Patents

Literature

650results about How to "Improve food quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

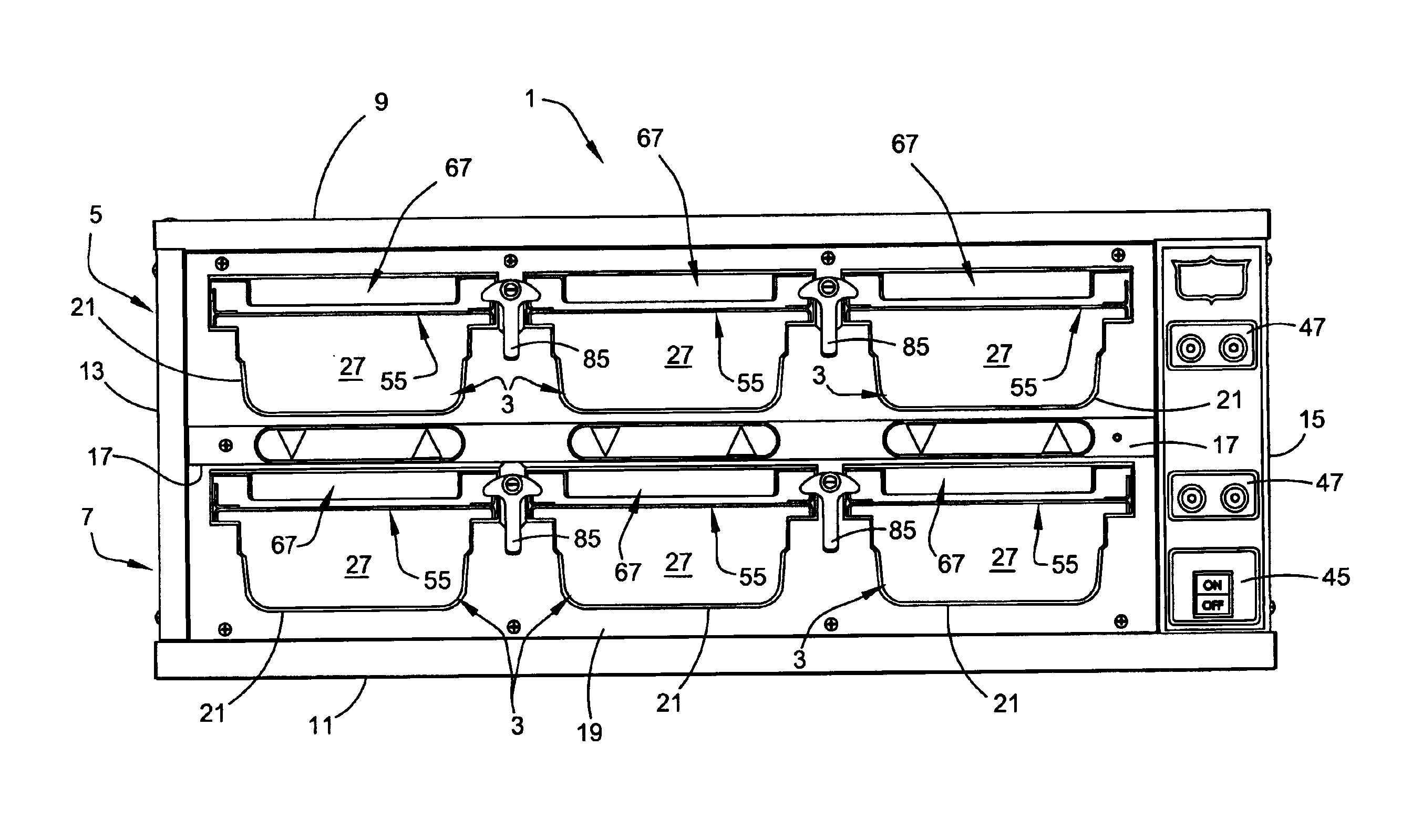

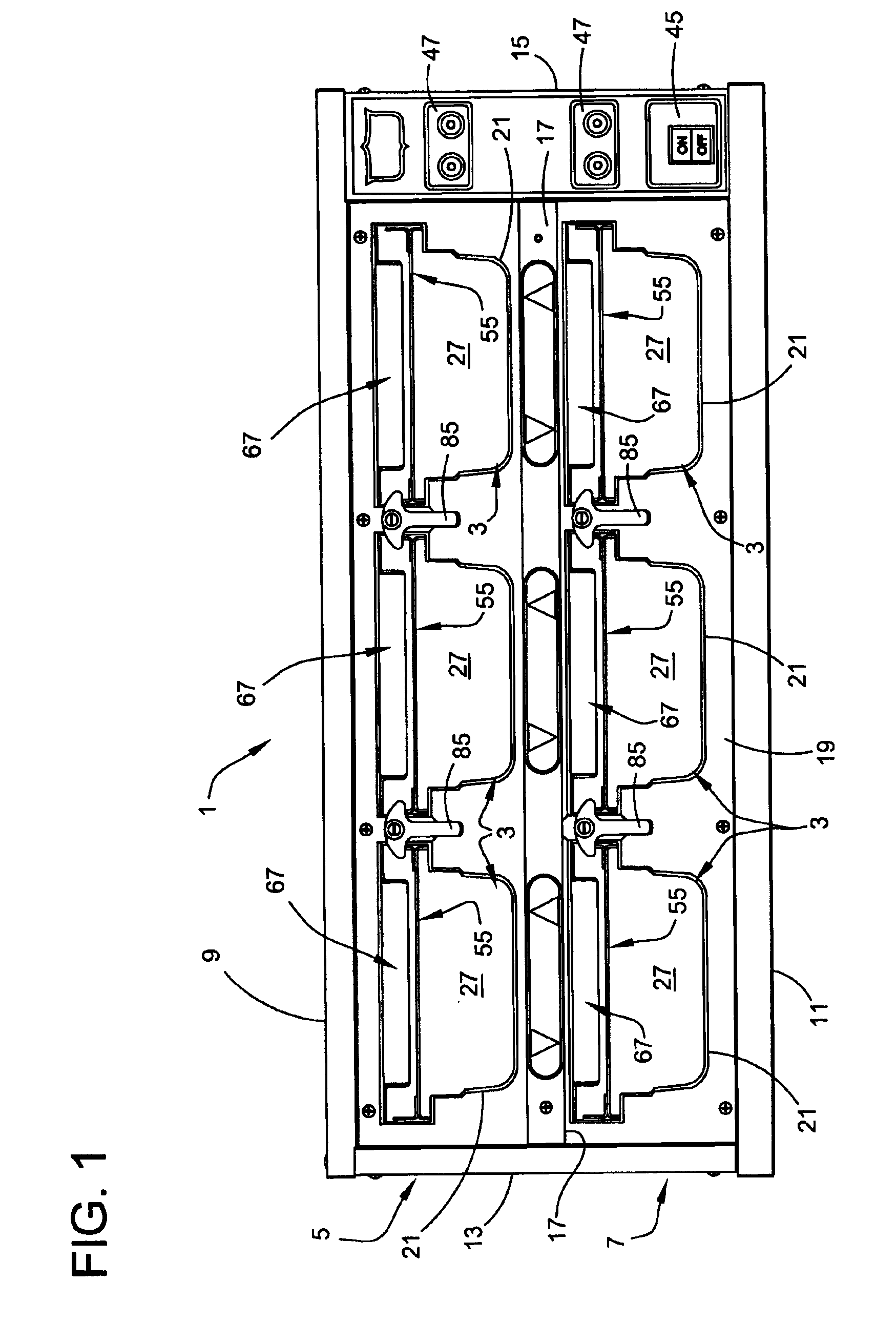

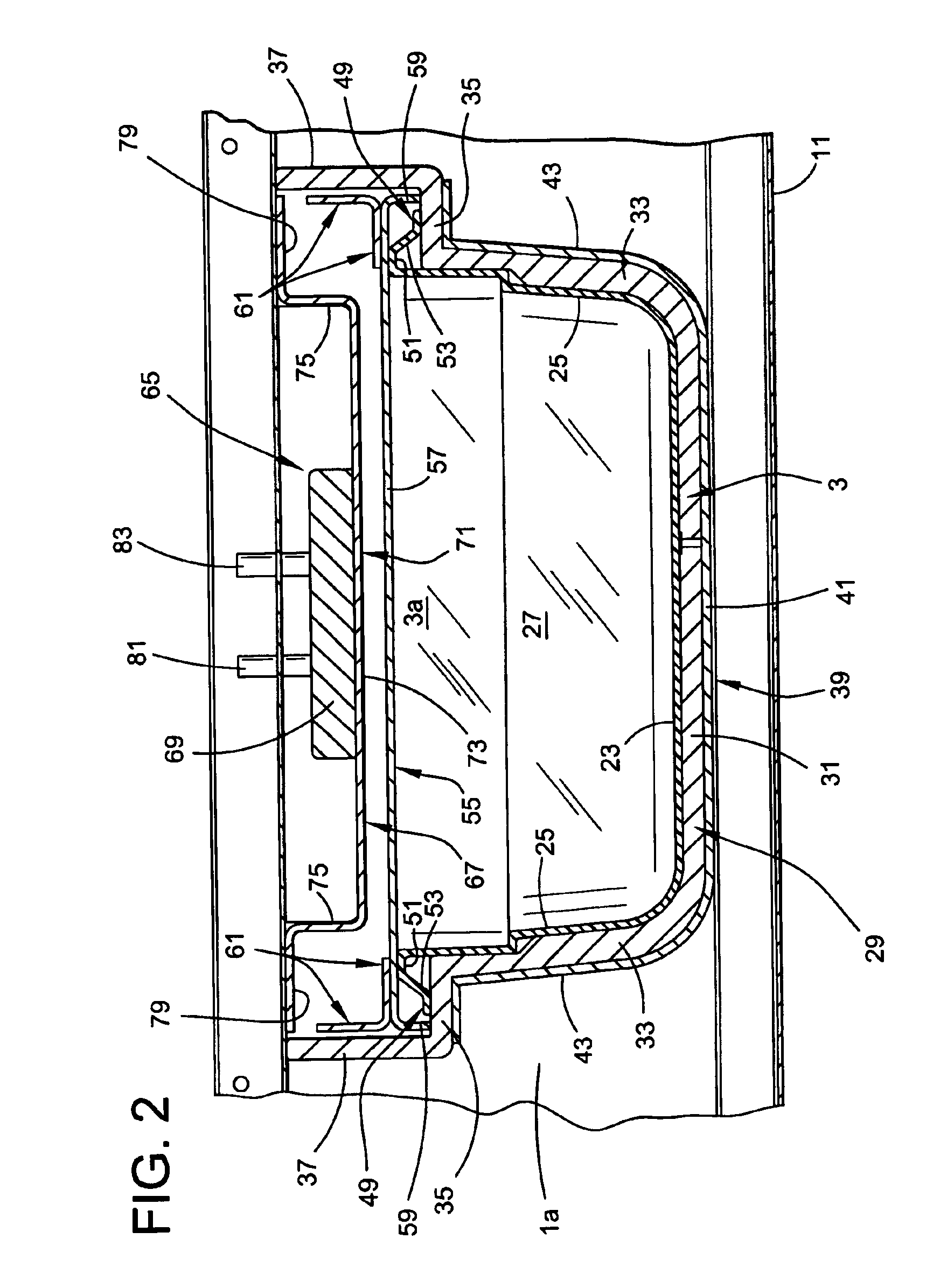

Food warming apparatus and method

InactiveUS7105779B2Less spaceImprove food qualityDomestic stoves or rangesStoves/ranges shelves or racksEngineeringRadiant heat

In general, one embodiment of the invention is directed to food holding apparatus for holding pre-cooked food at a selected holding temperature. The apparatus comprises a cabinet having at least one holding compartment therein, and pre-cooked food in the holding compartment, the food having been previously cooked in a cooking appliance. At least one radiant heat source is spaced above the food a distance less than 12 inches for delivering radiant heat to the food. A control mechanism varies the amount of radiant heat delivered by the heat source to the food to maintain the food at the selected holding temperature. A related method is also disclosed.

Owner:DUKE MANUFACTURING COMPANY

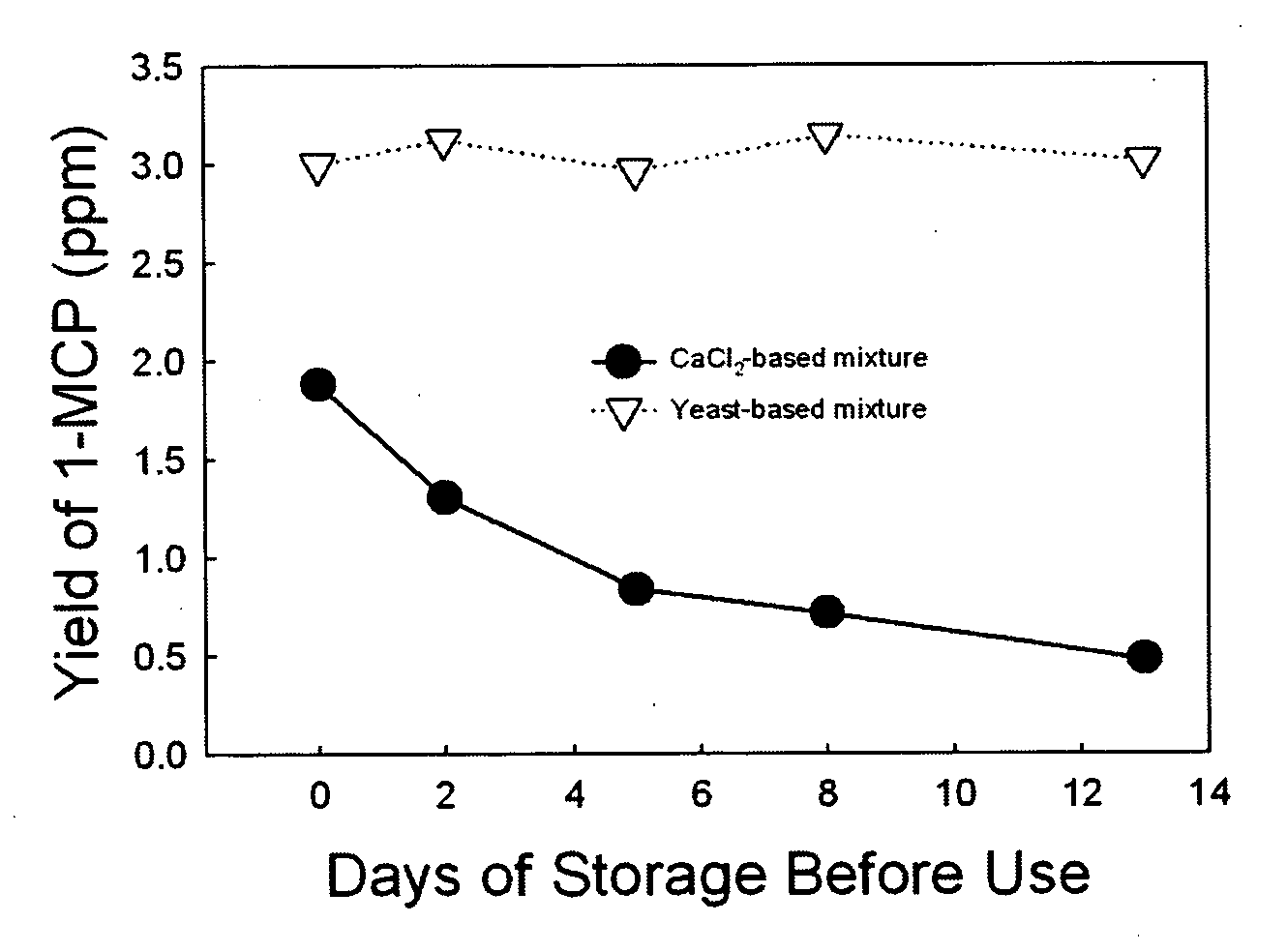

Compositions and methods to improve the storage quality of packaged plants

InactiveUS20060154822A1Increased shelf stabilityImprove publishing efficiencyBiocideDead animal preservationAlcoholCyclodextrin

