Interior wall coating and preparation method thereof

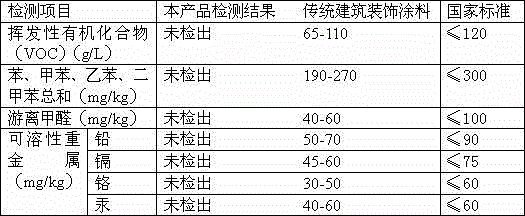

An interior wall paint and paint technology, applied in the field of paint, can solve problems such as fire safety hazards, poor flame retardant effect, harm to human health, etc., and achieve the effects of good insect repellent, good anti-corrosion effect, and good decorative function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 150kg of water, 4kg of dispersant, and 2kg of defoamer into the reactor, and disperse for 40 minutes at a speed of 750-850 rpm; then add 200kg of titanium dioxide, 75kg of calcium carbonate powder, and 5kg of flame retardant agent, 3kg of antiseptic and antibacterial agent, 5kg of ethanol, stirring for 30 minutes at a speed of 800-1000 rpm, and sanding until the fineness of the material is below 50um; then add 200kg of pure acrylic emulsion and 2kg of defoamer 1. Put 2kg of plant extracts into the reactor, stir for 40 minutes at a speed of 700 rpm; finally adjust the viscosity with 50kg of water so that the viscosity at room temperature is (90-110) KU, and pass through a 200-mesh sieve After that, it is a qualified product, which is packaged and preserved.

[0021] Wherein, the weight ratio of each component of the flame retardant is magnesium hydroxide: aluminum hydroxide: iron oxide: zinc borate=1:1:0.5:0.2; the weight ratio of each component of the antiseptic and...

Embodiment 2

[0024] Add 200kg of water, 6kg of dispersant, and 1kg of defoamer into the reactor, and disperse for 40 minutes at a speed of 750-850 rpm; then add 240kg of titanium dioxide, 60kg of calcium carbonate powder, and 3kg of flame retardant agent, 4kg of antiseptic and antibacterial agent, 6kg of ethanol, stirring for 30 minutes under the condition of rotating speed of 800-1000 rpm, and sanding until the fineness of the material is below 50um; then add 160kg of pure acrylic acid emulsion, 1kg of defoamer 1. Put 1kg of plant extract into the reaction kettle, stir for 40 minutes at a speed of 700 rpm; finally adjust the viscosity with 100kg of water so that the viscosity at room temperature is (90-110) KU, and pass through a 200-mesh sieve After that, it is a qualified product, which is packaged and preserved.

[0025] Wherein, the weight ratio of each component of the flame retardant is magnesium hydroxide: aluminum hydroxide: iron oxide: zinc borate=1:1:0.5:0.2; the weight ratio of...

Embodiment 3

[0028] Add 120kg of water, 5kg of dispersant, and 1.5kg of defoamer into the reactor, and disperse for 40 minutes at a speed of 750-850 rpm; then add 220kg of titanium dioxide, 70kg of calcium carbonate powder, and 6kg of Combustion agent, 2kg antiseptic and antibacterial agent, 4kg ethanol, stirring for 30 minutes under the condition of rotating speed of 800-1000 rpm, and sand milling until the material fineness is below 50um; then add 180kg of pure acrylic emulsion, 1.5kg of disinfectant Foaming agent, 3kg of plant extracts into the reaction kettle, stirring for 40 minutes at a speed of 700 rpm; the last 30kg of water to adjust the viscosity so that the viscosity at room temperature is (90-110) KU, over 200 After the mesh sieve, it is a qualified product, which is packaged and preserved.

[0029] Wherein, the weight ratio of each component of the flame retardant is magnesium hydroxide: aluminum hydroxide: iron oxide: zinc borate=1:1:0.5:0.2; the weight ratio of each componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com