Patents

Literature

100results about How to "Realize large-scale industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

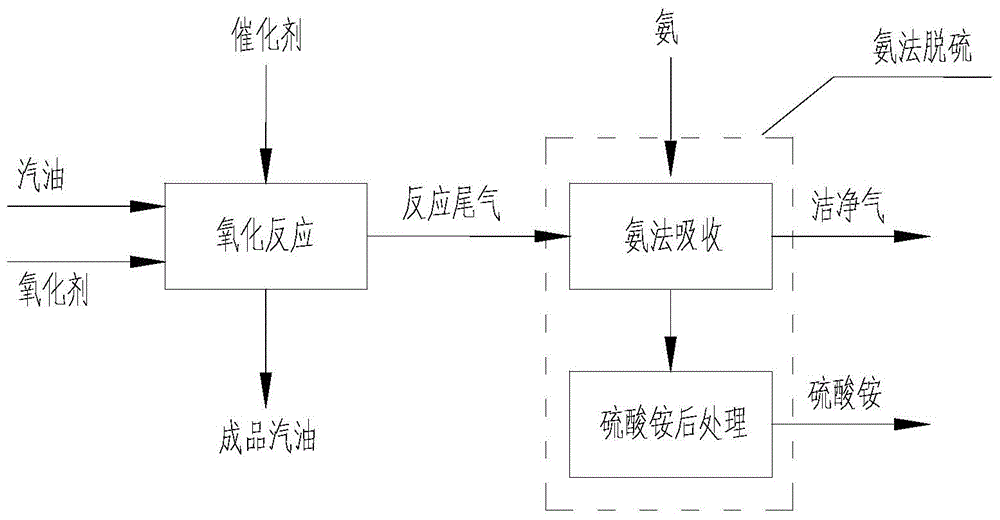

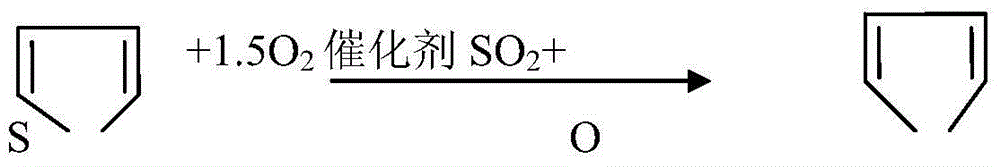

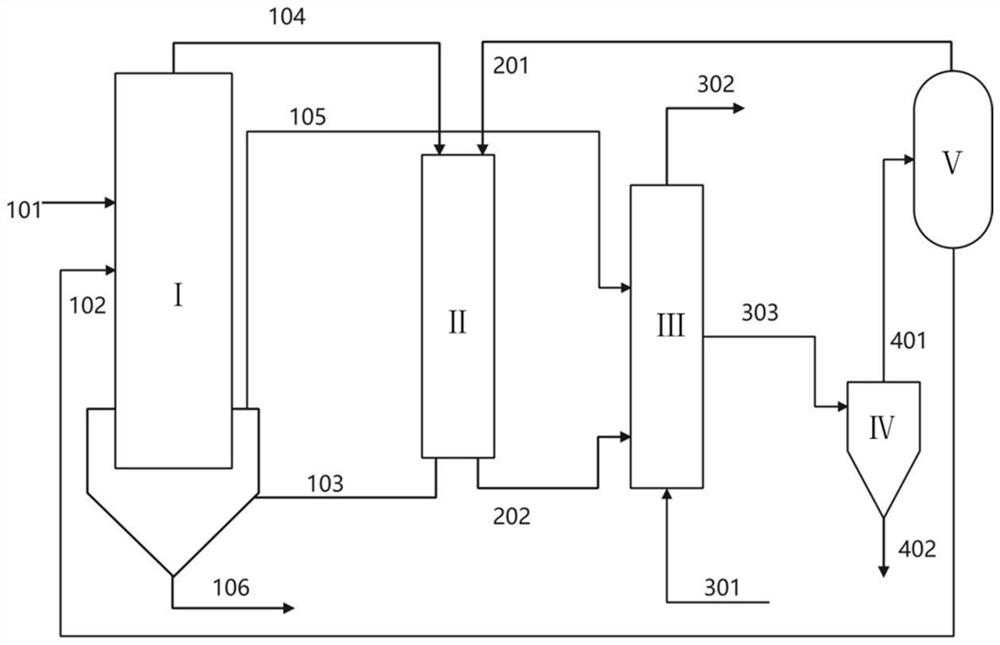

Gasoline-oxidation ammonia-process desulfurization method

InactiveCN104946296ARealize recycling of resourcesImprove desulfurization efficiencyRefining with oxygen compoundsDispersed particle separationGasolineComponents of crude oil

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

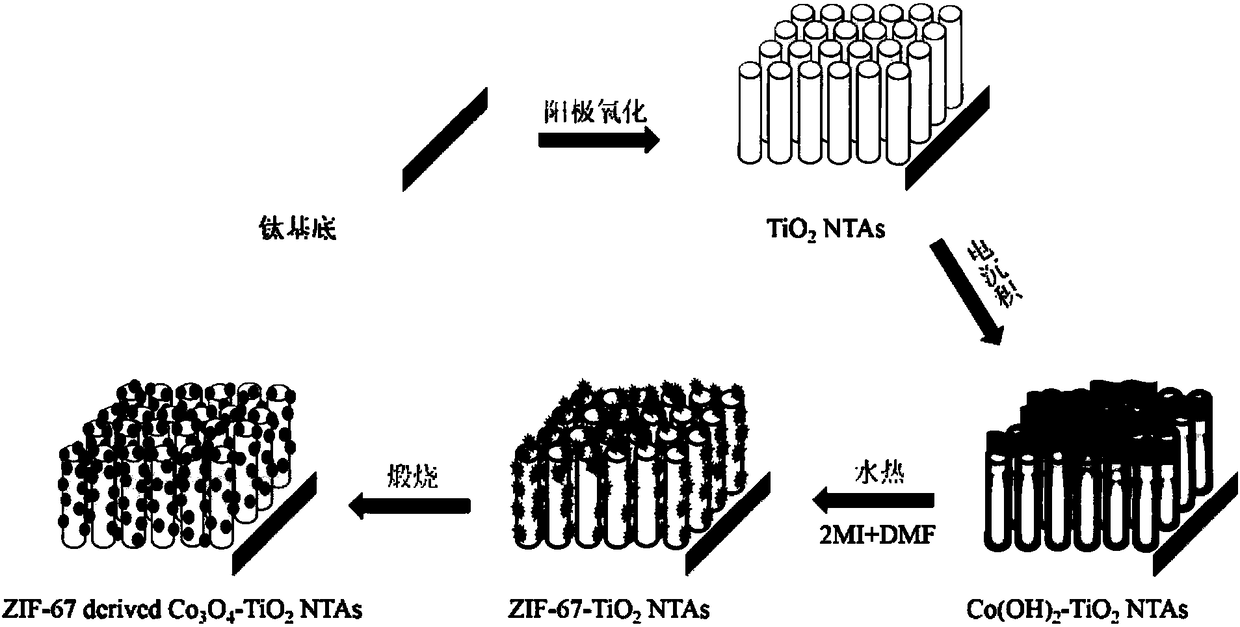

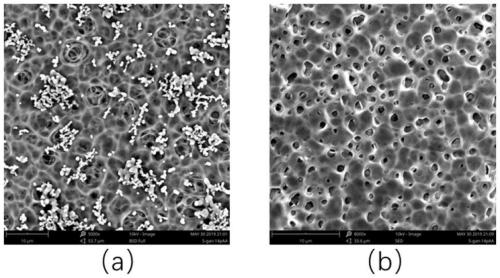

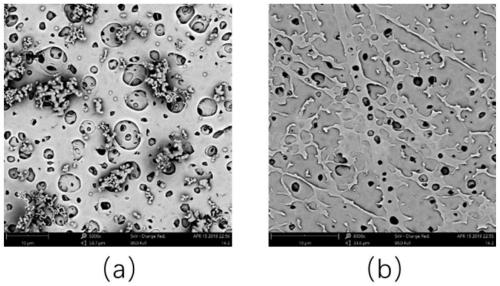

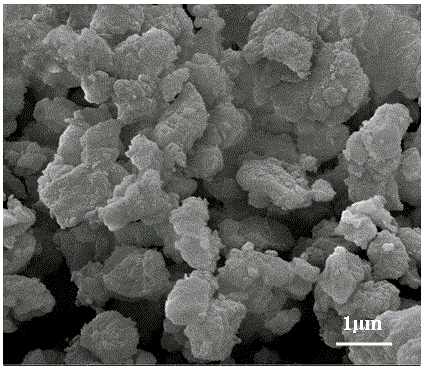

Preparation method for metal organic framework-derived tricobalt tetroxide-modified titanium dioxide nanotube array

InactiveCN108525667ASolve the repeatabilityFix stability issuesWater/sewage treatment by irradiationElectrolytic inorganic material coatingAbsorption capacityWorkstation

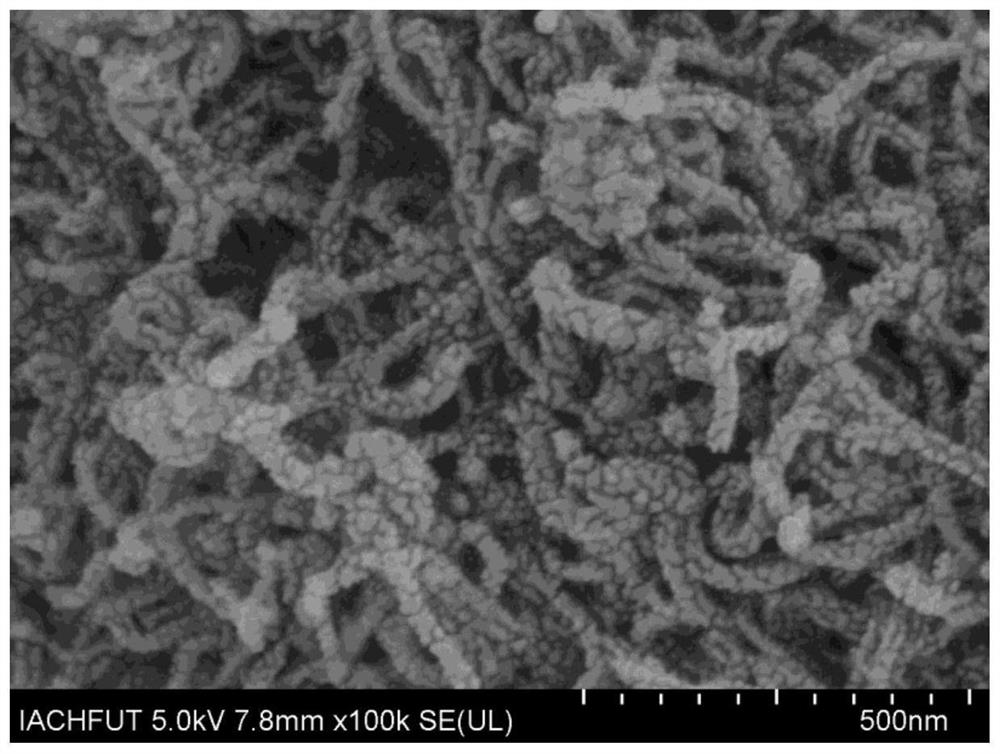

The invention discloses a preparation method for a metal organic framework-derived tricobalt tetroxide-modified titanium dioxide nanotube array. The method comprises the following steps: firstly performing pretreatment on a titanium sheet substrate material; performing electrochemical treatment on the treated titanium substrate material by using an ethylene glycol solution containing ammonium fluoride and water as an electrolyte, and performing calcination by using a muffle furnace to change a titanium dioxide crystal form; secondly, performing cobalt hydroxide electrodeposition by means of athree-electrode electrochemical workstation and by using cobalt nitrate hexahydrate as an electrolyte, a titanium dioxide nanotube array as a working electrode, a platinum sheet as a negative electrode and silver / silver chloride as a reference electrode; performing hydrothermal treatment on the titanium dioxide nanotube array to form ZIF-67 in situ; and finally, performing secondary calcination byusing a muffle furnace to obtain the ZIF-67-derived porous tricobalt tetroxide-modified titanium dioxide nanotube array. The method disclosed by the invention can effectively improve absorption capacity of TiO2 on visible light, promote separation of electron hole pairs, and improve photocatalytic degradation efficiency of organic pollutants.

