Patents

Literature

999 results about "Circulating current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Circulating current flows in the loop shown above in such a manner that it discharges the power source having the greater voltage and charges the voltage source having the smaller voltage till the voltage level of the two sources becomes equal, at which point the circulating current stops flowing.

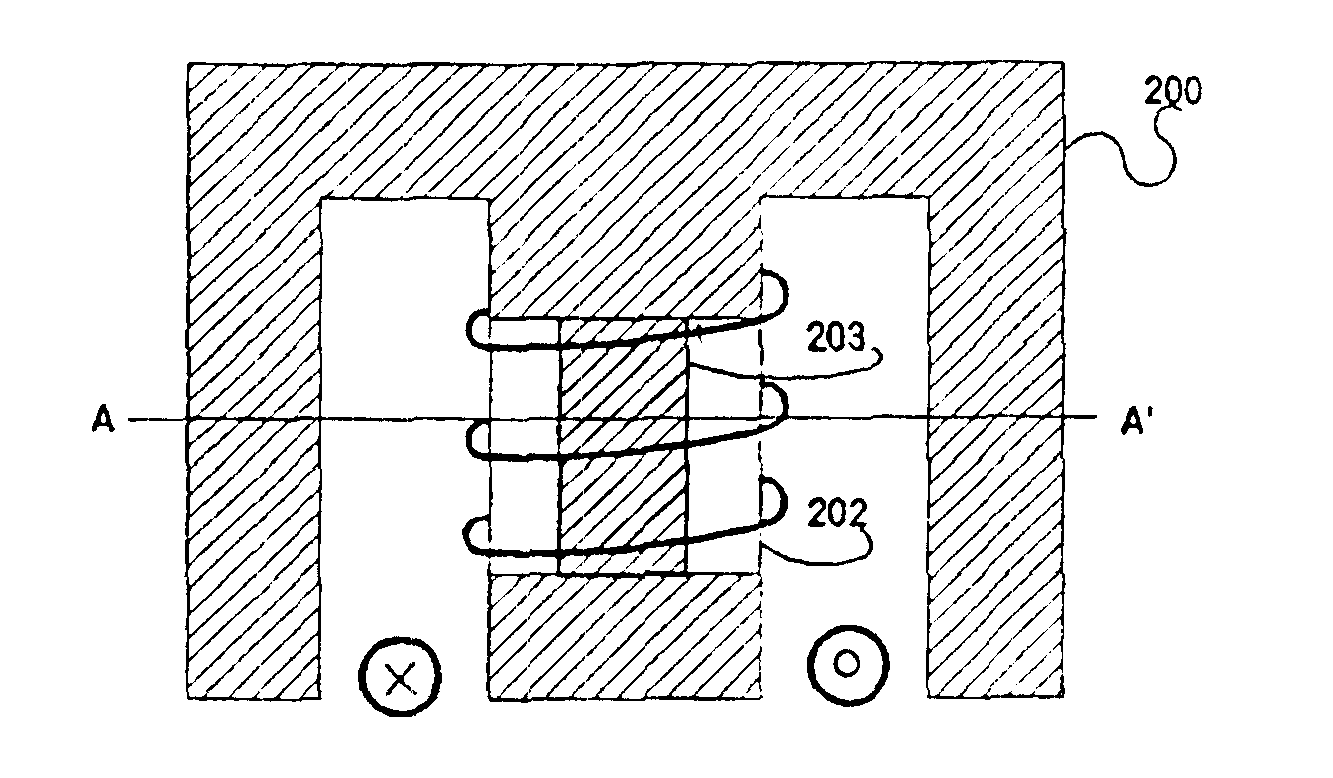

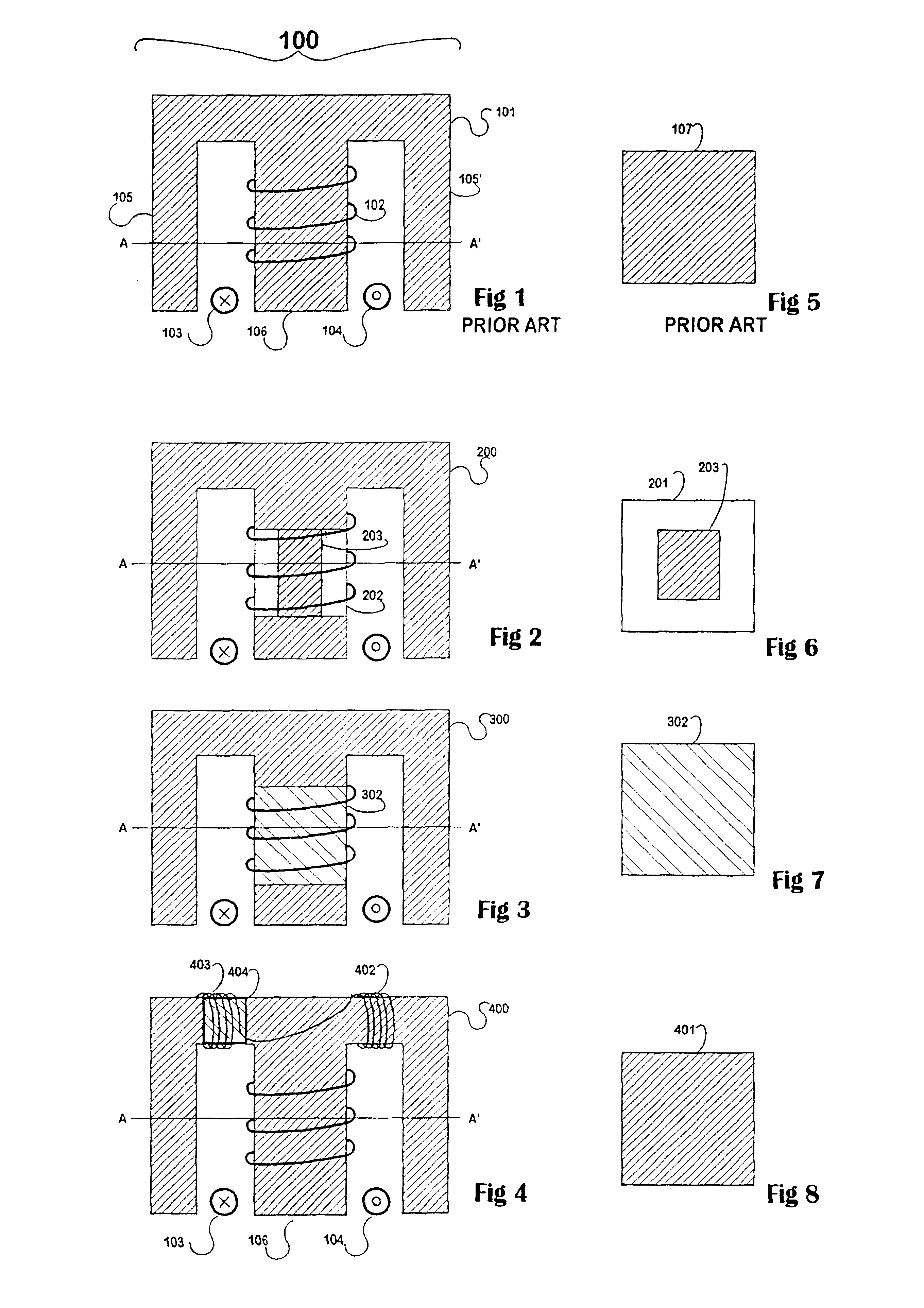

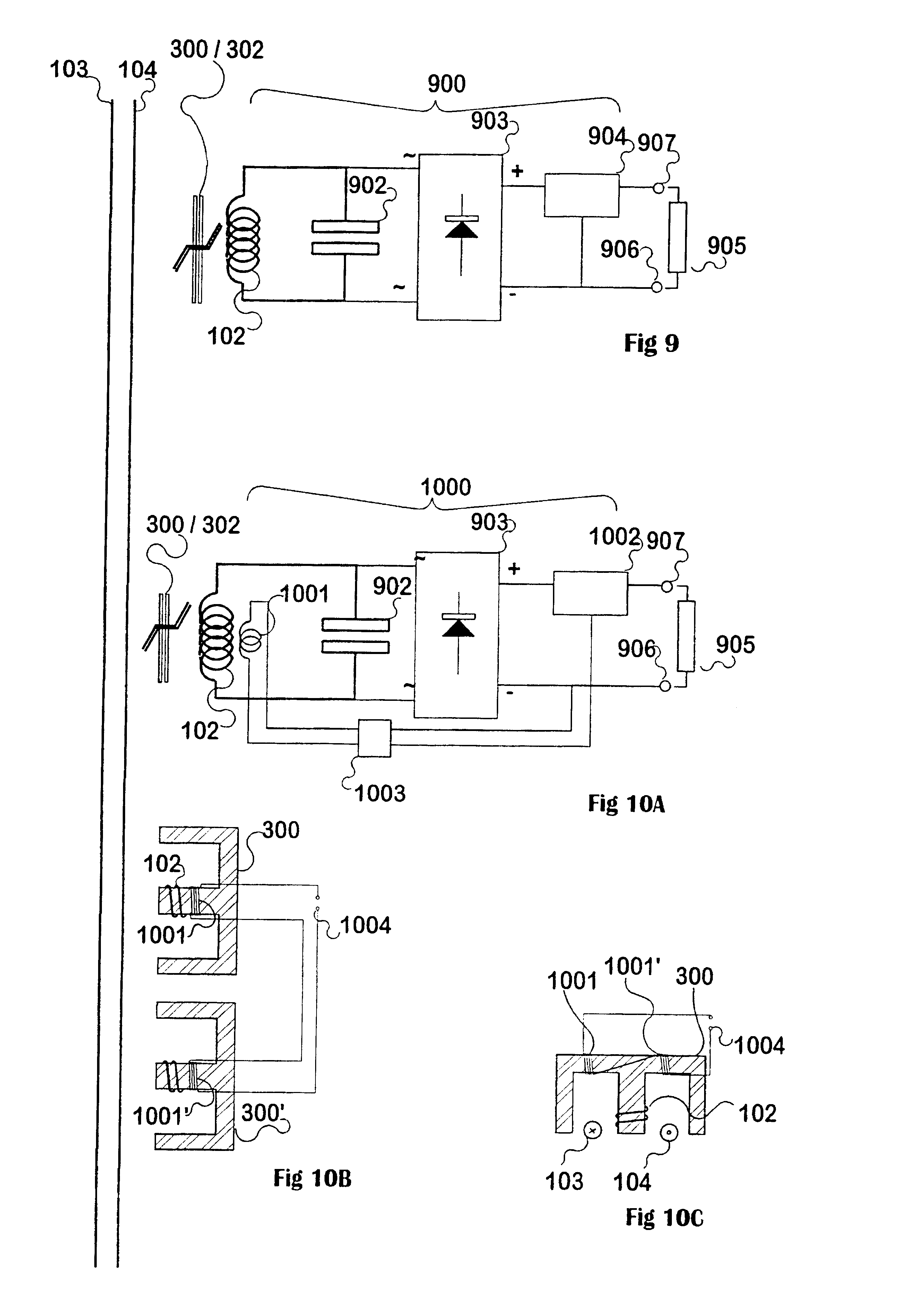

Control of inductive power transfer pickups

InactiveUS6483202B1Reliable fail-safe control featureDecrease in saturation capacityRail devicesElectromagnetic wave systemDc currentEngineering

Secondary resonant pickup coils (102) used in loosely coupled inductive power transfer systems, with resonating capacitors (902) have high Q and could support large circulating currents which may destroy components. A current limit or "safety valve" uses an inductor designed to enter saturation at predetermined resonating currents somewhat above normal working levels. Saturation is immediate and passive. The constant-current characteristic of a loosely coupled, controlled pickup means that if the saturable section is shared by coupling flux and by leakage flux, then on saturation the current source is terminated in the saturated inductor, and little detuning from resonance occurs. Alternatively an external saturable inductor (1101, 1102) may be introduced within the resonant circuit (102 and 902), to detune the circuit away from the system frequency. Alternatively DC current may be passed through a winding to increase saturation of a saturable part of a core. As a result, a fail-safe pickup offering a voltage-limited constant-current output is provided.

Owner:AUCKLAND UNISERVICES LTD

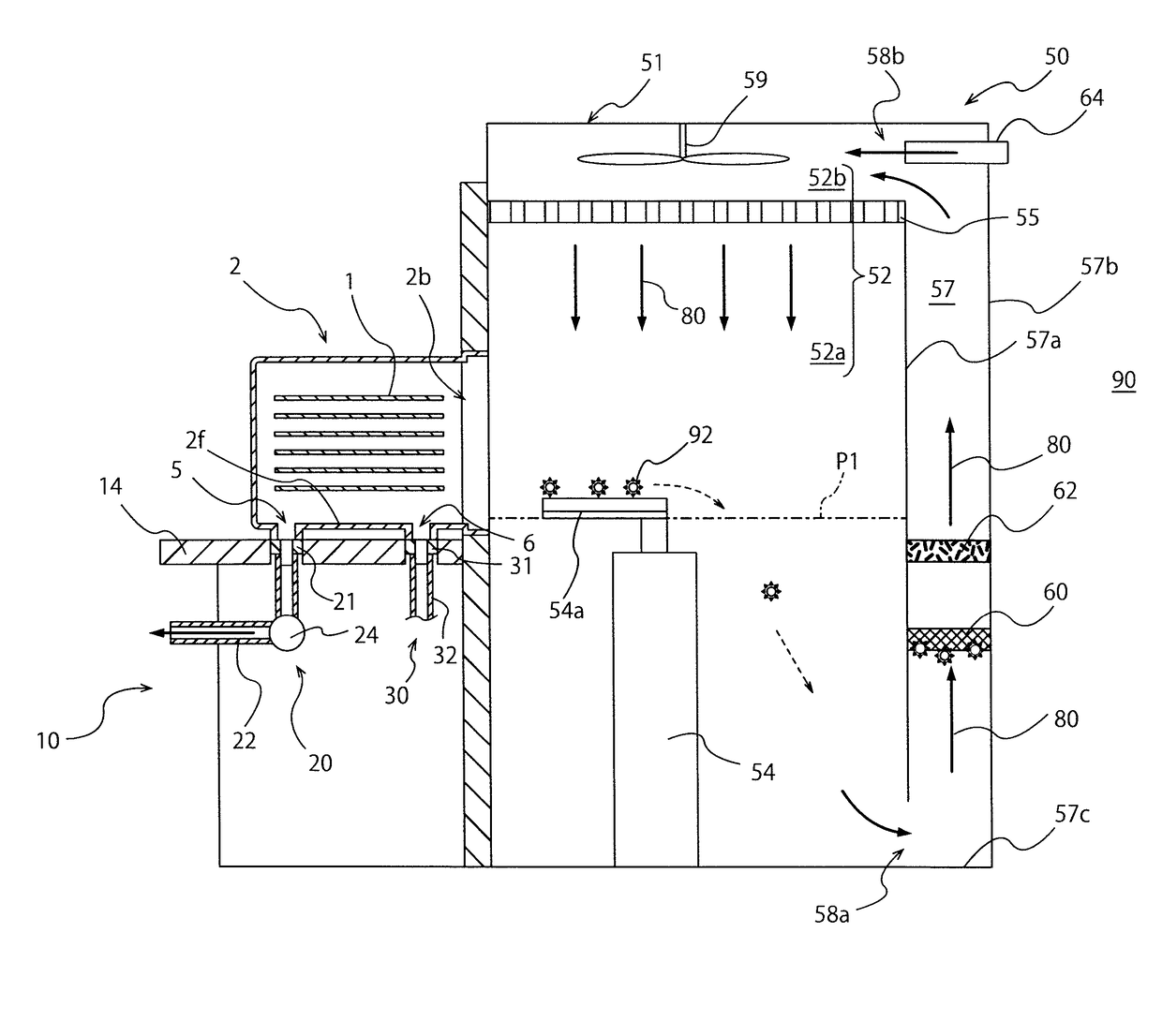

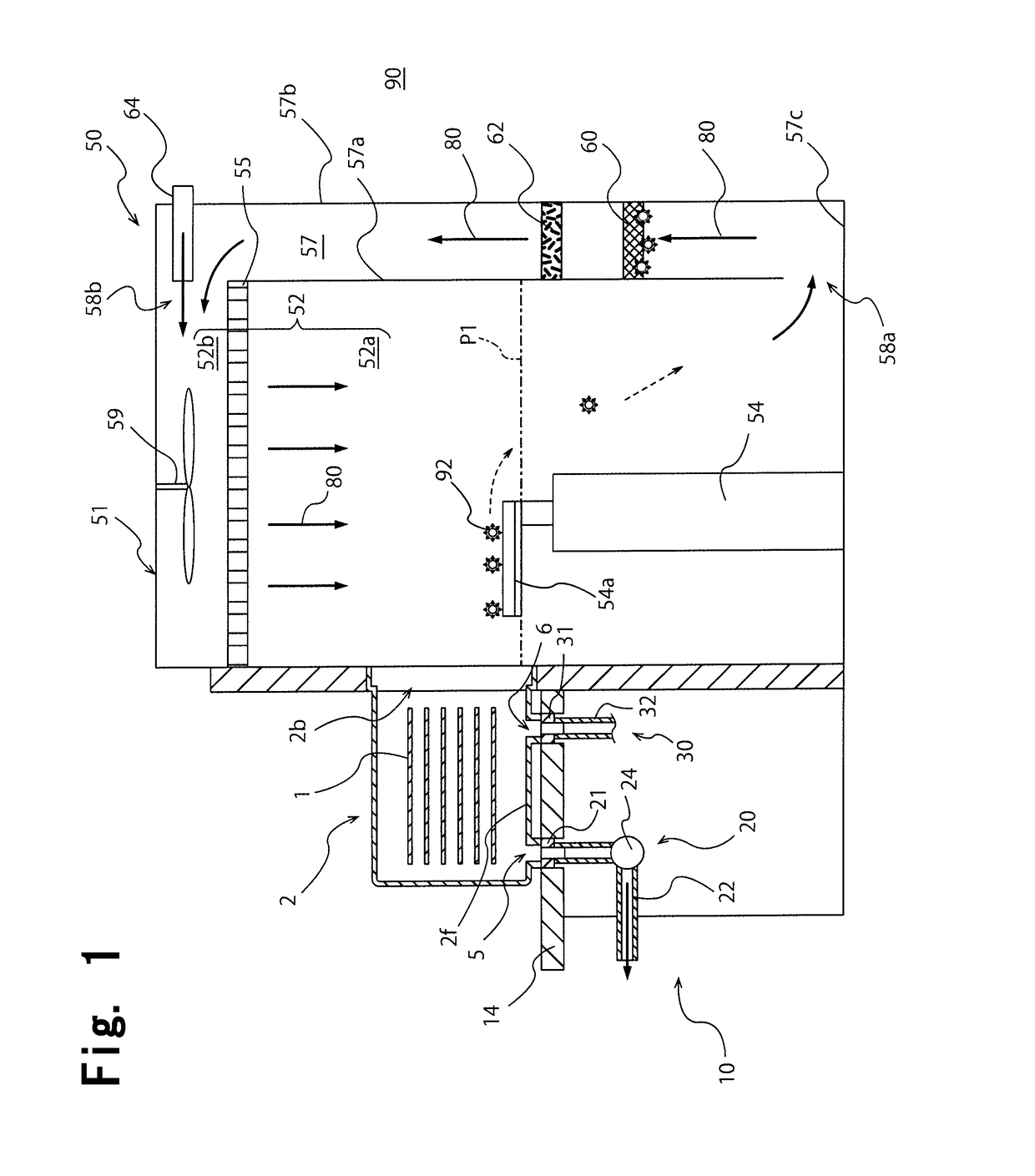

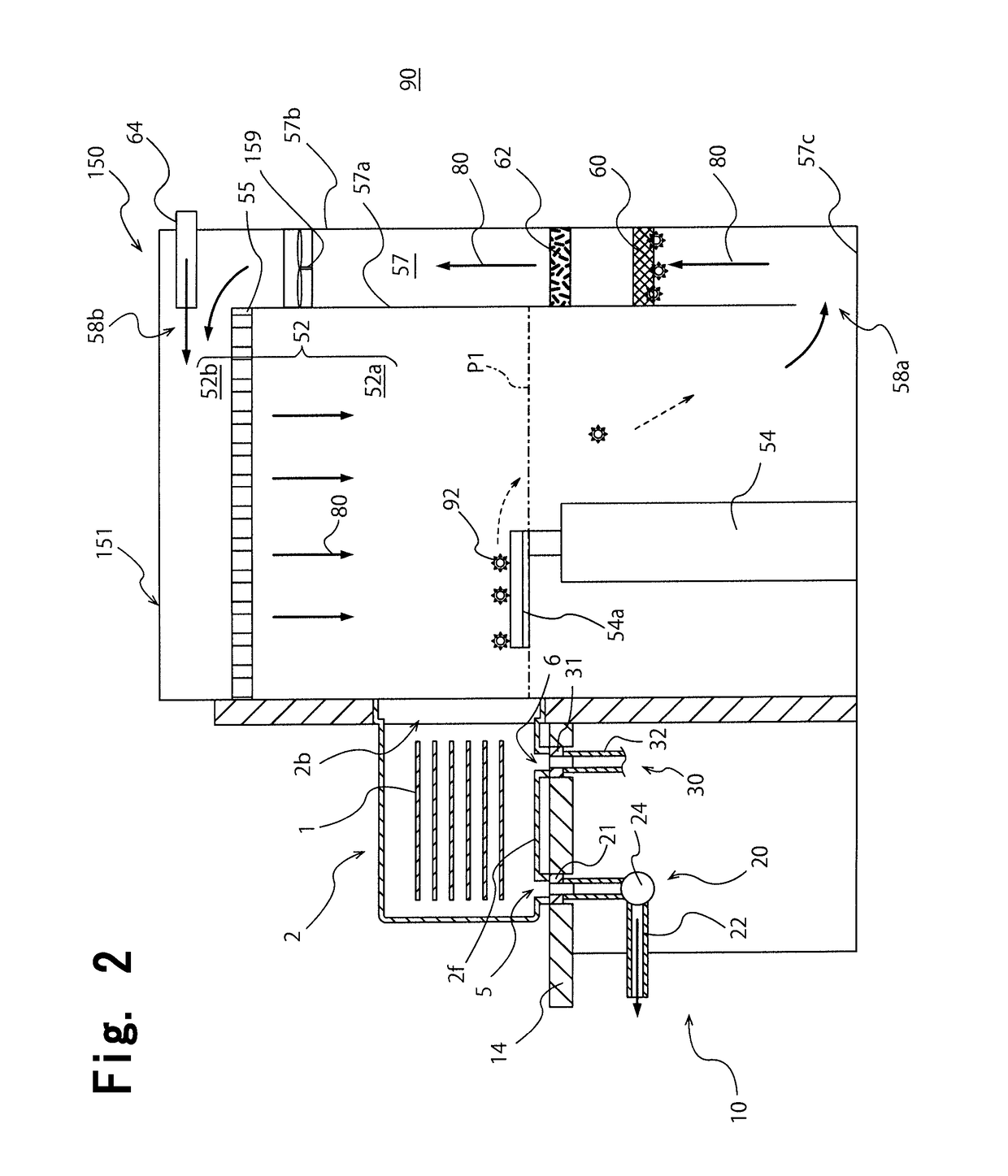

Mini-environment apparatus

ActiveUS20170170033A1Keep the environment cleanEasy to replaceMechanical apparatusLighting and heating apparatusCirculating currentTransport engineering

A mini-environment apparatus includes a wafer transportation machine transporting a wafer, a wafer transportation room having the machine and passed by the wafer transported to a processing room, a circulating passage where a gas detoured from the transportation room flows, a blowing means forming a circulating current falling in the transportation room and rising in the passage, a current member arranged in a ceiling part of the transportation room and laminarizing the current and introducing this laminarized current into the transportation room, a particle removal filter arranged in either the ceiling part of the transportation room or the passage, and a chemical filter arranged in the passage detachably and separately from the removal filter. The chemical filter is arranged at a position lower than a lowest position where the wafer may pass through in the transportation room.

