Patents

Literature

79results about How to "Increase product yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

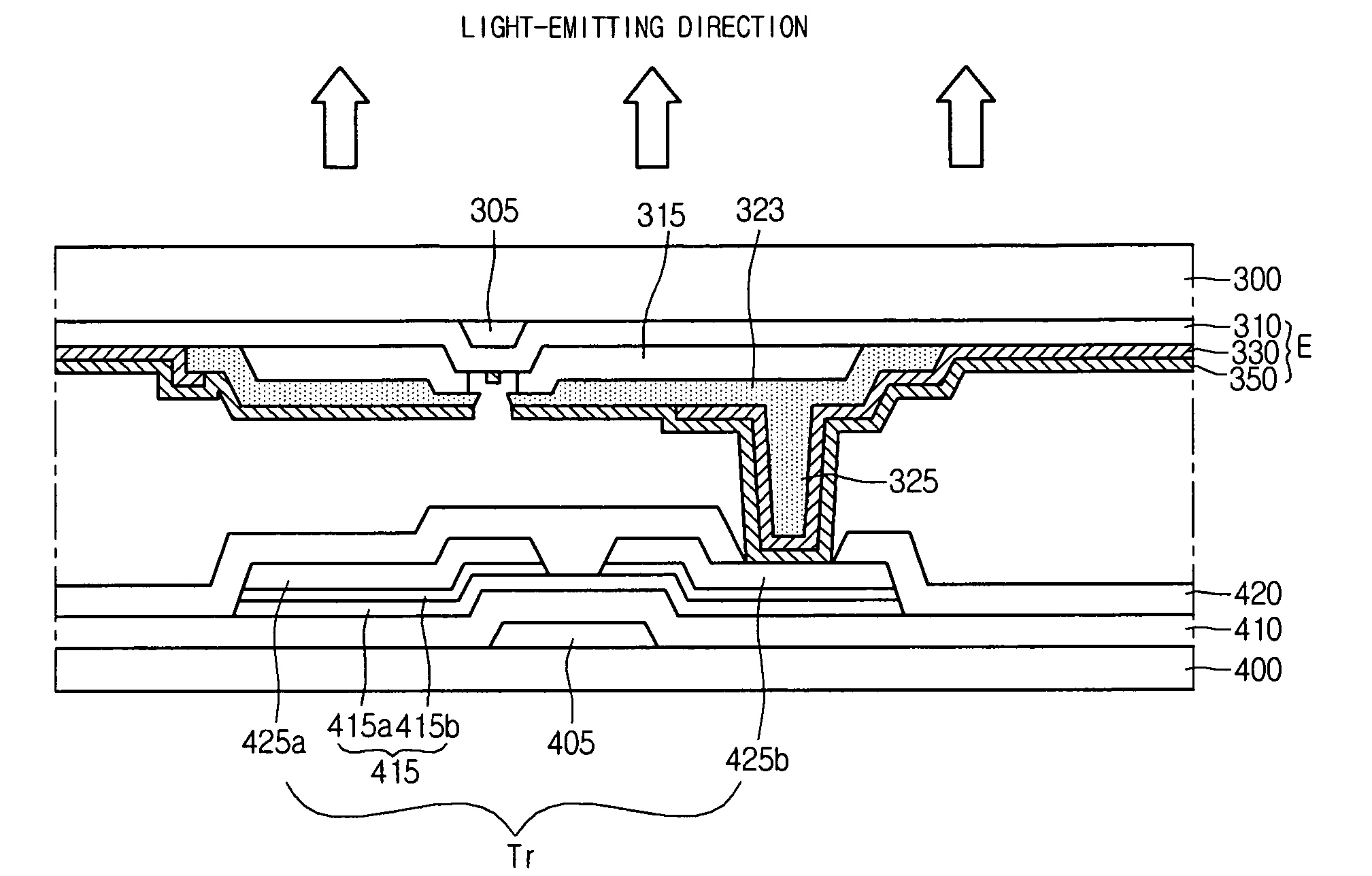

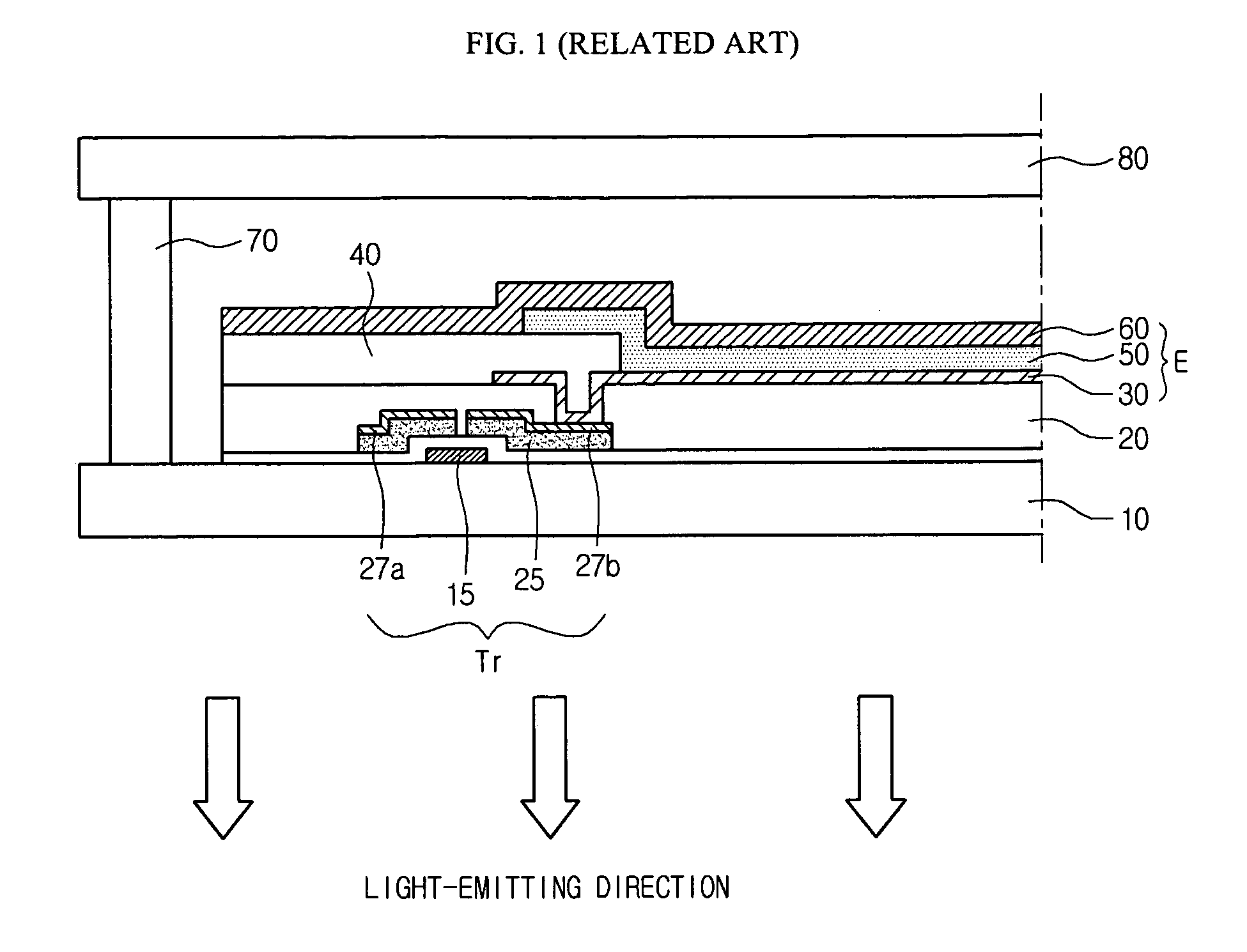

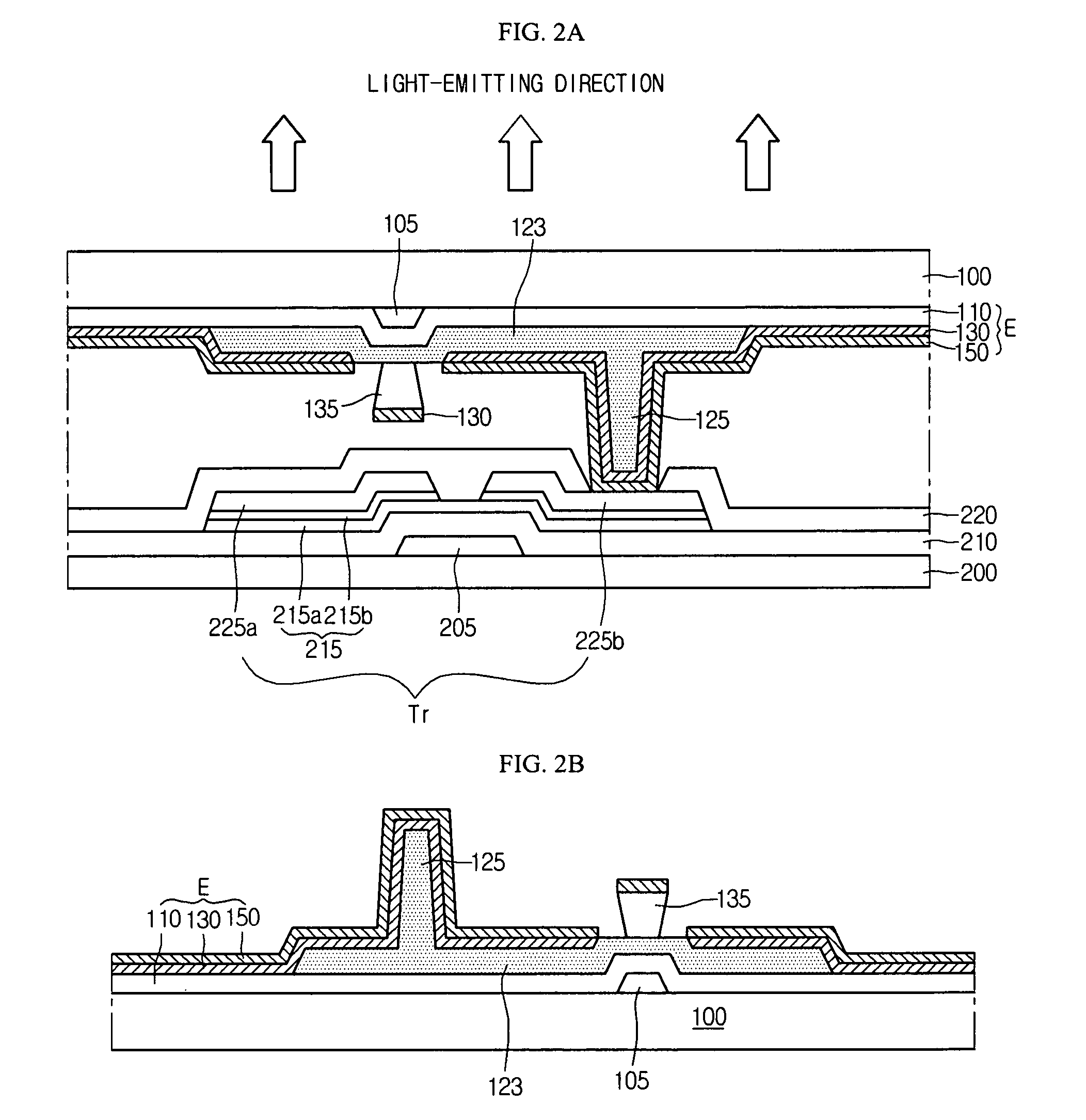

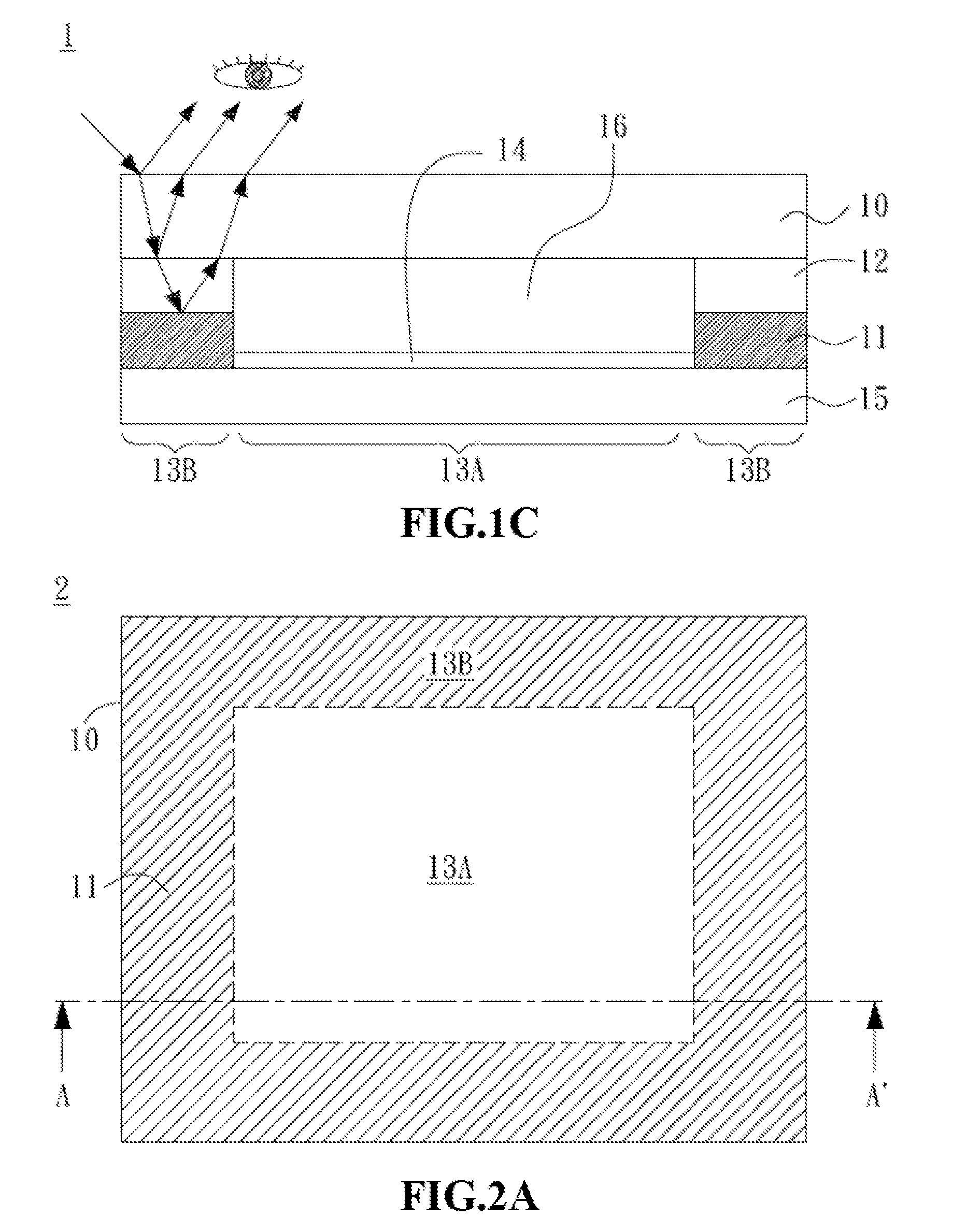

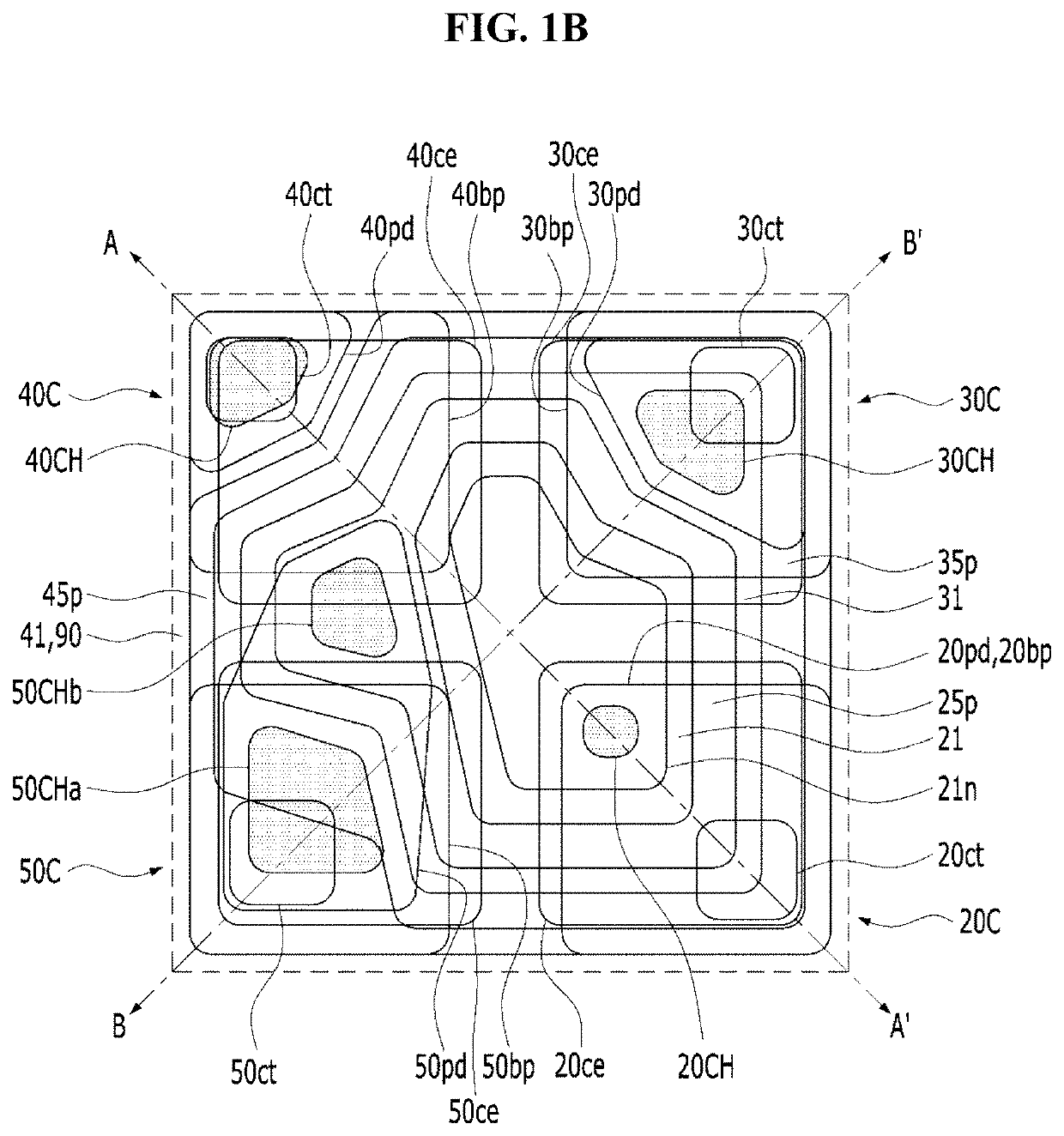

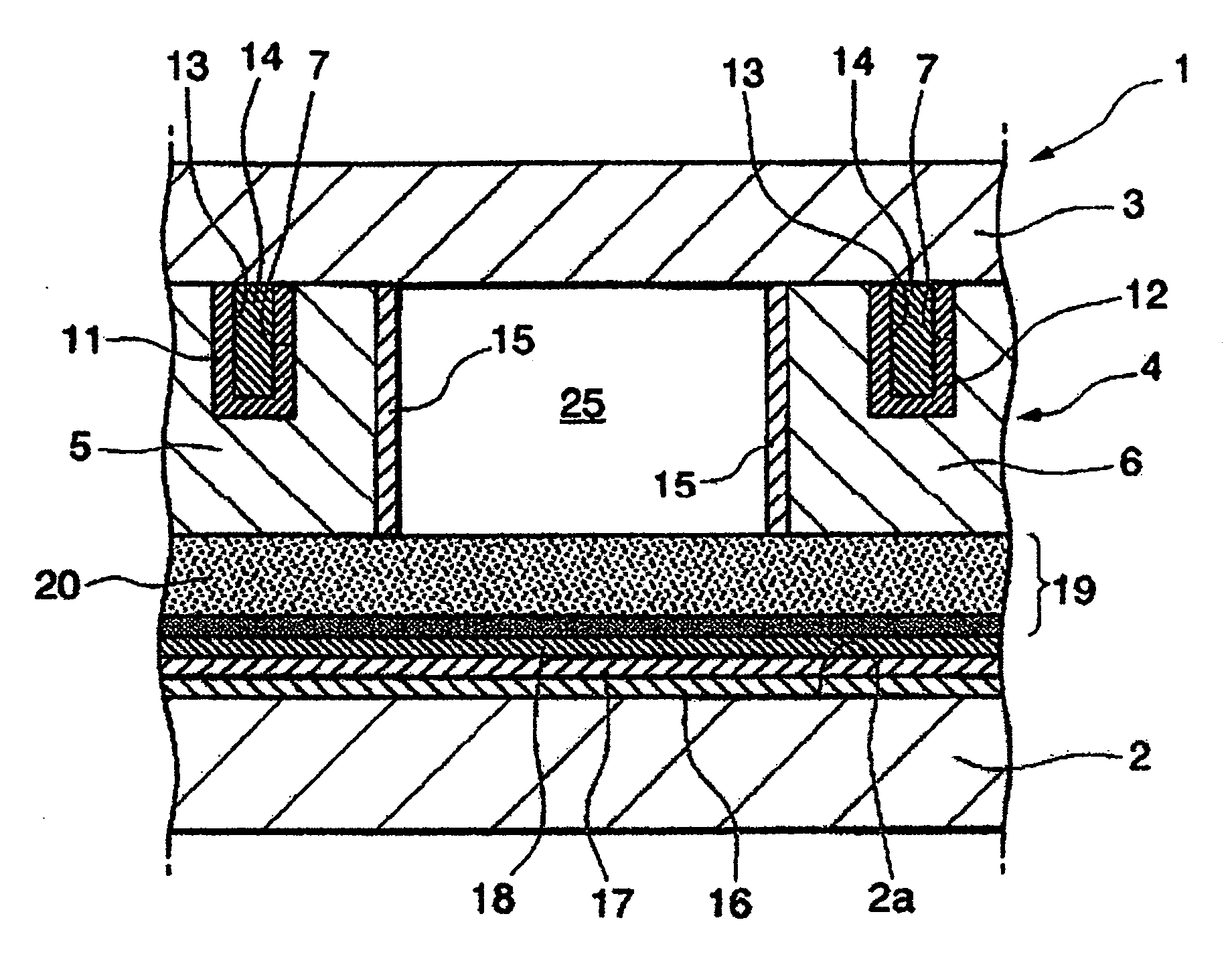

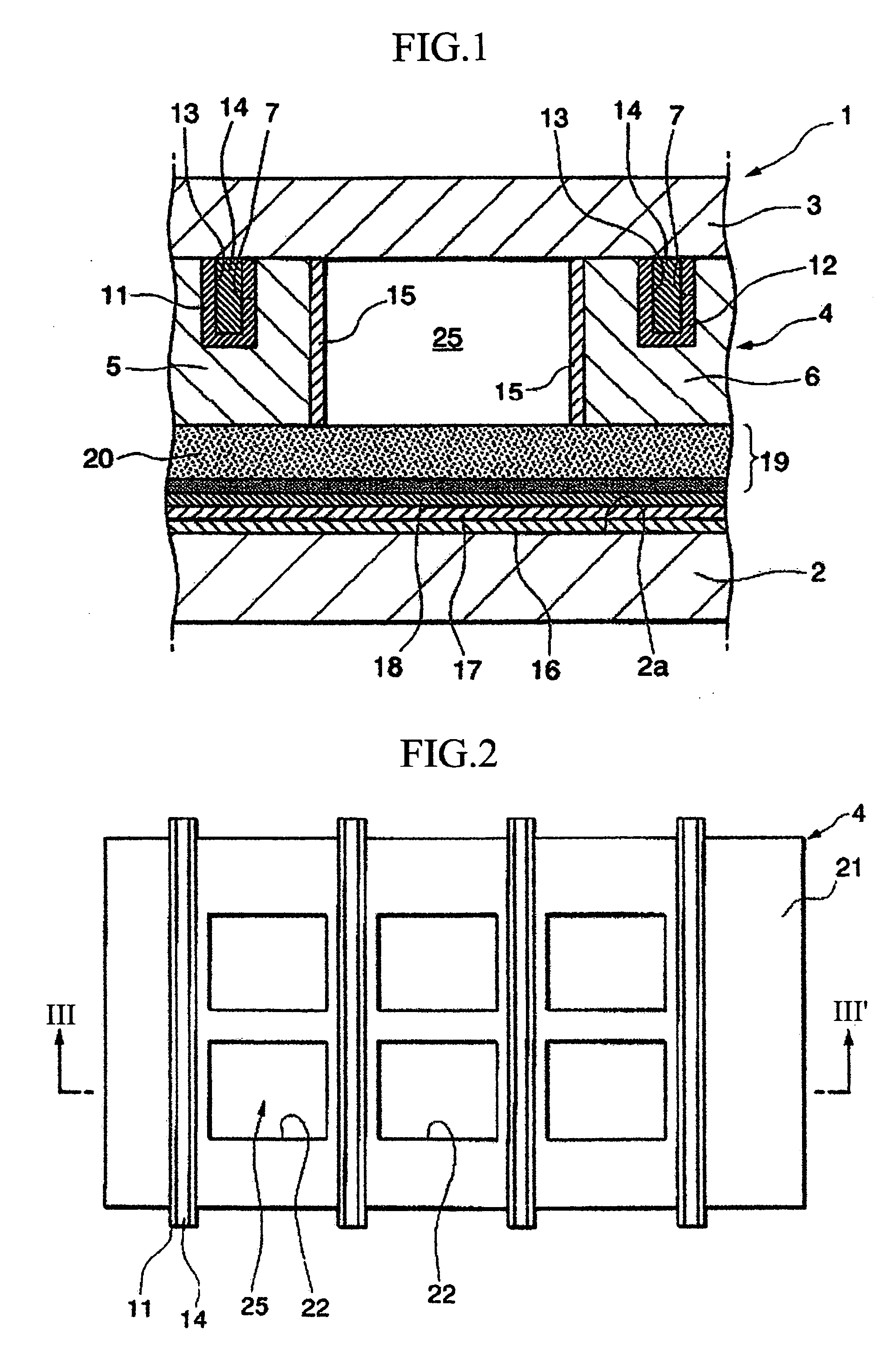

Organic electro-luminescence display device and method for fabricating the same

ActiveUS20070132374A1Increase product yieldReduce defect rateDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceDisplay device

An organic electro-luminance display device includes a first substrate including a plurality of sub-pixels, a first electrode on the first substrate, a buffer layer on the first electrode of a region that partitions each of the sub-pixels, a spacer on the buffer layer, the buffer layer and the spacer being integrally formed, an organic light-emitting layer on the first electrode that corresponds to each of the sub-pixels and the spacer, and a second electrode on the organic light-emitting layer.

