Patents

Literature

492 results about "Benzopyrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A benzopyrene is an organic compound with the formula C₂₀H₁₂. Structurally speaking, the colorless isomers of benzopyrene are pentacyclic hydrocarbons and are fusion products of pyrene and a phenylene group. Two isomeric species of benzopyrene are benzo[a]pyrene and the less common benzo[e]pyrene. They belong to the chemical class of polycyclic aromatic hydrocarbons.

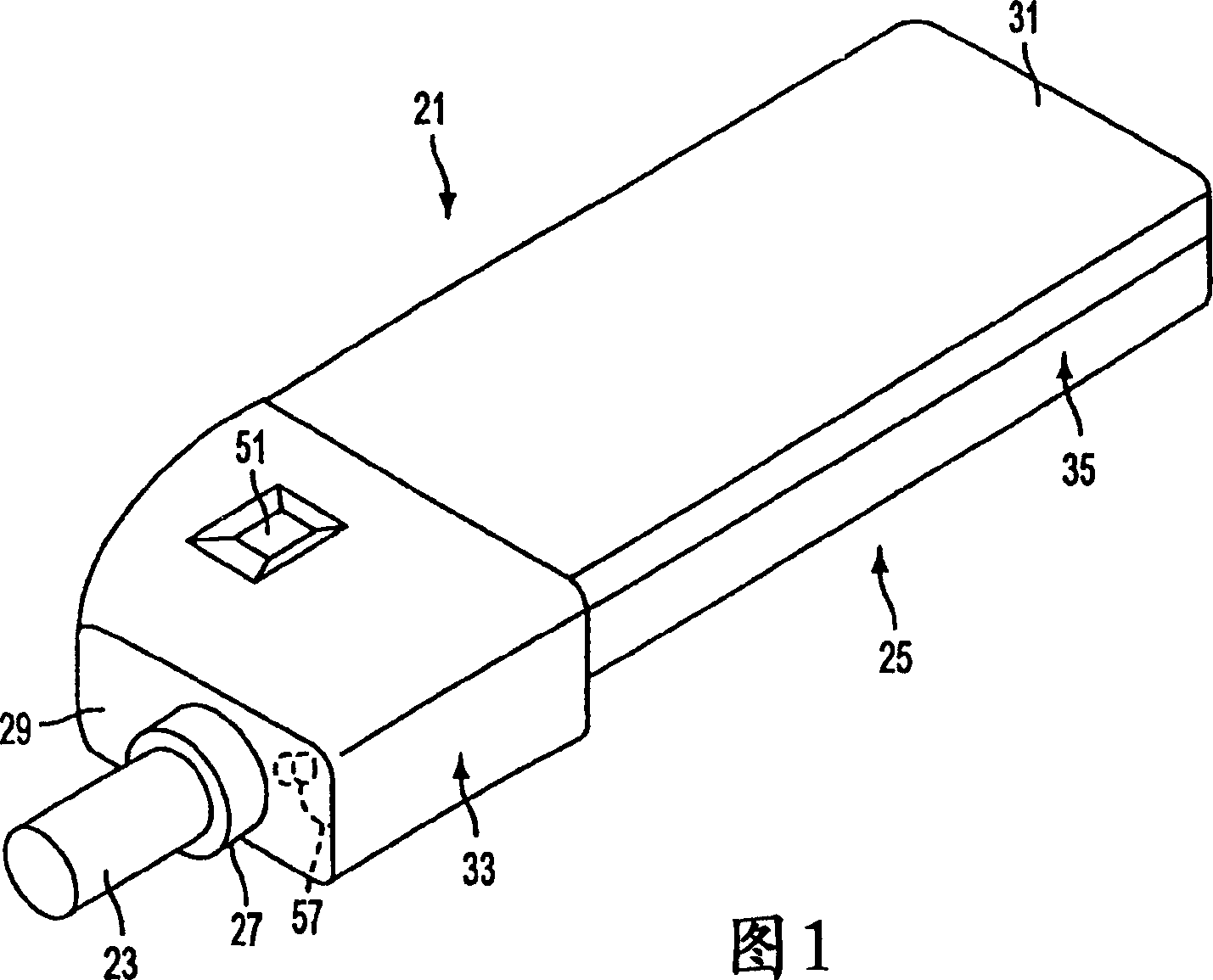

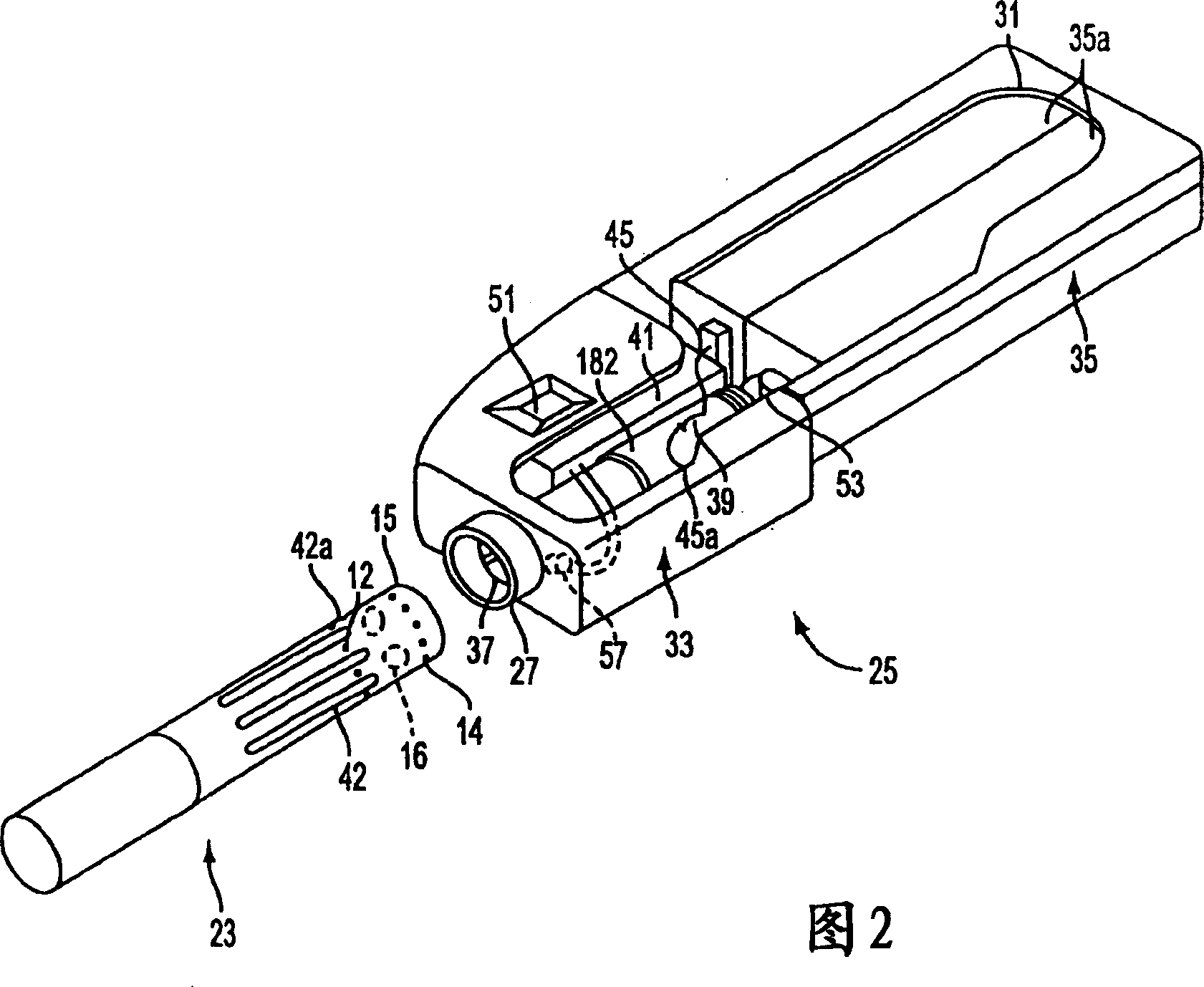

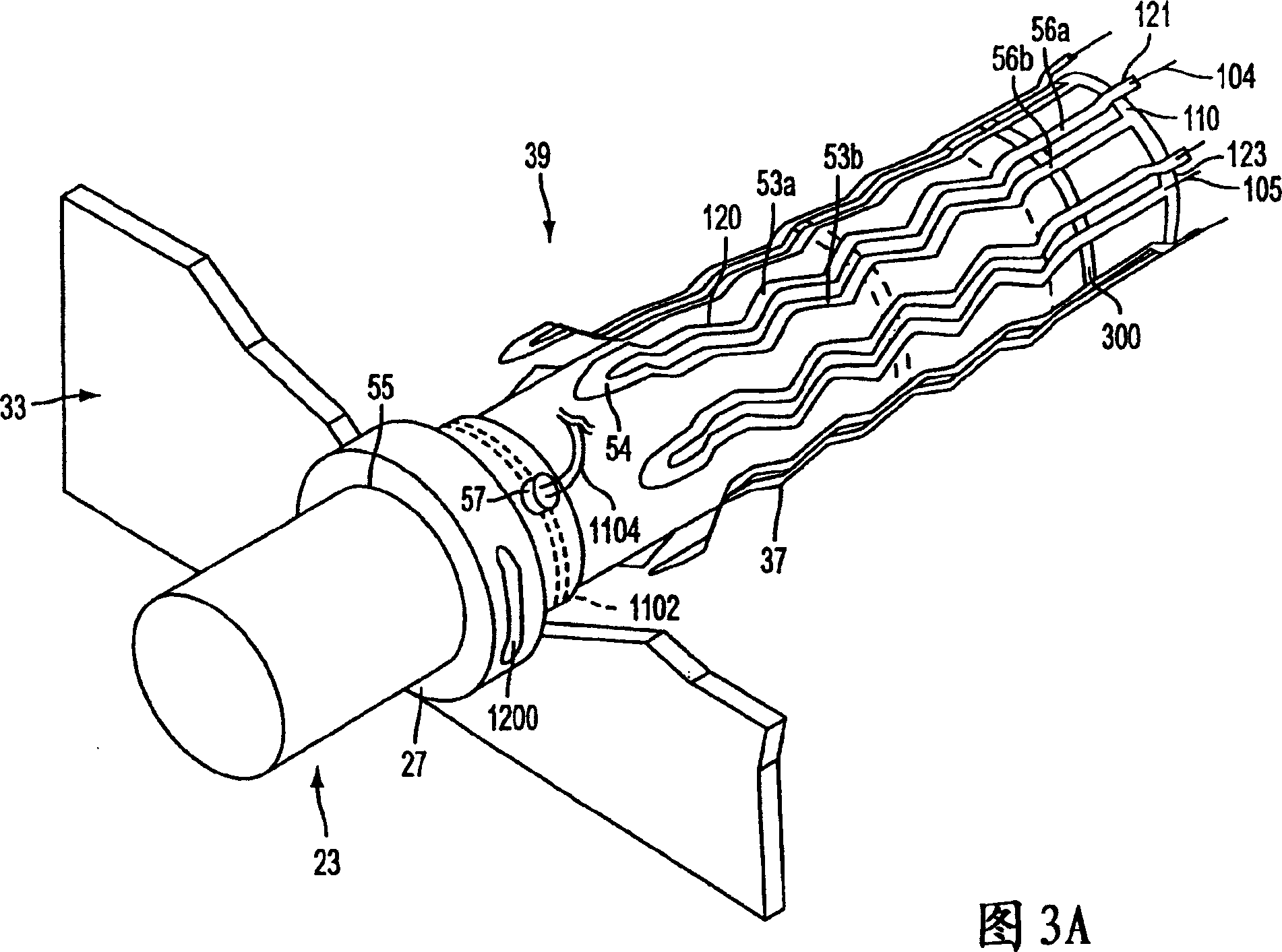

Electrical smoking system and method

InactiveCN1633247AReduce gaseous componentsIncandescent ignitionCigar manufactureIntegratorAcrylonitrile

An electric smoking system includes a cigarette including a cylindrical tobacco web partially filled with tobacco material to define a filled tobacco rod portion and an unfilled tobacco rod portion, and an electric lighter. The wrapper includes a filler of ammonium-containing compounds effective to reduce the gaseous constituents of the smoke produced during smoking. The system includes a pilot burner including at least one heating vane and a controller adapted to control heating of the heating vane. The lighter is configured to at least partially contain the cigarette such that the heater blade heats the heating region of the cigarette. Manipulating the controller to limit the heating of the heater blades to a predetermined temperature range which allows the delivery of the smoke generated when the portion of the tobacco rod is heated while at least reducing the amount of smoke present in the smoke as compared to smoking a cigarette having only calcium carbonate as filler. A gaseous component. The gaseous components that can be reduced include carbon monoxide, 1,3 butadiene, isoprene, acrolein, acrylonitrile, hydrogen cyanide, 0-toluidine, 2-naphthylamine, nitrogen oxide, benzene, NNN, Phenol, catechol, benzanthracene and benzopyrene.

Owner:PHILIP MORRIS PROD SA

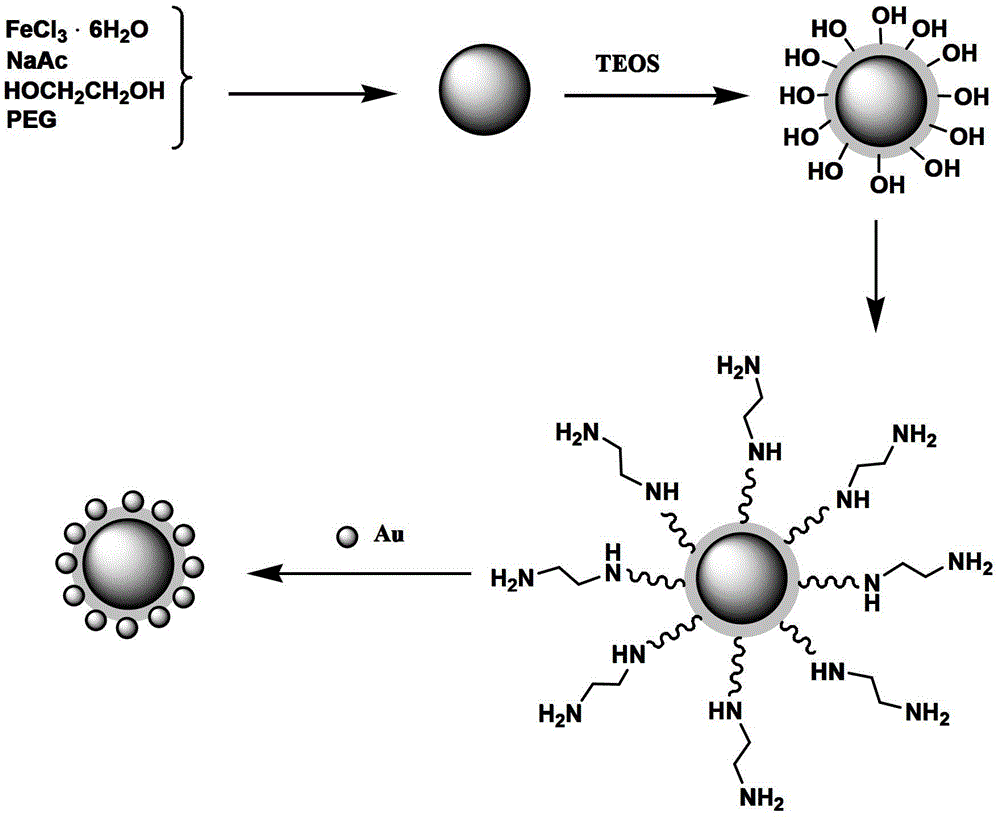

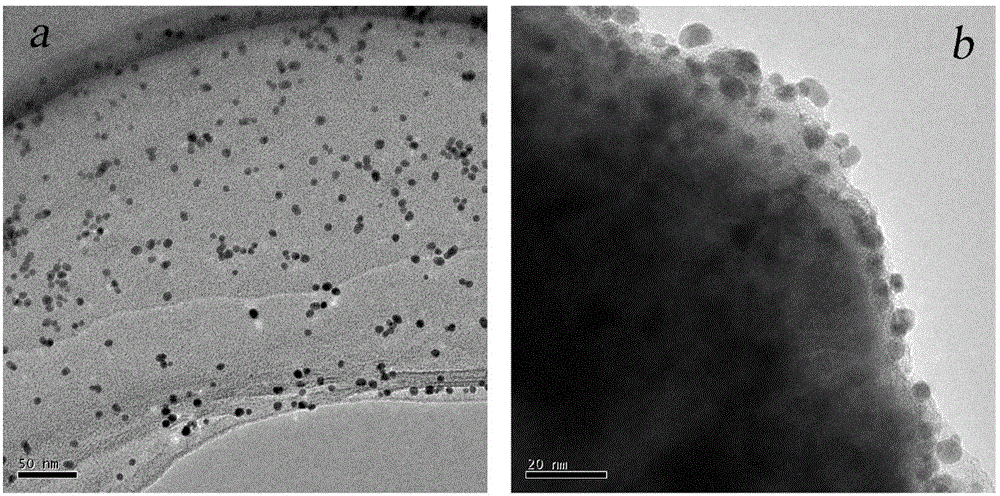

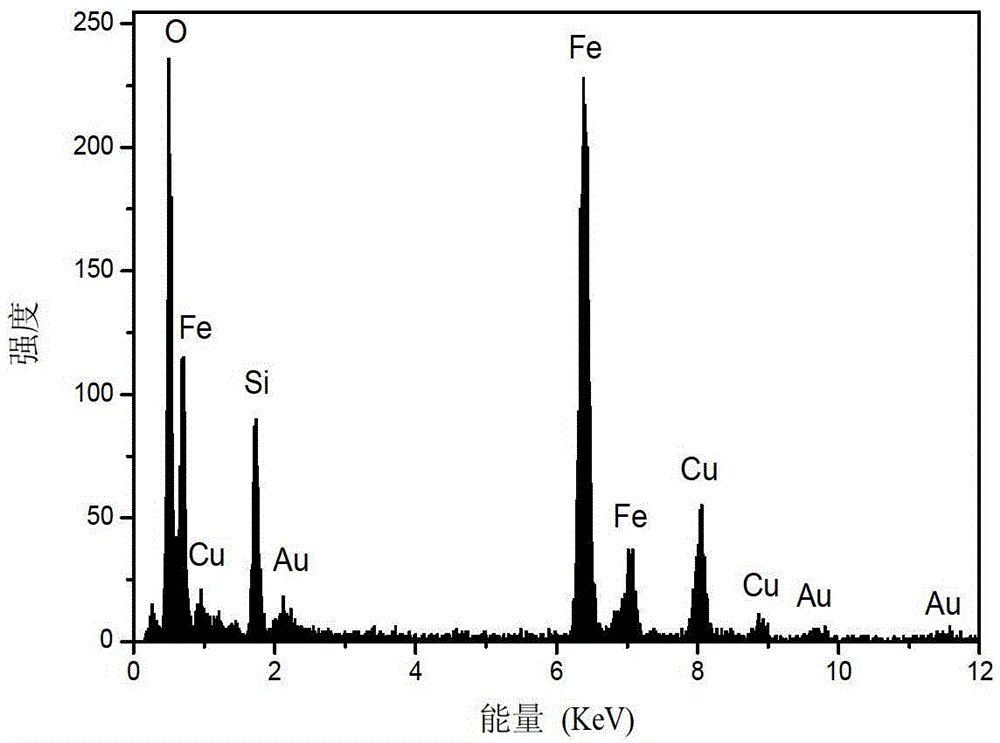

Magnetic gold nanoparticle composite material, and preparation method and application thereof

InactiveCN102974314AEasy to controlGood reproducibilityOther chemical processesAlkali metal oxides/hydroxidesMicrosphereMagnetite Nanoparticles

The invention discloses a magnetic gold nanoparticle composite material, and a preparation method and application thereof. The preparation method comprises the following steps: synthesizing ferroferric oxide magnetic microspheres, adding tetraethoxyl silicon to implement hydrolysis and polymerization on the magnetic microsphere surfaces, adding N-(2-aminoethyl)-3-aminopropyltrimethoxysilane to obtain surface-modified double-amino-group Fe3O4 / SiO2 magnetic microspheres, and compounding the surface-modified double-amino-group magnetic microspheres with gold nanoparticles. The chelation action of the double amino groups is utilized to adsorb the gold nanoparticles more firmly; and the material combines the surface selectivity of the gold nanoparticles and the superparamagnetism of the magnetic nanoparticles, can extract benzopyrene in water, and can implement quick and efficient separation.