Owner:TDK CORPARATION

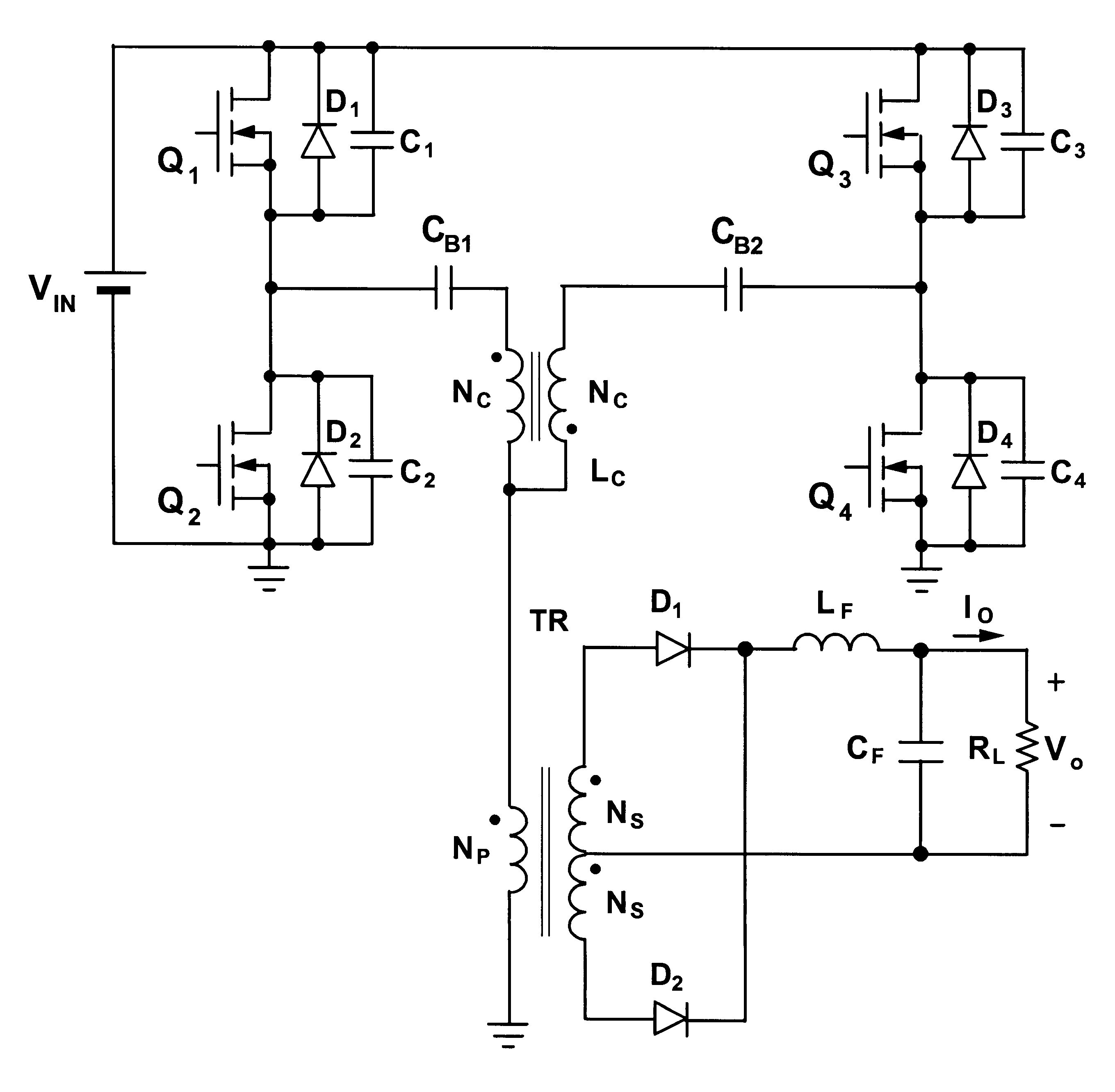

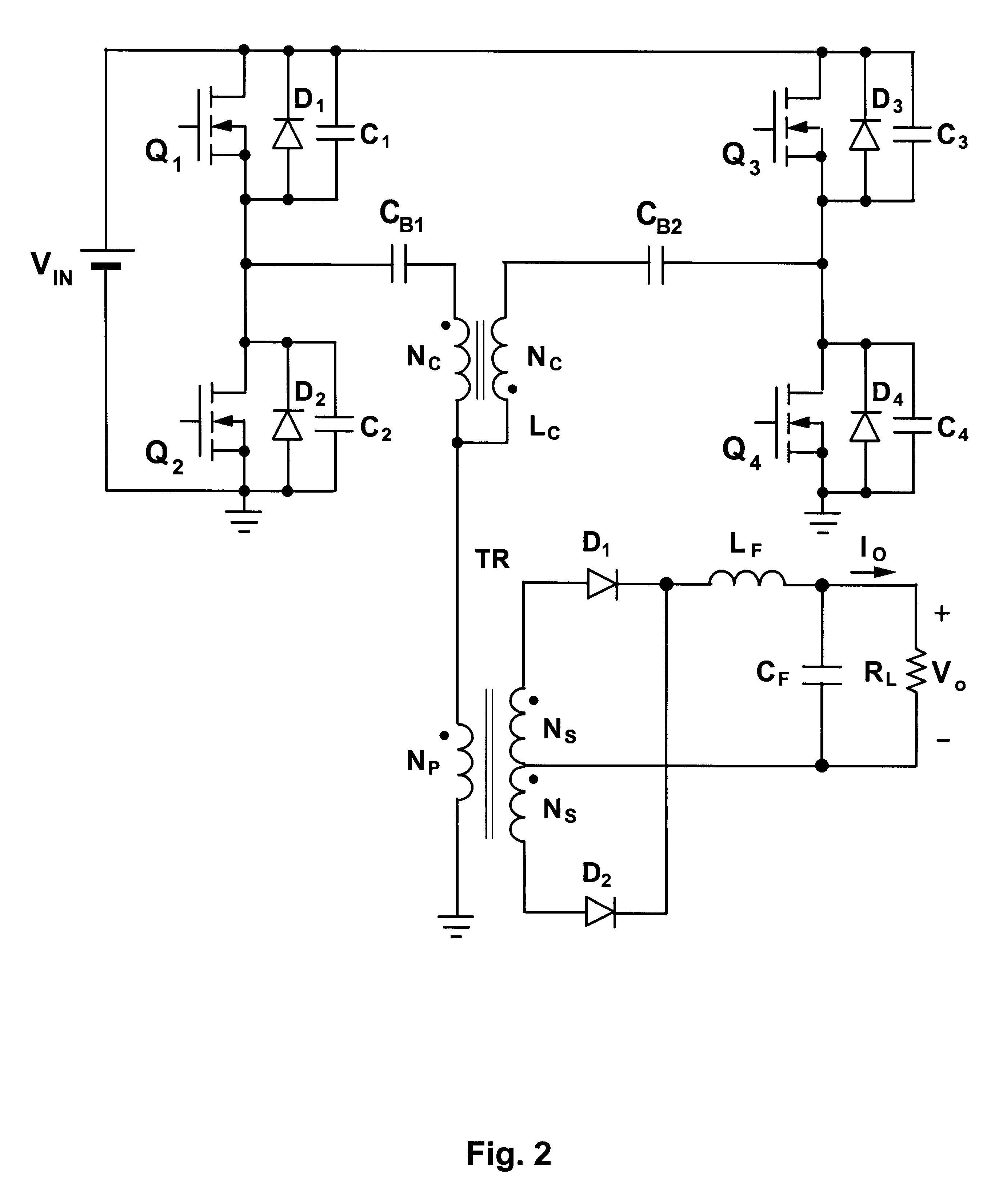

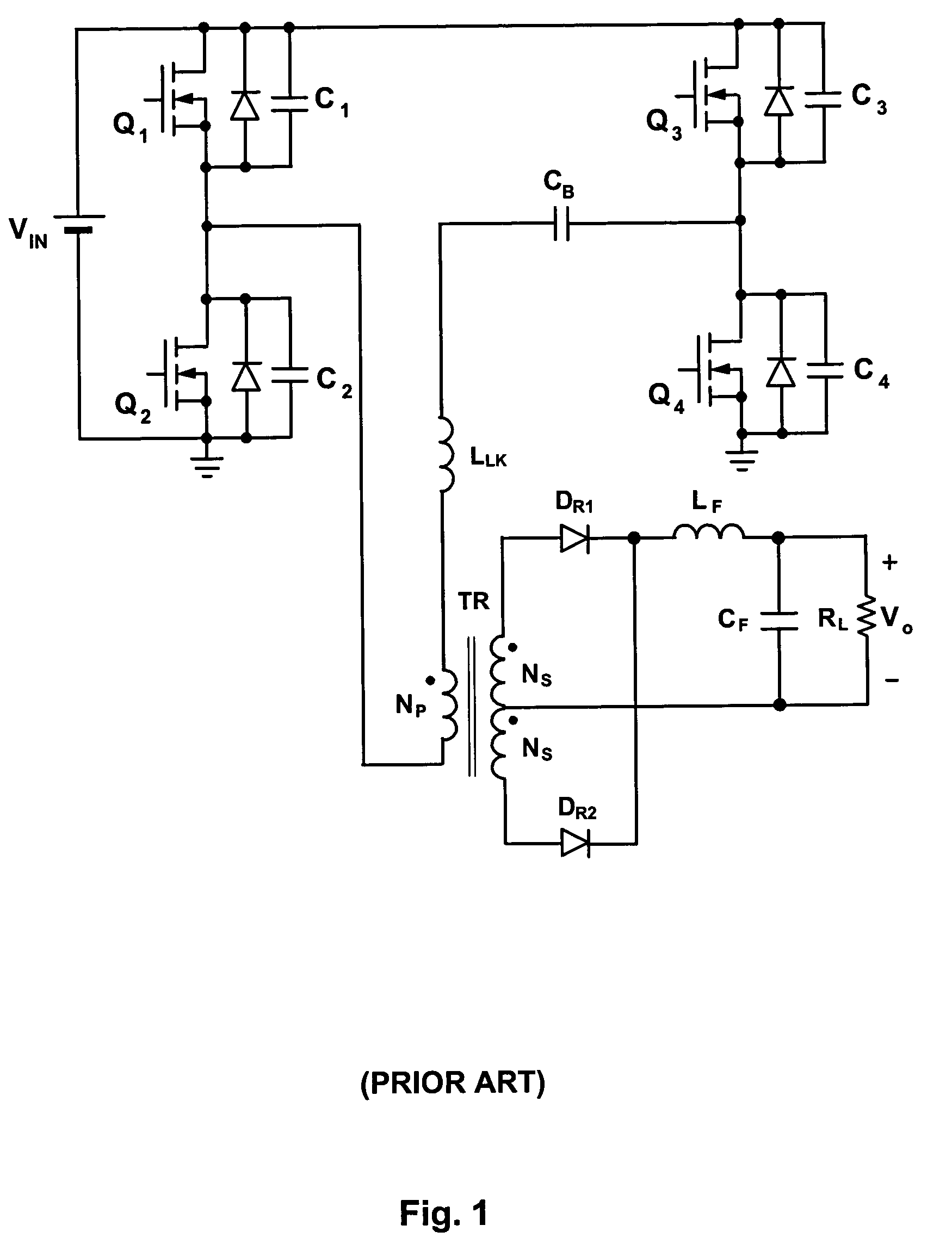

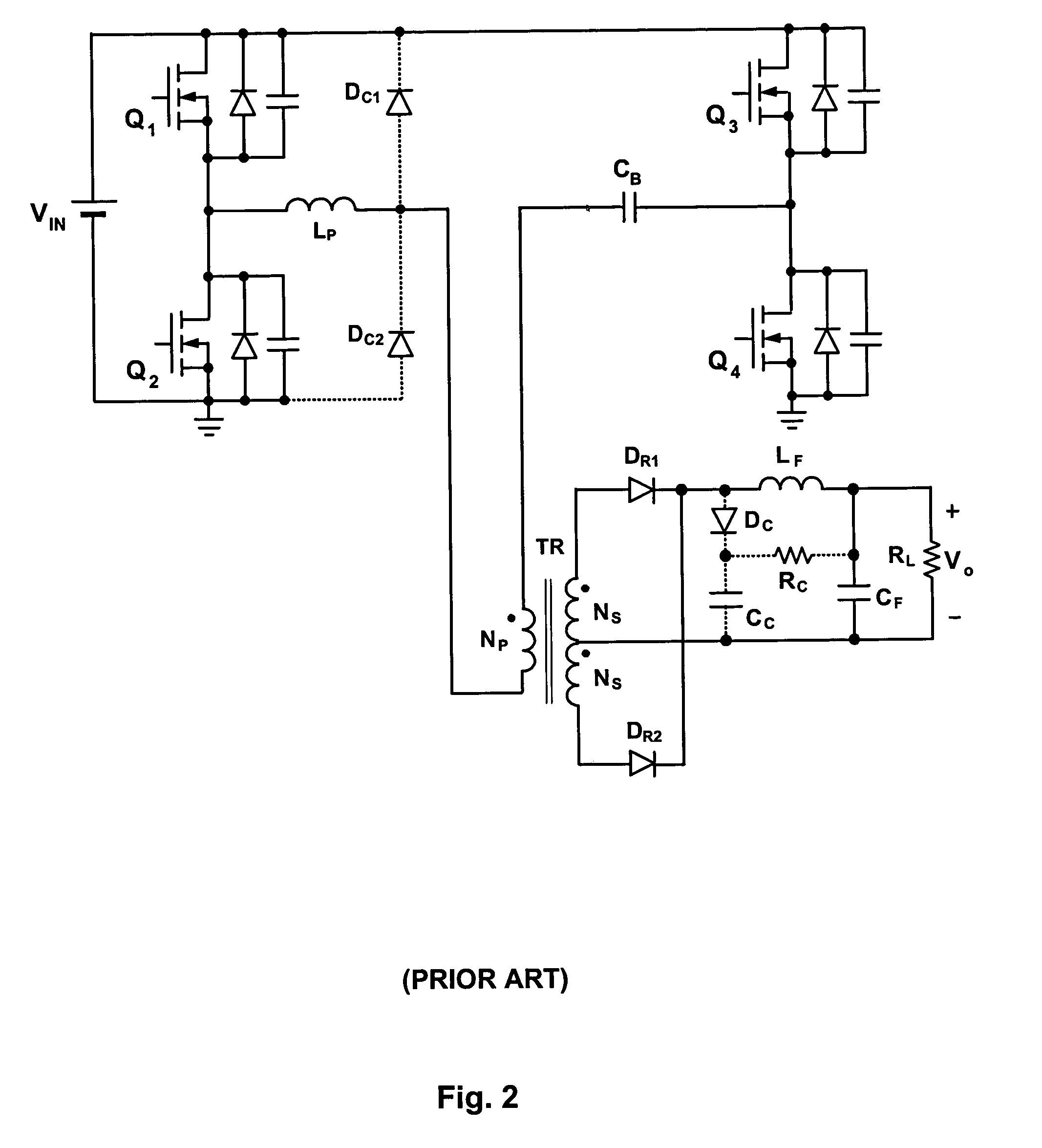

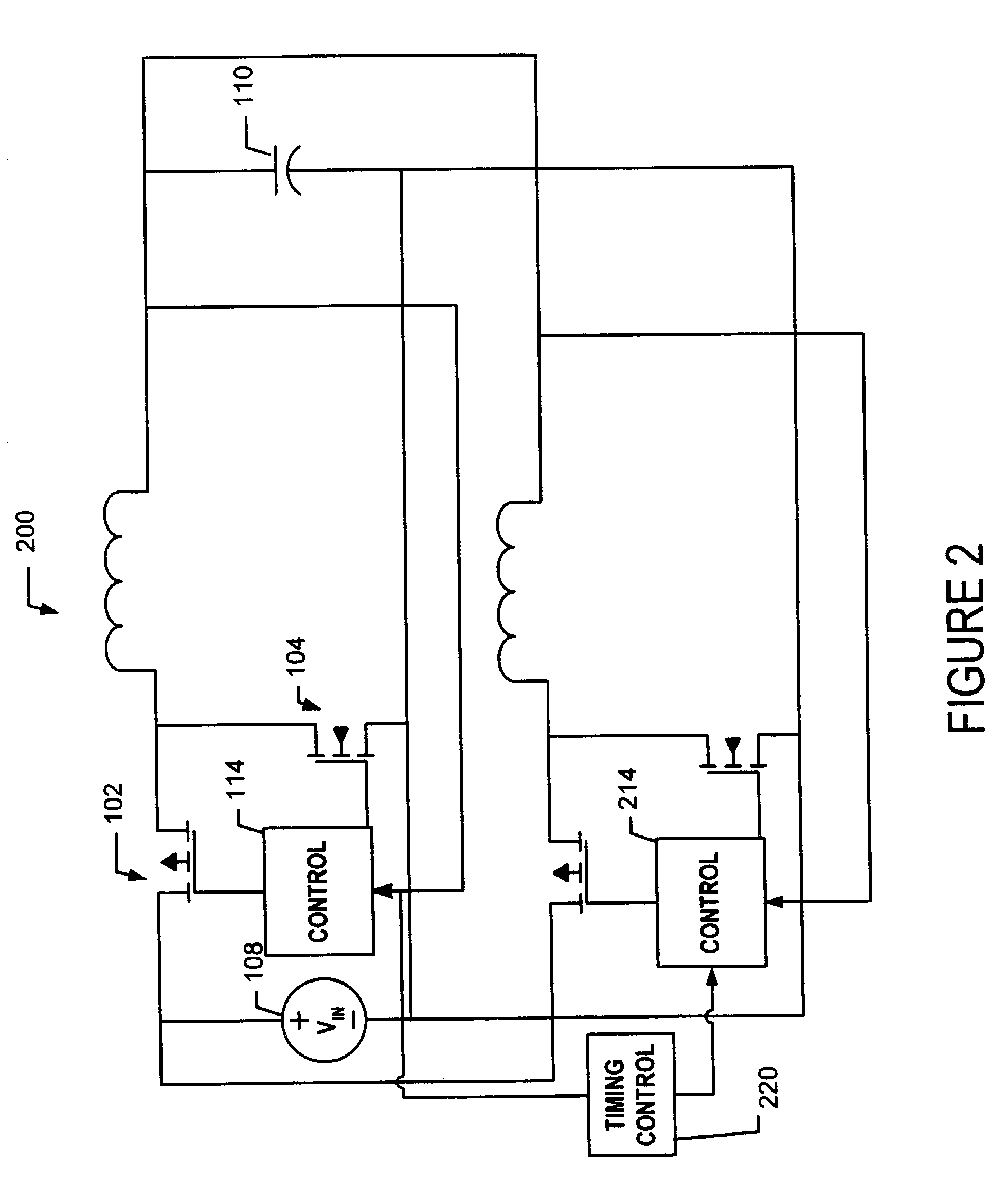

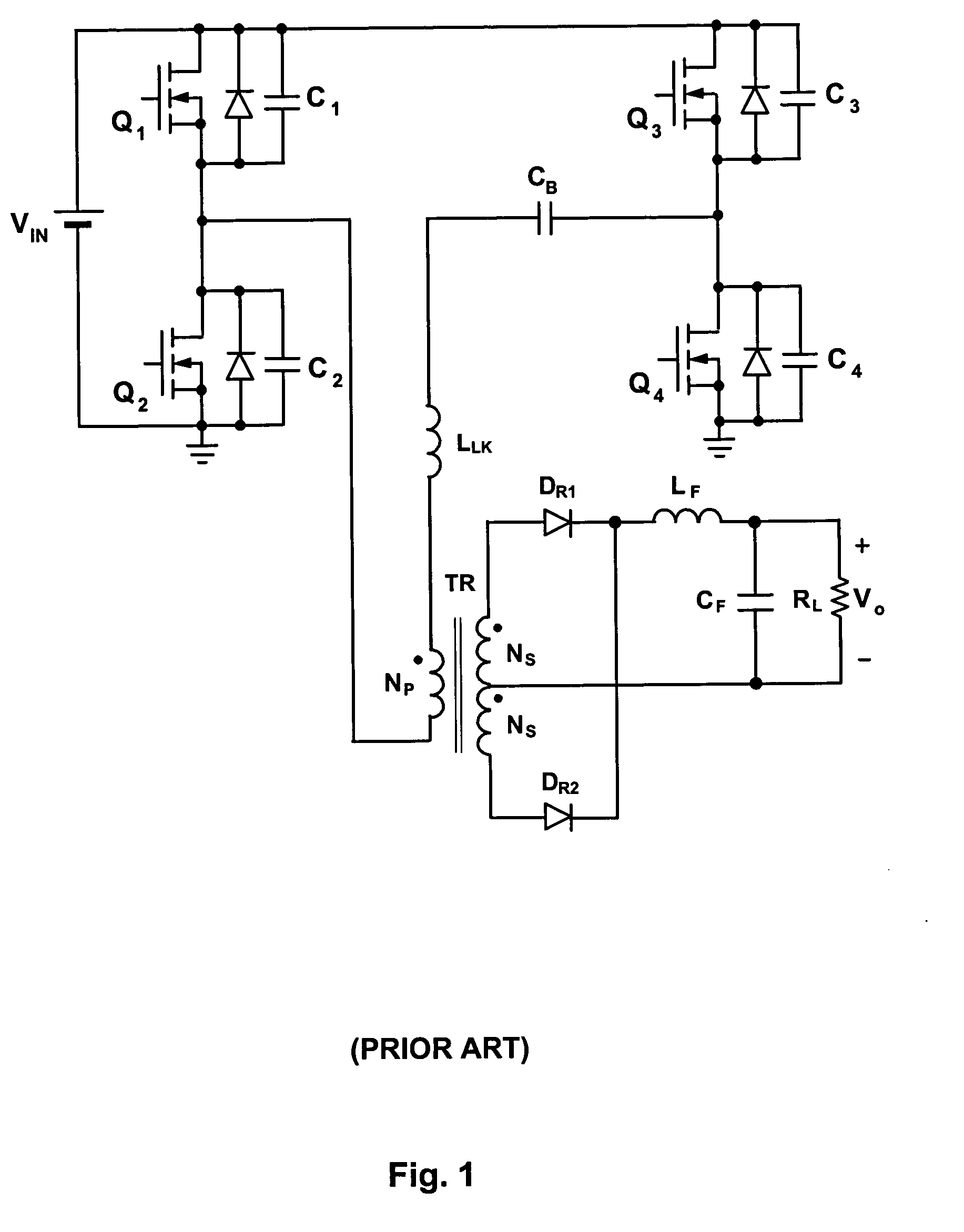

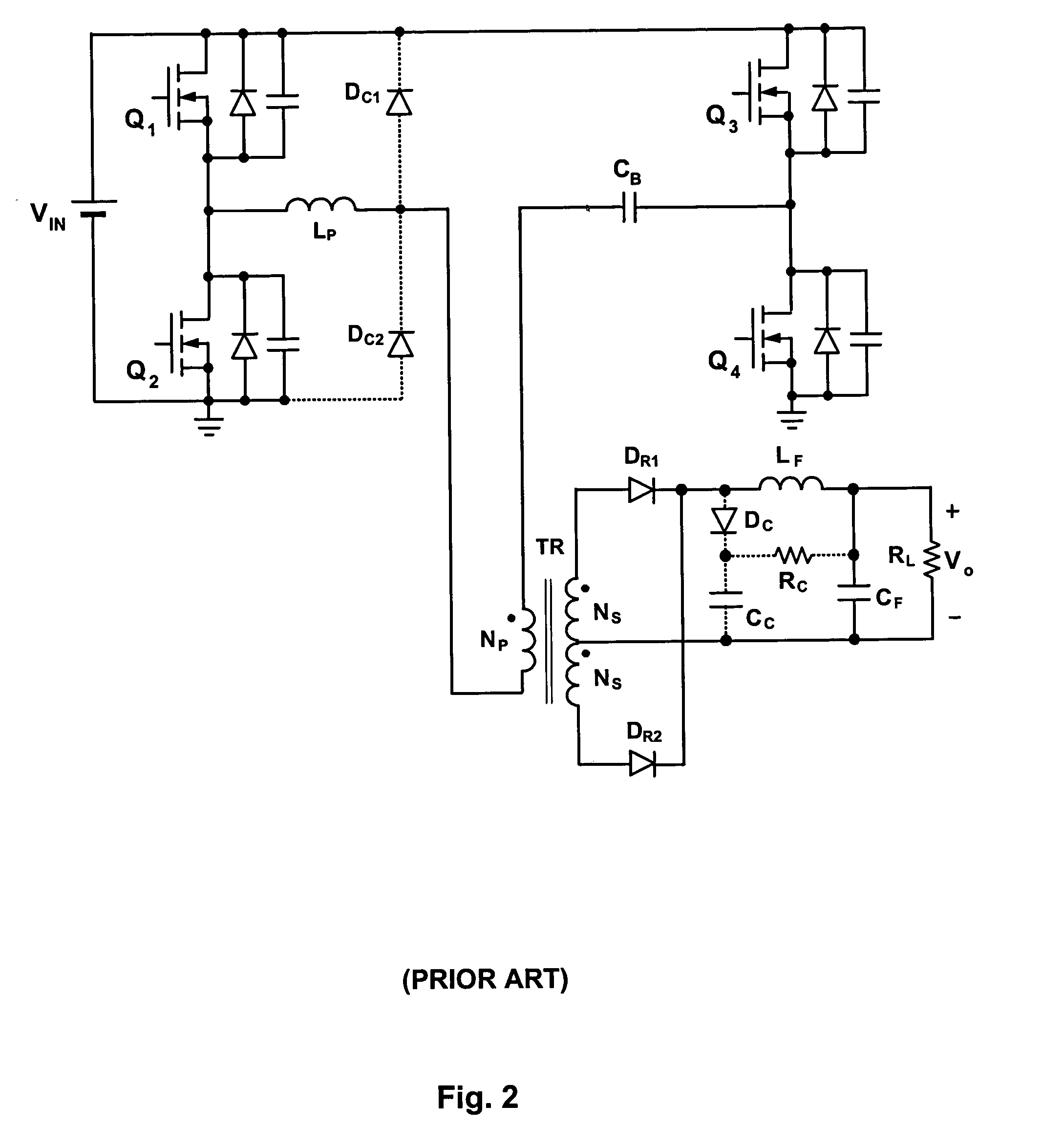

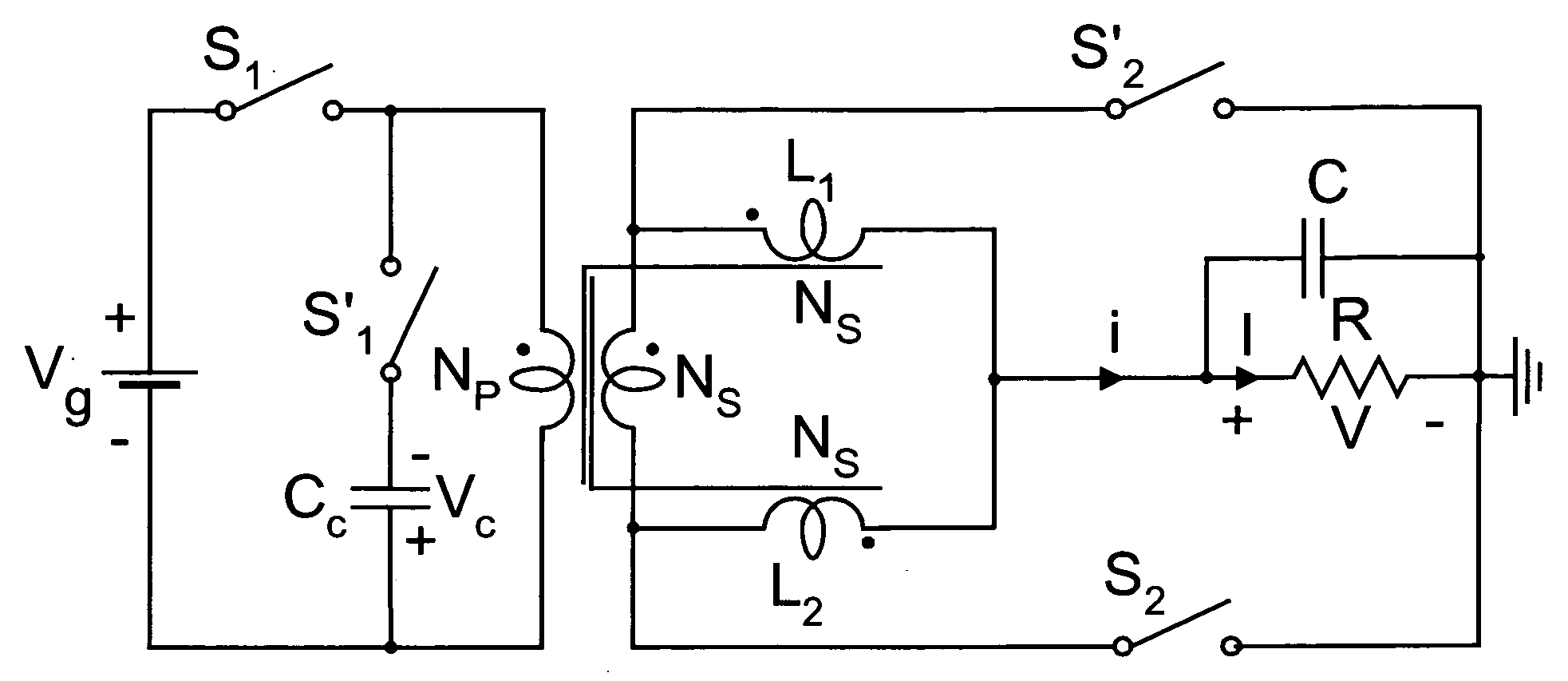

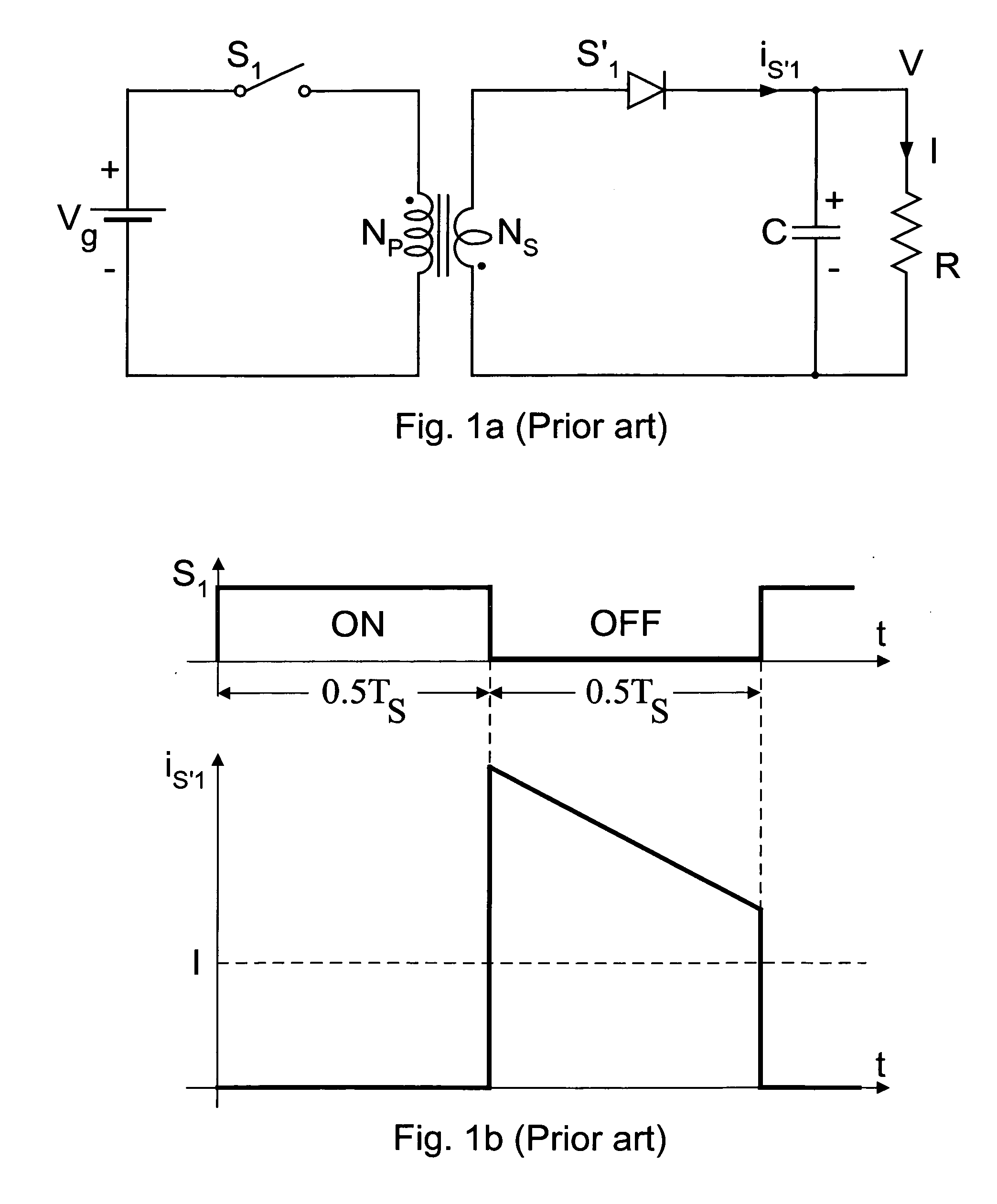

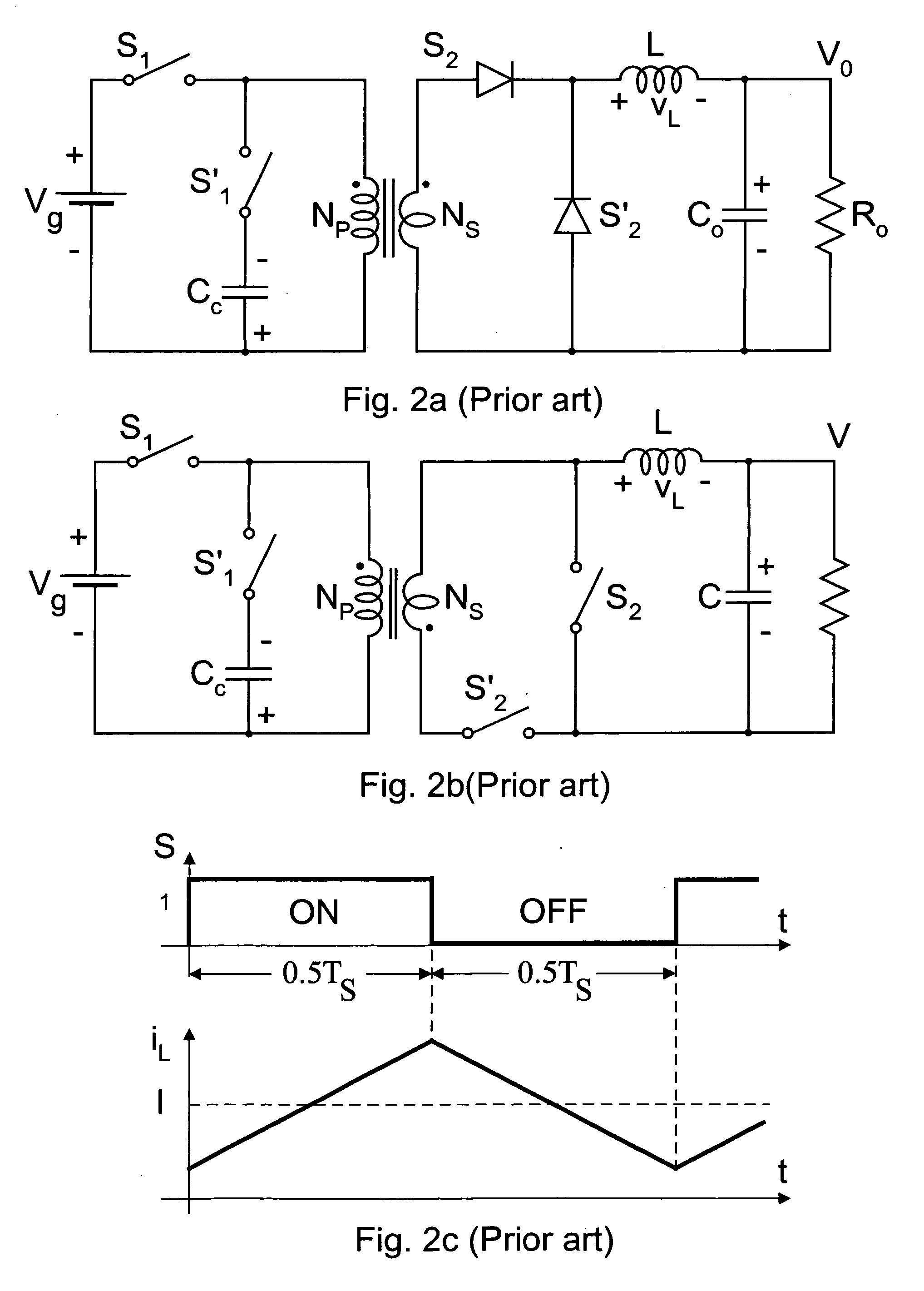

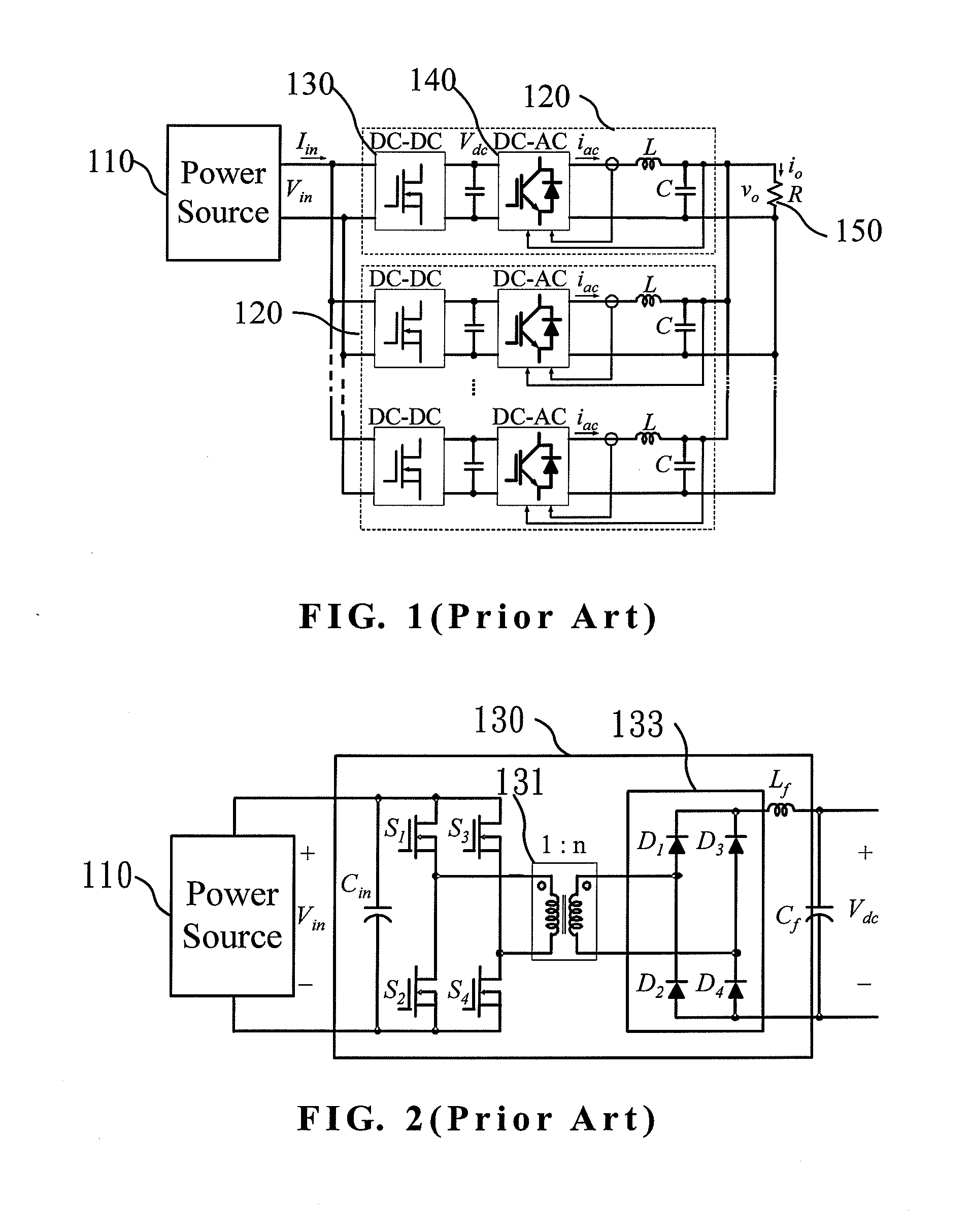

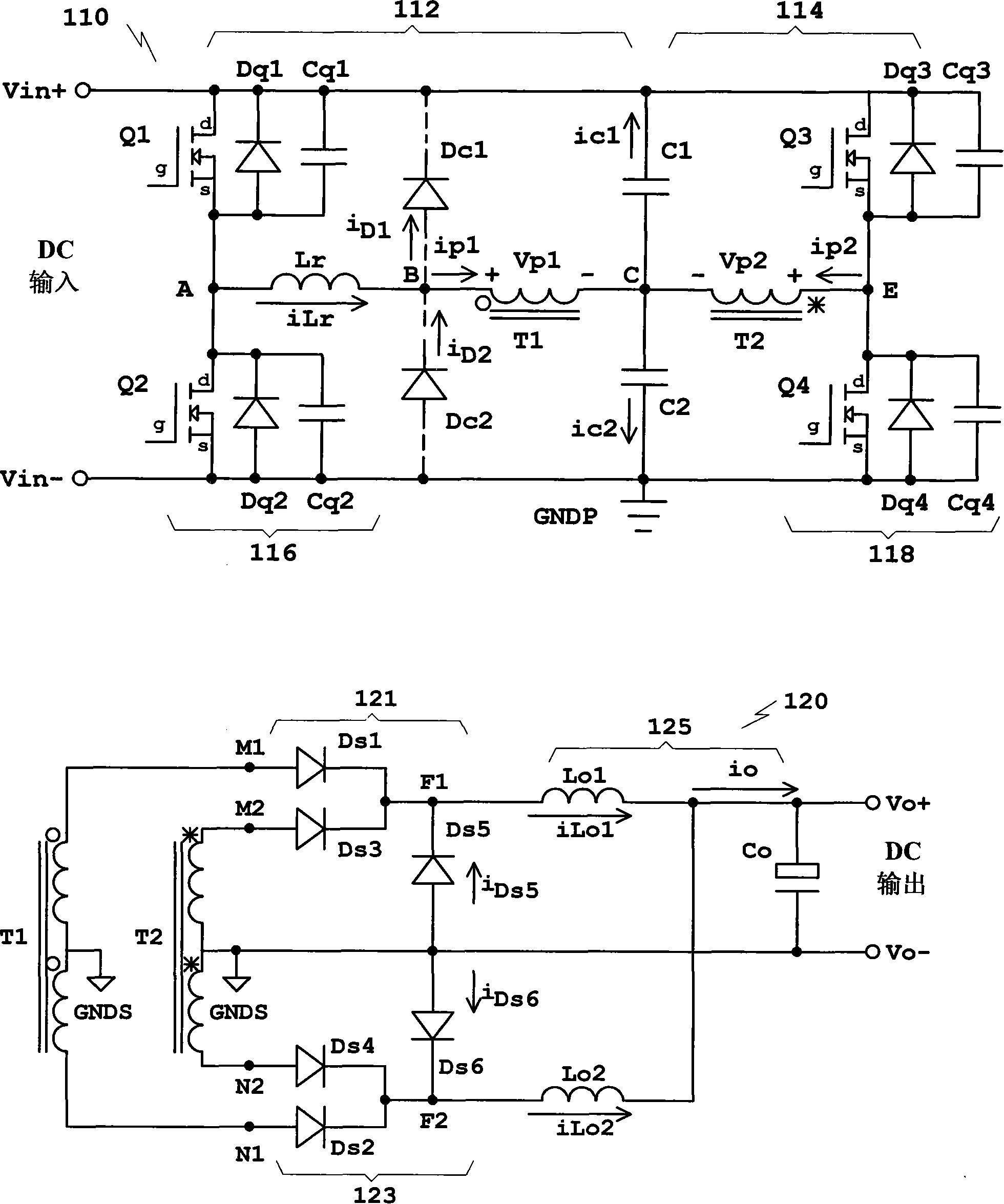

Soft-switched full-bridge converters

InactiveUS6356462B1Minimizes the duty-cycle lossImprove conversion efficiencyEfficient power electronics conversionDc-dc conversionFull bridgeCirculating current

A family of soft-switched, full-bridge pulse-width-modulated (FB PWM) converters provides zero-voltage-switching (ZVS) conditions for the turn-on of the bridge switches over a wide range of input voltage and output load. The FB PWM converters of this family achieve ZVS with the minimum duty cycle loss and circulating current, which optimizes the conversion efficiency. The ZVS of the primary switches is achieved by employing two magnetic components whose volt-second products change in the opposite directions with a change in phase shift between the two bridge legs. One magnetic component always operates as a transformer, where the other magnetic component can either be a coupled inductor, or uncoupled (single-winding) inductor. The transformer is used to provide isolated output(s), whereas the inductor is used to store the energy for ZVS.

Owner:DELTA ELECTRONICS INC

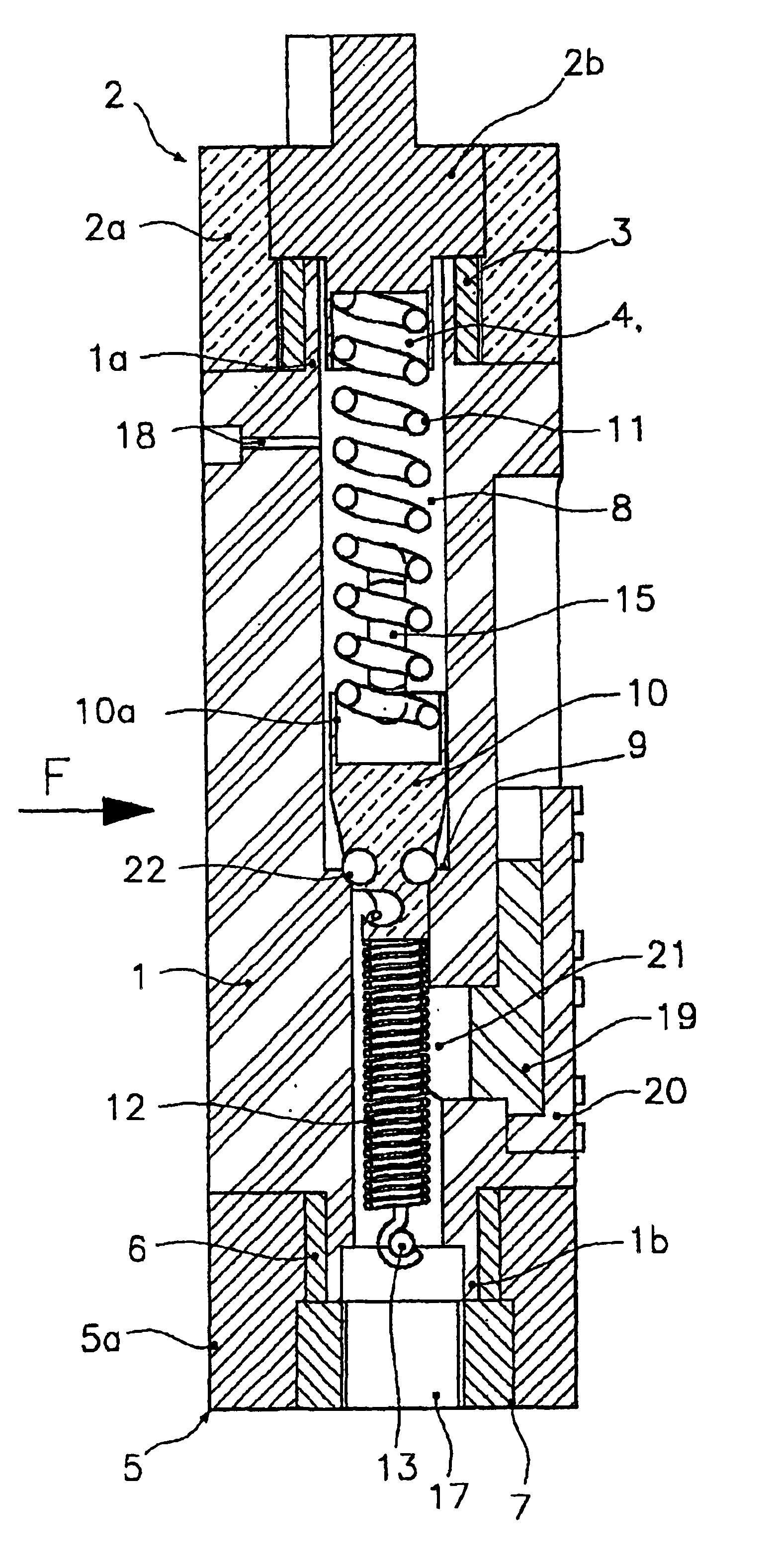

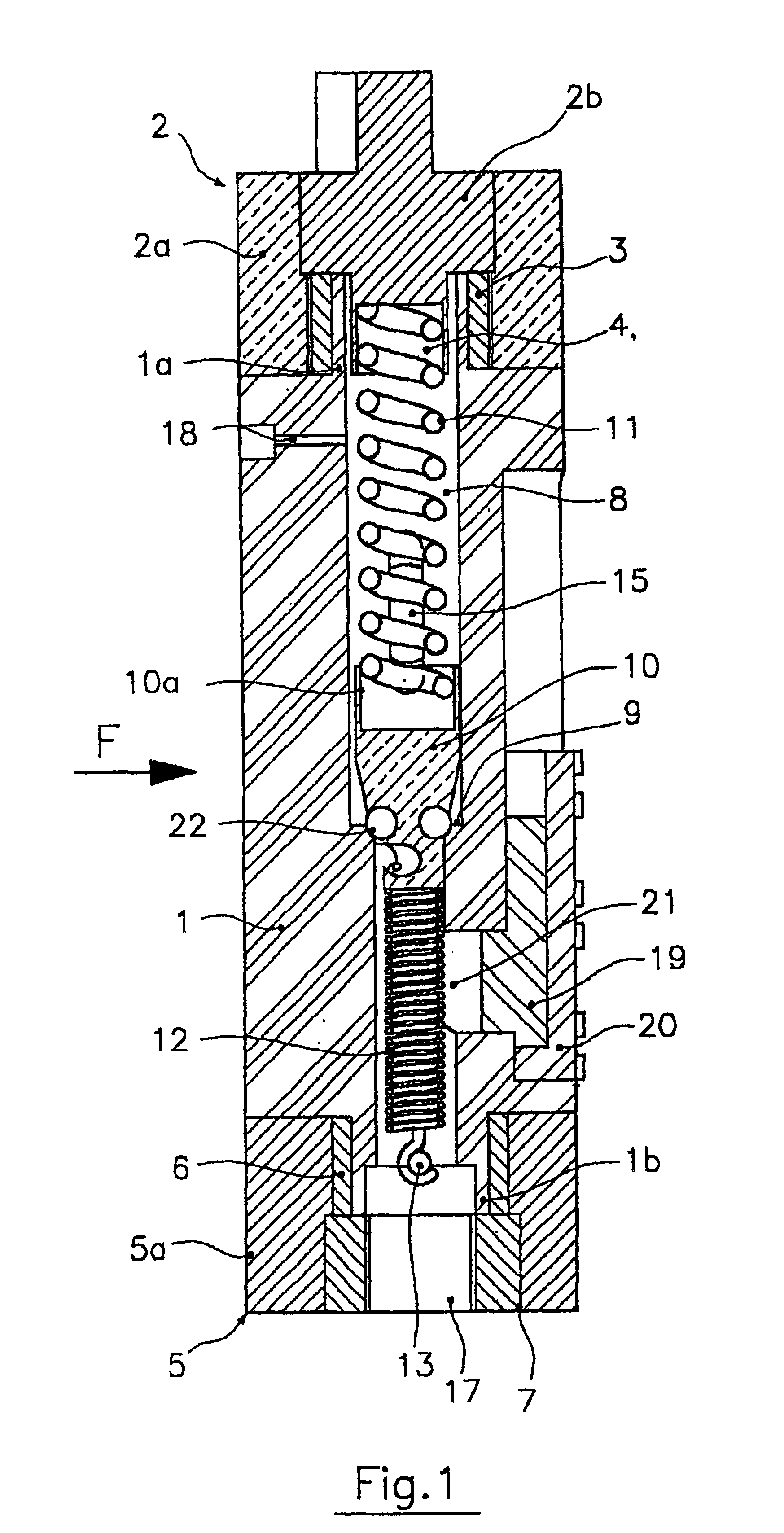

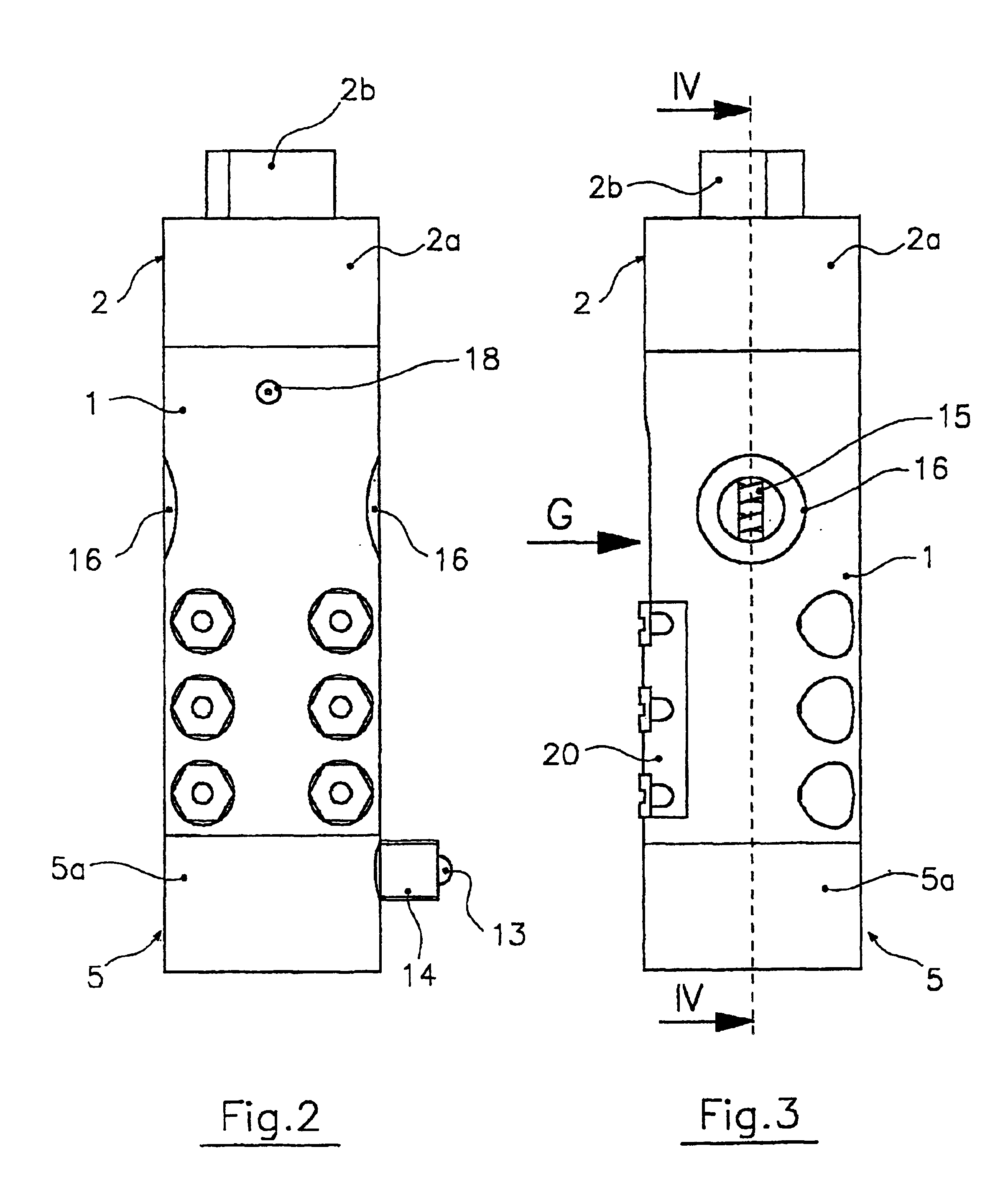

Proportional valve with shape memory alloy actuator

InactiveUS6840257B2Limited sizeReduce weightTemperature control without auxillary powerOperating means/releasing devices for valvesClosed loopAlloy

A proportional valve is disclosed for controlling the outlet pressure of a fluid flowing therethrough. The valve comprises a valve body having an inlet port and an outlet port for the fluid. The valve also has an inner chamber, within which there is formed a valve seat that may be opened and closed variably by a shutter axially movable from and towards the valve seat. Movement of the shutter is controlled by a shape memory alloy (SMA) actuating member operating antagonistically to an elastic member, the temperature of the fluid being lower than the transition temperature of the shape memory alloy. The actuating member and the elastic member are connected to the body valve at opposite sides relative to the valve seat. A power control circuit is also provided for circulating an electric current through the actuating member so as to heat the same by Joule effect from a temperature lower than the transition temperature to one that is higher. At least one vent hole is formed in the valve body for putting a portion of the chamber upstream of the valve seat into fluid communication with the outside or a collection network. The actuating member is housed in that portion of chamber corresponding to the inlet port of the fluid, whereby a continuous flow of fluid around the actuating member is ensured for accelerating the cooling process. A closed-loop control circuit for the power control circuit controls the circulating current as a function of a pressure signal generated by fluid pressure sensing means and in such a way as to offset the retarding effect produced by the fluid during heating of the actuating member.

