Patents

Literature

361results about "Nanostructure application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

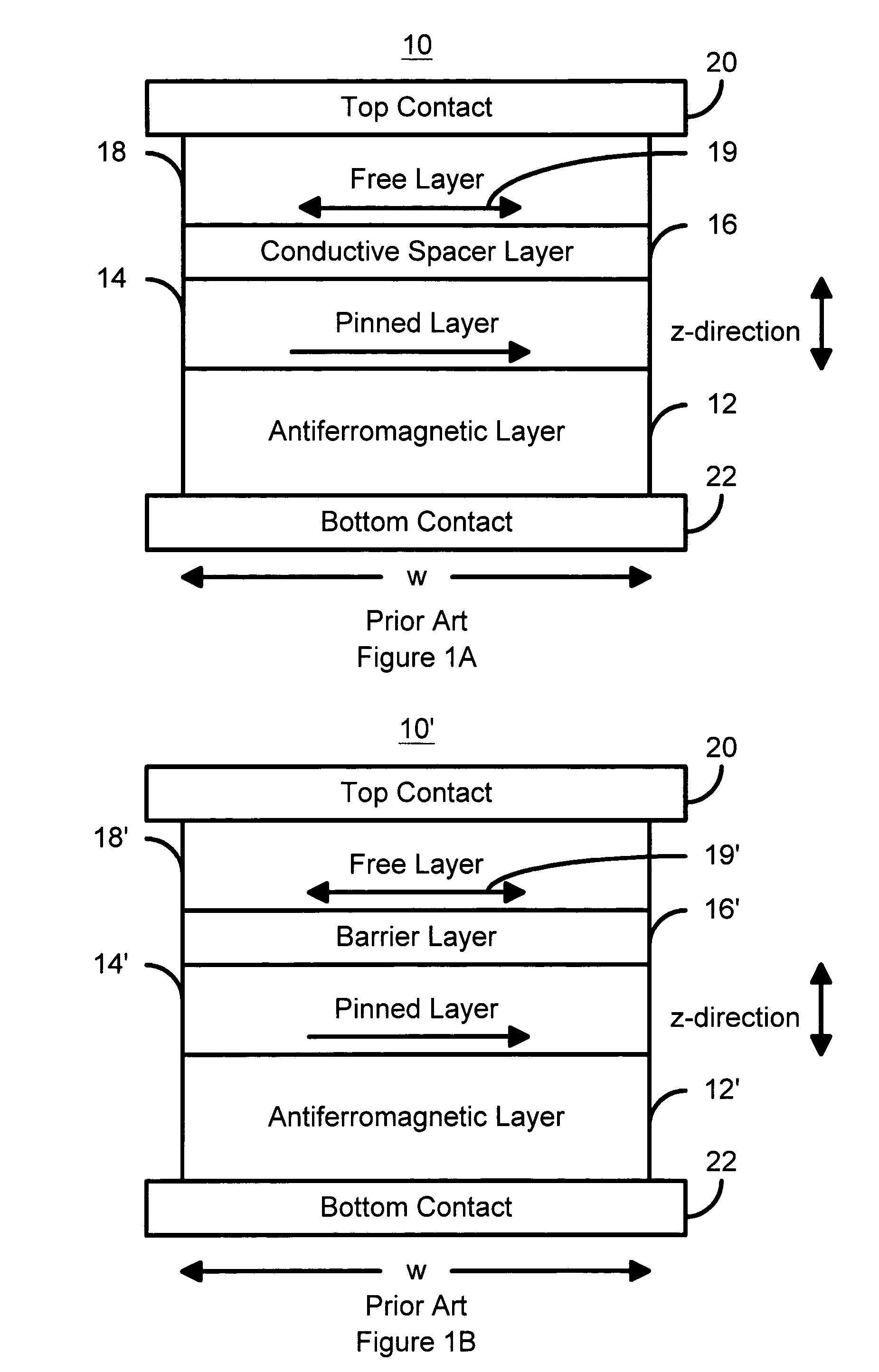

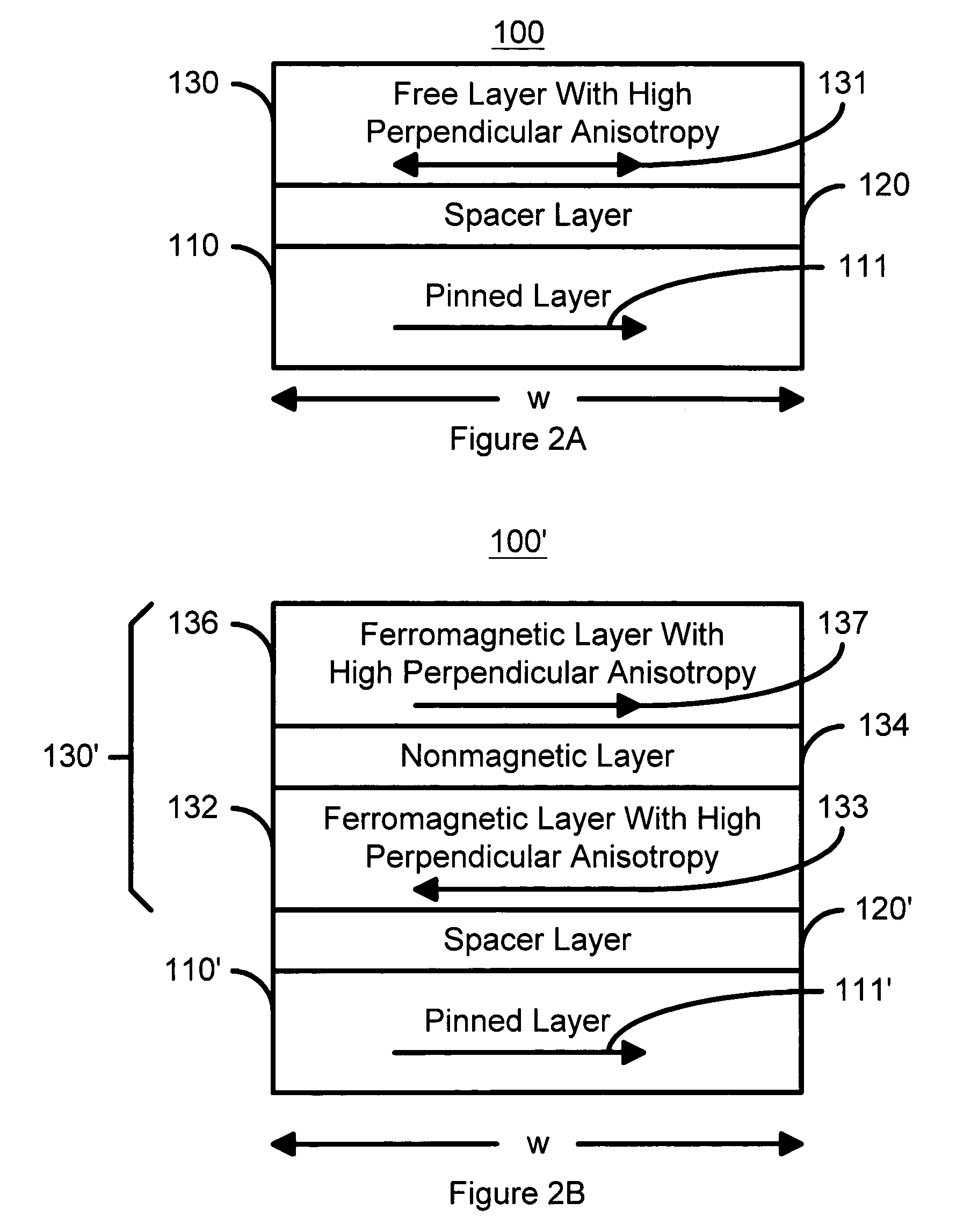

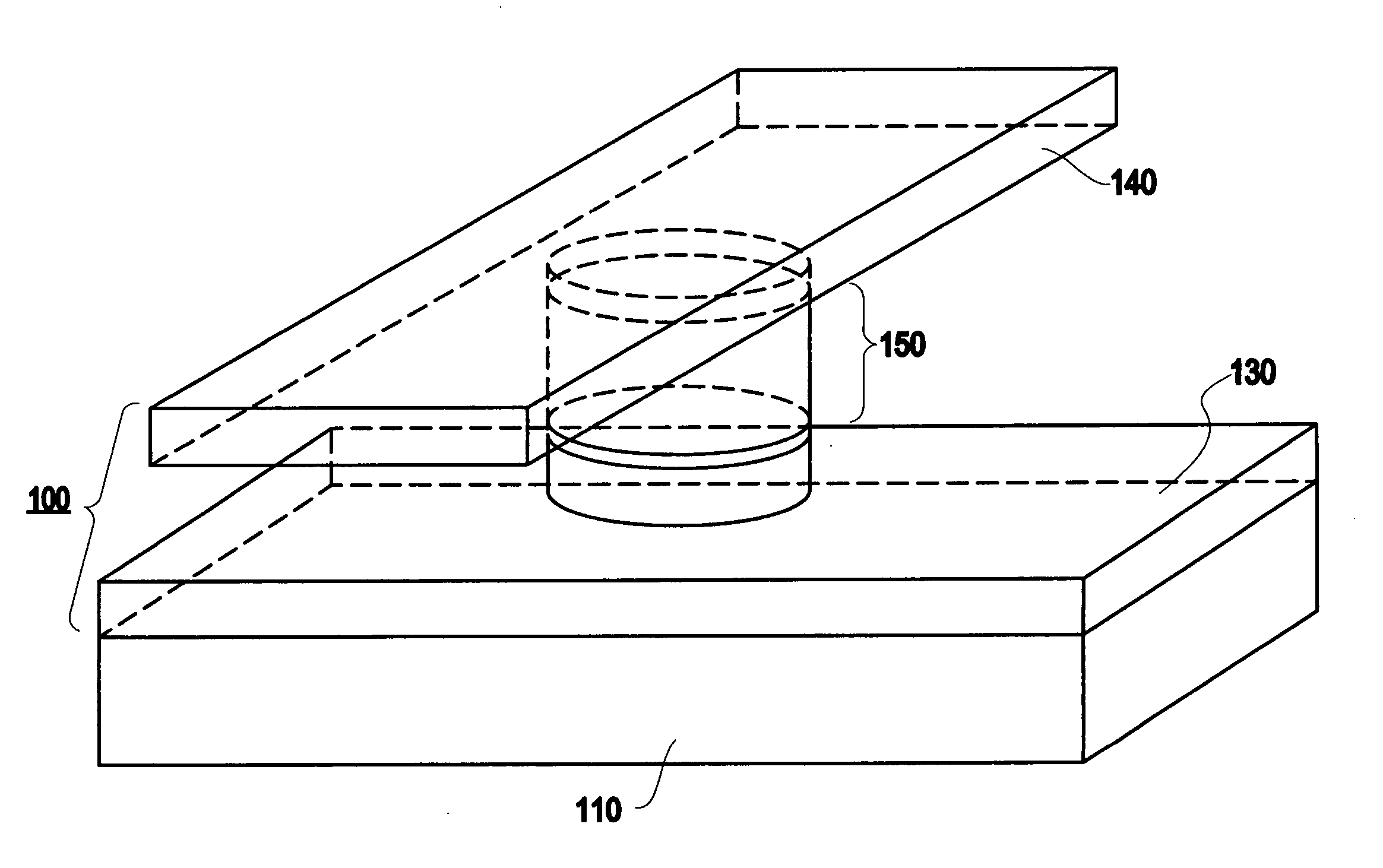

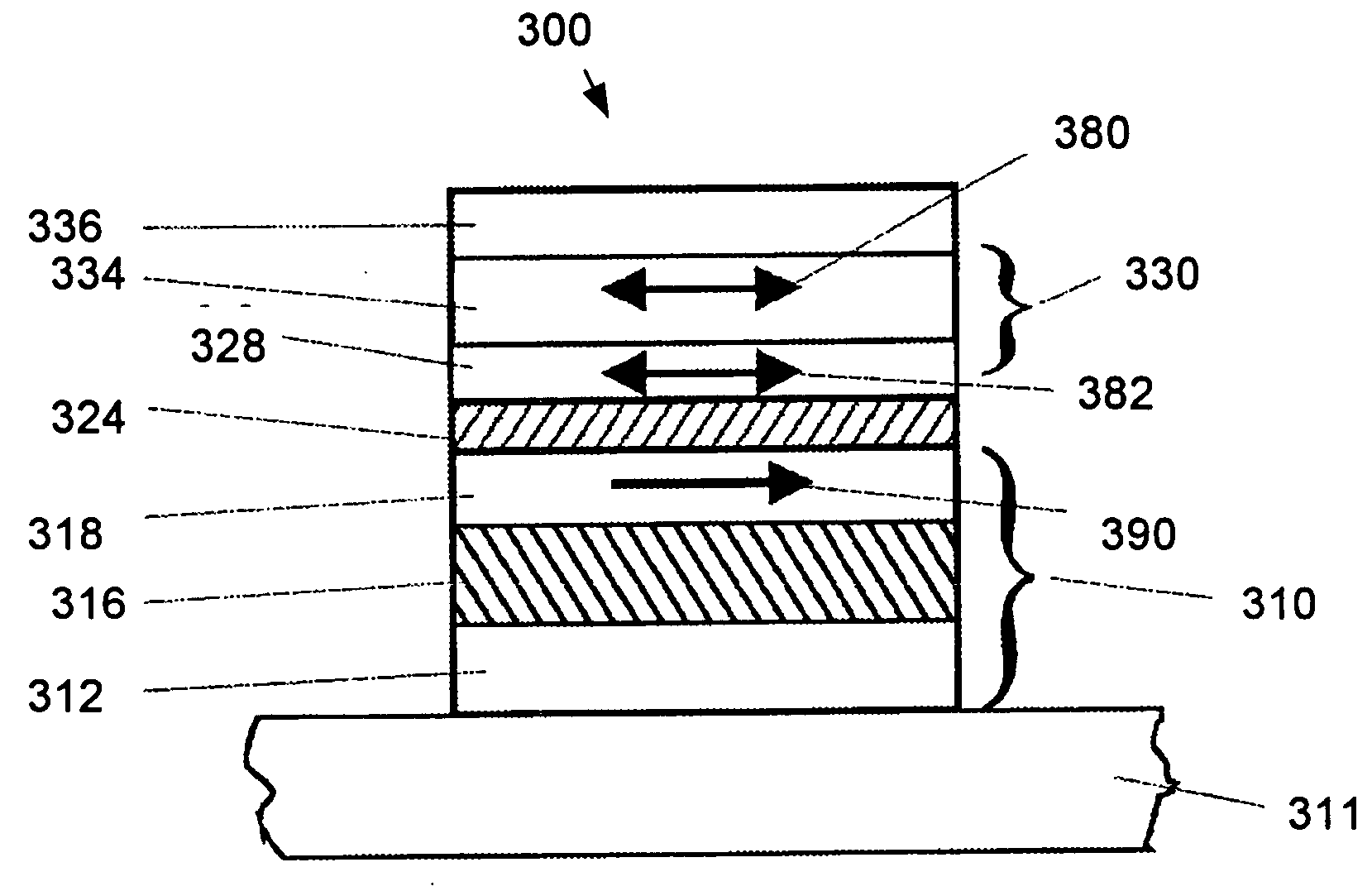

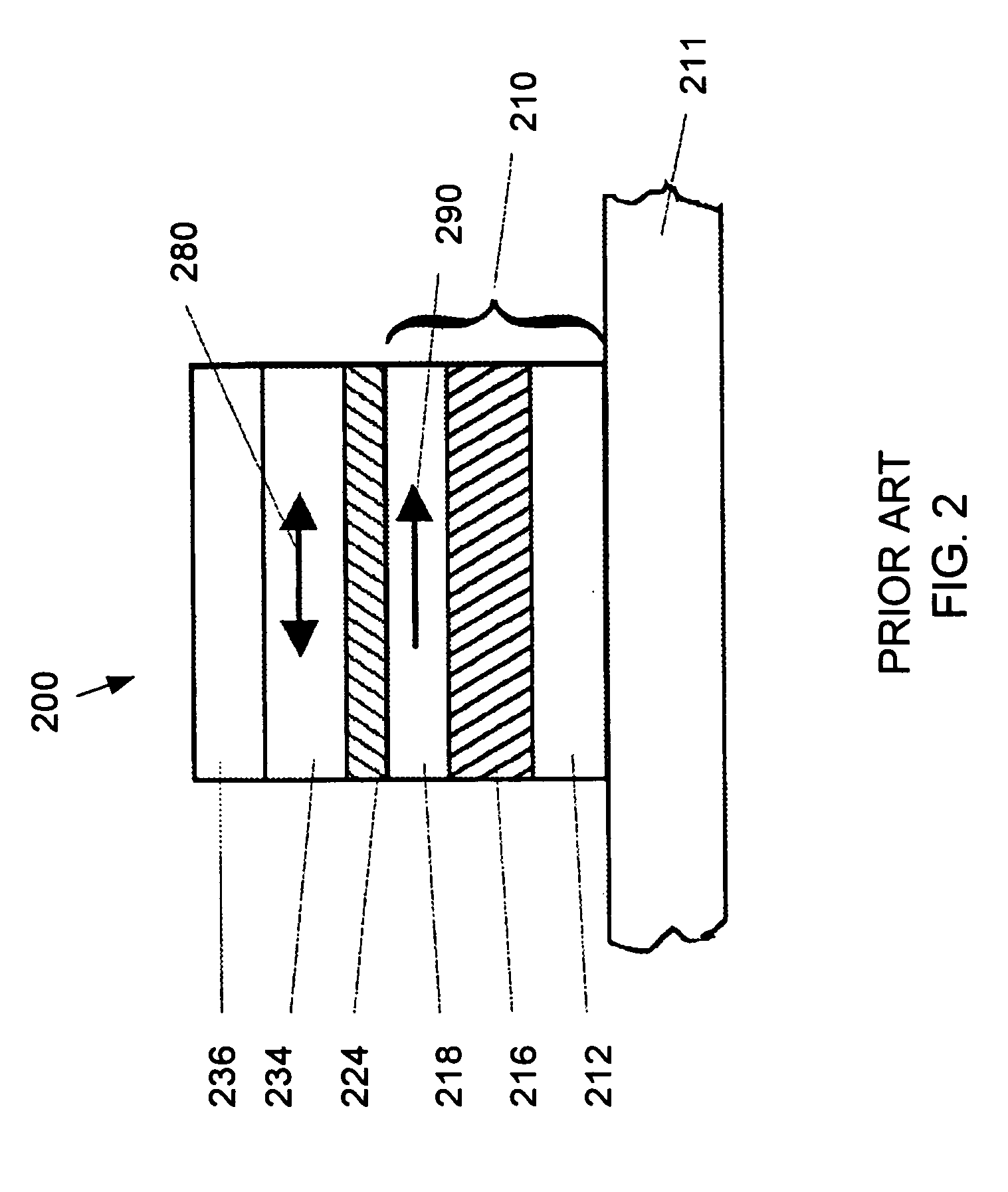

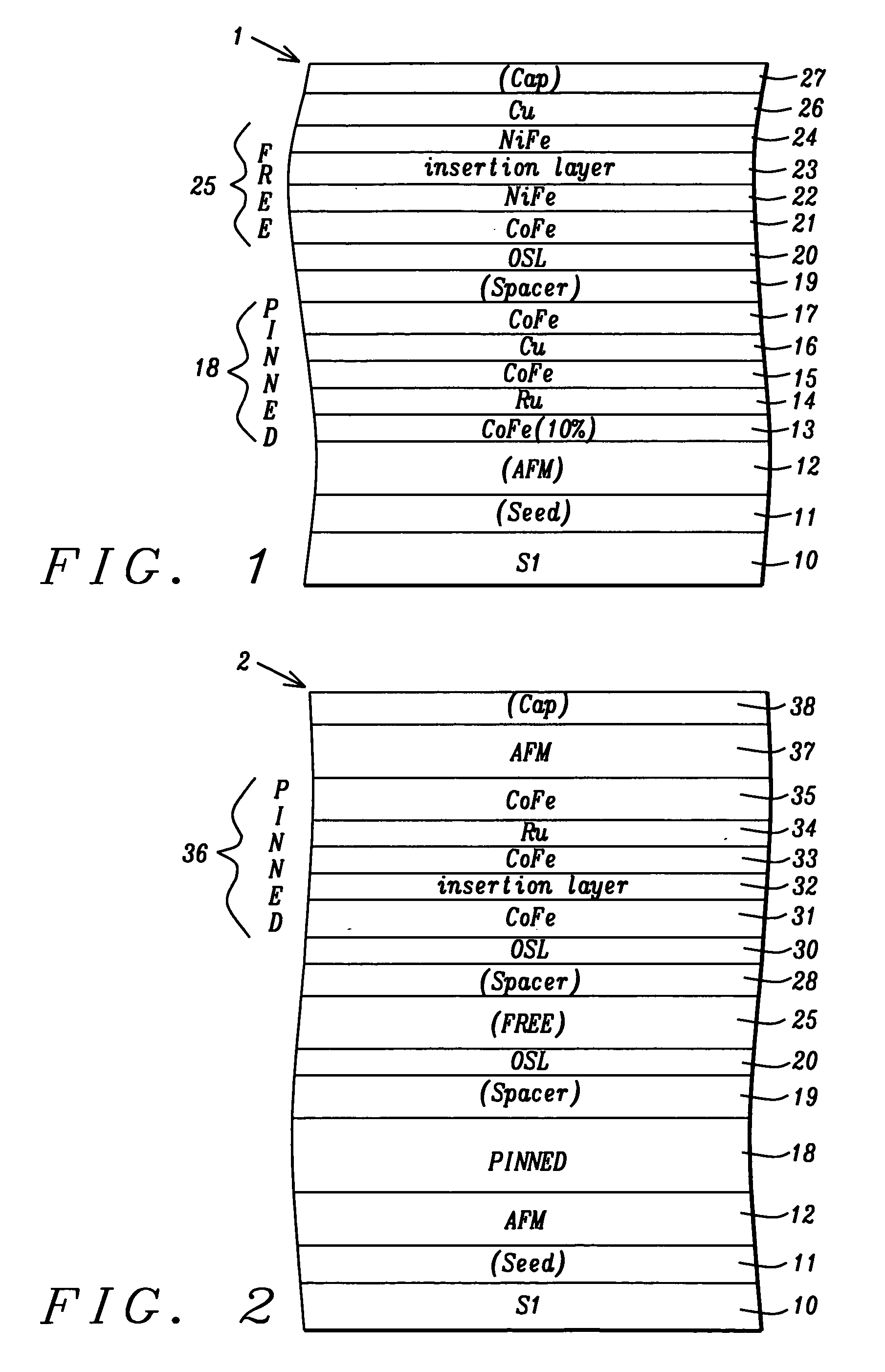

Spin transfer magnetic element with free layers having high perpendicular anisotropy and in-plane equilibrium magnetization

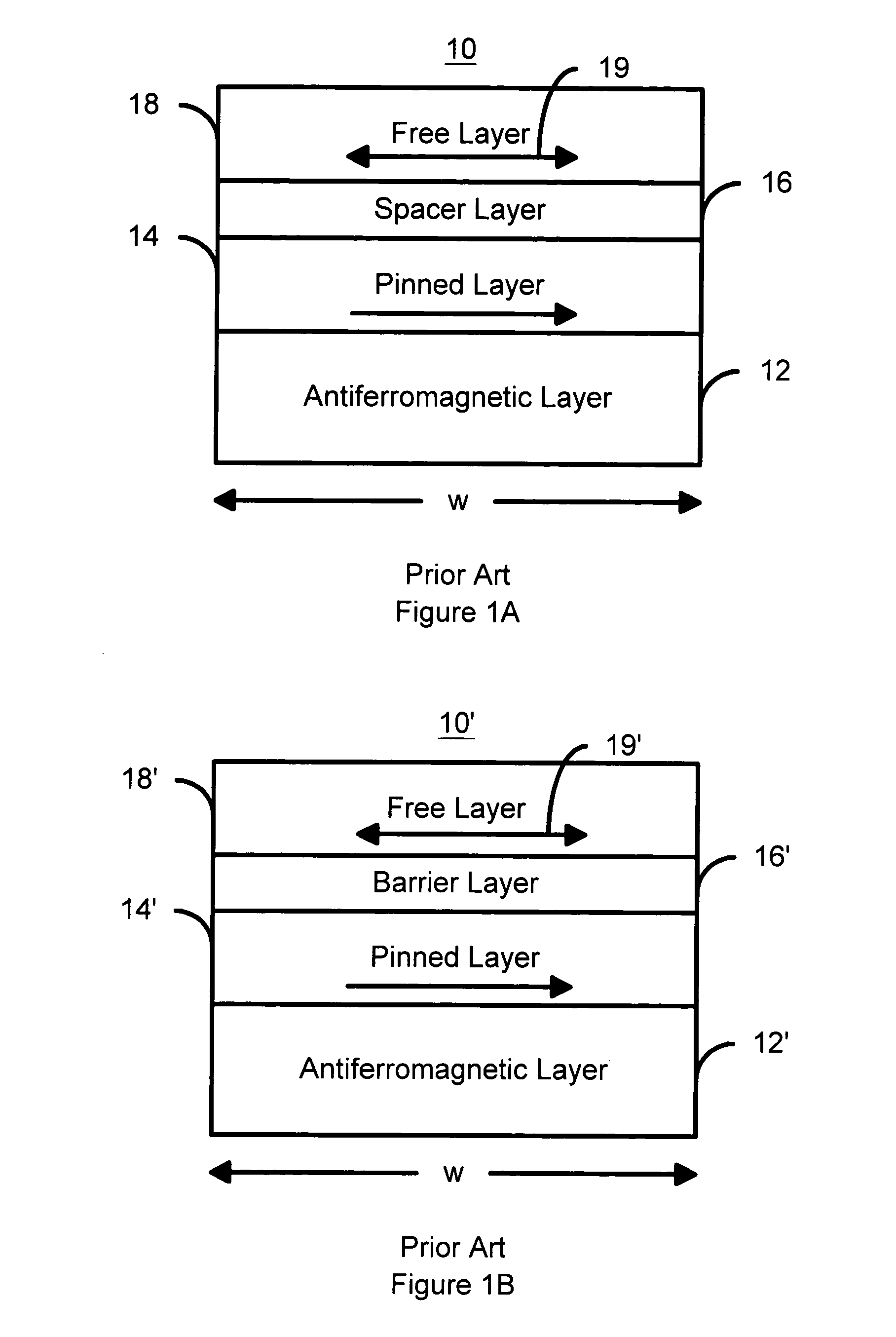

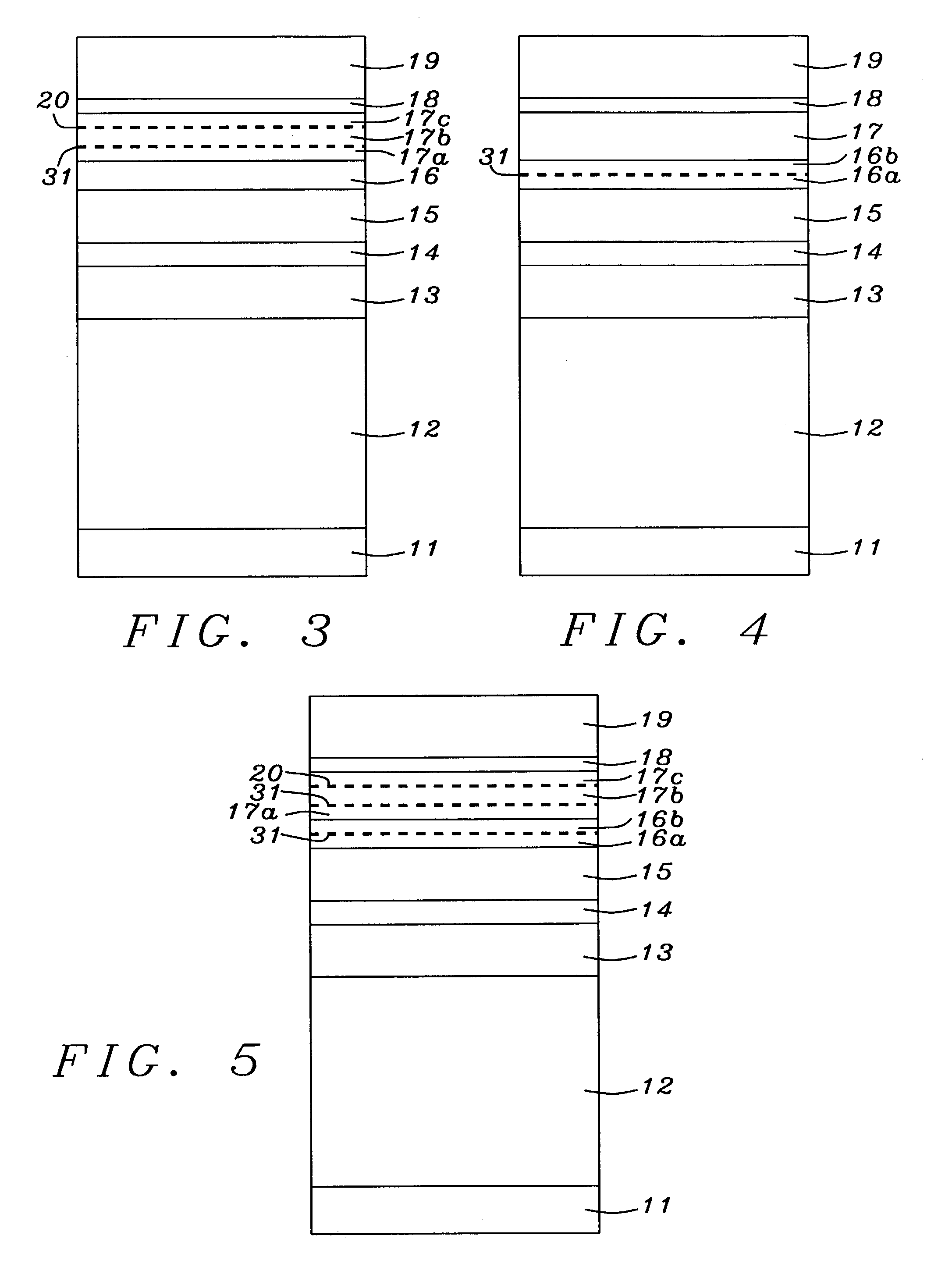

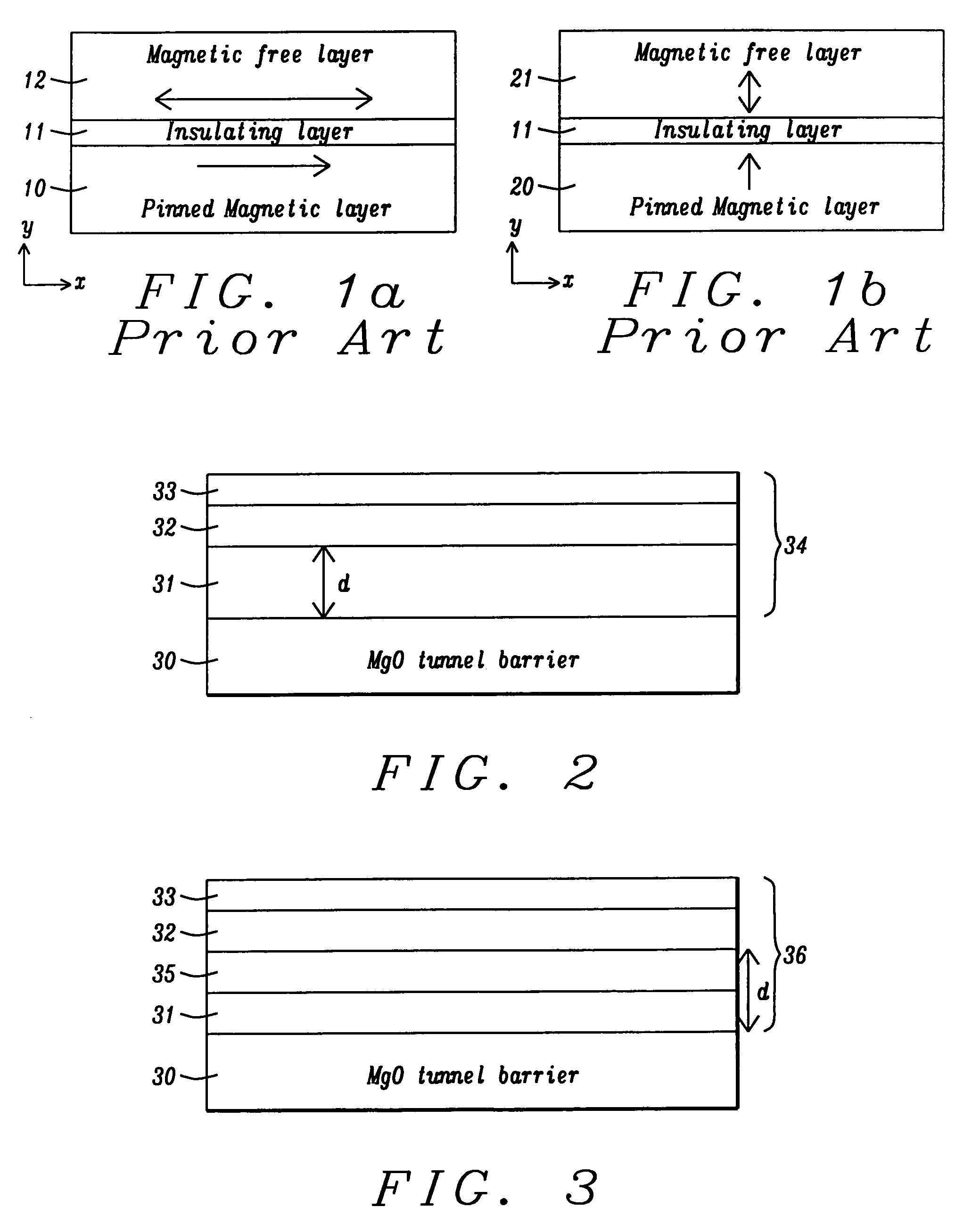

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. At least one free layer has a high perpendicular anisotropy. The high perpendicular anisotropy has a perpendicular anisotropy energy that is at least twenty and less than one hundred percent of the out-of-plane demagnetization energy.