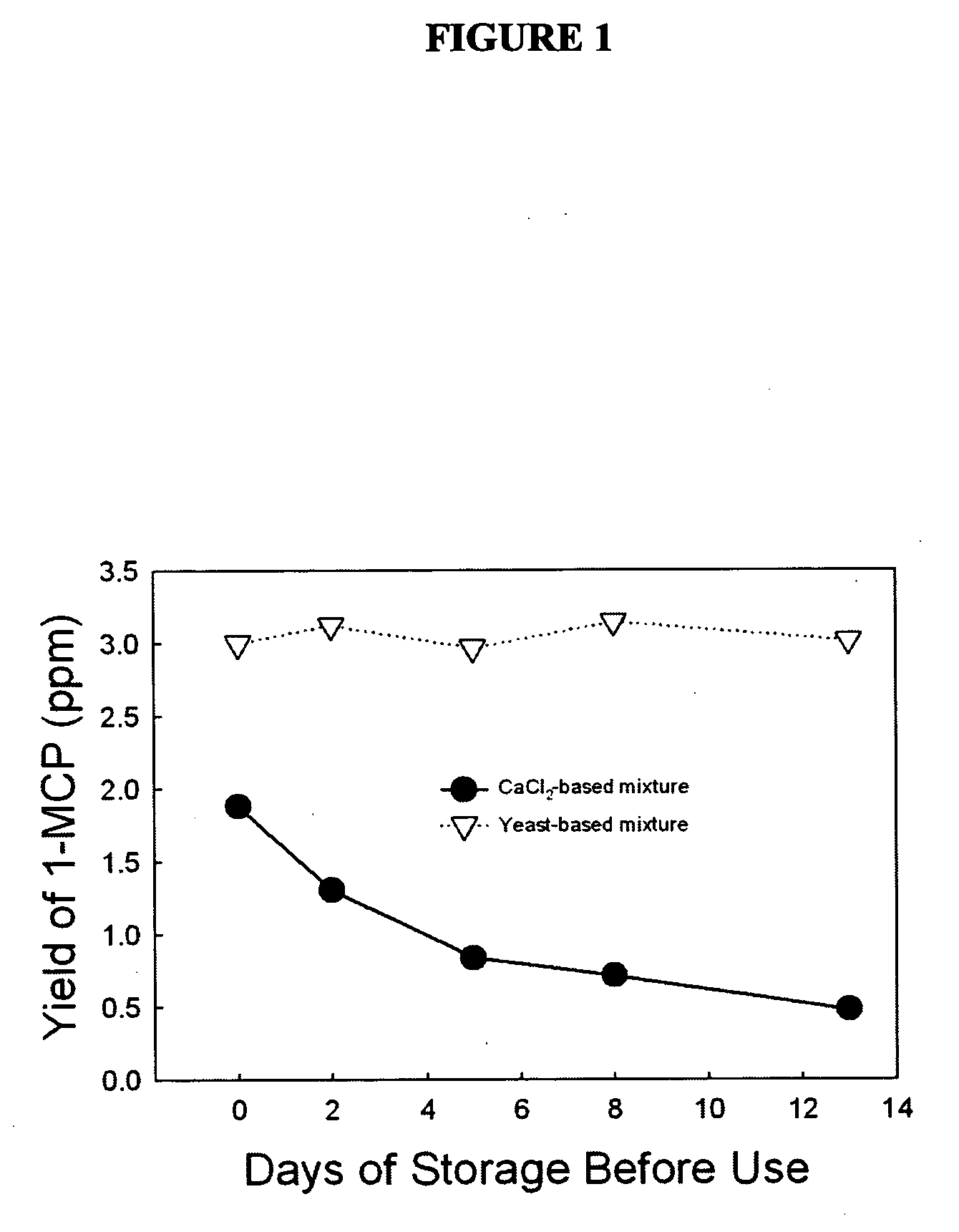

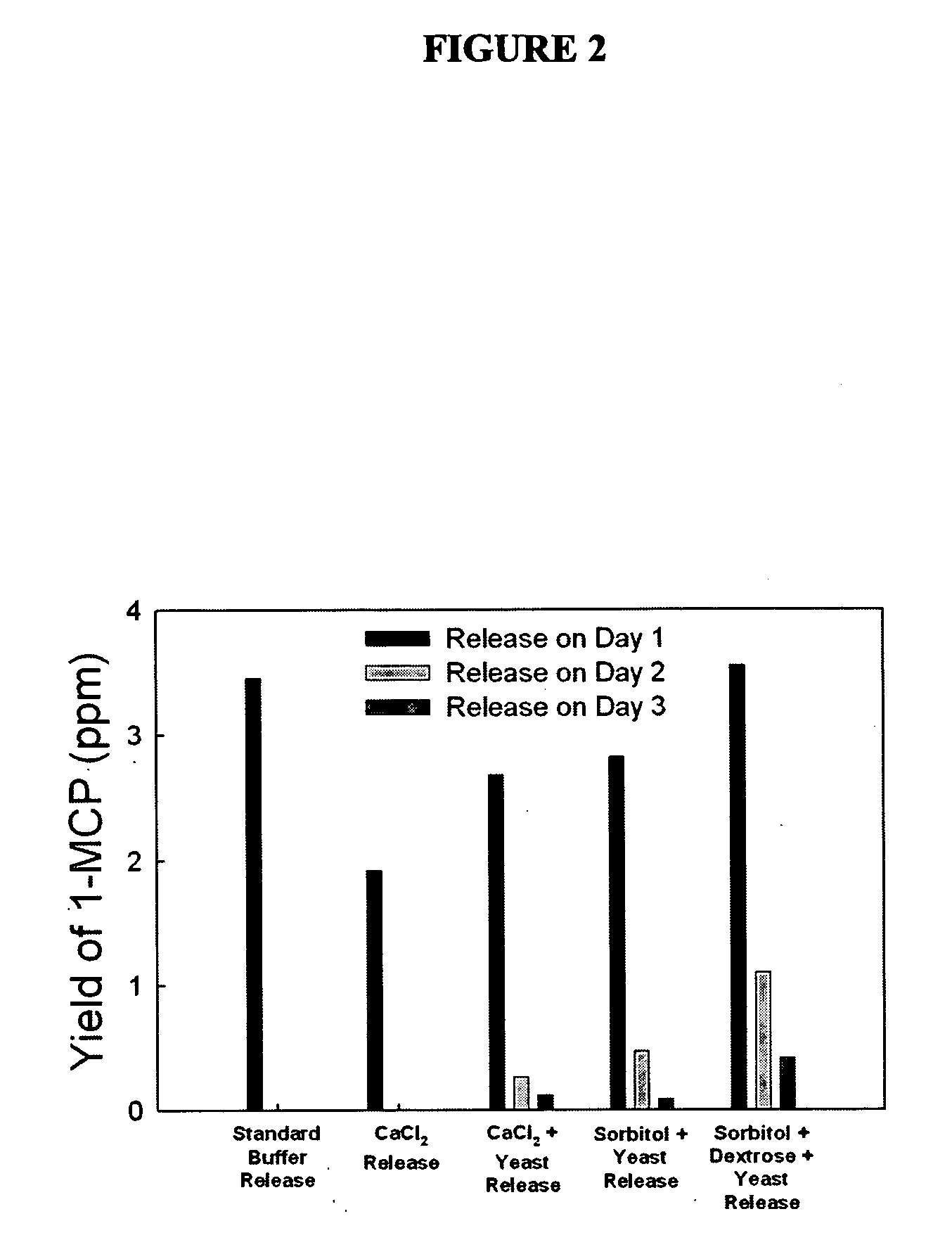

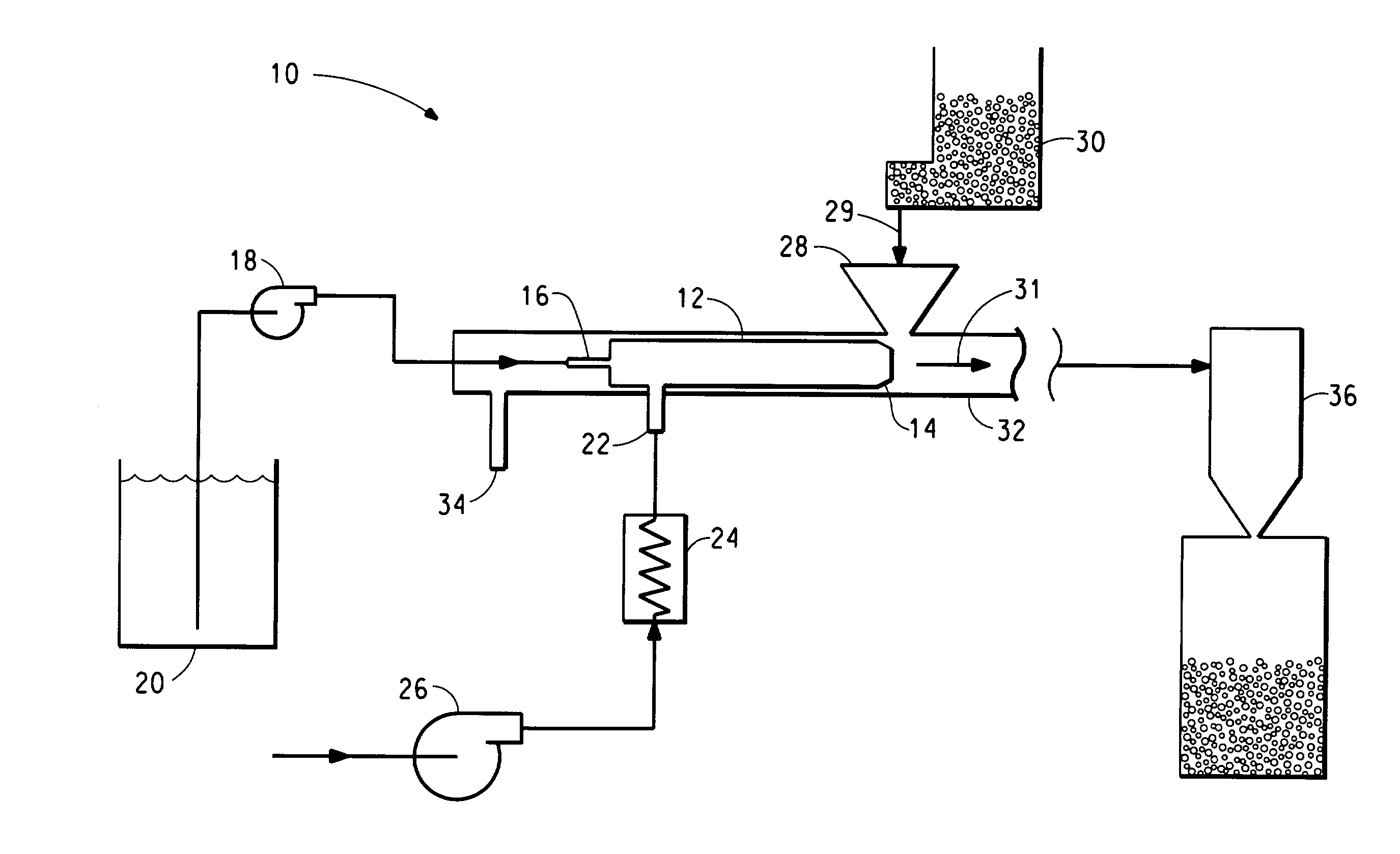

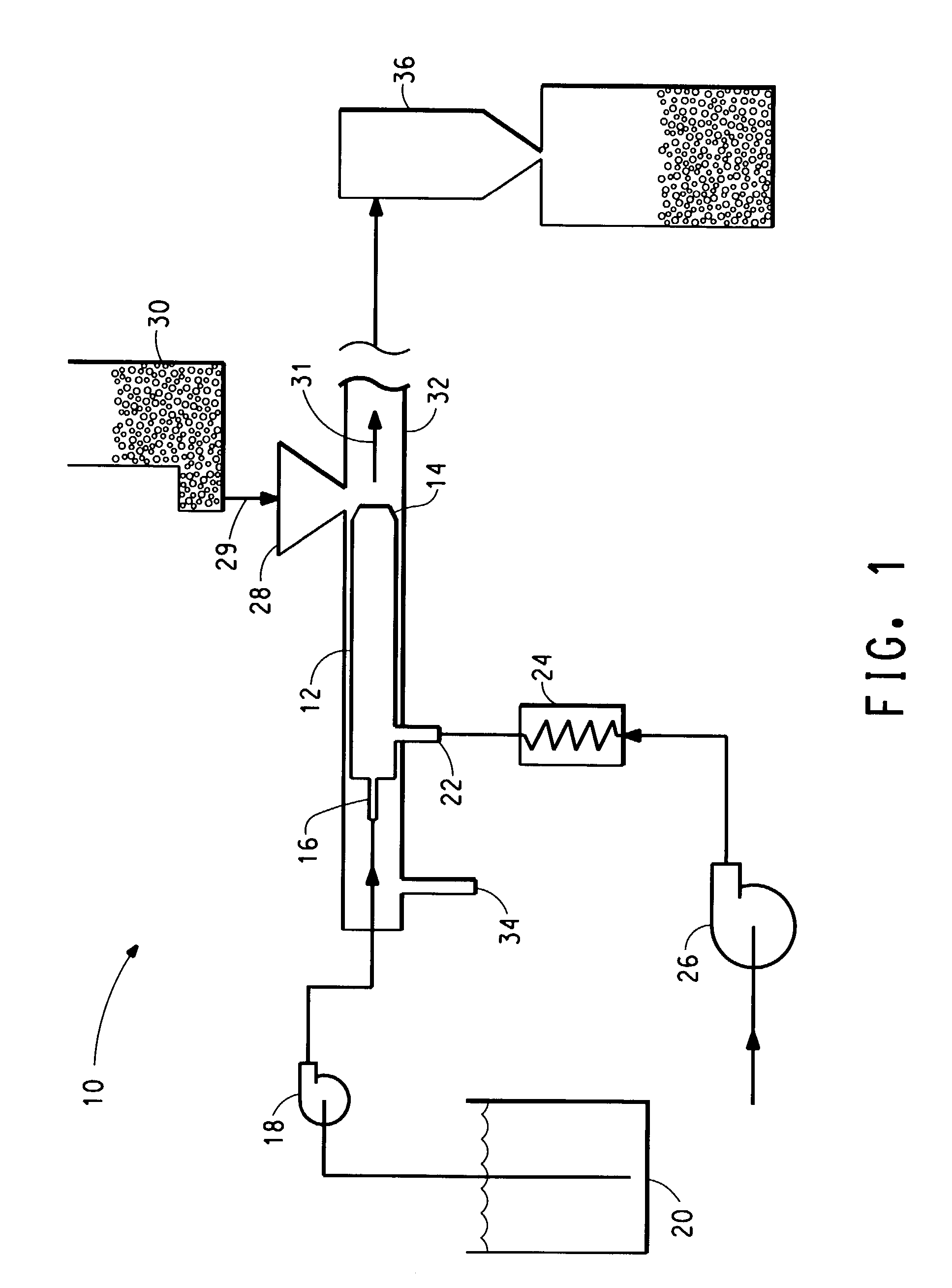

The present invention relates to a composition comprising a cyclopropene, for example 1-MCP, encapsulated in a cyclodextrin matrix, a hygroscopic compound, yeast and / or other enzymes involved in the production of alcohols and aldehydes from organic substrates, and, optionally an organic substrate for the enzymes. The composition of the present invention provides, under controlled conditions, the co-release of the cyclopropene, alcohols, aldehydes and carbon dioxide, which work together to improve the quality of plants during storage. Methods and commercial packages employing these compositions are also disclosed.

Owner:AGRI & AGRI FOOD

Process for dry coating a food particle or encapsulating a frozen liquid particle

InactiveUS7163708B2Shorten the timeCost efficientSeed preservation by coatingFrozen sweetsMicrometerMoisture