Owner:ARENA ALBERTO +2

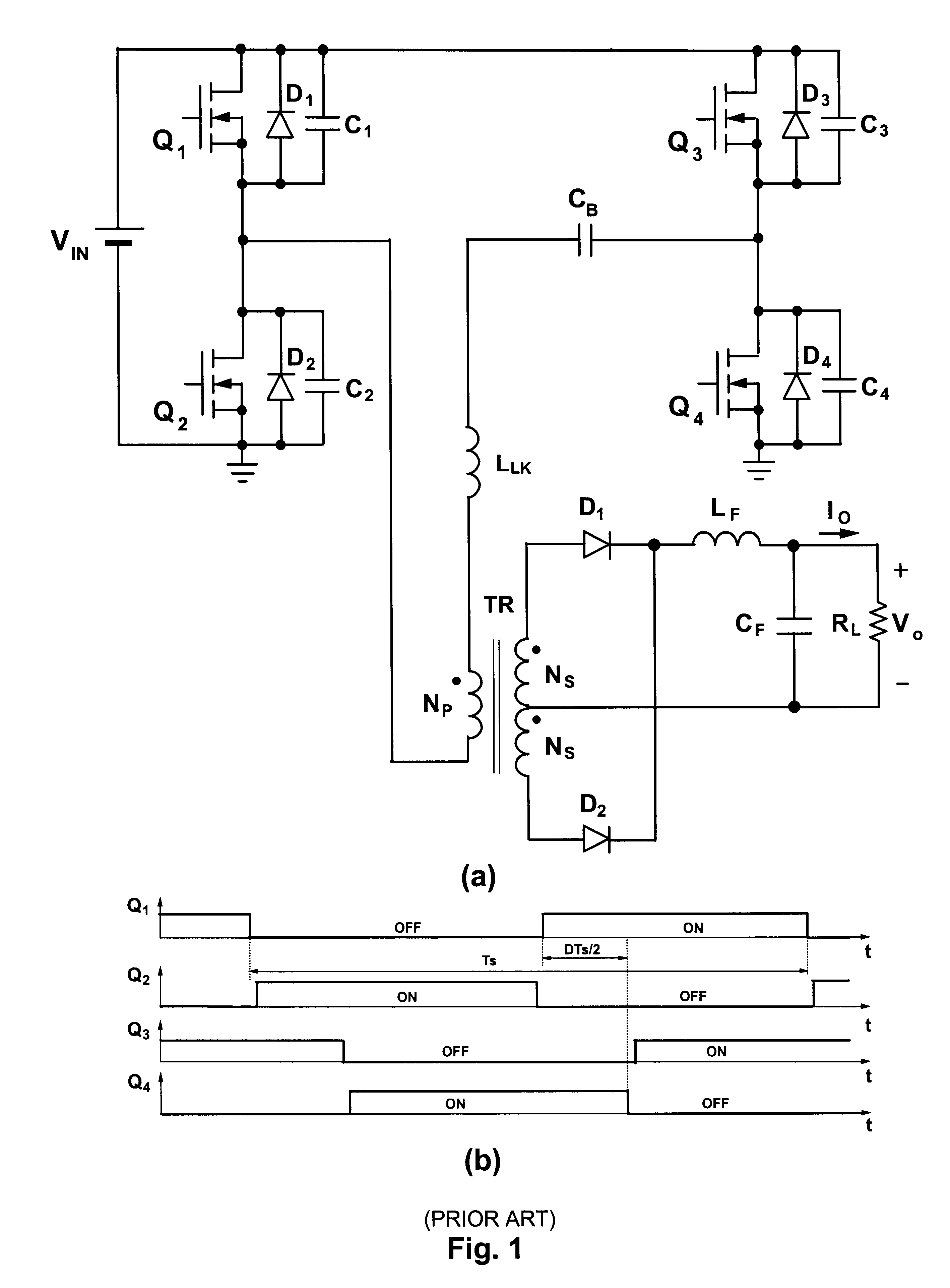

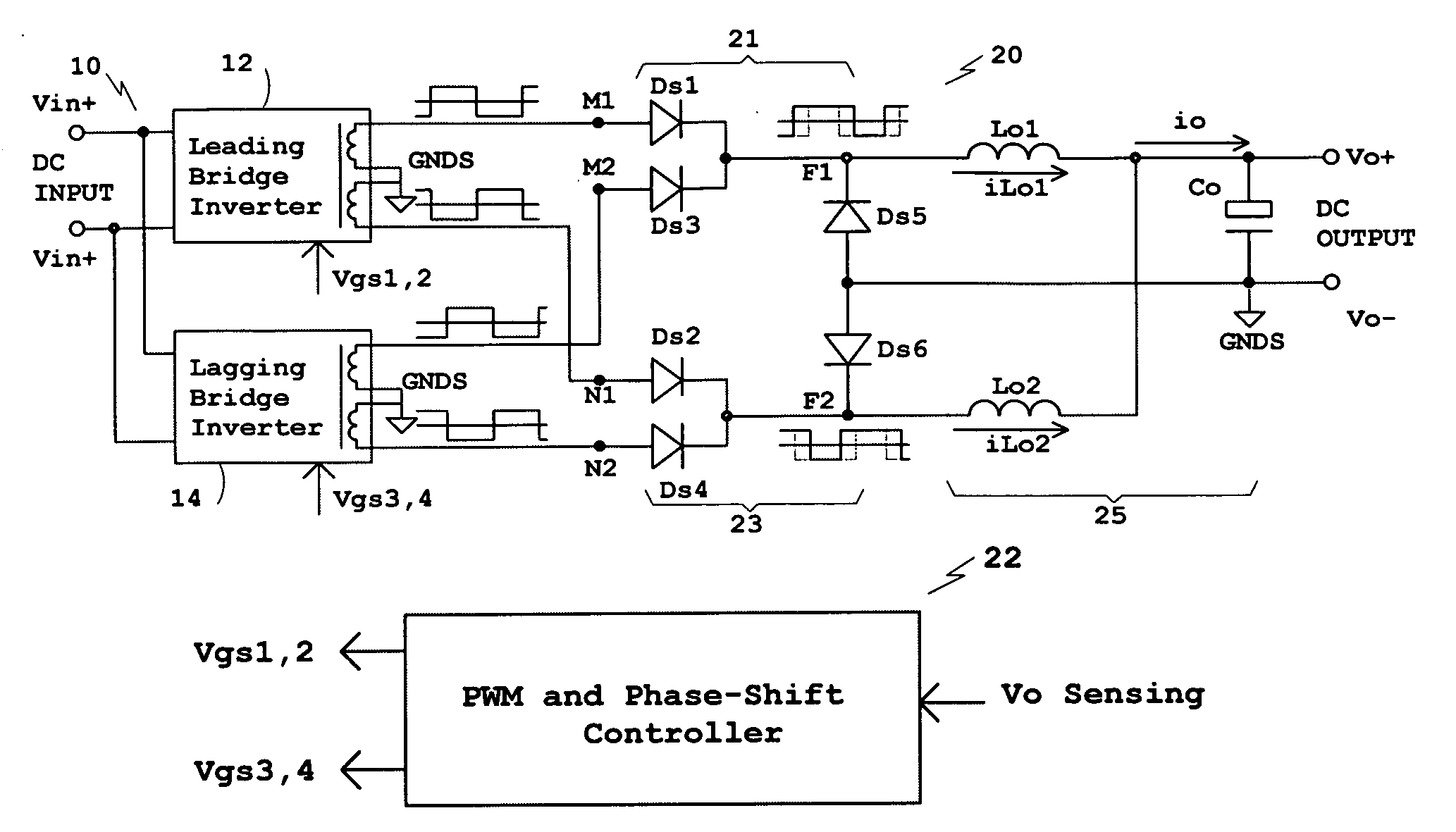

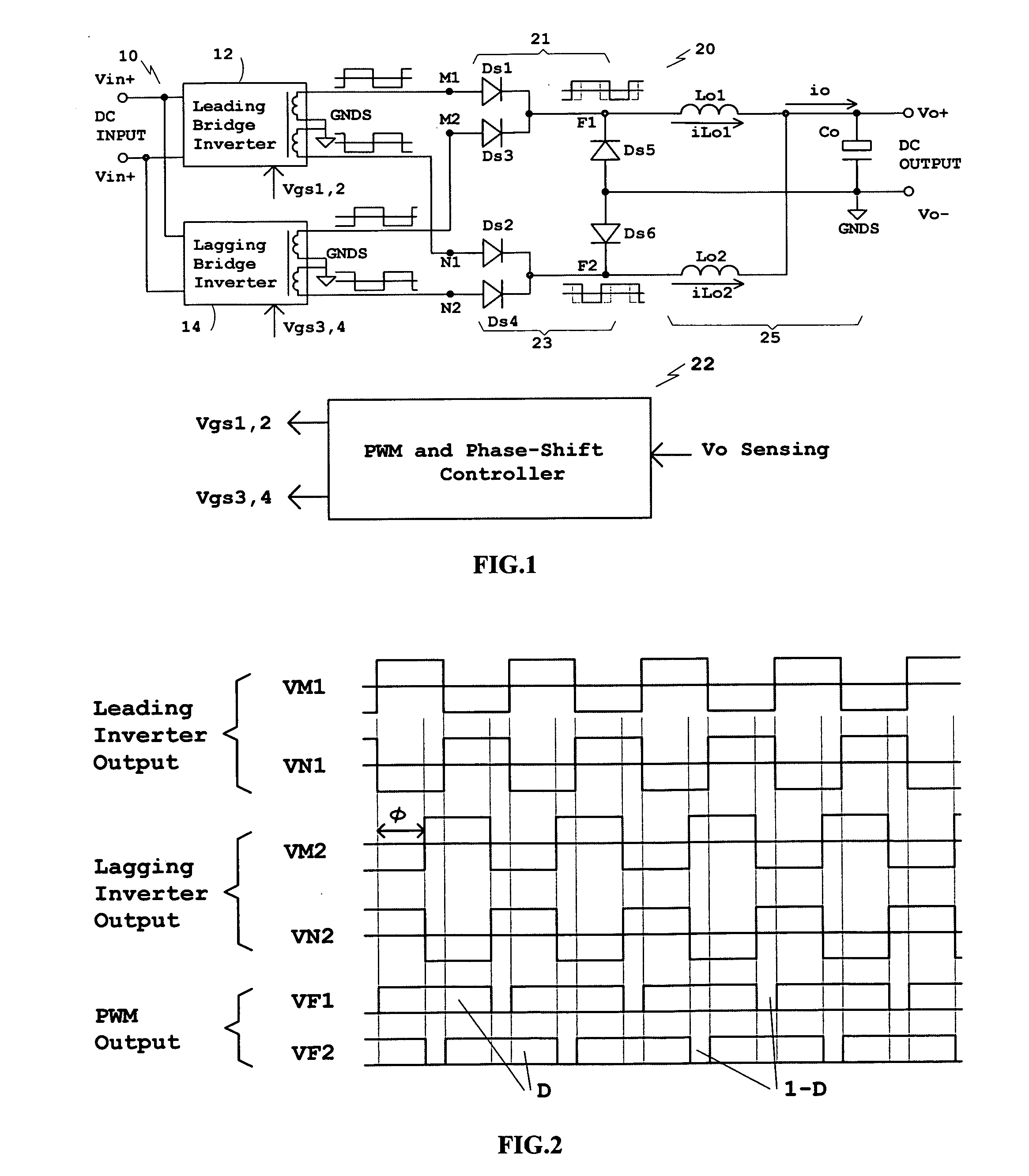

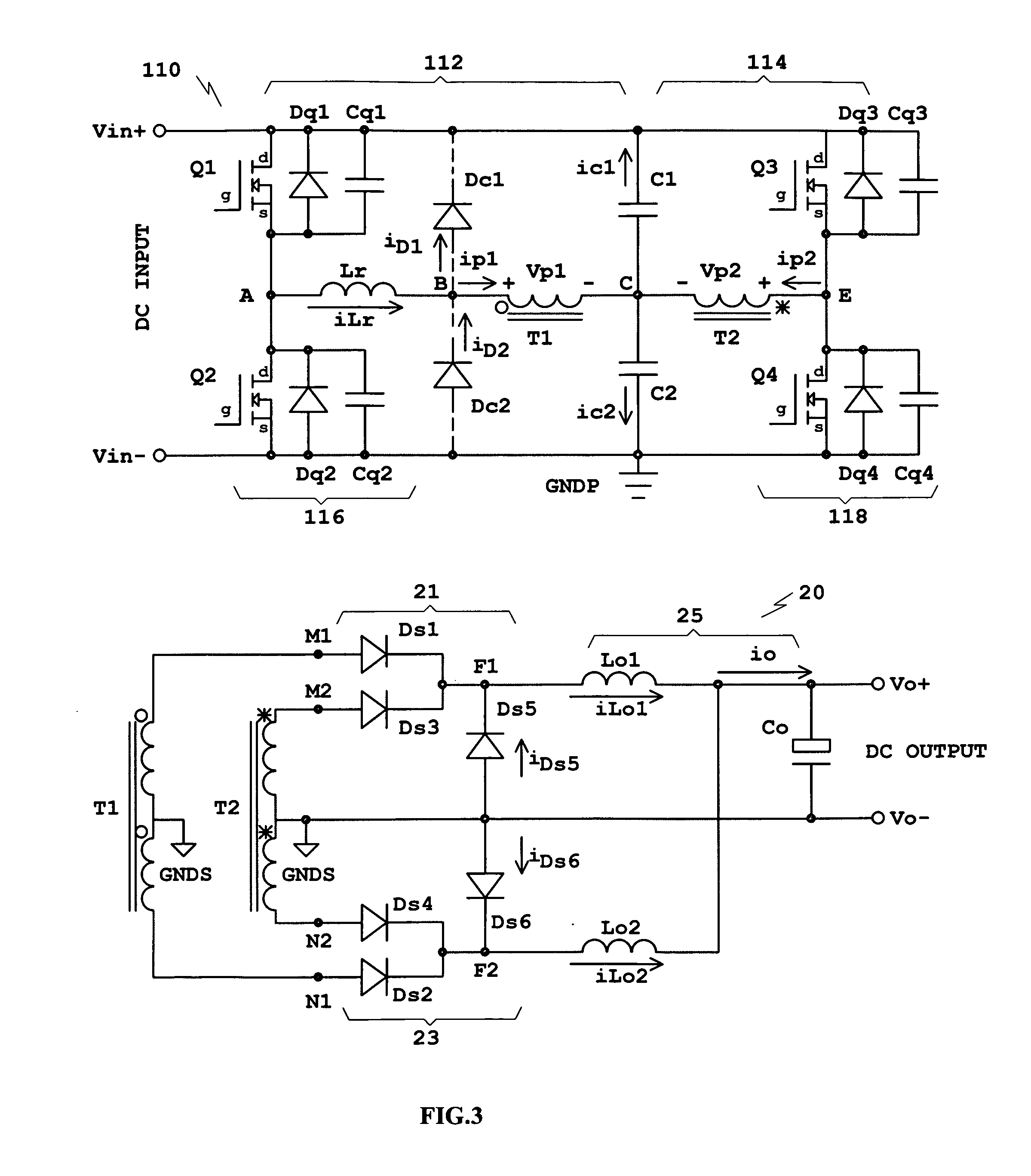

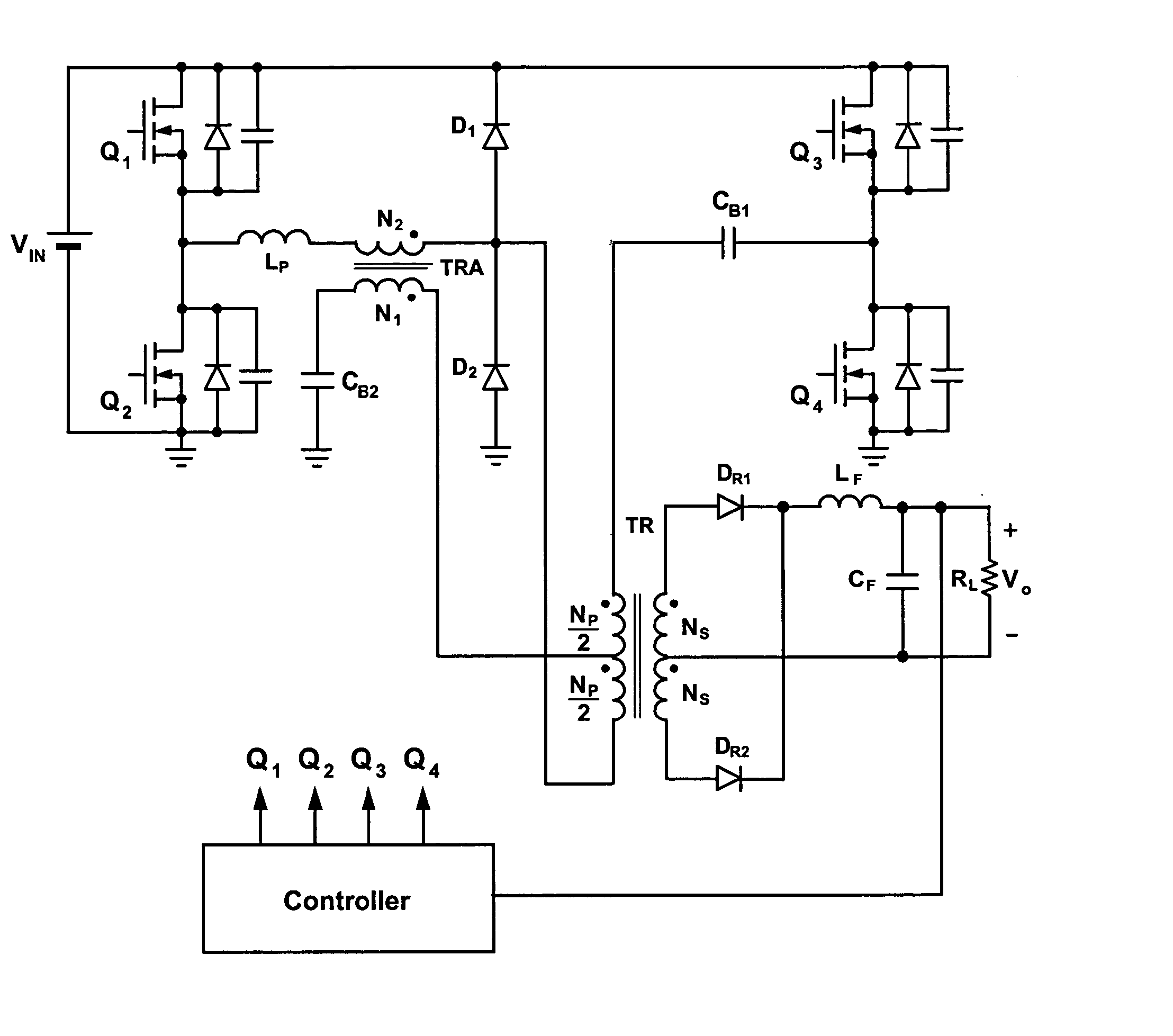

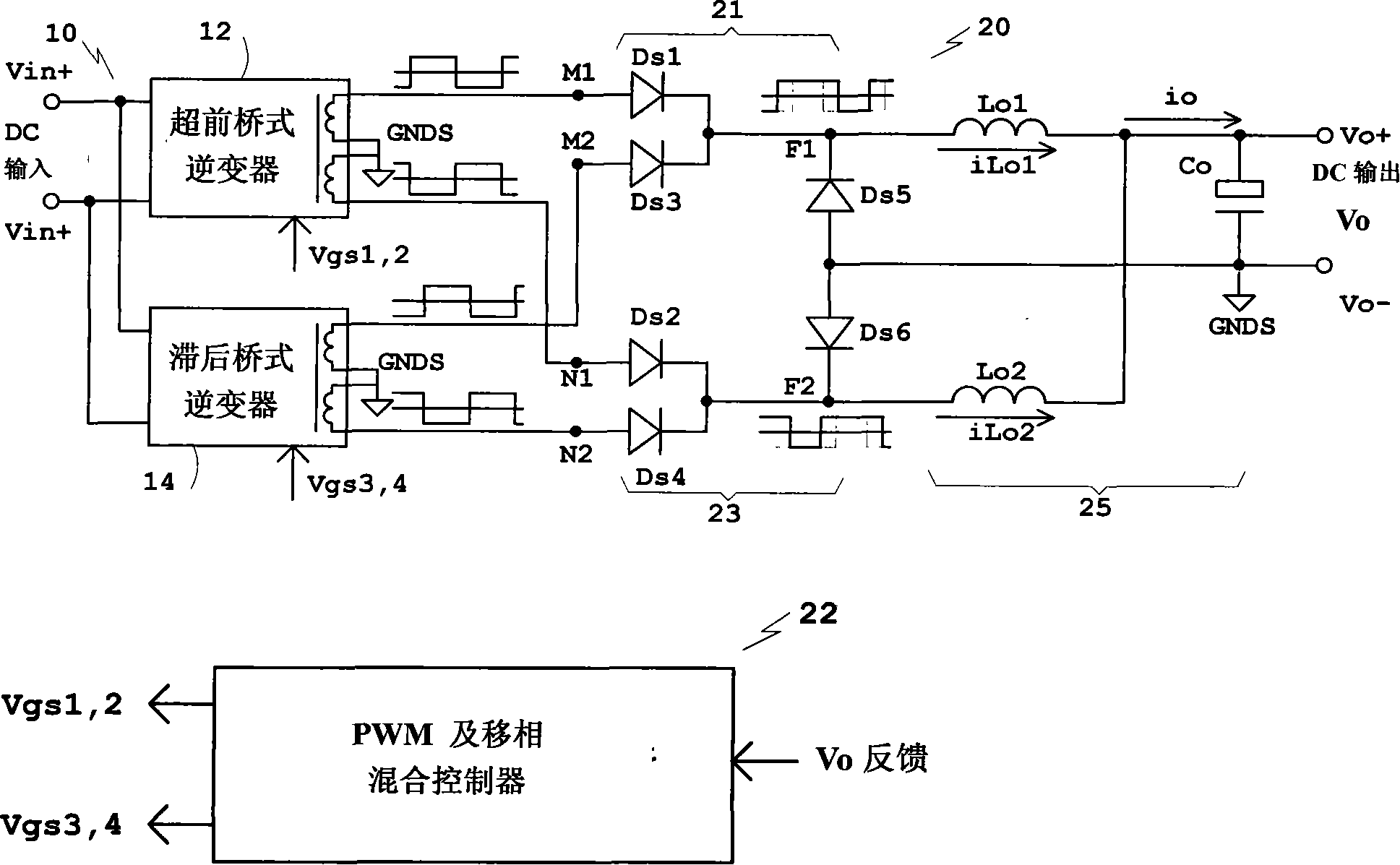

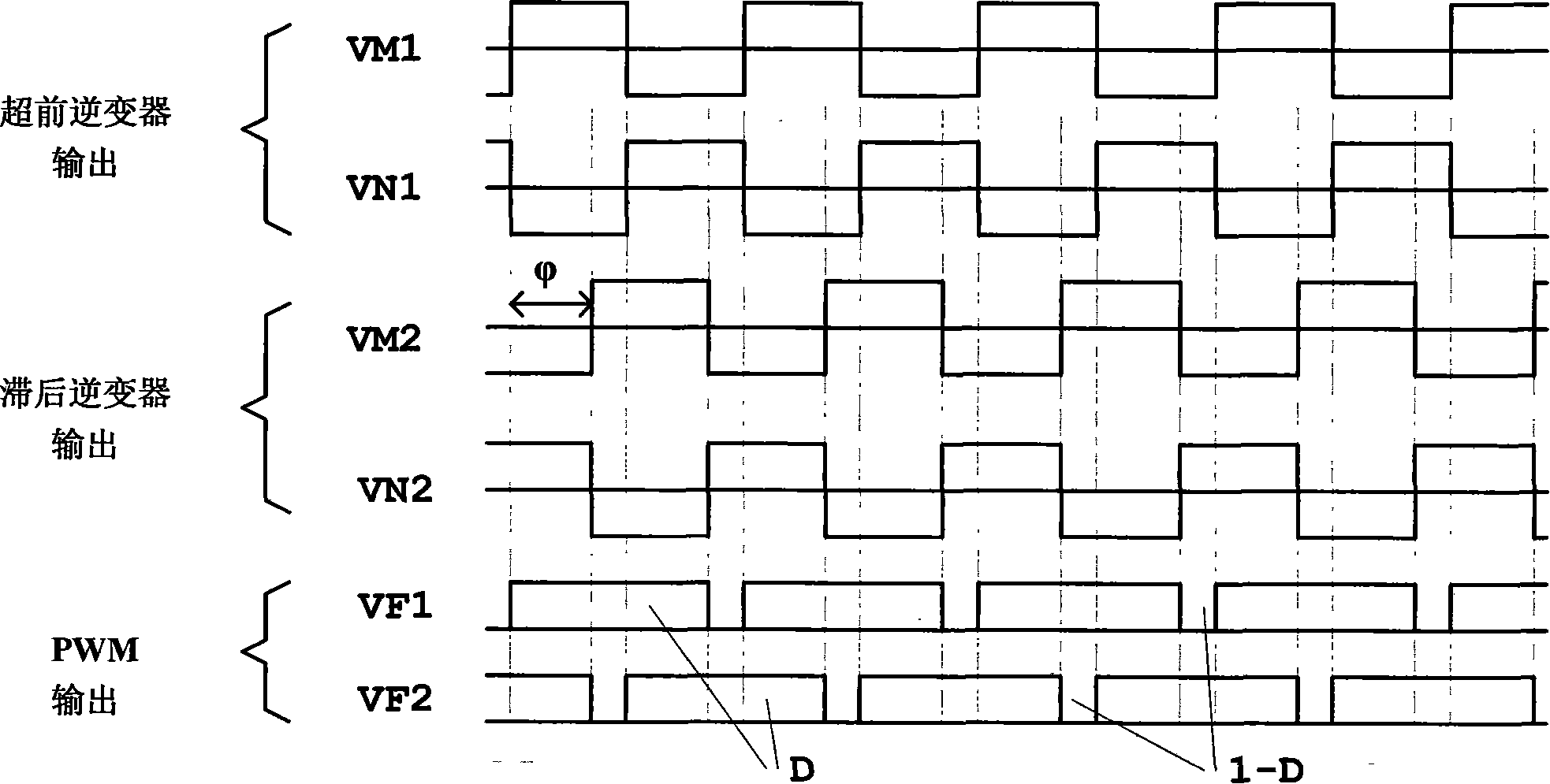

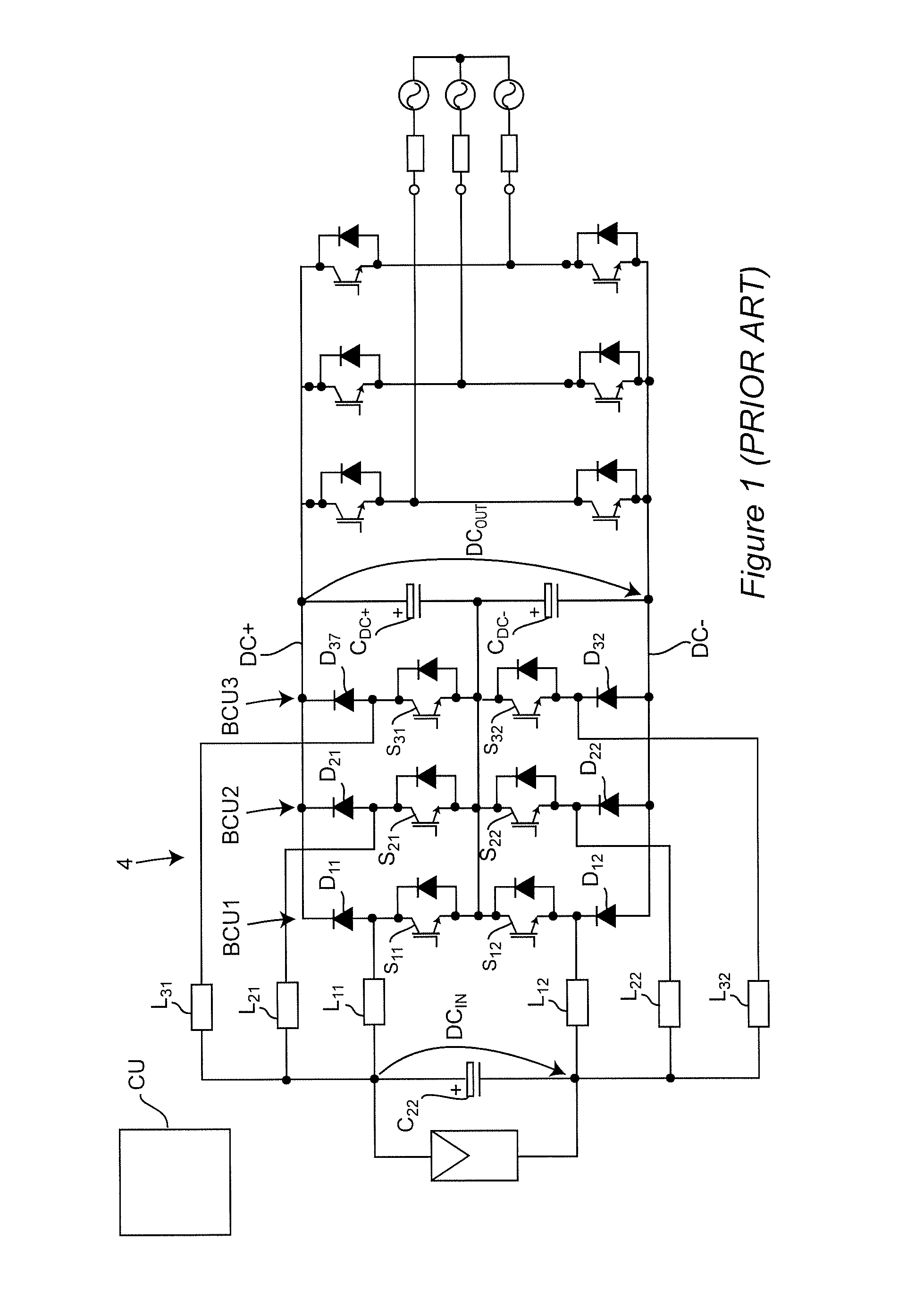

Phase-shifted dual-bridge DC/DC converter with wide-range ZVS and zero circulating current

ActiveUS20090196072A1Solve insufficient storage spaceMinimizes voltage ringingAc-dc conversionDc-dc conversionFull wavePhase difference

Disclosed is a family of new DC / DC converters and a new control method. The converter comprises two bridge inverters, two full-wave rectification circuits and a current-doubler filter. Each inverter is able to generate a symmetrical and isolated AC output voltage. Phase-shift control is employed to control the phase difference between the two bridge inverters. By shifting the phase, the converter changes the two inverters' output voltage overlapping area to regulate its output voltage. The bridge inverters always operate at 50% duty cycle, like an open loop Bus Converter, to achieve wide-range zero voltage switching and eliminate circulating current for normal operation. For low output voltage regulation and soft start, Pulse Width Modulation (PWM) control is used. The converters and the control method improve power conversion efficiency, maximize magnetic component utilization, reduce semiconductor stress and decrease EMI emission.

Owner:TEXAS INSTR INC

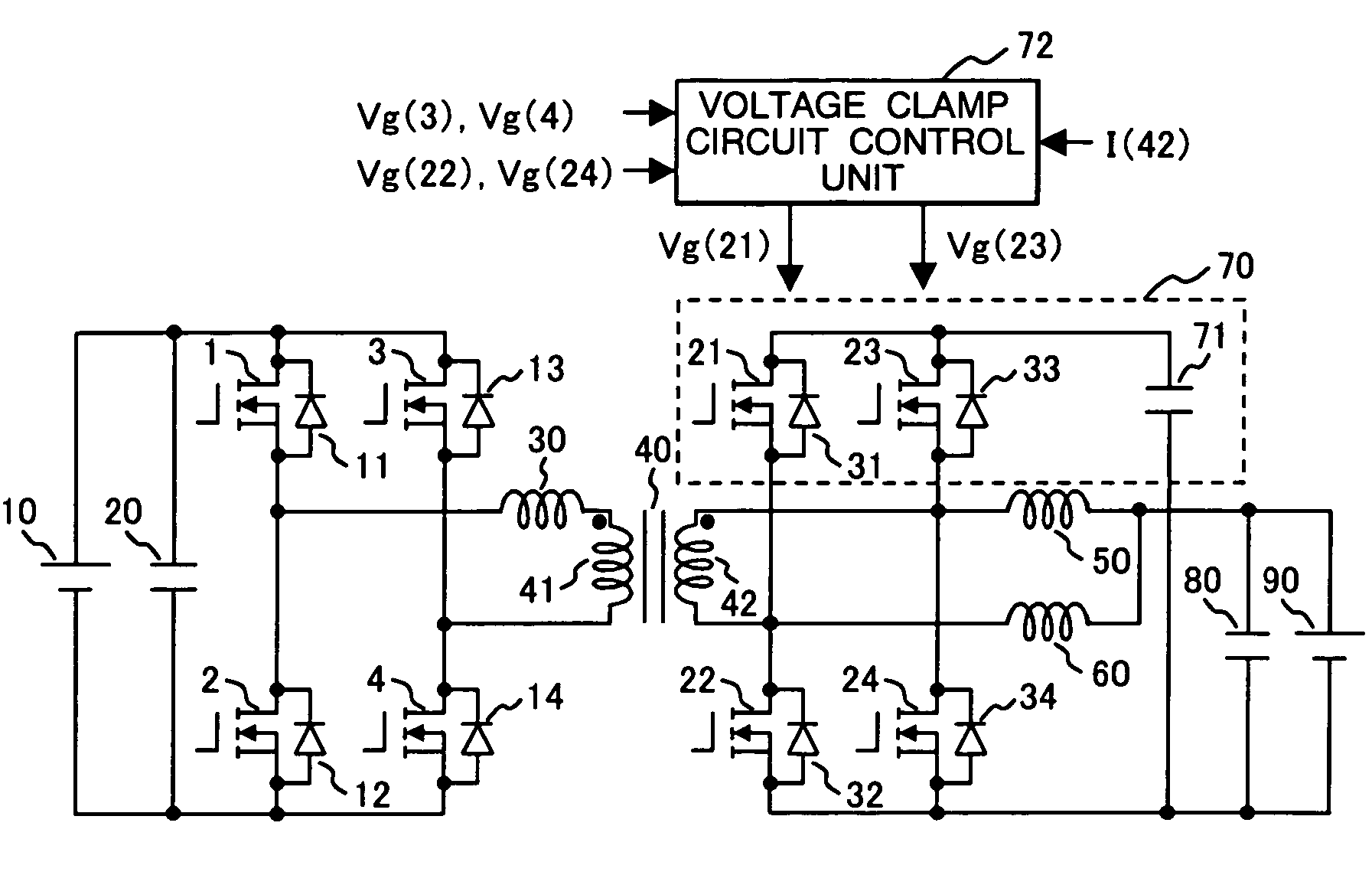

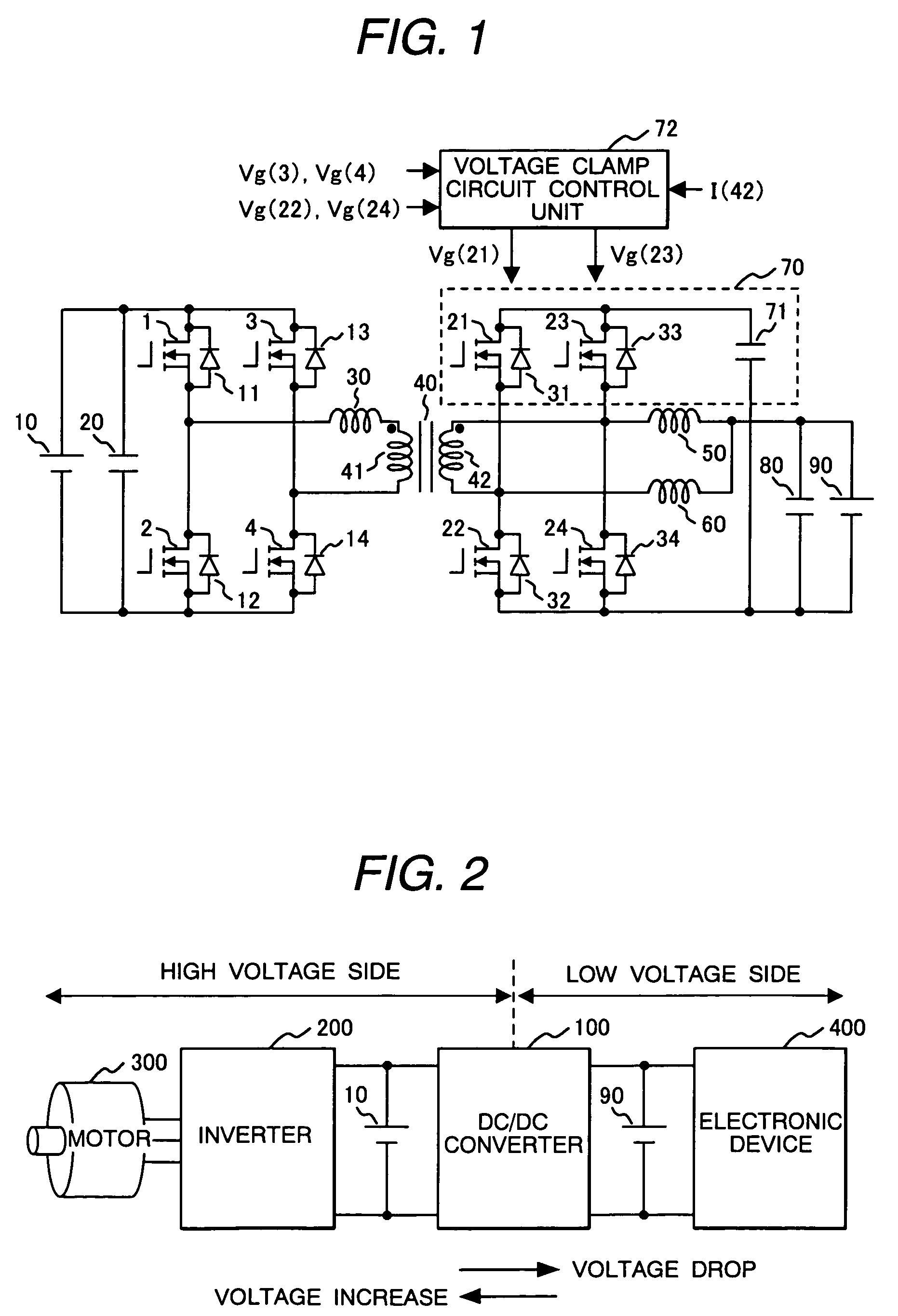

Isolated bidirectional DC-DC converter

ActiveUS20060139823A1Total current dropReduce lossesEfficient power electronics conversionDc-dc conversionClamp capacitorLow noise

Owner:HITACHI ASTEMO LTD

Full bridge converter with ZVS via AC feedback

InactiveUS6992902B2Increase inductanceIncreases the amount of current deliveredConversion with intermediate conversion to dcDc-dc conversionFull bridgeCirculating current

A soft-switched, full-bridge pulse-width-modulated converter and its variations provide zero-voltage-switching conditions for the turn-on of the bridge switches over a wide range of input voltage and output load. The FB PWM converters of this invention achieve ZVS with a substantially reduced duty cycle loss and circulating current. The ZVS of the primary switches is achieved by employing an auxiliary circuit having an inductor and transformer to store energy for ZVS turn-on of the bridge switches.