Owner:SAMSUNG SEMICON

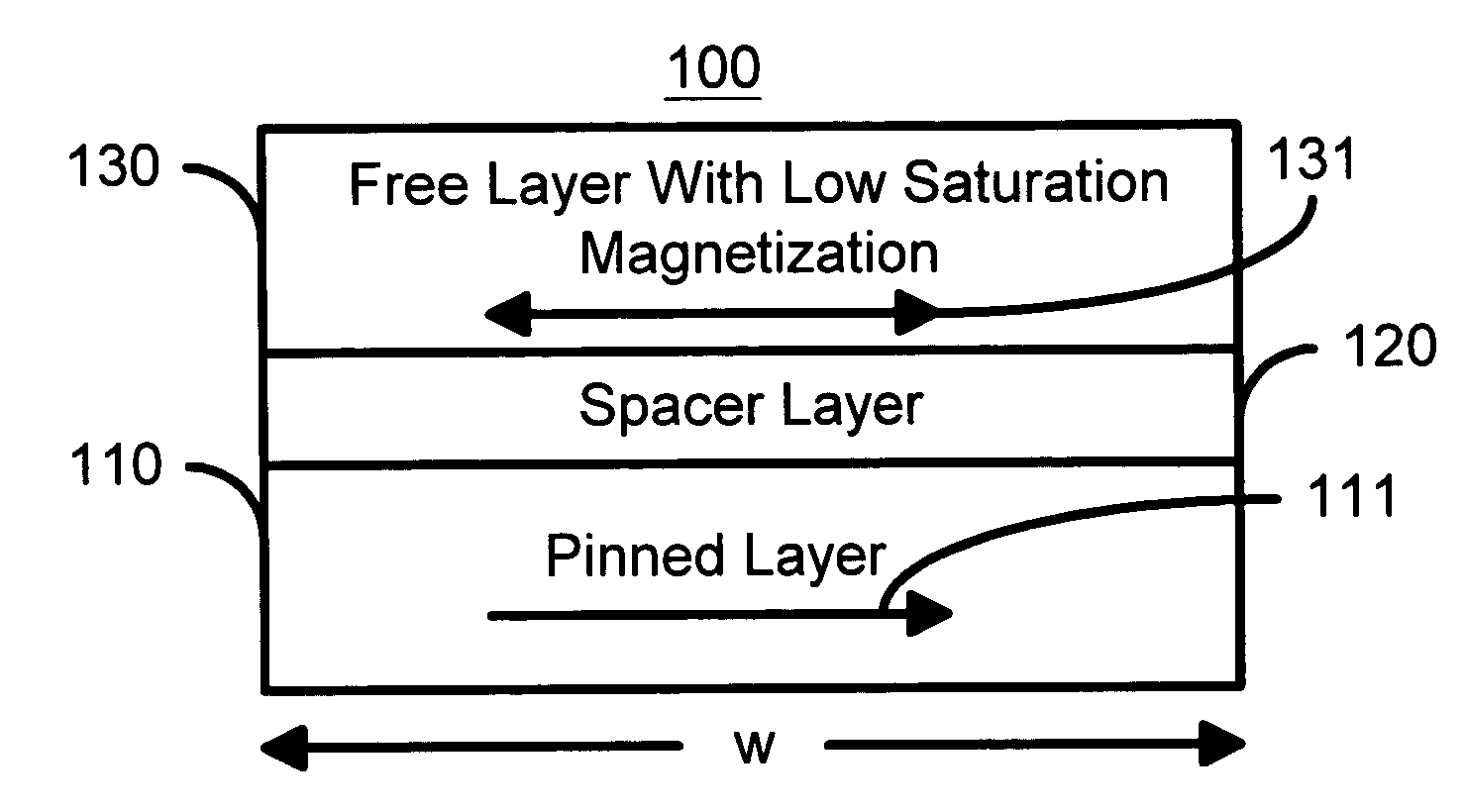

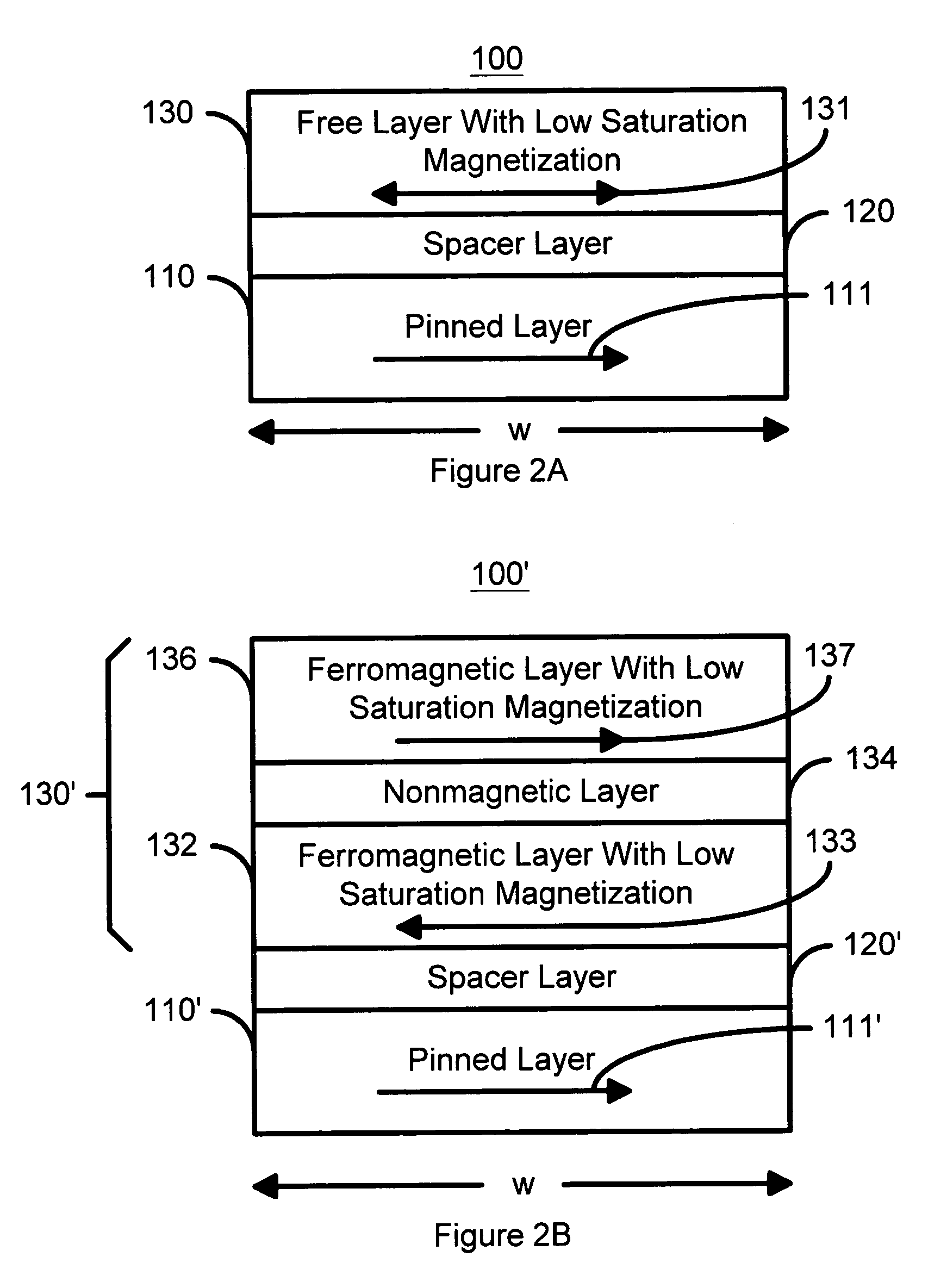

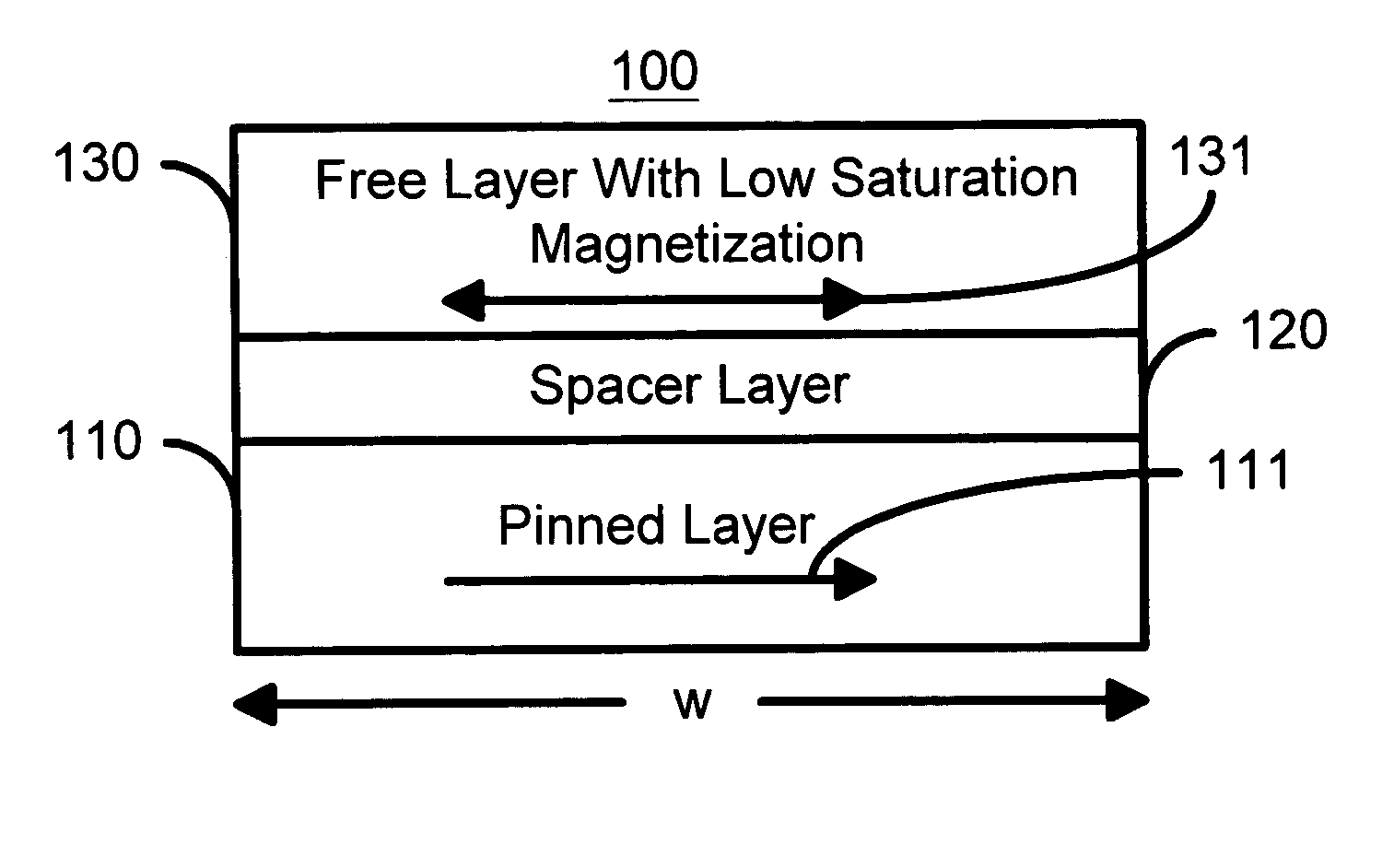

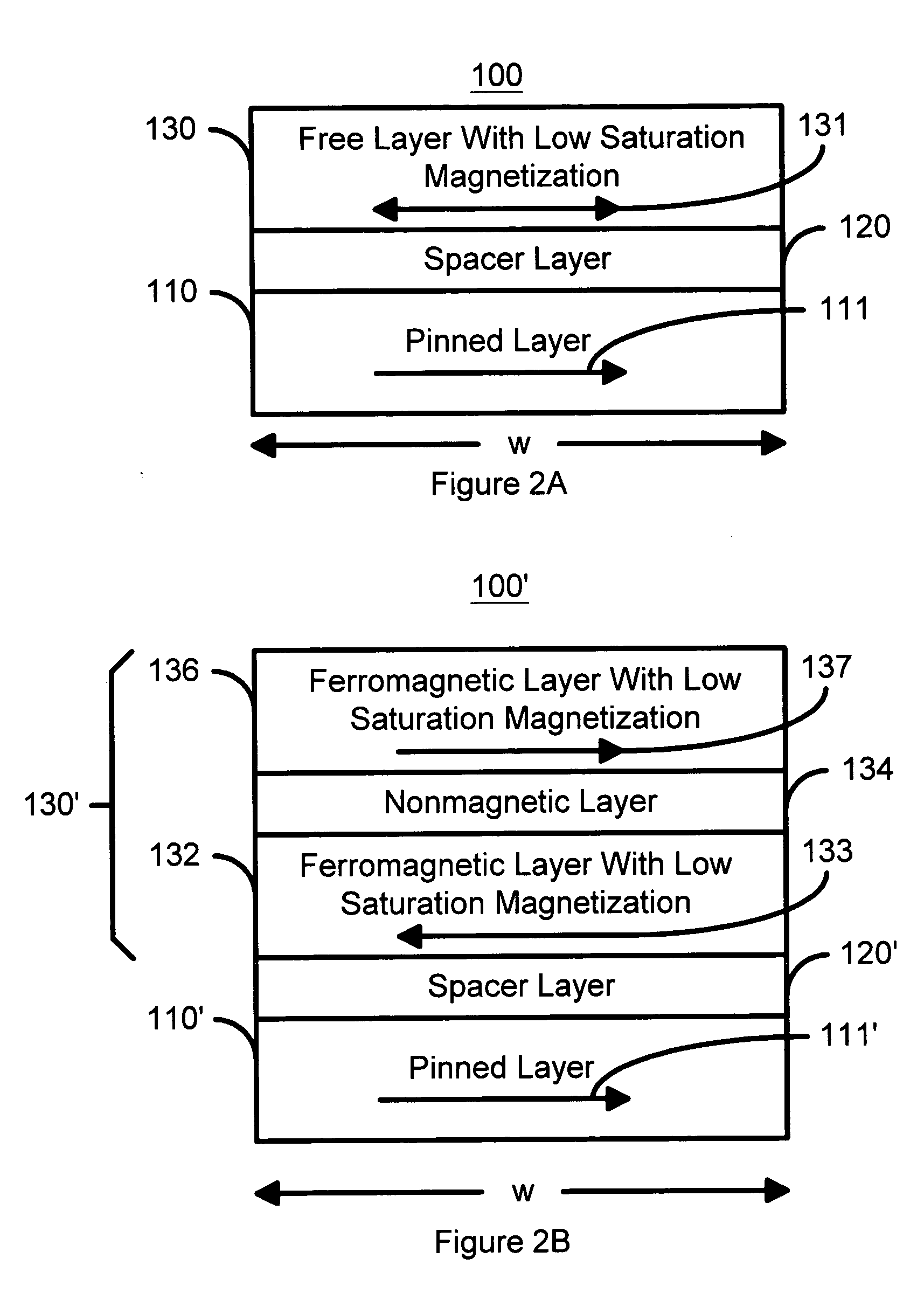

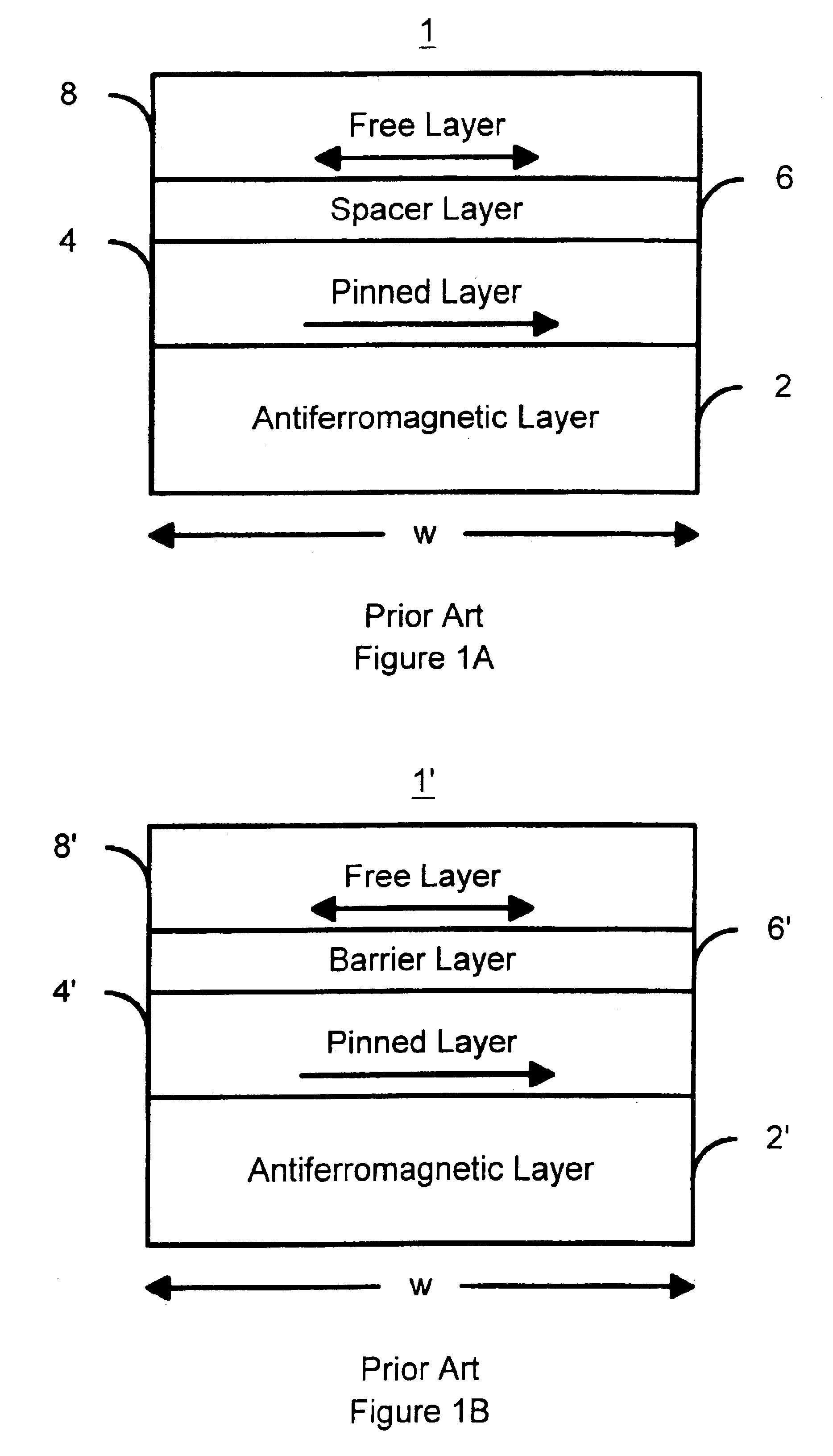

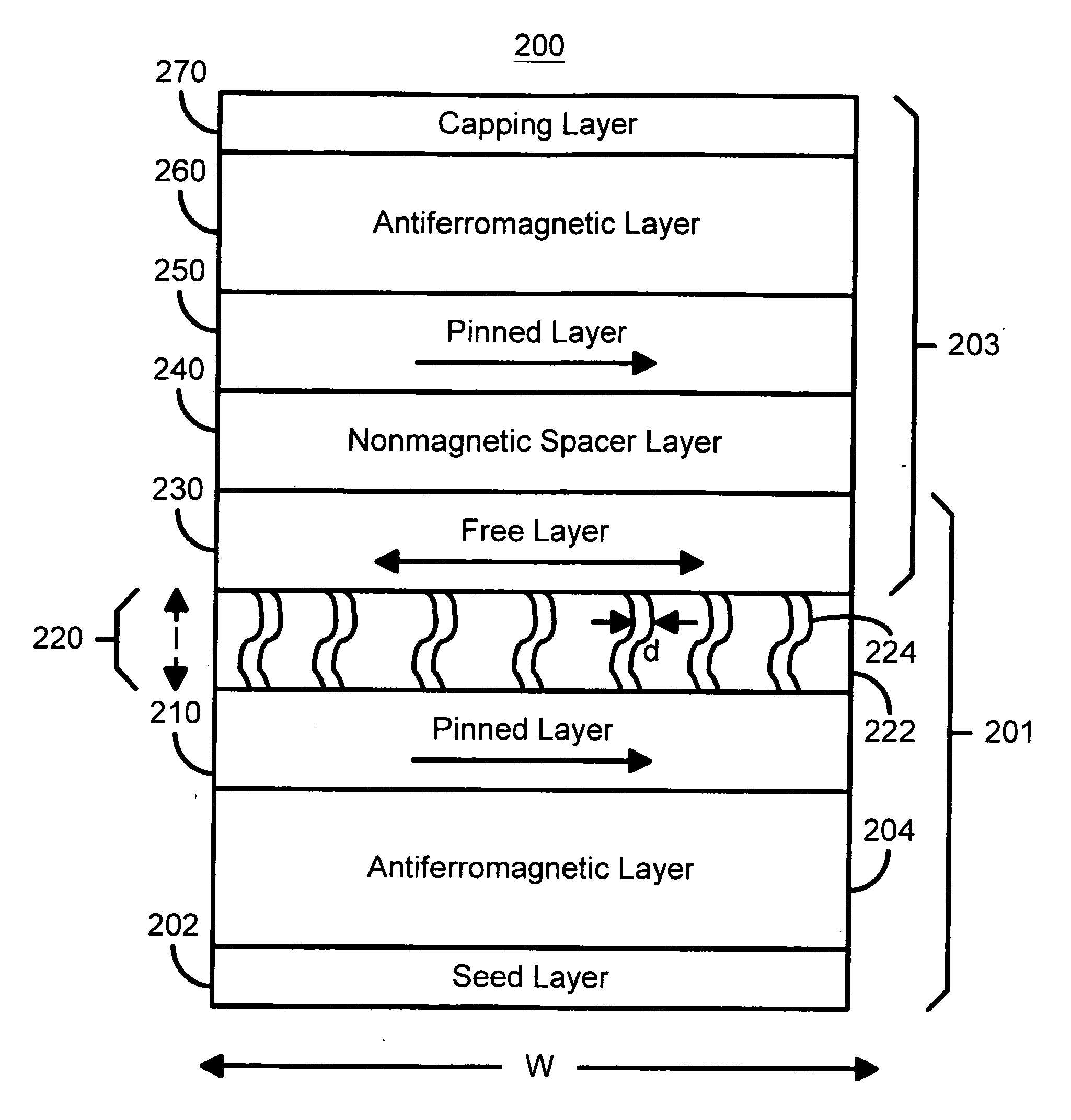

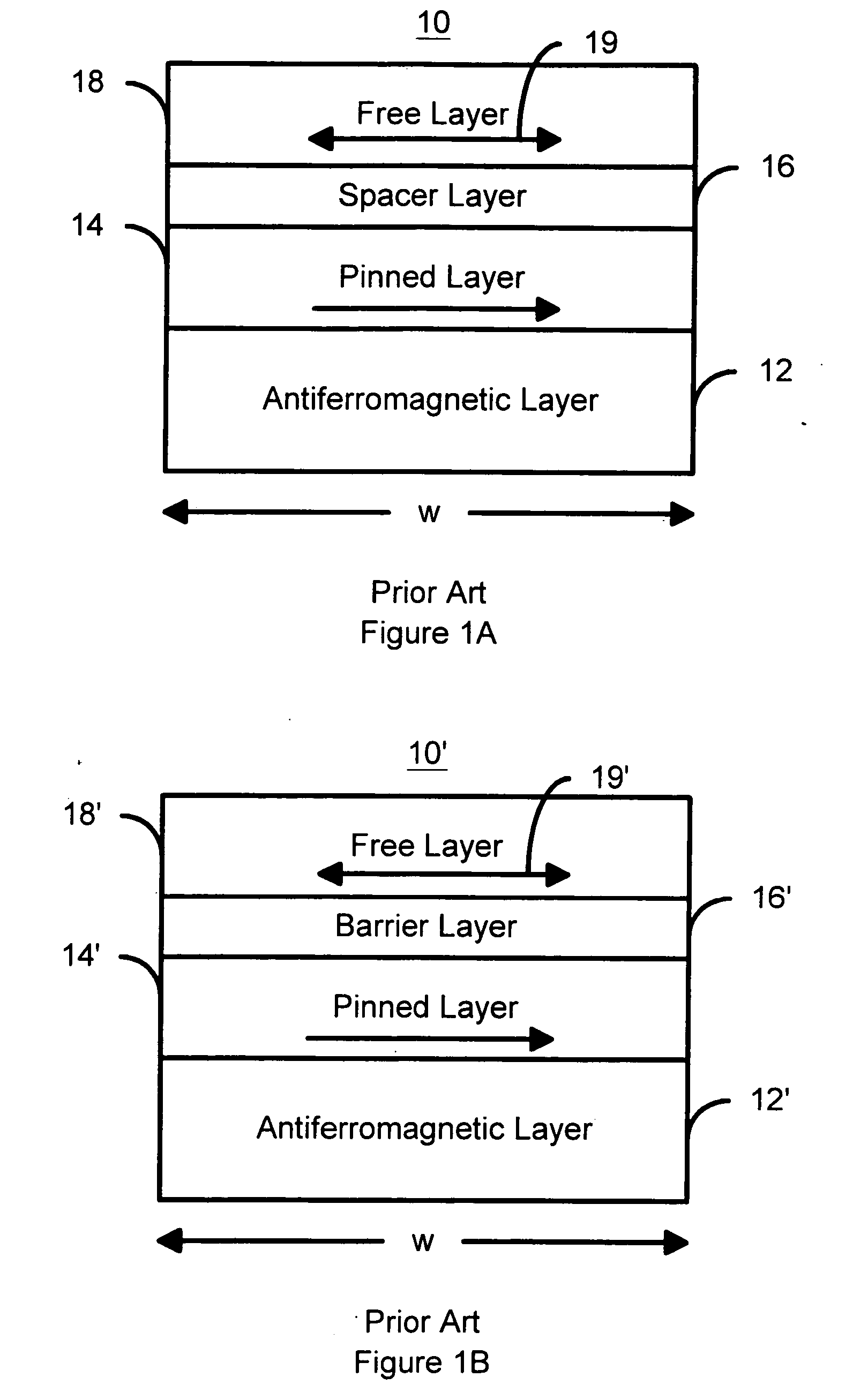

Spin transfer magnetic element having low saturation magnetization free layers

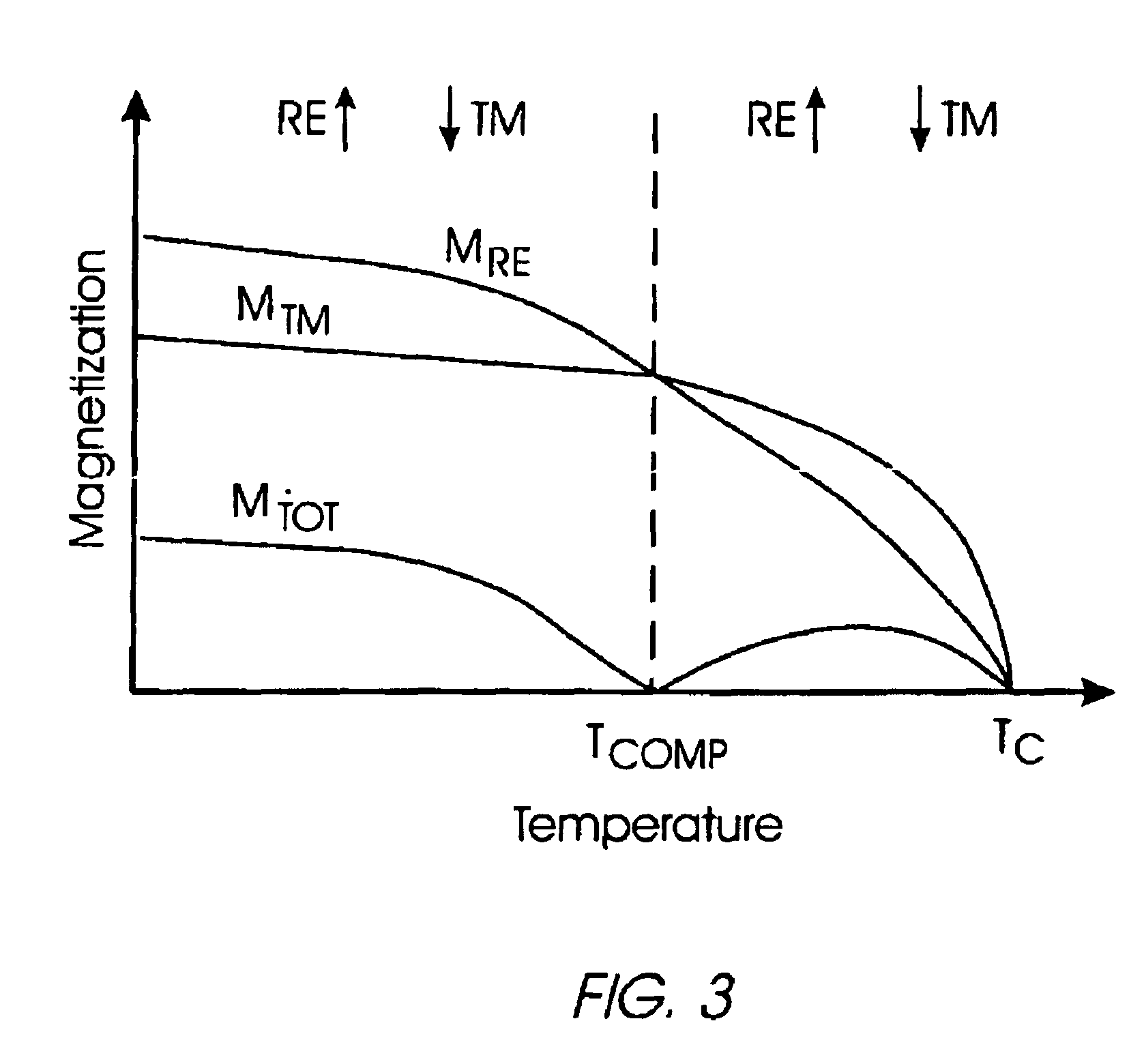

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. In one aspect, the free layer(s) include ferromagnetic material(s) diluted with nonmagnetic material(s) and / or ferrimagnetically doped to provide low saturation magnetization(s).

Owner:SAMSUNG SEMICON

Spin transfer magnetic element having low saturation magnetization free layers

ActiveUS20050184839A1Current densityNanostructure applicationNanomagnetismMagnetic memoryNon magnetic

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. In one aspect, the free layer(s) include ferromagnetic material(s) diluted with nonmagnetic material(s) and / or ferrimagnetically doped to provide low saturation magnetization(s).

Owner:SAMSUNG SEMICON

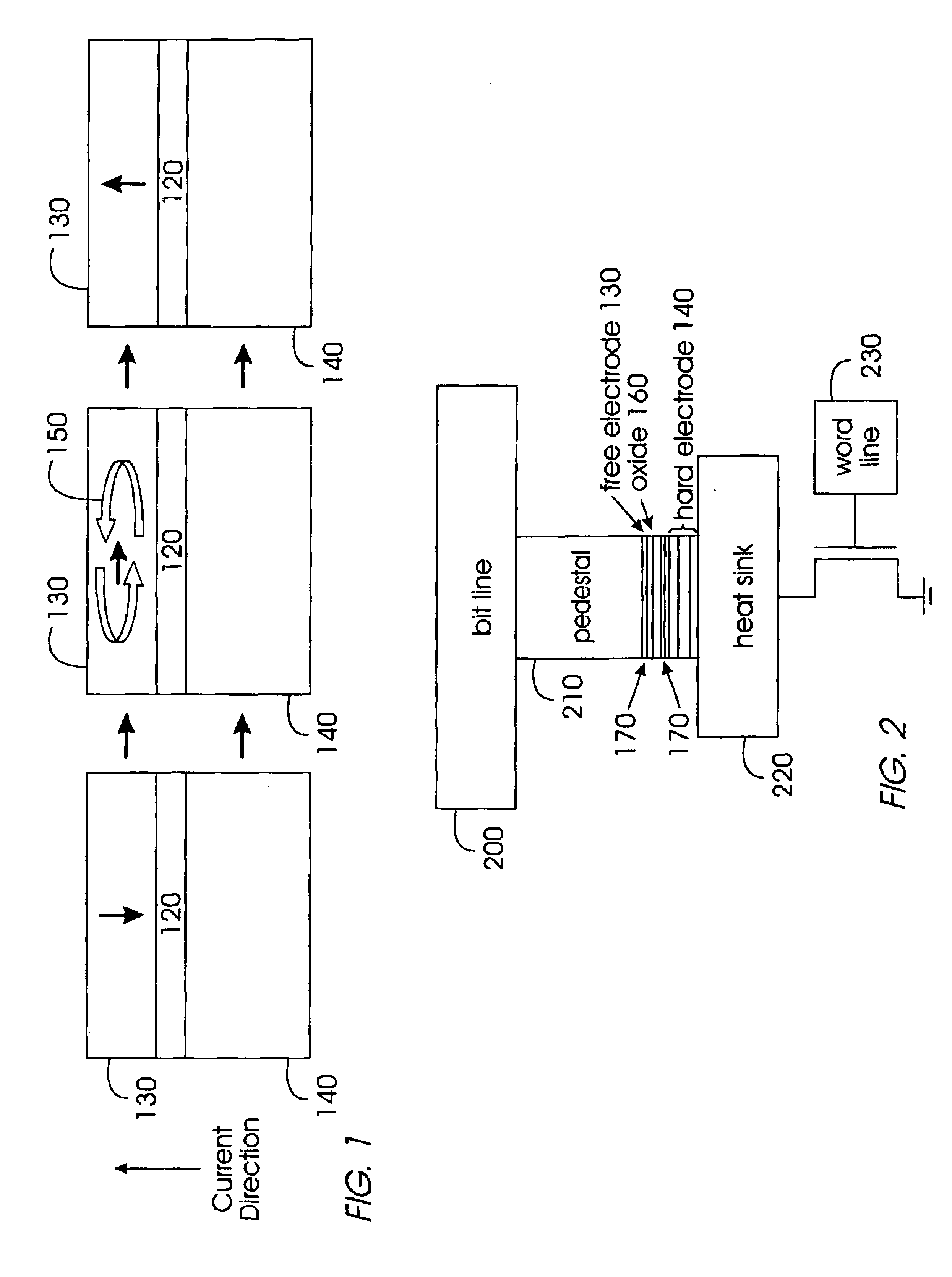

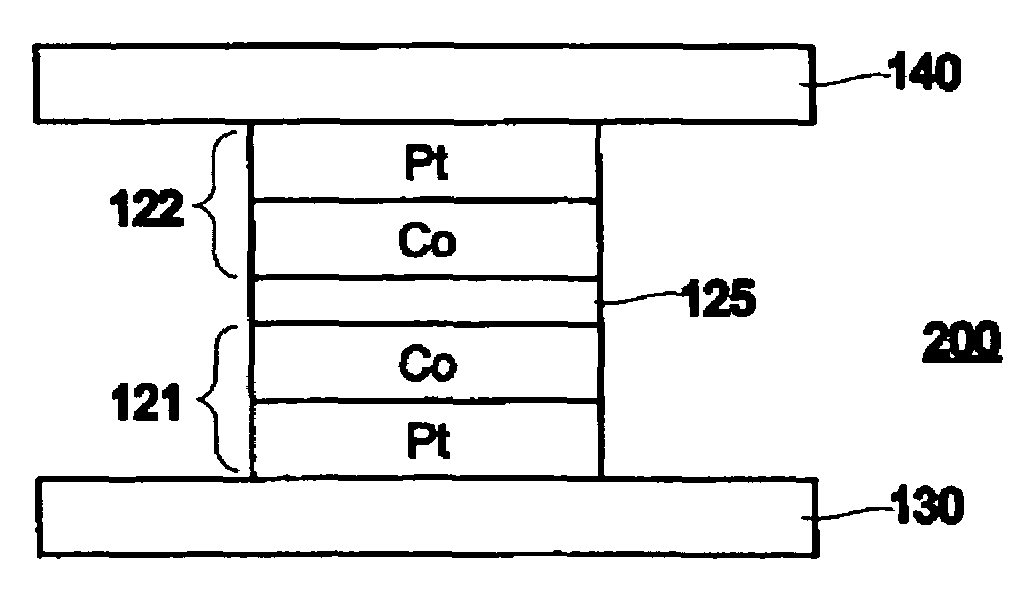

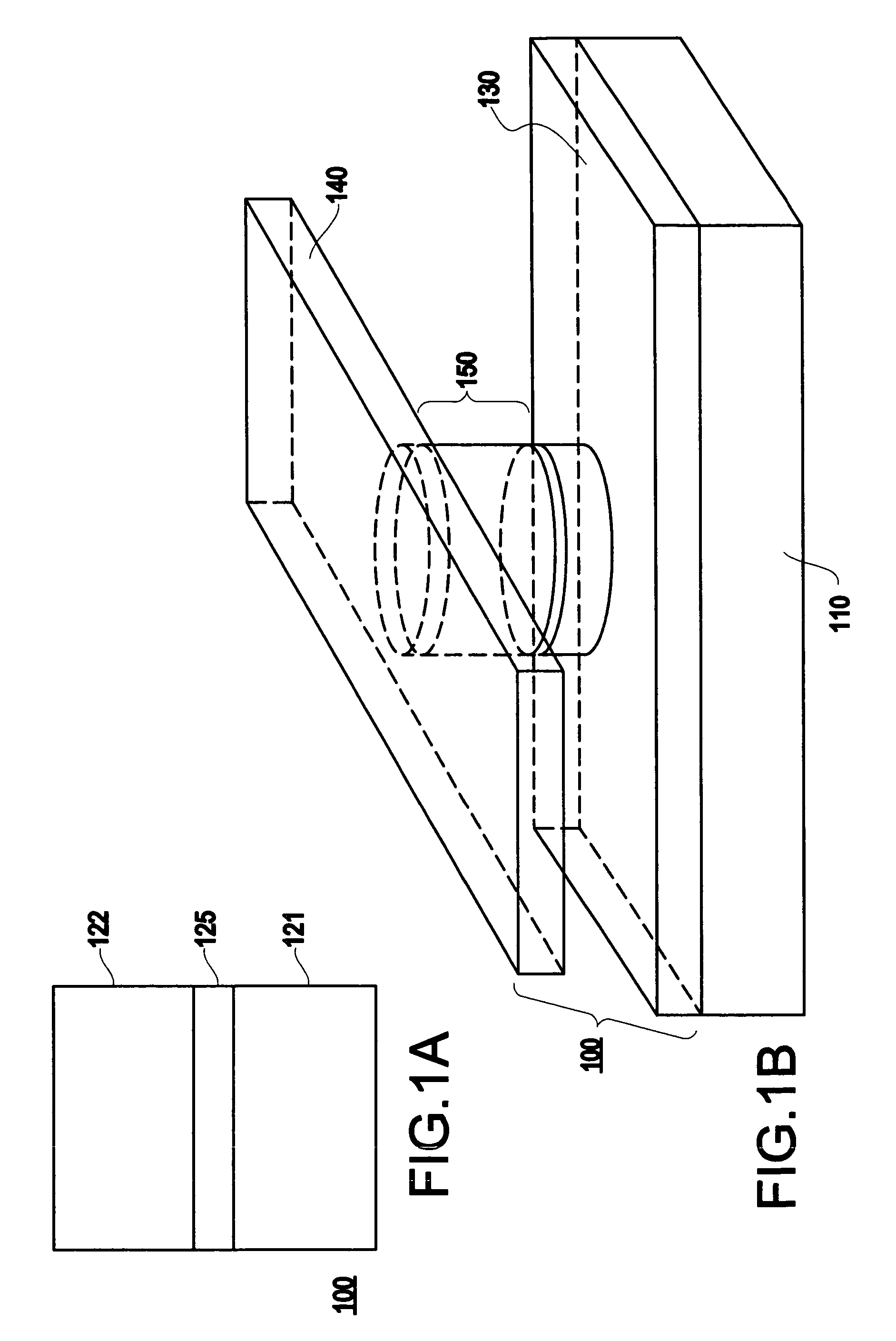

Spin-current switched magnetic memory element suitable for circuit integration and method of fabricating the memory element

A magnetic memory element switchable by current injection includes a plurality of magnetic layers, at least one of the plurality of magnetic layers having a perpendicular magnetic anisotropy component and including a current-switchable magnetic moment, and at least one barrier layer formed adjacent to the plurality of magnetic layers (e.g., between two of the magnetic layers). The memory element has the switching threshold current and device impedance suitable for integration with complementary metal oxide semiconductor (CMOS) integrated circuits.

