Patents

Literature

37934 results about "Calcium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used to prevent or treat low blood calcium levels in people who do not get enough calcium from their diets. It may be used to treat conditions caused by low calcium levels such as bone loss (osteoporosis), weak bones (osteomalacia/rickets), decreased activity of the parathyroid gland (hypoparathyroidism), and a certain muscle disease (latent tetany). It may also be used in certain patients to make sure they are getting enough calcium (e.g., women who are pregnant, nursing, or postmenopausal, people taking certain medications such as phenytoin, phenobarbital, or prednisone).

Mineral Composite Beverage Brewing Cup and Cartridge

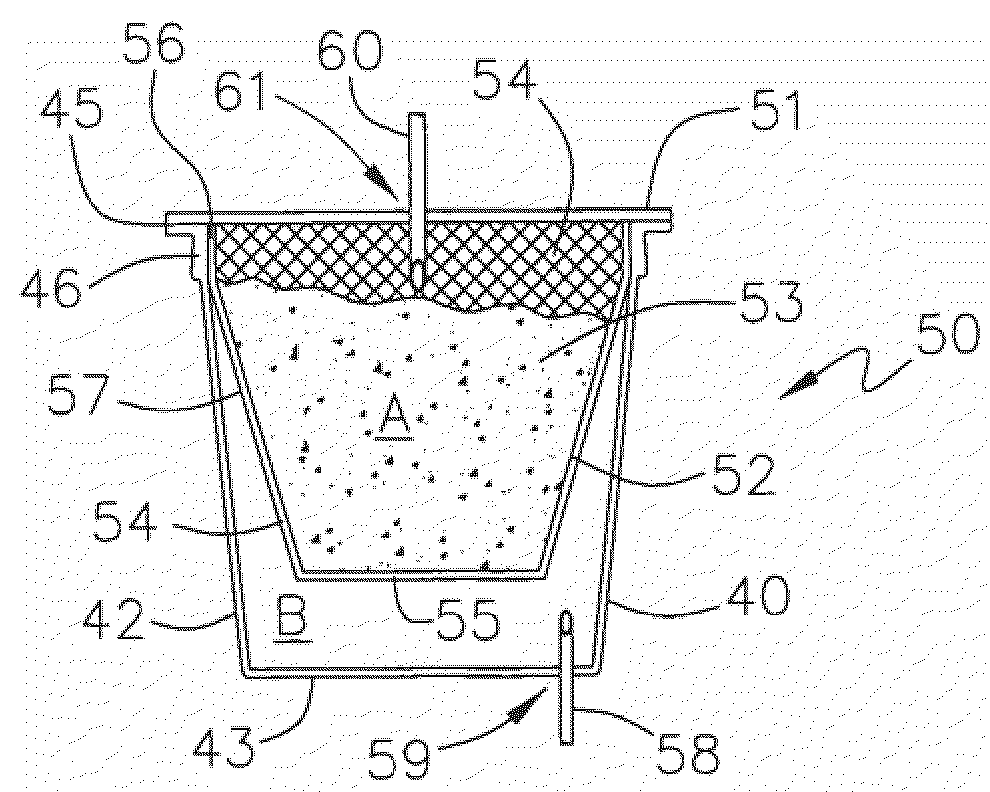

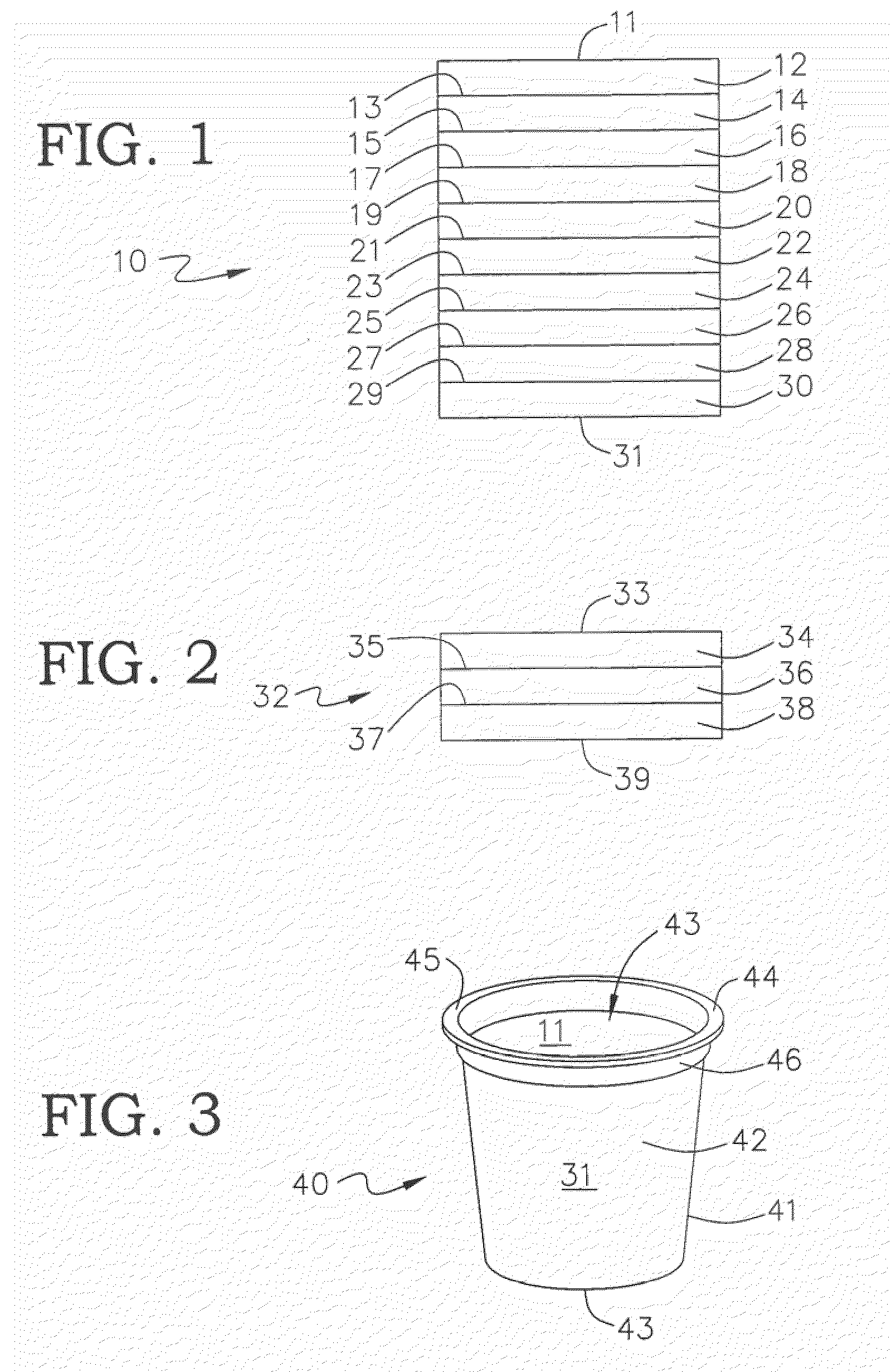

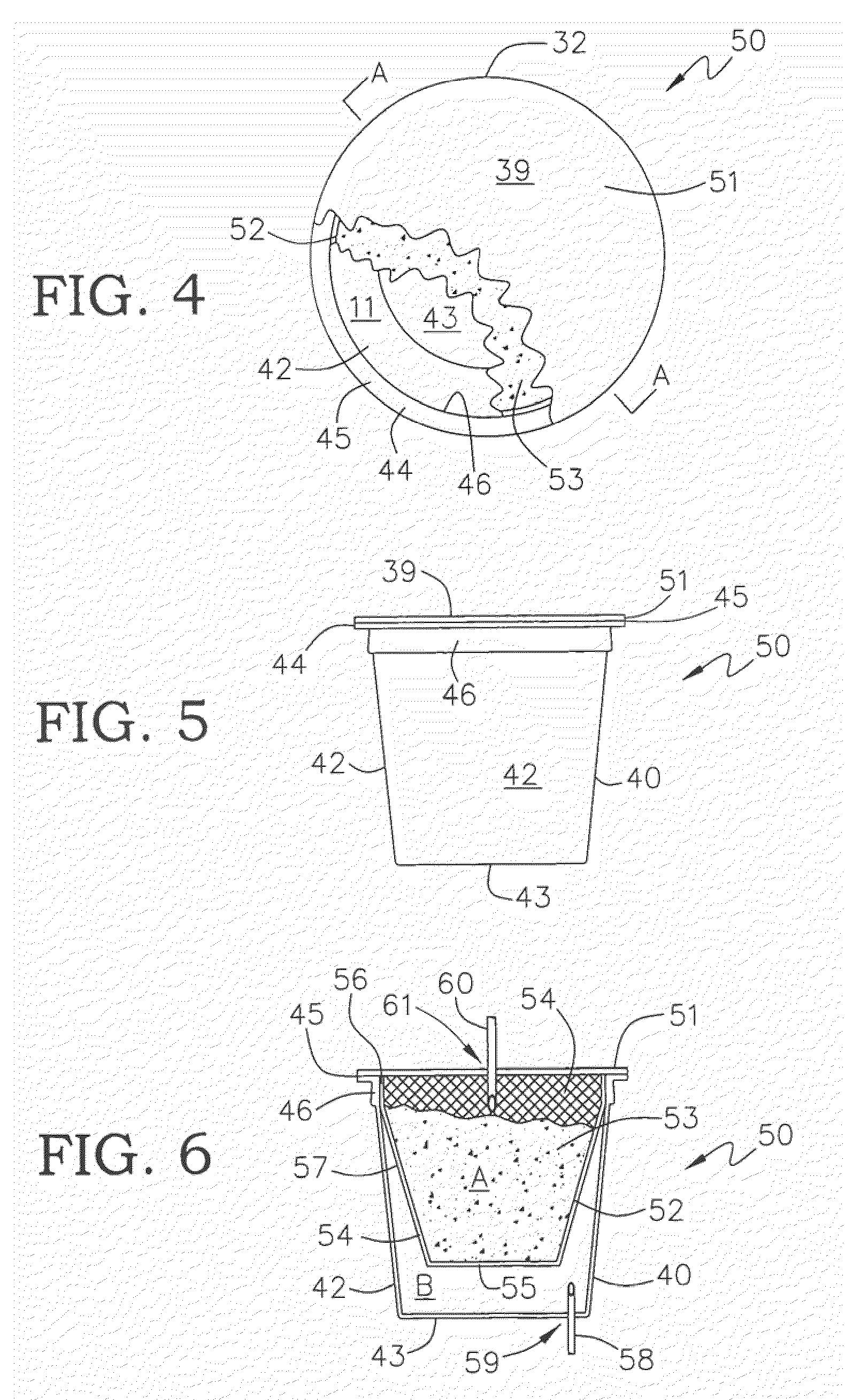

A beverage filter cartridge having a cup, a filter, a lid and at least one beverage ingredient is provided where the cup and lid are sealed together to form an interior chamber which is separated into a first and second compartments by the filter, which is preferably basket or cone shaped, and a beverage ingredient such as coffee is contained inside first compartment, and at least one of the cup, lid and filter contains calcium carbonate in an amount effective to either improve the ability of beverage makers to pierce the cup or to provide a means for the cartridge to absorb CO2 emitted by the ingredient thereby reducing the hold time to packing and reducing the number of defective cartridges.

Owner:BEMIS COMPANY INC

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

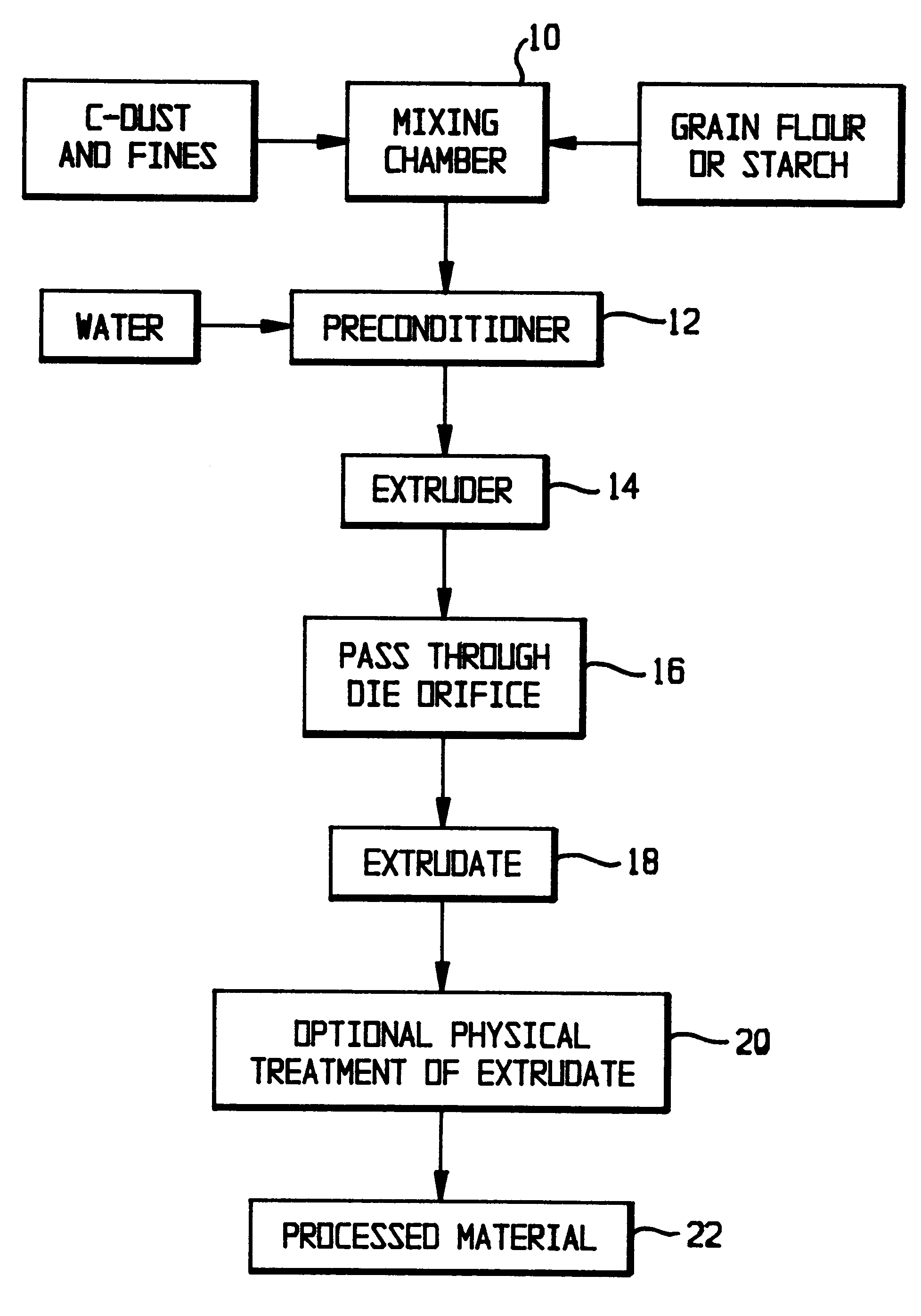

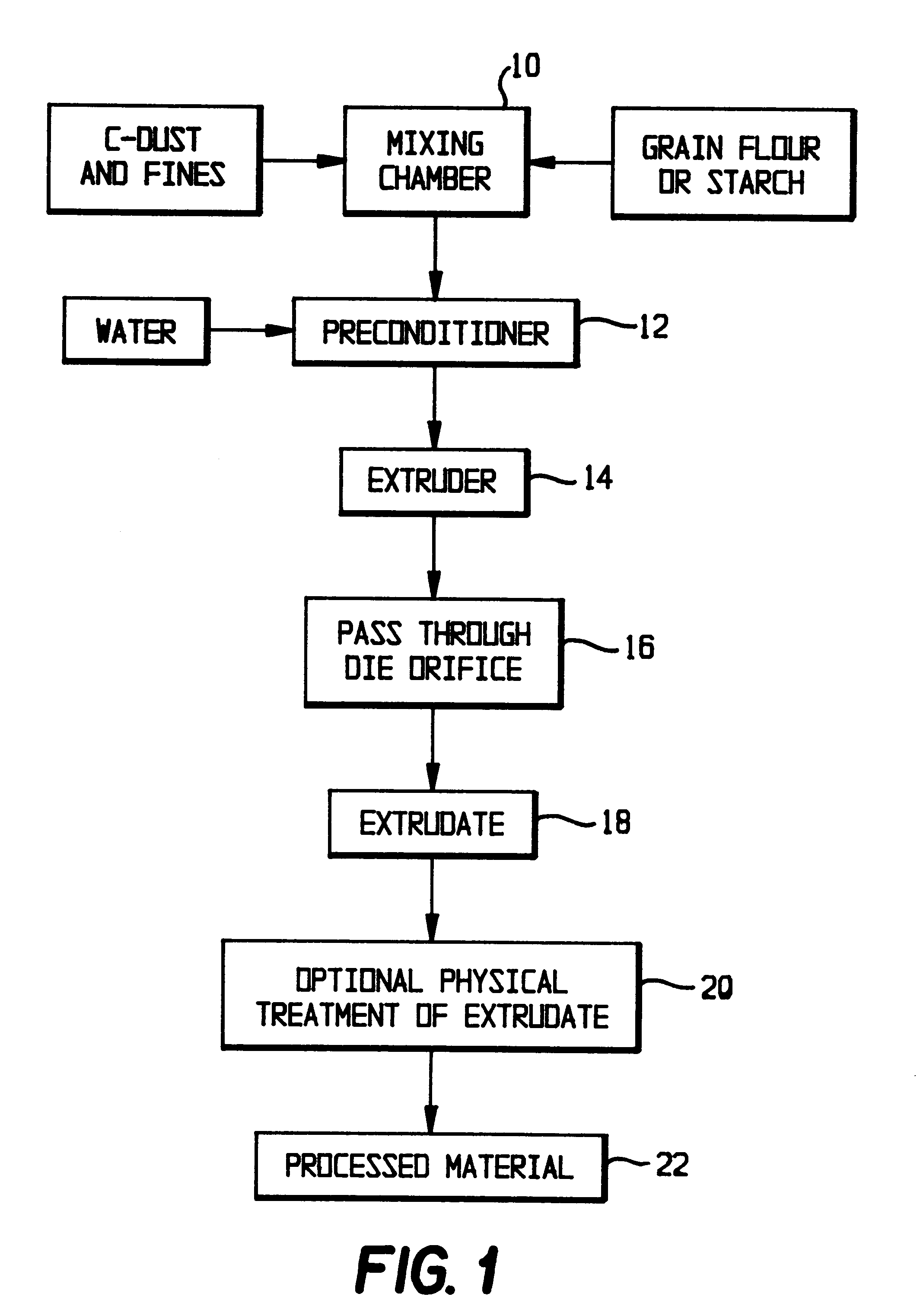

Low-density tobacco filler and a method of making low-density tobacco filler and smoking articles therefrom

InactiveUS6182670B1Pleasing tobacco odorImprove the smoke effectTobacco preparationDough treatmentSolventLow density

A low-density filler material for cigarettes from either a low-density tobacco composition or an extruded grain or starch composition. The low-density tobacco composition and a method of making the low-density tobacco composition by extruding a mixture of tobacco and flour or tobacco and starch under conditions whereby the solvent in the extruded mixture flashes into vapor upon release from the extrusion head. The low-density tobacco composition is formed without the aid of an added binder. The low-density flour or starch material and a method of making it by extruding flour or starch with a filler material such as calcium carbonate under conditions whereby the solvent in the extruded mixture flashes into vapor upon extrusion through the orifice die. The extruded composition can then be cut and used in place of cut tobacco filler.

