Patents

Literature

210 results about "Intermittent heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The key point of the intermittent heating strategy is to predict the warm-up time of the heating system for each working day based on weather forecast data. The warm-up time of the intermittent heating system ranges from several minutes to several hours.

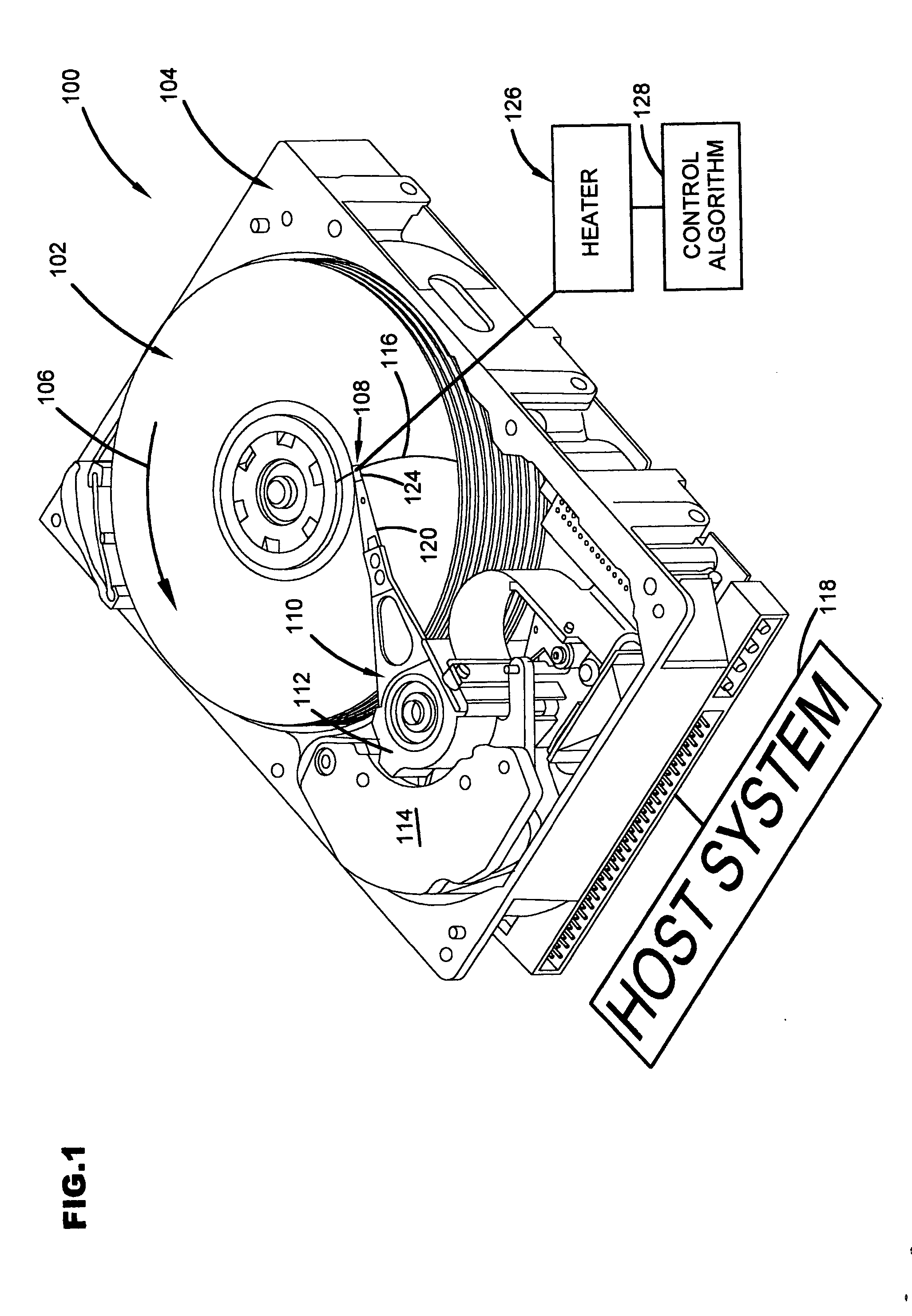

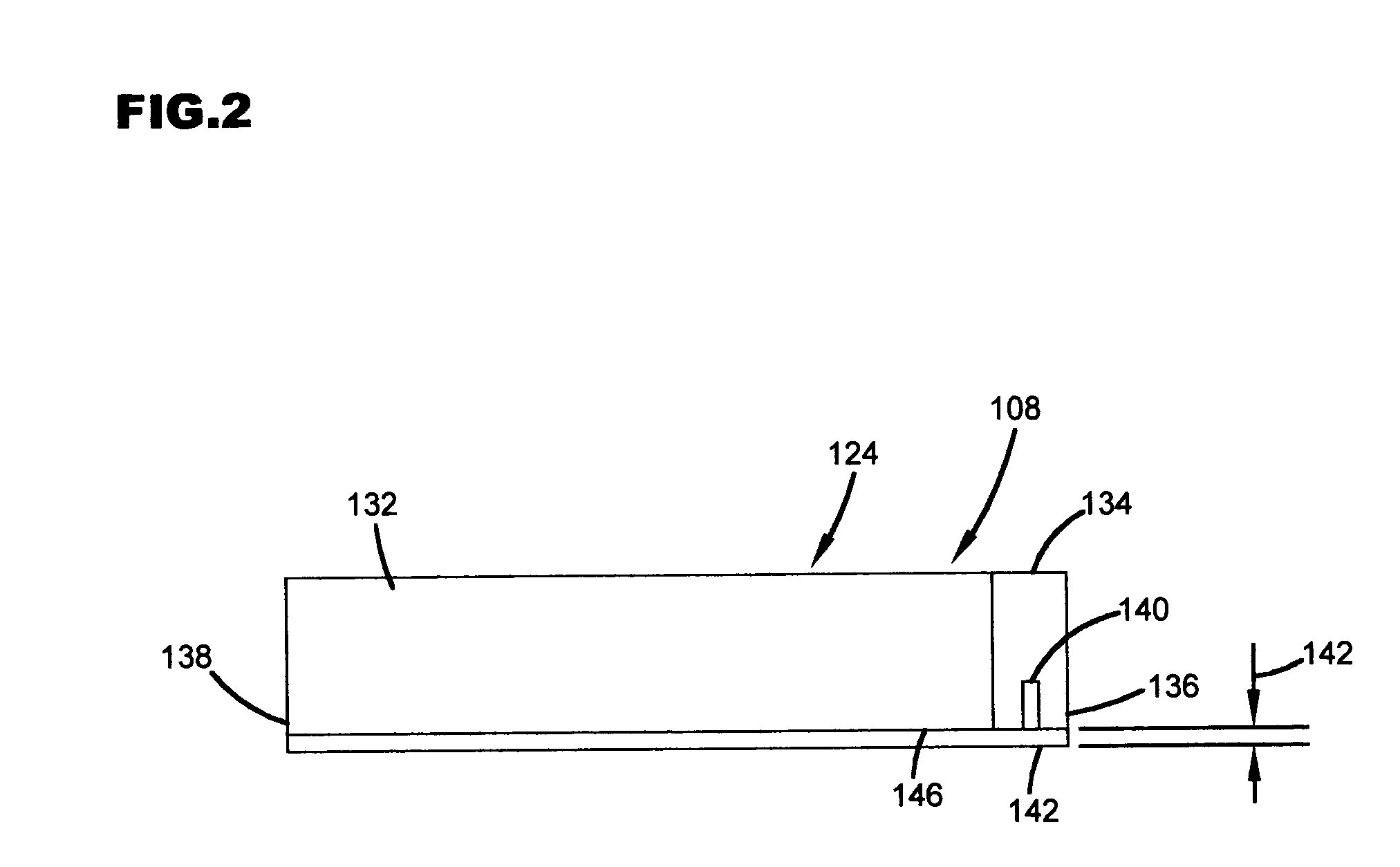

Head with heating element and control regime therefor

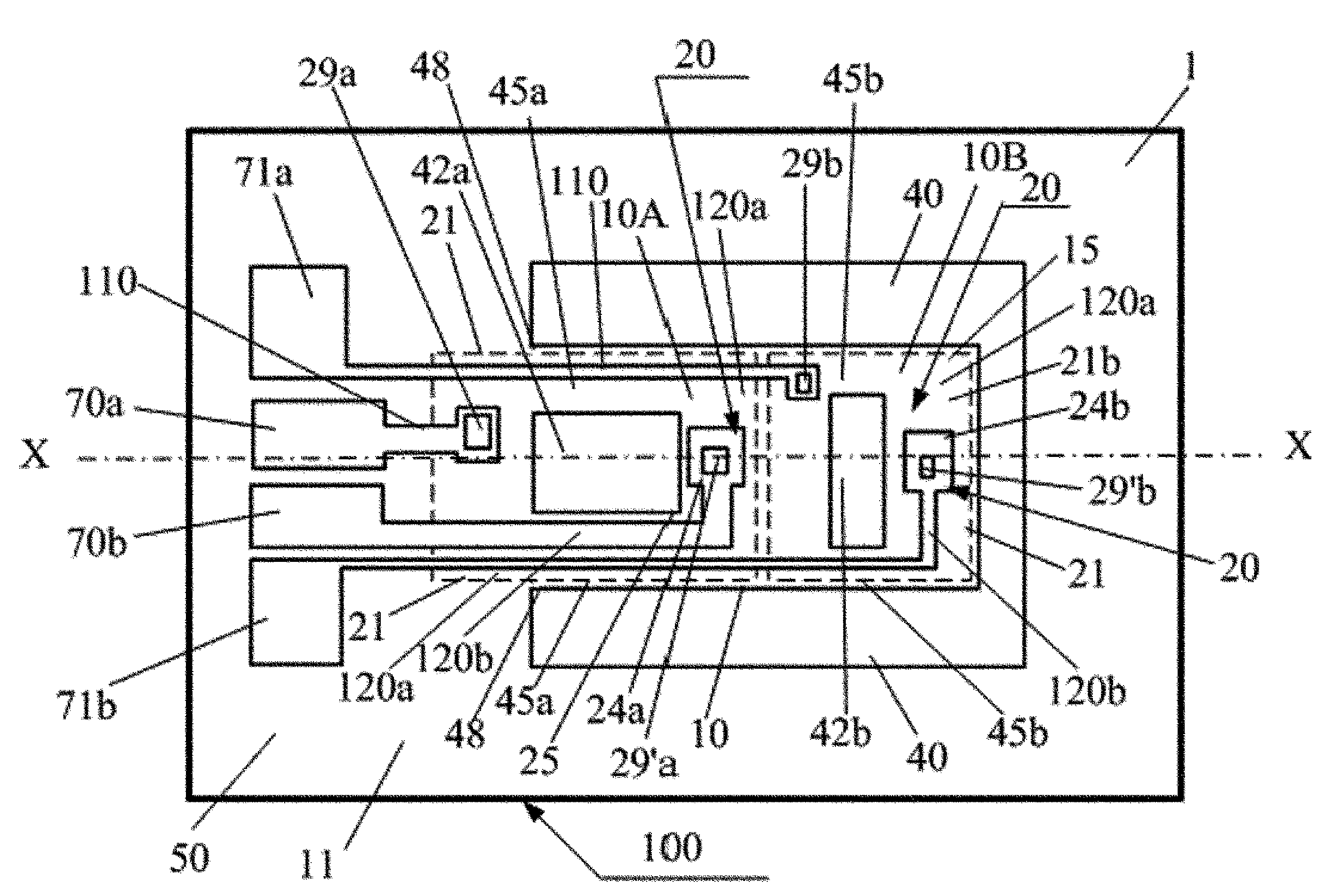

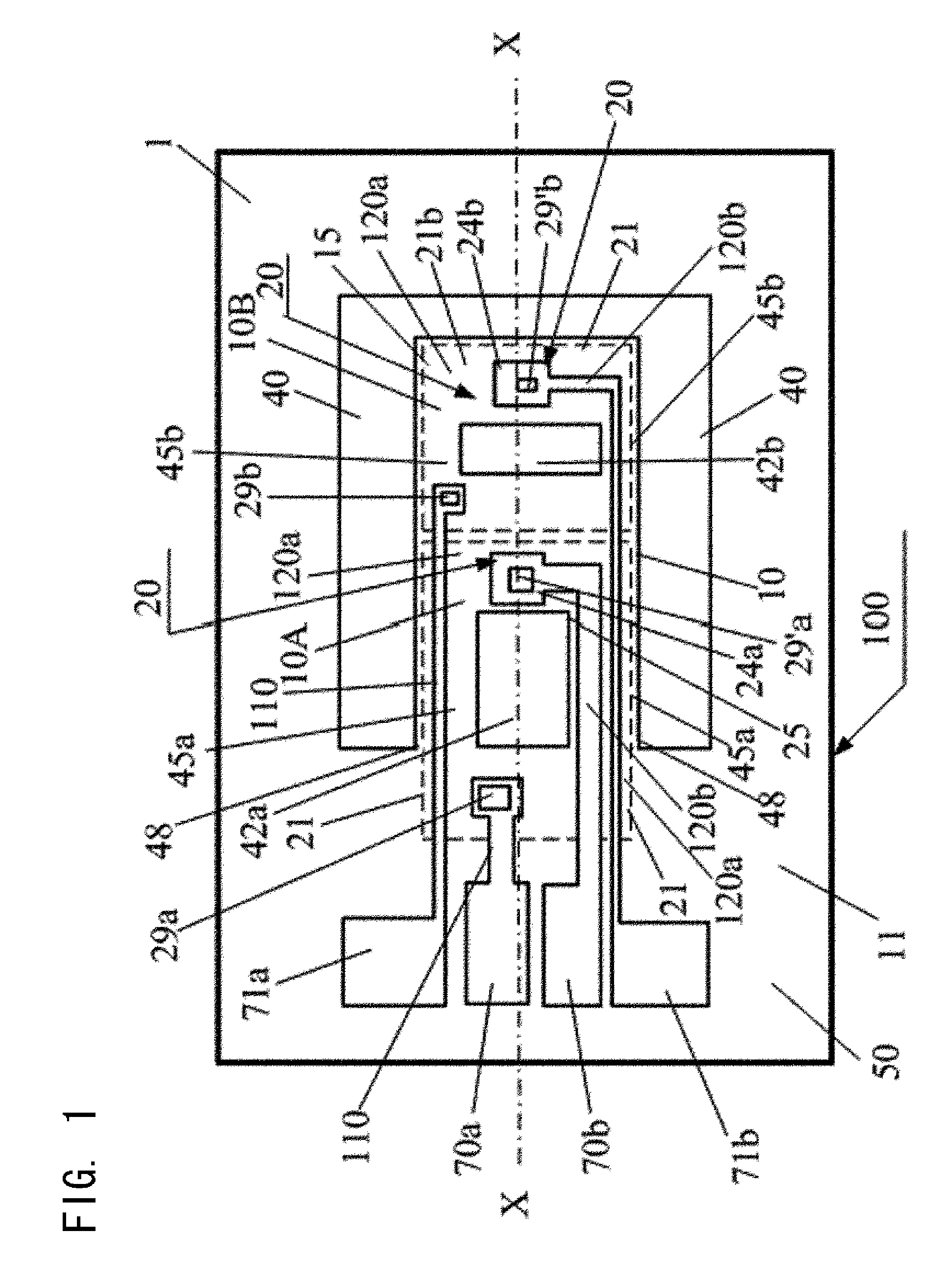

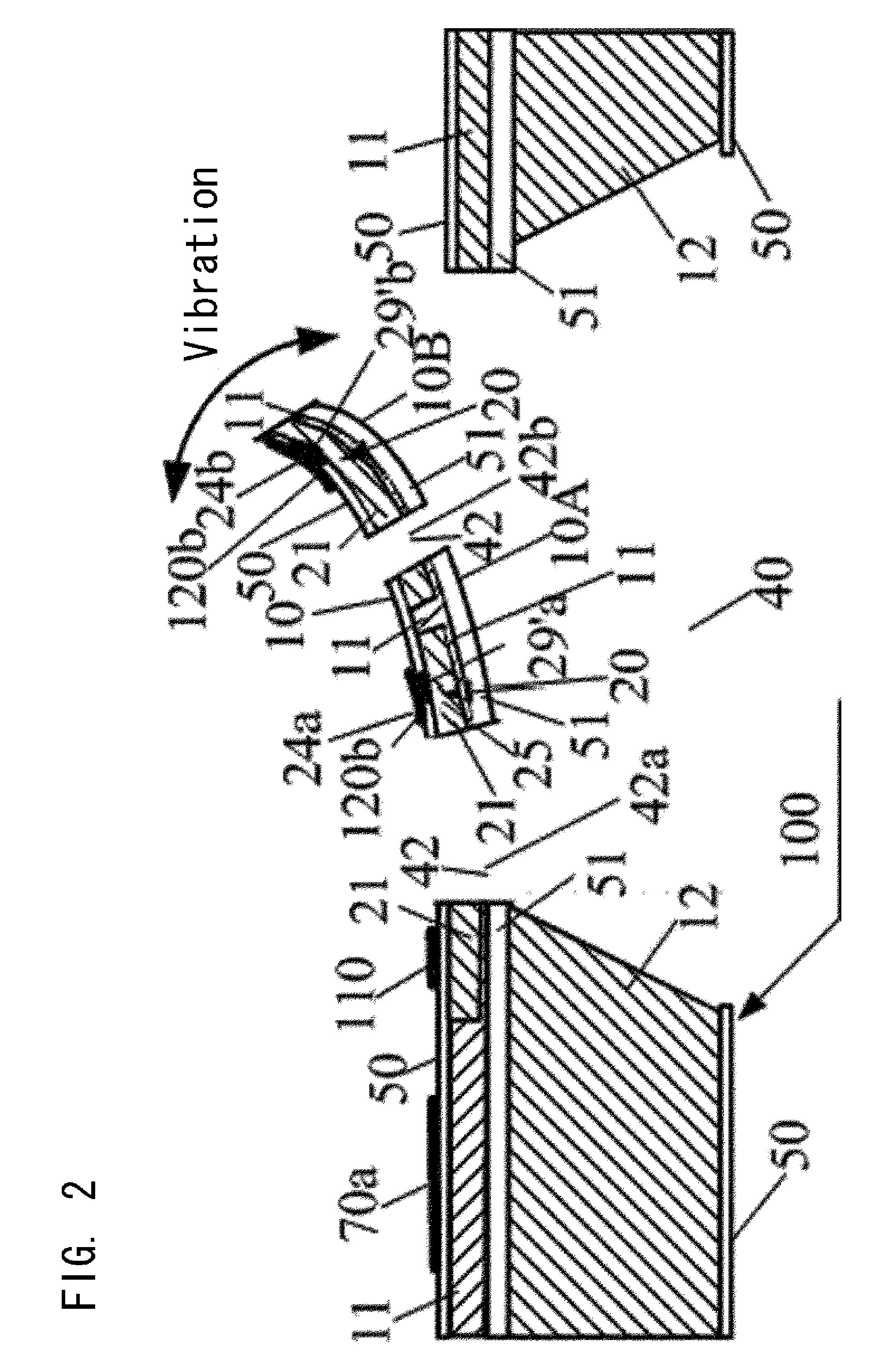

InactiveUS6975472B2Disposition/mounting of recording headsDriving/moving recording headsLower gradeTransducer

