Patents

Literature

615results about "Furniture waste recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

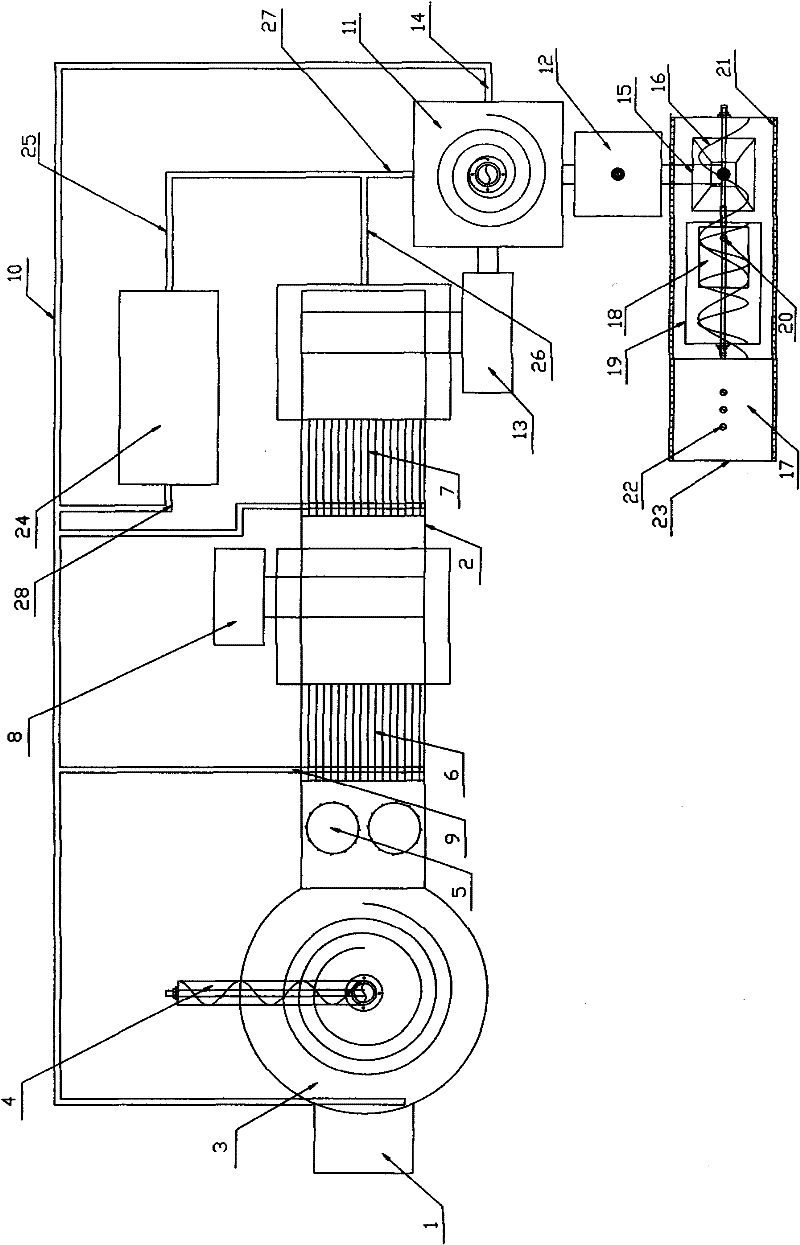

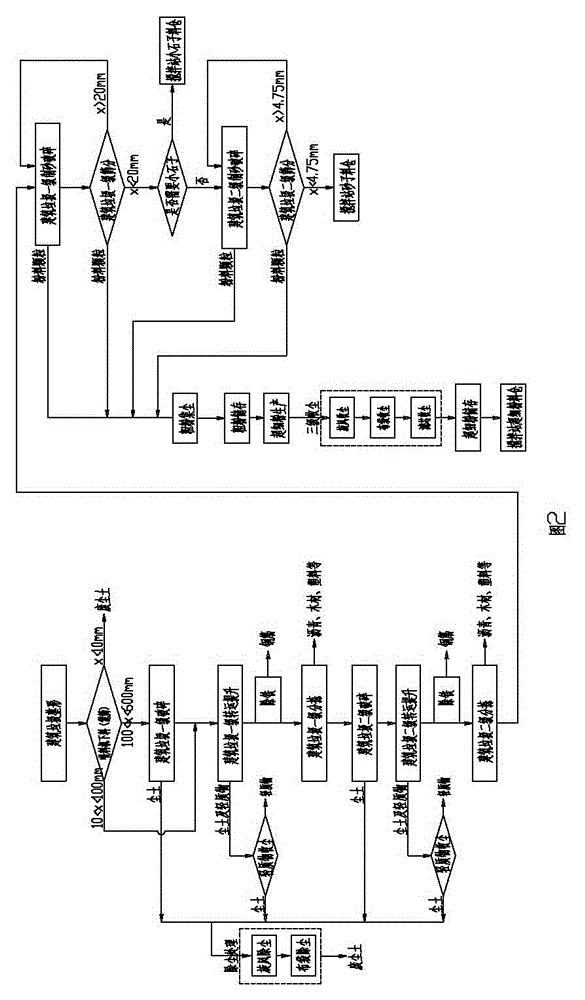

Method for sorting and comprehensively using urban mixed garbage

InactiveCN102671928AStructural innovationRealize full mechanizationBio-organic fraction processingSolid waste disposalRefuse-derived fuelPulp and paper industry

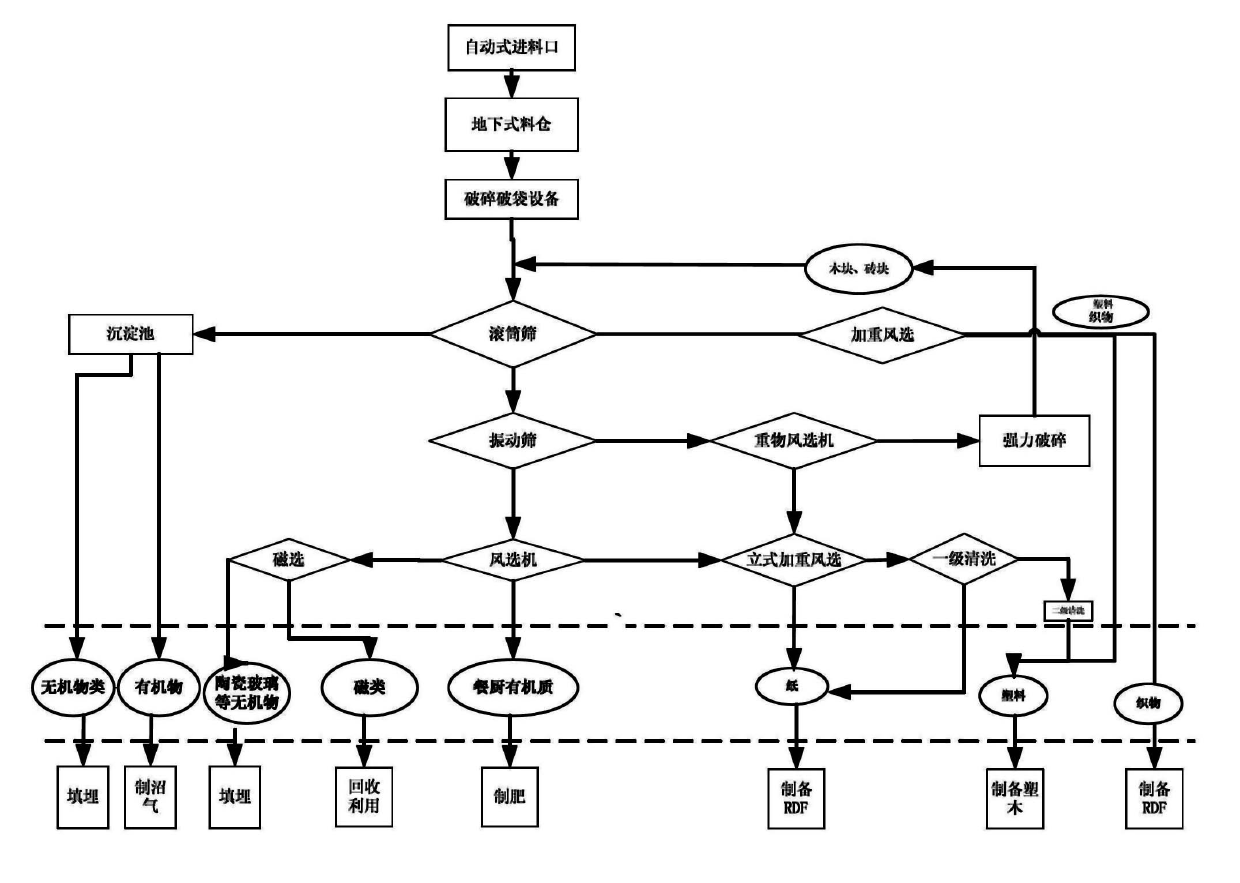

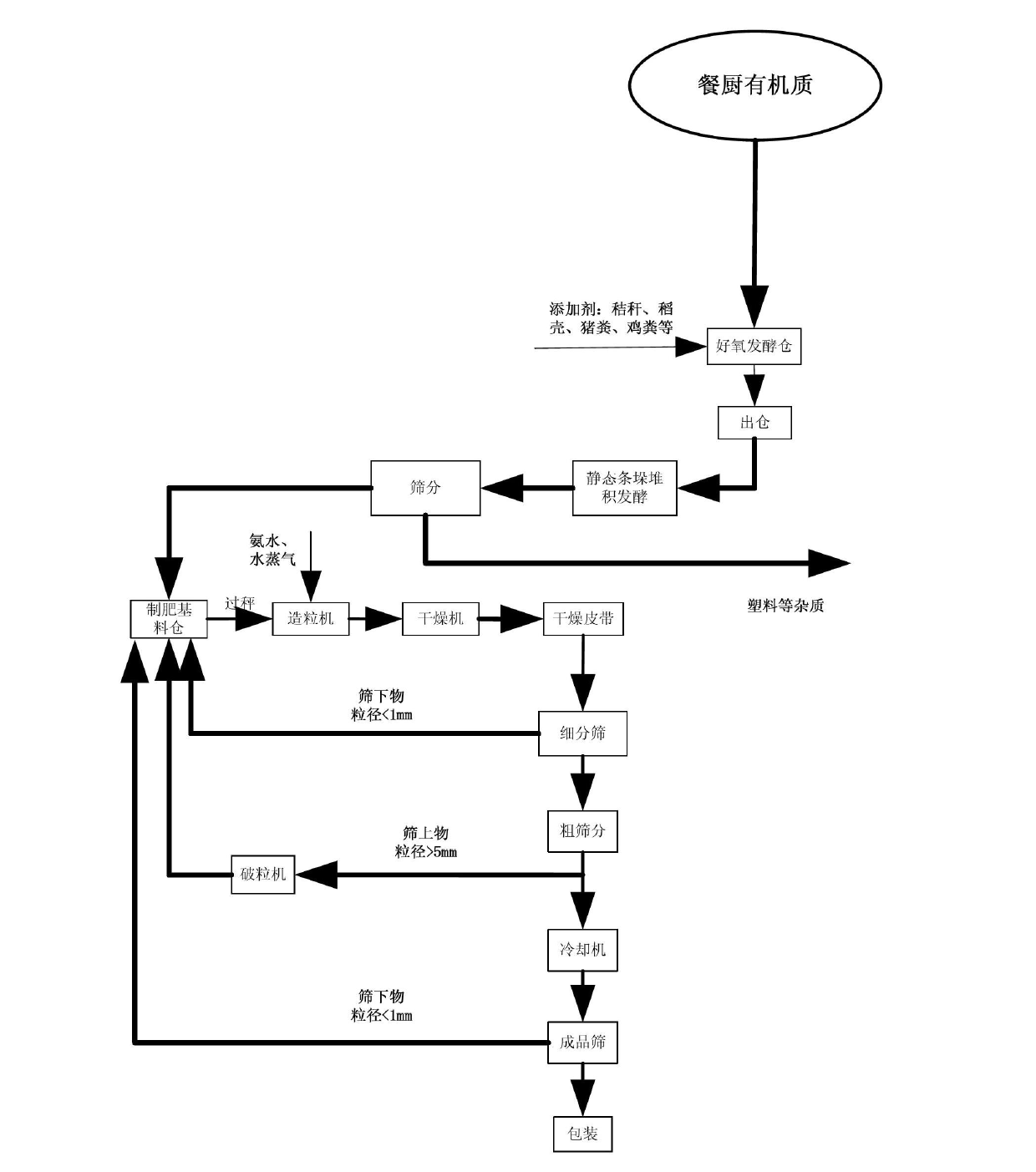

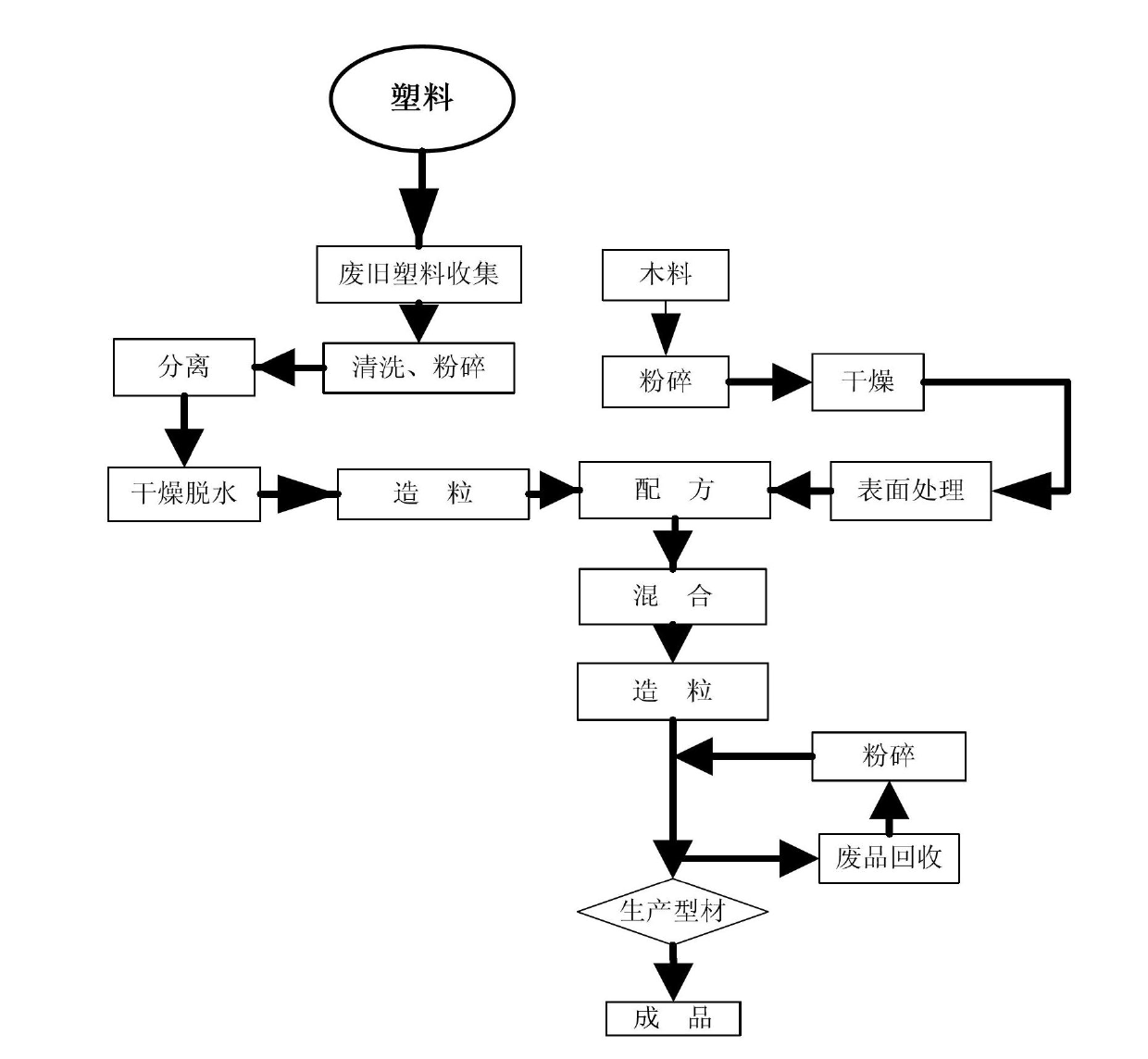

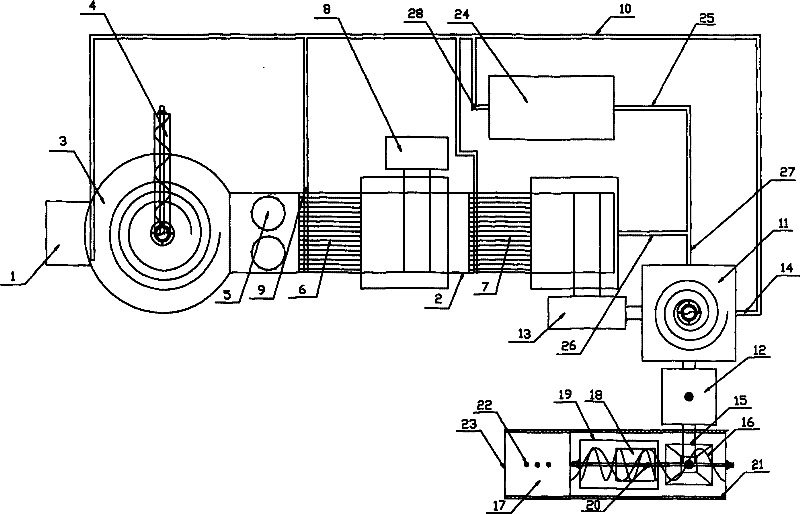

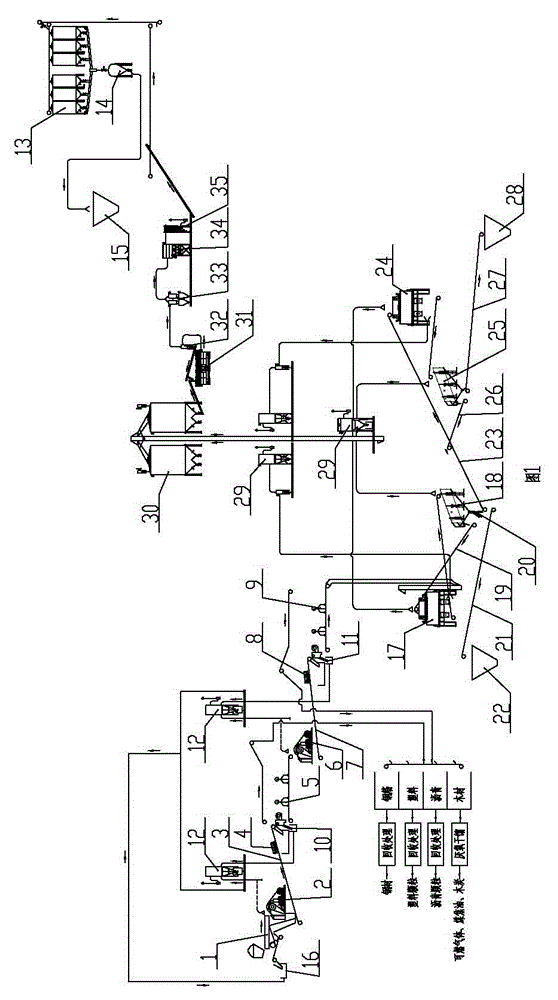

The invention discloses a method for sorting and comprehensively using urban mixed garbage. The method comprises the following steps: 1) allowing the urban mixed garbage to enter a feed bin through a feeding hole, discharging, and introducing into crushing and bag breaking equipment; 2) breaking garbage bags and crushing block garbage by using the crushing and bag breaking equipment; 3) feeding the garbage subjected to crushing and bag breaking into a two-stage rotary screen, screening out dust of which the grain size is less than 3mm, and picking out strip substances; and 4) feeding the mixed garbage into a vibration screen, separating inorganic cakes, large-sheet plastics and paper from an oversize material by using a heavy winnowing machine, and winnowing heavy substances, light substances and intermediate substances from an undersized material in a double-wind chamber multifunctional winnowing machine. Sorting equipment is effectively combined, so that the mixed garbage is efficiently sorted and recycled; and the sorted paper and textiles, plastics and kitchen organics are respectively used for preparing garbage derived fuel, plastic wood and fertilizers.

