Steering arm shaft induction heating tempering technology

A technology of induction heating and technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve problems such as thread breakage, quenching cracks, delayed cracks, etc., and achieve the effects of high production efficiency, simple structure and short process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

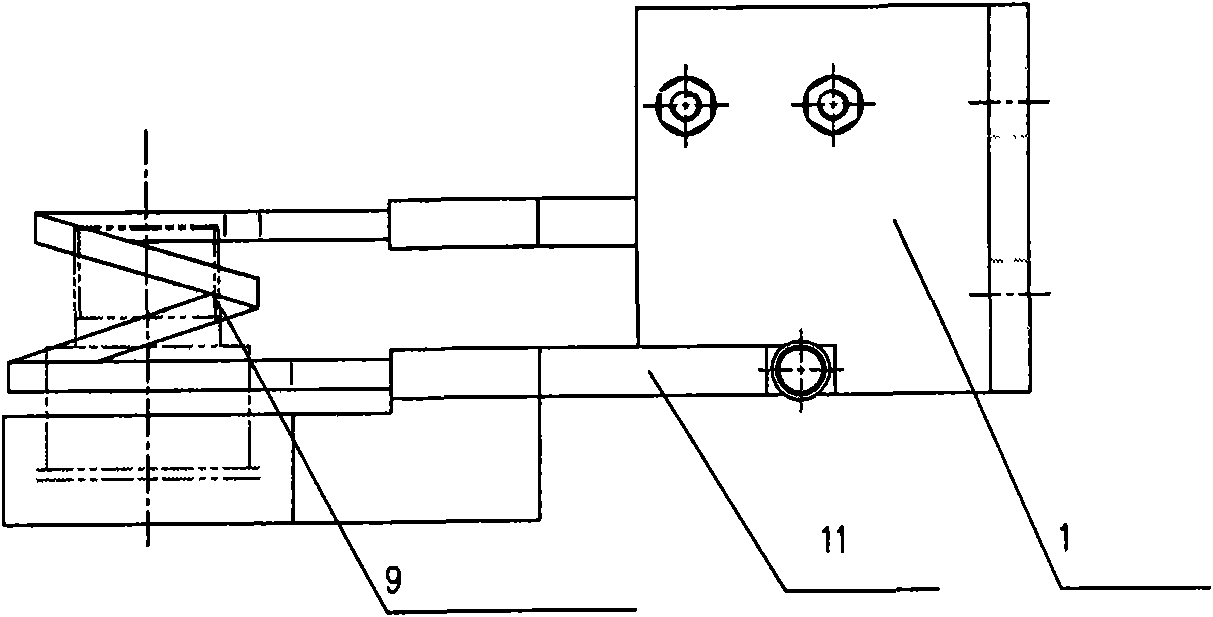

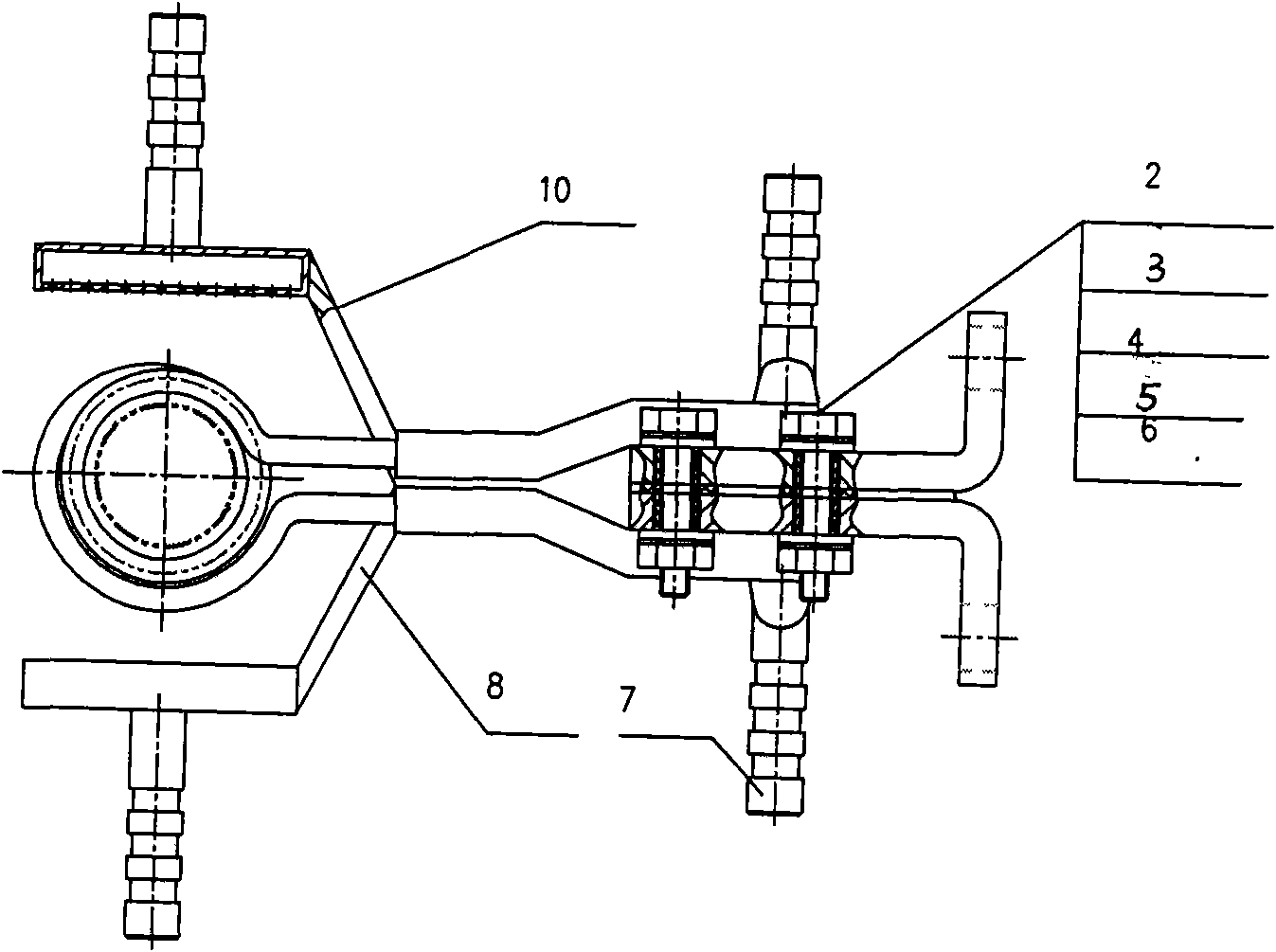

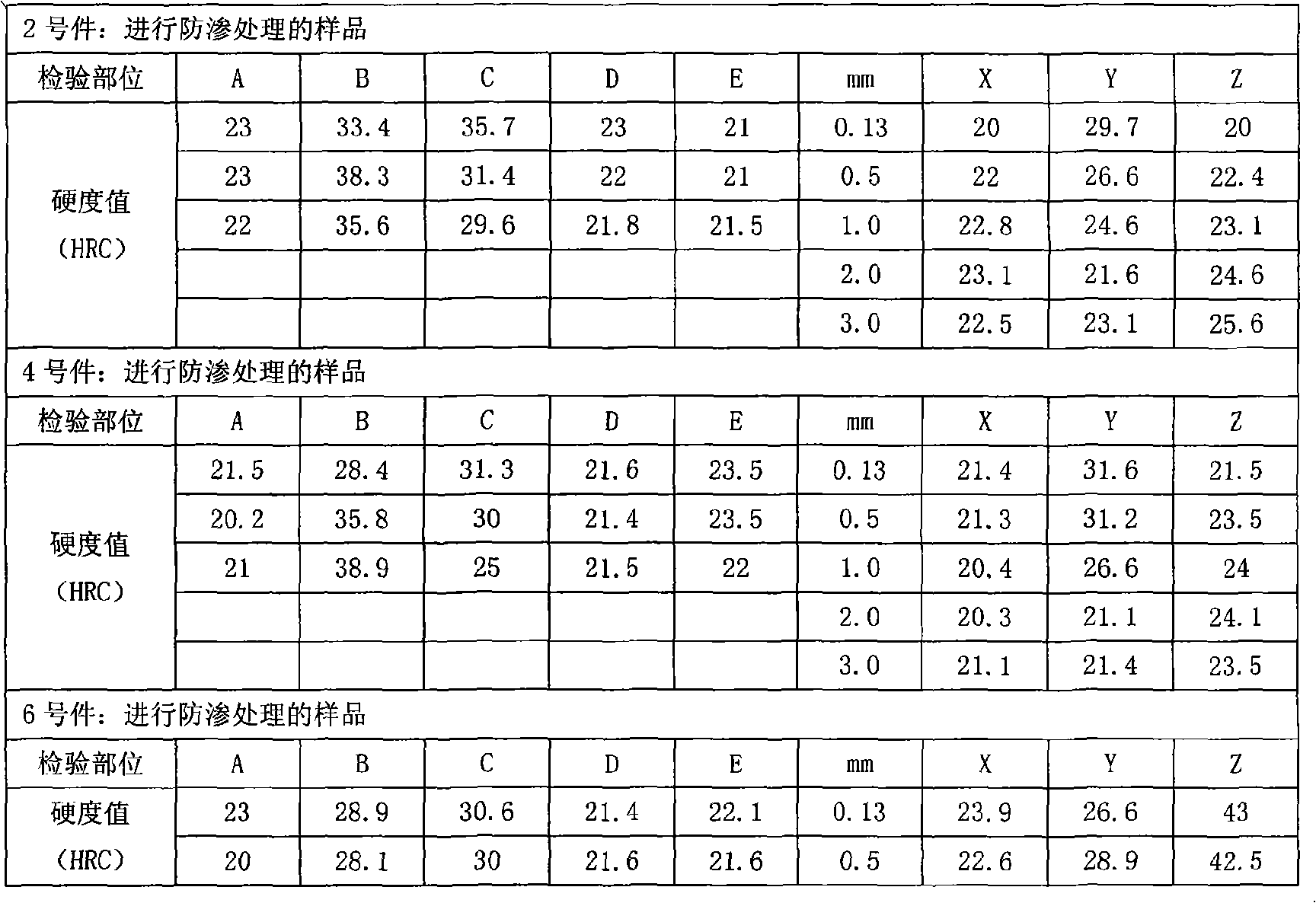

[0017] Below in conjunction with accompanying drawing, the present invention is further described: a kind of steering arm shaft induction heating tempering technology, it is characterized in that: its technological process is as follows: (A) the contact plate 1 of inductor is fastened on the quenching transformer of quenching lathe together; under the condition that the cooling water and quenching water channel are guaranteed to be unobstructed, put the threaded end to be tempered upwards and clamp it between the upper and lower centers of the quenching machine tool; (B) press the start button, the workpiece starts to rotate, and the sensor quickly Descend to the position where the part needs to be heated and start heating. At this time, the alternating current passes through the two plates of the quenching transformer and the inductor to form a circulating current. The frequency of the induction heating power supply is 8-35kHz, and a magnetic field is generated near the effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com