Owner:R J REYNOLDS TOBACCO COMPANY

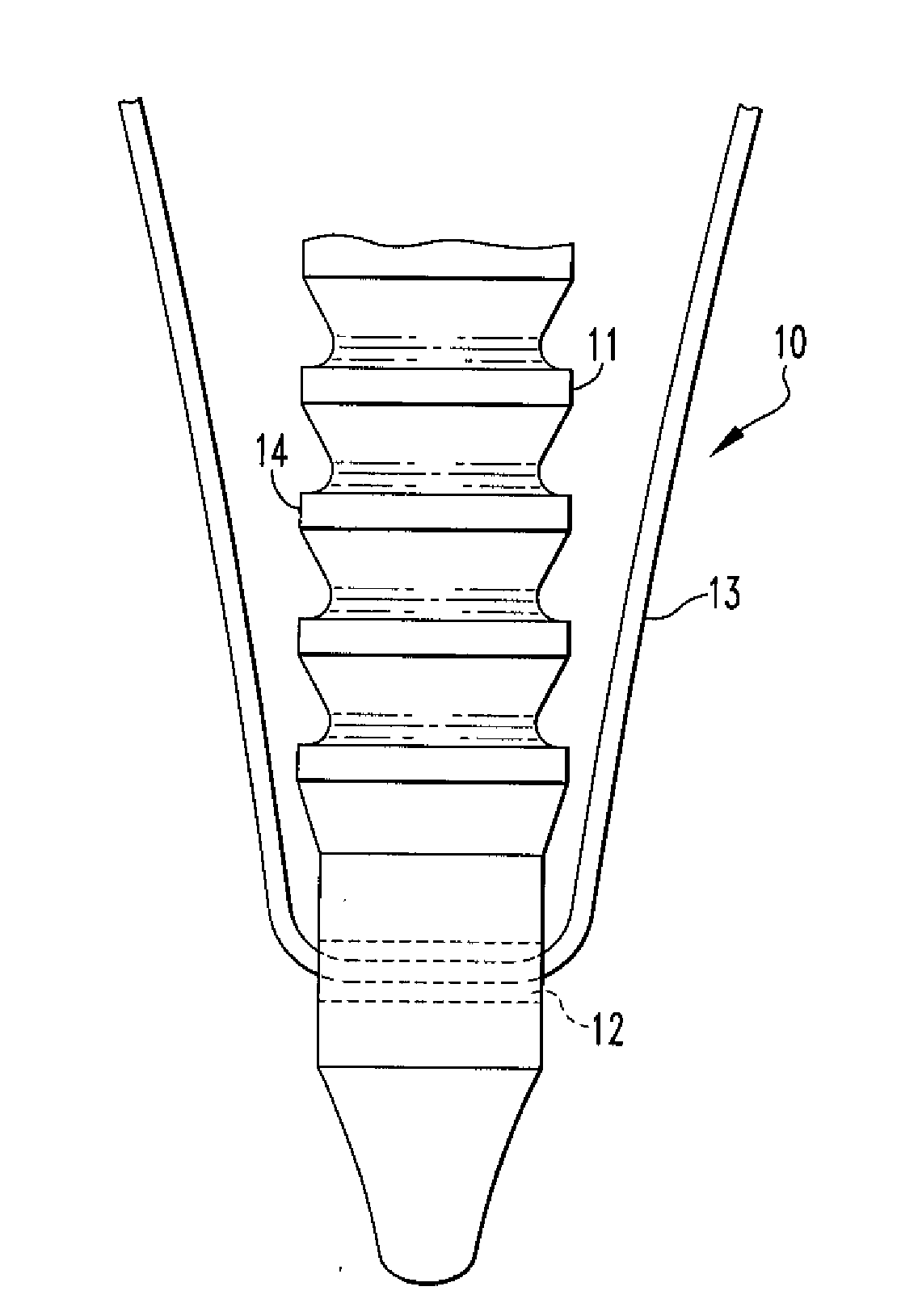

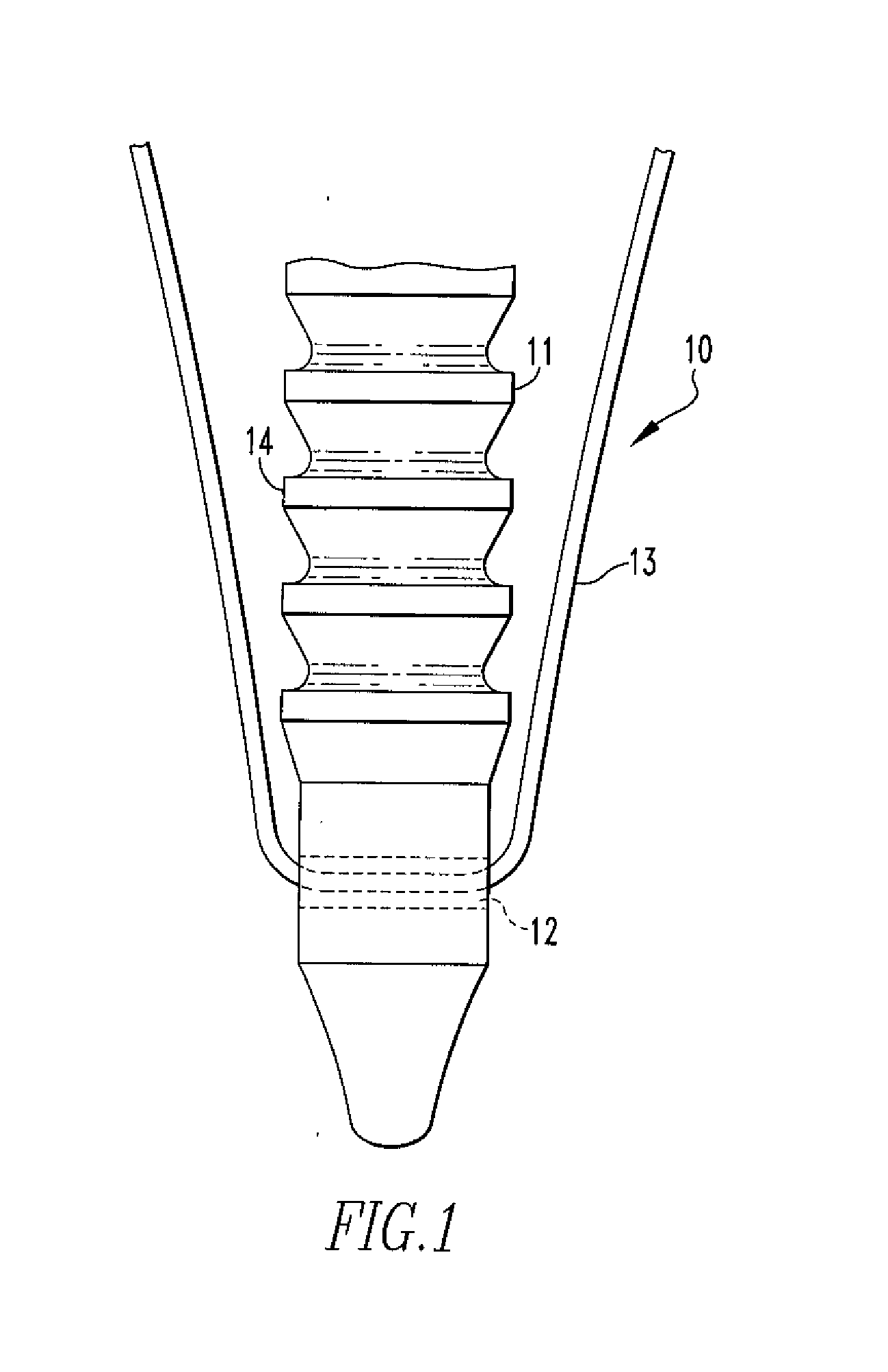

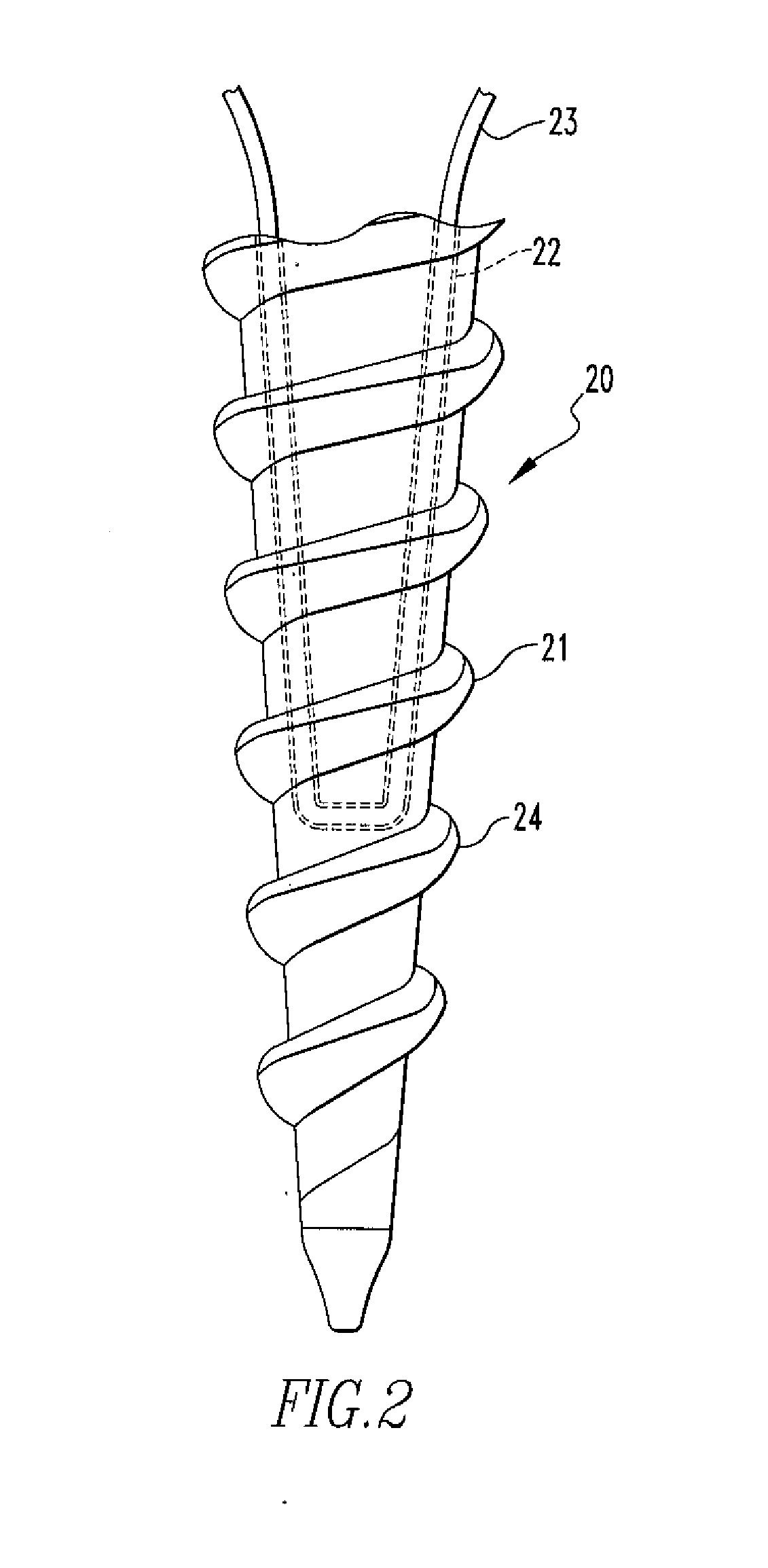

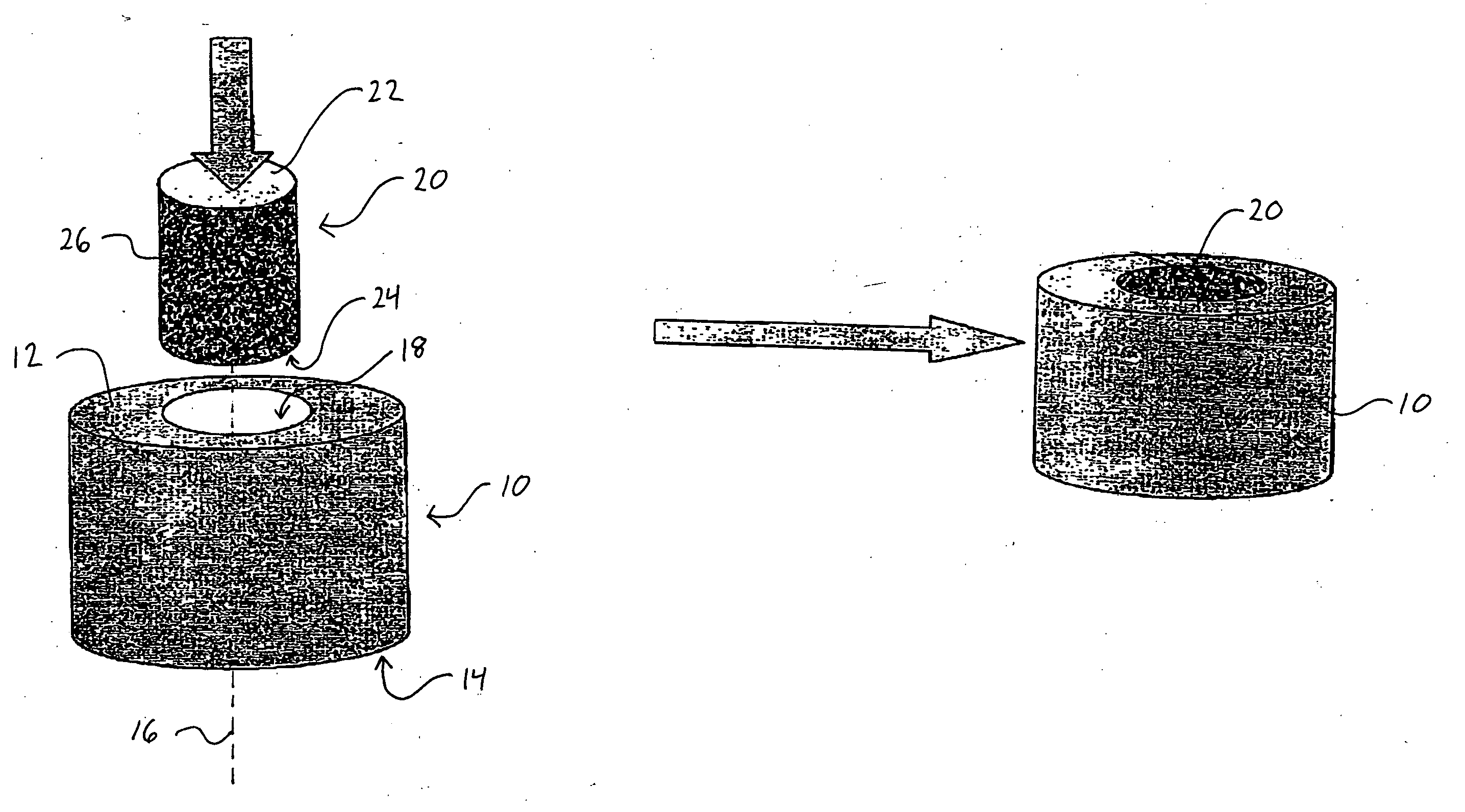

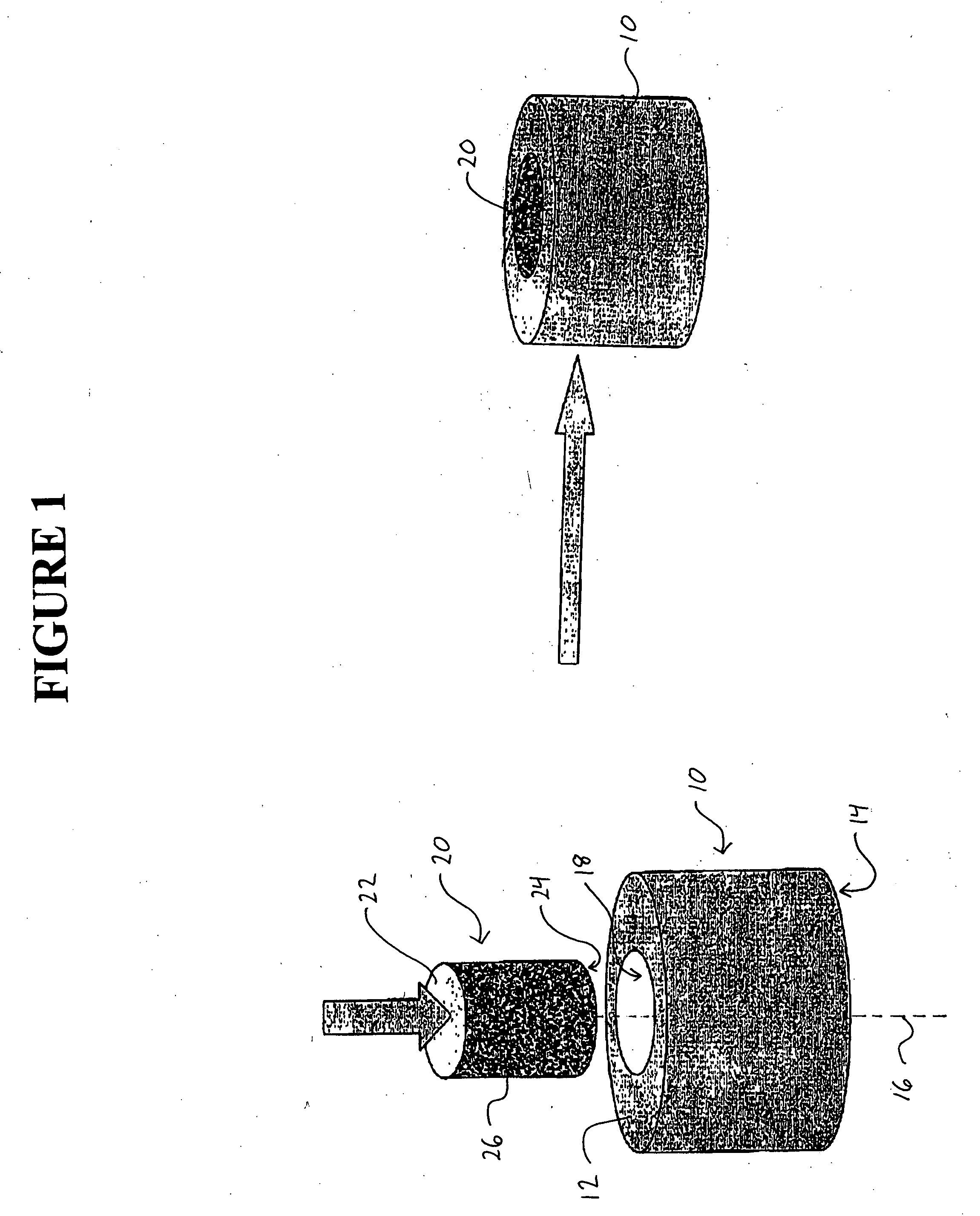

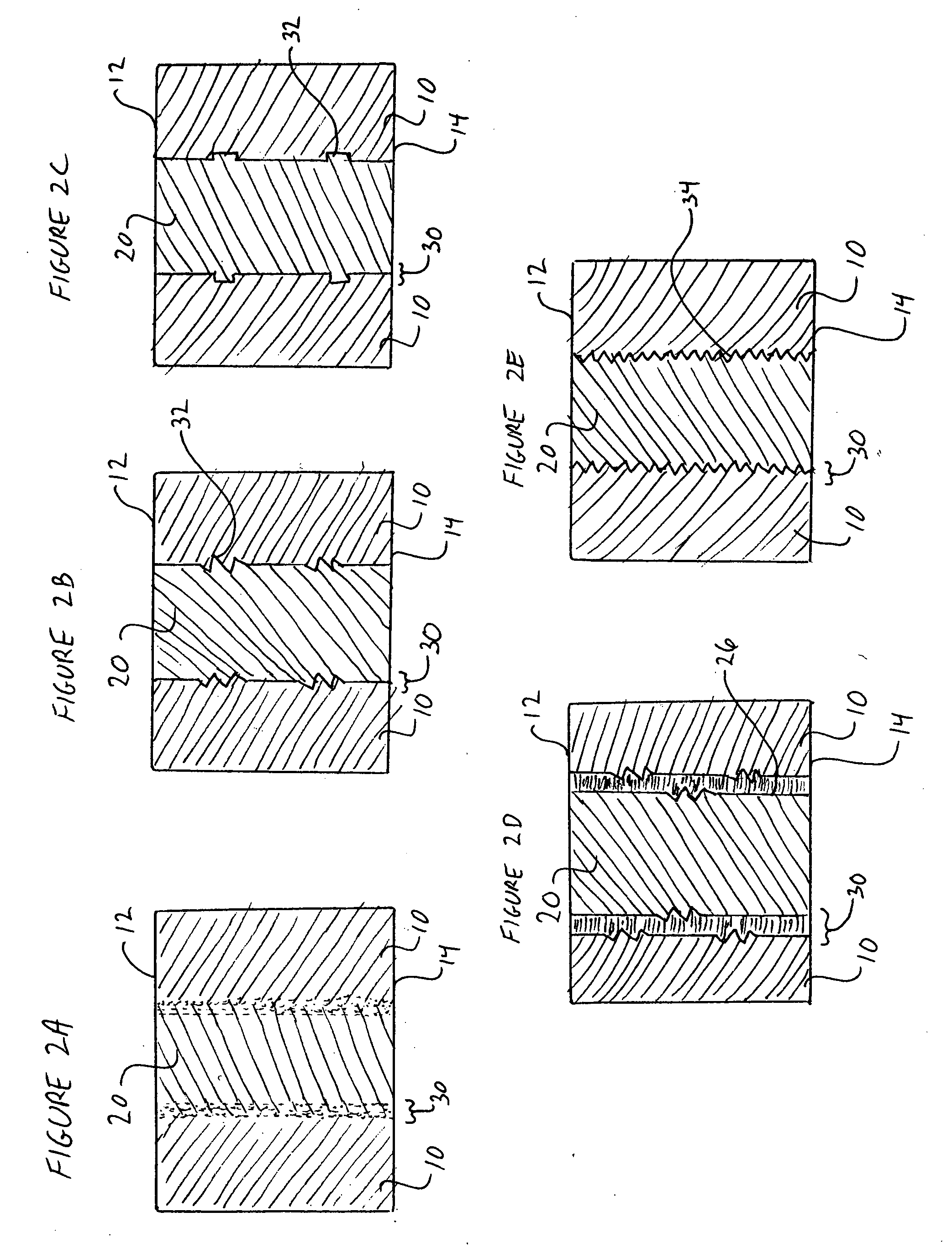

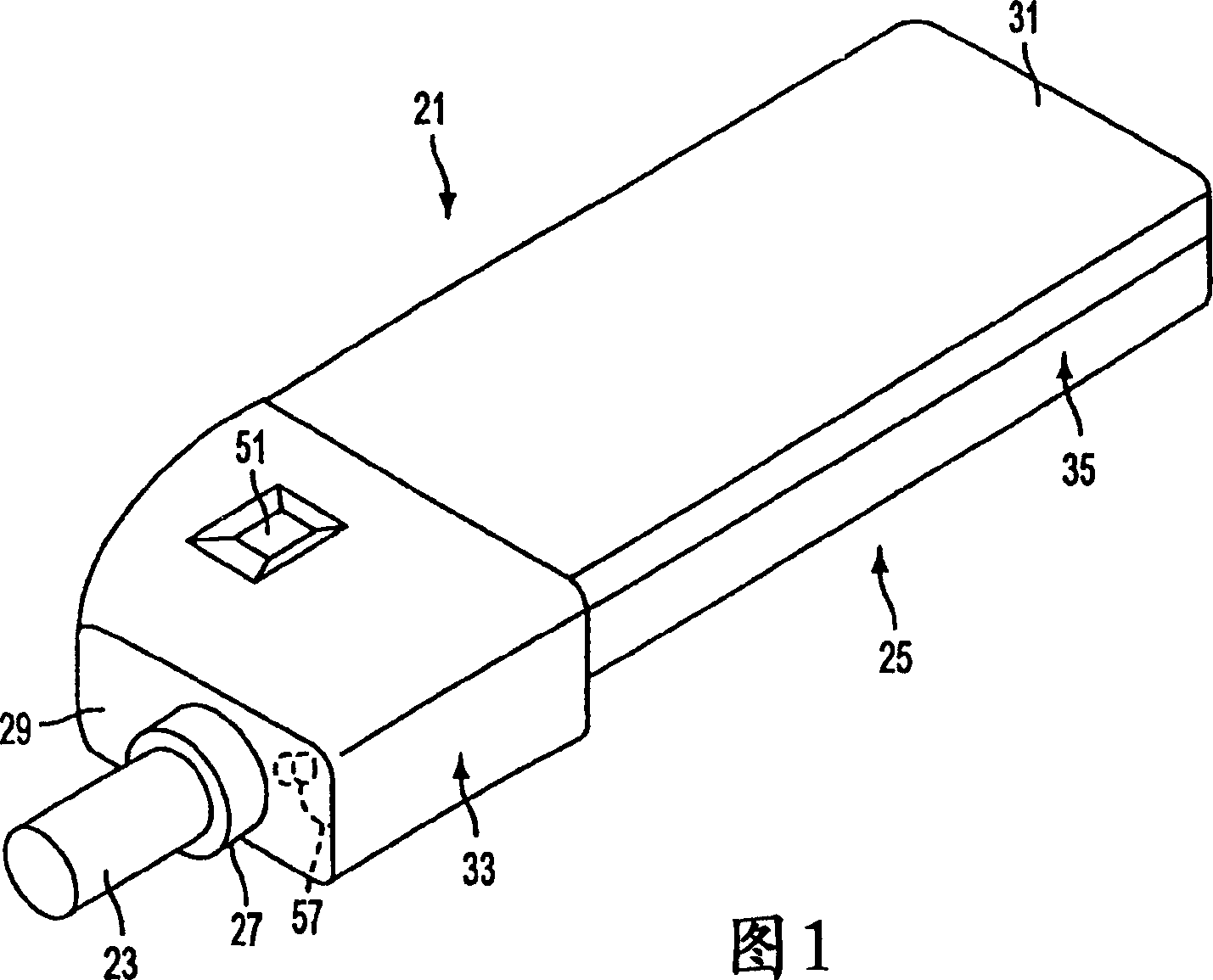

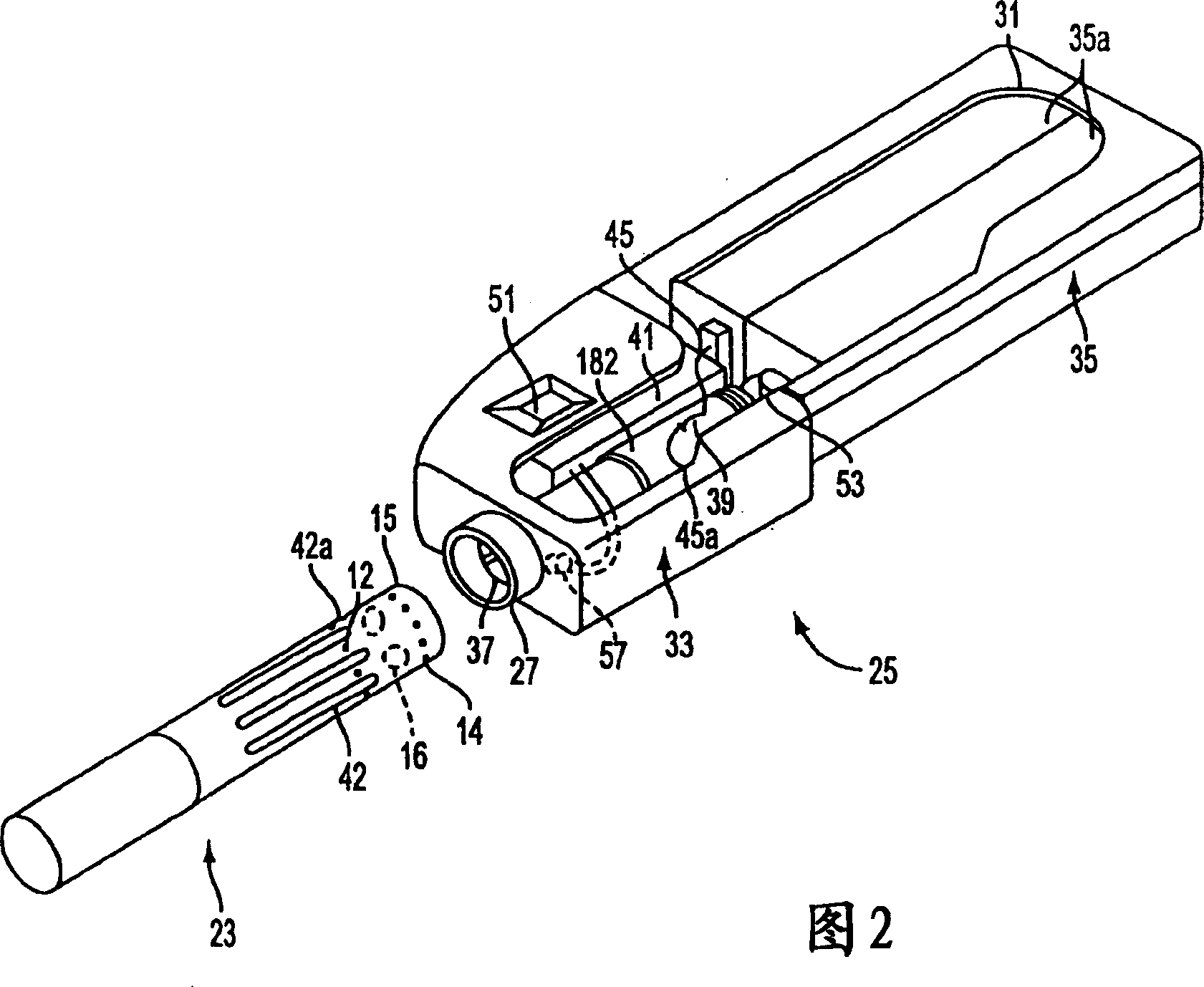

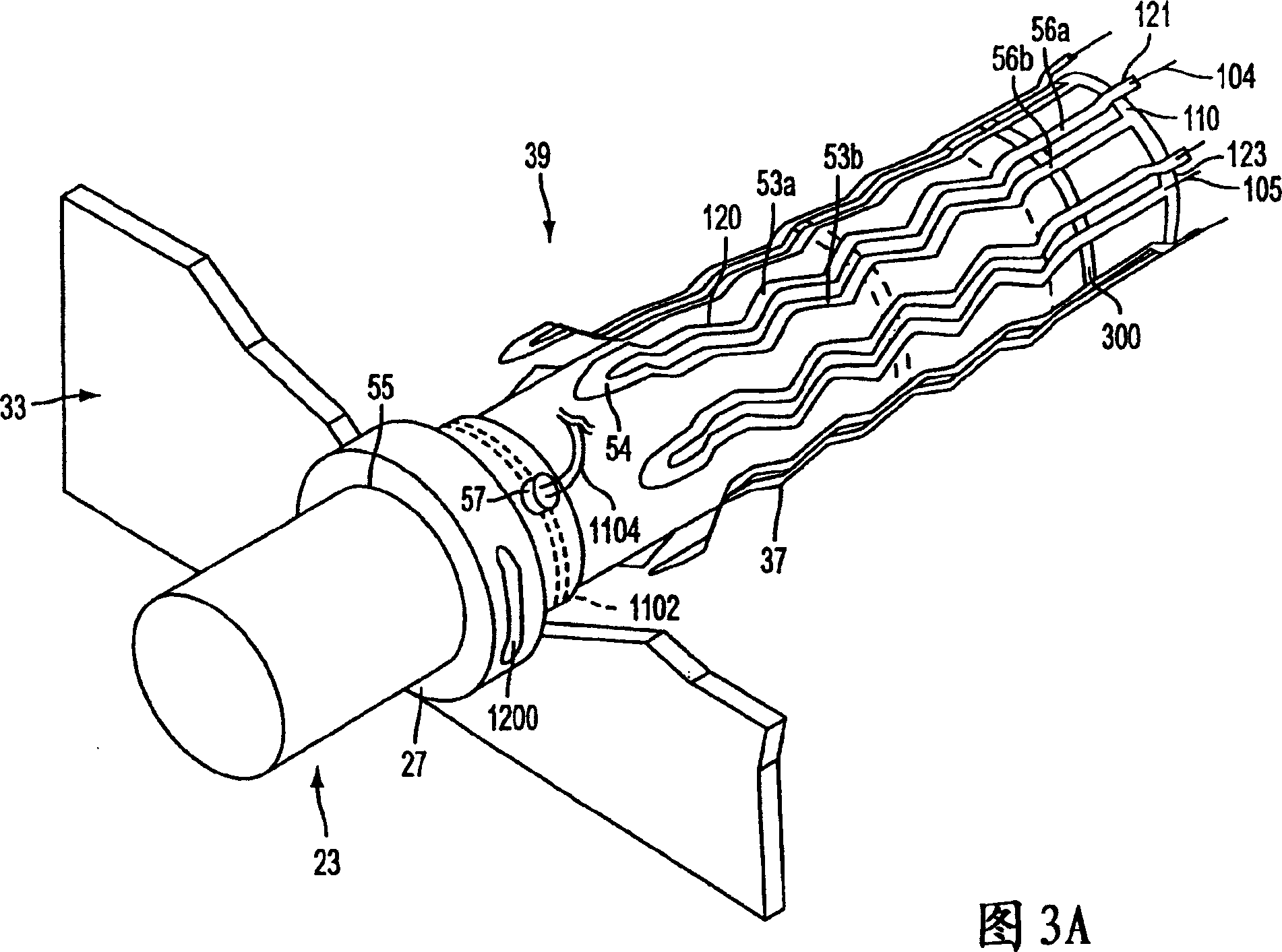

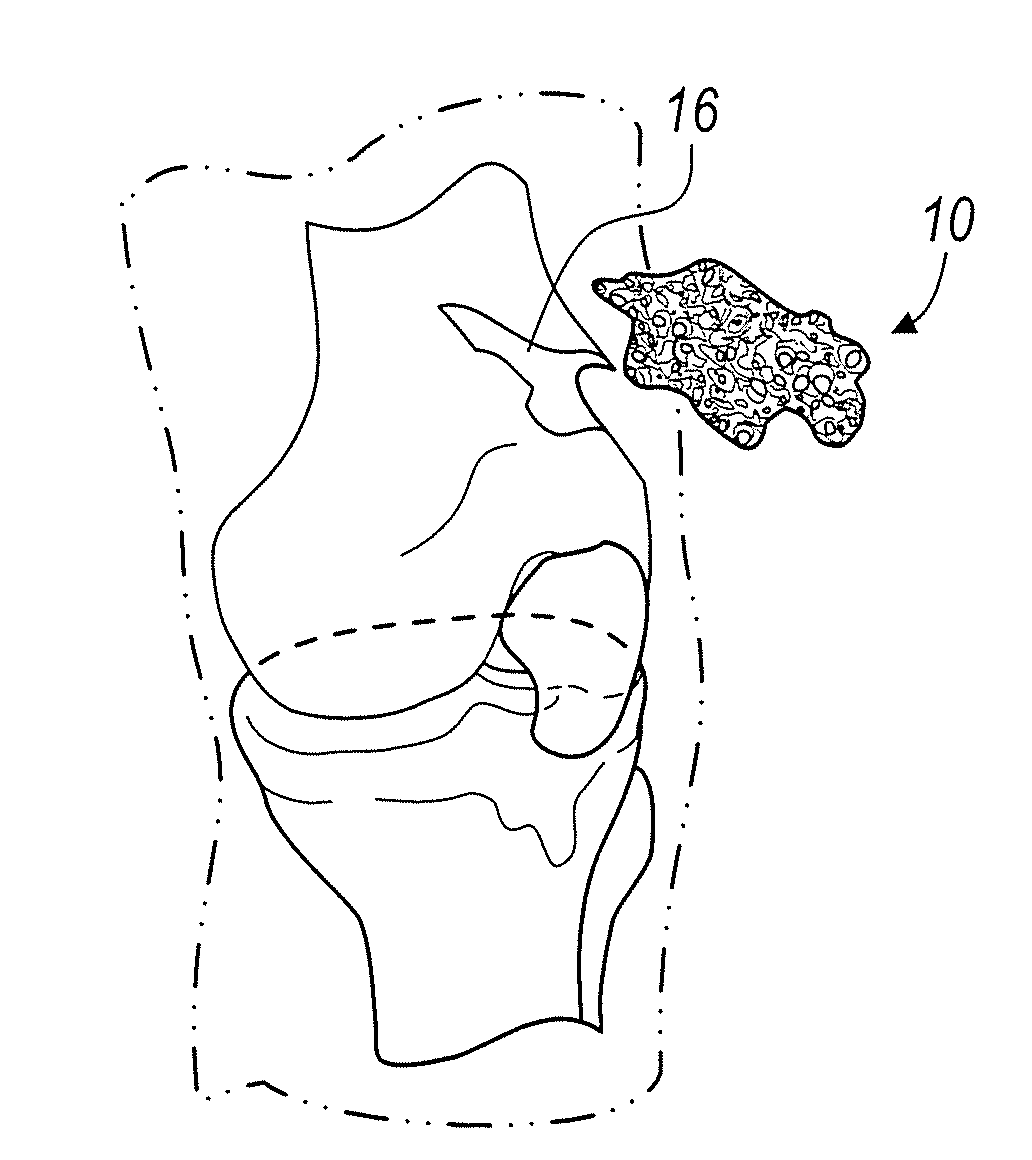

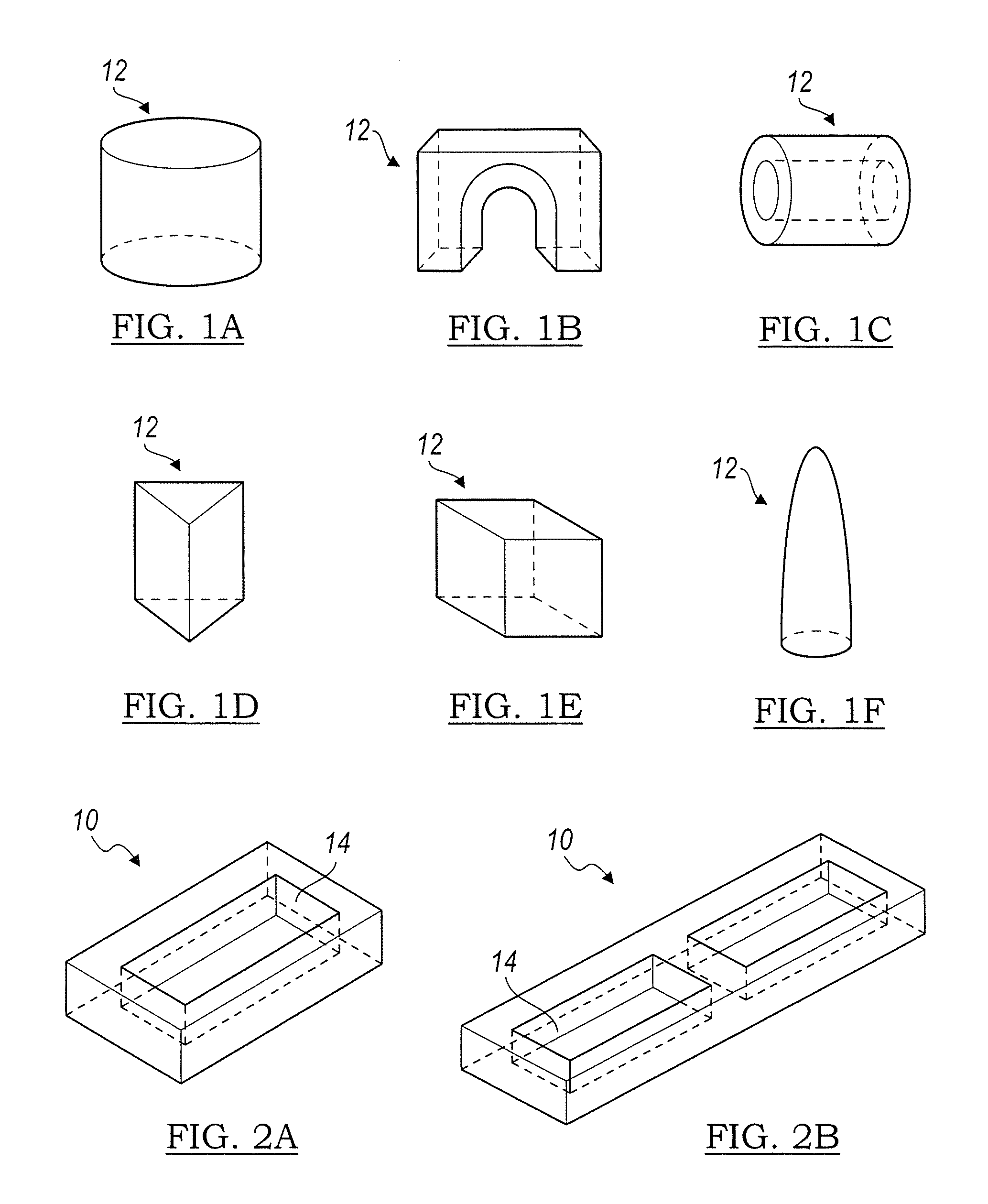

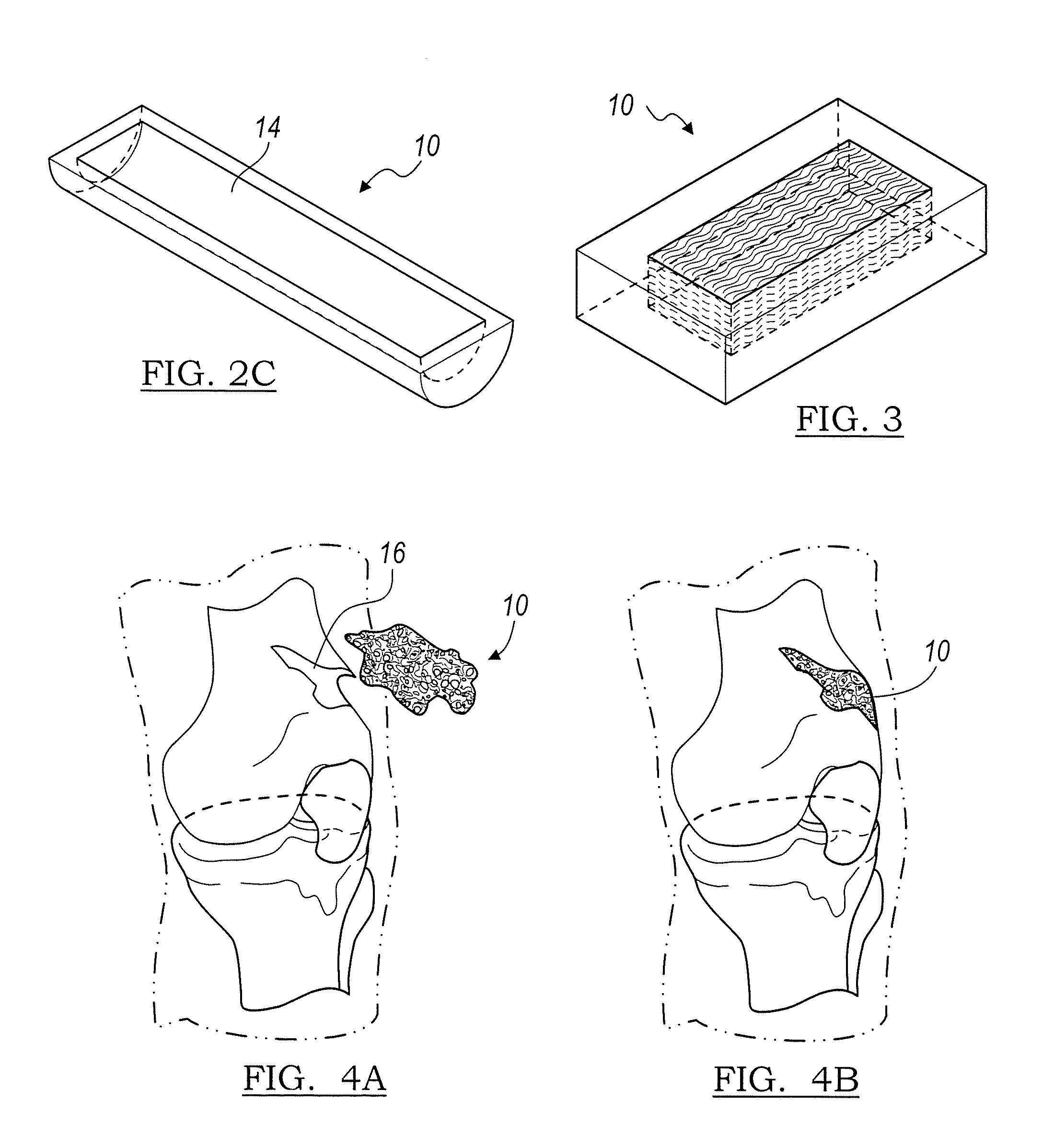

Fixation Devices and Method of Repair

InactiveUS20080234730A1Easy to fixShorten the lengthSuture equipmentsLigamentsRepair methodSurgical device

In one aspect, the present disclosure relates to a surgical device including an anchor body having an opening, the anchor body having a copolymer composition including polylactide-co-glycolide and calcium carbonate, wherein the calcium carbonate comprises more than 30% but less than 40% of the weight