Patents

Literature

391results about How to "Efficient deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

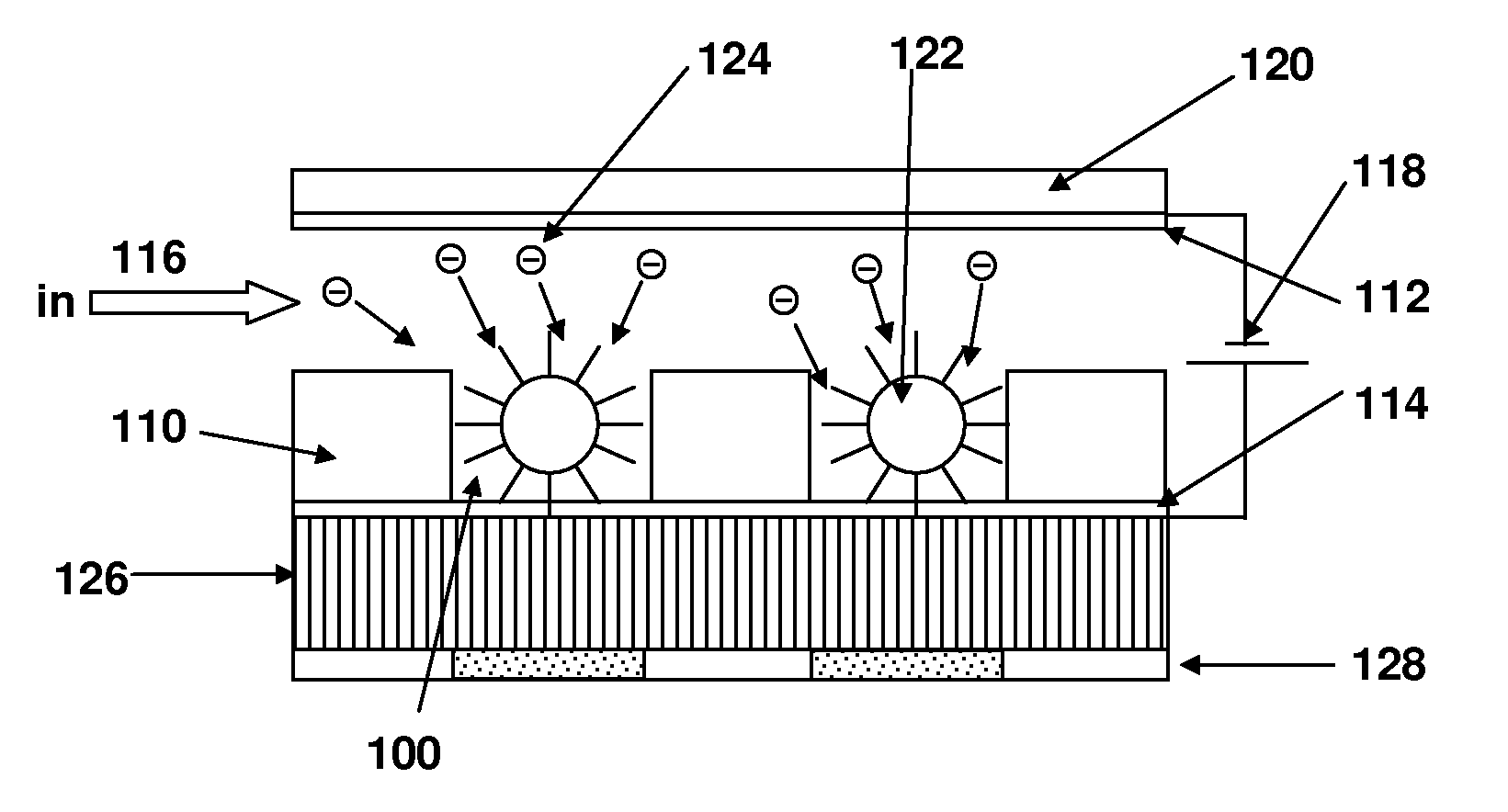

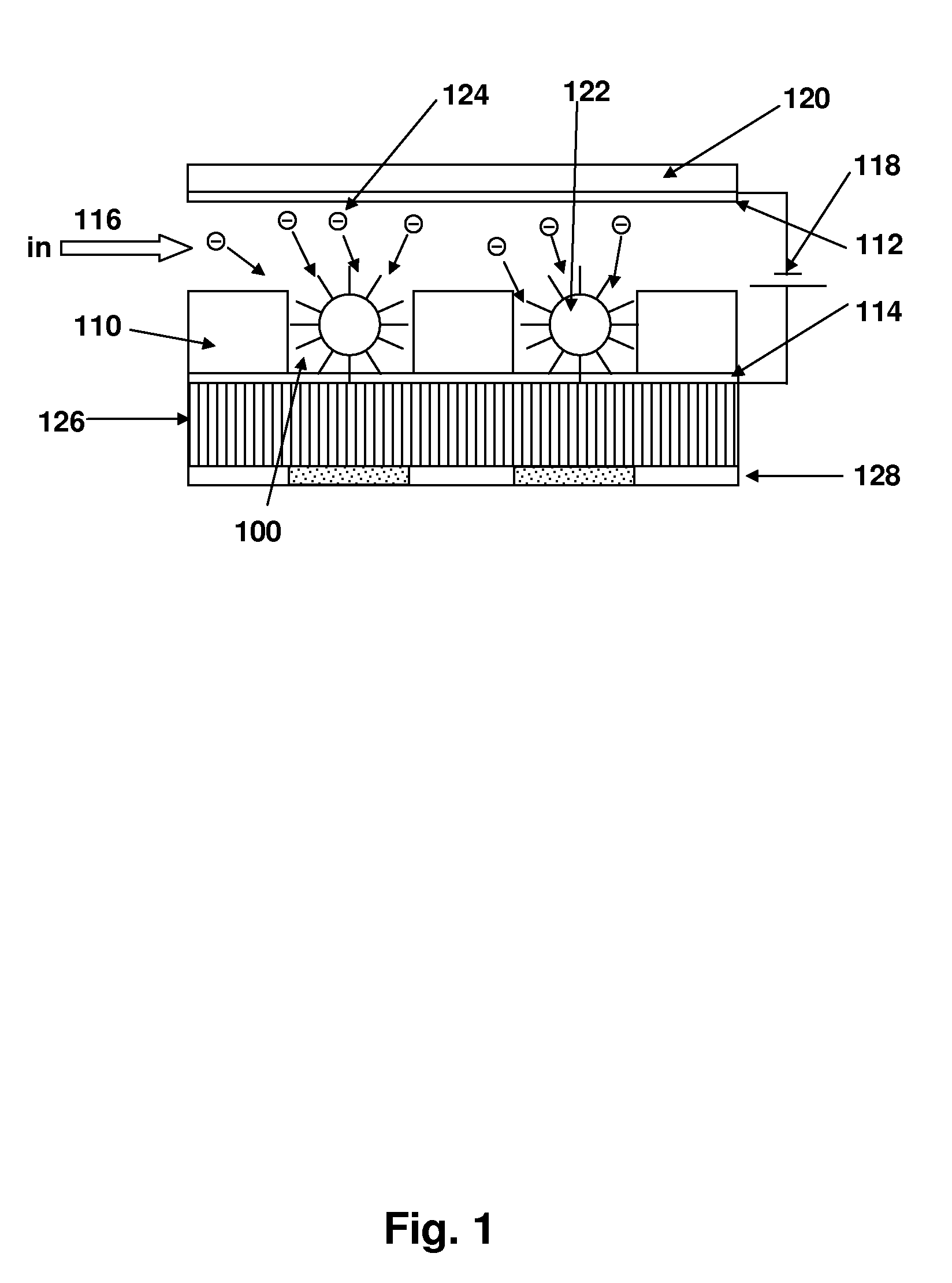

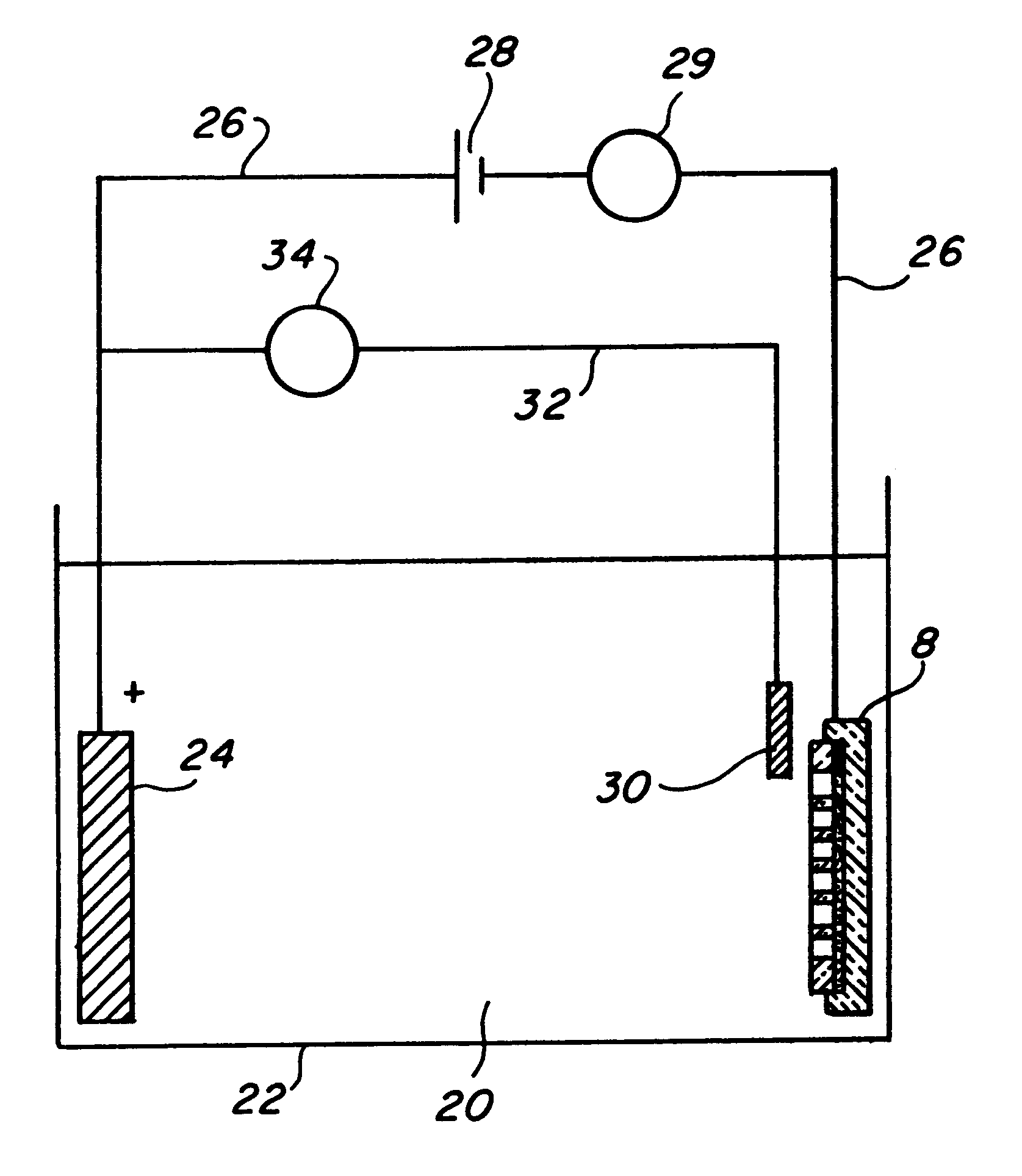

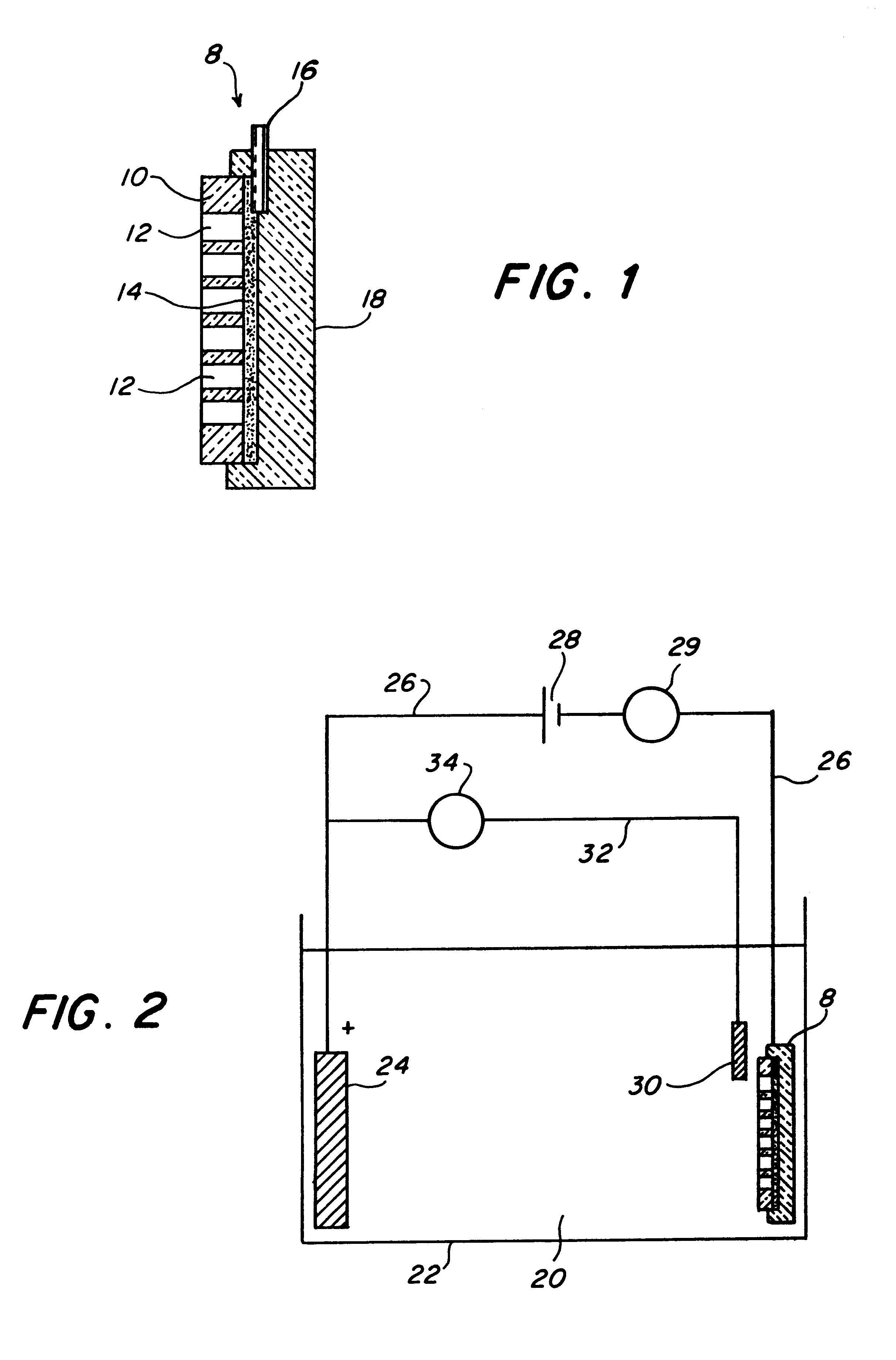

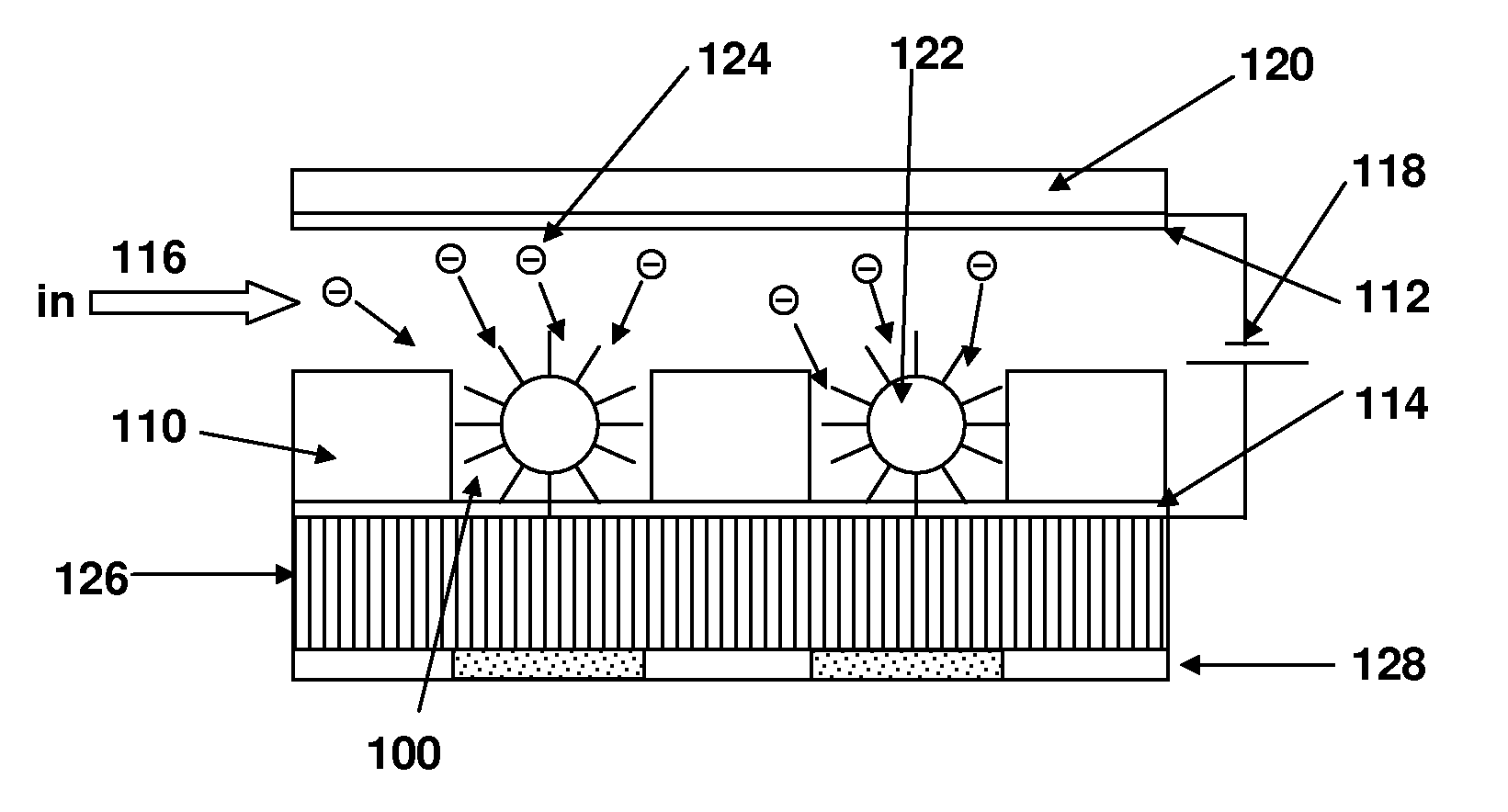

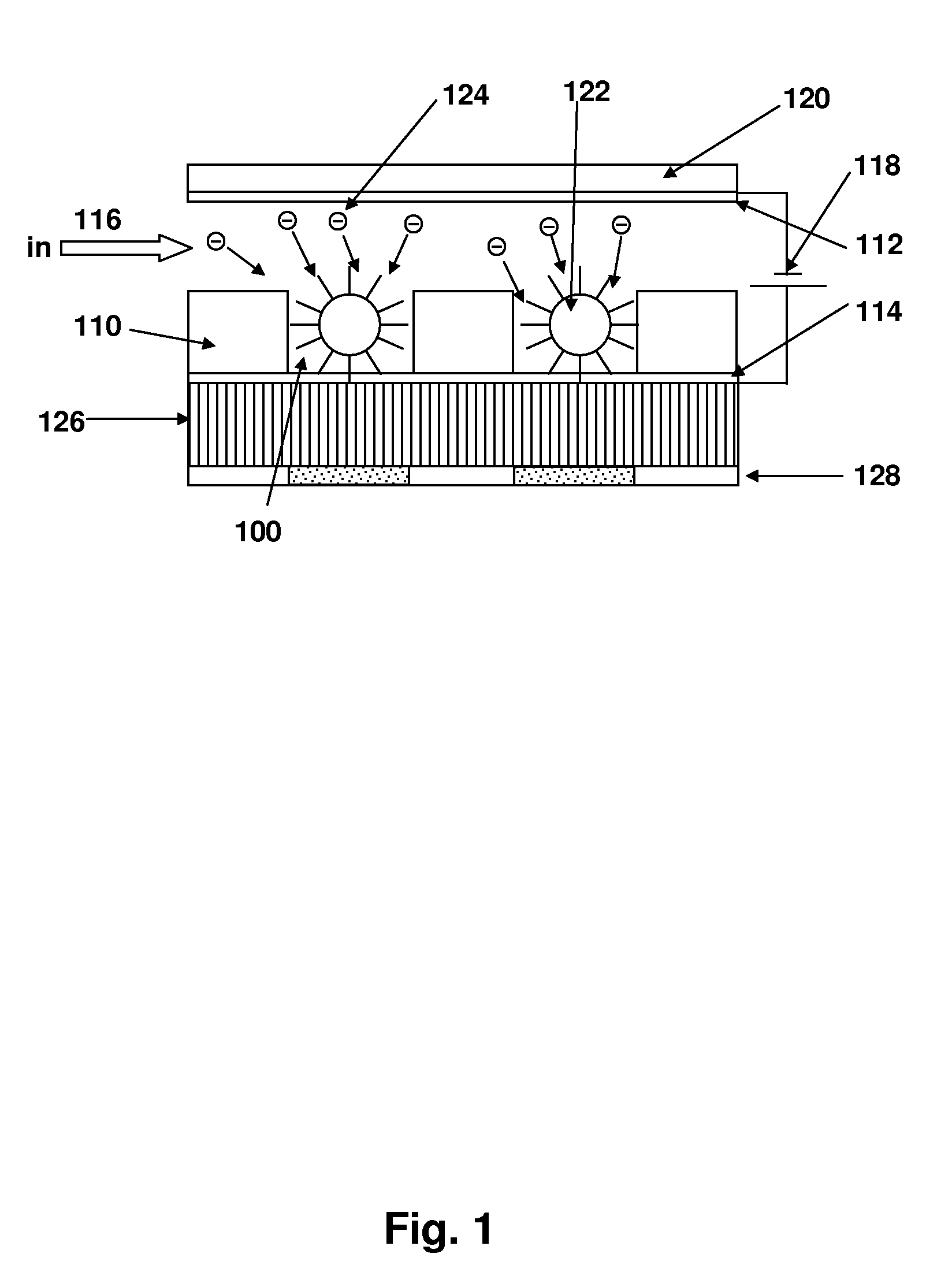

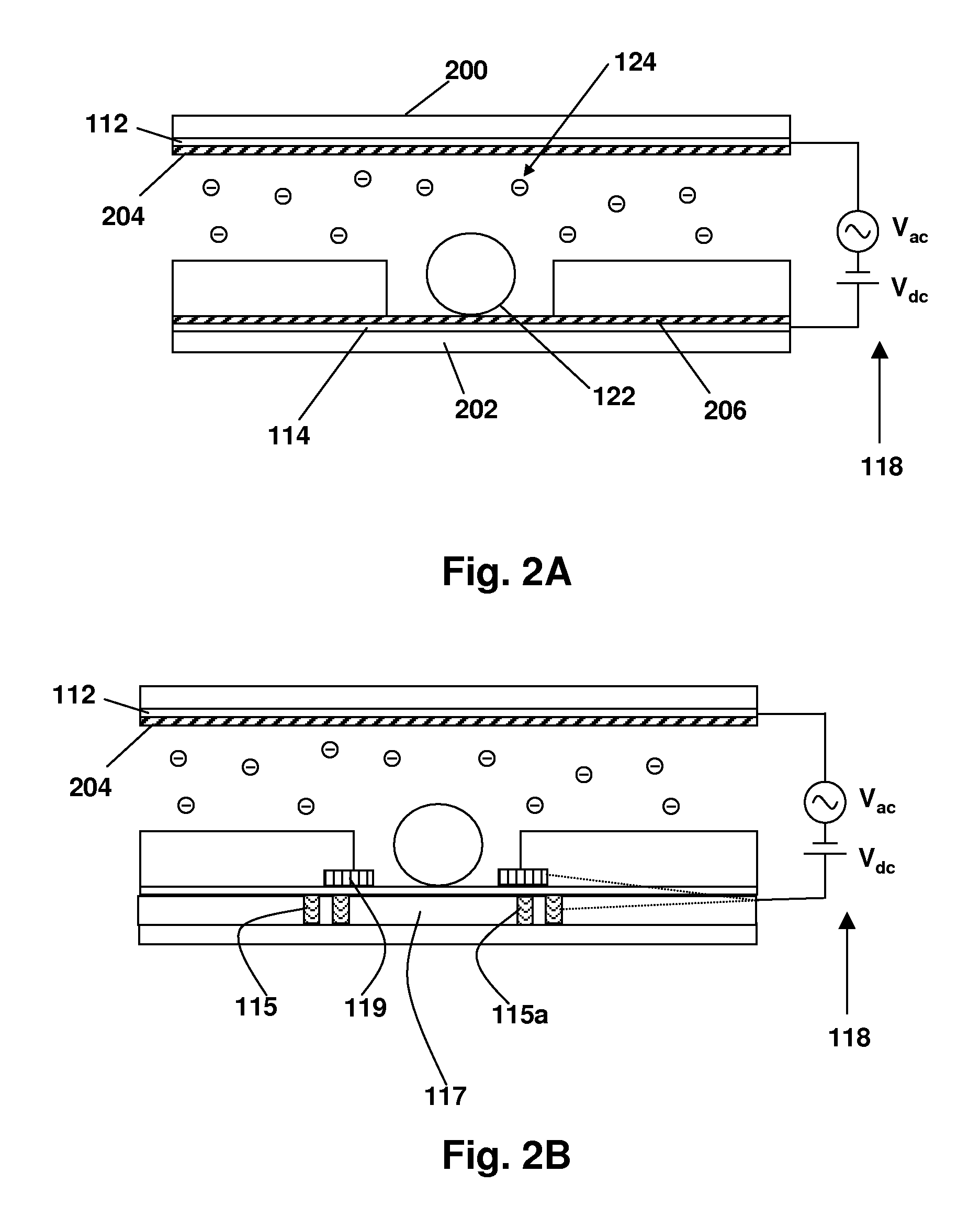

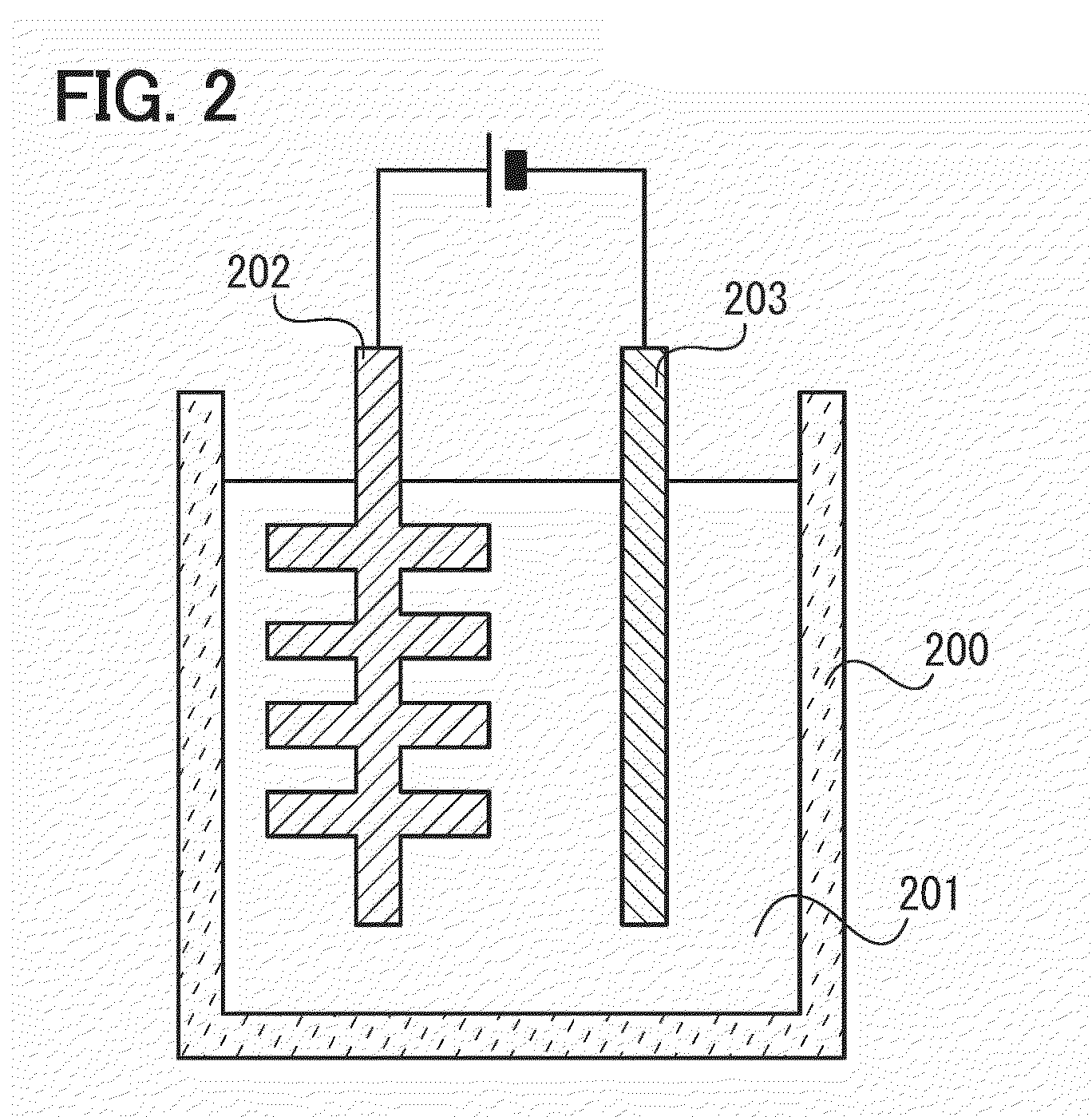

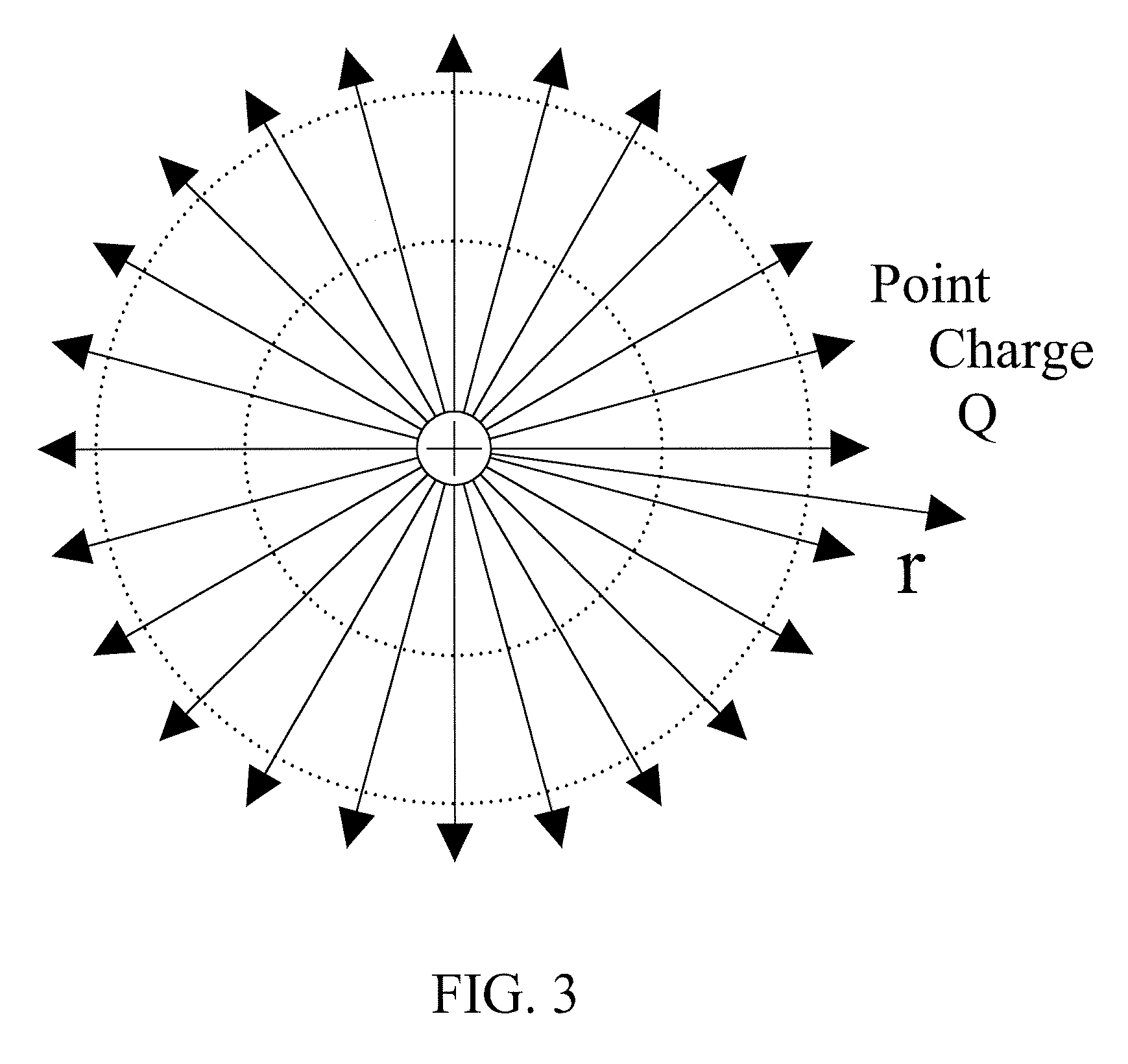

Method and Apparatus Using Electric Field for Improved Biological Assays

ActiveUS20090032401A1Avoid corrosionIncrease electric fieldElectrostatic separatorsSludge treatmentPresent methodEngineering

Disclosed are a method and apparatus that use an electric field for improved biological assays. The electric field is applied across a device having wells, which receive reactants, which carry a charge. The device thus uses a controllable voltage source between the first and second electrodes, which is controllable to provide a positive charge and a negative charge to a given electrode. By controlled use of the electric field charged species in a fluid in a fluid channel are directed into or out of the well by an electric field between the electrodes. The present method involves the transport of fluids, as in a microfluidic device, and the electric field-induced movement of reactive species according to various assay procedures, such as DNA sequencing, synthesis or the like.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Device

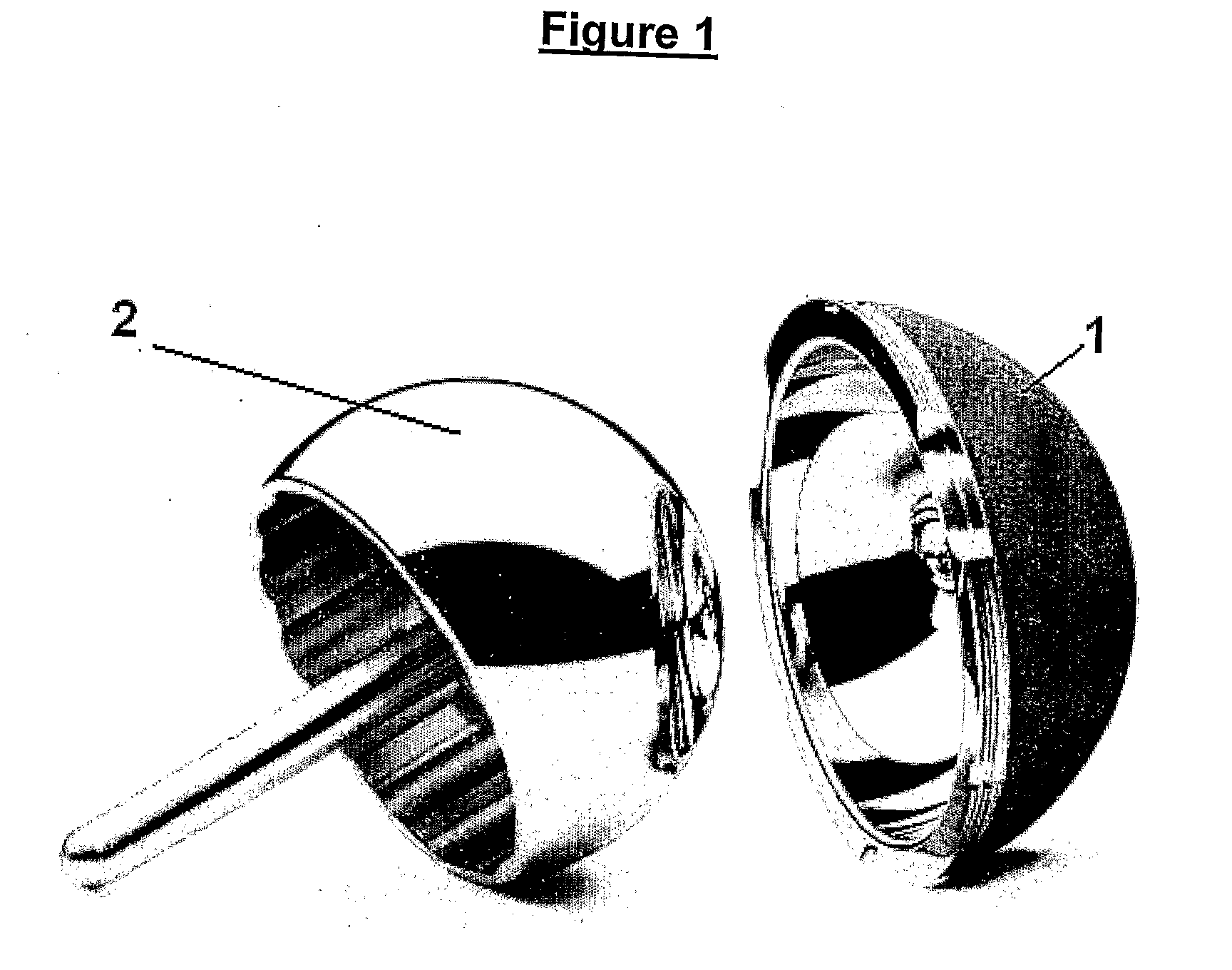

InactiveUS20100094430A1High porositySusceptible to corrosive attackBone implantPretreated surfacesBone replacementMaterials science

An implant for bone replacement and attachment in an animal's body including, a structural portion having an outer porous surface, a ceramic material applied to the porous surface of the structural portion, characterised in that the thickness of the ceramic material as applied utilizing pulsed pressure MOCVD is such that at least some of the pores of the porous surface are not completely closed.