Owner:SICHUAN CRUN ENVIRONMENTAL PROTECTION ENERGY TECH CO LTD +1

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

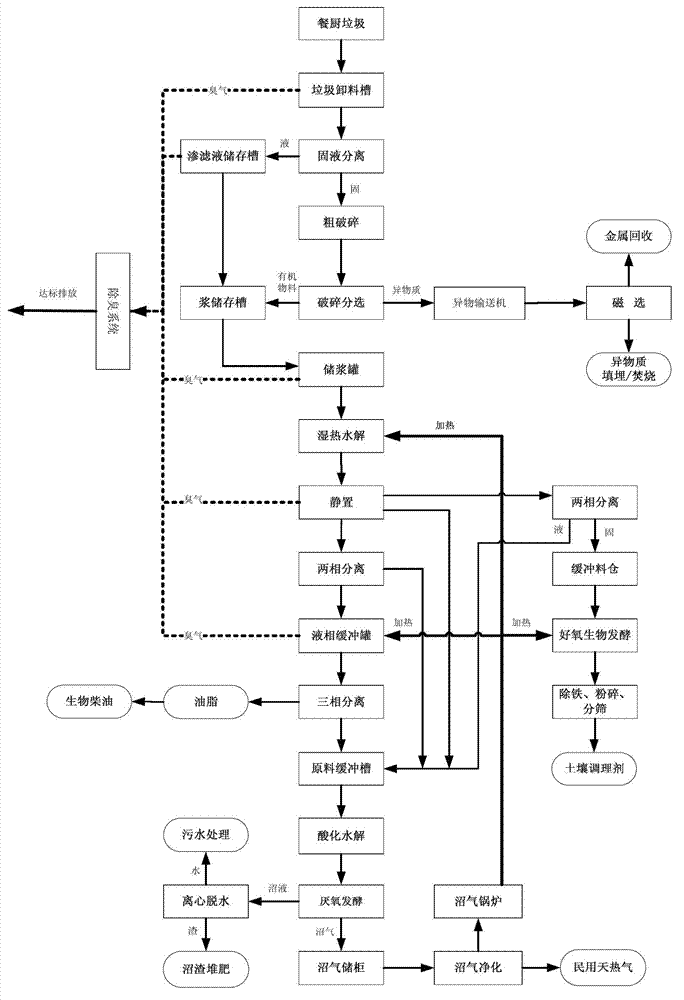

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

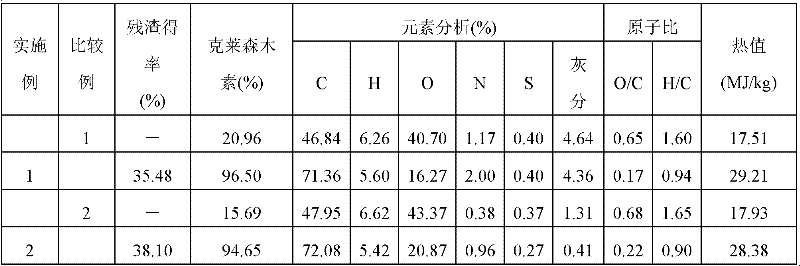

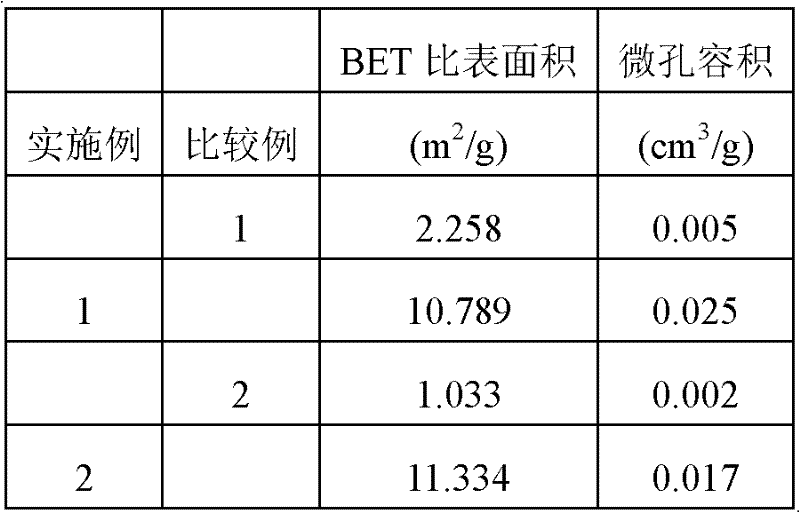

Method for preparing biomass carbon by utilizing agricultural and forestry waste

InactiveCN102583311AImprove protectionRaw materials are easy to getSolid waste disposalCarbon preparation/purificationBiomass carbonSorbent

The invention relates to a method for preparing biomass carbon by utilizing agricultural and forestry waste, belonging to the technical fields of preparation of carbon materials and utilization of biomass resources. The method comprises the following steps of: adopting agricultural and forestry waste as raw materials; under the condition of subcritical water, fully mixing dried biomass materials and deionized water according to the proportion of 1:(10-30); under the protection of inert atmosphere, carbonizing for 2-6 hours at the temperature of 220-250 DEG C; and then carrying out vacuum filtration and hot-water cleaning, and drying to obtain the biomass carbon. The biomass carbon prepared by the invention is coaly carbon material with an aromatic-ring structure, is high in carbon content and calorific value and large in specific surface area, and can be used as a soil conditioner or an absorbent. The method has the advantages that the materials are low in cost and easy to obtain, the process is simple, the operation is convenient, the manufacturing cost is low, the industrial promotion is convenient, and the application range and the application value of biomass resources are further expanded in the aspect of carbon materials.

Owner:BEIJING FORESTRY UNIVERSITY

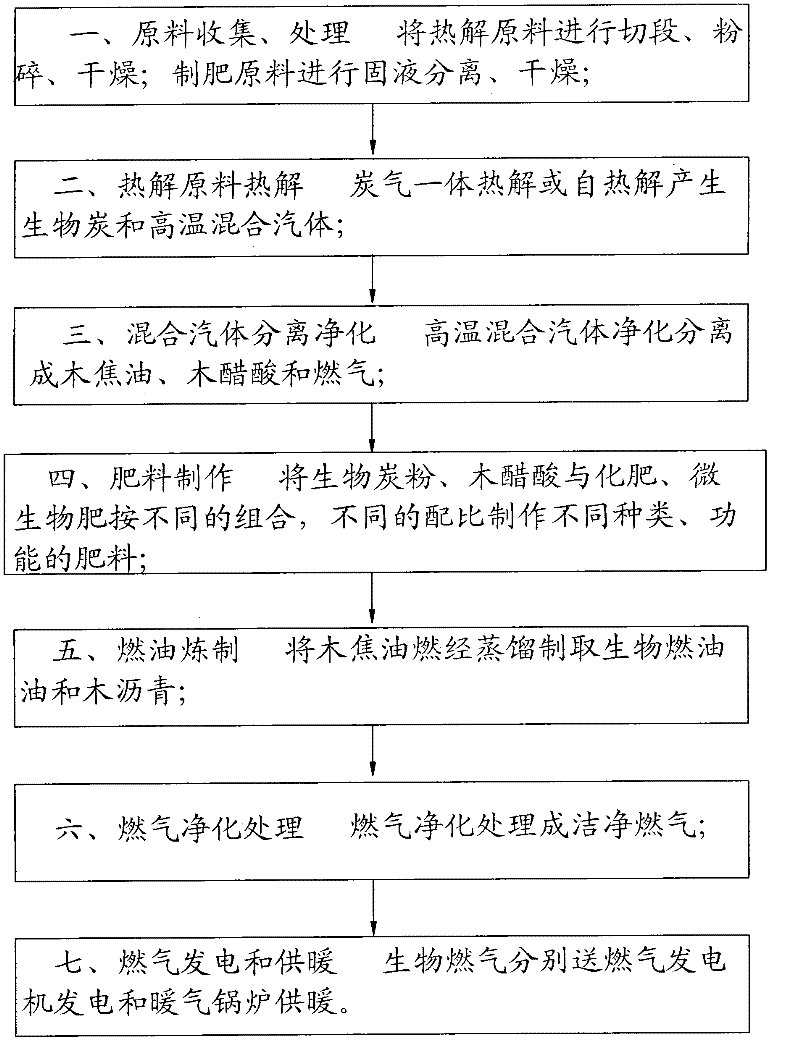

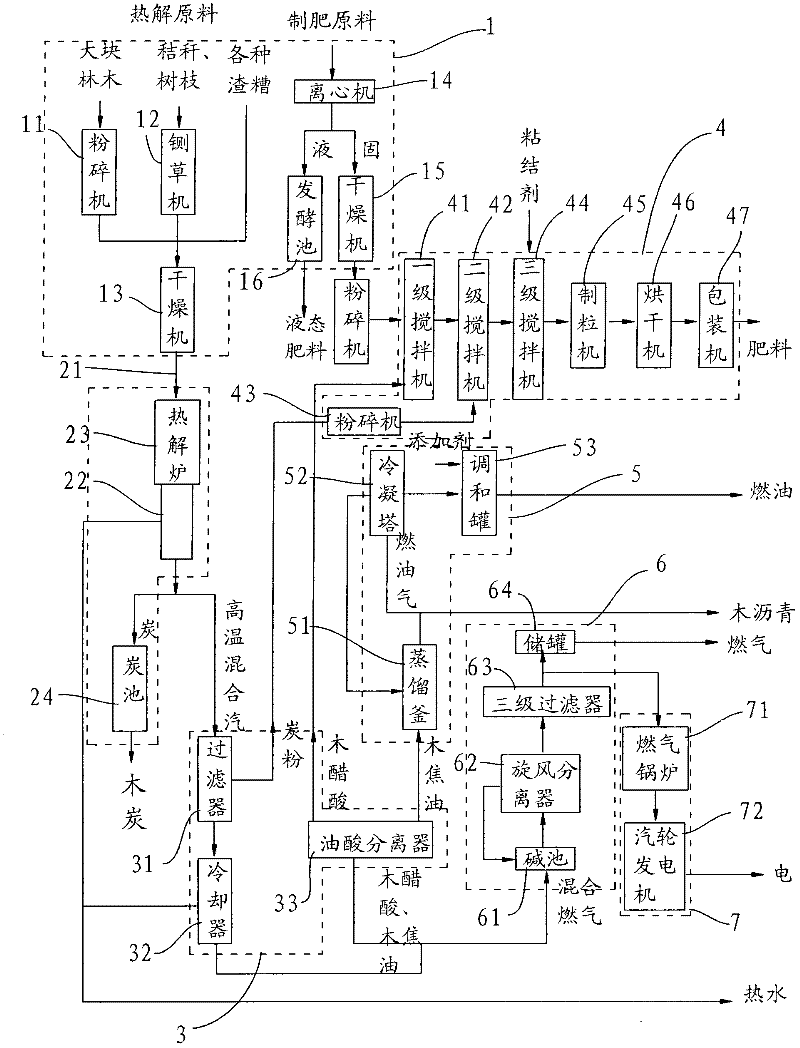

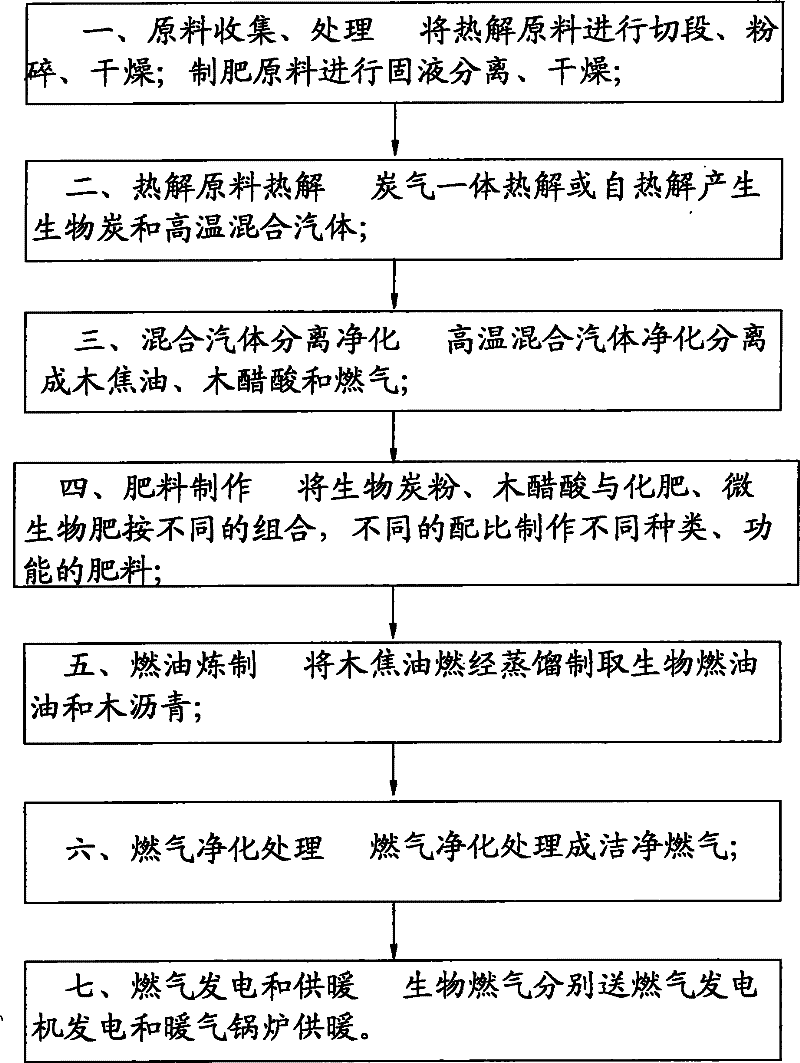

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

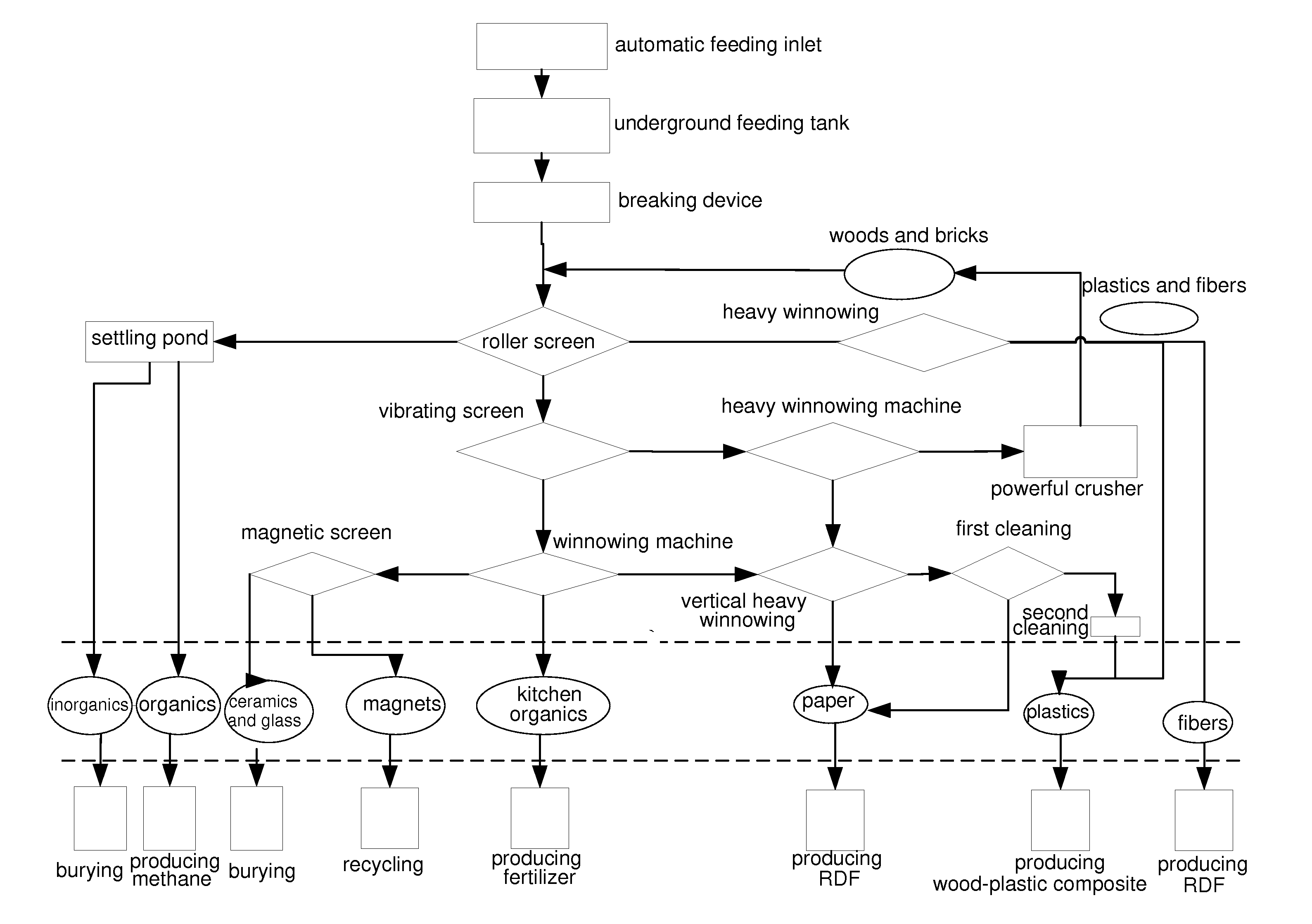

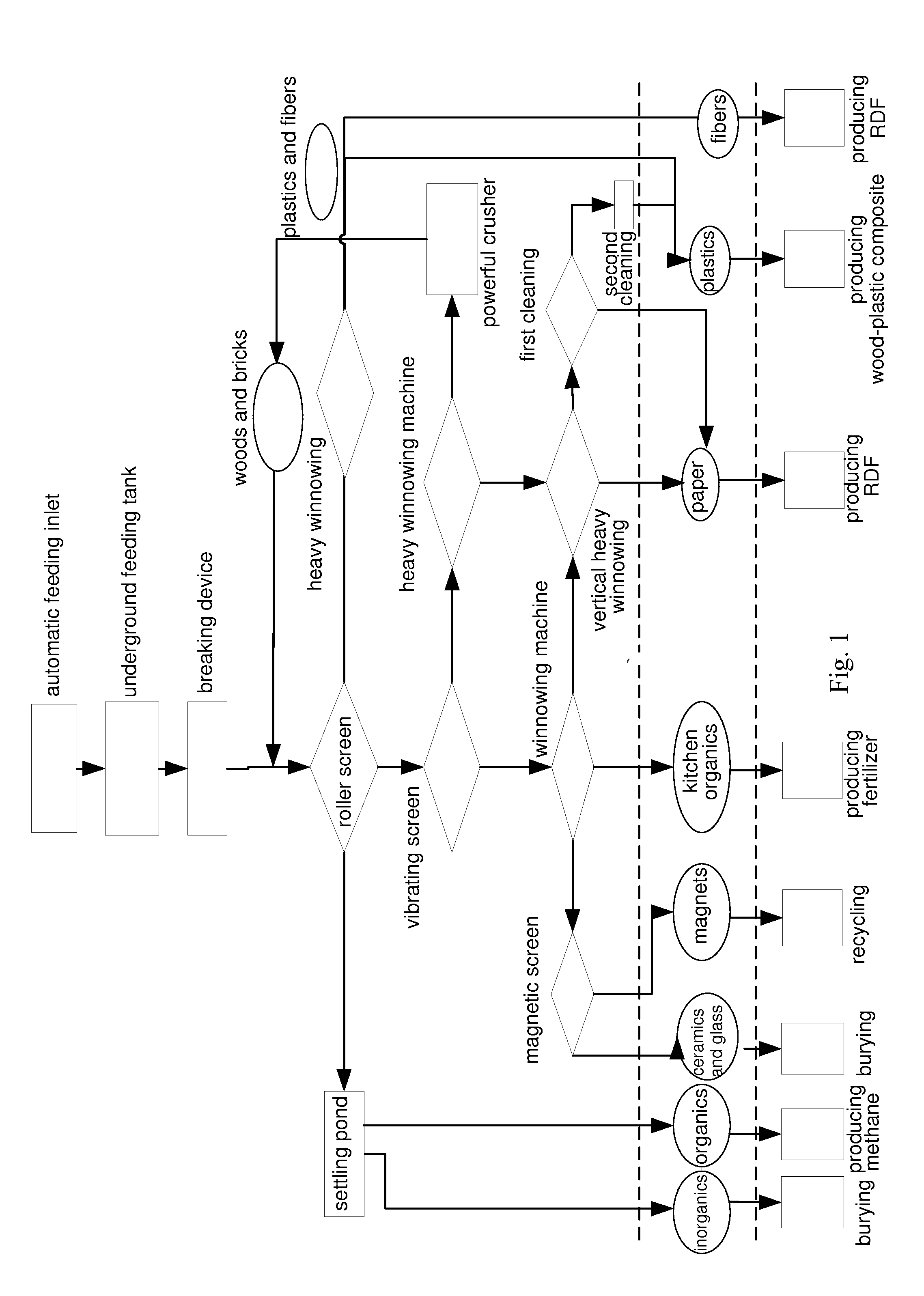

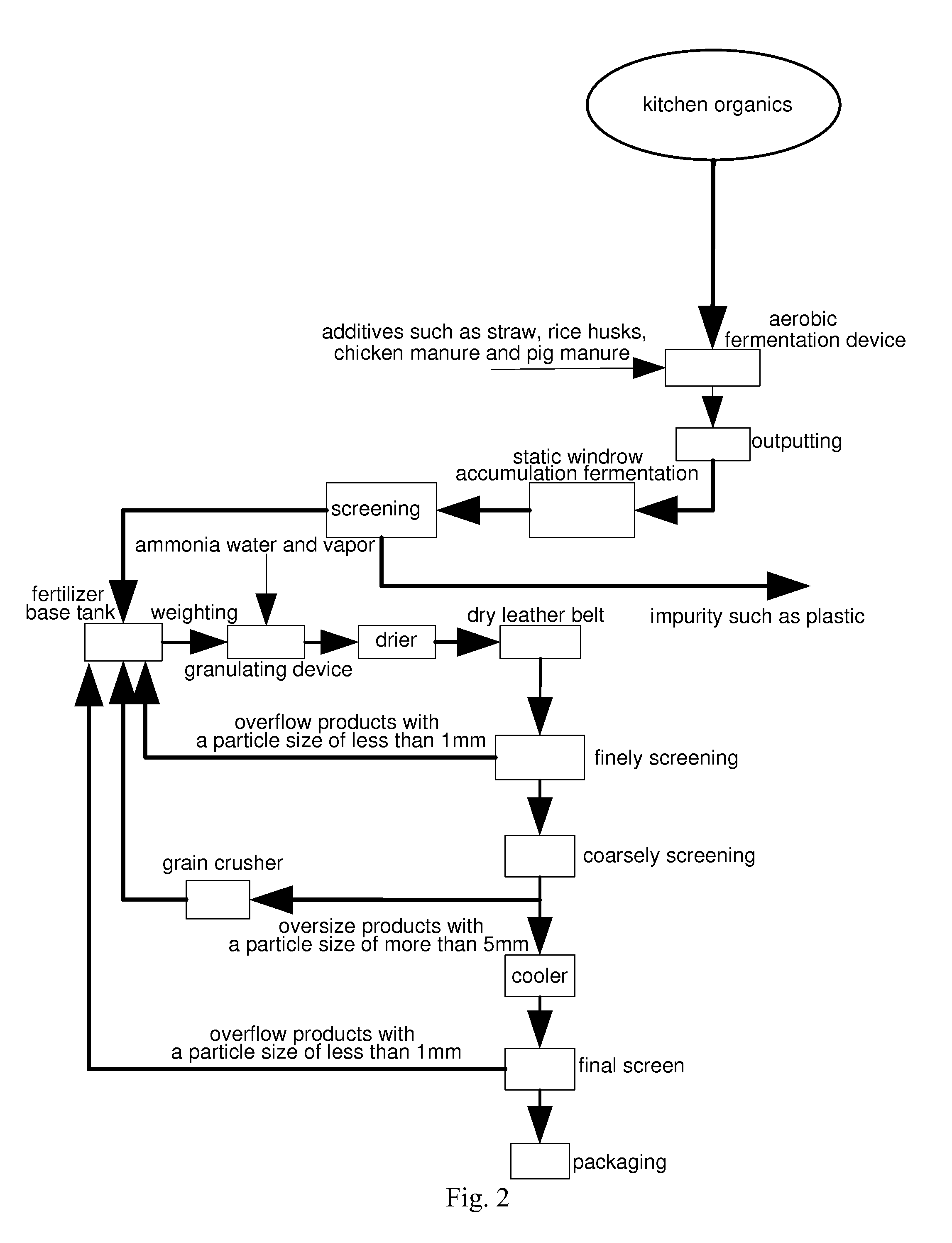

Method for sorting and comprehensively utilizing municipal solid waste

InactiveUS20150135785A1Maximize resource utilizationEfficient combinationBio-organic fraction processingSolid waste disposalRefuse-derived fuelFiber

A method for sorting and comprehensively utilizing municipal solid waste includes steps of: 1) feeding the municipal solid waste into a feeding tank through a feeding inlet, then outputting into a breaking device; 2) breaking refuse bags and large blocks by the breaking device; 3) transporting broken refuse into a two-stage roller screen for screening out dusts with a particle size of less than 3 mm, and hanging strips; and 4) transporting mixed refuse screened by the two-stage screen into a vibrating screen; screening oversize products by a heavy winnowing machine for separating inorganic blocks, large plastics and paper; transporting underflow products into a two-room multi-functional winnowing machine for dividing into heavy materials, light materials and medium materials. By effectively combining sorting devices, effective sorting and reutilization of mixed refuse are achieved. Thereafter, paper, fibers, plastics and kitchen organic refuse are respectively for producing refuse derived fuel, wood-plastic composite and fertilizer.