of the composition; and a flexible member passing through the opening, wherein deformation of the device occurs at body temperature. The present disclosure also relates to an oriented polymer material having a copolymer composition including a polylactide-co-glycolide and calcium carbonate, the calcium carbonate comprising more than 30% but less than 40% of the weight of the composition, wherein the material changes shape upon introduction to an environment having a temperature that is lower than a relaxation temperature of the material. A method of repairing soft tissue and other surgical devices are also disclosed.

Owner:SMITH & NEPHEW INC

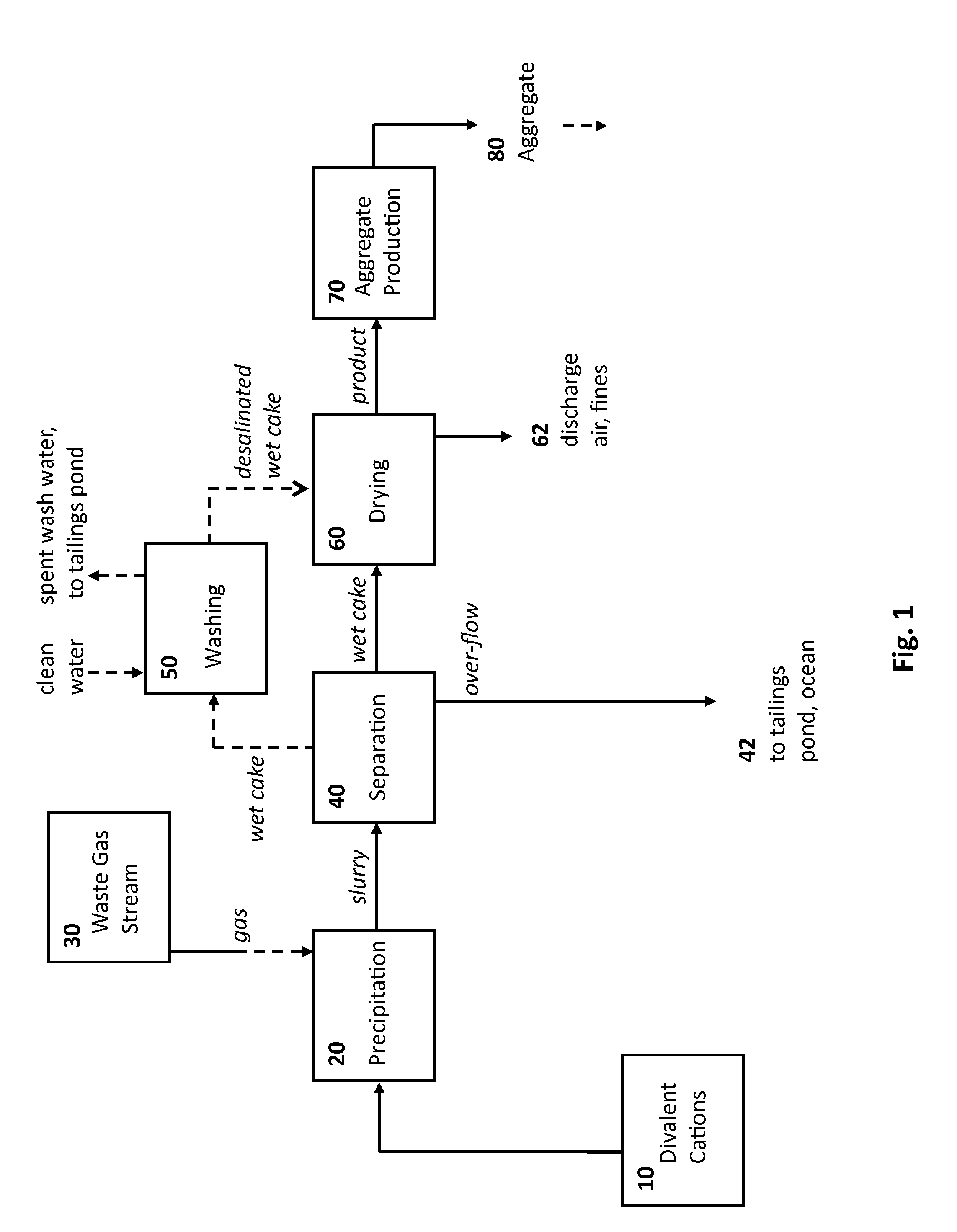

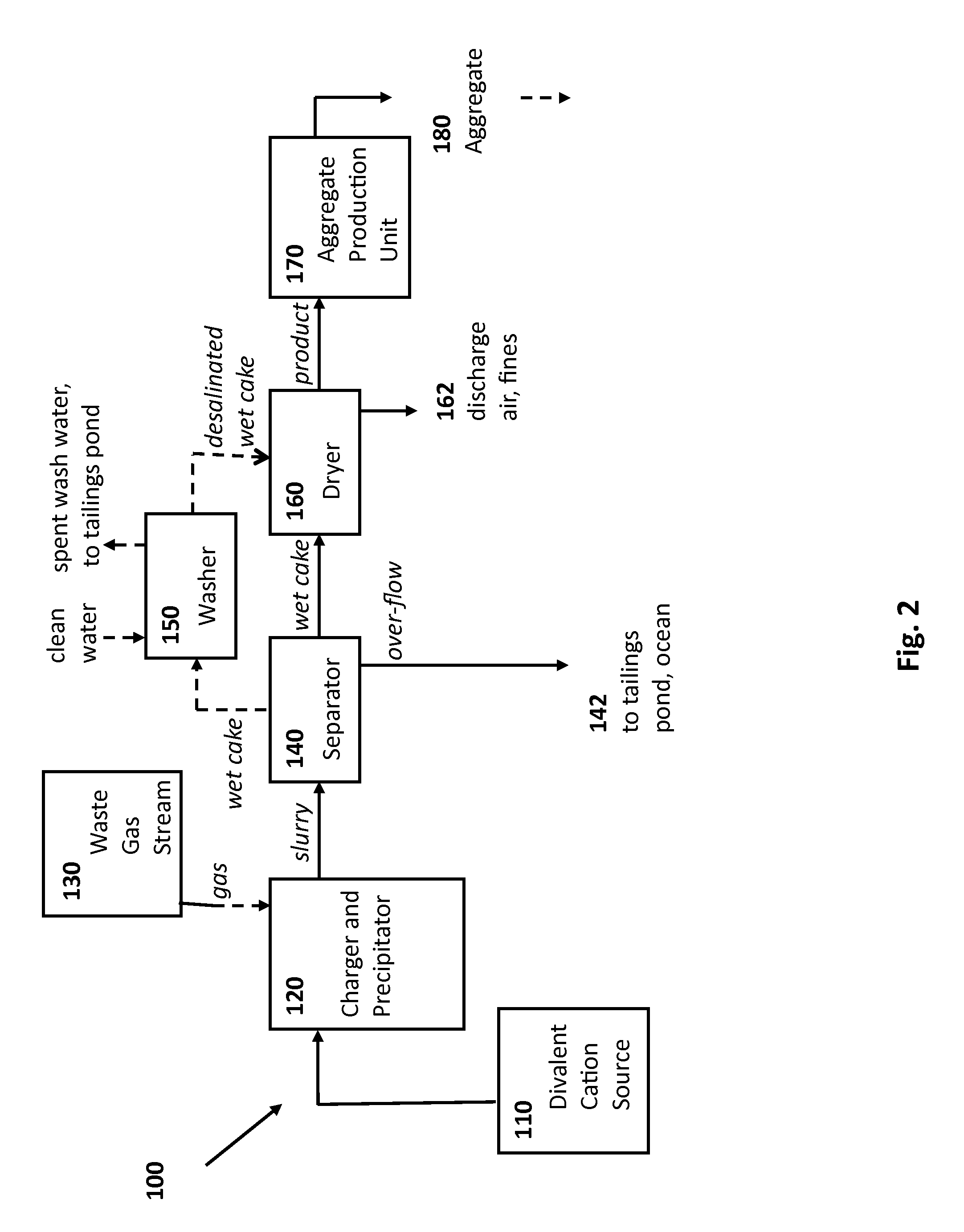

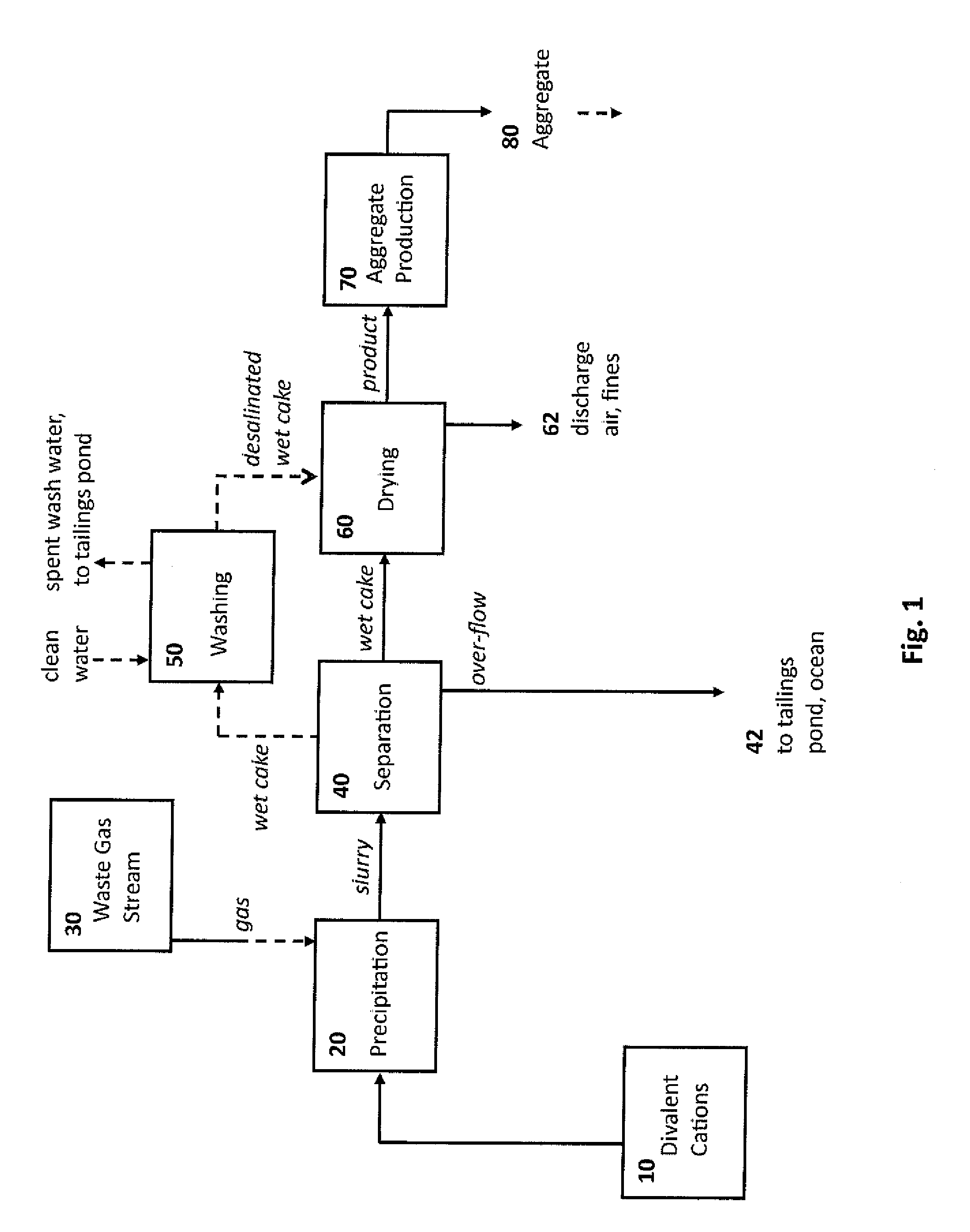

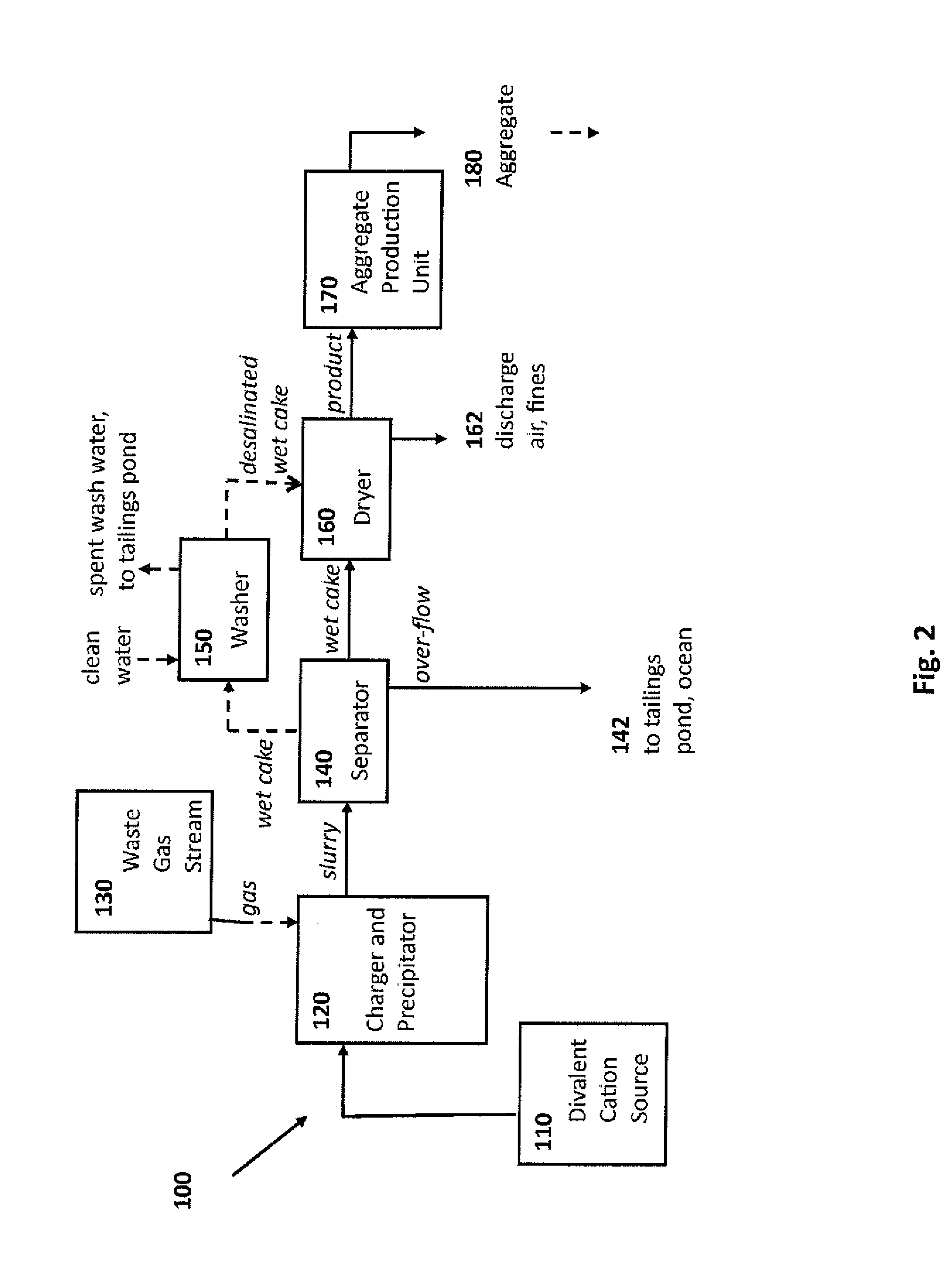

Rocks and aggregate, and methods of making and using the same

ActiveUS20100024686A1Calcium/strontium/barium carbonatesPigmenting treatmentCarbonateToxic industrial waste