Owner:DELTA ELECTRONICS INC

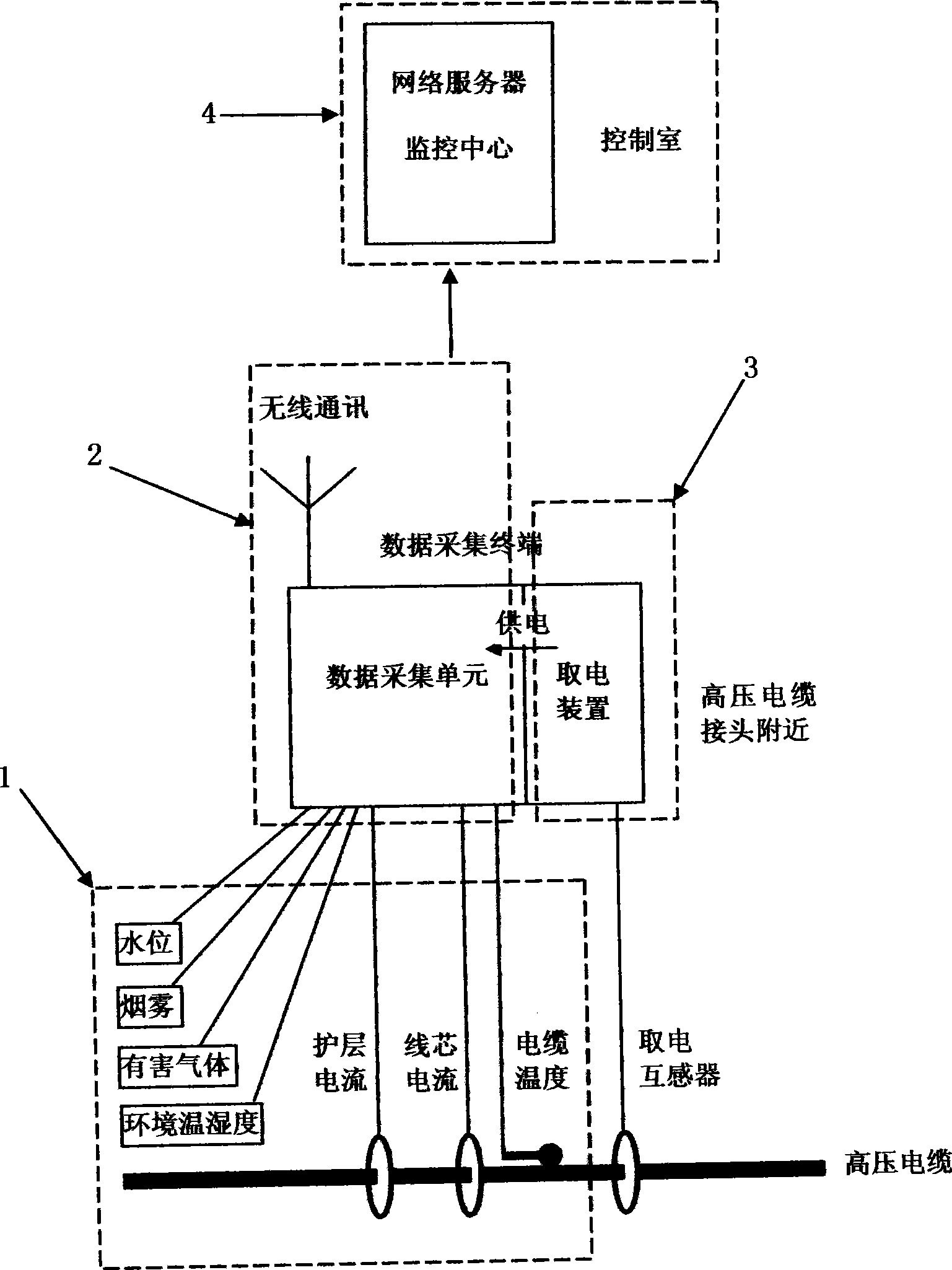

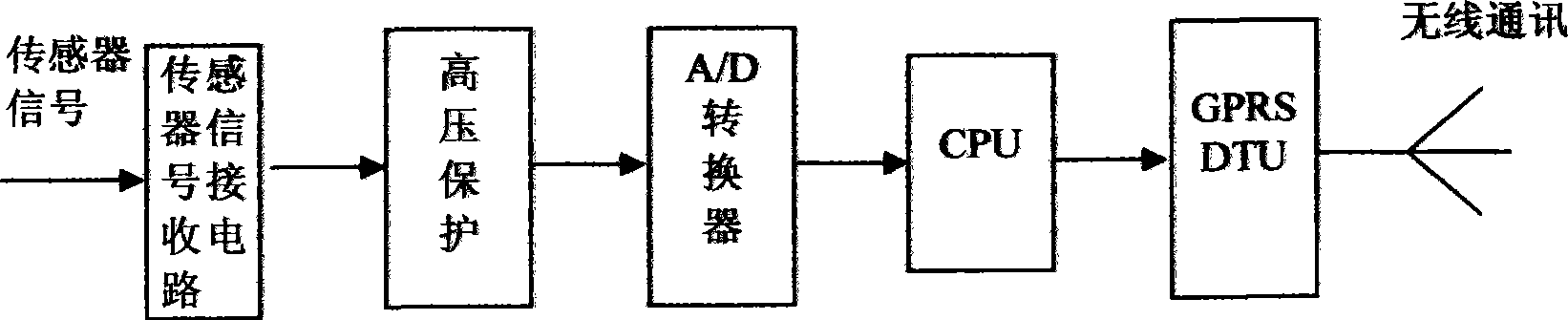

On-line monitoring system for high voltage cable

ActiveCN101464488AAvoid electrical accidentsTransmission systemsFault locationCirculating currentEngineering

The invention relates to an online monitoring system for high-voltage cables, which comprises a sensor, a data collection unit, a power supply device, and a network server. The sensor is arranged at the joint of a high-voltage cable and is used for collecting data such as the shield circulating current of the high-voltage cable joint, the core current, the surface temperature of the cable, and the ambient humidity and temperature and transmitting the data to the data collection unit. The data collection unit is arranged nearby the high-voltage cable joint and is used for collecting the data transmitted from the sensor and transmitting the date to the network server via a wireless network. The power supply device acquires power from the high-voltage cable and provides power to the data collection unit. The network server is installed in a control room and is used for receiving the data transmitted from the data collection unit in order to determine whether the power cable is in safe operation condition via special data analysis, thereby serving the purpose of helping maintenance personnel monitor the operation condition of the power cable at any time, and preventing the electrical faults from happening. In case that faults occur with the cable, the online monitoring system can send alarms promptly and locate fault points, thereby providing assistance for cable repair.

Owner:上海慧东电气设备有限公司 +3

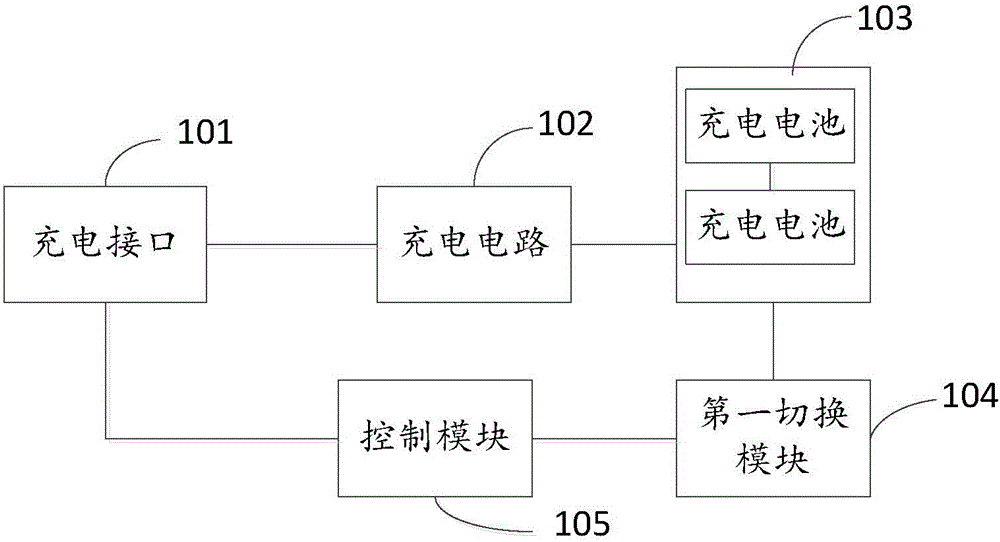

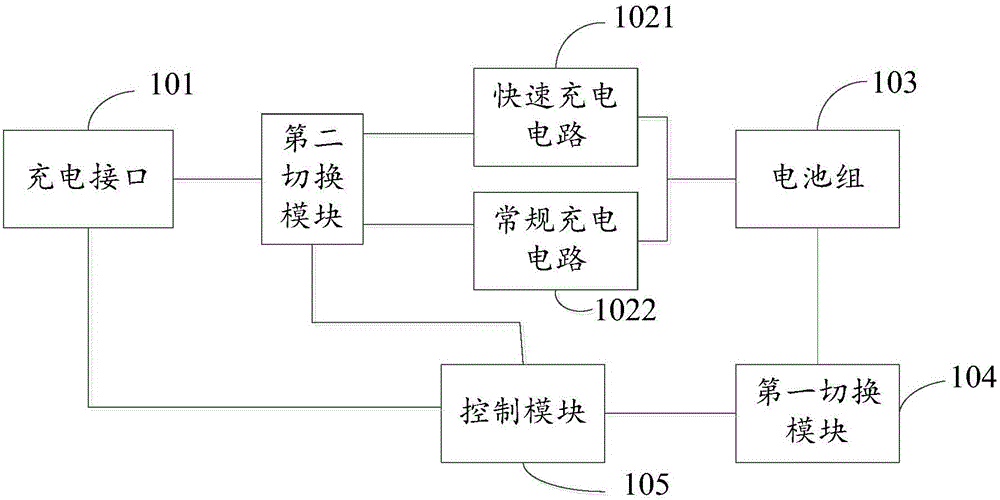

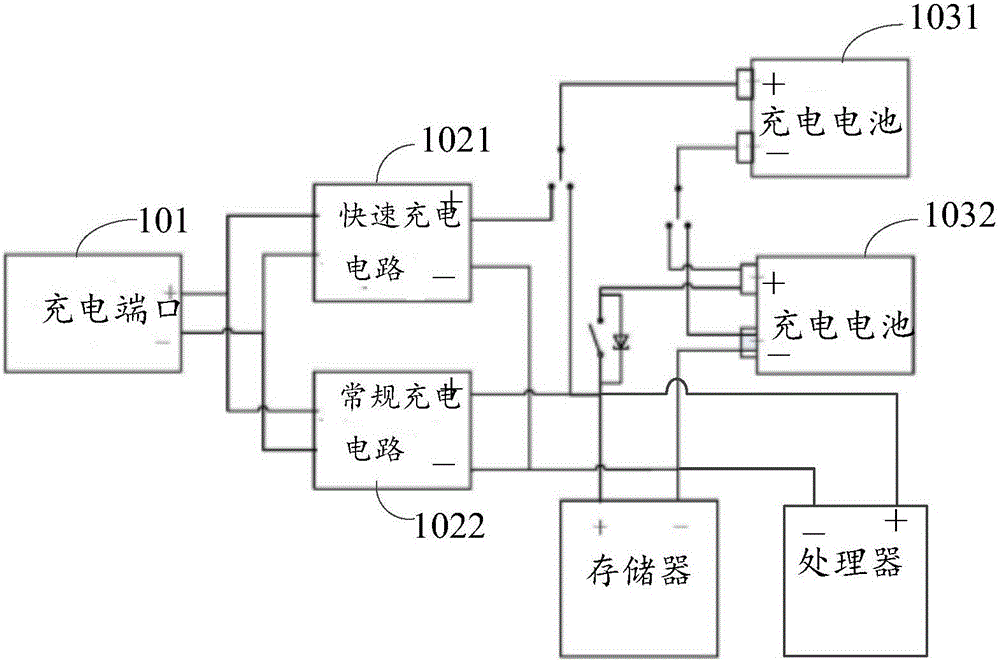

Charging device and mobile terminal

InactiveCN105896670ADoes not cause heat problemsSolve fever problemCharge equalisation circuitParallel/serial switchingElectricityElectrical battery

The embodiment of the invention provides a charging device and a mobile terminal, and belongs to the technical field of charging of batteries. The charging device comprises a charging interface, a charging circuit, a battery pack, a first switching module and a control module, wherein the battery pack comprises at least two charging batteries; the charging circuit is connected between the charging interface and the battery pack in series; the first switching module is electrically connected with the battery pack; and the control module is connected with the first switching module and controls the first switching module to switch the connection state between the charging batteries into a parallel state or a series state. The problem of heating of the batteries caused by over-high circulating currents of the batteries is solved, so that, by the charging device provided by the embodiment, the problem of heating of the batteries caused by current rise of battery bodies can be effectively solved when the batteries are quickly charged.

Owner:LETV HLDG BEIJING CO LTD +1

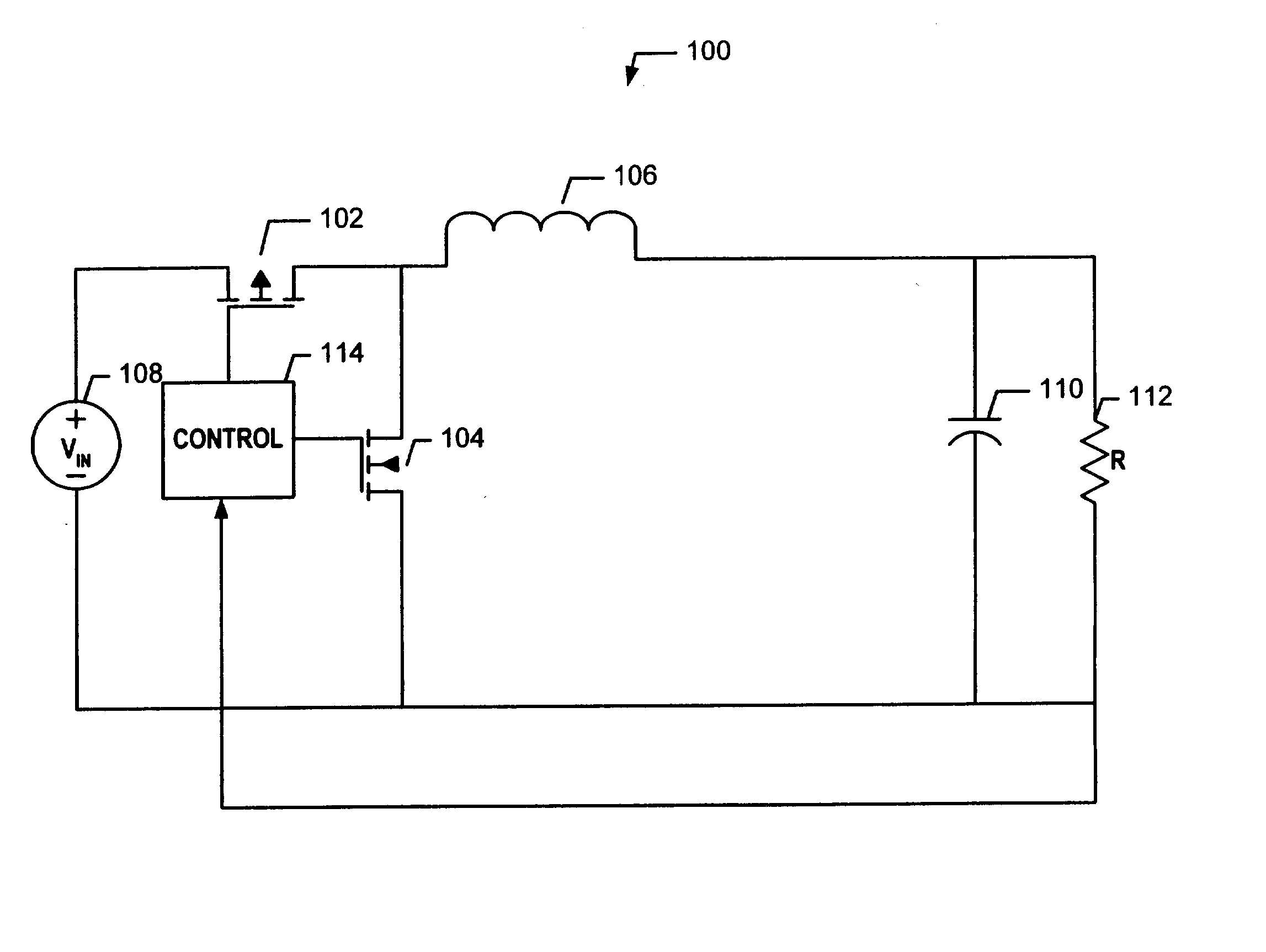

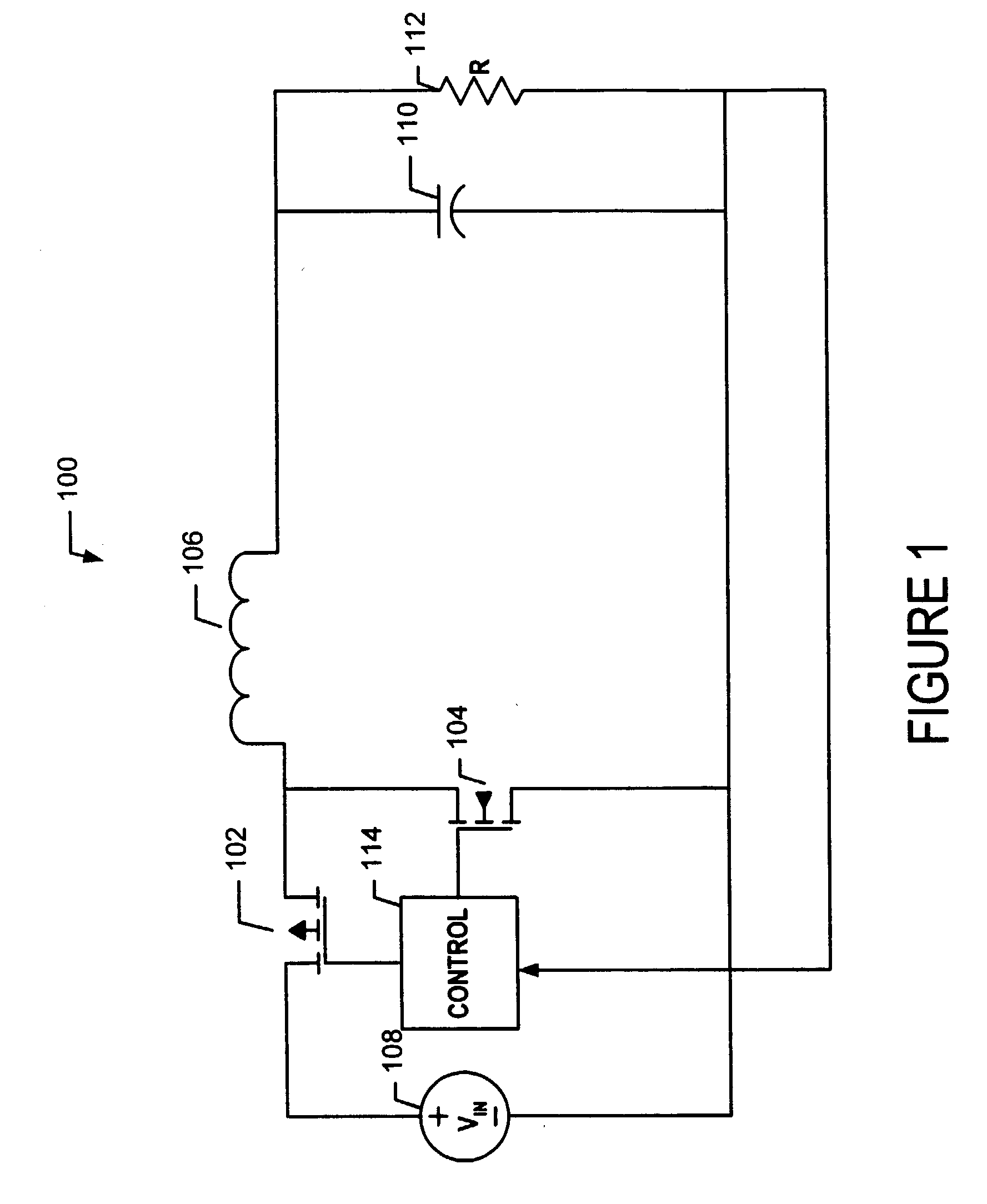

Multislice DC-DC converter

InactiveUS20030090244A1Energy efficient ICTEfficient power electronics conversionCapacitanceDead time

A novel monolithic step-down dc-dc buck converter that uses two or more ("n") parallel slices to achieve a high output current with a small filter capacitor is provided. Each of the n slices may be operated with a phase difference of 360° / n. Each of the converter slices may be based on a synchronous rectifier topology to avoid the excessive power losses introduced by the diode component of conventional step-down buck converters. Hysteretic control may be used (with or without pulse-width modulation and pulse-frequency modulation) to provide an internal gate-drive waveform without the need to provide a dedicated clock signal or oscillator circuit. The hysteretic control is further refined using digital control techniques to enforce a brief dead time between the activation of each slice such that undesirable circulating currents are prevented. A significant advantage of the proposed multi-slice step-down dc-dc buck converter and its associated control is that the semiconductor switches, filter inductors and capacitor, and the control circuit may be fabricated as part of a single monolithic integrated circuit.

Owner:SHAKTI SYST

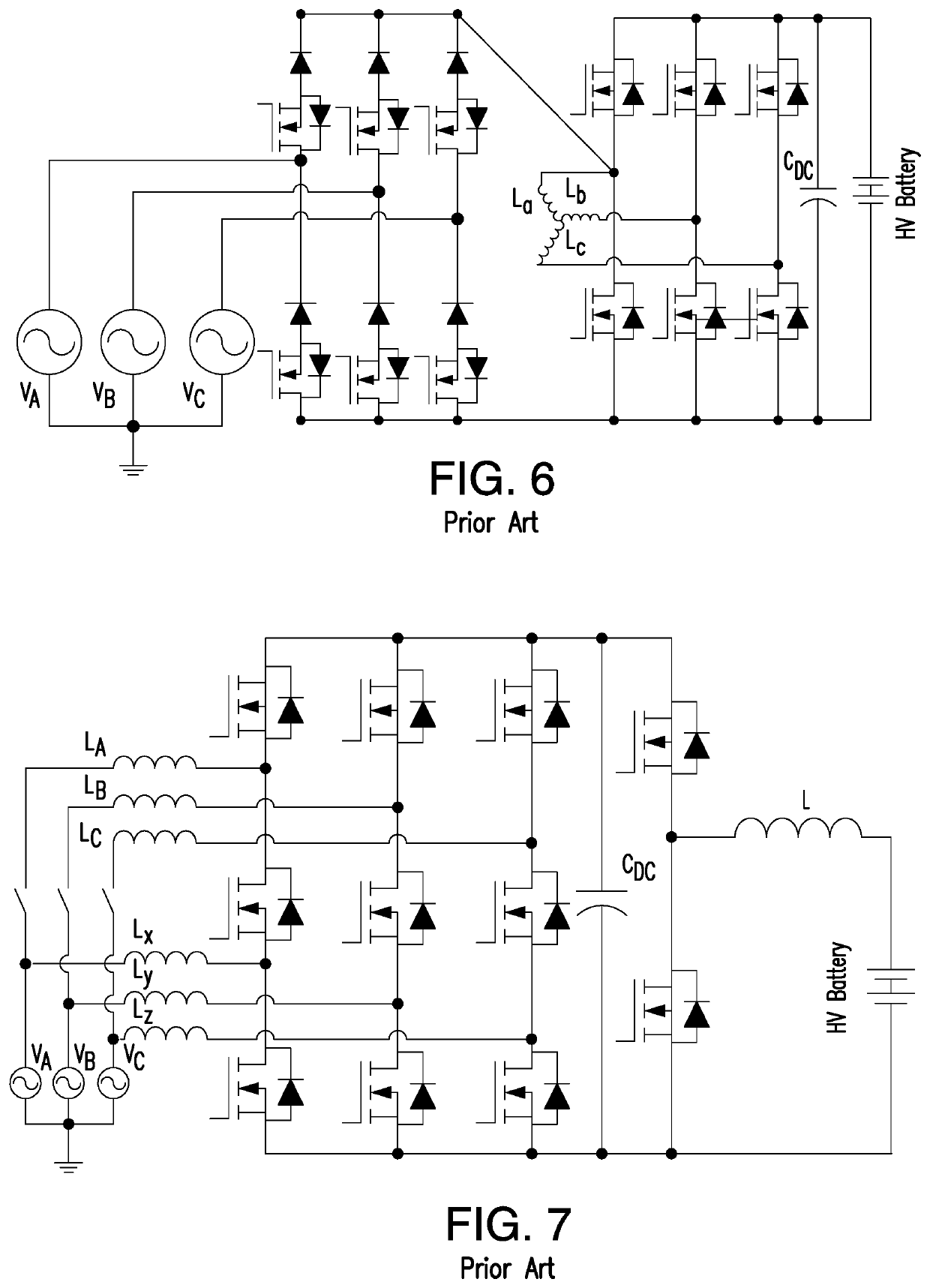

Full bridge power converters with zero-voltage switching

InactiveUS20050041439A1Increase inductanceIncreases the amount of current deliveredConversion with intermediate conversion to dcDc-dc conversionFull bridgeTransformer

A soft-switched, full-bridge pulse-width-modulated (FB PWM) converter and its variations provide zero-voltage-switching (ZVS) conditions for the turn-on of the bridge switches over a wide range of input voltage and output load. The FB PWM converters of this invention achieve ZVS with a substantially reduced duty cycle loss and circulating current, which optimizes the conversion efficiency. The ZVS of the primary switches is achieved by employing an auxiliary circuit comprising an inductor and transformer to store energy for ZVS turn-on of the bridge switches.

Owner:DELTA ELECTRONICS INC

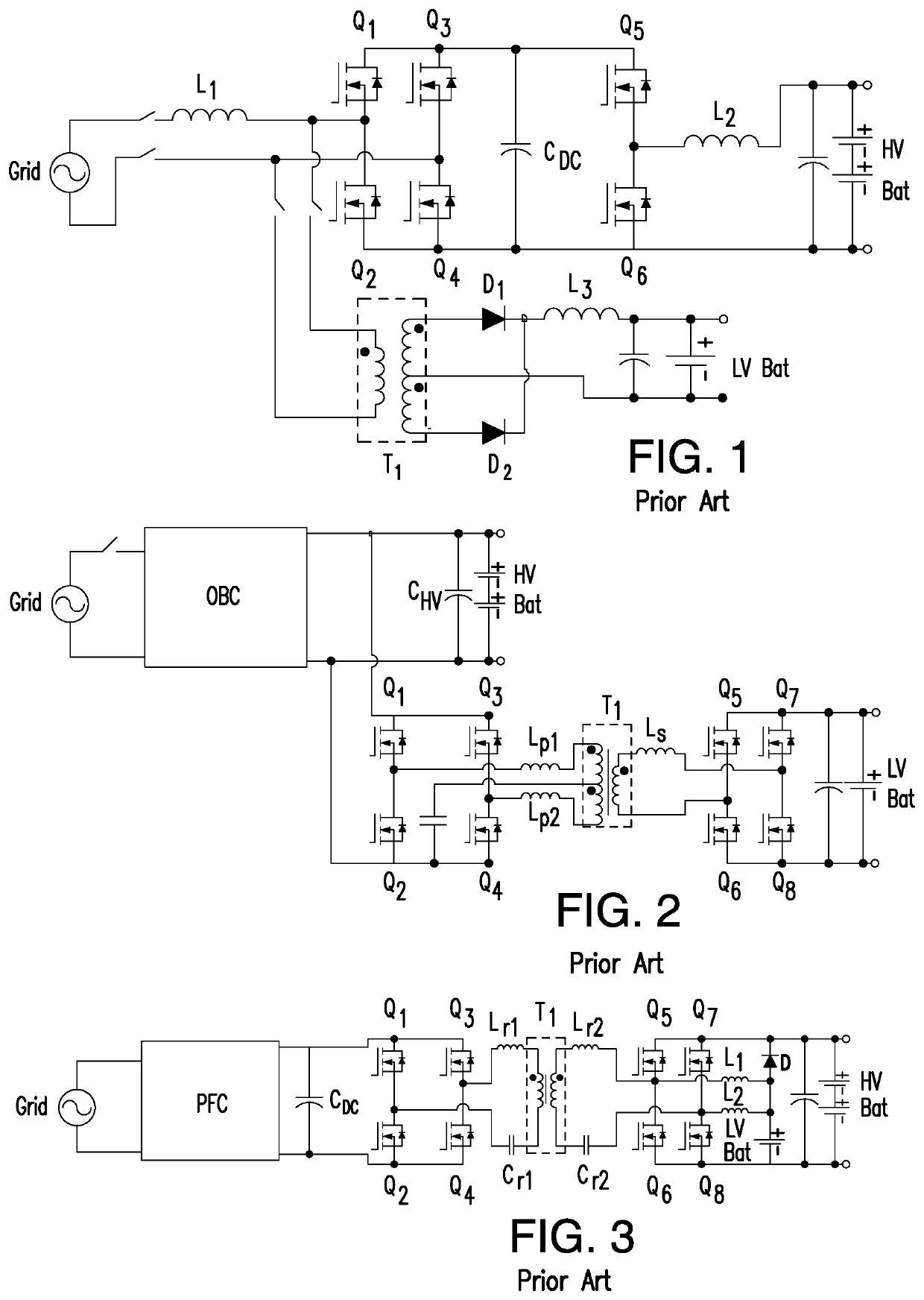

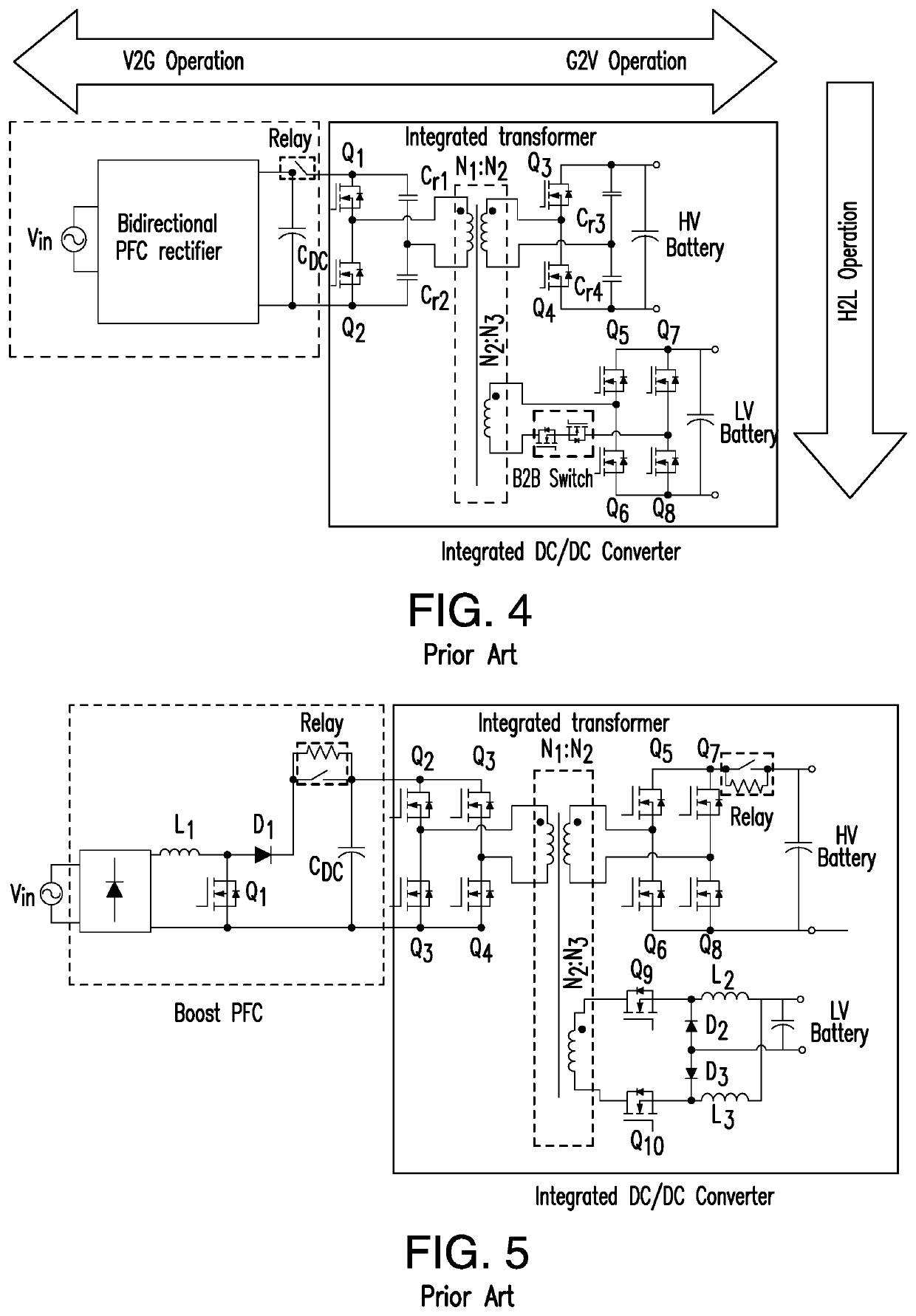

Vehicle on-board charger for bi-directional charging of low/high voltage batteries

ActiveUS20210155100A1Improve efficiencyImprove compactnessBatteries circuit arrangementsCharging stationsMOSFETElectric power transmission

Compact light-weight on-board three-port power electronic system built in various configurations of triple-active-bridge-derived topologies, including modular implementations, with control strategies capable of bi-directional power transfer among the three ports, including simultaneous charging of HV and LV batteries from a single phase or three phase power grid with minimized reactive power and active circulating current, with ensured soft-switching for MOSFET devices, and with enhanced synchronous rectification and reduced power losses.

Owner:UNIV OF MARYLAND

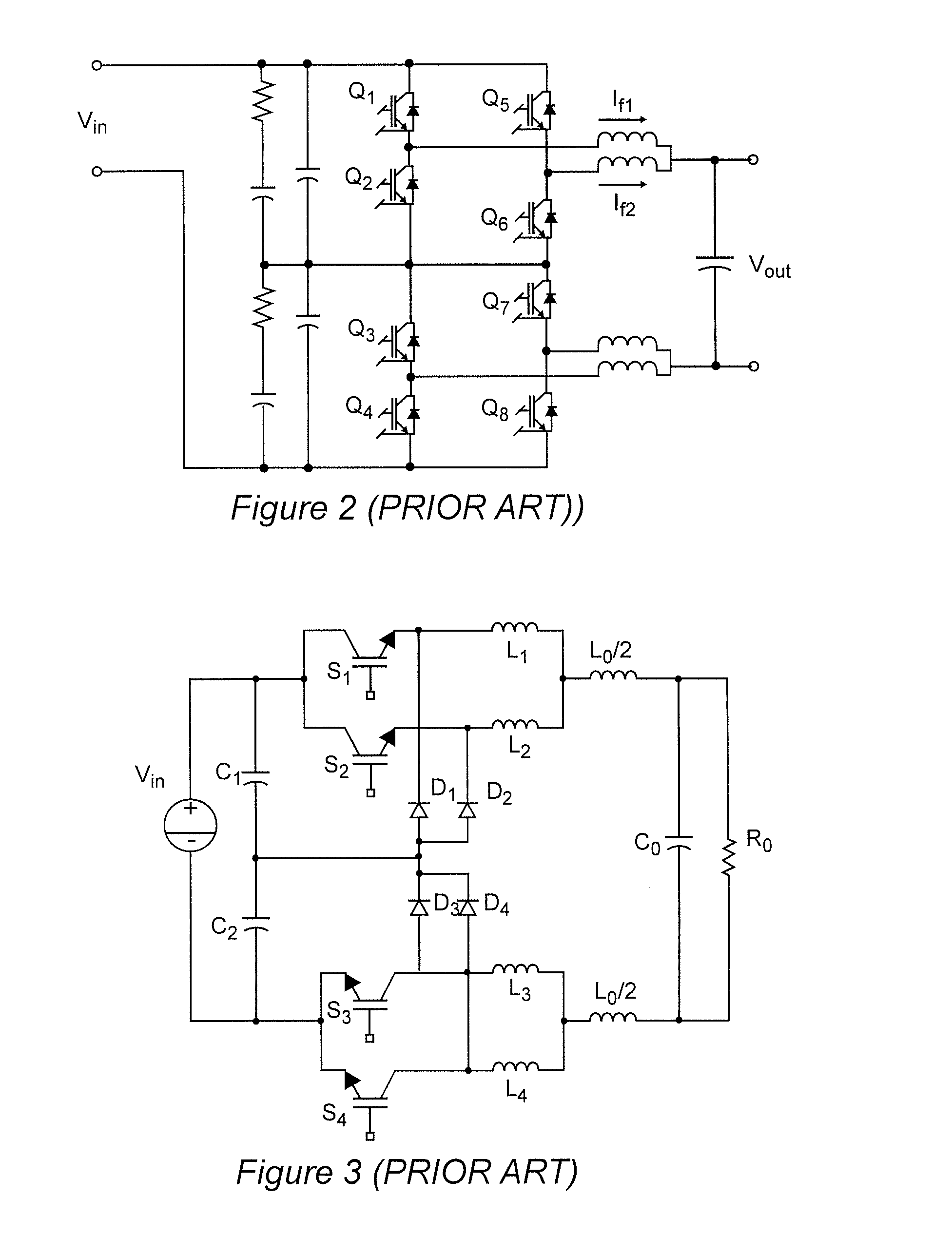

Integrated magnetics switching converter with zero inductor and output ripple currents and lossless switching

InactiveUS20090185398A1Lower average currentEliminate switching lossesEfficient power electronics conversionConversion with intermediate conversion to dcInductorCirculating current

Switching Converter with a novel two-loop Integrated magnetic structure integrates transformer and two output inductors and eliminates large circulating current in the transformer secondary side resulting in ultra high efficiency and zero ripple output current as well as zero ripple currents in both output inductors simultaneously. The novel lossless switching method eliminates the primary side switching losses to result in switching converter with highest efficiency, compact size and additional performance advantages, such as ultra low output ripple voltage, low EMI noise and improved reliability with additional benefits when operated with a front-end Power Factor Converter for computer server applications.