Owner:SOLAE LLC

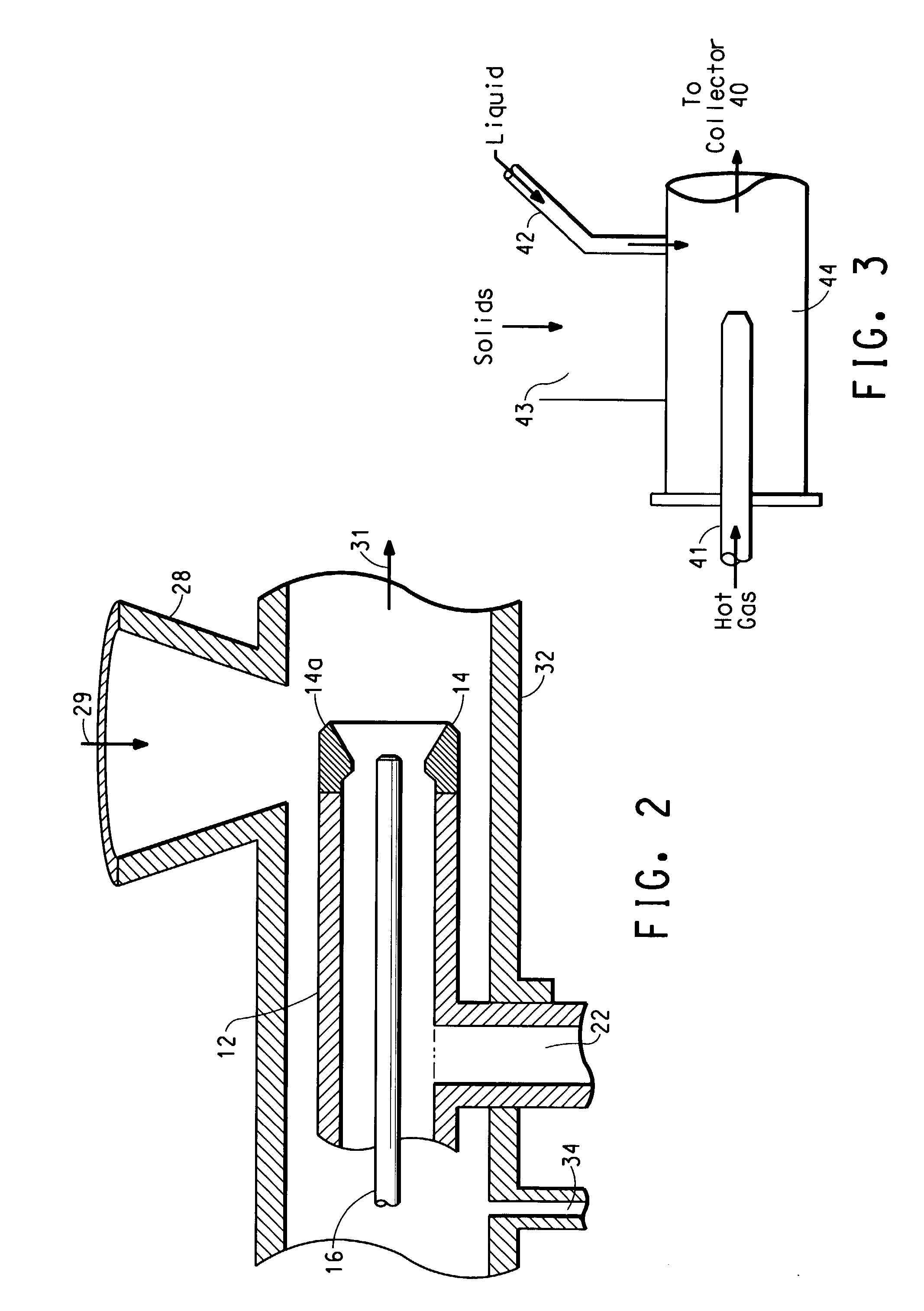

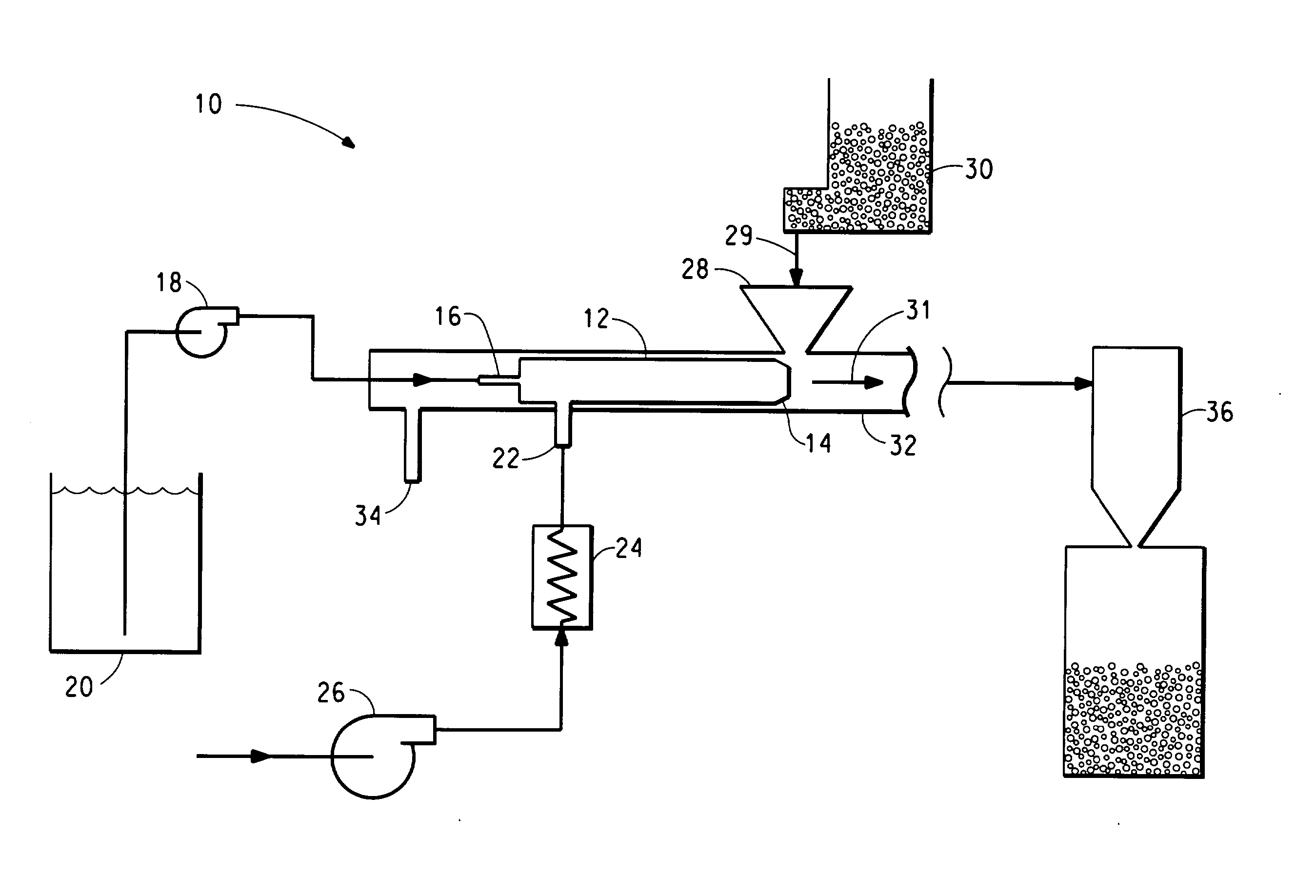

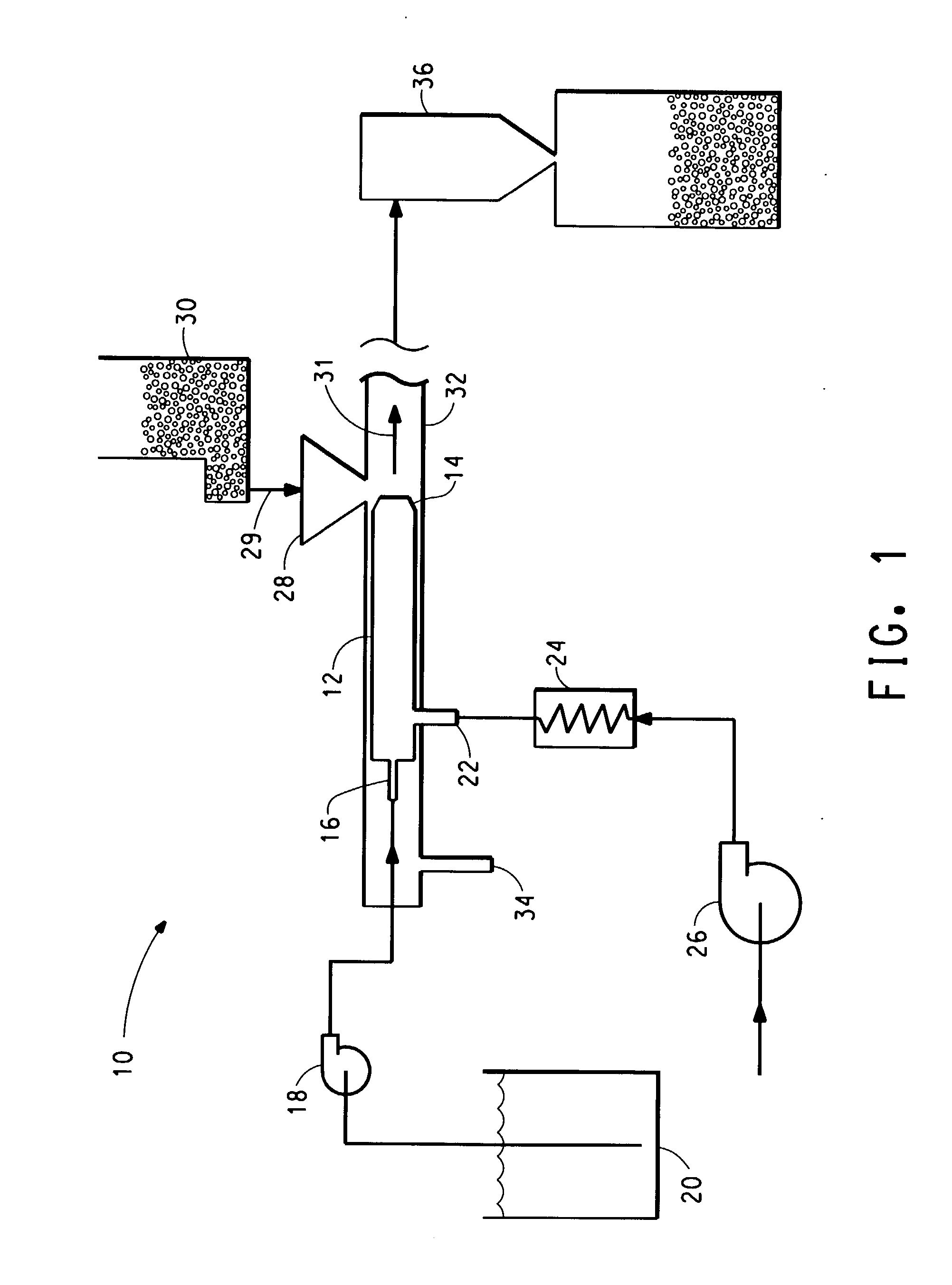

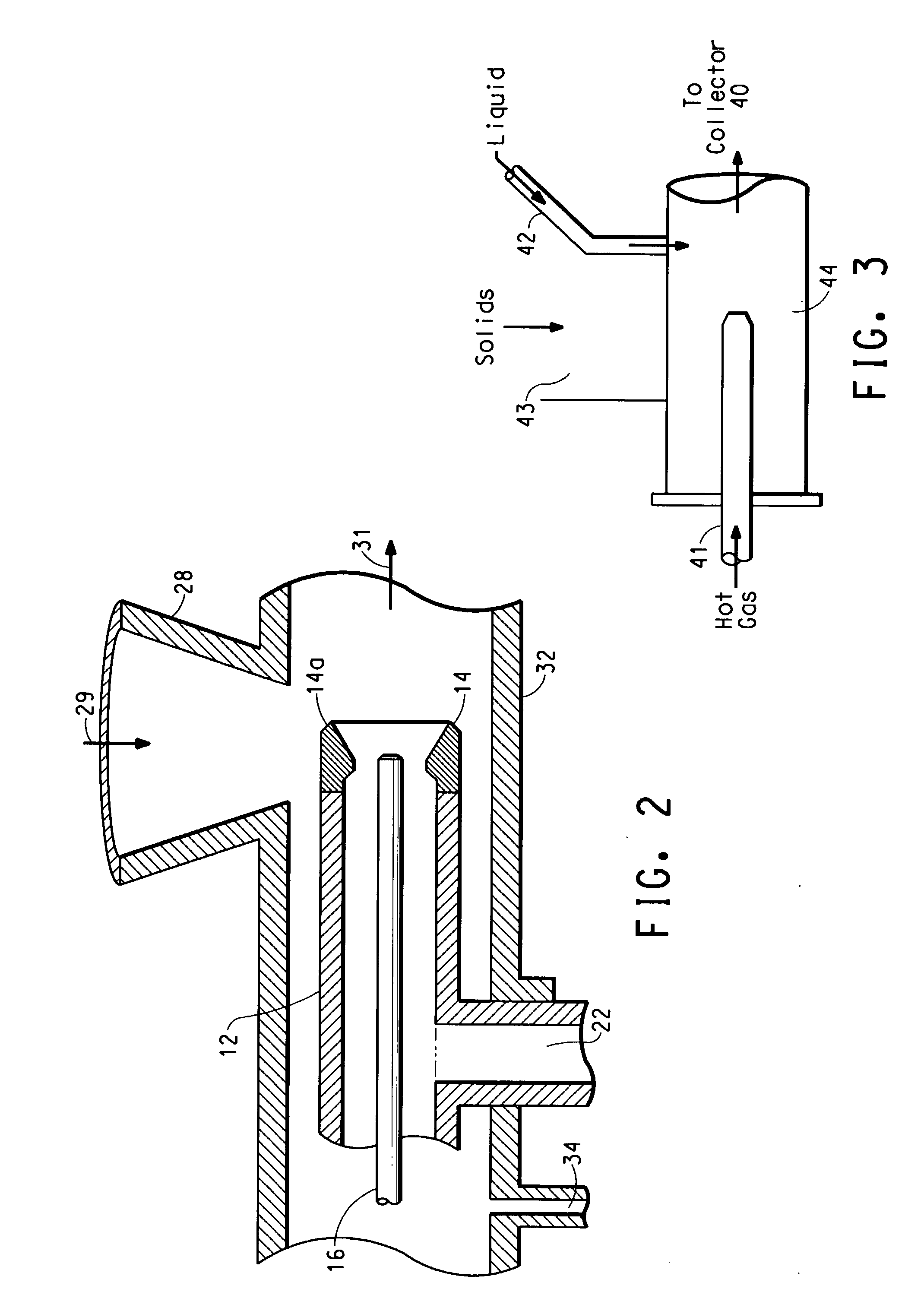

Process for dry coating a food particle or encapsulating a frozen liquid particle

InactiveUS20030031768A1Shorten the timeCost efficientMeat/fish preservationFrozen sweetsMicrometerMoisture

A process for dry coating a food particle having a size in the range from about 0.5 mm to about 20.0 mm is disclosed. The resulting coated food particle has a moisture level that is substantially the same as the moisture level of the uncoated food particle. A process for encapsulating a frozen liquid particle having a size in the range from 5 micrometers to 5 millimeters with a liquid coating material is also disclosed. Also disclosed are coated food particles and encapsulate frozen liquid particles made by one of the processes of the invention.

Owner:SOLAE LLC

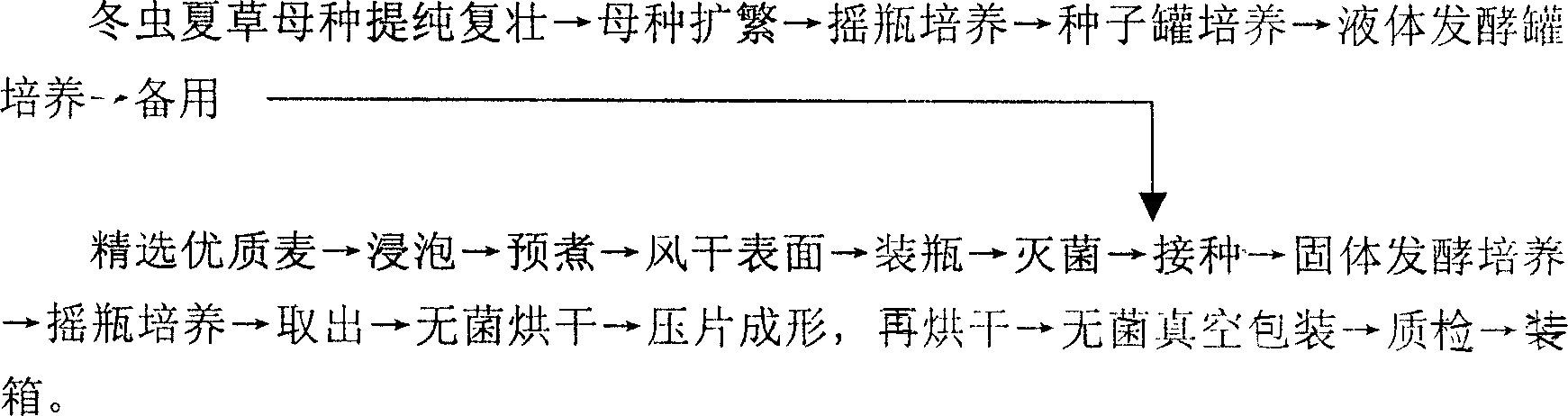

Activated yellow slurry water lactic acid beverage and production process thereof

InactiveCN104621253AHigh nutritional valueImprove food qualityMilk preparationFood preparationLactic acid fermentationFruit juice

The invention relates to an activated yellow slurry water lactic acid beverage and a production process thereof, belonging to the technical field of beverage processing. The production process of the activated yellow slurry water lactic acid beverage comprises the following steps: taking yellow slurry water produced in the process of producing bean curd by using sprouted soybeans enriched in gamma-aminobutyric acid as a main raw material, adding fresh milk and a sweetening agent, sterilizing, inoculating 0.3-0.6 percent of Streptococcus thermophilus and 0.1-0.3 percent of Lactobacillus bulgaricus according to the weight percent in volume, performing lactic acid fermentation, adding fruit juice and a stabilizer, homogenizing, degassing, cooling and performing sterile filling, thereby obtaining the activated yellow slurry water lactic acid beverage. The yellow slurry water resources can be fully utilized, the product is diversified in flavors and fine and smooth in taste, does not have beany flavor and is enriched in gamma-aminobutyric acid, soy isoflavone, oligosaccharide, polypeptides and amino acids, the content of the gamma-aminobutyric acid is 2-5mg / 100mL, the content of the soy isoflavone is 1-4mg / 100mL, and the product is an ideal health type lactic acid beverage.

Owner:SUZHOU JINJI FOODS

Preparation method of carcinogen-free food smoking solution

The invention discloses a preparation method of carcinogen-free food smoking solution, and belongs to the technical field of meat and aquatic product processing. A eucalyptus smoking agent dry distillation device is adopted in the method; eucalyptus granules and sucrose are added into the dry distillation device in a ratio and subjected to dry distillation to form the smoking solution, the smoking solution is taken out and stood for over 12 hours at the room temperature of between 22 and 32 DEG C, and the supernate formed after the smoking solution is demixed is adsorbed twice by using macroporous absorption resin polymerized by aromatic hydrocarbon compounds to remove carcinogens in the smoking solution; the eucalyptus smoking solution obtained by the method contains 7 to 9 mg / mL of phenolic substances and 8 to 10 g / 100mL of carbonyl compounds, does not contain the carcinogens such as 3,4-benzopyrene and the like, and has good food smoking solution flavor; and the long-time confused problem that the product contains the carcinogens in the field of smoked meat and aquatic products can be solved, the method plays a positive role in improving food quality and food safety in the field of smoked meat and aquatic products, high-quality smoked meat and aquatic products are provided for the market, and economic benefit and social benefit of a processing enterprise are improved.

Owner:GUANGDONG OCEAN UNIVERSITY

Composite fresh-keeping method for large yellow croaker

ActiveCN103976005ANo effect on sensory qualityImprove food qualityMeat/fish preservation by coatingMeat/fish preservation using chemicalsAcetic acidSterile water

The invention relates to a fresh-keeping method for aquatic products, specifically to a composite fresh-keeping method for large yellow croaker. The fresh-keeping method mainly comprises a step of modified atmosphere packaging of cultured large yellow croaker with tea polyphenol, nisin and chitosan as biological fresh-keeping agents after sterilization with ozone water. The method comprises the following concrete steps: freezing fresh and alive cultured large yellow croaker to death with crushed ice; treating the frozen cultured large yellow croaker with ozone water for 1 to 8 min; soaking the treated large yellow croaker in a solution for 20 to 40 min, wherein the solution is prepared by fully dissolving tea polyphenol and nisin in sterile water; taking the soaked large yellow croaker in a chitosan (dissolved with 1% acetic acid) solution for 30 s; and carrying out draining and film forming and then successively carrying out modified atmosphere packaging and refrigeration at a temperature of 0 to 4 DEG C. The composite fresh-keeping method has a scientific conception, poses no influence to sensory quality of the cultured large yellow croaker, is safe and harmless to human health, can substantially prolong the shelf life of the cultured large yellow croaker under refrigeration conditions, improves eating quality of large yellow croaker and broadens the marketing range of large yellow croaker.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