Owner:LG DISPLAY CO LTD

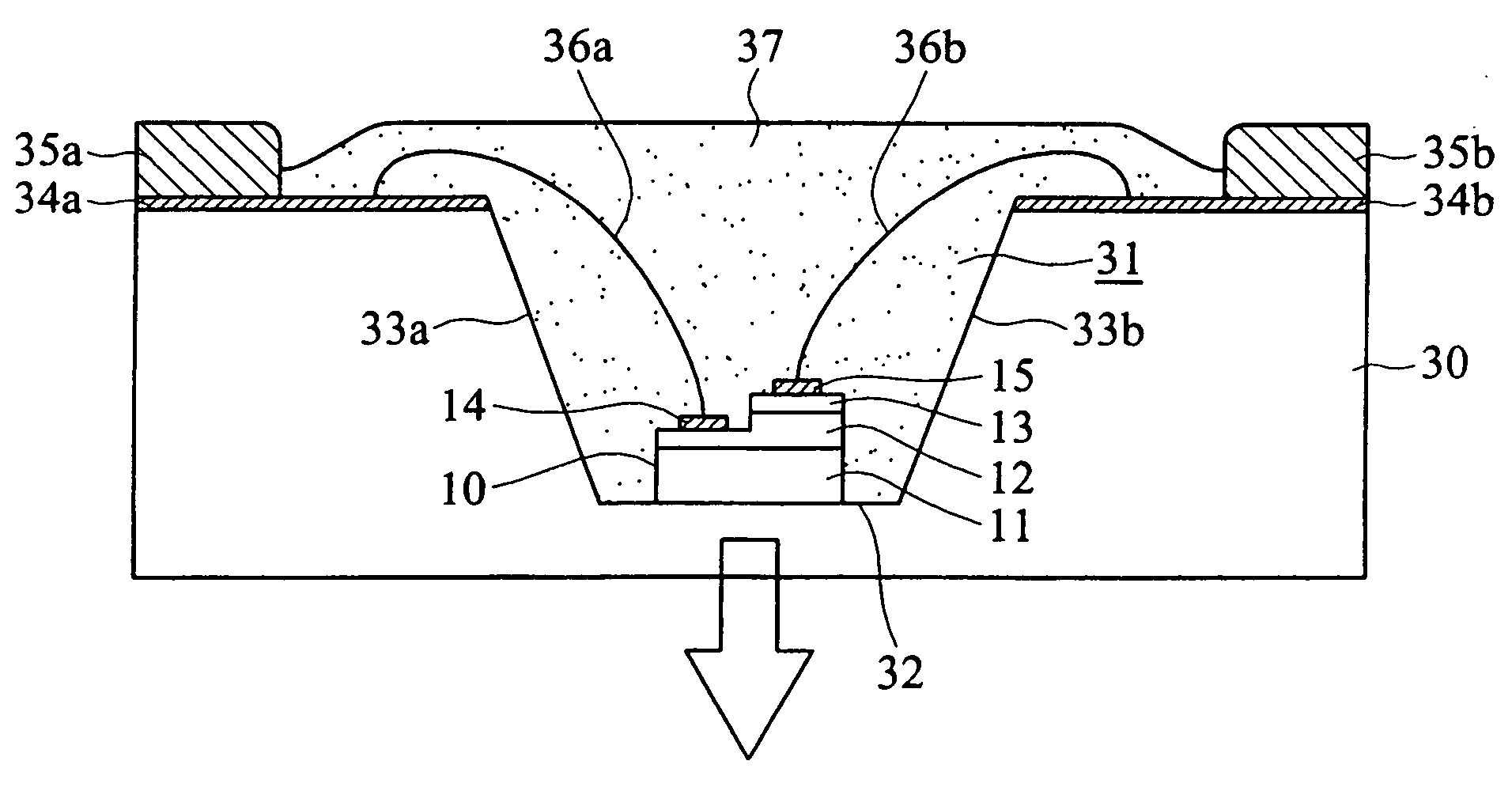

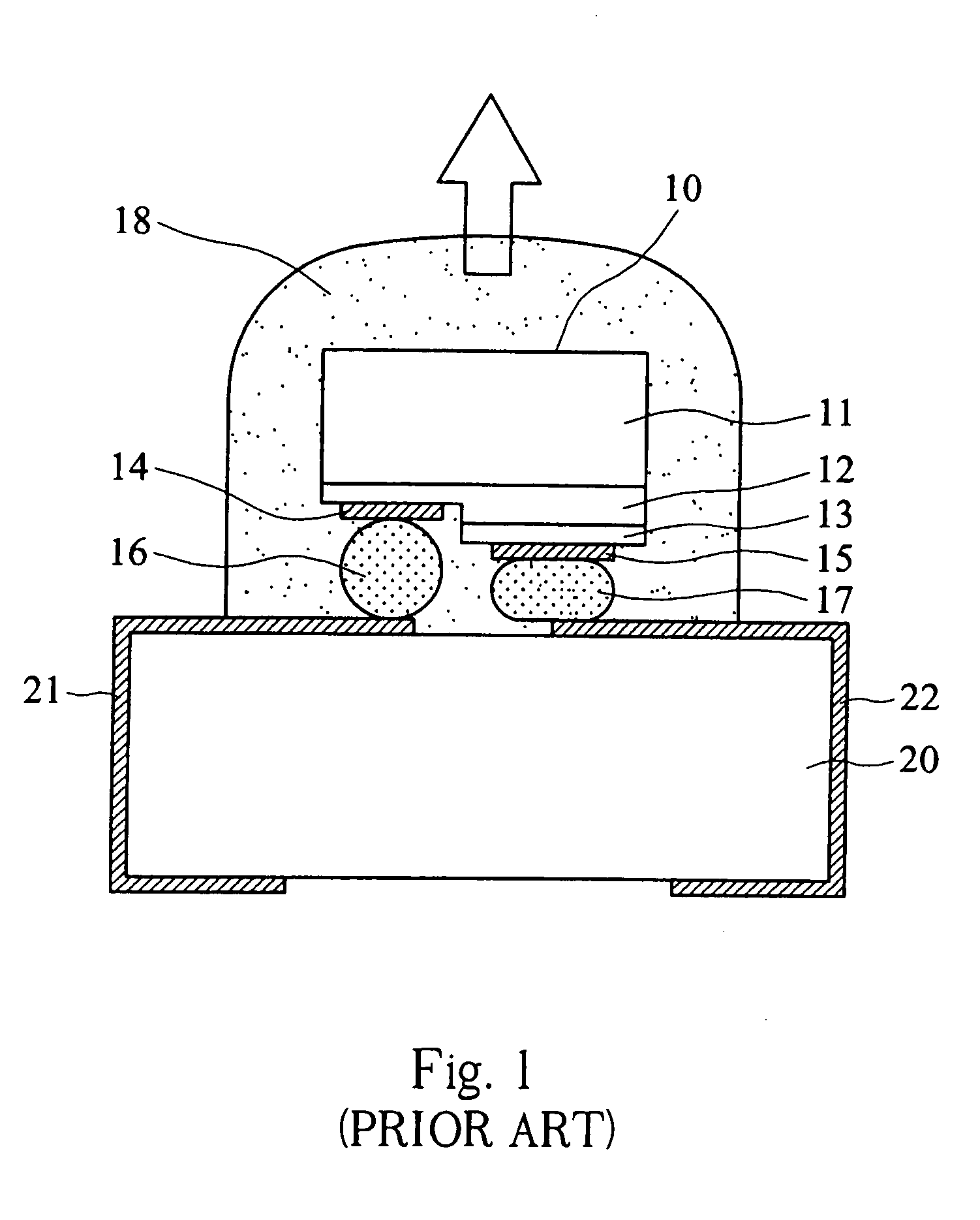

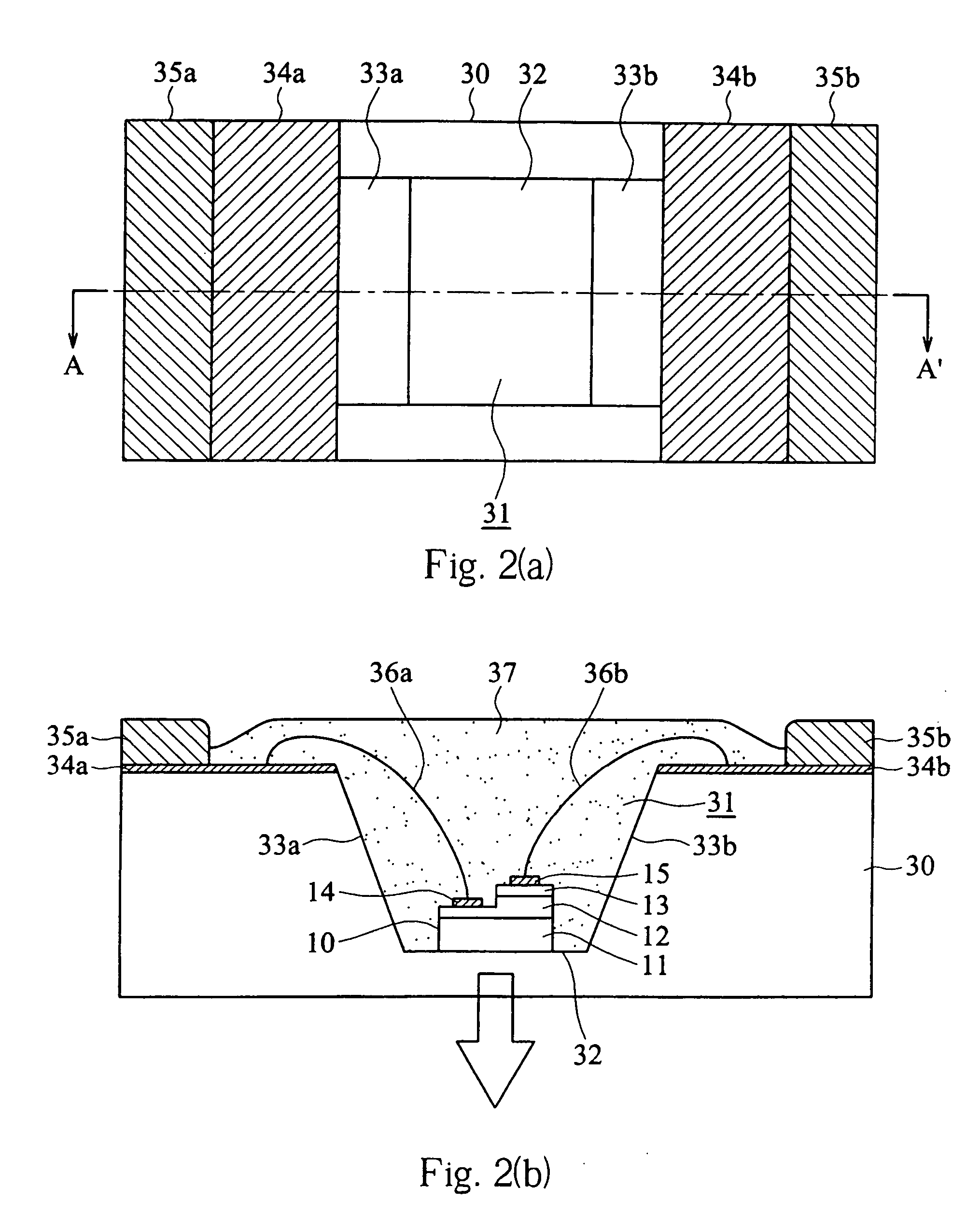

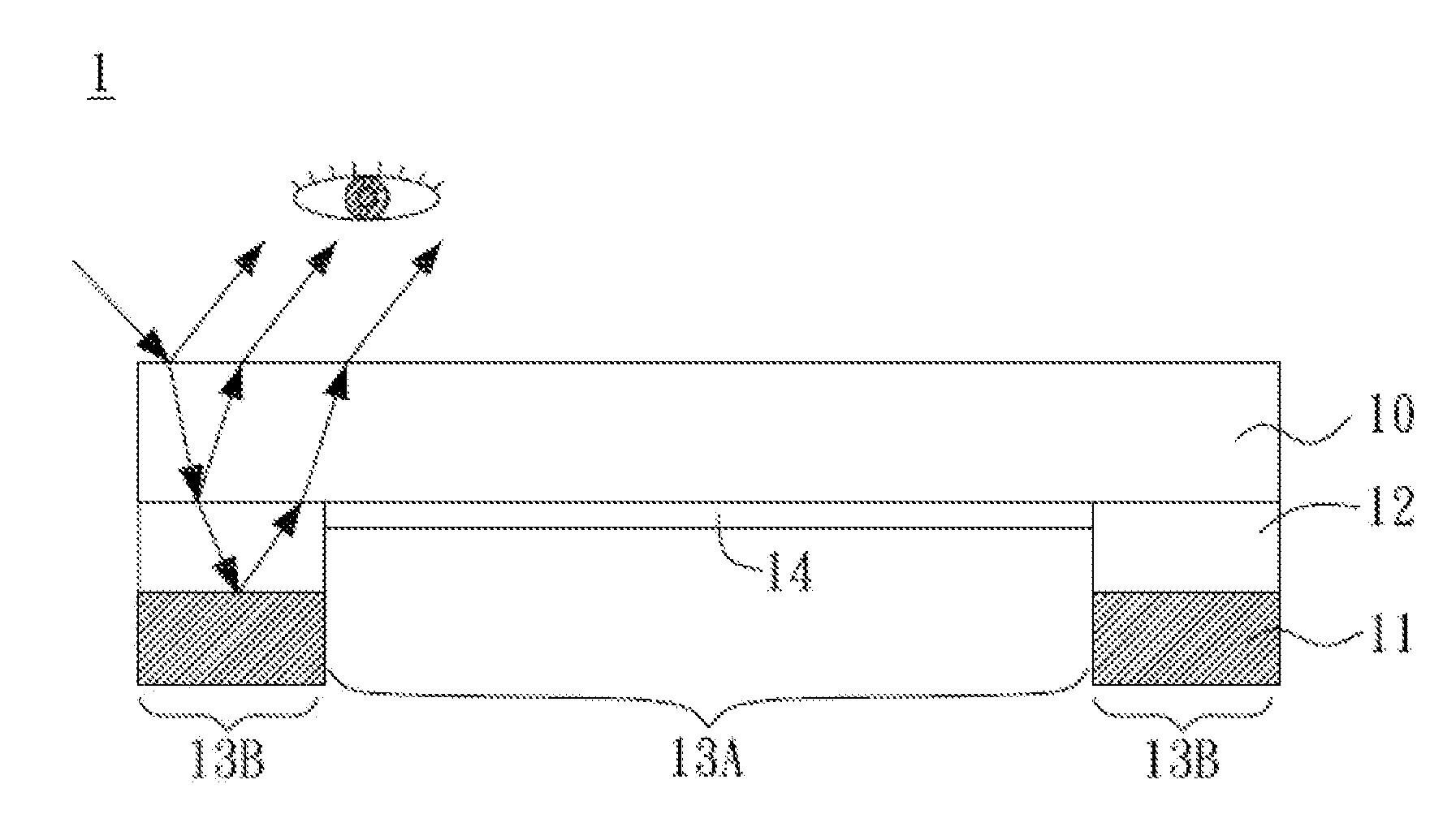

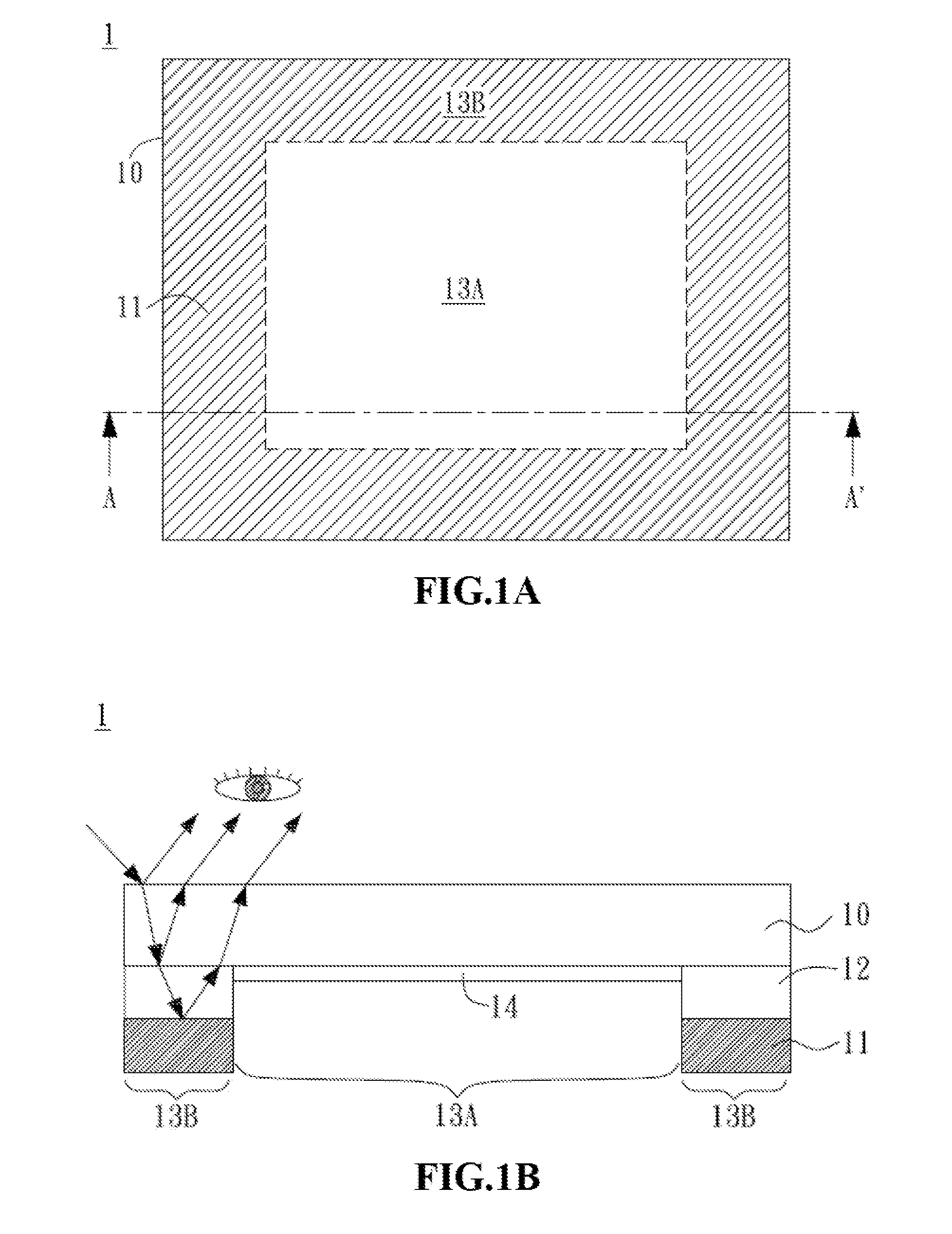

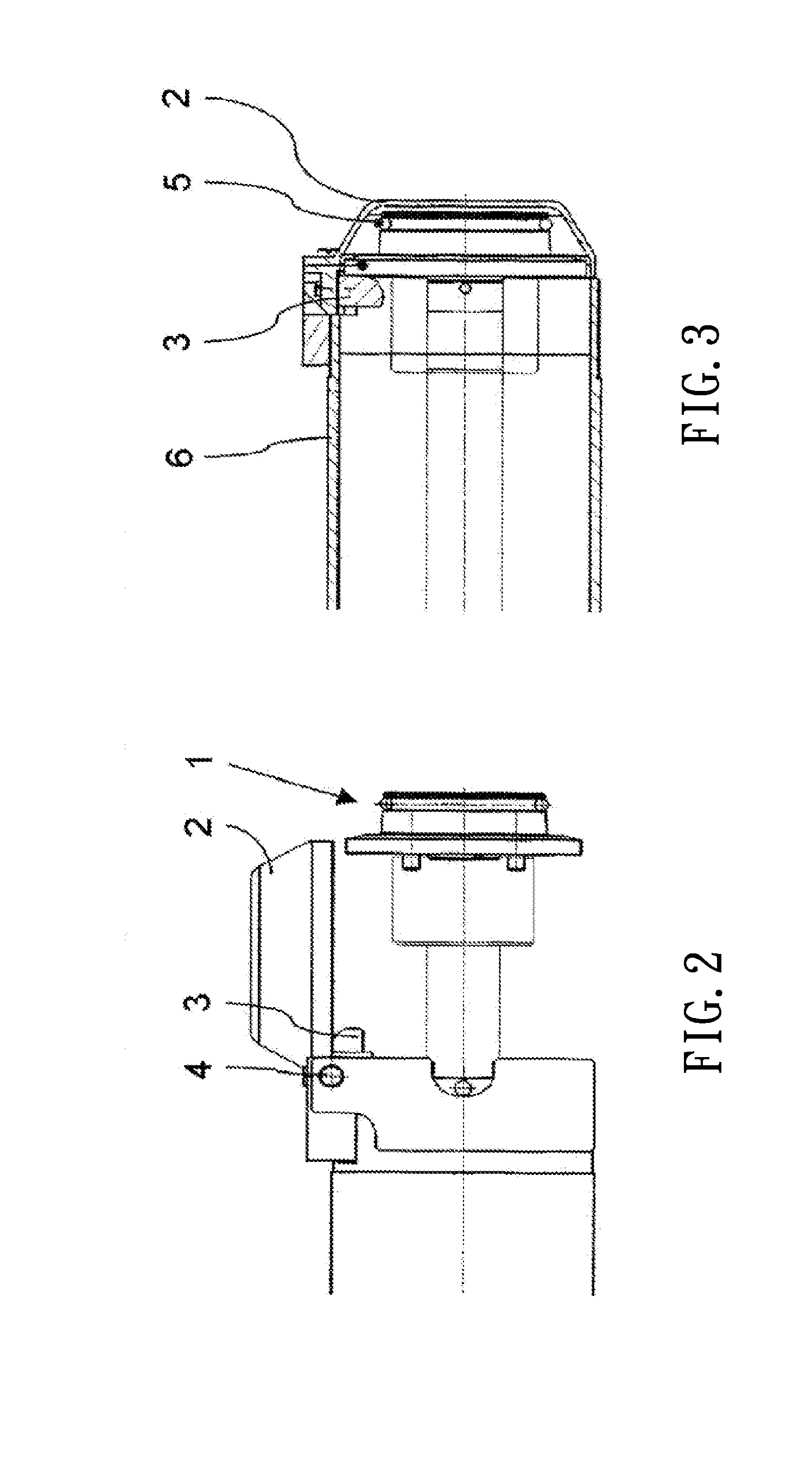

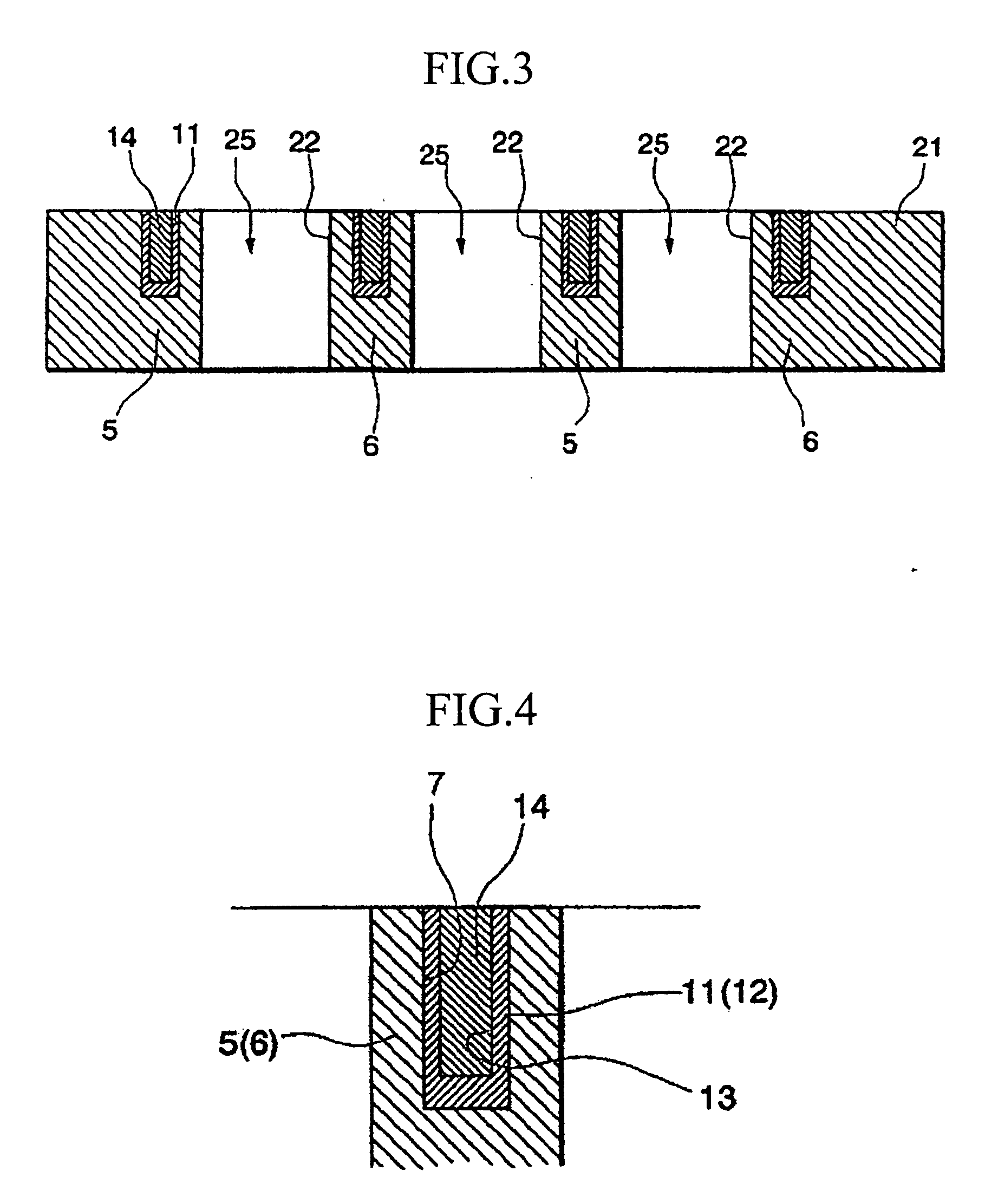

Light emitting diode package structure

InactiveUS20050012108A1Increase product yieldDecrease production costSolid-state devicesCoupling light guidesEngineeringMetal

A light emitting diode package structure includes an insulating carrier base formed with a recess or a through hole. The recess or the through hole has a depth enough for completely accommodating a light emitting diode. The recess or the through hole may have two stepwise portions for providing two intermediate mesa planes. Two planar metal layers are separately formed on the two intermediate mesa planes and, respectively, connected to two metal pads which are arranged outside of the recess or the through hole. Two wiring lines connect two electrodes of the light emitting diode with the two planar metal layers, respectively. A resin fills the recess or the through hole for sealing all of the light emitting diode and the two wiring lines.