Owner:GLOBALFOUNDRIES US INC

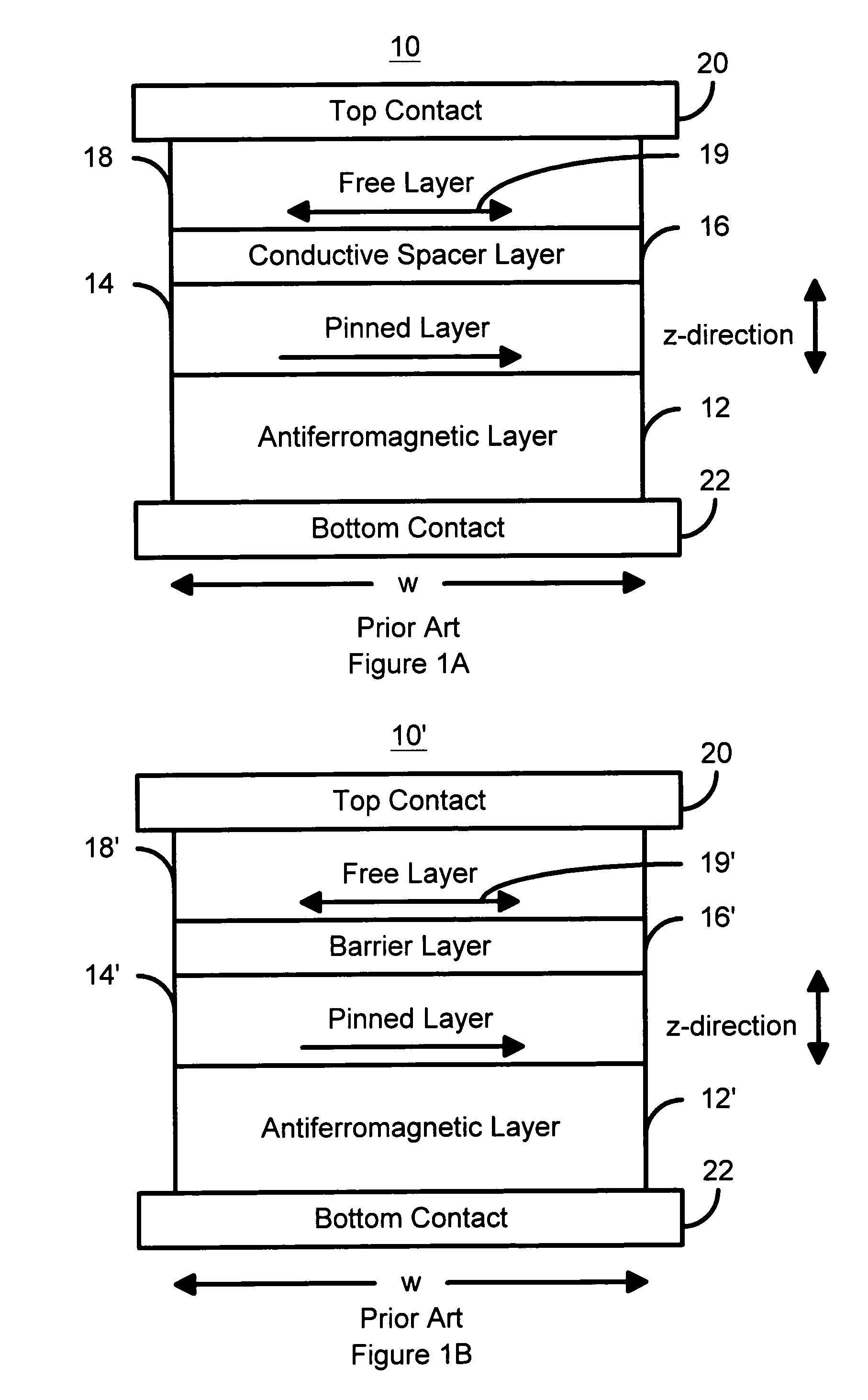

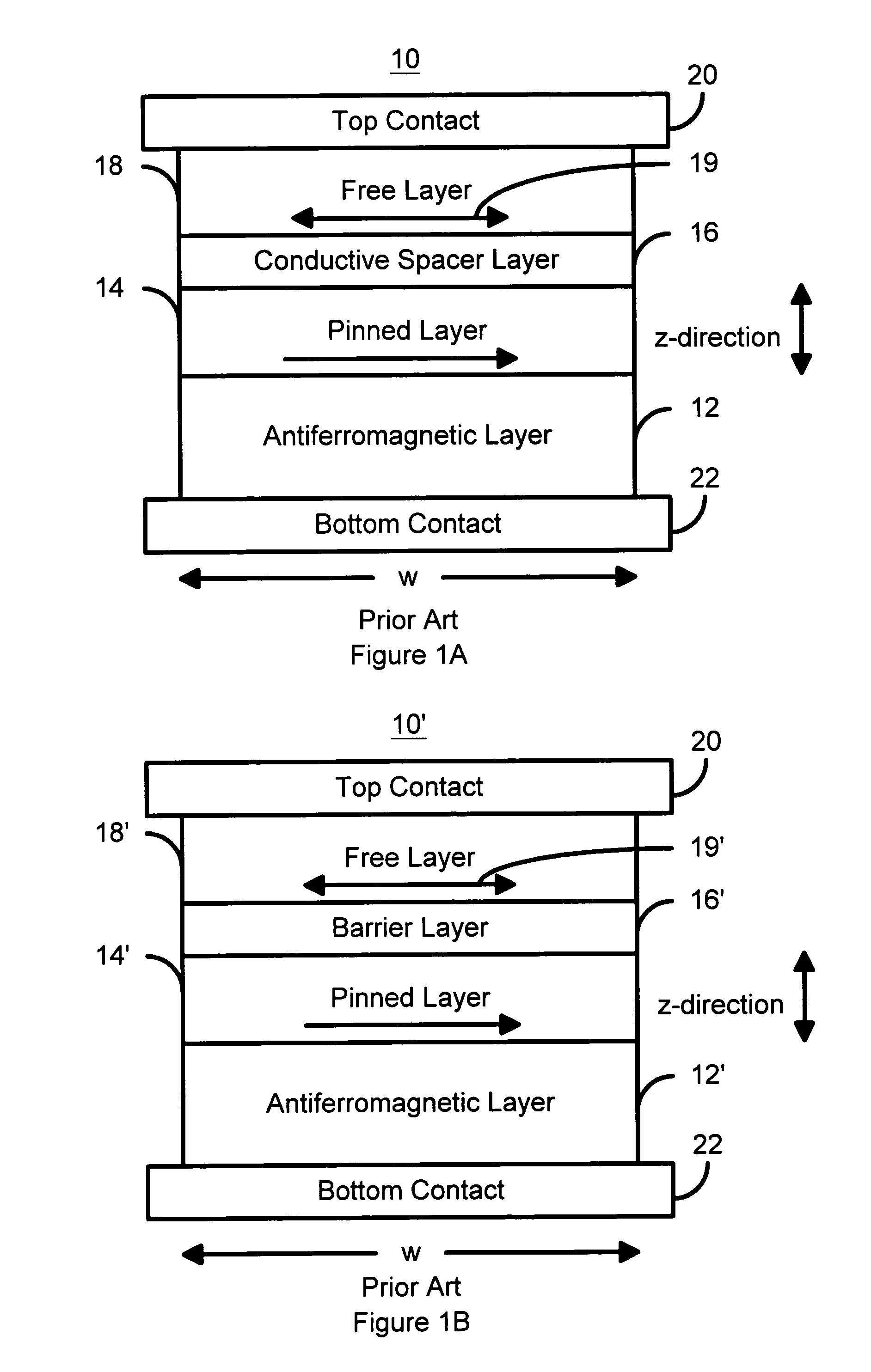

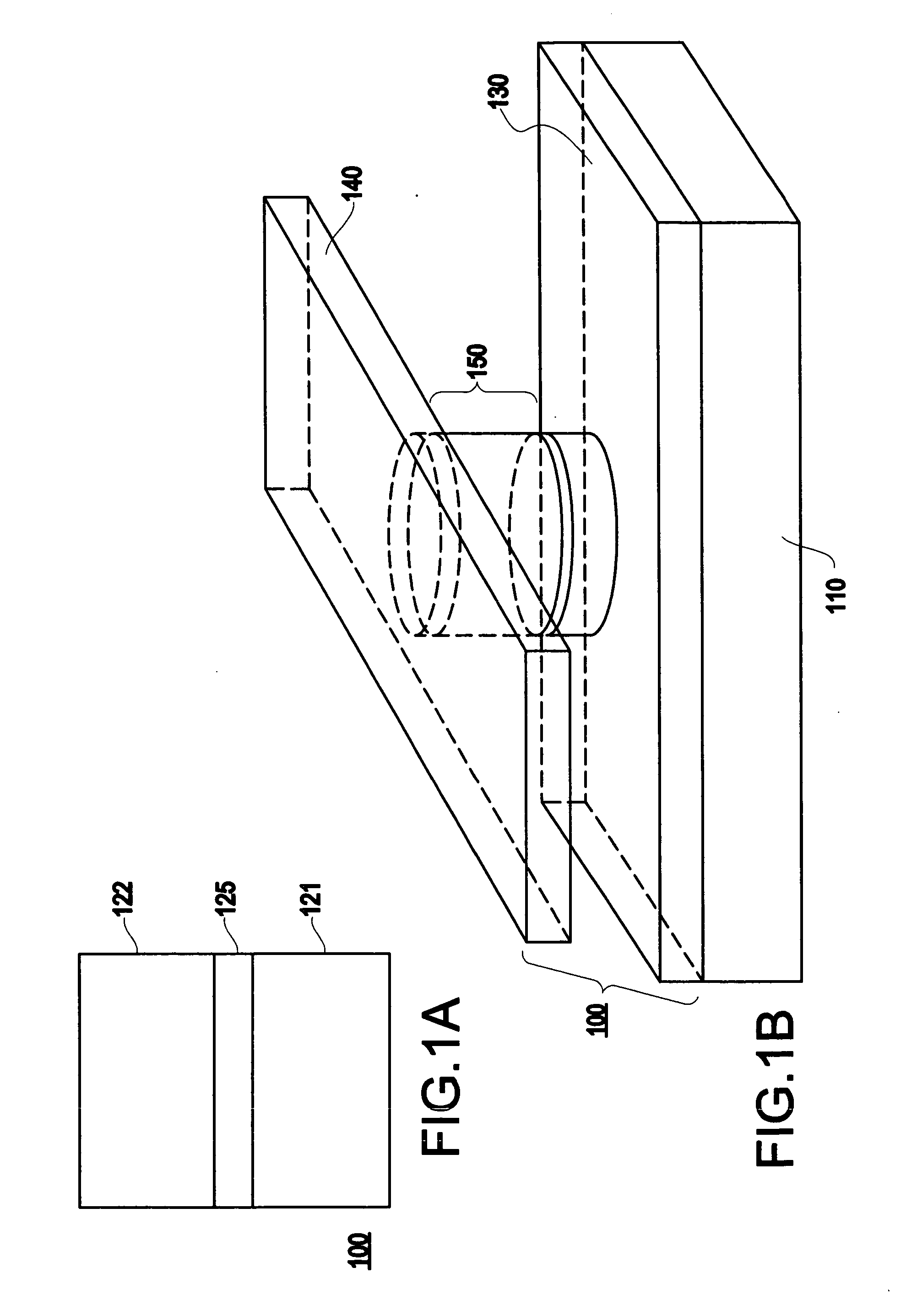

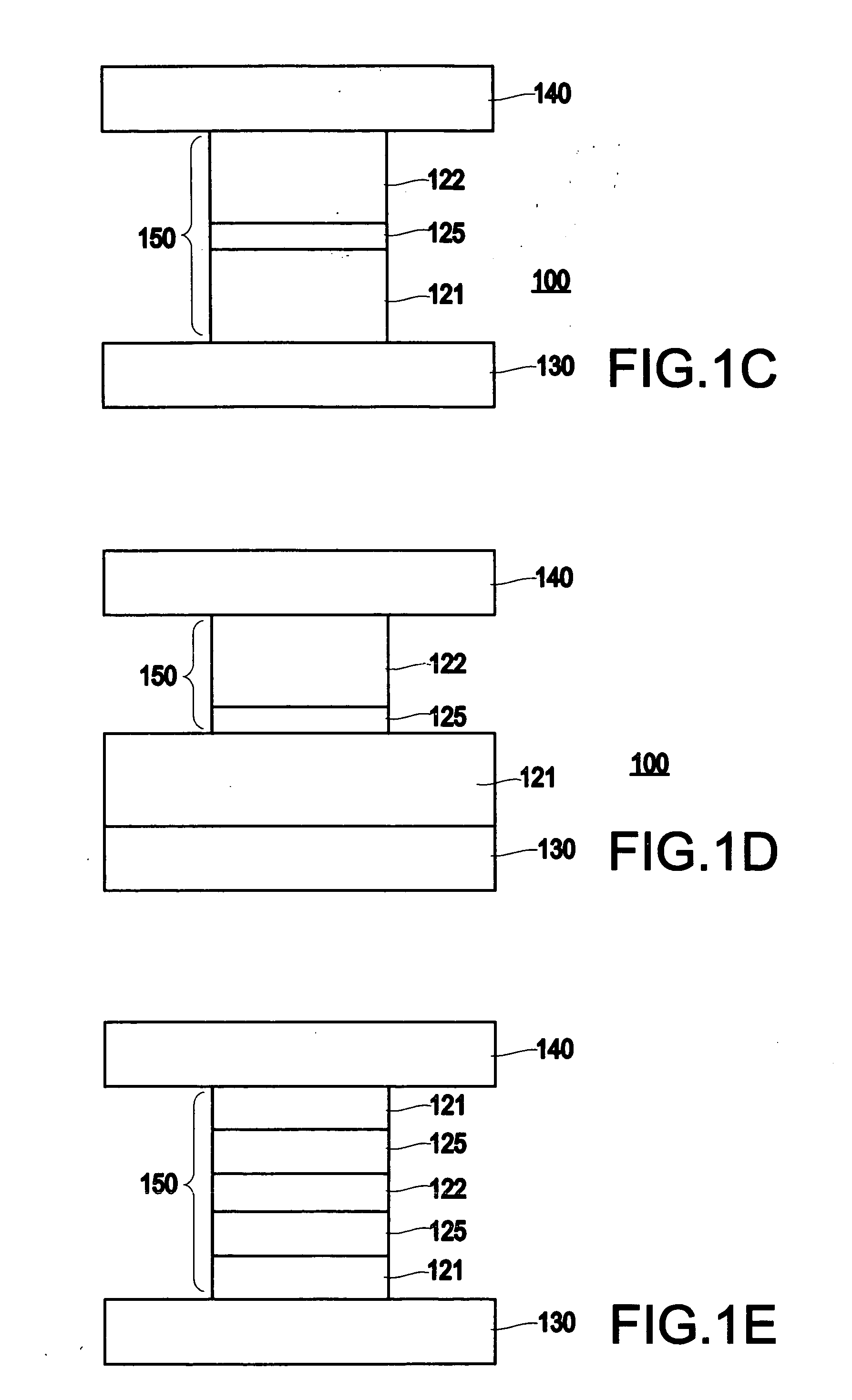

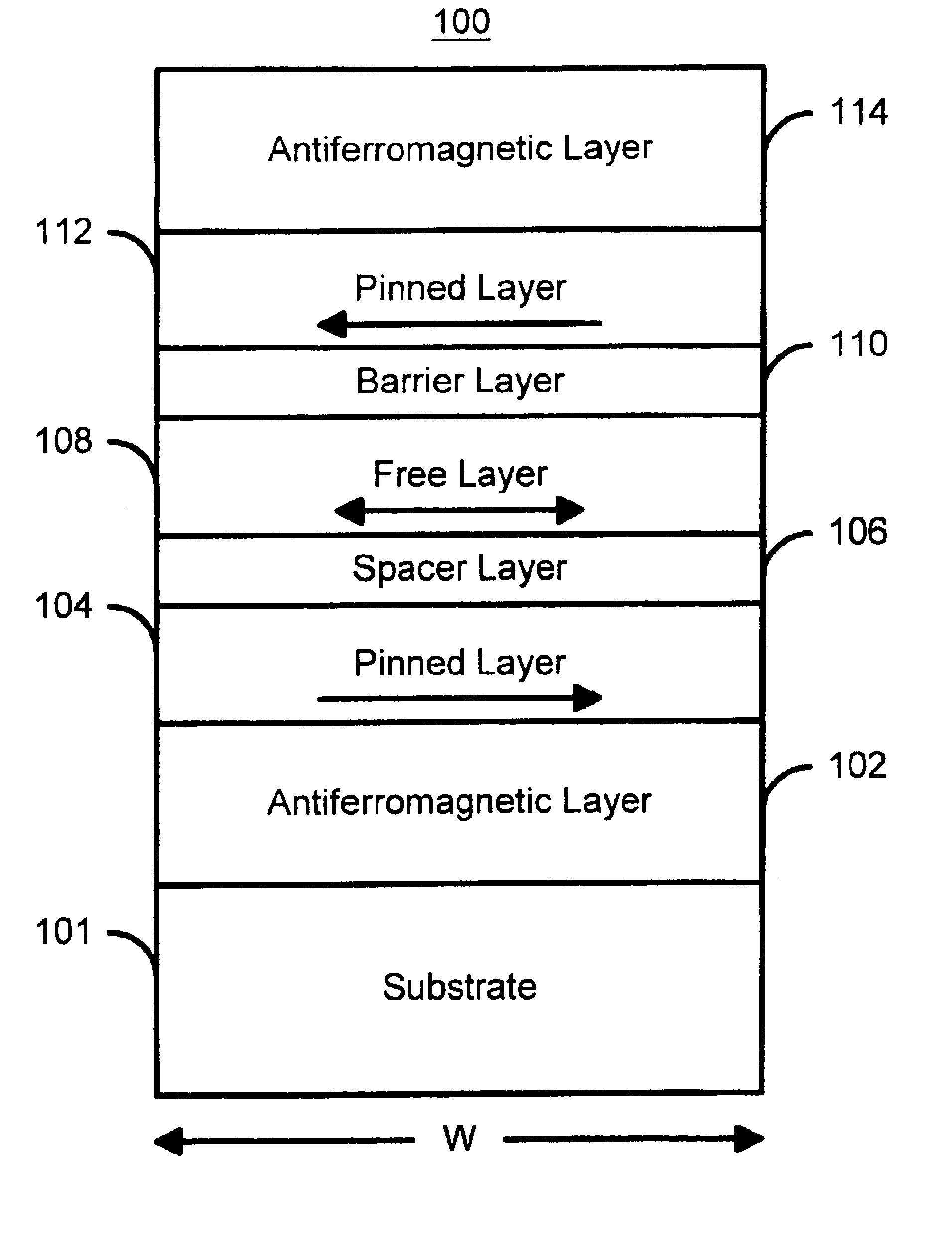

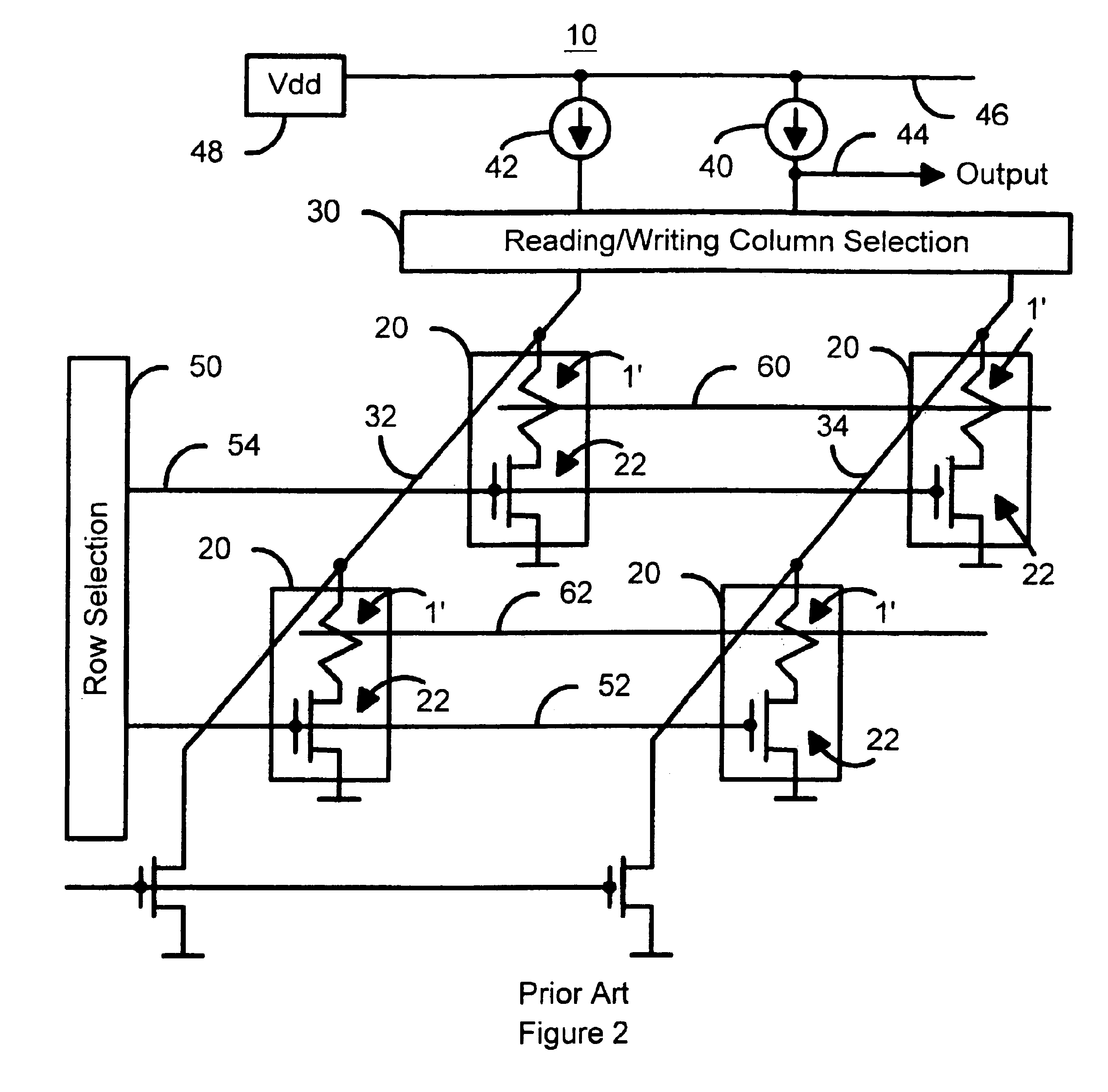

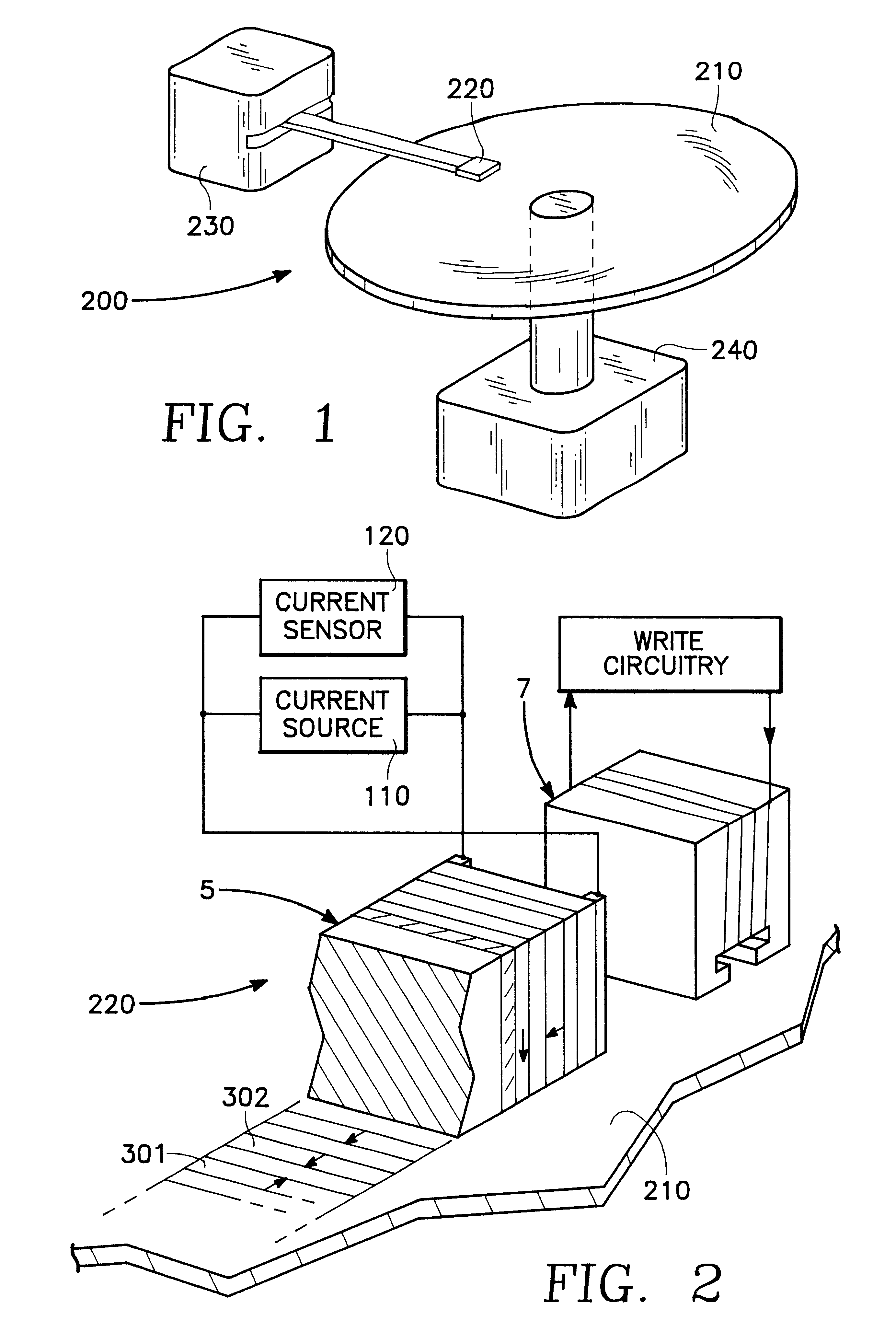

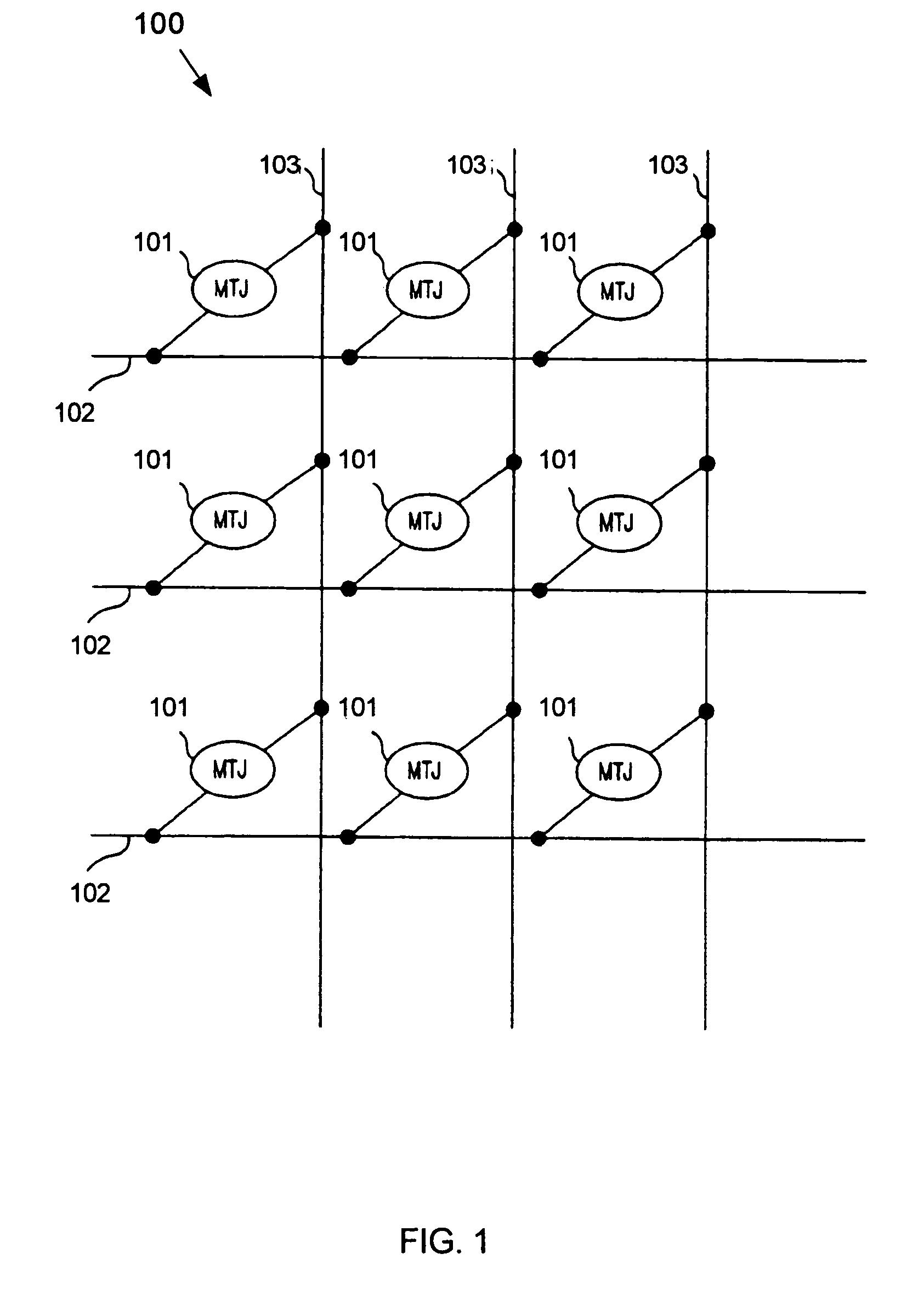

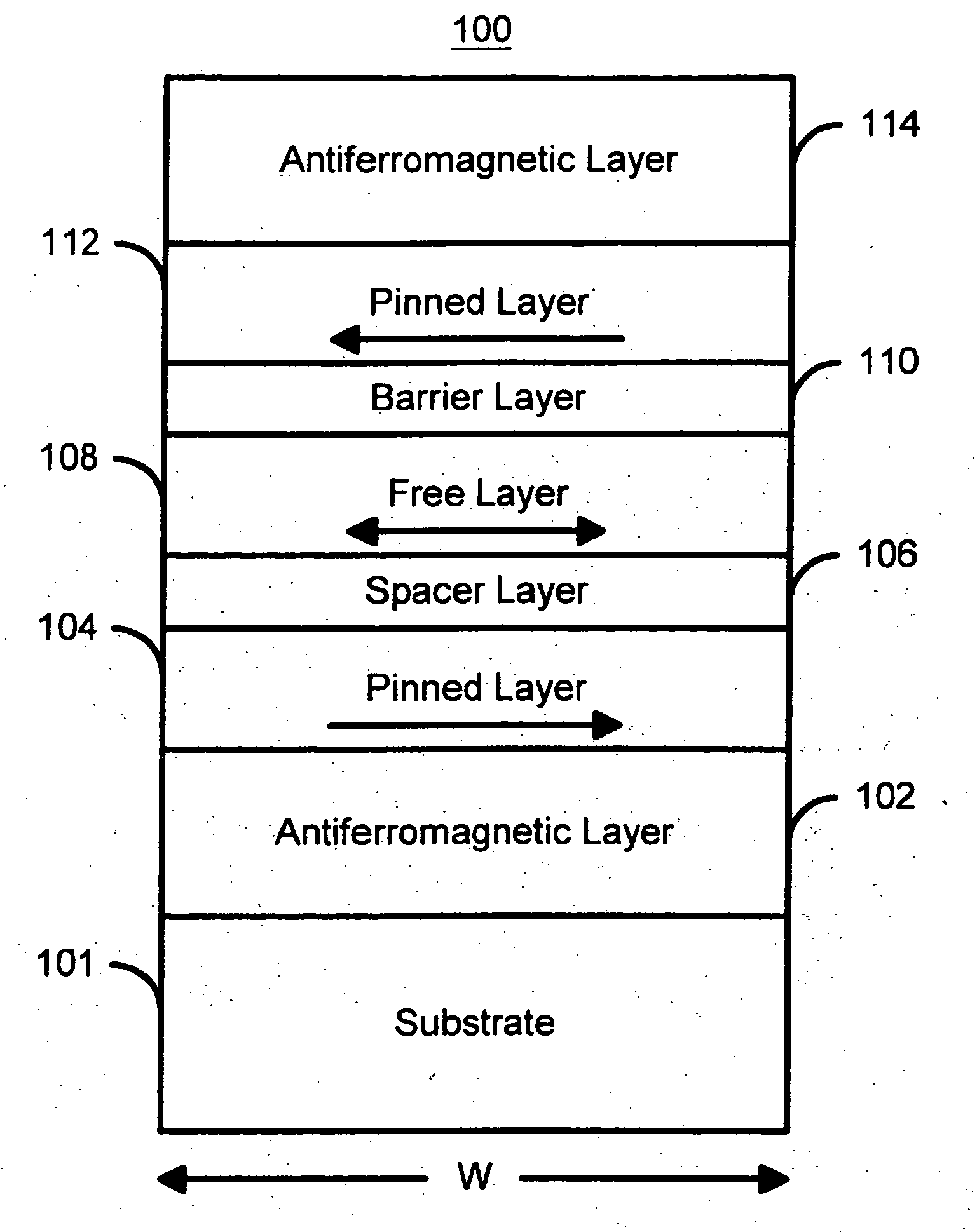

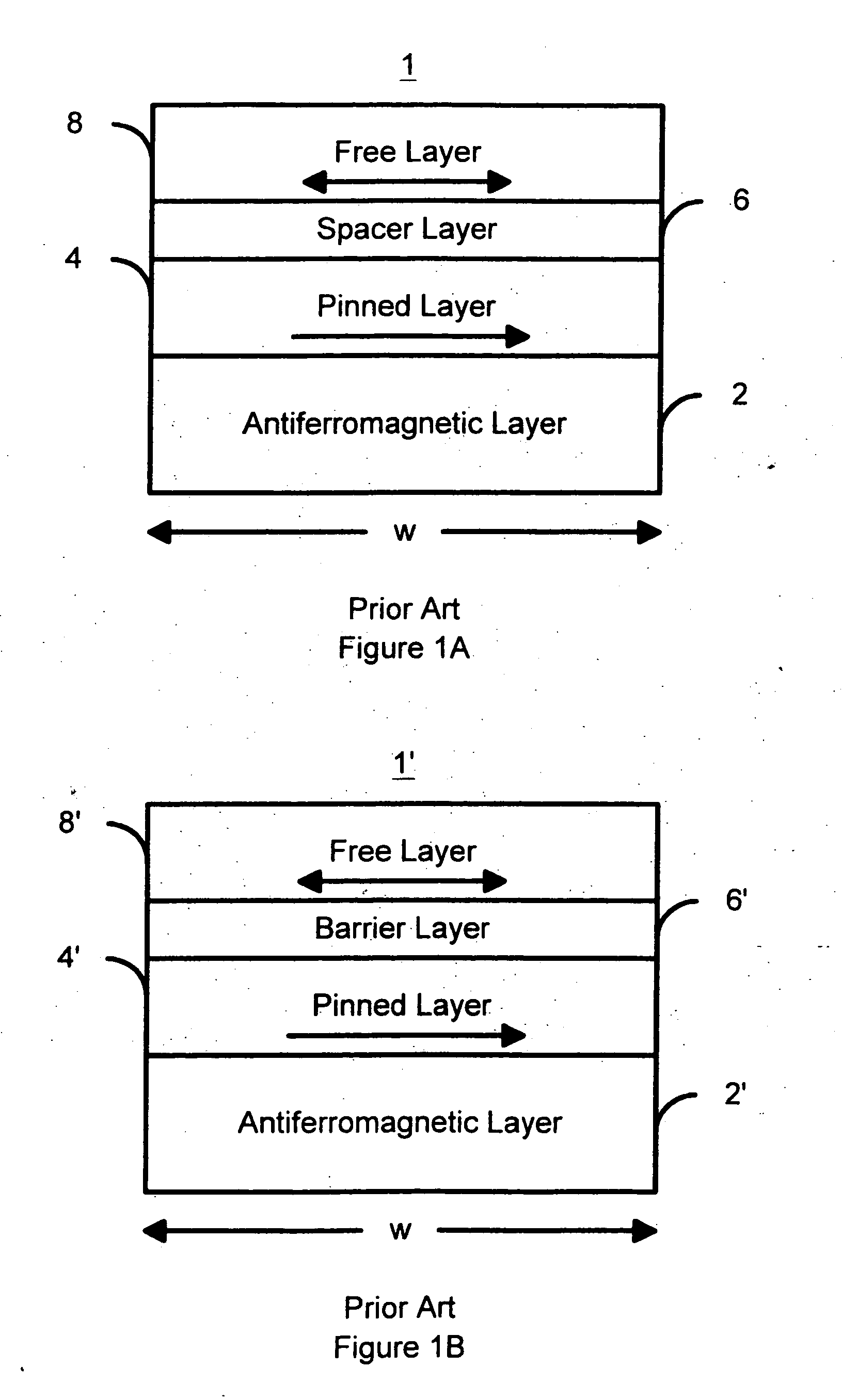

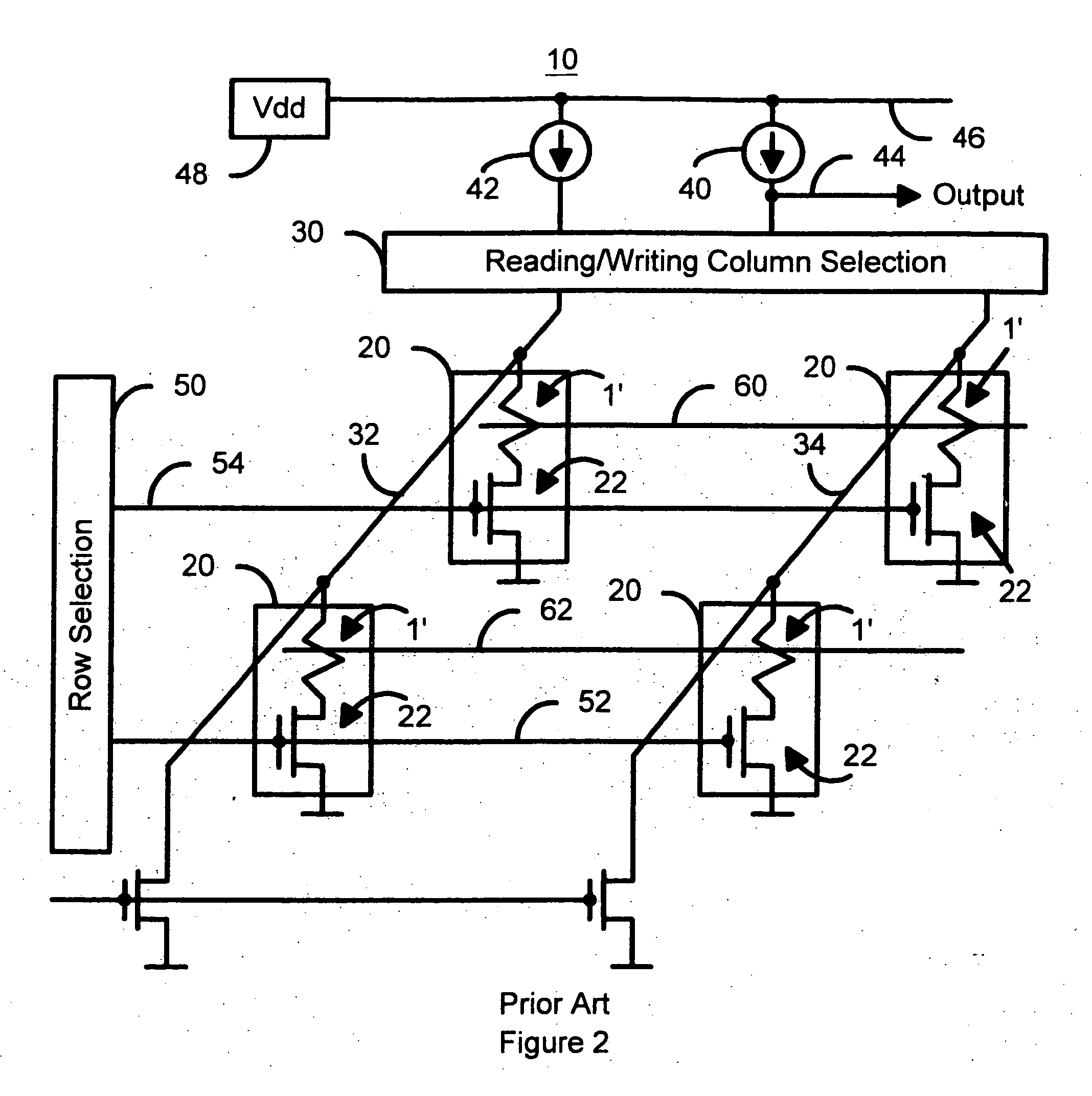

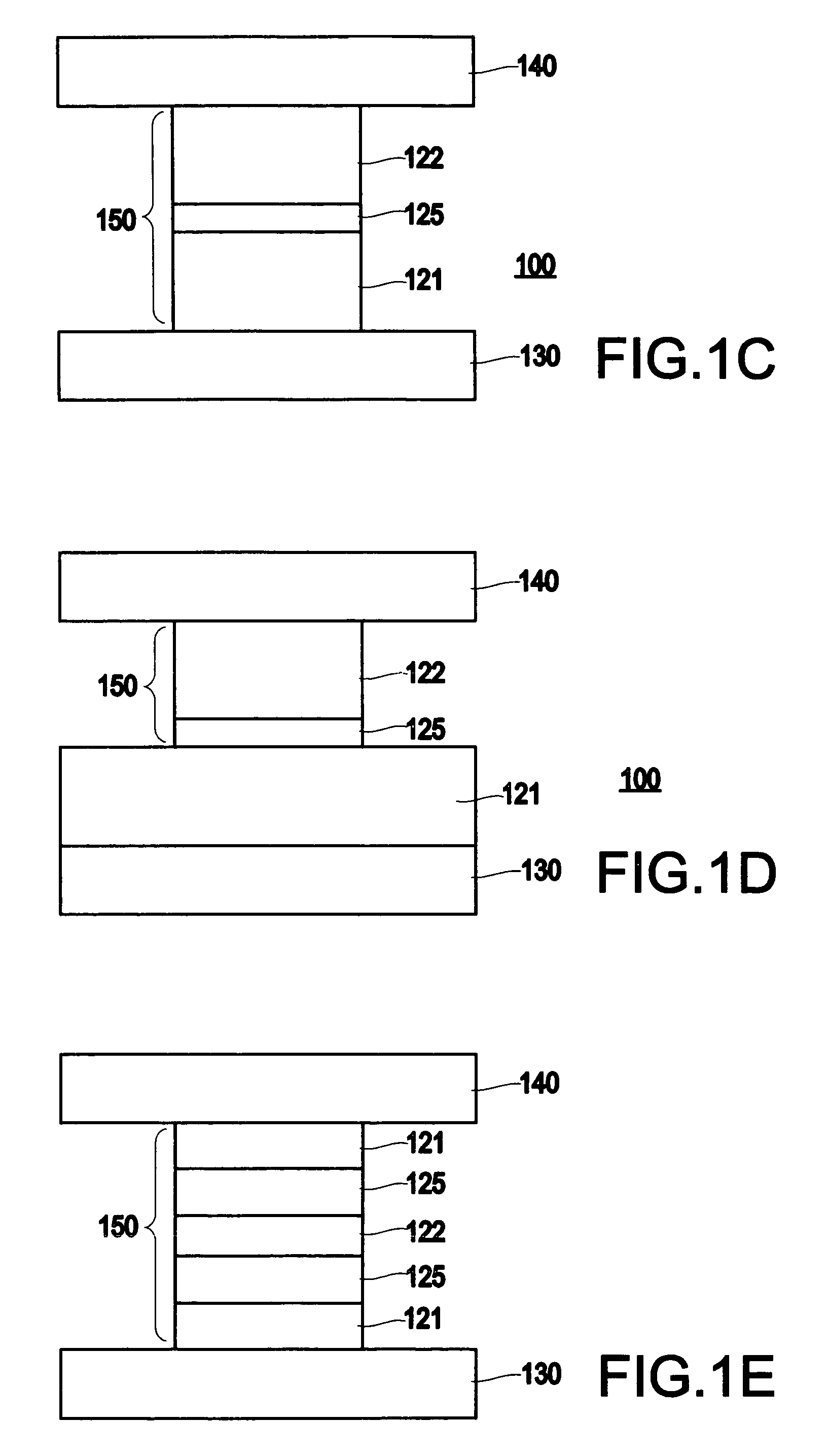

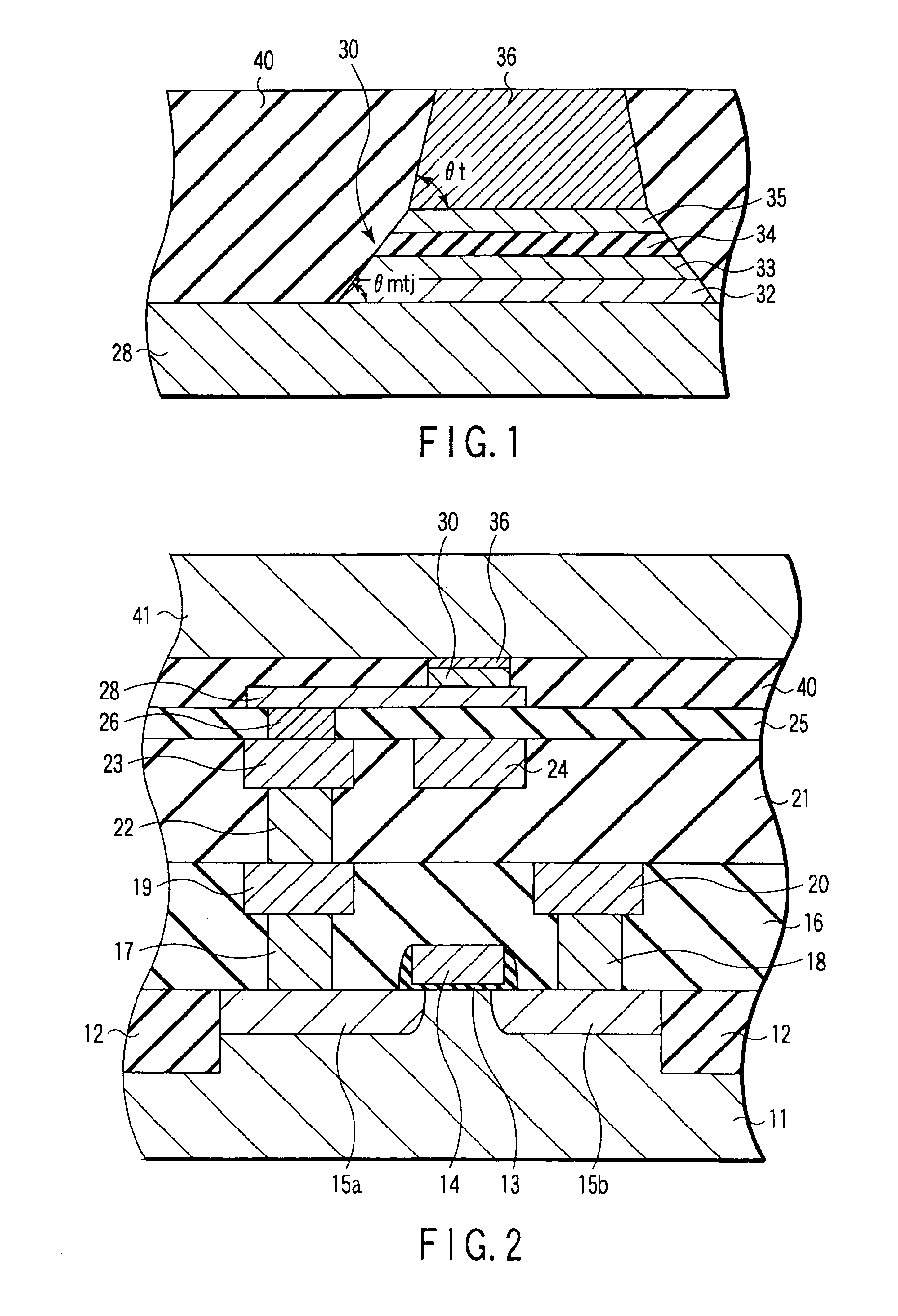

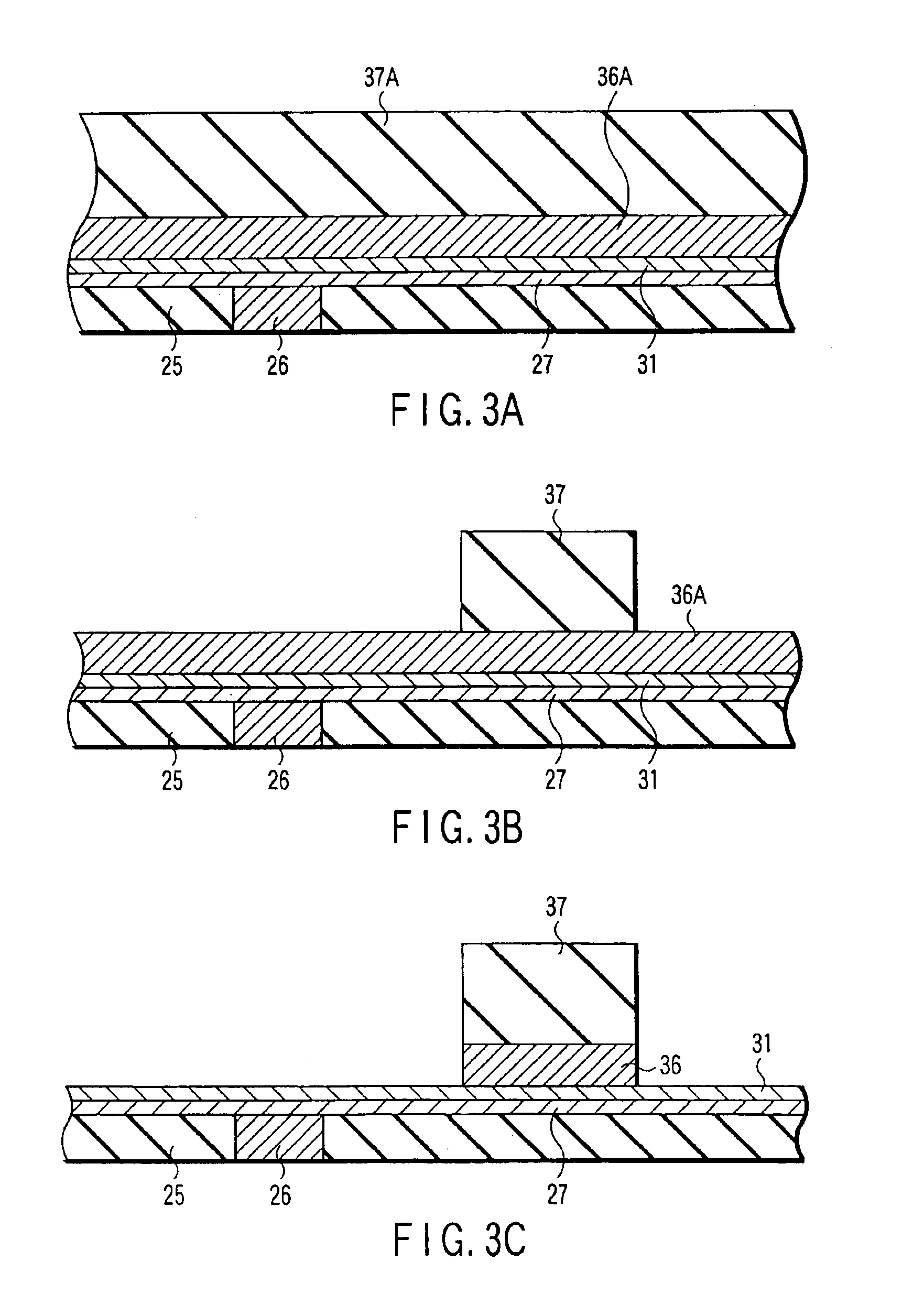

Magnetic element utilizing spin transfer and an MRAM device using the magnetic element