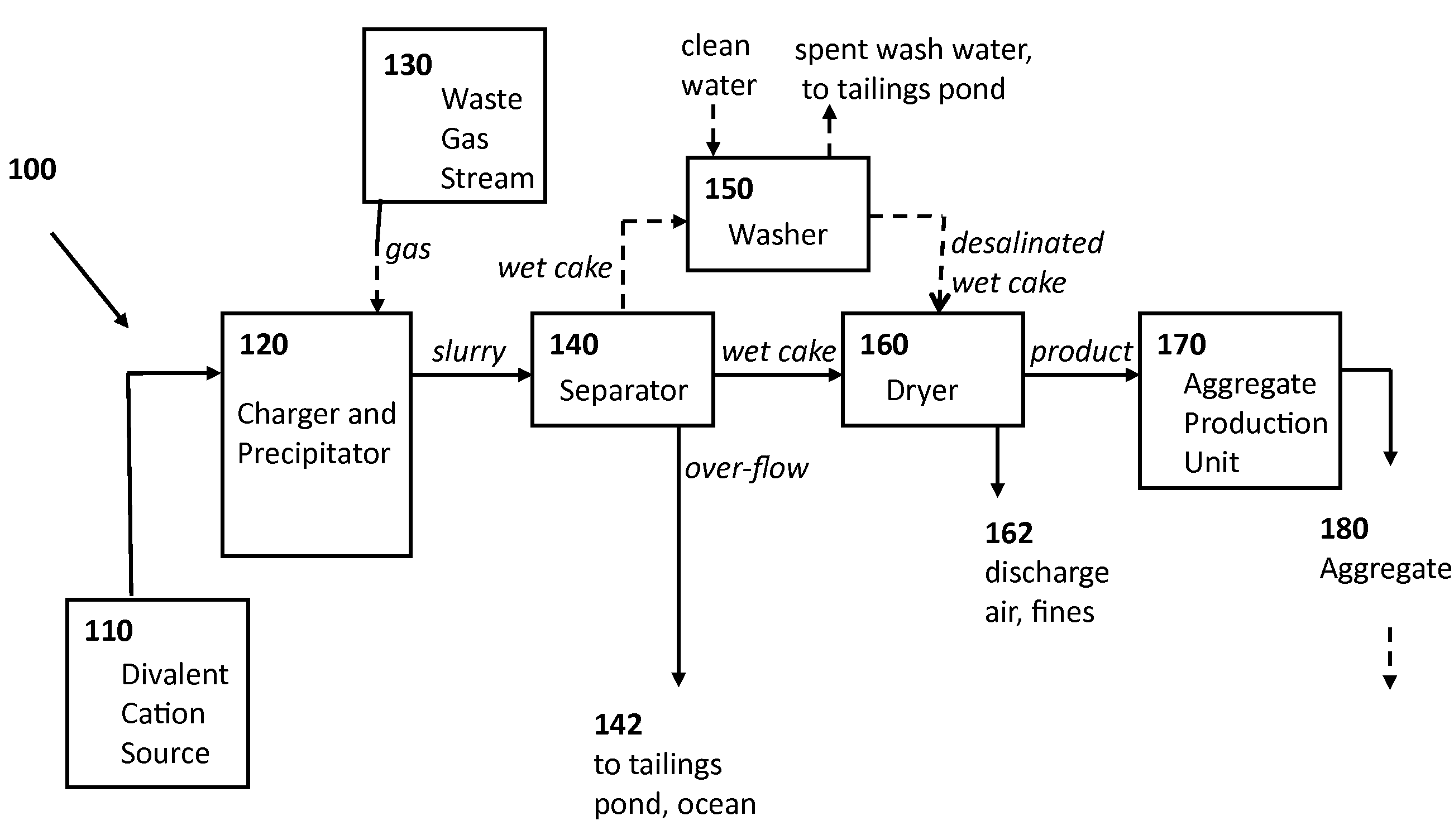

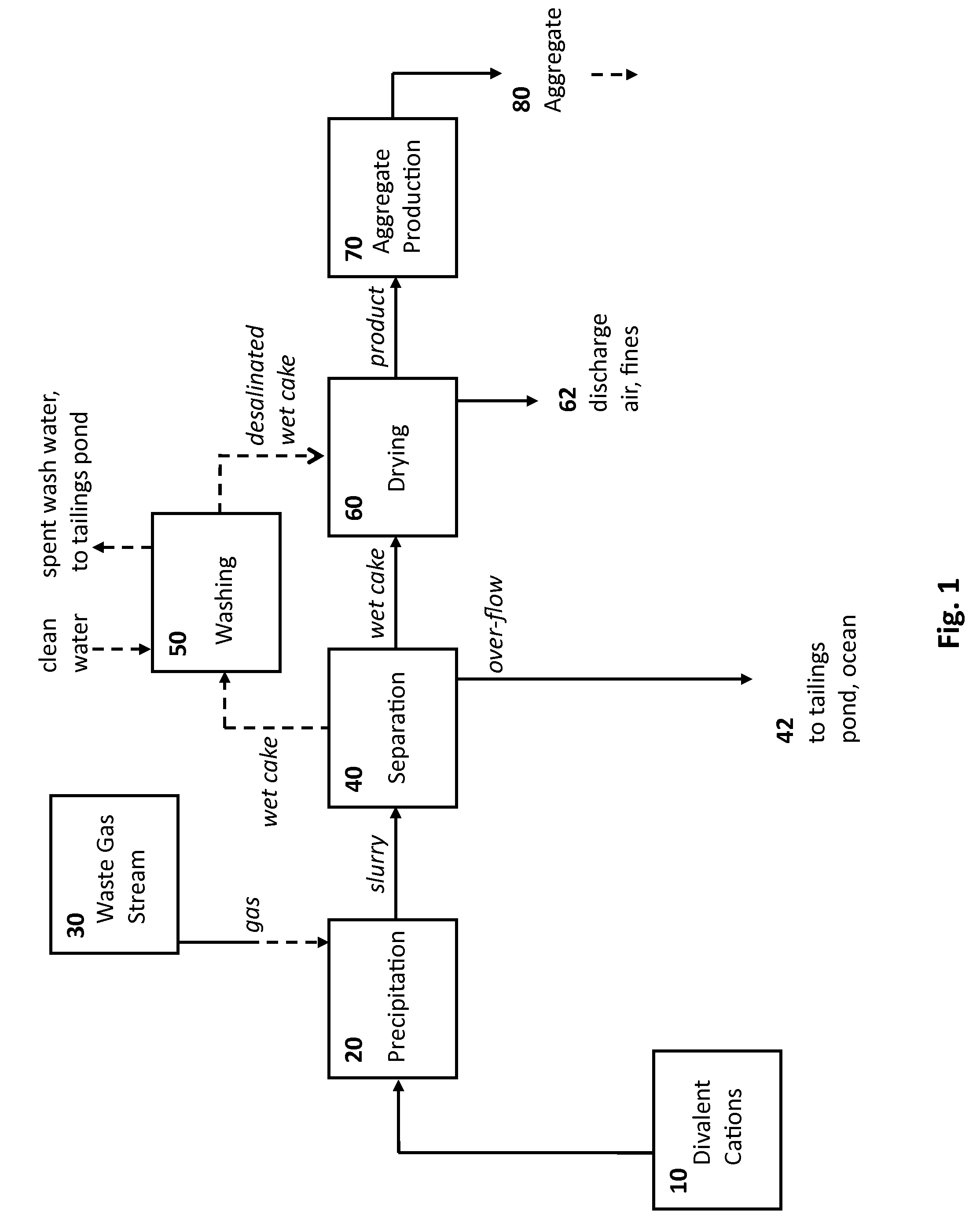

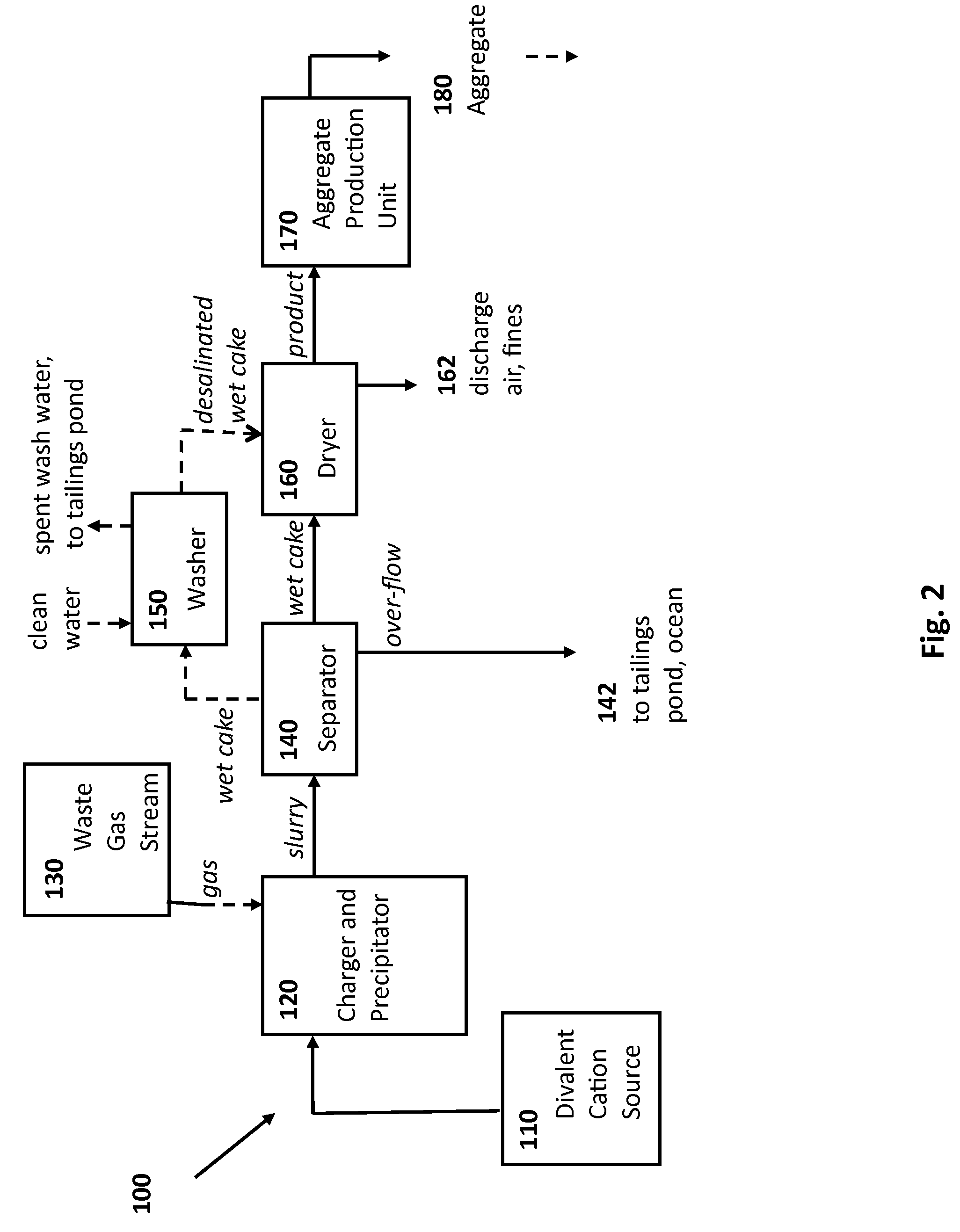

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:ARELAC INC

Use Of A Surface-Reacted Calcium Carbonate In Tissue Paper, Process To Prepare A Tissue Paper Product Of Improved Softness, And Resulting Improved Softness Tissue Paper Products

ActiveUS20120031576A1Good flexibilityNatural cellulose pulp/paperCoatings with pigmentsSurface responseTissue paper

The present invention related to the use of a surface-reacted natural calcium carbonate as filler in tissue paper products, to a process to prepare tissue paper products, and to a tissue paper product featuring an improved softness, wherein said surface-reacted natural calcium carbonate is the reaction product of a natural calcium carbonate with an acid and carbon dioxide, which is formed in situ by the acid treatment and / or supplied externally.

Owner:OMYA INT AG

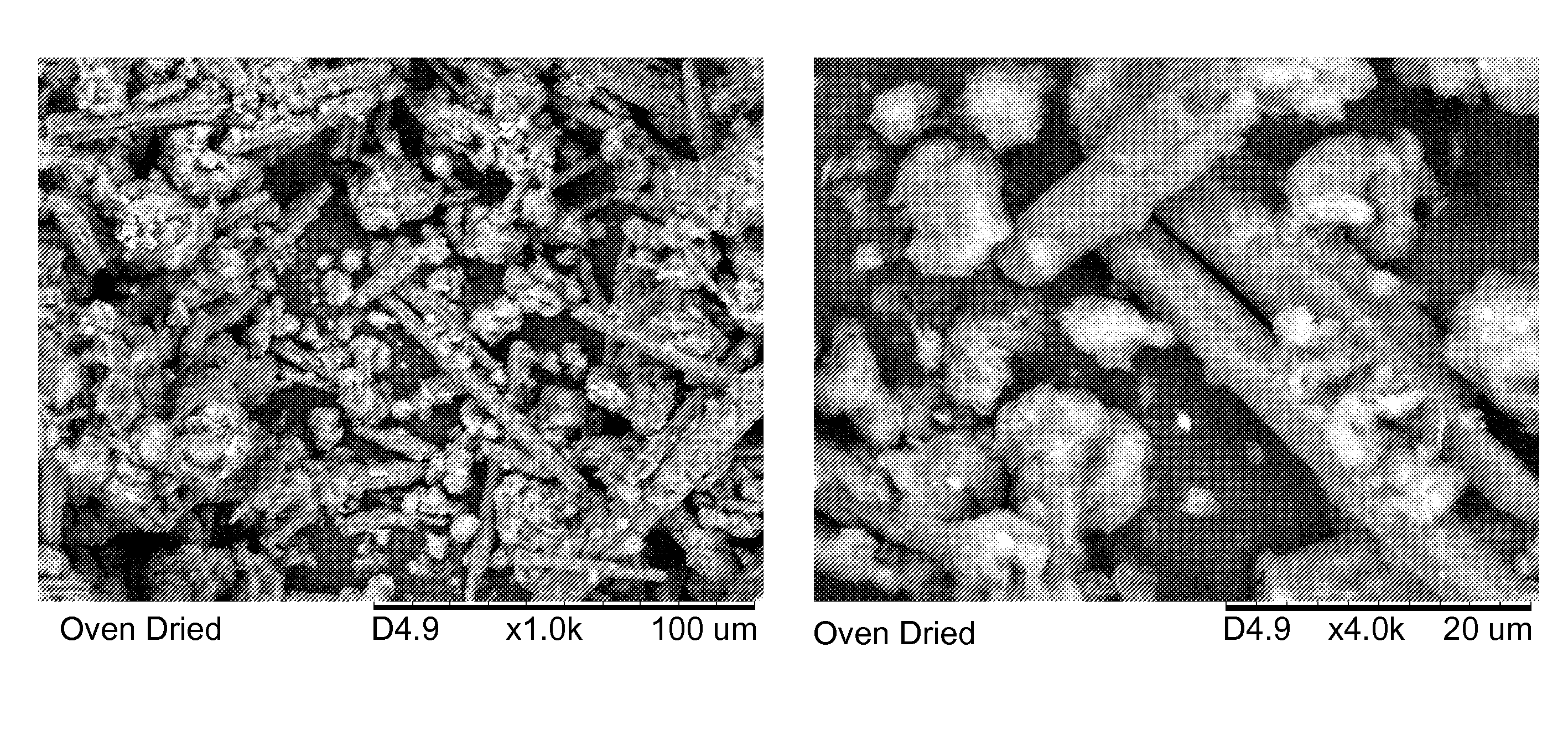

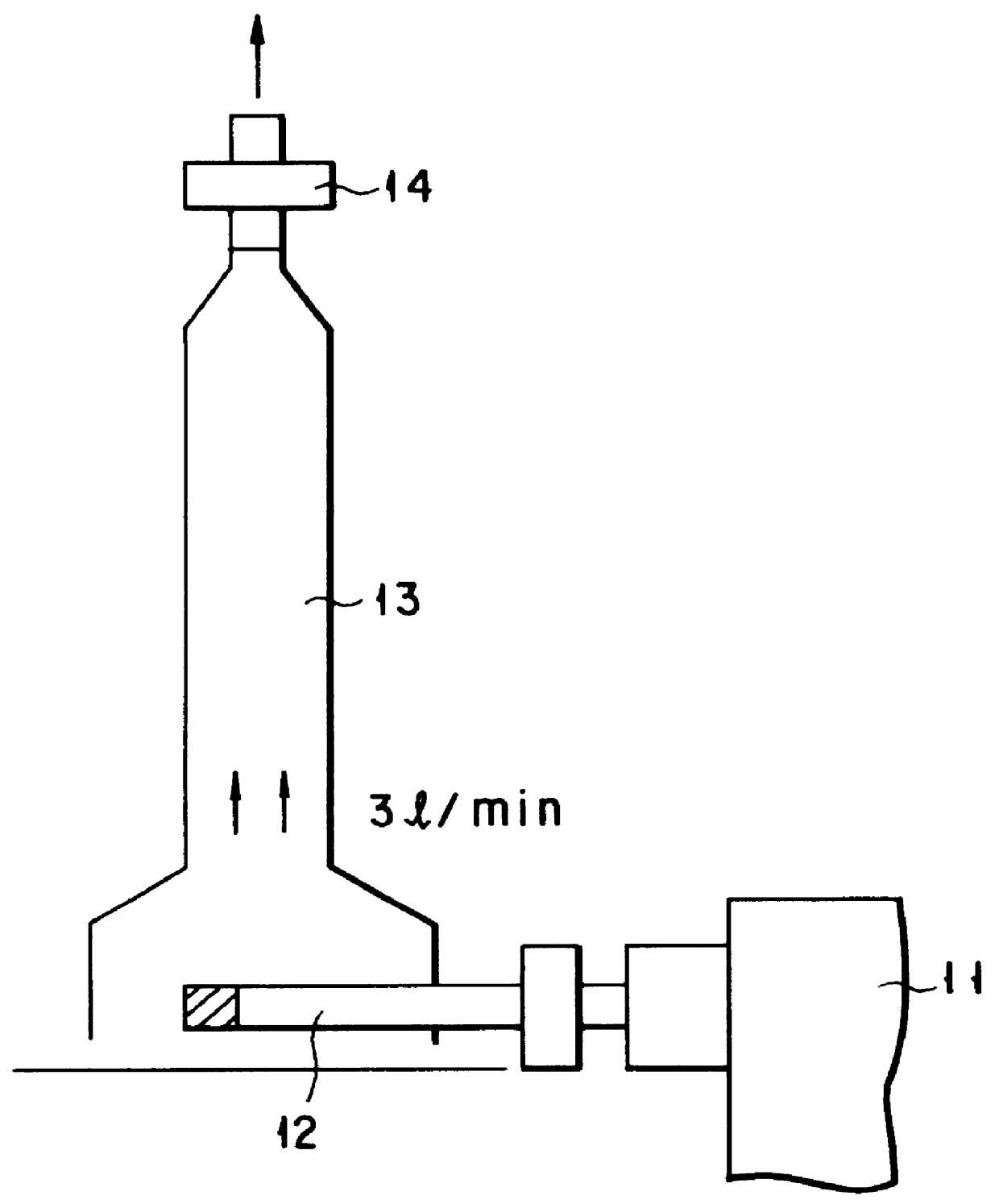

Separation of carbon dioxide (CO2) from gas mixtures

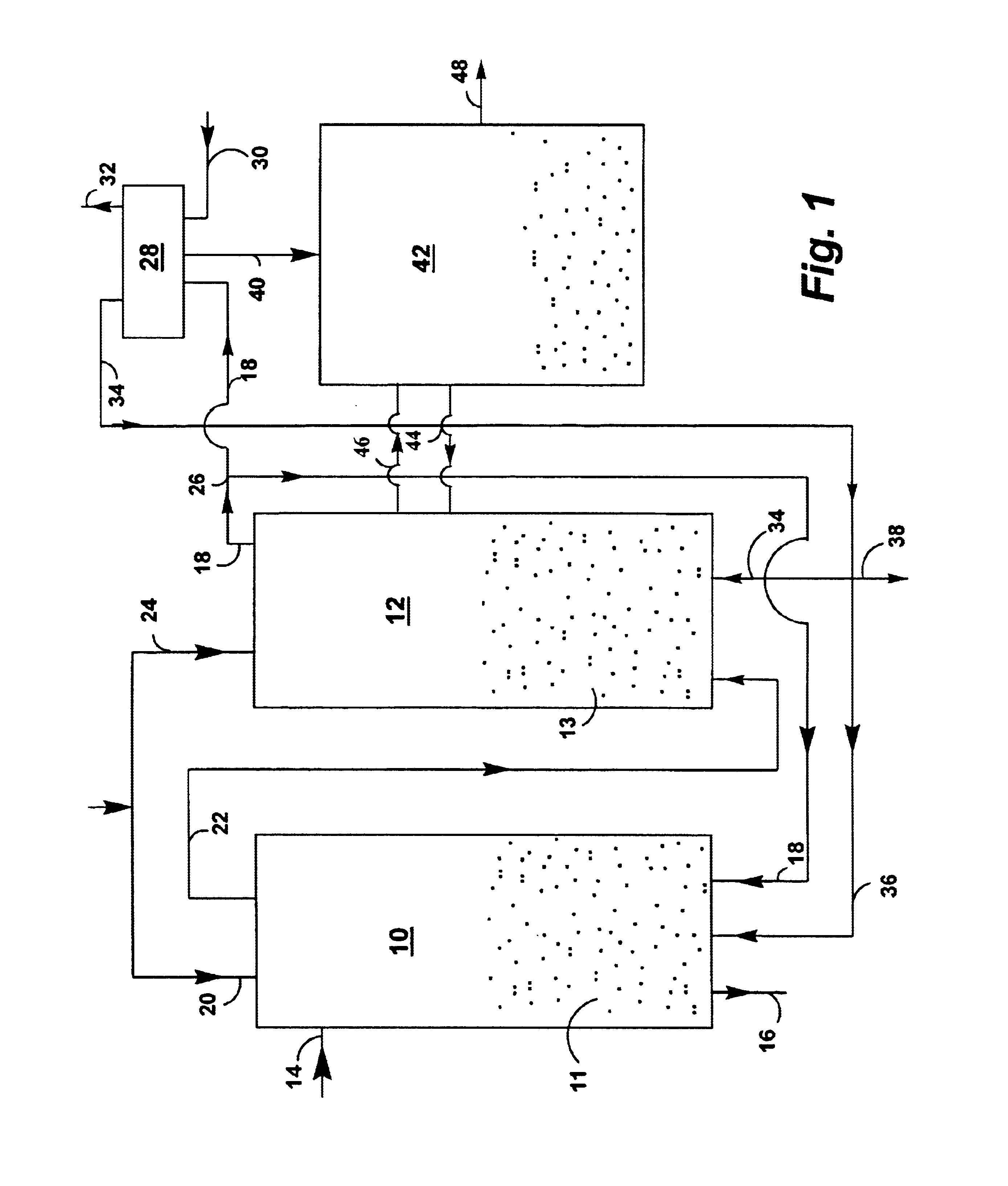

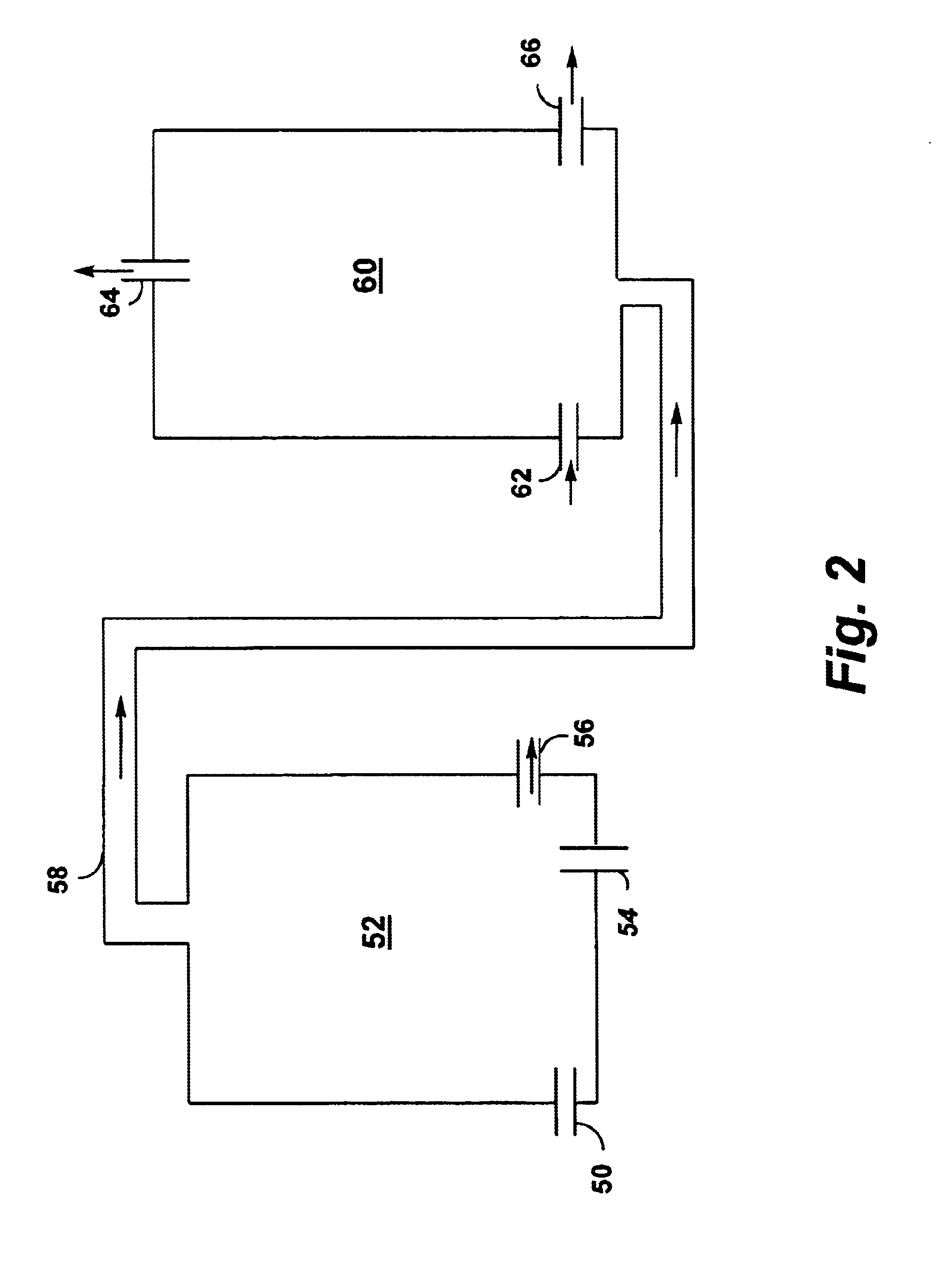

ActiveUS7618606B2Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentCo2 removalSorbent