Owner:LIN MING DER +2

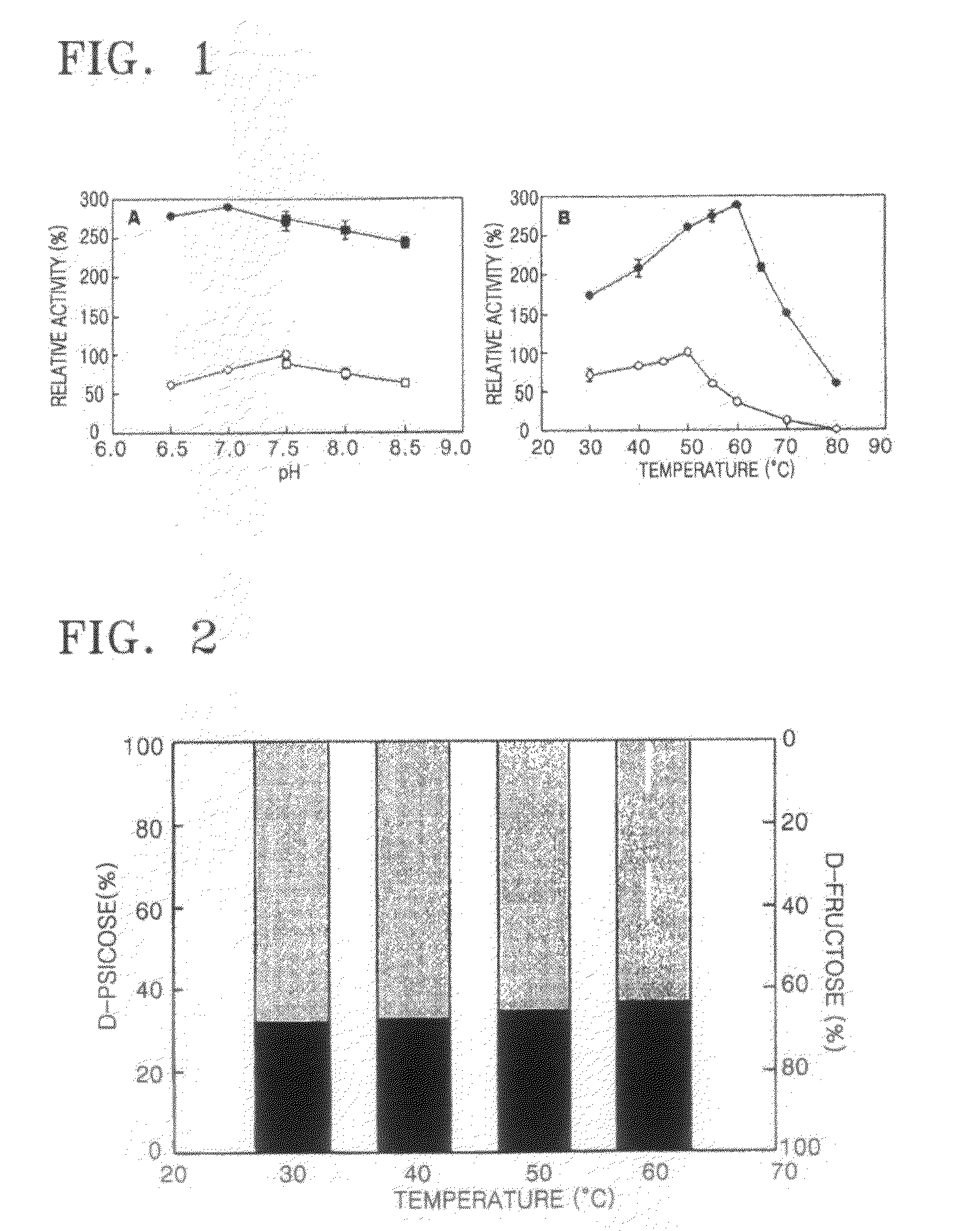

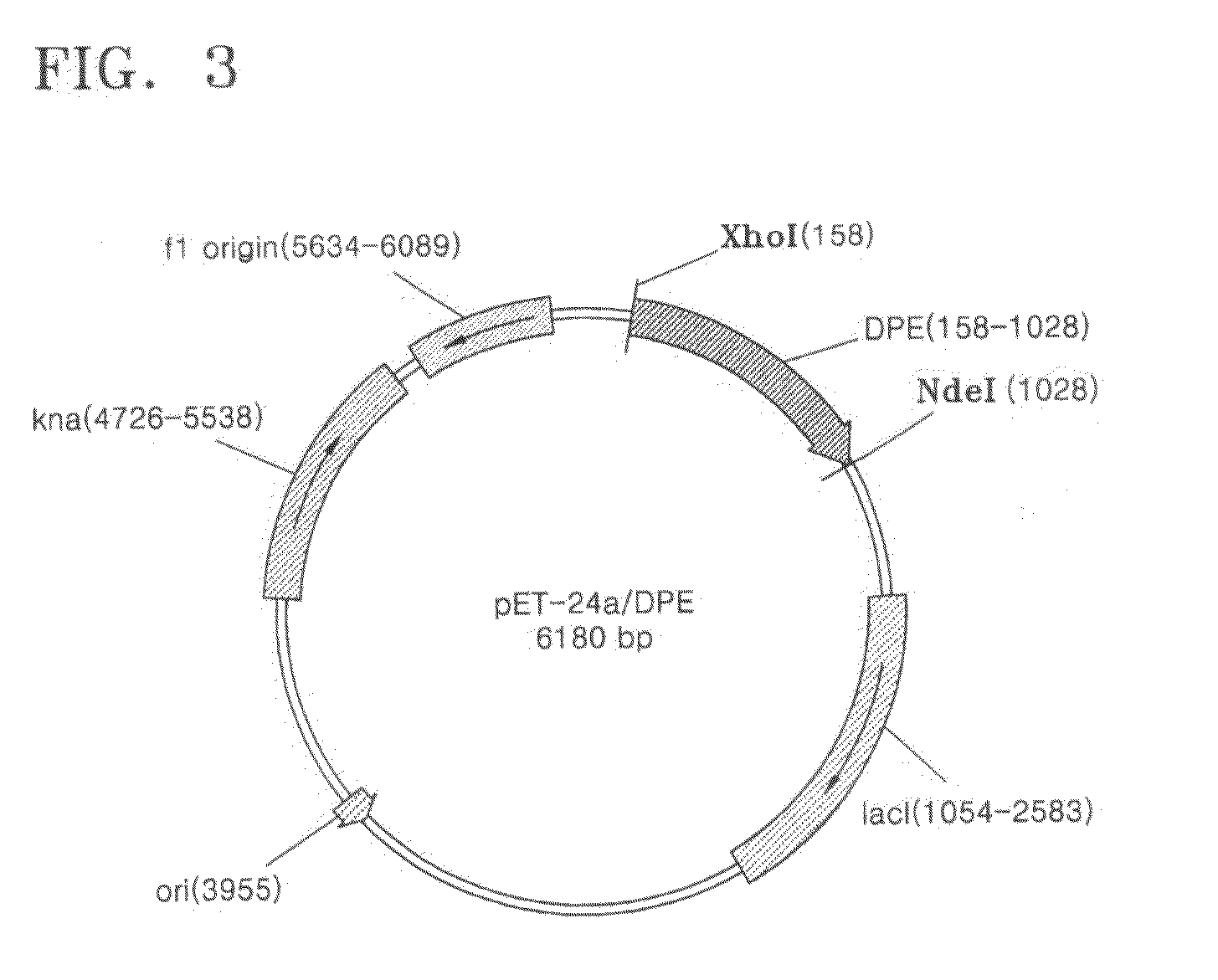

D-psicose production method by d-psicose epimerase

ActiveUS20100190225A1Increase product yieldProduction cost be reduceSugar derivativesIsomerasesEnzymeProtein formation

Provided is a method of producing D-psicose using a D-psicose epimerase derived from Agrobacterium tumefaciens. Provided are a protein having an amino acid sequence of SEQ ID NO:1 and having a psicose 3-epimerase activity, a gene encoding the protein, a recombinant expression vector containing the gene, and a method of producing D-psicose by reacting the protein produced on a mass scale with D-fructose. The method of producing D-psicose is an environmentally friendly method using a new enzyme, in which an inexpensive substrate is used, and the activity of the enzyme can be retained for a prolonged time period. Thus, the method can be efficiently used for the mass production of D-psicose.

Owner:CJ CHEILJEDANG CORP

Method for producing anti-evolving-gas additive of transformer oil and its using method

InactiveCN1438299AReduce pollutionEasy to dehydrateHydrocarbon oils refiningDistillates petroleumDistillation

The invention is a producing method of anti-gas yeilding additive of transformer oil. At first, it uses petroleum distillation, boiling point 250-500 deg.C, as raw material, adopts any one or more of the hydrogenation catalyzer; Co-Mo, Ni-Mo, W-Ni and Mo-Co-Ni to make hydrogenation process; secondly, and at constant pressure distils the produced oil after the hydrogenation process to get the distillation, boiling point 280-360 deg.C, so as to get the additive; the usage: adding the additive to common transformer oil, concocting to get super-high transformer oil.

Owner:克拉玛依市金龙特种油品公司

Low-temperature salting and multi-layer continuous fume smoking method for cured meat

InactiveCN101502329AShorten marinating timeIncrease product yieldFood preparationMeat/fish preservation by dryingNutrientClear Layer

The invention discloses a bacon low-temperature pickling and multi-layer continuous smoking method, belonging to the processing method of bacon. On the basis of traditional firewood bacon, the bacon is produced by combining the traditional processing technique and the current technique. The processing method comprises: pre-processing the fresh pork; pickling the pre-process pork at low-temperature; air-drying the pickled pork; multi-layer continuously smoking the air-dried pork; removing dust and testing the quality of the smoked pork; vacuum packaging the tested pork. The bacon has golden yellow color, dry and compact meat, clear layer, transparent fat lining, red lean meat, fresh taste, rich nutrient and long shelf-life of up to 10 months and so on. The human keeps fit and the life is prolonged after eating the bacon for a long time and the bacon is a common food for guest and a good gift for friend.

Owner:冯廷萃

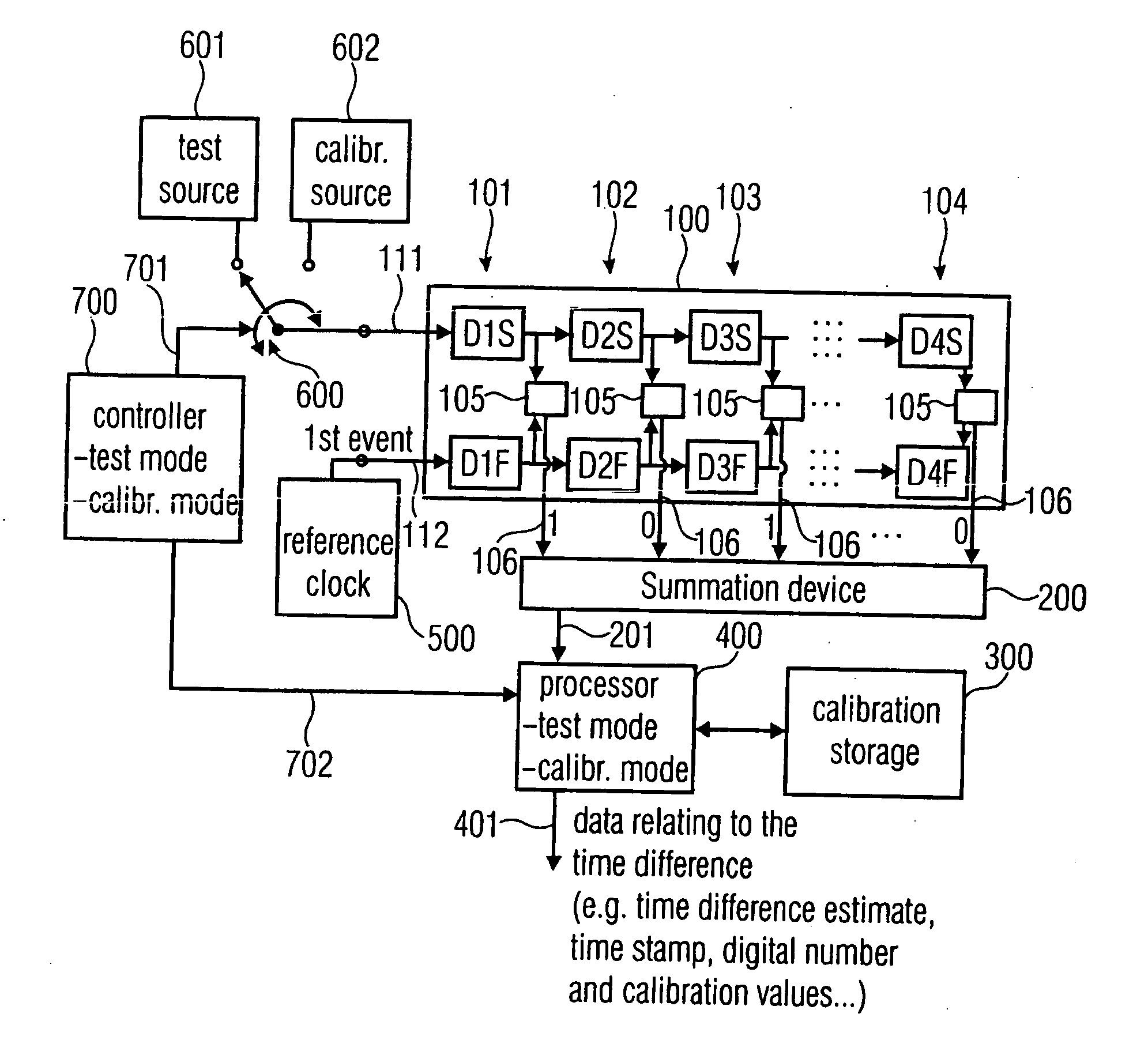

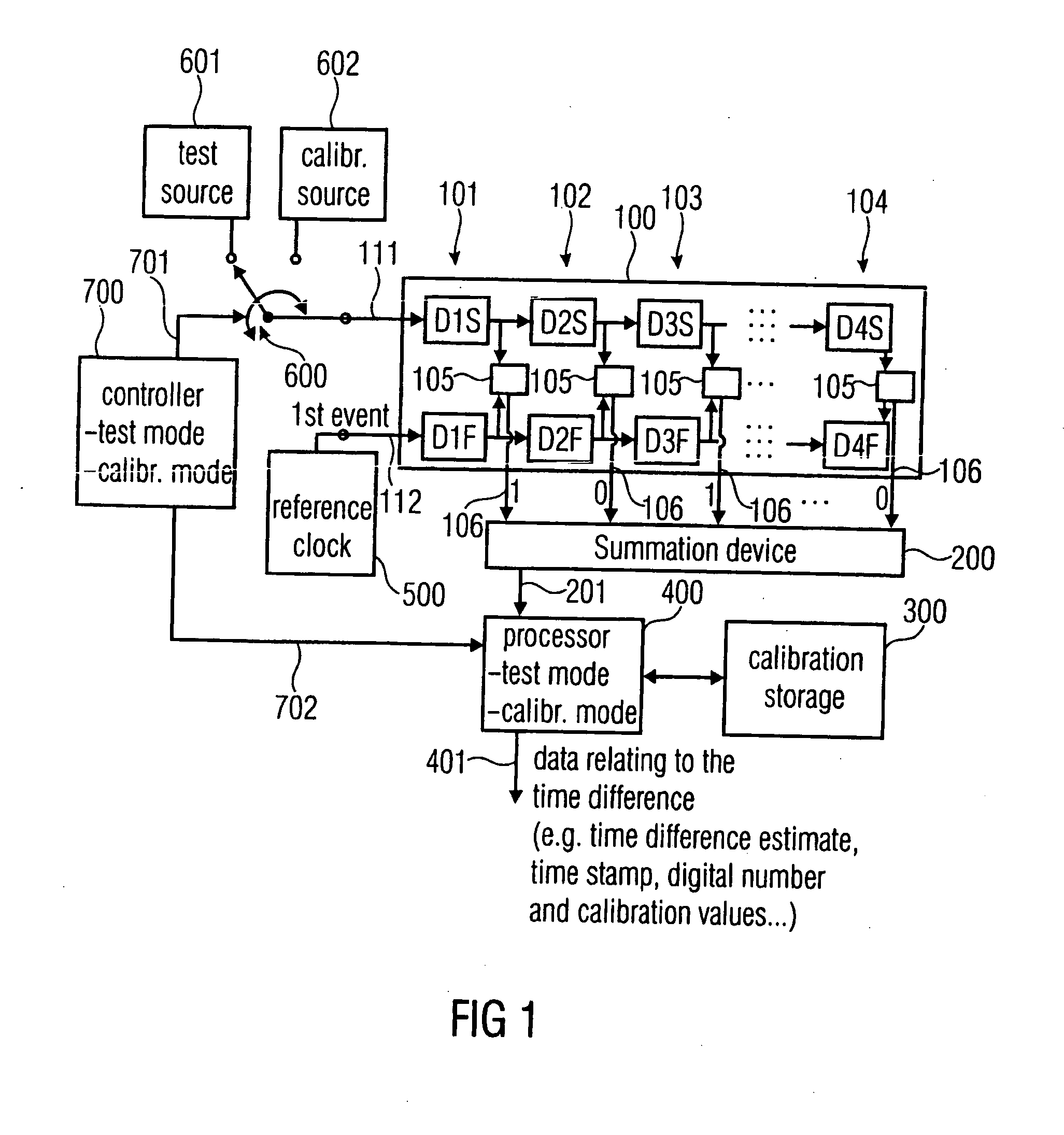

Apparatus and method for estimating data relating to a time difference and apparatus and method for calibrating a delay line

ActiveUS20110140737A1Increase product yieldImprove characteristicVoltage-current phase angleOscillations comparator circuitsTime differenceComputer science

An apparatus for estimating data relating to a time difference between two events includes a delay line having a plurality of stages. Each stage has a delay difference between a first delay in a first part and a second delay in a second part. This delay difference is measured by a phase arbiter in each stage, which outputs an indication signal indicating whether the first event of two events in the first part precedes or succeeds a second event of the two events in the second part. A summation device is provided for summing over the indication signals of the plurality of stages to obtain a sum value. The sum value indicates a time difference estimate.

Owner:ADVANTEST CORP

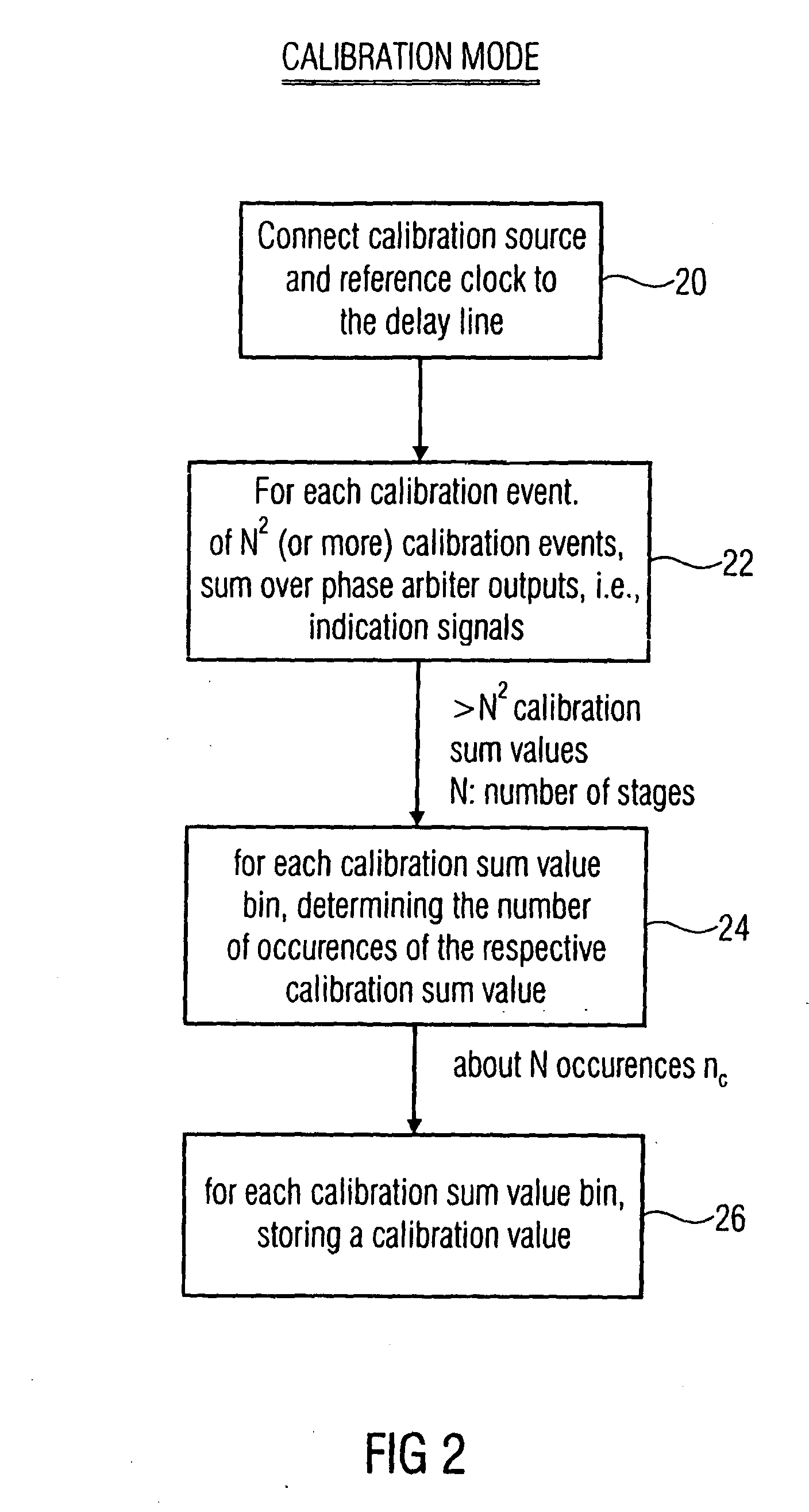

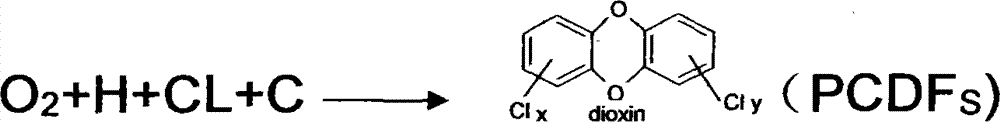

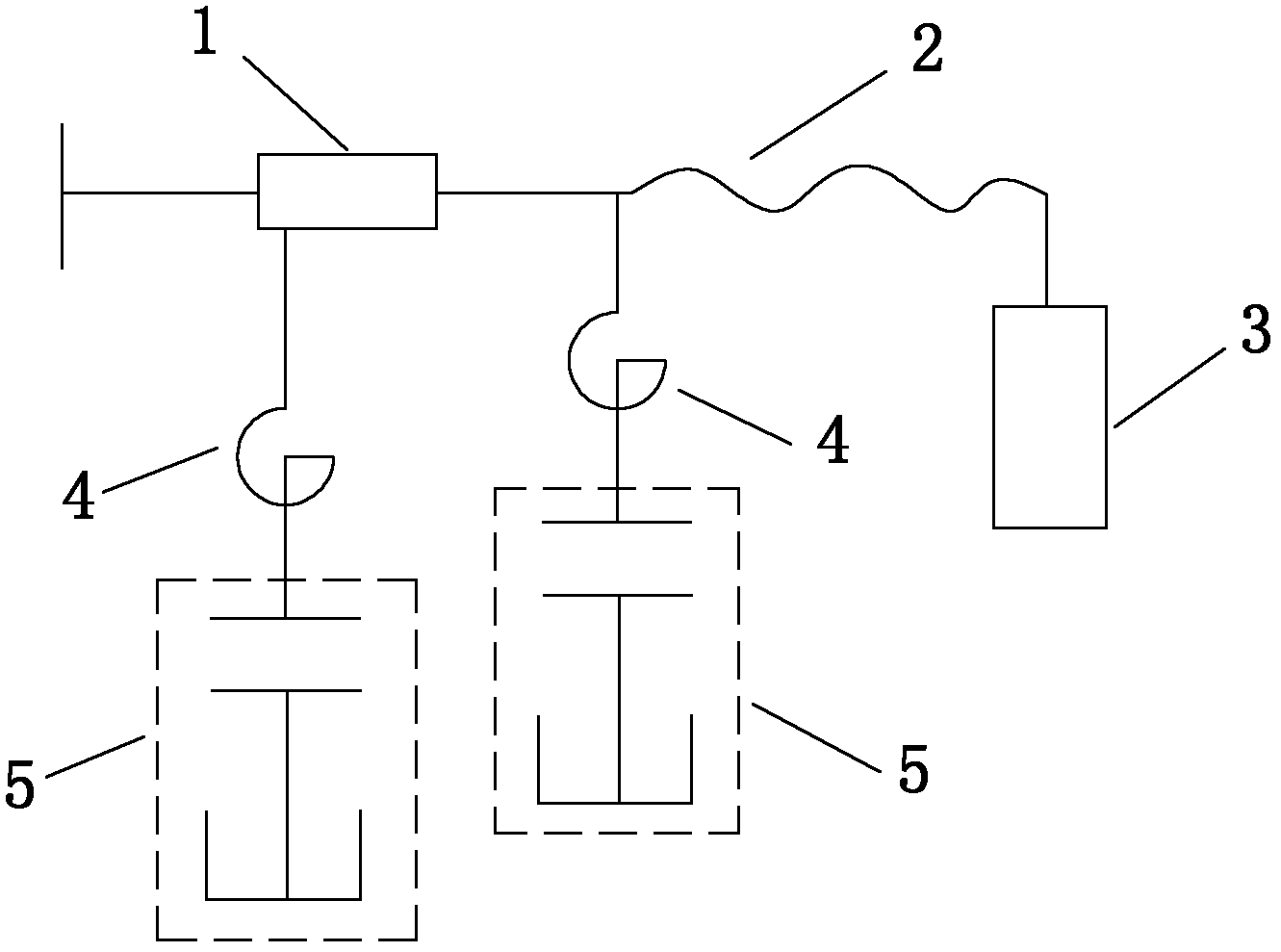

Method and equipment for preparing fuel from household garbage for suppressing dioxin

InactiveCN103045273ATemperature controlControl and regulate temperatureSolid waste disposalDirect heating destructive distillationGas phaseProduct gas

The invention relates to a method and equipment for preparing fuel from household garbage for suppressing dioxin. The method comprises the following steps of: introducing a heat source into vertical heat treatment equipment by using high-temperature gas as the heat source to ensure that the heat source is in direct contact with the household garbage in the vertical heat treatment equipment to cause heat transfer; performing thermal cracking reaction after the raw materials are heated; recovering and utilizing the cracked gas phase product; burning out residues caused by thermal cracking; and introducing high-temperature smoke gas generated by burning into the heat treatment equipment to heat the raw materials. The equipment for preparing the fuel from the household garbage for suppressing dioxin provided by the invention mainly comprises the vertical heat treatment equipment for drying the household garbage and performing thermal cracking on the household garbage, equipment for burning the cracked residues and collection and utilization equipment for the gas phase product. The method and the equipment have the advantages that equipment structure is simple, large-scale, continuity, reclamation and minimization treatment of the household garbage can be realized, and the like.