Owner:TIANJIN UNIV

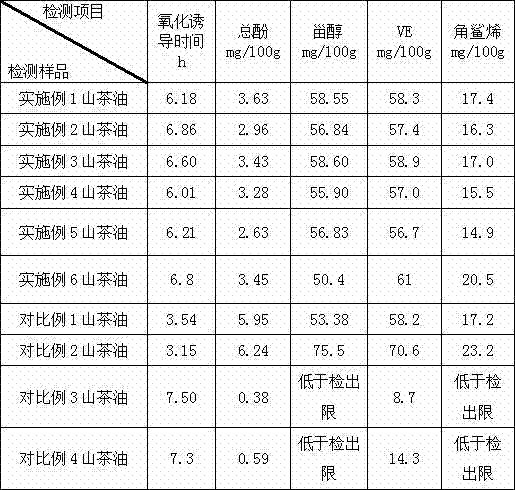

Refining process for cold-pressed camellia oil at low temperature

InactiveCN104277906AEfficient removalEffective odorlessFatty-oils/fats refiningFatty-oils/fats separationCamellia cuspidataProcess engineering

The invention discloses a refining process for cold-pressed camellia oil at low temperature. The process disclosed by the invention comprises the following steps: processing raw materials; cold-pressing to obtain oil; carrying out high-precision filtration; hydrating and degumming; deacidifying; decolorizing; deodorizing; and dewaxing. According to the process disclosed by the invention, the harmful ingredients (for example, benzopyrene, free fatty acid, colloid, trace heavy metals, residual soap, debris, aflatoxin and the like) existing in the camellia oil and generated in the production process, and a unique unfavorable smell of the camellia oil are effectively removed; various unique natural beneficial nutrients of the camellia oil can be preserved to the maximal extent after the camellia oil is refined; and no harmful substance is generated in the processing process.

Owner:杭州千岛湖瑶记实业有限公司

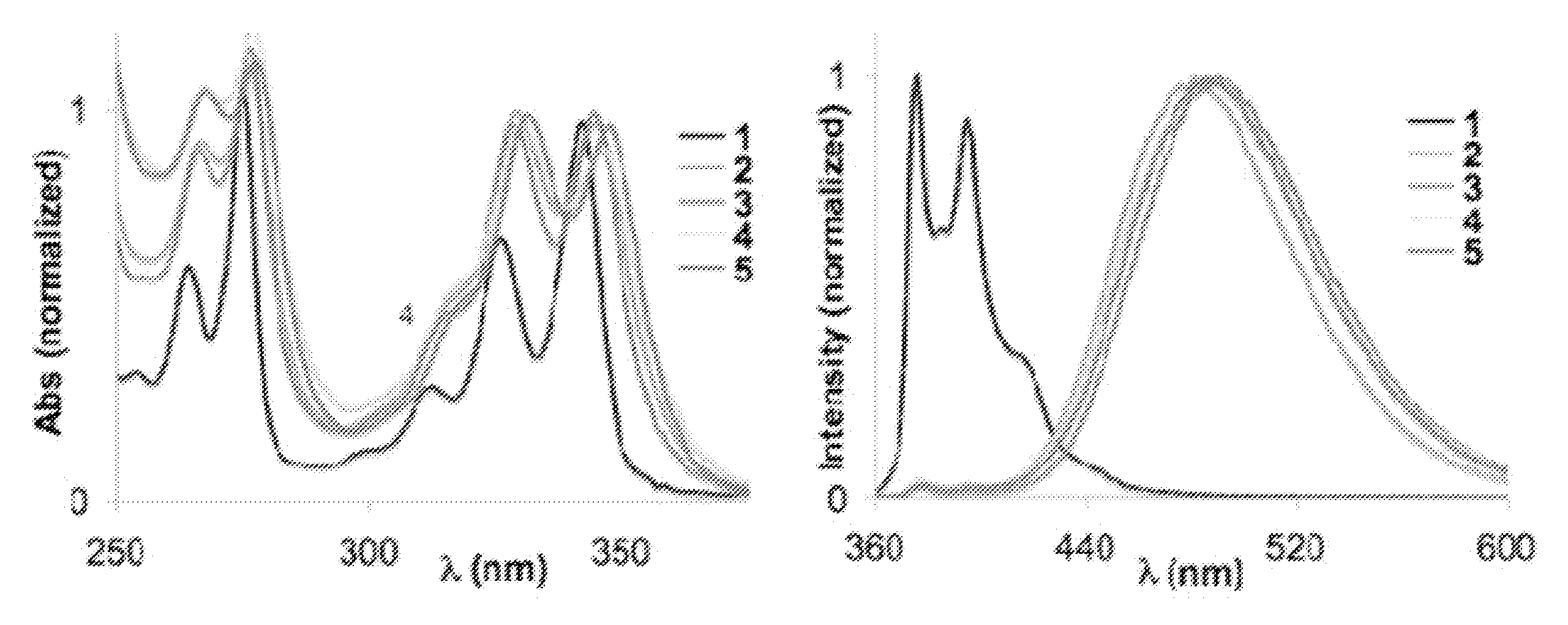

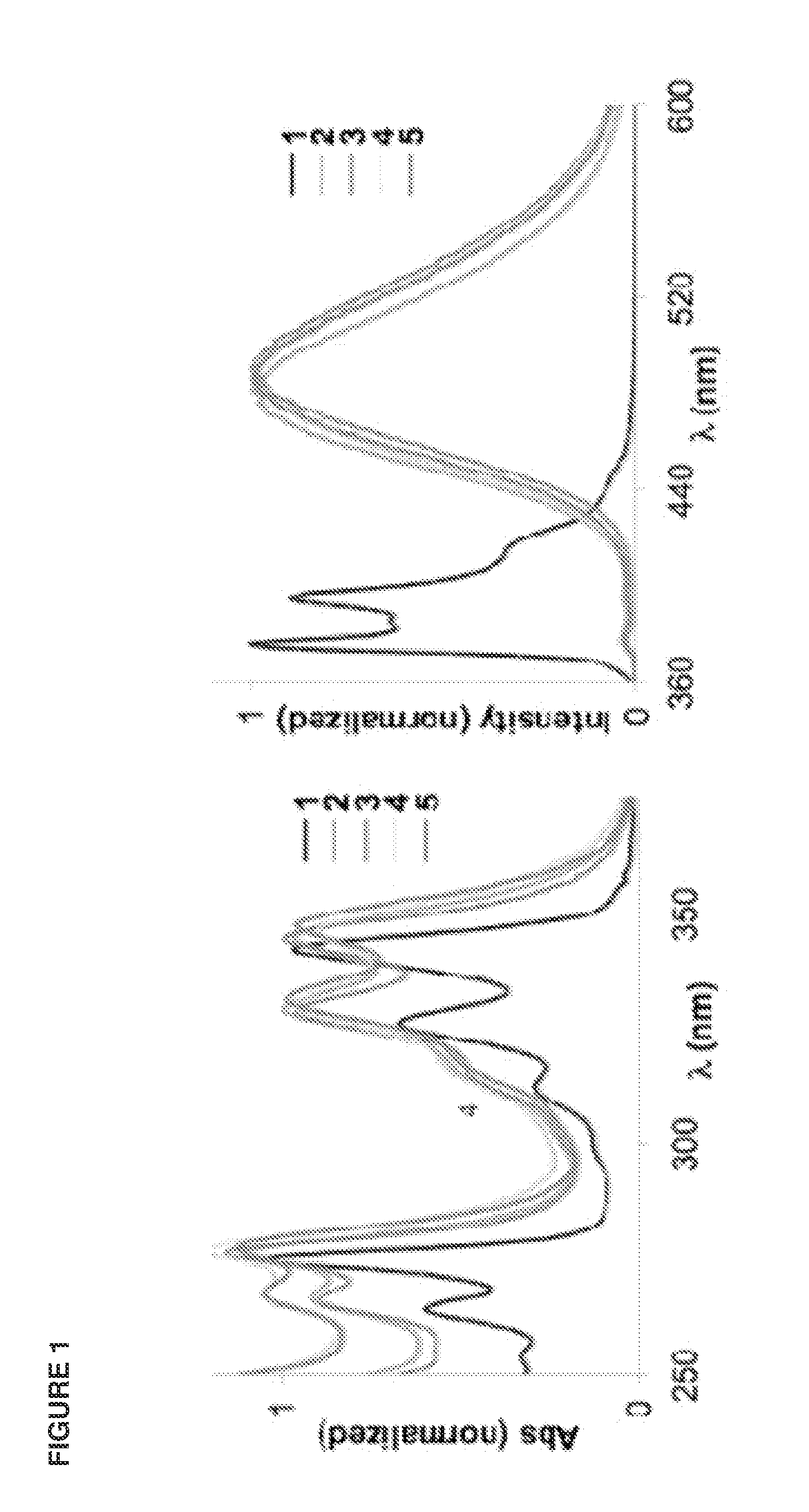

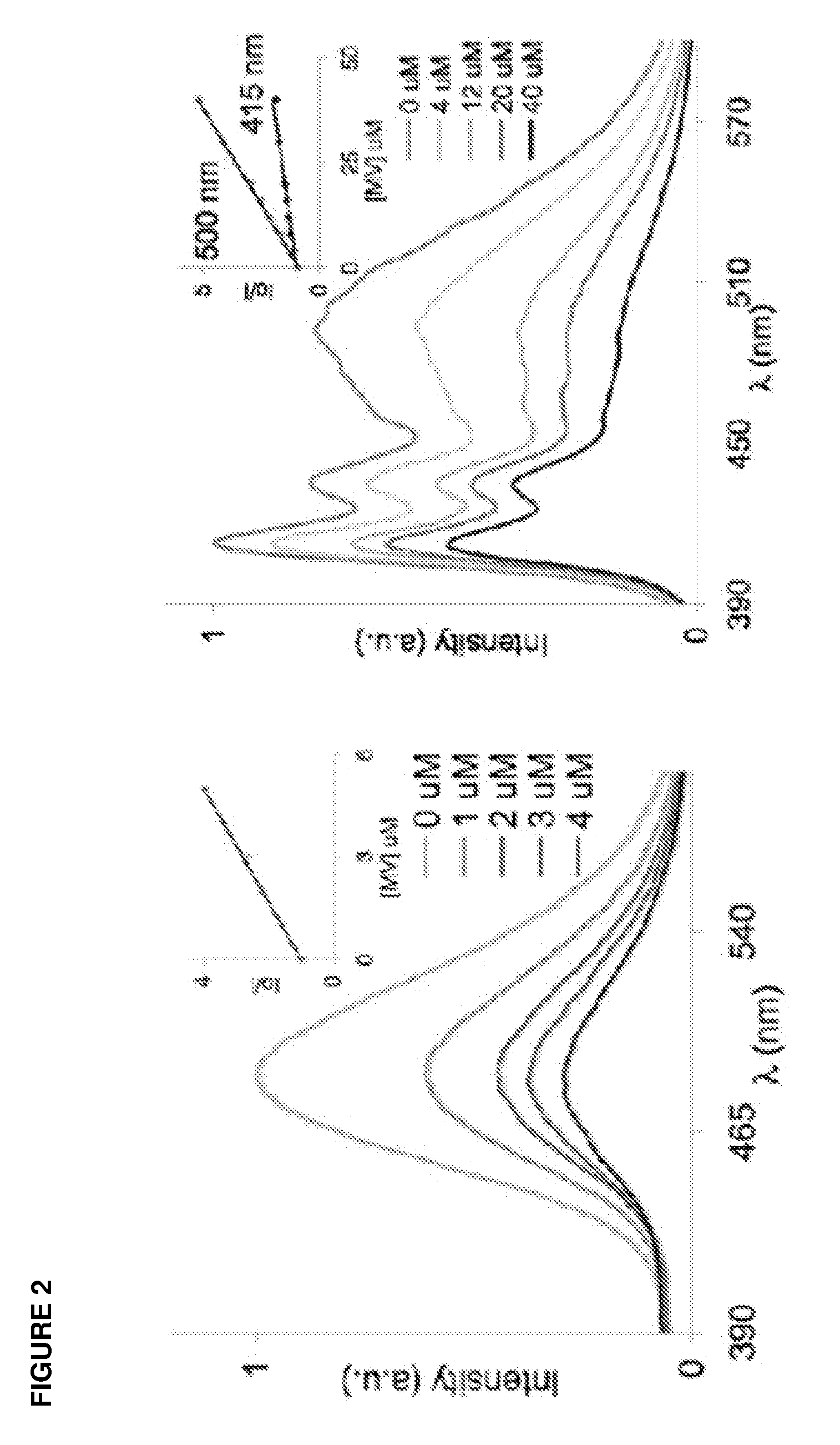

Strongly quenching oligomeric excimer/quencher pairs for detection schemes

InactiveUS20100129820A1High efficiency quenchingEfficiently quenchedSaccharide with carbocyclic radicalsSugar derivativesOligomerPerylene

Compositions and systems are provided for the high efficiency quenching small water-soluble oligomers, or oligofluors, of from about 1-10 kd in size, where the oligofluors comprise multiple excimeric or exciplex forming fluorophores arranged on a scaffold, which are efficiently quenched by a quencher entity linked to the oligomer through a cleavable moiety. Fluorophores of interest include, without limitation, aromatic fluorophores such as pyrenes, e.g. benzopyrene, perylene, pyrene, etc. In some embodiments the oligofluor / quencher combination provides for a Stern-Vollmer constant (KSV) of greater than about 106 M−1, and may be greater than about 107 M−1, greater than about 108 M−1, or more. In some embodiments of the invention, the scaffold is a phosphodiester / glycoside backbone, e.g. an analog of a polynucleotide. The system of oligofluors and quenchers can be used in qualitative and quantitative screening and detection methods to detect any enzymatic, chemical or catalytic activity that can cleave the moiety between the quencher and scaffold.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

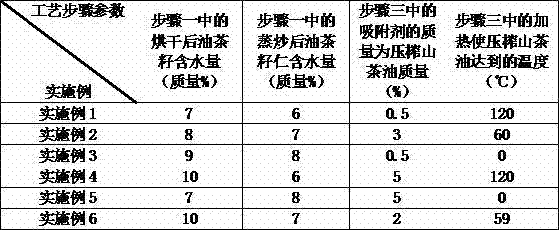

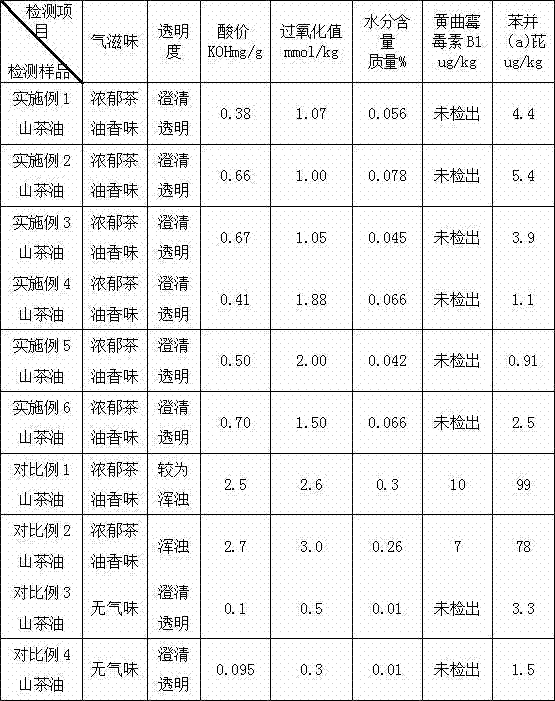

Original-fragrant camellia oil rich in active components and producing method thereof

ActiveCN102807918AThe method flow is simpleLow requirements for process conditionsFatty-oils/fats refiningCamellia oleiferaBenzopyrene

The invention discloses a producing method of original-fragrant camellia oil rich in active components. The producing method mainly comprises the following technical steps of: 1, enabling fresh camellia fruits to suffer from electing, retting, cleaning, drying, seed un-shelling, seed-selecting, sterilizing and cooking to obtain cured camellia seeds; 2, squeezing the cured camellia seeds obtained in the step 1 by an oil press and filtering to obtain clean squeezed camellia oil; 3, stirring and adsorbing, to be specific, placing the squeezed camellia oil obtained in the step 2 in a mixing tank, adding an adsorbent for mixing and filtering to obtain the camellia oil after the adsorption treatment; and 4, degreasing the camellia oil after the adsorption treatment to obtain the original-fragrant camellia oil. According to the invention, no chemical reagent is necessary for the method, the original-fragrant camellia oil rich in the active component has a low content of benzopyrene and has the quality index reaching to the national first-level standard, and the original great flavor and the active nutrient contents of the camellia oil are kept.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

Preparation method of carcinogen-free food smoking solution

The invention discloses a preparation method of carcinogen-free food smoking solution, and belongs to the technical field of meat and aquatic product processing. A eucalyptus smoking agent dry distillation device is adopted in the method; eucalyptus granules and sucrose are added into the dry distillation device in a ratio and subjected to dry distillation to form the smoking solution, the smoking solution is taken out and stood for over 12 hours at the room temperature of between 22 and 32 DEG C, and the supernate formed after the smoking solution is demixed is adsorbed twice by using macroporous absorption resin polymerized by aromatic hydrocarbon compounds to remove carcinogens in the smoking solution; the eucalyptus smoking solution obtained by the method contains 7 to 9 mg / mL of phenolic substances and 8 to 10 g / 100mL of carbonyl compounds, does not contain the carcinogens such as 3,4-benzopyrene and the like, and has good food smoking solution flavor; and the long-time confused problem that the product contains the carcinogens in the field of smoked meat and aquatic products can be solved, the method plays a positive role in improving food quality and food safety in the field of smoked meat and aquatic products, high-quality smoked meat and aquatic products are provided for the market, and economic benefit and social benefit of a processing enterprise are improved.