InactiveUS6920063B2Efficient and localized phenomenonEnhanced output signalNanostructure applicationNanomagnetismMagnetic memorySpin transfer

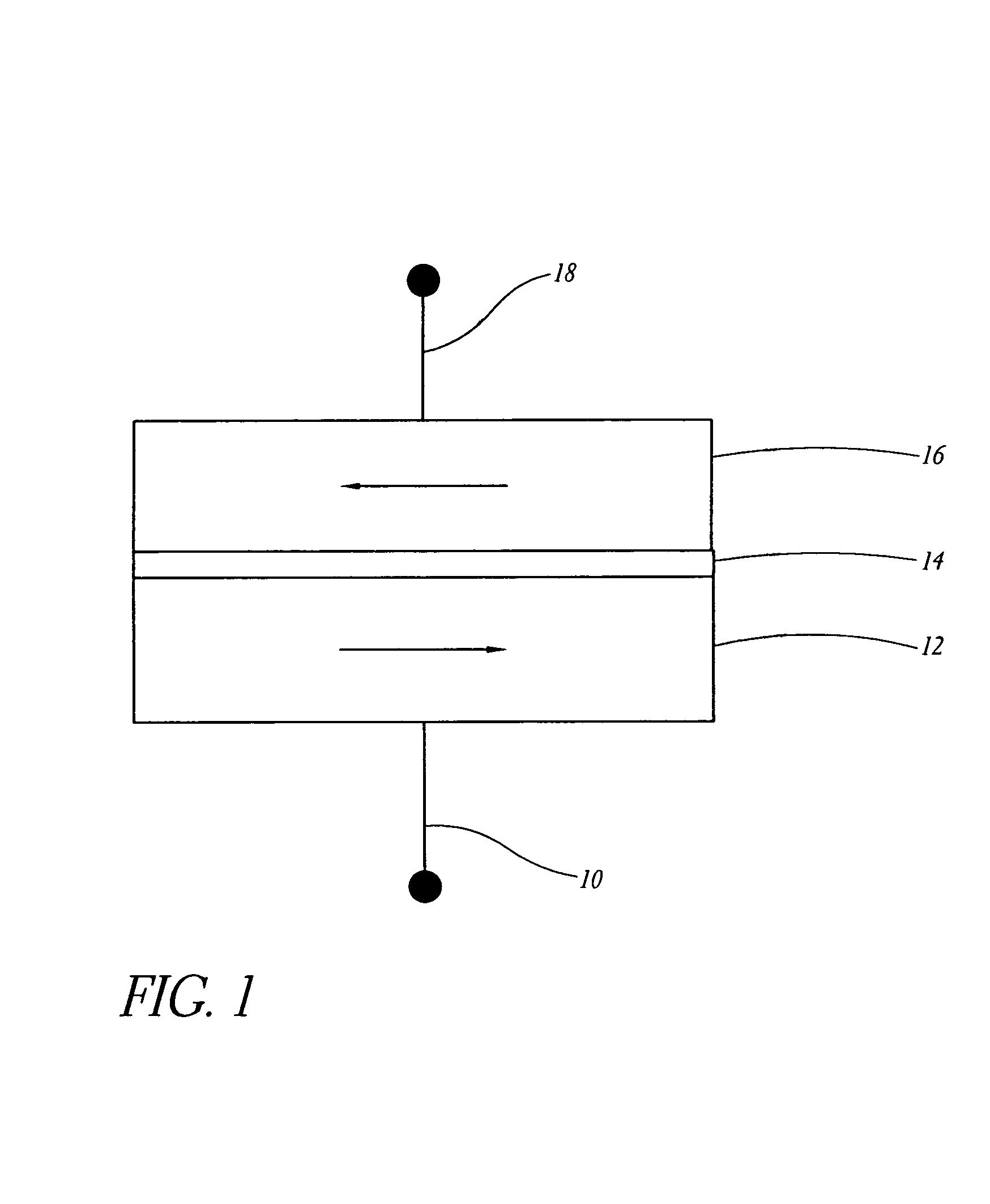

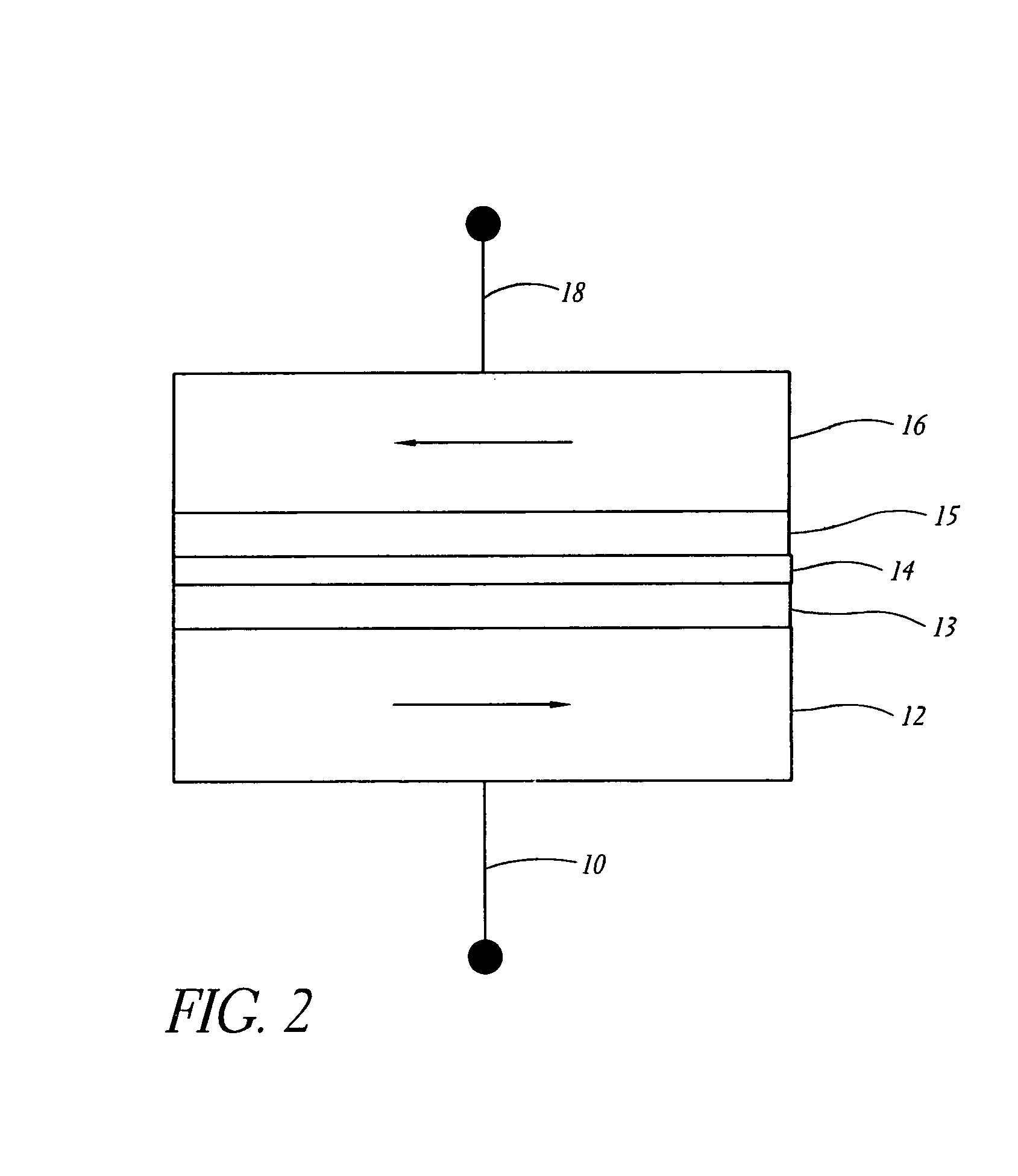

A method and system for providing a magnetic element capable of being written using spin-transfer effect while generating a high output signal and a magnetic memory using the magnetic element are disclosed. The magnetic element includes a first ferromagnetic pinned layer, a nonmagnetic spacer layer, a ferromagnetic free layer, an insulating barrier layer and a second ferromagnetic pinned layer. The pinned layer has a magnetization pinned in a first direction. The nonmagnetic spacer layer is conductive and is between the first pinned layer and the free layer. The barrier layer resides between the free layer and the second pinned layer and is an insulator having a thickness allowing electron tunneling through the barrier layer. The second pinned layer has a magnetization pinned in a second direction. The magnetic element is configured to allow the magnetization of the free layer to change direction due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

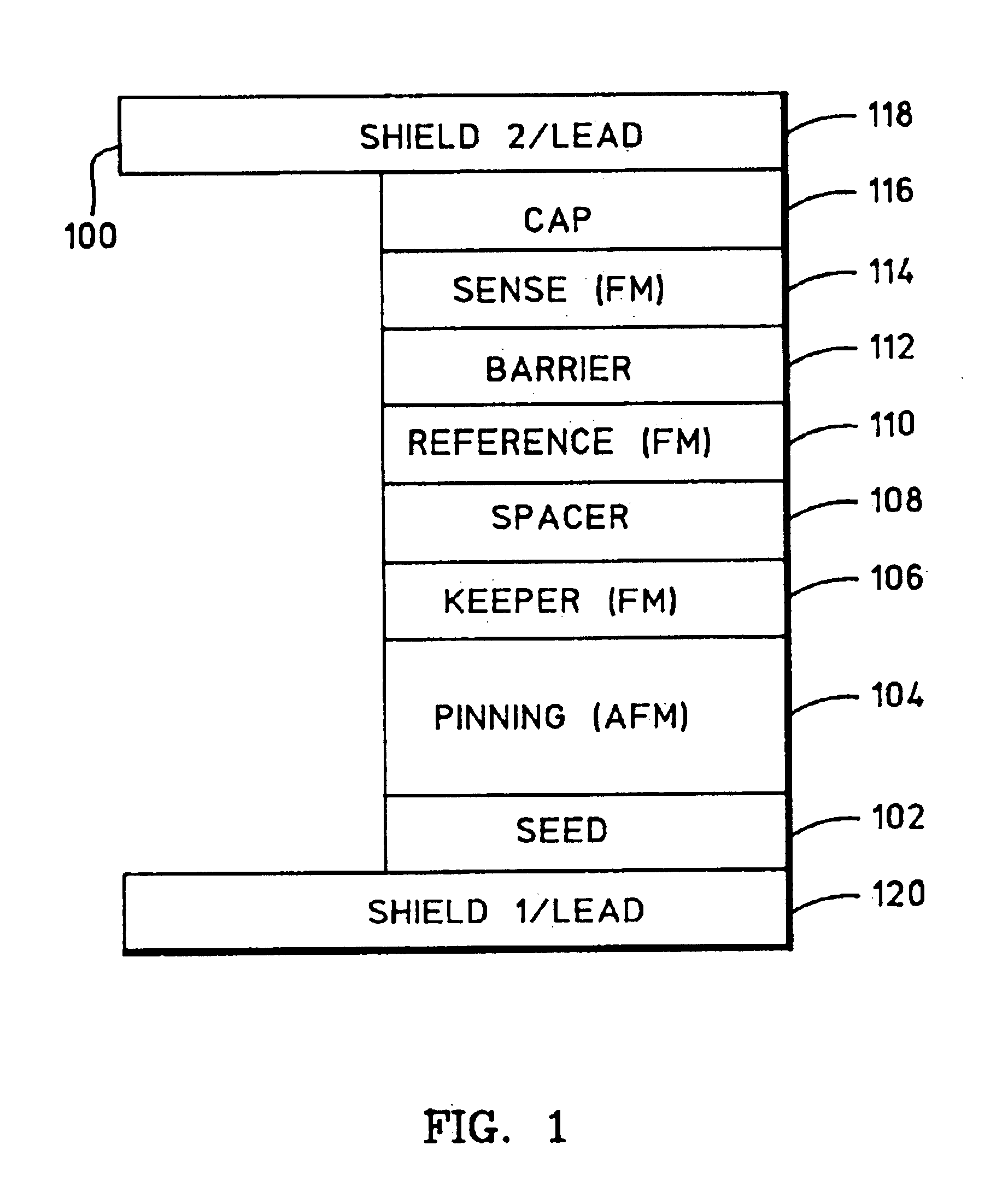

Top spin valve with improved seed layer

InactiveUS6687098B1Improved exchange bias fieldNanostructure applicationNanomagnetismEngineeringHigh resistivity

The present invention provides an improved top spin valve and method of fabrication. In the preferred embodiment of the top spin valve of the present invention, a seed layer is formed of non-magnetic material having the elements Ni and Cr. In the preferred embodiments, the seed layer material has an ion milling rate comparable to that of the free layer material. This allows free layer sidewalls to be formed with shorter tails, improving free layer-to-magnetic bias layer junction, thus improving free layer domain structure and track width. In one embodiment, the seed layer may have NiFeCr, with Cr from about 20% to 50%. In another embodiment, the seed layer may have NiCr, with about 40%. Some embodiments may have the seed layer formed on an optional Ta pre-seed layer. Such embodiments provide an improved fcc (111) texture particularly for NiFe and for NiFe / CoFe free layers grown on a seed layer improving spin valve performance, and especially in embodiments having very thin NiFe free layers, ultra thin NiFe free layers, and free layers without NiFe, such as a free layer of CoFe. Such a seed layer can improve AFM pinning layer texture to improve the exchange bias, thus providing better thermal stability. Such a seed layer also provides high resistivity and can improve the magnetostriction of adjacent NiFe free layer material or improve the soft properties of an adjacent CoFe free layer.

Owner:WESTERN DIGITAL TECH INC

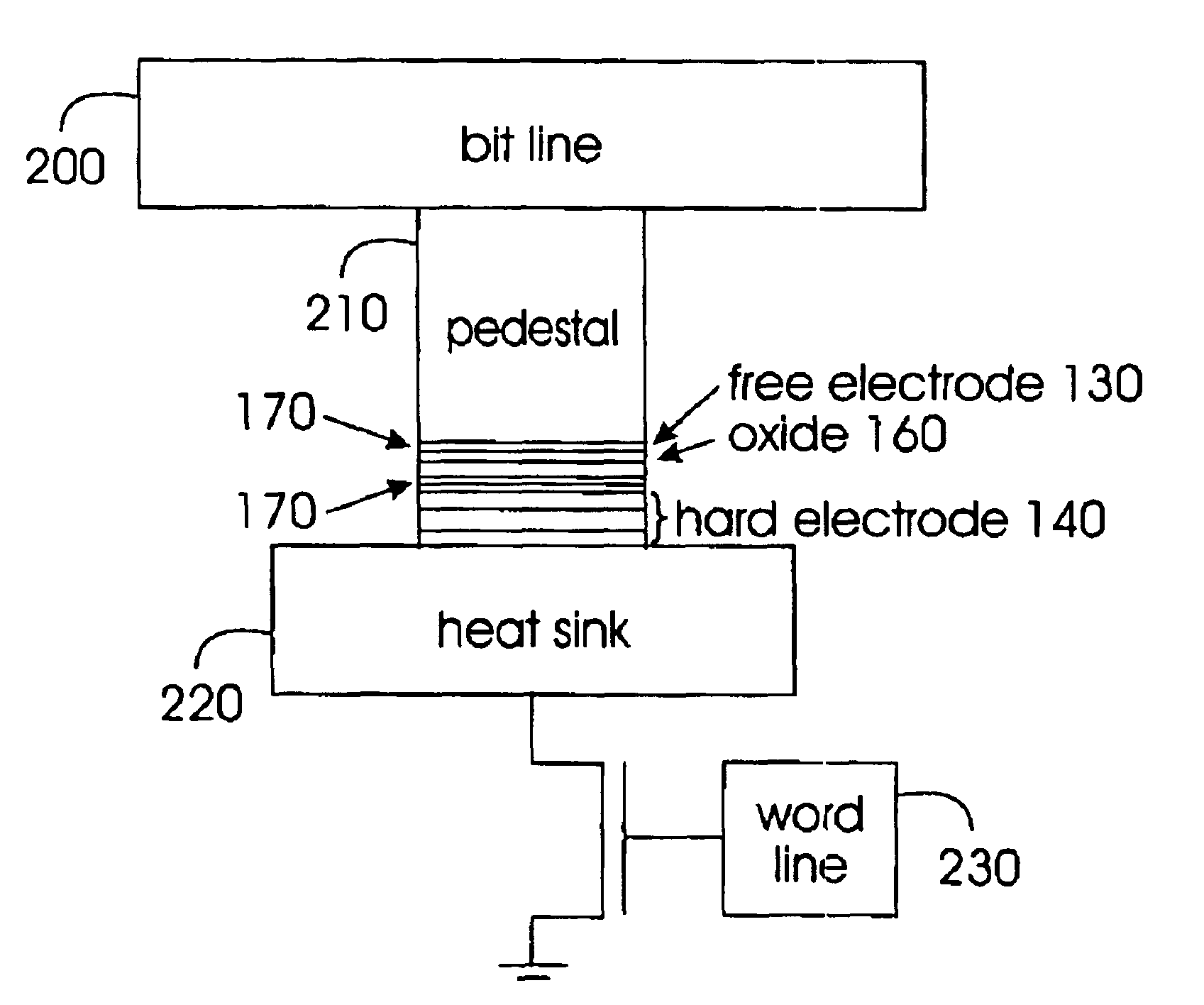

Thermally-assisted magnetic writing using an oxide layer and current-induced heating

InactiveUS6771534B2Increase in sizeIncrease in coercivityNanostructure applicationNanomagnetismElectrical resistance and conductanceElectrical conductor

A method and structure for a non-volatile magnetic random access memory (MRAM) device that has a stable magnetic electrode, an oxide layer adjacent the stable magnetic electrode, and a free magnetic electrode. The oxide layer is between the stable magnetic electrode and the free magnetic electrode. In the invention, a conductor is connected to a stable magnetic electrode. The oxide layer has a resistance at levels to allow sufficient power dissipation to lower the anisotropy of the free magnetic electrode through current induced heating. Current-induced heating is used in combination with spin-transfer torque or a magnetic field to switch the free magnetic electrode.

Owner:GLOBALFOUNDRIES U S INC

Magnetic elements with ballistic magnetoresistance utilizing spin-transfer and an MRAM device using such magnetic elements

InactiveUS20050136600A1Improve signal outputTransistorNanostructure applicationMagnetic currentCharge carrier

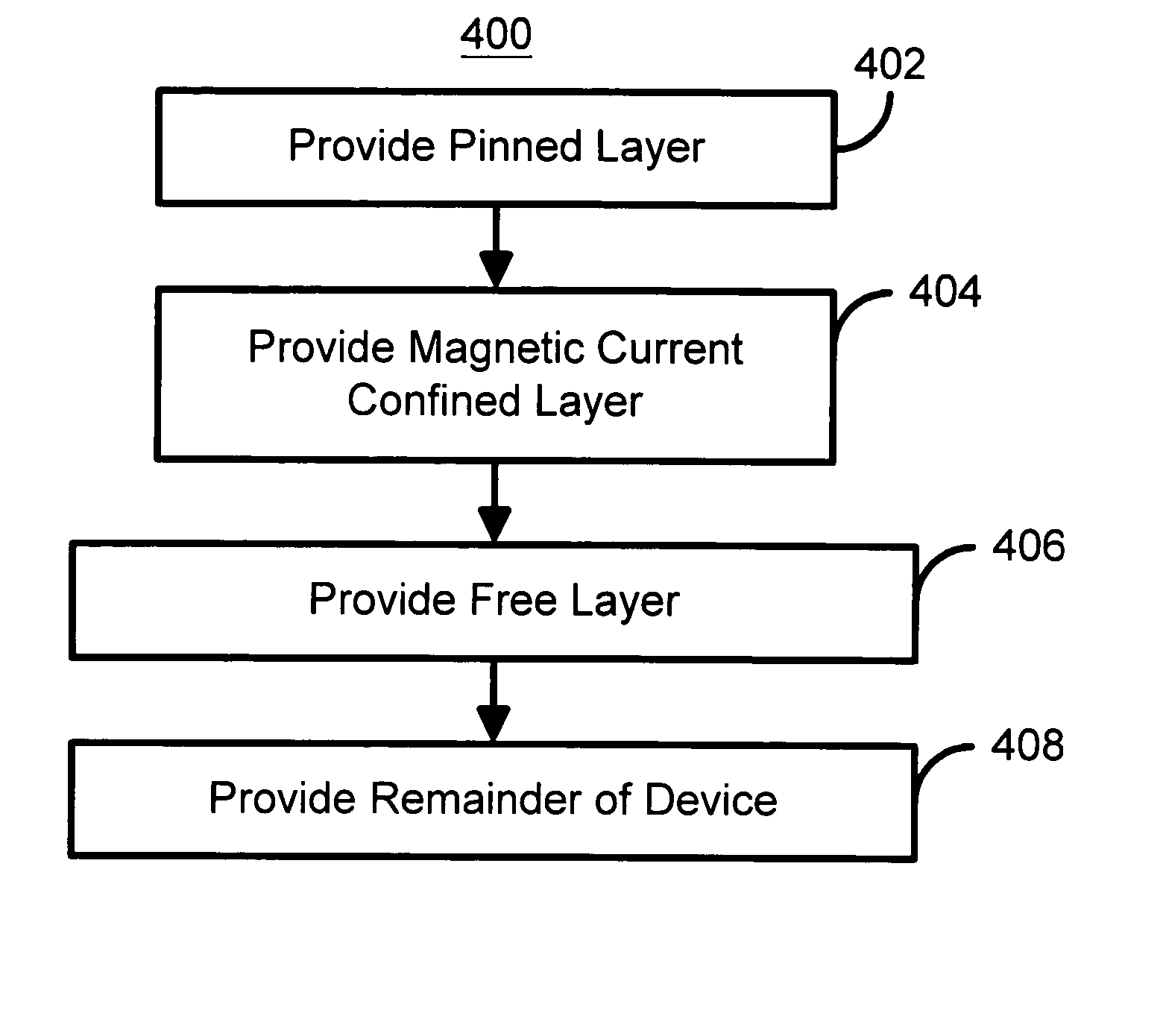

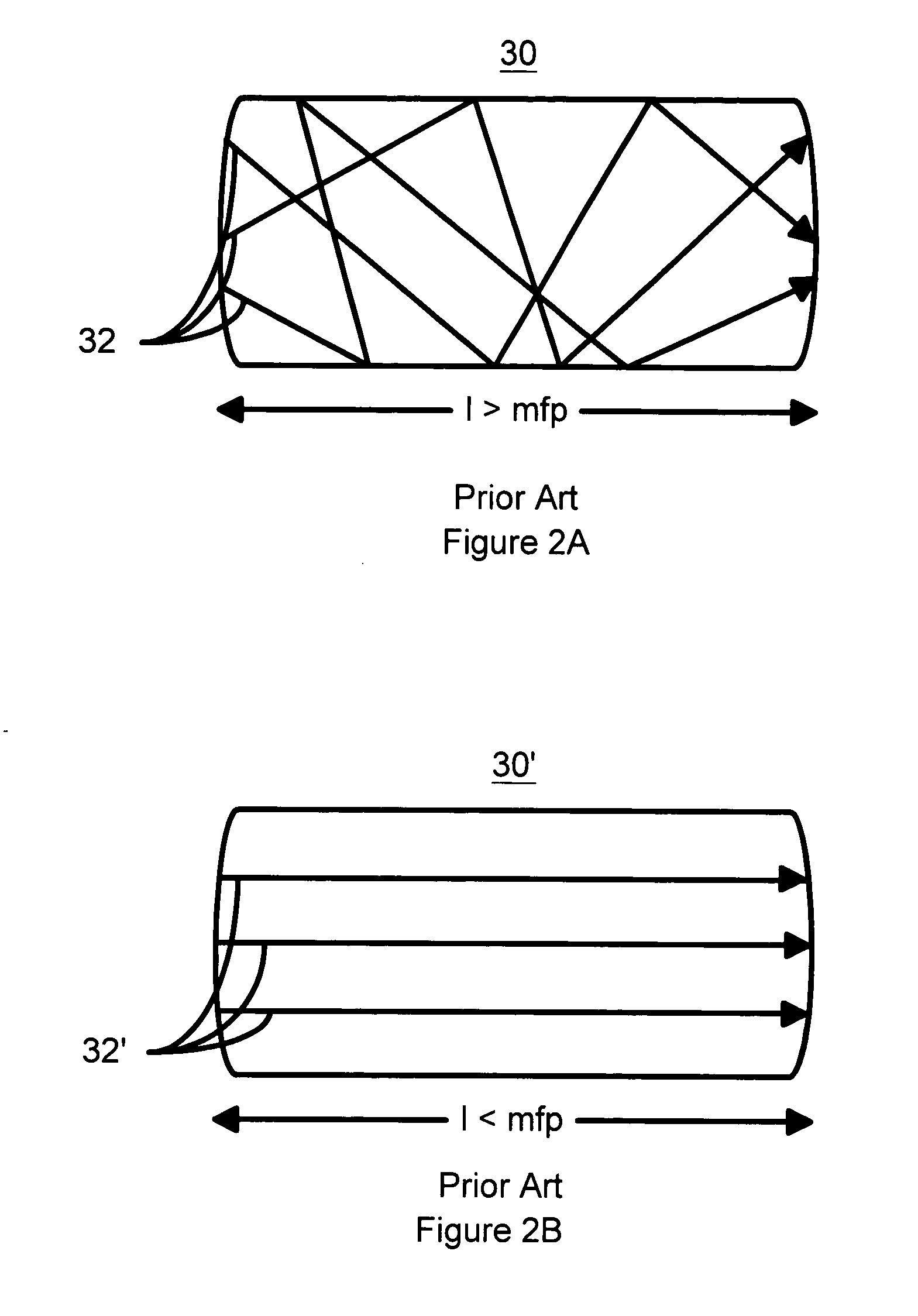

A method and system for providing a magnetic element is disclosed. The method and system include providing a pinned layer, a magnetic current confined layer, and a free layer. The pinned layer is ferromagnetic and has a first pinned layer magnetization. The magnetic current confined layer has at least one channel in an insulating matrix and resides between the pinned layer and the free layer. The channel(s) are ferromagnetic, conductive, and extend through the insulating matrix between the free layer and the pinned layer. The size(s) of the channel(s) are sufficiently small that charge carriers can give rise to ballistic magnetoresistance in the magnetic current confined layer. The free layer is ferromagnetic and has a free layer magnetization. Preferably, the method and system also include providing a second pinned layer and a nonmagnetic spacer layer between the second pinned layer and the free layer. In this aspect, the magnetic element is configured to allow the free layer magnetization to be switched using spin transfer.

Owner:GRANDIS

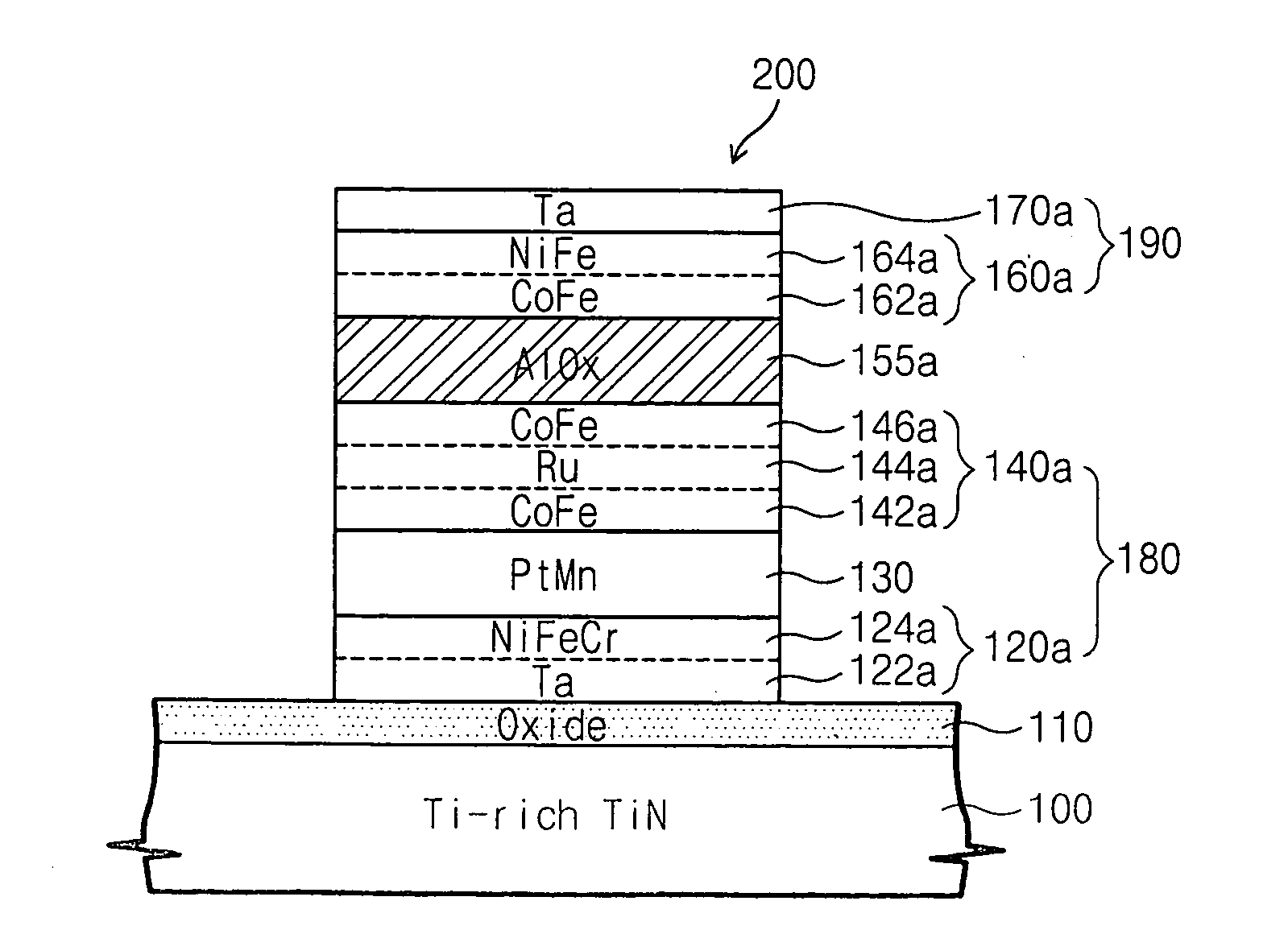

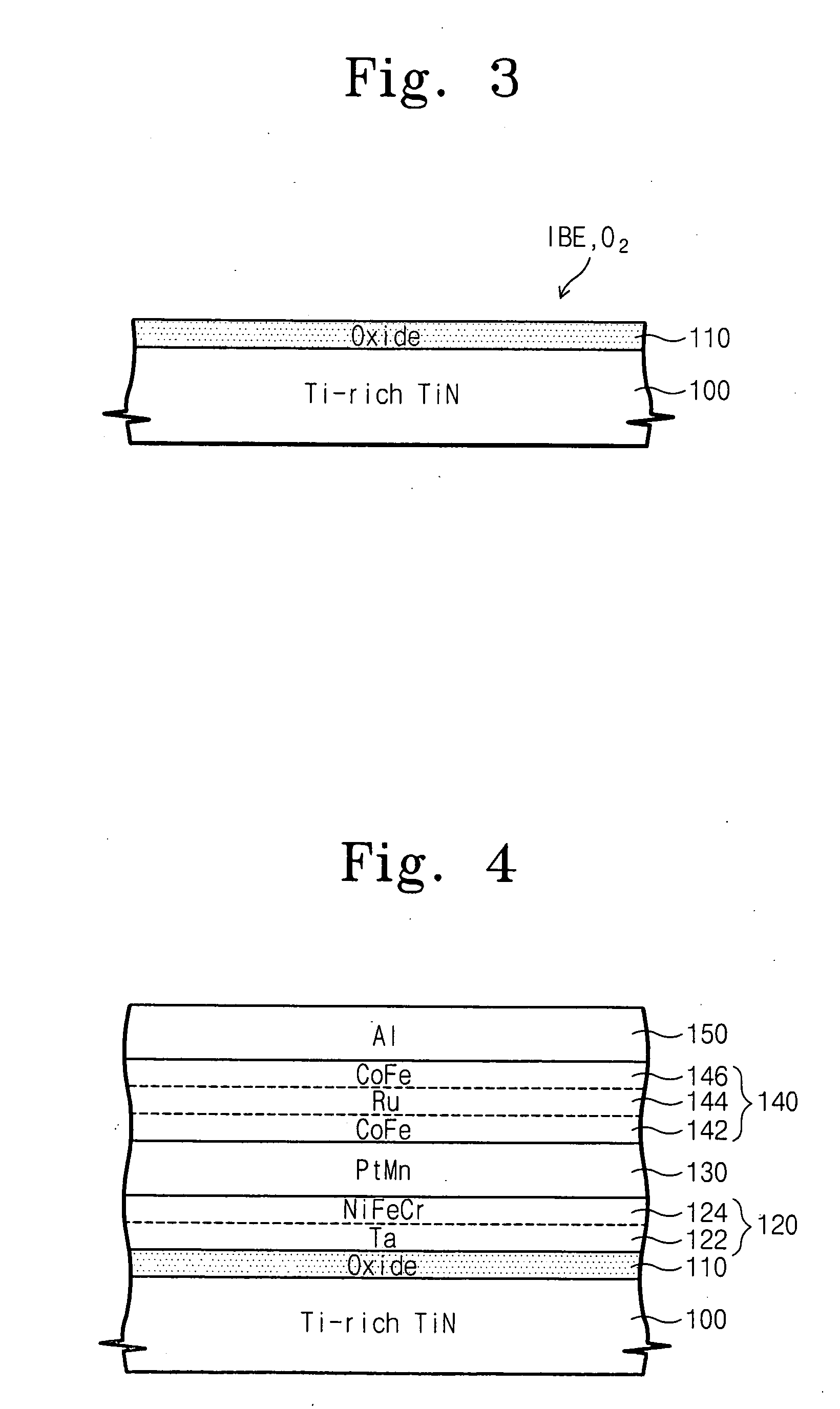

Magnetic random access memory devices having titanium-rich lower electrodes with oxide layer and oriented tunneling barrier, and methods for forming the same

ActiveUS20050006682A1Addressing Insufficient ControlLow polishing rateNanostructure applicationNanomagnetismRandom access memoryTitanium

Magnetic Random Access Memory (MRAM) devices include a lower electrode and a magnetic tunnel junction on the lower electrode. The magnetic tunnel junction includes a seed layer and a tunneling barrier that is oriented in a same direction as the most closely packed plane direction of the seed layer. An oxide layer may be provided between the lower electrode and the magnetic tunnel junction. The lower electrode may be a titanium-rich TiN layer having more than 50 atomic percent titanium content. Analogous fabrication methods are also described.

Owner:SAMSUNG ELECTRONICS CO LTD

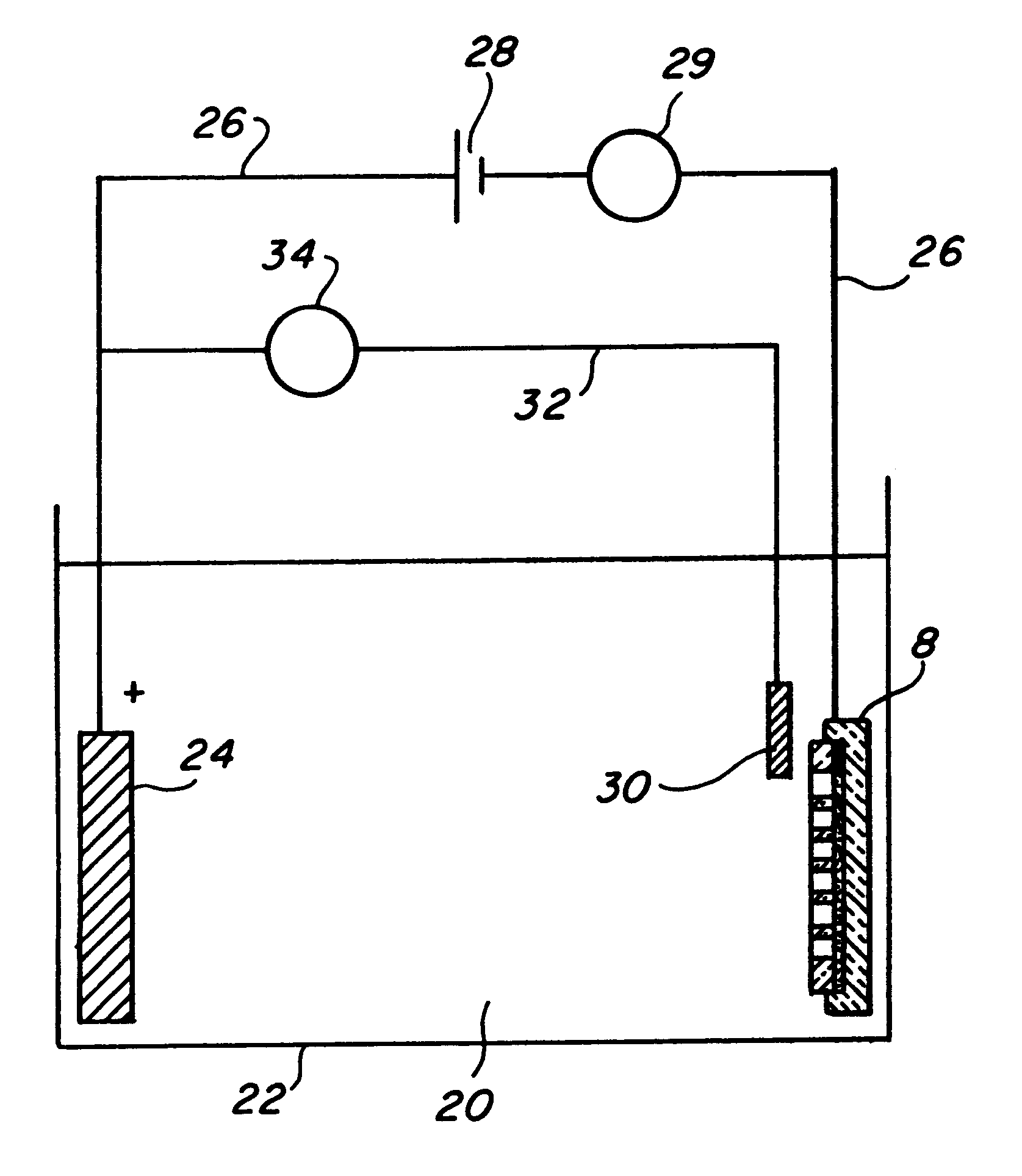

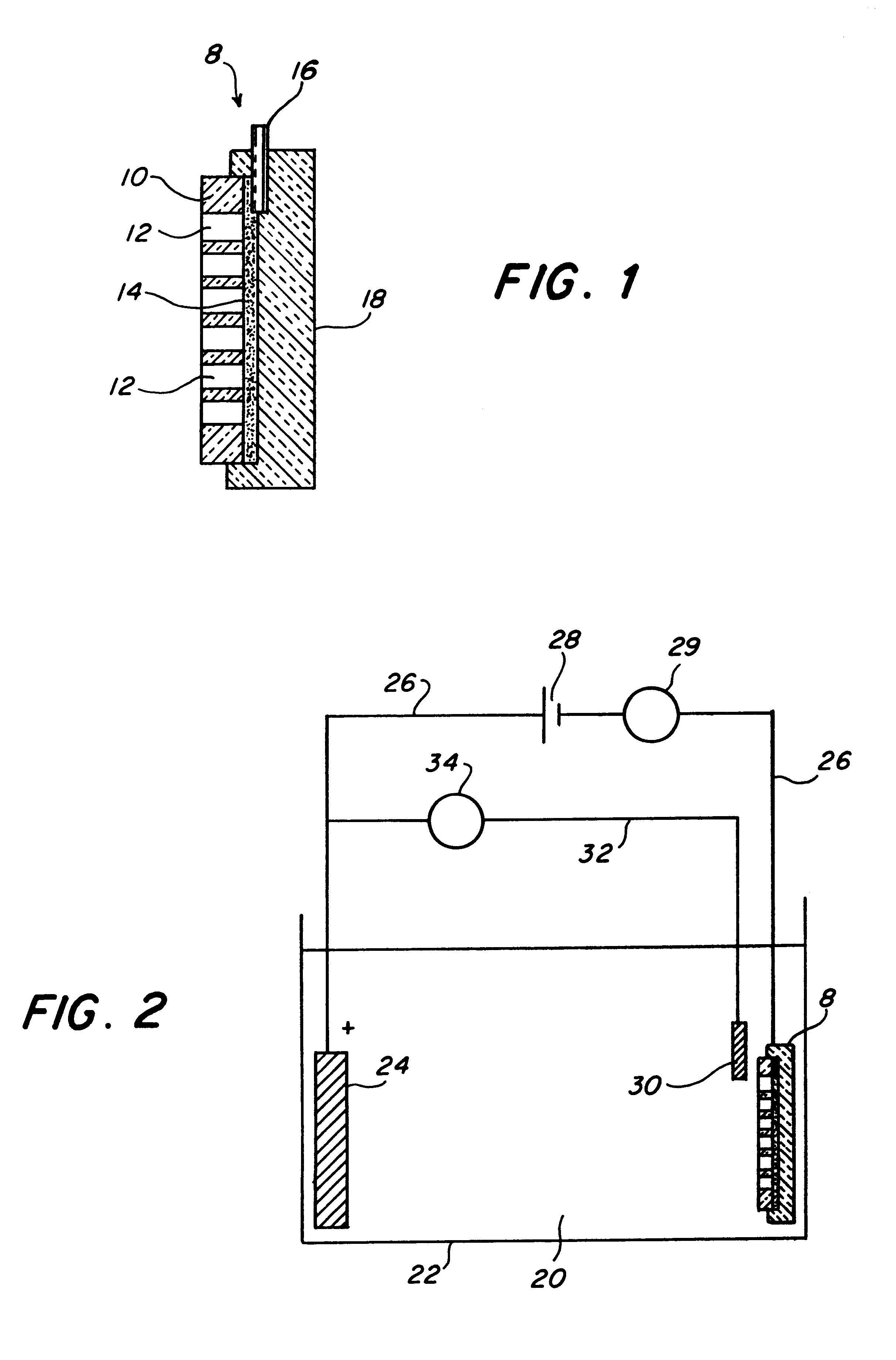

Nanopost arrays and process for making same

InactiveUS6185961B1Efficient depositionEfficiently magnetic materialNanostructure applicationNanomagnetismNanopillarEngineering

A nanopost glass array contains up to 1012 / cm2 of magnetizable nanoposts having diameter of 10-1000 nm that are straight and parallel to each other and are typically of a uniform diameter relative to each other and along the post length. The array is made using a reference electrode and a nanochannel glass template structure connected to each other electrically through an electrical source and both disposed in a plating solution. A magnetizable material is electroplated from the plating solution into the channels of the template structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Magnetic tunnel junction with improved tunneling magneto-resistance

InactiveUS20050110004A1Improve featuresNanostructure applicationNanomagnetismInterface layerMagnetic memory

A magnetic tunnel element that can be used, for example, as part of a read head or a magnetic memory cell, includes a first layer formed from an amorphous material, an amorphous tunnel barrier layer, and an interface layer between the first layer and the tunnel barrier layer. The interface layer is formed from a material that is crystalline when the material is in isolation from both the first layer and the tunnel barrier layer. Alternatively, the thickness of the interface layer is selected so that the interface layer is not crystalline. The first layer is formed from at least one material selected from the group consisting of amorphous ferromagnetic material, amorphous ferrimagnetic materials, and amorphous non-magnetic materials. The interface layer is formed from a material selected from the group consisting of a ferromagnetic material and a ferrimagnetic material.