Owner:周鼎力 +1

Method for extracting sturgeon skin collagen

InactiveCN101475638AChange textureAvoid denaturationConnective tissue peptidesPeptide preparation methodsFreeze-dryingCentrifugation

The invention discloses an extracting method for a sturgeon skin collagen. The extracting method comprises the following steps: (1) preliminary treatment: taking and slicing a sturgeon skin, firstly immersing the sturgeon skin in alkaline solution, immersing the sturgeon skin in an acidic solution after rinsing, and then taking the sturgeon skin out for rinsing and standby; (2) extraction: adding water into the preprocessed sturgeon skin for leaching at 45 to 55 DEG C, and carrying out the filtration to remove impurities and obtain the collagen extracting solution; and (3) freeze drying: obtaining sturgeon skin collagen powder through the refrigerated centrifugation of the collagen extracting solution. The collagen product has higher quality. The extracting method has a higher collagen extraction rate, and not only improves the product yield, but also saves the cost in a simple way, thereby improving the economic benefits of a manufacturing enterprise.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

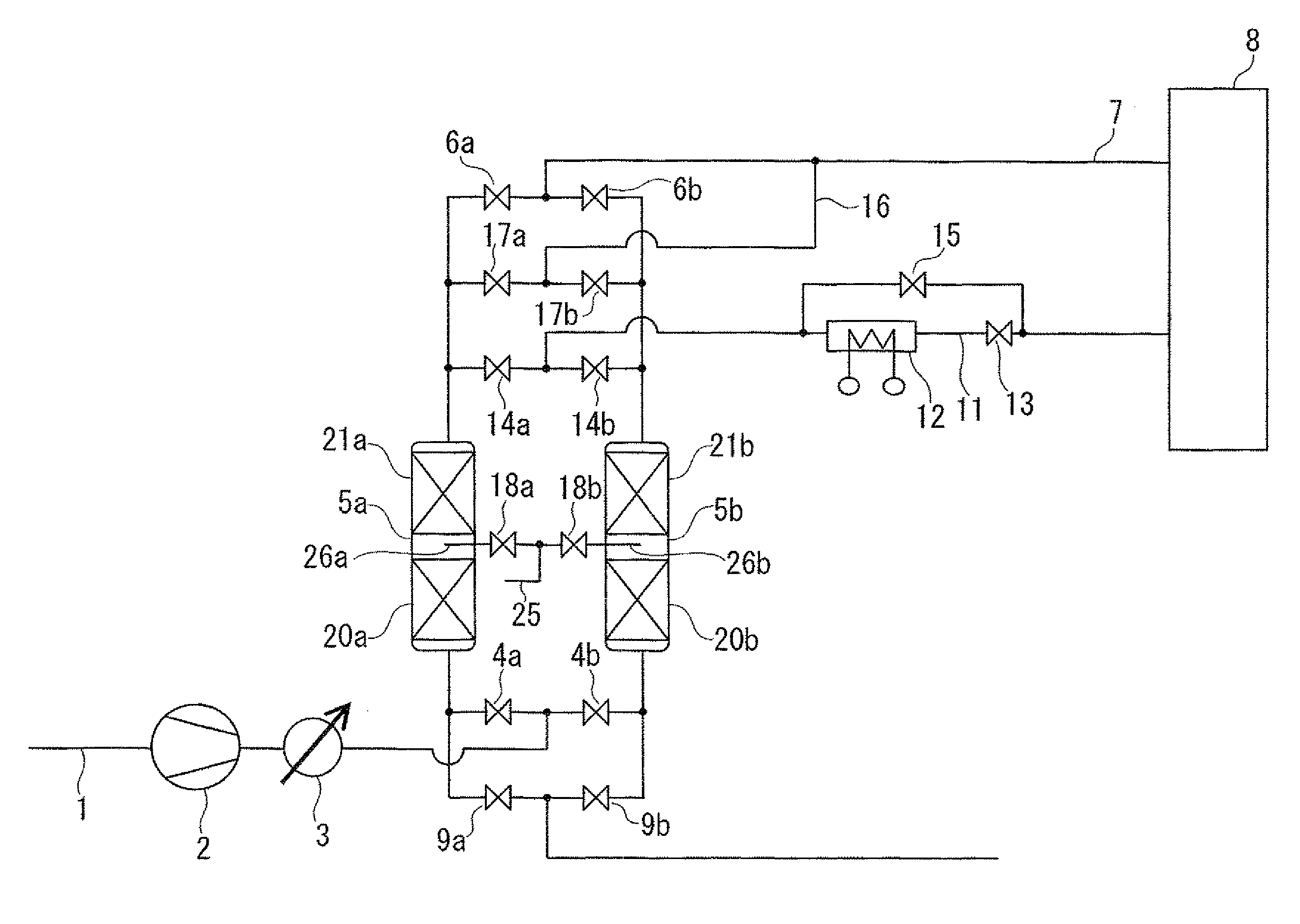

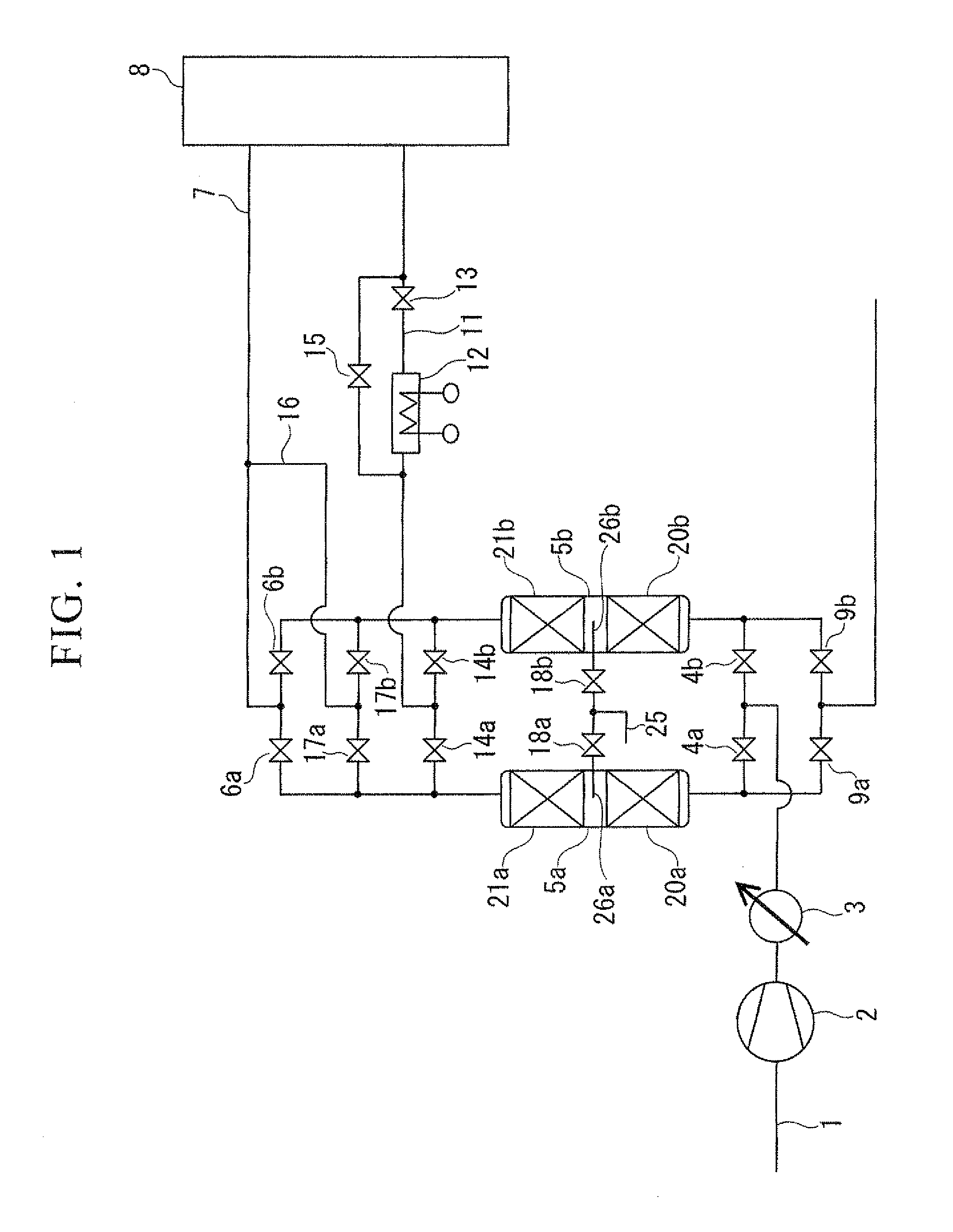

Method of purifying air

ActiveUS20120011887A1Increase product yieldExcellent reproductionSolidificationGas treatmentChemistryCarbon dioxide

A pre-purification method of feed air for cryogenic air separation, which includes; (a) an adsorption step wherein a compressed feed air is supplied in an adsorption column, wherein a moisture adsorbent and a carbon dioxide adsorbent are filled in this order from the side where the feed air is introduced in the column, to remove water and carbon dioxide from the feed air; (b) a decompression step wherein pressure in the adsorption column is reduced; (c) a heating step wherein the adsorbents in the decompressed column are heated and regenerated, and the heating step includes a total heating step wherein the moisture adsorbent and the carbon dioxide adsorbent are heated and a partial heating step wherein the moisture adsorbent is heated; (d) a cooling step wherein the adsorbents are cooled by introducing a purge gas, which is not heated, to the adsorption column; and (e) a pressurization step wherein the cooled adsorbents are pressurized by purified air.

Owner:TAIYO NIPPON SANSO CORP

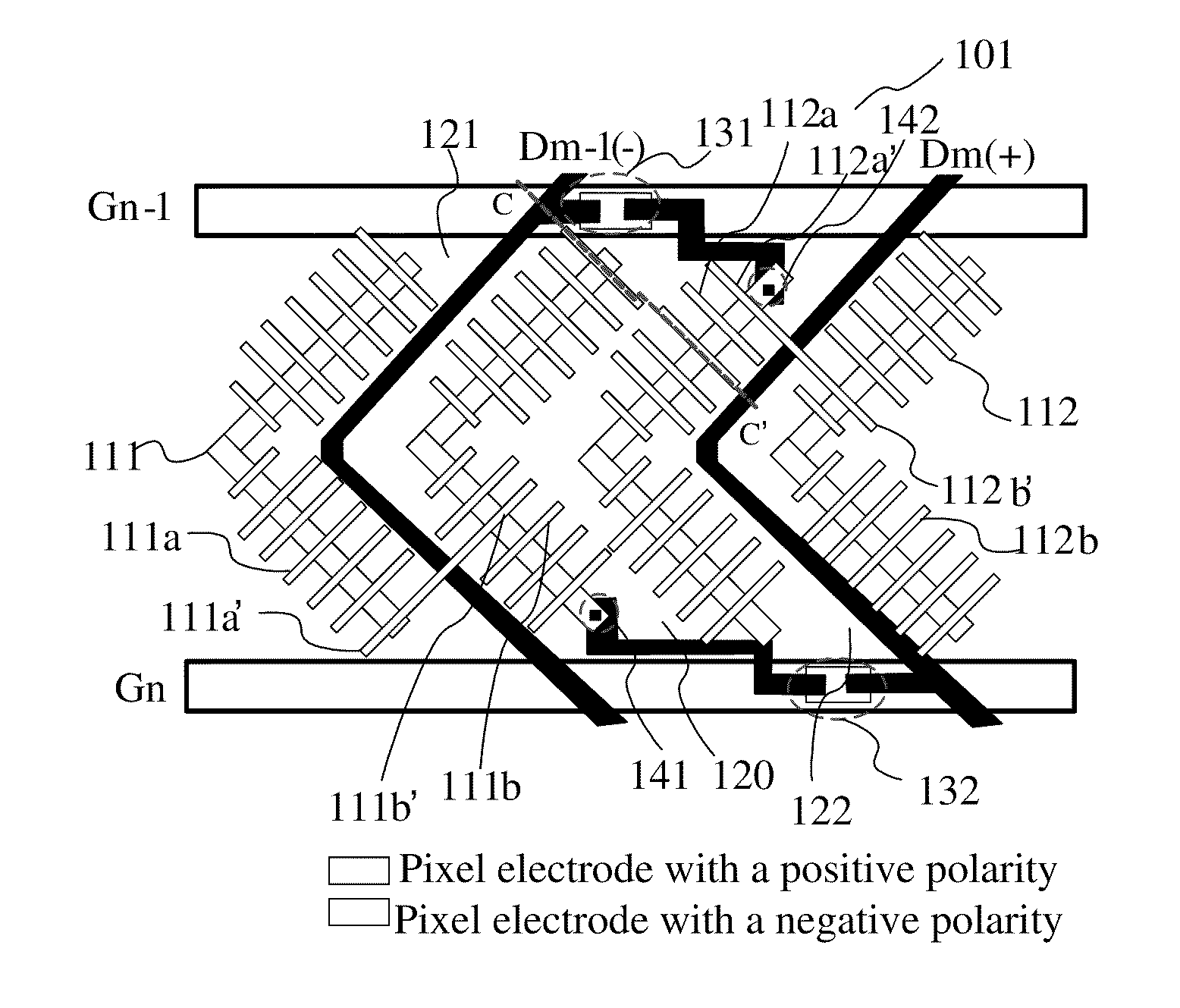

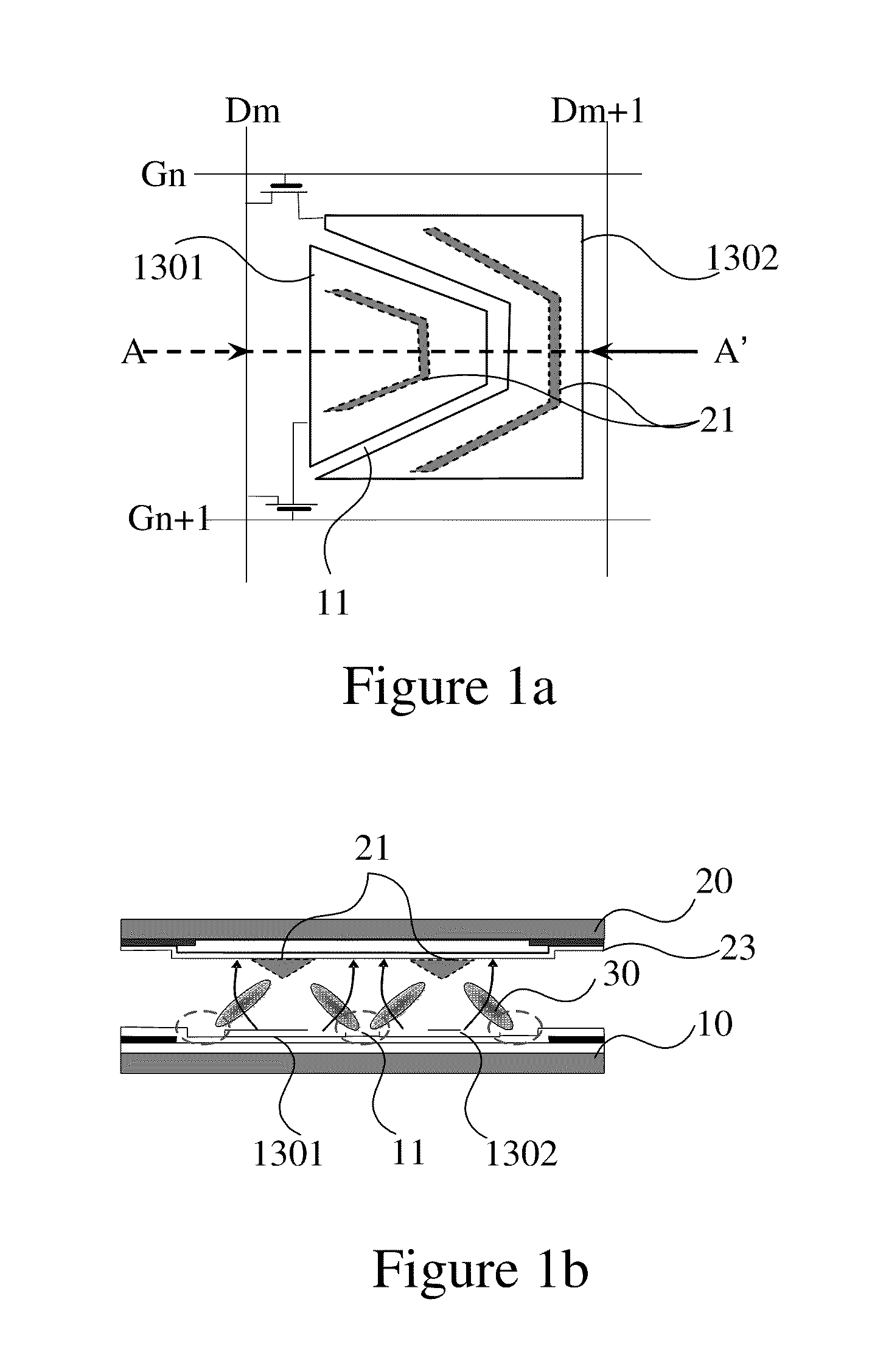

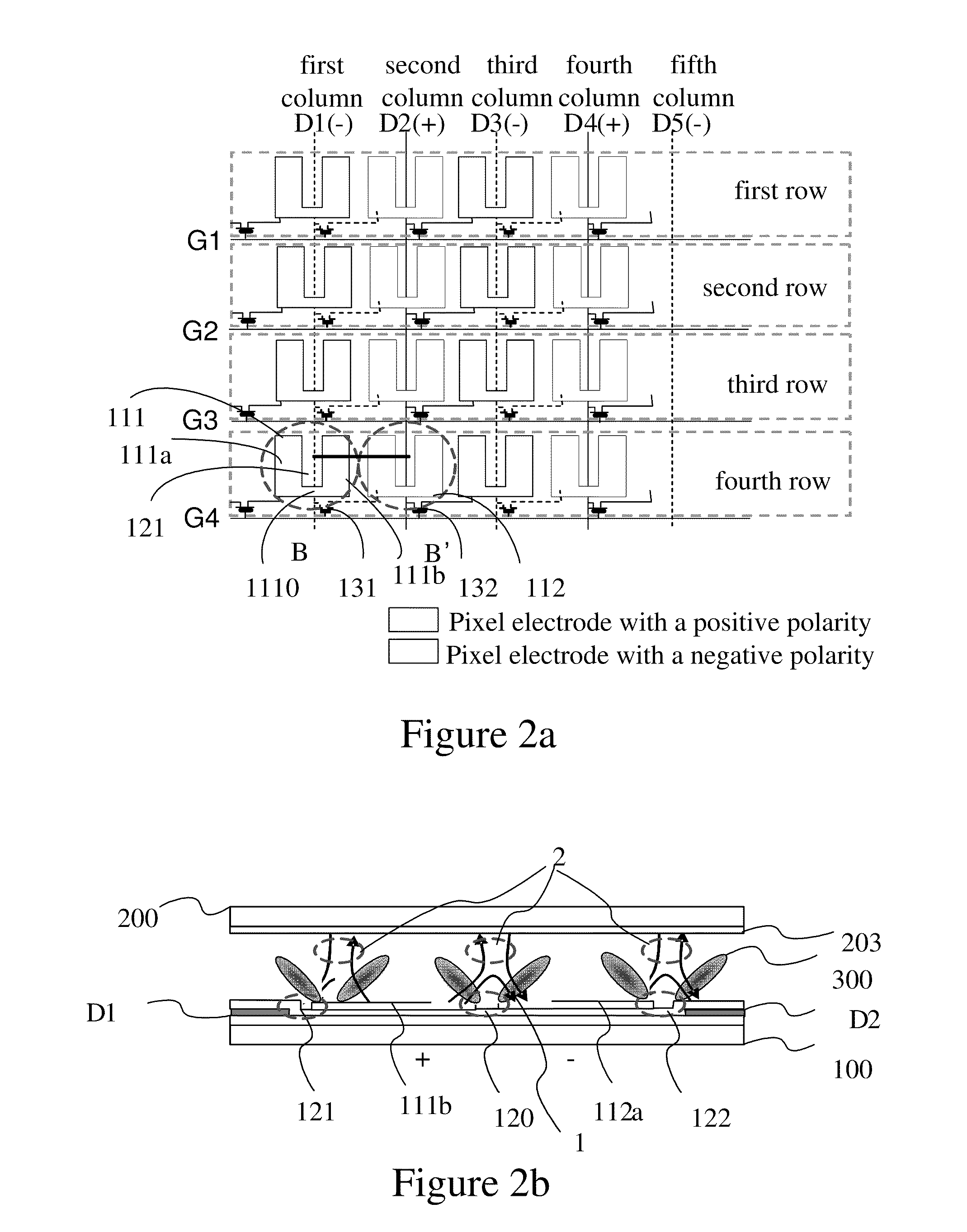

Liquid Crystal Display Panel and Liquid Crystal Display

ActiveUS20110157502A1Reduce manufacturing complexityIncrease product yieldStatic indicating devicesNon-linear opticsLiquid-crystal displayDark state

A liquid crystal display panel includes a first and second substrates which are opposite, and further includes scanning lines, data lines, pixel electrodes and switches, intersection of two adjacent scanning lines and data lines forming a pixel region. The pixel electrodes are disposed in pixel regions. Each pixel electrode crosses one data line and includes a first and second sub-pixel electrodes which are electrically connected to each other; the first and second sub-pixel electrodes are arranged on two sides of the data line; there is a gap between the first and second sub-pixel electrodes, and the data line is configured in the gap. A problem that conventional liquid crystal display panel has a complex manufacture process, leaks light at a dark state and has a low penetrability can be solved, thereby improving yield of the products.

Owner:KUSN INFOVISION OPTOELECTRONICS

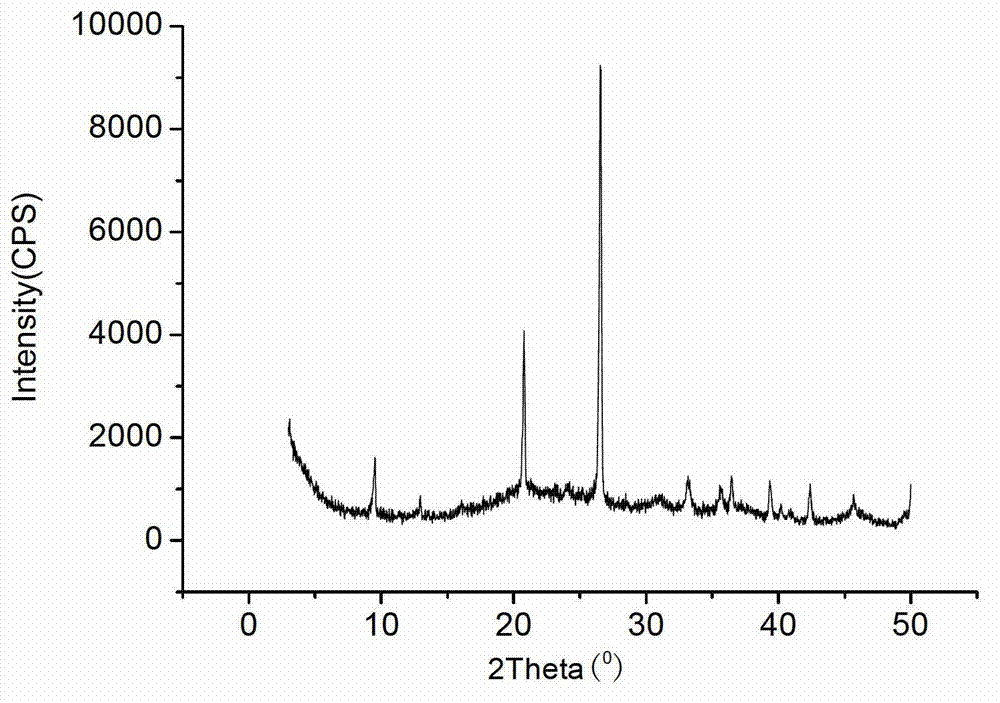

Graphene synthesis method

The invention relates to a graphene synthesis method, and relates to the technical field of chemical synthesis methods. The invention especially relates to the graphene synthesis method. The graphene synthesis method is simple, and has the advantage of high product yield. The method comprises the following steps: (1) a reaction bottle is assembled in an ice-water bath; concentrated sulfuric acid is added; under magnetic stirring, a solid mixture of graphite powder and sodium nitrate is added; potassium permanganate is slowly added; the reaction speed is controlled; stirring is carried out under an ice bath condition and the reaction bottle is taken out; and a stirring reaction is carried out under room temperature; (2) an H2SO4 solution is used for diluting; after stirring, H2O2 is added and the solution is turned bright yellow; a stirring reaction is carried out, and centrifugation is carried out; and (3) a mixed solution of H2SO4 and H2O2, and HCl are used for washing repeatedly; and washing is carried out a few times with distilled water, such that a yellowish brown precipitate is obtained. the precipitate is graphite oxide.

Owner:郭琳

Method for preparing monopotassium phosphate through feed-grade calcium hydrophosphate

ActiveCN103879980AIncrease product yieldIncrease productionPhosphorus compoundsPhosphoric acidPotassium hydroxide

The invention discloses a method for preparing monopotassium phosphate through feed-grade calcium hydrophosphate. The method comprises steps of carrying out conversion reaction on the raw material feed-grade calcium hydrophosphate and phosphoric acid solution, then carrying out extraction reaction with sulfuric acid, filtering so as to obtain filtrate, regulating pH of the filtrate to be 7.1-8.5 with industrial-grade phosphoric acid, then adding potassium carbonate and potassium hydroxide solution into the filtrate for neutralizing, after finishing the reaction, regulating pH to be 8.5-9.5, filtering so as to obtain filtrate, continuously regulating pH of the filtrate to be 4-4.5 through industrial-grade phosphoric acid, regulating the density of the reaction liquor, and after completely dissolving out the crystal, centrifugally drying so as to obtain monopotassium phosphate. The method is simple; the product can meet the requirement of first-grade goods of national industrial standard, the content of monopotassium phosphate is over 98%, and the yield of the product monopotassium phosphate is high, so that the method is applicable to large-scale industrial application; the method lowers the cost of the product by adopting low-cost feed-grade calcium hydrophosphate and returning the dehydration mother liquor back to a reaction kettle for cycle use, and avoids strong corrosion to equipment in the technological process.

Owner:上海新增鼎数据科技有限公司

Touch panel

ActiveUS20130265253A1Increase product yieldImprove appearanceInput/output processes for data processingTouch panelElectrical and Electronics engineering

The present disclosure provides a touch panel including a plate, a sensing layer, a border, and an optical compensation layer, wherein the plate has an upper surface and a lower surface opposite to the upper surface, wherein the lower surface is planned with a conducting wire region and a sensing region. The border is overlaid on the conducting wire region, and the sensing layer is disposed in the sensing region. An optical compensation layer is disposed on the border, and is located between the plate and the border. The border has a first color, which appears as a second color if a user sees the border through the optical compensation layer, and thus achieves diversification of the border color.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