Owner:GUANGDONG OCEAN UNIVERSITY

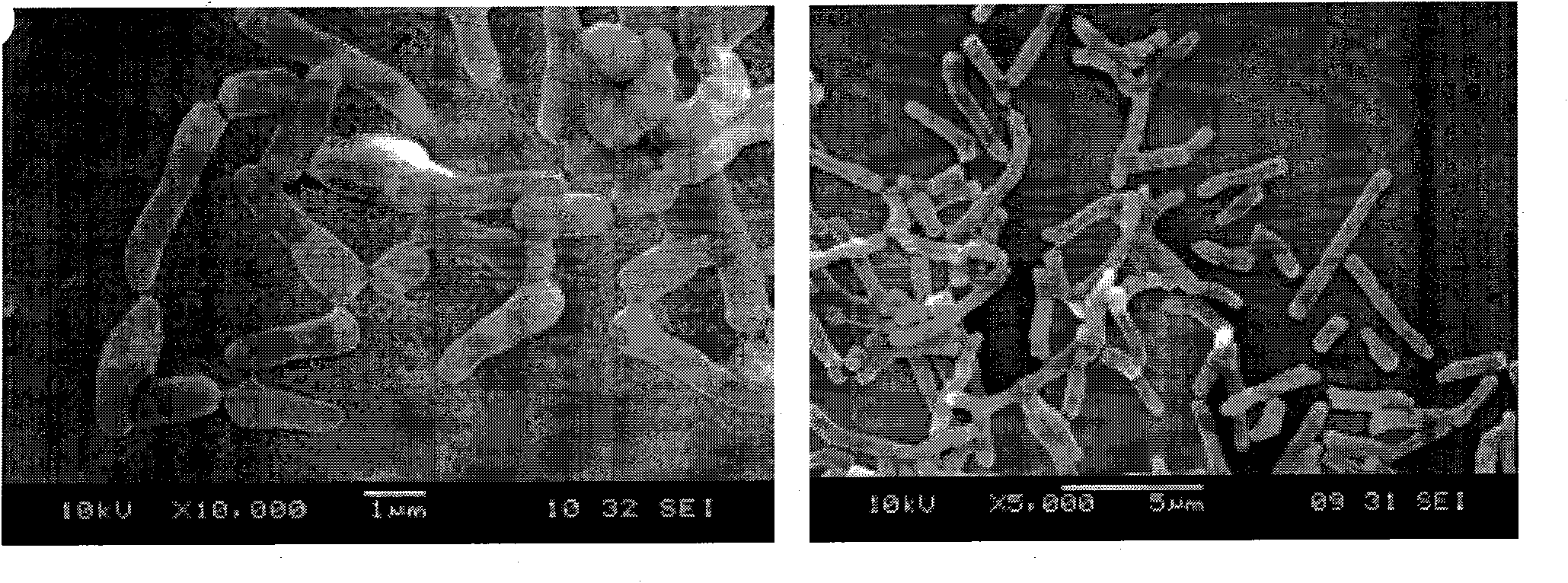

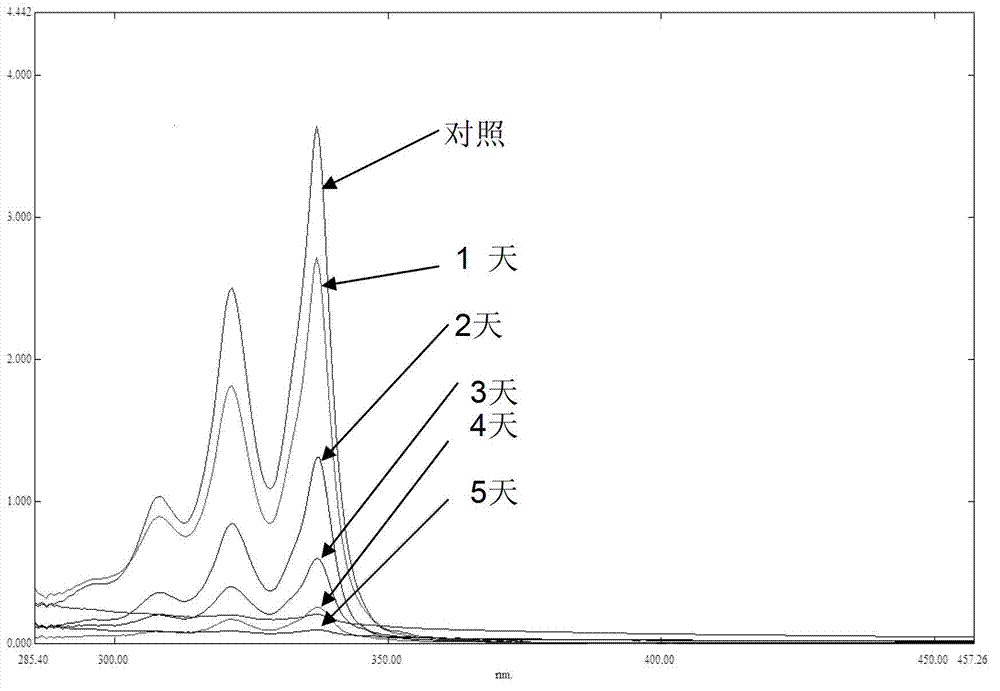

Rhodococcus ruber and application thereof in degradation of hydrocarbon compounds

InactiveCN101580808ABacteriaContaminated soil reclamationPolycyclic aromatic hydrocarbonPhenanthrene

The invention relates to a bacterial strain of Rhodococcus ruber P14 CGMCC NO.2343. The bacterial strain has the characteristic of floating up from oil matters; the bacterial strain can grow by taking the oil matters as unique carbon source and energy source and degrade the oil matters; and the bacterial strain can grow by taking polycyclic aromatic hydrocarbon as unique carbon source and energy source and degrade hydrocarbon compounds, such as phenanthrene, pyrene, benzopyrene, and the like. The bacterial strain can degrade the oil matters and hydrocarbon compounds, especially the polycyclic aromatic hydrocarbon can be applied in the biological treatment of oily waste water and the biological repair (biological remediation) of oil-contaminated soil.

Owner:SHANTOU UNIV

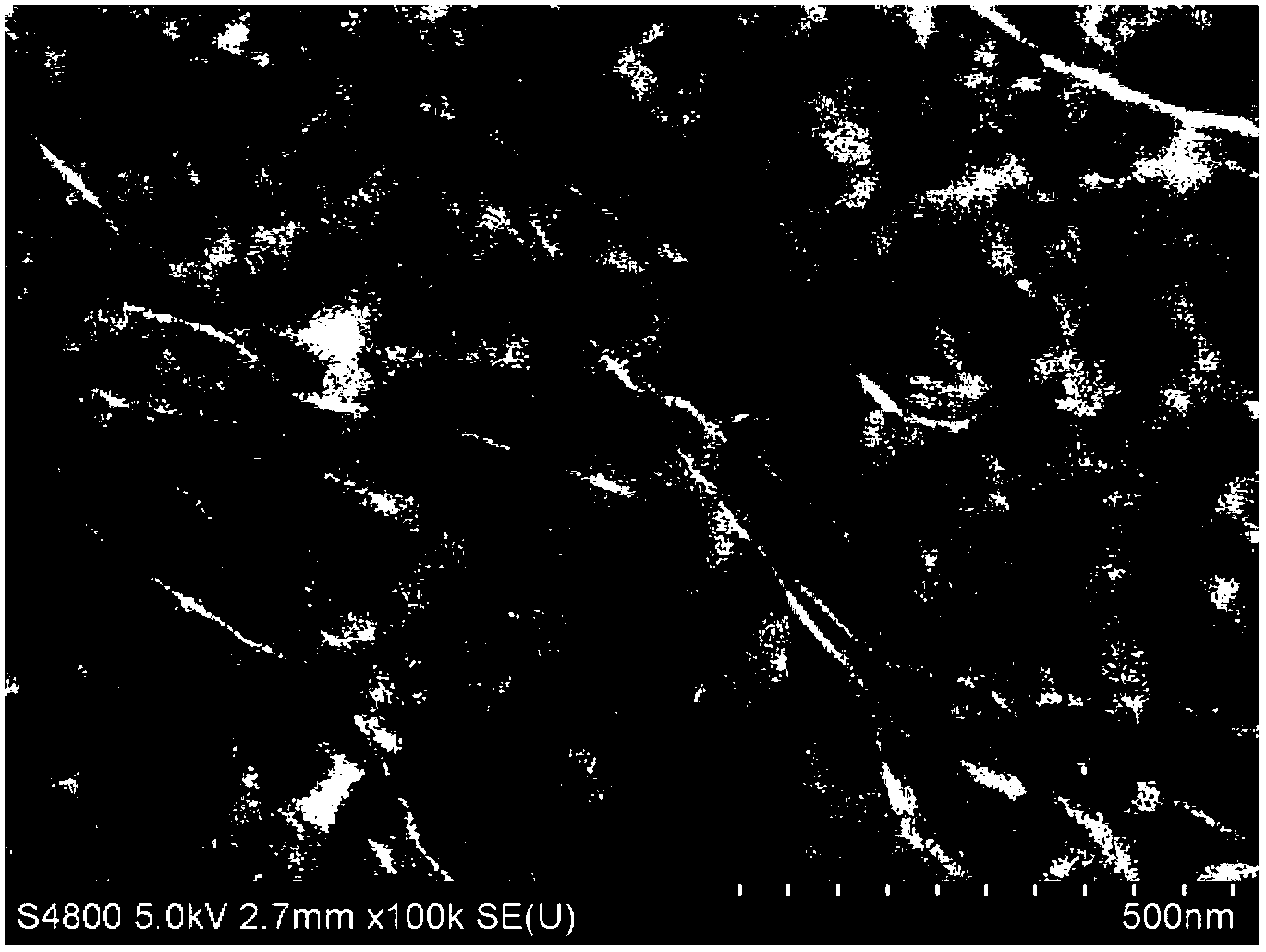

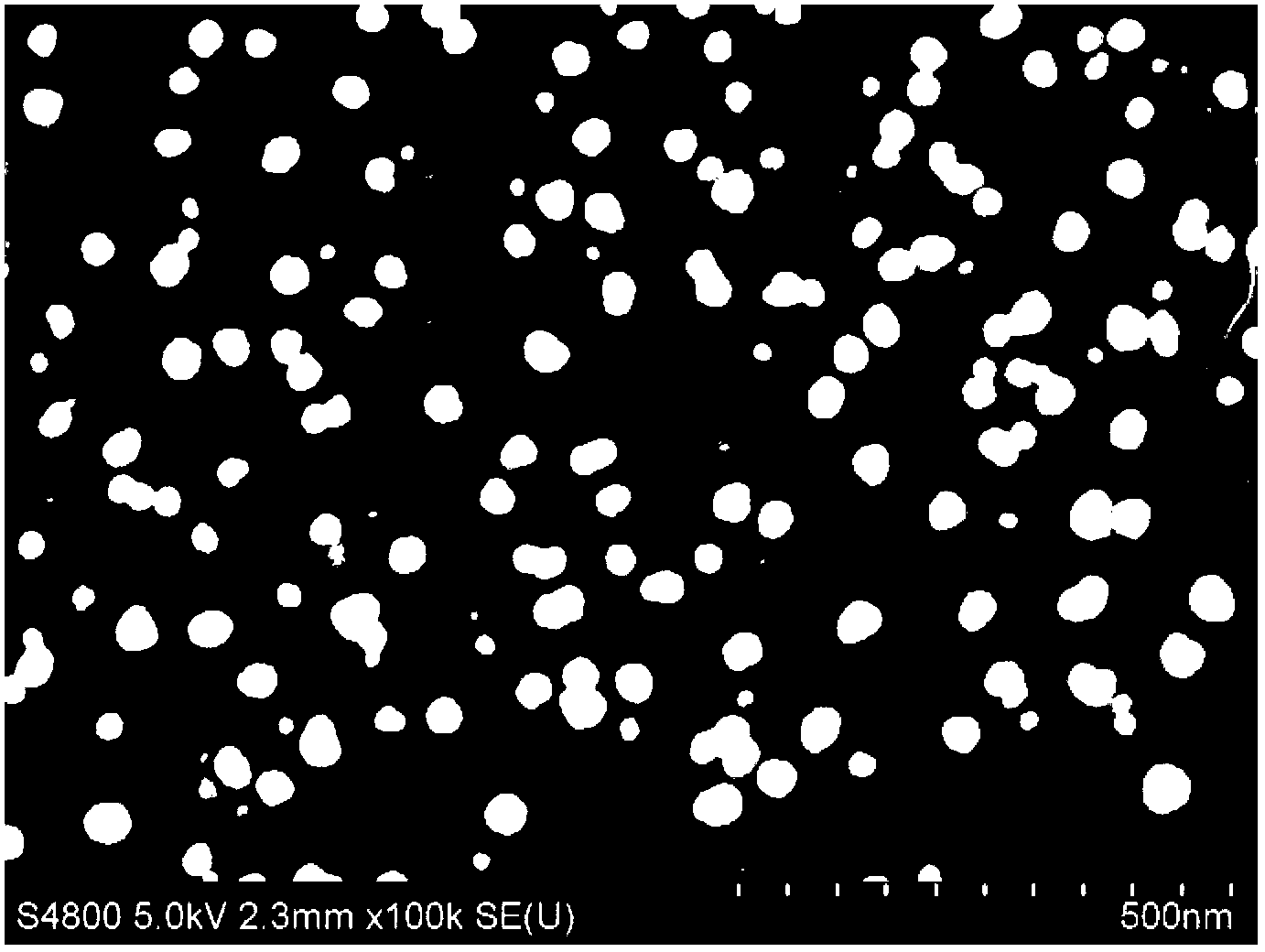

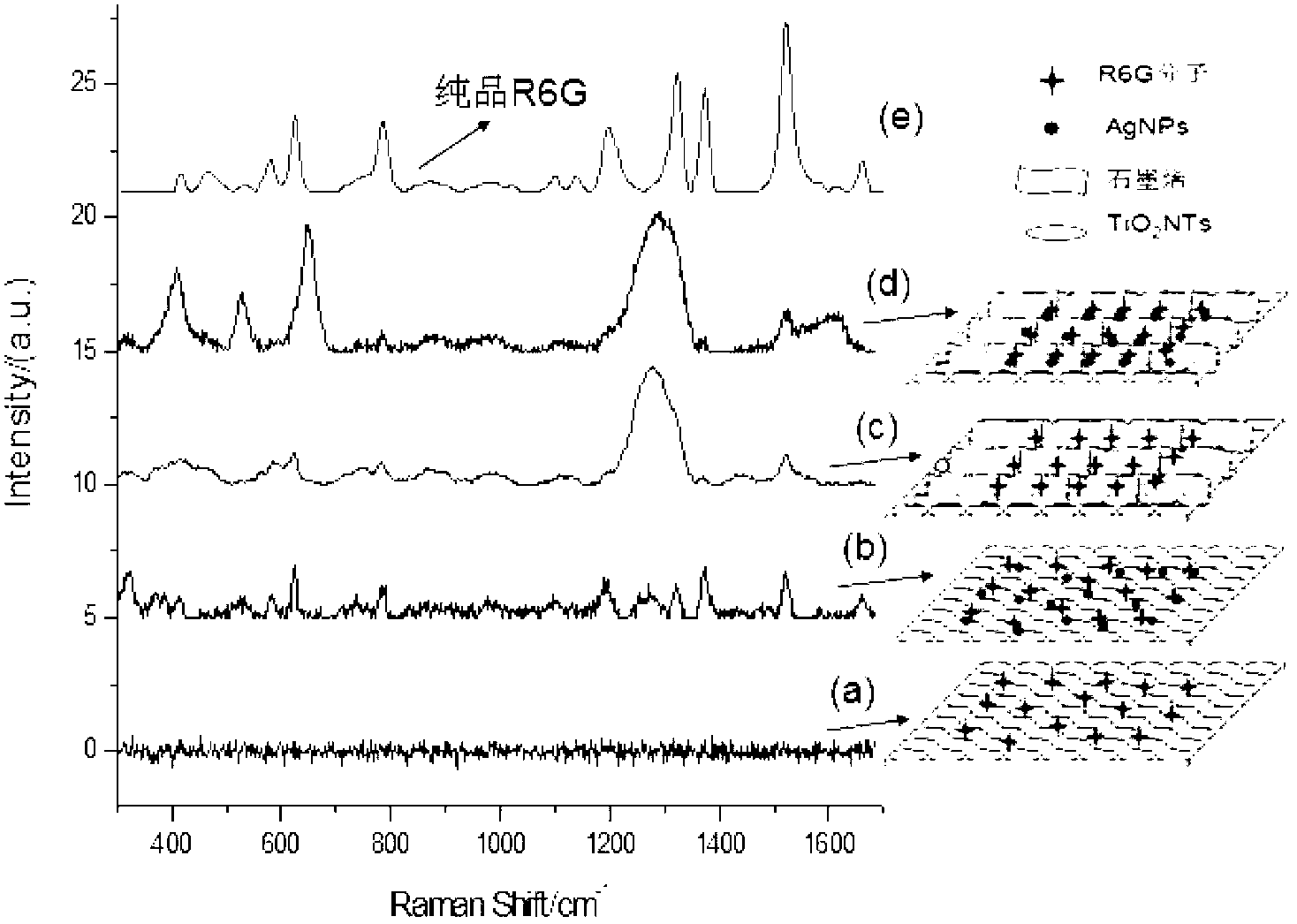

Raman reinforced substrate material, preparation and application methods thereof

InactiveCN102706853AShort detection timeEasy to handleRaman scatteringNanotechnologyHazardous substanceSimple sample

The invention discloses a raman reinforced substrate material, preparation and application methods thereof. A preparation method comprises the following steps: firstly, preparing a TiO2 nanometer tube array; depositing graphene on the TiO2 nanometer tube array; and lastly, dropwise adding nanometer silver sol to the surface of a substrate, thereby forming a compound material after the nanometer silver sol is dried. The convenient and quick detection for various harmful substances in an environmental sample, especially for benzo (a) pyrene, can be realized by using a raman reinforced substrate. A new method for detecting the benzo (a) pyrene is provided according to an application method of the raman reinforced substrate material. Compared with a traditional method, a surface reinforced raman detection method using the raman reinforced substrate material has the advantages of short detection time and simple sample treatment.