Owner:CANTERPRISE LTD

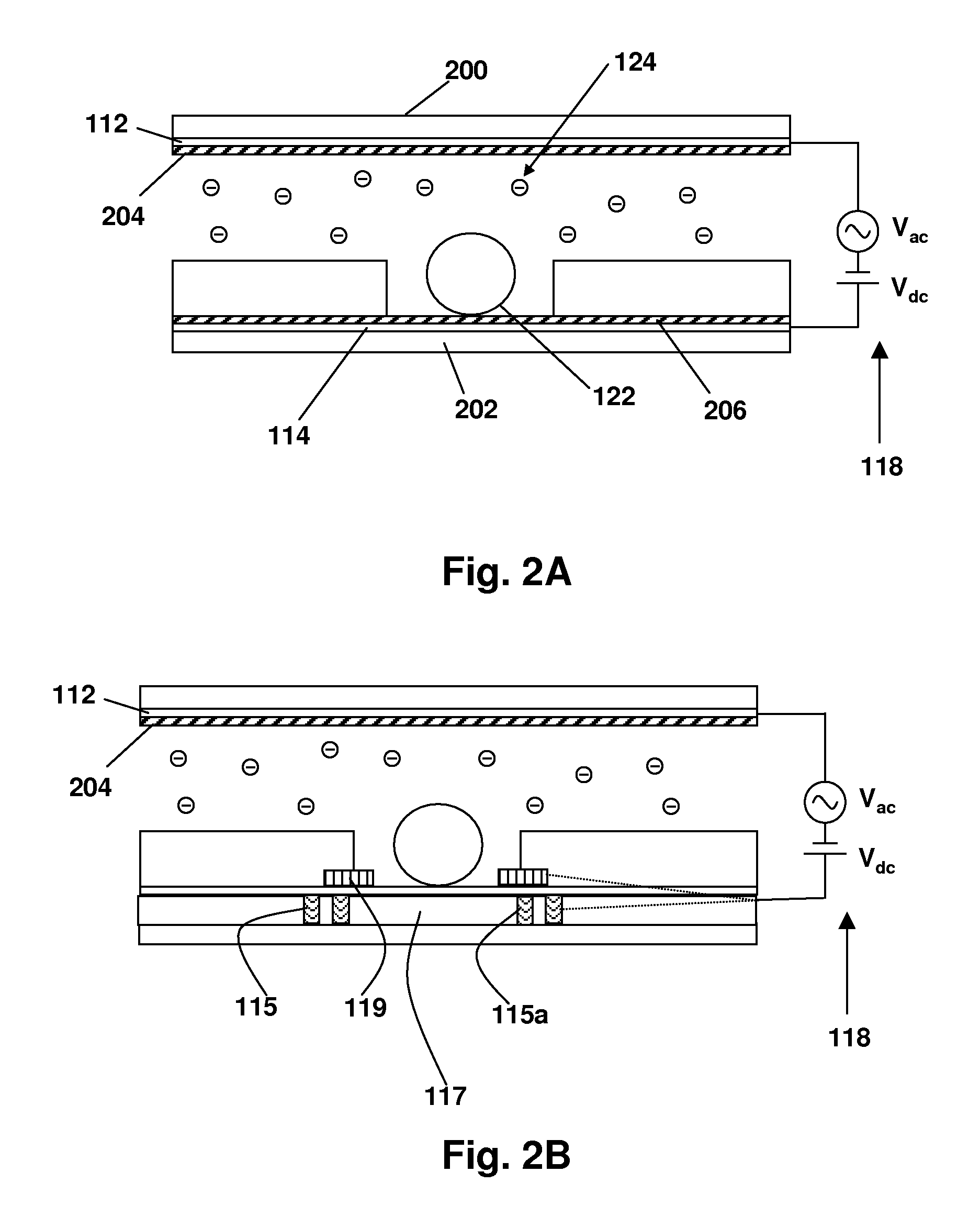

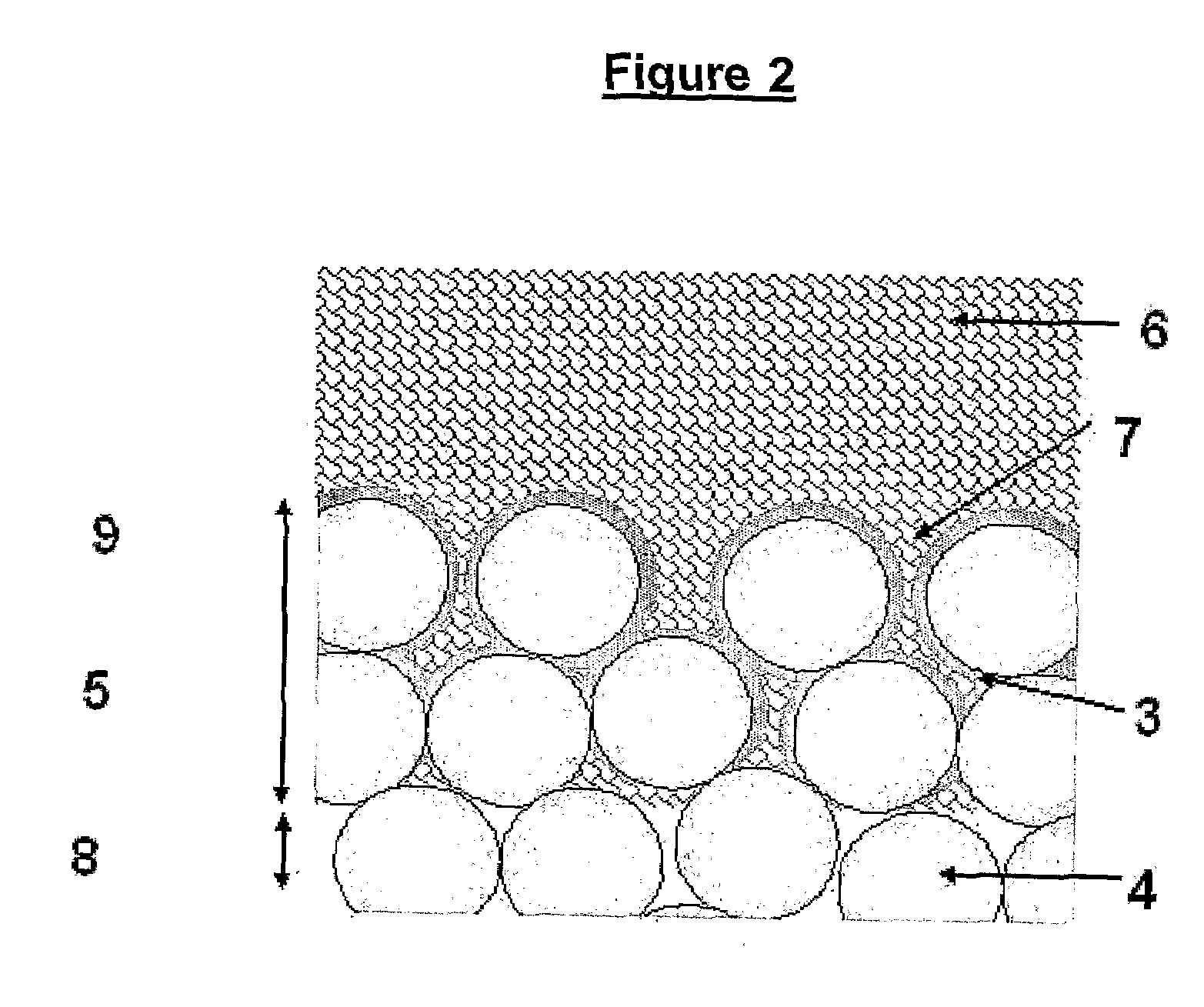

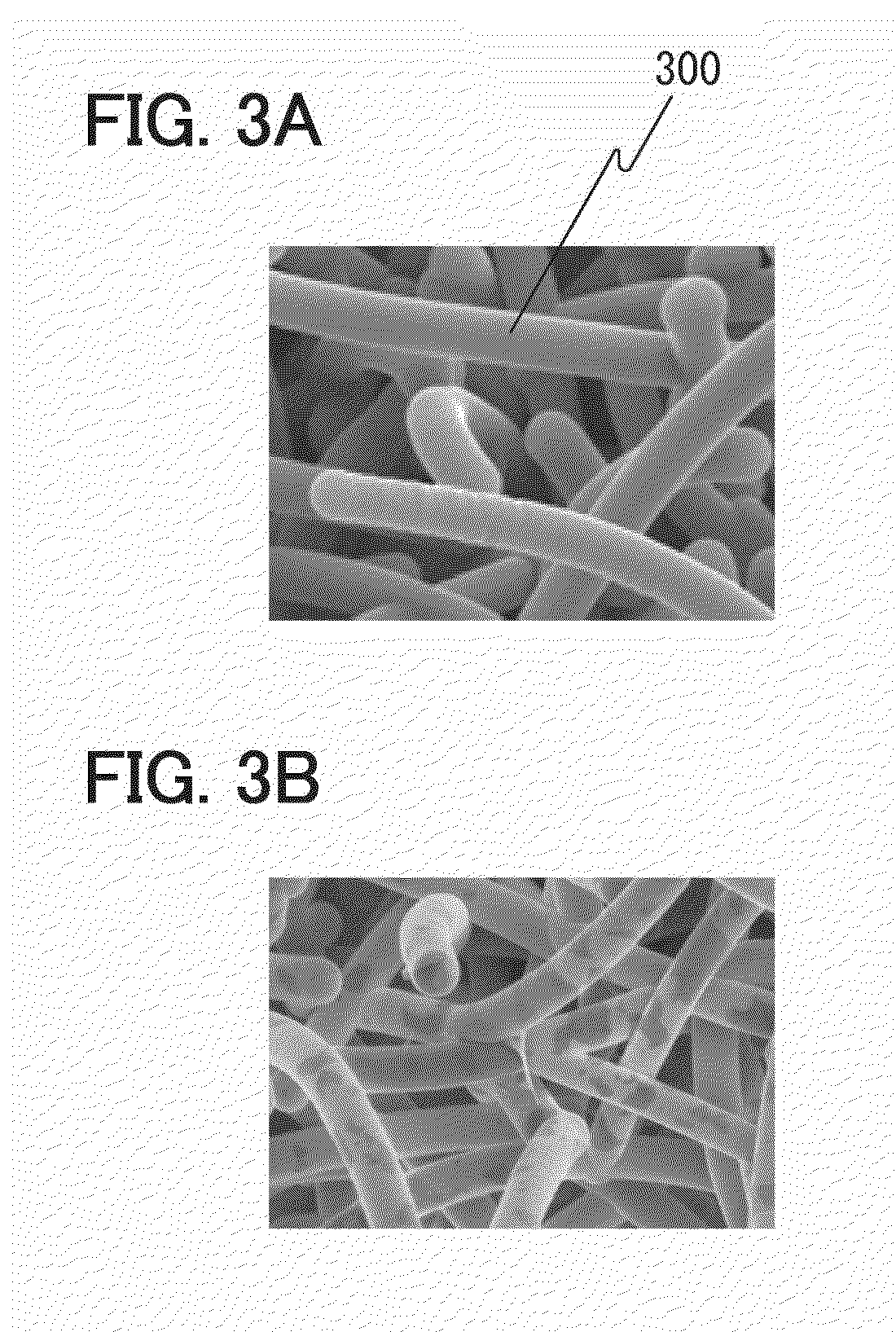

Nanopost arrays and process for making same

InactiveUS6185961B1Efficient depositionEfficiently magnetic materialNanostructure applicationNanomagnetismNanopillarEngineering

A nanopost glass array contains up to 1012 / cm2 of magnetizable nanoposts having diameter of 10-1000 nm that are straight and parallel to each other and are typically of a uniform diameter relative to each other and along the post length. The array is made using a reference electrode and a nanochannel glass template structure connected to each other electrically through an electrical source and both disposed in a plating solution. A magnetizable material is electroplated from the plating solution into the channels of the template structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method of forming organic polymer thin film and an apparatus for forming the organic polymer thin film

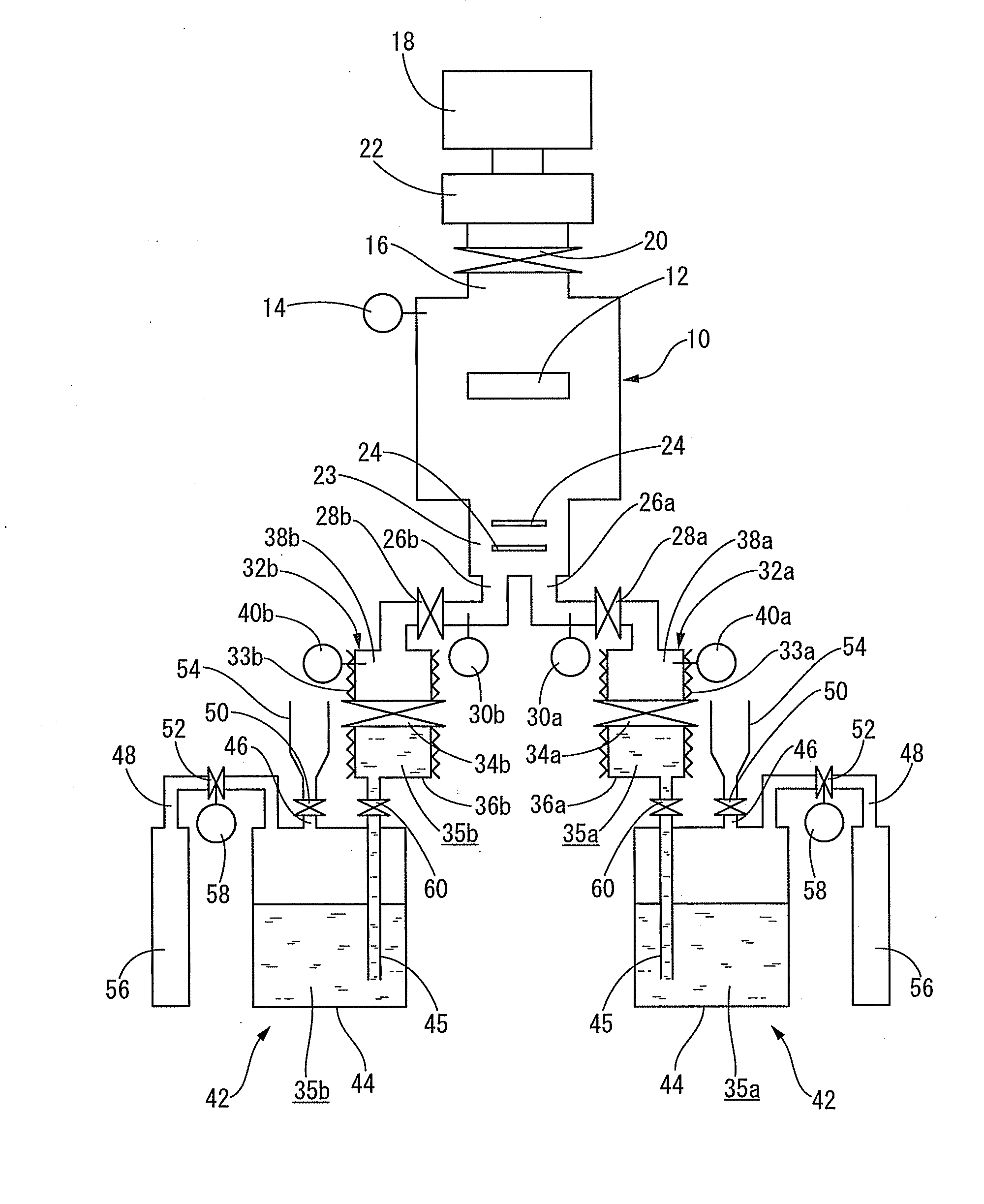

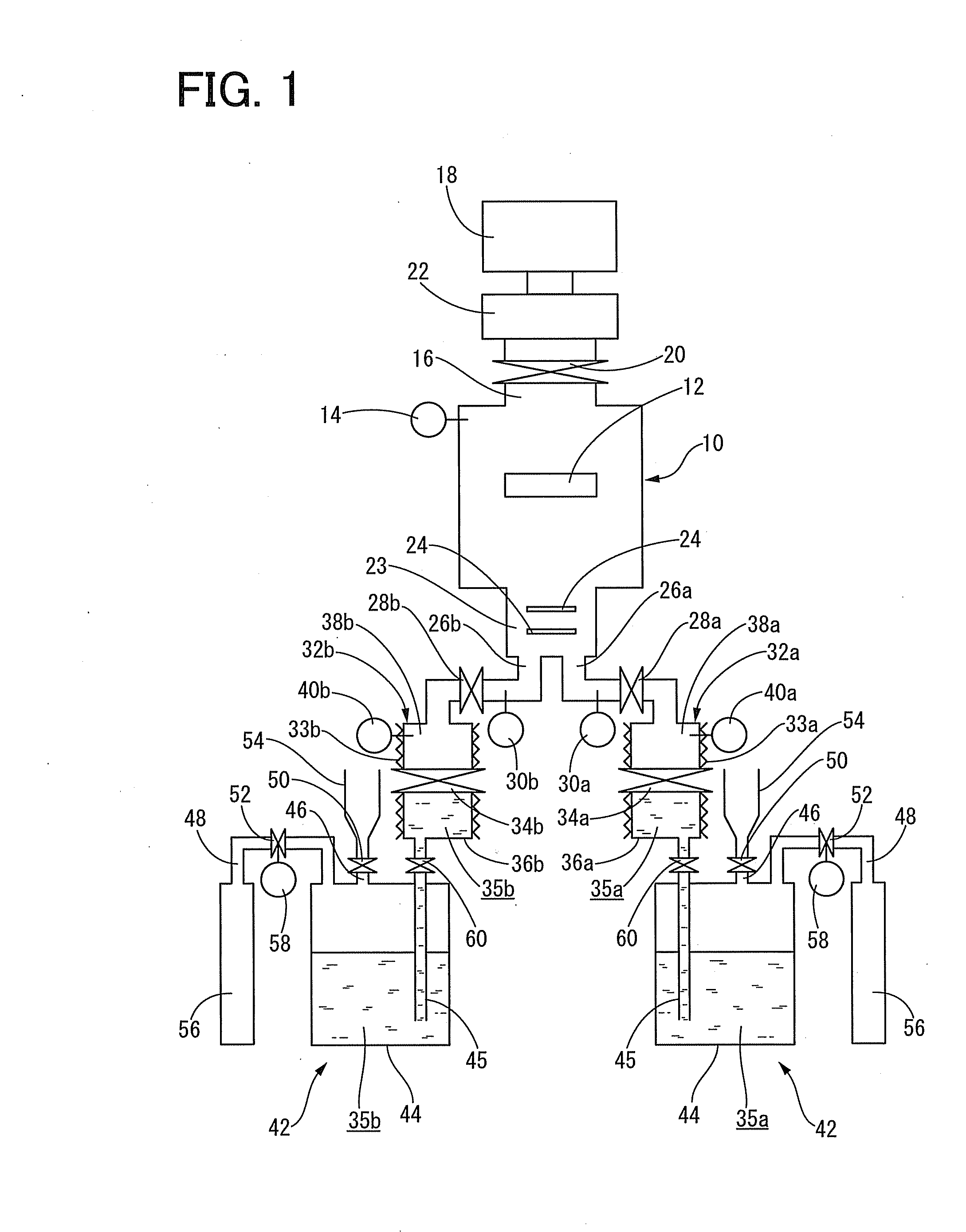

ActiveUS20110091650A1Small pressureHigh film formation efficiencyVacuum evaporation coatingSputtering coatingPolymer thin filmsOptoelectronics

A technique for forming an organic polymer thin film on a surface of a substrate with high film formation efficiency and excellent reproducibility and stability is provided. When a vacuum deposition polymerization for forming an organic polymer thin film is performed on a surface of a substrate 12 repeatedly, in which a plurality of kinds of monomers evaporated in a plurality of evaporation source containers 32a, 32b in vacuum state are introduced into a deposition chamber 10 in a vacuum state and polymerized on a surface of the substrate 12 arranged in the deposition chamber 10, each of the monomers in a liquid form is present in the evaporation source containers 32a, 32b in a constant amount every time, at the beginning of the evaporation operation of monomers.

Owner:KOJIMA PRESS IND CO LTD +1

Apparatus for forming a film and an electroluminescence device

InactiveUS20050005848A1Improve utilization efficiencyExcellent uniformity and throughputElectroluminescent light sourcesSolid-state devicesManufacturing cost reductionEvaporation

A device having three evaporation sources and a unit for moving the respective evaporation sources in one chamber is used, whereby it becomes possible to increase efficiency of use of an evaporation material. Consequently, manufacturing cost can be reduced, and a uniform thickness can be obtained over an entire surface of a substrate even in the case in which a large area substrate is used.

Owner:SEMICON ENERGY LAB CO LTD

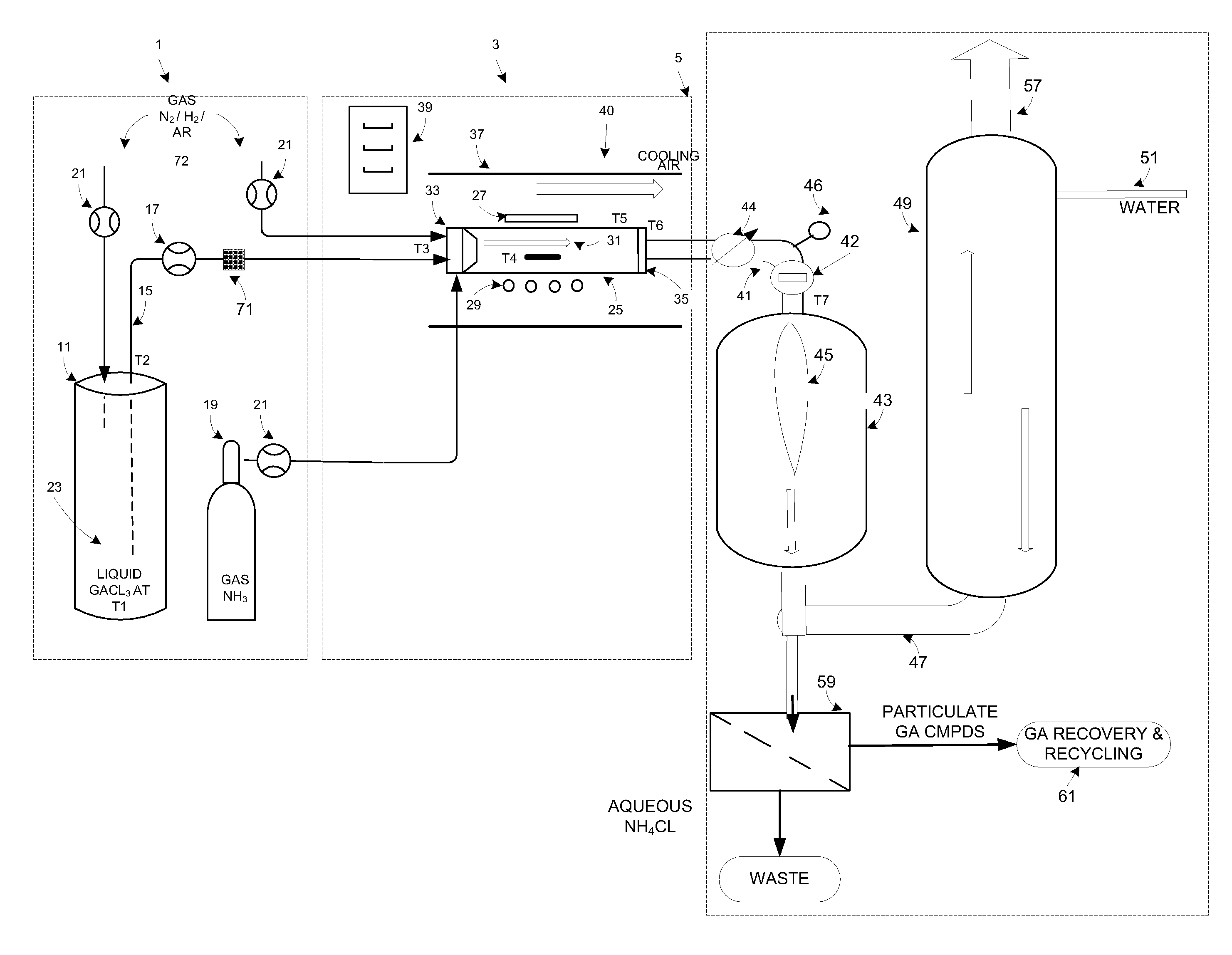

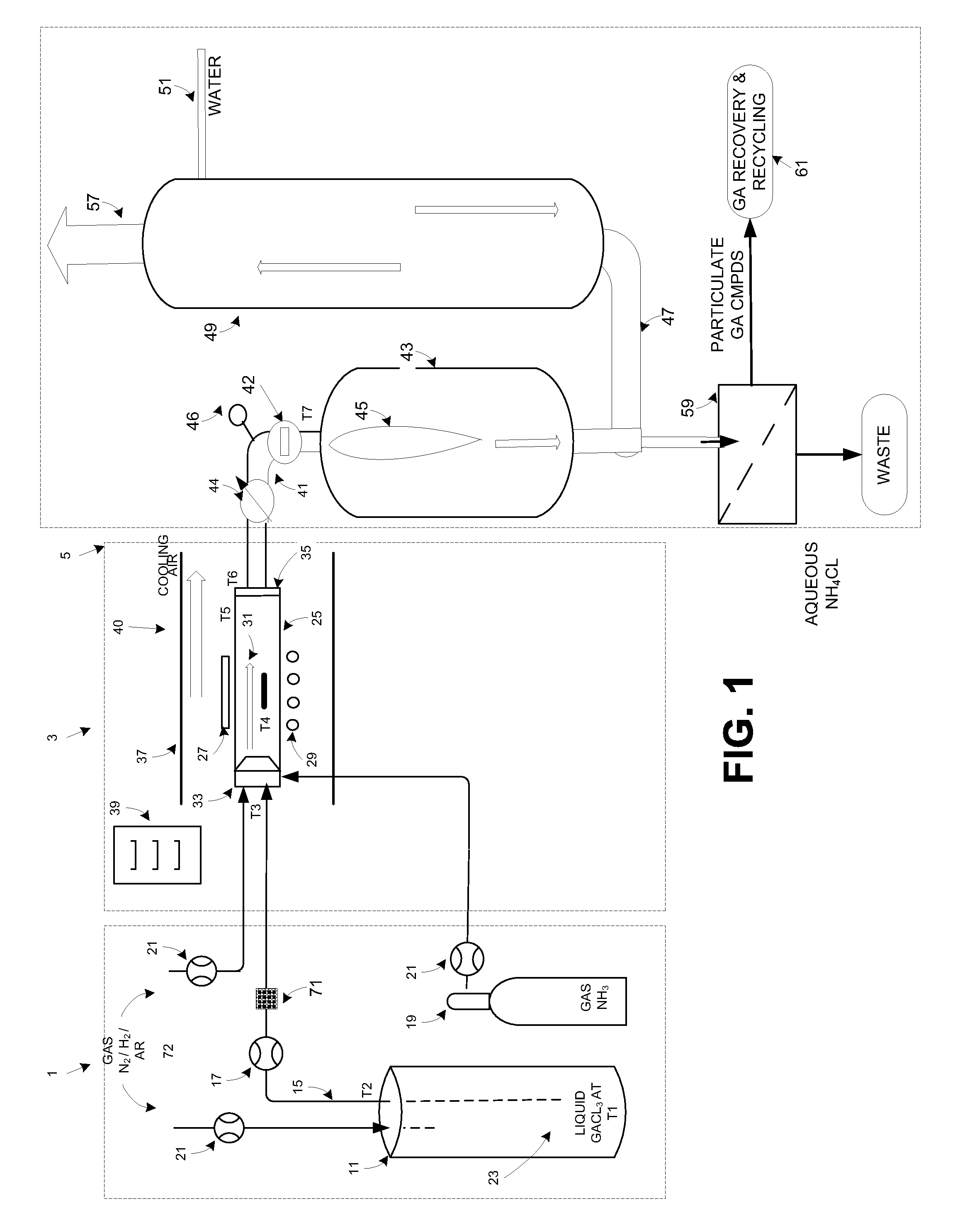

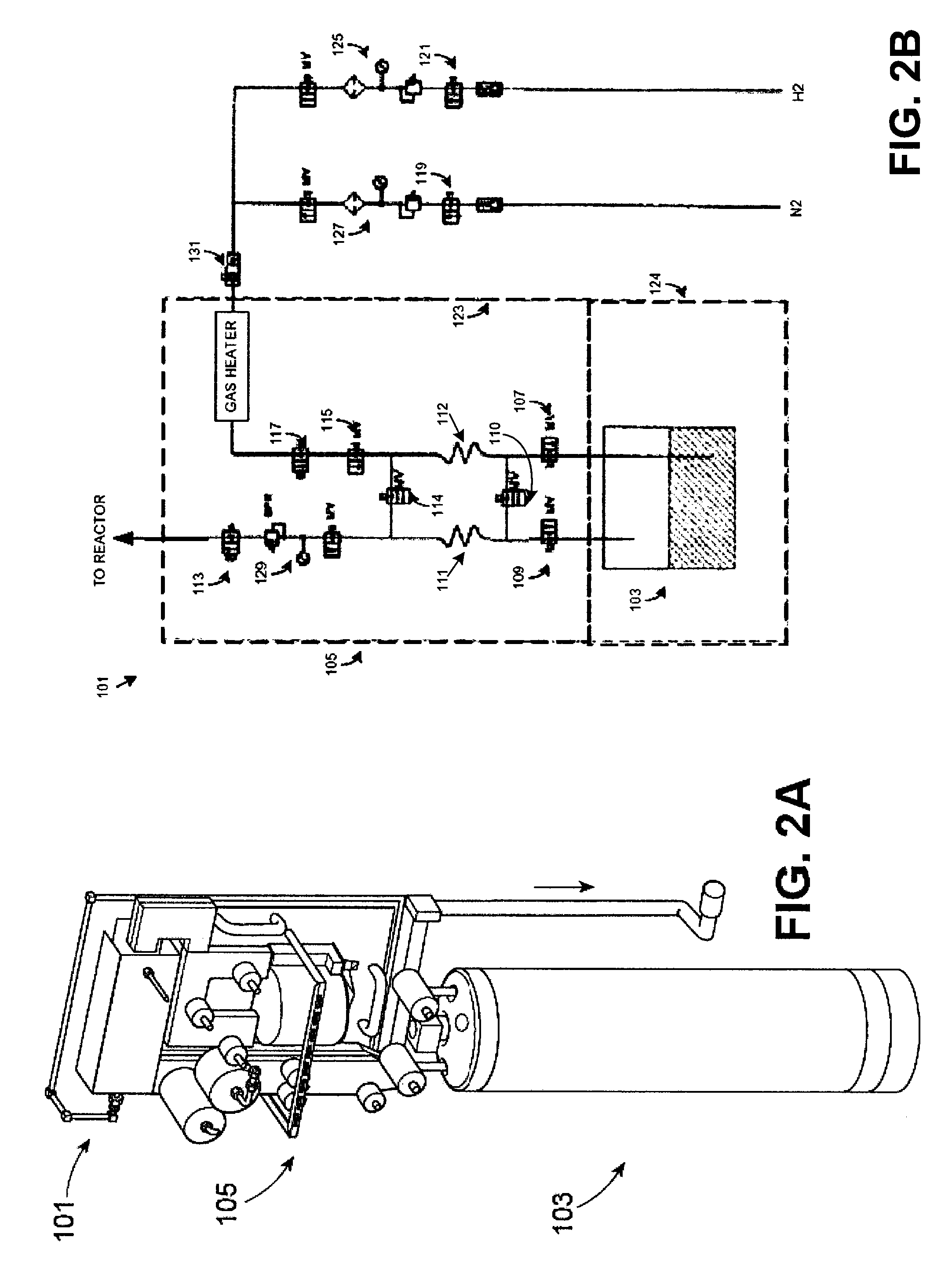

Methods for high volume manufacture of group iii-v semiconductor materials

InactiveUS20090223442A1Long operating timeEfficient depositionPolycrystalline material growthFrom chemically reactive gasesHigh volume manufacturingSemiconductor materials

The present invention is related to the field of semiconductor processing equipment and methods and provides, in particular, methods for the sustained, high-volume production of Group III-V compound semiconductor material suitable for fabrication of optic and electronic components, for use as substrates for epitaxial deposition, for wafers and so forth. In preferred embodiments, these methods are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the method includes reacting an amount of a gaseous Group III precursor as one reactant with an amount of a gaseous Group V component as another reactant in a reaction chamber under conditions sufficient to provide sustained high volume manufacture of the semiconductor material on one or more substrates, with the gaseous Group III precursor continuously provided at a mass flow of 50 g Group III element / hour for at least 48 hours.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Method and apparatus using electric field for improved biological assays

ActiveUS8277628B2Quality improvementEfficient removalElectrostatic separatorsSludge treatmentPresent methodEngineering

Disclosed are a method and apparatus that use an electric field for improved biological assays. The electric field is applied across a device having wells, which receive reactants, which carry a charge. The device thus uses a controllable voltage source between the first and second electrodes, which is controllable to provide a positive charge and a negative charge to a given electrode. By controlled use of the electric field charged species in a fluid in a fluid channel are directed into or out of the well by an electric field between the electrodes. The present method involves the transport of fluids, as in a microfluidic device, and the electric field-induced movement of reactive species according to various assay procedures, such as DNA sequencing, synthesis or the like.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