Owner:SUZHOU UNIV

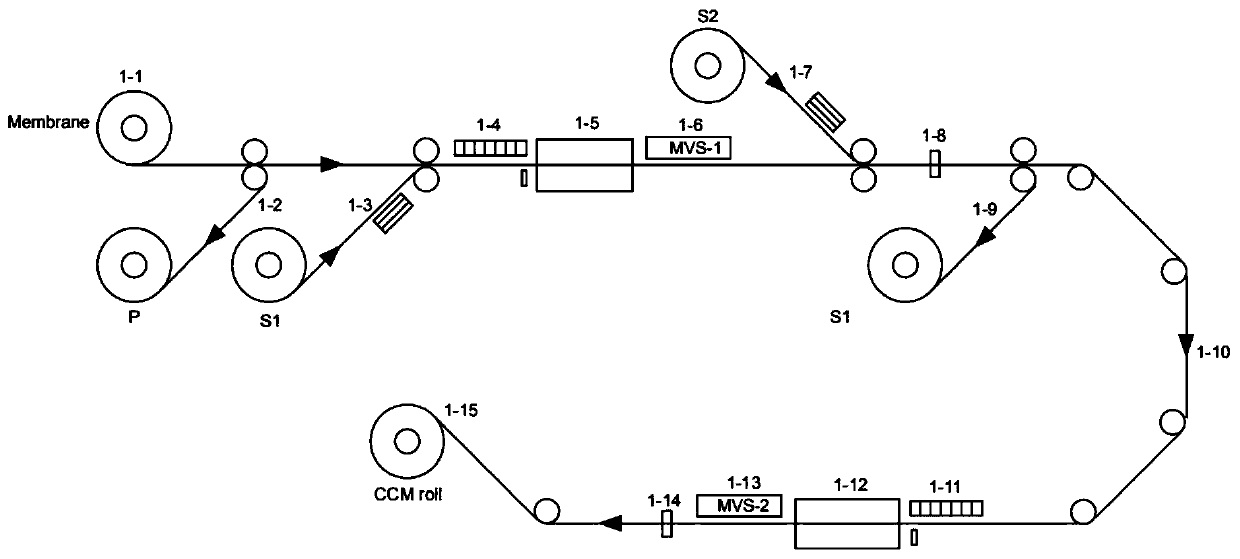

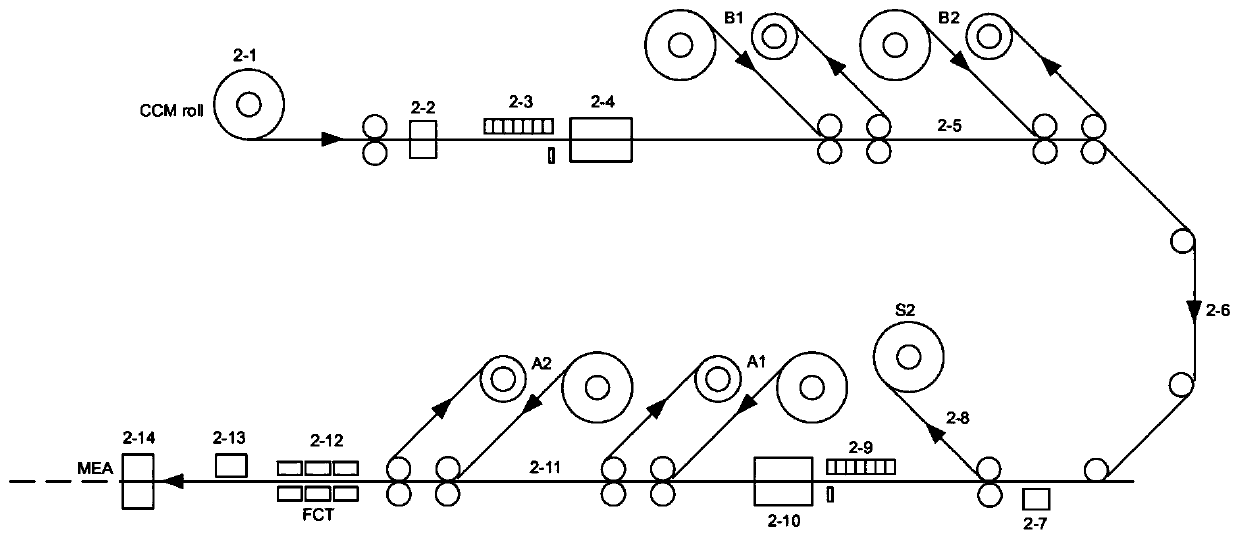

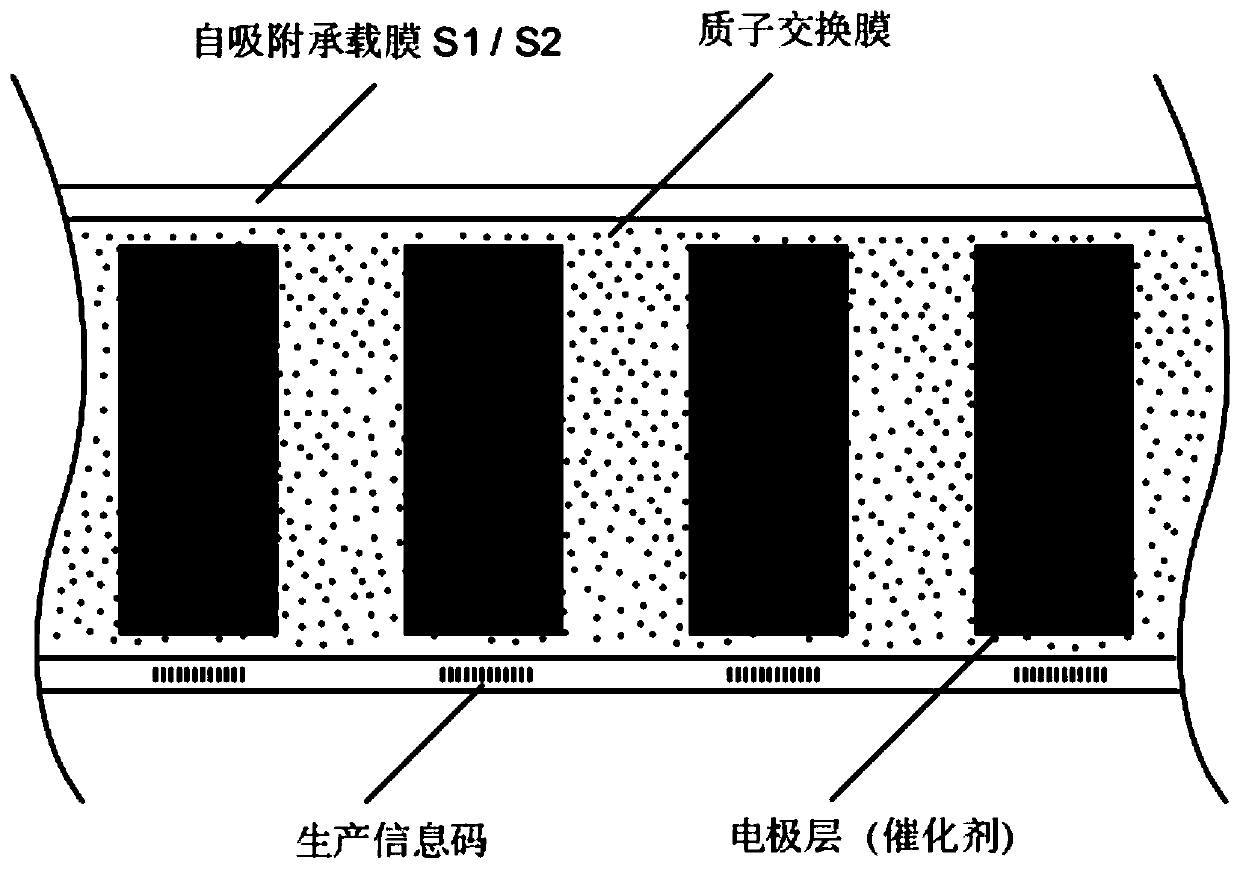

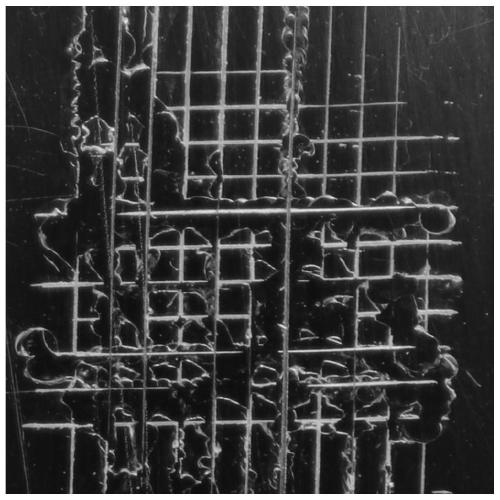

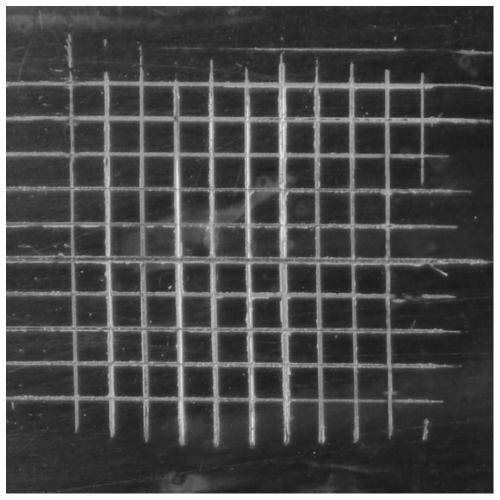

Continuous preparation device and method for fuel cell membrane electrode

ActiveCN110611113AReduce surface friction coefficientNo mechanical damageCell electrodesFinal product manufactureFuel cellsProton

The invention discloses a continuous preparation device and method for a fuel cell MEA membrane electrode. The device comprises a continuous preparation device for a roll fuel cell CCM membrane electrode and a continuous preparation device for a sheet fuel cell MEA membrane electrode. According to the device and method, which are provided by the invention, electrode layers are coated on both sidesof a proton exchange membrane; a self-adhesive carrier membrane capable of repeated simultaneous attachment and peeling is used as a carrier and a production information recorder to prepare a continuous CCM membrane electrode coil, wherein the surface of the self-adhesive carrier membrane is processed; the self-adhesive carrier membrane is further used as the carrier; relying on a precise conveying system, the processes of gas diffusion layer bonding and gas sealing layer bonding are carried out to prepare an MEA membrane electrode monomer; and synchronous cutting is carried out to acquire the MEA membrane electrode monomer meeting industrial standards. The high-efficiency, intelligent, integrated and fully-closed device disclosed by the invention can greatly improve the production capacity and greatly reduce the cost of the membrane electrode monomer.

Owner:上海好世材料科技有限公司

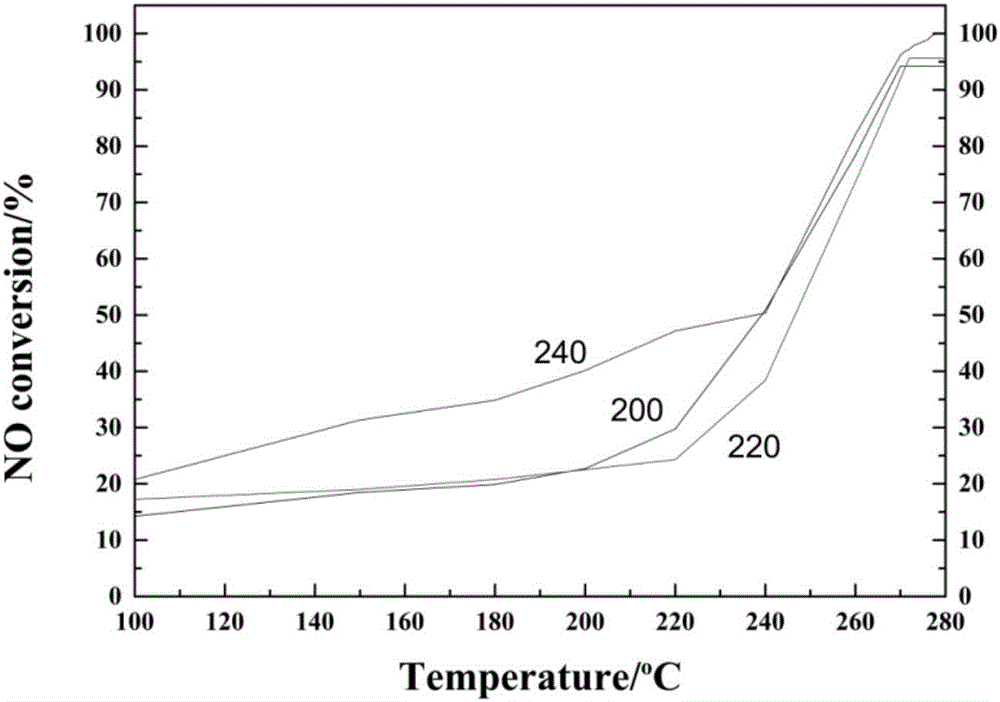

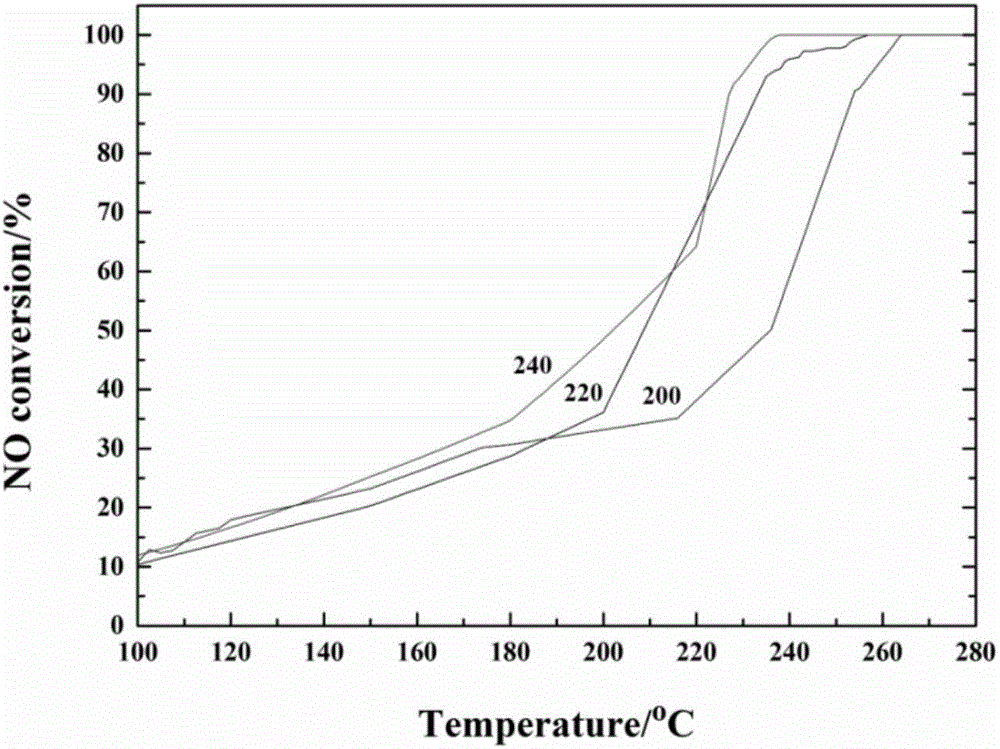

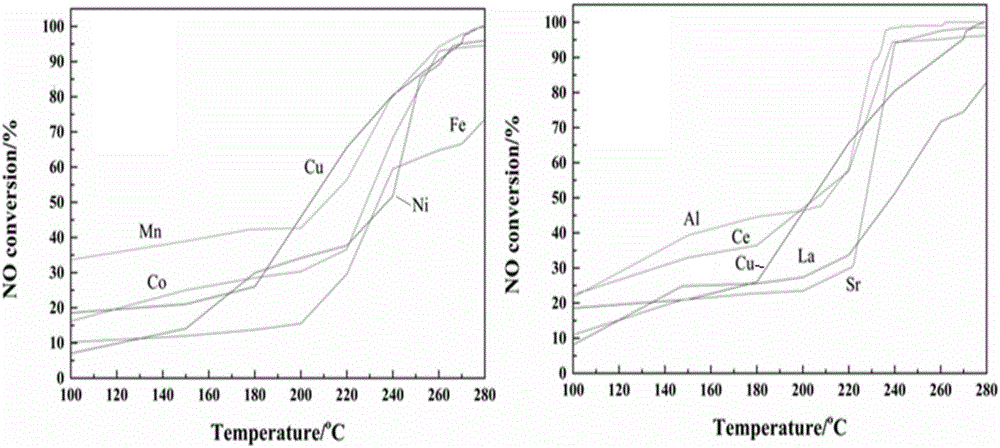

Treatment method for flue gas denitrification by catalysis of carbon-based metal organic framework type oxide

ActiveCN106215692AImprove denitrification efficiencyReduce energy consumptionDispersed particle separationCatalyst activation/preparationMetal-organic frameworkEmission standard

The invention provides a treatment method for flue gas denitrification by catalysis of a carbon-based metal organic framework type oxide. According to the invention, a metal organic framework material is calcined in weak reduction atmosphere to obtain a carbon-based metal organic framework type oxide catalyst, and a redox reaction is carried out on carbon monoxide and flue gases of nitric oxide or nitrogen dioxide at low temperature through the catalyst, so that carbon monoxide and nitric oxide or nitrogen dioxide are respectively converted to carbon dioxide and nitrogen gas, and exhaust gases are recycled through lime water to achieve low-temperature catalysis denitrification and treatment on wastes by using wastes. The denitrification efficiency is 99.9% or above, the nitrogen recovery rate is 95% or above and the exhaust gases reach the existing emission standards.

Owner:CENT SOUTH UNIV

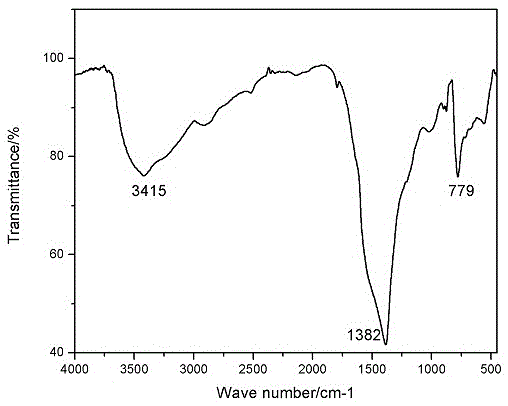

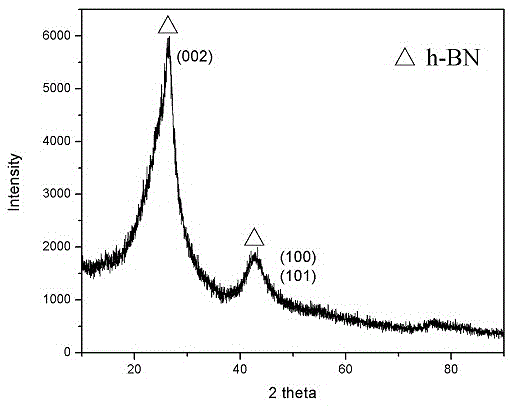

Low-temperature low-pressure preparation method of boron nitride coating

InactiveCN105669253AStrong penetration abilityUniform and controllable thicknessChemical vapor deposition coatingBoron nitrideBoron trichloride

The invention discloses a low-temperature low-pressure preparation method of a boron nitride coating. The method of the invention is used for solving the problem that required preparation temperature is high by a chemical vapor deposition method in the prior art. Boron trichloride (BCl3) and ammonia gas (NH3), which are used as main raw materials, undergo chemical vapor deposition under the condition of low temperature; a sample obtained undergoes high-temperature heat treatment; and through Fourier transformed infrared and X-ray diffraction detection, a boron nitride coating which has stronger infiltration capacity, uniformly and controllable thickness and high degree of crystallization is prepared. The method can be used for preparation of a composite material boron nitride interface and for preparation of a sample surface coating. By the method, deposition temperature of boron nitride chemical vapor deposition is reduced from 1300-1800 DEG C to 300-800 DEG C. The method mainly comprises low-temperature chemical vapor deposition and high-temperature heat treatment.

