Patents

Literature

175results about How to "Won't emit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

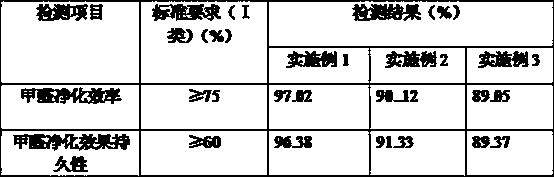

Nanocomposite diatom ooze material and construction method thereof

The invention discloses a nanocomposite diatom ooze material and a construction method thereof. The material consists of a diatom ooze powder material and nano-titanium dioxide dispersion liquid, wherein the diatom ooze powder material consists of calcined diatomite, quartz sand, gray calcium powder, bentonite, wollastonite, seaweed gel, cellulose ether and negative ion powder. The construction method comprises the following steps of: mixing the diatom ooze powder material and water according to the weight ratio of 1:0.9 in the field; after stirring for 15 minutes by using an electric stirrer, performing batch-scraping coating texture modeling construction; uniformly spraying the nano-titanium dioxide dispersion liquid, namely photocatalyst solution to a construction surface by using a spraying gun after the surface is dried; and drying for 48 hours. By using the construction method, the problems that nano-titanium dioxide powder is difficult to disperse and easy to agglomerate, and has large additive amount, the production cost is high, and a nano-titanium dioxide material is wasted in the preparation process of the diatom ooze are solved, the functionality of the diatom ooze for purifying and decomposing harmful gases is improved, and the overall cost of the product is reduced.

Owner:JILIN PROVINCE LANSHE DIATOM NEW MATERIALS

Method for preparing micro expanded inorganic heat insulation mortar

ActiveCN102010166AWide variety of sourcesLow priceSolid waste managementCeramicwareMethyl celluloseEther

The invention discloses a method for preparing micro expanded inorganic heat insulation mortar. Materials such as common silicate cement, desulfuration ash, calcium carbonate powder, re-dispersible latex powder, hydroxypropyl methyl cellulose ether, wood fiber, polypropylene fiber, surfactant, foam stabilizer, water, vitrified micro bubbles and the like are adopted; and the mortar is obtained by adopting the steps of stirring, mixing, shaping, curing and the like. The method has the advantages of low cost, early micro expansion, low later linear shrinkage rate, fire resistance, durability and the like, is easy to construct, and achieves good effect of preparing the I-type building heat insulation mortar by using the III-class vitrified micro bubbles.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV +1

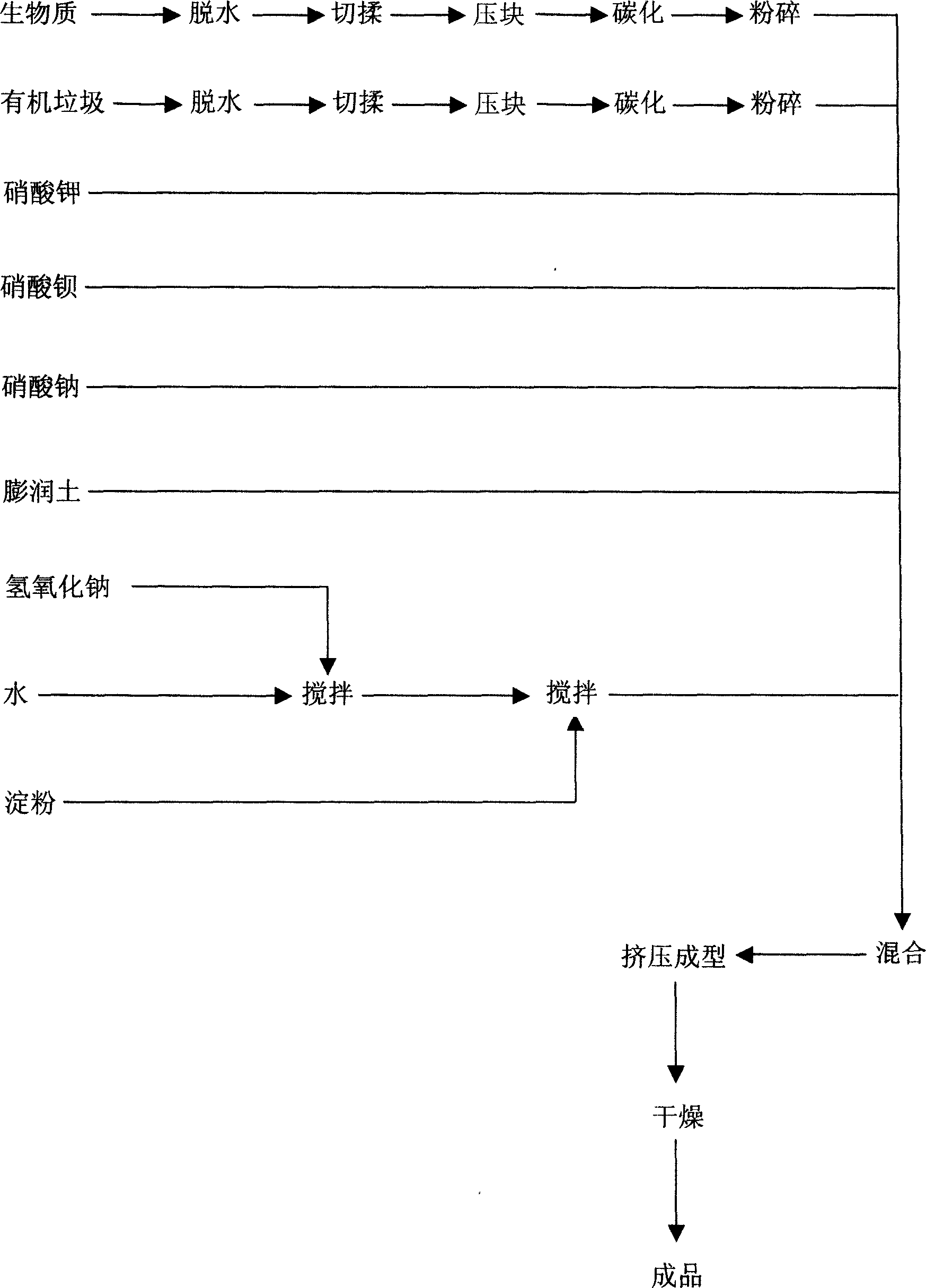

Biomass quick-combustion synthetic charcoal

InactiveCN1995297AReduce processing costsWon't emitBiofuelsSolid fuelsCarbonizationBiological materials

The invention synthesizing method of biological rapid-combustion charcoal, which comprises the following steps: adopting organic rubbish and biological material as main raw material; squeezing; moulding under 800-1000 deg. c; grinding into semi-charcoal from biological by-product and waste material; carbonating under 400-550 deg. c; grinding into charcoal powder with charcoal proportion at 25%-45% and semi-coal powder at 45%-65%; adding adhesive, water, combustion adjuvant, stabilizer, oxidant and or smoke suppressor.