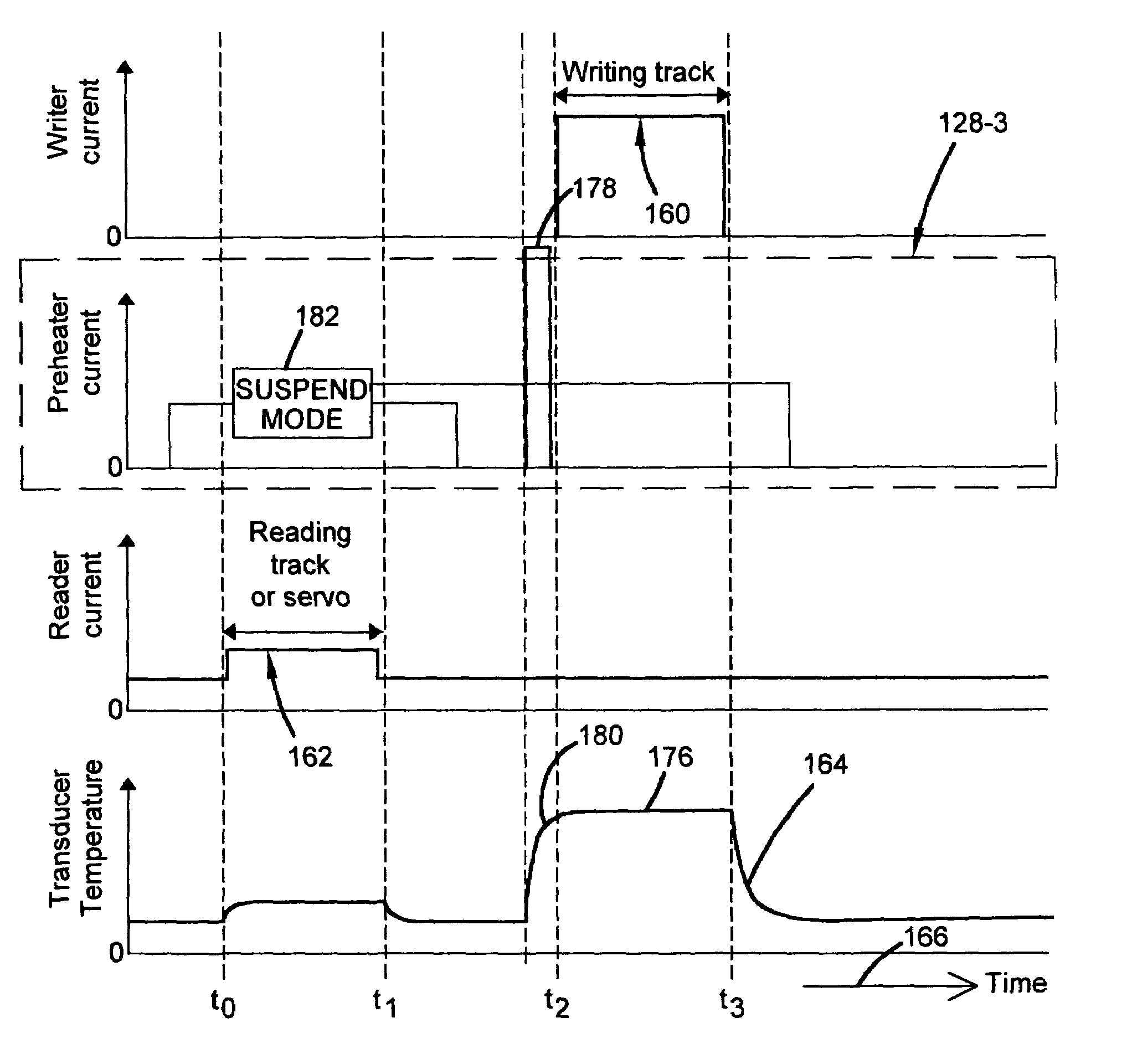

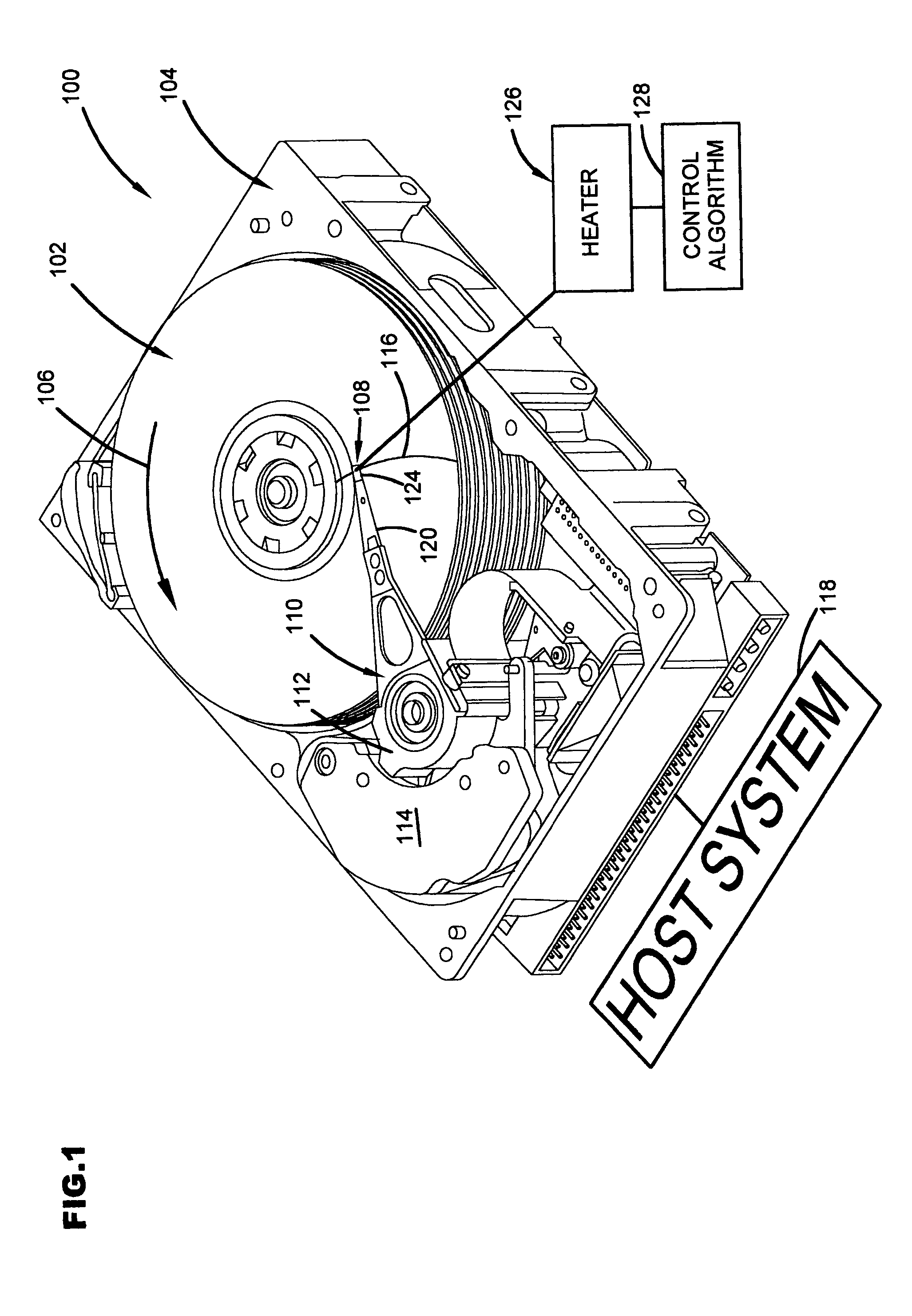

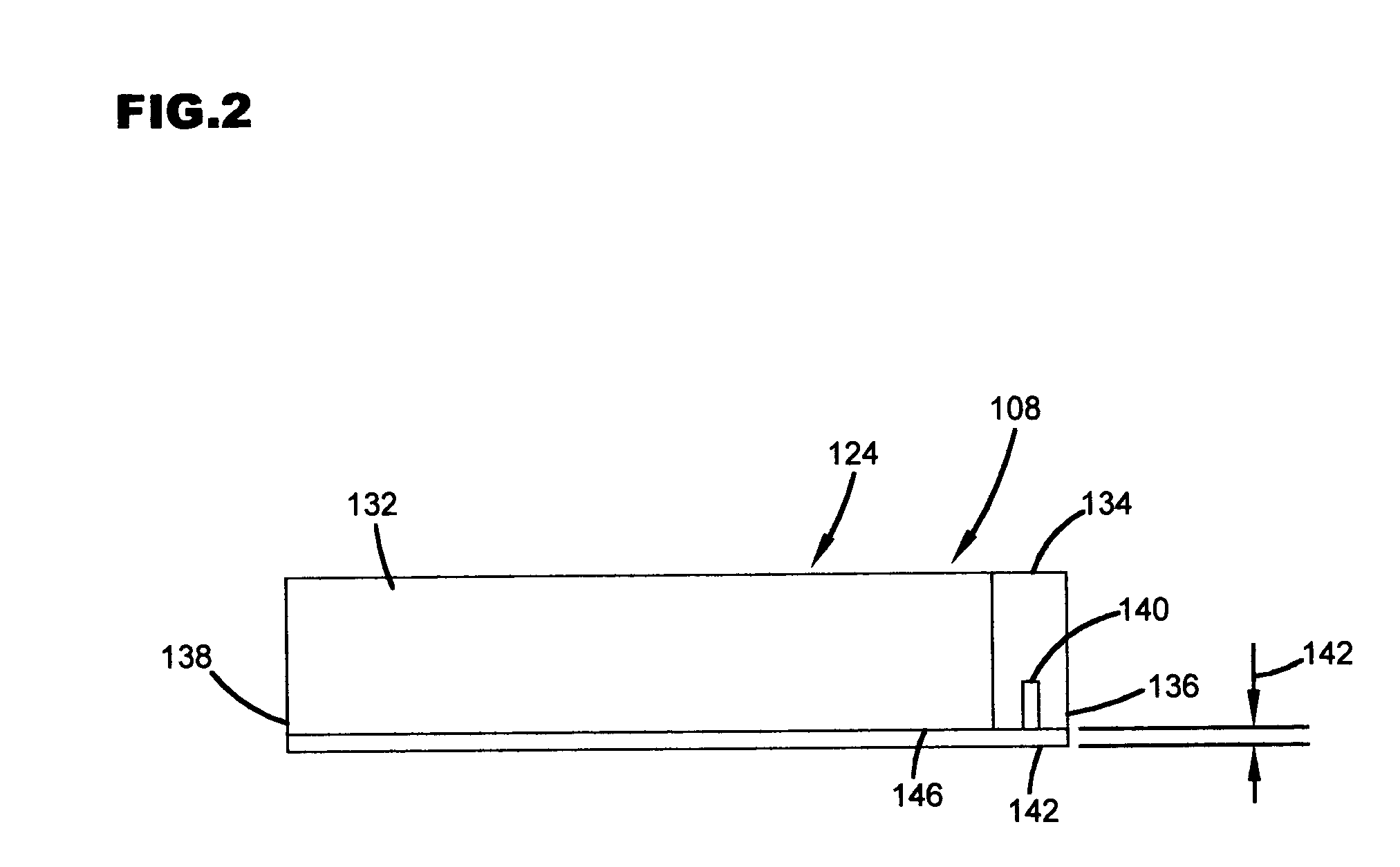

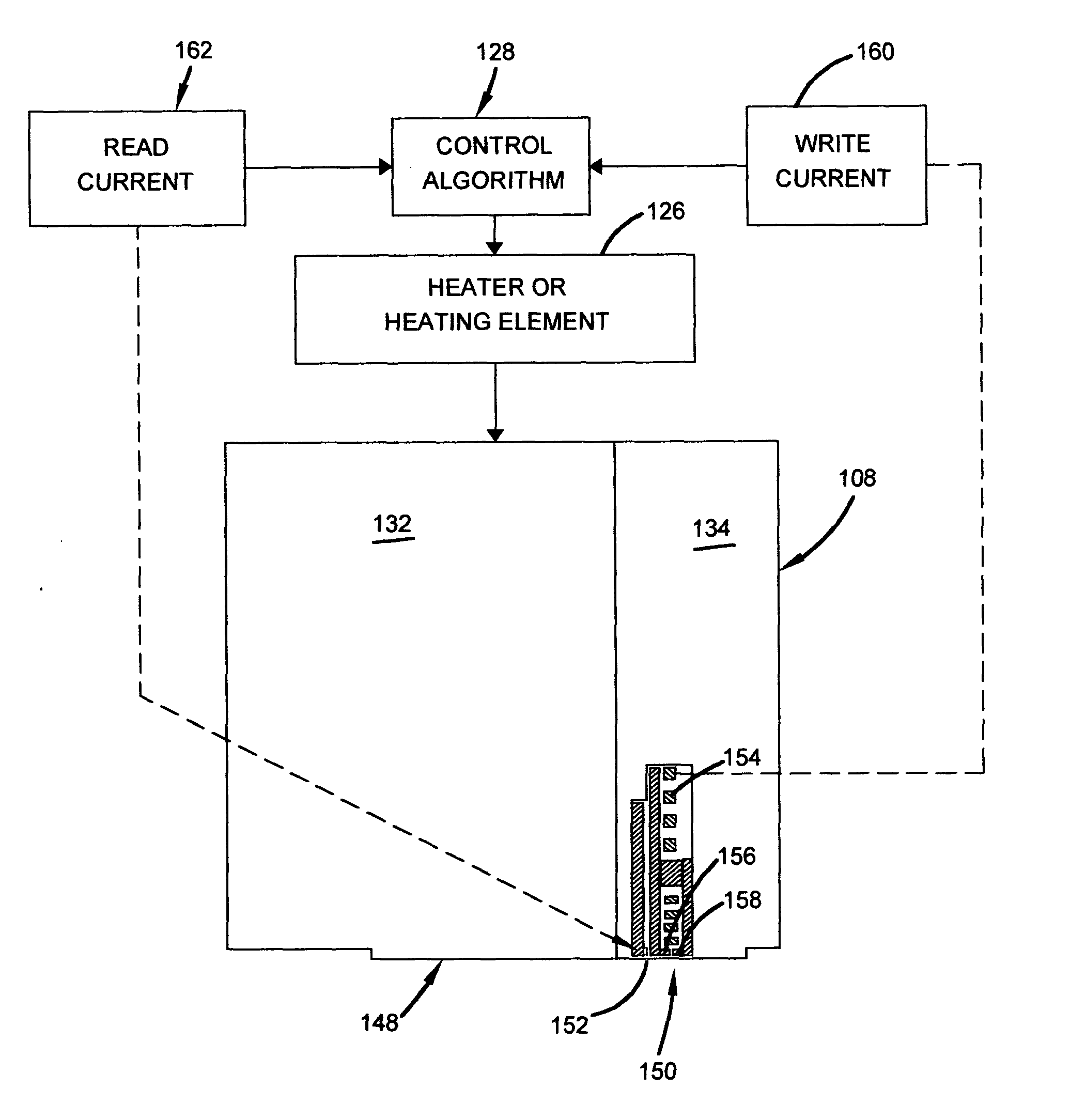

A head with a heating element and control regime therefor is disclosed. In embodiments described, the control regime or controller energizes the heater or heating element to provide intermittent heating between read or write operations to optimize transducer temperature and operating characteristics or parameters of a data storage device. In particular, in one embodiment described, the controller provides a low amplitude signal or current to provide low grade thermal heating. In another embodiment, the controller provides a high amplitude signal or current to preheat the transducer portion for write operations.

Owner:SEAGATE TECH LLC

Head with heating element and control regime therefor

InactiveUS20050057841A1Disposition/mounting of recording headsDriving/moving recording headsTransducerLower grade

A head with a heating element and control regime therefor is disclosed. In embodiments described, the control regime or controller energizes the heater or heating element to provide intermittent heating between read or write operations to optimize transducer temperature and operating characteristics or parameters of a data storage device. In particular, in one embodiment described, the controller provides a low amplitude signal or current to provide low grade thermal heating. In another embodiment, the controller provides a high amplitude signal or current to preheat the transducer portion for write operations.

Owner:SEAGATE TECH LLC

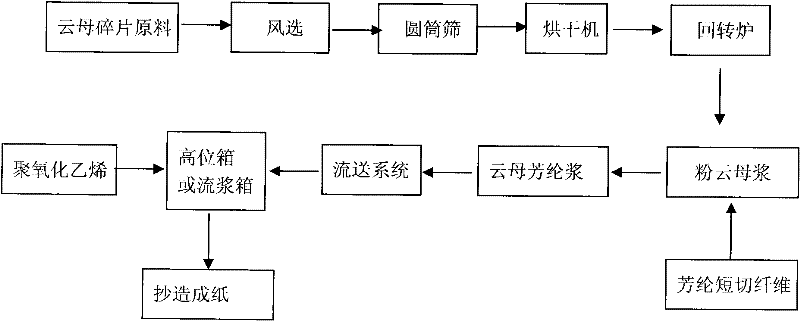

Method for making mica paper by reinforcement of aramid short fiber and chemical pulping

InactiveCN101748648AHigh strengthHigh dielectric strengthSynthetic cellulose/non-cellulose material pulp/paperPulp material addition processesEngineeringRotary furnace

The invention relates to a method for making mica paper by reinforcement of aramid short fiber and chemical pulping. The method comprises the following steps: cleaning mica flakes to remove impurities; putting the mica flakes to an intermittent heating rotary furnace for calcination to remove a part of crystal water in the crystal of mica and generate remarkable expansion and delamination along the vertical direction of a cleavage plane so as to make the mica loose and flexible; dipping the mica in acid or alkali solution at a certain concentration, delaminating into mica sheets, and classifying the mica sheets into chemical mica pulp with certain beating degree; and adding 3 to 15 percent of aramid fiber (based on the mass of the mica flakes) into the pulp, preparing mica aramid pulp, and making the mica aramid pulp into paper by a paper machine. The framework effect of the aramid improves the strength of the mica paper.

Owner:SHAANXI UNIV OF SCI & TECH

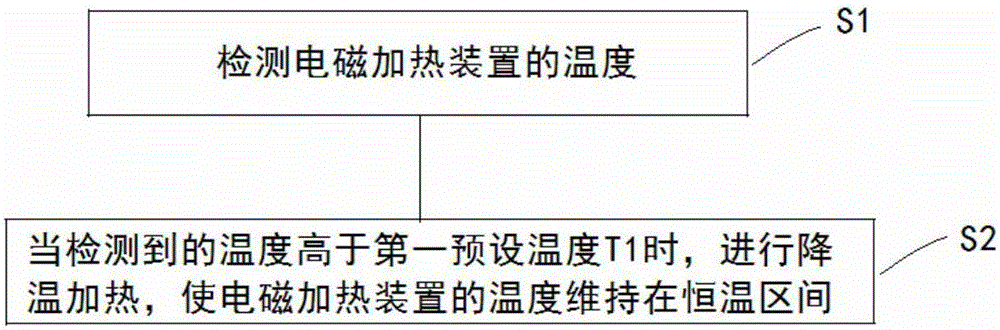

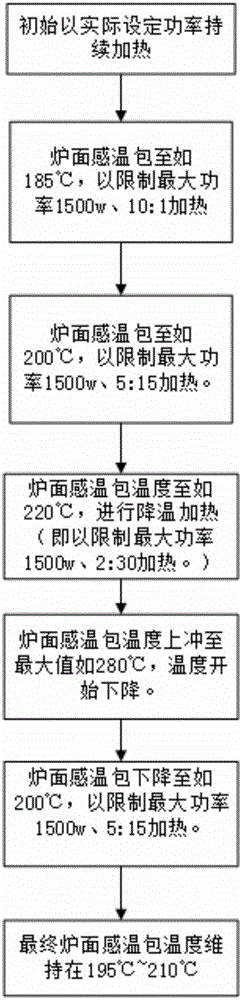

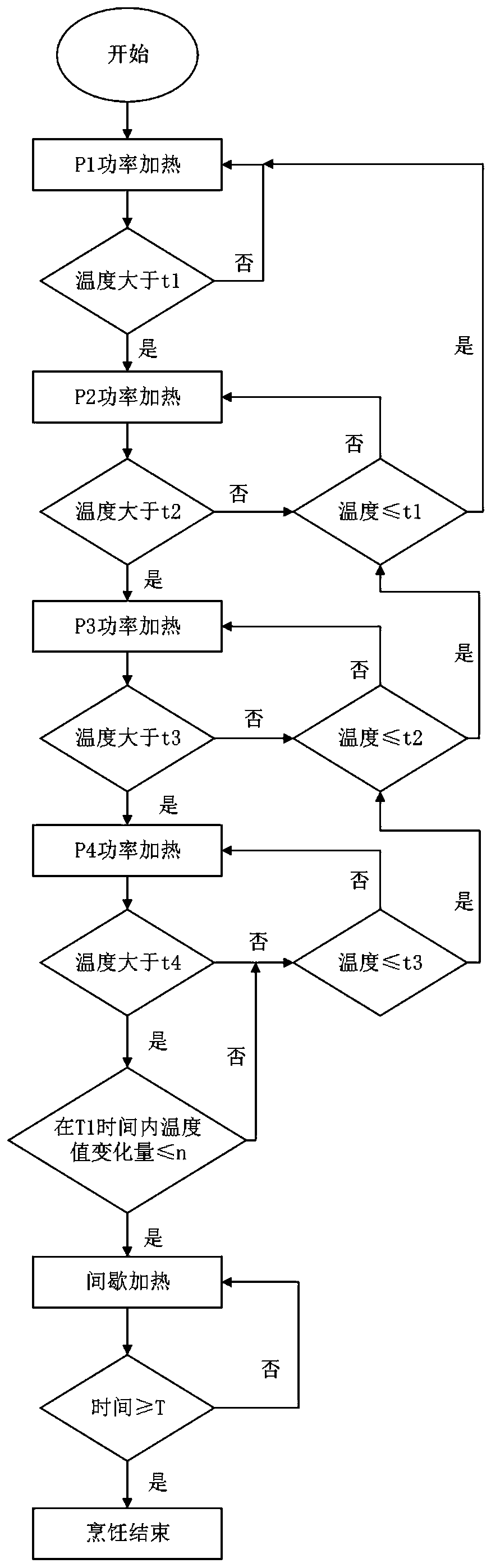

Heating control method of electromagnetic heating apparatus

ActiveCN106211395ATemperature controlStable temperature controlDomestic stoves or rangesLighting and heating apparatusHeat controlElectromagnetic heating

The invention proposes a heating control method of an electromagnetic heating apparatus. The method comprises the steps of detecting a current temperature of the electromagnetic heating apparatus; and performing output power limitation and intermittent heating adjustment on the electromagnetic heating apparatus according to the detected current temperature for enabling the electromagnetic heating apparatus to keep a predetermined temperature interval. By use of the heating control method, the electromagnetic heating apparatus can be subjected to multilevel control, so that the bottom of a pan is slowly heated or cooled during cooking and can be further kept in a specific temperature range, and various cooking demands are better met.

Owner:GREE ELECTRIC APPLIANCES INC

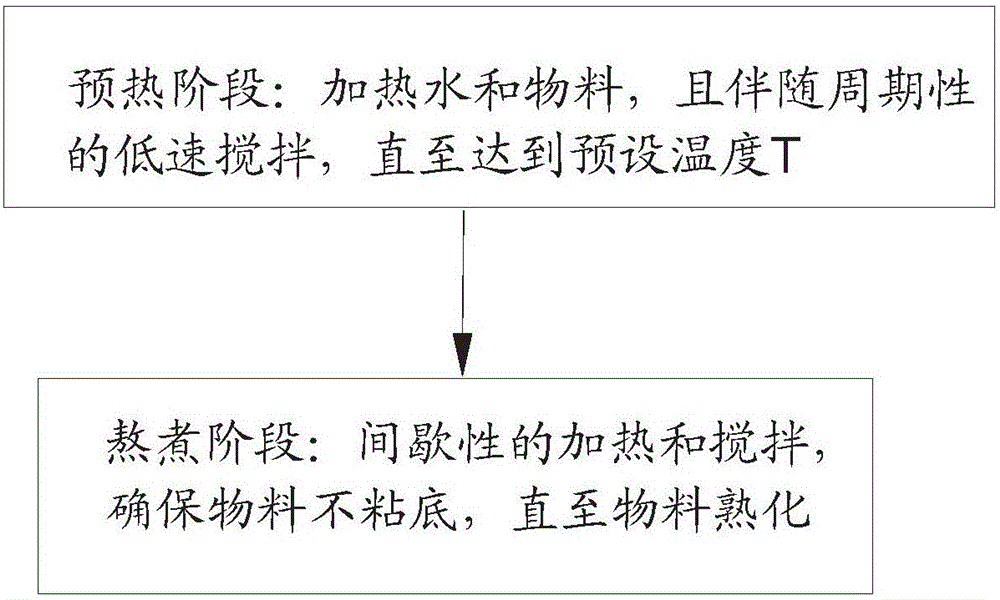

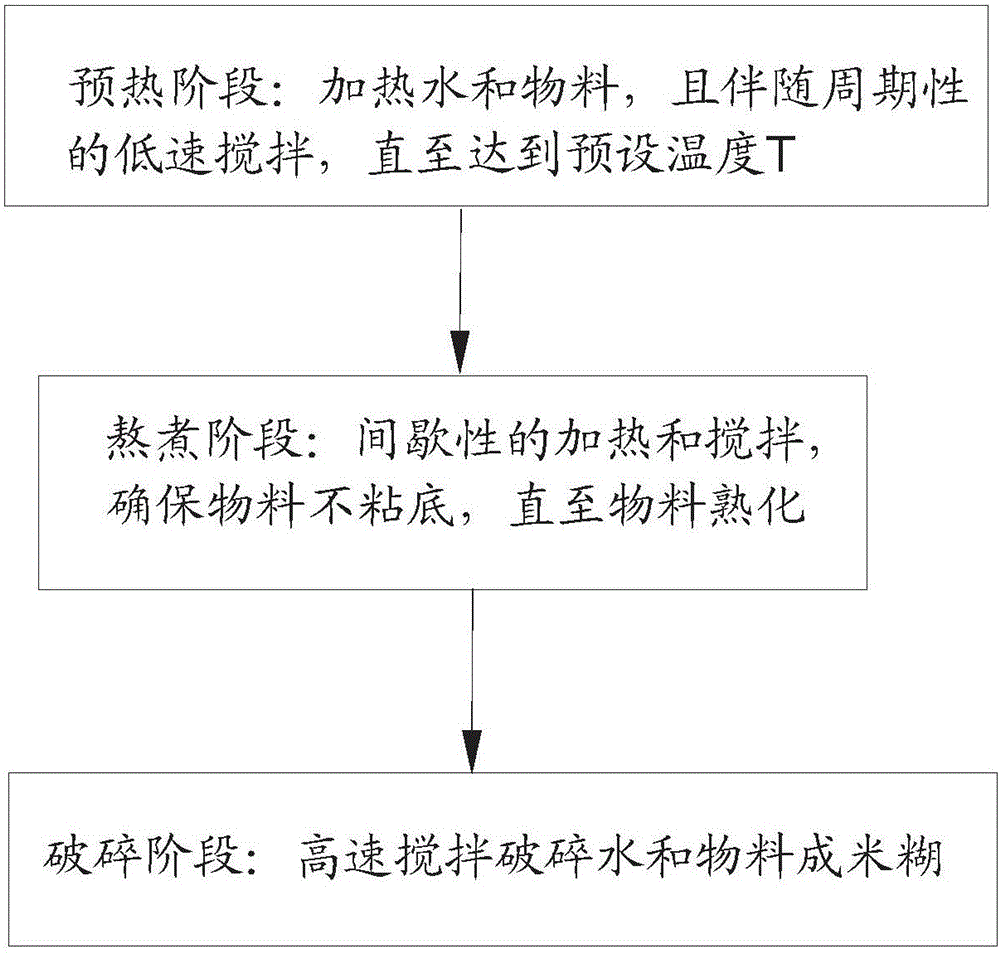

Food processing method of food processer

InactiveCN105725859AHeating evenlyCook evenlyBeverage vesselsVessels with intergral heatingLow speedIntermittent heating

The invention discloses a food processing method of a food processor. The food processing method comprises the following steps: continuously heating food along with periodic low-speed stirring to make sure that heating is more uniform and that materials are not stuck to a base plate; then providing stable heat through intermittent heating to make sure that the materials and water are kept 95 DEG C or hotter and that the materials can be cooked more quickly without overflowing. As the intermittent heating process and the low-speed stirring process are combined, the materials cannot be stuck to the base plate or burnt at the base plate, and can be boiled more uniformly.

