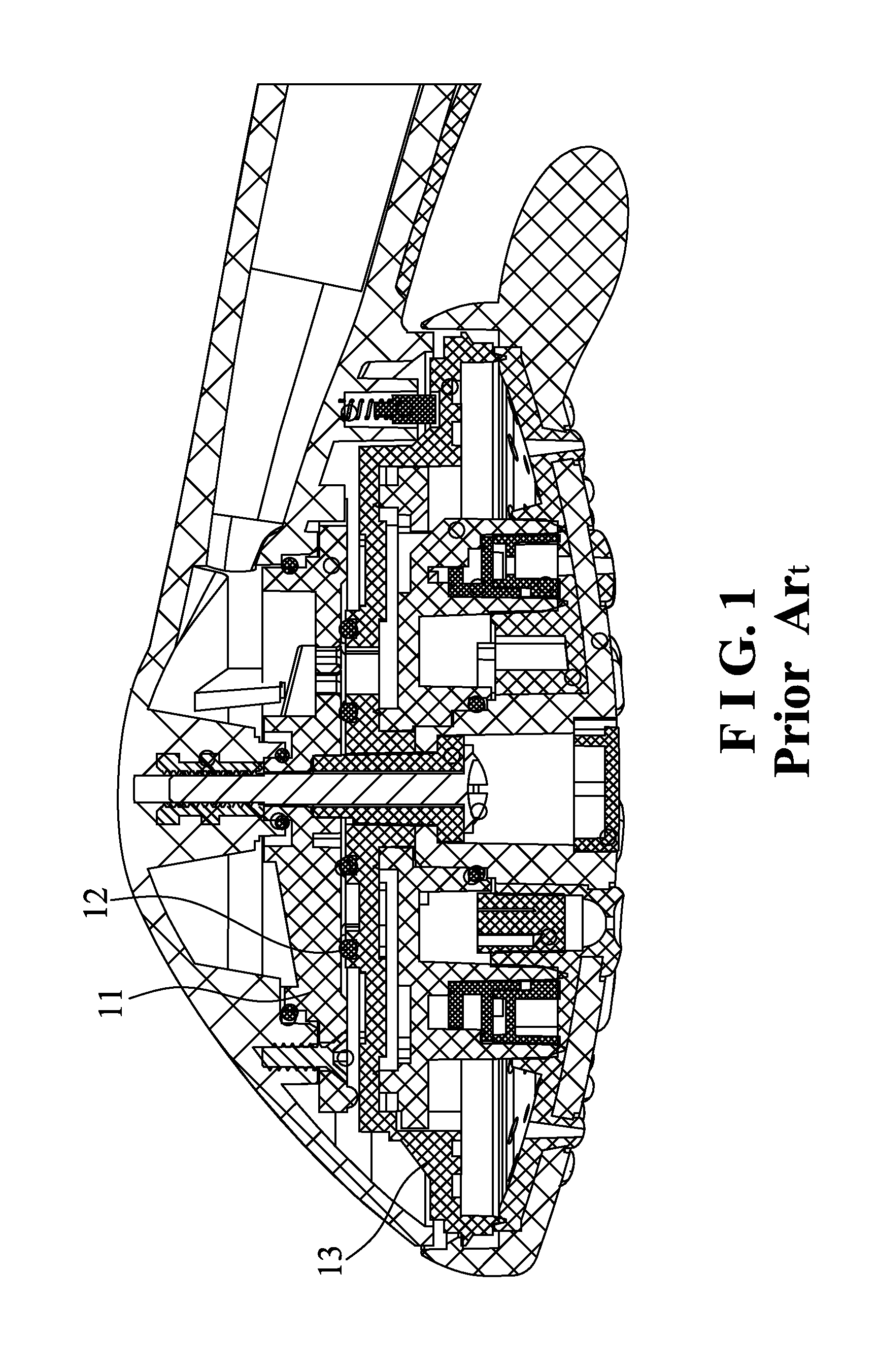

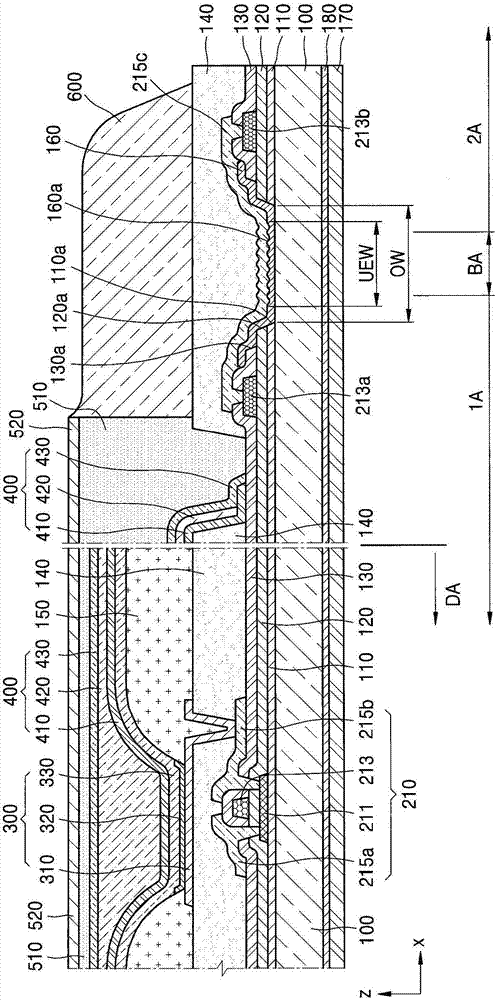

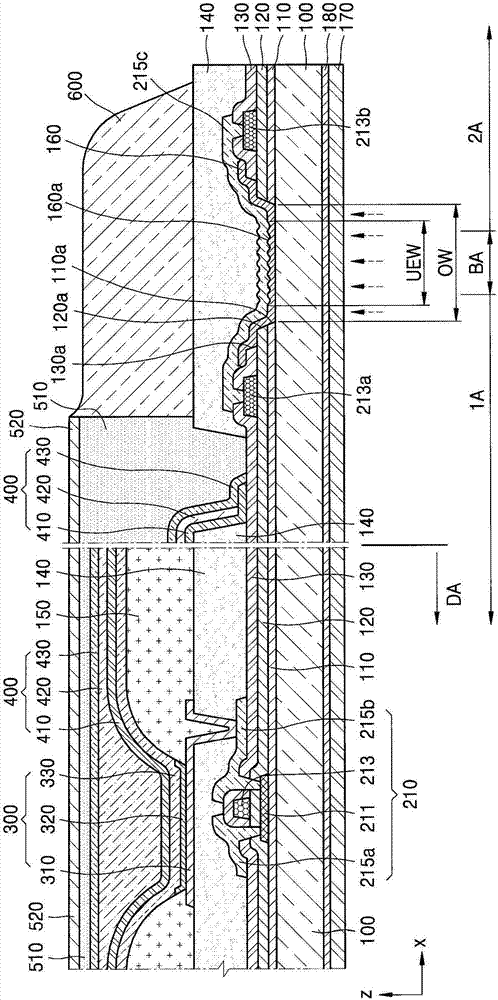

Display device

ActiveCN107221606AReduce manufacturing costReduce defective rateFinal product manufactureSolid-state devicesDisplay deviceHardness

A display device includes a substrate including a bending area between a first region and a second region and configured to be bent at the bending area, a display portion above the substrate in the first region, a protective film below the substrate and including a protective film base and an adhesive layer, wherein the protective film base has an opening corresponding to the bending area or the protective film base corresponds to at least a portion of the first region, and wherein the adhesive layer is between the substrate and the protective film base and forms an integral body above the first region, the bending area, and the second region, and at least a portion of the adhesive layer that corresponds to the bending area has a hardness different from that of at least a portion of the adhesive layer corresponding to the first region.

