Preparation and application of bismuth tungstate and carbon nitride composite photocatalytic material

A photocatalysis and composite light technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of natural environment damage and lack of fossil energy. , to achieve the effects of environmental friendliness, simple preparation process, and enhanced electron transport capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

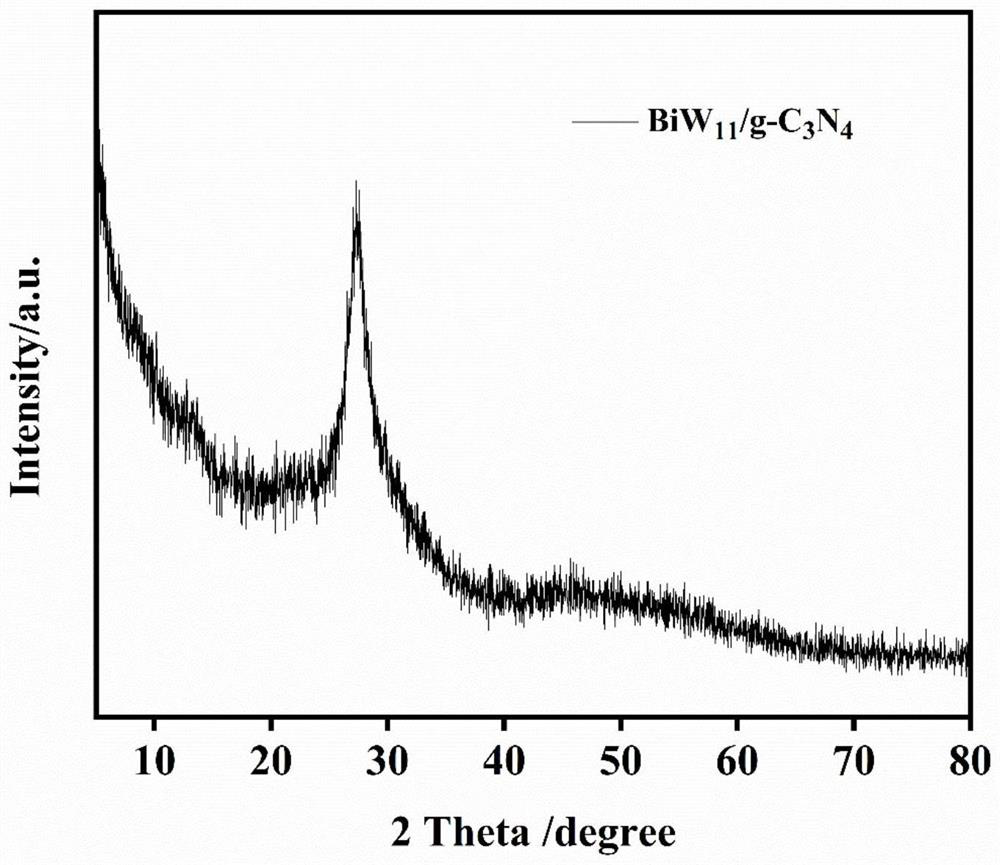

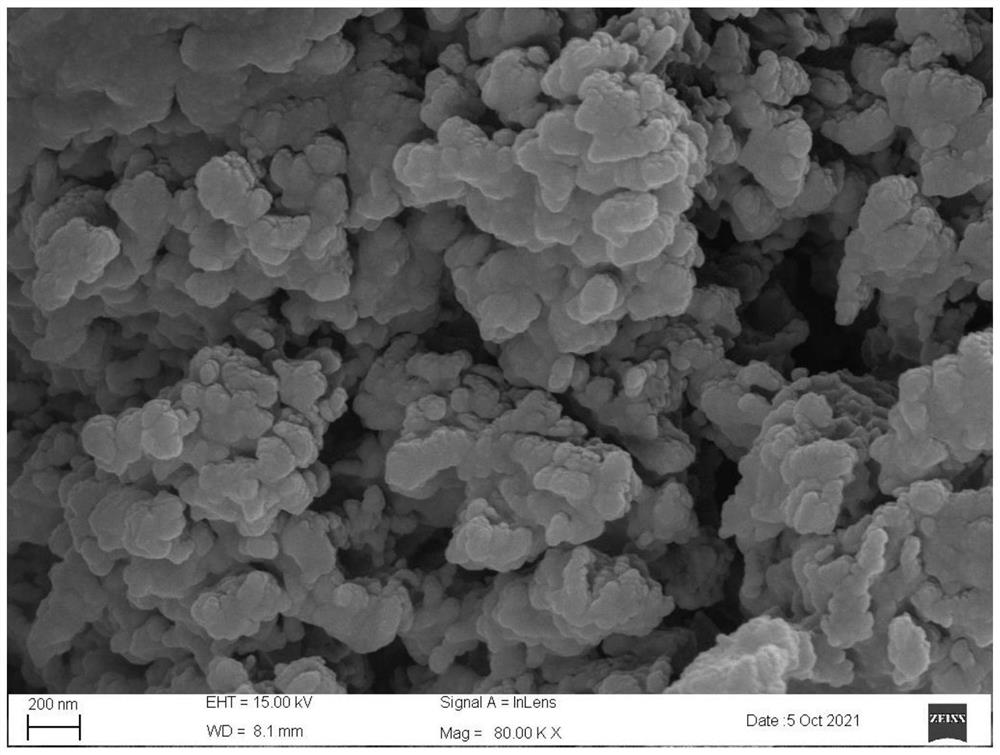

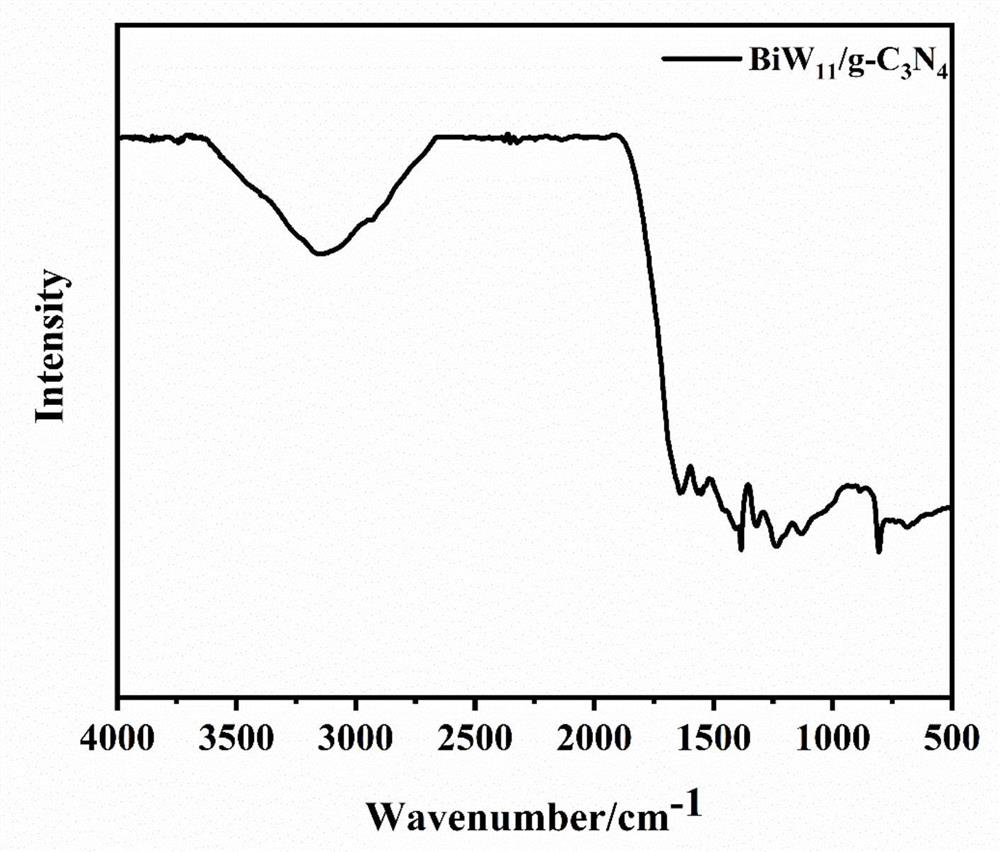

[0030] (1) 5g NaWO 4 2H 2 O and 1g NaOH were dissolved in 20mL deionized water, and glacial acetic acid was added dropwise to adjust the pH to 6.5, then the solution was heated to 100°C and cooled to room temperature to form solution A. Weigh 0.67g BiNO 3 ·5H 2 O dissolved in 1 mL concentrated HNO 3 , then add deionized water, and stir evenly to form bismuth nitrate solution B. Then add solution B dropwise to solution A under stirring until solution B is completely added dropwise. Turn on the heating, heat the mixed solution to 95° C., and keep stirring at this temperature for 2 h. Heating was stopped after 2h, cooled to room temperature, evaporated at room temperature for 48h, the solution was concentrated to 1 / 5 of the original solution, and colorless needle-like crystals were precipitated. Vacuum drying at 60°C for 8 hours to obtain mono-deficient bismuth tungstate: BiW 11 .

[0031] (2) Mix 1.75g melamine and 0.75g NH 4 HCO 3 Put it in a porcelain boat, 5°C·min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com