Owner:江门市贝尔斯顿电器有限公司

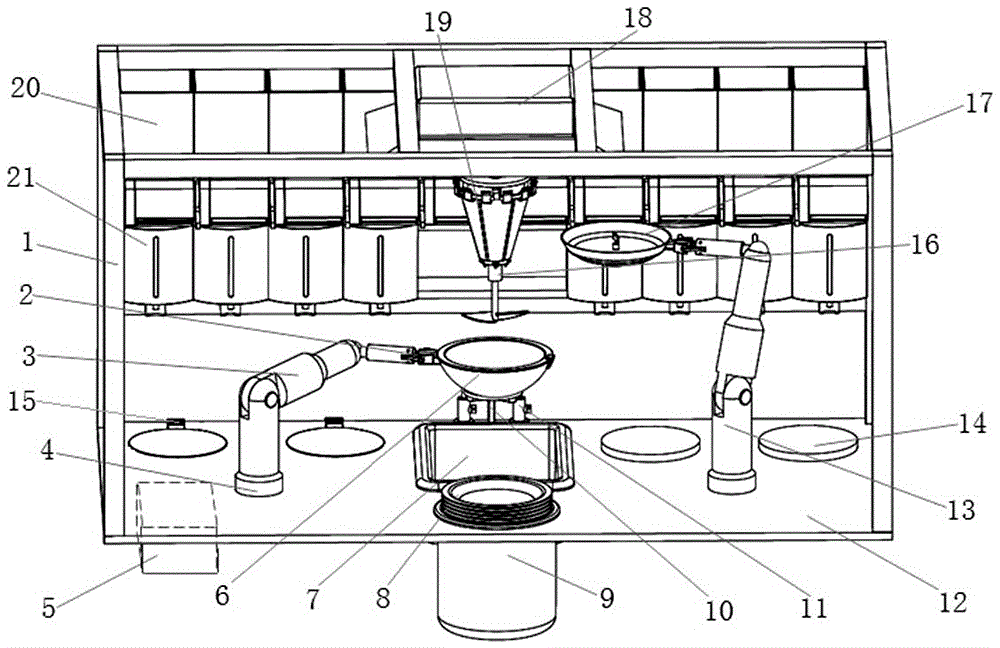

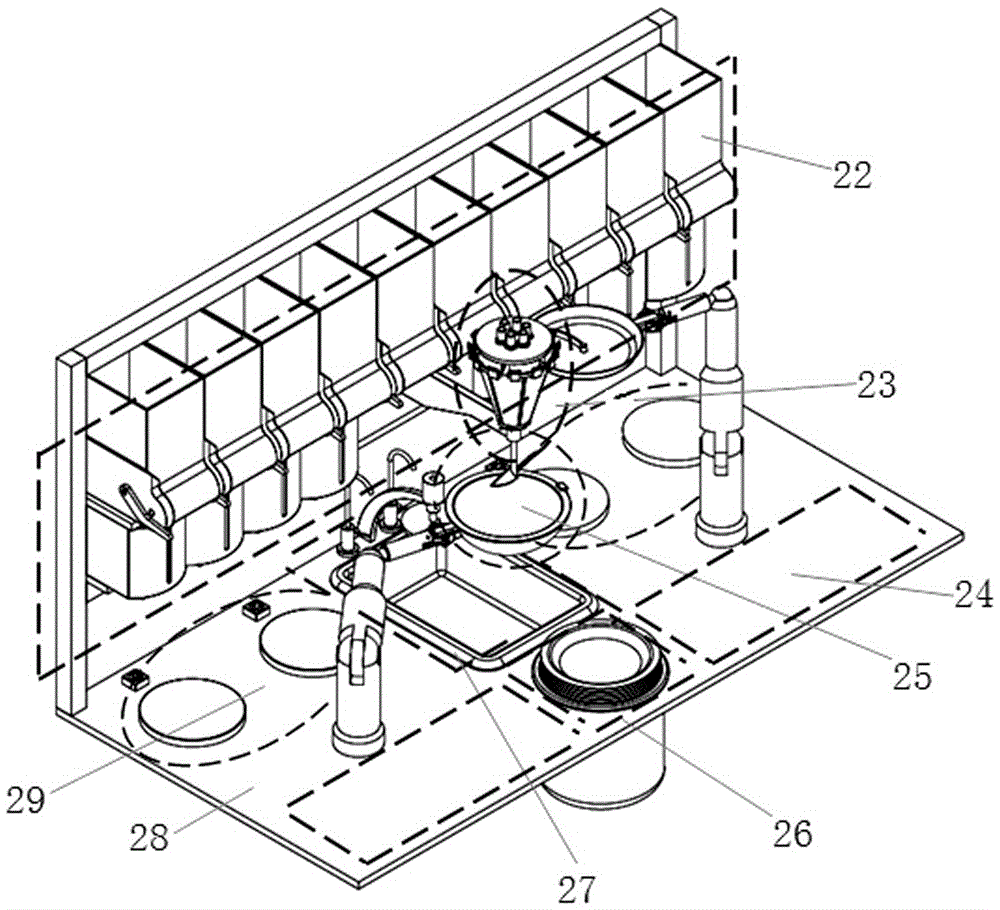

Automatic cooking method

InactiveCN105534273AEasy to useOptimize the cooking processWarming devicesTemperature controlProcess engineering

The invention relates to the technical field of robots, in particular to an automatic cooking method. The automatic cooking method is characterized by at least comprising the steps that energy is provided for a cooker through a mechanical arm to perform cooker heating control and enable the cooker to be continuously heated in the whole cooking process; the mechanical arm drives the cooker to move among function zones and complete corresponding cooling operations within a plurality of function zones. The automatic cooking method has the advantages that the required different cooling process operations are completed in the different function zones; intermittent heating and temperature-control cooking of the cooker in the spatial moving process are achieved; the duration and degree of heating and a food material adding sequence can be flexibly changed to perform personalized cooking; working zones can be set as required to optimize the cooking process; multiple dishes can be simultaneously cooked according to the demands; food materials are effectively used; the cooking time is shortened, and the cooking efficiency and cooking quality are improved; the robots are simple and reasonable in structure, powerful in function, convenient to use and suitable for popularization.

Owner:坤同勃志智能科技(上海)有限公司 +1

Preparation method of metal organic framework loaded Pt-base catalyst

InactiveCN103191778ADistribute quicklySmall particlesOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystAlcohol

The invention discloses a preparation method of a metal organic framework loaded Pt-base catalyst. The method comprises putting the metal organic framework into an alcoholic solution, vibrating with ultrasonic, adding drop by drop a mixed solution of chloroplatinic acid and cobalt oxide, adding NaOH, stirring, putting into a microwave oven for intermittent heating, cooling, filtering by pumping, and drying under vacuum to obtain the metal organic framework loaded Pt-base catalyst. The catalyst is small in particle, not easy to agglomerate, good in dispersibility and high in electrochemical catalytic activity.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

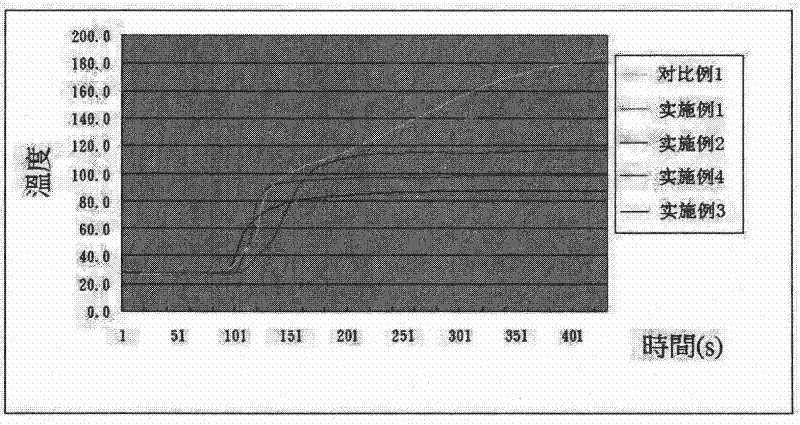

Abrasive block for high-speed multiple unit trains and preparation method

InactiveCN107915951AAvoid high temperature stress cracksAvoid heat cracksBraking elementsTemperature stressCarbon fibers

The invention discloses an abrasive block for high-speed multiple unit trains. The abrasive block is prepared from a composite material composed of phenolic resin, steel fibers, copper-aluminum powder, carbon fibers, tungsten carbide, aramid fibers, iron oxide black, acrylonitrile-butadiene rubber and accelerant. The invention further provides a method for preparing the abrasive block, which prevents the occurrence of high-temperature stress cracks and hot cracks in the process of using the abrasive block by optimizing the component ratio and a processing technique. Moreover, by adopting an intermittent heating method and multiple times of heat treatment, the problems, such as stripping and easy abrasion, which take place in the process of using abrasive blocks at present are optimized.

Owner:上海国由复合材料科技有限公司

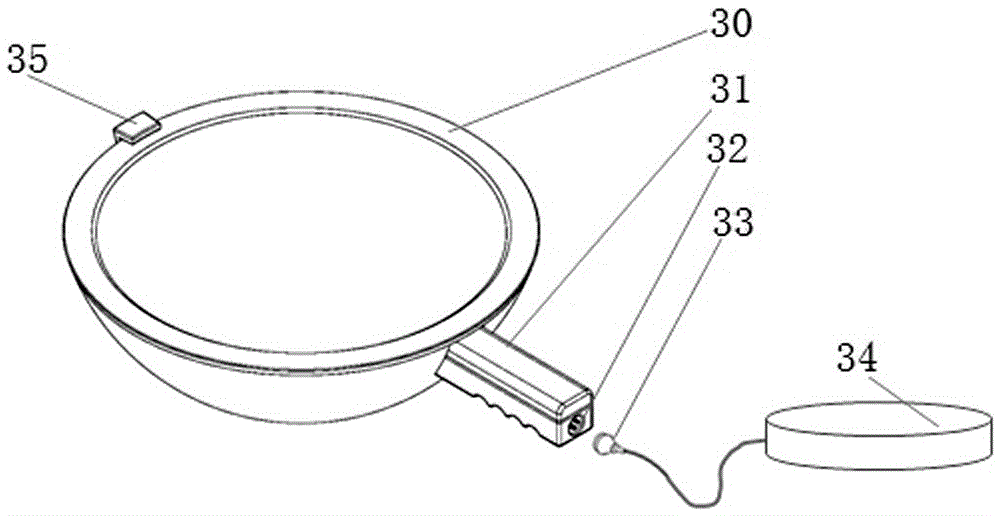

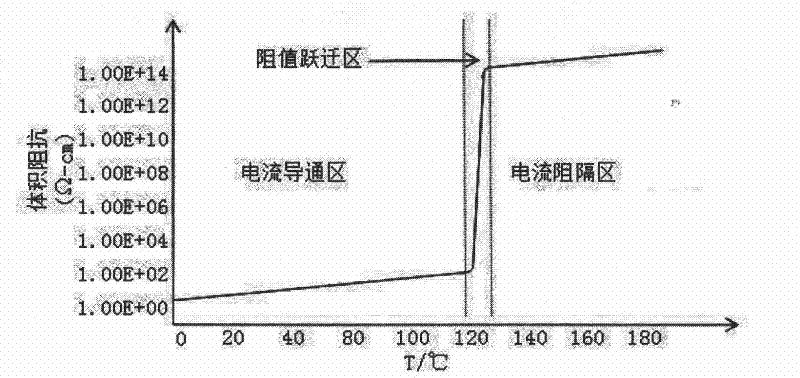

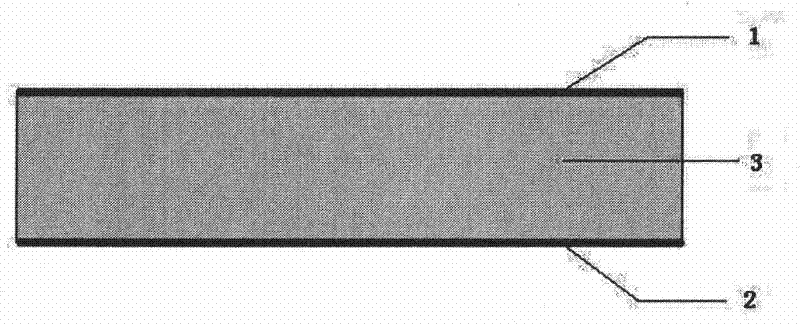

Positive temperature coefficient (PTC) self-temperature-control hand warmer and manufacturing method thereof

InactiveCN102342869ASimple structureEasy to manufactureTherapeutic coolingTherapeutic heatingElectricityState of art

The invention discloses a hand warmer using composite conducting macromolecules as heating chips and a manufacturing method for the hand warmer. Compared with the prior art, the hand warmer has a simple structure and is easy and convenient to manufacture, wherein the composite conducting macromolecule heating chips have high PTC intensity, little current leakage and high safety; and the hand warmer has a self-temperature-control function, so a temperature-control circuit system is not required. The chip composite material adopts different polymers as matrixes to realize limited temperature self-control of different temperature, and adopts different polymer-based heating elements, which are connected in parallel, to realize different self-control temperature of the same hand warmer. The hand warmer can heat by plugging into a socket and through a self-contained battery, has continuous heating and intermittent heating functions, and can be used outdoors for a long time.

Owner:谢志军

Preparation method of nano-grade electro-catalyst based on graphene

InactiveCN103212421ANot easy to reuniteEvenly distributedCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFiltrationAlcohol fuel

The invention relates to a preparation method of a nano-grade electro-catalyst based on graphene. According to the method, a templating agent is added into an alcohol solution of graphene oxide; ultrasonic processing is carried out, and the mixture is uniformly stirred and oscillated; a mixed solution of chloroplatinic acid and a transition metal salt is dropped in; the mixture is well mixed and is subjected to an intermittent heating reaction in a microwave oven; the mixture is cooled, and the templating agent is removed by using dilute hydrochloric acid; and pump-filtration and vacuum bake-drying are carried out, such that the nano-grade electro-catalyst with graphene as a carrier is obtained. The catalyst provided by the invention has the advantages of small particles, agglomeration prevention, uniform distribution, simple preparation steps, and short preparation process. The catalyst provided by the invention can be used in alcohol fuel batteries and lithium-air batteries.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

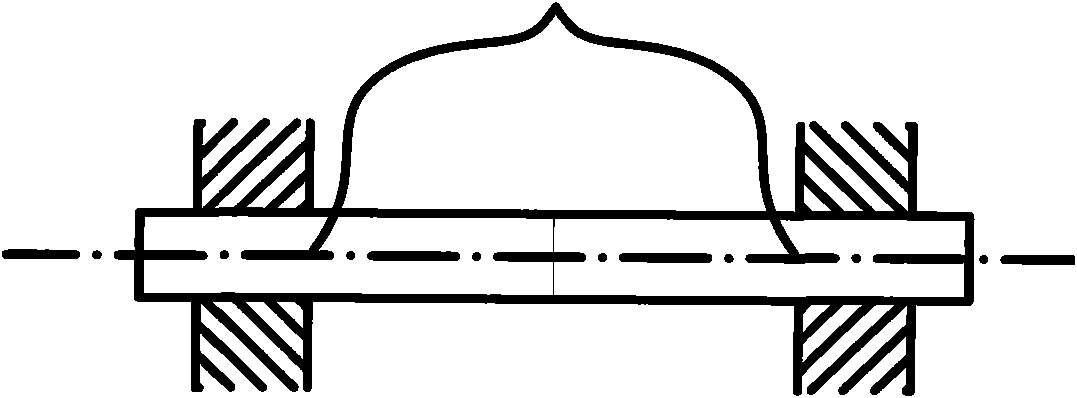

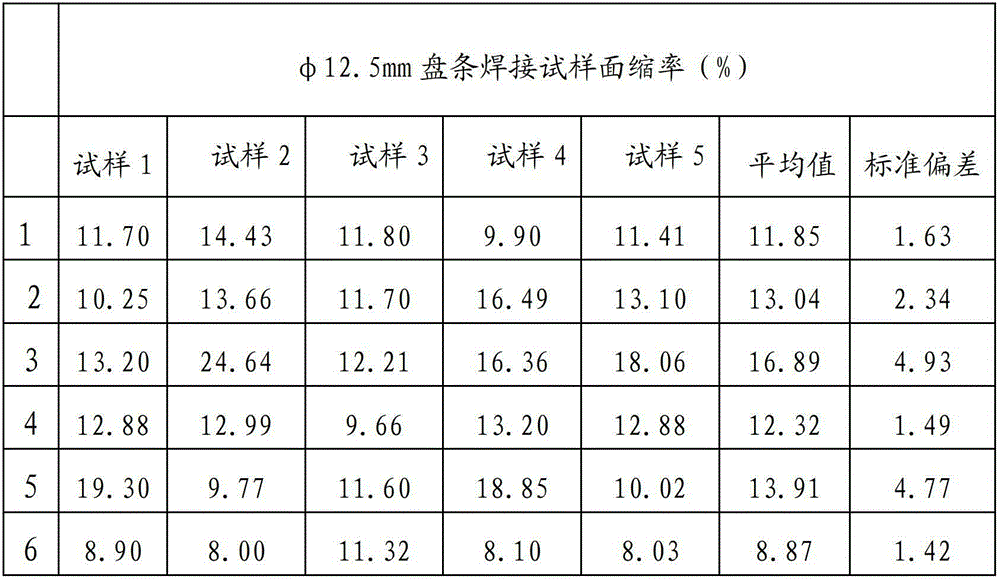

Butt welding method of small caliber metallic resistances

ActiveCN101596643ALess heat productionReduce the impactResistance welding apparatusButt weldingEngineering

Owner:BEIJING UNIV OF TECH

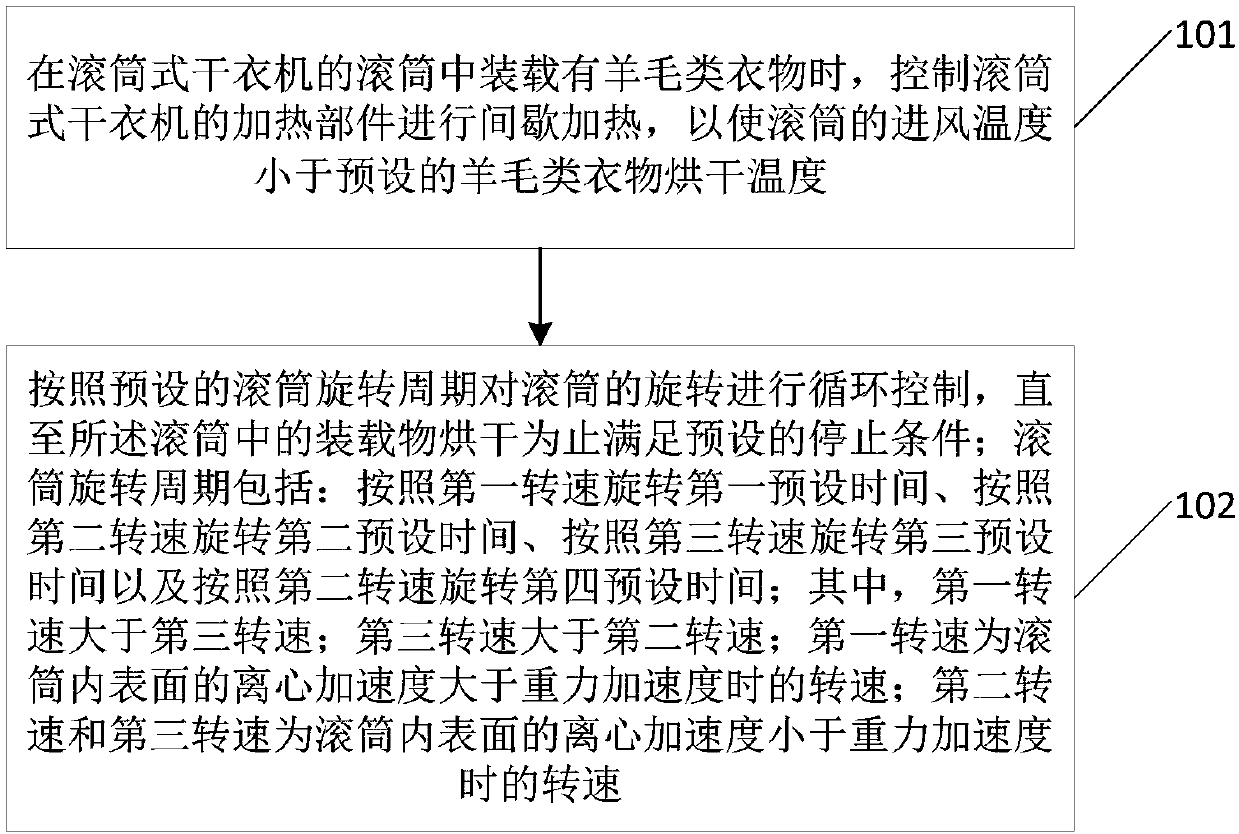

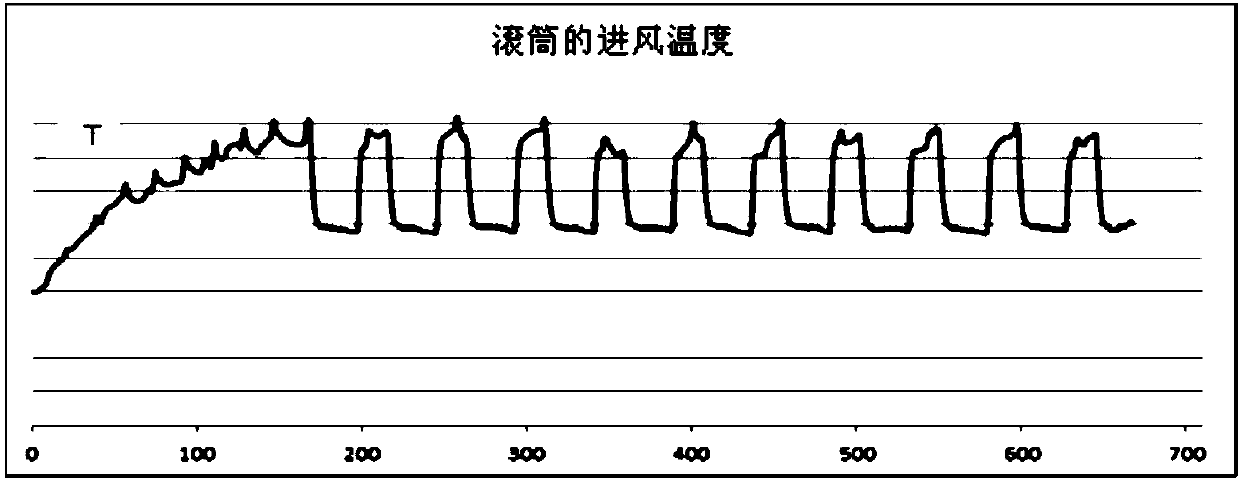

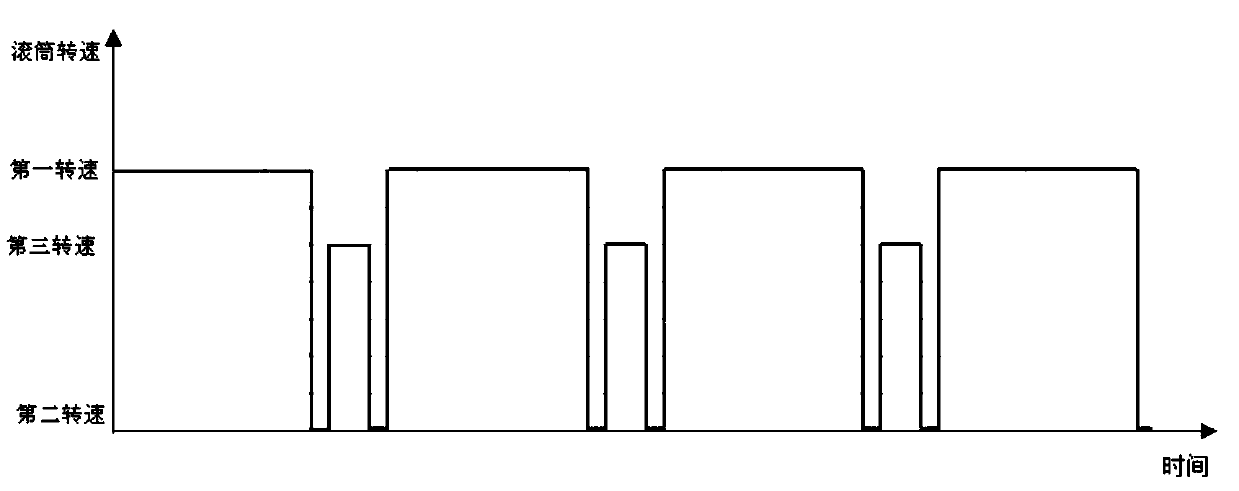

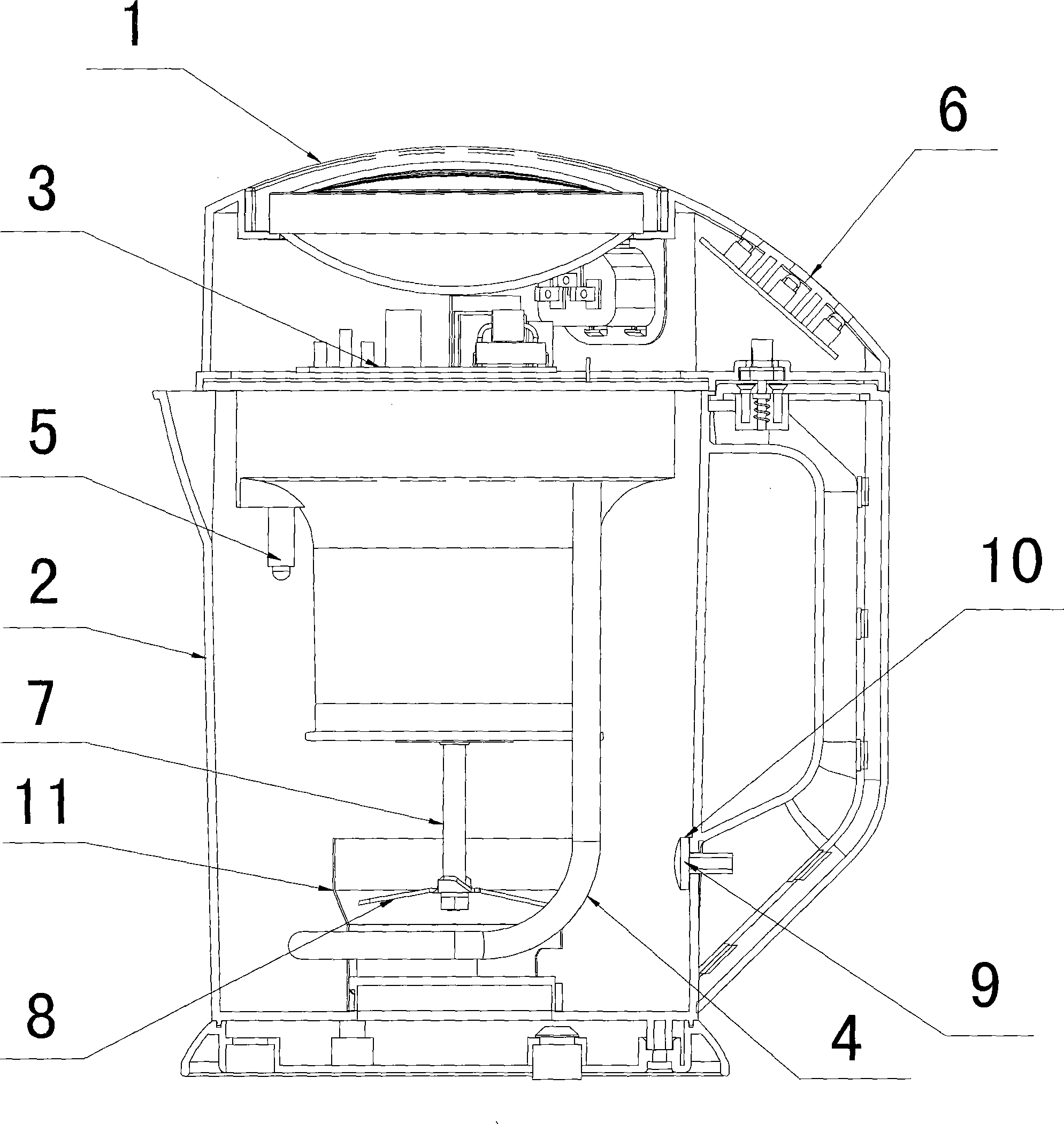

Clothes drying method and device and drum-type clothes dryer

InactiveCN107747204AEvenly heatedImprove drying effectTextiles and paperLaundry driersIntermittent heatingControl theory