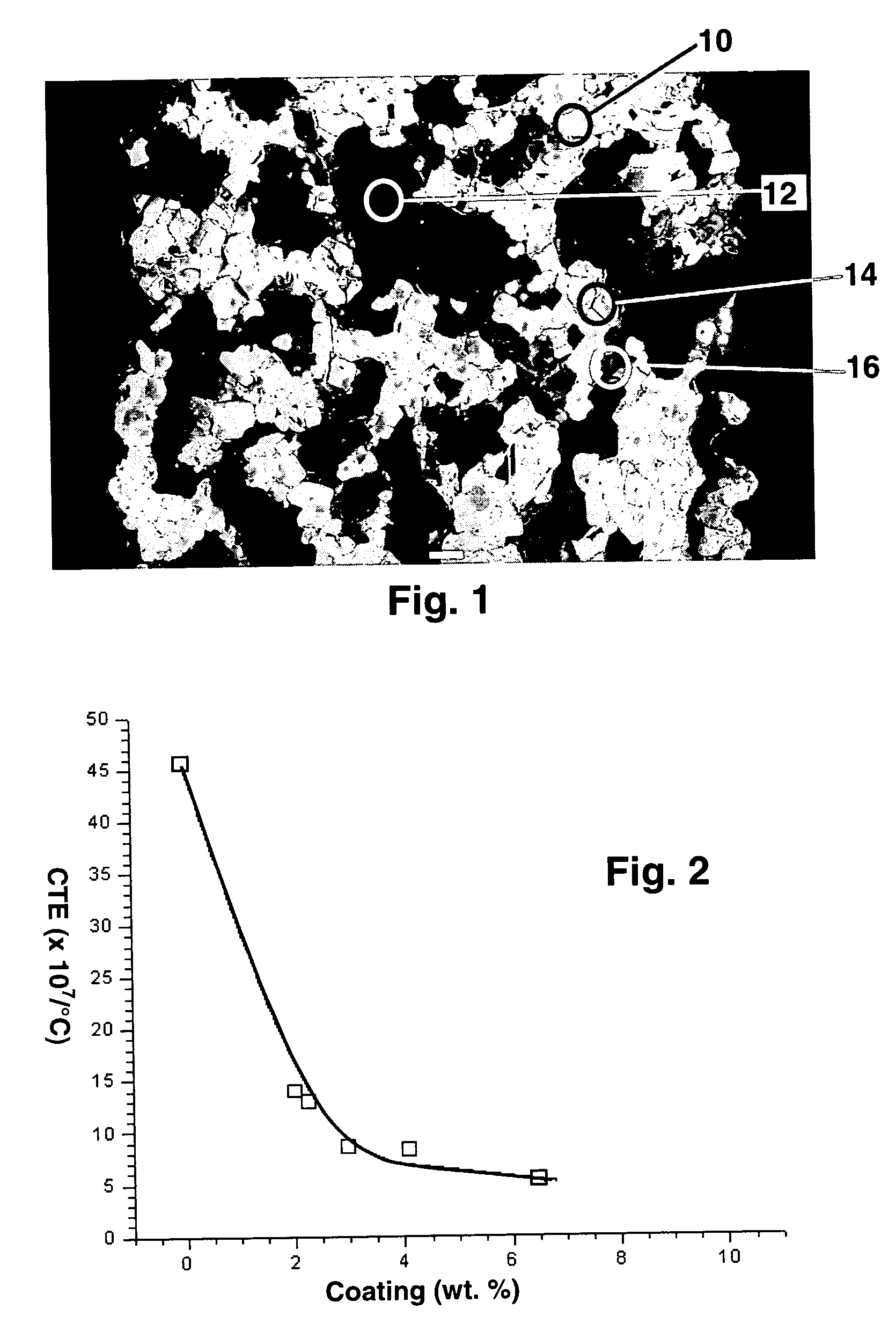

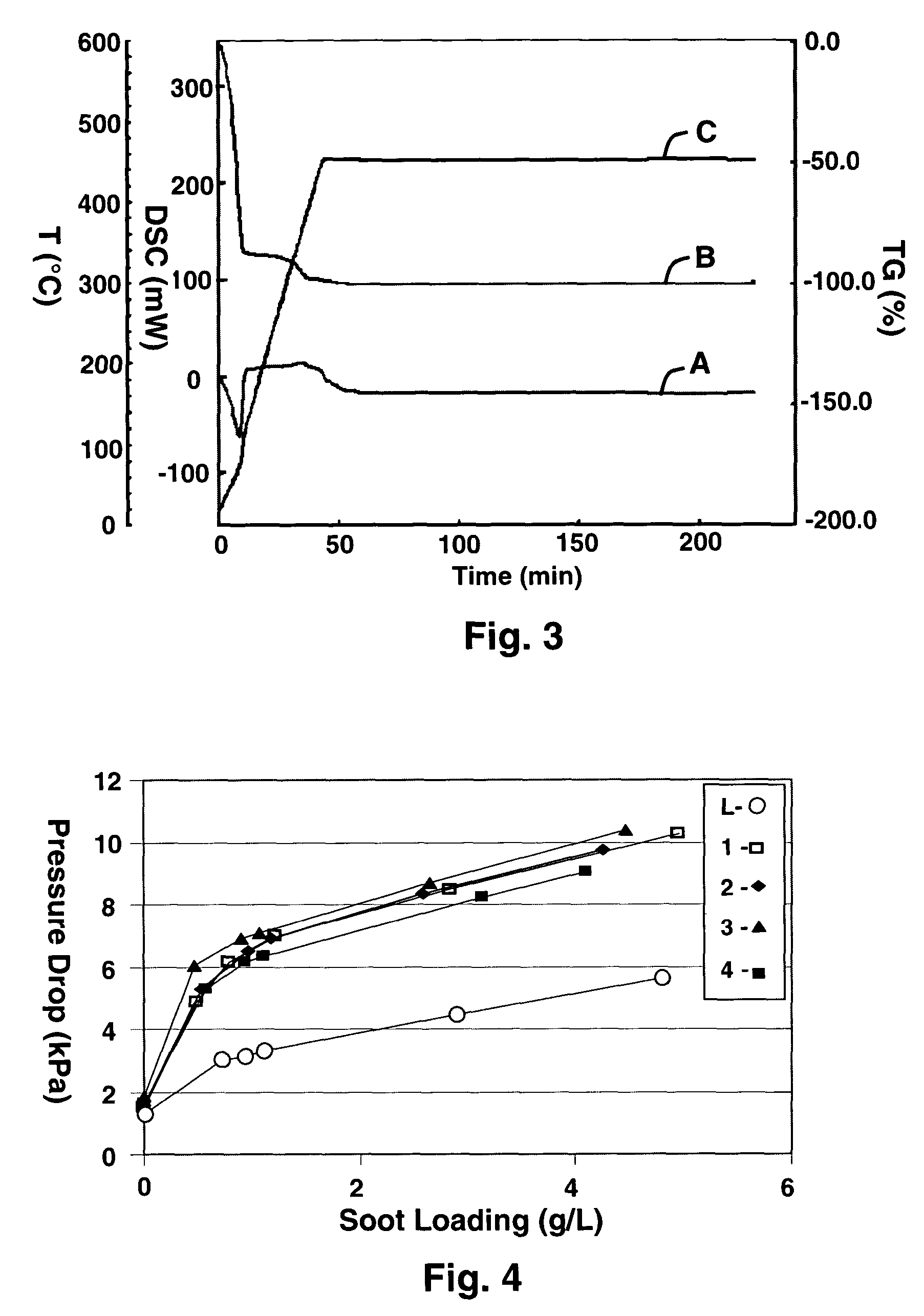

Porous ceramic filters with catalyst coatings

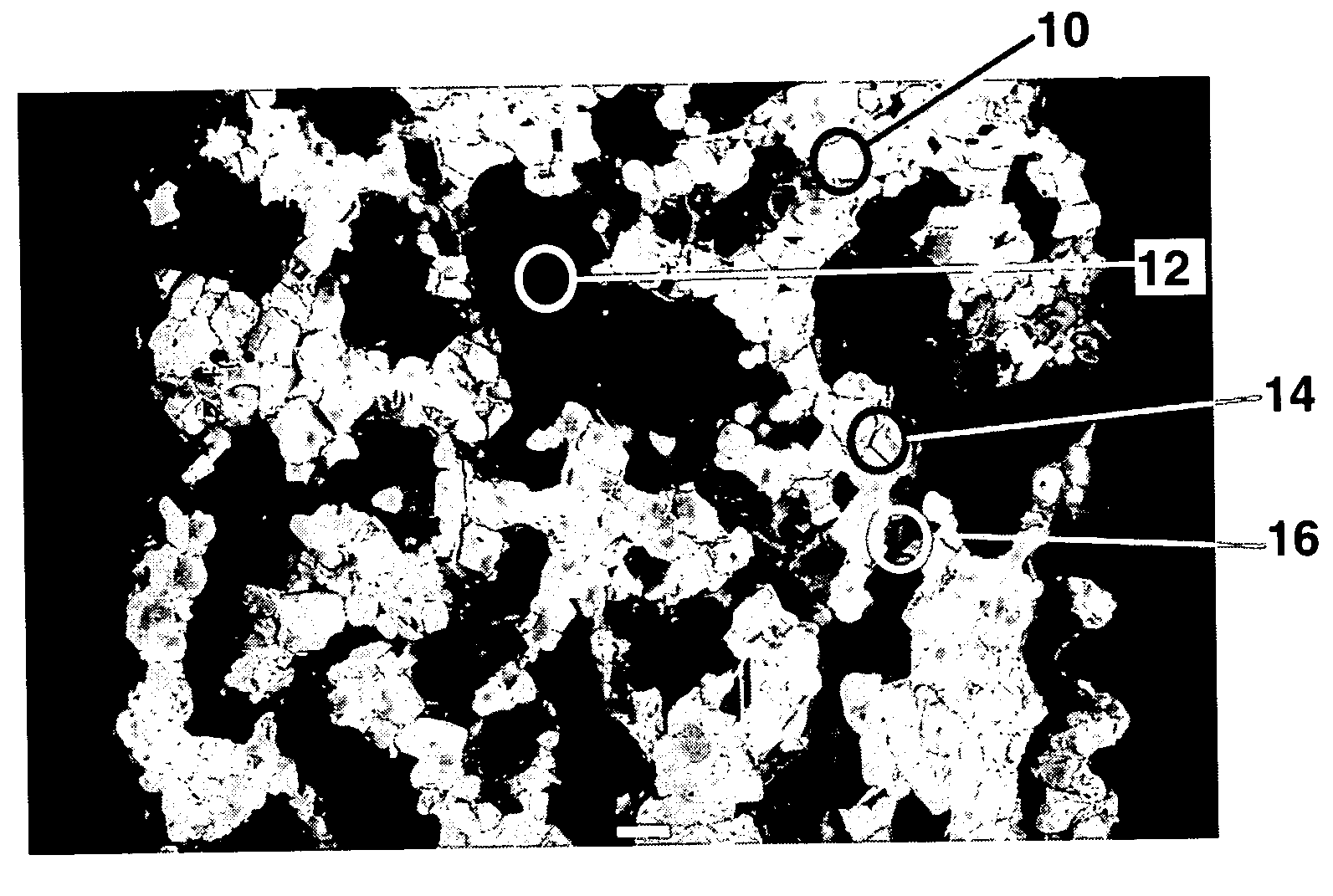

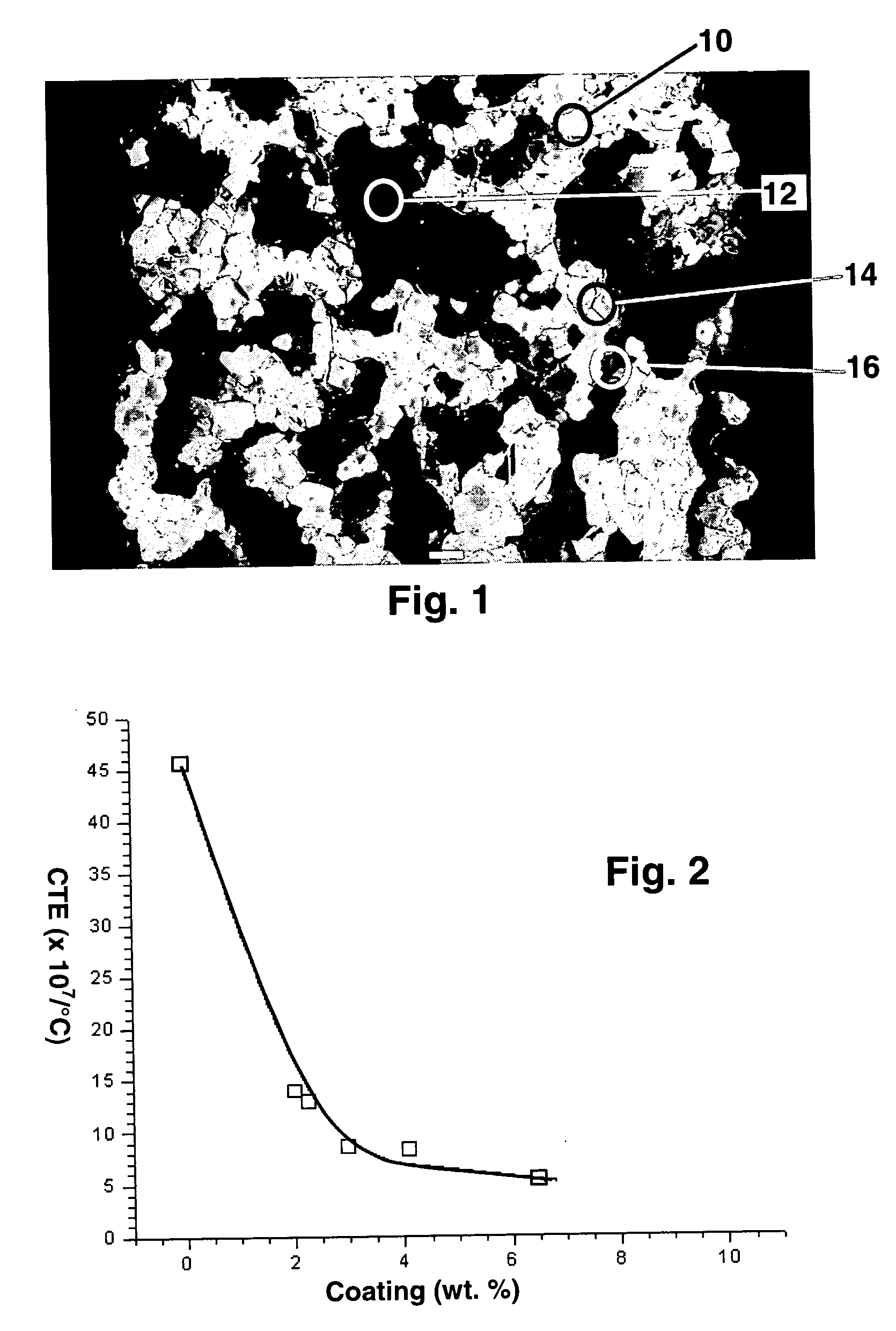

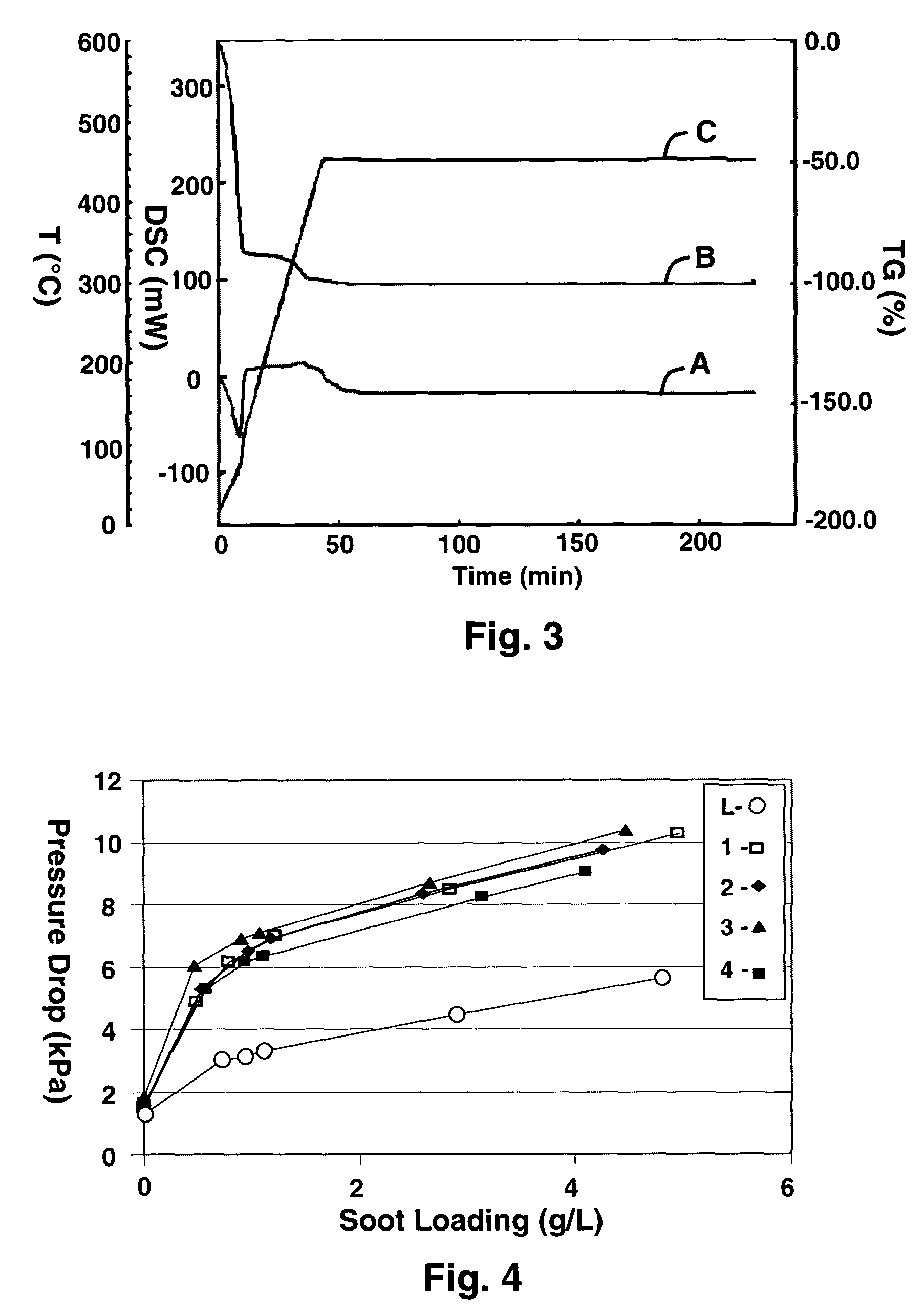

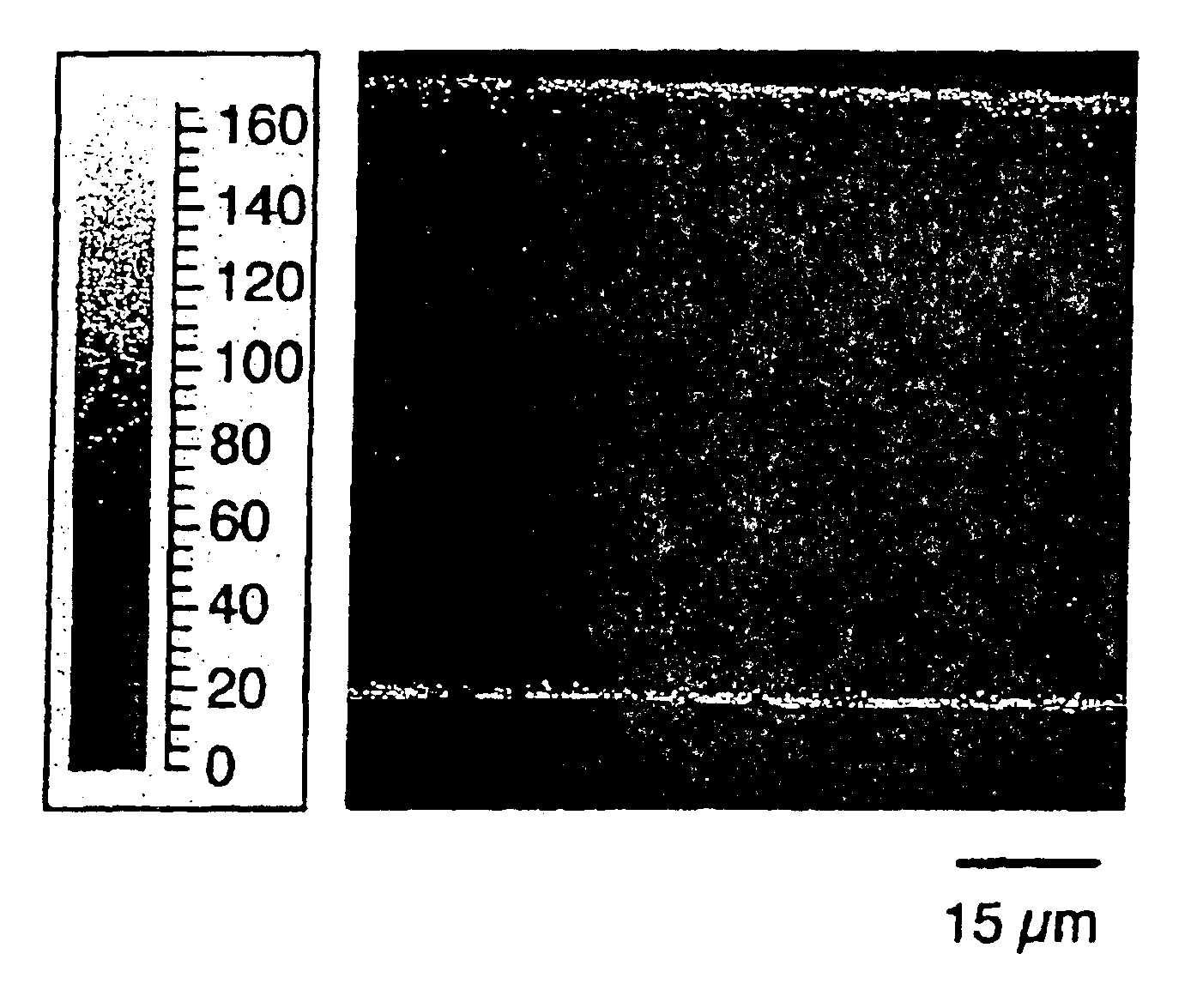

ActiveUS20050037147A1Easy to disassembleHigh porosityDead plant preservationArtificial flowers and garlandsNanoparticleBiological activation

Porous ceramic catalyst supports or filters to be provided with catalyst coatings via oxide washcoating processes are pre-coated with polymer barrier layers to prevent washcoat nanoparticle intrusion into the microcracked and / or microporous surfaces of the ceramics, the barrier coatings being formed of hydrocarbon polymers that are soluble or dispersible in polar media, capable of forming neutral or hydrophilic surfaces on porous ceramic supports, and completely vaporizable at moderate washcoat stabilization or catalyst activation temperatures.

Owner:CORNING INC

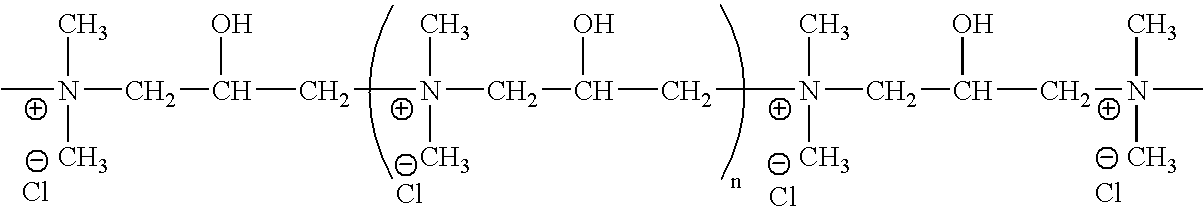

Detergent composition with enhanced depositing, conditioning and softness capabilities

InactiveUS6908889B2Efficient depositionSignificantly deposit therapeutic agentsCosmetic preparationsOrganic detergent compounding agentsShower gelWater soluble

Novel “two-in-one” detergent compositions comprised of at least one water soluble silicone agent, at least one cationic conditioning agent, and a detergent. These compositions are suitable for use in shampoos, baths, and shower gels. Also described is a novel delivery system for depositing benefit agents into and onto the skin, nails, and / or hair comprised of at least one water soluble silicone and at least one cationic conditioning agent.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