Owner:XI AN JIAOTONG UNIV

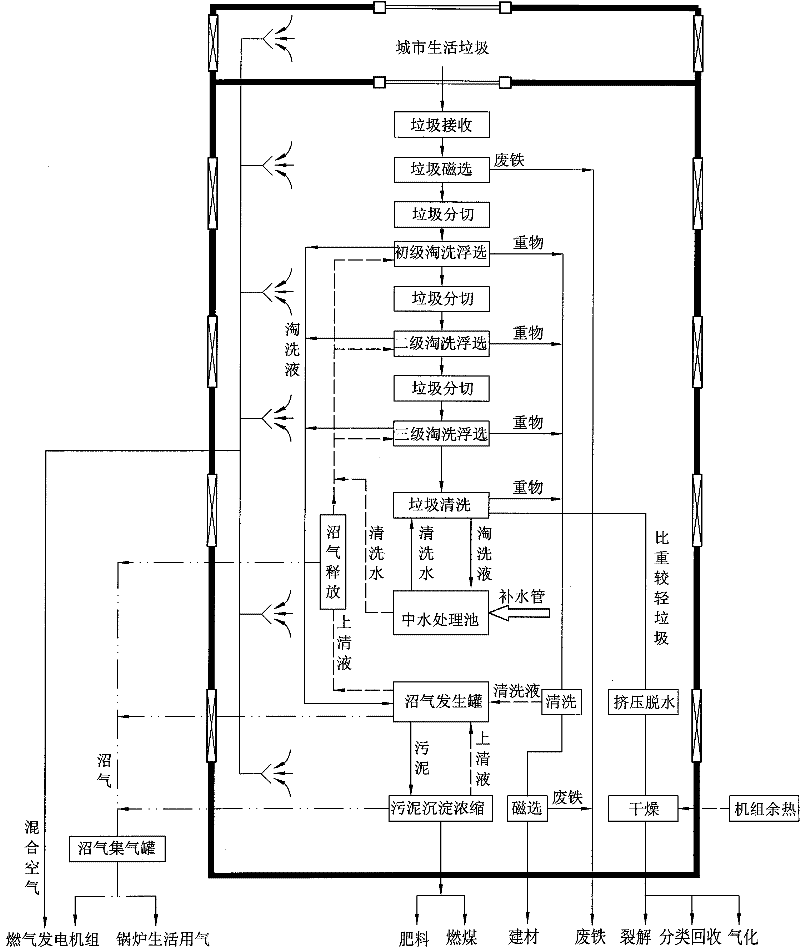

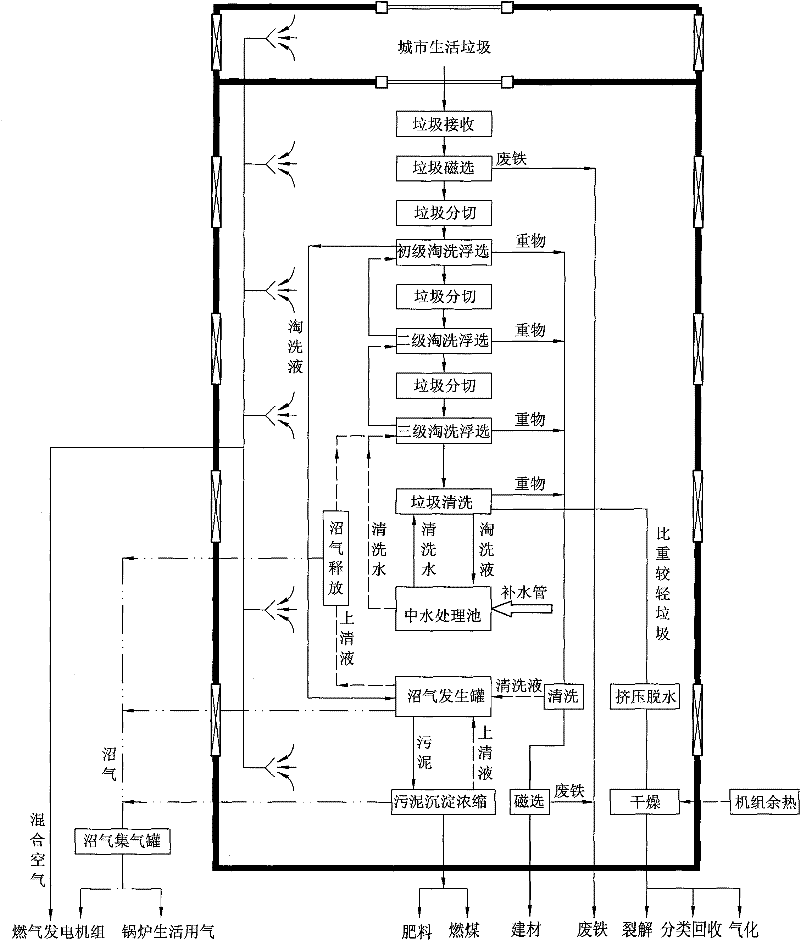

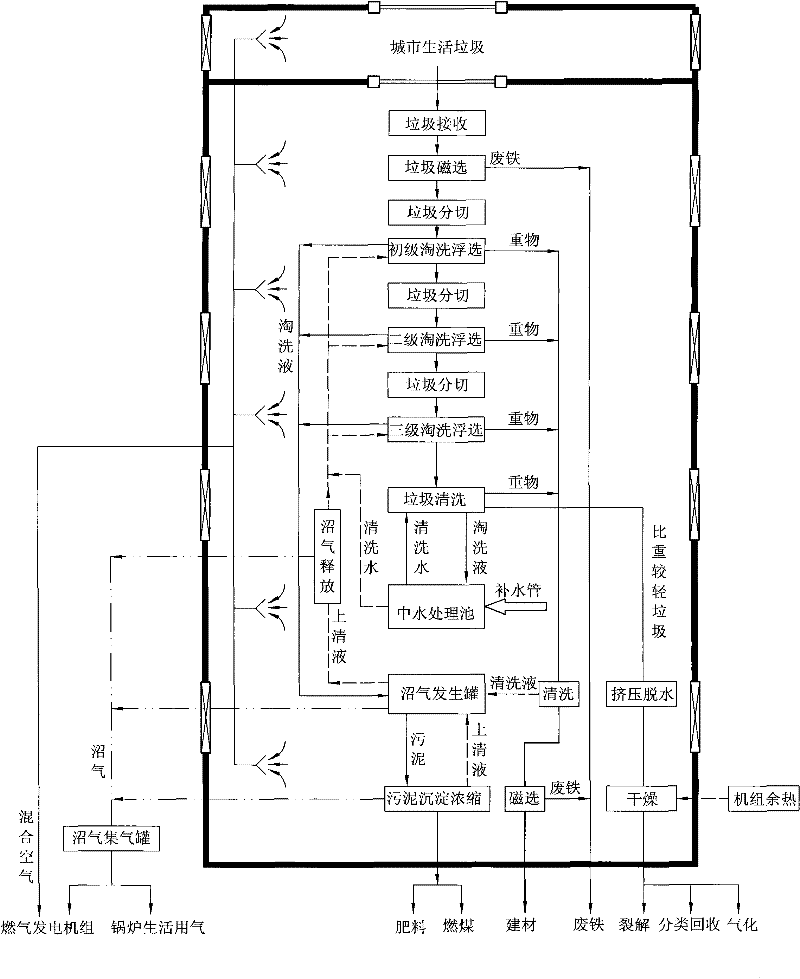

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

Ceramic material with multi-stage duct structure and manufacture method thereof

InactiveCN101885620ALow costMeet environmental protection requirementsSolid waste disposalFurniture waste recoveryMetallurgyDecomposition

The invention provides a ceramic material with a multi-stage duct structure and a manufacture method thereof. The ceramic material is characterized by being provided with a plurality of macropores with millimeter grade, tens of middle pores with millimeter grade exist on the walls of the macropores, micropores with sizes less than microns exist on the walls of the middle pores. The ceramic material is manufactured by using 10-50 percent by mass of waste and 20-60 percent by mass of natural porous mineral and matching with 10-30 percent by mass of clay through the steps of adding water for mixing, forming, drying, preheating and sintering at a temperature of 1000-1200 DEG C, wherein the waste can be expanded at high temperature or has large ignition lost and easy decomposition and volatilization. The ceramic material has excellent water-absorbing and water-retaining properties, better water permeability, excellent absorption and filtration and light weight, and can be used as a water-absorbing material, a water-retaining material, a water permeating material, a sound insulating material, a heat insulating material, an indoor deodorizing material, an absorbing material, a filtering material and the like to be widely applied to various fields.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

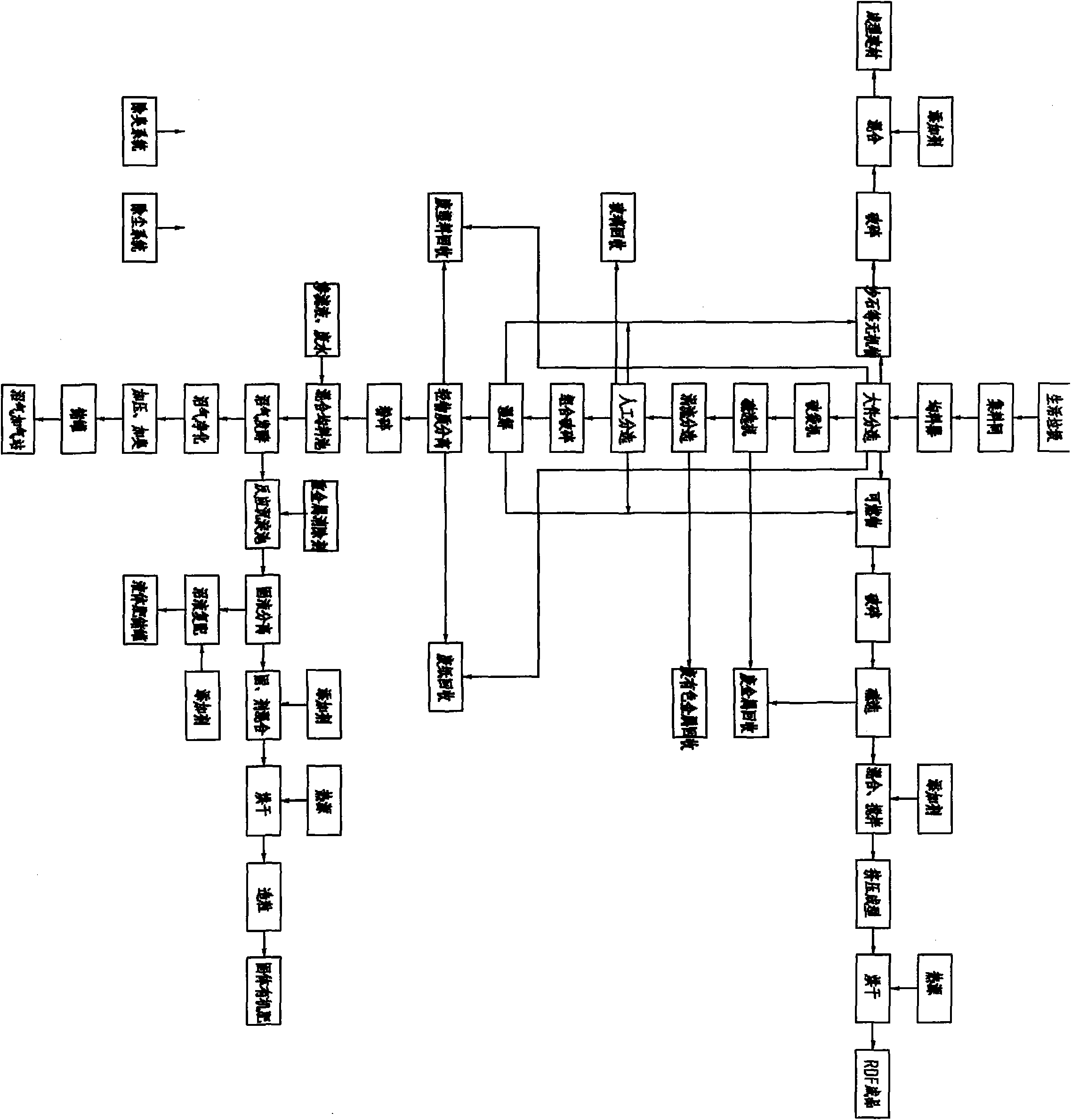

Technology for full classification recycling treatment on household waste

InactiveCN102728601ASolve problems in the treatment processRealize recycling of resourcesBio-organic fraction processingSolid waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a technology for full classification recycling treatment on household waste and relates to the field of recycling integrated utilization of household waste. A main process route of the technology comprises that household waste is homogenized by a homogenizer, is subjected to large object sorting (wherein large objects comprise large combustibles and inorganic matters), is treated by a bag breaking device (for scratching a plastic packaging bag), is treated by a magnetic separator (for separating out magnetic materials), is treated by an eddy sorting machine (for separating out nonferrous metals), is subjected to artificial sorting, then is broken, is fed into a hydrothermal degradation tank, is treated by a light material separator (for separating out papers and plastics), and then is crushed; then mixed organic matters and percolate are mixed and then are subjected to methane fermentation so that methane is produced; and methane residues and a methane liquid are prepared into an organic fertilizer and inorganic matters are prepared into a building material and the combustibles are prepared into a refuse derived fuel (RDF). The technology really realizes reduction, harmlessness and recycling of waste.

Owner:张希曾 +1

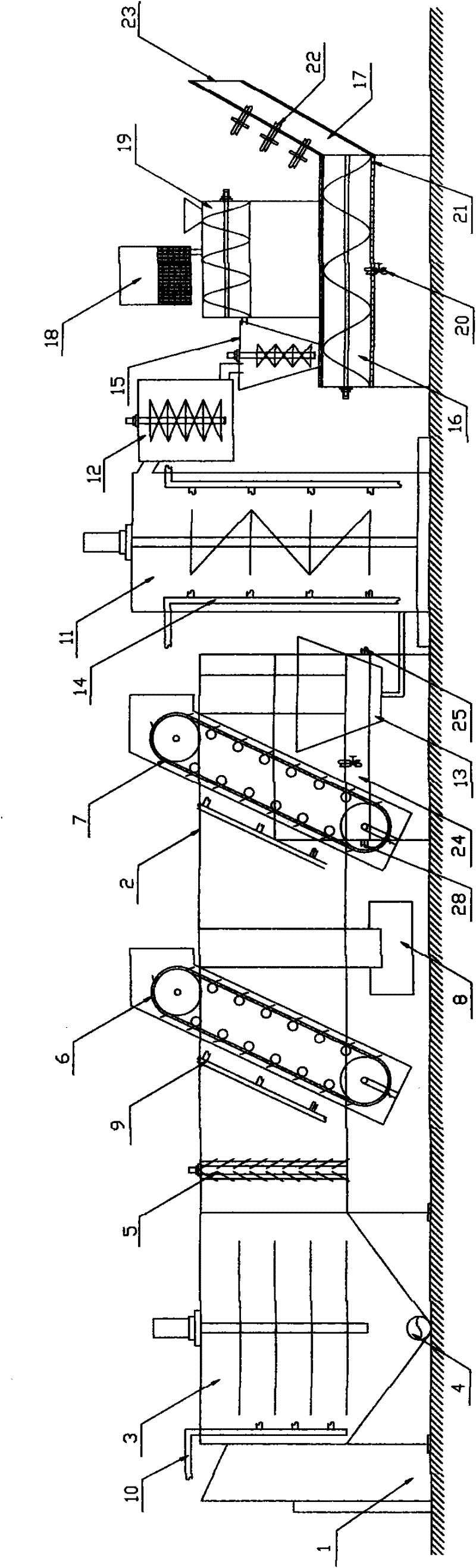

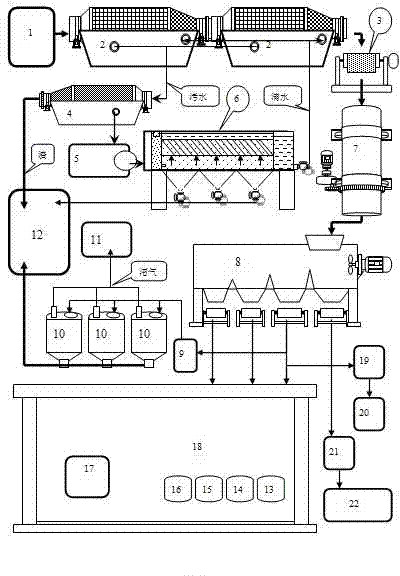

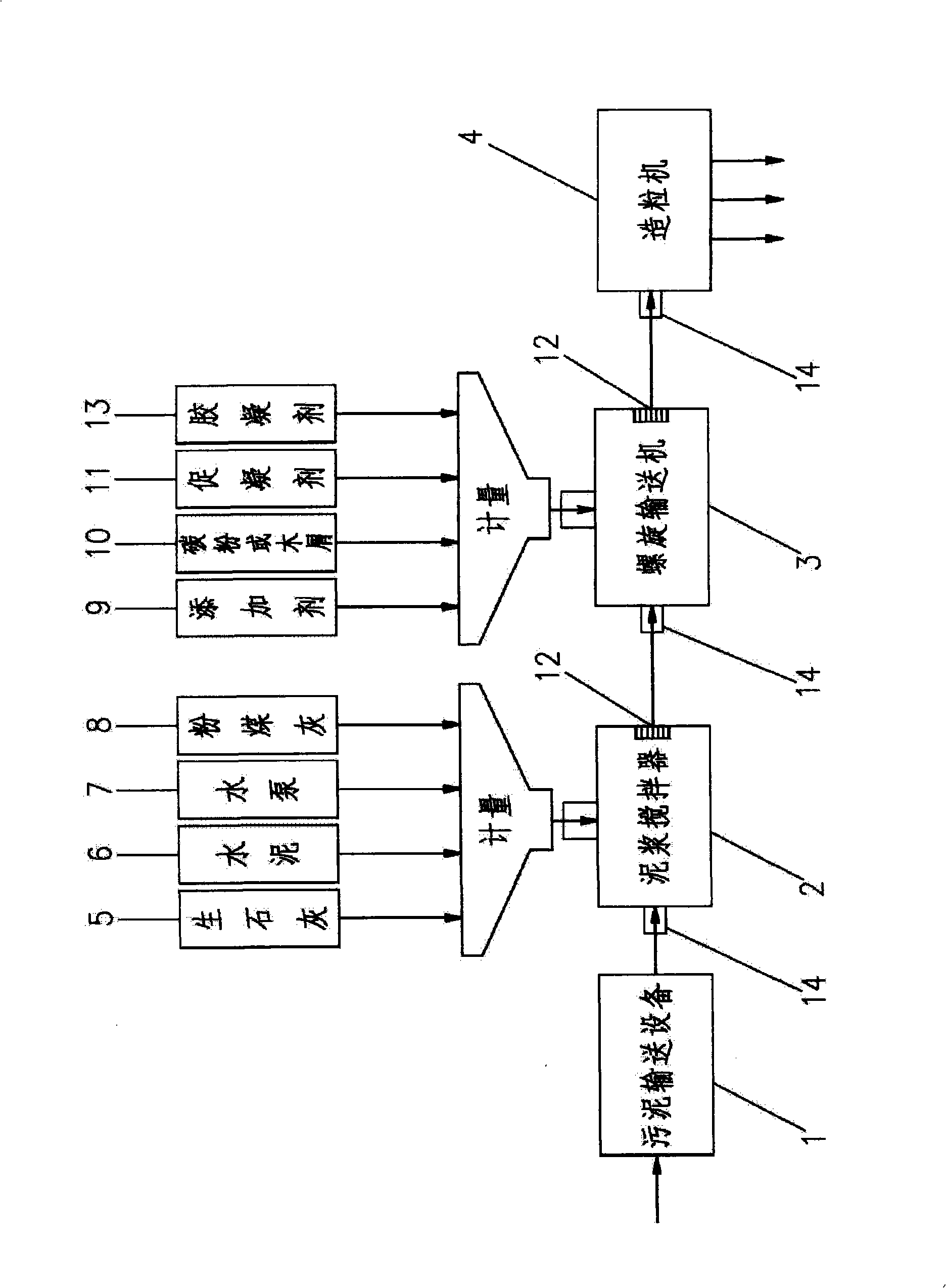

Processing method and processing system for kitchen garbage resourcilization

InactiveCN102690134AReduce moisture contentWater content automatic controlBio-organic fraction processingSolid waste disposalOil and greaseWater use

The invention relates to a processing method and a processing system for kitchen garbage resourcilization. The processing method comprises waterpower decomposition, fragmentation, sorting, dehydration, crushing, anaerobic fermentation and oil-water separation; the processing system comprises a feeding device, a waterpower conveying decomposition tank, a fragmentation preselection apparatus, a dehydration crushing apparatus, an anaerobic fermentation mixing apparatus and an oil-water separation apparatus. The method and system provided in the invention adopt sorting by using water. Advanced treatments of sorting to remove impurity, fragmentation, dehydration, desalination, oil removing and the like are automatically carried out to substances of different properties in the kitchen garbage by using water as a carrier combining with mechanization equipment, according to dissolvability and different proportion of the substances; organic substances separated from the kitchen garbage are fermented and prepared into organic fertilizers; and grease in separated oil-contained sewage is recycled by oil-water separating. The method and the system in the invention thoroughly remove substances of oil, salinity, soy sauce, vinegar and the like in the kit garbage that against fermentation composting. The method and the system have the characteristics of high removal rate of salinity and grease, high dehydration efficiency, good automatic sorting effect, realization of resource regeneration and no secondary pollution.

