Metal-based/diamond laser composite coating and preparation method thereof

一种复合涂层、金刚石的技术,应用在金属材料涂层工艺、激光焊接设备、金属加工设备等方向,能够解决金刚石体积含量难以超过45%、涂层与基体结合力差、金刚石颗粒易脱落等问题,达到避免容易分解和溶解、不易脱落、结合良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

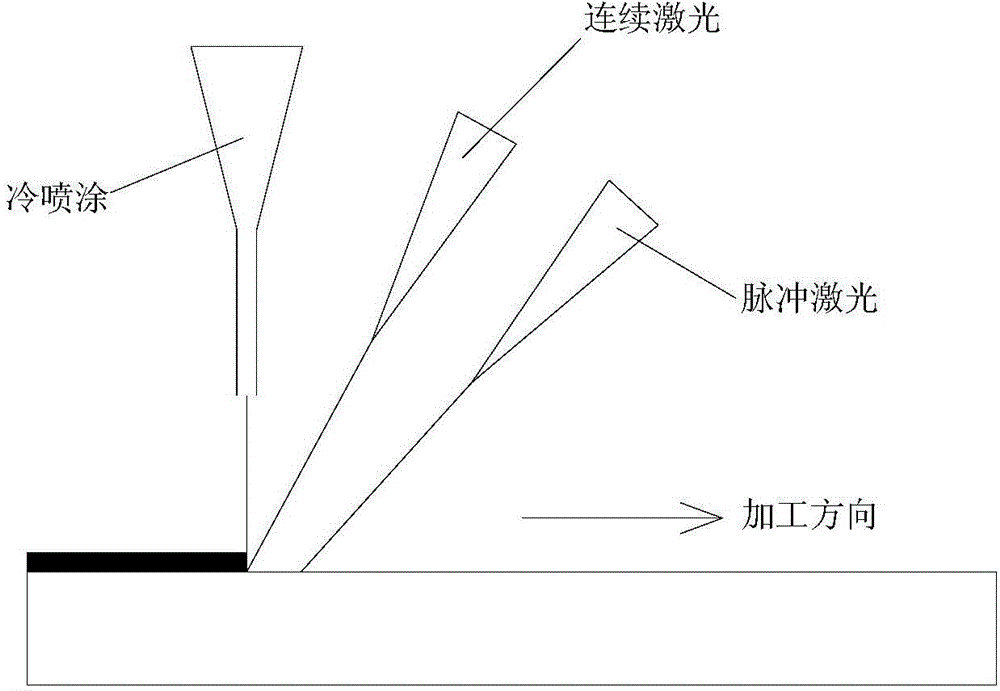

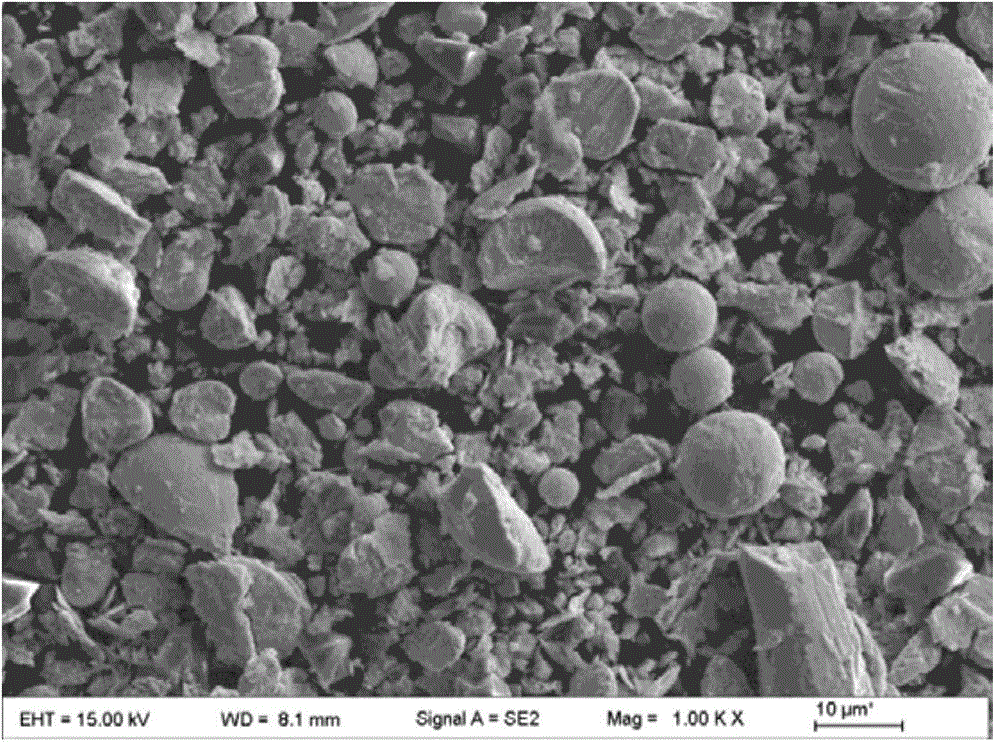

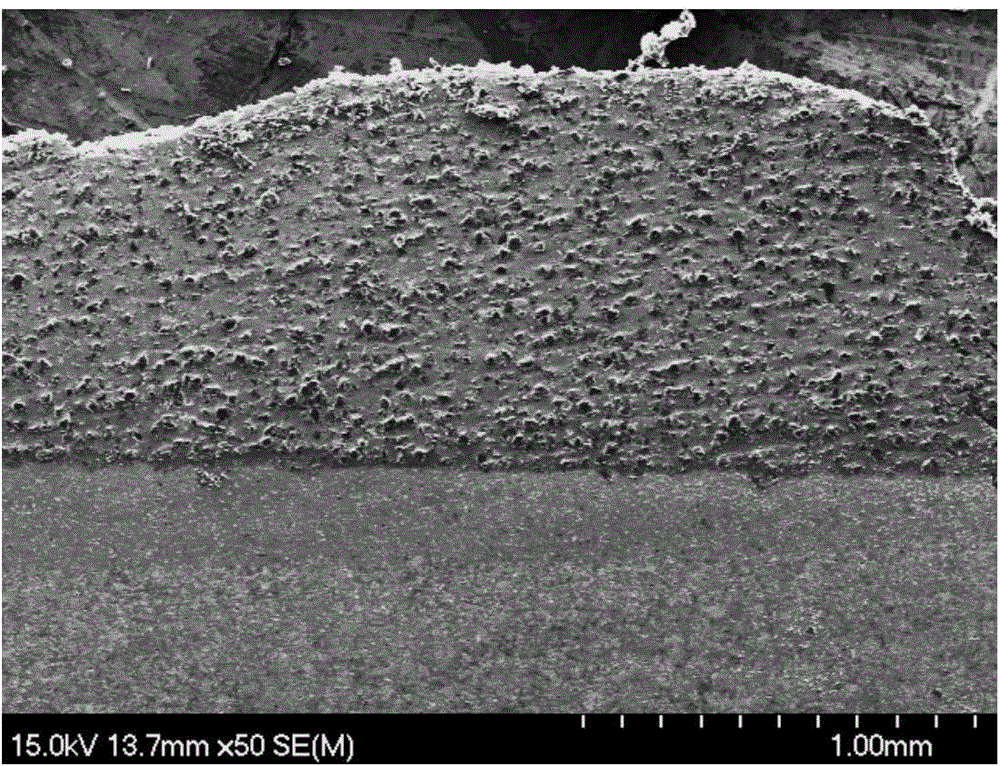

[0041] Ni60 powder is selected as the binder phase to mix with diamond particles, the average particle size of Ni60 powder is 18 μm, and diamond is selected as -400 mesh; Ni60 powder and diamond powder are mixed in a planetary ball mill at a mass ratio of 4:1, and the ball-to-material ratio is 30:1 , the ball milling speed is 500r / min, the mixing time is 2h, the microscopic appearance of the composite powder after ball milling is as follows figure 2 As shown; the base material is 45# steel plate of 100×50×10mm; the high hardness metal matrix / diamond composite coating is prepared synchronously by laser texturing and laser-assisted cold spraying technology; the laser texturing adopts fiber laser, and the laser pulse energy density is 106W / cm 2 , the pulse width is 1ms, the wavelength is 1510nm; the spraying carrier gas is 3MPa compressed nitrogen, and the preheating temperature of the carrier gas is 500°C; the closed-loop feedback temperature control mode is used to adjust the ...

example 2

[0044] Ni60 powder is selected as the binder phase and mixed with diamond particles. The average particle size of Ni60 powder is 18 μm, and the diamond is selected from -400 mesh; Ni60 powder and diamond powder are mixed in a vibratory ball mill with a mass ratio of 3:2, and the ball-to-material ratio is 30: 1. The ball milling time is 60min, and