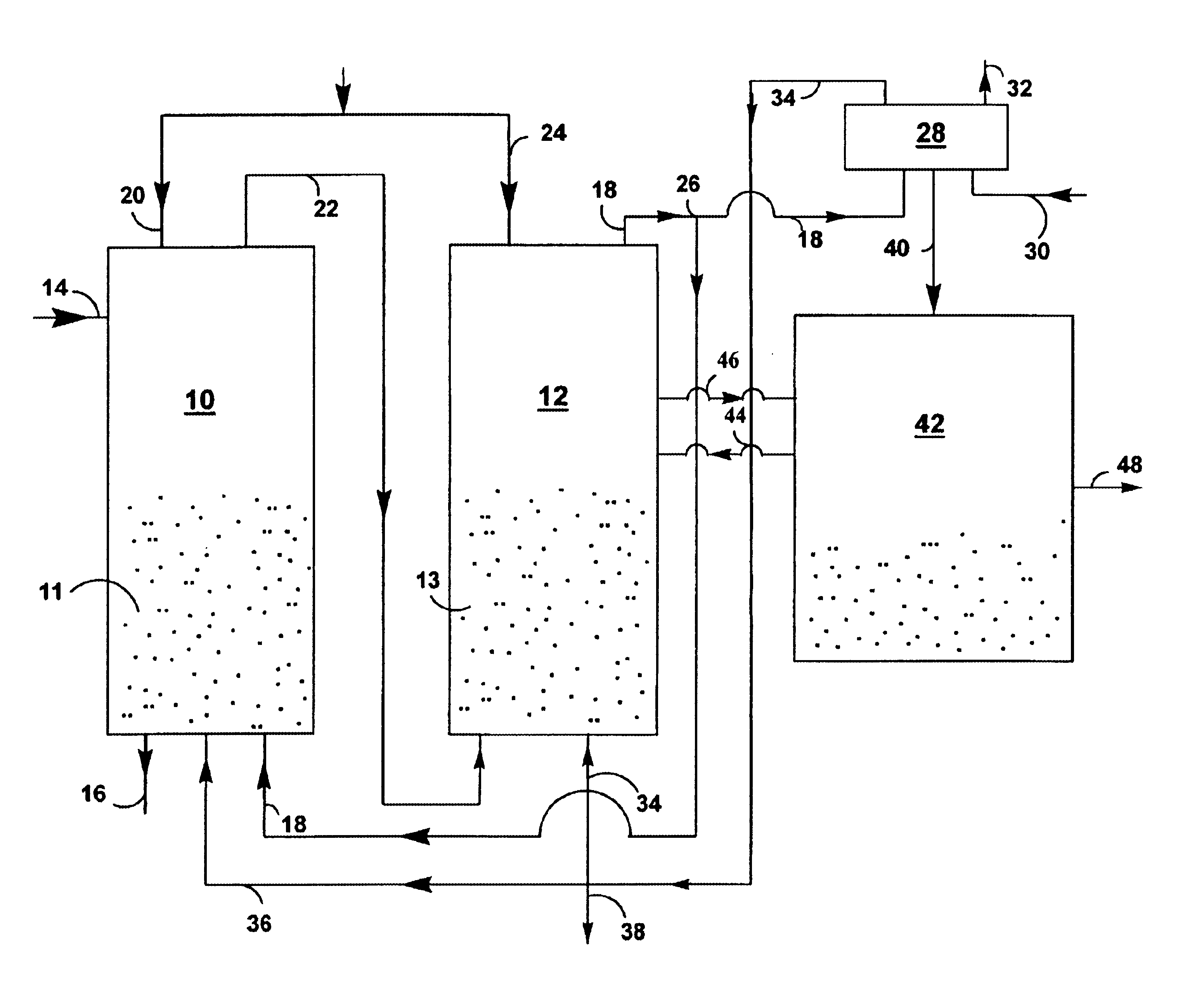

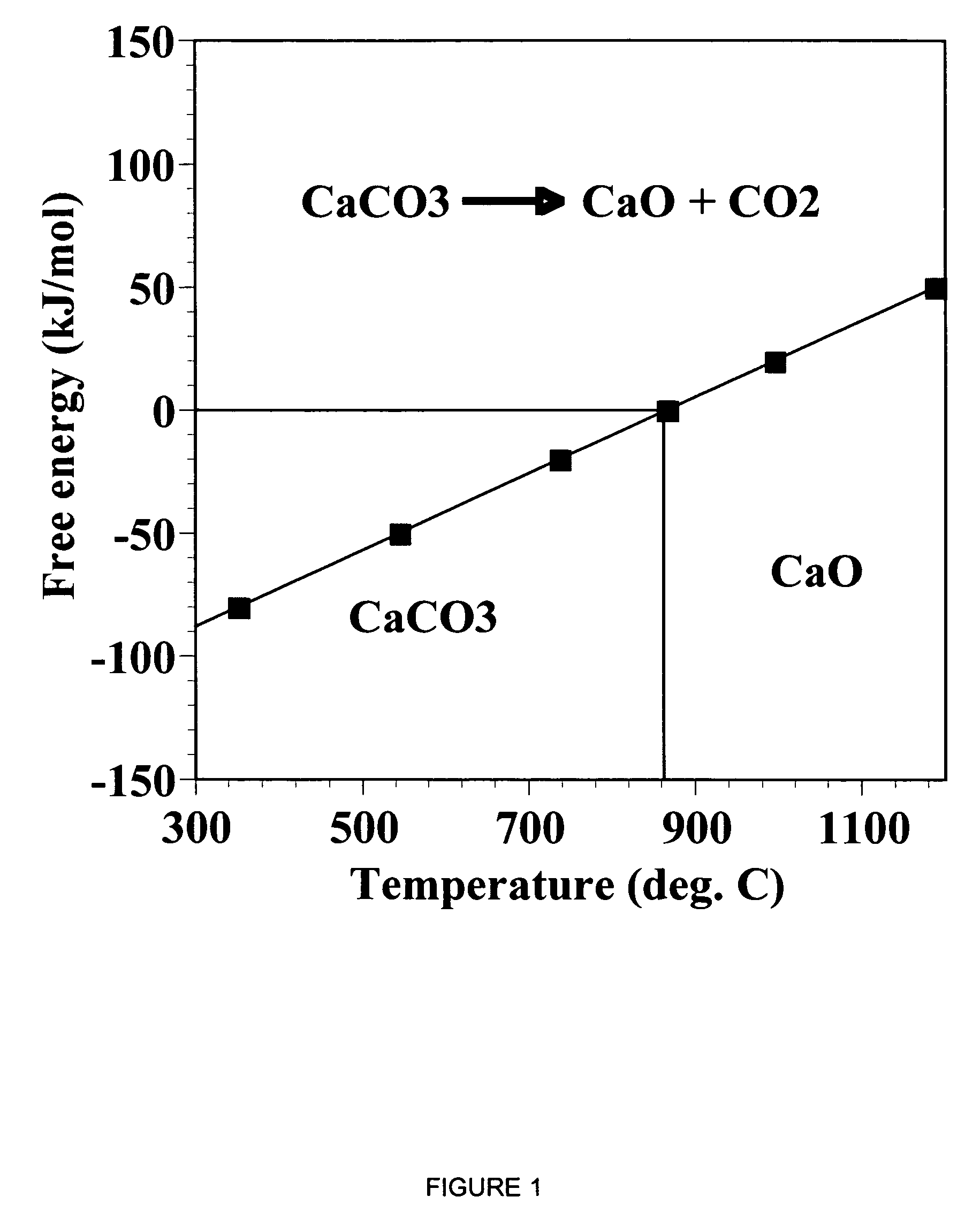

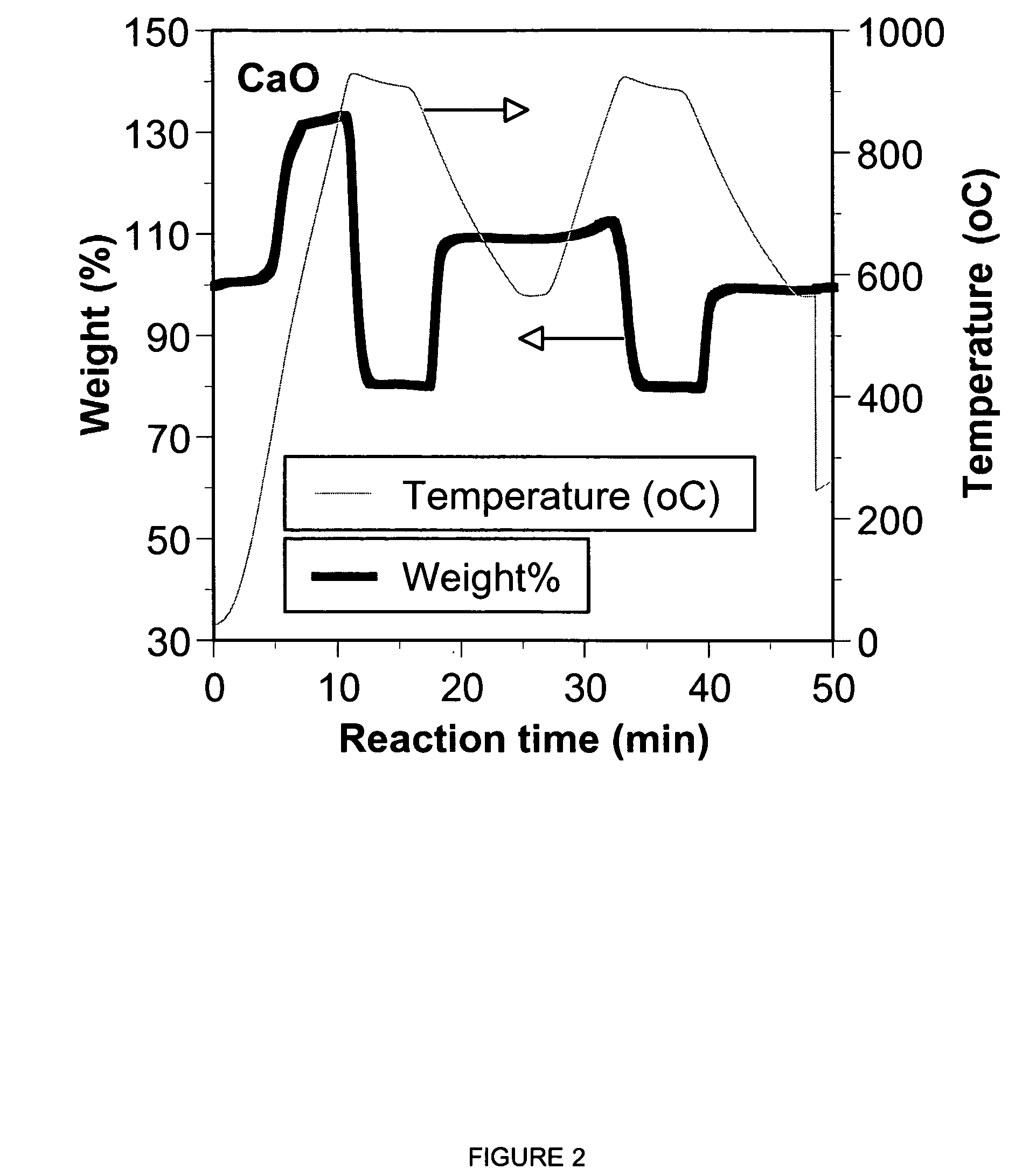

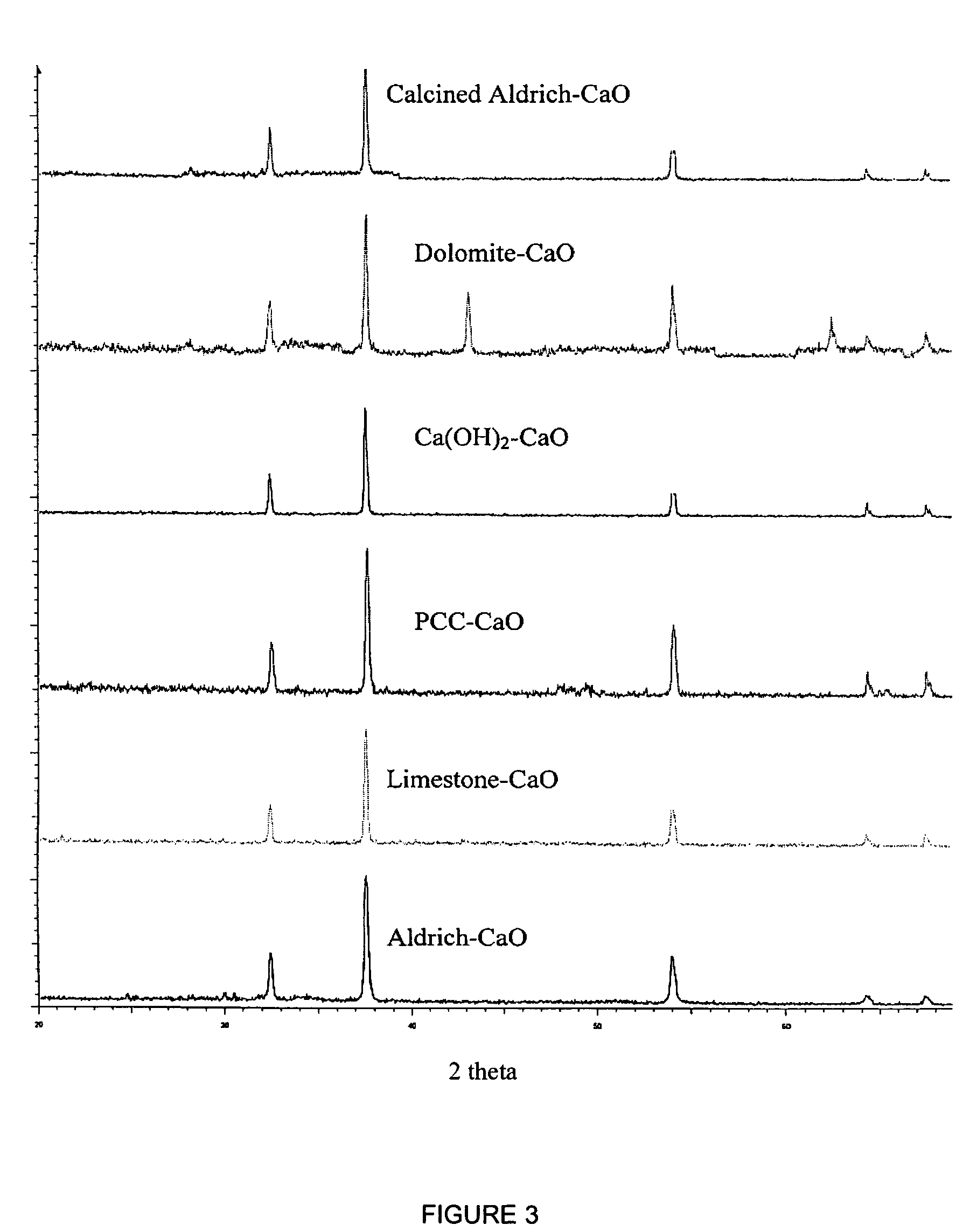

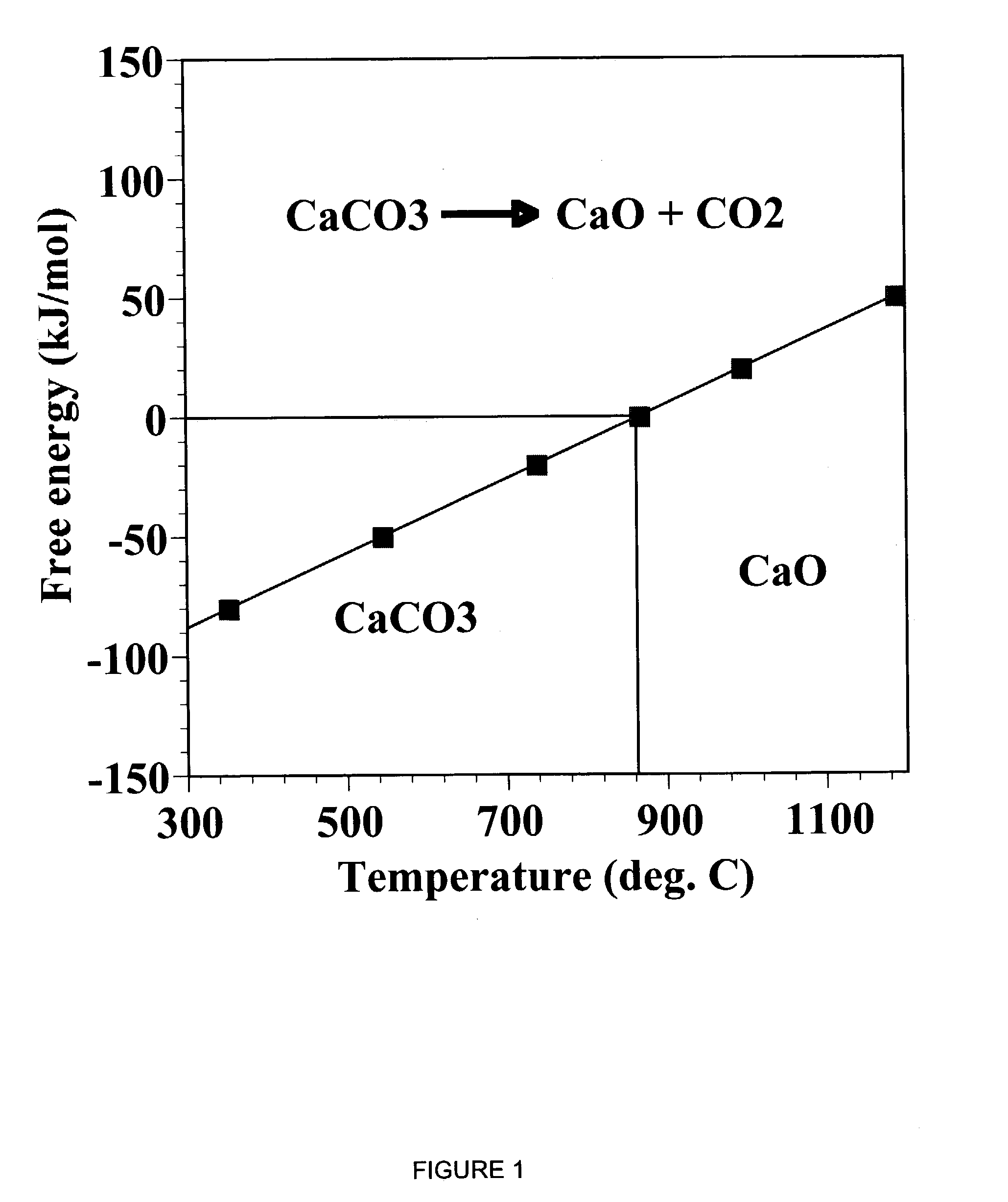

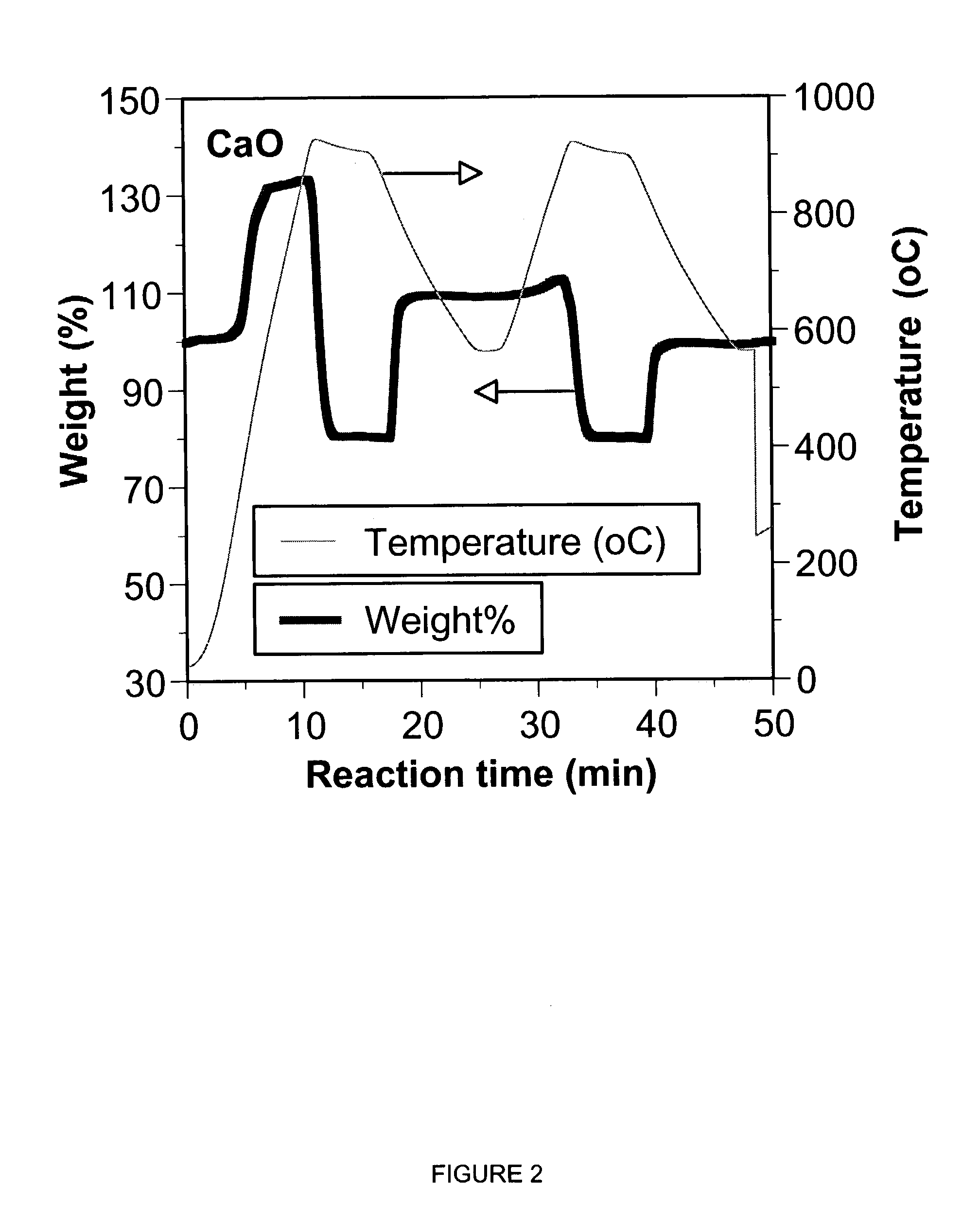

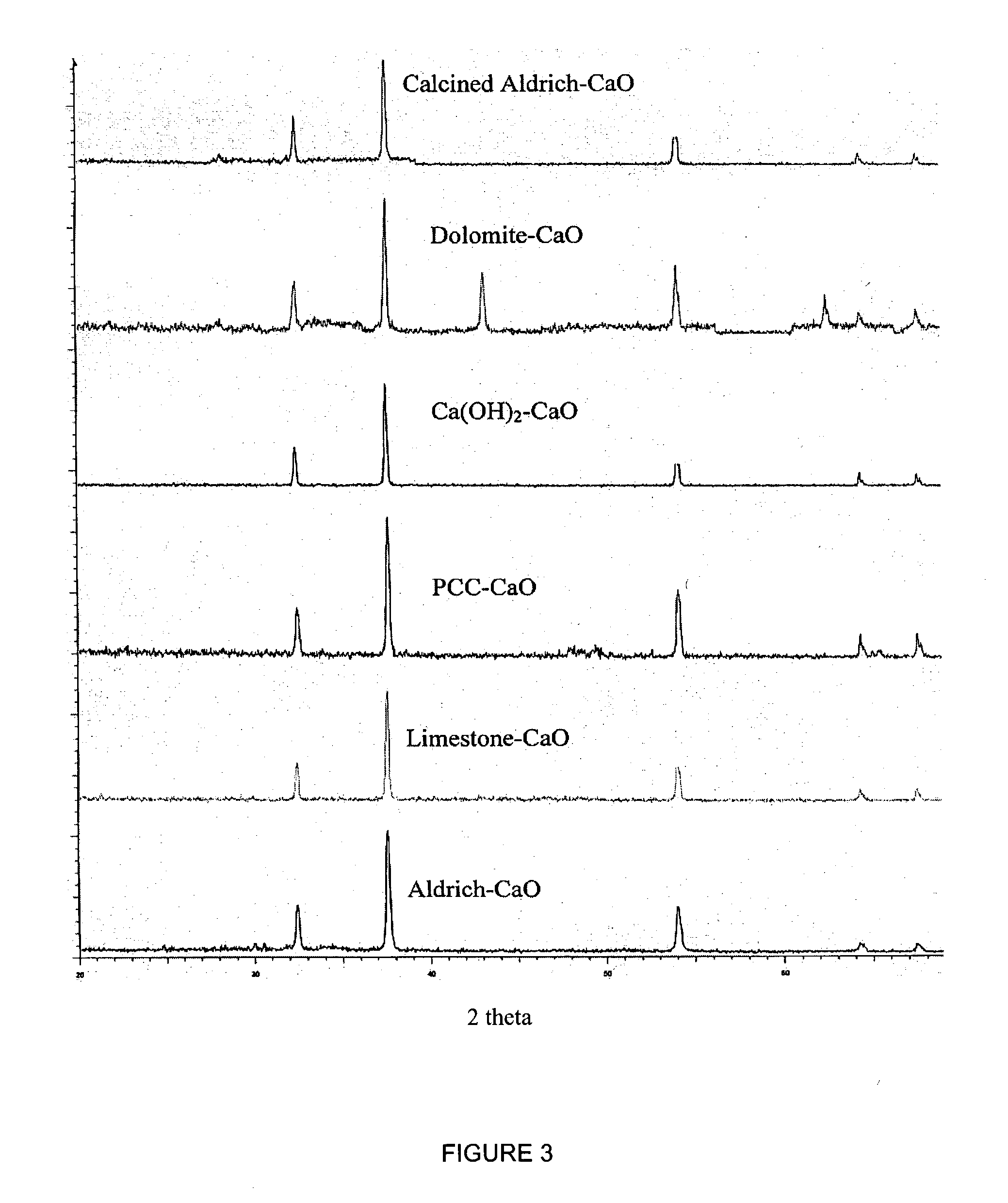

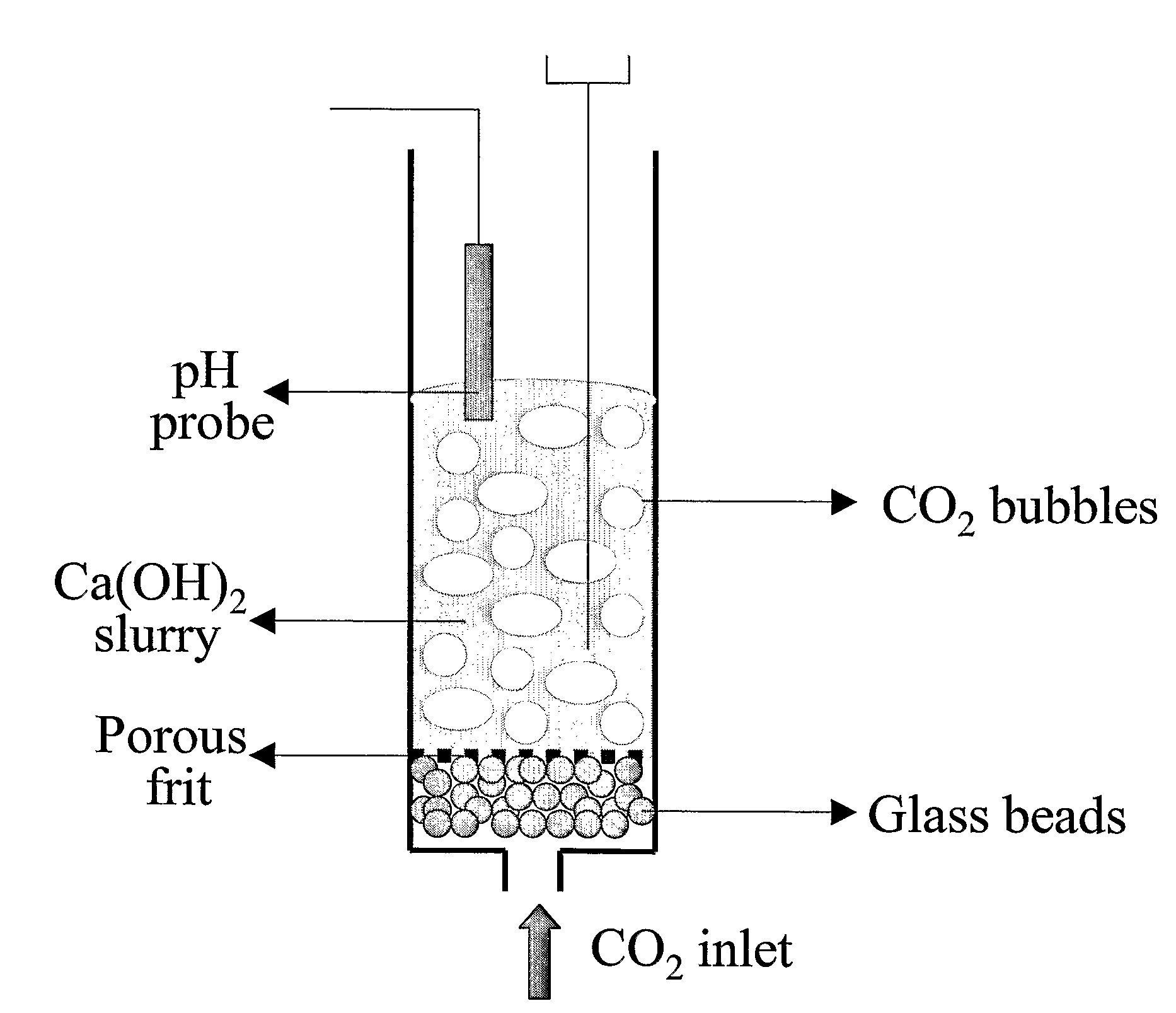

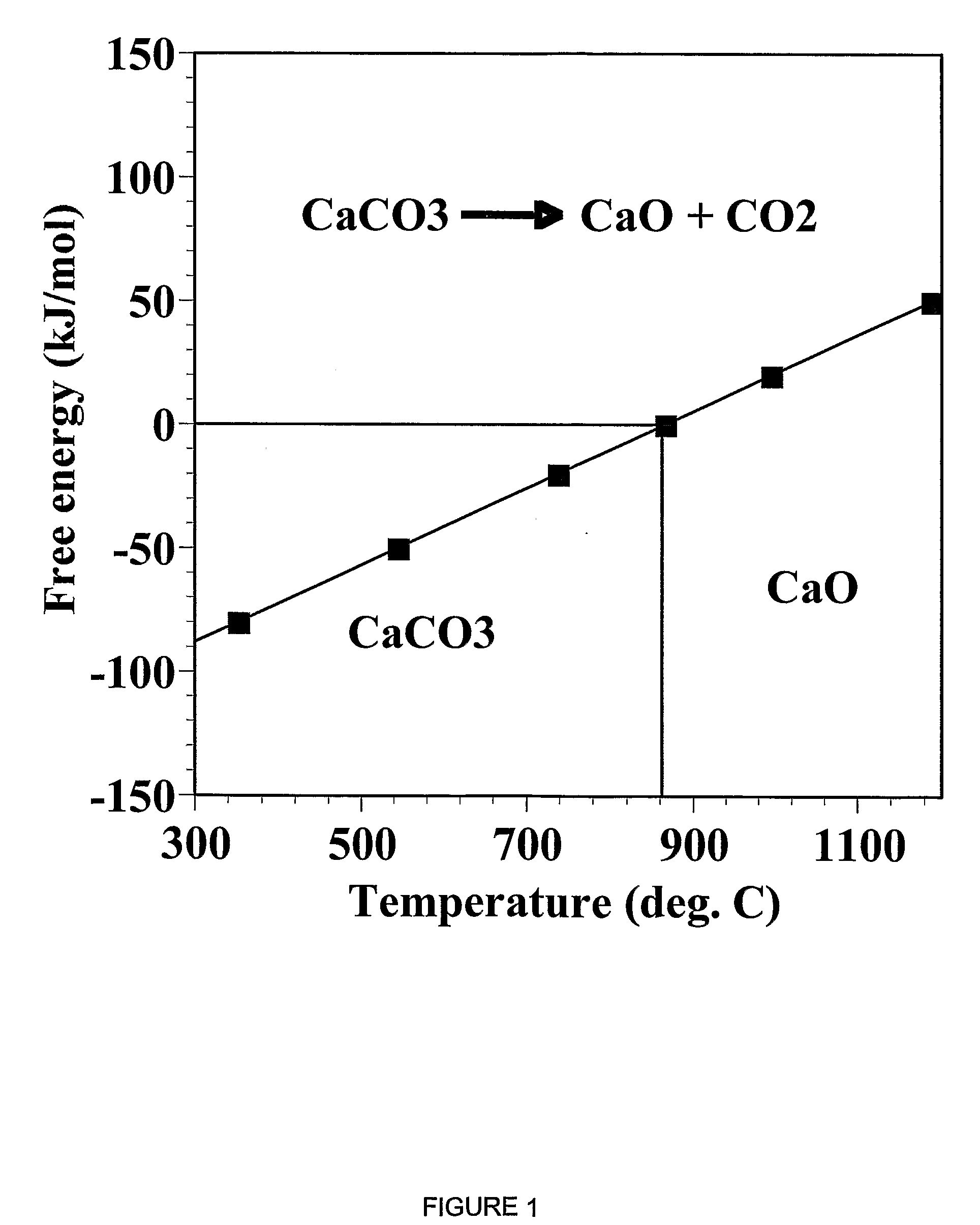

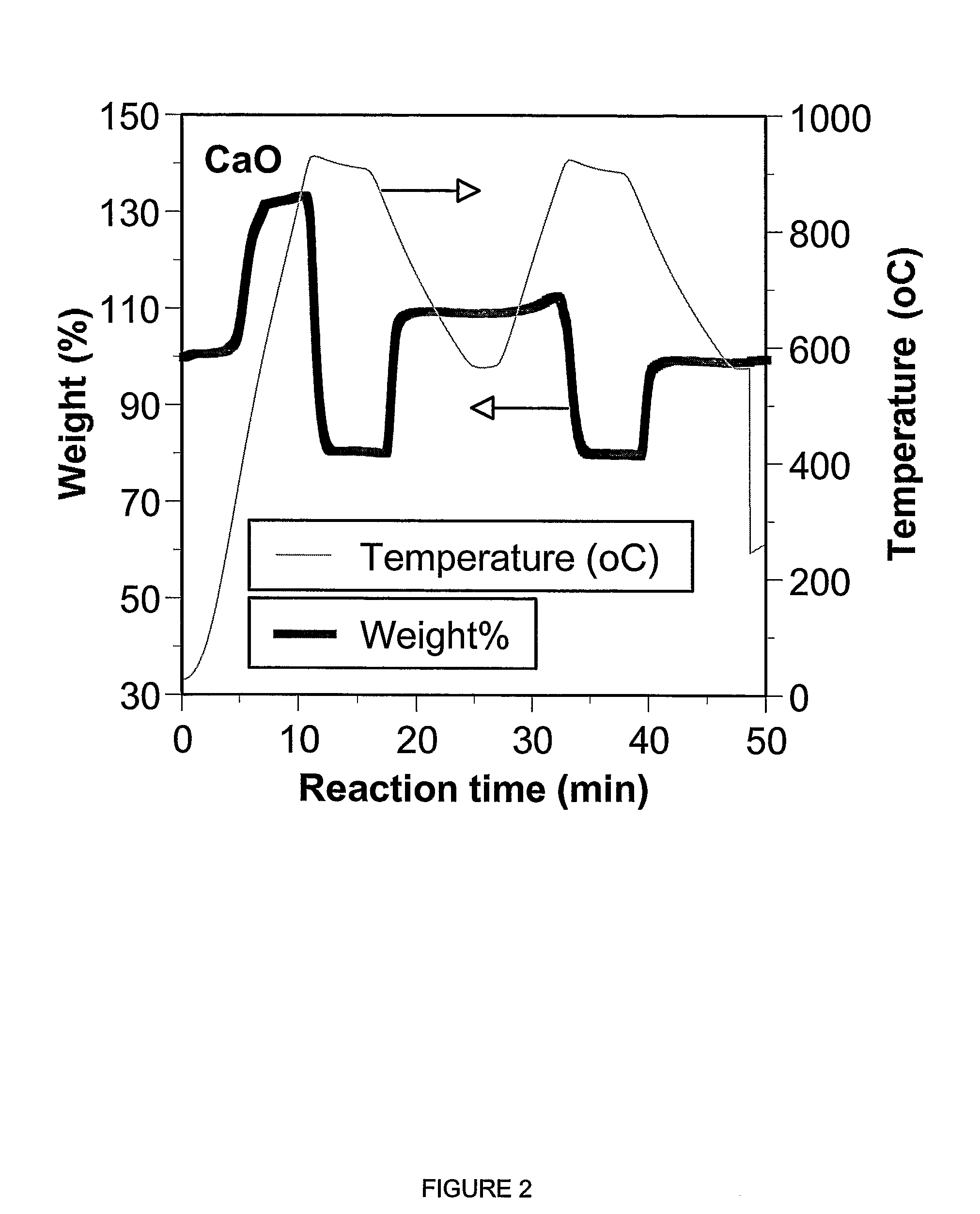

A reaction-based process has been developed for the selective removal of carbon dioxide from a multicomponent gas mixture. The proposed process effects the separation of CO2 from a mixture of gases by its reaction with metal oxides. The Calcium based Reaction Separation for CO2 process consists of contacting a CO2 laden gas with calcium oxide in a reactor such that CaO captures the CO2 by the formation of calcium carbonate. Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent. The “regenerated” CaO is then recycled for the further capture of more CO2. This process also identifies the application of a mesoporous CaCO3 structure, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

Oil based compositions and method for temporarily sealing subterranean zones

InactiveUS6887833B2High viscosityLow viscosityOther chemical processesFlushingOrganoclayHydrochloric acid

The present invention provides oil based compositions and methods of using the compositions for temporarily sealing subterranean zones. The compositions are basically comprised of oil, a hydratable polymer, an organophilic clay, a water-swellable clay, and an acid soluble material such as calcium carbonate. These compositions will form a viscous gel when contacted with water. The gelled mass may then be dissolved with an acidic fluid, such as 15% hydrochloric acid.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods of drilling and completing well bores

Methods of drilling and completing open hole well bores and methods of removing filter cake comprised of a gelling agent and calcium carbonate are provided. A method of the invention for removing filter cake comprised of a gelling agent and calcium carbonate from the walls of an open hole well bore is basically comprised of the steps of contacting the filter cake with a delayed clean-up solution comprised of water and a formate ester and removing the clean-up solution from the well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

Sorbent for separation of carbon dioxide (CO2) from gas mixtures

A reaction-based process has been developed for the selective removal of carbon dioxide (CO2) from a multicomponent gas mixture to provide a gaseous stream depleted in CO2 compared to the inlet CO2 concentration in the stream. The proposed process effects the separation of CO2 from a mixture of gases (such as flue gas / fuel gas) by its reaction with metal oxides (such as calcium oxide). The Calcium based Reaction Separation for CO2 (CaRS-CO2) process consists of contacting a CO2 laden gas with calcium oxide (CaO) in a reactor such that CaO captures the CO2 by the formation of calcium carbonate (CaCO3). Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent and the evolution of a concentrated stream of CO2. The “regenerated” CaO is then recycled for the further capture of more CO2. This carbonation-calcination cycle forms the basis of the CaRS-CO2 process. This process also identifies the application of a mesoporous CaCO3 structure, developed by a process detailed elsewhere, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