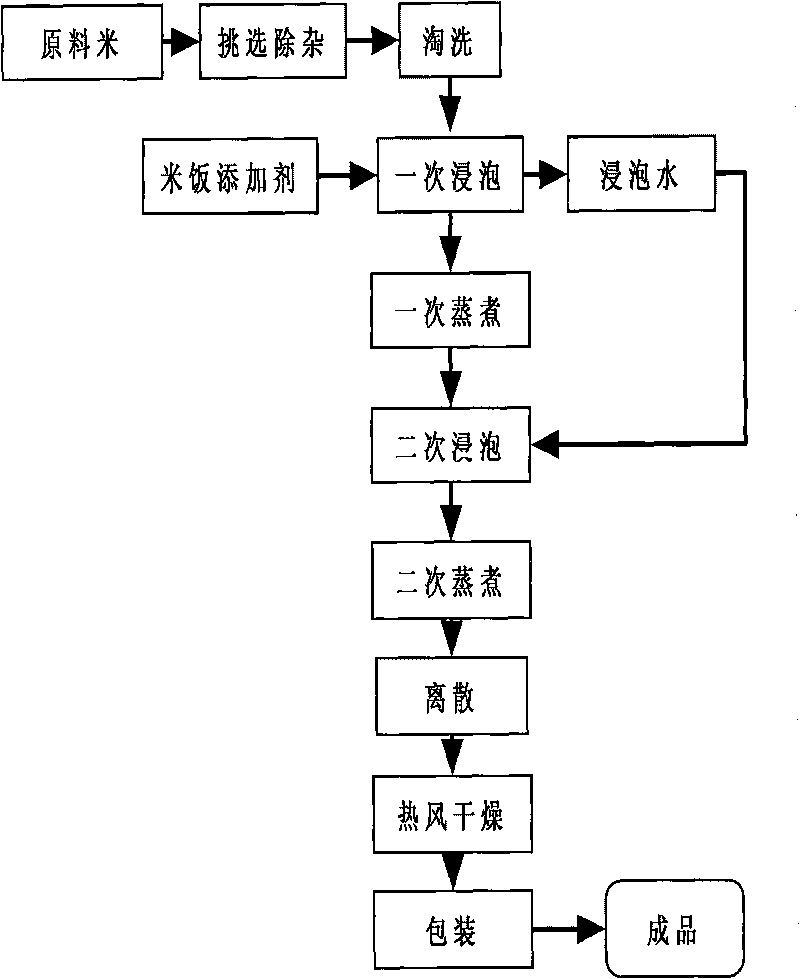

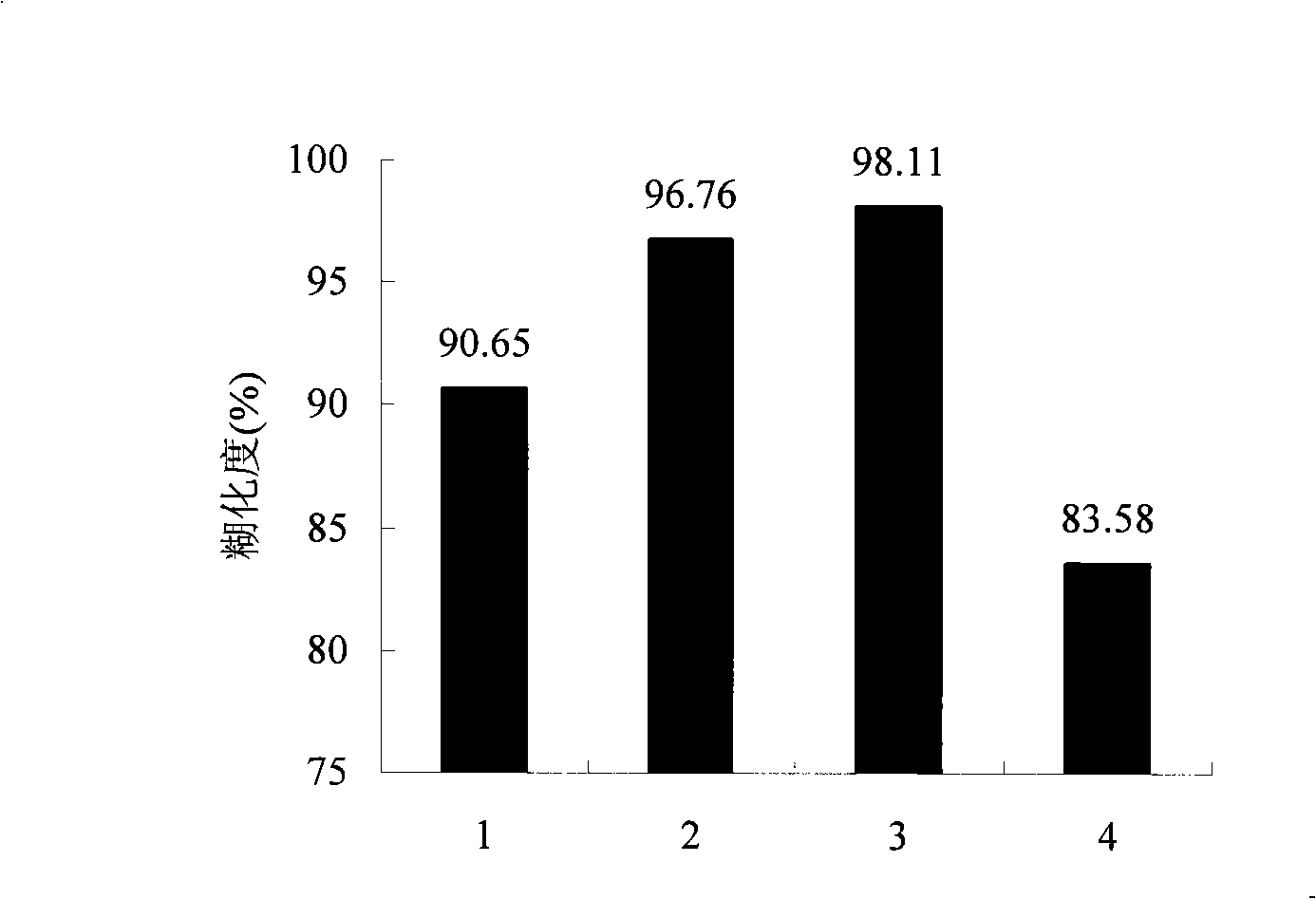

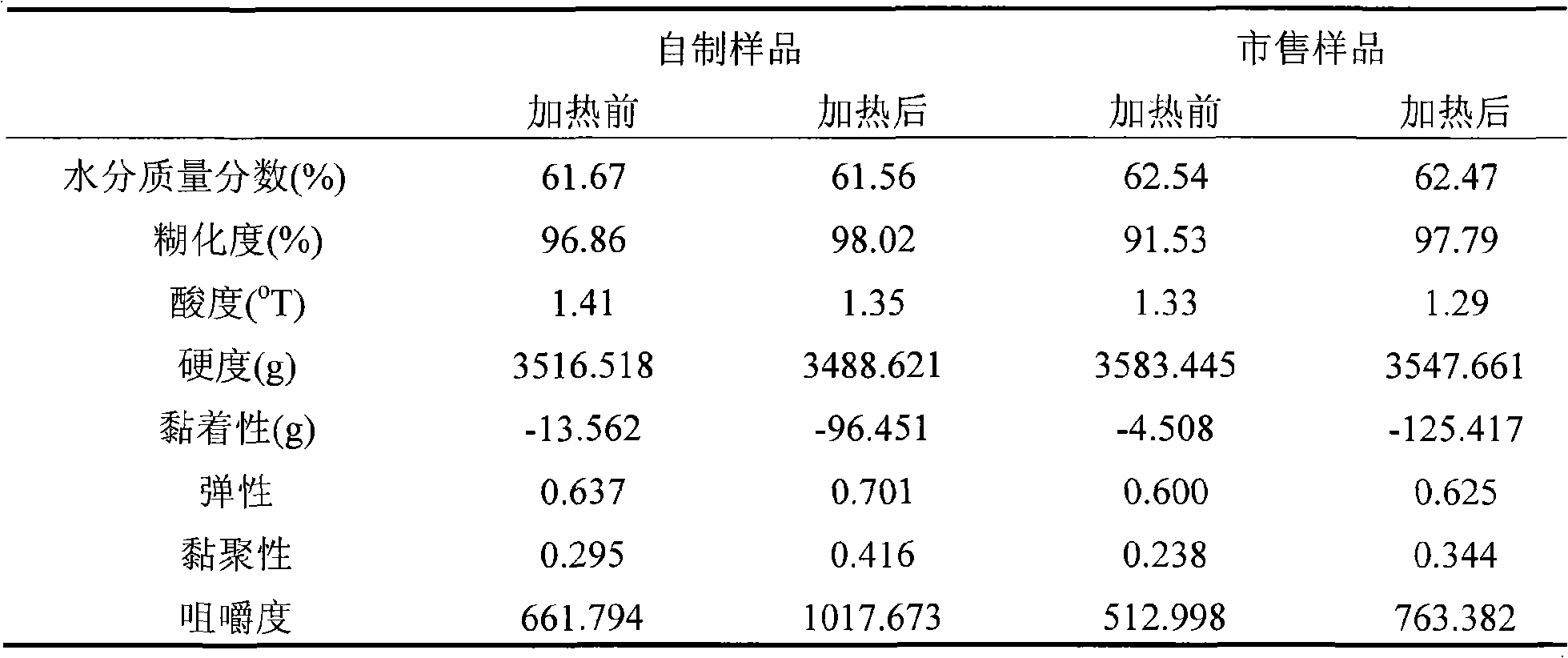

Preparation process of convenient rice

The invention relates to a preparation process of convenient rice, which comprises the following operational steps: A, washing rice; B, soaking the rice for the fist time; C, stewing the rice for the first time; D, soaking the rice the second time; E, stewing the rice for the second time; F, dispersing the rice; G, drying the rice to obtain finished products; and H, packaging the finished products, wherein soaking liquid contains 0.2 to 0.6 percent of citric acid, 0.1 to 0.3 percent of beta-cyclodextrin and 0.1 to 0.3 percent of sucrose fatty acid ester. The soaking liquid improves the edible quality of the convenient rice and strengthens the anti-retrogradation performance of the convenient rice while shortening the rehydration time of the convenient rice, so that the edible quality of the convenient rice is the same as that of fresh rice; and the gelatinization degree of the rice is improved by adopting the process of the two-time soaking and two-time stewing, so that the rehydration time of the convenient rice is shortened to 8 minutes. The preparation process has the advantages of reasonable process design, low equipment requirement, conveniently-eaten product, long quality guarantee period and good edible quality, and has the high popularization and use values.

Owner:HEFEI UNIV OF TECH

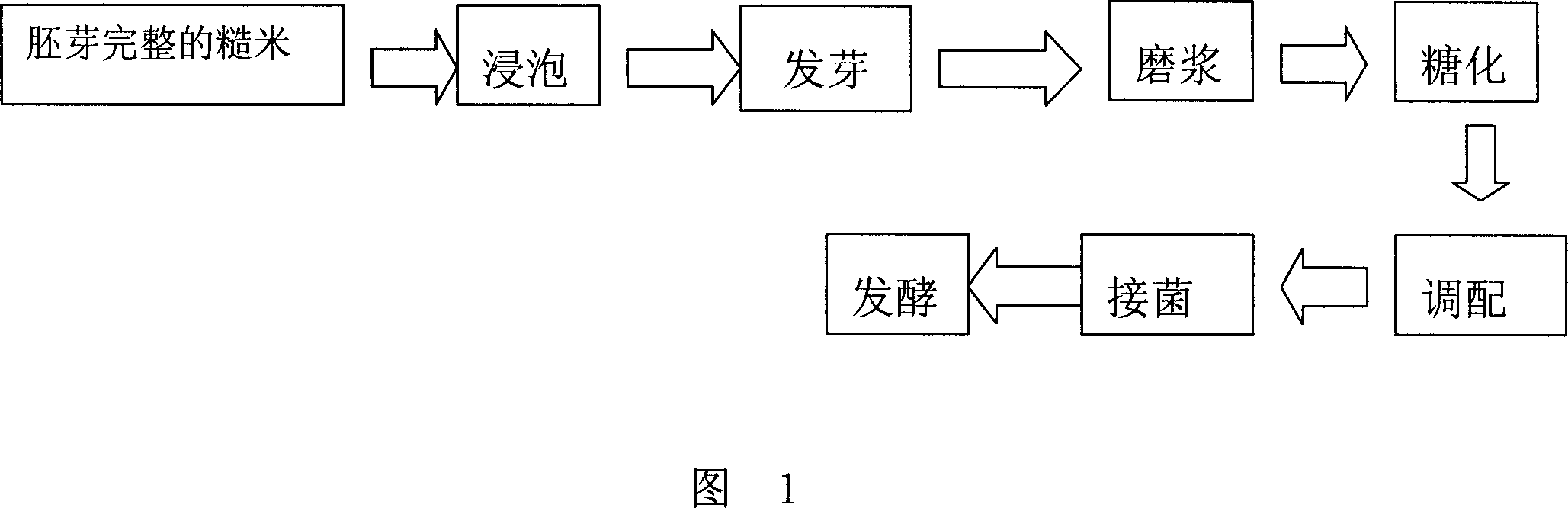

Non-alcoholic fermentation germinating unpolished rice beverage and its preparation method

The invention discloses a making method of non-alcohol fermenting germinating unpolished rice beverage, which comprises the following steps: choosing unpolished rice; immersing; germinating; grinding; insulating; allocating; isotroping; sterilizing; inactivating enzyme; seeding bacteria; fermenting; displaying tasty flavour; improving digestive adsorption effect.

Owner:CHINA AGRI UNIV

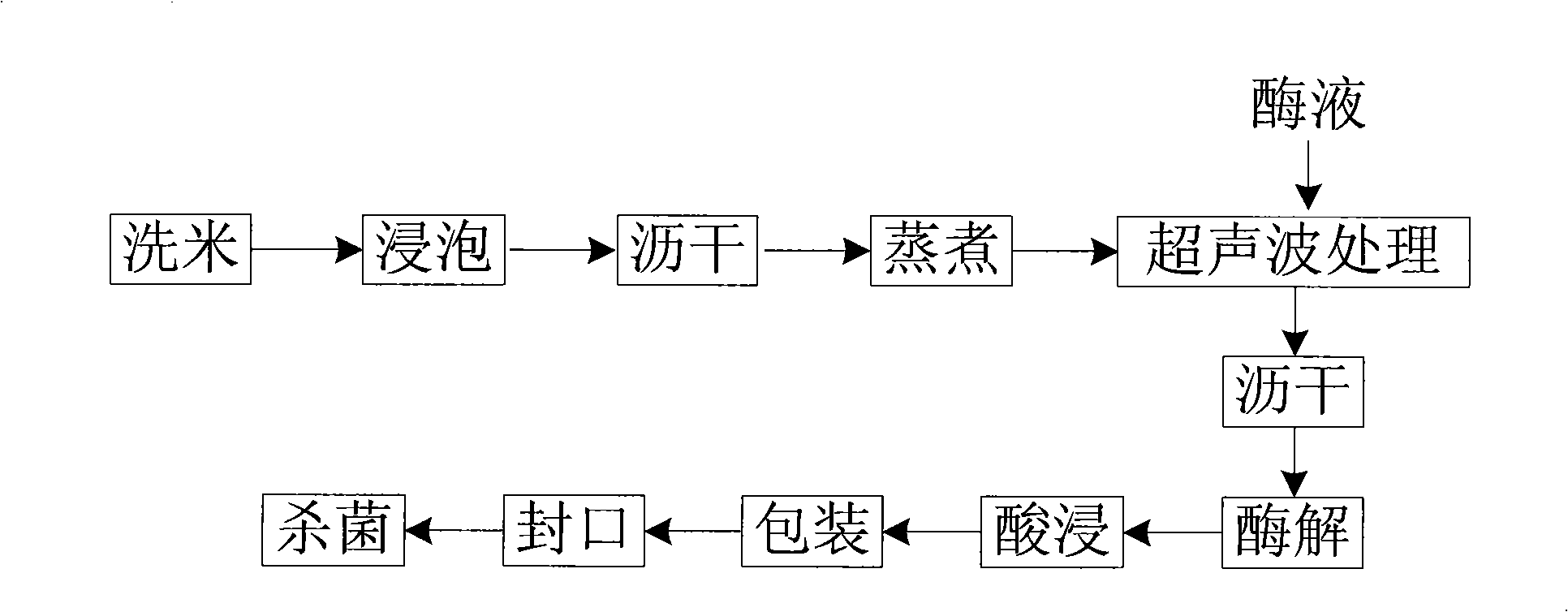

Method for producing fresh-keeping instant rice

InactiveCN101406269ASimple production processMaintain textureFood preservationFood preparationFood industryMicrowave oven

The invention provides a method for preparing fresh-keeping instant cooked rice, belongs to the technical field of agricultural product deep processing and food industry, and mainly relates to application of the ultrasonic treatment technique and the enzyme preparation in the instant cooked rice. In the method, the refined rice is used as a raw material, and the ultrasonic treatment technique and the enzyme preparation are utilized to control the aging and fresh-keeping of the instant cooked rice. The preparation method of the instant cooked rice comprises the following steps: the refined rice is washed, soaked in water, water-drained, pre-boiled, and then subjected to enzyme liquid soak and ultrasonic treatment, drainage, enzymolysis, acid soak, water drainage, packaging, sealing and sterilization to obtain the finished production of the fresh-keeping instant cooked rice. The fresh-keeping instant cooked rice prepared by the method has the advantages of low cost, convenient use and convenient eating, and can be eaten instantly or after heated; and if the hot food is needed, the rice bag is heated in boiled water or a microwave oven over medium-high heat for 1 to 2 minutes.