Owner:HUNAN UNIV

Preparation method of filter tip fibers for selectively adsorbing benzopyrene and phenol

InactiveCN104815630AImprove adsorption capacityImprove featuresOther chemical processesTobacco smoke filtersFiberGraphite oxide

The invention relates to a preparation method of filter tip fibers for selectively adsorbing benzopyrene and phenol. The preparation method comprises the steps of firstly, performing oxidation treatment on graphite to obtain graphene oxide, performing ultrasonic treatment on the graphene oxide to prepare an aqueous solution or preparing a mixed aqueous solution from the graphene oxide with chitosan, next, dipping the fibers into the aqueous solution of the graphene oxide or in the mixed solution of the graphene oxide and the aqueous solution of the chitosan, drying in vacuum for 6 hours at 80 DEG C, and finally, obtaining the filter tip fibers. According to the preparation method, the chitosan is evenly attached on the surface of the fibers and a remarkable effect of reducing phenol harmful substances can be achieved. Meanwhile, due to strong Pi-Pi interaction between the graphene and the benzopyrene, the graphene modified filter tip is capable of effectively retaining the strong carcinogenic substance benzopyrene in the smoke of cigarette. The preparation method is simple, relatively high in efficiency and low in environmental pollution; meanwhile, the fibers can be modified after the graphene and the chitosan are compounded, and the synergistic effect of the graphene and the chitosan in removing arene harmful substances can be developed; as a result, the preparation method has favorable application prospect.