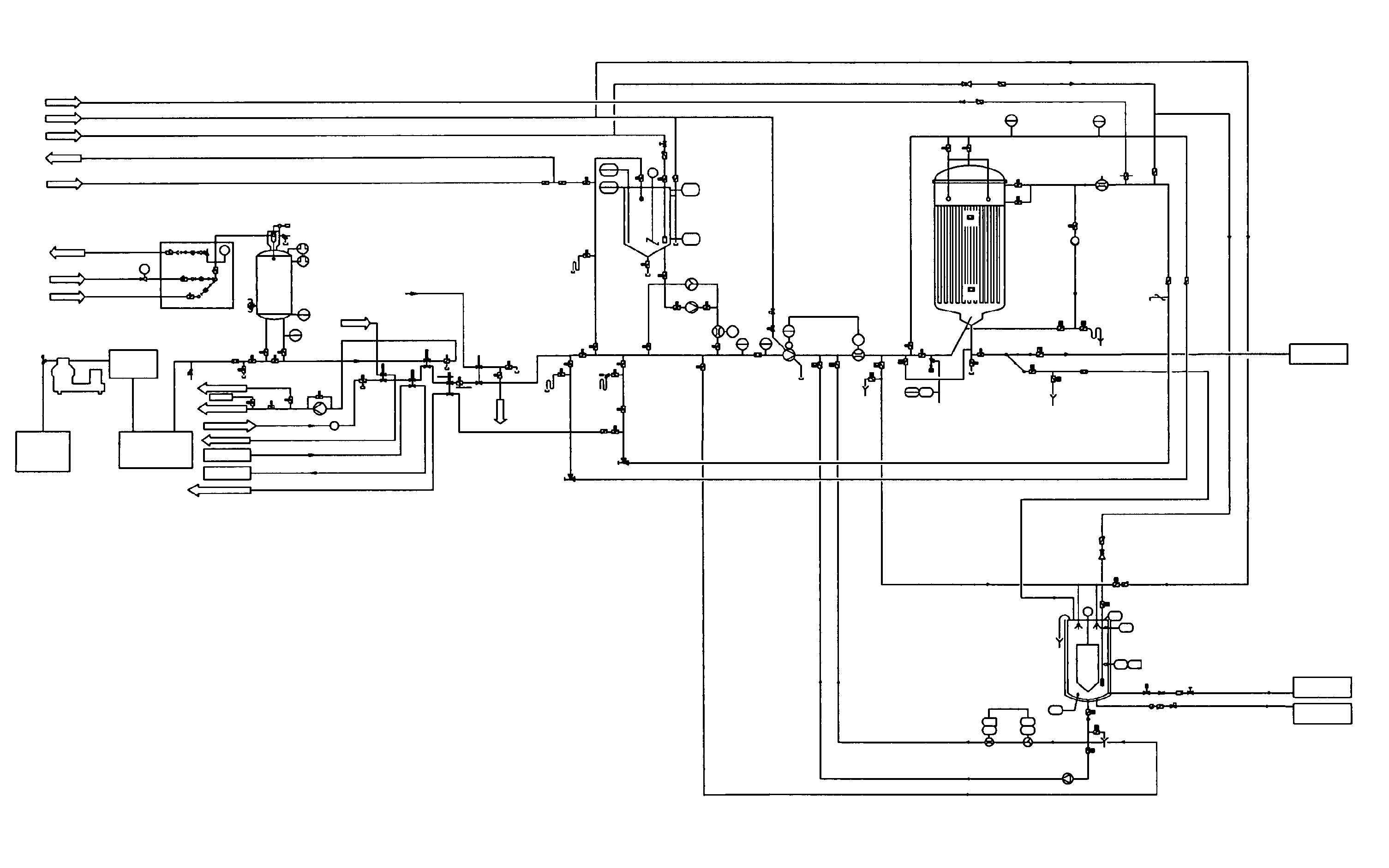

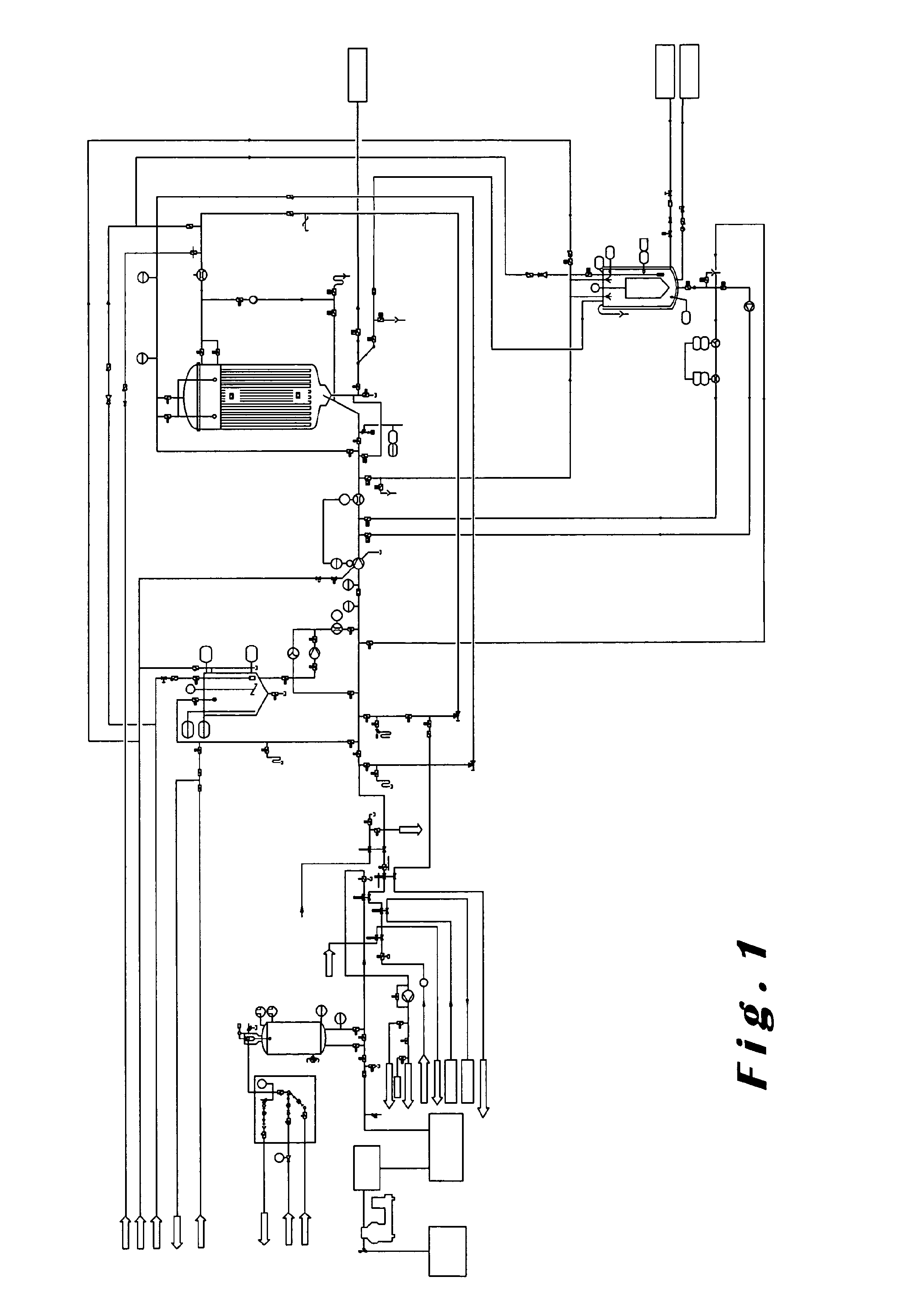

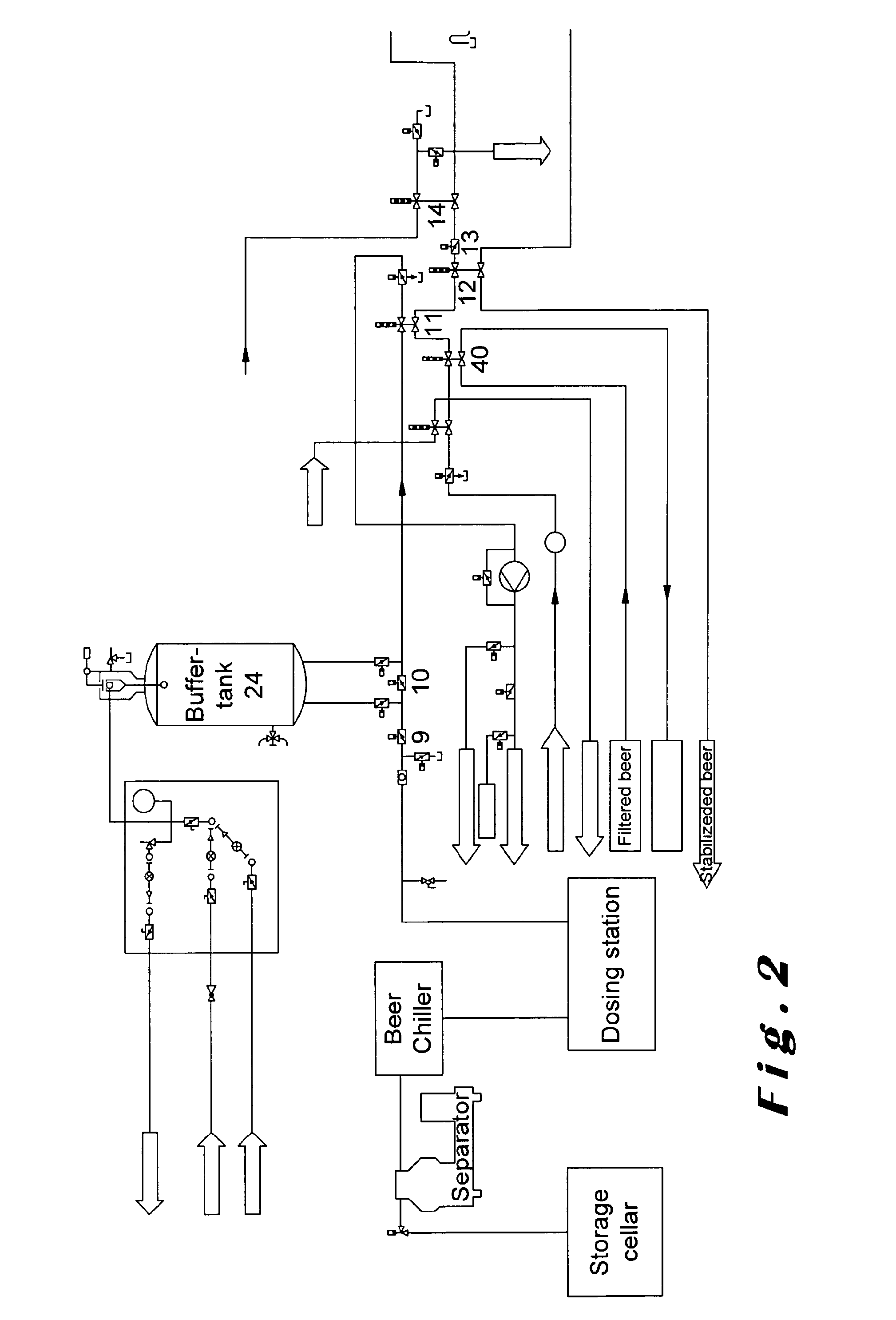

Use of a primary liquid filtration/stabilization installation for triple purpose

InactiveUS20100032372A1Increase flexibilityIncrease product yieldIon-exchange process apparatusIon-exchanger regenerationSingle useFeed line

The present invention relates to a primary liquid filtration / stabilization installation comprising in combination, a liquid in-feed line, a conventional dosing tank system for single use filter-aid and / or stabilization-aid, and an alternate dosing / storage tank system for regenerable filter-aid and / or stabilization-aid, wherein the installation is adapted to selectively operate one or the other of the dosing systems to meter doses of their respective charges into liquid that is delivered through the in-feed line, and a filter adapted to retain filter-aid material thereon, while passing liquid from which retained material has been removed.

Owner:ADAM PIERRE +3

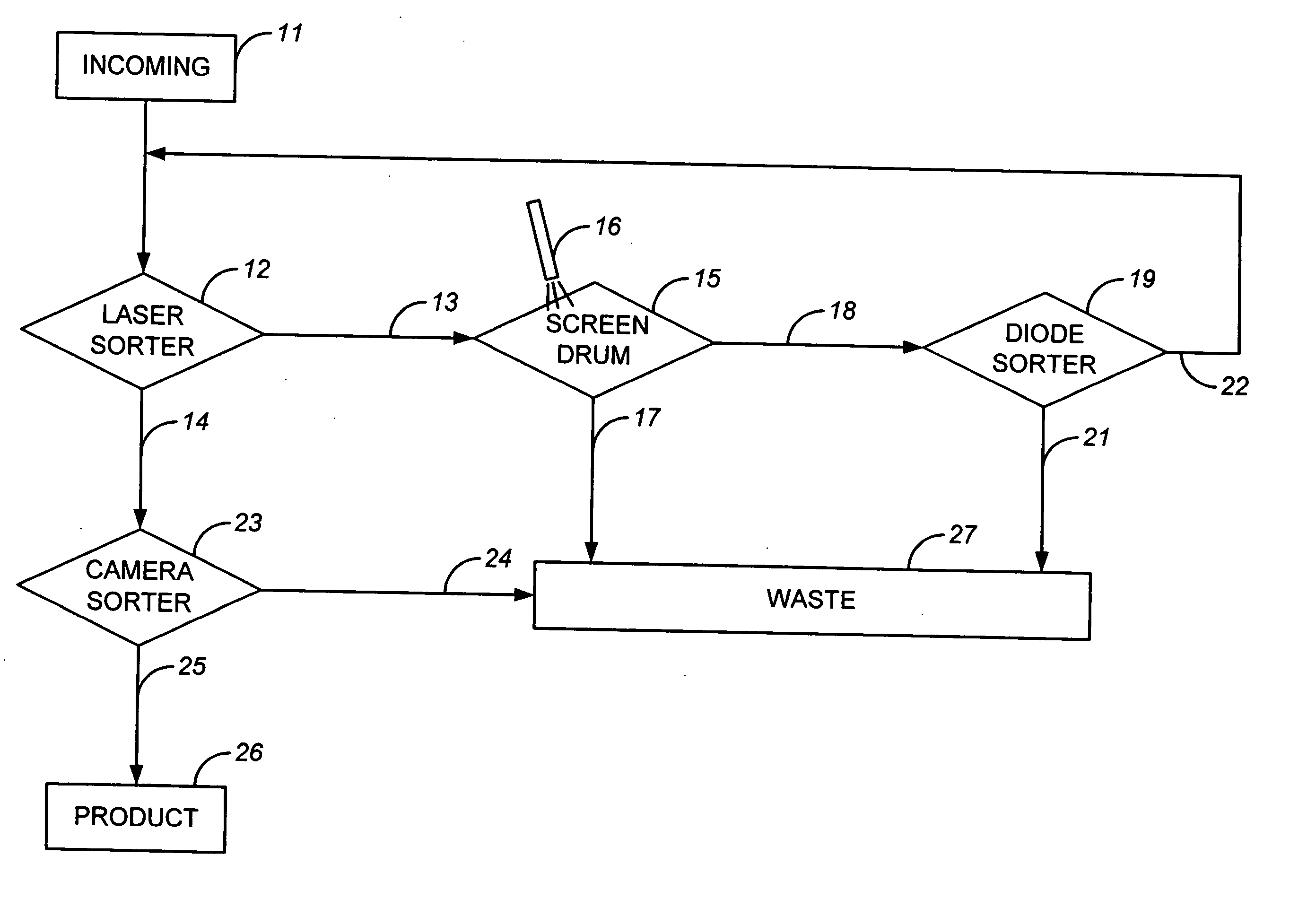

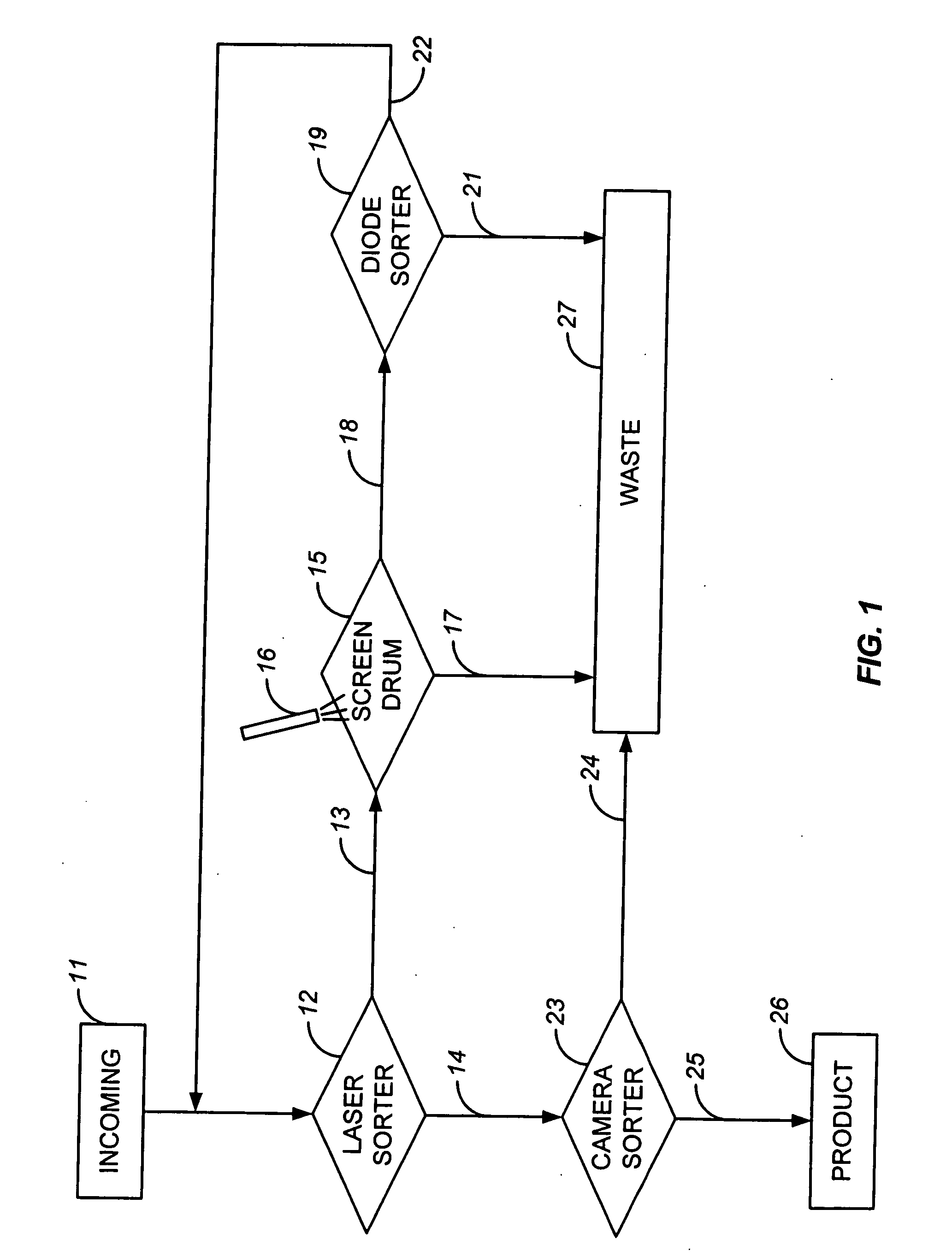

Process and system for sorting and pitting fruit

Drupaceous fruit pieces, including fruit flesh with and without pit matter adhering to the flesh as well as loose pits and pit pieces themselves, are passed through an integrated system of multiple sorting units utilizing different sorting methodologies. The sorting units include a laser-based sorting unit that sorts according to differences in light scattering, a diode-based sorting unit that sorts according to differences in light reflectance, and in certain embodiments a camera-based sorting unit that sorts according to differences in color. The system also includes an impact separator that dislodges pit material from fruit flesh from which the pit material has not been dislodged by any preceding units, most notably by pitting machinery through which the fruit has passed prior to entering the system of the invention.

Owner:SUNSWEET GROWERS

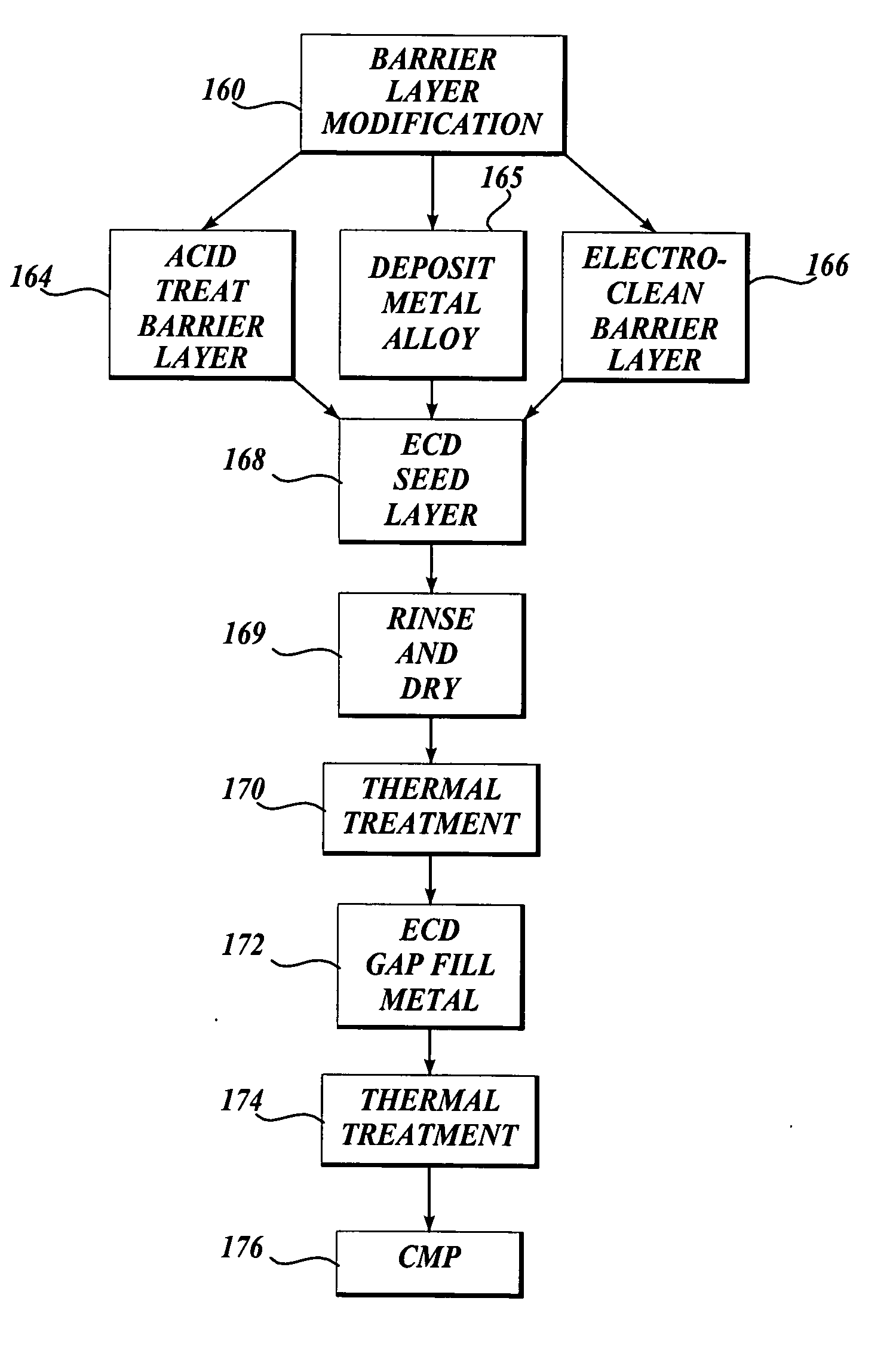

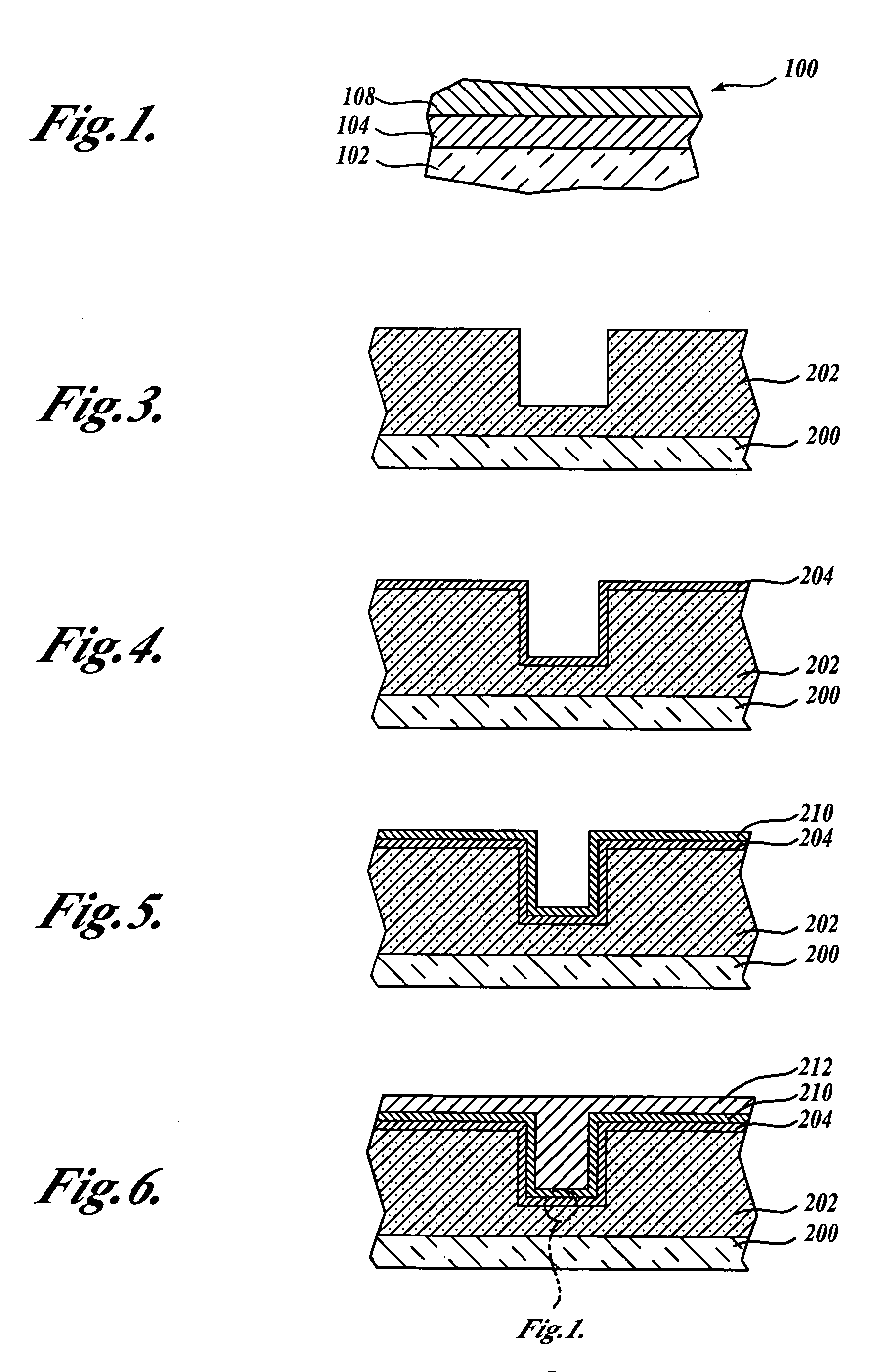

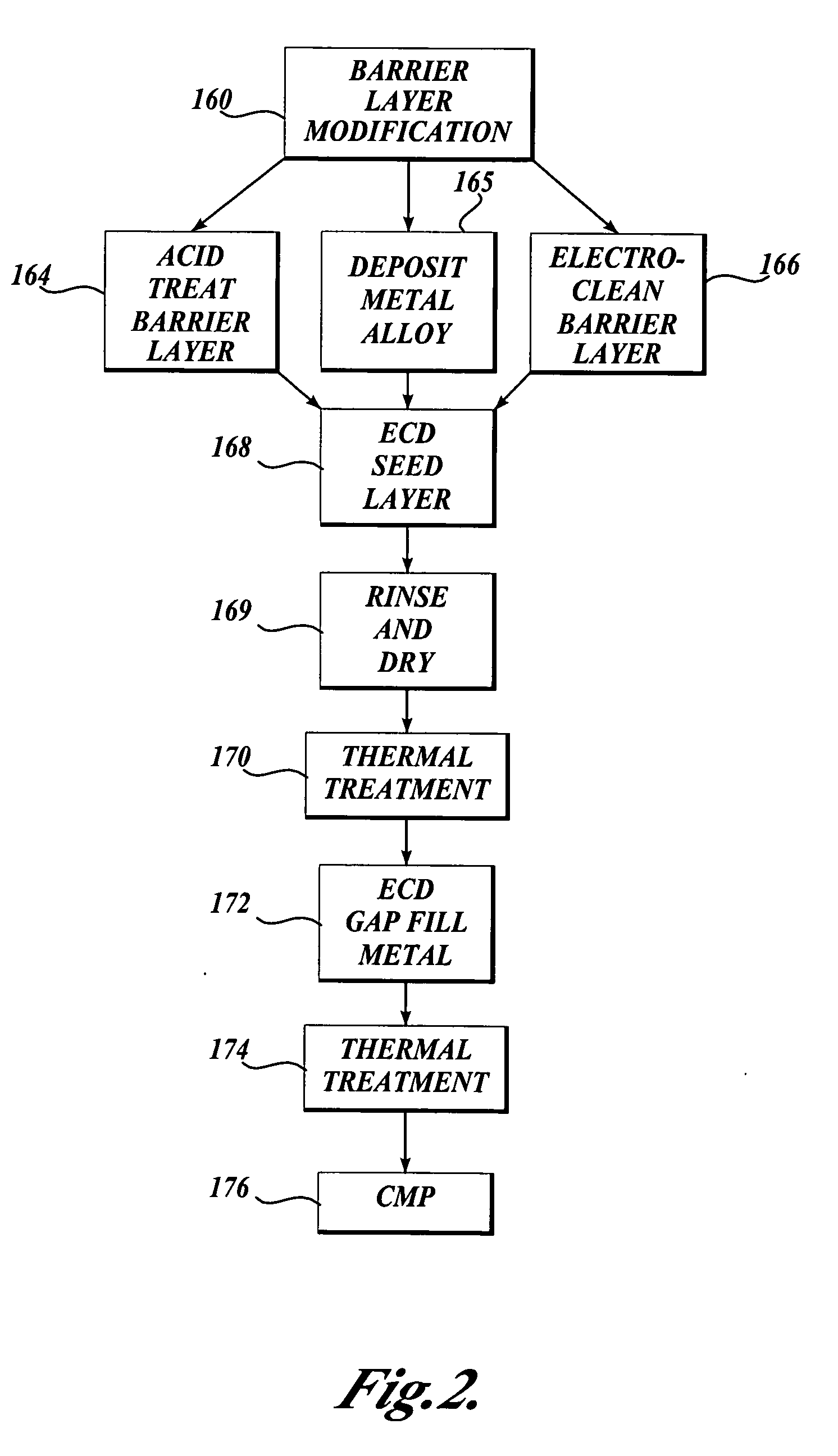

Method for applying metal features onto metallized layers using electrochemical deposition using acid treatment

InactiveUS20060079083A1Increase throughputIncrease product yieldSolid-state devicesSemiconductor/solid-state device manufacturingAcid treatmentDeposition process

The present invention is directed to a process for producing structures containing metallized features for use in microelectronic workpieces. The process treats a barrier layer to promote the adhesion between the barrier layer and the metallized feature. Suitable means for promoting adhesion between barrier layers and metallized features according to the invention include an acid treatment of the barrier layer, an electrolytic treatment of the barrier layer, or deposition of a bonding layer between the barrier layer and metallized feature. The present invention thus modifies an exterior surface of a barrier layer making it more suitable for electrodeposition of metal on a barrier, thus eliminating the need for a PVD or CVD seed layer deposition process.