Owner:SAMSUNG DISPLAY CO LTD

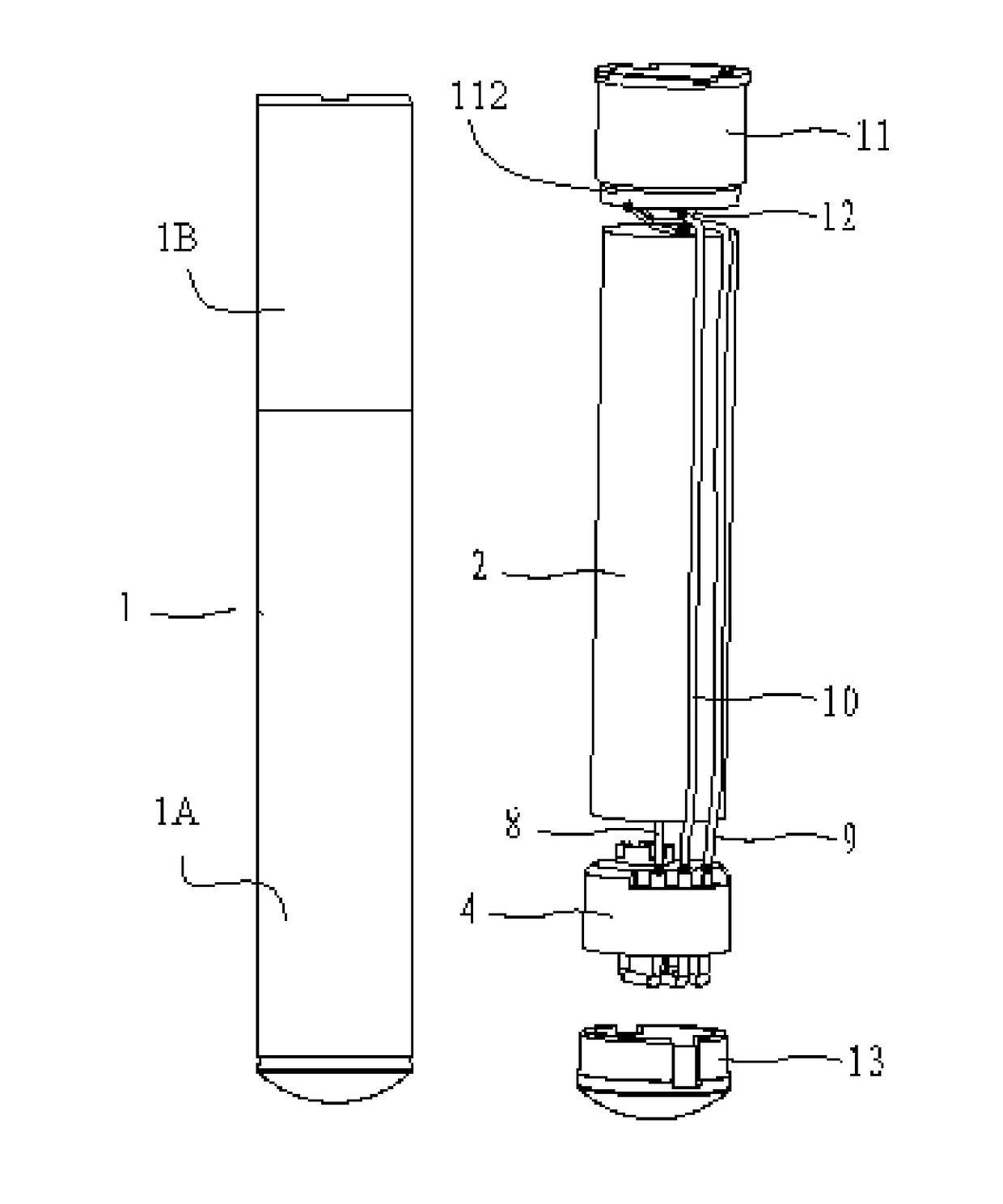

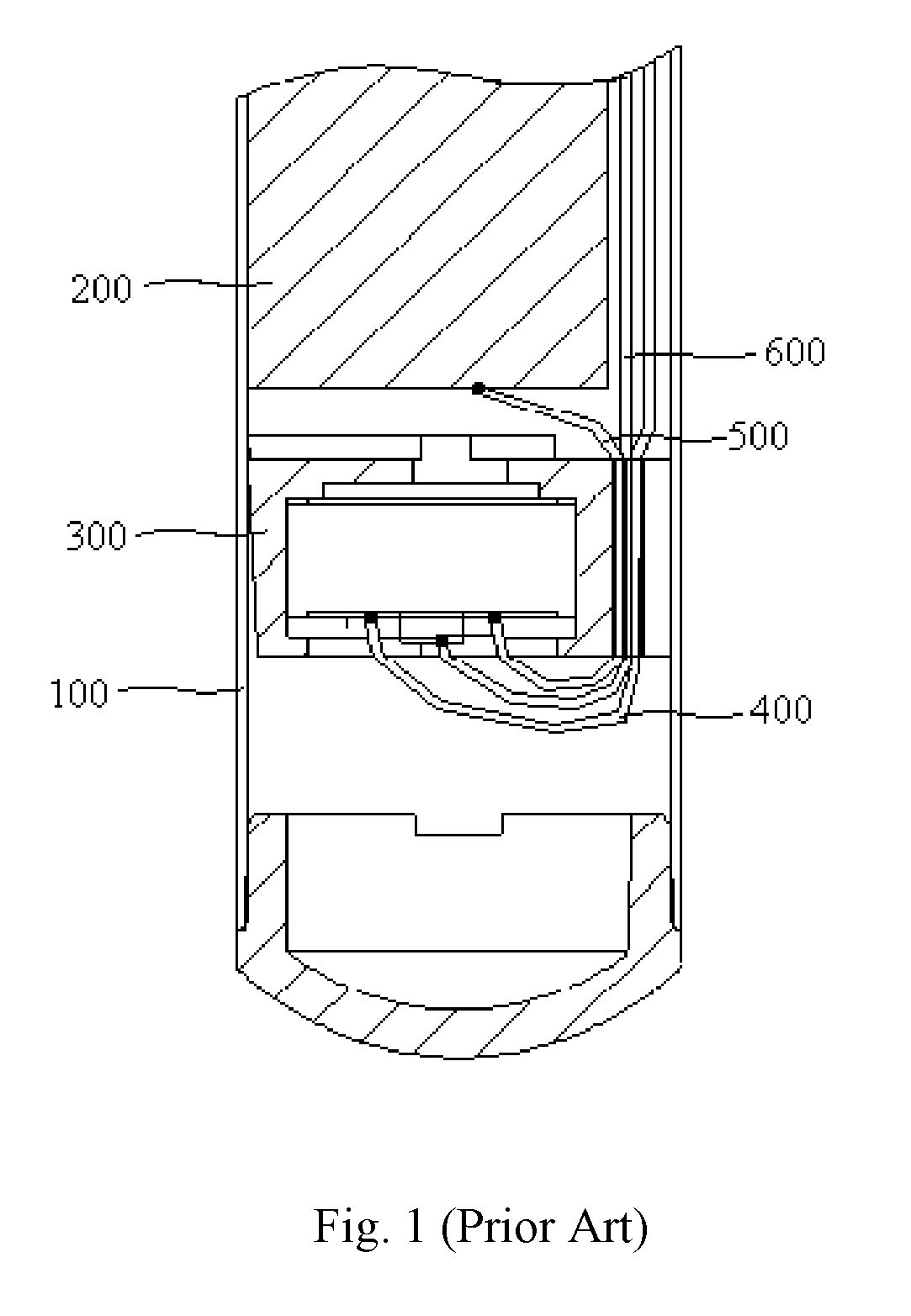

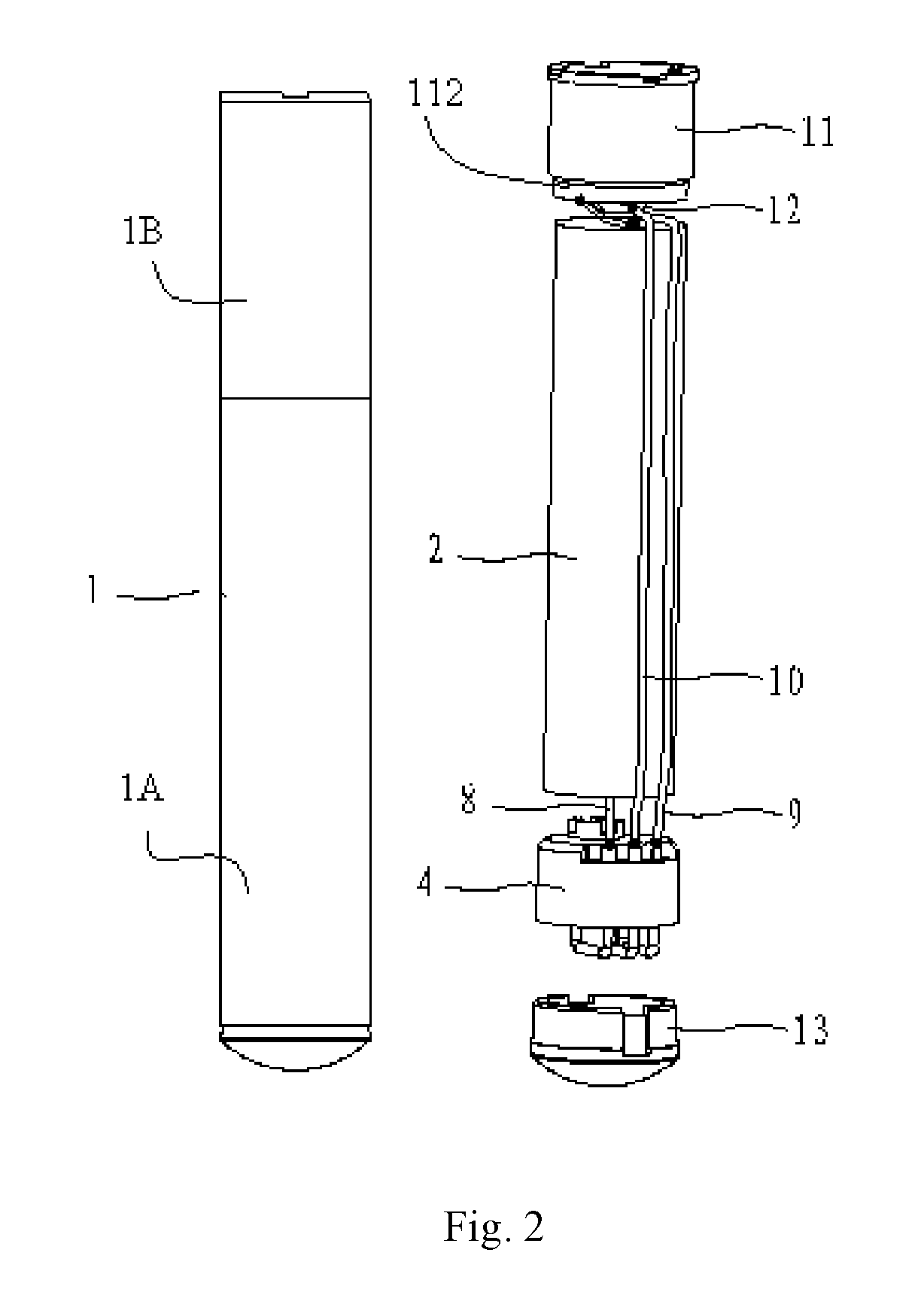

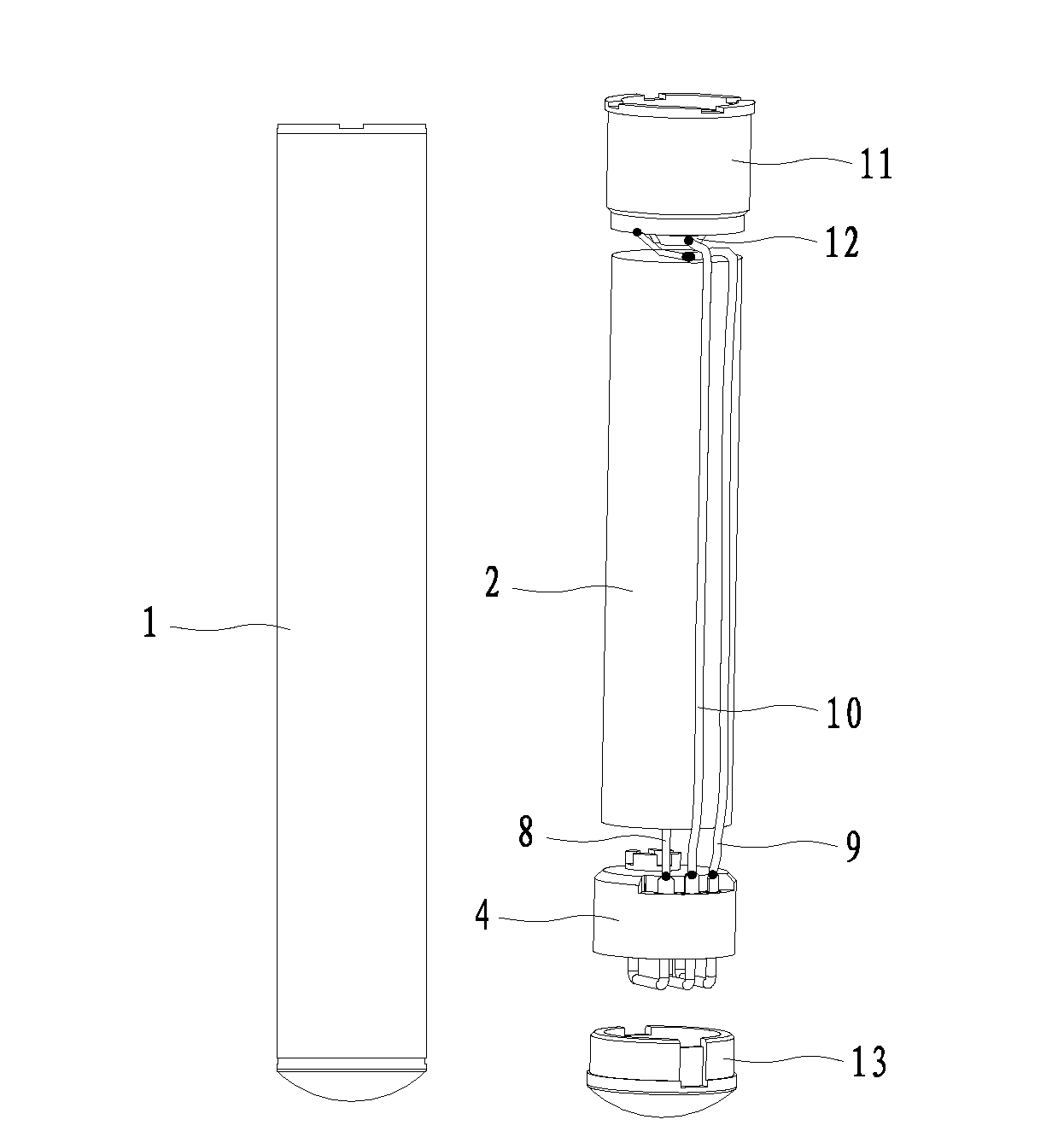

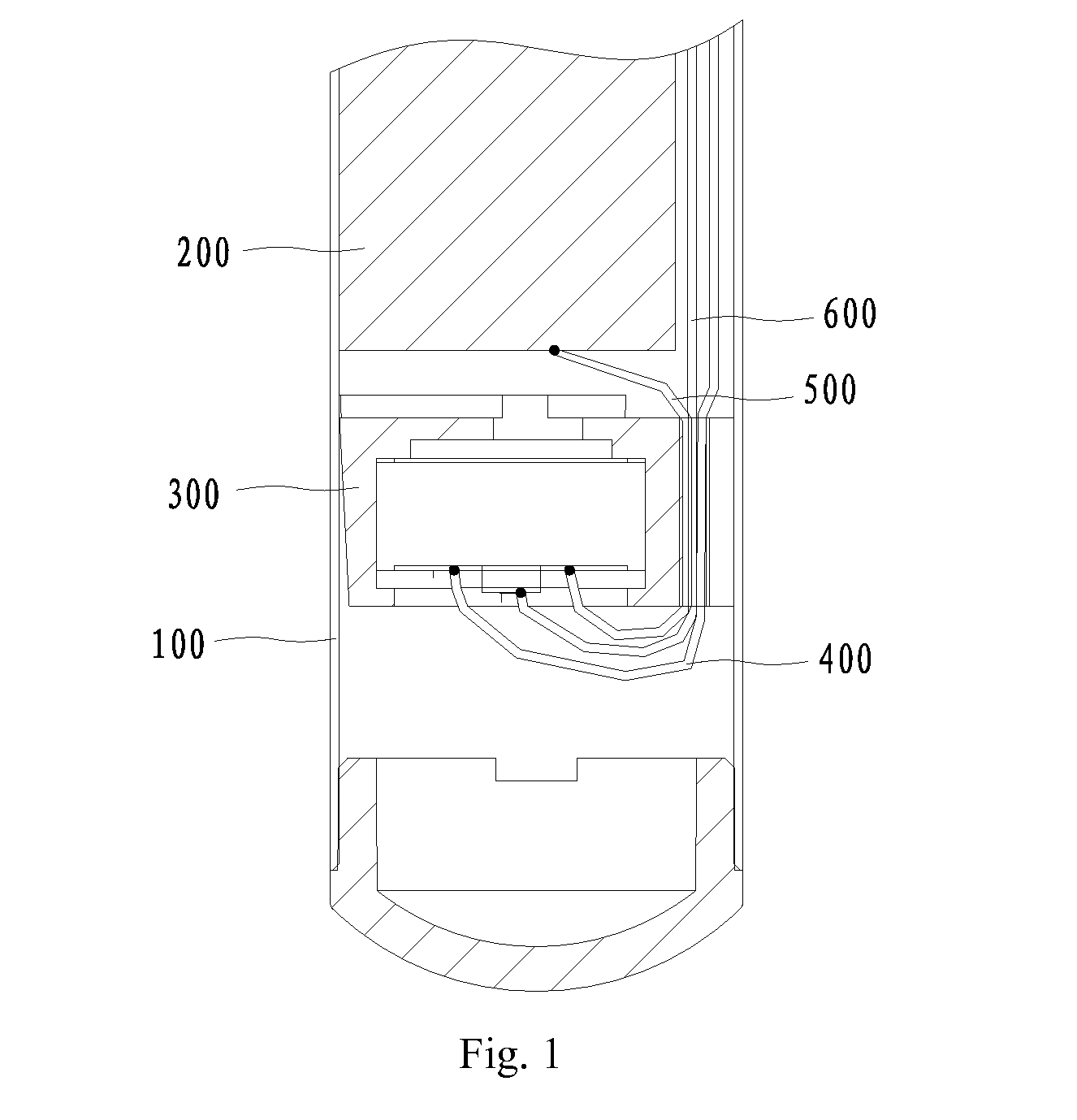

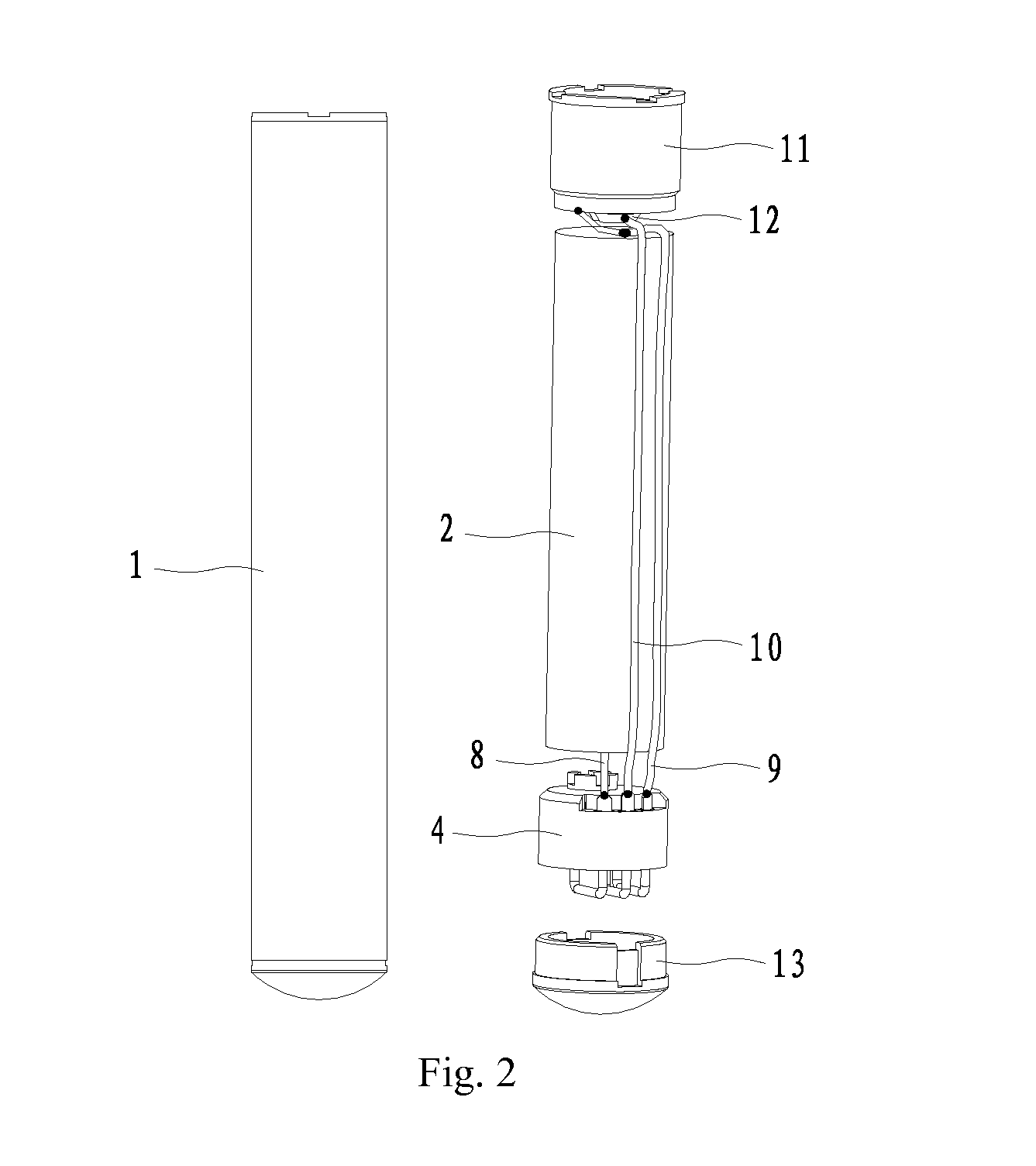

Electronic cigarette

InactiveUS9668517B2Increase productivityReduce in quantityTobacco devicesElectricityElectrical battery

An electronic cigarette is provided, and the electronic cigarette comprises an outer sleeve, a battery and a controlling module both mounted inside the outer sleeve; the electronic cigarette further comprises a mounting seat which the controlling module is mounted on, and an electrode terminal mounted on the mounting seat and electrically connected to the controlling module; an end of the electrode terminal, aloof from the controlling module, is connected to a conductive wire by soldering. By implementing the electronic cigarette in the present application, the following advantages can be achieved. The electronic cigarette adopts that the conductive wire is soldered on the first electrode terminal, the second electrode terminal or the third electrode terminal, so that the conductive wire is electrically connected to the controlling module, and soldering operation can be easily achieved, which can improve production efficiency of the electronic cigarettes and decrease product defective rate.