Owner:WUHAN TEXTILE UNIV

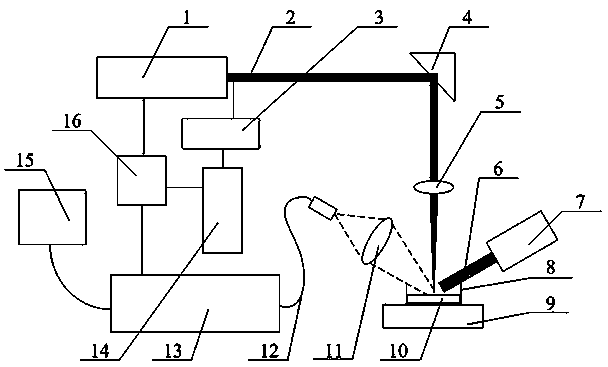

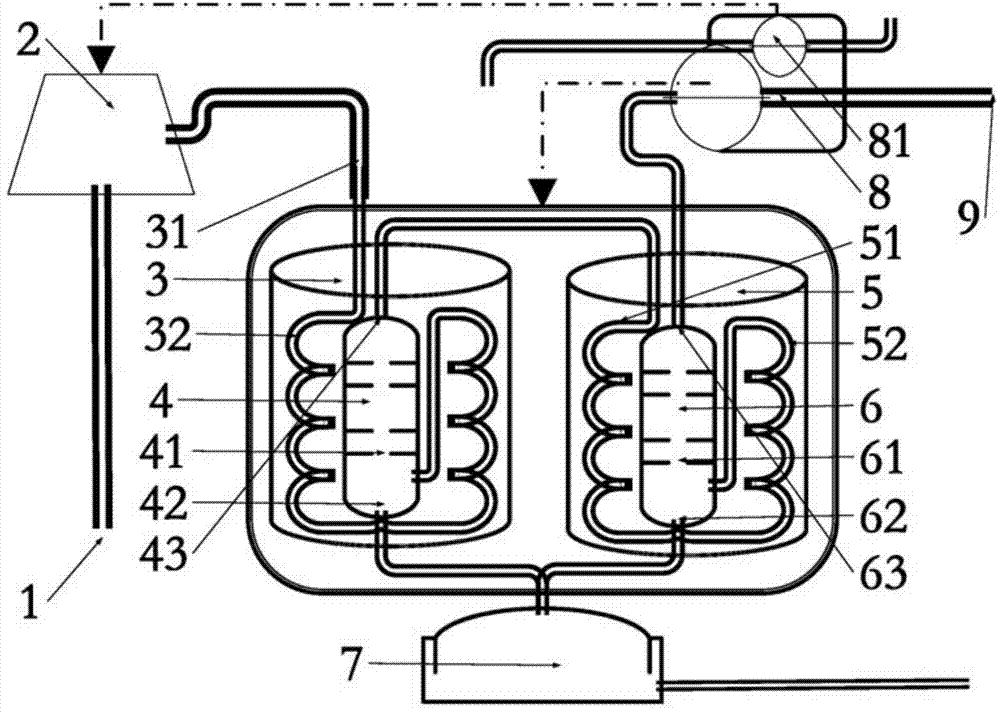

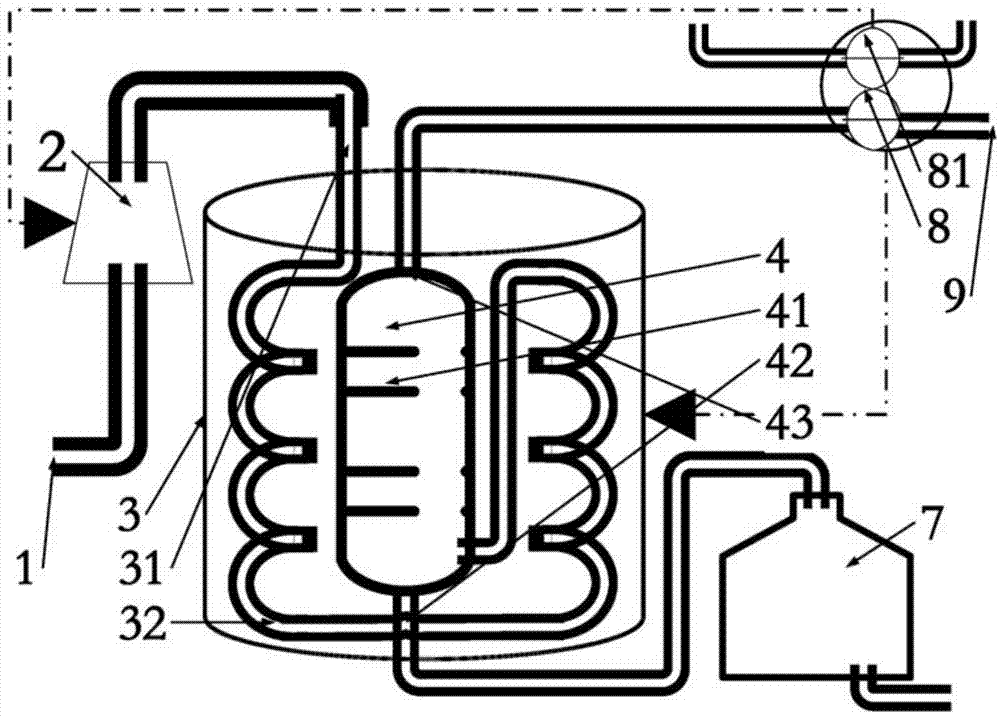

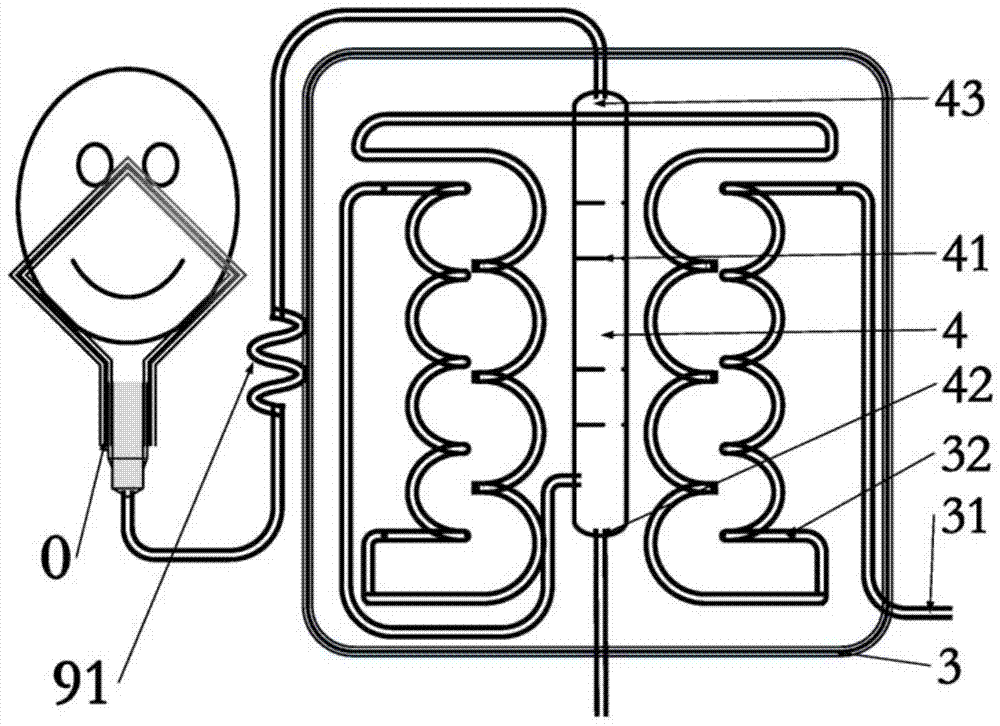

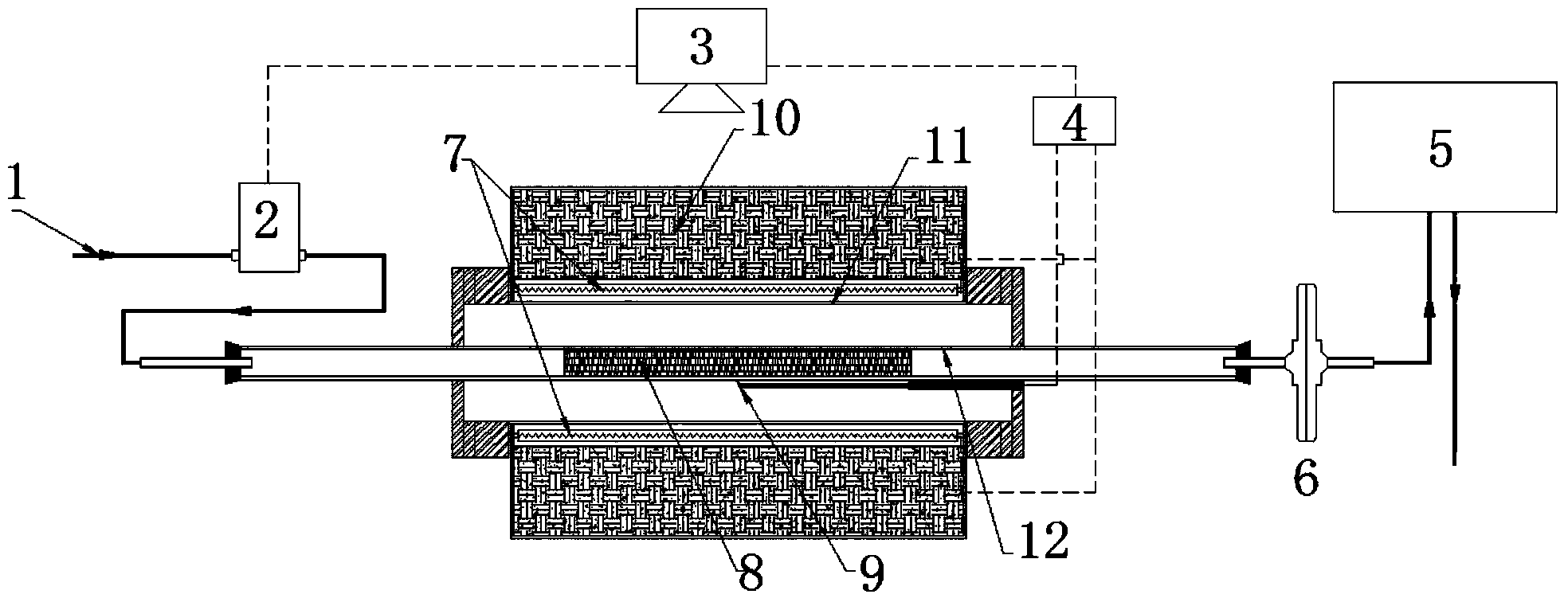

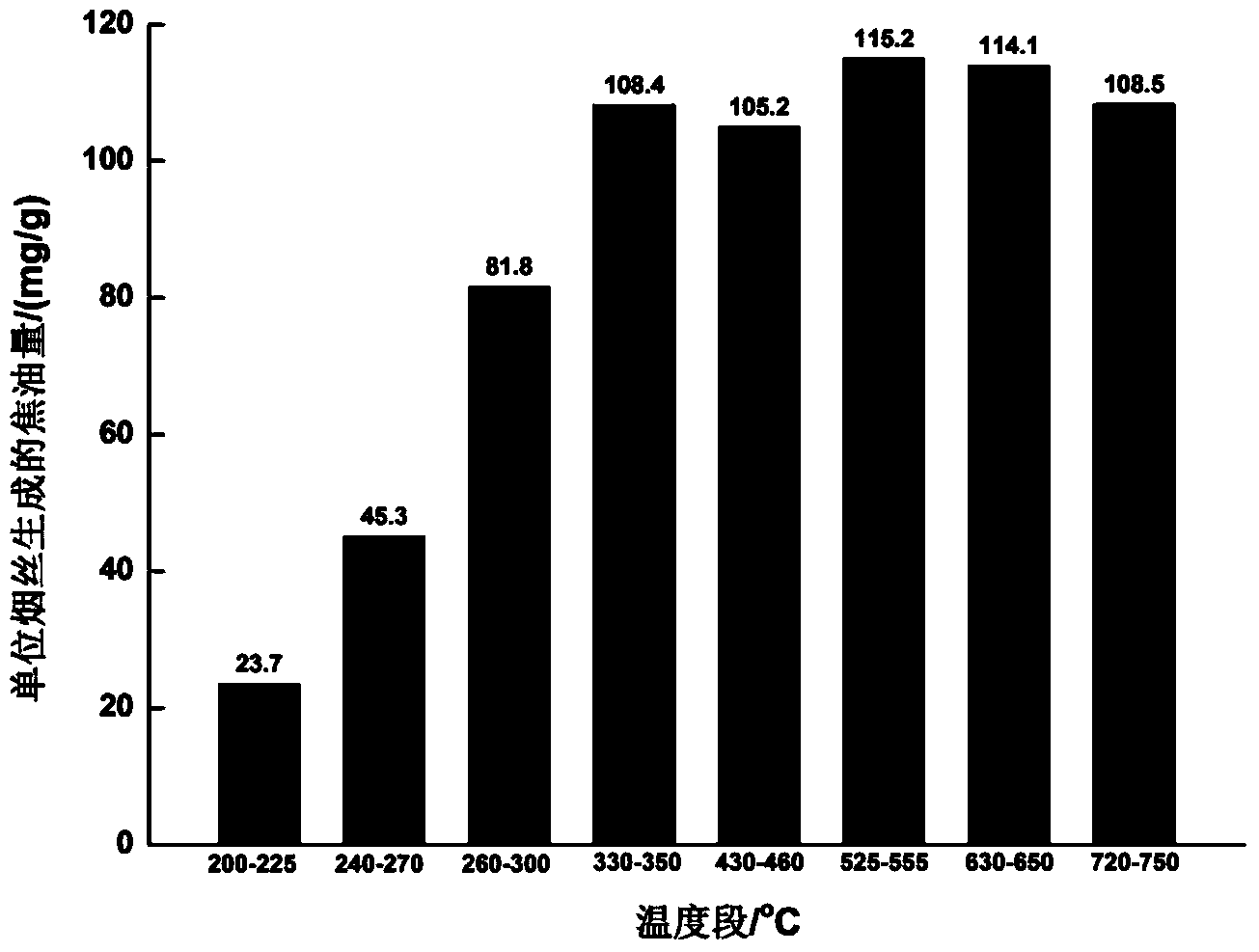

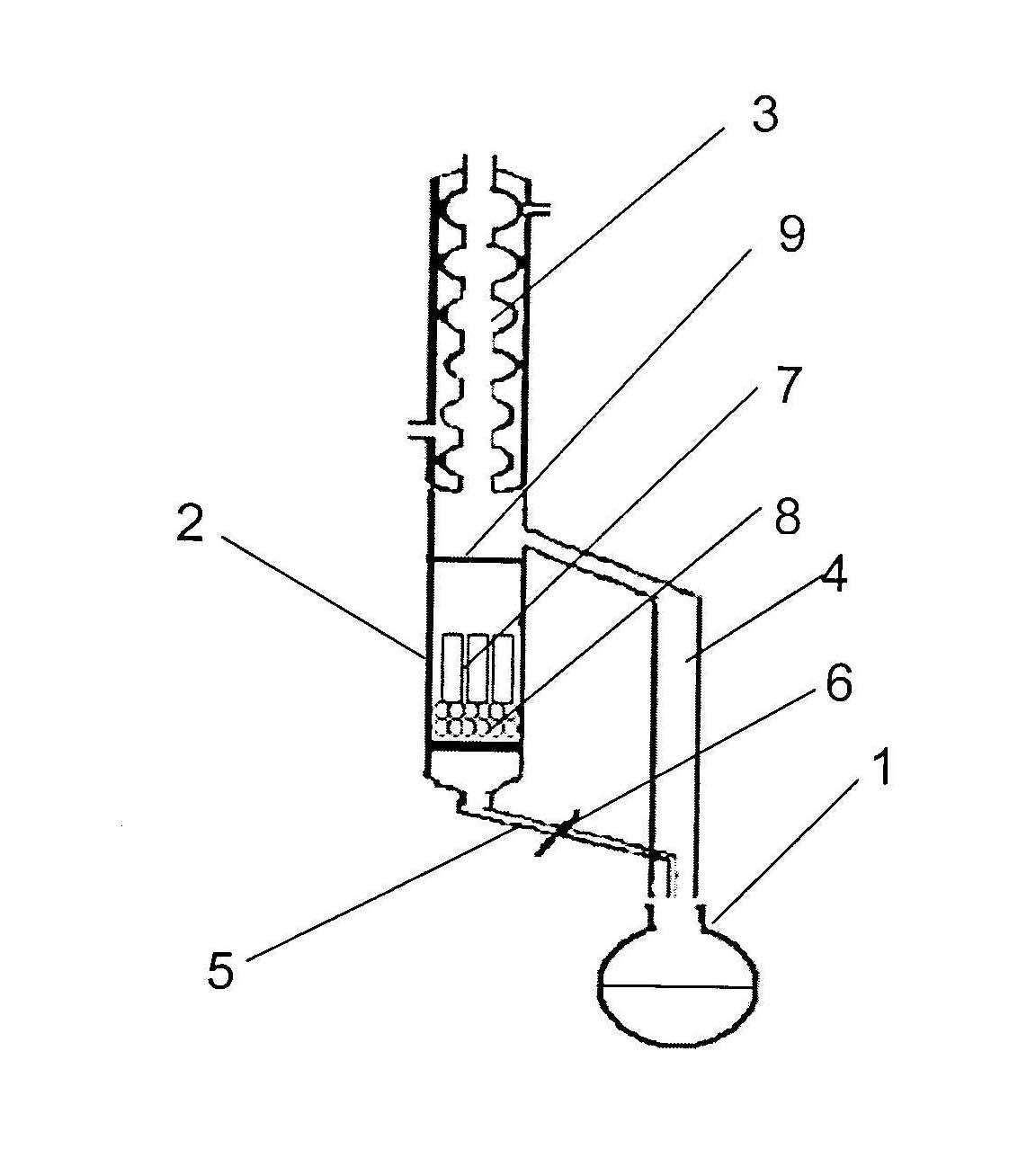

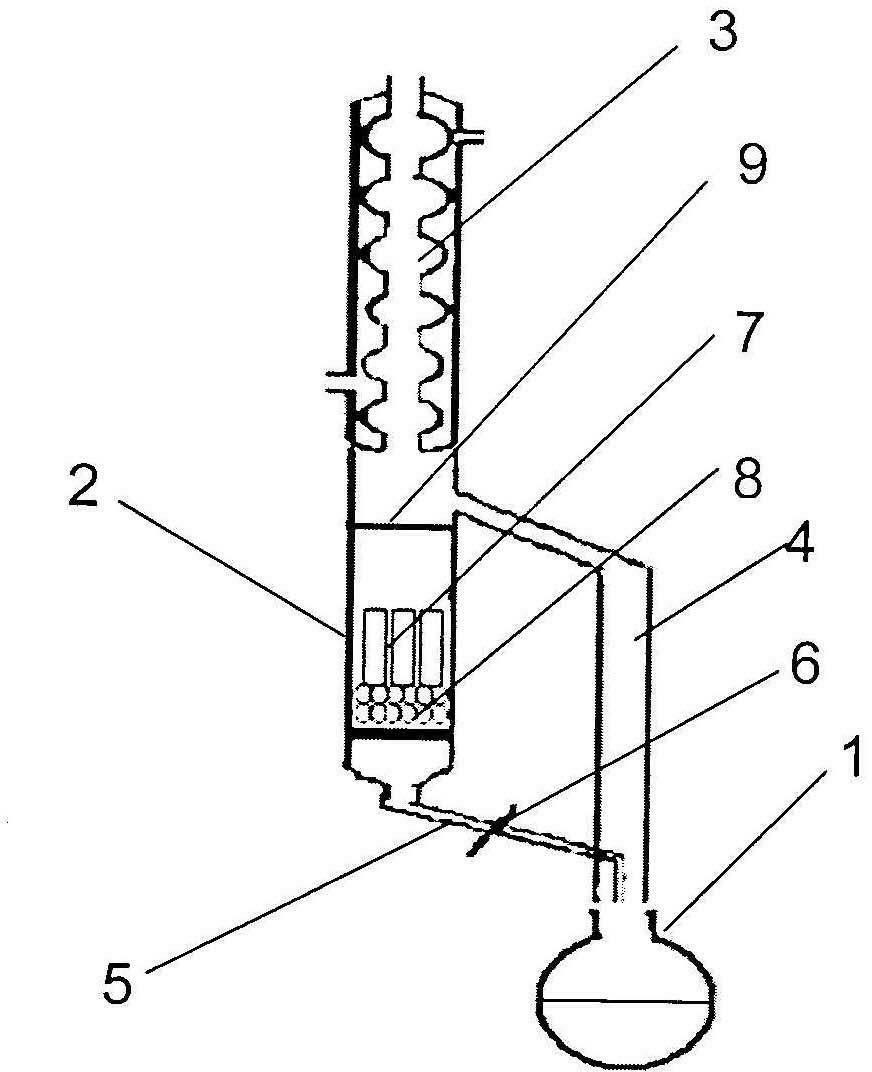

Tobacco pyrolysis and combustion reactor, analysis system and method

ActiveCN104267140AControl combustion temperatureControl burn timeChemical analysis using combustionTobacco devicesTarCoal tar

The invention belongs to the field of tobacco industry and relates to a tobacco pyrolysis and combustion reactor, an analysis system and a method. The tobacco pyrolysis and combustion reactor, the analysis system and the method have the benefits that the fast pyrolysis and combustion reaction of a lot of tobacco shreds under different atmosphere and different temperature conditions can be realized, and the online detection can be carried out on gas phase components like CO, CO2, O2 and H2 in flue gas; meanwhile, a Cambridge filter is used for collecting particle phase components, so that the generation situations of moisture, tar, nicotine, aroma components and / or other harmful components (NH3, HCN, phenol, crotonaldehyde, polycyclic aromatic hydrocarbon, benzopyrene and the like) can be obtained. Through the analysis system, an experimental platform is provided for the mechanism study on the generation of main flue gas components in the tobacco pyrolysis and combustion processes.

Owner:CHINA TOBACCO FUJIAN IND +1

Pickling method of preserved meat

InactiveCN101816434AGuaranteed to be moderately saltyKeep freshFood preparationBurned skinAbsorption capacity

The invention discloses a pickling method of preserved meat, which mainly comprises the following steps: cutting into strips-smearing seasonings-pickling-smoking-burning skin-cleaning-baking; the pickling steps of the method can lead a meat product to be tasty fast and have good tasting effect, the meat product is salty moderately and can avoid fat oxidation during the pickling process and preserve the fresh flavor of meat; the smoking temperature and the time are reasonably controlled during the smoking process, thereby leading the aroma of smog to be fully absorbed in the meat product and simultaneously avoiding meat stiffening due to excessive dehydration of cells; a condensing tube is adopted for condensing benzopyrene in the smog, thereby reducing the absorption capacity of the benzopyrene on the surface of the meat product and reducing the residual rate; the skin burning step can not only remove hair roots in the meat skin, but also lead the meat skin to be soft after boiling the preserved meat and facilitate the consumption; the cleaning step can clean dust particles on the surface of the meat product and further reduce the residue of the benzopyrene; and the meat product is dried at the specific temperature till the water content reaches 20%-25%, the meat product has good elasticity and high viscosity during the consumption, a consumer can not feel dry and astringent, and the taste is more comfortable.

Owner:巫溪县红池腊鲜食品有限公司

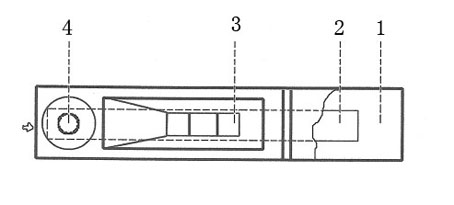

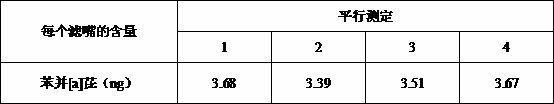

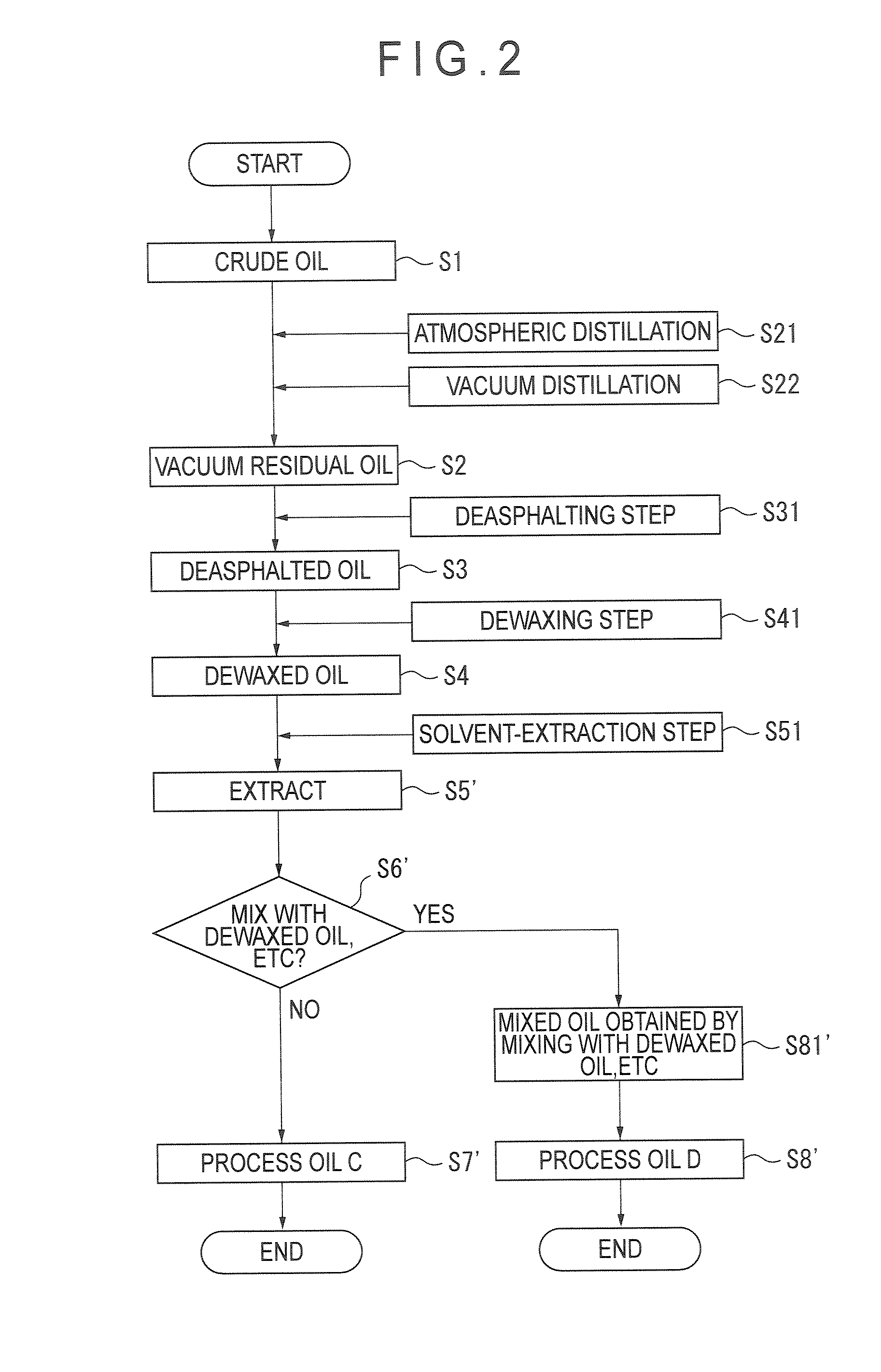

Method for measuring interception amount in filter tip to benzo(a)pyrene in main stream smoke of cigarette

The invention provides a method for measuring the interception in a filter tip to benzo(a)pyrene in a main stream smoke of a cigarette, which is characterized by comprising the following steps of: 1) selecting an extracting agent; (2) heating and gasifying the extracting agent, so as to enable condensed liquid of the gasified extracting agent to flow through the filter tip to extract the benzo(a)pyrene in the filter tip; 3) purifying extracted liquid by using a purifying material, and then heating and gasifying again; (4) circularly heating, gasifying, extracting and purifying; and 5) carrying out GC-MS (Gas Chromatograph-Mass Spectrometer) quantitative analysis the final extracted liquid. According to the principles disclosed by the invention, a boiling point of the benzo(a)pyrene is higher than that of the extracting agent, and therefore, the extracting agent in the extracted liquid is heated and gasified again, and the benzo(a)pyrene is remained. After the operations are carried out in a circulating way for a while, the benzo(a)pyrene in the filter tip is entirely extracted and a residual extracting agent is finally gasified out. Finally, the GC-MS quantitative analysis is carried out on concentrated liquid. The method disclosed by the invention integrates extraction, purification and concentration, has few operation steps and is simple and liable to operate.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

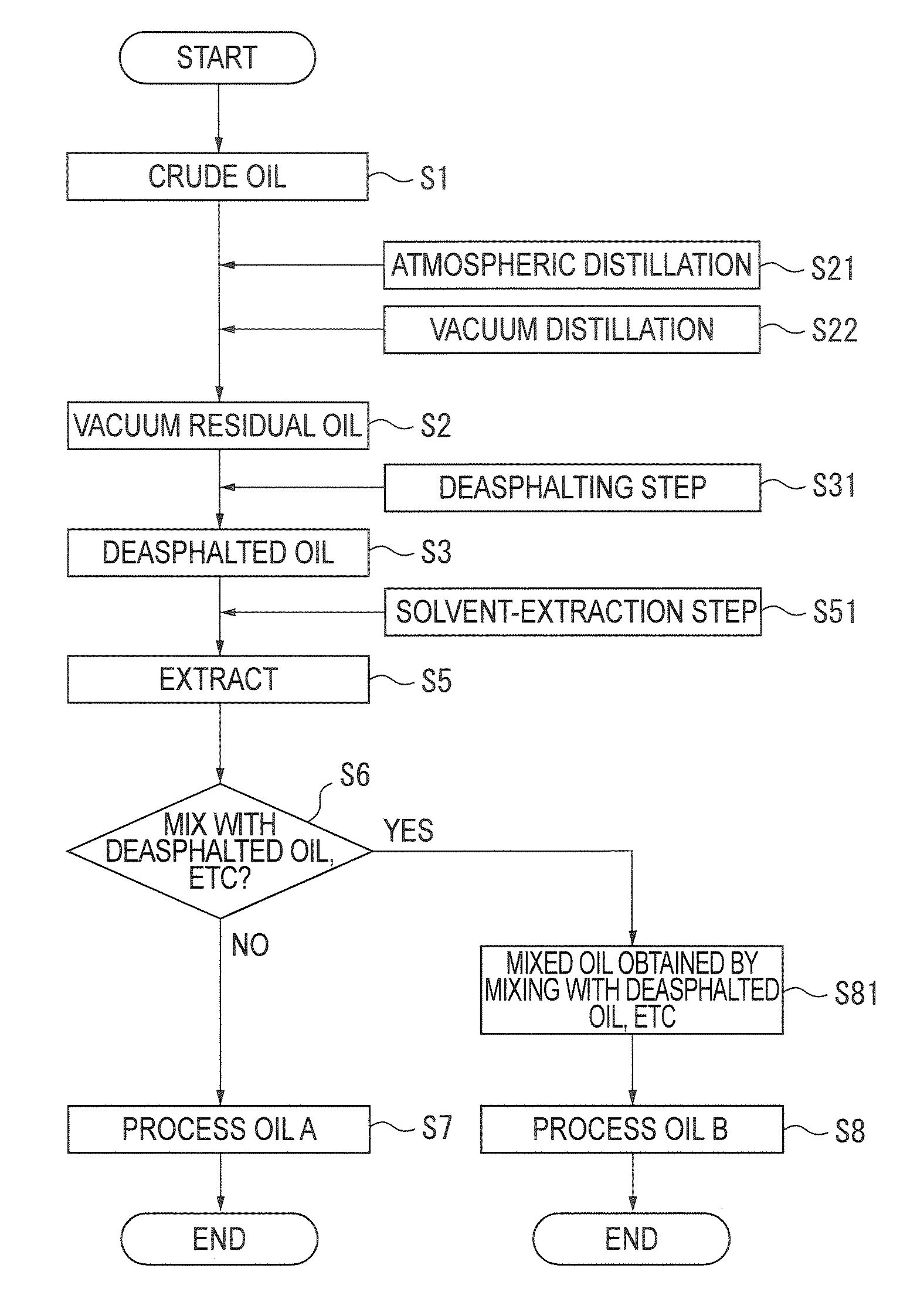

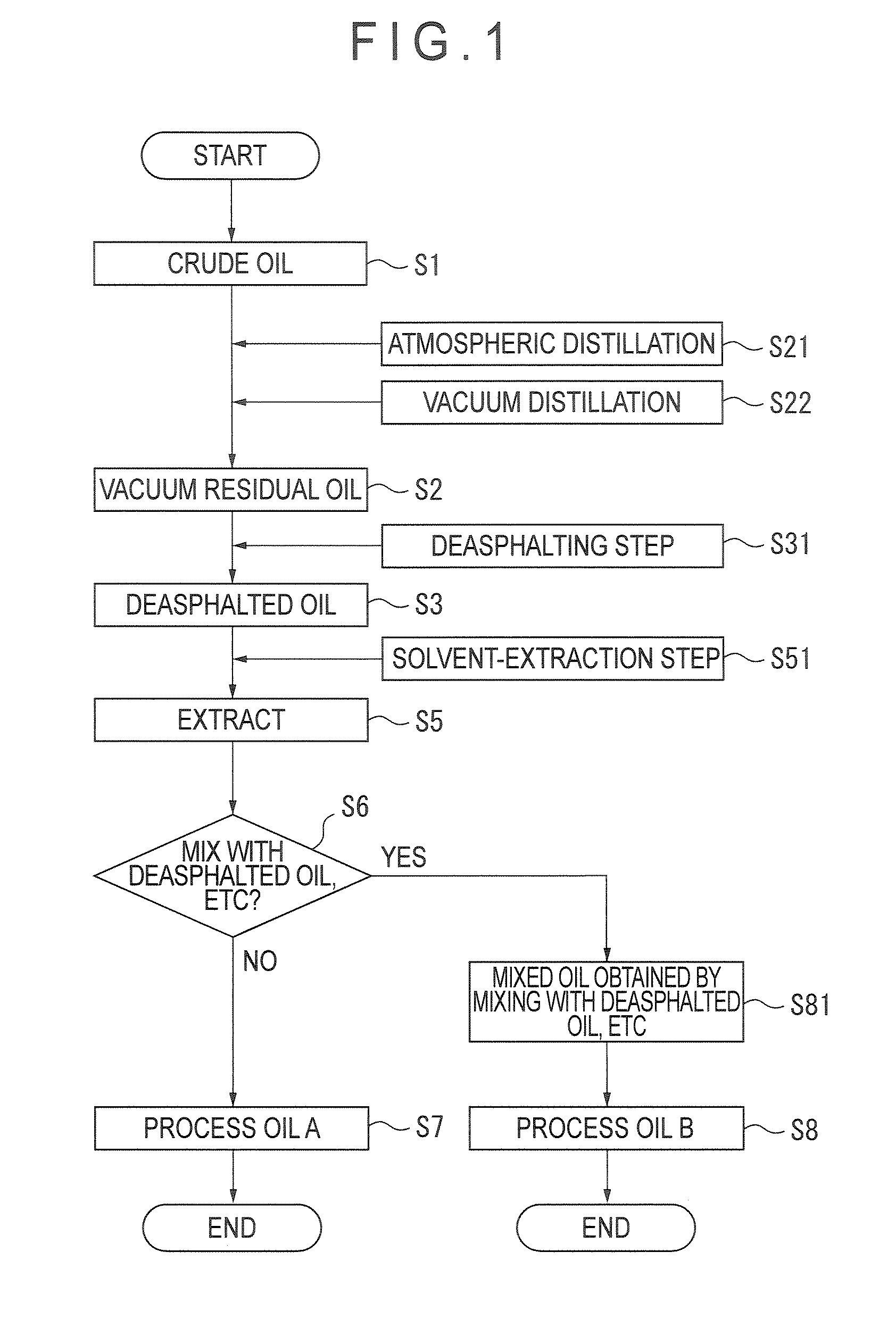

Process oil, process for production of deasphalted oil, process for production of extract, and process for production of process oil

InactiveUS20090020453A1Improve securityProvide accuratelyWorking-up pitch/asphalt/bitumen by selective extractionLiquid carbonaceous fuelsAniline pointResidual oil

The present invention is related to a process oil using as a raw material a deasphalted oil obtained by deasphalting a vacuum residual oil of a crude oil and a manufacturing method of the process oil, the process oil having properties of:(a) a polycyclic aromatics (PCA) content of less than 3 mass %;(b) a viscosity (100° C.) of 40 to 70 mm2 / s;(c) an aniline point of 85 to 100° C.;(d) a flash point of 250° C. or higher;(e) an aromatic hydrocarbon content of 40 to 55 mass %; and(f) a polar substance content of 10 to 15 mass %.The present invention is also related to a process oil and a manufacturing method of the process oil, the process oil obtained by mixing: an extract obtained by deasphalting and solvent-extracting a vacuum residual oil of a crude oil; and a lubricant base oil having a polycyclic aromatics (PCA) content of less than 3 mass %, and having properties of:(a) a polycyclic aromatics (PCA) content of less than 3 mass %;(i) a viscosity (100° C.) of 30 to 80 mm2 / s;(j) an aniline point of 90° C. or lower;(k) a flash point of 240° C. or higher;(l) a benzo(a)pyrene content of 1 mass ppm or less;(m) a specified aromatic compound content of 10 mass ppm or less; and(n) a polar substance content of 10 to 30 mass %.