Owner:SHANGHAI UNIV +1

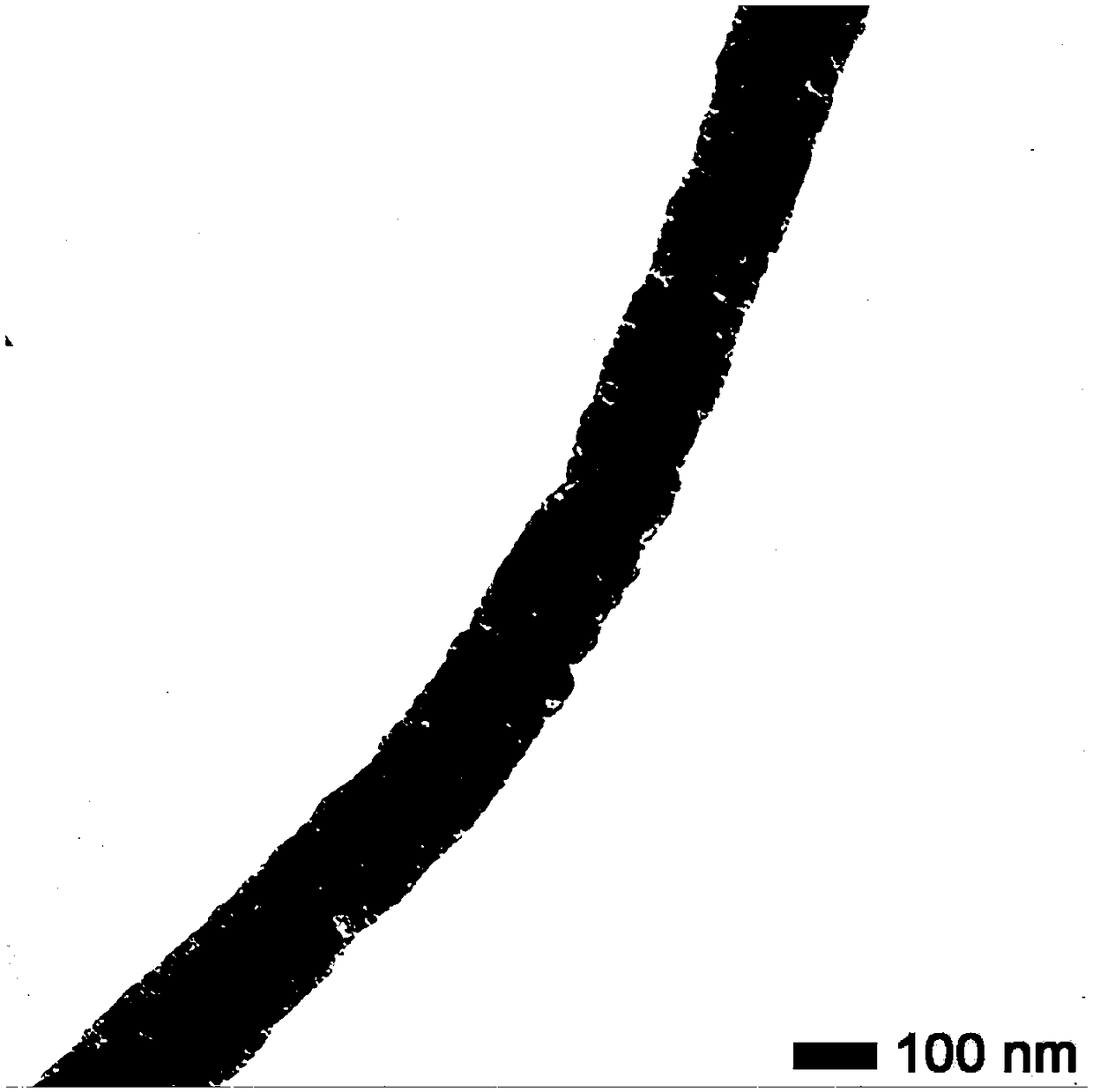

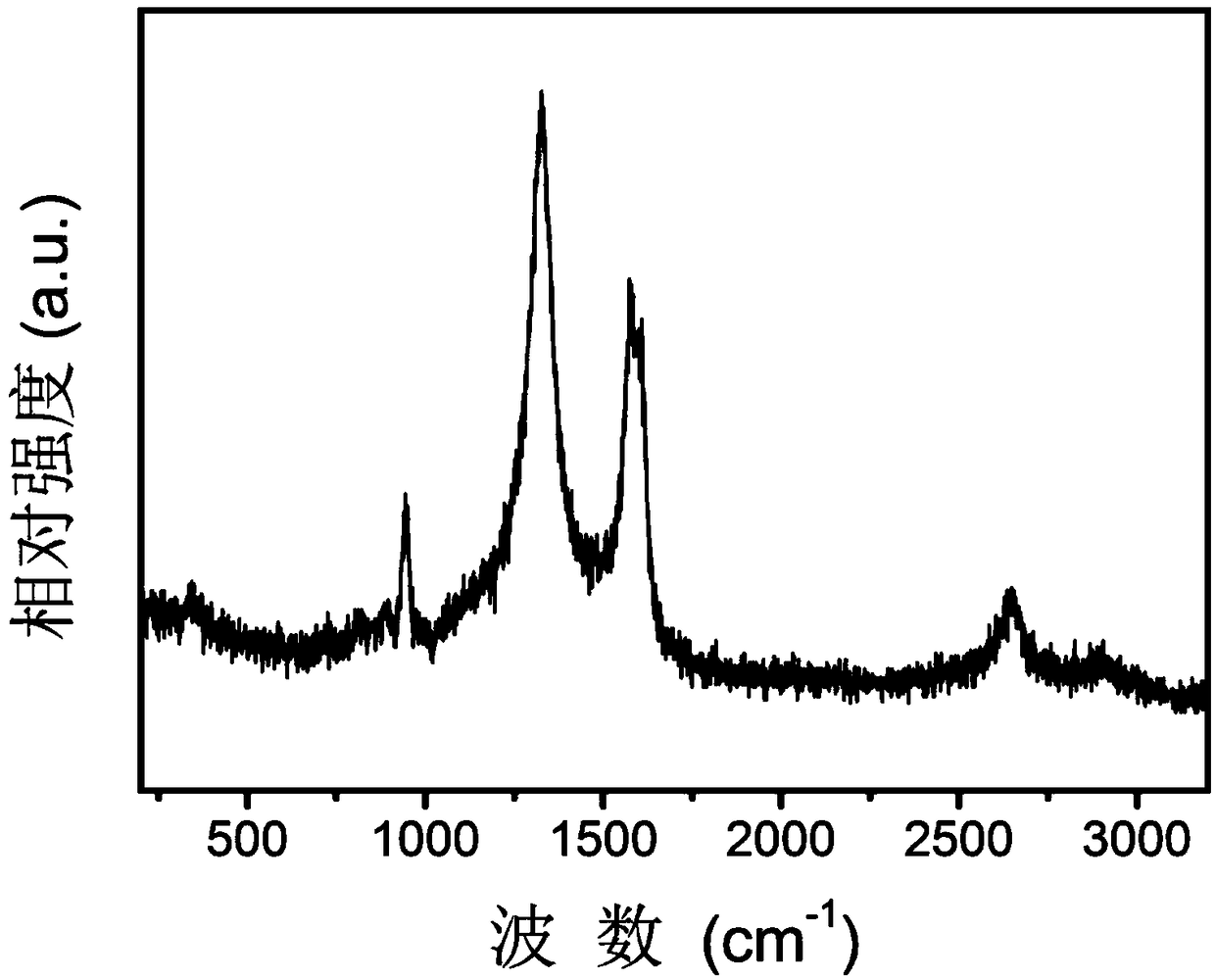

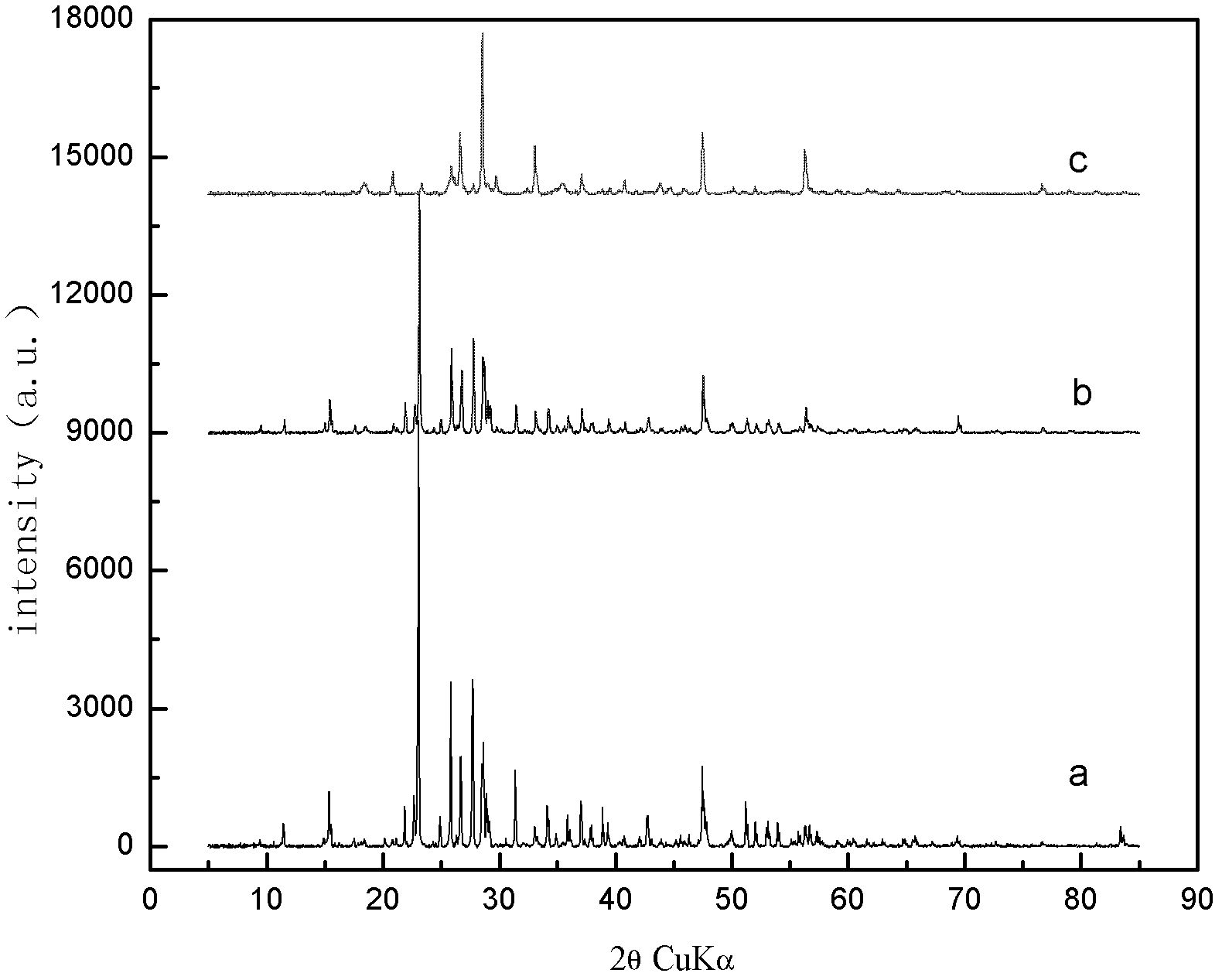

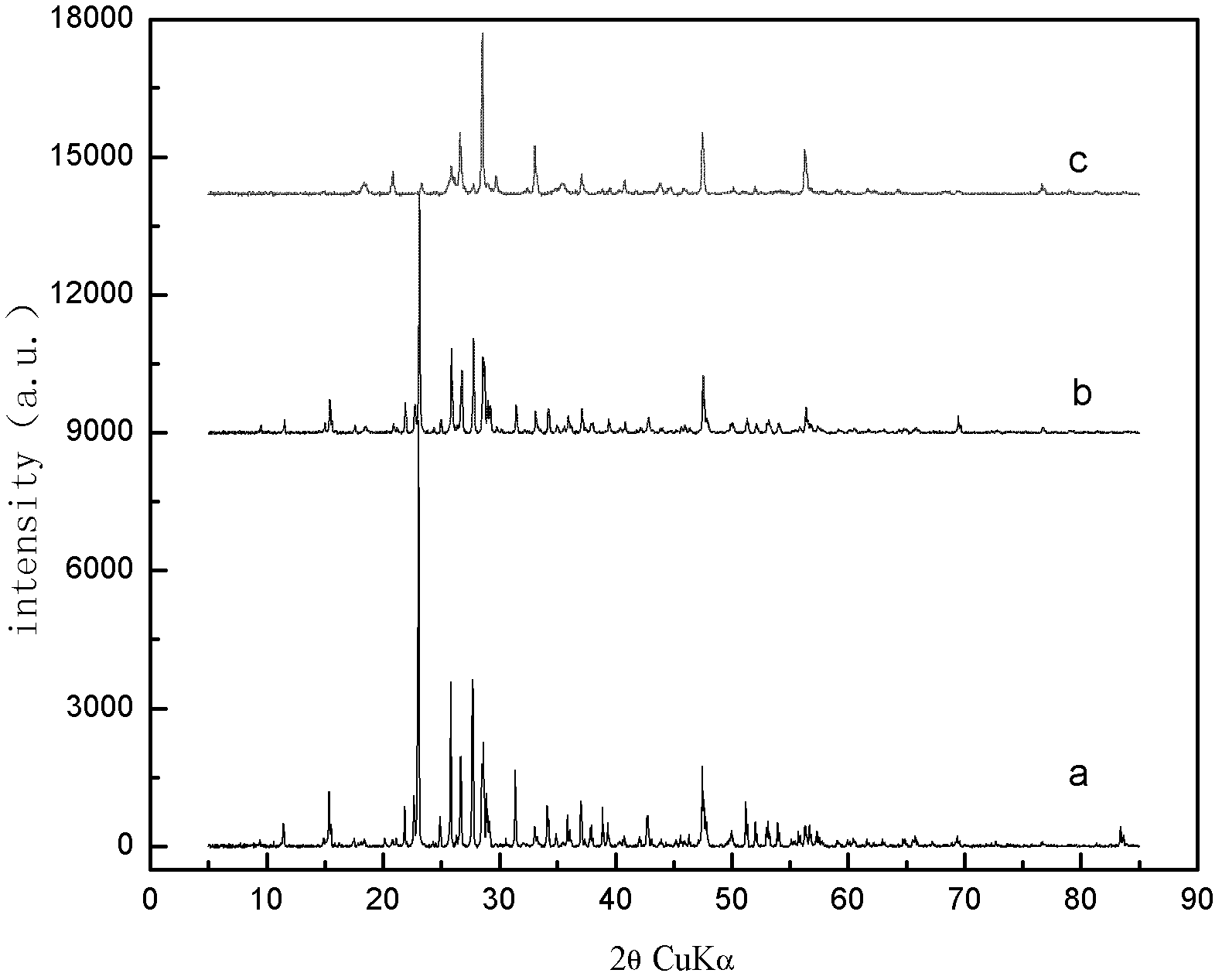

Nickel-molybdenum carbide nanoparticle/carbon fiber composite nano material, preparation method and application of nickel-molybdenum carbide nanoparticle/carbon fiber composite nano material

ActiveCN108823600ALow costGood catalytic activityMaterial nanotechnologyPhysical/chemical process catalystsAir atmosphereDecomposition

The invention discloses a nickel-molybdenum carbide nanoparticle / carbon fiber composite nano material, a preparation method and application of the nickel-molybdenum carbide nanoparticle / carbon fiber composite nano material in electrocatalytic hydrogen evolution or oxygen evolution, and belongs to the technical field of controllable preparation of non-precious metal-based carbon fiber composite nano materials. The nickel-molybdenum carbide nanoparticle / carbon fiber composite nano material is prepared by utilizing three steps of electrospinning, low-temperature calcining in an air atmosphere andhigh-temperature calcining in an argon atmosphere. The nickel-molybdenum carbide nanoparticle / carbon fiber composite nano material disclosed by the invention exists in fiber morphology, and nickel nanoparticles and molybdenum carbide nanoparticles are uniformly distributed inside or outside carbon fiber. The preparation method disclosed by the invention is low in cost, is simple and easy and canrealize large-scale industrial application. The nickel-molybdenum carbide nanoparticle / carbon fiber composite nano material prepared by the invention is used as an electrocatalysis and water decomposition dual-functional electrocatalyst, excellent catalytic activity is shown, high-efficiency preparation of a pollution-free hydrogen energy source is realized, a new strategy is provided for responding increasingly serious environment problems, and important practical application value is obtained.

Owner:JILIN UNIV

Method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores

InactiveCN102633233AFast sublimation volatilizationHigh puritySulfur compoundsEnergy inputVacuum pumpSulfur containing

The invention discloses a method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores, and particularly relates to the recovery of sulfur in lead-zinc ore leached residues through vacuum distillation, belonging to the field of reclamation and reuse of solid waste resources. The method comprises the following steps of: placing atmospheric-pressure oxygen-rich leached residues, subjected to drying, milling and screening pretreatment, of lead-zinc ores into a vacuum distillation furnace, heating the residues to 200-400 DEG C, and controlling the pressure of the inside of the furnace to 600-10000 Pa, so that sulfur in the leached residues is sublimated and volatilized; pumping sulfur-containing vapor out of the distillation furnace by a vacuum pump; and cooling the sulfur-containing vapor so as to obtain a sulfur product. After the distillation is completed and the sulfur is completely volatilized, high-boiling-point residues are discharged out of the distillation furnace in a solid powder form. In the whole process, the furnace is internally sealed, thereby avoiding the oxidation and environmental pollution of elemental sulfur. The method is simple in technological process and equipment, high in sulfur recovery rate and product quality, low in energy consumption, strong in adaptability to raw materials and pollution-free, so that the method disclosed by the invention is an economic and efficient sulfur extraction method and can realize the zero discharge of waste smelting residues in a lead-zinc wet process, thus the method has broad application prospects.

Owner:CENT SOUTH UNIV

Real-time driving risk evaluation method and device based on equivalent force

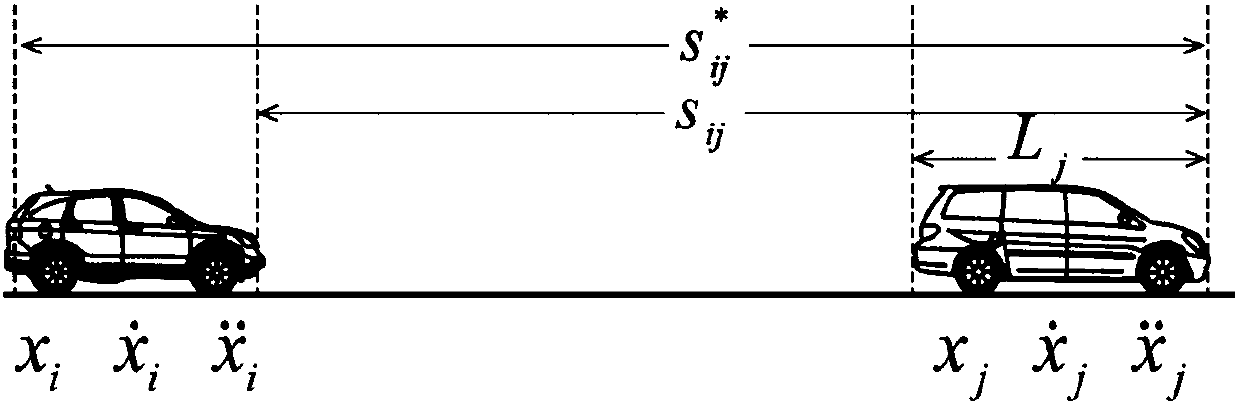

ActiveCN108573357ADecision securityRealize large-scale industrial applicationAnti-collision systemsForecastingDriving riskRoad traffic

The invention discloses a real-time driving risk evaluation method and device based on an equivalent force. The method comprises that S1) traffic environment information and different types of trafficenvironment using object information of a road environment of an area to be evaluated are collected; S2) the traffic environment using object information and the environment information obtained in the step S1 are input to an electronic control unit of a vehicle, and a road risk evaluation model based on distribution of the equivalent force is pre-arranged in the electronic control unit; and S3)via the road risk evaluation model based on distribution of the equivalent force, equivalent force distribution Fij between the road traffic risk E and the vehicle i and the object j in different traffic environments of the vehicle i is obtained, and the object j represents essential traffic factors besides the vehicle i in the different types of traffic environment using object information. Thus,services can be provided for traffic safety management, road construction, driving assistance and information interaction in the different types of traffic environment.