Owner:HUIZHOU KIMREE TECH

Electronic cigarette

InactiveUS20150027463A1Easy to operateIncrease productivityTobacco pipesTobacco devicesElectricityElectrical battery

An electronic cigarette is provided, and the electronic cigarette comprises an outer sleeve, a battery and a controlling module both mounted inside the outer sleeve; the electronic cigarette further comprises a mounting seat which the controlling module is mounted on, and an electrode terminal mounted on the mounting seat and electrically connected to the controlling module; an end of the electrode terminal, aloof from the controlling module, is connected to a conductive wire by soldering. By implementing the electronic cigarette in the present application, the following advantages can be achieved. The electronic cigarette adopts that the conductive wire is soldered on the first electrode terminal, the second electrode terminal or the third electrode terminal, so that the conductive wire is electrically connected to the controlling module, and soldering operation can be easily achieved, which can improve production efficiency of the electronic cigarettes and decrease product defective rate.

Owner:HUIZHOU KIMREE TECH

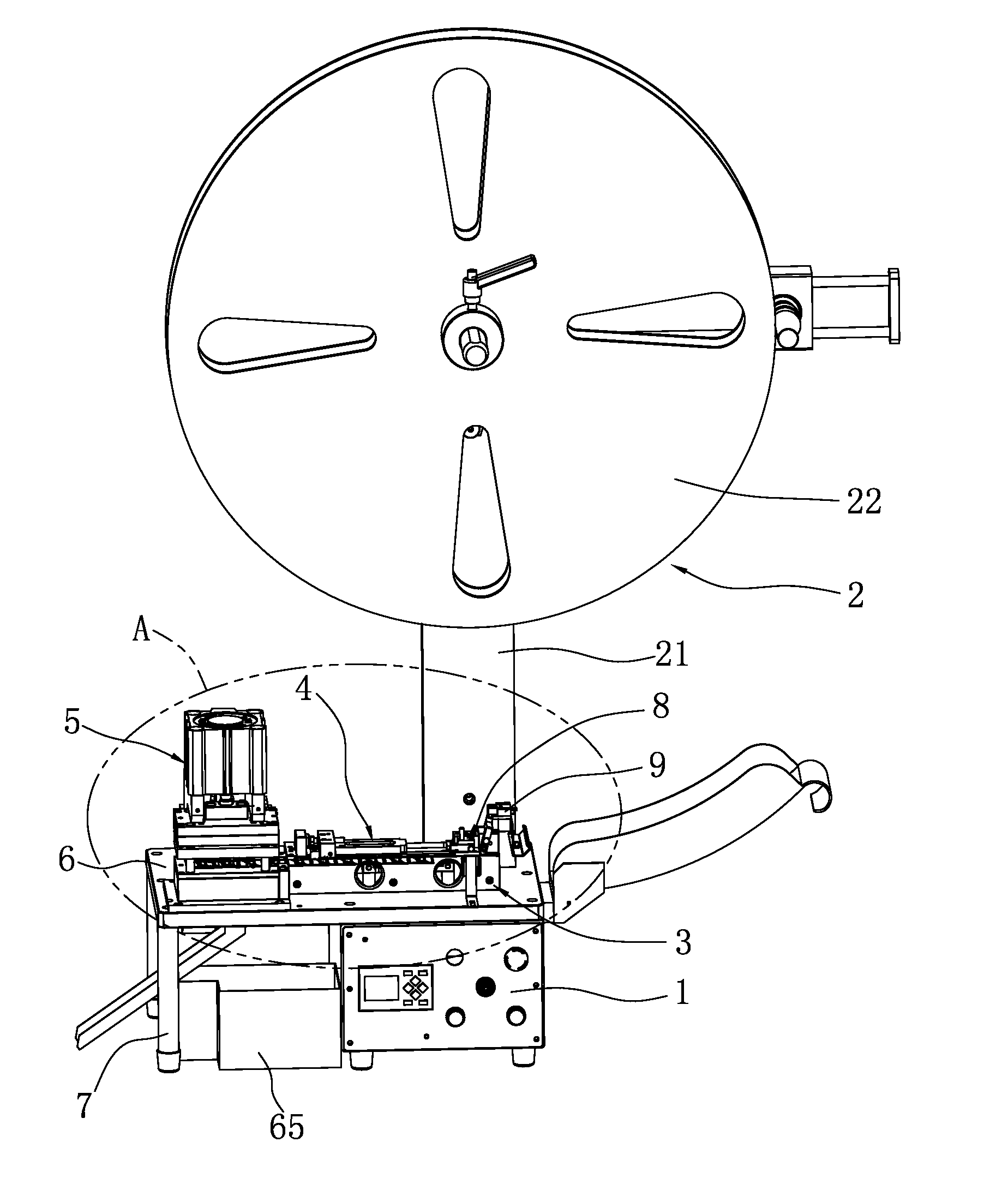

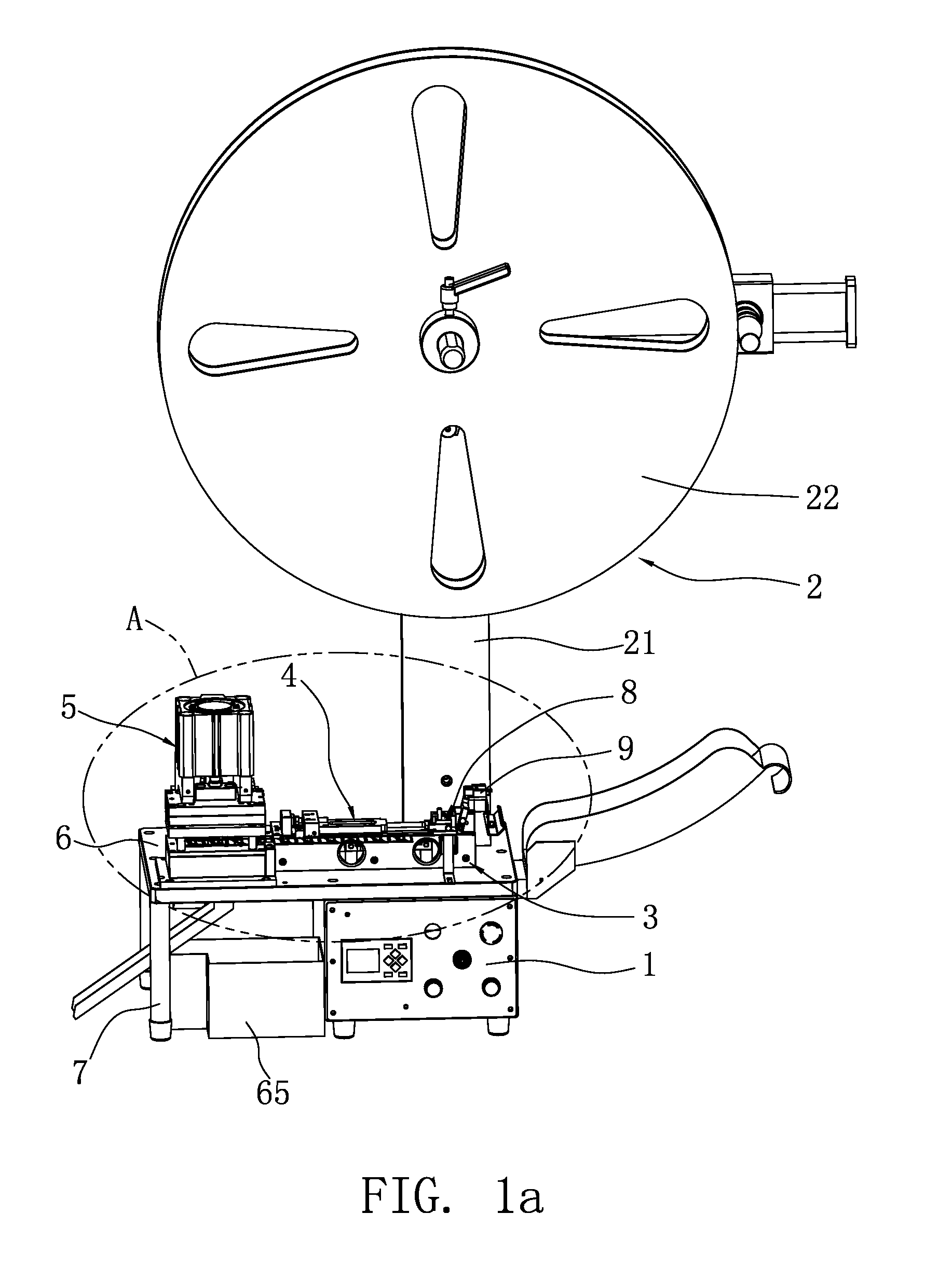

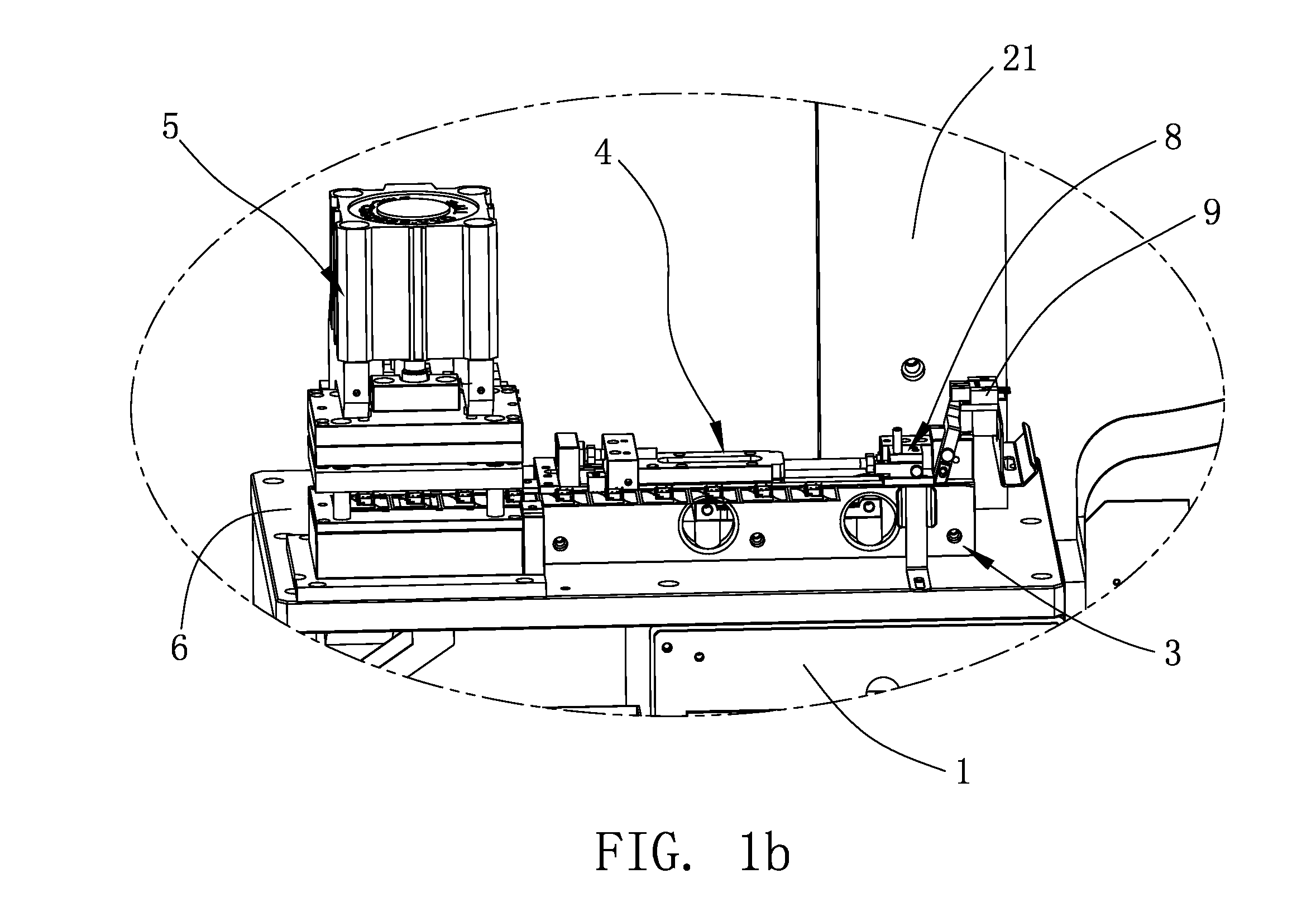

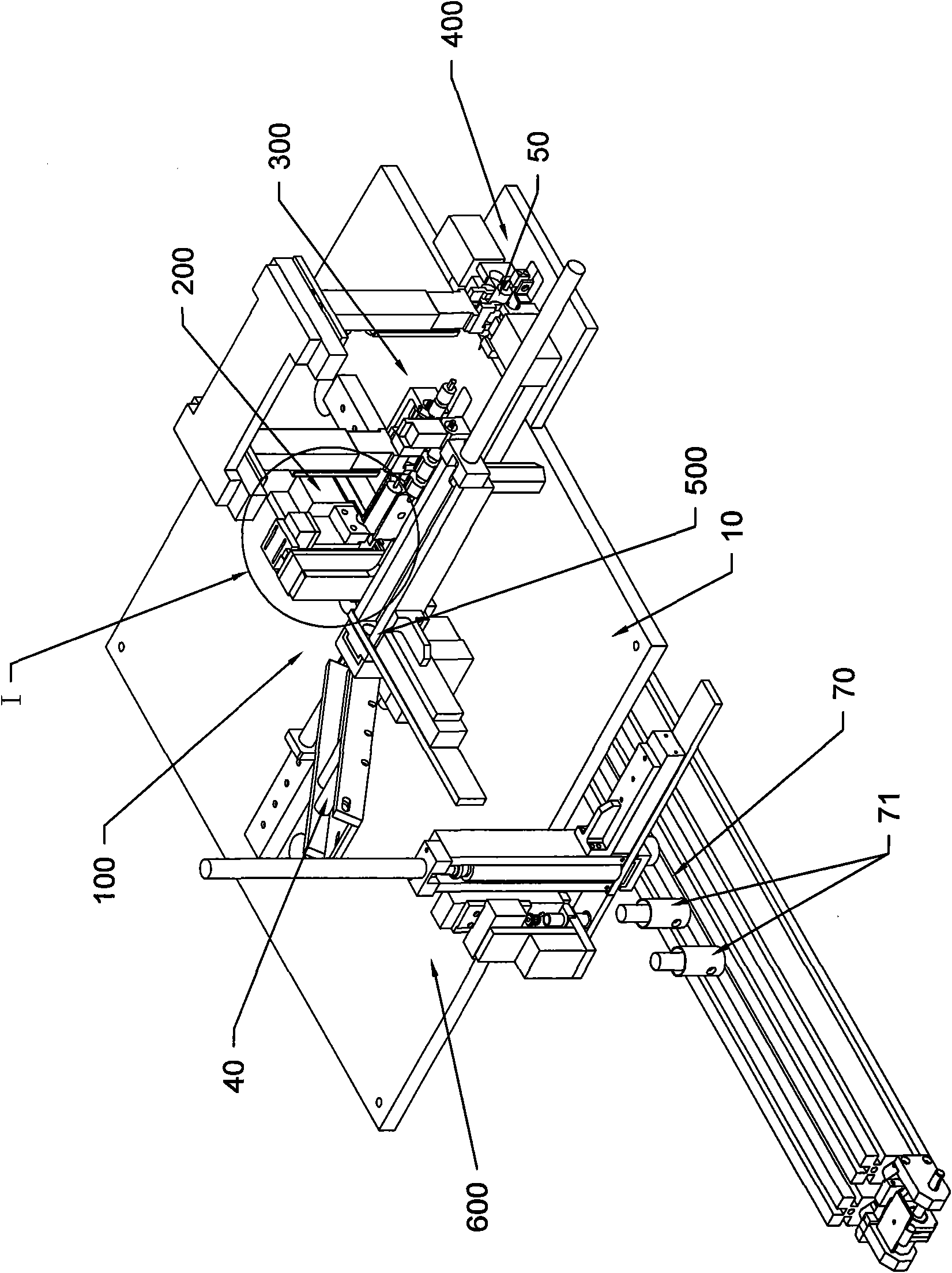

Cutting equipment

InactiveUS20120055304A1Enhancement in workReduce defect rateGang saw millsMetal working apparatusElectrical controlMaterial transfer

Provided is a cutting equipment for automatically cutting off workpieces from a material tape. The cutting equipment includes an electrical control box, a base board, a material-feeding mechanism, a material-transferring mechanism, a material-pulling mechanism and a cutting mechanism. The material-feeding mechanism includes a supporting bracket, a material disc and a disc-driving device. The material-transferring mechanism mounted on the base board includes a pad board, a first supporting board and a second supporting board. The material-pulling mechanism disposed above the material-transferring mechanism includes a driving component and a material-pulling component. The cutting mechanism