Owner:IDEMITSU KOSAN CO LTD

2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds and organic light emitting device containing same

ActiveCN104649961AGood electron transport propertiesGood chemical and thermal stabilityOrganic chemistrySolid-state devicesCyclic compoundPhotochemistry

The invention relates to a kind of 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds shown by formula (1) in the specification, wherein R1 and R2 are selected from C6-C50 aryl, substituted C6-C50 aryl or C1-C20 alkyl; or R1 and R2 are bonded through other groups to form a cyclic compound, Ar1 and Ar2 are separately selected from C5-C30 electron-deficient nitrogen-containing heterocyclic aromatic hydrocarbon, substituted nitrogen heterocyclic aromatic hydrocarbon or thick nitrogen-containing heterocyclic aromatic hydrocarbon or C6-C30 aromatic hydrocarbon or polycyclic aromatic hydrocarbon with the nitrogen-containing heterocyclic aromatic hydrocarbon substituent. The invention also provides an application of the compounds in an organic light emitting device (OLED) and particularly application of the compounds as an electron transport material and a fluorescent or red phosphorescence host material in the OLED device.

Owner:GUAN ETERNAL MATERIAL TECH

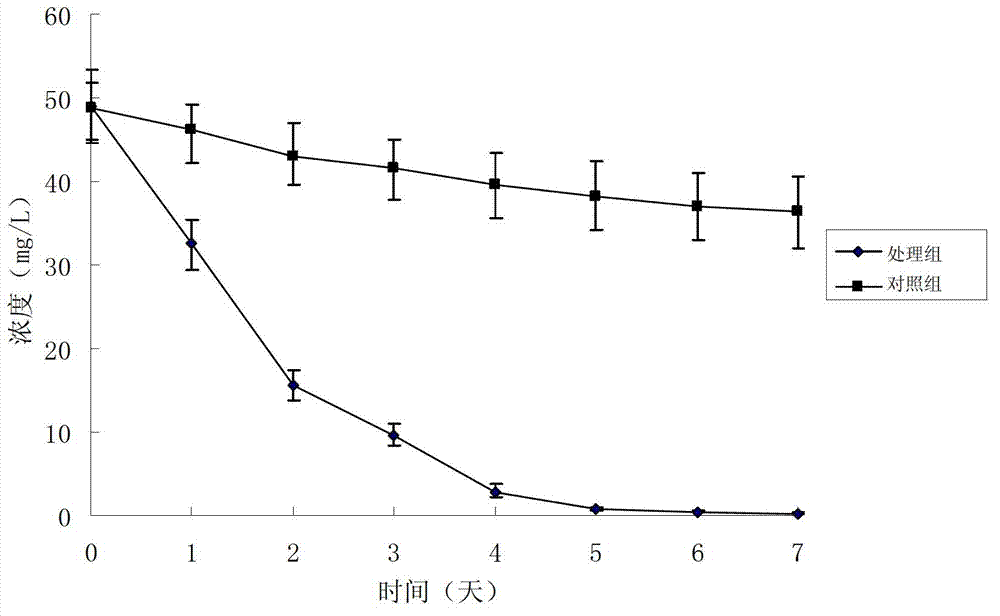

Mycobacterium 16F for efficiently degrading polycyclic aromatic hydrocarbons and benzene organic matters and application thereof

ActiveCN102899271AEfficient degradationDegradation safetyBacteriaMicrobiological testing/measurementKanamycinM-Xylene

The invention provides a strain of Mycobacterium sp.16F for efficiently degrading polycyclic aromatic hydrocarbon and benzene organic matters, which has a preservation number of CGMCC No.6367. The mycobacterium 16F can efficiently, safely and rapidly degrade polycyclic aromatic hydrocarbons and benzene organic matters, can grow and degrade by using fluorene, naphthalene, anthracene, acenaphthene, phenanthrene, pyrene and benzopyrene as the sole carbon source and energy in aerobic condition, and can utilize benzene, m-xylene, toluene, salicylic acid, catechol and other multiple aromatic organic matters. The mycobacterium 16F is sensitive to streptomycin, rifampin, tetracycline, kanamycins and other antibiotics, has good degradation effects to mixed polycyclic aromatic hydrocarbons in aging soils and monocyclic benzene organic matters in water bodies, can be used for restoring and purifying the water-soil environment combinedly polluted by aromatic hydrocarbon organic matters, is important for promoting sustainable development, and has a wide application prospect.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

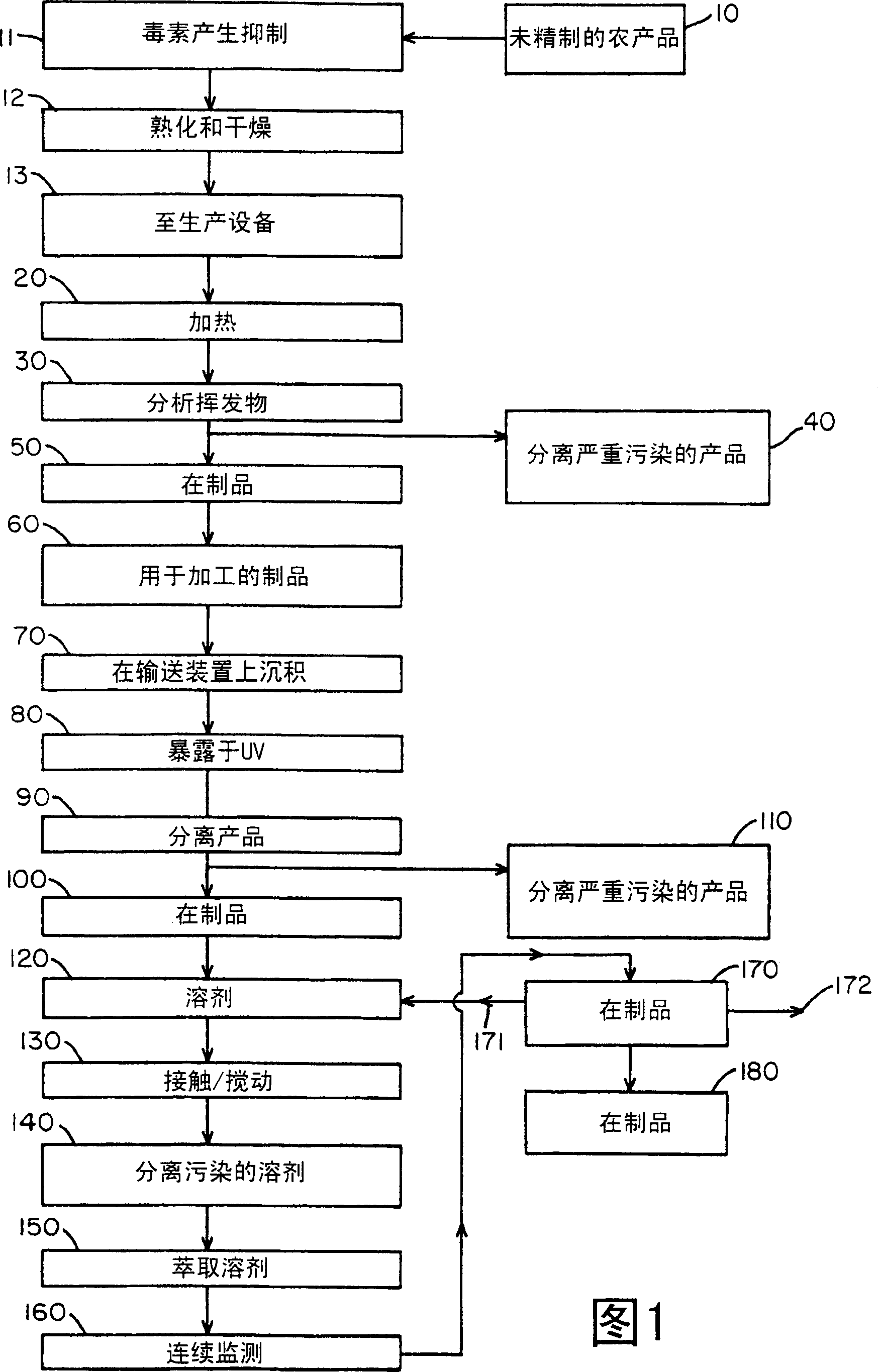

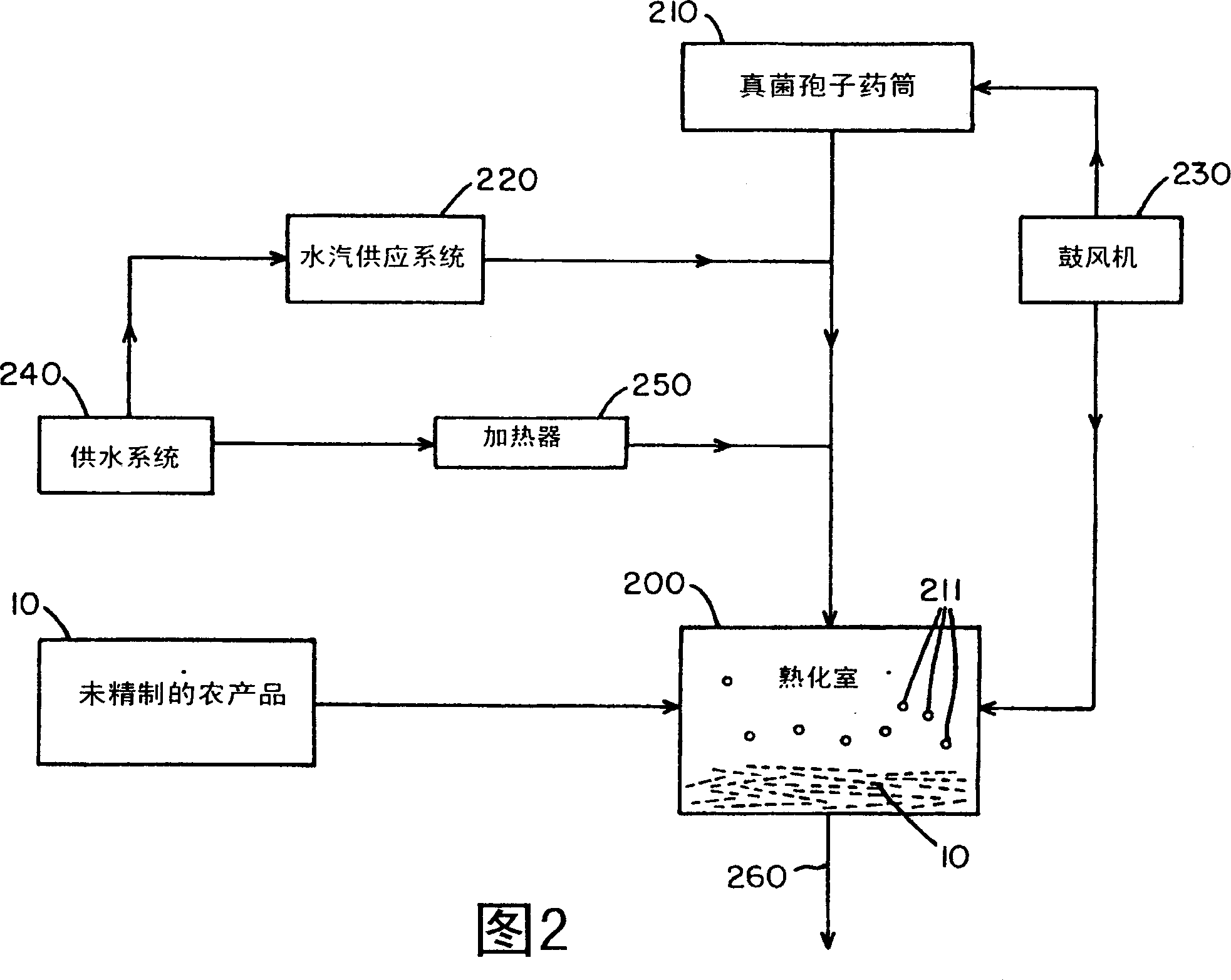

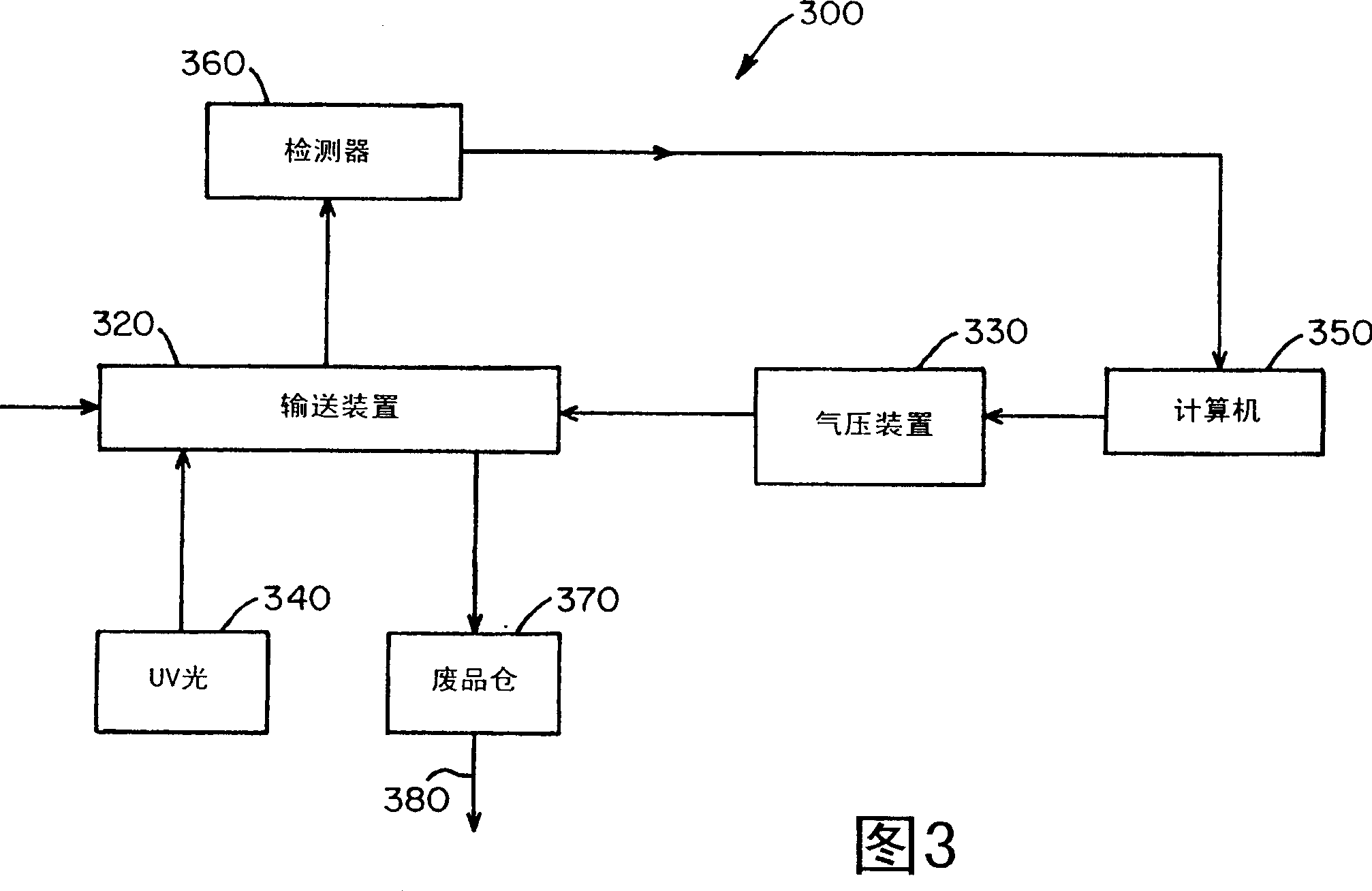

Method and system for assay and removal of harmful toxins during pocess of tobacco products

InactiveCN1384714AInhibitionReduce toxin levelsTobacco preparationOrganic chemistryQuality controlEndotoxin Contamination

The present invention relates to methods and systems for the continuous analysis (160) and removal (410) of toxins from tobacco. Products, such as tobacco contaminated with mycotoxins, especially aflatoxins and benzopyrene and their precursors, are treated, usually in a solvent medium, to remove the toxin contamination from the tobacco. As an example, all noxious toxins eluted from the wash solvent (150) are continuously monitored (160) by immunoantibody UV fluorescence analysis. A quality control process ensures that harmful toxins are removed from the tobacco before further processing. Purification of extraction solvent streams and readditives ensures safe reuse or disposal of solvents or readditives.

Owner:凯丽·斯科特·莱恩

Method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine

InactiveCN103063791AOptimizing enzymatic conditionsOptimizing Solid Phase Extraction ConditionsComponent separationChromatographic separationRotary evaporator

The invention discloses a method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine. The method comprises sequentially using beta-glucuronidase for enzymatic hydrolysis of samples, performing solid-phase extraction and purification, concentrating the samples with a vacuum rotary evaporator, and determining by using a liquid chromatography-tandem mass spectrometer, thereby rapidly, accurately and simultaneously detecting contents of 1-hydroxy pyrene (1-OHP), 3-hydroxy benzo [a] pyrene (3-OHB [a] P) and 3-hydroxy benzo [a] anthracene (3-OHB [a] A) in the urine. The method uses deuterated standards as quantitative analysis substances of internal standards and thus can reduce errors in a pretreatment process for the samples; uses a tandem mass spectrometer to relatively improve selectivity and accuracy of the method; and selects a method of preparing standards by matrices, wherein, compared with a method of preparing the standards by pure water, the method of preparing standards by matrices is relatively good in accuracy and can eliminate interference from matrix effects. Through selecting and optimizing chromatographic columns and gradient elution conditions, the method relatively improves a chromatogram separating process and shortens a chromatographic analysis time.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

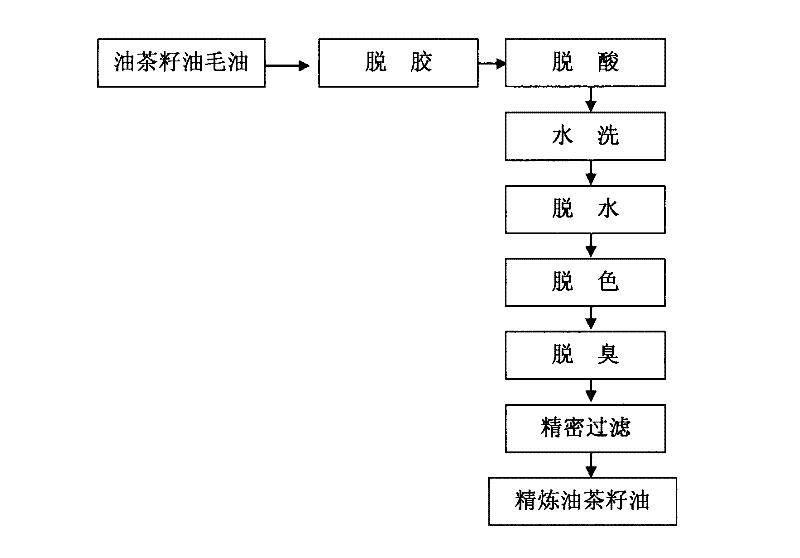

Method for removing benzopyrene in oil-tea camellia seed oil

Provided is a method for removing benzopyrene in oil-tea camellia seed oil. Crude oil-tea camellia seed oil with benzopyrene exceeding the standard serves as a raw material, by means of the processes including degumming, deacidification, washing, adsorption and deodorization refining, particularly selection and control of an adsorbent, benzopyrene in the original oil-tea camellia seed oil with benzopyrene exceeding the standard can be removed or reduced to meet the requirement of national standard. The method for removing benzopyrene in oil-tea camellia seed oil is simple and practical and can remarkably reduce content of benzopyrene in the oil-tea camellia seed oil, and extra refining equipment is not needed.