Owner:SEMITOOL INC

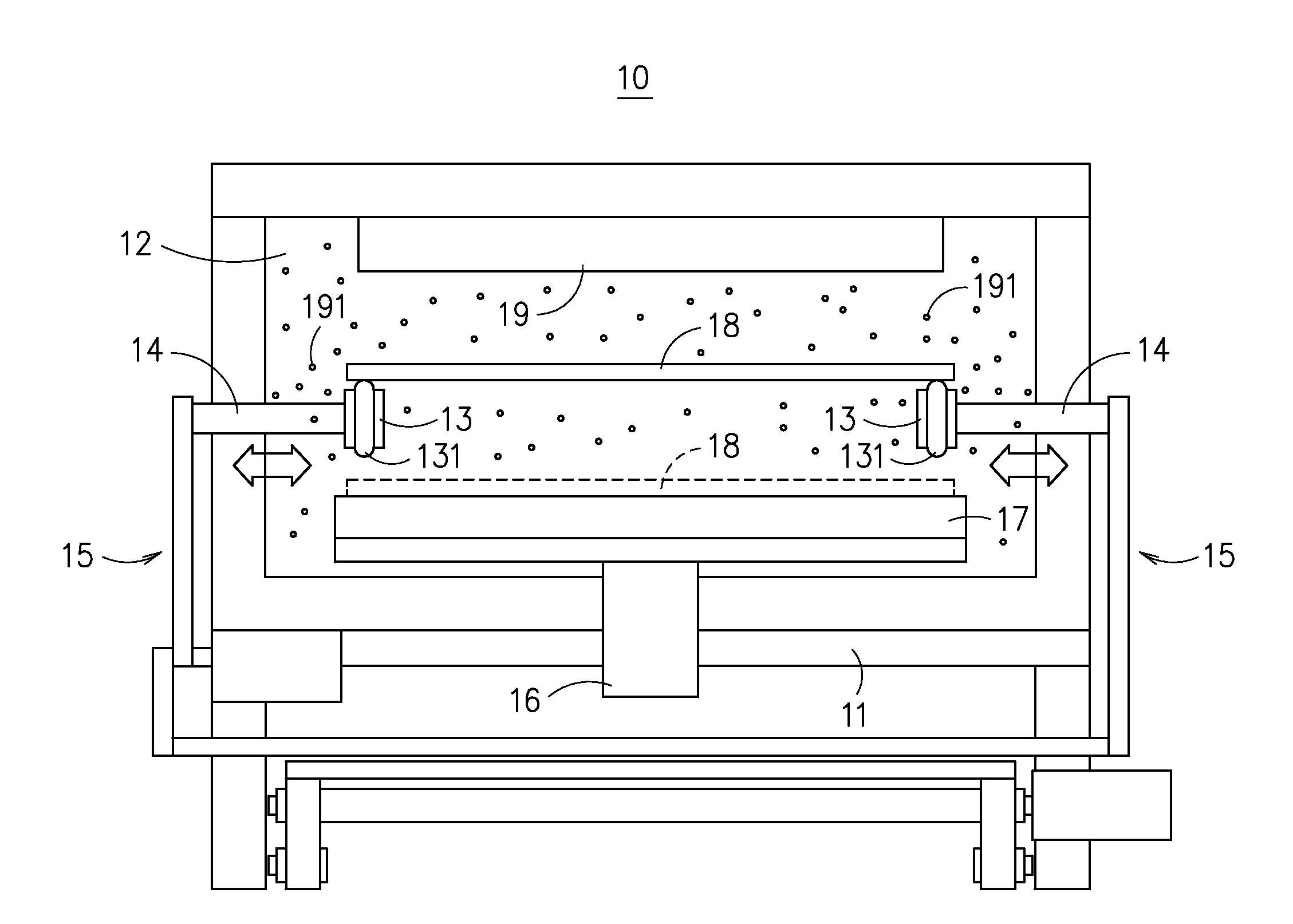

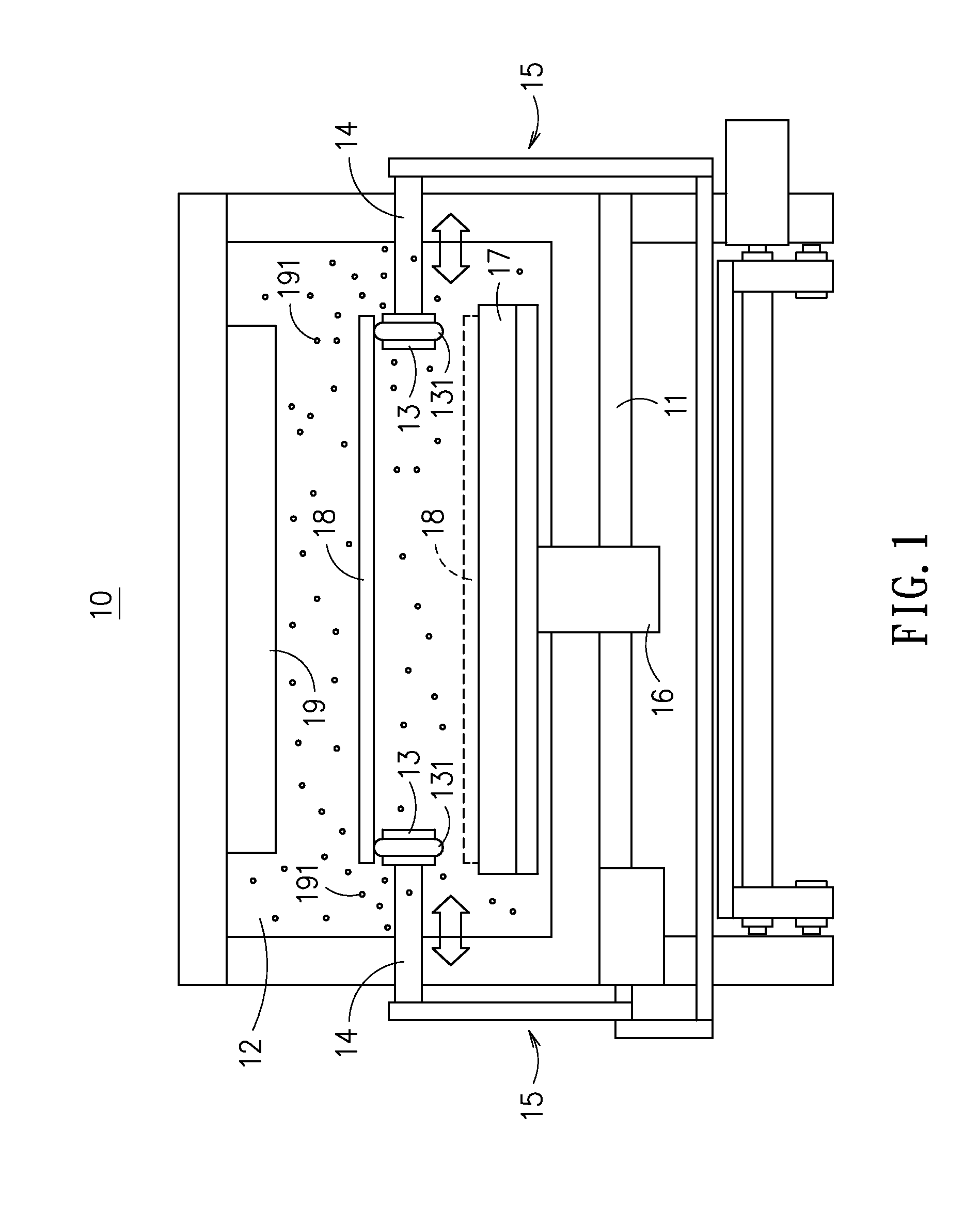

Transmission mechanism and the deposition apparatus using the same

InactiveUS20120240855A1Increase product yieldRun cost be decreaseGearboxesVacuum evaporation coatingEngineeringDrive wheel

The deposition apparatus has a plurality of said transmission mechanisms arranged therein in a symmetrical manner. Each transmission mechanism comprises: a drive shaft, formed with a tapered end; a driving wheel, configured with a shaft hole for the tapered end to bore coaxially therethrough; a plurality of slide pieces, radially mounted to the driving wheel; a first elastic member, mounted enabling the plural slide pieces to be ensheathed thereby; a second elastic member, disposed between the first elastic member and the first axial end of the drive shaft while being mounted to the periphery of the driving wheel; an enclosure, configured with an opening; wherein, the driving wheel that is moving in a reciprocating manner drives the sliding pieces to slide in radial directions, thereby, causing the outer diameter of the first elastic member to change accordingly and enabling the opening of the enclosure to open or close in consequence.

Owner:IND TECH RES INST

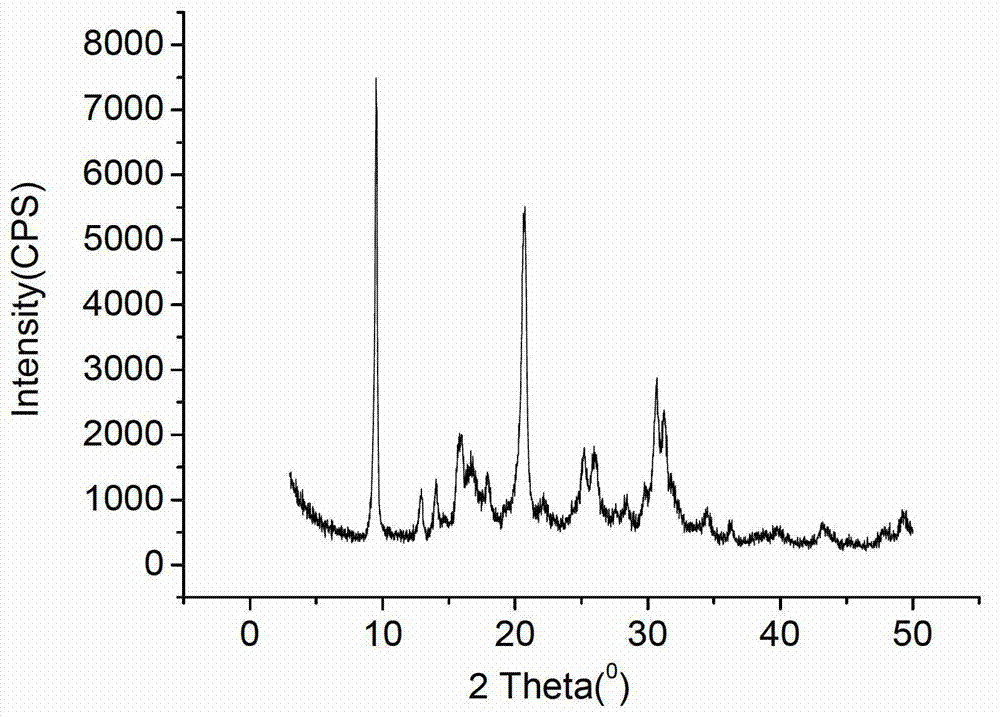

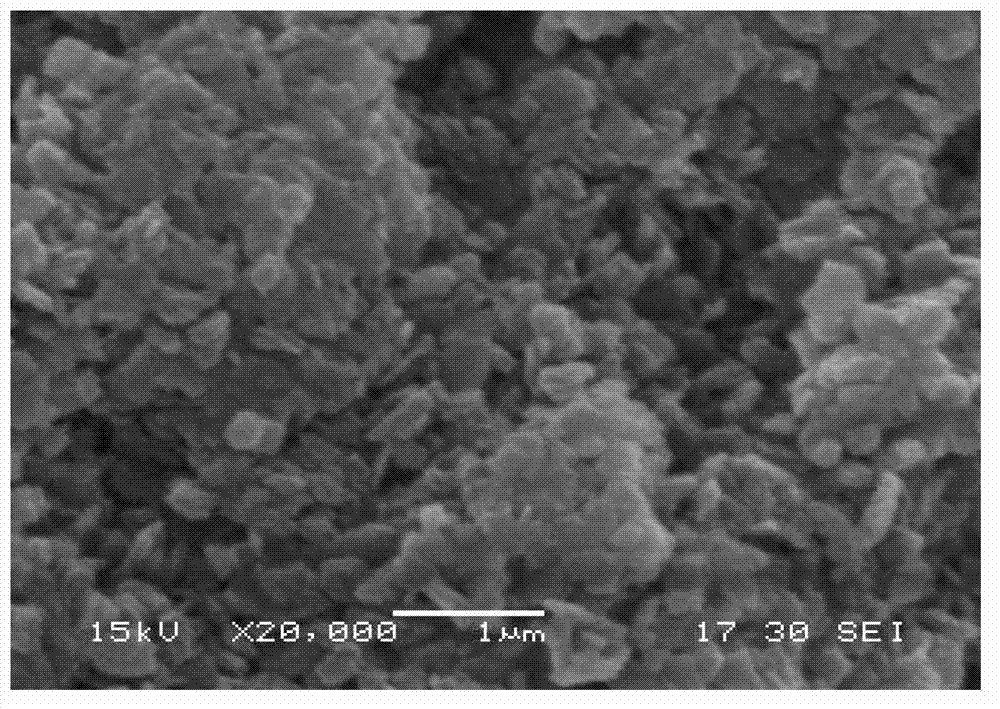

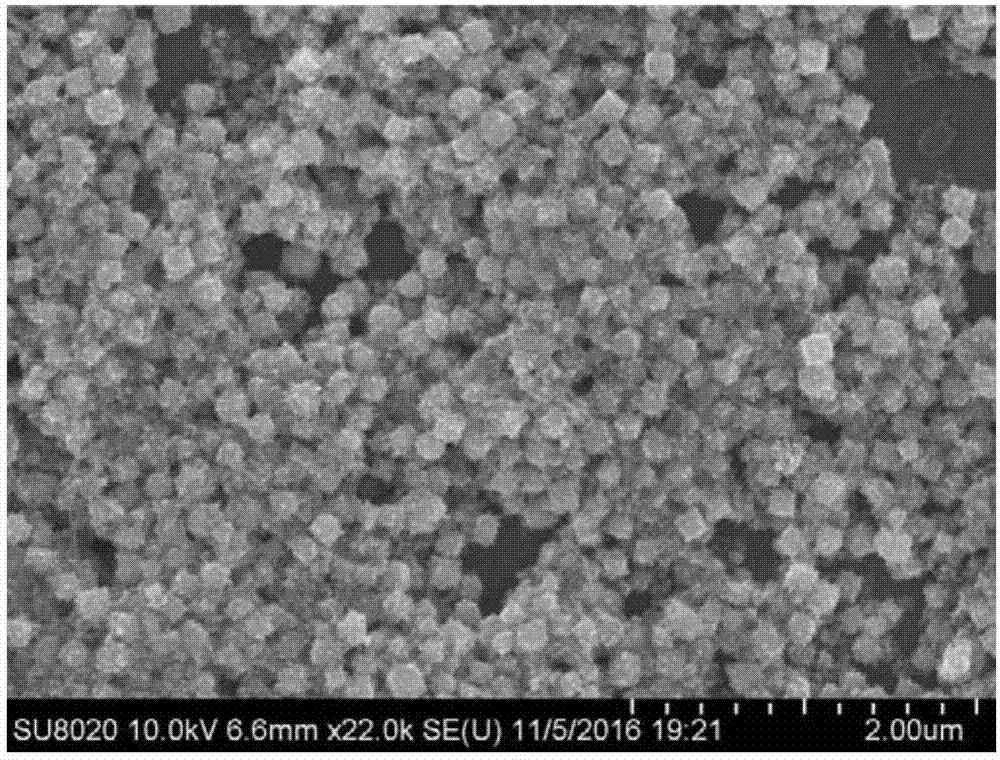

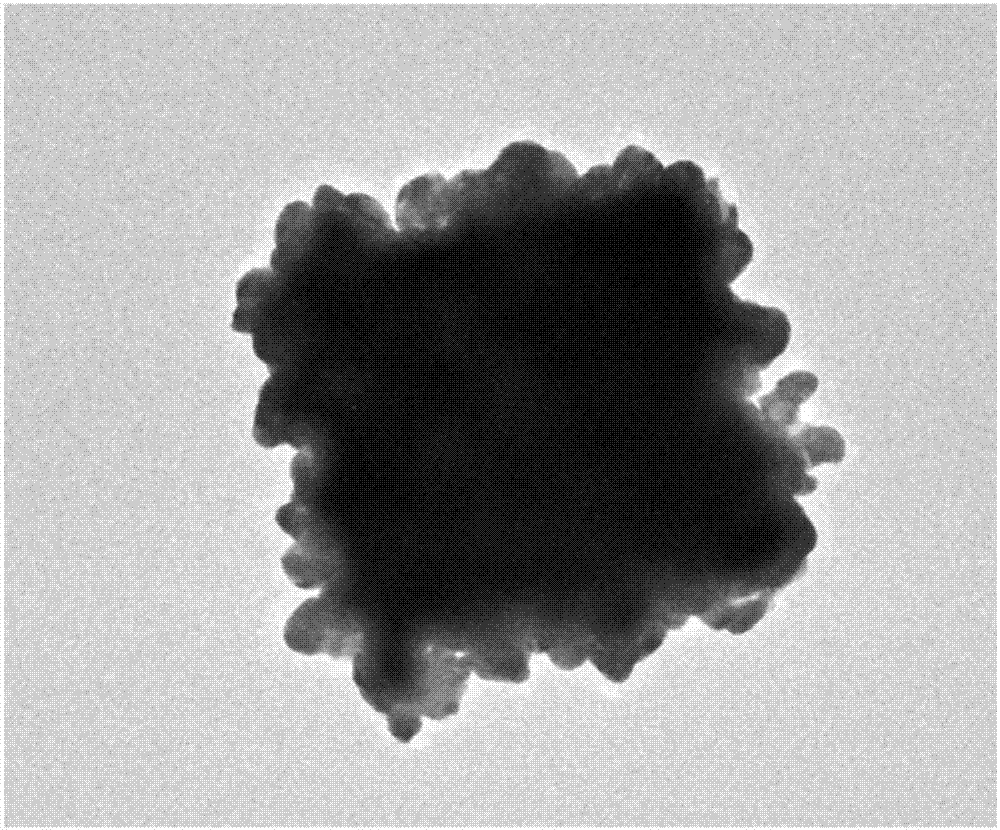

Method for preparing nano molecular sieve microspherical catalyst

ActiveCN102962095AImproves growth uniformityIncrease product yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsBoehmitePhosphoric acid

The invention relates to a method for preparing a nano molecular sieve microspherical catalyst. The method comprises the following steps of: mixing pseudo-boehmite, silica solution, phosphoric acid and a template agent in a rotary reaction tank, rotating the rotary reaction tank around a horizontal central shaft, heating and nucleating at the temperature of 100 to 160 DEG C for 2 to 4 hours, adding an abrasion-resistant carrier and water, heating by microwave at the temperature of 150 to 180 DEG C, crystallizing for 40 to 80 minutes, and obtaining the nano molecular sieve microspherical catalyst. Compared with the prior art, the method has the advantages that the process is simple and is suitable for production. The prepared nano molecular sieve microspherical catalyst is high in uniformity and has the characteristics of high specific area and high catalyst activity. The nano molecular sieve microspherical catalyst is applied to reaction of methyl alcohol and dimethyl ether in preparing low-carbon olefin, has the characteristic of low abrasion consumption and is favorable for industrial production.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

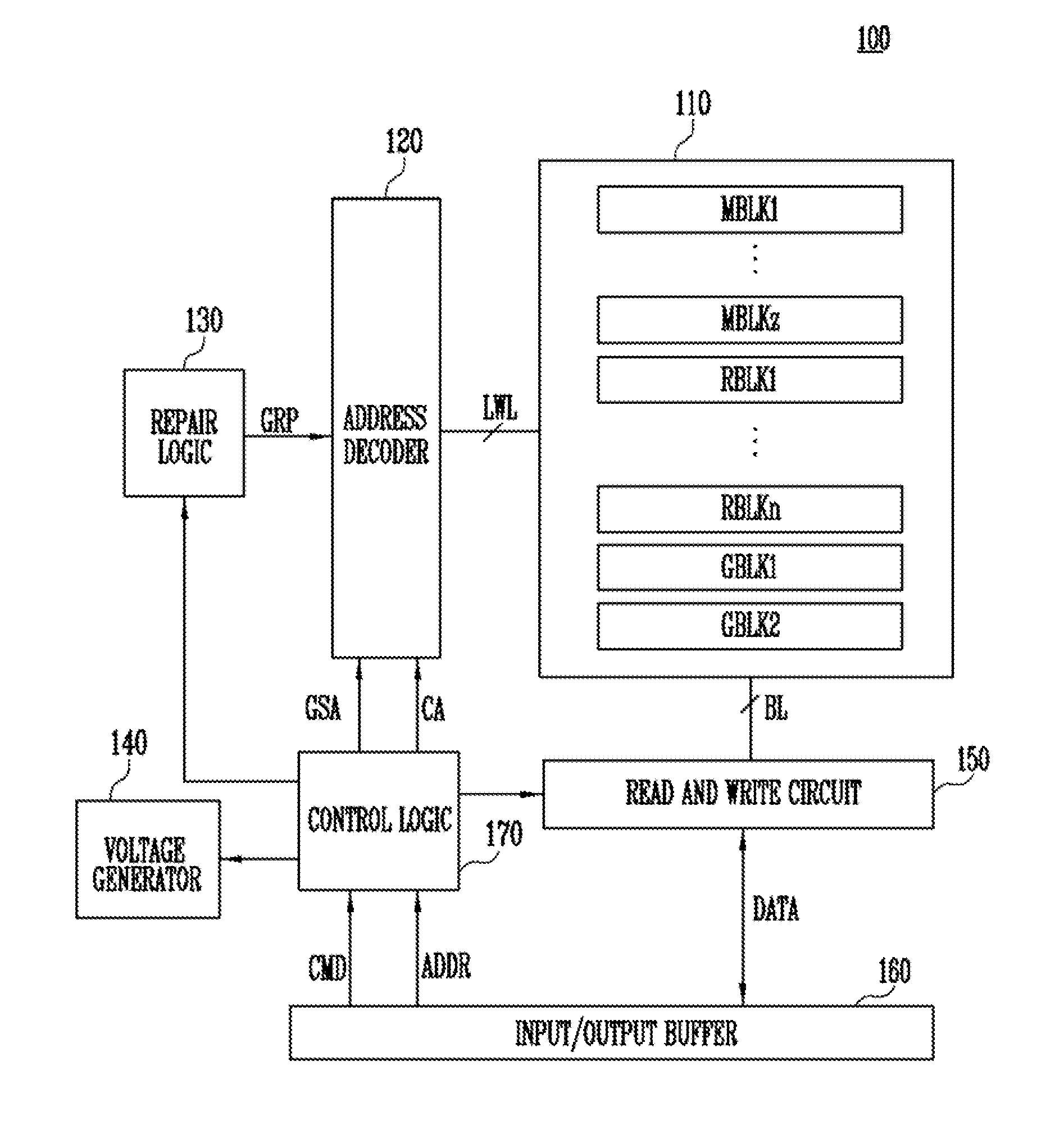

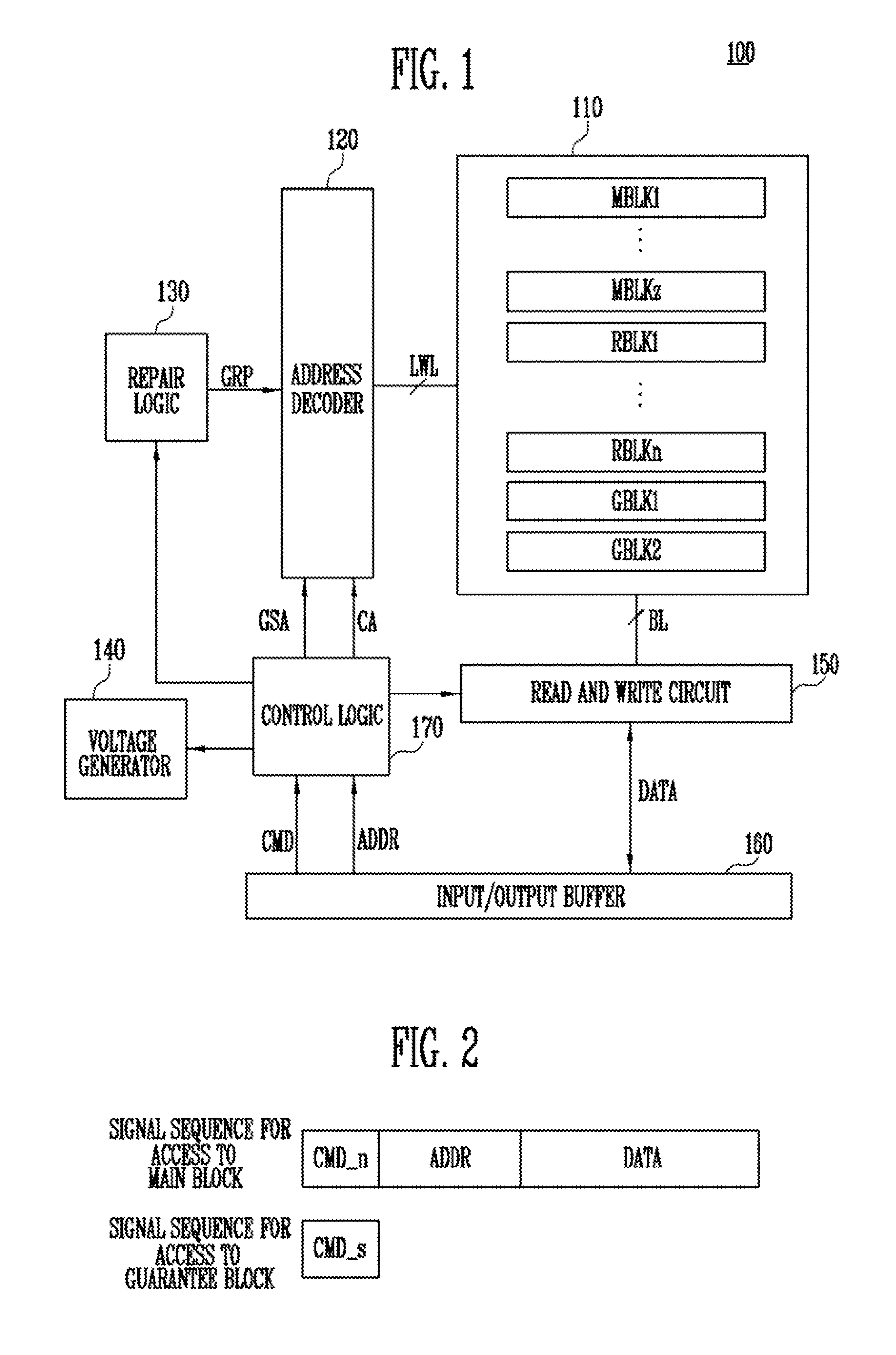

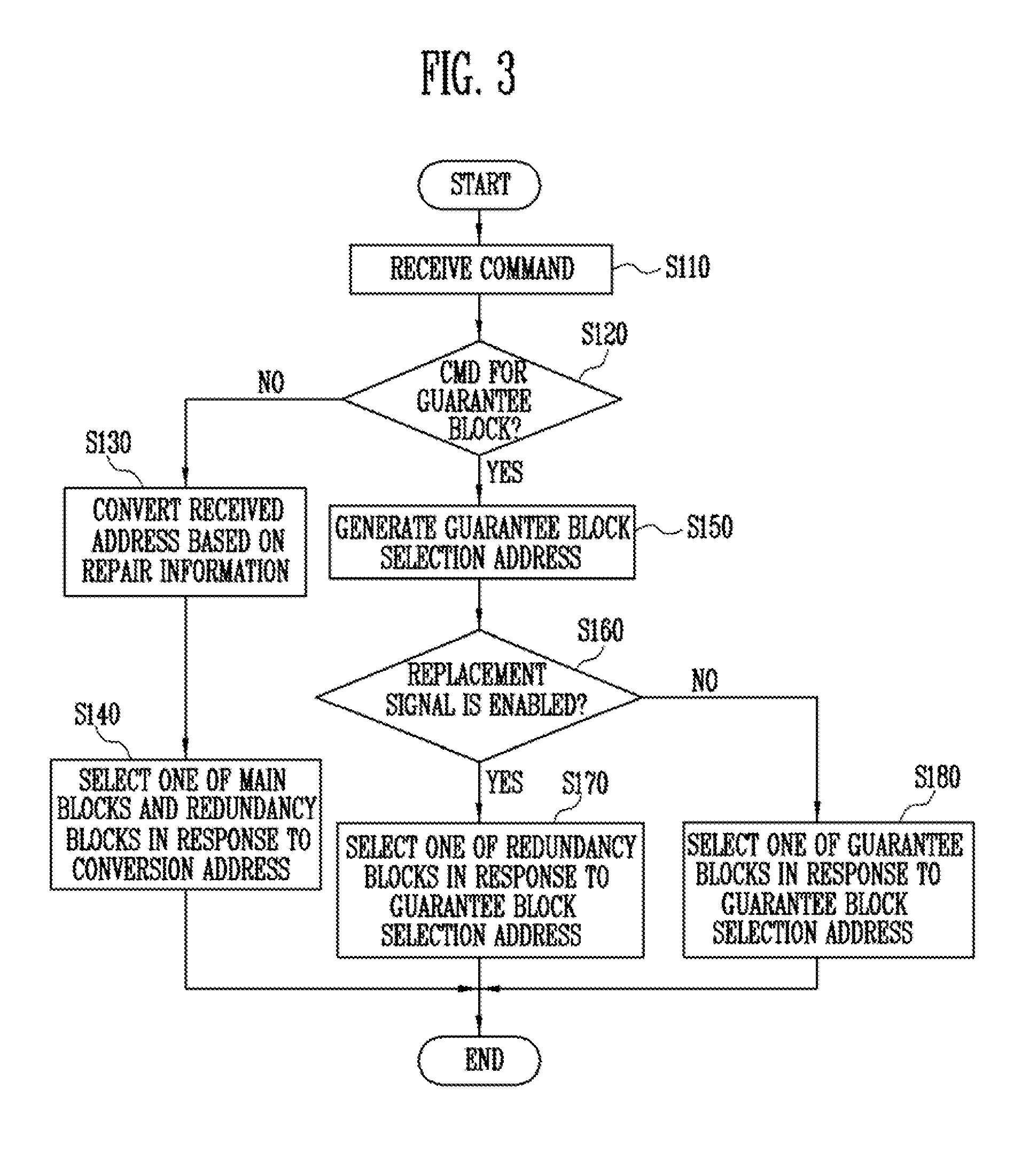

Semiconductor memory device and method of operating the same

ActiveUS20150135040A1Increase product yieldImprove production yieldRead-only memoriesRedundant hardware error correctionAddress decoderStorage cell

A semiconductor memory device includes a memory cell array having a first group of main blocks, a second group of main blocks and redundancy blocks replacing the first group of main blocks or the second group of main blocks, a repair logic suitable for enabling a replacement signal when one or more of the second group of main blocks are defective, a control logic suitable for generating an address for the second group of main blocks in response to a dedicated command for access to one or more of the second group of main blocks, and an address decoder suitable for selecting one or more of the redundancy blocks based on the address for the second group of main blocks when the replacement signal is enabled.