Separation of Carbon Dioxide (Co2) From Gas Mixtures By Calcium Based Reaction Separation (Cars-Co2) Process

InactiveUS20080233029A1Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentSorbentTransformation ratio

A reaction-based process has been developed for the selective removal of carbon dioxide (CO2) from a multicomponent gas mixture to provide a gaseous stream depleted in CO2 compared to the inlet CO2 concentration in the stream. The proposed process effects the separation of CO2 from a mixture of gases (such as flue gas / fuel gas) by its reaction with metal oxides (such as calcium oxide). The Calcium based Reaction Separation for CO2 (CaRS—CO2) process consists of contacting a CO2 laden gas with calcium oxide (CaO) in a reactor such that CaO captures the CO2 by the formation of calcium carbonate (CaCOa). Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent and the evolution of a concentrated stream of CO2. The “regenerated” CaO is then recycled for the further capture of more CO2. This carbonation-calcination cycle forms the basis of the CaRS—CO2 process. This process also identifies the application of a mesoporous CaCO3 structure, developed by a process detailed elsewhere, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

Settable composition and uses therefor

InactiveUS6200381B1Decrease decarbonisation temperaturePromote decompositionSolid waste managementWaste productSlurry

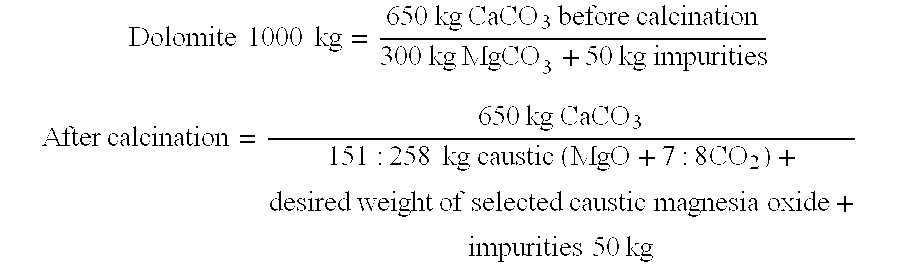

A dry powdered flowable cement composition contains calcium carbonate and a partially decarbonated magnesium carbonate. A slurry of the composition will set hard with various organic fillers including waste products and toxic waste. The composition can be slurried with contaminated water such as sea water, mineral laden ground water and muddy water. A high percentage of filler can be added while still having an acceptable set.

Owner:DOLOMATRIX INT LIMITED ACN 091 340 920

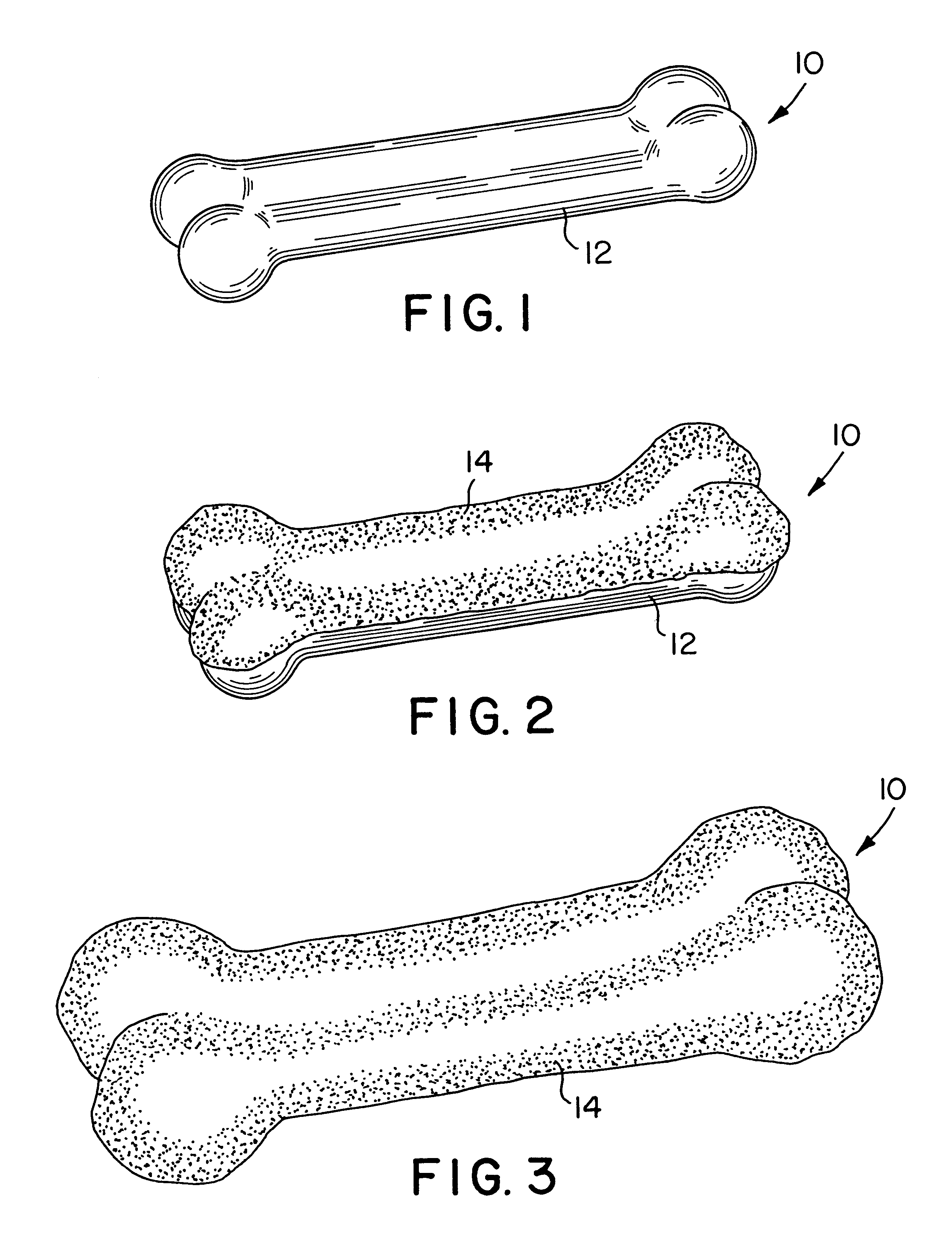

Heat modifiable edible dog chew

A completely digestible highly nutritious dog chew formulated primarily of beaded corn starch or a mixture of beaded corn starch and potato starch, and calcium carbonate, the texture of hardness or which is easily modified to suit a particular dog by the dog owner. By irradiating the chew in a microwave oven, the chew is caused to expand and is thereby rendered more easily chewable.

Owner:T F H PUBLICATIONS

Osteoconductive integrated spinal cage and method of making same

The spinal cage comprises a structural component having sufficient strength to withstand the compressive loading between vertebral bodies. The structural component is integrated with an osteoconductive component to facilitate bone growth between the vertebral bodies. The structural component may comprise any of PEEK, PEKK, or other structural material. The osteoconductive component may comprise any of allograft, natural bone, tricalcium phosphate, hydroxyapatite or a blend of calcium carbonate, calcium lactate and other calcium salts. A method for making the spinal cage involves molding polymers around an osteoconductive component, heat staking, and may further include ultrasonically welding, snap fit or mechanically assembling and / or adhesively bonding components.