Owner:JIANGNAN UNIV

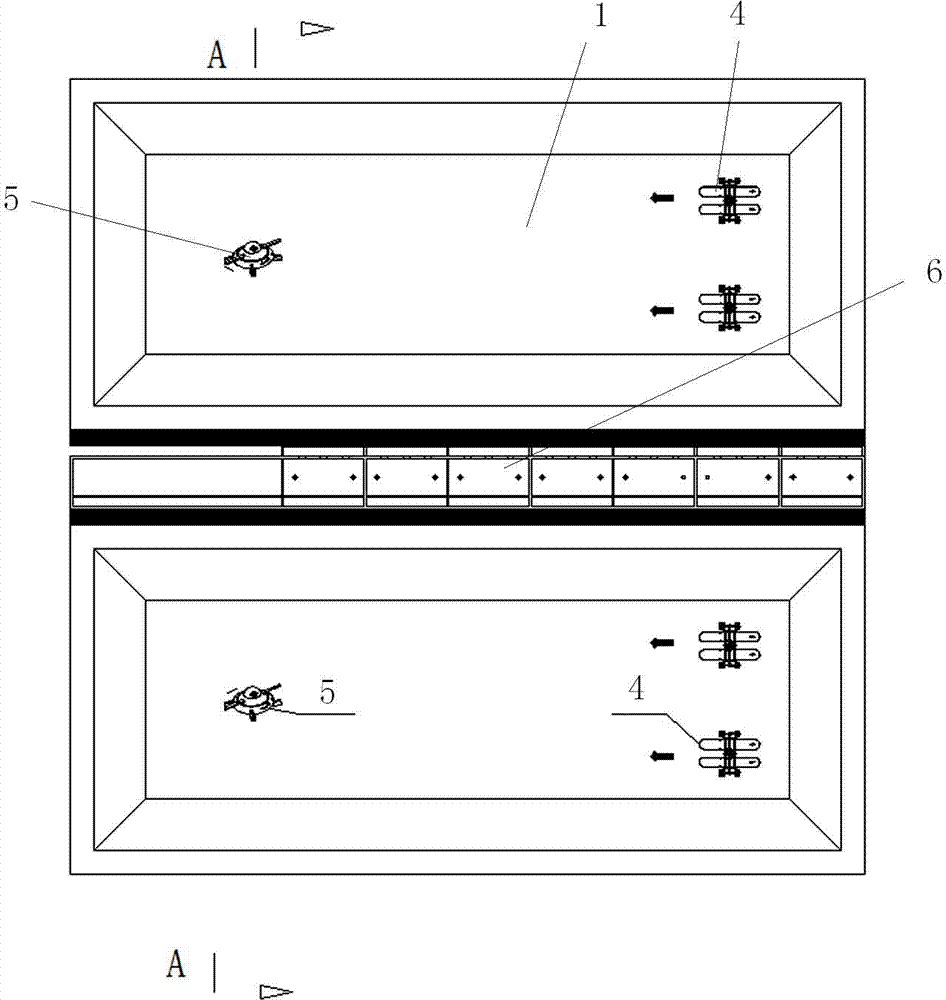

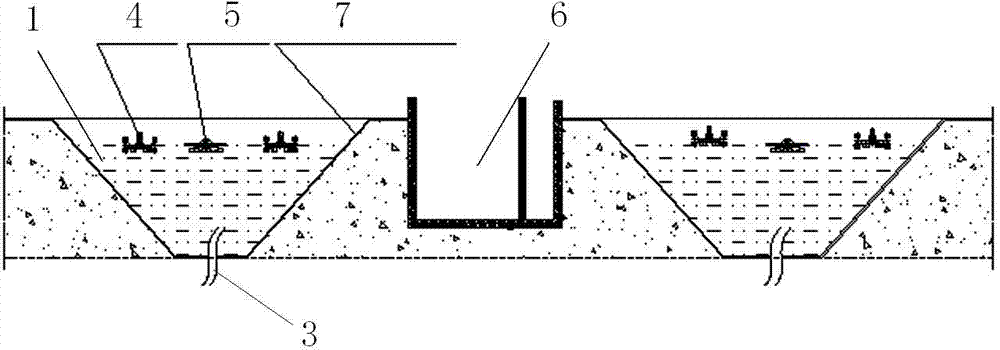

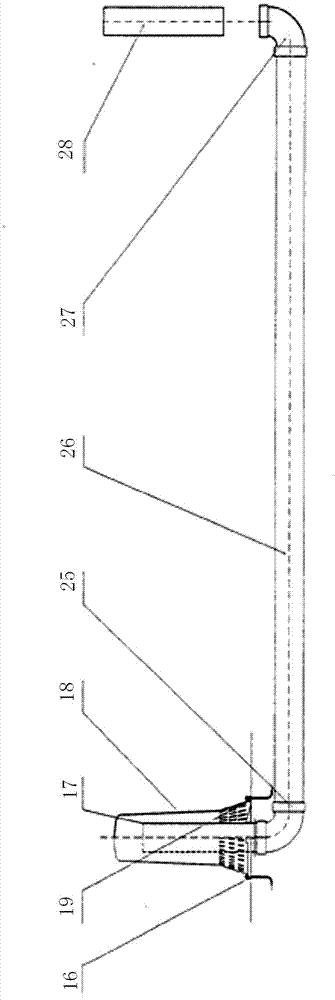

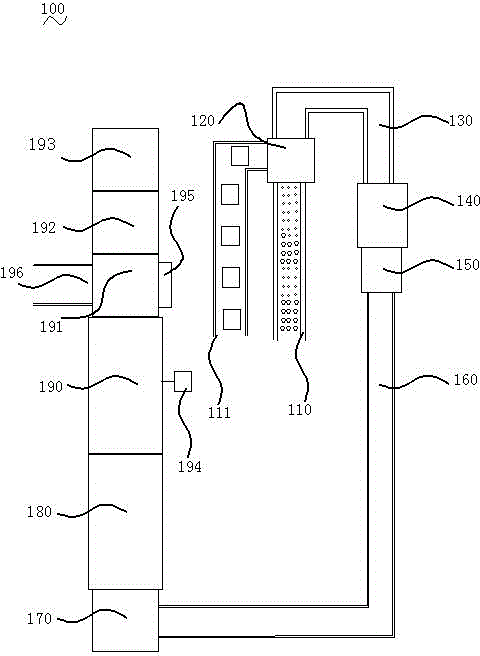

Centralization indoor constant temperature circulation aquaculture system

ActiveCN103081843ANo secondary pollutionFree from pollutionPisciculture and aquariaThermal insulationAquatic product

The invention discloses a centralization indoor constant temperature circulation aquaculture system which includes two aquaculture ponds arranged side by side. A water inlet and a water outlet are arranged in each aquaculture pond. An aerator and a swell machine are arranged in each aquaculture pond. The centralization indoor constant temperature circulation aquaculture system is characterized in that the two aquaculture ponds are made of thermal insulation materials. A sewage treatment system is arranged between the two aquaculture ponds. A suction sewage device is arranged at the end of water outputting of each aquaculture pond. The suction sewage device is connected with the sewage treatment system through a sewage pipe. A water outlet of the sewage treatment system communicates with each aquaculture pond. The centralization indoor constant temperature circulation aquaculture system has the advantage that circulation utilization of water for aquaculture is achieved so that the quality of aquaculture aquatic products is improved and pollution of sewage discharges to environment is reduced.

Owner:喃嵘实业(上海)有限公司

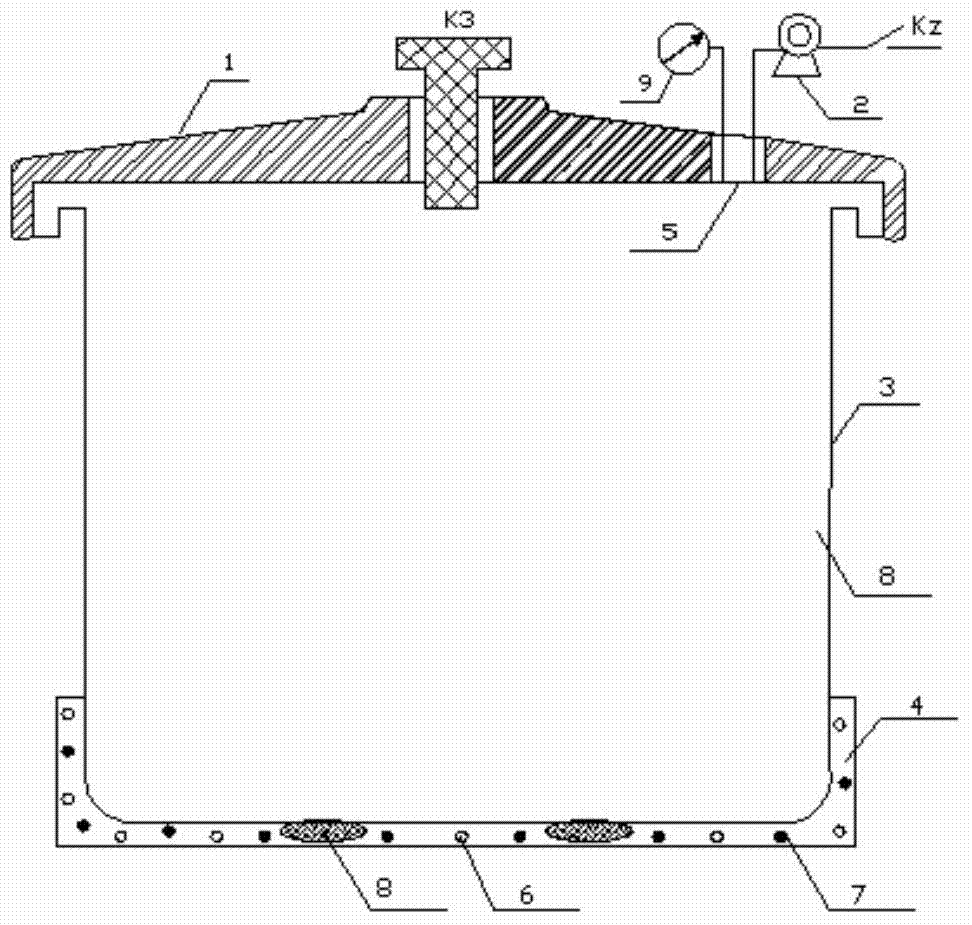

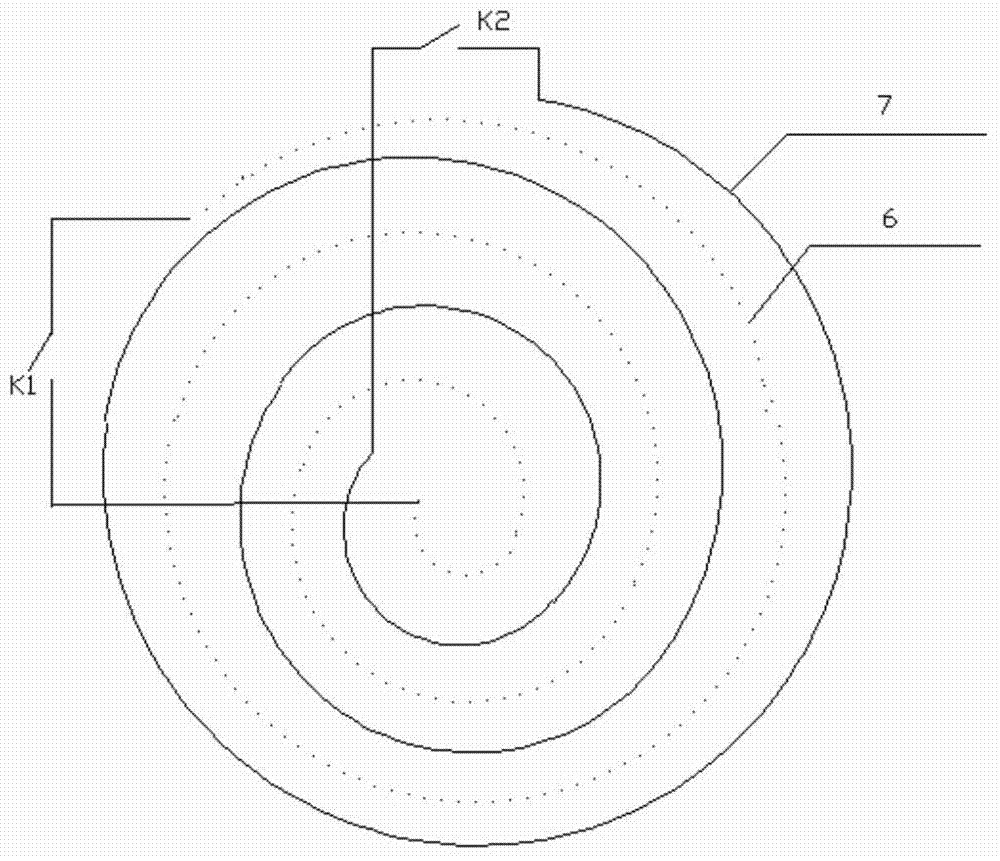

Food cooker with temperature pressure control and cooking method

The invention discloses a food cooker with a temperature pressure control. The food cooker comprises a pot body, wherein the bottom part of the pot body is provided with an interlayer, and a heating channel and a cooling channel which are aligned at intervals are arranged in the interlayer; the heating channel is heated and stopped heating through a switch K1, and the cooling channel is cooled and stopped cooling through a switch K2. The food cooker further comprises a sealing spot cover; an air suction opening towards the pot body and a vacuum opening used for vacuumizing are arranged on the sealing spot cover; the air suction opening is opened and closed under the controlling of an air suction valve K3, and a vacuum opening is connected with a vacuum pump through a vacuum pump switch Kz. The invention further discloses a cooking method by means of the food cooker with the temperature pressure control. Compared with an ordinary electric heating spot, the vacuum device is employed, thus the tasty is quick and the food quality is good. By employing a special standard cooking curve and a cooking controller, the good food taste is guaranteed. After adopting the cooling device, the overheat phenomenon can be avoided.

Owner:HUAZHONG AGRI UNIV

Deep-fry cereal instant noodles and preparation method thereof

The invention discloses deep-fry cereal instant noodles and a preparation method thereof. The deep-fry cereal instant noodles are prepared from wheat flour, solanum tuberdsm, tapioca starch, guar gum, sodium polyacrylate, composite phosphate and sodium carbonate in parts by weight. The preparation method comprises the following steps of: putting the materials into a dough mixer, adding water to prepare paste, and curing the paste; compositing the cured paste to be strips through a laminating machine, and cutting the strips and shaping; and cooking the shaped noodles, spraying condiments, frying, finally carrying out regular air cooling and then packaging. The deep-fry cereal instant noodles prepared according to the technical scheme are good in mouth feeling, rich in nutrition and few in oil content, and are beneficial to the health of people.

Owner:河南面之缘食品有限公司

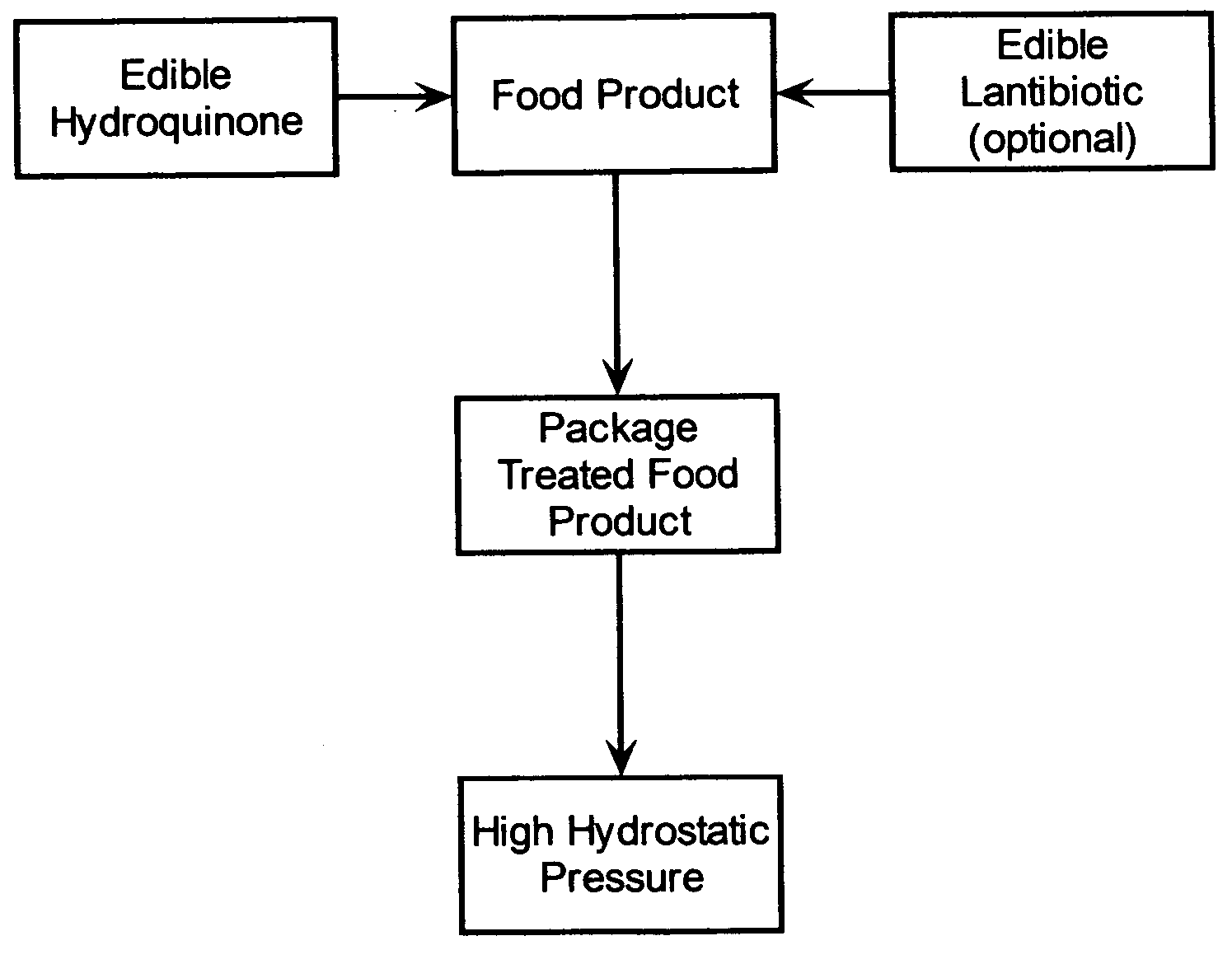

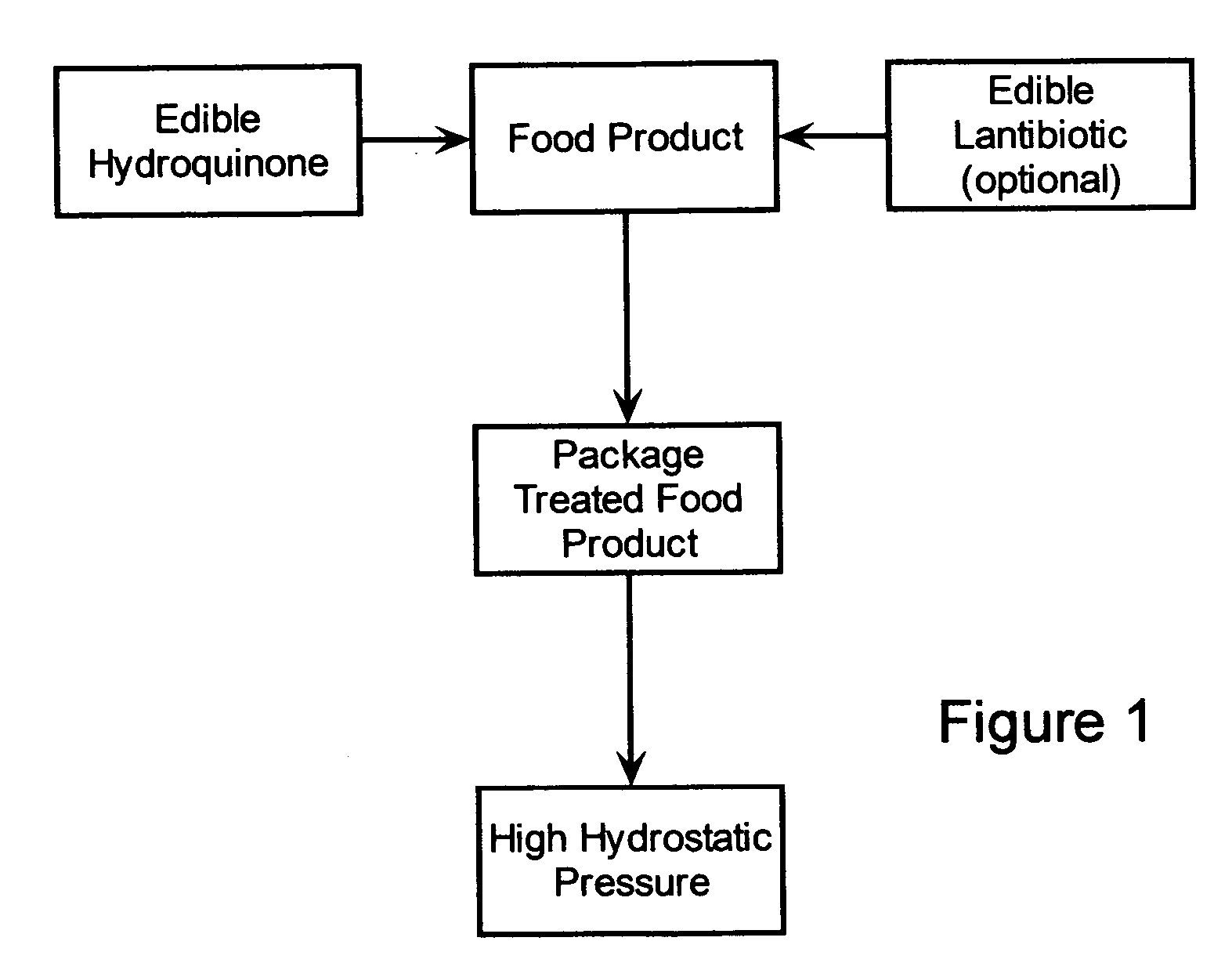

Methods for preserving food products

InactiveUS20060024414A1Efficient and economical treatmentReduce microbesEggs preservation using chemicalsPre-baking dough/flour preservationChemical treatmentMicroorganism

An improved method is provided for inactivating microorganisms in food products by introducing an edible phenolic compound in a food product and subjecting the resulting food product containing phenolic compound to high pressure conditions. This particular combination of physical and chemical treatments on the food products inactivates undesirable microorganisms in a food product to a significantly greater degree possible than achieved with any one of the treatments by itself, and the combined antimicrobial effect of these different types of treatments is synergistically greater than any additive effect that might be expected from the individual treatments.