Owner:SK HYNIX INC

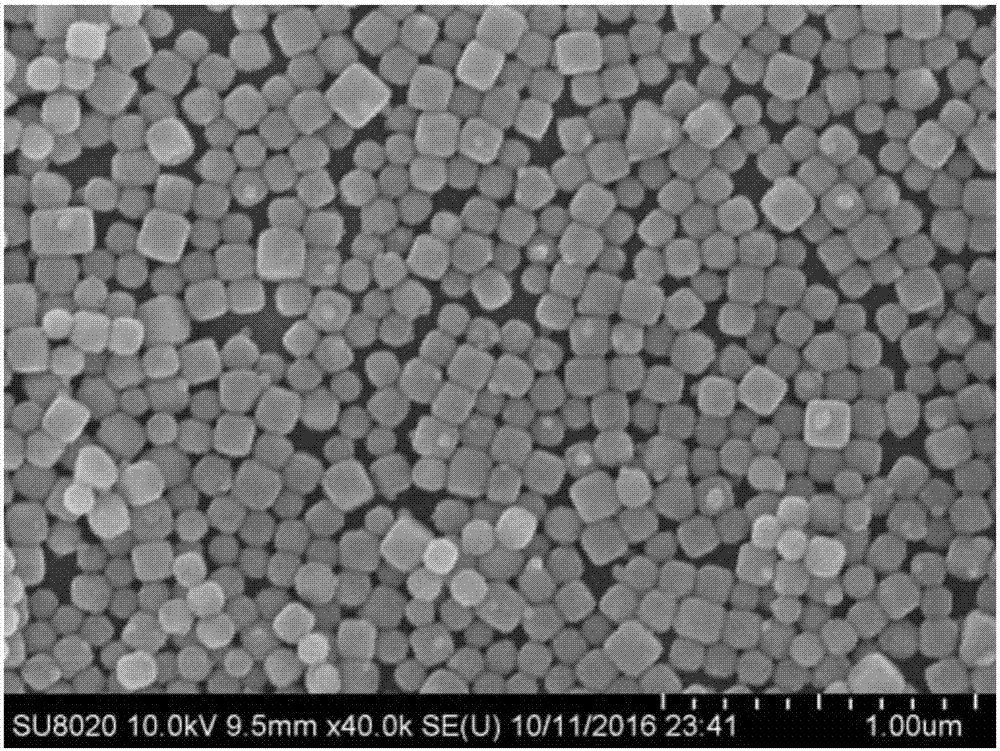

Method for preparing silver/silver chloride composite nanocube

ActiveCN107159275AEasy to operateIncrease product yieldMaterial nanotechnologyPhysical/chemical process catalystsNanometreAllylamine

The invention discloses a method for preparing silver / silver chloride composite nanocubes. The method comprises the following steps: by taking poly(allylamine) hydrochloride as a stabilizer, firstly, adding certain ratios of silver nitrate and sodium chloride or potassium chloride to synthesize silver chloride nanocubes, and performing diglycol reduction on the obtained silver chloride nanocubes, thereby obtaining the silver / silver chloride composite nanocubes. By adopting the method, a relatively long reaction time is not needed, a complex pH regulation process is not needed, the operation is simple, the amount of reduced Ag is effectively controlled by controlling the reduction reaction time, then the silver / silver chloride composite nanocubes which are high in yield, high in purity and controllable in component are prepared, and moreover the obtained nanocubes are regular in shape, uniform in size and applicable to large-scale production.

Owner:SHAANXI NORMAL UNIV

Reactive compensation structure for metallurgical submerged-arc furnace

InactiveCN102222926AReduce energy consumptionIncrease product yieldReactive power adjustment/elimination/compensationReactive power compensationEngineeringEnergy consumption

The invention relates to a reactive compensation structure for a metallurgical submerged-arc furnace, comprising an electric furnace transformer connected with input current; the backward position of the electric furnace transformer is connected with an electric furnace body by a short network; a main circuit is connected in parallel with a medium voltage compensation unit at the medium voltage side of the electric furnace transformer; and a low voltage compensation unit is connected in parallel at the front end of the short network. The reactive compensation structure of the metallurgical submerged-arc furnace has the advantages of reducing the energy consumption of the metallurgical submerged-arc furnace, achieving the aim of saving energy and reducing consumption, simultaneously keeping the natural power factor of the metallurgical submerged-arc furnace more than 0.9, improving product output and running stably.

Owner:四川伟力得能源股份有限公司

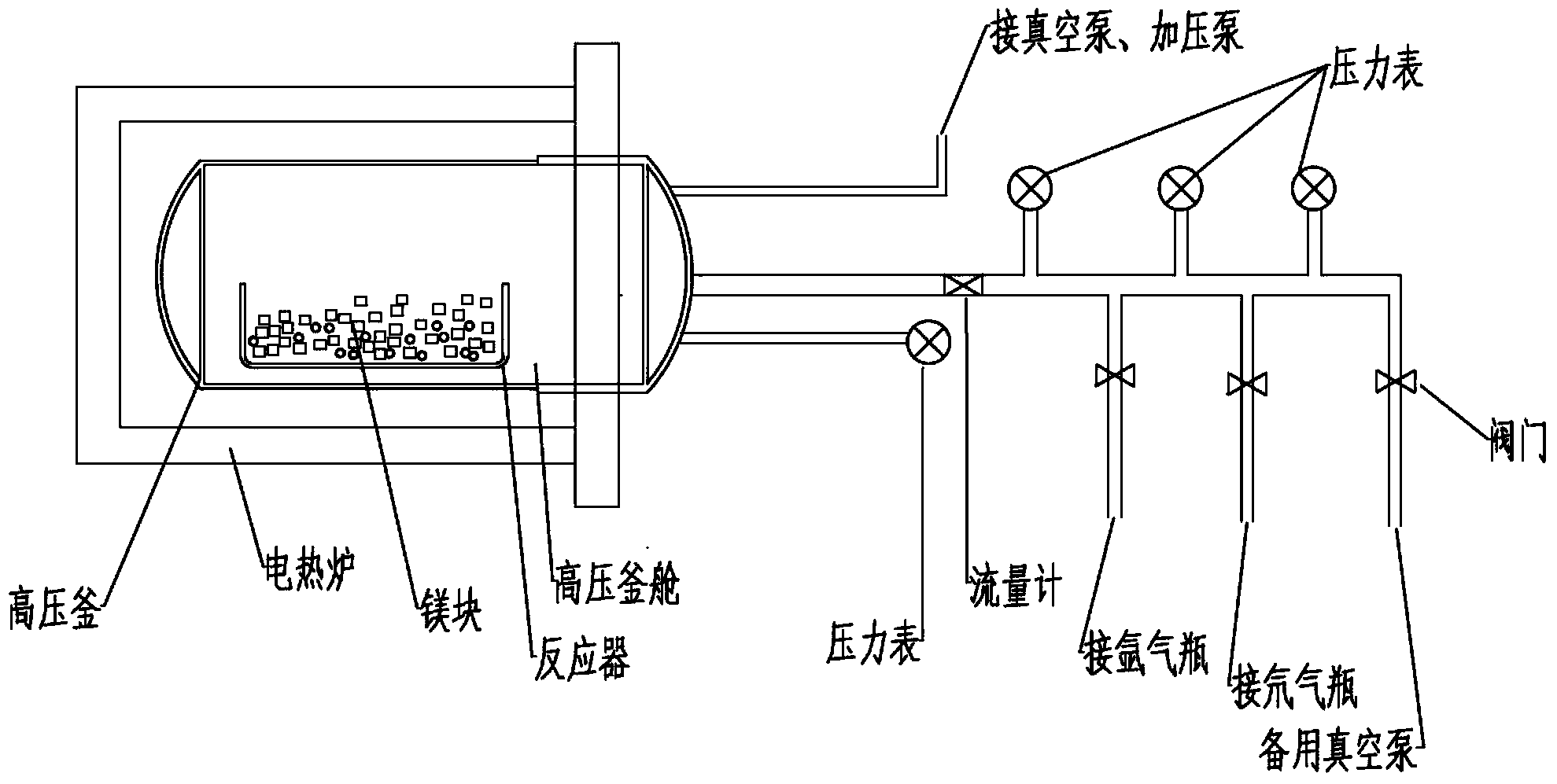

Method for preparing magnesium deuteride by adopting high-temperature direct process

ActiveCN104176750ASimple operation processIncrease product yieldMagnesium compoundsMagnesiumDeuterium

The invention relates to a method for preparing magnesium deuteride by adopting a high-temperature direct process, belonging to the crossing field of material science and nuclear technology. According to the method, magnesium reacts with deuterium gas at the high temperature to generate magnesium deuteride; the problems of large-scale industrialized preparation technology and preparation purity of magnesium deuteride are solved, no complicated production device is used, the required preparation device is simple and easily purchased, and a magnesium deuteride production line can be safely built under the existing factory conditions; a preparation process is simple and easy to carry out and is safe and reliable due to protection of inert gas; the product yield is relatively high, the product purity and stability are relatively good, and magnesium deuteride can be stored for a long term; no three wastes are generated in the preparation process, and the preparation process is harmless to a human body and the environment, is environment-friendly and is of great significance on large-scale industrialized safe preparation and large-scale application of high-purity magnesium deuteride.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

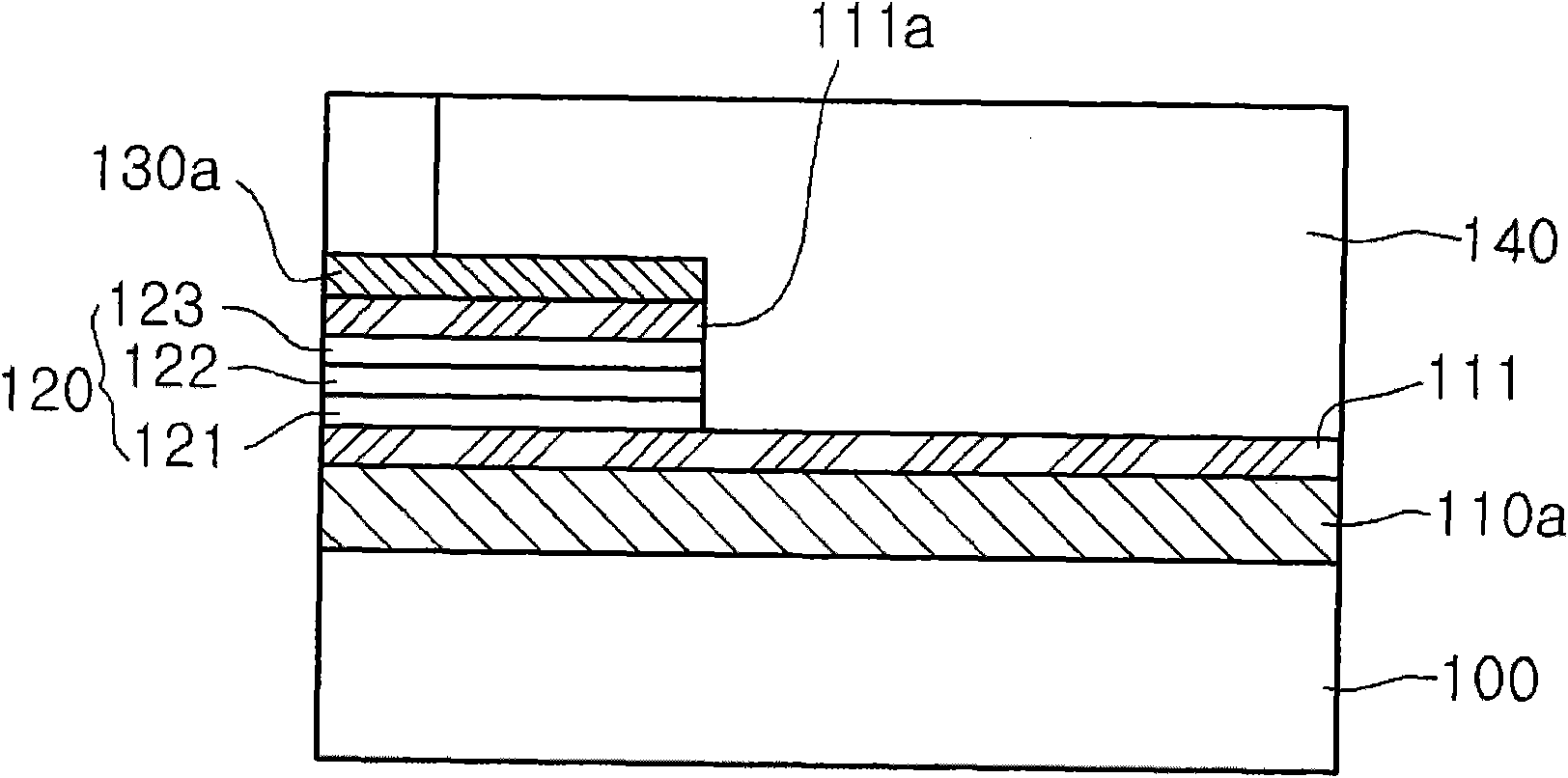

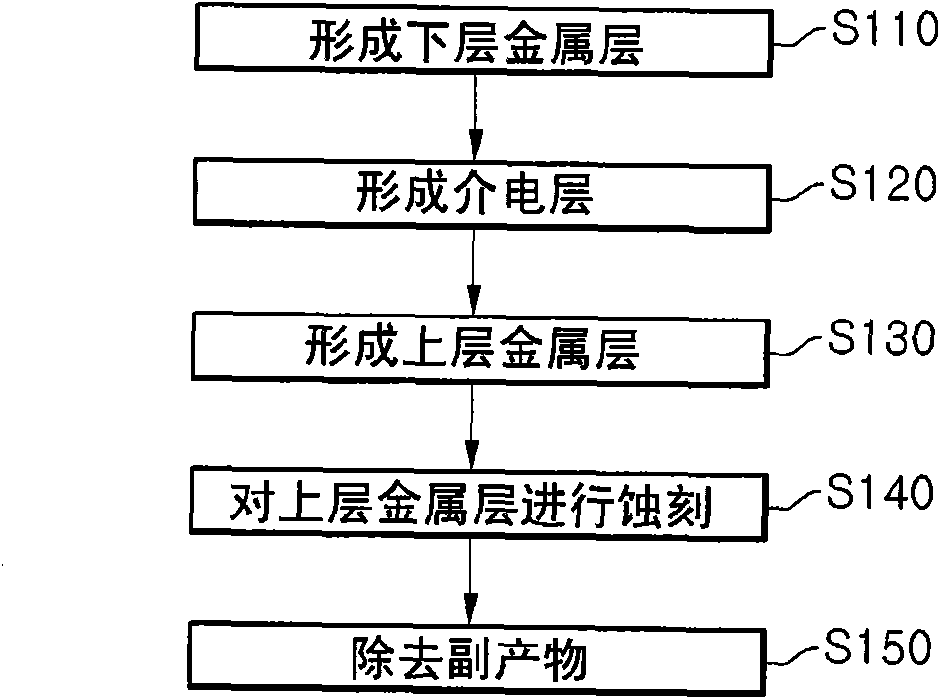

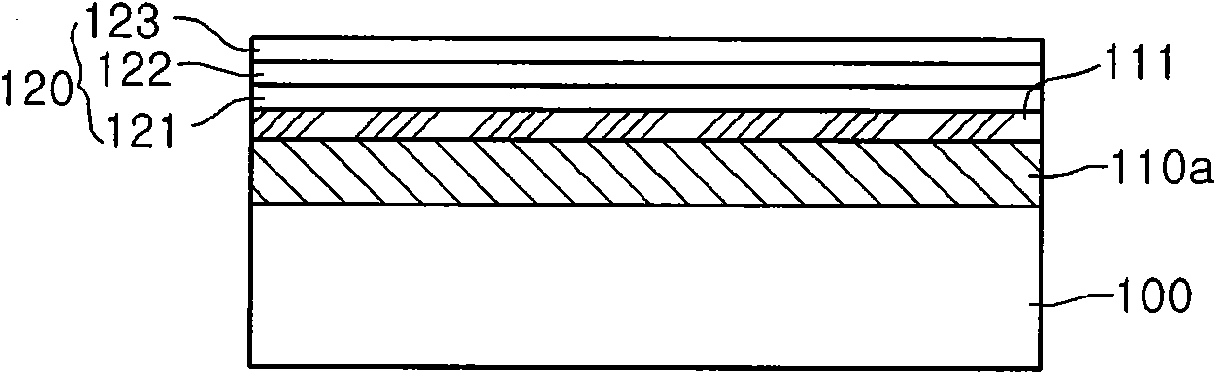

Method for manufacturing capacitor of semiconductor device

InactiveCN101599426AAvoid short circuitIncrease product yieldTransistorSemiconductor/solid-state device manufacturingReactive-ion etchingDielectric layer

A method for manufacturing a capacitor of a semiconductor device includes forming a lower metal layer over a substrate, forming a dielectric layer over the lower metal layer, forming an upper metal layer over the dielectric layer, forming an upper electrode and a dielectric layer pattern by performing a reactive ion etching process with respect to the upper metal layer using the dielectric layer as an etch stop layer, and exposing a top surface of the lower metal layer, and performing a chemical down-stream etch (CDE) process to remove a by-product of a sidewall of the upper electrode.

Owner:DONGBU HITEK CO LTD

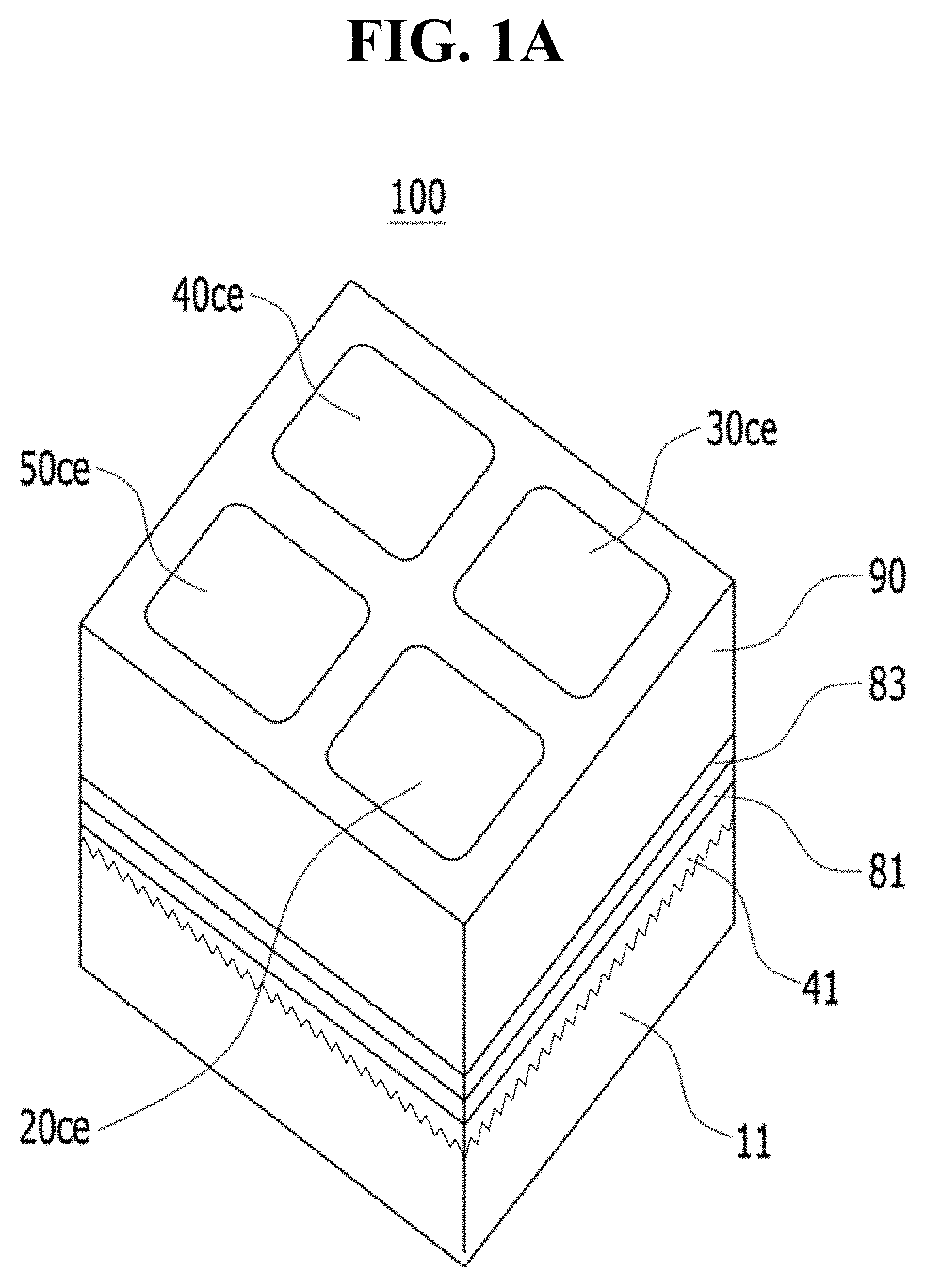

Light emitting device for display and light emitting package having the same

ActiveUS20210082887A1Reduce timeIncrease product yieldSemiconductor/solid-state device detailsSolid-state devicesLong wavelengthDisplay device

A light emitting device for a display including a first LED sub-unit, a second LED sub-unit disposed on the first LED sub-unit, and a third LED sub-unit disposed on the second LED sub-unit, in which the third LED sub-unit is configured to emit light having a shorter wavelength than that of light emitted from the first LED sub-unit, and to emit light having a longer wavelength than that of light emitted from the second LED sub-unit.

Owner:SEOUL VIOSYS CO LTD

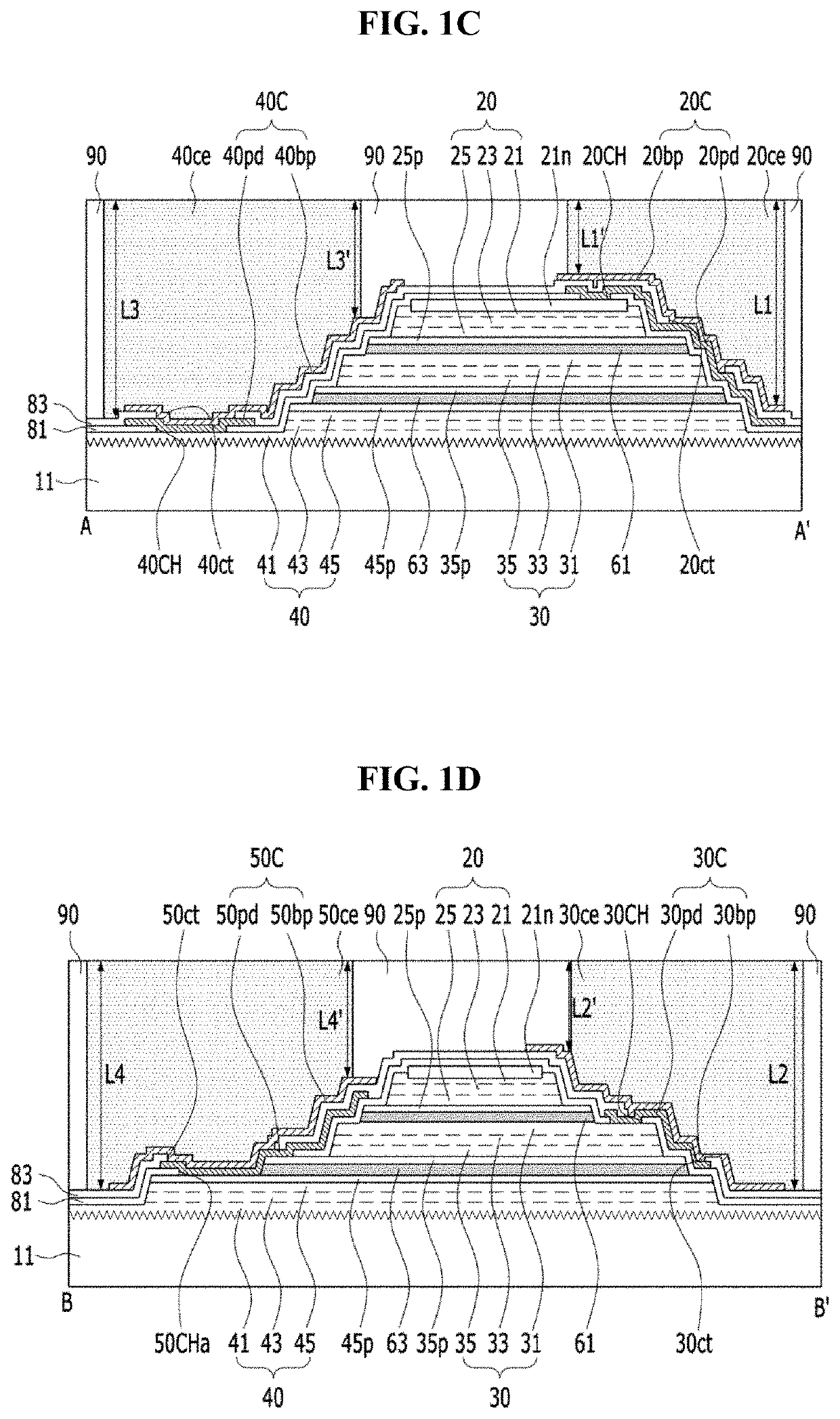

Multi-functional upper expanding device for producing antimony trioxide

ActiveCN103508490APromote aggregationWon't cause cloggingAntimony compoundsEngineeringAntimony trioxide

A multi-functional upper expanding device for producing antimony trioxide comprises an inlet pipe, an abdomen pipe, and an air exhausting pipe, wherein the inlet pipe, the abdomen pipe and the air exhausting pipe are orderly connected and communicate with each other; the inner diameter of the abdomen pipe is larger than those of the inlet pipe and the air exhausting pipe; the inlet end of the inlet pipe is arranged on the outlet end of the antimony trioxide reaction chamber, and the outlet end of the air exhausting pipe is connected to the inlet end of the antimony trioxide crystallization device. The multi-functional upper expanding device can adjust the particle size of antimony trioxide product at will, effectively controls the antimony trioxide product quality, timely recycles the agglomerated oxides generated during the antimony trioxide production process, and improves economic and technical indexes such as product yield, and the like.