Owner:CUKS

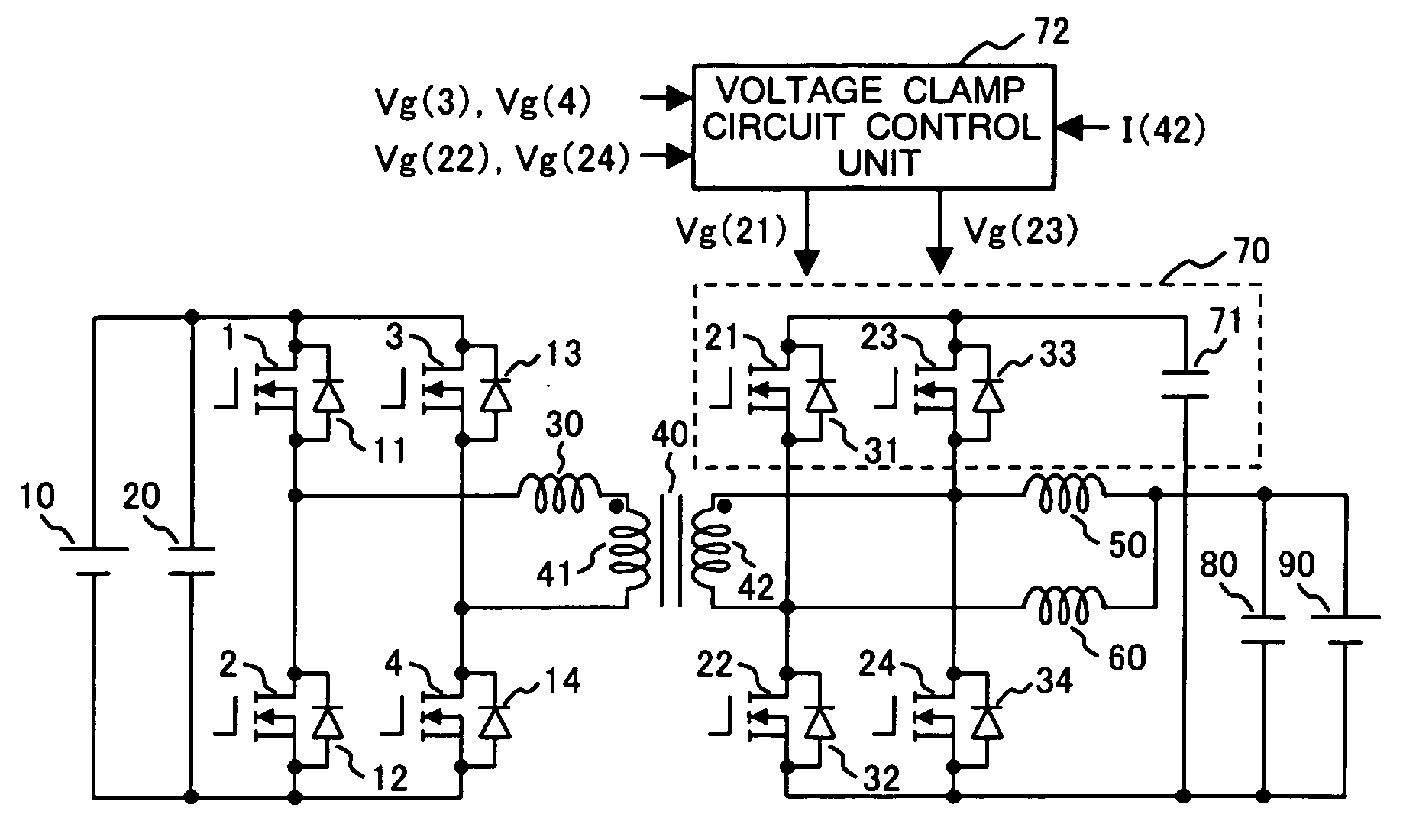

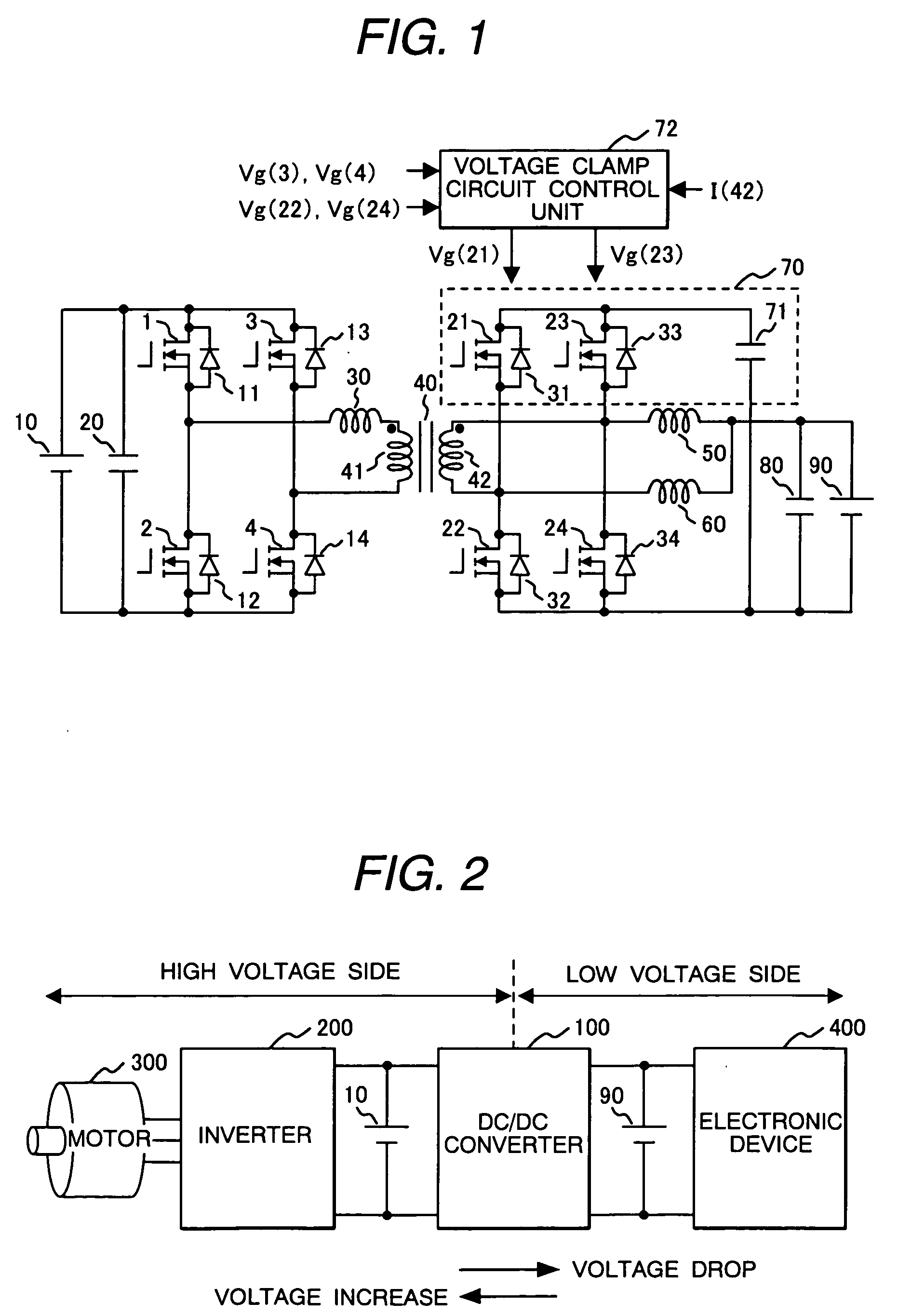

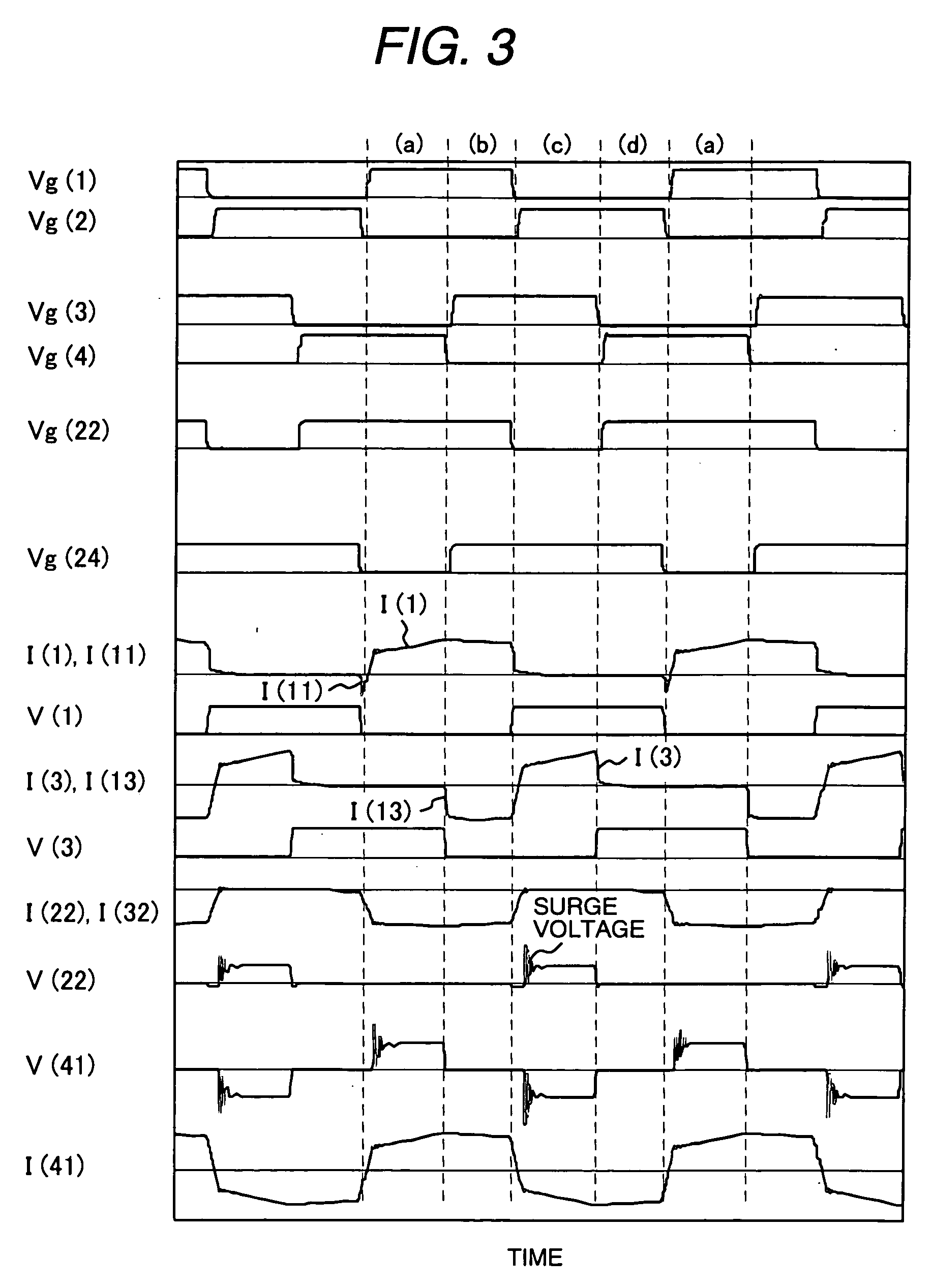

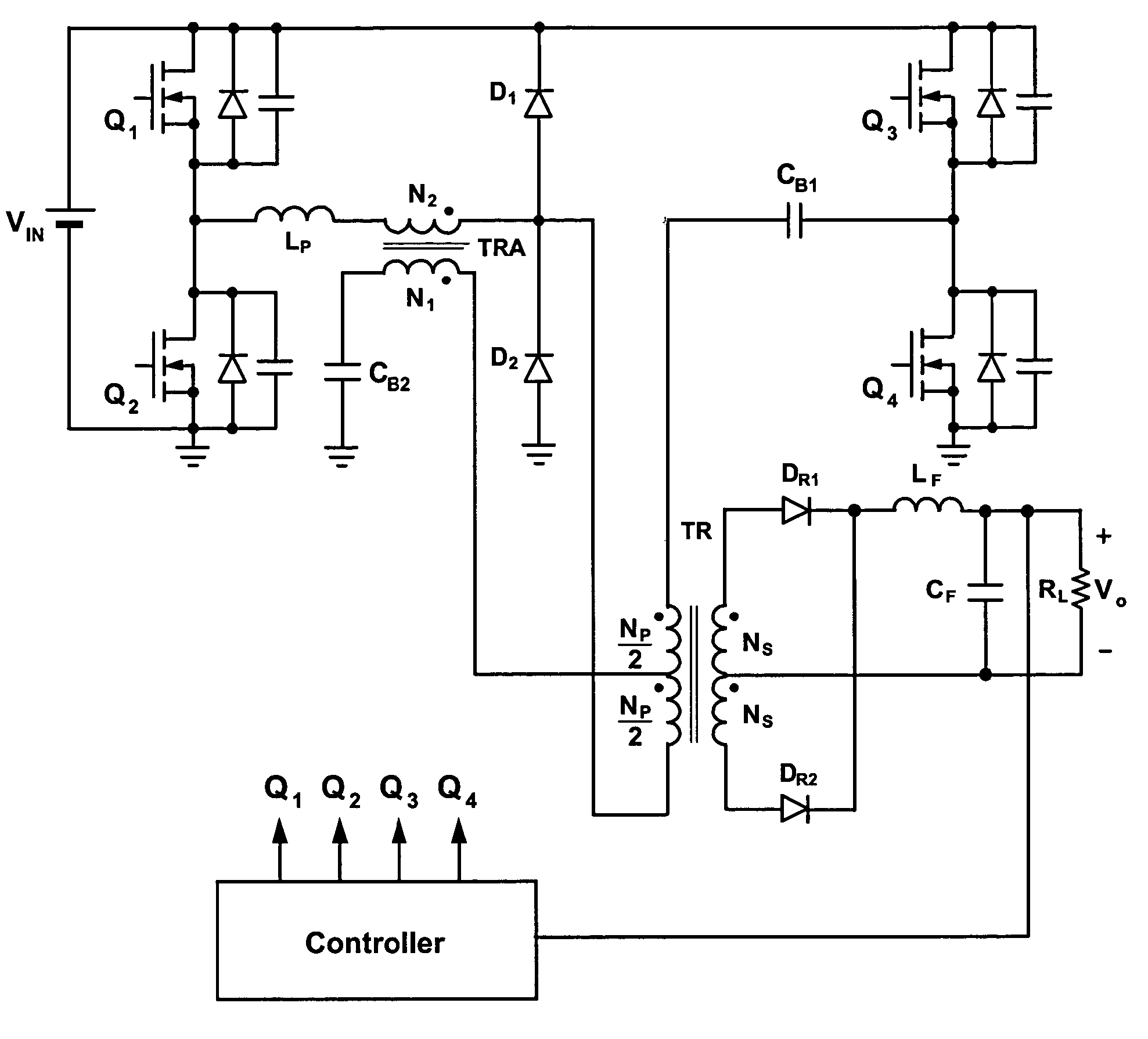

Isolated bidirectional DC-DC converter

ActiveUS7638904B2Effectively miniaturizedTotal current dropEfficient power electronics conversionDc-dc conversionClamp capacitorConverters

The DC-DC converter connects a first and a second switching circuit for converting power mutually between direct current and alternating current respectively to a first DC power source and a second DC power source and has a transformer between the AC terminals thereof. Here, between the AC terminals of the second switching circuit and the negative pole terminal of the DC power source, a voltage clamp circuit composed of a series unit of switching devices with a reverse parallel diode and a clamp condenser is connected.An isolated bidirectional DC-DC converter which prevents a reduction in a circulating current at time of buck and an occurrence of a surge voltage at time of voltage boost and realizes highly efficiency, low noise, and miniaturization is provided.

Owner:HITACHI ASTEMO LTD

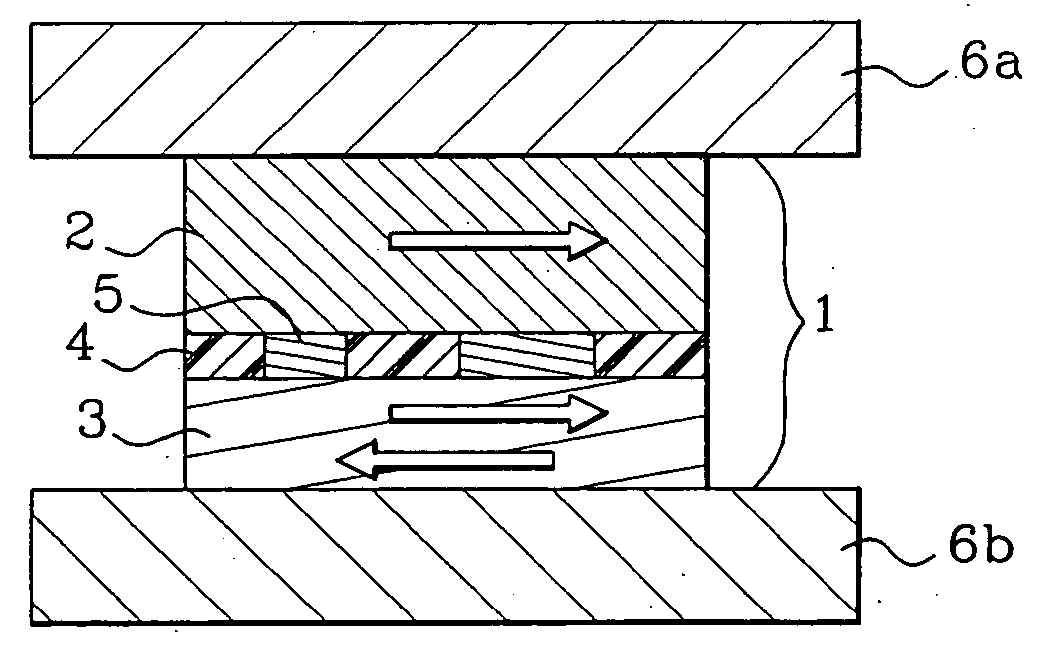

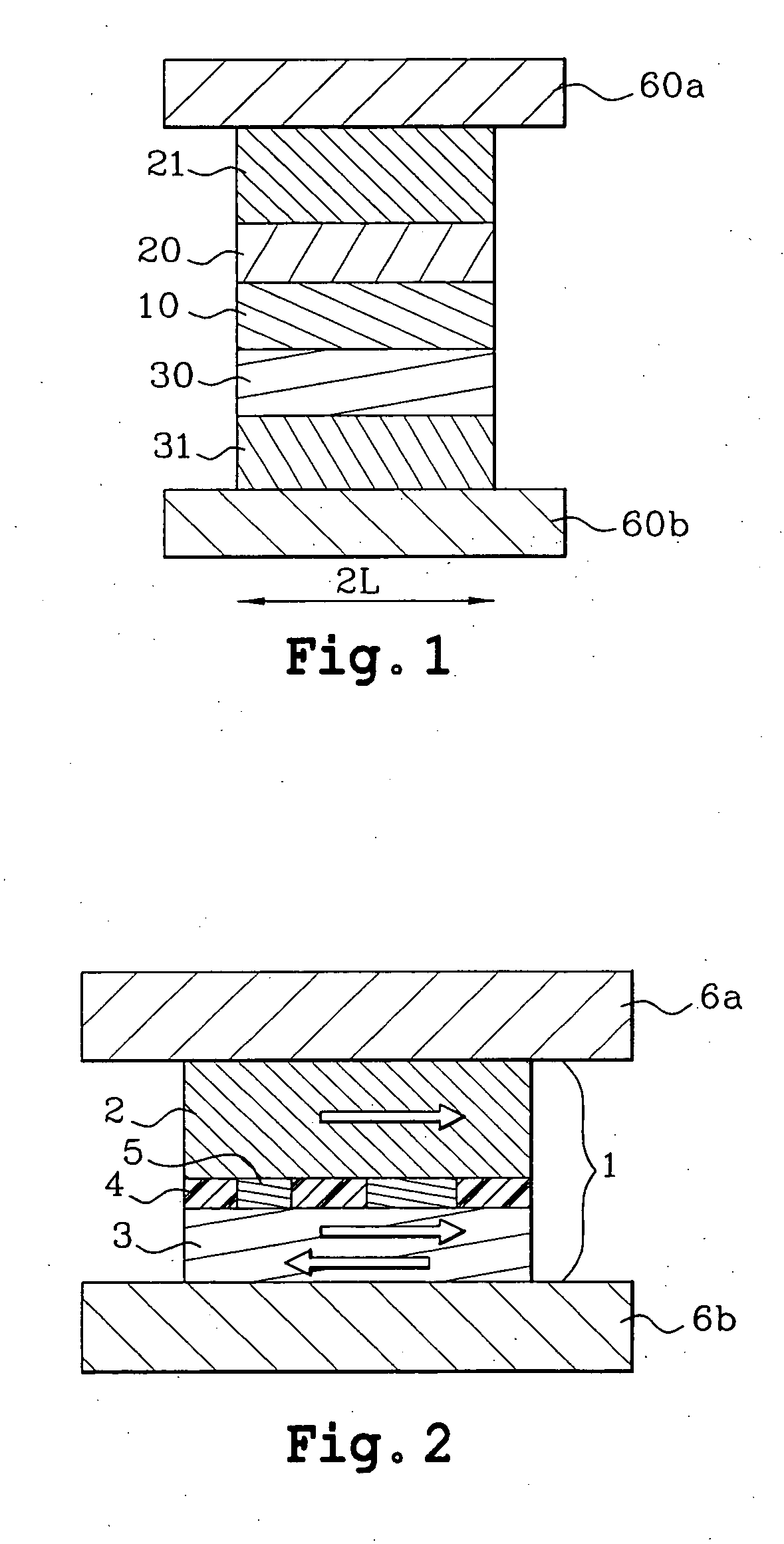

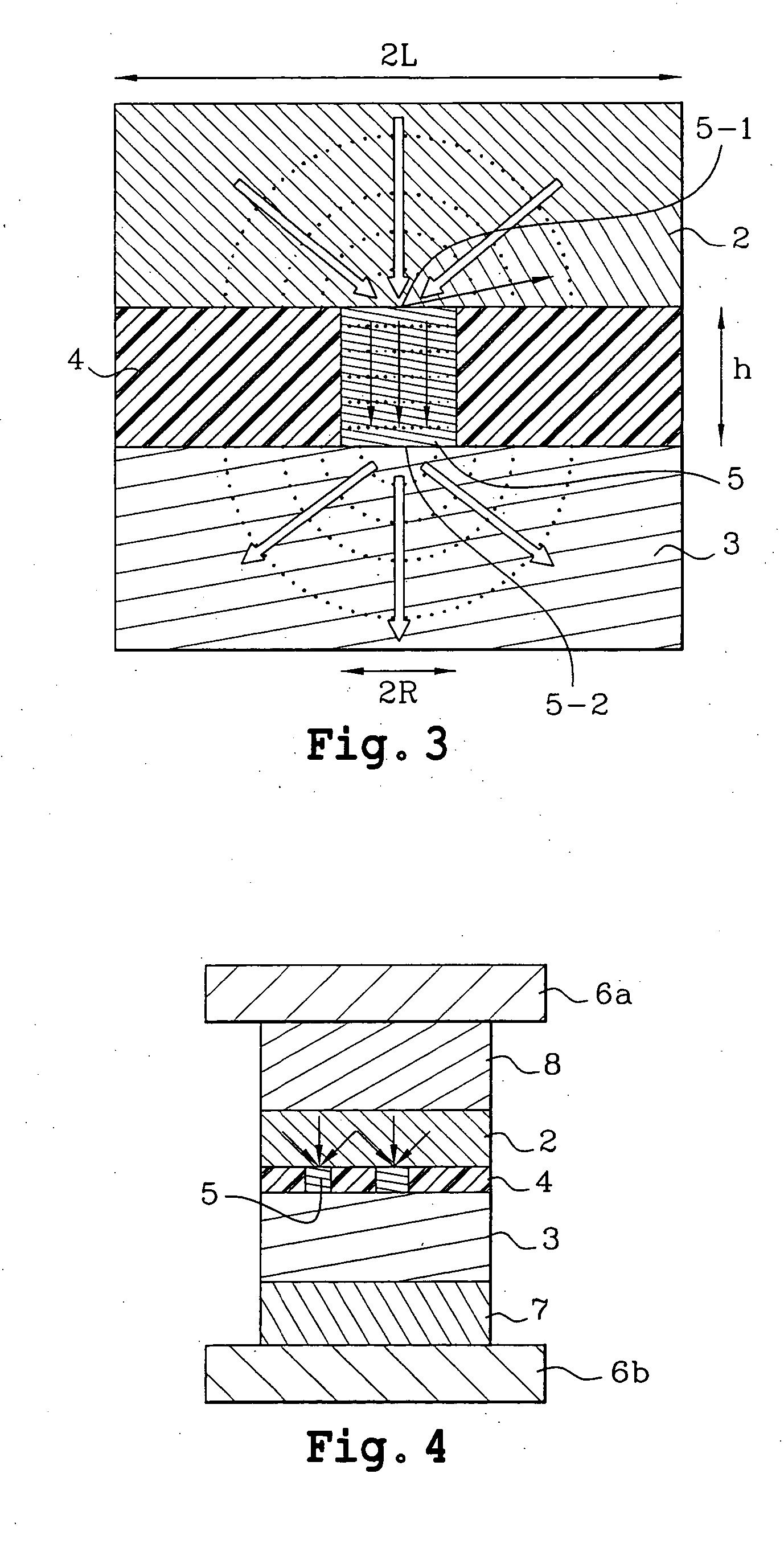

Spin valve magnetoresistive device with enhanced performance

The invention relates to a magnetoresistive device with a spin valve (1) formed from a stack of layers including at least two magnetic layers (2, 3) for which the relative orientation of their magnetisation directions can vary under the influence of a magnetic field, and comprising means (6a, 6b) of circulating a current in the spin valve transverse to the plane of the layers. The spin valve (1) comprises at least one discontinuous dielectric or semiconducting layer (4) in the stack, with electrically conducting bridges (5) passing through the thickness of the dielectric or semiconducting layer, these bridges (5) being designed to locally concentrate the current that passes transversely through the stack. Application particularly suitable for magnetic read heads, and random access memories.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

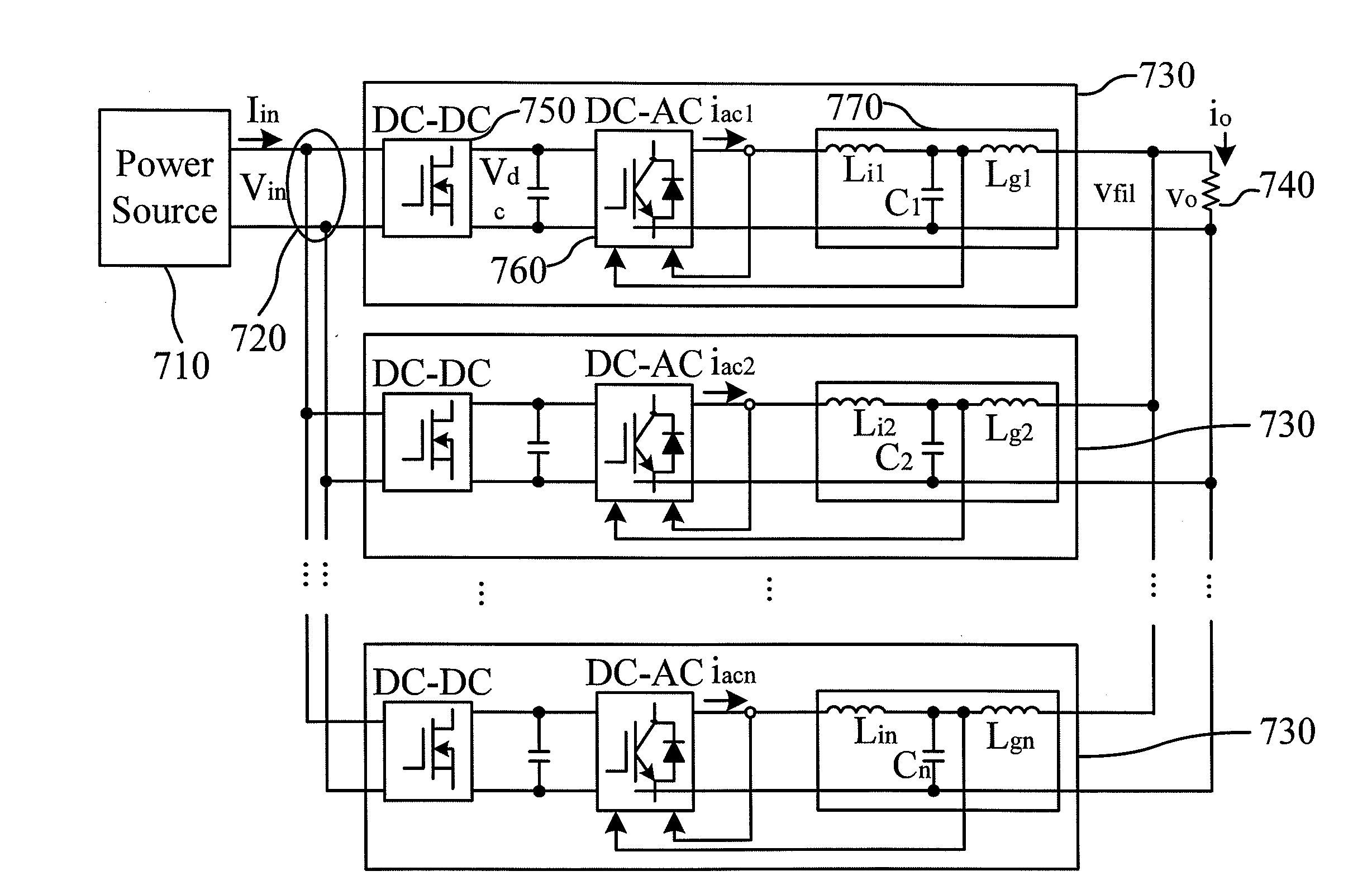

Paralleled power conditioning system with circulating current filter

InactiveUS20090116266A1Total current dropEfficient reductionAc-dc conversionCirculating currentDc voltage

This present invention relates to a paralleled power conditioning system with circulating current filter, comprising: an input terminal for receiving a input power; a plurality of power conditioning units; and a load. Each power conditioning unit includes: a DC / DC converter coupled to the input for receiving the input power so as to convert the input power to a DC voltage; a DC / AC inverter coupled to the DC / DC converter for converting the DC voltage to a AC voltage; and a filter coupled to the DC / AC inverter for eliminating the noise generated by the AC voltage and the circulating current among the plurality of power conditioning units so as to generate a filter voltage. The load is connected to the plurality of power conditioning units. The plurality of power conditioning units are connected in parallel to the load.

Owner:TATUNG COMPANY

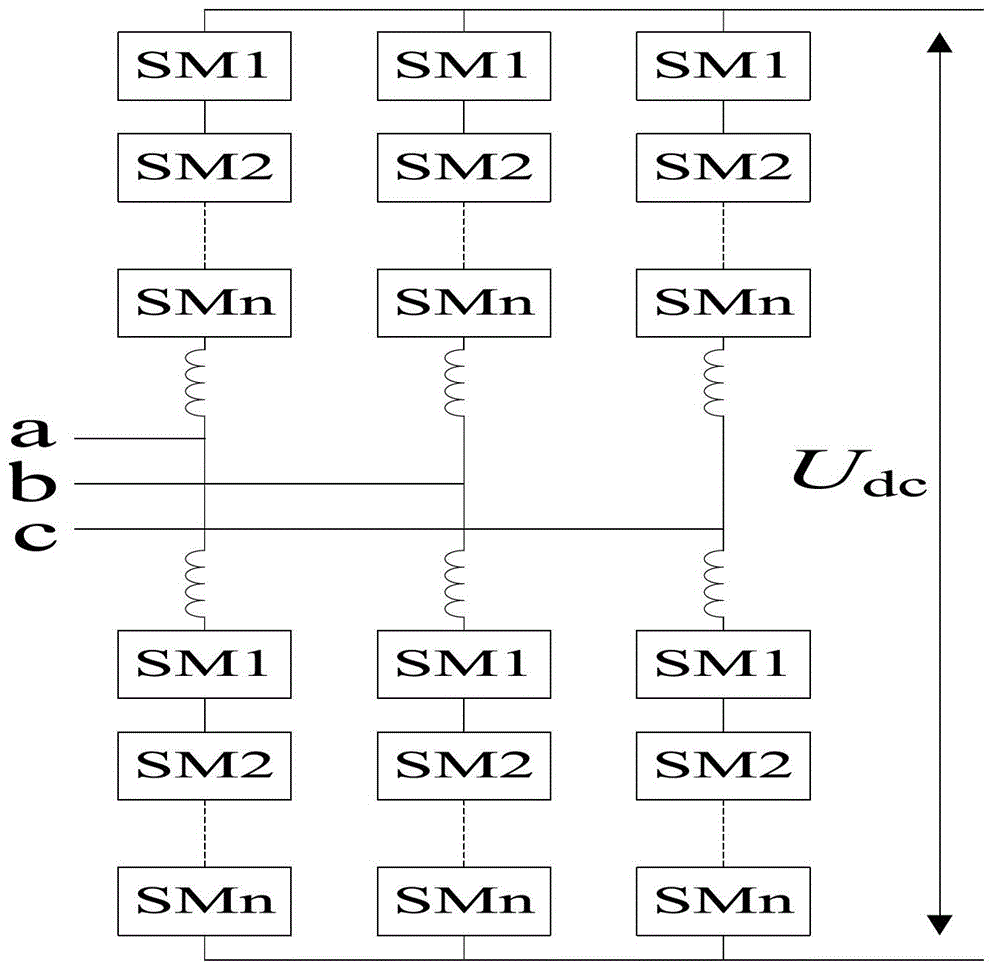

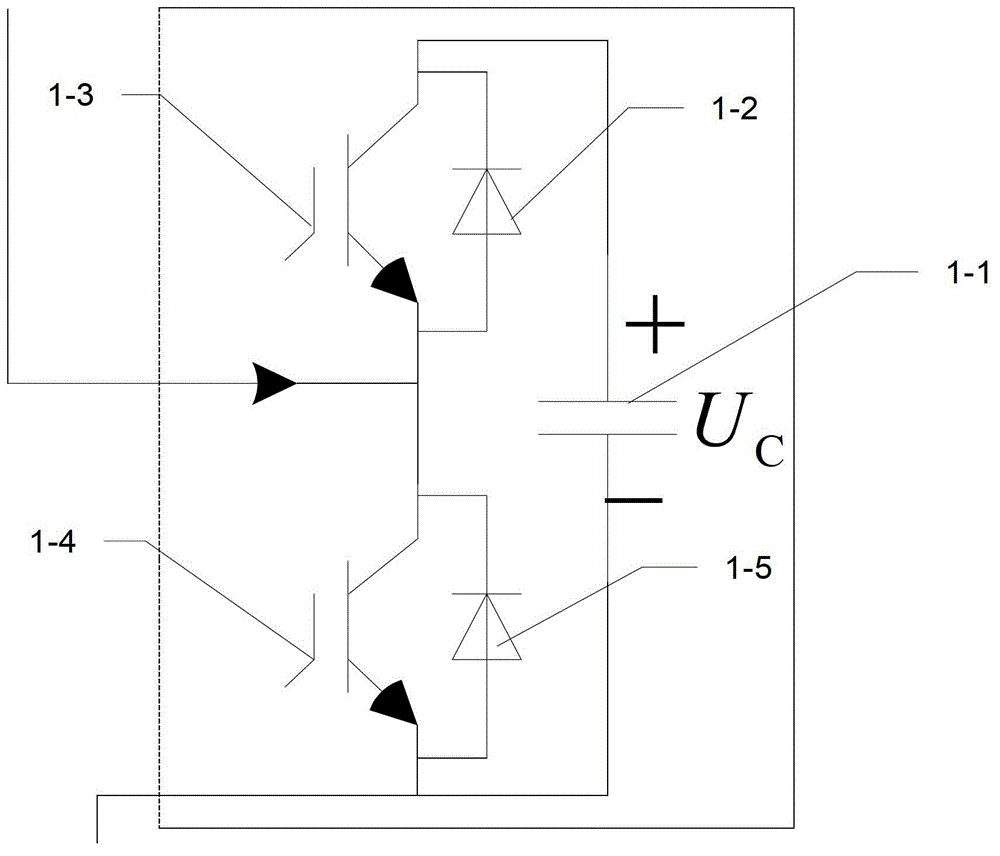

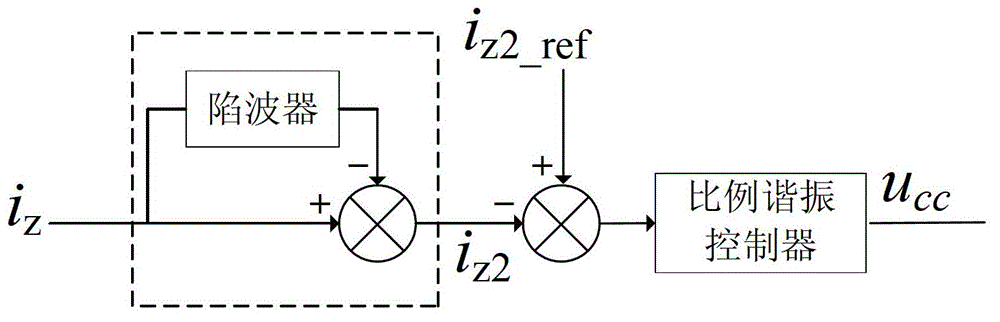

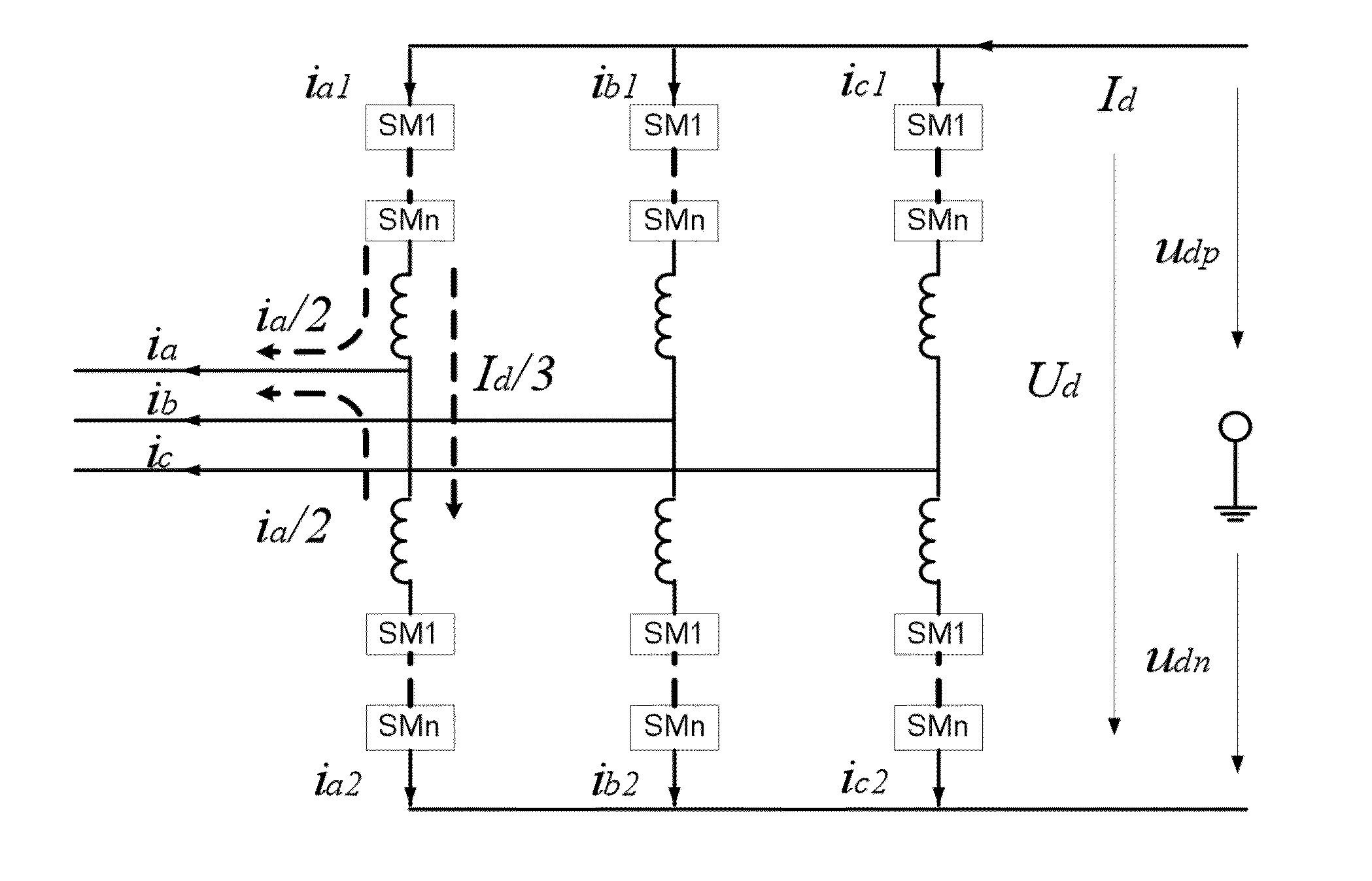

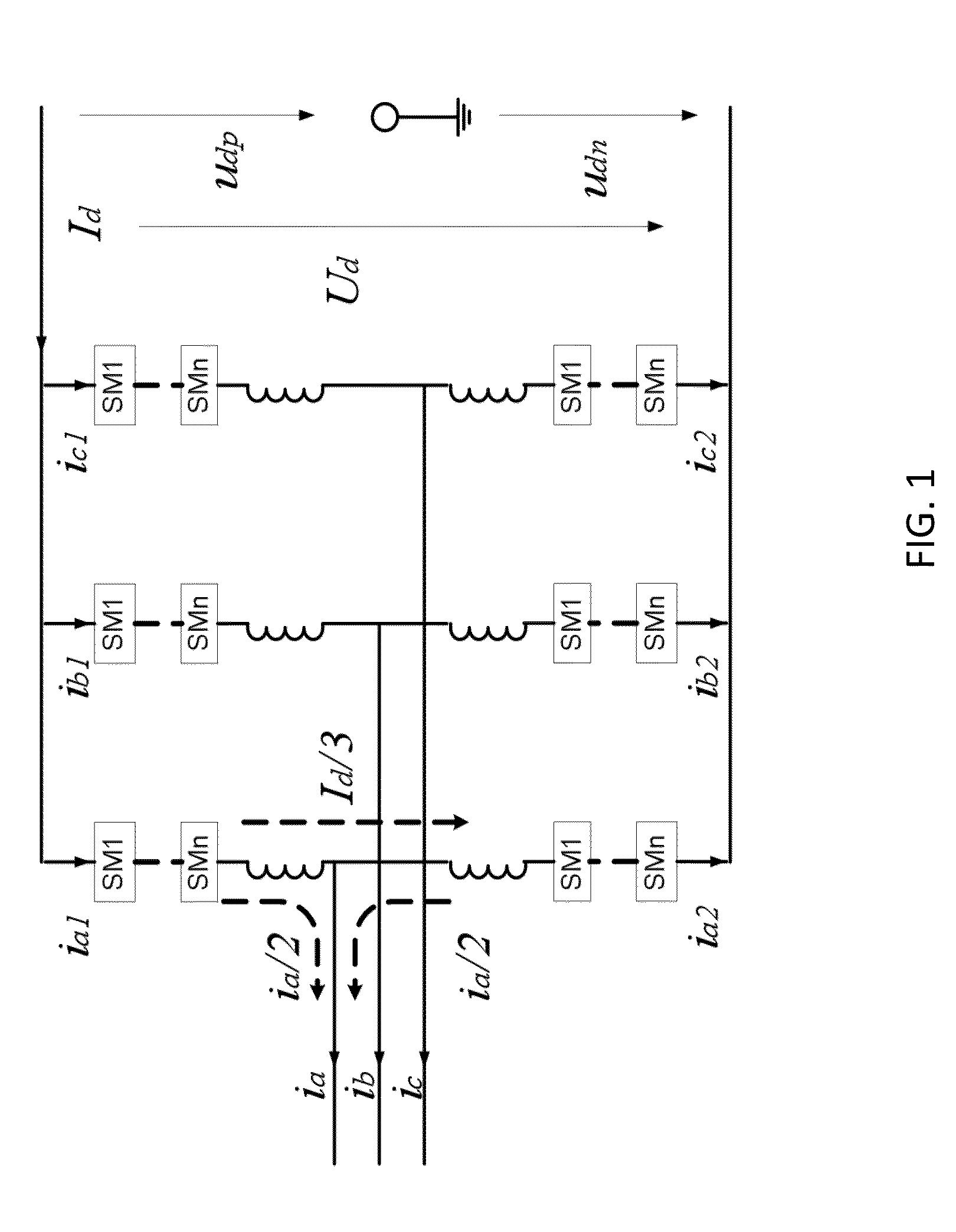

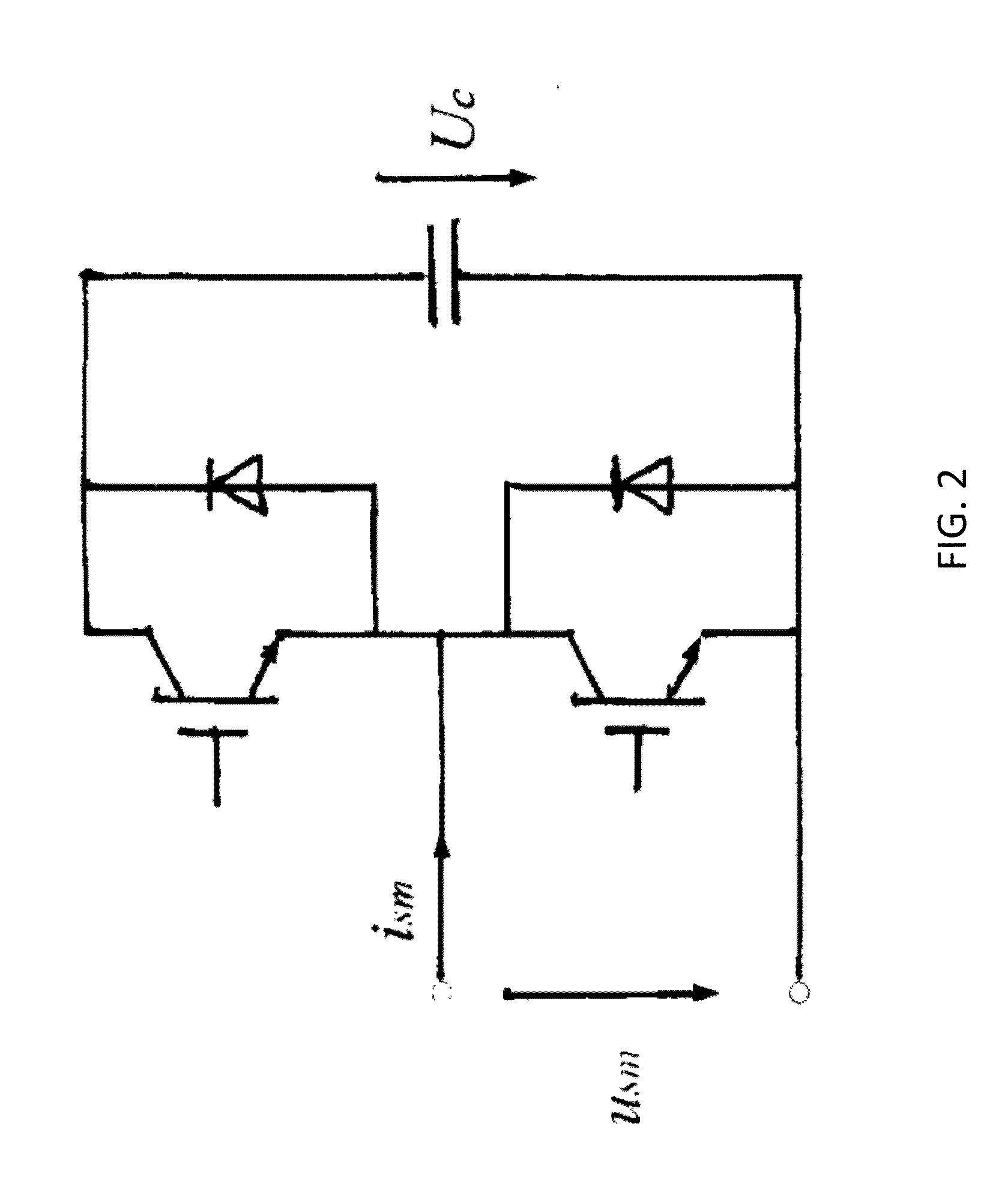

Modular multilevel converter (MMC) circulating current suppression method

InactiveCN103337980AReduce circulationReduce lossDc-ac conversion without reversalSingle phaseCirculating current

A modular multilevel converter (MMC) circulating current suppression method is provided. The invention belongs to the technical field of electrical engineering, specifically relates to a suppression method for suppressing internal circulating current of an MMC, and solves problems of incompatibility with single phase and three phase systems, poor circulating current suppression capability and a complicated control method in conventional MMC circulating current suppression methods. According to the MMC circulating current suppression method, a wave trap is used for acquiring secondary harmonic signals in phase current; the harmonic signals in the phase current are subtracted from the average current of the phase current so that average current signals of an upper bridge arm and a lower bridge arm in which secondary harmonic waves are subtracted are acquired; the average current signals of an upper bridge arm and a lower bridge arm in which secondary harmonic waves are subtracted is taken to do subtraction with a reference current, and thus secondary harmonic signals of the circulating current is acquired; a proportional resonant controller is used for performing current tracing on the secondary harmonic waves of the circulating current, and thus voltage compensation signals are acquired; the compensation signals are processed and then are given back to sub-modules of the upper bridge arm of the MMC, and thus circulating current suppression is realized. The MMC circulating current suppression method is suitable for the technical field of electrical engineering.