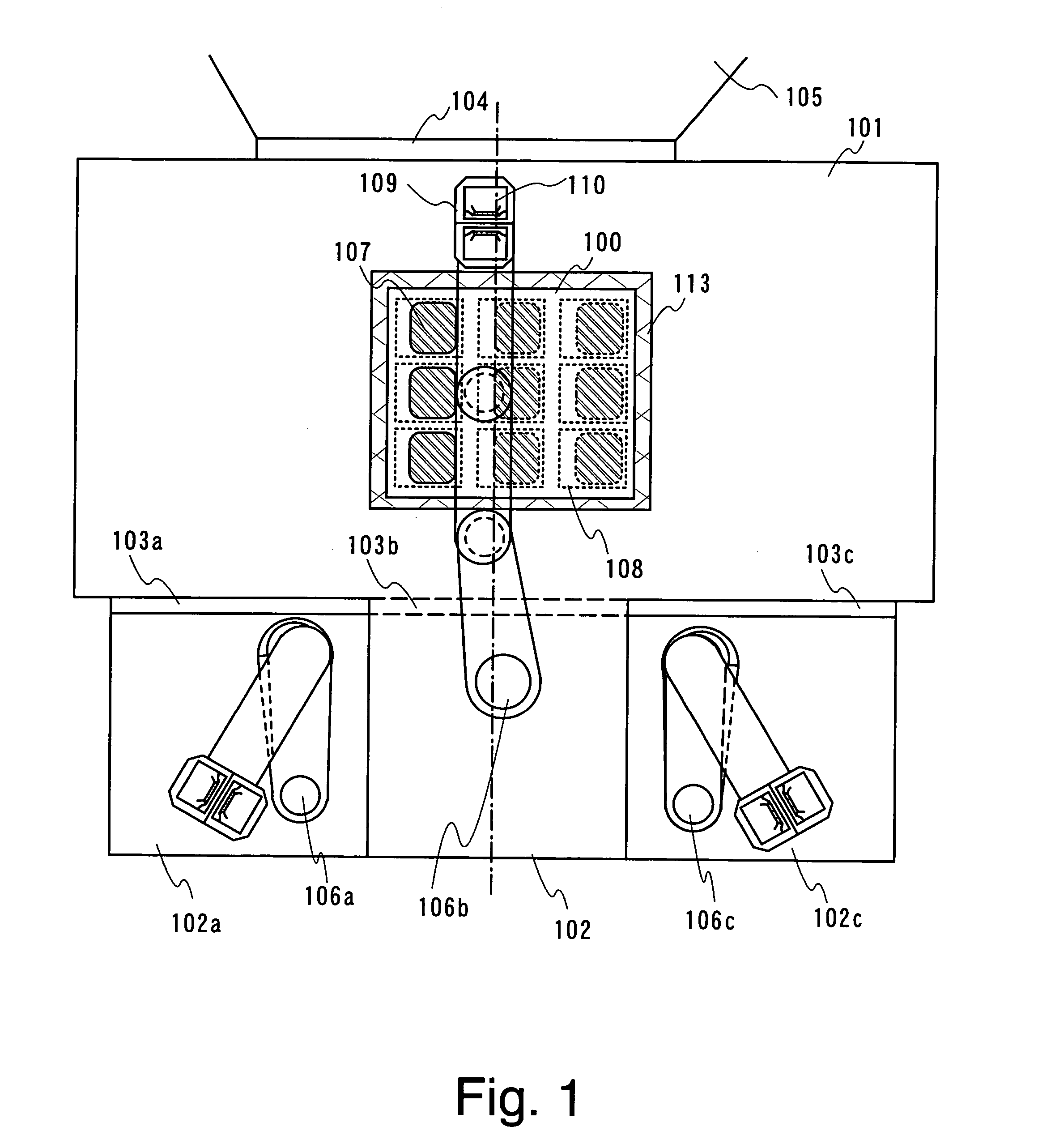

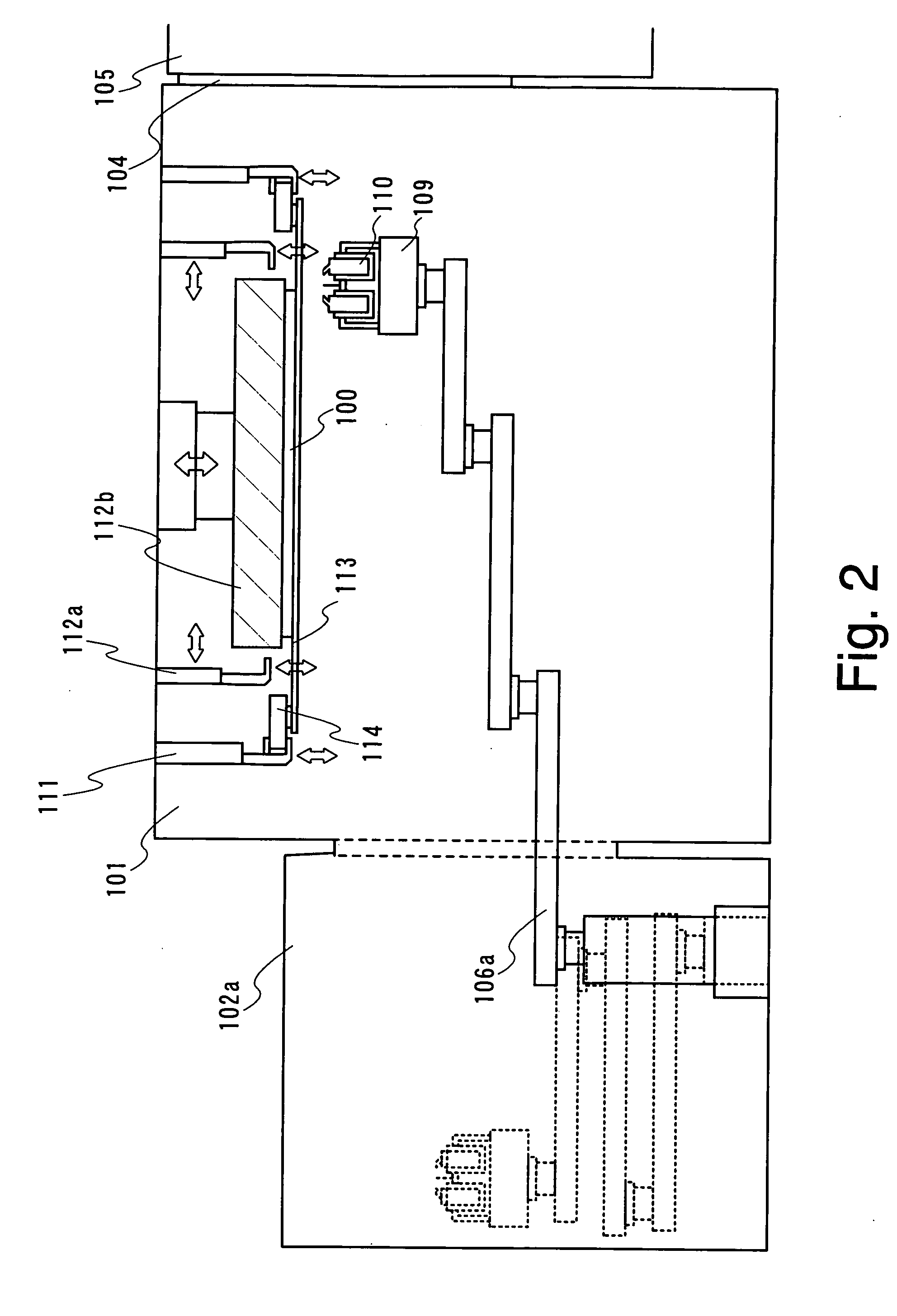

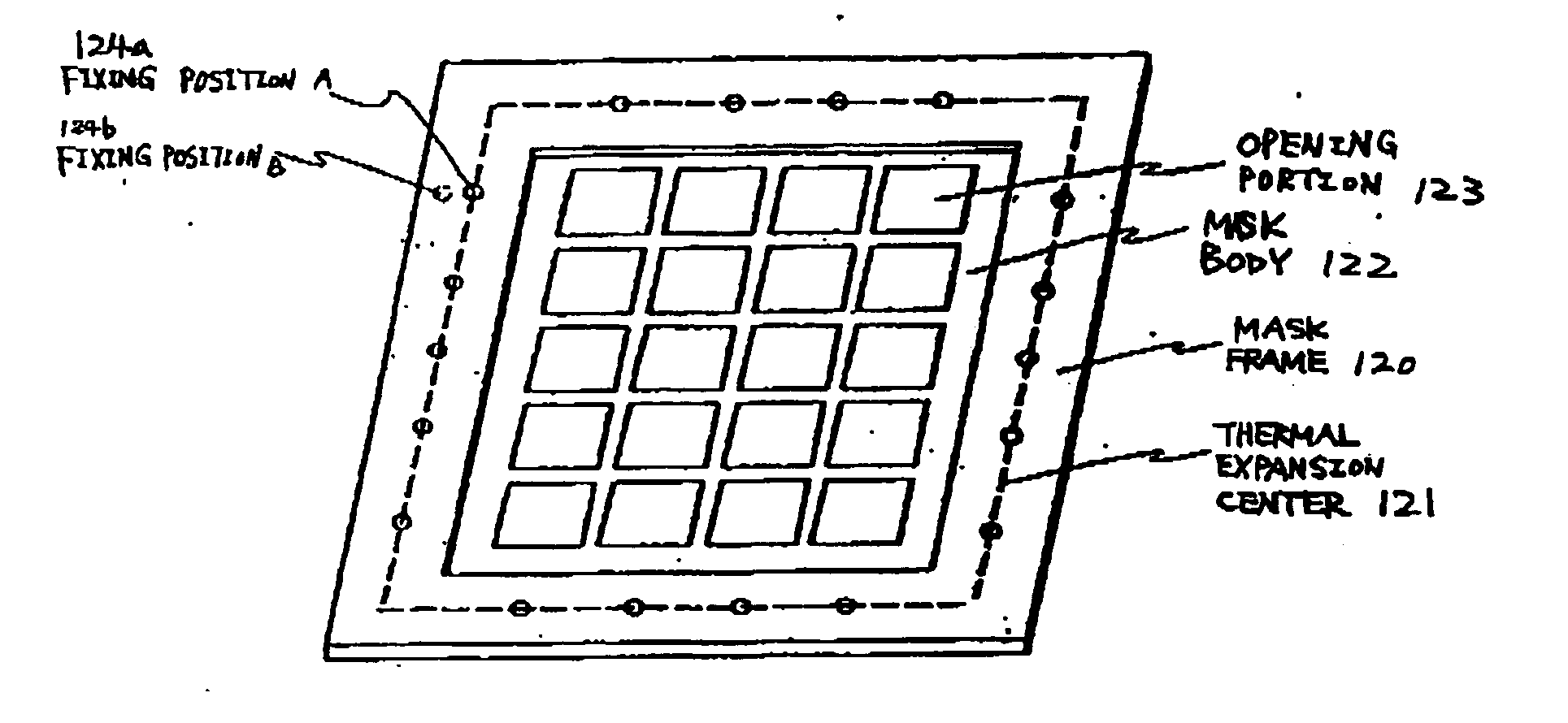

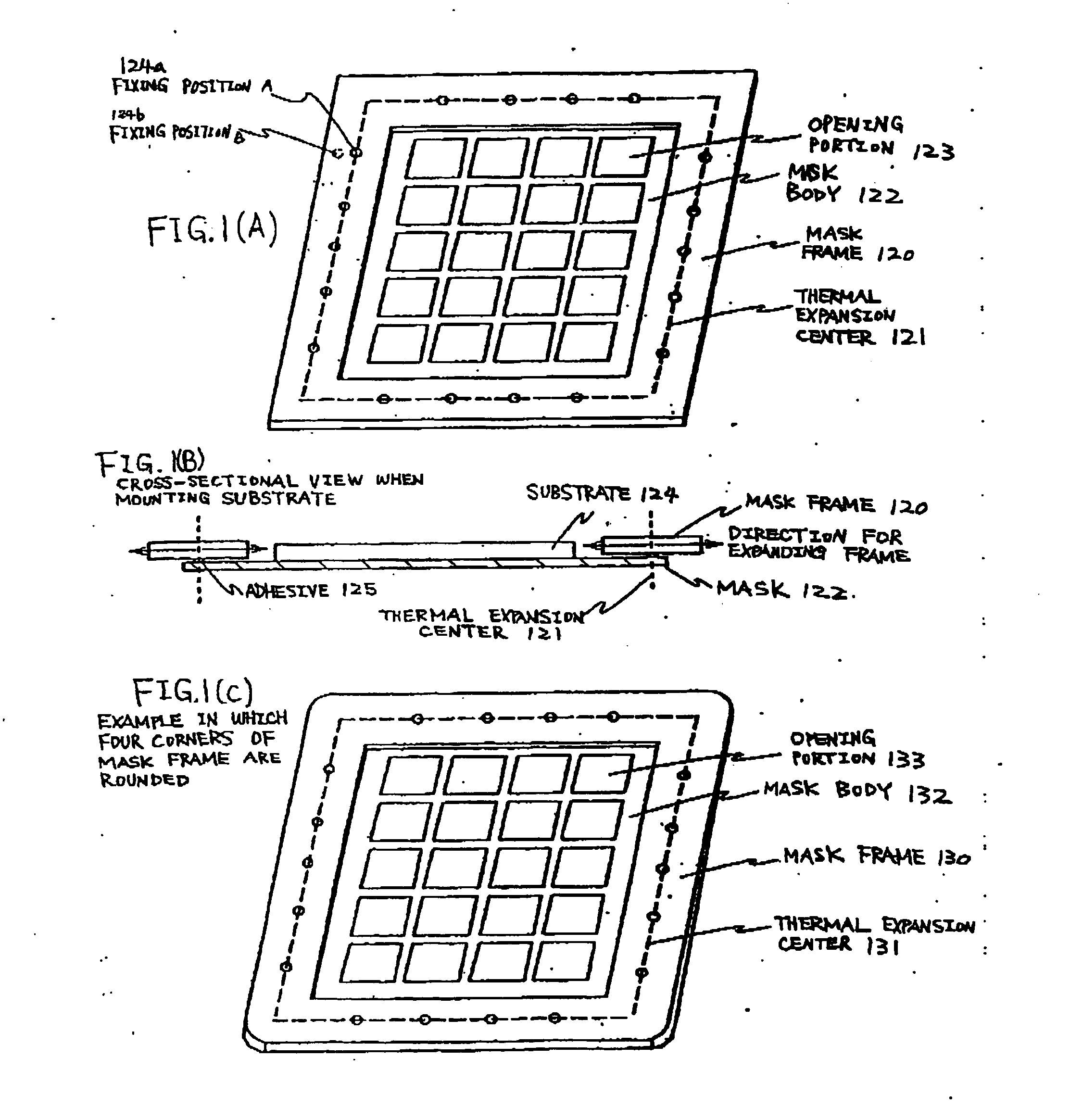

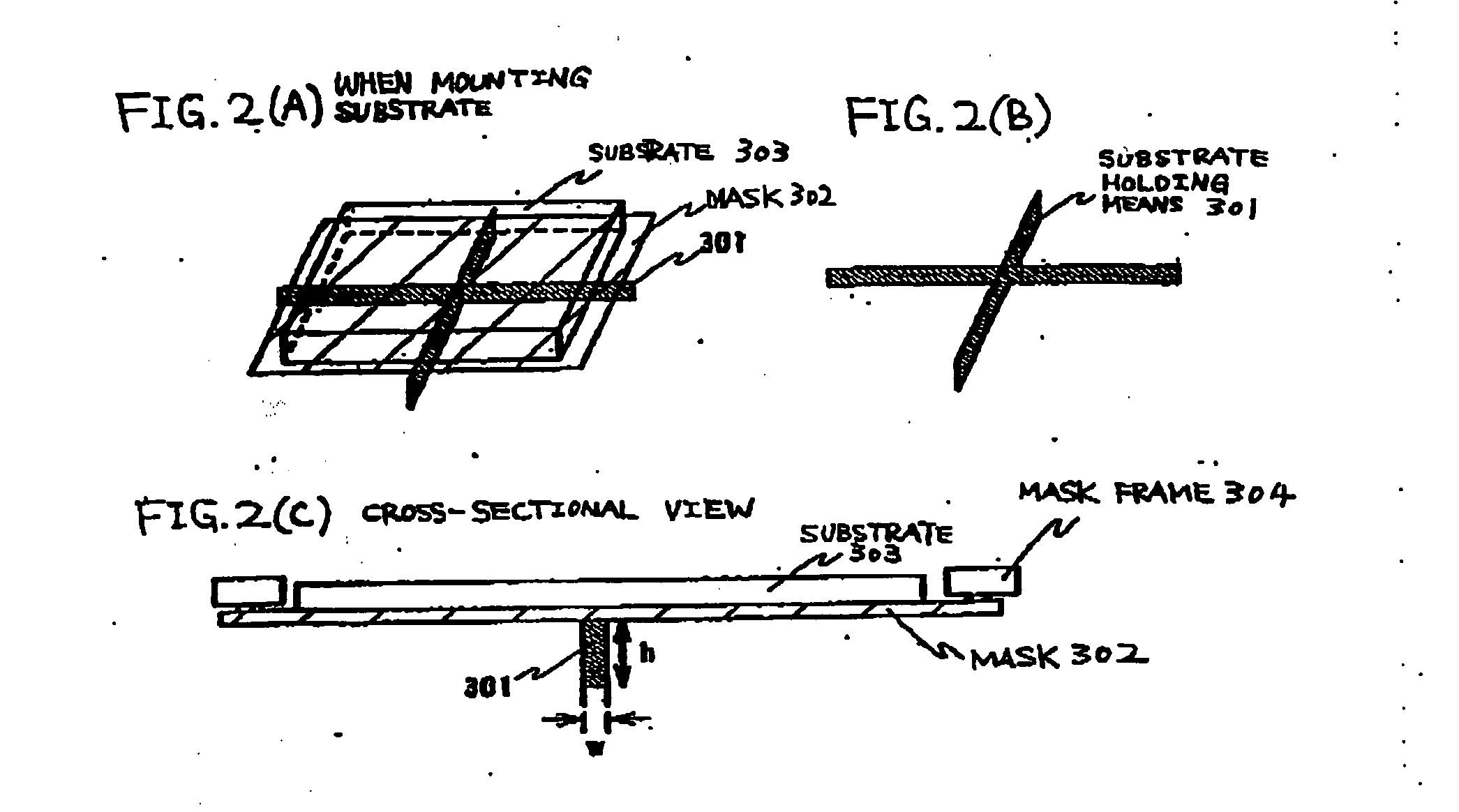

Mask and container and manufacturing apparatus

InactiveUS20050034810A1Improve utilization efficiencyExcellent uniformity and throughputElectroluminescent light sourcesSolid-state devicesThermal expansionSelective deposition

The present invention provides a large mask with a high mask accuracy for conducting selective deposition on a substrate with a large surface area. In accordance with the present invention, the mask body is fixed in a fixing position disposed on a line passing through a thermal expansion center in the width of the mask frame. Further, in accordance with the present invention, the substrate and mask body are fixed and deposition is carried out by moving the deposition source in the X direction or Y direction. A method comprising moving the deposition source in the X direction or Y direction is suitable for deposition on large substrates.

Owner:SEMICON ENERGY LAB CO LTD

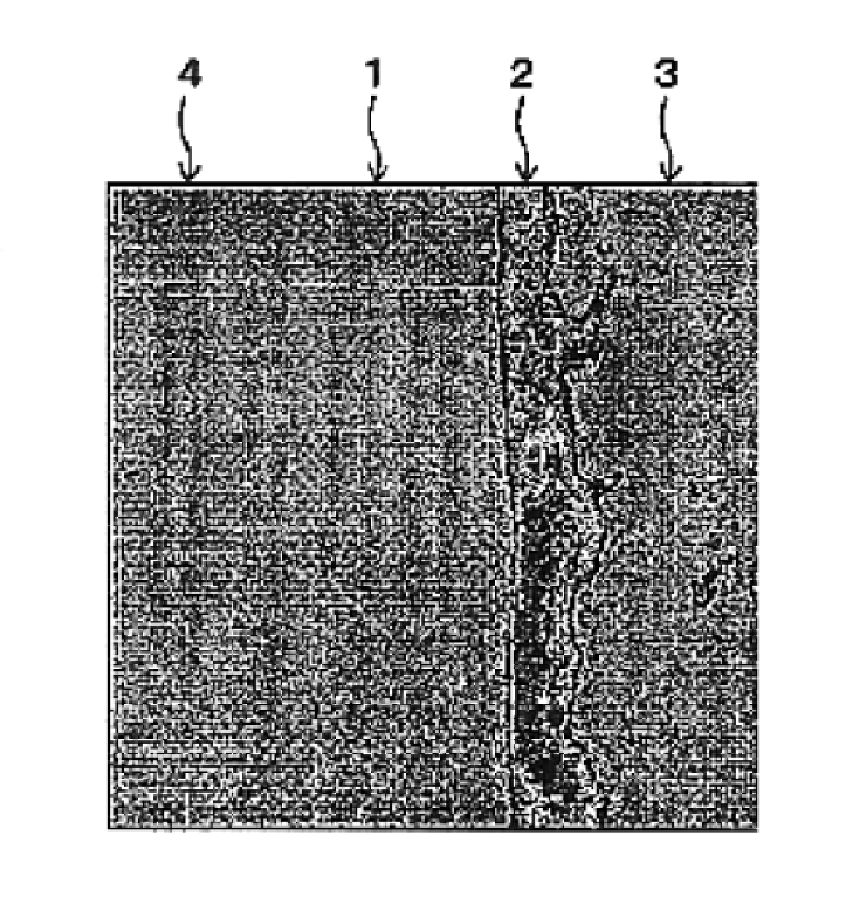

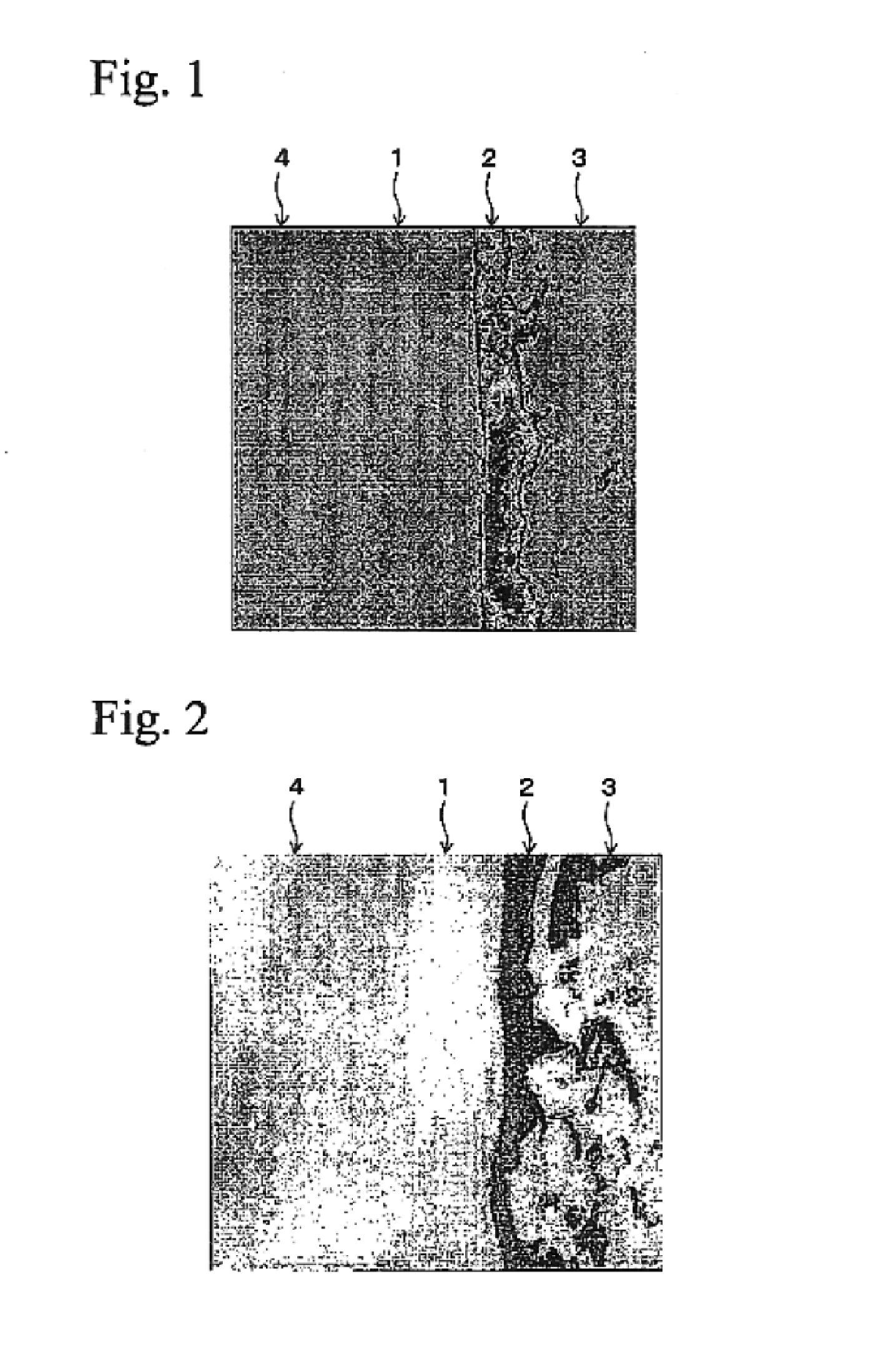

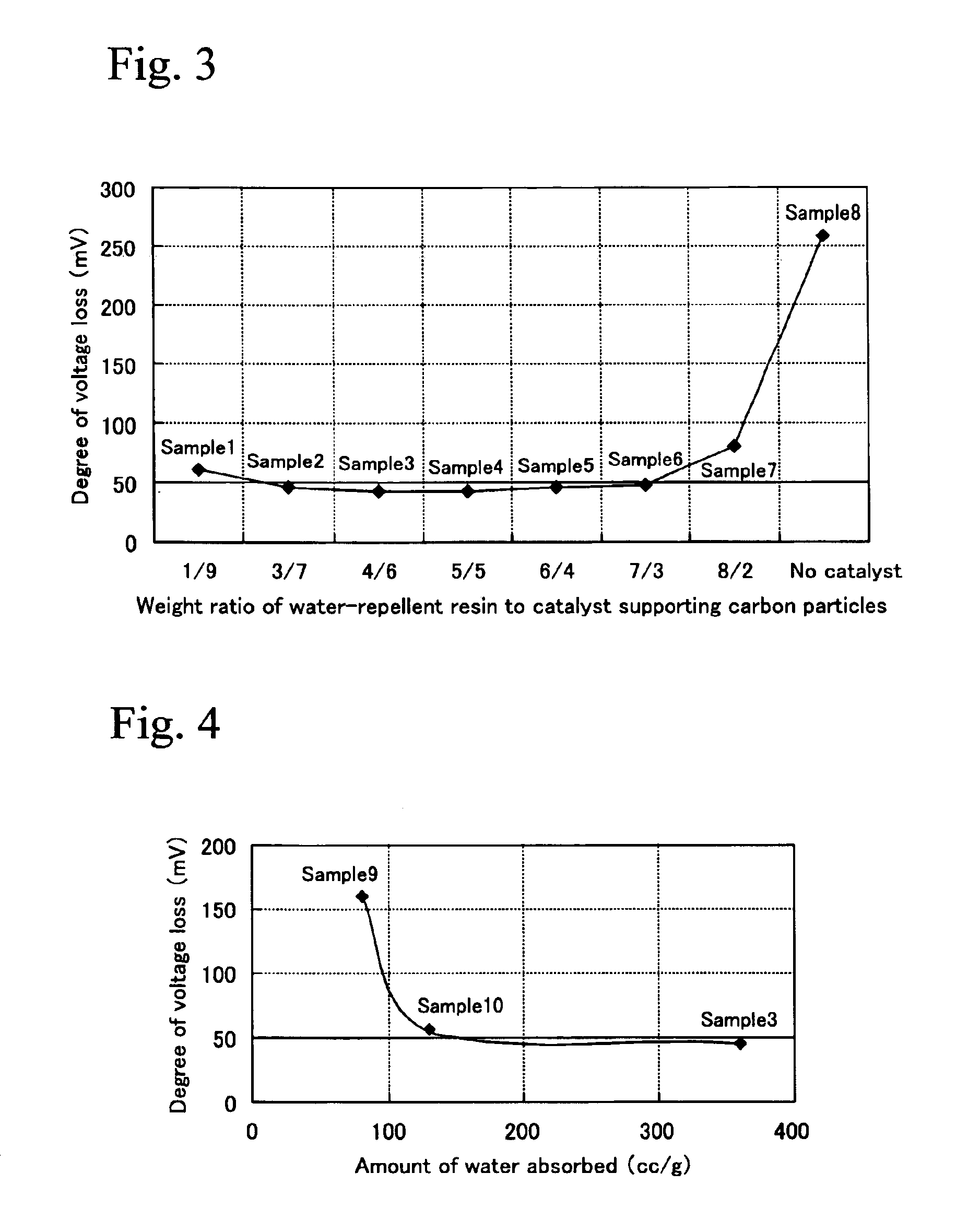

Membrane electrode assembly for polymer electrolyte fuel cell

ActiveUS6847518B2Reduce depositionPower generation efficiency deterioratesLiquid electrolytic capacitorsCell electrodesPolymer electrolytesFuel cells

A membrane electrode assembly for a polymer electrolyte fuel cell has a polymer electrolyte membrane, an anode, and a cathode having a catalytic layer and a diffusion layer. The alloy catalyst contains ruthenium in the anode diffusion layer. The assembly has less loss of efficiency, particularly when operated at high potentials.

Owner:HONDA MOTOR CO LTD +1

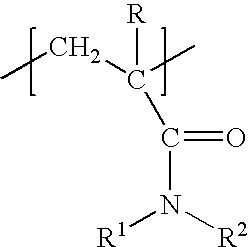

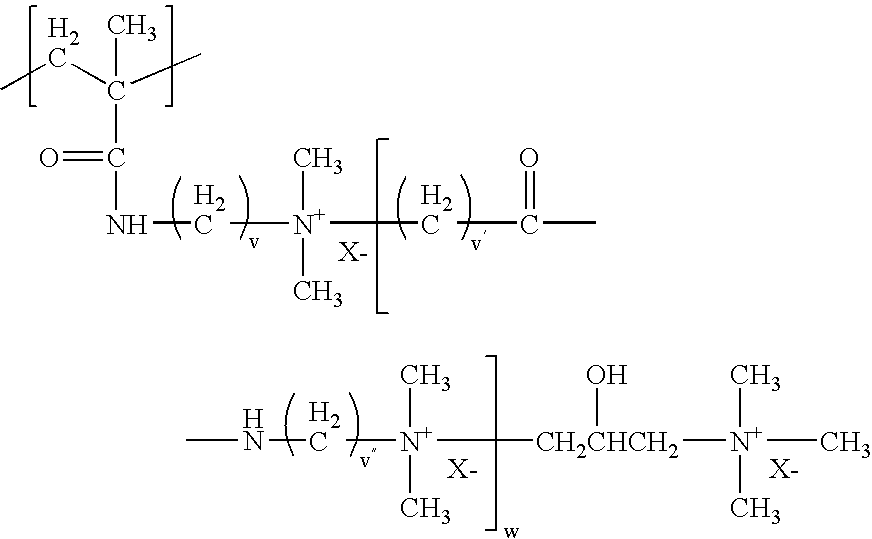

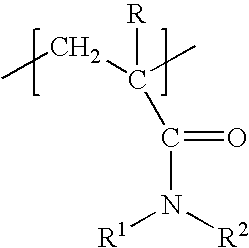

Personal Care Compositions Containing Cationic Synthetic Copolymer and a Detersive Surfactant

InactiveUS20080206179A1Good conditionEfficient depositionCosmetic preparationsHair cosmeticsPersonal careSalicylic acid

A personal care composition comprising:a) a synthetic random copolymer having a net positive charge comprising;i.) a nonionic monomer unit of the following formula:where R is H or C1-4 alkyl; and R1 and R2 are independently selected from the group consisting of H, C1-4 alkyl, CH2OCH3, CH2OCH2CH(CH3)2, and phenyl, or together are C3-6cycloalkyl; andii.) a cationic monomer unit with 2 or more positive charges of the following formula:where each of v, v′, and v″ is independently an integer of from 1 to 6, w is zero or an integer of from 1 to 10, and X− is an anion.and;b) a detersive surfactant;c) an azole;d) salicylic acid ande) an aqueous carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Method for manufacturing graphene-coated object, negative electrode of secondary battery including graphene-coated object, and secondary battery including the negative electrode

ActiveUS20130045418A1Uniform thicknessEfficient depositionMaterial nanotechnologyElectrolysis componentsGrapheneMaterials science

To form graphene to a practically even thickness on an object having an uneven surface or a complex surface, in particular, an object having a surface with a three-dimensional structure due to complex unevenness, or an object having a curved surface. The object and an electrode are immersed in a graphene oxide solution, and voltage is applied between the object and the electrode. At this time, the object serves as an anode. Graphene oxide is attracted to the anode because of being negatively charged, and deposited on the surface of the object to have a practically even thickness. A portion where graphene oxide is deposited is unlikely coated with another graphene oxide. Thus, deposited graphene oxide is reduced to graphene, whereby graphene can be formed to have a practically even thickness on an object having surface with complex unevenness.

Owner:SEMICON ENERGY LAB CO LTD

Fabric article treating system

InactiveUS20050000031A1Efficient depositionEfficient deliveryDetergent mixture composition preparationOther washing machinesWater savingLaundry

A fabric article treating system, including the apparatus and the process, to provide improved fabric cleaning, fabric appearance and / or fabric care benefits. More particularly, the present system provides an effective delivery of detergent actives and rinse actives by depositing the actives directly upon a fabric article being treated. The detergent composition and fabric care composition suitable for use in such apparatus and process are also provided. The system is water-saving and energy efficient, compared to conventional immersive aqueous laundry system.

Owner:THE PROCTER & GAMBLE COMPANY

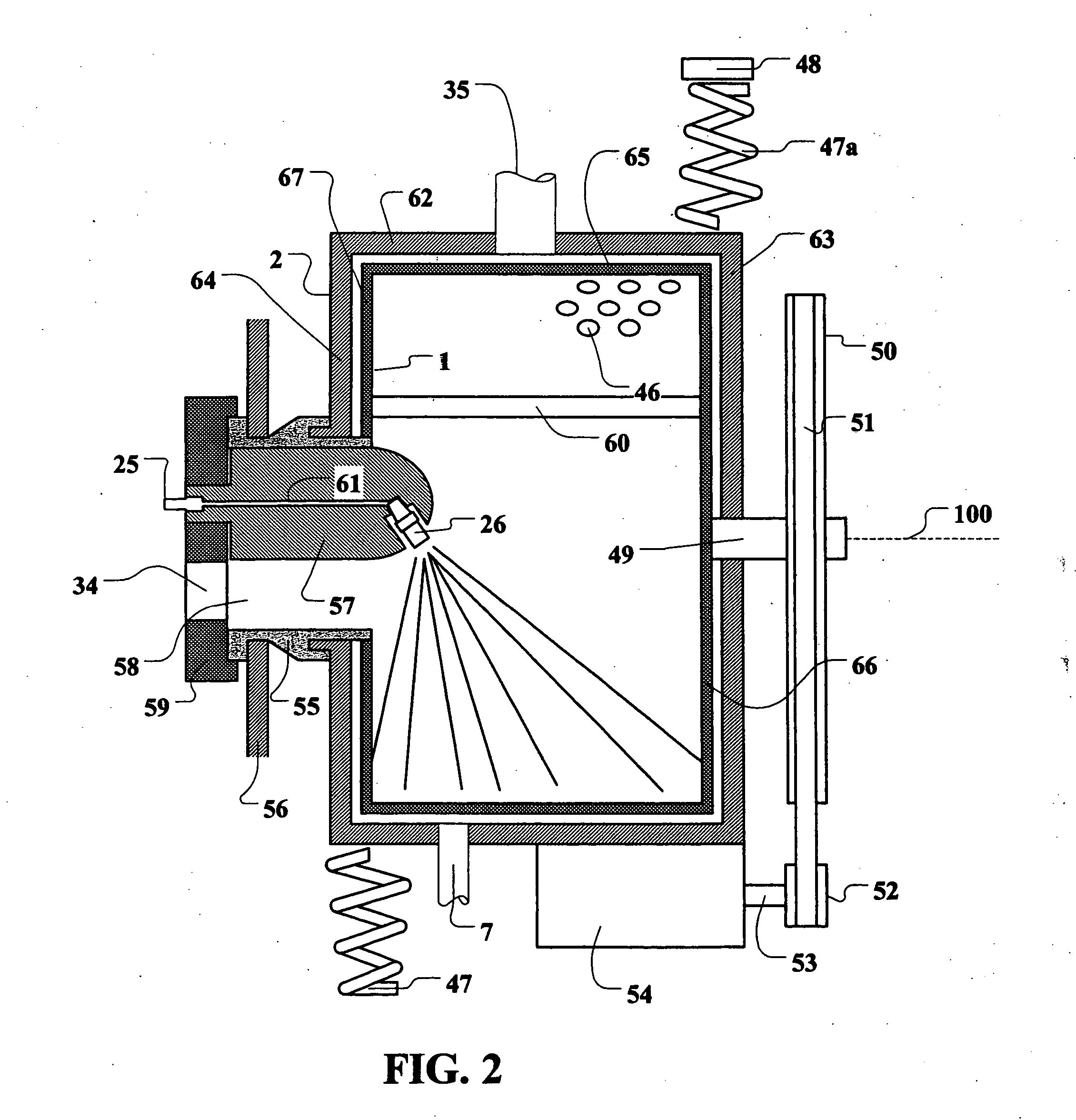

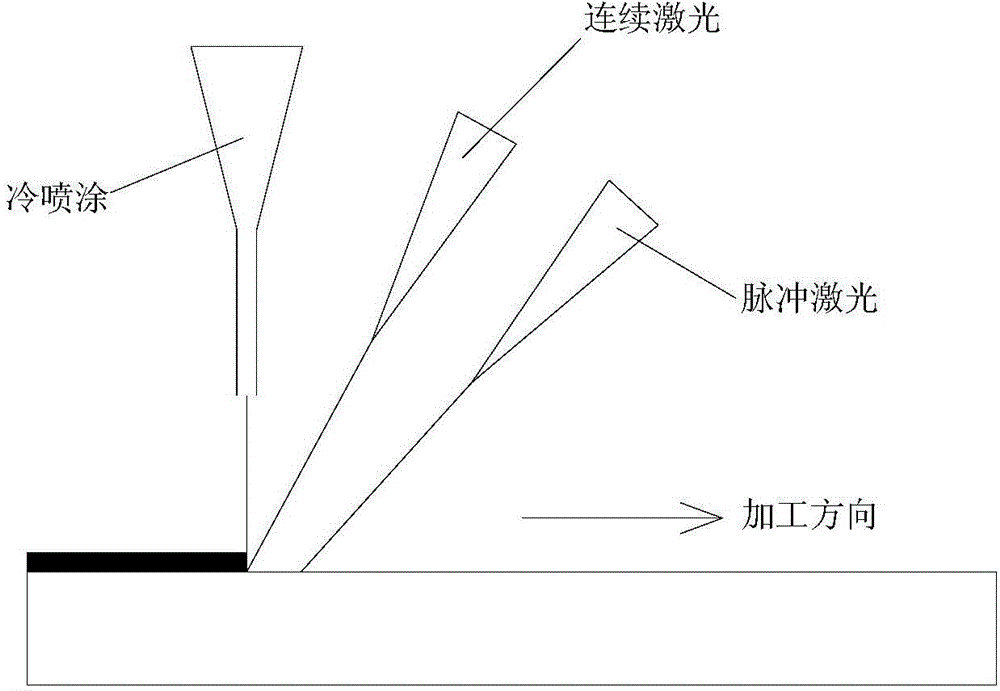

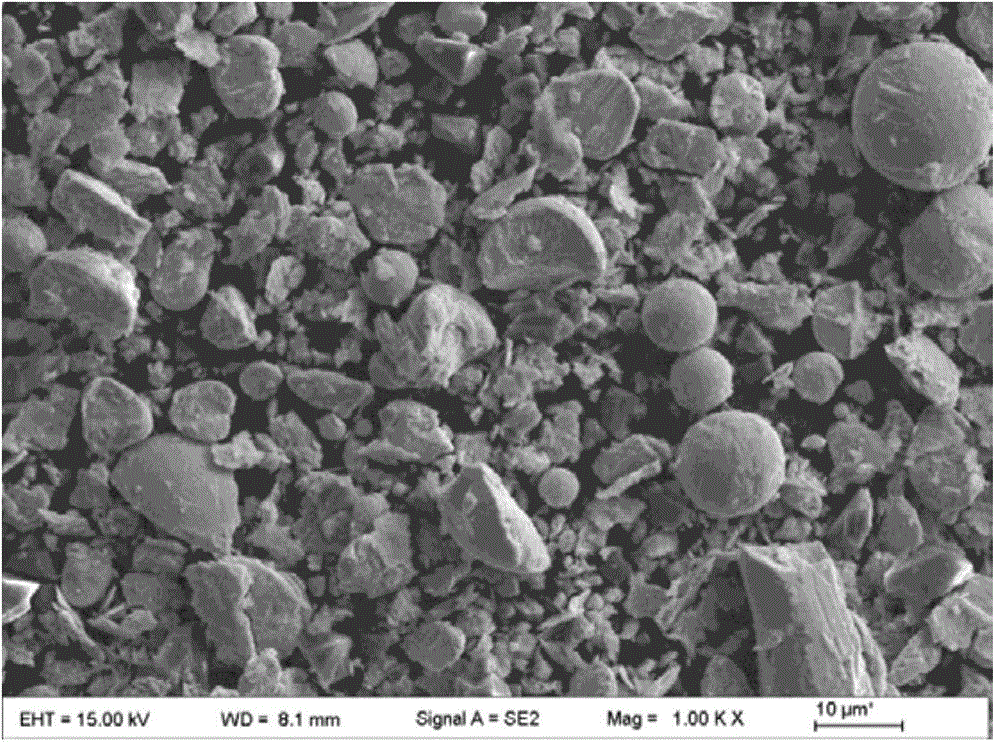

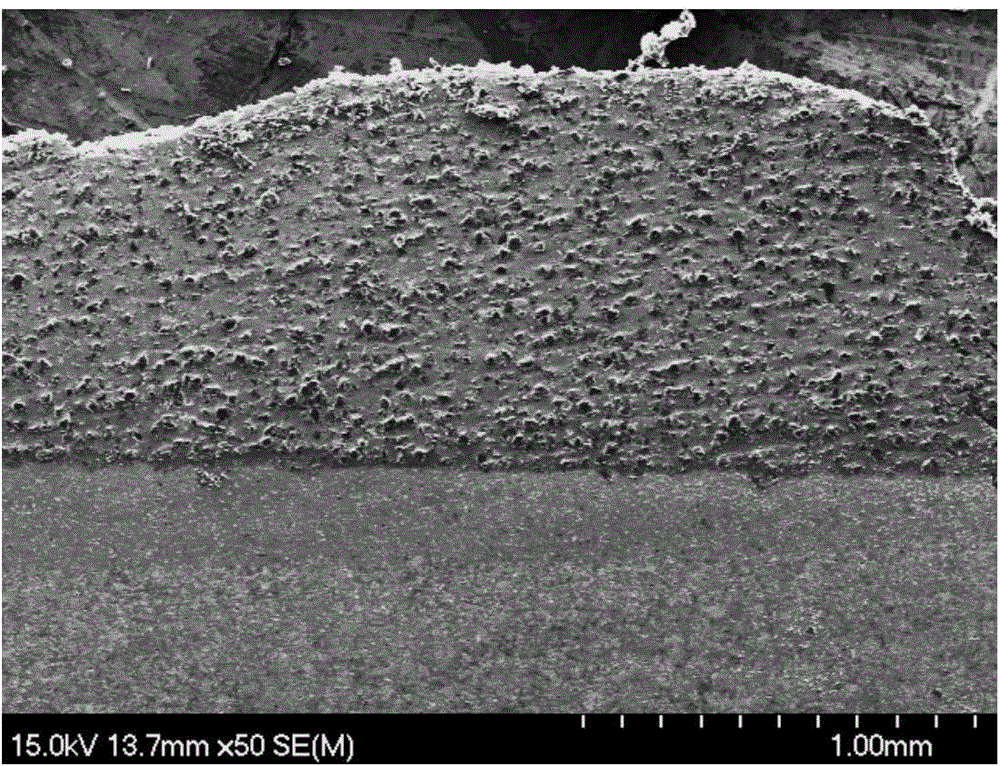

Metal-based/diamond laser composite coating and preparation method thereof

ActiveCN104018156AAvoid easy decompositionInhibition of dissolutionMovable spraying apparatusLaser beam welding apparatusCompound aHardness

The invention discloses a metal-based diamond laser composite coating and a preparation method thereof. The preparation method comprises the following steps: firstly selecting high-hardness metal powder and diamond powder with proper grain size and shape, uniformly mixing the high-hardness metal powder and the diamond powder by using a ball-milling method, and finally preparing the composite coating on a matrix by using a method of synchronously compounding a laser texturing technology, a laser heat treatment technology and a cold spraying technology. The thickness of the composite coating is over 1mm, and the diamond volume content in the coating is more than 45%. The preparation of the composite coating by using the high-hardness metal powder as the diamond binding phase is realized, and the binding strength of the composite coating and the matrix is improved through the pulse texturing treatment, and finally the stable and high-quality high-hardness metal-based / diamond composite high wear-resisting coating is prepared, and the integration, the automation and the efficiency of the matrix surface treatment and the coating deposition treatment are realized.

Owner:ZHEJIANG UNIV OF TECH +1

Porous ceramic filters with catalyst coatings

ActiveUS7132150B2Improve washcoating characteristicEasy to disassemblePretreated surfacesLight effect designsNanoparticleNanometre

Porous ceramic catalyst supports or filters to be provided with catalyst coatings via oxide washcoating processes are pre-coated with polymer barrier layers to prevent washcoat nanoparticle intrusion into the microcracked and / or microporous surfaces of the ceramics, the barrier coatings being formed of hydrocarbon polymers that are soluble or dispersible in polar media, capable of forming neutral or hydrophilic surfaces on porous ceramic supports, and completely vaporizable at moderate washcoat stabilization or catalyst activation temperatures.