The invention provides a clothes drying method and device and a drum-type clothes dryer. The method comprises the steps of controlling a heating part to conduct intermittent heating to make the air inlet temperature of a drum smaller than a preset temperature for drying wool clothes when the drum is loaded with wool clothes; conducting circulating control over the rotation of the drum according toa preset drum rotation cycle till preset stopping conditions are met, wherein during the drum rotation cycle, the drum rotates for a first preset time at a first rotational speed, rotates for a second preset time at a second rotational speed, rotates for a third preset time at a third rotational speed and rotates for a fourth preset time at the second rotational speed, the first rotational speedis greater than the third rotational speed, the third rotational speed is greater than the second rotational speed, and the first rotational speed is the rotational speed when the centrifugal acceleration of the inner surface of the drum is greater than the gravity acceleration. By means of the method, the temperature for drying the wool clothes can be reduced, the wool clothes are evenly mixed bycombining the second rotational speed and the third rotational speed to rotate the drum, and the effect of drying the wool clothes is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Method for synchronously removing shell and peel of Chinese chestnut through microwaves

The invention discloses a method for synchronously removing the shell and peel of a Chinese chestnut through microwaves. The method comprises the following steps: the shell of the Chinese chestnut is cut, the Chinese chestnut is subjected to microwave processing for the first time, the Chinese chestnut is cooled after the microwave processing for the first time, then, the Chinese chestnut is subjected to microwave processing for the second time, the shell and the peel of the Chinese chestnut are removed after the microwave processing for the second time, and therefore the kernel of the Chinese chestnut is obtained. According to the method for synchronously removing the shell and peel of the Chinese chestnut through the microwaves, the microwaves are used for instantaneous intermittent heating with a high power, as a result, the kernel of the Chinese chestnut shrinks due to dehydration and is separated from the shell and the peel, and the phenomenon that the kernel of the Chinese chestnut is cooked and exploded due to an excessively quick temperature rise in the one-time heating process can be well avoided; meanwhile, the hot Chinese chestnut is cooled for a short time, as a result, water in the shell of the Chinese chestnut is evaporated, brittleness is further improved, and original color and luster, a special flavor and nutrition of the kernel of the Chinese chestnut are guaranteed to the maximum.

Owner:ZHEJIANG UNIV

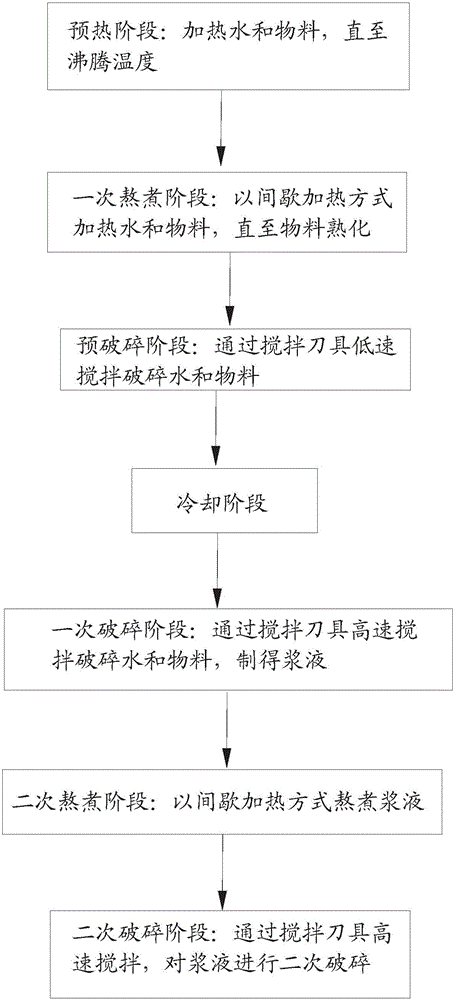

Method for producing soya-bean milk and rice paste using full automatic soybean milk machine

InactiveCN101474038AGreat tastePrevent the phenomenon of sticky electric heating tubeBeverage vesselsFood preparationEngineeringIntermittent heating

The invention discloses a method for making soybean milk and rice paste by a full-automatic soybean milk machine. The method comprises the steps of heating, pulping, boiling, continuous boiling and the like performed by the full-automatic soybean milk machine under the control of a single-chip microcomputer program. A motor is started up for more than one time for stirring during intermittent heating of the continuous boiling step. In the method for making the soybean milk and the rice paste by the full-automatic soybean milk machine, the motor is started up for more than one time for stirring during the intermittent heating of the continuous boiling step, which effectively prevents blockage of an electric heating tube by paste. The method is more favorable for making the soybean milk and the rice paste with better taste compared with the existing methods for making the soybean milk and the rice paste by the full-automatic soybean milk machine.

Owner:KINGCLEAN ELECTRIC

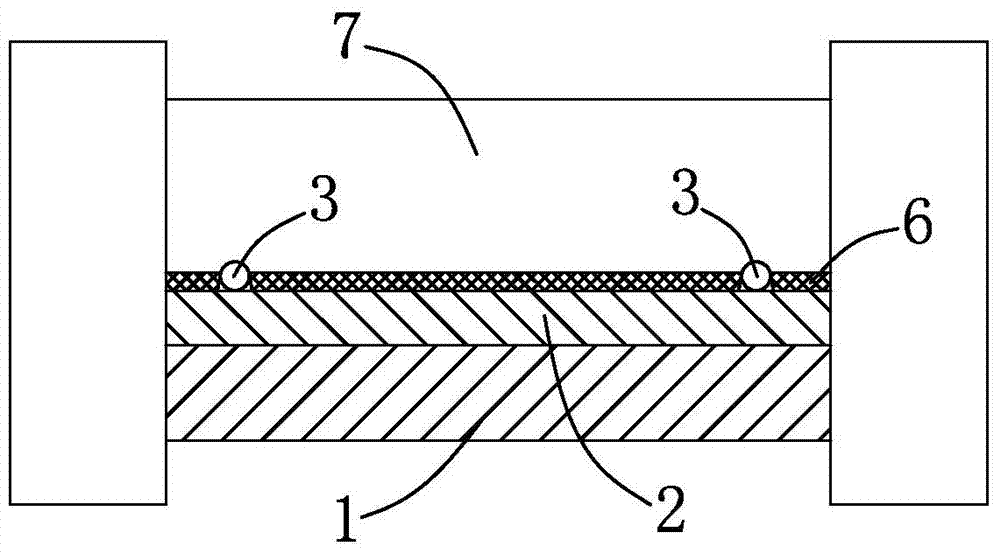

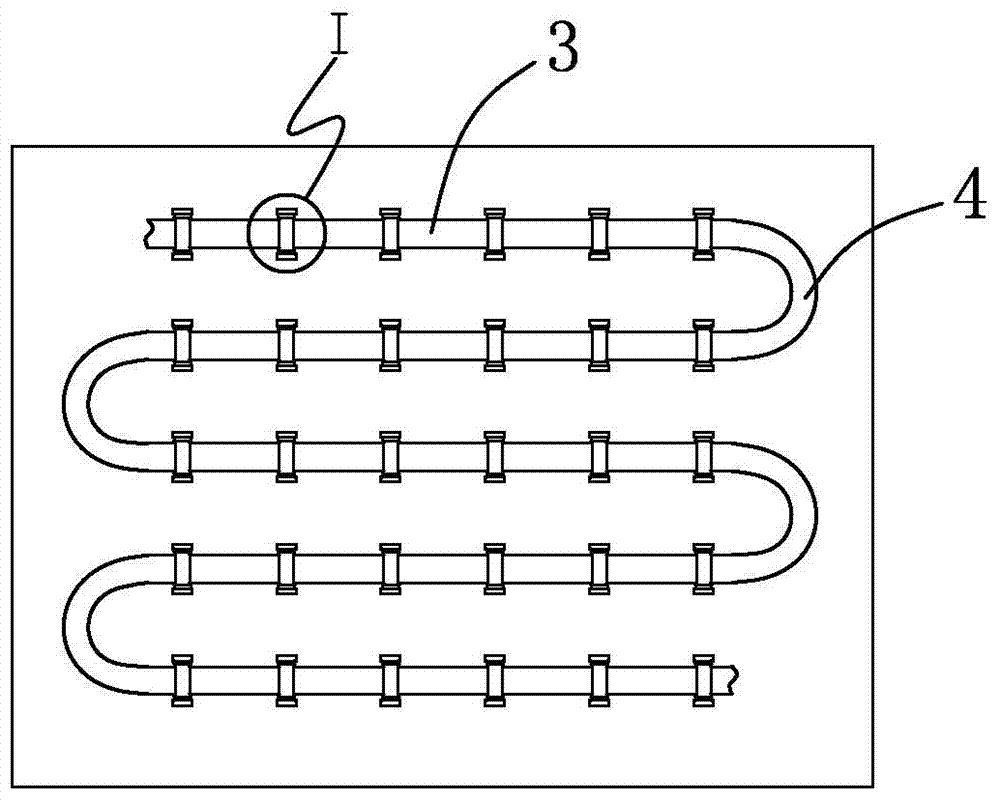

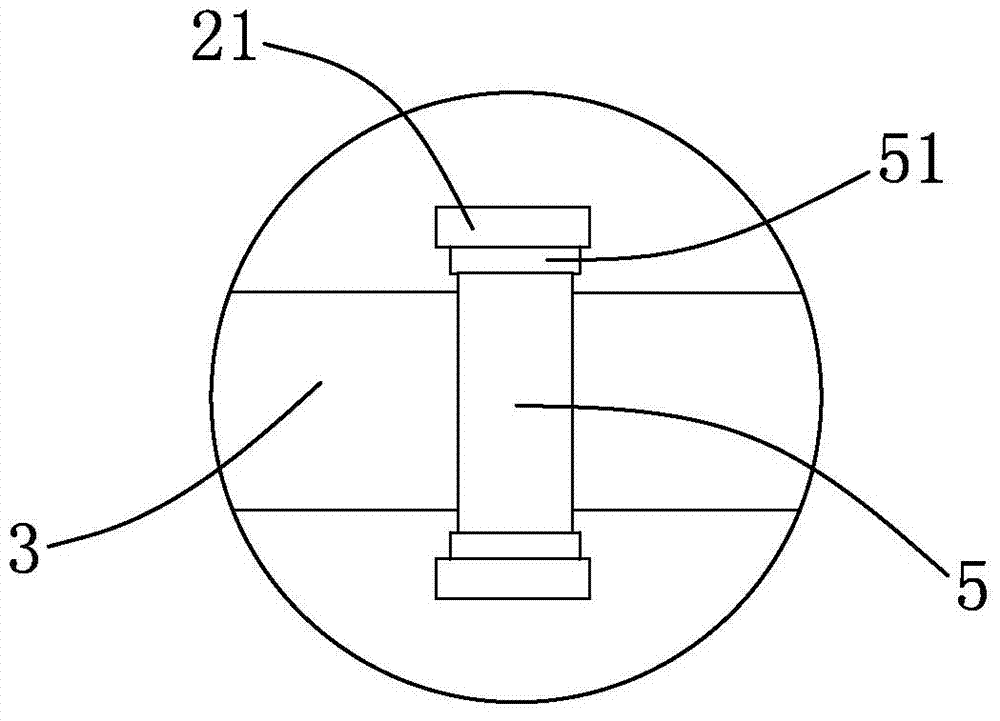

Floor radiant heating construction method

InactiveCN103591628AIncrease the usable areaImprove insulation effectLighting and heating apparatusSustainable buildingsHeat stabilityEngineering

The invention discloses a floor radiant heating construction method. The floor radiant heating construction method comprises the first step of structure layer leveling, the second step of heat insulation plate paving, the third step of floor heating pipe installing, the fourth step of steel wire net paving, the fifth step of floor heating pipe, water distributing device and water collecting device connecting, the sixth step of pressure testing and the seventh step of concrete filling layer pouring. Heat is provided through pipelines embedded into the part below a bottom plate instead of a traditional radiator, the using area of a room is increased, a special ground structure is provided, heat insulating plates are arranged between the floor heating pipes and a structure layer, the heat insulating effect is improved, the sound insulation effect is also achieved, and the noise interference to the lower layer from the upper layer is greatly reduced; the heat storing quantity of the ground layer and the concrete layer is large, the indoor temperature change is slow under the intermittent heating situation, the heat stability is good, the indoor temperature is even, and a user can feel comfortable; the floor radiant heating construction method is efficient, energy is saved, operating cost is low, and service life is long.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

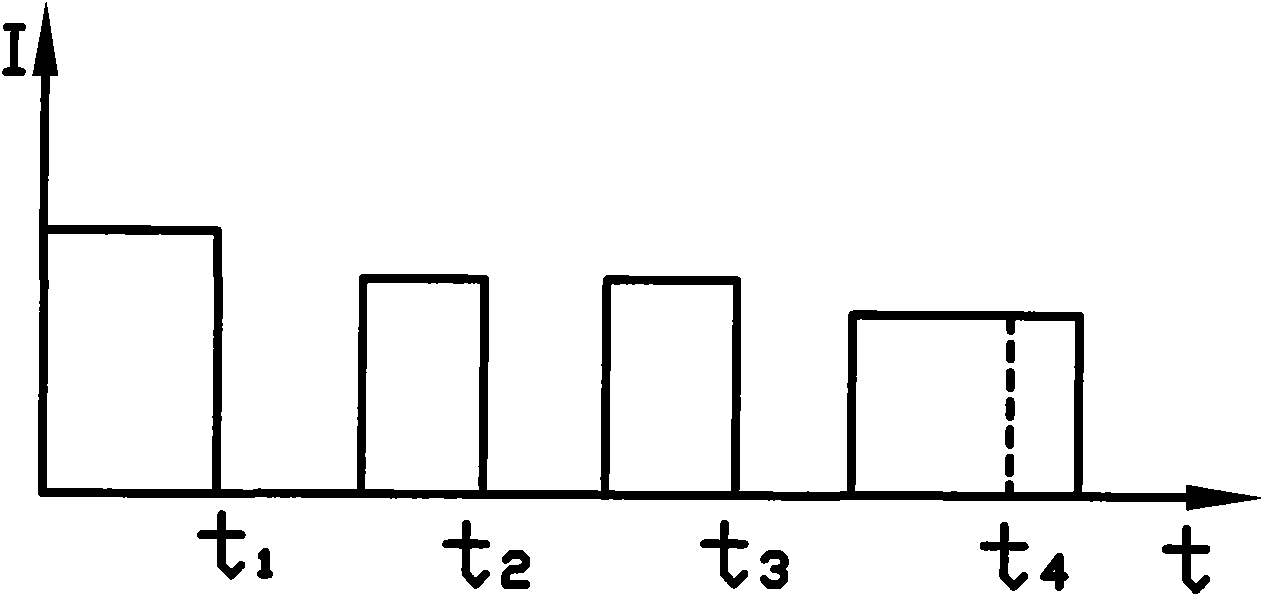

Steel wire connecting method

InactiveCN102873447AImprove toughnessGood elastic limitFurnace typesHeat treatment furnacesTwo temperatureFree cooling

The invention discloses a steel wire connecting method, and provides a steel wire connecting method capable of preventing end breakage of a welding position during a drawing process, and reducing end breakage rate. The method comprises the following steps of: clamping a polished welding seam at a tempering jaw, and raising the temperature intermittently for 4-5 times, with 1-2 seconds of interval between every two temperature rises, and stopping temperature rise when reaching 750-820 DEG C; continuously raising the temperature to 750-820 DEG C when naturally cooling to the temperature of 650 DEG C in the air, stopping temperature rise, repeating the above cooling-raising temperature process for three to four times, and then naturally cooling to 650 DEG C in the air; then continuously raising the temperature to 750-820 DEG C, and keeping the temperature for 1 minute through intermittent heating; and after naturally cooling to 570-590 DEG C, instantly electrifying and raising the temperature by 20-50 DEG C, and naturally cooling. The steel wire connecting method provided by the invention has the beneficial effects that through high temperature tempering processing at the weld part, the internal stress generated in welding is reduced, the tenacity of the welding part is improved, the phenomenon of end breakage at the welding position in the drawing process is prevented, and the end breakage rate is lowered.

Owner:天津市新天钢中兴盛达有限公司

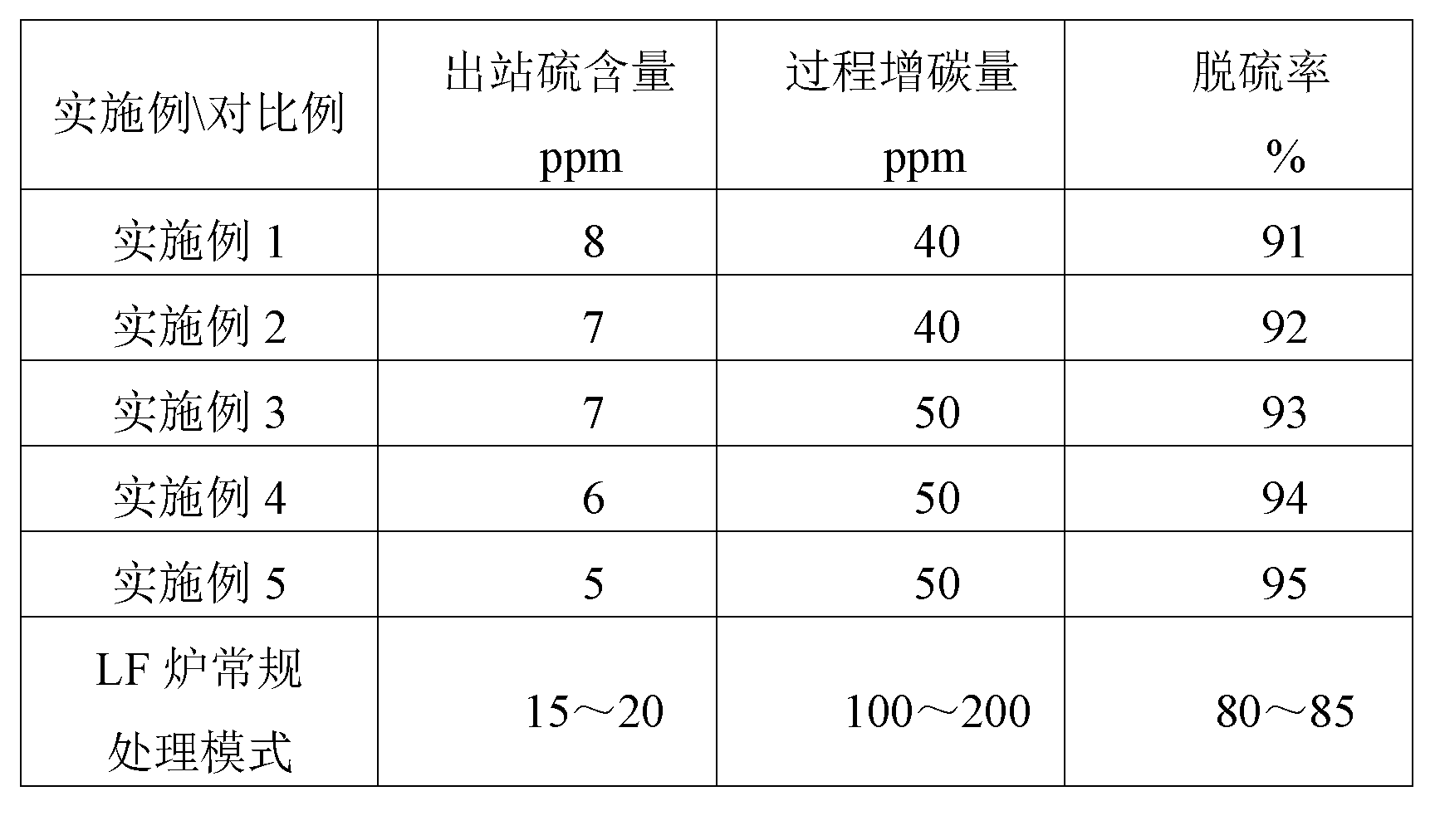

Low-carbon deep-desulfurization refining method of LF (ladle refining) furnace

ActiveCN103233096AAvoid violent tumblingGuaranteed desulfurization effectProcess efficiency improvementElectricityGraphite electrode

The invention discloses a low-carbon deep-desulfurization refining method of an LF (ladle refining) furnace, which comprises the following steps of: 1) heating and slagging; 2) power-off forced stirring and deep desulfurization; 3) slag regulation and component adjustment; 4) secondary power-off forced stirring and deep desulfurization; and 5) power transmission temperature regulation. According to the method disclosed by the invention, by optimizing a whole-course argon blowing gas supply model of the LF furnace and dynamically controlling the argon flow in stages, enough argon blowing stirring work is provided to guarantee the desulfurization effect, and violent rolling of steel and slag caused by excessive argon flow in a heating process and consequent contact reaction between steel, slag and graphite electrodes leading to recarburization are avoided; by adopting an intermittent heating mode of alternate power supply and power cut and reallocating the tasks in the power supply period and power-cut period, the stirring intensity is reduced by reducing the argon flow in the power supply period, and recarburization is reduced during desulfurization; and meanwhile, the stirring is enhanced by increasing the argon flow in the power-cut period to finish deep desulfurization. Thus, the deep desulfurization is finished while effectively controlling the recarburization in the whole refining process.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