Owner:HARBIN INST OF TECH

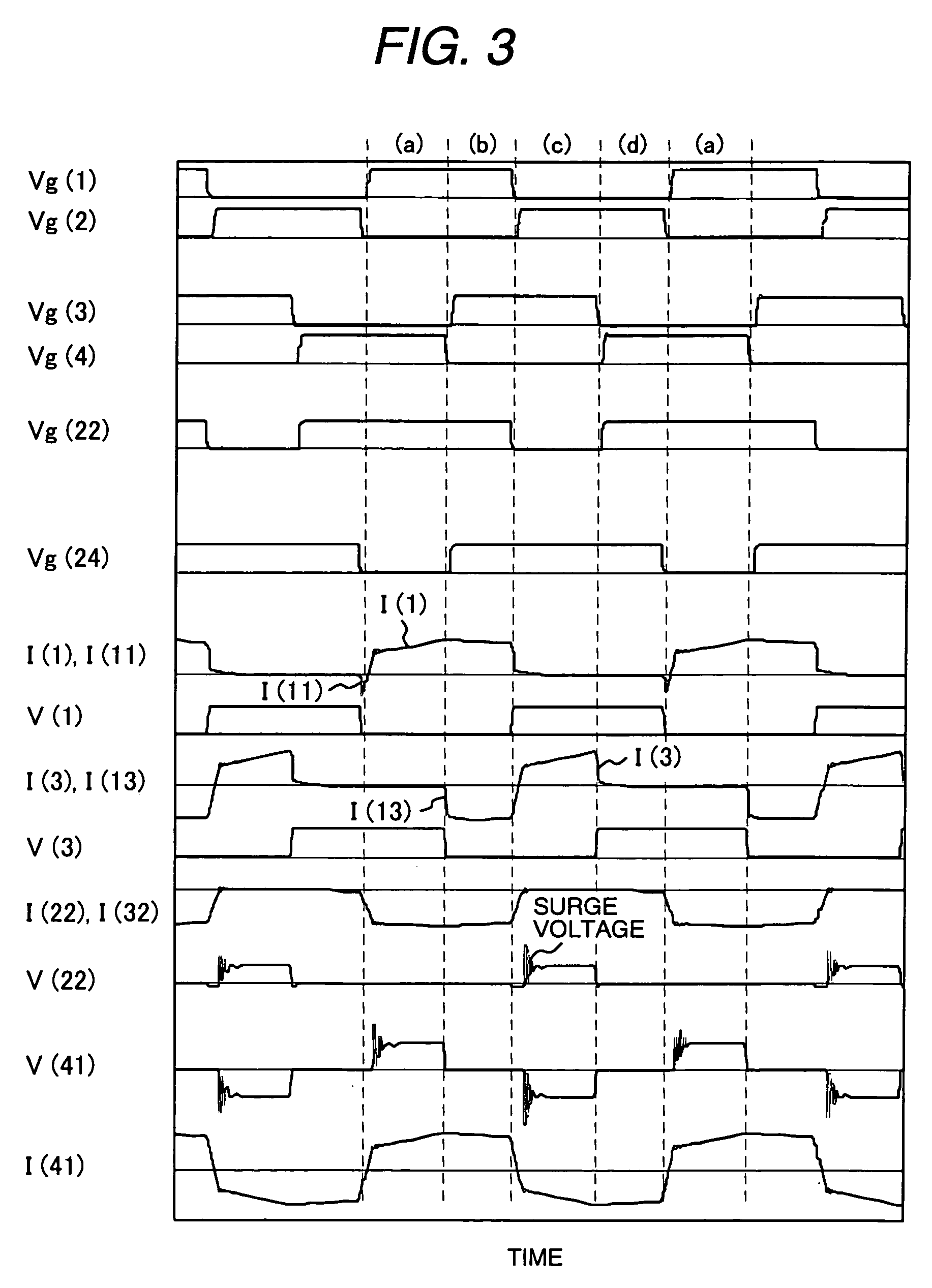

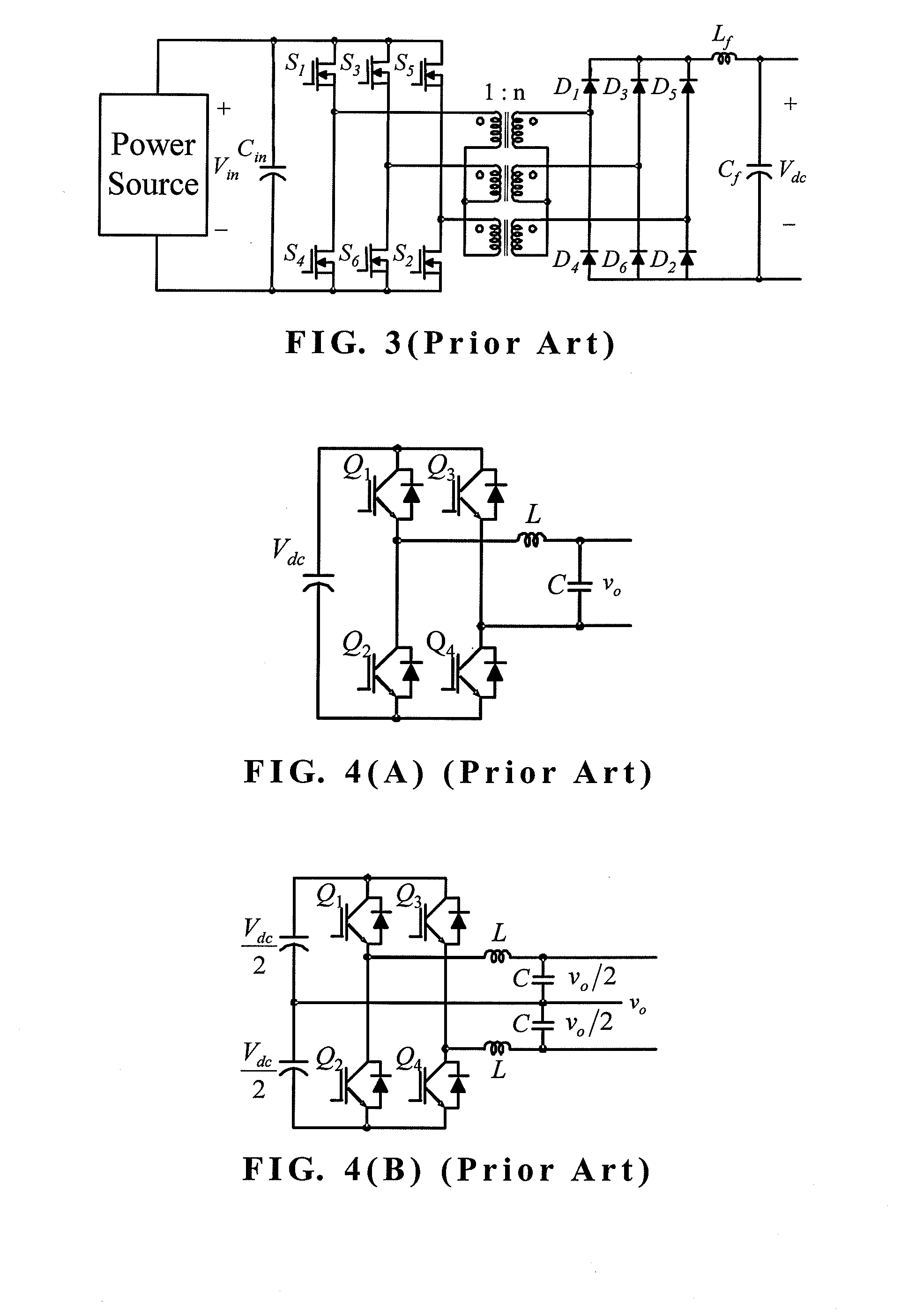

Dual-bridge DC-DC converter and its control method

ActiveCN101170279ADC-AC is easy to implementImprove transmission efficiencyApparatus with intermediate ac conversionElectric variable regulationFiltrationFull bridge

The invention discloses a DC-DC converter circuit and a relevant control method; wherein, the converter comprises two DC-AC inverters; each can create symmetrical and isolated square waves or other similar AC output voltage. Through the movement of the phase of one of the DC-AC inverters, the overlapping part of the corresponding voltage of a DC output filtration circuit, which is the two DC-AC inverters can be applied to, will be changed accordingly, so as to reach the target of regulating the output voltage. A double half-bridge and double full-bridge DC-DC converters are two typical types of the converters. During normal running process, the bridge-type inverter is always running in a 50 percent of duty cycle, so as to fulfill Zero Voltage Switching (ZVS) in broad loads. Meanwhile, the invention can also eliminate circulation current, so as to improve the efficiency of power conversion. As for the adjustment and startup of low output voltage, the circuit can work in a Pulse Width Modulation (PWM) status.

Owner:叶忠

Valve current control method based on modular multi-level converter

InactiveUS20140003101A1Improve output characteristicsRealize stability of dynamic performanceDc-ac conversion without reversalCapacitor voltageDc current

The present invention relates to valve current control method based on modular multi-level converter, this method includes the control of the low frequency oscillations of the current and that of double frequency harmonic component; For said low frequency oscillations of the current, the control method includes some steps as below: first, calculate the half of the sum of the upper arm current and the lower arm current, it is the valve DC current component, said DC current component is arm circulating current; Secondly, comparing the actual value of the arm circulating current to setting value of that, the error is obtained, after some signal processing, additional output set voltage is obtained. For said the double frequency harmonic component of current, the control method includes some steps as below: firstly, figure out capacitor voltage fluctuation prediction value of the sub module; secondly, the output voltage is divided by the sum of the sub module reference voltage and the capacitor voltage fluctuation prediction value, and get the actual output set number of sub module. This method not only can realize stability of the dynamic performance of the system, but also can suppress the arm double frequency harmonic component, at the same time under the abnormal conditions of the AC system; the valve current has good output characteristics.

Owner:STATE GRID CORP OF CHINA +1

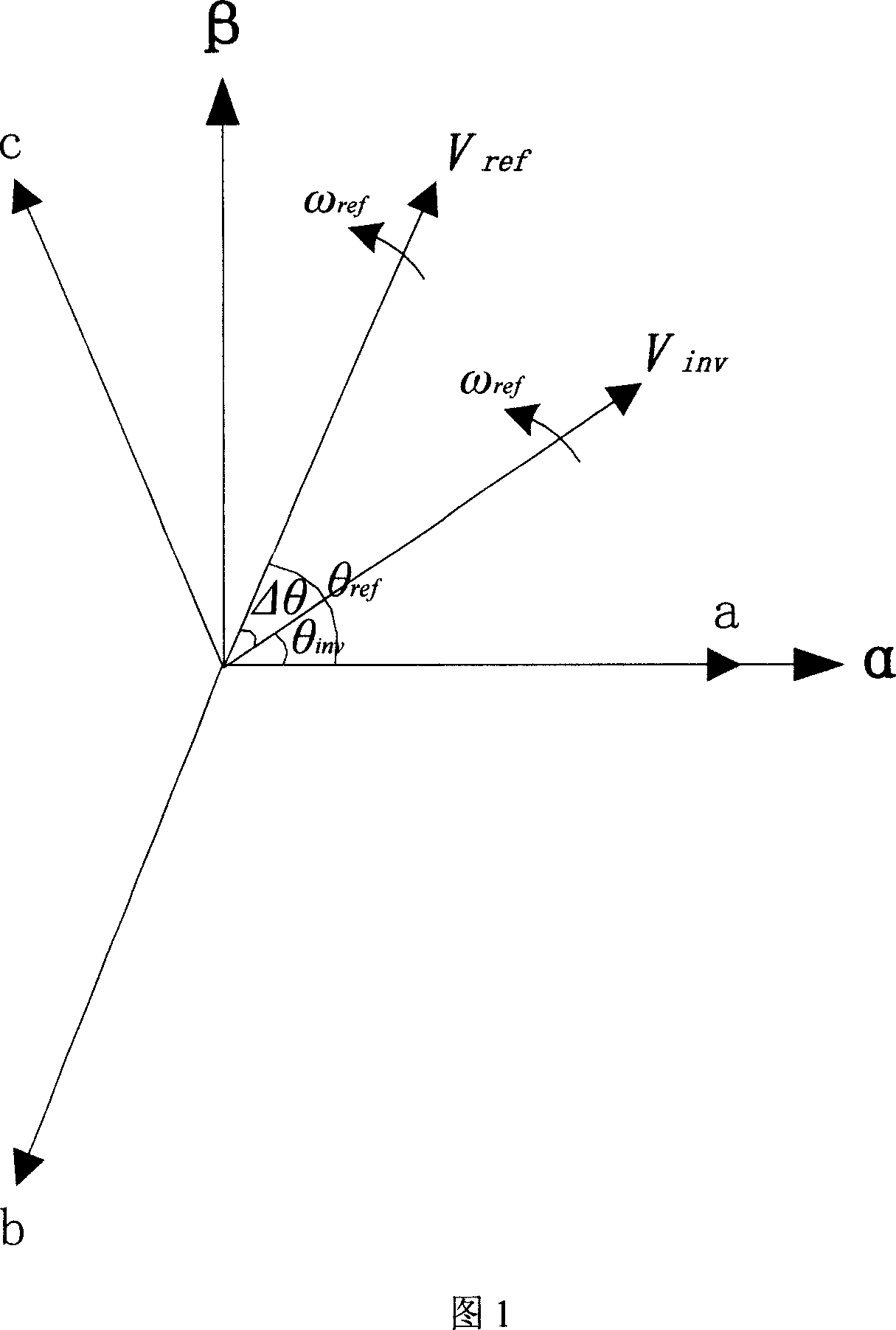

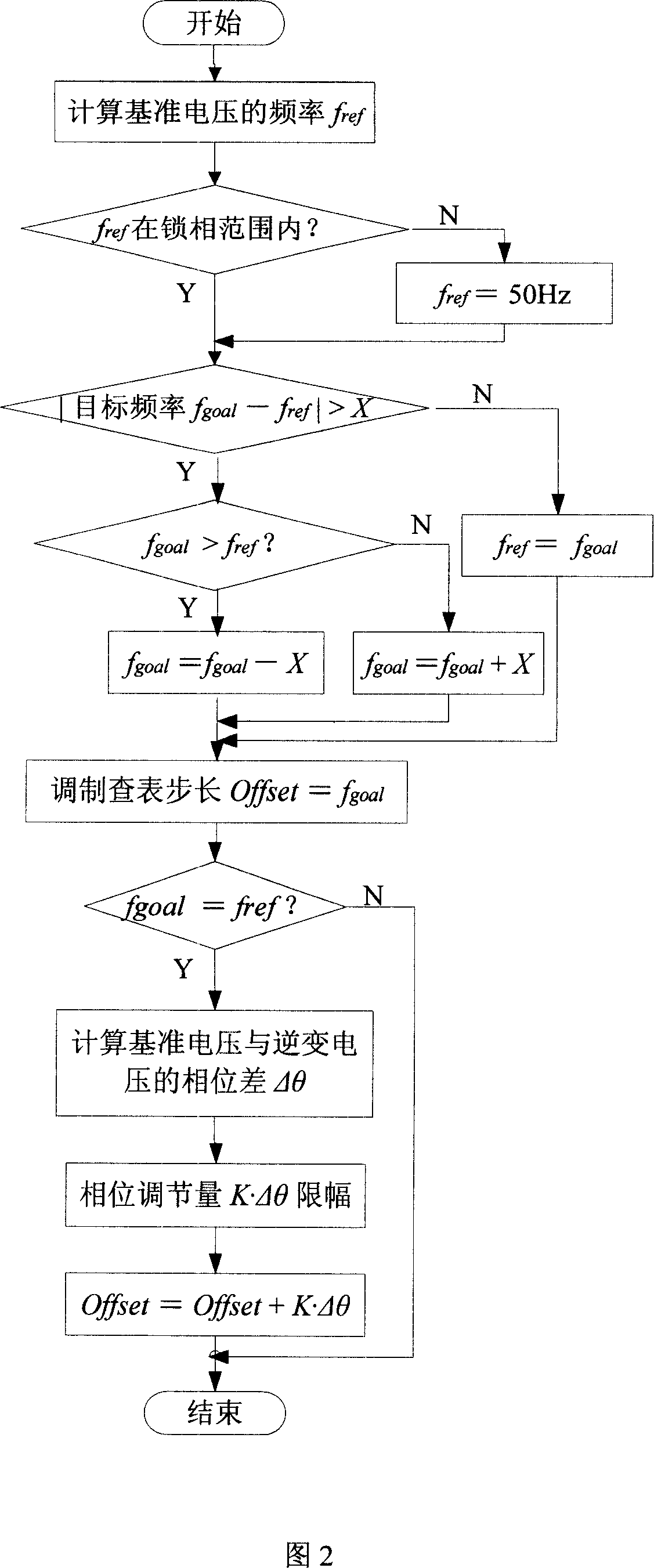

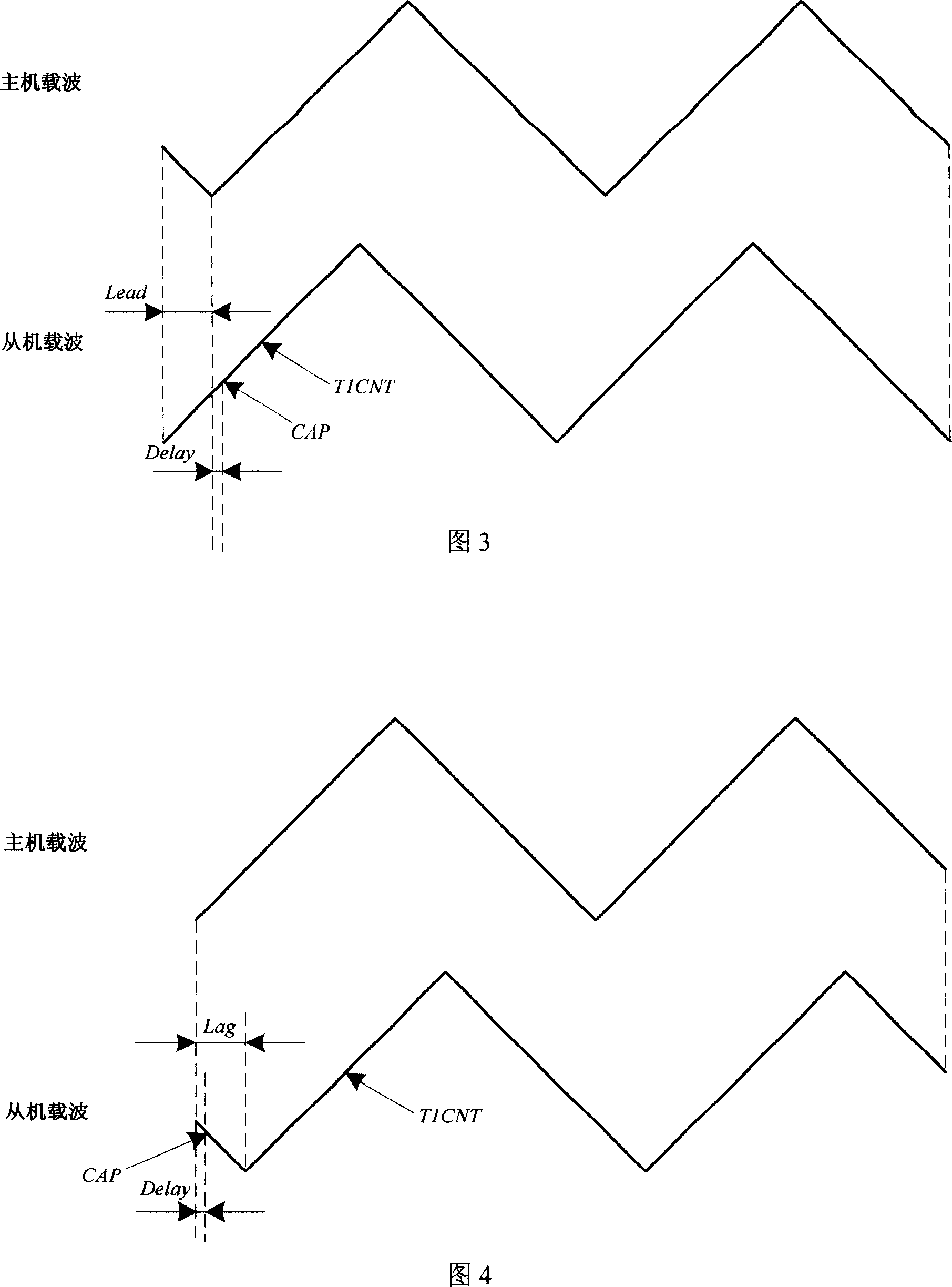

Method for synchronization of three-phase parallel type inversion module

ActiveCN101110518AEliminate High Frequency Content ProblemsSolve the three-phase phase lock problemSingle network parallel feeding arrangementsCarrier signalCirculating current

A three-phase parallel-connection reversal module synchronization method is provided. In a system, each reversal module realizes free competition by seizing a bus to confirm a host machine and an auxiliary machine. Wherein, the main machine and the auxiliary machine respectively take a bypass voltage and a main machine output voltage as a phase locking tracking source. Each module samples a three-phase tracking source and a three-phase output voltage and calculates frequency of the tracking source voltage and the output voltage, frequency difference and phase difference. Based on the frequency difference between the tracking source and the output voltage, look-up length of a PWM modulation sine wave is adjusted to gradually fix frequency of the tracking source. And then, the look-up length of the PWM modulation sine wave is slightly adjusted according to the phase difference between the tracking source and the output voltage to reduce phase difference between them and fix the phase. A synchronous pulse is transmitted at a zero passage of a main counter through the main machine. The auxiliary machine captures the pulse and sends the pulse to a rectification method of the main counter for carrier wave synchronization. The present invention solves a problem of three-phase locking and eliminates high-frequency component in circulating currents.

Owner:ZTE CORP

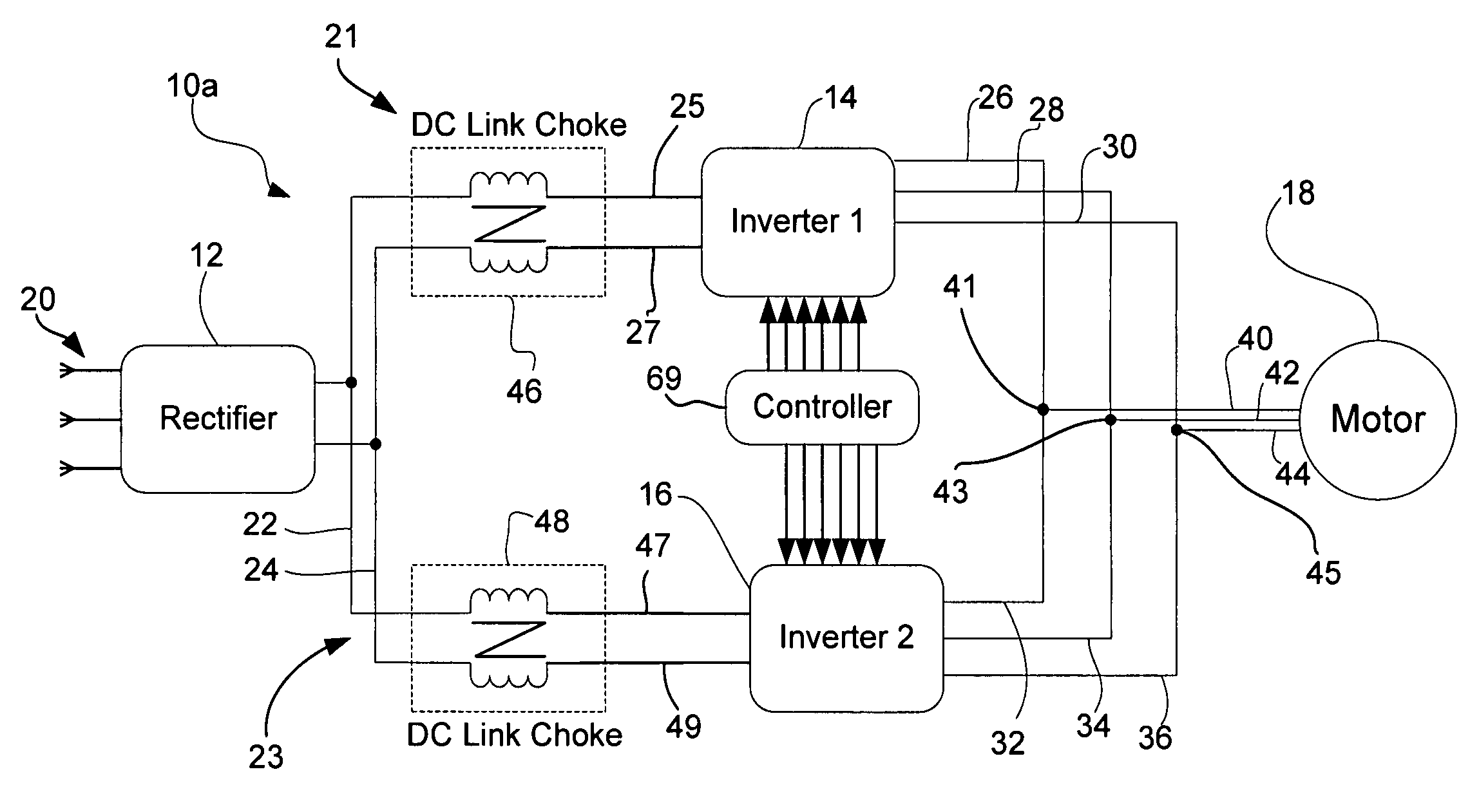

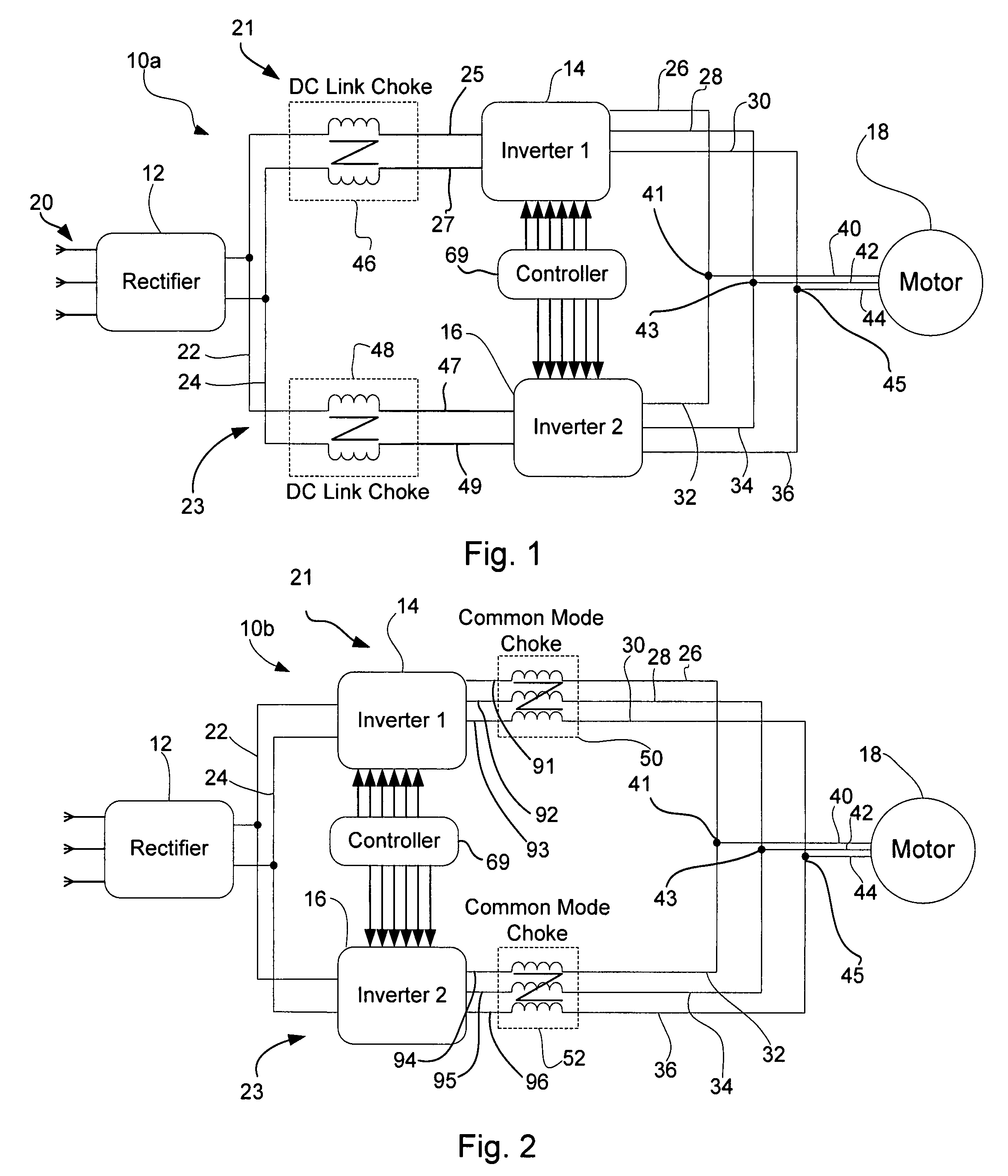

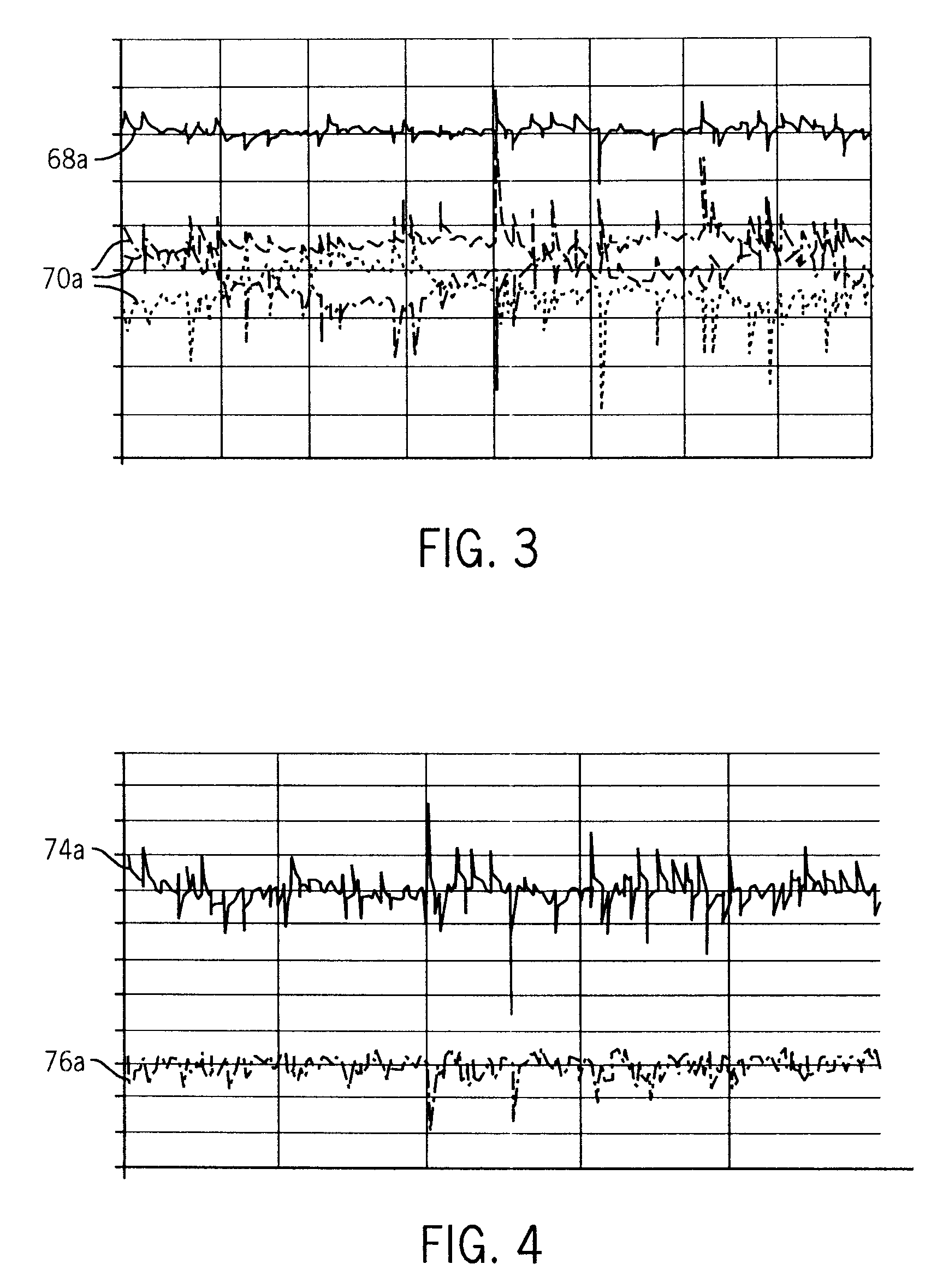

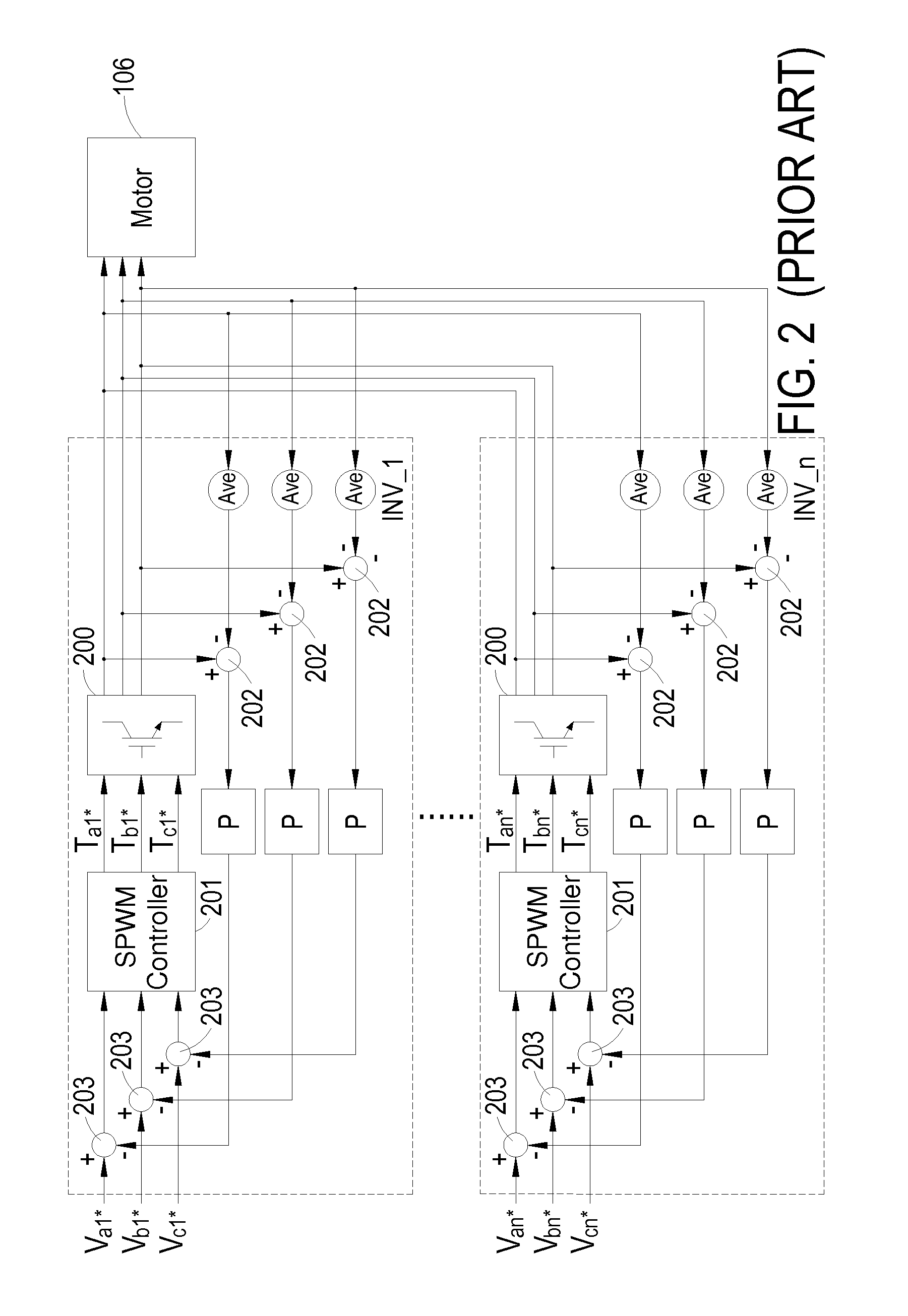

Method and apparatus for synchronized parallel operation of PWM inverters with limited circulating current

InactiveUS7564703B1Conversion with intermediate conversion to dcAc-dc conversionSoftware engineeringCirculating current

An apparatus and method for converting DC voltage across positive and negative DC buses to three phase AC voltages on first, second and third AC output lines, the method comprising the steps of providing first and second three phase inverters that include a first subset of inverter switches and a second subset of inverter switches, respectively, linking a first choke in series with the first three phase inverter between the positive and negative DC buses and the AC output lines, linking a second choke in series with the second three phase inverter between the positive and negative DC buses and the AC output lines and synchronously controlling the first and second inverter switch subsets so that switching of first and second inverter switch subsets is substantially synchronized among the three phases.