mounted on the base board includes a lower supporting plate, an upper cutting plate and a transferring cylinder. The upper cutting plate disposes at least one cutting blade. The cutting equipment can enhance the working efficiency, reduce the defective rate and the manufacture cost, lighten the labor intensity of operators, and be suitable for mass production.

Owner:CHENG UEI PRECISION IND CO LTD

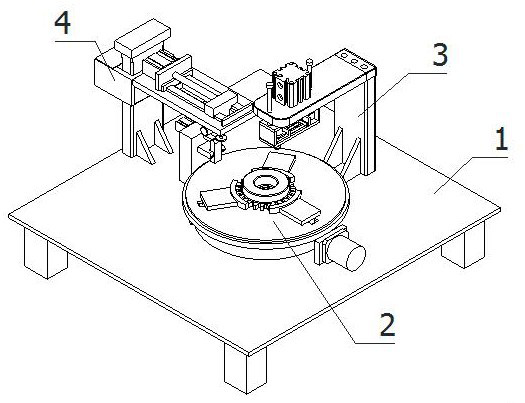

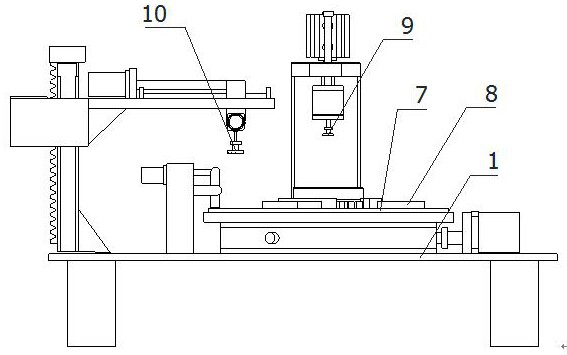

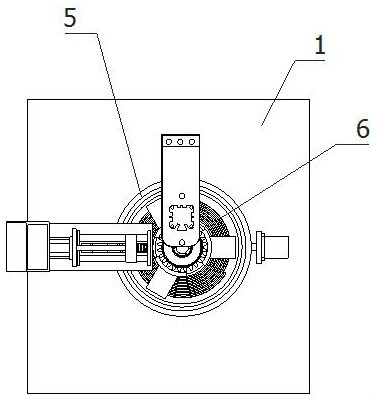

Multi-angle synchronous efficient grinding equipment for automobile brake disc

ActiveCN112025432AEffective positioningSynchronous and efficient grinding equipment can be positioned accurately and efficientlyRevolution surface grinding machinesGrinding drivesEngineeringSurface grinding

The invention relates to the technical field of automobile brake disc grinding machining, in particular to multi-angle synchronous efficient grinding equipment for an automobile brake disc. The equipment further comprises a machining platform, a clamping rotating assembly, a top surface grinding assembly and a side wall chamfering and grinding assembly, wherein the clamping rotating assembly comprises a mounting disc, a transmission disc, a positioning disc, a clamping jaw and a pressing mechanism; the top surface grinding assembly comprises a first lifting mechanism, a first horizontal displacement mechanism and a top end horizontal grinding mechanism, and the top end horizontal grinding mechanism comprises a horizontal grinding disc capable of grinding the top surface of the automobile brake disc; and the side wall chamfering and grinding assembly comprises a second lifting mechanism, a second horizontal displacement mechanism, an angle adjusting mechanism and a side wall chamferingand grinding mechanism, and the side wall chamfering and grinding mechanism comprises a side wall grinding disc. The equipment shown can precisely and efficiently position and clamp the automobile brake disc, and the surface, the side wall and the edge of the brake disc are synchronously and accurately ground, such that the working efficiency is greatly improved, and repositioning is avoided.