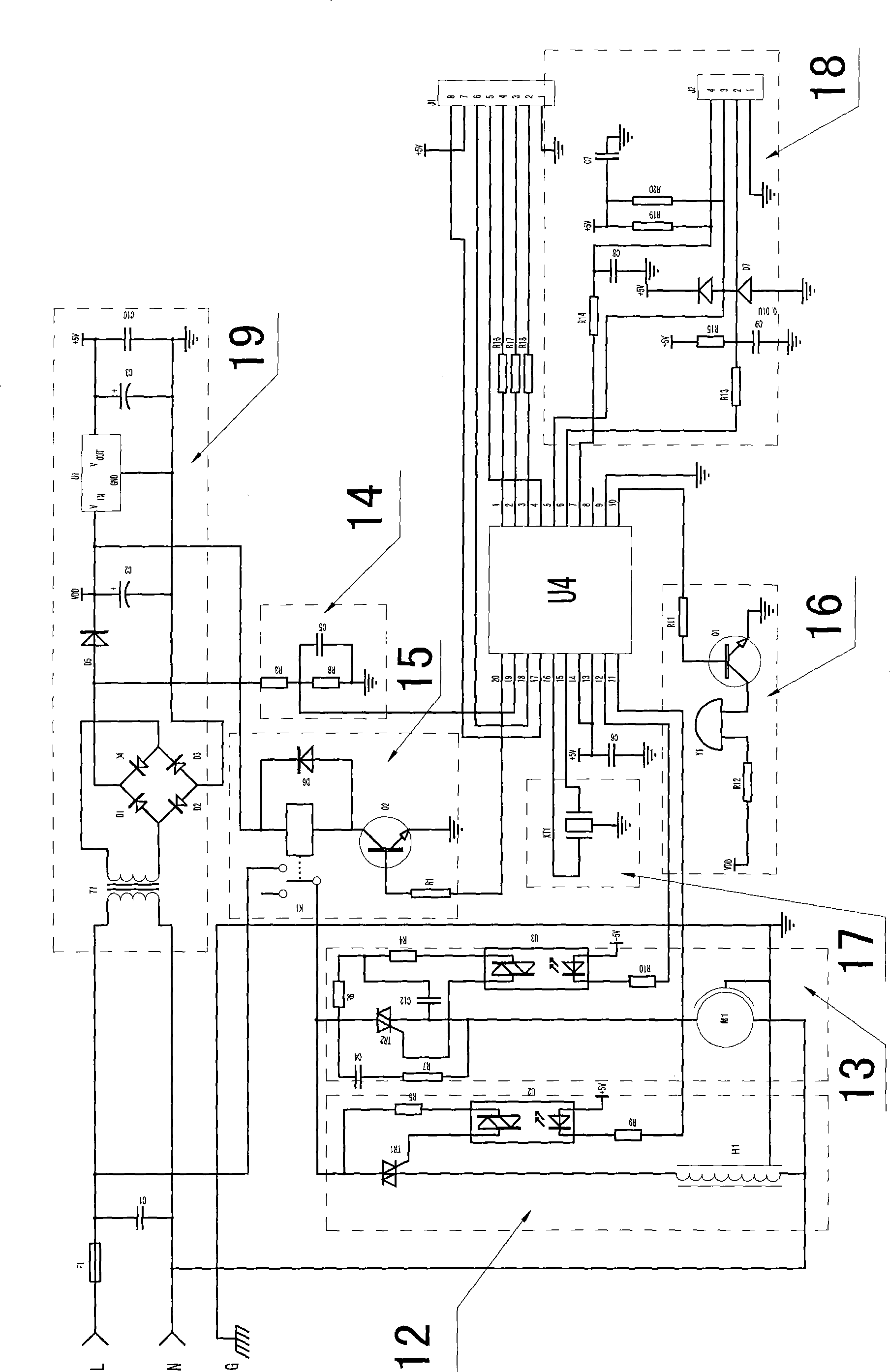

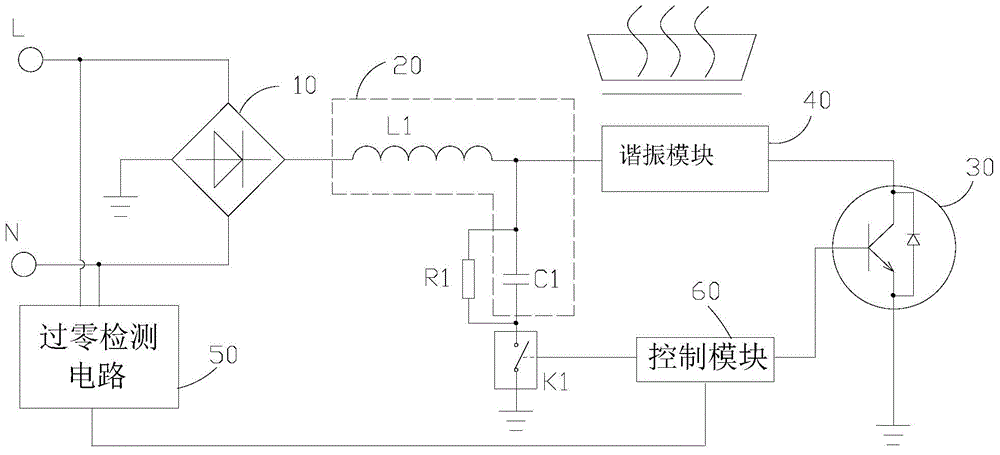

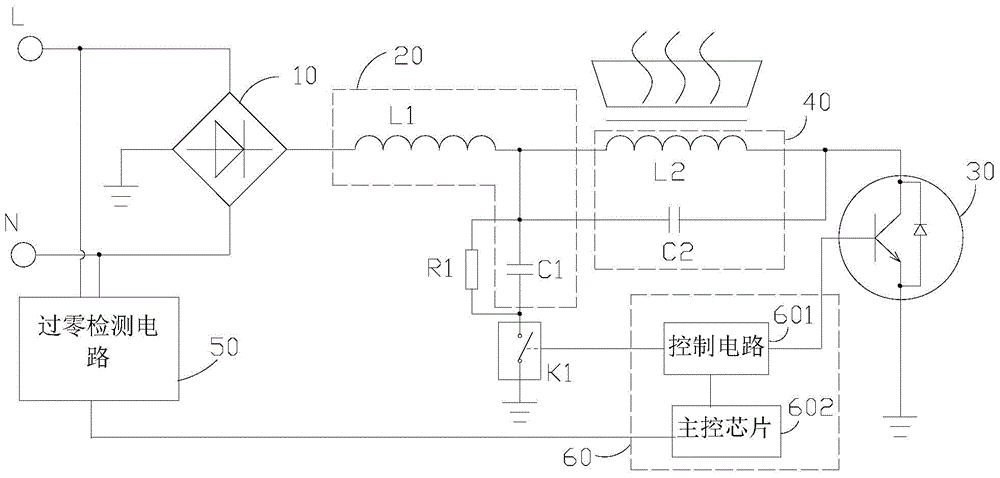

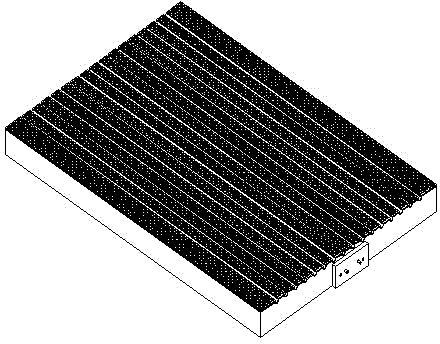

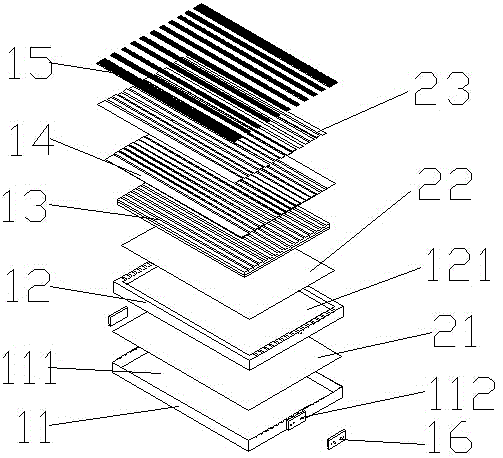

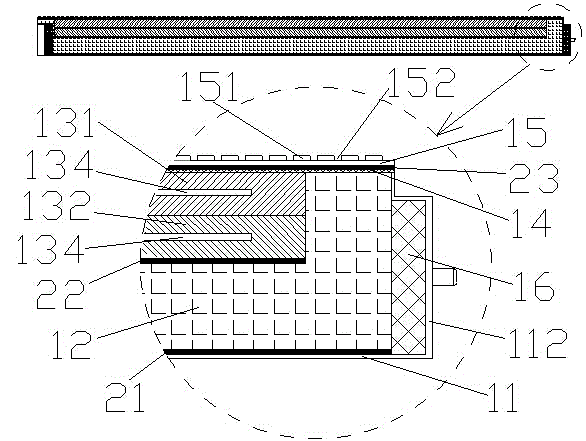

Cooking utensil, cooking utensil electromagnetic heating device and heating control method thereof

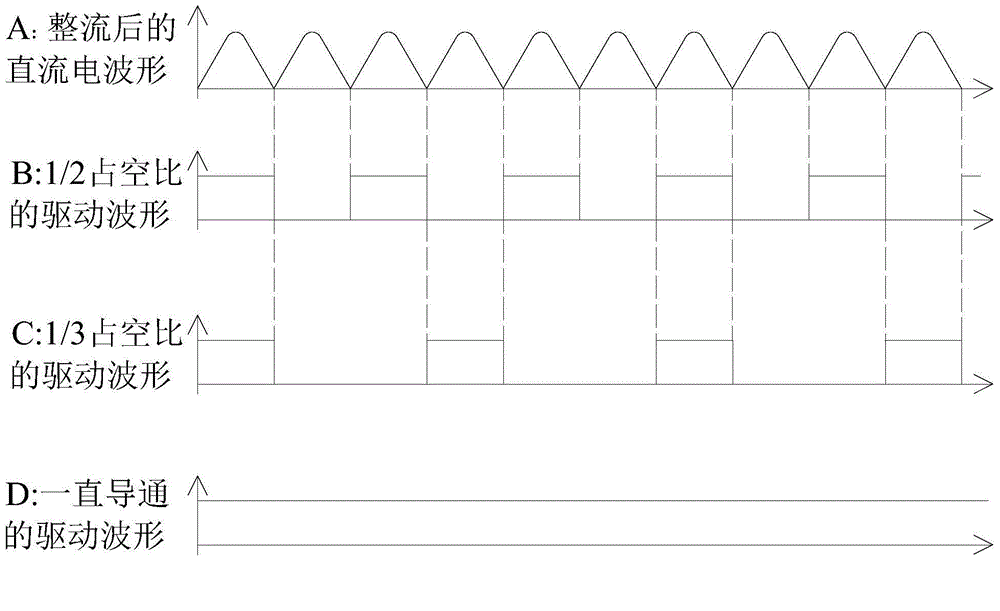

ActiveCN106160534AAvoid damageImprove severe feverAc-dc conversionElectric/magnetic/electromagnetic heatingCapacitanceEngineering

The invention discloses a cooling utensil, a cooking utensil electromagnetic heating device and a heating control method thereof. The device comprises a rectifier bridge stack, a filter circuit, a discharge resistor, a transfer switch, a resonant switch transistor, a resonant module, a zero-crossing detection circuit and a control module, wherein the filter circuit comprises a filter inductor and a filter capacitor, one end of the filter inductor is connected with the first output end of the rectifier bridge stack, the other end of the filter inductor is connected with one end of the filter capacitor, and a first node is arranged between the other end of the filter inductor and one end of the filter capacitor; the discharge resistor is in parallel connection with the filter capacitor; one end of the transfer switch is connected with the other end of the filter capacitor and the other end is grounded; the resonant module is connected between the first node and the collector of the resonant switch transistor; the zero-crossing detection circuit is used for detecting inputted AC zero-crossing signals; and the control module executes control on the resonant switch transistor and the transfer switch respectively according to the zero-crossing signals to change the heating mode of the electromagnetic heating device. Thus, in the case of low-power intermittent heating, hard turn on of the switch transistor is avoided, and the switch transistor can be prevented from being damaged.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Heat conduction-type barometric sensor utilizing thermal excitation

InactiveUS20120118060A1Improve accuracySimple structureFluid pressure measurement using pressure-sensitive liquidThermometers using electric/magnetic elementsThermal expansionIntermittent heating

A heat conduction type barometric sensor has high sensitivity and high accuracy that has simple structure and circuit configuration and can measure a barometric pressure in the range of a very low barometric pressure to ≧1 atm using one sensor chip. The sensor includes a cantilever-shaped thin film provided with a thin-film temperature sensor, a heating element, and an excitation element. The excitation element utilizes warpage and bending based on a difference in thermal expansion between two main layers constituting the thin film during intermittent heating by a thin-film heater as the heating element. The two main layers are a silicon layer and a thermally oxidized film of silicon which are significantly different from each other in the coefficient of thermal expansion. A circuit in which the sensitivity is enhanced by the integration of a seebeck current for a predetermined period of time can be also provided.

Owner:KIMURA GIKEN KK

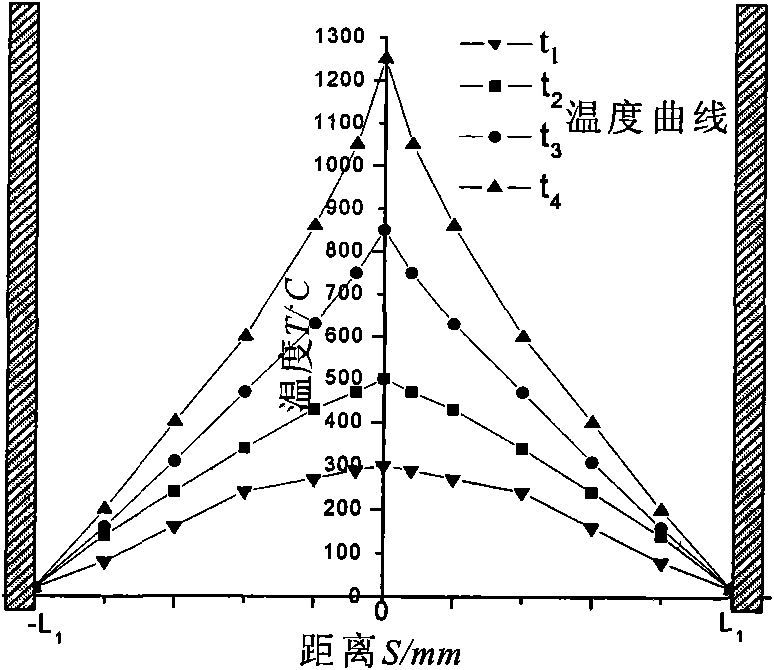

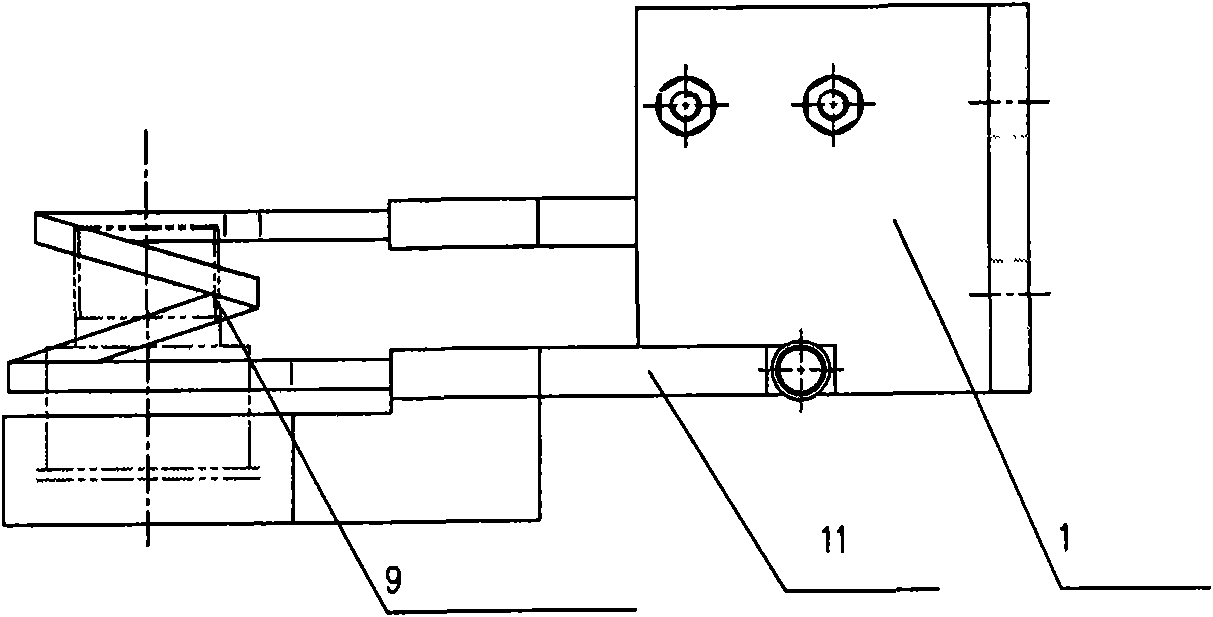

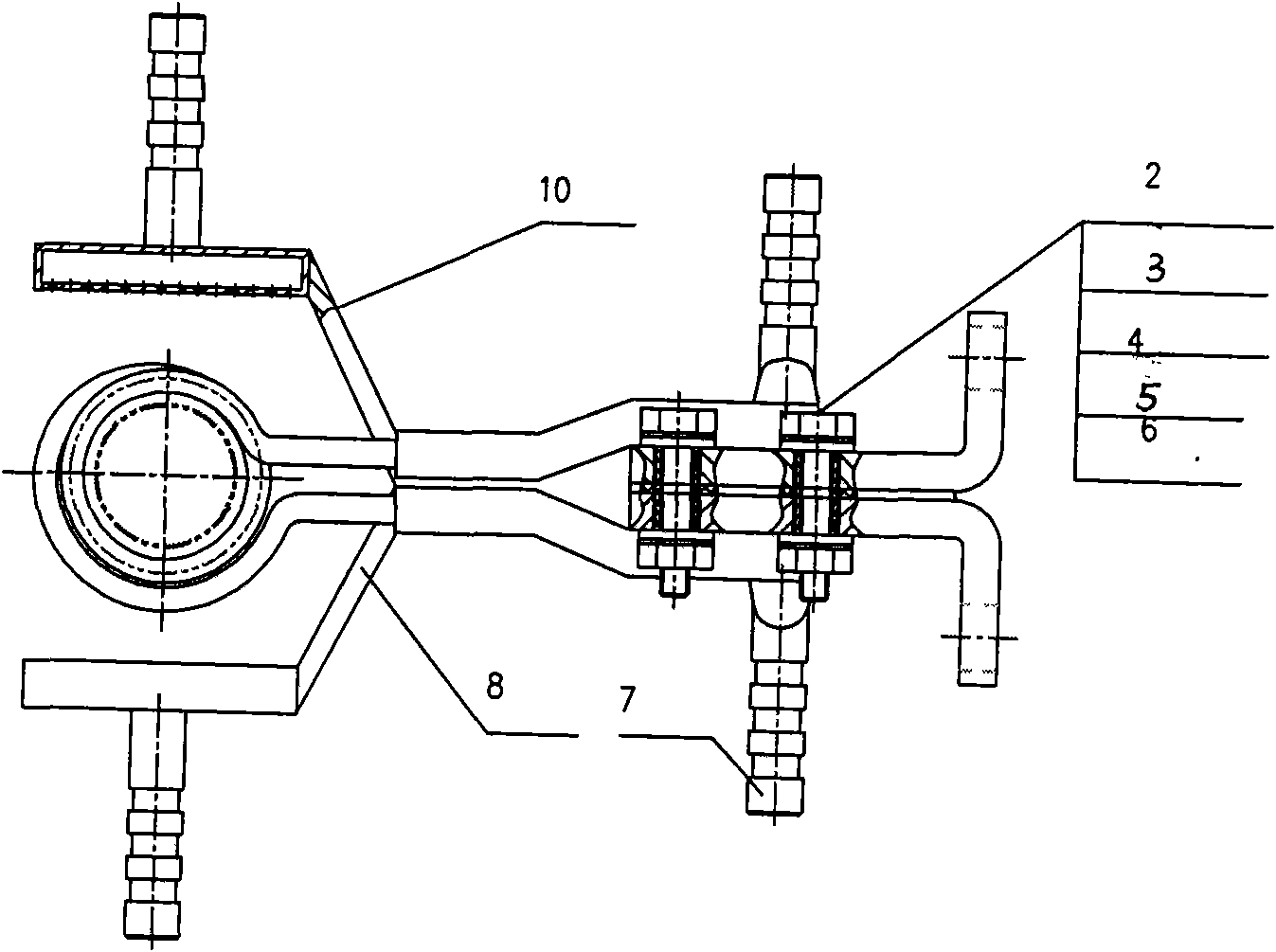

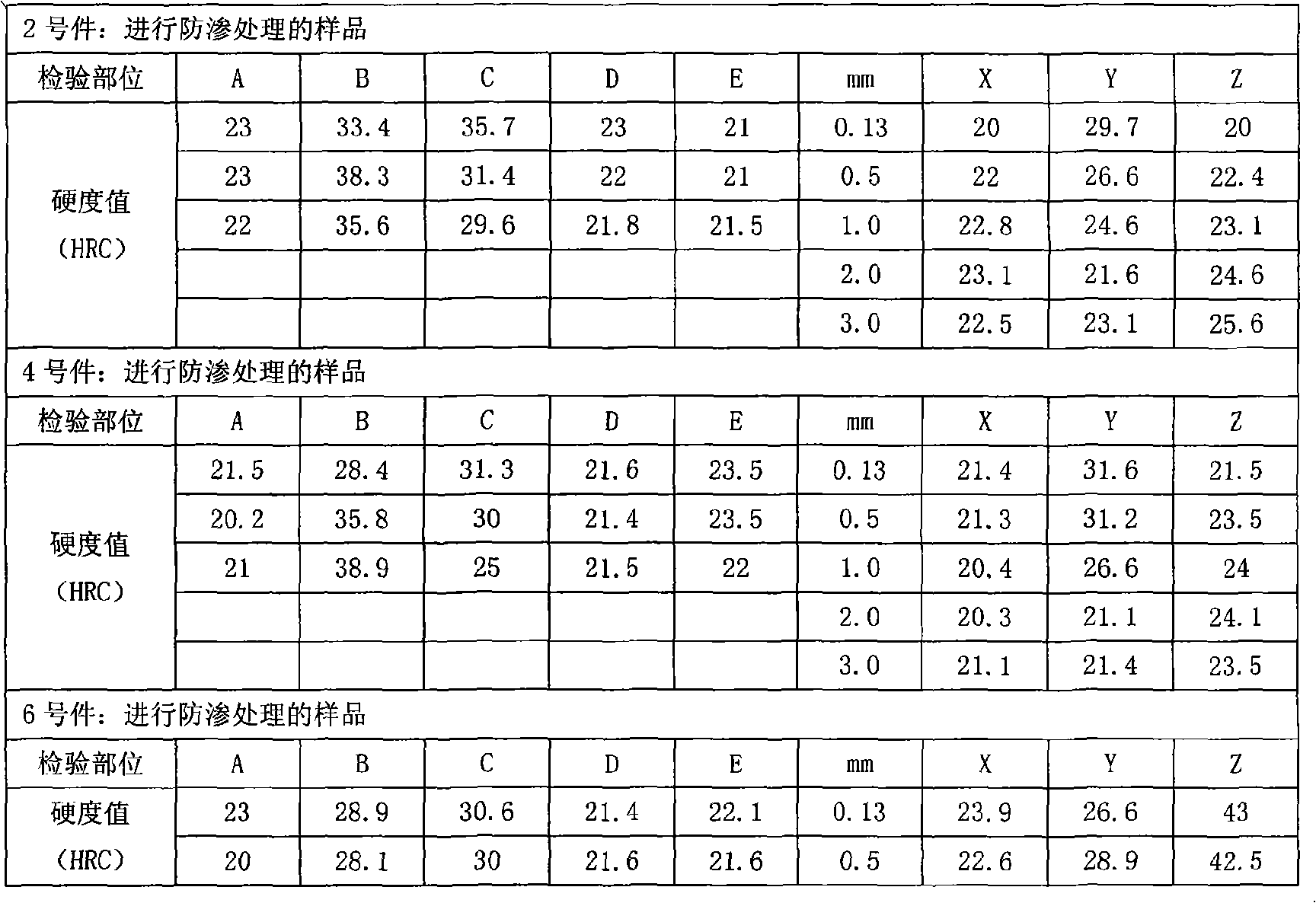

Steering arm shaft induction heating tempering technology

InactiveCN101570812ASimple structureShort processing timeFurnace typesIncreasing energy efficiencyHardnessEngineering

The invention relates to steering arm shaft induction heating tempering technology. The technology is characterized in that a screw end to be tempered is upward placed between upper tip and lower tip of a quenching machine to be clamped tightly; a start button is pressed, and the work piece starts to rotate and to be heated; in the whole process of heating, an axial protective spray case constantly sprays water, and water spraying is stopped when delay time is up; rotation is stopped, a sensor rises to the original position; the component is fetched to complete tempering. The technology fulfils the induction heating tempering quality and application performance of the component; the sensor has simple structure, short process time, high production efficiency, energy conservation and low process cost; the tempering temperature on a C point round angle can achieve the process requirement with hardness being reduced below 45HRC and other positions being over 20HRC, by adopting an intermittent heating mode through the effect of heat conduction.