Owner:TSINGHUA UNIV

Grading technology for cold-pressed pelletizing and shaft furnace magnetization roasting of powdery refractory iron oxide ore

ActiveCN102747217ARaise the gradeHigh recovery rateProcess efficiency improvementShaft furnaceShaft furnaceRoasting

A grading technology for cold-pressed pelletizing and shaft furnace magnetization roasting of powdery refractory iron oxide ore comprises the following steps: 1, preparing a combined binder through using clay or bentonite, and industrial magnesium chloride; 2, fragmenting the powdery refractory iron oxide ore, mixing with the combined binder to prepare cold-pressed balls, and sieving; or grinding the powdery refractory iron oxide ore, grading through a strong magnetic process, dehydrating, mixing with the combined binder to prepare the cold-pressed balls, and sieving; or carrying out strong magnetic selection to produce ore tailings, enriching through an ore selection process, dehydrating, mixing with the combined binder to prepare the cold-pressed balls, and sieving; 3, drying materials which cannot pass through a sieve, sieving the dried materials, returning materials which pass through the sieve to a pelletizing operation, sending balls which cannot pass through the sieve to a double combustion chamber shaft furnace to undergo a reduction reaction, cooling, and completing ore grinding and weak magnetic grading through an ore grinding and grading system. According to the technology, a large amount of idle or abandoned low-grade powdery iron oxide ore is recycled, the particle size range of ore roasted in the shaft furnace is enlarged, the shaft furnace magnetization roasting of the powdery refractory iron oxide ore is realized, and the shaft furnace is maximally utilized to complete the ore roasting.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Porous polyimide film and preparation method and application thereof

InactiveCN110256717AReduced control accuracyReduce porosityCell component detailsPorosityPolyamic acid

The invention discloses a porous polyimide film and a preparation method and application thereof. Binary anhydride and diamine are subjected to low-temperature polycondensation reaction in a polar solvent to generate a precursor polyamic acid PAA solution; additives are added into the precursor polyamic acid PAA solution and stirred to form a casting film solution; the casting film solution is defoamed, scraped, coated on a glass plate and immersed in a coagulation bath; then the glass plate is taken out and naturally dried; and the porous polyimide film is obtained through thermal imidization or chemical imidization treatment. The preparation method does not need high temperature and high pressure, has simple requirements on film making equipment, and is favorable for realizing large-scale industrial application. In addition, the film has adjustable thickness, porosity of more than 40%, high liquid absorption rate, good lithium ion electrolyte wettability and excellent high temperature resistance, and is expected to become one of the diaphragm materials for the next generation of lithium ion batteries.

Owner:杭州阳名新能源设备科技有限公司

Double-liquid-phase fermentation method of coupling in-situ extraction antrodia camphorate active product antrondin C

ActiveCN102827895AEfficient synthesisEfficient extractionOrganic chemistryMicroorganism based processesNegative feedbackCell membrane

The invention discloses a double-liquid-phase fermentation method of coupling in-situ extraction antrodia camphorate active product antrondin C. According to the method, different surfactants are added into a liquid culture medium for changing the permeability of an antrodia camphorate bacterial cell membrane, the negative feedback inhibition effect of the target product antrondin C synthesis is reduced, on the basis, different extracting agents are coupled for carrying out in-situ extraction double-liquid-phase fermentation, and active products which are secreted from cells and attached on the bacterial ball surface are extracted into the extracting agents, so the negative feedback inhibition intensity of the target product is reduced, the surfactant coupling in-situ extraction fermentation technology is adopted, the efficient synthesis and extraction of the antrodia camphorate active product can be realized in the same fermentation period, the yield of the antrodia camphorate active product antrondin C can be obviously improved, the active product in the extraction agents is extracted into ethanol phases through ethanol extraction agents, the post-processing process is simple, the extraction and the purification of the active product are convenient, and the production cost can be effectively reduced.

Owner:JIANGNAN UNIV

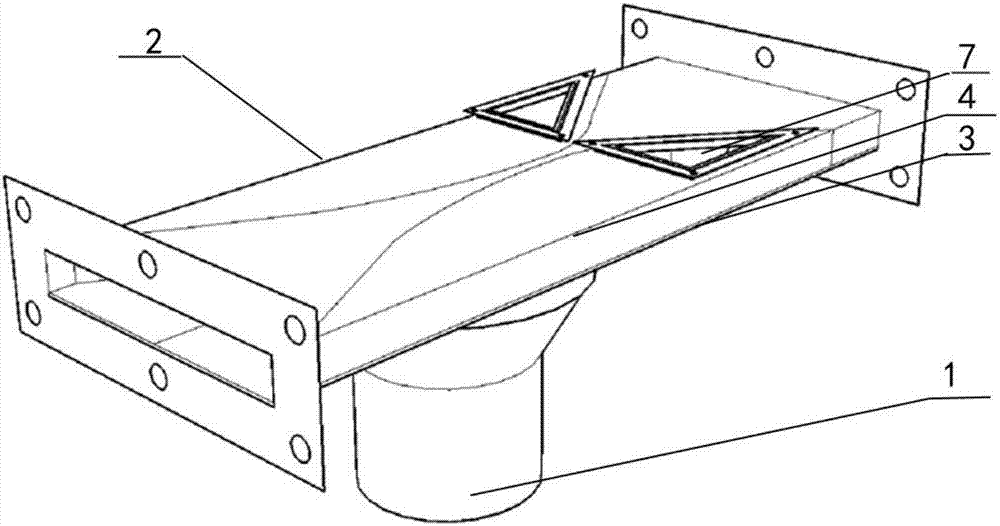

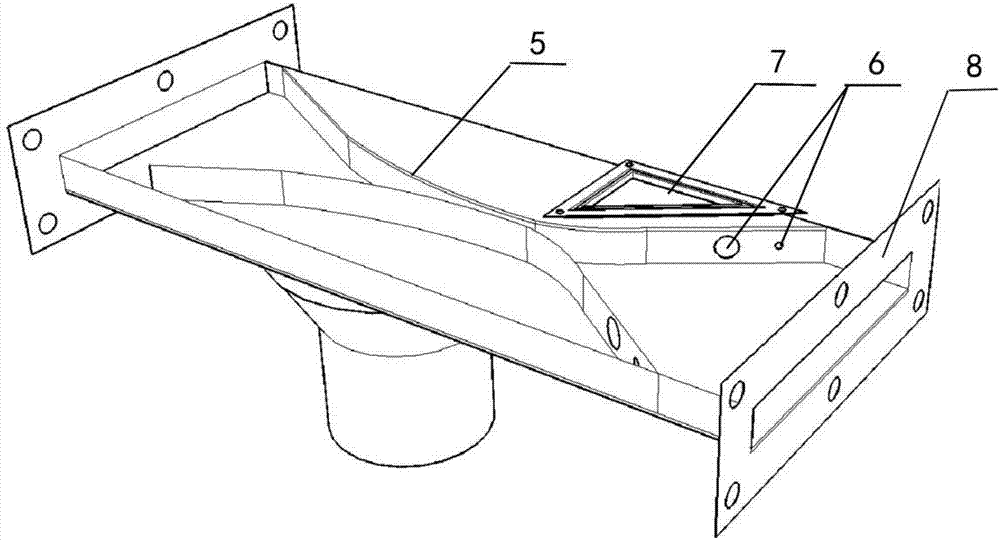

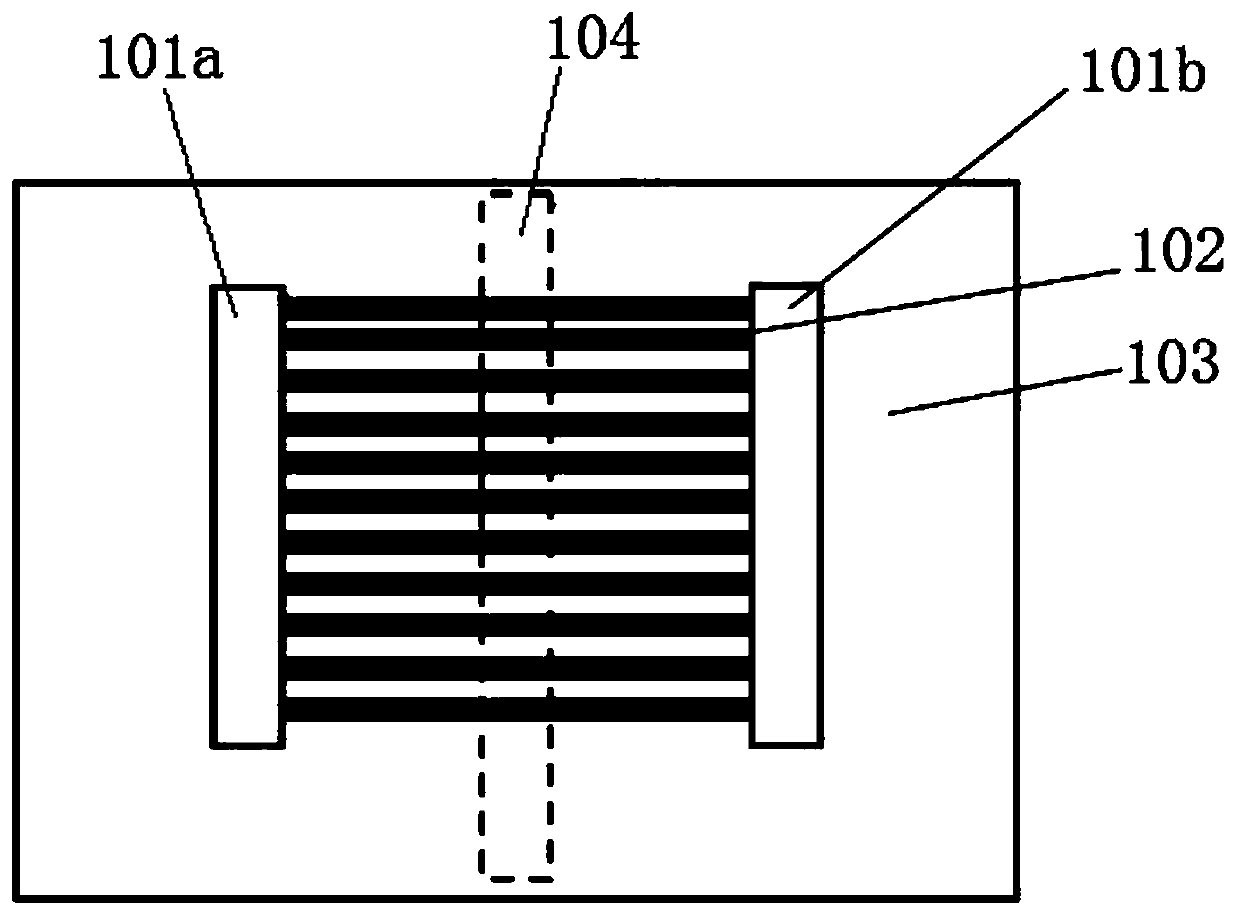

Water treatment device and system and water treatment method

ActiveCN107986388AMeet processing needsEasy to handleWater/sewage treatment with mechanical oscillationsUltrasonic cavitationCoupling

The invention relates to a water treatment device and system and a water treatment method. The device comprises an ultrasonic transducer and a thin-layer treatment chamber, wherein the thin-layer treatment chamber is provided with a first cover plate, a second cover plate and a tapered and gradually-enlarged flow channel; the tapered and gradually-enlarged flow channel is provided with one or morevalves; liquid is remained between the first cover plate and the second cover plate; a radiation surface of the ultrasonic transducer is fixed on the first cover plate; the ultrasonic transducer is used for emitting ultrasonic waves; the thin-layer treatment chamber is used for receiving the ultrasonic waves and generating ultrasonic cavitation; the tapered and gradually-enlarged flow channel isused for generating hydraulic cavitation; the hydraulic cavitation and the ultrasonic cavitation are coupled to grenade coupling cavitation; the coupling cavitation is used for treating water. According to the water treatment device provided by the invention, the washing groove type ultrasonic transducer is adopted and the diameter of the radiation surface is greater than that of a piezoelectric sheet, so that the device has the advantages of low price, stability in working and strong adaptability; a large radiation area covers a coupling region and an external region with an independent ultrasonic effect, so that wastes of ultrasonic energy are avoided.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

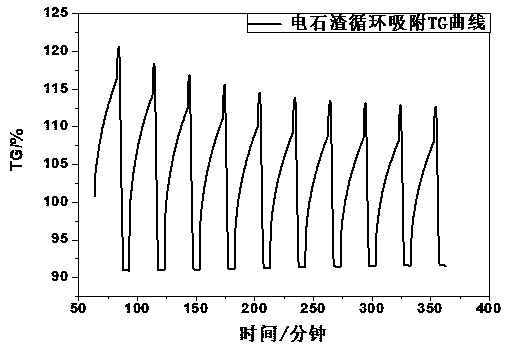

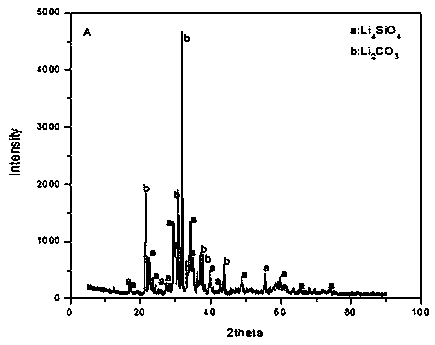

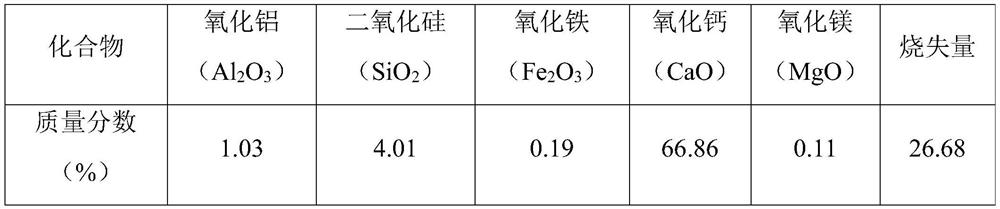

Preparation method of doped CO2 (carbon dioxide) calcium base adsorbent

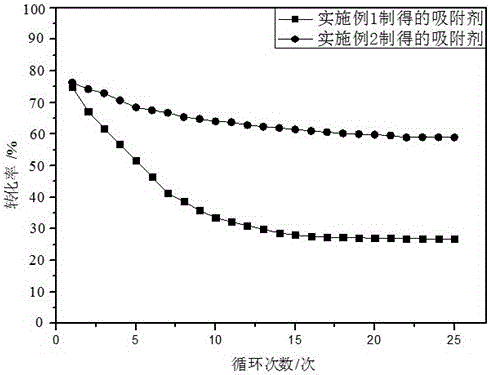

ActiveCN108499515AAchieve reuseImprove the defect of reduced cycle adsorption performanceGas treatmentOther chemical processesLithium carbonateSorbent

The invention discloses a preparation method of a doped CO2 (carbon dioxide) calcium base adsorbent. The preparation method comprises the following steps of using waste as a precursor for calcium base, cleaning, crushing, calcining, and extracting, wherein a doping agent Li4SiO4 is prepared from raw materials of Li2CO3 (lithium carbonate) and fly ash or SiO2 (silicon dioxide) by a high-temperaturesolid-phase method; adsorbent prepared by the process that the doping agent Li2SiO4 and the calcium base are mixed and pre-calcined obviously improves the CO2 cycle adsorbing conversion rate and stability; the modifying of the calcium base adsorbent by the doping agent Li2SiO4 is put forwards for the first time. The preparation method has the advantages that after Li2SO4 doping, the phase is changed after pre-calcining to support the structure of the calcium base adsorbent, and prevent the sintering; the operation of the preparation process is simple, the CO2 adsorbing property of the prepared doped calcium base adsorbent is good, and the development prospect is better.

