Mud granulizing method, mud granule produced thereby and application thereof

A technology of sludge granulation and sludge, which is applied in water/sludge/sewage treatment, method of granulating raw materials, sludge treatment, etc. Treatment and sludge treatment troubles the sewage treatment industry and the working environment is harsh, so as to facilitate storage, improve efficiency, and improve the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

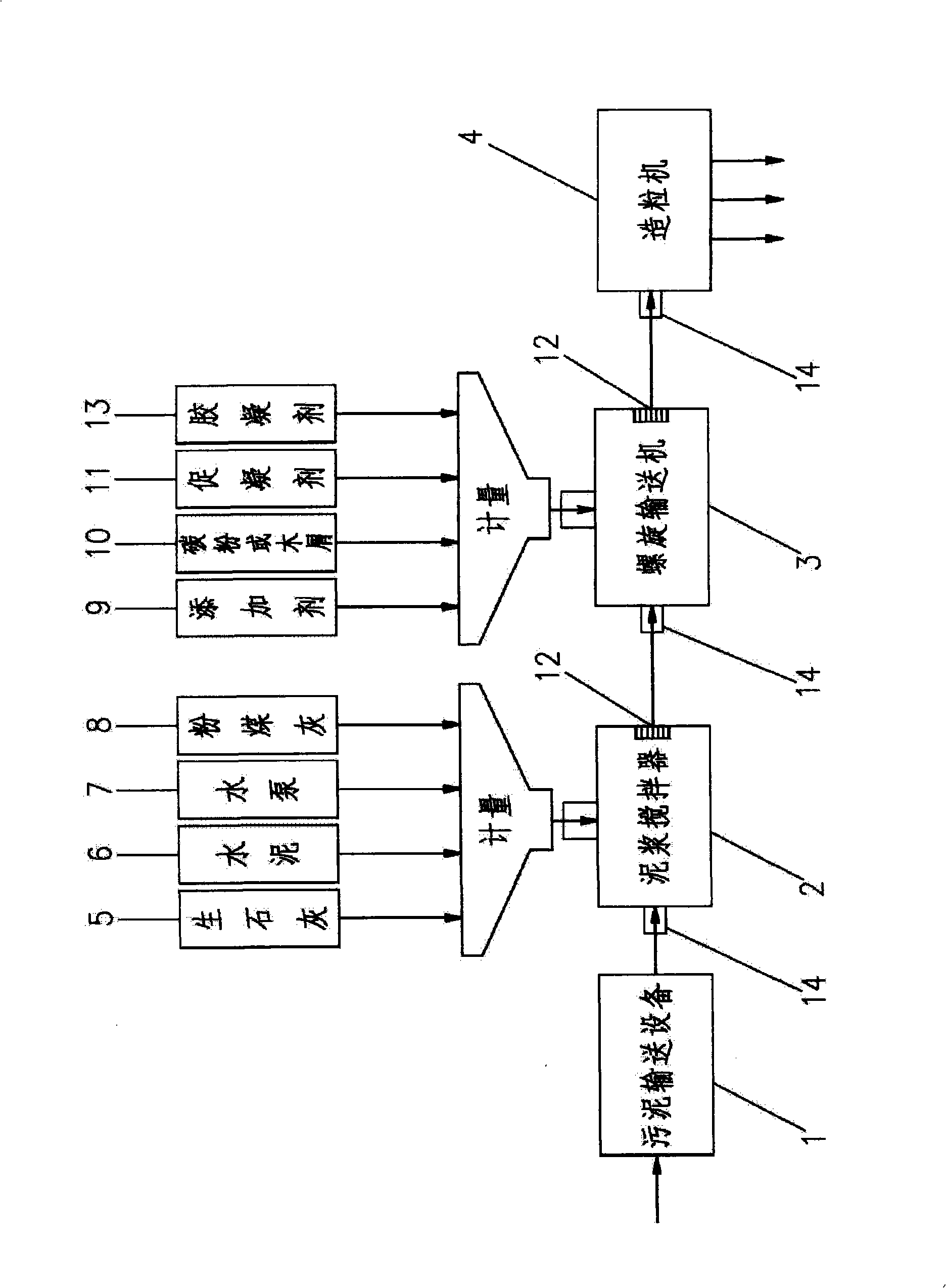

[0030] As shown in the figure, the sludge is continuously transported from the sludge outlet or the sludge storage tank of the sewage treatment plant to the mud agitator 2 by using the sludge conveying equipment 1. According to the conveying speed of the sludge, the lime adder is used respectively 5. Cement adder 6, water pump 7, and fly ash adder 8 continuously add quicklime powder, cement, water and fly ash to the mud mixer 2; Mud and quicklime are fully mixed and chemically reacted to form slaked lime, which is mixed with other materials; the mixed material is continuously conveyed to the screw conveyor 3, and the additive adder located at the entrance of the screw conveyor 3 is used according to the transmission speed of the mixed material 9. The coagulant additive 11 and the gelling agent additive 13 add an appropriate amount of water-repellent additives, coagulants and gelling agents, and further mix under the rotation and advancement of the screw conveyor 3; the further ...

Embodiment 2

[0034]As shown in the figure, the sludge is continuously transported from the sludge outlet or the sludge storage tank of the sewage treatment plant to the mud agitator 2 by using the sludge conveying equipment 1. According to the conveying speed of the sludge, the lime adder is used respectively 5. The water pump 7 and the fly ash adder 8 continuously add quicklime powder, water and fly ash to the mud mixer 2; under the action of continuous stirring, the sludge and quicklime in the mud mixer 2 are fully mixed and generated The chemical reaction forms slaked lime and mixes it with other materials; the mixed material is filtered through the filter screen 12, and is continuously transported to the screw conveyor 3. According to the conveying speed of the mixed material, the carbon powder arranged at the entrance of the screw conveyor 3 Or the sawdust adder 10 adds an appropriate amount of carbon powder or sawdust, and further mixes under the rotation and advancement of the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com