Owner:浙江杭万汽车零部件实业有限公司

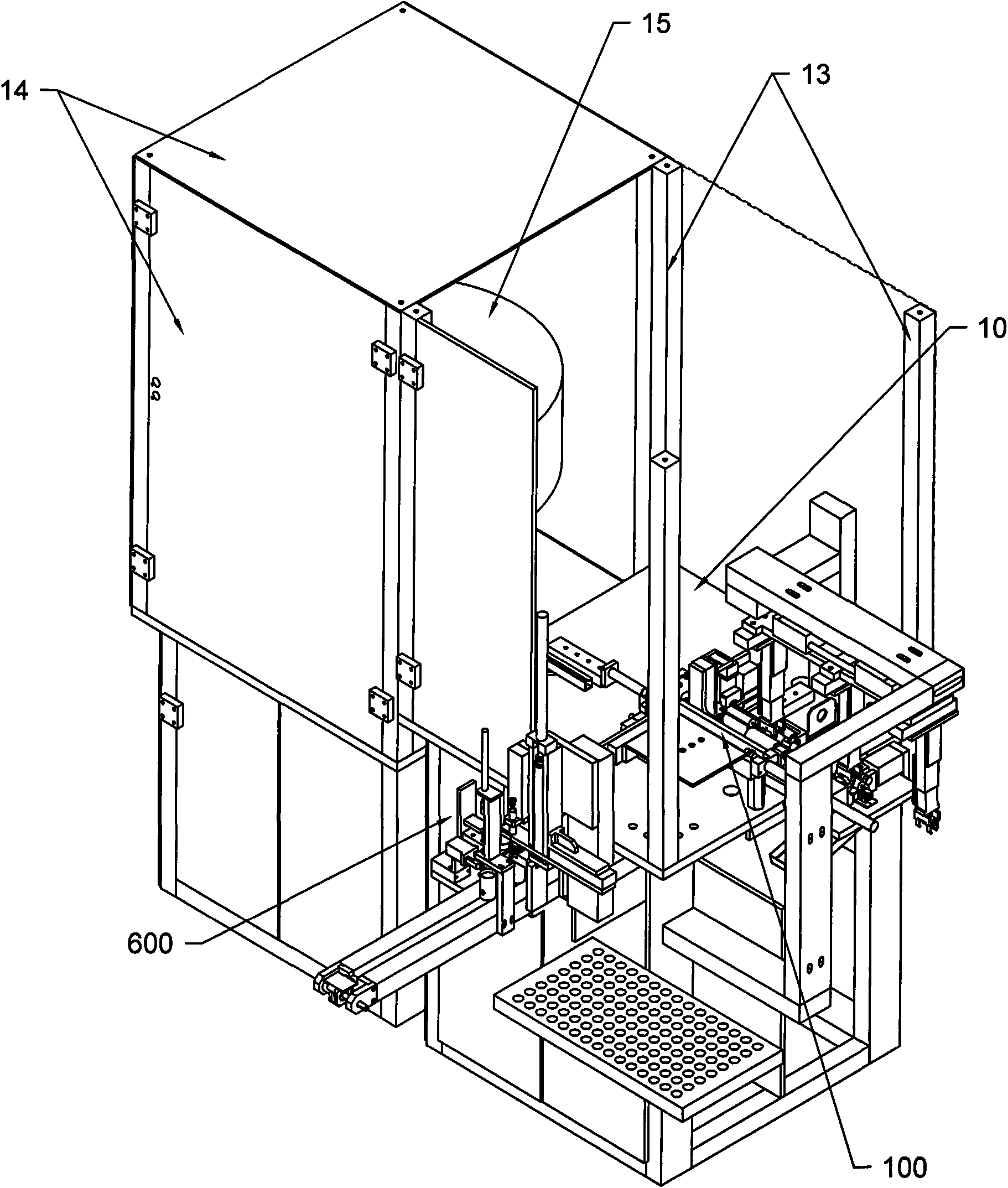

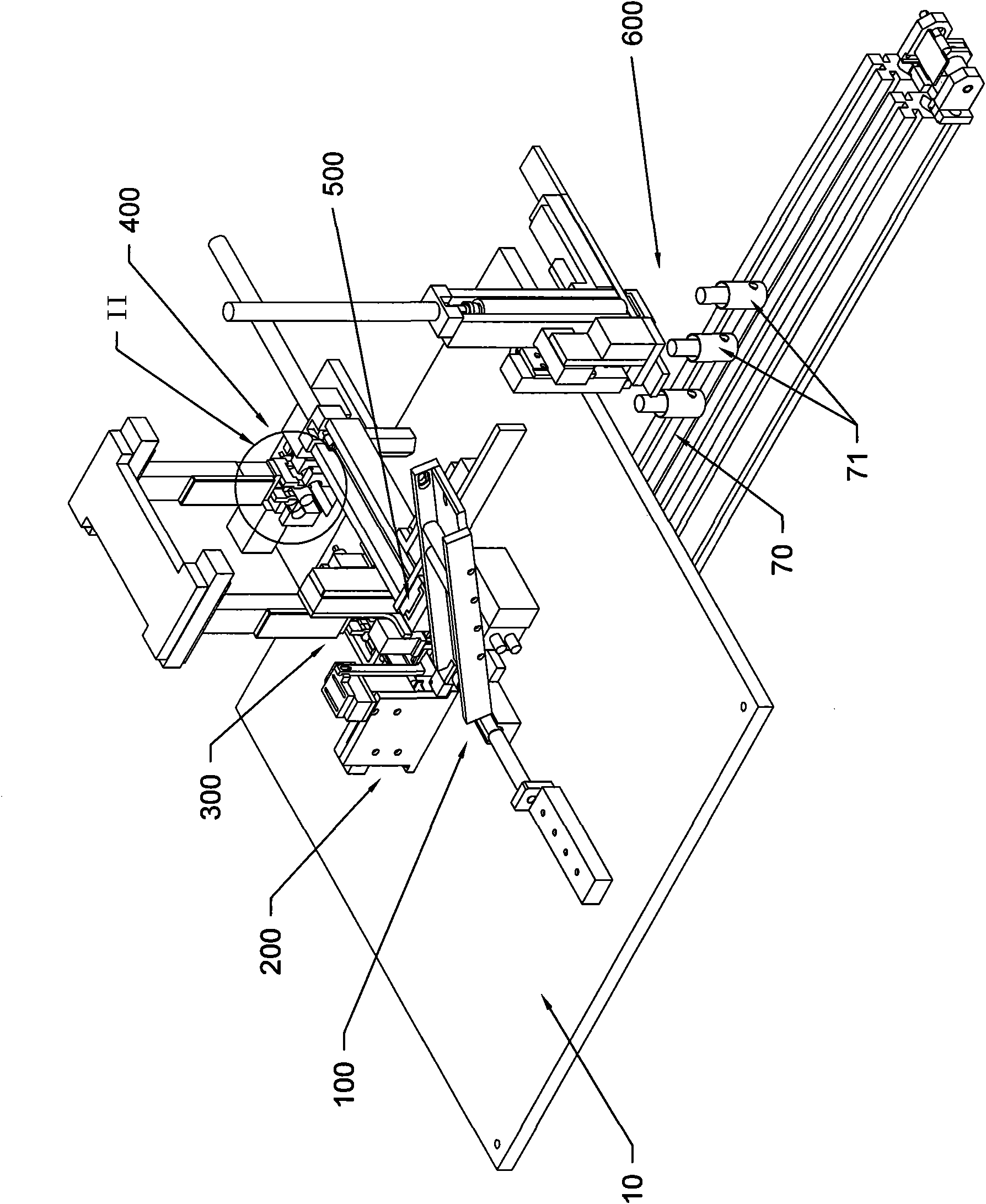

Package machine of cylindrical battery roll core

ActiveCN101635335AIncrease productivityImprove work efficiencyFinal product manufactureSmall-sized cells cases/jacketsEngineeringMechanical engineering

The invention relates to a package machine of a cylindrical battery roll core, comprising a stander, a work table, a driving system and an electric control system. The work table is provided with a roil core inputting device, a shell inputting device and a roil core package machine which are driven by the driving system and controlled by the electric control system; and the roil core package machine comprises a shell positioning mechanism, a shell conveying mechanism and a roil core conveying mechanism. The roil core package machine is controlled by the electric control system to be capable for conveying the shell conveyed by the shell input device into the shell positioning mechanism, is fixed by the shell positioning mechanism, and conveys the roil core conveyed by the roil core input device into the fixed shell, so as to realize the work procedure of automatic package, and greatly improve the work efficiency of package. The invention further discloses a roil core shaping device, a circumference positioning device, a cathode ear bending device, a lower insulating sheet conveying device and an upper insulating sheet conveying device, which are corresponding to the work proceduressuch as roil core shaping, circumference positioning, cathode ear bending, lower insulating sheet inputting, upper insulating sheet inputting, etc.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