Owner:焦社杰 +2

Method and apparatus for image forming and optical writing device installed therein capable of reducing adhering dust

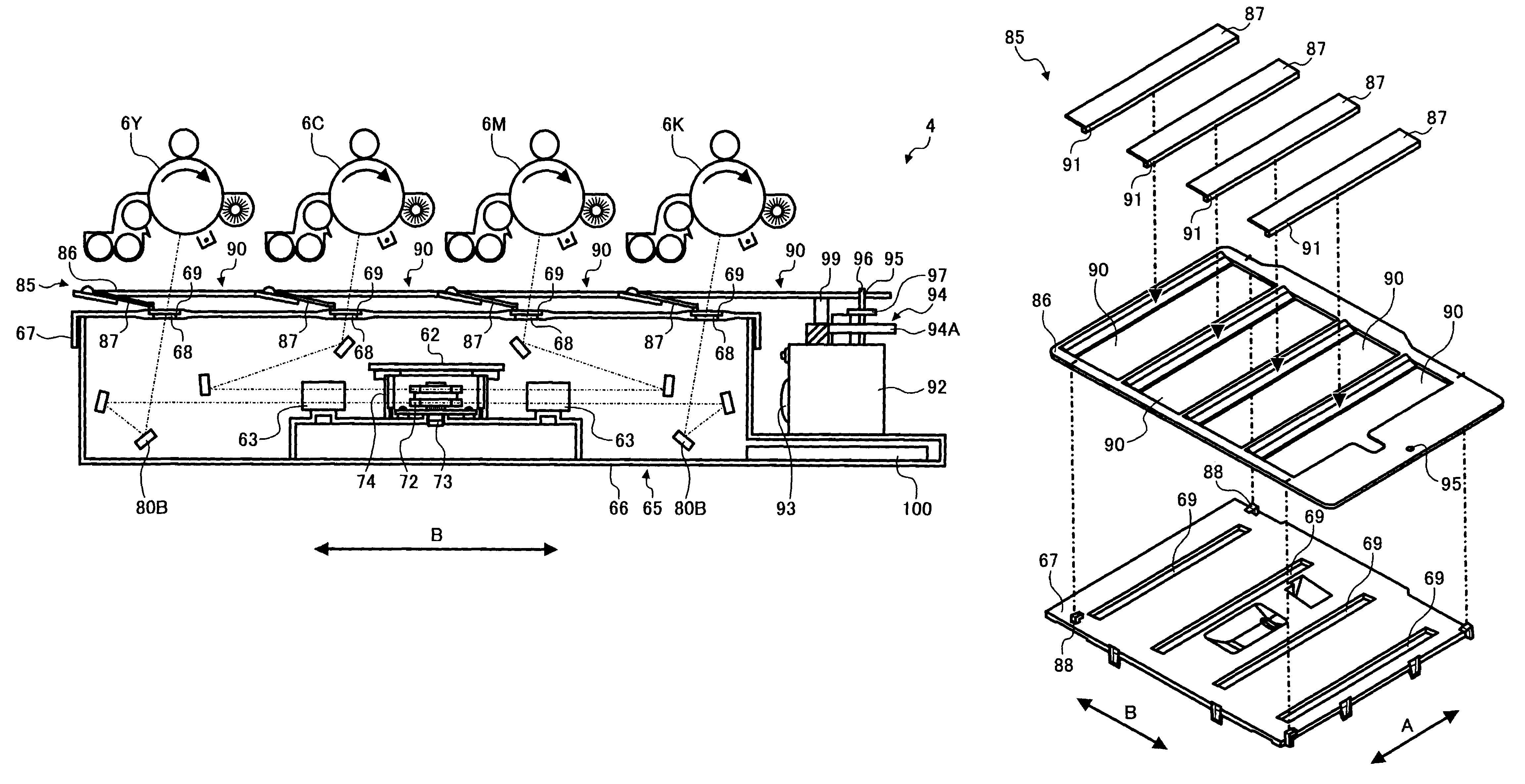

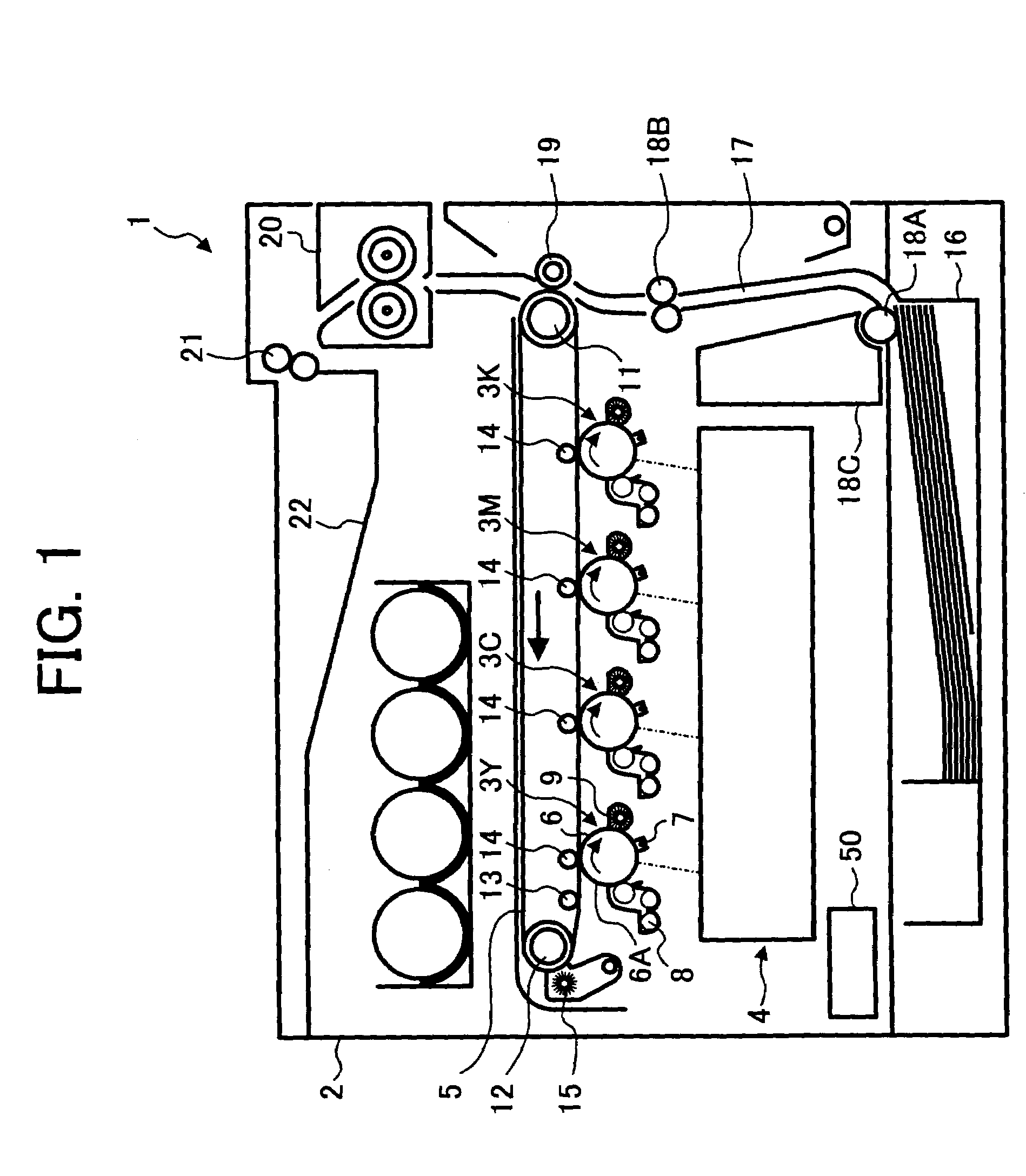

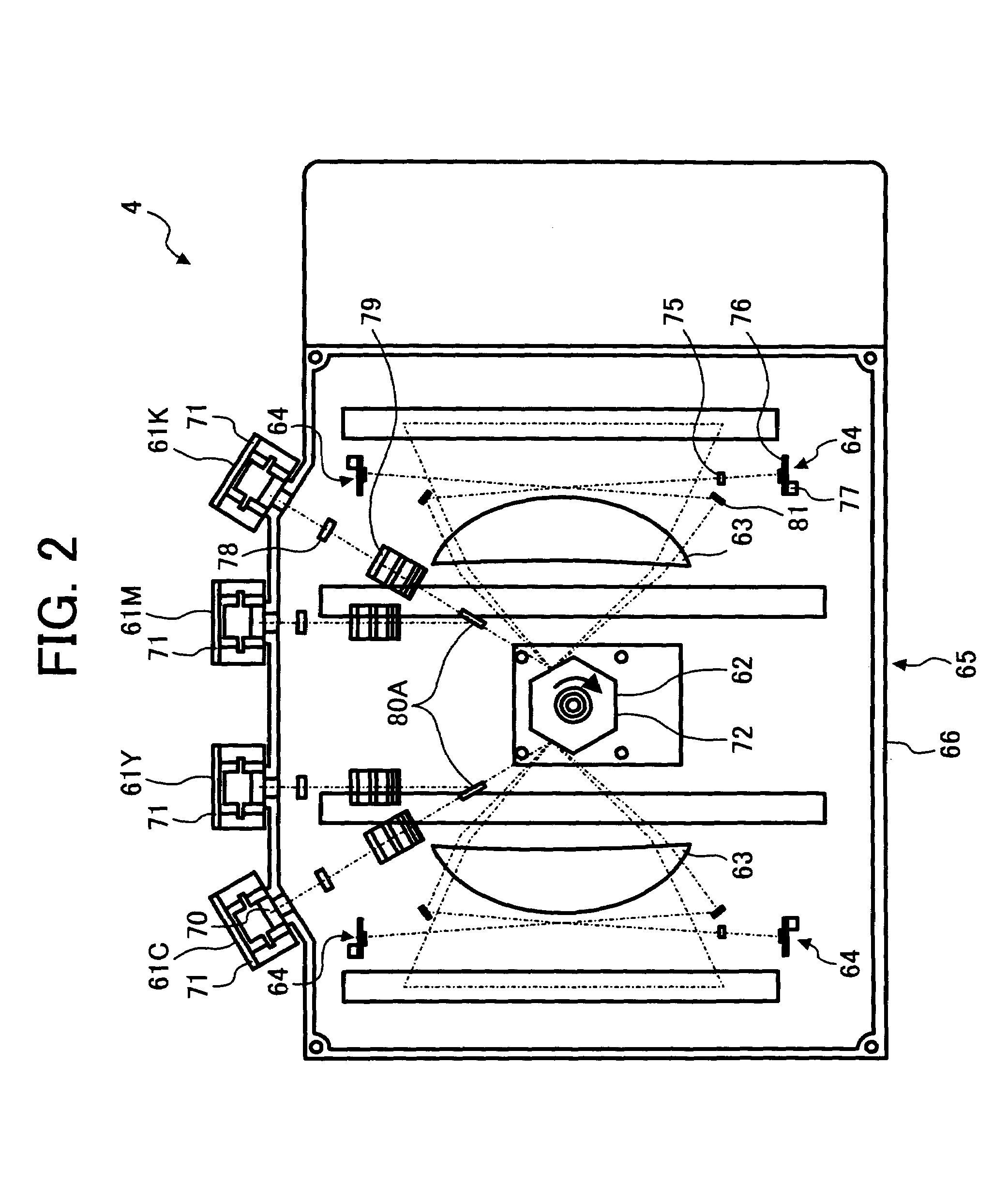

InactiveUS7203444B2Reduce the amount requiredCleans toner and dustBiofuelsSolid fuelsImage formationLight beam

A method and apparatus of image forming includes an optical writing device and an image carrier. The optical writing device includes a housing, a dustproof member, a light source, and a shield. The housing is provided with an opening. The dustproof member is light permeable and closes the opening. The light source is installed in the housing and irradiates the image carrier with a light beam through the dustproof member. The shield is movable between a first position to cover the dustproof member and a second position to uncover the dustproof member. The optical writing device also includes a cleaner attached to the shield and contact the dustproof member. The optical writing device also includes a driver for moving the shield. The optical writing device further includes a positioning mechanism for positioning the shield to the first position by using the driver.

Owner:RICOH KK

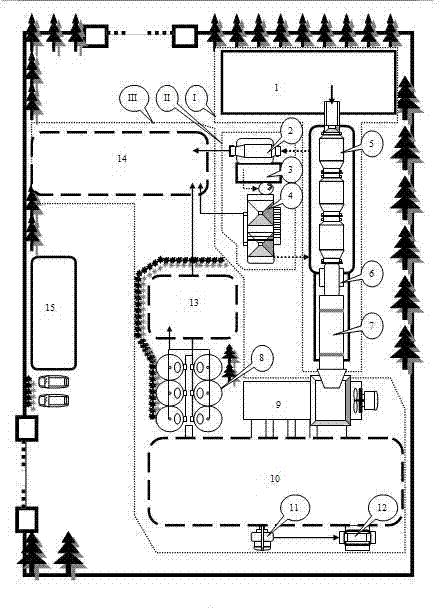

Water washing garbage cleaning production treatment method

InactiveCN102896135ANo emissionsEasy dischargeBio-organic fraction processingWaste processingRefuse DisposalsFermentation

The invention relates to a water washing garbage treatment method, wherein a purpose of the invention is to achieve urban garbage resource comprehensive utilization. According to the method, urban garbage is cleaned by using a running water washing manner, processes of dehydration, drying, winnowing, ??fine sorting and the like are performed, and classification centralization comprehensive utilization is performed; the water washing garbage sewage is treated through a sewage purifier to be rapidly recycled; and the production process adopts a cleaning production process, and no secondary pollution is generated. According to the present invention, the integrated design comprises water washing garbage sorting classification, fertilizer production through organic matter fermentation, heat supply through combustible combustion, a biogas engineering technology, a sewage treatment system and a plurality of mature application technologies; the urban garbage is adopted as a new urban mineral resource, and a water washing garbage resource comprehensive utilization workshop is established in a garbage landfill collection field so as to eliminate garbage pollution hazards; and sustainable development of large-scale garbage treatment industry is promoted, high economic benefits, social benefits and environmental benefits are generated, and good benefits are provided for humans.

Owner:唐义龙

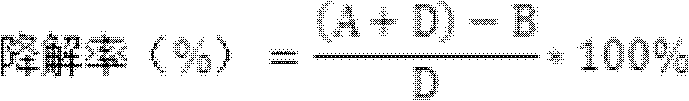

Microbial bacterium agent for degrading Chinese kitchen refuses and preparing method thereof

The invention discloses a microbial bacterium agent for degrading Chinese kitchen refuses, which contains the components by mass ratio: protein degrading bacteria: starch degrading bacteria: fat degrading bacteria: cellulose degrading bacteria= (1-2):(1-2): (1-2):(2-3). Simultaneously, the invention further discloses a preparing method of the microbial bacterium agent. Aiming at components of refuses in domestic kitchens, the corresponding microbial bacteria are adopted for gradual degrading, finally the purpose of completely degrading the refuses is achieved, not thorough degrading and long time consumption of the traditional land filling mode and large secondary pollution and high energy consumption of the burning mode are avoided, and the microbial bacterium agent for degrading Chinese kitchen refuses and the preparing method of the microbial bacterium agent can meet the present low carbon, environmental protection and energy saving requirements.

Owner:田兴军 +1

Harmless gasification treating process for medical waste

InactiveCN102641880ASave on shipping costsSave on processing costsSolid waste disposalIncinerator apparatusWater vaporExhaust pipe

The invention discloses a harmless gasification treating process for a medical waste. By the process, the water content of a biomass gasification auxiliary material is less than 40 percent, and the particle diameter is controlled to be between 0 and 10mm. The treating process comprises the following steps of: mixing the medical waste with the biomass gasification auxiliary material in volume ratio into a mixture, wherein metal and glass are removed from the medical waste and the medical waste is subjected to solid-liquid separation, adding the mixture into a medical waste treating gasification furnace at the speed of 1 to 50kg / h, operating a balance wheel to compress the mixture, covering a top cover, opening an exhaust pipe and a valve which is arranged on a primary air supply pipe, closing a valve on a secondary air supply pipe, starting a fan, and adjusting the temperature of the medical waste treating gasification furnace; and when flue gas which contains much and steam is exhausted, closing a valve on an exhaust pipe, opening a valve of the secondary air supply pipe, filtering crude gas generated by the medical waste treating gasification furnace through a silk bamboo net in a purified gas conveying pipe, and conveying purified gas into a gas burning tower. The treating process for the medical waste can perform harmless gasification treatment on the medical waste, saves transportation cost and treatment cost, and is obvious in social benefit and environment-friendly benefit.

Owner:罗江平

Comprehensive treatment method of architectural garbage

InactiveCN1868597AReduce processing costsMethod securitySievingConstruction waste recoveryStone particleLitter

A comprehensive treating method for the building garbage includes such steps as proper breaking, separating metals, bamboo, wood and plastics out, adding the rest into a washing pool with three-class layered sieve, washing with water while stirring to separate silt sludge, sand and stone particles and big blocks from each other, multi-stage mechanical separation of silt sludge to obtain sludge and sand-stone particles, depositing sludge to become water and clay, drying clay, and cyclic use of water.