Owner:BEIJING AOKE RUIFENG NEW ENERGY

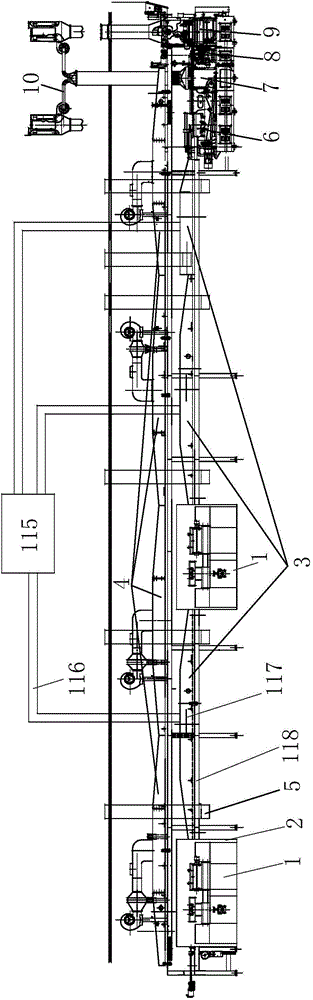

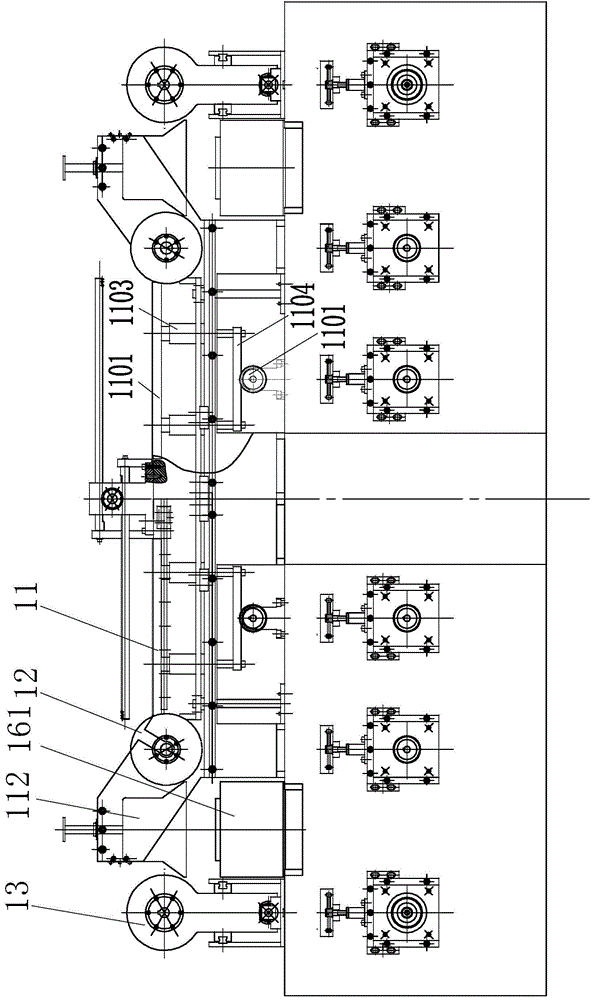

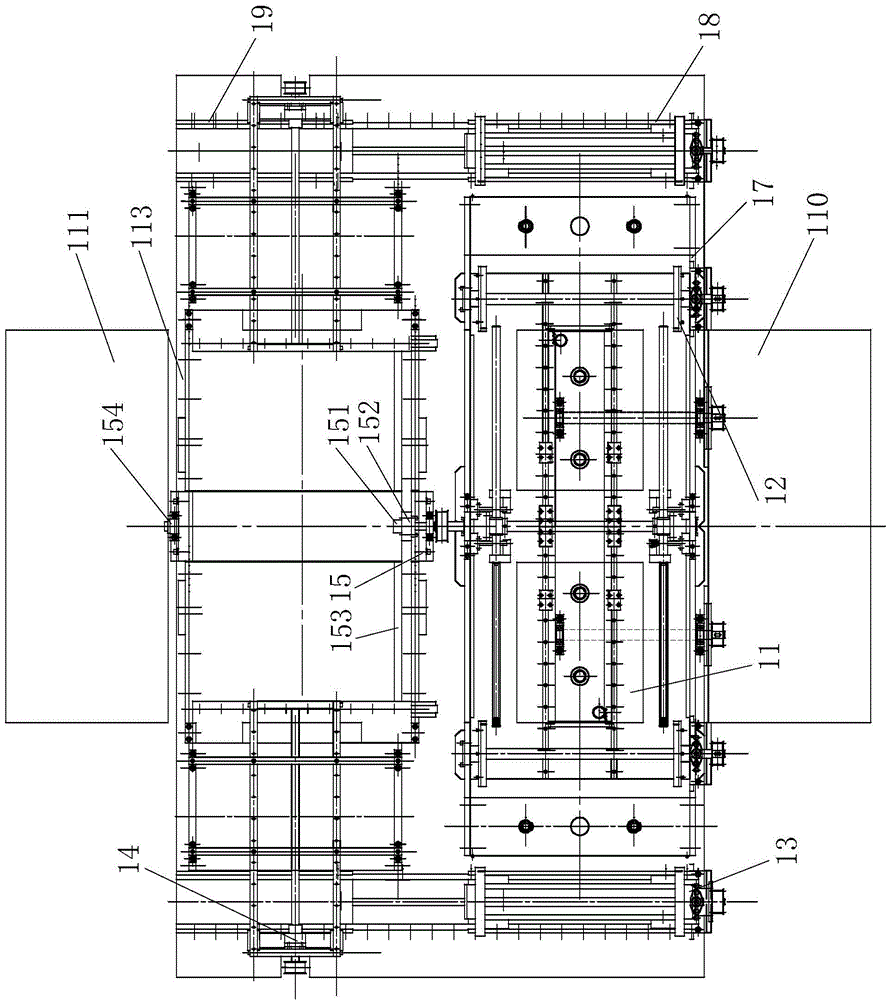

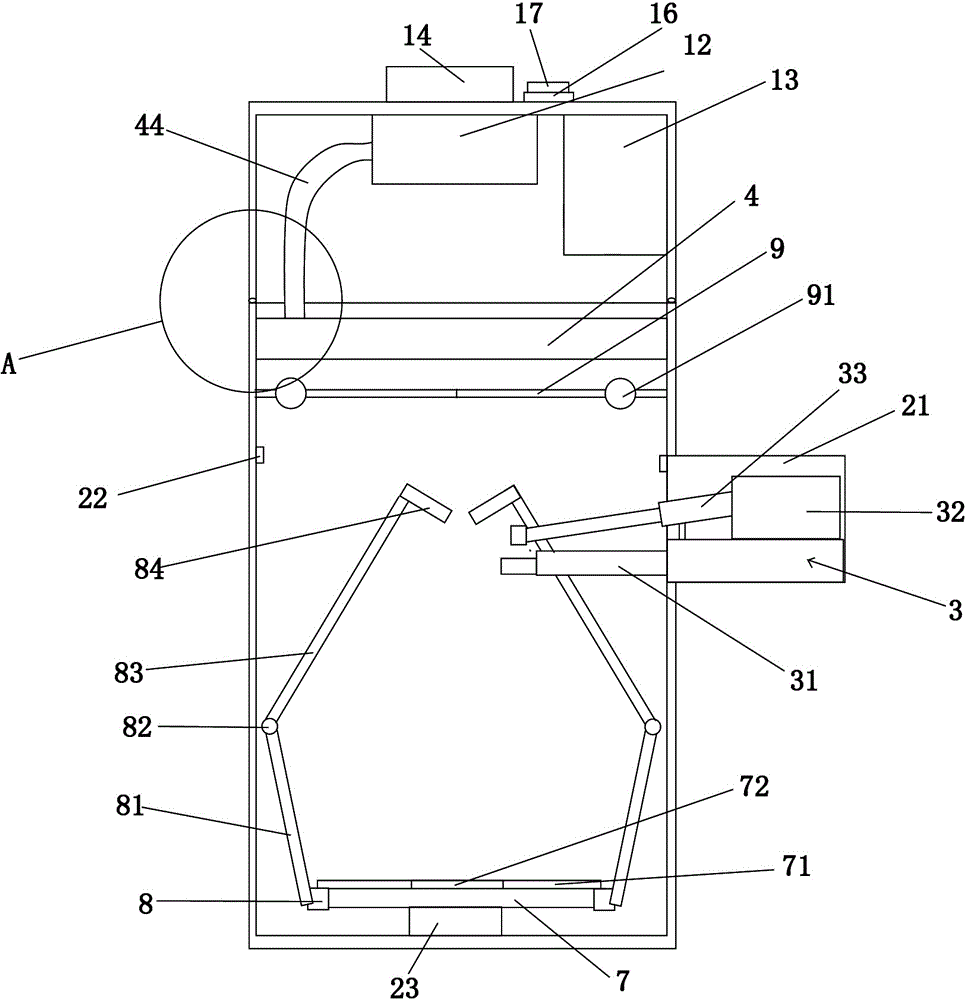

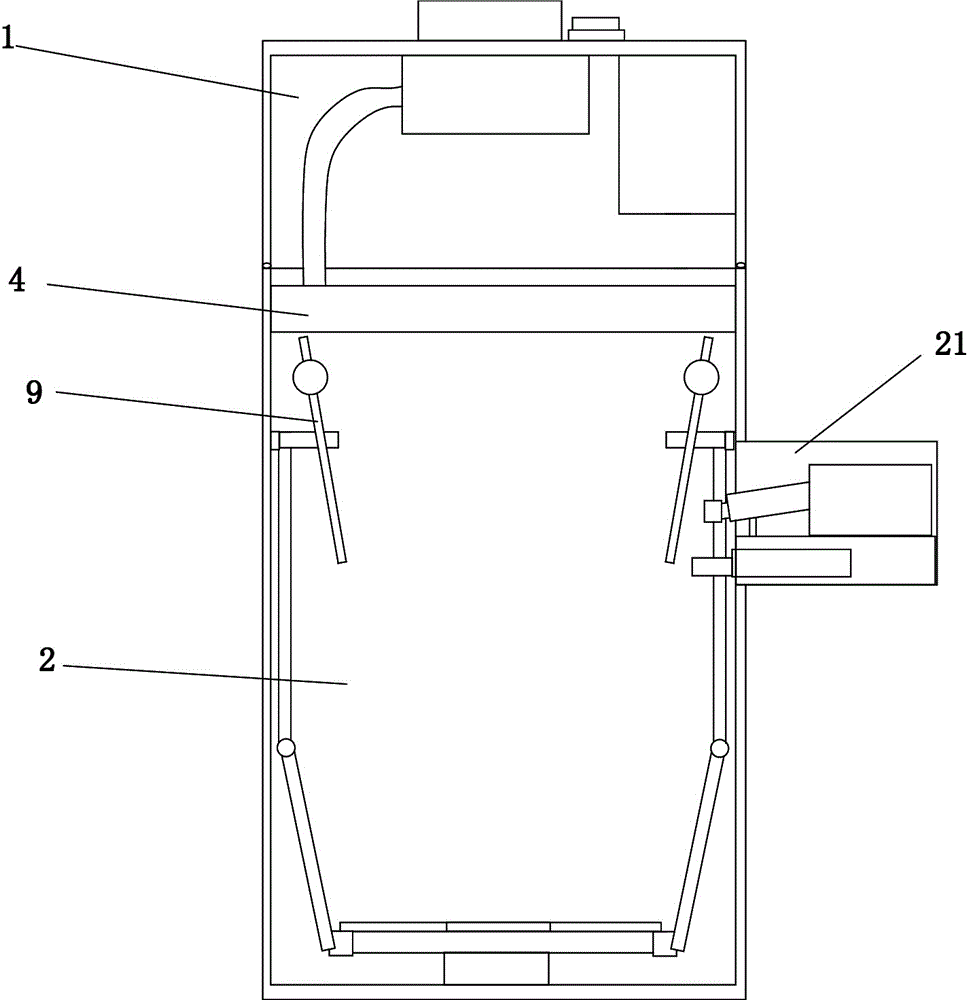

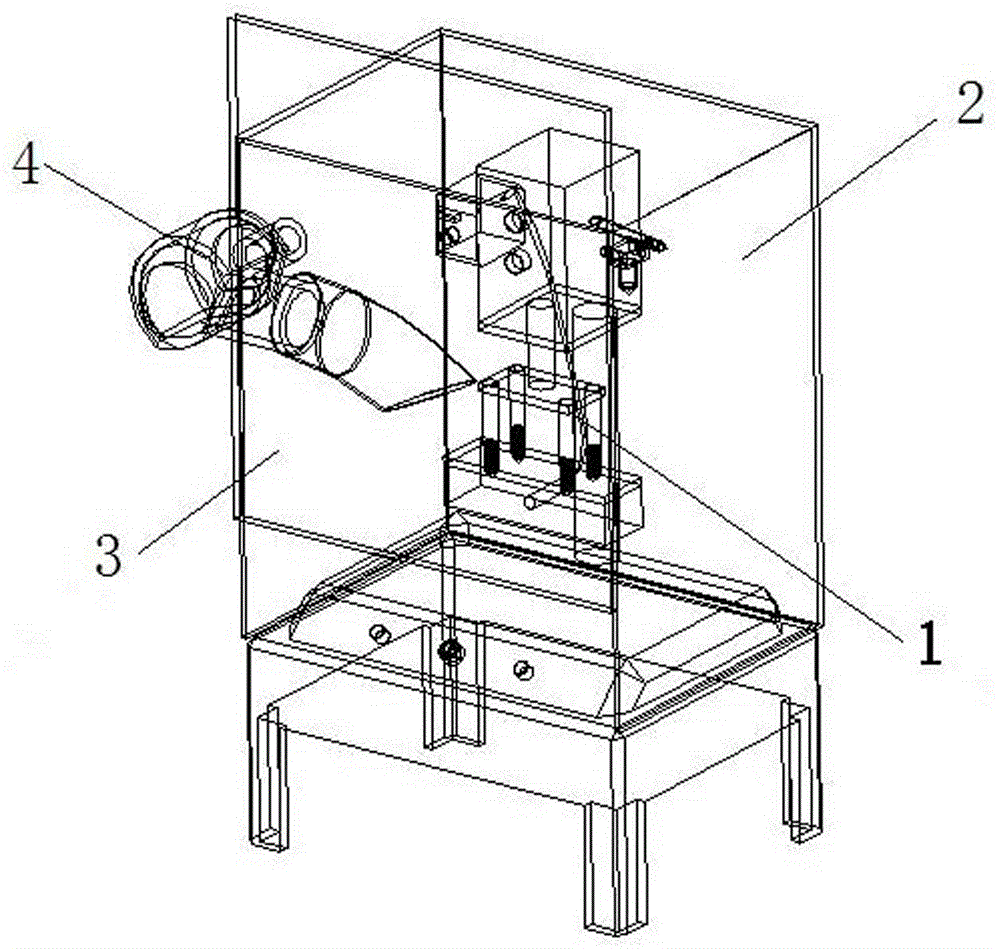

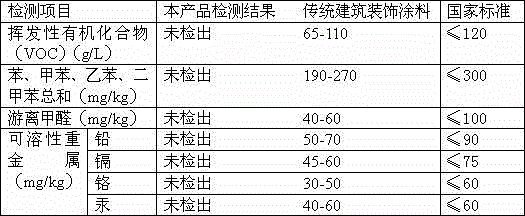

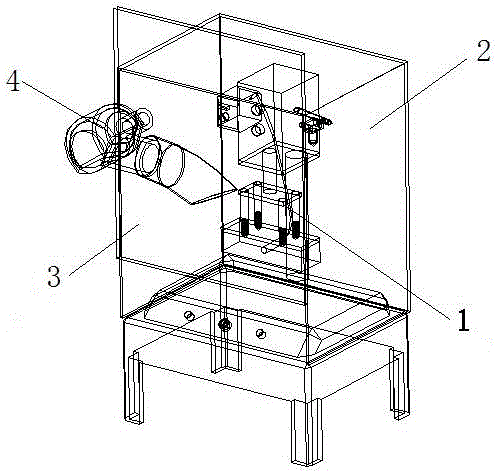

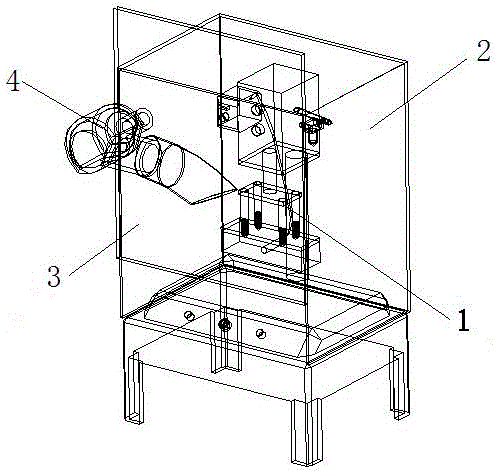

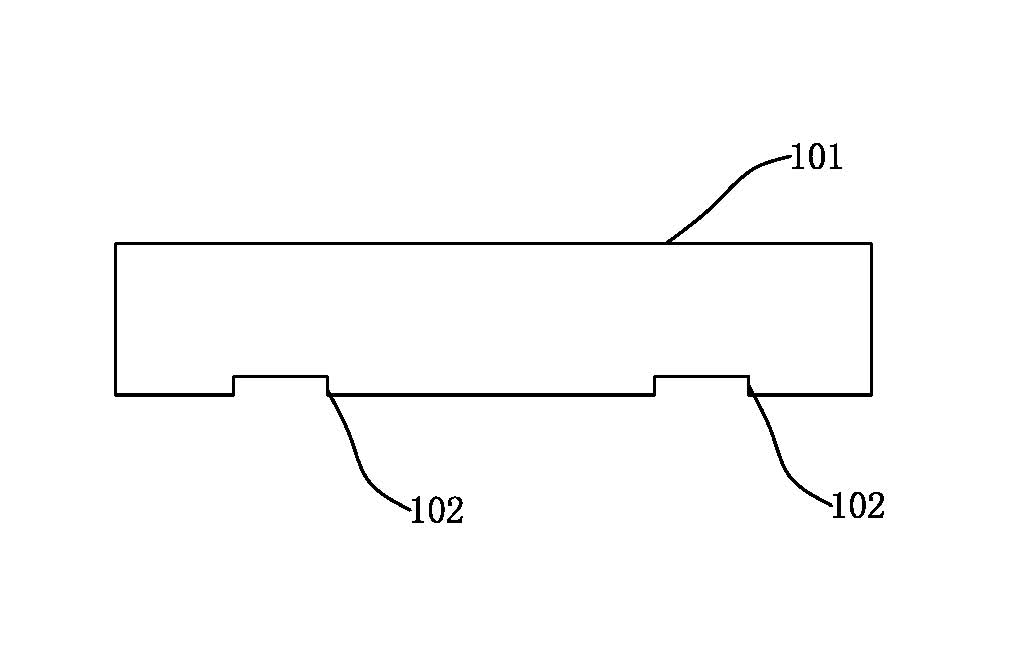

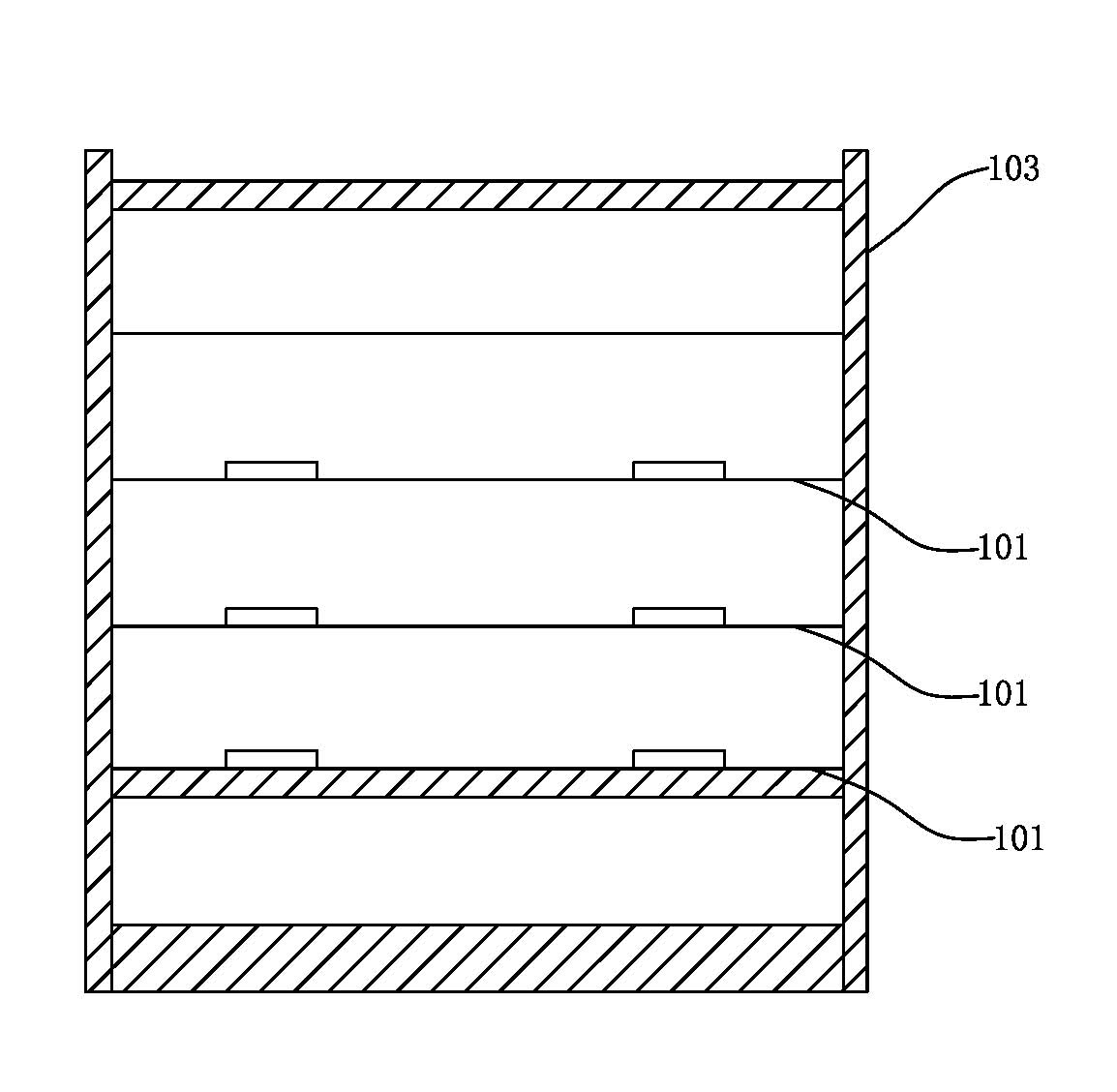

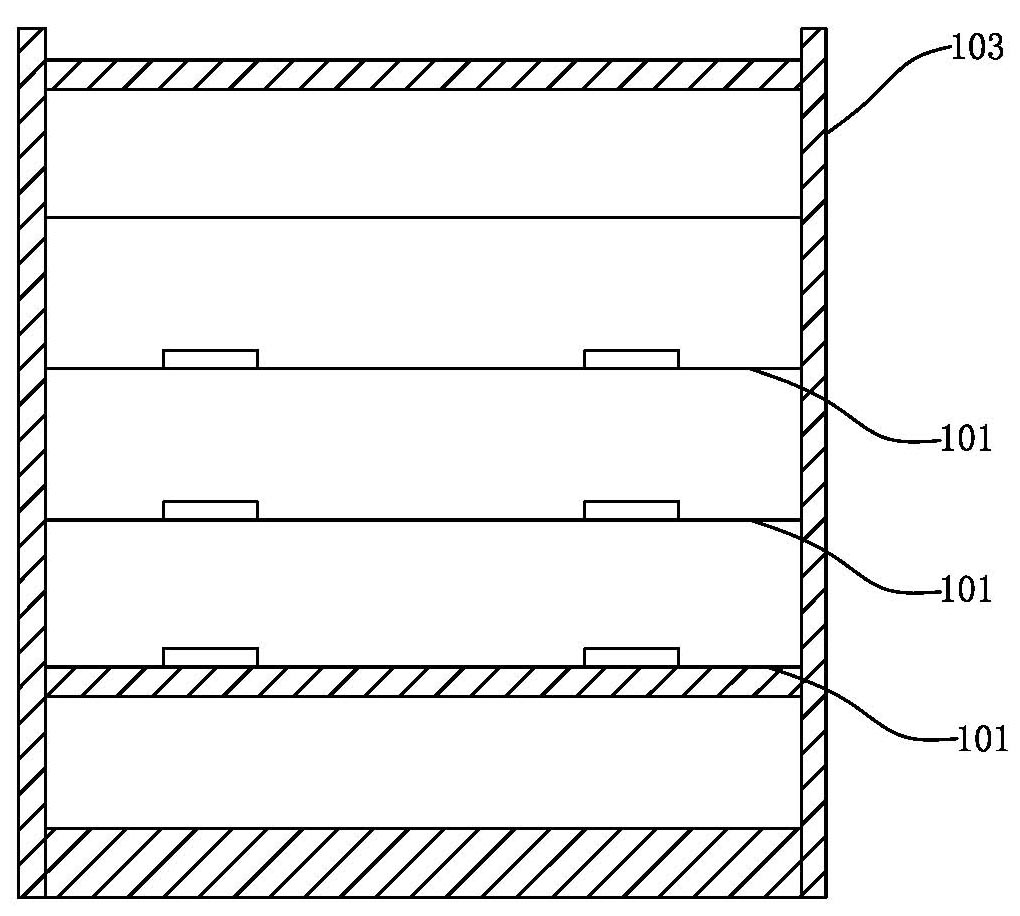

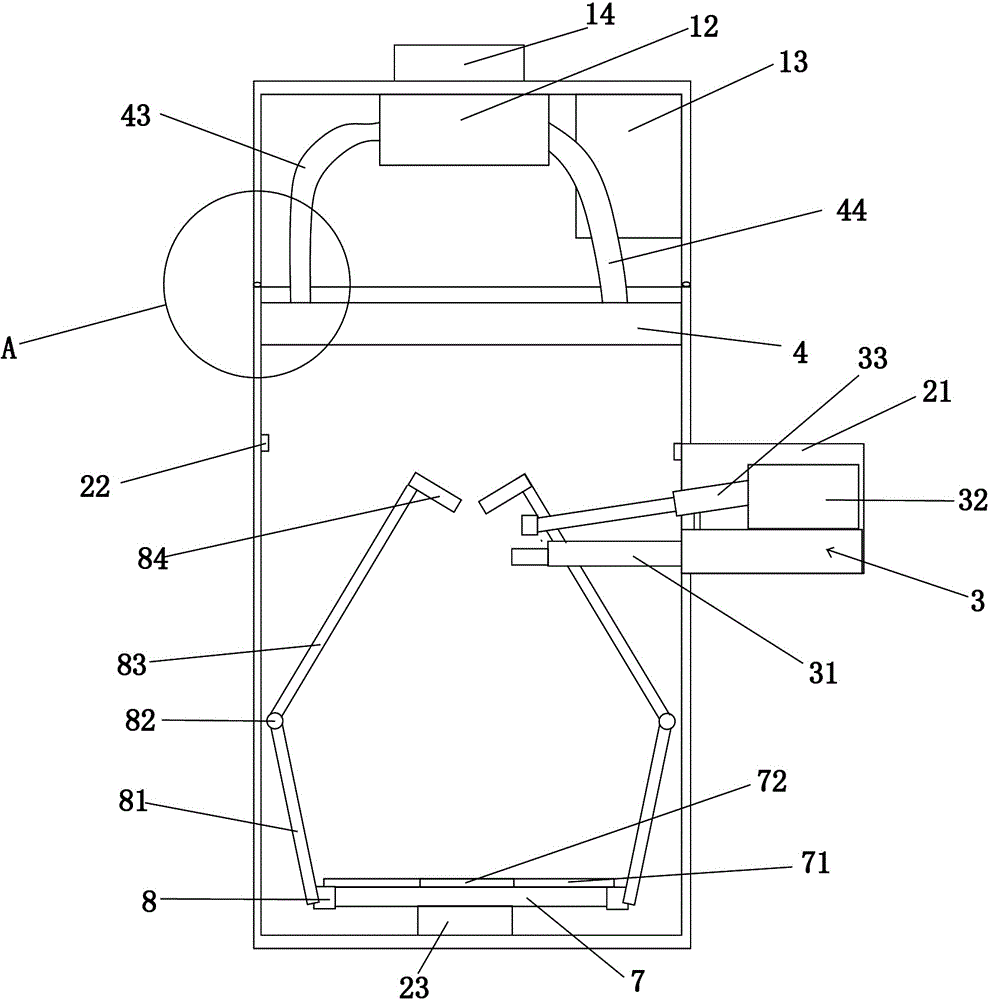

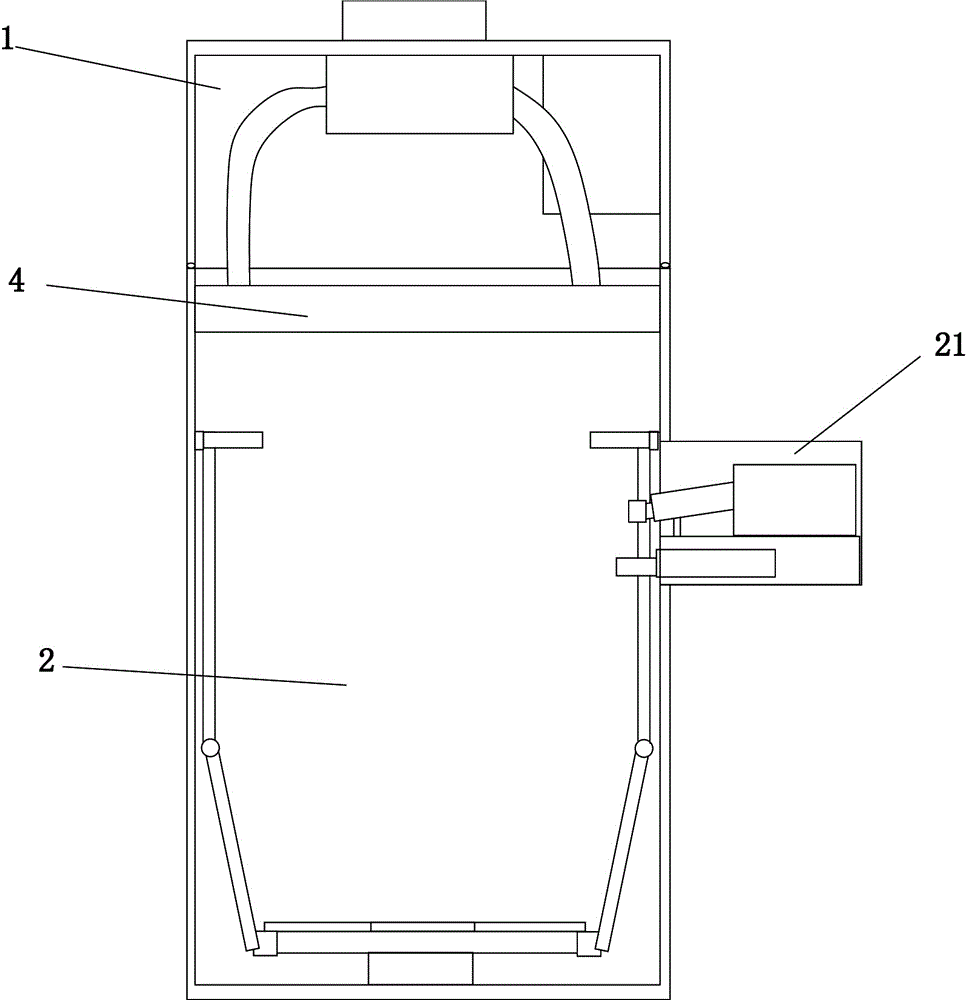

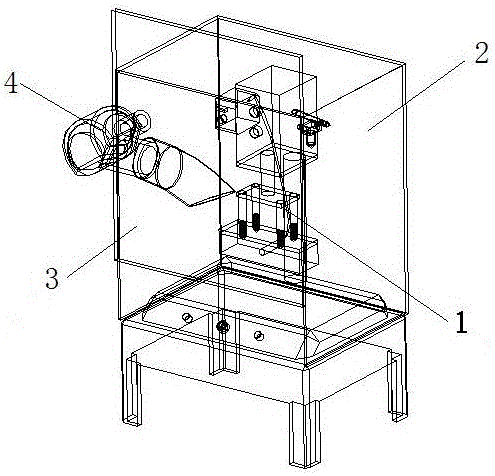

Fully-automatic enteric capsule production line

InactiveCN104546487AWon't emitProduction Process AutomationCapsule deliveryProduction lineVacuum pumping

The invention discloses a fully-automatic enteric capsule production line and belongs to the technical field of capsule production equipment. The fully-automatic enteric capsule production line comprises a platform machine, an automat, an oiling machine, a glue dipping machine, a waste material absorbing system, an upper baking channel, a lower baking