Owner:GLOBALFOUNDRIES INC

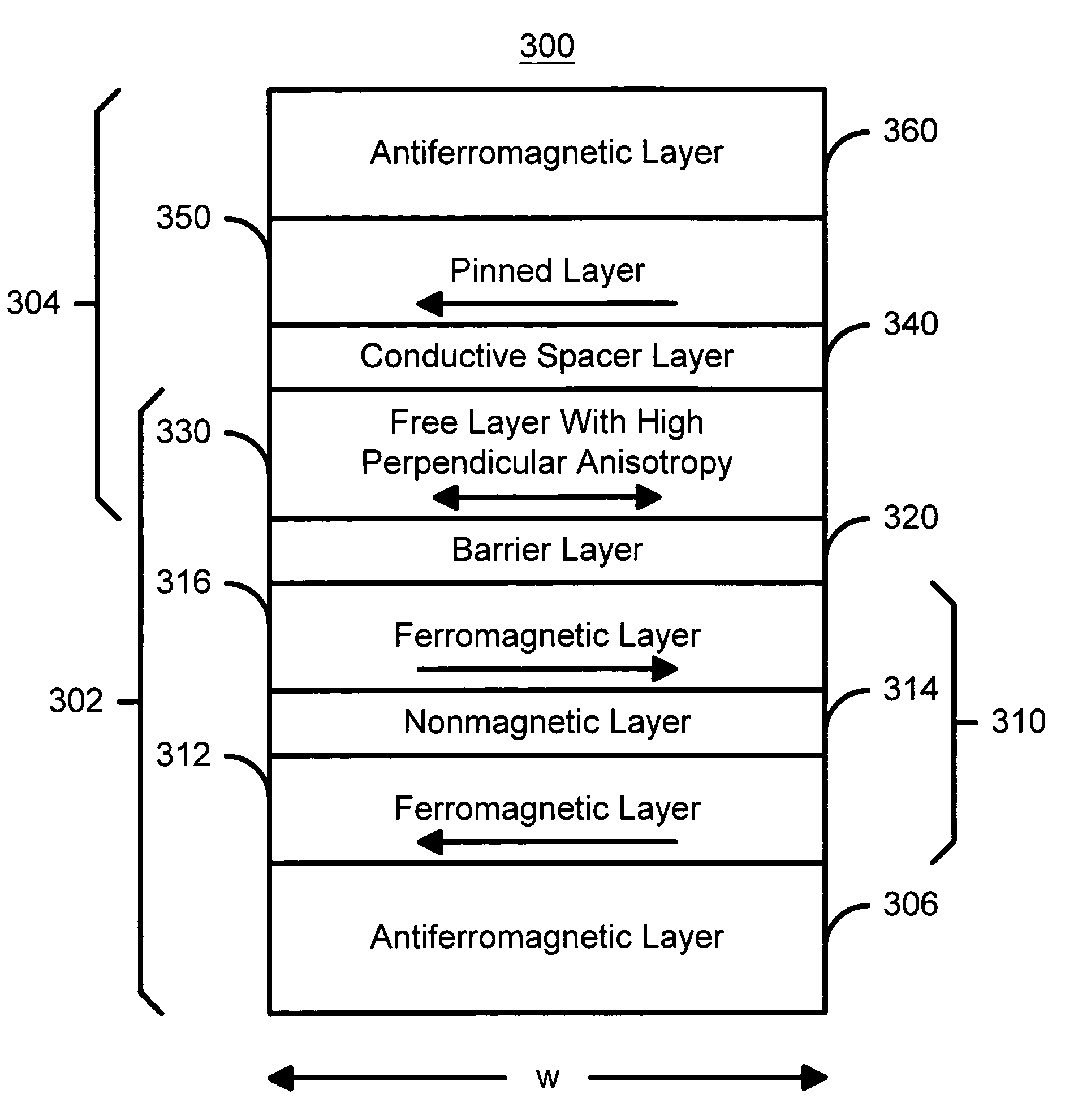

Magnetic element utilizing spin transfer and an MRAM device using the magnetic element

InactiveUS20050201023A1Efficient and localized phenomenonEnhanced output signalNanostructure applicationNanomagnetismMagnetic memorySpin transfer

A method and system for providing a magnetic element capable of being written using spin-transfer effect while generating a high output signal and a magnetic memory using the magnetic element are disclosed. The magnetic element includes a first ferromagnetic pinned layer, a nonmagnetic spacer layer, a ferromagnetic free layer, an insulating barrier layer and a second ferromagnetic pinned layer. The pinned layer has a magnetization pinned in a first direction. The nonmagnetic spacer layer is conductive and is between the first pinned layer and the free layer. The barrier layer resides between the free layer and the second pinned layer and is an insulator having a thickness allowing electron tunneling through the barrier layer. The second pinned layer has a magnetization pinned in a second direction. The magnetic element is configured to allow the magnetization of the free layer to change direction, due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

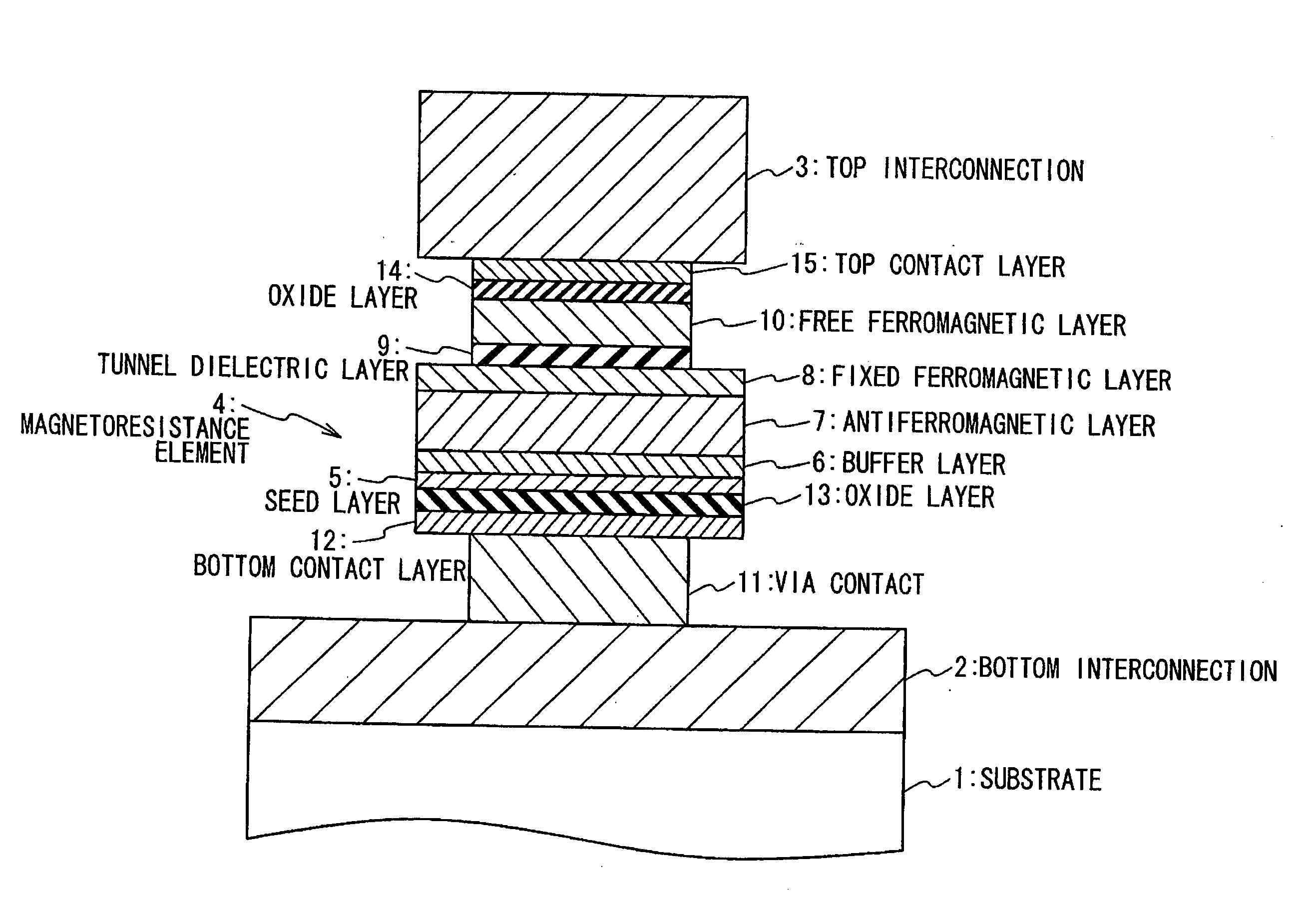

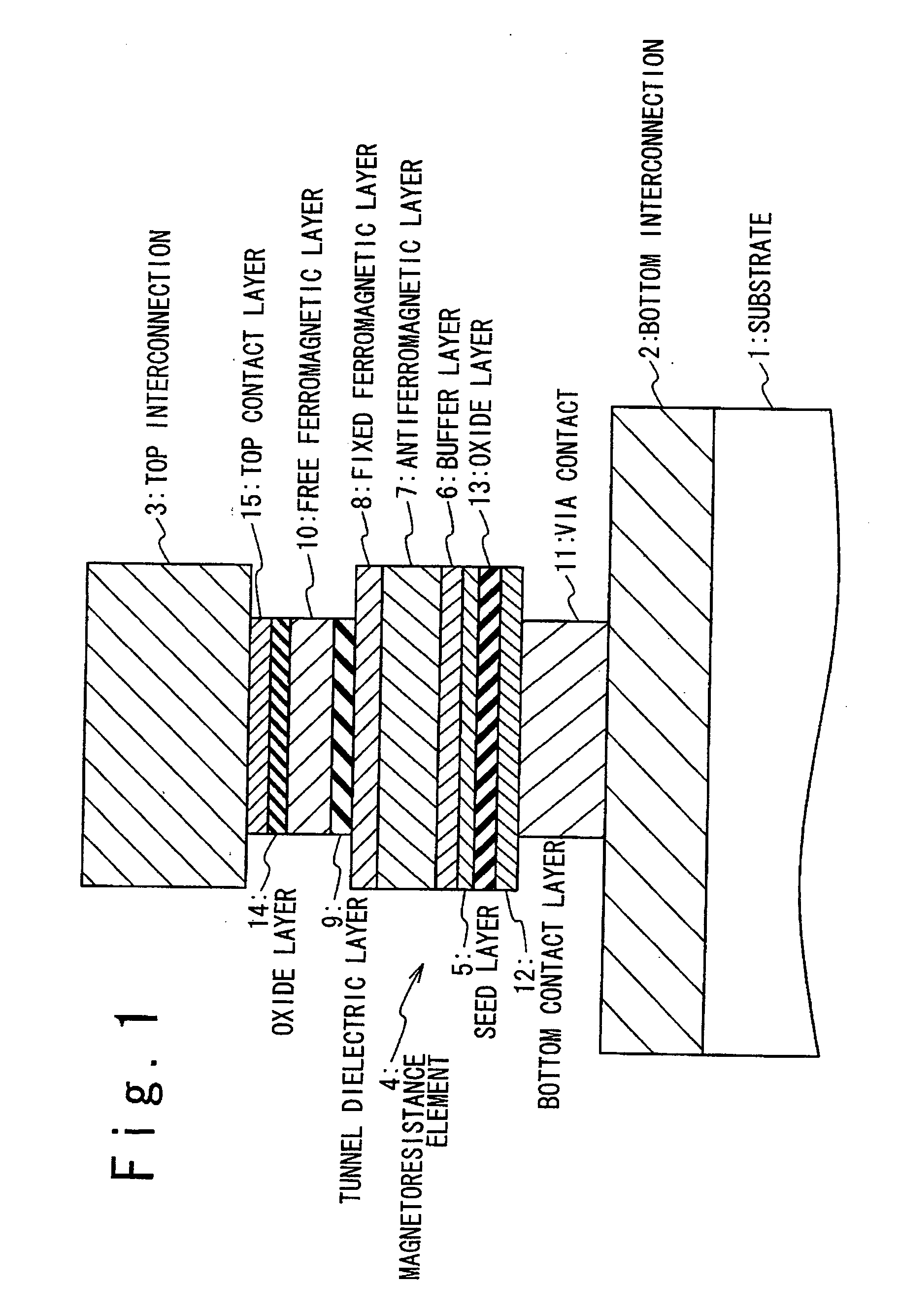

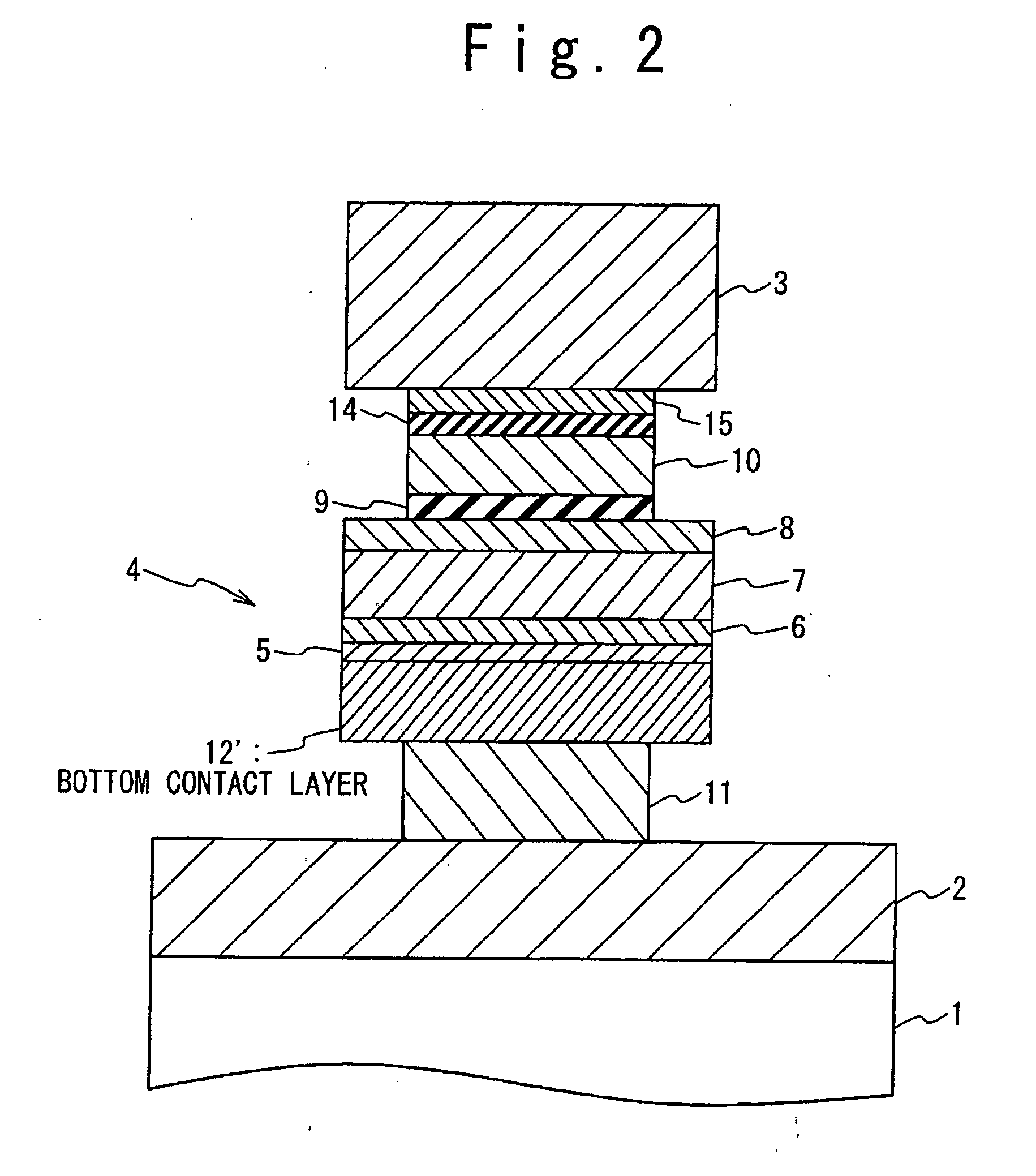

Magnetoresistance device and method of fabricating the same

ActiveUS20040145850A1Nanostructure applicationNanomagnetismElectrical conductorElectrical connection

A magnetoresistance device is provided for improving thermal stability of a magnetoresistance element by preventing interdiffusion between a conductor (such as a via and an interconnection) for connecting the magnetoresistance element to another element and layers constituting the magnetoresistance element. A magnetoresistance device is composed of a magnetoresistance element, a non-magnetic conductor providing electrical connection between said magnetoresistance element to another element, and a diffusion barrier structure disposed between said conductor and said magnetoresistance element, the magnetoresistance element including a free ferromagnetic layer having reversible spontaneous magnetization, a fixed ferromagnetic layer having fixed spontaneous magnetization, and a tunnel dielectric layer disposed between said free and fixed ferroelectric layer.

Owner:NEC CORP

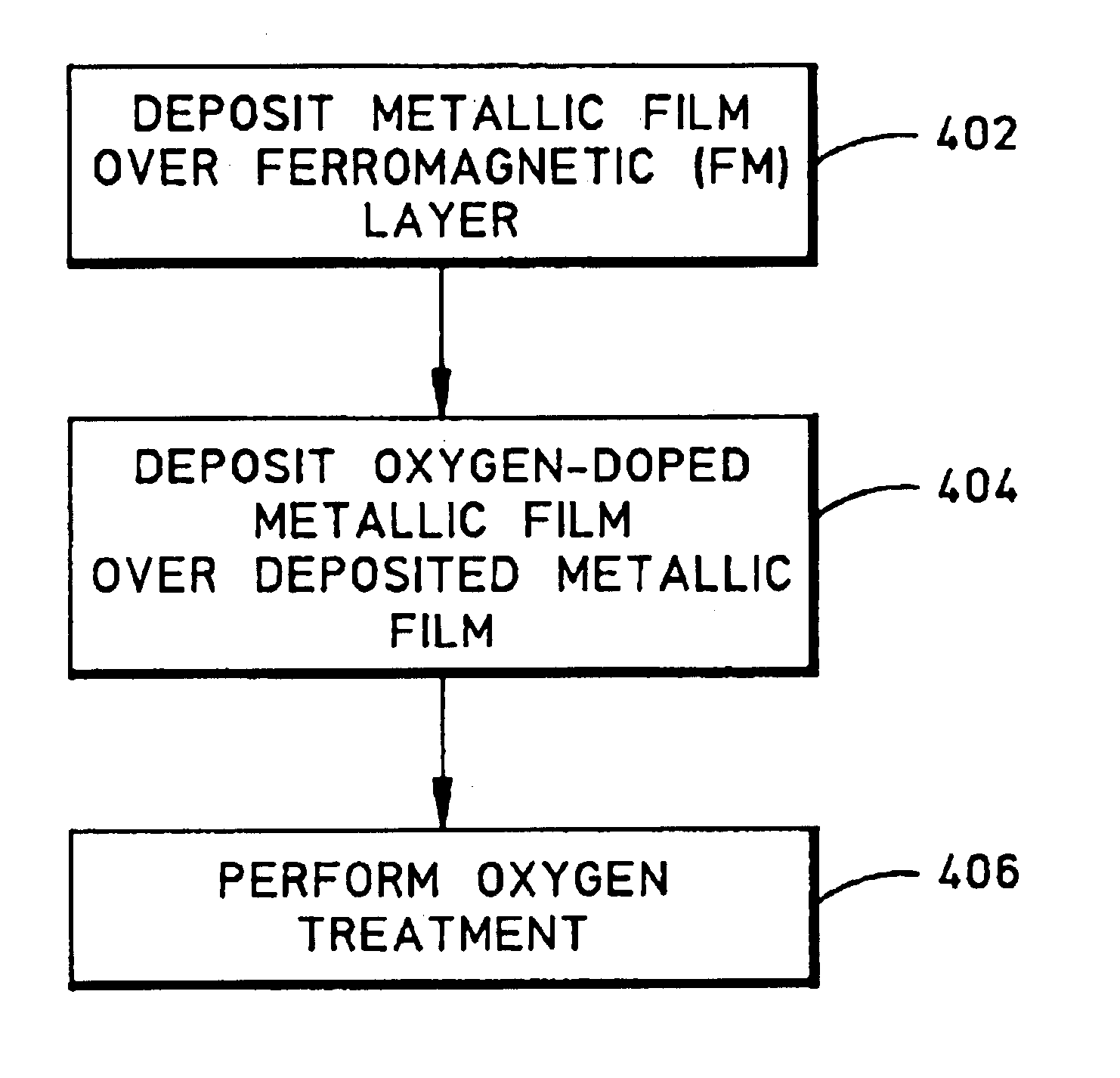

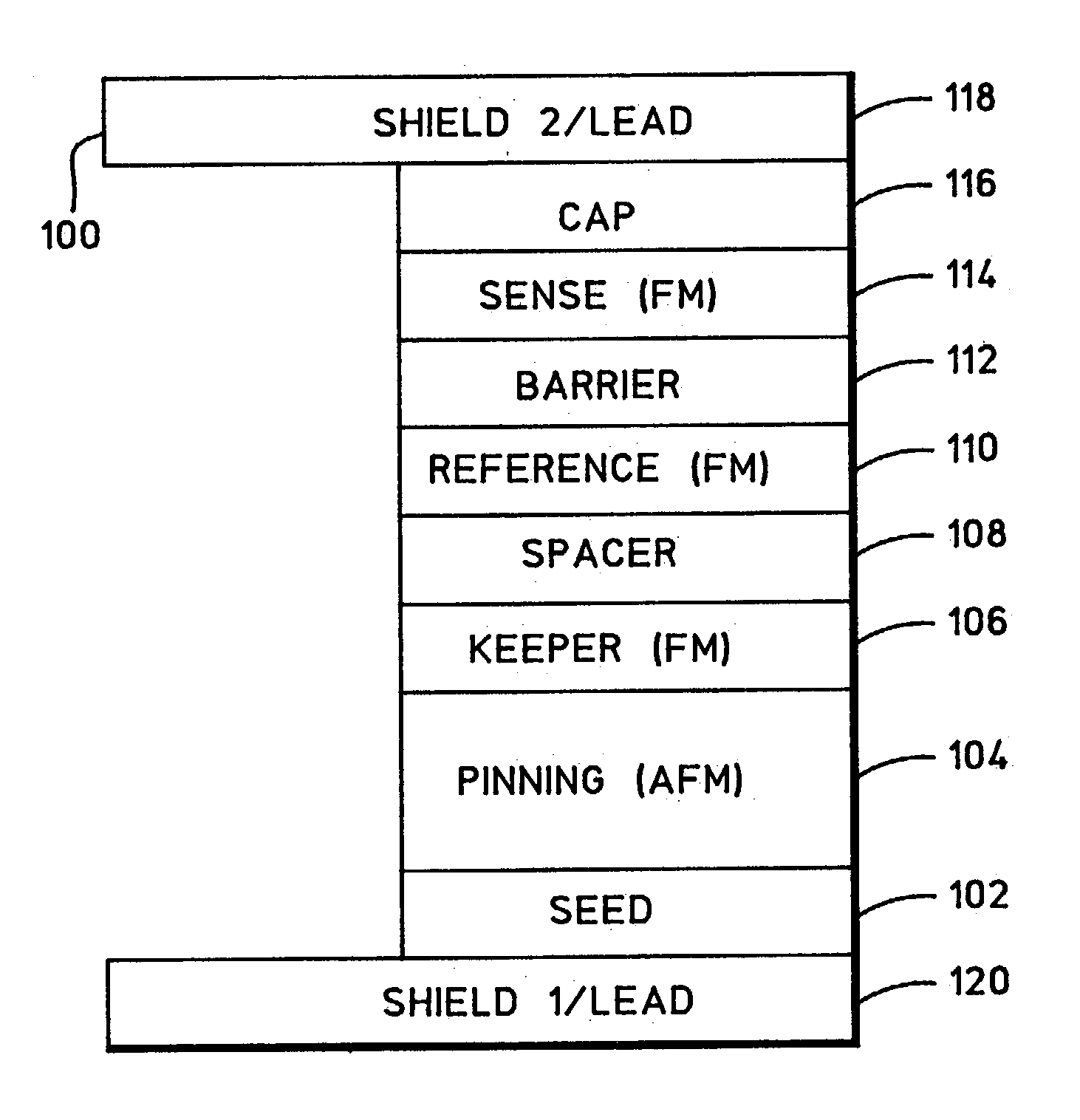

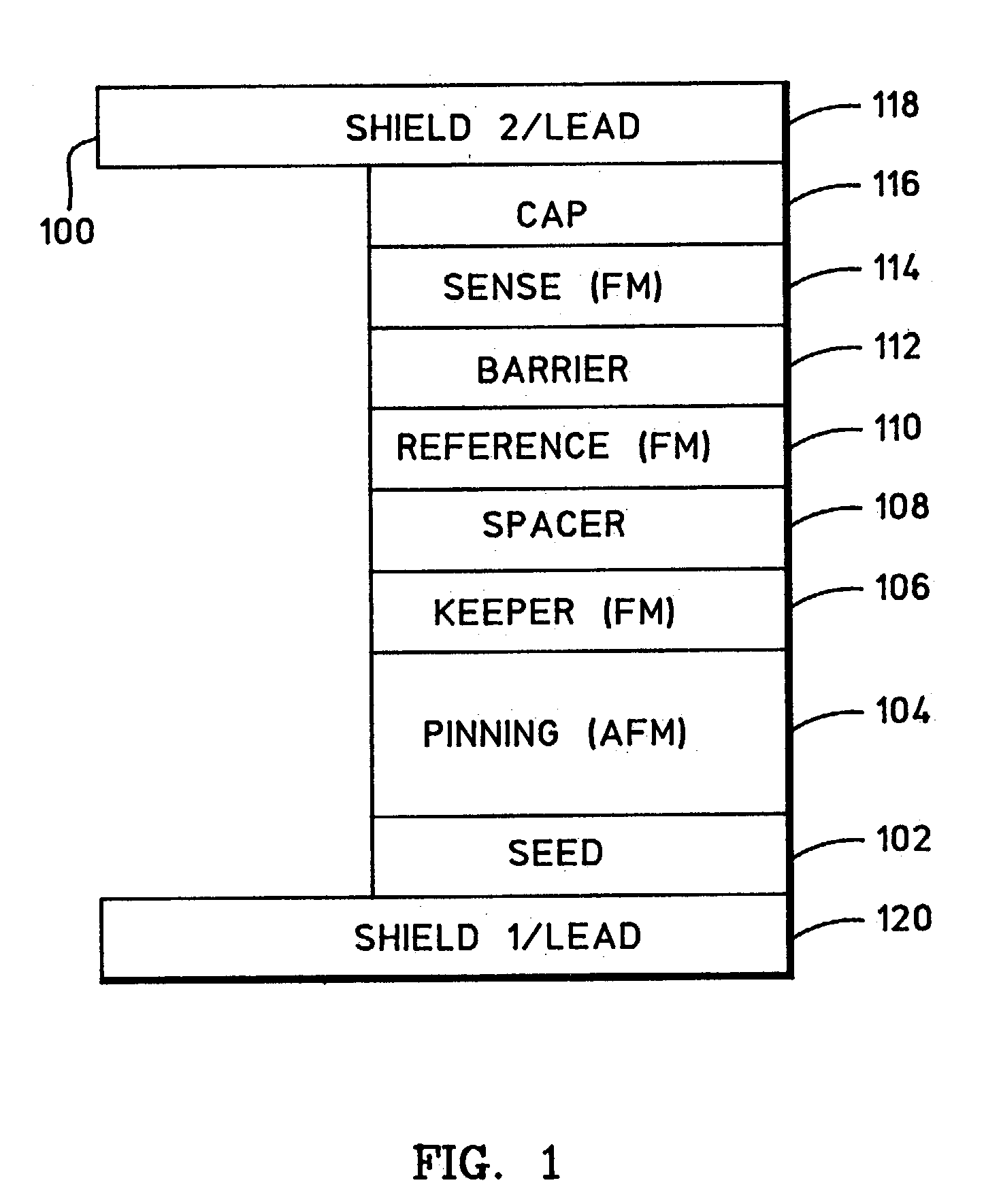

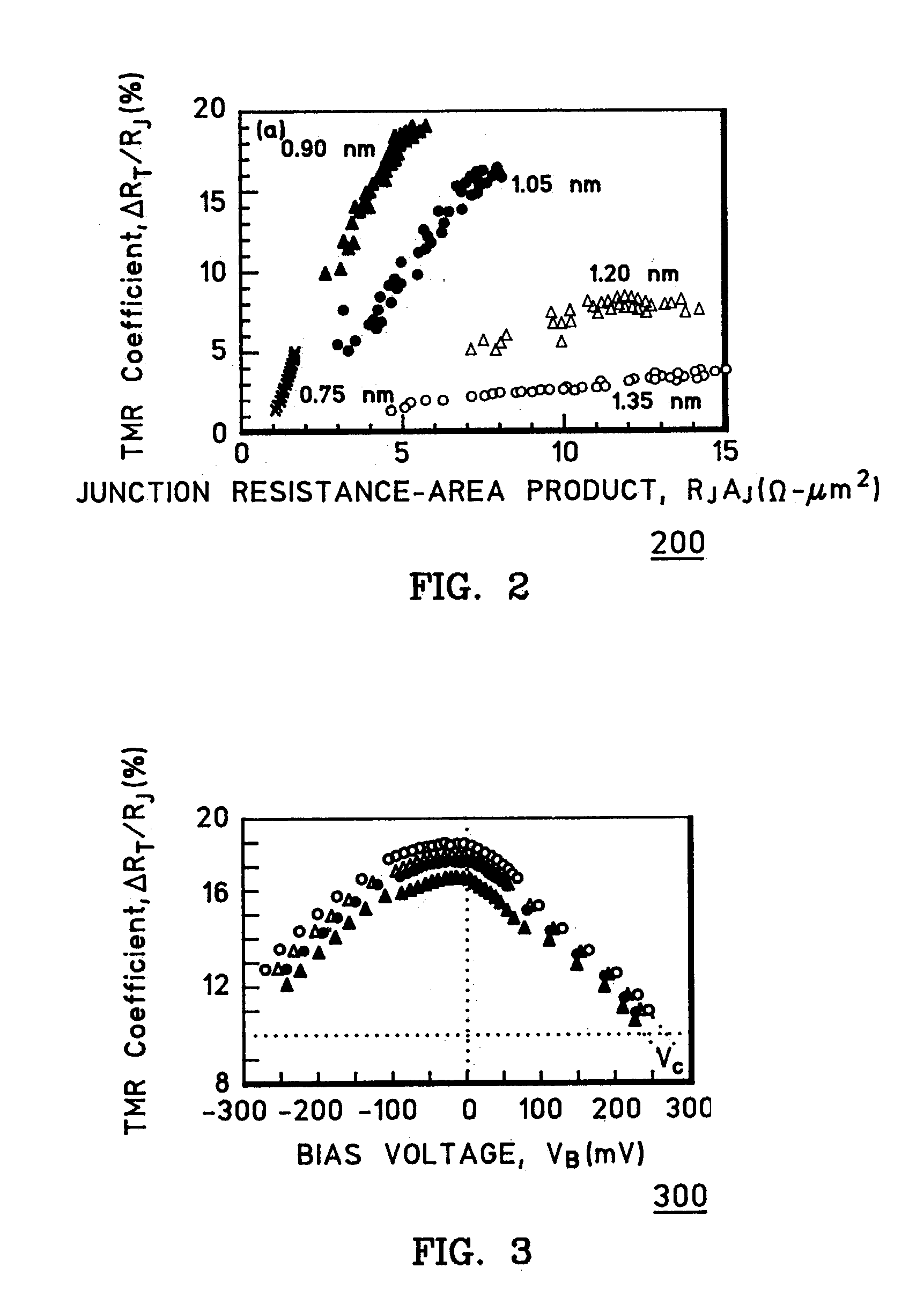

Method of forming a barrier layer of a tunneling magnetoresistive sensor

InactiveUS6841395B2Prevent electrostatic dischargeMagnetic and TMR propertyNanostructure applicationNanomagnetismIon beamXenon

Owner:GLOBALFOUNDRIES INC

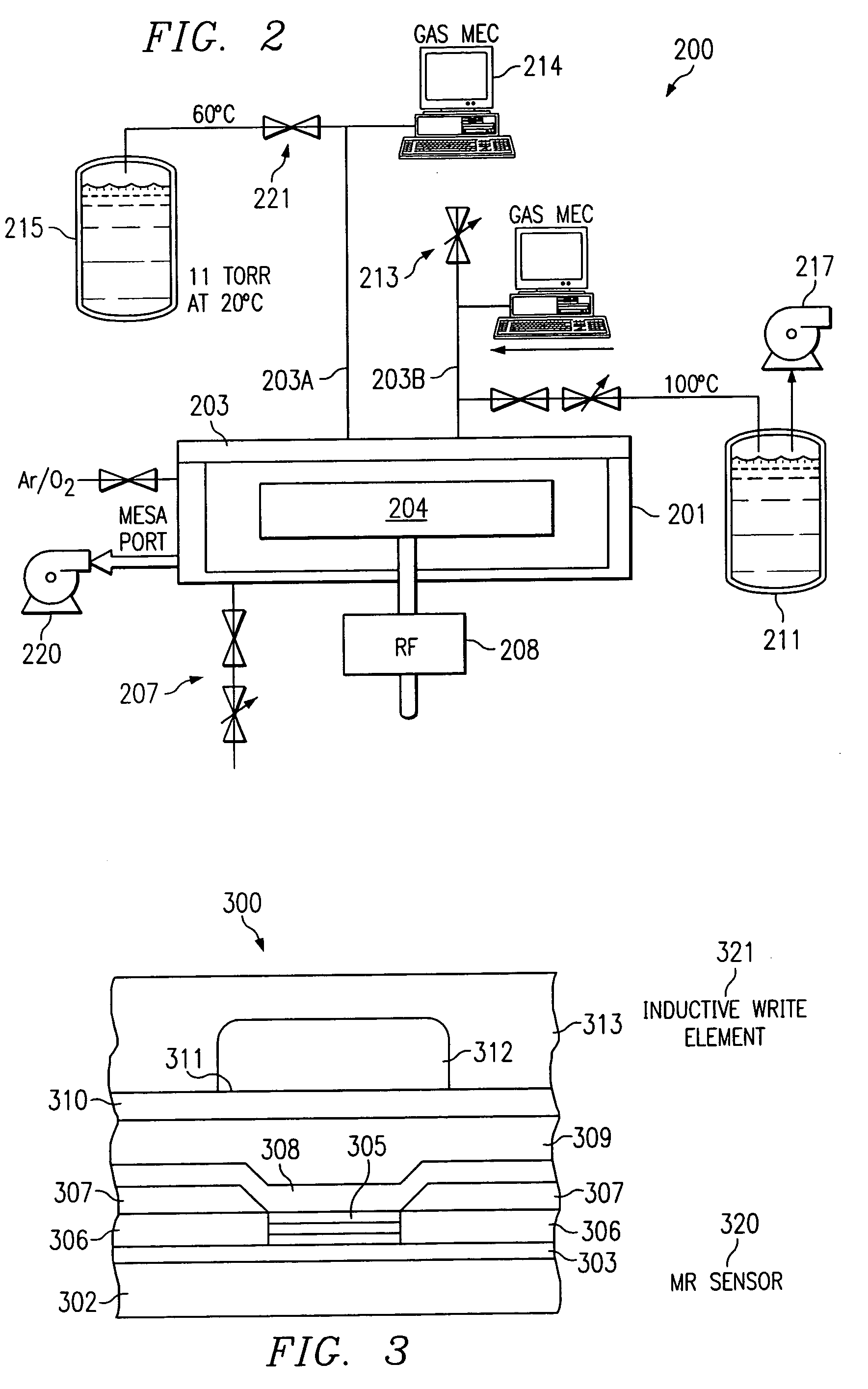

Thin films for magnetic device

InactiveUS7220669B2Inhibit migrationIncreasing the thicknessNanostructure applicationNanomagnetismDielectricThin layer

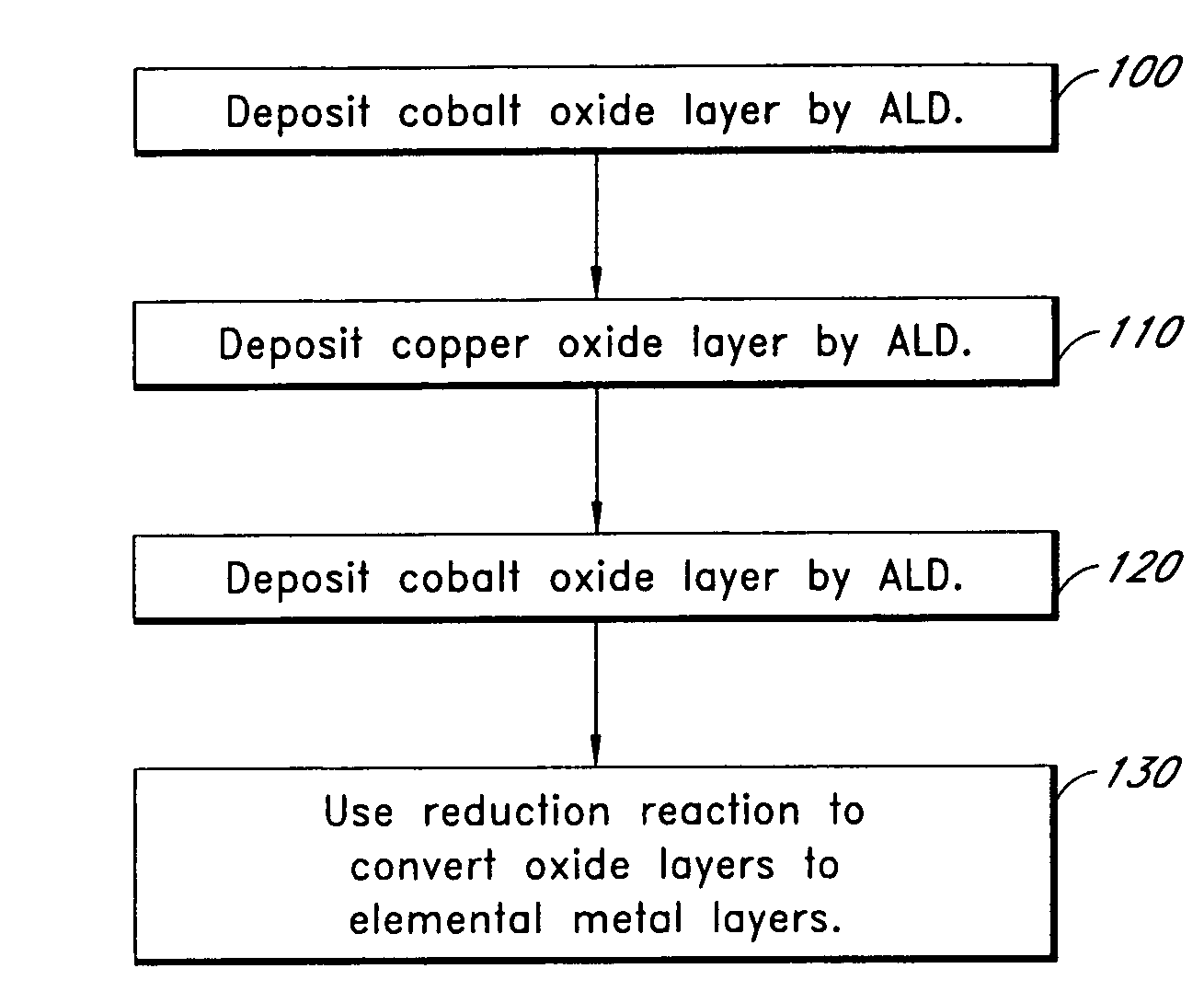

Methods are provided for forming uniformly thin layers in magnetic devices. Atomic layer deposition (ALD) can produce layers that are uniformly thick on an atomic scale. Magnetic tunnel junction dielectrics, for example, can be provided with perfect uniformity in thickness of 4 monolayers or less. Furthermore, conductive layers, including magnetic and non-magnetic layers, can be provided by ALD without spiking and other non-uniformity problems. The disclosed methods include forming metal oxide layers by multiple cycles of ALD and subsequently reducing the oxides to metal. The oxides tend to maintain more stable interfaces during formation.