Owner:GUANGZHOU ZHENGLV ENVIRONMENTAL PROTECTION TECH CO LTD

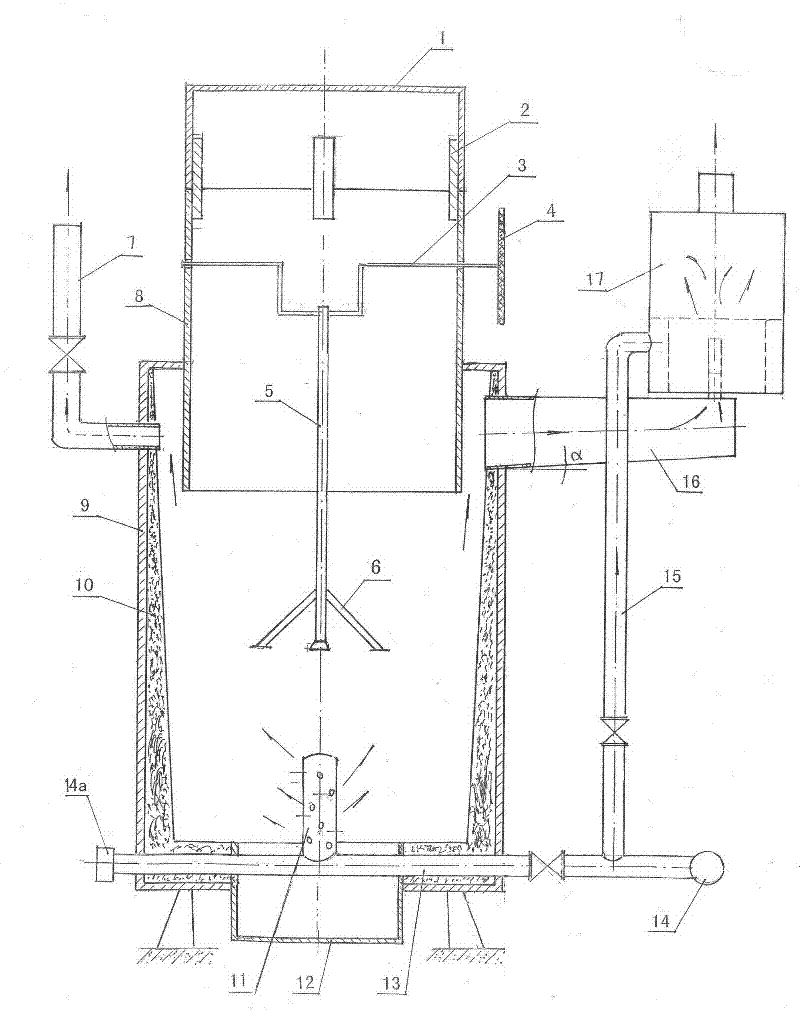

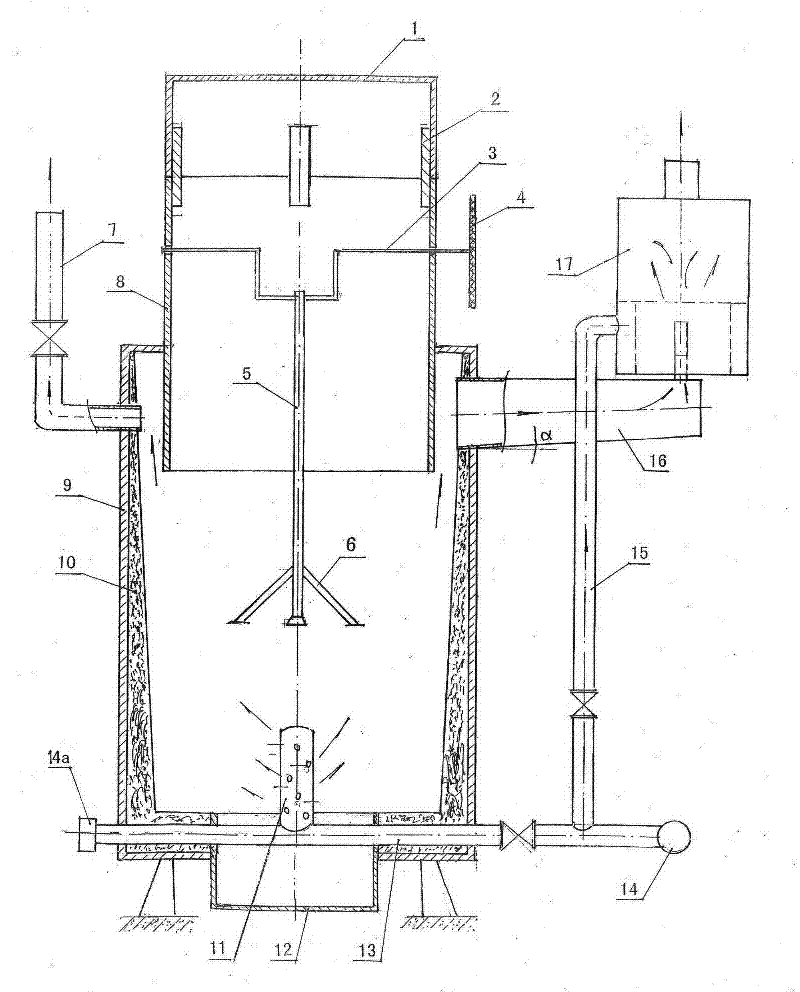

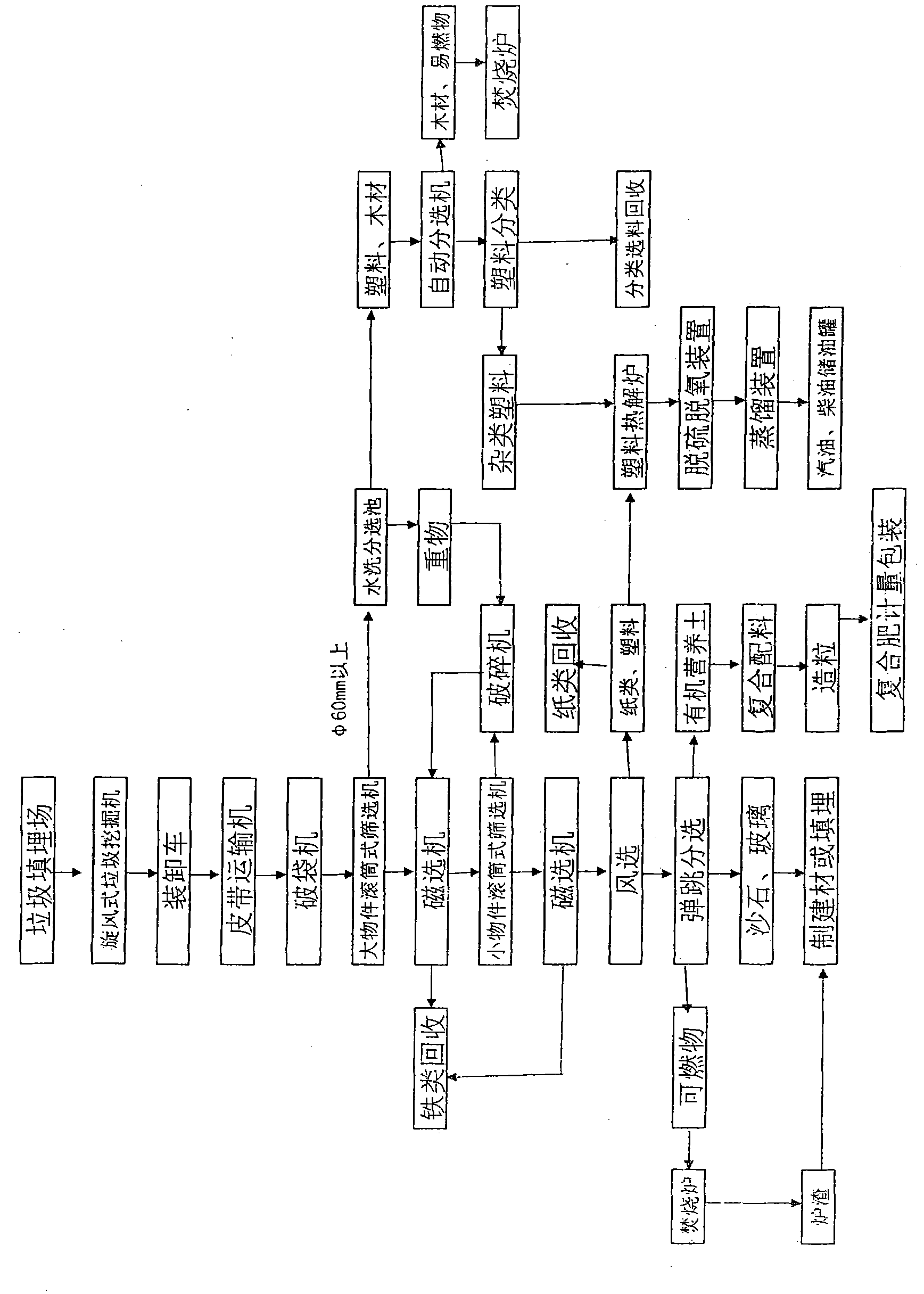

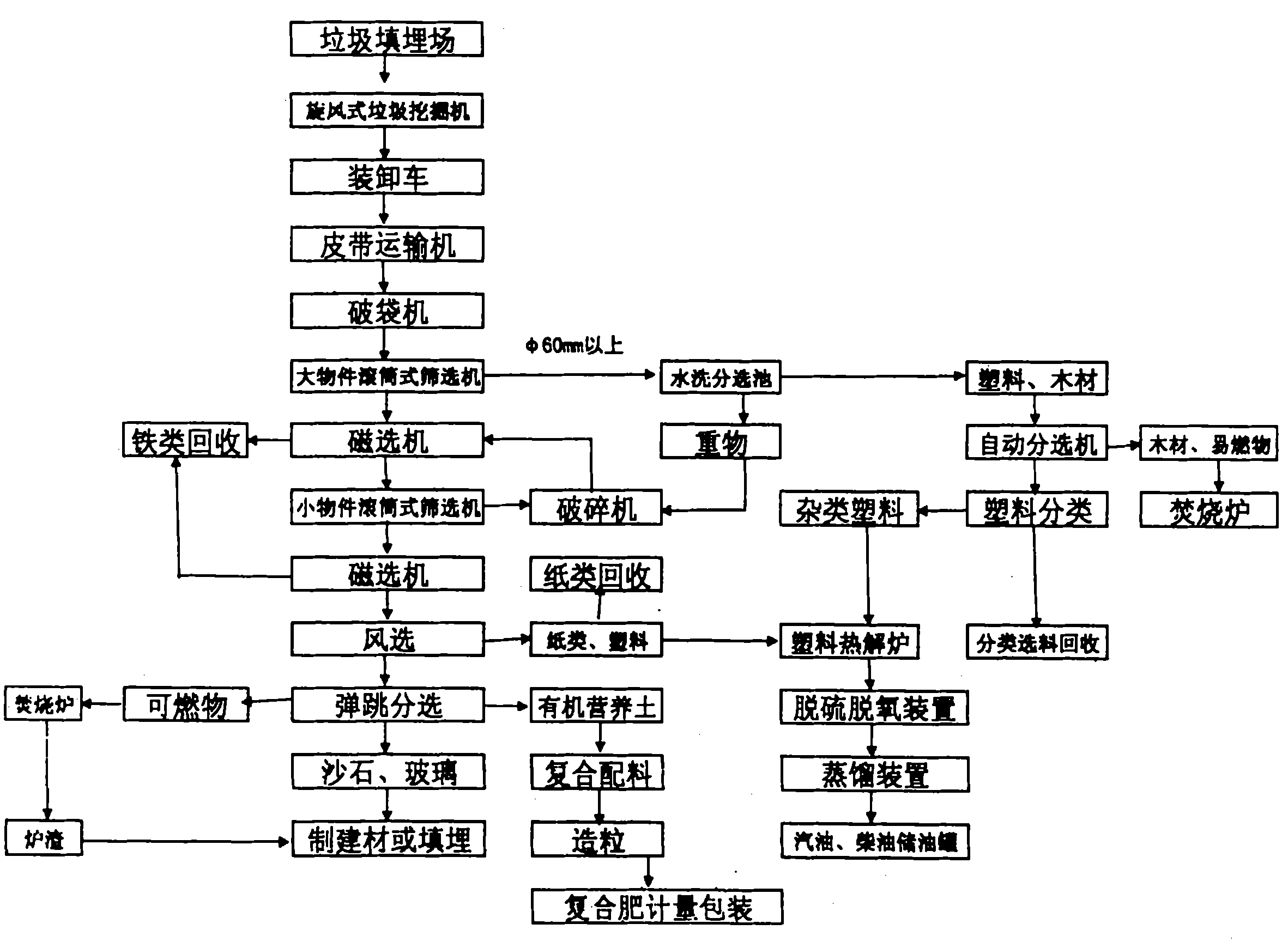

Processing method of garbage landfill

InactiveCN102335669ASave valuable landEliminate pollutionSolid waste disposalClimate change adaptationDistillationLitter

The invention relates to a processing method for rapidly and completely clearing a garbage landfill. With the method, secondary pollution is not occurred. First, a garbage landfill is divided into zones with areas of 1000 to 10000 square meters, and garbage is cleared zone-by-zone. Garbage clearing is carried out by using a comprehensive system with subsystems of an excavation and transportation system, a garbage sorting system, a plastic pyrolysis and distillation system, an organic nutrient soil fertilizer-producing system, and a burning and vapor-producing system, which are related to each other. With the method provided by the invention, an original garbage landfill can be completely cleared and reused, such that a conflict between old garbage landfills and urban construction caused by rapid urban extension can be solved, and a large amount of valuable lands can be saved. The garbage is sorted, such that resources of metals, papers, and plastics can be obtained and reclaimed. With the method provided by the invention, resources that can be utilized are completely turned into resources, wastes are turned into valuable substances, and a pollution problem caused by garbage landfills is eliminated. Therefore, high management costs of garbage landfills are saved. According to the invention, garbage is comprehensively processed, and great economic benefits are generated in each link.

Owner:HUNAN YIDING ENVIRONMENTAL PROTECTION

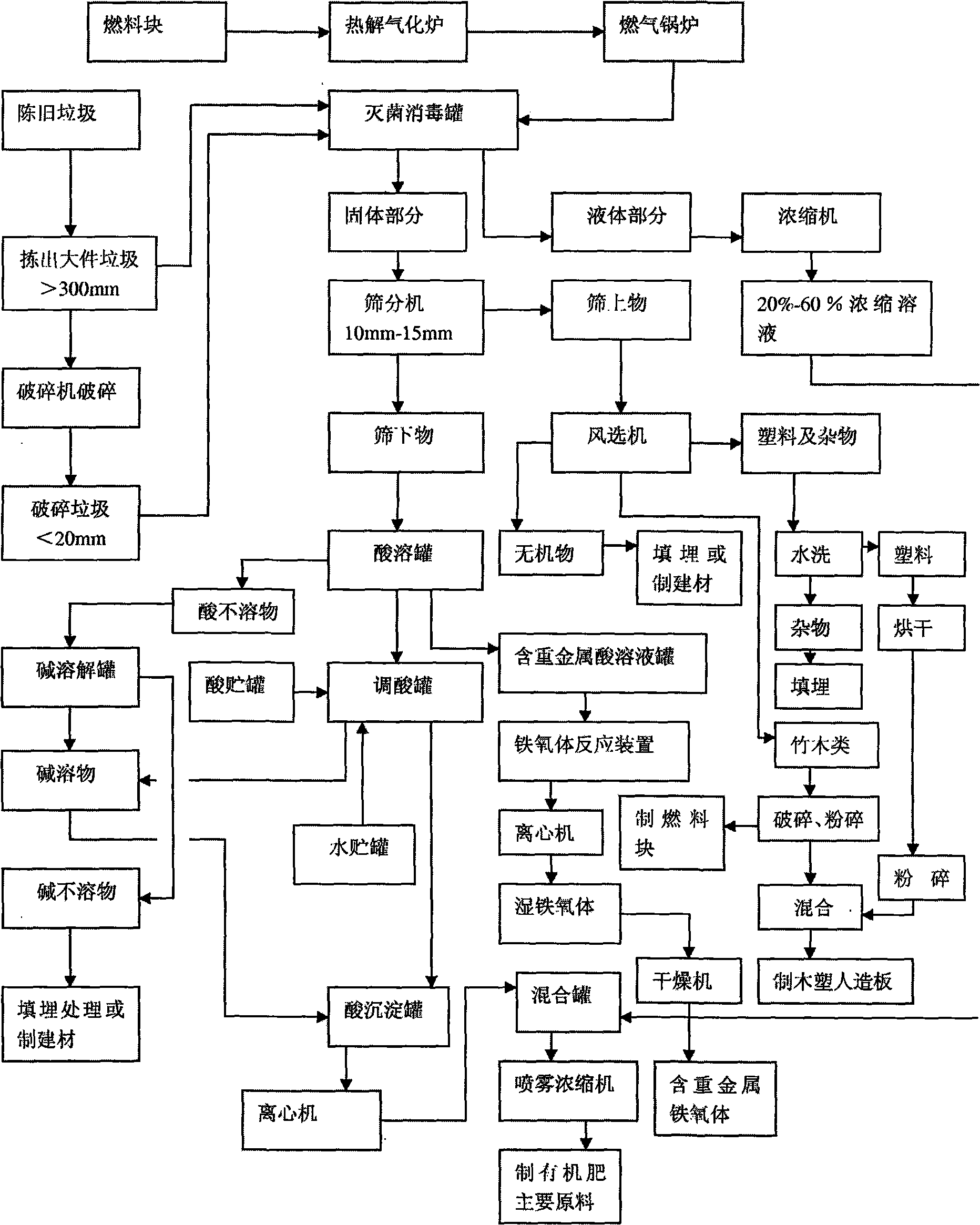

Reclamation processing method for poor garbage

InactiveCN101314163AEliminate pollutionAvoid flammable and explosive hazardsSolid waste disposalPlastic recyclingLiquid wasteEcological environment

The invention provides a completely innocent and utmost resource treatment method for old garbage, which comprises the following steps that: a wood-plastic man-made board is produced after pretreatments such as disinfection, sterilization, screening and air separation of waste bamboo wood and plastics; and septic soil and concentrated waste liquid are prepared into a main raw material of high-quality organic fertilizer. The method used to treat the old garbage has the advantages that: 1. the method eliminates foul odor, foreign odor, and pollution to the environment which are produced by the prior treatment of the old garbage, and avoids the problems of greenhouse pollution and heavy metal pollution as well as flammability and explosibility due to produced inflammable gas when the old garbage is added with fresh organic matters and is prepared into compost through secondary fermentation; 2. the method avoids the atmospheric pollution produced by incineration treatment, particularly dioxin pollution; 3. the method can reclaim and reuse useful substances in the old garbage to the utmost extent, and produces good social benefit, economic benefit and ecological environment benefit.

Owner:费爱民 +2

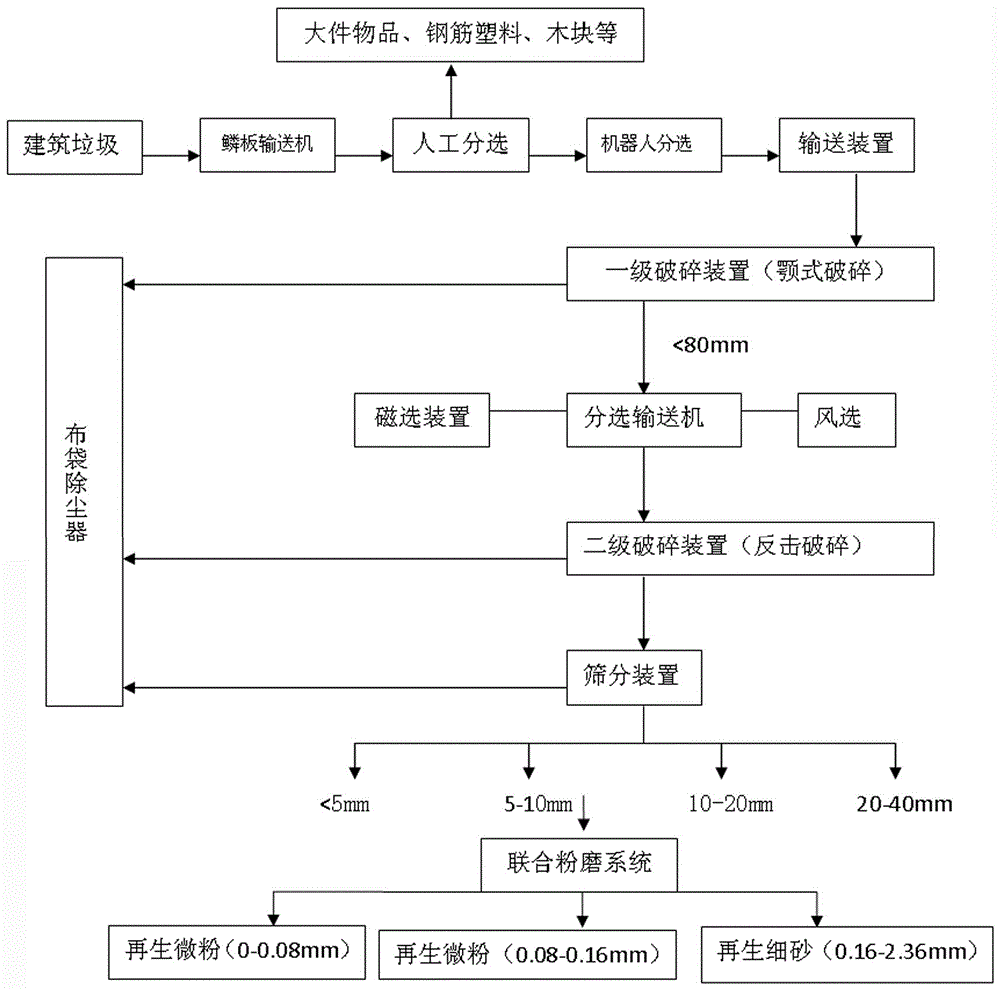

Construction waste treatment method

InactiveCN106111665AReduce consumptionReduce pollutionConstruction waste recoverySolid waste disposalSewagePollution

The invention discloses a construction waste treatment method. The construction waste treatment method comprises the following steps of 1, manual sorting and robot sorting, 2, primary crushing, 3, iron removing and winnowing, 4, secondary crushing, 5, screening and 6, joint powder grinding. According to the construction waste treatment method, the problems that a lot of land is consumed, and air dust, sewage pollution and the like are produced due to landfill of construction waste are solved, and construction waste recycled materials are produced.

Owner:HANGZHOU ENVIRONMENTAL GROUP

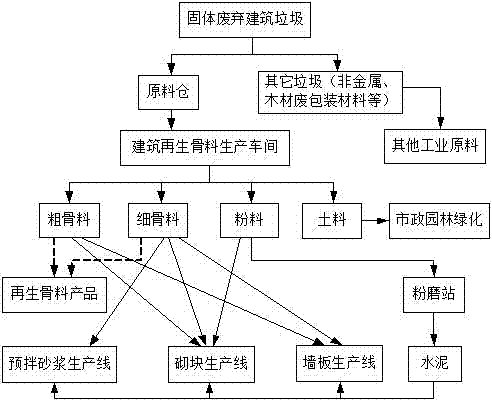

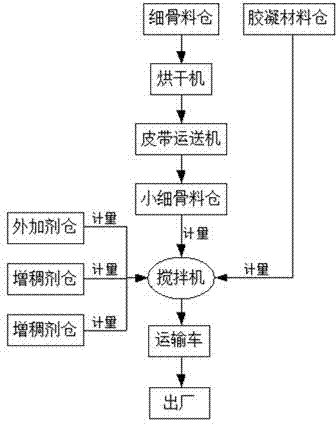

Construction waste recycling technology

InactiveCN104261715AImprove land occupationAvoid pollutionConstruction waste recoveryWaste processingMixed materialsRenewable resource

The invention discloses a construction waste recycling technology. The technology comprises an aggregate production technology, a premixed mortar production technology, a building block production technology, and a wallboard production technology. The construction wastes are graded, grinded, and sieved to produce aggregate that can replace the natural sand and stones. Part of the aggregate can be used to produce premixed mortar, cement mixed material, and concrete products. The residual aggregate is packed as commercial aggregate for sale, and can be used in concrete mixing plants, premixed mortar plants, and road structural foundation backfilling. The produced powder can be used to product concrete products, and the produced soil can be directly used as greening soil. The construction wastes are graded, removed, or grinded, and then subjected to a series of technological procedures, so that the wastes are converted into renewable resources and reutilized, and the economic profit is prominent. The sprayed dusts and sands which cause severe environmental pollution during the transportation and storage process are avoided. Solved is the problem that plants cannot grow on the soil that is used to bury construction wastes.