channel and a main control system, wherein an air supply pipeline and an air returning pipeline are arranged on the lower baking channel at an interval; two coating machines are also arranged on the lower baking channel at an interval and are respectively arranged in separating spaces; the separating spaces are connected with a vacuum pumping device. The coating machines are arranged in the sealed separating spaces, and the vacuum pumping device absorbs volatile substances in coating liquid, so that the volatile substances are prevented from being dispersed into a workshop to cause explosion in case of open flame. A capsule produced by the fully-automatic enteric capsule production line satisfies enteric standards, the wall thickness of the capsule is uniform, and the quality of the capsule is good.

Owner:DANDONG JINWAN GRP

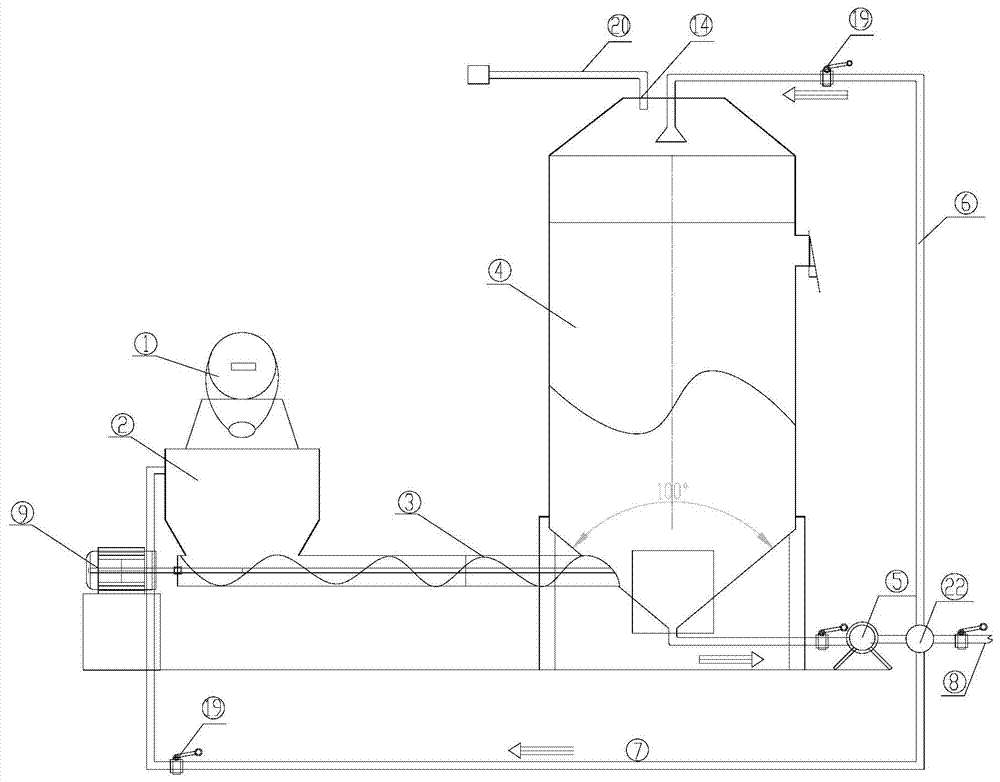

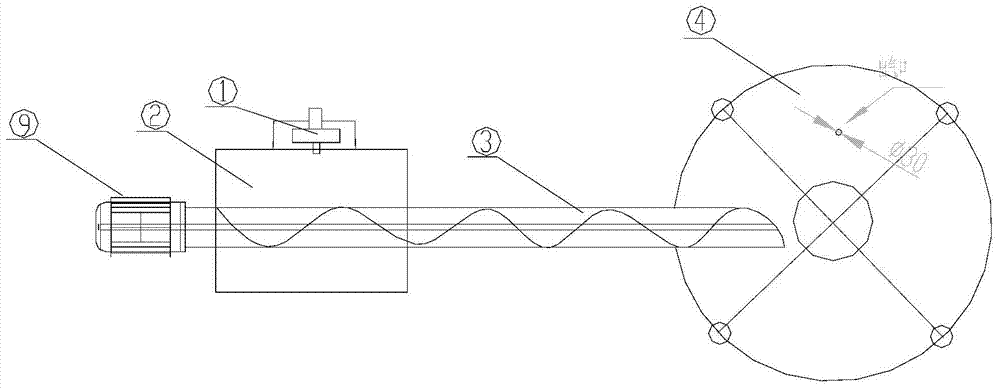

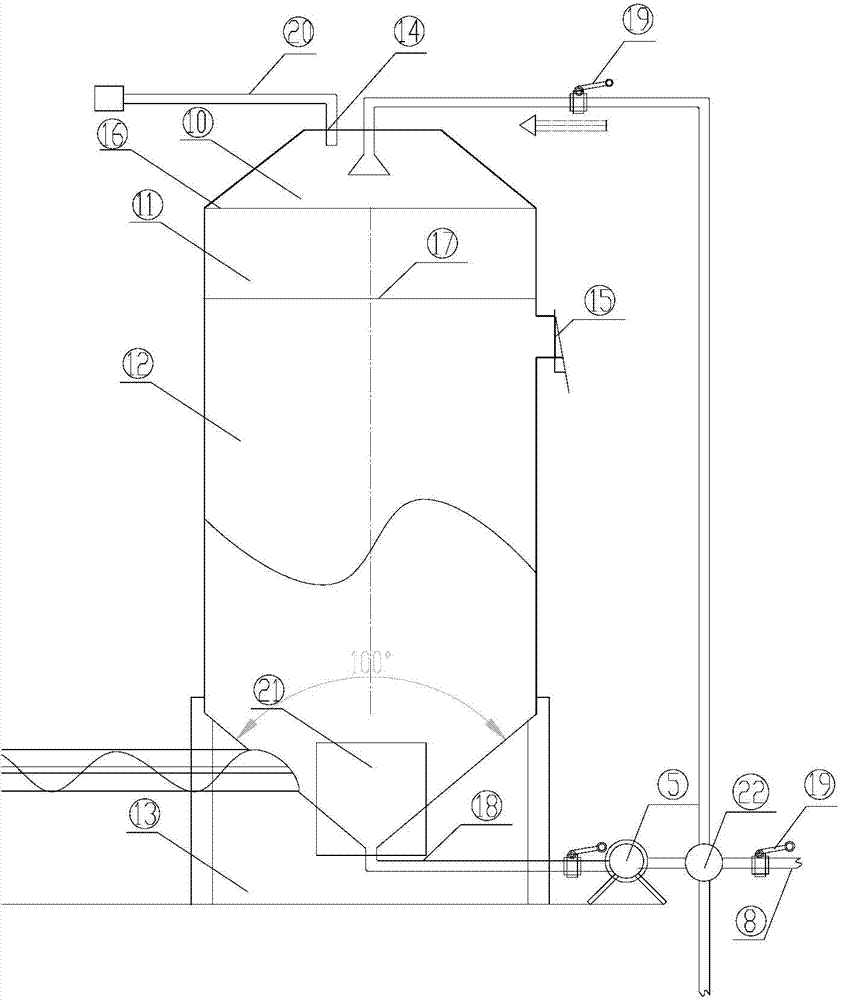

High-solid anaerobic reaction device and method for organic garbage

ActiveCN103614288AImprove processing efficiencyGuaranteed uptimeBiological substance pretreatmentsGas production bioreactorsPipe fittingSmall footprint