Owner:KUNMING UNIV OF SCI & TECH

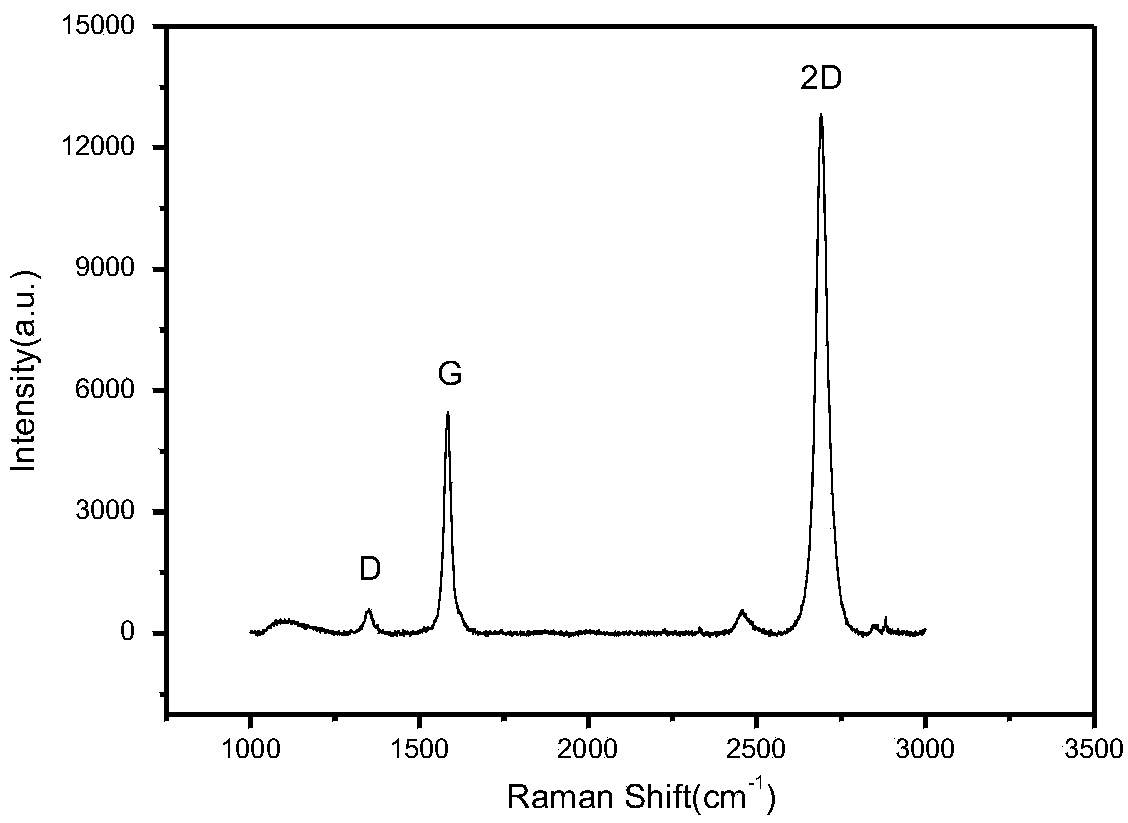

Ammonia gas sensor loaded with platinum particles and preparation method thereof

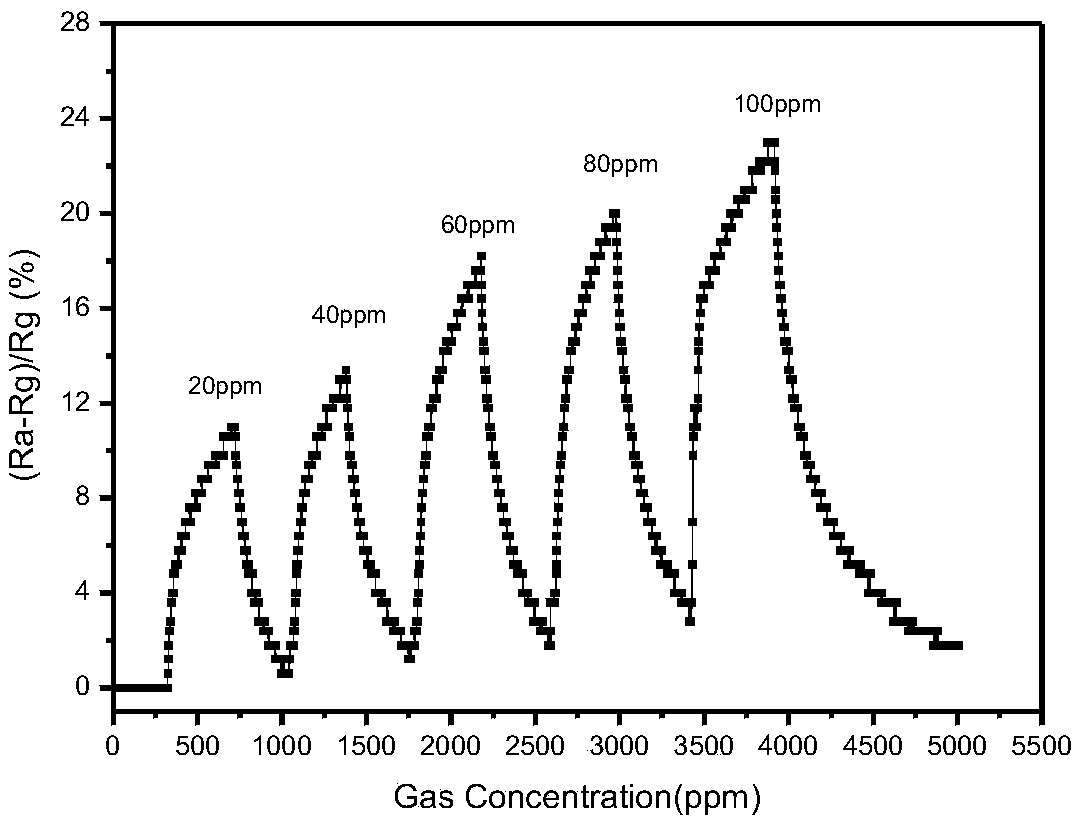

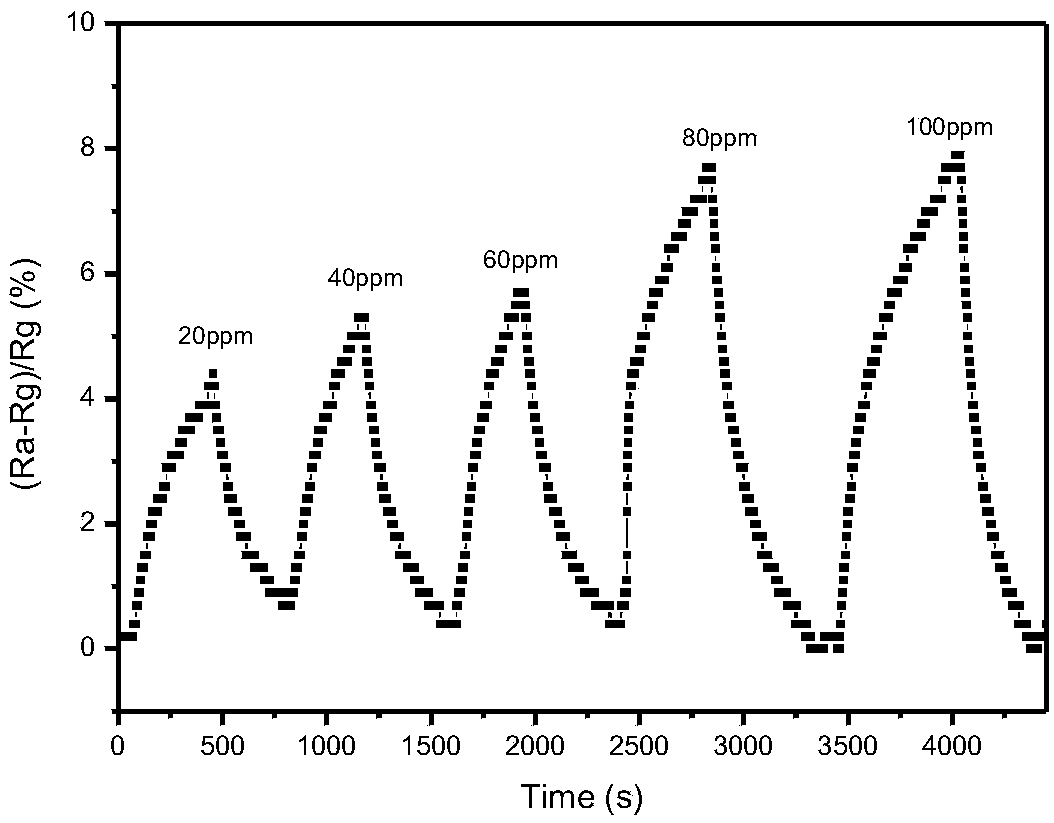

InactiveCN108896621AAdd defect siteImprove responsivenessCarbon compoundsMaterial resistanceElectrical resistance and conductanceGas detector

The invention relates to an ammonia gas sensor loaded with platinum particles and a preparation method thereof, and belongs to the field of gas sensors. A gas sensitive material is composed of the platinum particles and a graphene film. The platinum particles are loaded on the graphene film carrier. The method includes the following steps: (1) preparing the graphene film and keeping for later use;(2) using ultraviolet ozone to modify the graphene film obtained in the step (1) and keeping for later use; and (3) impregnating the modified graphene film in the step (2) in a platinum chloride solution, and heating and insulating the graphene film after the impregnation so as to decompose chloroplatinic acid into the platinum particles to obtain the ammonia gas sensitive material loaded with the platinum particles on the graphene film. According to the preparation method, through the ultraviolet ozone treatment, the graphene film is firstly modified by introducing an oxygen-containing functional group, increasing defect sites and adsorption sites of the film, changing resistance characteristics and wettability of the film and loading the platinum particles onto the graphene film. The gas sensitive sensor prepared according to the method has excellent room temperature response performance to ammonia gas.

Owner:SHANDONG UNIV

Preparation method and application of calcium-based adsorbent

ActiveCN105903458AAntioxidantHigh temperature strengthGas treatmentOther chemical processesDesorptionSorbent

The invention discloses a preparation method of a calcium-based adsorbent. According to the preparation method, natural quartz stone powder (including a main component SiO2) and active carbon powder are taken as raw materials for preparing silicon oxynitride by adopting a carbon thermal reduction method; and silicon oxynitride is used as an inert supporting material and is treated by a process of immersing, drying and calcining to load CaO so as to prepare the calcium-based adsorbent. By controlling the CaO precursor and calcining conditions, relatively good circulating stability is obtained. The raw material has a wide source, the preparation method is simple and convenient and the operability is strong; and the problem that the adsorption capacity of the high-temperature CO2 calcium-based adsorbent is reduced after a plurality of times of CO2 adsorption / desorption cycles is improved very well.

Owner:KUNMING UNIV OF SCI & TECH

High-entropy ceramic modified coating with controllable components and controllable microstructure, and preparation method thereof

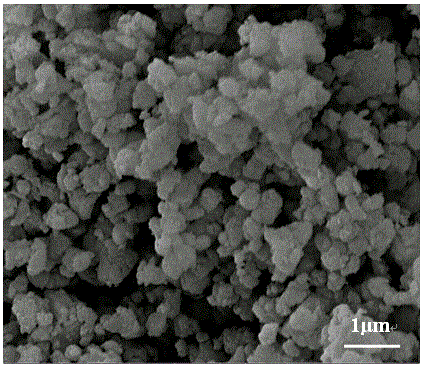

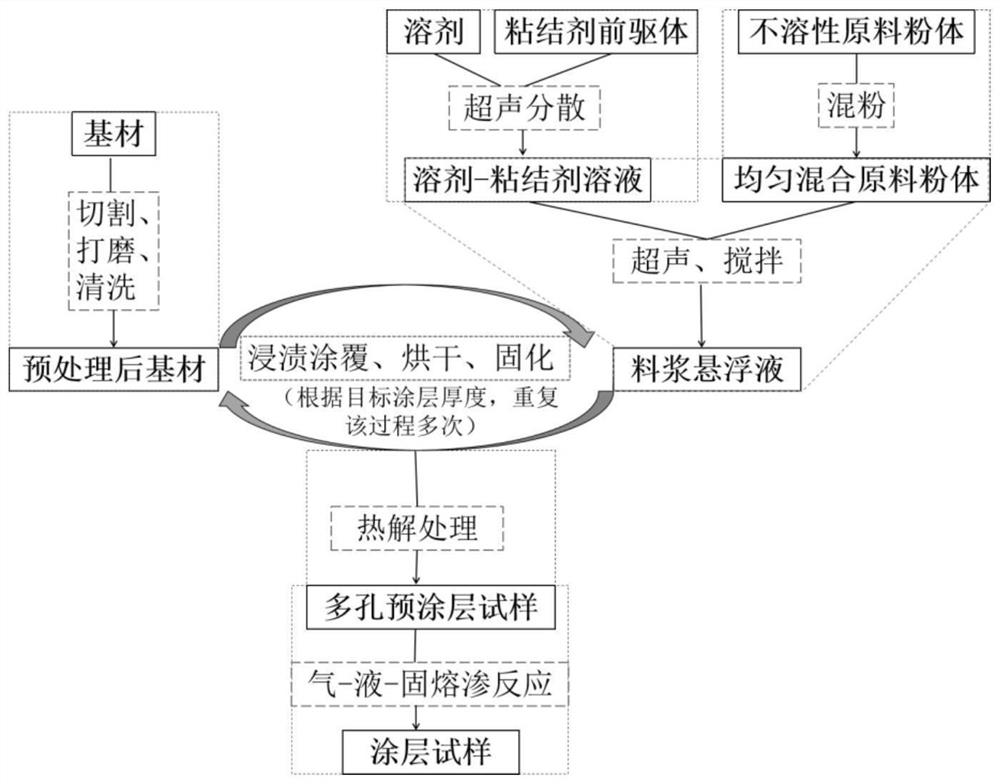

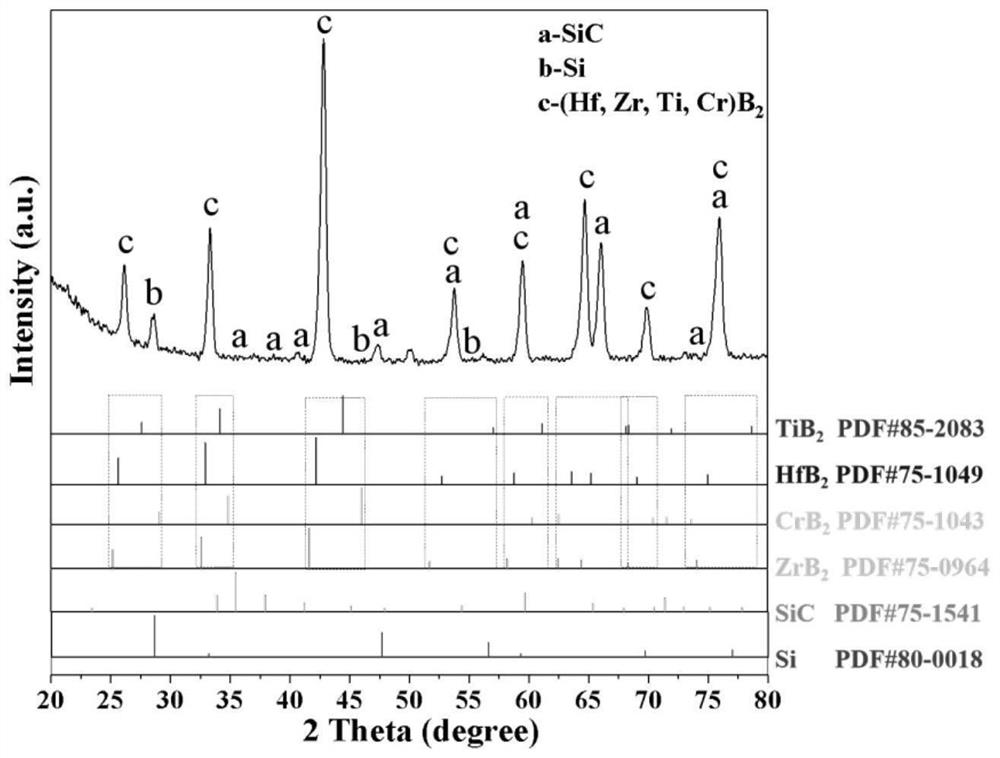

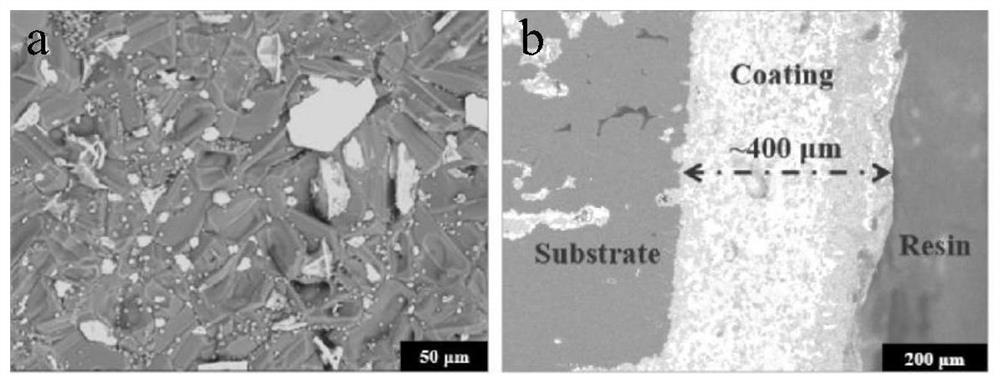

The invention relates to a high-entropy ceramic modified coating with controllable components and a controllable microstructure, and a preparation method thereof. The high-entropy ceramic modified coating is a mixed coating formed by any four or more elements selected from zirconium (Zr), titanium (Ti), hafnium (Hf), tantalum (Ta), niobium (Nb), vanadium (V), chromium (Cr), molybdenum (Mo) or tungsten (W) and a substrate coating. The substrate coating comprises SiC-Si, ZrC-ZrSi2 or TiC-Ti. The preparation method comprises the following steps: pre-treating a base material; and mixing a solvent and a binder, carrying out ultrasonic dispersion, then adding a corresponding high-entropy ceramic precursor raw material TMxOy and other raw materials to prepare a uniform slurry suspension solution, and carrying out dipping-drying curing to obtain a pre-coating layer. According to the method, the high-entropy ceramic does not need to be prepared in advance, only the corresponding precursor raw materials are used for coating the surface of the base material through a simple material coating method, and a (carbon, nitrogen, carbon nitrogen or boron) compound high-entropy ceramic solid solution is generated in situ in a infiltration process, so solid solution strengthening effect can be achieved, the cohesion binding force of the coating is high, the hardness and high-temperature oxidation corrosion resistance of the coating can be further improved, and large-scale industrial application can be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