Owner:GUANGDONG XINGU TECH

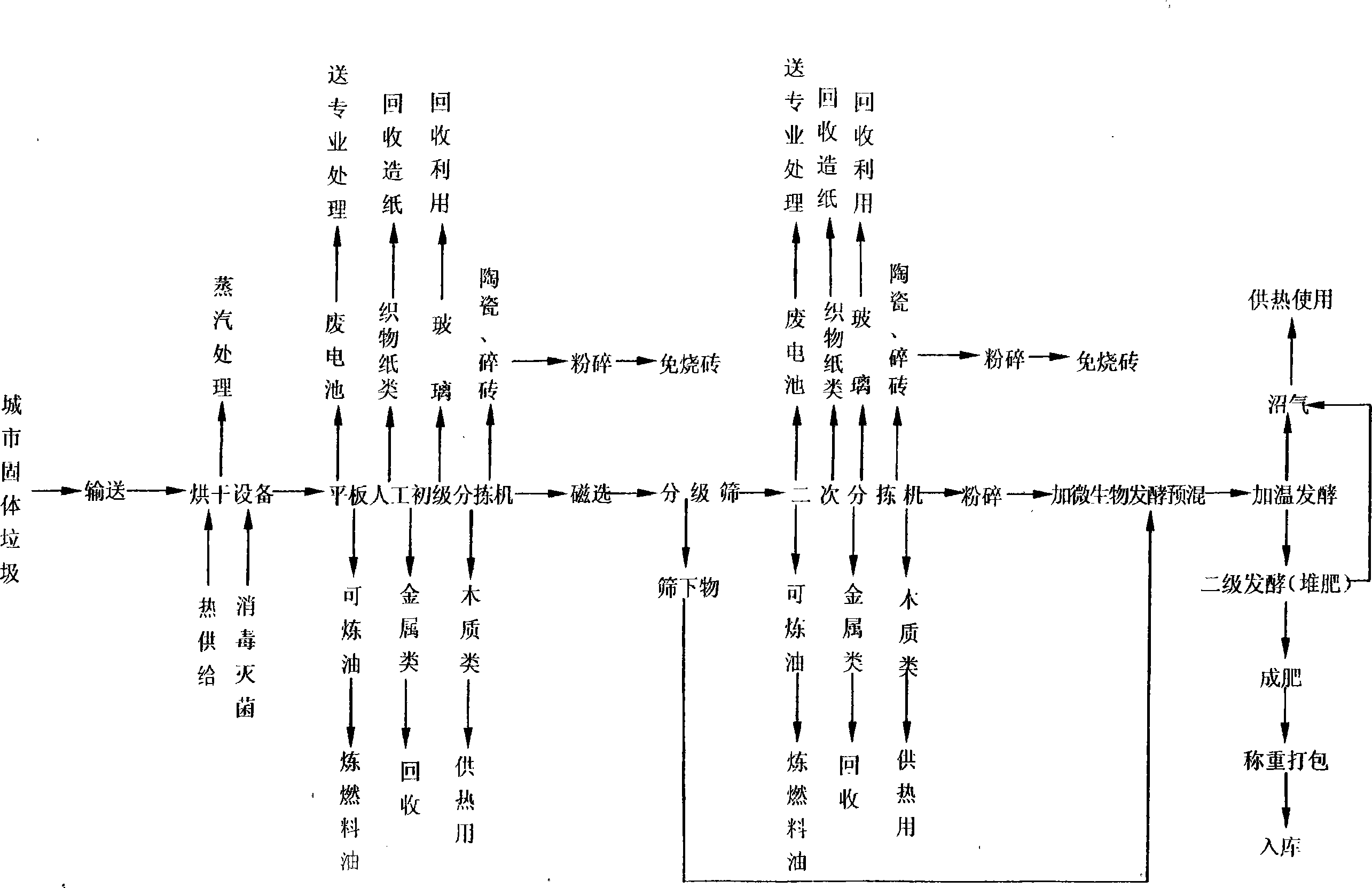

Integrated ulilization processing system for treating daily-life garbage without environmental pollution by reclaiming and regenerating

InactiveCN101081402ABe harmlessBe resourcefulBio-organic fraction processingSolid waste disposalBrickLitter

The present invention is one comprehensive innocuous city solid refuse treating system. In the system, the city solid refuse is first stoved, sterilized and sorted, then magnetically separated to separate out iron containing waste, and finally sieved into the undersize fed to one mixing tank and the oversize further sorted, with the rest matter being crushed and fed also to the mixing tank for fermentation to produce organic fertilizer. The sorted fabric, paper, iron, glass are reused; the sorted building refuses are crushed and further produced into no-burning brick; the waste battery is specially treated; the waste plastic and rubber are treated to produce oil; and the marsh gas generated in the fermentation process is used to provide heat for stoving refuse and refining oil. The present invention has excellent refuse treating effect.

Owner:周建华 +1

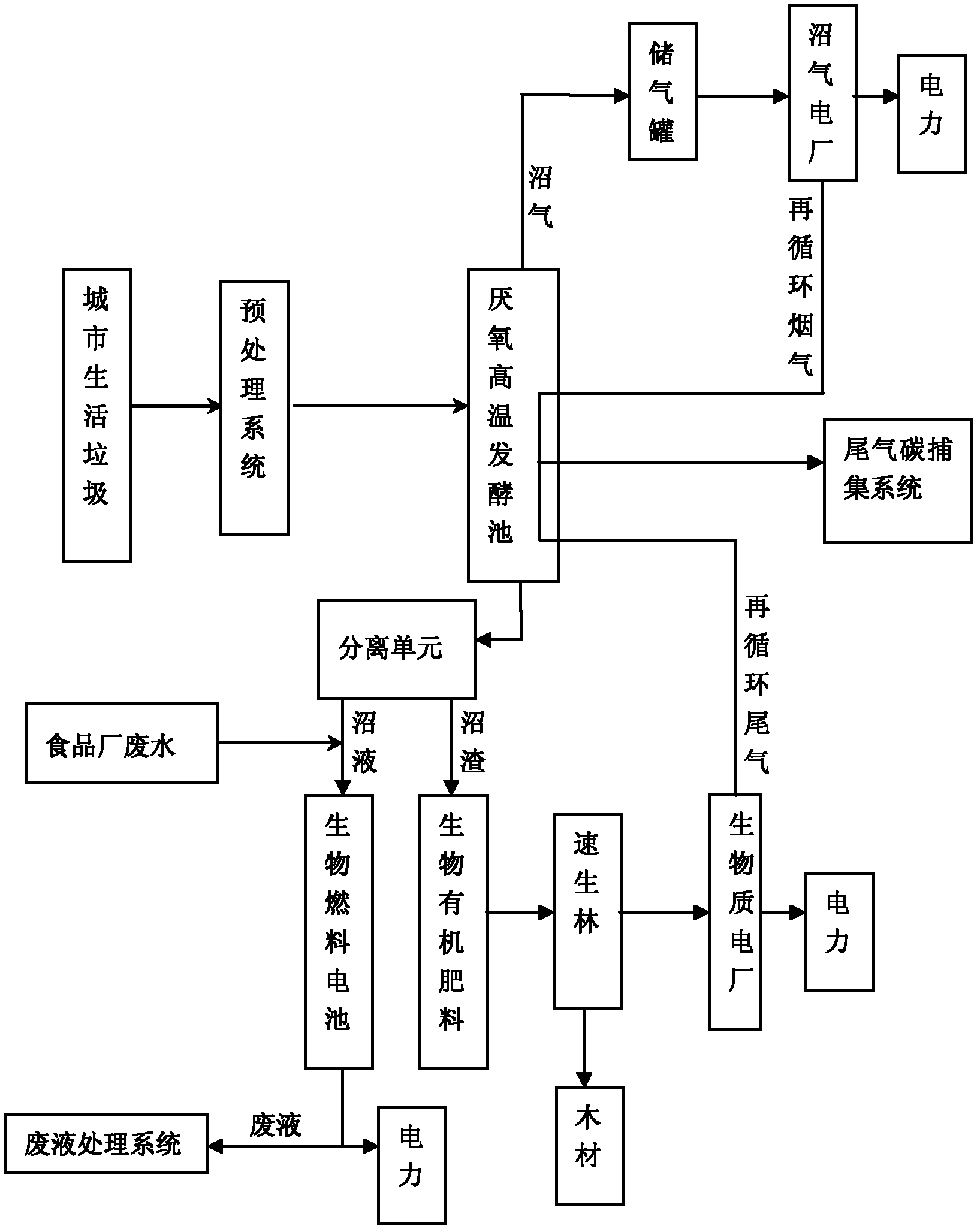

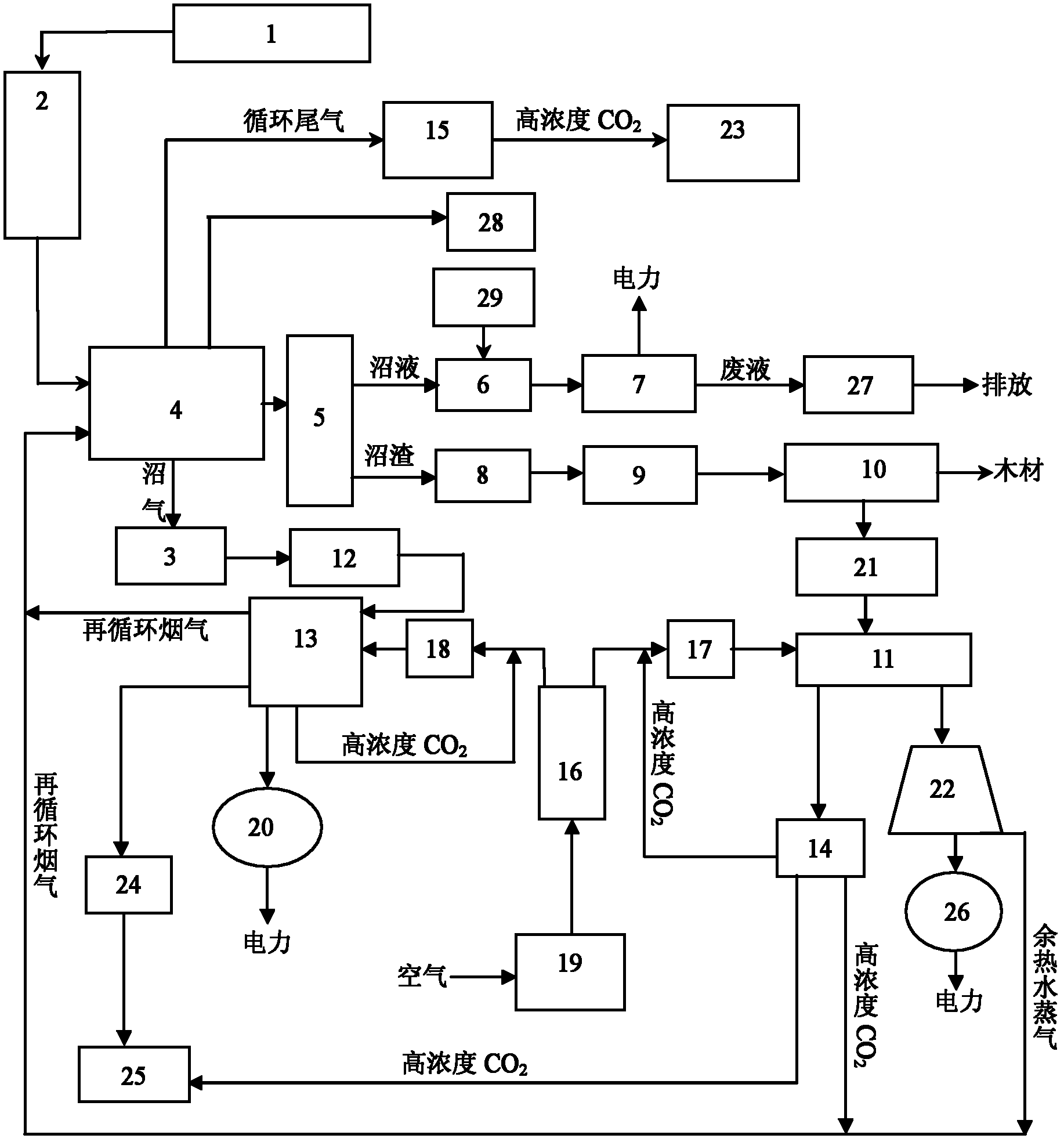

Household solid garbage recycling and renewable biological carbon circulating technology

ActiveCN102500604ARemarkable effectSignificant innovationWaste processingSolid waste disposalBiogas productionSlurry

The invention discloses household solid garbage recycling and renewable biological carbon circulating technology, which solves the problem that biogas generated from household garbage is difficult to ferment at places with low temperature, and realizes an integral circulating zero-carbon emission system and a large-size renewable biological carbon circulating system simultaneously. The technical scheme includes that pretreated household garbage is fed into a large-size biogas digester to ferment, biogas is supplied for oxygen-enriched combustion of a gas turbine gas to generate power, biogas slurry is used as a biofuel cell substrate and is cleaned and used for power generation, and biogas residue is used as biological organic fertilizer and used for growth of fast-growing trees for biomass fuel power plants. Flue gas generated in combustion in the power plants circulates to guarantee fermenting temperature of the biogas digester so as to realize biogas production stably and efficiently. Pure oxygen and recycled tail gas are used as combustion supporting gas of the power plants, and accordingly combustion efficiency can be improved while cost for treatment of tail gas is reduced. CO2 in the flue gas is captured according to the carbon capture technology, and accordingly the zero-carbon emission system is realized. In addition, the renewable biological carbon cycling system is realized by means of biological treatment to biogas slurry and biogas residue.

Owner:UNIV OF SCI & TECH LIAONING

Solid fuel for sludge anhydration

ActiveCN101503643AReduce moisture contentWide variety of sourcesSludge treatment by de-watering/drying/thickeningBiofuelsFiberDewatered sludge

The invention discloses a dried sludge solid fuel, which relates to a formula of a solid fuel prepared by drying sludge. The dried sludge solid fuel is prepared by mixing and press forming or powdering the sludge and an additive, wherein according to the weight of the sludge, the additive comprises the following components by weight percentage: 5 to 10 percent of wooden meal, 0 to 20 percent of coal powder, 5 to 15 percent of screen residues of aged refuse, and 1 to 5 percent of dewatering agent; the sludge is dewatered sludge with an initial moisture content of 80 percent and a dry base heatvalue of 7,000 to 18,000 kJ / kg from a sewage plant; the dewatering agent comprises calcium oxide, magnesium oxide, magnesium chloride and aluminum chloride in a mass portion ratio of 1:5.5-10:1:2.5-3; and the screen residues of aged refuse are screen residues mainly comprising plastic, fibers and paper which are landfilled for 8 to 10 years, initially ground and passed through a screen with an aperture of 60 millimeters. By changing the conventional method for preparing a fuel by using sludge as an additive, the method can fully realize the stabilization and recycling of the sludge and fulfill the aim of treatment of wastes with processes of wastes against one another. The product of the method completely meets the requirement on stable burning for power generation and has better economicand social benefits.