Owner:SPINAL ELEMENTS INC

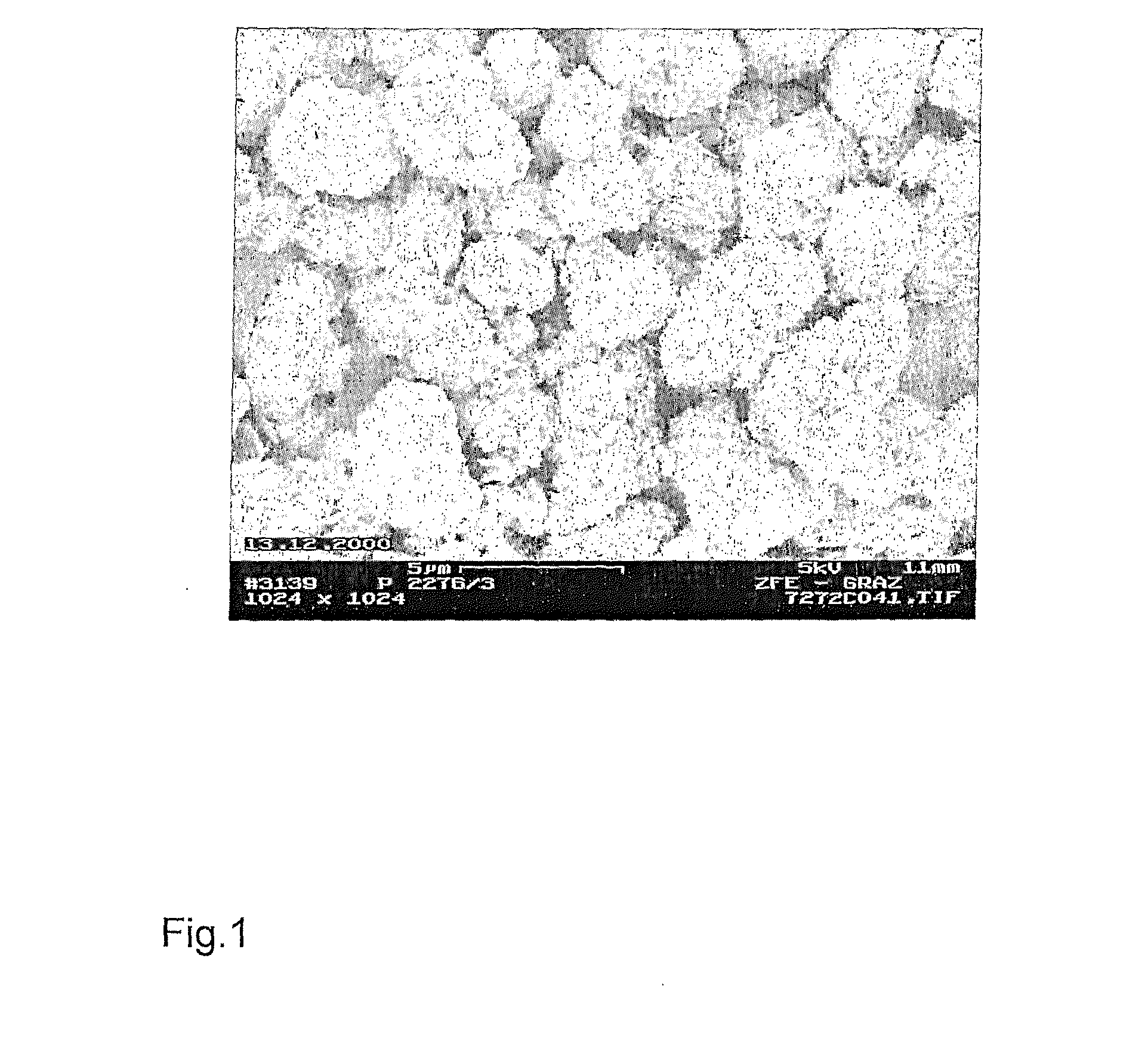

Acicular calcite and aragonite calcium carbonate

InactiveUS6071336AIncrease costIncrease production costCalcium/strontium/barium carbonatesPigmenting treatmentToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

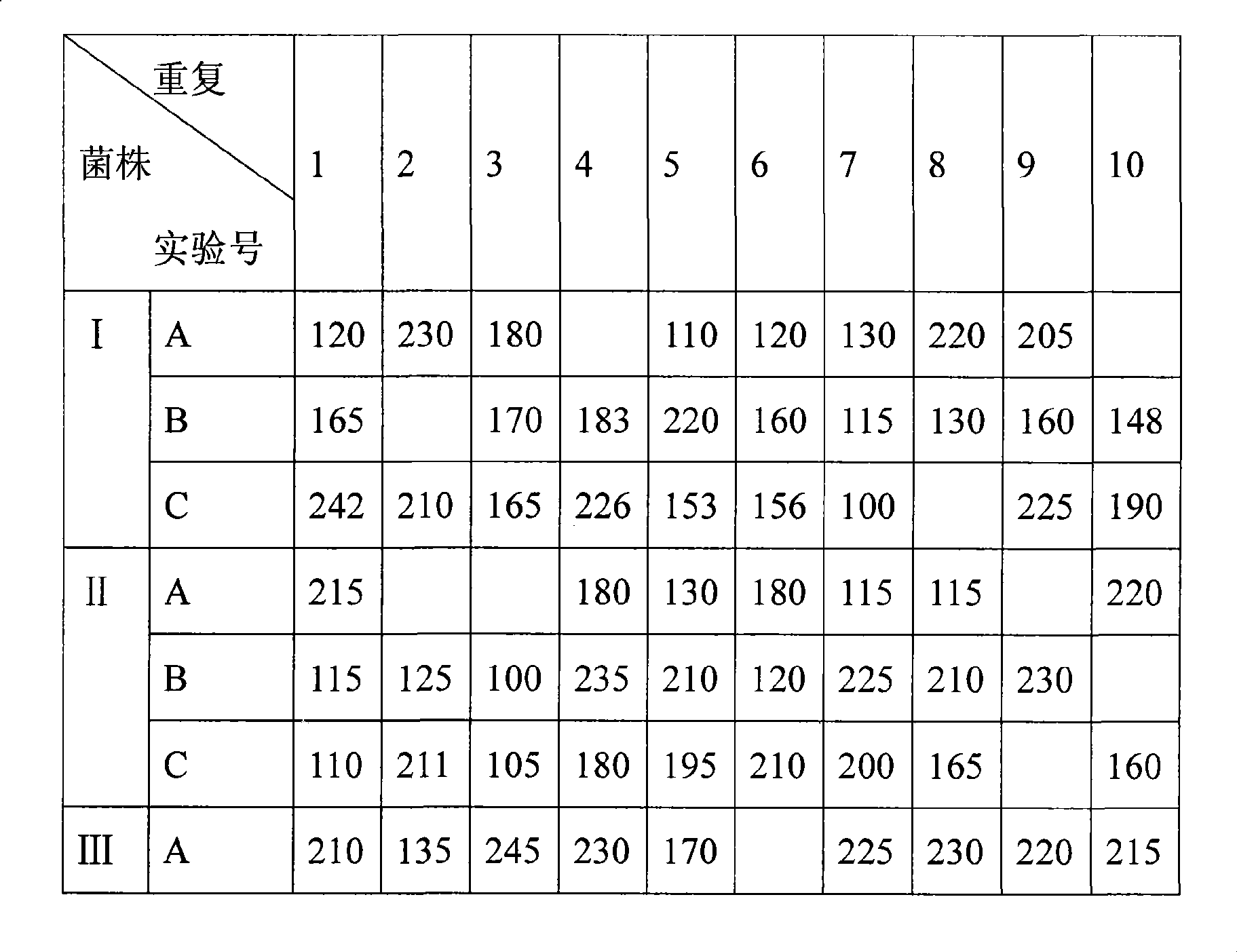

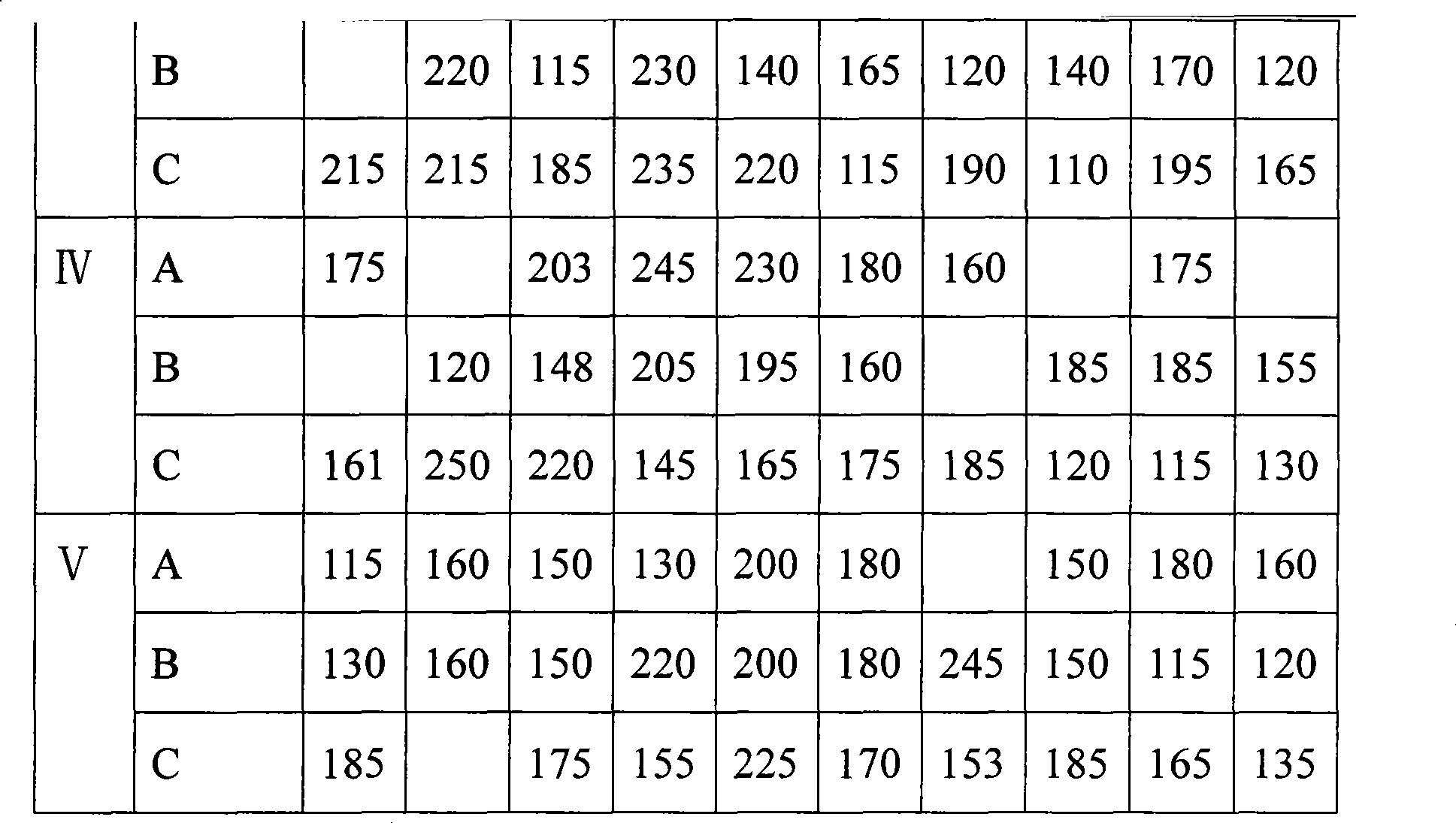

Clear-white gold needle mushroom cultivation method

InactiveCN101366346AAvoid pollutionNo diseaseBio-organic fraction processingOrganic fertiliser preparationSucroseSaccharum

The invention discloses a method for cultivating pure white needle mushrooms. The method comprises the following steps: a strain is prepared; a culture material is prepared; bagging and sterilization are carried out; inoculation is carried out; a mycelium is cultured; nutrition, humidity, temperature, light, air and other culture conditions are strictly controlled during a fruiting period; and harvesting is carried out in an optimum period. the formulation of the culture material is 0 to 32 percent of weed tree sawdust, 0 to 93 percent of cotton seed hulls or wheat straw, straw, corncob and other crop straw, 0 to 20 percent of wheat bran, 0 to 10 percent of corn meal, 0 to 10 percent of soybean meal, 0 to 1 percent of calcium carbonate, 0 to 0.2 percent of monopotassium phosphate, 0 to 0.2 percent of magnesium sulfate, 1 to 1.2 percent of sucrose, 0 to 10 percent of rice bran, 0 to 1 percent of plaster and 0 to 0.02 percent of urea. Quicklime and wettable carbendazim are added during the preparation of the culture material so as to prevent the pollution of undesired bacteria. The technical proposal aims to select proper breeds, popularize local large scale planting and improve cultivation benefit.

Owner:WUHU YESHULIN BIOTECH

Electrical smoking system and method

InactiveCN1633247AReduce gaseous componentsIncandescent ignitionCigar manufactureIntegratorAcrylonitrile

An electric smoking system includes a cigarette including a cylindrical tobacco web partially filled with tobacco material to define a filled tobacco rod portion and an unfilled tobacco rod portion, and an electric lighter. The wrapper includes a filler of ammonium-containing compounds effective to reduce the gaseous constituents of the smoke produced during smoking. The system includes a pilot burner including at least one heating vane and a controller adapted to control heating of the heating vane. The lighter is configured to at least partially contain the cigarette such that the heater blade heats the heating region of the cigarette. Manipulating the controller to limit the heating of the heater blades to a predetermined temperature range which allows the delivery of the smoke generated when the portion of the tobacco rod is heated while at least reducing the amount of smoke present in the smoke as compared to smoking a cigarette having only calcium carbonate as filler. A gaseous component. The gaseous components that can be reduced include carbon monoxide, 1,3 butadiene, isoprene, acrolein, acrylonitrile, hydrogen cyanide, 0-toluidine, 2-naphthylamine, nitrogen oxide, benzene, NNN, Phenol, catechol, benzanthracene and benzopyrene.

Owner:PHILIP MORRIS PROD SA

Temporary blocking agent for hydrocarbon reservoir crack

InactiveCN101311243AWide range of temporary blockingTemporary blocking range is smallDrilling compositionFiberWell drilling

The invention relates to a hydrocarbon zone protective agent specific to fractured hydrocarbon zone in oil and gas drilling, in particular to a fractured temporary plugging additive, which is mixed by the components with the following mixture ratio: 40-85 percent of 60-1100 meshes of calcium carbonate superfine powder, 10-40 percent of plant fibers and 5-20 percent of oxidized asphalt. After the temporary plugging additive of the invention enters the stratum with the drillingfluid, a layer of compact and tenacious mud cake is quickly formed near the well wall for ensuring the original permeability of the stratum near the well wall to rapidly reduce to be nearly zero, thus preventing the intrusion of drilling fluid filter, various finishing agents, rock debris and the like which causes the reduction of oil and gas yield and capacity. The temporary plugging additive of the invention reaches more than 99 percent of temporary plugging rate to fractured core and more than 80 percent of pressure flowback and acidification flowback rate. Furthermore, the temporary plugging additive is characterized by wild temporary plugging range, little dosage, low cost and no pollution, thus being an ideal hydrocarbon zone protective agent.

Owner:浙江仁智股份有限公司

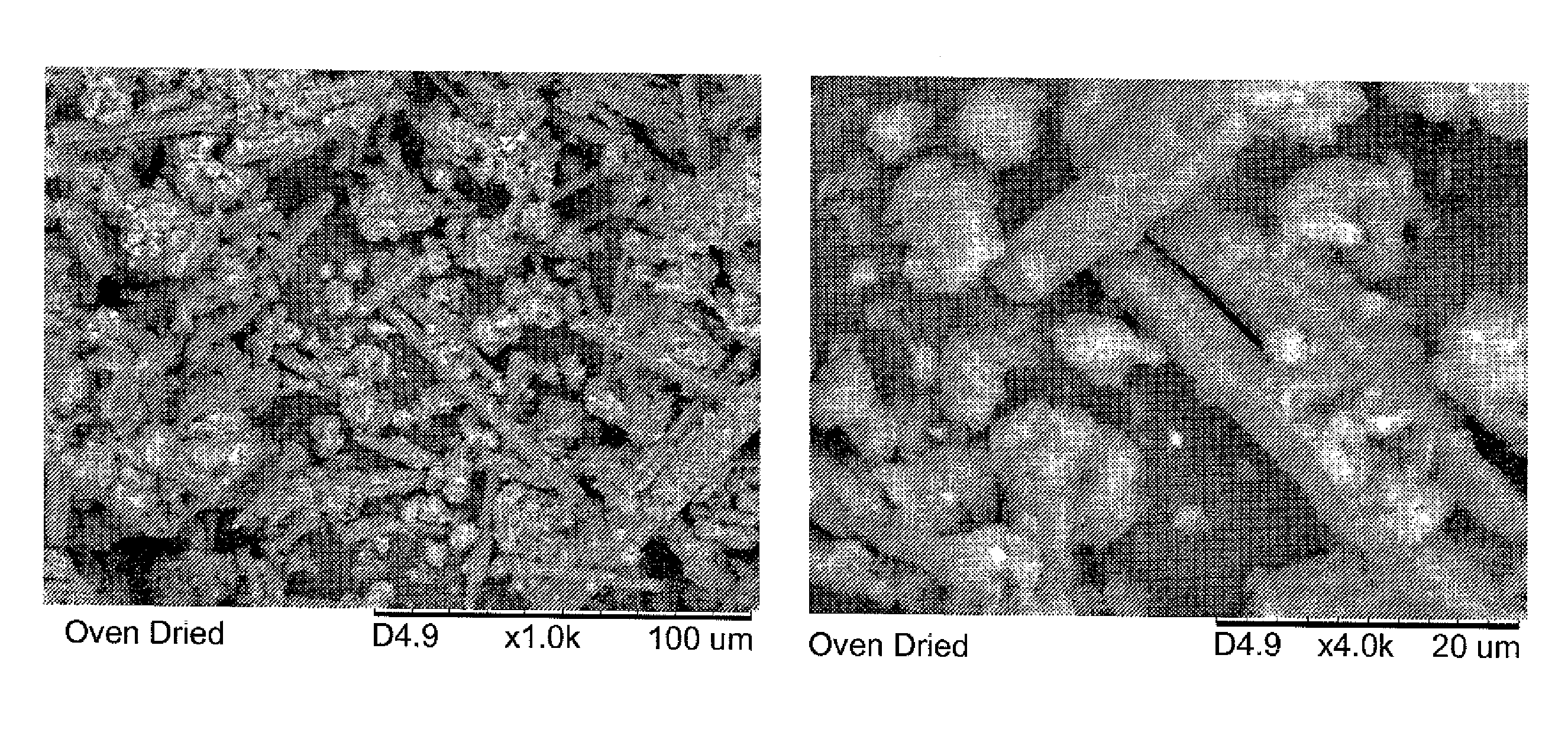

Rocks and aggregate, and methods of making and using the same

ActiveUS7753618B2Calcium/strontium/barium carbonatesUsing liquid separation agentCarbonateIndustrial waste

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:ARELAC INC

Rocks and Aggregate, and Methods of Making and Using the Same

InactiveUS20100144521A1Calcium/strontium/barium carbonatesGas treatmentCarbonateToxic industrial waste

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:CALERA CORP

Smoking paper for smoking article

InactiveUS6138684AReduce decreaseExcellent in optical characteristicTobacco preparationNon-fibrous pulp additionPulp and paper industrySmoke paper

PCT No. PCT / JP96 / 01630 Sec. 371 Date May 7, 1997 Sec. 102(e) Date May 7, 1997 PCT Filed Jun. 14, 1996 PCT Pub. No. WO97 / 09483 PCT Pub. Date Mar. 13, 1997The paper for rolling a smoking article of the present invention contains particle-form calcium carbonate (30 to 60 wt %), calcined clay (5 to 30 wt %) and pulp. Furthermore, an alkaline metal salt is contained as a chemical additive. In addition, kaolin is contained in the paper. The basis weight of the paper falls within the range of 20 to 70 g / m2. Optical characteristics of the paper and the burning characteristics and ash characteristics of a cigarette are improved and the side stream smoke is reduced.

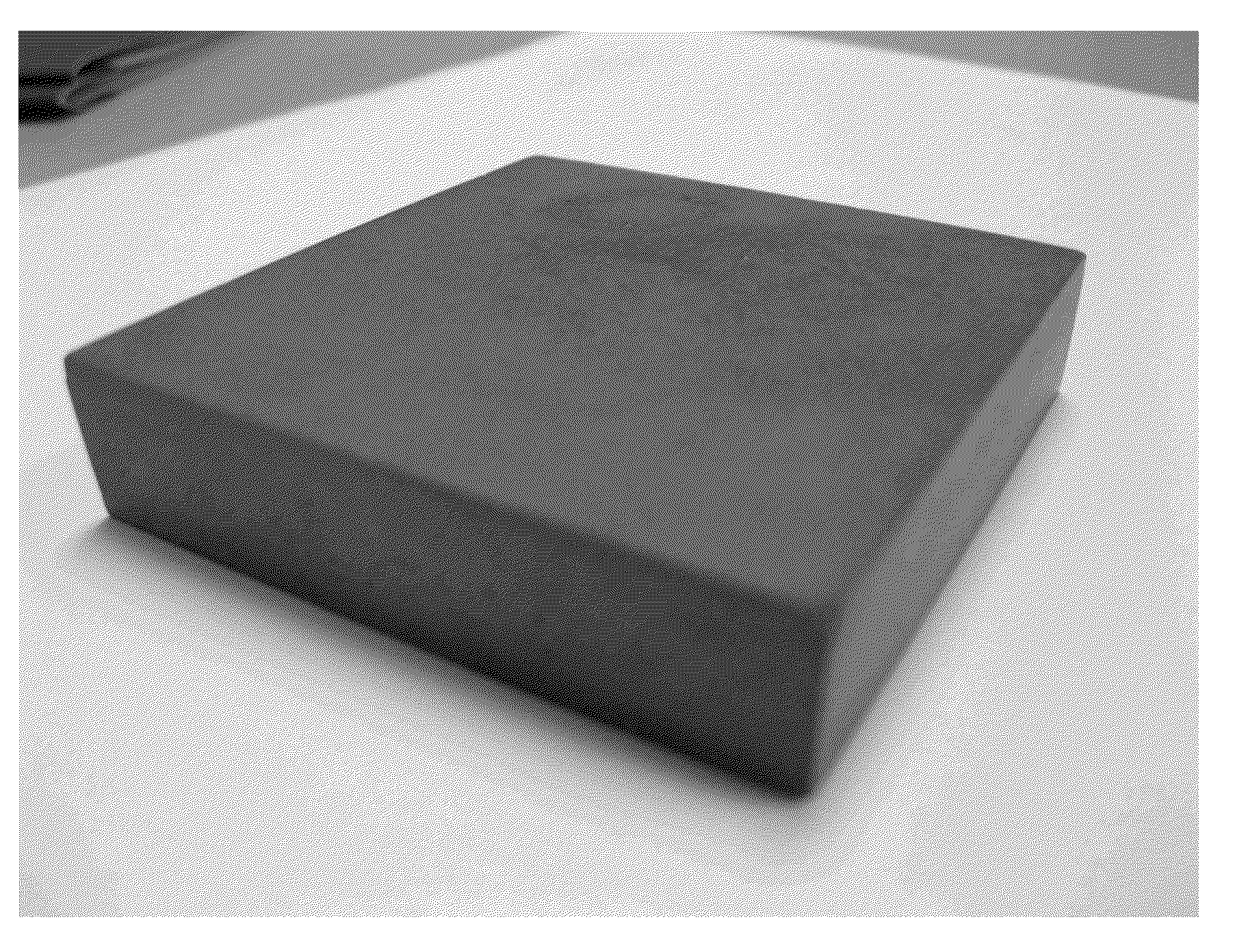

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

Antioxidant and ultravioresistant polypropylene woven bag raw material

InactiveCN102766918AImprove antioxidant capacityImproves UV resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureUv absorberStearic acid

The invention discloses an antioxidant and ultravioresistant polypropylene woven bag raw material. The polypropylene woven bag raw material is added with anti-oxidant B215, anti-oxidant 1010, auxiliary anti-oxidant DLTP (dilauryl thiodipropionate) or DSTP (distearyl thiodipropionate), ultraviolet absorber UV531, light stabilizer GW-480, stearic acid, calcium stearate, calcium carbonate, mono-alkoxy titanate coupling agent YDH-101, and zinc stearate in powdered polypropylene, and then subjected to wiredrawing treatment in a drawing machine. Compared with the prior art, the raw material provided by the invention has advantages of good antioxidant and ultravioresistant properties, the raw material is particularly suitable for being used as woven bag raw materials, especially for being used as the raw material for manufacturing container bags.

Owner:尚勇

Method for preparing magnetic filling with biological affinity, hydrophilicity and activity for water treatment

InactiveCN1522972AEasy to grow and compactGood compatibilitySustainable biological treatmentBiological water/sewage treatmentInjection molding machineInjection moulding

The present invention relates to a preparation method of biological affinity hydrophilic active magnetic seed filling material for treating water. It is characterized by that said method includes the following steps: mixing biological affinity substance, hydrophilic substance, magnetic powder and active carbon or magnetic powder and calcium carbonate in the high-molecular base material, and adding dispersion lubricating agent, uniformly stirring them, placing them into injection moulding machine, utilizing filling mould to make extrusion moulding and magnetizing, so as to obtain the invented filling material. It has biological affinity and hydrophilicity, at the same time can induce microbial activity and enzyme activity, and can raise oxygen utilization rate in water and water treatment efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Sprayable water-based adhesive

InactiveUS20070224395A1Efficient use ofProlong lifeAdhesive processesRoof covering using sealantsWet bondingWater based

Water-based adhesive compositions are improved by the incorporation of hollow polymeric microspheres having outer surfaces coated with one or more barrier materials such as calcium carbonate particles. The adhesive compositions exhibit enhanced rheology, sprayability, drying time, tack and storage stability as compared to analogous adhesives that are not modified with coated hollow polymeric microspheres. Such compositions are useful as both contact adhesives as well as wet bonding one-way adhesives.