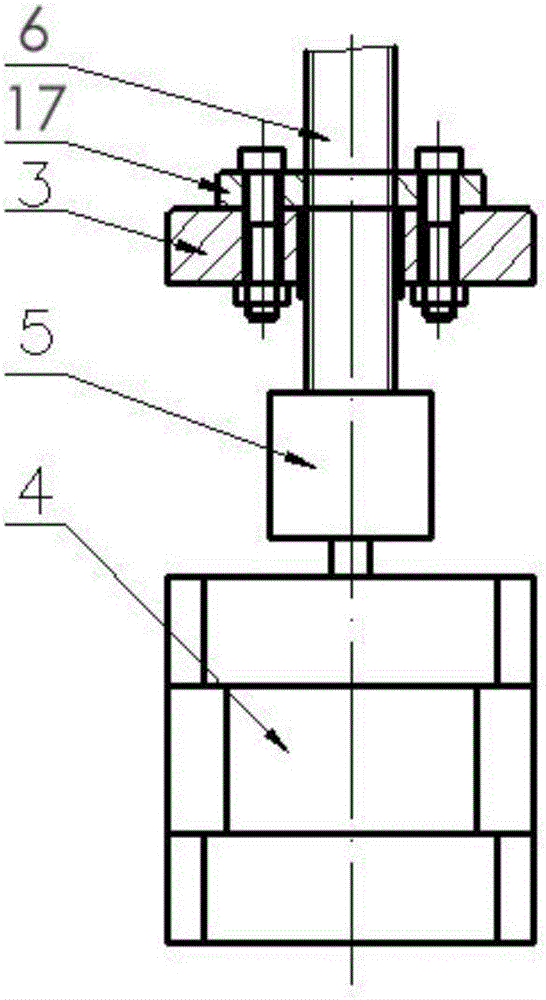

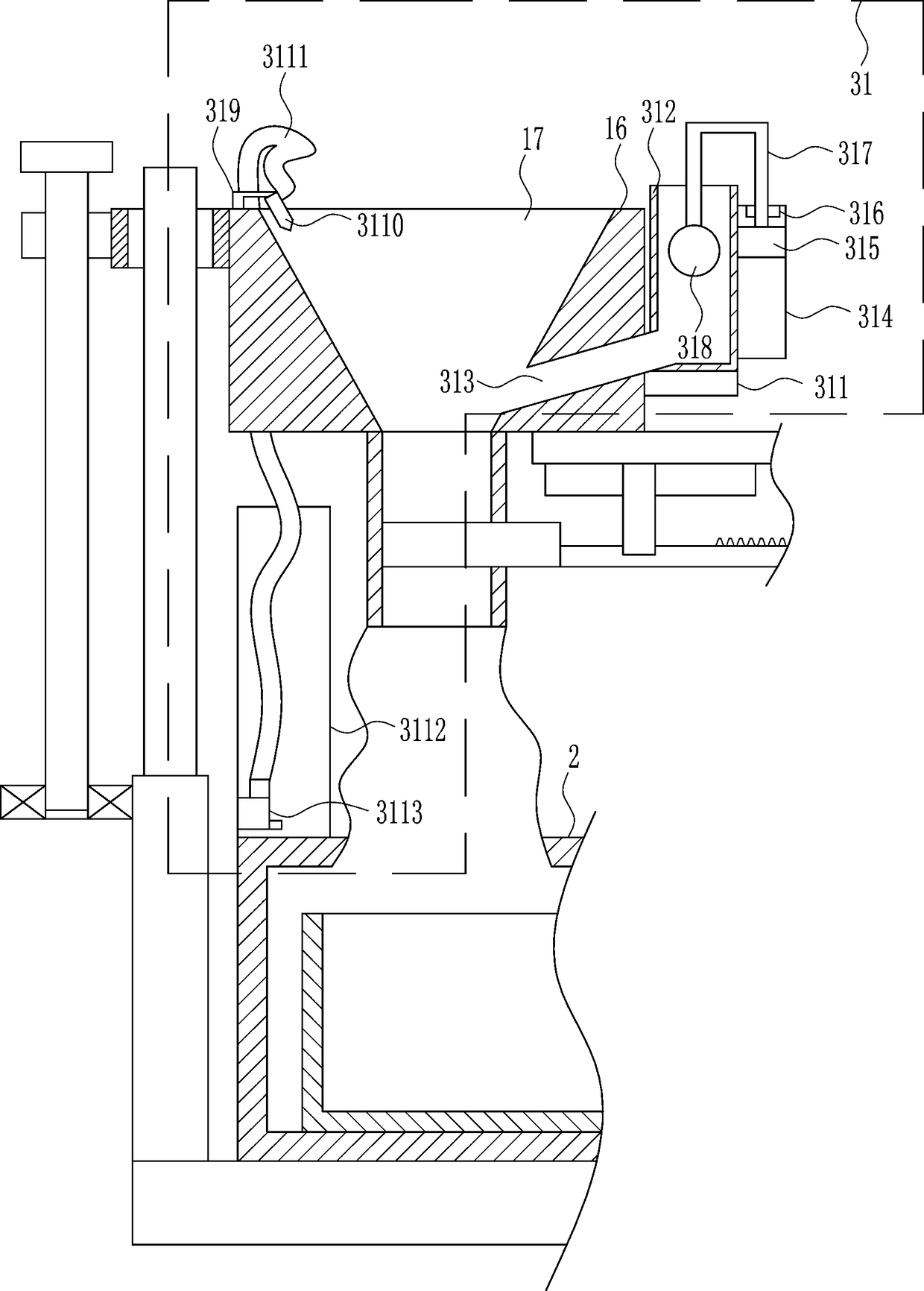

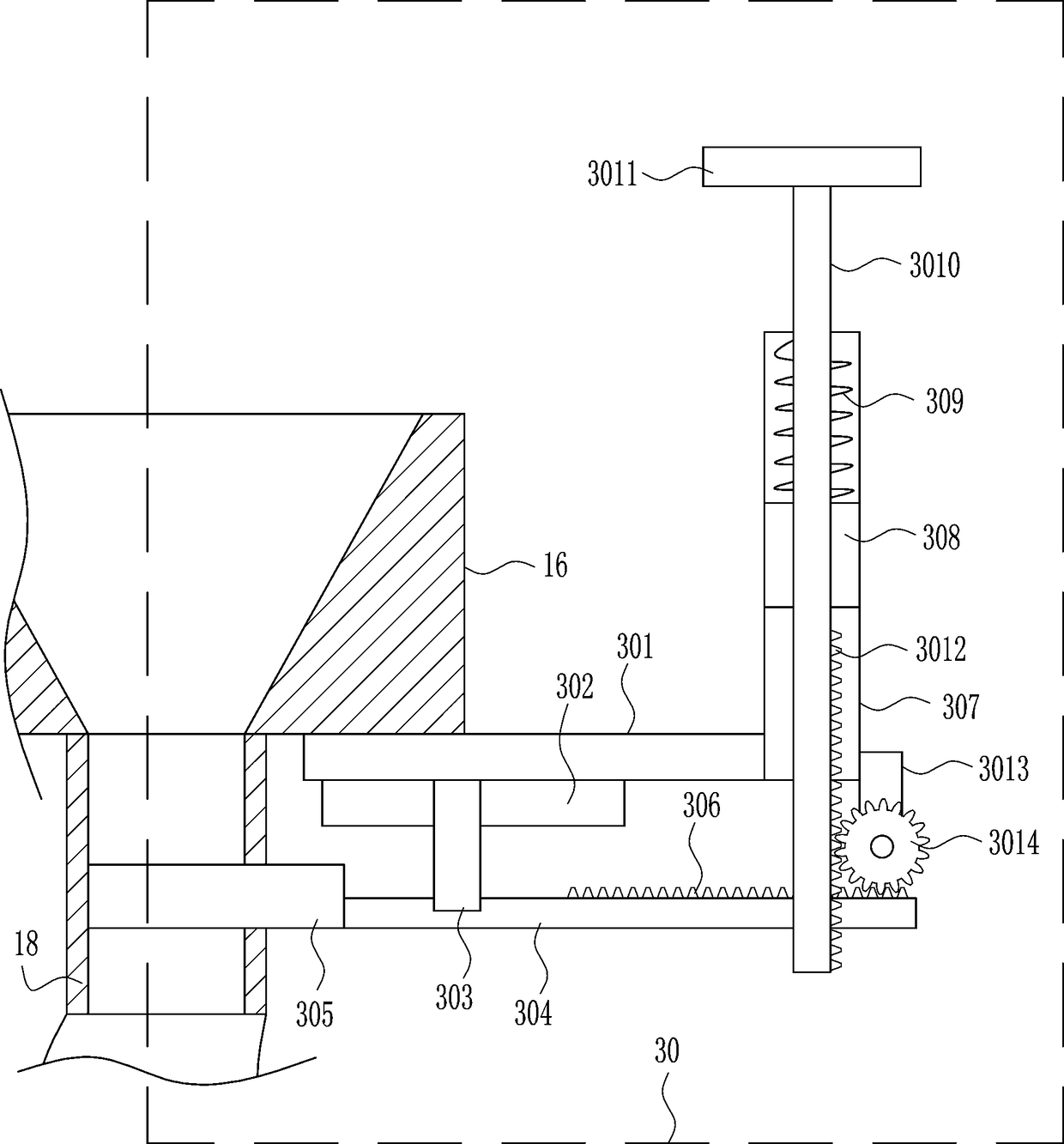

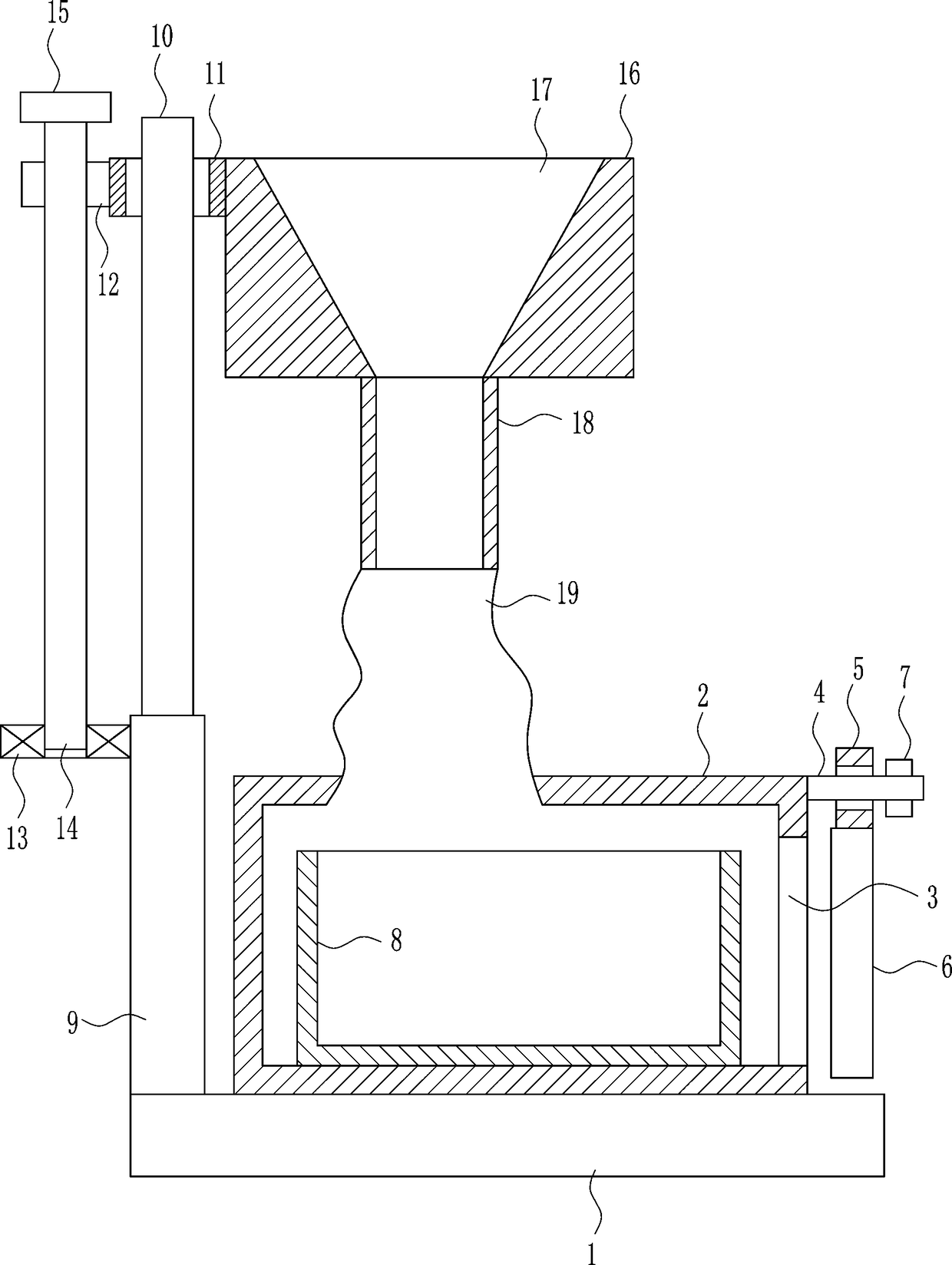

The invention relates to a high-solid anaerobic reaction device and method for organic garbage. The device comprises a pulverizer, a pretreatment pond and an anaerobic fermentation tank, wherein the pulverizer is arranged above the pretreatment pond; a spiral conveying device is arranged below the material outlet of the pretreatment pond and connected with the anaerobic fermentation tank; a liquid-collecting pipe is connected to the bottom of the anaerobic fermentation tank and connected to a four-way pipe fitting; the other three ports of the four-way pipe fitting are connected with a water draining pipe, a pretreatment pond backflow pipe and a biogas slurry spraying return pipe respectively; the anaerobic fermentation tank is internally sequentially provided with a spraying perforated plate and a sieve plate from top to bottom. According to the anaerobic reaction device for the organic garbage with the high solid content, the material pulverization, pretreatment and fermentation are integrated, the material uniformity is guaranteed, an anaerobic fermentation process is facilitated, the solid concentration and uniformity of a material are regulated through fermentation liquor backflow, and the stable fermentation of organic garbage is realized; the anaerobic reaction device has the characteristics of wide adaptability, high treatment efficiency, compact layout, stable operation, small land occupation area and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Carbon-based composite building wave absorption and heat preservation material and preparation method thereof

The invention discloses a carbon-based composite building wave absorption and heat preservation material and a preparation method thereof. According to the preparation method, carbon-based wave absorbing agent, common silicate cement, expanded and vitrified small balls, re-dispersible latex powder, hydroxypropyl methyl cellulose, wood fiber, polypropylene fiber, surfactant, foam stabilizer, waterreducing agent, coupling agent, water and the like are adopted; and the material is obtained by adopting the steps of stirring, pouring molding, curing and the like. The material has the advantages of good wave absorption performance and heat insulation performance, low apparent density, low cost, high fire resistance, durability and the like, and is easy to construct. The material can be used for pouring roofs and walls of buildings, so that aims of electromagnetic radiation protection and energy conservation of the buildings are fulfilled.