Owner:ROCKWELL AUTOMATION TECH

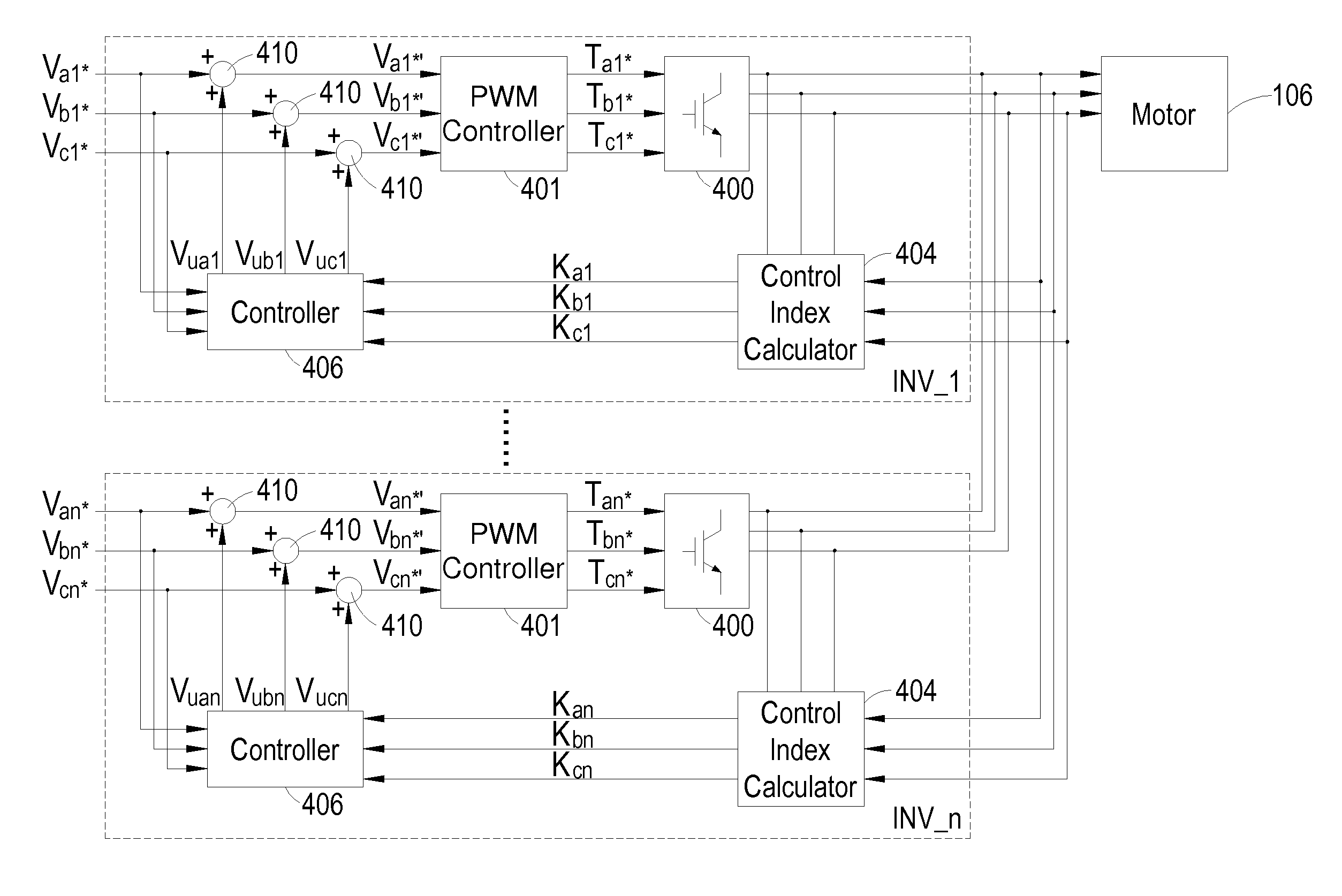

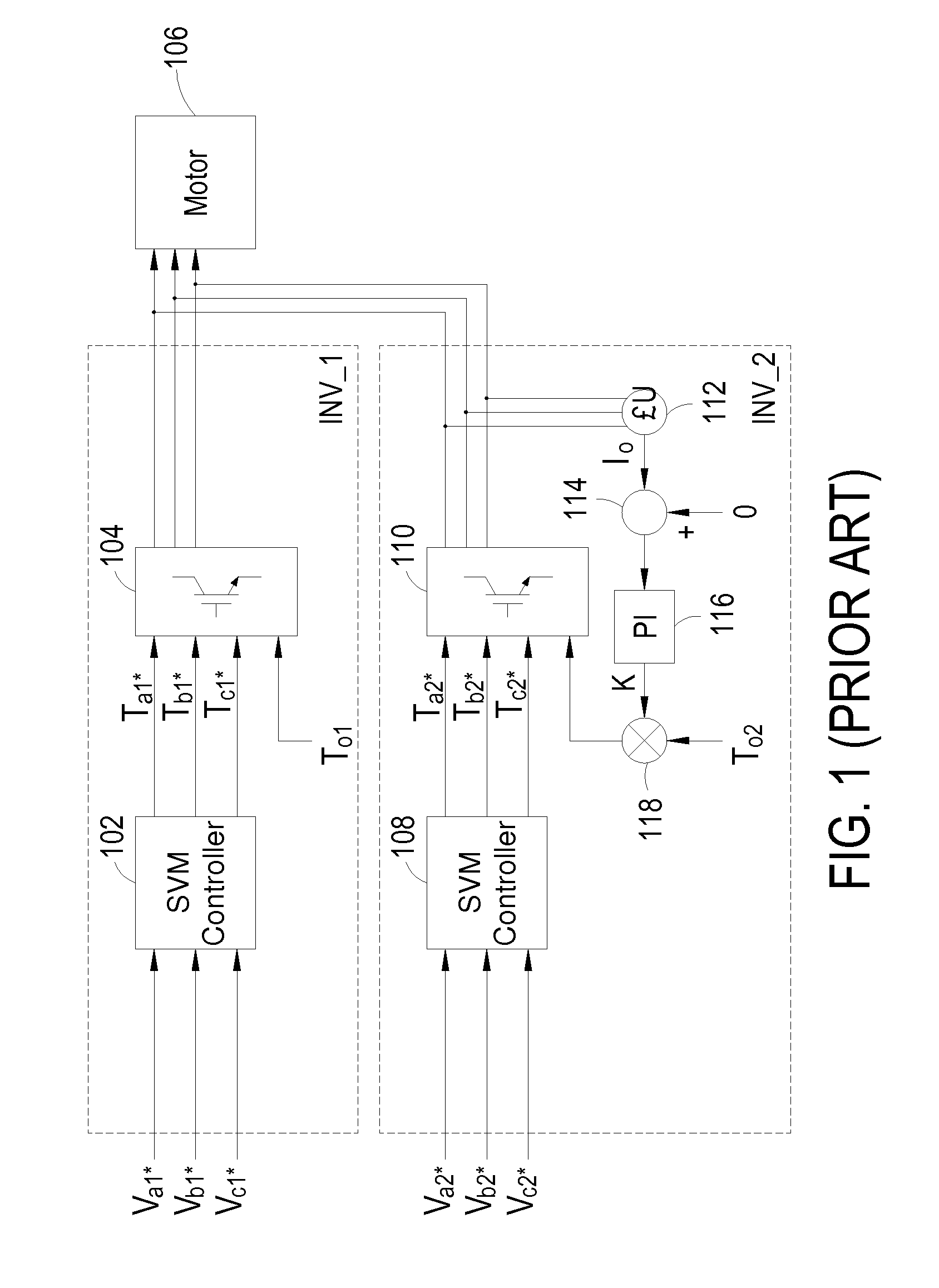

Parallel inverter drive system and the apparatus and method for suppressing circulating current in such system

ActiveUS20130063063A1Minimize impactMore cost-effectiveMotor/generator/converter stoppersAC motor controlFrequency changerPower inverter

Proposed is a parallel inverter drive system including includes a plurality of inverter drives connected in parallel with each other, in which each inverter drive includes a switch; a PWM controller connected to the switch for controlling switching operations of the switch device according to a duty cycle signal; and a circulating current suppressor for collecting current information associated with the current of each inverter drive and a summation current, and generating an index according to the collected current information and the desired circulating current quantity. A zero-sequence voltage is generated for each phase of a three-phase voltage command according to the index and the voltage command and the operating mode of the inverter drive, thereby injecting the zero-sequence voltage into the voltage command with a feed-forward configuration so as to fix the voltage command. The PWM controller can generate the duty cycle signal according to the fixed voltage command.

Owner:DELTA ELECTRONICS INC

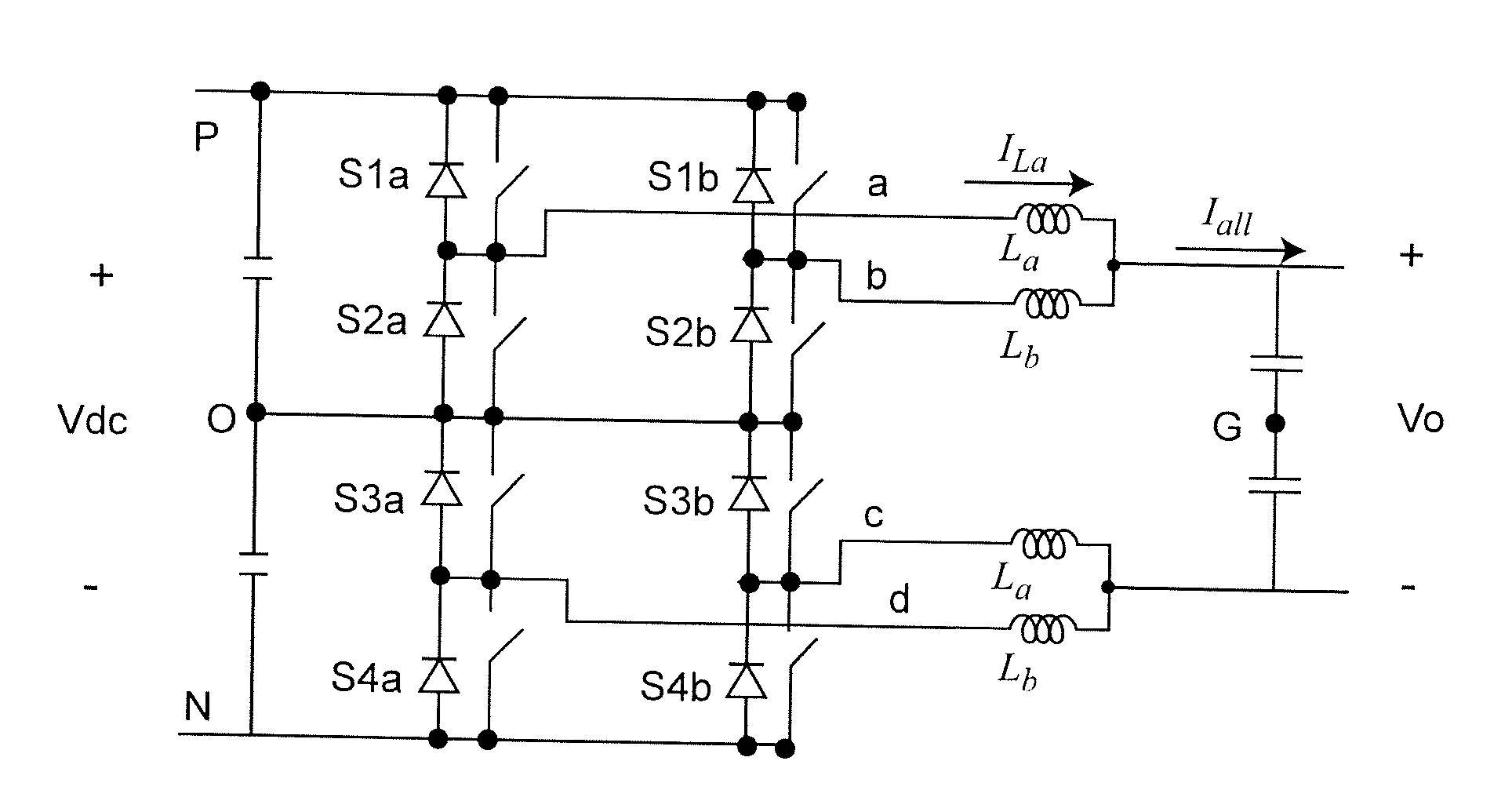

Coupled Inductor for Interleaved Multi-Phase Three-Level DC-DC Converters

ActiveUS20160172976A1Reduces current circulatingTotal current dropAc-dc conversionDc-dc conversionThree levelEngineering

Output current ripple is reduced in a three-level DC-DC power converter by connecting a plurality of phase legs in parallel between a source of input power and an output of the power converter and conducting power from the source of input power to the power converter output in an interleaved manner. The large current that results from such interleaved operation is reduced to acceptable levels, potentially less than the output current ripple of the power converter by providing inversely coupled inductors having a mutual inductance preferably greater than the inductor of the power converter in respective phase legs and in series in the circulating current path to avoid any need to increase the power converter inductance due to the circulating current. The inductor and inversely coupled inductors are preferably integrated into a single magnetic element of compact design.

Owner:VIRGINIA TECH INTPROP INC

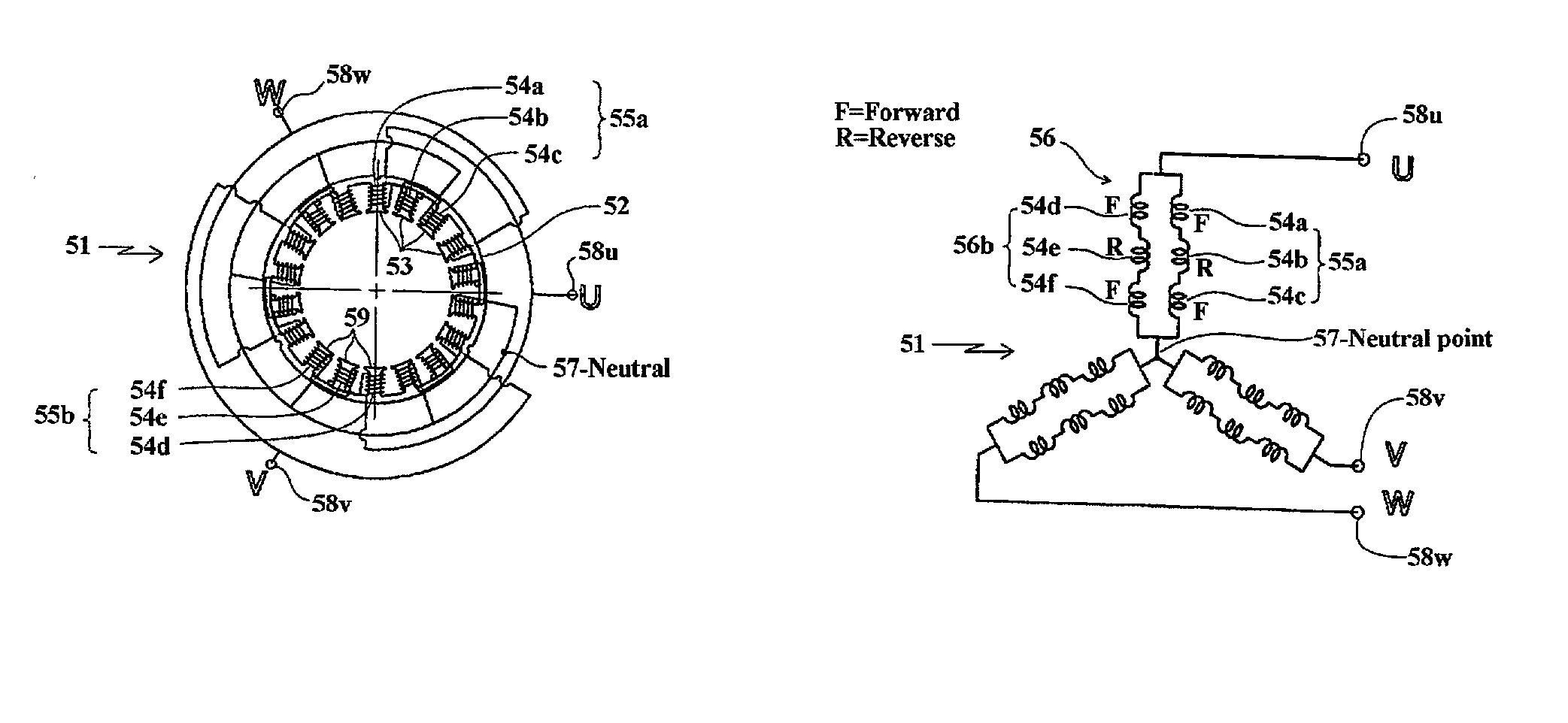

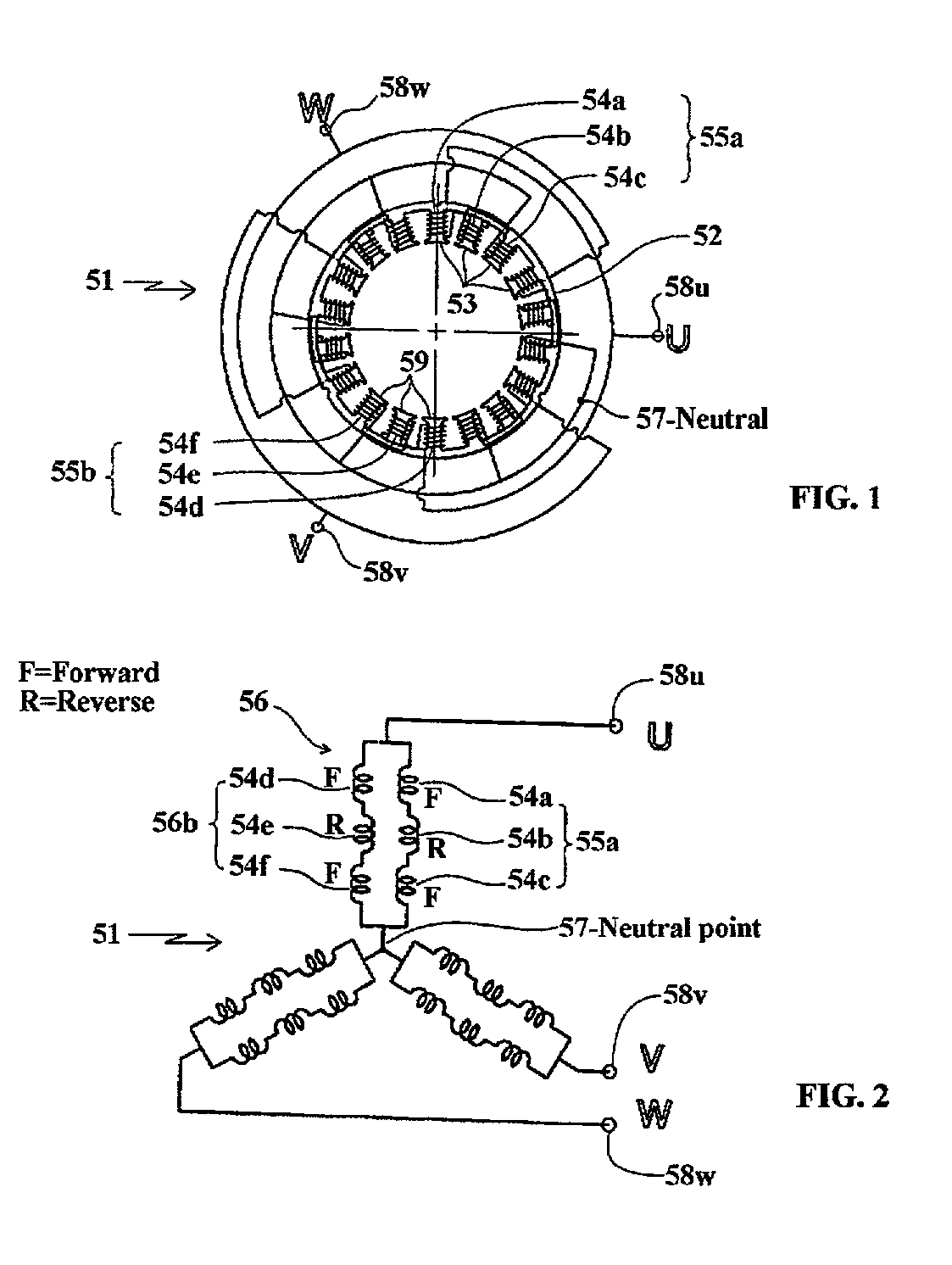

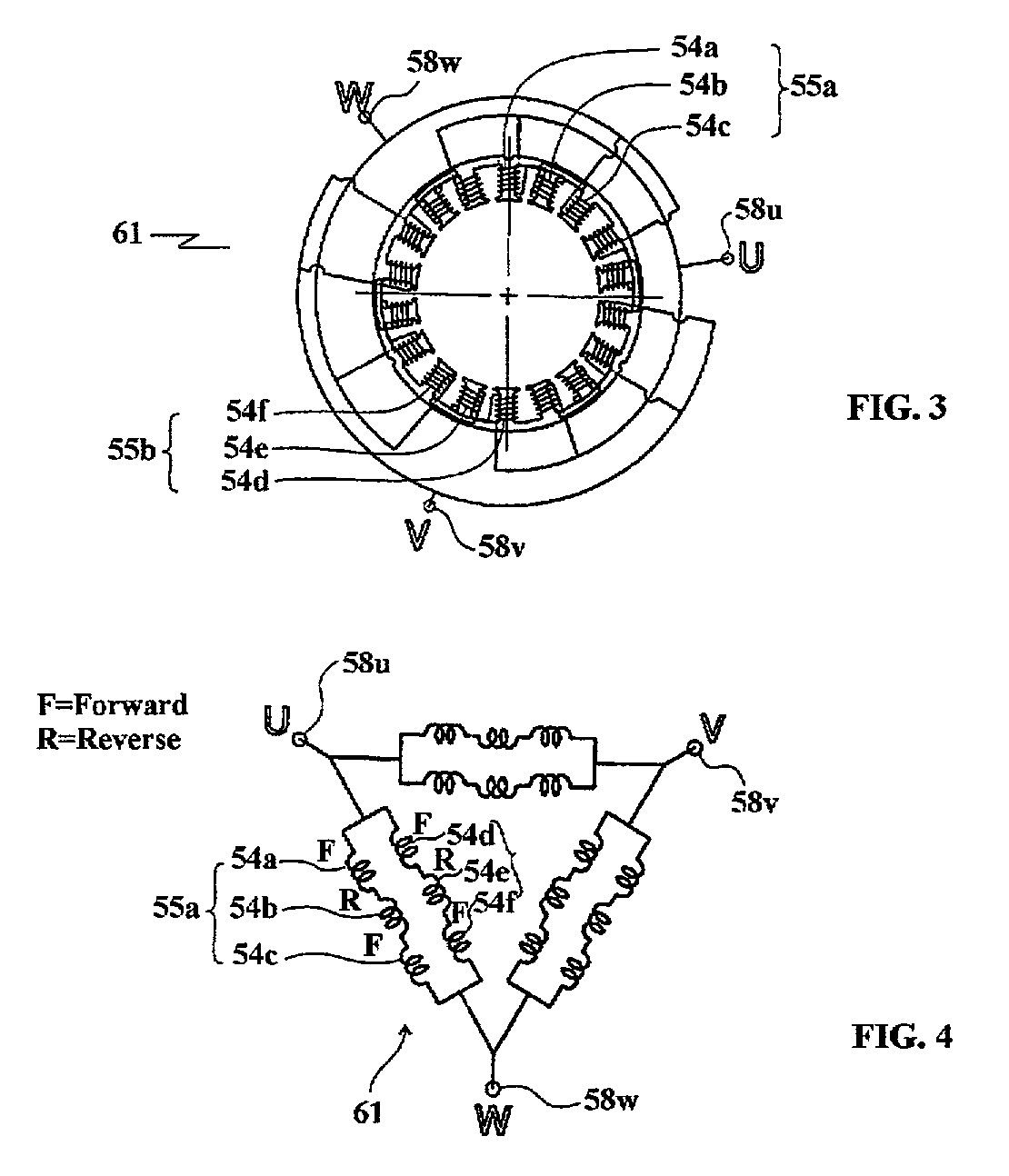

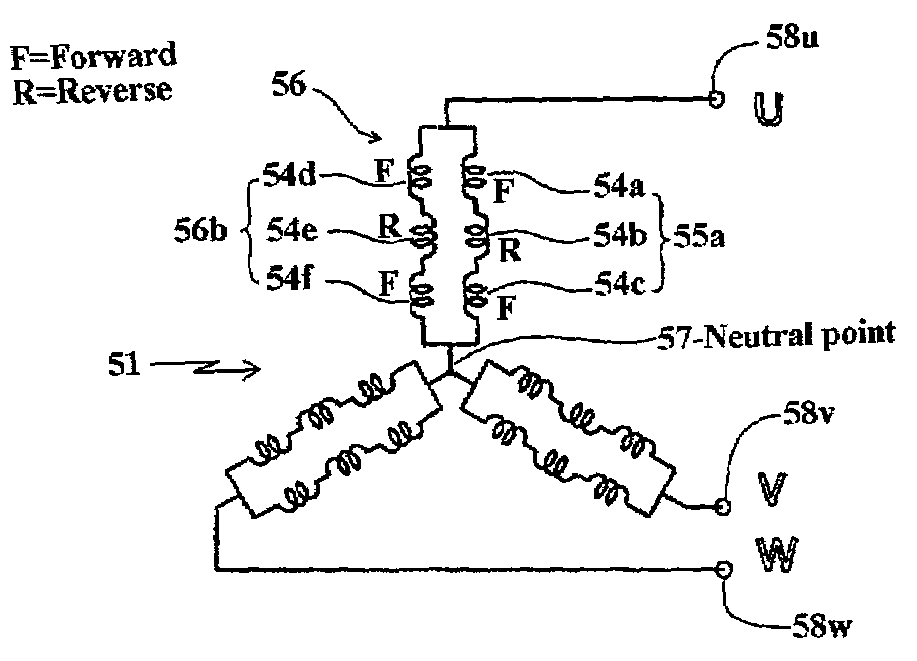

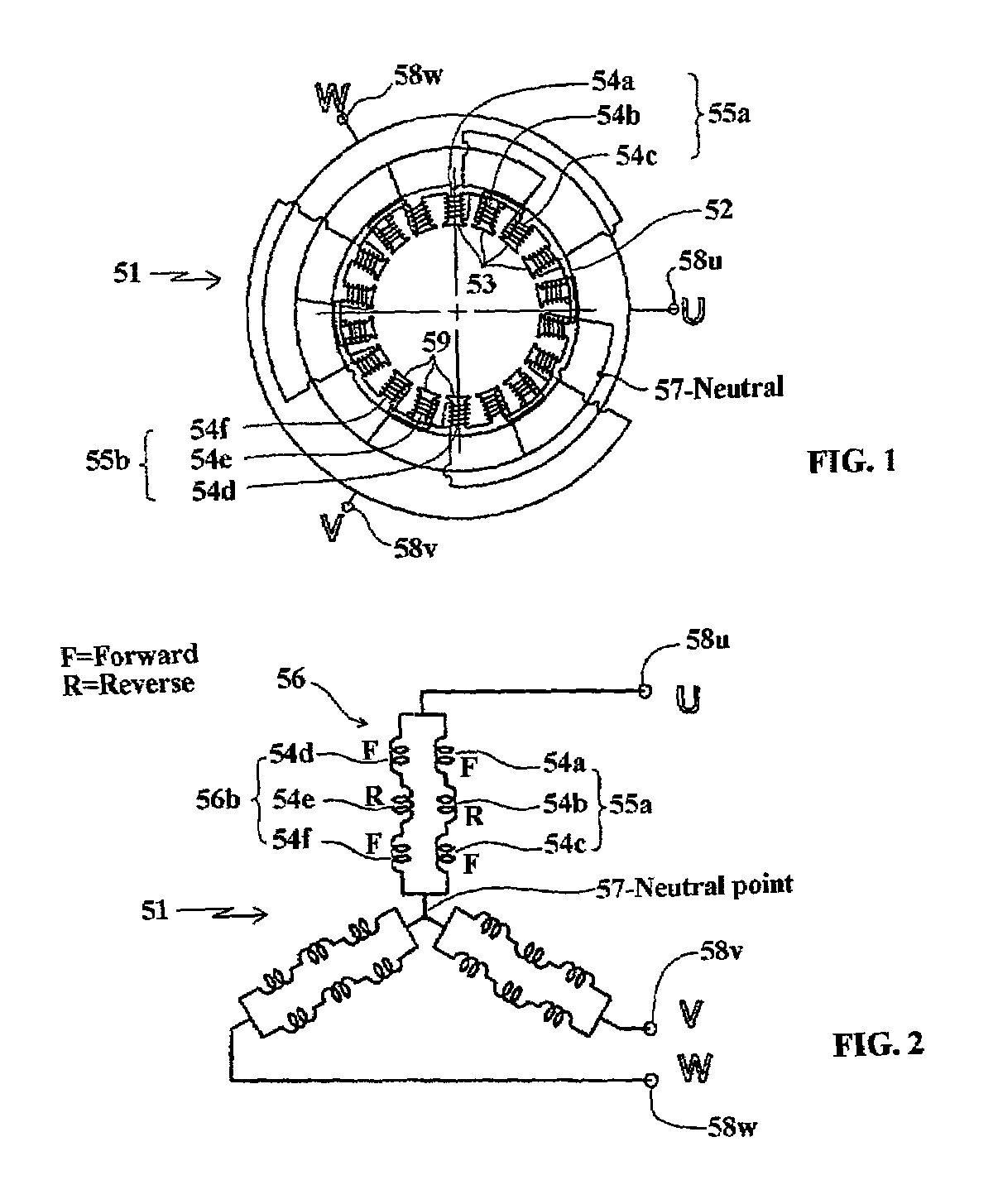

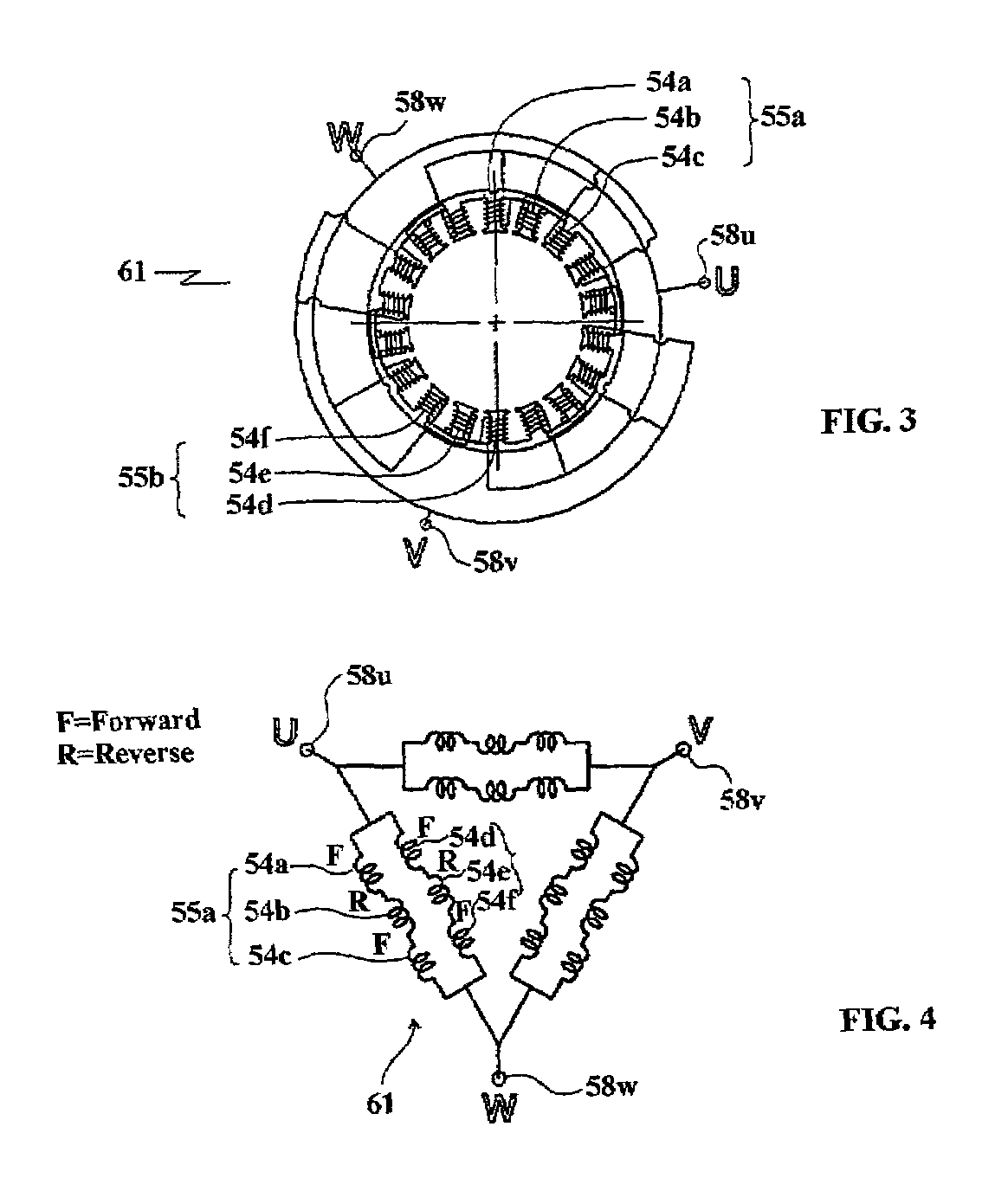

Permanent magnet type three-phase AC rotary electric machine

InactiveUS20020130578A1Avoid it happening againSynchronous generatorsMagnetic circuitMagnetCirculating current

Several embodiments of permanent magnet type three-phase AC rotary electric machines wherein the phase current flow is formed by parallel circuits formed by a plurality of serial circuits each comprising one or a plurality of stator coils so that electromagnetic voltage or counter electromagnetic voltage generated across opposite ends of the plural serial circuits may be always almost the same. Thus, a circulating current does not flow in the parallel circuits, whereby the efficiency of the rotary electric machine can be improved. Also, since the line current circuit of each of the phases is constituted of a parallel circuit, the current flowing in each of the stator coils is small so that the diameter of the stator coil wire can be small. Thus, the winding of the coils can be improved. Also, the processing of the coil terminals is facilitated and the processed portions of the terminals can be made small, resulting in a compact rotary electric machine.

Owner:YAMAHA MOTOR ELECTRONICS CO LTD

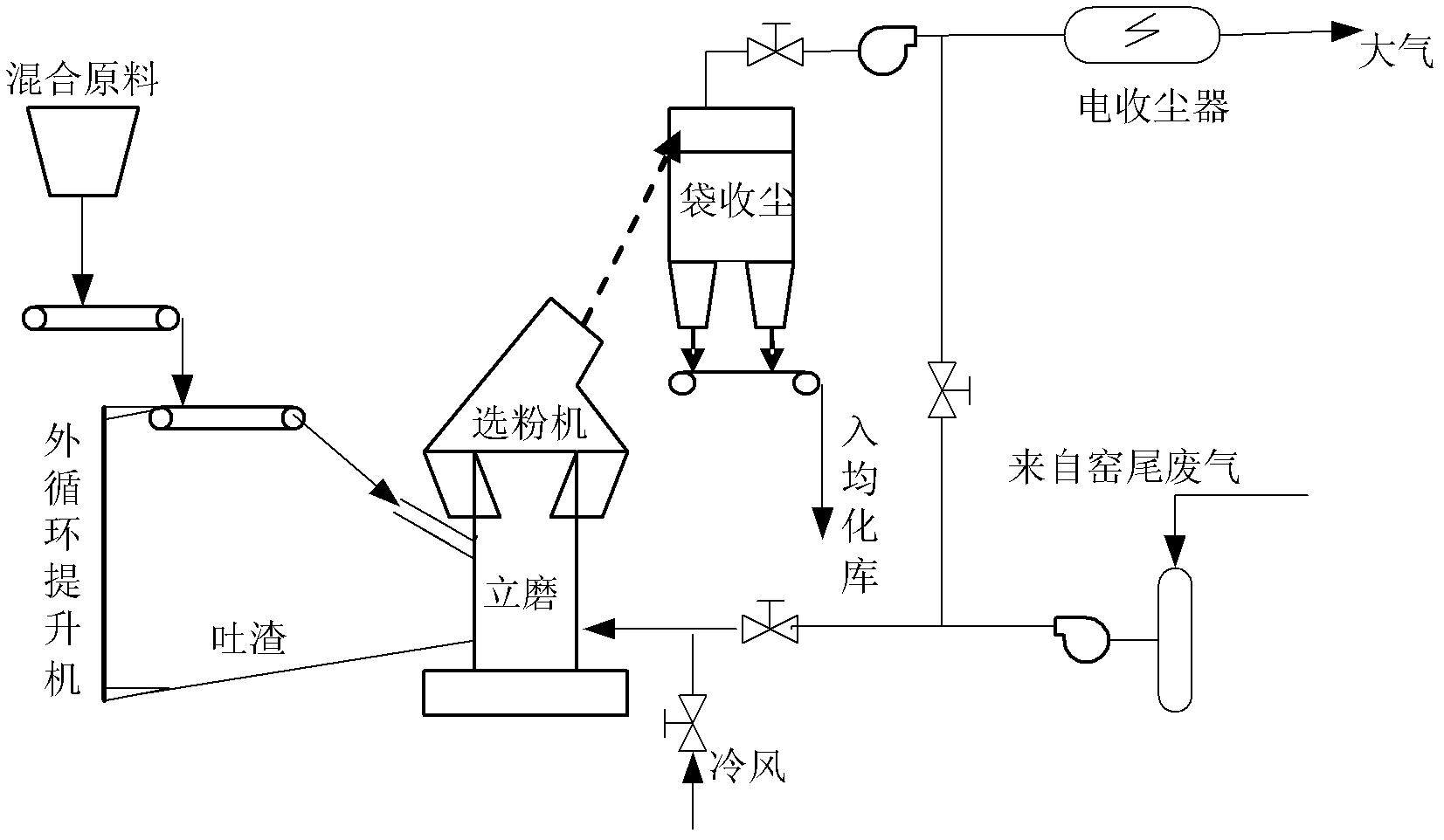

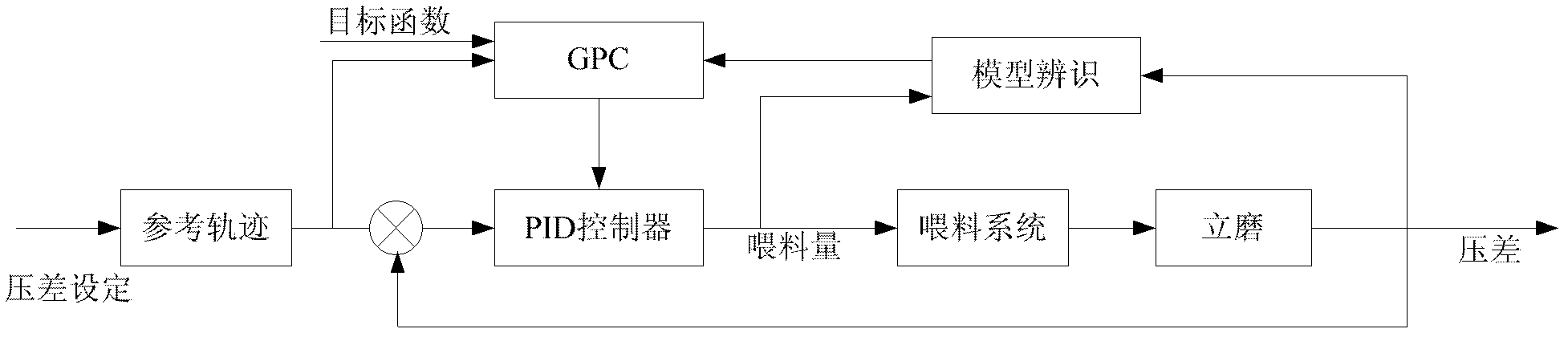

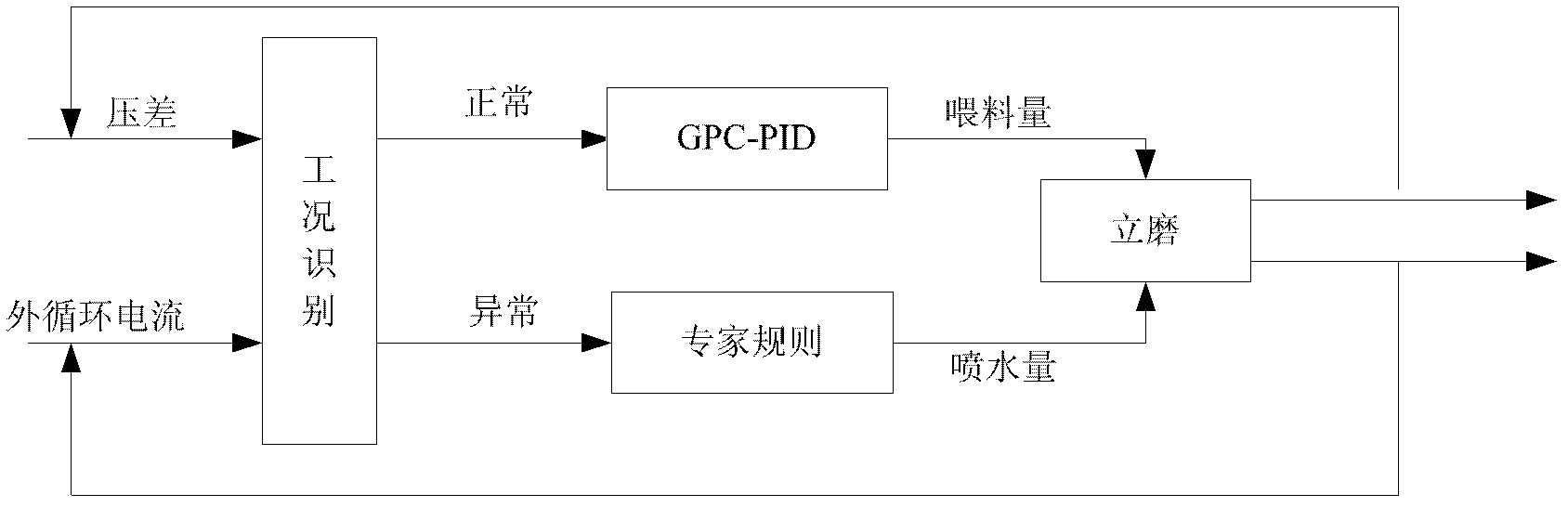

Method for intelligently controlling pressure difference of cement raw meal vertical mill