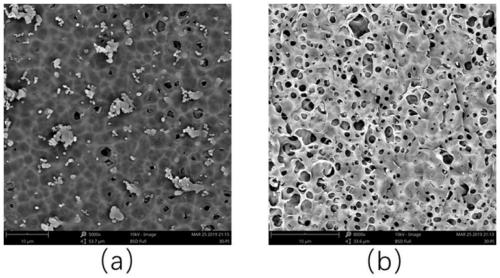

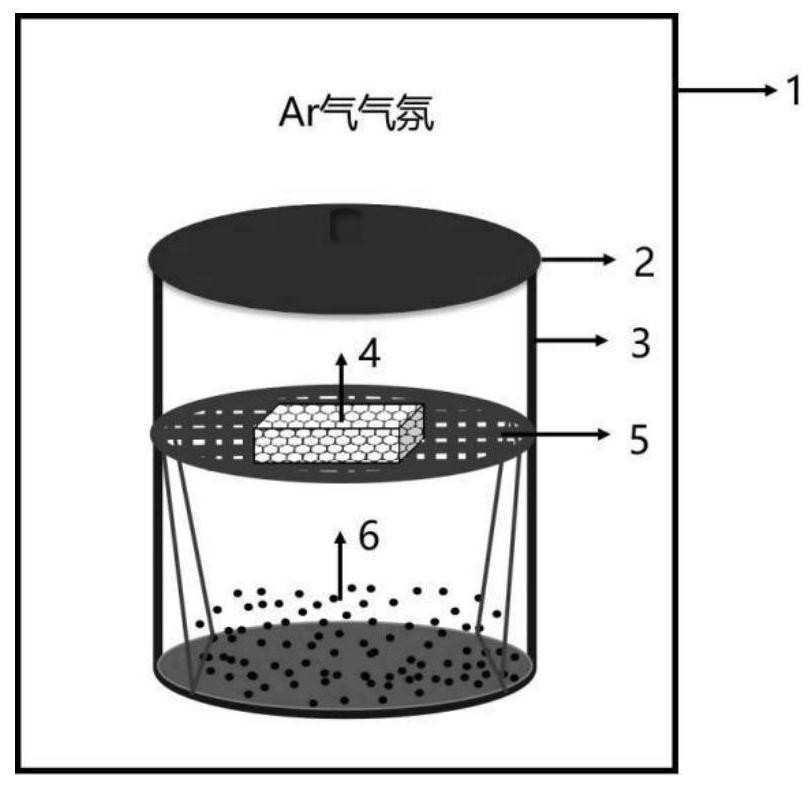

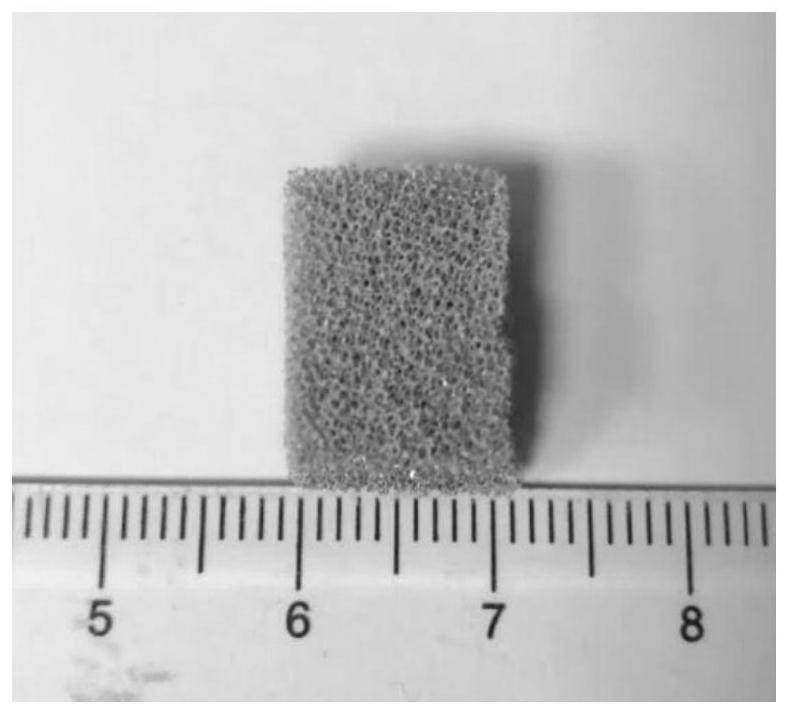

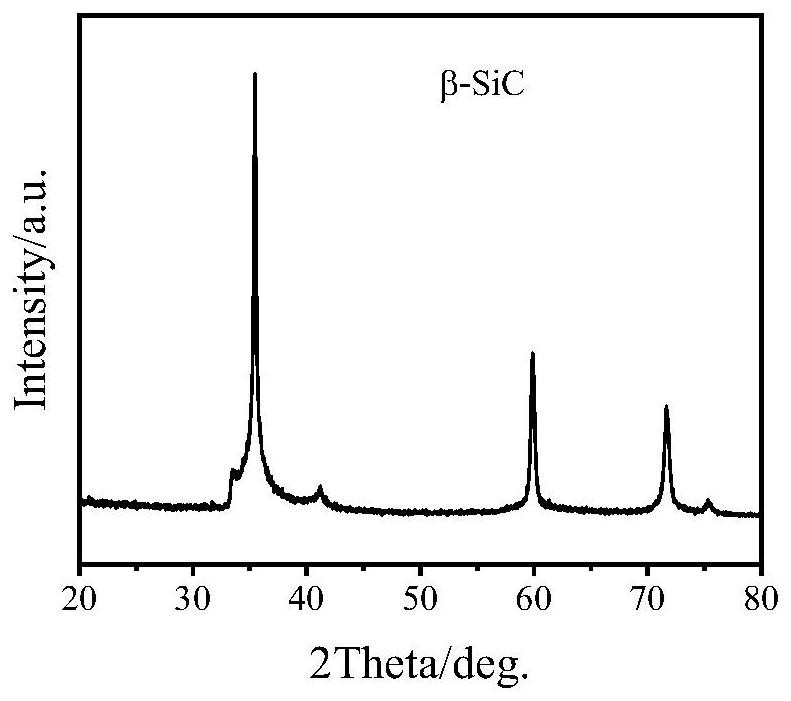

Lightweight and high-strength silicon carbide foamed ceramic and preparation method thereof

The invention discloses lightweight and high-strength silicon carbide foamed ceramic and a preparation method thereof, and belongs to the technical field of foamed ceramic preparation. Polyurethane foam is used as a template, and high-carbon-residue resin and absolute ethyl alcohol are uniformly mixed to prepare slurry with different viscosities. A foamy carbon precursor with a controllable pore rib structure and strength is obtained through the steps of slurry hanging, drying and pyrolysis carbonization, and then the lightweight and high-strength silicon carbide foamed ceramic is prepared through in-situ gas-solid carbon thermal reduction reaction sintering. Compared with a traditional template method, the method of the invention has the following advantages that the residual carbon amount of a carbonized foamy carbon skeleton is regulated by controlling the slurry hanging amount, so that the pore rib structure, porosity and strength of the silicon carbide foamed ceramic product are controlled. The silicon carbide foamed ceramic prepared by the method is of a three-dimensional open-pore internet-shaped skeleton structure, and has the structural characteristics of hollow pore rib core part, smooth and compact pore rib wall and the like, and the product has the characteristics of light weight and high strength.

Owner:咸阳瞪羚谷新材料科技有限公司

Serratia marcescens strain and synchronous extraction and fermentation method thereof

InactiveCN103627650AIncrease productionPurification and recovery process is simple and fastBacteriaMicroorganism based processesOxygen fluxSerratia species

The invention provides a Serratia marcescens Xd-1 strain with an accession number of CGMCC No. 7734 and a synchronous extraction and fermentation production method for prodigiosin by using the strain. The method is characterized by comprising the following steps: preparing primary seed liquid of the strain; preparing secondary seed liquid of the strain; mixing a liquid fermentation medium with a volume of V and the secondary seed liquid with a volume of 1 to 8% of V in a container and carrying out fermentation for 6 to 18 h under the fermentation conditions of a rotating speed of 130 to 200 r / min, oxygen flux of 0.5 to 1.5 v / (v.m) and fermentation temperature of 25 to 35 DEG C; and adding an extractant with a volume of 8 to 20% of V into the container and continuing fermentation under the fermentation conditions, wherein total fermentation time is 32 to 64 h.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Coal dealkalization method

The invention discloses a coal dealkalization method. The method comprises the following steps: (1) grinding raw coal to be dealkalized to obtain coal powder; (2) mixing the coal power obtained in the step (1) with eluent to obtain a mixed solution of coal and water, wherein the eluent is a water solution of a water-soluble organic solvent and the volume fraction of the water-soluble organic solvent is in a range of 5 to 20%; introducing gas containing carbon dioxide into the coal-water mixed solution obtained in the step (2), stirring the mixed solution to soak and wash the coals for 3 to 24 hours at a temperature of 20 to 60 DEG C to make carbon dioxide become excess; (4) subjecting the coal-water mixed solution, which has been processed in the step (3) to solid-liquid separation to obtain solids, and finally drying the solids to obtain the dealkalized coal. The provided method has the advantages of good dealkalization effect, mild reaction conditions, simple technology, and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

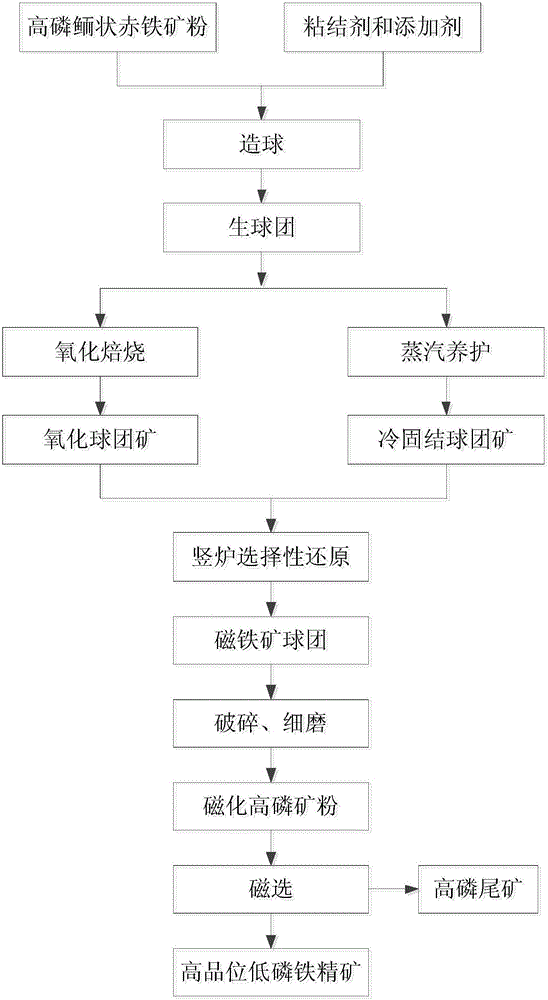

Industrial production method for conducting iron increase and phosphorous reduction on high-phosphorus oolitic hematite

InactiveCN105695734AExpand production scaleRealize large-scale industrial applicationShaft furnaceMagnetic separationIron increasedMagnetite

The invention relates to an industrial production method for conducting iron increase and phosphorous reduction on high-phosphorus oolitic hematite. The method comprises the steps that high-phosphorus oolitic hematite powder, bonding agents and dephosphorization agents are mixed uniformly and prepared into green pellets, and the green pellets are subjected to oxidizing roasting, so that pellets are obtained; oxide pellets or cold bonded pellets are placed in a two-section shaft furnace and induced into magnetite pellets containing gangue through a selective direct-reduction method; high-temperature CO-CO2 mixed gas is introduced into the bottom of a reduction section of the shaft furnace, and normal-temperature CO-CO2 mixed gas is introduced into the bottom of a cooling section; and the reduced magnetite pellets are crushed and fine ground, magnetized high-phosphorus ore powder is obtained and conveyed into a magnetic separator to be subjected to magnetic separation, and finally high-grade low-phosphorus iron ore concentrate and high-phosphorus tailings are produced. The industrial production method has the remarkable advantages of being suitable for large-scale industrial production, environmentally friendly, low in energy consumption, good in economic benefit and the like.

Owner:WUHAN UNIV OF SCI & TECH

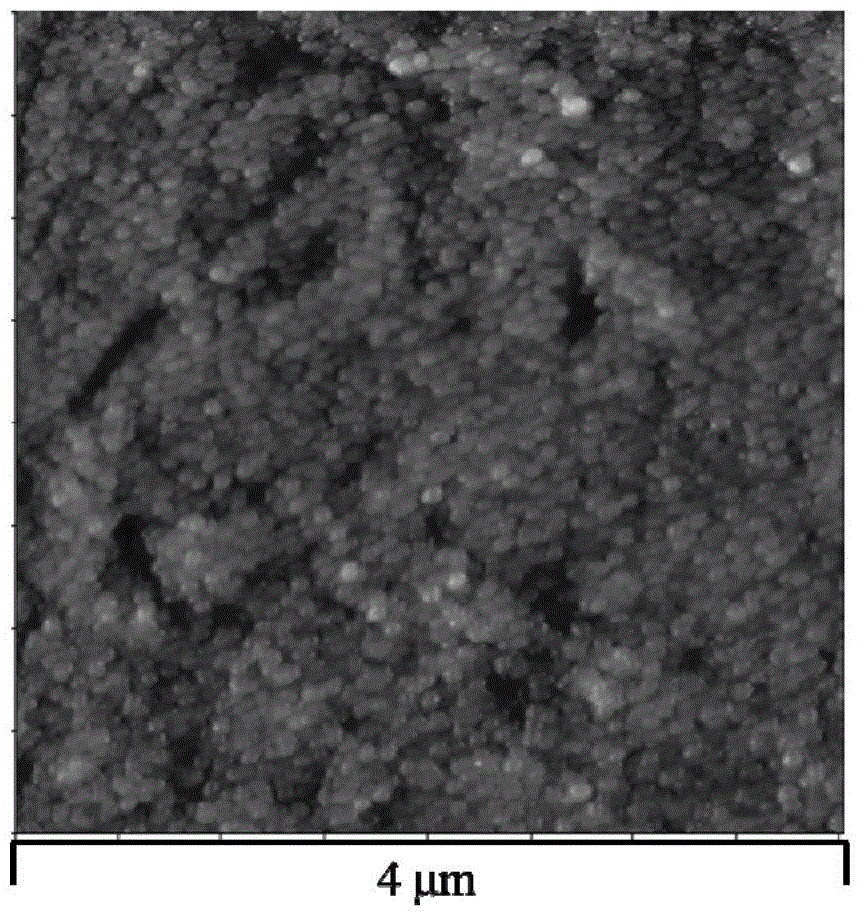

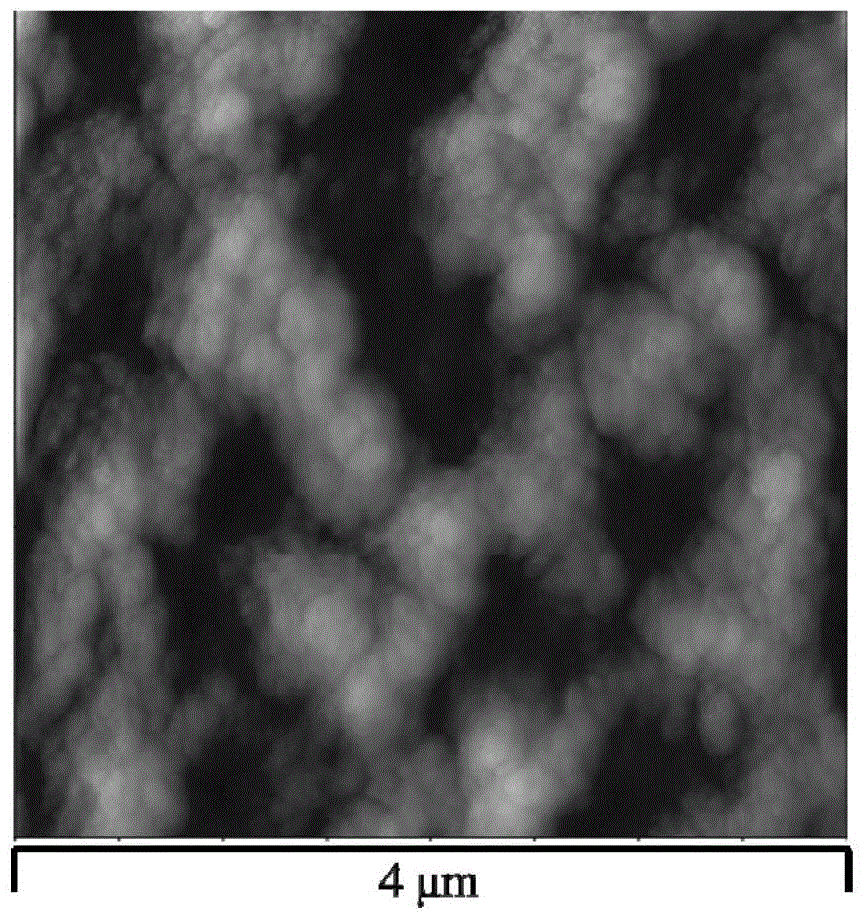

Metal surface treatment method based on chitosan and mussel adhesion protein composite membrane

ActiveCN104862757AGood biocompatibility and degradabilitySimple surface treatmentElectrolytic organic material coatingChemistryMetal

The invention discloses a metal surface treatment method based on a chitosan and mussel adhesion protein composite membrane, and relates to high-molecular compounds. The method comprises specific steps that step-by-step polishing, ultrasonic cleaning and drying are carried out on a metal material surface to be treated, and then an electro-deposition is adopted to enable chitosan and mussel adhesion protein to form a composite membrane layer on the metal material surface; and electro-deposition specifically comprises the steps that chitosan is added into a chitosan buffer solution to form a chitosan solution; the mussel adhesion protein is added into a mussel adhesion protein buffer solution to form a mussel adhesion protein solution; and the metal material to be treated is sequentially immersed into the chitosan solution and the mussel adhesion protein solution to be electrically deposited, and after drying, the composite membrane layer is formed on the metal material surface. The composite membrane layer is formed on the metal material surface, and the electro-deposition step can be repeatedly carried out to form multiple composite coatings. The method is simple, easy to implement and particularly suitable for corrosion prevention of metallic biomaterials.