Owner:CHONGQING UNIV

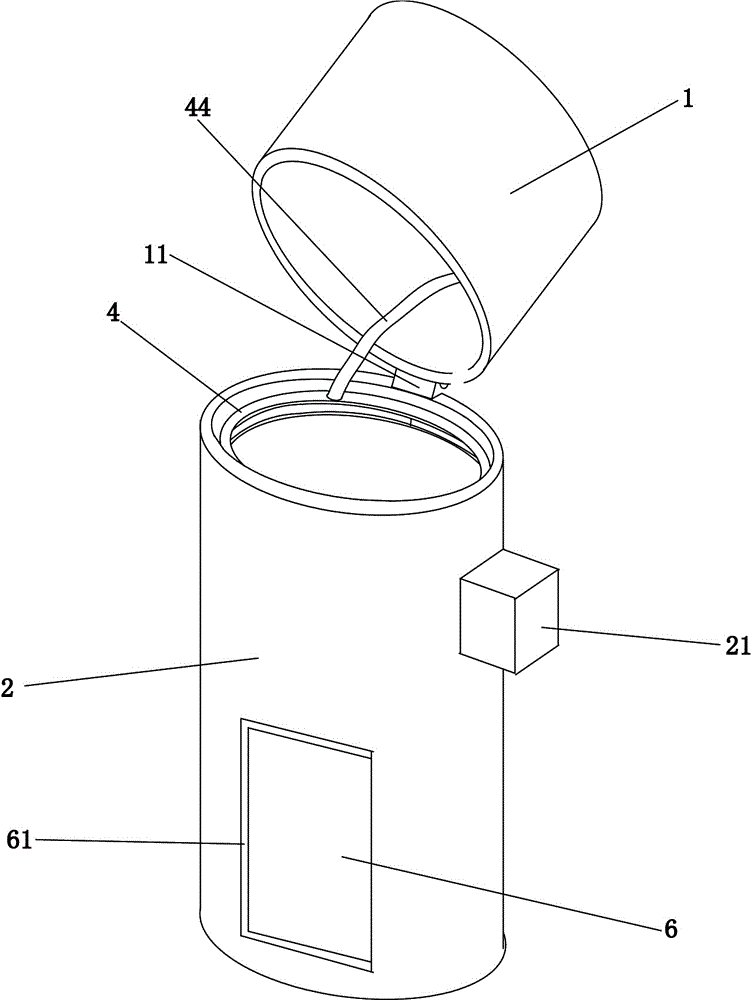

Deodorization trash can

ActiveCN106185121AEliminate the problem of odor emissionThe home environment is clean and tidy without peculiar smellRefuse receptaclesLitterEngineering

Owner:ZHEJIANG ZNC TECH CO LTD

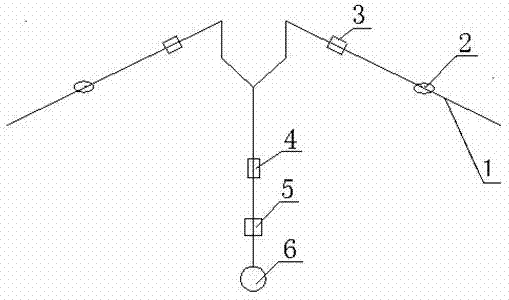

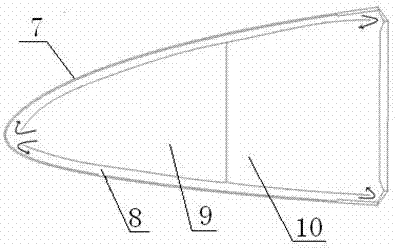

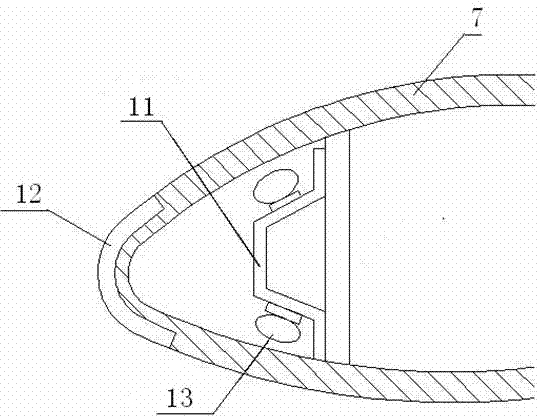

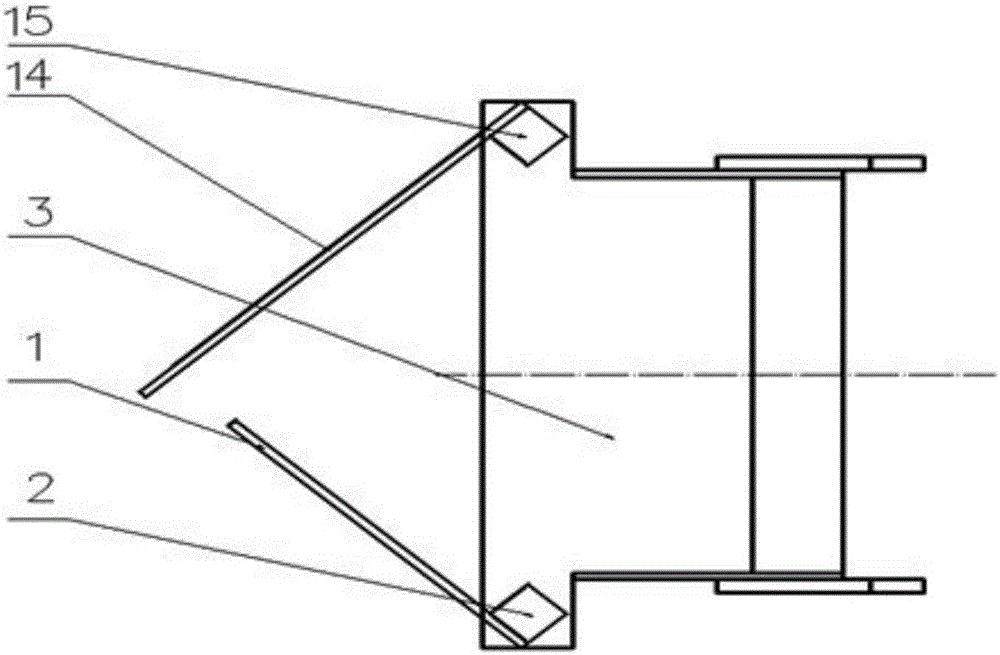

Unmanned aerial vehicle icing protection device

InactiveCN107985607AExtend your lifeImprove thermal performanceDe-icing equipmentsStagnation pointElectricity

The invention relates to an unmanned aerial vehicle icing protection device comprising wings, a heat conduction device and a heating device. The outer walls of the wings are covered with skins, and anti-icing cavities are formed in the wings. The heat conduction device comprises an engine compressor, a flow limiter, a one-way valve and anti-icing valves, and the anti-icing valves are arranged on the wings. The heating device comprises icing sensors, electric heating layers and pulse devices which are connected sequentially. According to the unmanned aerial vehicle icing protection device, heatof an engine and the electric heating and pulse devices are mixed for deicing, the advantages of the heat of the engine and the electric heating and pulse devices are combined, a good icing protection effect is formed, namely it is guaranteed that no ice layer exists nearby important parts such as stagnation points at the front edges of the wings, damage of icing to the aerodynamic shape of a vehicle is also reduced, and the power consumption of the vehicle is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

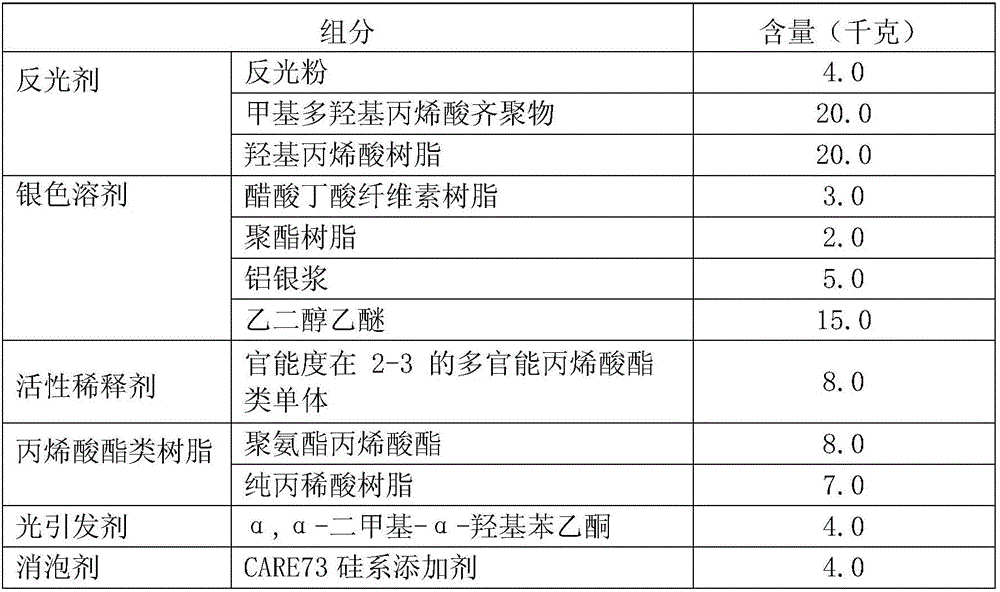

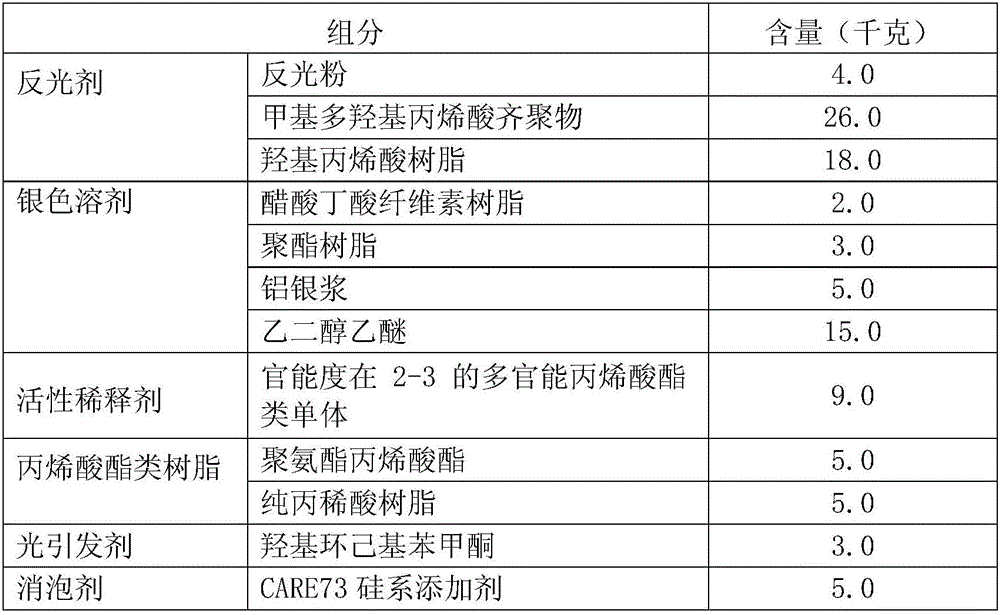

UV reflective paint, and preparation method and application thereof

The invention discloses a UV reflective paint, and a preparation method and application thereof, belonging to the technical field of paint. The UV reflective paint is prepared from, by weight, 40 to 50% of a reflective agent, 25 to 35% of a silver solvent, 8 to 10% of an active diluent, 10 to 15% of acrylate resin, 3 to 5% of a photoinitiator and 2 to 5% of an antifoaming agent. The UV reflective paint contains no volatile organic compound and does not give off harmful gas in the process of both production and usage; after curing, the UV reflective paint has better sun-shading and reflection effect, and sunlight reflectivity is 90% or above; after being cured by ultraviolet rays, the paint can firmly adhere on the surface of a shading cloth matrix and has heat resistance, cold resistance, ageing resistance, rain resistance, moisture resistance, good toughness, high tensile strength and high impact strength; and through usage of ultraviolet curing technology, the UV reflective paint immediately undergoes a cross-linking reaction, energy conservation and high efficiency are realized, exhaust gas and waste water are not produced, and environmental friendliness is realized.

Owner:田绍鸿

Novel hot melt welding machine

InactiveCN104786484AEasy to operateOperation will not affectDirt cleaningToxic gasWorking environment

The invention discloses a novel hot melt welding machine and relates to the technical field of automobile part manufacturing. The novel hot melt welding machine comprises a main engine and an isolation hood, wherein the isolation hood is arranged outside the main engine; a perspective window is formed in the front side of the isolation hood; and an exhaust fan is arranged on the rear of the isolation hood. According to the novel hot melt welding machine disclosed by the invention, toxic gases produced during hot melting of plastics can be timely eliminated under the condition that the operations of the staff are not influenced, and the operating environment of operators is greatly improved.