Owner:CHINA FIRST AUTOMOBILE

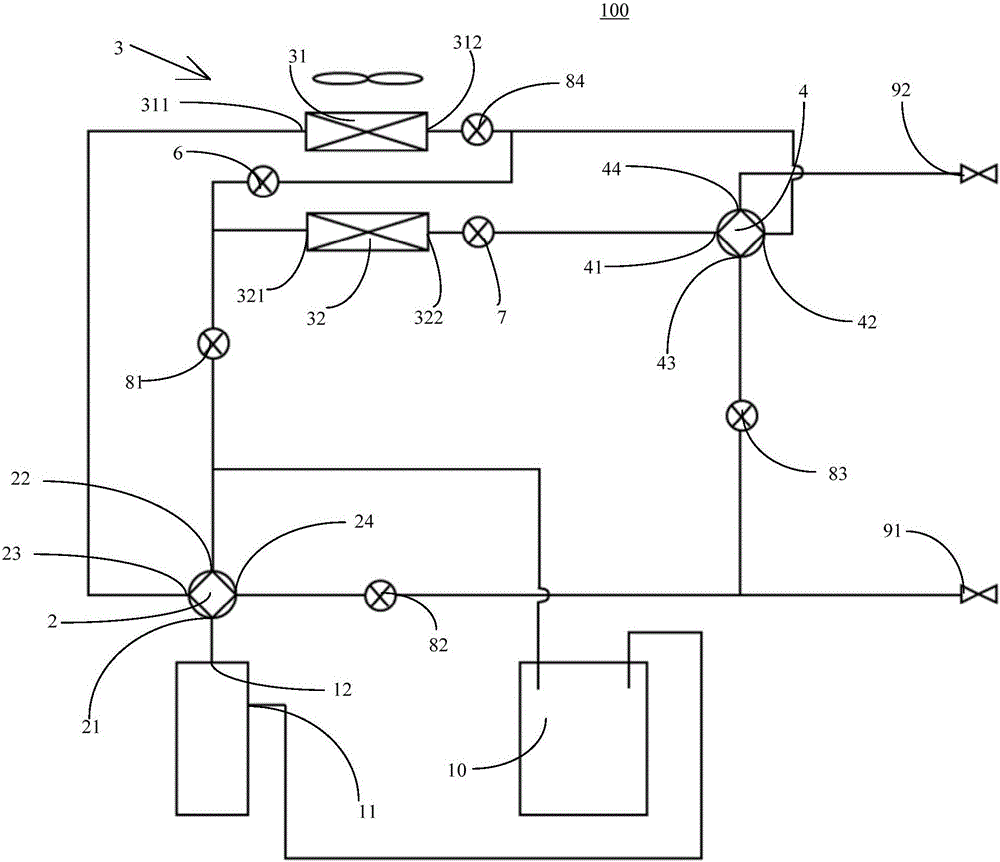

Air conditioner system and control method thereof

ActiveCN106052181AEffective protectionTemperature effectMechanical apparatusCorrosion preventionFour-way valveLow load

The invention discloses an air conditioner system and a control method thereof. The air conditioner system comprises a compressor, a main four-way valve, an auxiliary four-way valve, an indoor heat exchanger, a first throttling device, a second throttling device, a first on-off valve, a second on-off valve and a third on-off valve. According to the air conditioner system, the outdoor heat exchanger can be dismounted into two portions or multiple portions, and through combination of all parts and a pipeline and control over all valves, intermittent heating defrosting and low-load running control can be achieved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

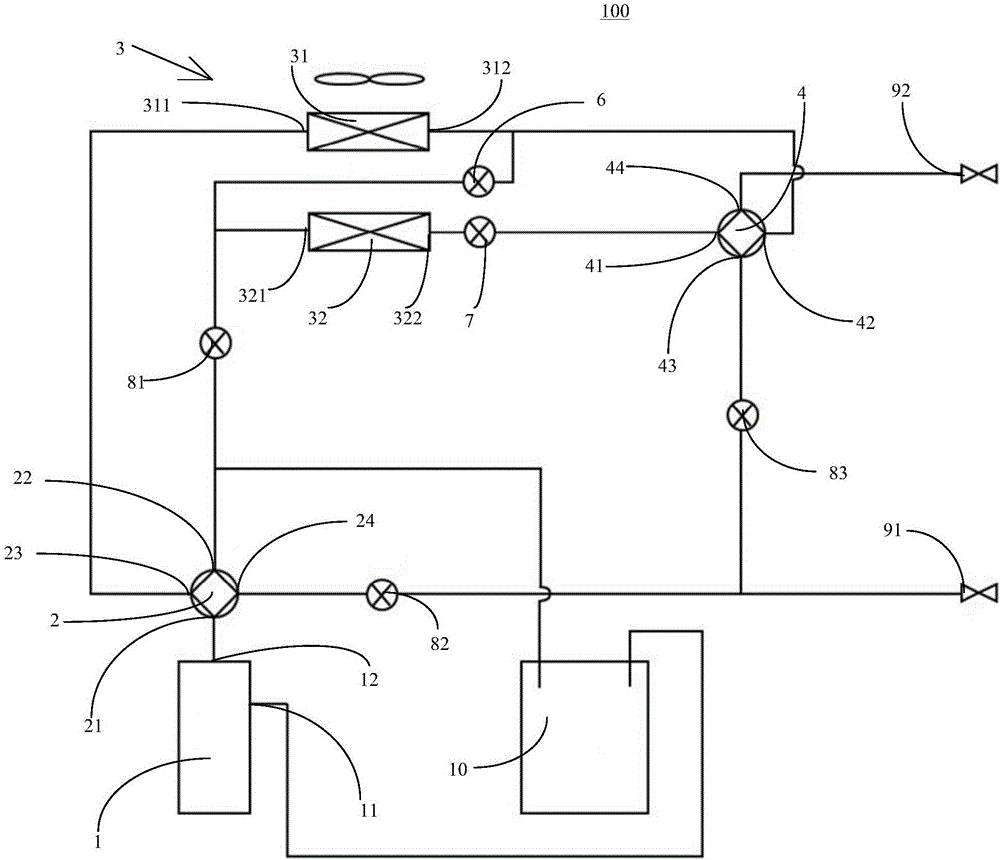

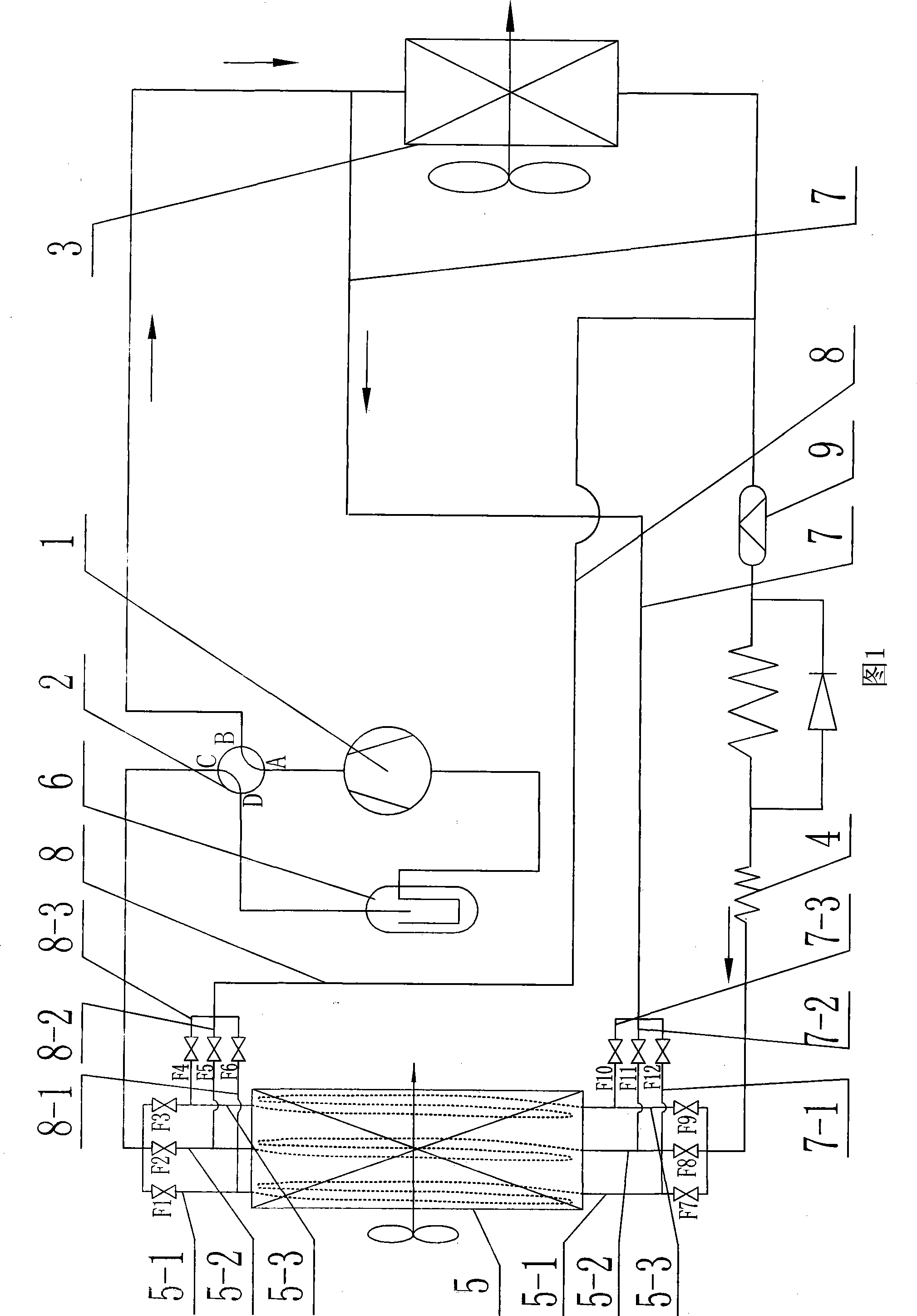

Air source heat pump system capable of intermittently supplying heat under defrosting operating condition

InactiveCN101435639AReduces drastic changes in inspiratory pressureRealize uninterrupted heatingHeat pumpsCorrosion preventionVapor–liquid separatorEngineering

The invention discloses an air source heat pump system which can unintermittently supply heat under the working condition of defrosting and relates to an air source heat pump system. The system solves the problems that the prior defrosting mode has drastic change of air suction pressure, stops heat supply and blows cold wind indoors in the defrosting process. The outlet end of a compressor is communicated with a first port of a four-way reversing valve; a second port of the four-way reversing valve is communicated with the inlet end of an indoor machine; the outlet end of the indoor machine is respectively communicated with one end of a first bypass shunt circuit, one end of a second bypass shunt circuit and one end of a third bypass shunt circuit through a throttling mechanism; the other end of the first bypass shunt circuit, the other end of the second bypass shunt circuit and the other end of the third bypass shunt circuit are communicated with a third port of the four-way reversing valve; a fourth port is communicated with the inlet end of a gas-liquid separator; and the outlet end of the gas-liquid separator is communicated with the inlet end of the compressor. The system realizes unintermittent heat supply in the defrosting process, simultaneously reduces drastic change of air suction pressure of the compressor and is more stable in the conversion process of heat supply and defrosting.

Owner:HARBIN INST OF TECH

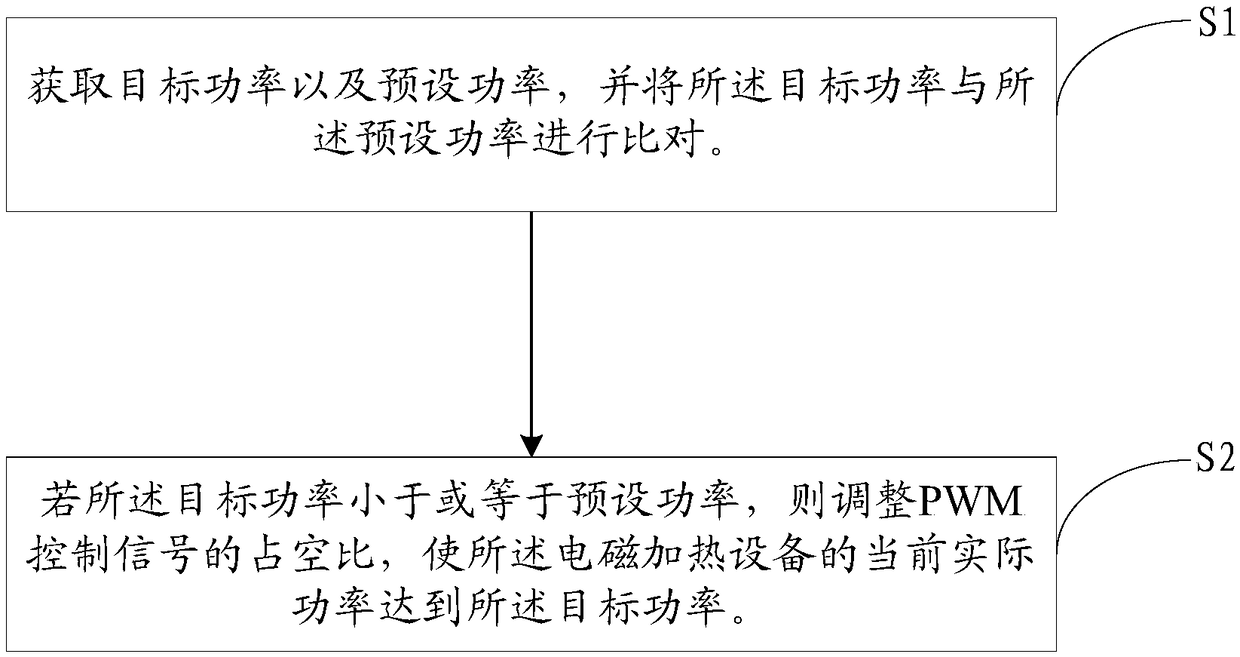

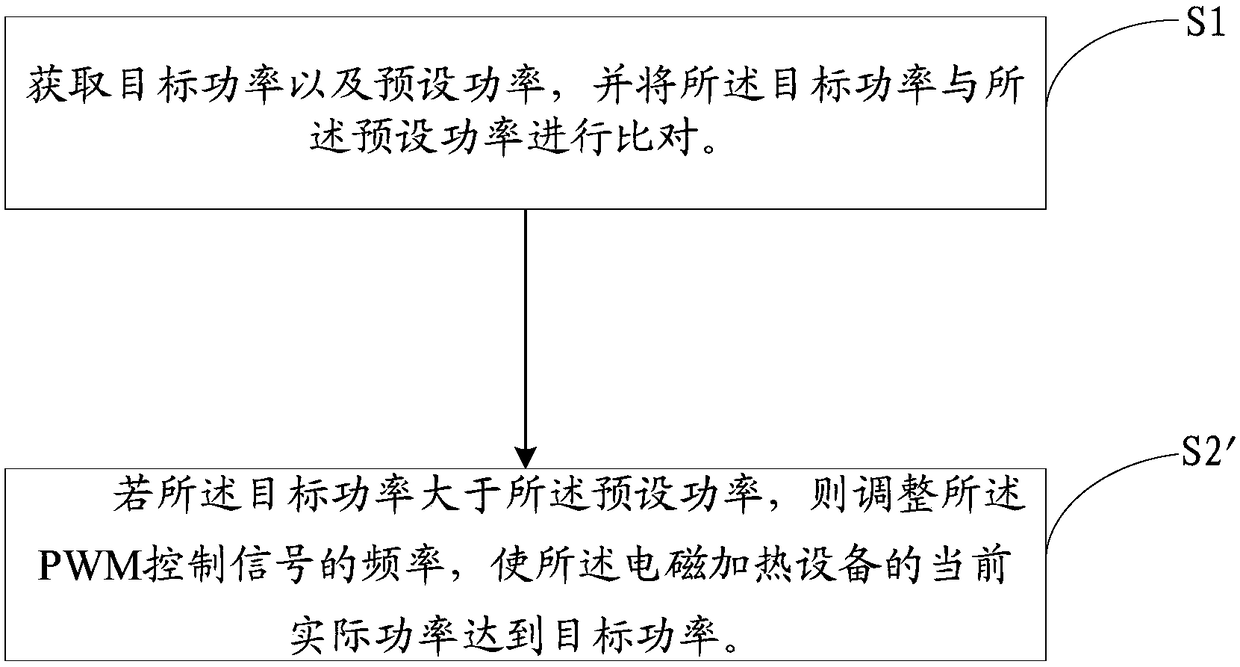

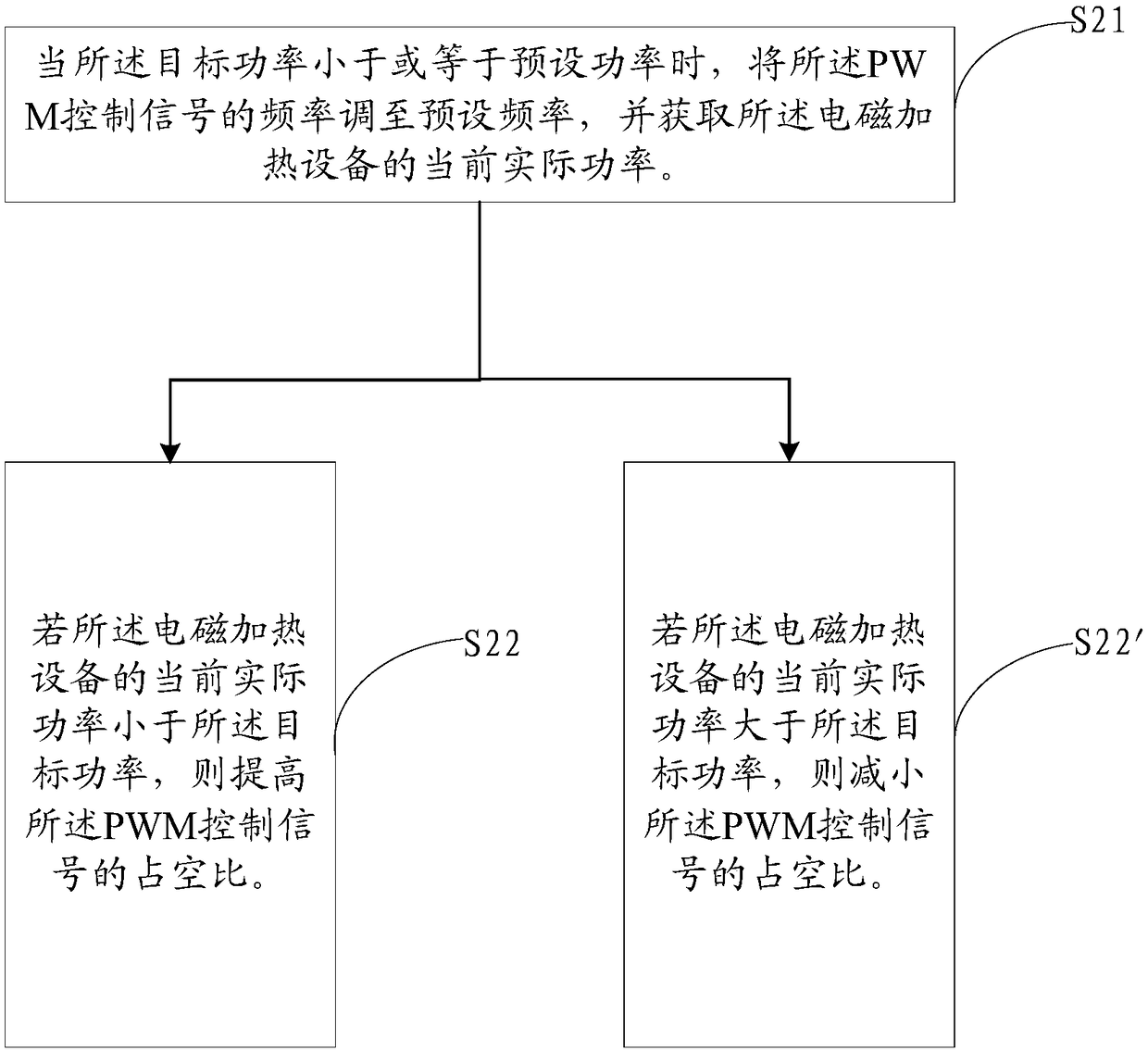

Power control method and device for electromagnetic heating device and electromagnetic heating device

ActiveCN108243516AEasy cookingGood cooking effectInduction heating controlControl signalElectromagnetic heating

The invention is applicable to the field of household appliances, and provides a power control method and device for an electromagnetic heating device and an electromagnetic heating device, wherein the power control method is applied to an electromagnetic heating device of a half bridge topology. The method comprises the following steps of: obtaining a target power and a preset power, and comparing the target power with the preset power; and if the target power is less than or equal to a preset power, adjusting a duty ratio of a PWM control signal to enable the current actual power of the electromagnetic heating device to reach the target power. The power control method for the electromagnetic heating device provided by the invention achieves the purpose of outputting low power of the electromagnetic heating device by reducing the duty ratio of the PWM control signal when the target power is less than the preset power, without intermittent heating, so as to make food boiling and cooking better and give users a better experience.

Owner:宁波拓邦智能控制有限公司

Tunnel anti-icing composite plate based on phase-change material

InactiveCN105587325ARealize phase change heat storageAvoid working long hoursUnderground chambersDrainageFiberInsulation layer

The invention discloses a tunnel anti-icing composite plate based on a phase-change material. The tunnel anti-icing composite plate comprises an outer shell, a heat insulation layer, a phase change material heat storage module, a waterproof layer, a flow guide sheet and a wiring terminal, wherein heat stored in the phase change material heat storage module is released through the waterproof layer and the flow guide sheet so as to achieve the anti-icing and ice thawing effects. When the temperature of the phase change material is lower than a critical temperature T, a carbon fiber heating cable starts a heating mode; and the generated heat is directly transferred into the phase change material to realize phase change heat accumulation. The tunnel anti-icing composite plate has the advantages that the composite phase change material and the carbon fiber heating cable are combined; the intermittent heating, heat storage and ice thawing mode is realized; the initial cost and operation cost are reduced; and the anti-icing efficiency is improved. Meanwhile, the phase change material heat storage module, the waterproof layer, a heat insulation module and a system control module are combined and integrated; and the system structure is simplified, so that the installation is convenient, and the safety is improved.

Owner:GUANGDONG UNIV OF TECH +1

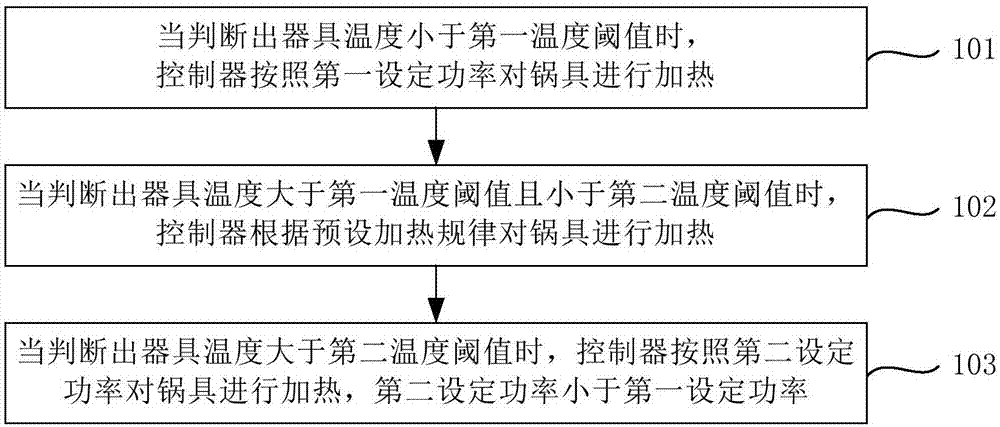

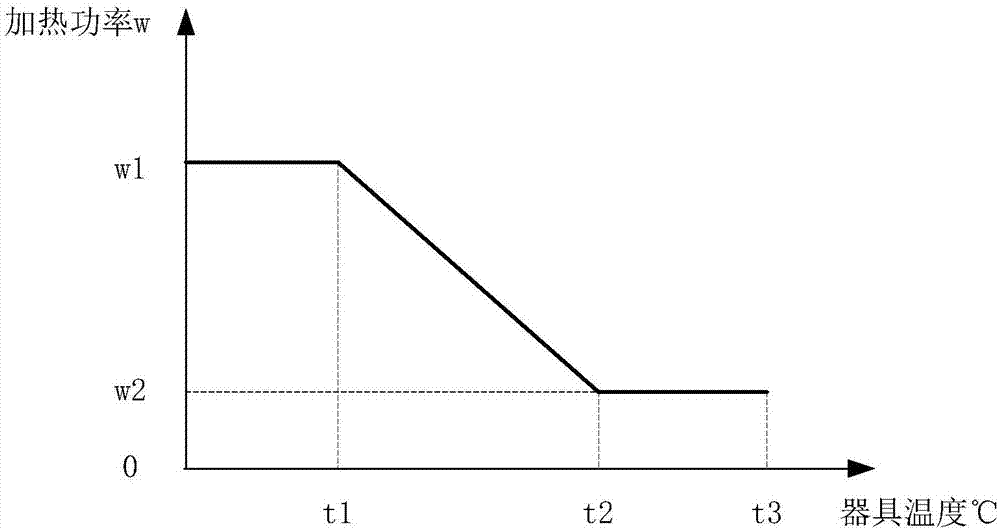

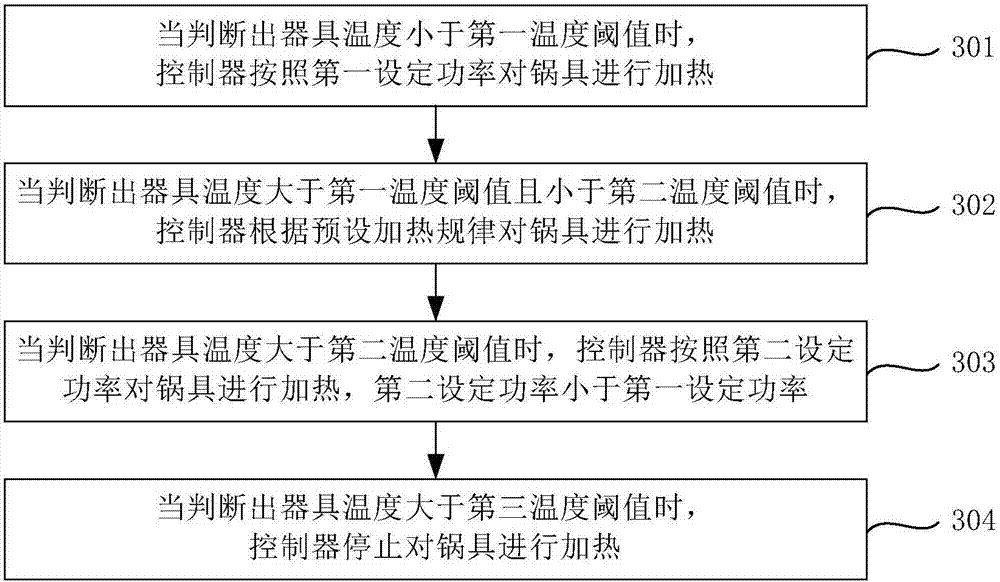

Cooking utensil heating control method and device, electric heating component and electric cooking utensil