Owner:XIAMEN UNIV

Composite heat storage material based on steel slag-coal gangue and preparation method thereof

ActiveCN113512408AEfficient use ofReduce pollutionHeat-exchange elementsCeramic materials productionCompression moldingSlag

The invention relates to a composite heat storage material based on steel slag-coal gangue and a preparation method thereof. The heat storage material comprises the following components in percentage by mass: 35-45% of steel slag, 40-50% of coal gangue, 0-10% of a sintering aid and 0-10% of a modifier. According to the invention, after the raw materials are subjected to the procedures of crushing, grinding, mixing, compression molding, sintering and the like, the obtained heat storage material is high in strength, the specific heat capacity is 1.1-1.3 J / g.DEG C, the heat conductivity is 2-3 W / m.K, and the cost is only 1 / 3 of that of a current marketized heat storage material; the heat storage material is wide in application range, low in cost, safe, reliable, long in service life, and simple in related preparation process, special process and equipment requirements do not exist, and further industrial production can be realized; and industrial wastes such as steel slag, coal gangue and the like are fully utilized in the formula, so that the environmental pollution caused by the solid wastes and the like can be greatly relieved, and the resource utilization of the solid wastes is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

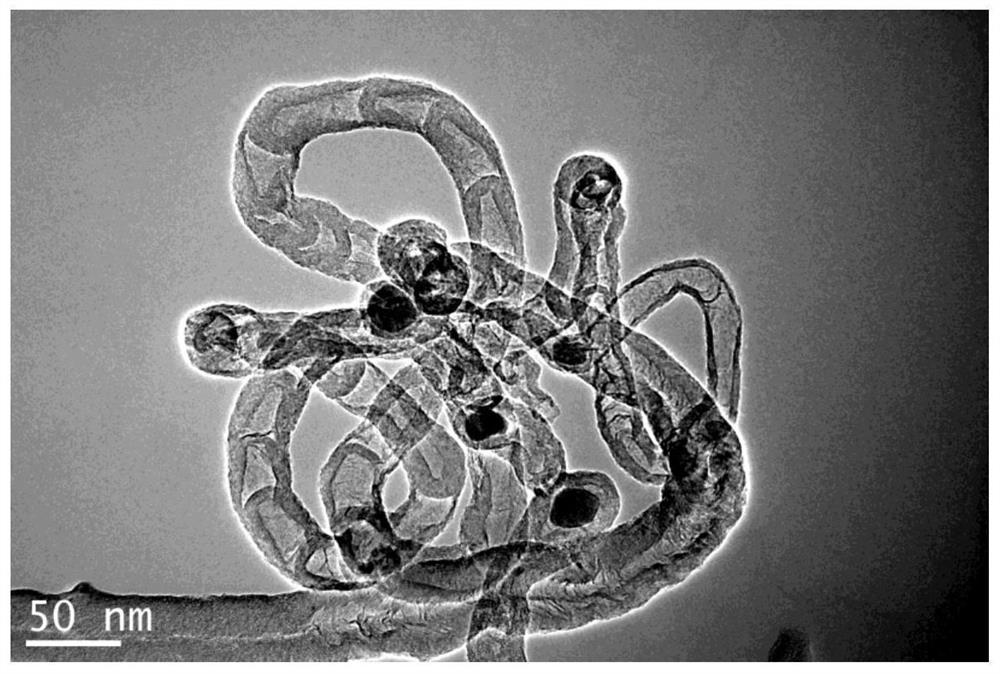

Preparation method of copper-iron bimetal confinement nitrogen-doped carbon nanotube composite material

PendingCN113477270AHigh porosityStrong modifiabilityPhysical/chemical process catalystsWater contaminantsPtru catalystMetal-organic framework

The invention discloses a preparation method of a copper-iron bimetal confinement nitrogen-doped carbon nanotube composite material, which comprises the following steps: firstly, obtaining a copper-iron bimetal metal organic framework precursor by a liquid phase diffusion method, and then transferring the precursor into a tubular furnace by an in-situ pyrolysis method, and calcining and pyrolyzing in inert gas to obtain a target product. According to the obtained catalyst, monatomic iron and copper nanoparticles are anchored on carbon nanotubes through coordination, the catalytic site density is high, the specific surface area is large, the conductivity is good, and the catalyst shows excellent performance and wide application prospects in the fields of adsorption separation, catalysis, energy storage and the like; the preparation method is simple in preparation process and low in cost, and has wide application prospects and practical value.

Owner:HEFEI UNIV OF TECH

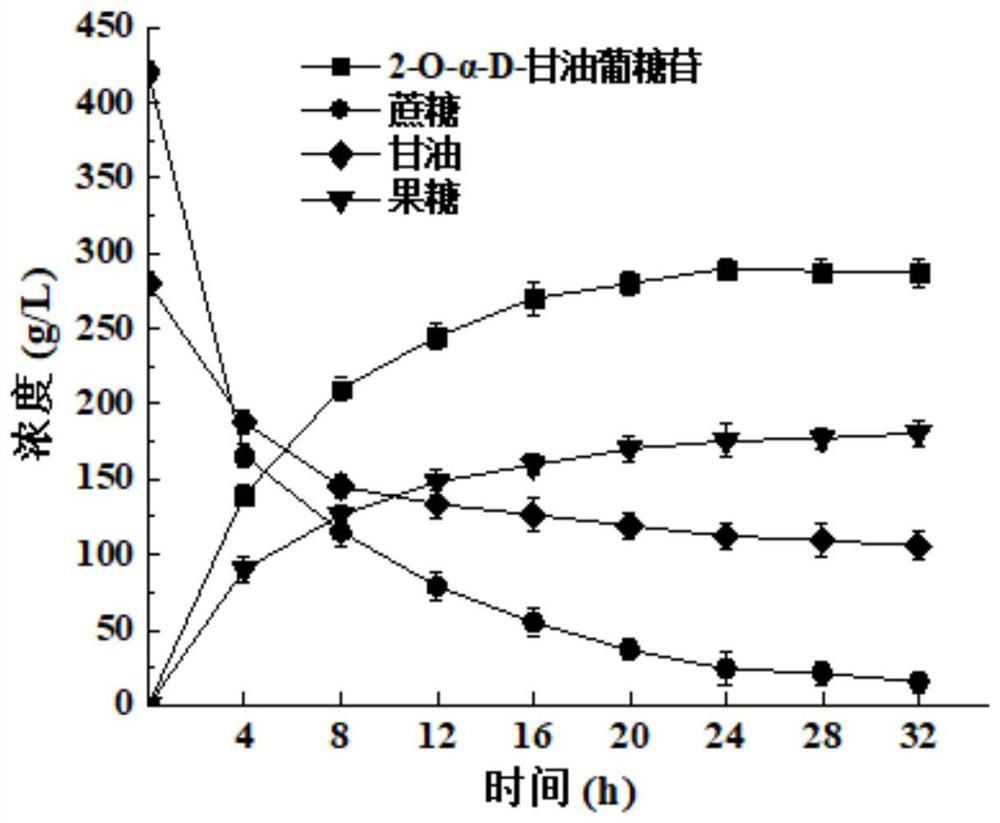

Method for synthesizing 2-O-alpha-D-glyceroglucoside by utilizing microorganisms

PendingCN111690624AIncreased potential for industrial applicationsIncrease enzyme activityBacteriaMicroorganism based processesBiotechnologyEscherichia coli

The invention discloses a method for synthesizing 2-O-alpha-D-glyceroglucoside by utilizing microorganisms, and belongs to the technical field of gene engineering. An amino acid sequence of a mutant is as shown in SEQ ID NO:1. According to the mutant disclosed by the invention, site-specific mutagenesis is carried out to improve the enzyme activity of sucrose phosphorylase on the basis of sucrosephosphorylase derived from leuconostoc mesenteroides; a mutant enzyme is expressed in escherichia coli and is used as a whole-cell catalyst to produce the 2-O-alpha-D-glyceroglucoside; and a large amount of 2-O-alpha-D-glyceroglucoside can be produced within a short time at the level of a 5L fermentation tank, so that the industrial application prospect of production of the 2-O-alpha-D-glyceroglucoside by the sucrose phosphorylase can be easily expanded, and the large-scale industrial application is achieved.

Owner:JIANGNAN UNIV

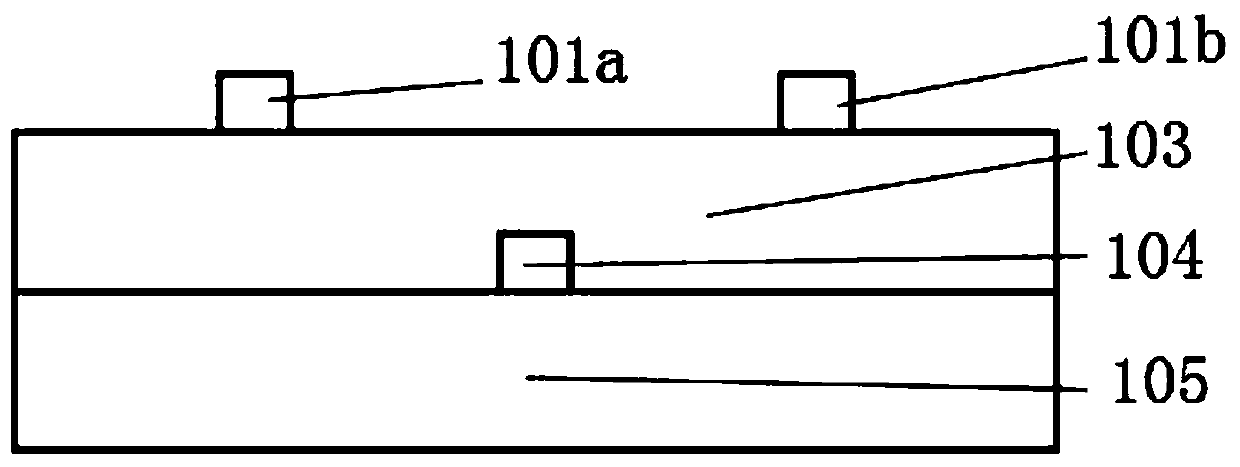

Flexible nanofiber zinc tin oxide field effect transistor and preparation method thereof

PendingCN110534568ALow costEasy to operateSemiconductor/solid-state device manufacturingSemiconductor devicesZinc tin oxideNanofiber

The invention discloses a flexible nanofiber zinc tin oxide field effect transistor and a preparation method thereof. The flexible nanofiber zinc tin oxide field effect transistor comprises a top source electrode layer, a top drain electrode layer, a carrier channel layer of a nanofiber structure, a dielectric layer, a bottom gate electrode layer and a substrate which are arranged from top to bottom, wherein the carrier channel layer of the nanofiber structure is a zinc tin oxide filament cluster which is prepared by a sol method and has the diameter of about 100-300 nm. The preparation methodcomprises the following steps of: a) cleaning the substrate; b) preparing the bottom gate electrode layer, c) preparing a hafnium oxide dielectric layer, d) preparing a carrier channel layer with a nanofiber structure, and e) preparing a top source electrode layer and a top drain electrode layer. According to the scheme, the nanofiber (NF) filaments are prepared by adopting a sol method, the operation is simple and convenient, the distribution and direction are easy to control, the cost is low, the uniformity is relatively high, and large-scale industrial application can be realized; the advantages of environmental protection, high mobility and the like are achieved; the method can be applied to the field of flexible wearable circuits; and the whole device is transparent, and has good application potential in the optical field.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

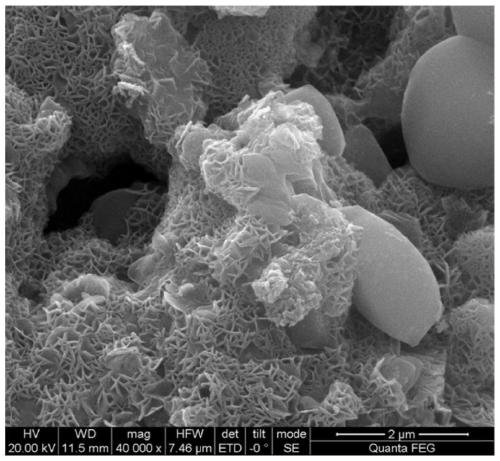

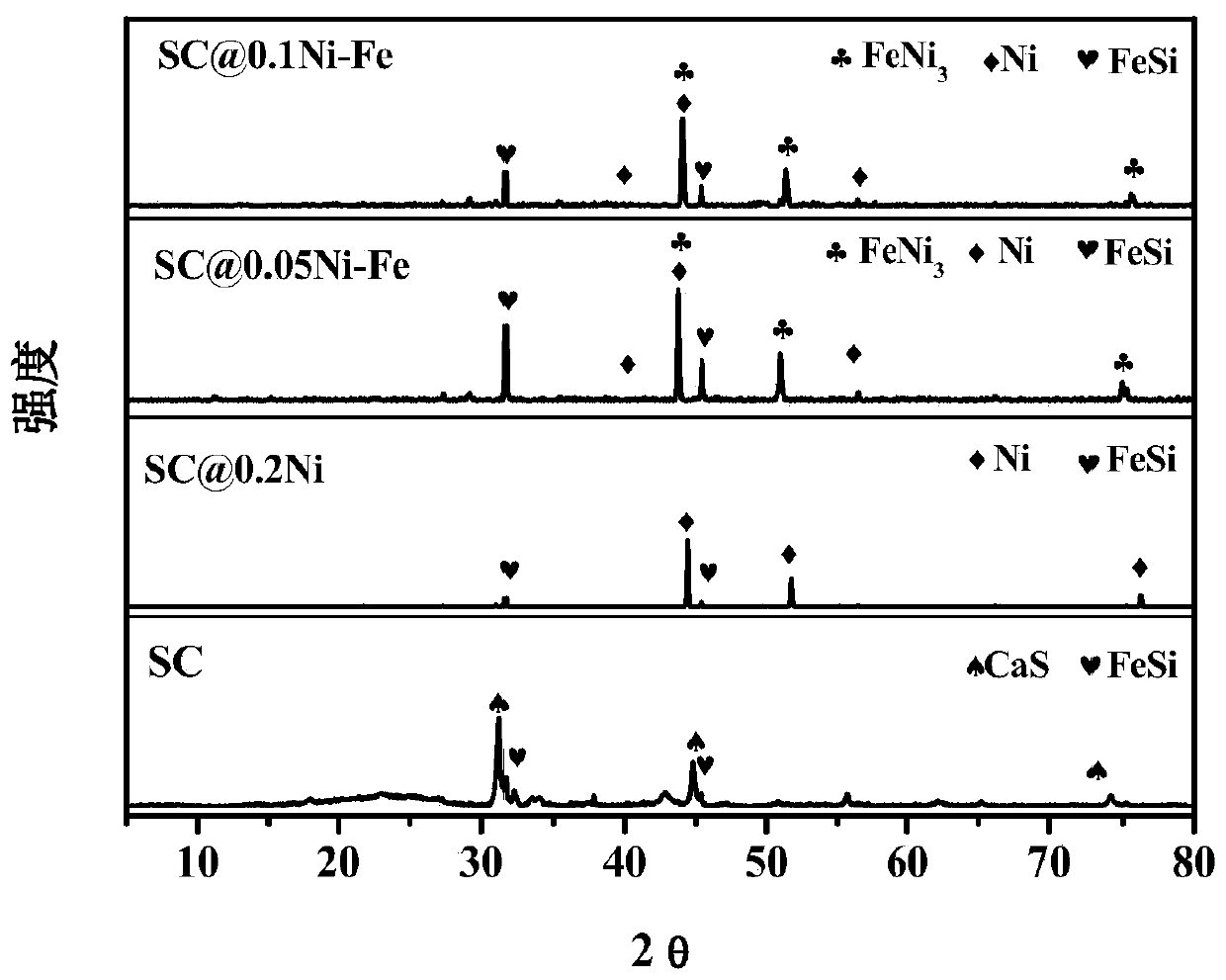

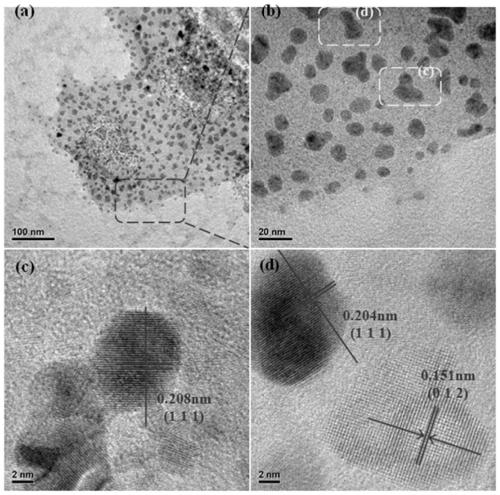

Preparation method and application of biomass honeycomb semicoke loaded nickel-iron nanoparticle catalyst

ActiveCN111250092AAchieve direct conversionWide variety of sourcesBiofuelsCatalyst activation/preparationPtru catalystMetallurgy

The invention discloses a preparation method and an application of a biomass honeycomb semicoke loaded nickel-iron nanoparticle catalyst. According to the method, gulfweed is used as a raw material, feCl3.6H2O and NiCl2.6H2O are introduced to serve as a chemical activating agent and a metal endowing substance, gulfweed is mixed with a mixed solution of FeCl3.6H2O and NiCl2.6H2O according to a certain ratio for dipping, carrier gas N2 is introduced into a tubular furnace for heat treatment to directly convert the gulfweed raw material into an excellent catalyst with a high specific surface area, multiple active sites and a special honeycomb structure, and the catalyst is applied to the catalytic cracking process of biomass pyrolysis tar. The waste seaweed biomass is used for treating biomass pyrolysis tar, waste is treated with waste, the biomass growth cycle is short, the preparation process is simple, the cost is low, environmental pollution is small, and the prepared gulfweed carbon-based honeycomb catalyst achieves a stable and ideal effect in biomass tar catalytic cracking.