Owner:KRAFT FOODS INC

Processing and fresh-keeping method for fresh-eating walnut

InactiveCN101209067ACrunchy and sweetGood tasteFood preparationFruits/vegetable preservation by freezing/coolingFreeze thawingBiotechnology

The invention relates to a processing and preservation method for eating fresh walnut, which includes the fresh walnuts is selected after being picked firstly; attacked and rotten walnuts are picked out; a freeze thawing method is utilized to shuck off the green peels of the walnuts and then the freeze thawing method is utilized to shuck off the seed capsules of the walnuts; the walnut meat, the seed capsules of which are shucked off, is dipped in a VC solution with the chroma of 0.1 to 0.8 percent for 1 to 2 hours to carry through color protection; simultaneously, the water content is controlled and then vacuum or inert gas packing is carried through by classification; then the product is frozen to keep fresh until being sold and used. During the whole processing and preservation process, no antiseptic and antistaling agent are used, thus according with the requirement of nuisance-free products and belonging to green healthy food. The prepared walnut meet keeps the fragrance of the walnuts with the flavor of crisp and sweet; the nutrition matters are not washed away and the flavor as well as the quality of the walnut meet is better; and the walnut meet is convenient to eat. The invention has the advantages of keeping the nutrition component of the walnut meet to the utmost extent, improving the using value and eating quality, belonging to nuisance-free green food and being convenient to eat, etc.

Owner:SHANDONG INST OF POMOLOGY

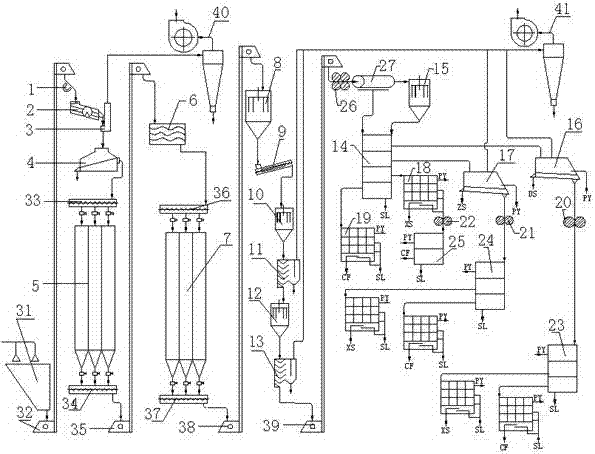

Packaged food packaging system

InactiveCN104554910AReduce labor intensityReduce security risksPackage sterilisationWrapper twisting/gatheringFood safetyEngineering

The invention discloses a packaged food packaging system and belongs to the technical field of mechanical equipment for food. The packaged food packaging system solves the problem of low production efficiency of the prior art. The packaged food packaging system comprises a charging orbit, a packaging bag opening / closing mechanism, a bag discharge orbit, a plate filling mechanism, a plate stacking mechanism, a plate transfer orbit, a bag discharging mechanism, a sterilizing mechanism, a drying mechanism, a bag arranging mechanism, a binning mechanism and an automatic bin sealing mechanism connected in sequence. The packaged food packaging system integrates automatic feeding, automatic sealing, automatic bag discharge, automatic plate filling, automatic plate stacking, automatic plate transfer, automatic bag discharging, automatic sterilizing, automatic drying, automatic bag arranging, automatic binning and automatic bin sealing, the production staff number in a workshop is greatly reduced, the labor intensity is lowered, and the production efficiency is improved; because the packaged food packaging system rarely depends on manpower, the probability of carrying bacteria and impurities into food packaging bags by operators is less, and the potential safety hazard of food is lowered; the system is compact and centralized, and accordingly the space is saved.

Owner:HANGZHOU FUYANG FUSHIDE FOOD CO LTD

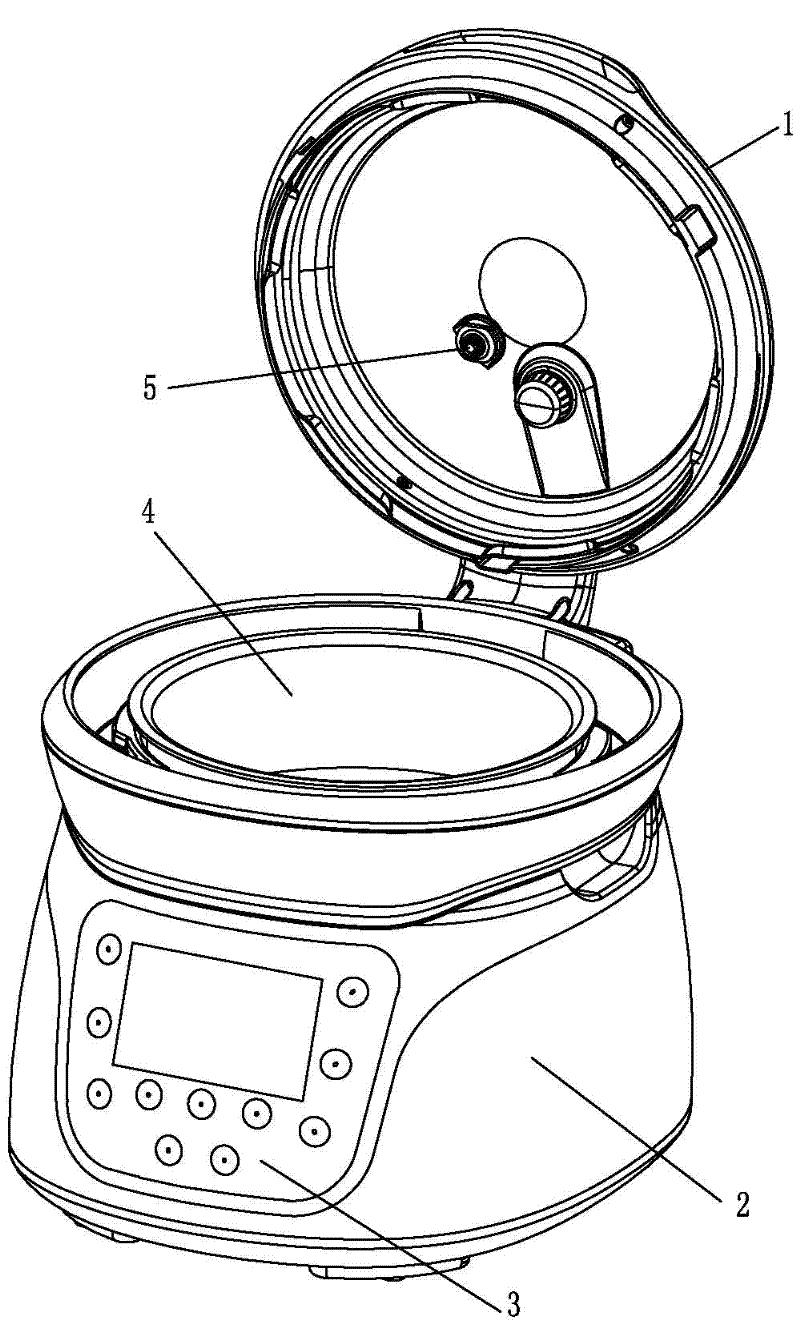

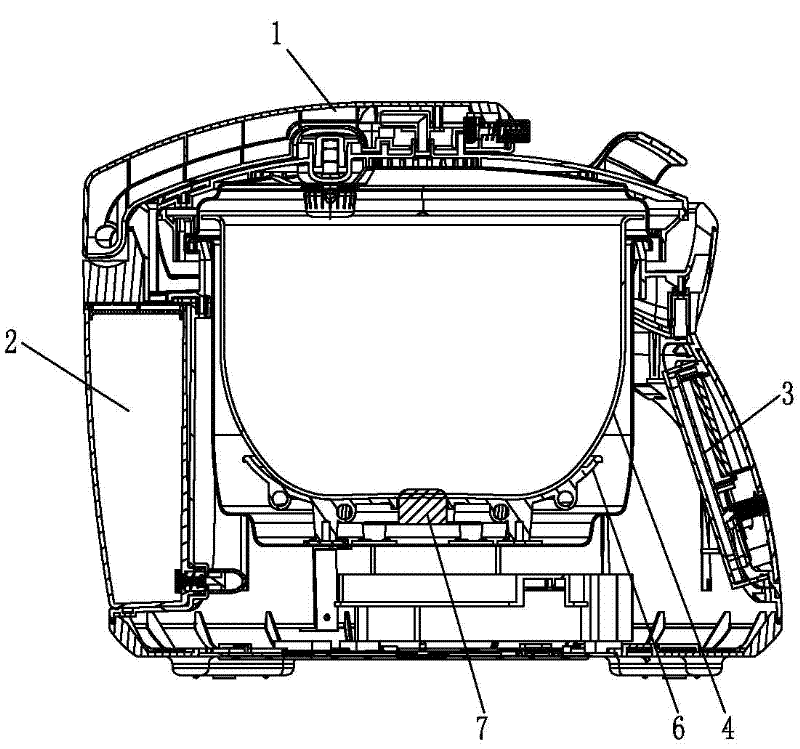

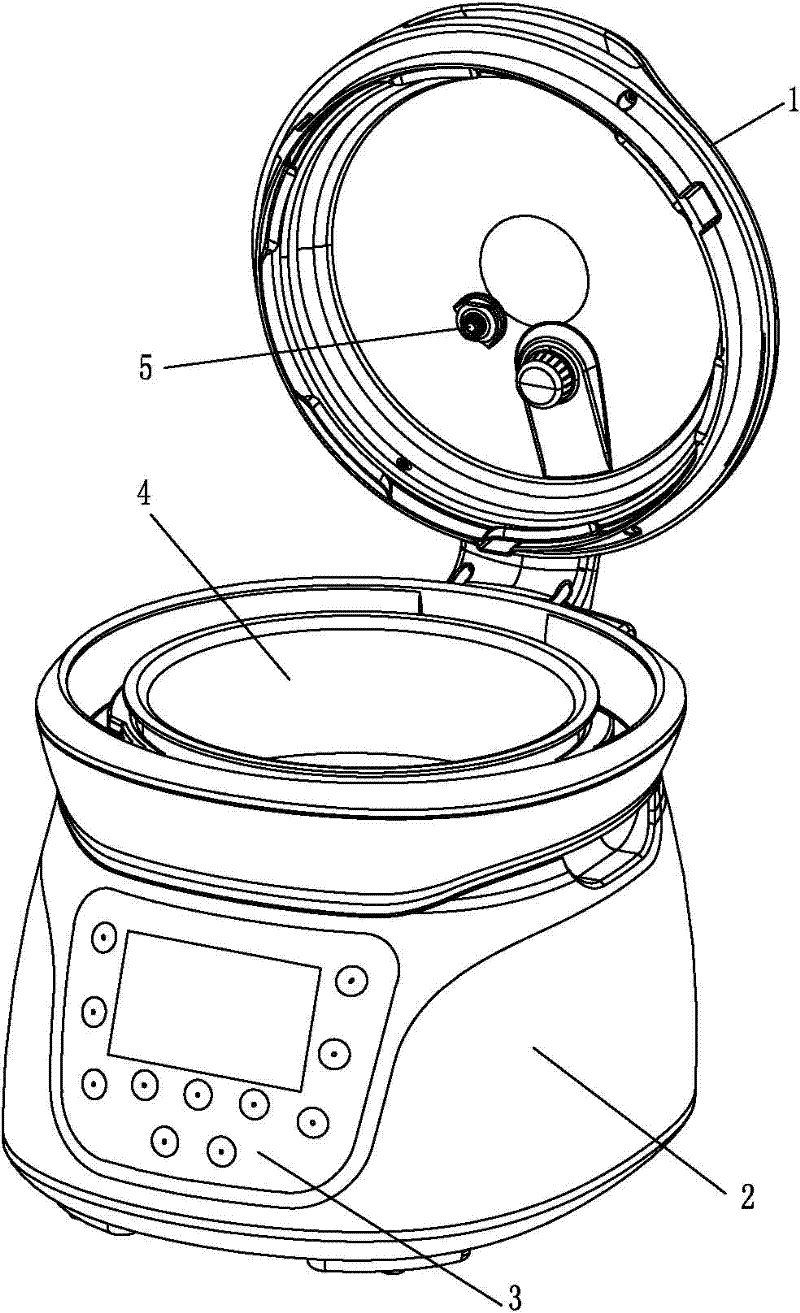

An electric pressure cooker for finely cooking rice and its control method

ActiveCN102293584AAvoid overcookedGreat tasteAuxillary controllers with auxillary heating devicesPressure-cookersThermodynamicsRice dishes

The invention discloses an electric pressure cooker for finely cooking rice and a control method thereof. The electric pressure cooker for finely cooking rice comprises a cover body, a cooker body, an inner tank, a heating disk, and a control device for controlling the heating disk to heat or stop heating; the control device comprises a soft fire heating process module, a low-temperature water-absorption process module, a medium-temperature water-absorption process module, a big fire heating process module, a sufficient boiling process module and a rick-stewing process module. The control method for finely cooking rice comprises a preparation process, a soft fire heating process, a medium-temperature water-absorption process, a big fire heating process, a sufficient boiling process and a rice-stewing process. In different heating process stages, different control temperatures and heating time are adopted according to the rice characteristics so that each grain of rice can sufficiently absorb water from outside to inside to guarantee the edible quality of the rice grains such as grain form, color, taste, flavor and the like; since the adopted heating manner mainly is an intermittent heating form, the finely cooked rice has better edible quality and contains more nutrient components.

Owner:GUANGDONG LUBY ELECTRONICS

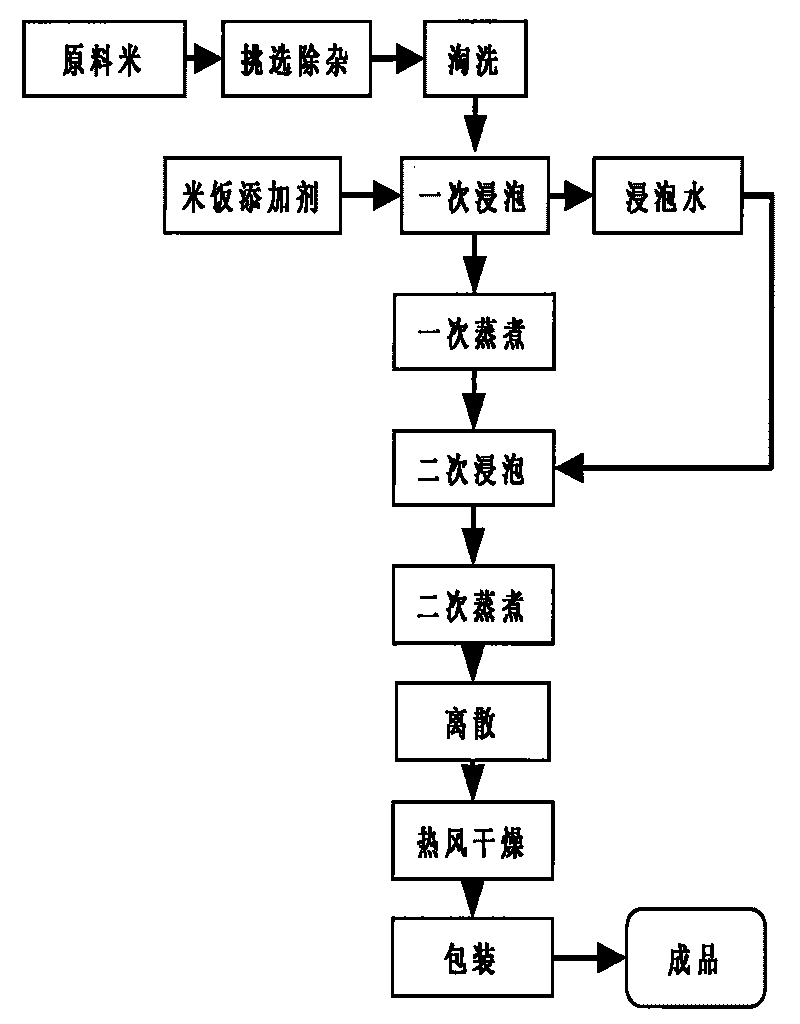

A kind of production method of instant rice with good anti-retrogradation performance

InactiveCN102283350AImprove anti-retrofit performanceImprove enzymatic hydrolysis efficiencyFood preparationMonoglycerideProteinase activity

The invention discloses a production method for convenient rice with a favorable retrogradation resisting performance, which comprises the steps of raw material rice washing, primary soaking, primary cooking, secondary soaking, secondary cooking, dispersing, drying and packaging, wherein a primary soaking solution is a water solution containing 0.2-0.8 percent by weight of beta-cyclodextrine and 0.1-0.4 percent by weight of monoglyceride; and a secondary soaking solution is a water solution containing 0.2-0.8 percent by weight of beta-cyclodextrine, 0.1-0.4 percent by weight of monoglyceride,1000-8000U / 100g of alkali protease of raw material rice and 300-3000U / 100g of beta- cyclodextrine of the raw material rice. According to the production method disclosed by the invention, the process is simple, the favorable retrogradation resisting performance of the dehydrated convenient rice can be improved, the mouthfeeling of the rice is improved and the rehydration time of the convenient rice is shortened; and the production method is more convenient to use.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Rice grain brewing type instant convenient porridge and preparation method thereof

ActiveCN103652592AEnhanced anti-retrofit propertiesFor long-term storageFood dryingFood ultrasonic treatmentMonoglycerideSucrose

The invention belongs to the technical field of food processing, and relates to rice grain brewing type instant convenient porridge and a preparation method thereof. The method comprises the following technical steps of: preparing raw materials; preparing raw material soak solution; carrying out ultrasonic immersion; dewatering; curing; drying until the moisture content is less than 10%; packaging. The raw material soak solution is prepared from the following components in parts by weight: 0.1-0.9 part of citric acid, 0.02-0.5 part of sodium carbonate, 0.1-1.5 parts of beta-cyclodextrine, 0.1-0.9 part of monoglyceride, 0.1-0.3 part of sucrose fatty acid ester and 100 parts of water. According to the raw material soak solution, the raw returning resistance of rice grains can be enhanced, the convenient porridge can be favorably stored for a long time, the brewing type instant convenient porridge rehydration time is shortened, the effective nutritional ingredients of raw materials can be sufficiently reserved, and the edible quality of the instant convenient porridge is improved. The preparation method for the rice grain brewing type instant convenient porridge, which is disclosed by the invention, has the advantages of simple operation, no need of rice frying and low-temperature freezing operation, high production efficiency and small energy consumption and is favorable for industrialized production, the manufacture technology time is shortened, and the production cost is lowered.

