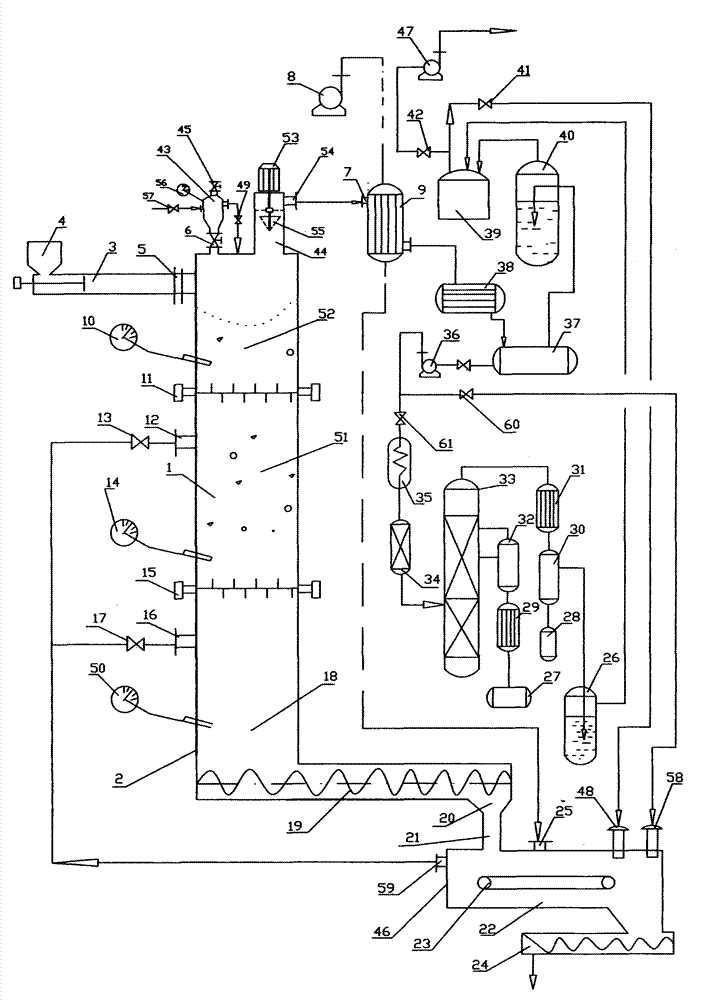

[0003] The composition of domestic waste is complex, and the existing domestic waste (or including

medical waste) heat treatment technology and equipment, such as gasification

incineration method, direct

incineration method, etc., all have the defect that the

tail gas contains dioxin; The organic waste is pyrolyzed in the reduction zone and cracking zone at 500-900°C into a low calorific value (5000KJ / Nm 3 left and right) gas (CO, CH 4 、C 2 -C 5 , N 2 、H 2 , CO 2 ); At present, the heat

utilization rate of the most advanced gas-fired power generation in the world is at most 33%, and the remaining heat is lost from the high-temperature

flue gas discharged from the gas-fired generator, while the direct incineration method uses the organic waste in domestic waste All incinerated to ashes, the high-temperature

flue gas produced is used as the heat source of the steam boiler to generate

water vapor, while the heat utilization conversion rate of the steam-driven

steam turbine generator is only about 22%, and a large amount of energy is lost and cannot be recycled, resulting in garbage The

resource utilization rate is low;

[0004] The prior art has disclosed some technical schemes to solve this problem; the inventor disclosed a method for producing hydrocarbons from domestic garbage and / or organic waste in USP6,133,491, USP6,270,630B1 and ZL98117823.5 and equipment, discloses the first-stage and second-stage thermal cracking and catalytic cracking treatment methods for the same

raw material using steel reaction equipment at two different temperatures, low and high; however, to make various organic substances in domestic waste Complete

decomposition must reach a high temperature environment of 800-1100°C, but a single steel rotary reactor is easily deformed and cannot be rotated in a high temperature environment for a long time, and the

cracking reaction cannot be carried out to the end, resulting in a certain amount of

organic matter remaining in the residue of the

cracking reaction.

Macromolecular substances cannot be completely decomposed, and the thorough reduction and harmlessness of domestic waste cannot be implemented; the inventor disclosed a method for

continuous treatment of domestic waste in ZL200710130127.5. The garbage is transported to the closed

pyrolysis equipment, and the steel equipment is heated indirectly under anaerobic conditions to generate thermal cracking of the raw materials; however, the

thermal efficiency of indirect heating is low, the

energy consumption is high, the

pyrolysis time is long, and the cost of garbage treatment is high. Knownly, a single domestic waste incinerator is usually horizontal or vertical, such as Martin incinerator, fluidized incinerator, reciprocating grate incinerator, various vertical or horizontal incinerators, and

fluidized bed incinerators. ...and so on, the furnace body is huge, the heat dissipation area is large, the comprehensive

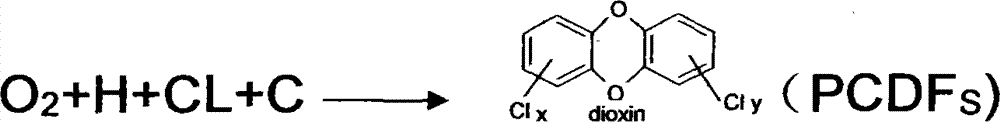

utilization rate of heat is low, and the investment is large, the profit return rate is low, it is not suitable for economically underdeveloped countries and small and medium-sized towns, and the promotion and application value is low; With the transmission of the incineration grate, in the process of moving domestic waste from the

drying area (low-medium temperature area) to the

combustion area (high-temperature area), it must pass through a temperature range of 500-700 ° C. In this temperature range, the waste contained in the domestic waste

Chlorine-containing substances such as salt or

chlorine-containing plastics (PVC) and C and H elements and

oxygen O in the air 2 Combined into harmful dioxins (PCDFs), it has caused serious

pollution and harm to the environment, which is an unavoidable objective fact

In ZL201120082883.7, "A Garbage

Dry Distillation Pyrolysis and Gasification Device Effectively Containing Dioxins" is disclosed, and in ZL201110073735.3, "A Comprehensive

Waste Treatment and Utilization Method Effectively Containing Dioxins" is disclosed, The

dry distillation or

decomposition equipment of the above two kinds of domestic wastes all belong to the conventional gasification incinerator. "Gasification-incineration" combined

biomass gas production furnace, domestic waste raw materials are added into the furnace from the upper part of the furnace body, and continuously move down until the bottom of the furnace turns into ashes, and domestic waste moves down to the cracking area (500- 700°C) or reduction zone (about 850°C), affected by the

eddy current or kick flow of the upwardly flowing air, some

chlorine-containing substances such as salt or

chlorine-containing plastics contained in domestic garbage will react with

oxygen in the air, which will inevitably A considerable amount of dioxins (PCDFs) are produced objectively and objectively; especially, if this kind of gasification incinerator is used as a

pyrolysis device for domestic waste, a large amount of recyclable energy contained in domestic waste can produce high-value Commodity organic hydrocarbons (such as plastic or rubber) are burned in the reduction zone and

combustion zone at a high temperature of 850-1100 °C, and only a small part is converted into a low calorific value

combustible gas containing a large amount of 40-50% (V%)

nitrogen , cannot better implement the

resource utilization of domestic waste;

Login to View More

Login to View More