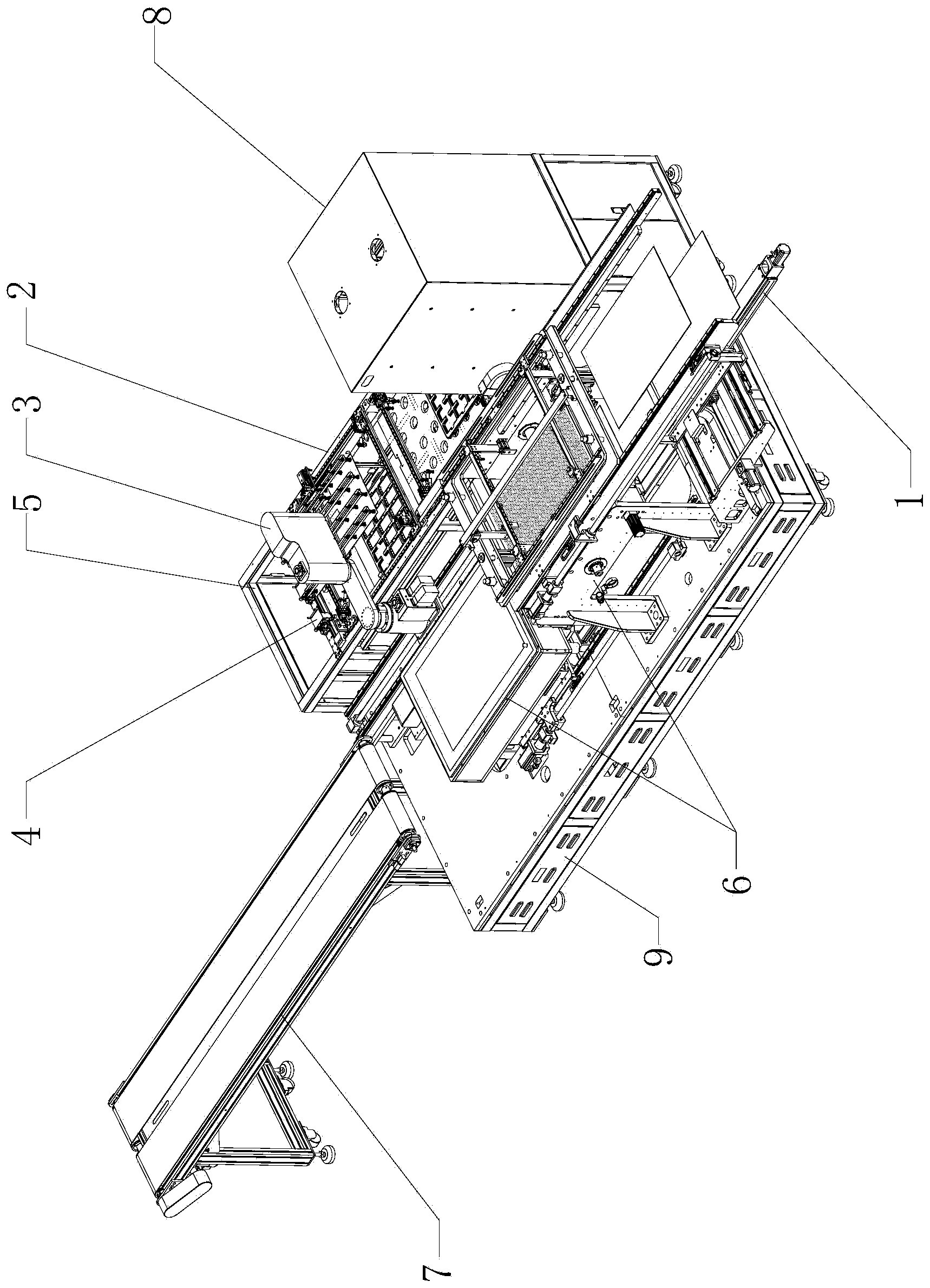

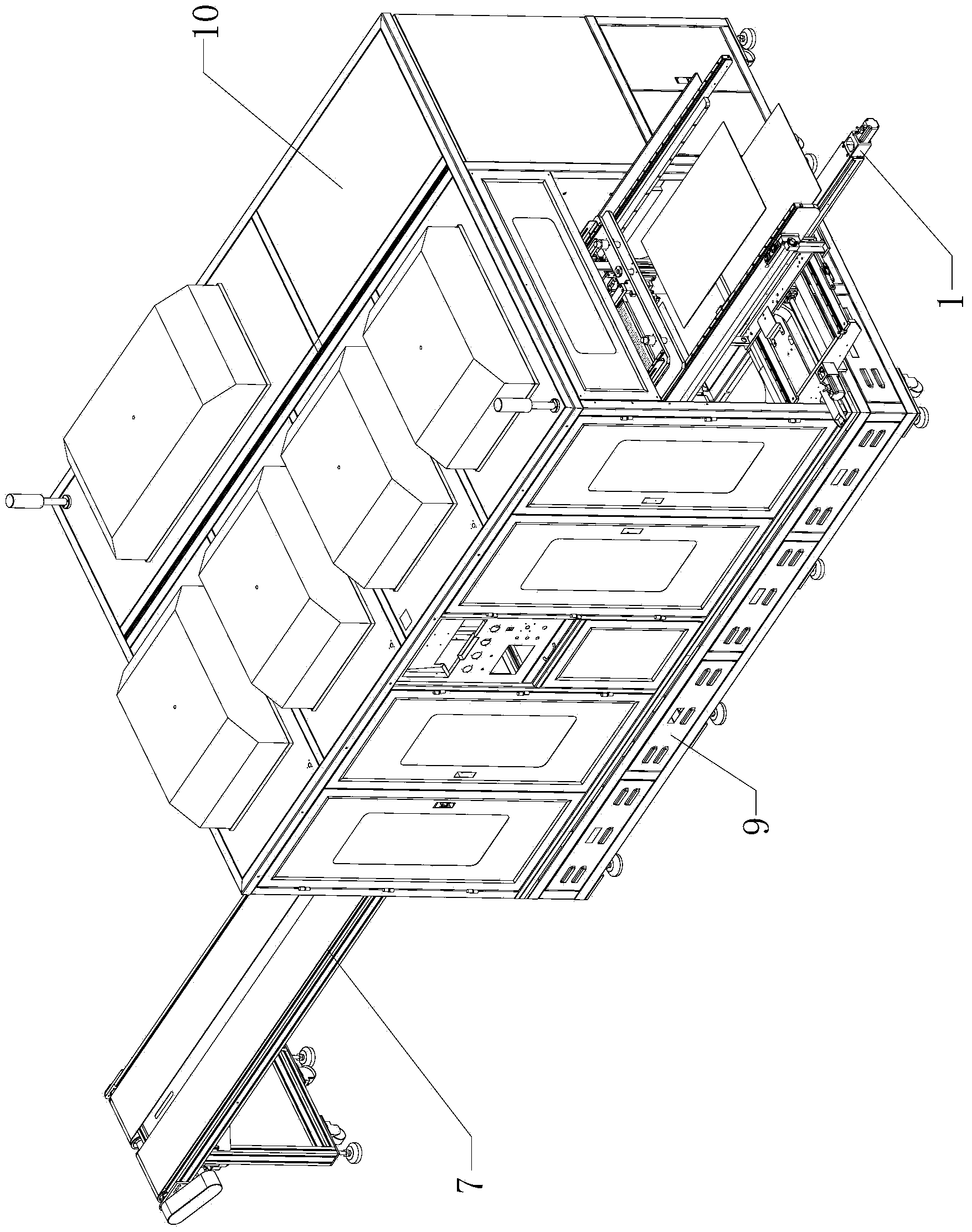

CG laminating fully-automatic combination production line

ActiveCN103522722AEasy to operateHigh degree of automationLamination ancillary operationsControlling laminationProduction lineEngineering

The invention discloses a CG laminating fully-automatic combination production line. The CG laminating fully-automatic combination production line comprises a liquid crystal glass automatic take-up system, a functional sheet automatic take-up system, an upper and lower material carrying system, an automatic correction system, an automatic laminating system and an electric control system which are installed on a frame, and also comprises a blanking conveying system arranged adjacent to the frame; and the upper and lower material carrying system comprises a guide rail system, a power element and a horizontal multi-joint manipulator driven by the power element to move along the guide rail system, and the protruding end of the horizontal multi-joint manipulator is provided with a sucker mechanism used for sucking a functional sheet. The CG laminating fully-automatic combination production line adopting an automatic combination mode has the advantages of simple and convenient operation, high automation degree and substantially increased work efficiency.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

Preparation method of regenerated cotton

InactiveCN104593910AReduce pollutionReduce defective rateMechanical cleaningPressure cleaningYarnFiber

The invention discloses a preparation method of regenerated cotton. The method comprises the following steps: a, sorting: firstly performing vibratory screening treatment on leftover, scrap, waste silk and yarn ends to obtain various cotton textile scraps; b, pretreating: performing alkaline cleaning, primary washing, hydrogen peroxide bleaching and secondary washing treatment on the obtained various cotton textile scraps respectively to obtain a pure white fabric stock with moisture content of being smaller than 1 percent; c, reprocessing: cutting the pure white fabric stock into fabrics with a physical character of being smaller than 1,200 mm, then reducing the fabrics into wool cotton, next loosening the wool cotton, and finally fluffing the wool cotton to form the regenerated cotton; d, packing: collecting fibers with length of 26-28 mm in the regenerated cotton, and packing the collected fibers to obtain the qualified regenerated cotton. According to the method, the waste textiles such as the leftover, the cloth scrap, the waste silk and the yarn ends are recovered and recycled.