Owner:合肥凯蒙新材料有限公司

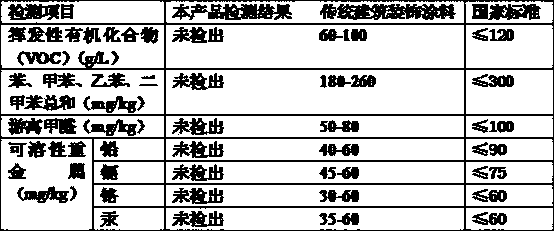

Wall coating and preparation method

ActiveCN103965719AInflatable bustyGood decorative functionAntifouling/underwater paintsPaints with biocidesBenzeneEmulsion

The invention discloses a wall coating. The coating comprises the following components by weight: 200-400 parts of water, 10-40 parts of pulp mixtures, 2-4 parts of foam killers, 50-150 parts of titanium dioxide, 100-350 parts of synthetic resin emulsion, 2-5 parts of acid-alkali modulation agents, 20-50 parts of vegetable gelatin compositions and 3-5 parts of plant extracts. According to the invention, the pulp mixtures are adopted, so that the cost is relatively low, and the technology is simple; the synthetic resin emulsion, the plant extracts and vegetable gelatin are cooperatively adopted for achieving the effects of mold prevention, desinsectization and sterilization, so that the wall coating has fresh smell; composite alkali with high alkalinity can be used for adjusting PH values, has the effects of emulsion breaking and coagulation improving, can form hydroxide precipitation with heavy metals to remove the heavy metals, and is good for health and environment protection; the coating is free from toxic substances of formaldehyde, benzene, ammonia and the like, and volatile toxic substances reach zero emission; the coating is an internal wall coating that is nontoxic, environment-friendly and low in manufacturing cost, has the antibacterial effect, and generates no adverse impacts on human health.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

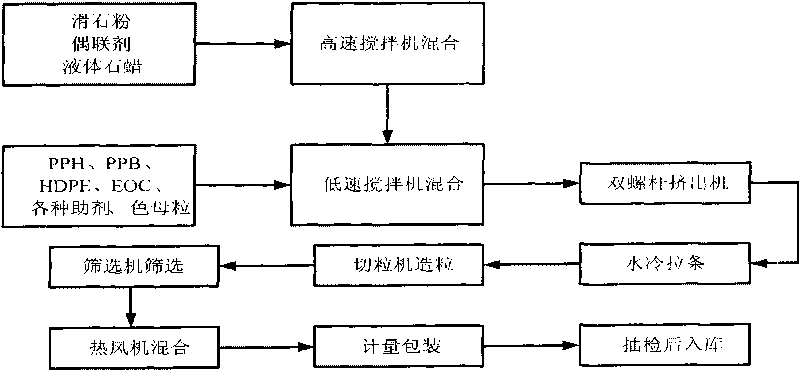

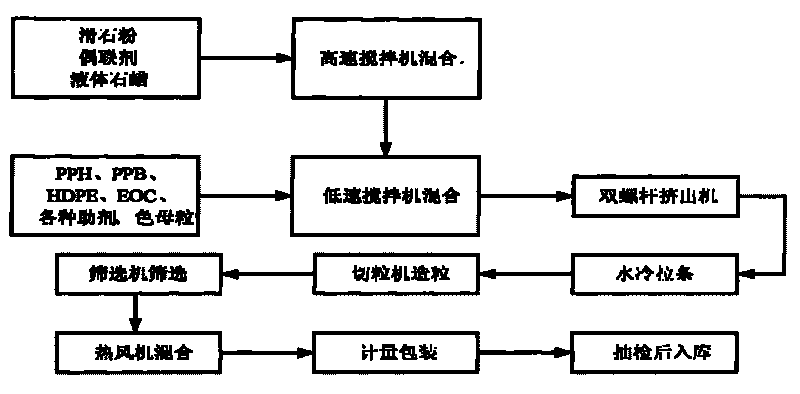

Modified PP automobile special material and production method thereof

The invention discloses a modified PP (polypropylene) automobile special material which comprises the formula of resin matrixes PPH and PPB, reinforcing filler talcum powder, high-density polyethylene HDPE, toughening agent EOC, age resister, compatilizer and master batch according to the parts by weight: 5-10 pats of PPH (homo polypropylene), 90-95 parts of PPB (co-polypropylene), 20-40 parts ofactive talcum powder or talc grain, 5-10 parts of HDPE (high-density polyethylene), 2-8 parts of EOC (flexibilizer), 0.3-0.6 part of age resister, 2-8 parts of PP-g-MA (compatilizer) and 2-4 parts of master batch. In the above formula, the sum of PPH (homo polypropylene) and PPB (co-polypropylene) is equal to 100 parts, and the PPH (homo polypropylene) and PPB (co-polypropylene) are both granular substance; the active talcum powder or talc grain is processed by silane coupling agent, and liquid paraffin is added; the age resister mainly comprises master antioxidant, slave antioxidant and uvioresistant agent which are all powdery substance; the color of the master batch is determined according to product requirements, and the master batch is granular substance. The invention utilizes the principle that solubility parameters are similar; other polymers and various auxiliary agents, such as age resister, compatilizer, flexibilizer, fillers and the like are added into the PP material and carry out molten mechanical mixing at certain temperature so as to obtain a new material applied on lorry parts.

Owner:CHINA FIRST AUTOMOBILE

Putty powder for building inner and outer walls and preparation method of putty powder

ActiveCN106590133AEvenly distributedImprove crack resistanceFireproof paintsAntifouling/underwater paintsCellulosePolyethylene glycol

The invention provides putty powder for building inner and outer walls and a preparation method of the putty powder. The putty powder is prepared from ash-calcium, talcum powder, cement, cellulose, rubber powder, a binding agent and reinforcing powder. The reinforcing powder is formed by mixing composite powder, diatomite and calcium oxide, and the composite powder is obtained by sintering clay, silicon carbide, carbon powder and aluminum hydroxide. The binding agent is prepared from alumina micro powder, modified nanosilicon dioxide, polyethylene glycol and water. The putty powder contains the reinforcing powder and binding agent with special ingredients, when the putty powder is manufactured, the ash-calcium, the binding agent and the reinforcing powder are mixed firstly, hot water is added, the materials are stirred, part of ash-calcium is injected into a microcellular structure or adheres to the surface, then the ash-calcium is fully bonded with the cellulose and the rubber powder added later, therefore, the bonding performance between all the ingredients in the putty powder is enhanced, the anti-cracking performance and hardness of the putty powder are enhanced, and the waterproof performance of the putty powder is also improved to a certain degree.

Owner:平顶山锦亦翔墙釉科技有限公司

Material for producing natural degradable deep-cavity thin-wall soft bottle for tableware and soft bottle thereof

InactiveCN101429328AGood glossGood tensile strengthFlexible coversWrappersSmokeLimiting oxygen index

The invention relates to a material for producing a soft bottle for natural degradable deep-cavity thin-walled tableware, and the soft bottle. The material consists of the following components in weight percentage: 85 to 90 percent of polylactic acid ester, 9 to 14 percent of polyethylene terephthalate, and the balance being additive of the polyethylene terephthalate. The soft bottle produced from the material has the characteristics of good glossiness, tensile strength and ductility, innocuity, no pungency, good biocompatibility, biodegradability and biological absorption and the like. The soft bottle does not pollute the environment and cannot distribute poison gas and cause pollution in combustion. The soft bottle has the advantages of higher limit oxygen index (LOI 24-29), good self extinguishing after ignition, low smoke development in combustion, better flame retardant property, and the same combustion value as that of paper incineration. The material is a sustainable ecological fiber. In the process of using the soft bottle, the advantages of health and innocuity, no need of cleaning, environmental protection, and natural degradation are achieved.

Owner:深圳市阳成世纪科技有限公司

Interior wall coating and preparation method thereof

InactiveCN104861807AInflatable bustyGood decorative functionFireproof paintsAntifouling/underwater paintsToxic materialFire retardant

The invention discloses an interior wall coating. The interior wall coating comprises the following components in parts by weight: 100-300 parts of water, 160-240 parts of titanium dioxide, 60-90 parts of calcium carbonate powder, 3-6 parts of a dispersing agent, 2-5 parts of an antifoaming agent, 160-240 parts of an acrylic emulsion, 4-6 parts of ethyl alcohol, 3-7 parts of a fire retardant, 2-4 parts of an antiseptic and antibiotic agent and 1-3 parts of a plant extract. The interior wall coating is lower in cost, the preparation process is simple, the effects of insect expelling and disinfecting can be achieved by the plant extract, and the interior wall coating smells fresh; the interior wall coating does not contain toxic substances such as formaldehyde, benzene and ammonia, the zero emission of volatile toxic substances is achieved, the own advantages and the mutual synergistic flame retardant effect of inorganic fire retardants are played to the greatest extent by using all components in the fire retardants cooperatively, the flame retardant temperature of the coating can be improved, a good fire retardant effect can be achieved, all components in the antiseptic and antibiotic agent play a role cooperatively, and a better antiseptic effect can be achieved.

Owner:湖州大周高分子材料有限公司

Novel hot melt welding machine

InactiveCN105563802AEasy to operateOperation will not affectDirt cleaningToxic gasWorking environment

The invention discloses a novel hot melt welding machine, and relates to the technical field of automobile component processing. The machine comprises a main engine and a shielding cover, the shielding cover is arranged outside the main engine, the front side of the shielding cover is provided with a perspective window, and the back side of the shielding cover is provided with a fan. The novel hot melt welding machine can timely eliminate toxic gases generated in hot melting of plastics without influencing the operation of employees, and greatly improves the working environment of the operating personnel.

Owner:合肥光裕机械有限责任公司

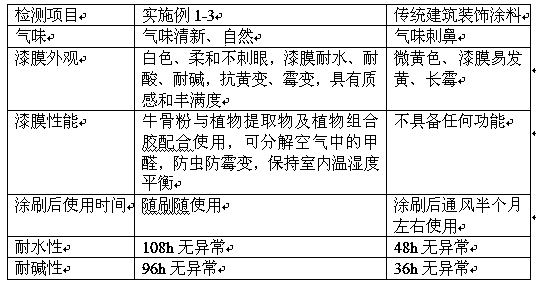

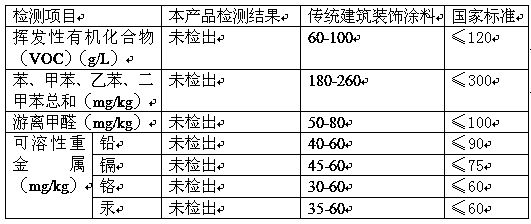

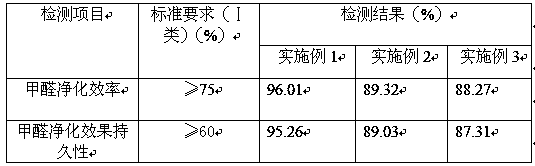

Special paint for internal walls and preparation method thereof

The invention discloses a special paint for internal walls, which is composed of the following components in parts by weight: 200-300 parts of water, 1-3 parts of alkaloid, 1-3 parts of wetting agent, 2-5 parts of dispersant, 2-4 parts of defoaming agent, 150-250 parts of titanium white, 50-100 parts of calcium carbonate powder, 50-100 parts of cattle bone meal, 150-250 parts of acrylic acid emulsion, 20-50 parts of vegetable jelly composition, 2-4 parts of ethanol and 3-5 parts of plant extract. The paint has the advantages of simple preparation technique and low cost, has favorable moldproof, insect expelling and sterilization effects by the combination of the cattle bone meal, plant extract and vegetable jelly, and smells fresh. The paint is free of formaldehyde, benzene, ammonia and other toxic substances, can achieve zero emission of volatile toxic substances, and can absorb formaldehyde and other harmful substances emitted by indoor floor, furniture and the like. The paint has favorable air permeability, enables the wall surface to have the function of ventilation, and automatically regulates the indoor air humidity.

Owner:HUZHOU BAISHENG PAINT

Novel hot melt welding machine

InactiveCN105563801AEasy to operateOperation will not affectDirt cleaningAgricultural engineeringWorking environment

The invention provides a novel hot melt welding machine, and relates to the technical field of vehicle part processing. The novel hot melt welding machine comprises a host machine and a separation shield, wherein the separation shield is arranged outside the host machine, the front surface of the separation shield is provided with a perspective window, and the back surface of the separation shield is provided with an exhaust fan. According to the present invention, with the novel hot melt welding machine, in the case of no influence on the operation of the staff, the toxic gas generated during the hot melting of the plastic can be timely discharged so as to substantially improve the working environment of the operator.

Owner:HEFEI KAIRUIDE NEW ENVIRONMENTAL PROTECTION BUILDING MATEIRAL CO LTD

Environment-friendly cold-set black ink and production process thereof

The invention relates to the technical field of cold-set black ink, in particular relates to environment-friendly cold-set black ink and a production process thereof. The environment-friendly cold-set black ink is prepared from the following components in percentage by weight: 20 percent to 35 percent of carbon black, 5 percent to 25 percent of rosin modified phenolic resin, 1 percent to 15 percent of petroleum resin, 15 percent to 45 percent of vegetable oil, 5 percent to 25 percent of mineral oil, 1 percent to 10 percent of alkyd resin, 1 percent to 25 percent of calcium carbonate, 1 percent to 25 percent of kaolin, and 1 percent to 5 percent of antidesiccant. The proportion of the petroleum resin, the calcium carbonate, and the kaolin in printing ink is improved, the production cost is reduced, due to the calcium carbonate and the kaolin, the solid-containing content of raw materials is improved, and the control of the petroleum resin to viscosity is improved, so that the ink has good ink piling adaptability. A kneader is used for dispersing the solid-containing content in the raw materials, the fineness of the solid-containing content is strictly controlled, and the adaptability of image weakening of the ink is enhanced.

Owner:茂名阪田油墨有限公司

Preparation method of eco-friendly glass fiber wall cloth

ActiveCN106381718AImprove bonding performanceGood UV resistanceElectro-spinningConstructions elementsHydrotalciteMagnesium

The invention provides a preparation method of an eco-friendly glass fiber wall cloth. Glass fibers are modified and combined with a specially-produced coating. After glass fiber modification, an aluminum-magnesium layer is arranged on the surfaces of the fibers so that combination performances of the fibers and the coating are improved and flame resistance is substantially improved. Through use of silane-modified beta cyclodextrin and a silane coupling agent, bonding properties of the coating and the glass fibers are improved. Through use of micron-order magnesium-aluminum hydrotalcite, flame retardation performances and UV resistance are improved. Through use of titanium dioxide, antibacterial effects are obtained and UV-resistant and shielding agent effects are obtained.

Owner:嘉兴杰特新材料股份有限公司

Welding apparatus

InactiveCN105562416AEasy to operateOperation will not affectDirt cleaningWorking environmentEngineering

A welding apparatus relates to the technical field of automobile part and component processing and comprises a main engine and a separation cover. The separation cover is arranged outside the main engine; the front surface of the separation cover is provided with a transparent window; and an air-drafting fan is mounted behind the separation cover. Without effects on worker operation, poisonous gas produced during plastic hot melting can be timely discharged, so work environment of operators can be greatly improved.