Owner:CORNING INC

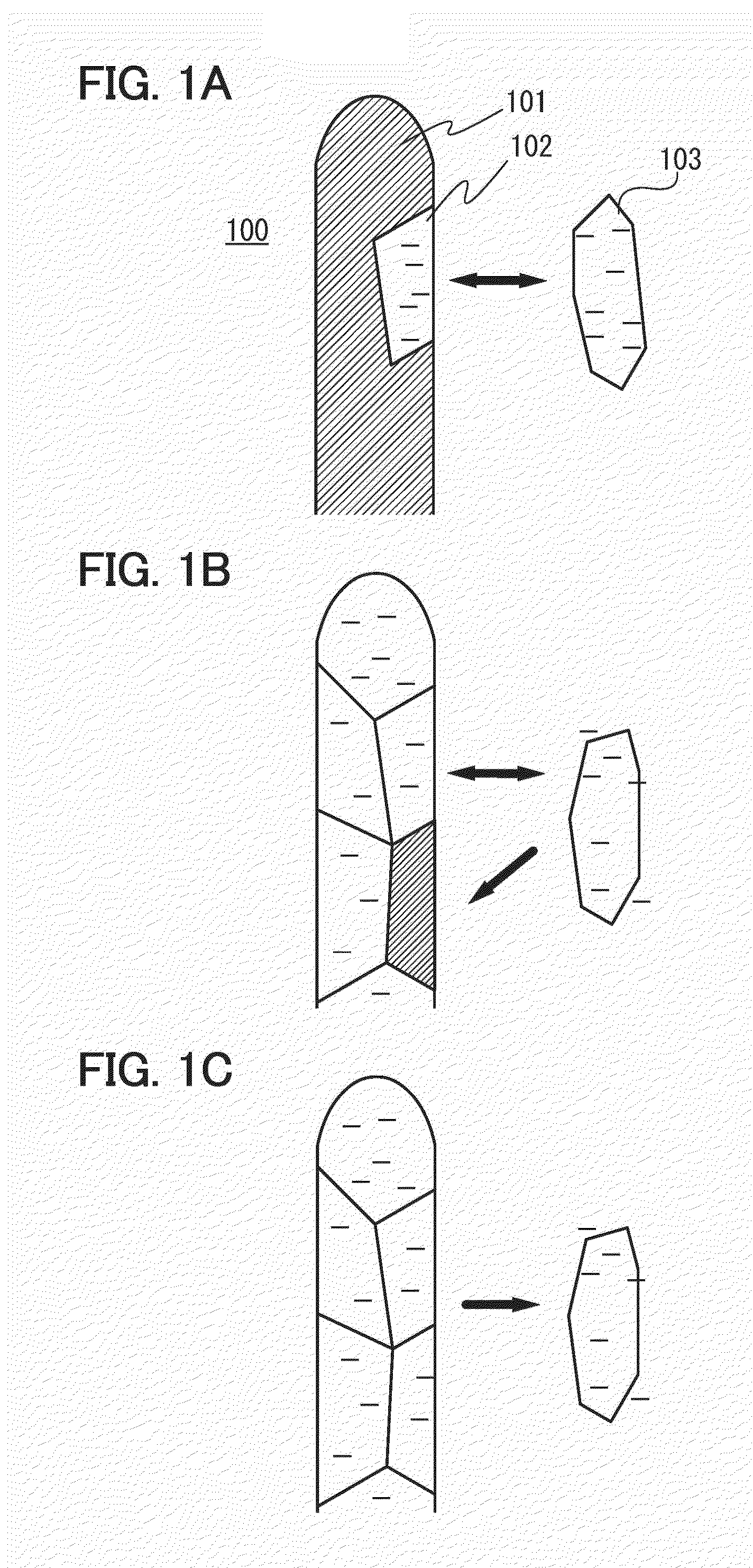

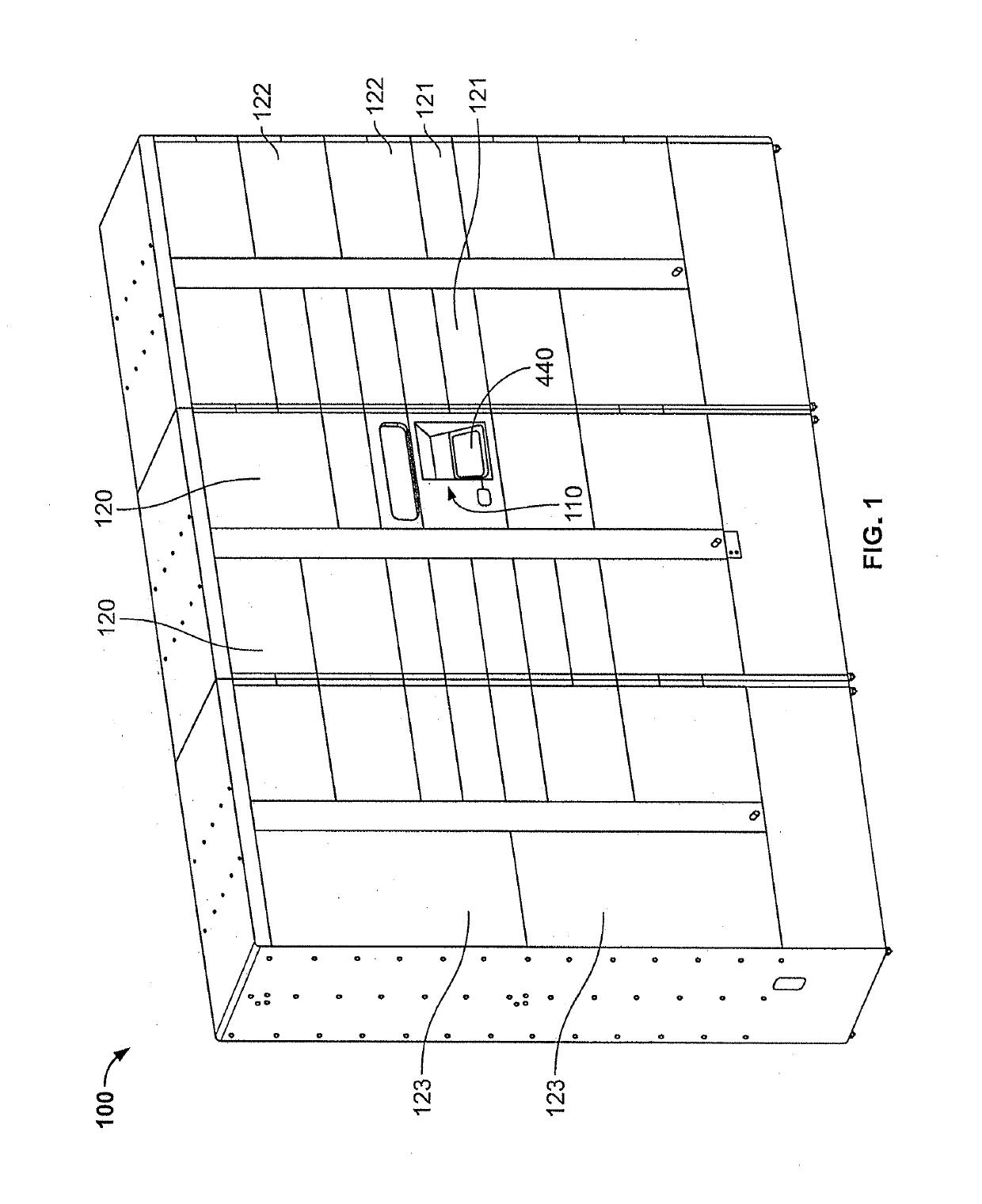

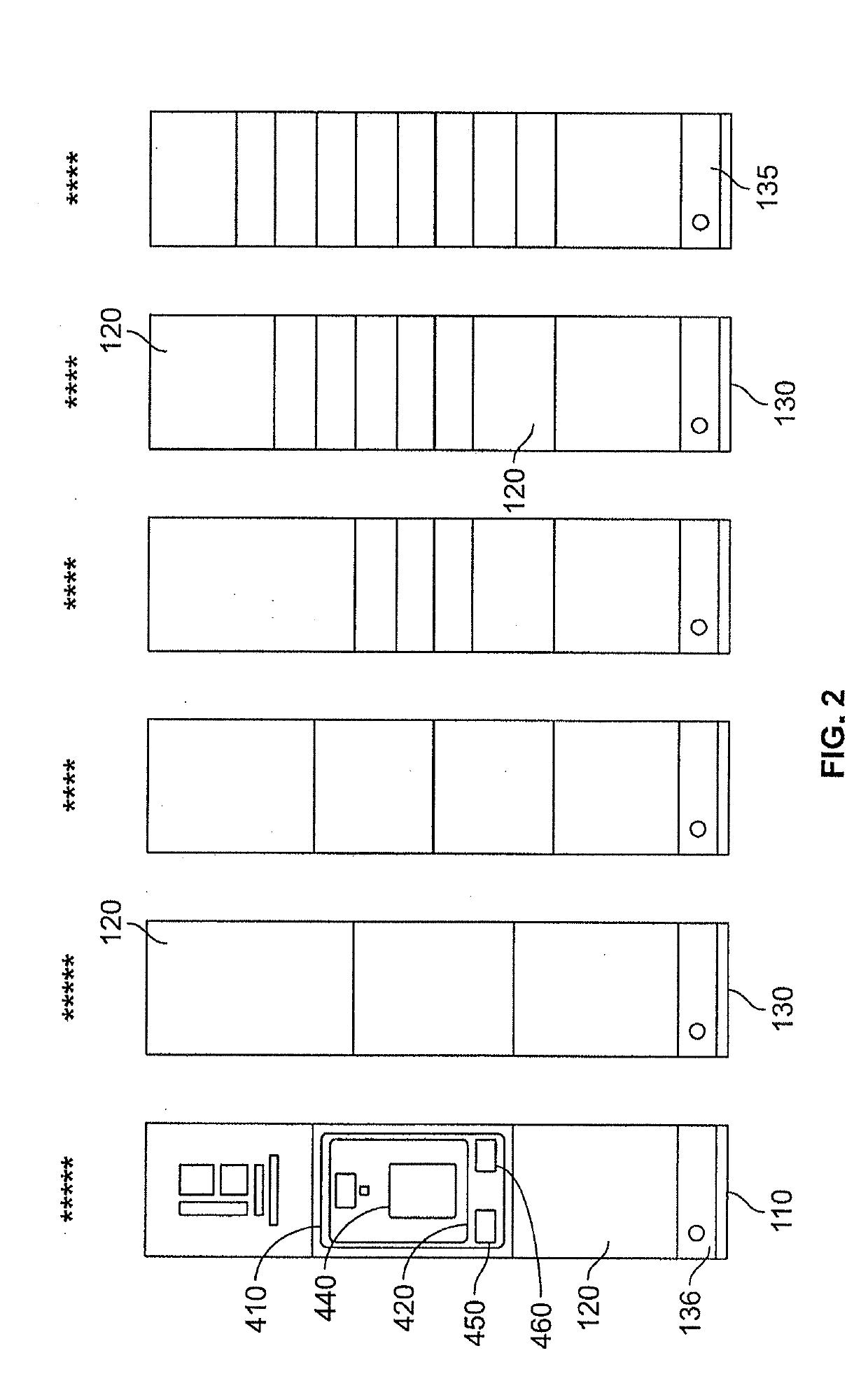

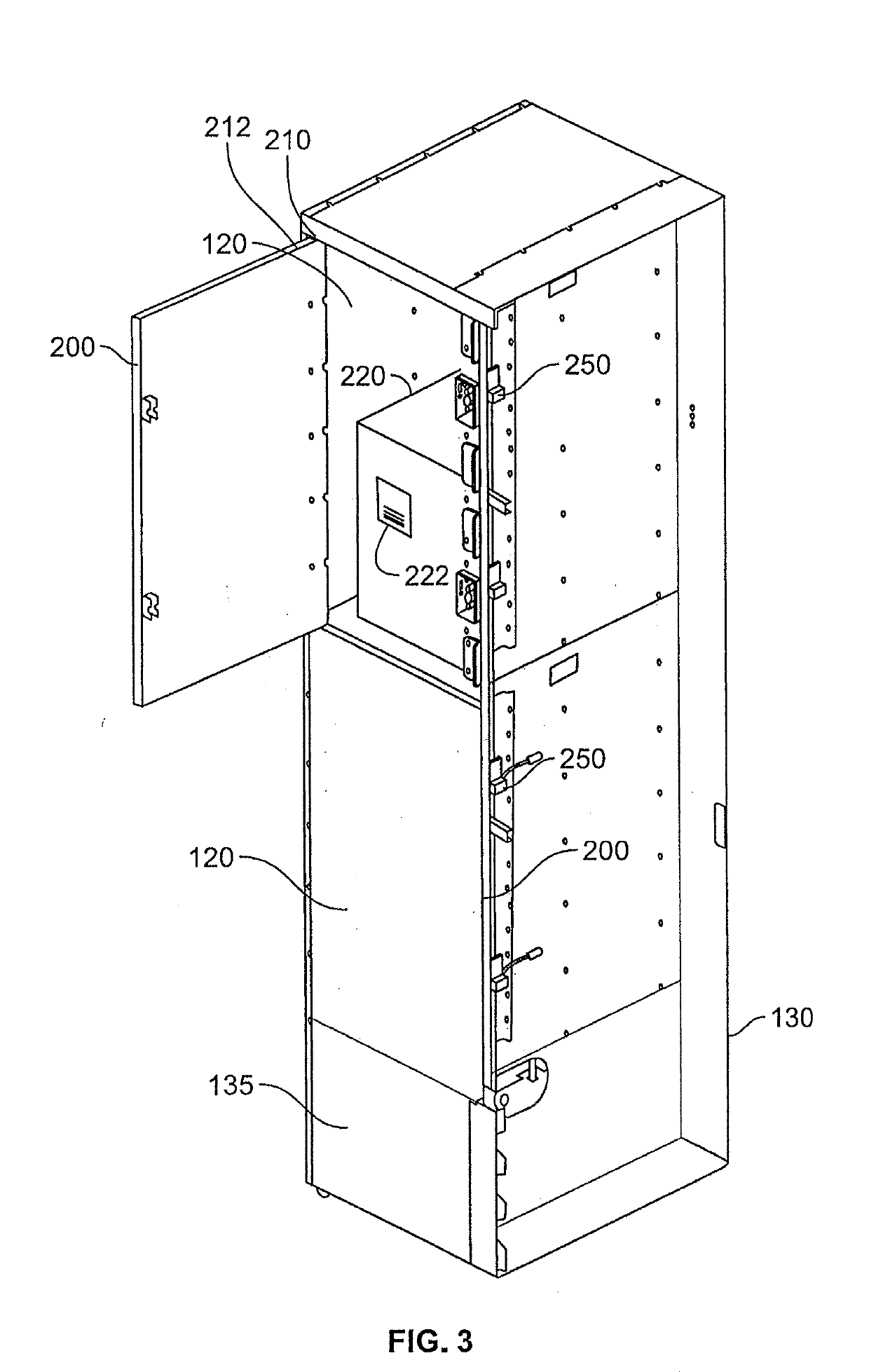

Package Management System with Accelerated Delivery

ActiveUS20190114585A1Efficient depositionSafe storagePayment architectureApparatus for meter-controlled dispensingInterior spacePackage management

A system is disclosed for delivering packages by a delivery person in a location with multiple recipients comprising a plurality of lockers, each locker having an interior space and a door that when opened allows access to the interior space, a locking portion associated with each door, a central control unit comprising an identifier to allow the delivery person to specify a recipient, an input device to allow the delivery person to specify the number of packages to be delivered to the recipient, and a controller configured to deactivate the locking portions on the individual lockers, wherein upon identification of a recipient and input of the number of packages to be delivered to the recipient, the controller deactivates the number of locking portions equal to the number of packages to be delivered to the recipient, and the delivery person places a package in each locker opened and closes the door.

Owner:FLORENCE CORP

Molecular plasma deposition of colloidal materials

ActiveUS7250195B1Efficiently processLimited solubilityElectric shock equipmentsPharmaceutical containersAmount of substancePlasma deposition

A molecular plasma discharge deposition method for depositing colloidal suspensions of biomaterials such as amino acids or other carbon based substances onto metal or nonmetal surfaces without loss of biological activity and / or structure is described. The method is based on generating a charged corona plasma which is then introduced into a vacuum chamber to deposit the biomaterial onto a biased substrate. The deposited biomaterials can be selected for a variety of medical uses, including coated implants for in situ release of pharmaceuticals.

Owner:NORTHEASTERN UNIV

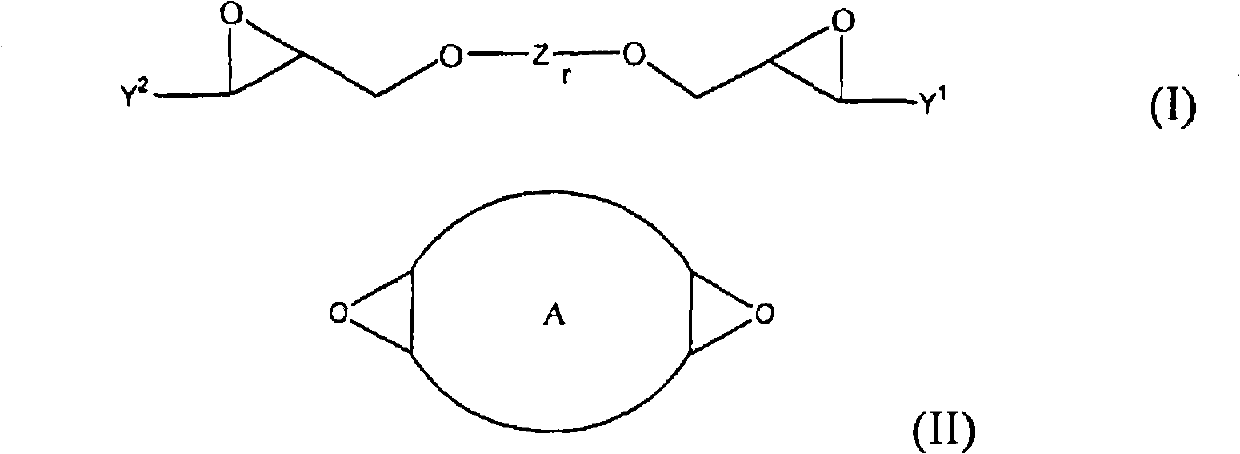

Plating solution and plating method

ActiveCN102276796ANodule reductionStrong dispersion abilityOrganic chemistryPrinted element electric connection formationEpoxideCopper plating

Copper plating baths containing a leveling agent that is a reaction product of a certain imidazole with a certain epoxide-containing compound that deposit copper on the surface of a conductive layer are provided. Such plating baths deposit a copper layer that is substantially planar on a substrate surface across a range of electrolyte concentrations. Methods of depositing copper layers using suchcopper plating baths are also disclosed. A reaction product of one or more nitrogenous compounds and one or more epoxy compounds indicated in formula 1 or 2 is also provided, wherein Y1 and Y2 are selected from H and (C1 - C4) alkyl group. Z is Ar, R12OarOR12, (R13O)aAr (OR13)A, Cy, R12CyR12 or (R13O)aCy(OR12)A; r=1-4; Ar=(C6-C18) aryl group; Cy=(C5-C12) naphthenic group; each R12 indicates (C1-C8) alkyl group; each R13 indicates (C2-C6) alkylene oxygen group; each a=1-10; and A indicates C5-C12 naphthenic group.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

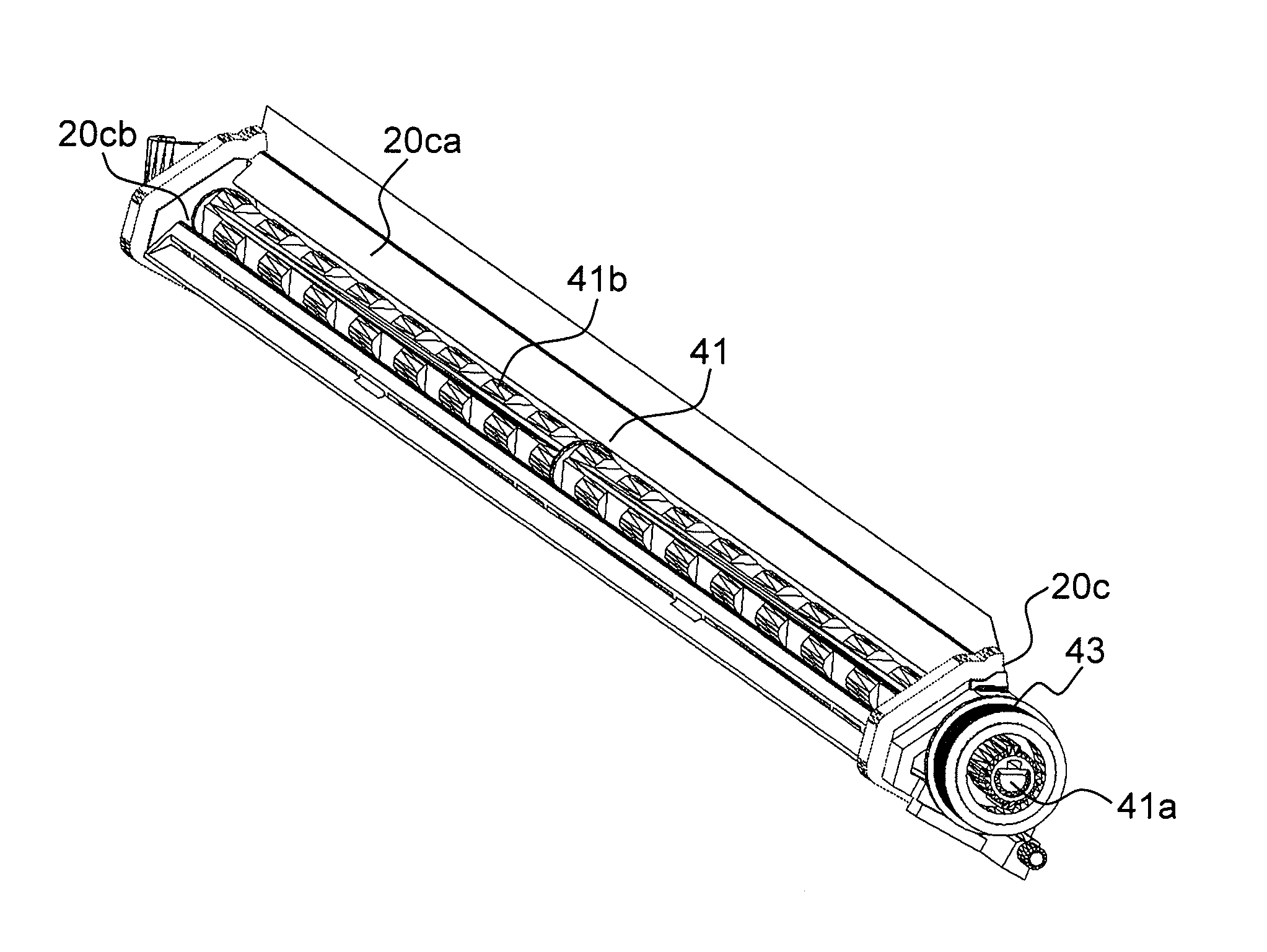

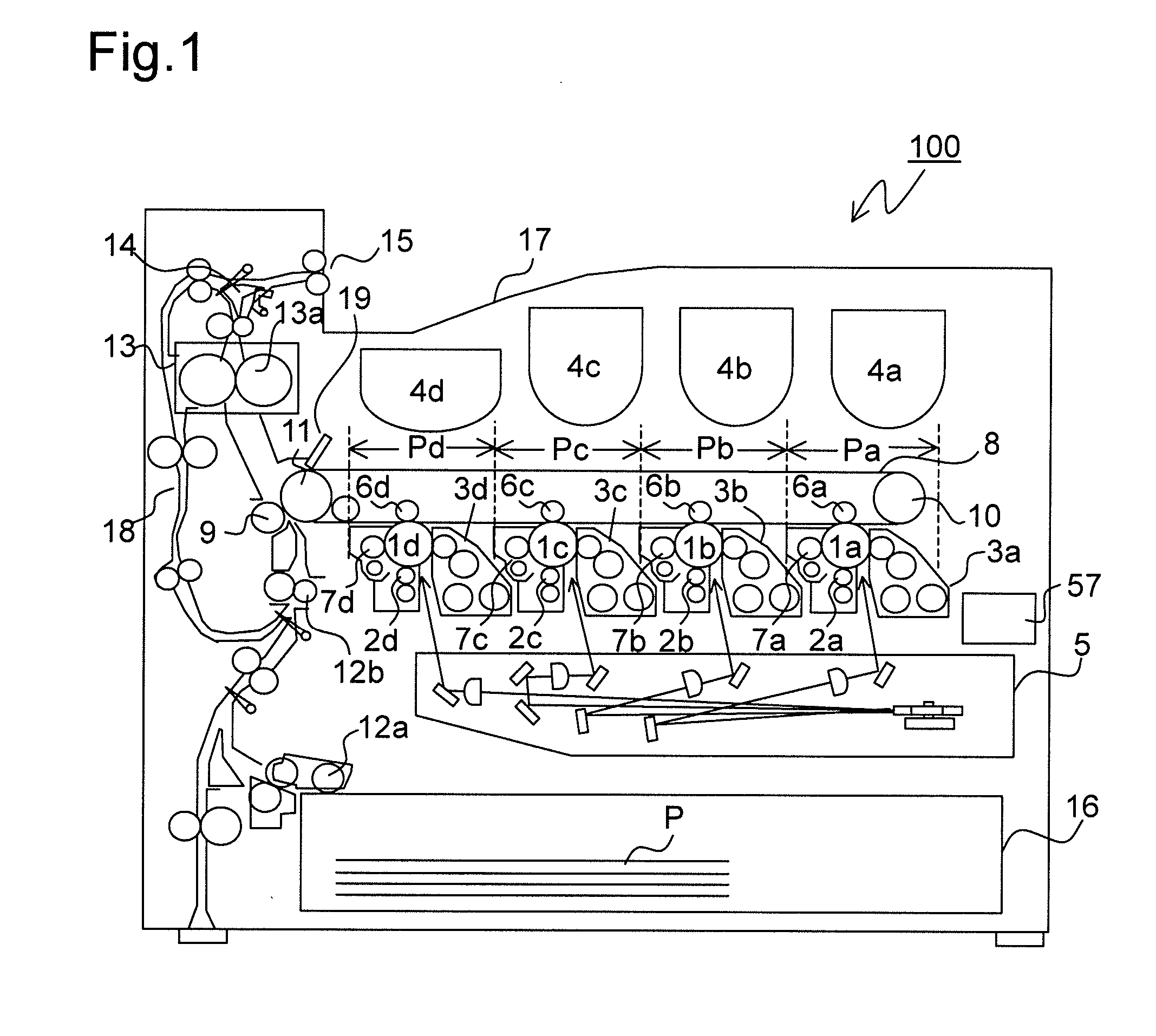

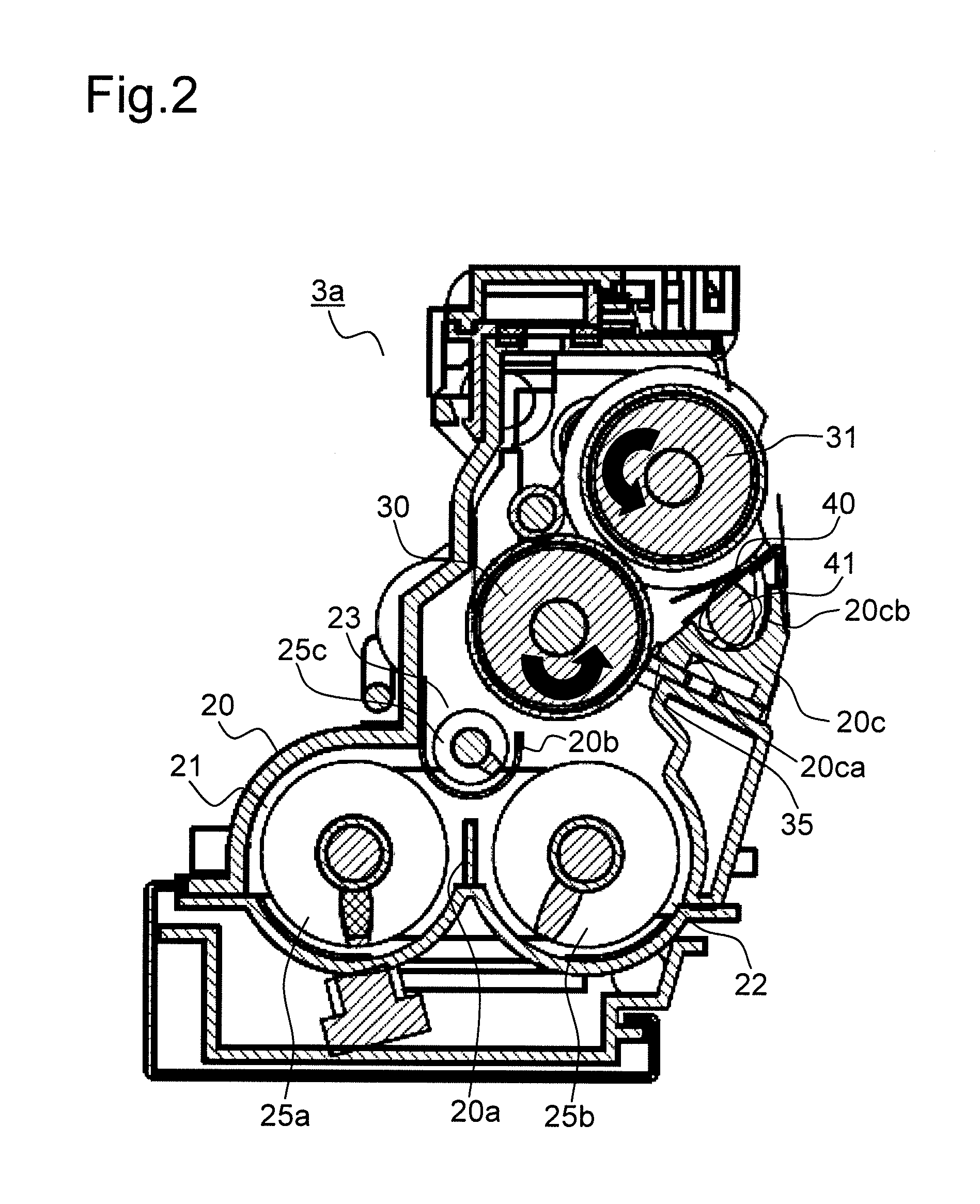

Developing device and image forming apparatus including the same

InactiveUS20110229184A1Efficient depositionEffective preventionElectrographic process apparatusLatent imageImage formation

A developing device includes: a developer carrying member for supplying a developer to an image bearing member at an opposing region opposing to the image bearing member, the developer carrying member being arranged so as to be opposed to the image bearing member on which an electrostatic latent image is to be formed; a blade for regulating an amount of the developer carried on the developer carrying member; a casing for housing the developer carrying member and the blade, the casing including a wall portion opposed to the developer carrying member between the blade and the opposing region; a sheet member that is flexible, provided on the wall portion, has a free end, forms a part of an inner wall surface of the wall portion, and is movable in a direction perpendicular to the inner wall surface; and a moving portion provided on the wall portion, for moving the sheet member.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