InactiveCN107544586AFast heatingReduce heating rateTemperatue controlTime-controlled ignitorsElectricityEngineering

The invention provides a cooking utensil heating control method and device, an electric heating component and an electric cooking utensil. The method comprises the steps of when it is judged that theutensil temperature is smaller than a first temperature threshold value, heating a pot according to first set power; when it is judged that the utensil temperature is larger than the first temperaturethreshold value and smaller than a second temperature threshold value, heating the pot according to a preset heating law; when it is judged that the utensil temperature is larger than the second temperature threshold value, heating the pot according to second set power, wherein the second set power is smaller than the first set power. The cooking utensil control method and device, the electric heating component and the electric cooking utensil can solve the problem in the prior art that the convenience is poor in the cooking process caused by intermittent heating.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

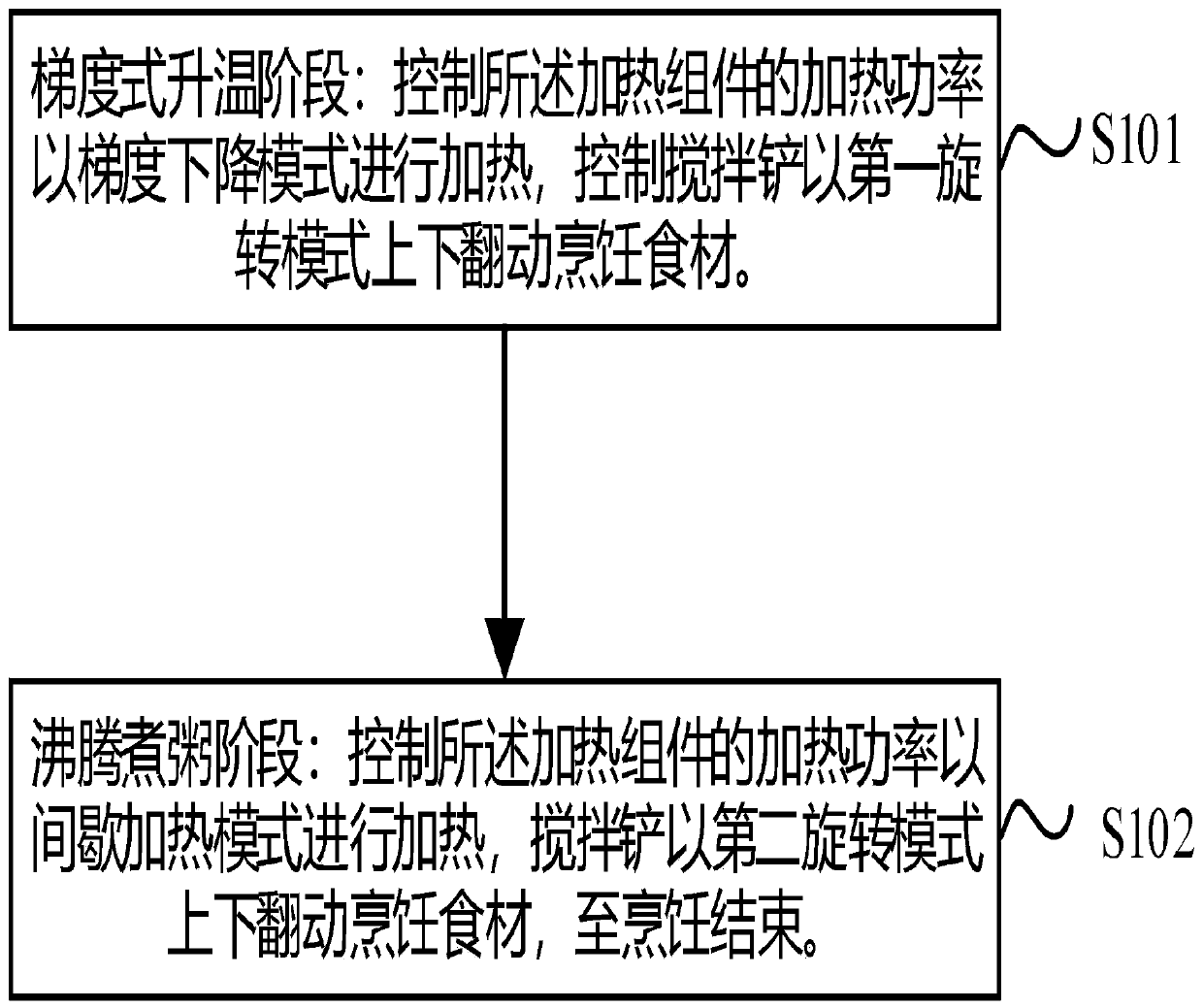

Stir-fry machine and porridge cooking control method thereof

ActiveCN111084537AFull heat absorptionBreak up fullyBoiling over preventionWarming devicesProcess engineeringFood material

The invention discloses a stir-fry machine and a porridge cooking control method thereof. The stir-fry machine comprises a heating assembly, a cooking cavity and a stirring shovel extending into the cooking cavity, wherein the stirring shovel is used for turning over cooking food materials that are placed in the cooking cavity up and down. The porridge cooking control method comprises the steps: agradient type temperature rising stage: controlling the heating power of the heating assembly to heat in a gradient descending mode, and controlling the stirring shovel to turn over the cooking foodmaterials in a first rotating mode; and a boiling porridge cooking stage: controlling the heating power of the heating assembly to heat in an intermittent heating mode, and turning over the cooking food materials up and down by the stirring shovel in a second rotating mode until the cooking is finished. According to the invention, in the stirring process, the food is gelatinized, the viscosity ismoderate, the taste of a user is good, and the pot overflowing phenomenon in the porridge cooking process can be avoided by combining segmented and stepped heating with stirring.

Owner:JOYOUNG CO LTD

Steam generation device, control method thereof and household electric steam box

ActiveCN101956970ASimple structureLow priceSteam generation heating methodsBoiler controlWater storage tankEngineering

The invention aims to provide an energy-saving steam generation device with an adaptive water supply function and low cost, and a control method thereof. The steam generation device comprises a shunt valve, a return pipe, at least one heating pipe, a steam-water separator and a control circuit, wherein the heating pipe is arranged between the steam-water separator and the shunt valve; a water inlet is reserved in the shunt valve; a one-way valve for controlling fluids to flow to the heating pipe from the water inlet is also arranged in the shunt valve; and the heating pipe comprises at least one intermittent-heating pipe I. The invention also discloses a household electric steam box comprising the steam generation device. The household electric steam box has the advantages of energy saving, adaptive water supply, low cost, no need of seal between a water storage tank and the steam-water separator, convenient design of appearance and internal structure, and convenient use.