Owner:YIBIN WEILUO TEXTILE

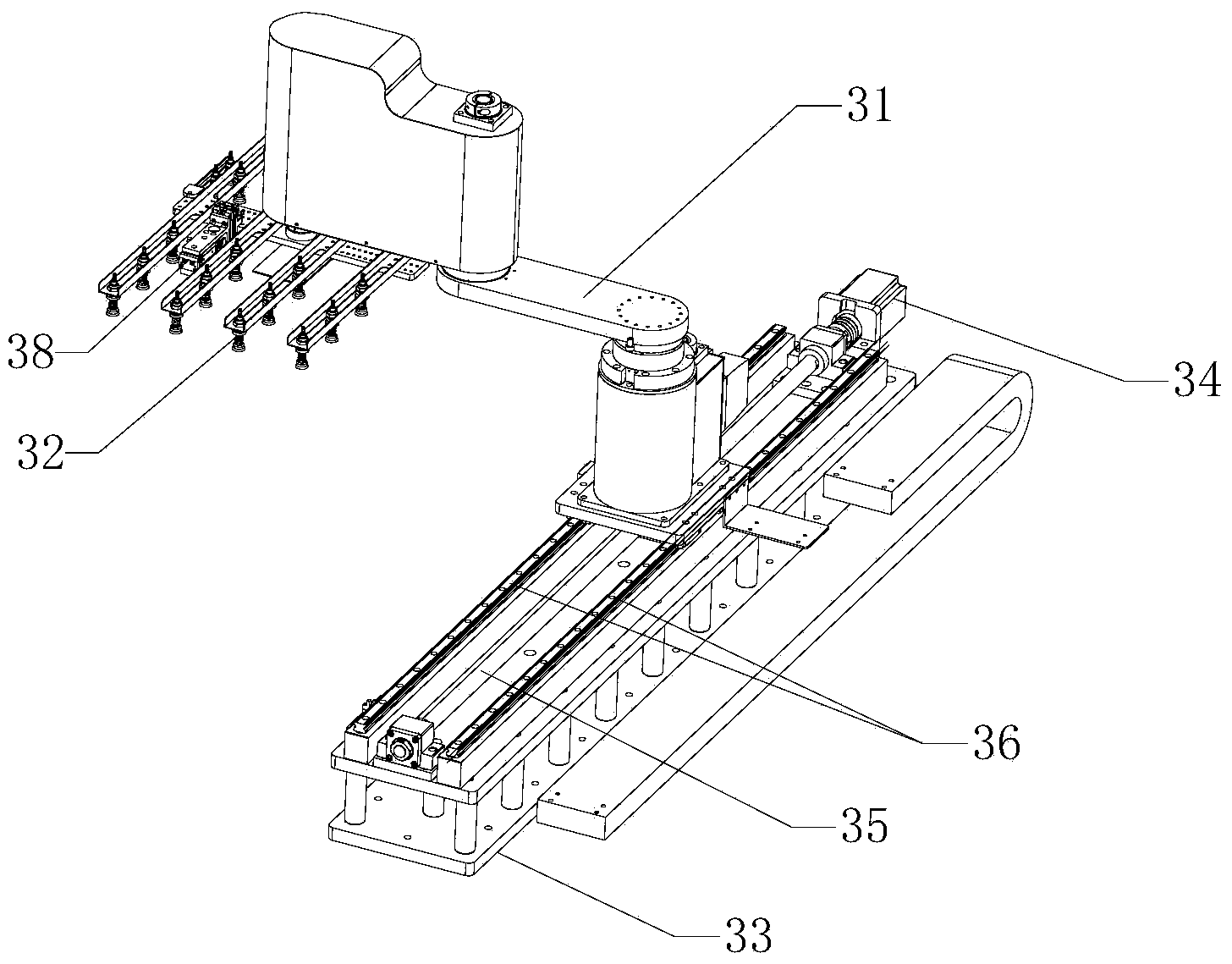

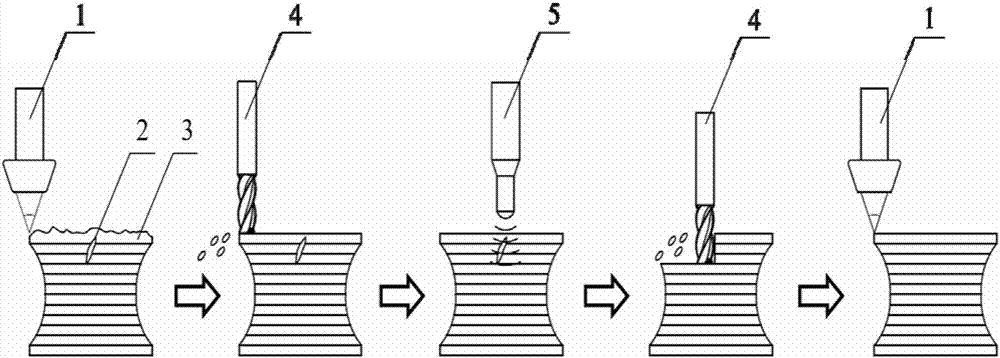

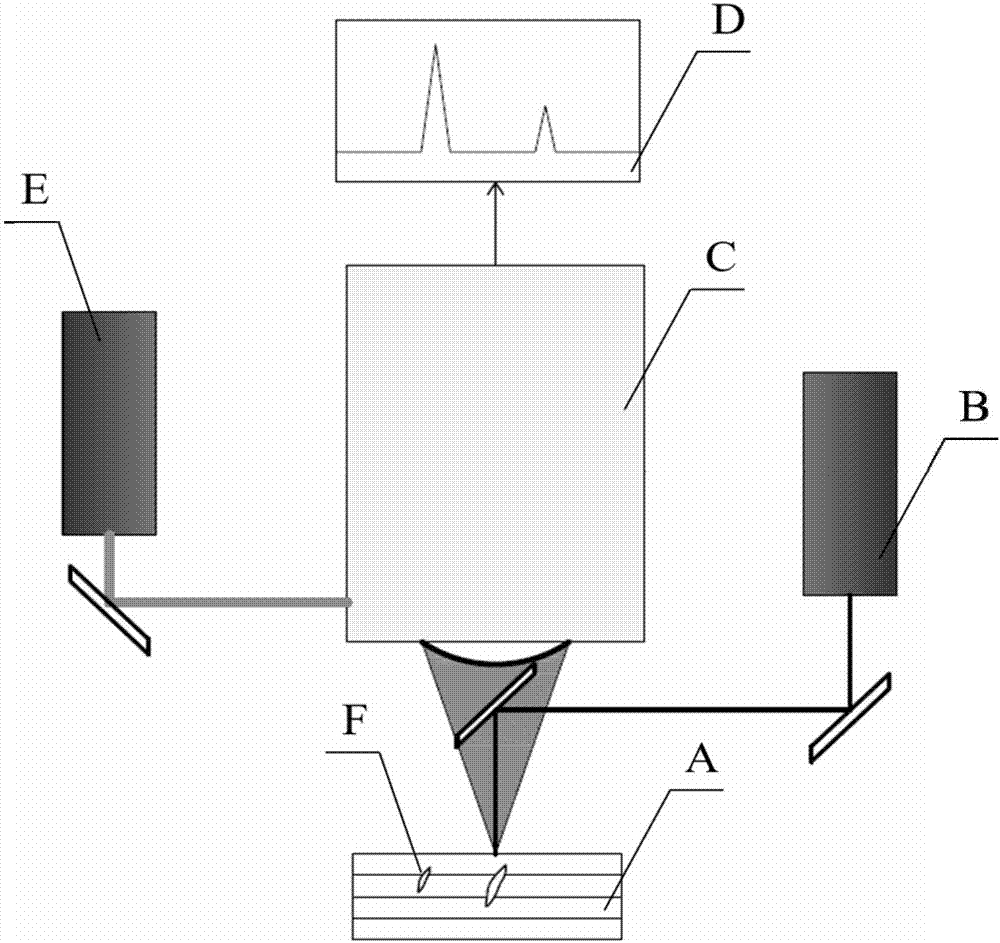

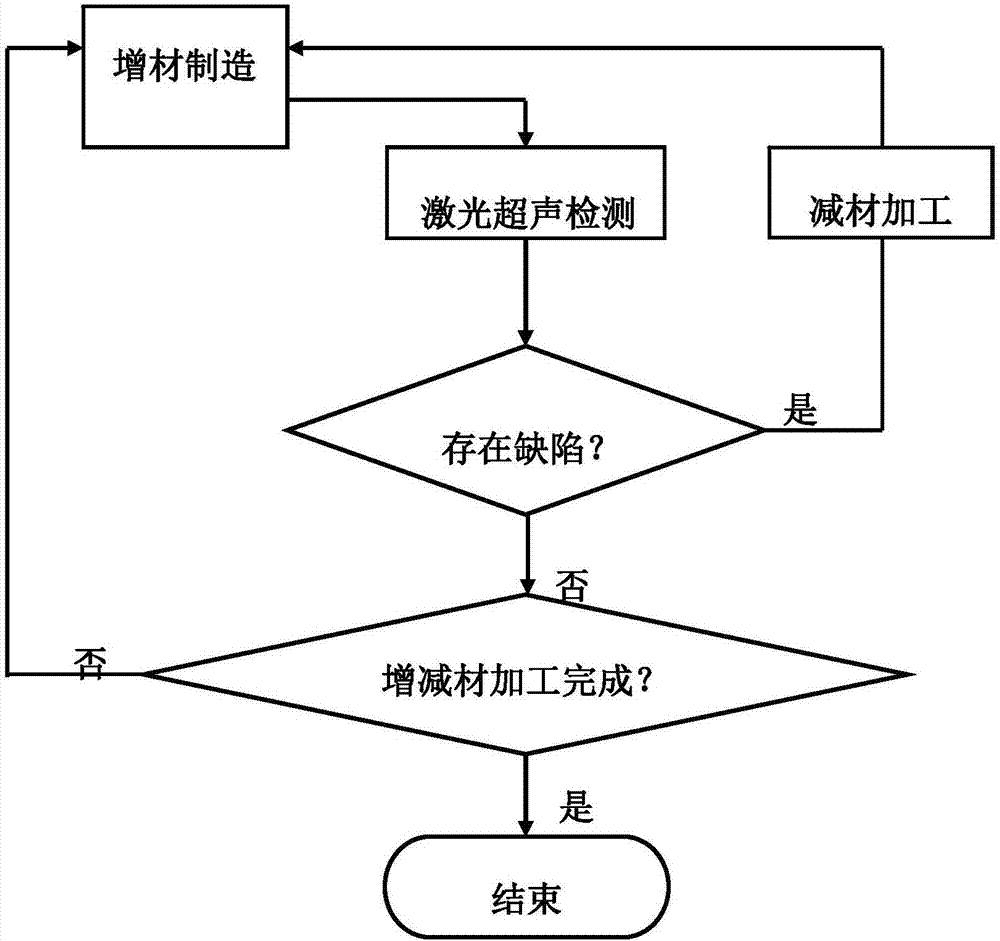

Metal material high-energy-beam additive/subtractive material and on-line laser ultrasonic detection composite processing method

ActiveCN107102061AReduce product defect rateSave time and costAnalysing solids using sonic/ultrasonic/infrasonic wavesNondestructive testingSuperficial mass

The invention relates to a metal material high-energy-beam additive / subtractive material and on-line laser ultrasonic detection composite processing method and belongs to the field of metal material additive / subtractive composite manufacturing (3D printing). The processing method includes the following steps: S1) additive moulding: performing layer-by-layer fusion / solidification stacking with a high-energy-beam fused metal material according to a predetermined route; S2) subtractive processing: performing subtractive processing to the deposited and shaped material to prepare a detection plane having high size-precision and surface quality; S3) laser ultrasonic detection: carrying out laser ultrasonic nondestructive detection on the surface to determine whether defects exist on the surface of or in interior of the material and determine the positions of the defects; and S4) detection determination and treatment: removing excessive surface or subsurface defects through subtractive processing, and adjusting an additive process to perform additive deposition until the whole metal component is completed, and if no defect exists, directly completing the on-line detection and performing high-quality work piece shaping circularly and repeatedly. The method solves a problem that a process of single additive manufacturing of components cannot achieve on-line detection and repair, and can reduce defection rate of products and save cost.

Owner:DALIAN UNIV OF TECH

Stacked semiconductor device

ActiveUS7352067B2High yieldReduce defective rateSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A stacked semiconductor device includes a plurality of semiconductor chips and a conductive path extending through at least one of the semiconductor chips. The semiconductor chips are stacked together. The semiconductor chips are electrically connected by the conductive path, and the conductive path has a plurality of through-connections extending through the corresponding semiconductor chip.

Owner:NEC CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com