Owner:ASM INTERNATIONAL

Nanowire structures and devices for use in large-area electronics and methods of making the same

A nanowire structure and device for use in large area electronics and methods of making the same is provided. The nanowire structure includes a nanowire defining an axis, where the nanowire includes a first end and a second end. The first end is axially spaced from the second end. Further, the nanowire structure includes magnetic segments that are coupled to the first and second ends of the nanowire.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Method of adjusting CoFe free layer magnetostriction

InactiveUS6998150B2Low constantLow coercivityNanostructure applicationNanomagnetismCopperOXYGEN EXPOSURE

It has been found that the insertion of a copper laminate within CoFe, or a CoFe / NiFe composite, leads to higher values of CPP GMR and DRA. However, this type of structure exhibits very negative magnetostriction, in the range of high −10−6 to −10−5. This problem has been overcome by giving the copper laminates an oxygen exposure treatment When this is done, the free layer is found to have a very low positive magnetostriction constant. Additionally, the value of the magnetostriction constant can be adjusted by varying the thickness of the free layer and / or the position and number of the oxygen treated copper laminates.

Owner:HEADWAY TECH INC

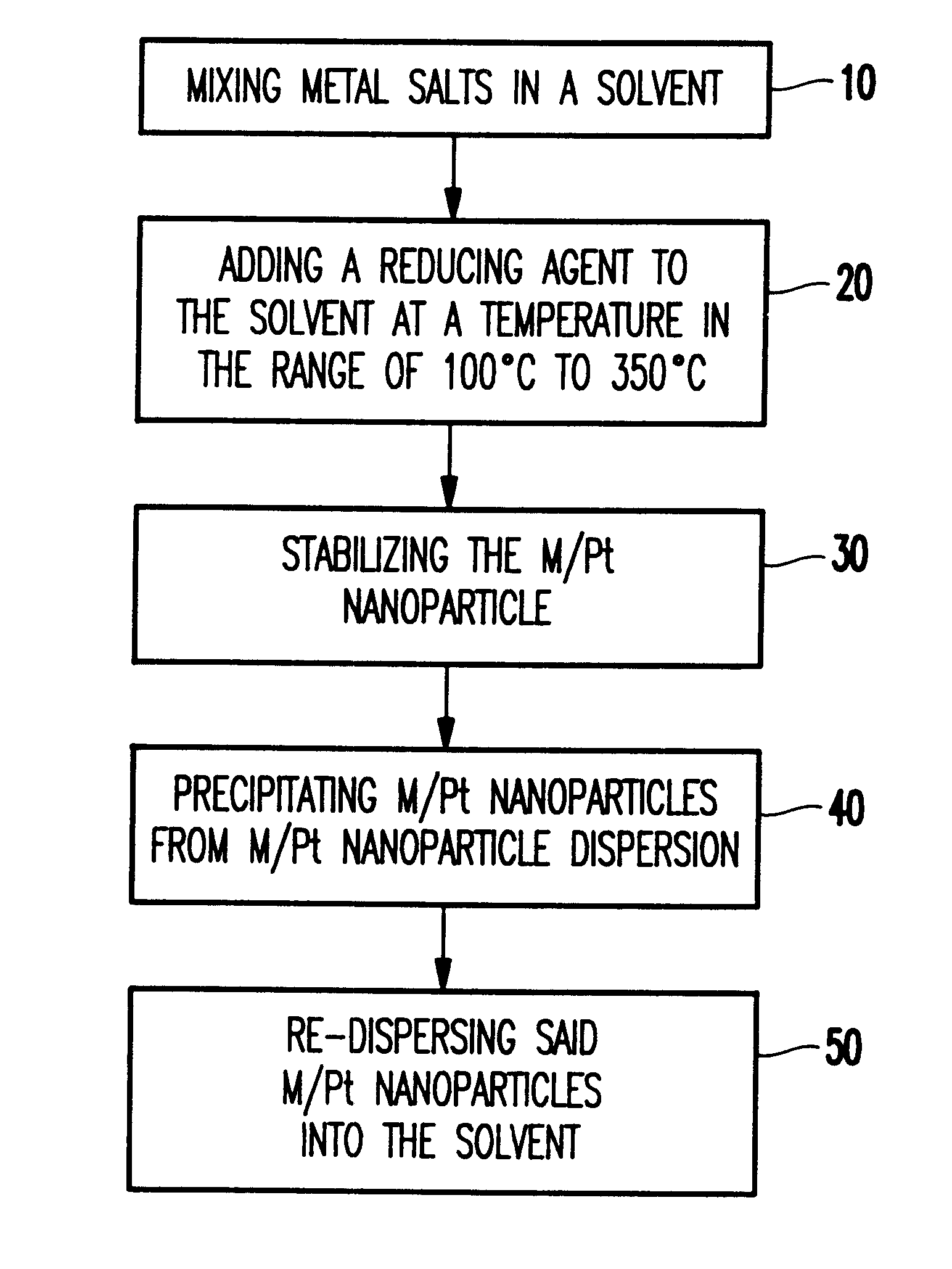

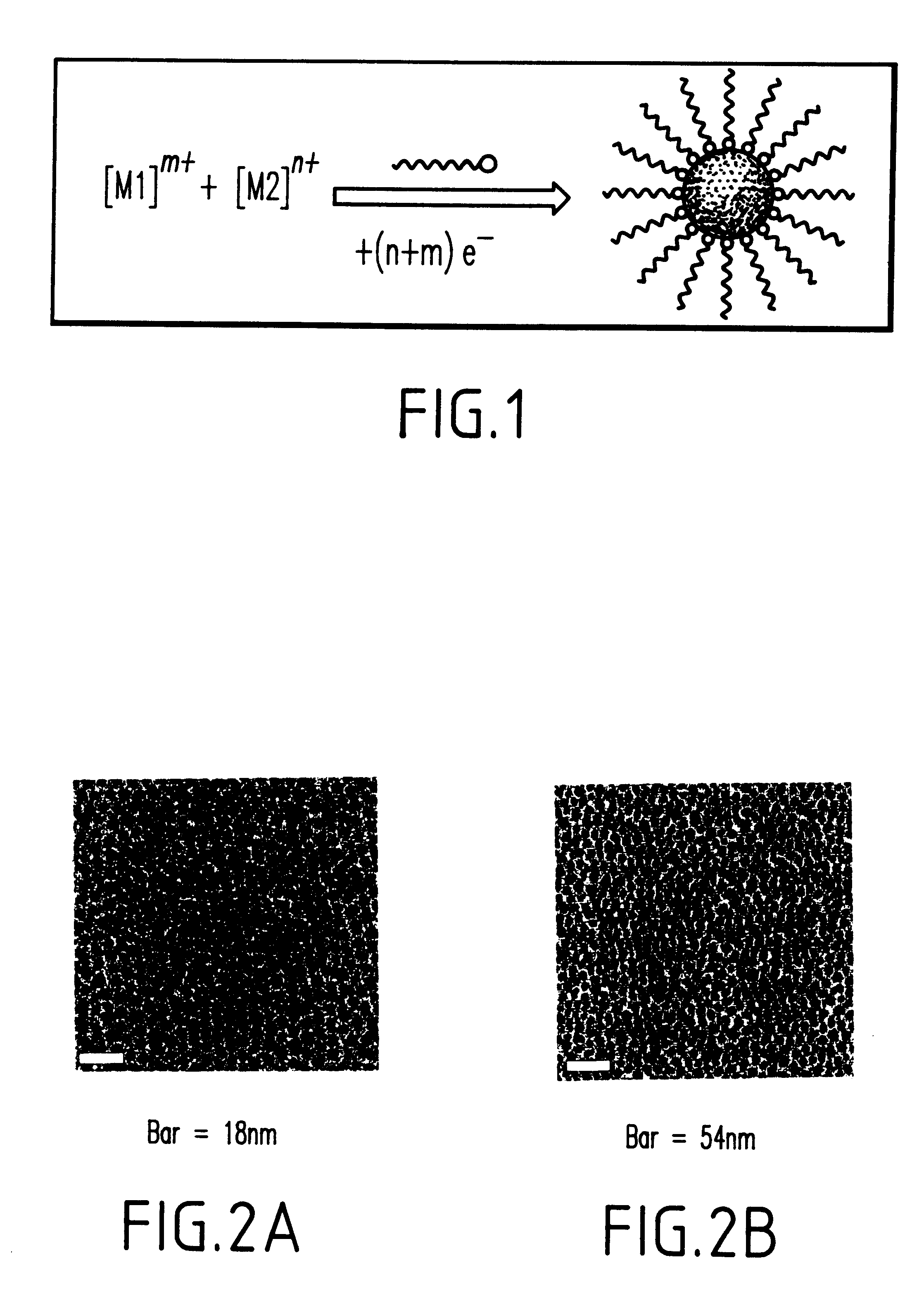

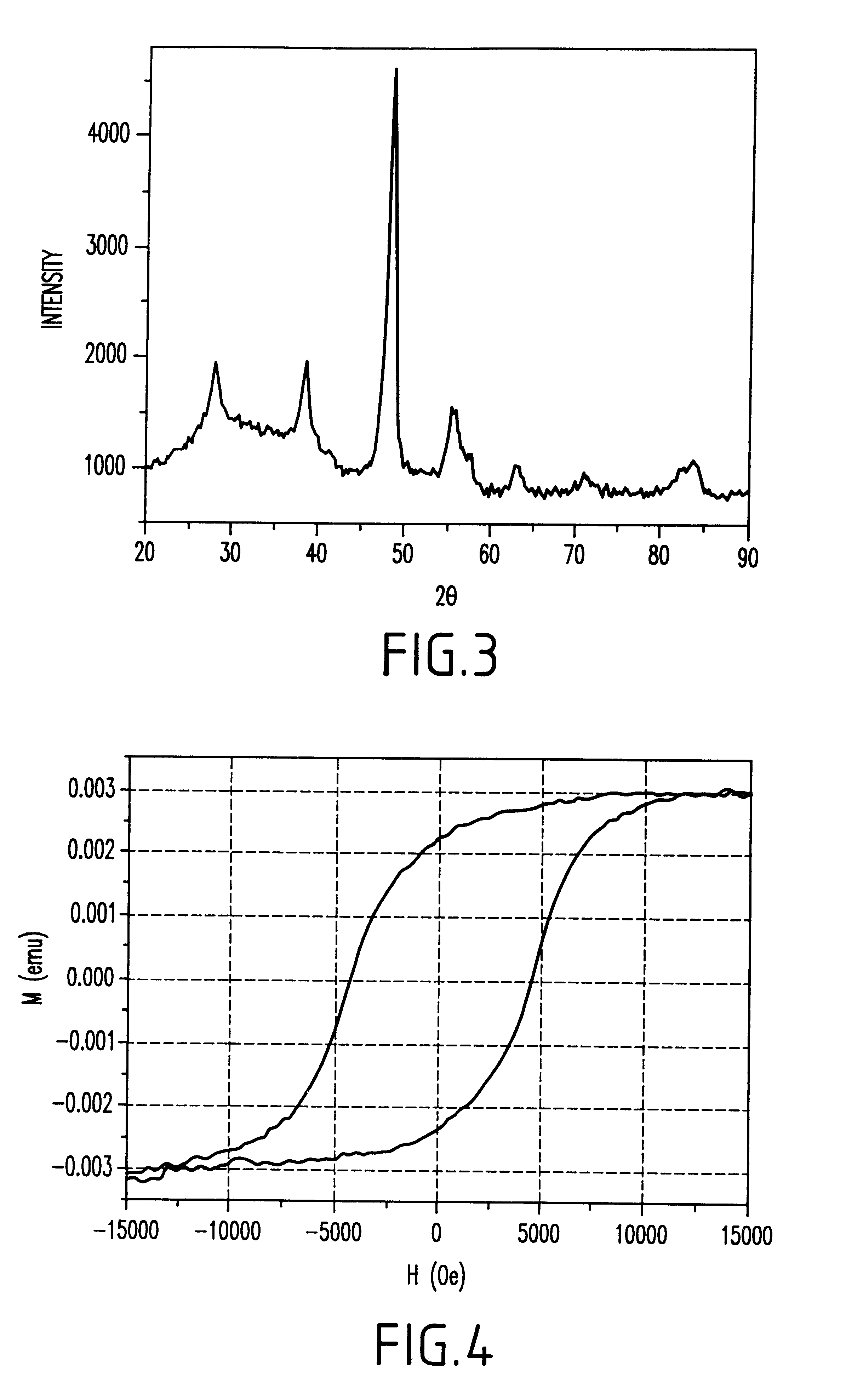

Metal salt reduction to form alloy nanoparticles

A method for making nanoparticles via metal salt reduction comprises, first, mixing metal salts in a solvent. Second, a reducing agent is added to the solvent at a temperature in the range of 100° C. to 350° C. Third, the nanoparticles dispersion is stabilized. Fourth, the nanoparticles are precipitated from the nanoparticle dispersion. Finally, the nanoparticles are re-dispersed into the solvent. The metal salt comprises a combination of FeCl2, FeCl3, Fe(OOCR)2, Fe(RCOCHCOR)3, CoCl2, Co(OOCR)2, Co(RCOCHCOR)2, and one of Pt(RCOCHCOR)2, PtCl2. The reducing agent comprises one of MBR3H, MH, M naphthalides, and polyalcohol; wherein R comprises one of H and an alkyl group, wherein M comprises one of Li, Na, and K. Long chain alkyl diols, and alkyl alcohol, can be used as a co-surfactant or a co-reducing agent to facilitate nanoparticle growth and separation.

Owner:GOOGLE LLC

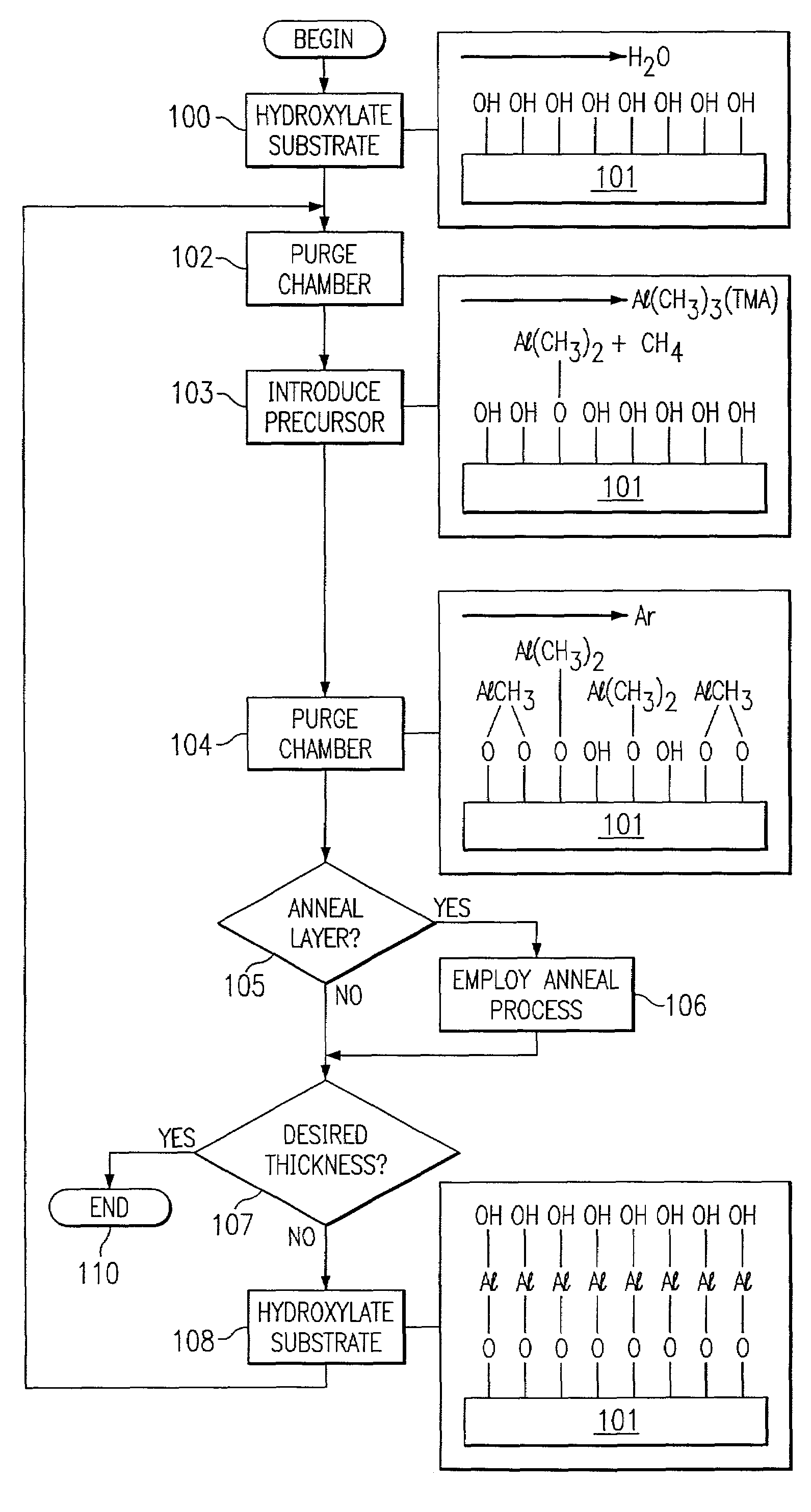

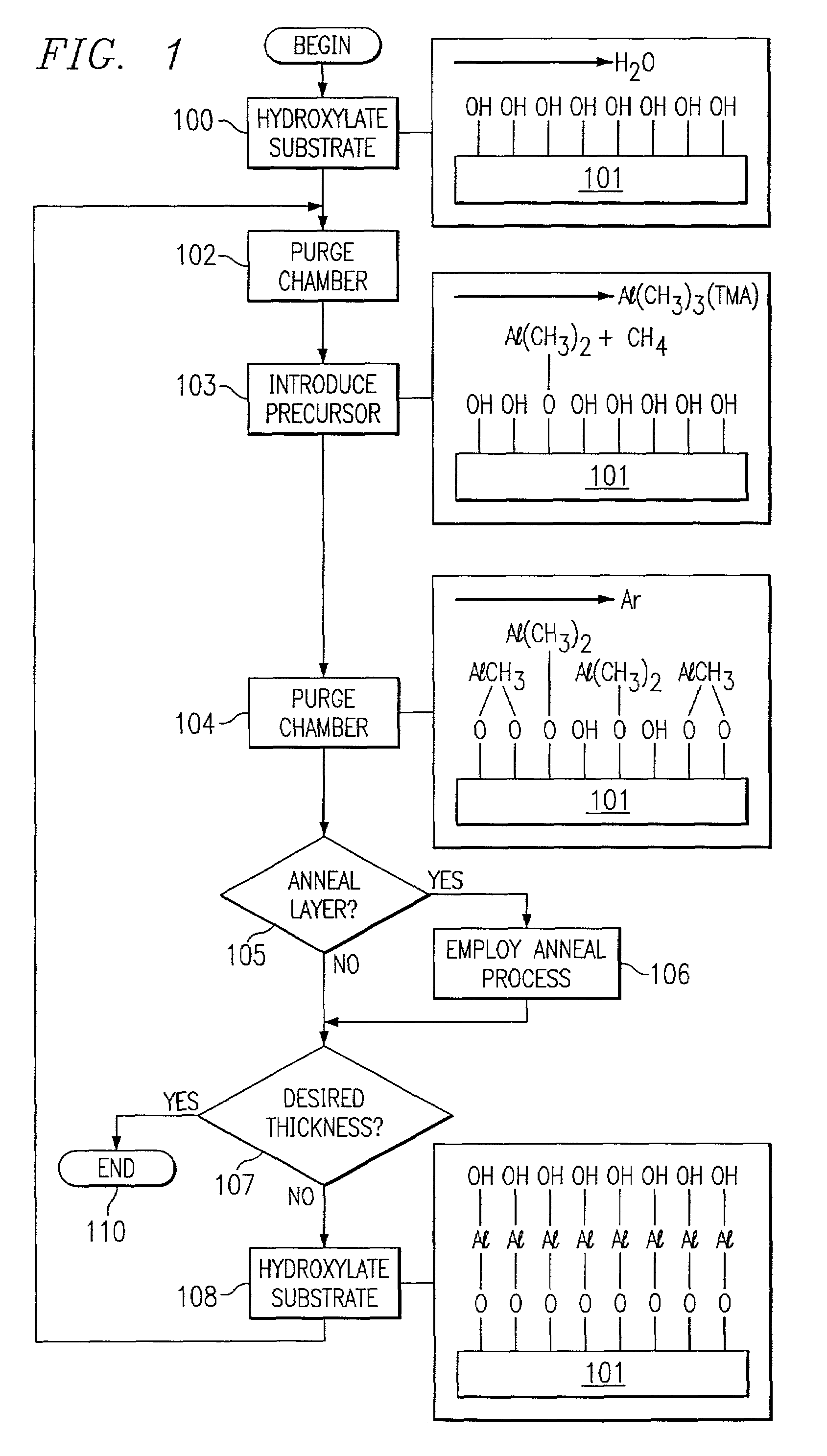

Atomic layer deposition for fabricating thin films

InactiveUS7037574B2High breakdown strengthImprove breakdown voltageNanostructure applicationLiquid surface applicatorsElectronic structureBreakdown strength

An atomic layer deposition (ALD) process deposits thin films for microelectronic structures, such as advanced gap and tunnel junction applications, by plasma annealing at varying film thicknesses to obtain desired intrinsic film stress and breakdown film strength. The primary advantage of the ALD process is the near 100% step coverage with properties that are uniform along sidewalls. The process provides smooth (Ra˜2 Å), pure (impurities<1 at. %), AlOx films with improved breakdown strength (9–10 MV / cm) with a commercially feasible throughput.

Owner:CVC PRODS

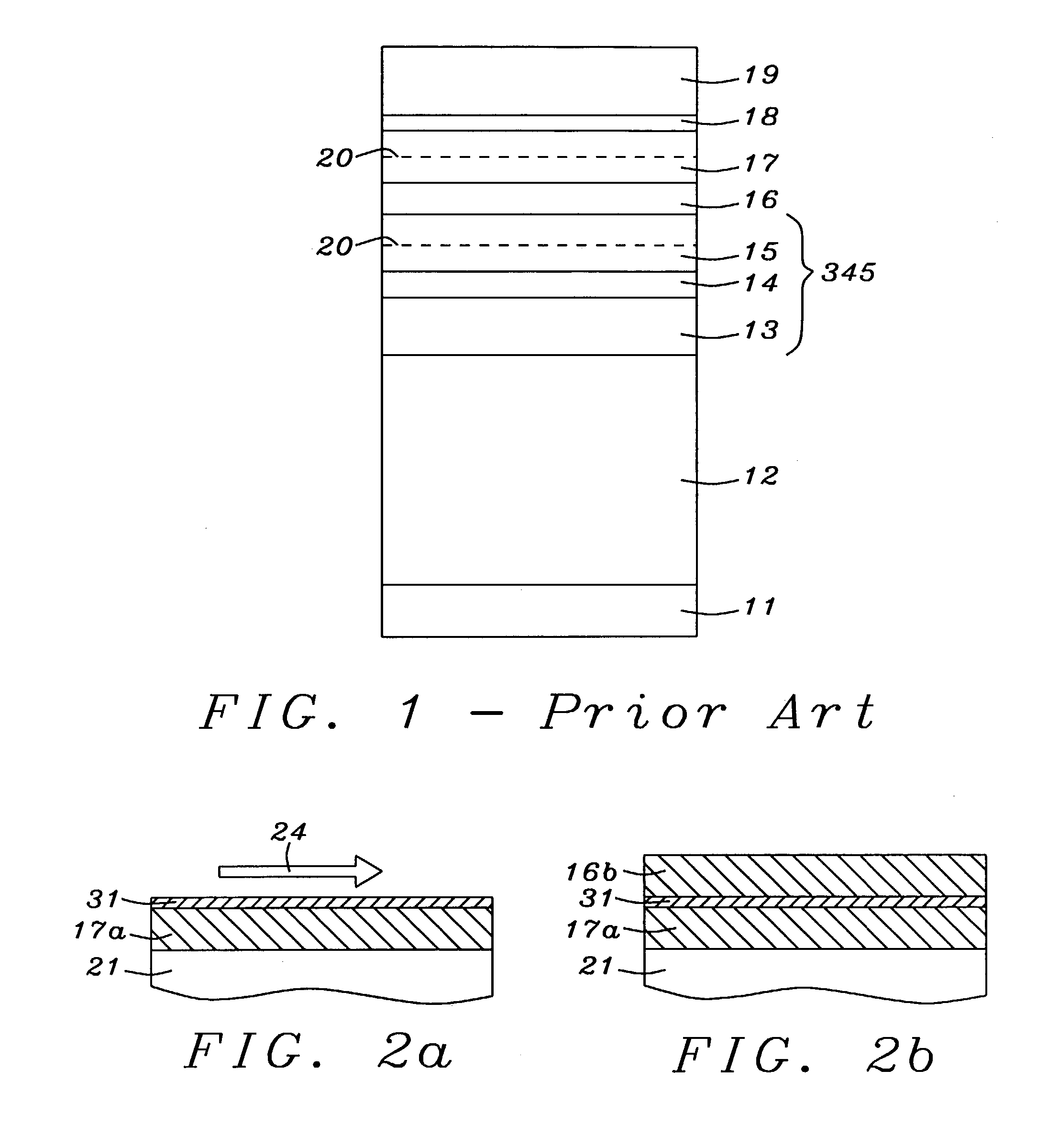

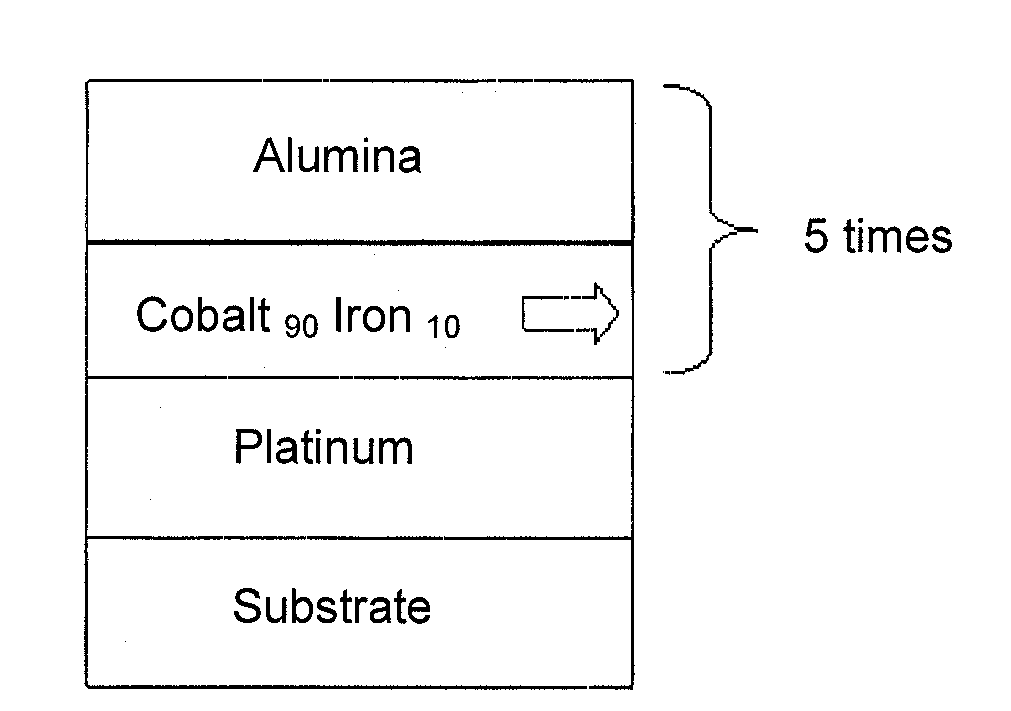

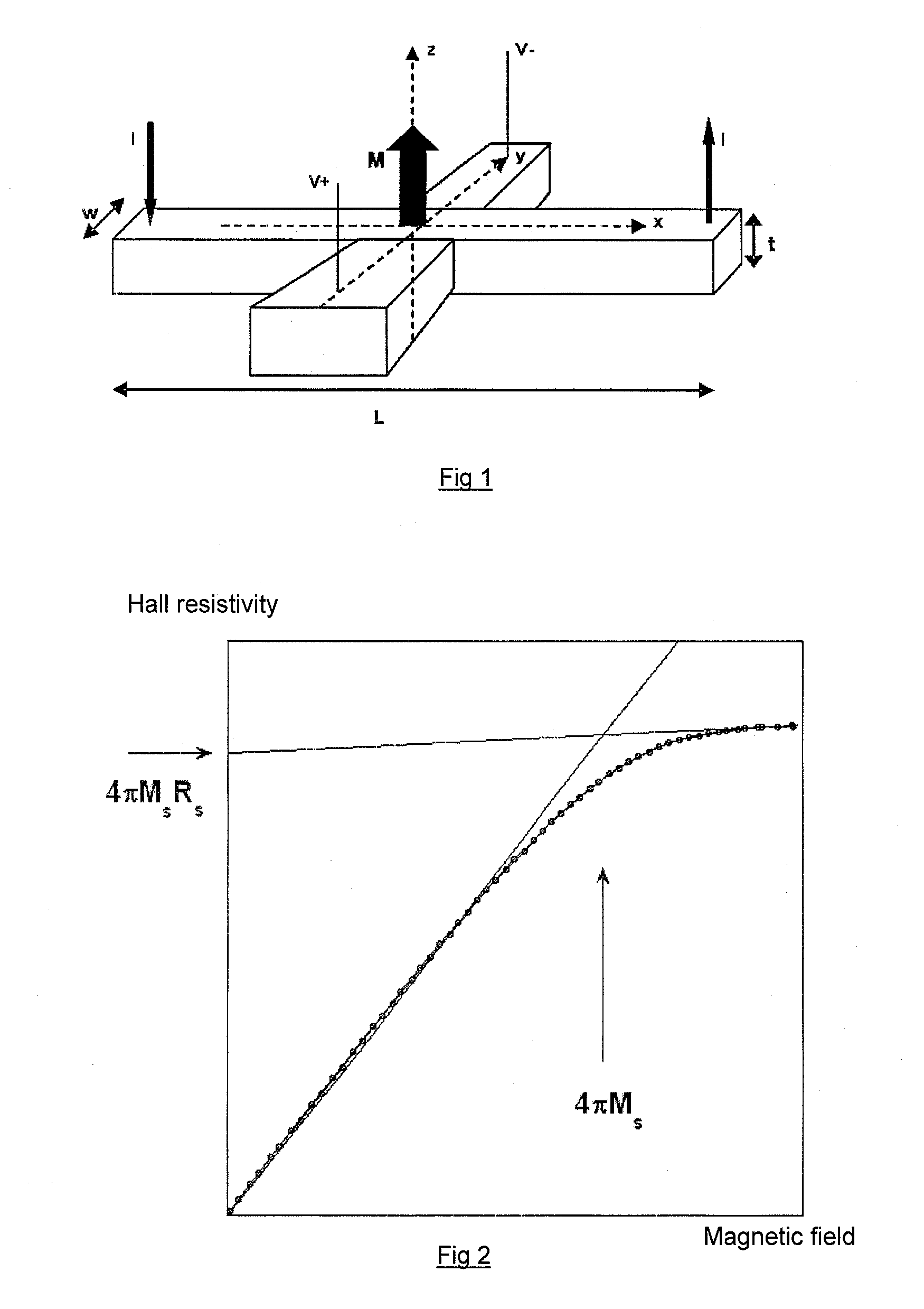

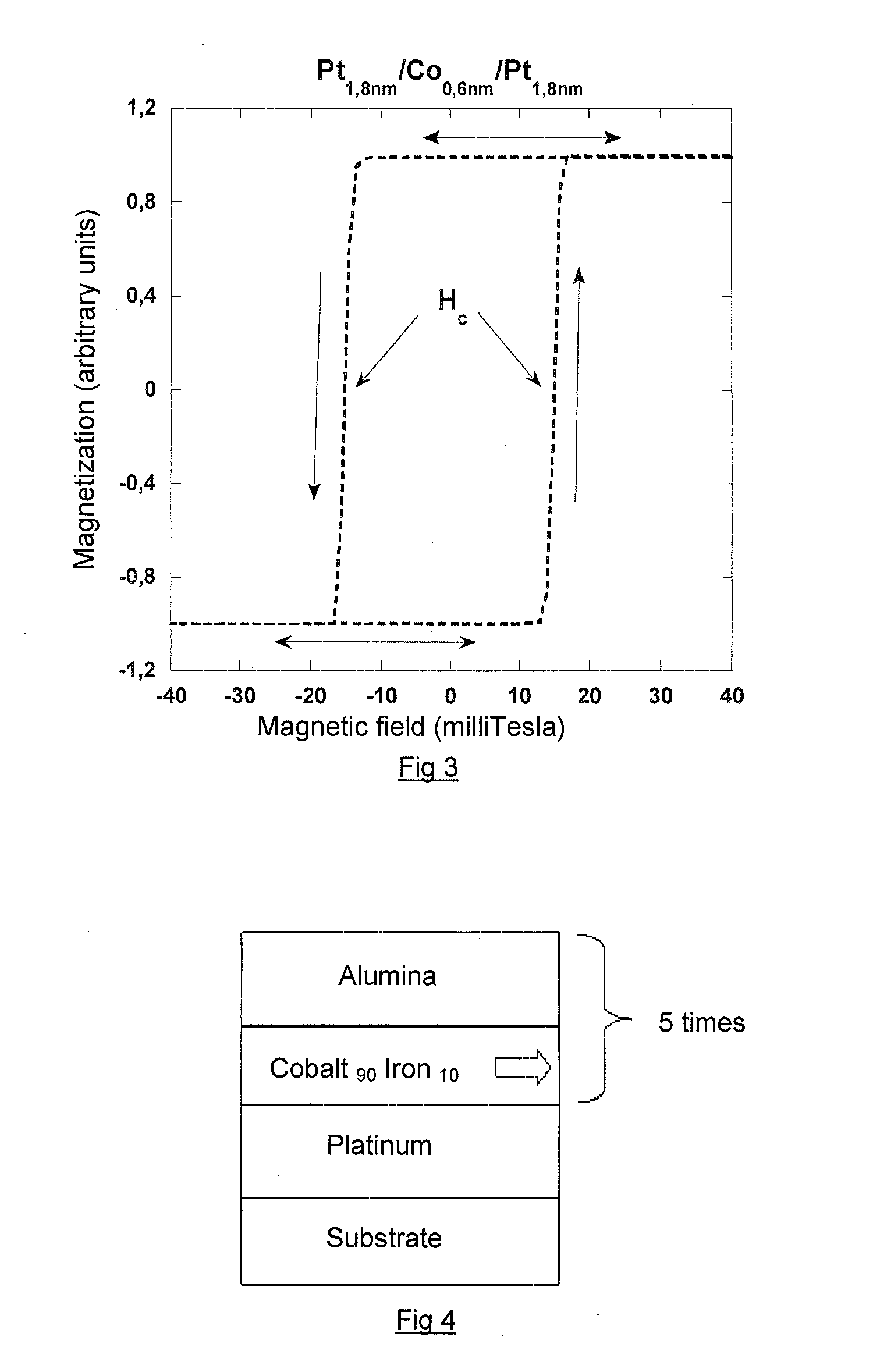

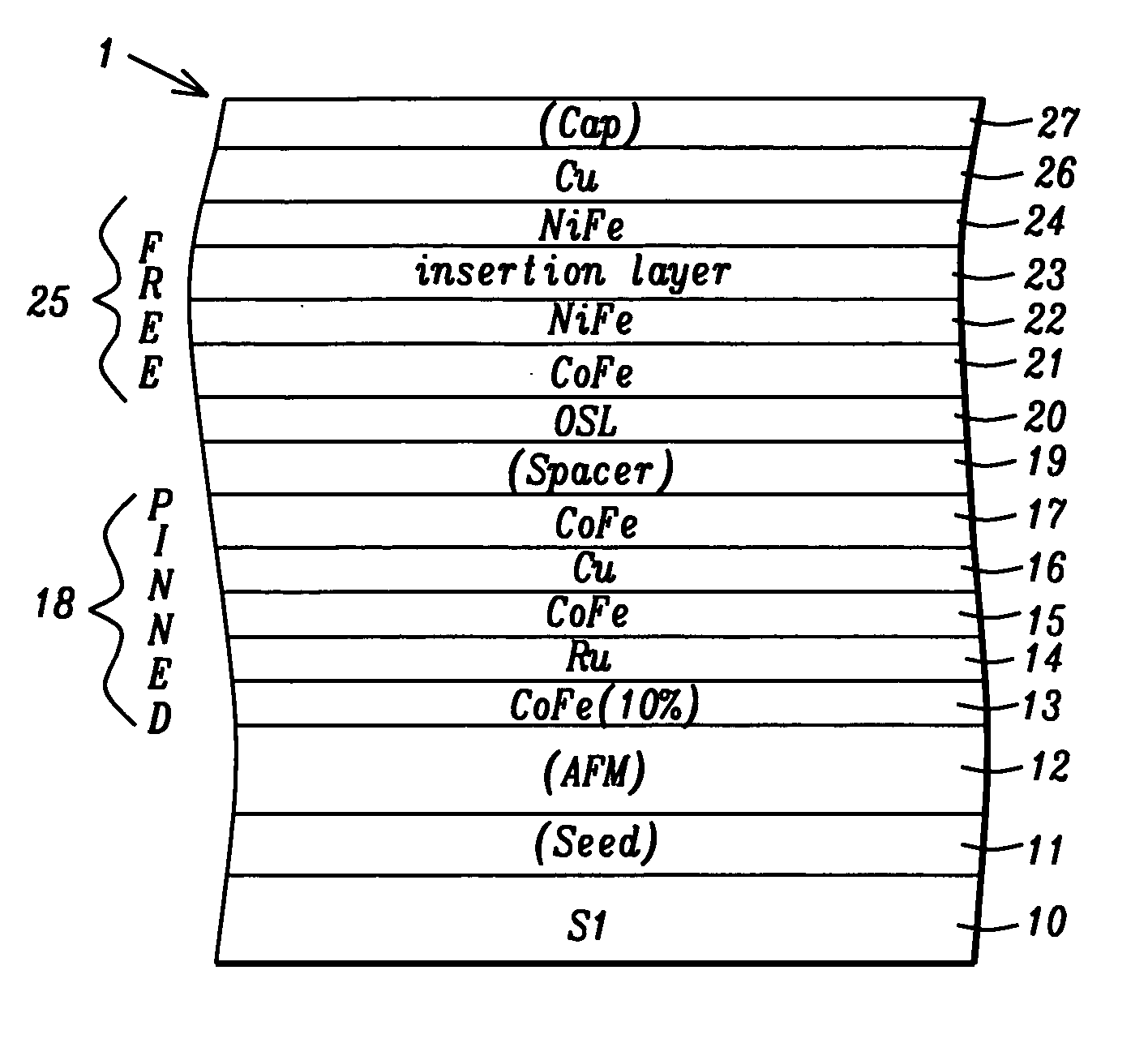

Magnetic multilayer device, method for producing such a device, magnetic field sensor, magnetic memory and logic gate using such a device

ActiveUS20080151615A1High perpendicular anisotropyHigh resistivityNanostructure applicationNanomagnetismMagnetic anisotropyMagnetic memory

This magnetic multilayer device comprises, on a substrate, an alternating sequence of magnetic metallic layers M and oxide, hydride or nitride layers O. The number of layers M equals at least two. The layers M are continuous. There is interfacial magnetic anisotropy perpendicular to the plane of the layers at the level of the M / O interfaces.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

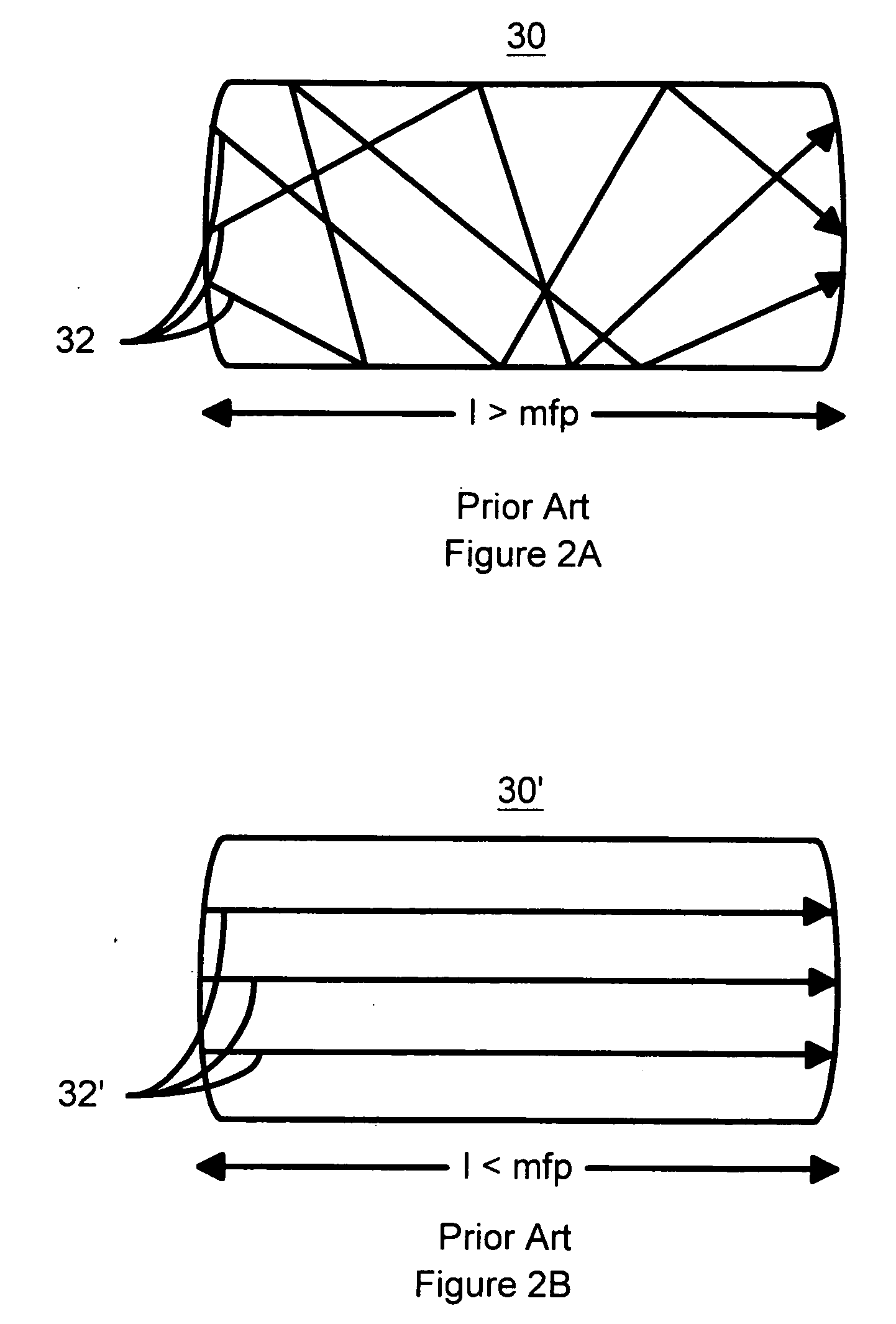

Novel process and structure to fabricate CPP spin valve heads for ultra-hing recording density

InactiveUS20050201022A1Enhanced Specular ReflectionIncrease bulk scatteringNanostructure applicationNanomagnetismDopantSpins

A CPP-GMR spin value sensor structure with an improved MR ratio and increased resistance is disclosed. All layers except certain pinned layers, copper spacers, and a Ta capping layer are oxygen doped by adding a partial O2 pressure to the Ar sputtering gas during deposition. Oxygen doped CoFe free and pinned layers are made slightly thicker to offset a small decrease in magnetic moment caused by the oxygen dopant. Incorporating oxygen in the MnPt AFM layer enhances the exchange bias strength. An insertion layer such as a nano-oxide layer is included in one or more of the free, pinned, and spacer layers to increase interfacial scattering. The thickness of all layers except the copper spacer may be increased to enhance bulk scattering. A CPP-GMR single or dual spin valve of the present invention has up to a threefold increase in resistance and a 2 to 3% increase in MR ratio.