Owner:INNER MONGOLIA YINGPAN LIANGNONG ANIMAL HUSBANDRYIND CO LTD

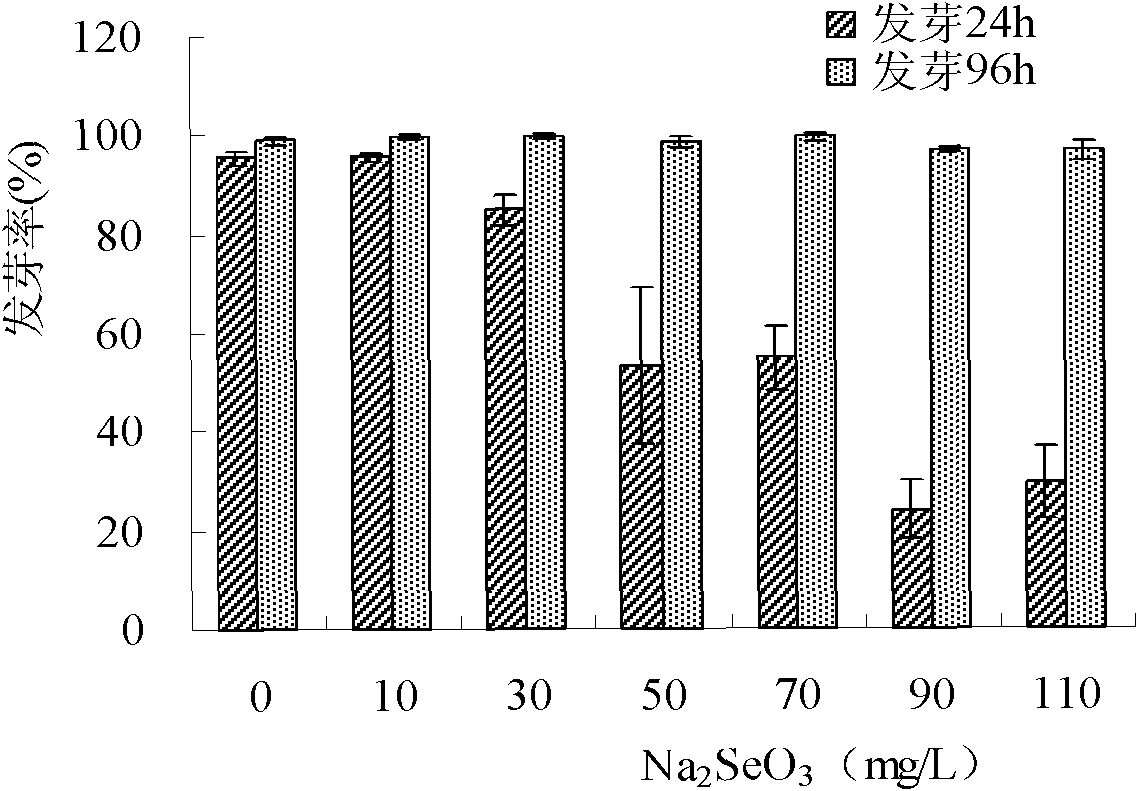

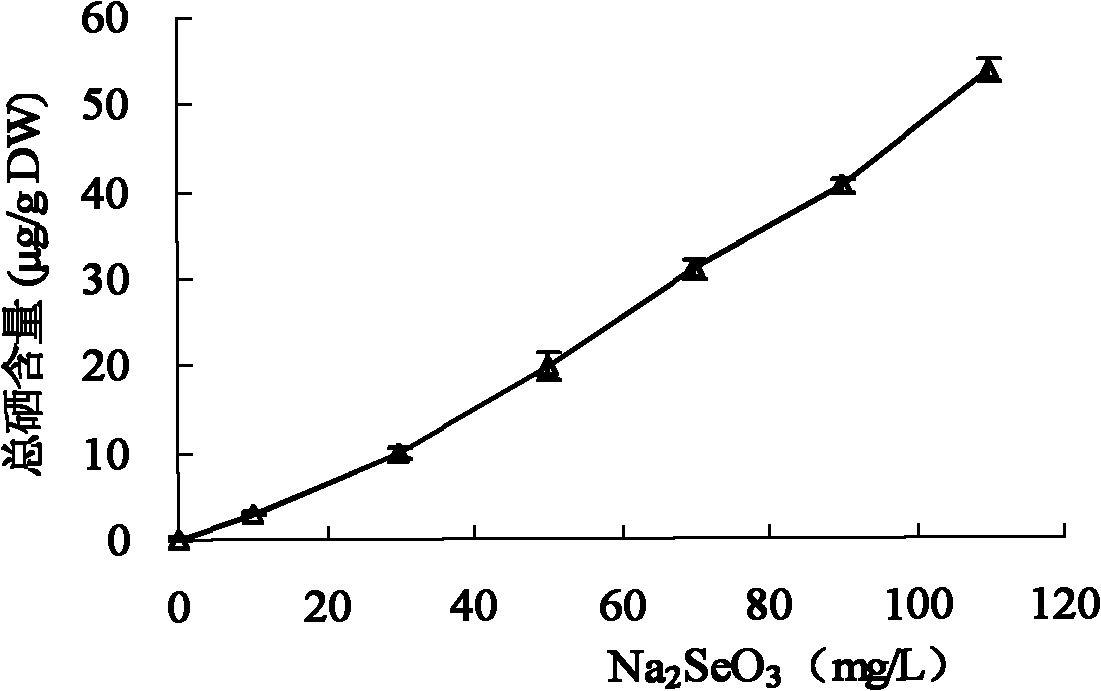

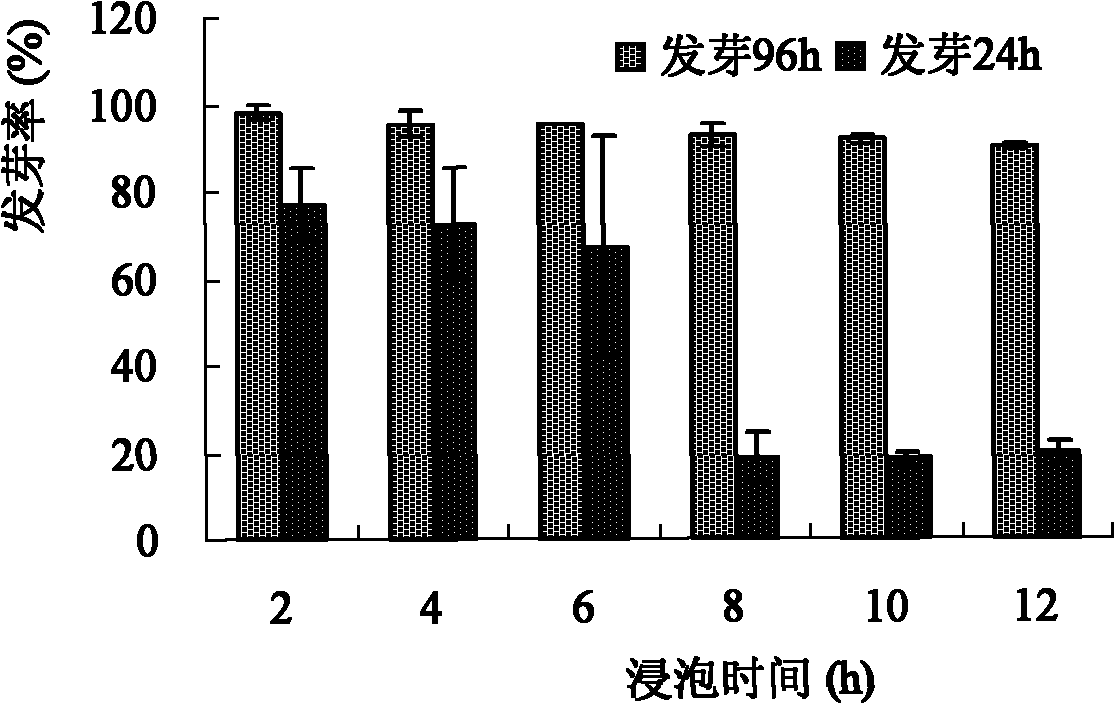

Method for cultivating selenium-rich bean sprouts

InactiveCN102090313AAdvantages of production processNo pollution in the processCultivating equipmentsSoilless cultivationSoybean sproutDrug biotransformation

The invention relates to selenium-rich bean sprouts and a production process thereof. The production process is to use sprouting of soybeans to perform the biotransformation of selenium to obtain a bean sprout product rich in organic selenium. The invention belongs to the field of deep processing of farm products, and also belongs to the field of the production of functional food. The production process comprises the following steps of: performing selection and impurity removal on the soybeans, then soaking in solution of sodium selenite, draining water, and then ensuring that the soybeans sprout in a mode of water spraying cultivation to obtain the selenium-rich bean sprouts.

Owner:常州五星禾绿蔬菜食品有限公司

Slaughtering method comprehensively utilizing giant salamander resources

ActiveCN104206502ADoes not affect the tasteReduce viscosityElectric current slaughtering/stunningMeat/fish preservation by freezing/coolingSaline waterGiant salamander

The invention discloses a slaughtering method comprehensively utilizing giant salamander resources. A giant salamander is subjected to electric shock anesthetization after being temporarily cultured and cleaned, then white mucus on the body surface of the grown giant salamander is lightly scraped by a stainless steel spoon and the mucus is collected in a preservation box and is cryopreserved at the temperature of minus 20 DEG C; after collection of the mucus is finished, the processed giant salamander is soaked and washed with vinegar solution to remove residual mucus colloid, the washed giant salamander is placed on a slaughtering table, the head of the giant salamander is pressed, the head and the trunk are directly cut off and the slaughtered giant salamander is hung upside down to carry out bloodletting; after bloodletting, cutting is carried out, wherein the cutting operation comprises the following steps: (a) cutting off limbs; (b) ripping along the medioventral line to take out internal organs and peeling off livers; (c) flushing the giant salamander with salt water; (d) peeling off the skin; (e) taking out the lateral line and grease of the tail of the giant salamander; (f) separating out spine and coccyx; (g) cutting into meat slices and finally carrying out sterilization, deodorization, packaging and cryopreservation. The slaughtering method disclosed by the invention can sufficiently show edible and medicinal value of each part of the giant salamander.

Owner:CHONGQING KUIXU BIOLOGICAL SCI & TECH

Dry method processing process and device for corn

InactiveCN102500446ASolve the problem of difficult germinationEasy to separateGrain treatmentsFood scienceBiotechnologyBLENDER/MIXER

The invention relates to a dry method processing process for corn, which is mainly composed of processes of clearing, hardening and tempering, peeling, degerming, hominy chop breaking, embryo choosing and hominy chop extraction. The peeling process is sequentially composed of primary stirring peeling, water addition and secondary stirring peeling. The water addition process comprises adding water with the weight to be 0.5-5% of the weight of the corn to the corn by utilizing a water addition machine and enabling the water temperature to be 10-60 DEG C. After water addition, the corn is sent to the stirring peeling process within 10min to be processed, the height of the corn is controlled within 0.5-3m during the stirring peeling process, a blender is adopted during stirring, and the speed of a stirring rod line of the blender is controlled to be at 1-6m / S. The dry method processing process for the corn can remarkably improve yield rates of hominy chop with fat content below 1%, corn starch and embryos with purity to be over 80%, particularly embryo extracting rate and purity of the extracted embryos, and is remarkable in economic and social benefits.

Owner:王洪福

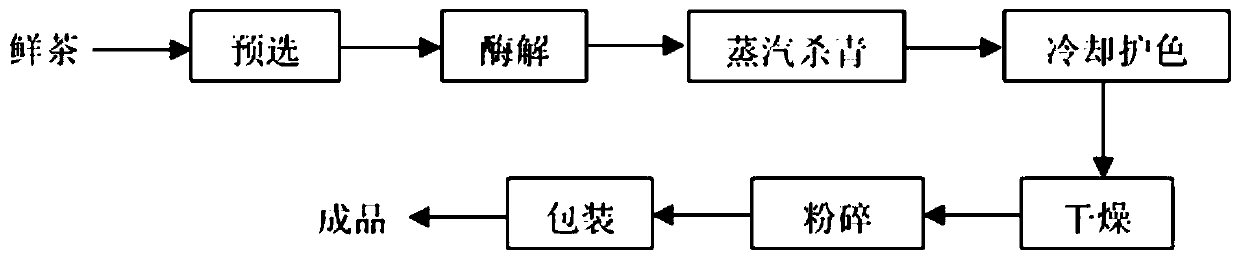

Ultrafinely pulverized green tea powder preparation method

The invention relates to the technical field of tea processing. A method comprises the steps of first washing and draining fresh tea, then pulverizing to large particles, spraying 1 / 10 enzymatic hydrolyzate on the surfaces of tea leaves, and turning the tea during enzymolysis; after the enzymolysis technology, performing enzyme deactivation by an enzyme deactivation machine until the fresh leavesare evenly and thoroughly evaporated to be free of grassy taste, then immersing the fresh leaves in a color protection solution at 20-25 DEC, repeatedly soaking in ice water for cooling, draining water, and then performing liquid nitrogen freezing treatment and vacuum freeze-drying treatment; after that, performing air jet pulverization at 15 DEC by an air flow ultrafine pulverizer to form ultrafinely pulverized green tea powder with an average particle diameter smaller than 20 microns. The ultrafinely pulverized green tea powder prepared by a preparation process provided by the invention usesconventional green tea as a raw material, thereby reducing production cost and labor cost; the final finished product is low in bitterness, moreover the green tea powder is more emerald green in color and better in solid fragrance and solubility, and can effectively maintain the original color and flavor quality of the tea, increase the quality of tea soup, and make the overall quality of the green tea powder closer to the quality of matcha.