Owner:GUANGXI FORESTRY RES INST

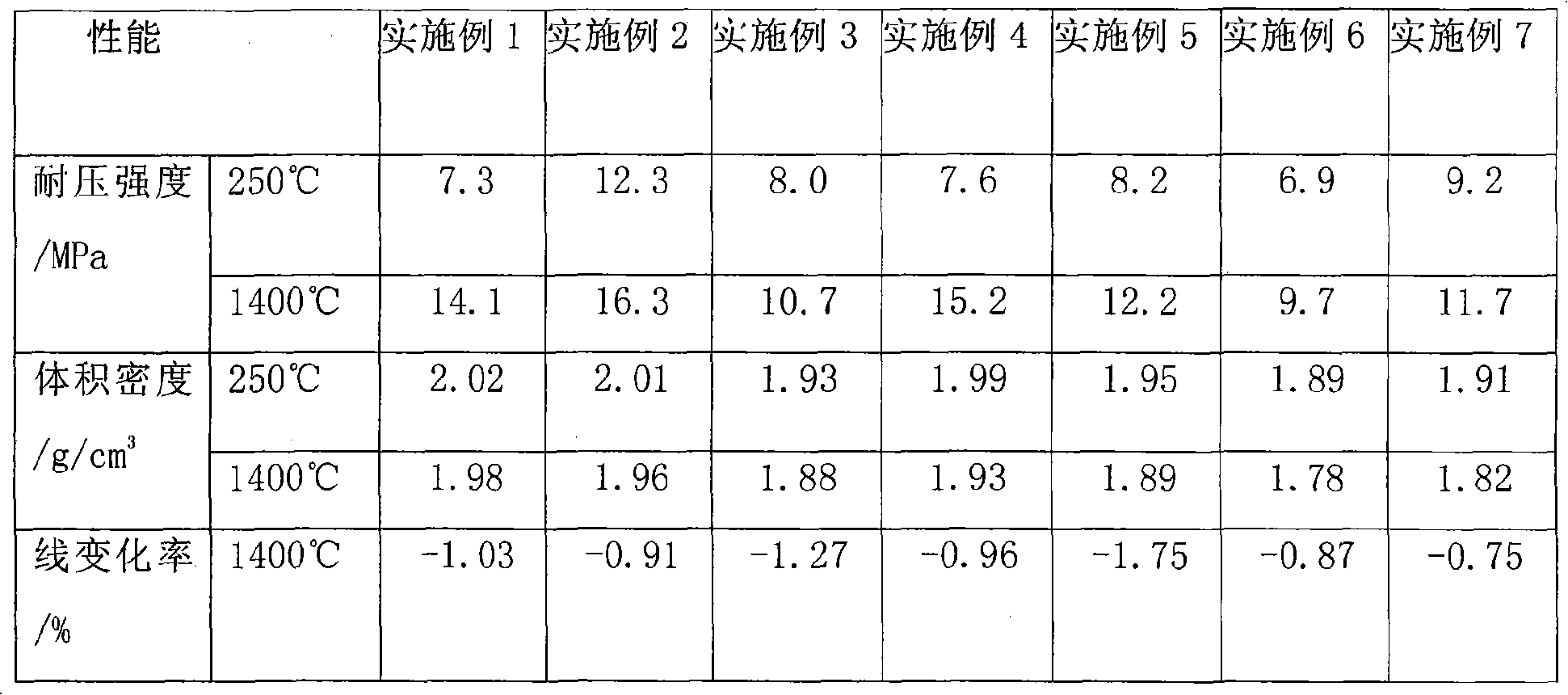

Blast furnace mud gun with low content of benzopyrene

InactiveCN101580397AHigh temperature strengthEasy to operateBlast furnace componentsBlast furnace detailsRefractorySolvent

The invention discloses a blast furnace mud gun with low content of benzopyrene which is not more than 1000 ppm. The invention comprises the following components according to the parts by weight: 10-25 parts of carbonaceou resin with 30-85% of fixed carbon content (weight percentage), 75-121 parts of fire proof material matrix, and 0.06-15 parts of carbonaceou resin solvent. The invention has low content of benzopyrene which is not more than 1000 ppm; the amount of harmful gases is greatly reduced, the operation performance of the mud gun is improved, the high temperature intensity of the mud gun is high, the combination performance is good, and after sintering the anti-corrosion property is increased, therefore the durability of the mud gun is improved so as to play an active role of maintaining the service life of blast furnace.

Owner:武汉钢铁有限公司

Cigarette filter tip adsorbing material and preparation method thereof

InactiveCN102553543AEffective filteringProtect healthOther chemical processesTobacco smoke filtersHazardous substanceN nitrosamines

The invention discloses a cigarette filter tip adsorbing material and a preparation method thereof. The adsorbing material has a porous structure and is processed by pickling shaddock skin inner layer, drying, crushing and granulating. The adsorbing material can effectively filter out tar, nitrosamine, benzopyrene and other hazardous substances generated during cigarette burning, thereby well protecting smoker health, has no off-flavor or off-odor when cigarette smoke gas passes, can also improve smoking mouthfeel and cigarette grade, has good processability and is favorable to manufacture of the cigarette filter tip adopting the material.

Owner:丰顺县洋西坑生态农业科技有限公司

2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound and organic electroluminescence device containing same

ActiveCN104628581AImprove luminous efficiencyReduce the driving voltageOrganic compound preparationSolid-state devicesAnthraceneBenzene

The invention relates to a 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound as shown in the formula (I), wherein R1 and R2 are selected from C6-C50 aryls, substituted C6-C50 aryls and C1-C20 alkyls or form a ring compound through being connected through other groups; A1 and A2 are respectively and independently selected from diarylamino as shown in the general formula (2'), or A2 is hydrogen, and A1 is selected from diarylamino as shown in the general formula (2); and Ar3 and Ar4 are independently selected from benzene rings with 6-50 carbon atoms, substituted benzene rings or other thick aromatic rings such as naphthalene and anthracene. The invention also discloses application of the compound to an organic electroluminescence device and particularly discloses application of the compound as a fluorescent material, a hole-transport material and a hole-injection material in an OLED (organic light emitting diode) device.

Owner:BEIJING ETERNAL MATERIAL TECH

Method for quickly detecting benzopyrene content of edible oil based on collinear double-pulse LIBS (Laser-induced Breakdown Spectroscopy) technique

InactiveCN104020143AReduce testing costsGuaranteed stabilityAnalysis by material excitationNon destructiveLaser-induced breakdown spectroscopy

The invention relates to a method for quickly detecting the benzopyrene content of edible oil based on a collinear double-pulse LIBS (Laser-induced Breakdown Spectroscopy) technique. The method comprises the following steps of collecting edible oil samples with different sources and different benzopyrene contents first; then performing analytical processing on the collected edible oil samples, and establishing a benzopyrene content prediction model; finally, processing to-be-detected edible oil, and then inputting into the established benzopyrene content prediction model, so as to quickly obtain the benzopyrene content of the to-be-detected edible oil. The method has the advantages of no need of sample pretreatment, no destruction, rapidity and real-time performance in detection, simplicity and convenience in operation and low time consumption, additionally, the real-time monitoring and the on-site quick sampling detection of the benzopyrene content in the production process of the edible oil can be satisfied, the working efficiency is effectively improved, and the labor intensity and the manufacturing cost are reduced.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Toxin reduced body building type cigarette and its producing method

InactiveCN1473519AReduce tar contentKeep it originalTobacco treatmentCigar manufactureNitrosamineAir temperature

The present invention relates to toxin reducing and body building cigarette and its production process. The material for the cigarette includes 15 kinds of Chinese medicinal materials epimedium, madder root, date, etc. and 7 kinds of Western medicine materials zinc sulfate, zinc oxide, etc. The cigarette is produce through a scientific process and each cigarette has tar content as low as less than 10 mg, nicotine content as low as less than 1 mg, nitrosamine and benzopyrene content lowered by 70 % and free radical content lowered by 60 %. It has the functions of antibiosis, diminishing inflammation, clearing away heat, eliminating phlegm, refreshment, etc.