the vibration frequency is 800r / min; the base material is a stainless steel plate of 100×50×10mm, and a high-hardness metal-based / diamond composite coating is prepared simultaneously by laser texturing and laser-assisted cold spraying technology; laser roughening The chemical fiber laser is used, and the laser pulse energy density is 106W / cm 2 , the pulse width is 1ms, the wavelength is 1510nm; the spraying carrier gas is 3MPa compressed nitrogen, and the preheating temperature of the carrier gas is 550°C; the closed-loop feedback temperature control mode is used to adjust the power of the semiconductor laser, and the control temperatu...

example 3

[0047] Choose stellite20 powder as the binder phase and mix it with diamond particles. The average particle size of stellite20 powder is 20 μm, and the diamond is selected from -400 mesh; stellite20 powder and diamond powder are mixed in a vibratory ball mill with a mass ratio of 4:1, and the ball-to-material ratio is 60: 1. The ball milling time is 60min, and the vibration frequency is 1200r / min; the base material is 45# steel rod; the high hardness metal matrix / diamond composite coating is prepared synchronously by laser texturing and laser-assisted cold spraying technology; the laser texturing adopts fiber laser , the laser pulse energy density is 106W / cm 2 , the pulse width is 1.5ms, the wavelength is 1640nm; the spray carrier gas is 3MPa compressed nitrogen, and the preheating temperature of the carrier gas is 600°C; the semiconductor laser power is adjusted by the closed-loop feedback temperature control mode, and the control temperature is 900°C; the laser spot is textur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com