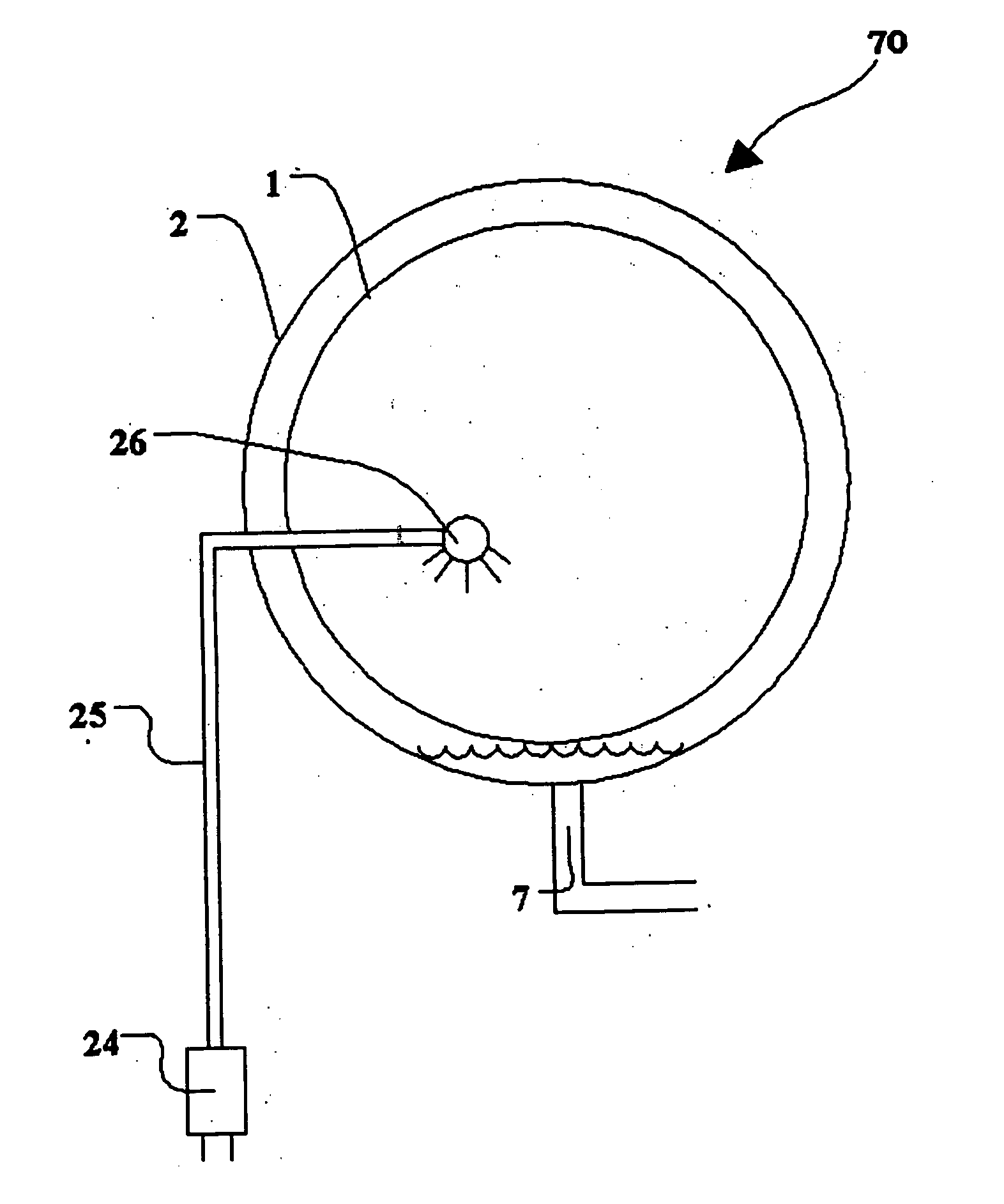

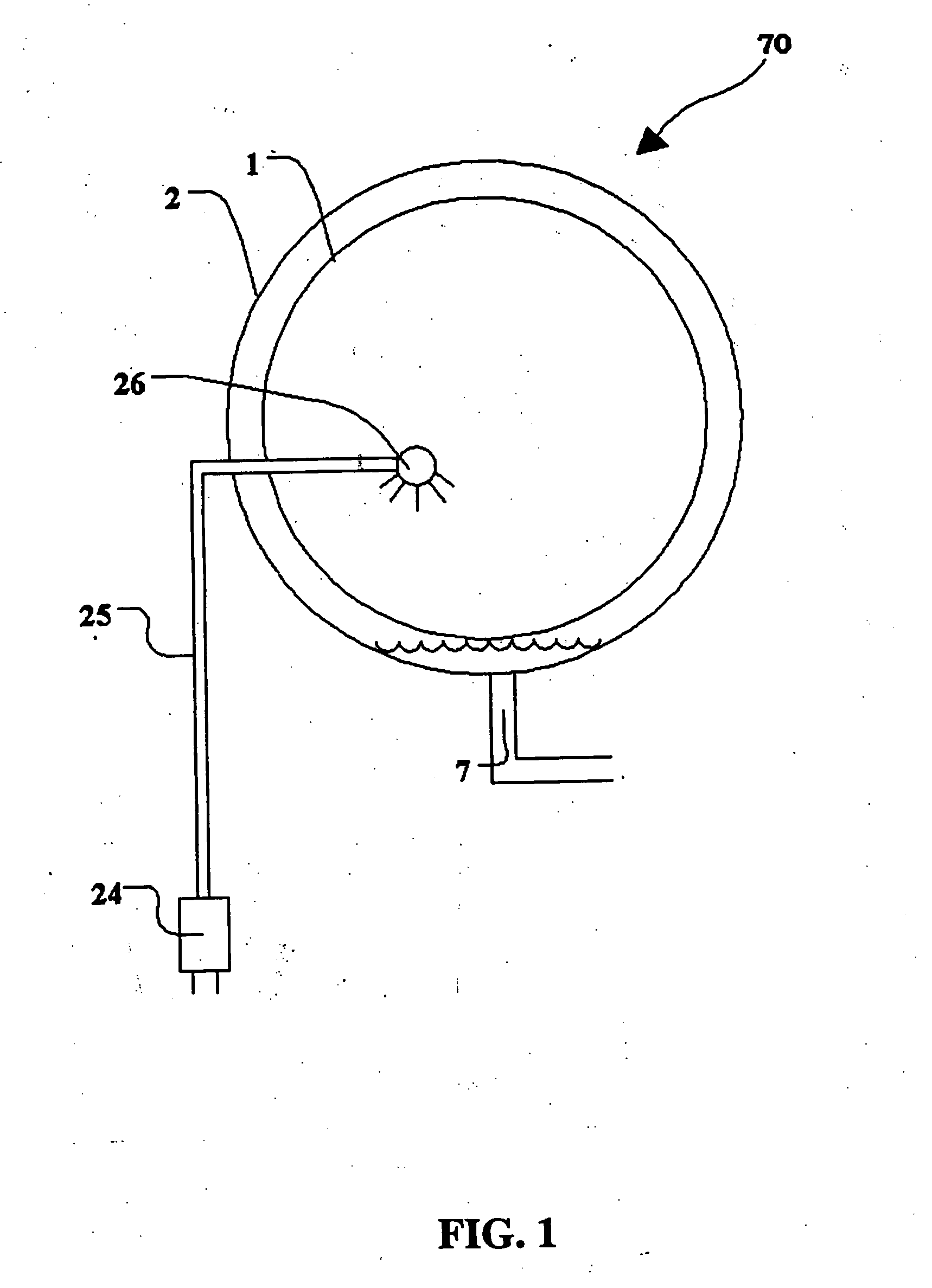

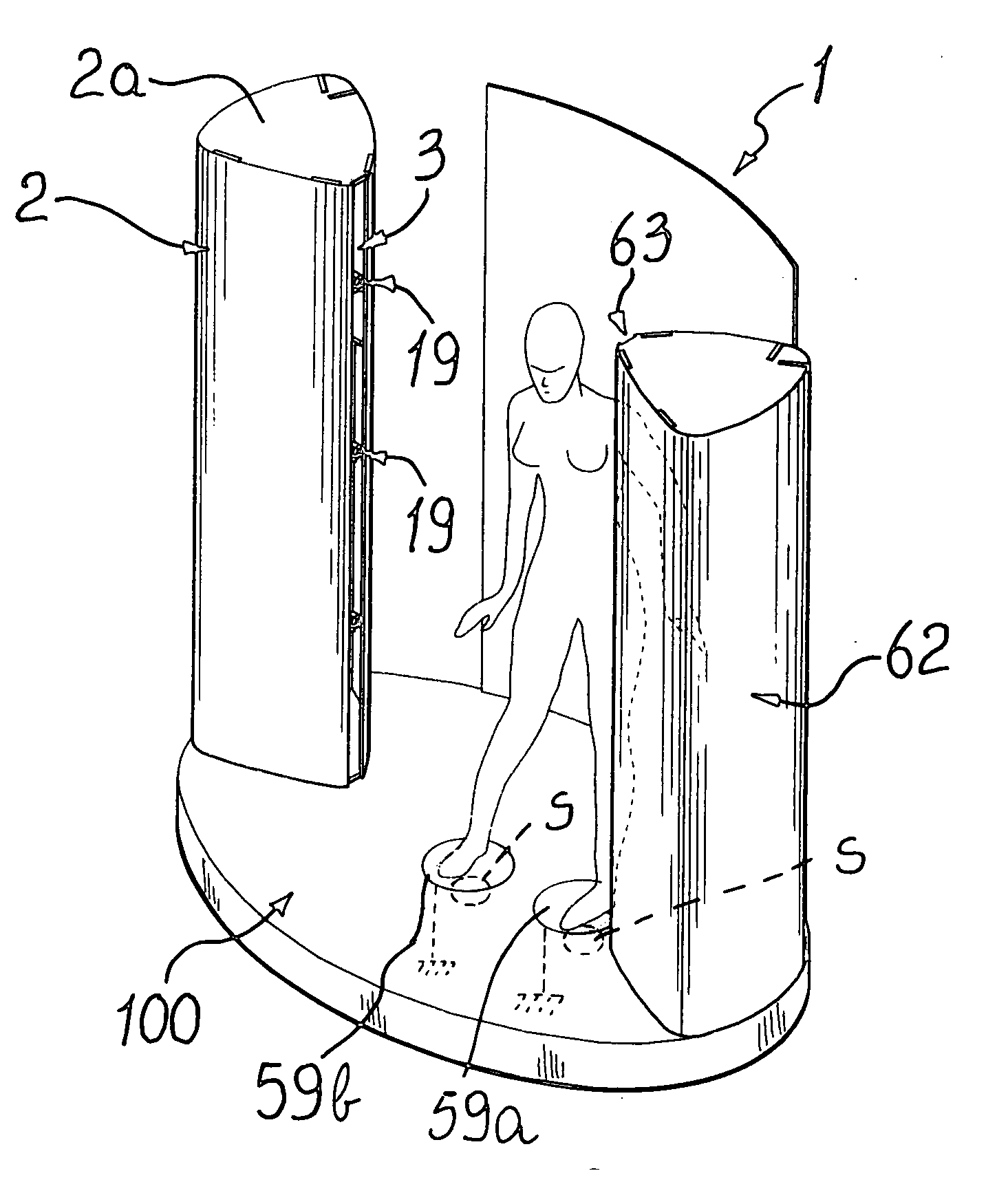

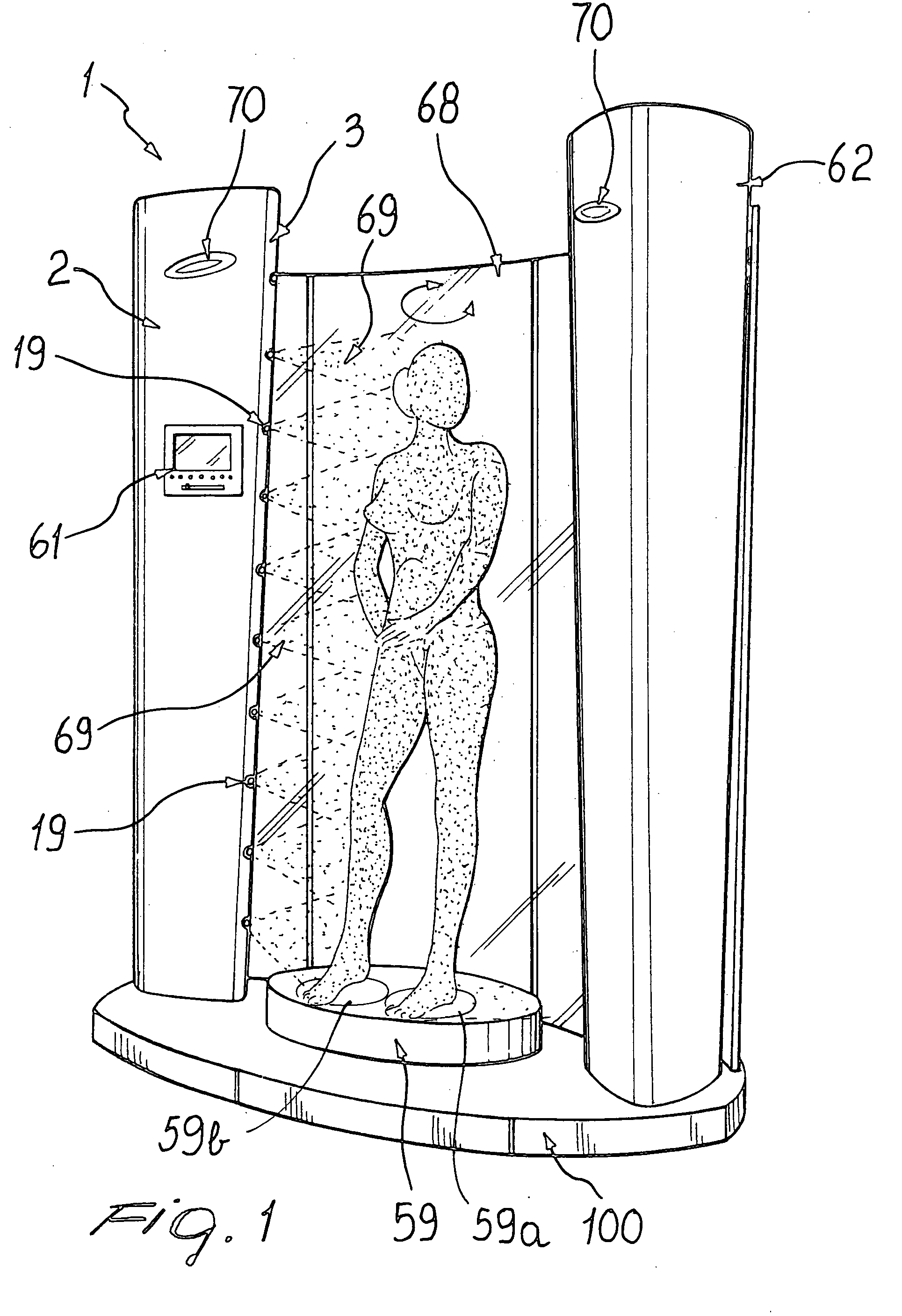

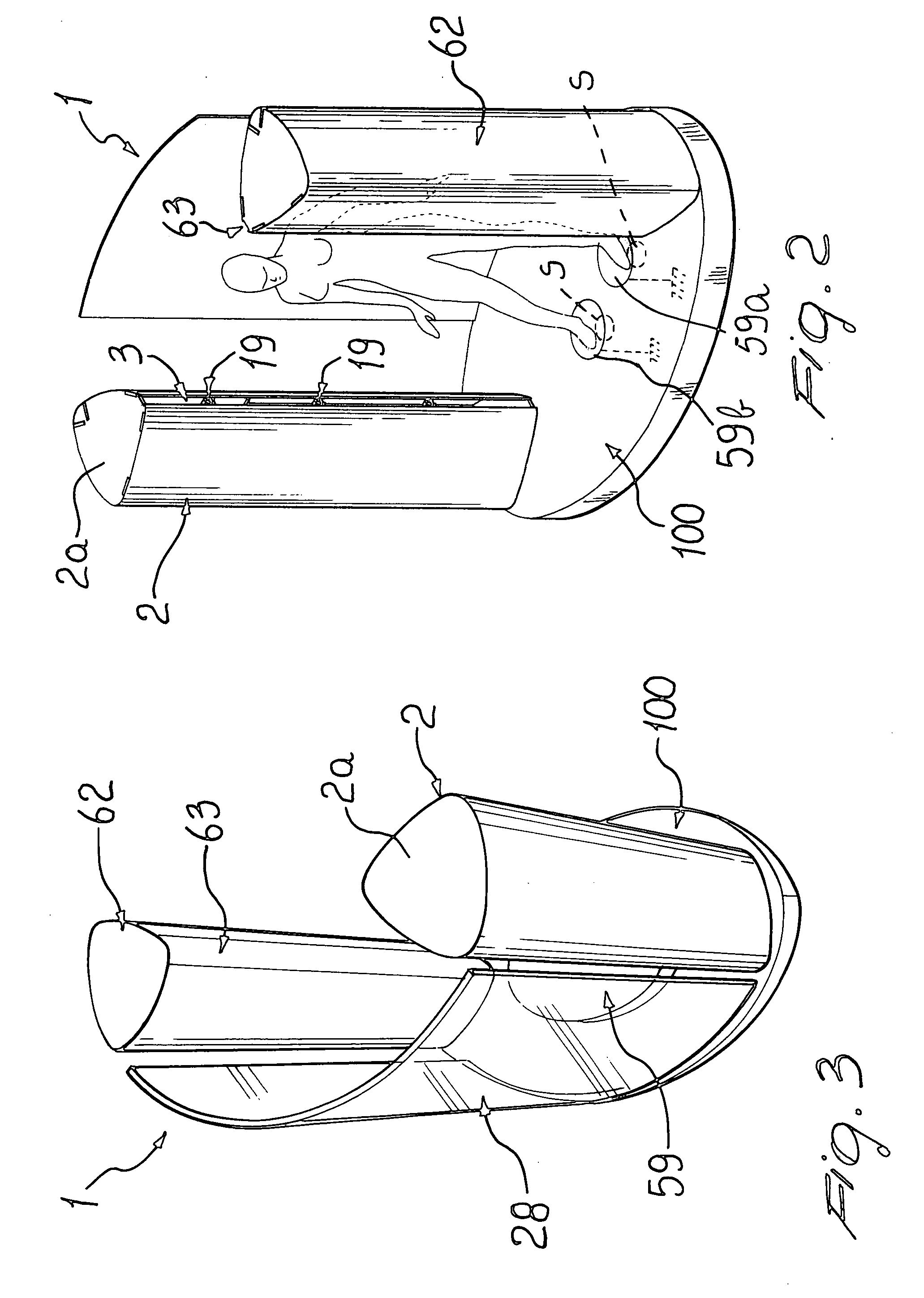

Device for applying a cosmetic product to the human body

InactiveUS20060032439A1Efficient depositionDispersion limitedLiquid surface applicatorsPhysical therapyHuman bodyBiomedical engineering

A device for applying a cosmetic product to the human body, constituted by at least one first column, which is arranged in an open space and is provided with a plurality of nozzles whose height can be adjusted for spraying a beneficial or cosmetic product that has been electrically precharged. The device further comprises a stand for the user, which is connected electrically to the ground at the post-positioning regions.

Owner:QUADRA MEDICAL

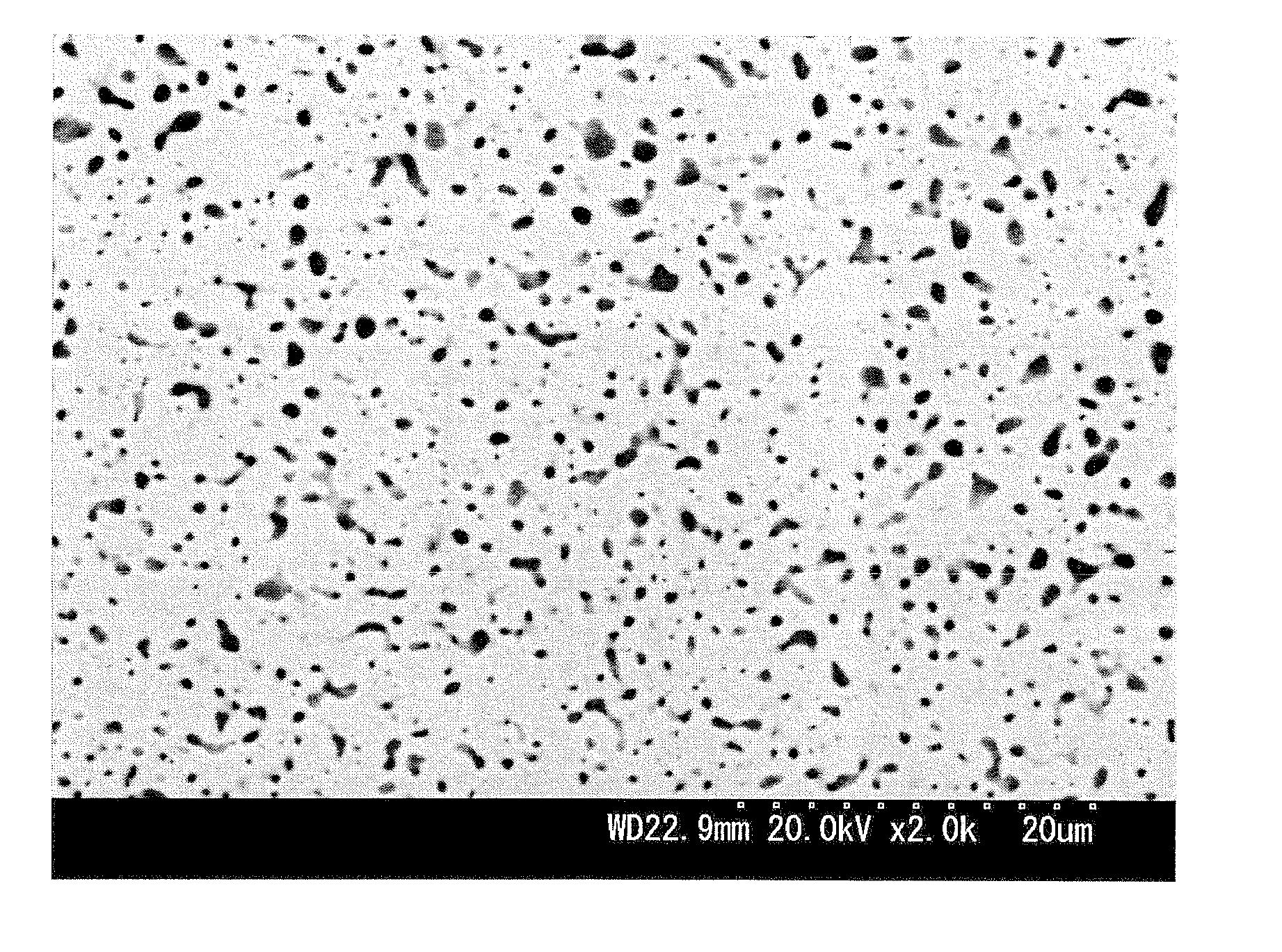

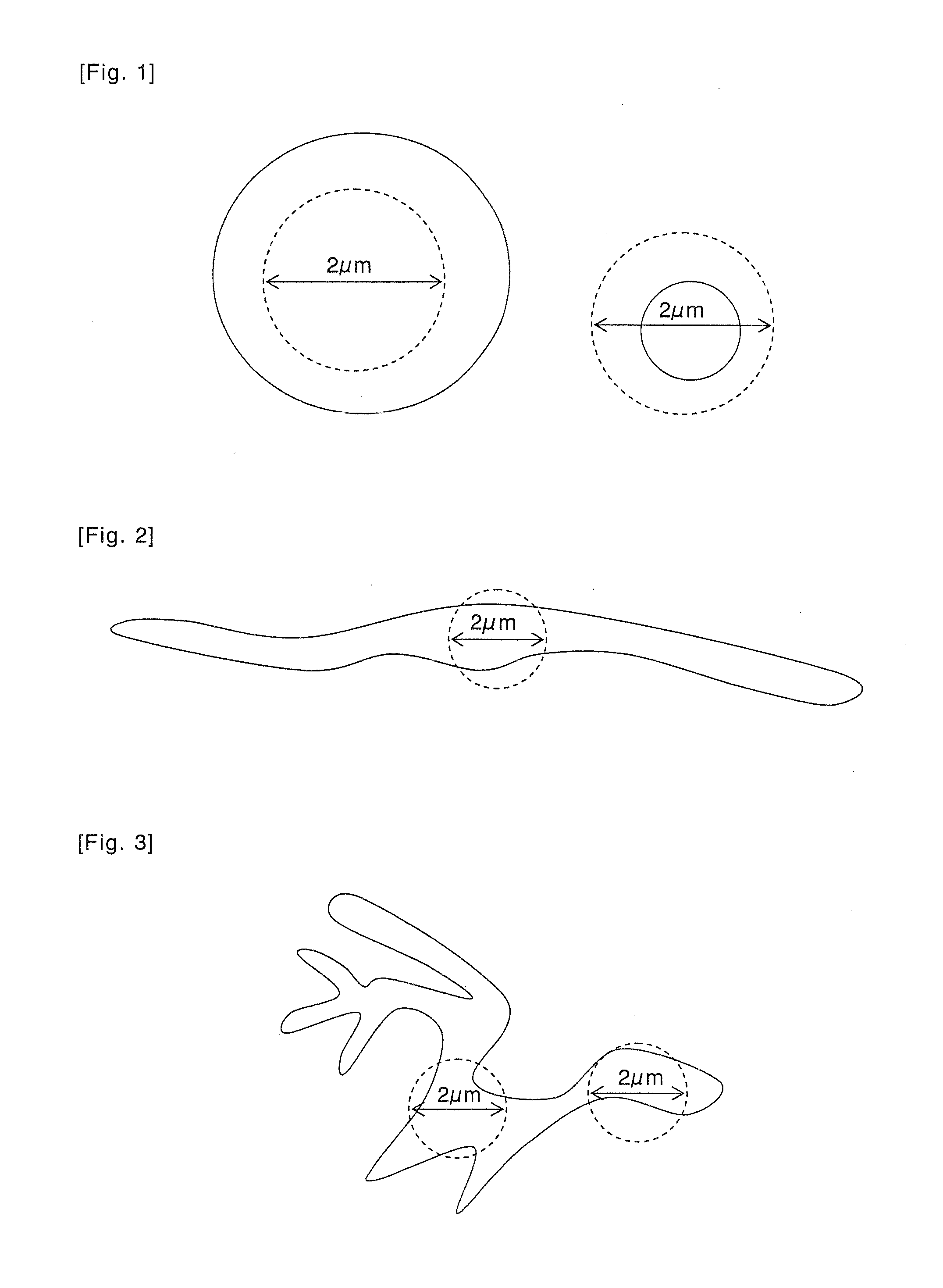

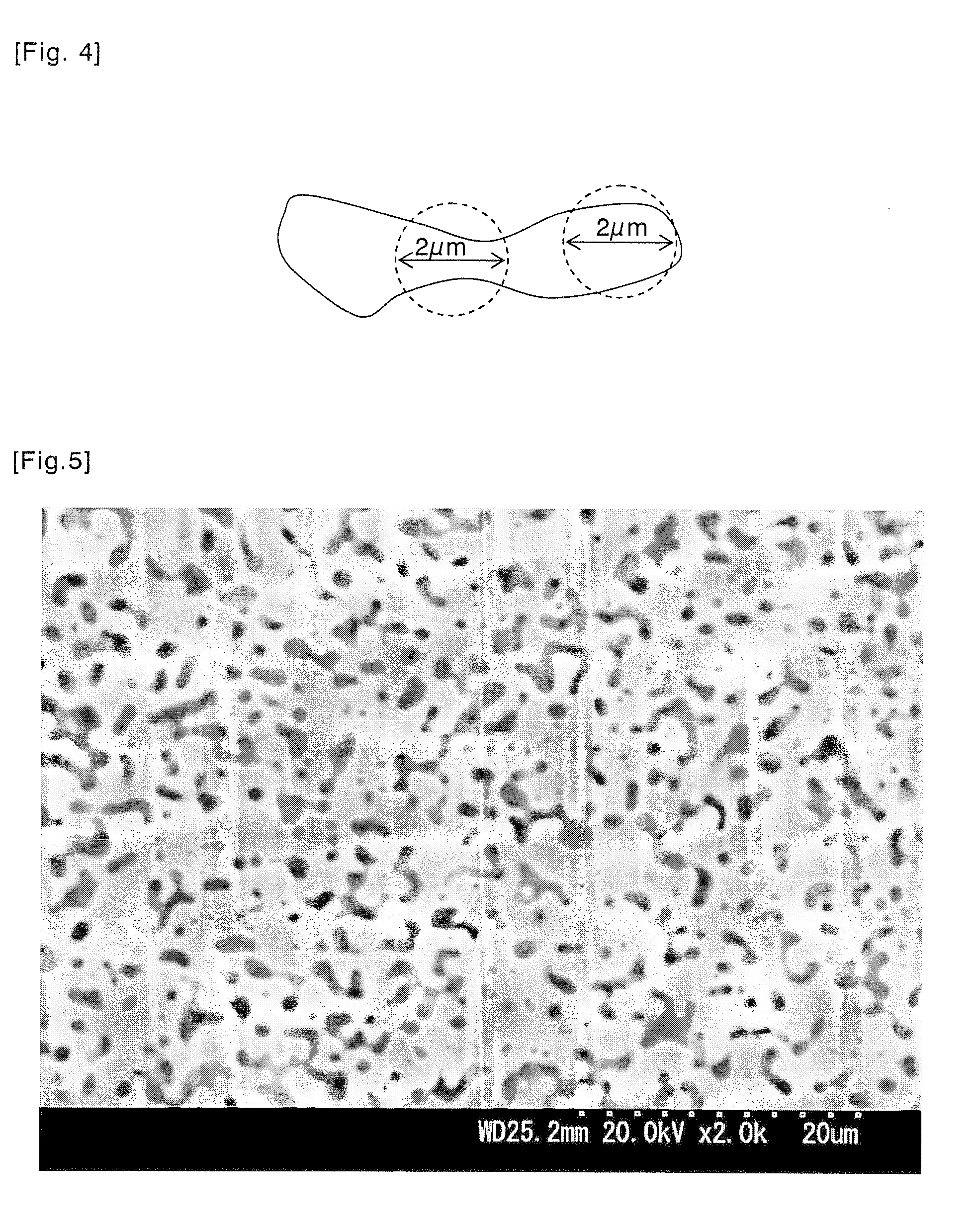

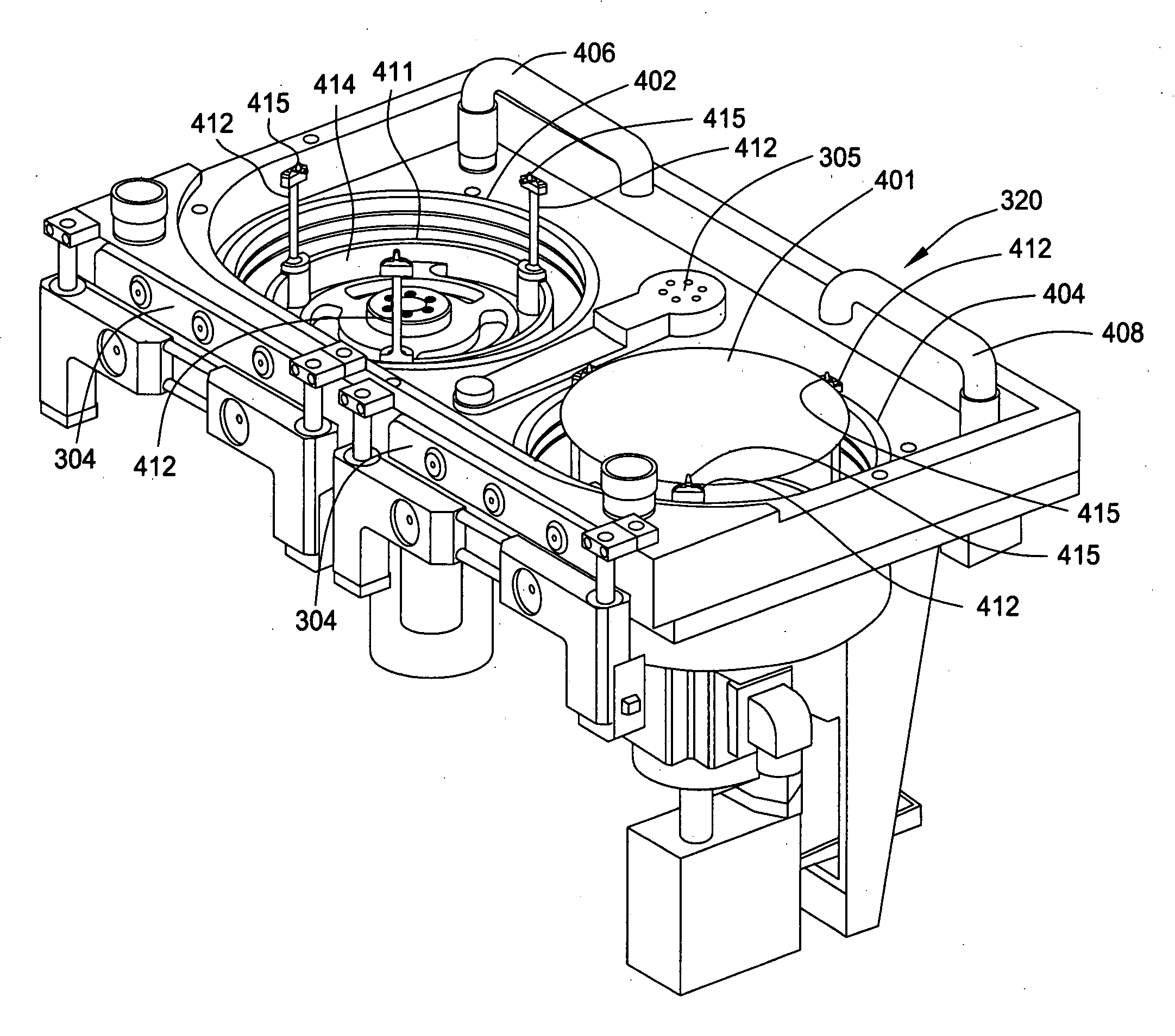

Sputtering Target of Nonmagnetic-Particle-Dispersed Ferromagnetic Material

ActiveUS20100320084A1Good effectDeposition speed is fastCellsConductive materialProduction rateSputtering

Provided is a sputtering target of nonmagnetic-particle-dispersed ferromagnetic material comprising a phase (A) such that nonmagnetic particles are dispersed in a ferromagnetic material formed from a Co—Cr alloy containing 5 at % or more and 20 at % or less of Cr and Co as the remainder thereof, and schistose textures (B) with a short side of 30 to 100 μm and a long side of 50 to 300 μm formed from a Co—Cr alloy phase in the phase (A); wherein each of the foregoing nonmagnetic particles has such a shape and size that the particle is smaller than all hypothetical circles with a radius of 1 μm around an arbitrary point within the nonmagnetic particle, or a shape and size with at least two contact points or intersection points between the respective hypothetical circles and the interface of the ferromagnetic material and the nonmagnetic material. Consequently, obtained is a high-density sputtering target of nonmagnetic-particle-dispersed ferromagnetic material whose crystal grains are fine, which realizes improvement of PTF (pass through flux) of the target, high-speed deposition with a magnetron DC sputtering system, reduction in the particles (dust) and nodules generated during the sputtering process, minimal variation in quality, and improvement of mass productivity.