Owner:FEIXI FAERDA METAL PROD CO LTD

Method for treating urban domestic sludge by using earthworms

InactiveCN102153260ANo dripSolve difficult worldwide problemsClimate change adaptationExcrement fertilisersVermicompostSludge

The invention provides a method for treating urban domestic sludge by using earthworms. The method comprises the following steps of: collecting the sludge to earthworm production trays; putting the earthworms on the sludge surfaces in the earthworm production trays; conveying the earthworm production trays to a production plant, and stacking the earthworm production trays on a tray rack; placing the earthworm production trays in the production plant for 1 to 2 days; putting dry cow dung into the earthworm production trays, and performing trapping collection on the earthworms; and transferring the mixture of the earthworm excretion and the cow dung to a solar drying shed, and drying the mixture. After the urban sludge is converted into the earthworm excretion by using the earthworms, the earthworm excretion can be used as the nutrient soil of parks or the garbage coverage soil of garbage landfills, so that the method is environmentally-friendly, has low cost and is beneficial to solution to the worldwide problem of difficulty in treating the urban domestic sludge.

Owner:刘波

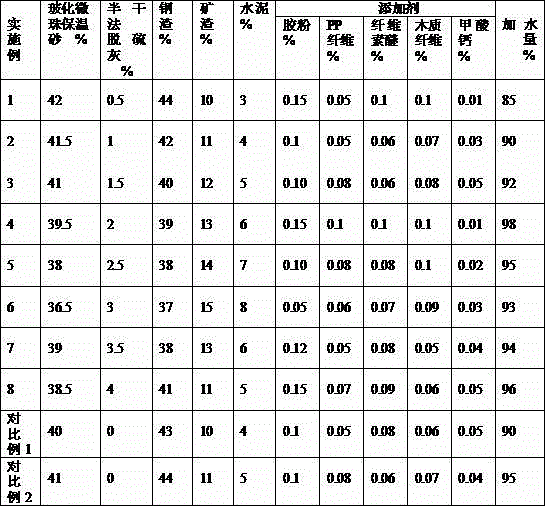

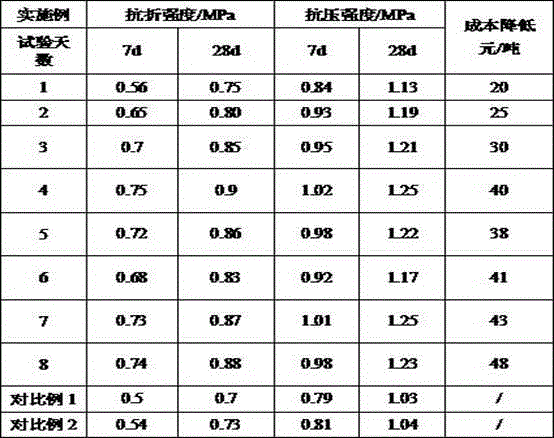

Thermal insulation mortar containing semidry method desulfurized fly ash and preparation method therefor

Provided is thermal insulation mortar containing semidry method desulfurized fly ash. The thermal insulation mortar containing semidry method desulfurized fly ash comprises the following raw materials, by weight, 10-15% of ore slag with a granularity of being less than or equal to 0.074mm, 36-42% of thermal insulation sands with a granularity of being less than 2mm, 0.5-4% of semidry method desulfurized fly ash with a granularity of being less than 1mm, 36-44% of steel slag with a granularity of being less than 2mm, 3-8% of cement and 0.2-0.5% of additives. In addition, water with a weight of being 85-100% of the total weight of the added glass bead thermal insulation sands is added. The preparation method is as follows: the semidry method desulfurized fly ash and the steel slag are dried; the semidry method desulfurized fly ash and the steel slag are crushed; the semidry method desulfurized fly ash, the steel slag, the cement, the ore slag and the additives are stirred and mixed; water is added and the mixture is stirred uniformly; glass bead thermal insulation sands are added and the mixture is stirred uniformly; packaging is carried out and the product is standby. The defect can be overcome that the stability is poor when steel slag is employed as an inorganic thermal insulation mortar materials, the pollution problem caused by desulfurized fly ash stockpiling can be solved effectively, and the desulfurized fly ash integration utilization is raised.

Owner:武钢集团有限公司

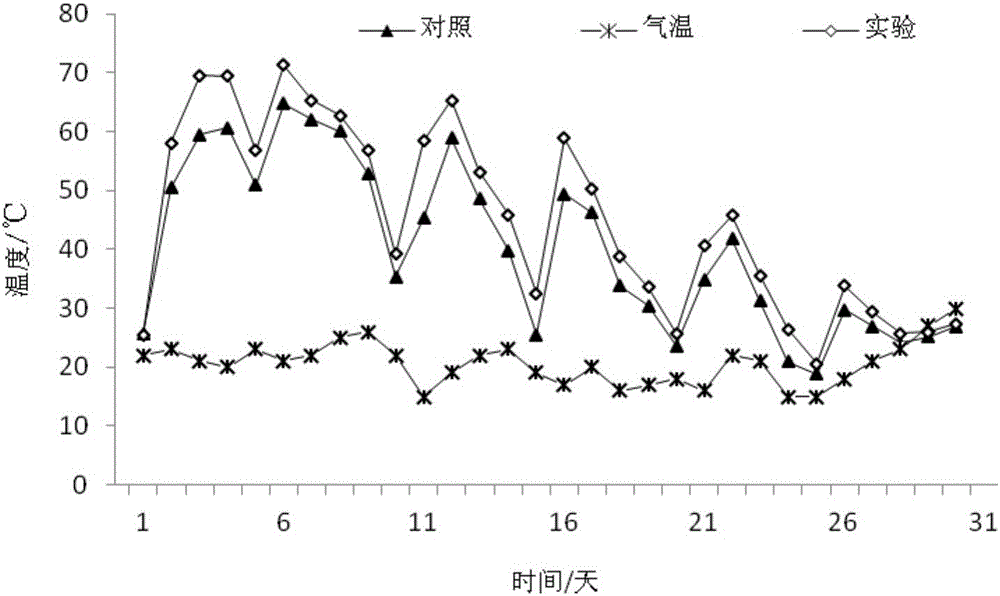

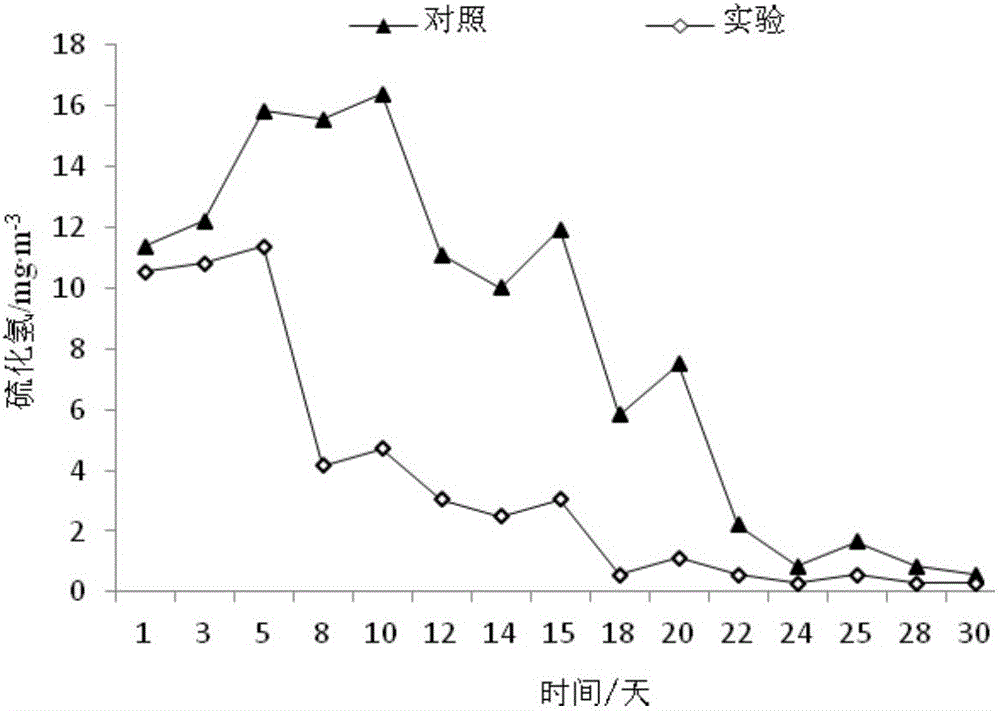

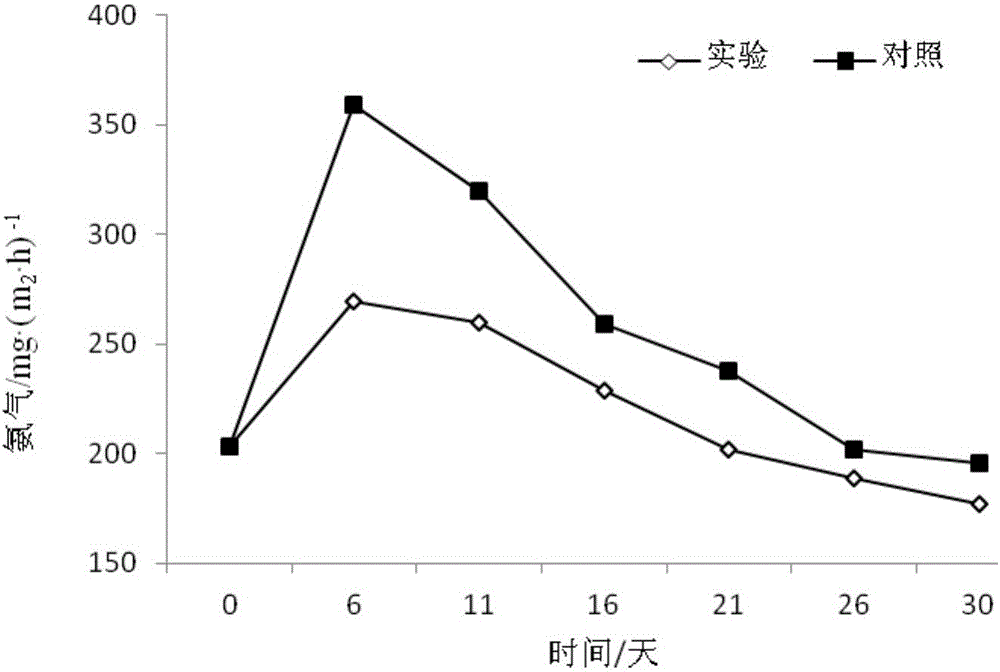

Deodorant organic compost fermentation inoculant and application thereof

InactiveCN105779357AImprove the atmospheric environmentQuality improvementFungiBacteriaPichia pastorisLivestock manure

The invention discloses a multi-strain compound inoculant for deodorization in fermentation of organic compost, a preparation method of the multi-strain compound inoculant and application of the multi-strain compound inoculant in deodorizing materials for organic compost. The multi-strain compound inoculant comprises or is composed of a Pichia pastoris inoculant, a pseudomonas inoculant, a Rhizopus oryzae inoculant and a Thiobacillus neapolitanus inoculant. The method includes the first step of preparing pure inoculum suspension for production, the second step of preparing solid inoculants for production and the third step of preparing the multi-strain compound inoculant. On the basis of common fermentation inoculants, it can be guaranteed that livestock manure does not emit many odorous substances in the fermentation process, the atmospheric environment and the working environment of a plant can be improved, the fertility of compost can be improved, and the production cycle can be shortened.