Owner:HEADWAY TECH INC

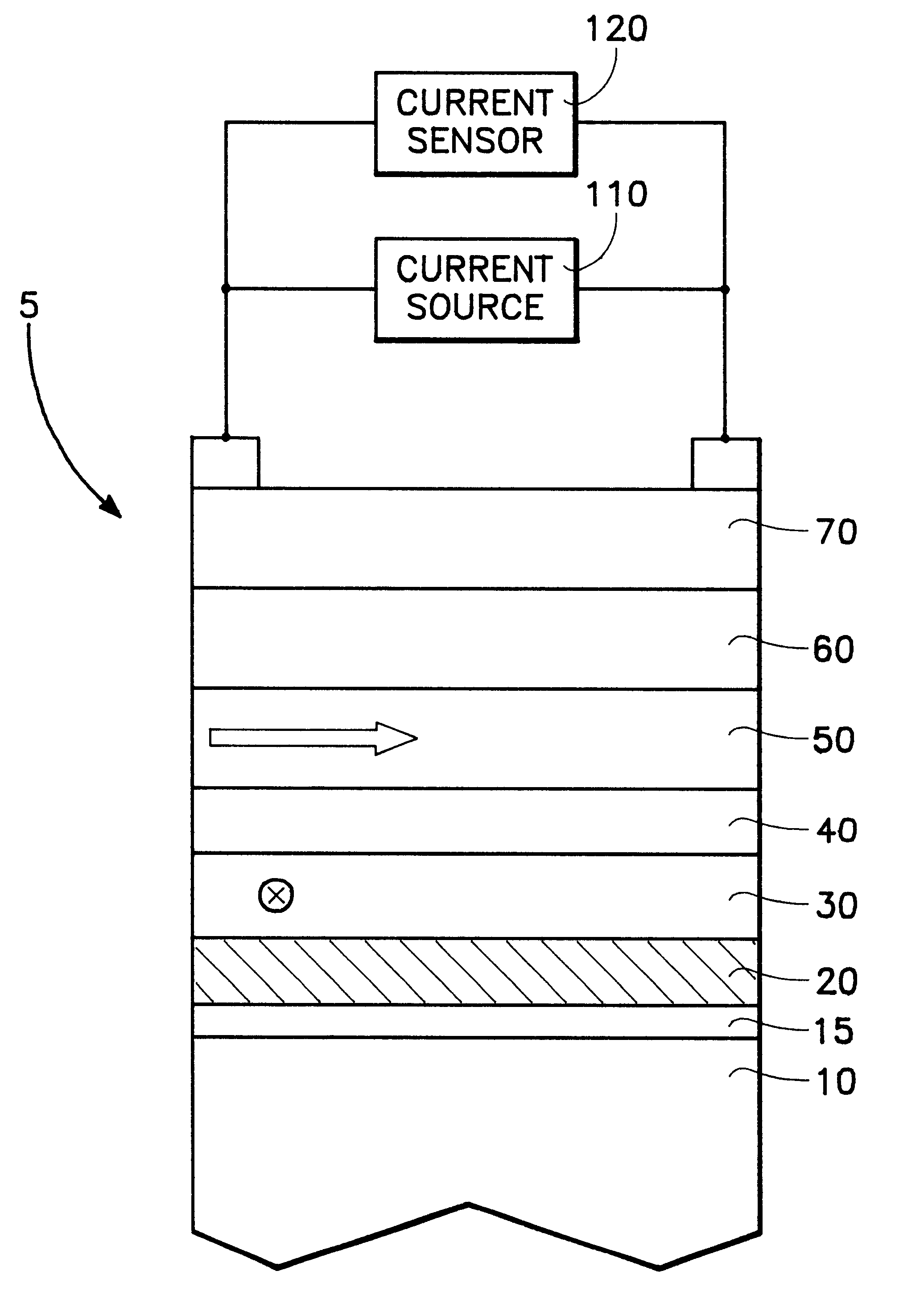

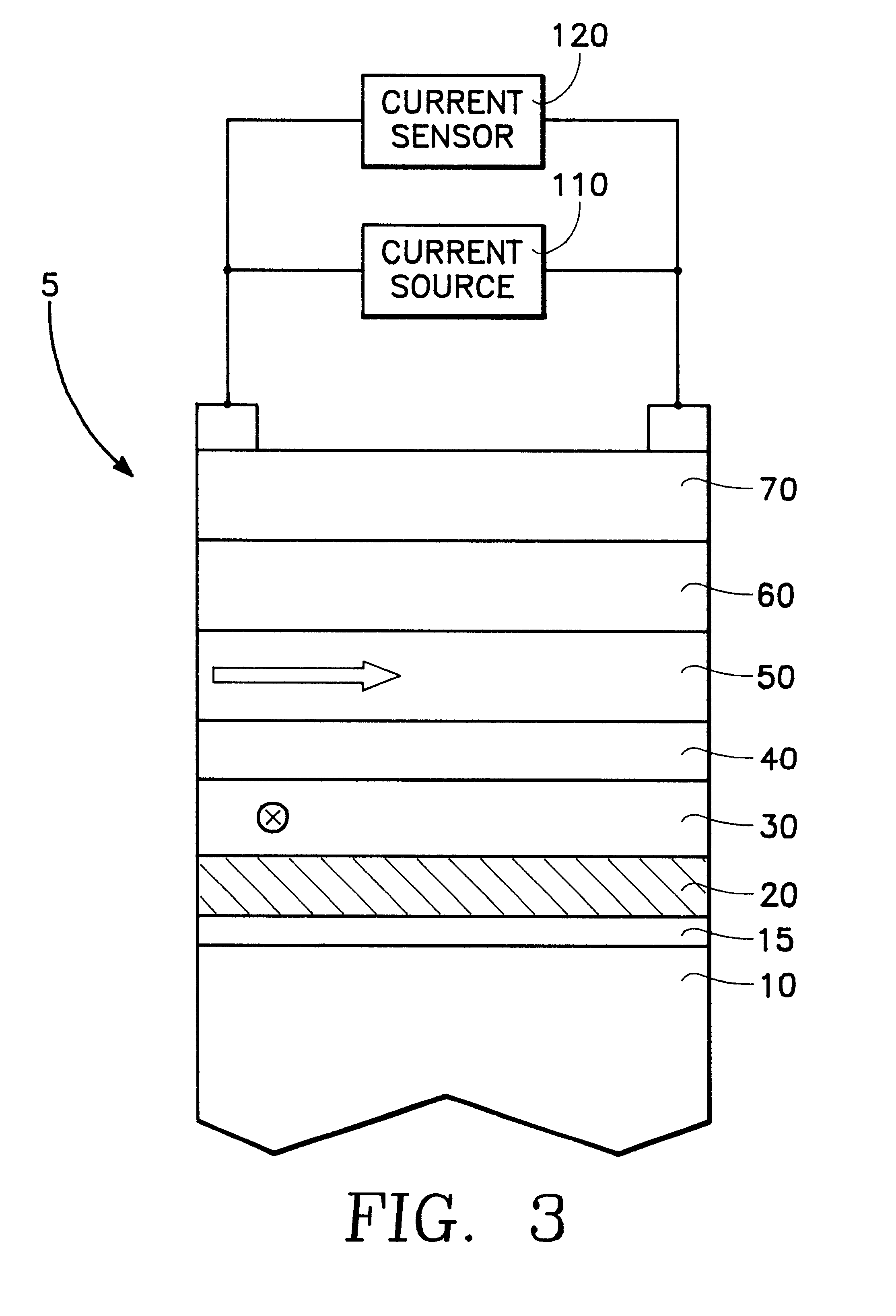

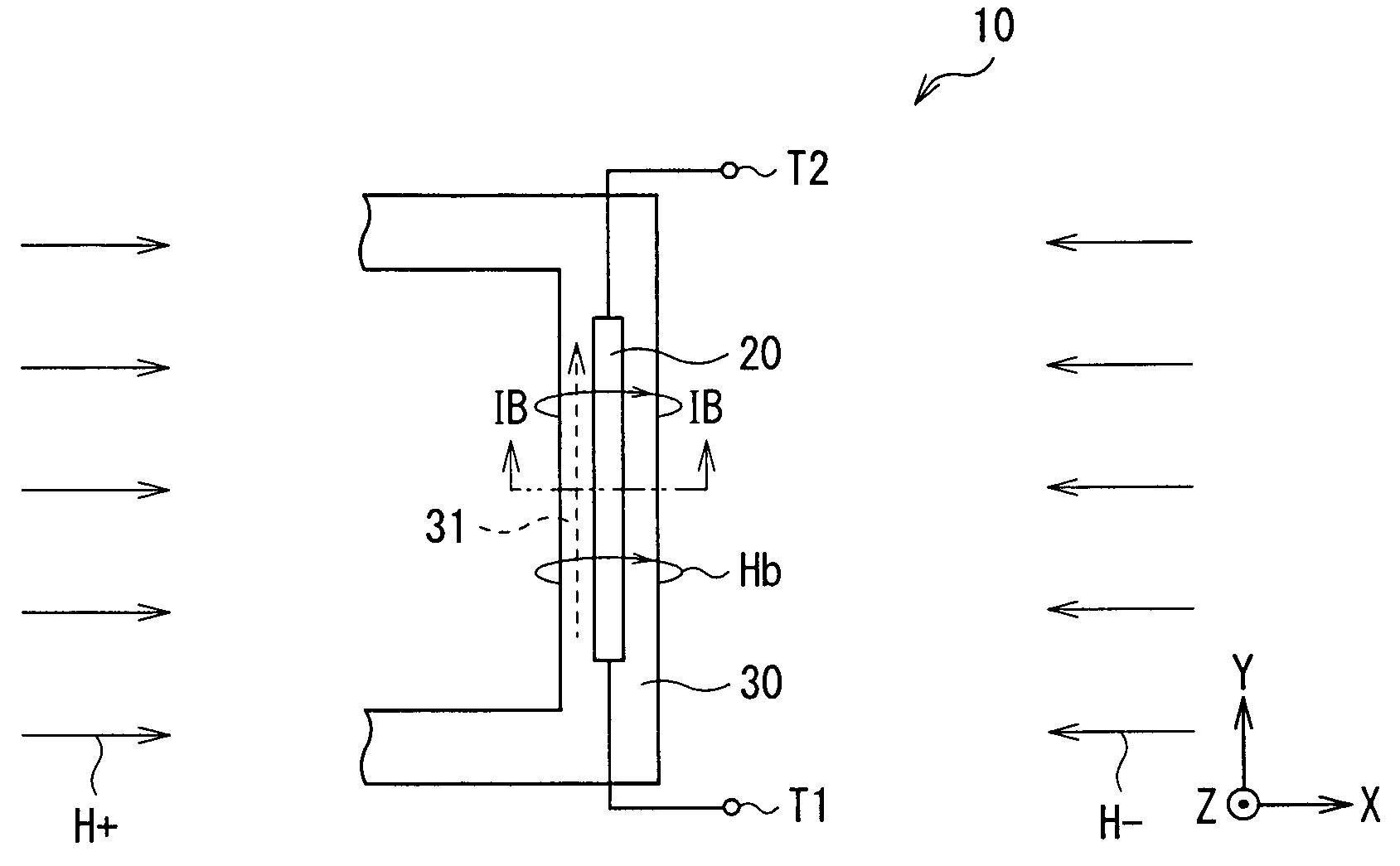

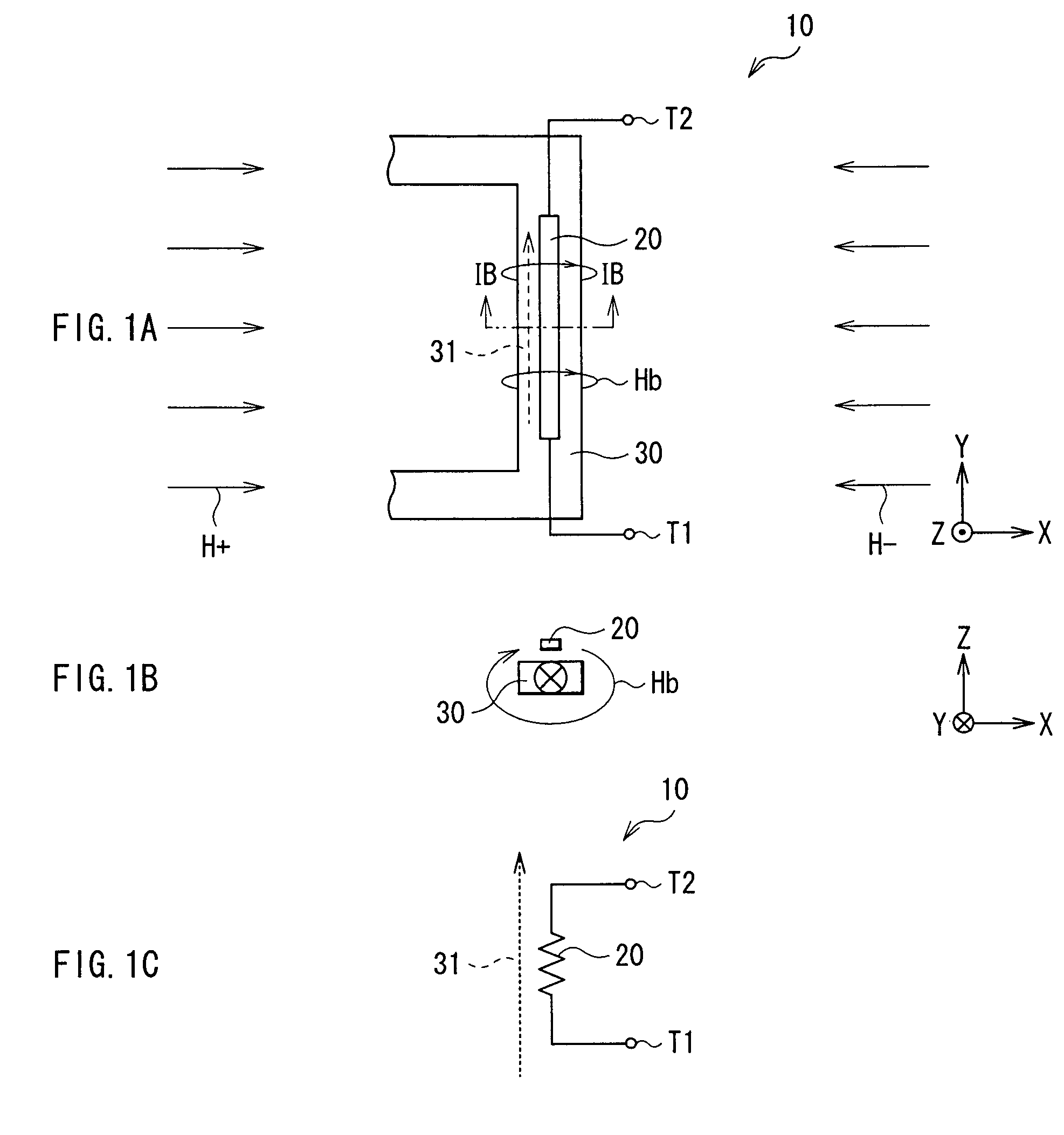

Magnetic sensing device, method of forming the same, magnetic sensor, and ammeter

ActiveUS7248045B2Suppressing appearanceInduction stabilityNanostructure applicationNanomagnetismHysteresisCurrent sheet

The present invention provides a magnetic sensing device capable of stably sensing a signal magnetic field with high sensitivity by suppressing occurrence of a hysteresis to reduce 1 / f noise. A magnetic sensing device has a stacked body including a pinned layer having a magnetization direction pinned to a predetermined direction (Y direction), a free layer having a magnetization direction which changes according to an external magnetic field and, when the external magnetic field is zero, becomes parallel to the magnetization direction of the pinned layer, and an intermediate layer sandwiched between the pinned layer and the free layer. Consequently, as compared with the case where the pinned layer and the free layer have magnetization directions which are orthogonal to each other when the external magnetic field is zero, variations in the spin directions of magnetic domains in the free layer can be reduced. In the case of passing read current, appearance of a hysteresis in the relation between a change in the external magnetic field and a resistance change can be suppressed. As a result, 1 / f noise is suppressed and a signal magnetic field can be stably sensed with high sensitivity.

Owner:TDK CORPARATION

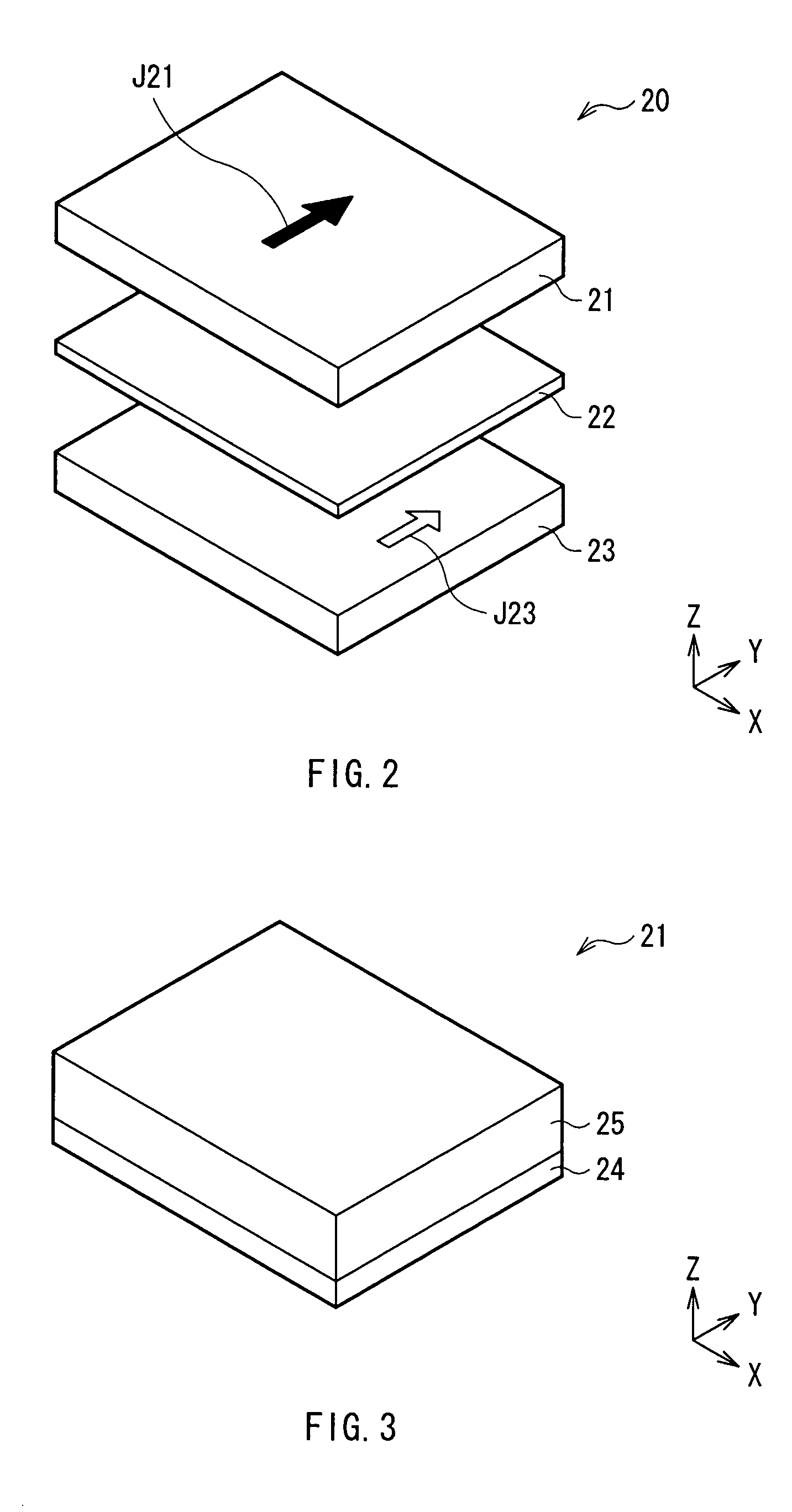

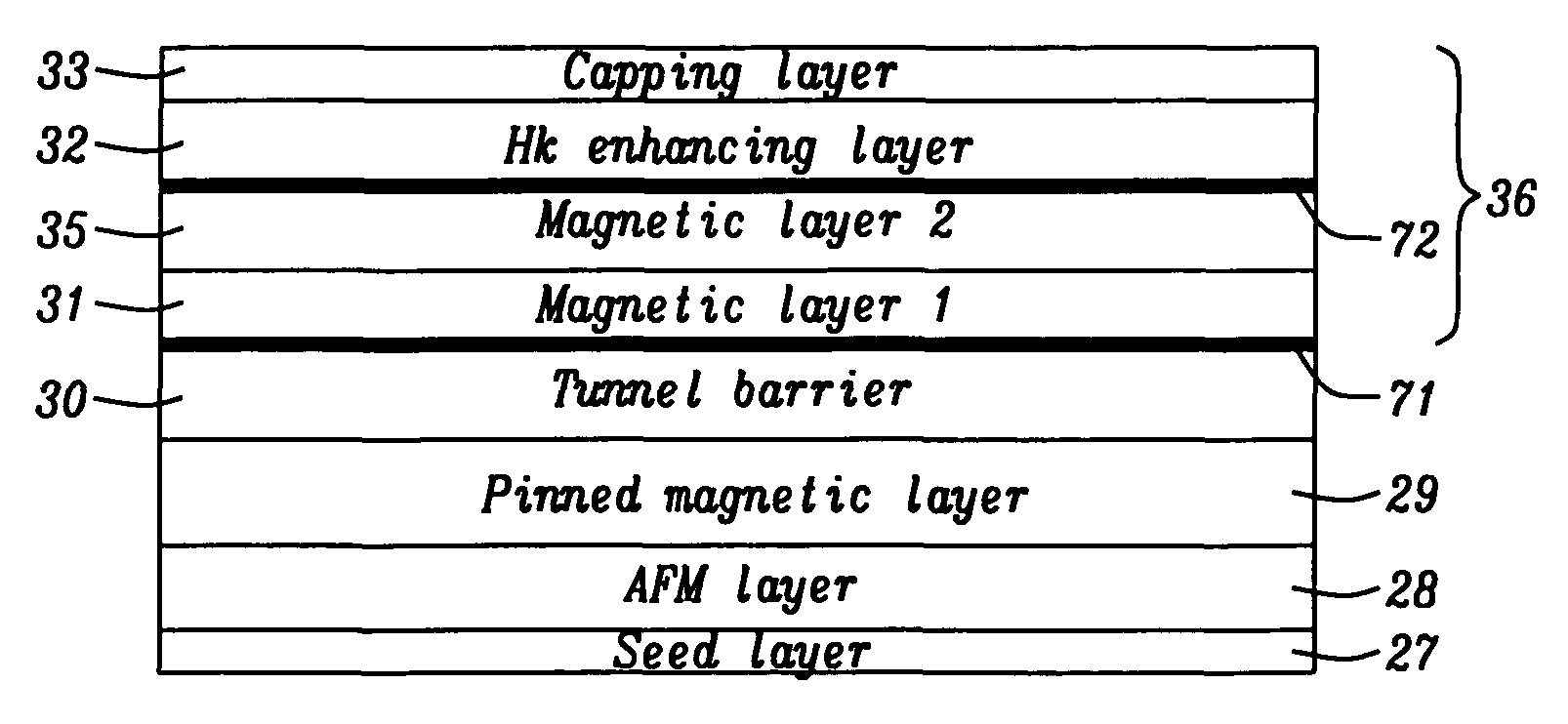

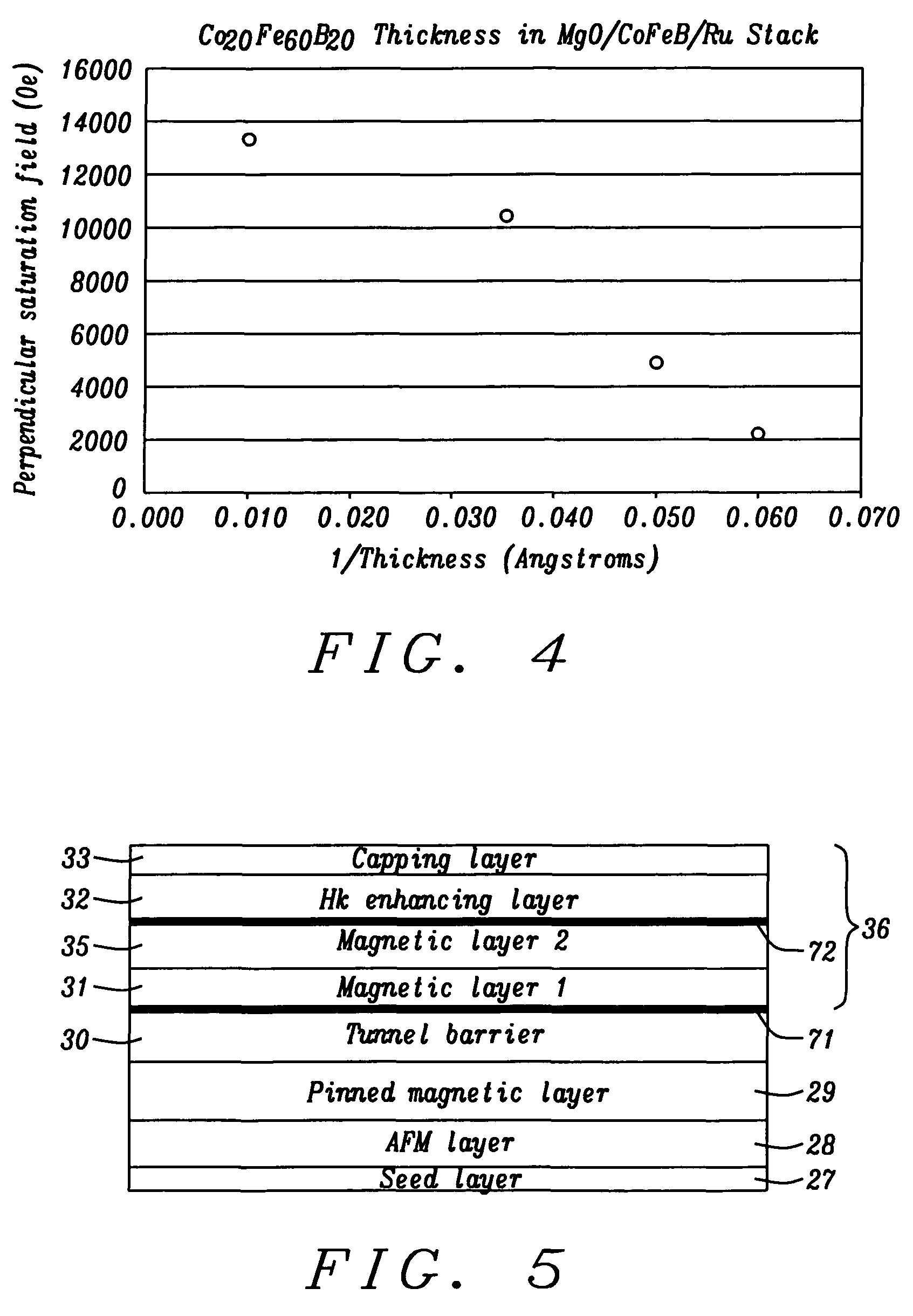

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS9006704B2Enhanced interfacial perpendicular anisotropyImprove thermal stabilityNanostructure applicationMagnetic-field-controlled resistorsPerpendicular anisotropyAlloy

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

Spin-current switched magnetic memory element suitable for circuit integration and method of fabricating the memory element

Owner:GLOBALFOUNDRIES U S INC

Method of forming a barrier layer of a tunneling magnetoresistive sensor

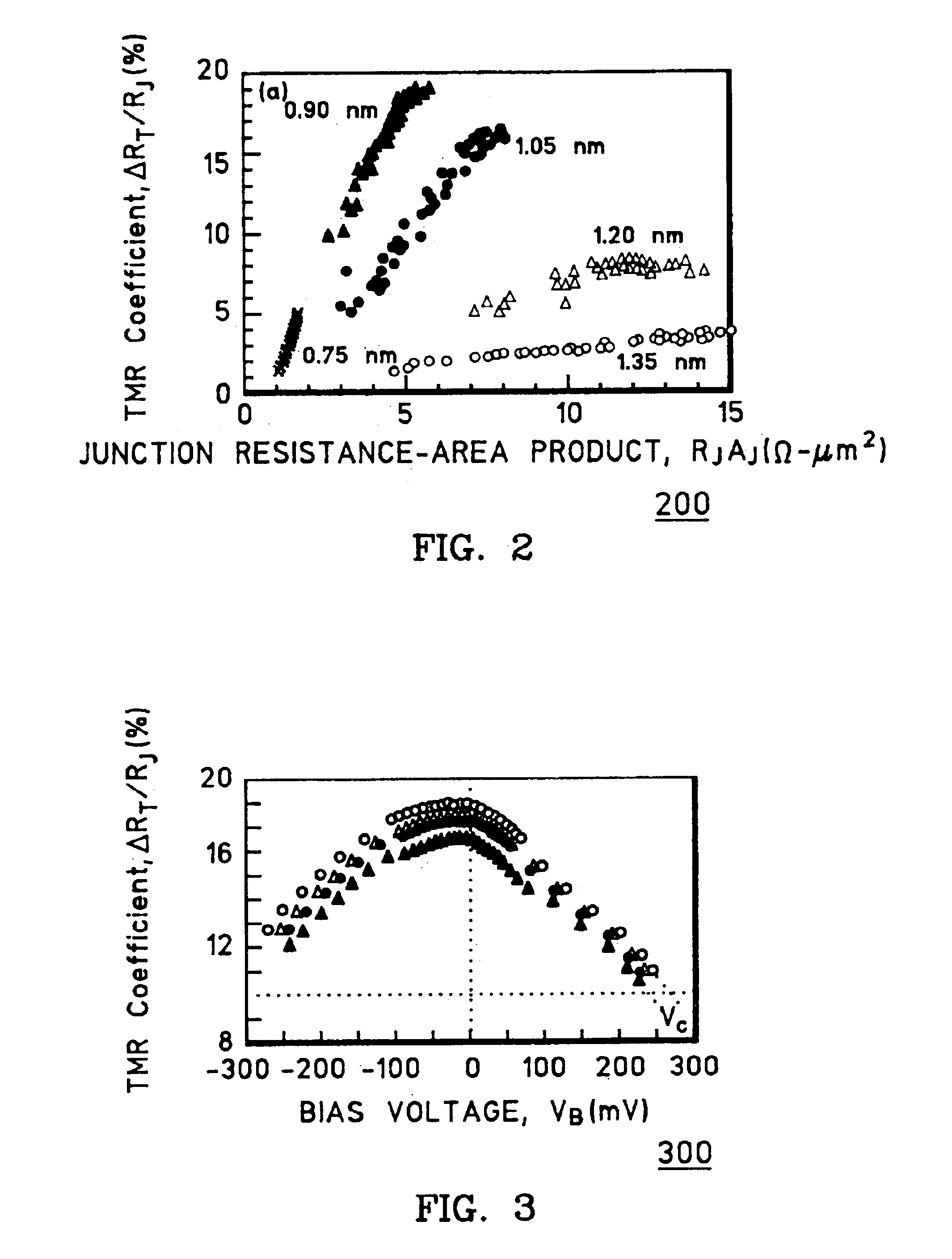

A fabrication process for a tunneling magnetoresistance (TMR) sensor is disclosed. In particular, a unique method of forming a barrier layer of the TMR sensor is utilized so that the TMR sensor exhibits good magnetic and TMR properties. In one particular example, the barrier layer is formed by depositing a metallic film in an argon gas in a DC magnetron sputtering module, depositing an oxygen-doped metallic film in mixed xenon and oxygen gases in an ion-beam sputtering module, and oxidizing these films in an oxygen gas in an oxygen treatment module. This three-step barrier layer formation process minimizes oxygen penetration into ferromagnetic (FM) sense and pinned layers of the TMR sensor and optimally controls oxygen doping into the barrier layer. As a result, the FM sense and pinned layers exhibit controlled magnetic properties, the barrier layer provides a low junction resistance-area product, and the TMR sensor exhibits a high TMR coefficient.

Owner:GLOBALFOUNDRIES INC

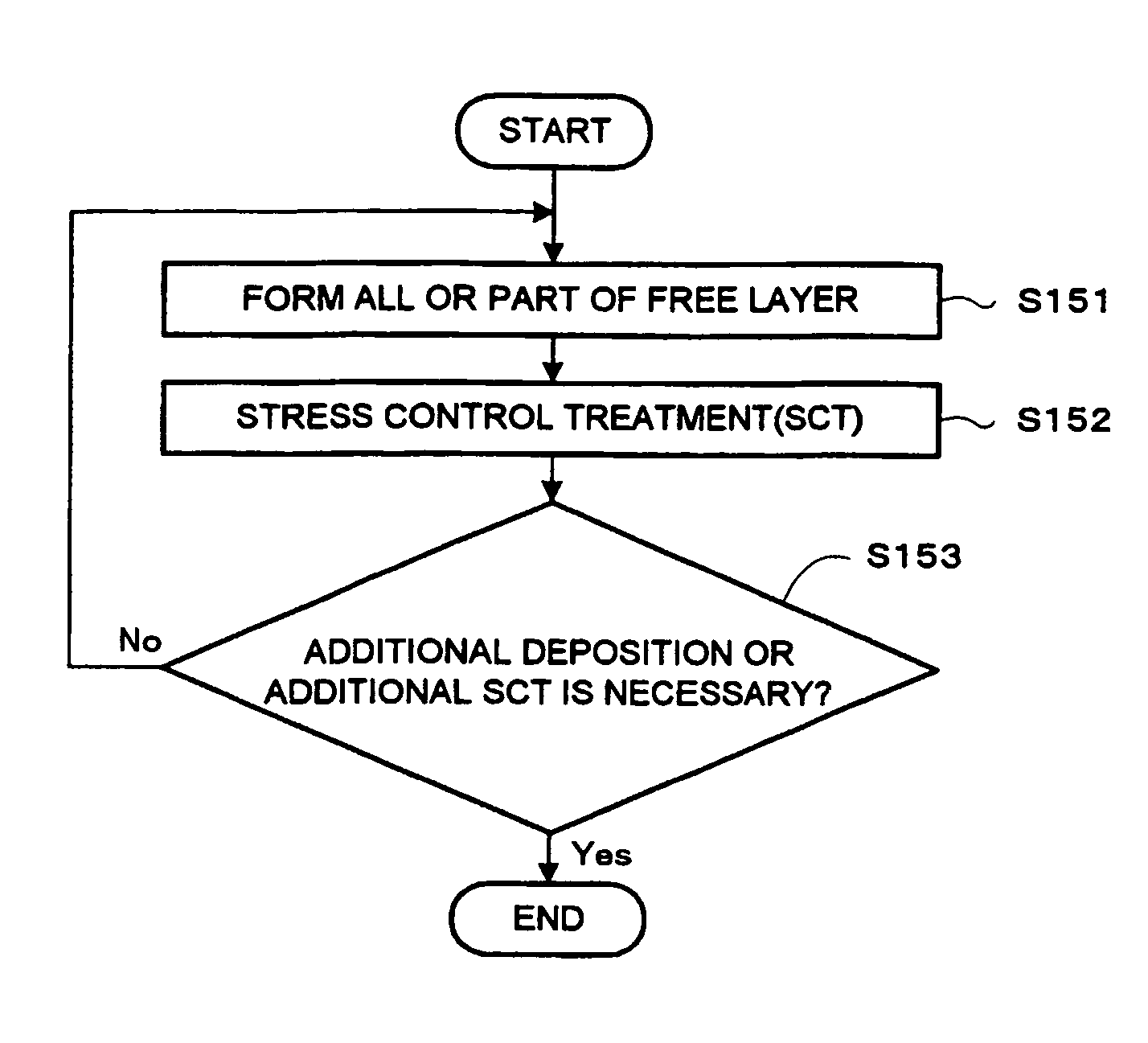

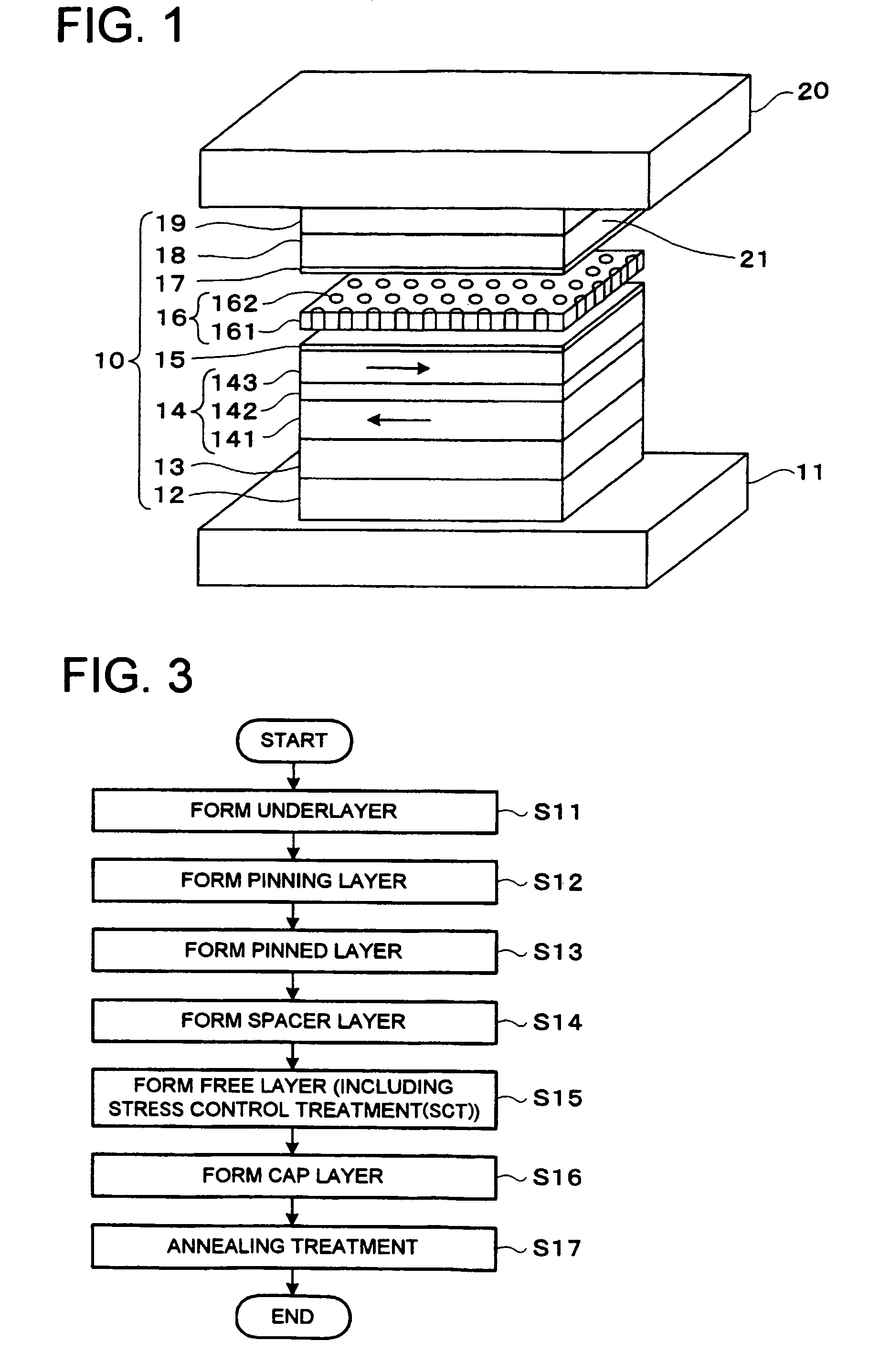

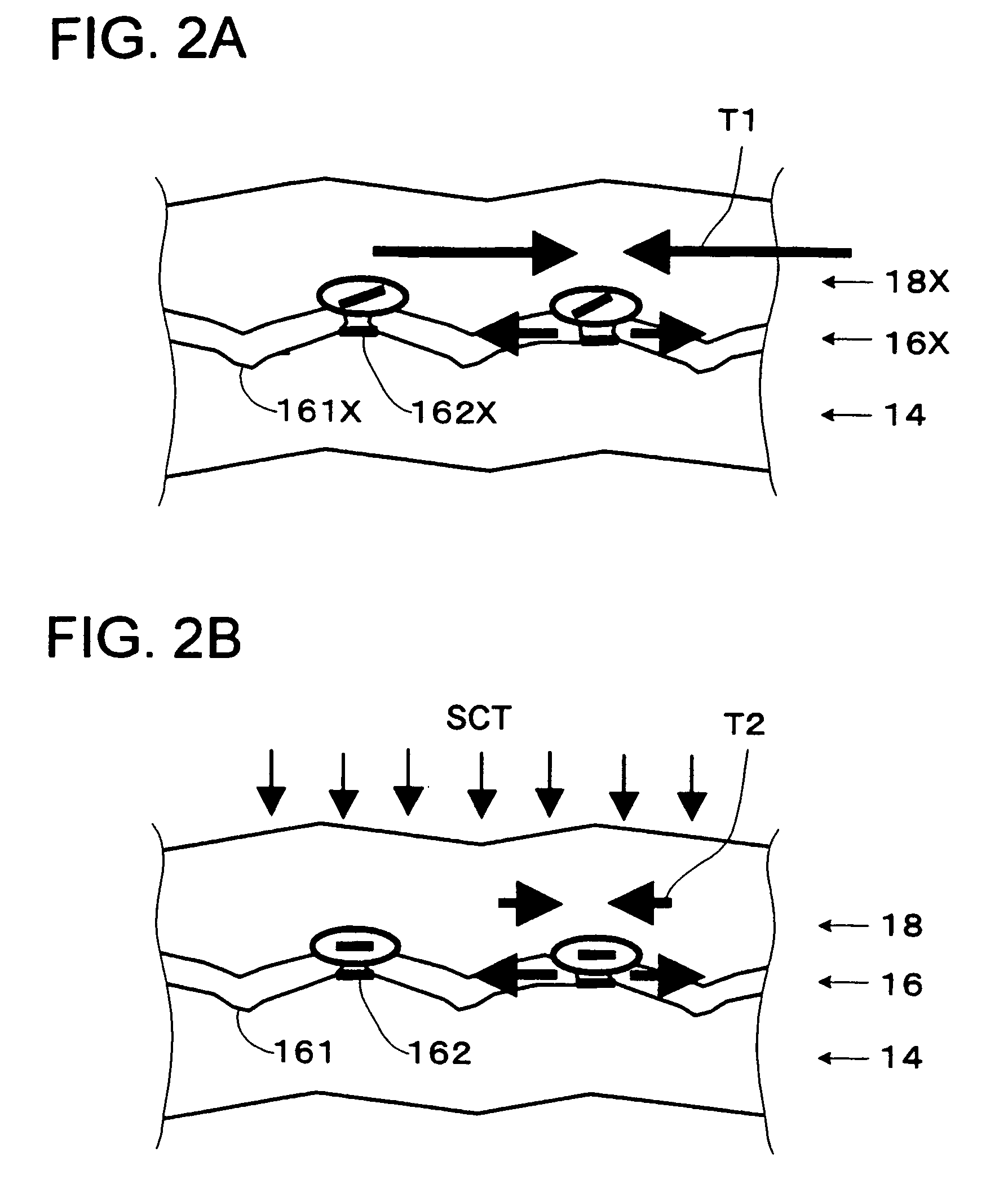

Magnetoresistive effect element and manufacturing method thereof

A magnetoresistive effect element is produced by forming a first magnetic layer, a spacer layer including an insulating layer and a conductive layer which penetrates through the insulating layer and passes a current, on the first magnetic layer, and a second magnetic layer all of which or part of which is treated with ion, plasma or heat, on the formed spacer layer.