Owner:王美岭

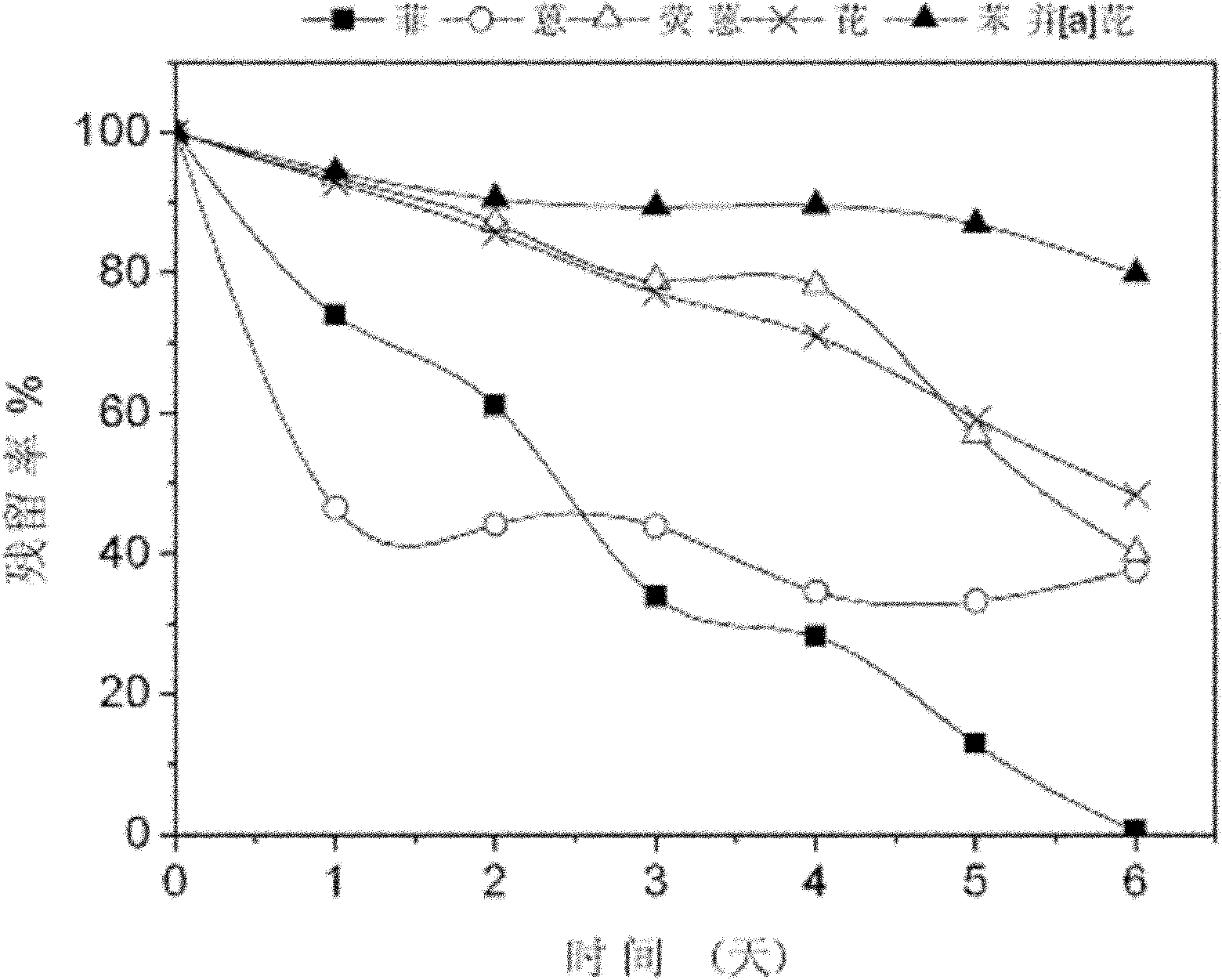

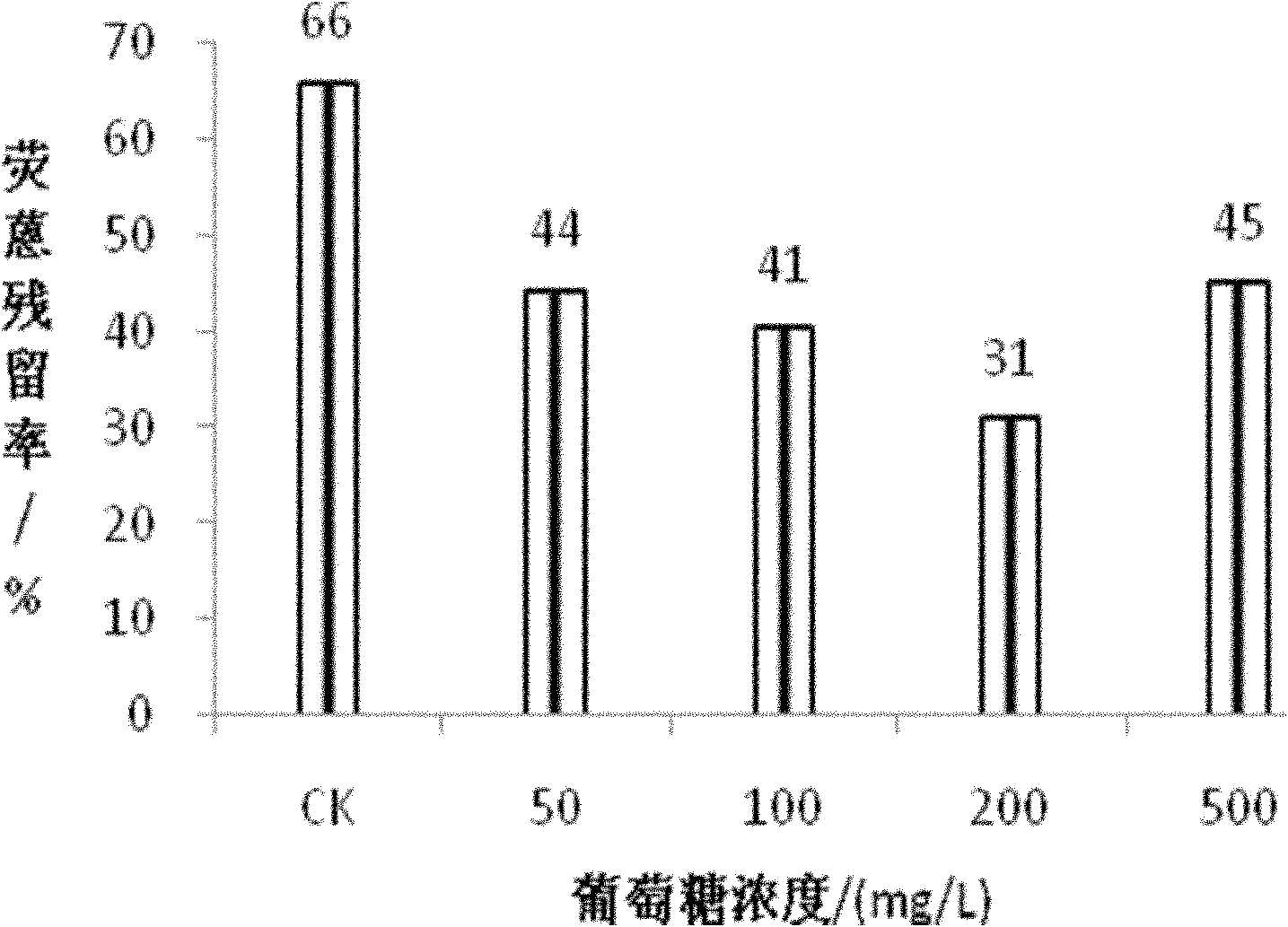

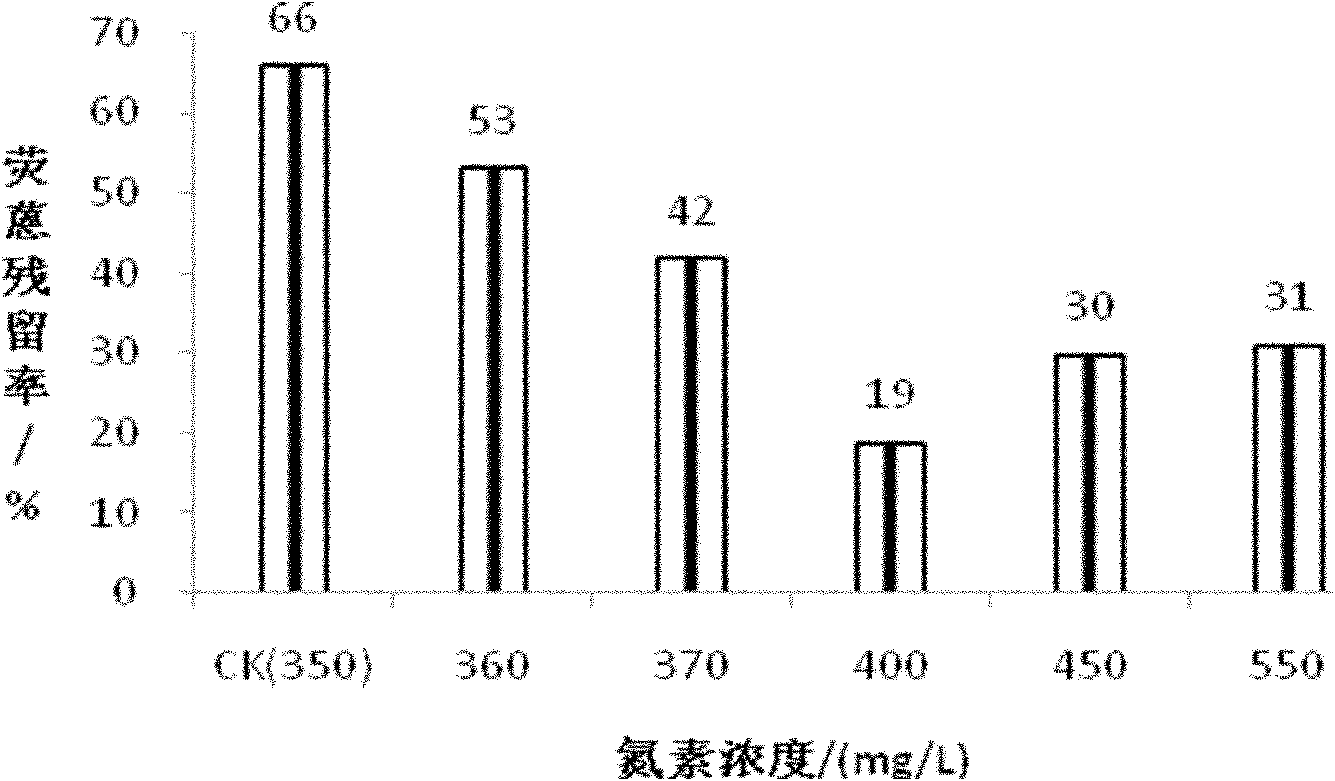

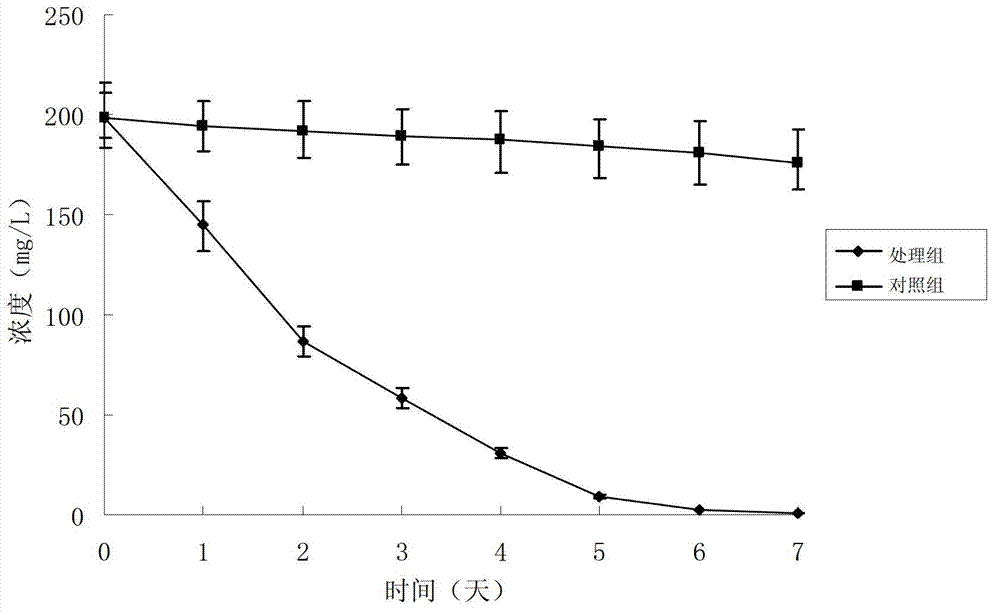

Sphingobium yanoikuyae and application thereof in degrading polycyclic aromatic hydrocarbon

The invention discloses a Sphingobium yanoikuyae and an application thereof in degrading polycyclic aromatic hydrocarbon. The Sphingobium yanoikuyae provided by the invention is named as LD29 with the strain collection number of CGMCC No.4400. The Sphingobium yanoikuyae LD 29 can grow and breed by respectively taking phenanthrene, anthracene, fluoranthene and pyrene as the only carbon source and energy source under the aerobic condition. In addition, the Sphingobium yanoikuyae LD 29 has a degrading effect on mixed polycyclic aromatic hydrocarbon, especially on pentacyclic benzopyrene [alpha] in the mixed polycyclic aromatic hydrocarbon. The Sphingobium yanoikuyae can be used for repairing soil and the water body polluted by the polycyclic aromatic hydrocarbon, and is quick, convenient and environmentally-friendly, and can be used for reducing the content of the polycyclic aromatic hydrocarbon in the environment, thereby providing new microorganism resources for bioremediation for polycyclic aromatic hydrocarbon pollution, and having an important value for environmental governance as well as considerable economic benefit and good social benefit.

Owner:CHINA AGRI UNIV

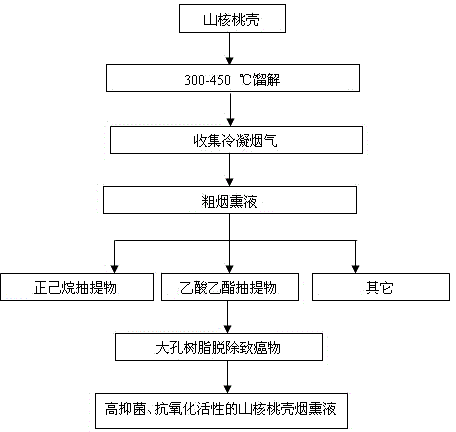

Method for preparing liquid smoking spice for meat from pecan shells

ActiveCN101999618ATake advantage ofRich diversityFood preparationBiotechnologyPolycyclic aromatic hydrocarbon

The invention relates to a method for preparing liquid smoking spice for meat from pecan shells. In the method, the byproduct shells of wild pecans in China are used as the materials. The method comprises the following steps: selecting the material, pulverizing, carrying out dry distillation, filtering, fractionating, and aging at variant temperatures to obtain the stable finished product. The liquid smoking spice can be used for meat. The content of smoking characteristic flavoring substance 2,6-dimethoxyphenol is up to 8.0-18.0 (mg / mL), and the content of polycyclic aromatic hydrocarbon 3,4-benzopyrene is controlled within 2.0 mu g / kg, thereby enriching the diversity of smoking spice products and fully utilizing the pecan shells. By combining variant temperature aging with micro-filtering to remove precipitated tar, the aging time is shorted to 4 days, which is shortened by more than half as compared with the current like products, thereby greatly enhancing the production efficiency.

Owner:HEFEI UNIV OF TECH

Modified coal tar pitch and preparation method thereof

ActiveCN103834423AReduce dosageSimple processWorking-up pitch/asphalt/bitumen by chemical meansPolycyclic aromatic hydrocarbonPtru catalyst

The invention relates to modified coal tar pitch and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the steps of firstly, putting 30-40 parts by mass of coal tar pitch into a reaction kettle with a reflux device, then adding 57-67 parts by mass of a mixed solvent into the reaction kettle at 75-95 DEG C, and stirring for 10-15 minutes at a stirring speed of 100-150r / min; secondly, under the condition that the temperature and stirring speed are same, adding 1.8-3.5 parts by mass of a modifier and 0.20-0.35 part by mass of a catalyst, and stirring for 1-4 hours to obtain a modified coal tar pitch mixture; finally, performing reduced pressure distillation on the obtained modified coal tar pitch mixture at 95-110 DEG C to recycle a solvent so as to obtain the modified coal tar pitch. The modified coal tar pitch and the preparation method thereof disclosed by the invention have the characteristics of simple process, low reaction temperature, small dose of the modifier, recyclable solvent and low cost, and can effectively reduce the content of polycyclic aromatic hydrocarbon 3,4-benzopyrene in the coal tar pitch.

Owner:宿迁博奕达建设有限公司

Preparation method for pecan shell smoke solution with high antibacterial and antioxidant activity

InactiveCN104783295AImprove utilizationImprove product performanceFood preservationFood ingredient for microbe protectionSucroseCarcinogen

The invention discloses a preparation method for a pecan shell smoke solution with high antibacterial and antioxidant activity, and belongs to the technical field of aquatic product processing. The preparation method comprises the following steps: using pecan shells as raw materials, adding the pecan shells and sucrose into a dry distillation device in proportion, performing dry distillation decomposition and smoke cooling to obtain a crude smoke solution, refining the crude smoke solution with ethyl acetate, and removing carcinogens with a macroporous resin to obtain the pecan shell smoke solution with high antibacterial and antioxidant activity. The pecan shell smoke solution prepared according to the method contains 18.1-20.5 mg / mL of polyphenols and 9.5-10.8 mg / mL of carbonyl compounds, and has a pH value of 2.3-2.6; 3,4-benzopyrene is not detected. The pecan shell smoke solution can be applied to aquatic products in two ways, namely, atomizing and soaking, has excellent antibacterial and antioxidant effects, and enables the aquatic products to have rich smoky flavor.

Owner:ZHEJIANG OCEAN UNIV

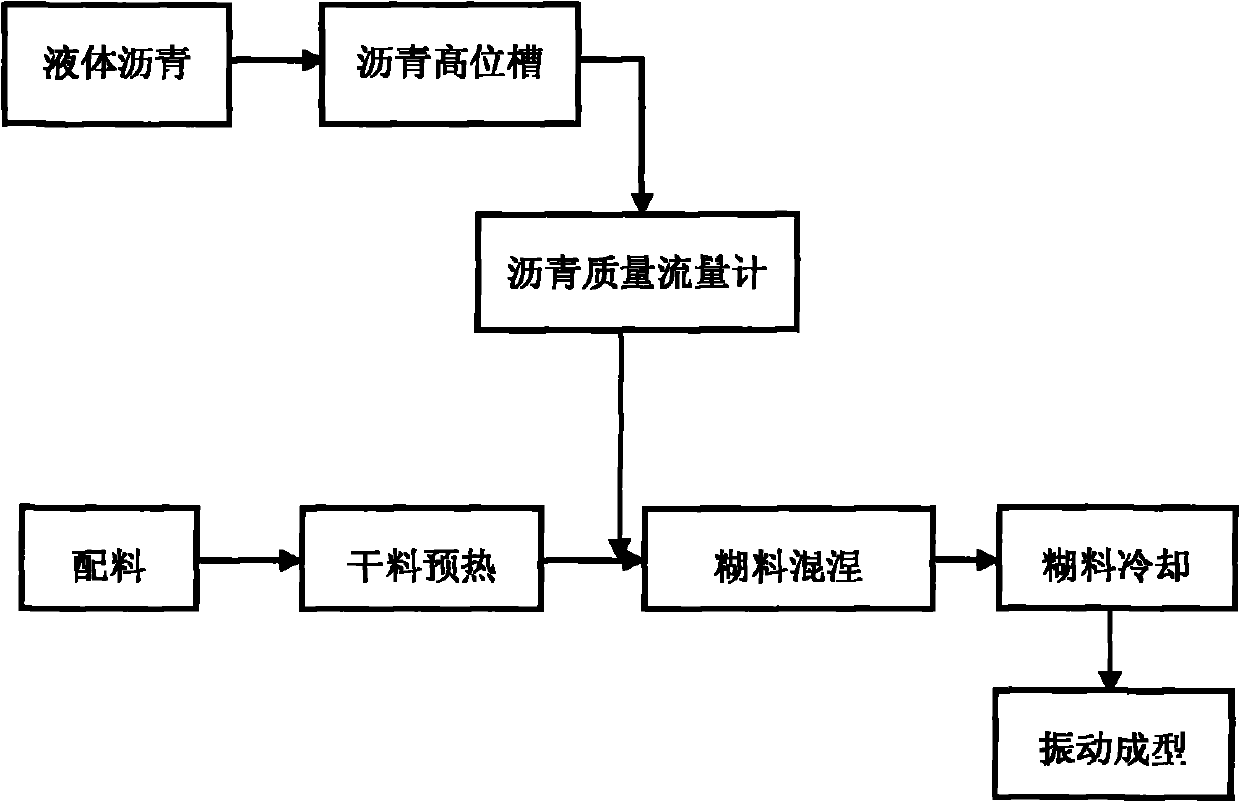

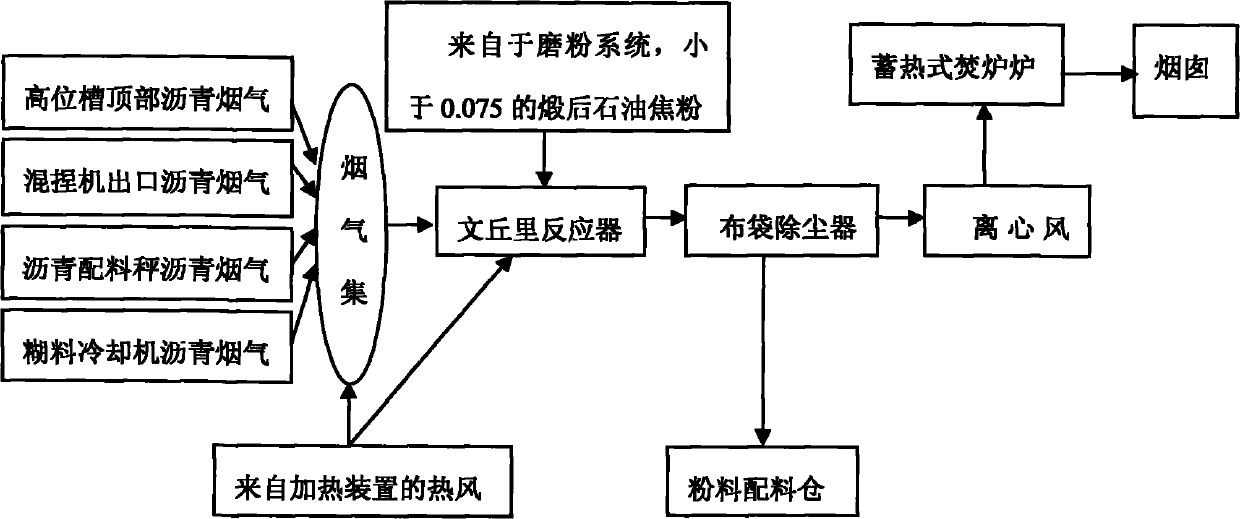

Method for treating asphalt gas efficiently and harmlessly

InactiveCN102000483ACollect completeEfficient collectionDispersed particle filtrationSecondary emissionBenzanthracenes

The invention discloses a method for treating asphalt gas efficiently and harmlessly. The method comprises the following steps of: performing reaction adsorption on the asphalt gas and calcined petroleum coke powder in a Venturi reactor; collecting dust and coke tar from the gas in a bag-type duster remover for recycle; after removing the coke tar and dust-containing steam in the asphalt gas, performing burning treatment by using a regenerative combustion furnace, wherein the burning temperature is higher than 800 DEG C and the burning time is 1 to 2 seconds; and decomposing polycyclic aromatic hydrocarbons such as benzopyrene, benzanthracene and carbazole in the gas after the burning treatment for effectively removing harmful substances of the polycyclic aromatic hydrocarbons such as the benzopyrene, the benzanthracene and the carbazole, wherein the harmful substance content of the treated gas is below 5 mg / m<3>. By using the method, the harmful substances of the polycyclic aromatic hydrocarbons such as the benzopyrene, the benzanthracene, the carbazole and the like are removed effectively; and the harmful substance content of the gas after the treatment is below 5 mg / m<3> which is far below a national secondary emission standard.

Owner:YUNNAN YUANXIN CARBON CO LTD

Method and device for purifying air pollution

The invention provides a method and a device suitable for completely and infinitely purifying indoor or closed space polluted air. The method and the device are characterized in that a pollutant component is separated and removed through a phase change method, air is circularly introduced into a phase change device to generate phase change on the pollutant component in a gas phase to form liquid or solid so as to separate the pollutant component from a clean gas phase component, the pollutant component is stored and treated, and the clean air is continuously conveyed back into the original space. The technology does not need to use, consume or change any active material nor supplement external air, only electric energy or potable refrigeration equipment is adopted to infinitely remove any pollution component in air necessary for human respiration, and the pollution component includes but not limited to carbon monoxide, ammonia, formaldehyde, sulfur dioxide, acetaldehyde, acrolein, benzene, toluene, ethyl benzene, dimethylbenzene, styrene, benzopyrene, volatile organic compounds, PM2.5 and nano particles. By reforming an existing refrigeration component, the technology can be used for purifying various civil, industrial, military and other indoor or closed space polluted air.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Benzopyrene rapid detection card

A benzopyrene rapid detection card belongs to the technical field of food detection. A test strip is arranged in the casing of the benzopyrene rapid detection card; the test strip is formed by sticking a sample pad, a colloidal gold film, a nitrocellulose film and a water absorbent film on a test strip support back plate in turn, wherein the colloidal gold film is a fiberglass membrane containing the anti-benzopyrene antibody colloidal gold marker; and the nitrocellulose film is provided with two display belts, one is a detection belt containing benzopyrene-protein conjugate, the other is a quality control containing anti-rabbit antibody or anti-rat antibody. The invention has the advantage that the immunological method is used to directly detect the content of benzopyrene in samples such as edible oil and fried food. The benzopyrene rapid detection card is easy to prepare and convenient and fast to use, and the detection result is accurate.

Owner:无锡安迪生物工程有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds and organic light emitting device containing same 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds and organic light emitting device containing same](https://images-eureka.patsnap.com/patent_img/78c8cc7d-11d9-423a-aceb-073362f67dfb/HDA0000666937930000011.PNG)

![2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds and organic light emitting device containing same 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds and organic light emitting device containing same](https://images-eureka.patsnap.com/patent_img/78c8cc7d-11d9-423a-aceb-073362f67dfb/HDA0000666937930000012.PNG)

![2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds and organic light emitting device containing same 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compounds and organic light emitting device containing same](https://images-eureka.patsnap.com/patent_img/78c8cc7d-11d9-423a-aceb-073362f67dfb/HDA0000666937930000021.PNG)

![Method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine Method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine](https://images-eureka.patsnap.com/patent_img/1ddef151-5fe8-4064-a572-cbb073af4b27/HDA00002539623800011.PNG)

![Method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine Method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine](https://images-eureka.patsnap.com/patent_img/1ddef151-5fe8-4064-a572-cbb073af4b27/HDA00002539623800012.PNG)

![Method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine Method of simultaneously determining contents of 1-OHP ,3-OHB[a]P and 3-OHB[a]A in urine](https://images-eureka.patsnap.com/patent_img/1ddef151-5fe8-4064-a572-cbb073af4b27/HDA00002539623800021.PNG)

![2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound and organic electroluminescence device containing same 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound and organic electroluminescence device containing same](https://images-eureka.patsnap.com/patent_img/81efbb56-11ba-4995-9c4d-760607c24644/HDA0000667020270000011.PNG)

![2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound and organic electroluminescence device containing same 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound and organic electroluminescence device containing same](https://images-eureka.patsnap.com/patent_img/81efbb56-11ba-4995-9c4d-760607c24644/HDA0000667020270000012.PNG)

![2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound and organic electroluminescence device containing same 2,6,6,8-tetra-substituted-6H-benzo[cd]pyrene compound and organic electroluminescence device containing same](https://images-eureka.patsnap.com/patent_img/81efbb56-11ba-4995-9c4d-760607c24644/HDA0000667020270000021.PNG)