Owner:HENKEL IP & HOLDING GMBH

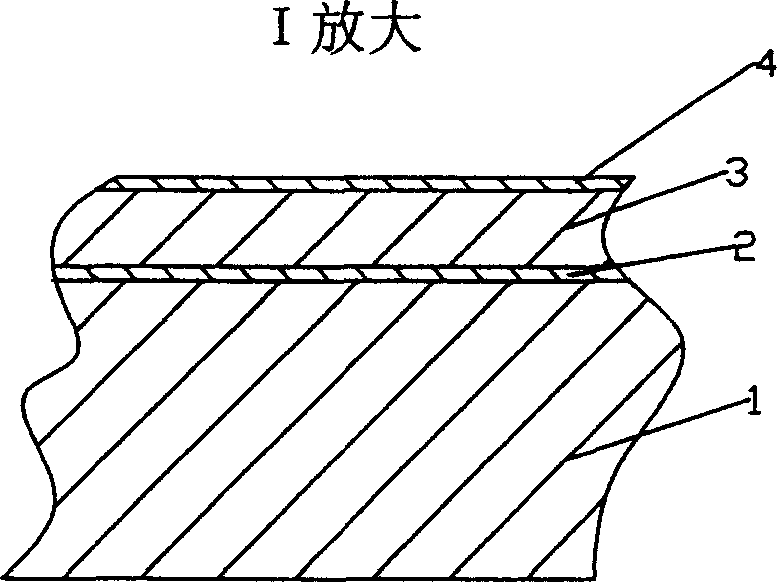

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

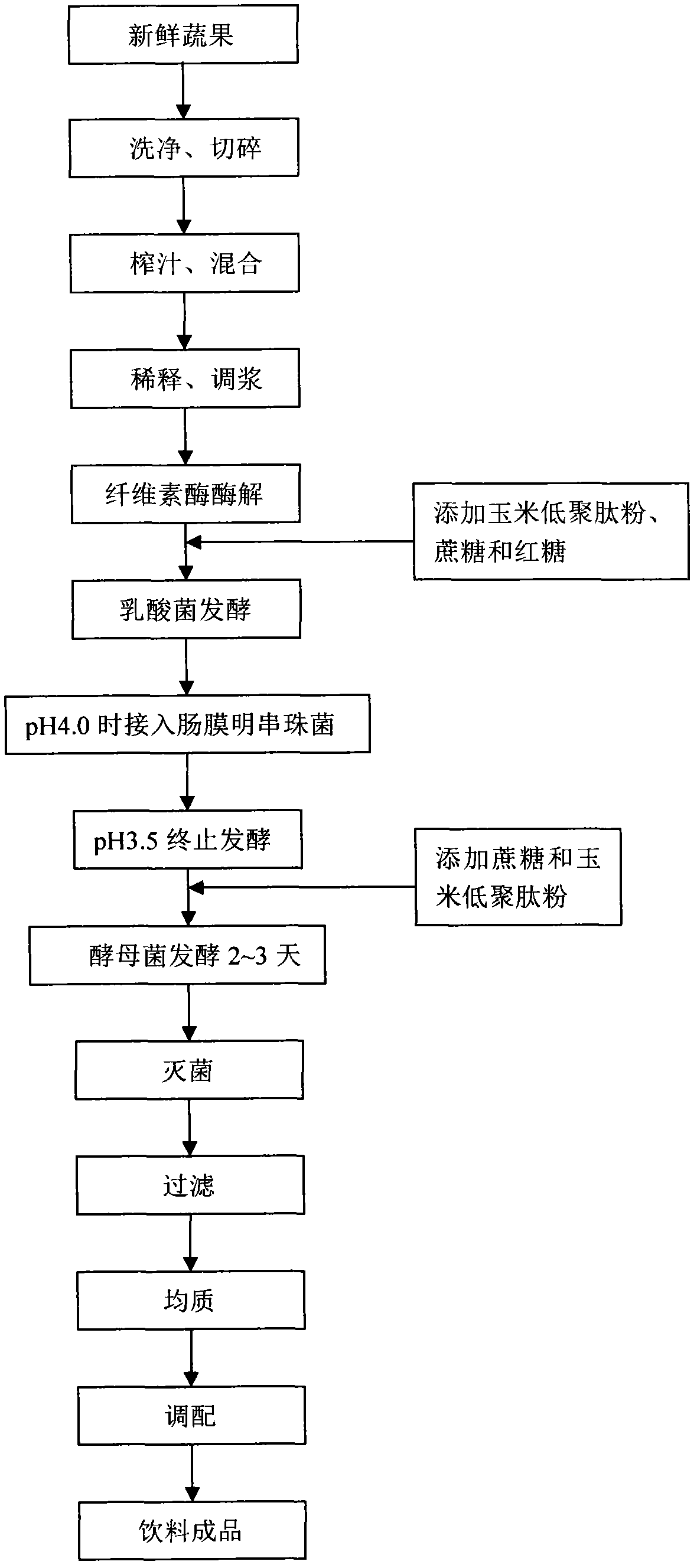

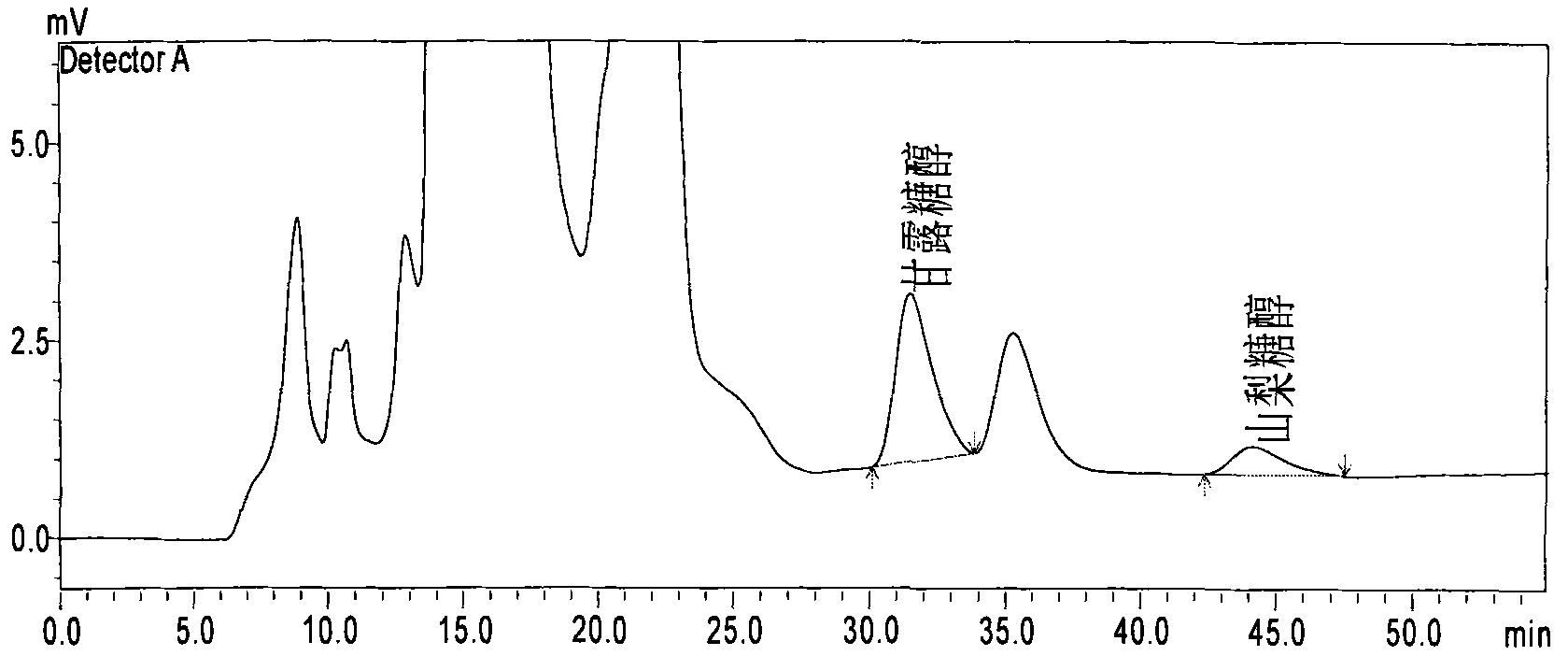

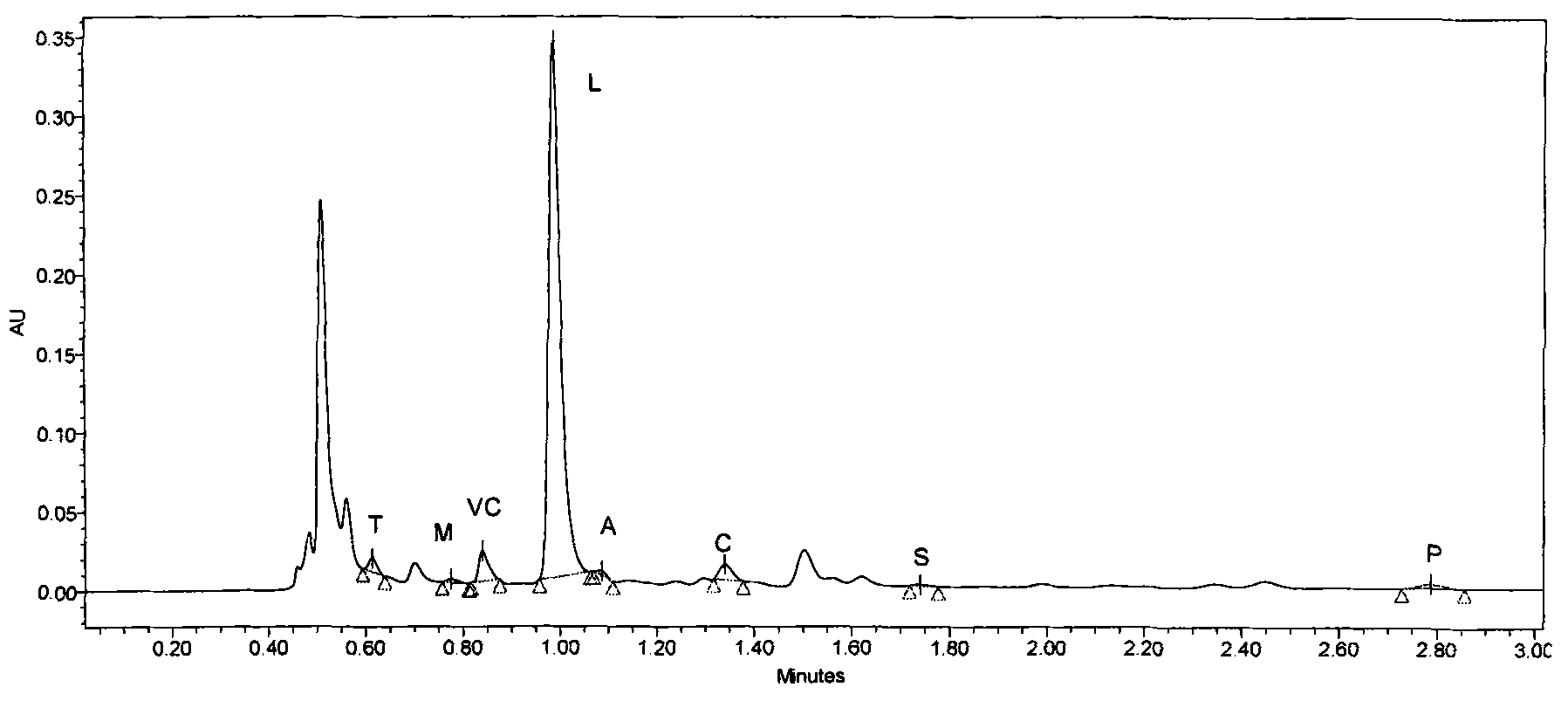

Natural vegetable and fruit fermented beverage

The invention discloses a preparation method of a novel vegetable and fruit fermented beverage. The preparation method comprises the steps of: firstly carrying out enzymolysis on mixed fresh juice of fresh vegetables and fruits after dilution and size mixing by adopting cellulase, fermenting by adopting a mixed lactic acid starter after adding sugar and corn oligopeptide as fermentation substrates and sterilizing, adding calcium carbonate when the pH reaches 4.0, and then inoculating leuconostoc mesenteroides for continuous fermentation; adding a feed supplement and sterilizing when the pH reaches 3.5, and then adding high-activity dry yeast for the fermentation for 2-3 days; and finally performing sterilization, centrifugation, homogenizing, blending, sterilizing and filling to obtain the novel vegetable and fruit fermented functional beverage. The enzymolysis is firstly carried out on a product by the cellulase, then lactic acid bacteria and saccharomycetes are utilized for the step-by-step fermentation of the mixed fresh juice of the fresh vegetables and fruits, and the corn oligopeptide is added to promote the growth and the metabolism of fermentation strains, so that the novel vegetable and fruit fermented beverage has clear composition of functional components, contains abundant oligopeptide, organic acids, reducing sugars, sugar alcohols and soluble dietary fiber, and integrates nutrition and health care, thus being a novel vegetable and fruit fermented beverage.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

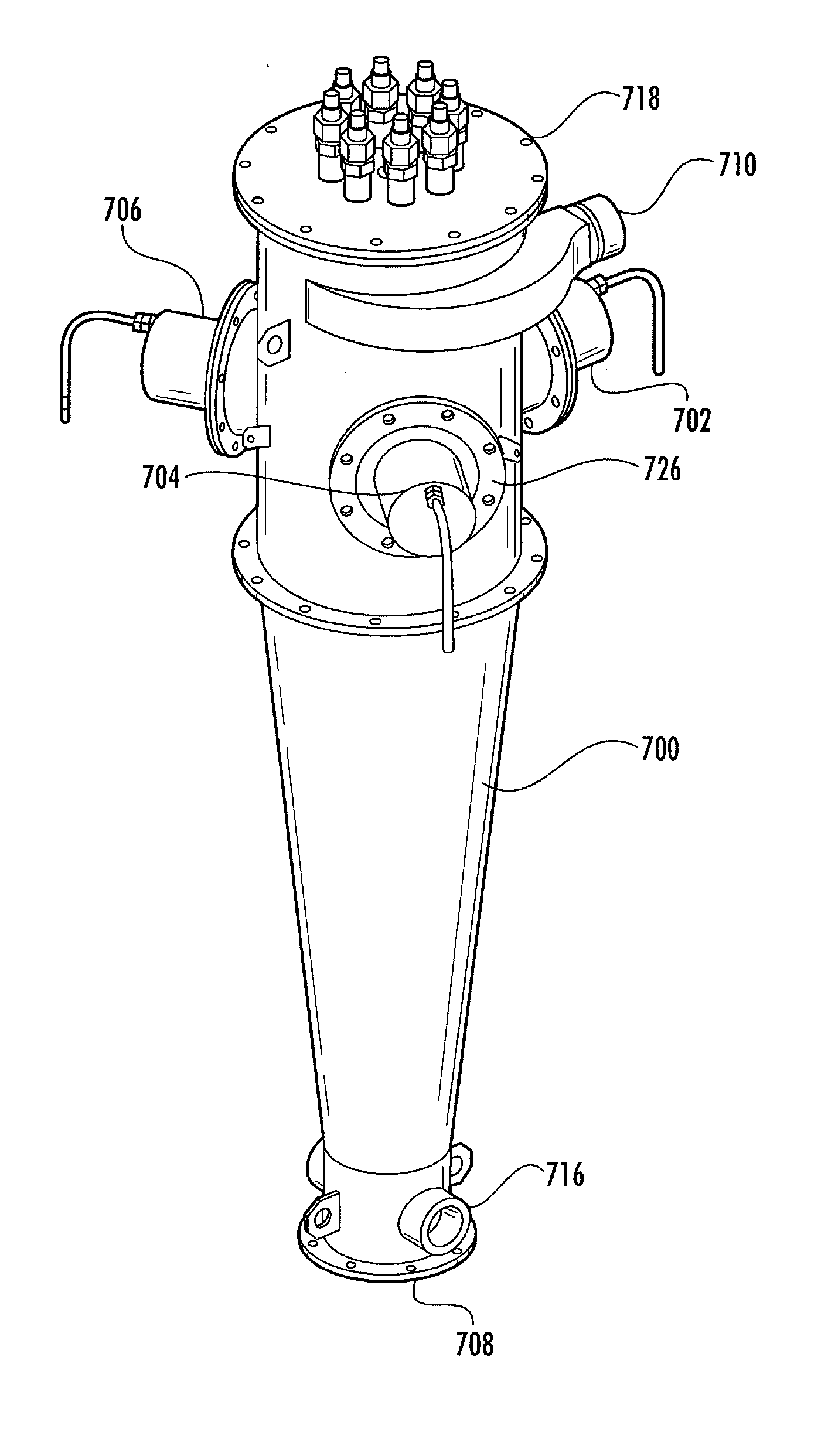

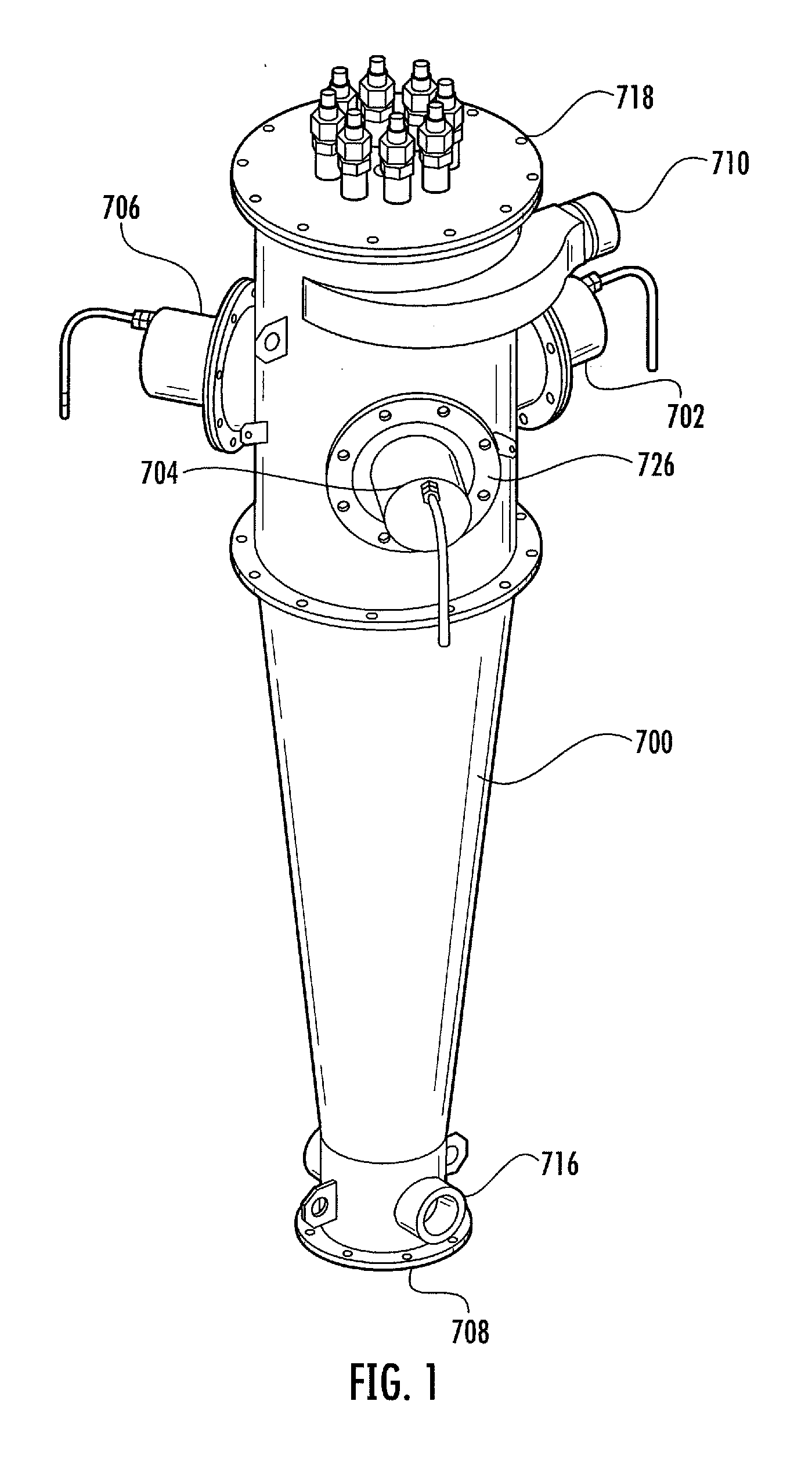

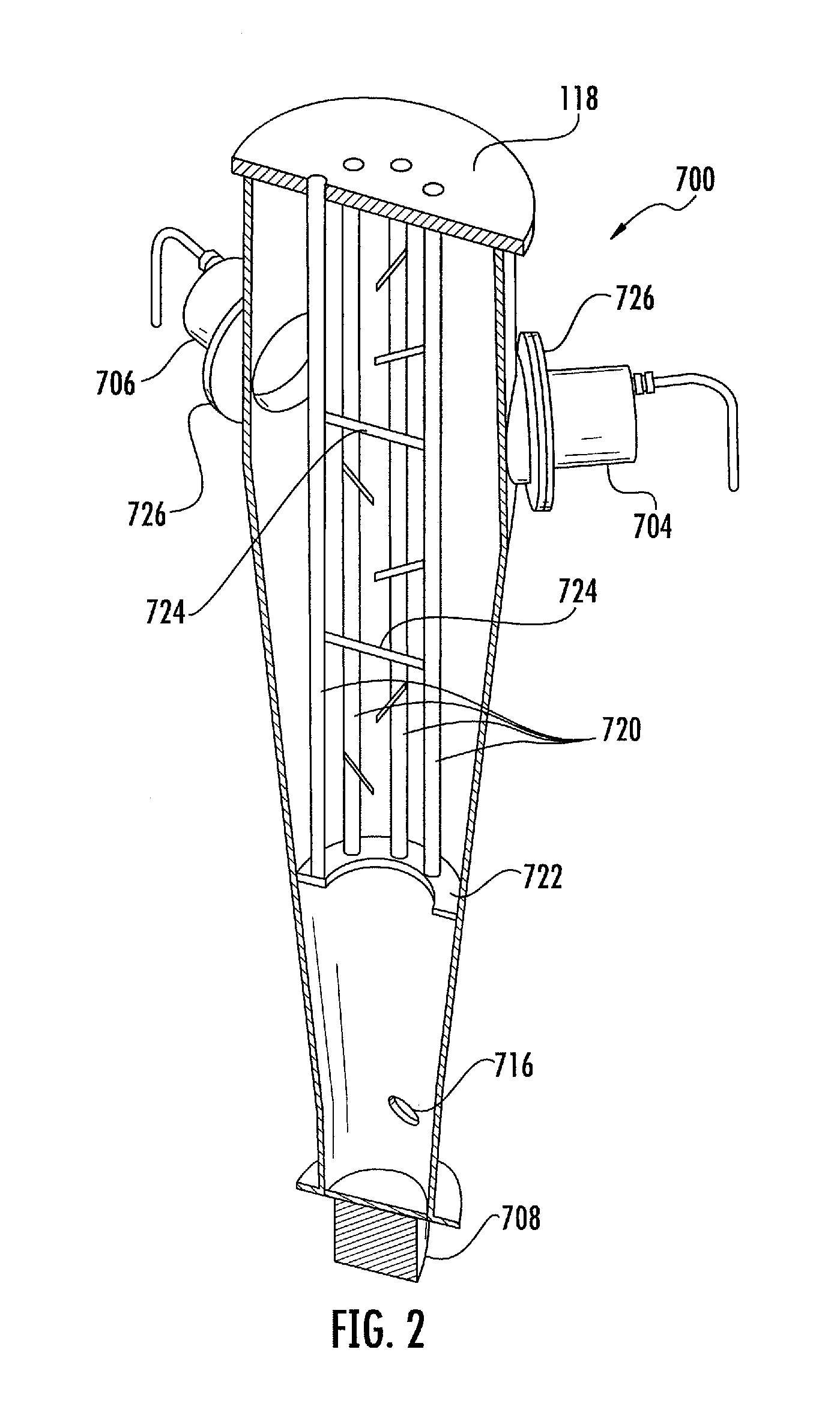

Reactor tank

ActiveUS20100320147A1Faster rateEnhanced mass transferElectrostatic separatorsSedimentation separationCavitationAnaerobic bacteria

Disclosed is an improved water treatment cavitation reactor cone. The tank operates on a continuous flow of fluids which are subjected to ultrasonic waves in combination with a high level of injected ozone. The treatment tank includes a tangential inlet that induces a rotating flow into the tank thereby increasing the mixing of the ozone within the effluent. The effluent is further treated with DC current. The treatment tank provides a cost efficient and environmentally friendly process and apparatus for cleaning and recycling fluids as contaminated as frac water, used to stimulate gas production from shale formations, as well as other types of fluids having various levels of contaminants such as aerobic and anaerobic bacteria and suspended solids. The calcium carbonate scaling tendency is reduced to an acceptable level without the use of acids, ion exchange materials, or anti scaling chemicals which is of economical and environmental significance and benefit.

Owner:BRISBEN WATER SOLUTIONS

Crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and preparation method

ActiveCN106699026AStrong adaptability to high alkaline environmentAdaptableOn/in inorganic carrierWater reducerMechanical property

The invention discloses crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and a preparation method. The crack self-remediation regenerated concrete comprises components, namely, expanded perlite carried with urease production microorganisms, cement, stone, sand, silica fume, water, urea, calcium chloride, a urease production microorganism suspension and a water reducing agent. The urease production microorganisms are adopted as a concrete crack remediation agent, urease can be generated through metabolism through the urease production microorganisms, and the urea can be decomposed into NH4<+> and CO3<2+>, and furthermore the calcium carbonate can be mineralized and deposited to remedy cracks. In the preparation process, a part of the crack remediation agent is directly mixed with the concrete, then cracks and holes in regenerated crude aggregate self and weak adhesion areas between regenerated aggregate and a new cement stone base can be remedied, and thus the mechanical property of the regenerated concrete can be improved; meanwhile, the other part of the crack remediation agent is firstly adsorbed into an expanded perlite carrier and is further mixed into the concrete, then the crack self-remediation property of the regenerated concrete in the service period can be improved, and thus the anti-penetrability performance and the durability of the regenerated concrete can be improved.

Owner:TAIYUAN UNIV OF TECH

Resorbable bone graft materials

Ceramic materials operable to repair a defect in bone of a human or animal subject comprising a porous ceramic scaffold having a bioresorbable coating, and a carrier comprising denatured demineralized bone. The ceramic may contain a material selected from the group consisting of hydroxyapatite, tricalcium phosphate, calcium phosphates, calcium carbonates, calcium sulfates, and combinations thereof. The compositions may also contain a bone material selected from the group consisting of: bone powder, bone chips, bone shavings, and combinations thereof. The bioresorbable coating may be, for example, demineralized bone matrix, gelatin, collagen, hyaluronic acid, chitosan, polyglycolic acid, polylactic acid, polypropylenefumarate, polyethylene glycol, or mixtures thereof.

Owner:BIOMET MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com