Owner:上海同济环境工程科技有限公司

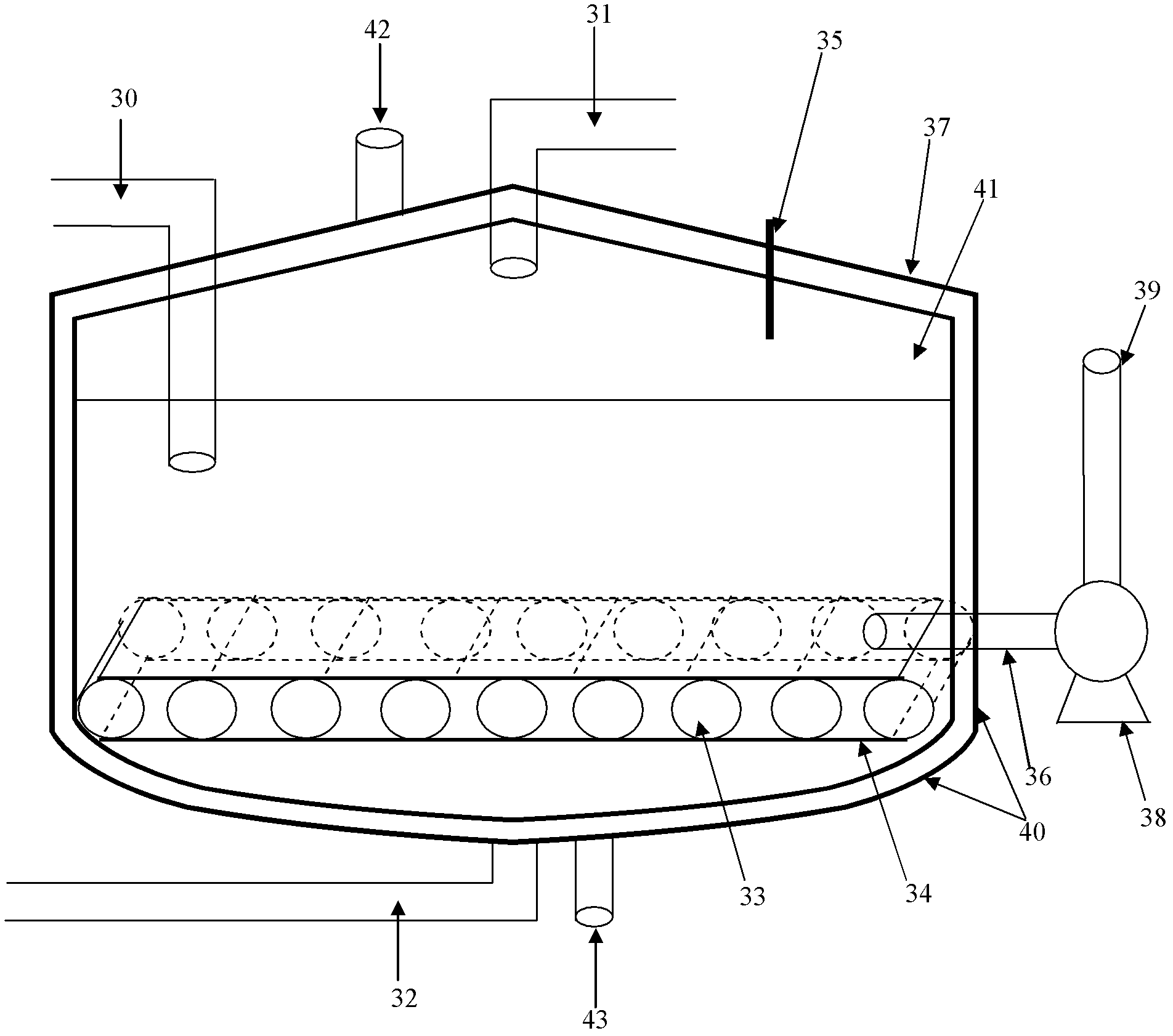

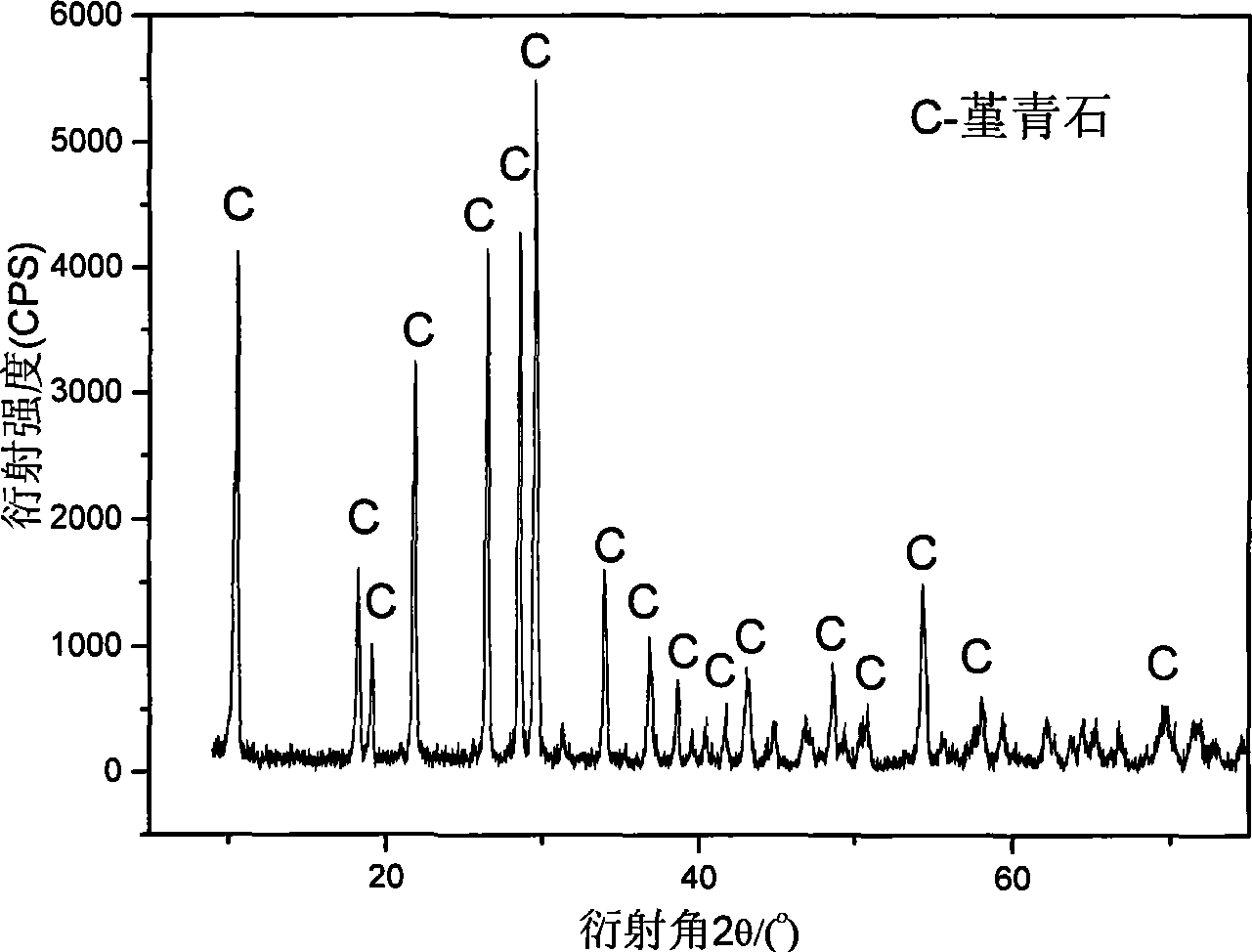

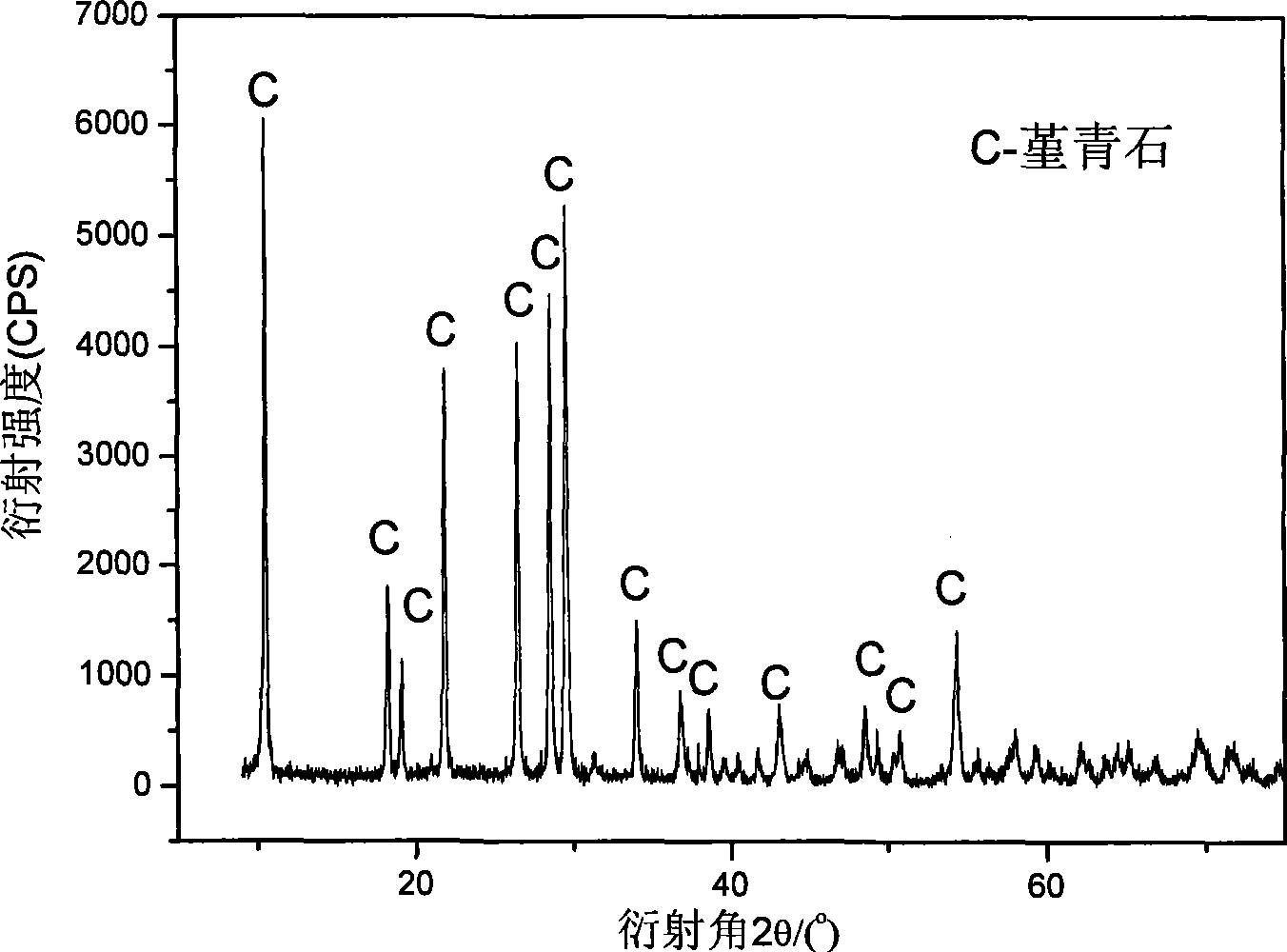

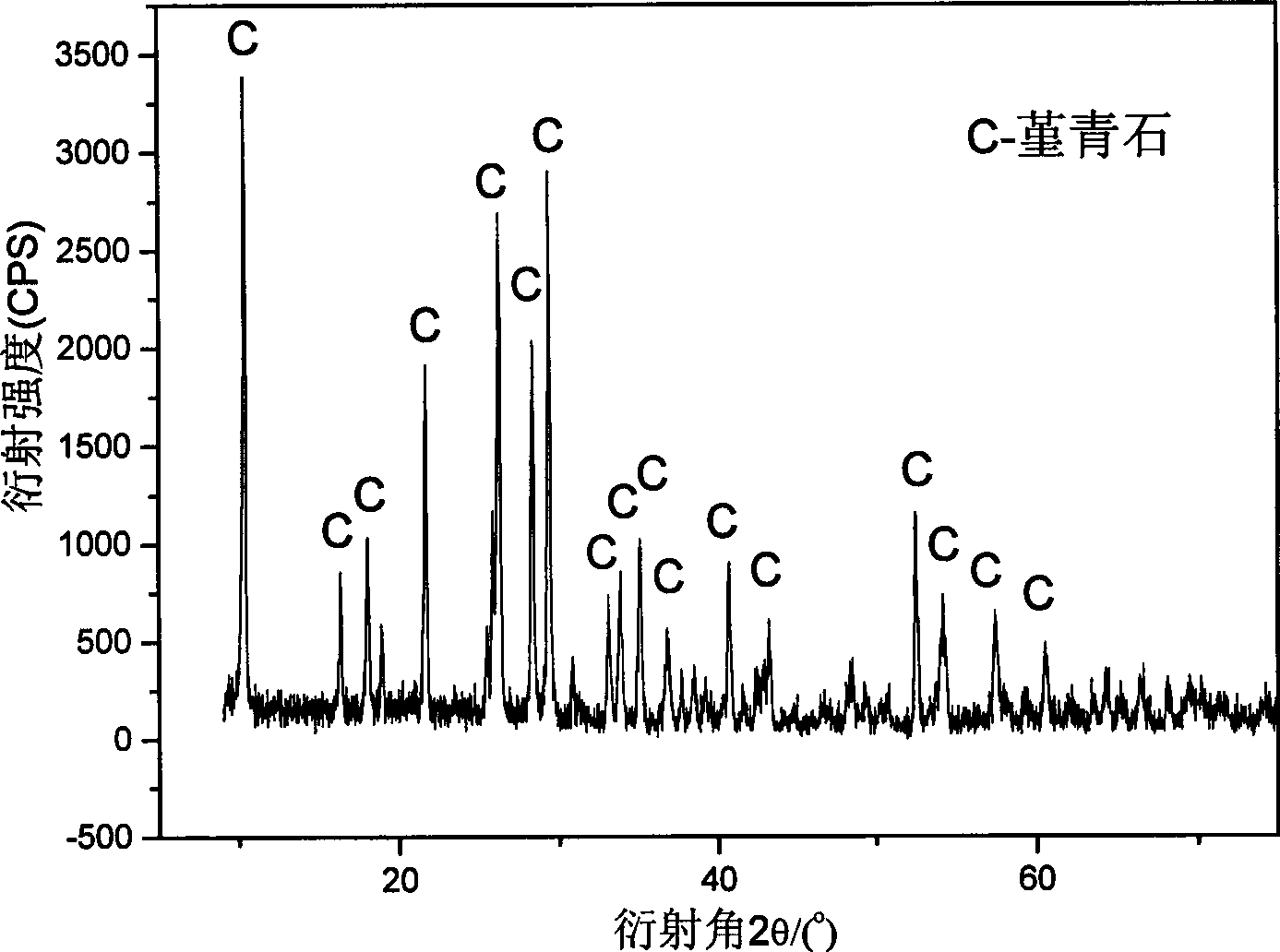

Method for synthesizing porous cordierite ceramic material by gangue and waste refractory material

InactiveCN101531526AAvoid pollutionRich reservesSolid waste disposalFurniture waste recoveryAir atmosphereBrick

A method for synthesizing porous cordierite ceramic material by gangue and waste refractory material belongs to the technical field of synthesis of inorganic non-metal material. The invention comprises the steps of using gangue, waste refractory material (magnesia carbon brick and sliding brick) and saw dust pore-forming material as raw materials, mixing 45-75% of gangue, 8-13% of used magnesia carbon brick and 8-13% of used sliding brick with 5-40% of saw dust in a mass ratio, performing ball milling, drying and forming, and then keeping temperature for 2-6 hours at the temperature of 1320-1420 DEG C in the air atmosphere, so as to obtain the synthesized sintered blank. The cordierite porous ceramic material synthesized by the invention has an apparent porosity of 36%, a volume concentration of 1.30g / cm3 and rupture strength of 9MPa. The invention not only solves the pollution of solid waste to environment due to accumulation, but also the synthesized cordierite porous ceramic material can be applied to industrial production as the heat insulating material, and the invention saves production cost.

Owner:BEIJING JINGYEYUAN NEW MATERIALS

Mud granulizing method, mud granule produced thereby and application thereof

InactiveCN101514072AImprove processing efficiencyEasy to storeSludge treatmentSolid waste disposalFilling materialsSludge

The invention discloses a mud granulizing method, mud granules produced by the method and application of the mud granules. The method comprises the following steps: mixing mud and quicklime evenly, granulizing with a granulator to form mud granules, adding moderate amount of cement to enhance the strength of the mud granules which can be used as building filters, and adding moderate amount of carbon powder or sawdust to improve the combustibility of the mud granules which can be used as fuel. The mud granulizing method of the invention can be directly combined with the sewage disposal process, and mud is taken as raw material to produce mud granules with multiple uses to ensure that the mud produced by mud disposal can be recycled, thus resolving the mud disposal problem of the sewage disposal industry. The method can realize continuous and automatic work, avoid manual work directing at mud, and improve work environment.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD +1

Phosphogypsum-sludge combined curing treatment method

InactiveCN101579683APrevent affecting the curing effectIn situ pavingsSolid waste disposalSludgePhosphogypsum

The invention discloses a phosphogypsum-sludge combined curing treatment method. The method can combine curing treatment for sludge and industrial waste phosphogypsum produced in civil engineering and hydraulic engineering. The method comprises the following implementation steps: a, measuring the water content of the phosphogypsum, water content of the sludge and clay content; b, fragmentizing the phosphogypsum; c, mixing the phosphogypsum and the sludge; d, adding a curing agent into the mixture; and e, shelving the mixture. The phosphogypsum-sludge mixed aggregates after curing treatment can be used as an earthwork stuffing for paving roads, filling dams and the like, and also can be used as solid wastes to be piled or directly embedded so as to save large amount of heap site selection charge and anti-seepage treatment charge; therefore, the method has large economic benefit and environmental benefit.

Owner:HOHAI UNIV

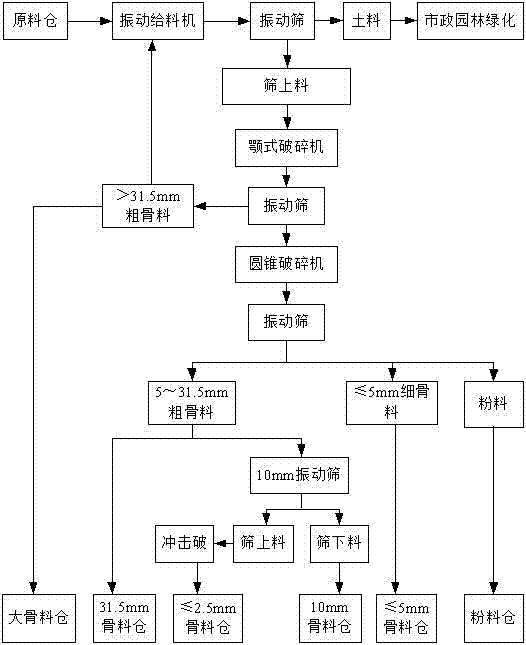

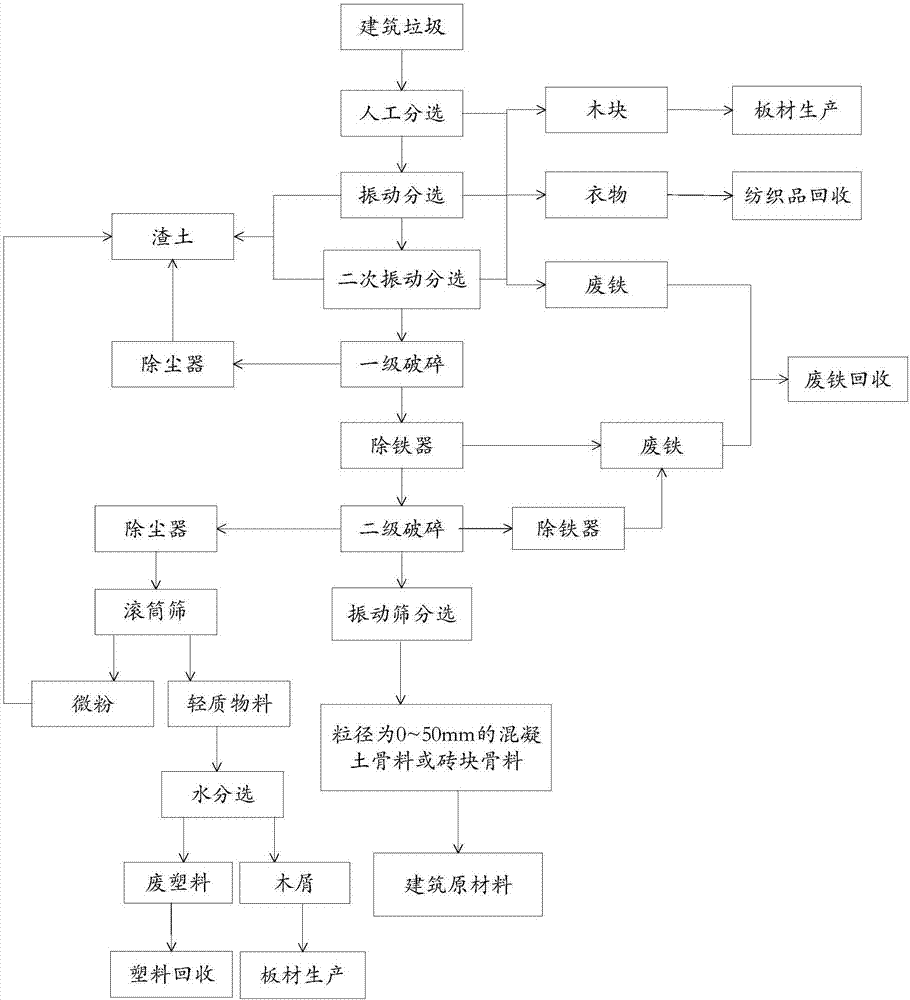

Method for recycling construction wastes

InactiveCN107377584AIncrease profitQuality improvementConstruction waste recoverySolid waste disposalEnvironmental resistancePrill

The invention discloses a method for recycling construction wastes. The method comprises the following steps: artificial sorting, vibratory sorting, primary crushing, iron removing, secondary crushing and sorting through a vibrating screen. According to the method for recycling the construction wastes, steps are reasonable and orderly, selected equipment is advanced, and the running cost is low. By the method, the sorting efficiency is high, a large quantity of recycled aggregates which are good in quality and are fine-grained can be produced, and the recycled aggregates which are produced by the method do not contain other impurities, and belong to high-quality recycled materials. Meanwhile, residue soil, scrap iron, clothes, wood blocks, plastics, micro-powder and the like in the construction wastes can further be recycled and are fully utilized, the construction wastes are sorted thoroughly, the utilization rate of raw materials is high, and therefore, the method has high benefit of environmental protection and marketization popularization prospect.

Owner:赵长强

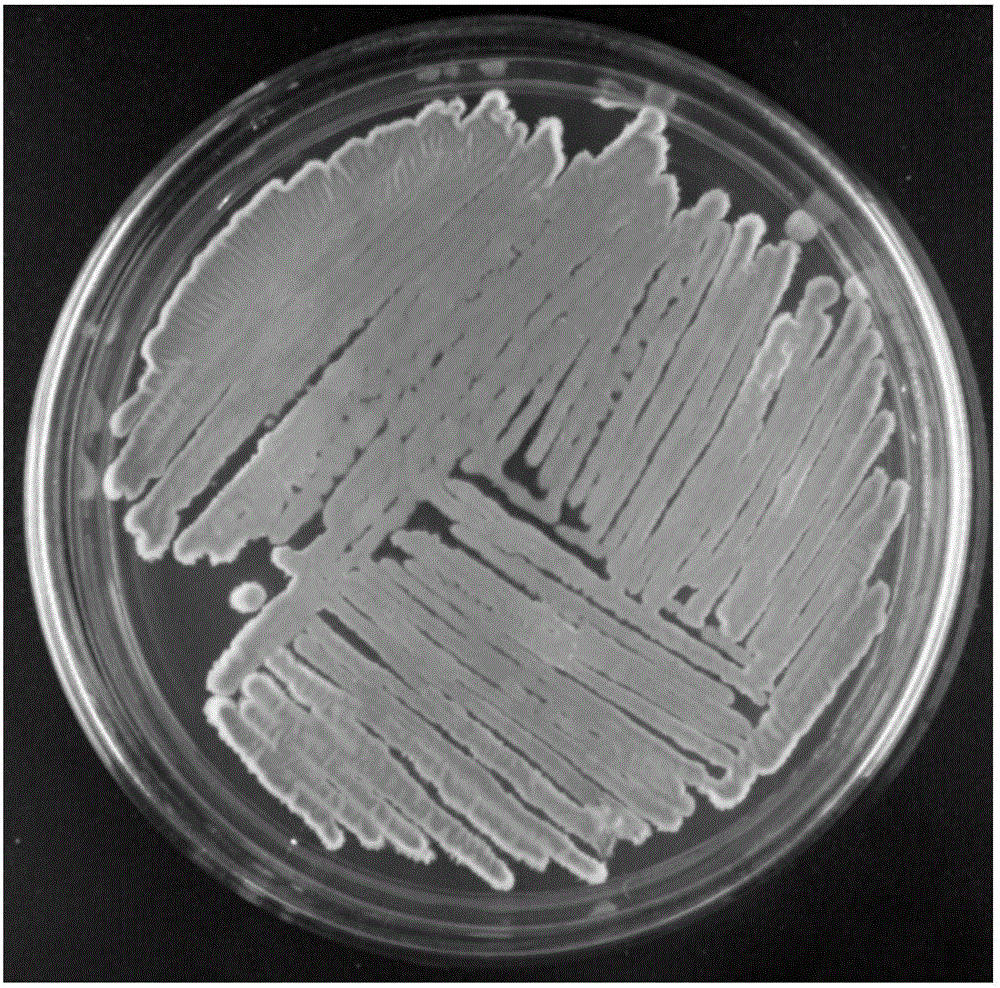

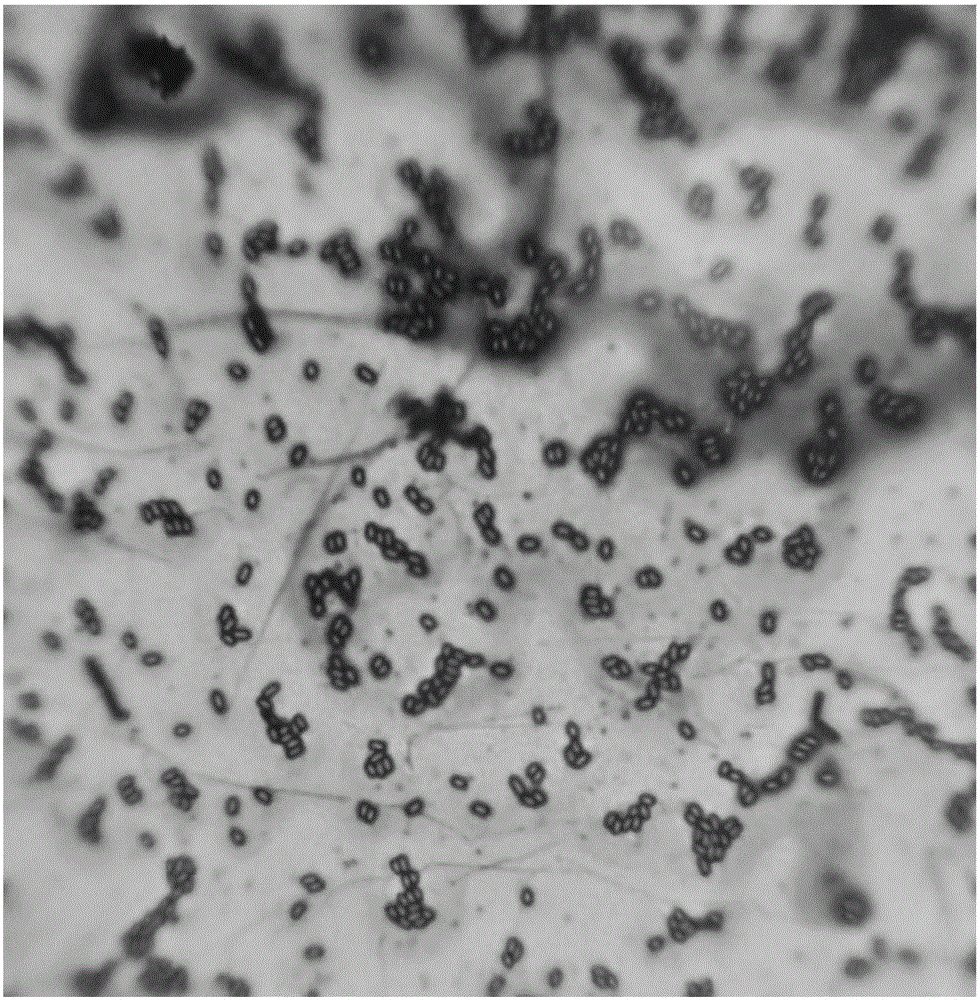

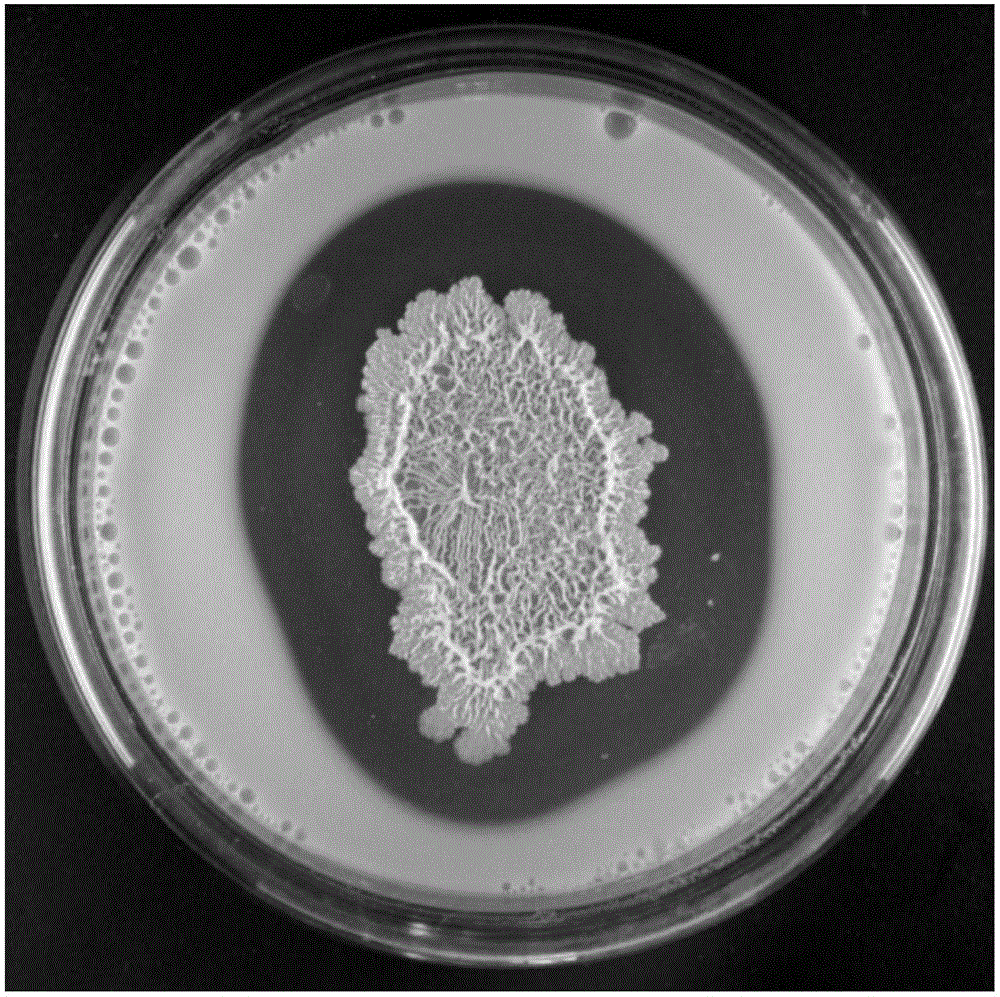

Bacillus licheniformis and applications thereof in kitchen waste

ActiveCN106190900AHigh activity proteaseHigh lipohydrolase activityBacteriaSolid waste disposalAcid-fastBacillus licheniformis

The invention provides bacillus licheniformis, wherein the classification name is bacillus licheniformis CY-1, the bacillus licheniformis CY-1 is preserved in the China General Microbiological Culture Collection Center (CGMCC), the address is the Institute of Microbiology of Chinese Academy of Sciences located in 3, Courtyard 1, West Beichen Road, Chaoyang District, Beijing, the postal code is 100101, the accession number is CGMCC NO.12448, and the preservation date is May 13, 2016. The invention further provides applications of bacillus licheniformis in kitchen waste treatment. The bacillus licheniformis has the activities of high-activity protease, amylase and oil hydrolase, can degrade glucose for generating acid, and is a thermophilic bacterium with high salt tolerance and high acid tolerance, and through effective combination of the bacillus licheniformis with a carrier, the weight of the fed kitchen waste is rapidly and efficiently reduced by 85%.