Owner:CHINA UNIV OF MINING & TECH

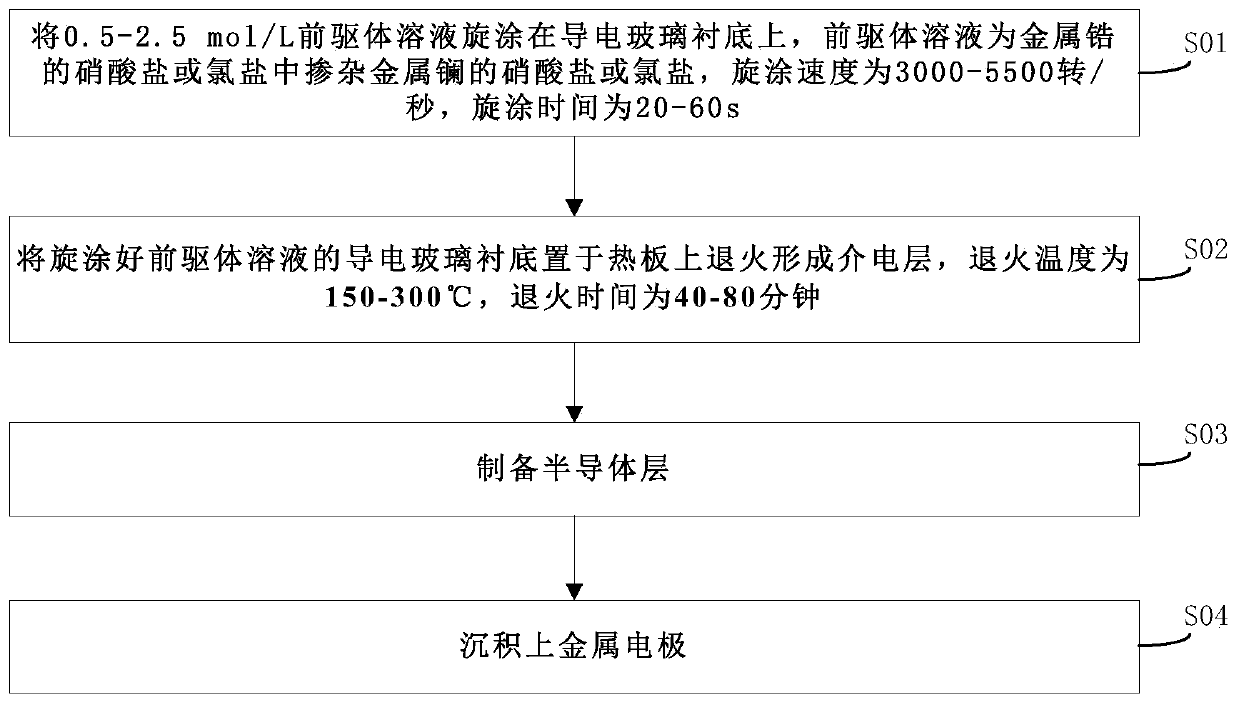

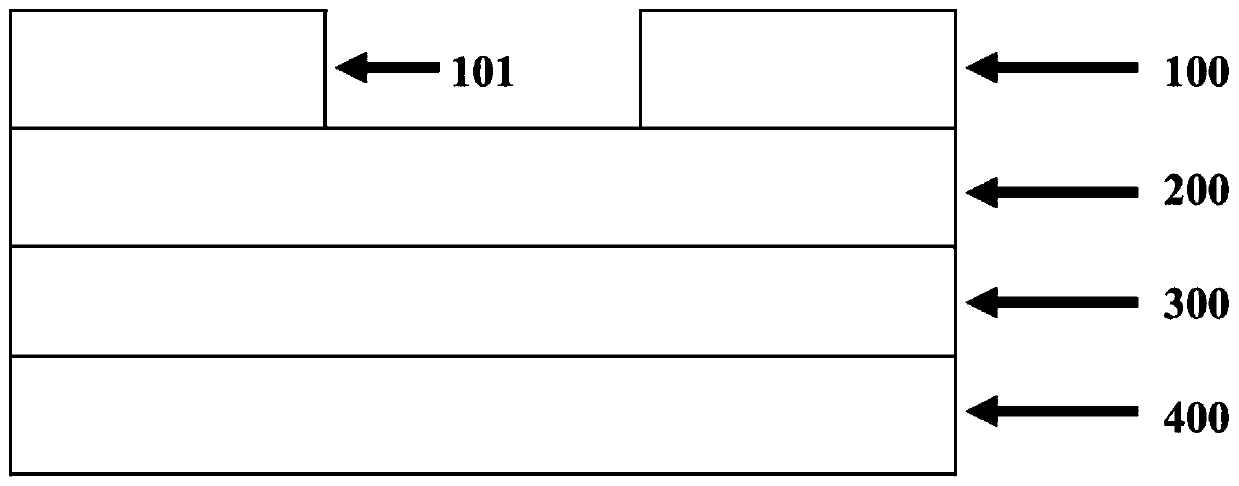

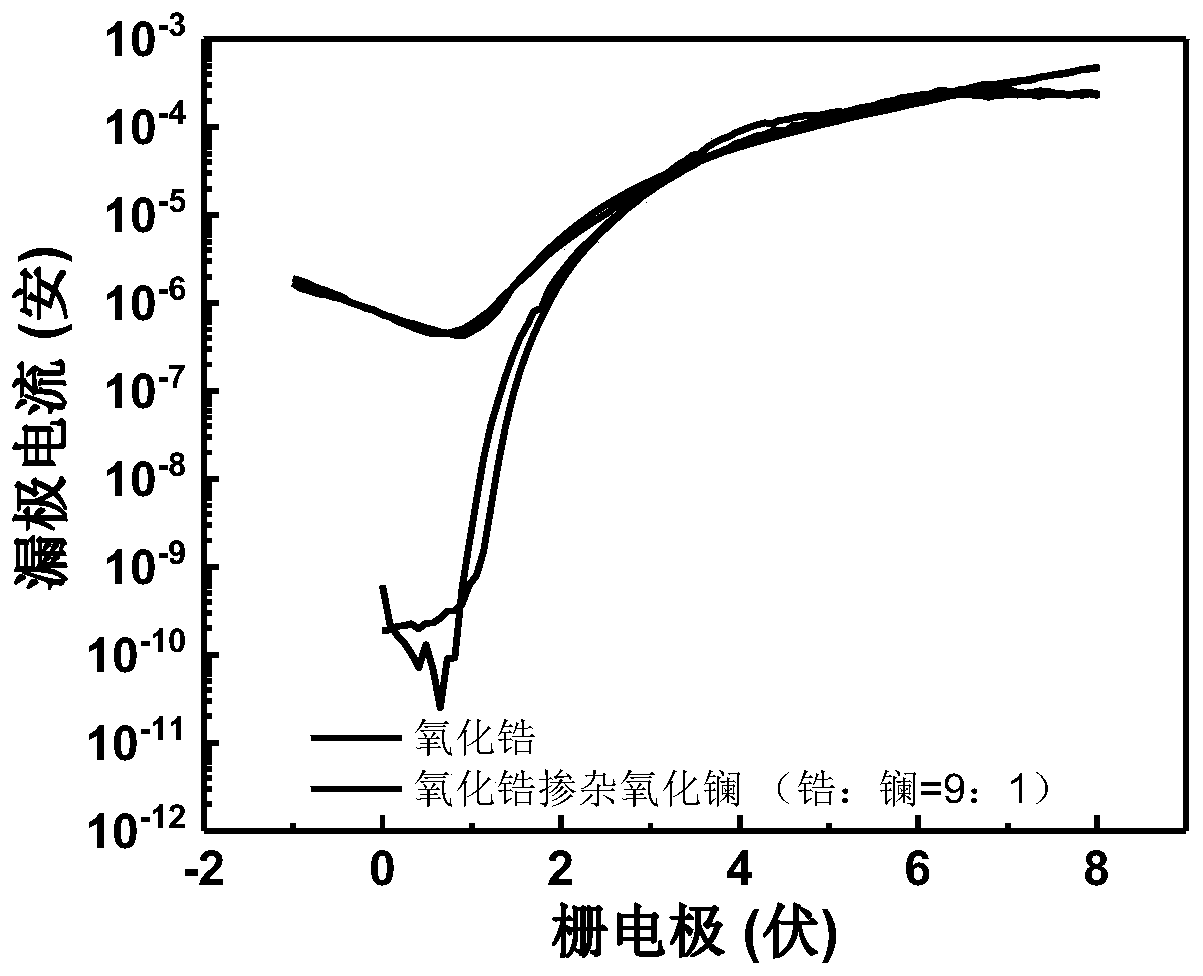

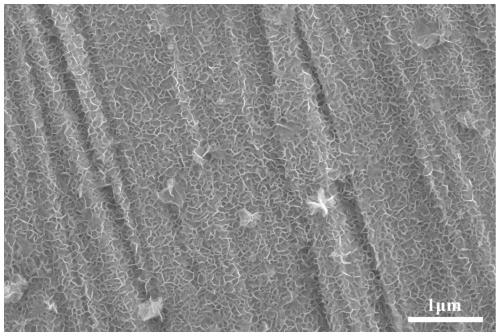

Transparent thin film transistor device based on zirconium oxide and lanthanum oxide and preparation method thereof

PendingCN111129160APrevent crystallizationReduce absorptionTransistorSemiconductor/solid-state device manufacturingMetallic electrodeThin membrane

The invention discloses a transparent thin film transistor device based on zirconium oxide and lanthanum oxide, which comprises a conductive glass substrate, a dielectric layer, a semiconductor layerand an upper metal electrode which are sequentially arranged from bottom to top, the upper metal electrode comprises a source electrode and a drain electrode, and the dielectric layer is made of a mixed oxide of zirconium oxide and lanthanum oxide. The insulating layer and the semiconductor layer of the TFT are prepared by adopting a solution method, so that low-cost and large-area TFT preparationis realized, and equipment and raw material investment is relatively low; and the method is compatible with a traditional process in process, and the preparation cost can be effectively controlled.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

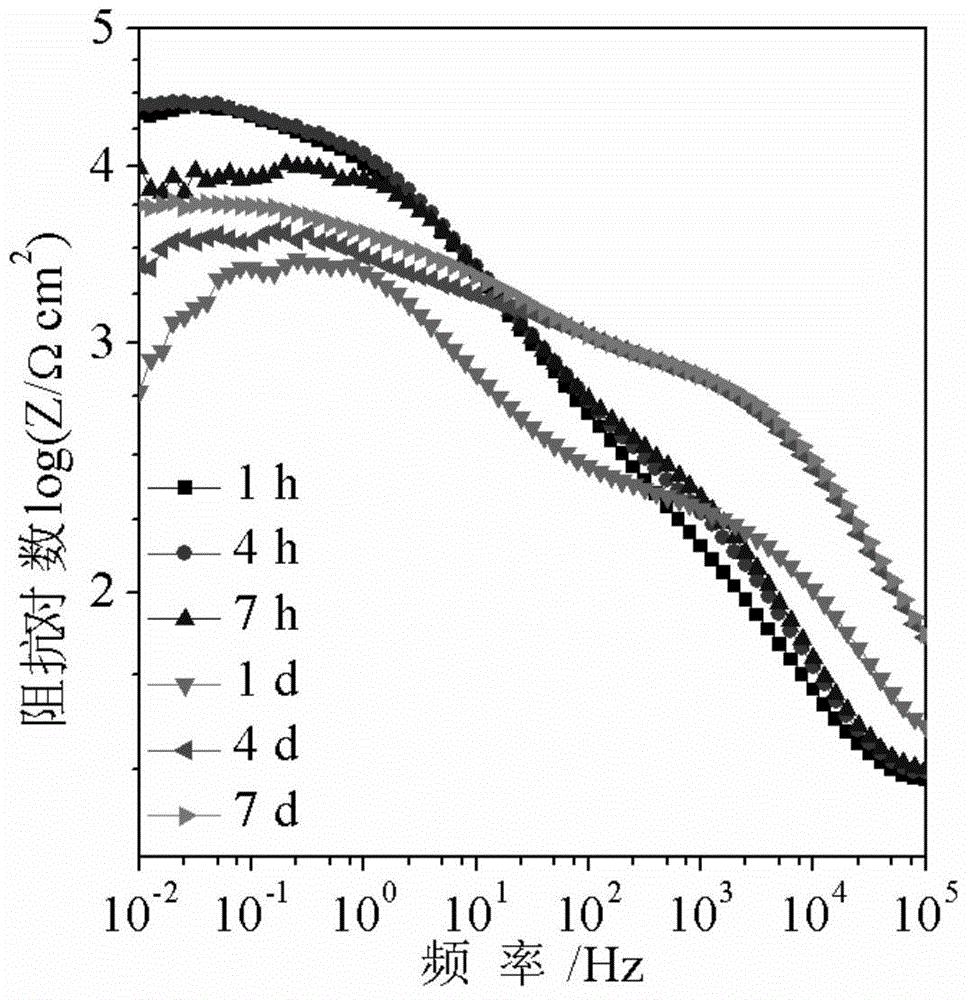

Surface treatment method for improving corrosion resistance of carbon steel

InactiveCN109750280ASimple structureImprove corrosion resistanceLiquid/solution decomposition chemical coatingAnion intercalationCarbon steel

The invention provides a surface treatment method for improving the corrosion resistance of carbon steel, and belongs to the technical field of material surface treatment. According to the surface treatment method, an iron-based layered double hydroxide film with a corrosion inhibiting anion intercalation is prepared on the surface of the carbon steel directly, the corrosion resistance of the carbon steel can be improved, the adhesion of an organic coating applied to the surface of the carbon steel is increased, and the long-term corrosion resistance of the carbon steel is enhanced. The surface treatment method mainly comprises the following steps that (a) pretreatment is carried out on the surface of the carbon steel; (b) an iron-based layered double hydroxide film is prepared on the surface of the carbon steel; and (c) the iron-base layered double hydroxide film obtained in the step (b) is subjected to corrosion inhibiting anion exchange to prepare the iron-based layered double hydroxide film with the corrosion inhibiting anion intercalation. The surface treatment method is easy to operate, low in cost and stable in performance, and has high practical application value.

Owner:UNIV OF SCI & TECH BEIJING

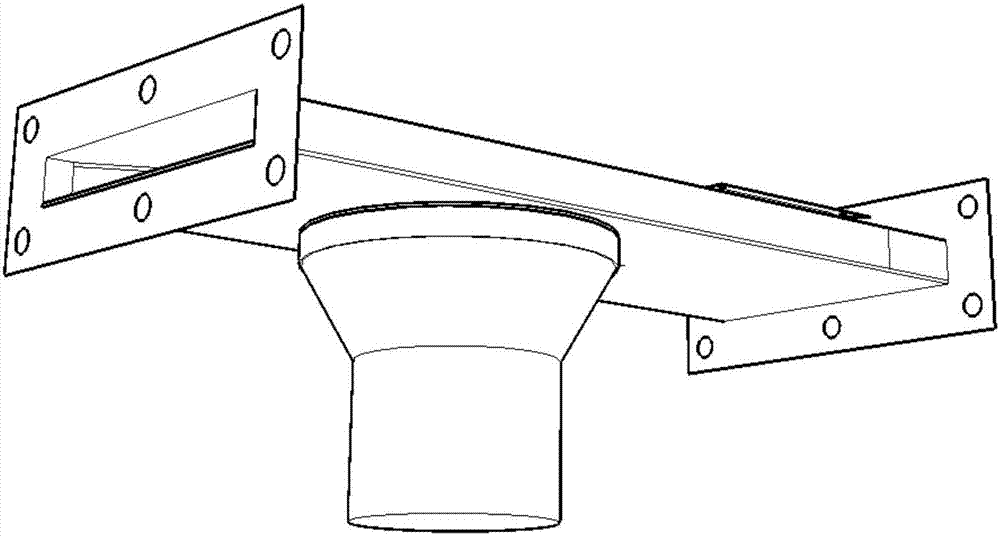

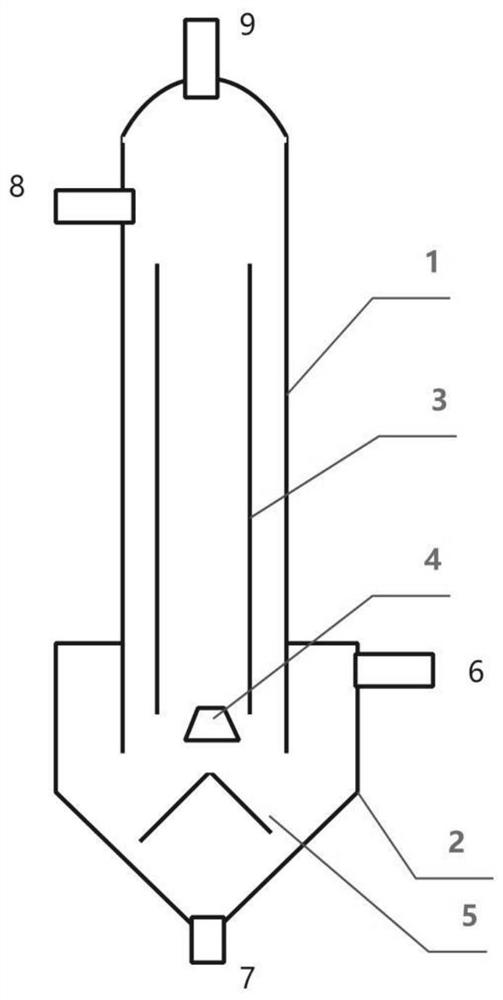

Device and method for mineralizing and fixing CO2 and preparing fine calcium carbonate by carbide slag

PendingCN112573554AEasy to zoom inFacilitate the realization of large-scale industrial applicationCalcium/strontium/barium carbonatesAmmonia preparation/separationSlagPhysical chemistry

The invention discloses a device and method for mineralizing and fixing CO2 and preparing fine calcium carbonate by carbide slag. The device is a novel circulation-separation-integrated slag dissolving reactor for leaching calcium components in carbide slag, and comprises an airlift circulation reactor, a solid-liquid separator and other accessories. The invention also provides a novel method forpreparing calcium carbonate by mineralizing and fixing CO2 by using carbide slag, which comprises the following circulation processes: a), putting carbide slag and a NH4Cl solution into a circulation-separation-integrated slag dissolving reactor, and introducing air to form circulation so as to obtain CaCl2 solution and NH3-containing air; b), absorbing the NH3-containing air with water to obtainammonia water; recycling air after NH3 is removed; c), introducing the CaCl2 solution and ammonia water into a mineralization tower to react with CO2 in the waste gas, and performing separating to obtain calcium carbonate and NH4Cl solution; and d), evaporating and concentrating the NH4Cl solution for recycling, and using evaporated water for absorbing ammonia gas to finish circulation; the device is easy to amplify, and large-scale industrial application is facilitated.

Owner:YUANCHU TECH (BEIJING) CO LTD

A method for efficient separation and comprehensive utilization of iron, aluminum and sodium in high-iron red mud

ActiveCN102851425BWon't breakReasonable useCombustible gas chemical modificationProcess efficiency improvementRed mudSlag

The present invention proposes a method for efficient separation of iron, aluminum and sodium from high-speed iron red mud. The method uses high-speed iron red mud as raw material, appropriately adds iron concentrate and coke powder, and then presses it into red mud pellets; after drying and preheating, it uses a rotary bottom The furnace directly reduces iron, sodium and other metal oxides; the reduced metallized pellets are sent to the iron bath type oxygen coal smelting reduction furnace for high-temperature melting and separation; the separated iron is used for steelmaking, and the high-aluminum slag is recycled after modification Aluminum oxide; sodium metal oxide is recovered from the smoke carried by the exhaust gas; the mixed gas produced by the oxygen coal smelting reduction furnace is modified and returned to the rotary hearth furnace for use. The invention can effectively realize efficient recovery and large-scale industrial comprehensive utilization of red mud resources.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com