Owner:JX NIPPON MINING& METALS CORP

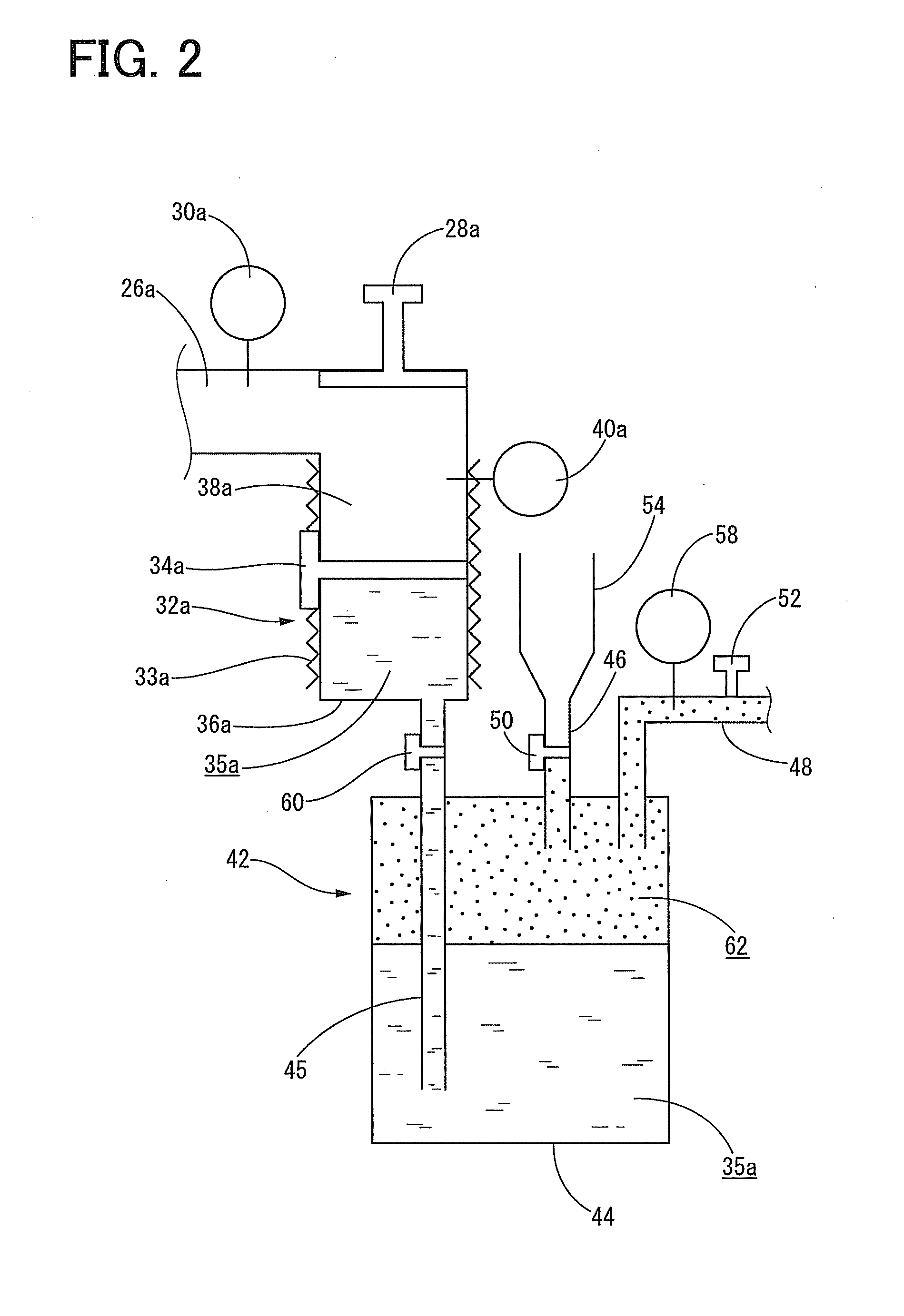

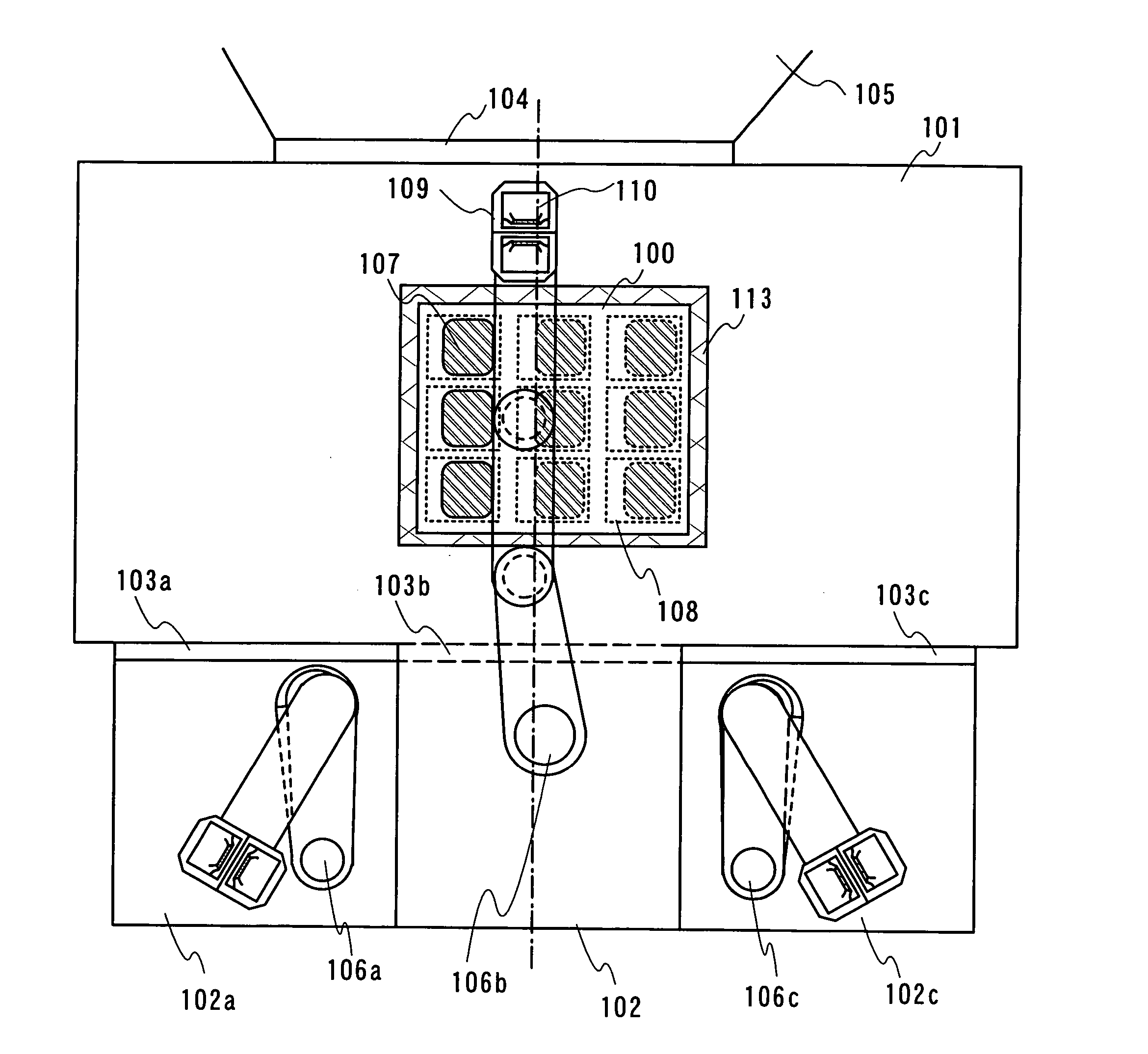

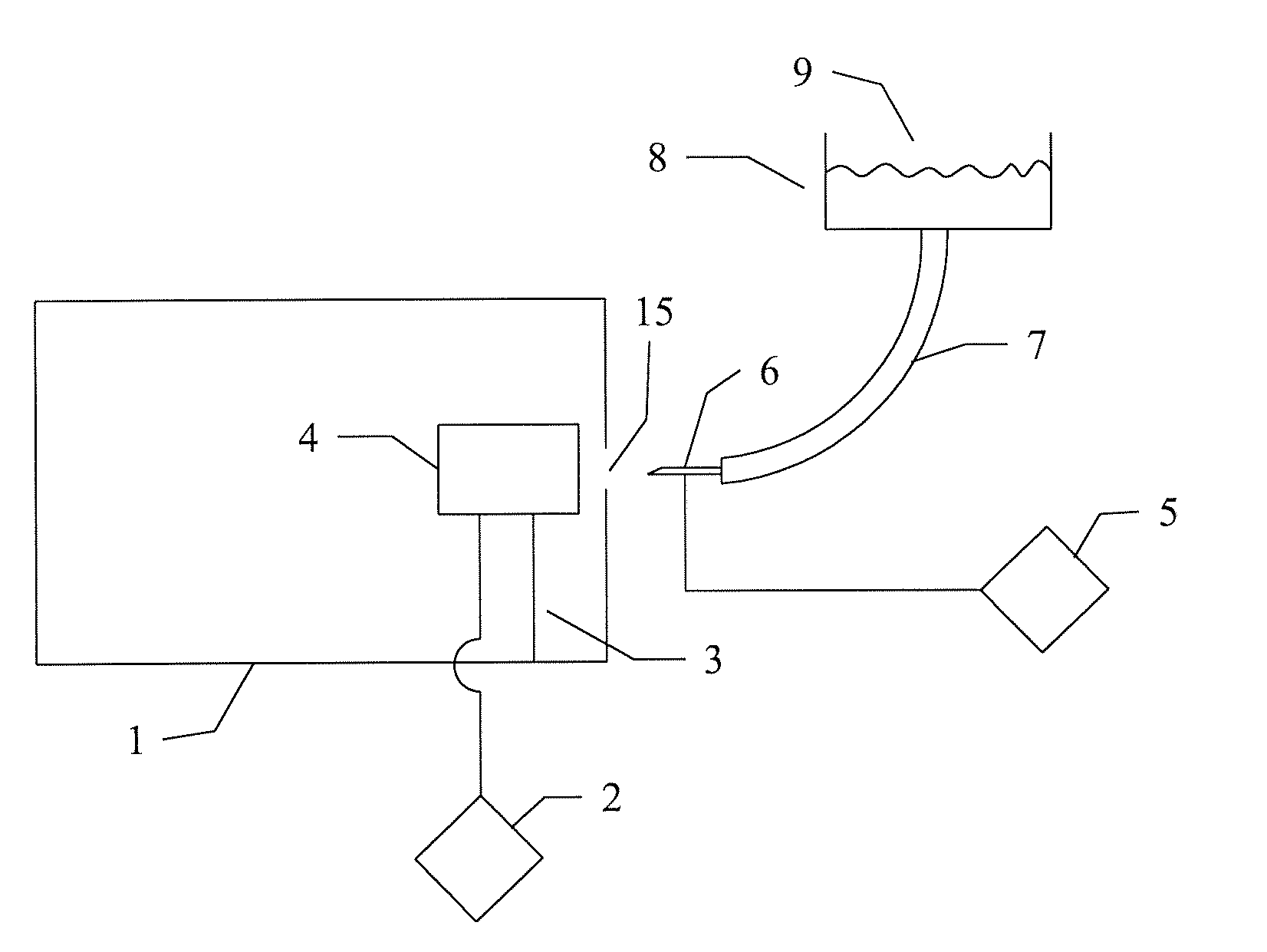

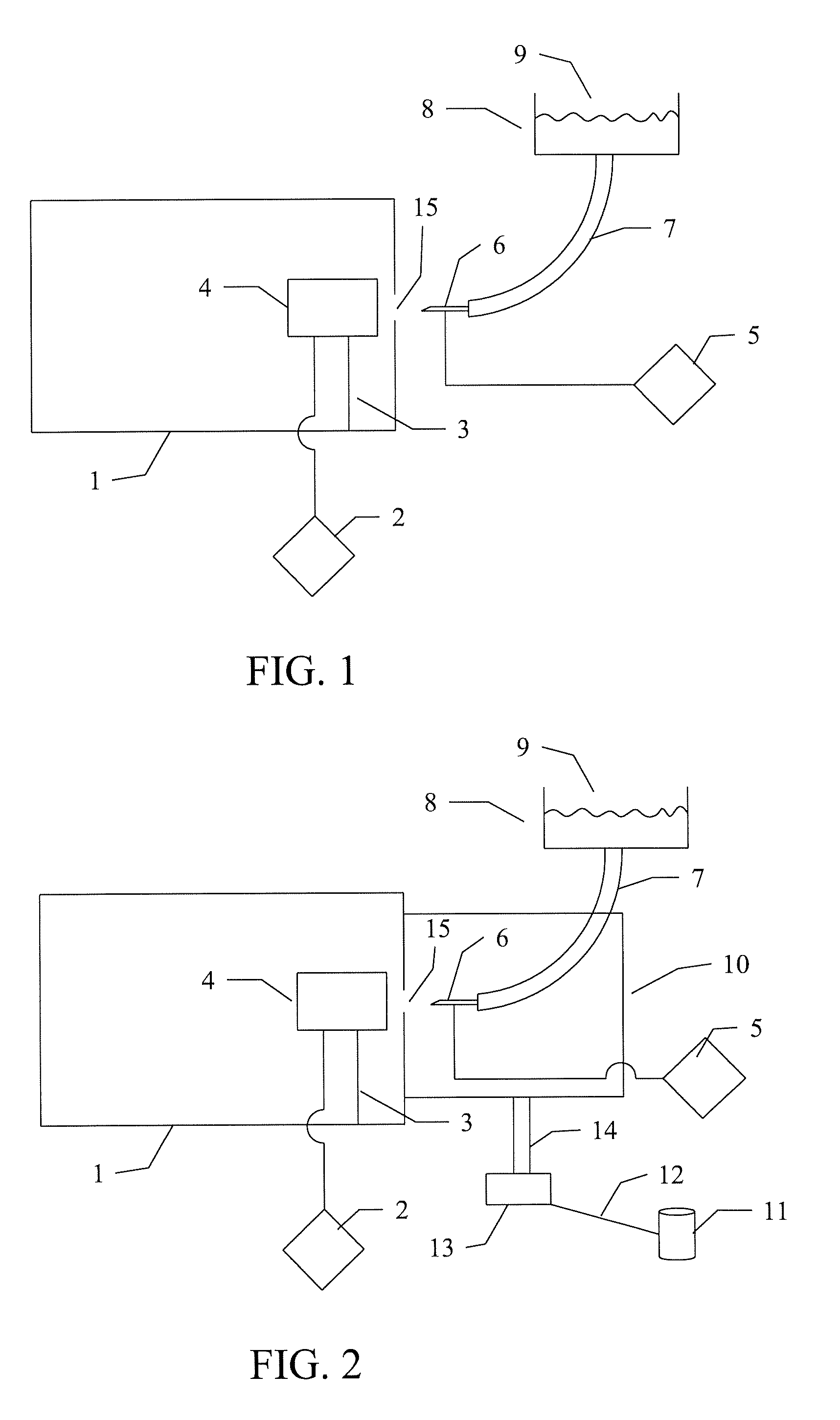

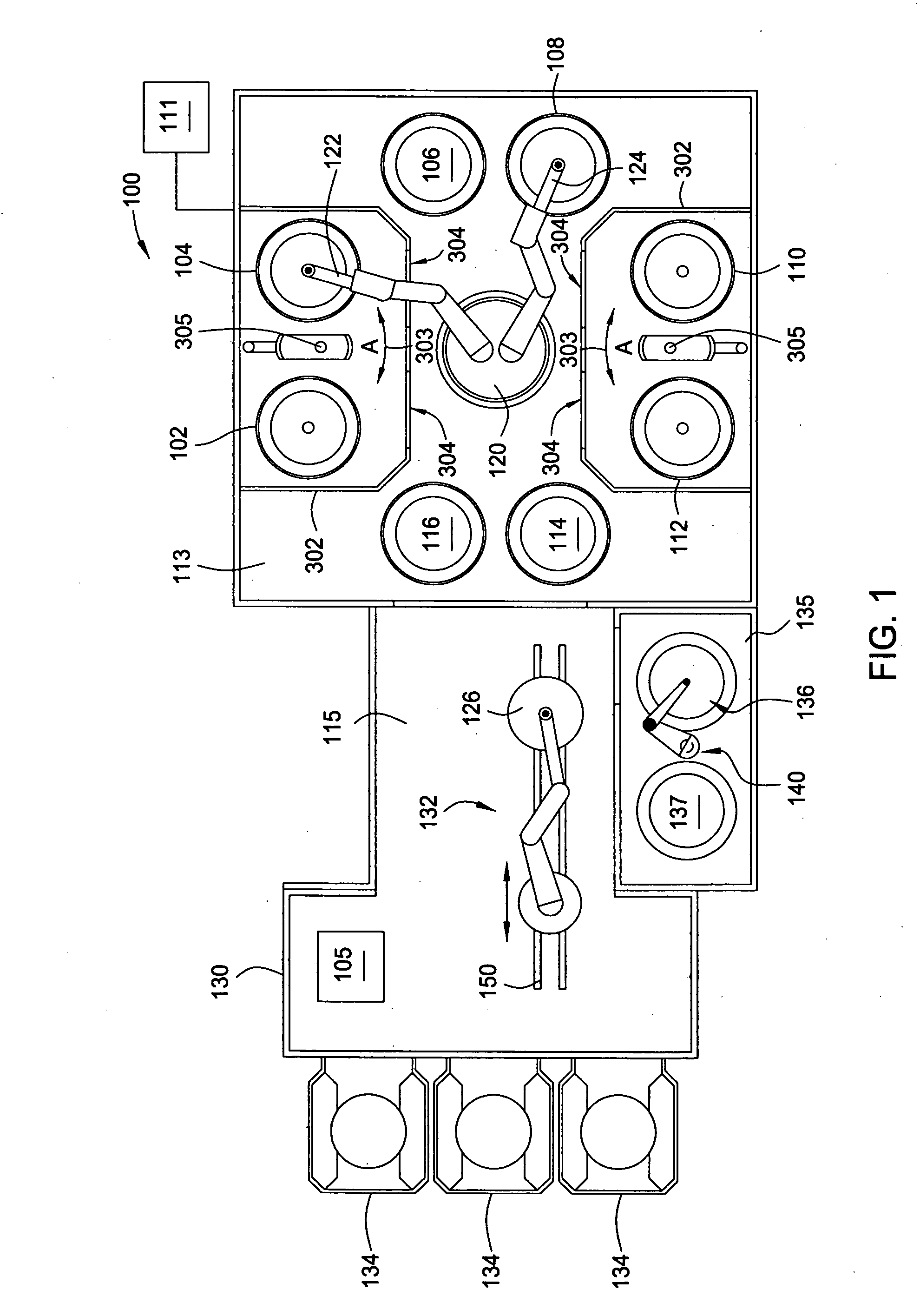

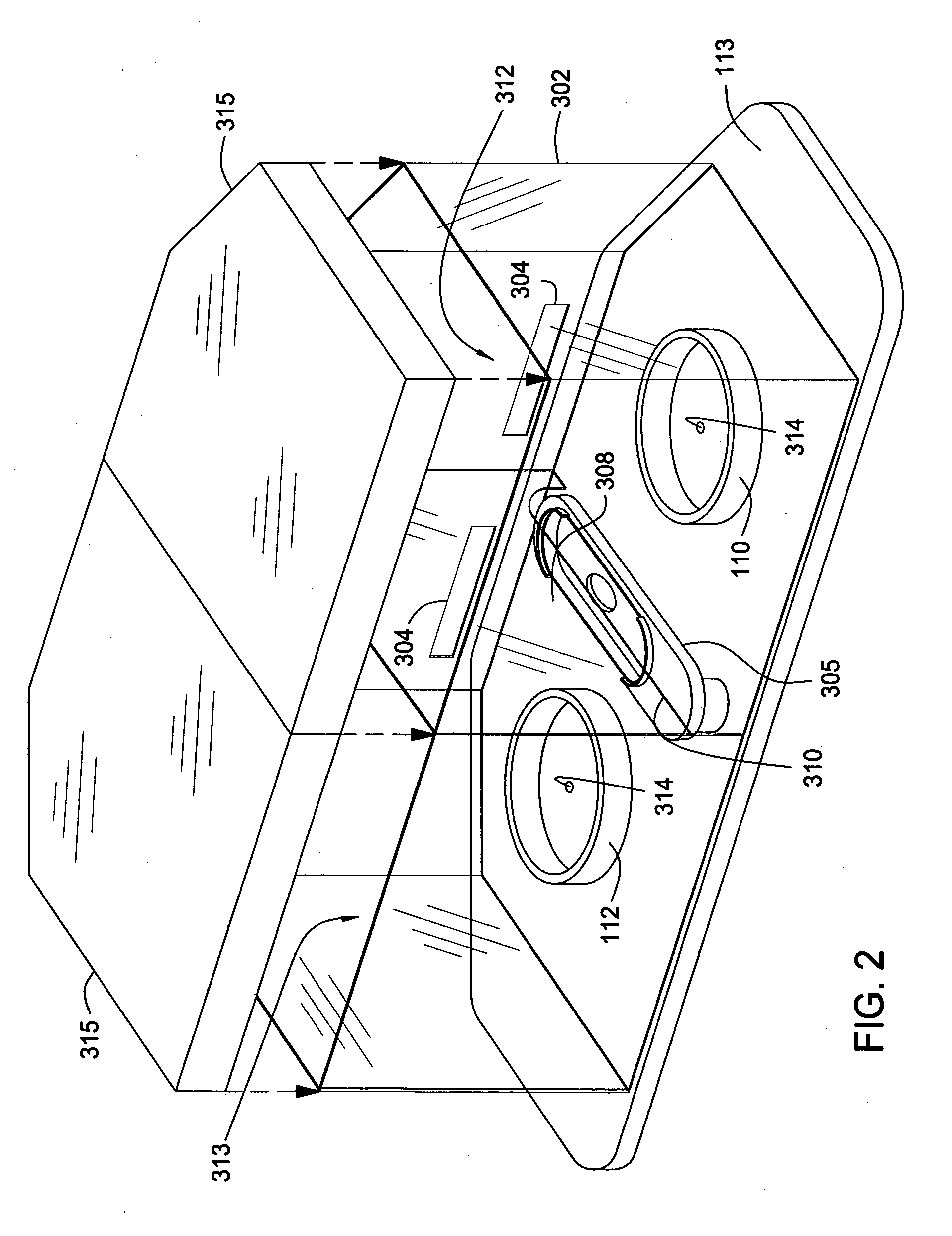

Apparatus for electroless deposition of metals onto semiconductor substrates

ActiveUS20050160990A1Efficient depositionMinimal defectCellsLiquid surface applicatorsRobot positionEngineering

An electroless deposition system is provided. The system includes a processing mainframe, at least one substrate cleaning station positioned on the mainframe, and an electroless deposition station positioned on the mainframe. The electroless deposition station includes an environmentally controlled processing enclosure, a first processing station configured to clean and activate a surface of a substrate, a second processing station configured to electrolessly deposit a layer onto the surface of the substrate, and a substrate transfer shuttle positioned to transfer substrates between the first and second processing stations. The system also includes a substrate transfer robot positioned on the mainframe and configured to access an interior of the processing enclosure.

Owner:APPLIED MATERIALS INC

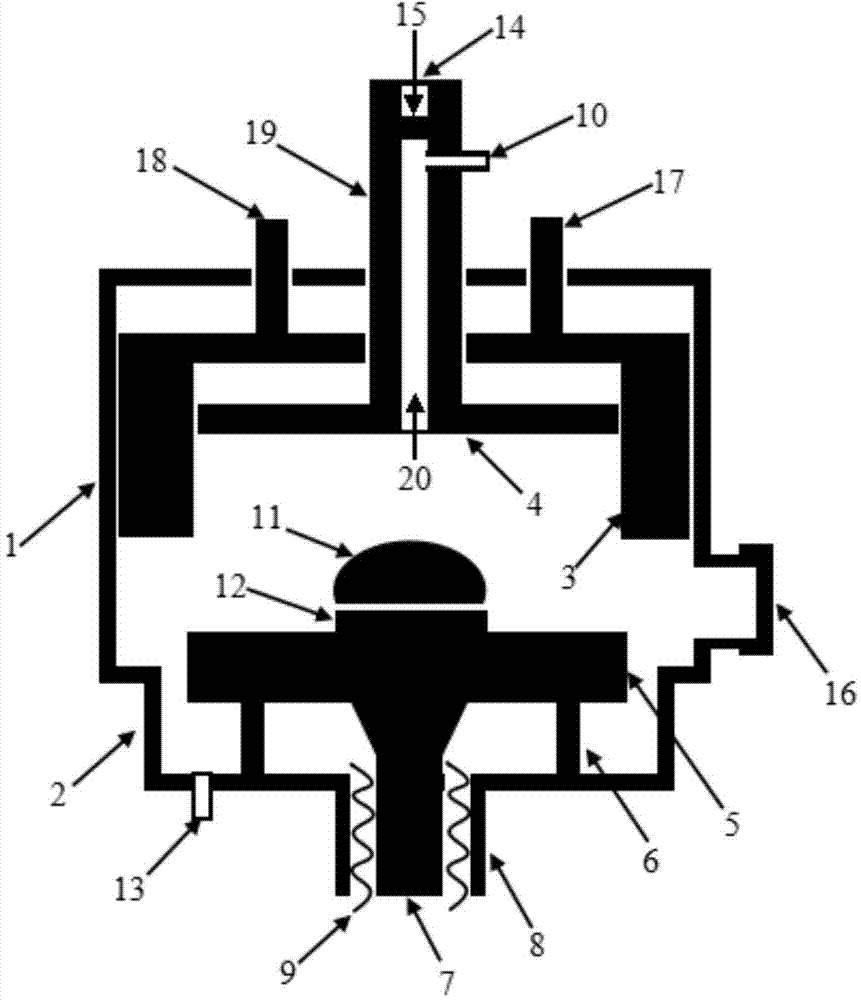

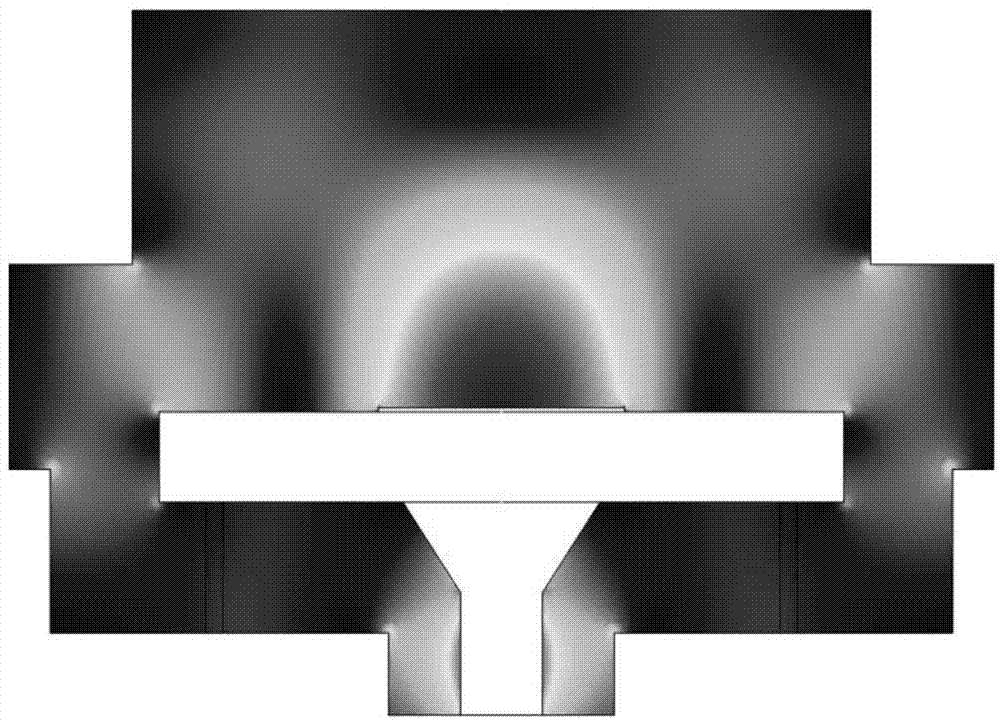

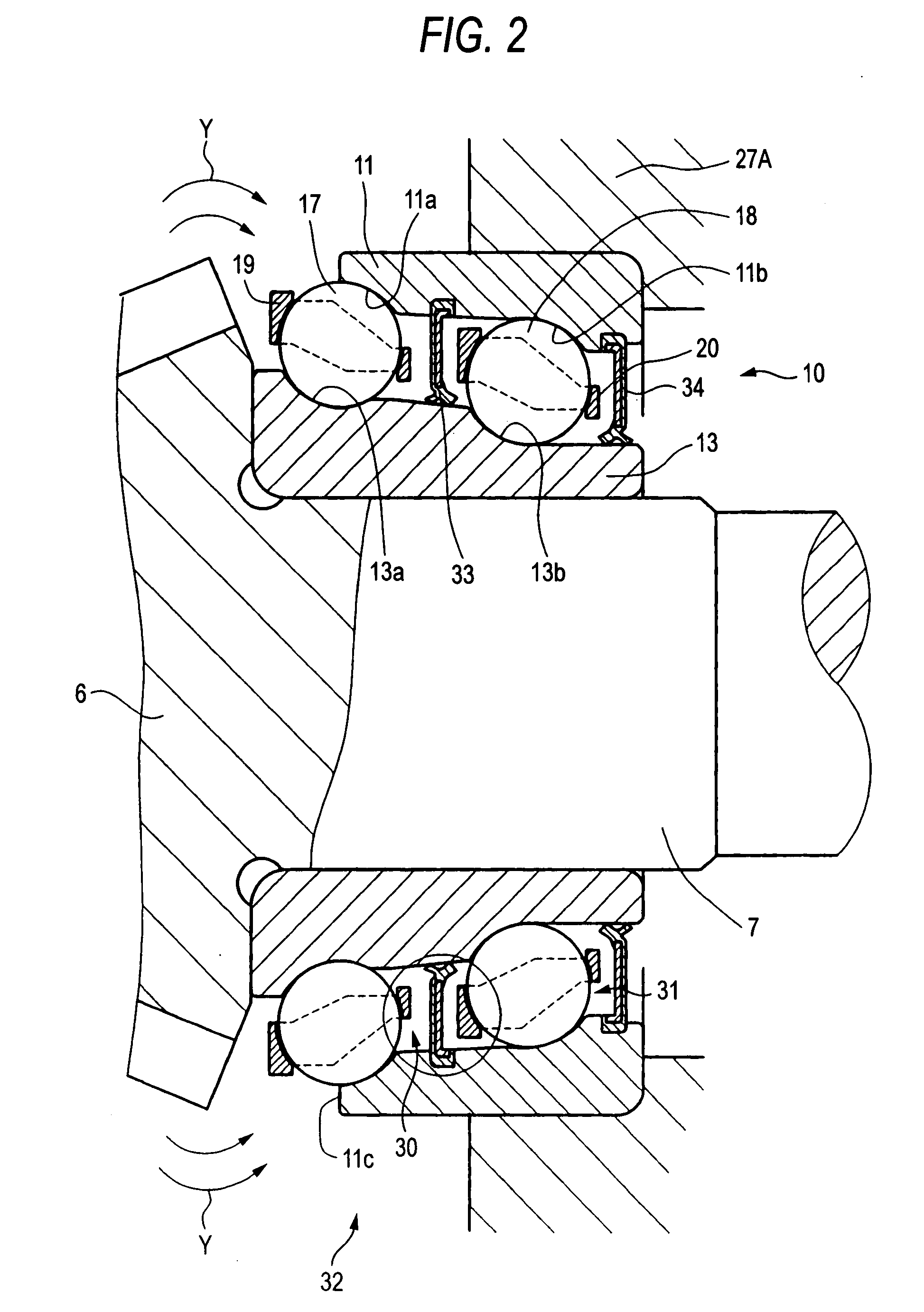

TM021 modal high-power microwave plasma diamond film deposition device

ActiveCN103695865ADeposition high speedStable positionElectric discharge tubesChemical vapor deposition coatingResonant cavityMaterials science

The invention provides a TM021 modal high-power microwave plasma diamond film deposition device. The TM021 modal high-power microwave plasma diamond film deposition device comprises an upper cylinder, a lower cylinder, an adjustable upper cavity, a microwave reflecting plate, a deposition table, a microwave coaxial excitation port, a microwave quartz port, a gas inlet, a gas outlet, a temperature measuring hole, an observing window and the like. The TM021 modal high-power microwave plasma diamond film deposition device has TM021 modal electric field distribution and the characteristics of centralized electric field distribution in a microwave resonator and stable excited plasma locations. The distribution of plasmas in the device can be optimized in real time through a regulating mechanism of the device. An annular microwave quartz window placed below the deposition table can be prevented from being excessively heated, polluted and etched by the plasmas. The inner wall of a resonant cavity is far away from a high-temperature plasma zone, so that the thermal radiation on the inner wall of the cavity is weakened, and foreign matter deposition is avoided. Each main part of the device can be directly water-cooled. Due to the advantages, the device can be applied to the input of relatively high-power microwaves, and the high-efficiency deposition of large-area high-quality diamond films is realized.

Owner:HEBEI PLASMA DIAMOND TECH

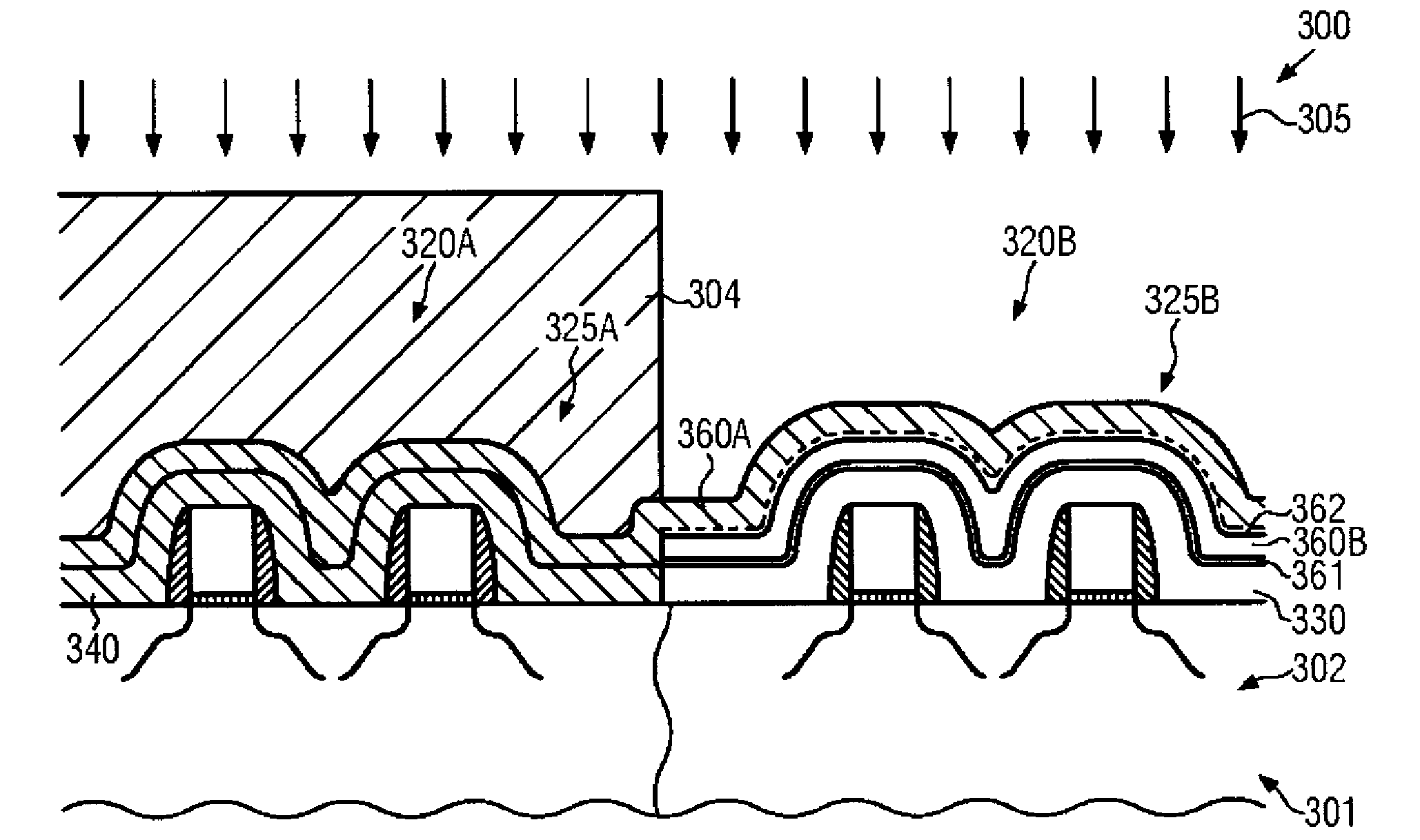

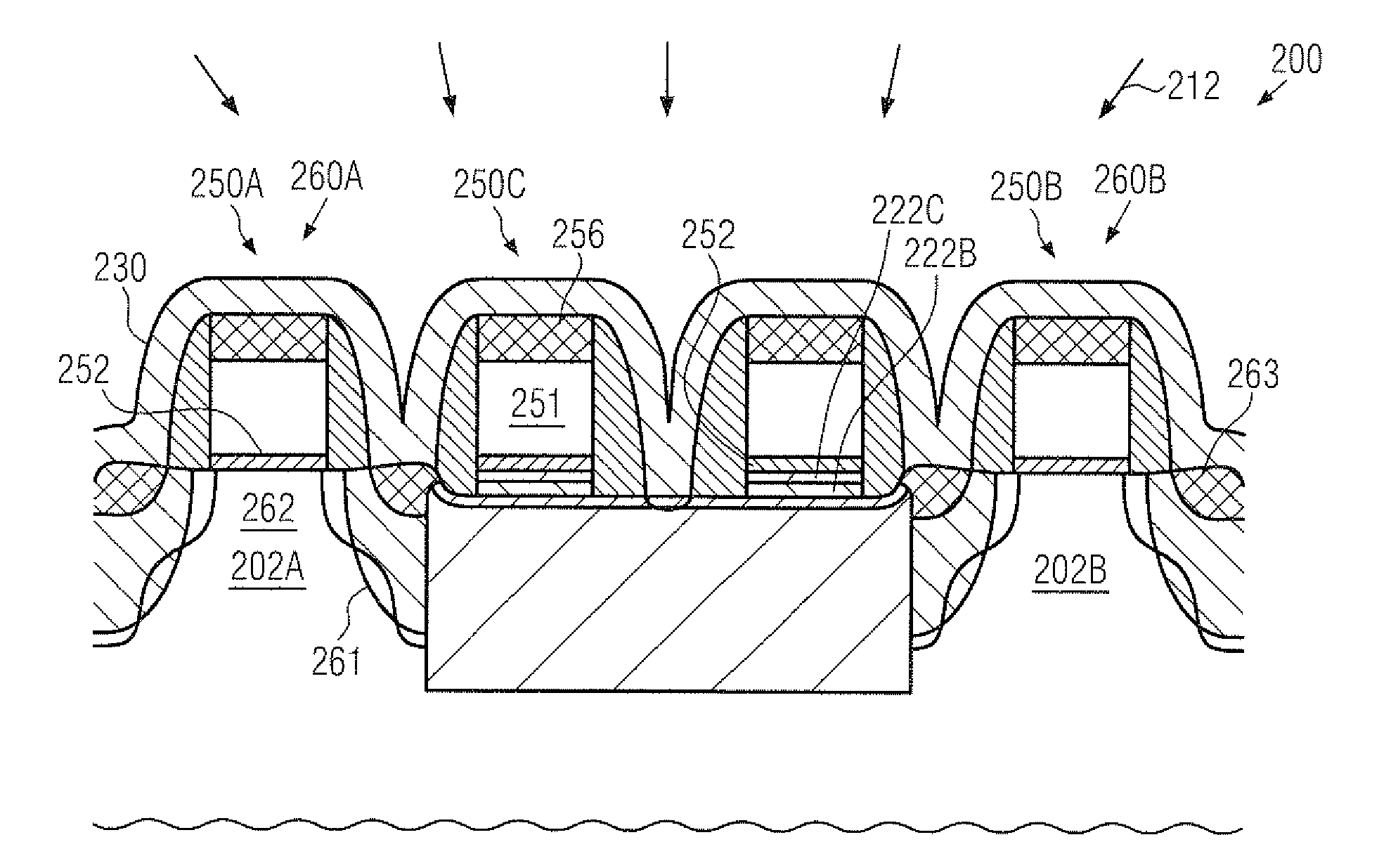

Enhanced stress transfer in an interlayer dielectric by using an additional stress layer above a dual stress liner in a semiconductor device

ActiveUS20080179661A1Low efficiencyEfficient depositionTransistorSemiconductor/solid-state device manufacturingPattern sequenceEngineering

By forming an additional stressed dielectric material after patterning dielectric liners of different intrinsic stress, a significant increase of performance in transistors may be obtained while substantially not contributing to patterning non-uniformities during the formation of respective contact openings in highly scaled semiconductor devices. The additional dielectric layer may be provided with any type of intrinsic stress, irrespective of the previously selected patterning sequence.