Owner:BIOMAX ECOLOGICAL ENG

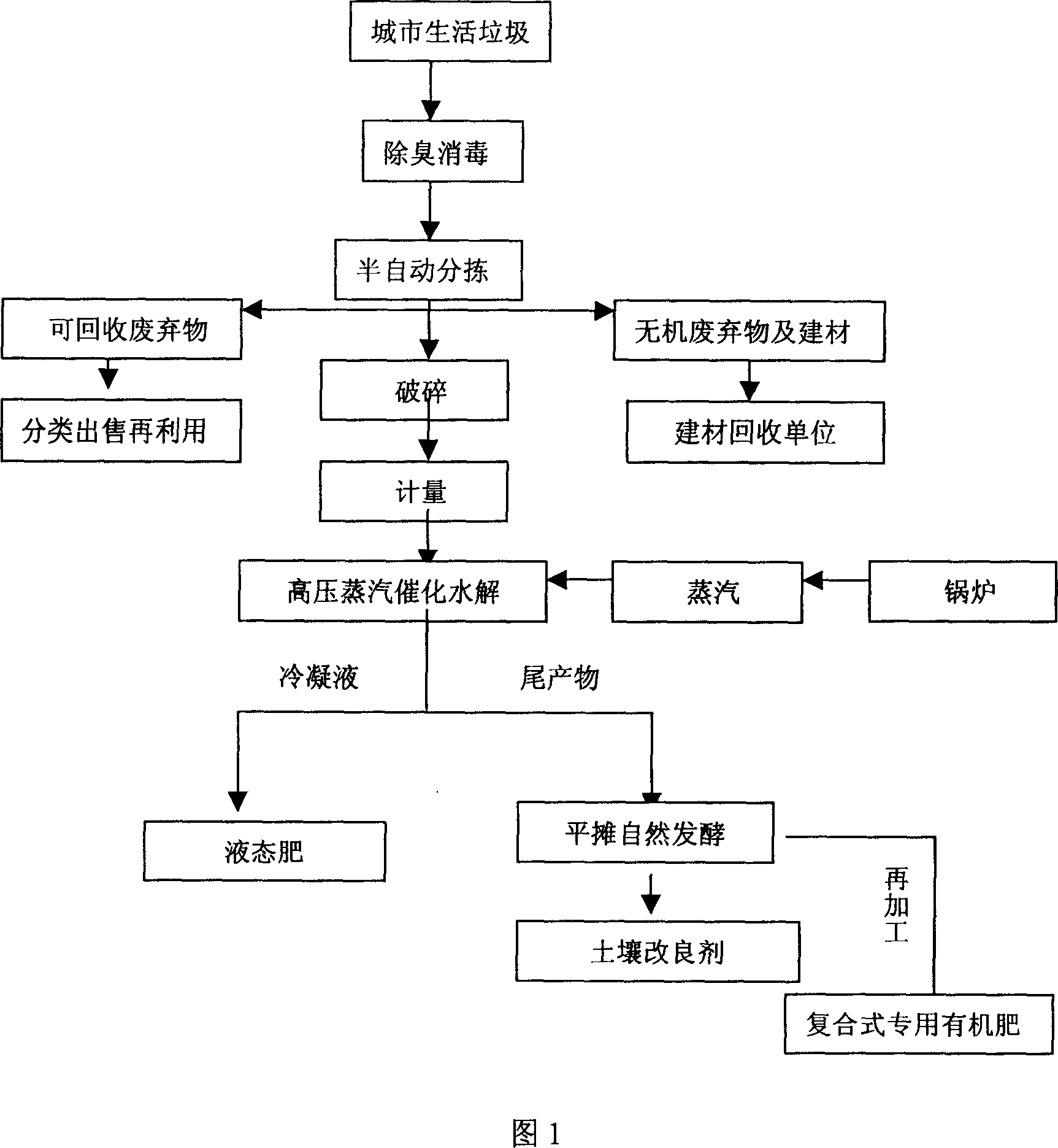

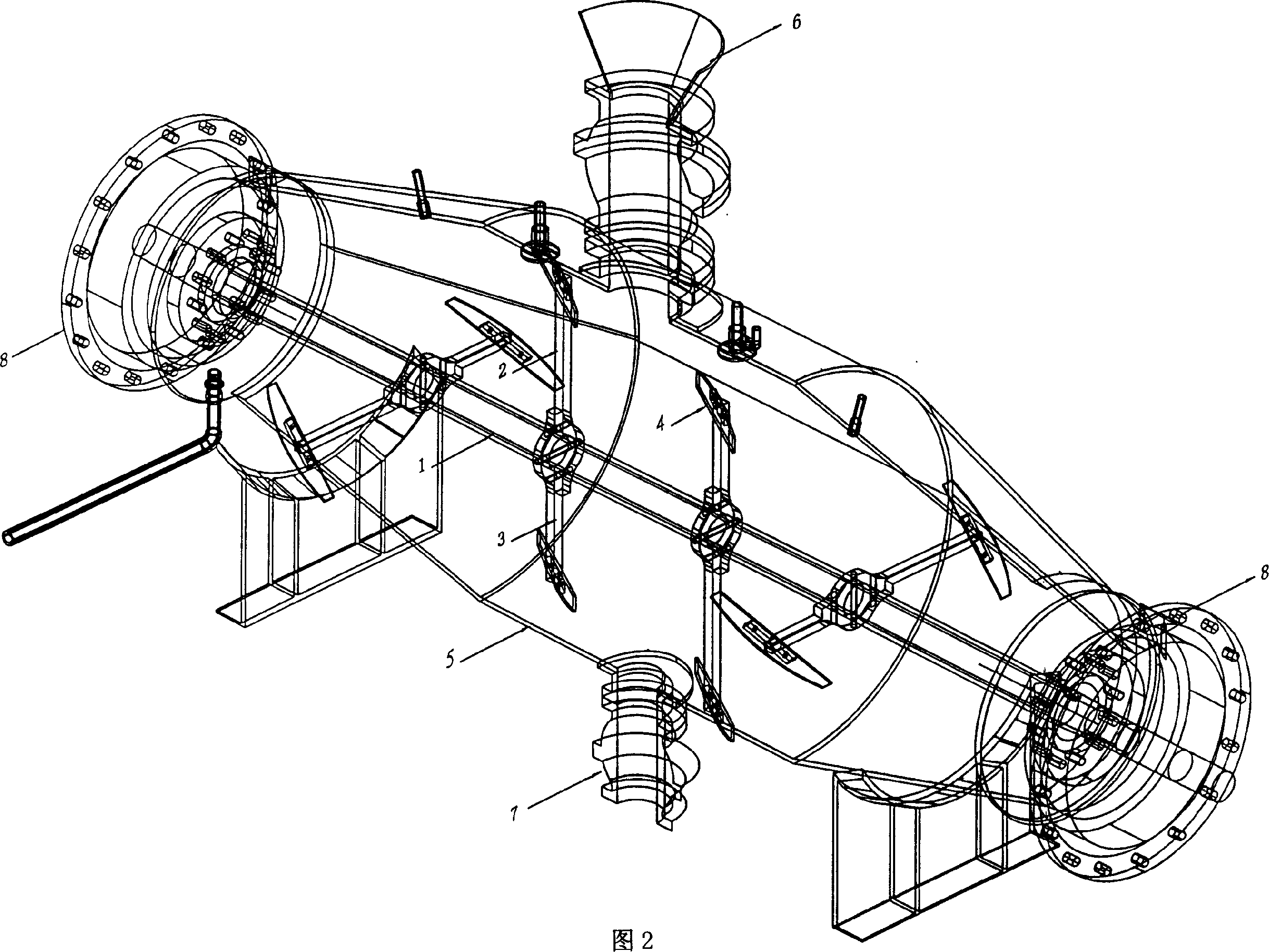

High pressure steam catalysis hydrolysis process for treating domestic refuse

InactiveCN1923383AReach the goal of reducingAchieve the goal of harmlessSolid waste disposalClimate change adaptationChemical reactionSaturated water vapor

The invention relates to a method for treating life waste. Wherein, it uses high-pressure steam catalyst hydrolysis processor; and the treatment comprises that: first using high-pressure steam treated chip condensed liquid to disinfect the waste; then classifying and selecting to picking the un-treated waste as glass, metal and rubber, and the ones which can be recycled; breaking left organic waste and feeding into high-pressure steam catalyst hydrolysis processor; chemically reacting at certain pressure, temperature and saturated steam, the energy generated in water molecule structure change will break off the molecule chain of macromolecule polymer, to reduce it into micromolecule polymer which can be absorbed by plant.

Owner:周钜洸

Building-rubbish resource treatment and use integrated treating method and treating system thereof

InactiveCN105127176AEfficient use ofEasy to useConstruction waste recoverySolid waste disposalBrickArchitectural engineering

The invention relates to the technical field of building rubbish recycling treatment, in particular to a building-rubbish resource treatment and use integrated treating method and a treating system thereof. The building rubbish treating method includes the steps that soil, steel, plastic, asphalt and wood in building rubbish are separated out through a separation treating device, classified and recycled; the building rubbish is smashed through a smashing device, red bricks are manufactured into brick powder, stone is manufactured into scree or sand or stone powder; and the obtained brick powder, the obtained stone powder, the obtained scree and the obtained sand are used as raw materials for manufacturing concrete, and therefore the building rubbish is completely used. The treating method and the treating system are convenient to use; and by means of the treating method, on the premise that the environment and soil are not polluted, the building rubbish is converted into the production raw materials through separation and smashing of the building rubbish, and the building rubbish is efficiently used.

Owner:XINJIANG KELI MACHINERY EQUIP

Method for treating and recycling industrial, construction and domestic wastes

InactiveCN103143548AConstruction waste recoverySolid waste disposalEnvironmental engineeringDomestic waste

The invention relates to waste treating and recycling. A method for treating and recycling industrial, construction and domestic wastes comprises the following steps of: by utilizing industrial wastes, construction wastes and domestic wastes as raw material additives of solidifiable materials, stabilizing the industrial wastes, construction wastes and domestic wastes through solidifying the solidifiable materials, and recycling the stabilized industrial wastes, construction wastes and domestic wastes as a part of a solidified material. By adopting the method, the wastes can be recycled as a part of the solidified material at first; and secondarily, the performances of the solidified material can be improved with low cost through adding the wastes.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

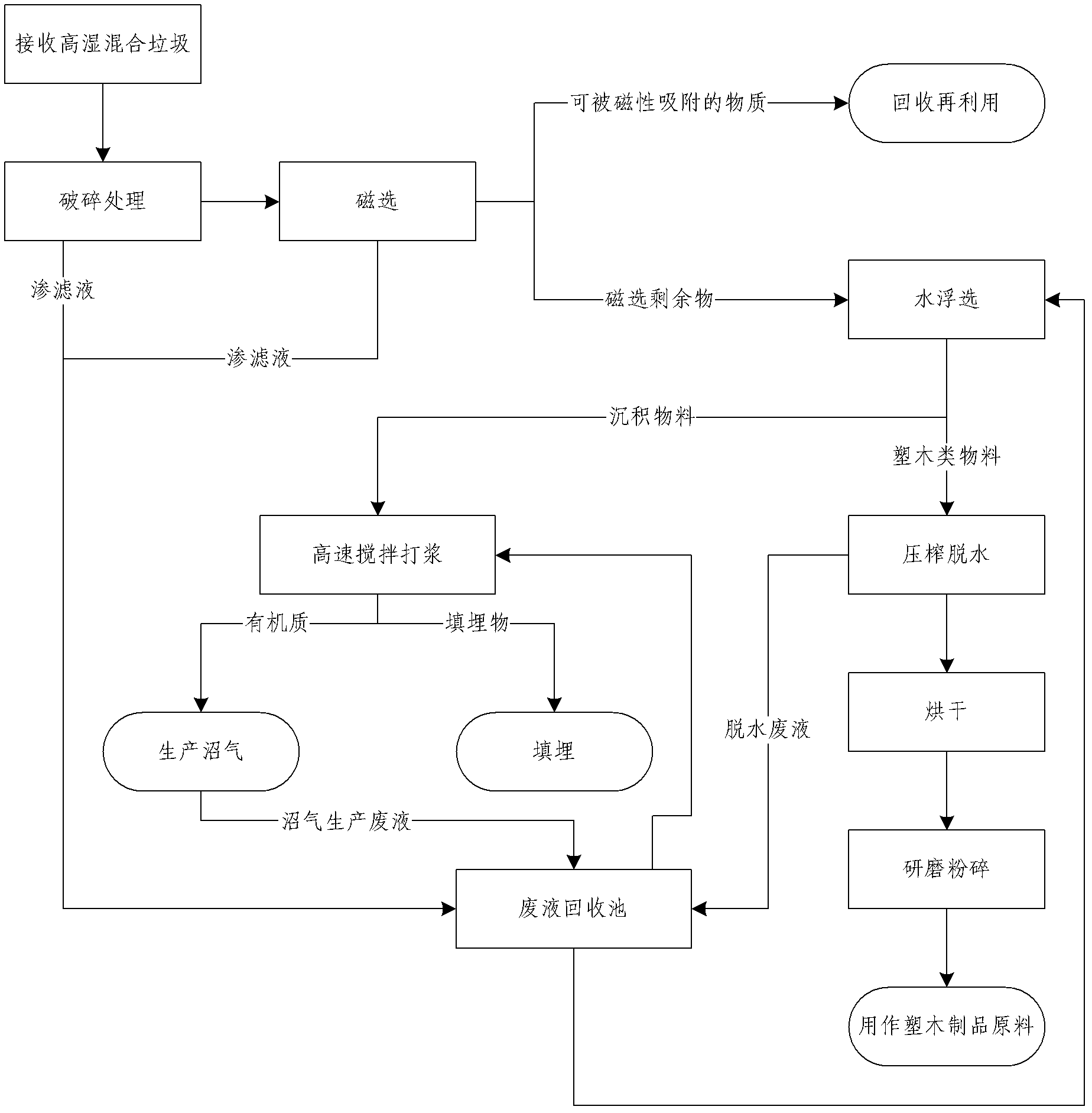

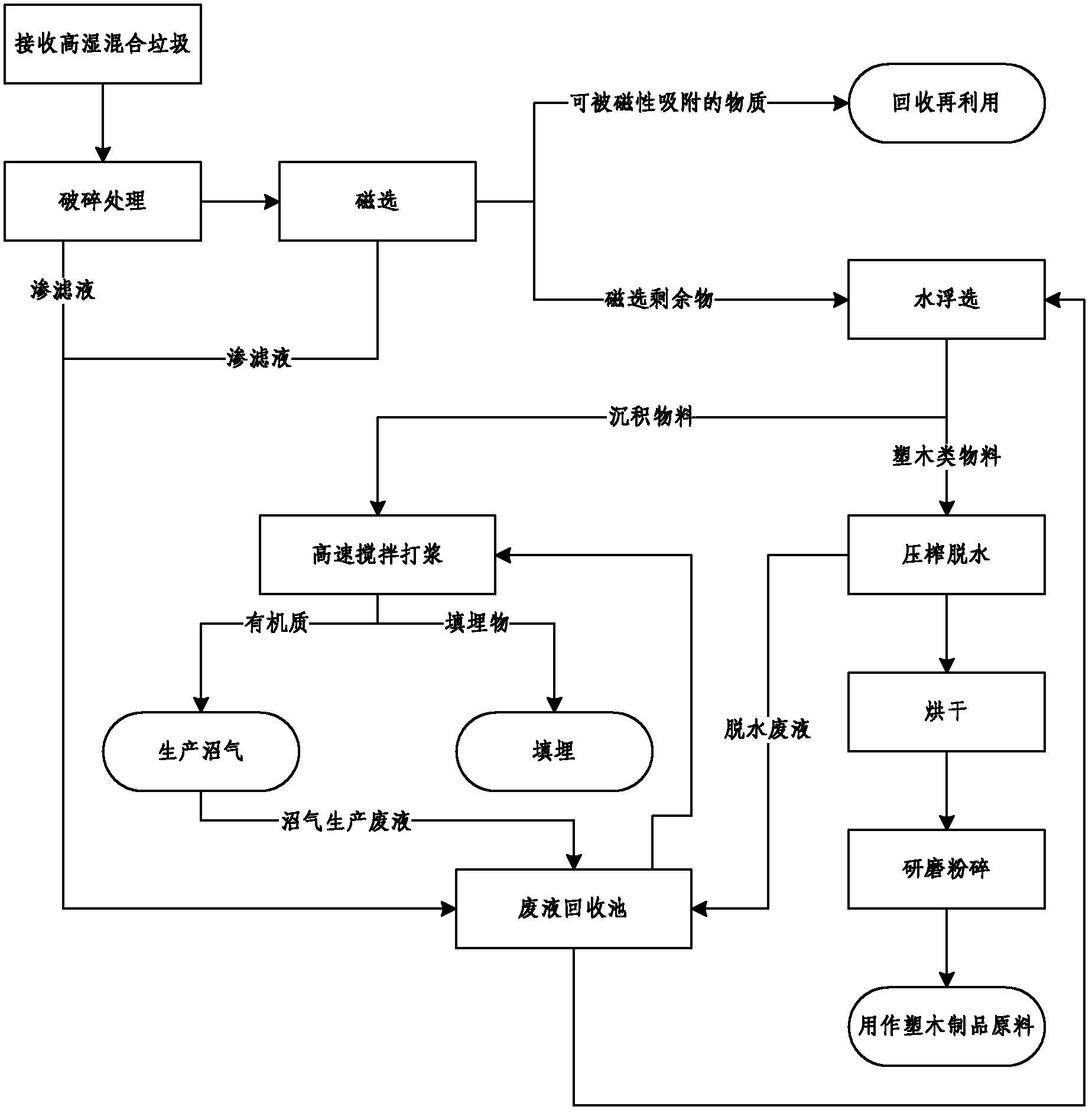

Municipal solid waste compressive classification treatment method

The invention provides a municipal solid waste compressive classification treatment method. The method comprises the following steps of: crushing: carrying out crushing treatment on the high humidity mixed waste; magnetic separation: sorting the matters which can be magnetically adsorbed through magnetic adsorption; water flotation: transporting the residues after magnetic selection treatment into a flotation tank, and with matching of stirring, dividing the materials into two layers, wherein the upper plastic wood materials are blown out from an upper discharge hole; and the bottom deposited materials are discharged from the bottom; and organic matter and landfill material separation: feeding the matters discharged from the bottom of the flotation tank into a high-speed wet type stirrer to undergo beating treatment so that the materials are divided into two layers, wherein the upper materials are slurry which mainly comprises degradable organic matters and is output by a slurry pump to be used for producing biogas; and the bottom materials are discharged via a gate valve to undergo landfill treatment. The method has the following beneficial effects that: firstly the municipal solid waste undergoes mechanical crushing and then the matters which can be magnetically adsorbed, the plastic wood raw materials, the organic matters which can be used for producing biogas and the landfill materials are separated from the municipal solid waste in sequence, thus effectively utilizing the useful components.

Owner:SHENZHEN ICOSTAR INVESTMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com