Owner:KK TOSHIBA

Magnetic memory device and method of manufacturing the same

Owner:KIOXIA CORP

Magnetic elements with ballistic magnetoresistance utilizing spin-transfer and an MRAM device using such magnetic elements

InactiveUS20060192237A1Improve signal outputTransistorNanostructure applicationMagnetic currentCharge carrier

A method and system for providing a magnetic element is disclosed. The method and system include providing a pinned layer, a magnetic current confined layer, and a free layer. The pinned layer is ferromagnetic and has a first pinned layer magnetization. The magnetic current confined layer has at least one channel in an insulating matrix and resides between the pinned layer and the free layer. The channel(s) are ferromagnetic, conductive, and extend through the insulating matrix between the free layer and the pinned layer. The size(s) of the channel(s) are sufficiently small that charge carriers can give rise to ballistic magnetoresistance in the magnetic current confined layer. The free layer is ferromagnetic and has a free layer magnetization. Preferably, the method and system also include providing a second pinned layer and a nonmagnetic spacer layer between the second pinned layer and the free layer. In this aspect, the magnetic element is configured to allow the free layer magnetization to be switched using spin transfer.

Owner:SAMSUNG SEMICON

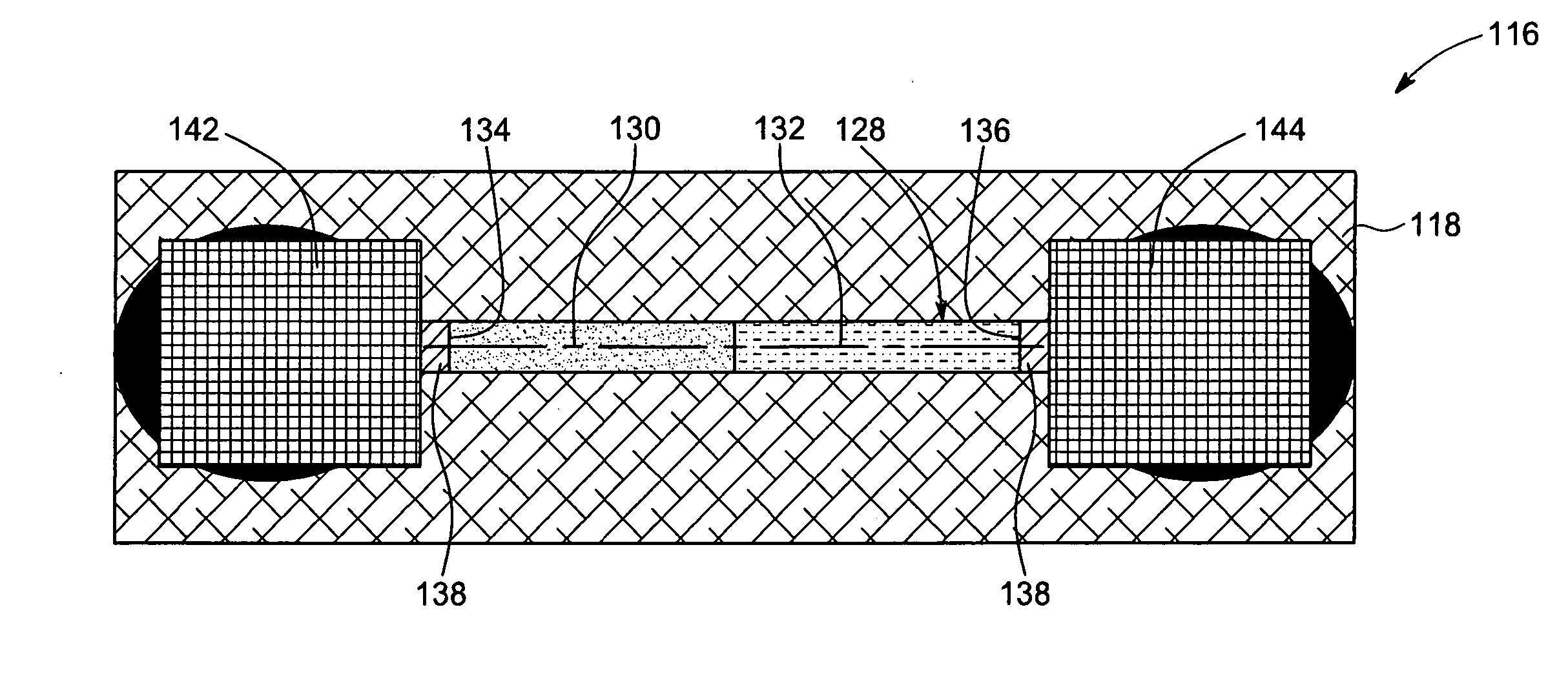

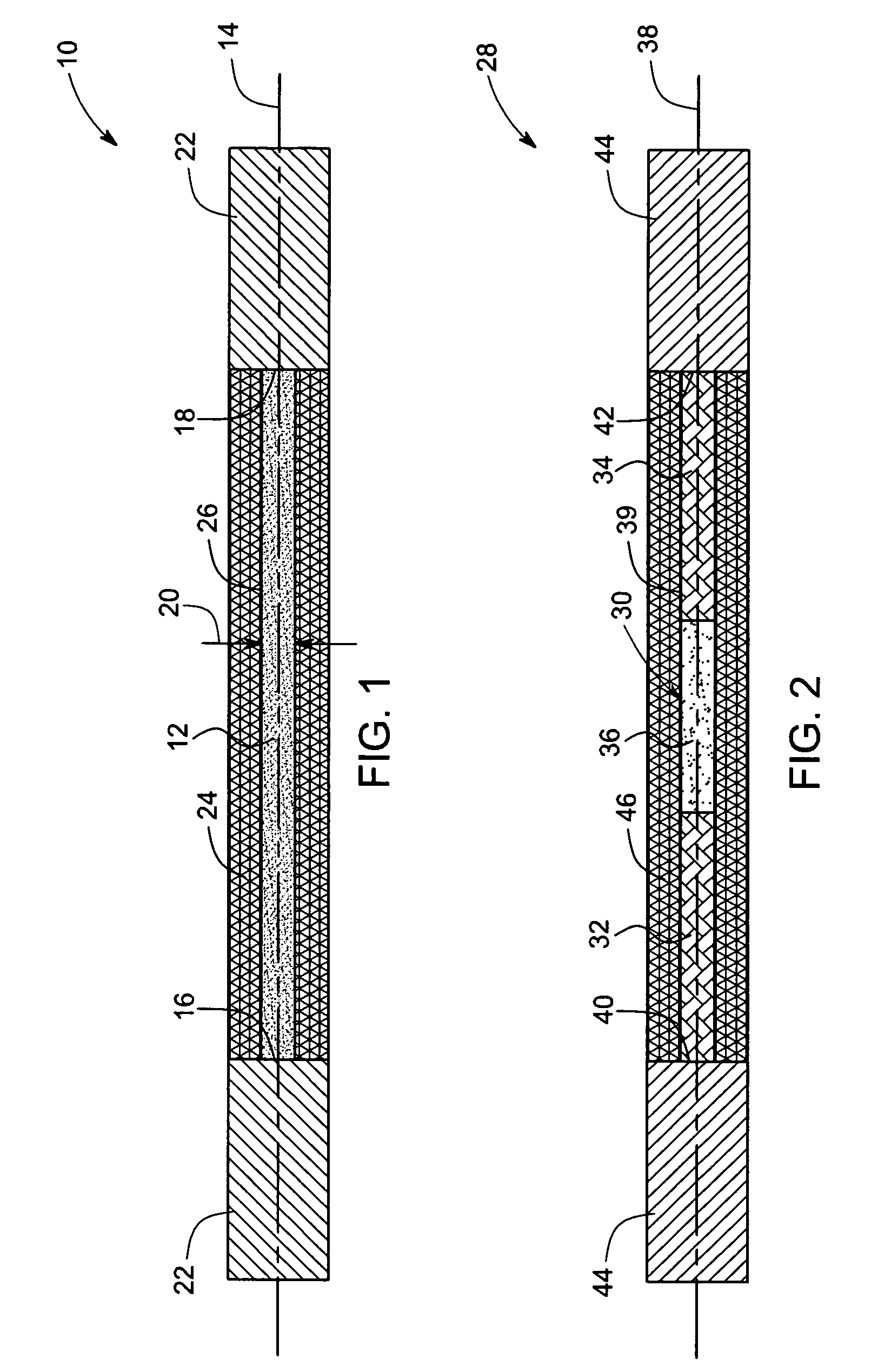

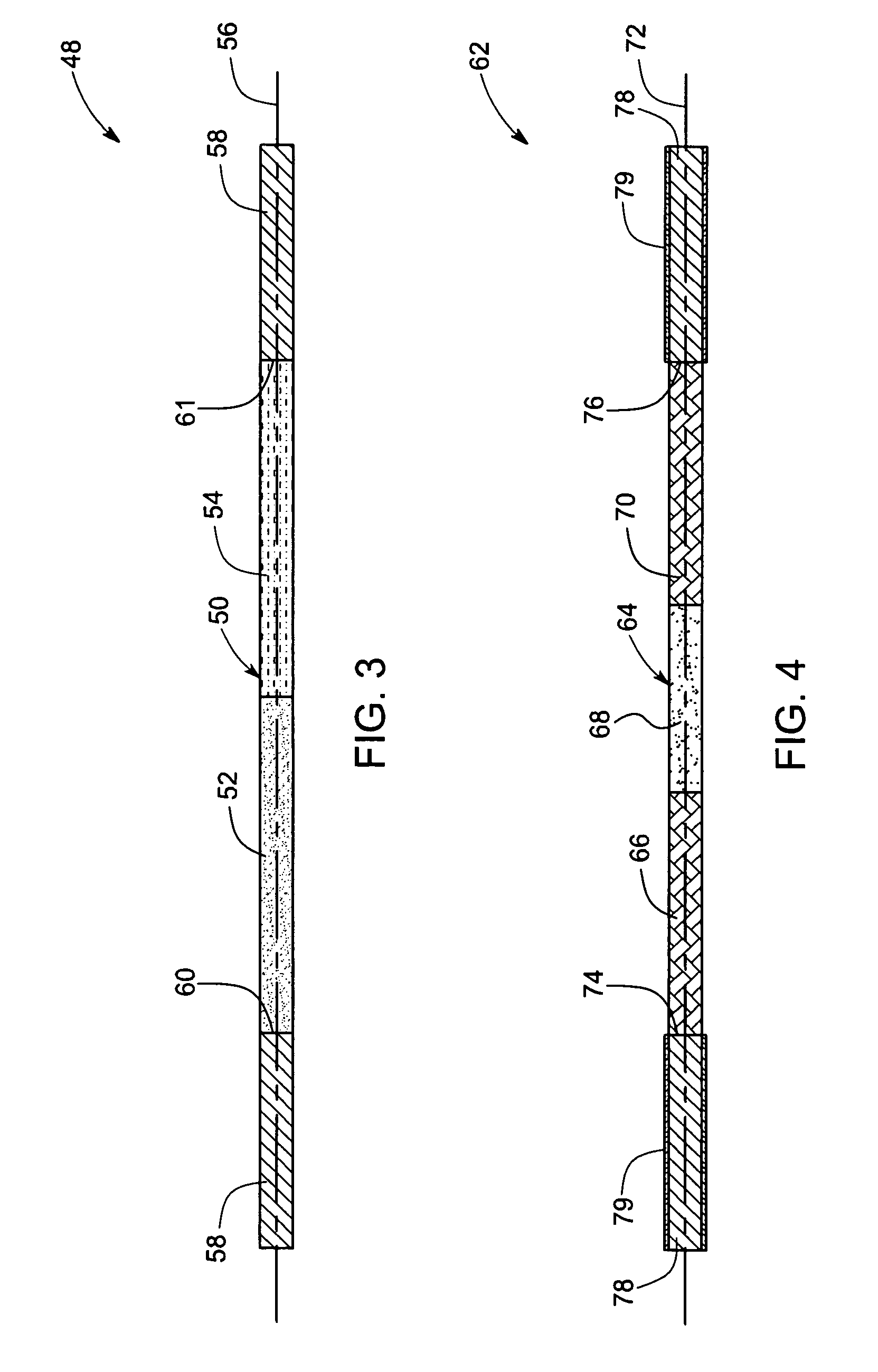

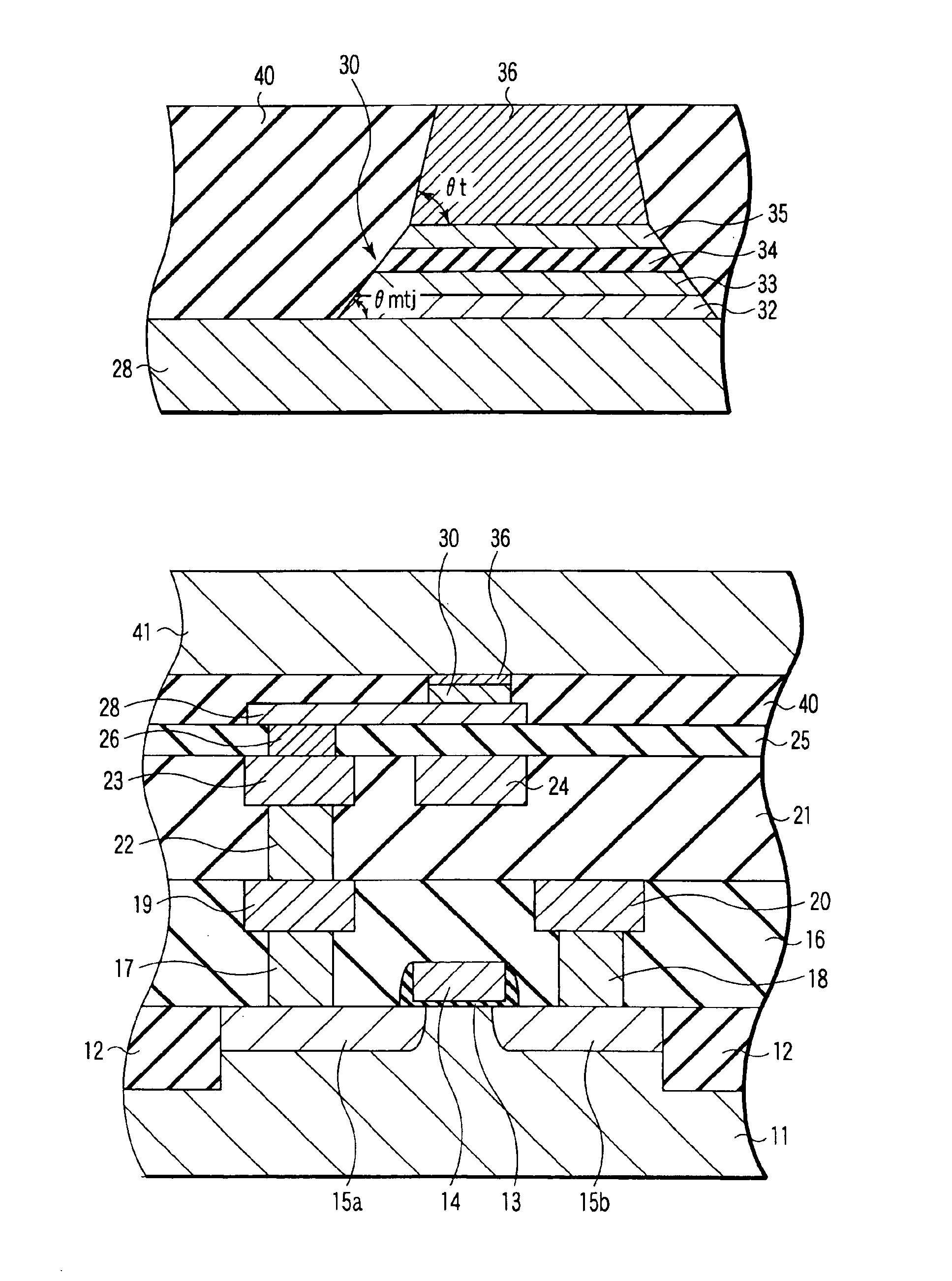

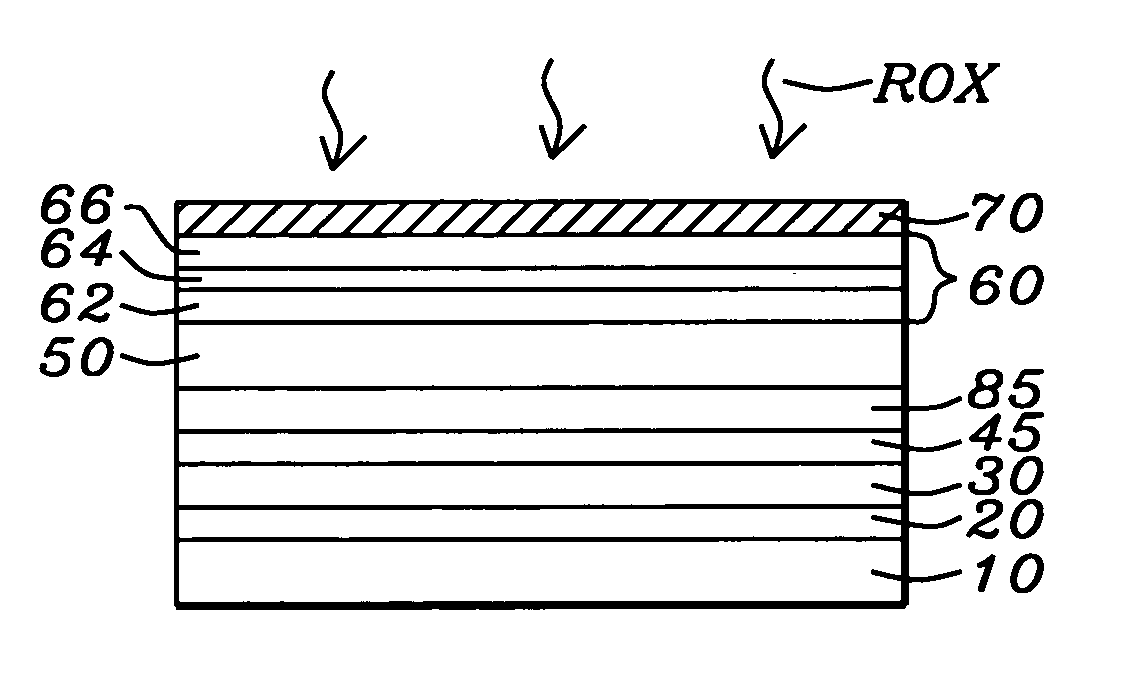

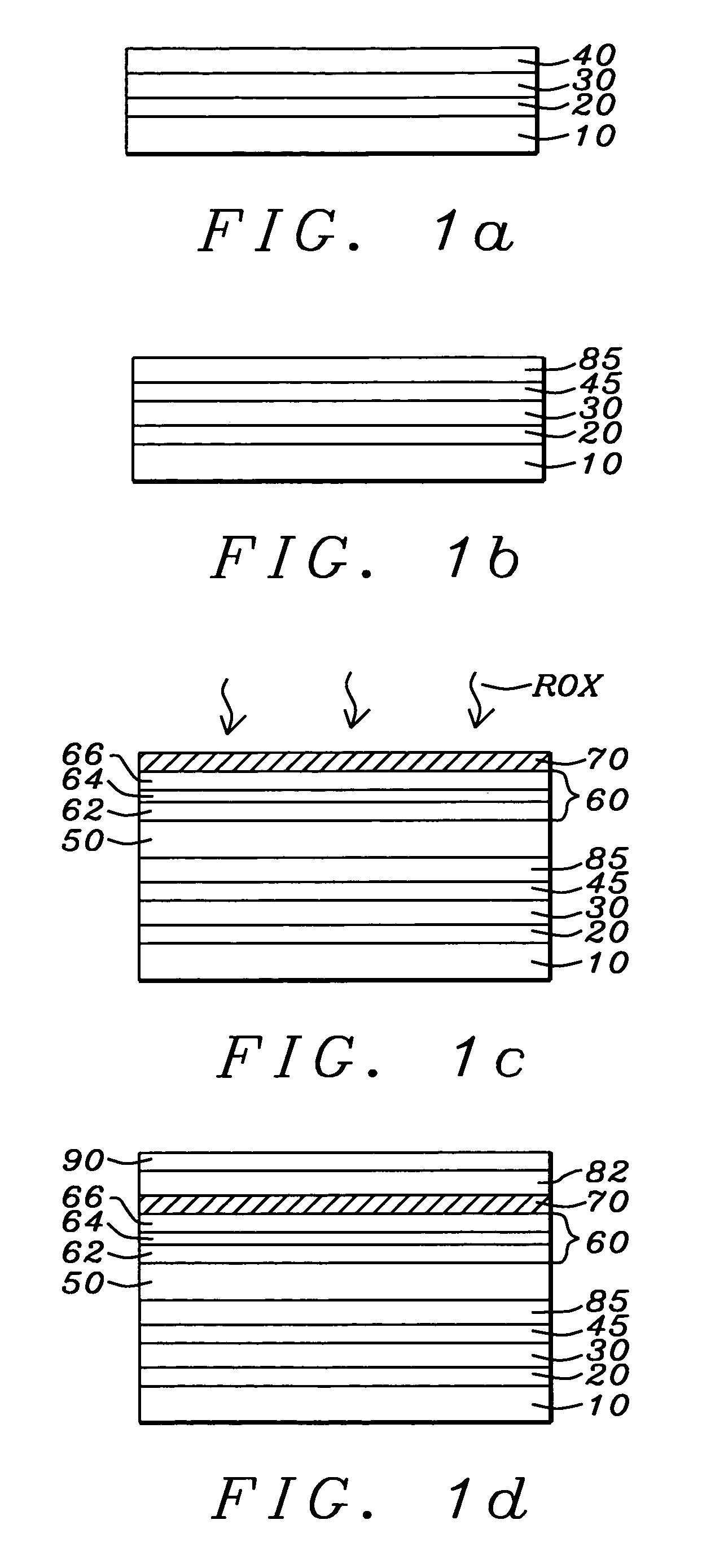

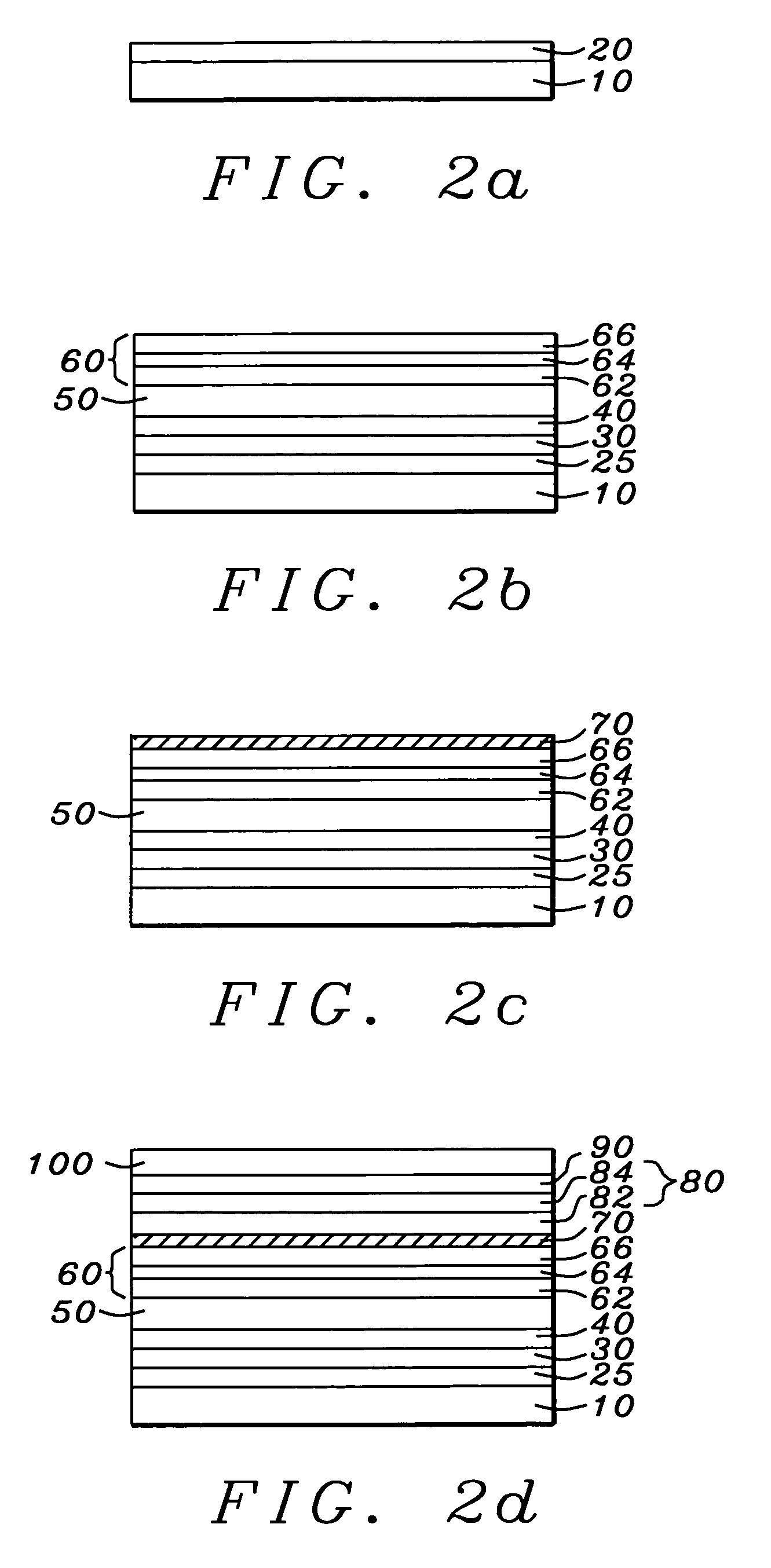

Method of forming a magnetic tunneling junction (MTJ) MRAM device and a tunneling magnetoresistive (TMR) read head

ActiveUS6960480B1Easy to controlSignificant exchangeNanostructure applicationNanomagnetismRandom access memoryThin layer

An MTJ (magnetic tunneling junction) device particularly suitable for use as an MRAM (magnetic random access memory) or a tunneling magnetoresistive (TMR) read sensor, is formed on a seed layer which allows the tunneling barrier layer to be ultra-thin, smooth, and to have a high breakdown voltage. The seed layer is a layer of NiCr which is formed on a sputter-etched layer of Ta. The tunneling barrier layer for the MRAM is formed from a thin layer of Al which is radically oxidized (ROX), in-situ, to form the layer with characteristics described above. The tunneling barrier layer for the read sensor formed from a thin layer of Al or a HfAl bilayer which is naturally oxidized (NOX), in situ, to form the barrier layer. The resulting device has generally improved performance characteristics in terms of GMR ratio and junction resistance.

Owner:APPLIED SPINTRONICS +1

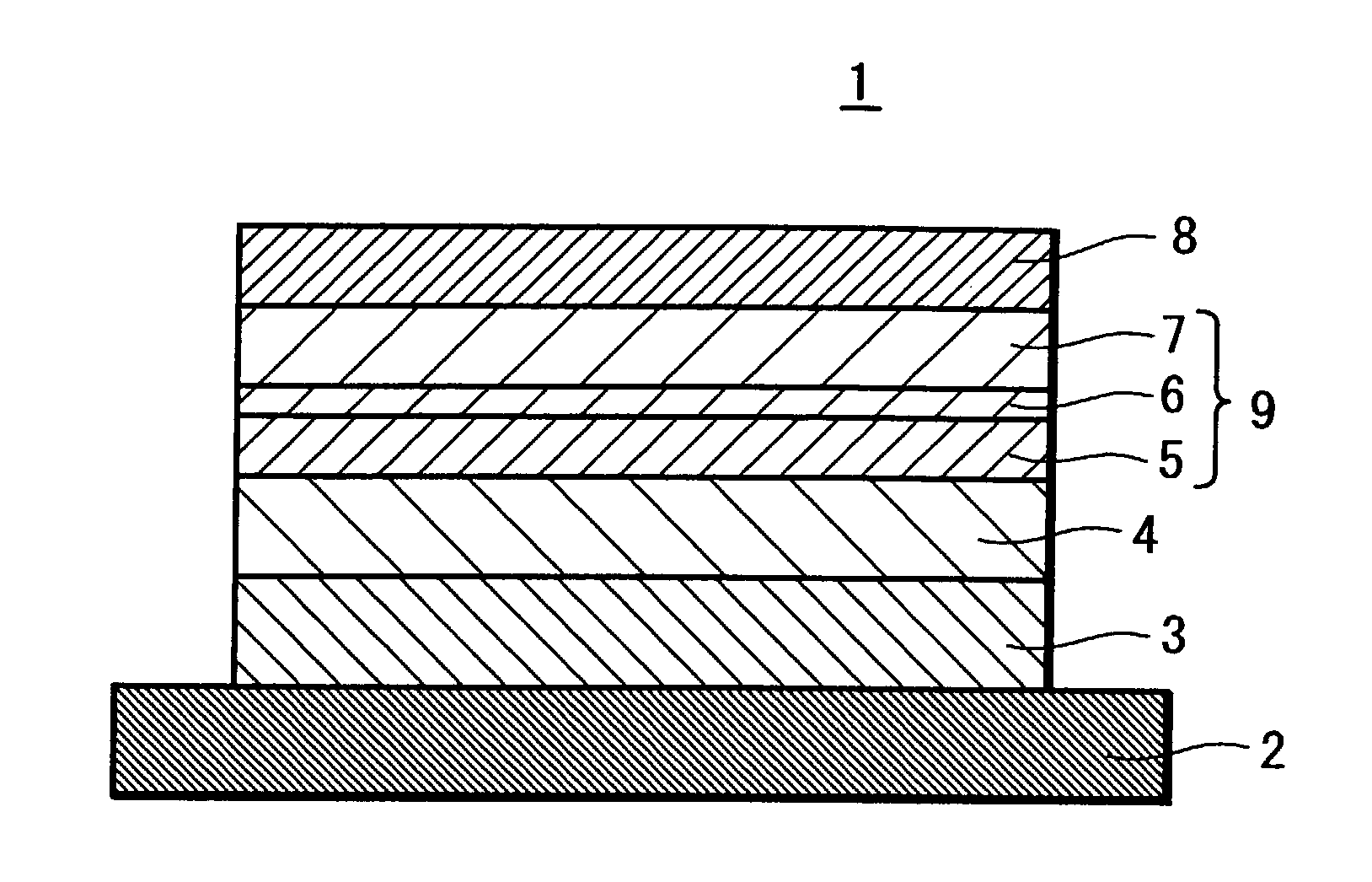

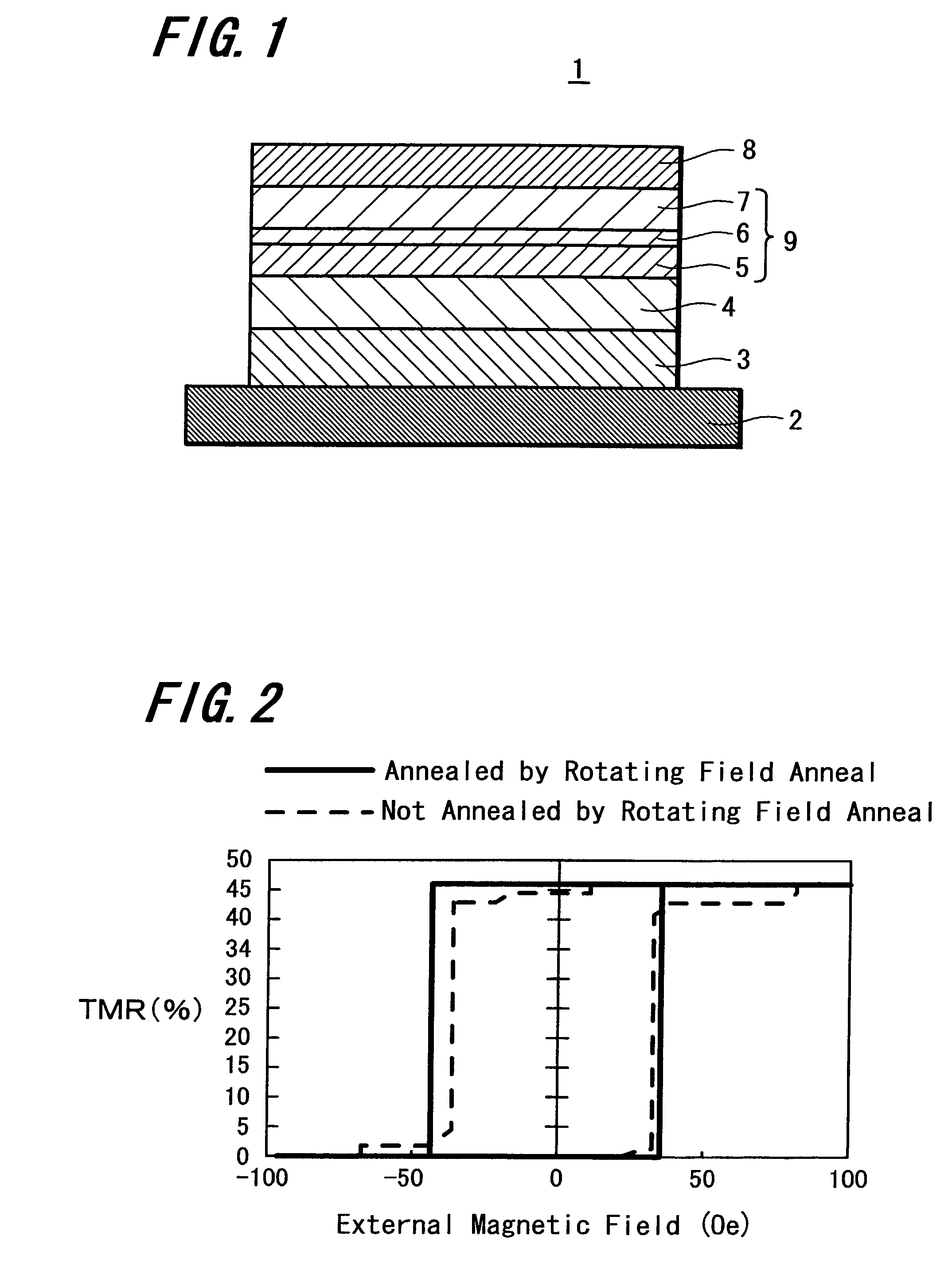

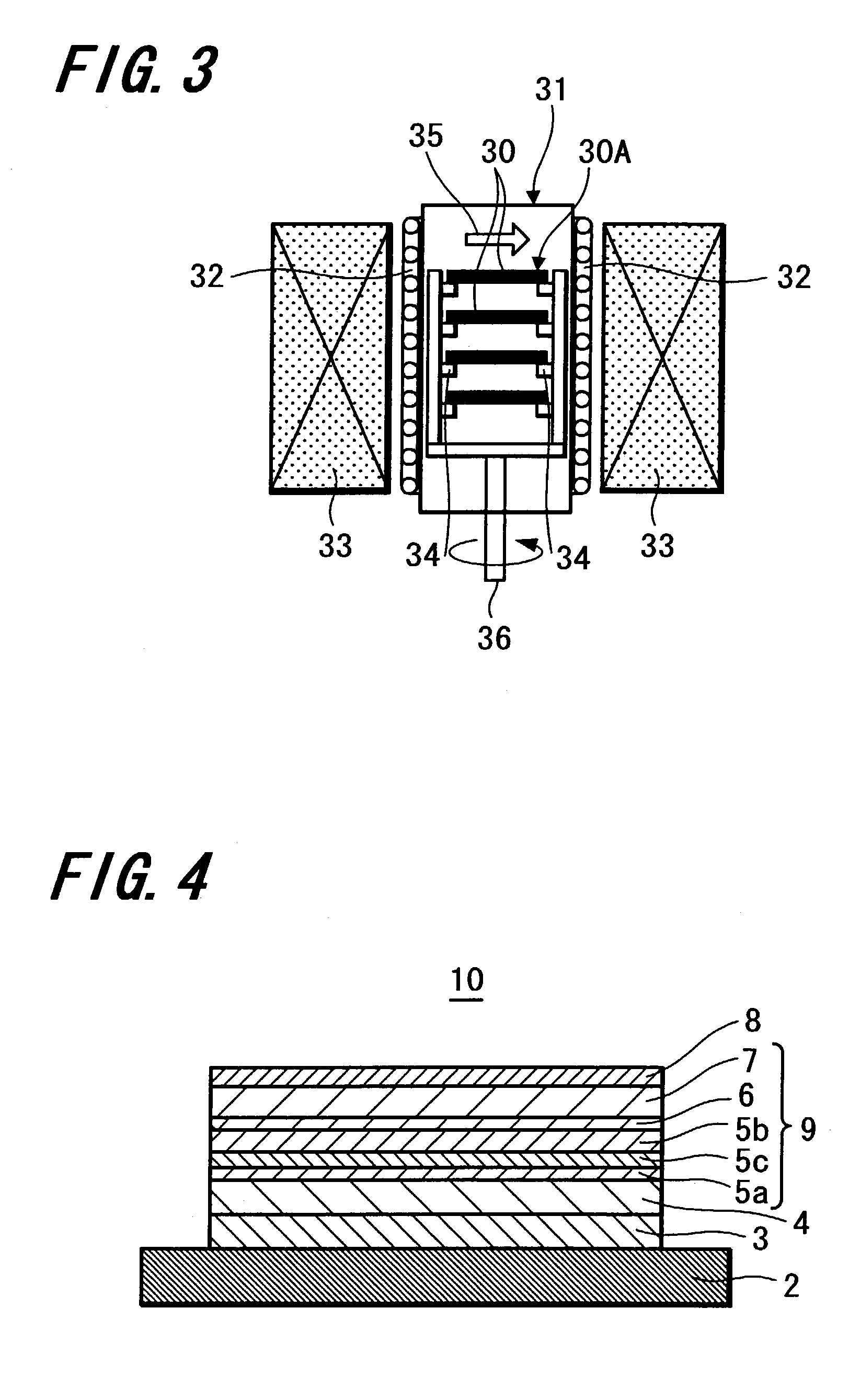

Magnetoresistive effect element, magnetic memory device and manufacturing method of magnetoresistive effect element and magnetic memory device

ActiveUS7026671B2Improve rectangle propertyImprove coercive forceNanostructure applicationNanomagnetismMagnetic anisotropyMagnetic memory

A magnetoresistive effect element (1) has an arrangement in which a pair of ferromagnetic material layers (magnetization fixed layer (5) and magnetization free layer (7)) is opposed to each other through an intermediate layer (6) to obtain a magnetoresistive change by causing a current to flow in the direction perpendicular to the layer surface and in which the ferromagnetic material layers are annealed by anneal including rotating field anneal and the following static field anneal. A magnetic memory device comprises this magnetoresistive effect element (1) and bit lines and word lines sandwiching the magnetoresistive effect element (1) in the thickness direction. When the magnetoresistive effect element (1) and the magnetic memory device are manufactured, the ferromagnetic material layers (5, 7) are annealed by rotating field anneal and the following static field anneal. There are provided the magnetoresistive effect element that can obtain excellent magnetic characteristics by controlling magnetic anisotropies of the ferromagnetic material layers, the magnetic memory device including this magnetoresistive effect element and which may have excellent write characteristics, and methods for manufacturing these magnetoresistive effect element and magnetic memory device.

Owner:DEXERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com