Owner:ADVANCED MICRO DEVICES INC

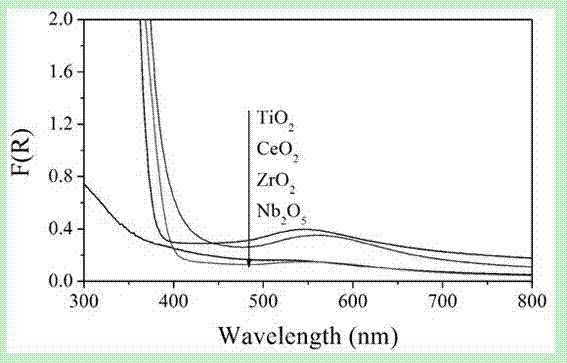

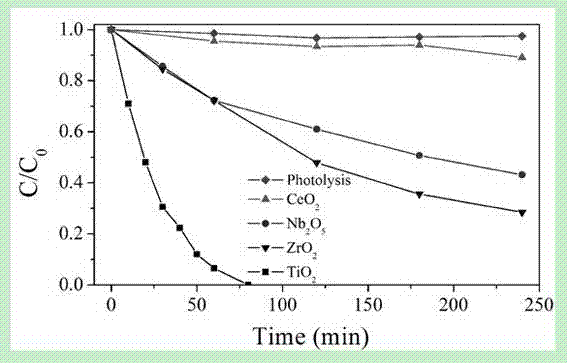

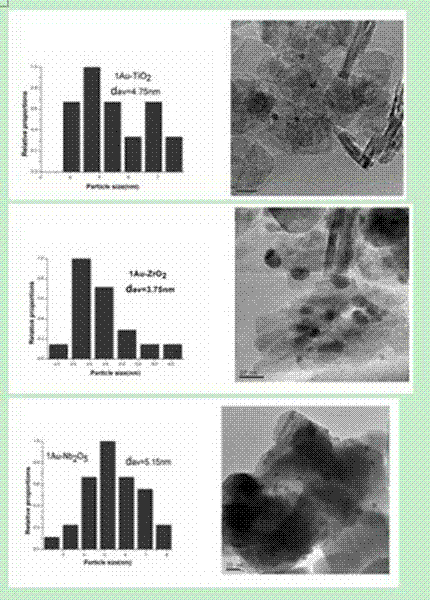

Preparation method of visible light catalyst with surface plasmon effect and application thereof

InactiveCN102350346AEfficient depositionControllable sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentNanoparticle

The invention relates to a preparation method of a visible light catalyst with a surface plasmon effect and application thereof. The active component of the visible light catalyst is a precious metal Au, and the carrier is one of TiO2, CeO2, Nb2O5, SiO2, Ta2O5, Al2O3 and ZrO2, wherein, Au accounts for 0.2-5% in mass content, and the particle size of Au particle is 2-20nm. Preparation of the catalyst consists of two steps: the first step is to prepare a carrier; the second step is to prepare an Au / TiO2 (CeO2, SiO2, Al2O3, Nb2O5, Ta2O5, ZrO2) visible light catalyst with a plasmon effect througha sol precipitation method. Au nanoparticles prepared by the method of the invention have good dispersibility, easily controllable size, high active component utilization rate, as well as the effect of high efficiency photocatalytic degradation of organic pollutants by visible light.

Owner:FUZHOU UNIV

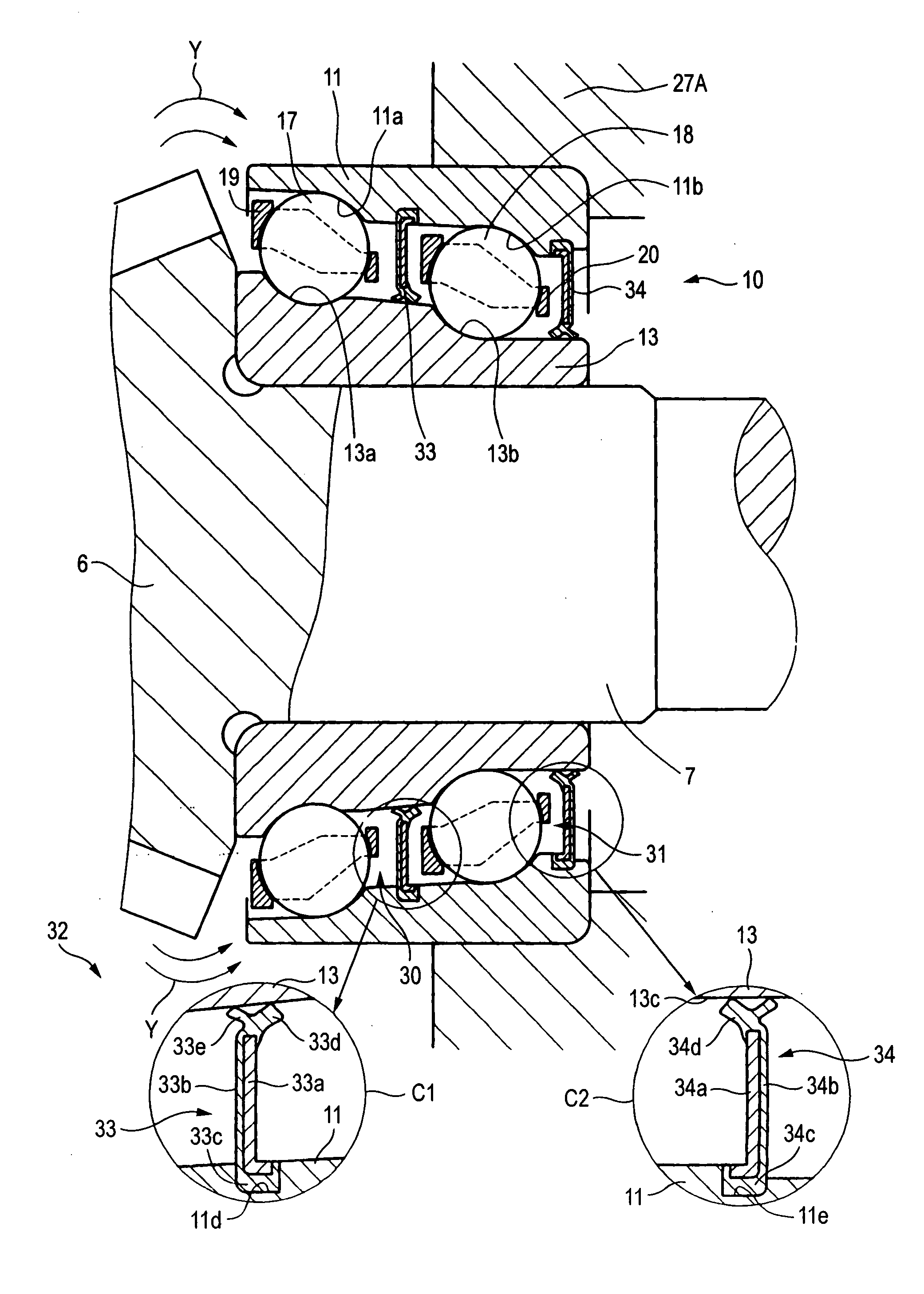

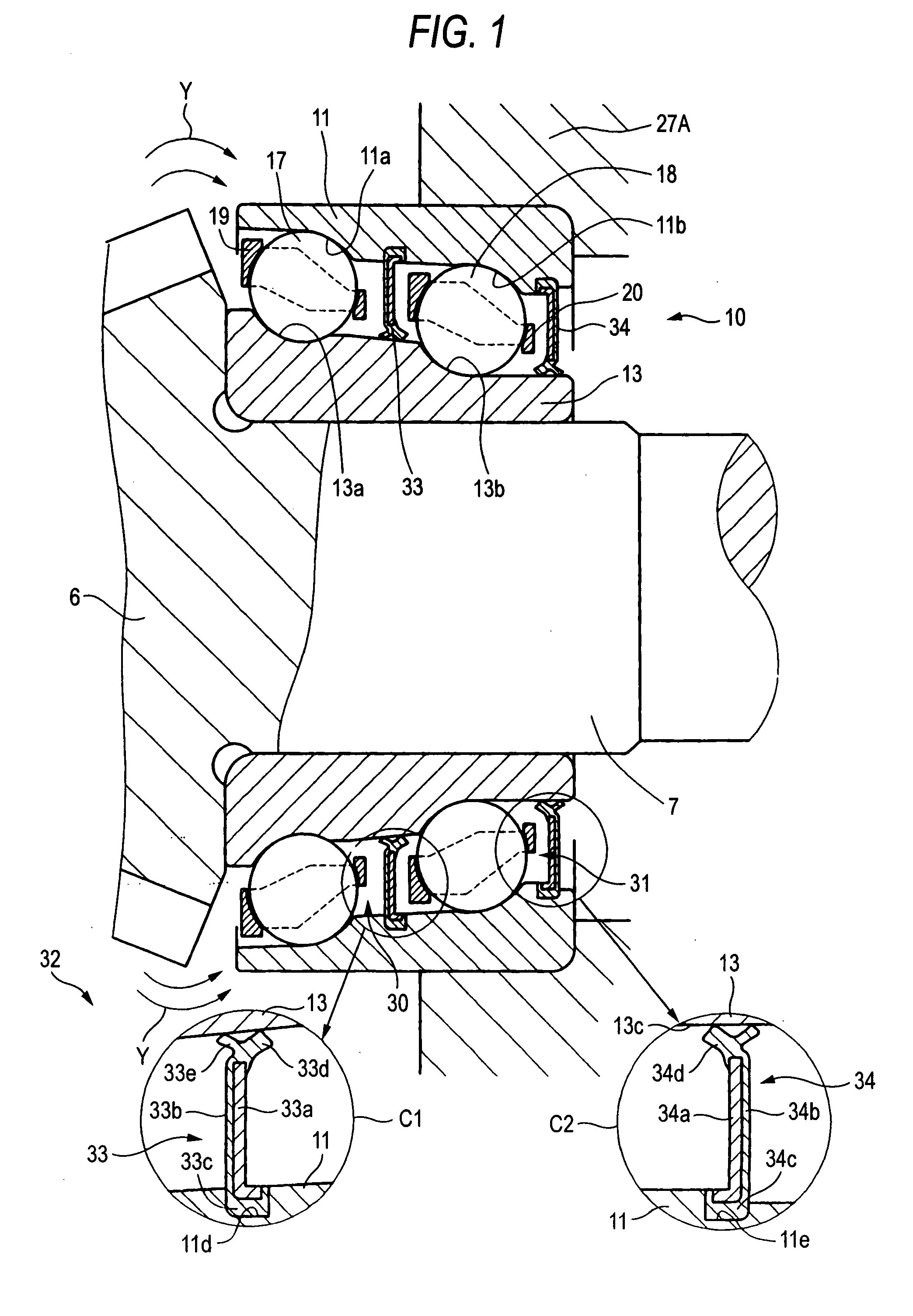

Rolling bearing device for supporting pinion shaft

InactiveUS20070242913A1Improve the rotation effectReducing a torque lossGearboxesShaftsInterior spaceBall bearing

In a bearing device, a double row rolling bearing for supporting a pinion gear-side portion of a pinion shaft on a case (annular wall) is formed by a tandem-type double row angular contact ball bearing. A first row of balls having a larger pitch circle diameter are disposed between inner and outer rings of the double row angular contact ball bearing at a region near to the pinion gear, and a second row of balls having a smaller pitch circle diameter are disposed between the inner and outer rings at a region remote from the pinion gear. A bearing internal space is divided into a first bearing internal space containing the first ball row and open toward the pinion gear and a second bearing internal space containing the second ball row and sealed by partition walls formed respectively by bearing seals, lubricating grease being sealed in the second bearing internal space.

Owner:JTEKT CORP

Ellipsoidal high-power microwave plasma diamond film deposition device

ActiveCN104164658AEfficient depositionStable positionElectric discharge tubesChemical vapor deposition coatingForeign matterEtching

The invention relates to an ellipsoidal high-power microwave plasma diamond film deposition device which is composed of a staisecase annular microwave coupled system, an annular quartz microwave window arranged at the staircase of an annular antenna, an ellipsoidal microwave resonant cavity, an adjustable deposition table, a conical upper reflecting body, an adjustable cylindrical lower reflecting body, an inlet and outlet, a temperature measurement hole, a view window and the like. By utilizing the design of the ellipsoidal upper and lower focal points, the conical upper microwave reflecting body is positioned on the upper focal point, the deposition table is positioned on the lower focal point, and the electric field is distributed centrally, so the excited plasma has high position stability and high density; the hidden microwave window can be protected from plasma heating, pollution and etching; the adjustable microwave lower reflecting body and the deposition table optimize the plasma distribution in real time; the inner wall of the ellipsoidal resonant cavity is far from the high-temperature plasma region, so that the heat radiation of the plasma to the inner wall of the cavity is reduced, thereby avoiding depositing foreign matters; and all the components of the device are cooled with water. The device can implement high-efficiency deposition of a large-area high-quality diamond film under the condition of high power.

Owner:HEBEI PLASMA DIAMOND TECH

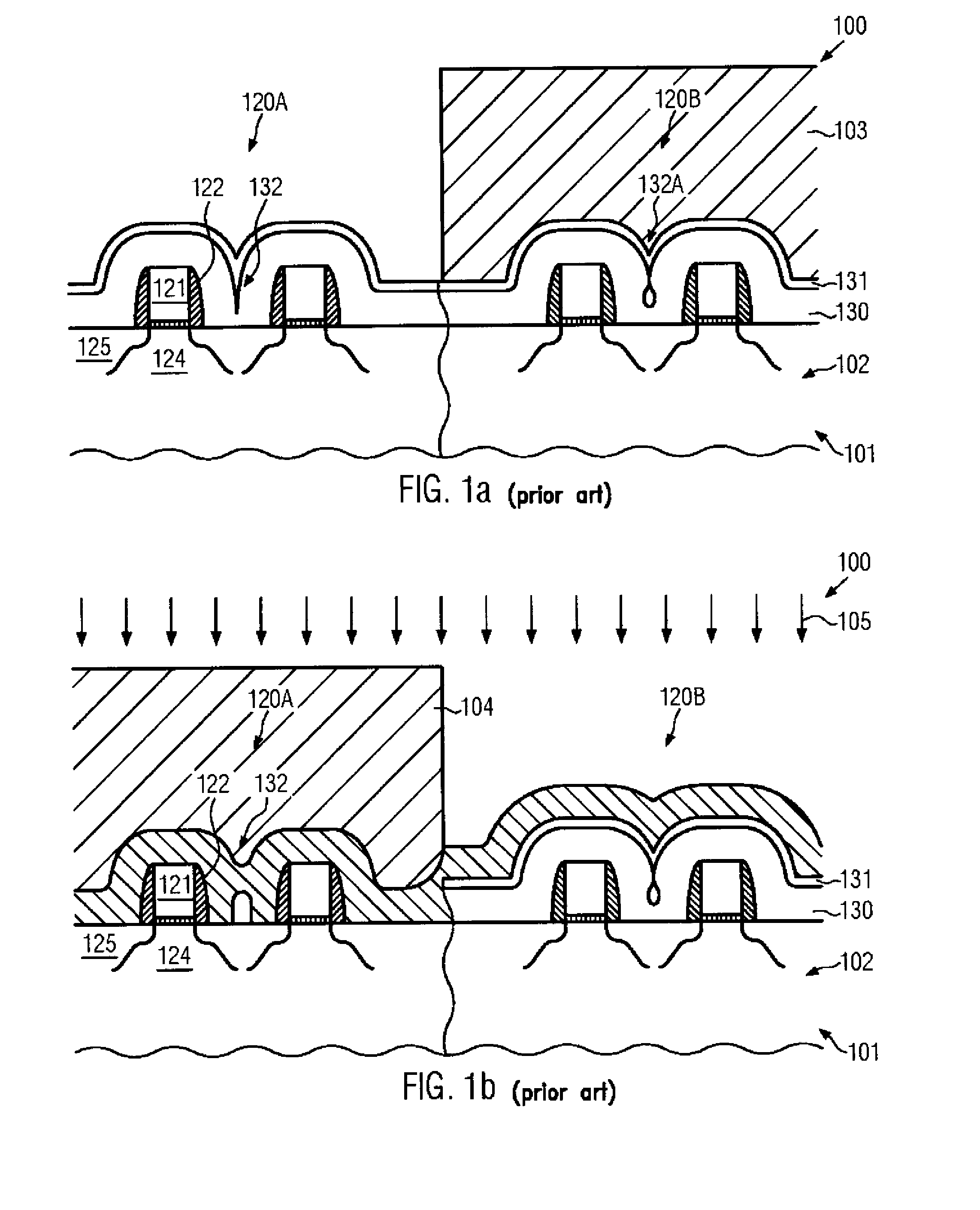

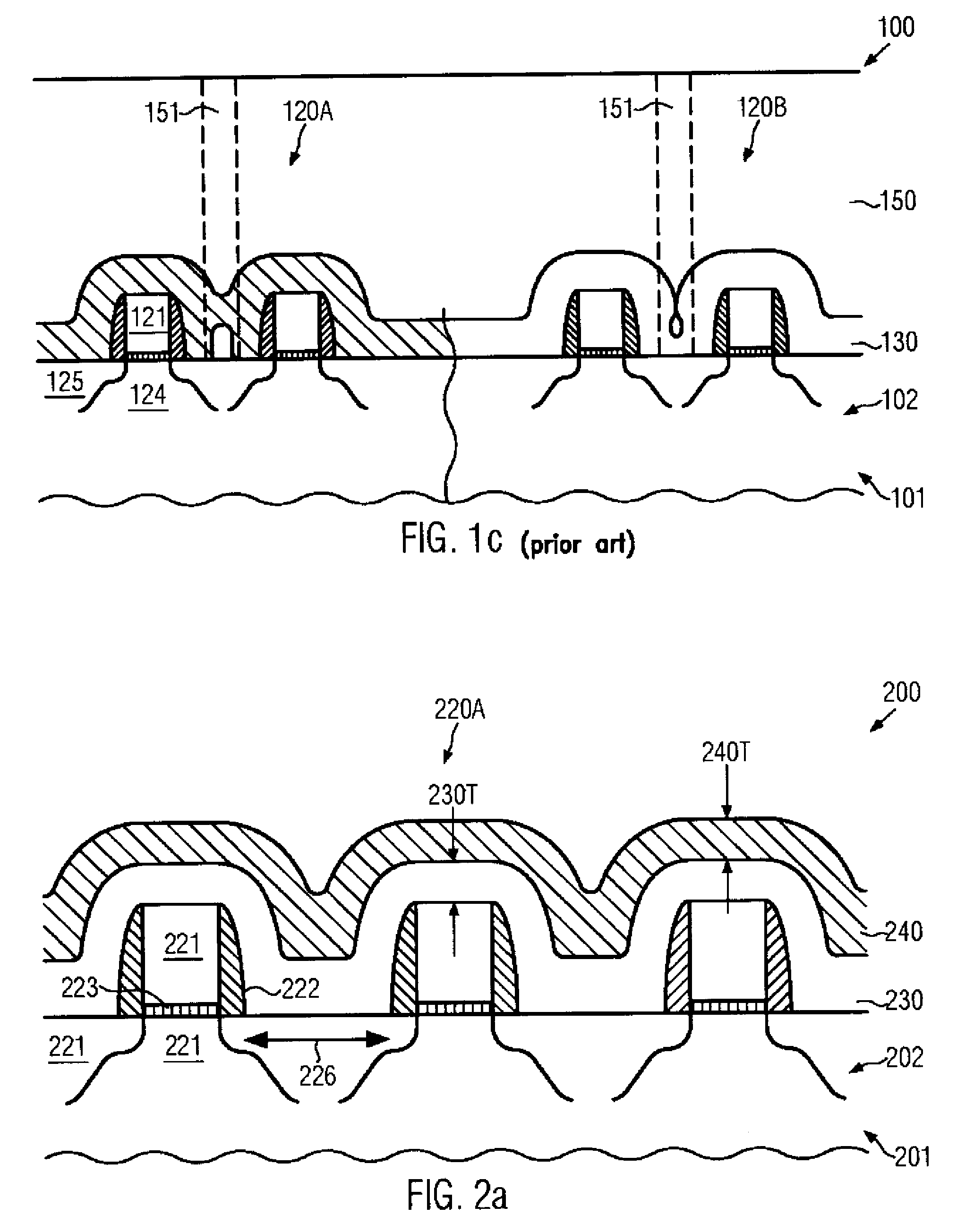

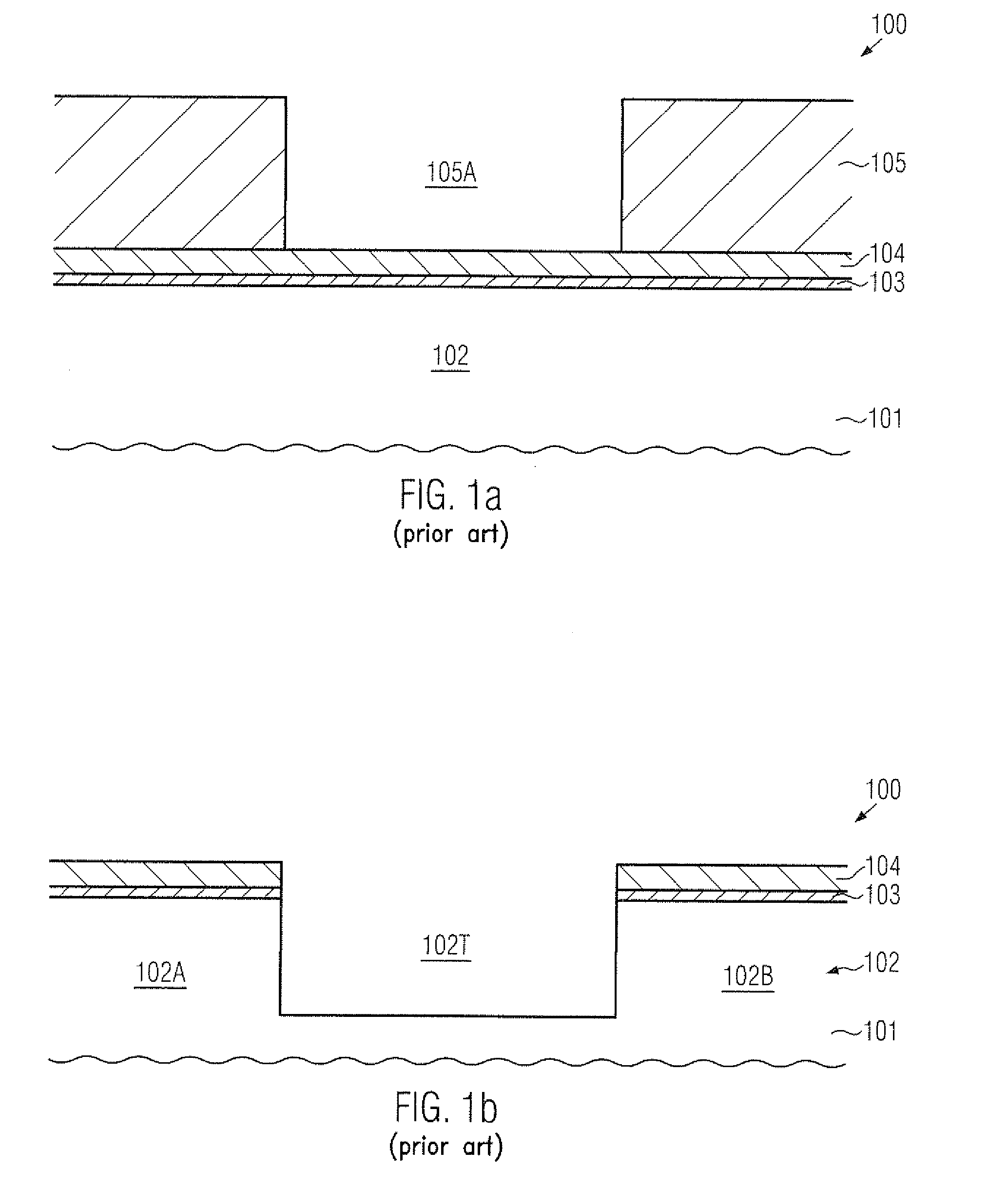

Buried etch stop layer in trench isolation structures for superior surface planarity in densely packed semiconductor devices

InactiveUS20110049637A1Suppress material erosionSuppress erosionTransistorSemiconductor/solid-state device manufacturingSilicon nitrideMaterial Erosion

Material erosion of trench isolation structures in advanced semiconductor devices may be reduced by incorporating an appropriate mask layer stack in an early manufacturing stage. For example, a silicon nitride material may be incorporated as a buried etch stop layer prior to a sequence for patterning active regions and forming a strain-inducing semiconductor alloy therein, wherein, in particular, the corresponding cleaning process prior to the selective epitaxial growth process has been identified as a major source for causing deposition-related irregularities upon depositing the interlayer dielectric material.

Owner:ALSEPHINA INNOVATIONS INC

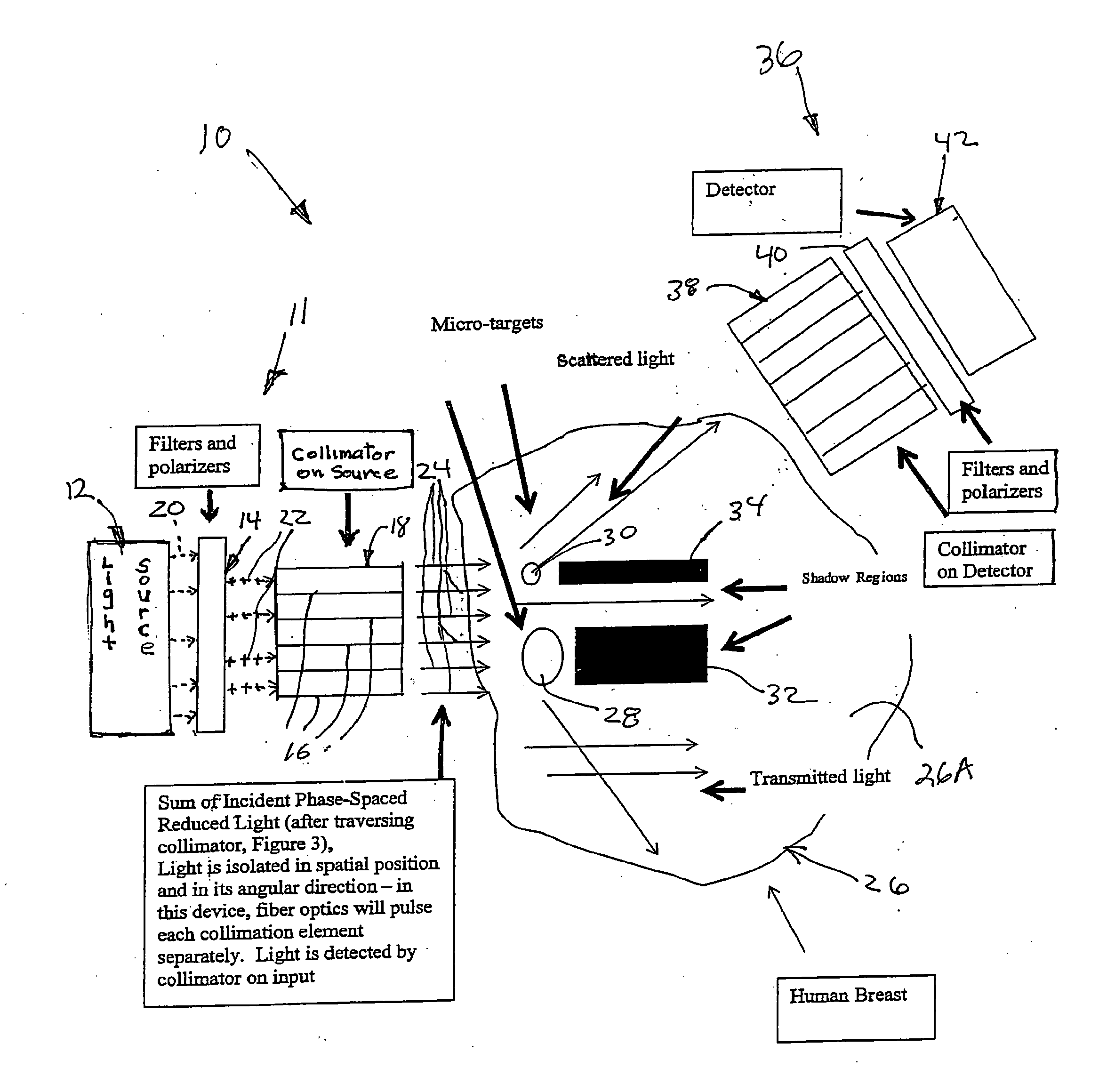

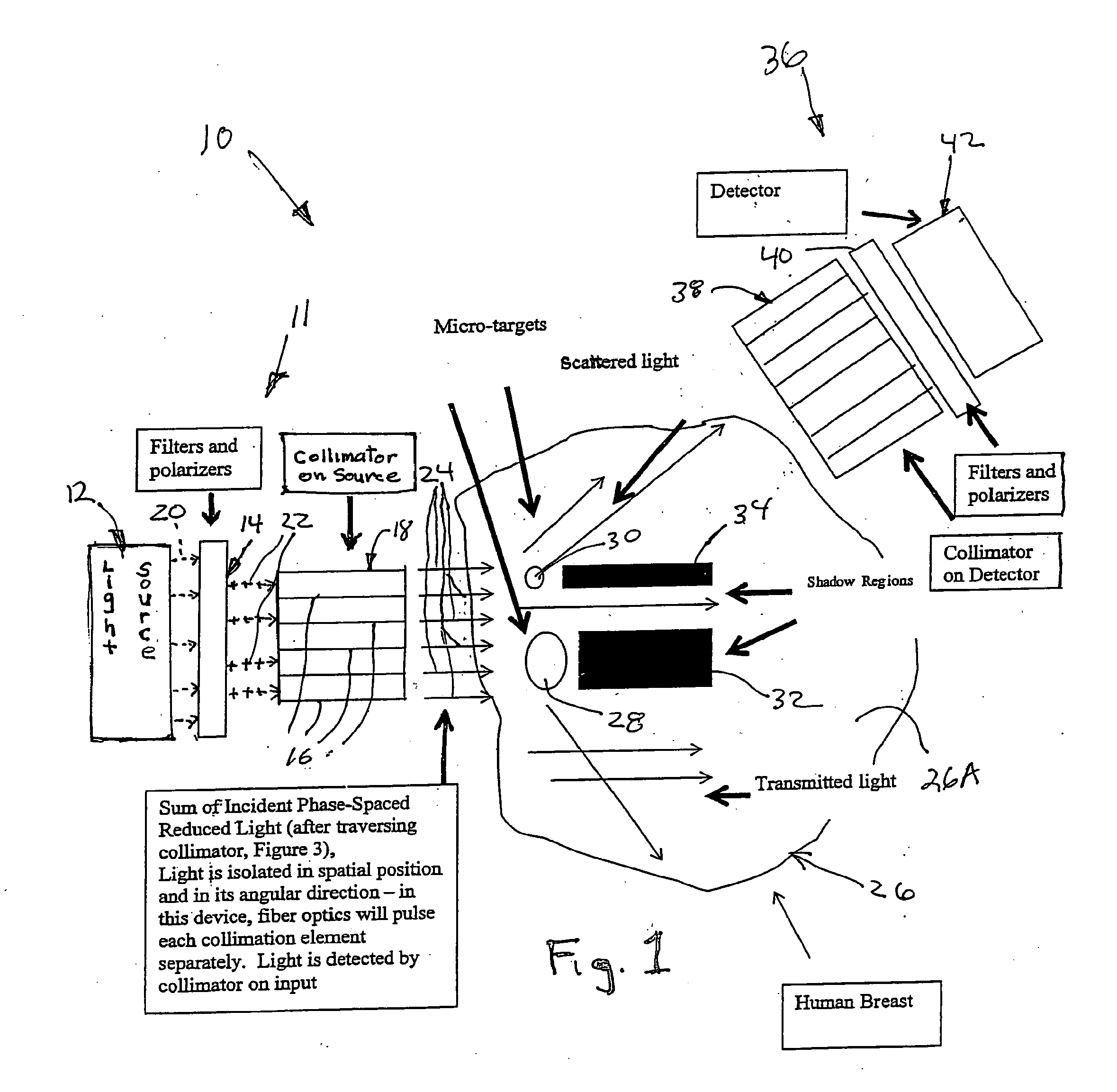

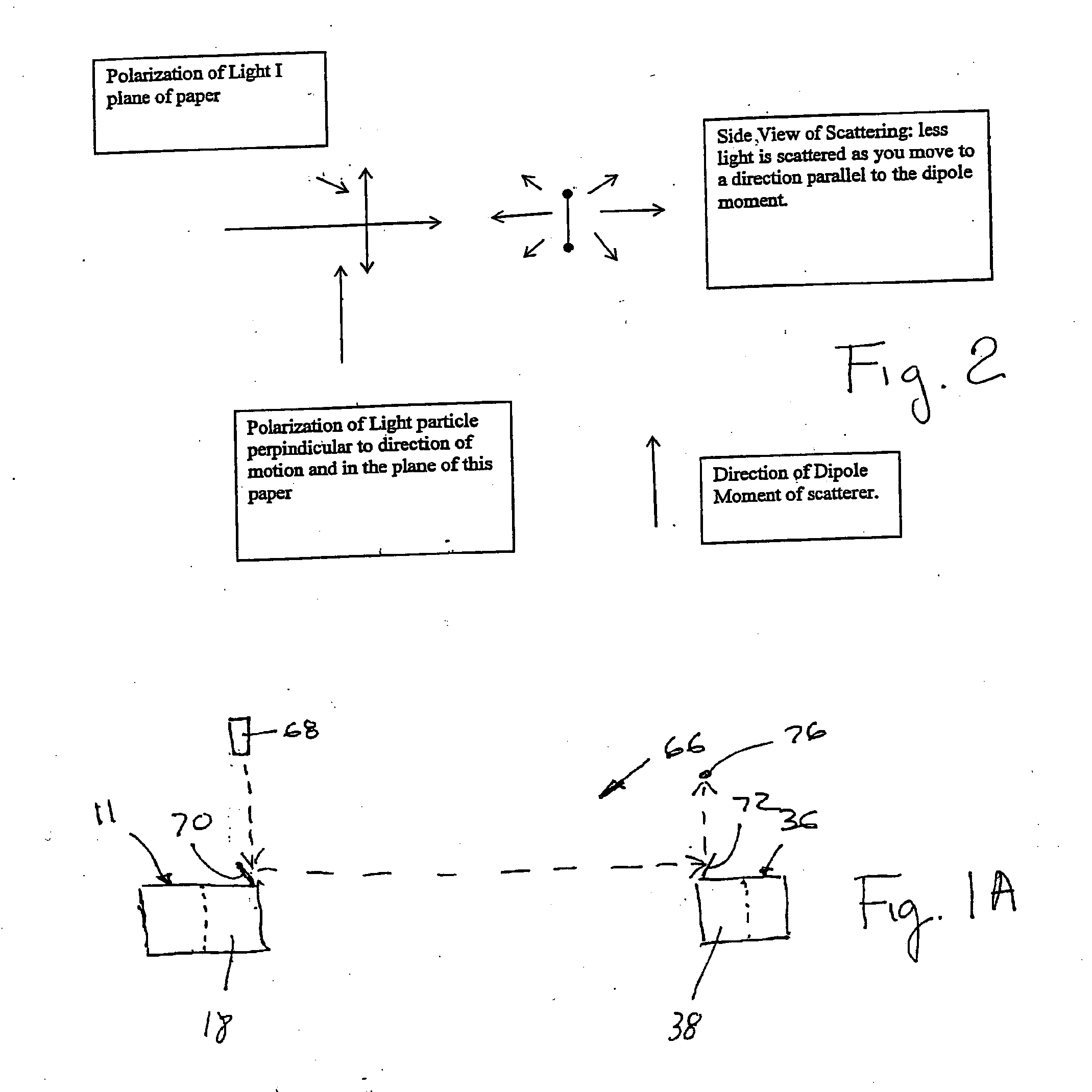

Apparatus and method for phase-space reduction for imaging of fluorescing, scattering and/or absorbing structures

InactiveUS20120059254A1Ease of use and safetyMaximum safetyEndoscopesLuminescent dosimetersInfraredFluorescence

A method and apparatus are disclosed for utilizing light, including ultraviolet, optical and / or infrared, for detecting a body in an object, such as biomaterial or tissue, animal and / or human tissue. The body or object may be made fluorescent by the use of dyes or agent. Light is used to illuminate the body and object and the scattered light, fluorescent and / or emitted light, reflected light and transmitted light are detected and used to reconstruct the body and / or object using an iterative analysis. Further, the method and apparatus may be extended to endoscopic applications to make subcutaneous images of internal tissue above, on, in or beyond endoscopic pathways such as esophagus, stomach, colon, bronchial tubes and / or other openings, cavities and spaces animate or inanimate, and in man-made or industrial materials as carbon / resin structures.

Owner:LIFAN WANG +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com