Owner:福建美家园生物科技股份有限公司

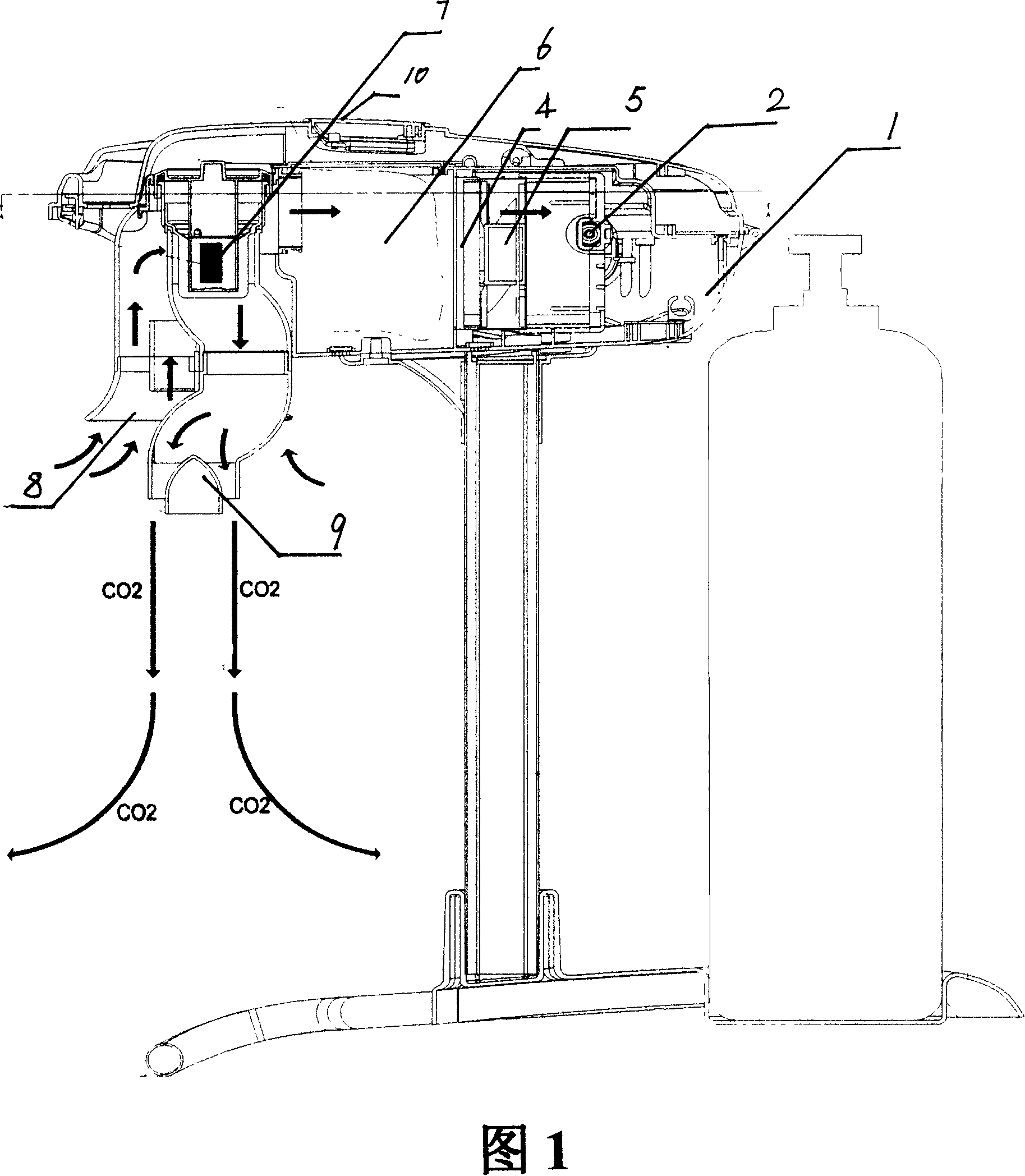

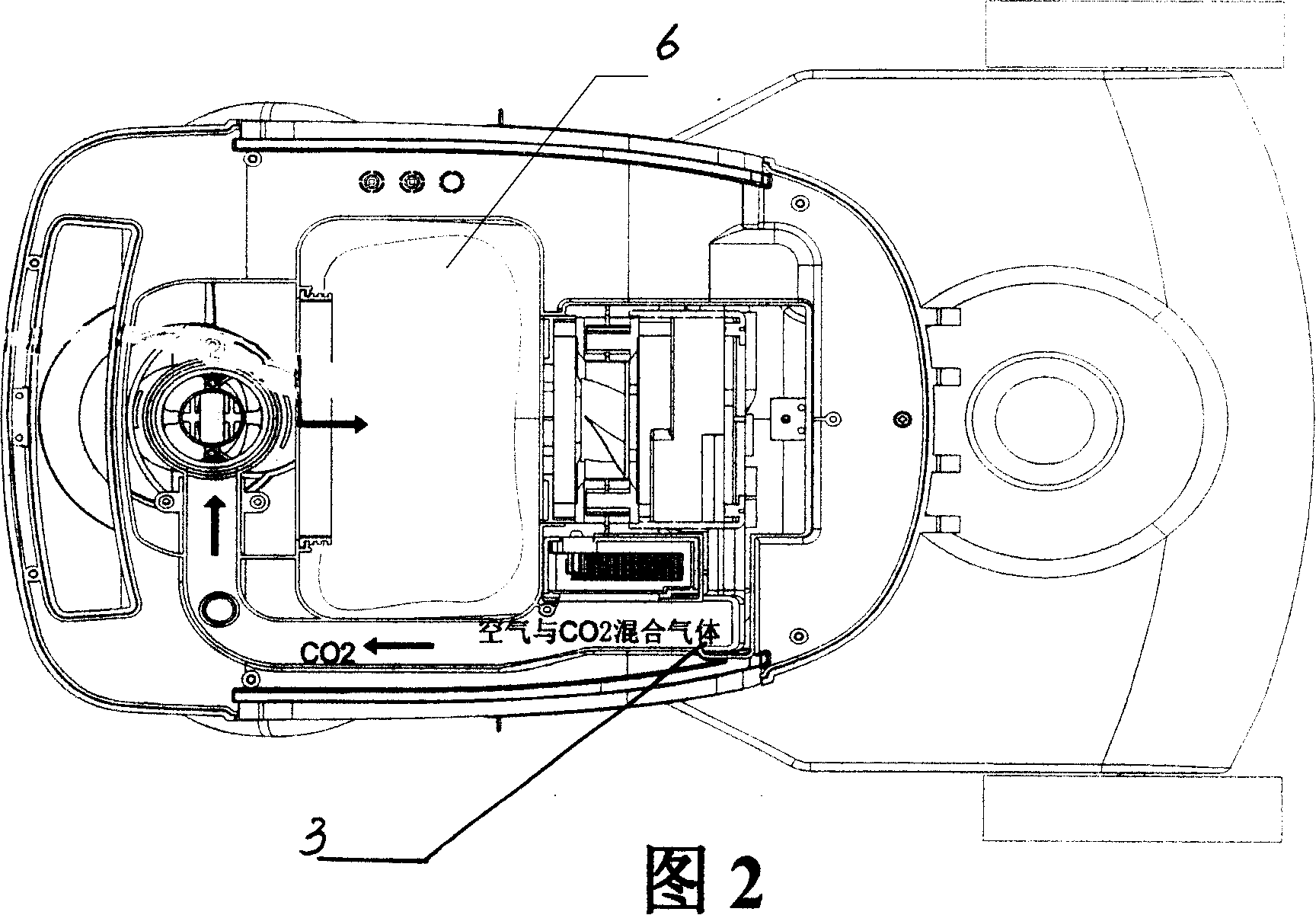

Carbon dioxide gas mixture mosquito eradication machine

InactiveCN101116435AWon't emitImprove the effect of attracting mosquitoesInsect catchers and killersAgainst vector-borne diseasesHazardous substanceProduct gas

The invention discloses a carbon dioxide mixed gas mosquito killer, which is characterized in that: one side of a killer shell is provided with a carbon dioxide nozzle which is communicated with an air duct via pipe; the killer shell is provided with a protecting net which is provided with a fan at one side and a mosquito killing pocket at the other side in the chamber of the killer shell; the pocket mouth of the mosquito killing pocket is sleeved on an opening of a bait room, and the other opening of the bait room is communicated with a mosquito bait passage; and the lower portion of the bait room is provided with a mixed gas outlet. The product has simple and practical integral structure and markedly mosquito baiting effect and mosquito catching effect and mosquito killing effect. The mosquito killer is suitable for indoor use or outdoor use, and achieves great effect at outdoor that killing thousands of mosquitoes a day particularly at place where mosquitoes aggregation. The great advantage of the utility model is that the mosquito killer can not generate toxic and harmful substance in the mosquito killing process, and make no resistant by mosquito.

Owner:上海威锐工具有限公司

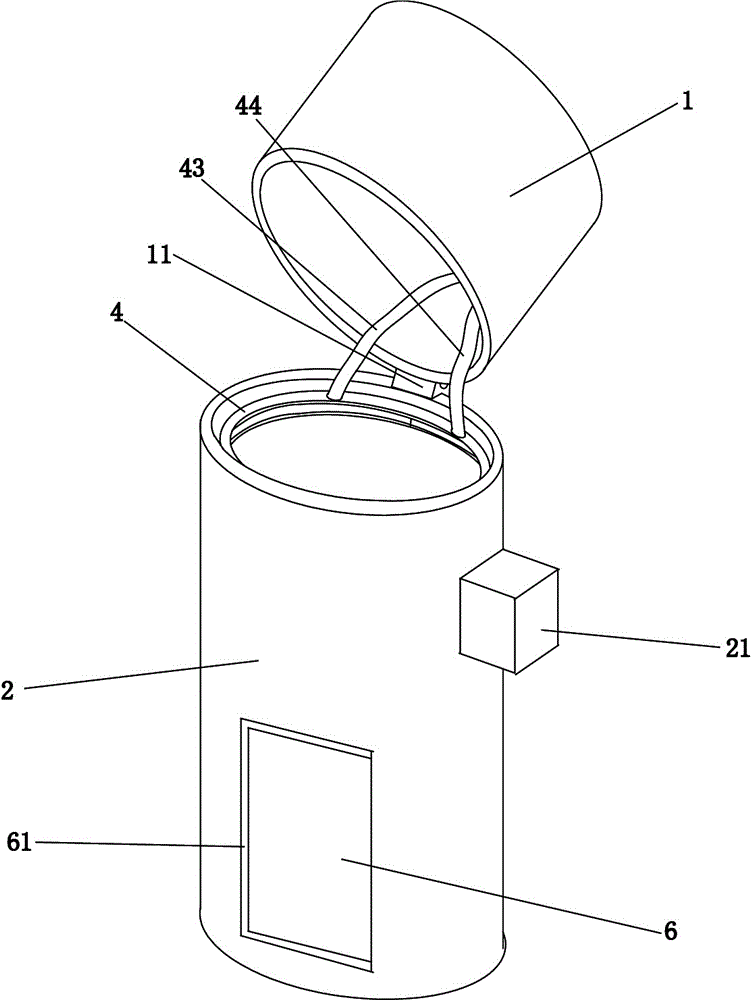

Odor-resistant garbage can

The invention discloses an odor-resistant garbage can, and relates to a living supply. The odor-resistant garbage can comprises a can body and a can cover. An annular air curtain ring is arranged on the can body. A suction pump connected with an air curtain spray tank and an air inlet duct is arranged on the can cover. An annular rail is arranged at the bottom of the can body. A plurality of moving rods are movably arranged on the annular rail. Placing frames used for propping a garbage bag mouth open are rotationally arranged on the moving rods. An accommodating box is arranged on the can body. A telescoping mechanism is arranged in the accommodating box. An arc buckle is arranged on the telescoping mechanism. A sealers used for sealing a garbage bag is arranged in the arc buckle. A bag taking opening is formed in the side wall of the can body. Compared with the prior art, escaping of odor in the garbage can is completely eradicated, odor cannot diffuse even if garbage is thrown in the garbage can and the garbage bag is taken out from the garbage can, and the problem that the home life is influenced since odor diffuses from the garbage can in the past is solved.

Owner:ZHEJIANG ZNC TECH CO LTD

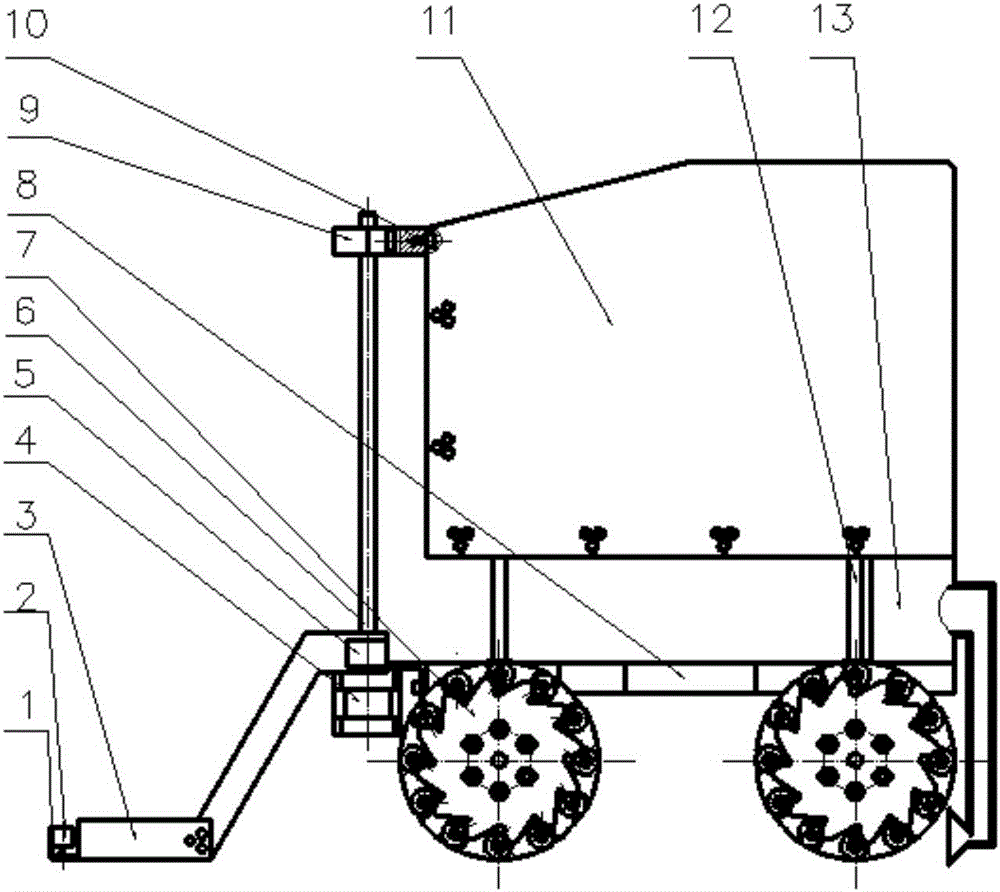

Waste recovery robot

ActiveCN106113059AClean up comprehensivelyImprove work efficiencyRoad cleaningManipulatorWaste productBottle

The invention provides a waste recovery robot. The waste recovery robot comprises a cleaning mechanism, a car body mechanism and a walking mechanism. The cleaning mechanism comprises a dust suction device used for sucking up paper scraps and a grabbing device used for grabbing waste bottles. The dust suction device is arranged at the lower end of the car body mechanism, and the grabbing device is arranged at the front end of the car body mechanism. The walking mechanism is arranged below the car body mechanism to drive the waste recovery robot to walk. According to the waste recovery robot, garbage can be comprehensively cleaned away, largish garbage such as waste bottles and peels can be cleaned away, and small paper scraps and garbage bags can be cleaned away; intelligent control and manual control are combined, and therefore the robot is more practical; compared with traditional manual operation, work efficiency is greatly improved; and according to the characteristics of a cleaning place, a manufactured grabbing mechanism and the manufactured cleaning mechanism can be simple and effective.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for preparing resin grinding wheel

The invention discloses a method for preparing a resin grinding wheel. The method comprises the following steps: (1) placing 70-85 parts by weight of white corundum into 10-15 parts by weight of acrylic emulsion to be soaked, evenly mixing 6-8 parts by weight of polytetrafluoroethylene powder, 1-2 parts by weight of boron nitride, 15-20 parts by weight of cryolite and 30-35 parts by weight of phenolic resin powder with the soaked white corundum, and enabling the mixture to pass through 20-25-mesh standard screens to obtain a grinding wheel mixture; (2) taking a glass fiber cloth, coating the two faces of the glass fiber cloth with phenolic resin, then placing the glass fiber cloth into a drying oven, and baking the glass fiber cloth at the temperature of 135-140 DEG C for 15-20min to obtain glass fiber pieces; (3) placing the glass fiber mixture into a forming mold, spreading the glass fiber mixture, completely embedding the glass fiber pieces into the grinding wheel mixture, and conducting compression forming to obtain a grinding wheel green body; (4) placing the grinding wheel green body into a sintering furnace to be sintered; (5) machining the sintered grinding wheel green body on a lathe and a grinding machine to obtain the finished resin grinding wheel. When resin grinding wheel prepared by the method is used, harmful gas caused by oxidation can not emit.

Owner:CHANGSHU JULI GRINDING WHEEL

Bedside filth collecting device for patients of gastroenterology department used for medical care

InactiveCN108578248AWon't leakPrevent fullNursing bedsSpittle receiving devicesEmergency medicineGastroenterology department

The invention relates to a medical care device, in particular to a bedside filth collecting device for patients of the gastroenterology department used for medical care. The invention aims at providing the bedside filth collecting device for patients of the gastroenterology department used for medical care, which enables the patients to vomit towards the proper position, and can rapidly collect filth and isolate odor. The technical scheme is as follows: the bedside filth collecting device for patients of the gastroenterology department used for medical care comprises a bottom plate, a closingbox, a first threaded rod, a sliding sleeve, a cover board, a first nut and the like, wherein the closing box is connected to the bottom plate, a rectangular hole is formed in the right side of the closing box, the first threaded rod is connected to the upper part of the right side of the closing box, and the sliding sleeve is connected to the first threaded rod in a sliding manner. With the bedside filth collecting device, the effects that the patients vomit towards the proper position, the filth is collected rapidly, and the odor is isolated, are achieved, due to the adoption of the manner that a crank is rotated so that a collecting table is driven to move vertically till reaching the position enabling the patients to conveniently vomit, the patients can rapidly realize alignment and vomit, and the filth can not leak out.

Owner:李龙燕

Welding machine

The invention provides a welding machine and relates to the technical field of automobile part machining. The welding machine comprises a main engine and an isolating hood. The isolating hood is arranged outside the main engine. A viewing window is arranged in the front of the isolating hood, and a draft fan is arranged on the back of the isolating hood. Under the circumstance of not influencing operation of staff, toxic gas generated in the plastic hot-melting process can be eliminated in time, and the working environment of operators is improved greatly.

Owner:HEFEI YONGTAI FIREPROOF DOOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com