Owner:SICHUAN UNIV

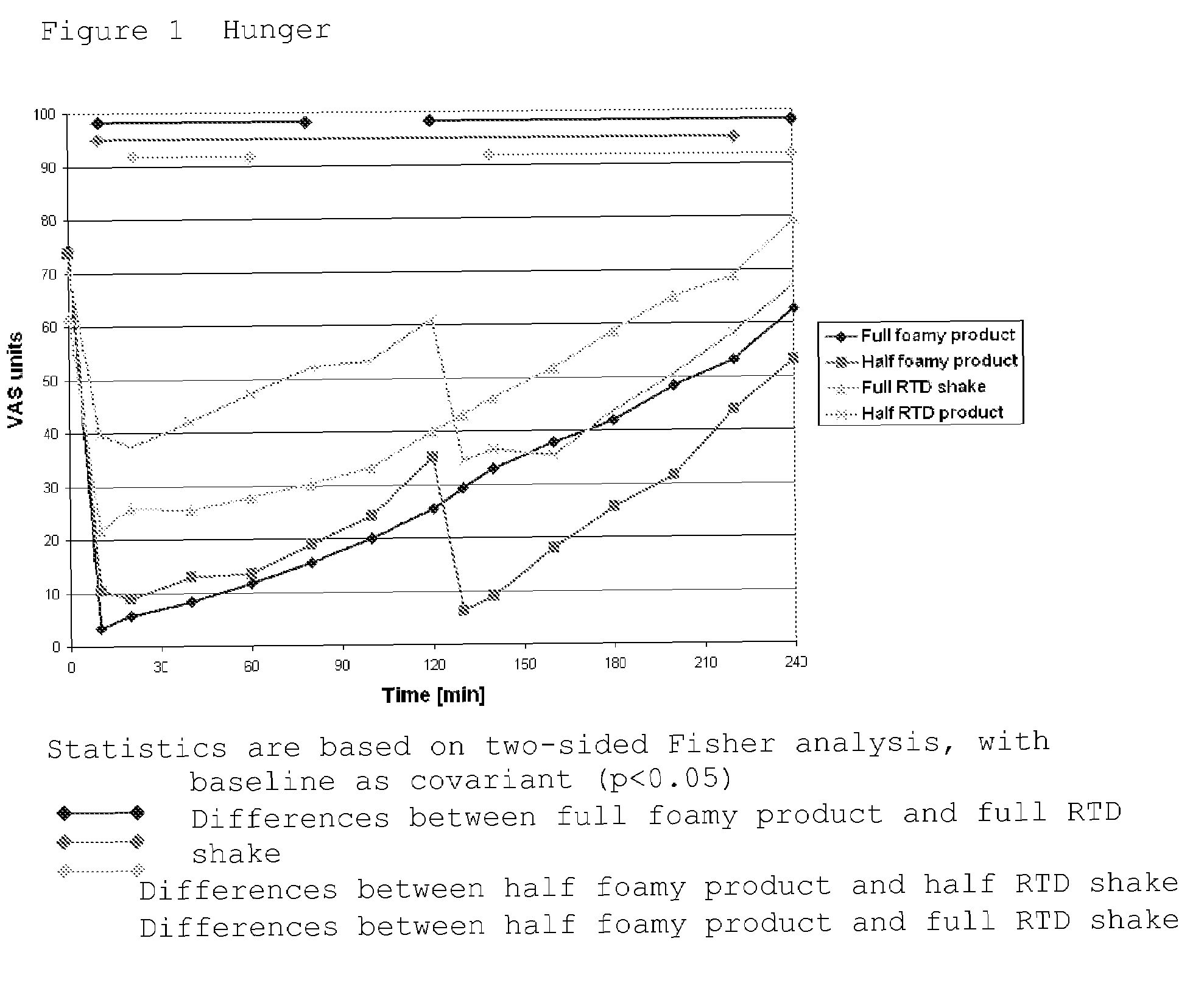

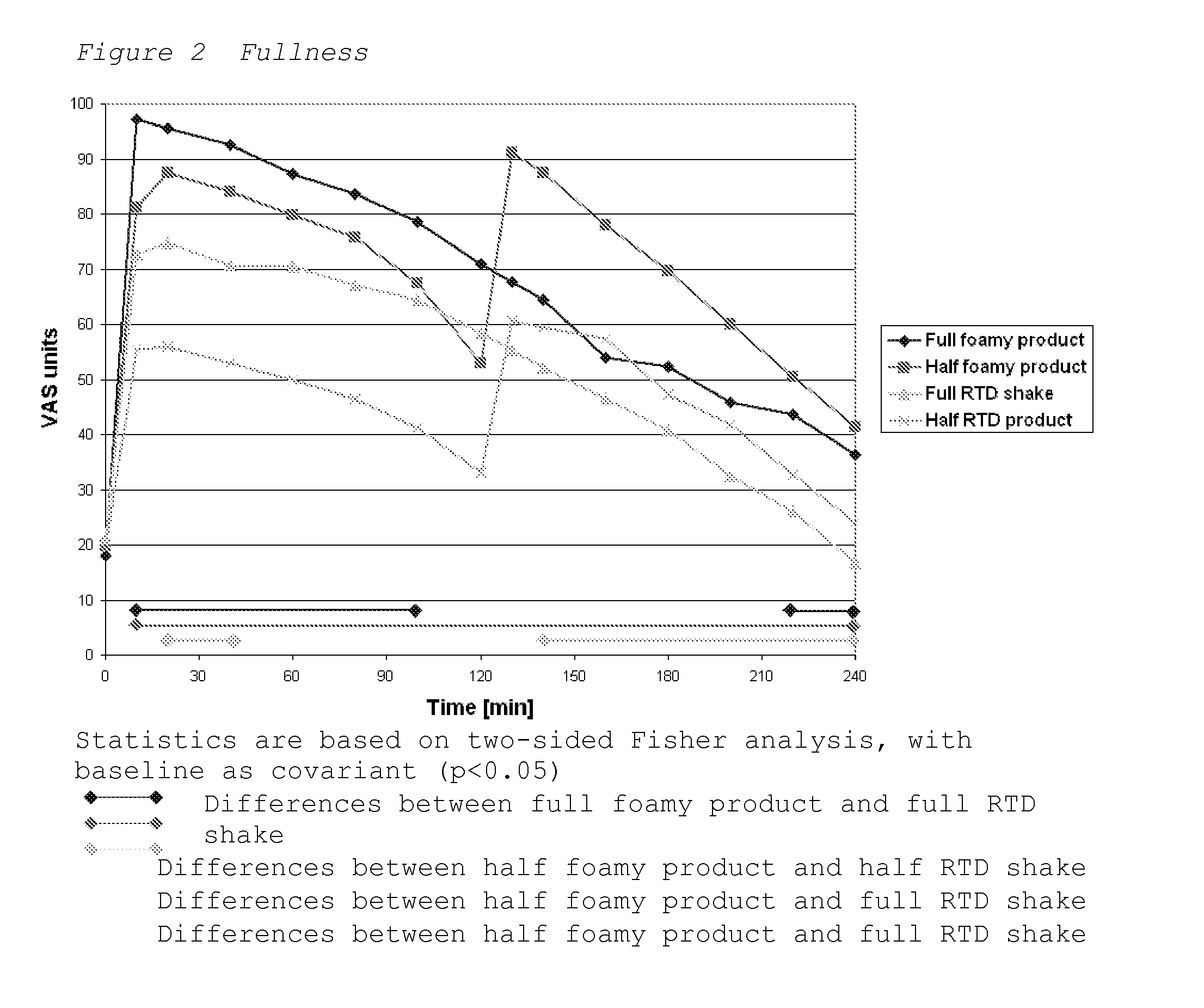

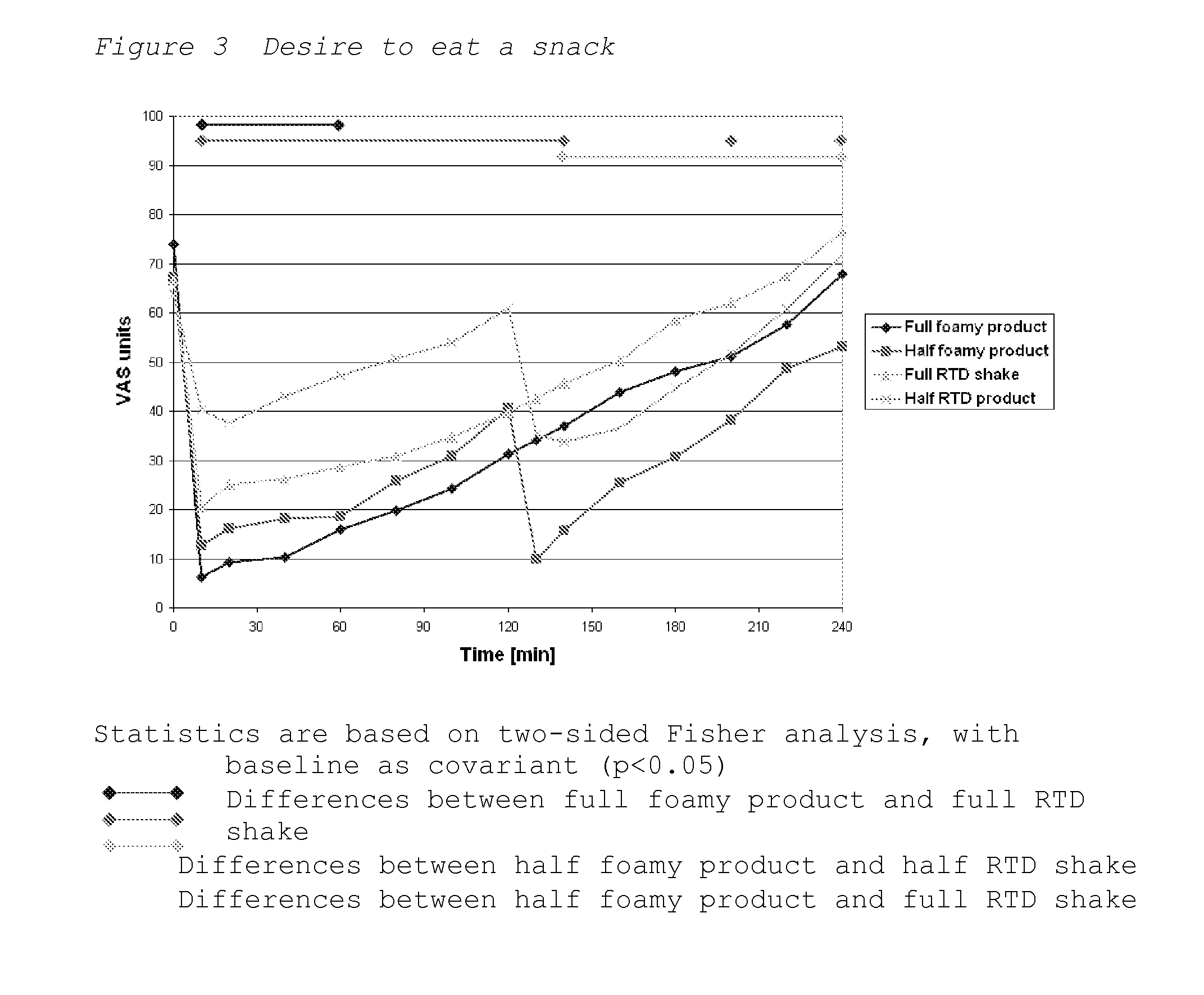

Edible foam product for the treatment or prevention of obesity

InactiveUS20100034753A1Reduce energy densityHigh in-mouthMetabolism disorderAerosol deliveryOverweightLiquid composition

The present invention relates to an edible foam product that can advantageously be used in the treatment or prevention of obesity. More particularly, the present invention provides an edible foam product of pourable or spoonable consistency having an overrun of at least 100%, said foam product containing at least 60 wt. % of water, from 1 to 7 wt. % of protein and from 1 to 20 wt. % of carbohydrates, and further being characterised by a high in-mouth stability as evidenced by a reduction in overrun of less than 35% under in-mouth shear conditions and a high gastric stability as evidenced by a t½>30 minutes, t 1 / 2 representing the time needed to achieve a reduction in overrun of 50% under gastric conditions. Another aspect of the invention relates to the use of an edible foam product in the treatment or prevention of overweight or obesity, said edible foam product having a pourable or spoonable consistency, an overrun of at least 100% and a high gastric stability as evidenced by t 1 / 2 >30 minutes. Yet another aspect of the invention concerns a pressurised container holding an edible liquid composition and a propellant, which liquid composition can be released from the container by activating a valve to produce an edible foam product having a pourable or spoonable consistency, an overrun of at least 100% and a high gastric stability as evidenced by t 1 / 2 >30 minutes.

Owner:KSF ACQUISITION

Composite antistaling agent for restraining lignification of bamboo shoot, and method of use

InactiveCN1726789AInhibition of the lignification processImprove food qualityFruit and vegetables preservationSalicylic acidAcoric acid

A composite antistaling agent for suppressing the lignification of bamboo shoot is proportionally prepared from salicylic acid, citric acid and ascorbic acid through dissolving in water. Its application method includes such steps as immersing the fresh bamboo shoots in said antistaling liquid, drying in air, vertically loading them in paper board case, and storage at 1-3 deg.C for 55-65 days.

Owner:ZHEJIANG UNIV

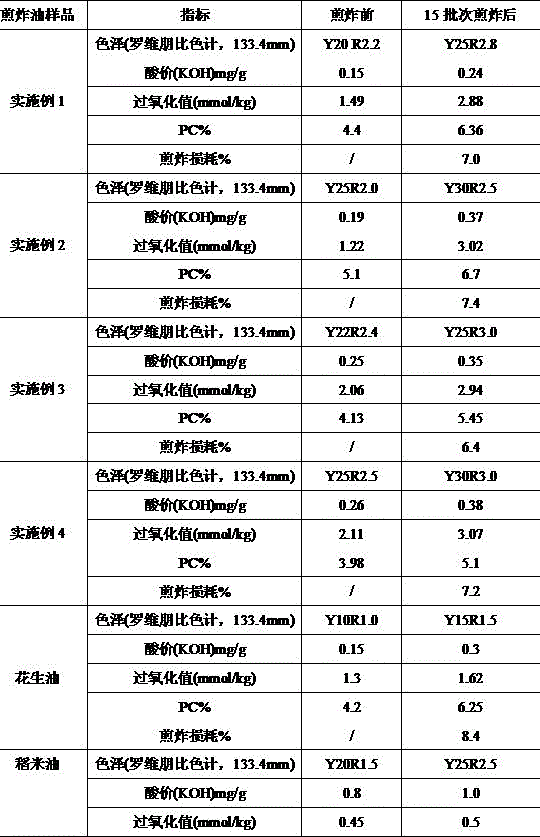

Special blend oil for frying and preparation method thereof

The invention discloses special blend oil for frying. The special blend oil for frying contains 10-50% by weight of high oleic acid peanut oil and 10-50% by weight of rice oil. The blend oil for frying is prepared by compounding any two or more than two of sunflower seed oil, olive oil, soybean oil, corn oil, cottonseed oil, palm oil, rapeseed oil, safflower oil, linseed oil and sesame oil in different proportions. The blend oil for frying is rich in fragrance, bright in color, high in content of oleic acid, rich in oryzanol and vitamin E, reasonable in composition of fatty acids and free of stickiness. Through a high-temperature frying test, the blend oil is high in smoke point, low in content of trans-fatty acids and high in frying stability. The fried food is small in oil content, good in crispy property, excellent in taste and nutritional and healthy. The blend oil disclosed by the invention can be used for frying different food materials, is suitable for being used as special fat for frying food in family and catering industry, is long in expiration date, and is novel nutritional and healthy special blend oil for frying.

Owner:山东金胜粮油食品有限公司

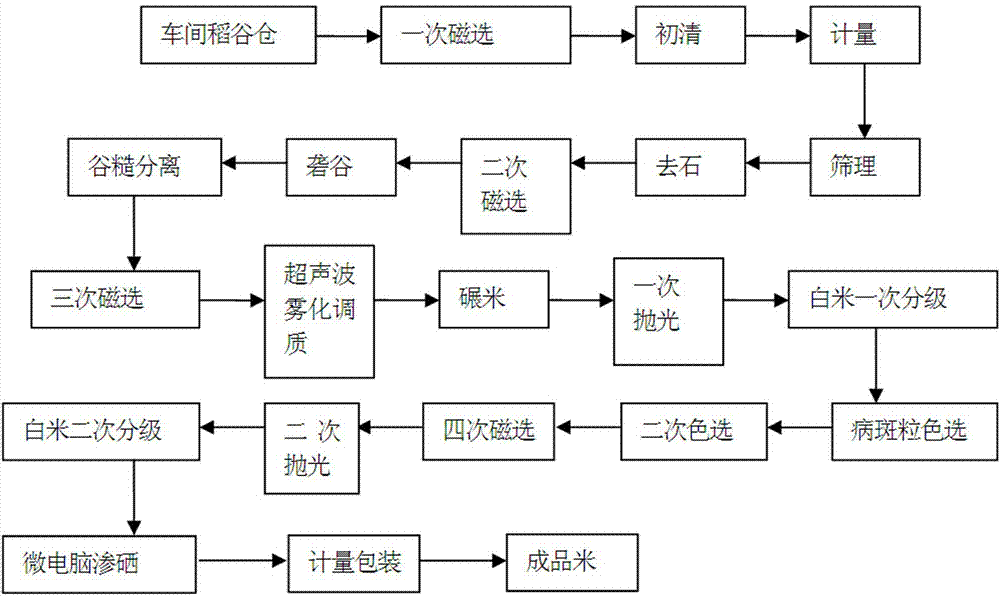

High-quality rice fine processing process

ActiveCN104772178AImprove Sorting Efficiency and PurityImprove the quality of finished riceSortingGrain millingSecondary colorChemistry

The invention provides a high-quality rice fine processing process, which comprises the processing flow processes of primary magnetic separation, primary cleaning, metering, sieving, stone removing, secondary magnetic separation, husking, husked rice separation, tertiary magnetic separation, ultrasonic atomization tempering, rice milling, primary polishing, polished rice primary grading, spotted rice color separation, secondary color separation, fourth magnetic separation, secondary polishing, polished rice secondary grading and metering and packaging. According to the ultrasonic atomization tempering, an ultrasonic atomization humidification mode is used for humidifying the rice, the tempering time is 10 to 20 minutes, the tempering temperature is controlled to be between 30 DEG C and 40 DEG C, the unit humidification quantity is 0.5 to 5 percent, the actual seeping quantity is 2 to 3 percent, and the moisture content of the polished rice finally obtained through processing is not greater than 14 percent; tempering agents adopt ultrasonic atomization water; during the spotted rice color section, a photoelectric color separation device is used for automatically picking out different-color rice, the full-process temperature reduction is carried out in the whole processing flow process, and the temperature rice in the processing process is controlled not to exceed 5 DEG C. The high-quality rice fine processing process has the advantages that the high-quality rice can be subjected to integrated utilization and deep processing, and the final product quality is improved.

Owner:YUNNAN HONGHE WOLONG RICE IND CO LTD

Composite bamboo shoot fermenting agent and preparation method of fermented bamboo shoots

InactiveCN101999450AAppropriate proportionLow alcoholFruits/vegetable preservation using acidsFlavorAlcohol

The invention discloses a composite bamboo shoot fermenting agent and a preparation method of fermented bamboo shoots. The composite bamboo shoot fermenting agent contains monascus vinasse and liqueur koji. The preparation method of the fermented bamboo shoots comprises the following steps of: firstly, blanching bamboo shoots; and then, fermenting the bamboo shoots under the action of the composite bamboo shoot fermenting agent. Under the action of the composite bamboo shoot fermenting agent, aromatic substances, pigments, and the like in the vinasse are infiltrated in the bamboo shoot tissues. The prepared vinasse-processed bamboo shoots have the characteristics of unique fragrance and flavor, mellow and pleasant taste, elegant flavor, attractive color and rich nutrition. The preparation method can effectively prevent fresh bamboo shoots from aging, lessen the loss of nutrient contents, preserve the nutrient contents of the bamboo shoots and ensure the quality and the grade of the bamboo shoots. The fermented bamboo shoots prepared by using the method disclosed by the invention have appropriate proportions of liquor, sugar and acid, and have the advantages of low alcohol and sugar contents, stable resistance to acid and alkali, strong heat resistance and light resistance, stable resistance to oxidoreduction and favorable practical values and application prospects.

Owner:健盛食品股份有限公司

Preparation method of bran bread

InactiveCN104770428AEasy to prepareImprove processing qualityDough treatmentBakery productsYeastBran

The invention discloses a preparation method of bran bread. The preparation method comprises the following steps of (1) weighing material; (2) pretreating bran; (3) activating by active dry yeast; (4) mixing powder; (5) fermentating; (6) dividing into blocks and rolling into balls; (7) putting into a die and forming; (8) fermentating; (9) drying and cooling. The preparation method of the bran bread has the advantages that the preparation method is optimized and improved, and the technology step is simple; in the preparation process, the original nutrient elements of the bran are maintained; a quality improving agent after design optimizing is provided; the processing quality, sensing quality and eating quality of the bran bread are better, and the preparation method is suitable for being popularized and applied.

Owner:张立升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com