Owner:湖南黄金股份有限公司 +1

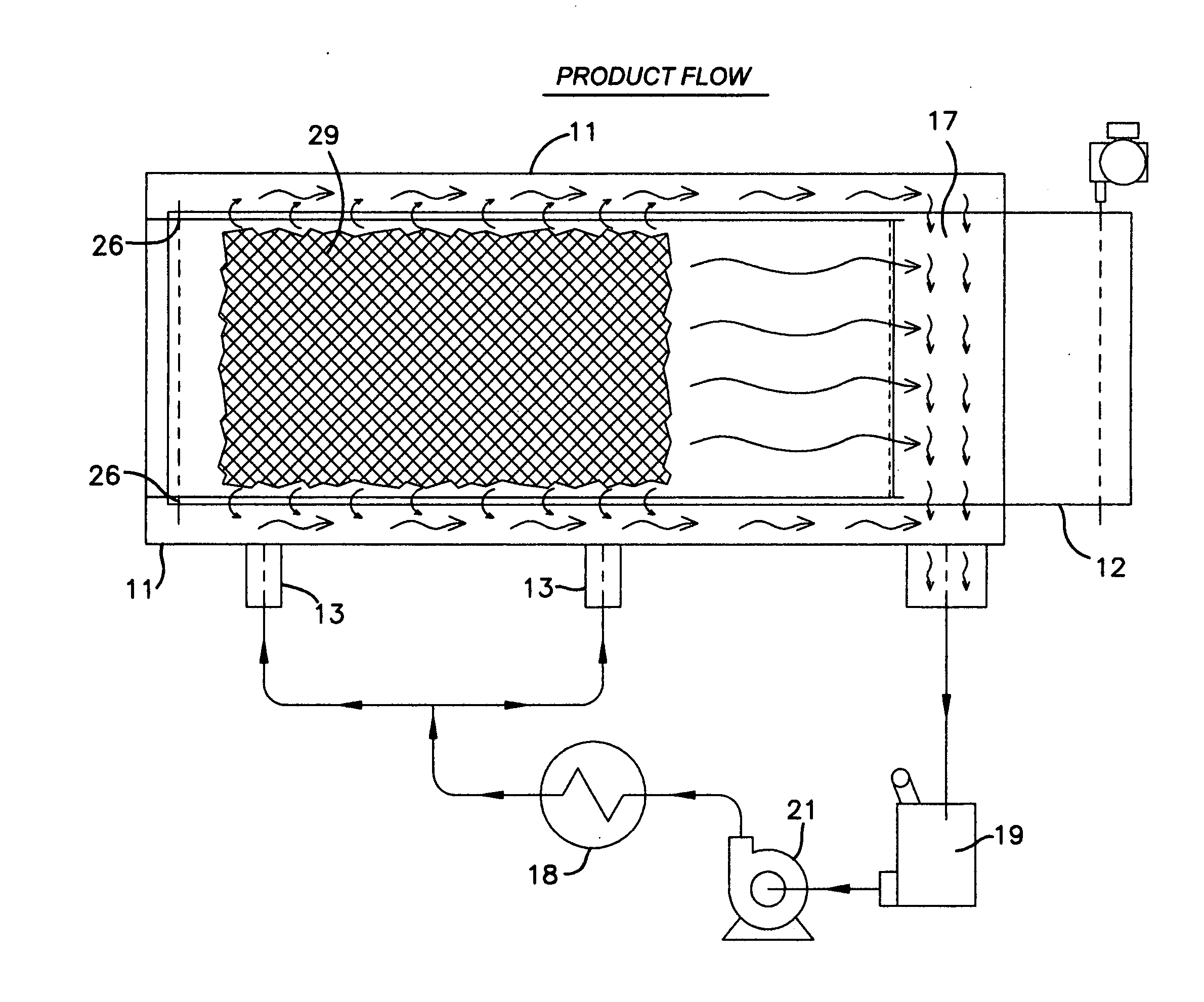

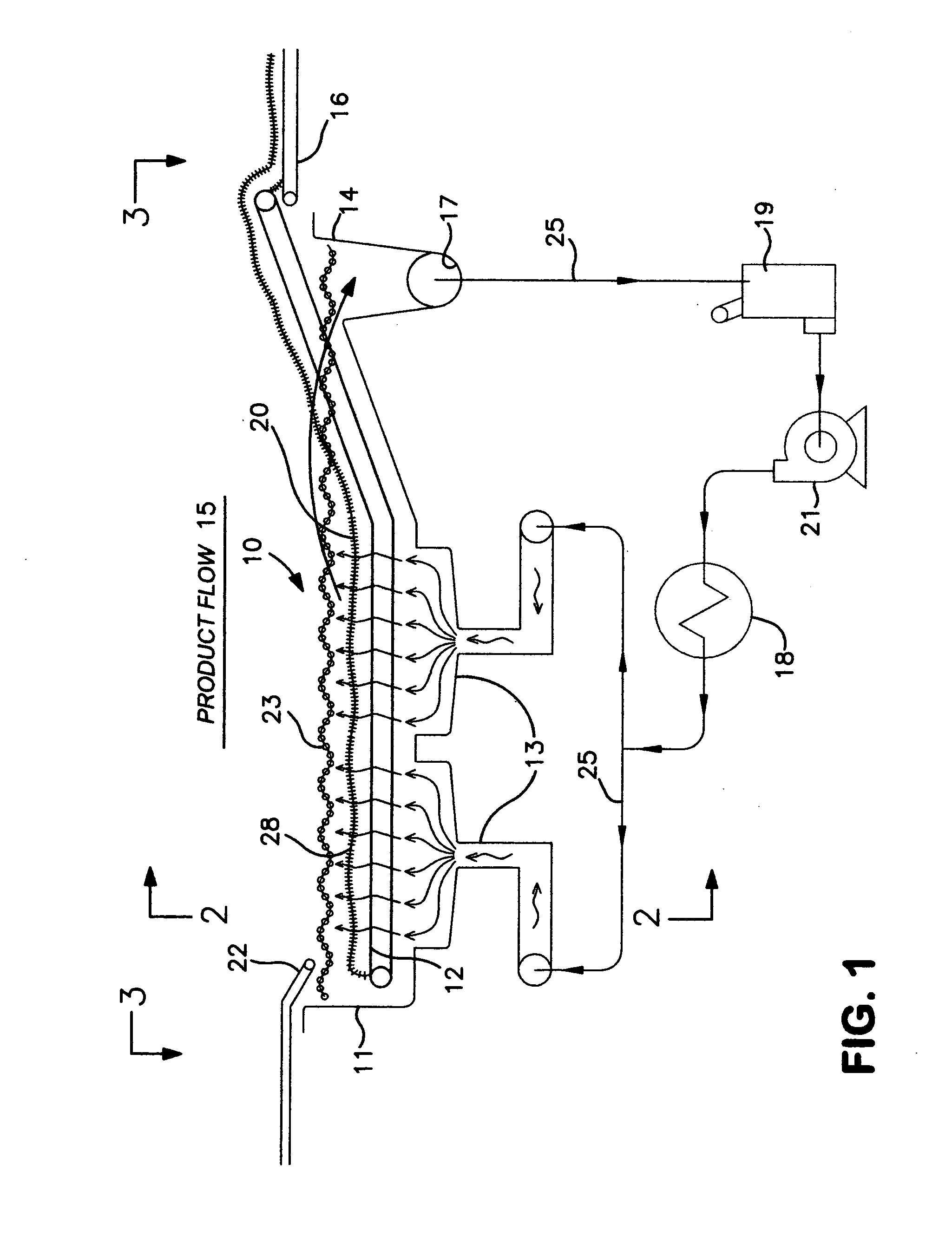

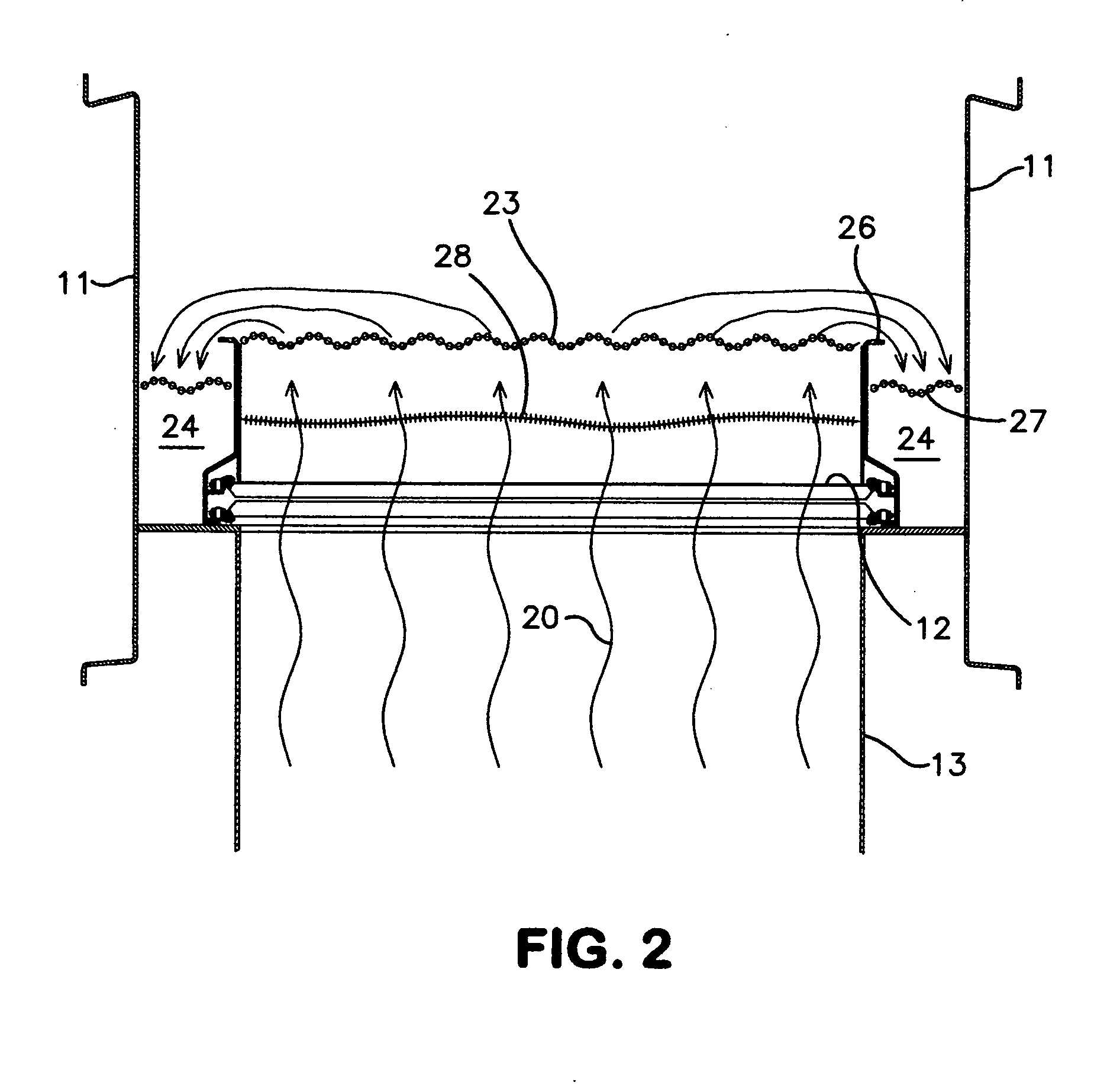

Vertical flow french fryer

ActiveUS20100227035A1Increase product yieldImprove uniformityFood preparationDeep fat fryersEngineeringConveyor belt

Cooking of French fried potatoes by facilitating a generally vertical arrangement of potato strips while in the frying operation is disclosed wherein the slices may be cooked within a very deep pack while oil is urged to flow upwardly through the pack and steam entrapment within the cooking slice pack is minimized. A conveyor belt carrying the slices through the cooker has a multiplicity of openings facilitating oil flow there through and the cooker is configured to permit oil discharge for reheating purposes both laterally and longitudinally of the processing path.

Owner:HEAT & CONTROL

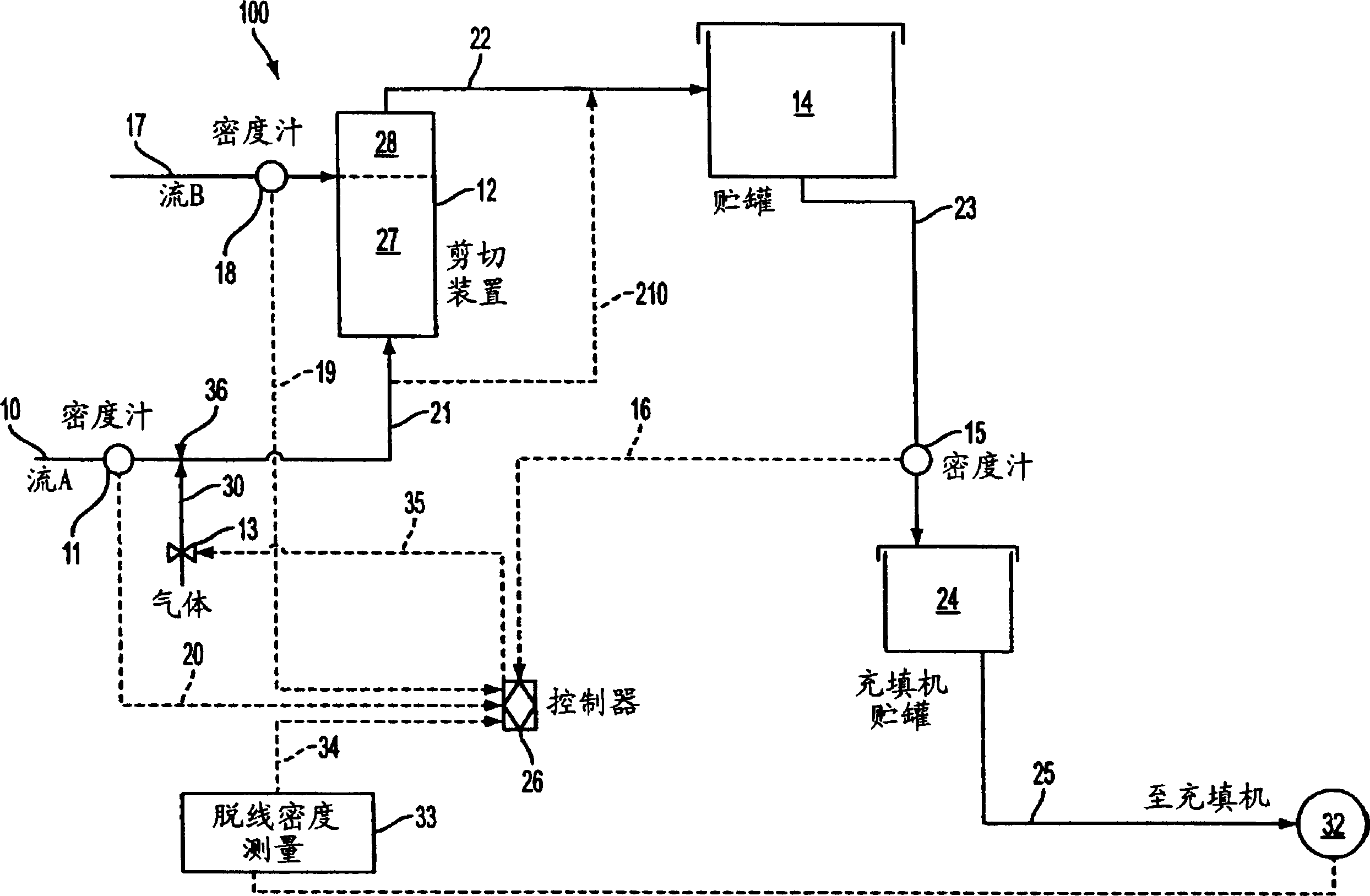

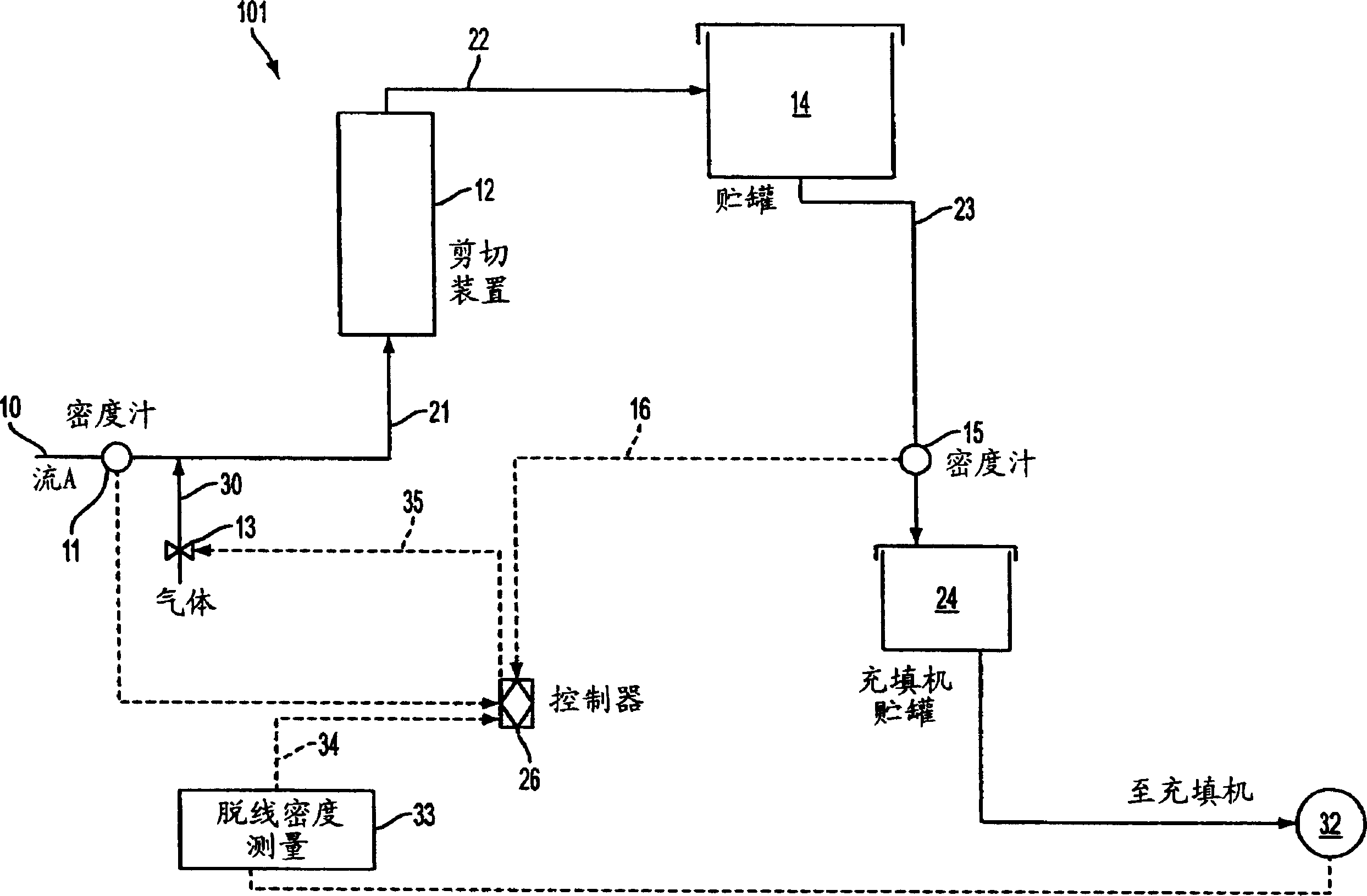

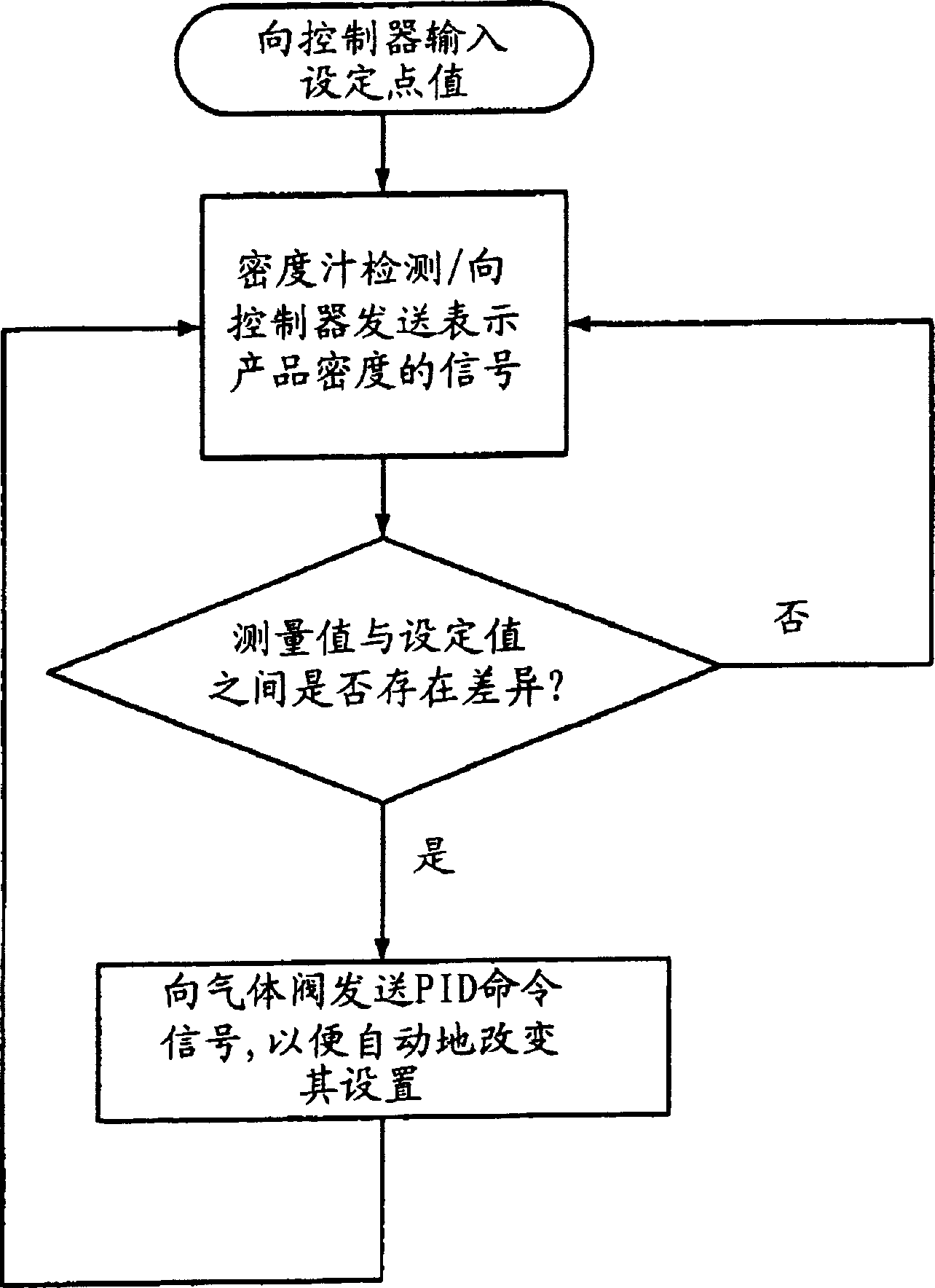

Method and system for controlling product density

InactiveCN1795758AReduce solubilityDensity characteristic monitoringCocoaOther dairy technologySolubilityProduct gas

Method and system for controlling the density to a predetermined level of an edible aerated foodstuff product during the preparation thereof A density measurement is acquired on the aerated product at a location sufficiently downstream of a shearing unit used to form the aerated material such that the product is in an equilibrated state. Consequently an adjustment can be made in the introduction rate of aeration gas at a location upstream of the shearing unit which is calculated to reduce any difference between the predetermined and measured product densities in a precise and reliable manner. Also, injection gas of reduced solubility may be used so that product density can reach equilibrium sooner. Upstream disturbances in the density of a formulation starter material also may be monitored and countered by adjustments made in the gas flow rate to assist in maintaining a desired product density.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Plasma display panel and manufacturing method of the same

InactiveUS20060181211A1Improve mechanical strengthIncrease product yieldIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationEngineeringPlasma display

A plasma display panel and manufacturing process therefor, providing an improved barrier rib strength in an opposing discharge structure. The plasma display panel may include a front substrate and a rear substrate, address electrodes extending in a predetermined direction on the rear substrate, and a barrier rib layer disposed between the front and rear substrates for defining a plurality of discharge spaces. The barrier rib layer includes barrier rib members for defining the plurality of discharge spaces, and display electrodes forming opposing electrodes with the discharge spaces therebetween, with grooves formed in a direction crossing the address electrodes on the barrier rib members facing the front substrate, and inner surfaces of the grooves that are coated with display electrodes.

Owner:SAMSUNG SDI CO LTD

Method for producing potassium dihydrogen phosphate with feed grade calcium hydrogen phosphate

ActiveCN103879980BIncrease product yieldIncrease productionPhosphorus compoundsPotassiumPotassium hydroxide

Owner:上海新增鼎数据科技有限公司

Method for producing anti-evolving-gas additive of transformer oil and its using method

InactiveCN1254523CReduce pollutionEasy to dehydrateHydrocarbon oils refiningDistillates petroleumBoiling point

The production method of the transformer oil anti-gassing additive of the present invention is as follows: firstly, the petroleum distillate with a boiling point of 250 to 500° C. is used as a raw material, and cobalt-molybdenum, nickel-molybdenum, tungsten-nickel, molybdenum-cobalt-nickel hydrogenation catalysts are used. Any one or more than one catalyst is subjected to a hydrotreating process; secondly, the resulting oil after the hydrotreating process is distilled at normal pressure to distill a fraction with a boiling point of 280 to 360°C to obtain a transformer oil anti-gassing additive; The method of use is as follows: the anti-gassing additive of transformer oil is added to ordinary transformer oil for blending to obtain ultra-high transformer oil; the invention has the following advantages: the pollution to the environment is reduced, and the blended ultra-high transformer oil makes dehydration easier Easy, so that the product output and quality have been greatly improved.

Owner:克拉玛依市金龙特种油品公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com