Owner:深圳市北鼎晶辉科技有限公司

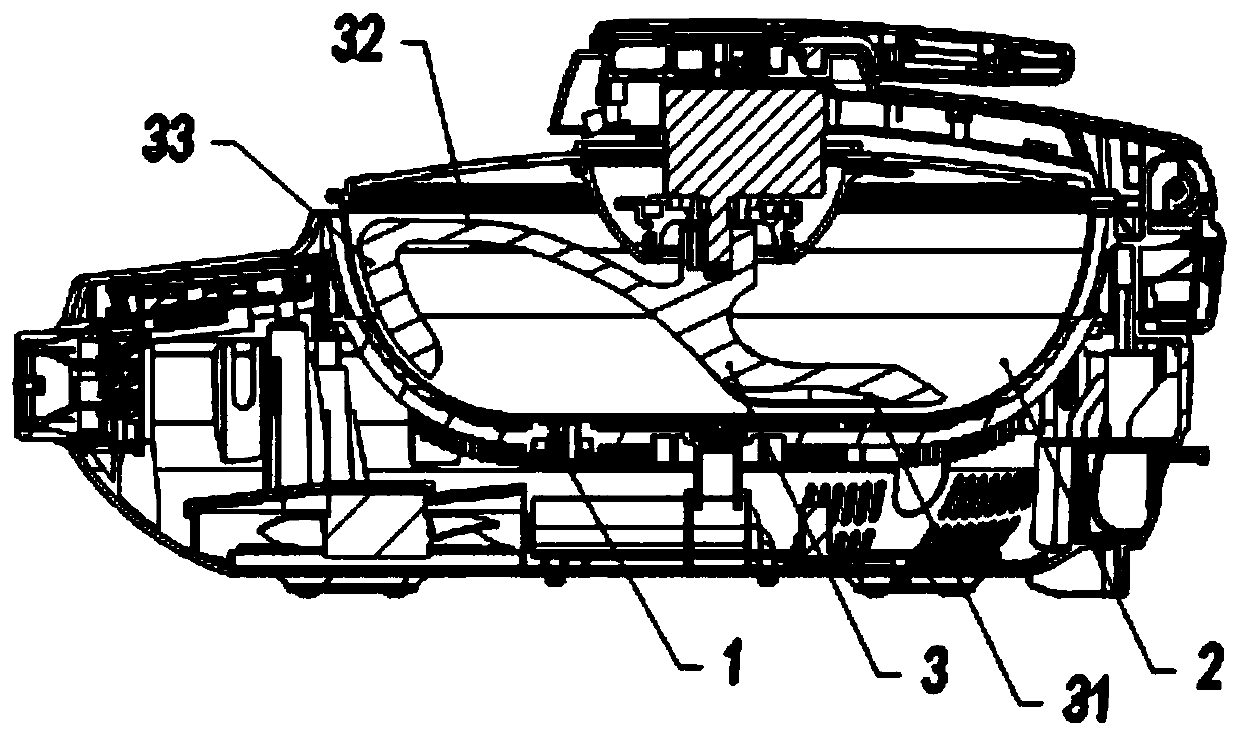

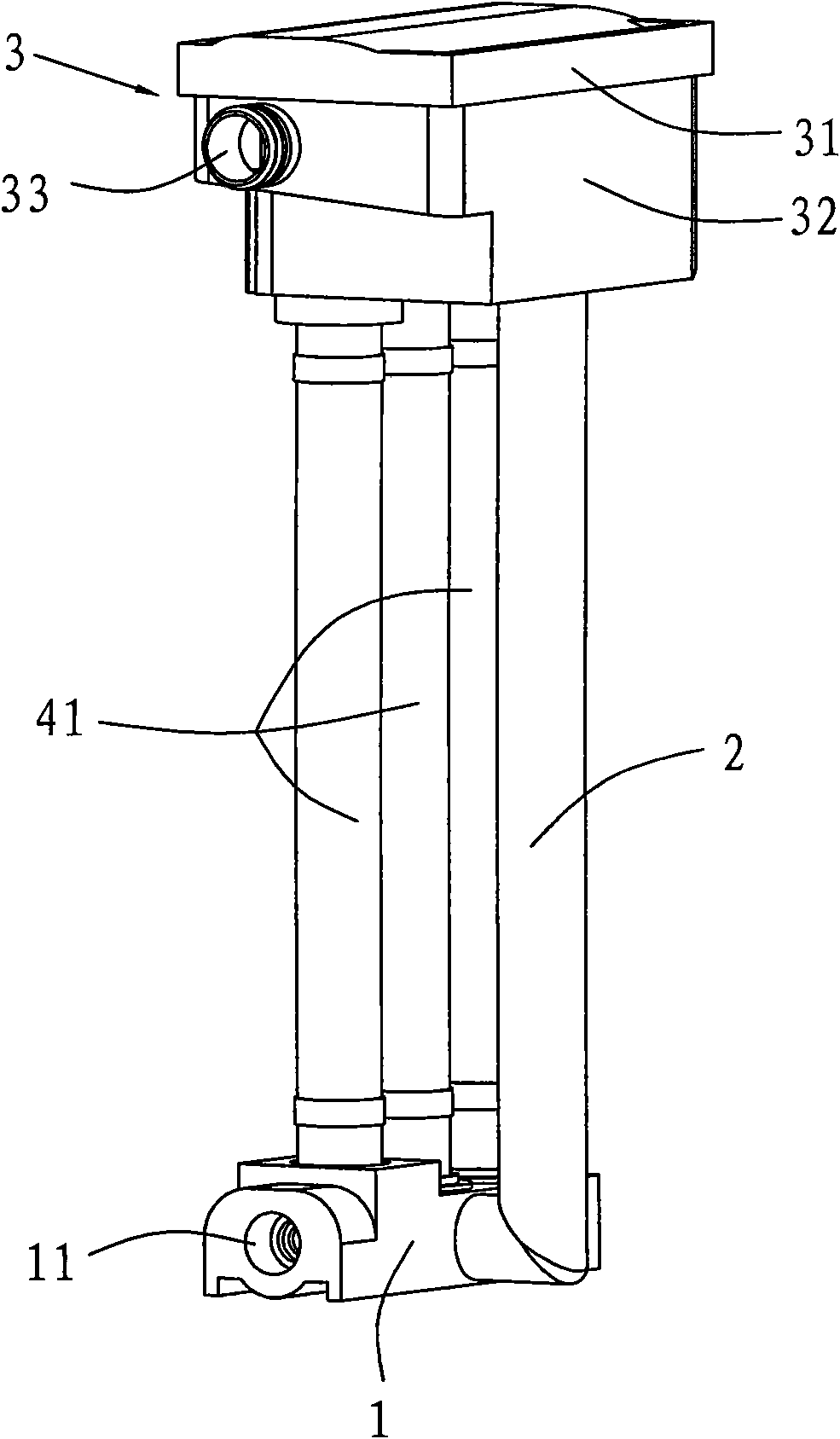

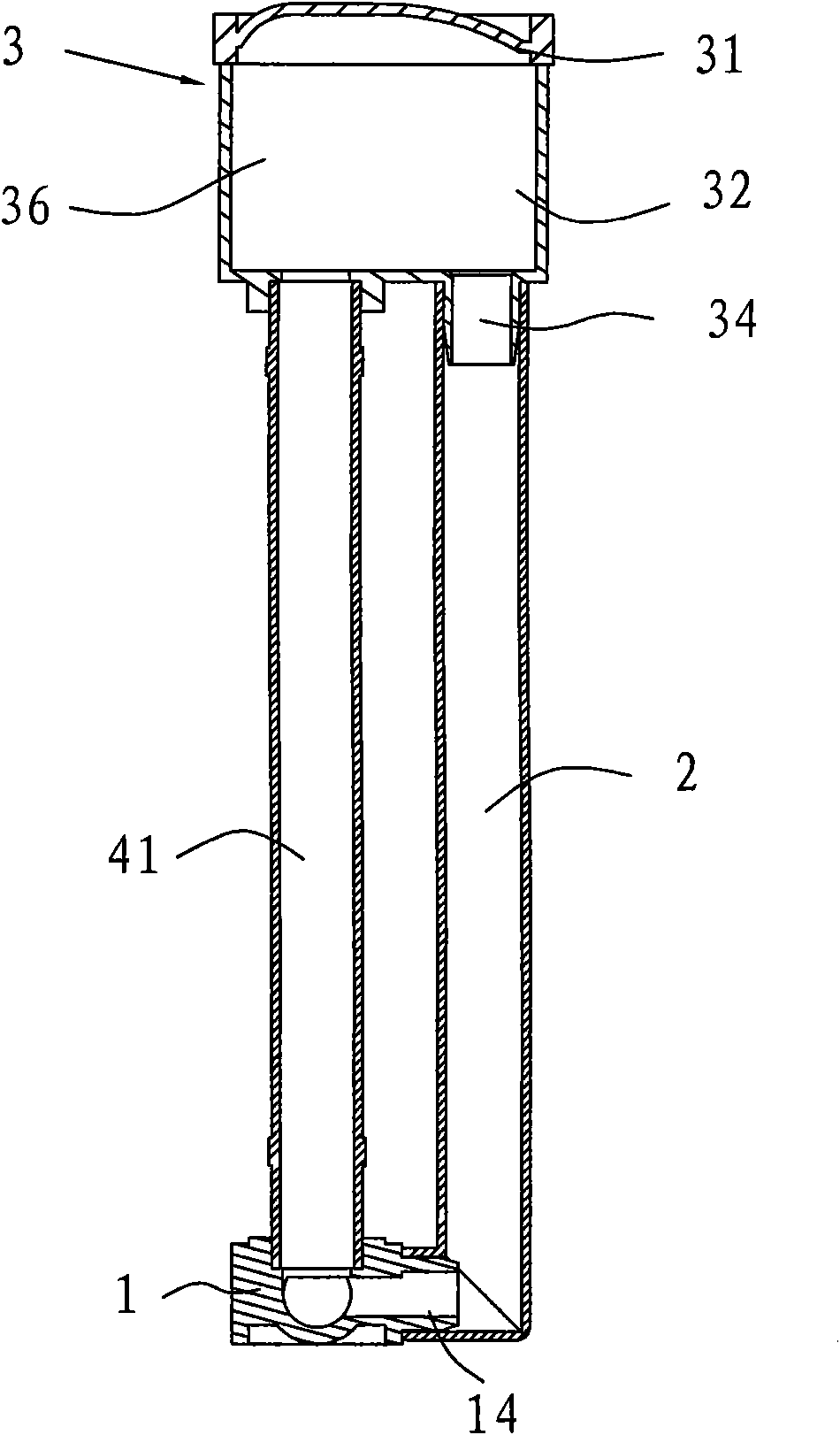

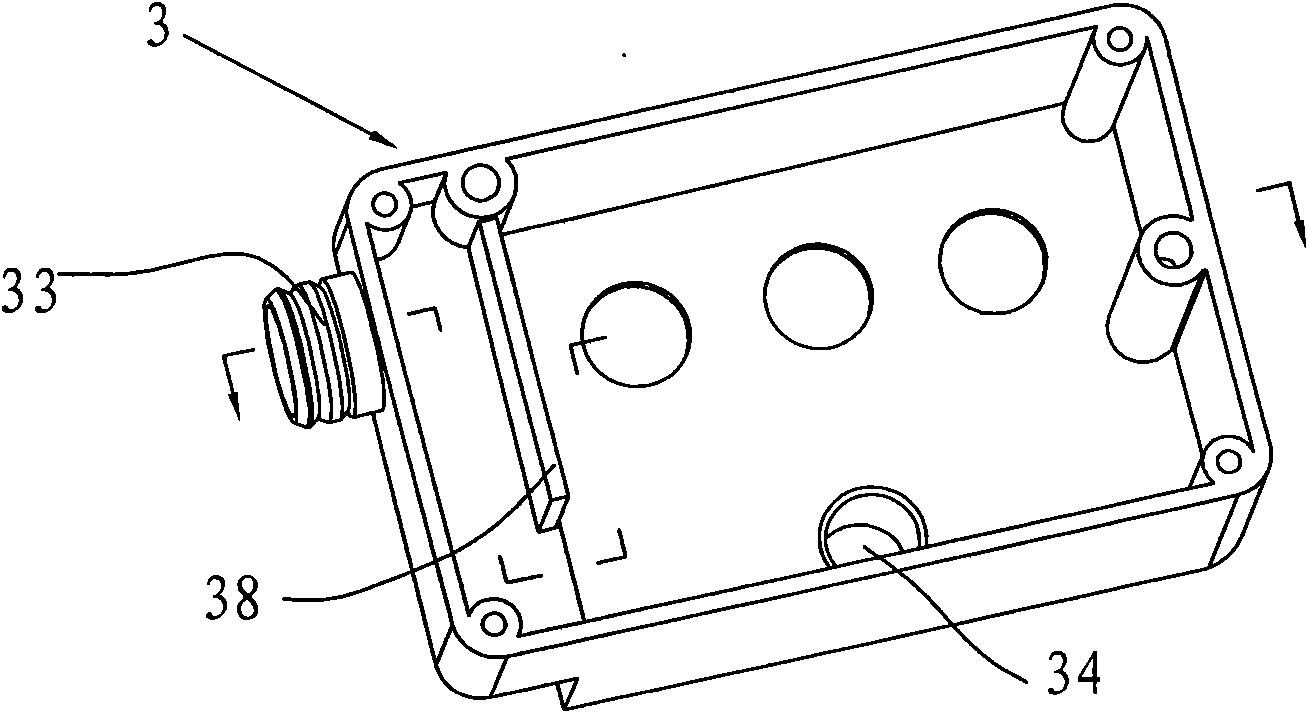

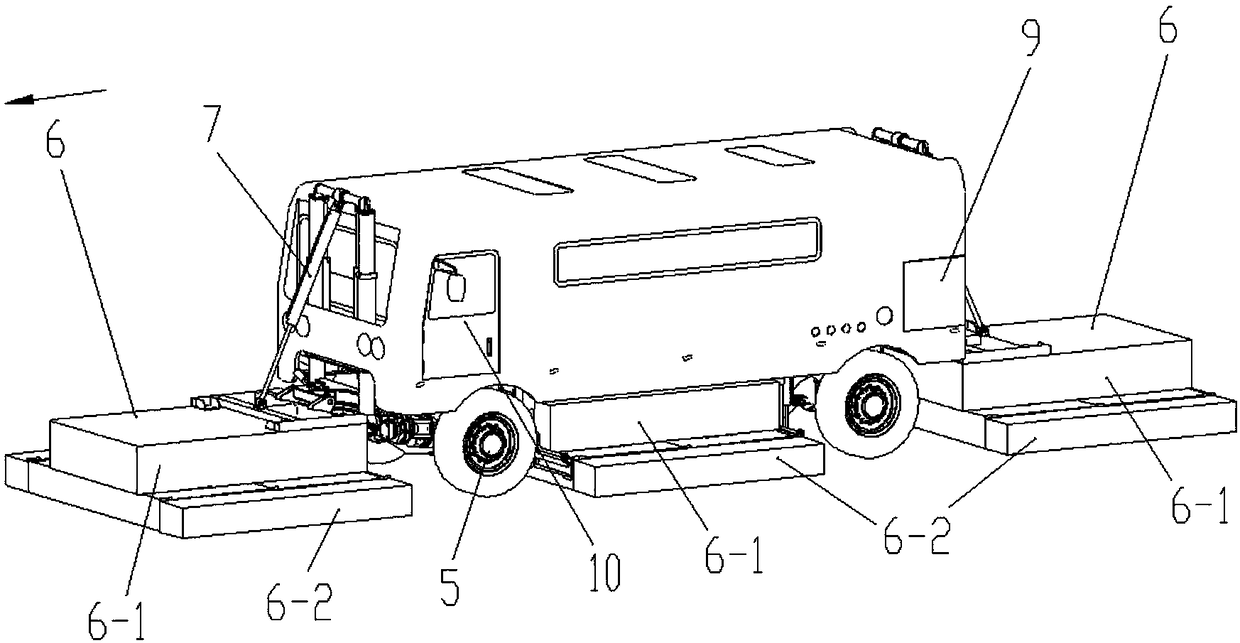

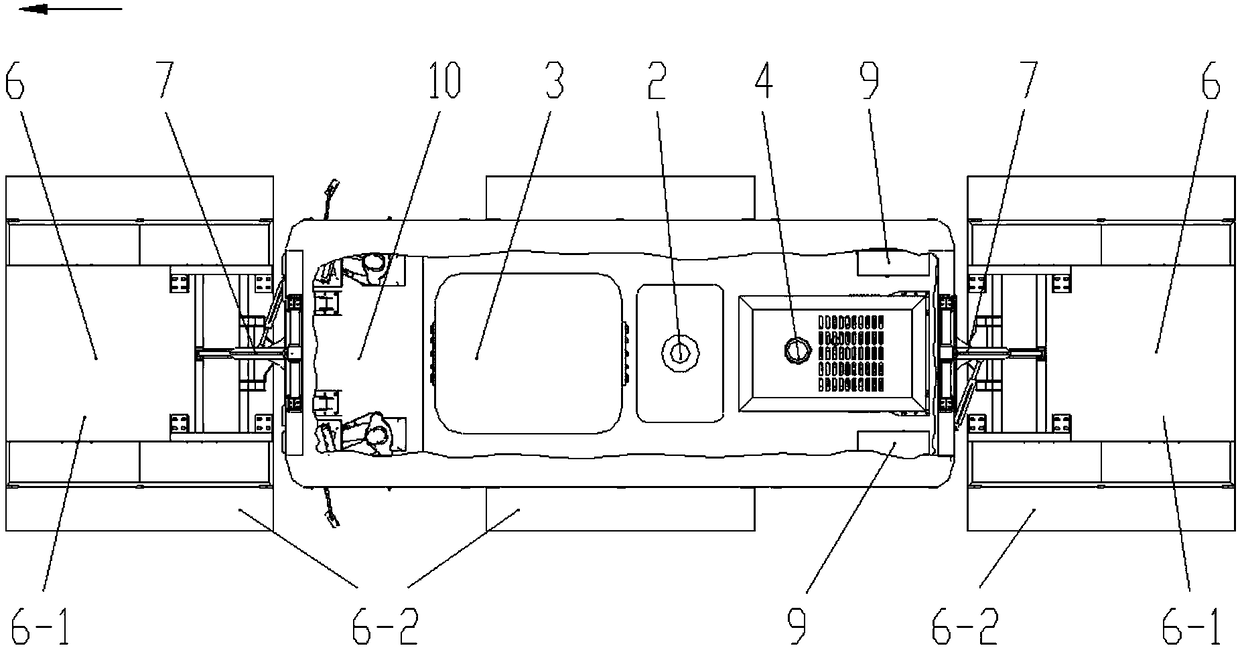

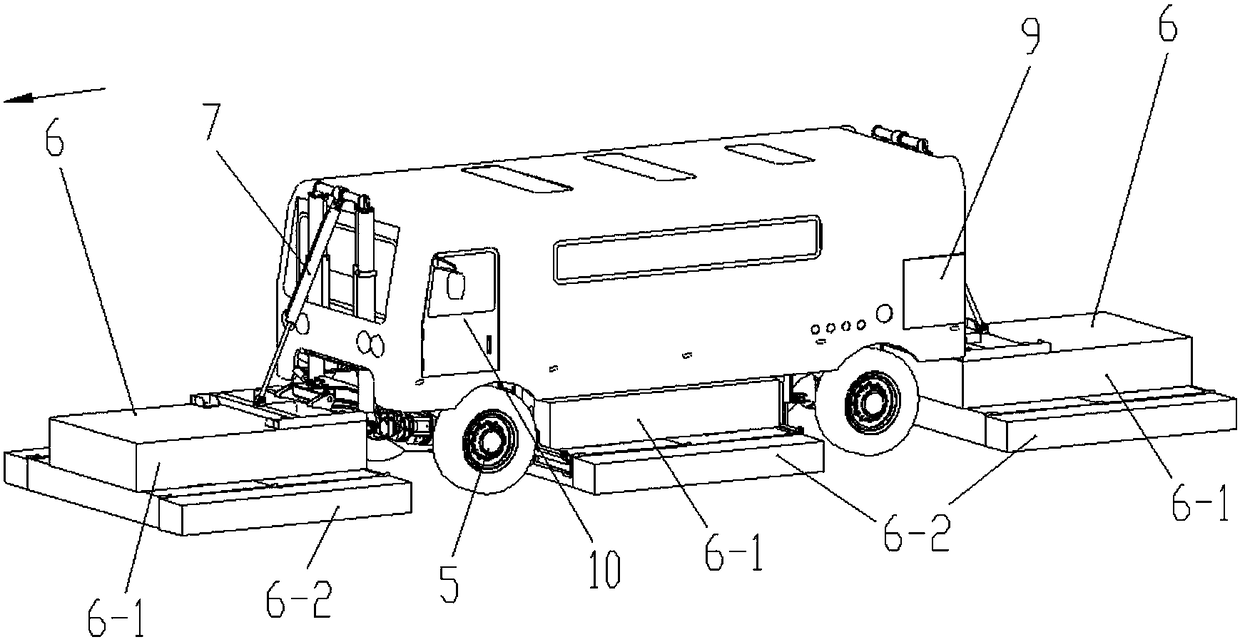

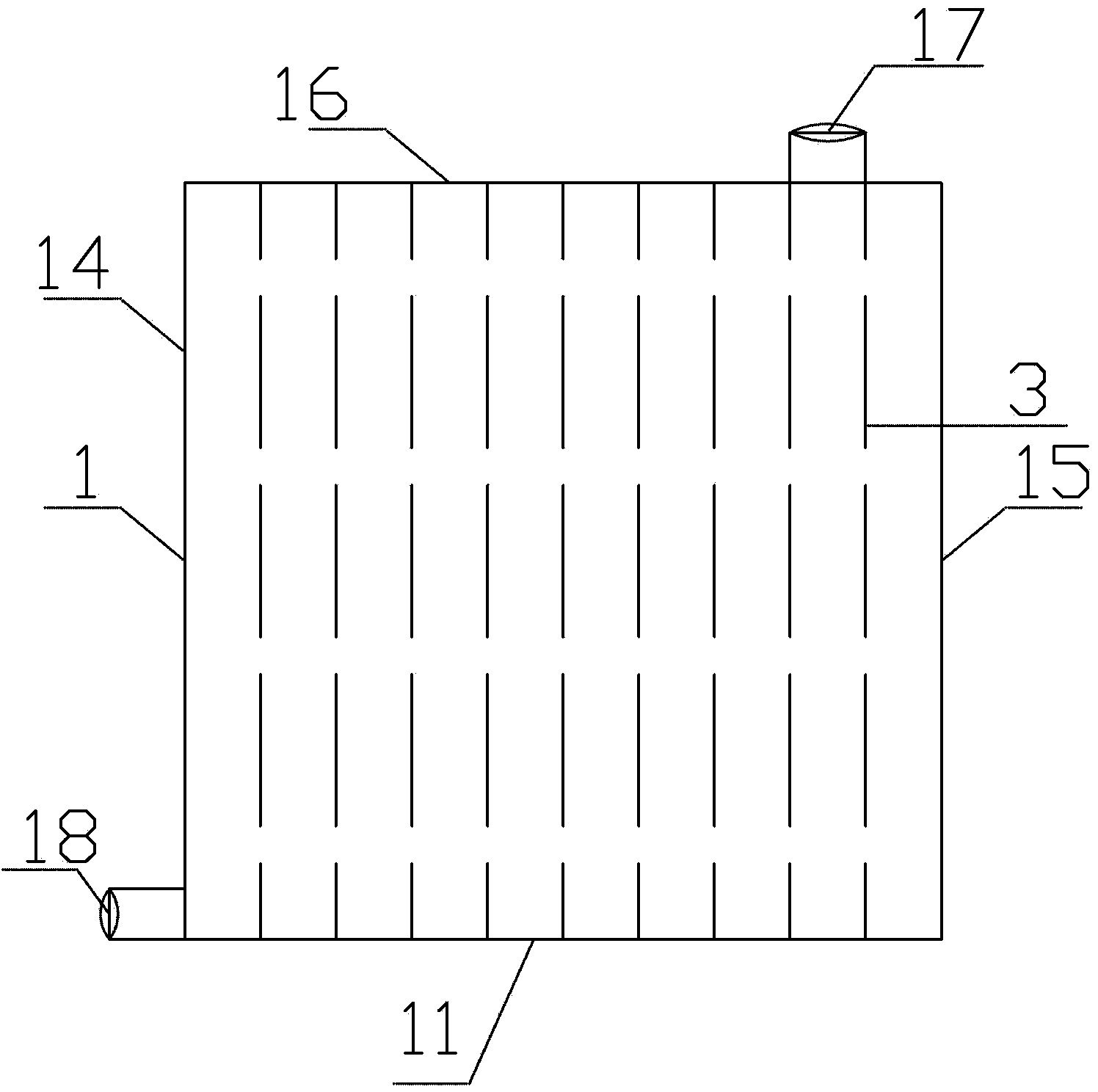

Modular partition hot air circulating-type bituminous pavement heating machine

The invention discloses a modular partition hot air circulating-type bituminous pavement heating machine which comprises a rack (1). A driving cab (10), an air tank assembly (3), a fuel tank (2) and apower device (4) are arranged above the rack (1) from front to back, and the left side and the right side of the power device (4) are provided with gasification devices (9). The front end and the rear end of the rack (1) are each movably connected with a set of heating walls (6) through a heating wall lifting and overturning swing frame assembly (7), and the position, between a front axle and a rear axle, of the lower portion of the rack (1) is movably connected with a set of heating walls (6) through a heating wall lifting sliding frame assembly (8). According to the modular partition hot air circulating-type bituminous pavement heating machine, the modular partition heating temperature is accurately controlled, and uniformity of the whole heating face is ensured; the machine has the good adaptability to large curve construction, large angle climbing, site-transferring transporting and the like; and modular heating wall variable-power and intermittent heating and machine-group control are achieved, the heating efficiency is high, the heating depth is large, and the adaptability to the disease damage working condition is high.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

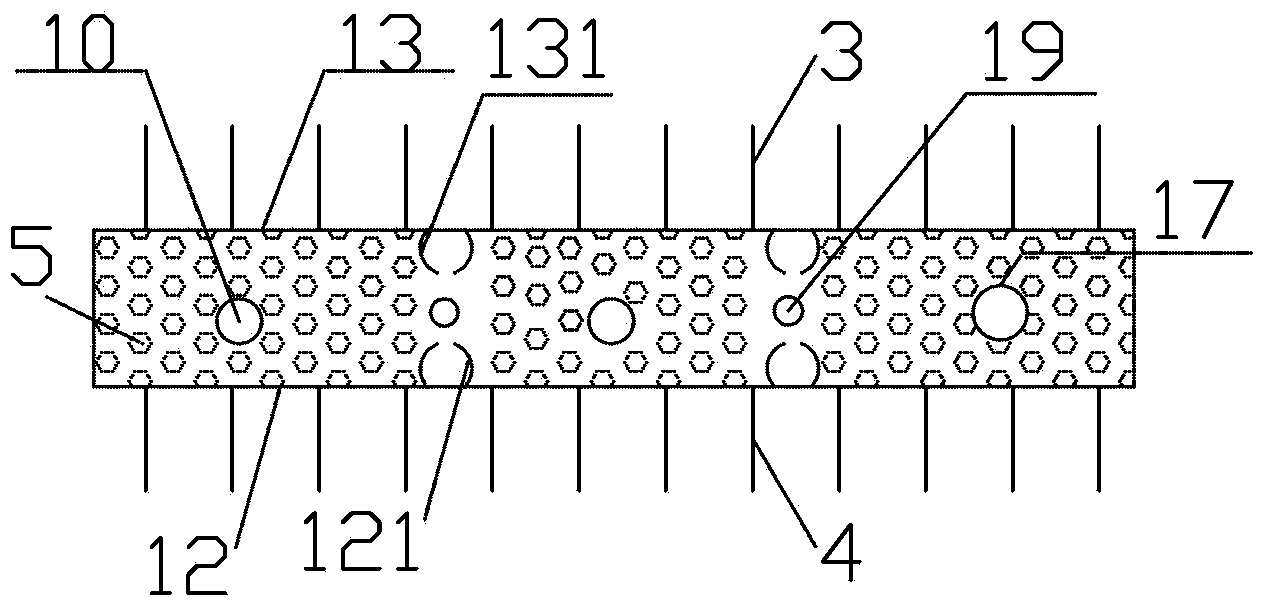

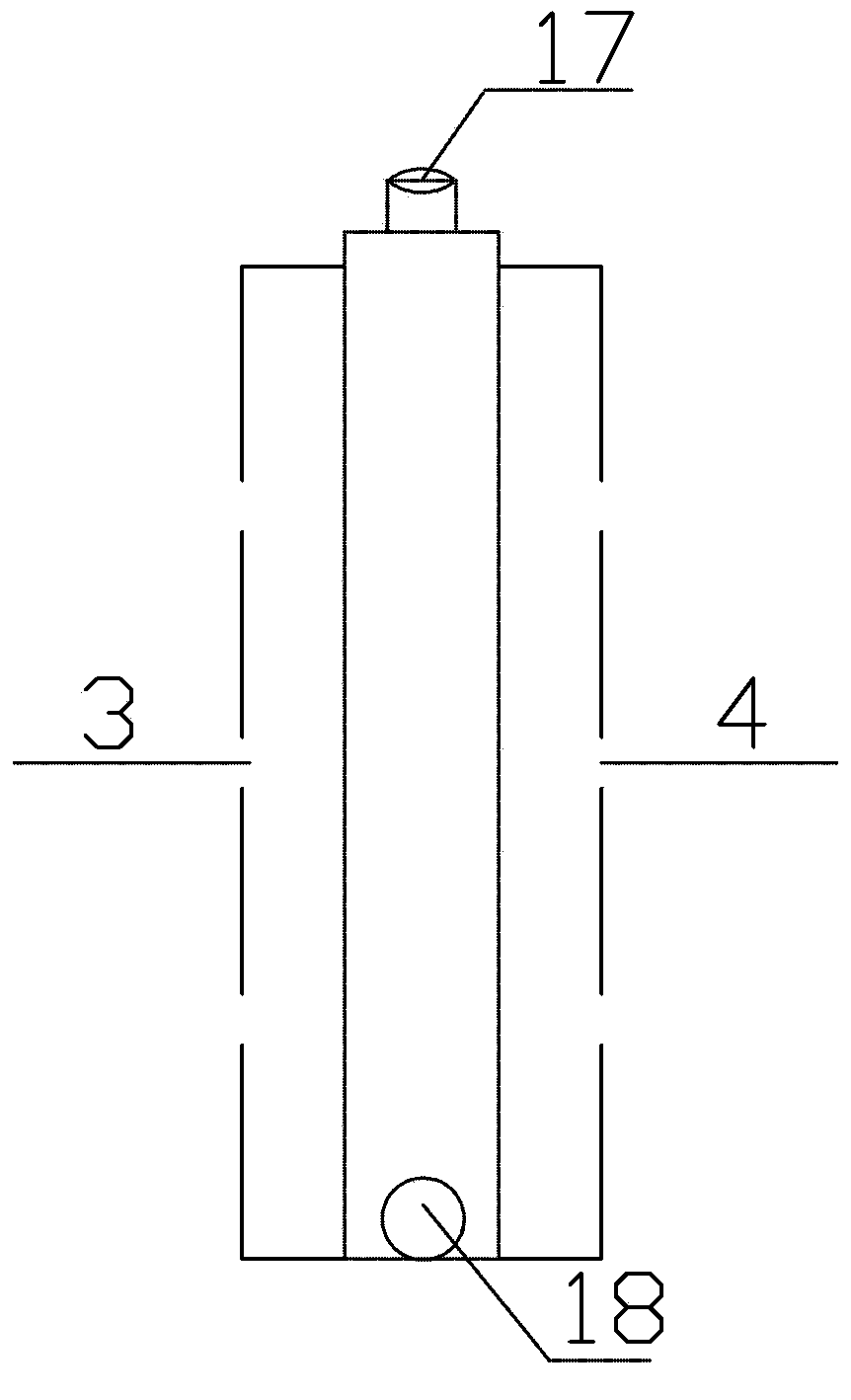

Heat exchanging device based on phase-change heat storage material and packaging method thereof

ActiveCN103925822APrevent burstEnough room for expansionHeat storage plantsHeat exchanger casingsLiquid stateHeat storage material

The invention relates to the technical field of intermittent heating, in particular to a heat exchanging device based on phase-change heat storage material and a packaging method of the heat exchanging device. The purpose is to solve the problem that a shell of the heat exchanging device is expanded and damaged due to volume expansion of the phase-change heat storage material in the phase change process. The device comprises a closed shell used for containing the phase-change heat storage material, and at least one expansion partitioning part used for expansion deformation is arranged in the shell. The packaging method mainly includes the steps that an upper cover face shell body of the shell is opened, and the expansion partitioning part is inserted in the shell and fixed; the upper cover face shell body is sealed after covering, and then a hole plug of a vent hole is pulled out, so that a communication device is formed in the shell partitioned by the expansion partitioning part through a communication hole formed in the expansion partitioning part; a funnel is erected on a feed port, a discharge port is sealed, the phase-change material in a liquid state is injected from the funnel, after the shell is full, the hole plug is plugged, and the feed port is sealed to complete packaging. The heat exchanging device has the advantages of being high in heat storage and conduction efficiency, convenient to package, capable of being used repeatedly, long in service life and the like.

Owner:HARBIN INST OF TECH

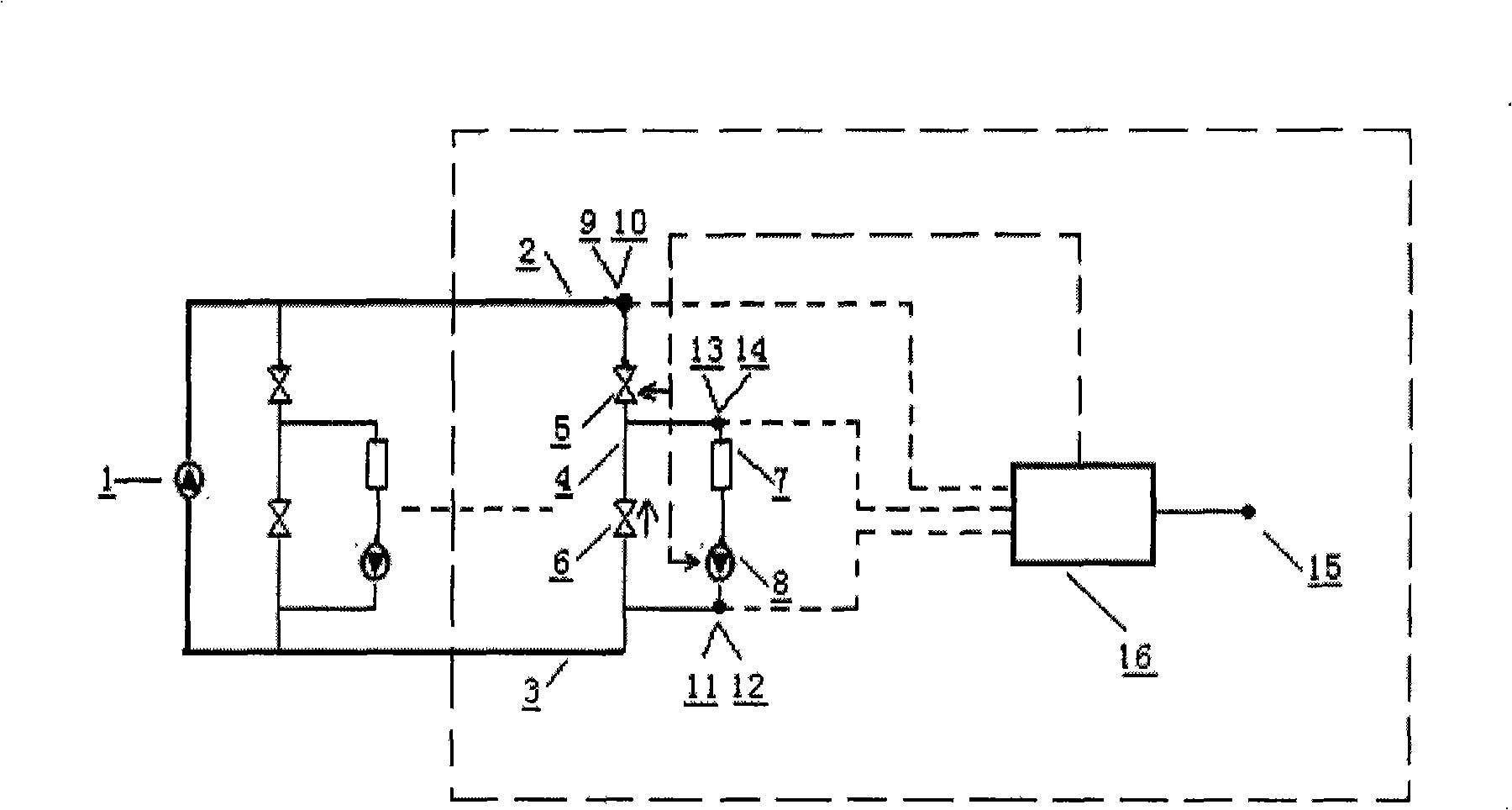

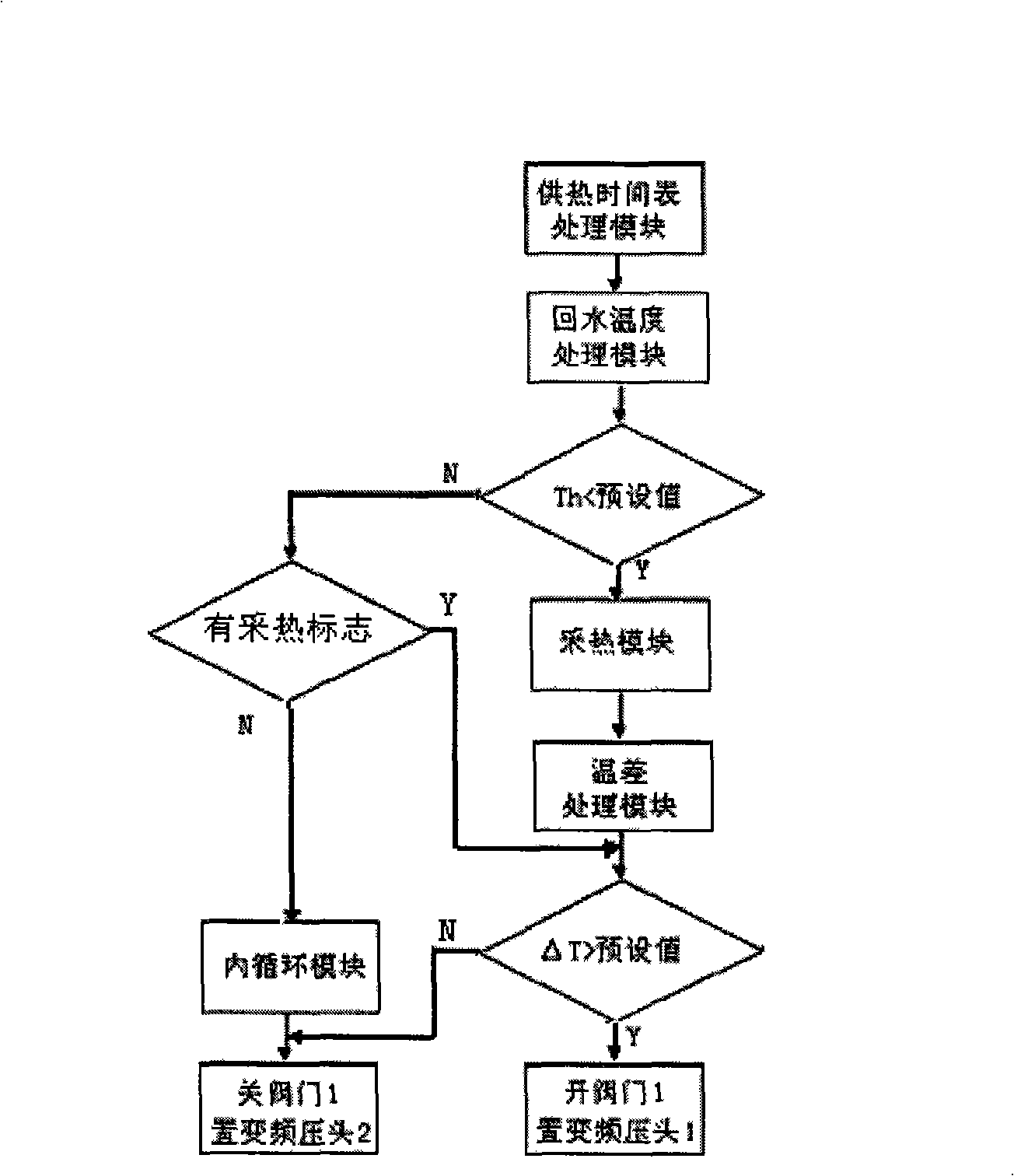

Distributed type intermittent thermal production control system

InactiveCN101334191AEliminate or reduce excess capital headReduce transmission and distribution energy consumptionLighting and heating apparatusSpace heating and ventilation detailsTraffic capacityMix network

The invention relates to a distributed-type intermittent heating controlling system, which belongs to the field of the building heat supplying system controlling technology. The heating controlling system aims to solve the energy wasting problems universally existing in the heat supplying operation in the northern cities that the Working Pressure Head is Redundant, the Temperature Difference is Small and the Flow is Large and the prior situation that the energy conservation force application point with enforcing actions is lack in the mixing network with different heat requirements. The purpose that the heat source intermittent heating and the continuous cycling heat supplying to the heat user according to the requirements are combined is realized through the distributed-type transportation and distribution controlling design, thereby the temperature difference of the supply and return water is enlarged, the flow of the systematic pipe network is reduced, the redundant working pressure head is decreased or eliminated, the different heat requirements of the heat user group at the different time interval is satisfied, and paving the way for adopting the measurement method according to the individual household. The enormous energy-saving space under the prior operation condition is converted into the distinct energy-saving reality through supplying the concrete force application point. The distributed-type intermittent heating controlling system has the advantages that the energy conservation effect is obvious, the heat supplying security is good, the adjustability is strong, and the heat controlling system is suitable for the new-building system and the reconstruction of the old system.

Owner:DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com