ActiveCN102319612AReduce labor intensityImprove robustnessGrain treatmentsMathematical modelEngineering

The invention discloses a method for intelligently controlling the pressure difference of a cement raw meal vertical mill. In the method, internal pressure difference of the mill is taken as a major controlled variable, external circulating current is taken as an auxiliary controlled variable, a feeding amount is taken as a major control variable, and a water spray amount is taken as an auxiliarycontrol variable. The method comprises the following steps of: judging a current production condition according to the internal pressure difference of the mill and external circulating current information with a production rule method; and under the normal working condition, controlling the internal pressure difference of the mill by adopting GPC-PID (Generalized Predictive Control-Proportion Integration Differentiation). In the method, a mathematic model for describing the change of the pressure difference along with the feeding amount can be established only by using input and output data of a process without analyzing the complex material milling process of the raw meal vertical mill, the identifying process is simple, and online identification is available; the method has certain adaptability to the change of the production condition; and the advantages of multistep prediction, rolling optimization and feedback correction of a GPC algorithm as well as the advantages of easiness and high robustness of a PID algorithm are fully utilized, so that the labor intensity of field operating personnel is lowered greatly.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

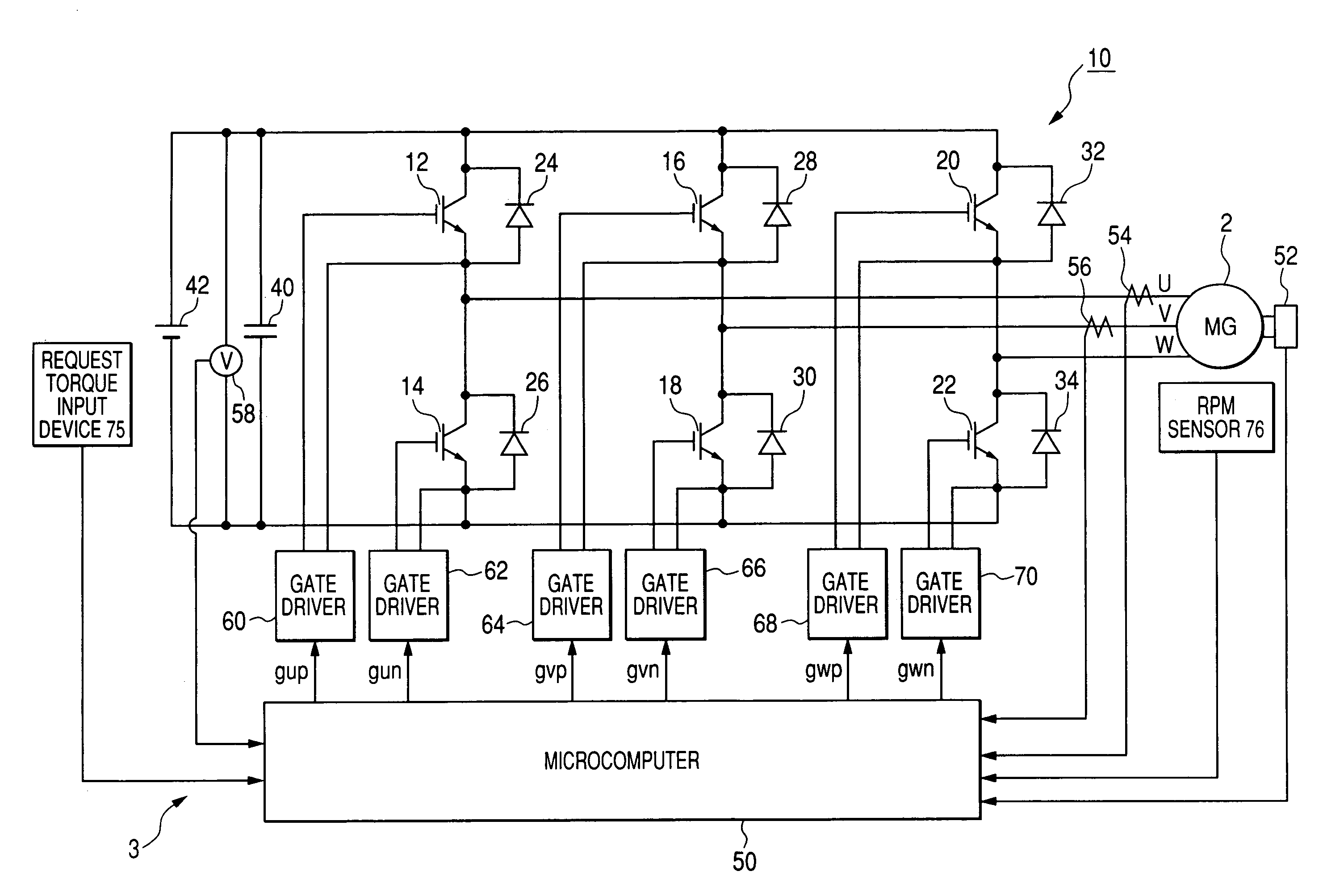

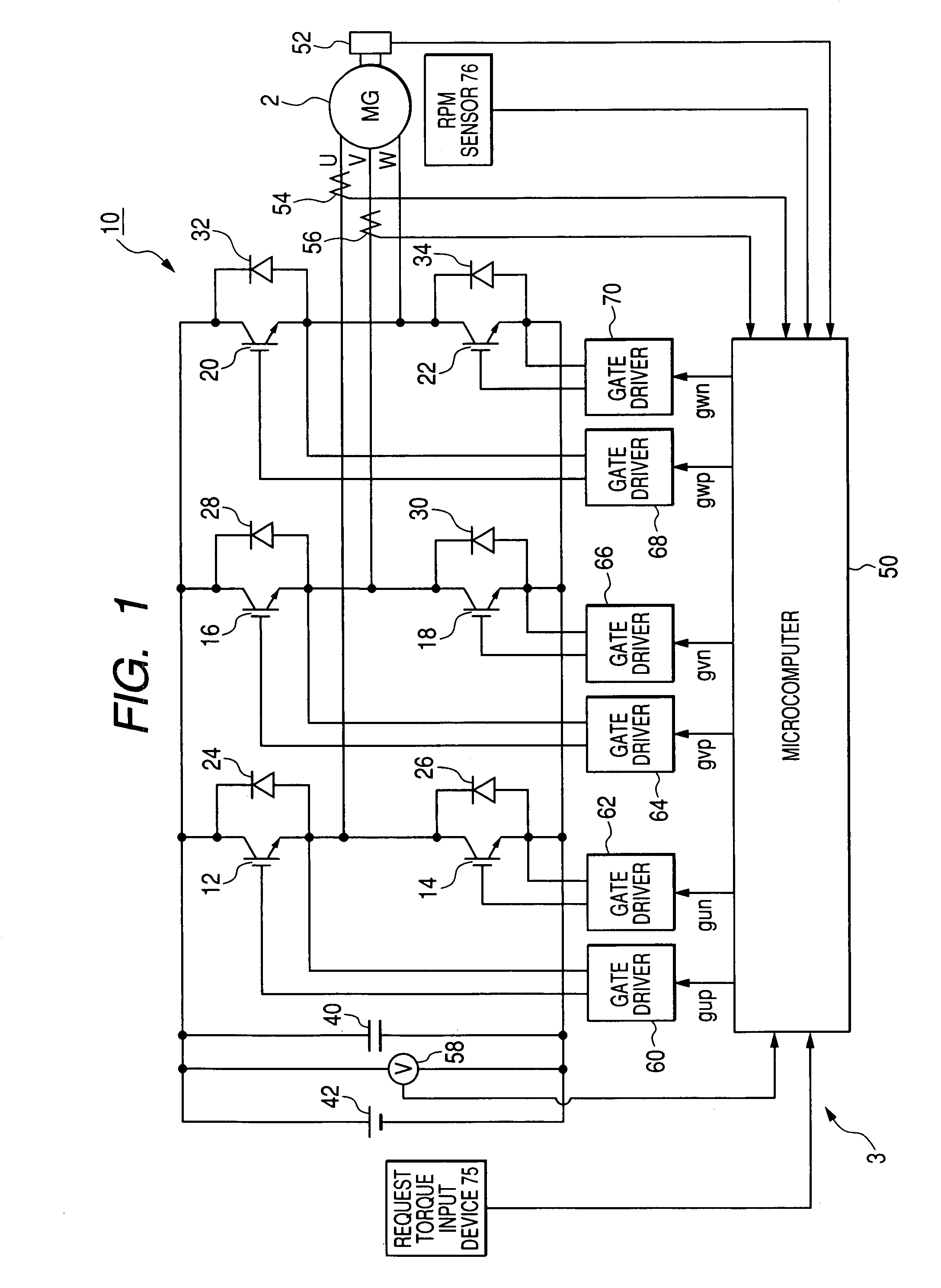

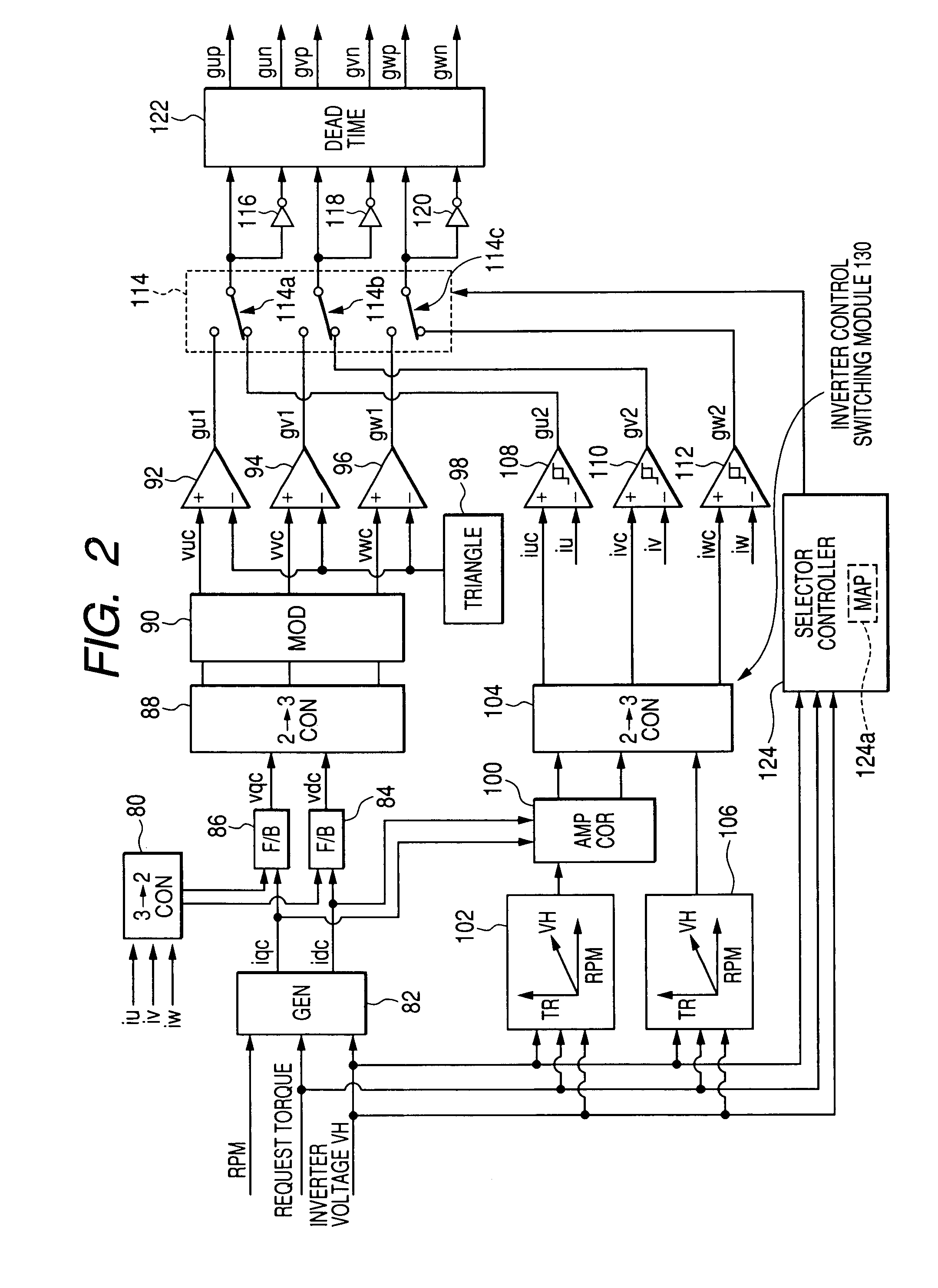

Control system for multiphase rotary electric machines

ActiveUS7504790B2Motor/generator/converter stoppersDC motor speed/torque controlPulse controlControl system

Owner:DENSO CORP

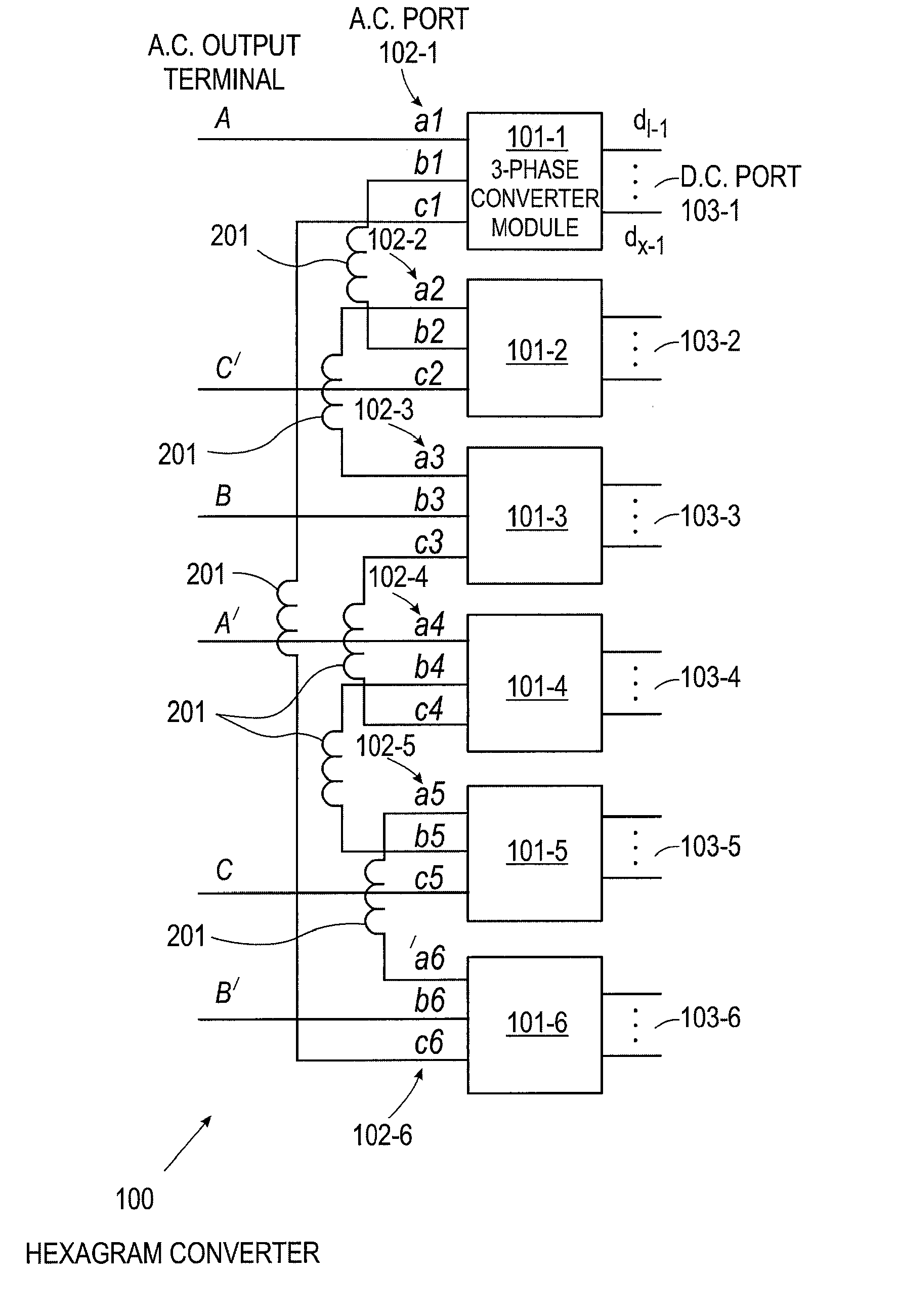

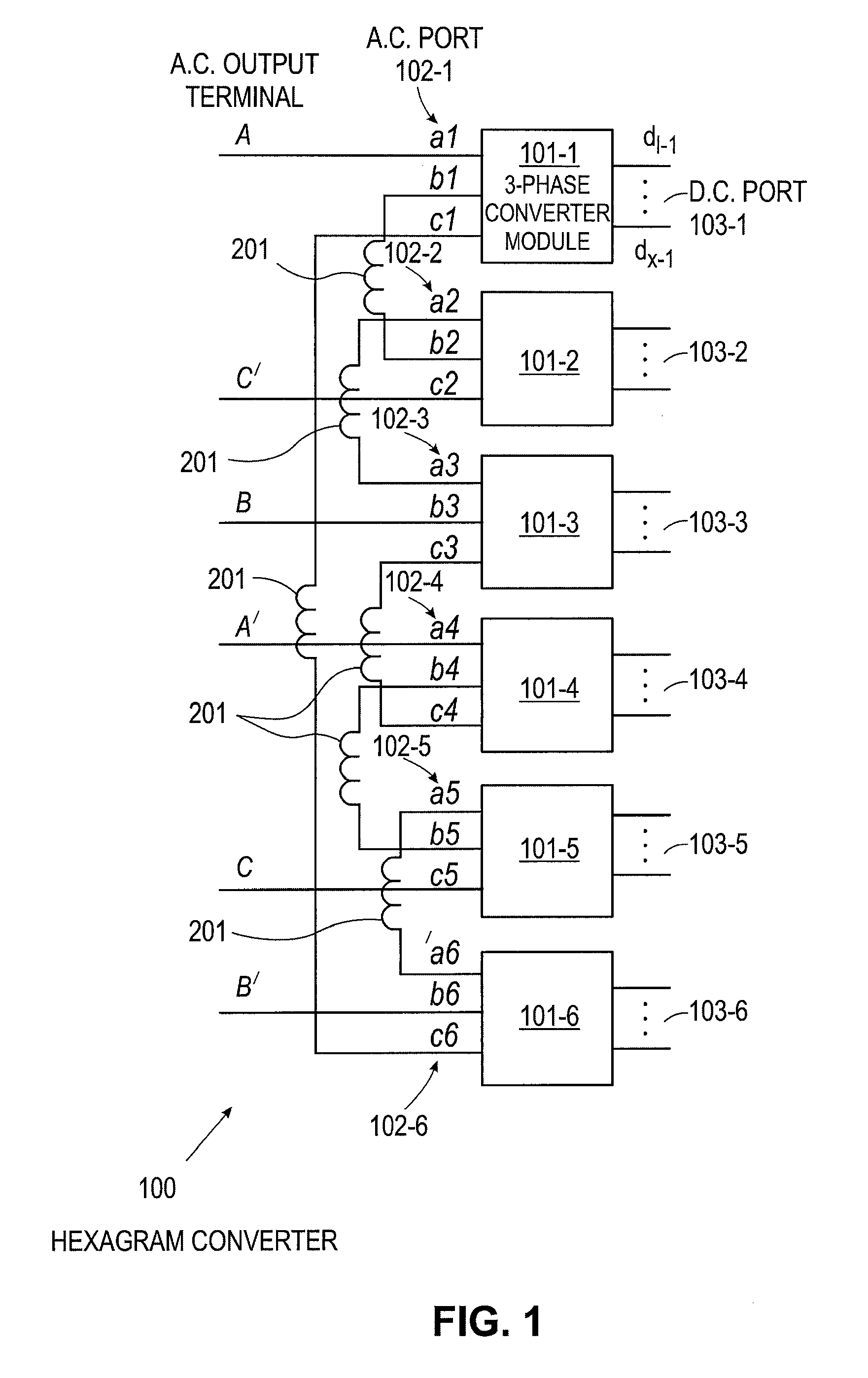

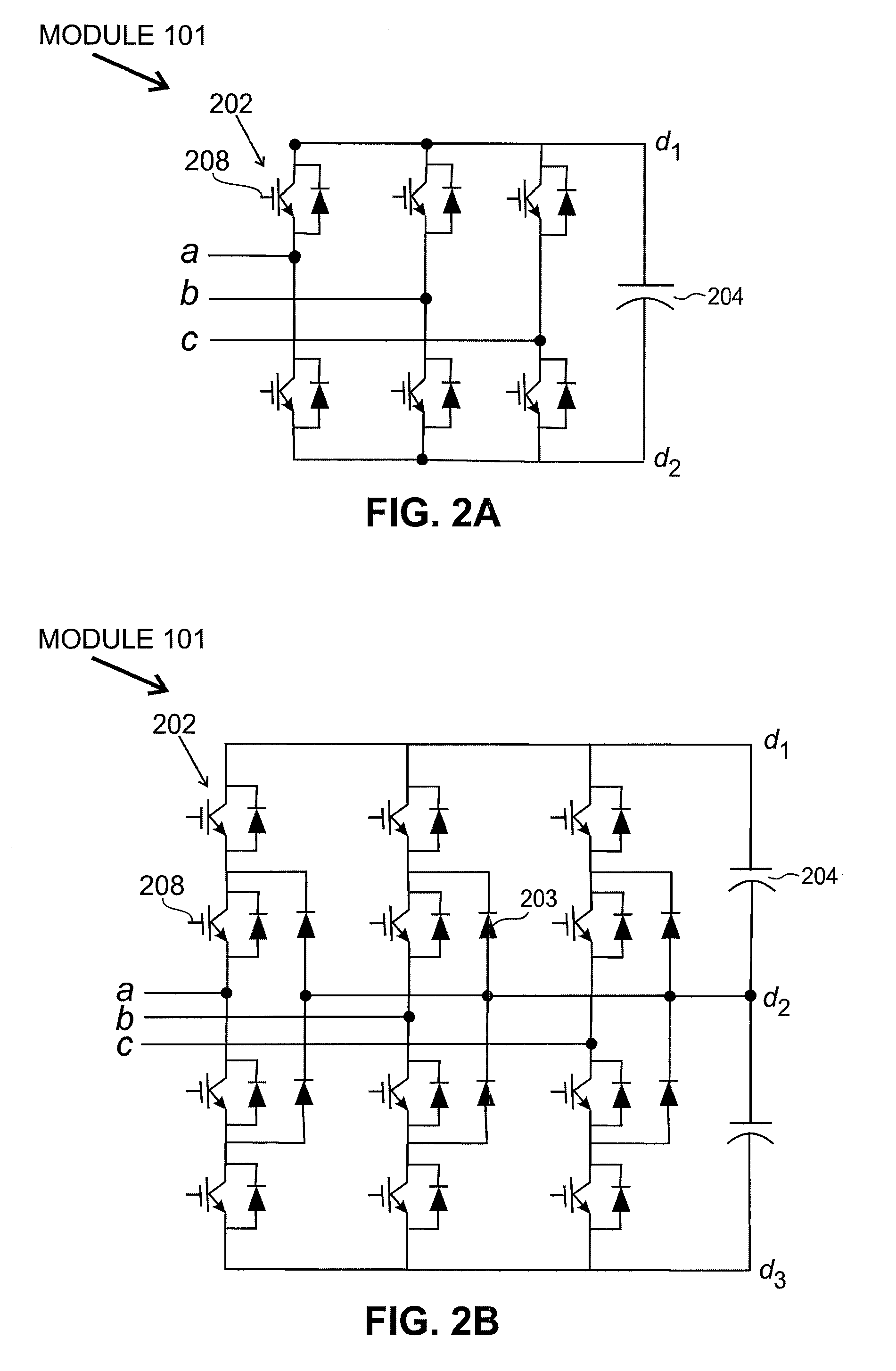

Converters For High Power Applications

Multilevel high power converters, referred to as hexagram converters, which preferably include a combination of six three-phase converter modules, are provided herein. The three-phase converter modules are interconnected and can be configured as any three-phase converter for any given application. One or more inductors can be used in the interconnections between the six modules to suppress potential circulating currents. Numerous applications exist in which the described converters can be implemented.

Owner:RGT UNIV OF CALIFORNIA

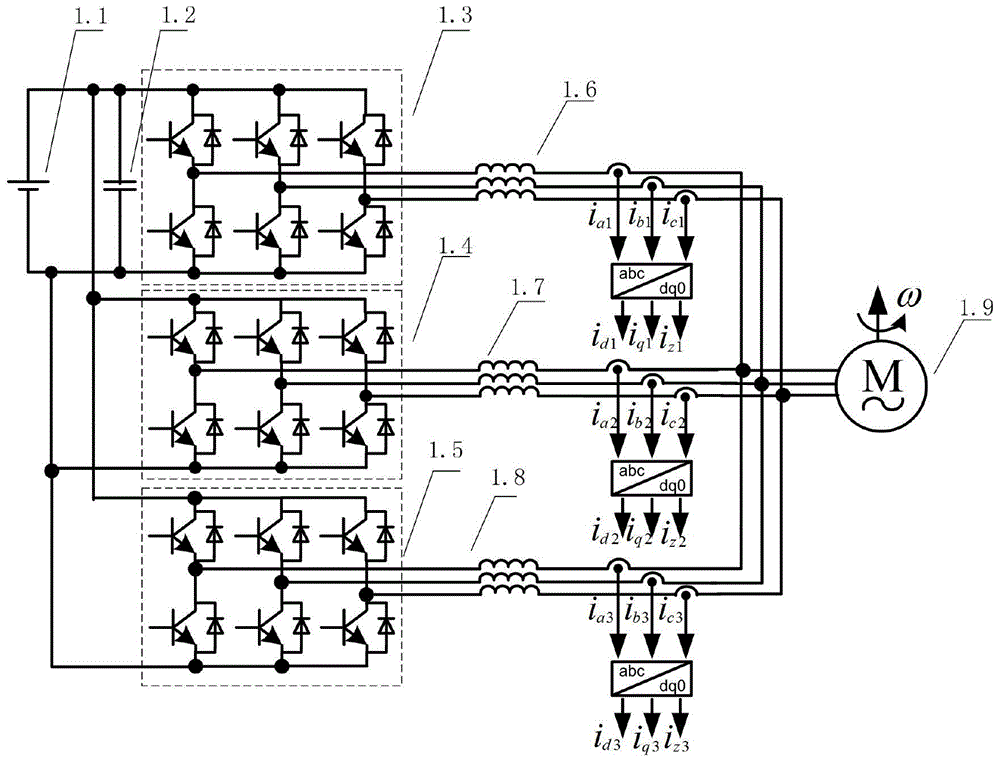

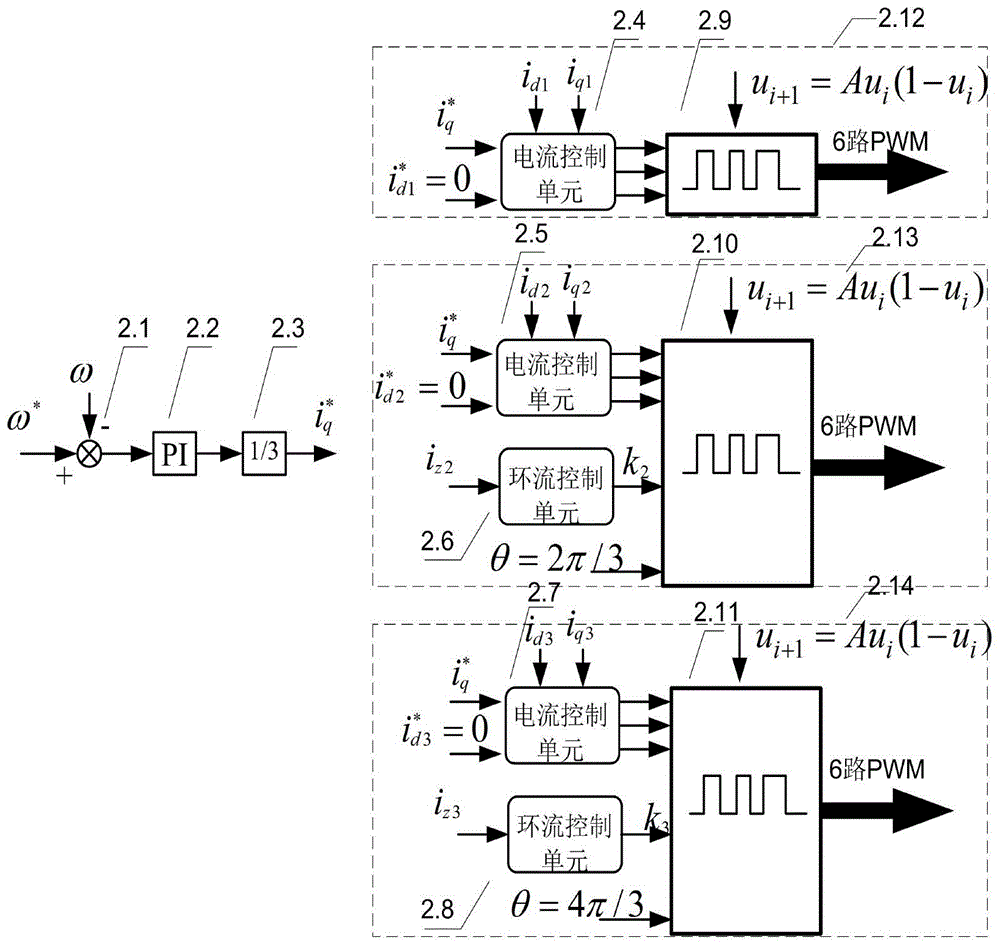

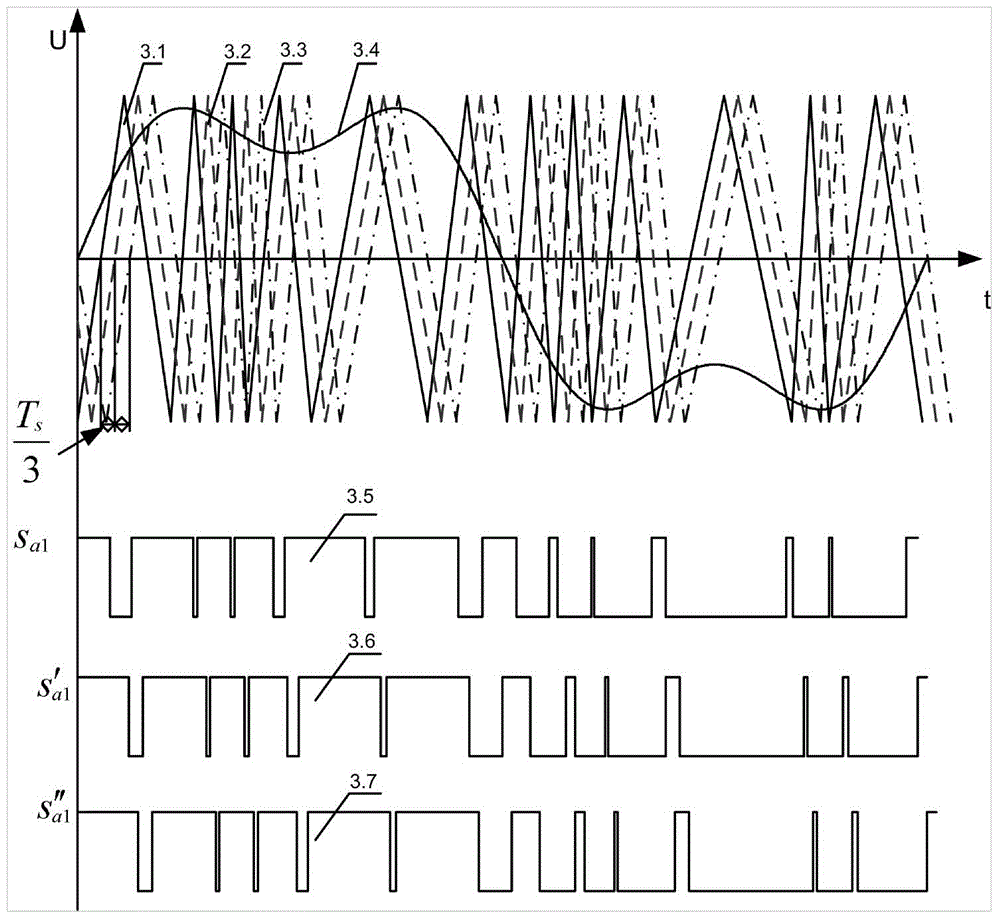

Multi-parallel inverter motor speed regulating system and control method thereof

ActiveCN103560746ALarge capacityEasy to Modular DesignElectronic commutation motor controlAC motor controlCapacitanceFault tolerance

The invention discloses a multi-parallel inverter motor speed regulating system and a control method of the multi-parallel inverter motor speed regulating system. The system is formed by connecting multiple inverter modules in parallel. The direct current sides of multiple inverter sub modules are directly connected with a direct current power supply with a direct current bus capacitor in parallel. The alternating current sides of the multiple inverter sub modules are connected with multiple sets of smoothing reactors respectively in series and then directly connected in parallel to drive an alternating current motor. By the adoption of the structure, modularization expansion of the motor speed regulating system is easily conducted, and the fault-tolerance performance of the motor speed regulating system is enhanced. By means of a random SVPWM method based on carrier phase shifting, switching frequency of parallel inverters is equivalently improved, switching subharmonic energy within narrow frequency bands is equalized, the harmonic performance of output currents of the parallel inverters is improved, and electromagnetic interference resistance of the motor speed regulating system is enhanced. By the adoption of a space vector synthetic technology for dynamically allocating SVPWM zero vectors, zero-sequence circulating currents between the parallel inverter modules are effectively eliminated, and normal operation of the system is guaranteed.

Owner:SOUTHEAST UNIV

Permanent magnet type three-phase AC rotary electric machine

InactiveUS6998750B2Avoid it happening againSynchronous generatorsMagnetic circuitPhase currentsElectric machine

Several embodiments of permanent magnet type three-phase AC rotary electric machines wherein the phase current flow is formed by parallel circuits formed by a plurality of serial circuits each comprising one or a plurality of stator coils so that electromagnetic voltage or counter electromagnetic voltage generated across opposite ends of the plural serial circuits may be always almost the same. Thus, a circulating current does not flow in the parallel circuits, whereby the efficiency of the rotary electric machine can be improved. Also, since the line current circuit of each of the phases is constituted of a parallel circuit, the current flowing in each of the stator coils is small so that the diameter of the stator coil wire can be small. Thus, the winding of the coils can be improved. Also, the processing of the coil terminals is facilitated and the processed portions of the terminals can be made small, resulting in a compact rotary electric machine.

Owner:YAMAHA MOTOR ELECTRONICS CO LTD

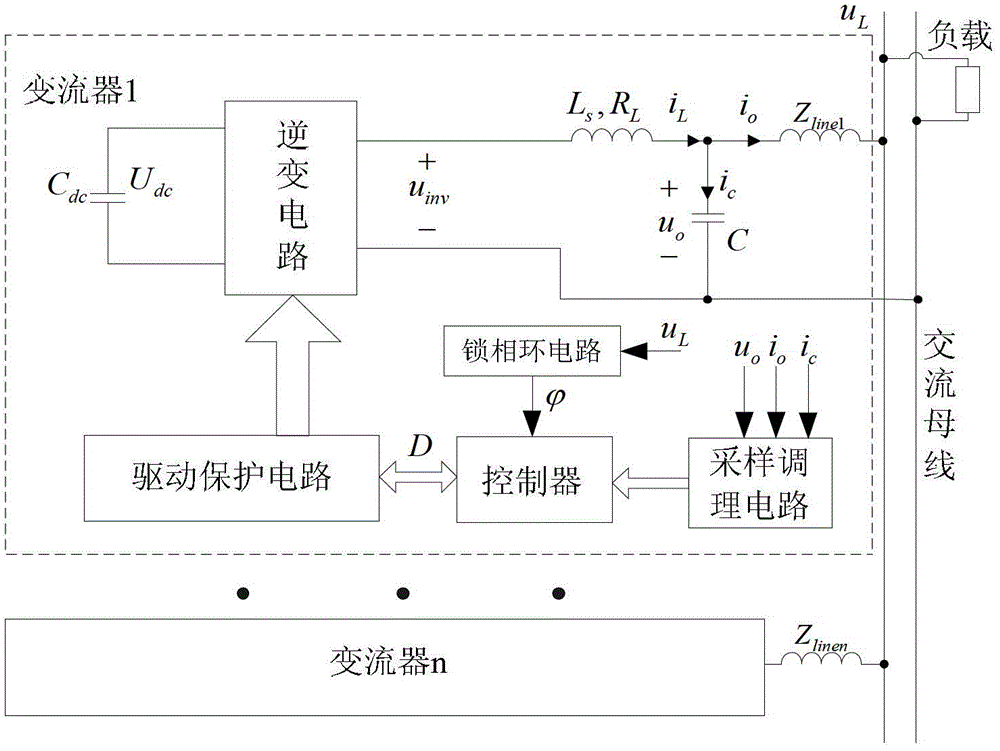

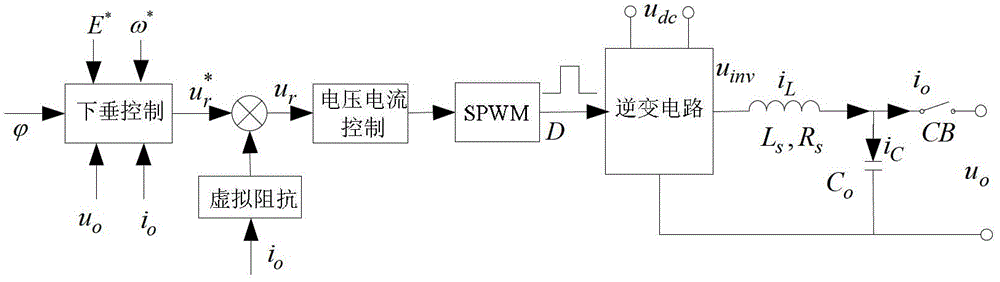

Multi-converter parallel circulating current restraining method with quick and reactive support

ActiveCN103151785ASuppress resonanceImprove voltage qualityAc network voltage adjustmentReactive power compensationResistance capacitanceControl system

The invention discloses a multi-converter parallel circulating current restraining method with quick and reactive support. For a single converter, drop control calculation is adopted, and an output reference voltage of the converter is synthesized; resistance-capacitance virtual complex impedance is guided in the output current feedback of the inverter, so that the equivalent output impedance of the converter is of resistance-capacitance performance, wherein capacity component realizes quick and reactive support of the inverter, the resonant vibration between the output impedance of the inverter and the impedance of an electrified wire fence is restricted through resistance component, and fundamental wave circulating currents and harmonic circulating currents are reduced; and through a voltage current control loop, the stability and control precision of a system are further strengthened, and accurate distribution of power is realized. According to the method, the problem that the existing method is not high in power equipartition precision, relatively large in circulating current and relatively large in voltage fluctuation, and the method can be applied to power generation parallel control systems of industrial special power supply and new power supply.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com